Patents

Literature

88results about How to "Improve flattening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

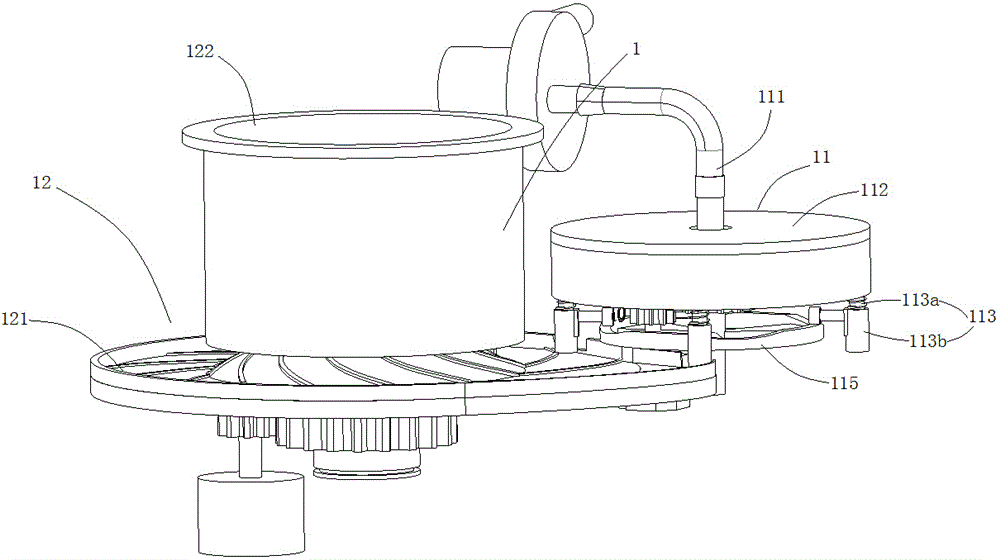

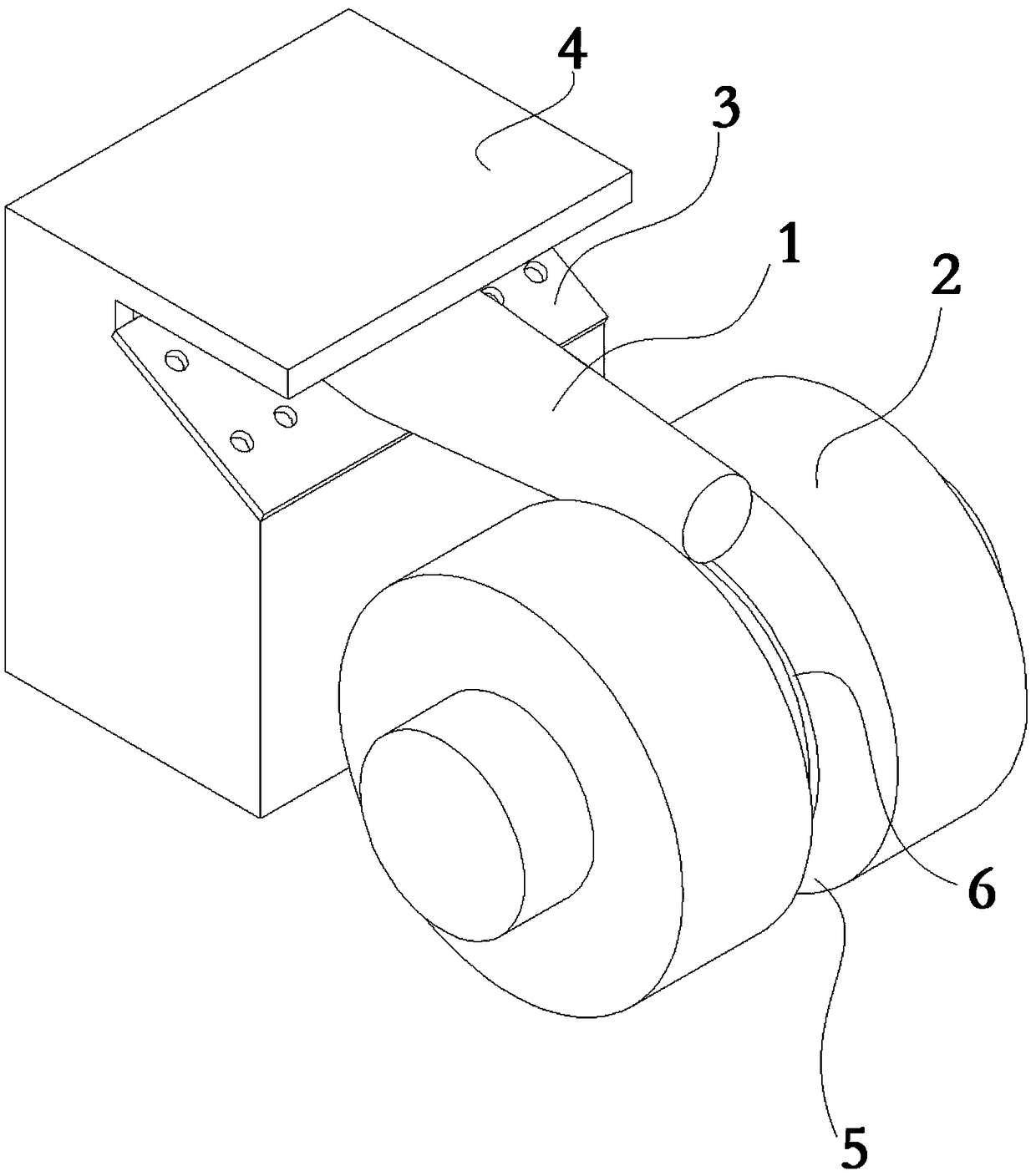

Paper money friction flattening device

InactiveCN105600531ARelieve pressureReduce frictionArticle feedersArticle deliveryPulp and paper industryTotal thickness

The invention discloses a paper money friction flattening device. The paper money friction flattening device is characterized in that: the paper money friction flattening device comprises a loading mechanism, and a flattening mechanism, a shaping mechanism and a paper money collecting box, which are connected sequentially, wherein the flattening mechanism comprises a rectangular bottom plate which is arranged obliquely in a length direction, so that the paper money can slip long the upper surface of the bottom plate; a friction mechanism is arranged above the bottom plate, one side of the friction mechanism, close to the bottom plate, can move downwards in a length direction of the bottom plate, and a gap between the friction mechanism and the bottom plate is smaller than the total thickness of two paper moneys; a material inlet is formed between the upper end of the bottom plate and the friction mechanism and is arranged under a material outlet end of the loading mechanism. In general, the paper money friction flattening device has the advantages that the device can realize the grabbing, loading, automatic flattening and collection of the paper money, can grab the paper money reliably, has appropriate loading pace, high flattening speed, high efficiency and good reliability, is favor for reducing the labor intensity of workers, and can improve the working efficiency.

Owner:CHONGQING UNIV OF TECH

Cloth flat pressing equipment

The invention relates to the technical field of mechanical equipment, in particular to cloth flat pressing equipment. The cloth flat pressing equipment comprises a host machine body and also comprises an operation table, an ascending and descending rail, a cross beam, a second flat pressing component, a first driving component, a second driving component and a first flat pressing component, wherein the second flat pressing component comprises a guide tube body, a main transmission shaft, a side edge sliding wing, a slide seat, an installing disc, a rotating connecting seat, a press disc and an inner regulating element. The cloth flat pressing equipment has the advantages that the operation is convenient; the regulation is convenient; the flat pressing effect is good; the flat pressing efficiency is high.

Owner:苏州盛泽科技创业园发展有限公司

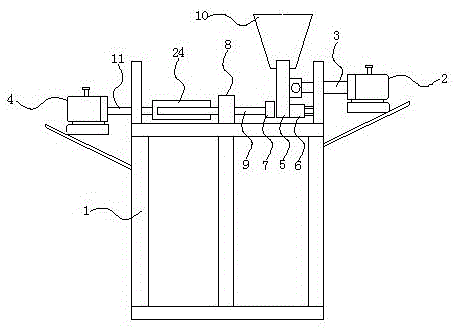

Efficient waste ring-pull can flatting mill

The invention discloses an efficient waste ring-pull can flatting mill which comprises a supporting frame, a flatting assembly, a fixed block, a first rotating shaft, a second rotating shaft, a first motor, a second motor, a rotating disc, a cylindrical cam, a feeding hopper and a feeding device. A material groove is formed in the edge of the rotating disc. The flatting assembly comprises a pneumatic tank, a pushing shaft and a movable block. The fixed block and the movable block are matched to form a cavity. A rolling piece is arranged inside a curve groove of the cylindrical cam and connected with the pushing shaft through a connecting rod. A first cavity is arranged inside the pushing shaft and communicated with the pneumatic tank through a pipeline. A second cavity communicated with the first cavity is arranged inside the movable block. An impact shaft which can move back and forth relative to the movable block is installed inside the second cavity. According to the efficient waste ring-pull can flatting mill, the labor intensity of operators can be remarkably lowered, the waste ring-pull can flatting efficiency can be improved greatly, and it is efficiently ensured that waste ring-pull cans are better flatted.

Owner:刘丽华

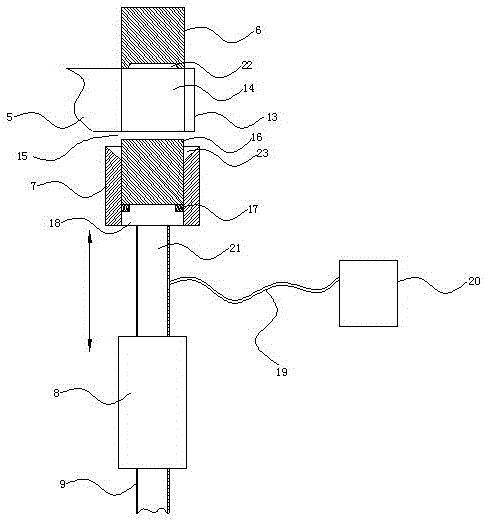

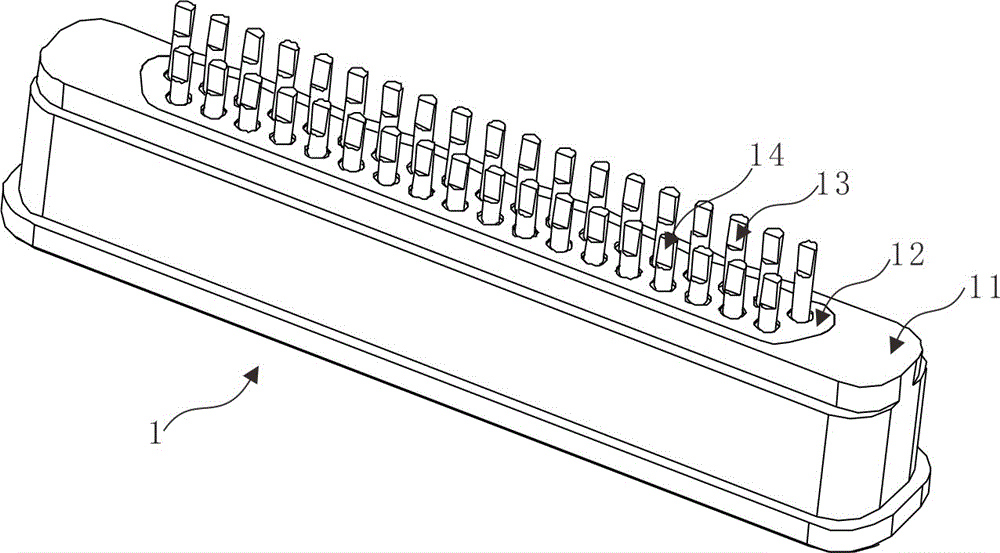

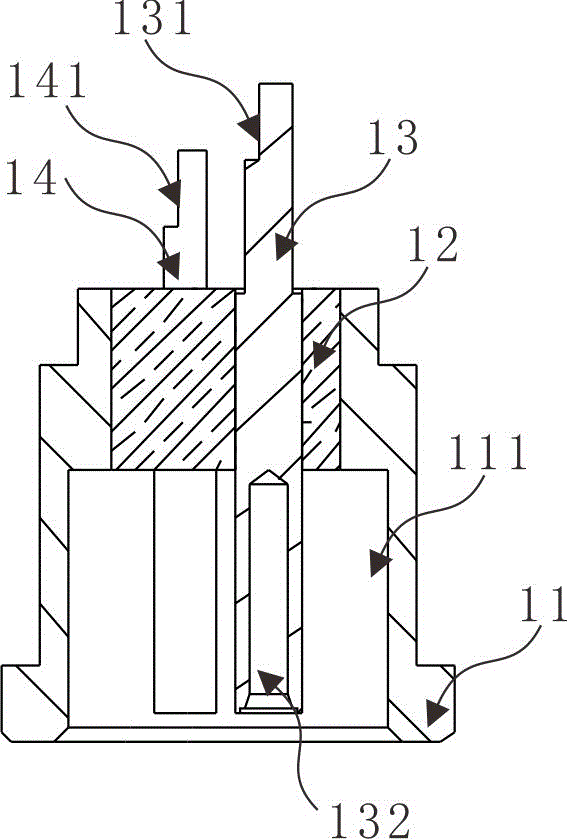

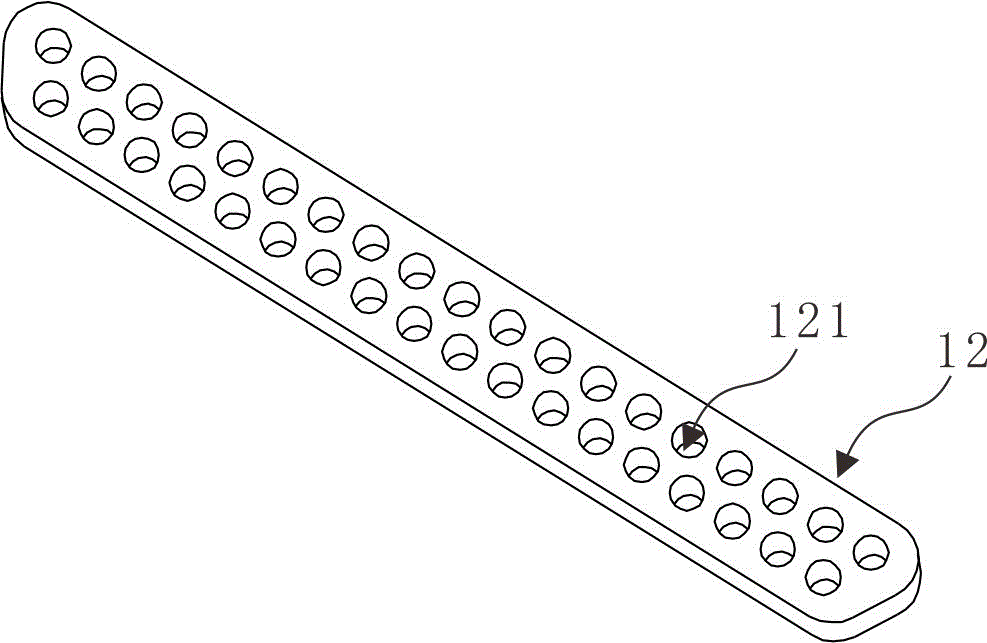

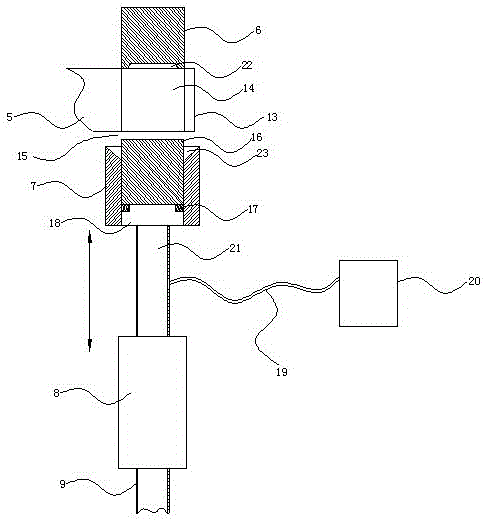

Micro-spacing glass sealing connector fusion sealing process

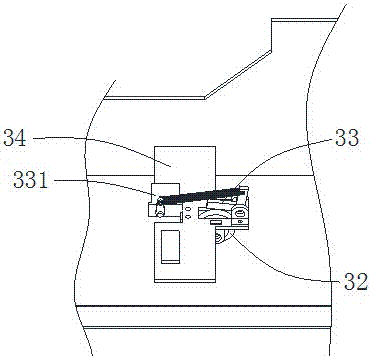

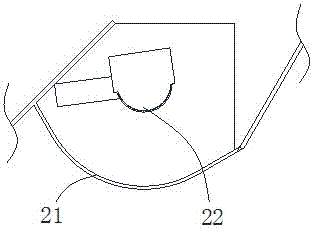

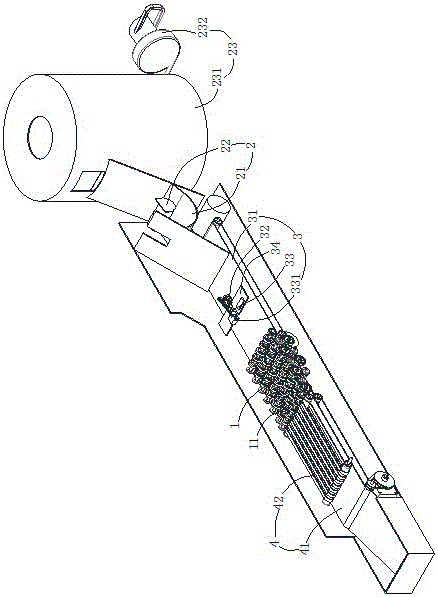

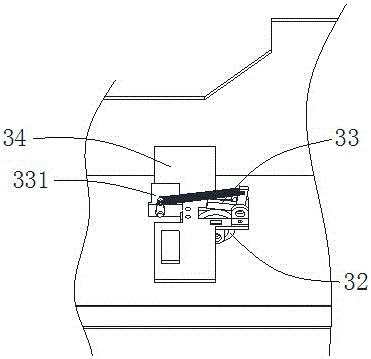

ActiveCN105633757APrecise positioningGuaranteed tightnessContact member manufacturingContact member cases/bases manufactureVitreous BodiesEngineering

The invention discloses a micro-spacing glass sealing connector fusion sealing process. The process comprises a formation tool for clamping a micro-spacing glass sealing connector during fusion sealing. During the fusion sealing, the technical process includes sintering a vitreous body, assembling the micro-spacing glass sealing connector and the formation tool, performing fusion packaging on the micro-spacing glass sealing connector, flattening the end portions, which are disposed outside a metal housing, of a first contact member and a second contact member, and performing secondary sintering on the micro-spacing glass sealing connector. According to the scheme, the formation tool designed according to the concrete structure of the micro-spacing glass sealing connector can realize accurate positioning of the micro-spacing glass sealing connector, guarantees the sealing performance of the connector during the fusion packaging, and at the same time, reduces formation of harmful internal stress. After a flattening process, potential cracks during flattening can be fused and internal stress of the vitreous body can be fully eliminated through a secondary sintering process (the fusion packaging is primary sintering), and the influence on airtightness is thoroughly eliminated.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

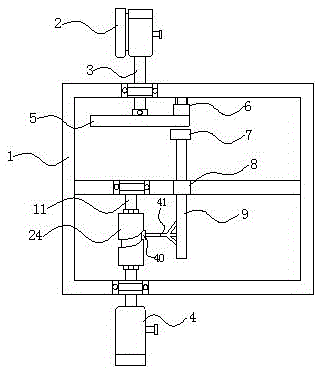

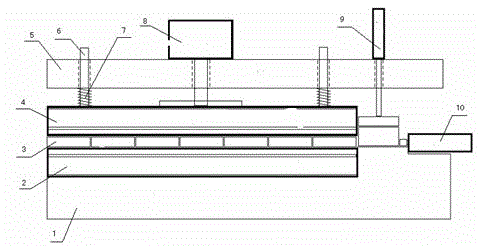

Paperboard pressing leveler

ActiveCN110370729AImprove flattening efficiencyMechanical working/deformationMaterial analysis by optical meansDrive motorLeveler

A paperboard pressing leveler comprises a device base used for placing paperboards, wherein a pressure levelling plate used for pressing and levelling the paperboards, a slide device used for assisting in sliding of the pressure levelling plate, a detection device used for measuring curvature and straightness of the paperboards and a control device used for controlling a motion trail of the pressure levelling plate are arranged on the device base, the detection device comprises an infrared ray emission element and an infrared ray receiving element, the infrared ray emission element and the infrared ray receiving element are kept on the same horizontal plane, the slide device comprises a sliding rod and a drive motor used for driving the sliding rod to slide downwards, the sliding rod is connected with the pressure levelling plate, and the control device comprises a control cabinet used for controlling the drive motor to work and a feedback element used for feeding signals received by the infrared ray receiving element back to the drive motor.

Owner:温州一诚包装有限公司

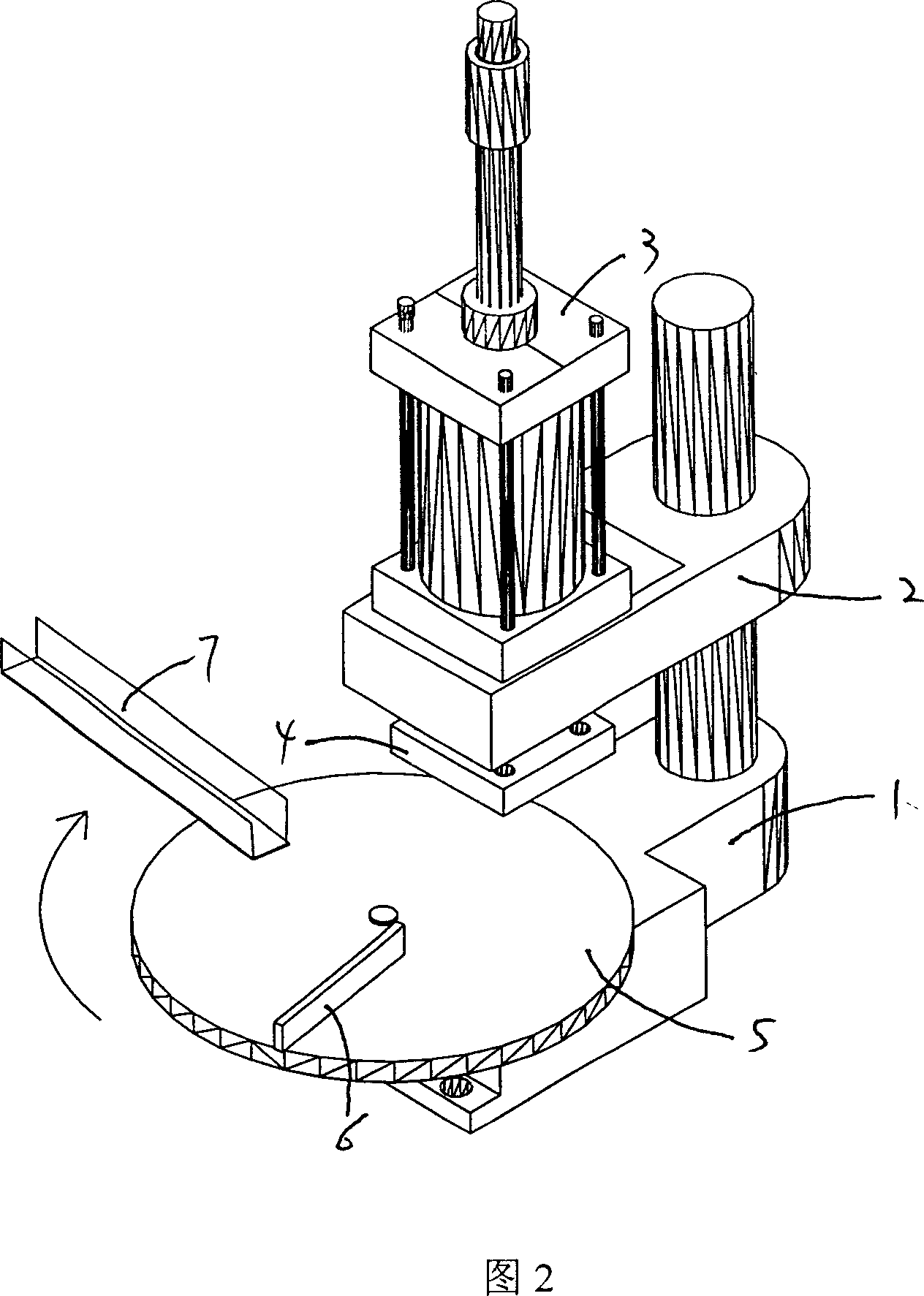

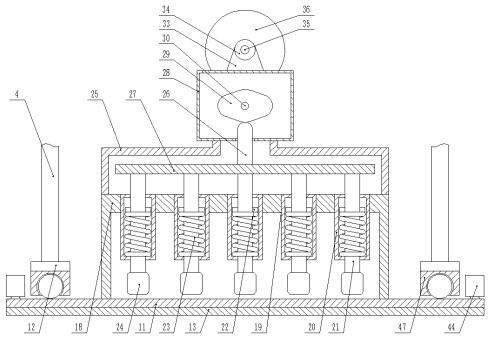

Flattening device for battery roll

InactiveCN1967924ASaves squishing timeImprove flattening efficiencyFinal product manufacturePrimary cellsEngineeringWorkbench

The invention relates to a battery corn flattening device, which comprises base, support, driver, and compressing plate that distantly fixed on support; the compressing plate and driver are connected and opposite on base; the device also comprises rotation workbench, incline groove and baffle plate; the workbench is on the base and opposite to compressing plate; the incline groove and baffle plate are above the base to lead in and out corn. The inventive rotation work bench can effectively reduce flatten time, improve efficiency, and it uses incline groove and baffle plate to lead corn in and out workbench, to improve flatten efficiency.

