Patents

Literature

168results about How to "Shorten polishing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

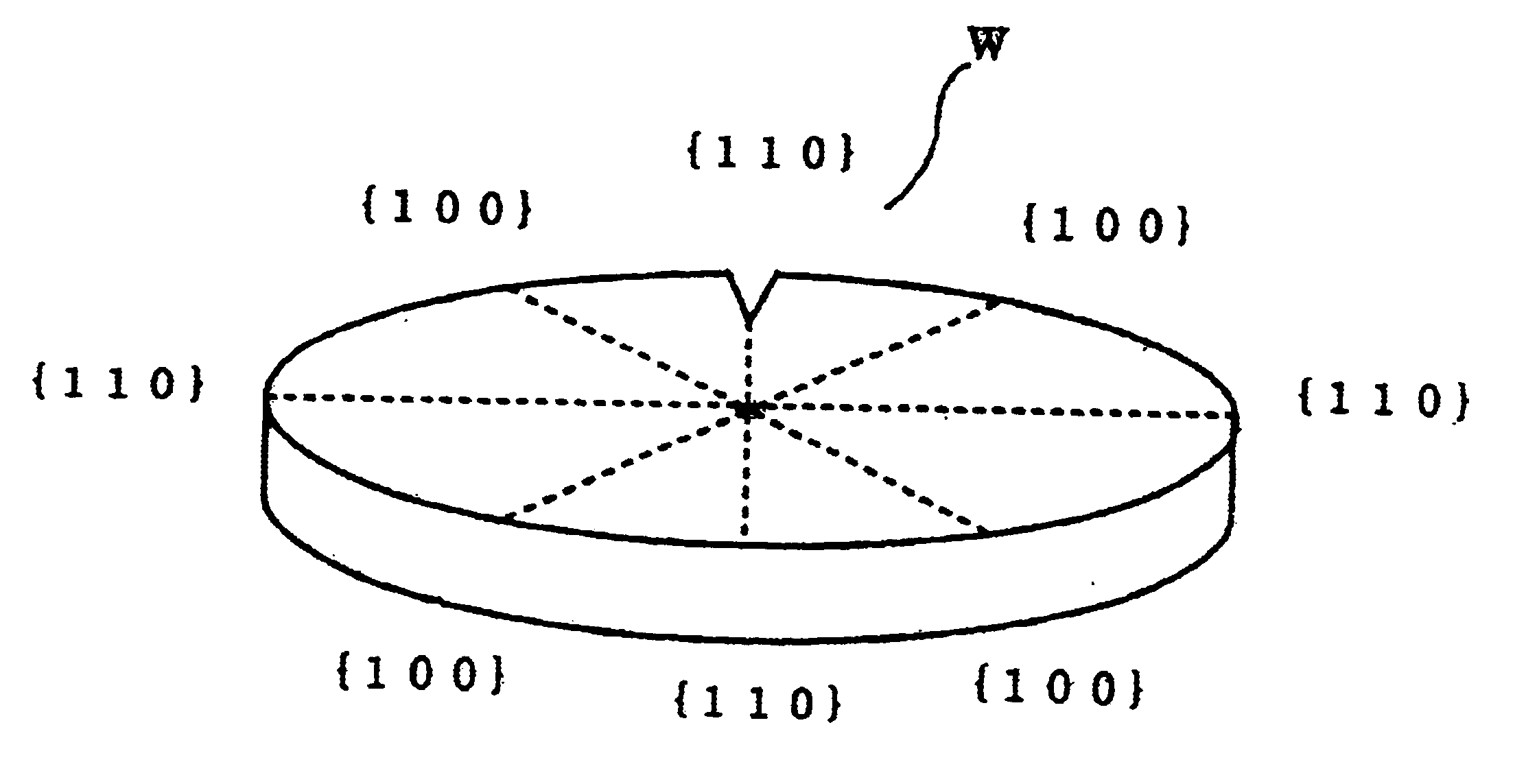

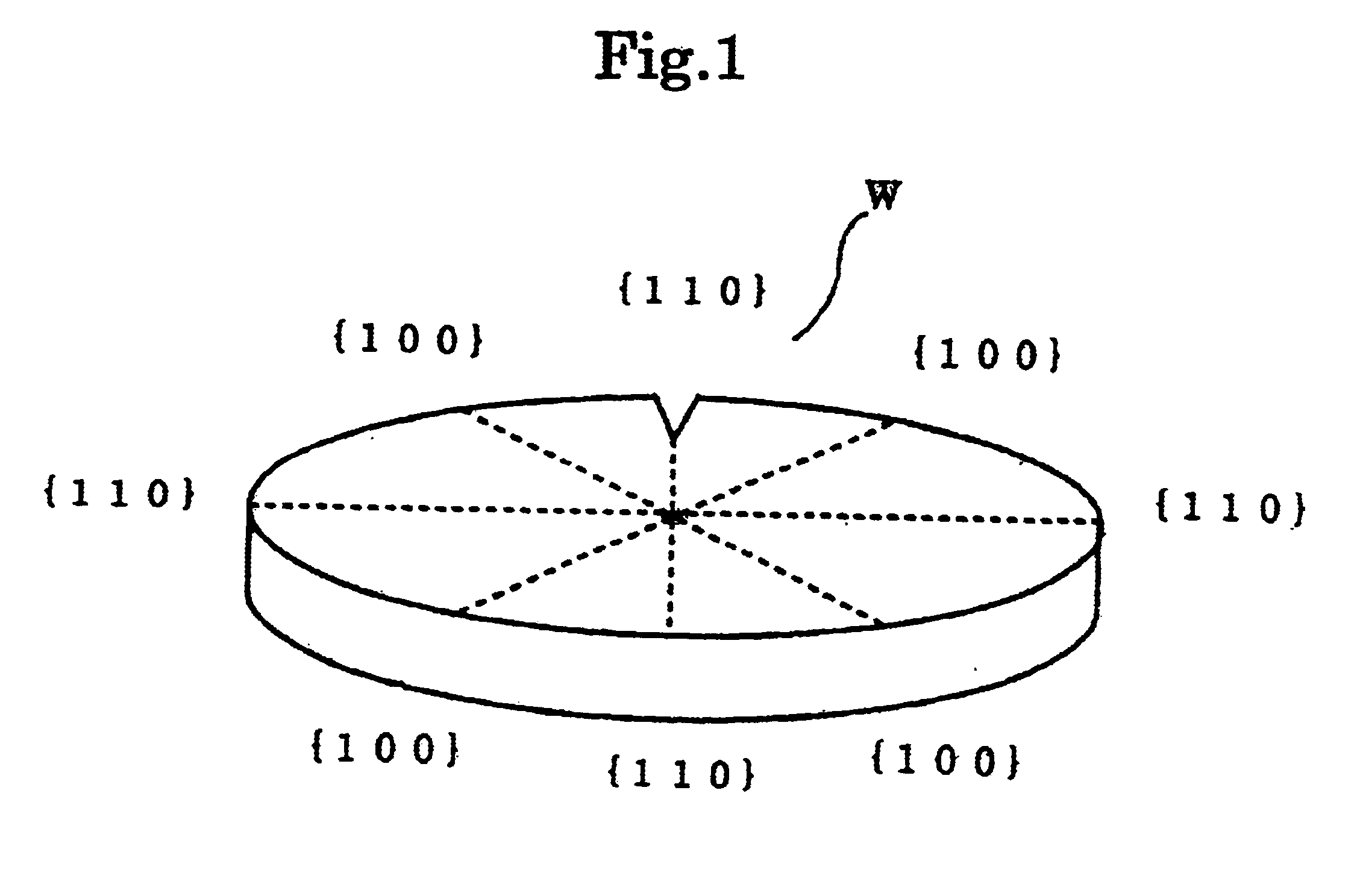

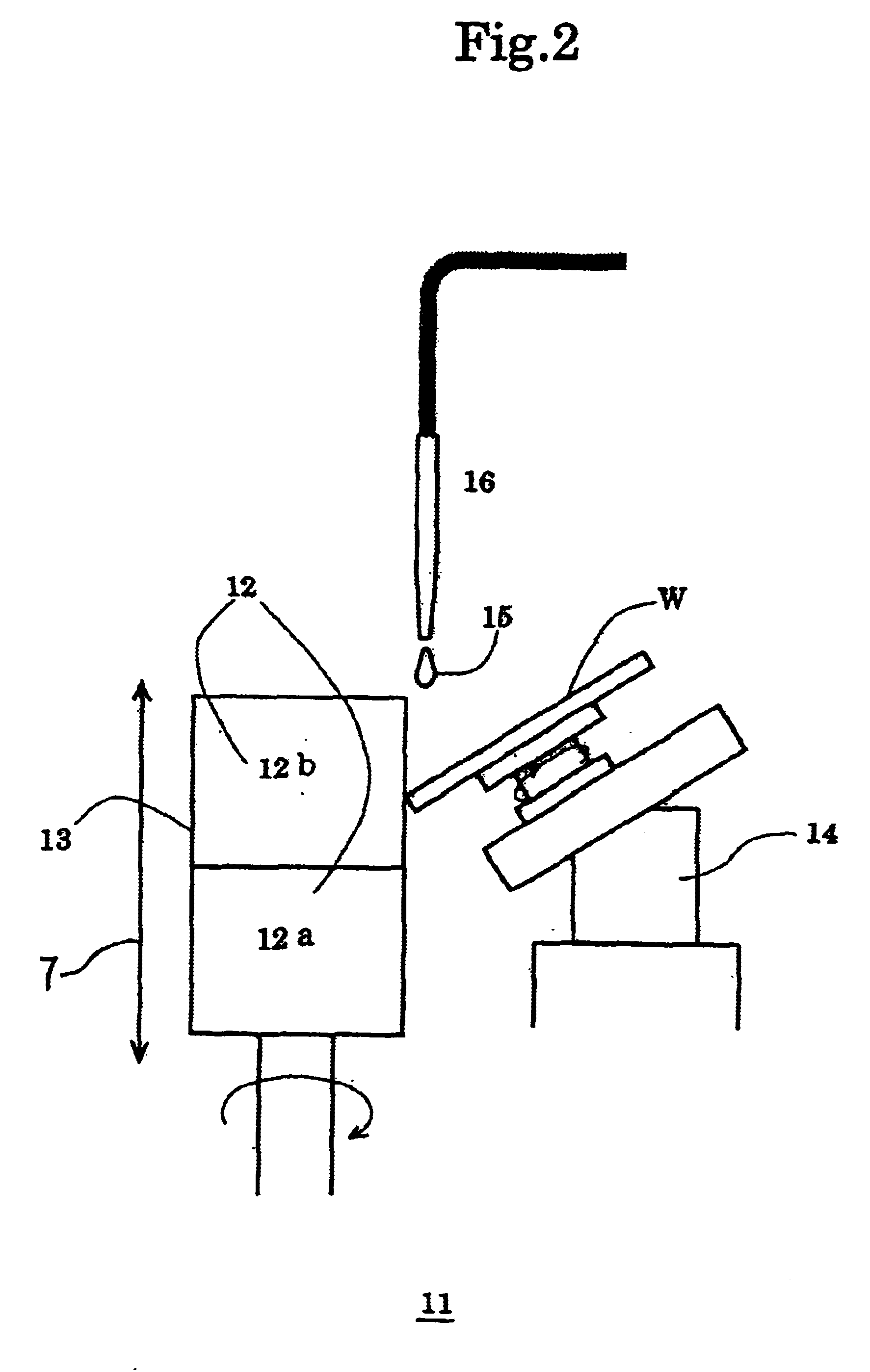

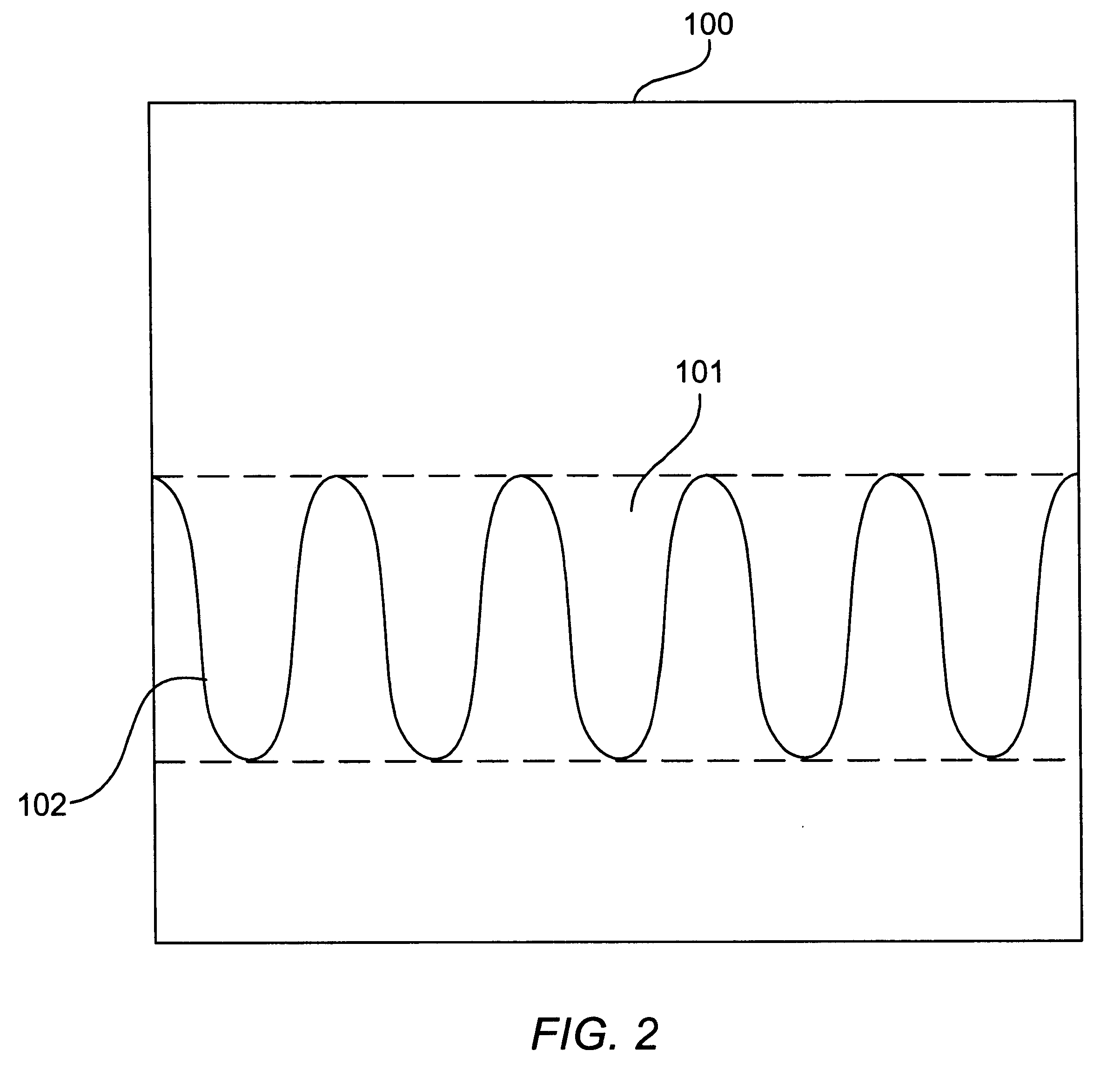

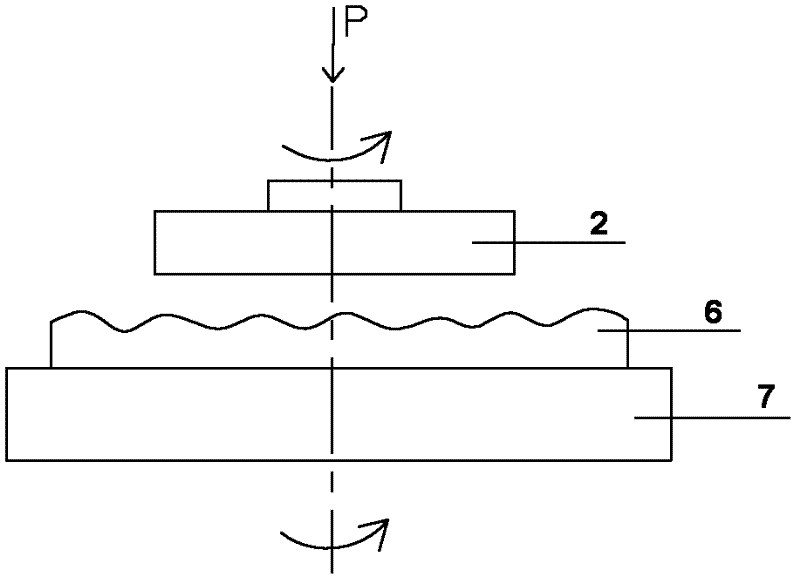

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

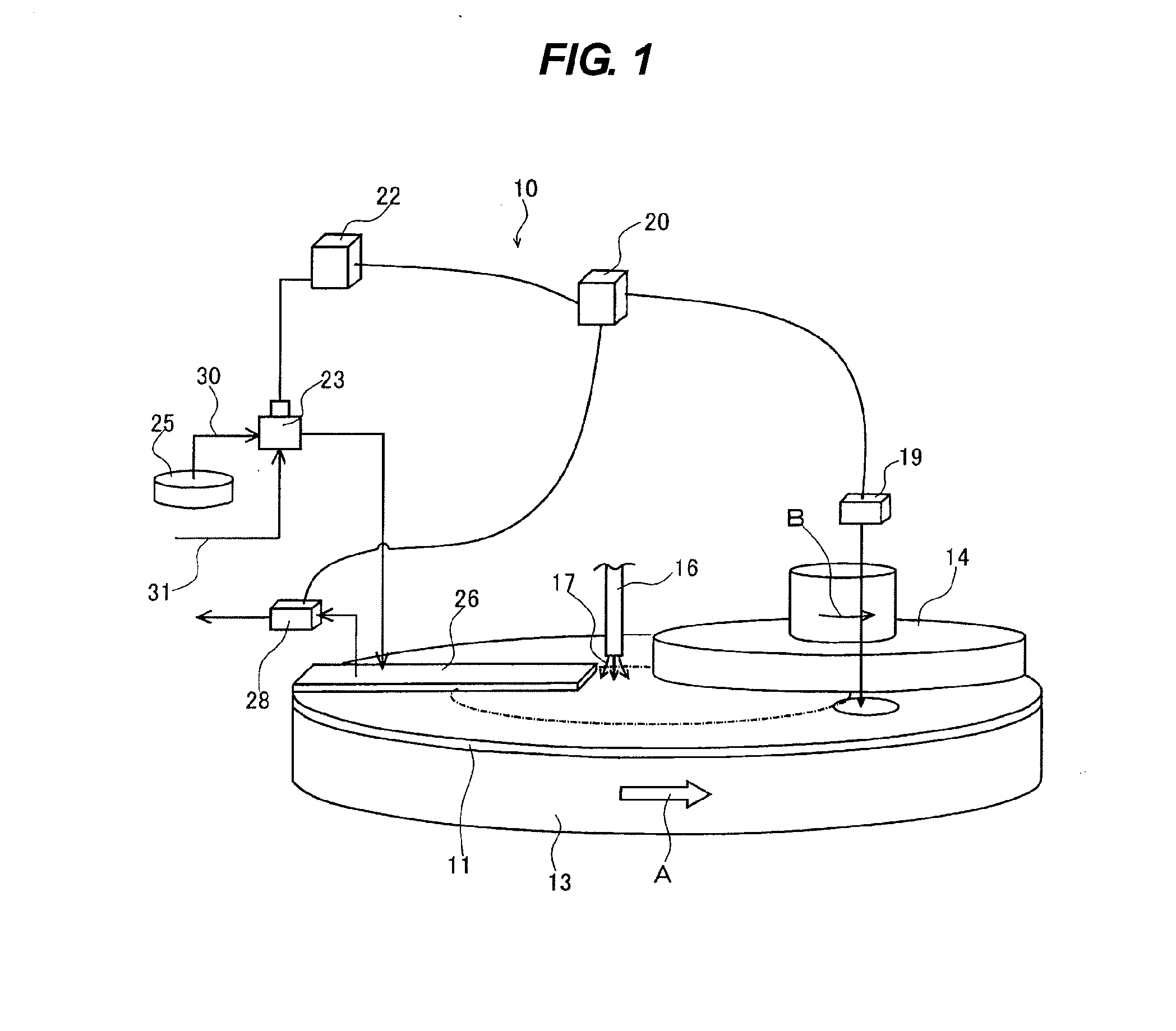

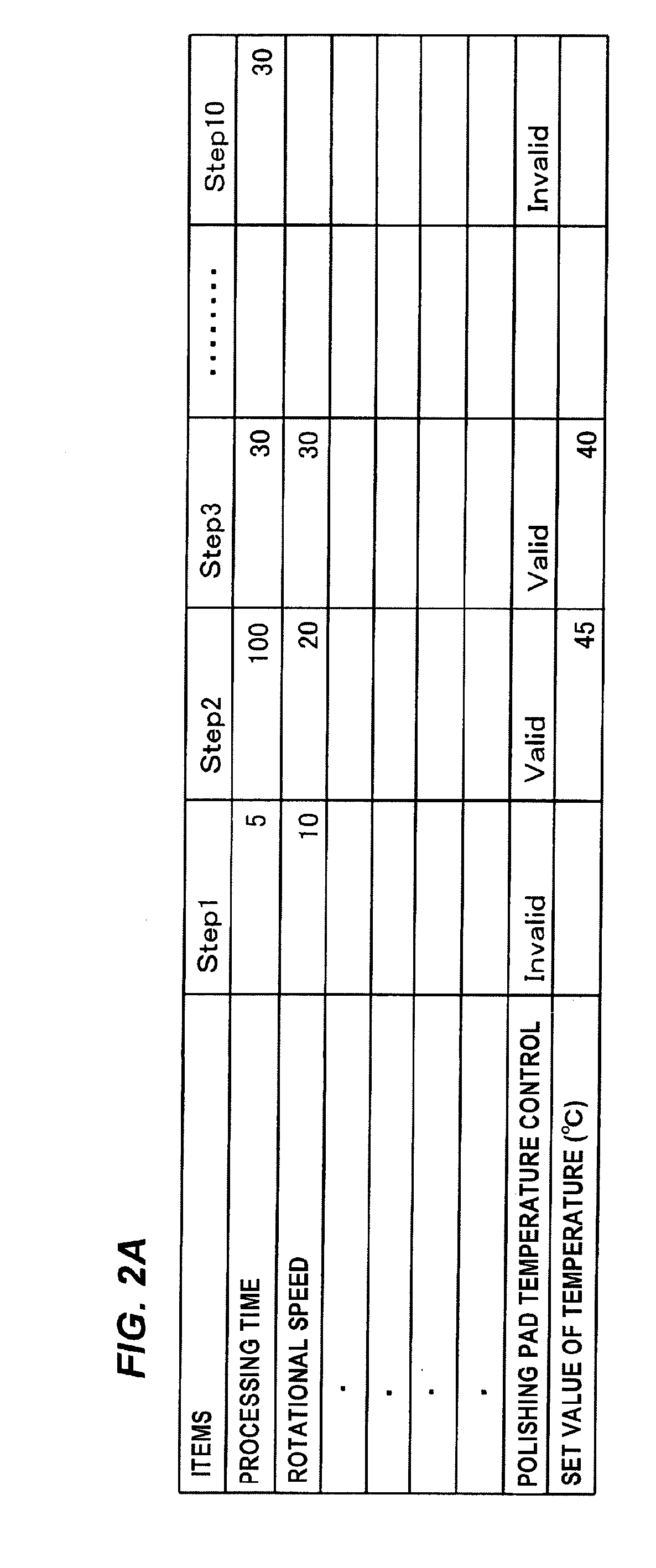

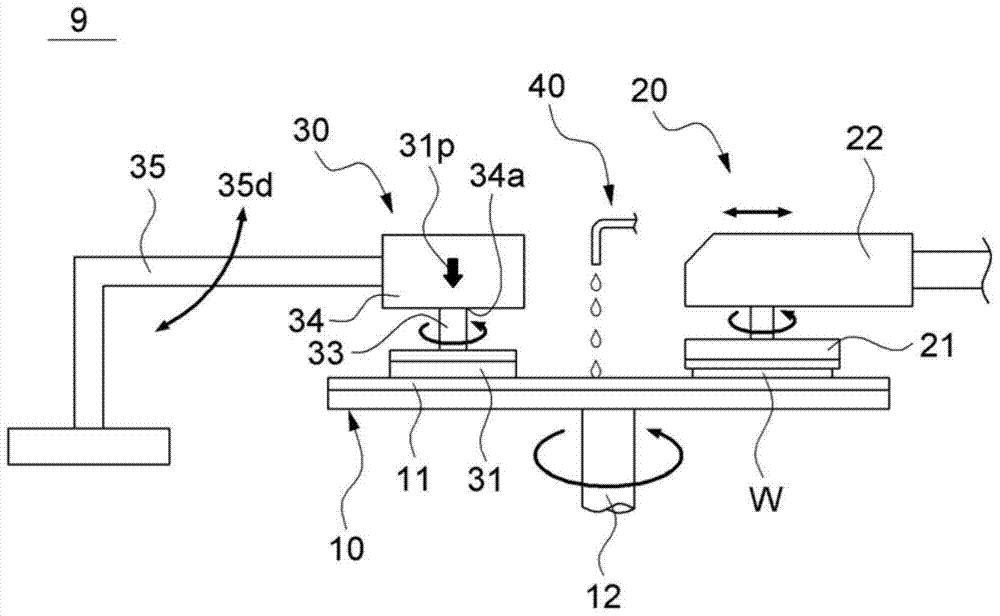

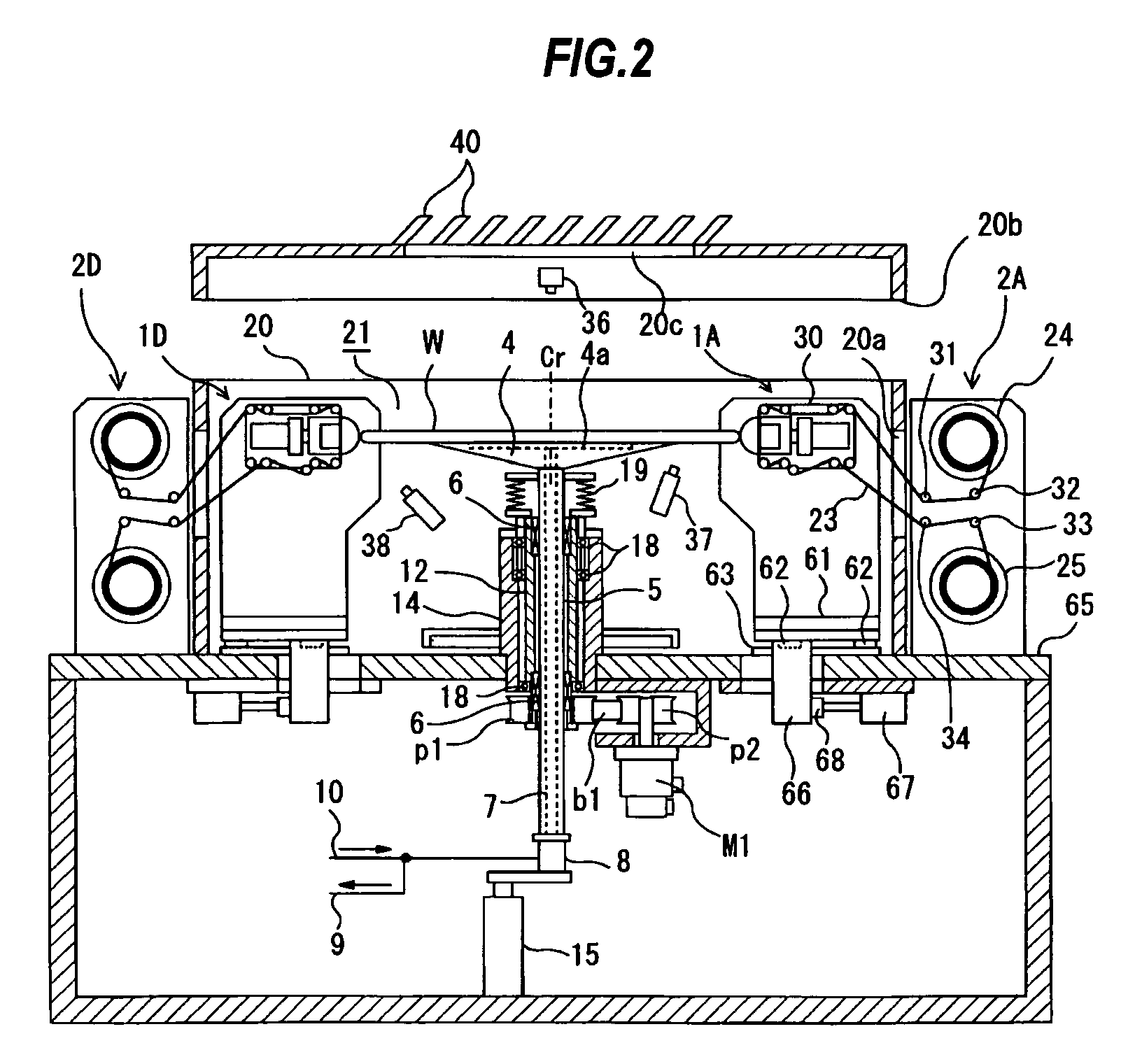

Substrate polishing apparatus, substrate polishing method, and apparatus for regulating temperature of polishing surface of polishing pad used in polishing apparatus

