Patents

Literature

304 results about "Sapphire wafer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition and method for polishing a sapphire surface

InactiveUS20060196849A1Simple compositionImprove methodOther chemical processesDecorative surface effectsColloidal silicaSlurry

An improved composition and method for polishing a sapphire surface is disclosed. The method comprises abrading a sapphire surface, such as a C-plane or R-plane surface of a sapphire wafer, with a polishing slurry comprising an abrasive amount of an inorganic abrasive material such as colloidal silica suspended in an aqueous medium having a salt compound dissolved therein. The aqueous medium has a basic pH and includes the salt compound in an amount sufficient to enhance the sapphire removal rate relative to the rate achievable under the same polishing conditions using a the same inorganic abrasive in the absence of the salt compound.

Owner:CABOT MICROELECTRONICS CORP

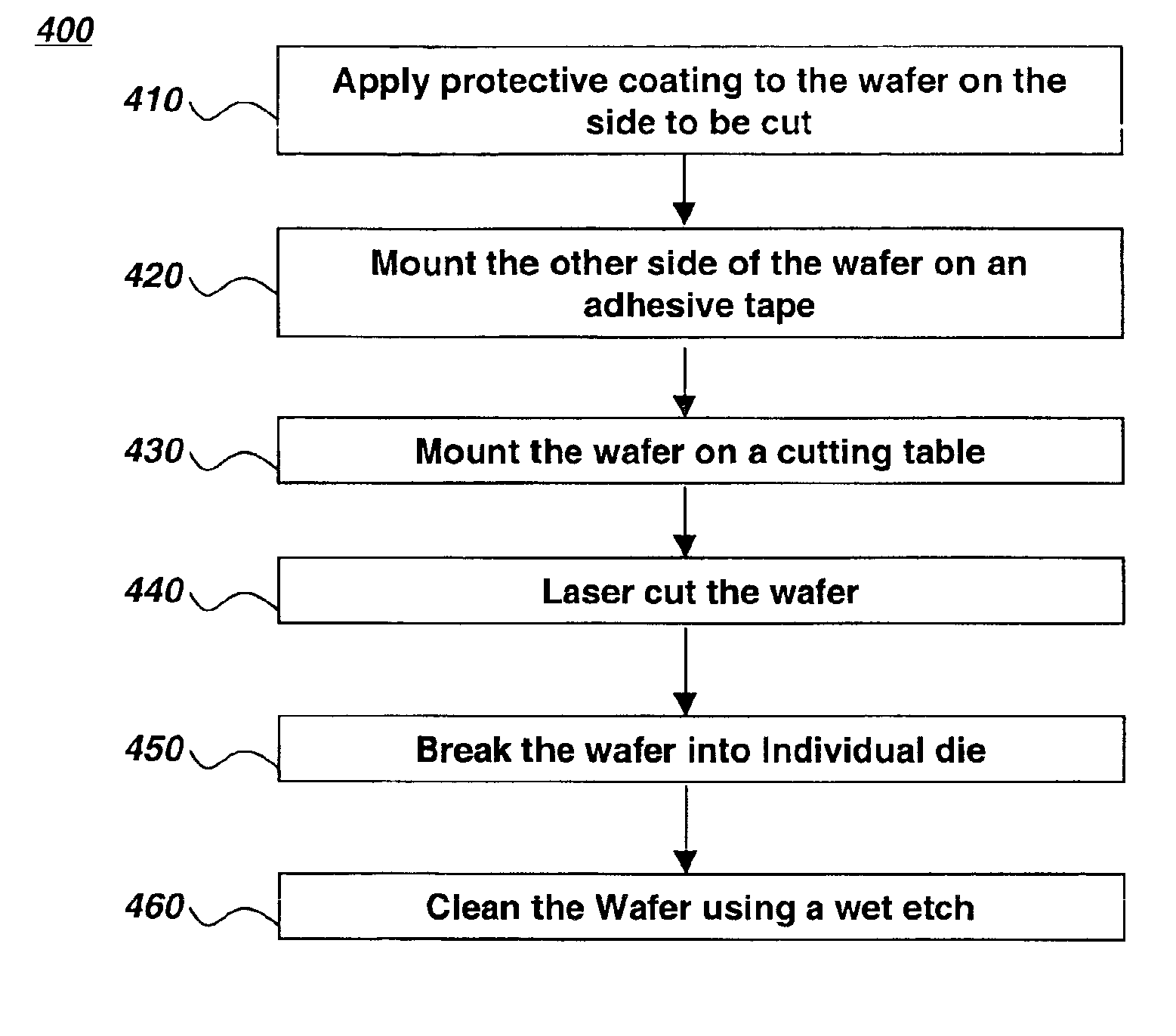

Semiconductor wafer protection and cleaning for device separation using laser ablation

InactiveUS6849524B2Improve processing efficiencyEasy to handleSolid-state devicesSemiconductor/solid-state device manufacturingWaferingSlag

A method of protecting and cleaning a semiconductor wafer using laser ablation includes the following steps: applies a protective coating on the side to be cut of a wafer with sapphire substrate, mounts the other side of the sapphire wafer on an adhesive tape, mounts the sapphire wafer on a cutting table, cuts the sapphire wafer with a laser, breaks the sapphire wafer into die, and cleans the sapphire wafer with a cleaning solution that removes slag resulting from the cutting, debris resulting from the breaking, and the protective coating, but the adhesive tape, the cleaning solution, and the protective coating are selected such that the cleaning solution does not damage the adhesive tape.

Owner:POWER INTEGRATIONS INC +1

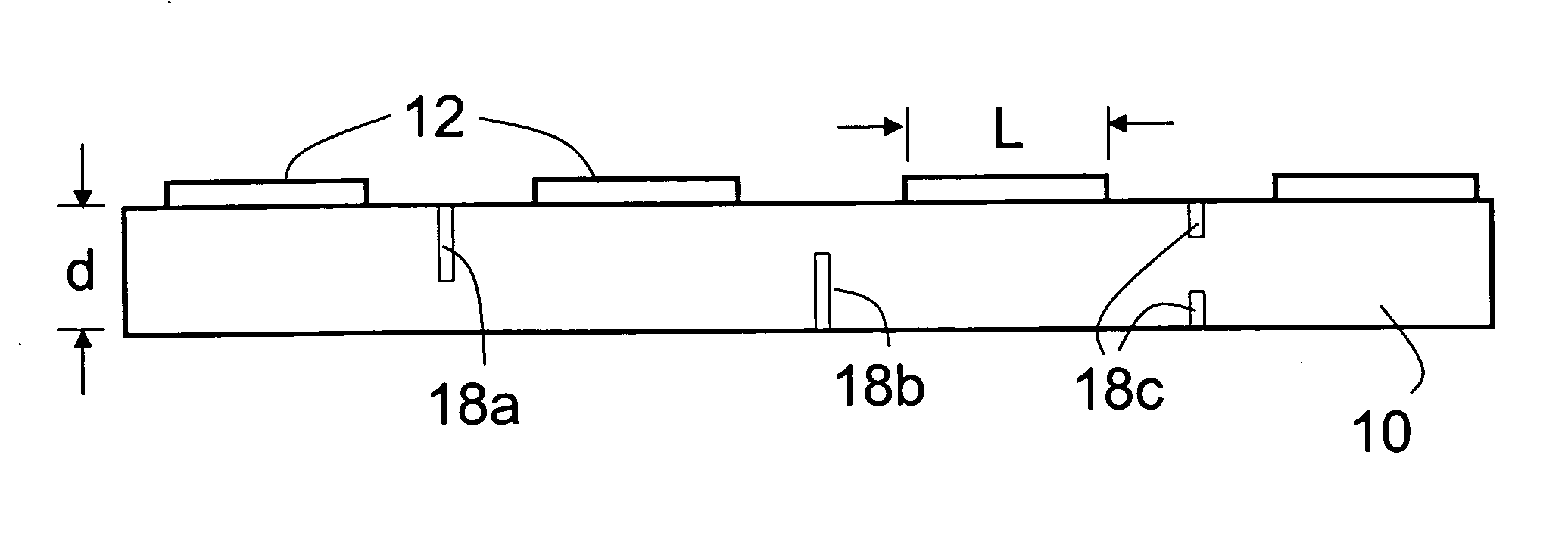

Thick laser-scribed GaN-on-sapphire optoelectronic devices

InactiveUS20050263854A1Semiconductor/solid-state device detailsSolid-state devicesWaferingTotal internal reflection

A sapphire wafer having a thickness greater than 125 microns and having devices disposed thereon is laser scribed to form a grid array pattern of laser scribe lines laser scribed into the sapphire wafer. The sapphire wafer is separated along the laser scribe lines to separate a plurality of device dice defined by the grid array pattern of laser scribe lines. Each device die includes (i) a device and (ii) a portion of the sapphire wafer having the thickness greater than 125 microns. In some embodiments, a GaN LED device die includes a GaN based LED device, and a sapphire substrate supporting the GaN based LED device. The sapphire substrate has: (i) a thickness greater than 125 microns effective for increased light extraction due to a lower critical angle for total internal reflection; and (ii) sides generated by laser scribing.

Owner:GELCORE LLC (US)

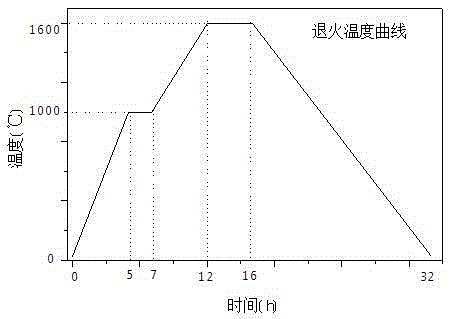

Annealing method of sapphire wafer

InactiveCN102634850AUniform annealingEliminate processing stressPolycrystalline material growthAfter-treatment detailsWaferingCrystalline materials

The invention relates to an annealing method of a sapphire wafer, belonging to the technical field of the machining of a crystalline material. The invention provides the annealing method of the high-quality sapphire wafer, comprising the following steps of: raising the temperature on the sapphire wafer which is cut, milled or polished by sections and keeping the heat for a period of time at 900-1600 DEG C; carrying out annealing treatment on the sapphire wafer so as to eliminate machining stress for cutting, milling or polishing; and rotating the wafer at a heat-preservation phase to uniformly anneal the whole wafer, so as to eliminate the influence that a temperature field of an annealing furnace is not uniform. The machining stress of the wafer annealed by the method is basically eliminated and the whole wafer is uniformly annealed; and the warping degree of the annealed wafer is small.

Owner:CHANGZHOU TONGTAI PHOTOELECTRIC

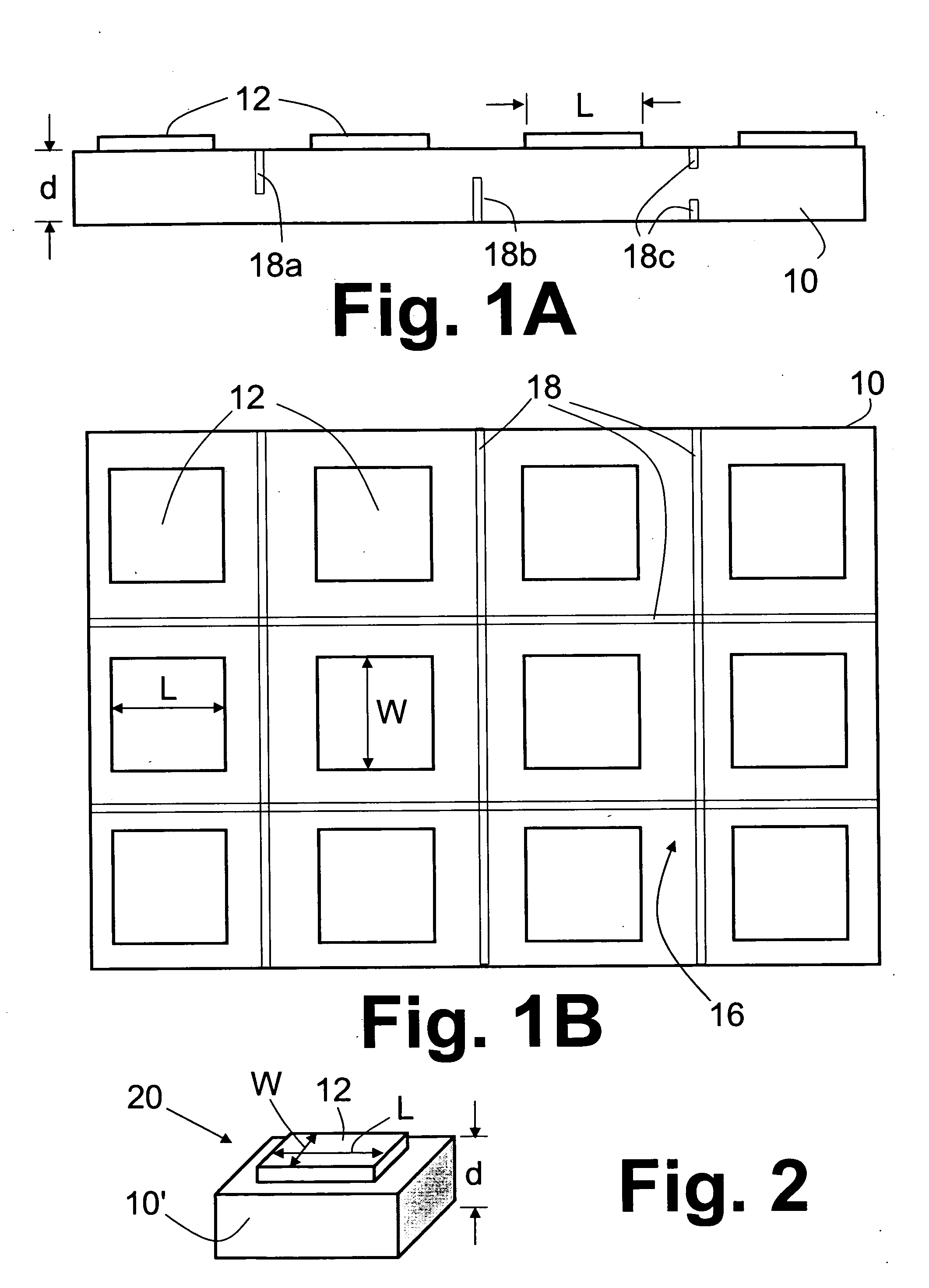

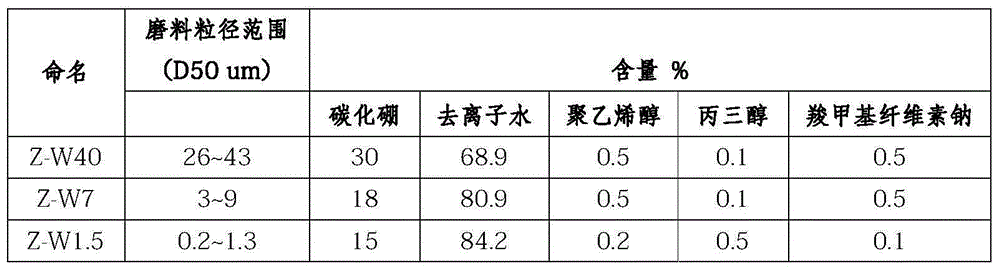

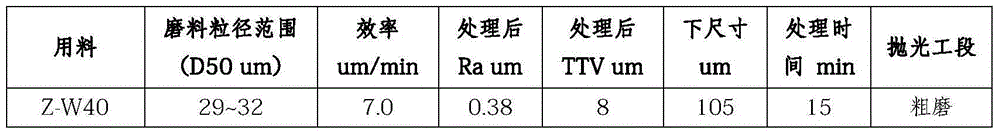

Sapphire wafer grinding and polishing method

ActiveCN104999365AGood processing surfaceReduce surface roughnessLapping machinesPlane surface grinding machinesSurface roughnessBoron carbide

The invention relates to the technical field of grinding and polishing of sapphire wafers, in particular to a sapphire wafer grinding and polishing method. The polishing of the sapphire wafers is finished by four stations of a rough grinding station, a medium grinding station, a finish grinding station and a polishing station, wherein the rough grinding station, the medium grinding station and the finish grinding station respectively adopt high-hardness micro powder with particle sizes of 26-43 microns, 3-9 microns and 0.2-3 microns as abrasives; de-ionized water, a dispersing agent and a suspending agent are added to prepare boron carbide hydrous sol as grinding liquid; in the previous grinding, small-particle-size grinding sands are used for grinding the sapphires, so that the sapphire wafers obtain more excellent machined surfaces, that is, the Ra value and the TTV are relatively lower, and the needed time of reaching the preset target Ra and TTV of the sapphires in the machining process is shortened; and as the method, provided by the invention, is used, the sapphire polishing process time can be controlled within 120-180 minutes, the pass percent of the wafers prepared in batches is higher than 90%, and the surface roughness is low to 0.5 nm.