Owner:SHENZHEN BAK BATTERY CO LTD

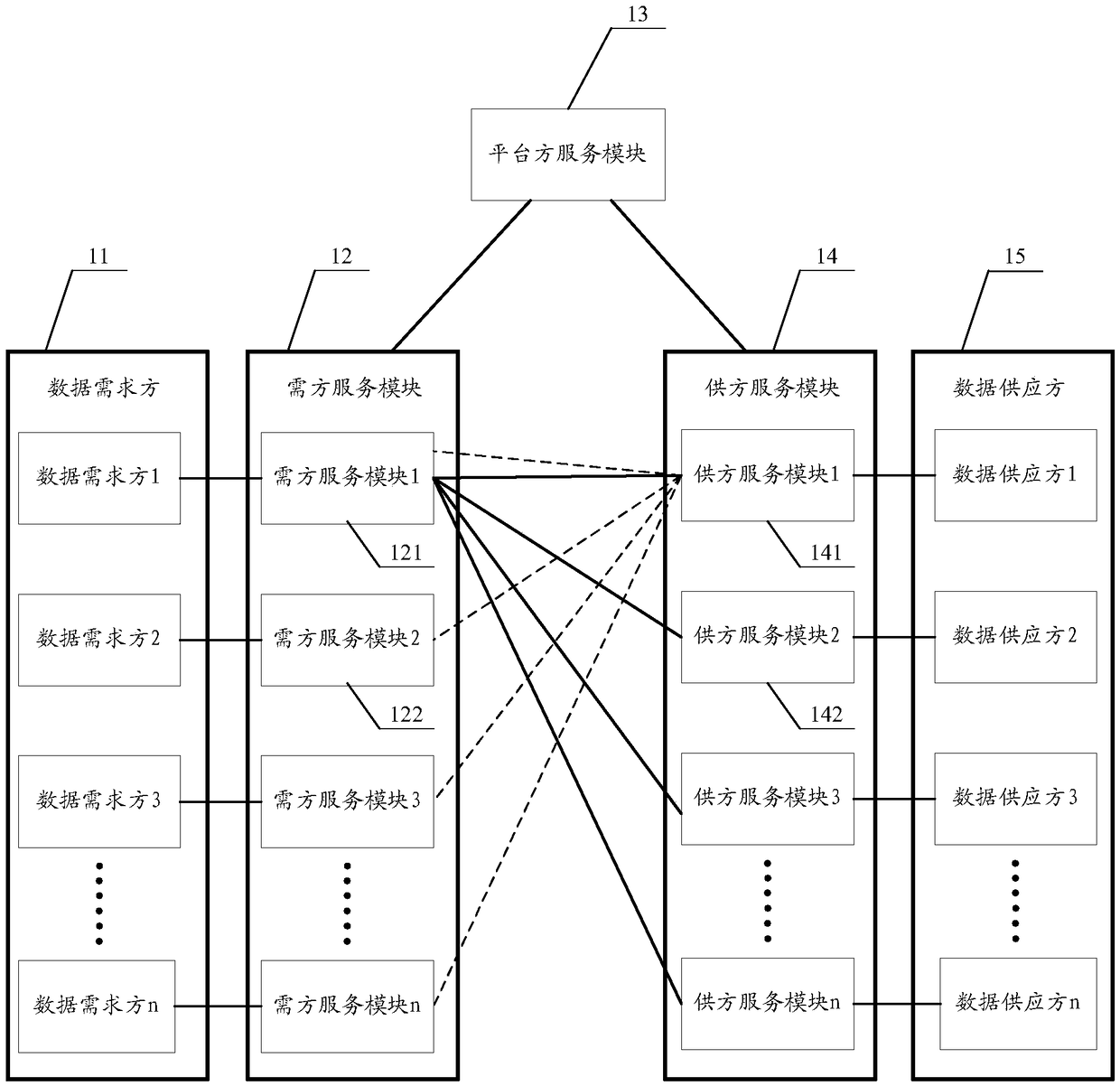

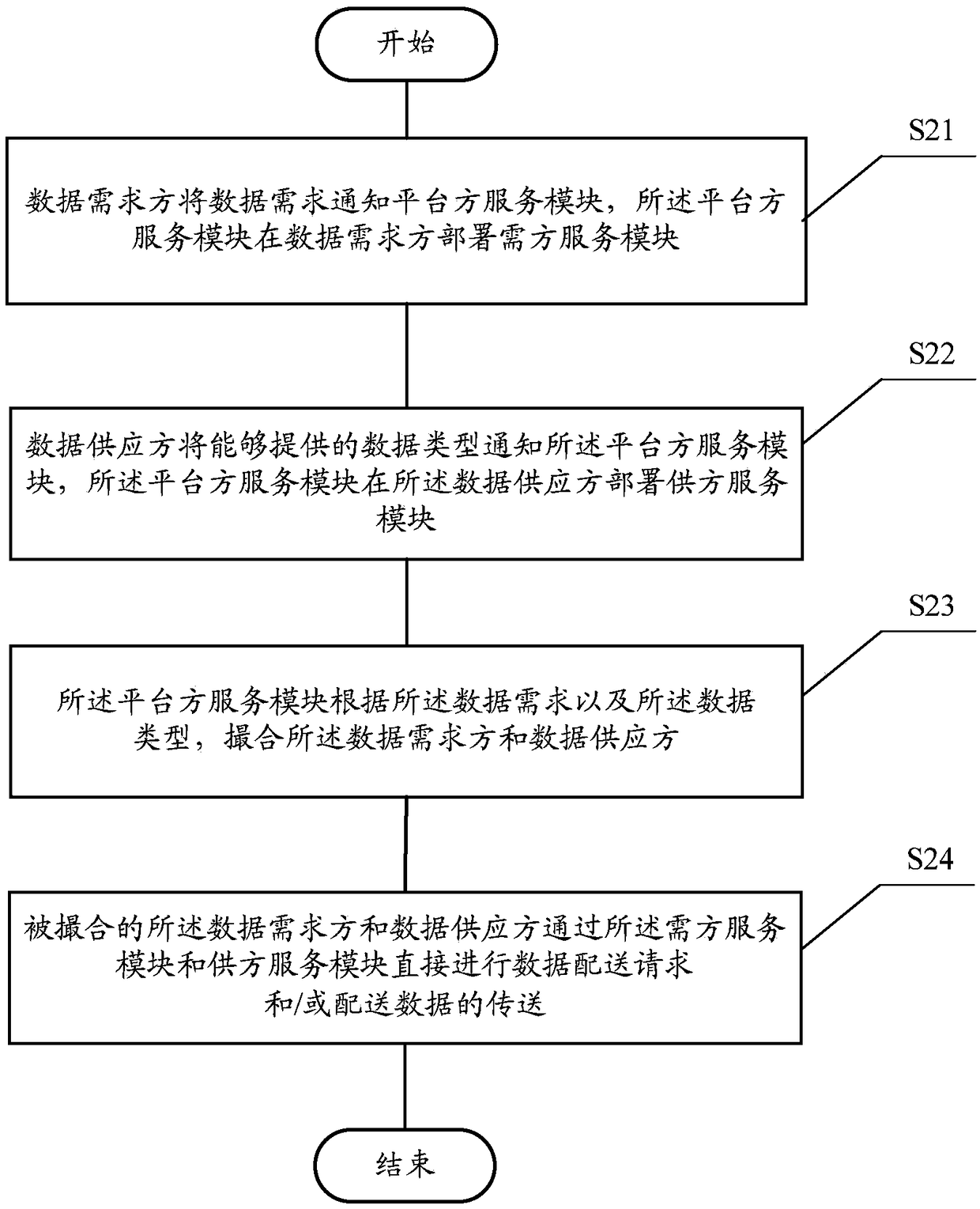

A data distribution system and distribution method

InactiveCN109034683AEnsure safetyImprove efficiencySoftware designLogisticsDistribution systemThird party

The invention relates to a data distribution system and distribution method. The data distribution system comprises a plurality of demander service modules, a plurality of supplier service modules anda platform service module. The demander service modules are arranged on the data demander; the supplier service modules are arranged at the data supplier; the platform service module is adapted to determine the data demand of the data demander and the data type that the data supplier can provide according to the notification of the data demander and the data supplier, and to match the data demander and the data supplier according to the data demand and the data type; the matched data demander and the data supplier directly carry out data distribution request and / or transmission of distribution data through the demander service module and the supplier service module. The technical proposal of the invention enables the data distribution request and the distribution data not to be touched bya third party in the transmission process, and effectively ensures the safety of the data transaction.

Owner:上海数据发展科技有限责任公司

Improved waste zip-top can flatting mill

The invention discloses an improved waste zip-top can flatting mill. The improved waste zip-top can flatting mill comprises a supporting rack, a flatting assembly, a fixed block, a first rotary shaft, a second rotary shaft, a first motor, a second motor, a rotary plate, a cylindrical cam, a feeding hopper and a feeding device. A material tank is arranged on the edge of the rotary plate. The flatting assembly comprises an air pressure tank, a push shaft and a movable block. The fixed block and the movable block are matched to form a cavity. A rolling element is arranged in a curve groove of the cylindrical cam and is connected with the push shaft through a connection rod, and a first cavity is arranged in the push shaft and is communicated with the air pressure tank through a pipeline. A second cavity communicated with the first cavity is formed in the movable block, and an impact shaft capable of moving forwards and backwards relative to the movable block is installed in the second cavity. By means of the improved waste zip-top can flatting mill, labor intensity of operators can be remarkably reduced, waste zip-top can flatting efficiency is greatly improved, and it is effectively guaranteed that waste zip-top cans are well flattened.

