Patents

Literature

14158results about "Polishing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

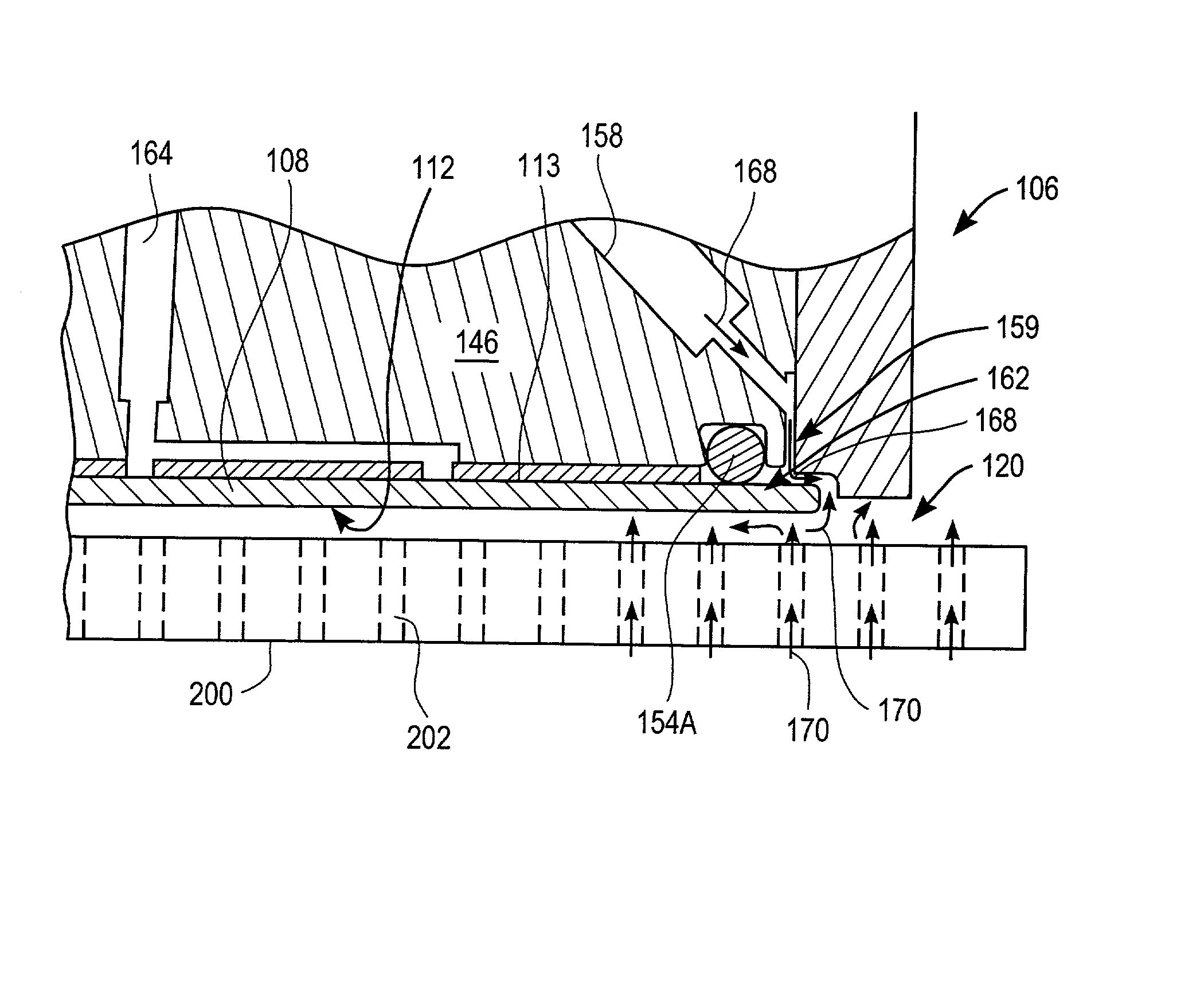

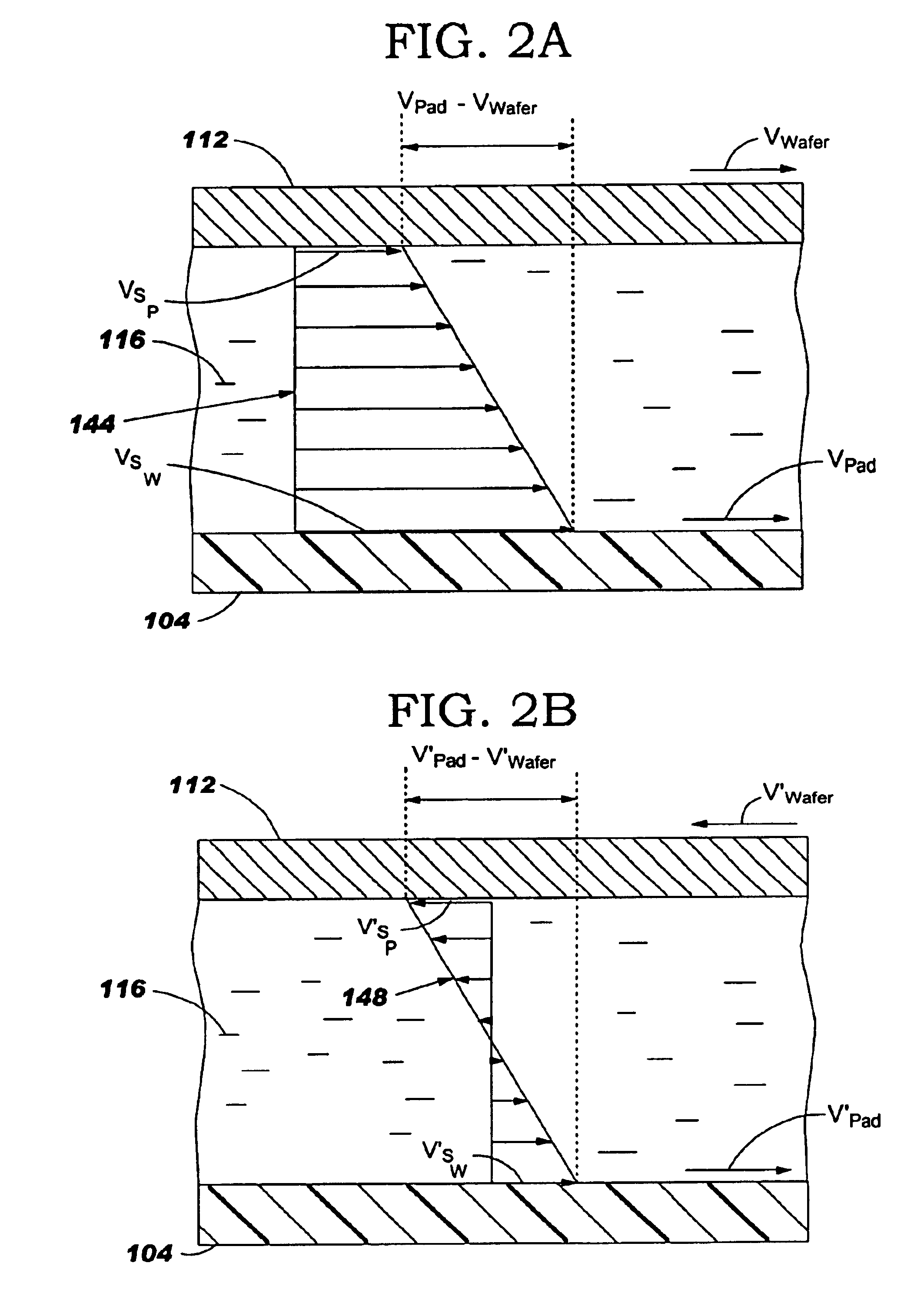

Methods for controlling the pressures of adjustable pressure zones of a work piece carrier during chemical mechanical planarization

ActiveUS7115017B1Polishing machinesRevolution surface grinding machinesEngineeringChemical-mechanical planarization

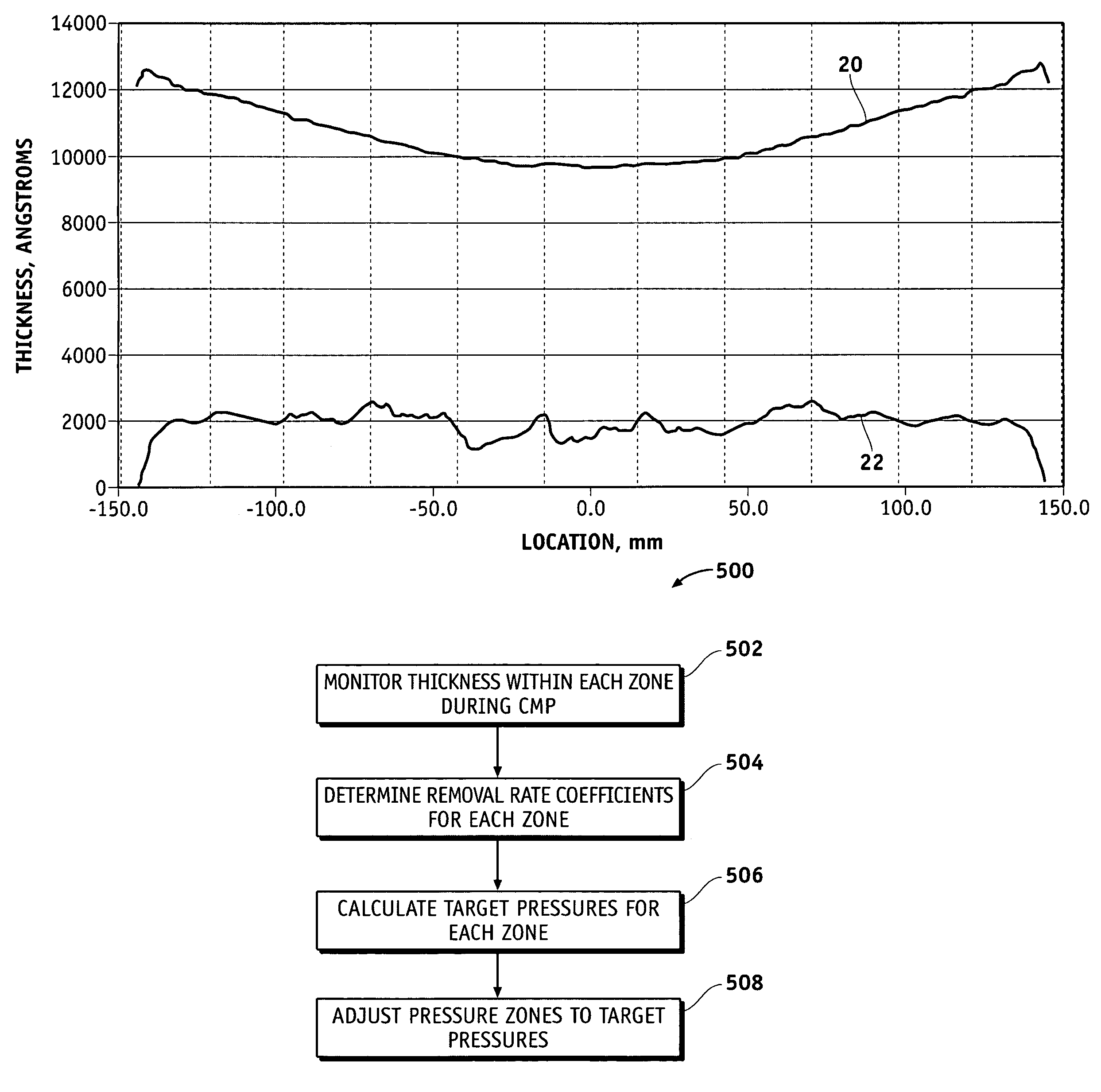

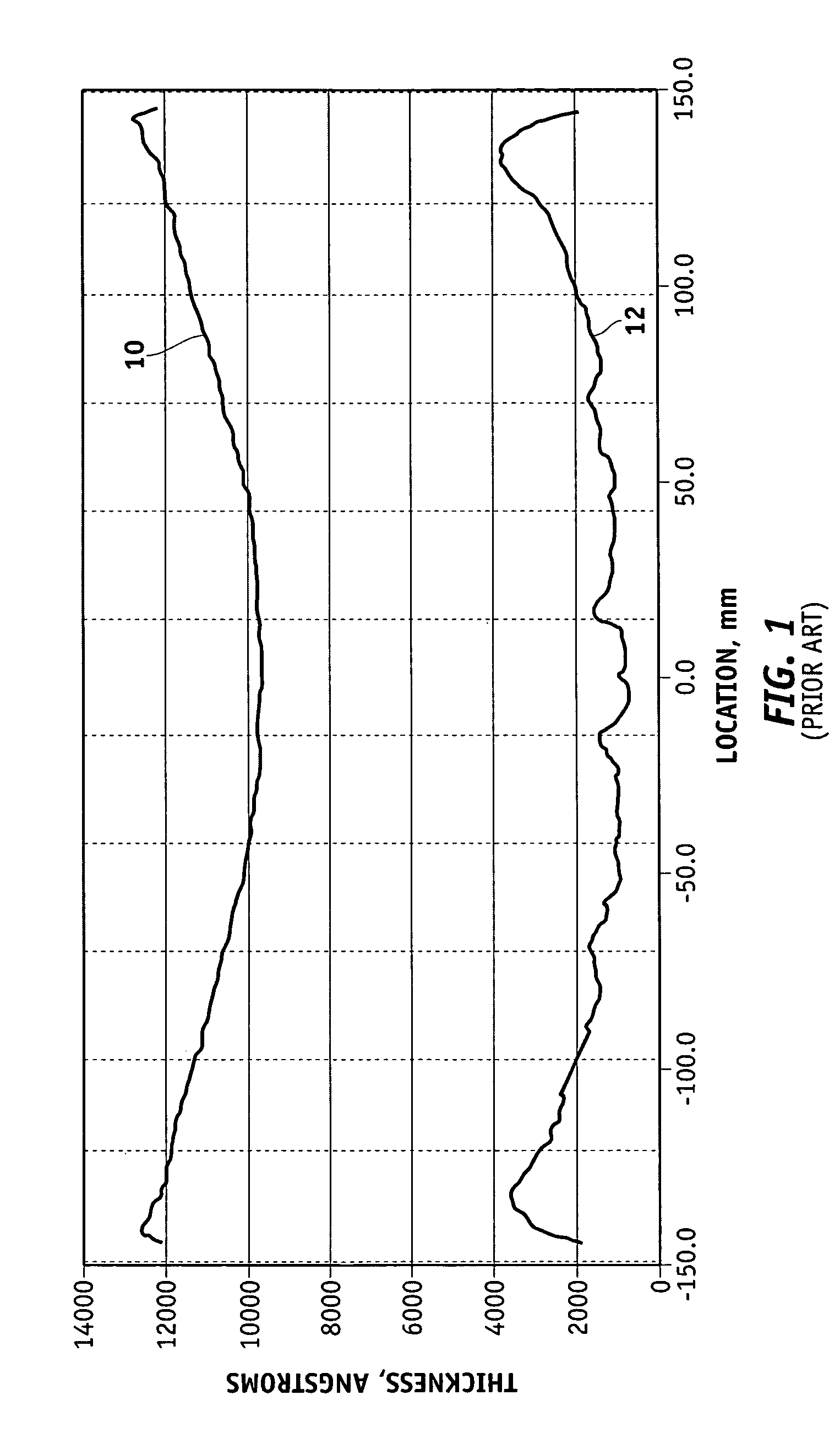

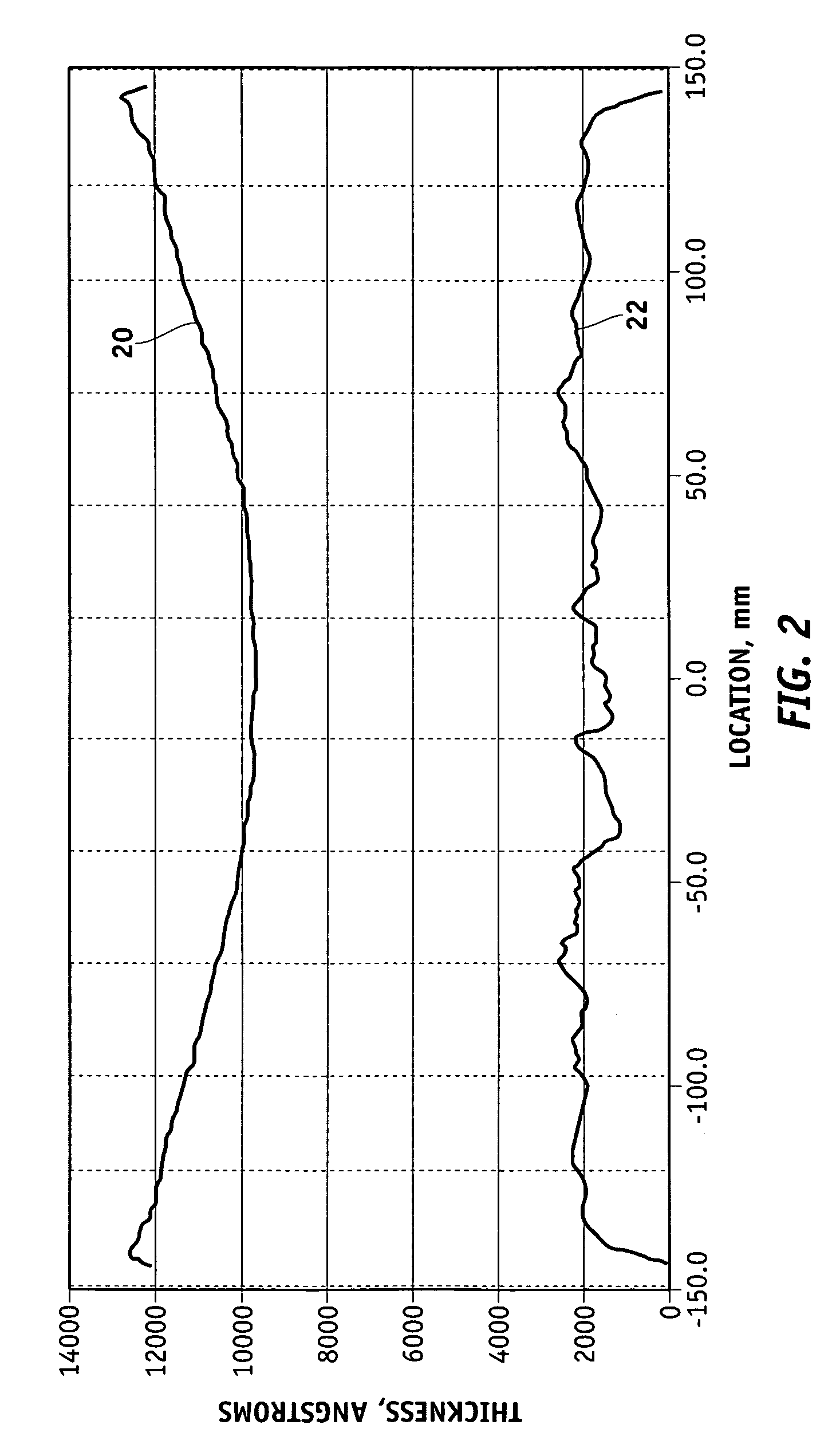

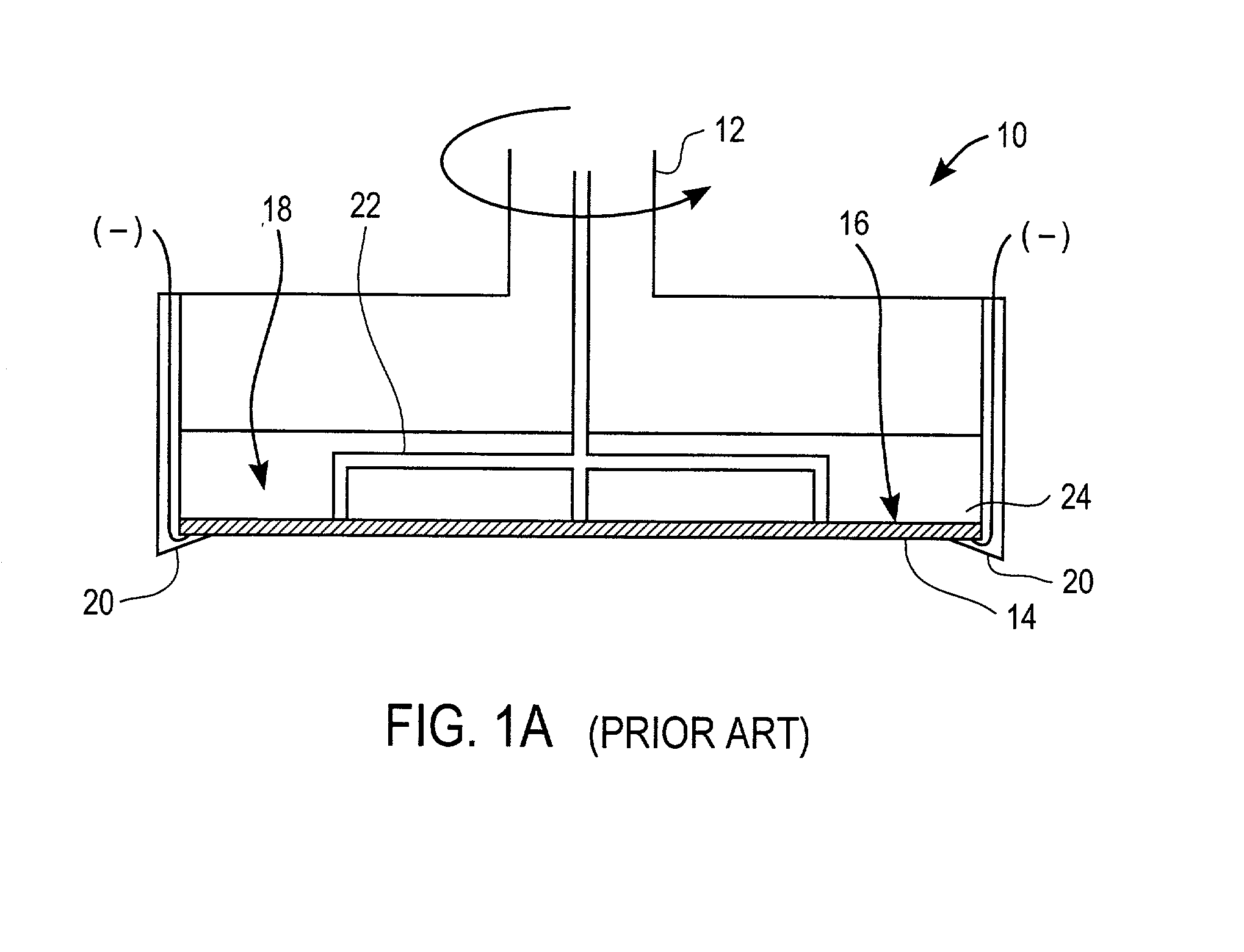

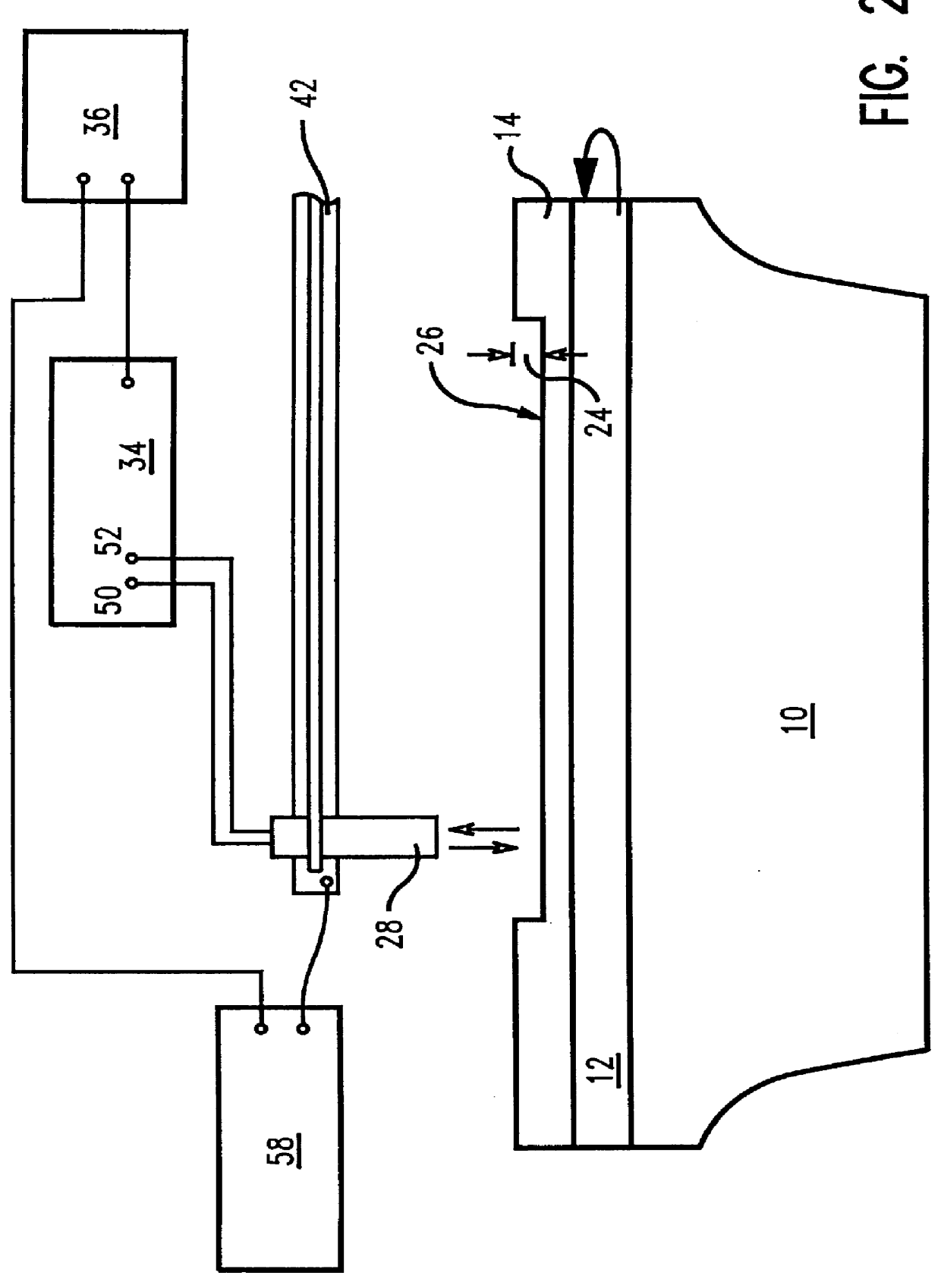

Methods are provided for controlling adjustable pressure zones of a CMP carrier. A method comprises determining a first thickness of a layer on a wafer underlying a first zone of the carrier. A first portion of the layer underlying the first zone is removed. The first zone is configured to exert a first pressure against the second surface of the wafer. A second thickness of the layer underlying the first zone is determined and a target thickness corresponding to a predetermined thickness profile is selected. A second pressure for the first zone is calculated using the first thickness, the second thickness, the first pressure, and the target thickness. The pressure exerted by the first zone against the second surface of the wafer is adjusted to the second pressure and the steps are repeated for a second zone.

Owner:NOVELLUS SYSTEMS

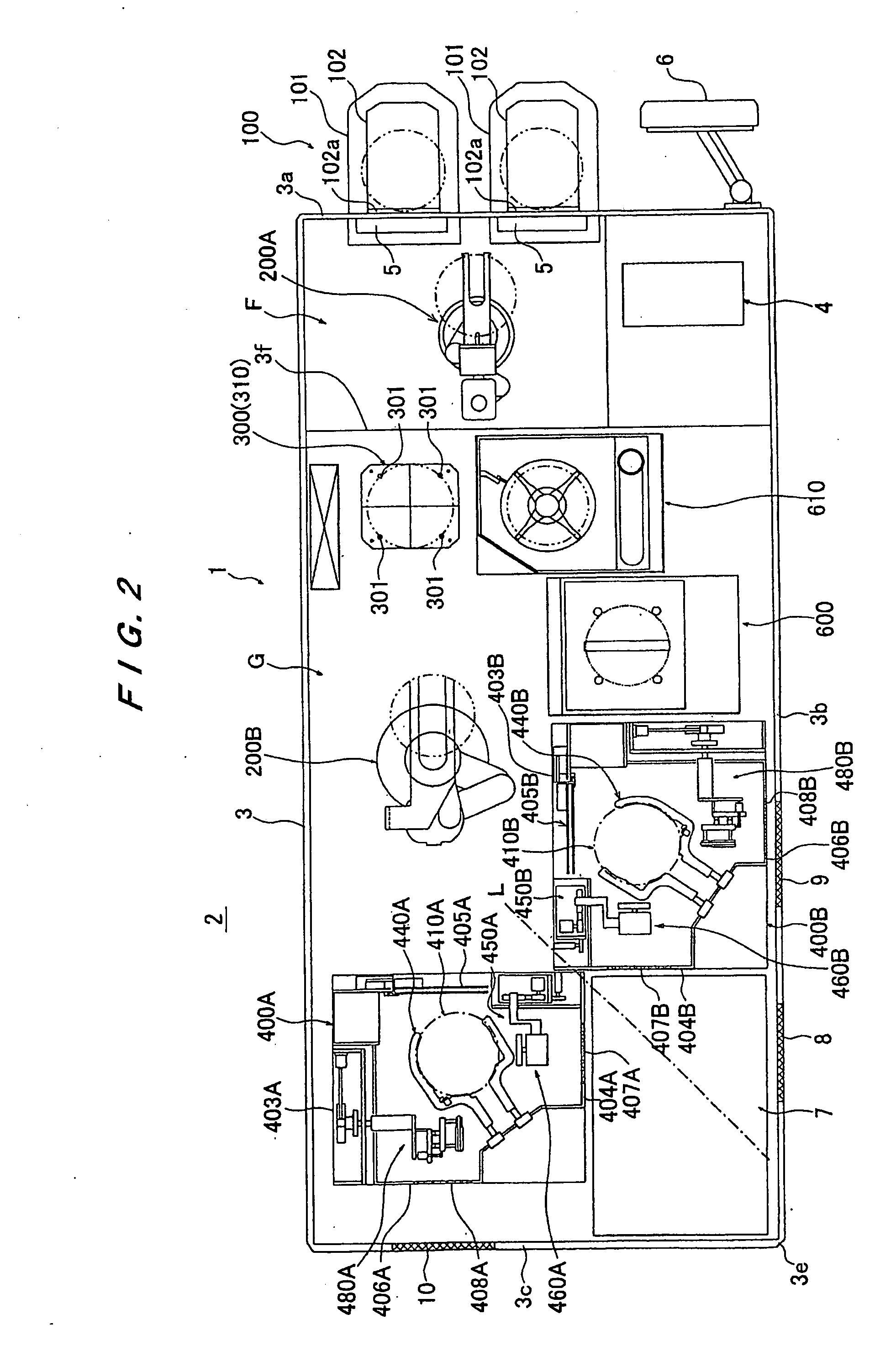

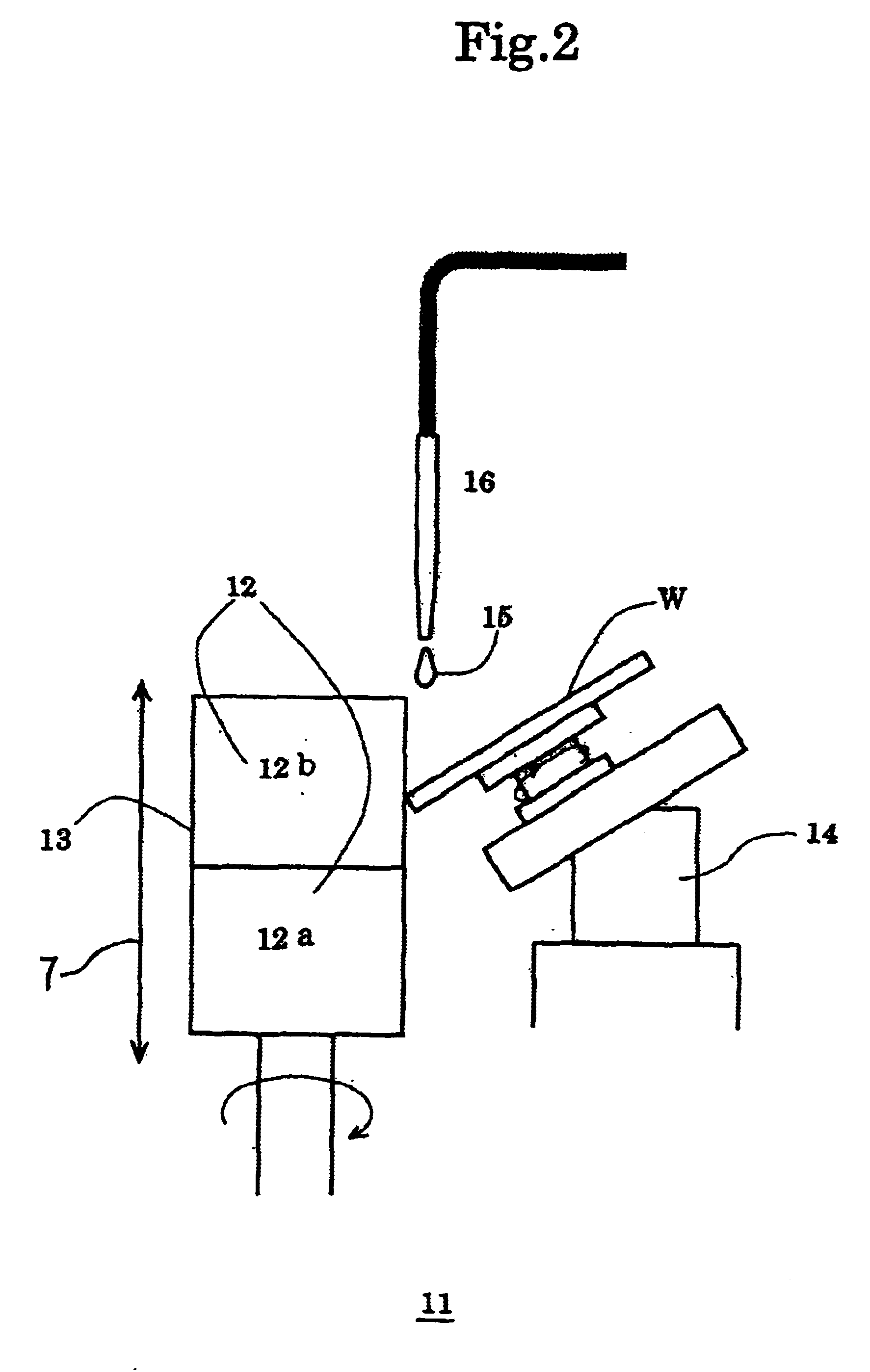

Substrate processing apparatus

InactiveUS20090017733A1Improve processing efficiencyEfficiently conductedEdge grinding machinesPolishing machinesEngineering

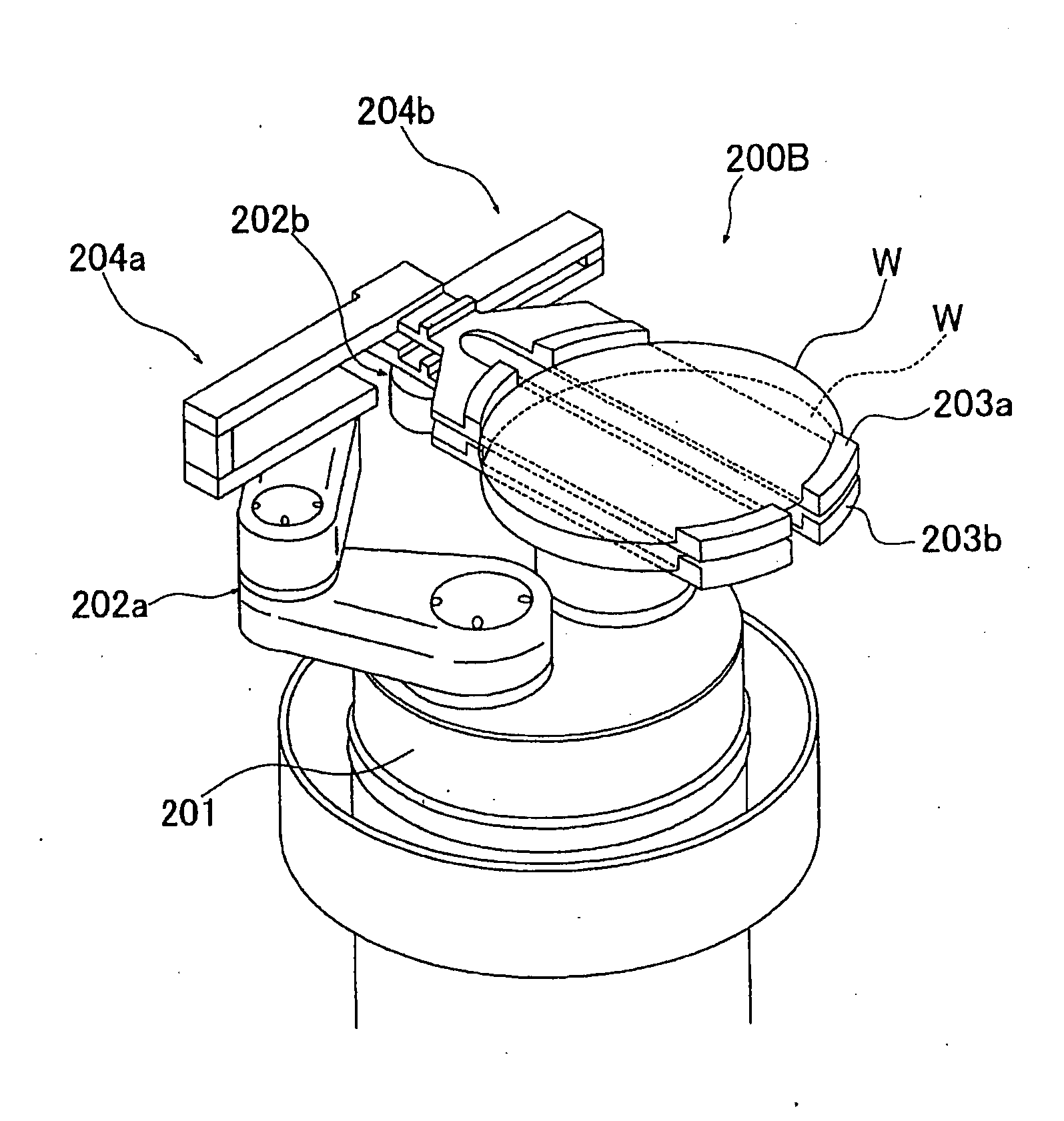

A substrate processing apparatus (1) has a first polishing unit (400A) and a second polishing unit (400B) for polishing a peripheral portion of a substrate. Each of the two polishing units (400A, 400B) includes a bevel polishing device (450A, 450B) for polishing a peripheral portion of a substrate and a notch polishing device (480A, 480B) for polishing a notch of a substrate. The substrate processing apparatus (1) has a maintenance space (7) formed between the two polishing units (400A, 400B). The bevel polishing devices (450A, 450B) in the two polishing units (400A, 400B) face the maintenance space (7) so as to be accessible from the maintenance space (7).