Owner:东莞市中微力合半导体科技有限公司

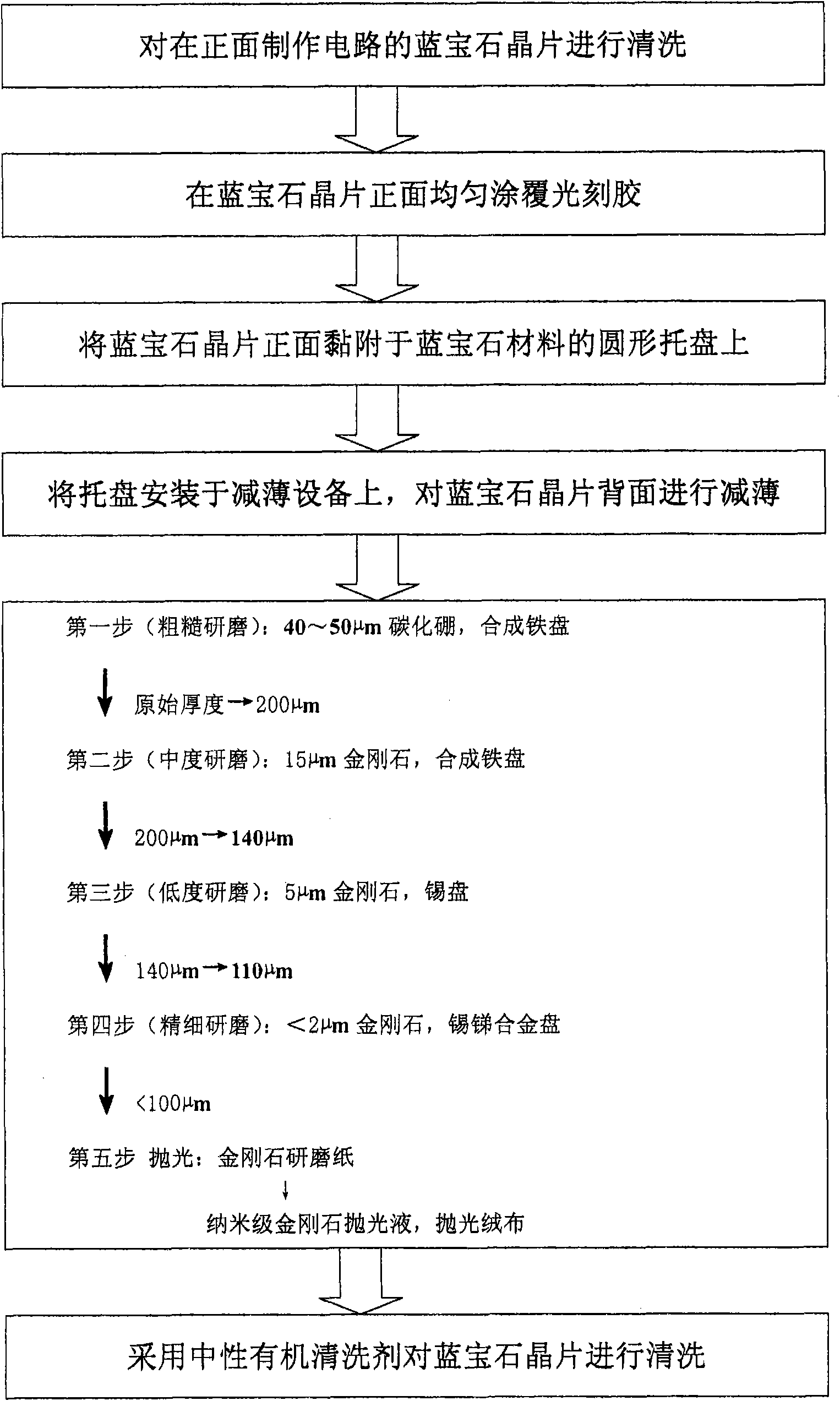

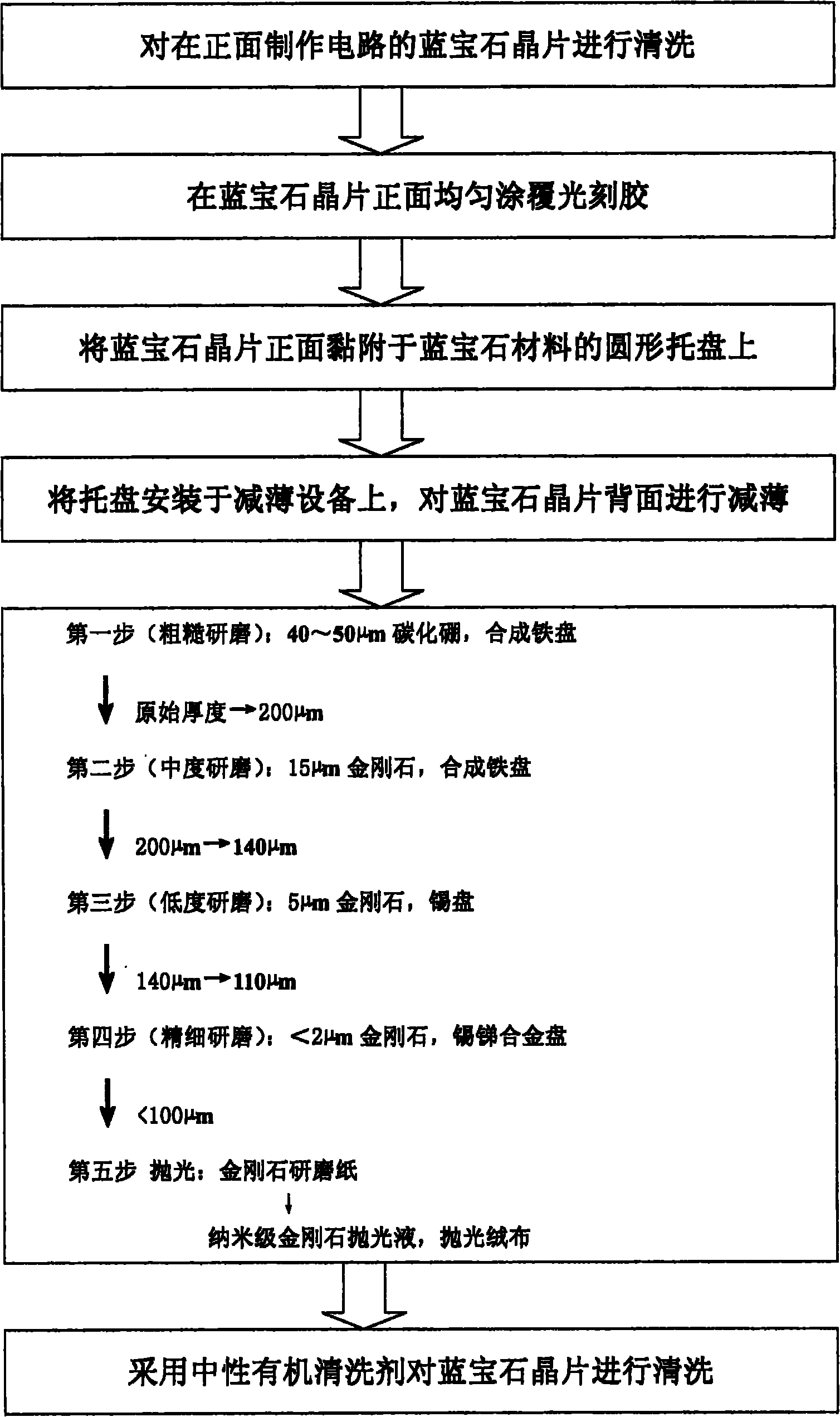

Method for thinning sapphire wafer

ActiveCN102214555AComplete structureReduce thicknessSemiconductor/solid-state device manufacturingFine working devicesWaferingEngineering

The invention discloses a method for thinning a sapphire wafer. The method comprises the following steps: step 1, cleaning a sapphire wafer of which a circuit is made on the front side; step 2, evenly coating a photoresist on the front side of the sapphire wafer; step 3, adhering the front side of the sapphire wafer to a sapphire rounded tray; step 4, installing the sapphire rounded tray on a thinning device to thin the back of the sapphire wafer; step 5, performing a rough grinding on the back of the sapphire wafer; step 6, performing a moderate grinding on the back of the sapphire wafer; step 7, performing a low grinding on the back of the sapphire wafer; step 8, performing fine grinding on the back of the sapphire wafer; step 9, polishing the back of the sapphire wafer; and step 10, washing the sapphire wafer. The method can be used to realize new technique achievements with quick operation, complete wafer structure, no major physical damage, fine and smooth surface and small deformation; and meanwhile, the total thickness of the thinned sapphire wafer is less than 100 mu m.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

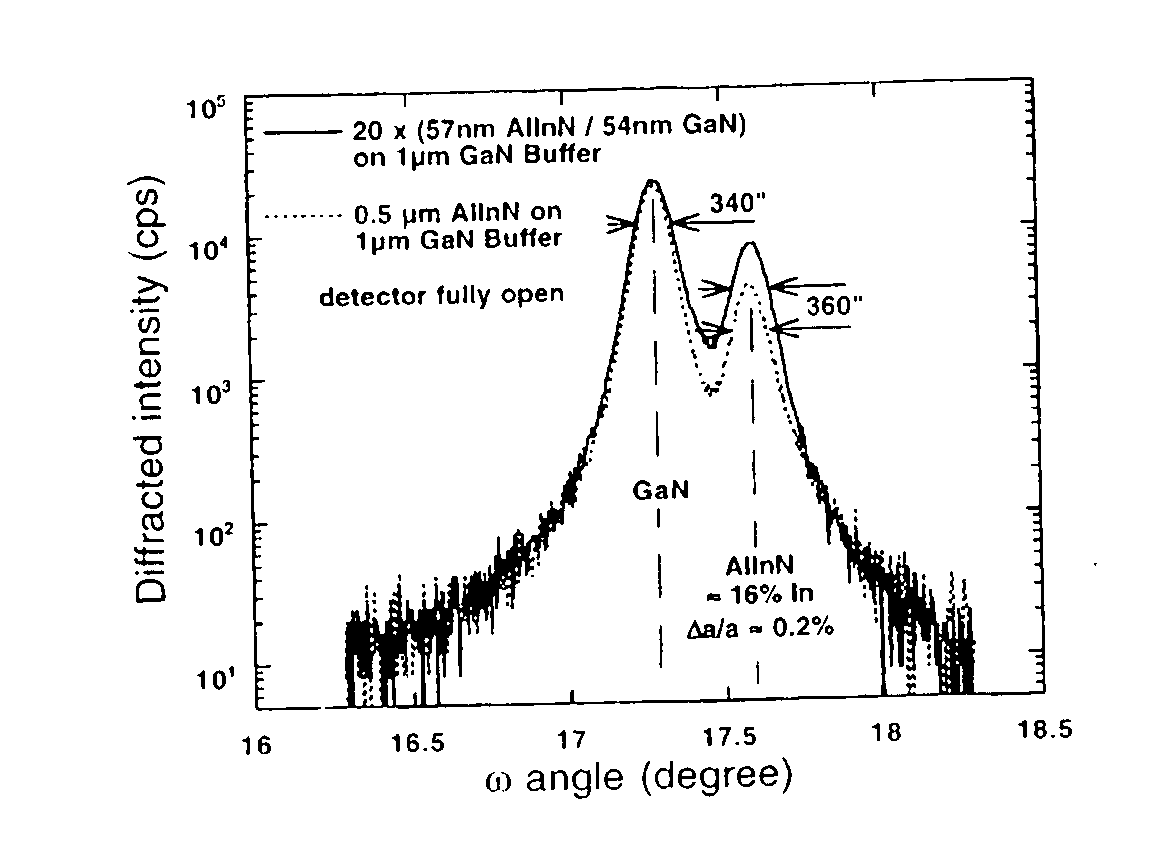

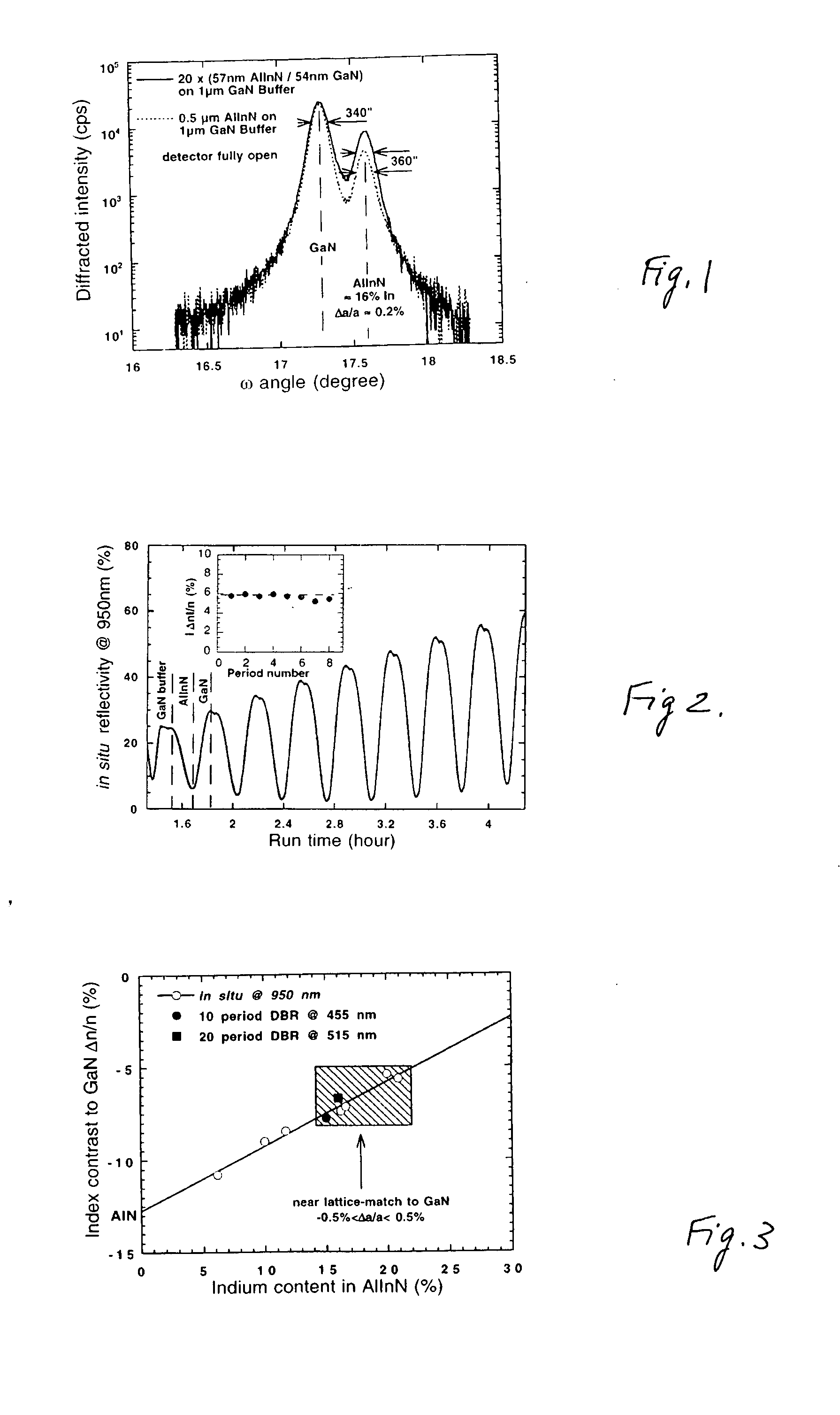

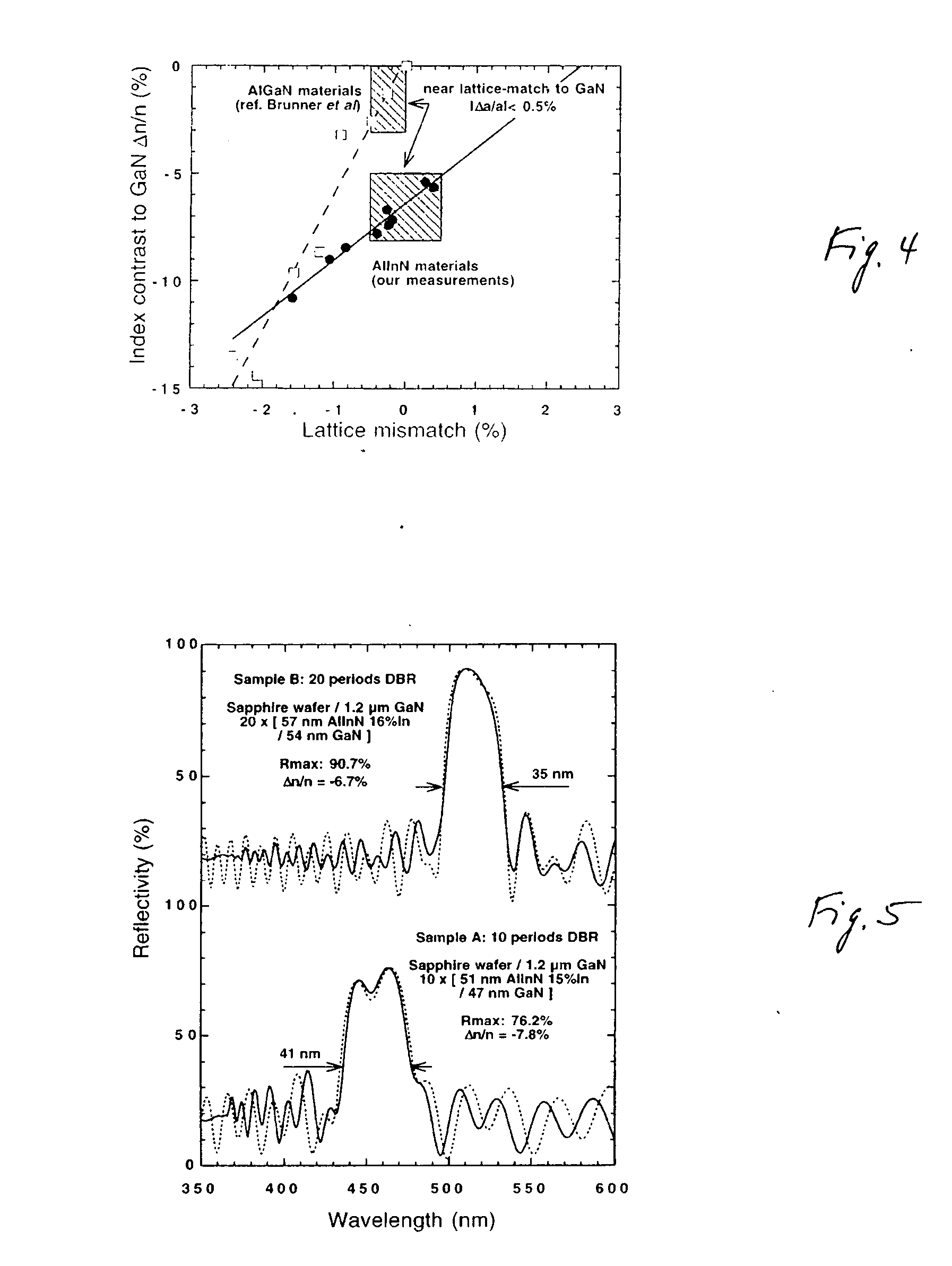

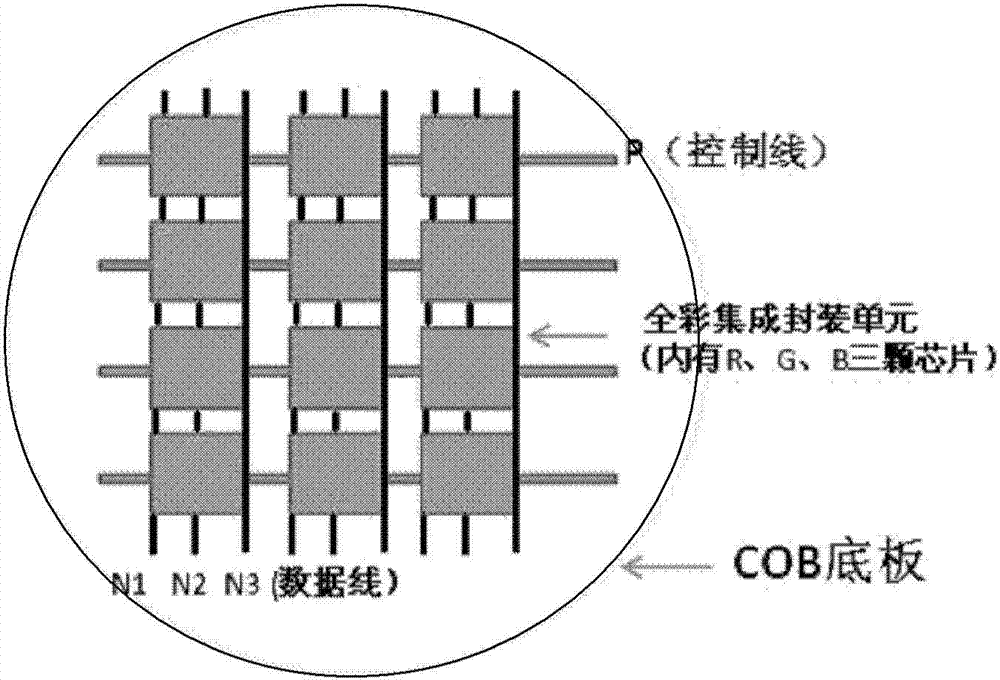

Lattice-matched AllnN/GaN for optoelectronic devices

InactiveUS20070003697A1Polycrystalline material growthLiquid surface applicatorsResonant cavityRefractive index contrast

High-quality Al1-xInxN layers and AlInN / GaN Bragg mirrors near lattice-matched to GaN layers are grown by metalorganic vapor-phase epitaxy on a GaN buffer layer with no cracks over full 2-inch sapphire wafers. The index contrast relative to GaN is 6.5% to 11% for wavelengths ranging from 950 nm to 380 nm. A crack-free, 20 pairs Al0.84In0.16N / GaN distributed Bragg reflector is grown, centered at 515 nm with over 90% reflectivity and a 35 nm stopband. High-quality AlInN lattice matched to GaN can be used in GaN-based optoelectronics, for waveguides and for mirror structures in resonant-cavity light-emitting diodes and monolithic Fabry-Pérot cavities, for example.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Technology for cleaning sapphire wafer

ActiveCN104259132AReduce usageEasy to cleanAfter-treatment detailsSemiconductor/solid-state device manufacturingStrong acidsMegasonic cleaning

The invention discloses a technology for cleaning a sapphire wafer. According to the technology, before coating and silk screen, the sapphire wafer is cleaned. The sapphire wafer is cleaned in an ultrasonic cleaner. The technology comprises the following steps of firstly, oil contamination removing, secondly, spraying, thirdly, dirty removing, fourthly, spraying, fifthly, residue removing; sixthly, spraying, seventhly, ultrasonic cleaning, eighthly, slow pull dehydration, and ninthly, drying and static electricity removing treatment after drying. According to the technology, using of strong acid and strong corrosive detergents is reduced, through separated multiple-time cleaning, the cleaning effect of the surface of the sapphire wafer is ensured, and the hazard to equipment and an operator is greatly reduced.