ActiveUS20110159782A1Polishing rate can be optimizedShorten polishing timeSemiconductor/solid-state device manufacturingLapping machinesTemperature controlEngineering

Owner:EBARA CORP

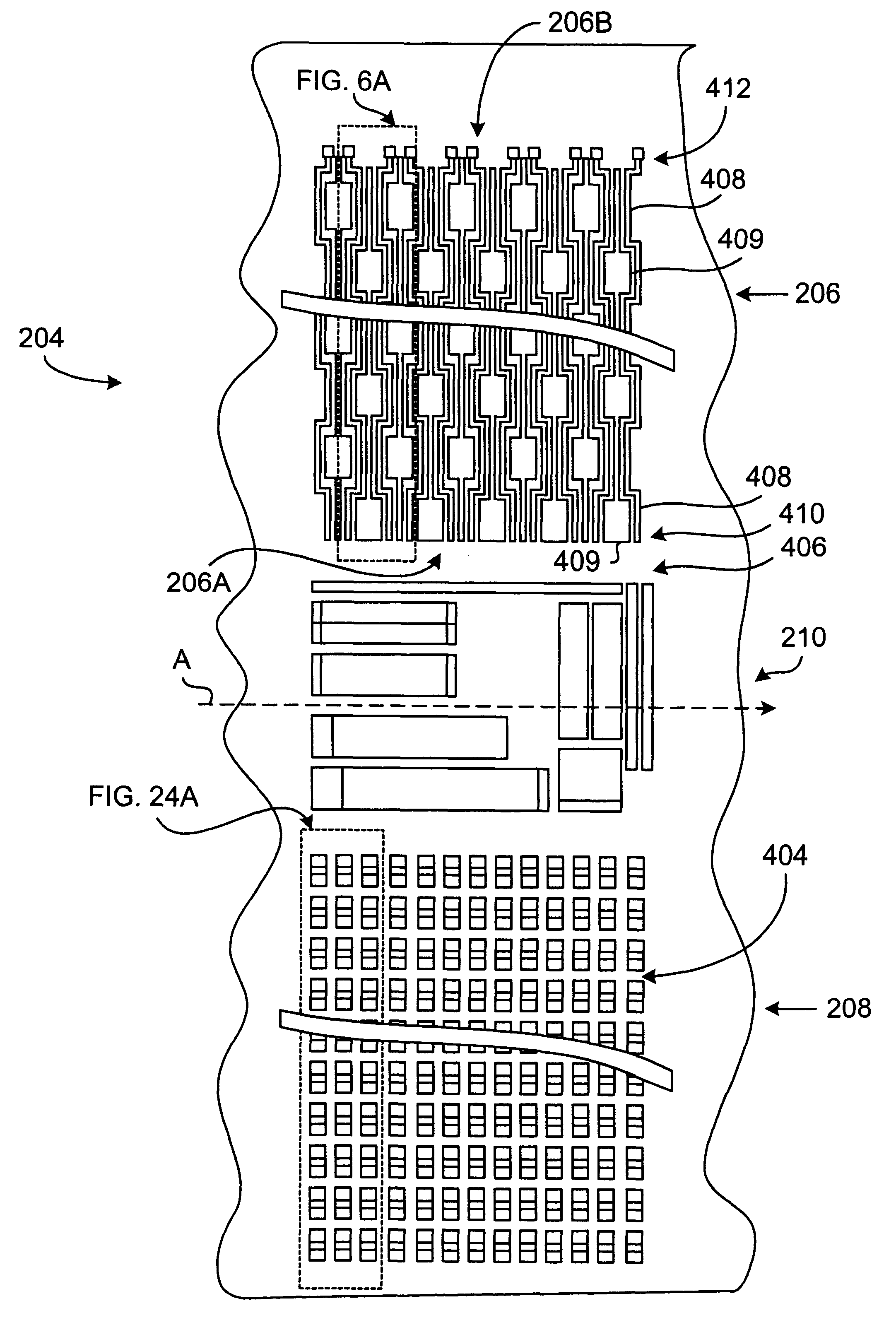

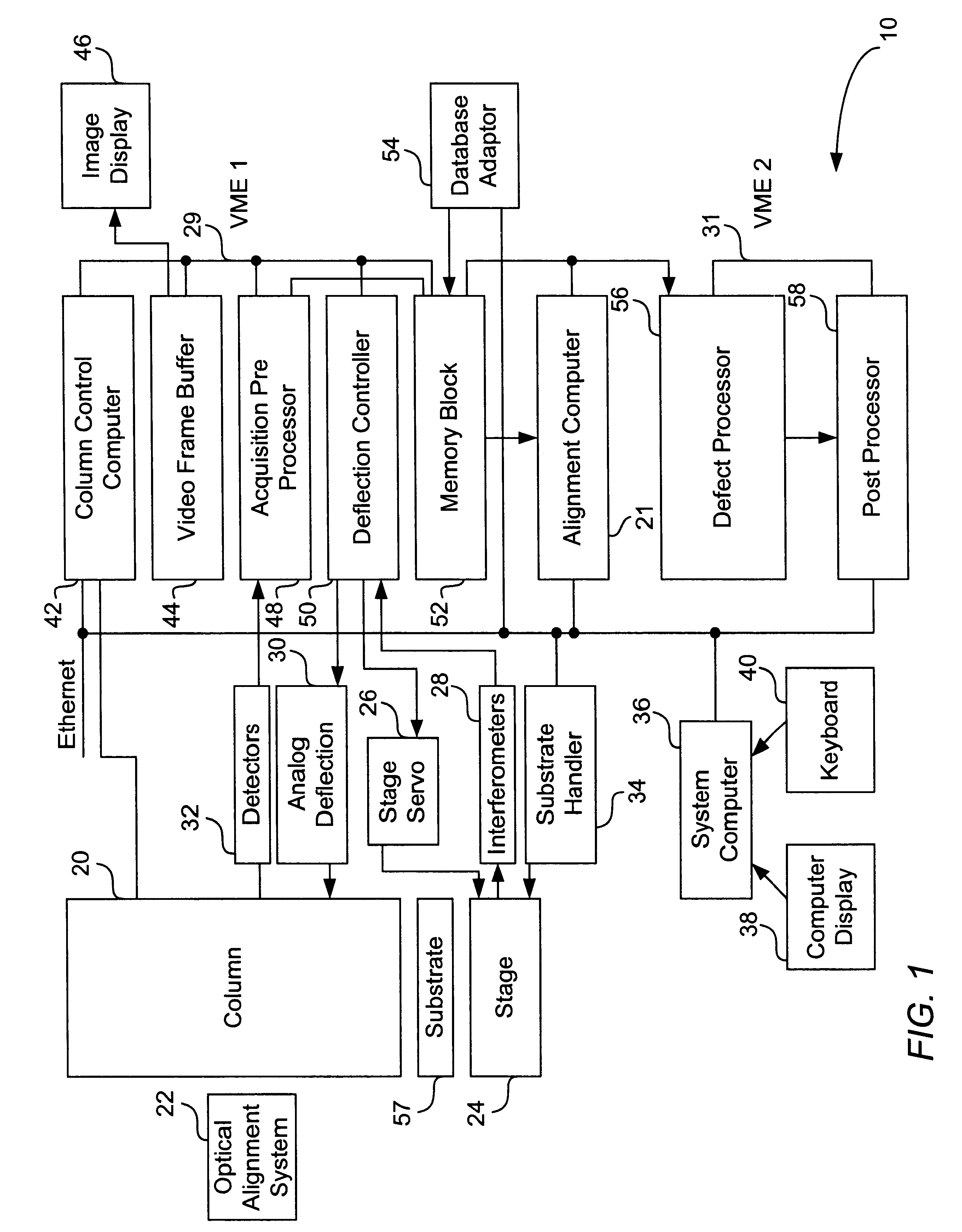

Test structures and methods for inspection of semiconductor integrated circuits

InactiveUS6528818B1Easily dry-etchedEasy to processSemiconductor/solid-state device testing/measurementElectric discharge tubesSemiconductor chipIntegrated circuit

Disclosed is a semiconductor die having a scanning area. The semiconductor die includes a first plurality of test structures wherein each of the test structures in the first plurality of test structures is located entirely within the scanning area. The semiconductor die further includes a second plurality of test structures wherein each of the test structures in the first plurality of test structures is located only partially within the scanning area. The test structures are arranged so that a scan of the scanning area results in detection of defects outside of the scanning area.