Owner:EBARA CORP

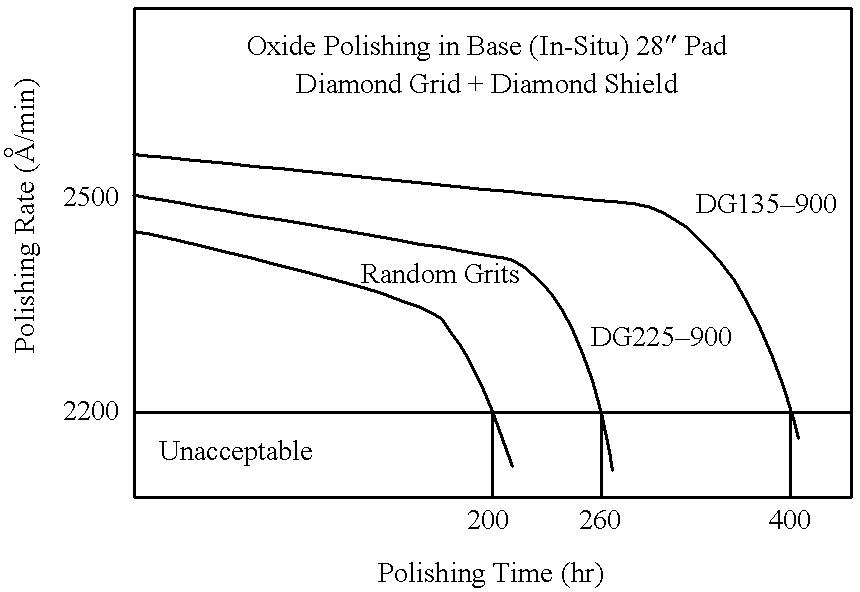

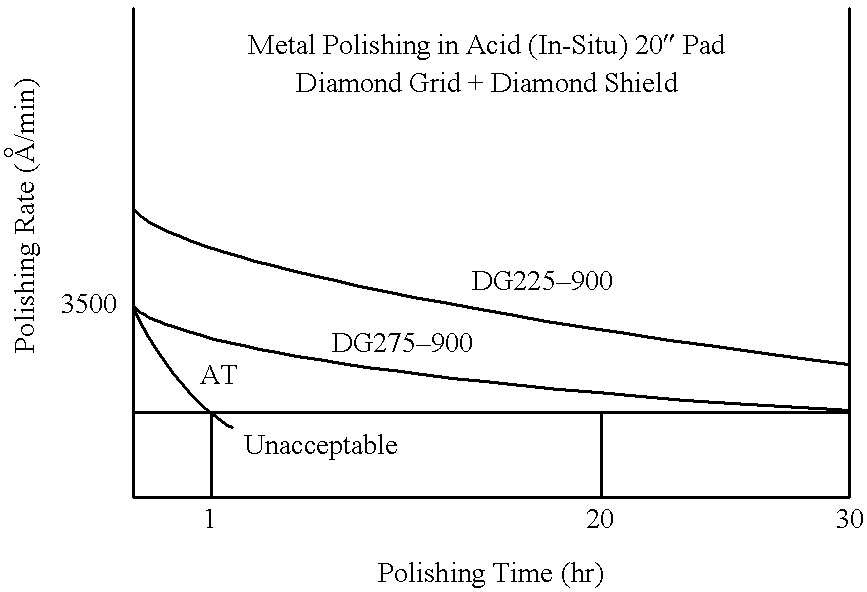

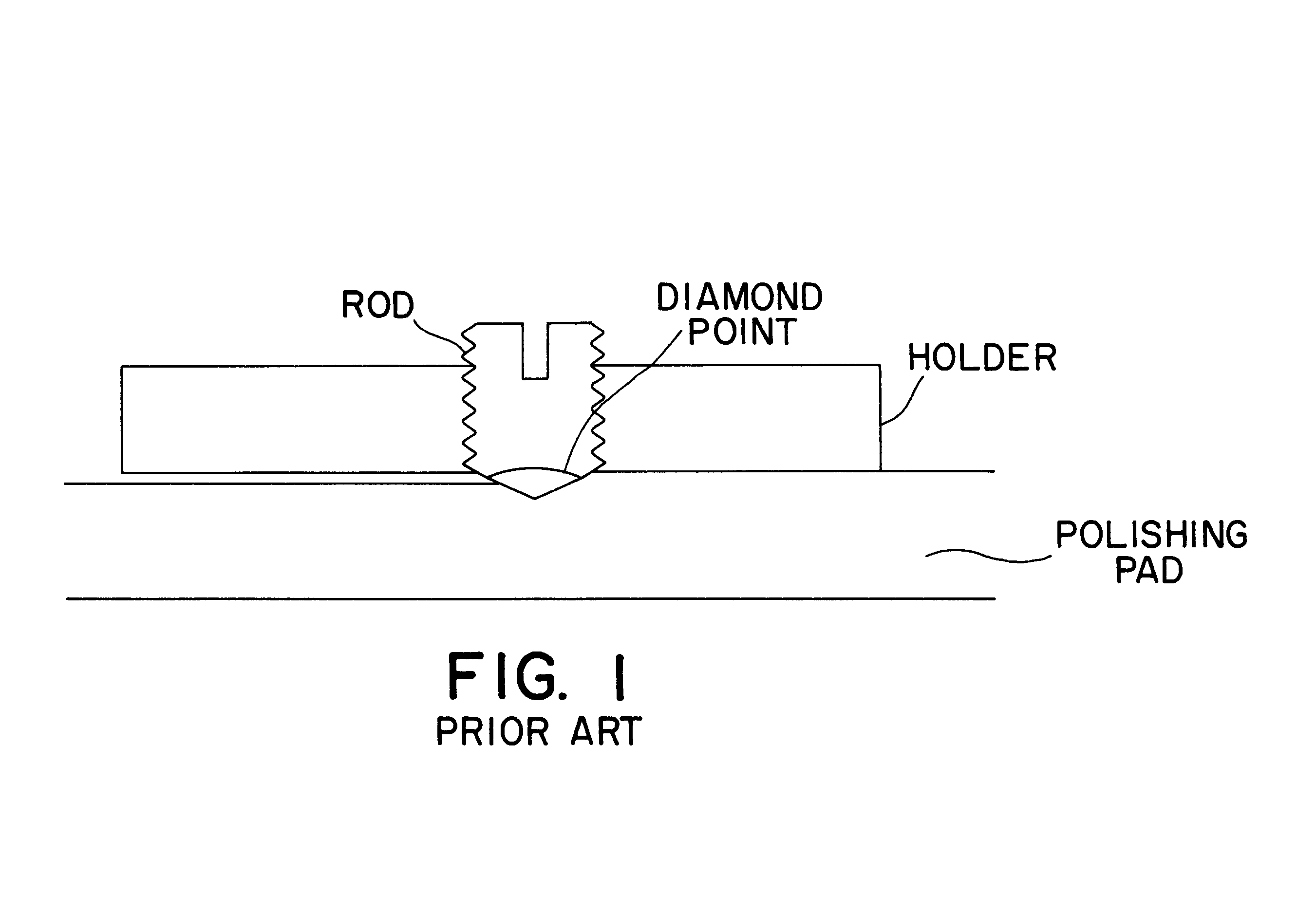

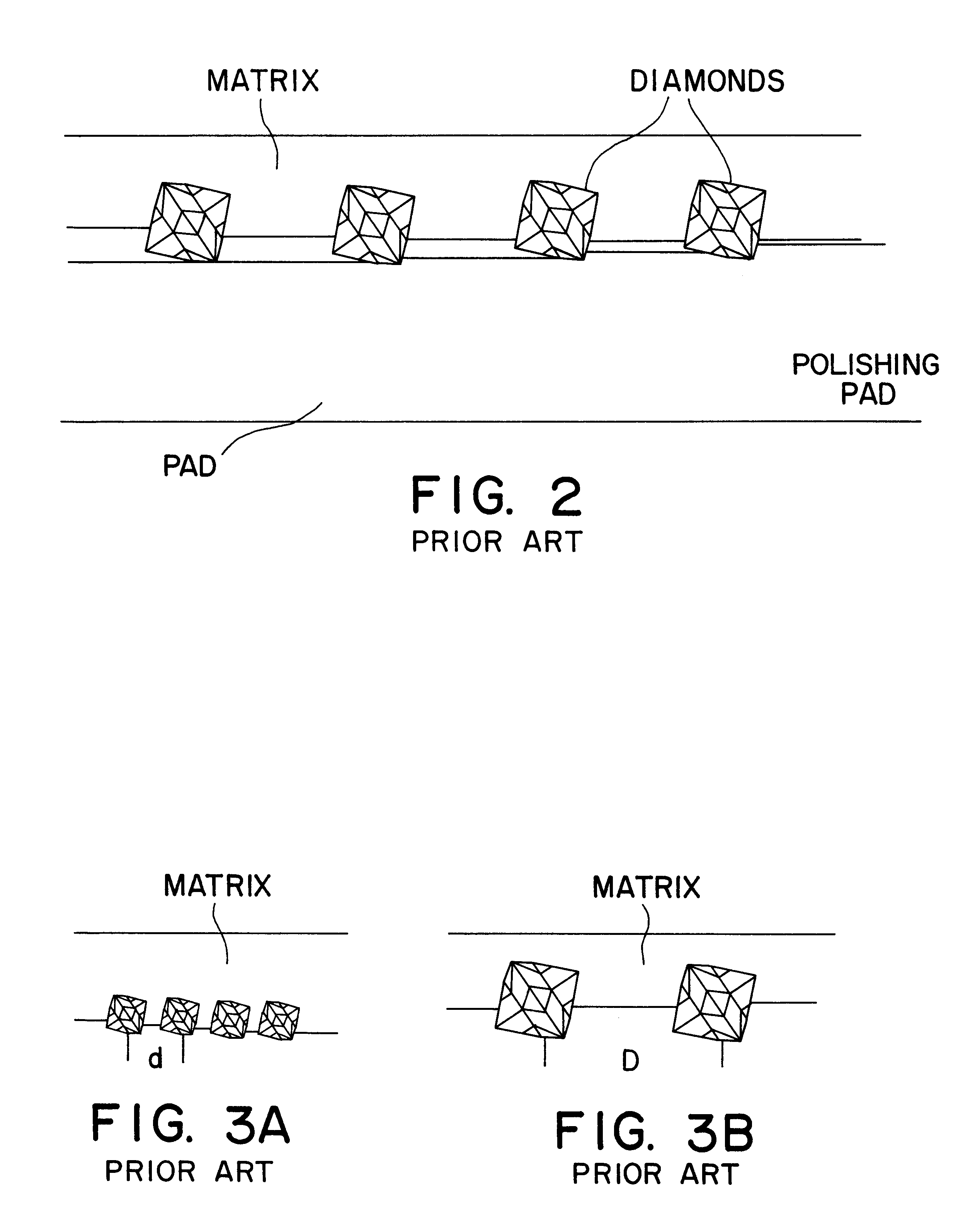

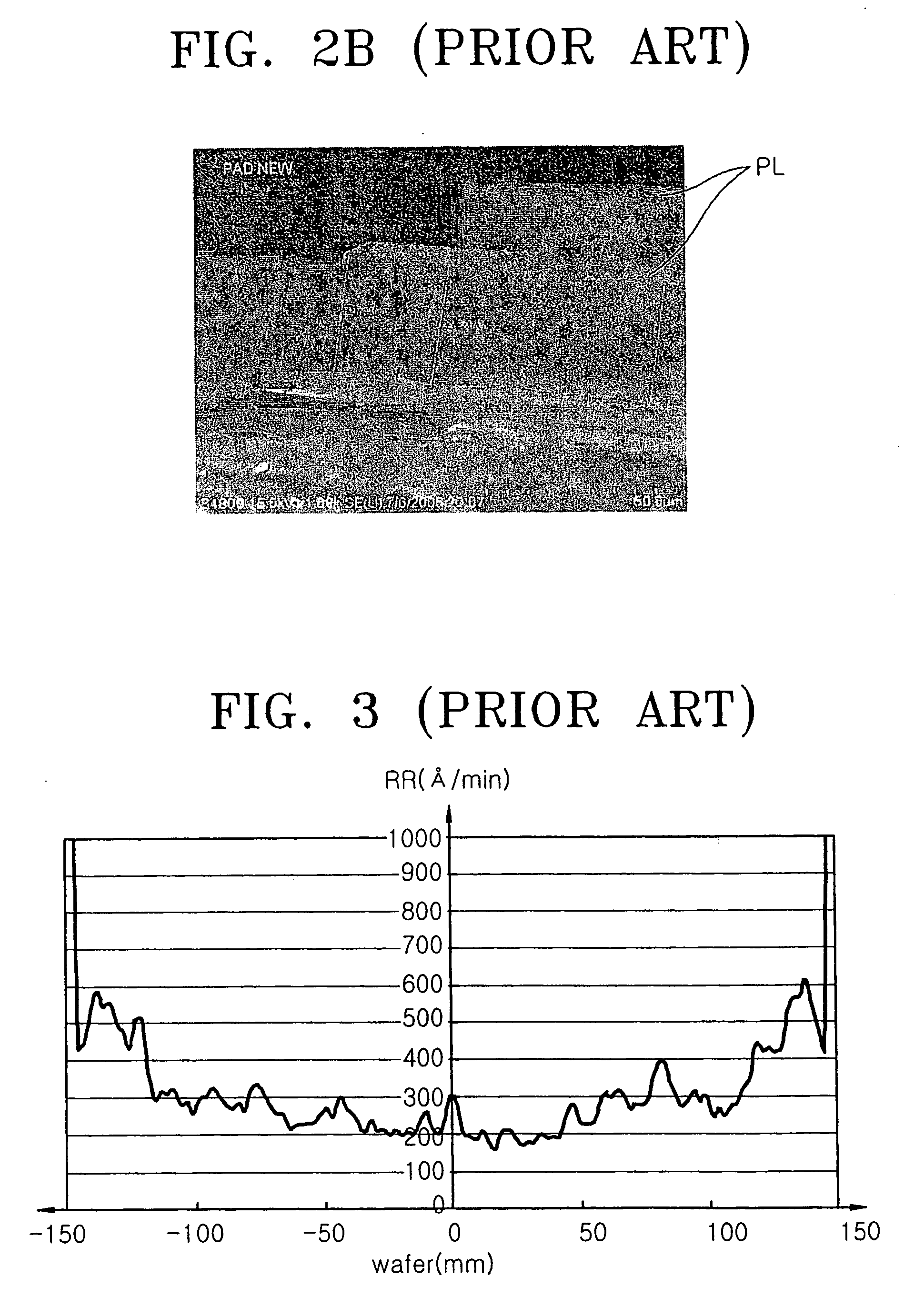

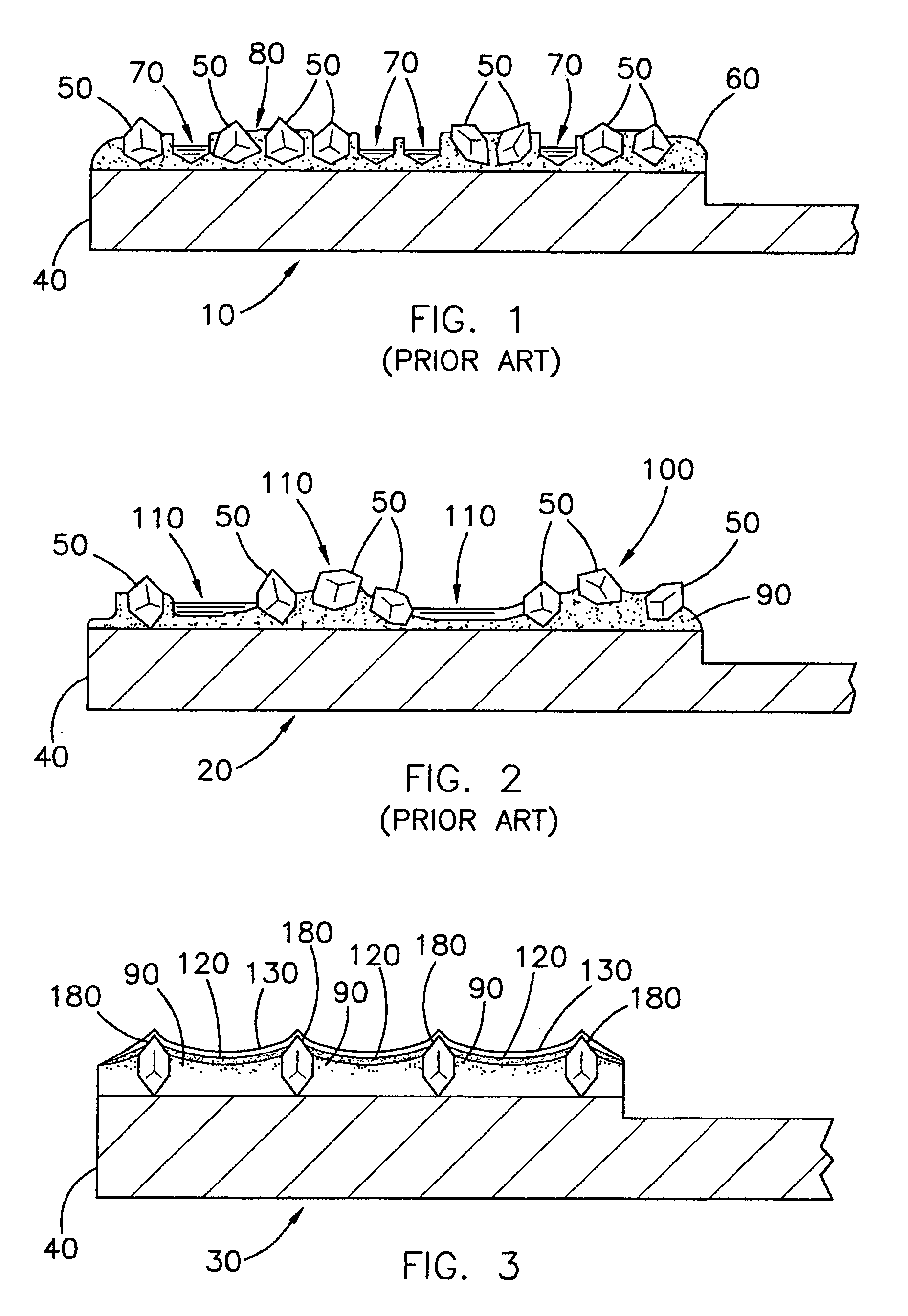

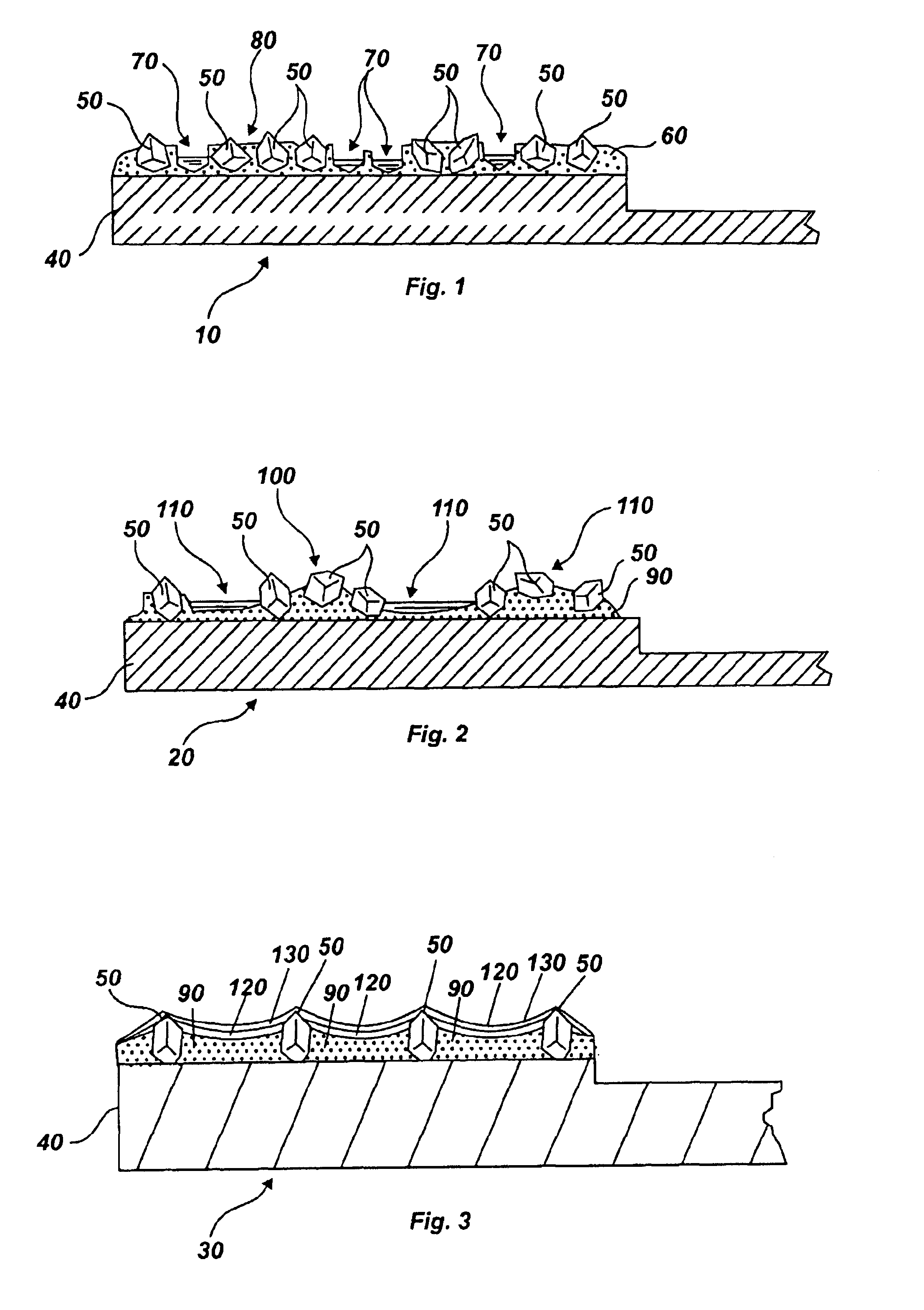

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

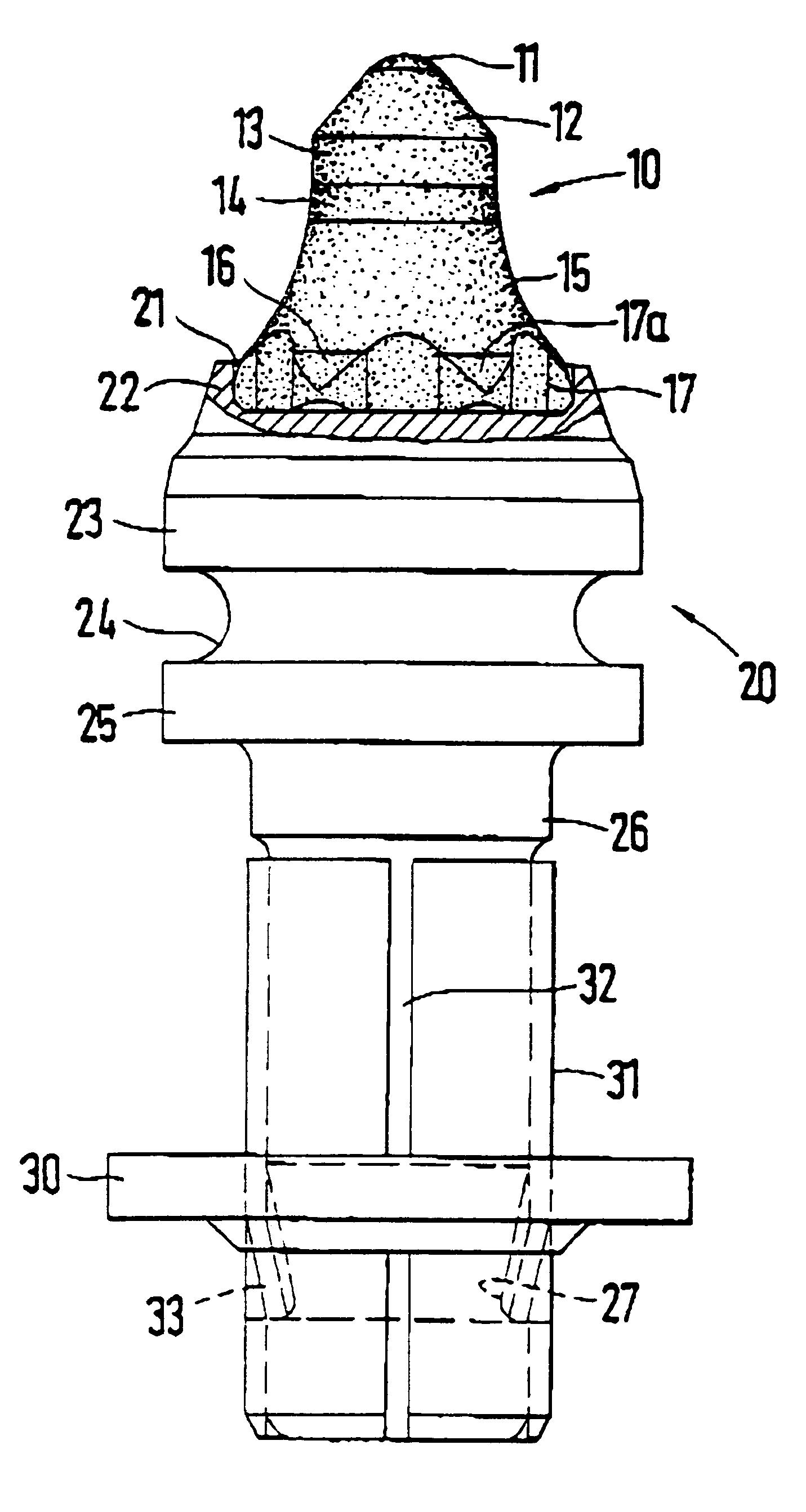

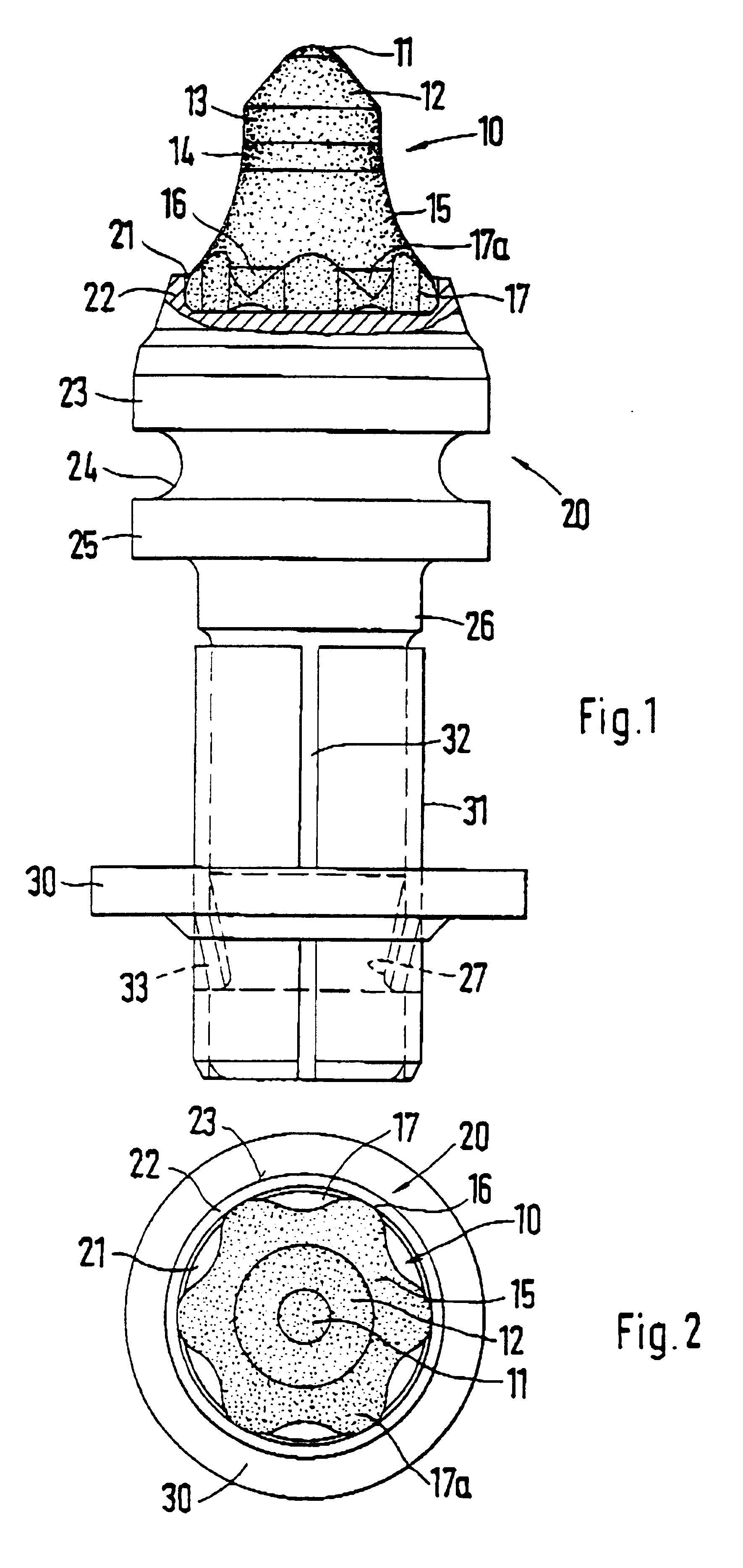

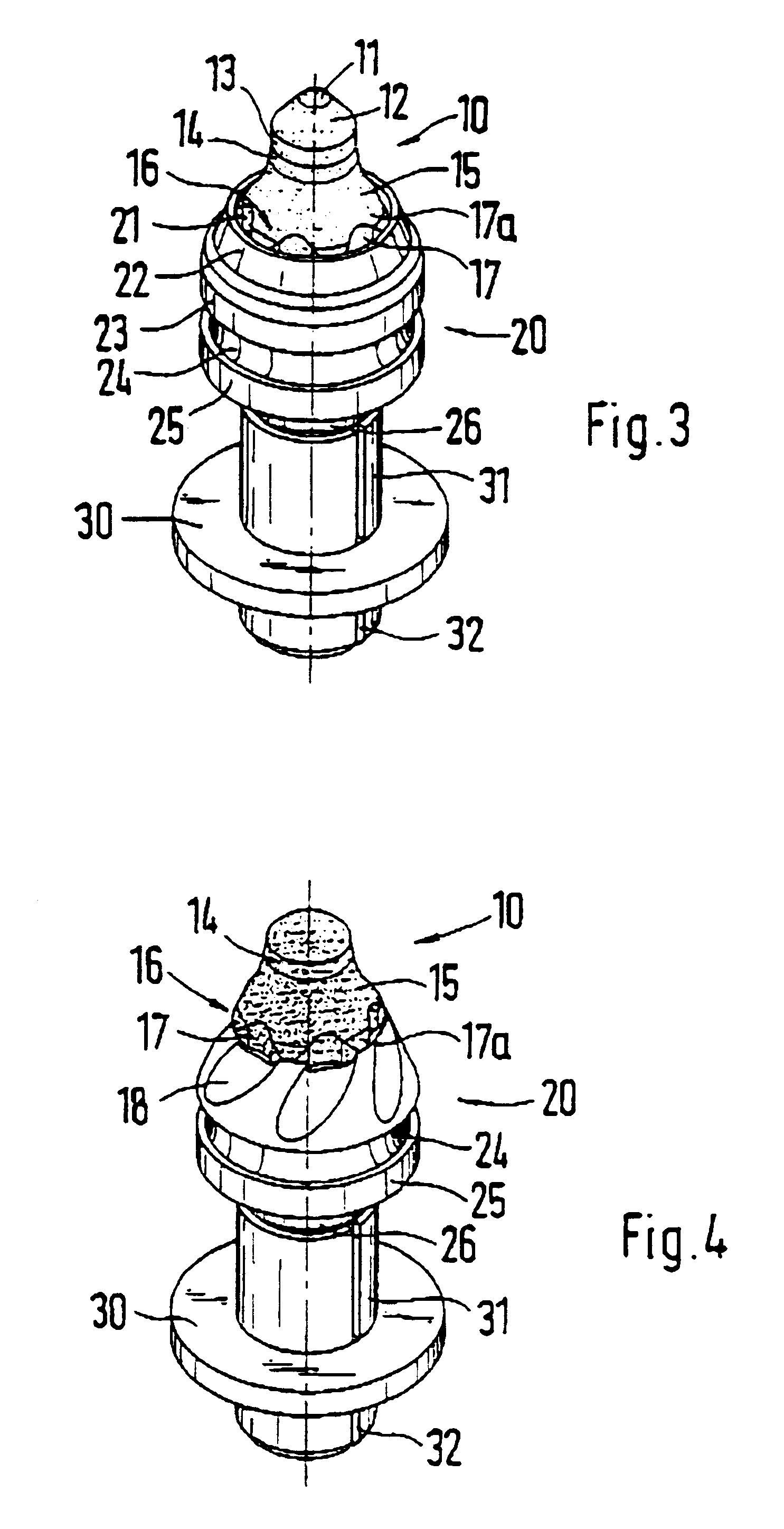

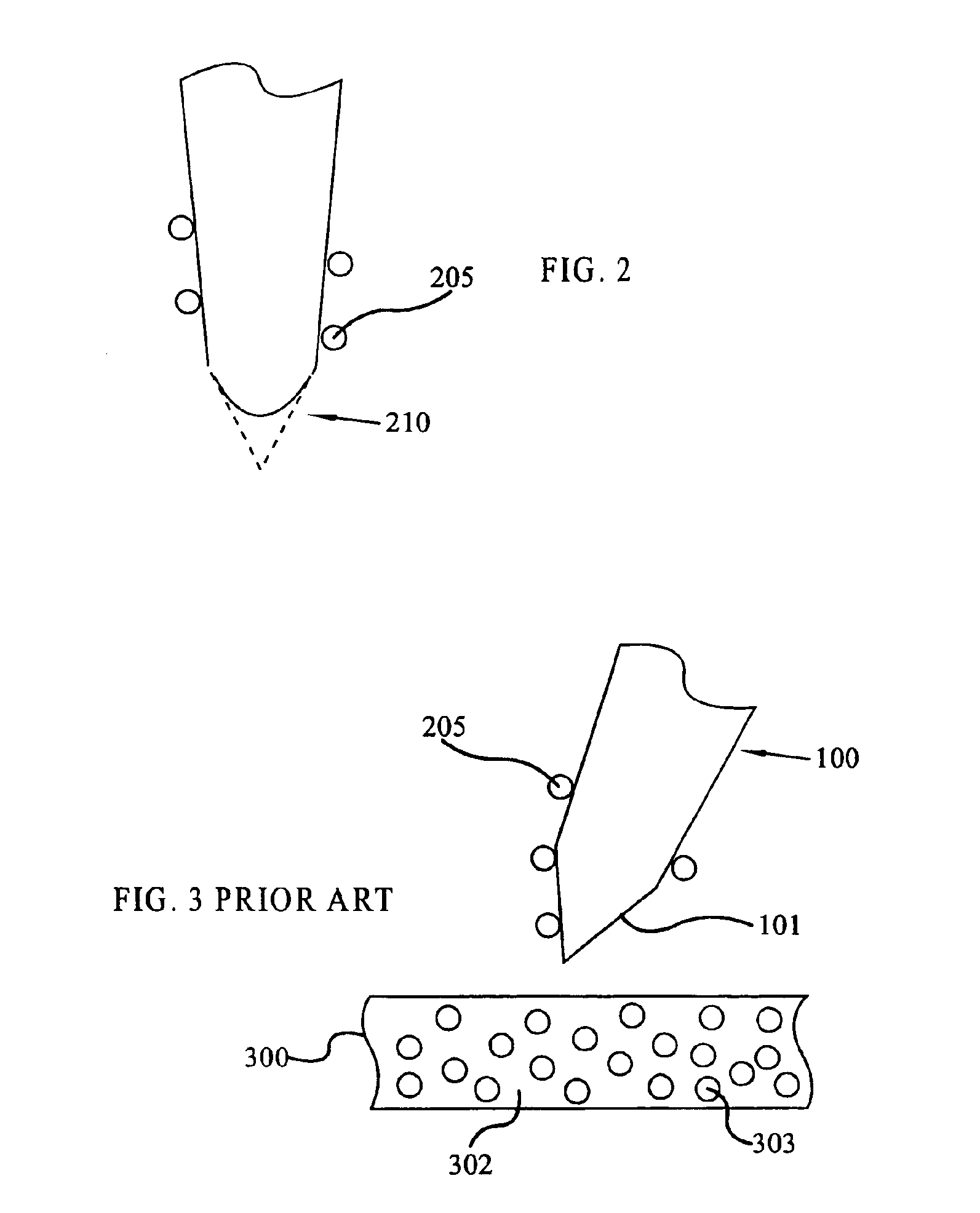

Round-shank bit for a coal cutting machine

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

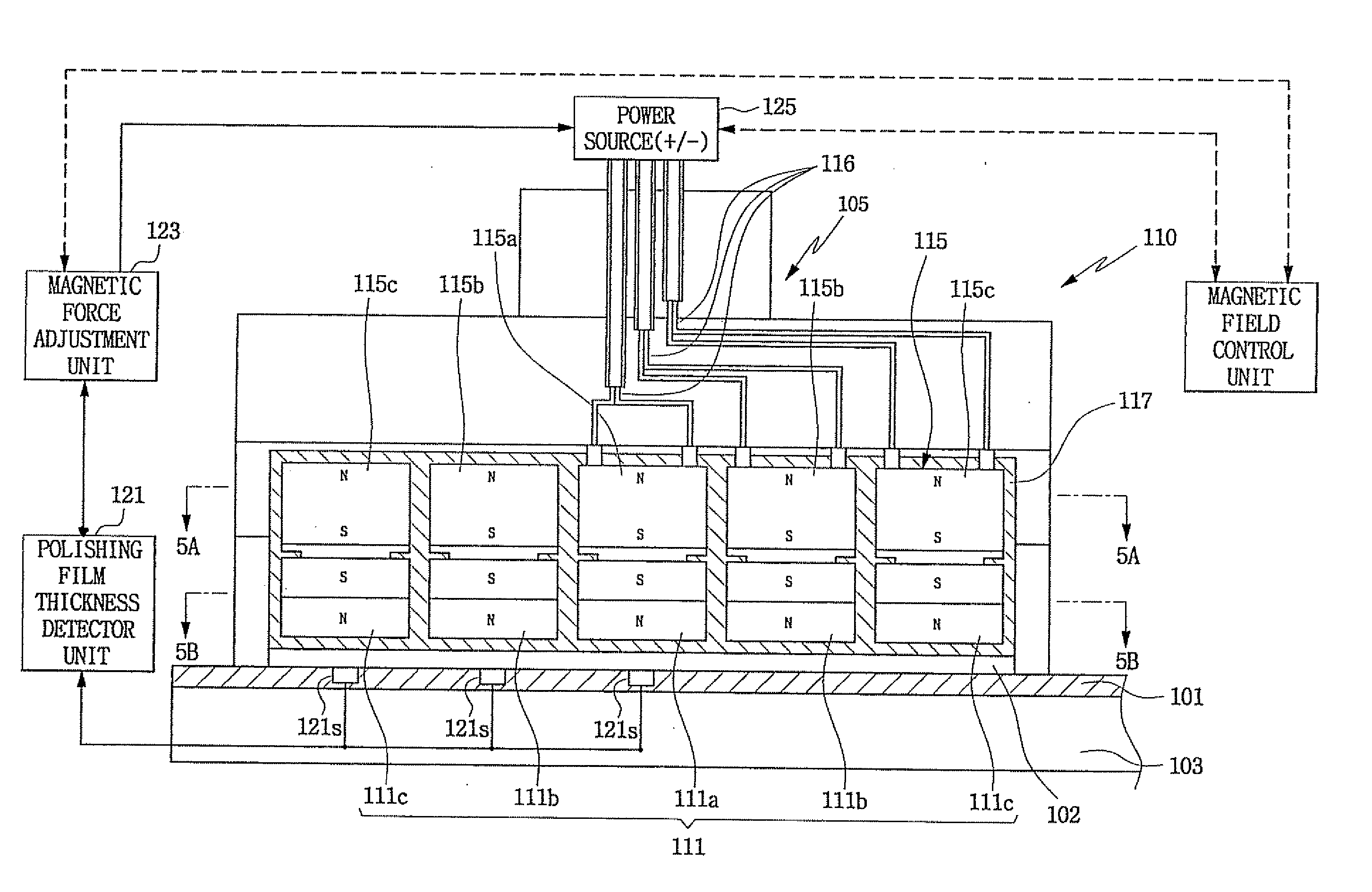

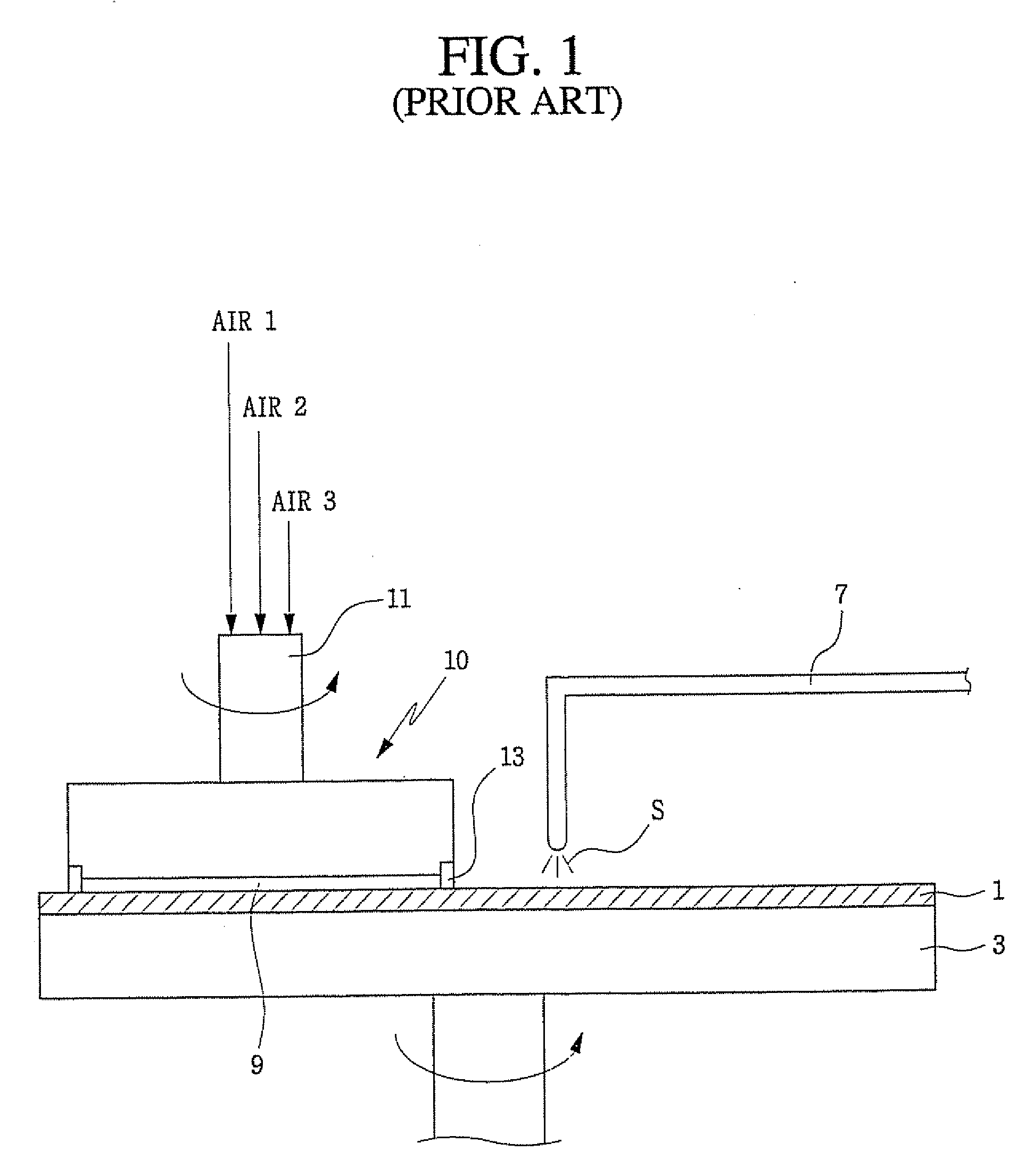

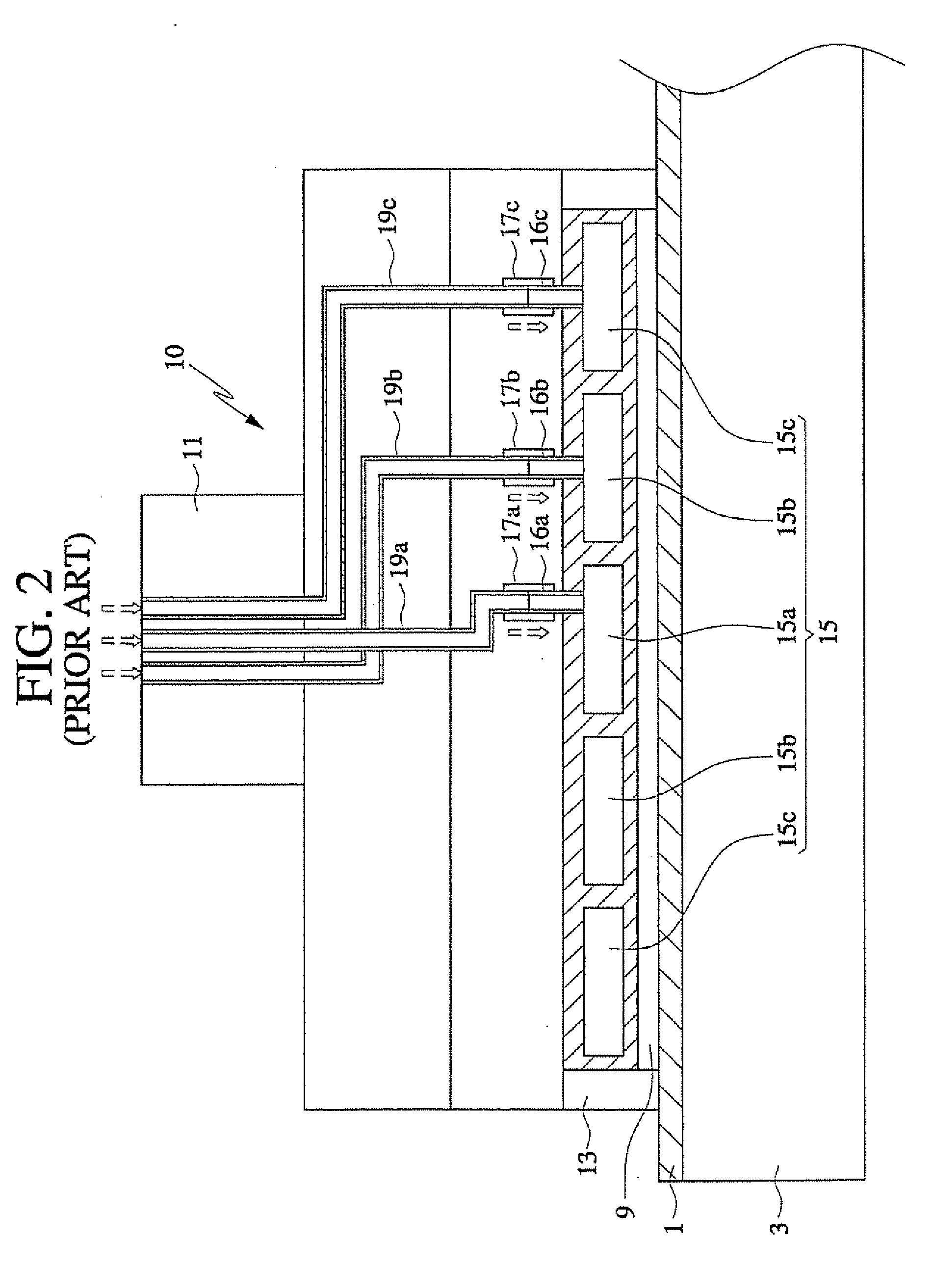

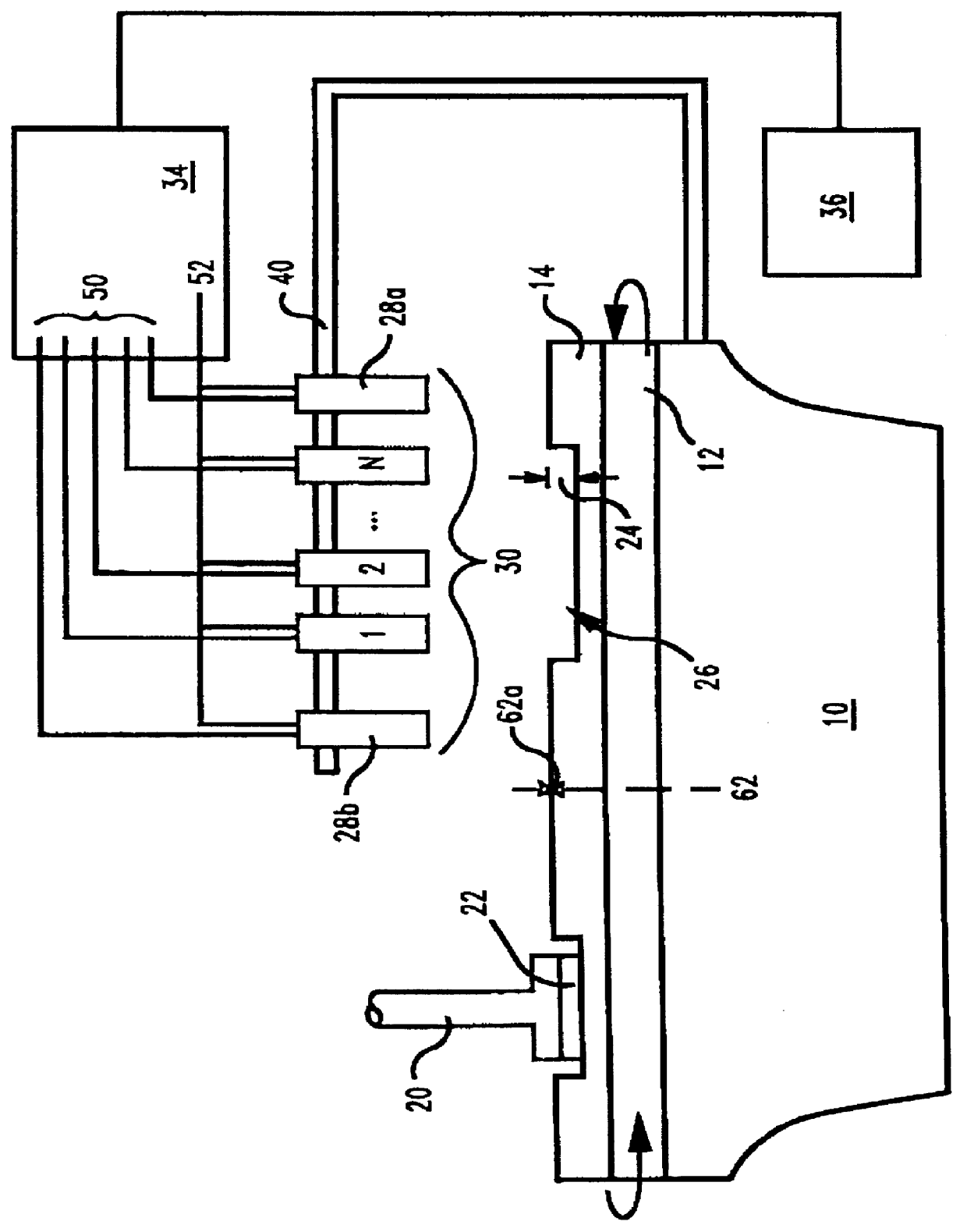

Polishing apparatus and related polishing methods

InactiveUS20060189259A1Uniform thicknessPolishing machinesRevolution surface grinding machinesEngineeringMagnetic field

Polishing apparatus and related methods employ aligned first and second magnetic field sources to adjust the compressive force and / or pressure applied by a carrier head against a target workpiece (such as a wafer) by selectively and controllably generating a repellant or attractive force between the two magnetic field sources.

Owner:SAMSUNG ELECTRONICS CO LTD

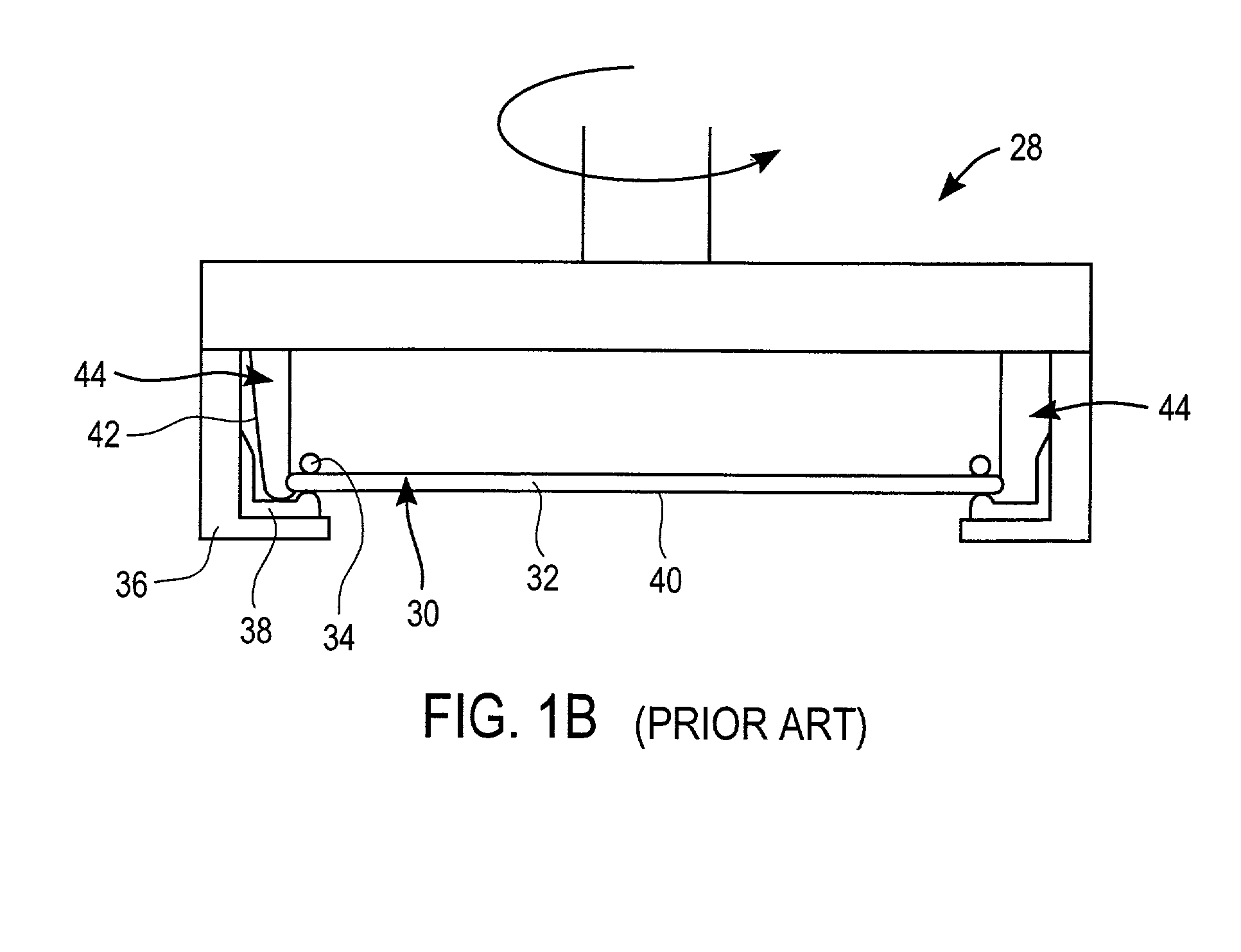

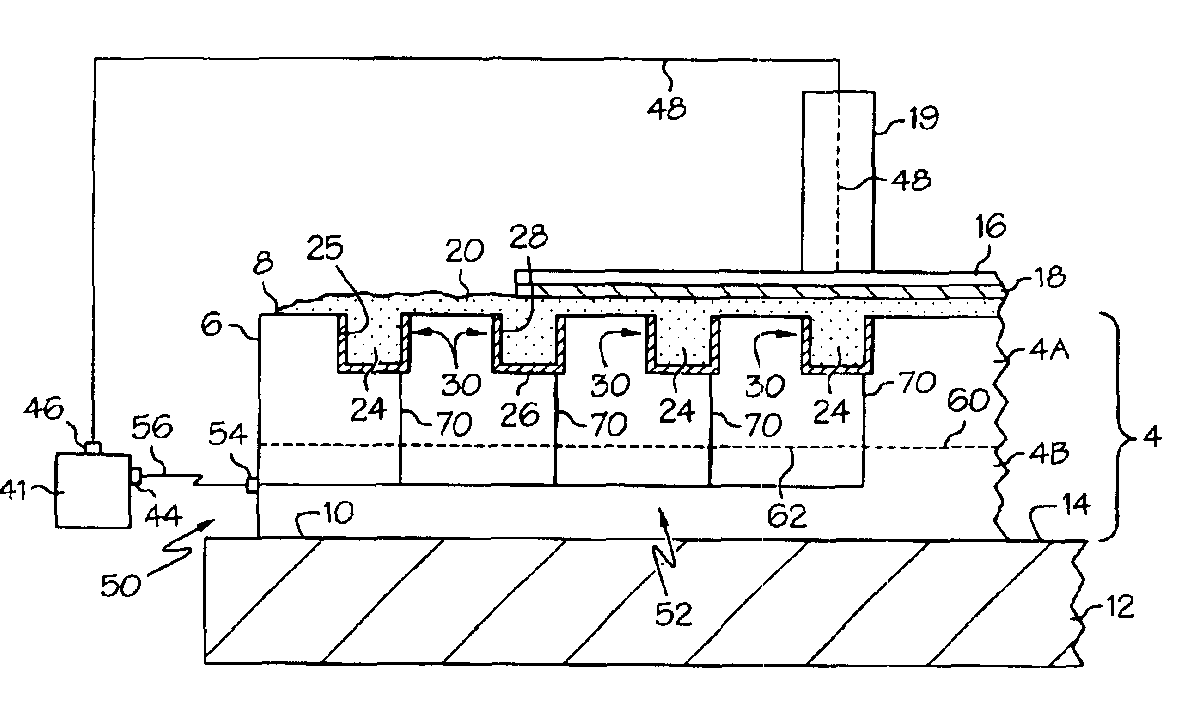

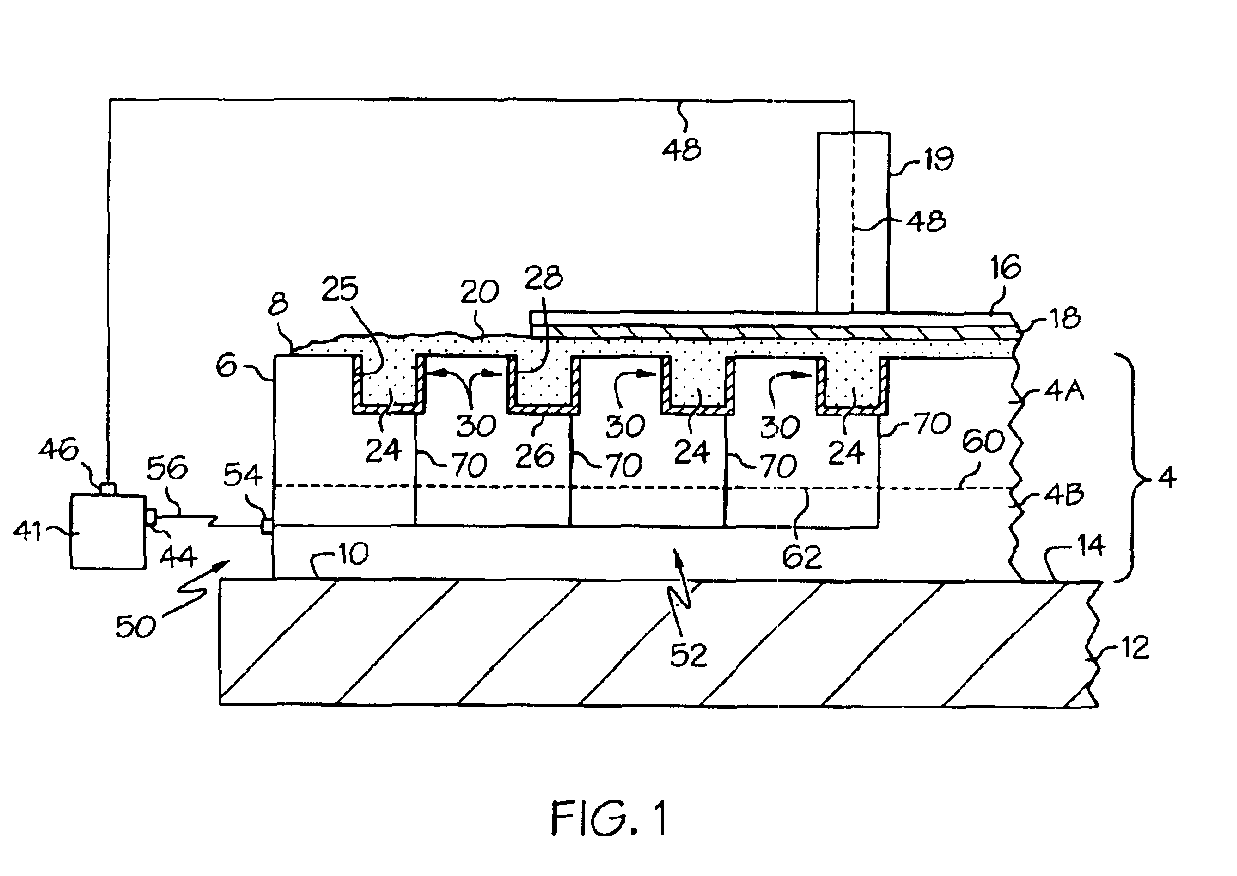

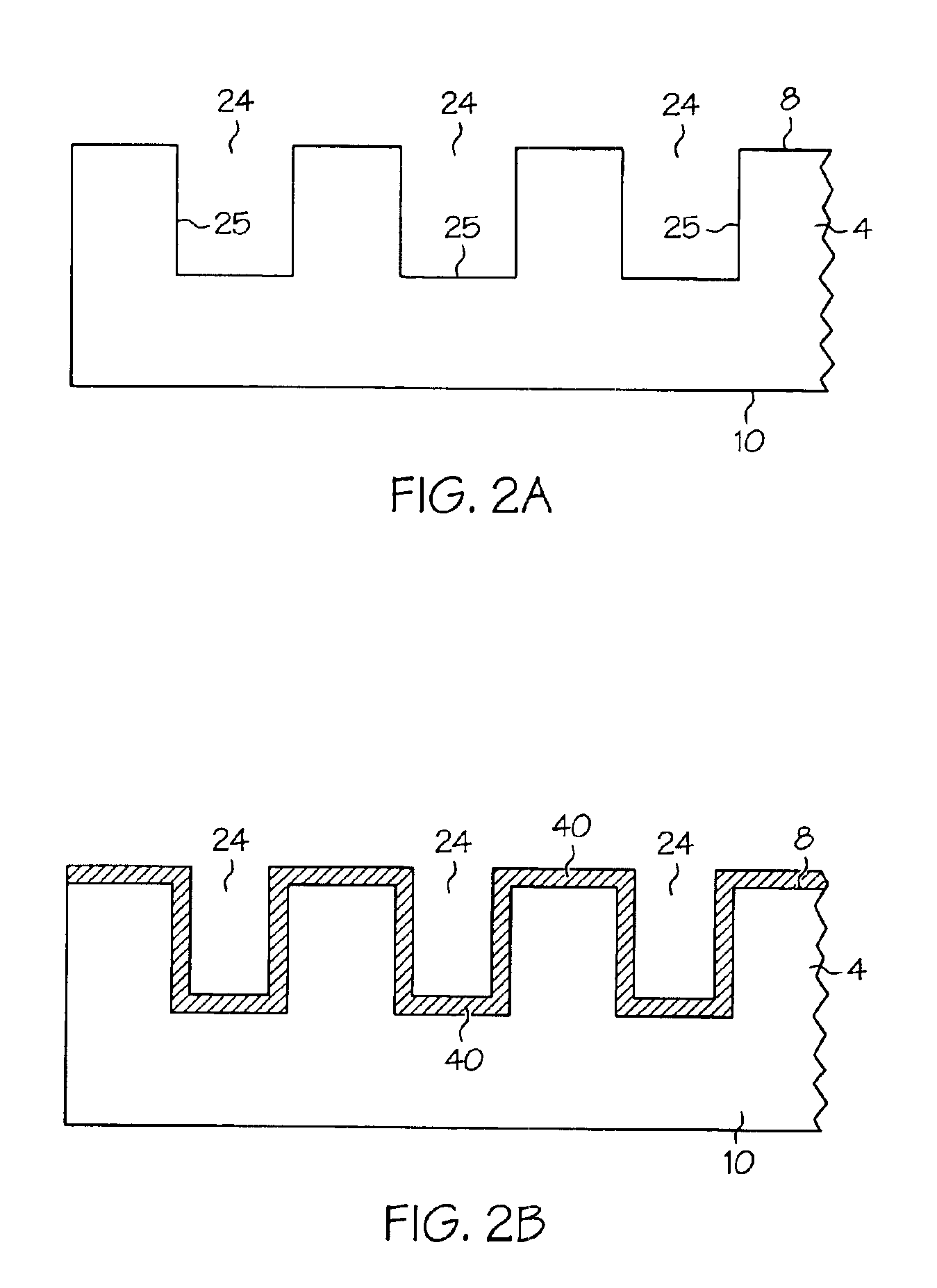

Method and apparatus of sealing wafer backside for full-face electrochemical plating

InactiveUS20030008602A1Efficient configurationMinimize irregularityEdge grinding machinesPolishing machinesMechanical engineeringElectroplating