Owner:LENS TECH

Annealing method applied to sapphire processing

ActiveCN103643300AStress reliefConducive to post-process processingPolycrystalline material growthAfter-treatment detailsMetallurgySapphire wafer

During sapphire processing, grinding causes relatively large stress, and consequently the angularity of a product is increased and the polishing difficulty is substantially increased. The invention aims at the above disadvantages in the prior art and provides a convenient practical annealing method applied to sapphire processing, and the method is mainly used for sapphire wafers subjected to cutting and grinding. By performing the annealing treatment on the sapphire wafers, the processing stress during cutting and grinding can be effectively removed; and the processing stress of the wafers employing the method for annealing is basically eliminated, the annealing of the wafers is uniform, the angularity of the wafers subjected to annealing is small, and the later-period polishing processing is facilitated.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

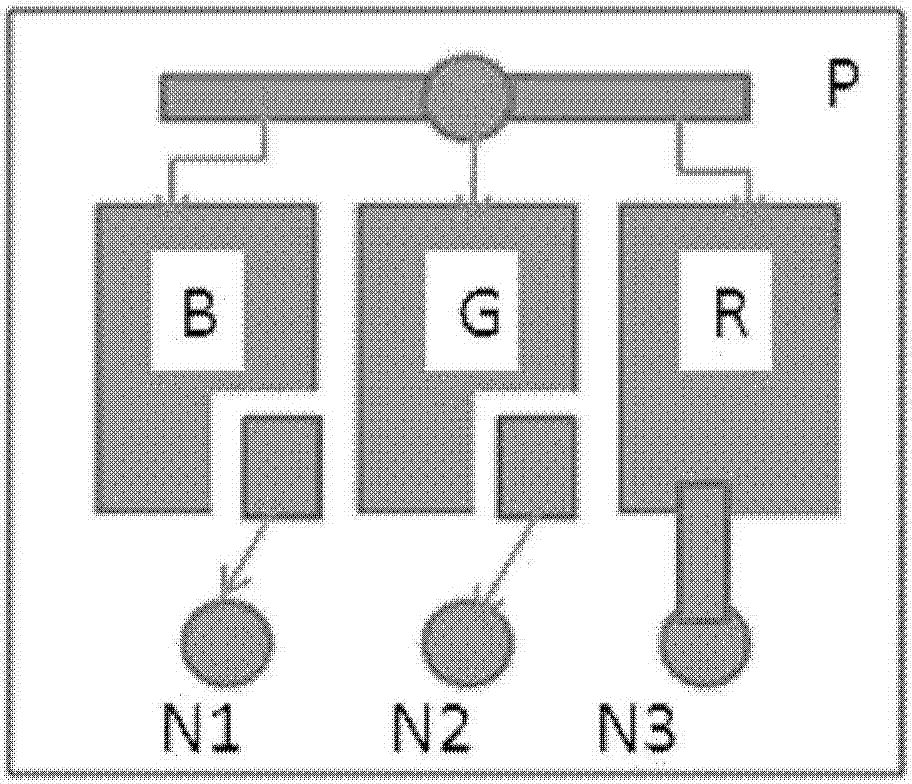

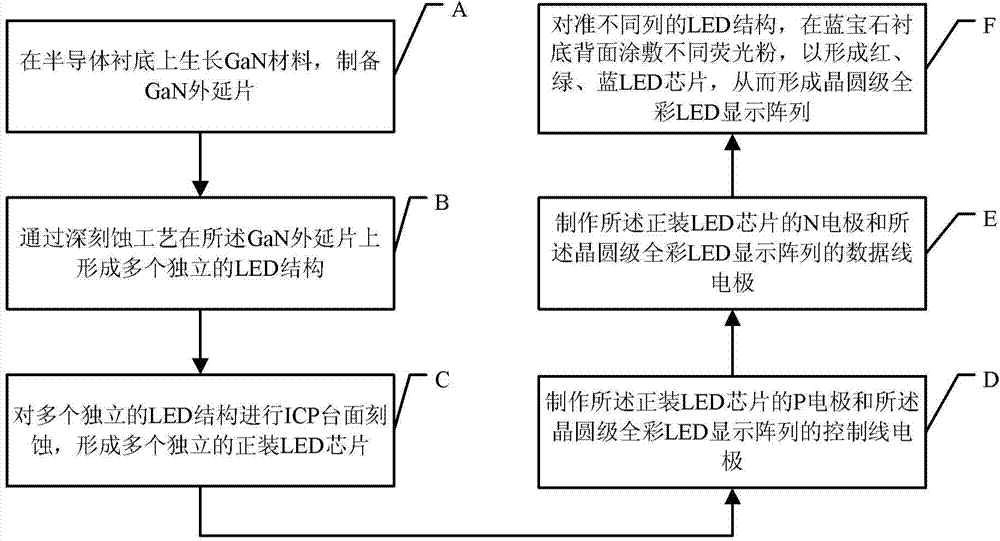

Method for manufacturing wafer full-color LED display array

ActiveCN103579461ASmall pixel sizeRealize full color displaySolid-state devicesSemiconductor/solid-state device manufacturingLED displayEngineering

The invention provides a method for manufacturing a wafer full-color LED display array. The method for manufacturing the wafer full-color LED display array includes the following steps that firstly, a GaN material grows on a substrate and a GaN epitaxial wafer is manufactured; secondly, multiple isolated LED structures are formed on the GaN epitaxial wafer through a deep etching technology; sixthly, the LED structures of different rows are directed and different fluorescent powder coats the back of the sapphire substrate to form a red, green and blue LED chip and thus, the wafer full-color LED display array is formed. According to the method for manufacturing the wafer full-color LED display array, the fluorescent powder coats the LED sapphire substrate row by row so as to directly achieve full-color display on the LED sapphire wafer and thus, the pixel size of the wafer LED display array is less than 500 microns.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

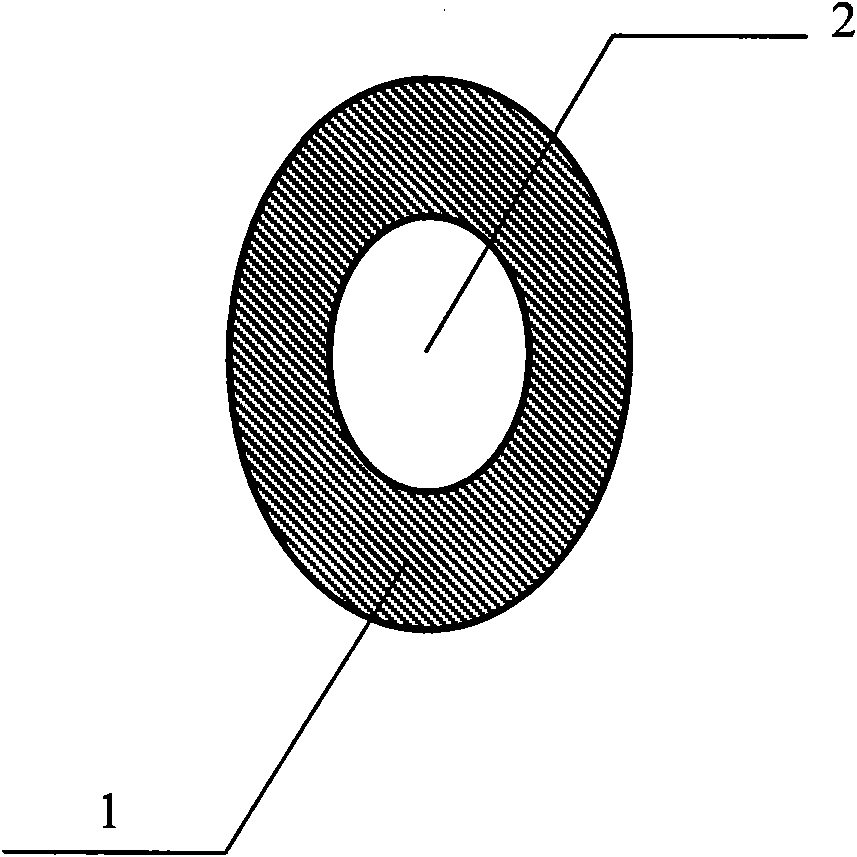

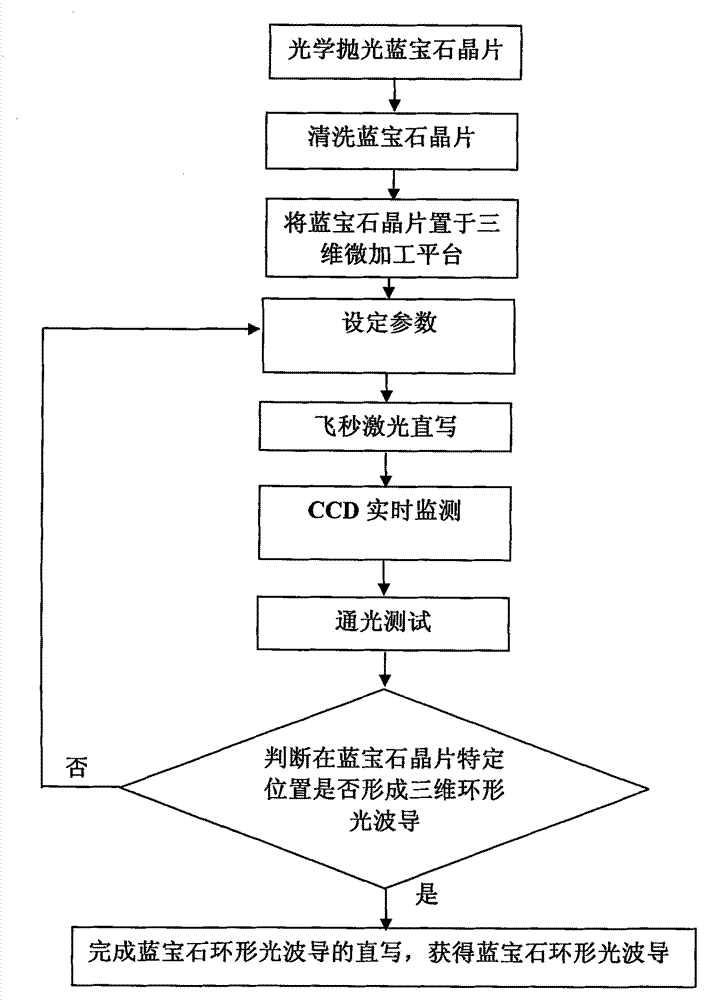

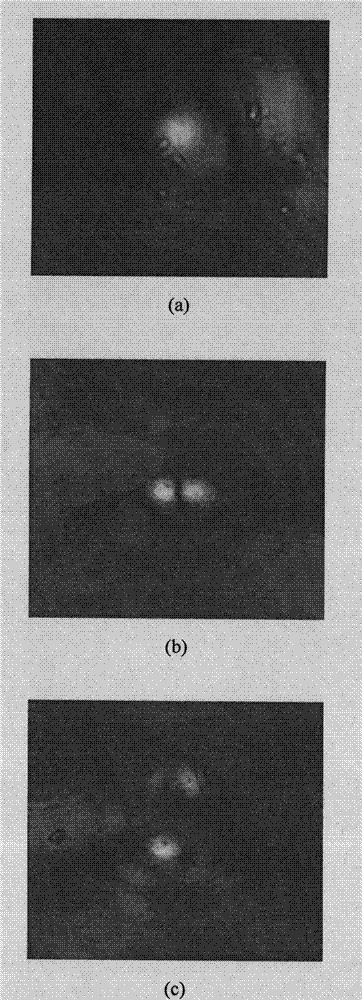

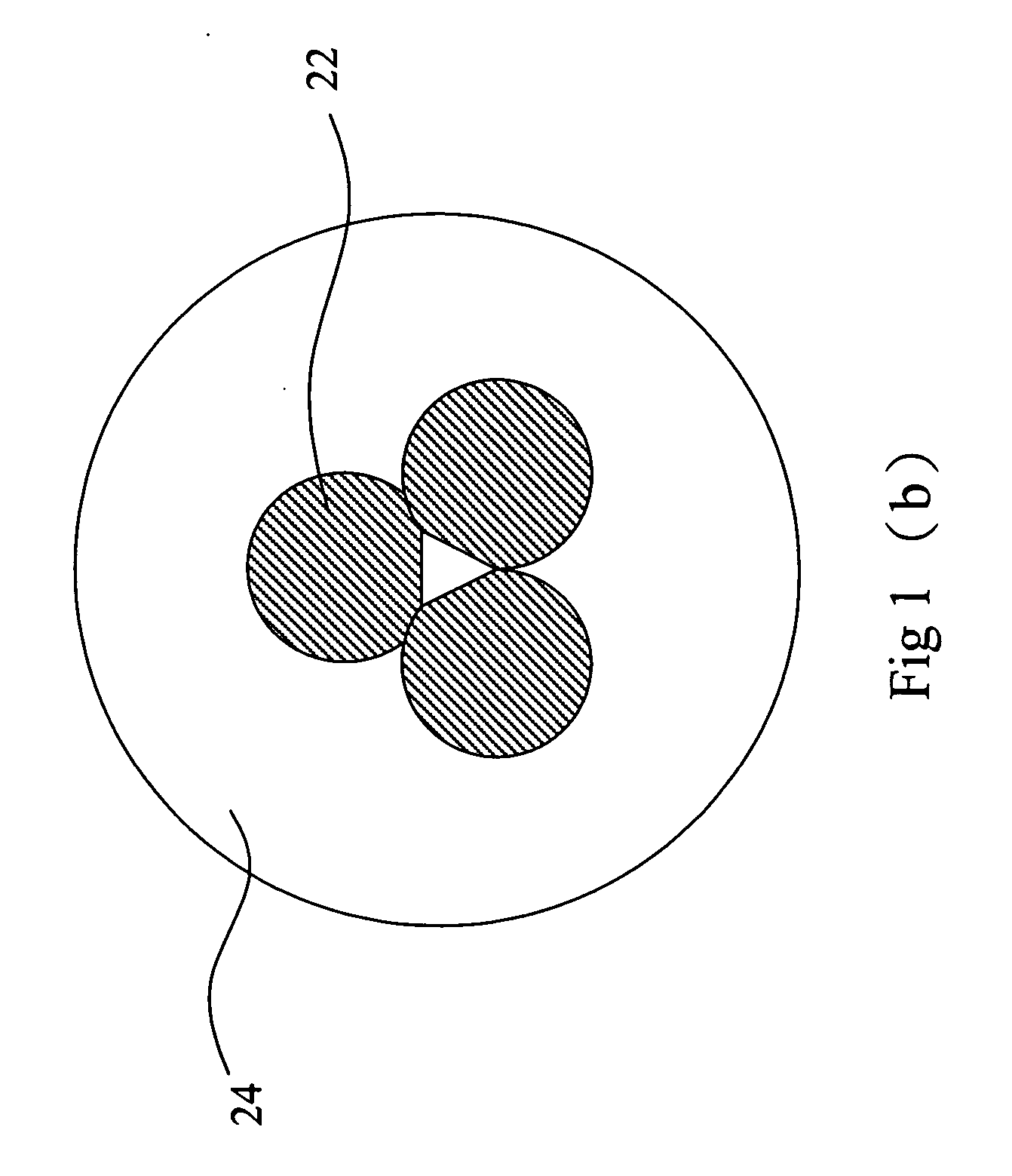

Femtosecond laser direct writing sapphire ring light guide and preparation method thereof

InactiveCN103399377AImprove corrosion resistanceHigh temperature resistantOptical waveguide light guideLaser beam welding apparatusLight guideDirect writing

The invention discloses a femtosecond laser direct writing sapphire ring light guide and a preparation method thereof. A cross section of the prepared femtosecond laser direct writing sapphire ring light guide is elliptic, a light guide part thereof is in a shape of a three-dimensional ring, which is close to a femtosecond laser acting region, and the outer circle of the ring is 200nm from the femtosecond laser acting region. The preparation method comprises the following steps of (1) optically polishing a sapphire wafer; (2) cleaning the sapphire wafer; (3) placing the sapphire wafer on a three-dimensional micromachining platform; (4) setting parameters; (5) carrying out femtosecond laser direct writing; (6) carrying out real-time monitoring through a CCD; (7) carrying out a light pass test; (8) judging whether a three-dimensional ring light guide is formed at a specific position of the sapphire wafer; (9) completing direct writing of the sapphire ring light guide so as to obtain the sapphire ring light guide. The invention is used for transmitting light signals in the environment with ultra-high intensity and ultra-high temperature, and the prepared ring light guide of micron dimension is further used for integration of an optical system.

Owner:XIDIAN UNIV

Composition and method for polishing a sapphire surface

An improved composition and method for polishing a sapphire surface is disclosed. The method comprises abrading a sapphire surface, such as a C-plane or R-plane surface of a sapphire wafer, with a polishing slurry comprising an abrasive amount of an inorganic abrasive material such as colloidal silica suspended in an aqueous medium having a salt compound dissolved therein. The aqueous medium has a basic pH and includes the salt compound in an amount sufficient to enhance the sapphire removal rate relative to the rate achievable under the same polishing conditions using a the same inorganic abrasive in the absence of the salt compound.

Owner:CABOT MICROELECTRONICS CORP

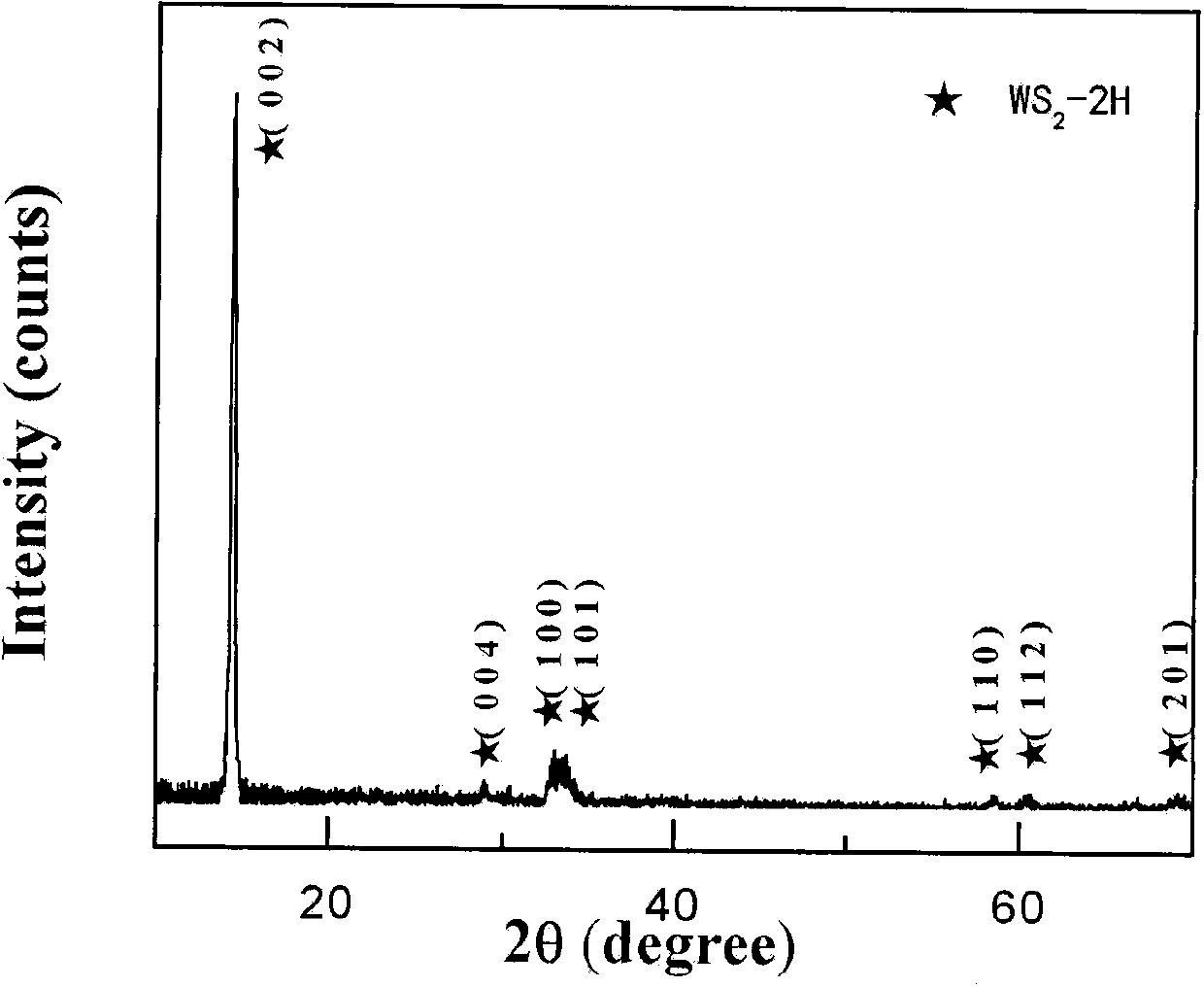

Preparation method for high-purity and high-density WS2 lamellar nano structure

InactiveCN103741224AUniform shapeControllable Diameter ThicknessPolycrystalline material growthNanotechnologyEvaporationSingle crystal

The invention relates to a preparation method for a high-purity and high-density WS2 lamellar nano structure and belongs to the technical field of material preparation. The preparation method adopts a vacuum pipe type furnace and takes tungsten oxide and sulfur powder as evaporation sources; the WS2 lamellar nano structure is deposited by one-step synthesis through a hot evaporation method on a silicon wafer, a gallium arsenide wafer, a sapphire wafer, a silicon carbide single crystal wafer or an aluminum oxide wafer which is flat in surface and bright and clean under the protection of carrier gas. The method has the advantages of strict and controllable deposition condition, simple equipment and process, large output, low cost, environmental friendliness and the like. The obtained nano structure product is high in purity; the diameter thickness distribution is uniformly distributed and the size and the thickness are controllable; the nano structure has a wide application prospect in the aspects of photocell electrodes, lubricants, catalysts, nanoelectronics and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Grinding method for a sapphire wafer

