Patents

Literature

41results about How to "Avoid manual pulling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

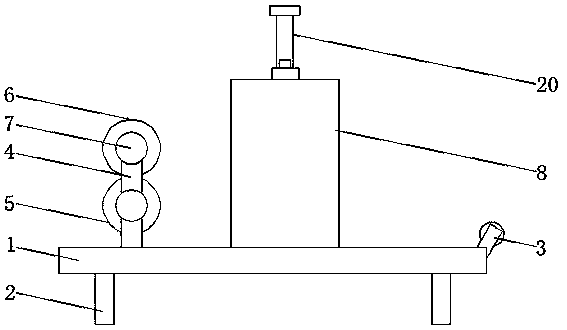

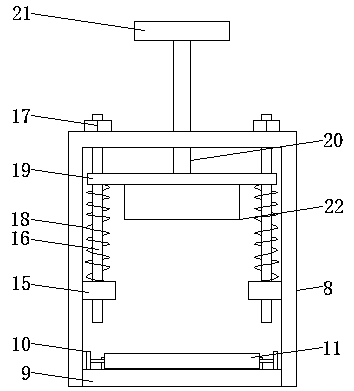

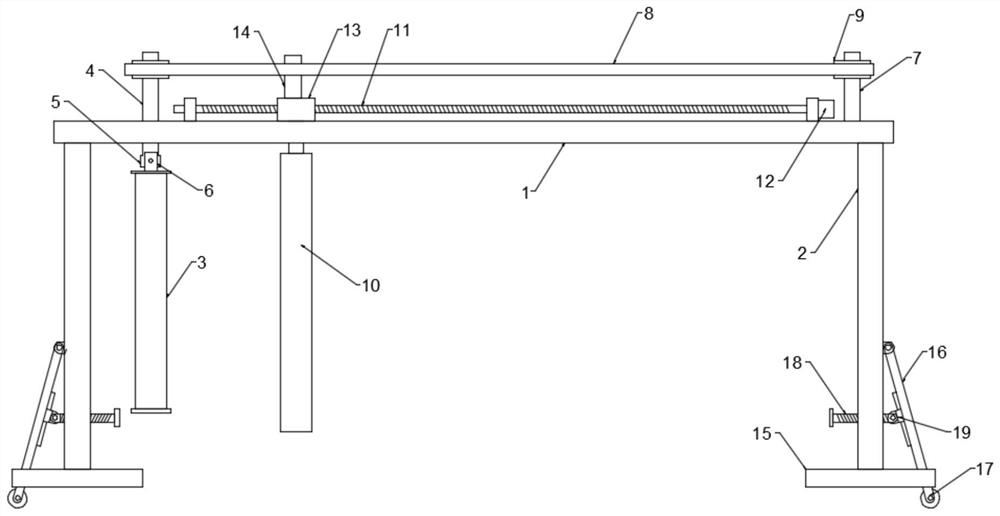

Cable pay-off device for power construction

ActiveCN110061451AReduce difficultyImprove laying efficiencyApparatus for laying cablesEngineeringConductor Coil

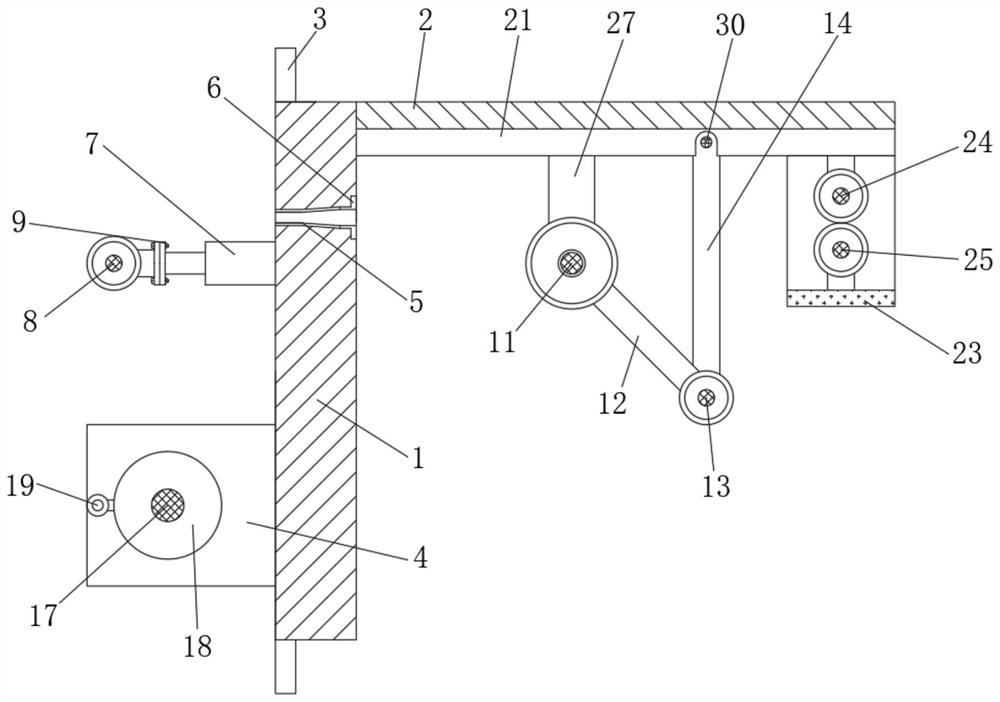

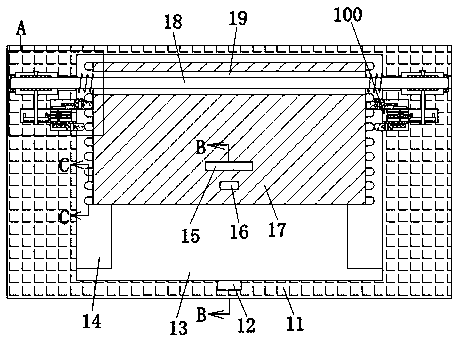

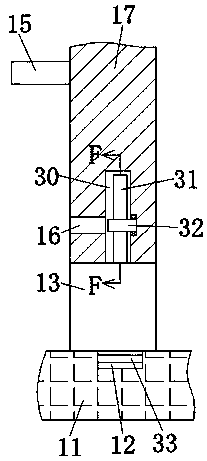

The invention discloses a cable pay-off device for power construction. Vertical posts are arranged at two ends of a bottom plate, a guide rail is arranged at one side of each vertical post, an air cylinder is fixedly arranged on the bottom plate, a first sliding block is arranged at an upper end of a piston rod of the air cylinder, upper ends of the vertical posts at two sides are connected by a top plate, two ends of a second connection rod are placed on the first sliding block, a plurality of cable discs are arranged on the second connection rod, a plurality of second supports are arranged at one side f the top plate, a first rotation shaft is arranged on the second supports, a plurality of winding wheels are movably arranged on the first rotation shaft, the numbers of the first windingwheels are equal to the numbers of the cable discs, and the first winding wheel slides among the second supports along an axial direction of the first rotation shaft. The cable disc is jacked up by the air cylinder, the cable disc is prevented from being contacted with ground, so that the friction between the cable disc and the ground is prevented, and the cable pay-off difficulty is reduced; andmoreover, multiple groups of cable discs are arranged on the second connection rod and are used for unwinding, the labor intensity of a worker is reduced, and the cable laying efficiency is greatly improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