Owner:刘丽华

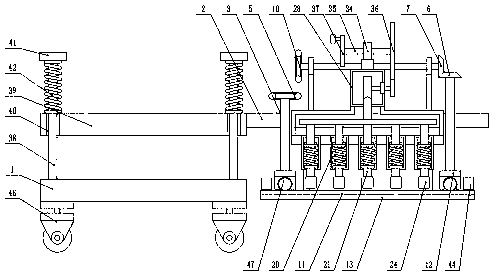

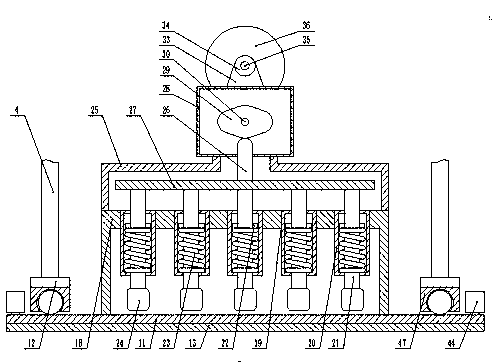

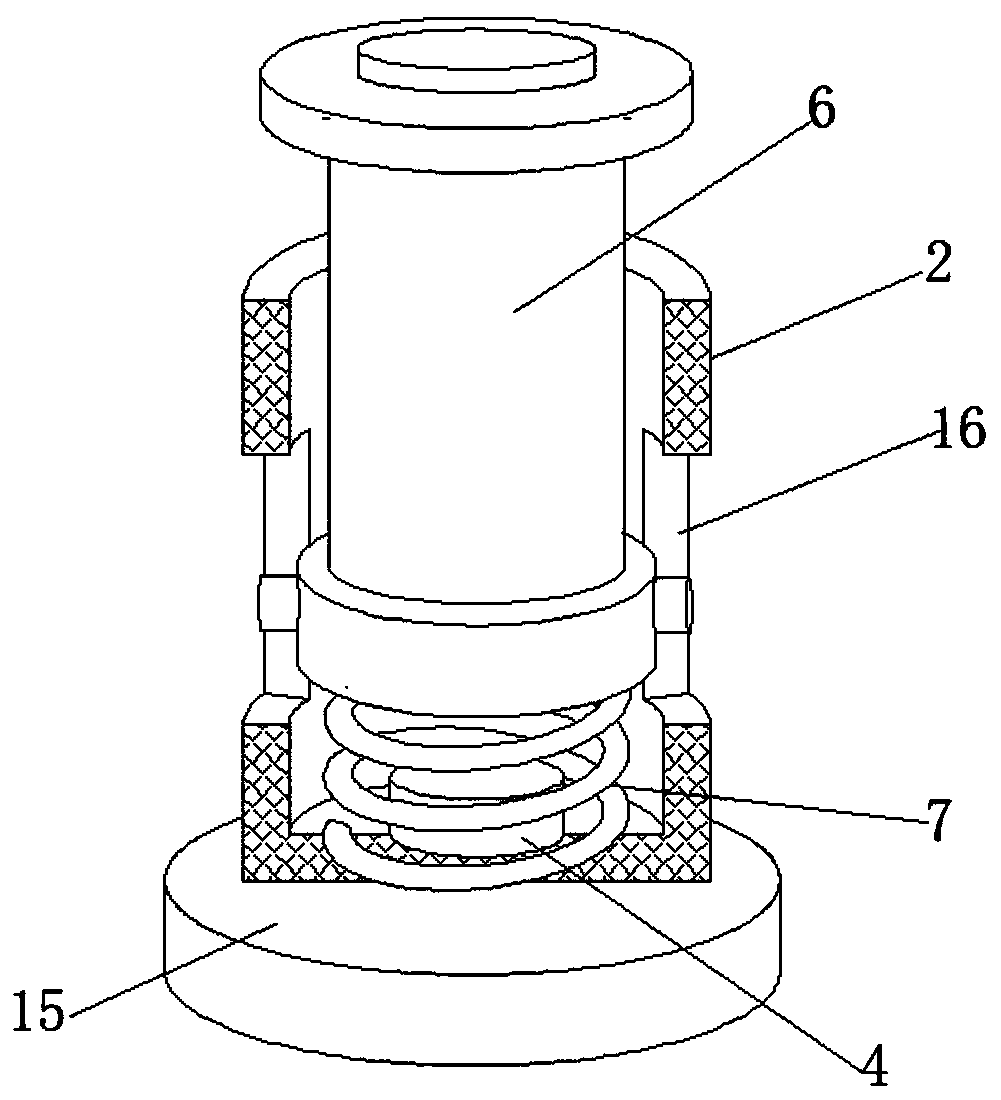

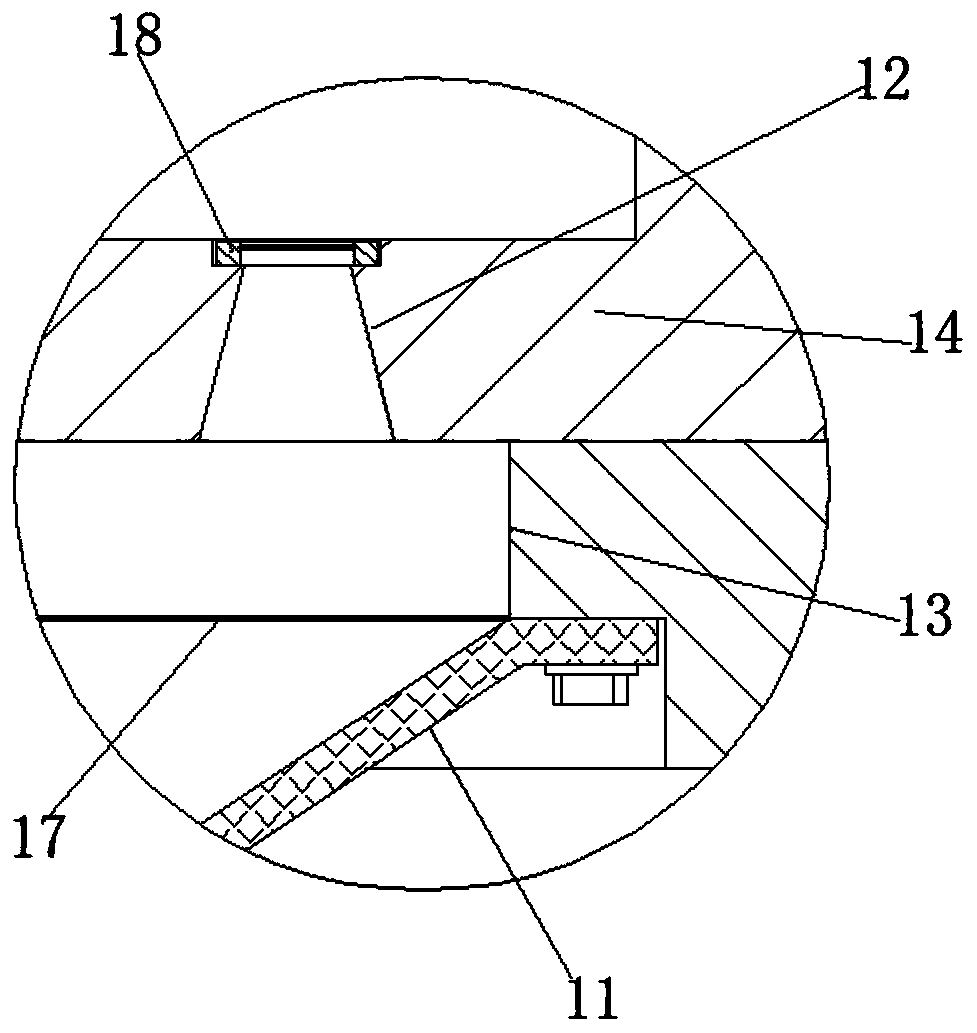

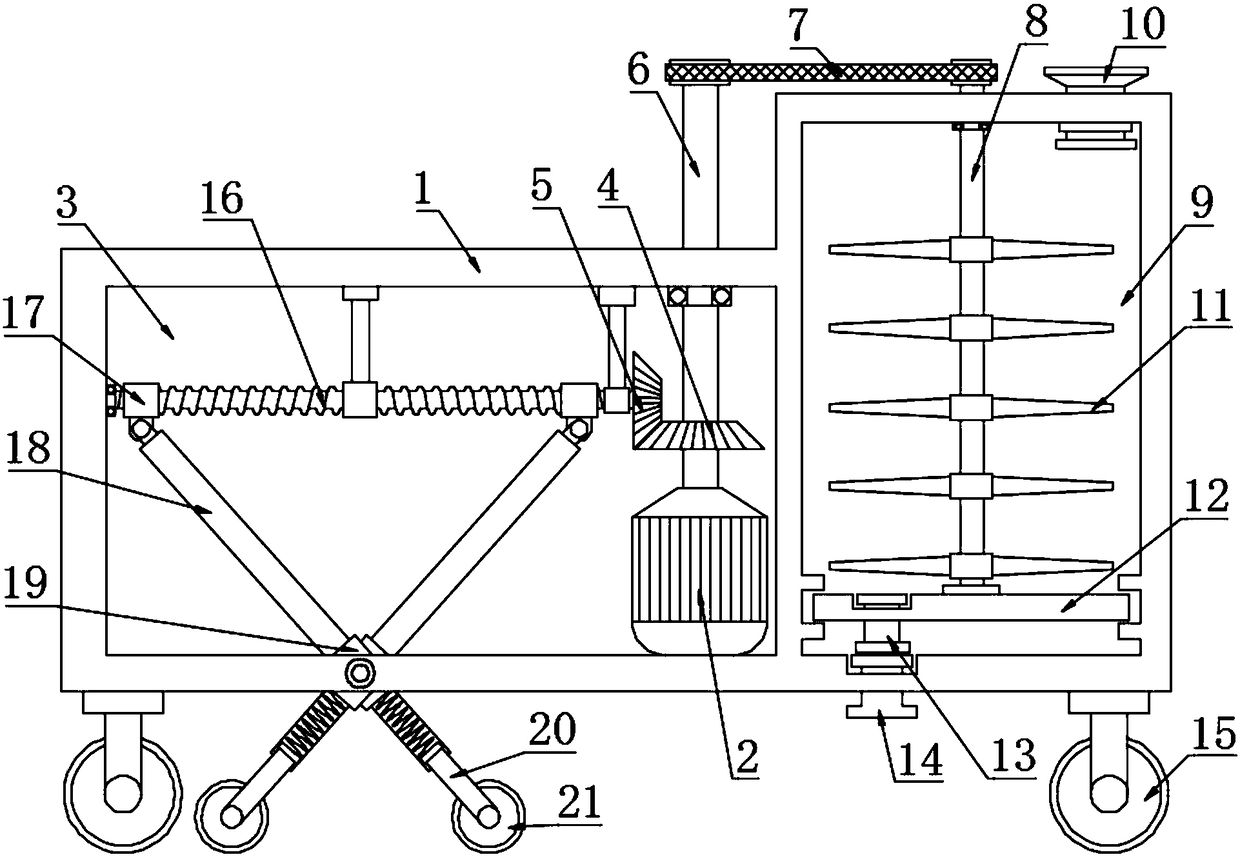

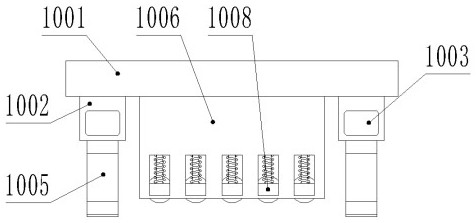

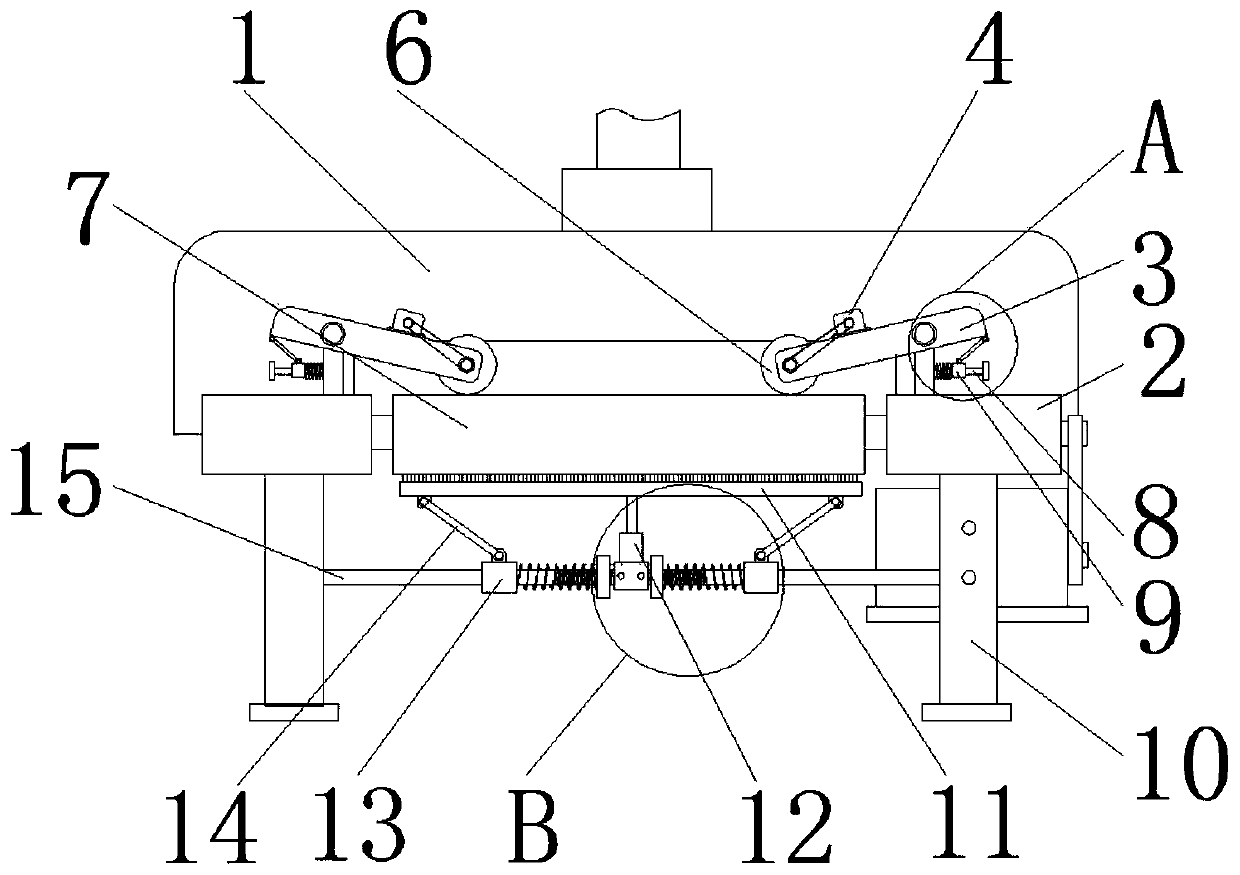

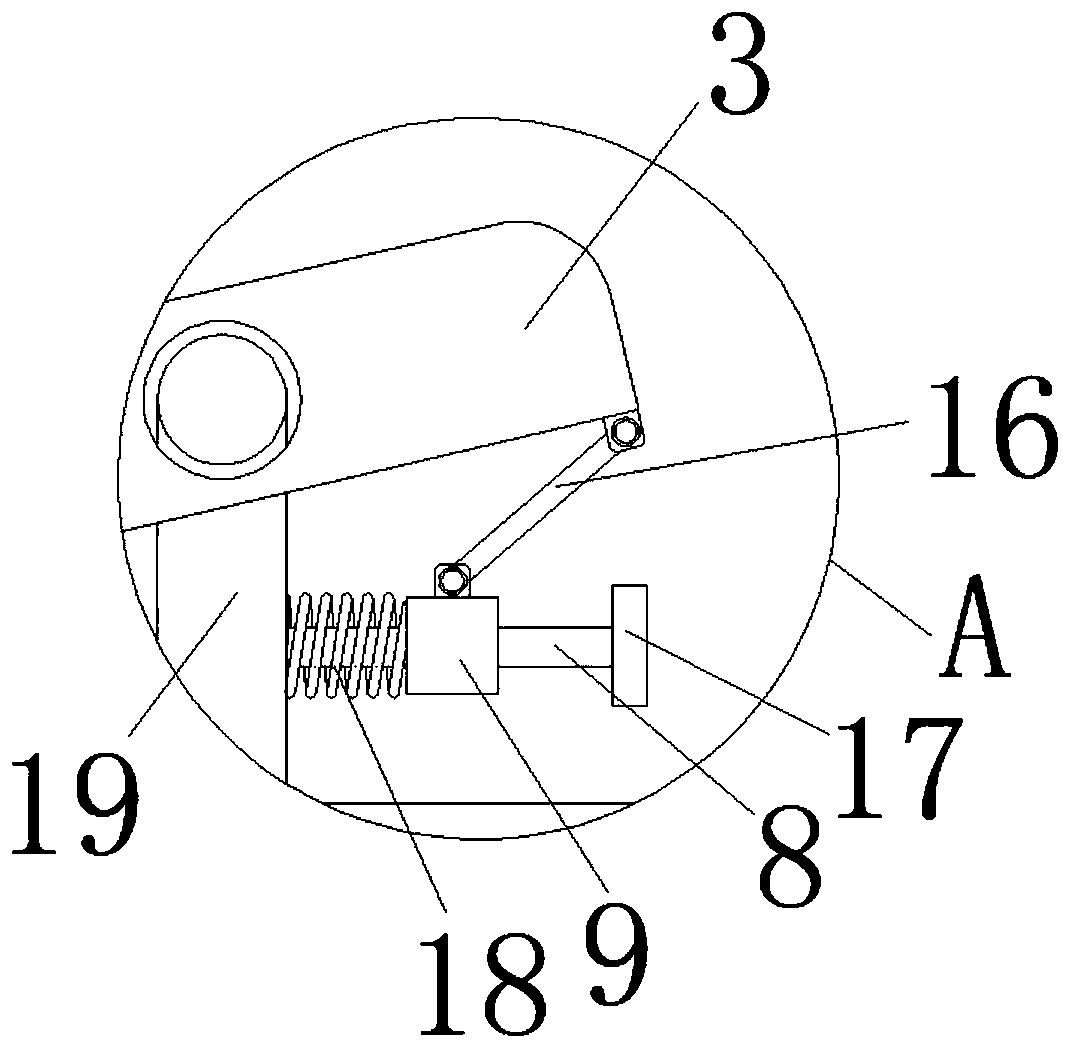

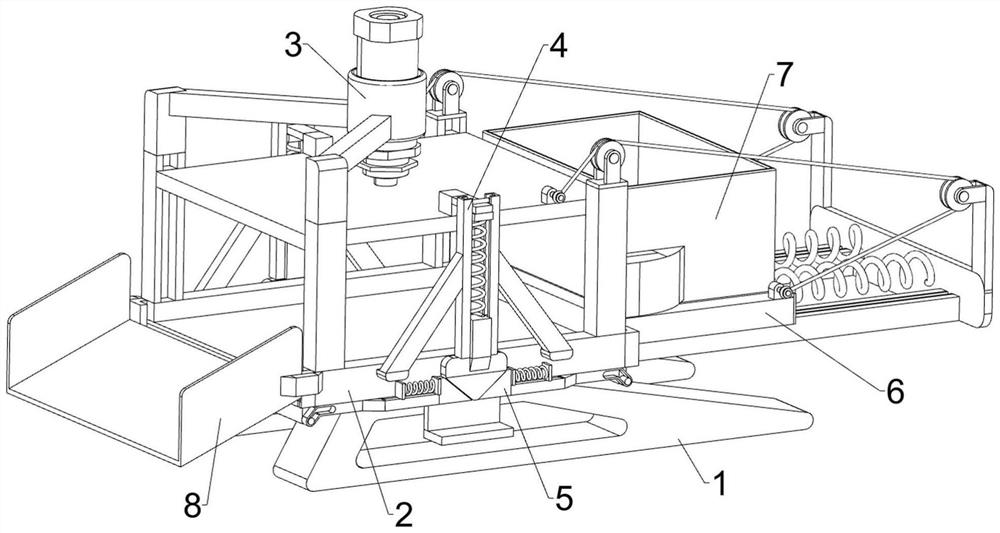

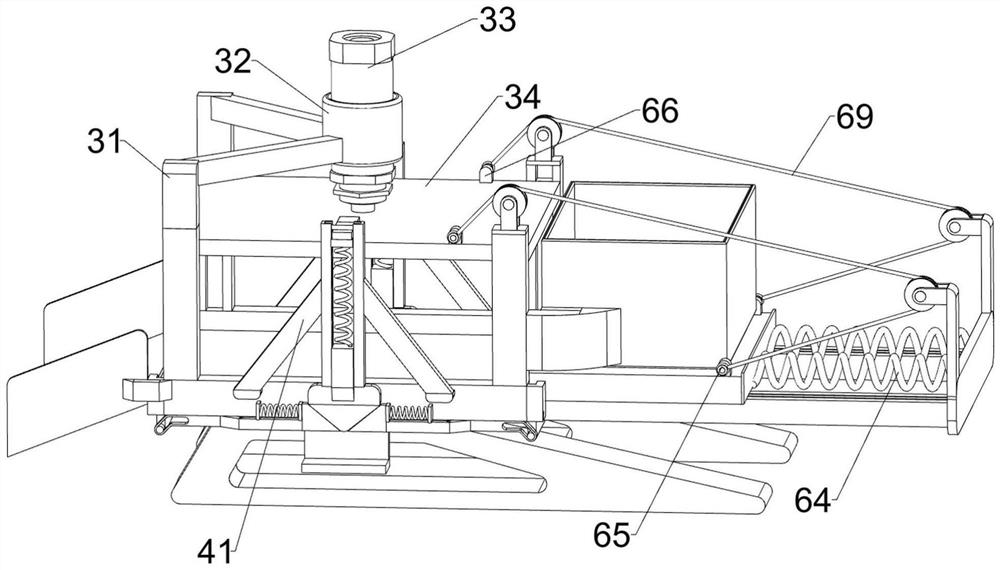

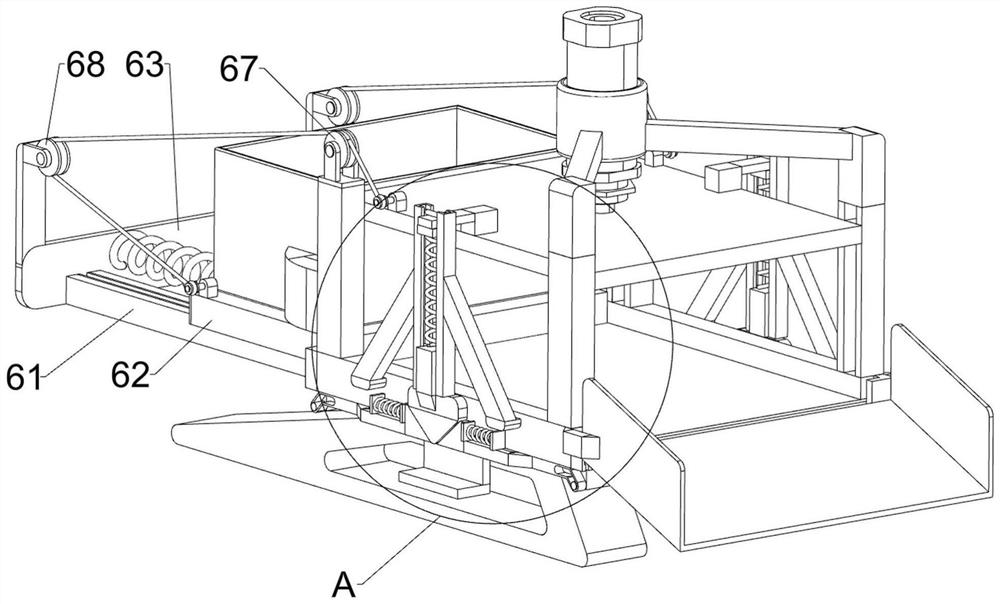

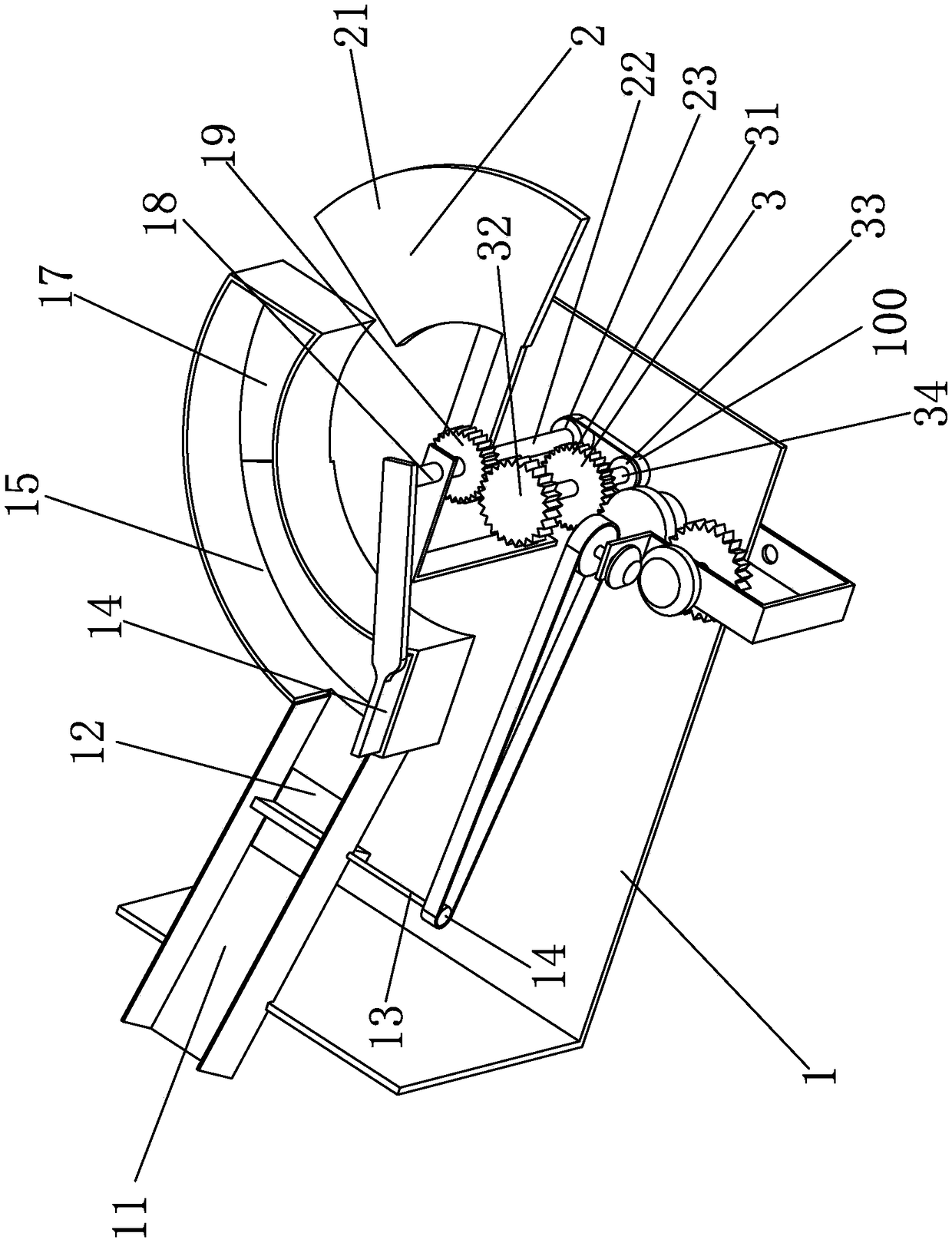

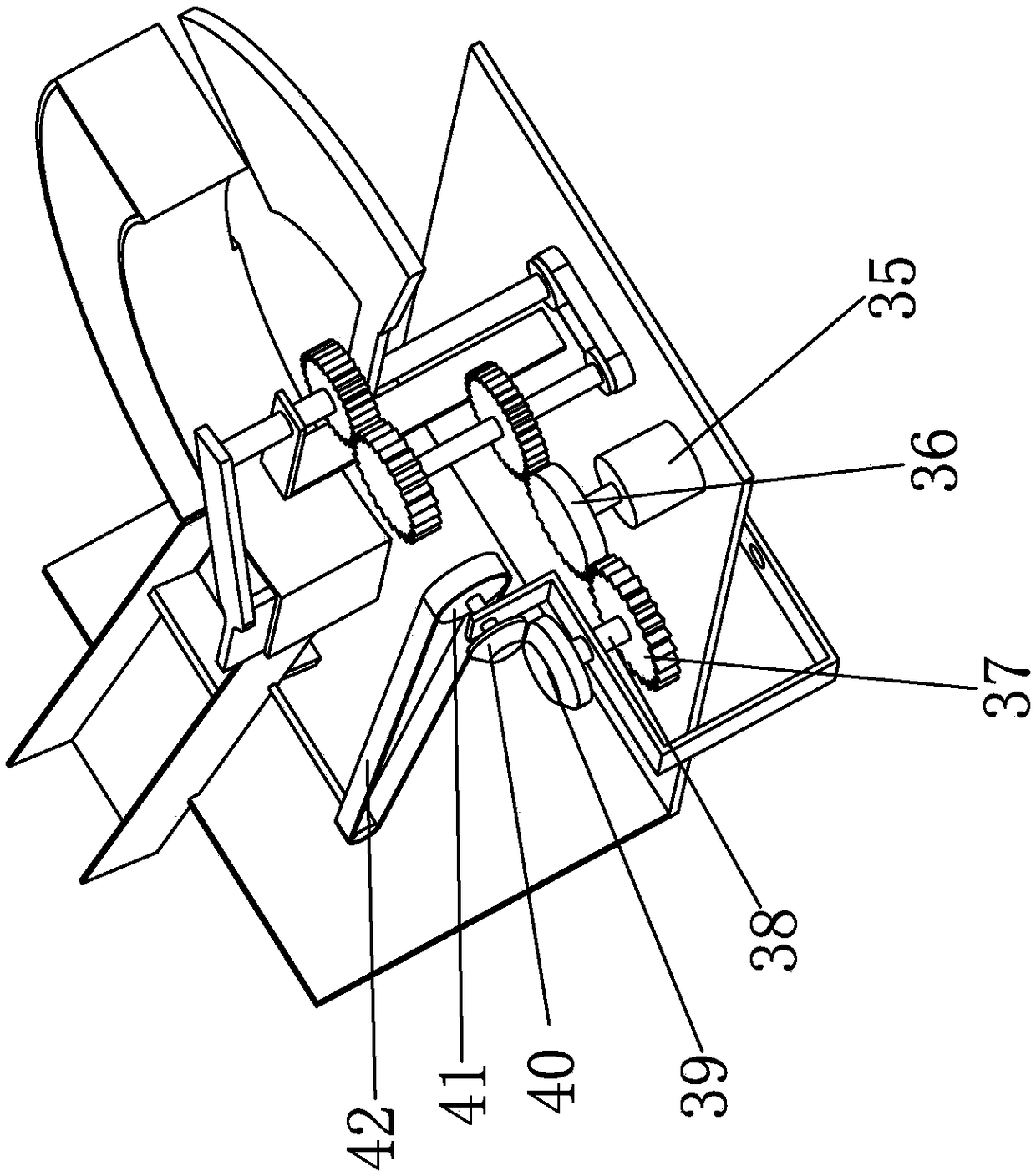

Flattening device for tile laying

ActiveCN110485688AQuickly flattenGuaranteed levelBuilding constructionsMechanical engineeringMulti directional

The invention discloses a flattening device for tile laying. The flattening device for tile laying comprises a base, wherein the base is provided with an elastic lifting device, the elastic lifting device is provided with a manual adjustment type flattening device, and the manual adjustment type flattening device is provided with a multi-directional hammering vibration device. By the rotation of an adjusting screw and observing through horizontal bubbles and a circular horizontal bubble, the level degree of a tile pressing plate can be quickly adjusted, meanwhile, the level degree between thetile being flattened and other tiles can be detected by the rotation of level bars, and thus, the tiles can be flattened quickly; and by the rotation of a hammering eccentric wheel and the cooperationof compression springs, the tile pressing plate is hammered repeatedly by rubber hammers at the lower ends of hammering telescopic columns, so that the tile pressing plate enables the vibration forcegenerated by hammering to be transmitted to the tiles, the tiles are fully combined with cement through vibration, the firmness of the tile bonding is ensured, meanwhile, the flattening speed of thetiles can be increased by the vibration, and the flattening efficiency can be improved.

Owner:CHINA AEROSPACE CONSTR ENG GRP CO LTD

Scrap iron recovery device for automobile part machining

InactiveCN111186163ASmall footprintPrevent reboundMaintainance and safety accessoriesPressesHydraulic pressureScrap

The invention discloses a scrap iron recovery device for automobile part machining. The device comprises a base with an upward opening and of a C-shaped steel structure, a fixing box with a downward opening and of a cuboid barrel-shaped structure is clamped to the middle of the top end of the base, a hydraulic ejector rod is arranged on the inner wall of the top end of the fixing box, and a compression spring is fixed to the bottom of a main pipe of the hydraulic ejector rod; a pressing barrel with an upward opening and of a barrel-shaped structure is arranged at the bottom end of the compression spring, a pressing disc is arranged at the bottom of the pressing barrel, a feeding opening is formed in the side face of the fixing box, and a material gathering frame is arranged on the side face of the feeding opening; and a partition plate is arranged in the middle of the base, a stepped mounting hole is formed in the middle of the lower surface of the partition plate, and a waste collecting frame is fixed above the upper surface, close to the stepped mounting hole, of the partition plate. According to the scrap iron recovery device, the hydraulic ejector rod can be used for driving the pressing disc to press fluffy scraps so that not only can mingled greasy dirt be removed, but also the occupied space of the waste collecting frame is reduced.

Owner:TIANMEN JINXINGDA AUTO PARTS

Steel pipe cutting and flattening device

PendingCN108817968AAchieve the purpose of flatteningGood for flattening and deformationOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention belongs to the technical field of steel pipe flattening mechanisms, and provides a steel pipe cutting and flattening device. The device comprises a stretching shaft, a conveying mechanism and a cutting mechanism, wherein the stretching shaft comprises a suspended end for allowing a steel pipe to sleeve externally and a fixed end connected to a machine frame, the shaft diameter of thestretching shaft is gradually increased from the suspended end to the fixed end, the conveying mechanism is used for conveying the steel pipe from the suspended end to the fixed end, the cutting mechanism is used for axially cutting the side wall of the steel pipe in the conveying process of the steel pipe. According to the device, the technical effect of rapidly and efficiently cutting and flattening the heated steel pipe can be realized.

Owner:山东联瑞石油技术有限公司 +5

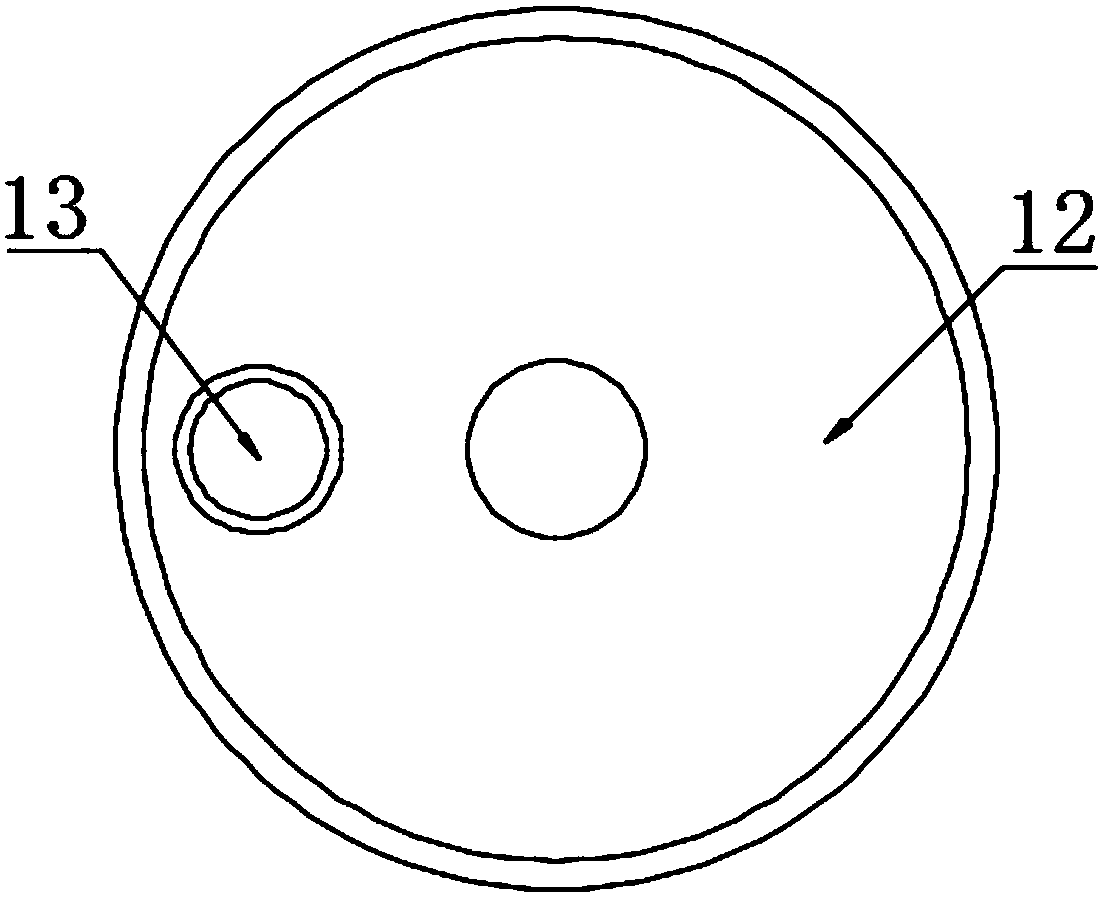

Flatting mill for waste ring-pull cans

The invention discloses a flatting mill for waste ring-pull cans. The flatting mill comprises a supporting frame, a flatting assembly, a fixed block, a first rotating shaft, a second rotating shaft, a first motor, a second motor, a rotating disc, a cylindrical cam, a feeding hopper and a feeding device. A material groove is formed in the edge of the rotating disc. The flatting assembly comprises an air pressure tank, a pushing shaft and a moving block. A cavity is formed between the fixed block and the moving block in a matched manner. A rolling piece is arranged in a curve groove of the cylindrical cam. The rolling piece is connected with the pushing shaft through a connecting rod. A first cavity is formed in the pushing shaft. The first cavity communicates with the air pressure tank through a pipeline. A second cavity communicating with the first cavity is formed in the moving block. An impacting shaft capable of moving front and back relative to the moving block is installed in the second cavity. By means of the flatting mill for the waste ring-pull cans, the labor intensity of operators can be obviously lowered, the flatting efficiency of the waste ring-pull cans is greatly improved, and it is effectively ensured that the waste ring-pull cans are well flatted.