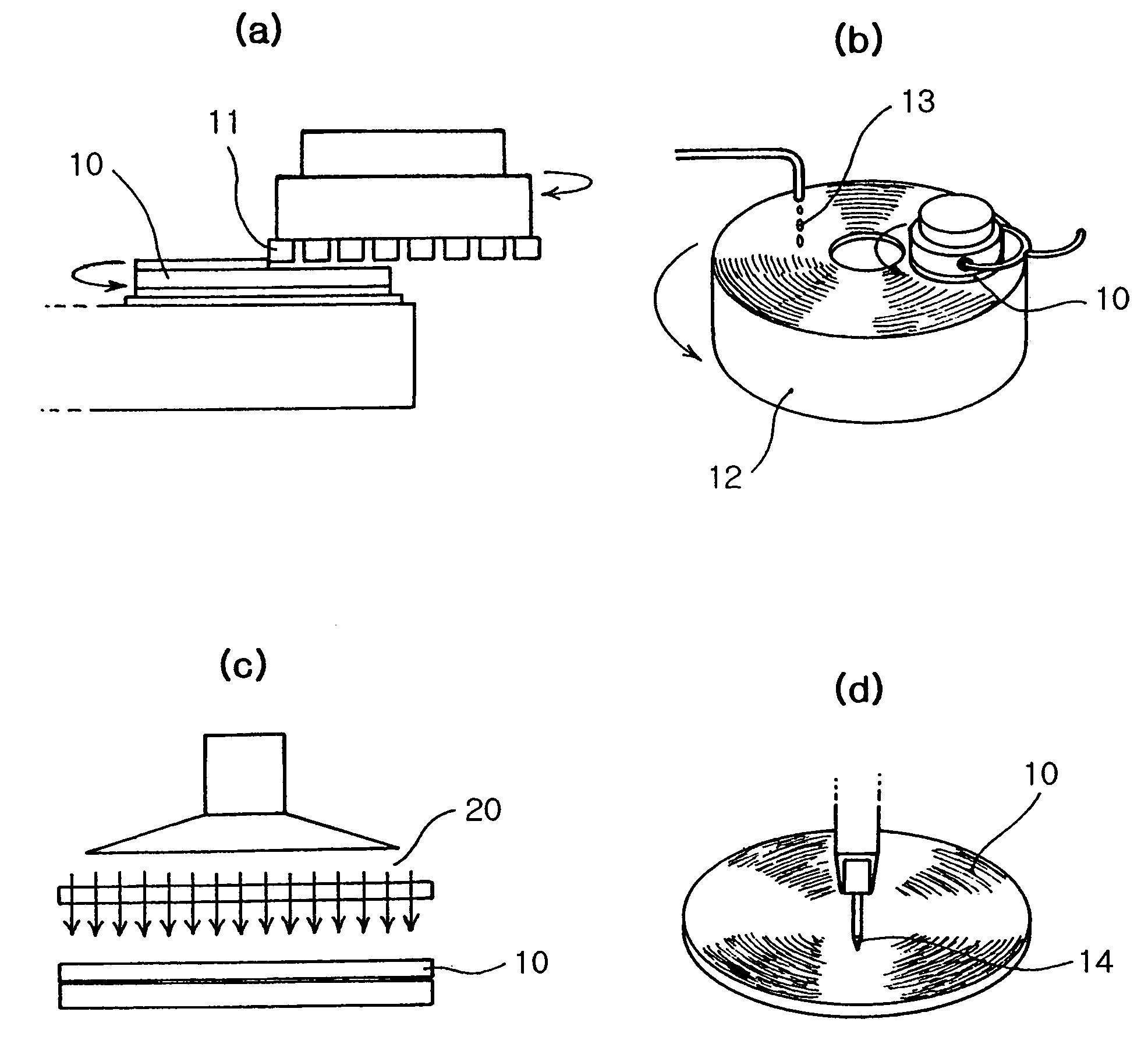

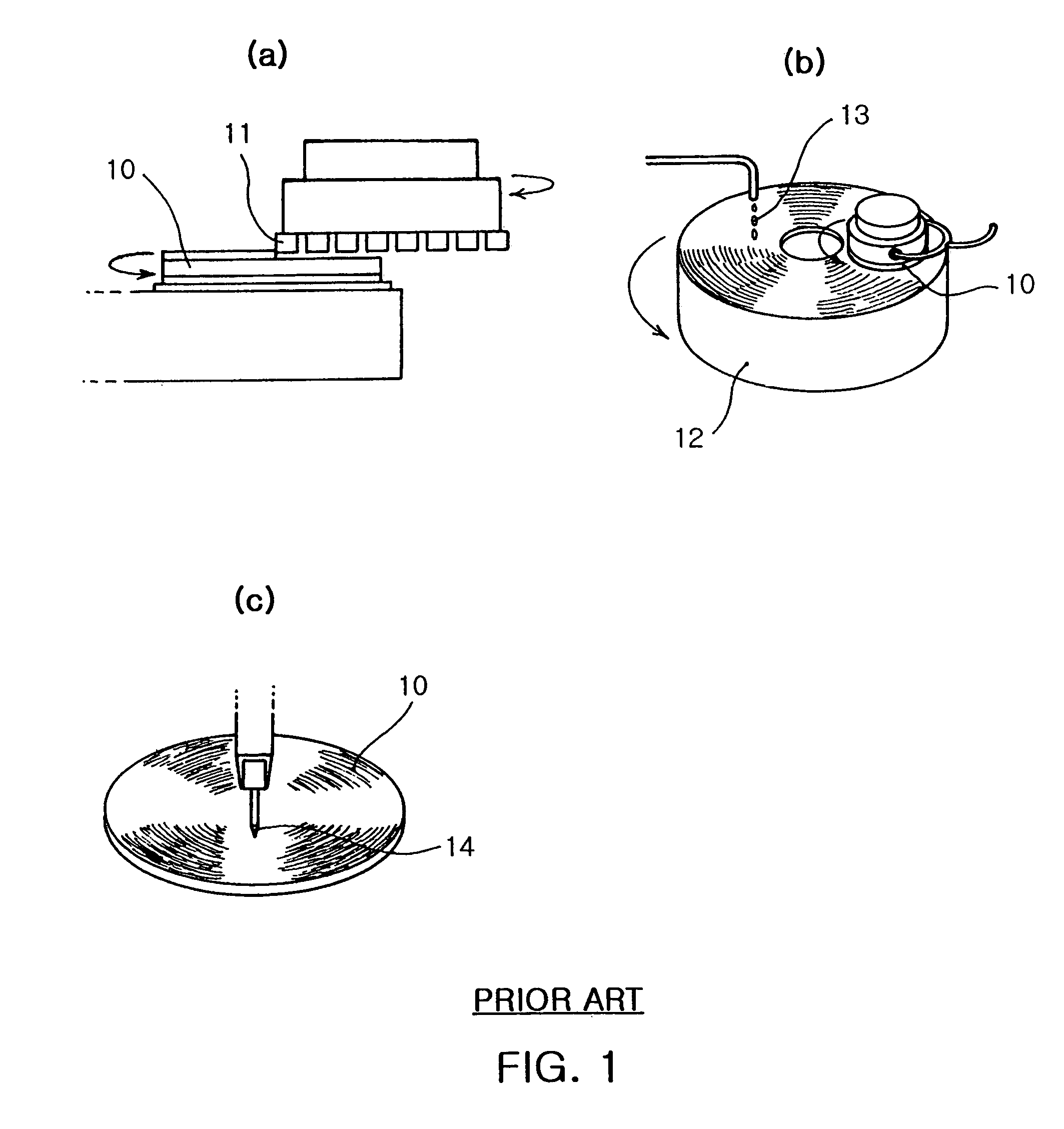

InactiveUS20060003587A1Reduce manufacturing costShorten the timePolycrystalline material growthAfter-treatment detailsWaferingEngineering

The present invention discloses a grinding method for a sapphire wafer, wherein a sapphire wafer is firstly provided, and the sapphire wafer has a substrate and an electrically-conductive layer; the sapphire wafer is fixed onto a fixing base; the fixing base is further fixed to a machining table, and the substrate of the sapphire wafer is ground thereon; then, the fixing base is placed on a polishing disc, and the substrate is further thinned thereon; and lastly, the substrate is completely removed via an etching method. The present invention can shorten the time for removing the substrate of a sapphire wafer and also shorten the time for LED fabrication process; thus, the cost is reduced. Further, LED can work normally at high temperature, and the danger resulting from LED's working at high temperature can also be lessened.

Owner:CLEAVAGE ENTERPRISE

Method for separating sapphire wafer into chips

InactiveUS7074652B2Easily and efficientlyAvoid shapePhotomechanical apparatusSemiconductor/solid-state device manufacturingWaferingSand blasting

Disclosed is a method for efficiently separating a sapphire wafer serving as a substrate, on which semiconductor elements are formed, into unit chips by scribing the sapphire wafer, after grinding and lapping a rear surface of the sapphire wafer and then sand-blasting the sapphire wafer. The method includes the steps of: (a) grinding a rear surface of the sapphire wafer so that the sapphire wafer has a designated thickness; (b) lapping the rear surface of the ground sapphire wafer so that the sapphire wafer has a designated thickness; (c) polishing the rear surface of the lapped sapphire wafer so that the sapphire wafer has a designated thickness; (d) sand-blasting the rear surface of the polished sapphire wafer by uniformly blasting particles at a designated pressure during a designated time onto the rear surface of the polished sapphire wafer; and (e) scribing the rear surface of the sand-blast ground sapphire wafer.

Owner:SAMSUNG ELECTRONICS CO LTD

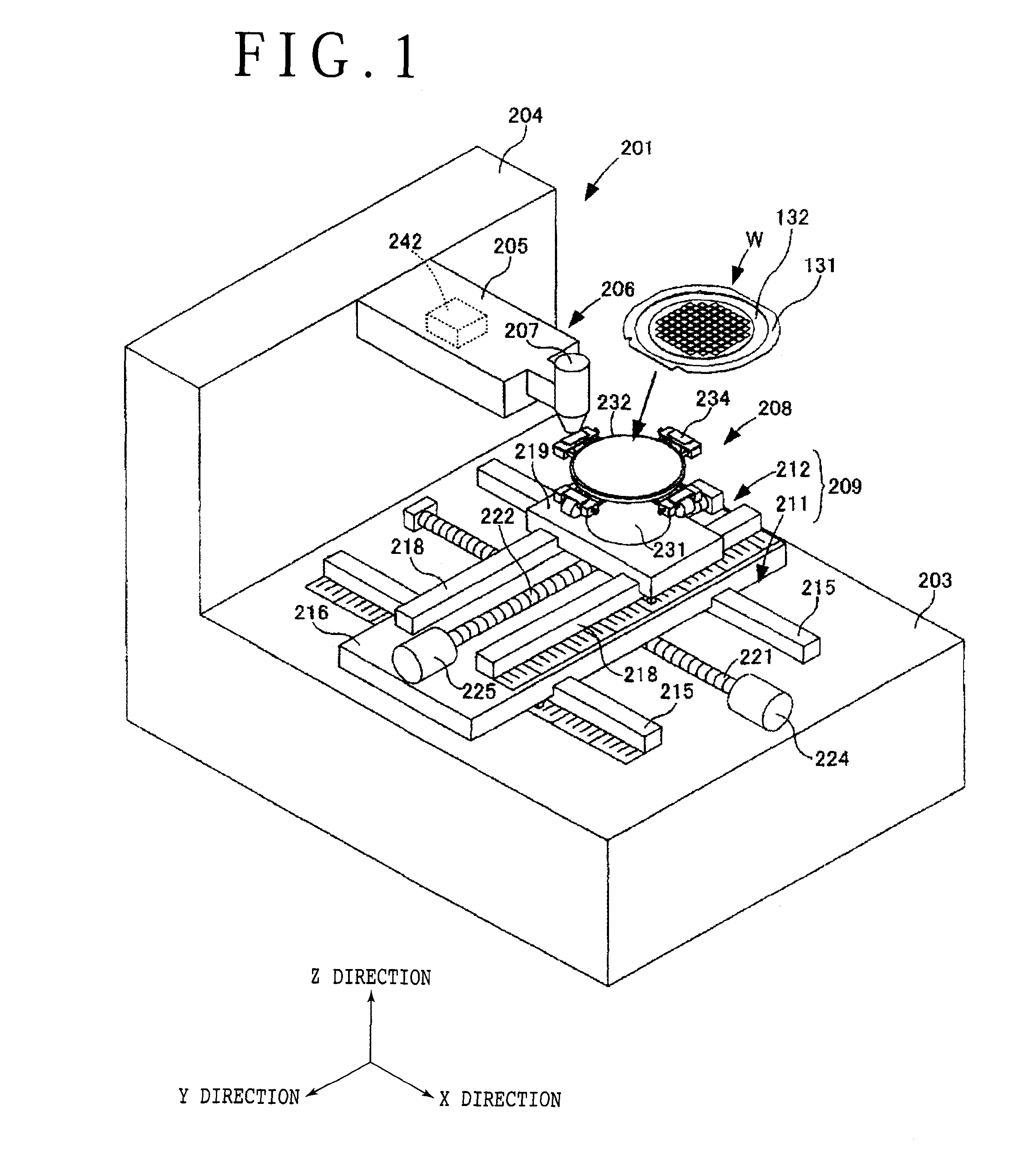

Sapphire wafer dividing method

ActiveUS20120156816A1Easily incidentIncrease brightnessSemiconductor/solid-state device manufacturingFine working devicesWaferingSplit lines

A sapphire wafer dividing method including a modified layer forming step of forming a plurality of modified layers inside a sapphire wafer along a plurality of crossing division lines formed on the front side where a light emitting layer is formed, and a chamfering and dividing step of forming a plurality of cut grooves on the back side of the sapphire wafer along the division lines, thereby dividing the sapphire wafer into individual light emitting devices along the modified layers as a division start point, wherein the corners of the back side of each light emitting device are chamfered by the formation of the cut grooves in the chamfering and dividing step.

Owner:DISCO CORP

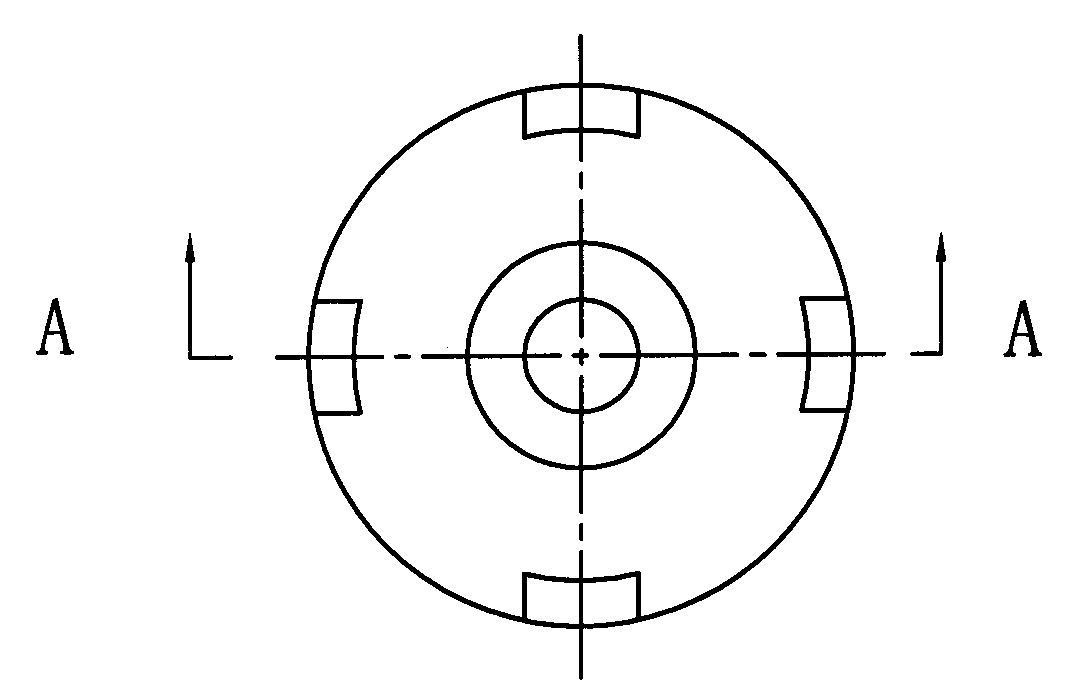

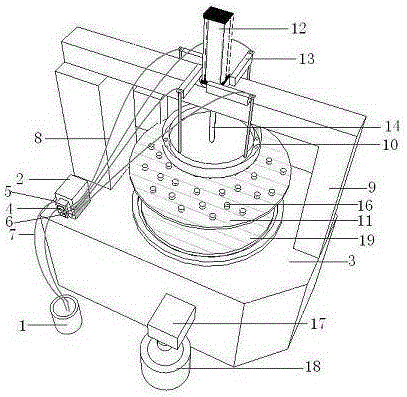

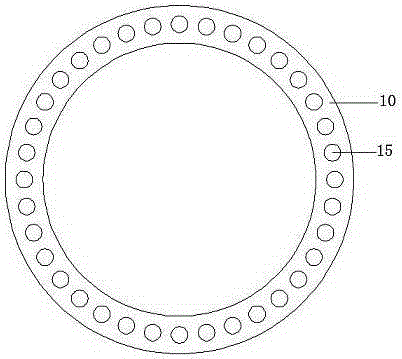

Polishing device and method of sapphire wafer

InactiveCN105382678AImprove uniformityImprove polishing qualityLapping machinesGrinding/polishing apparatusWaxMagnetic stirrer

The invention provides a polishing device and method of a sapphire wafer to make an improvement on an existing technical process. The method comprises the steps of diamond polishing solution vibration treatment, magnetic stirring treatment, polishing disk face flatness measuring and finishing, nozzle connection, wafer wax pasting treatment and sapphire wafer polishing, and a vibration machine, a heating magnetic stirrer and a polishing machine which are matched with the technology are designed and improved. The quality and uniformity of the diamond polishing liquid are improved, the polishing quality of the wafer is ensured, and the polishing removing rate is stabilized; and the surface scratching of the wafer is effectively reduced, the polishing quality of the polished wafer is better, and the surface flatness of the wafer is obviously improved. TTV can be controlled within 2, meanwhile, a corresponding automatic mechanism is adopted, a worker does not need to take additional time, and labor cost of manual shaking and stirring and the phenomenon of uneven stirring are reduced.

Owner:江苏吉星新材料有限公司

Cleaning technology for sapphire wafers

ActiveCN105280477AGood ratio of decontaminationImprove oxidation effectSemiconductor/solid-state device manufacturingWaferingSapphire wafer

The invention discloses a cleaning technology for sapphire wafers. The method comprises steps of firstly removing most of highly-adhered oil stains and dirty points on surfaces of wafers using a physical cleaning sheet with combination of an ultrasonic method, thoroughly cleaning residual stains on the surfaces using a mixed solution of sulfuric acid and hydrogen peroxide, then performing cleaning in a fast-exhaust rinsing tank, and performing spin drying and blow drying. The surface of a cleaned wafer is clean and damage-free, and the enforcement efficiency is extremely high. The method can be used for cleaning in the epitaxial layer growth process of sapphire wafer GaN-based LED chips, the PSS patterned growth and the tube core front segment manufacturing process.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Sapphire wafer polishing solution

ActiveCN104356950AEvenly distributedFully moistenedPolishing compositions with abrasivesReaction rateOrganic base

The invention discloses a sapphire wafer polishing solution which consists of the following components in percentage by weight: 20 to 30 percent of silica sol with solid content of 30 to 40 weight percent, 10 to 20 percent of alumina with a diameter of 80 to 200nm, 0.1 to 0.4 percent of organic base, 0.1 to 3 percent of a dispersing agent, 0.3 to 1 percent of nonylphenol polyethylene ether and the balance of de-ionized water. According to the sapphire wafer polishing solution, the silica sol and the alumina are compounded, so that the polishing speed is ensured, and machining scratches are avoided; furthermore, the nonylphenol polyethylene ether, the dispersing agent and the like are added to form a stable colloidal dispersion system to promote the full wetting of a polished wafer and a polishing pad and the stable and uniform distribution of the polishing solution between the polishing pad and the polishing wafer, so that the reaction rate of each part of the surface of the wafer can be balanced, and the polishing quality is ensured and improved; the sapphire wafer polishing solution can be used for the machining of a sapphire wafer.