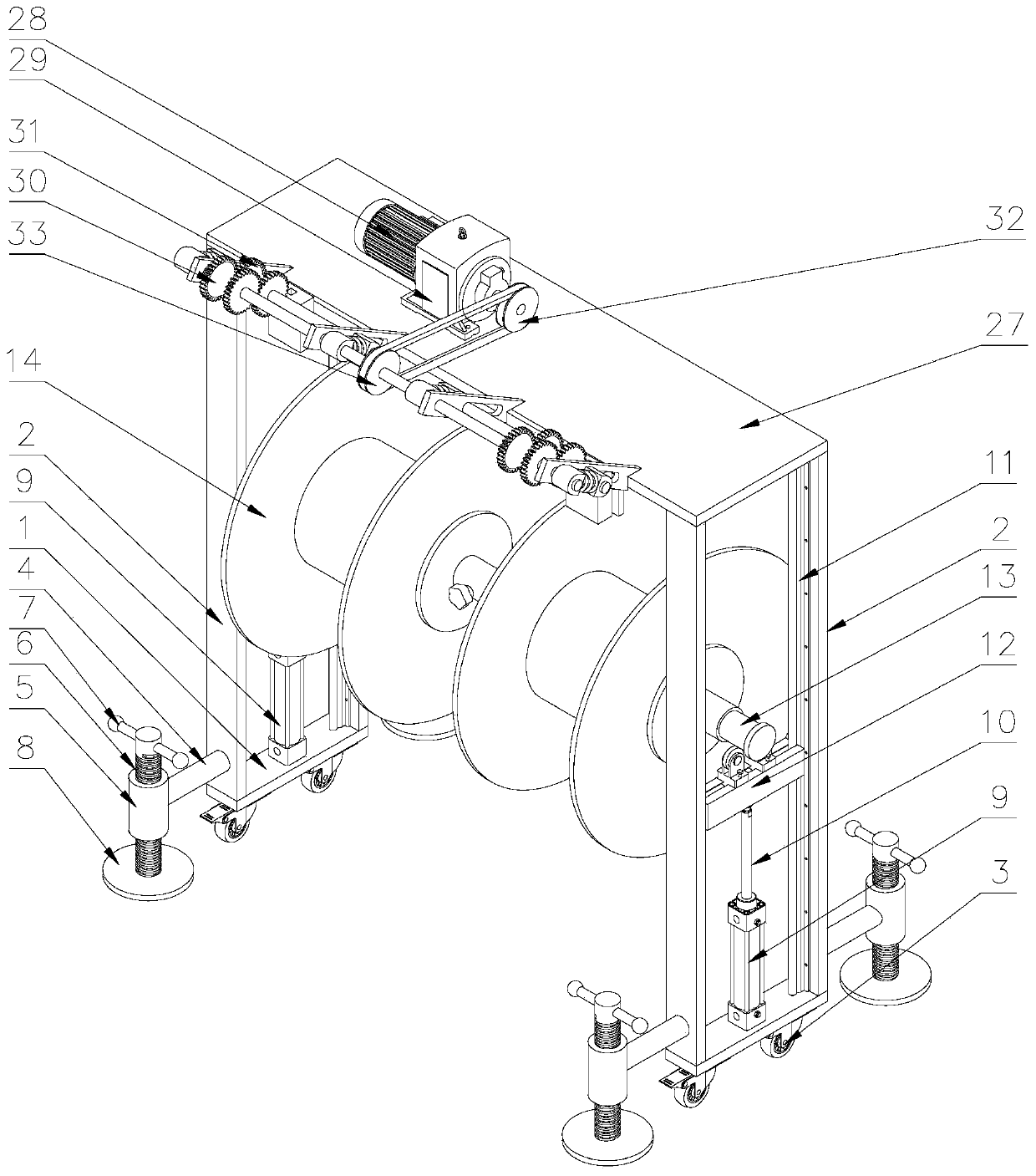

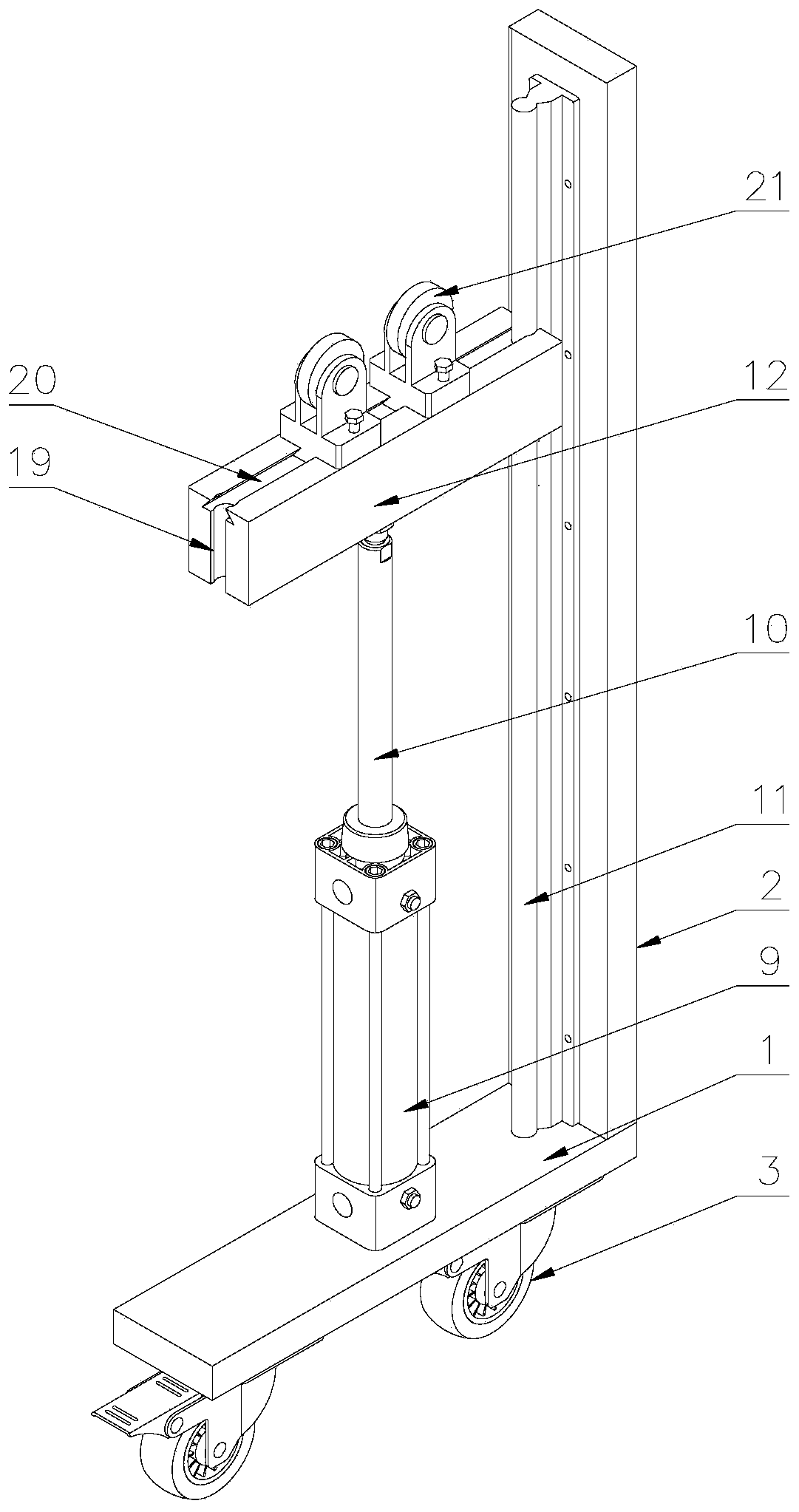

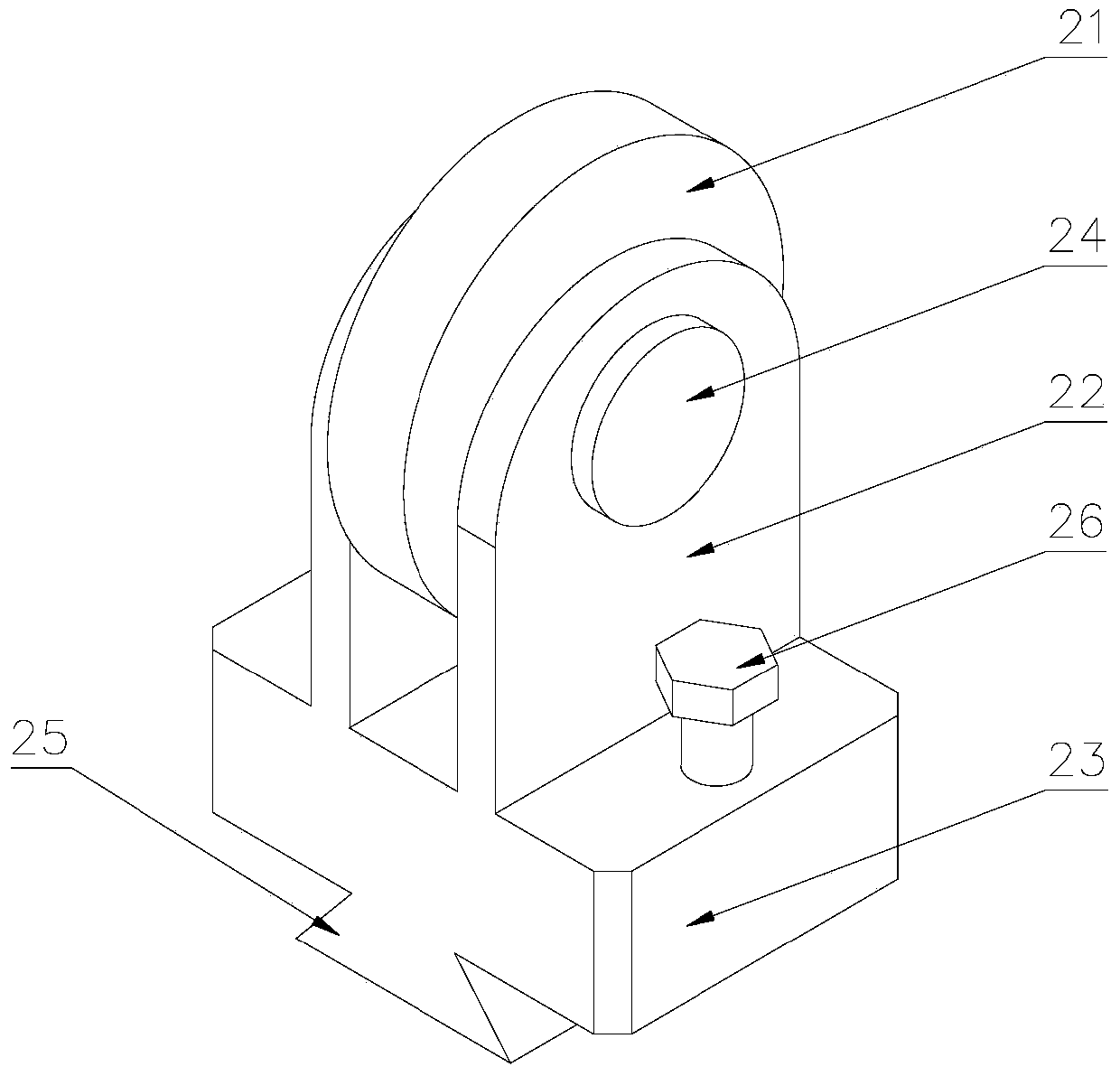

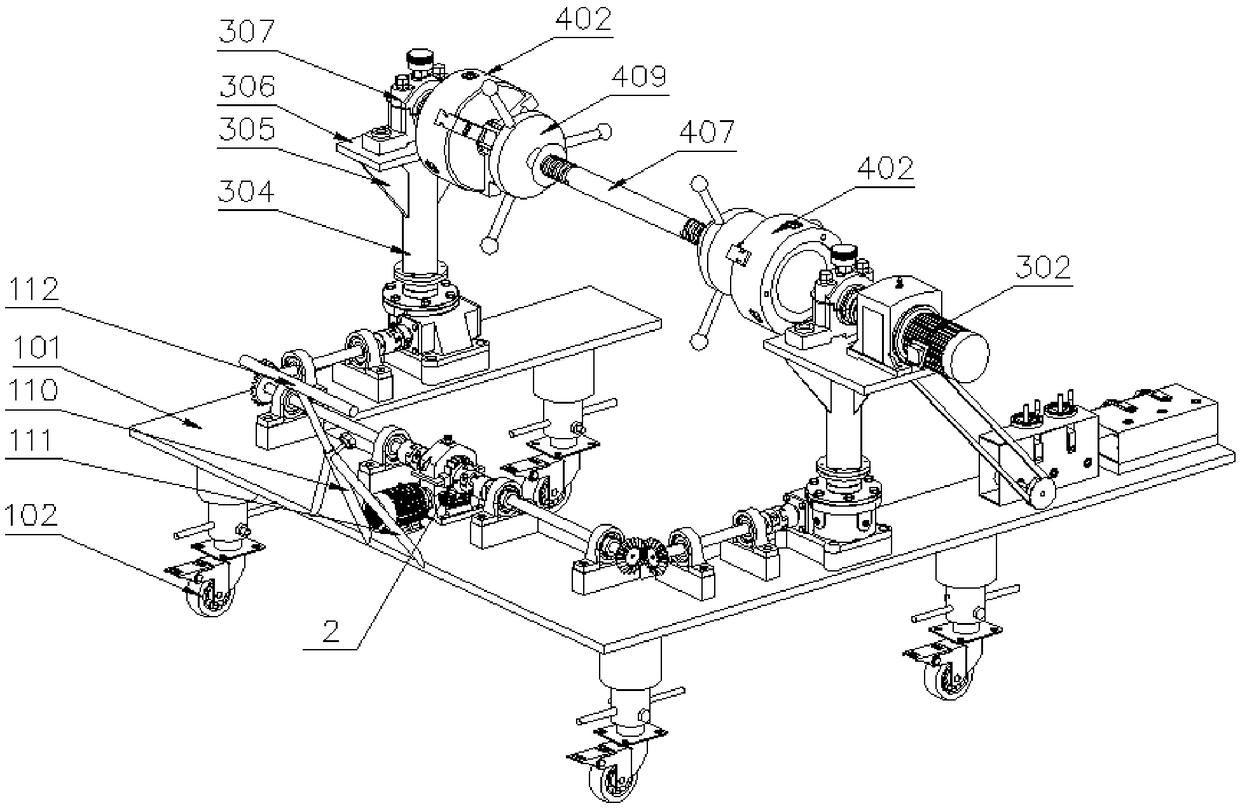

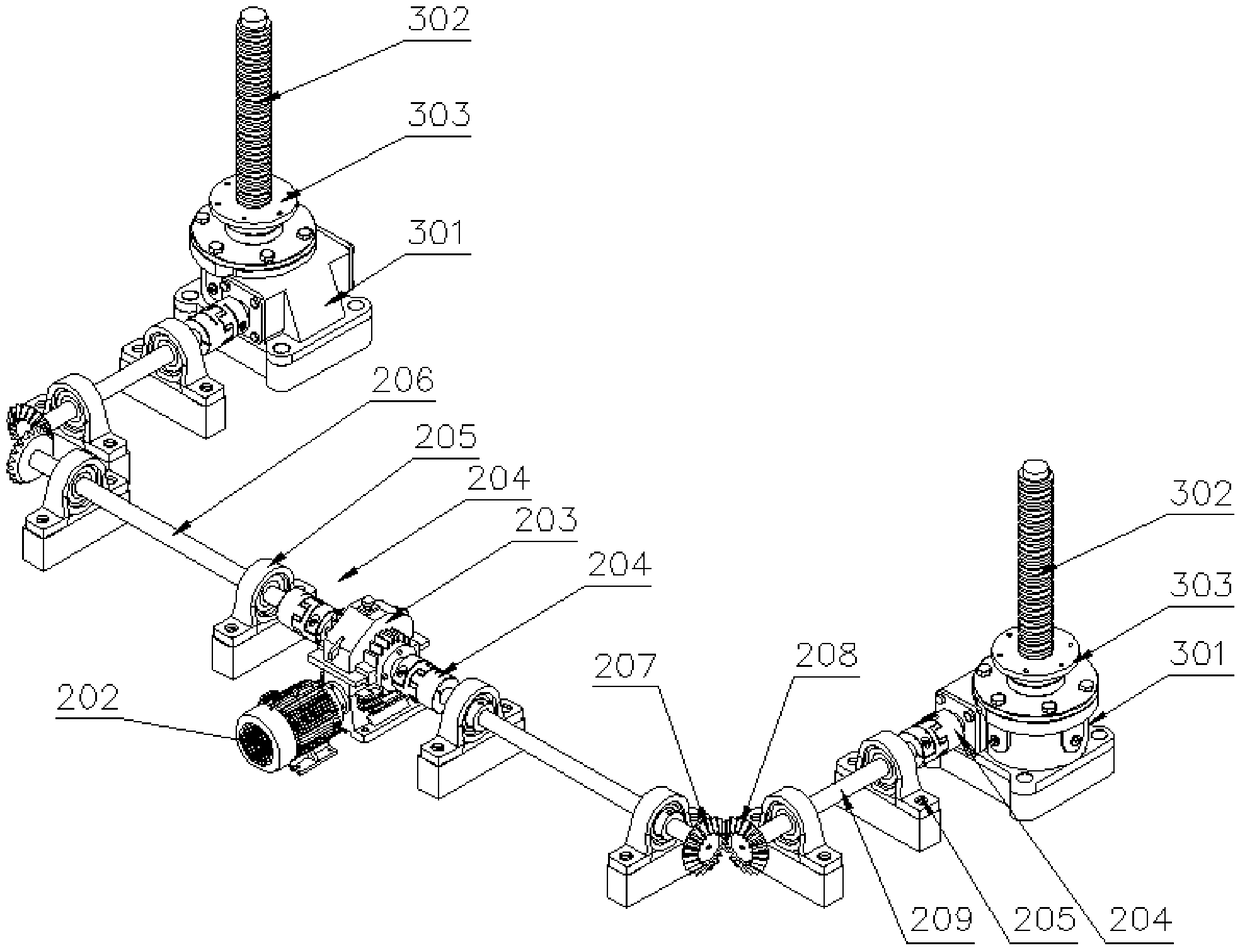

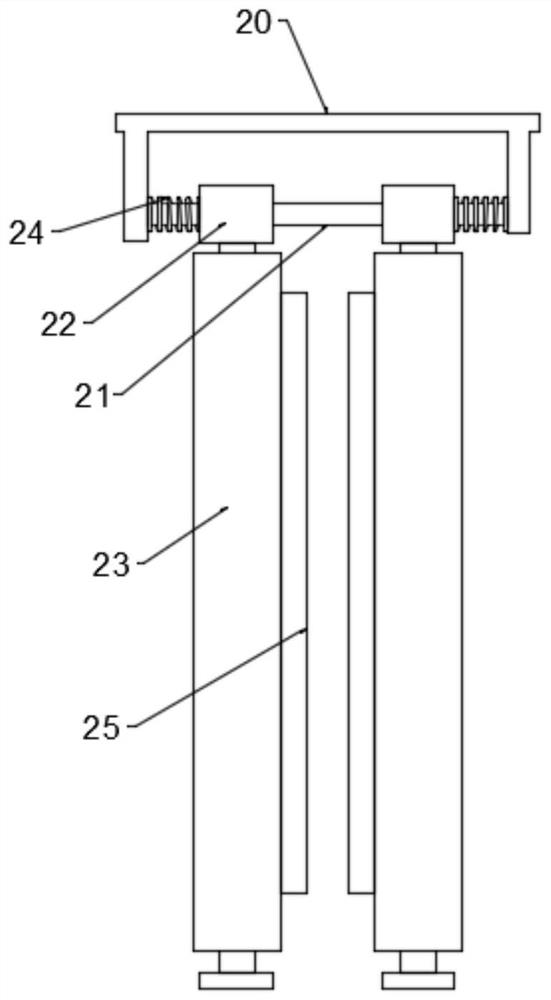

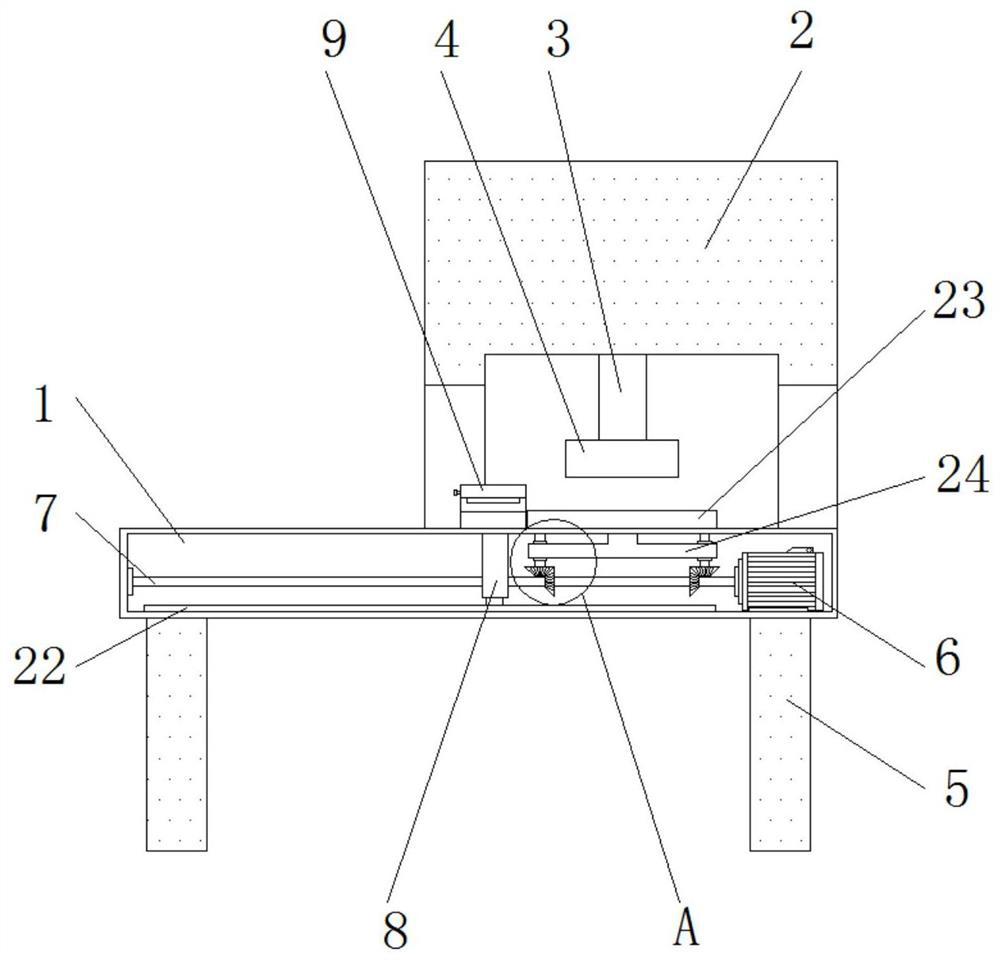

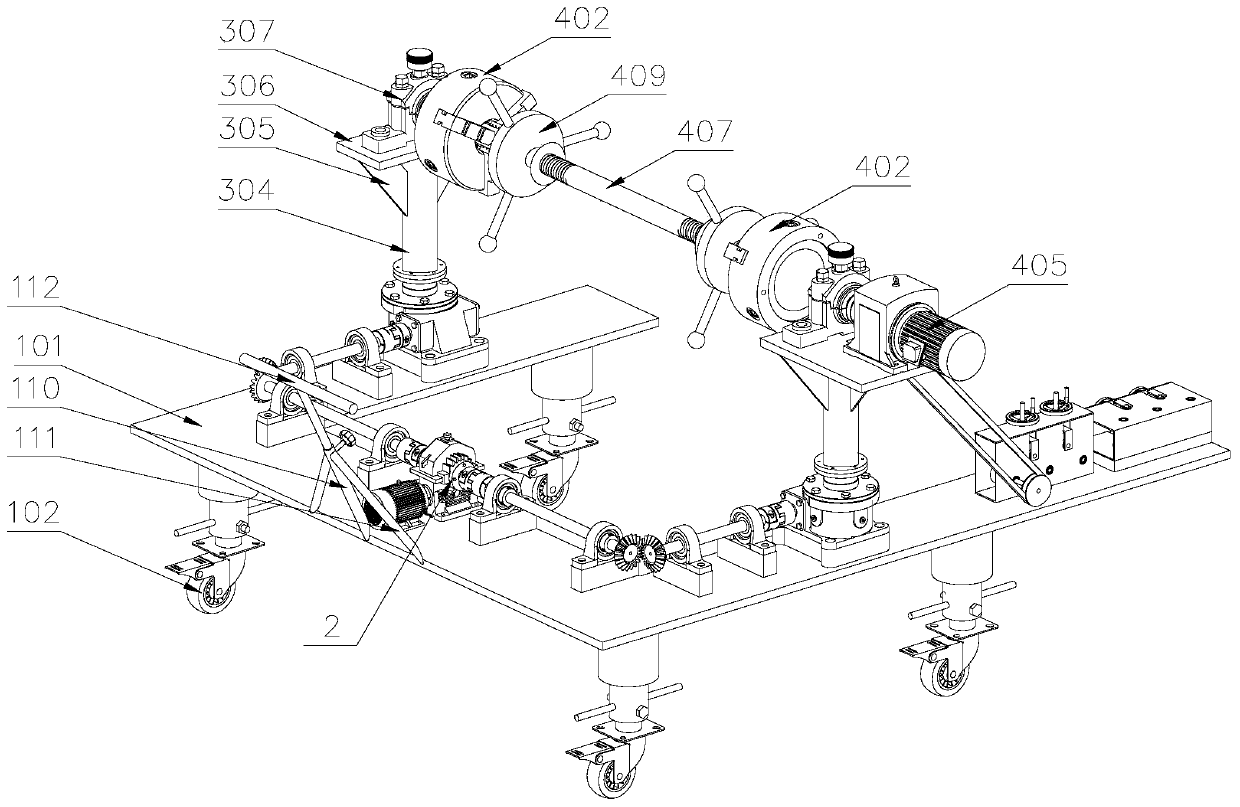

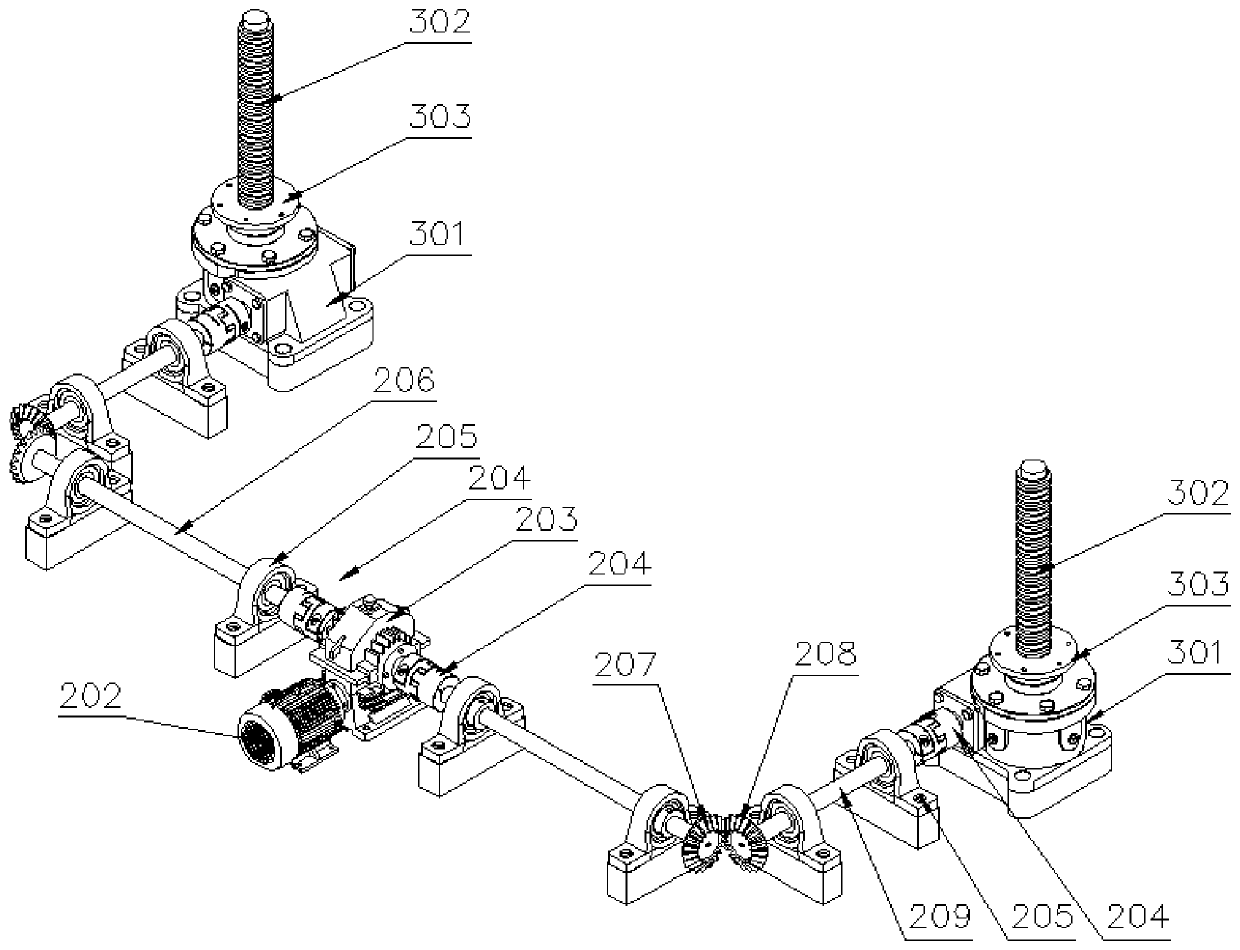

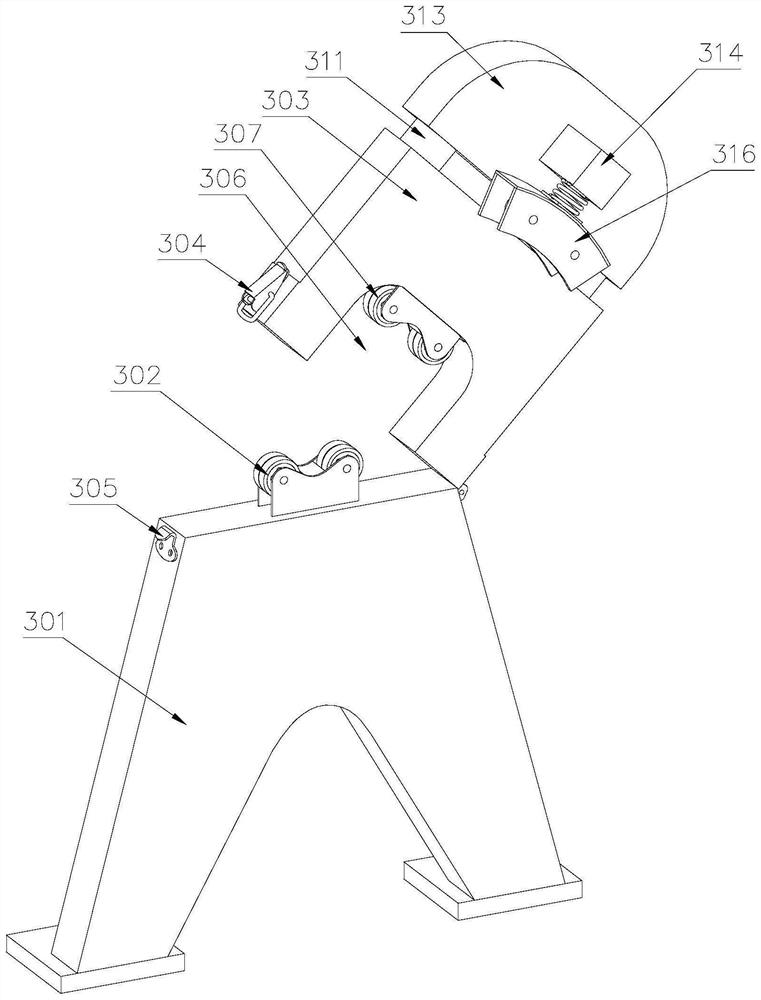

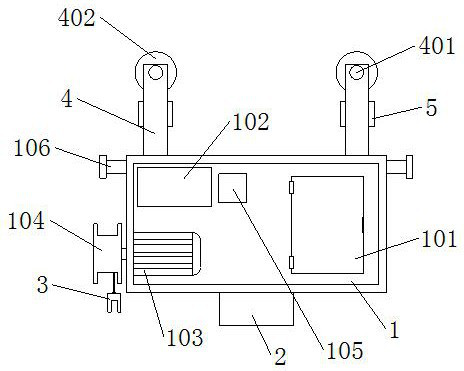

Cable laying assisting device

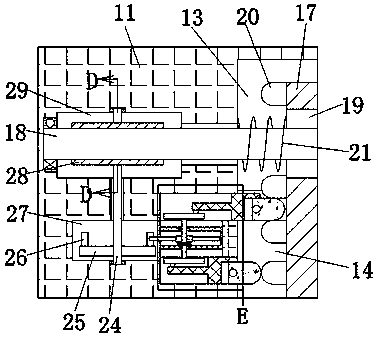

The invention discloses a cable laying assisting device. One side of a transmission motor is provided with a double-headed reducer; one end of each first transmission shaft is provided with a drivinggear; one end of each second transmission shaft is provided with a driven gear that is engaged with the corresponding driving gear; one side of each second transmission shaft is provided with a lifting device; the input shaft of each screw jack is connected with the corresponding second transmission shaft through a coupling; the upper part of each screw sleeve I is provided with a screw sleeve III; the upper parts of the supporting plates is provided with a rotating device; the rotating device comprises bearing seats II, rotating shafts I, chucks, and a rotating shaft II; the bearing seats IIare fixedly mounted on the upper parts of the supporting plates respectively; the bearing seats II are internally provided with bearings respectively; the rotating shafts I are installed in bearing inner rings inside the bearing seats II respectively; one end of each rotating shaft I is fixedly connected with the corresponding chuck; and two ends of the rotating shaft II are respectively installedinside the chucks at two sides. The cable laying assisting device of the invention is of an integrated structure. With the cable laying assisting device adopted, operation can be completed by one person, so that work efficiency is high; and the lifting device adopts a linkage manner, and the lifting rate of the lifting device is uniform, and therefore, the inclination of a cable reel can be avoided.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