The present invention provides a wafer carrier that includes a plurality of concentric sealing members that provide a seal, with the outer seal independently movable to allow cleaning of a peripheral backside of the wafer to occur while the wafer is still attached to the wafer carrier, and a plurality of vacuum openings that a re disposed only adjacent to an inner side of the inner seal at a location corresponding to the backside periphery of the wafer.

Owner:NOVELLUS SYSTEMS

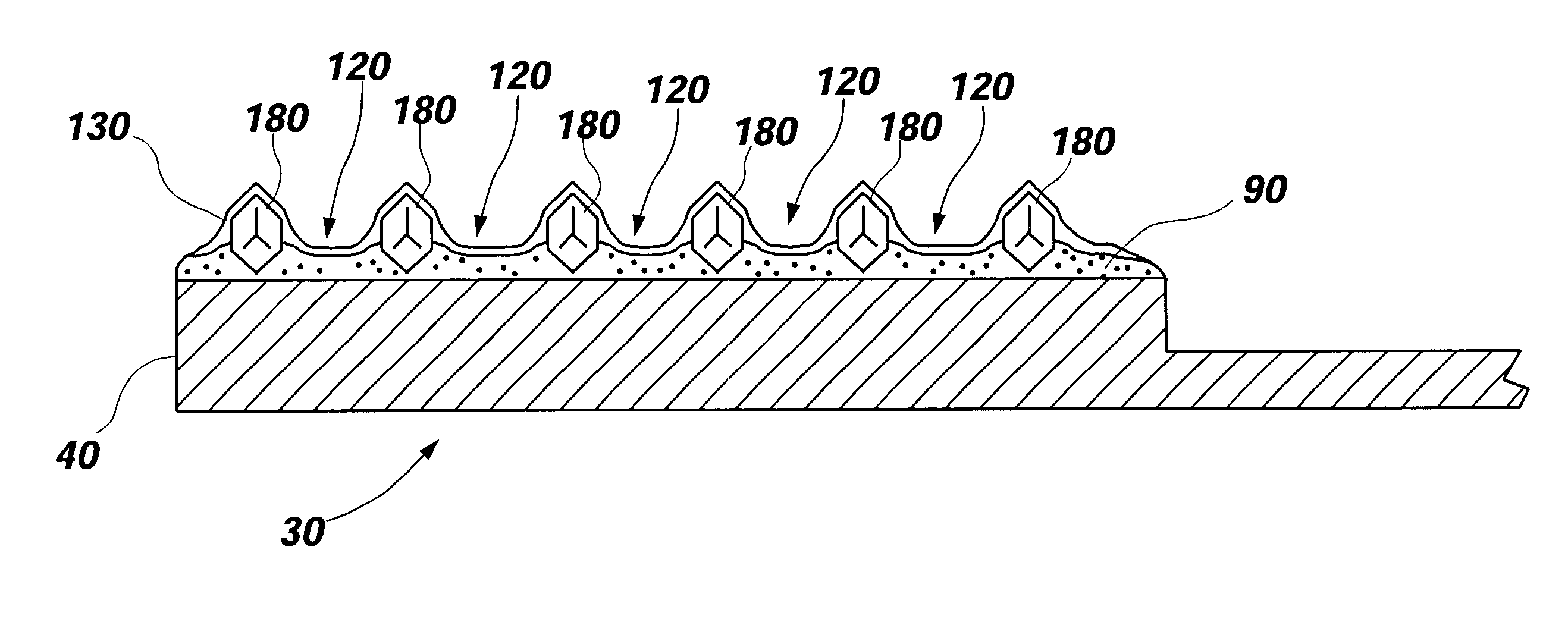

Polishing pads for chemical mechanical planarization

An improved pad and process for polishing metal damascene structures on a semiconductor wafer. The process includes the steps of pressing the wafer against the surface of a polymer sheet in combination with an aqueous-based liquid that optionally contains sub-micron particles and providing a means for relative motion of wafer and polishing pad under pressure so that the moving pressurized contact results in planar removal of the surface of said wafer, wherein the polishing pad has a low elastic recovery when said load is removed, so that the mechanical response of the sheet is largely anelastic. The improved pad is characterized by a high energy dissipation coupled with a high pad stiffness. The pad exhibits a stable morphology that can be reproduced easily and consistently. The pad surface resists glazing, thereby requiring less frequent and less aggressive conditioning. The benefits of such a polishing pad are low dishing of metal features, low oxide erosion, reduced pad conditioning, longer pad life, high metal removal rates, good planarization, and lower defectivity (scratches and Light Point Defects).