Owner:临汾博利士纳米材料有限公司

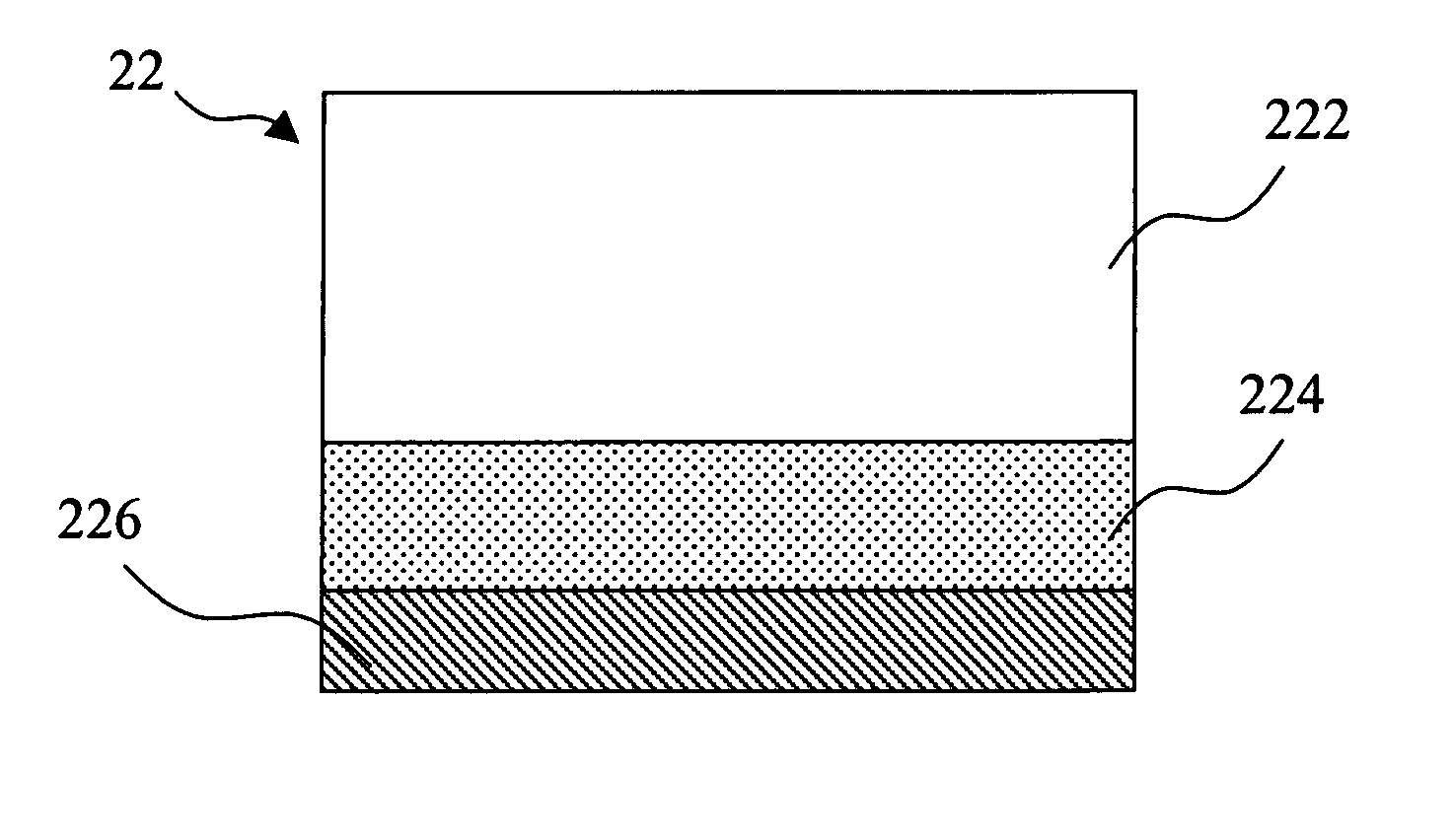

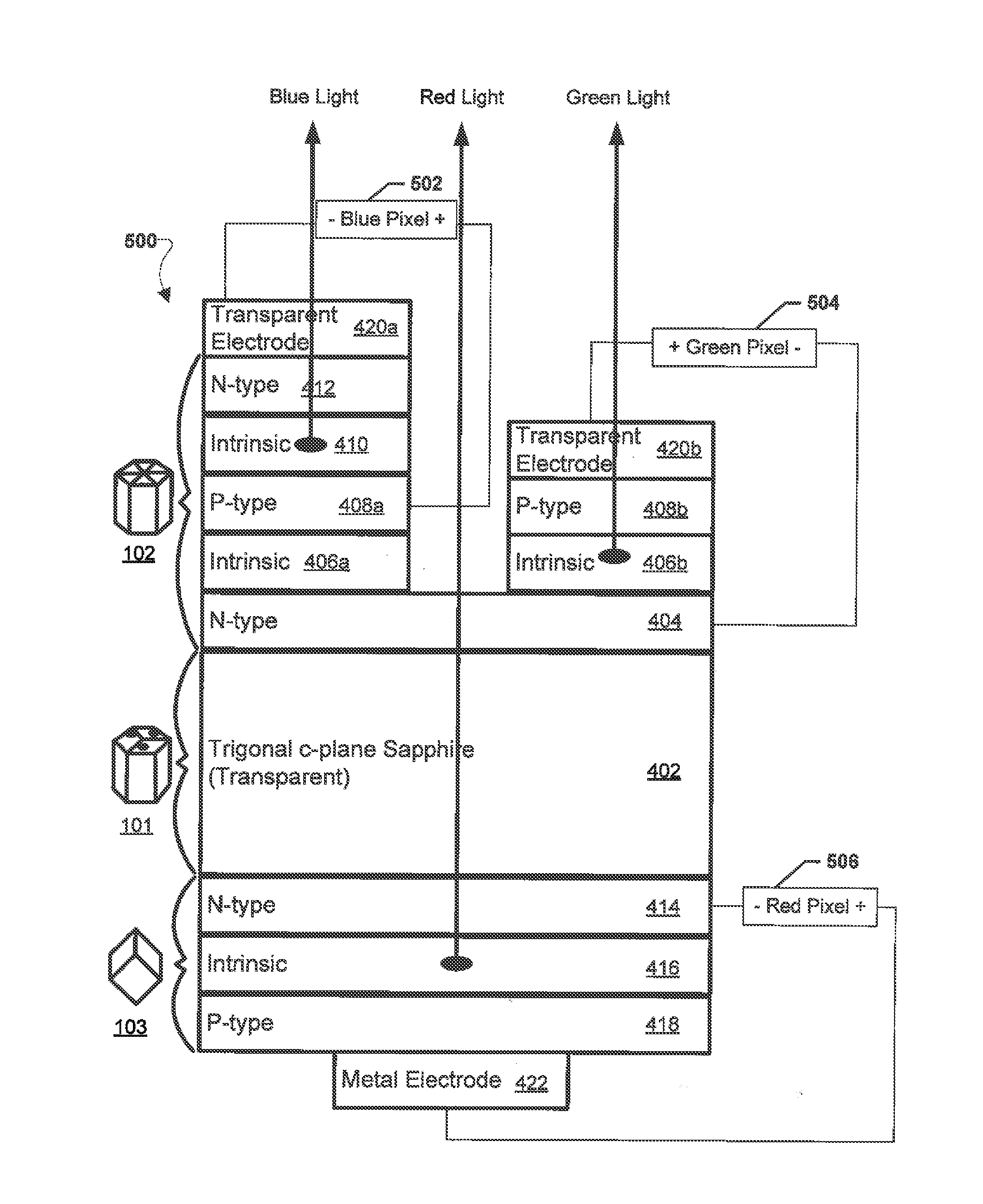

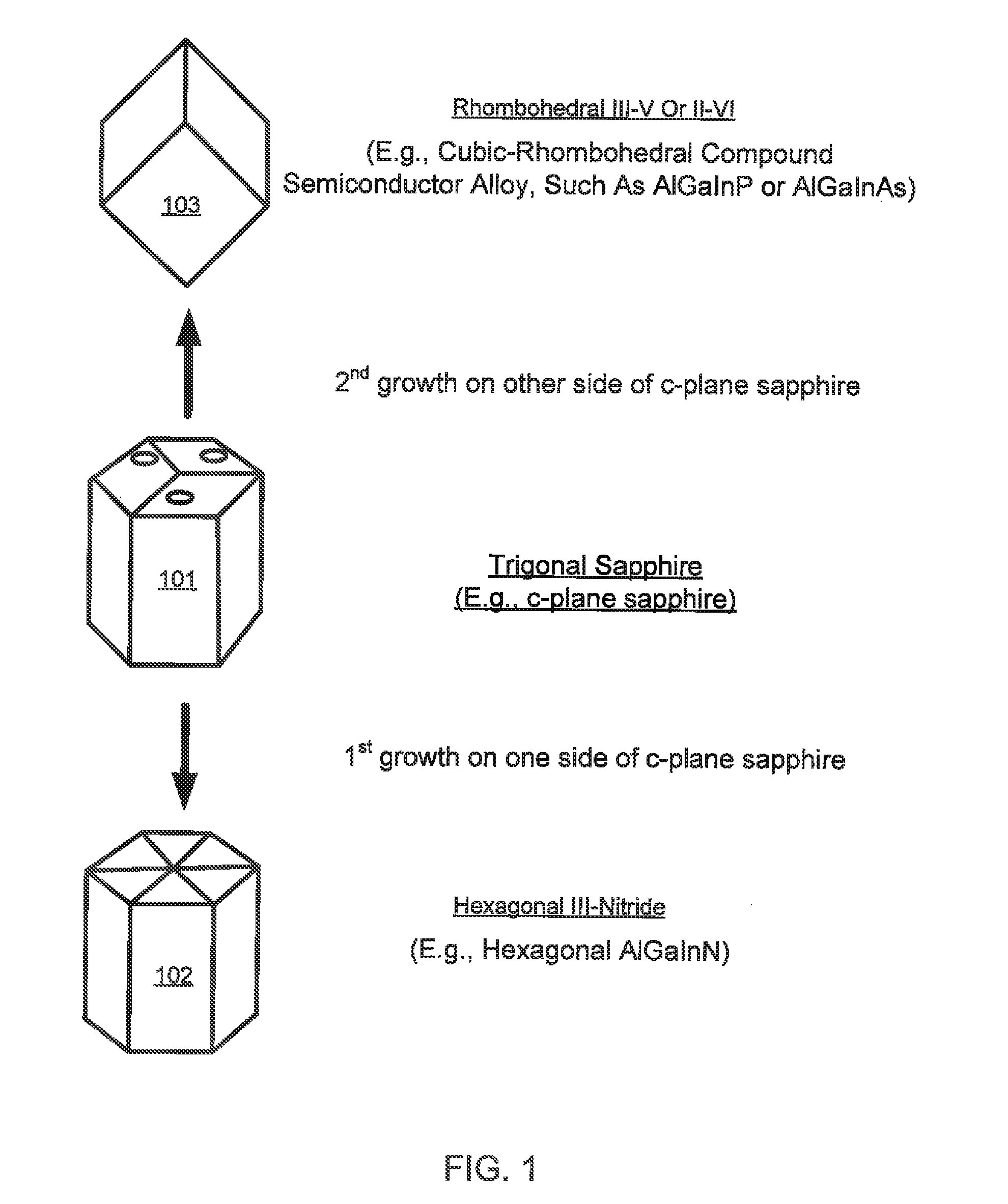

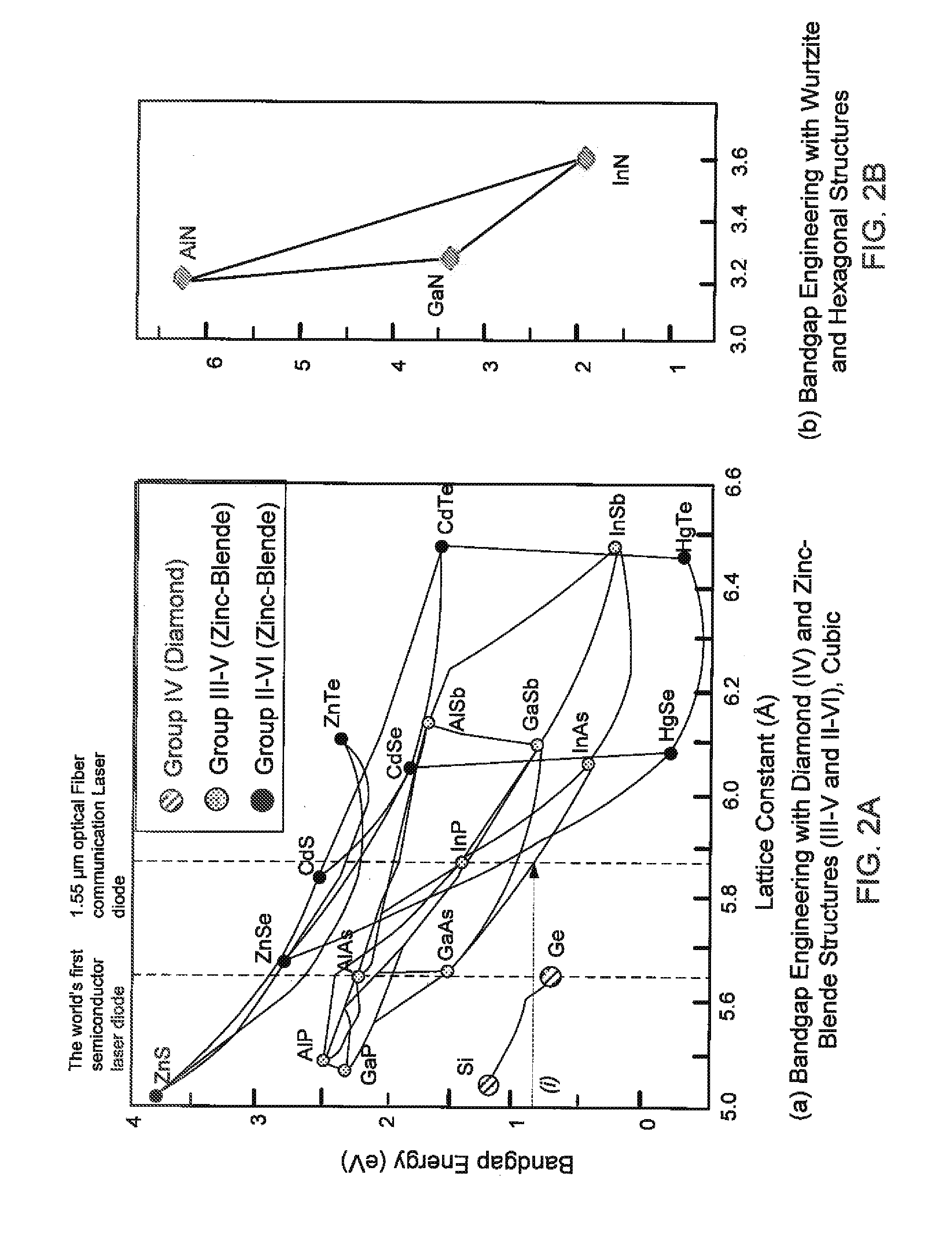

Integrated Multi-Color Light Emitting Device Made With Hybrid Crystal Structure

ActiveUS20140339580A1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSingle crystal

An integrated hybrid crystal Light Emitting Diode (“LED”) display device that may emit red, green, and blue colors on a single wafer. The various embodiments may provide double-sided hetero crystal growth with hexagonal wurtzite III-Nitride compound semiconductor on one side of (0001) c-plane sapphire media and cubic zinc-blended III-V or II-VI compound semiconductor on the opposite side of c-plane sapphire media. The c-plane sapphire media may be a bulk single crystalline c-plane sapphire wafer, a thin free standing c-plane sapphire layer, or crack-and-bonded c-plane sapphire layer on any substrate. The bandgap energies and lattice constants of the compound semiconductor alloys may be changed by mixing different amounts of ingredients of the same group into the compound semiconductor. The bandgap energy and lattice constant may be engineered by changing the alloy composition within the cubic group IV, group III-V, and group II-VI semiconductors and within the hexagonal III-Nitrides.

Owner:NASA

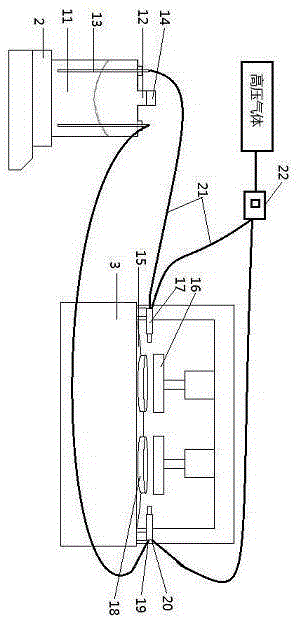

Composite technique for polishing sapphire by using green and ultraviolet laser

The invention relates to a composite technique for polishing sapphire by using green and ultraviolet laser, which comprises the following steps:1) scanning and polishing the surface of a sapphire wafer by green laser; 2) polishing the green laser polished surface of the sapphire wafer by ultraviolet laser. The green laser and the ultraviolet laser are pulsed laser. In the composite technique, the green laser is firstly used for polishing, and then the ultraviolet laser is used for precision polishing. Polishing by pulsed green laser replaces the traditional grinding, and by the light and heat coupling generated on the sapphire surface radiated by the laser, materials are removed mainly by evaporation, melting and other forms in company with tiny smashing and photochemical reaction so as to obtain a relatively flat surface in macroscopic view with a hump of curved surface in microscopic view. The complex technique has high polishing efficiency, and uneven areas and defects on the polished surface in microscopic view are easy to remove in the subsequent polishing processes. The composite technique can reduce and even eliminate the effects of heat on sapphire materials, and obtain polishing surfaces with low surface roughness and subsurface damage degree.