Owner:KLA TEMCOR

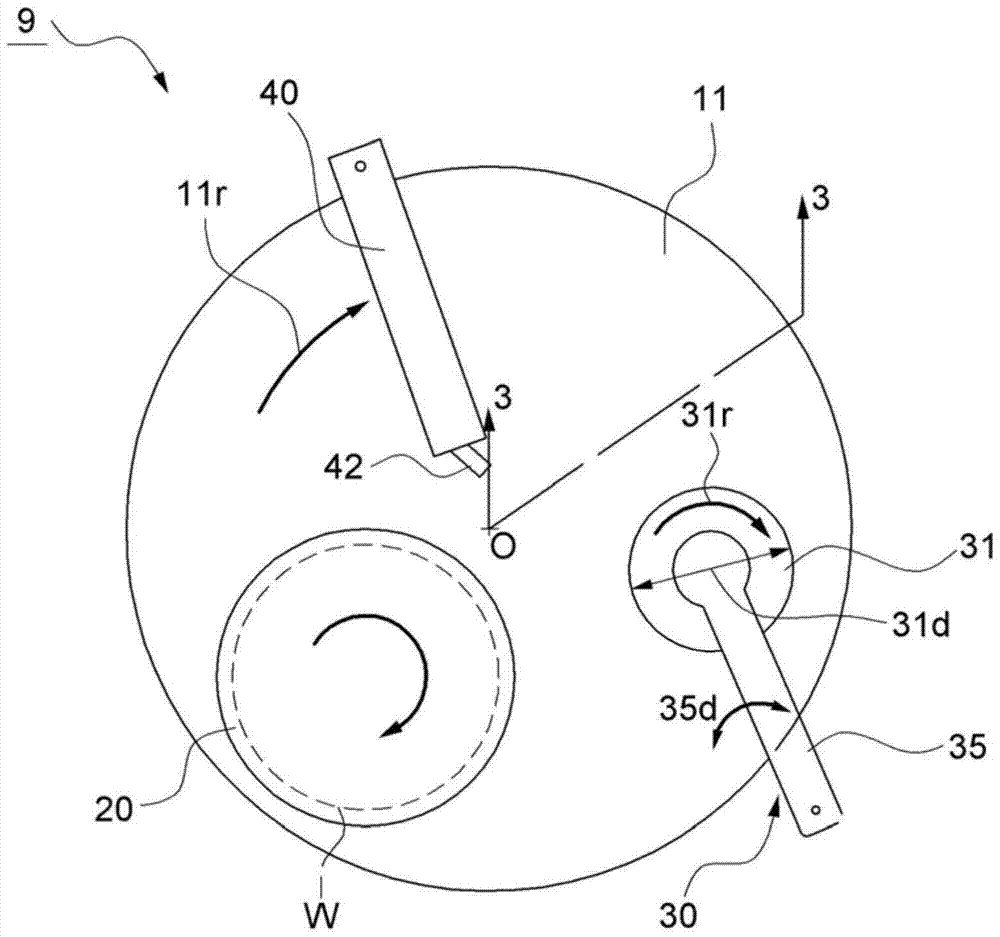

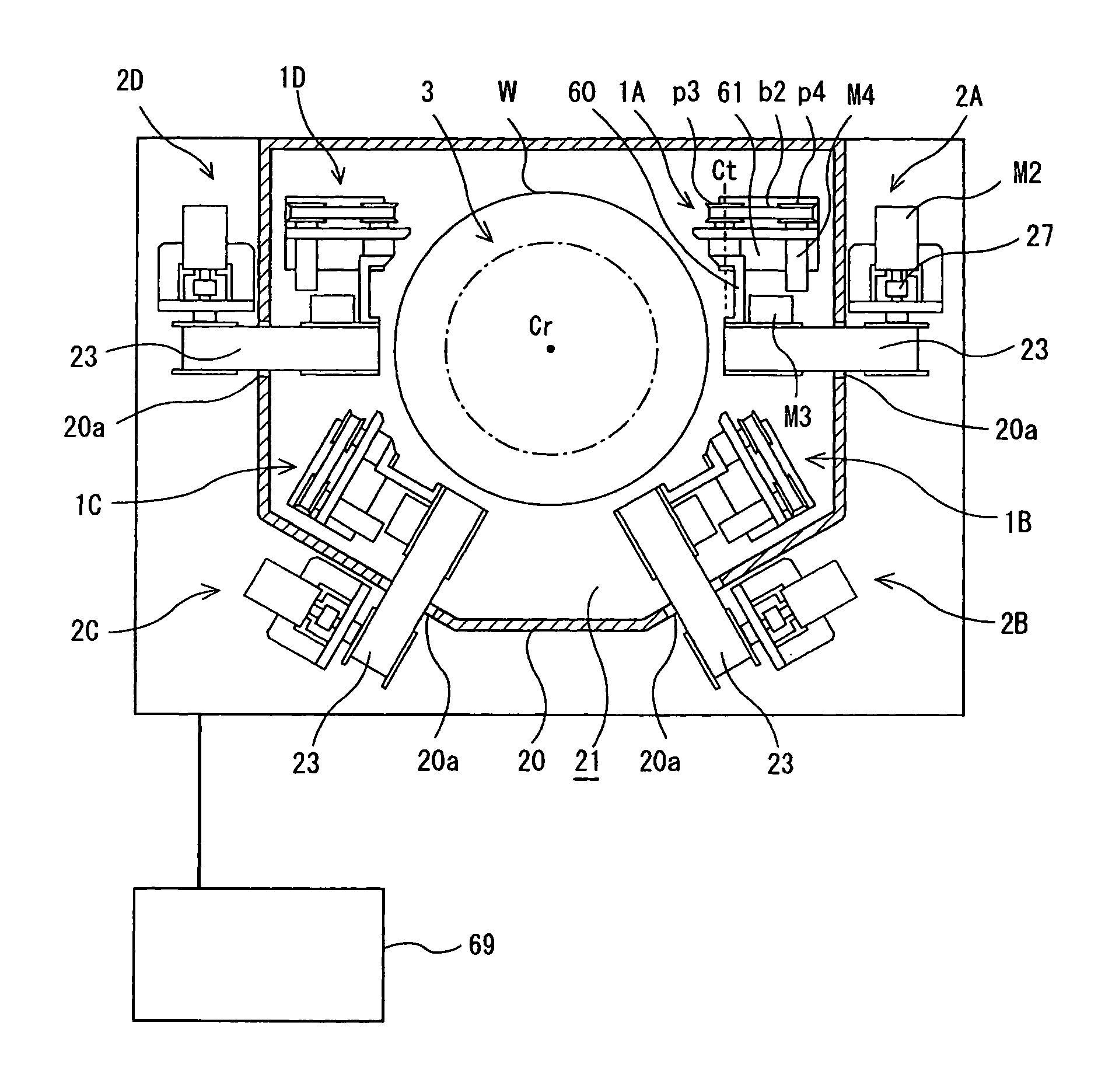

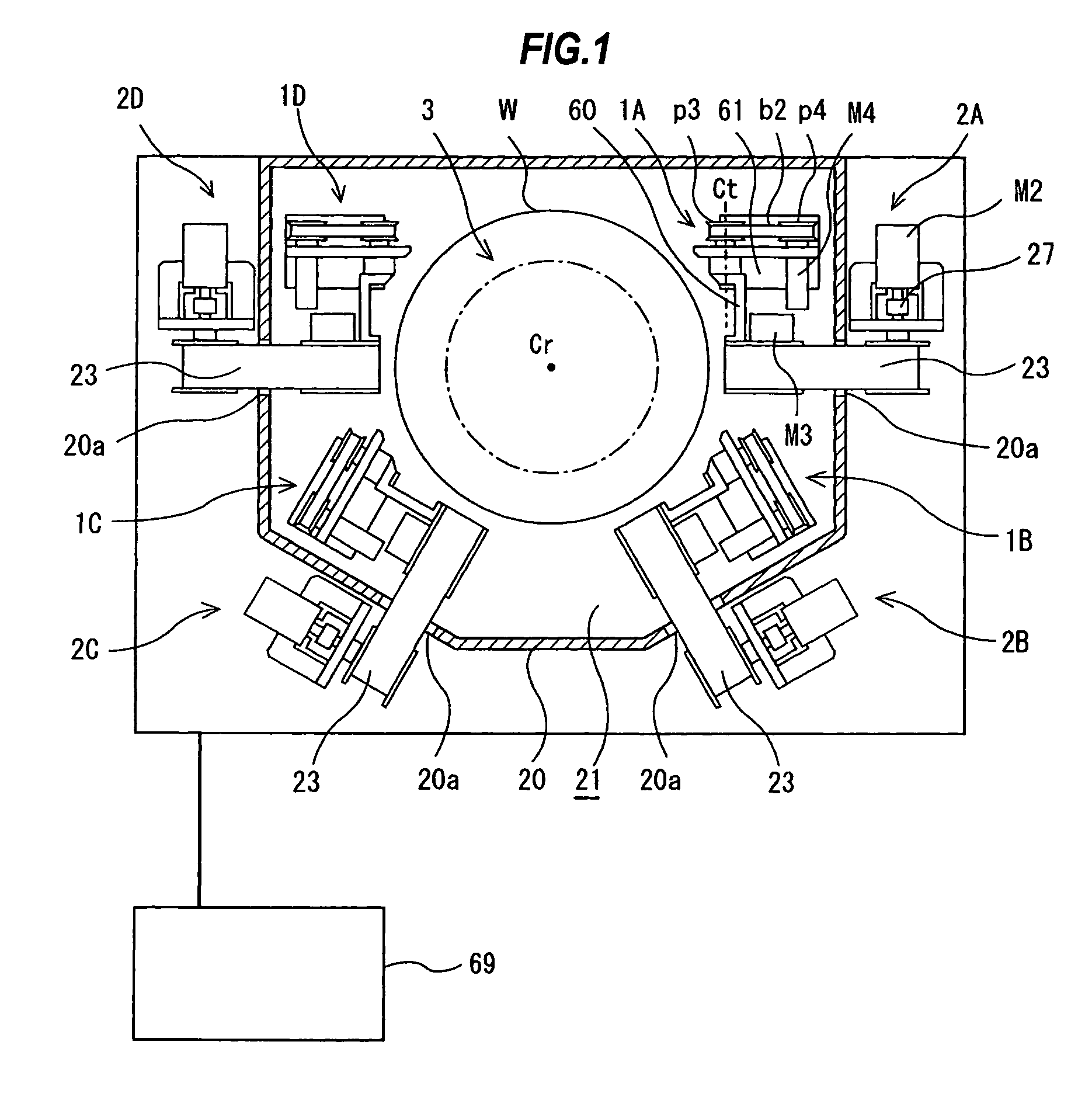

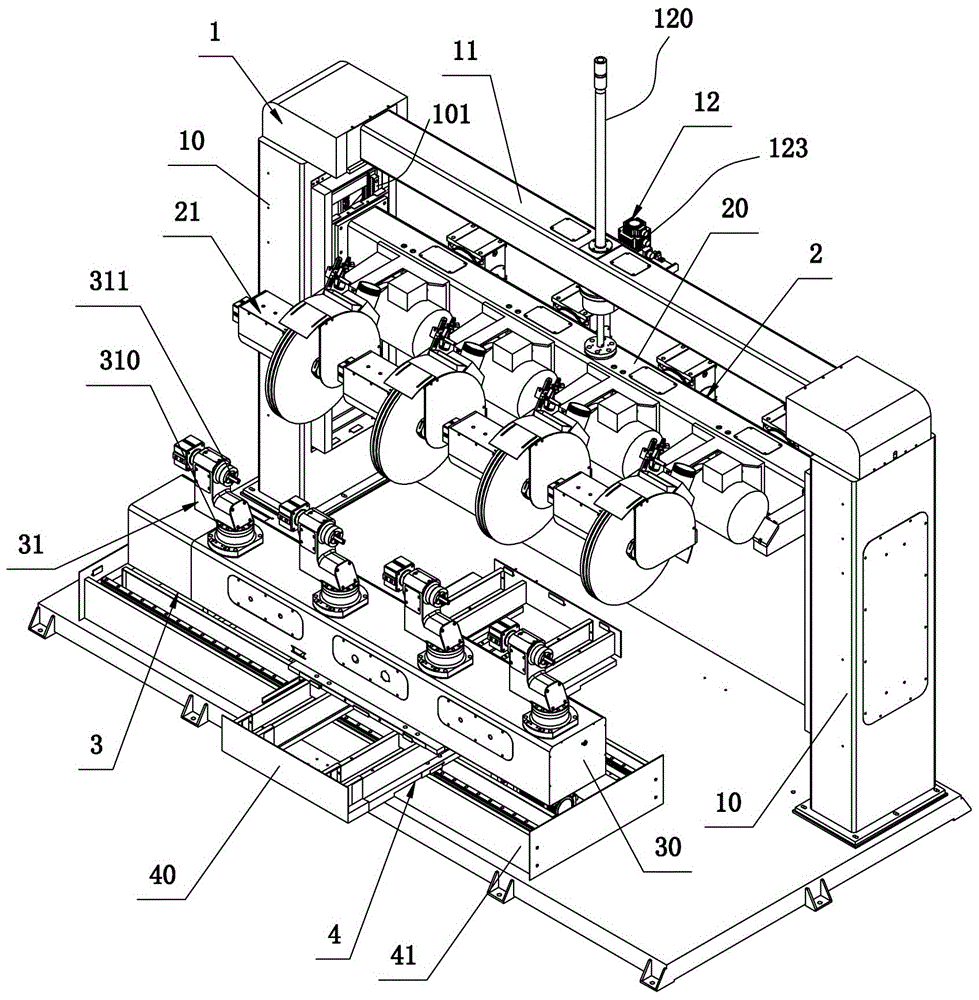

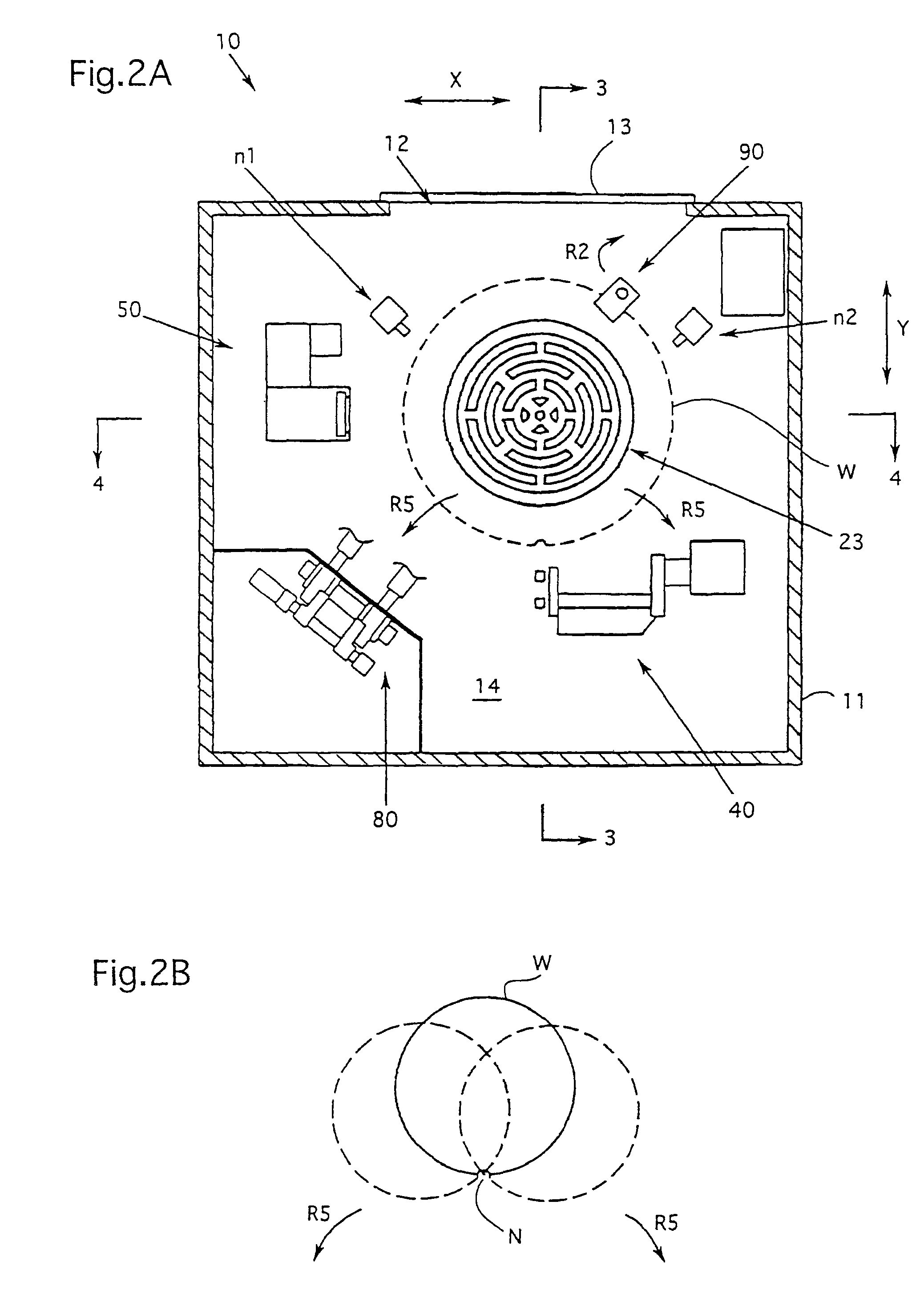

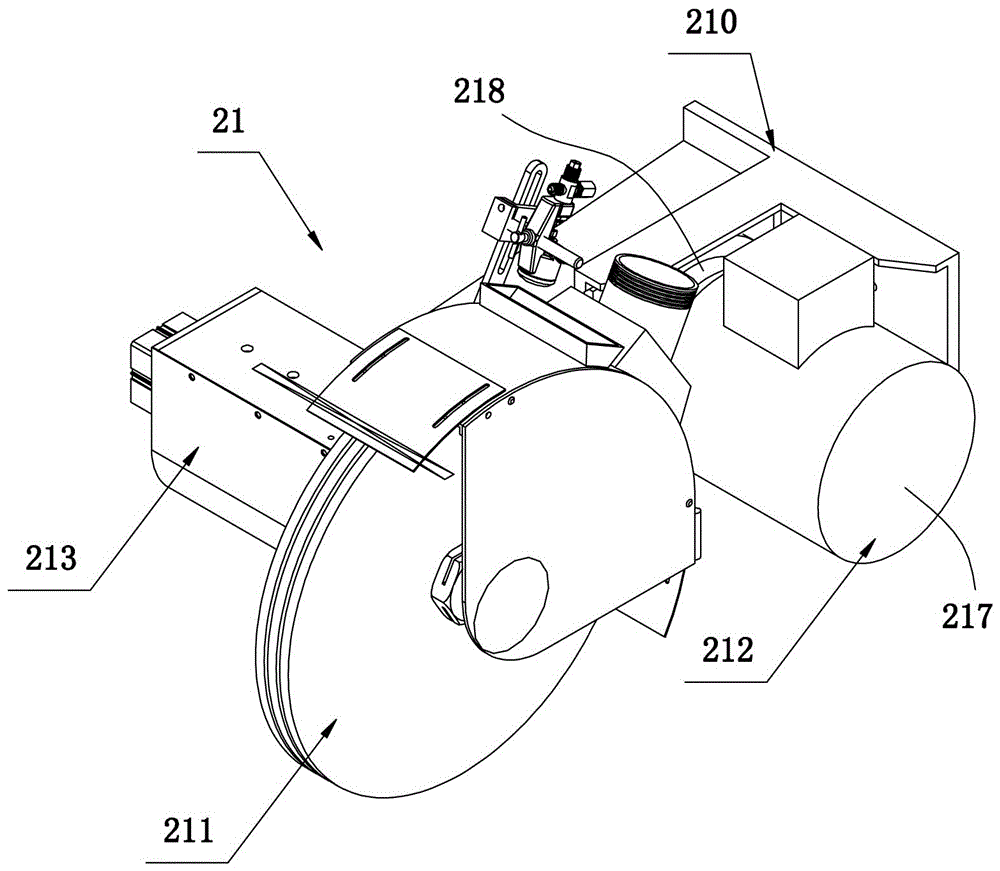

Polishing apparatus and polishing method

ActiveUS20090142992A1Easy to replaceShorten polishing timeGrinding drivesSemiconductor/solid-state device manufacturingMechanical engineeringEngineering

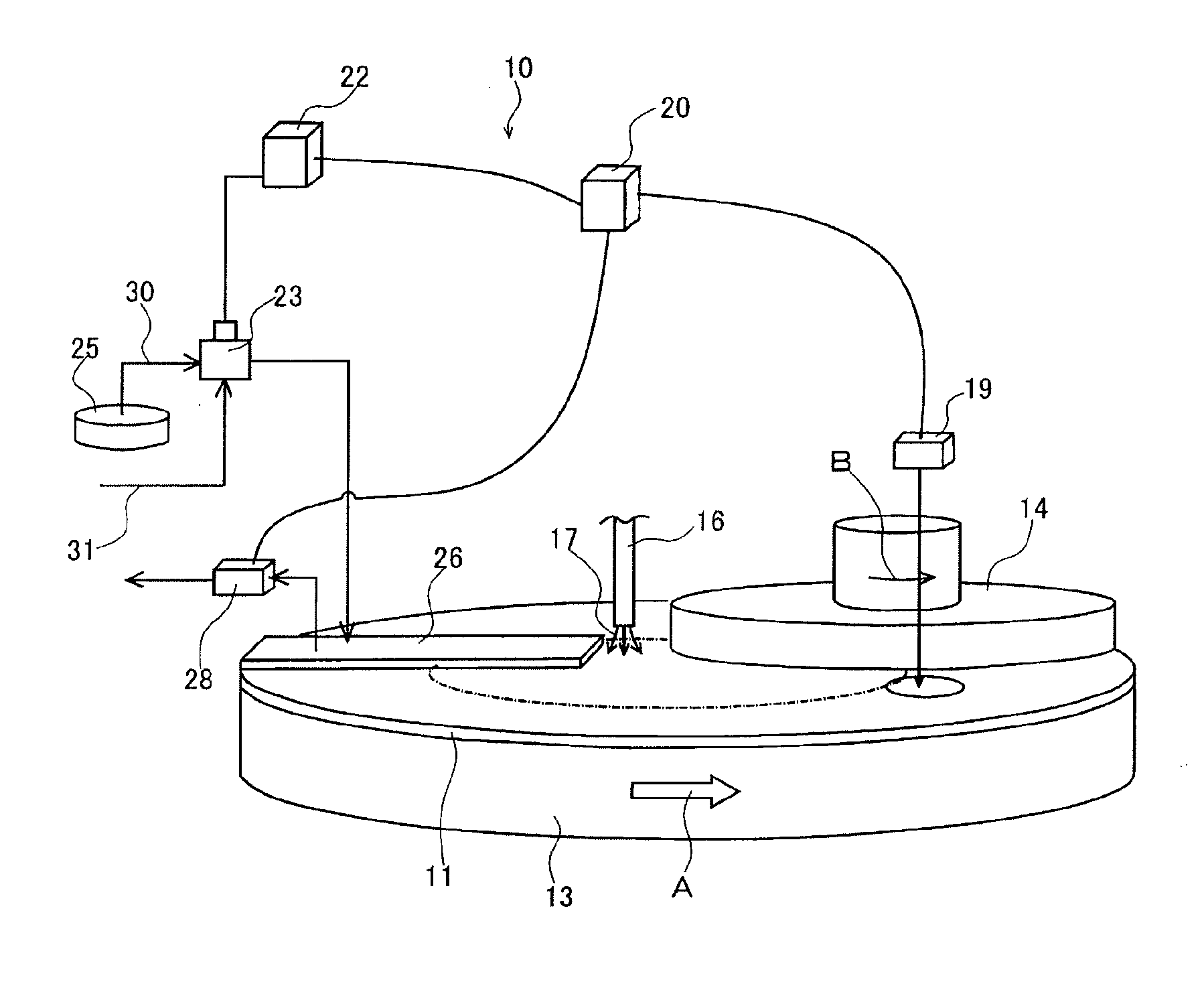

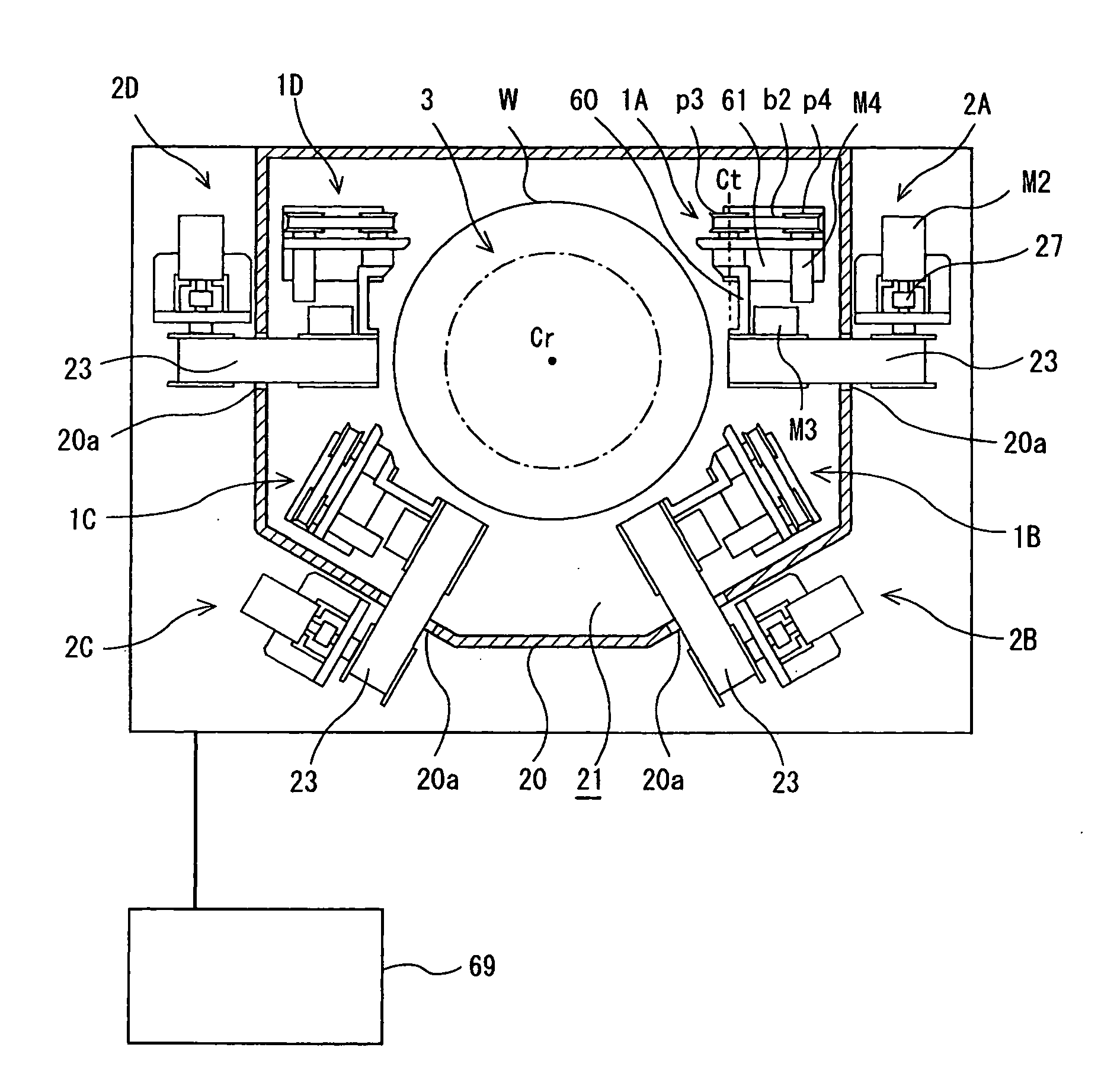

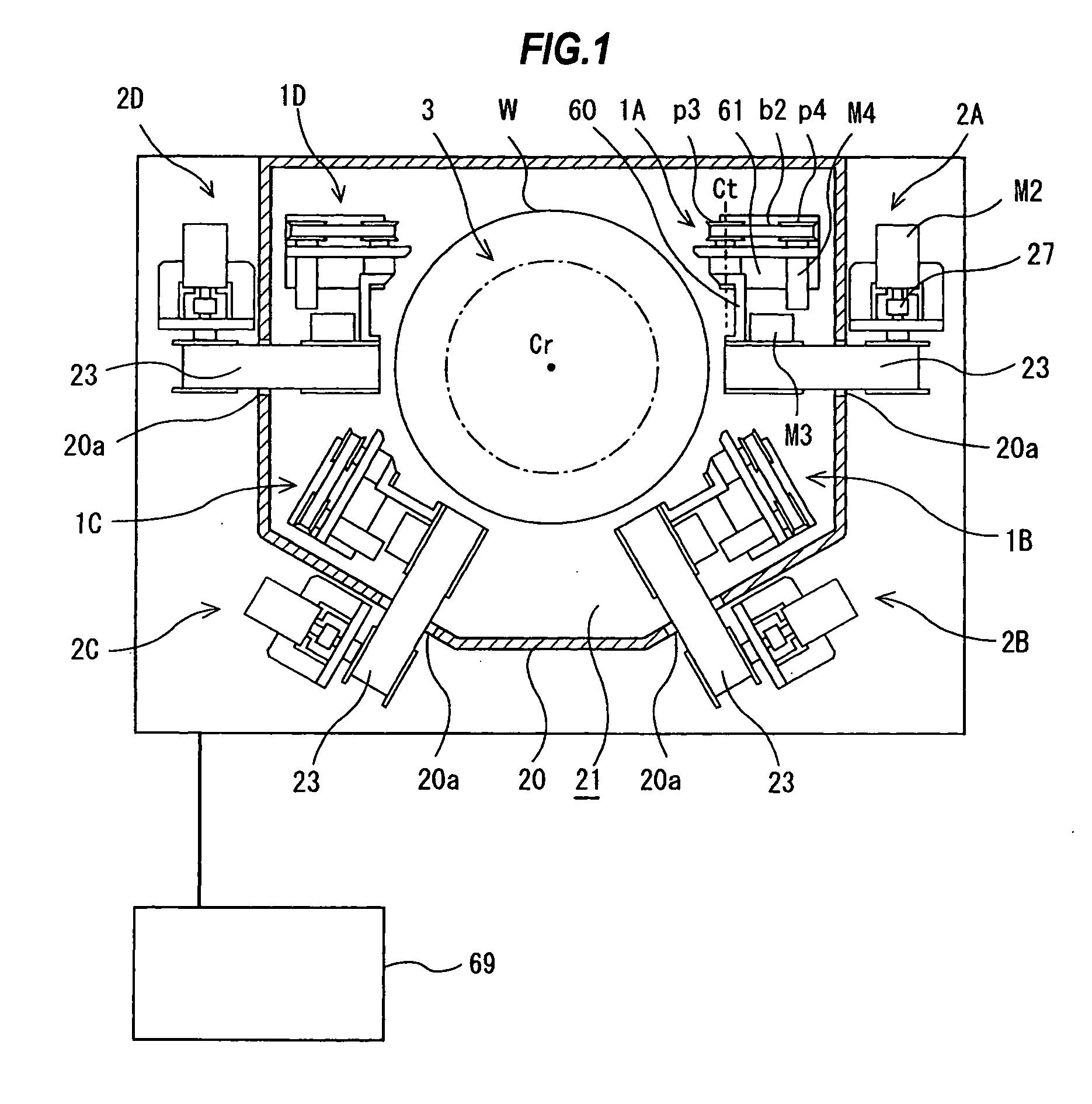

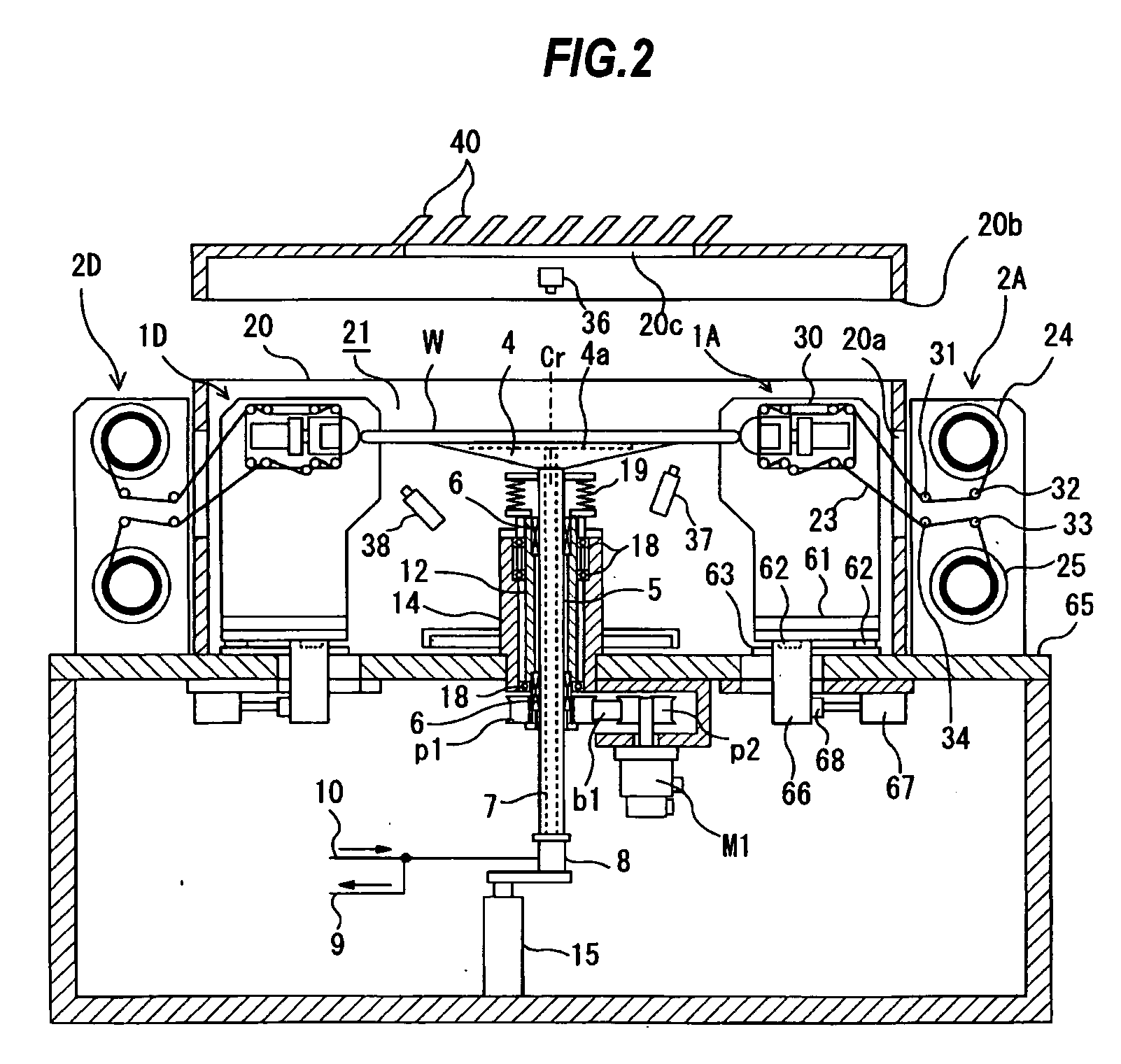

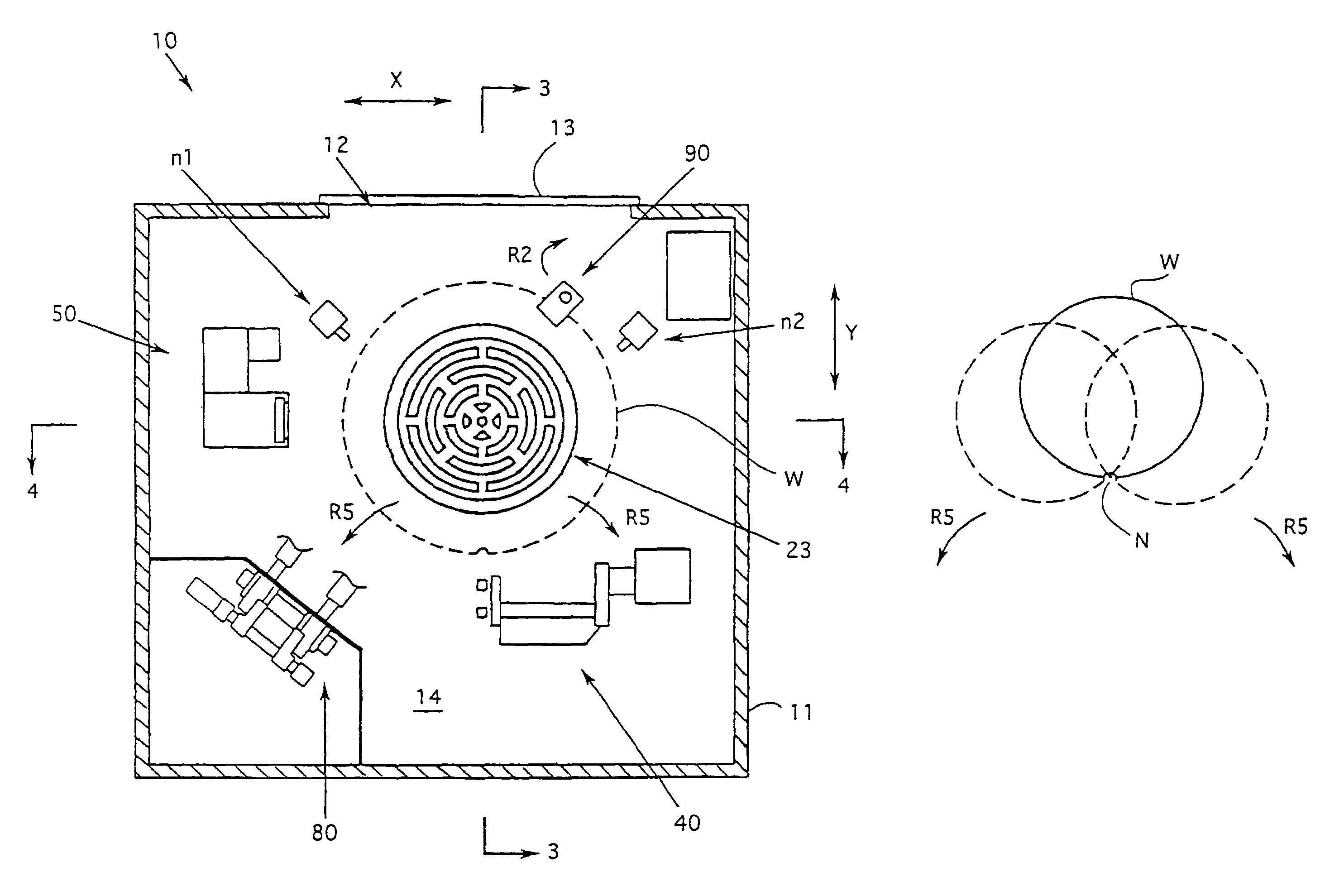

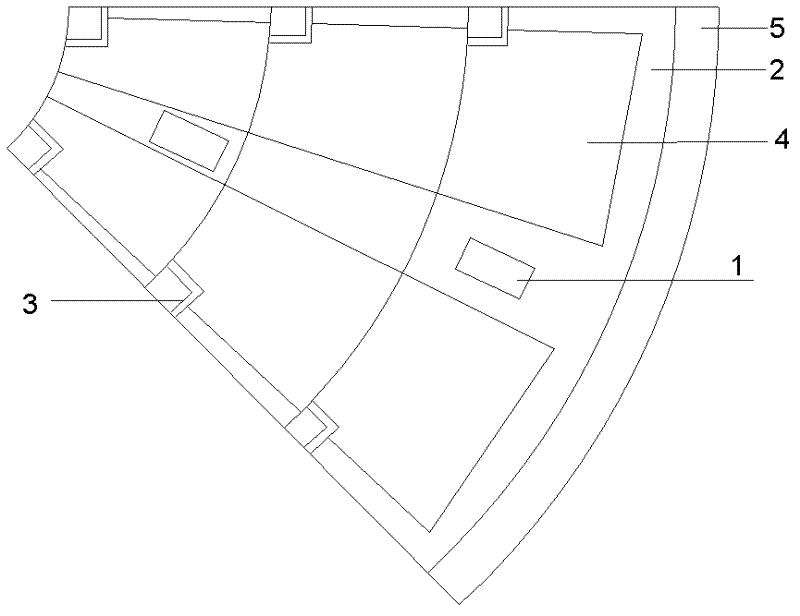

The present invention provides a polishing apparatus for polishing a periphery of a substrate. This polishing apparatus includes a rotary holding mechanism configured to hold the substrate horizontally and rotate the substrate, plural polishing head assemblies provided around the substrate, plural tape supplying and recovering mechanisms configured to supply polishing tapes to the plural polishing head assemblies and recover the polishing tapes from the plural polishing head assemblies, and plural moving mechanisms configured to move the plural polishing head assemblies in radial directions of the substrate held by the rotary holding mechanism. The tape supplying and recovering mechanisms are located outwardly of the plural polishing head assemblies in the radial directions of the substrate, and the tape supplying and recovering mechanisms are fixed in position.