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

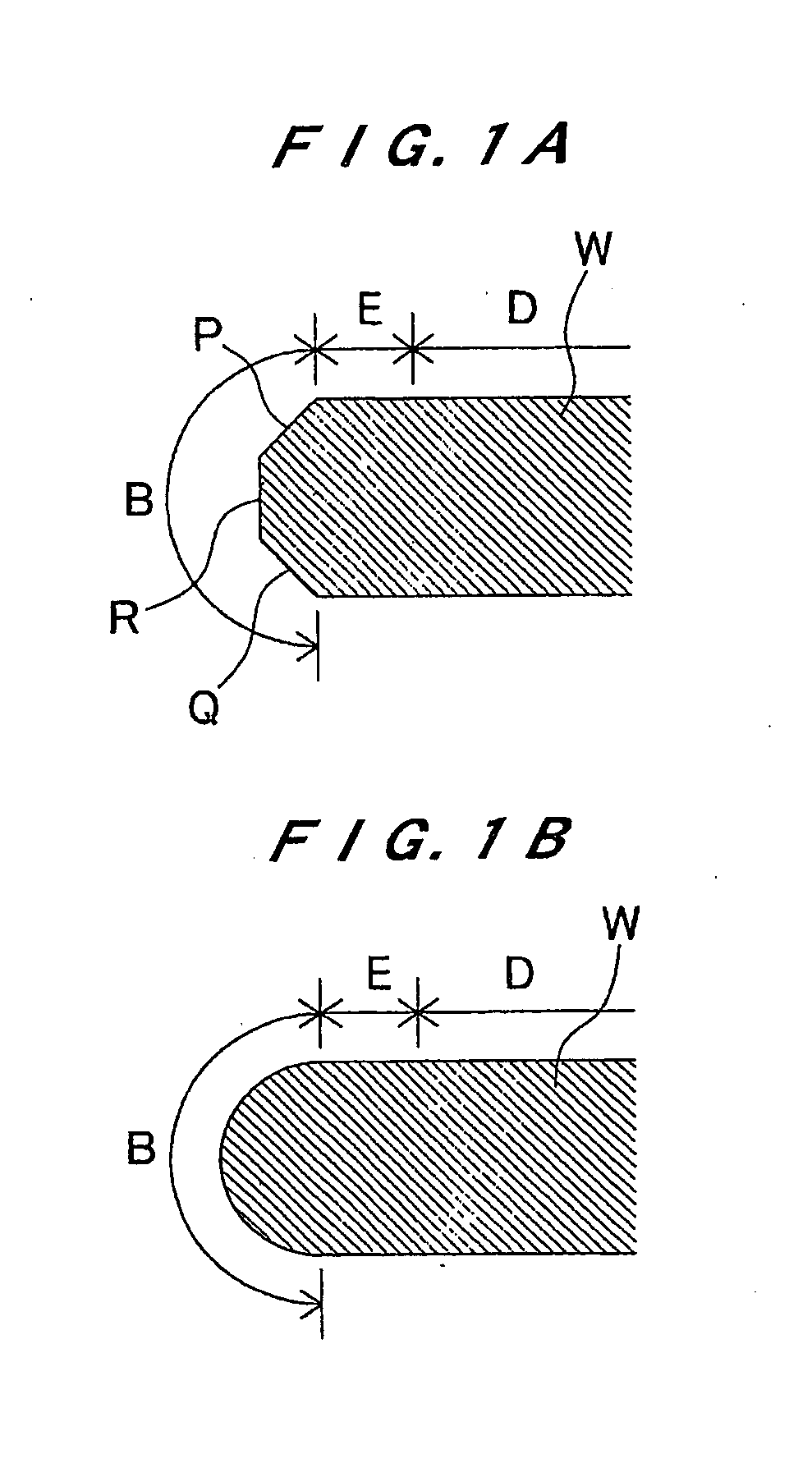

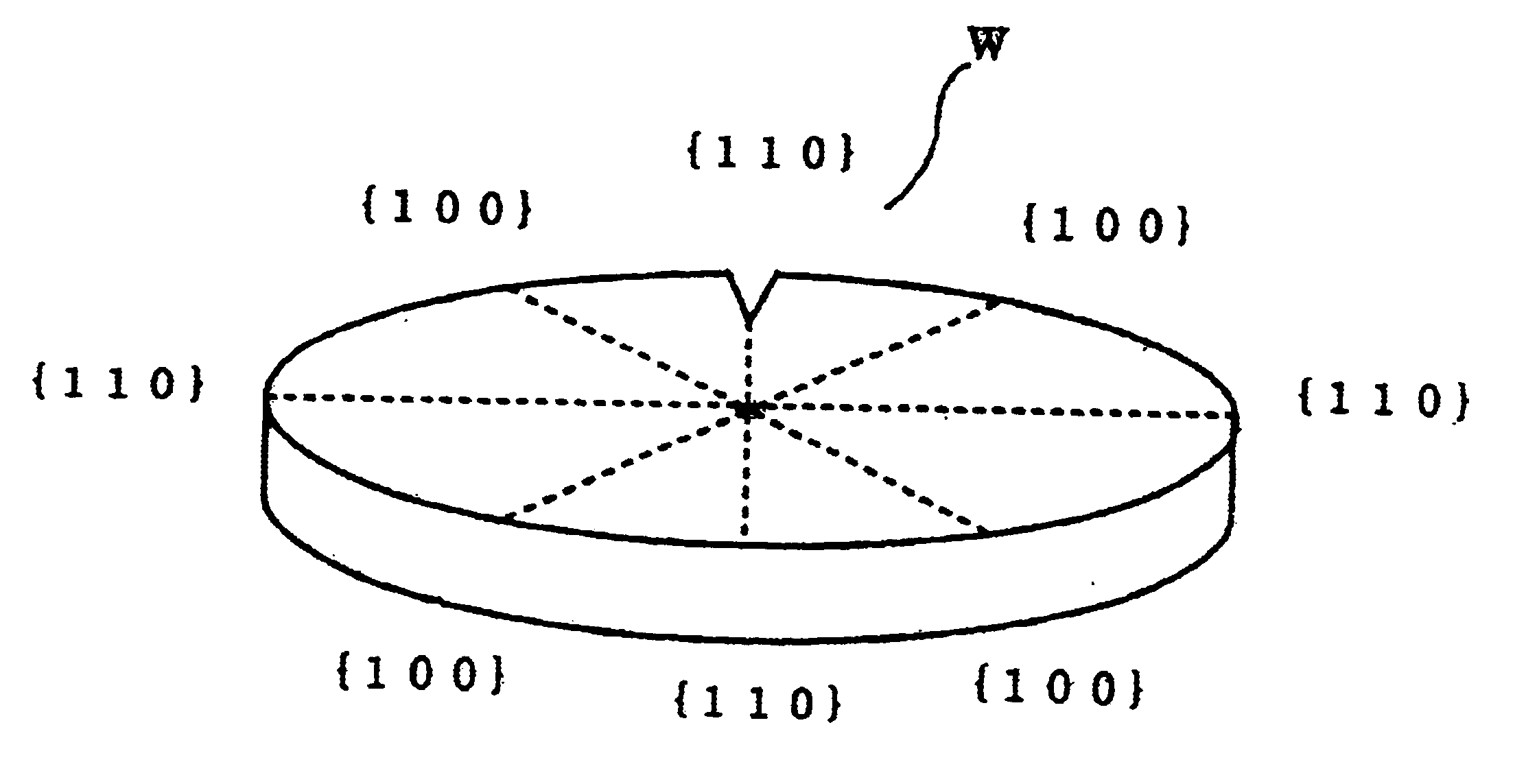

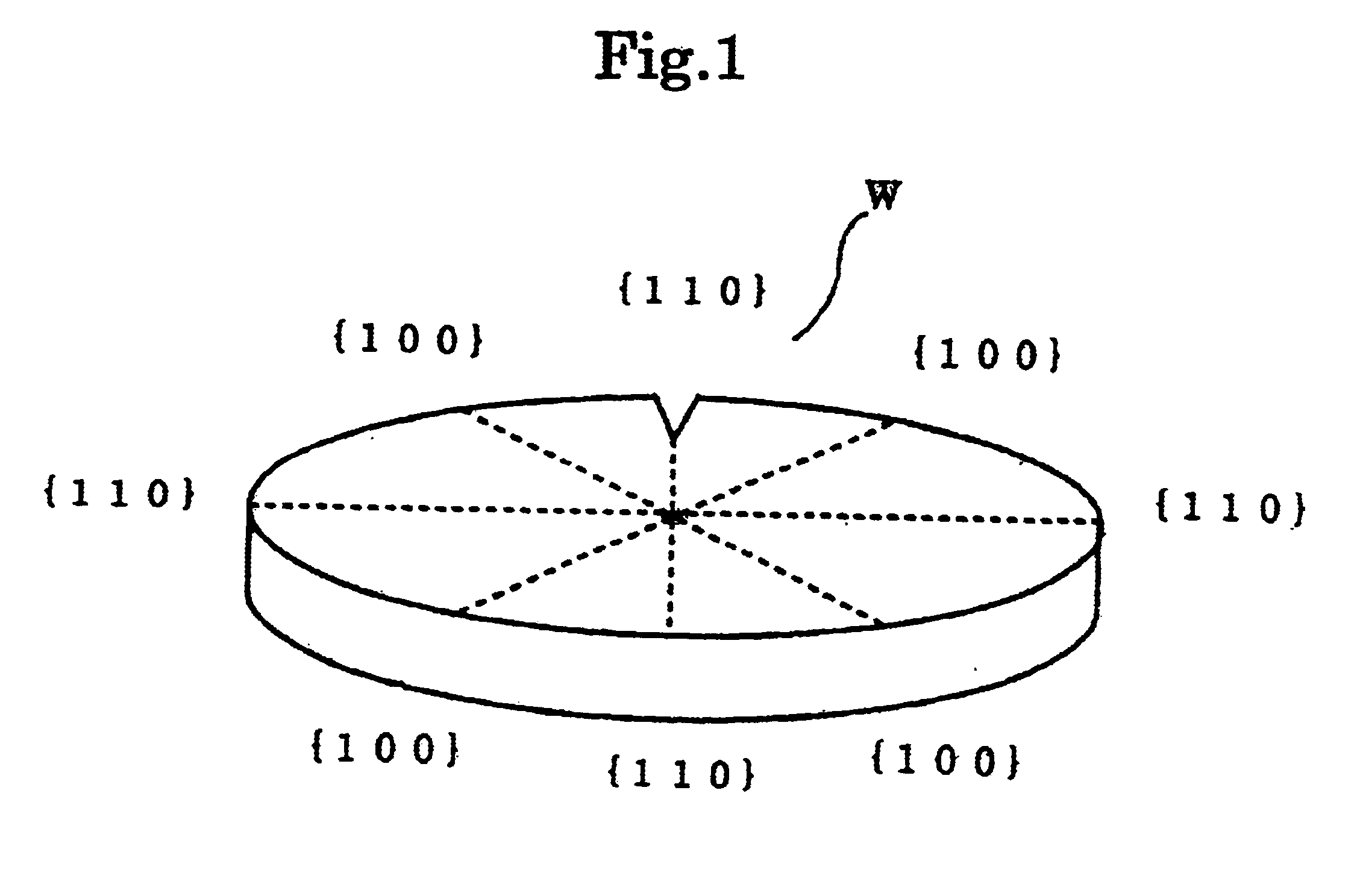

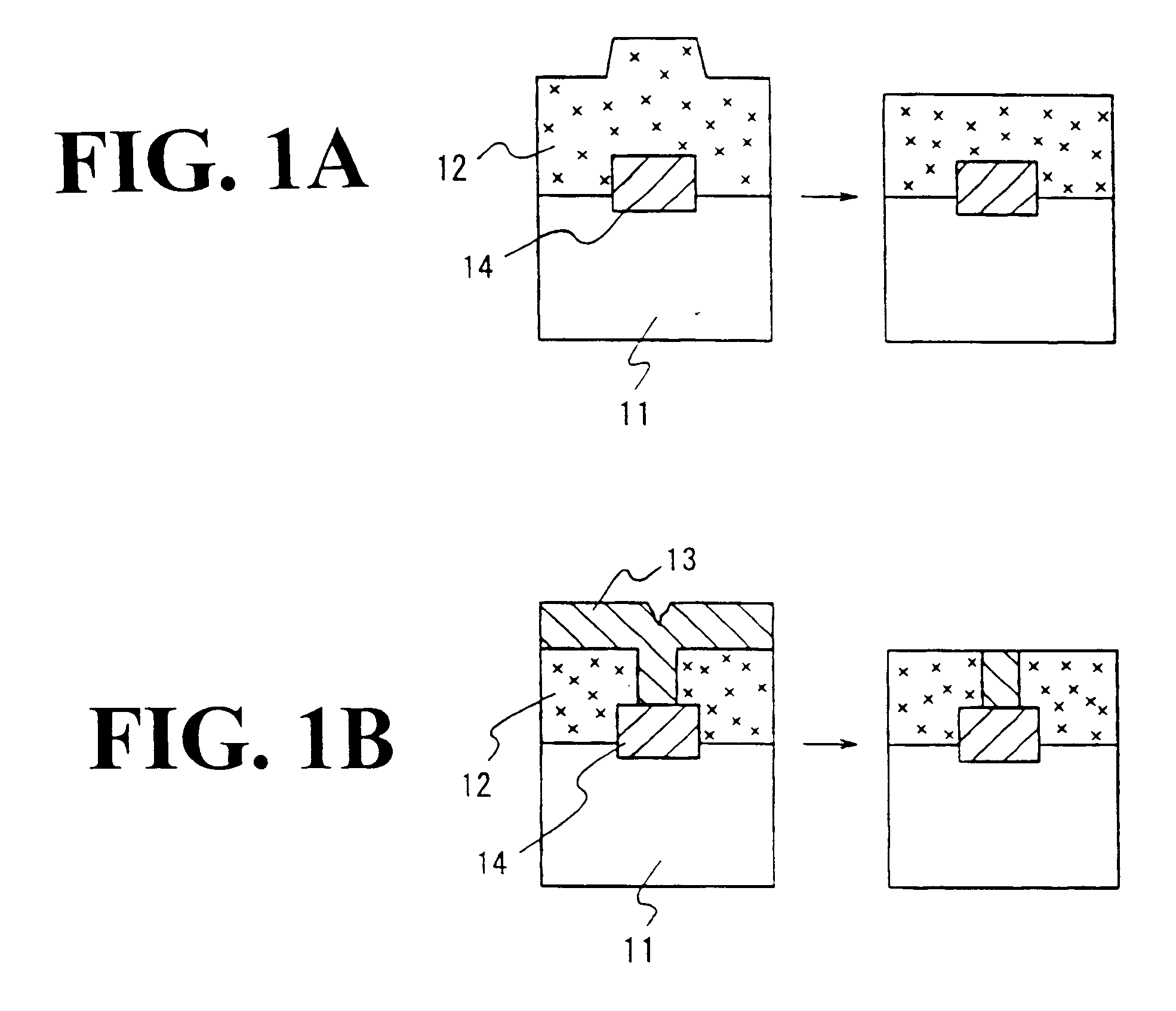

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

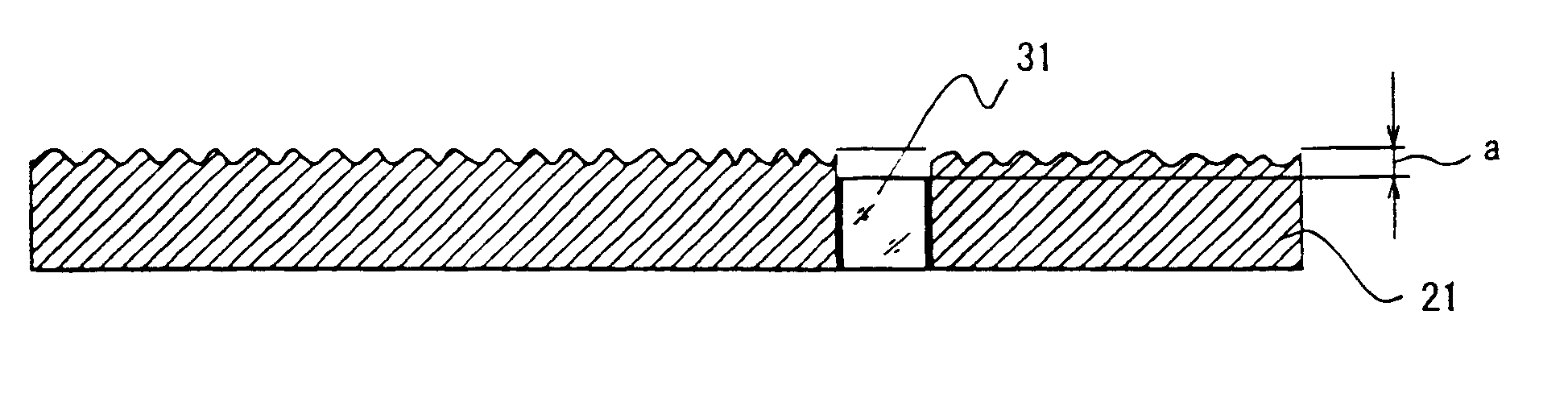

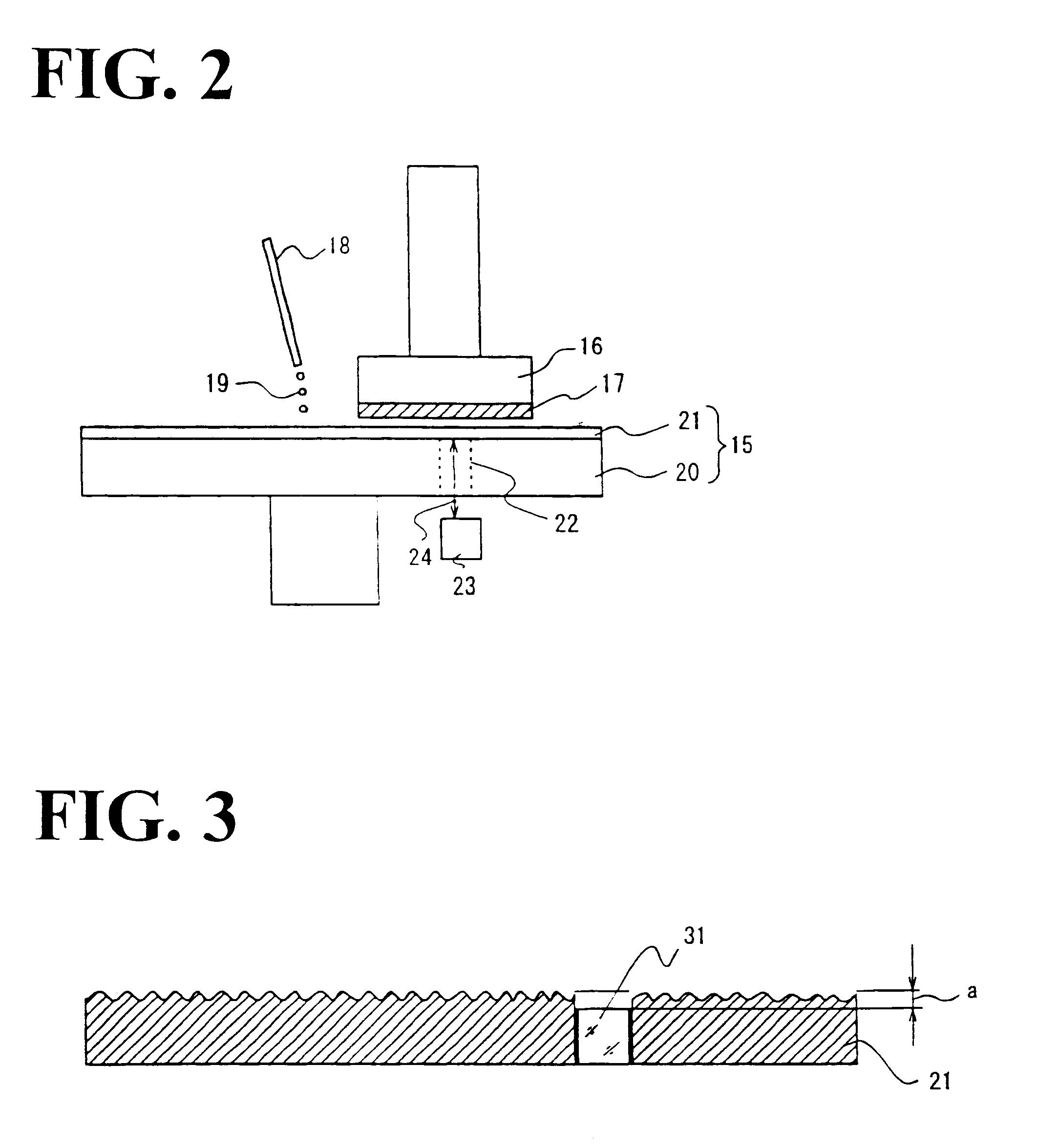

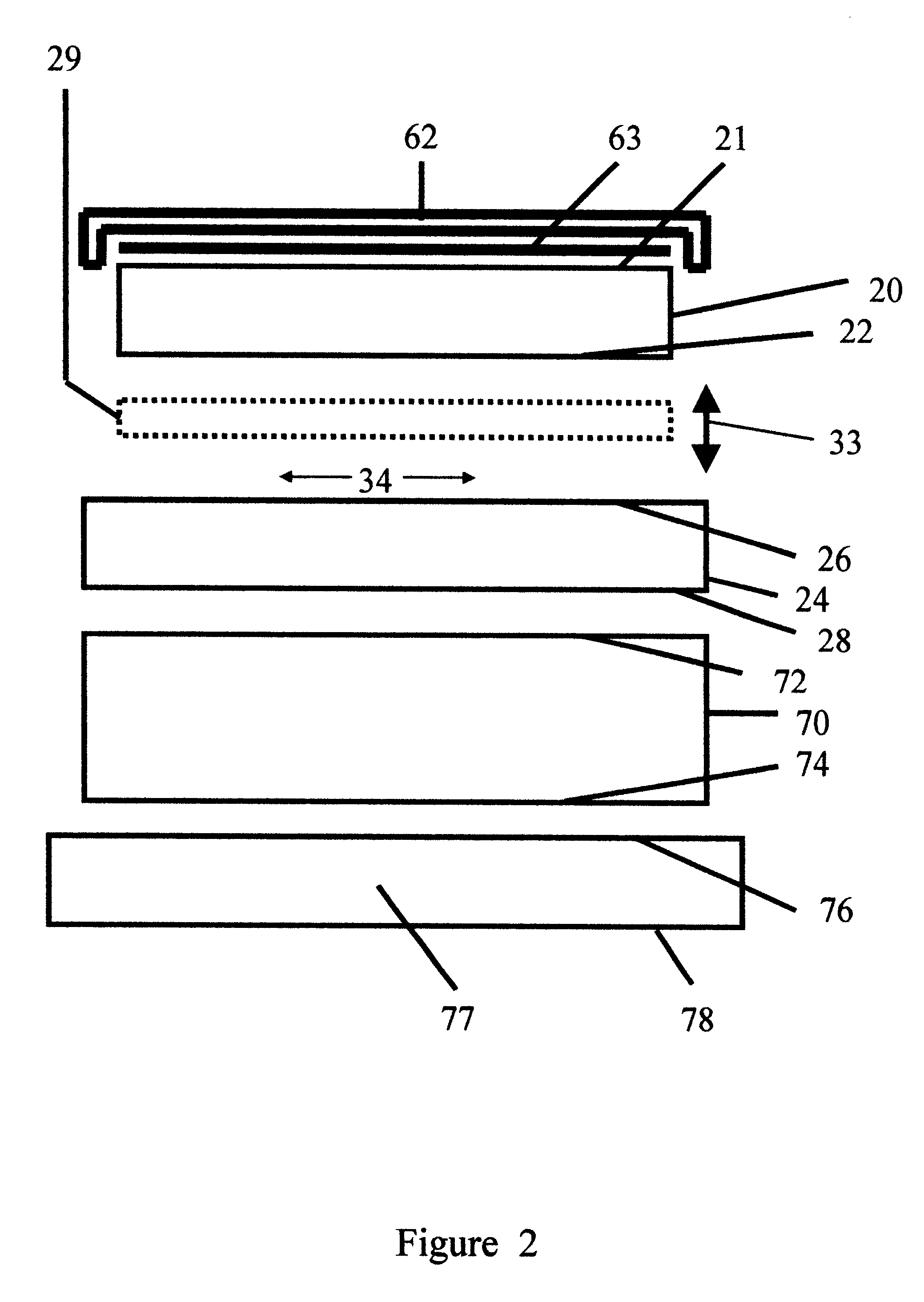

Polishing body, polishing apparatus, polishing apparatus adjustment method, polished film thickness or polishing endpoint measurement method, and semiconductor device manufacturing method

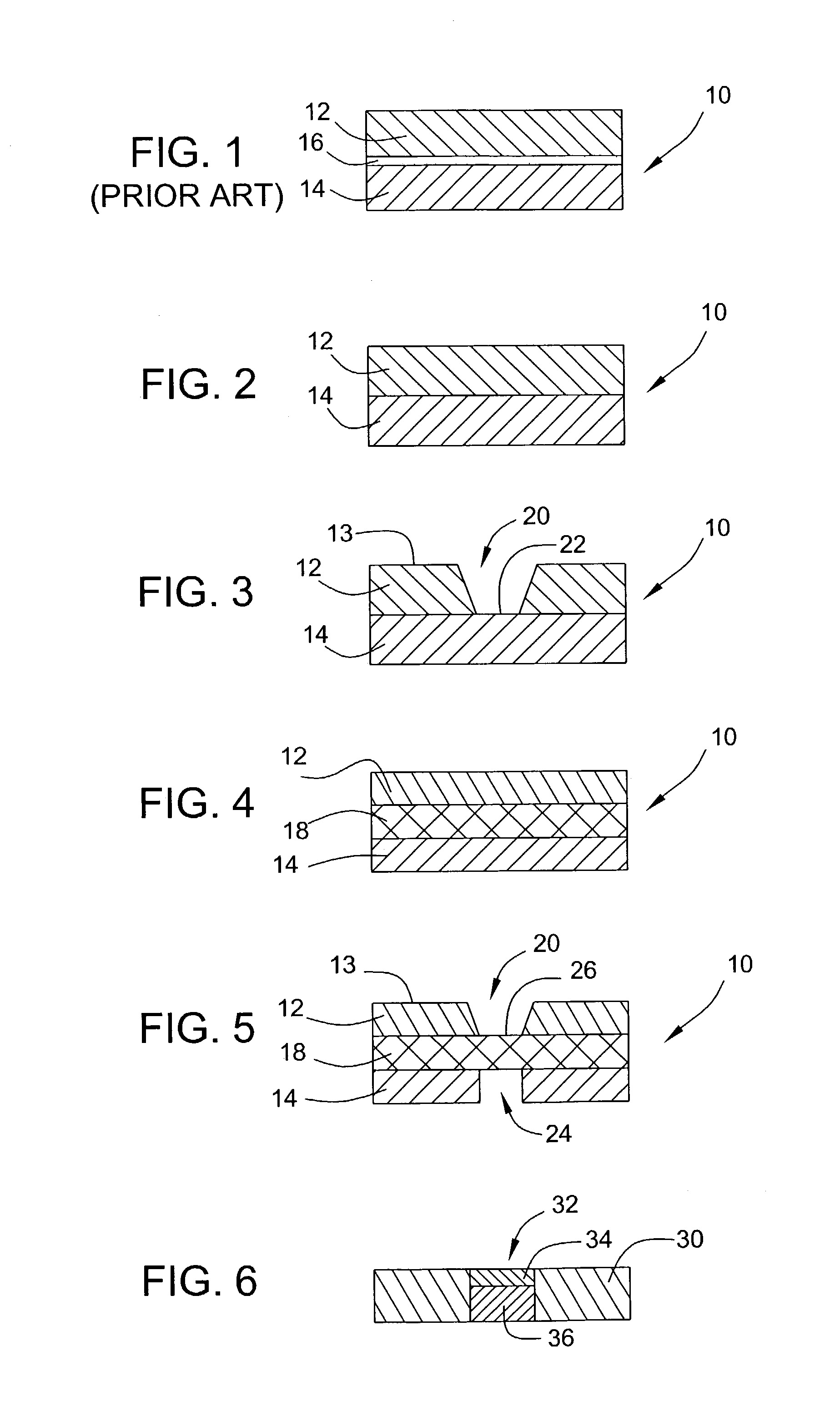

After a hole is formed in a polishing pad, a transparent window plate is inserted into the hole. Here, a gap is left between the upper surface of the transparent window plate and the outermost surface constituting the working surface of the polishing pad. During polishing, the polishing head holding the wafer applies a load to the polishing pad by means of a load-applying mechanism, so that the polishing pad and transparent window plate are compressed. In this case, the system is arranged so that the gap remains constant, and so that a dimension equal to or greater than a standard value is maintained. Since the upper surface of the transparent window plate is recessed from the upper surface of the polishing pad, there is no scratching of the surface of the transparent window plate during dressing. Accordingly, the polishing pad has a long useful life.

Owner:NIKON CORP

Polishing pad with high optical transmission window

ActiveUS6984163B2Spread the wordPolishing machinesRevolution surface grinding machinesEngineeringIsocyanate