Owner:GUANGDONG UNIV OF TECH

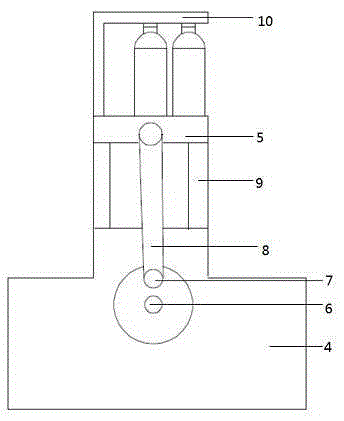

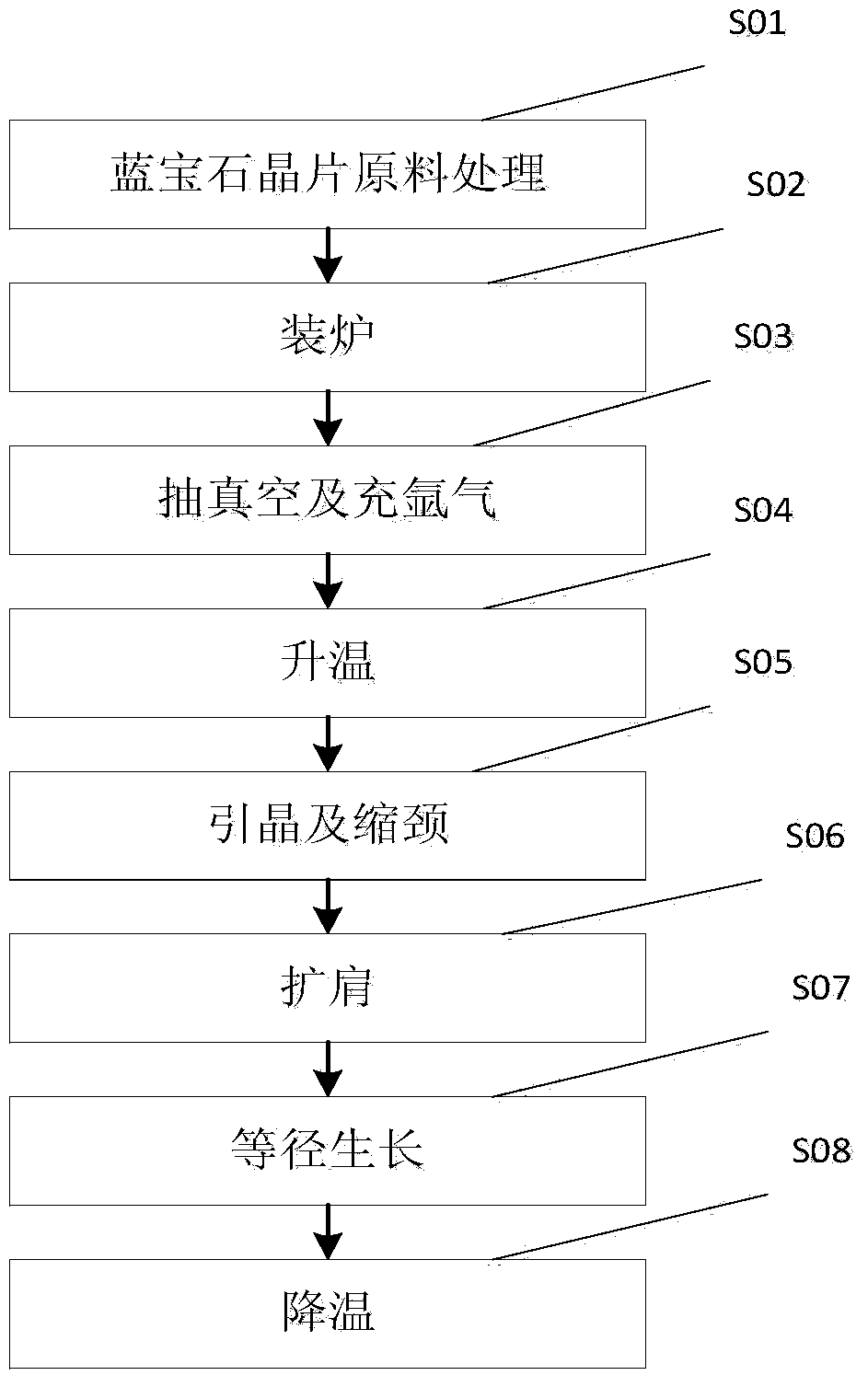

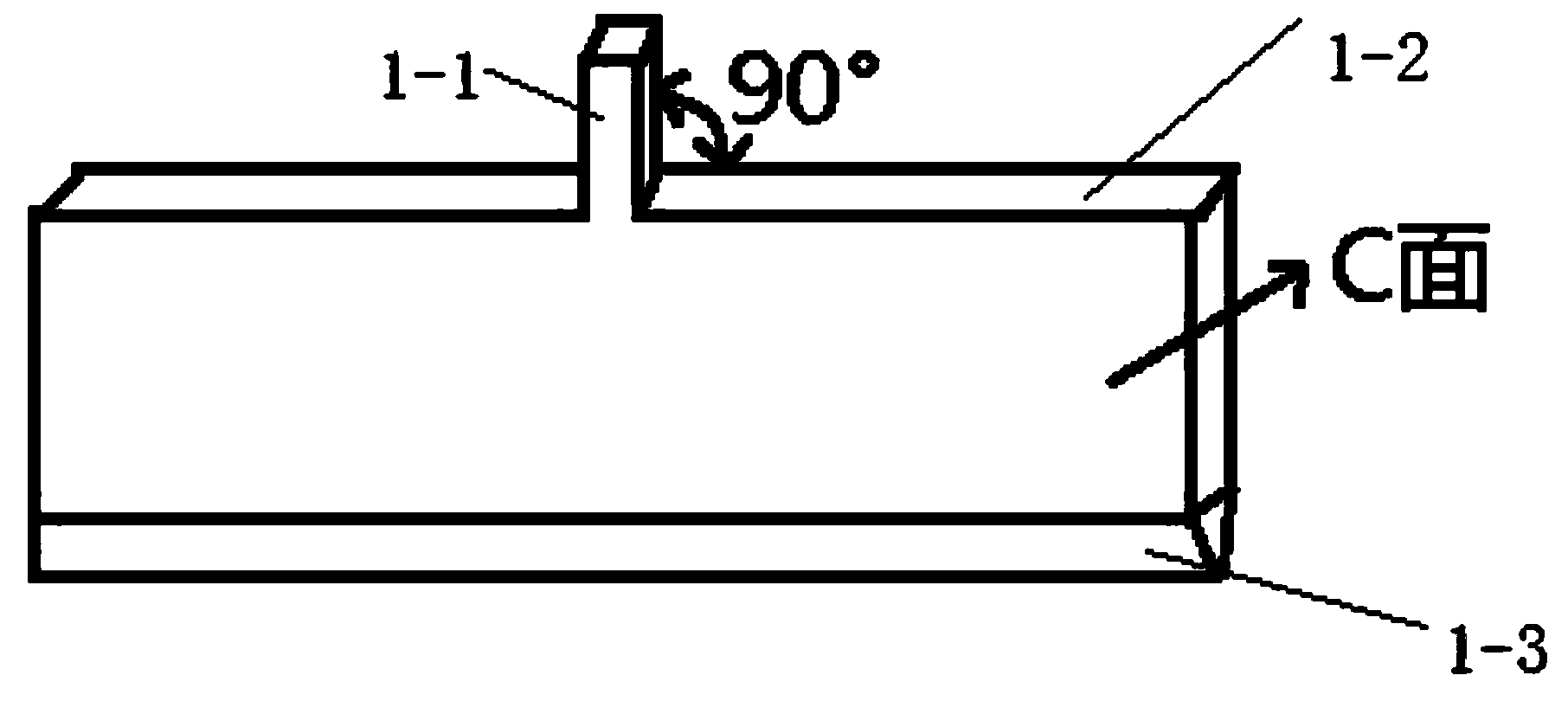

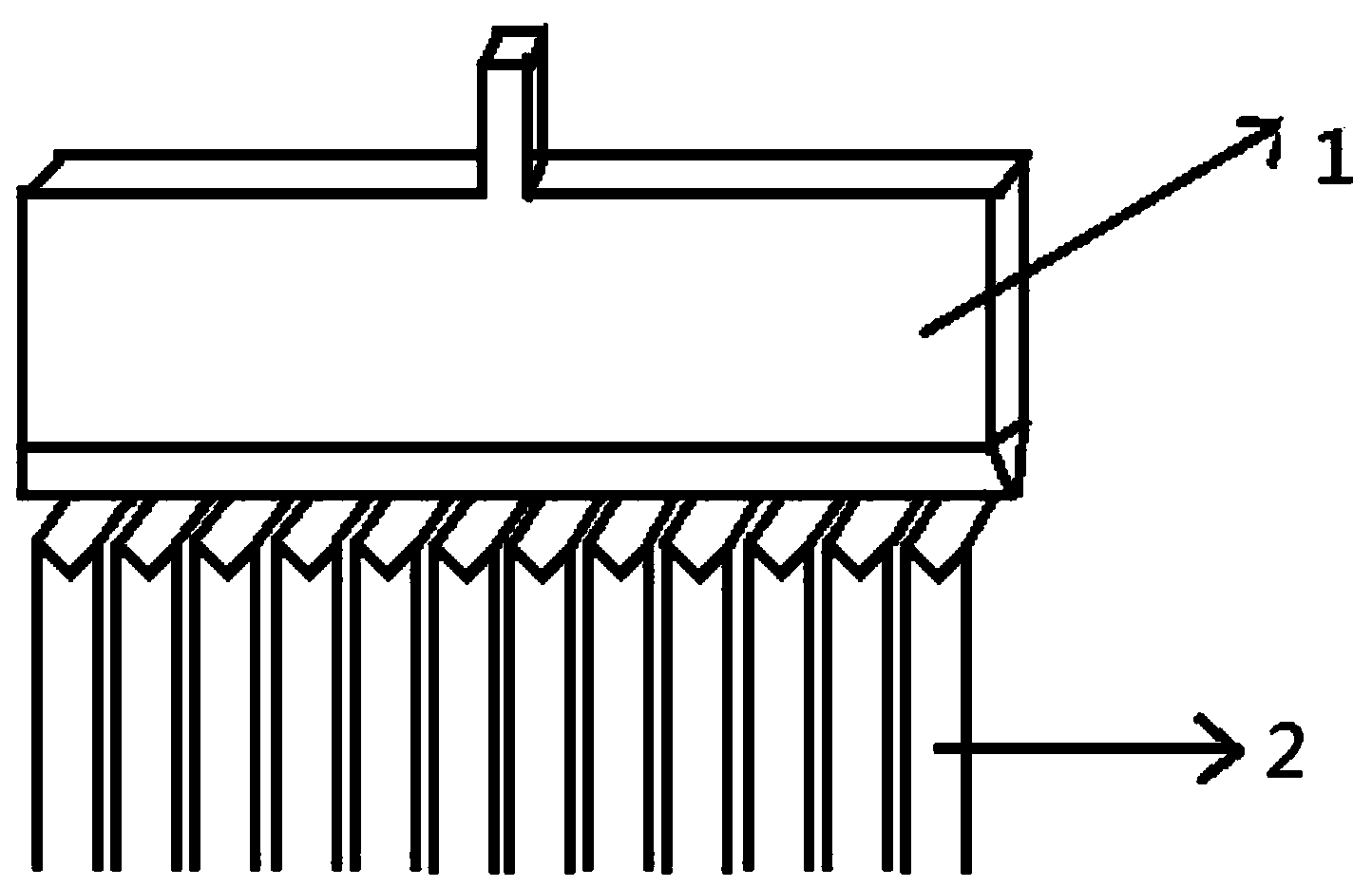

Multiple-piece guided mode method growth technology for sapphire wafer

InactiveCN103849928AImprove crystal orientation accuracyGood repeatabilityPolycrystalline material growthBy pulling from meltEngineeringSingle crystal

The invention discloses a multiple-piece guided mode method growth technology for a sapphire wafer. The multiple-piece guided mode method growth technology for the sapphire wafer comprises the following steps: S01, treating sapphire raw material; S02, charging; S03, vacuumizing and introducing argon; S04, heating up; S05, seeding and necking down; S06, widening shoulder; S07, performing isometrical growth; S08, cooling. According to the multiple-piece guided mode method growth technology for the sapphire wafer, an EFG (edge-defined film-fed growth) method is adopted, an optimal mould distribution and charging technique is designed, a scientific crystal growth control procedure is combined, reasonable circumferential and axial temperature gradients are applied, and multiple high quality flaky sapphire single crystals are grown.

Owner:JIANGSU SUBORUI PHOTOELECTRIC EQUIP TECH

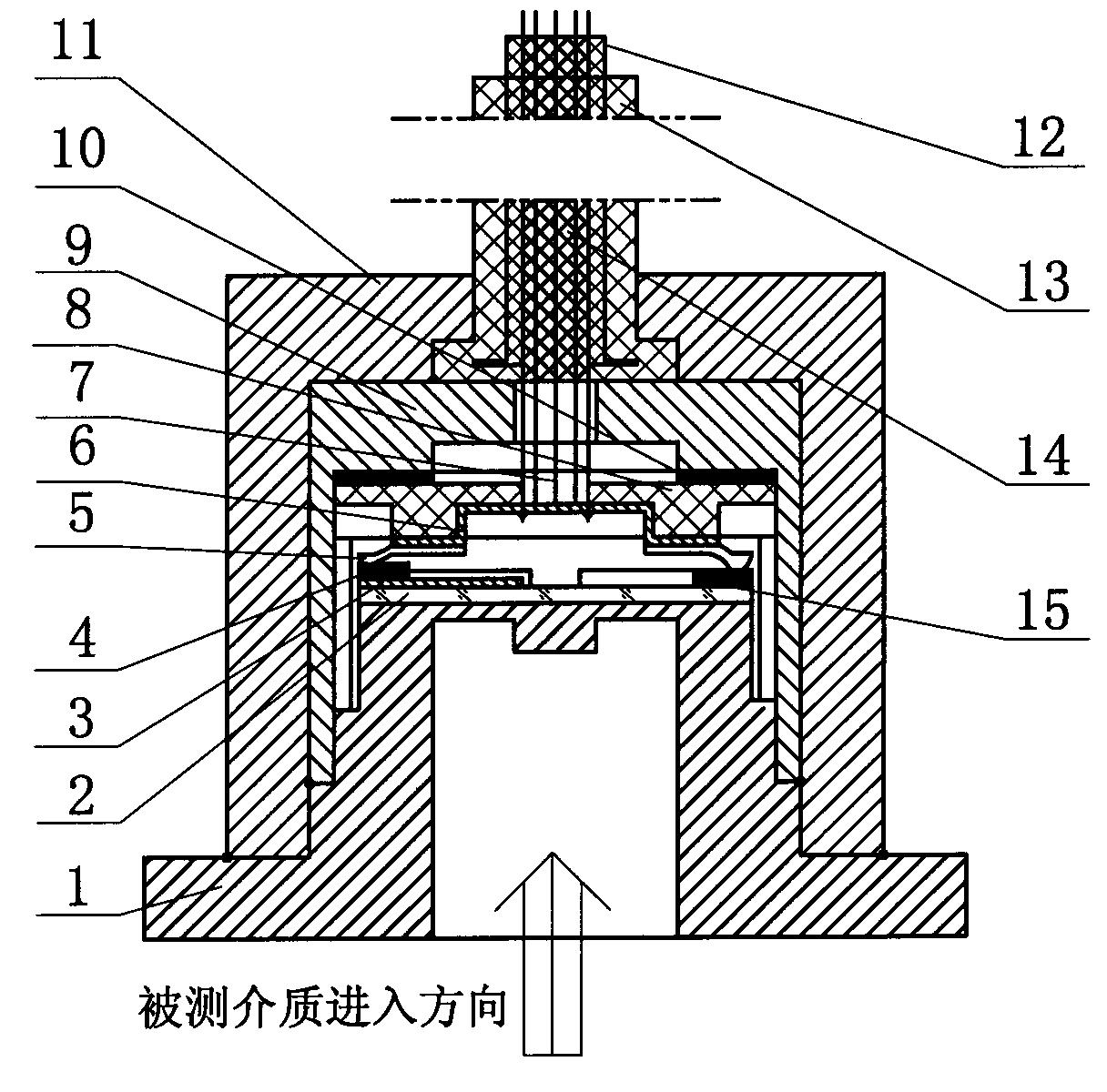

High-temperature pressure and temperature compounded sensor and preparation method thereof

ActiveCN102221429AAdd new featuresImprove reliabilityThermometers using electric/magnetic elementsUsing electrical meansManufacturing technologyMetal foil

The invention provides a high-temperature pressure and temperature compounded sensor and a preparation method thereof. The invention improves the structure of the previous patent of the inventor: silicon sapphire force sensor and the preparation method thereof. The manufacturing method comprises the following steps of manufacturing a platinum thermal resistor having same materials with a strain resistance leading-through platinum welding disc and a platinum welding disc of an internal leading-through at one corner of a non-stress area on a same sapphire wafer with a silicon strain resistor; adopting a welding metal foil strip to replace the original elastic metal contact or the internal leading-through in other forms, thus preparing the high-temperature pressure and temperature compoundedsensor with strong vibration resistance and large acceleration resistance. The method solves the problem that the high reliability can not be met when the pressure and the temperature are measured ata same point in the prior art. The high-temperature pressure and temperature compounded sensor remains the advantages of the existing silicon sapphire force sensor; furthermore, compared with the similar product, the high-temperature pressure and temperature compounded sensor has the advantages of more reasonable manufacturing technology, quick operation, low relative cost, high production efficiency and the like, and obviously improves the high reliability of the measurement under the severe conditions.

Owner:SHENYANG SENSOR TECH INST

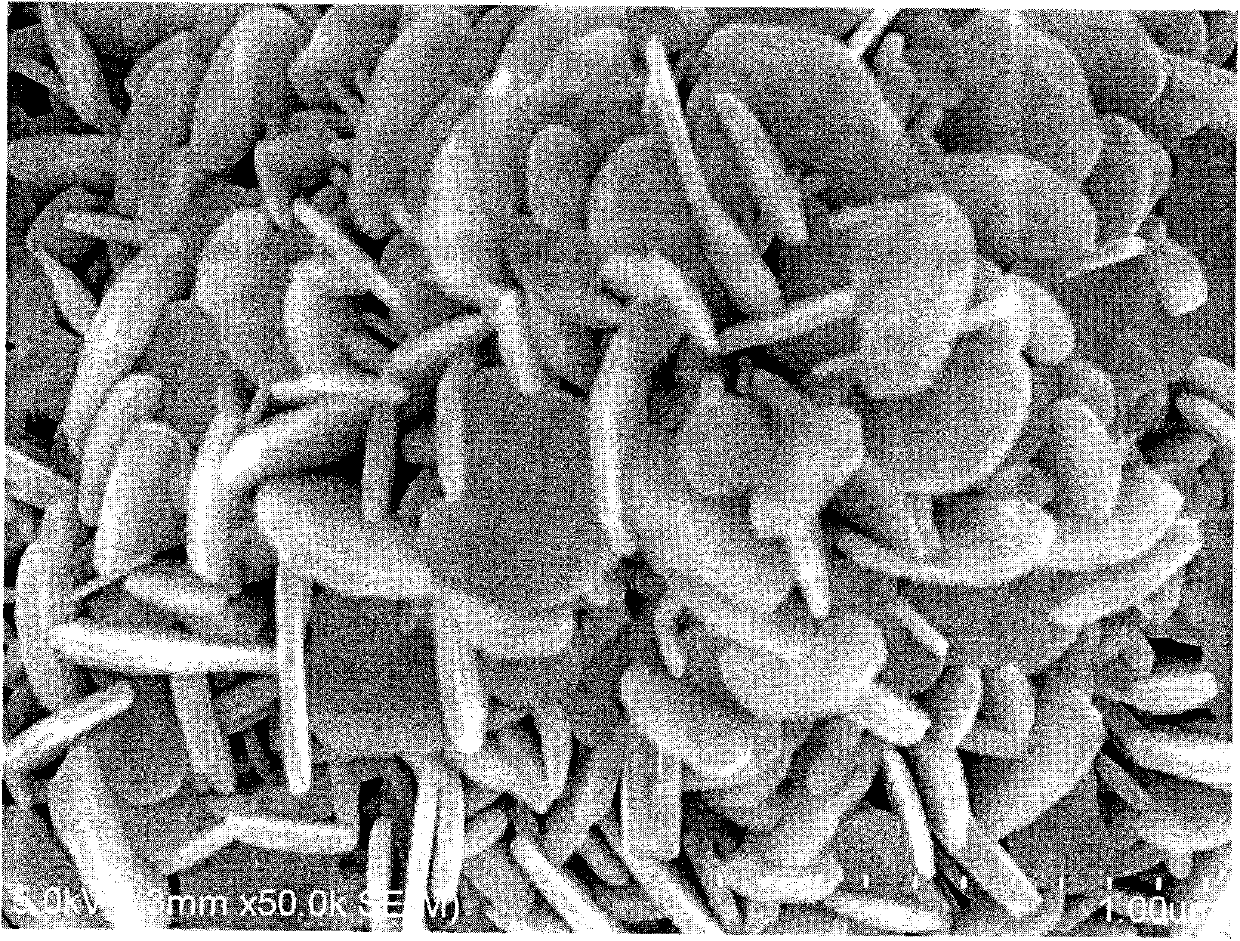

Self-sharpening diamond abrasive material and preparation method thereof

ActiveCN103709993AReduce carbonizationMultiple ground anglesOther chemical processesDiethylenetriamineManganese

The invention discloses a self-sharpening diamond abrasive material. The self-sharpening diamond abrasive material comprises the following raw materials by weight: 75-85% of a diamond abrasive materail, 13-20% of metal powder and 2-5% of a binding agent. The particle size of the diamond abrasive material is 0.5 [mu]m-100 [mu]m; the metal powder comprises iron, cobalt, manganese, or a mixture thereof, or an alloy; and the binding agent comprises diethylenetriamine, 1,3-cyclohexanebis(methylamine), trimethylhexamethylenediamine, or a mixture thereof or one of the above. The self-sharpening diamond abrasive material is rough in surface and has more grinding surface angles. When particles are suffering from stress, frangibility causes the particles broken, so that novel sharp cutting edge is generated and the self-sharpening property is better. The self-sharpening diamond abrasive material is particularly suitable for ultrafine grinding and polishing of magnetic heads, hard disks, optical glasses and sapphire wafers.