Owner:EBARA CORP

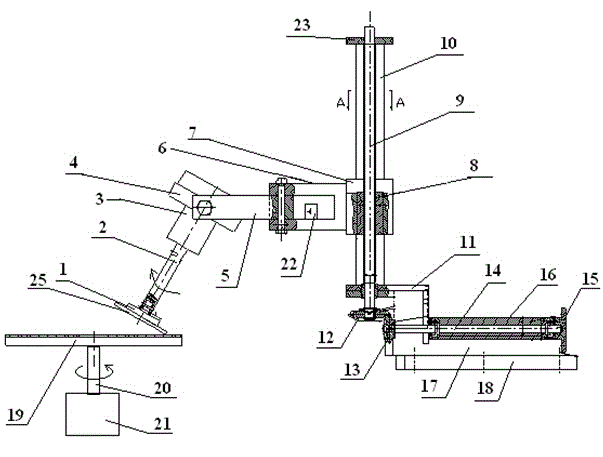

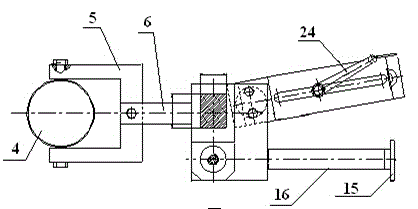

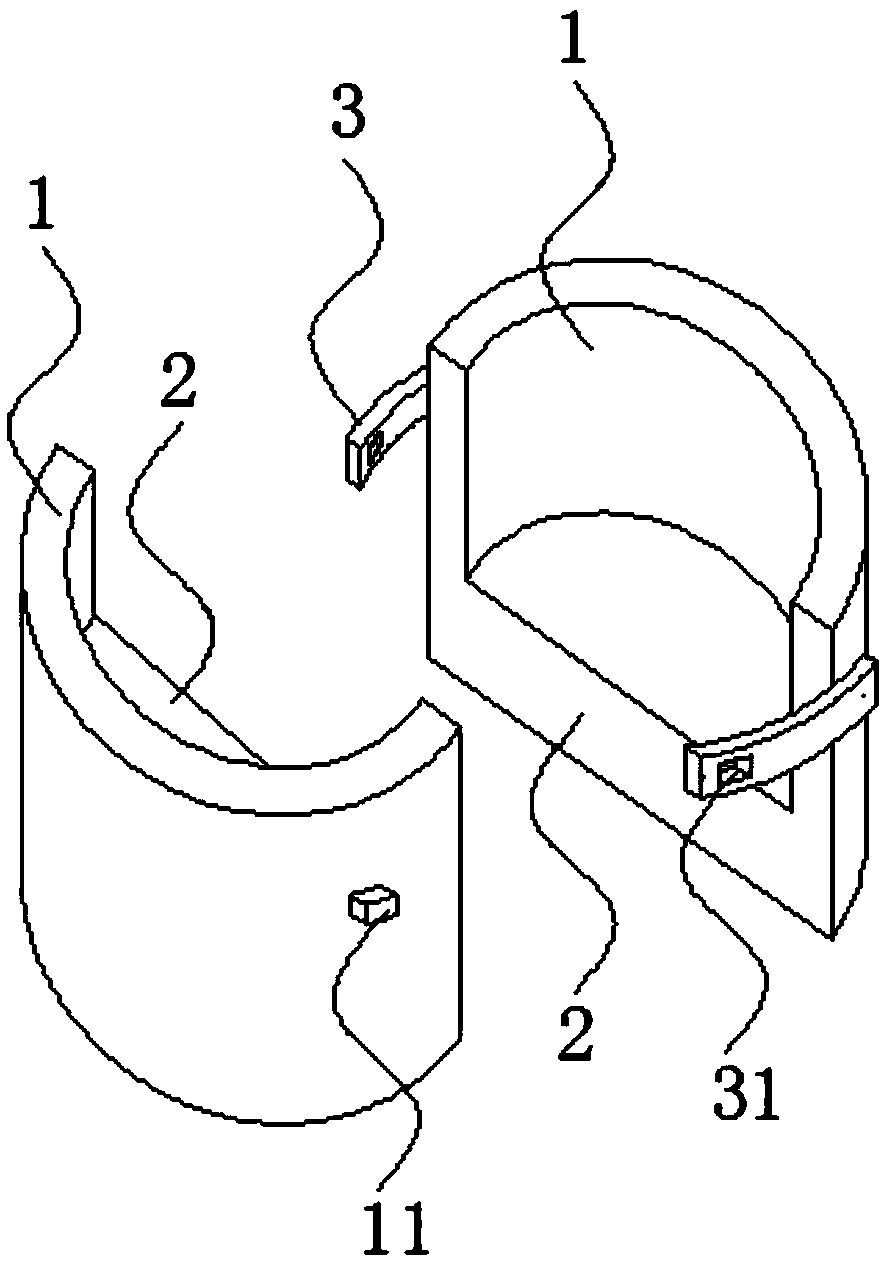

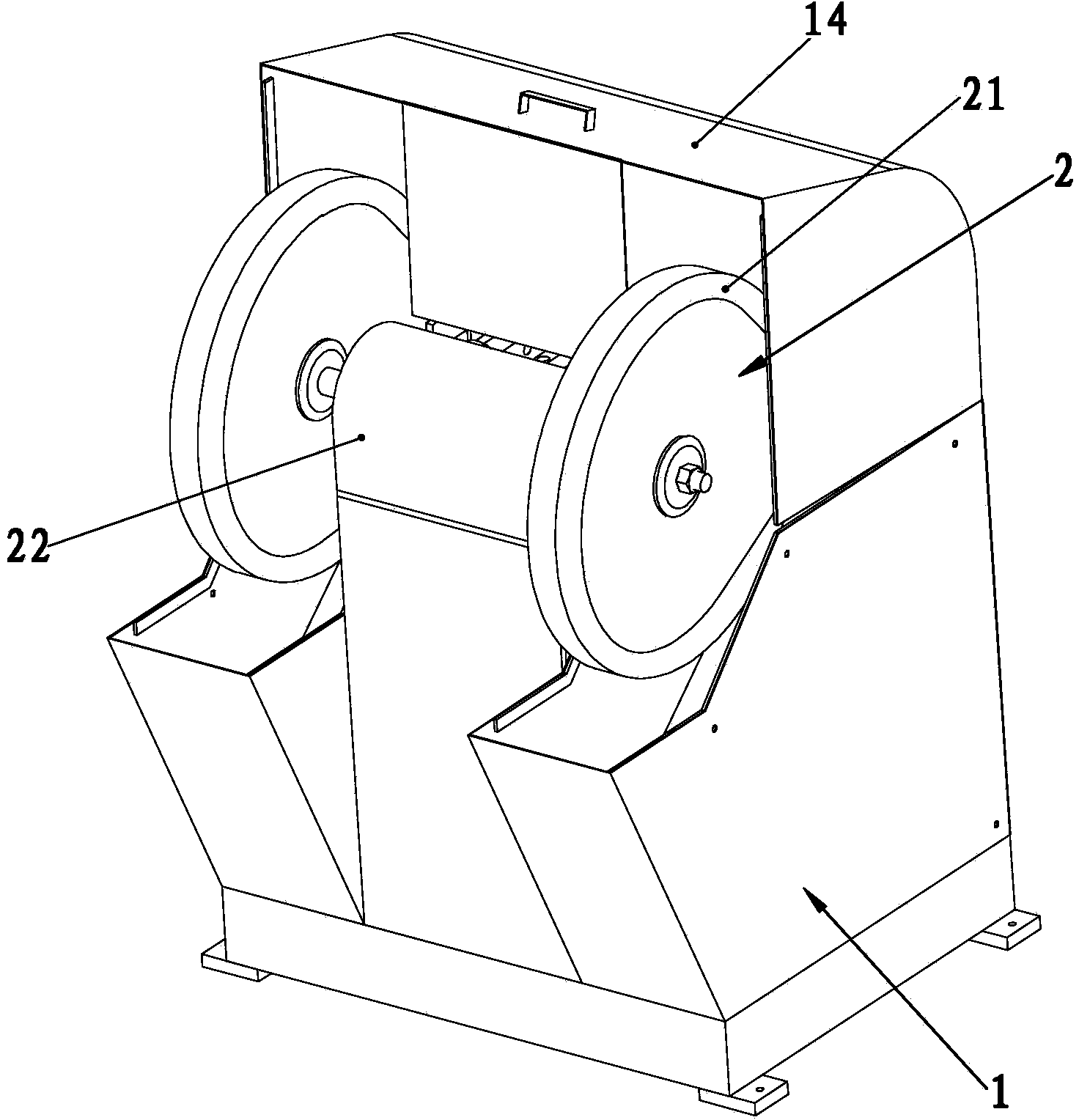

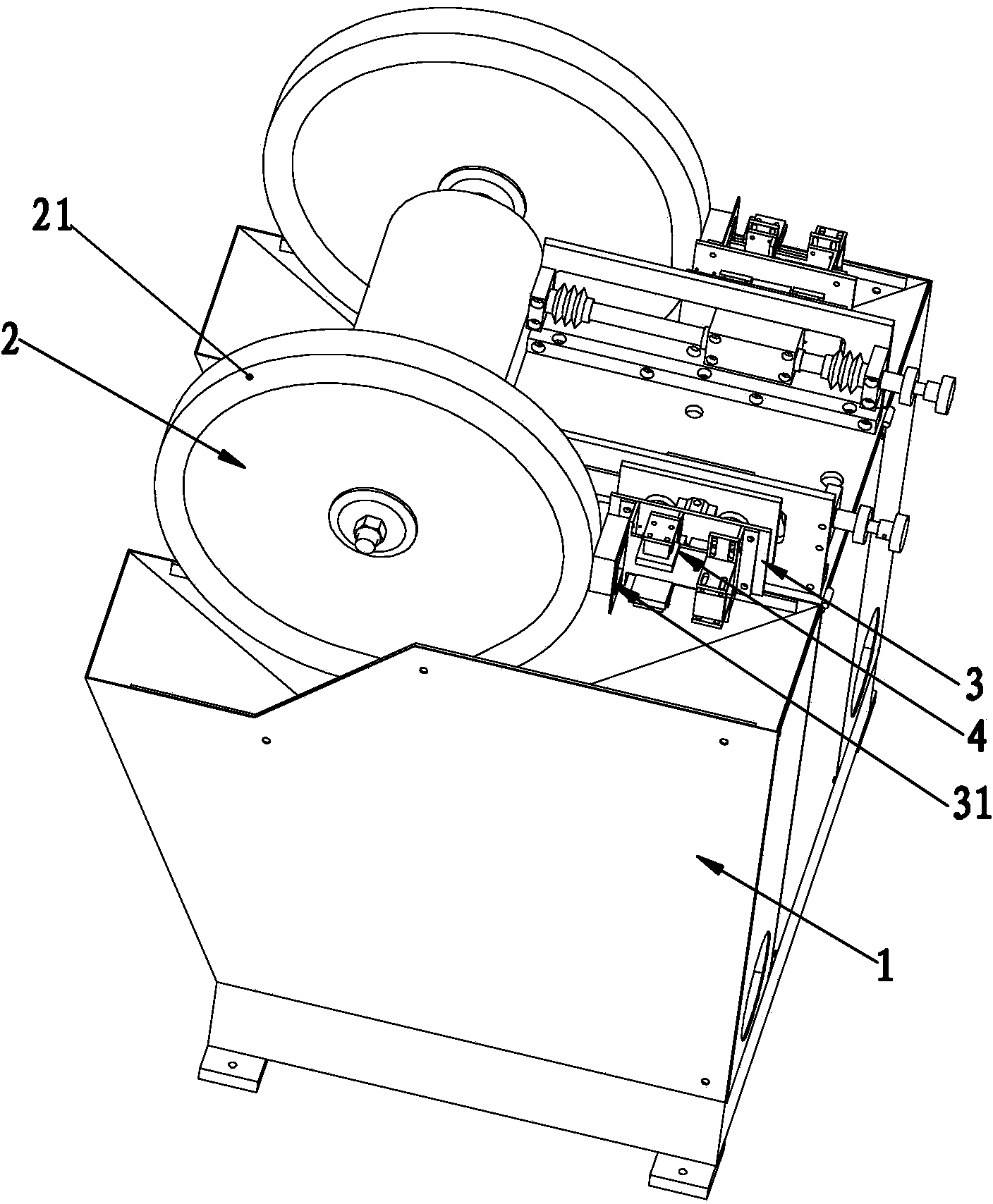

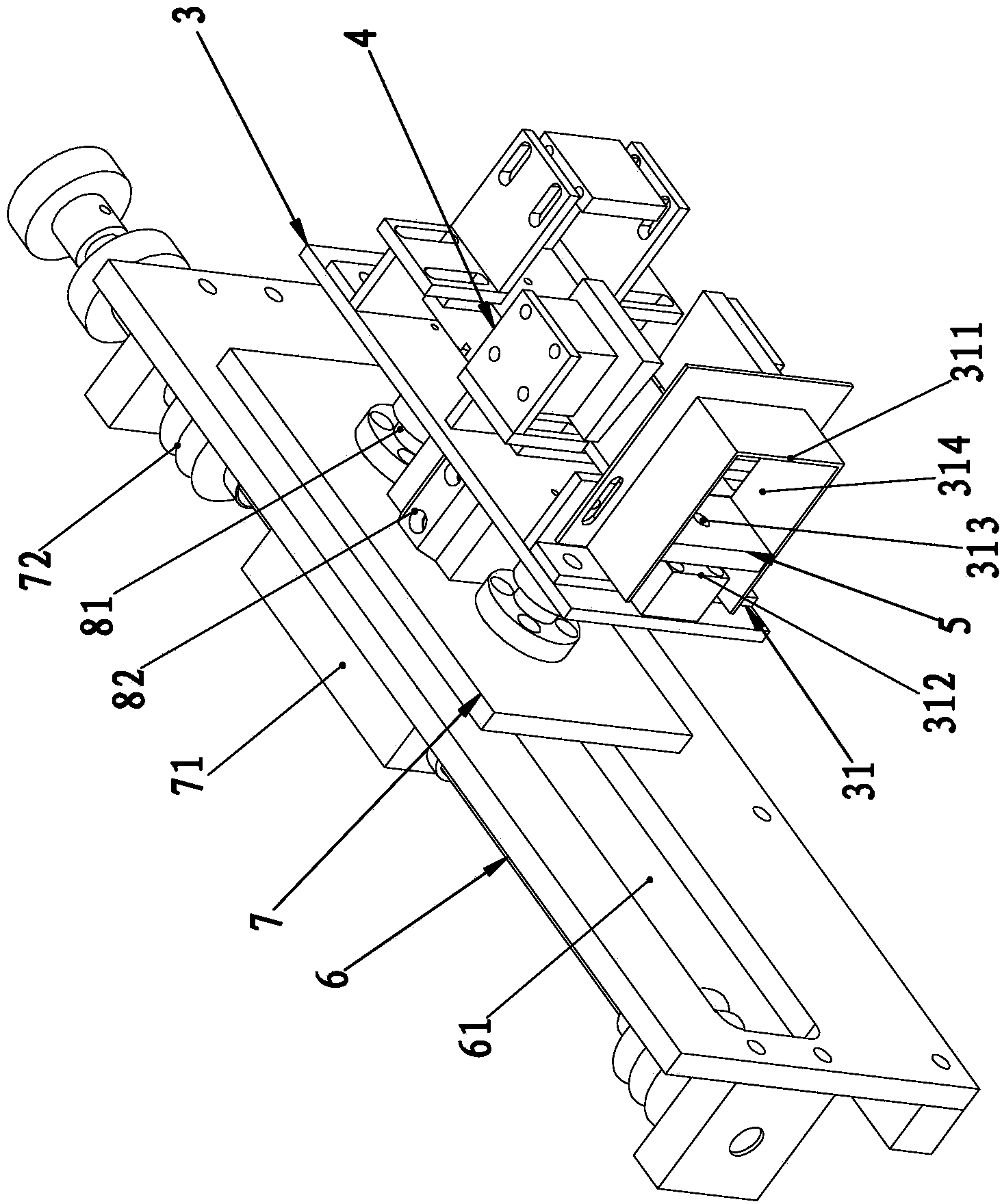

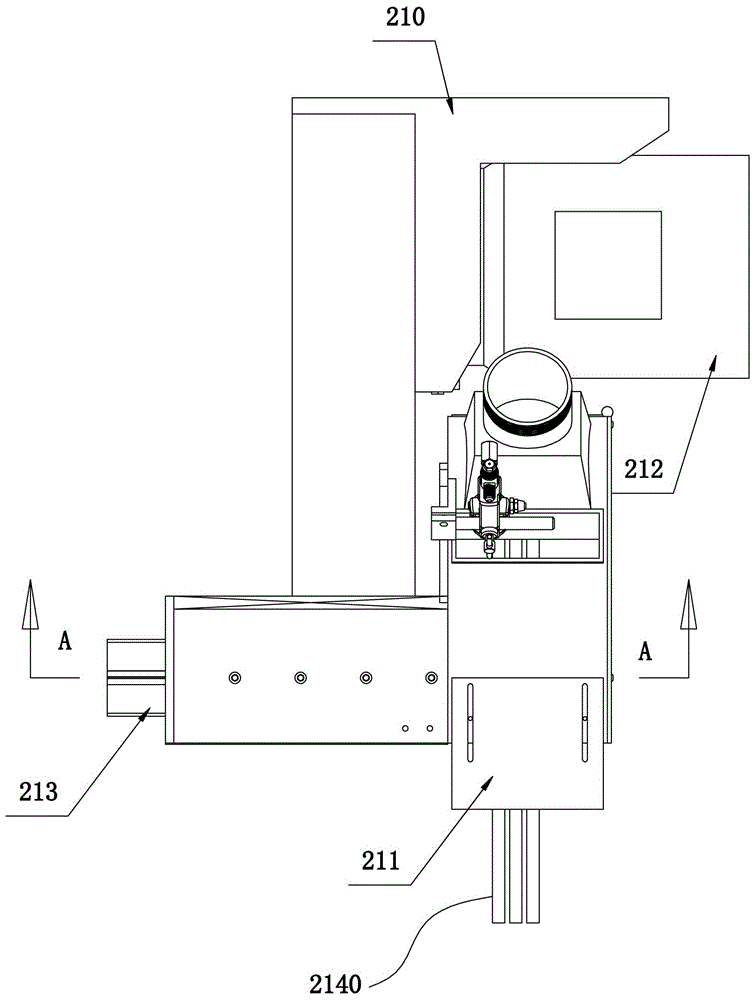

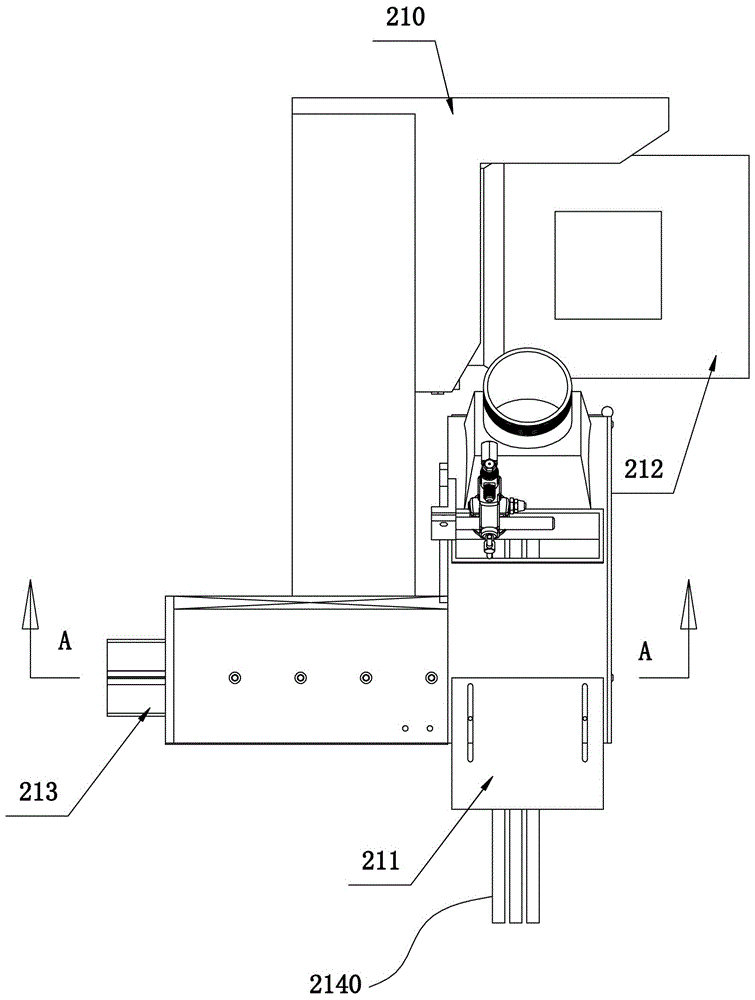

Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

ActiveCN104551900AAvoid chippingImprove processing qualityEdge grinding machinesPolishing machinesEngineeringDrive motor

The invention discloses a silicon carbide wafer bevel grinding, milling and polishing machine and an operation method thereof. The silicon carbide wafer bevel grinding, milling and polishing machine comprises a supporting sheet (1), a rotating shaft (2), a driving motor (3), a motor bracket (4), a vertical rotating arm (5), a horizontal rotating arm (6), a slide frame (7) and a screw rod (9) which are sequentially connected, wherein the lower end of the screw rod (9) is sequentially connected with a first cone gear (12), a second cone gear (13), an adjusting shaft (14) and a rotating wheel (15); a machining tool (19) of a silicon carbide wafer is arranged below the supporting sheet (1). The silicon carbide wafer bevel grinding, milling and polishing machine is reasonable in structural design, convenient to operate and high in working efficiency, bevel grinding, milling and polishing integrated machining can be performed on the silicon carbide wafer, the working efficiency is high, the roughness of a polished bevel can be smaller than 0.1 micron, the machining precision is high, and the applicability is high. The operation method can be applied to the bevel grinding, milling and polishing integrated machining on the silicon carbide wafer which is round or not round.