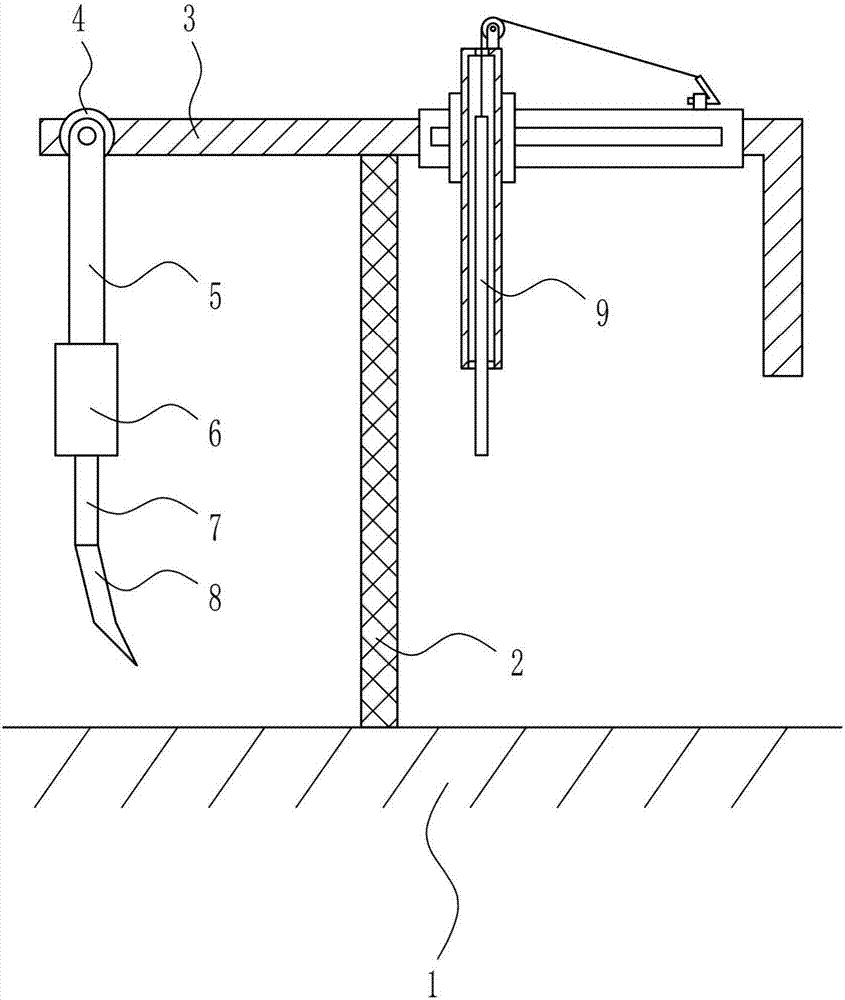

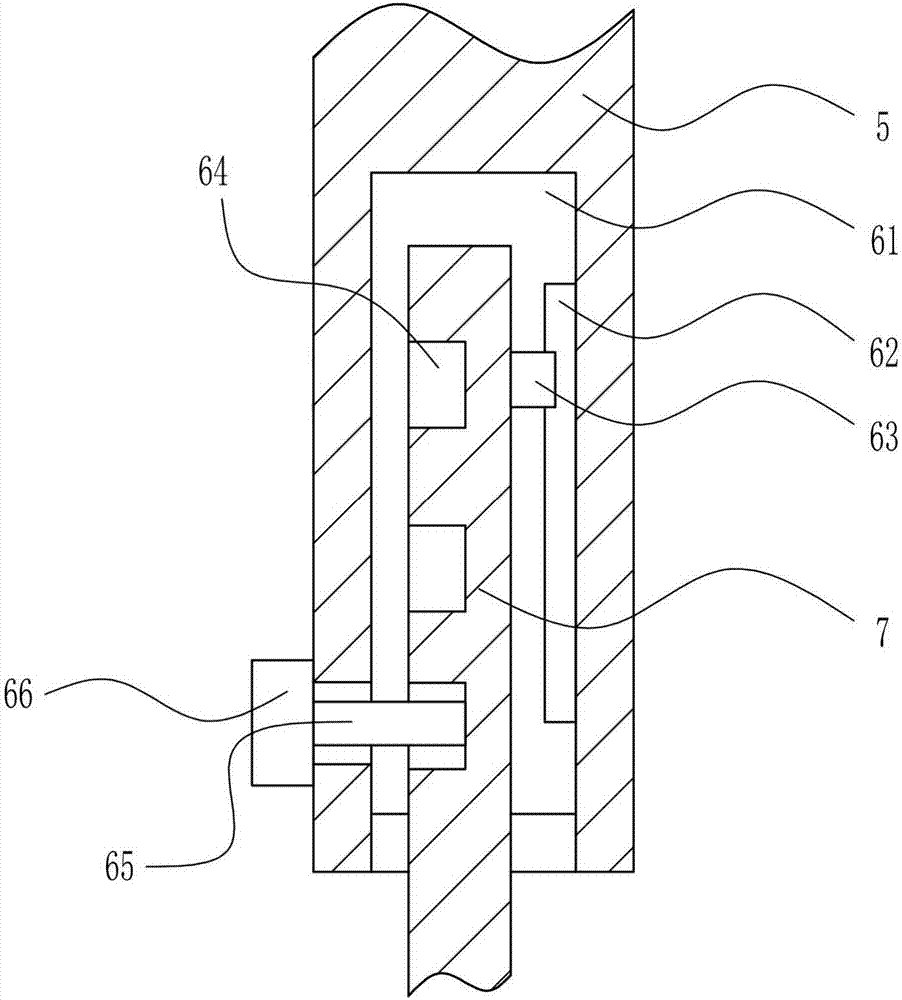

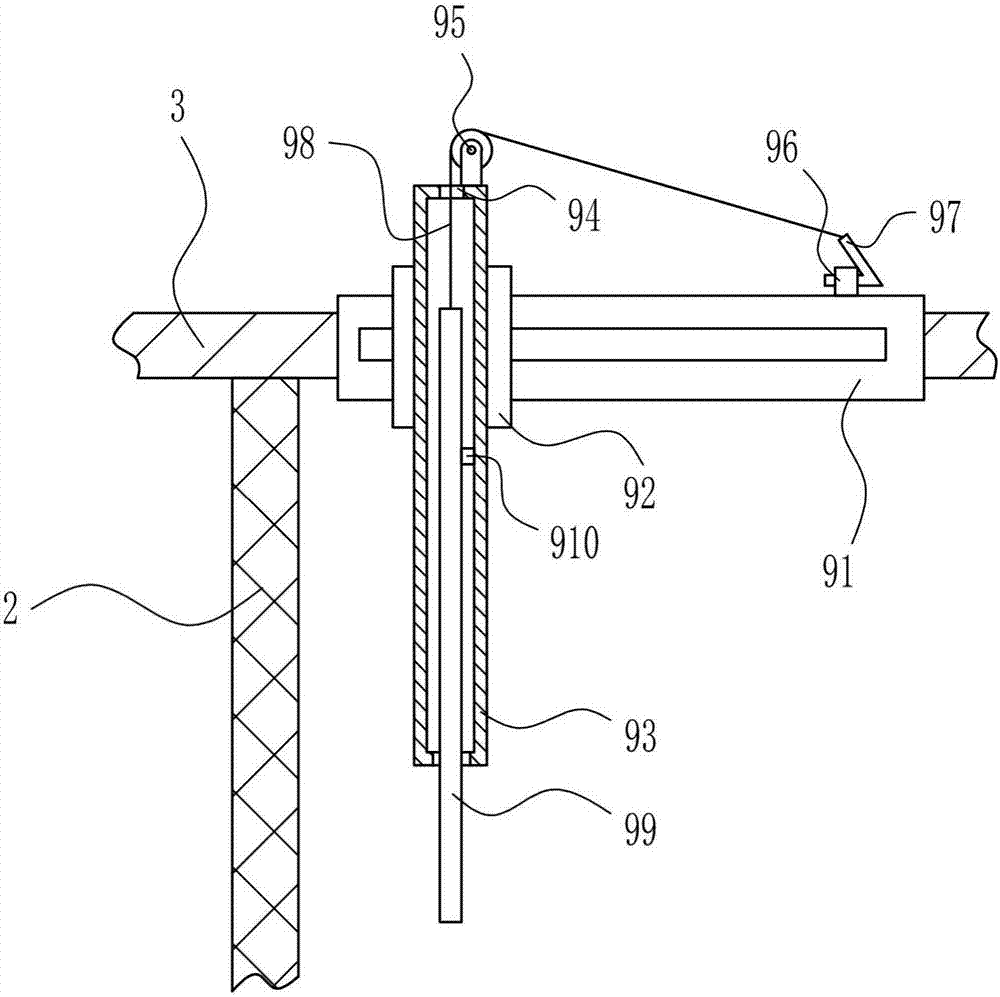

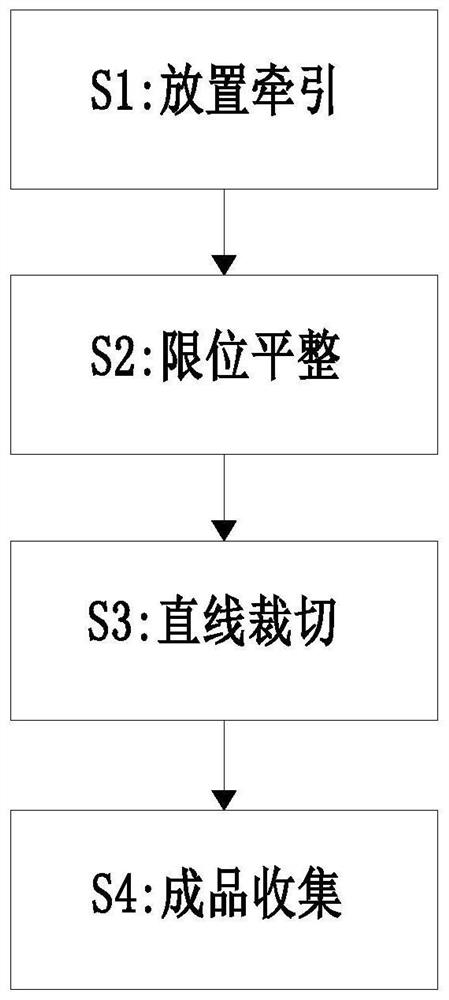

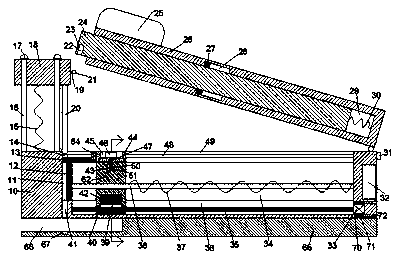

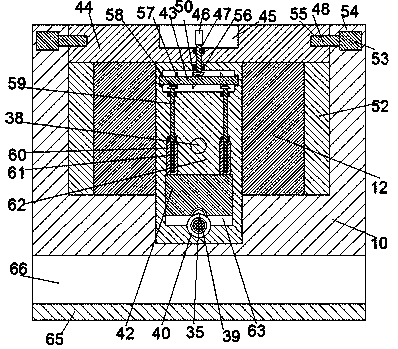

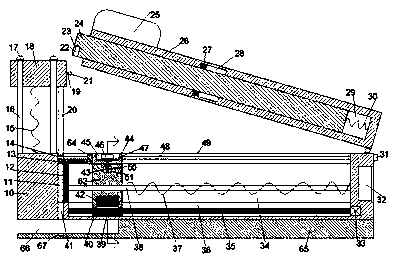

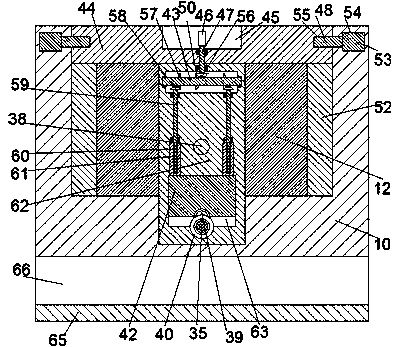

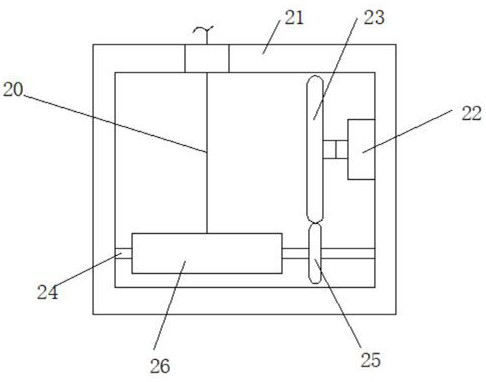

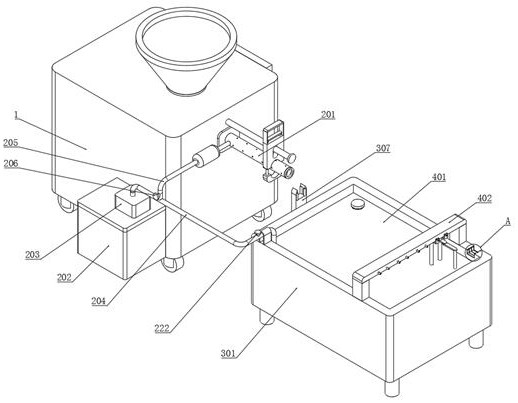

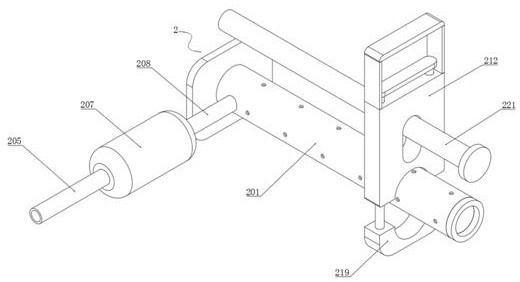

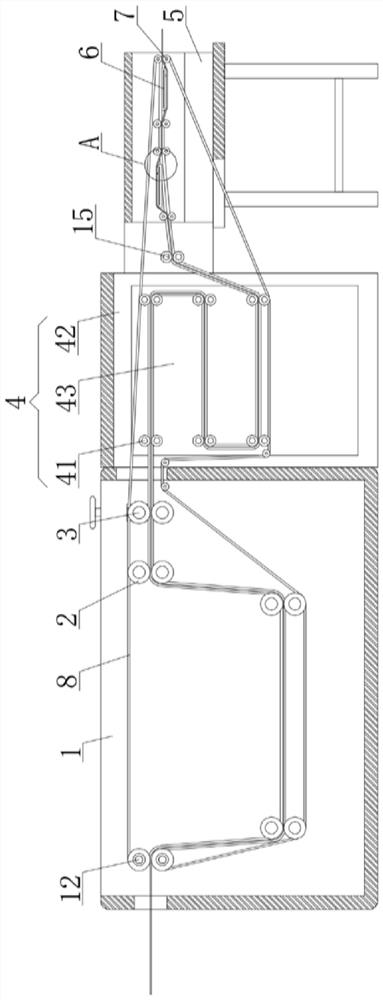

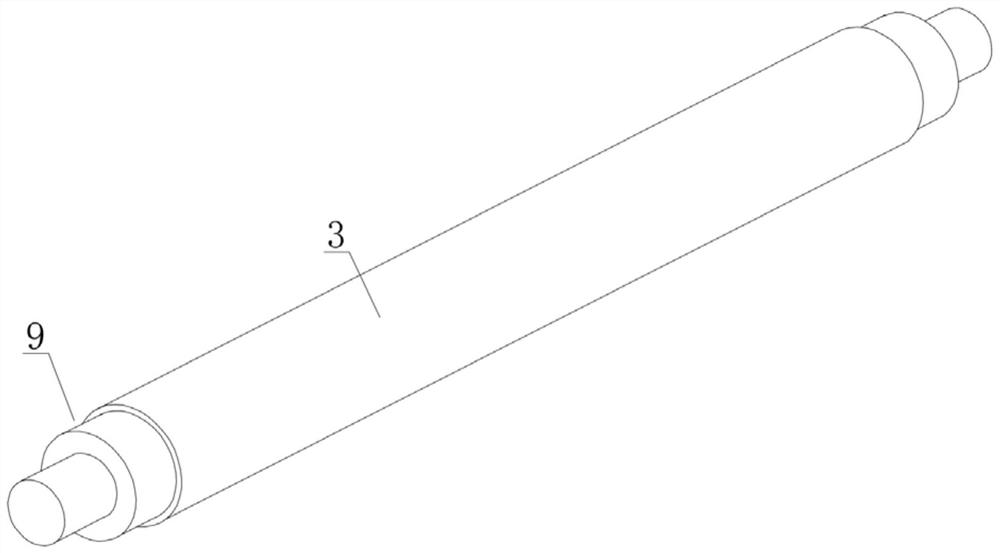

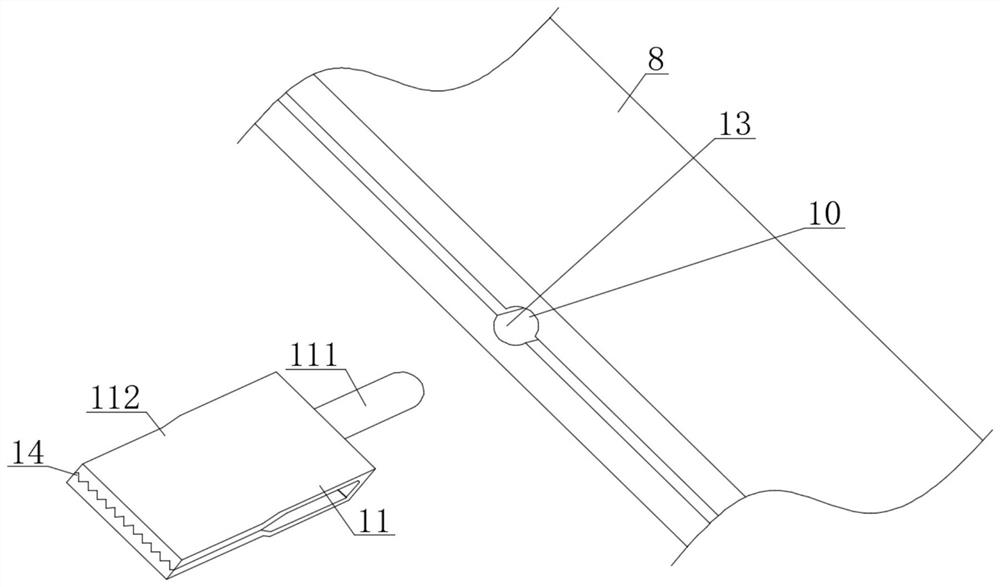

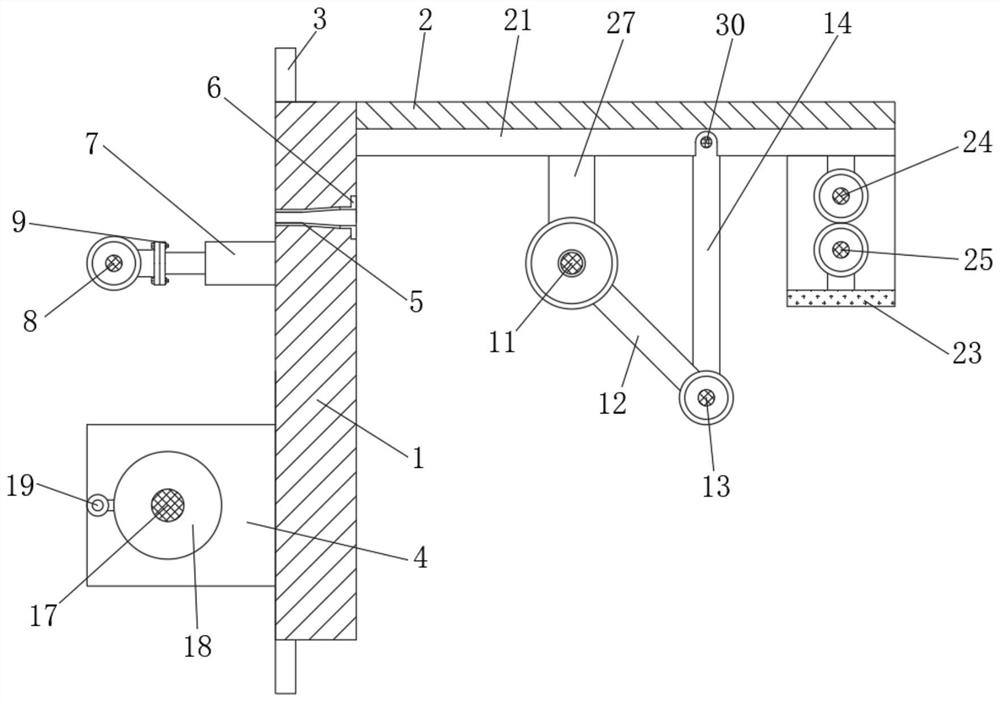

Film cutting equipment for agricultural greenhouse

InactiveCN108789527AAvoid manual pullingShear speed is fastMetal working apparatusArticle deliveryGreenhouseAgricultural engineering

The invention discloses film cutting equipment for an agricultural greenhouse. The film cutting equipment comprises a workbench; a vertical plate is fixedly connected to the upper surface of the workbench, and the back surface of the vertical plate is rotationally connected with a lower rotary roller and an upper rotary roller; the axis of the lower rotary roller and the axis of the upper rotary roller are fixedly connected with motors; one side of the vertical plate is provided with a cutting frame fixedly connected to the top of the workbench, and the bottom of the cutting frame is fixedly connected to a base; the top of the base is fixedly connected with a side plate, the back surface of the side plate is rotationally connected with a traction roller, and one side of the traction rolleris provided with a cutter holder fixedly connected to the base; and the inner wall of the cutting frame is fixedly connected with a slide seat. According to the film cutting equipment, by arranging aguide roller, the vertical plate, the lower rotary roller, the upper rotary roller, the motors, the traction roller, the cutter holder, a cutter groove, an elastic plate, slide seats, slide rods, fixed blocks, springs, a cutter handle and a cutter, the problems that manual pulling is needed, the cutting speed is low, and the greenhouse building efficiency is reduced are solved.