Owner:刘丽华

Roadbed soil filling and flattening device

The invention discloses a roadbed soil filling and flattening device. The upper end of a driving motor is rotationally connected with a driving shaft. A driving shaft bearing is rotationally connectedwith a transmission case. The top of the driving shaft is in rolling connection with the left end of a conveying belt. The right end of the conveying belt is in rolling connection with the upper endof a stirring shaft. A bearing on the upper portion of the stirring shaft is rotationally connected with a material storage barrel. The lower end of the stirring shaft is fixedly connected with a turnplate. The turnplate is rotationally connected with the inner wall of the material storage barrel. A material guide pipe is arranged on the turnplate in the peripheral direction. The lower end of thematerial guide pipe abuts against the bottom of the material storage barrel. The lower portion of the driving shaft is fixedly connected with a first bevel gear. A second bevel gear is fixedly connected with the right end of a bidirectional lead screw. According to the roadbed soil filling and flattening device, the conveying belt drives the stirring shaft to rotate, accordingly, stirring rods aredriven to rotate so as to stir crushed soil in the material storage barrel, the crushed soil is prevented from caking, the rotating stirring shaft drives the turnplate to rotate so as to drive the material guide pipe to rotate to be reciprocatively aligned with a discharging pipe, intermittent discharging is achieved, meanwhile, moving blocks moving left and right drive oscillating rods to oscillate reciprocatively, and accordingly, rolling wheels are driven to perform rolling compaction on the ground reciprocatively and to planish the crushed soil discharged out of the discharging pipe

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

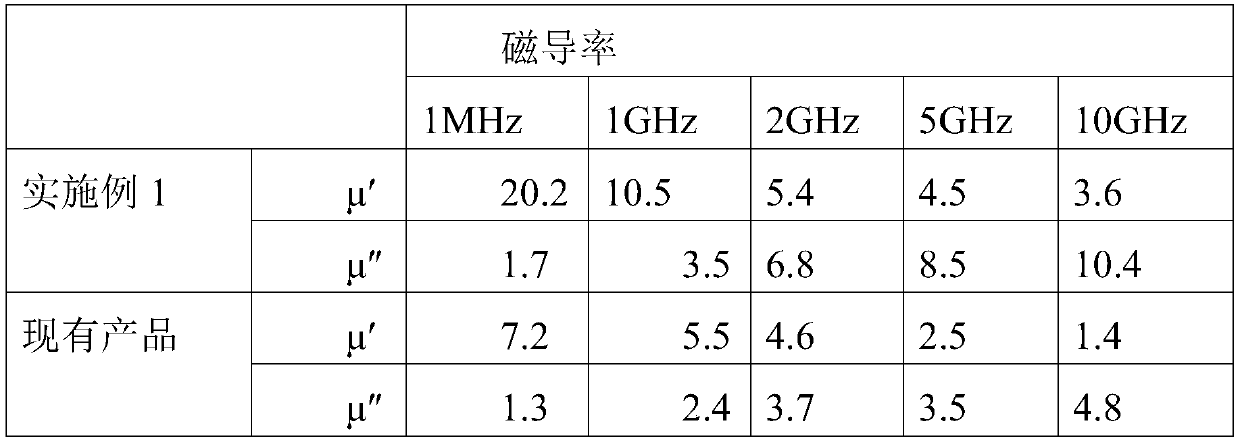

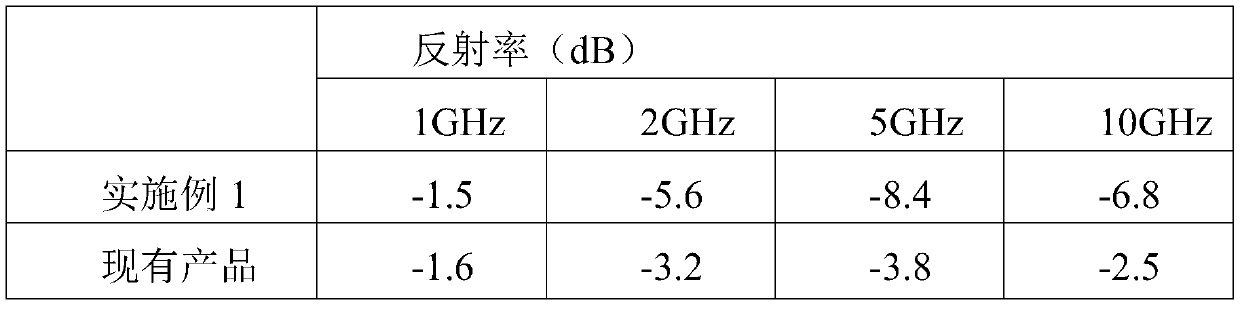

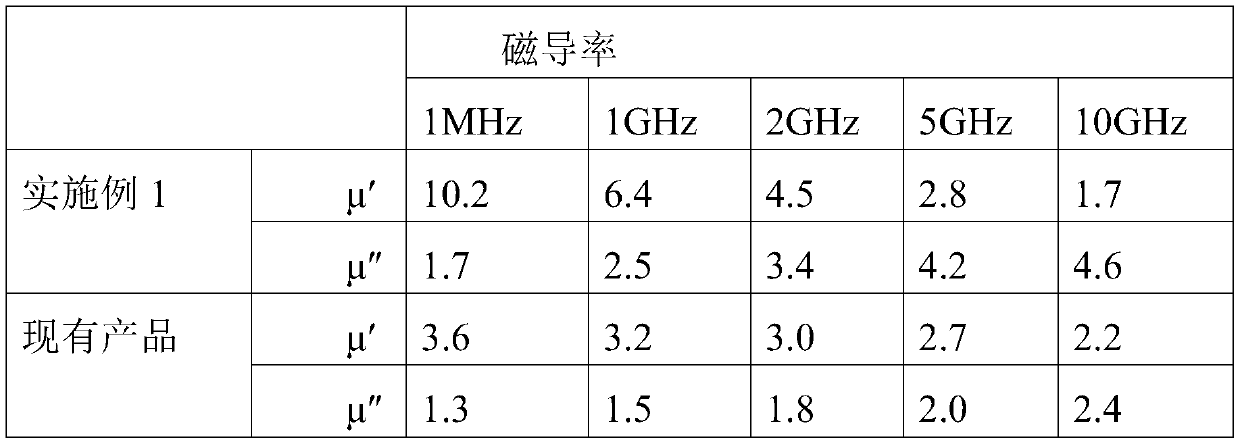

Preparation method of flat-shaped high-frequency wave-absorbing magnetic powder

InactiveCN111482595ASolve the problem of low flattening rateSolve efficiency problemsTransportation and packagingMetal-working apparatusOrganic solventMetal powder

The invention relates to a preparation method of flat-shaped high-frequency wave-absorbing magnetic powder. The preparation method comprises the following steps of, step 1, selecting materials, specifically, ferromagnetic metal powder and ball milling solvent, and selecting organic solvent; and step 2, ball milling, specifically, selecting a wear-resistant ball as a ball milling medium, mixing theferromagnetic metal powder with the ball milling solvent, a dispersing agent and other auxiliaries in a planetary ball mill, wherein the ball material ratio is 10:1-20:1, the mass percent of dosage of the dispersing agent and other auxiliaries of the ferromagnetic metal powder is less than or equal to 1%, and then carrying out ball milling for 2-6 h under the condition that the rotating speed ofthe planetary ball mill is greater than or equal to 400 r / min, carrying out preliminary flattening of the ferromagnetic metal powder, adjusting the rotating speed of the planetary ball mill to less than 200 r / min, reducing the impact force of the ball milling medium on the flat powder, reducing the breaking rate of the ferromagnetic metal powder, continuing the ball milling for 1-8 h, and carryingout discharging and drying so as to perform annealing treatment at 500-800 DEG C under the protection of reducing atmosphere of argon, hydrogen and nitrogen for eliminating stress. According to the preparation method, the flattening rate can be improved, the flattening time can be saved, and the performance of the magnetic powder can be improved.

Owner:苏州安洁新材料有限公司

Film laminating and heat sealing integrated production line

ActiveCN109941485ASave on transshipmentSave positioningConveyor wrappingWrapper twisting/gatheringProduction lineAssembly line

The invention provides a film laminating and heat sealing integrated production line, belongs to the field of packaging equipment. The film laminating and heat sealing integrated production line comprises a lower shovel flattening assembly, a corner folding assembly and an end surface flattening assembly which are sequentially arranged along the assembly line, wherein a heat sealing assembly is arranged over the lower shovel flattening assembly, and the heat sealing assembly and the lower shovel flattening assembly share a power source and move up and down relative to the corner folding assembly. A packaging box is coated with a film and then passes through the lower shoveling flattening assembly and the heat sealing assembly for connection after film laminating, the packaging box enters the corner folding assembly for the end face corner folding action and the end face sealing action after corner folding while the packaging box is continuously pushed, then the packaging box enters theend face flattening assembly for flattening and hot covering of the upper and lower sections, and finally the package box is discharged for the next procedure. The film laminating and heat sealing integrated production line integrates film laminating and heat sealing, the intermediate transfer link of the packaging box is omitted, the secondary feeding and repeated positioning are also avoided, therefore, the working efficiency is improved, and the manpower is saved.

Owner:天津树达科技发展有限公司

Multifunctional cloth pressing device for clothing processing

ActiveCN114875615AImprove aestheticsImprove flattening effectTextile shapingWebs handlingPolymer scienceEngineering

The invention discloses a multifunctional cloth pressing device for clothing processing, and relates to the technical field of textile processing, the multifunctional cloth pressing device comprises a textile box body, the surface of the textile box body is provided with a control device, the side wall of the textile box body is provided with an inlet and outlet, and an auxiliary part is arranged in the inlet and outlet; an adjusting mechanism, a cloth pressing mechanism and a flattening mechanism are further arranged in the spinning box body. According to the textile fabric folding flattening device, the flattening screw rod is in threaded transmission fit with the flattening block, so that the flattening block spreads the folded area of the textile fabric, and therefore, the cloth pressing mechanism can flatten creases conveniently, and compared with a traditional mode that the folded area of the textile fabric is spread manually, the flattening efficiency is improved. According to the textile fabric flattening device, the flattening efficiency of textile fabric is improved to a certain extent, the labor intensity of workers is reduced to a certain extent, the textile fabric is periodically ironed through an electric heating plate, wrinkles on the surface of the textile fabric can be flattened through a fabric pressing roller, and the flattening effect of the textile fabric flattening device on the wrinkles on the surface of the textile fabric is further improved.

Owner:江苏动泰运动用品有限公司

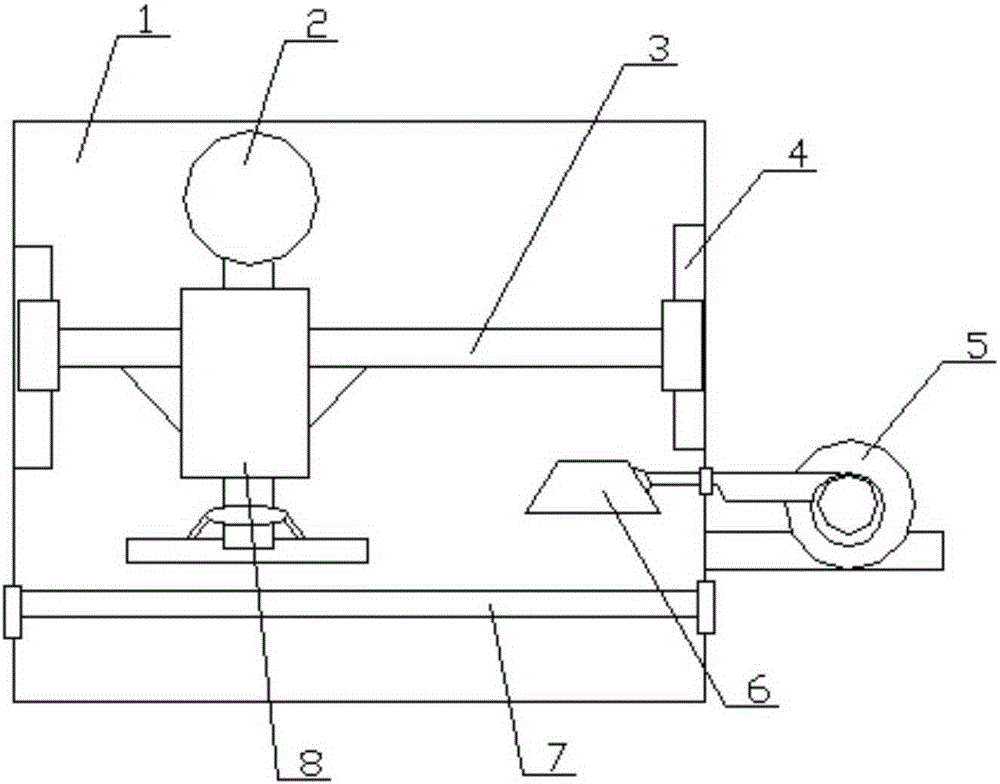

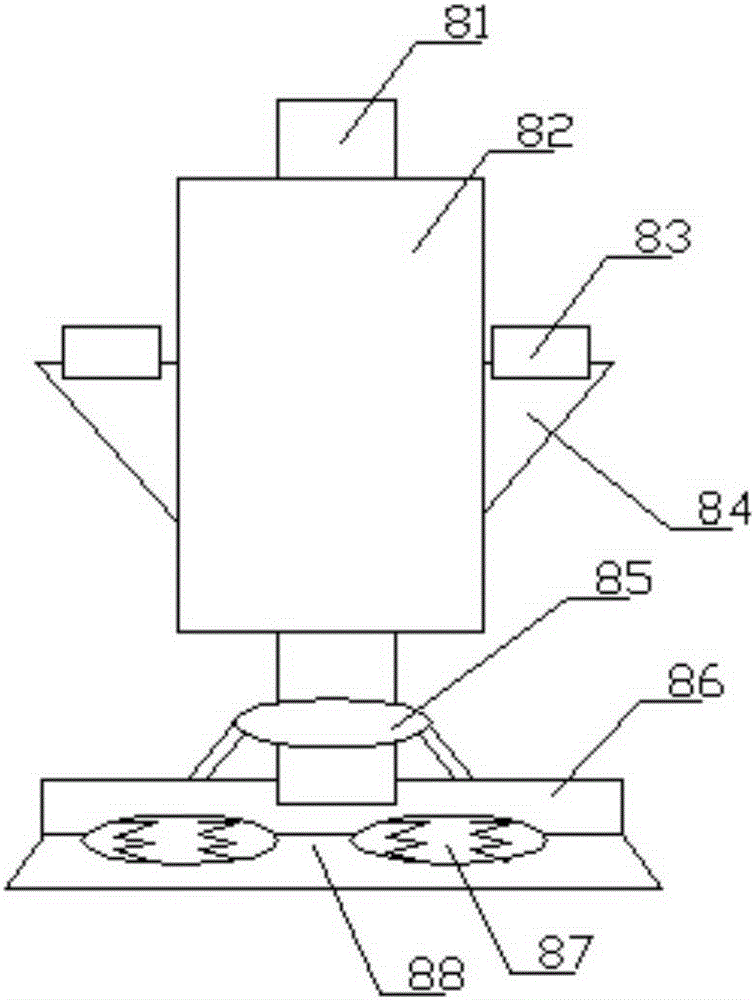

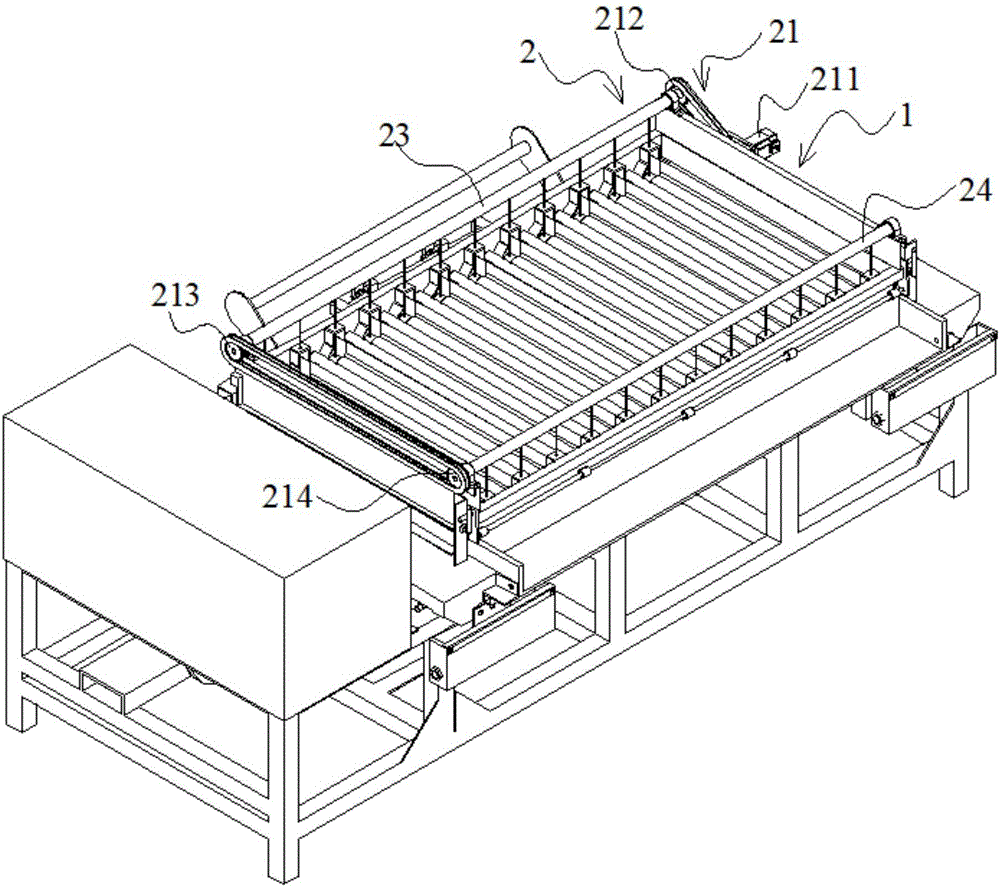

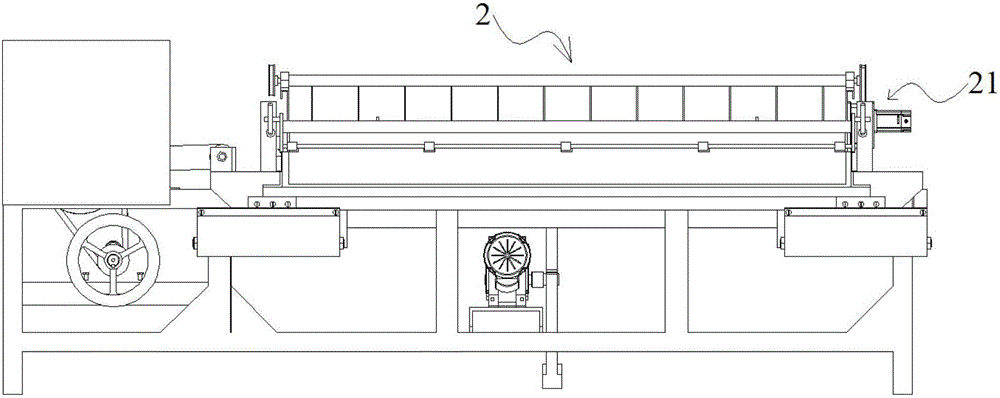

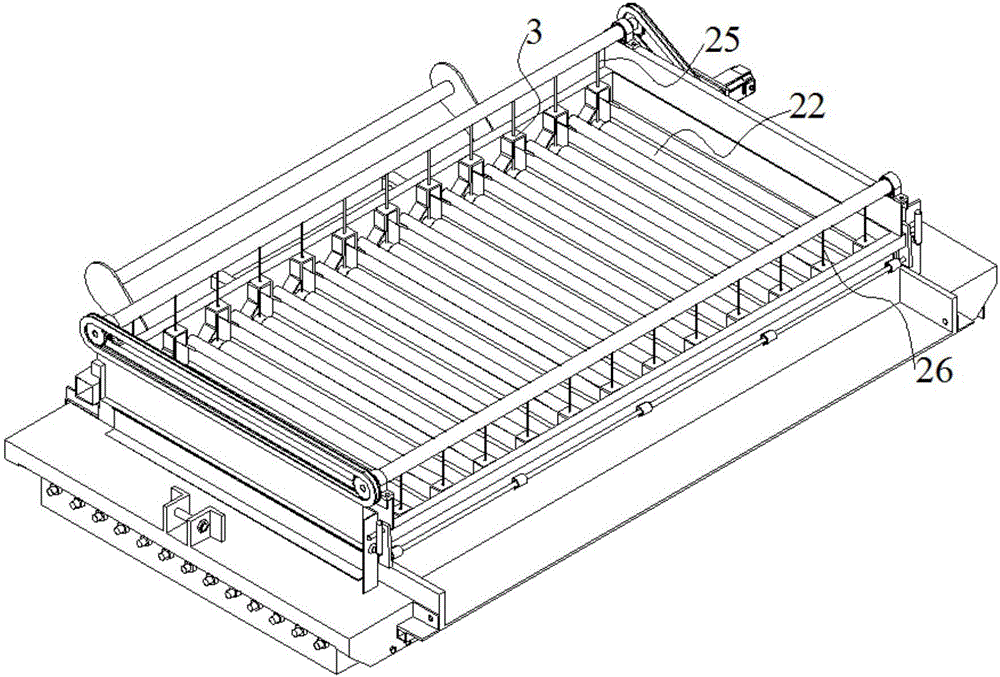

Tea strip sorting flattening machine

PendingCN106720518AImprove flattening efficiencyReduce work intensityPre-extraction tea treatmentEngineeringUltimate tensile strength

The invention provides a tea strip sorting flattening machine, and relates to a tea processing device. The tea strip sorting flattening machine comprises a machine frame, wherein a strip sorting pot and a driving device are arranged on the machine frame; a rod adding device is arranged on the strip sorting pot; the strip sorting pot comprises a plurality of strip sorting grooves in parallel arrangement; the rod adding device comprises a power unit, a rotating shaft, a flexible connecting element and press rods; each press rod at least corresponds to two flexible connecting elements; the power unit is fixedly arranged on the strip sorting pot; the rotating shaft is rotationally arranged above the strip sorting pot; one end of the rotating shaft is in transmission connection with the power unit; one end of each flexible connecting element is connected with the rotating shaft; the other end of each flexible connecting element is connected with the corresponding press rod; a plurality of press rods are positioned in the same plane; the rotating shaft enables the flexible connecting elements to wind onto the rotating shaft through being driven by the power unit. Through the rod adding device, the addition and the removal of the press rods can be realized; the tea strip sorting and flattening efficiency can be improved; the work intensity of operators can also be reduced.

Owner:CHONGQING ACAD OF AGRI SCI

Insulating paper flattening device for motor core

InactiveCN105634221AReasonable structural designEasy to useApplying solid insulationAssembly lineUltimate tensile strength

The invention relates to the technical field of motor devices, in particular to an insulating paper flattening device for a motor core. The insulating paper flattening device for the motor core comprises a placement rack for a drive belt I, a guide block, a console, a pressing cylinder fixing platform, a pressing cylinder, a horizontal push cylinder, a movement push block, a placement rack for a drive belt II and a guide cylinder. The insulating paper flattening device for the motor core can flatten insulating paper on the core once, so that the labor intensity of a worker is relieved; the insulating paper flattening efficiency and quality are improved; and the requirements of large-scale assembly line production can be met. In addition, the insulating paper flattening device for the motor core is reasonable in structural design, convenient to operate and use and suitable for popularization and application.

Owner:泰信电机(苏州)有限公司

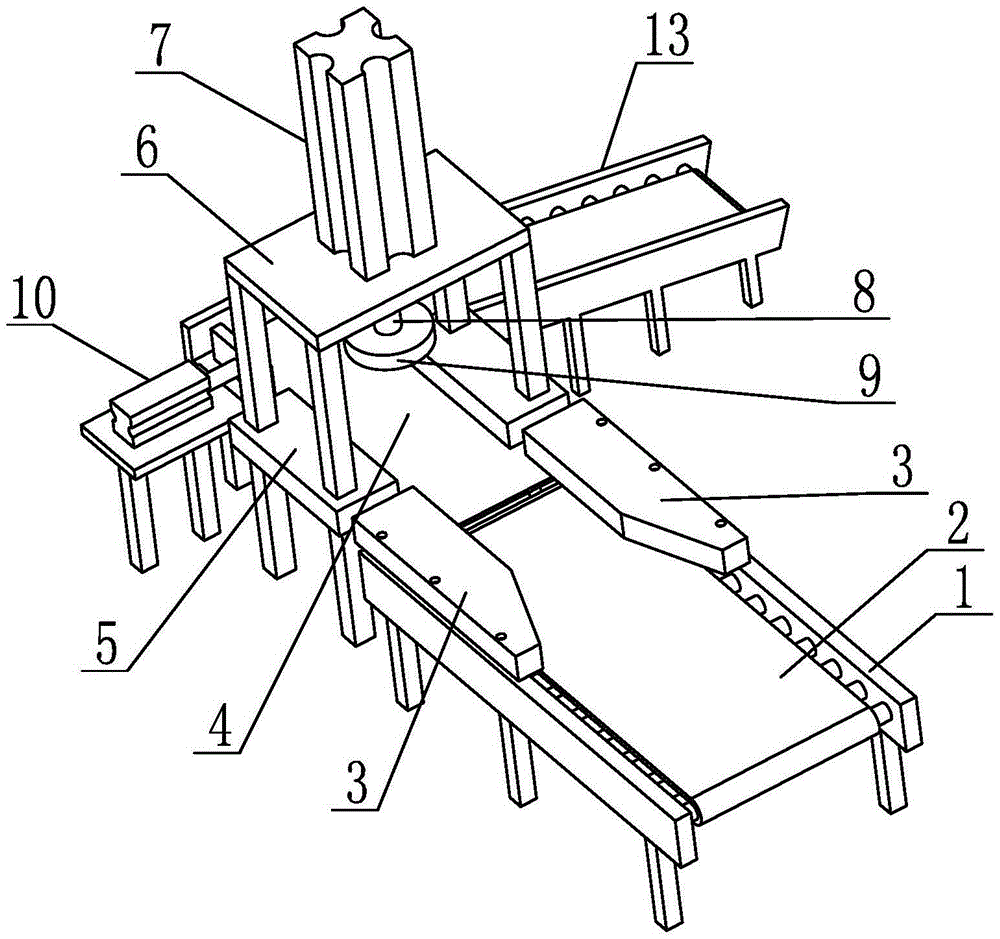

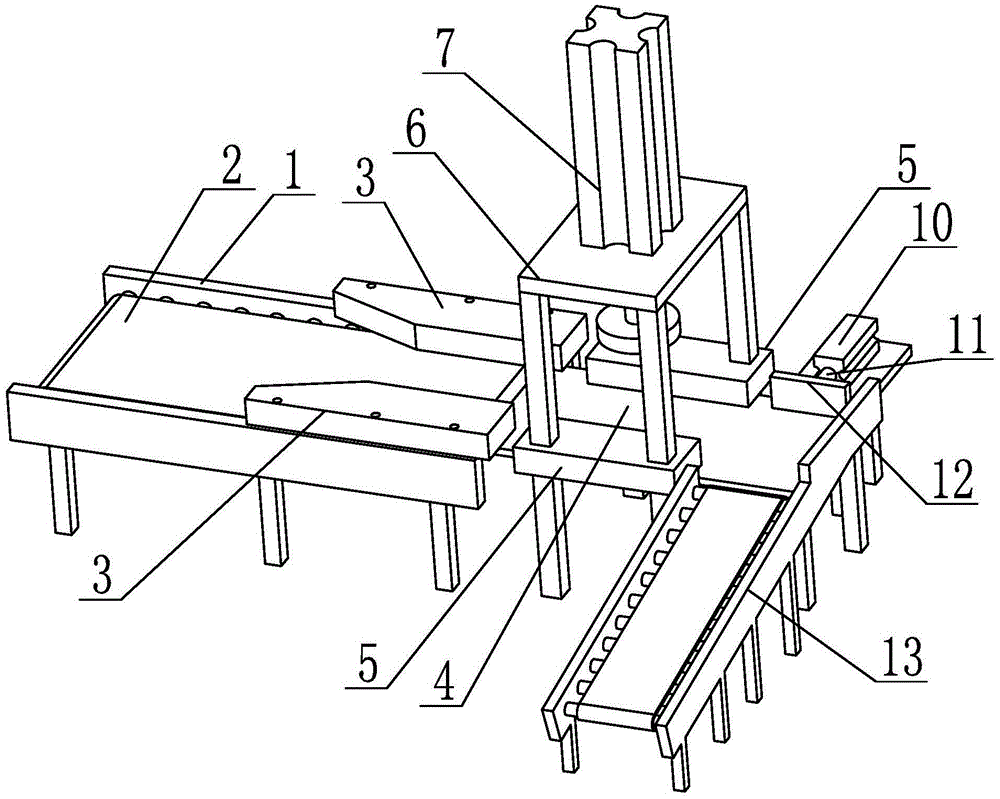

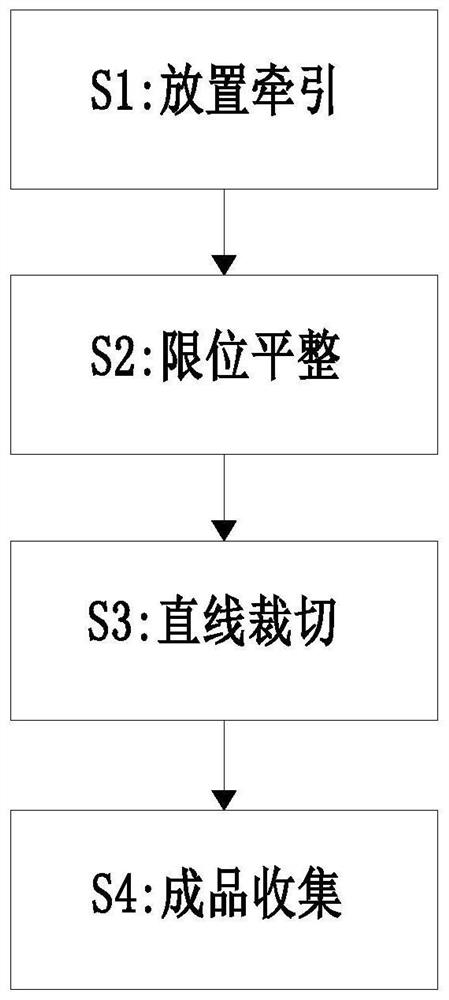

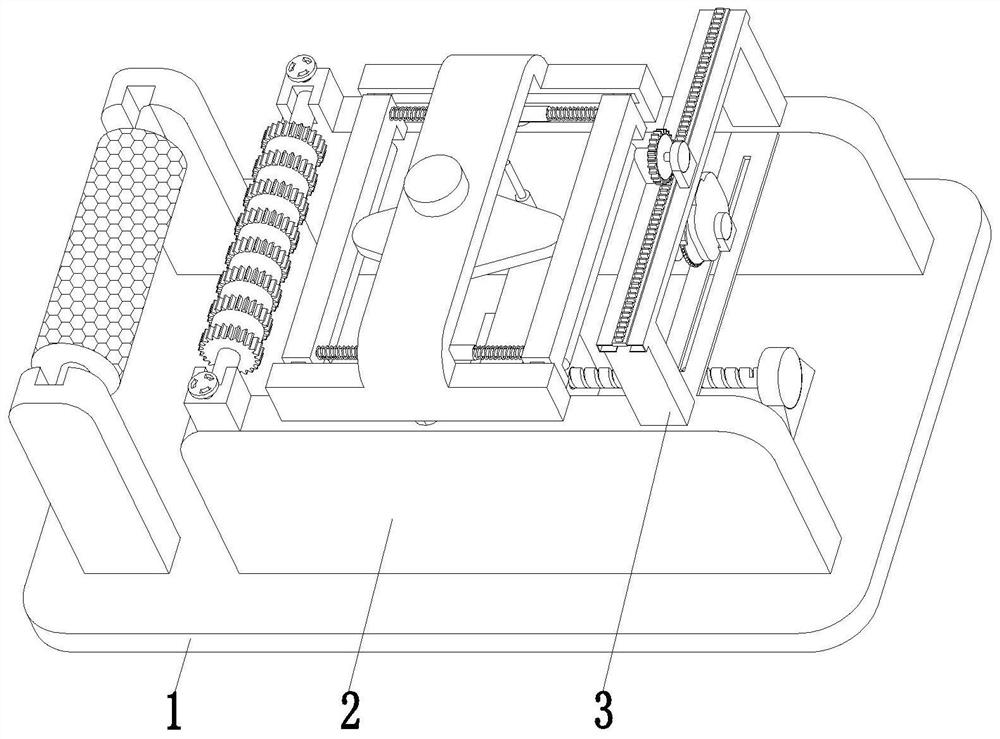

Production, manufacturing and processing technology for aluminum mesh oil fume filter screen