Owner:山东粤海金半导体科技有限公司

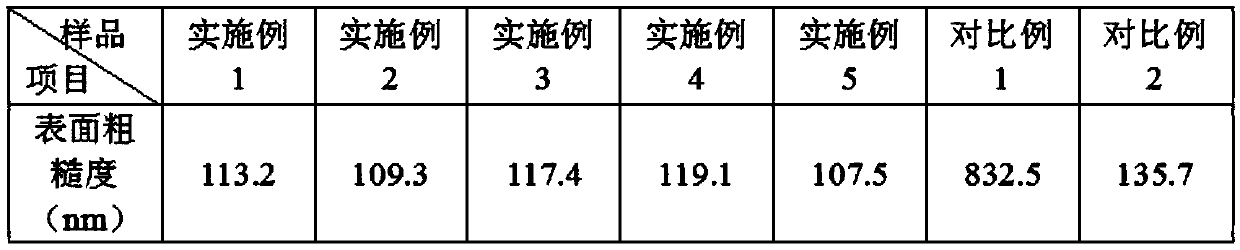

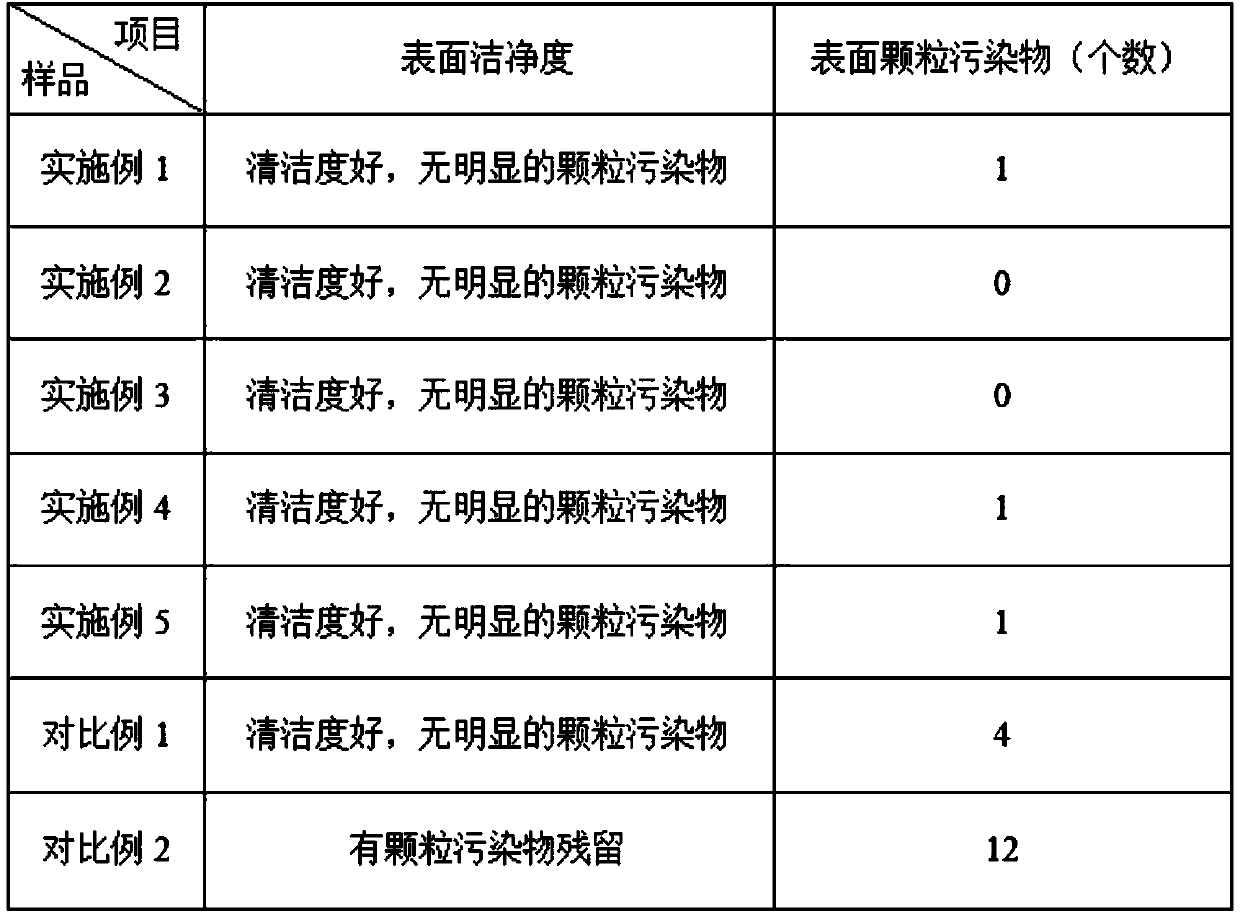

Compound polishing powder for polishing optical elements, preparation method and polishing technology

ActiveCN101362925BImprove effectivenessImprove machining accuracyOptical surface grinding machinesOther chemical processesSurface finishGranularity

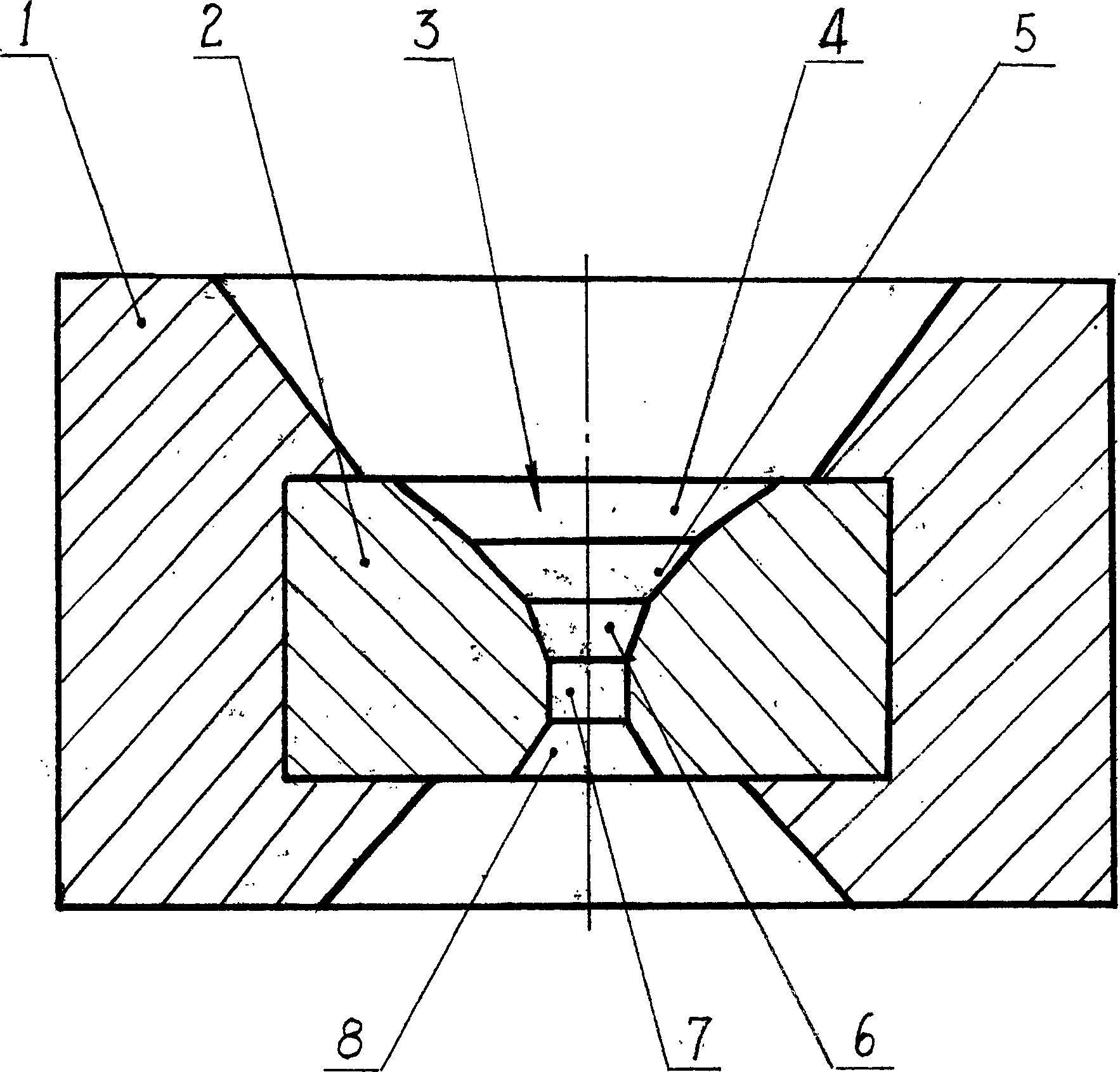

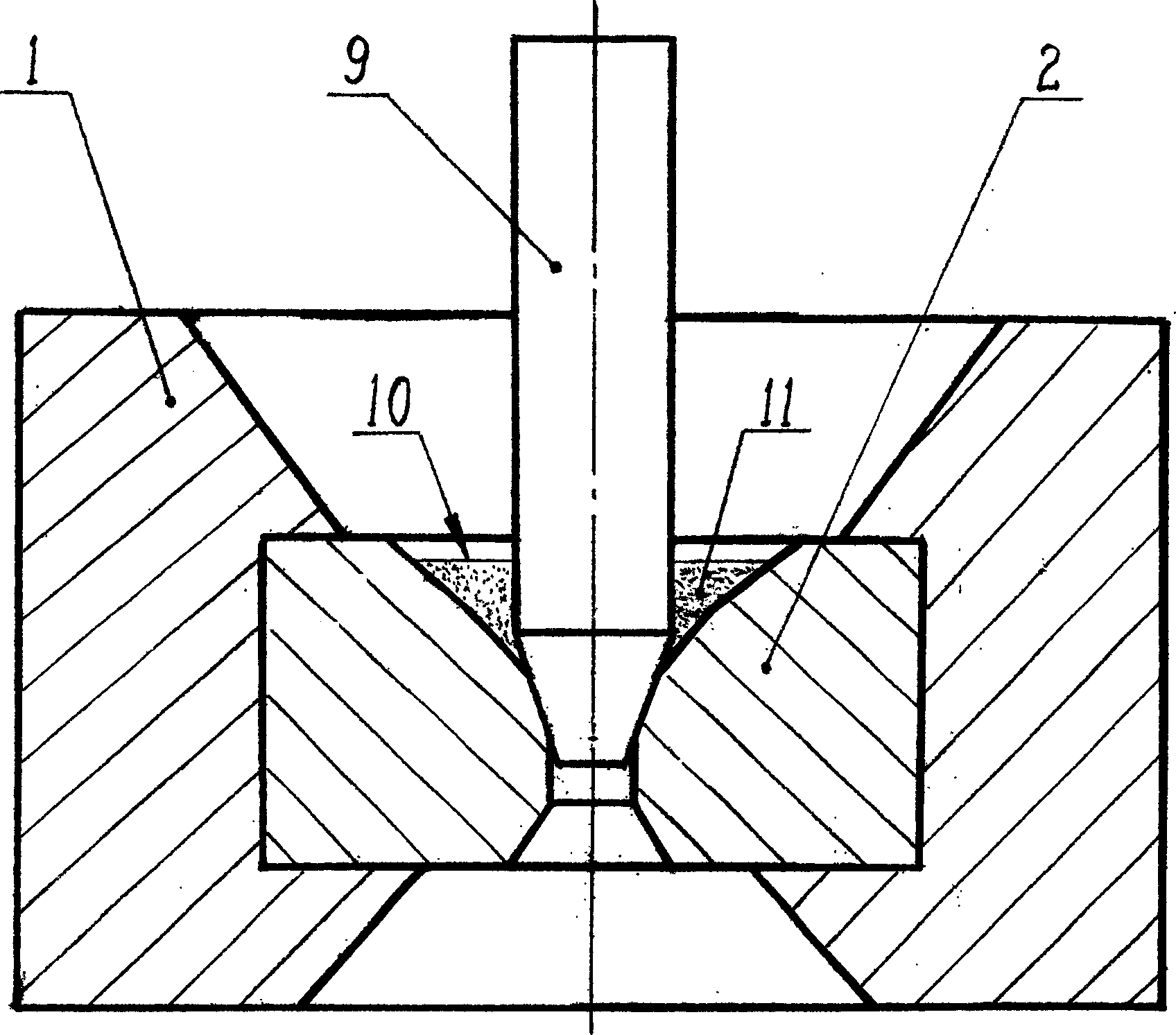

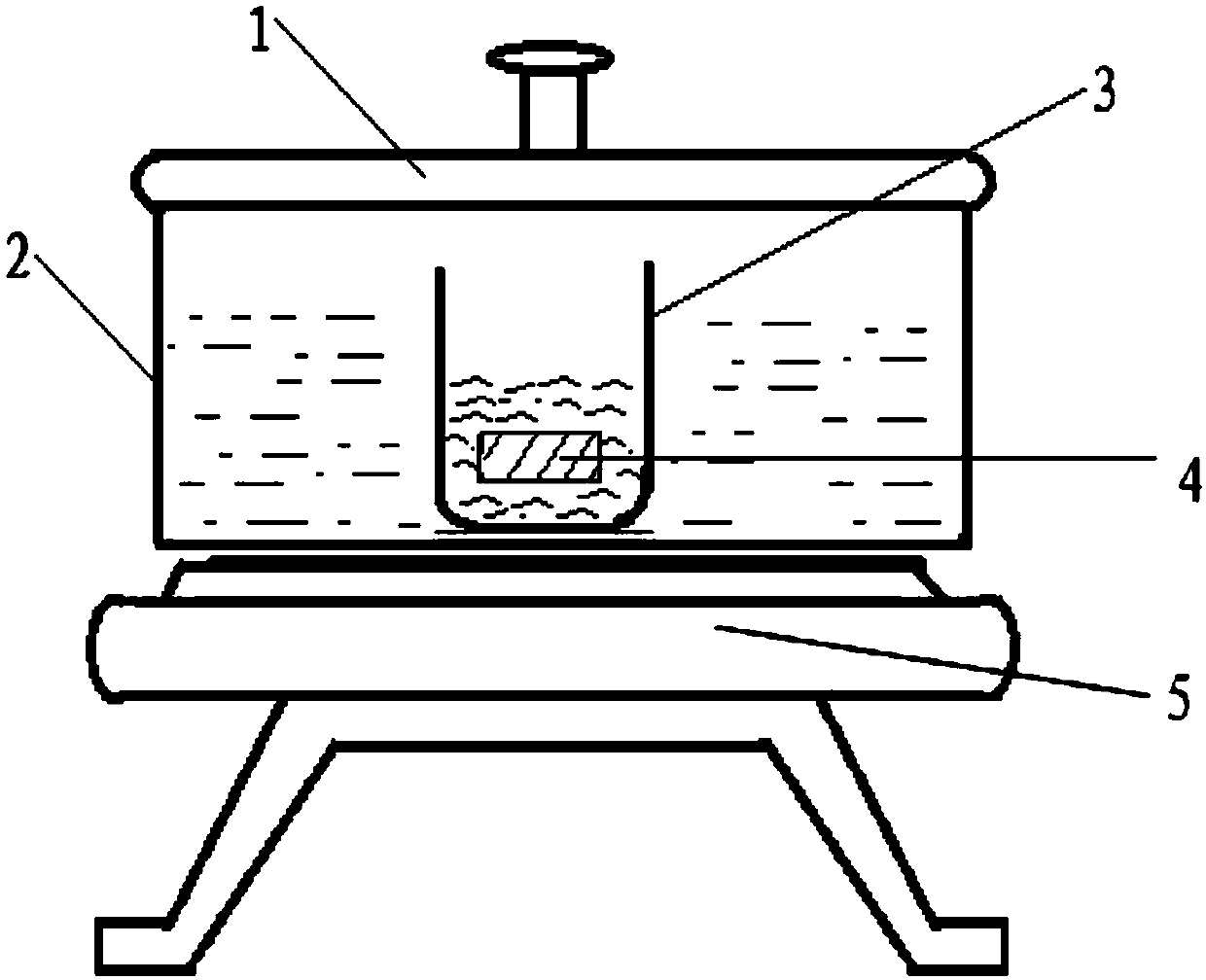

The invention provides a compound polishing powder of a polishing optical element, a preparation method and a polishing process, belonging to expendable material used for polishing the optical element, the preparation method and the polishing process of the polishing powder; wherein, the polishing powder comprises 0.5-3 of Cr2O3 powder and 1 of Al2O3 according to the weight proportion; the granularity of the Cr2O3 powder is ranging from 0.05 microns to 0.10 microns and the granularity of the Al2O3 powder is ranging from 0.05 microns and 0.10 microns; the polishing process comprises the steps as follows: 1) installing polishing formworks for the optical element; 2) filling the polishing powder; 3) arranging a lens disc; 4) fixing the lens disc; 5) rubbing and polishing. The polishing formwork comprises 500 of polishing asphalt and 20-200 of Al2O3 according to the weight parts; in the polishing process, the polishing powder and the polishing formwork can be used for polishing the optical element which is made of zinc selenide, with the surface smoothness of more than 20-10.

Owner:CHENGDU Z & Z OPTOELECTRONICS TECH

Chemical mechanical polishing apparatus and method thereof

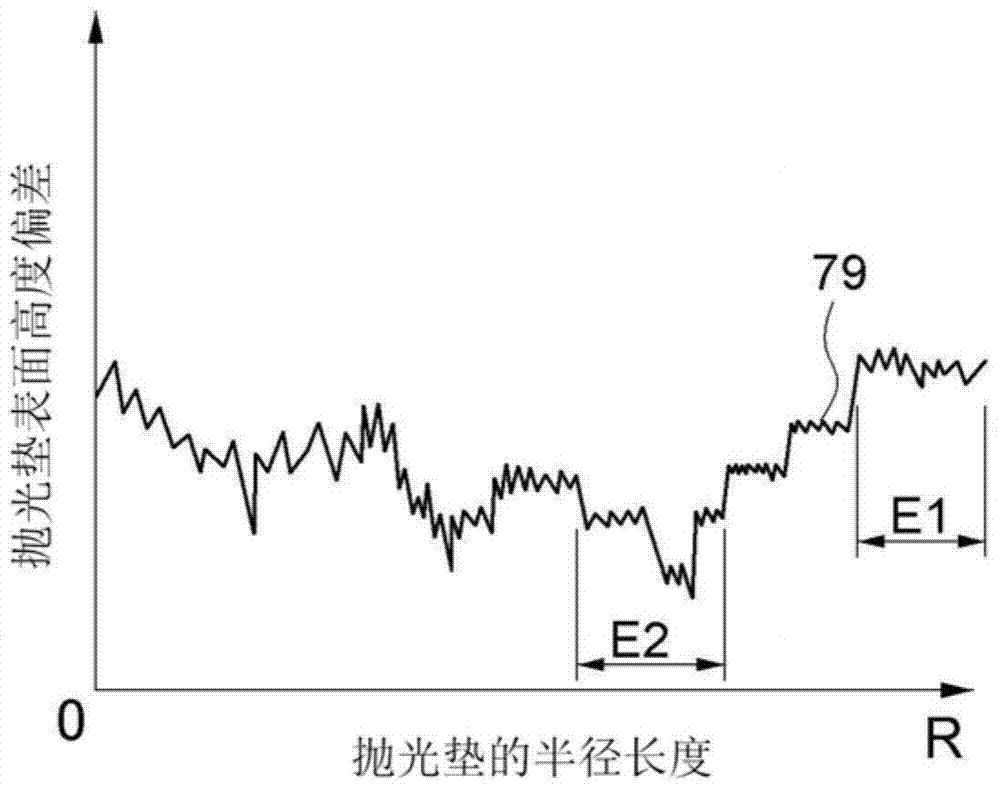

The invention relates to a chemical mechanical polishing apparatus and a method thereof. The apparatus comprises a polishing head for pressing and rotating a wafer in a state where the wafer is on a lower side; a height measuring portion for obtaining a height deviation in the radial direction of a polishing pad during the chemical mechanical polishing; a regulating device having an arm portion and an adjusting disc, the arm being rotated about a hinge axis to rotate at a predetermined angle, and the adjusting disc pressing the polishing pad against the lower side of the arm portion and rotating; and a control portion for adjusting the rotational speed of the arm portion with a second rotation speed at a second position, the height of the polishing pad at the second position being higher than the height at the first position, and the second rotational speed being smaller than the first rotational speed, such that, by adjusting the rotational speed of the adjusting disc, it is possible to alleviate the height deviation of the polishing pad at different positions. Therefore, even if the same pressure is applied to the wafer, the friction amount is different depending on the height deviation of the polishing pad, so that the polishing amount per hour of the wafer can be adjusted in each region.

Owner:K C TECH

Composite polishing solution for metal polishing and preparation method thereof

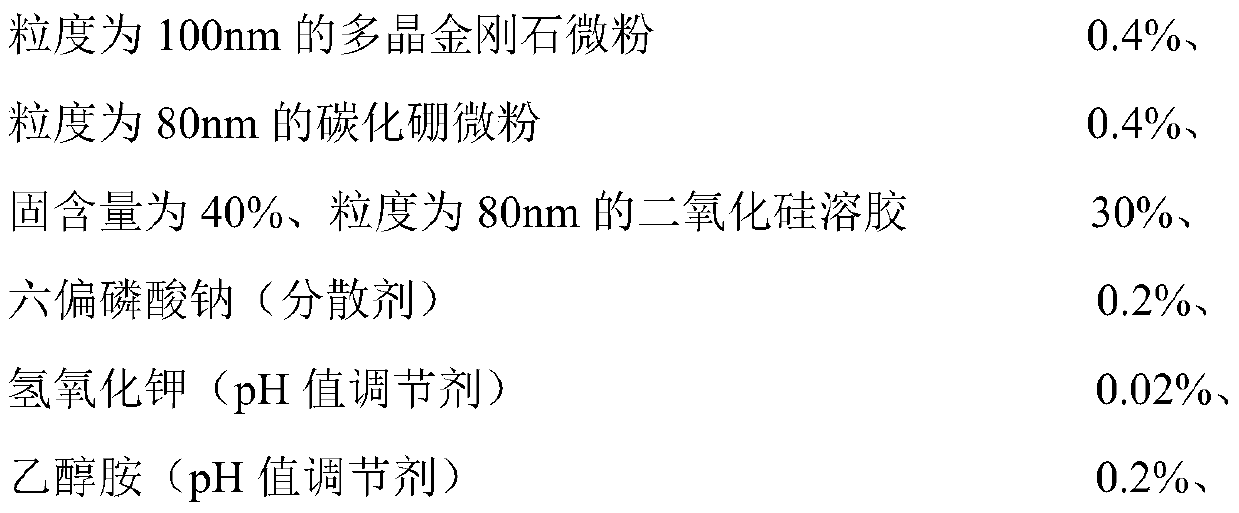

ActiveCN105505229APrevent mosaicIncrease brightnessPolishing compositions with abrasivesCompound aBoron carbide

The invention discloses a composite polishing solution for metal polishing and a preparation method thereof. The composite polishing solution is composed of the following components in percentage by mass: 0.1-2% of polycrystalline diamond micropowder, 0.1-2% of boron carbide micropowder, 5-60% of silicon dioxide sol, 0.02-5% of dispersing agent, 0.001-0.5% of pH regulator, 0-1% of corrosion inhibitor and the balance of water. The preparation method comprises the following steps: compounding a mixed abrasive from the polycrystalline diamond micropowder and boron carbide micropowder, adding the silicon dioxide sol as a polishing assistant, and adding the dispersing agent, pH regulator and corrosion inhibitor. The composite polishing solution can obviously enhance the polishing efficiency in the metal polishing process, prevents the abrasive from generating embedment on the metal part surface, enhances the brightness of the workpiece, reduces the treatment difficulty of the next procedure, and is suitable for popularization and application.