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

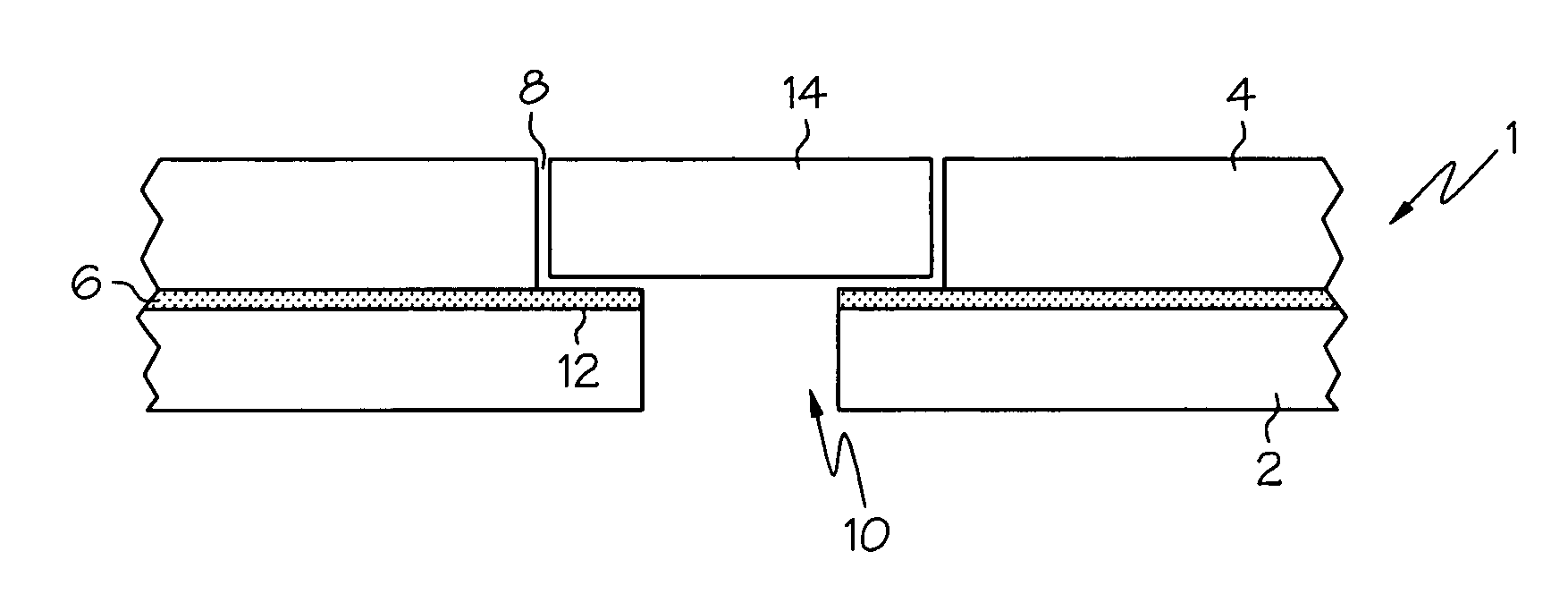

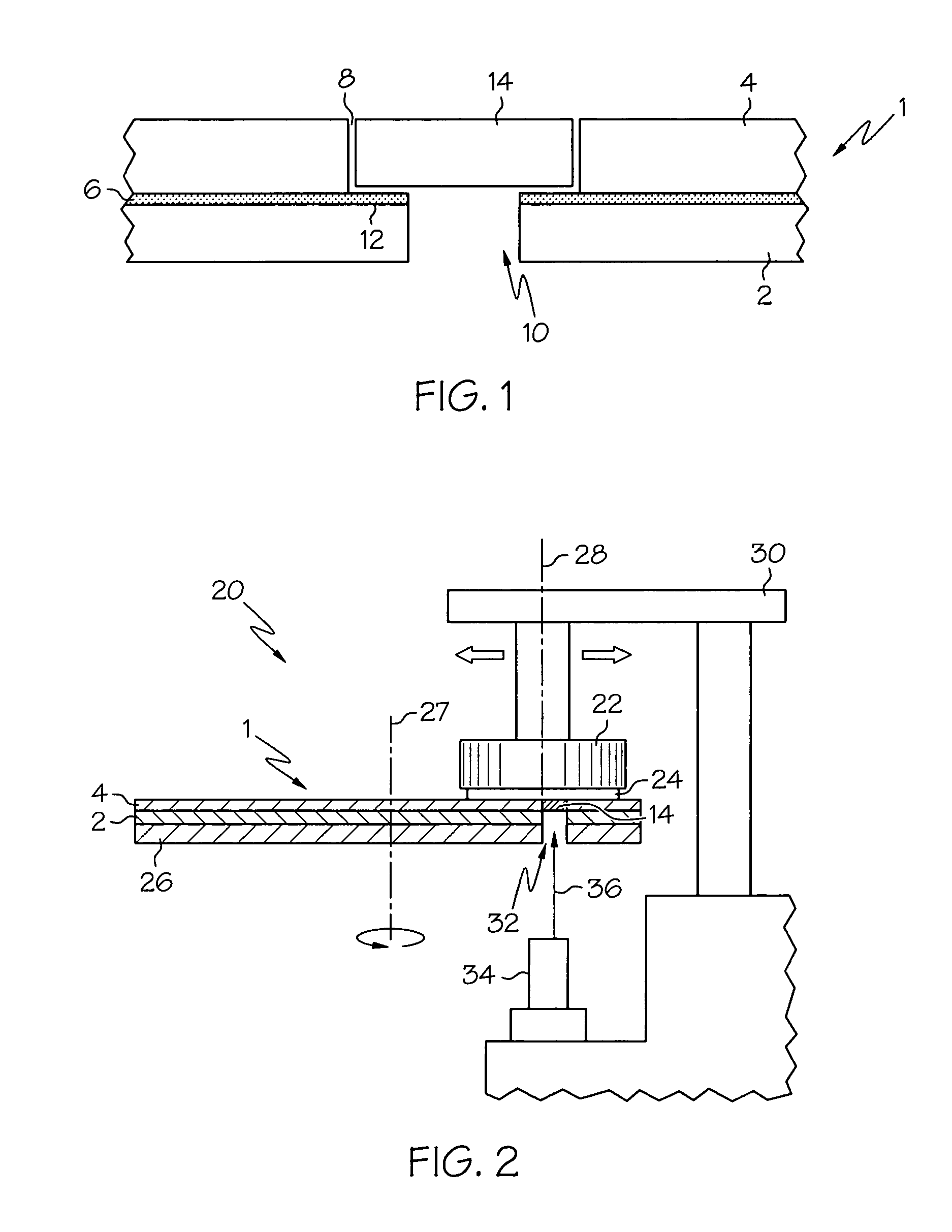

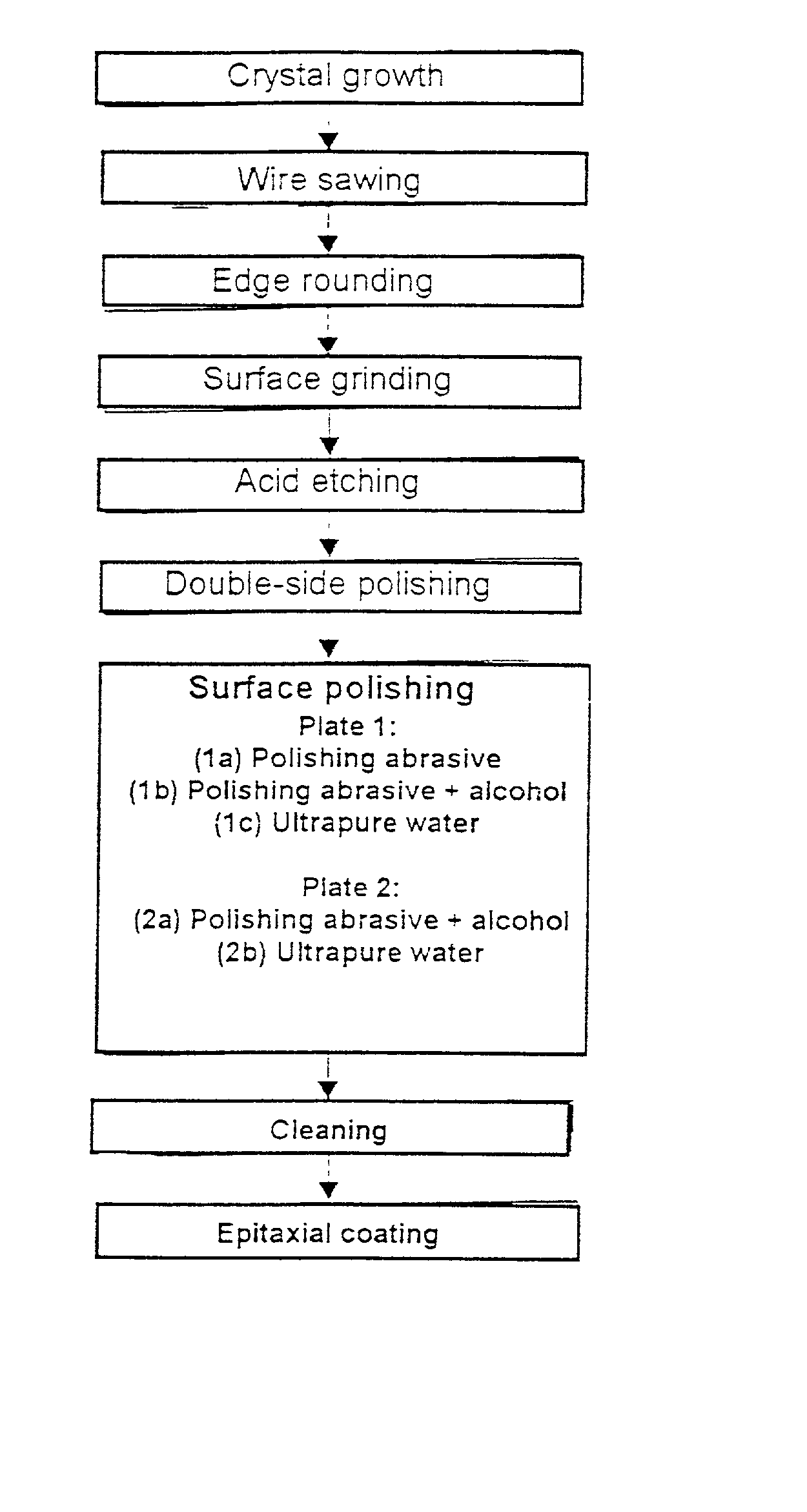

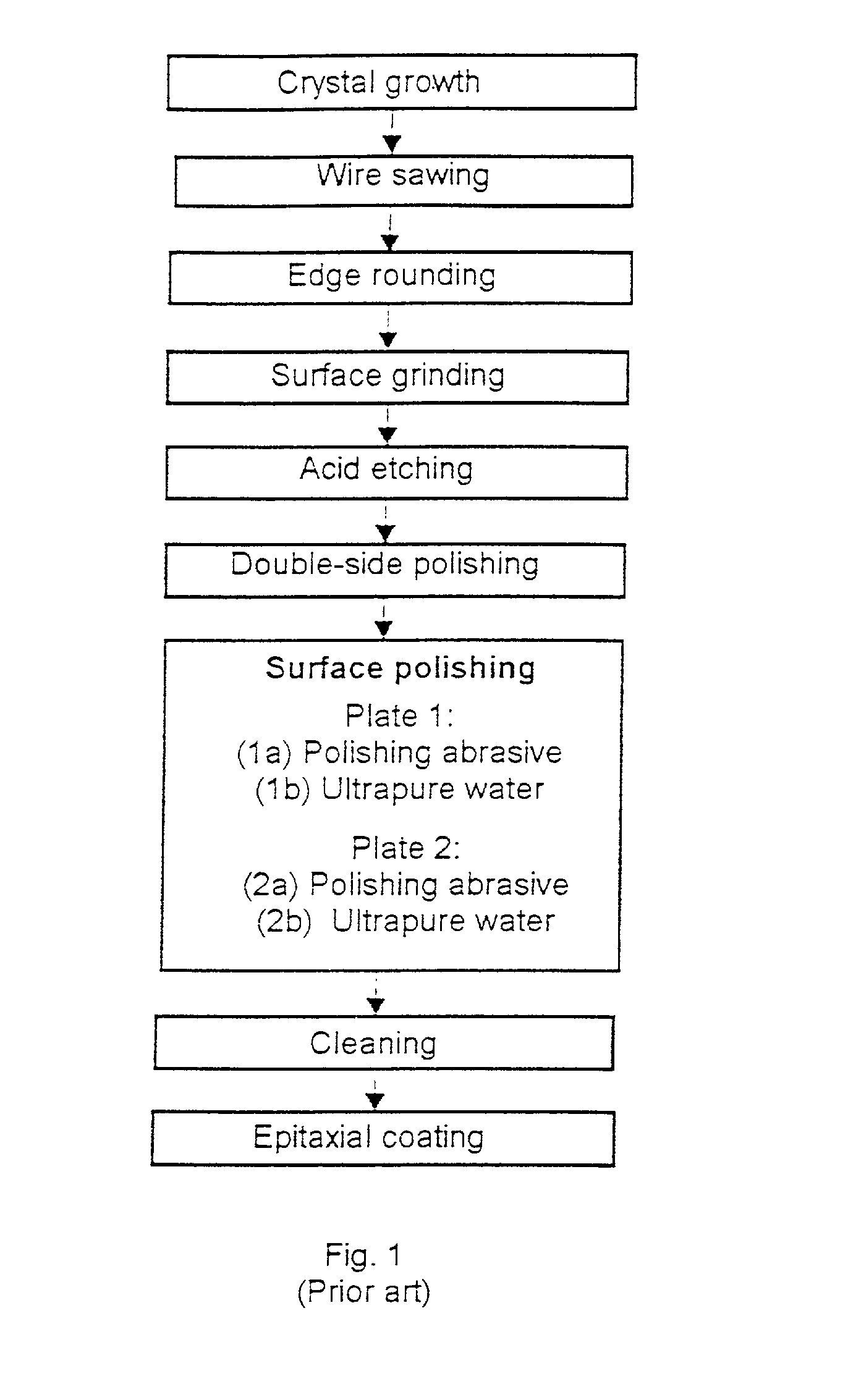

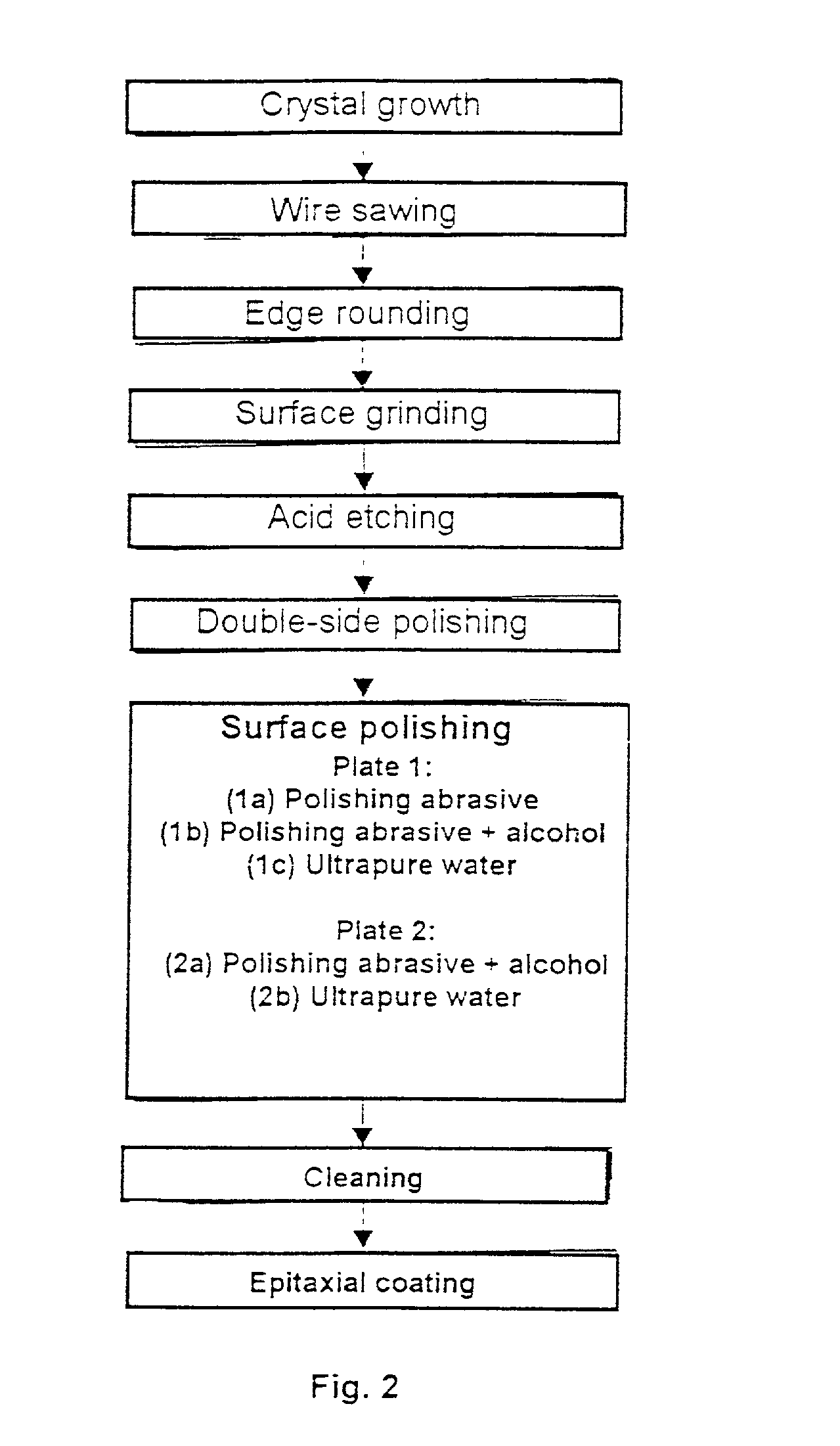

Process for the surface polishing of silicon wafers

InactiveUS20020077039A1High yieldLow costPigmenting treatmentPolishing machinesUltrapure waterAlcohol

A process for the surface polishing of a silicon wafer, includes the successive polishing of the silicon wafer on at least two different polishing plates covered with polishing cloth, with a continuous supply of alkaline polishing abrasive with SiO2 constituents, an amount of silicon removed during the polishing on a first polishing plate being significantly higher than on a second polishing plate, with the overall amount of silicon removed not exceeding 1.5 mum. A polishing abrasive (1a), then a mixture of a polishing abrasive (1b) and at least one alcohol, and finally ultrapure water (1c) are added to the first polishing plate, and a mixture of a polishing abrasive (2a) and at least one alcohol and then ultrapure water (2b) are added to the second plate.

Owner:SILTRONIC AG

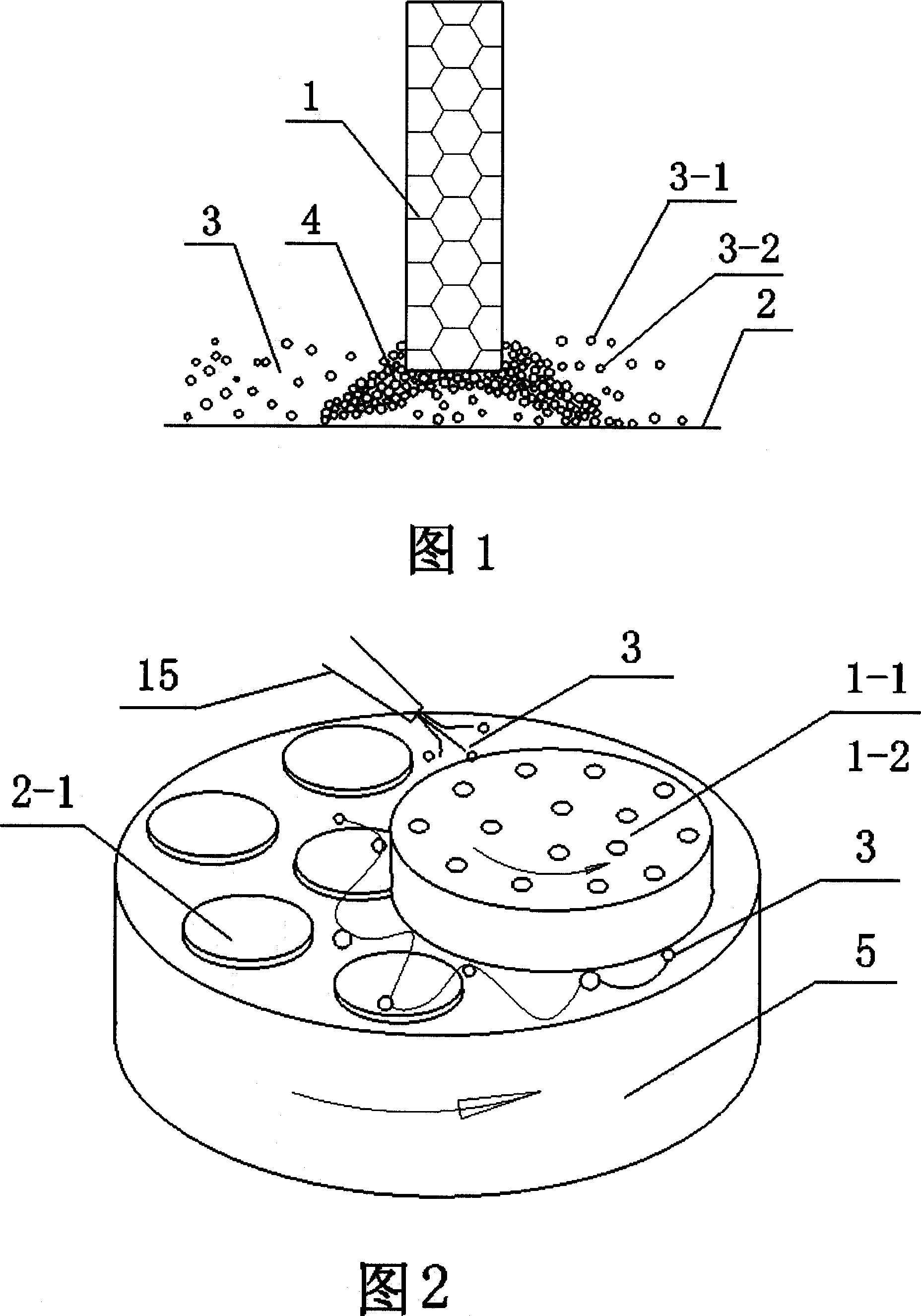

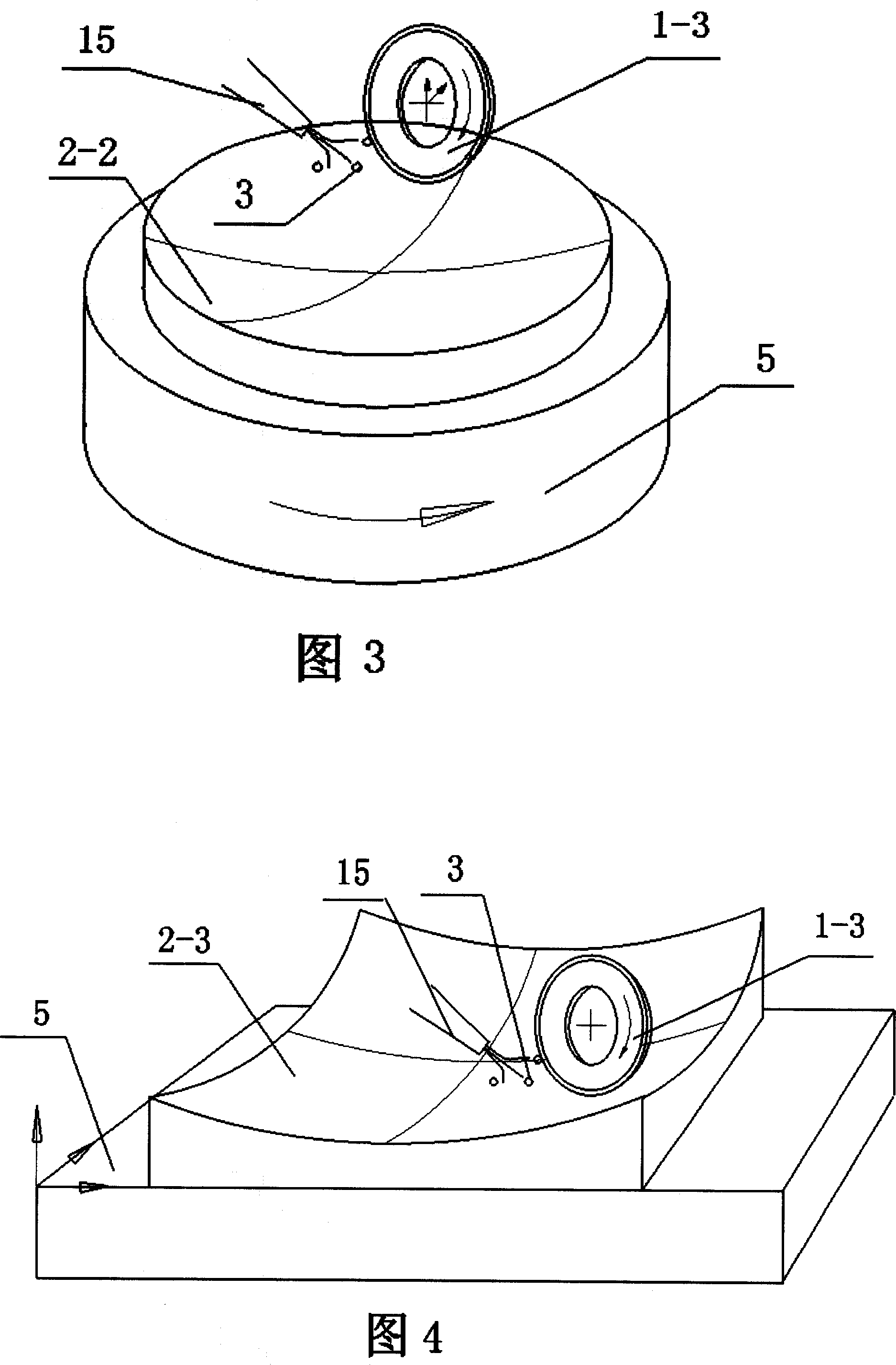

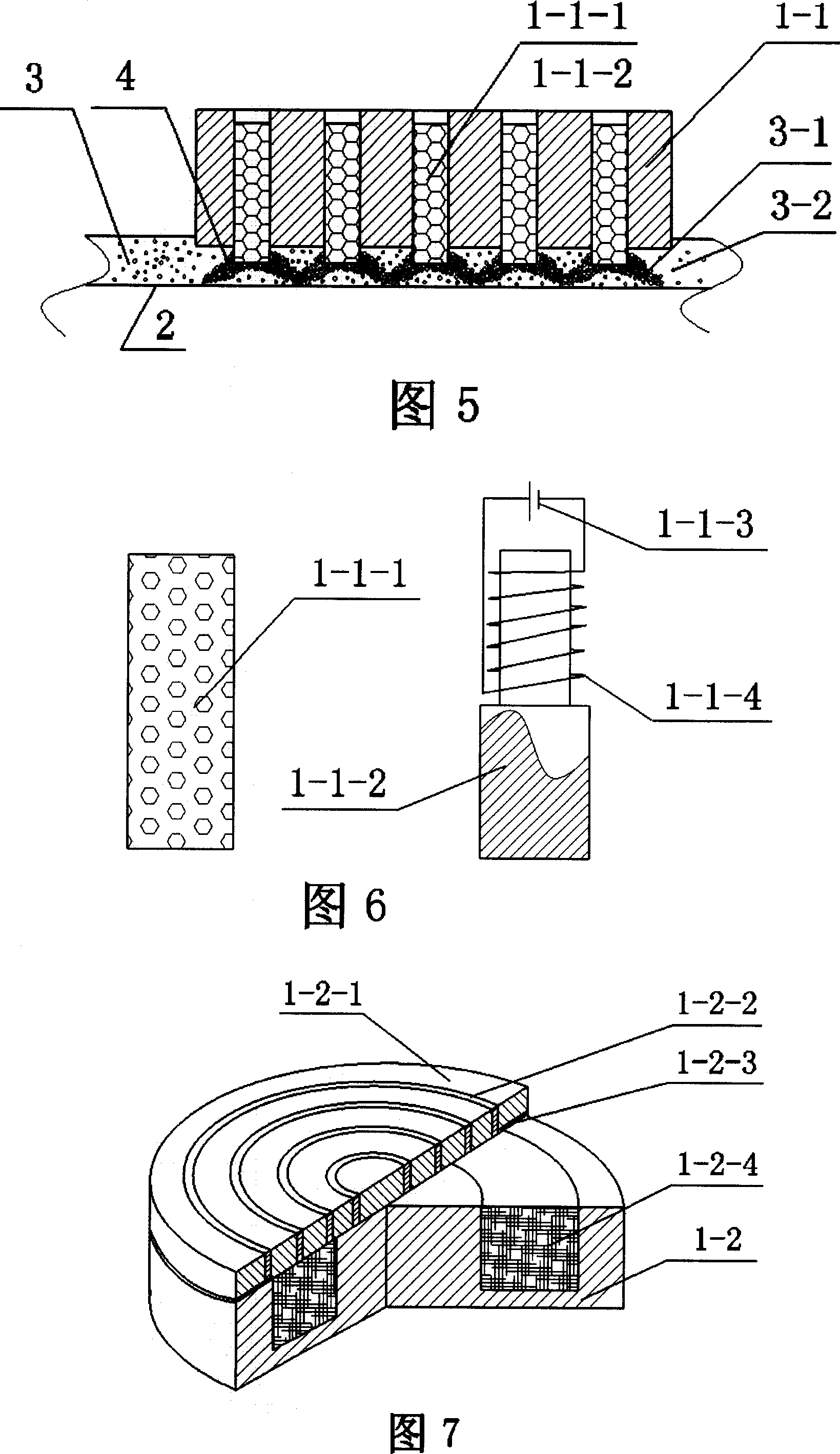

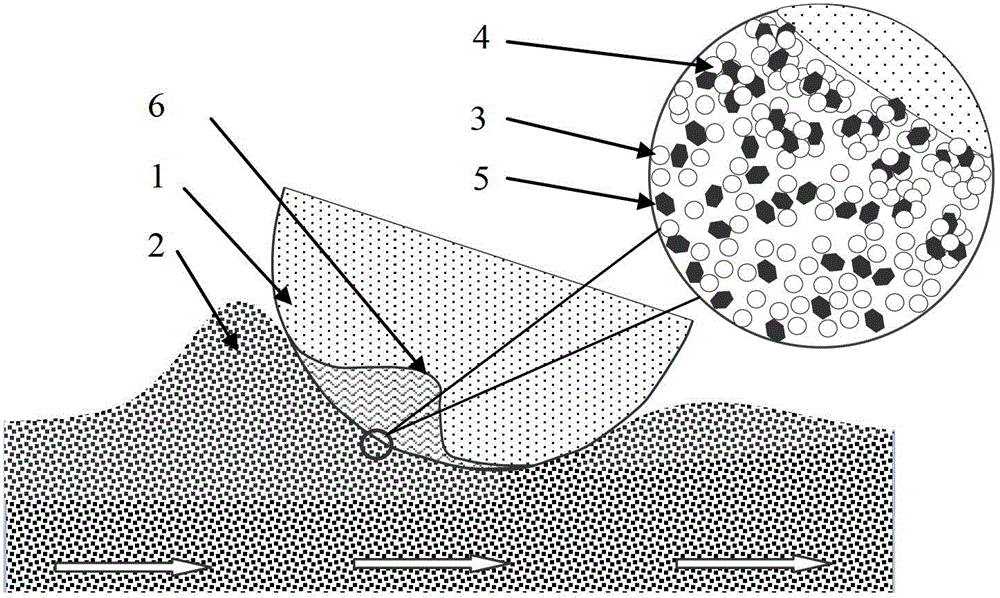

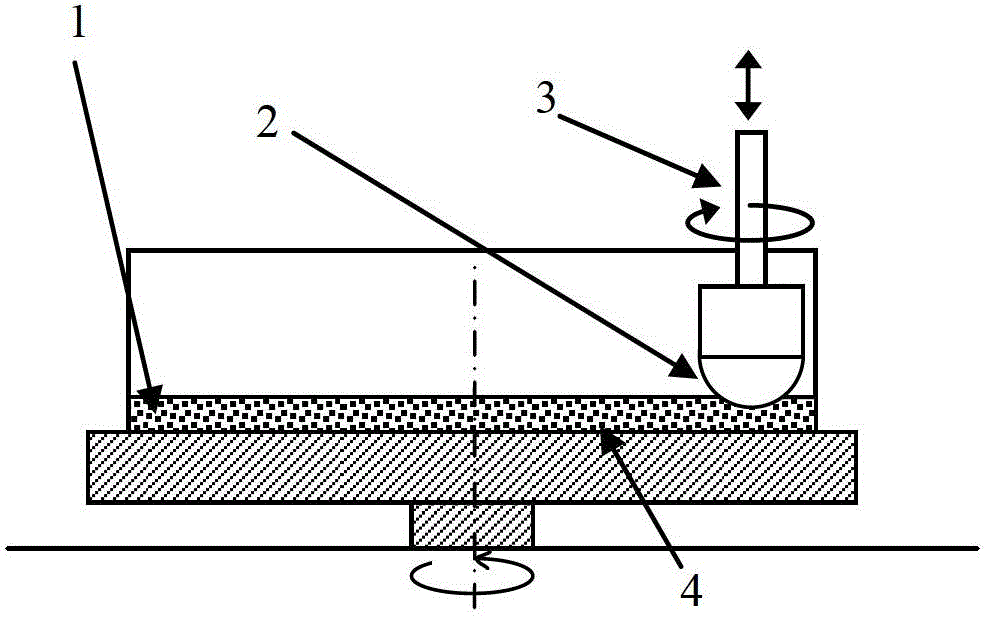

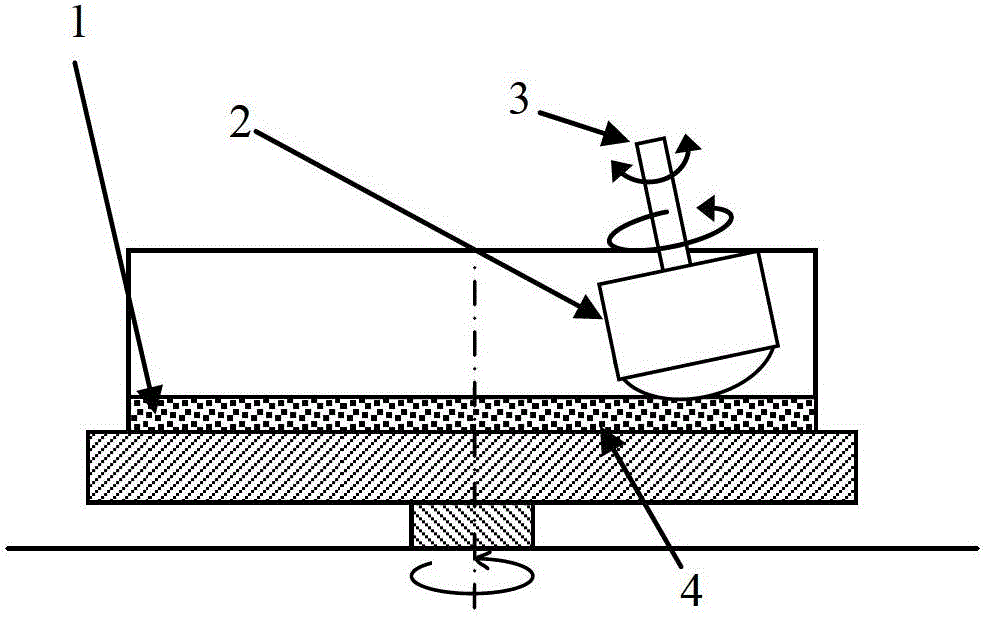

Grinding polishing method based on magnetic rheology effect and its polishing device

InactiveCN100999061AReduce removal rateReduce machining accuracyPolishing machinesPolishing compositions with abrasivesMagnetorheological fluidMaterials science

The present invention discloses a grinding-polishing method based on magnetorheological effect. Said method is characterized by that in the magnetorheological fluid a kind of free abrasive material is added, used as grinding-polishing liquor and injected into the between of magnetic body and workpiece surface, under the action of magnetic field the ferromagnetic particles in the magnetorheological fluid can be arranged by strings to cover the abrasive material pacticles and can be constrained in the end face of magnetic body to form magnetic grinding brush, said magnetic grinding brush can be used for grinding-polishing workpiece surface. Said invention also provides a grinding-polishing device for implementing said grinding-polishing method. Said device includes grinding tool mounted on main shaft connected with motor and working table for mounting workpiece.

Owner:GUANGDONG UNIV OF TECH

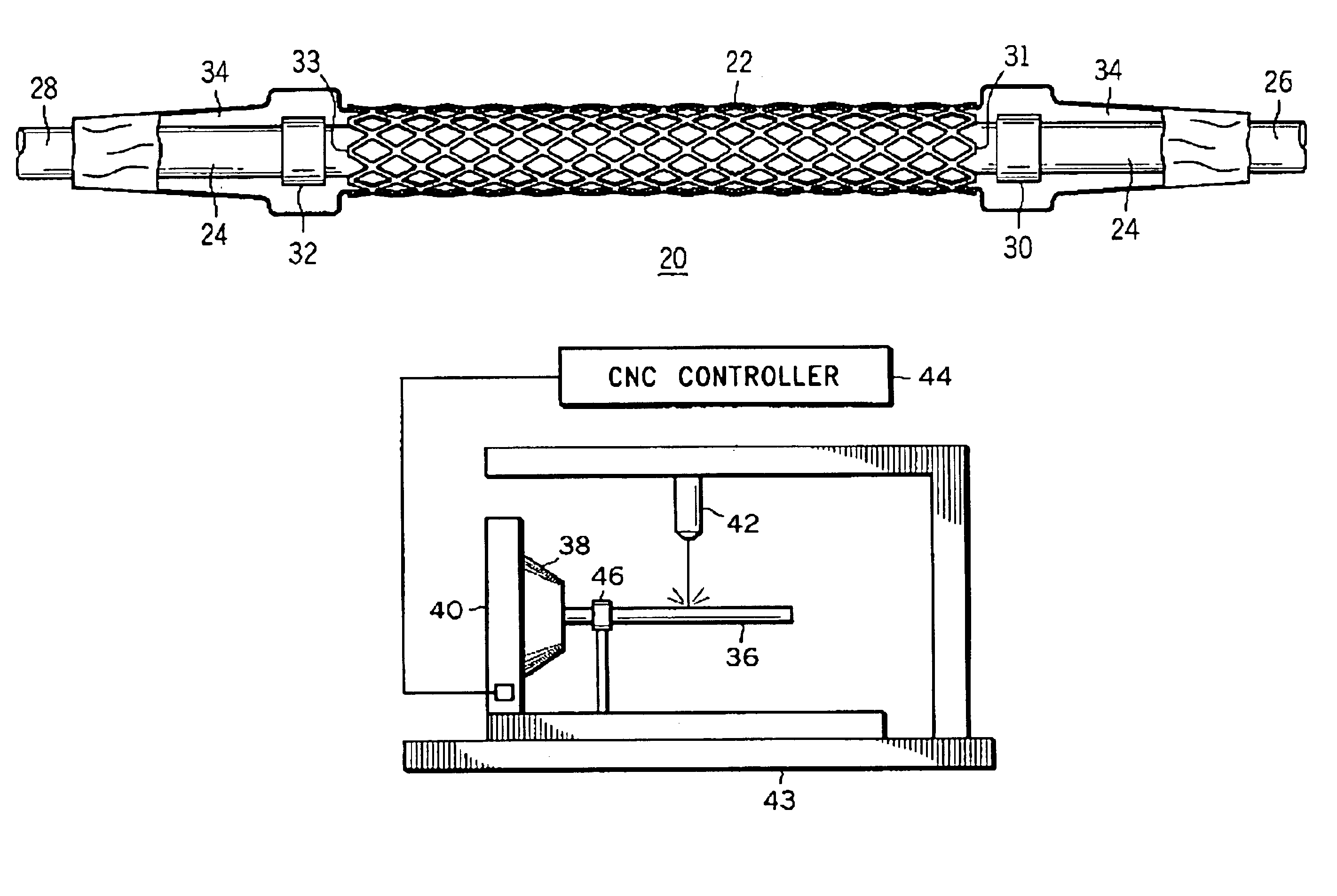

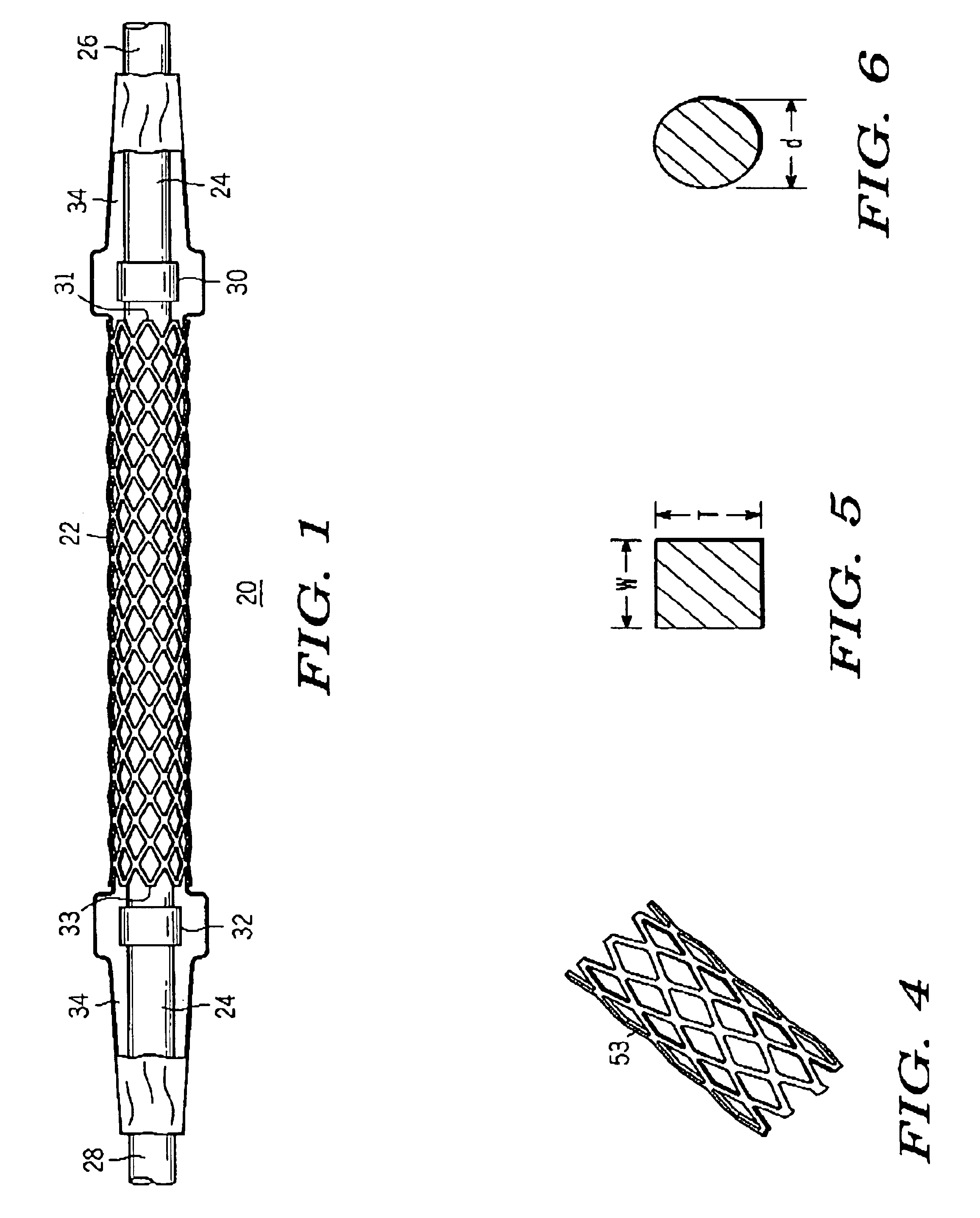

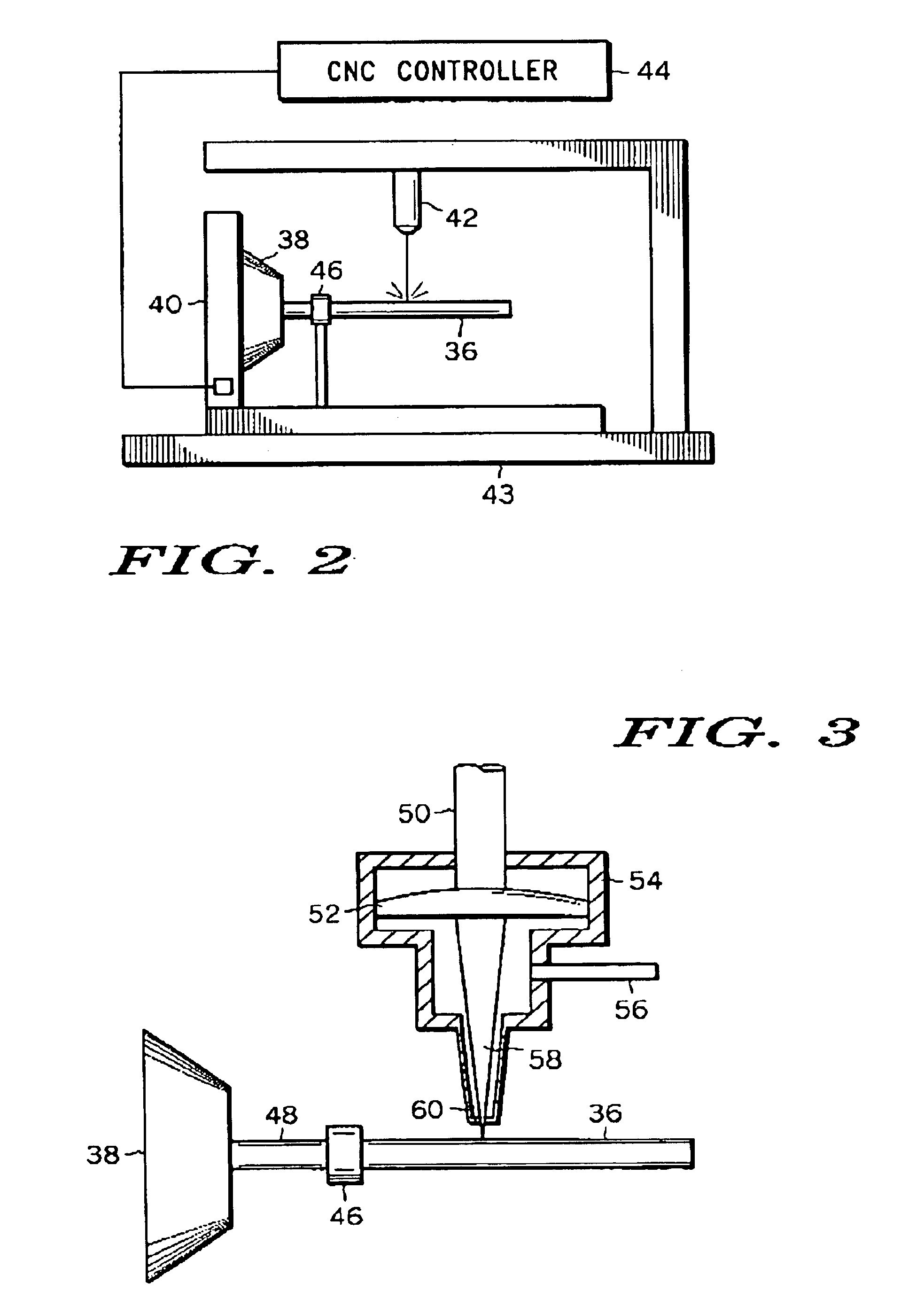

Method for manufacturing an endovascular support device

A method for manufacturing an endovascular support device comprises positioning a generally tubular member made of an implantable metal and having a generally cylindrical wall in a working relationship with a laser beam. A desired pattern is cut in the generally cylindrical wall in order to produce a stent having a plurality of openings and a plurality of edges. The stent is tumbled in a medium to round its edges and, in turn, to produce more rounded cross-sections of stent elements.