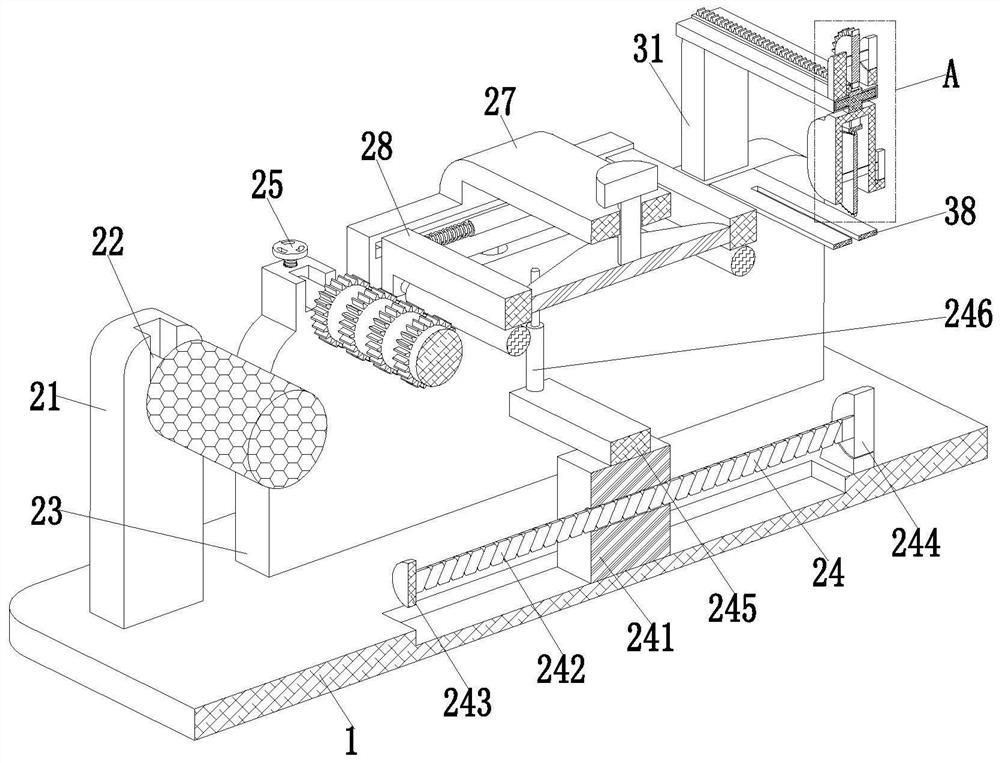

InactiveCN113210545ASolve the problem of uneven level and poor flatnessAvoid manual pullingMetal-working apparatusProcess engineeringMachining process

The invention relates to a production, manufacturing and processing technology for an aluminum mesh oil fume filter screen. A production, manufacturing and processing device for the aluminum mesh oil fume filter screen is used, the production, manufacturing and processing device for the aluminum mesh oil fume filter screen comprises a bottom plate, a flattening treatment mechanism and a filter screen cutting mechanism, the flattening treatment mechanism is installed in the middle of the upper end face of the bottom plate, and the filter screen cutting mechanism is installed on the flattening treatment mechanism. By means of the production, manufacturing and processing technology, the problems that an existing aluminum mesh filter screen processing device cannot flatten and limit an aluminum mesh before the aluminum mesh is cut, the rolled aluminum mesh curls up when being pulled out, the surface of the cut aluminum mesh is uneven, the aluminum mesh curls up again to be of a cylindrical structure, and the actual requirement cannot be met can be solved; and the problems that when the existing aluminum mesh filter screen processing device is used for cutting the aluminum mesh, linear cutting of a cutting knife cannot be guaranteed, deviation is prone to occurring, the surface of a notch is uneven, and the flatness is poor can be solved.

Owner:武汉地朴商贸有限公司

Cloth printing machining discharge assembly line

ActiveCN111453497AExpand wellImprove the use effectCylinder pressesPlaten pressesElectric machineryAssembly line

The invention belongs to the technical field of cloth printing machining, and particularly relates to a cloth printing machining discharge assembly line. The assembly line comprises a drying room, a conveying belt body is mounted on one side of the drying room, a conveying mesh belt is mounted on one side of the conveying belt body, a mounting plate is mounted on the upper side of the conveying belt body, a motor is mounted on the upper side of the mounting plate, a transmission belt is mounted at one end of the motor, mounting plates, rotating rollers, guide rods, first loops, convex blocks,attaching springs and supporting blocks are mounted on the upper side of the conveying belt body, dried cloth can be conveniently extended, the cloth can be prevented from being curled in the drying process after printing, a cleaning brush plate, telescopic rods, second loops, second connecting rods, fixed rods, cleaning springs, outer threads and adjusting screw rings are mounted on the lower side of the conveying mesh belt, the surface of the conveying mesh belt can be conveniently cleaned, and stacking of too much dust on the surface of the conveying mesh belt can be avoided.

Owner:安徽鼎兴纺织科技有限公司

Flattening device suitable for carton processing

InactiveCN111347721AEasy to useImprove use comfort performancePaper-makingBox making operationsCartonStructural engineering

The invention relates to the field of carton processing equipment, and particularly relates to a flattening device suitable for carton processing. The flattening device comprises a base, a housing, anash removing structure, flattening structures, a first height adjusting structure, an auxiliary structure, a second height adjusting structure, a flattening structure and a reset structure, wherein the housing is provided with the ash removing structure, then waste scraps on a carton can be conveniently removed and stored through the ash removing structure, the situation that the waste scraps arepressed on the carton, and consequently the carton deforms and even is damaged is effectively avoided, and then the flattening efficiency and quality of the carton are greatly improved; the first height adjusting structure is provided with the flattening structure used for flattening the carton, the housing is provided with the flattening structures in one-to-one correspondence with the flattening structures, tension can be conveniently applied to the carton through the flattening structures before the carton is flattened, the carton bears lateral tension, and the function of preliminarily resetting the wrinkle position is achieved; and meanwhile, through cooperation of use of the flattening structures, secondary wrinkles are effectively prevented, and the flattening efficiency and quality of the carton are improved.

Owner:周航天

Leveling machine for paper bag production

ActiveCN111923493AFlattening automaticPrevent movementEnvelopes/bags making machineryMechanical engineeringIndustrial engineering

The invention discloses a leveling machine for paper bag production. The leveling machine comprises a base, a flattening mechanism, a linkage mechanism and a baffle mechanism, wherein a mounting rackis connected to the base; the flattening mechanism is arranged on the mounting rack; the linkage mechanism is arranged on the mounting rack; the linkage mechanism is in transmission connection with the flattening mechanism; the baffle mechanism is arranged on the mounting rack; and the baffle mechanism is in transmission connection with the linkage mechanism. Through the cooperation of the flattening mechanism, the linkage mechanism and the baffle mechanism, a paper bag can be flattened, so that the paper bag is folded; the paper bag can be limited by the baffle mechanism, so that the paper bag is blocked, the movement of the paper bag during flattening is prevented, the paper bag does not need to be manually extruded by hands, the paper bag can be automatically flattened, the flattening efficiency is high, and the operation is easy; and a material pushing mechanism is arranged, so that the manual adding of the paper bags one by one is not needed, the paper bags do not need to be manually taken down one by one, and the time and labor are saved.

Owner:怀化市金阳包装有限公司

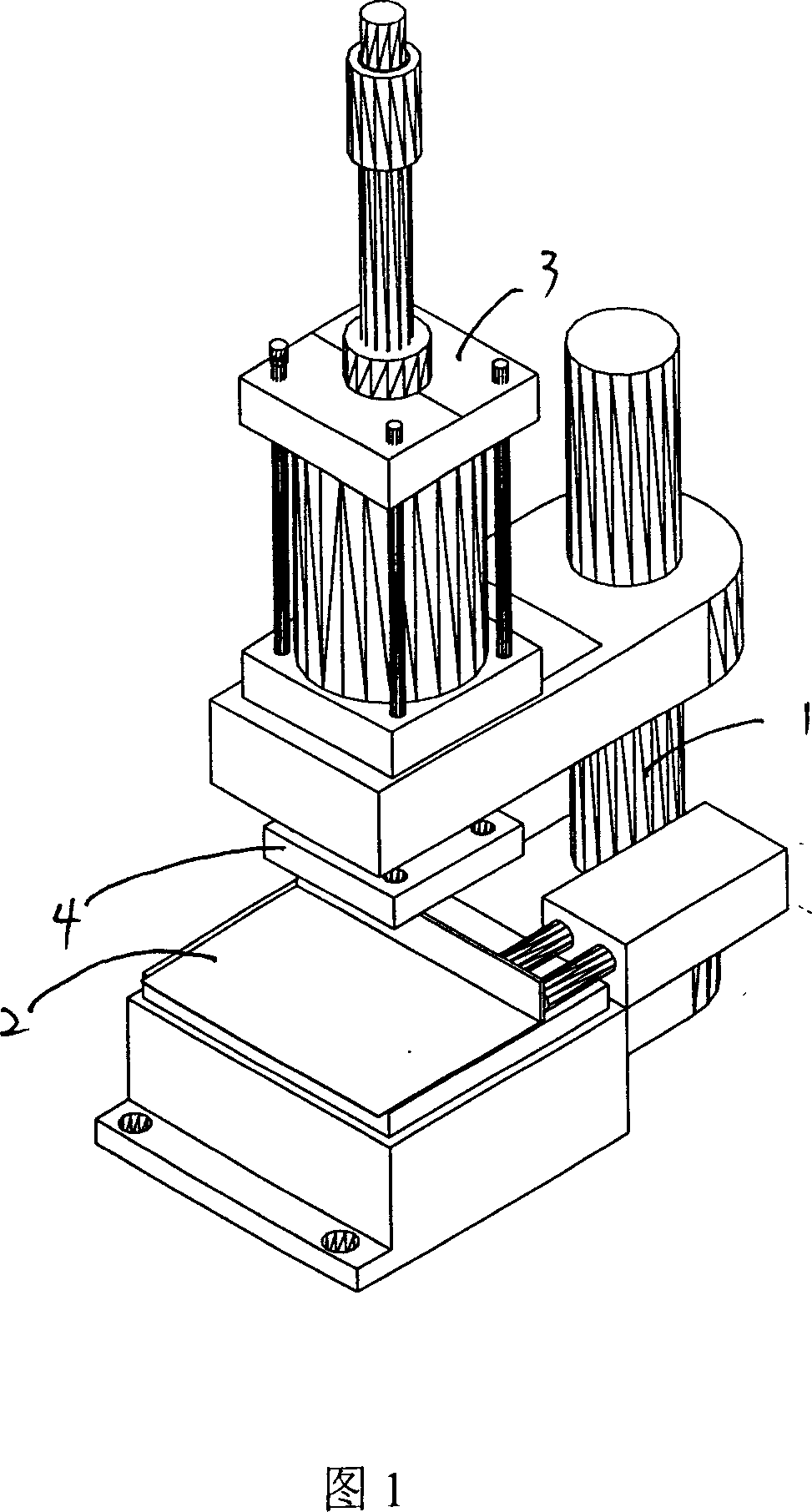

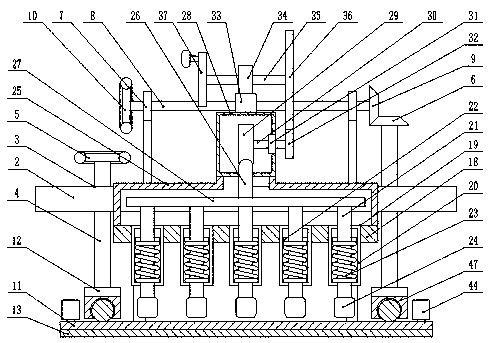

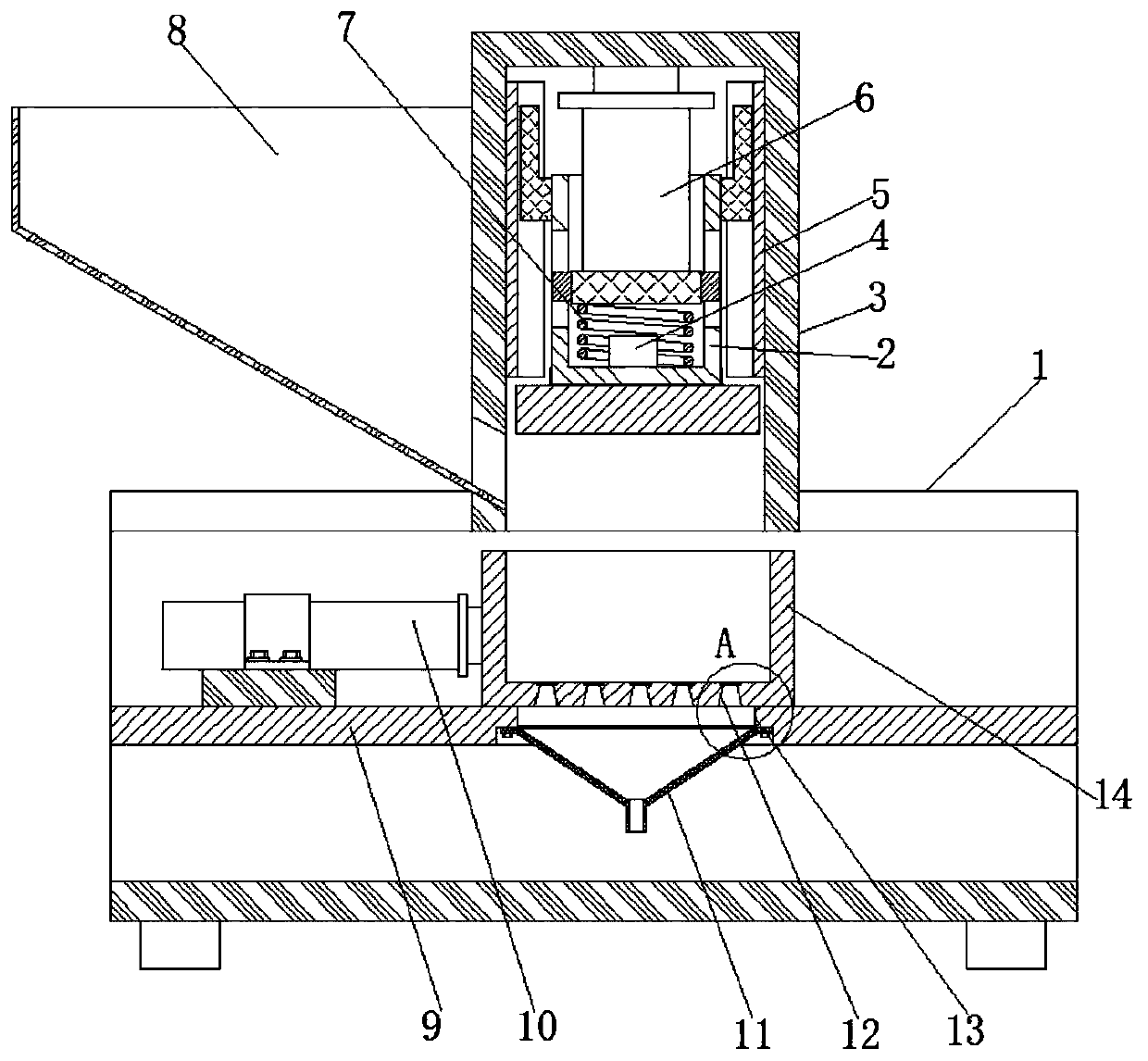

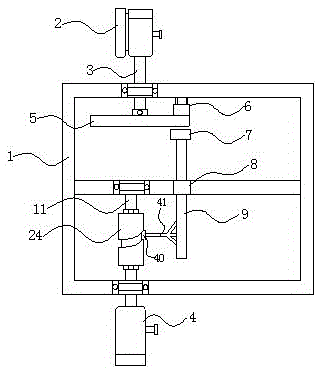

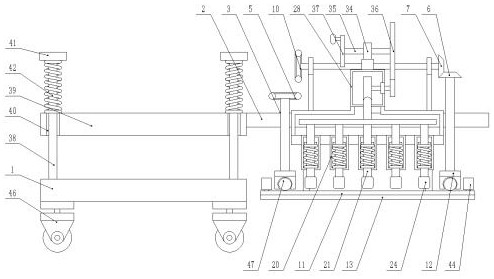

Capacitor core flattening device

InactiveCN104681309AImprove flattening efficiencyEasy to operateCapacitor manufactureEngineeringPiston rod

The invention discloses a capacitor core flattening device, which is characterized by comprising an upper fixing frame and a lower fixing frame. A lower pressing plate is fixed on the lower fixing frame; an upper pressing plate is fixed on the upper fixing frame; the upper fixing frame is provided with a plurality of guiding holes; each guiding hole is internally provided with a guiding column; the end part of the guiding column is fixedly connected with the upper pressing plate; a first cylinder is fixed on the upper fixing frame; the piston rod of the first cylinder is fixedly connected with the upper pressing plate to drive the upper pressing plate to move; the end part of the lower pressing plate of the lower fixing frame is provided with a working table; the working surface of the working table and the working surface of the lower pressing plate are consistent in height; a second cylinder is arranged above the working table; the second cylinder is fixed on the upper fixing frame; the side surface of the lower fixing frame is fixed with a third cylinder; and the piston rod of the third cylinder is located on the working table to push the core on the working table to enter the lower pressing plate. Due to the design of the invention, the flattening efficiency of the capacitor is improved by 300%, the bottleneck problem of the flattening procedure is solved, the operation is convenient, operation of an operator is facilitated, and the product quality can be effectively controlled.