Owner:徐州佳联农业发展有限公司

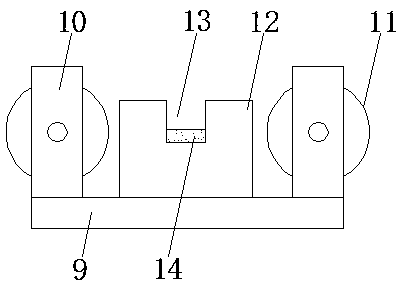

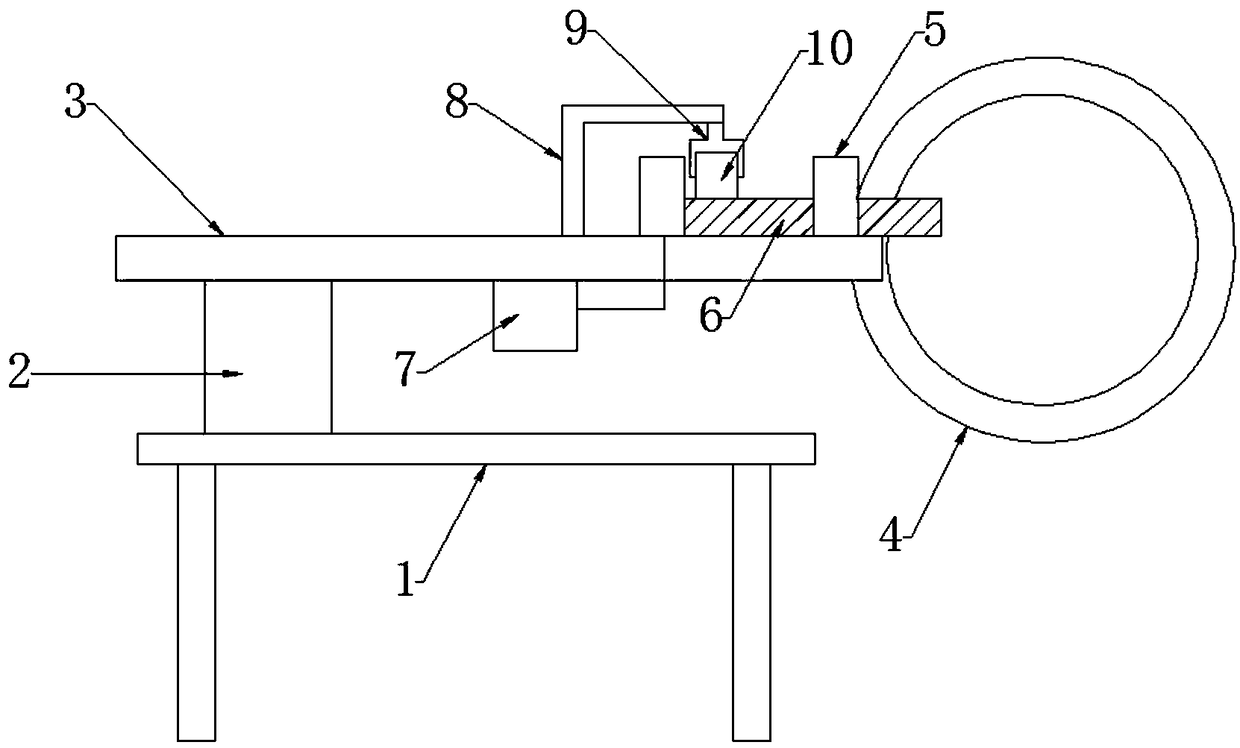

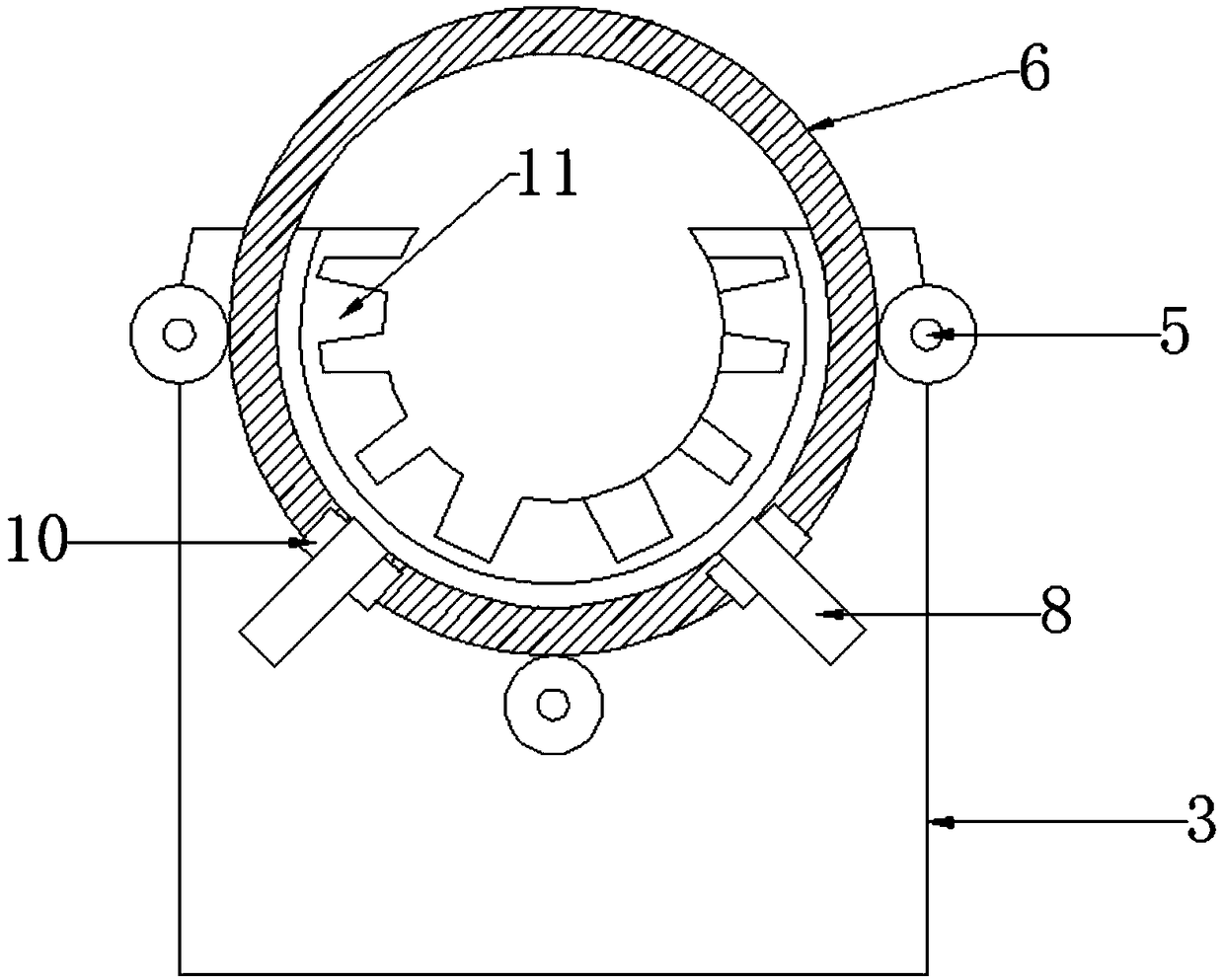

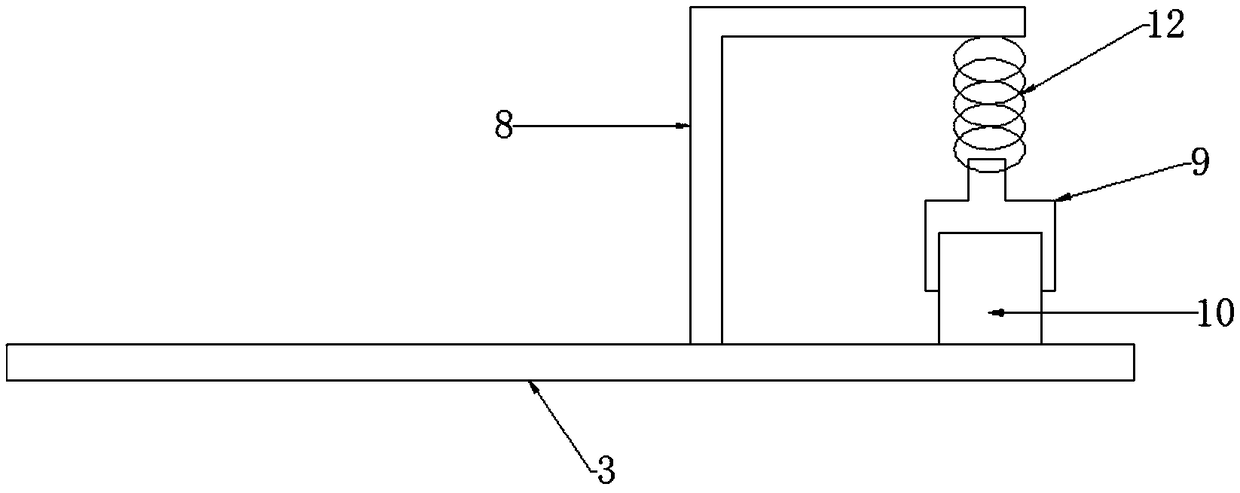