Owner:MEDTRONIC VASCULAR INC

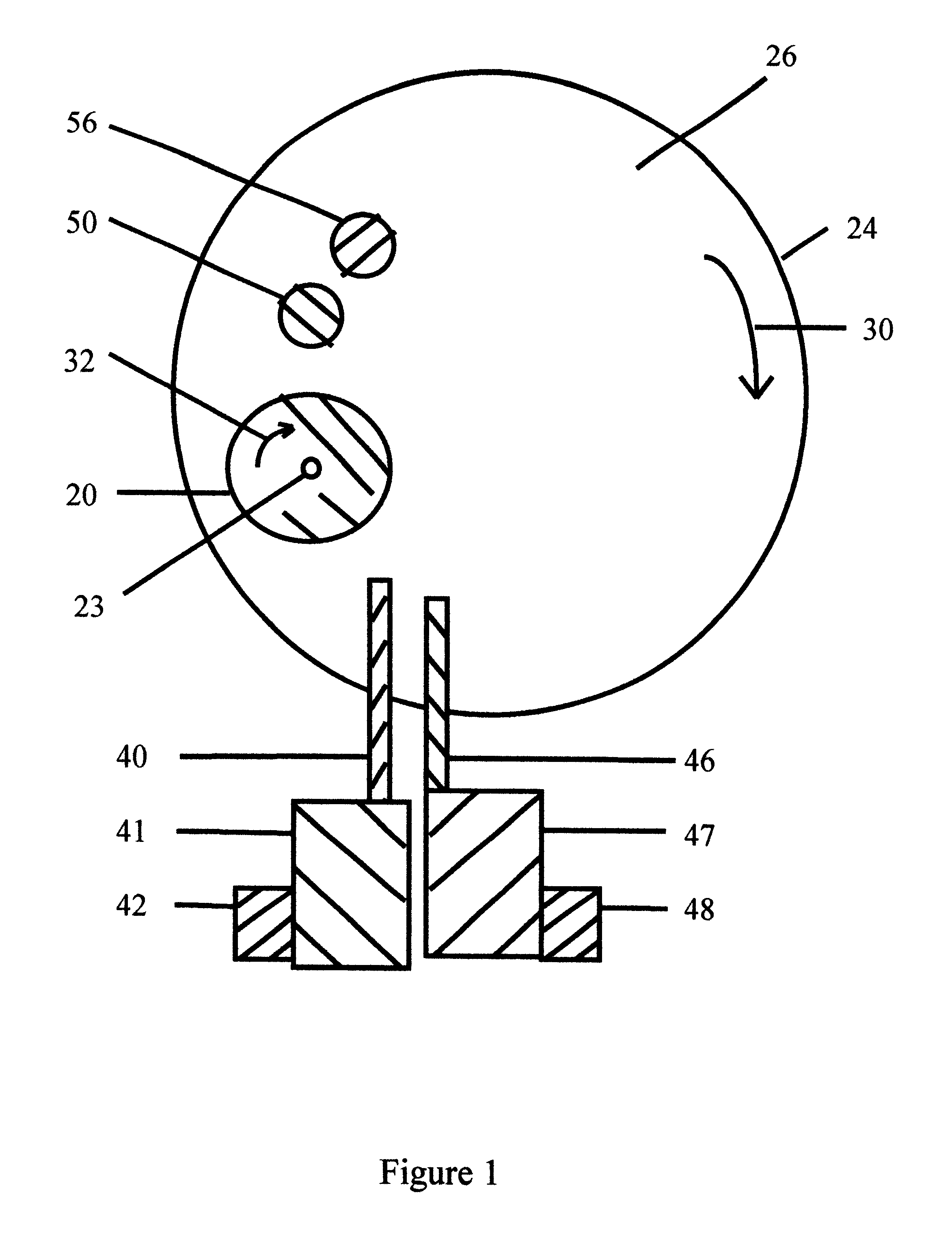

Polishing pad conditioning system

InactiveUS6508697B1Polishing machinesRevolution surface grinding machinesPiezo electricWaste material

A system for conditioning rotatable polishing pads used to planarize and polish surfaces of thin film integrated circuits deposited on semiconductor wafer substrates, microelectronic, and optical system. The system has a pad conditioning apparatus, process fluids, a vacuum capability to pull waste material out of the conditioning pad, self-contained flushing means, and a piezo-electric device for vibrating the pad conditioning apparatus.

Owner:BENNER ROBERT LYLE +2

Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

ActiveCN102717325AImprove gripAvoid damagePolishing machinesOther chemical processesSocial benefitsSurface finish

The invention discloses an ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect. The method includes: adding abrasive particles or micropowder into non-Newtonian fluid with shear thickening effect to prepare non-Newtonian fluid polishing solution, wherein the non-Newtonian fluid accounts for 50%-90% of the mass of the polishing solution, the abrasive particles or the micropowder account for 10%-50% of the mass of the polishing solution, and the particle size of the abrasive particles or the micropowder ranges from 0.05 micrometer to 50 micrometers. Relative motion is generated between a workpiece and the polishing solution during polishing, shear thickening is generated at a contact portion of the polishing solution and the workpiece under shearing action, viscosity of the polishing solution in the contact area is increased to enhance holding force to the abrasive particles or the micropowder, and removal of workpiece surface materials is achieved under the micro cutting or chemical mechanical action of the adding abrasive particles or micropowder with polishing effect in the polishing solution on the workpiece, so that polishing of the workpiece surface is achieved. The ultra-precise curved surface finishing method based on the non-Newtonian fluid shear thickening effect can achieve efficient and high-quality polishing to various curved surfaces, in particular to complex curved surfaces and has great economic and social benefits.

Owner:ZHEJIANG UNIV OF TECH

Polishing pad for electrochemical mechanical polishing

InactiveUS6848977B1Easy to moveElectrolysis componentsPolishing machinesEngineeringElectrical and Electronics engineering

The present invention provides a polishing pad for electrochemical mechanical polishing of conductive substrate. The pad comprises a plurality of grooves formed in a polishing surface of the polishing pad, the grooves being adapted to facilitate the flow of polishing fluid over the polishing pad. The conductive layers are respectively formed in the grooves and are in electrical communication with each other.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

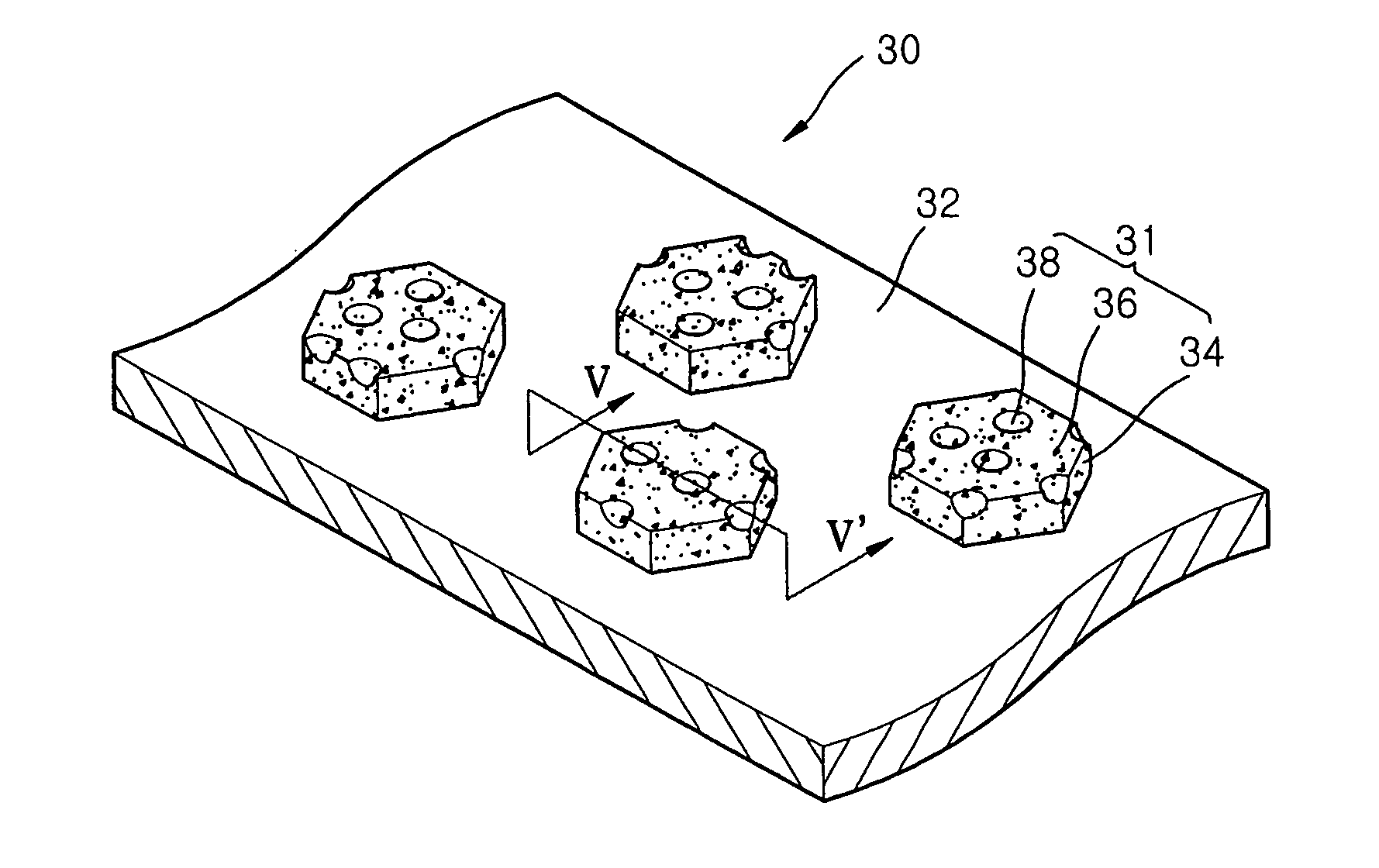

Fixed abrasive polishing pad, method of preparing the same, and chemical mechanical polishing apparatus including the same

InactiveUS20070128991A1Improve abilitiesPolishing machinesRevolution surface grinding machinesCompound (substance)Abrasive

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus of monitoring polishing pad wear during processing

InactiveUS6045434AMinimize degradationPolishing machinesRevolution surface grinding machinesClosed loopEngineering

A method and apparatus for monitoring polishing pad wear during processing is developed to extend the pad's useful life, and maintain pad uniformity. This is accomplished in the present invention by measuring and monitoring the diminished pad thickness using a non-intrusive measurement system, and creating a closed-loop system for adjusting the chemical-mechanical polishing tool process parameters. The non-intrusive measurement system consists of an interferometer measurement technique utilizing ultrasound or electromagnetic radiation transmitters and receivers aligned to cover any portion of the radial length of a polishing pad surface. The measurement system is sensitive to relative changes in pad thickness for uniformity, and to abrupt changes such as detecting wafer detachment from the CMP wafer carrier.

Owner:IBM CORP

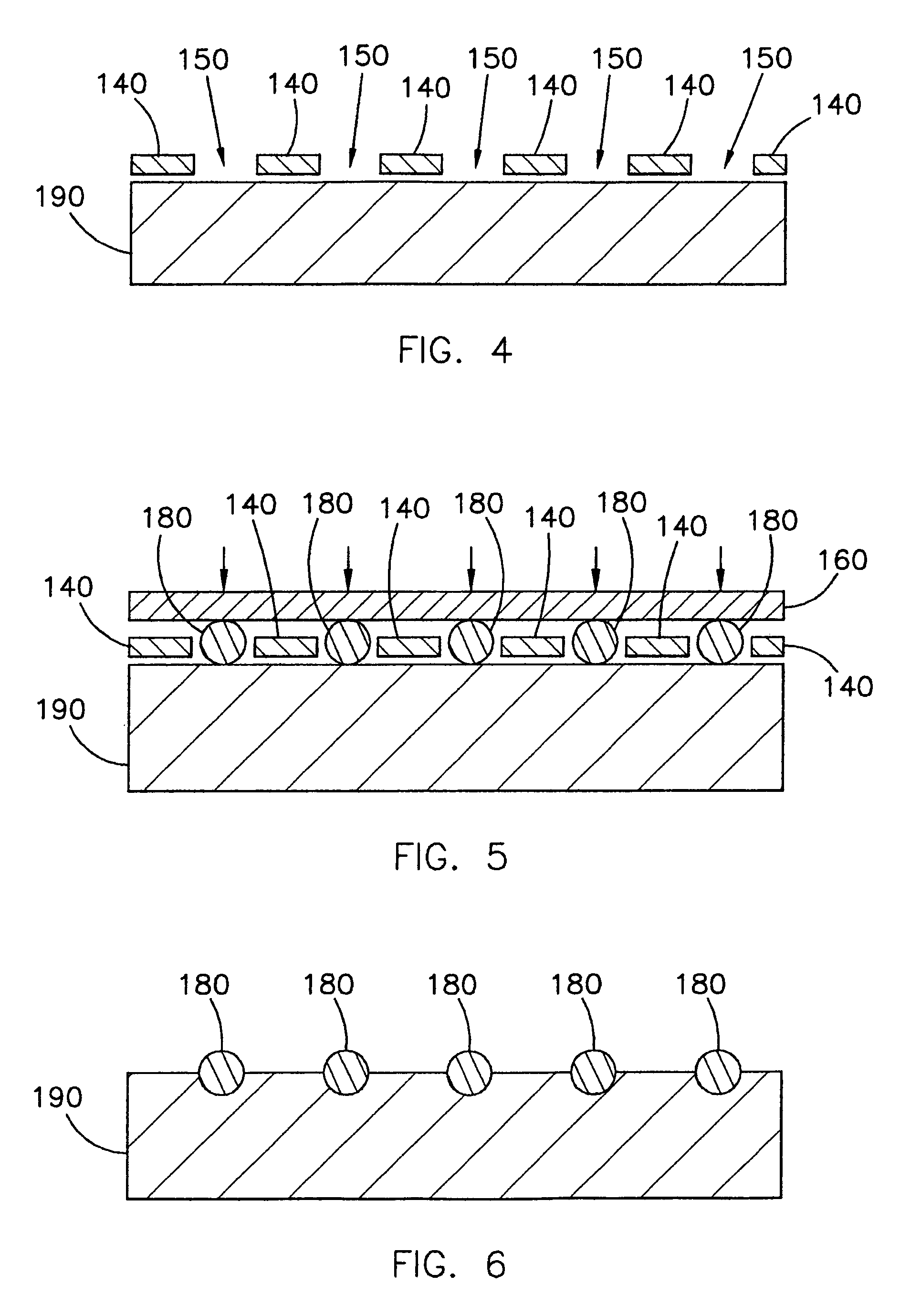

Multi-layer polishing pad material for CMP

InactiveUS6884156B2Polishing machinesRevolution surface grinding machinesAdhesiveBiomedical engineering

The invention is directed to a multi-layer polishing pad for chemical-mechanical polishing comprising a polishing layer and a bottom layer, wherein the polishing layer and bottom layer are joined together without the use of an adhesive. The invention is also directed to a polishing pad comprising an optically transmissive multi-layer polishing pad material, wherein the layers of the polishing pad material are joined together without the use of an adhesive.

Owner:CMC MATERIALS INC

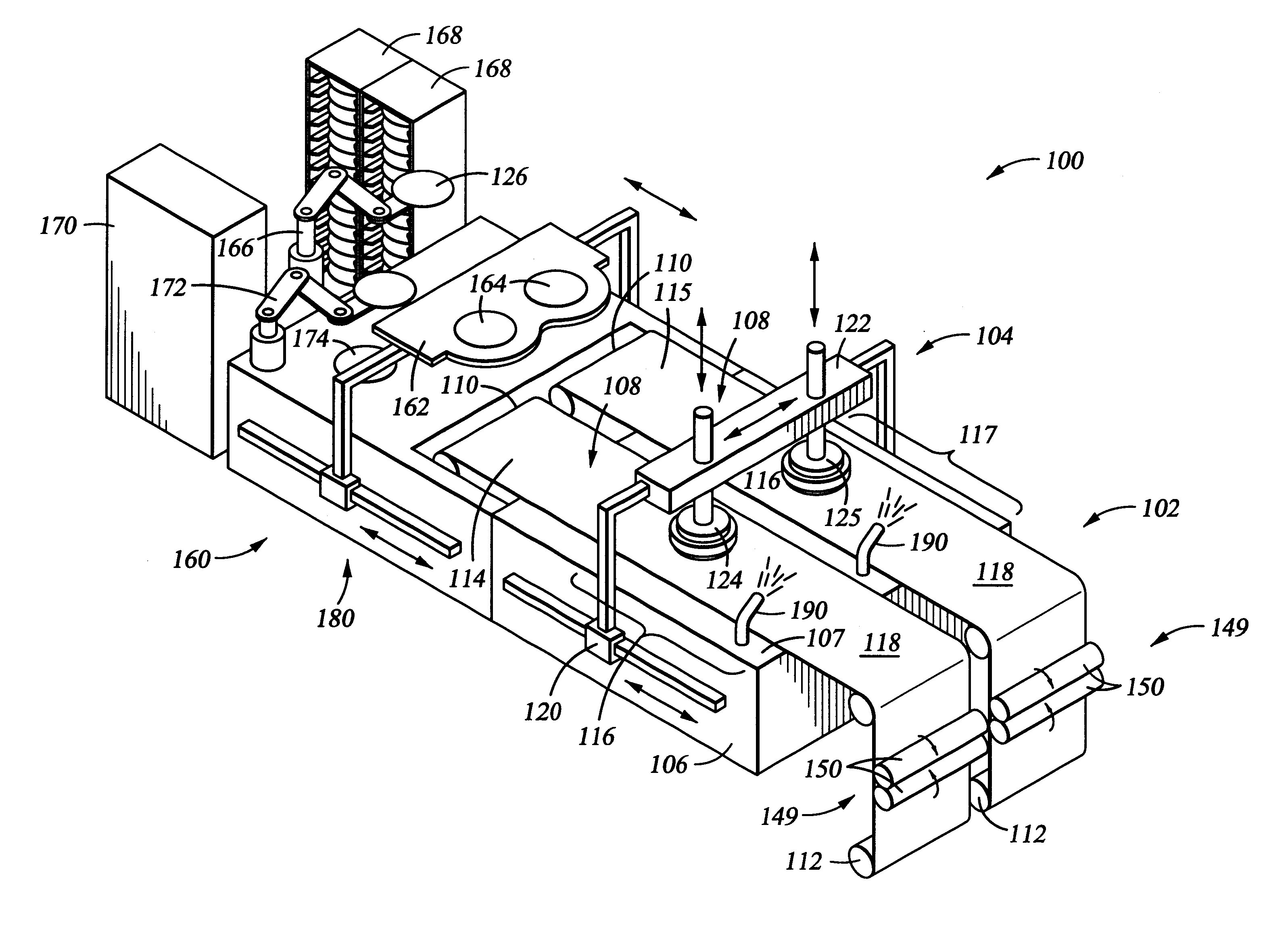

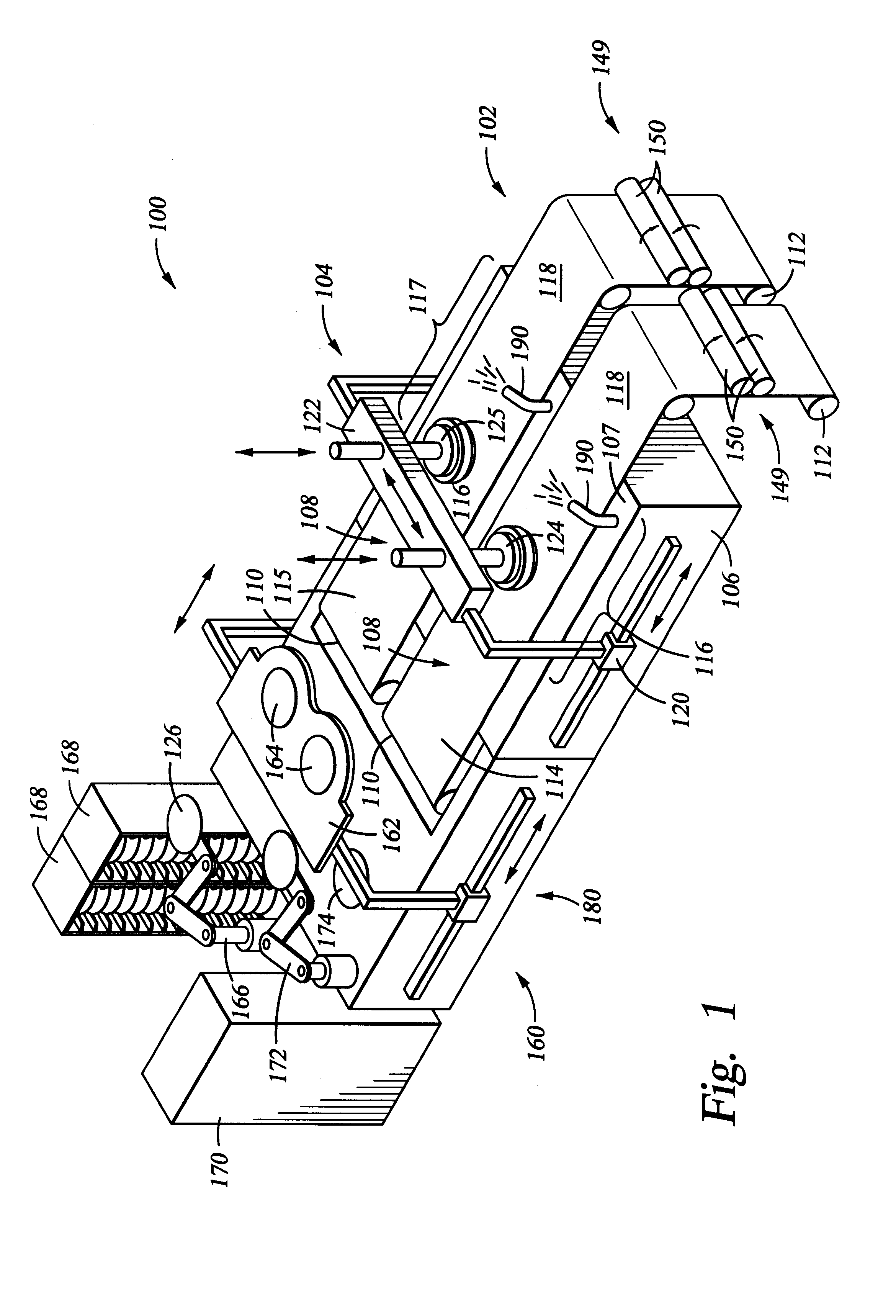

Load cup for chemical mechanical polishing

ActiveUS7044832B2Polishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

Embodiments of a load cup for transferring a substrate are provided. The load cup includes a pedestal assembly having a substrate support and a de-chucking nozzle. The de-chucking nozzle is positioned to flow a fluid between the polishing head and the back side of a substrate during transfer of the substrate from the polishing head to the substrate support.

Owner:APPLIED MATERIALS INC

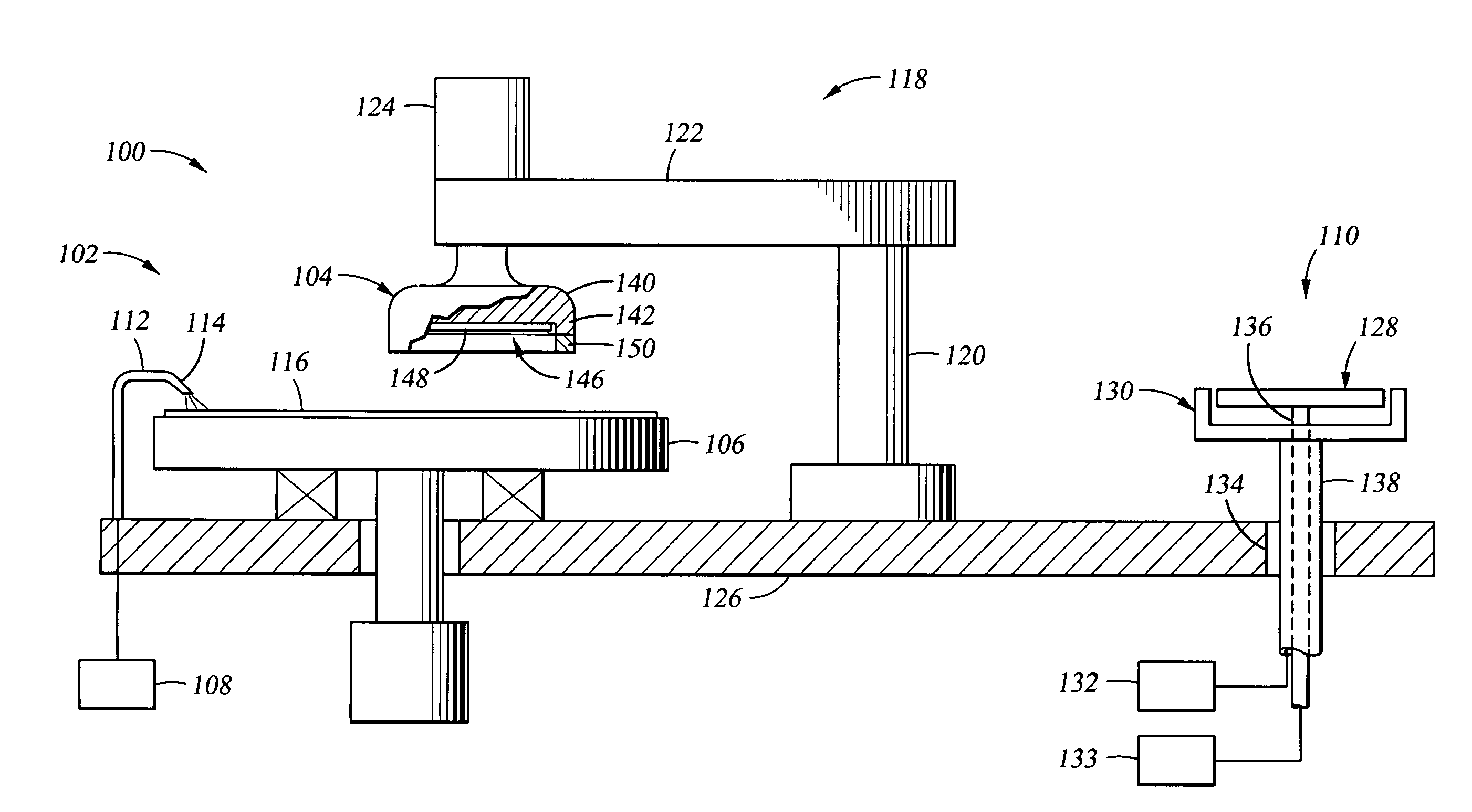

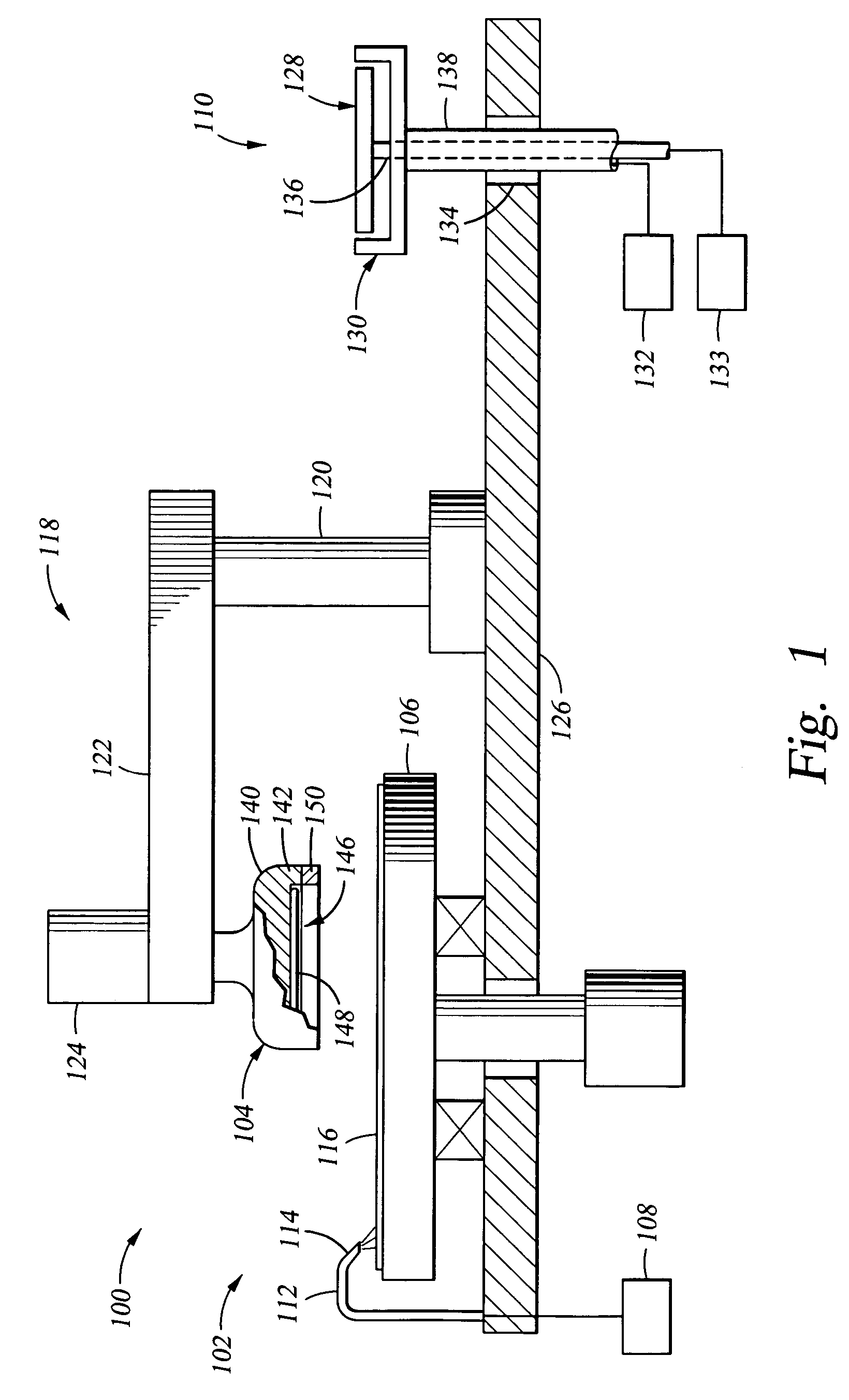

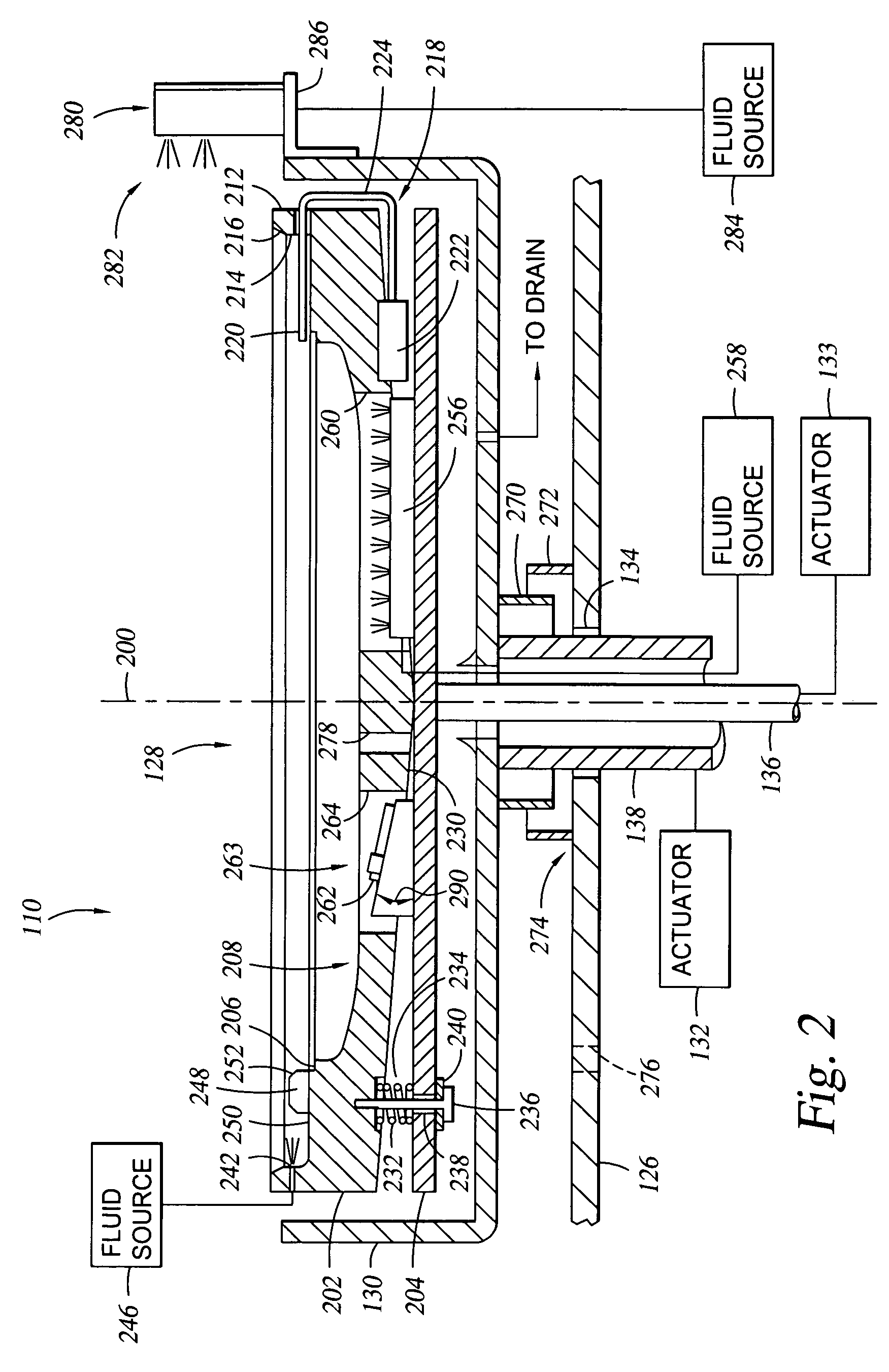

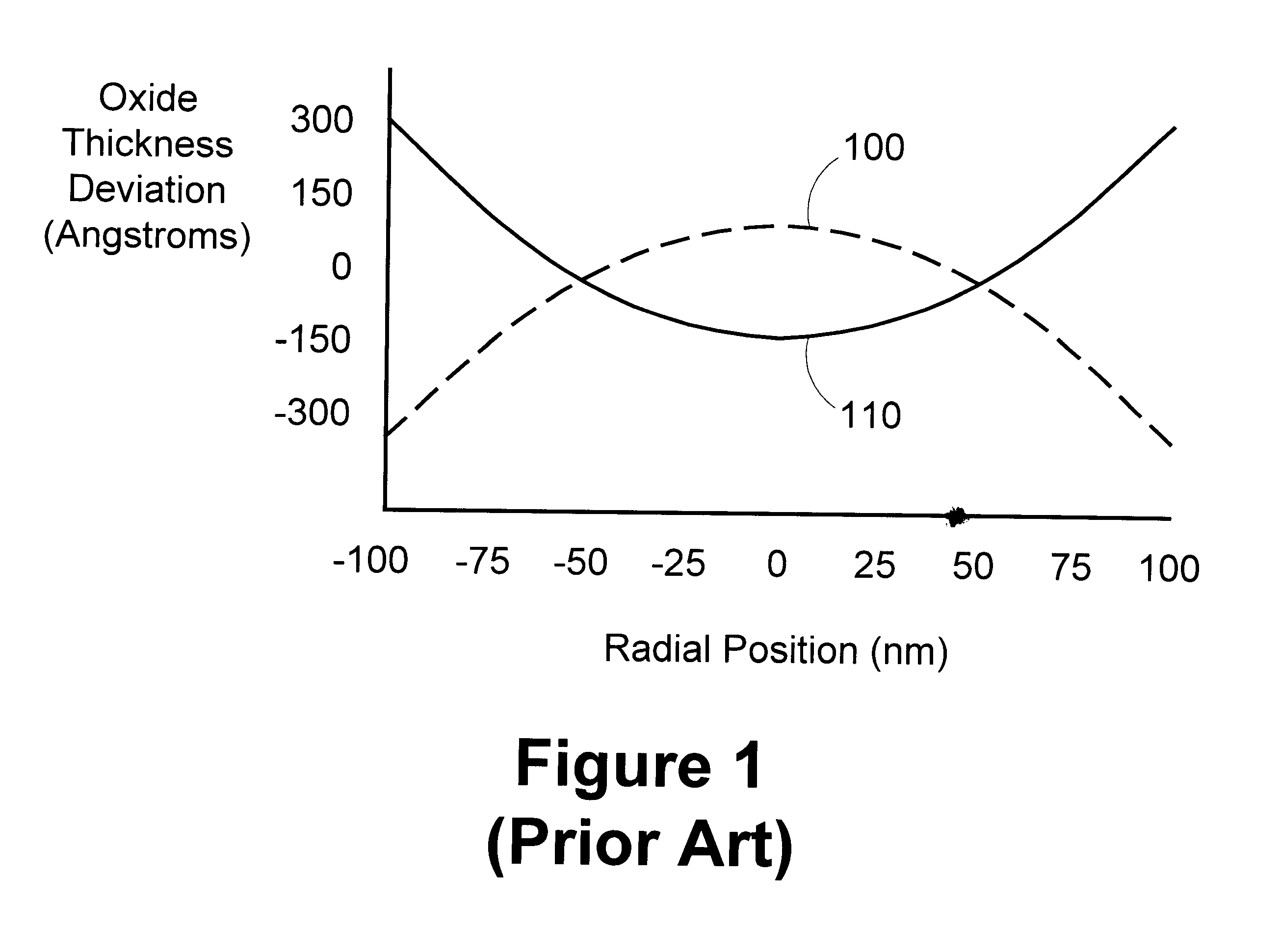

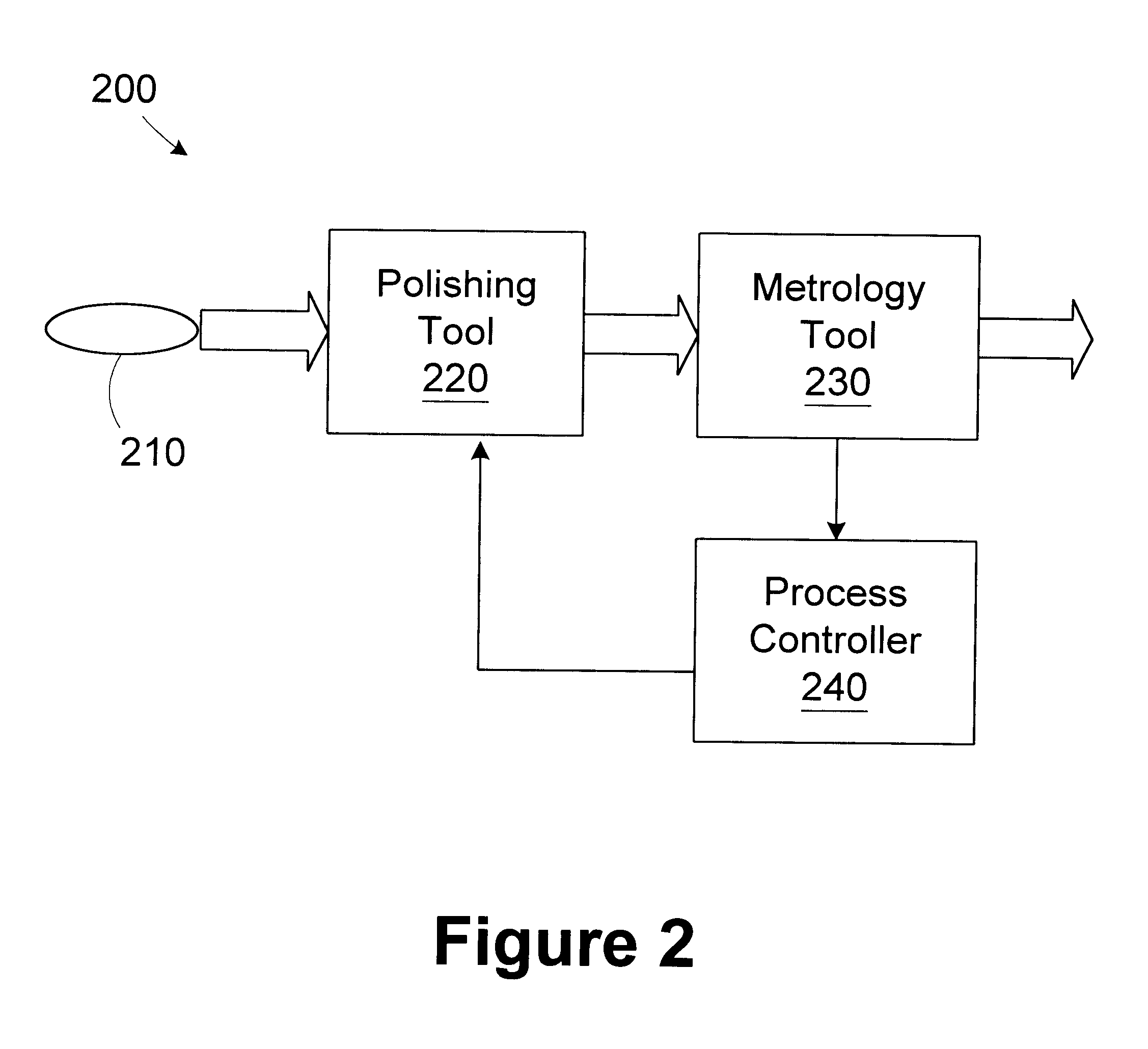

Method and apparatus for post-polish thickness and uniformity control

A method for polishing wafers includes providing a wafer having a process layer formed thereon; providing a polishing tool having a plurality of control zones and being adapted to polish the process layer based on an operating recipe, the operating recipe having a control variable corresponding to each of the control zones; measuring a pre-polish thickness profile of the process layer; comparing the pre-polish thickness profile to a target thickness profile to determine a desired removal profile; determining values for the control variables associated with the control zones based on the desired removal profile; and modifying the operating recipe of the polishing tool based on the values determined for the control variables. A processing line includes a polishing tool, a metrology tool, and a process controller. The polishing tool is adapted to polish a wafer having a process layer formed thereon based on an operating recipe. The polishing tool includes a plurality of control zones and the operating recipe includes a control variable corresponding to each of the control zones. The metrology tool is adapted to measure a pre-polish thickness profile of the process layer. The process controller is adapted to compare the pre-polish thickness profile to a target thickness profile to determine a desired removal profile, determine values for the control variables associated with the control zones based on the desired removal profile, and modify the operating recipe of the polishing tool based on the values determined for the control variables.