Owner:铜陵市精品工具模具有限责任公司

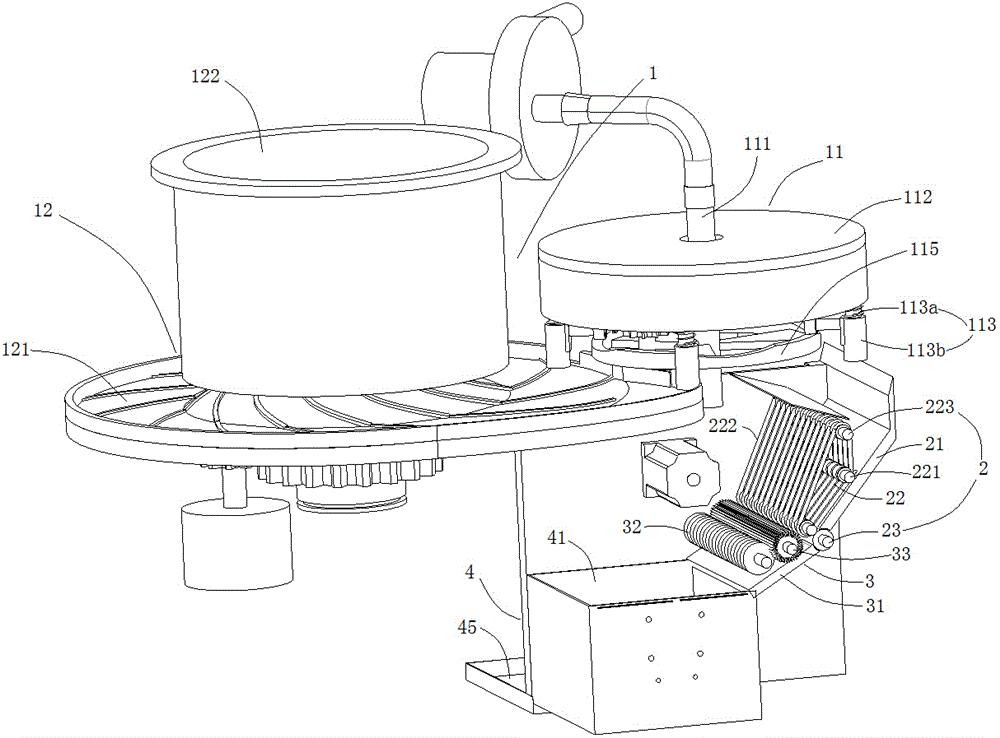

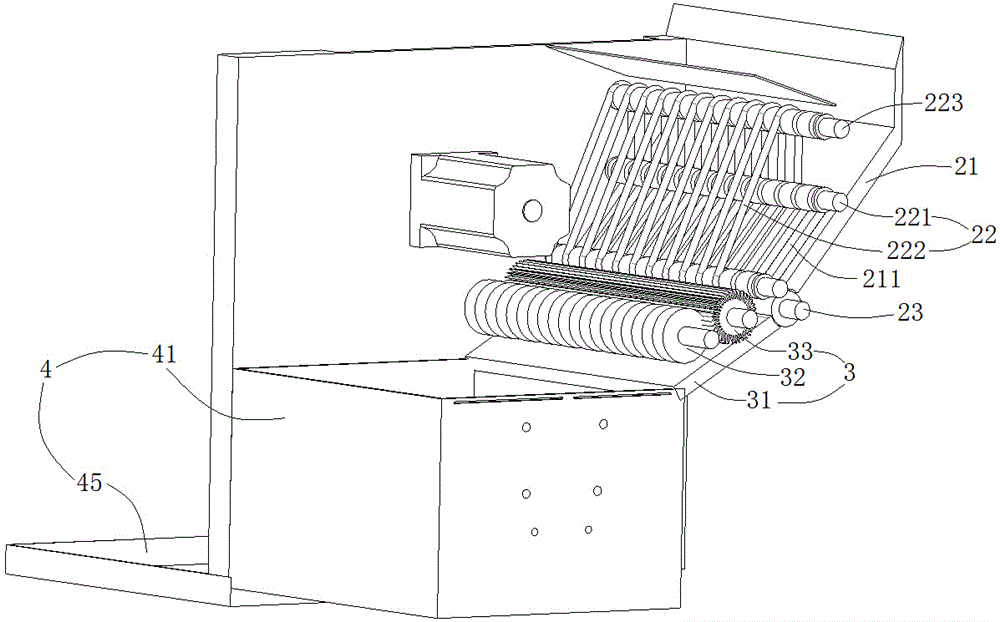

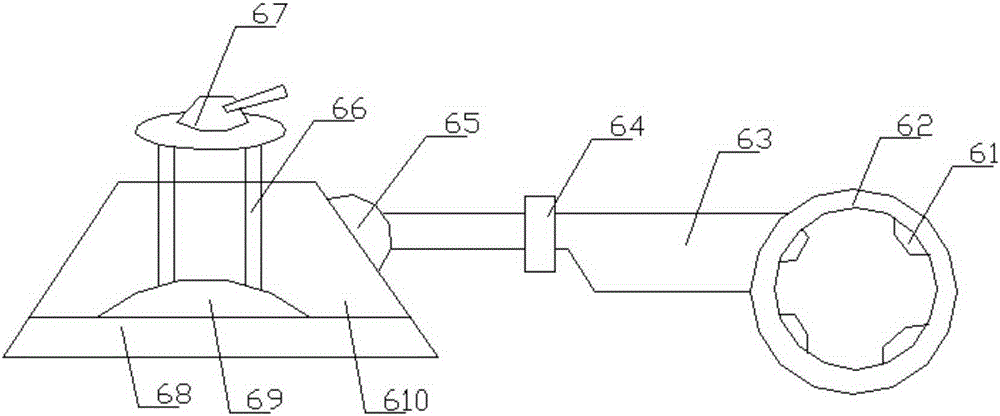

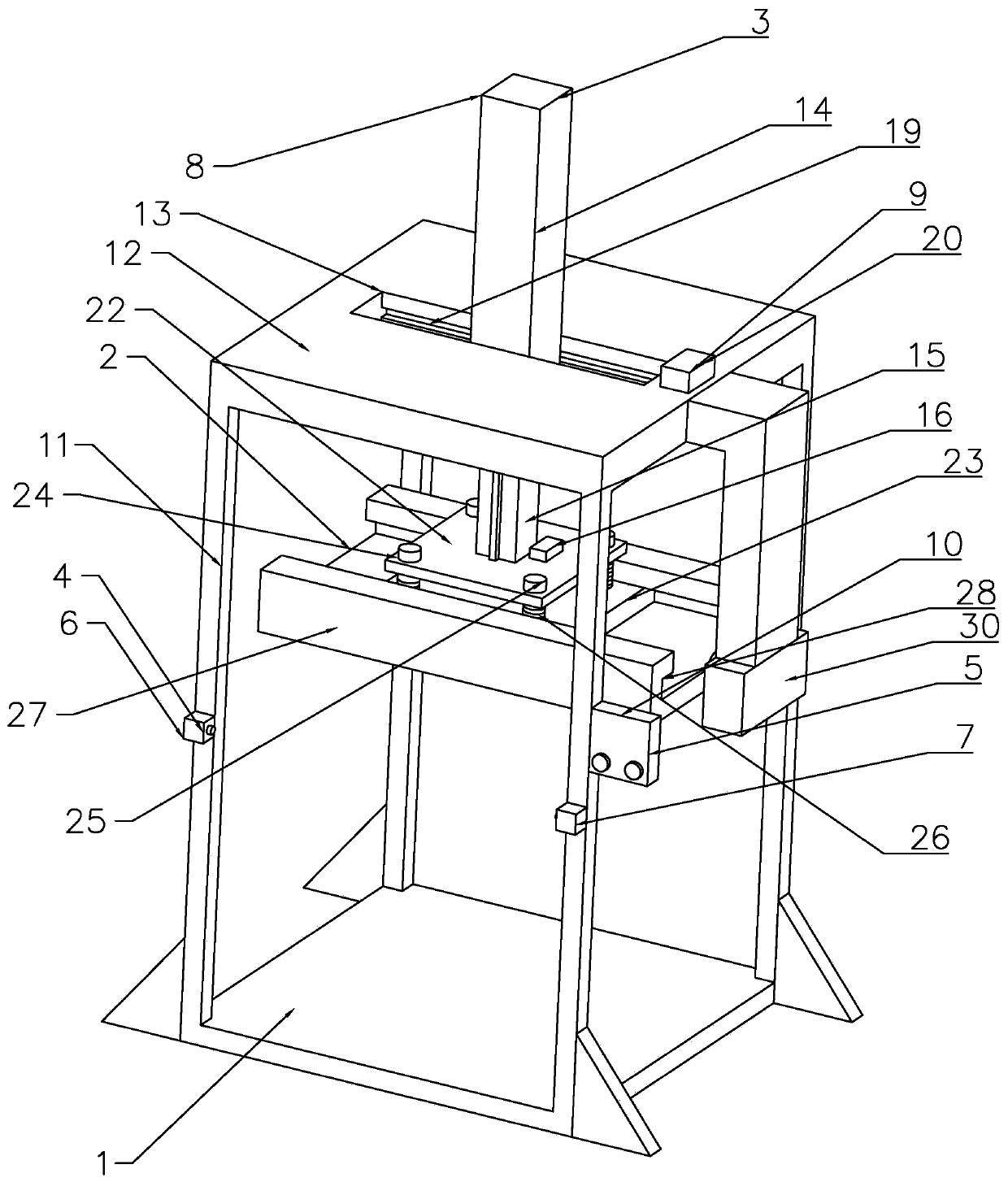

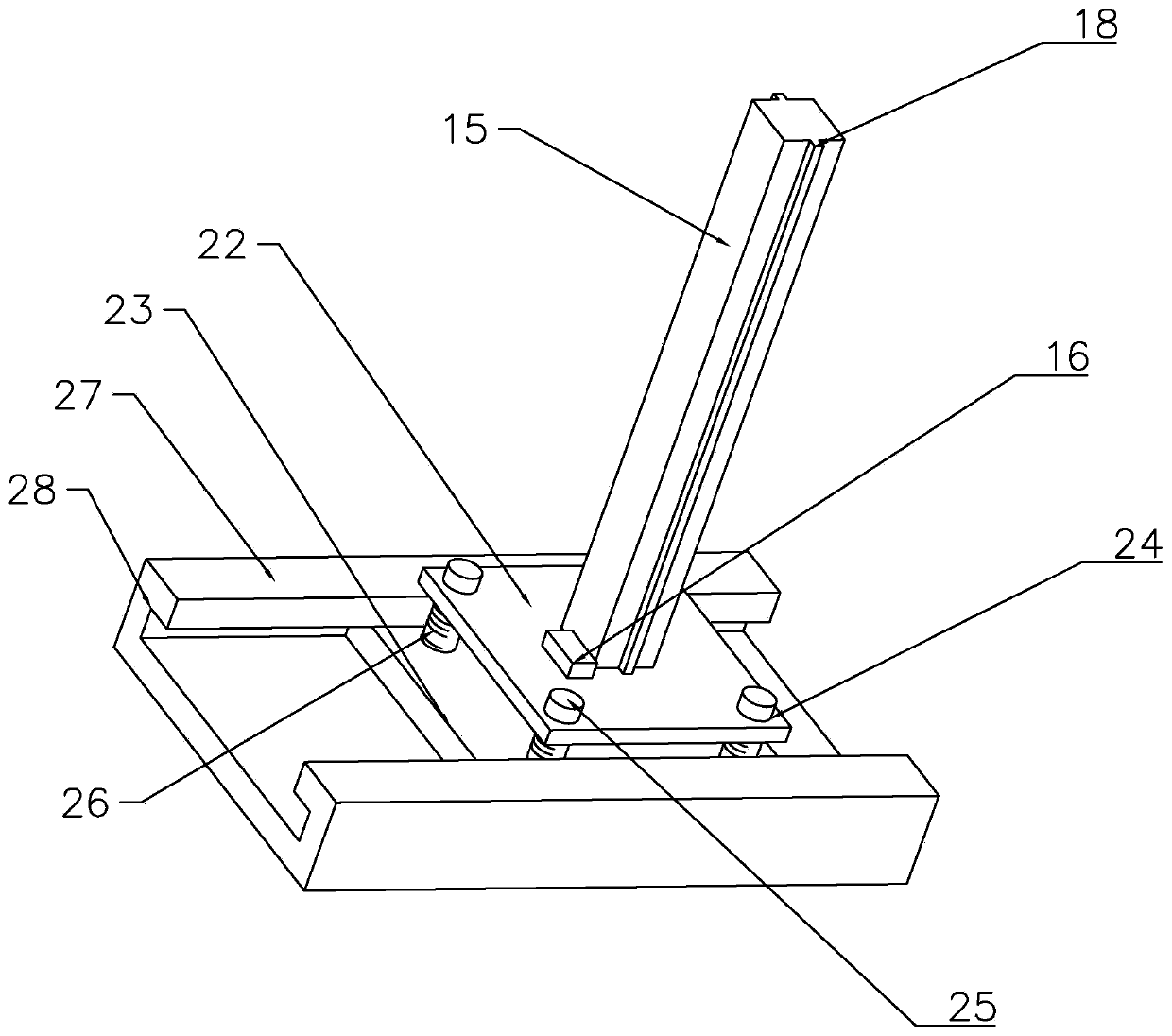

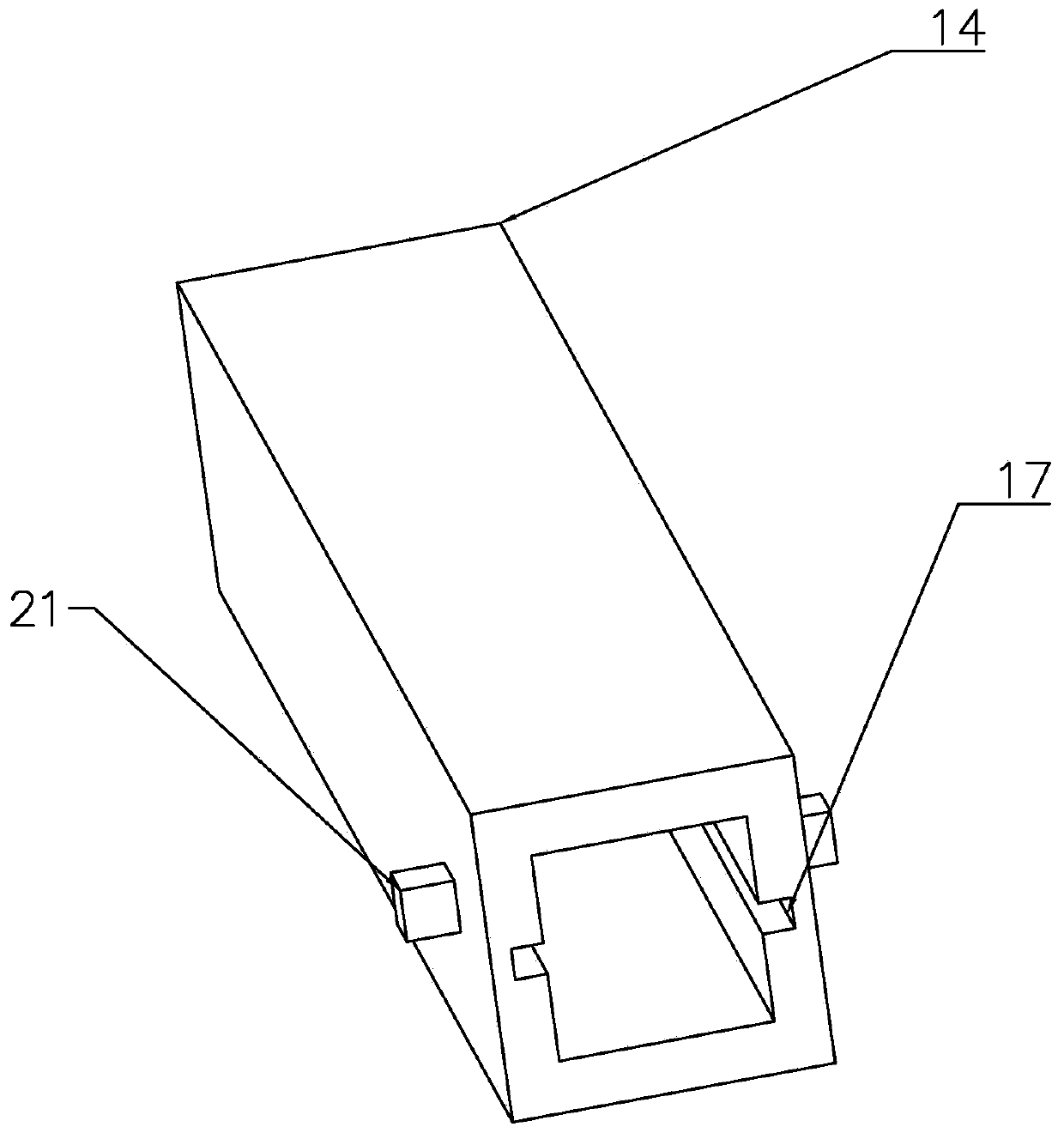

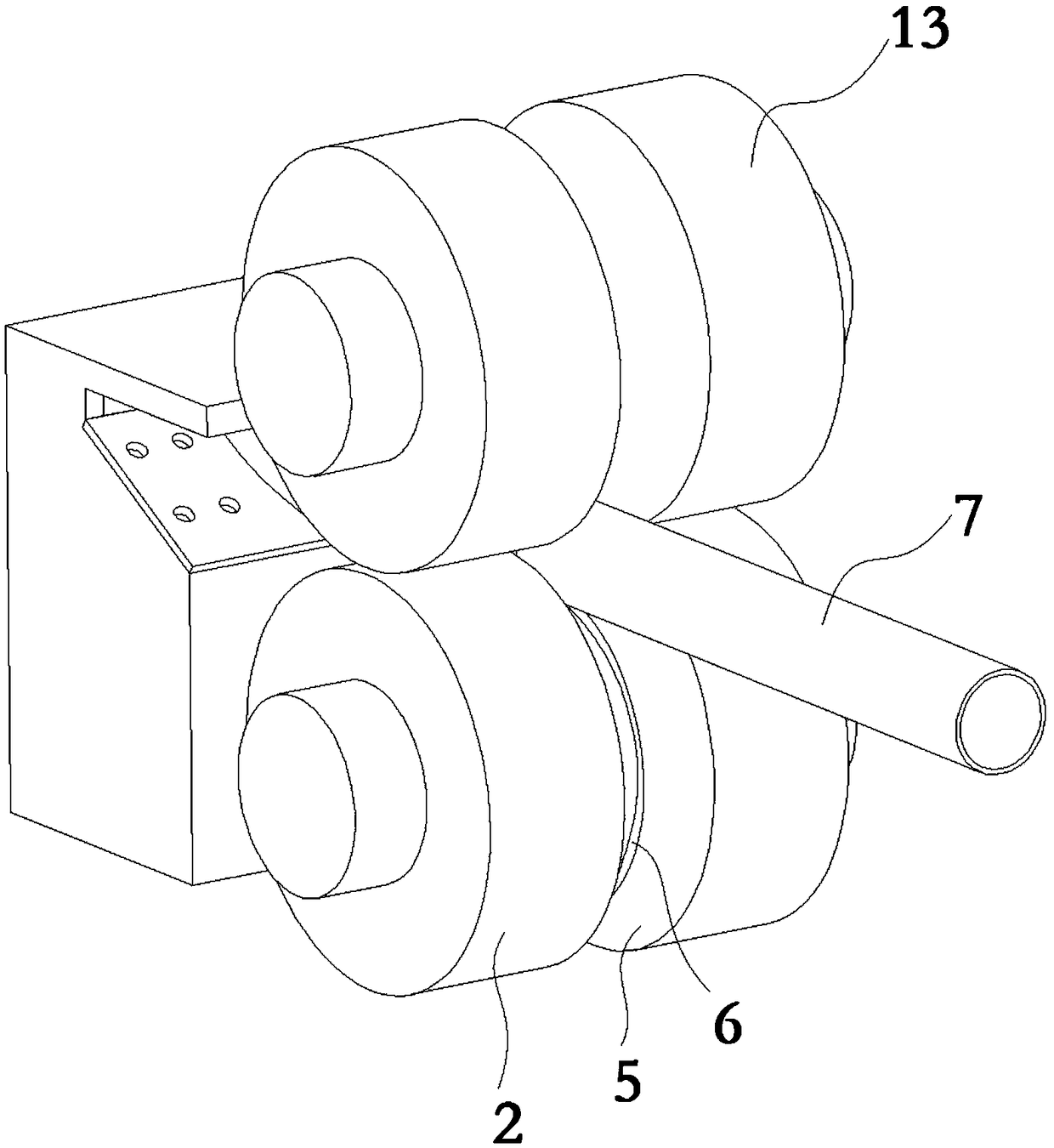

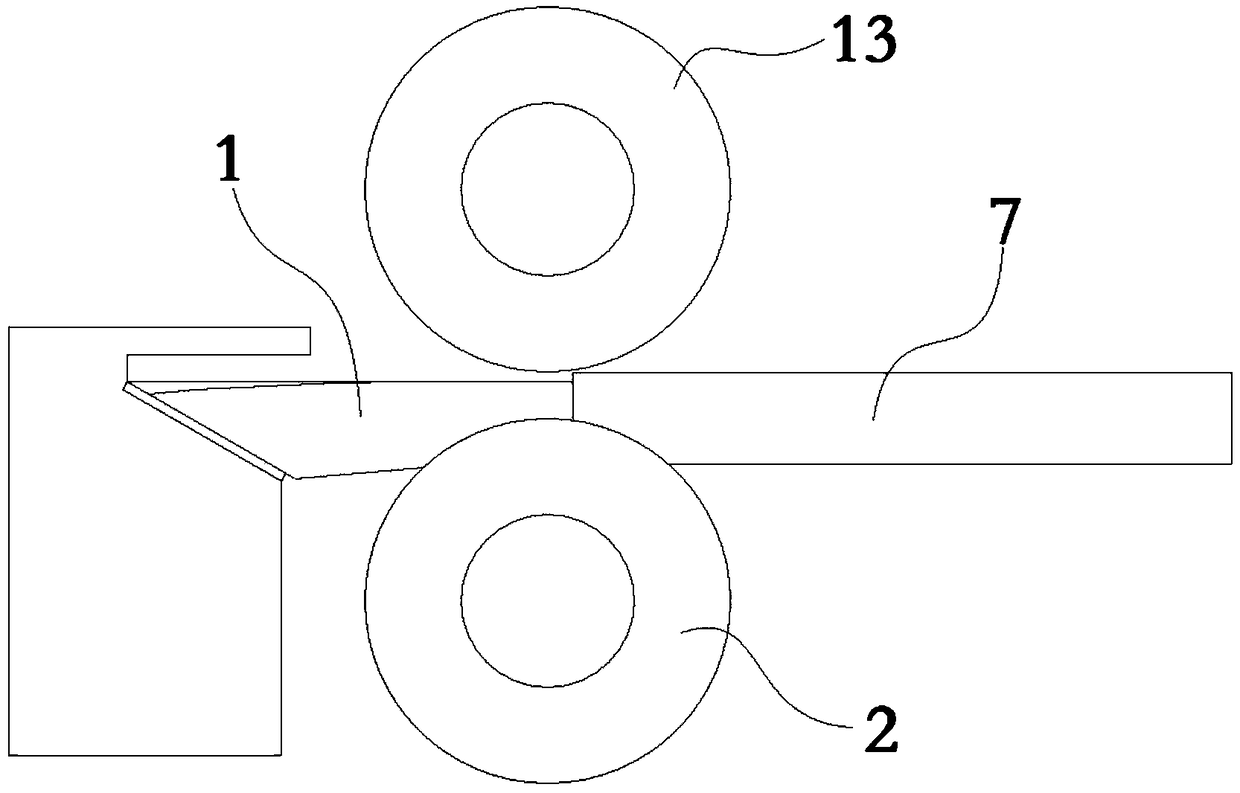

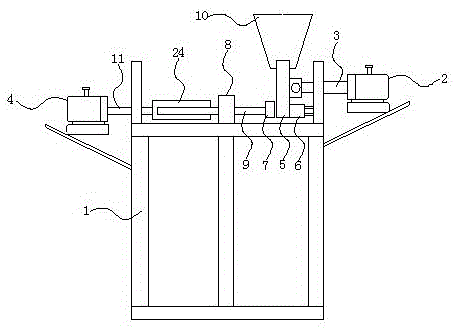

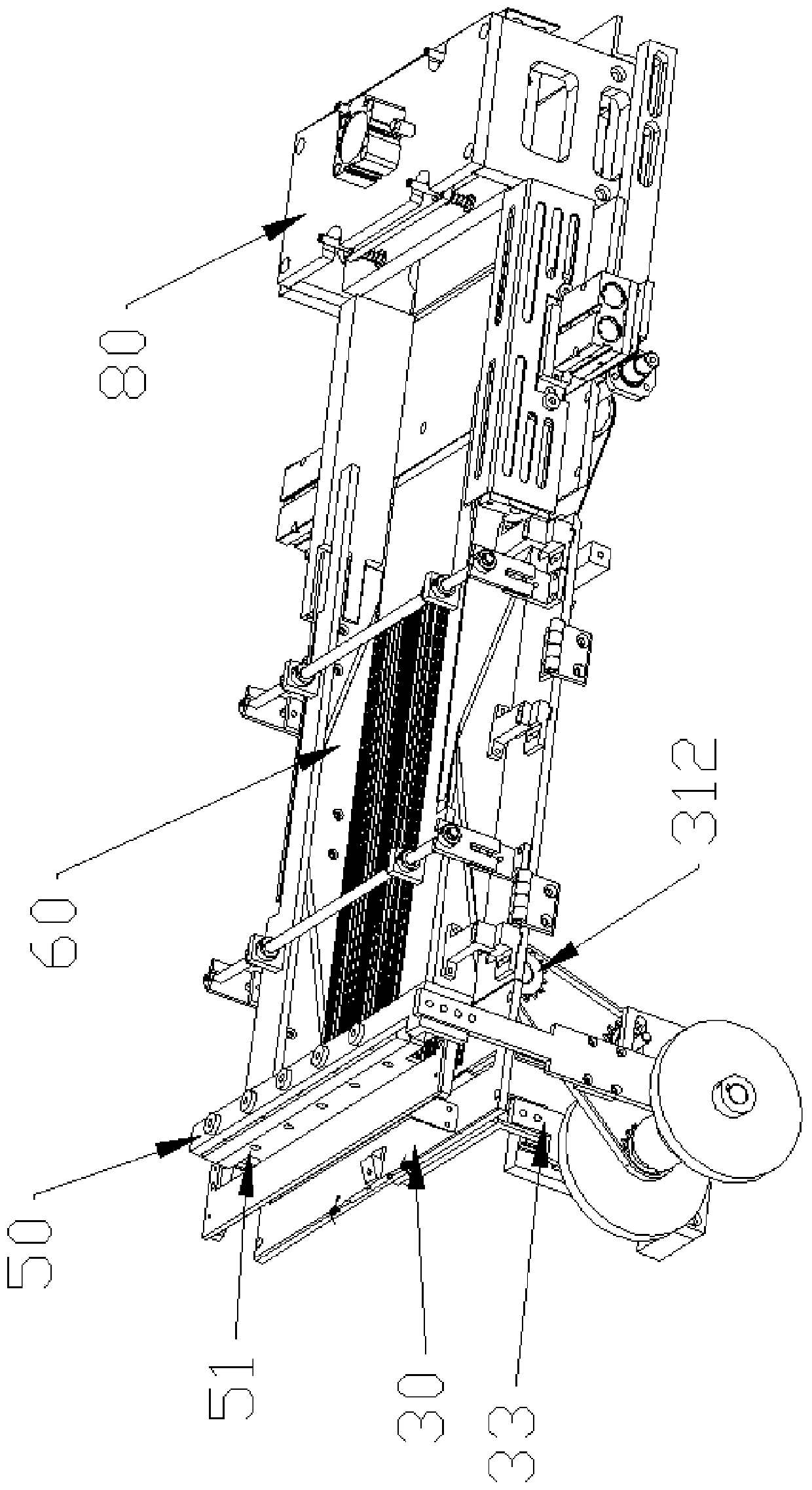

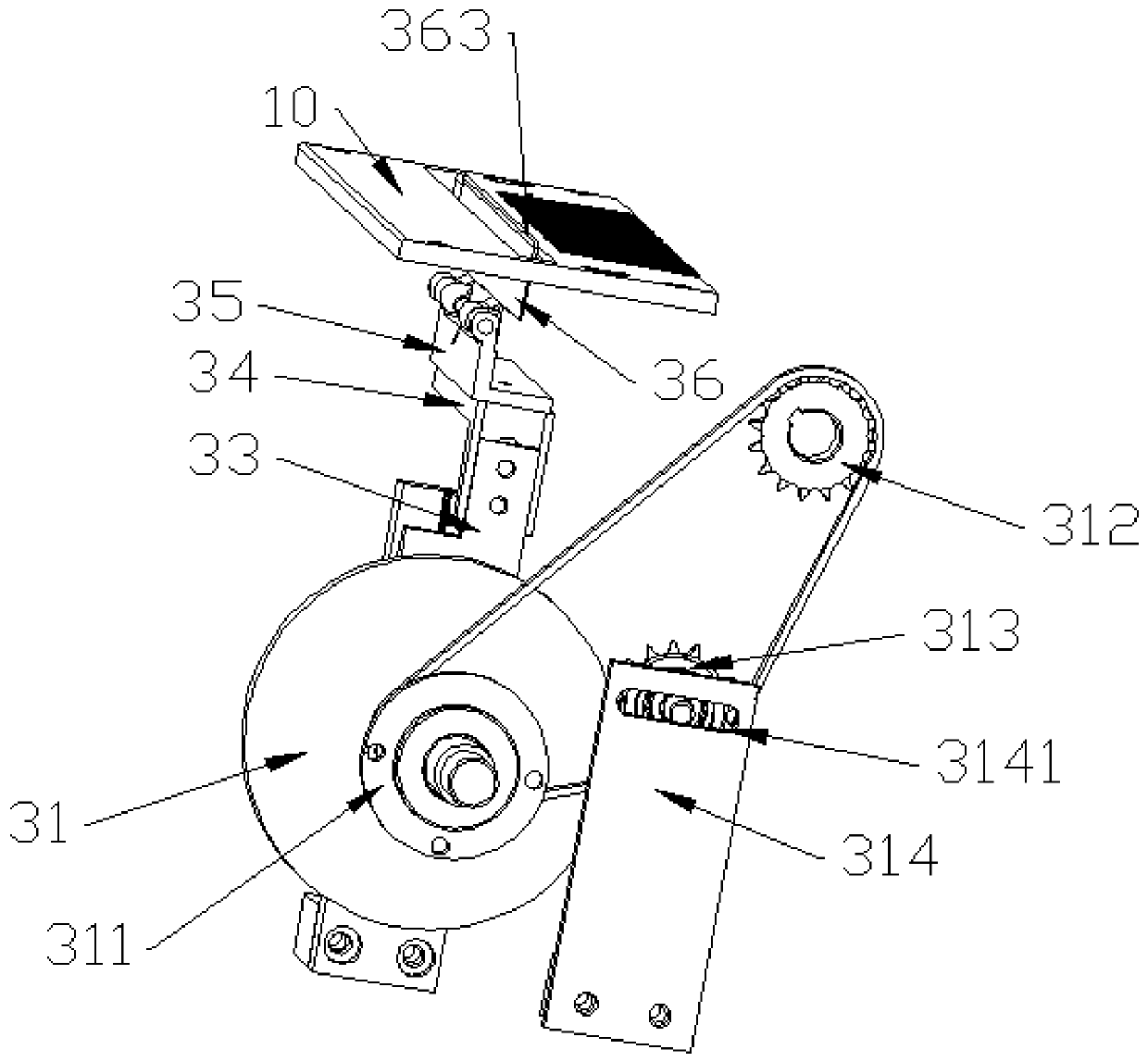

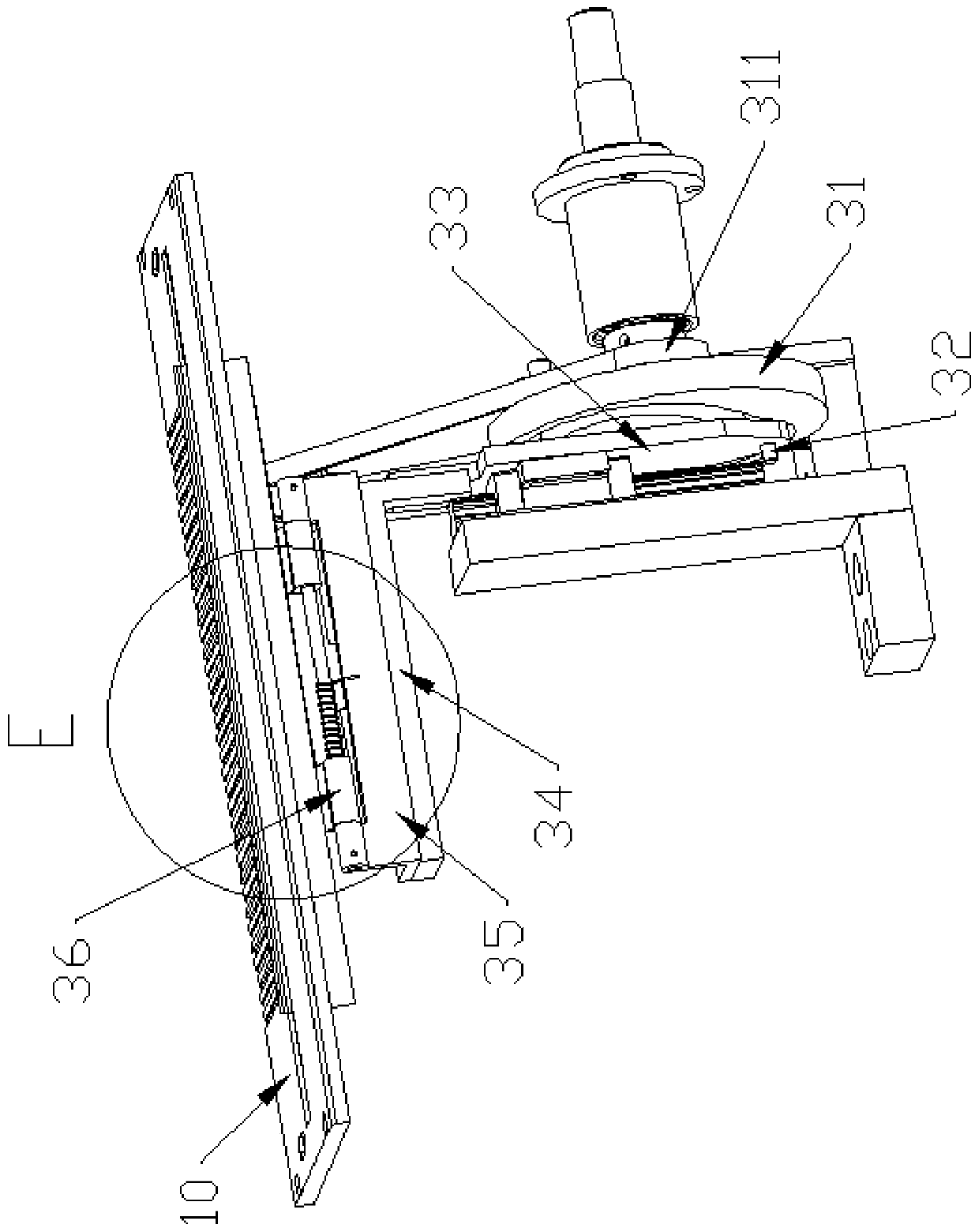

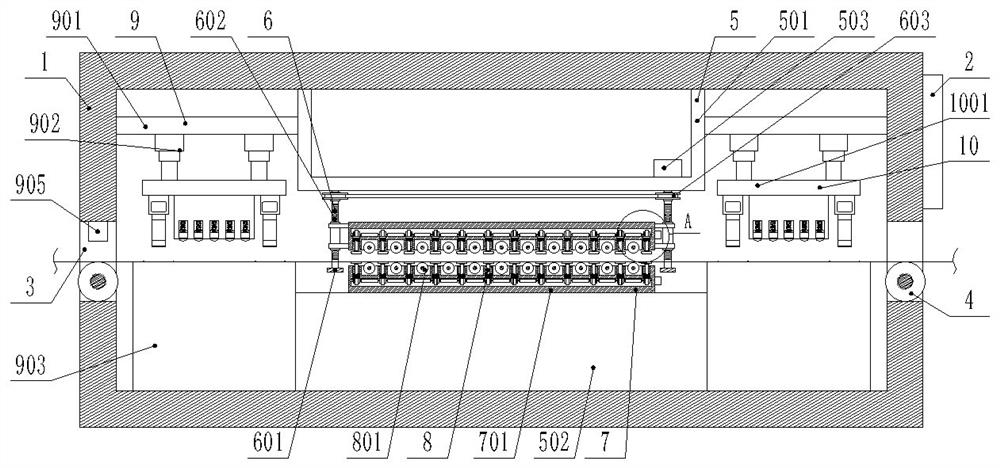

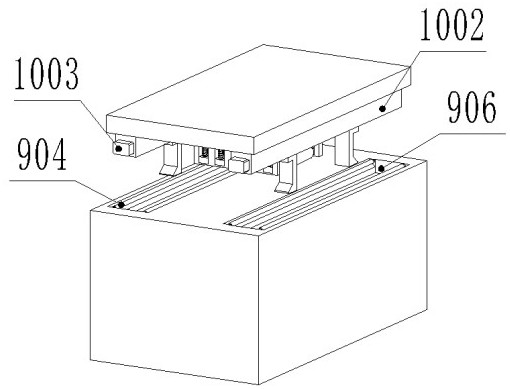

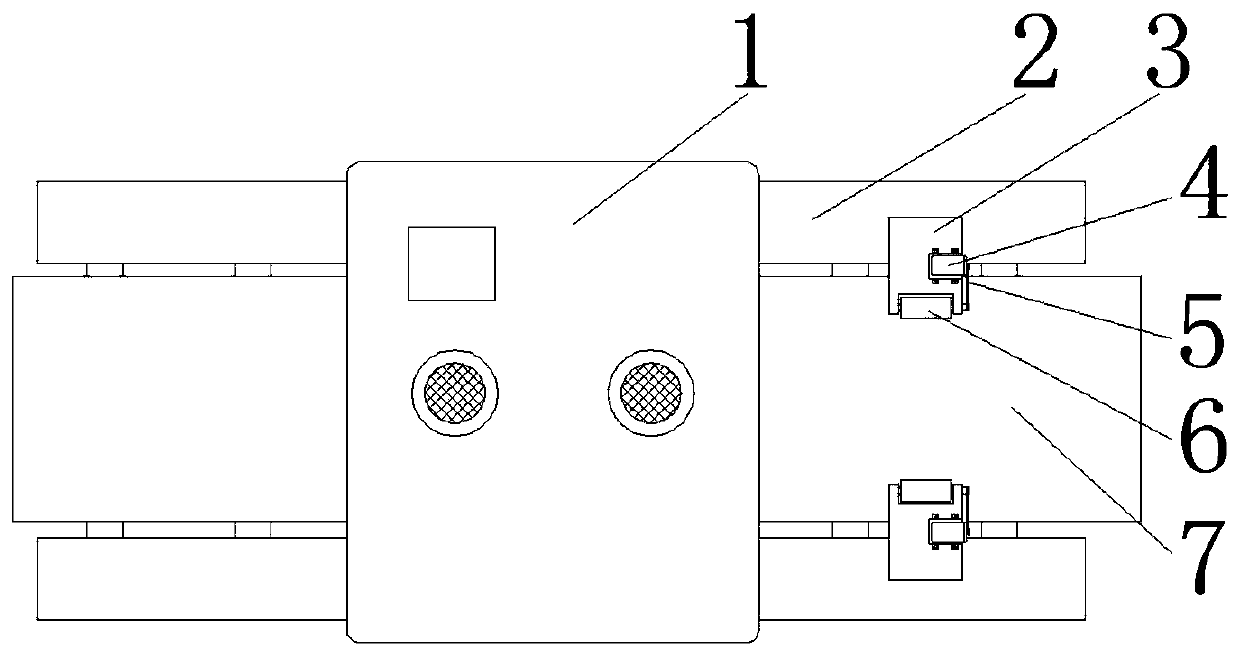

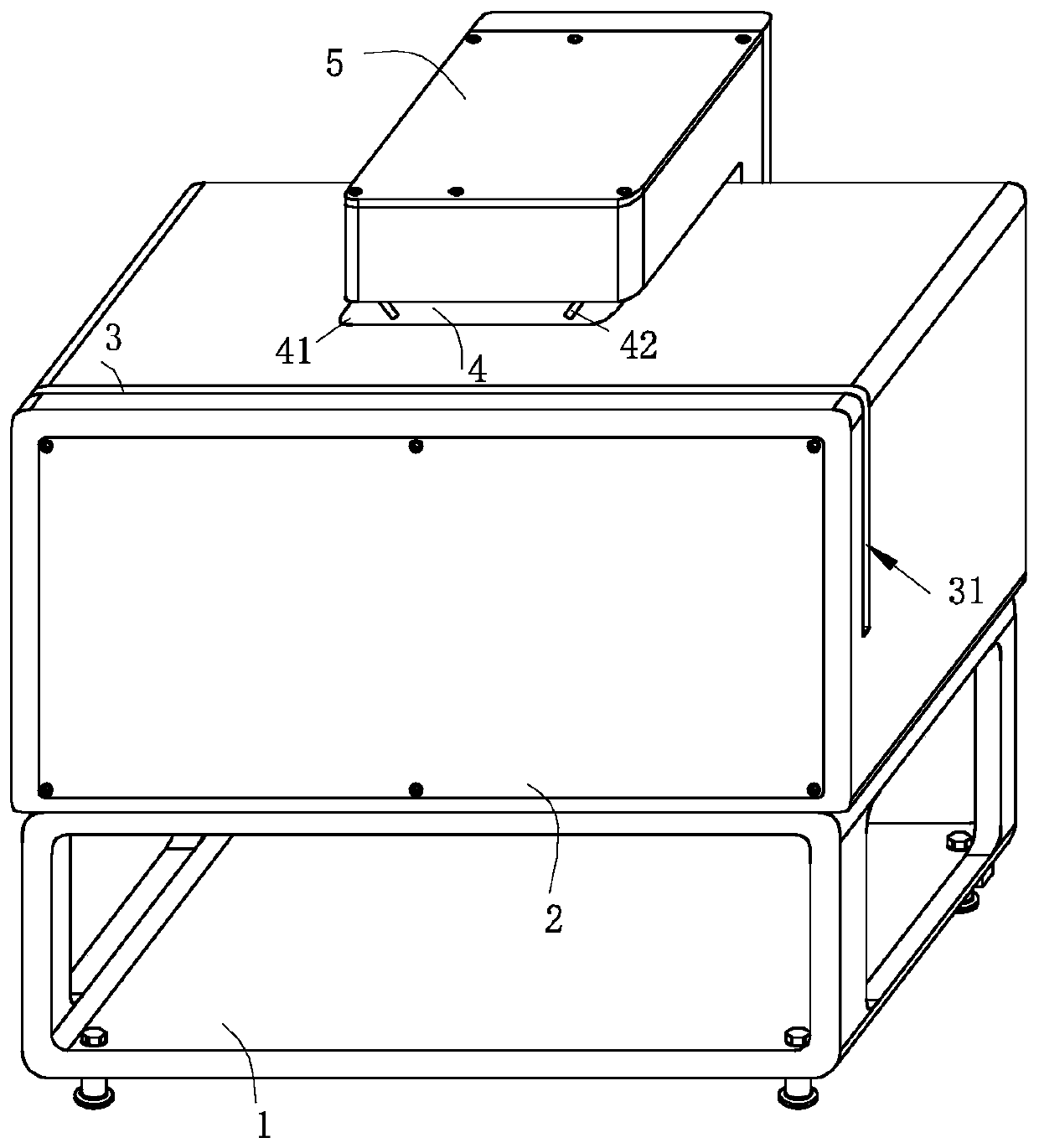

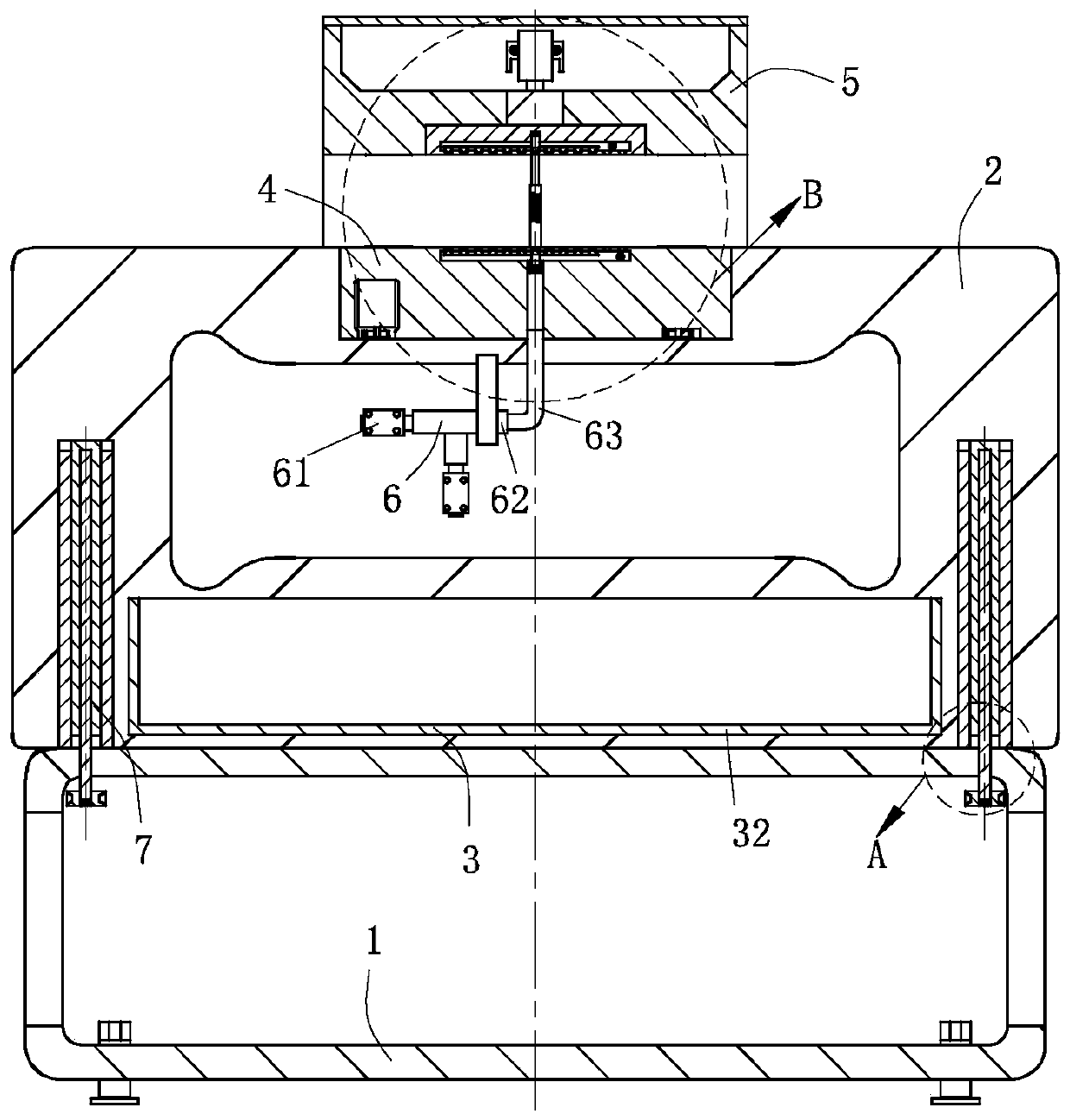

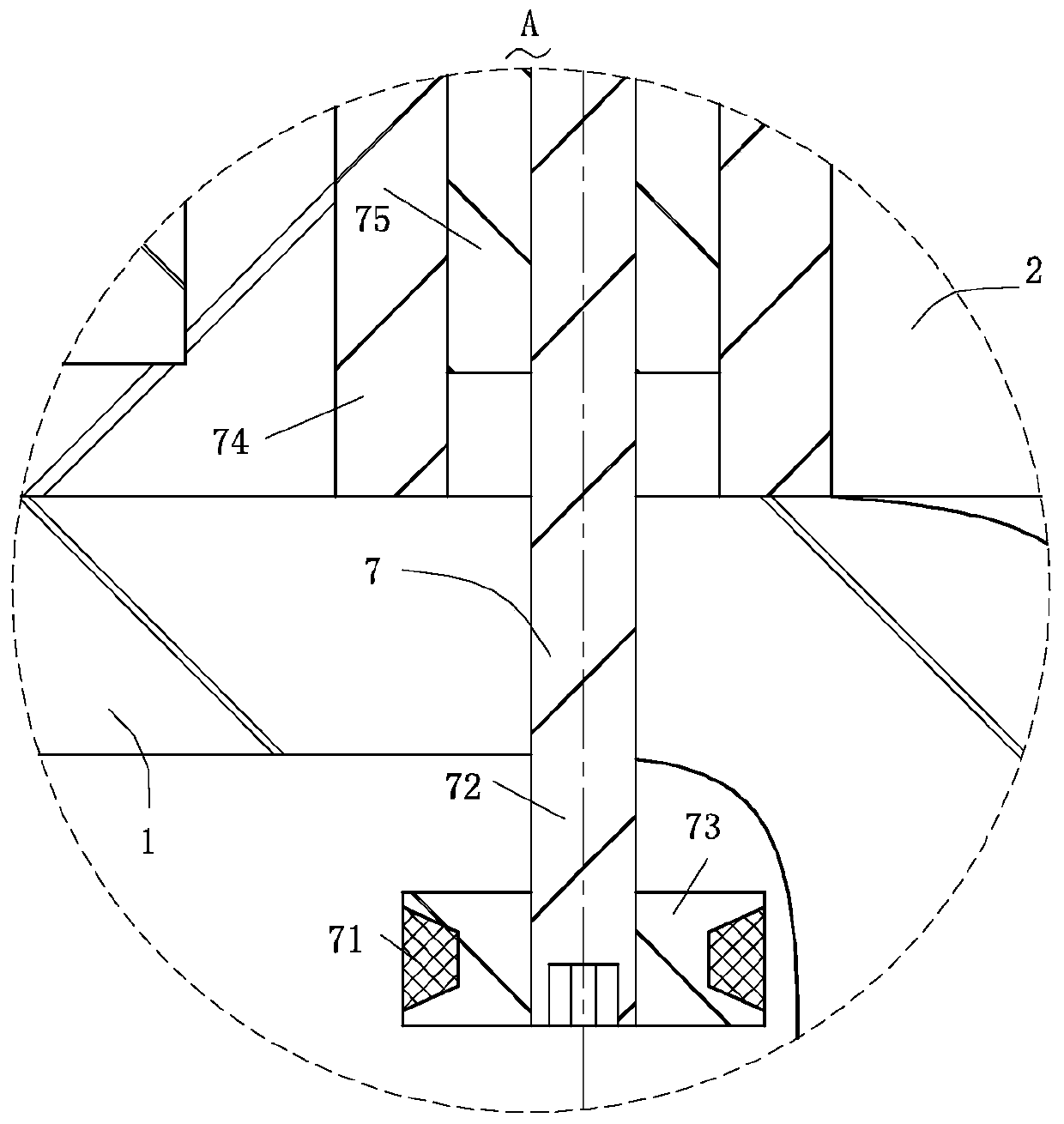

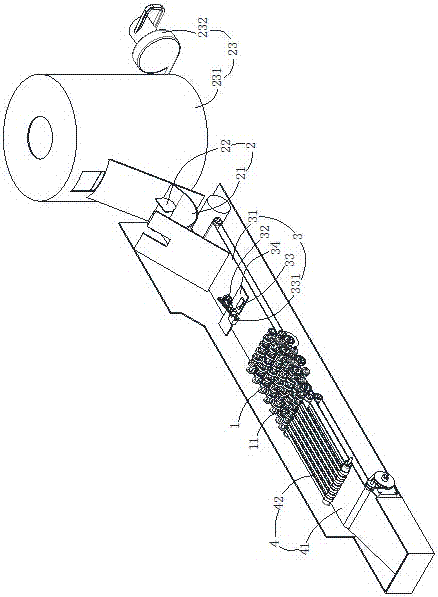

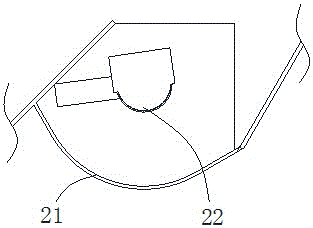

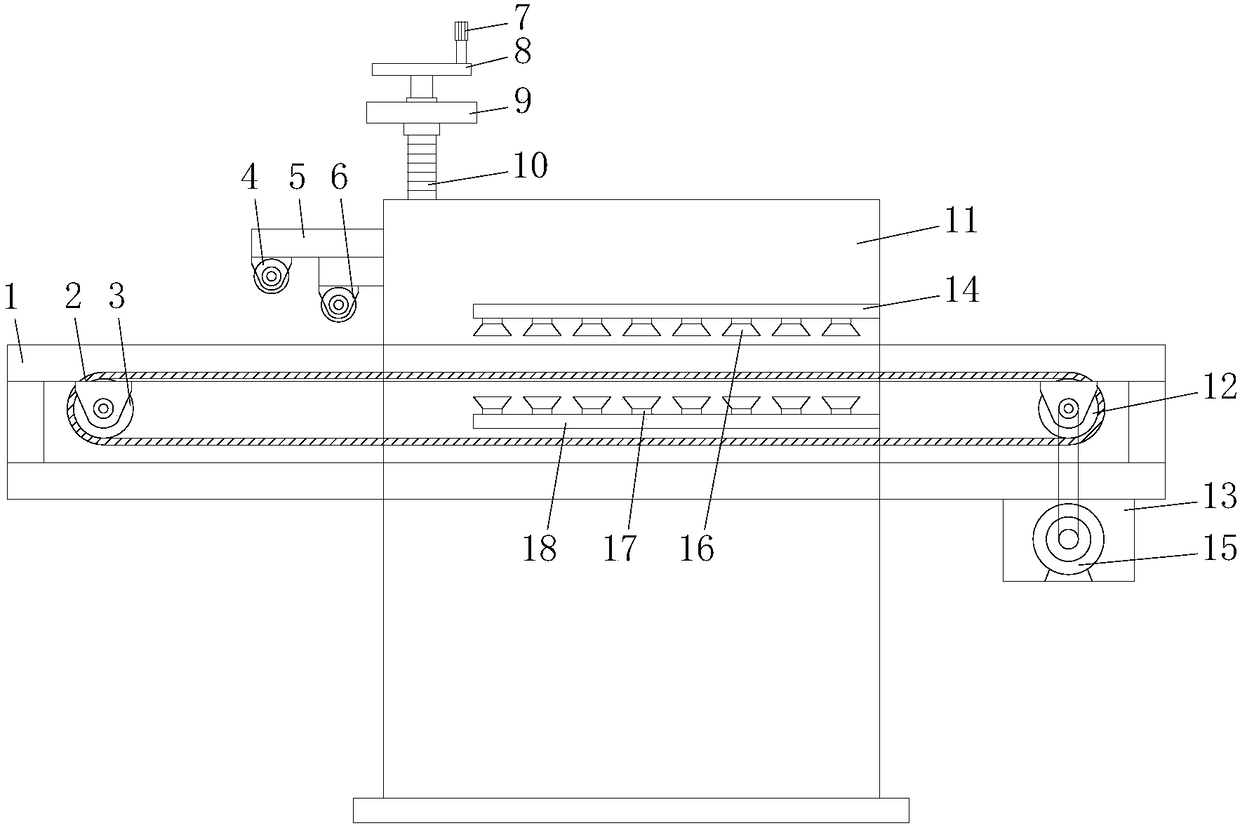

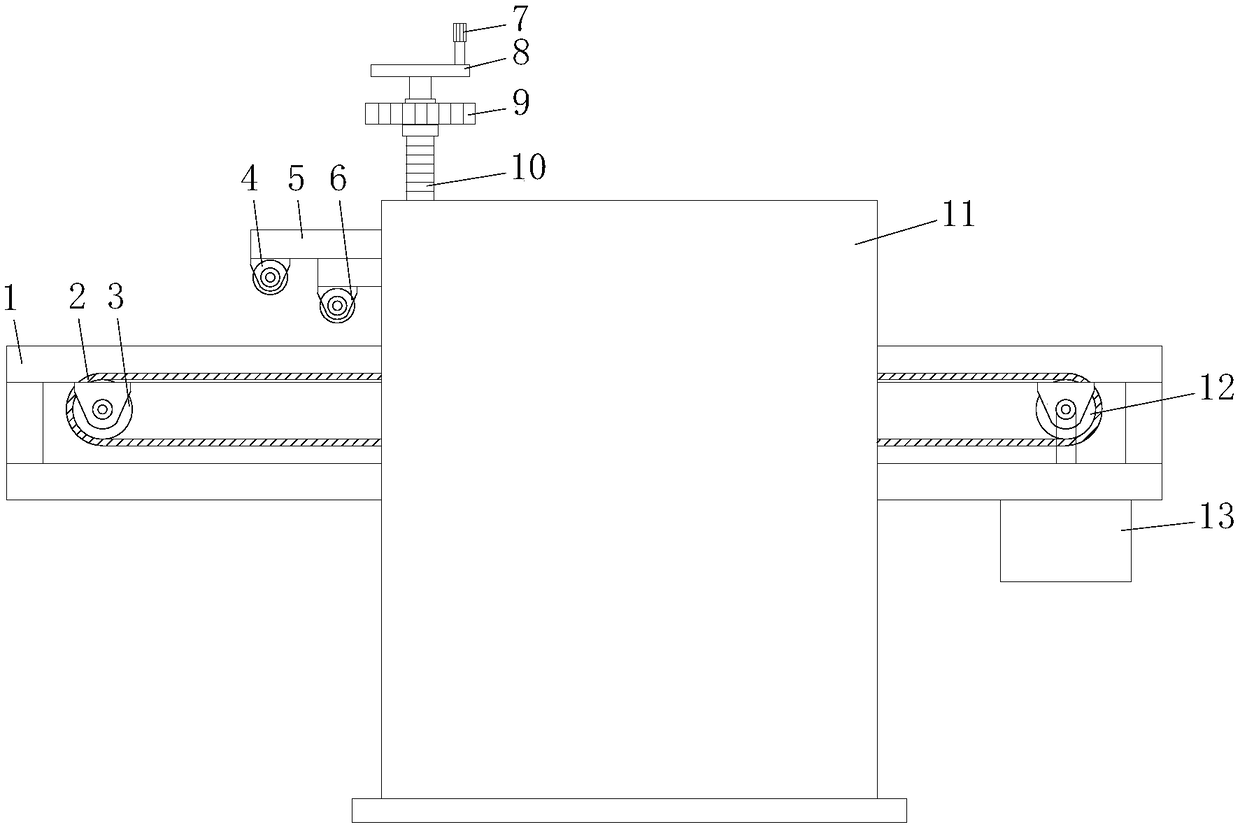

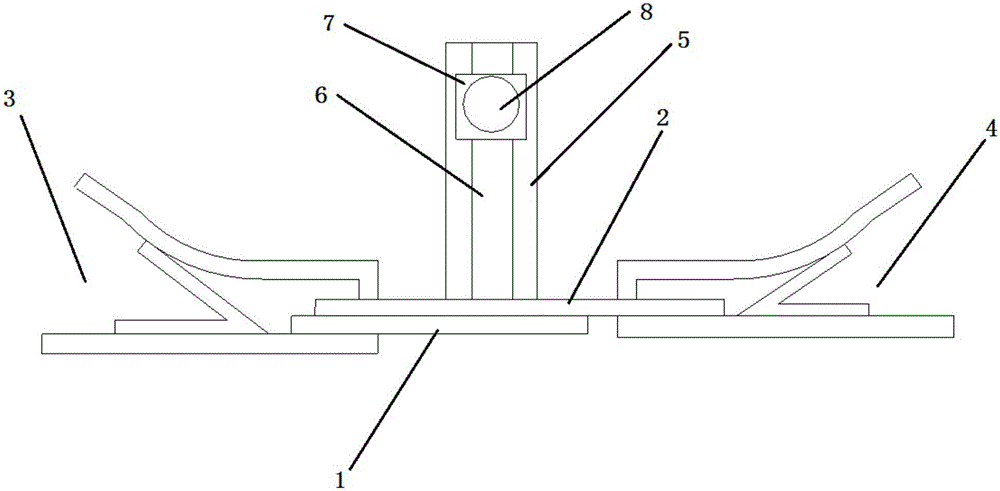

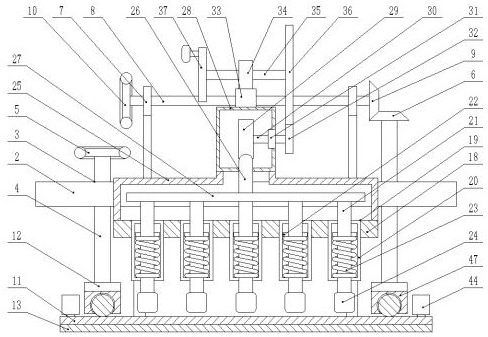

An automatic banknote flattening machine with straightening function

InactiveCN106395441BImprove feed directionImprove applicabilityArticle feedersArticle separationSingle foldPulp and paper industry

The invention discloses an automatic paper money flattening machine with the adjusting function. The automatic paper money flattening machine comprises a rubbing mechanism used for rubbing and unfolding folded paper money, and a feeding mechanism used for feeding the single folded paper money into the rubbing mechanism. The automatic paper money flattening machine is characterized in that a paper money adjusting mechanism is connected between the rubbing mechanism and the feeding mechanism; the paper money adjusting mechanism comprises a horizontally-arranged conveyor belt, a paper money locating piece and a control mechanism, and the paper money locating piece and the control mechanism are located above the conveyor belt; the lower end of the paper money locating piece is provided with a pressing end, and the pressing end can press the folded paper money passing by under the action of the control mechanism onto the upper surface of the conveyor belt, and form a pressing point at the local part of the folded paper money; the feeding end of the conveyor belt and the discharging end of the feeding mechanism are connected to be arranged; and the discharging end of the conveyor belt and a feeding opening of the rubbing mechanism are connected to be arranged. The automatic paper money flattening machine has the advantages of being capable of improving the feeding direction of the folded paper money, high in applicability, high in flattening efficiency, good in flattening effect and the like.

Owner:CHONGQING UNIV OF TECH

Automatic paper money flattening machine with adjusting function

InactiveCN106395441AImprove the efficiency of scoringAvoid bendingArticle feedersArticle separationSingle foldPulp and paper industry

The invention discloses an automatic paper money flattening machine with the adjusting function. The automatic paper money flattening machine comprises a rubbing mechanism used for rubbing and unfolding folded paper money, and a feeding mechanism used for feeding the single folded paper money into the rubbing mechanism. The automatic paper money flattening machine is characterized in that a paper money adjusting mechanism is connected between the rubbing mechanism and the feeding mechanism; the paper money adjusting mechanism comprises a horizontally-arranged conveyor belt, a paper money locating piece and a control mechanism, and the paper money locating piece and the control mechanism are located above the conveyor belt; the lower end of the paper money locating piece is provided with