Owner:HENAN UNION ABRASIVES

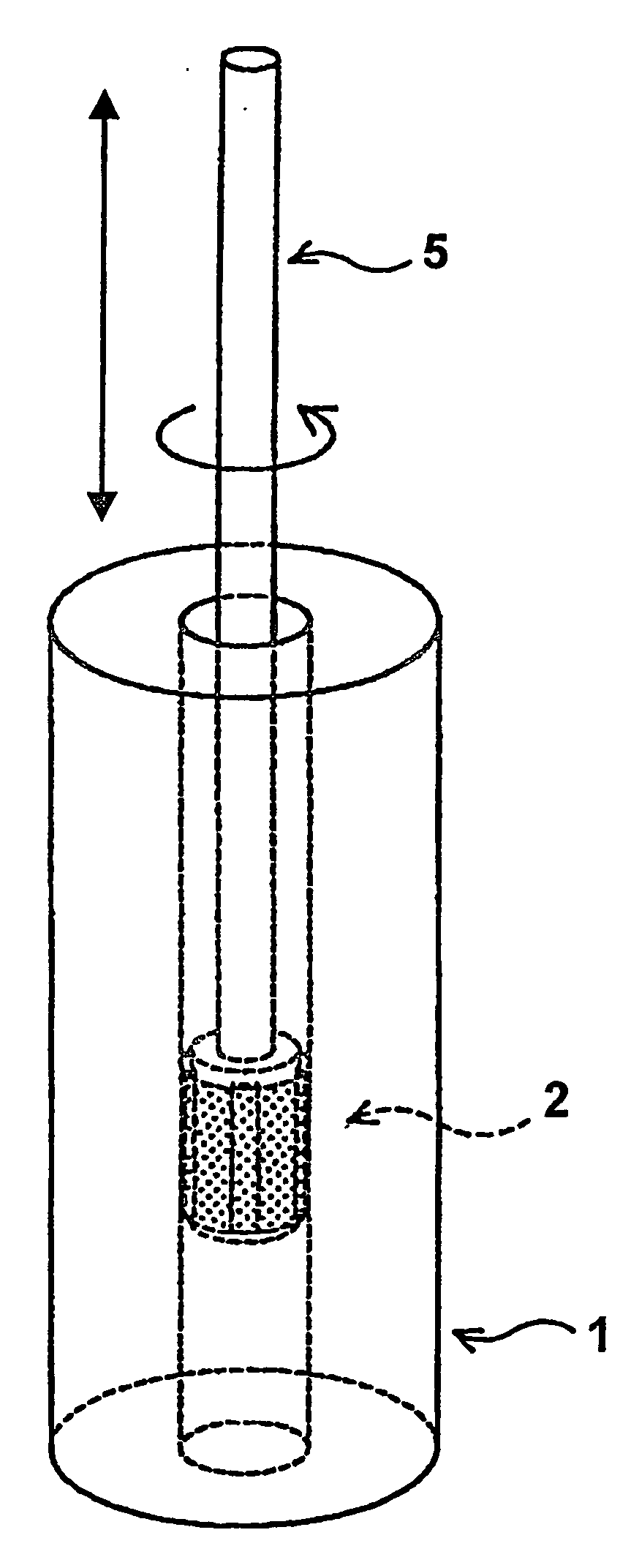

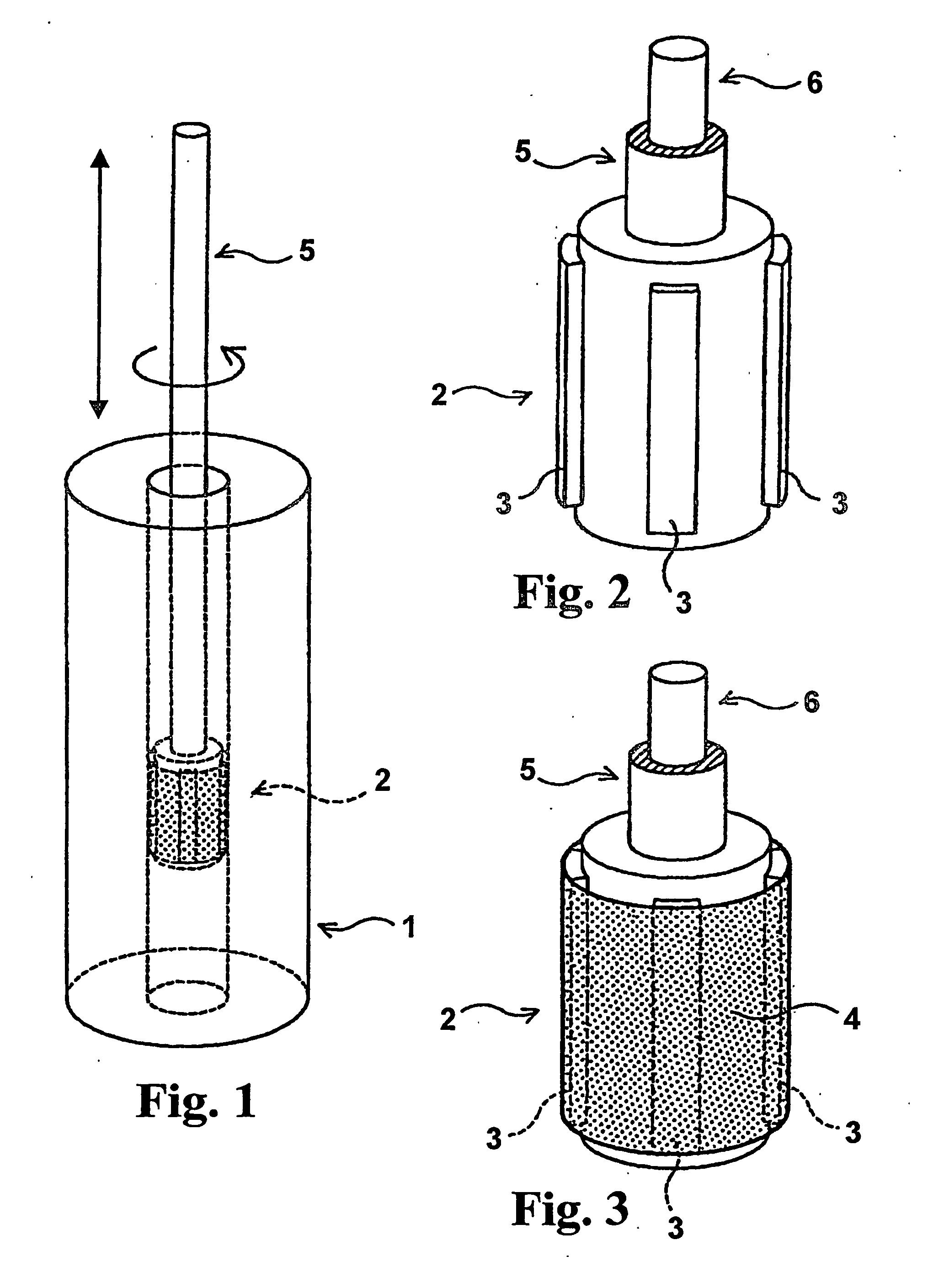

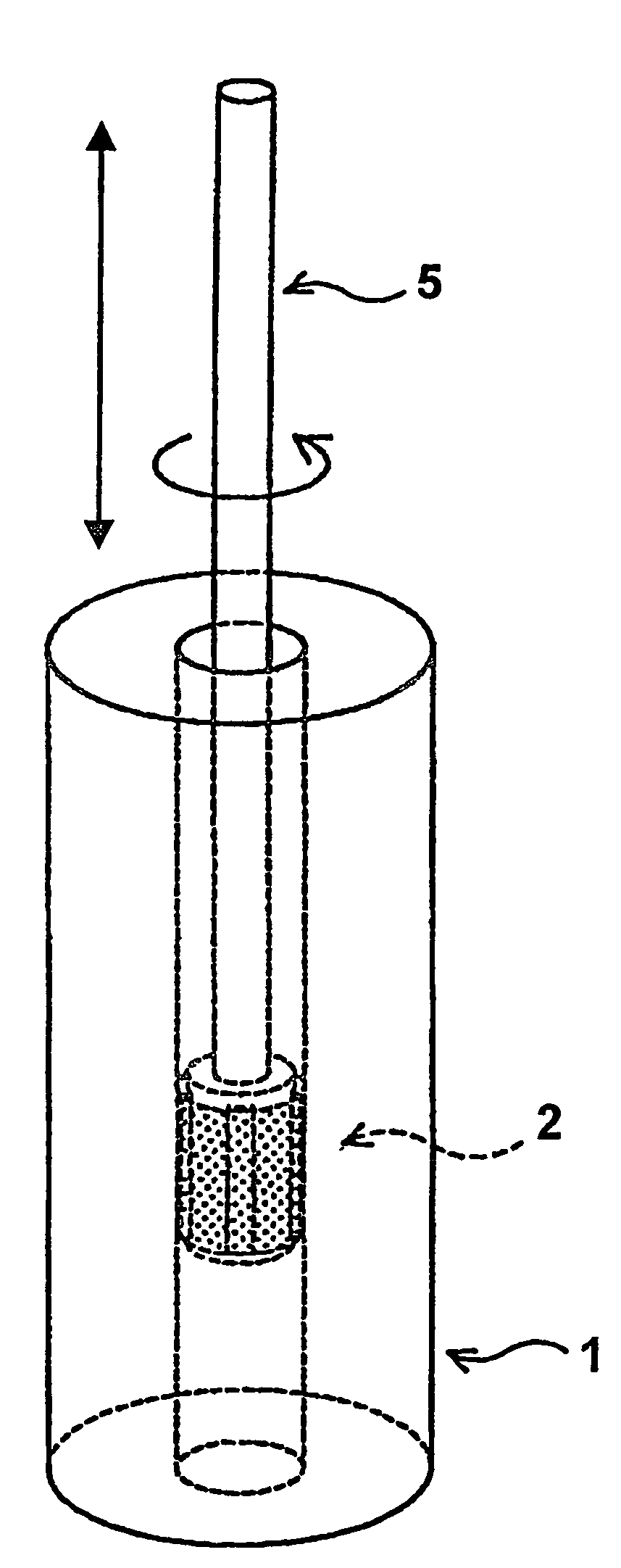

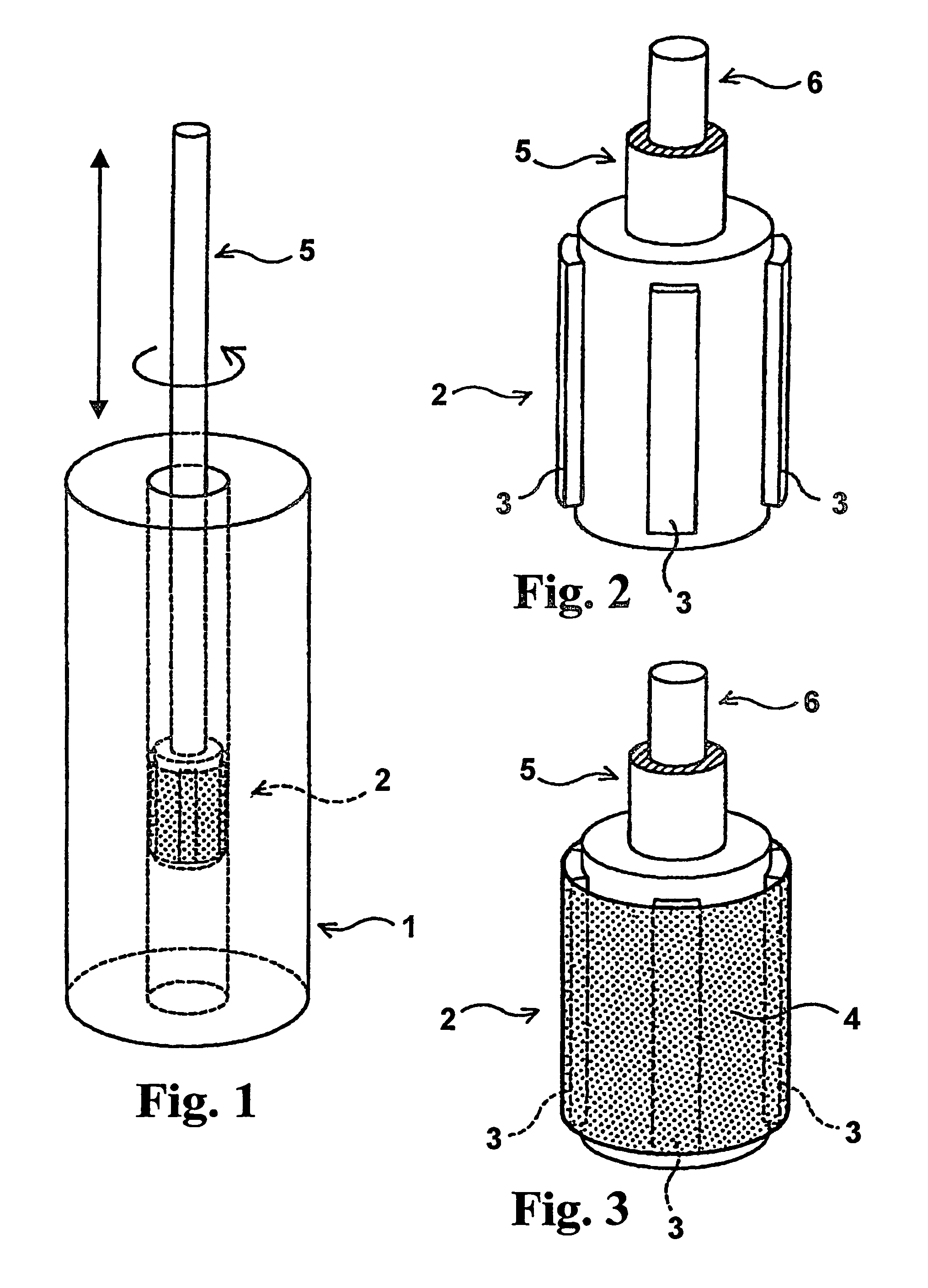

Polishing method for inner surface of tubular brittle material and tubular brittle material obtained by polishing method

ActiveUS20060223427A1High inner surface accuracyImprove accuracyRevolution surface grinding machinesHoning machinesHigh surfaceDiamond

An object of the present invention is to provide a polishing method for producing, in a relatively short period of time, a tubular brittle material having an inner surface of high surface precision with a maximum roughness Rmax of 0.1 μm or smaller and a center line average roughness Ra of 0.01 μm or smaller, and to provide a tubular brittle material with high precision using said polishing method. The polishing method according to the invention is characterized by that the inner surface of the tubular material being pre-cut into a tubular shape using a honing machine is further polished with a sheet material having diamond abrasives attached thereon. Also claimed is a tubular brittle material obtained by said polishing method.

Owner:HERAEUS QUARZGLAS +1

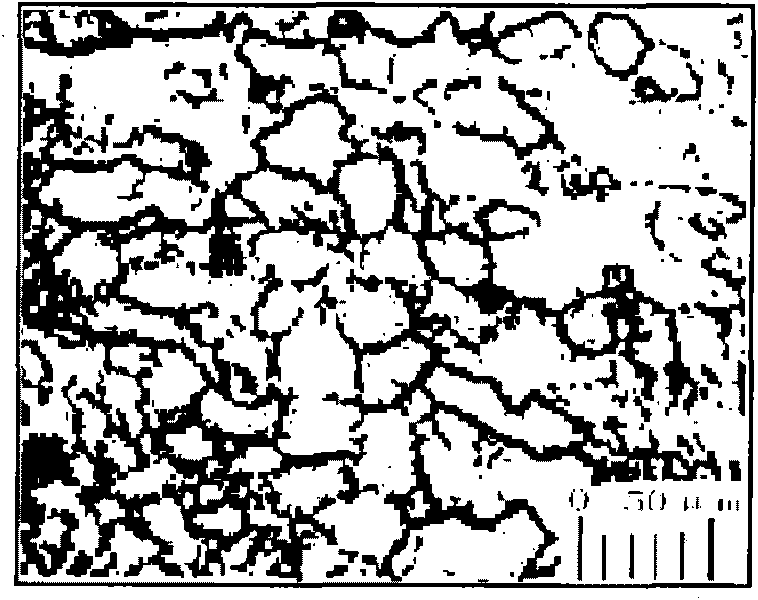

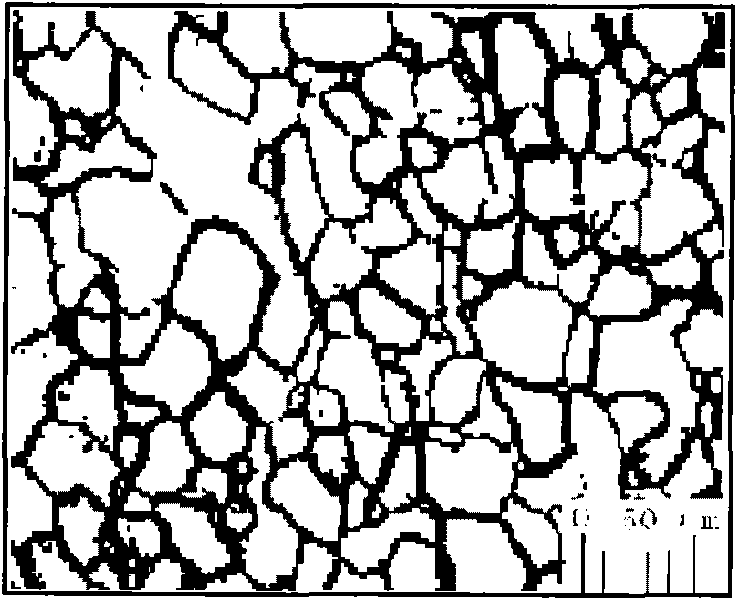

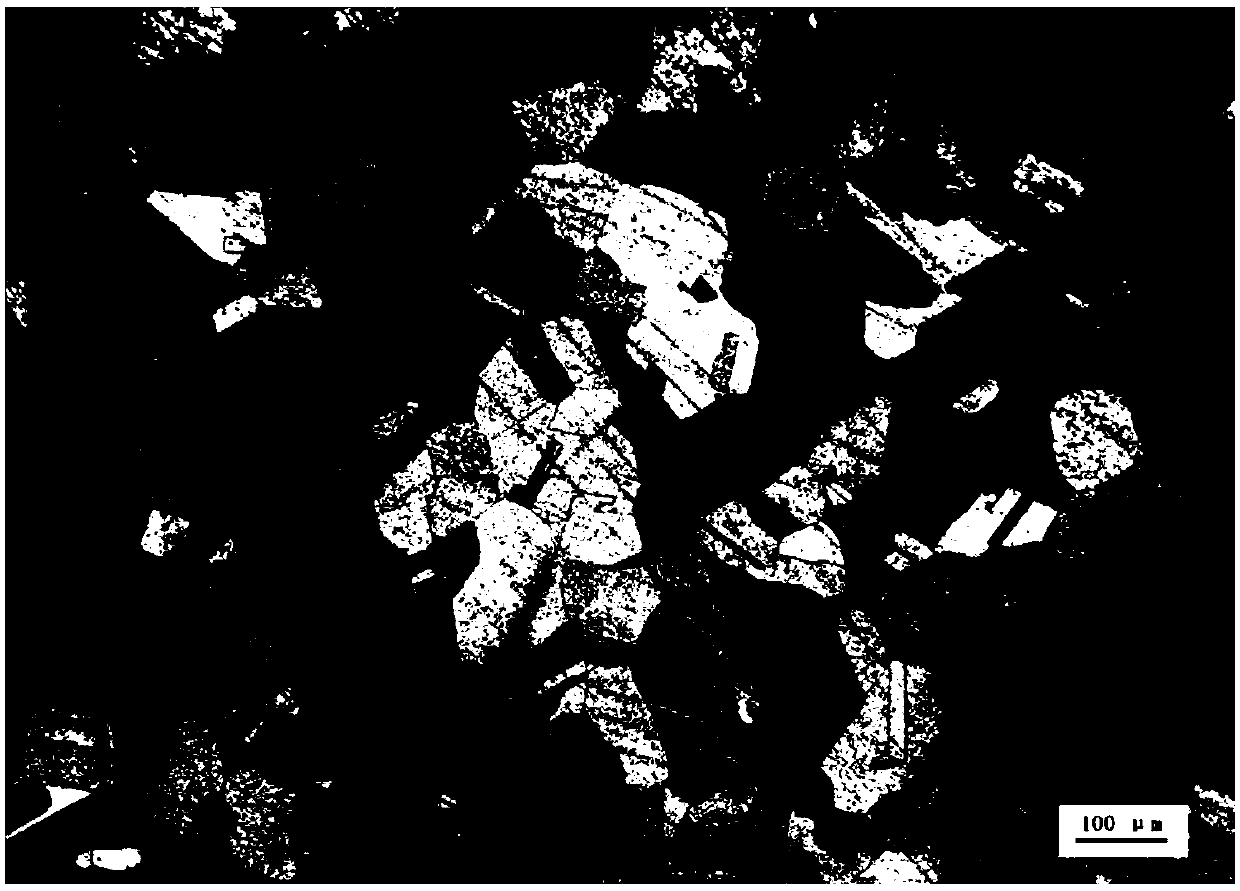

Method for preparing sample showing metallurgical structure of tantalum-tungsten alloy

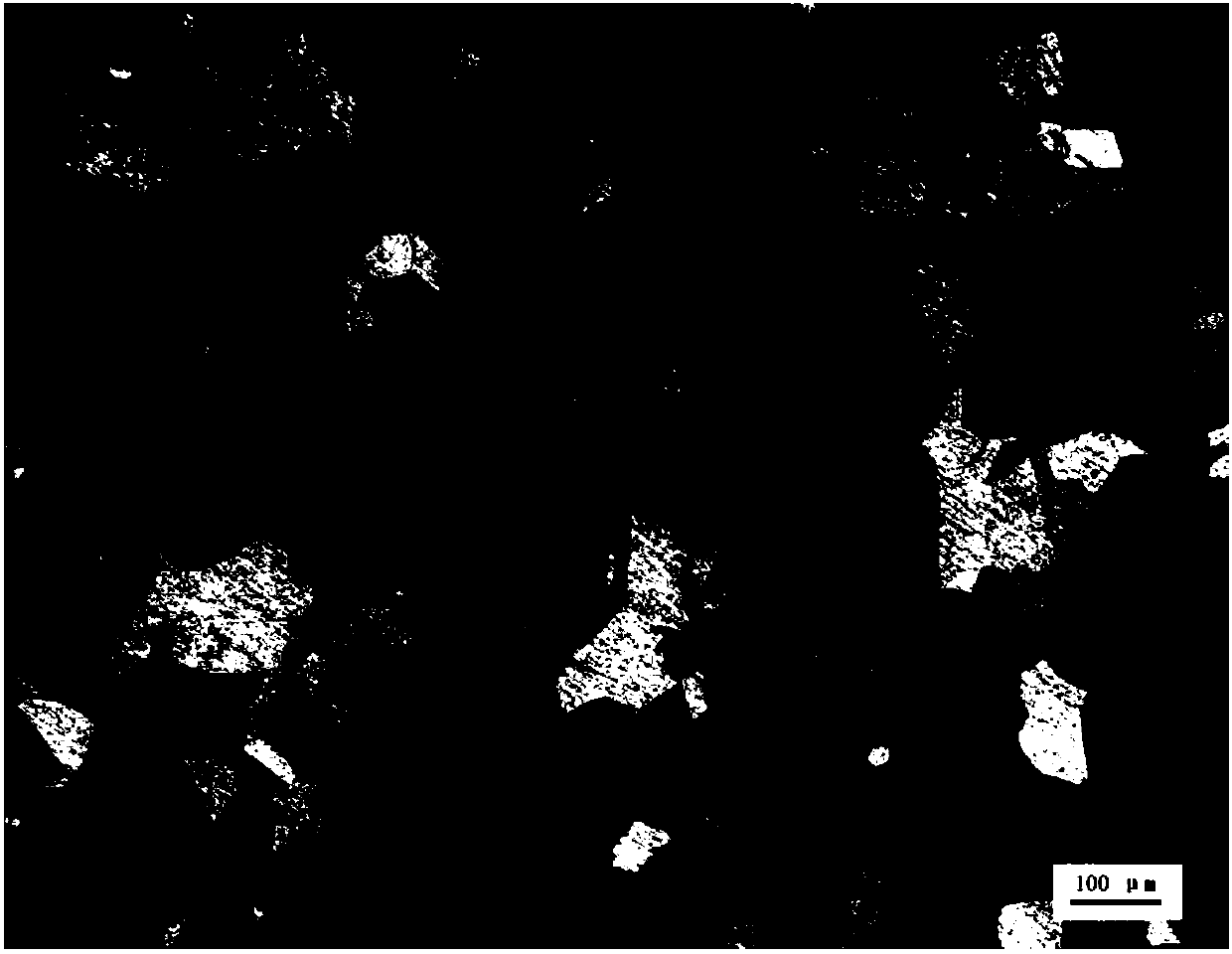

ActiveCN101738340AImprove the display effectEasy to manufacturePreparing sample for investigationSulfuric acidTa element

The invention discloses a method for preparing a sample showing a metallurgical structure of tantalum-tungsten alloy and belongs to the technical field of the preparation of metallographic samples. The method comprises the process steps of coarse grinding, washing, fine grinding, washing, polishing and etching, wherein in a formula of the cleaning liquid, a volume ratio of sulfuric acid to nitric acid to hydrofluoric acid to deionized water is 5:2:2:11; and in a formula of the etching liquid, a volume ratio of sulfuric acid to nitric acid to hydrofluoric acid to deionized water is 5:2:2:1. The method has simple process and easily prepares the metallurgical sample of the tantalum-tungsten alloy and obtains clear metallurgical photos of the tantalum-tungsten alloy.

Owner:GRIMAT ENG INST CO LTD

Preparation method of metallographic samples

InactiveCN108896339AAvoid it happening againEasy to observeWithdrawing sample devicesPreparing sample for investigationColloidMaterials science

The invention discloses a preparation method of metallographic samples. The preparation method includes the following steps: S1, a step of sampling, namely a step of cutting samples at the edge and center of a sample object; S2, a step of inlaying, namely a step of slowly guiding flows of colloid into an inlaying die through galvanized iron wires for curing; S3, a step of grinding; S4, a step of polishing; and S5, a step of corrosion, namely a step of corroding a metallographic detected surface with a corrosion solution. The method can effectively prevent bubbles from forming in the metallographic samples, improve the polishing effect, shorten the polishing time, facilitate metallographic observation of the metallographic detection surface, and improve the detection accuracy.

Owner:JIANGSU SCIENCE TEST TECHNOLOGY SERVICE CO LTD

Polishing method for inner surface of tubular brittle material and tubular brittle material obtained by polishing method

ActiveUS7238089B2Improve accuracyShorten polishing timeRevolution surface grinding machinesHoning machinesHigh surfaceBrittleness

An object of the present invention is to provide a polishing method for producing, in a relatively short period of time, a tubular brittle material having an inner surface of high surface precision with a maximum roughness Rmax of 0.1 μm or smaller and a center line average roughness Ra of 0.01 μm or smaller, and to provide a tubular brittle material with high precision using said polishing method. The polishing method according to the invention is characterized by that the inner surface of the tubular material being pre-cut into a tubular shape using a honing machine is further polished with a sheet material having diamond abrasives attached thereon. Also claimed is a tubular brittle material obtained by said polishing method.

Owner:HERAEUS QUARZGLAS +1

Polisher

ActiveCN103934743AEasy to operateOperation time savingPolishing machinesGrinding/polishing safety devicesWaxEngineering

The invention relates to a polishing device, in particular to a polisher which comprises a machine frame, a polishing wheel arranged on the machine frame, a polishing textile arranged on the polishing wheel in a sleeved mode and a drive motor driving the polishing wheel. A wax stone clamping seat and a clamping mechanism arranged on the wax stone clamping seat are arranged on the machine frame and located at the polishing wheel. The wax stone clamping seat is provided with a wax stone continuous conveying mechanism matched with the clamping mechanism. The polisher is convenient to operate, saves time, and improves polishing quality.