Owner:GLOBALFOUNDRIES INC

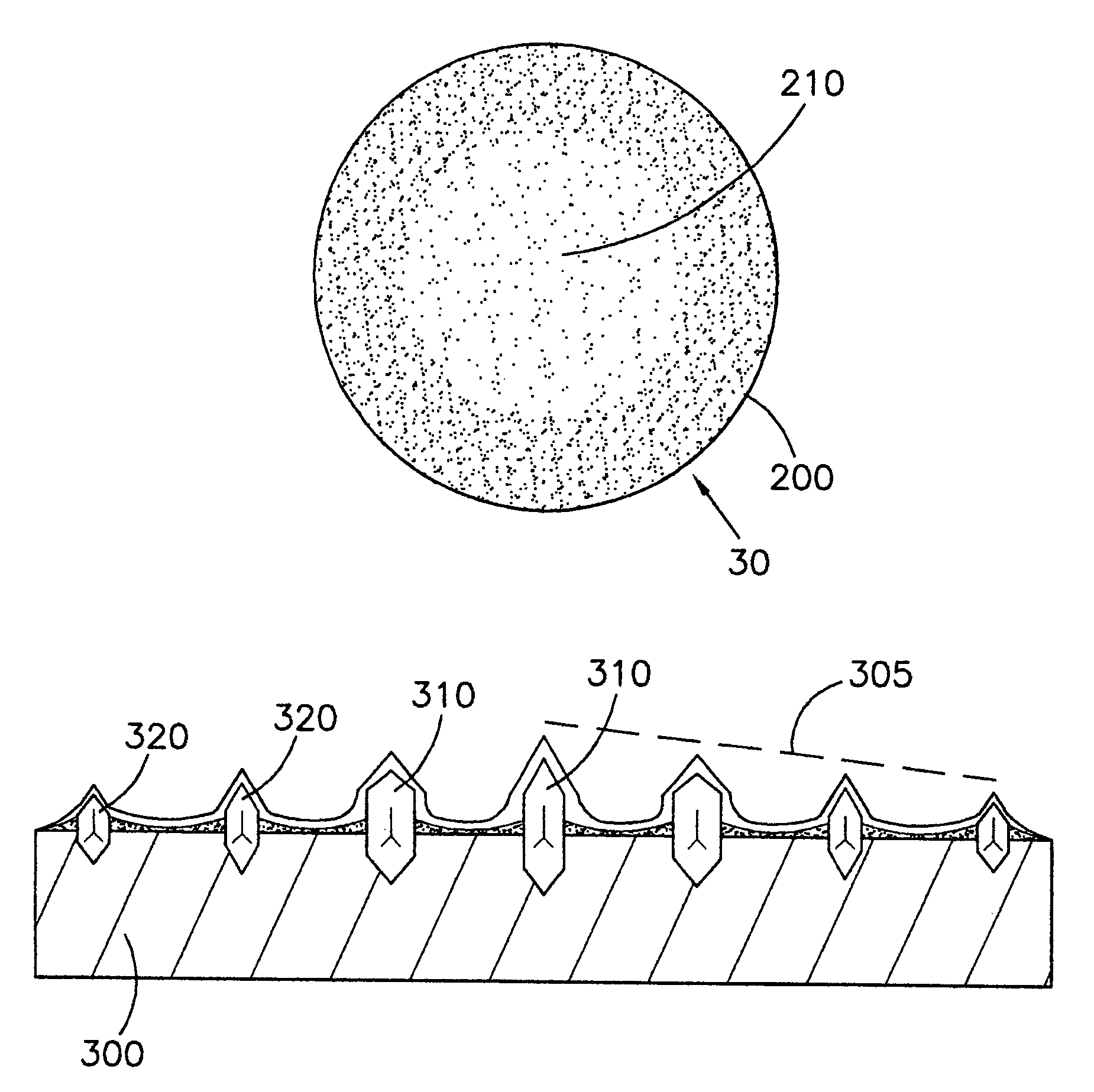

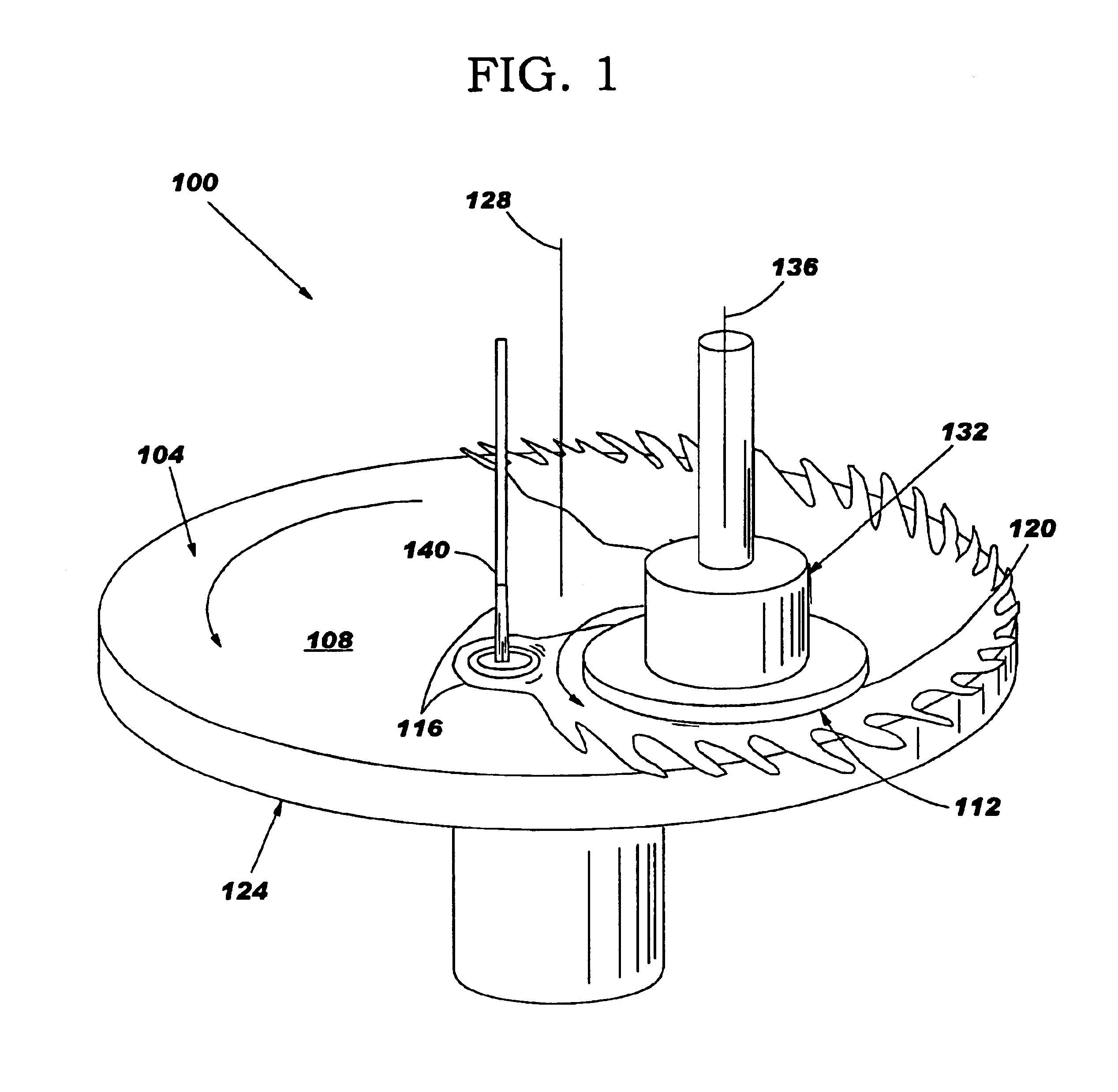

Contoured CMP pad dresser and associated methods

InactiveUS7201645B2Increase loadImprove permeabilityPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

Owner:KINIK

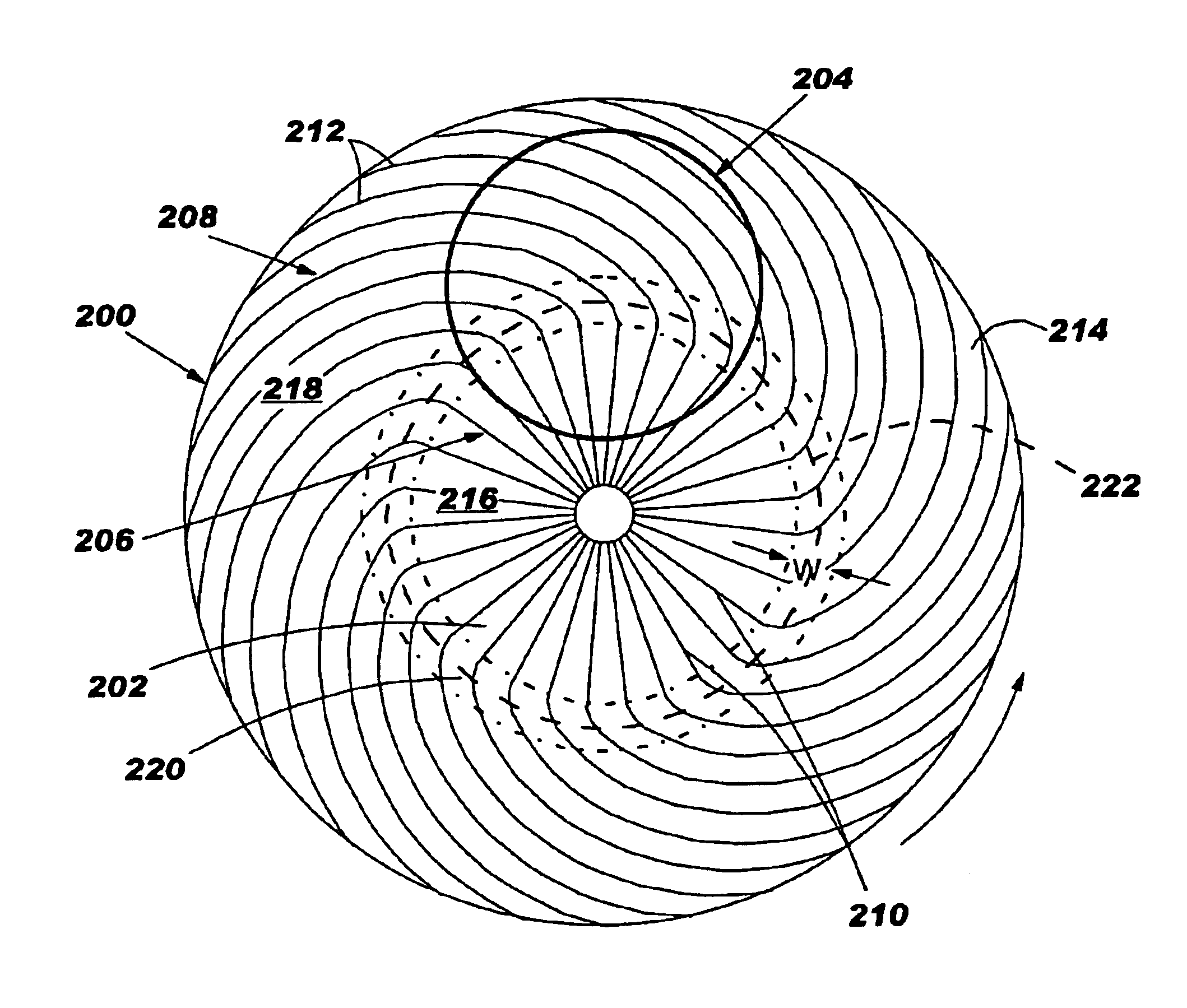

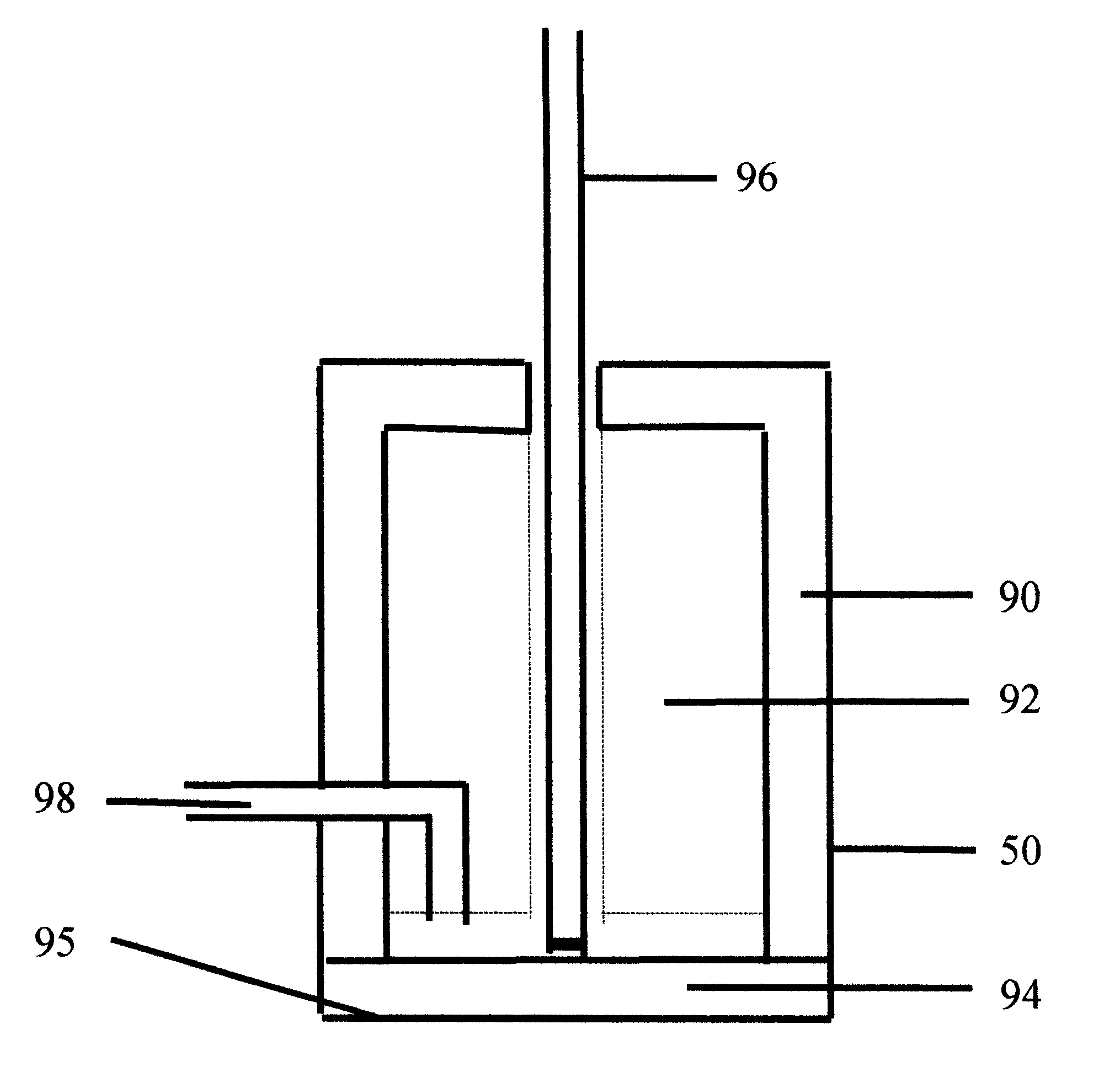

Chemical mechanical polishing pad having a process-dependent groove configuration

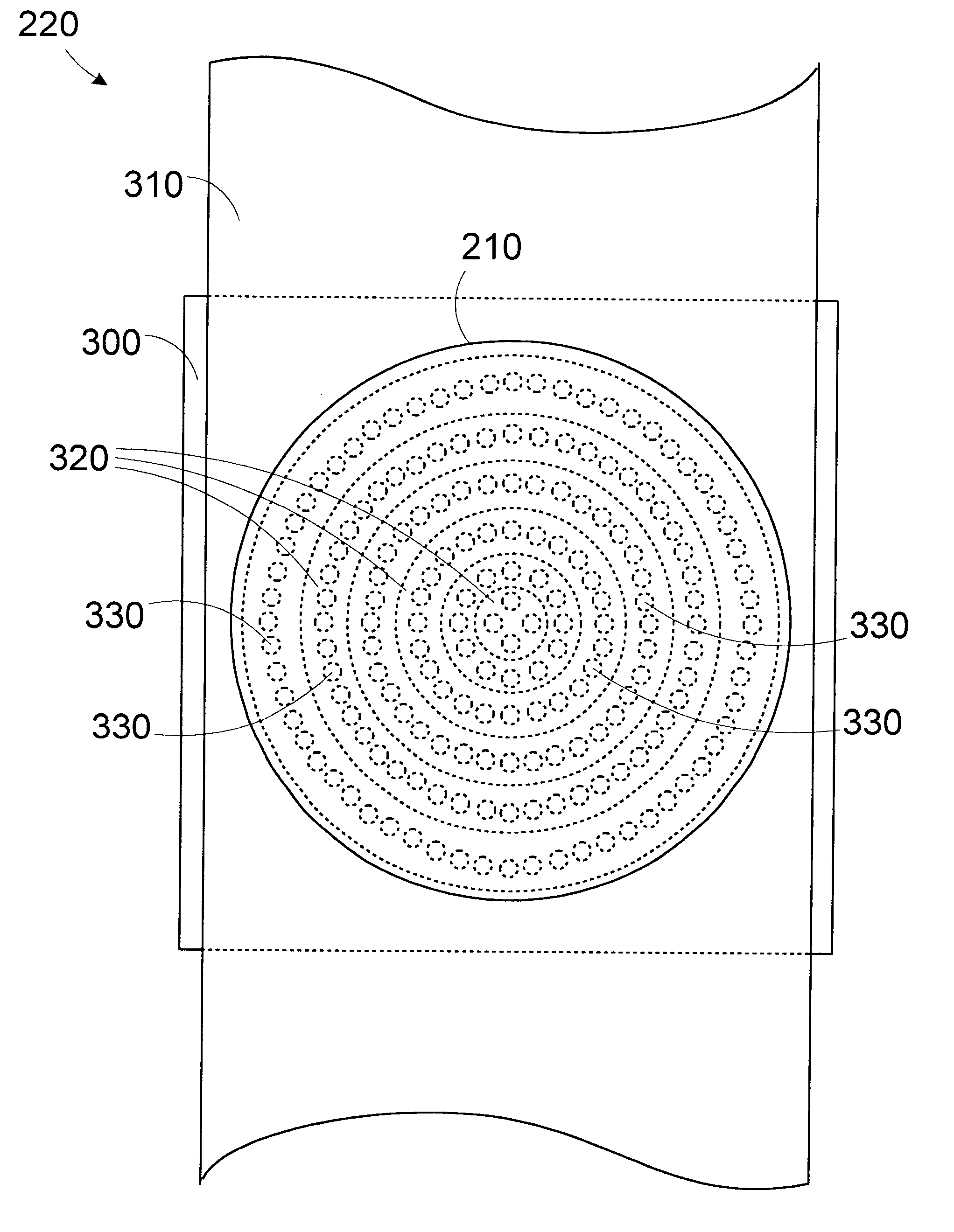

A polishing body, e.g., pad (200, 230, 260, 300) or belt (400, 500) having a polishing layer (214, 404) that includes a backmixing region (202, 232, 262, 308, 416, 508) wherein backmixing can occur within a slurry (116) between a wafer (204, 234, 264, 304, 408), or other article, and the polishing layer under certain conditions. The polishing layer includes a first groove configuration (206, 236, 266, 312, 428, 504) within the backmixing region and a second grove configuration (208, 238, 268, 320, 432, 520) outside of the backmixing region that is different from the first groove configuration. The first groove configuration is designed based upon whether or not the presence of spent slurry within the backmixing region is detrimental or beneficial to polishing the wafer.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Conductive polishing pad with anode and cathode

A conductive polishing pad that includes one or more anodes and one or more cathodes formed at or near the polishing surface of a polishing pad. The anodes and cathodes are connected to a wiring network that is part of an electrical connector system that allows for a current source to be connected to the polishing pad and provide a current to the anodes and cathodes even if the polishing pad is moving relative to the current source. An electrolytic polishing fluid introduced between the polishing surface and the metal layer of a wafer forms an electrical circuit between the anode, cathode and the metal layer. The conductive polishing pad allows for electrochemical mechanical polishing (ECMP) to be performed on a conventional chemical mechanical polishing (CMP) tool.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