a pressing end, and the pressing end can press the folded paper money passing by under the action of the control mechanism onto the upper surface of the conveyor belt, and form a pressing point at the local part of the folded paper money; the feeding end of the conveyor belt and the discharging end of the feeding mechanism are connected to be arranged; and the discharging end of the conveyor belt and a feeding opening of the rubbing mechanism are connected to be arranged. The automatic paper money flattening machine has the advantages of being capable of improving the feeding direction of the folded paper money, high in applicability, high in flattening efficiency, good in flattening effect and the like.

Owner:CHONGQING UNIV OF TECH

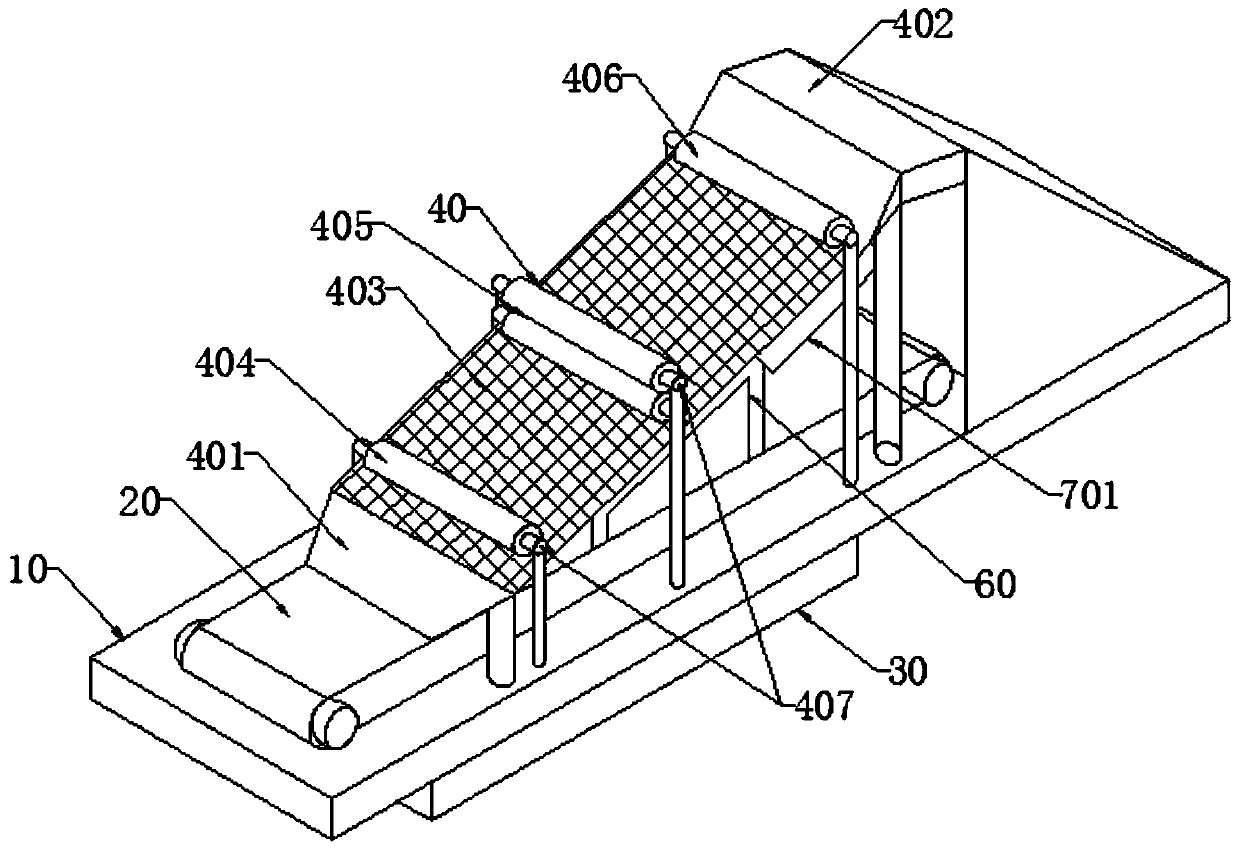

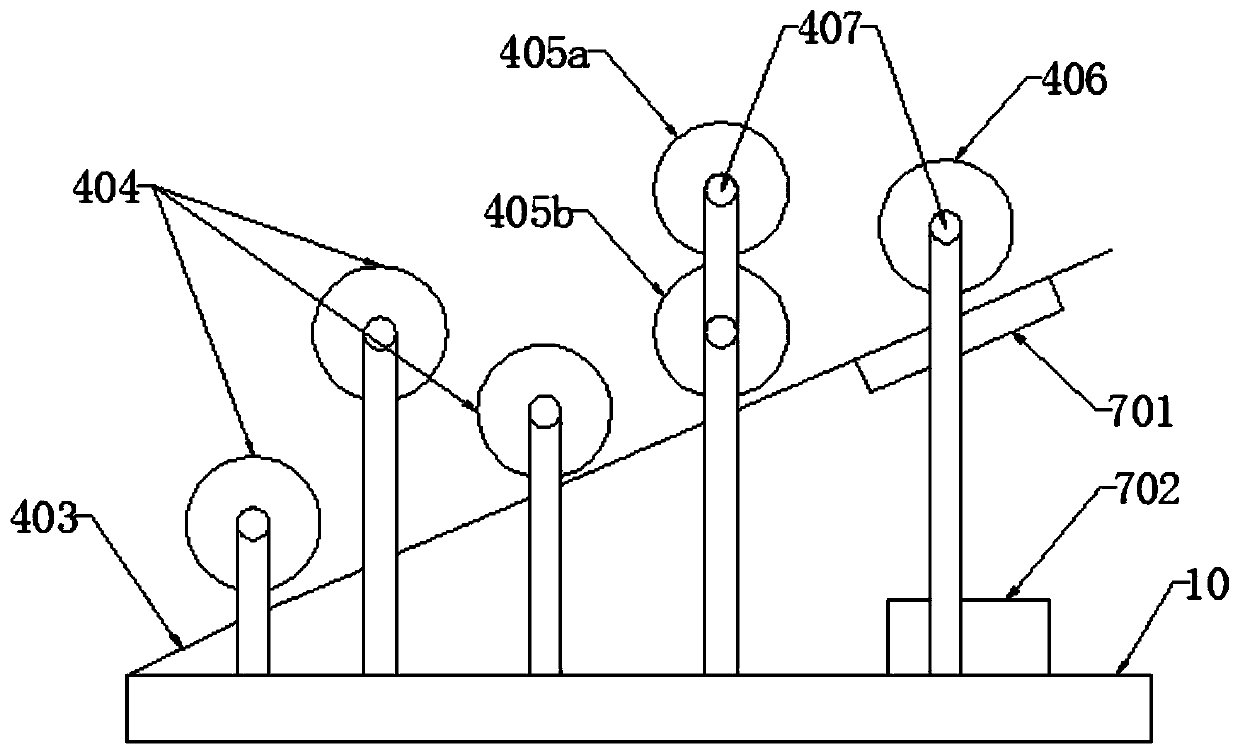

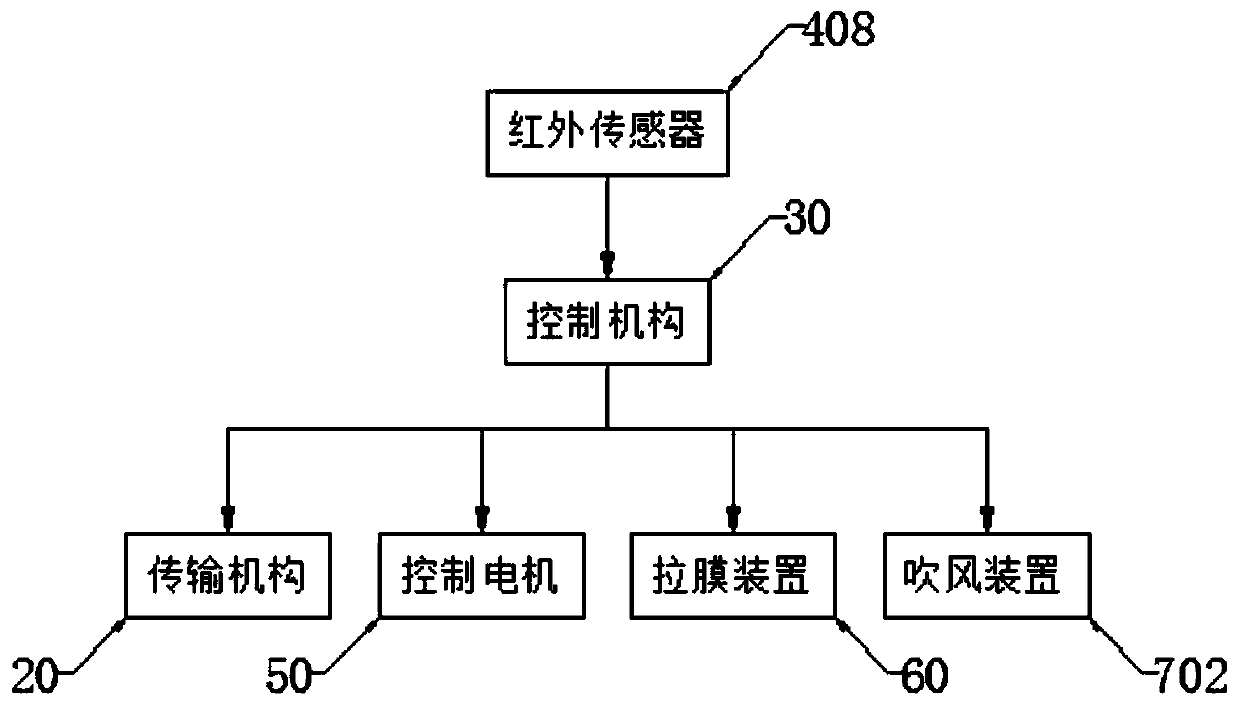

Film covering device and film covering method thereof

ActiveCN107972914BSimple structureEasy to useWrapping material feeding apparatusWebs handlingAgricultural engineeringFilm-coated tablet

The invention discloses a film coating device which comprises a base, a transmission mechanism arranged above the base, a control mechanism arranged below the base and a film coating mechanism arranged above the transmission mechanism, wherein the film coating mechanism comprises a feeding hole, a discharging hole, a film placement plate, a planishing roller, a film coating roller and an auxiliarycooling roller; the film placement plate is positioned between the feeding hole and the discharging hole and has an upward dip angle of 45-60 degrees; the planishing roller, the film coating roller and the auxiliary cooling roller are sequentially positioned above the film placement plate; two transmission rollers are arranged on two sides of each of the planishing roller, the film coating rollerand the auxiliary cooling roller; the transmission rollers are externally connected with a control motor; and the control mechanism controls and is connected with the transmission mechanism and the control motor. The invention further discloses a film coating method of the film coating device. The film coating device can realize automatic film coating to reduce the labor cost, can adjust the filmcoating direction and time, tightens the coated film, realizes a stagger planishing process to enable the films to be level and smooth enough and unified in structure and meet various production demands and improves the production efficiency and the film coating quality.

Owner:温州市创新晶彩科技有限公司

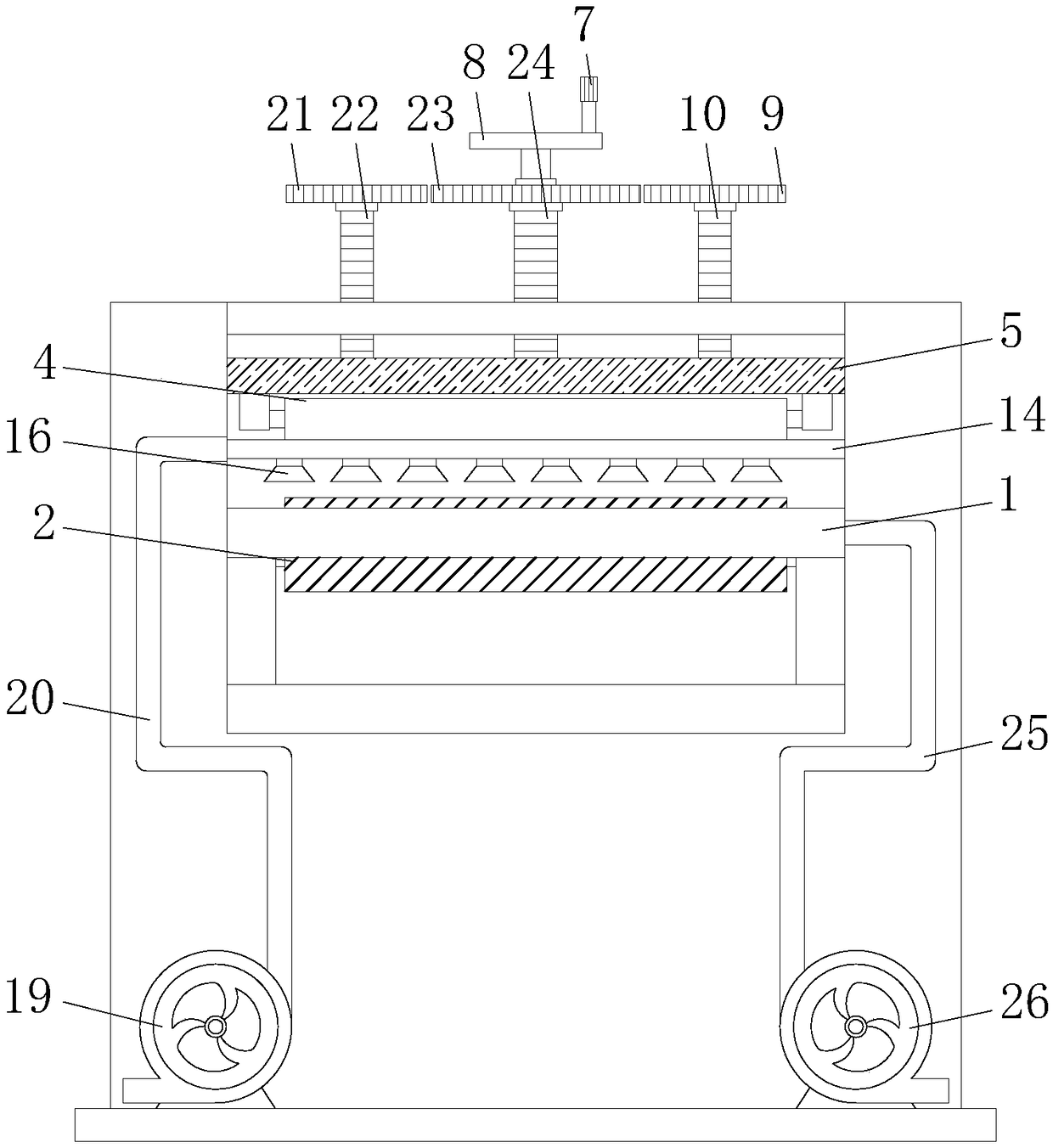

Efficient reshaping and blow-drying machine

ActiveCN108528805APrevent tiltingImprove flattening efficiencyPackaging under special atmospheric conditionsEngineeringThreaded rod

The invention discloses an efficient reshaping and blow-drying machine. The efficient reshaping and blow-drying machine comprises a fixing rack, and the fixing rack horizontally penetrates through theinterior of a machine body and is perpendicular to the machine body; a first threaded rod, a second threaded rod and a third threaded rod are perpendicularly fixed to one end of the top of the machine body, and the third threaded rod is located between the first threaded rod and the second threaded rod; and a first gear, a second gear and a third gear are connected to the top of the first threaded rod, the top of the second threaded rod and the top of the third threaded rod correspondingly, and the third gear is located between the first gear and the second gear and connected with the first gear and the second gear in a meshing mode. According to the efficient reshaping and blow-drying machine, the three threaded rods and the three gears meshing with one another are arranged, a hand wheeldrives the gear located at the middle position to rotate to drive the other two gears to rotate simultaneously, the three threaded rods are driven to vertically move simultaneously, and then a reshaping pressure roll always keeps a horizontal state when the spacing between the reshaping pressure roll and a conveyer belt is adjusted.