Owner:河南鑫泓研磨材料有限公司

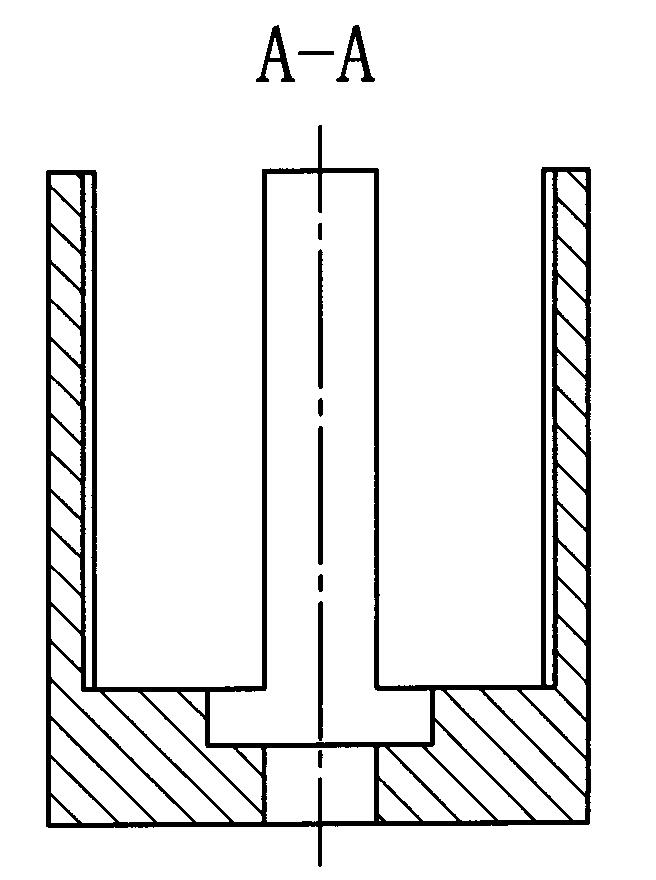

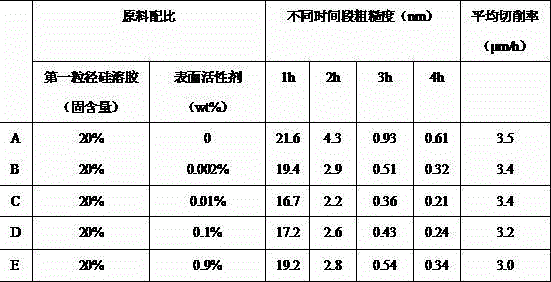

Efficient C-oriented sapphire polishing solution and preparation method thereof

InactiveCN104893587AHigh cutting rateImprove flattening efficiencyPolishing compositions with abrasivesSapphire waferSURFACTANT BLEND

The invention discloses an efficient C-oriented sapphire polishing solution and a preparation method thereof. The polishing solution contains the following components by weight percent: 0.6-80% of silica sol with first particle size, 0.6-80% of silica sol with second particle size, 0.002-0.9% of a surfactant, 0.05-5% of a complexing agent and the balance of water. The preparation method comprises the steps of: completely dissolving the surfactant in water and uniformly stirring; adding the silica sol with first particle size and the silica sol with second particle size, and stirring uniformly to prepare a suspension; adding the complexing agent into the suspension, and stirring uniformly; regulating the pH value to be 7-13. According to the polishing solution prepared by combining two types of silica sol with different particle sizes, on the premise of ensuring relatively high cutting rate in a C-oriented sapphire polishing process, the flattening efficiency is greatly improved, so that a ground sapphire wafer quickly achieves a flat and smooth mirror-surface effect; therefore, the polishing time is shortened and the efficiency is improved.

Owner:JIANGSU SINO KRYSTALS OPTROINCS

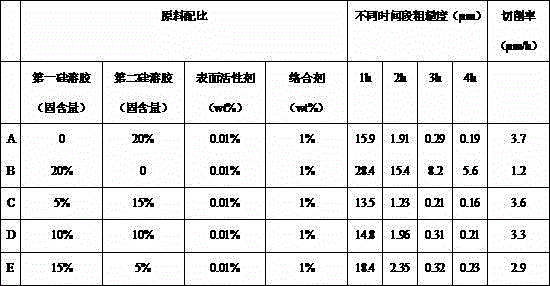

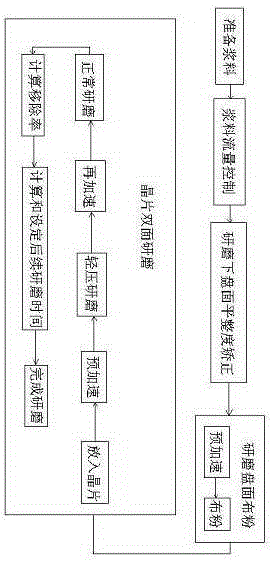

Grinding device for sapphire wafers and grinding method thereof

ActiveCN105215838AStir wellGood suspensionLapping machinesGrinding/polishing apparatusPeristaltic pumpPulp and paper industry

The invention discloses a grinding device for sapphire wafers. The grinding device for sapphire wafers comprises a pulp stock barrel, a peristaltic pump and a grinder, wherein a pulp stock trough is arranged on the grinder, and pulp stock enters into the grinder through the peristaltic pump and the pulp stock trough. The grinding method for the sapphire wafers comprises the following steps: 1, preparing the pulp stock: putting in raw materials by levels and layers; 2, controlling pulp stock flows: putting pulp stock accurately; 3, correcting the flatness of the surface of a grinding lower plate: repeatedly measuring by using a long gauge, a short gauge and a dial gauge, and correcting; 4, distributing powder on the surface of a grinding plate; and 5, grinding both sides of each wafer: firstly carrying out light pressing grinding. The grinding method provided by the invention is characterized in that raw material ratio of the pulp stock is optimized, the pulp stock supplying flow is more accurate, the conveying is more even, before normal grinding, light pressing grinding is performed firstly, the problem of wafer breakage during a grinding process can be prevented for the greatest possible, the wafer breakage rate is lowered, the merit factor of grinding is improved, the removing rate during grinding is stable, the problems of over grinding and low removing rate cannot be caused, and the efficiency is relatively high.

Owner:TUNGHSU GRP

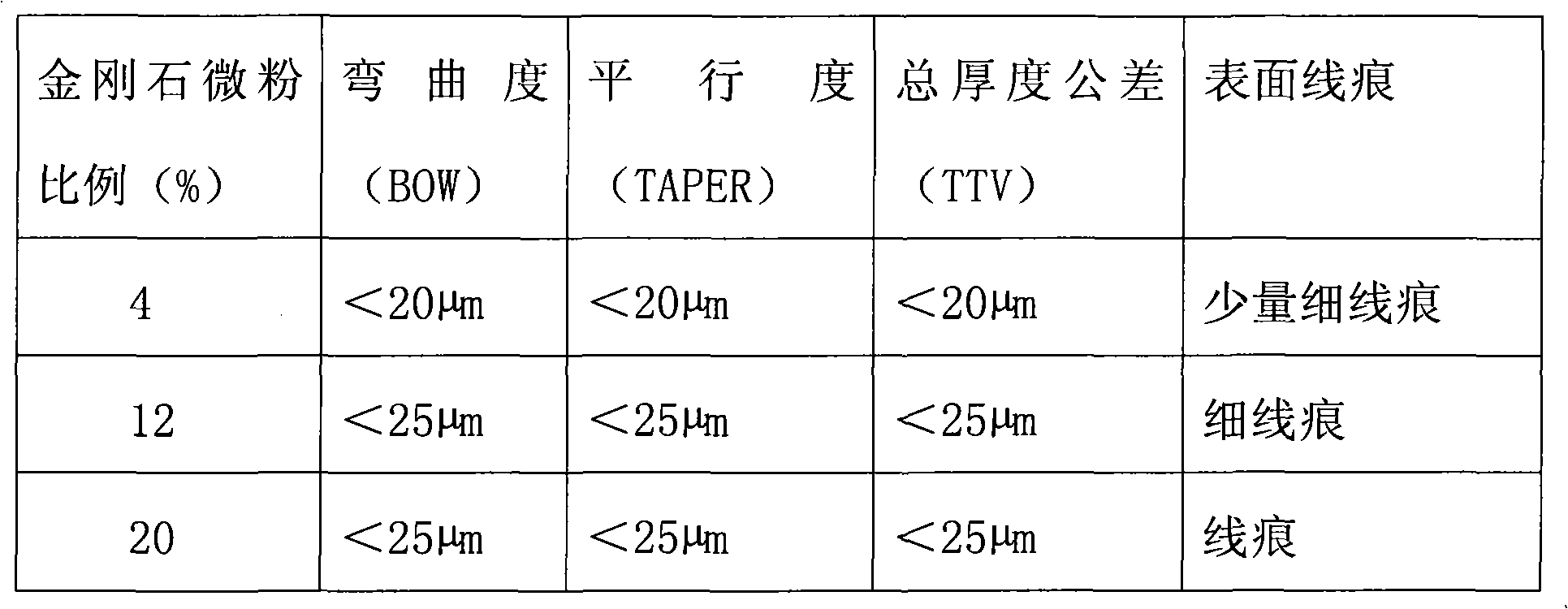

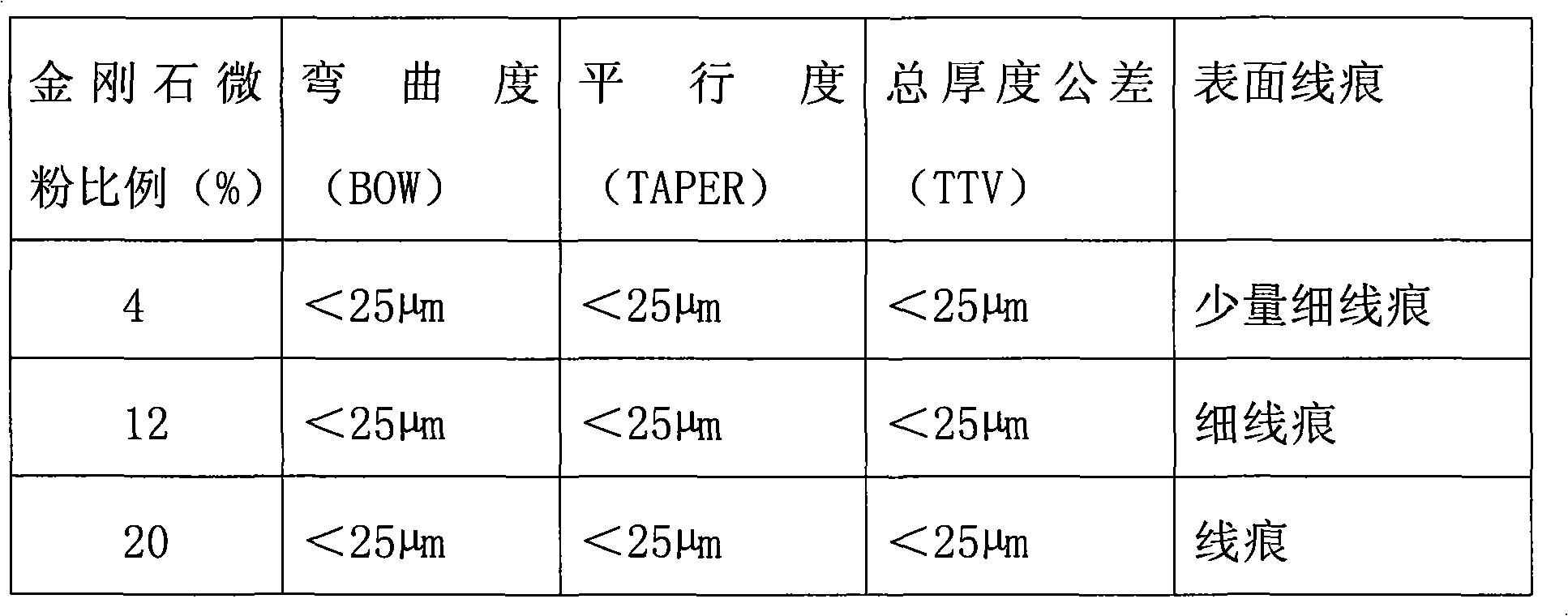

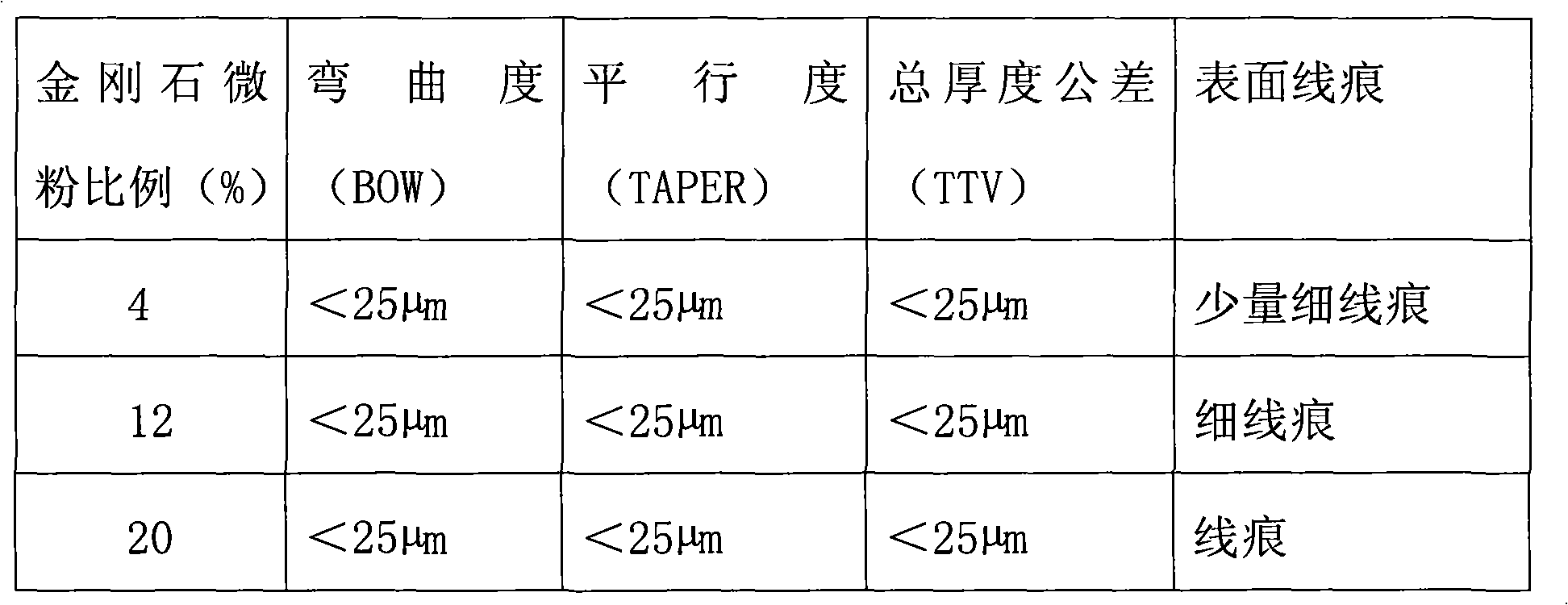

Sapphire wafer cutting method

InactiveCN101870084AImprove liquidityPrevent agglomeration and adhesionOther chemical processesGrinding machinesWaferingSapphire wafer

The invention discloses a sapphire wafer cutting method, which is characterized in that a free grinding material multi-line cutting method is adopted, cutting lines adopt metal lines, and grinding materials adopt diamond micro powder. The viscocity of cutting oil used by mortar preparation is between 20 and 50 mpa*s at the normal temperature, and the grain diameter of the diamond micro powder is between 4 and 12 mum. The invention provides the technical method for cutting the sapphire in a free grinding material mode. When the method is adopted, a multi-line cutting machine for cutting crystals can be used for processing sapphire wafers, and the invention has the advantages of high cutting efficiency, high precision, low equipment investment, small cutting loss and low cutting cost.

