Electric control type polishing device with adjustable polishing radius

A polishing device, electronically controlled technology, applied in surface polishing machine tools, grinding drives, grinding/polishing equipment, etc., can solve the problem that the polishing range cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

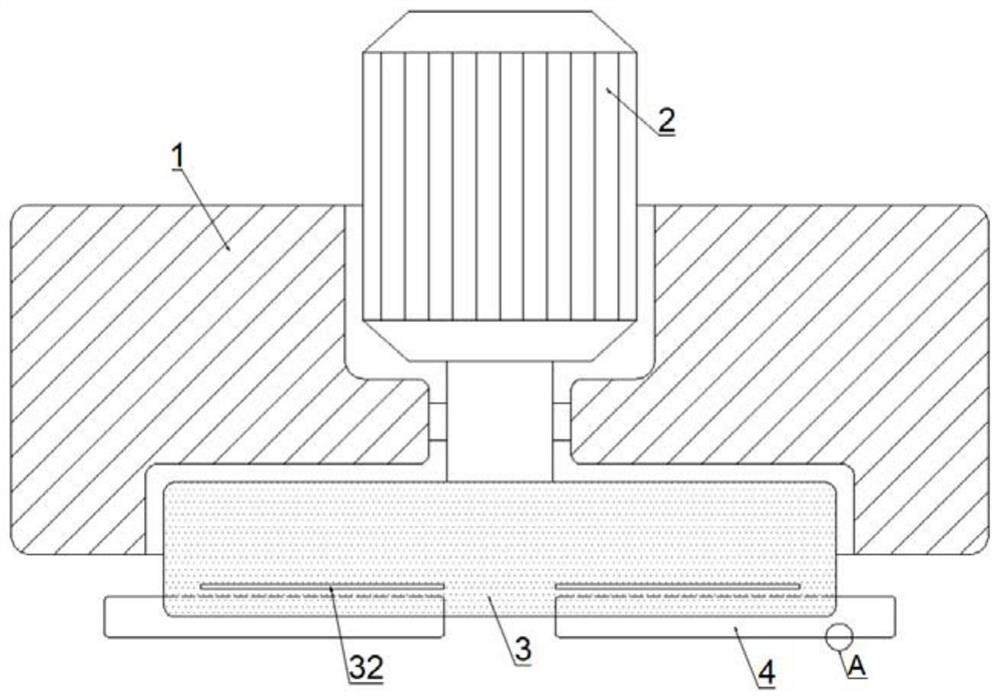

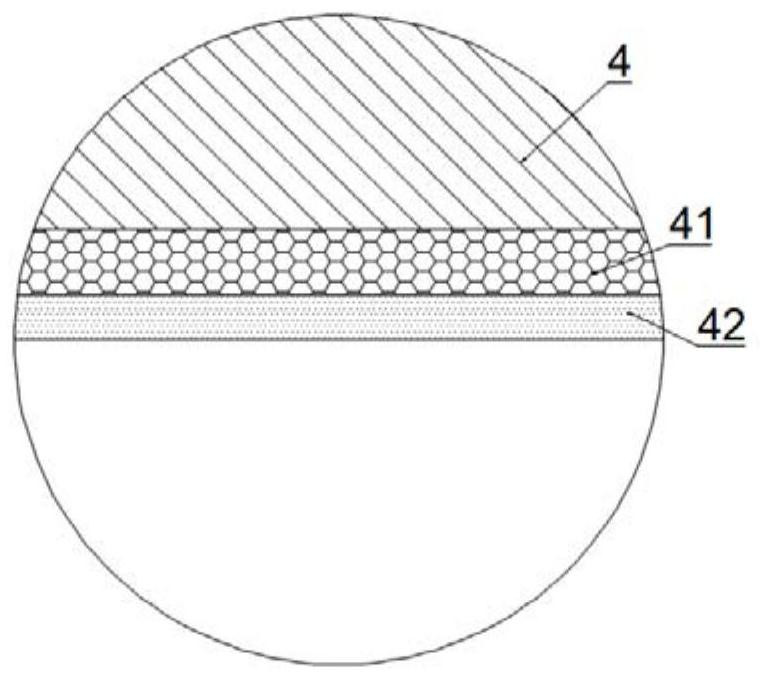

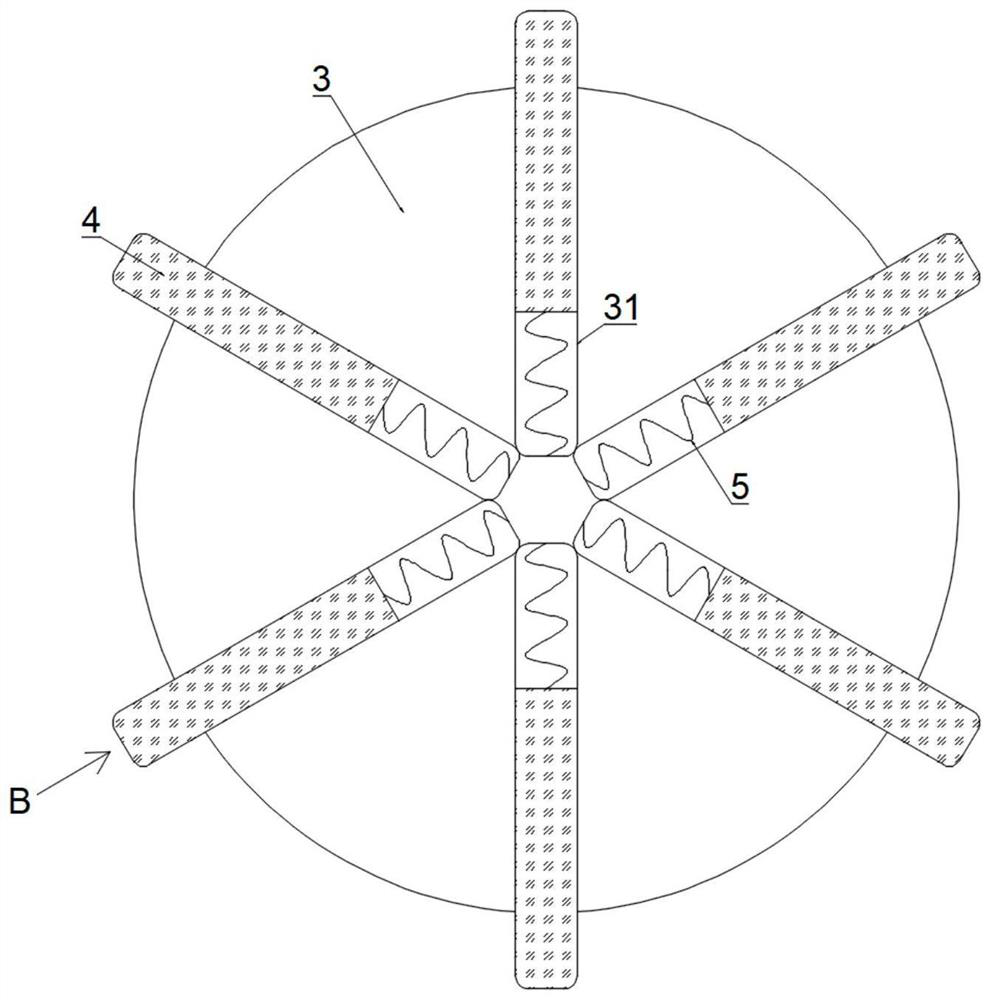

[0024]ReferFigure 1-6, A polishing apparatus for an electrically controlled polishing radius comprising a fixing frame 1, a drive motor 2 is attached to the top of the fastener 1, and the drive motor 2 outputs the coaxial fixed connection with the control block 3, wherein the drive motor 2 outputs The speed sensor is mounted, the control block 3 is rotated to the bottom of the fixing frame 1, the drive motor 2 operates its output to drive the control block 3 to rotate, the speed sensor is used to detect the driving motor 2 output end rotation speed and to the control circuit 6 Output the corresponding speed signal.

[0025]The bottom of the control block 3 is opened with a plurality of narro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com