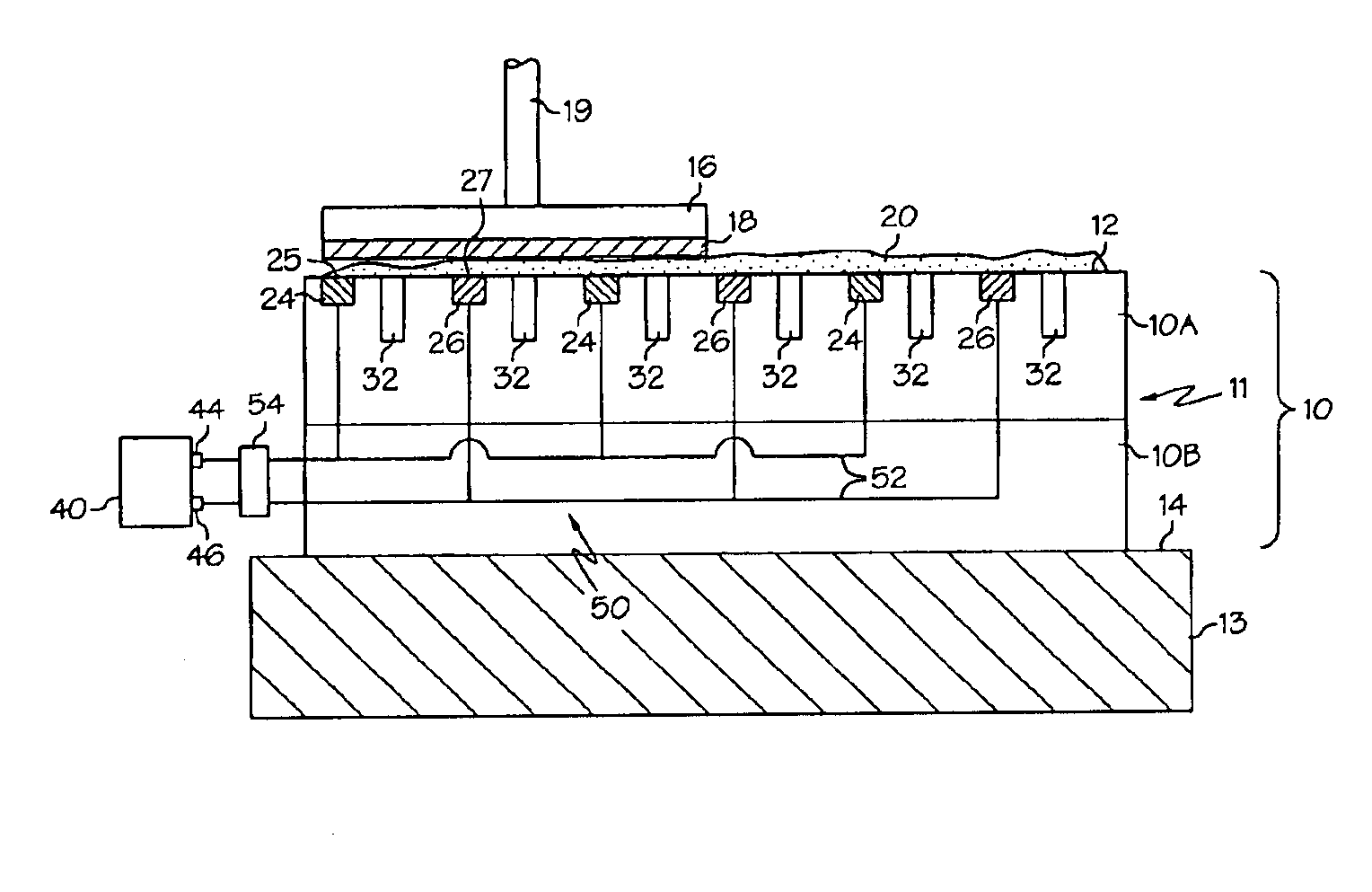

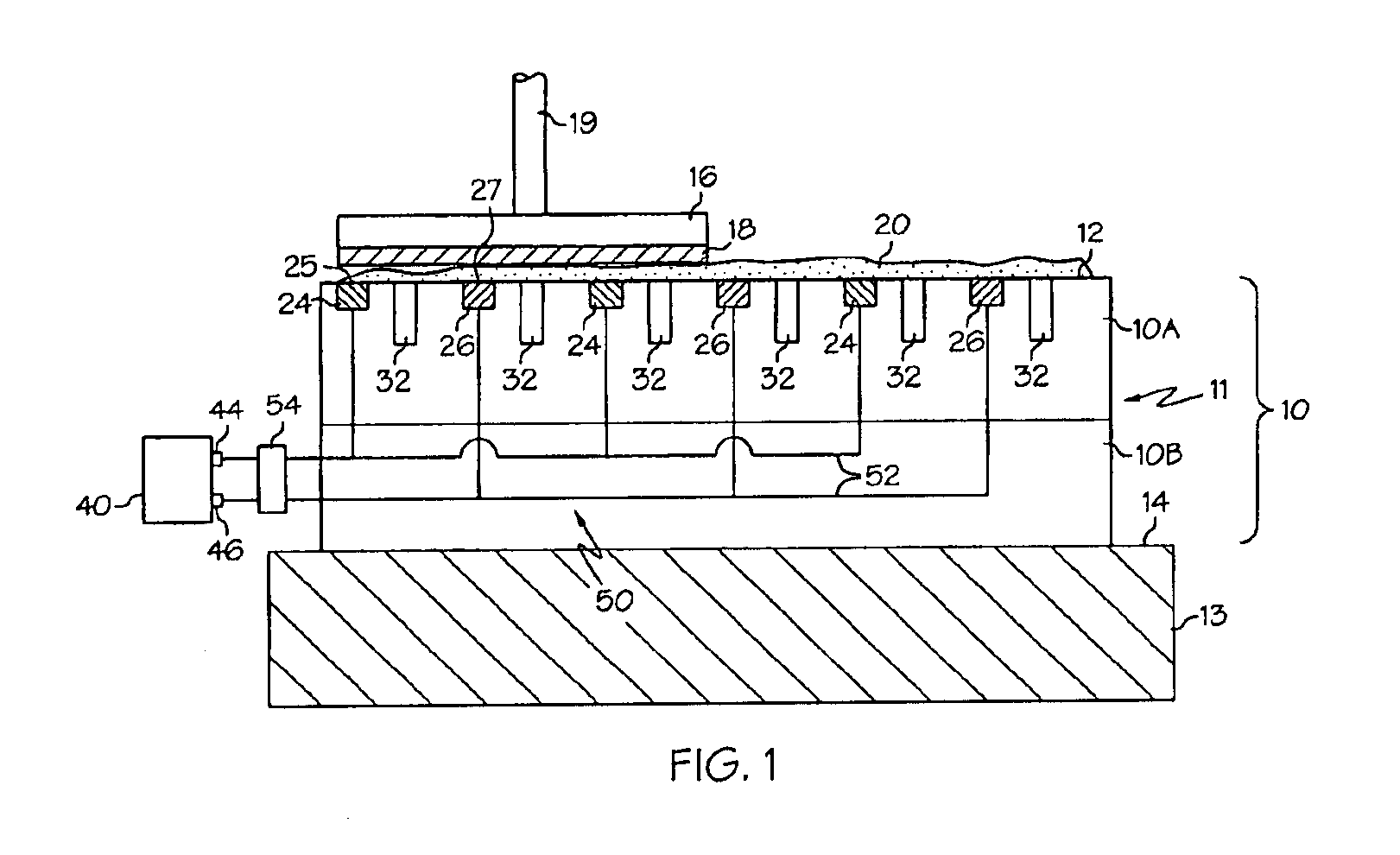

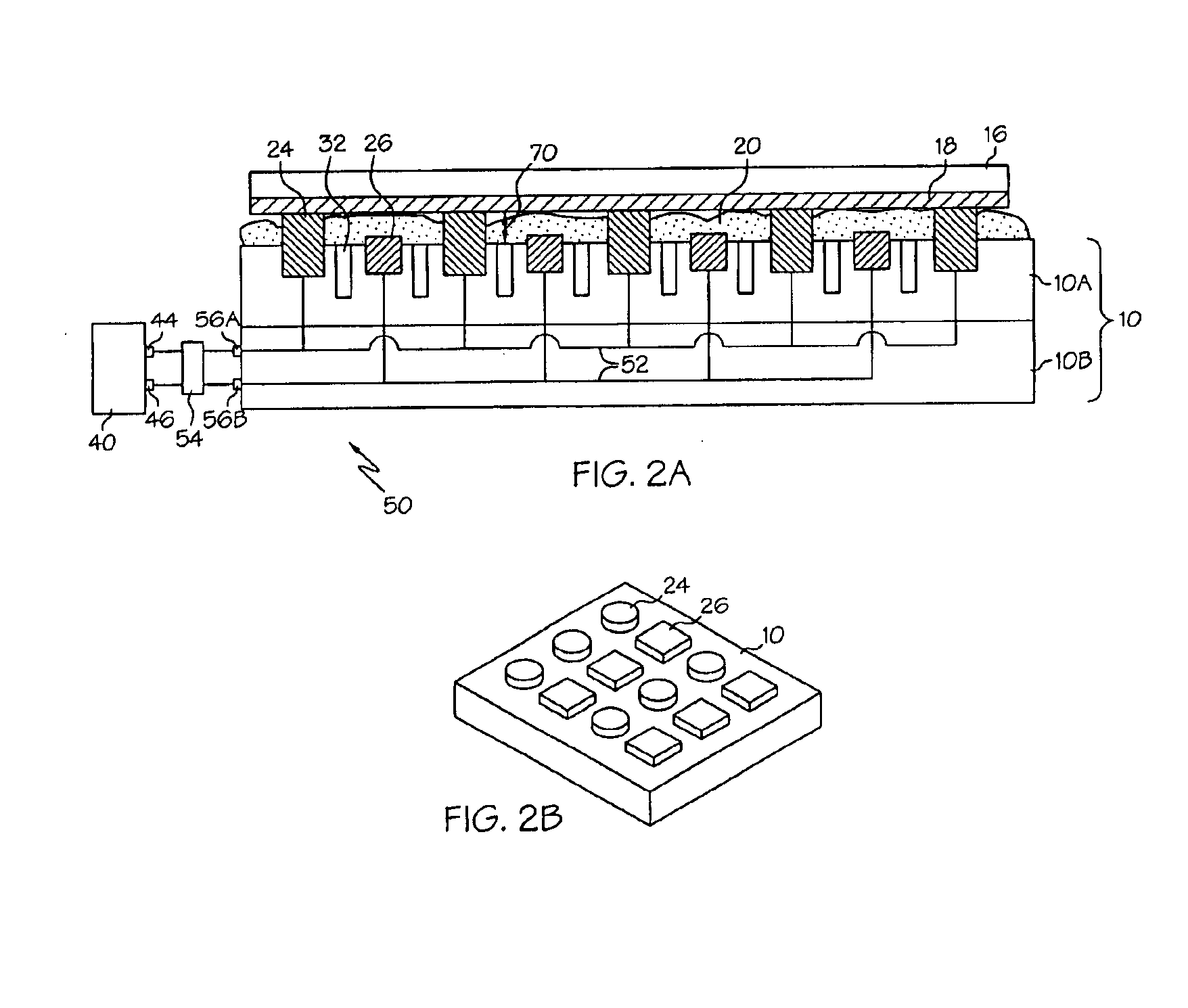

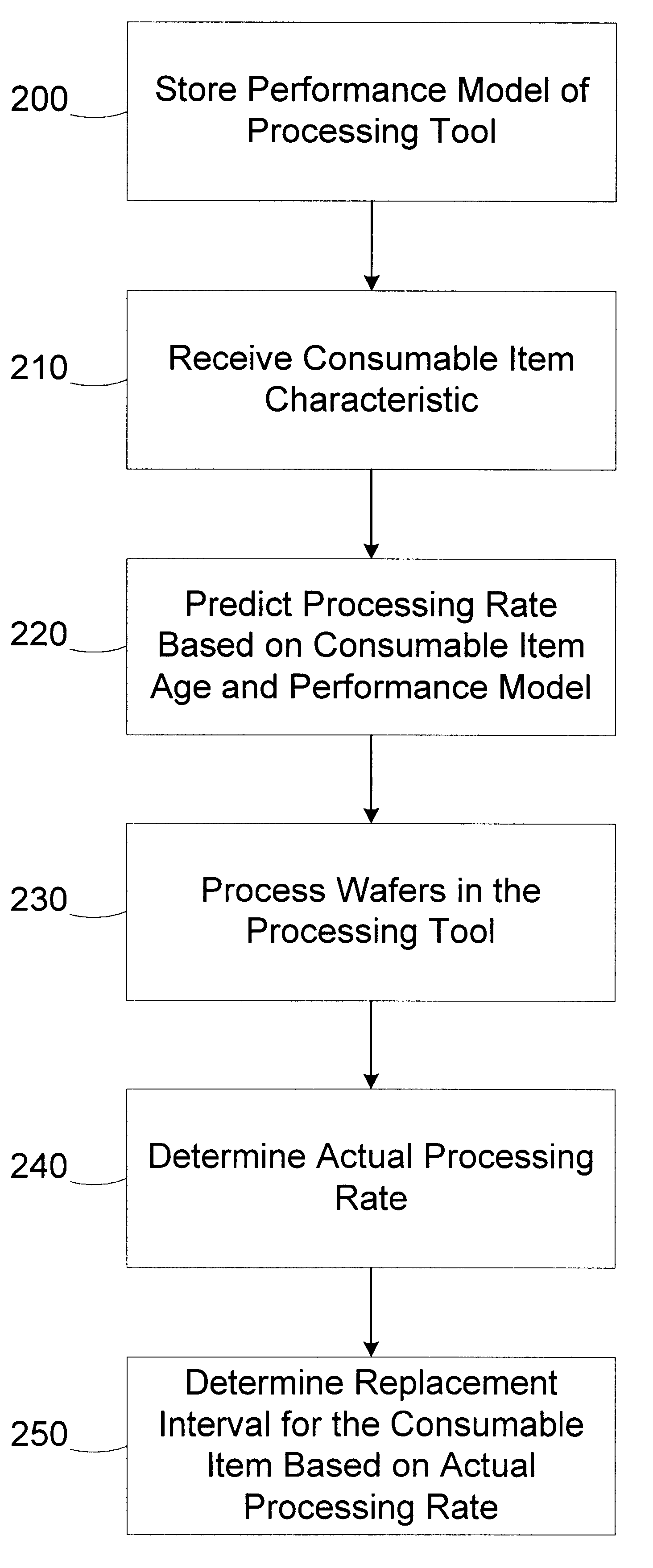

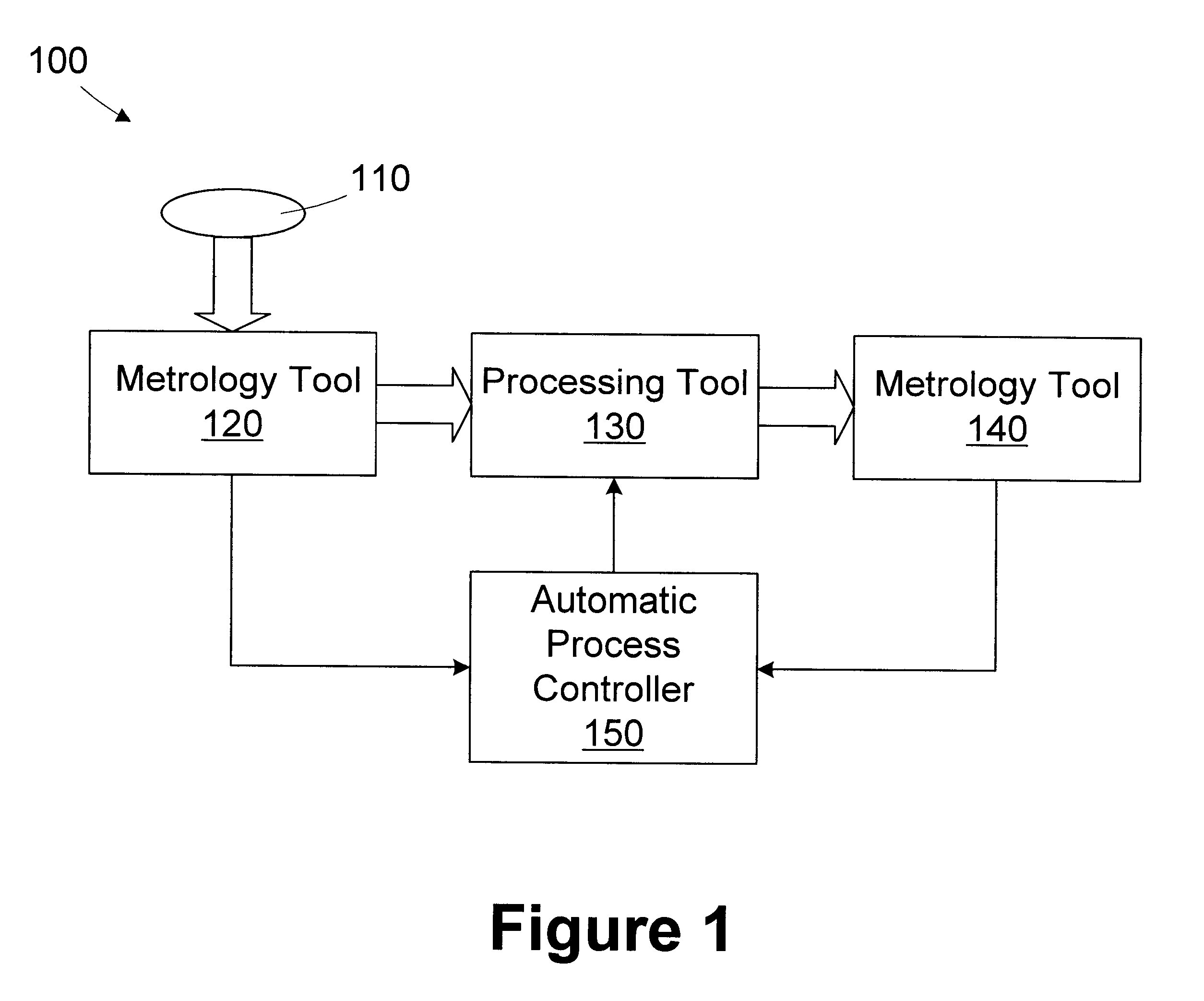

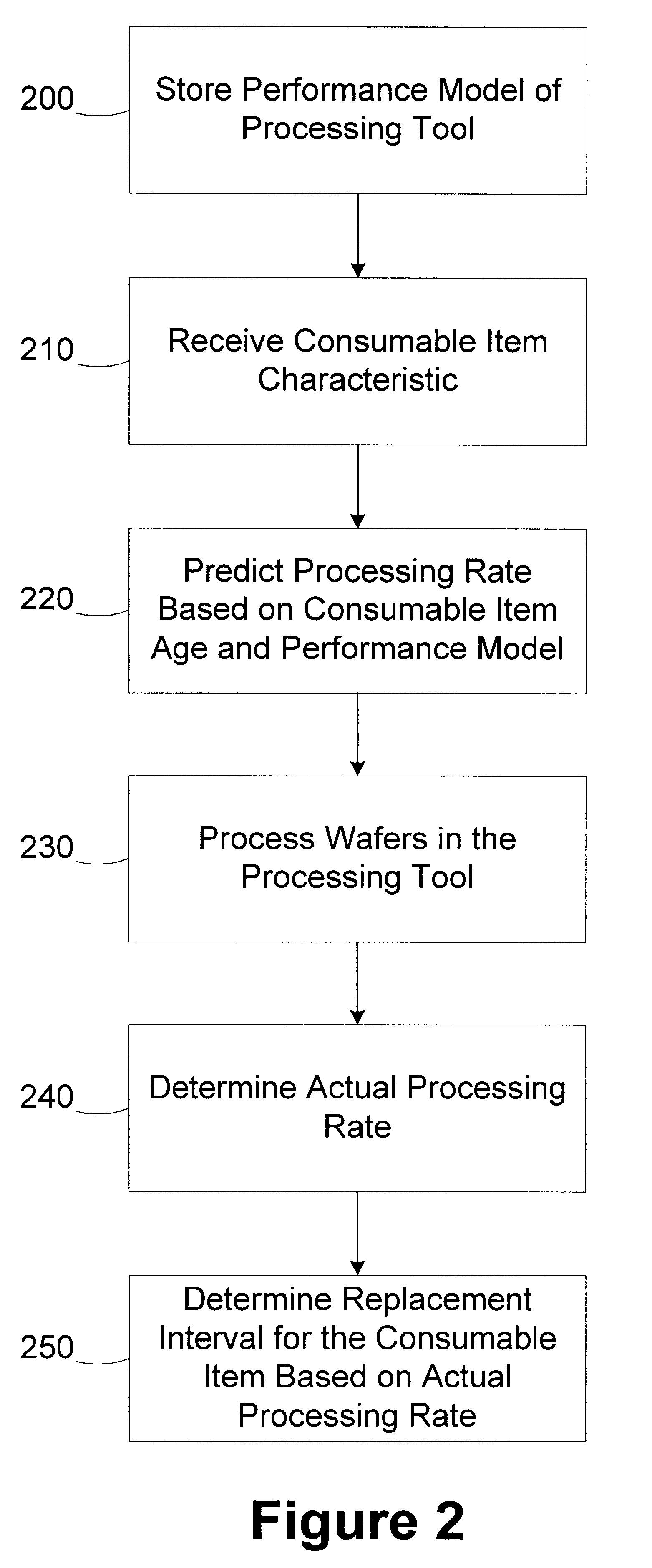

Method and apparatus for monitoring consumable performance

InactiveUS6567718B1Polishing machinesRevolution surface grinding machinesParallel computingAutomatic process control

A method for monitoring consumable performance in a processing tool comprises storing a performance model of the processing tool; receiving a consumable item characteristic of a consumable item in the processing tool; determining a predicted processing rate for the processing tool based on the consumable item characteristic and the performance model; determining an actual processing rate of the processing tool; and determining a replacement interval for the consumable item based on at least the actual processing rate. A processing system includes a processing tool and an automatic process controller. The processing tool is adapted to process wafers and includes a consumable item.

Owner:GLOBALFOUNDRIES US INC

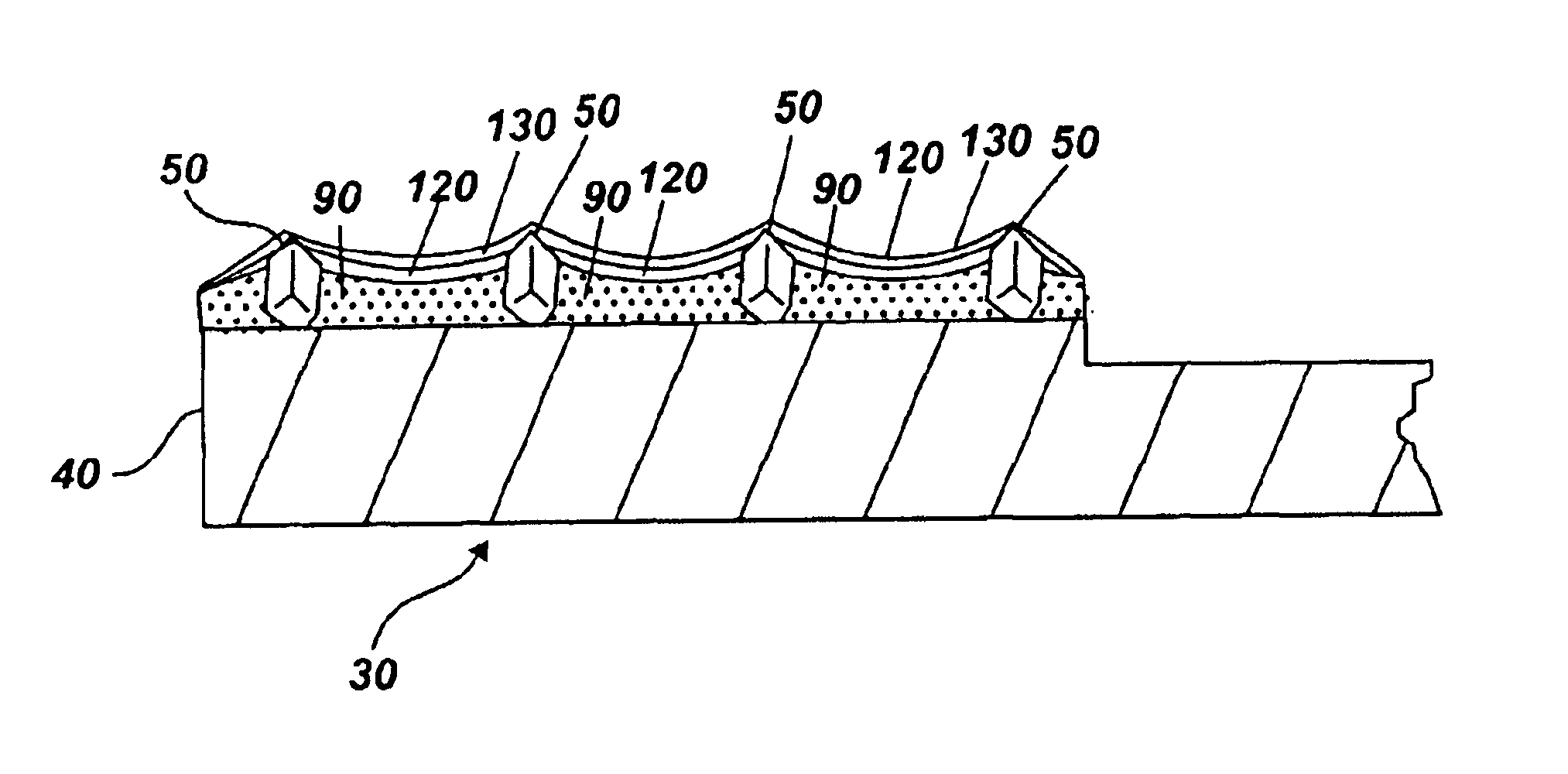

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

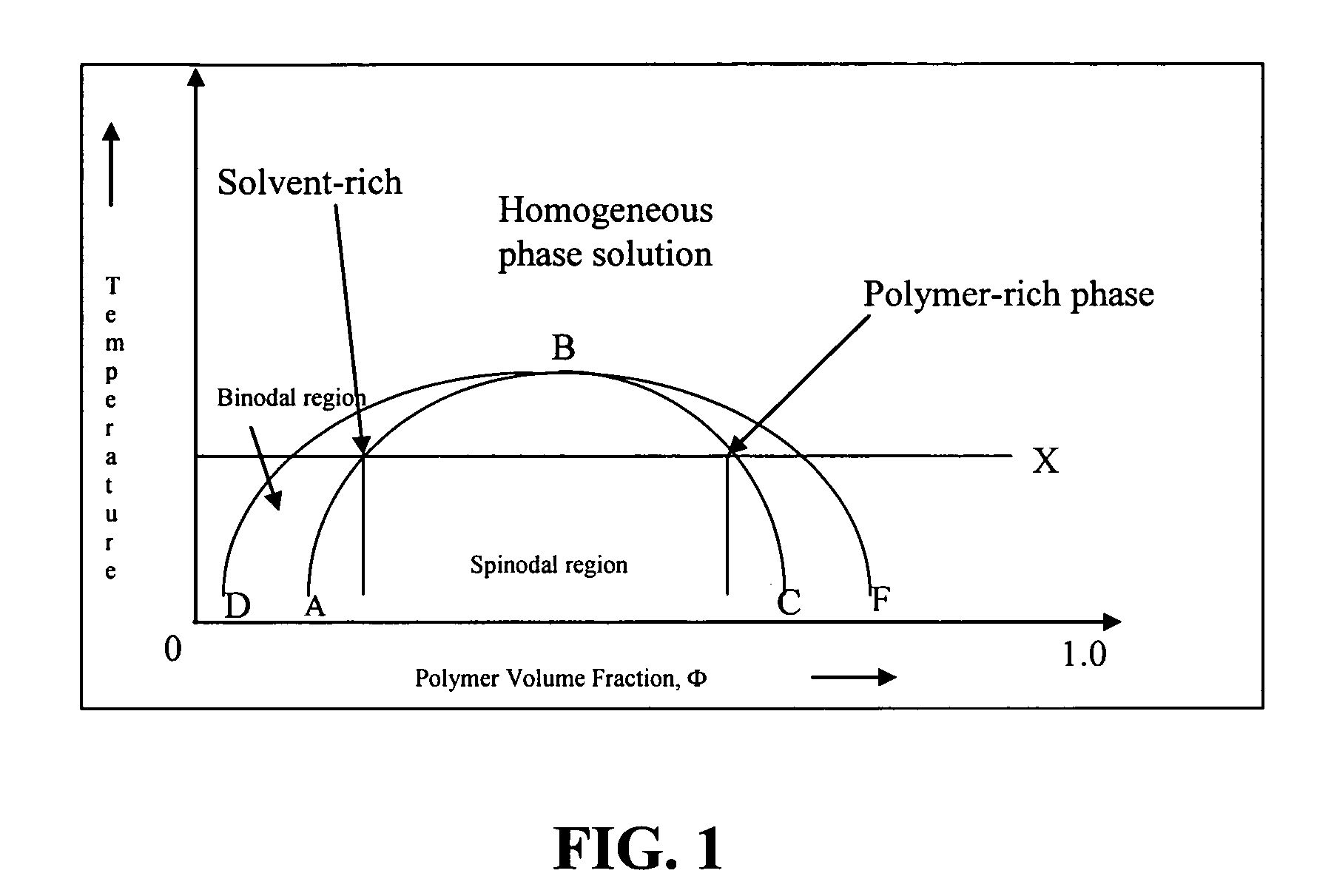

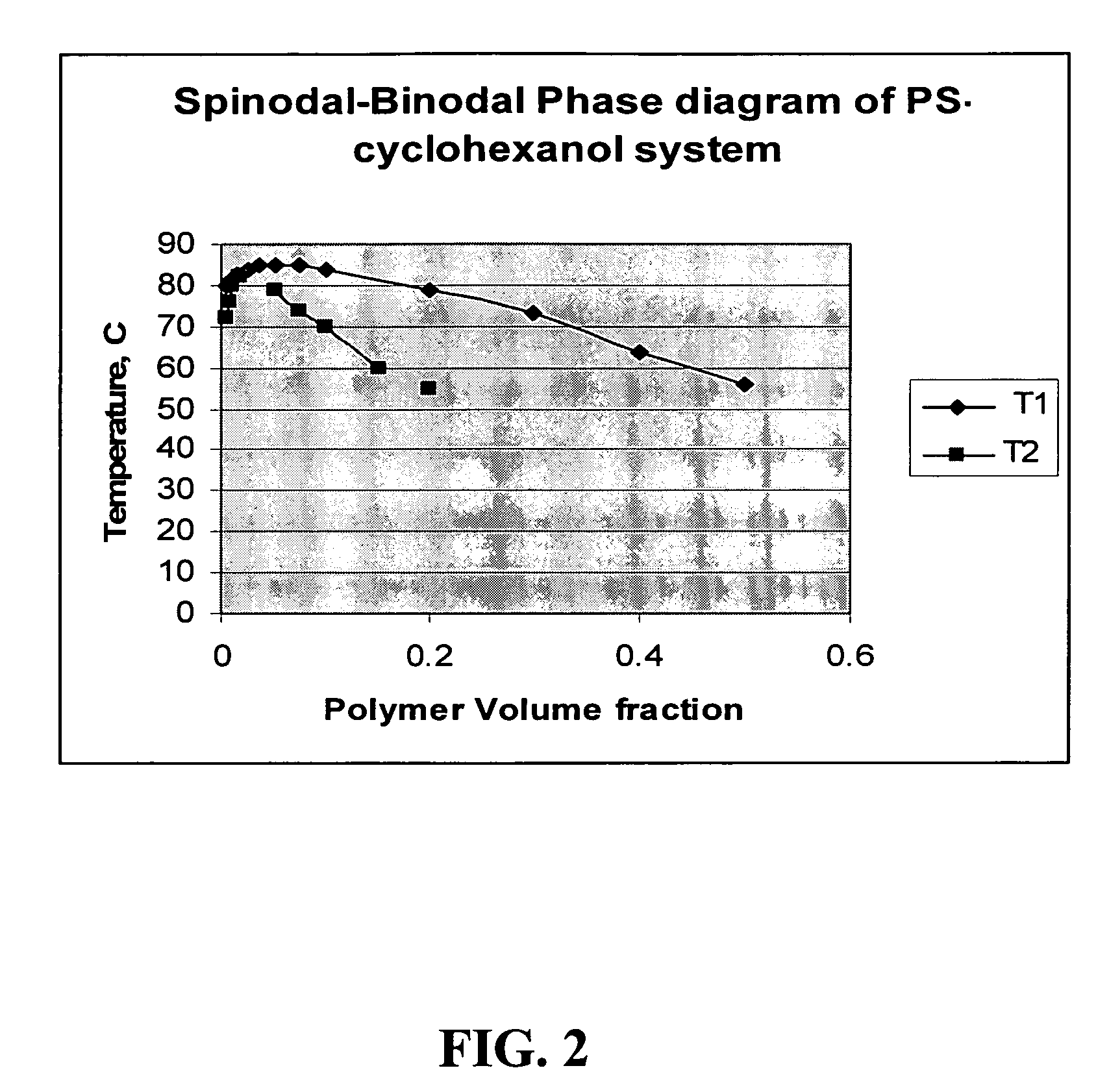

Method for manufacturing microporous CMP materials having controlled pore size

A method of manufacturing a chemical-mechanical polishing (CMP) pad comprises the steps of (a) forming a layer of a polymer resin liquid solution (i.e., a polymer resin dissolved in a solvent); (b) inducing a phase separation in the layer of polymer solution to produce an interpenetrating polymeric network comprising a continuous polymer-rich phase interspersed with a continuous polymer-depleted phase in which the polymer-depleted phase constitutes about 20 to about 90 percent of the combined volume of the phases; (c) solidifying the continuous polymer-rich phase to form a porous polymer sheet; (d) removing at least a portion of the polymer-depleted phase from the porous polymer sheet; and (e) forming a CMP pad therefrom. The method provides for microporous CMP pads having a porosity and pore size that can be readily controlled by selecting the concentration polymer resin in the polymer solution, selecting the solvent based on the solubility parameters of the polymer in the solvent polarity of solvent, selecting the conditions for phase separation, and the like.

Owner:CMC MATERIALS INC

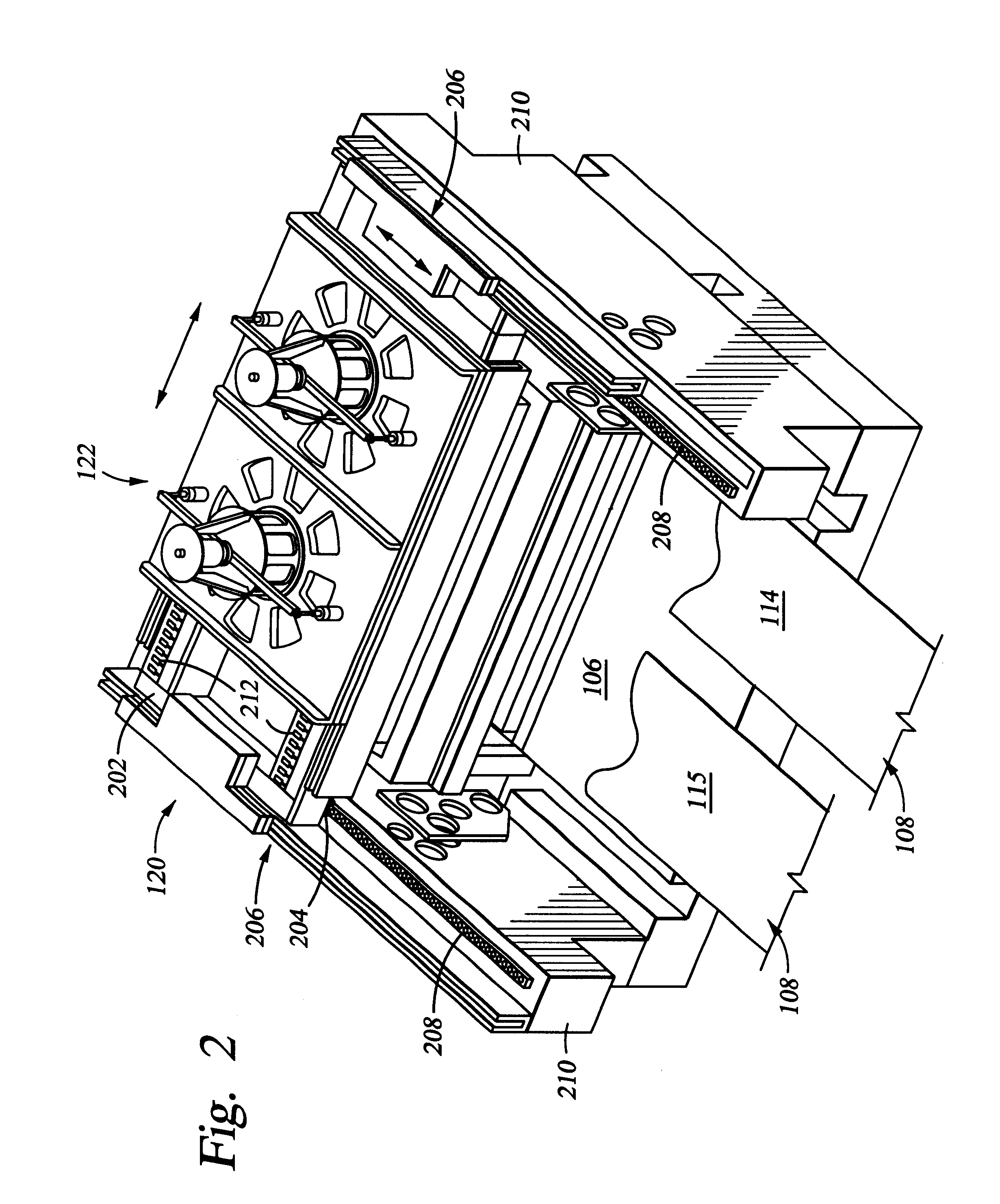

Planarization system with multiple polishing pads

InactiveUS6626744B1Edge grinding machinesPolishing machinesElectrical and Electronics engineeringHead position

An apparatus for simultaneously polishing wafers including at least a first and a second web of polishing media. At least two polishing heads are provided on a carrier coupled to a drive system such that one polishing head positions a wafer against the first web and a second polishing head positions a second wafer against the second web. The drive system imparts a programmed polishing motion or pattern to the polishing heads.

Owner:APPLIED MATERIALS INC

In situ friction detector method for finishing semiconductor wafers

A method of using of using a friction detector for finishing semiconductor wafers. The method uses secondary friction sensors which can interpolate and add improved control to finishing. The method aids control of finishing while using lubricating boundary layers in the operative finishing interface. The method aids control of differential lubricating boundary layers and improved differential finishing of semiconductor wafers. Planarization and localized finishing can be improved using differential lubricating boundary layer methods of finishing. Defects can be reduced using the in situ friction detector method.

Owner:SEMCON TECH +1

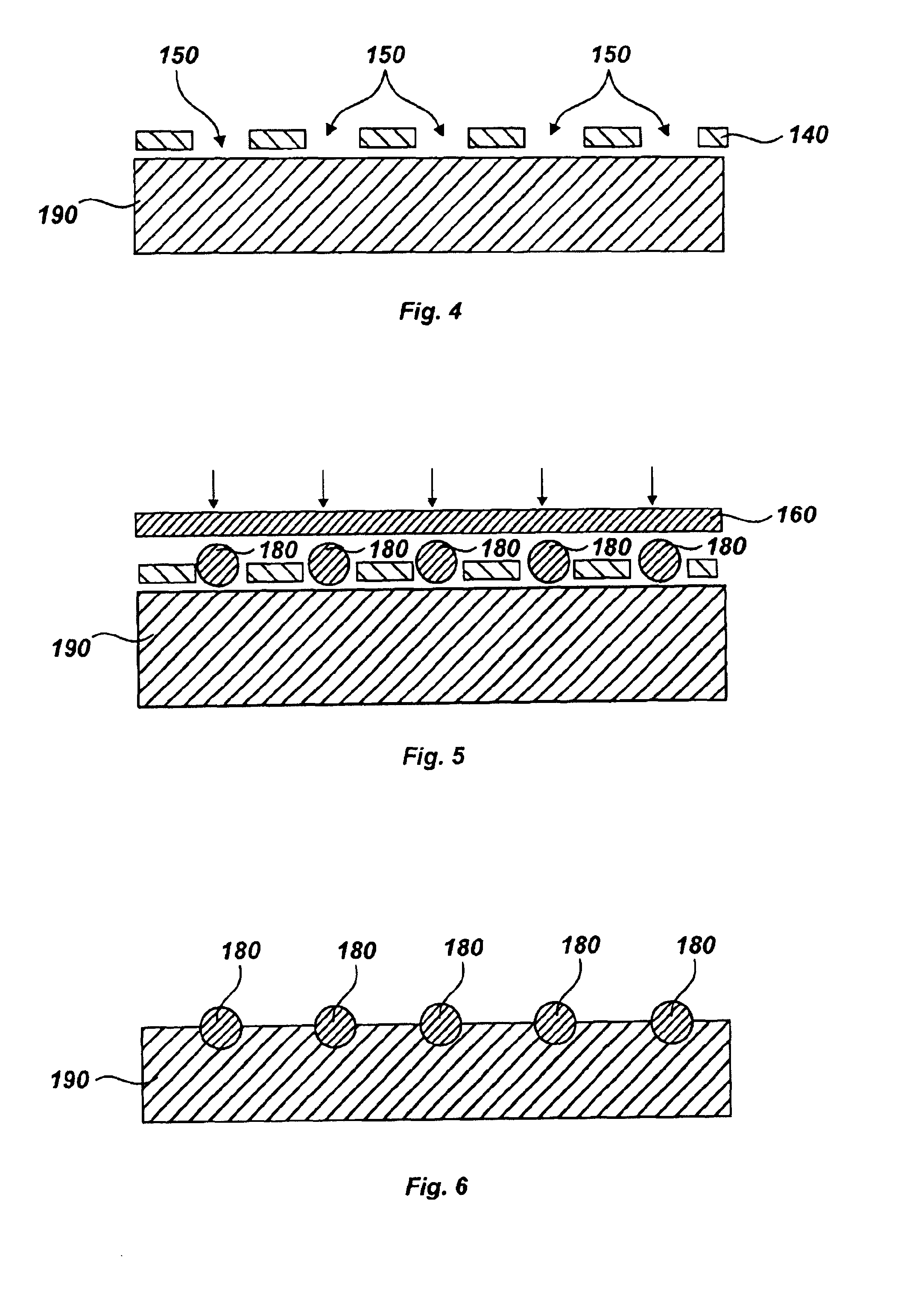

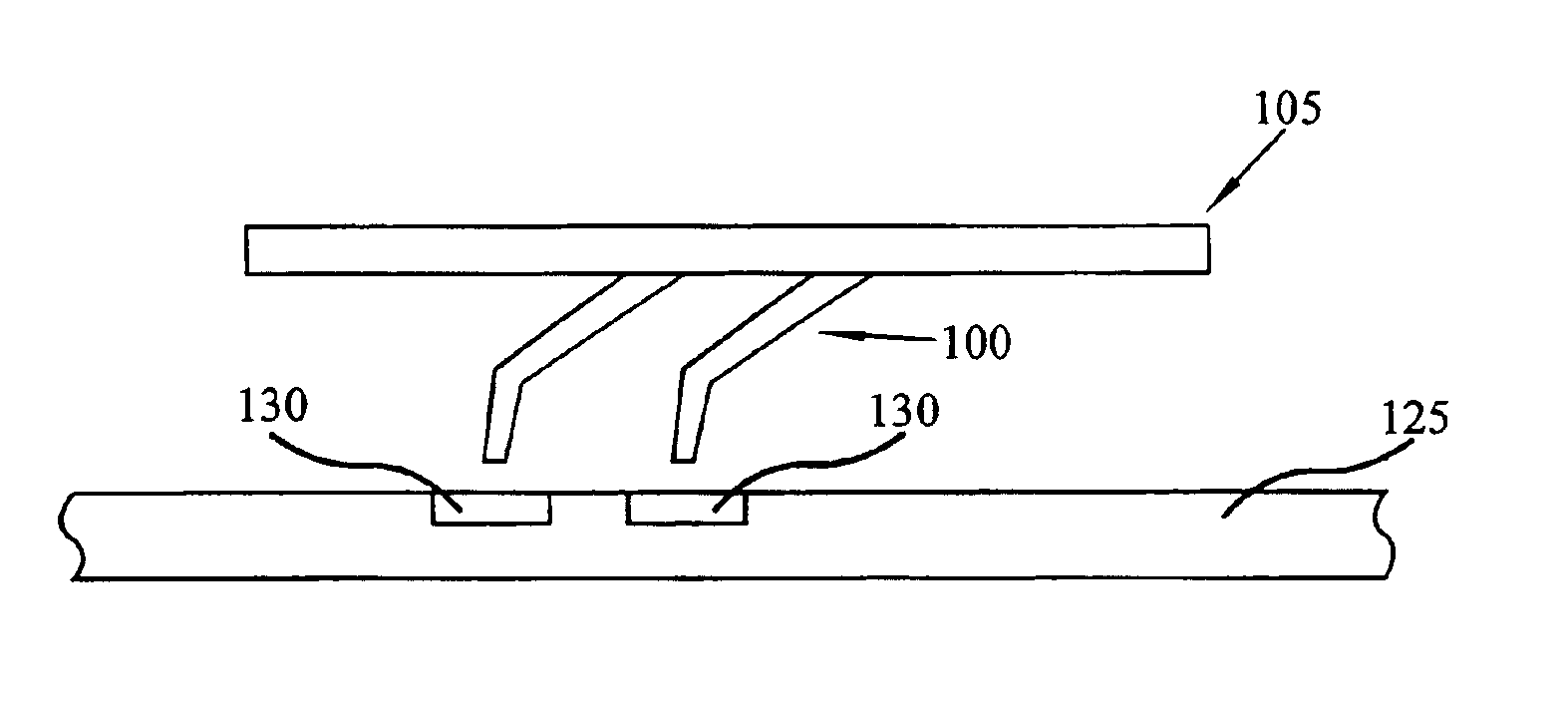

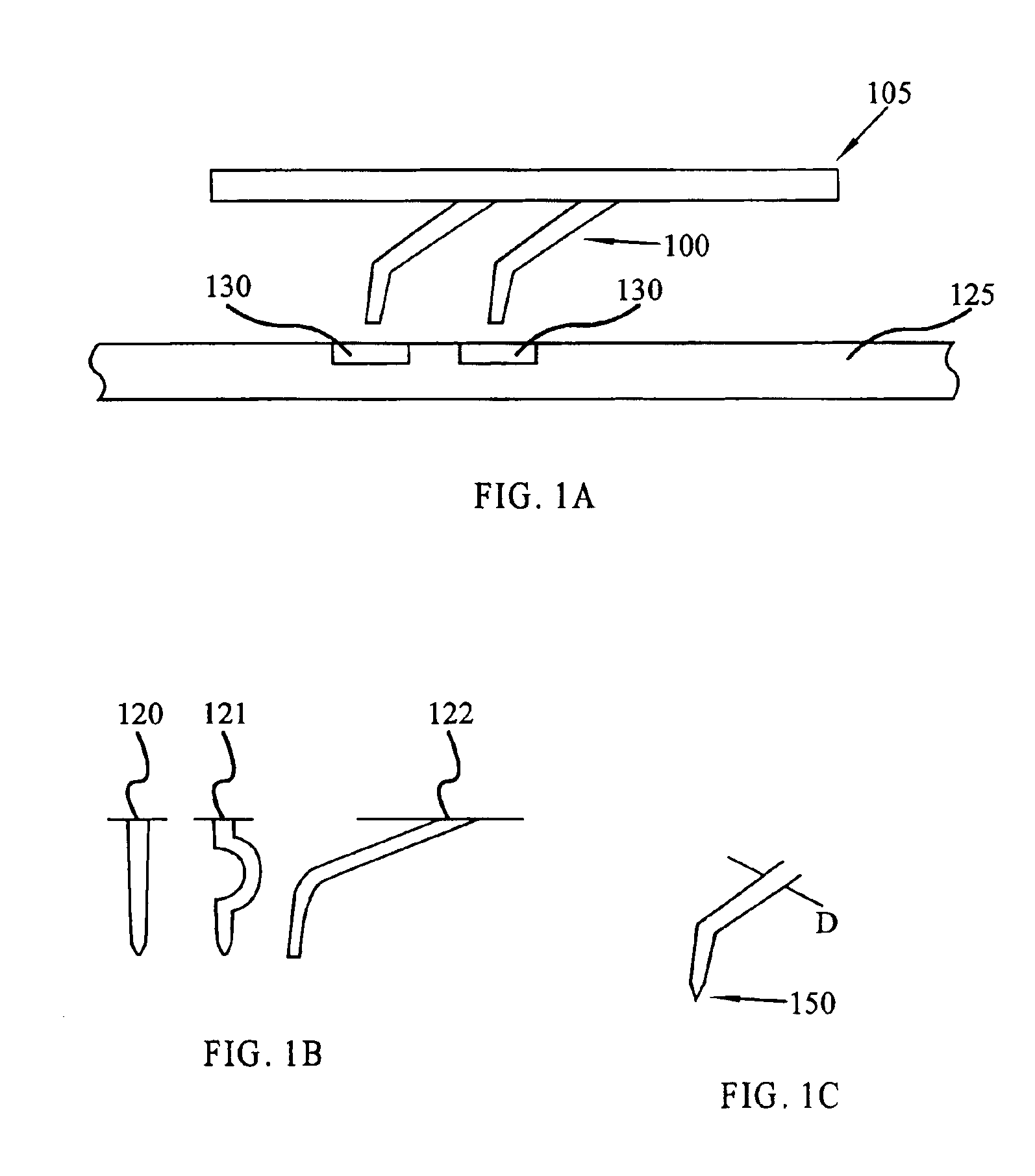

Method and apparatus for probe tip cleaning and shaping pad

A method and apparatus is provided for cleaning and shaping a probe tip using a multi-layer adhesive and abrasive pad. The multi-layer adhesive and abrasive pad is constructed on the surface of a support structure, such as a silicon wafer, and is made of an adhesive in contact with abrasive particles. Adhesive is applied in layers with abrasive particles in-between each layer of adhesive. Abrasive particles may vary in size and material from layer to layer to achieve cleaning, shaping and polishing objectives.

Owner:SV PROBE PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com