Owner:铜陵市琨鹏光电科技有限公司

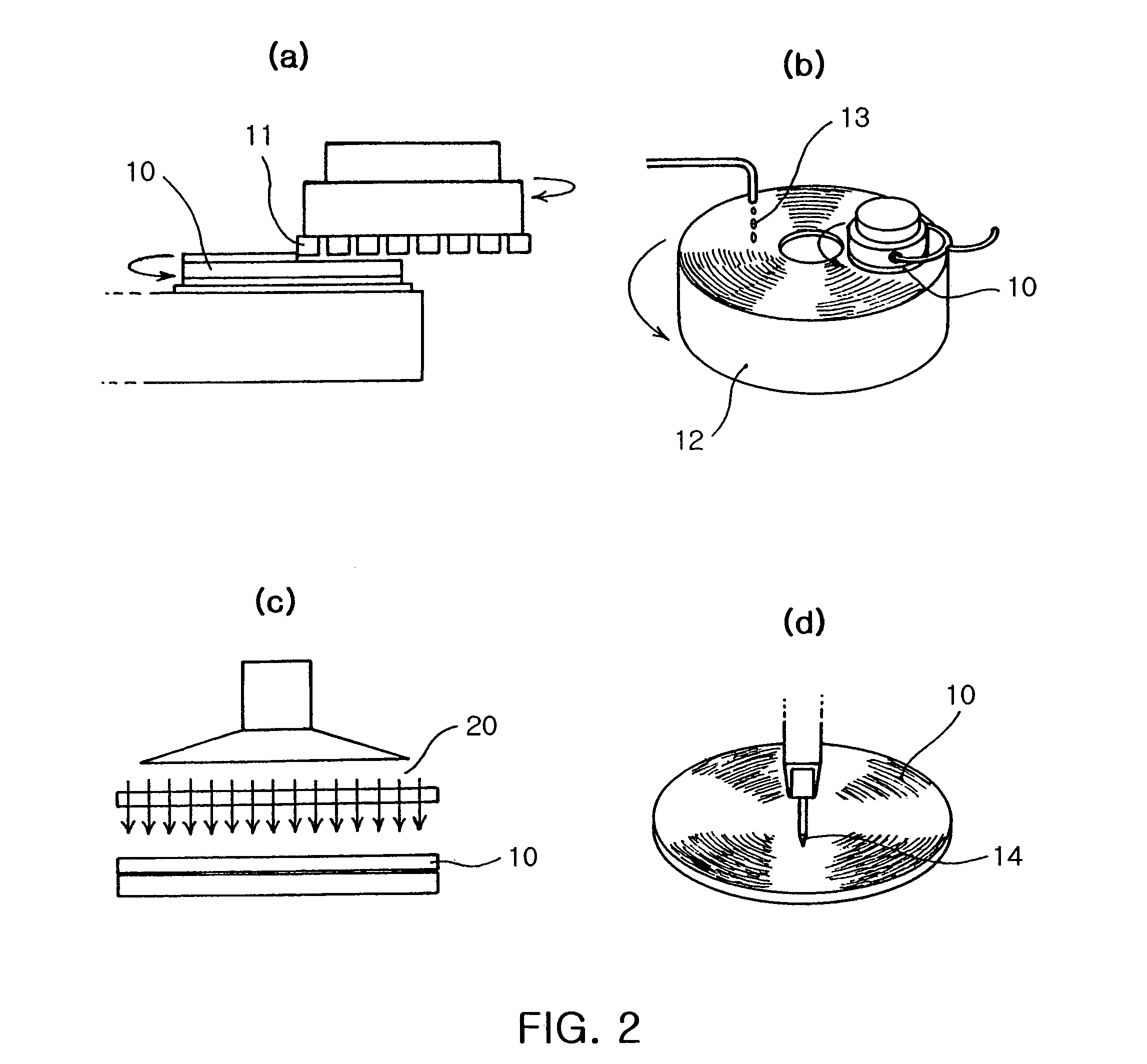

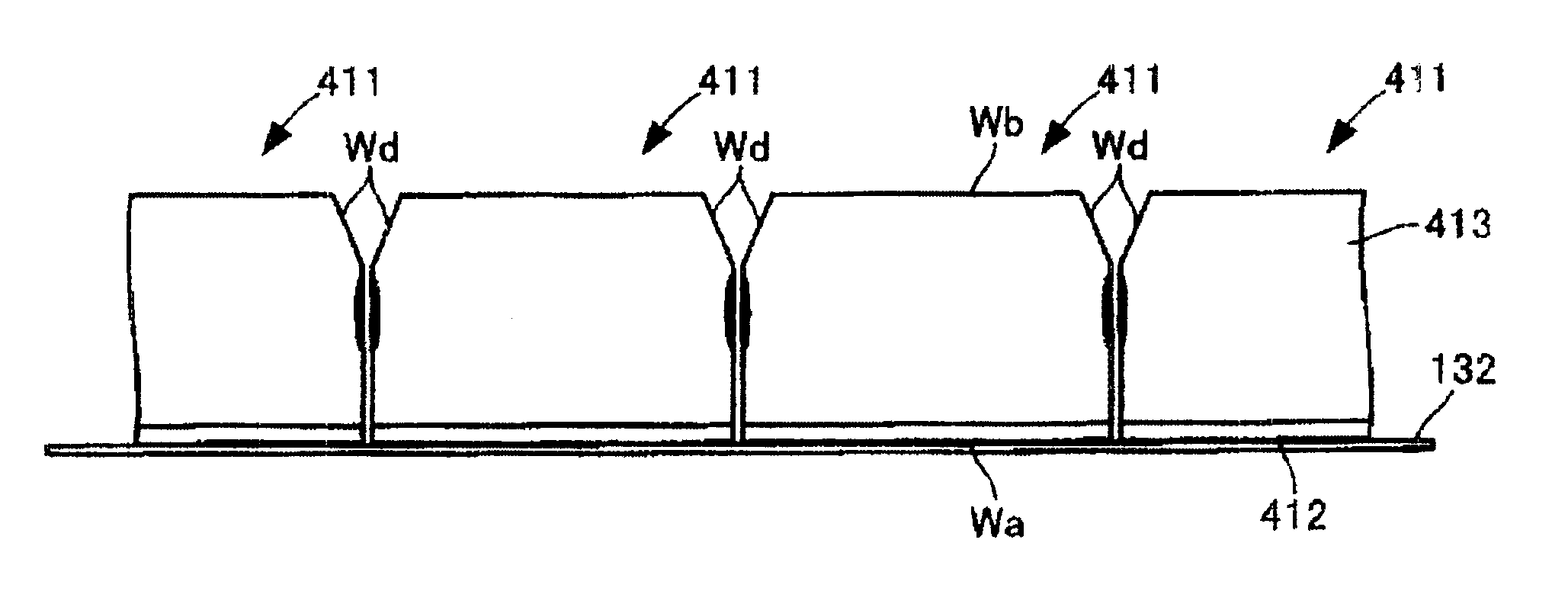

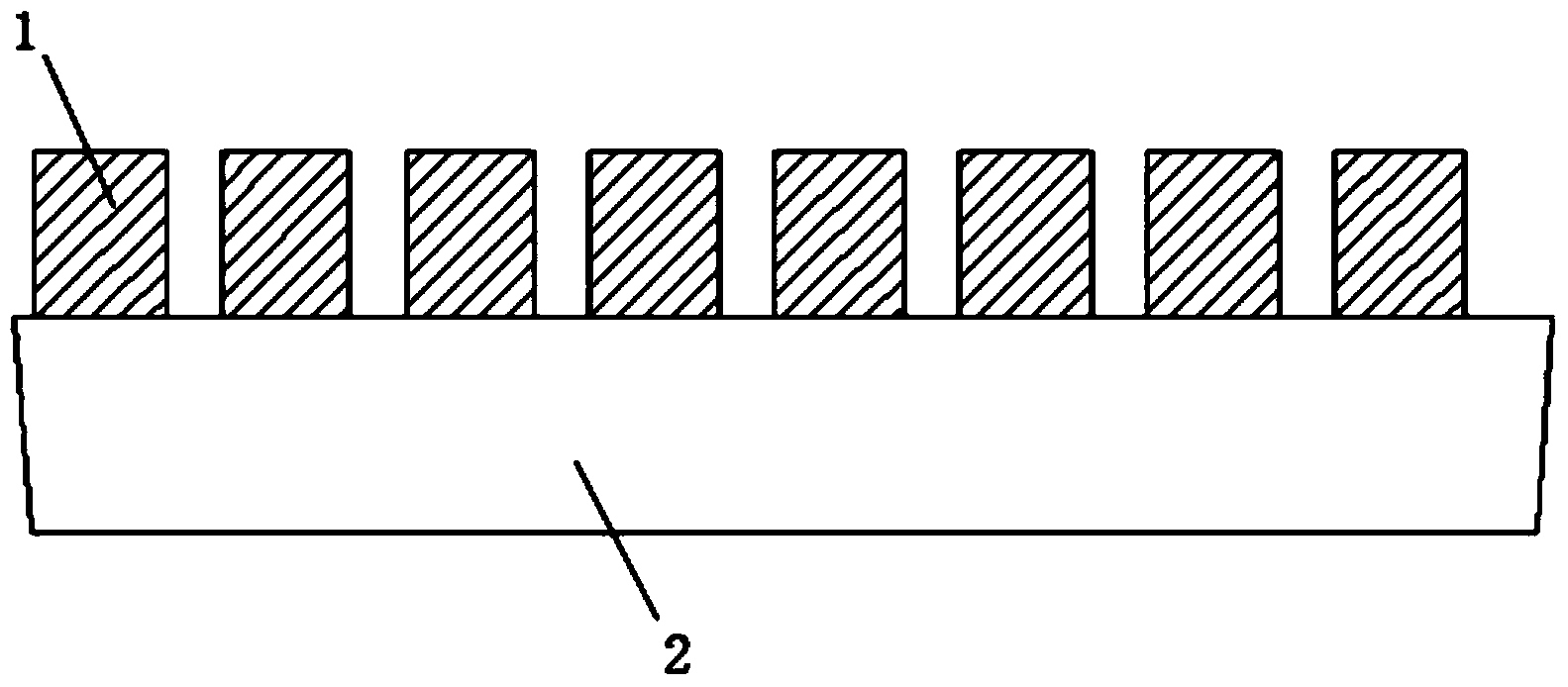

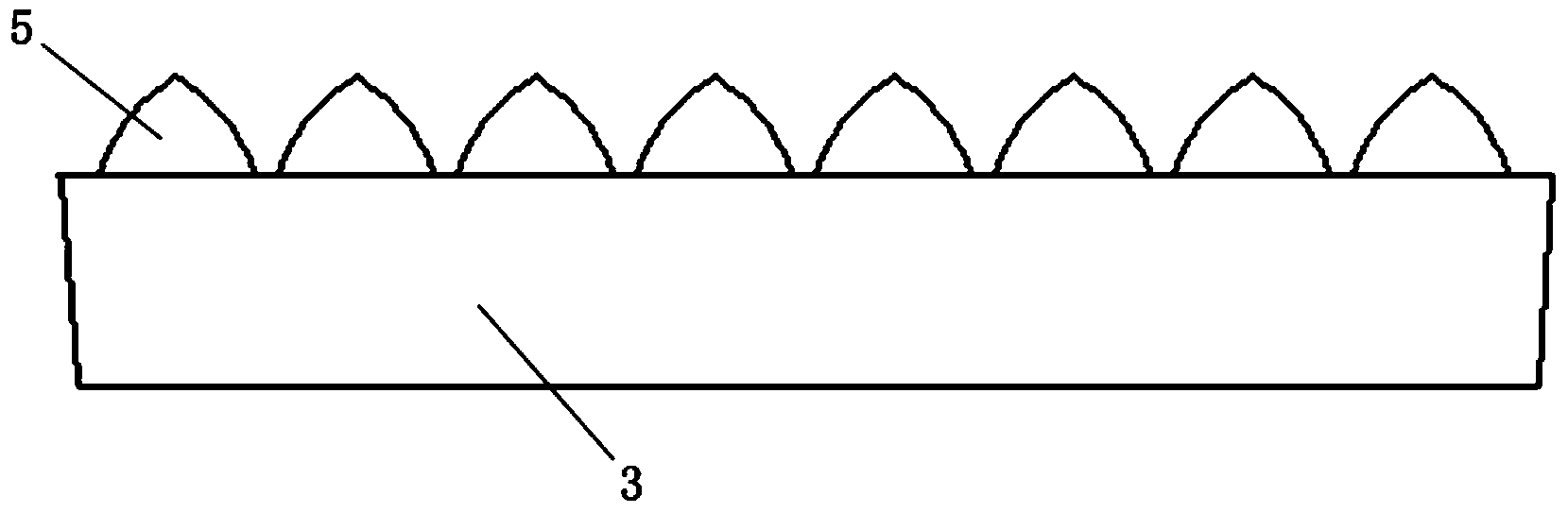

Composite patterned substrate and preparation method thereof

InactiveCN103956418AQuality improvementMismatch Rate ReductionSemiconductor devicesLattice mismatchOptoelectronics

The invention relates to a composite patterned substrate and a preparation method thereof. The composite patterned substrate comprises a sapphire wafer. The maximum ratio of the diameter of circumcircles of the root portions of patterns of the surface of the wafer to the distance between two adjacent pattern central points is 0.95. The surfaces of the upper portions of the patterns are exposed. AlN layers with the thickness ranging from 15 nm to 35 nm are deposited between the root portions of the patterns. According to the composite patterned substrate and the preparation method of the composite patterned substrate, the advantages of the sapphire patterned substrate are reserved; in addition, the AlN layer which is in low lattice mismatching with GaN materials is introduced below the patterned substrate, and the GaN nucleation quality of the substrate in the later using process is effectively improved, so that the GaN growth quality is improved; moreover, the using efficiency of MOCVD can be effectively improved, and productivity is improved.

Owner:项永昌

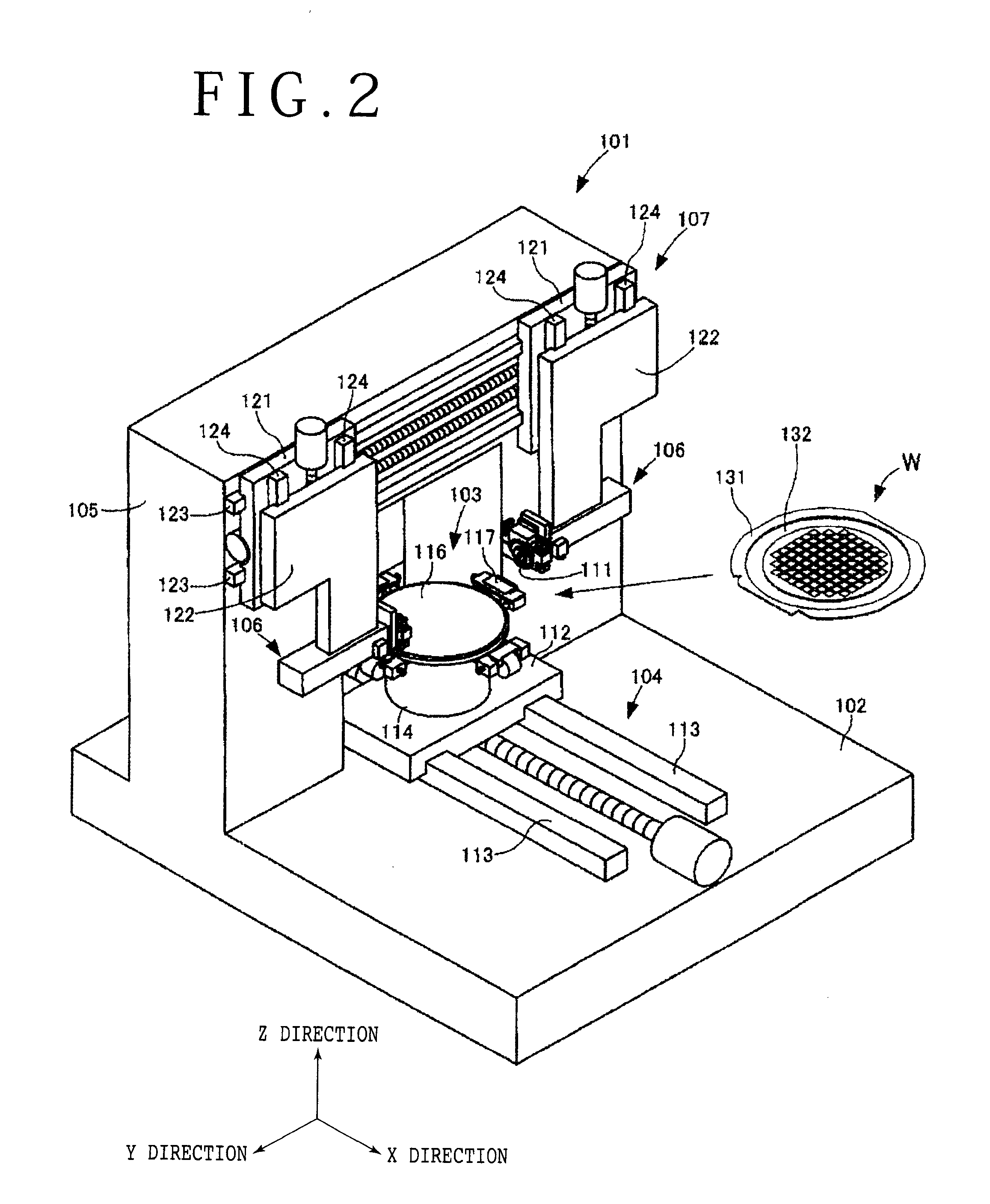

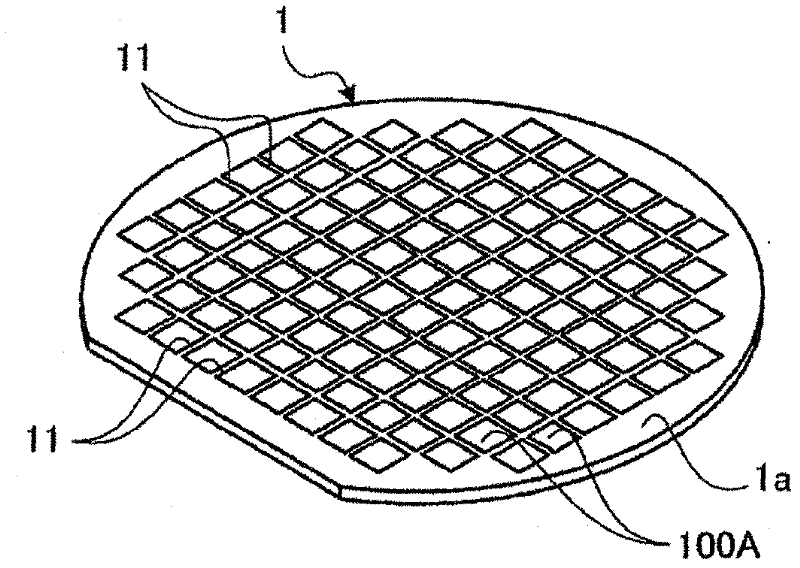

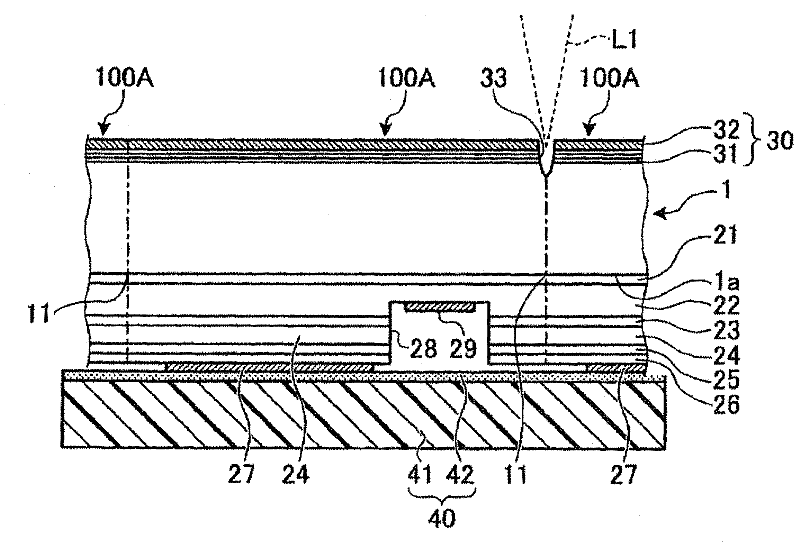

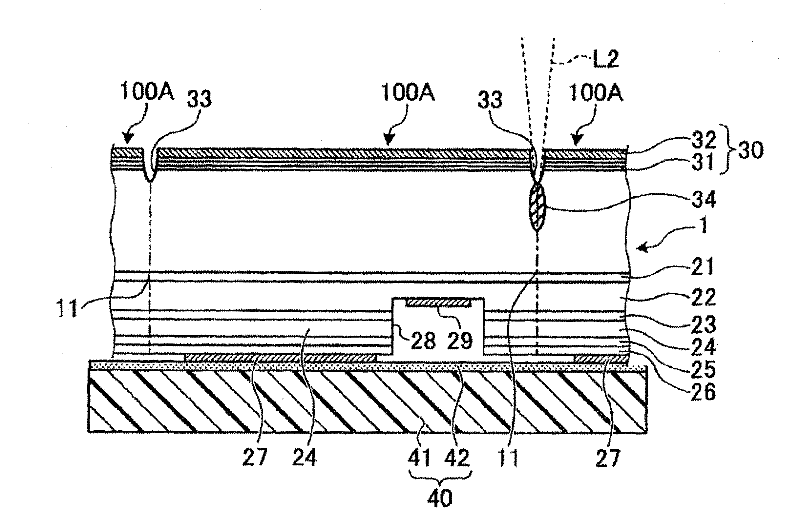

Sapphire wafer dividing method

ActiveCN102248607AImprove manufacturing yieldSemiconductor/solid-state device manufacturingFine working devicesSapphire waferWavelength

The invention provides a sapphire wafer dividing method, capable of performing a precise division processing to the sapphire wafer provided with a reflection film. A pulse laser absorbed by a reflection film 30 is illuminated from the back face side of the sapphire wafer 1 along a division predetermining line 11 in a convergence way; a groove 33 deeper than the reflection film 30 is formed on the division predetermining line 11; then the pulse laser L2 transmitting through the sapphire is illuminated inside the sapphire wafer 1 in the convergence way along the division predetermining line 11 passing through the groove 33 and exposed out of the sapphire surface; a modification layer 34 is formed inside; an external force is applied to the modification layer 34 so as to divide the sapphire wafer 1 along the division predetermining line 11.

Owner:DISCO CORP

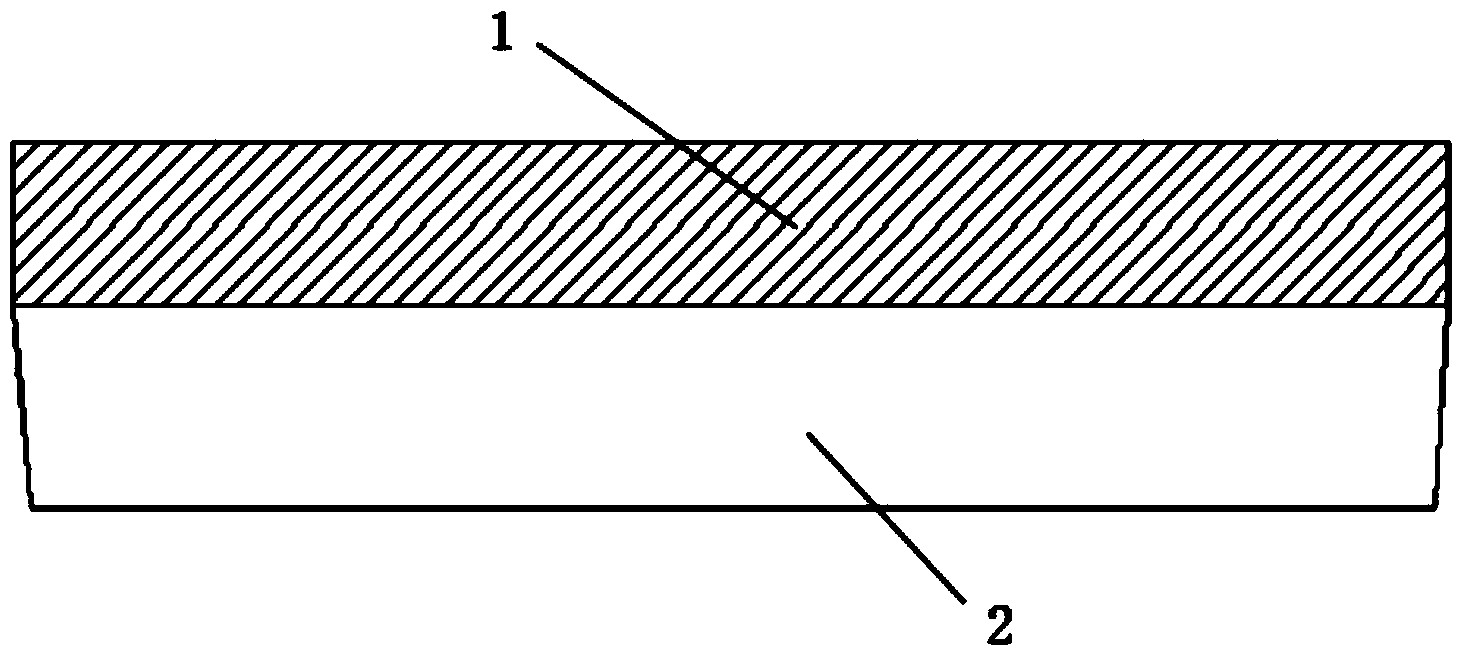

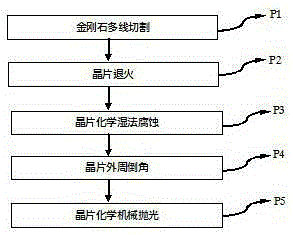

Processing method for double-sided polished sapphire wafers

ActiveCN105313234AEasy to control speedIncrease controlEdge grinding machinesAfter-treatment detailsWaferingEtching

The invention provides a processing method for double-sided polished sapphire wafers. The main technological process comprises the steps of multi-wire cutting, wafer annealing, wafer chemical wet etching, wafer periphery chamfering and wafer chemical-mechanical polishing. Since the sapphire wafers are processed through the method, the operation processes are simplified, operation is easier, and the processing cycle can be efficiency shortened. On the precise of guaranteeing the thickness and surface quality of the wafers, the reserved processing allowance for subsequent processing can be reduced in the slicing process, the utilization rate of crystals can be increased, and therefore the production and manufacturing cost of the sapphire wafers is reduced.

Owner:哈尔滨秋冠光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com