Owner:临沂高新区金迪科技信息服务中心

Pop can quick flattening equipment

Owner:中山市程博工业产品设计有限公司

Wheat straw piece ironing device and method

InactiveCN106426445AImprove flattening efficiencyAvoid scratchesPlant material mechanical workingElectric heatingEngineering

The invention discloses a wheat straw piece ironing device. The device comprises bottom plates arranged from left to right along a length direction, wherein the bottom plates are divided into two layers along a height direction and comprise a lower bottom plate and an upper bottom plate; the upper surface of the lower bottom plate and the lower surface of the upper bottom plate are connected via structures comprising sliding rails and sliding blocks; the lower bottom plate and the upper bottom plate can slide along the length directions of the bottom plates; a left fixing clamp and a right fixing clamp with same structures are arranged on the left side of the lower bottom plate and the right side of the upper bottom plate respectively; sliding chutes extending along the length direction of the bottom plate are formed in the front side and the back side of the upper surface of the upper bottom plate respectively; sliding blocks are embedded in the two sliding chutes; support plates vertical to the surface of the upper bottom plate along the height direction are arranged on the sliding blocks; a movable rod is arranged between the two support plates; sliding rails extending along the height directions of the support plates are arranged on opposite sides of the two support plates respectively; two ends of the movable rod are connected to the sliding rails on the two support plates respectively through the structures sliding rails and sliding blocks; an electric heating block is fixed on the movable rod. The device can be used for simultaneously flattening a plurality of wheat straw pieces; the flattening efficiency is improved.

Owner:丰县汉邦商贸中心

Flattening device for tile laying

ActiveCN110485688BQuickly flattenGuaranteed levelBuilding constructionsEngineeringStructural engineering

The invention discloses a flattening device for tile laying. The flattening device for tile laying comprises a base, wherein the base is provided with an elastic lifting device, the elastic lifting device is provided with a manual adjustment type flattening device, and the manual adjustment type flattening device is provided with a multi-directional hammering vibration device. By the rotation of an adjusting screw and observing through horizontal bubbles and a circular horizontal bubble, the level degree of a tile pressing plate can be quickly adjusted, meanwhile, the level degree between thetile being flattened and other tiles can be detected by the rotation of level bars, and thus, the tiles can be flattened quickly; and by the rotation of a hammering eccentric wheel and the cooperationof compression springs, the tile pressing plate is hammered repeatedly by rubber hammers at the lower ends of hammering telescopic columns, so that the tile pressing plate enables the vibration forcegenerated by hammering to be transmitted to the tiles, the tiles are fully combined with cement through vibration, the firmness of the tile bonding is ensured, meanwhile, the flattening speed of thetiles can be increased by the vibration, and the flattening efficiency can be improved.

Owner:CHINA AEROSPACE CONSTR ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com