Owner:ZHEJIANG KINGSTONE HOUSEWARES

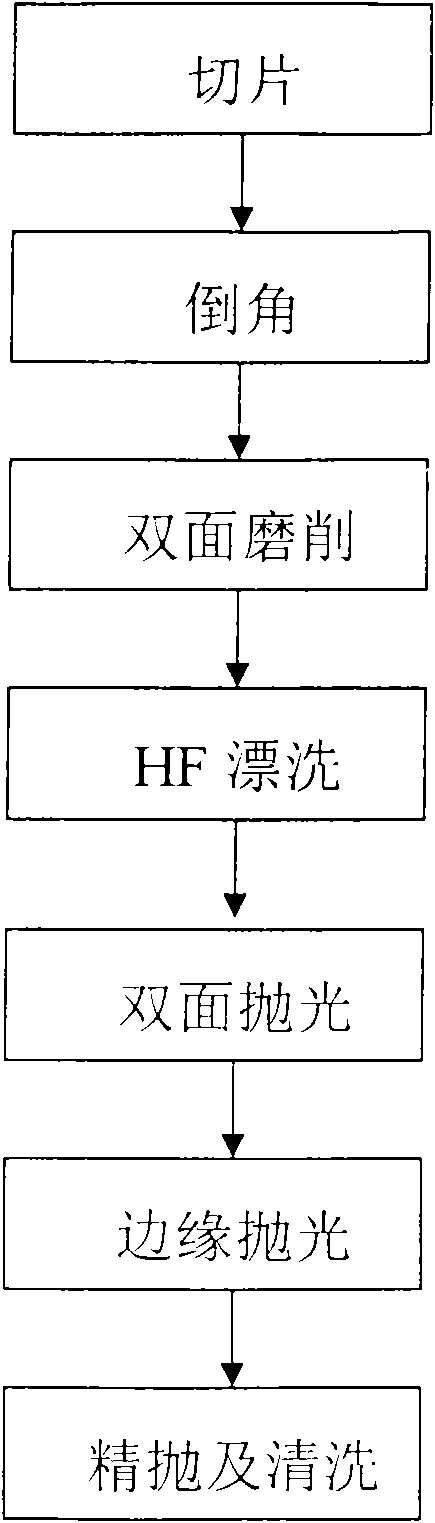

Method for manufacturing large-diameter silicon wafer

InactiveCN101656195ALow flatnessReduce removalSemiconductor/solid-state device manufacturingSingle crystalSilicon chip

The invention discloses a method for manufacturing a large-diameter silicon wafer, which comprises the following steps: (1) rinsing a ground silicon wafer with HF solution to remove an oxide layer onthe surface of the ground silicon wafer and improve the removal speed of double-side polishing; (2) performing conventional double-side polishing on the ground silicon wafer; and (3) performing single-side finishing polish and washing on the silicon wafer. The process method removes the oxide layer on the ground surface with the HF solution, better contributes to the double-side polishing, therebyreducing the polishing time greatly, reducing the removal amount of a silicon single crystal and improving the unit yield of the single crystal at the same time. Because of the reduction of a grinding amount and a corrosion amount, the method ensures machining accuracy of products powerfully, and can manufacture the large-diameter silicon wafer with high flatness. The method for manufacturing thelarge-diameter silicon wafer can be used for any technique for processing the large-diameter silicon wafer in commerce.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

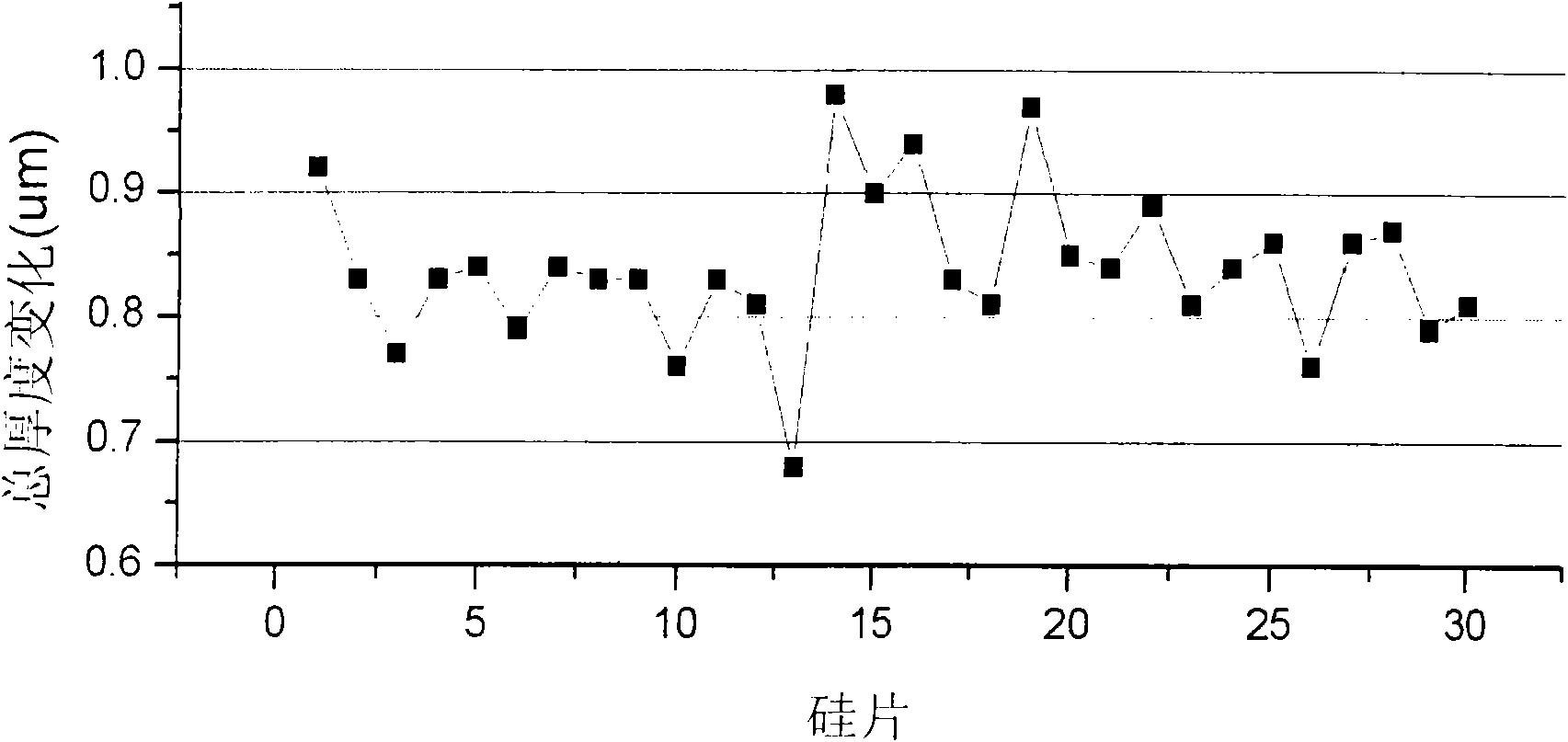

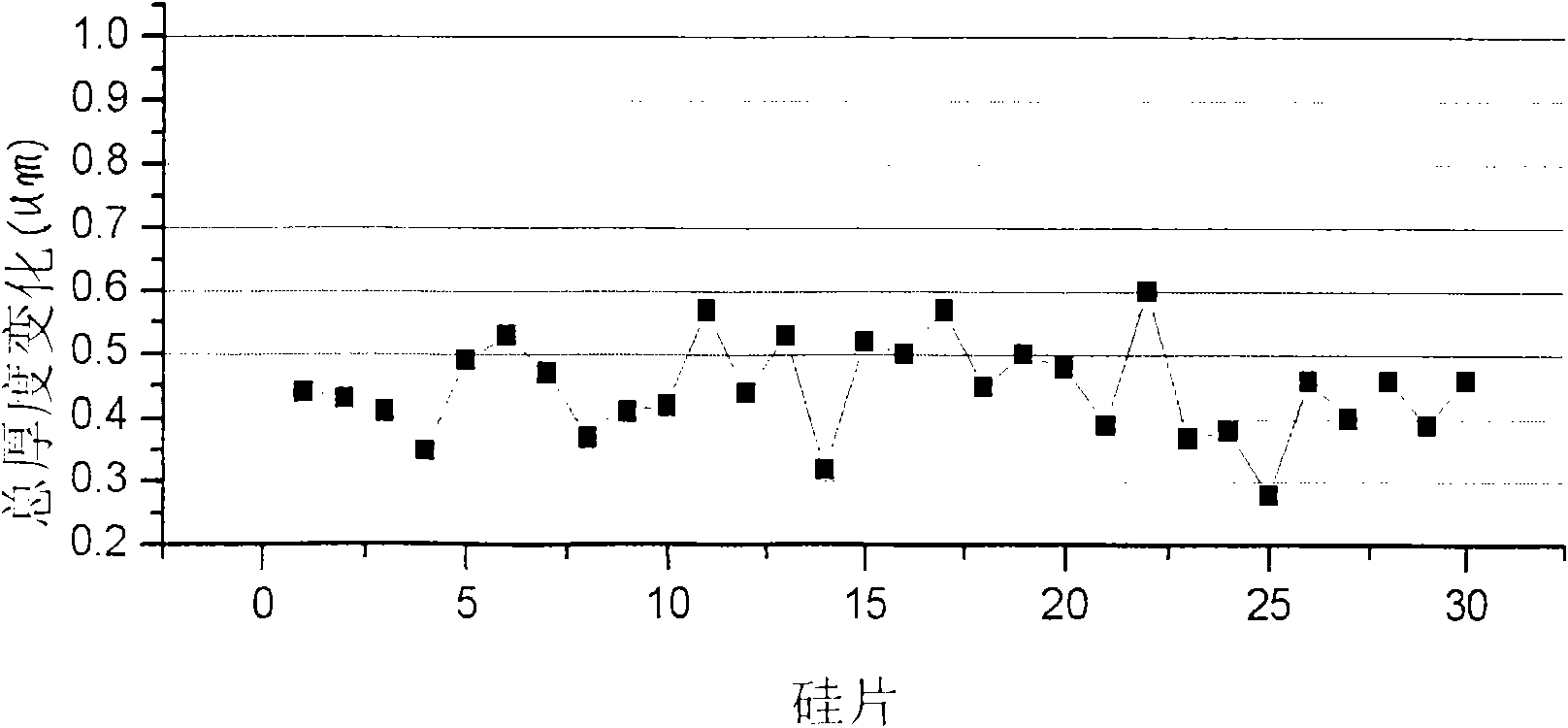

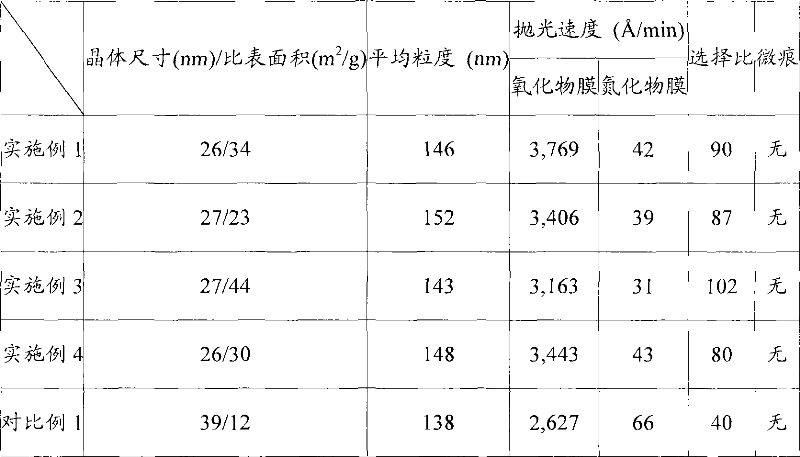

Method for preparing of cerium oxide powder for chemical mechanical polishing and method for preparing of chemical mechanical polishing slurry using the same

ActiveCN101039876ALarge specific surface areaIncrease chemical contact areaMaterial nanotechnologyOther chemical processesPore distributionCerium

The present invention relates to a method of preparing a cerium oxide powder for a CMP slurry and a method of preparing a CMP slurry using the same, and more particularly, to a method of preparing a cerium oxide powder for a CMP slurry and a method of preparing a CMP slurry using the same in which the specific surface area of the powder is increased by preparing a cerium precursor, and then decomposing and calcinating the prepared cerium precursor. The pore distribution is controlled to increase the chemical contact area between a polished film and a polishing material, thereby reducing polishing time while the physical strength of powder is decreased, which remarkably reduces scratches on a polished film.

Owner:LG CHEM LTD

Application of organic phosphate surfactant in self-stopping polishing

InactiveCN103865400AImprove removal rateCorrosion controlOther chemical processesPolishing compositions with abrasivesCopper wirePhosphate

The invention provides an application of an organic phosphate surfactant in self-stopping polishing. The organic phosphate surfactant has the advantages of maintenance of a high copper removal rate, improvement of the saucerization and the over polishing window of polished copper wires, few pollutants on the surface of polished copper, no corrosion and the like.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Polishing process for ultrathin sapphire wafers

ActiveCN108214260AEasy loading and unloadingReduce human and material resources inputPolishing machinesGrinding work supportsEngineeringSapphire wafer

The invention provides a polishing process for ultrathin sapphire wafers. The polishing process comprises the following steps of 1, grouping the sapphire wafers obtained after cutting according to thethickness; 2, providing an adsorption pad provided with multiple cavity holes used for containing the sapphire wafers, wetting the cavity holes with clear water, putting the sapphire wafers into thecavity holes, and making each sapphire wafer and the corresponding cavity hole be fixed relative to each other; 3, putting the adsorption pad on a copper disc of a polishing machine with openings of the cavity holes of the adsorption pad facing downwards, so that rough polishing is conducted on the sapphire wafers; and 4, putting the sapphire wafers obtained after rough polishing on a lower polishing disc of a double-face polishing machine for finish polishing. By means of the polishing process for the ultrathin sapphire wafers, the polishing time is greatly shortened, polishing efficiency isimproved, and production cost is lowered; the thickness of each sapphire wafer obtained after polishing is small and can reach 0.1-0.2 mm; polishing quality is stable and reliable; and the polishing process meets the trend that existing sapphire products develop to be lighter and thinner.

Owner:LENS TECH CHANGSHA

Polishing apparatus and polishing method

ActiveUS8187055B2Easy to replaceShorten polishing timeEdge grinding machinesPolishing machinesEngineeringMechanical engineering

A polishing apparatus polishes a periphery of a substrate. This polishing apparatus includes a rotary holding mechanism configured to hold the substrate horizontally and rotate the substrate, plural polishing head assemblies provided around the substrate, plural tape supplying and recovering mechanisms configured to supply polishing tapes to the plural polishing head assemblies and recover the polishing tapes from the plural polishing head assemblies, and plural moving mechanisms configured to move the plural polishing head assemblies in radial directions of the substrate held by the rotary holding mechanism. The tape supplying and recovering mechanisms are located outwardly of the plural polishing head assemblies in the radial directions of the substrate, and the tape supplying and recovering mechanisms are fixed in position.

Owner:EBARA CORP

Pickling method of surface of 430 stainless steel

The invention relates to a pickling method of a surface of 430 stainless steel, which comprises the following steps: directly putting the 430 stainless steel after annealing into a pickling tank for pickling, wherein the pickling solution in the pickling tank comprises an additive and hydrochloric acid of which the concentration is 1-7mol / L, the adding quantity of the additive is 0.1-3% of the molar number of the hydrochloric acid, the pickling temperature is 20-80 DEG C, and the pickling retention time is 100-500s; washing the 430 stainless steel after pickling by water for the first time, wherein the water washing temperature is 20-60 DEG C, and the retention time is 80-120s; and washing the 430 stainless steel after washing by water for the first time by water for the second time, wherein the water washing temperature is 20-60 DEG C, and the retention time is 80-120s. The additive is hydrogen peroxide, potassium chlorate or sodium hypochlorite. The invention can enable the stainless steel surface to have higher smoothness and do not have a residual oxide layer and a pickling passivation layer, thereby saving the pickling cost, avoiding NOx gas and nitrite solution and simultaneously shortening the polishing time of the pickling process.

Owner:NORTHEASTERN UNIV

Polishing mechanism of improved structure

InactiveCN106041699AIncrease intensityQuality improvementGrinding carriagesPolishing machinesMechanical engineeringEngineering

A polishing mechanism of an improved structure comprises a polishing fixing beam and at least one polishing head installed on the polishing fixing beam. Each polishing head comprises a polishing frame body rotationally installed on the polishing fixing beam, a polishing rotary part rotationally installed on the polishing frame body, a polishing motor assembly used for driving the polishing rotary part to rotate at high speed, and a polishing swing part used for driving the polishing rotary part to swing back and forth. According to the polishing mechanism of the improved structure, a polishing wheel can rotate at high speed and swing left and right, so that on the premise of the same rotation speed, the polishing force and quality can be effectively improved, the polishing time is shortened, the polishing efficiency is further improved, and the quality of products can be improved.

Owner:FUJIAN CHANGJIANG IND

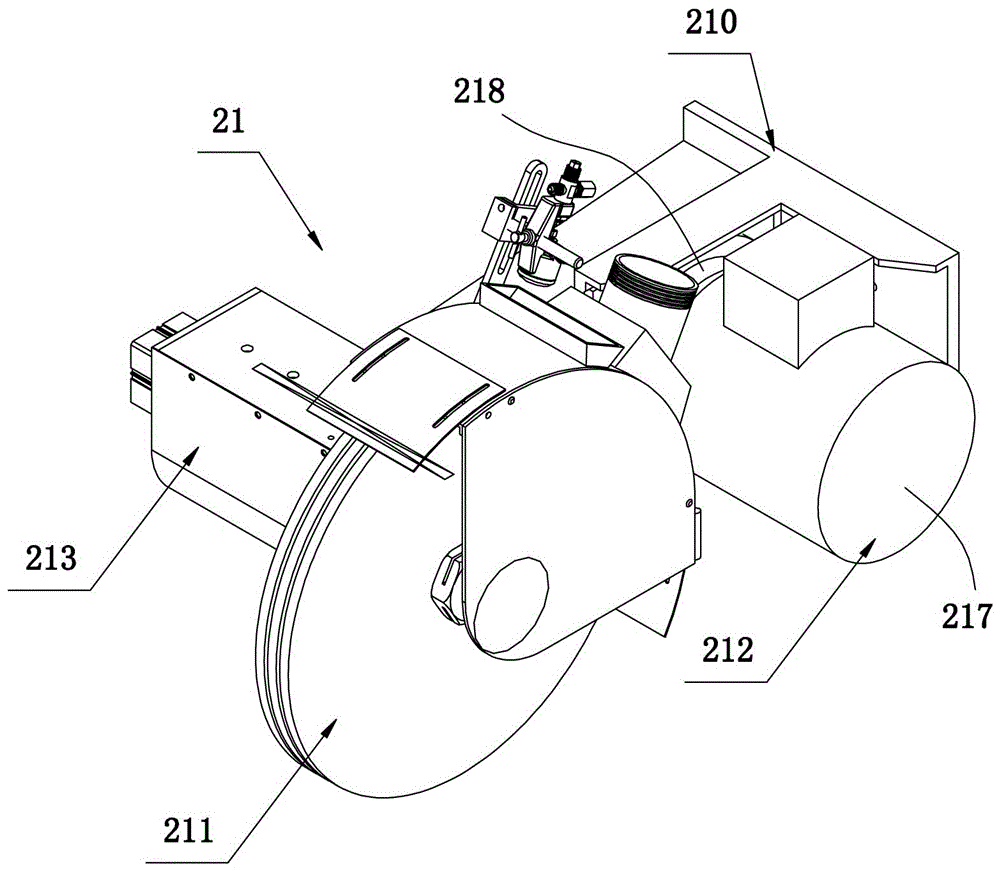

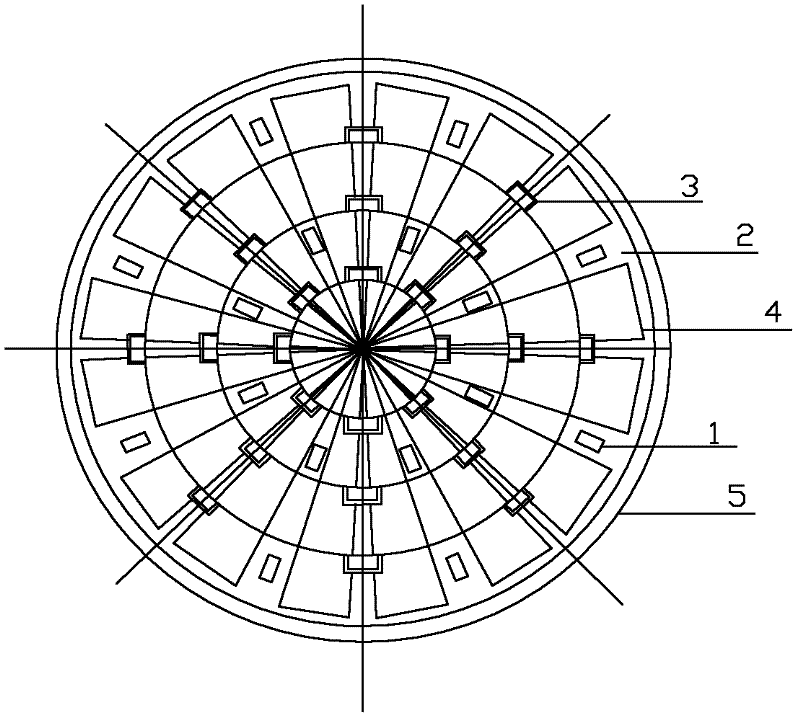

Device for polishing peripheral edge of semiconductor wafer

ActiveUS8029333B2Efficient polishingShorten polishing timeEdge grinding machinesRevolution surface grinding machinesReciprocating motionSemiconductor

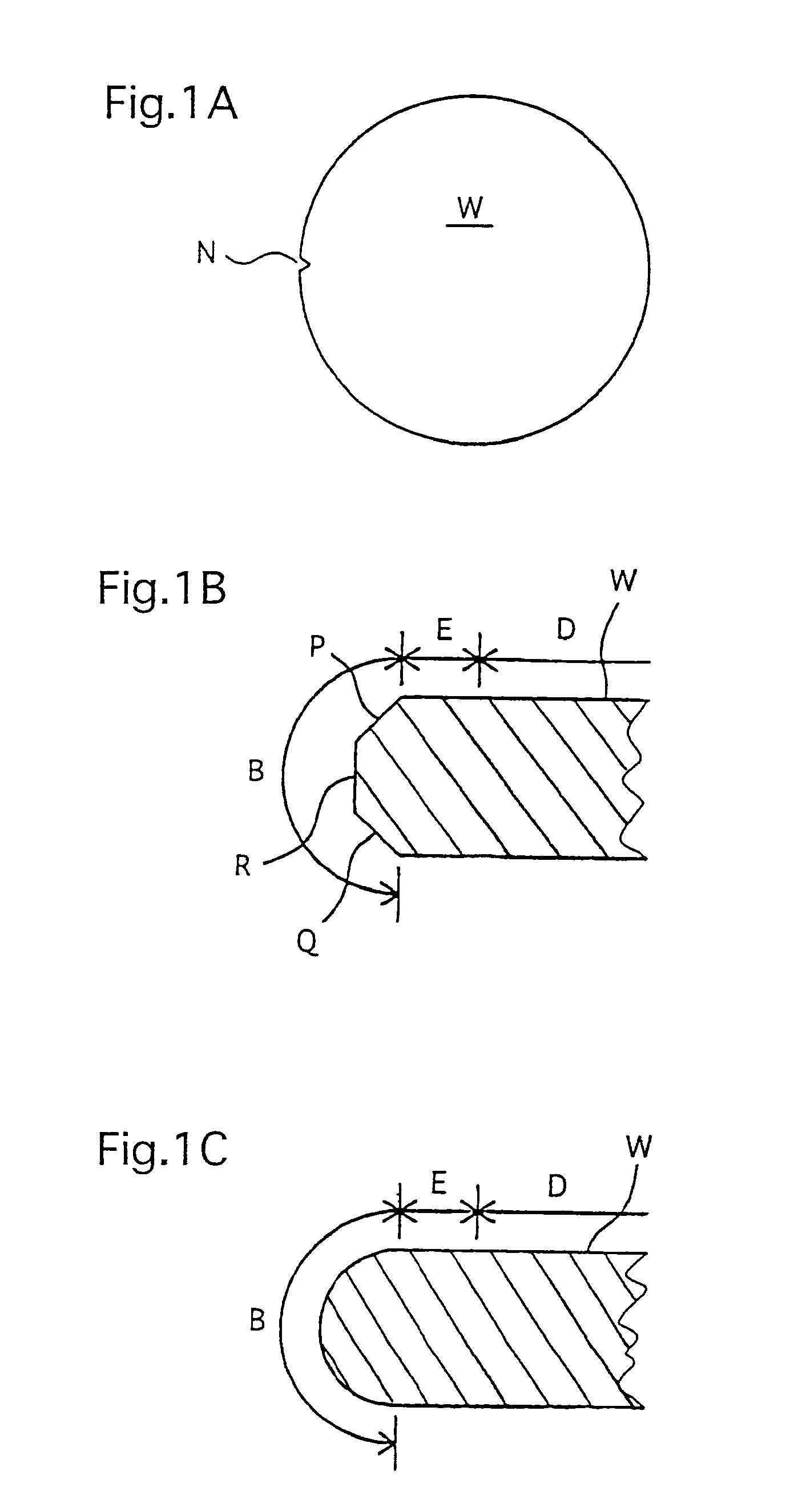

A device for polishing the peripheral edge part of a semiconductor wafer includes a wafer stage for holding the wafer, a wafer stage unit including devices for rotating the wafer stage, causing the wafer stage to undergo a rotary reciprocating motion within the same plane as the surface of the wafer stage, and moving the wafer stage parallel to the surface, a notch polishing part for polishing the notch on the wafer and a bevel polishing part for polishing the beveled part of the wafer. Pure water is supplied to the wafer to prevent it from becoming dry as it is transported from the notch polishing part to the bevel polishing part.

Owner:EBARA CORP +1

Polishing and cleaning process for precision component

InactiveCN109648450ANot prone to scratchesImprove polishing qualityPolishing machinesOrganic non-surface-active detergent compositionsSurface finishEngineering

The invention discloses a polishing and cleaning process for a precision component. The polishing and cleaning process comprises the following steps that a precision component to be polished is pressed on a polishing die to be polished; the polished precision component is soaked in a cleaning solution and is washed with deionized water; ultrasonic cleaning with ethanol is carried out; high-pressure spray cleaning with deionized water is carried out; and drying is carried out to obtain the precision component. According to the polishing and cleaning process, polishing asphalt and alumina powderare prepared into the polishing die according to a certain ratio, the polishing die is used for polishing the precision component, the precision component can achieve the very good surface smoothness, and the machining precision of the precision component is ensured. The cleaning solution can completely remove stains, white spots and the like on the surface of the precision component. The multi-frequency ultrasonic cleaning process is adopted so that the surface of the cleaned precision component has the very good cleanliness. The test results show that the polishing and cleaning process hasthe good polishing effect and the good cleaning effect on the precision component.

Owner:临安宇杰精密制品有限公司

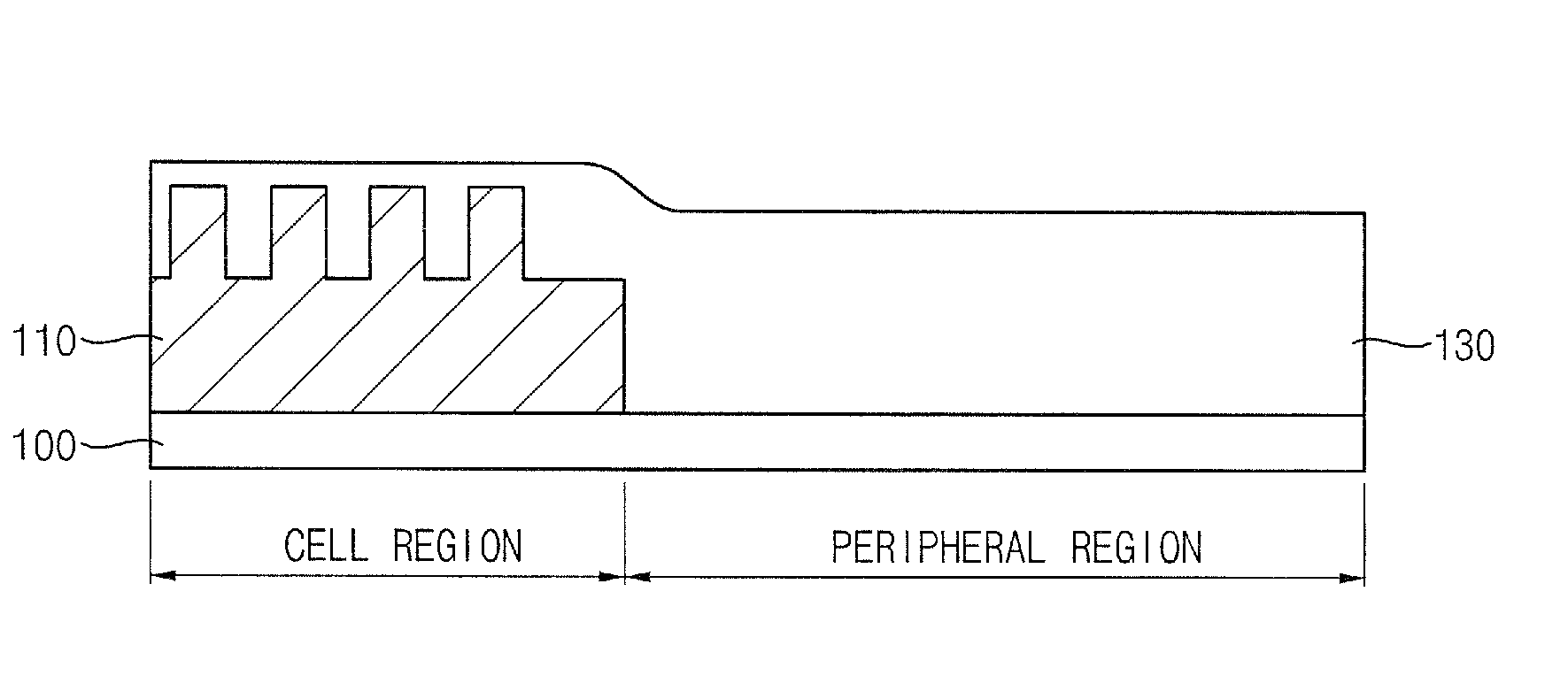

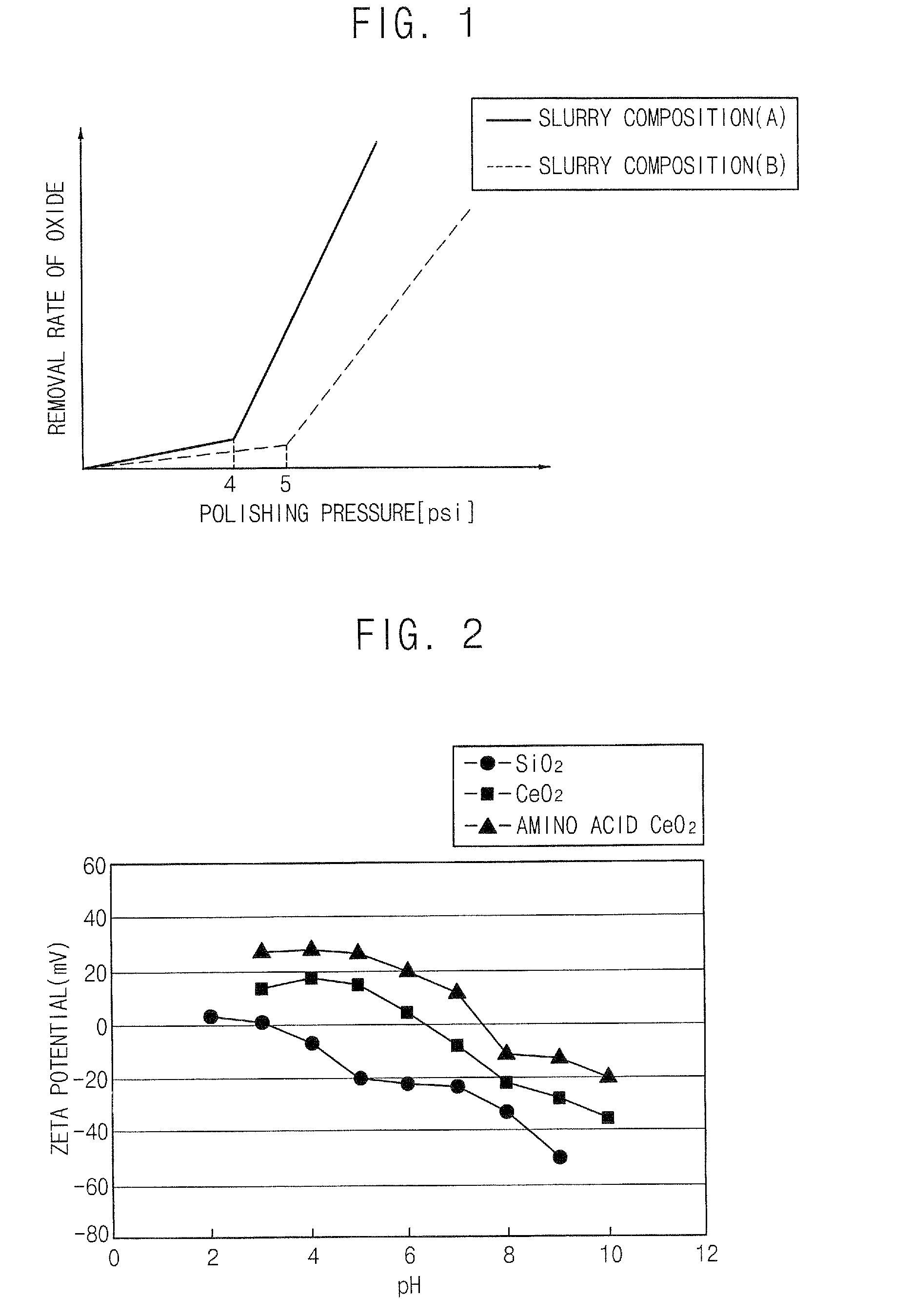

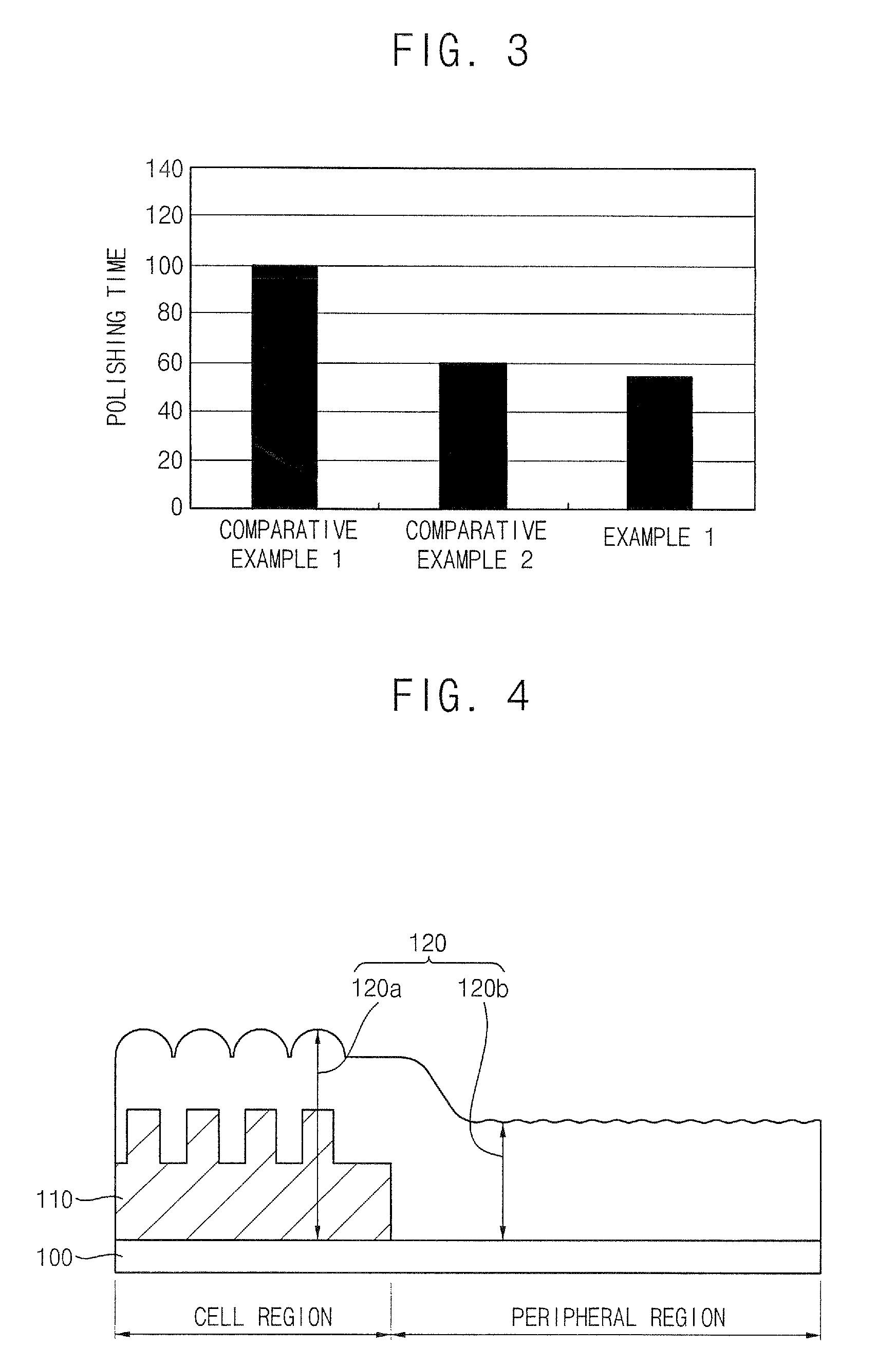

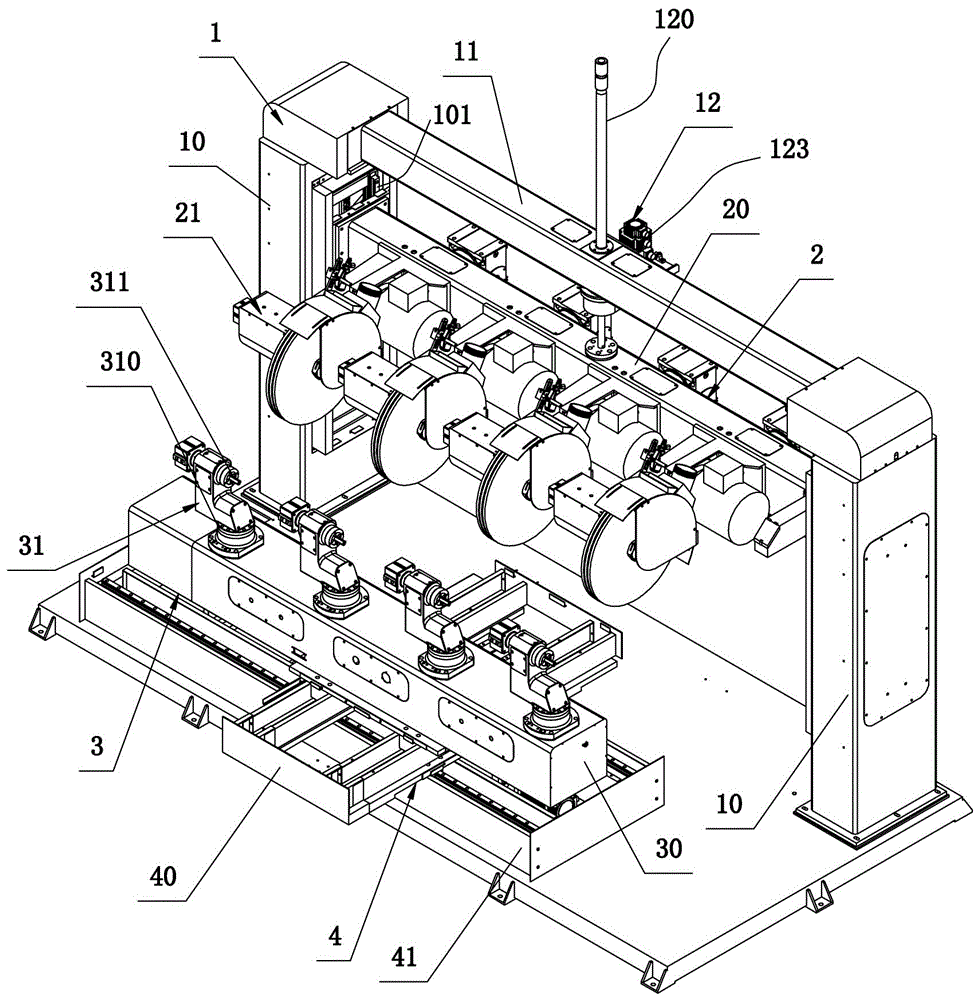

Slurry compositions and methods of polishing a layer using the slurry compositions

ActiveUS8314028B2Good planarityShorten polishing timePigmenting treatmentOther chemical processesPh controlSlurry

In a slurry composition and a method of polishing a layer using the slurry composition, the slurry composition includes from about 3 to 20 percent by weight of an abrasive, from about 0.1 to 3 percent by weight of an ionic surfactant, from about 0.01 to 0.1 percent by weight of a nonionic surfactant, from about 0.01 to 1 percent by weight of a polish accelerating agent including an amino acid compound, and a remainder of an aqueous solution including a basic pH-controlling agent and water. The slurry composition including the nonionic surfactant and the polish accelerating agent may be used for speedily polishing a stepped upper portion of a silicon oxide layer, and may also enable a lower portion of the silicon oxide layer to function as a polish stop layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Multi-station polishing machine capable of improving efficiency

InactiveCN106064342ASimple structureSimple control methodPolishing machinesGrinding drivesEngineeringMechanical engineering

A multi-station polishing machine capable of improving efficiency comprises a rack, a polishing mechanism mounted on the rack as well as a workpiece loading and synchronous rotating control working table arranged below the polishing mechanism, wherein the polishing mechanism comprises a polishing fixing beam and at least two polishing heads mounted on the polishing fixing beam at an interval; and the workpiece loading and synchronous rotating control working table comprises a loading fixing base, at least two workpiece clamping mechanical arms rotationally mounted on the top surface of the loading fixing base as well as a synchronous driving device for controlling all the workpiece clamping mechanical arms to rotate synchronously and swing synchronously. With the machine, all workpieces can be polished in the same environment at the same time, the polishing consistency of products is greatly improved, product polishing differences caused by polishing condition deviations are reduced, differences of polishing effects of the same batch of workpieces can be reduced to a certain extent, unified production is facilitated, meanwhile, the control method is simple and easy to implement, and the product polishing accuracy can be improved.

Owner:FUJIAN CHANGJIANG IND

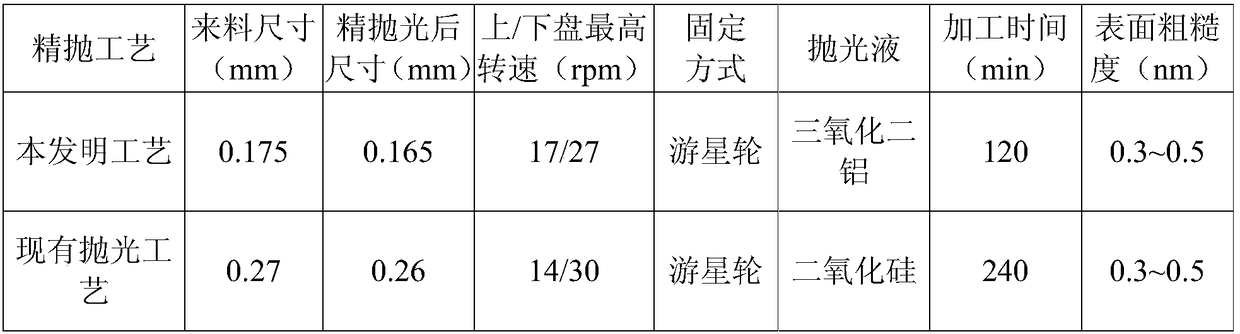

Sapphire polishing process

InactiveCN106271900AHigh hardnessImprove stabilityPolishing machinesLapping machinesChemical reactionActive agent

The invention discloses a sapphire polishing process. The sapphire polishing process comprises the following steps: performing raw material pre-treatment, performing accurate grinding, polishing, cleaning, testing and the like. According to the sapphire polishing process, the surface of a raw material is ground through the raw material pre-treatment and accurate grinding processes; the difficulty in polishing is reduced; the polishing time is saved; a polishing solution which is prepared from aluminium oxide is high in hardness, and a chemical reaction is produced in a process of rubbing a sapphire, so that CMP (Chemical Mechanical Polishing) is performed effectively; the stability is high; the cost is low; the stability of the polishing solution is improved through an FA / O compound active agent; the flatness of a polished surface and the work efficiency are improved; through experiments, the removal rate of the polishing is 6 mu m / hr when the pressure value is 4 psi, the rotating speed is 60 rpm, and the pH value is 10; the removal rate of the polishing is 8 mu m / hr when the pressure value is 5 psi, the rotating speed is 60 rpm, and the pH value is 10. The process flow of the sapphire polishing process is simple; meanwhile, the cost is saved; the sapphire polishing process is worth being popularized in the future.

Owner:TDG YINXIA NEW MATERIAL CO LTD

TFT (Thin Film Transistor) glass thinning pretreatment method

The invention provides a TFT (Thin Film Transistor) glass thinning pretreatment method, which comprises the following steps: injecting mixed acid liquor of concentrated sulfur acid, concentrated hydrochloric acid and hydrofluoric acid into an airtight container; heating the mixed acid liquor to 28-30DEG C and bubbling and evenly mixing; injecting the mixed acid liquor into etching equipment, continuously bubbling and mixing for 30-60 minutes until mixing evenly; soaking TFT glass to be-thinned in the mixed solution for 15-60 minutes, so as to remove the double layers of a glass surface by 50-80micrometers; washing and moisturizing the TFT glass, and thinning in the hydrofluoric acid etching solution. Pits in the surface of a pretreated TFT glass panel are reduced, the depths of the pits are shallower and size is obviously reduced in comparison with pits of the glass which is not treated or etched, and indirectly the polishing time can be shortened by 50-80% through the same machine platform under the same conditions, even the effect of no need of polishing can be achieved.

Owner:SUZHOU CRANE OPTOELECTRONICS TECH

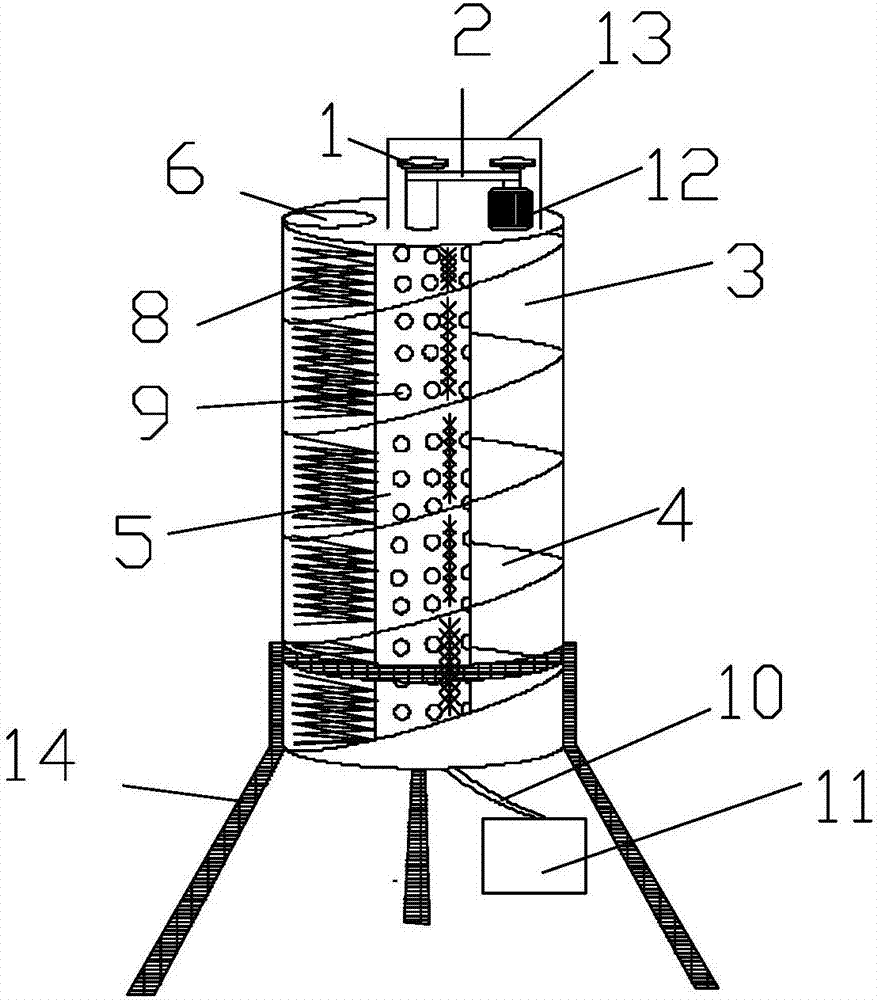

Vertical type spiral bamboo stick polishing machine

InactiveCN107030569ASave time on manual unloadingEffective absorptionPolishing machinesGrinding machinesArchitectural engineeringTime-Consuming

The invention discloses a vertical type spiral bamboo stick polishing machine. The vertical type spiral bamboo stick polishing machine comprises a machine frame, a polishing drum which is uprightly fixed on the machine frame, a three-dimensional spiral disc, a cylindrical tube, a motor and a dust collector, wherein a feed opening is formed in the upper end of the polishing drum; discharge openings and supporting ribs are arranged at the lower end of the polishing drum; the polishing drum, the three-dimensional spiral disc and the cylindrical tube are in sequential sleeving from outside to inside; the three-dimensional spiral disc is fixed on the outer wall of the cylindrical tube and is in fit with the outer wall of the cylindrical tube and the inner wall of the polishing drum; the upper end of the cylindrical tube is closed, and belt pulleys are mounted at the upper end of the cylindrical tube; a dust discharging opening is formed in the lower end of the cylindrical tube; through holes communicating with the dust discharging opening are formed in the side wall of the cylindrical tube in a penetrating manner; banister brushes are arranged on the outer wall of the cylindrical tube; the motor is arranged at the upper end of the polishing tube and is connected with the belt pulleys through a belt; and the dust collector is connected with the dust discharging opening of the cylindrical tube. Through the adoption of the vertical type spiral bamboo stick polishing machine disclosed by the invention, the problems that time consumed by manual discharging in bamboo stick polishing operation is long, and bamboo residues and impurities after polishing operation fly in the air are solved, so that bamboo stick polishing efficiency can be improved.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

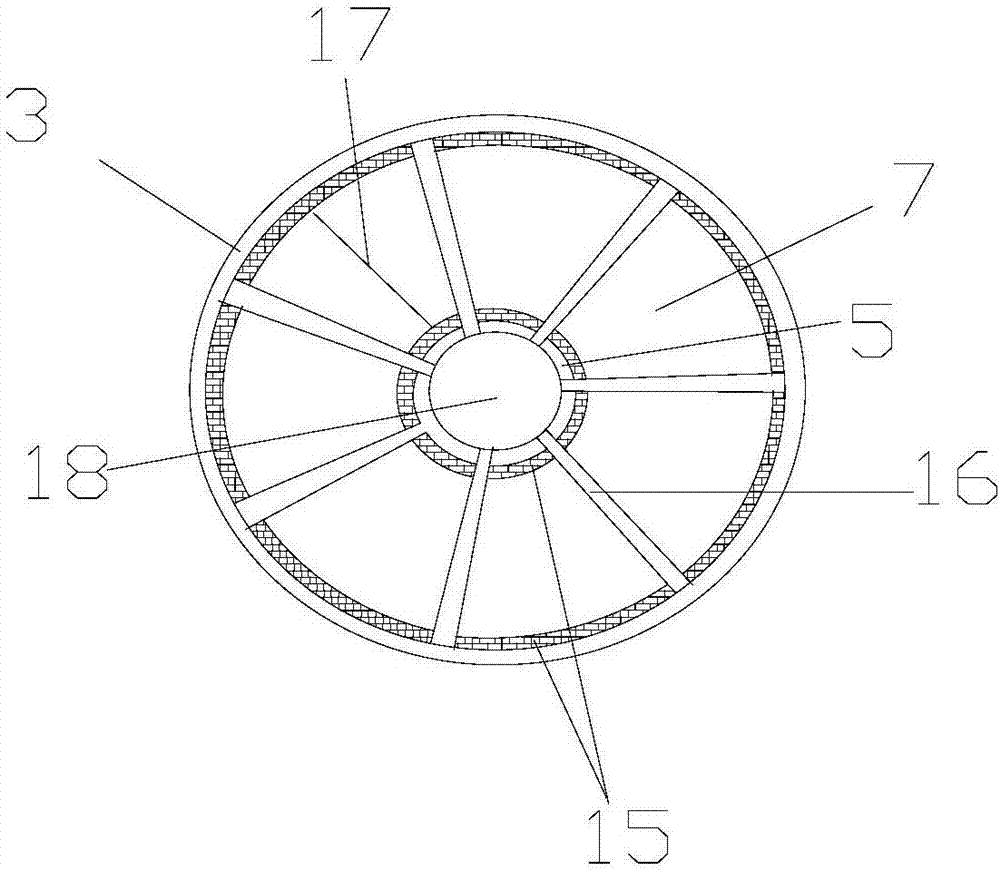

Polishing disk capable of adjusting regional pressure

InactiveCN102501187AUneven processing remains goodGuaranteed convergenceFlexible-parts wheelsLapping toolsEngineeringMechanical engineering

A polishing disk capable of adjusting regional pressure is disclosed, which relates to a mechanical polishing tool. The polishing disk capable of adjusting regional pressure is provided with a piezoelectric sensor, a polishing disk, slide block and slide groove pairs, polyurethane polishing plates and a circular chuck, wherein at least two circular rings are disposed on the polishing disk and divided into fan-shaped blocks; the slide block and slide groove pairs are disposed on the fan-shaped blocks; two polyurethane polishing plates are attached to the surface of each fan-shaped block; an inward groove for placing the piezoelectric sensor is disposed between the two polyurethane polishing plates; and the circular chuck for fixing the fan-shaped blocs is disposed on the outer edge of the polishing disk.

Owner:XIAMEN UNIV

Observing method of metallographic structure of equiatomic platinum-cobalt alloy

InactiveCN107727476AReduce risk of churnLower level requirementsPreparing sample for investigationMaterial analysis by optical meansPlatinumDenture base

The invention discloses an observing method of a metallographic structure of an equiatomic platinum-cobalt alloy. The observing method comprises the steps that 1, an equiatomic PtCo alloy sample is cut on a workpiece and fixed on denture base resin; 2, the alloy sample is ground by a grinding machine and then is ground level by level by sequentially adopting number 600 metallographic abrasive paper and number 1200 metallographic abrasive paper; the polished platinum-cobalt alloy sample is subjected to mechanical polishing, and the platinum-cobalt alloy sample without remarkable scratch and contamination point is obtained; 4, the platinum-cobalt alloy obtained after mechanical polishing is placed in a corrosive container filled with a corrosive solution for etching, after etching is completed, the platinum-cobalt alloy is placed under a metallographic microscope, and thus the metallographic structure of the equiatomic platinum-cobalt alloy is observed. The sample preparing method has low requirements for levels of experimental devices and operating personnel, is suitable for preparation of the equiatomic platinum-cobalt alloy in a normal laboratory, is quite low in alloy consumption, and greatly lowers the risk of loss and waste of precious metal.

Owner:西安诺博尔稀贵金属材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com