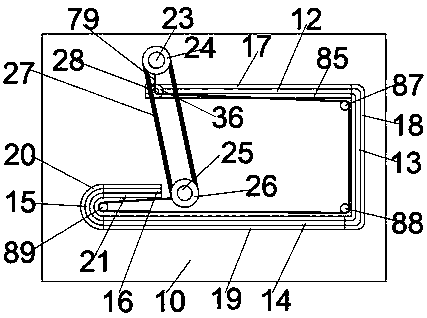

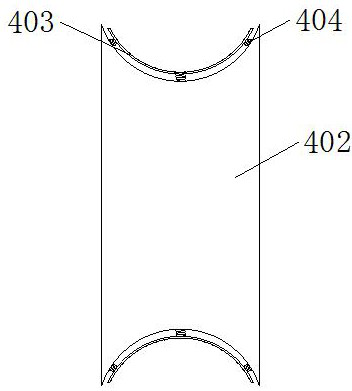

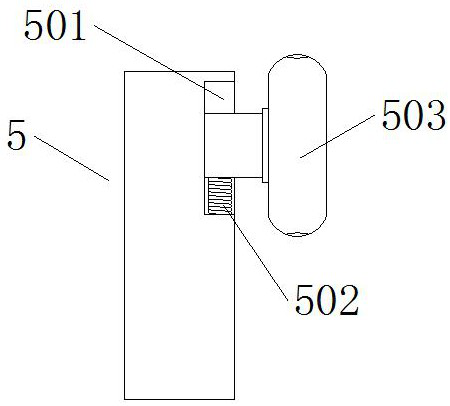

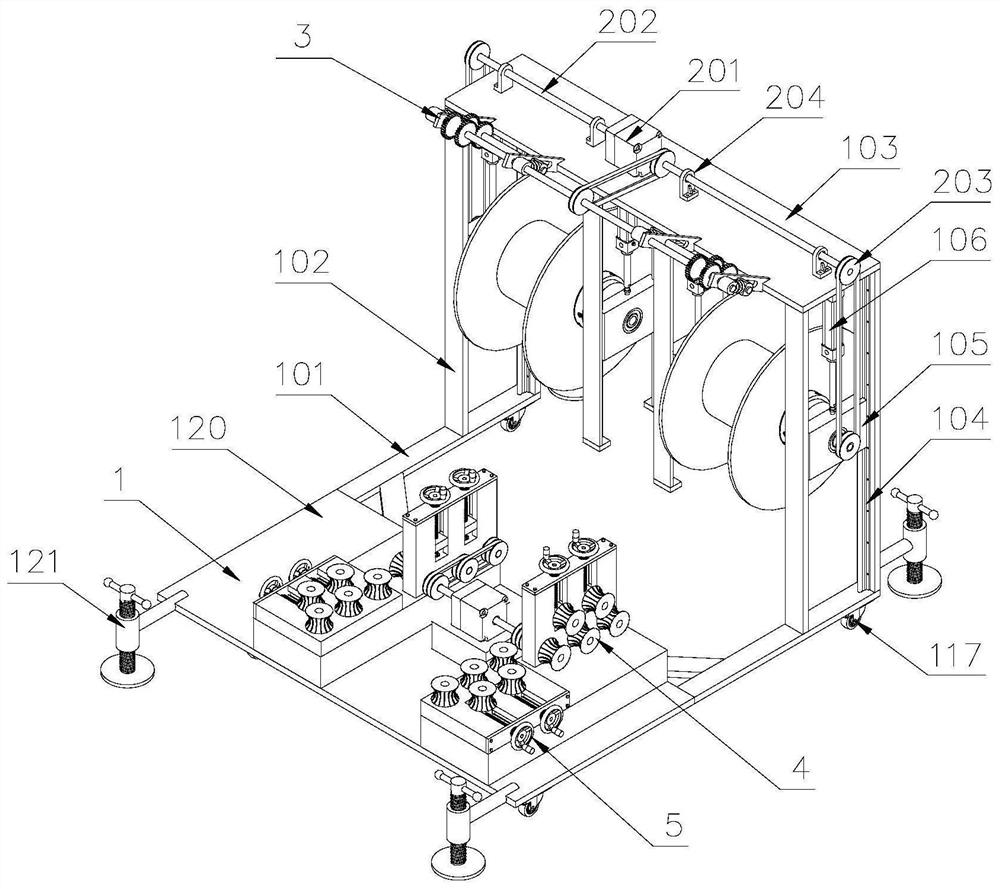

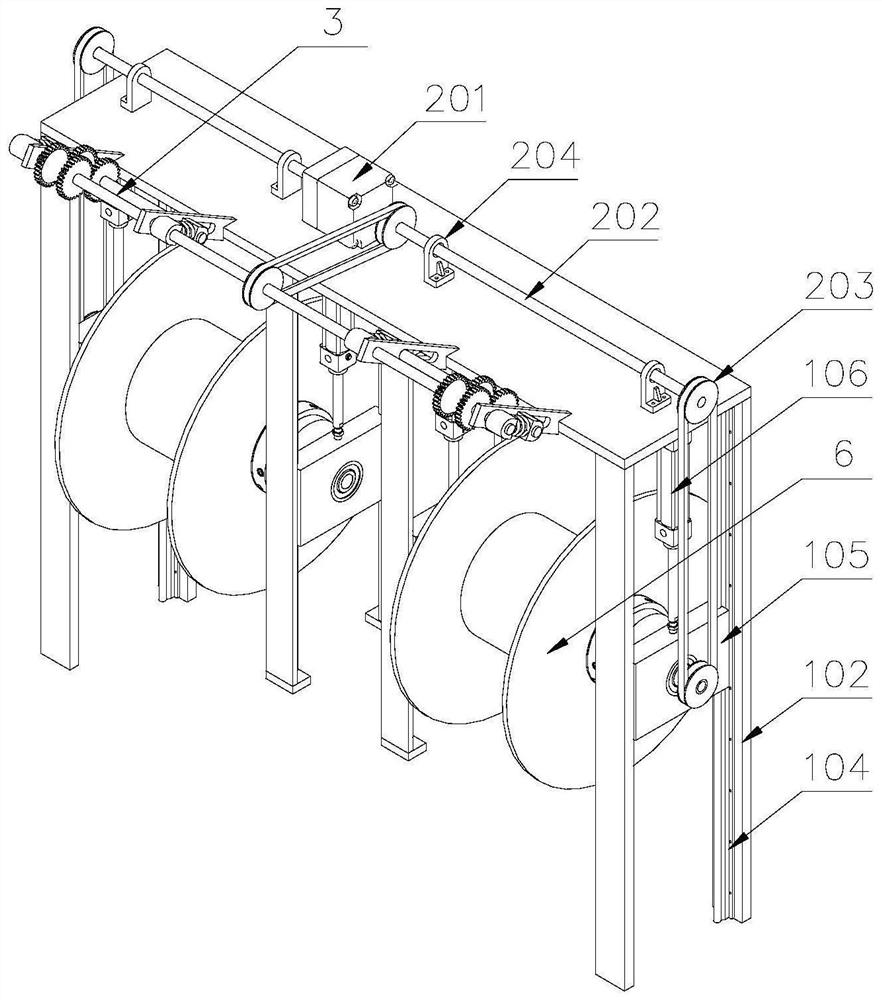

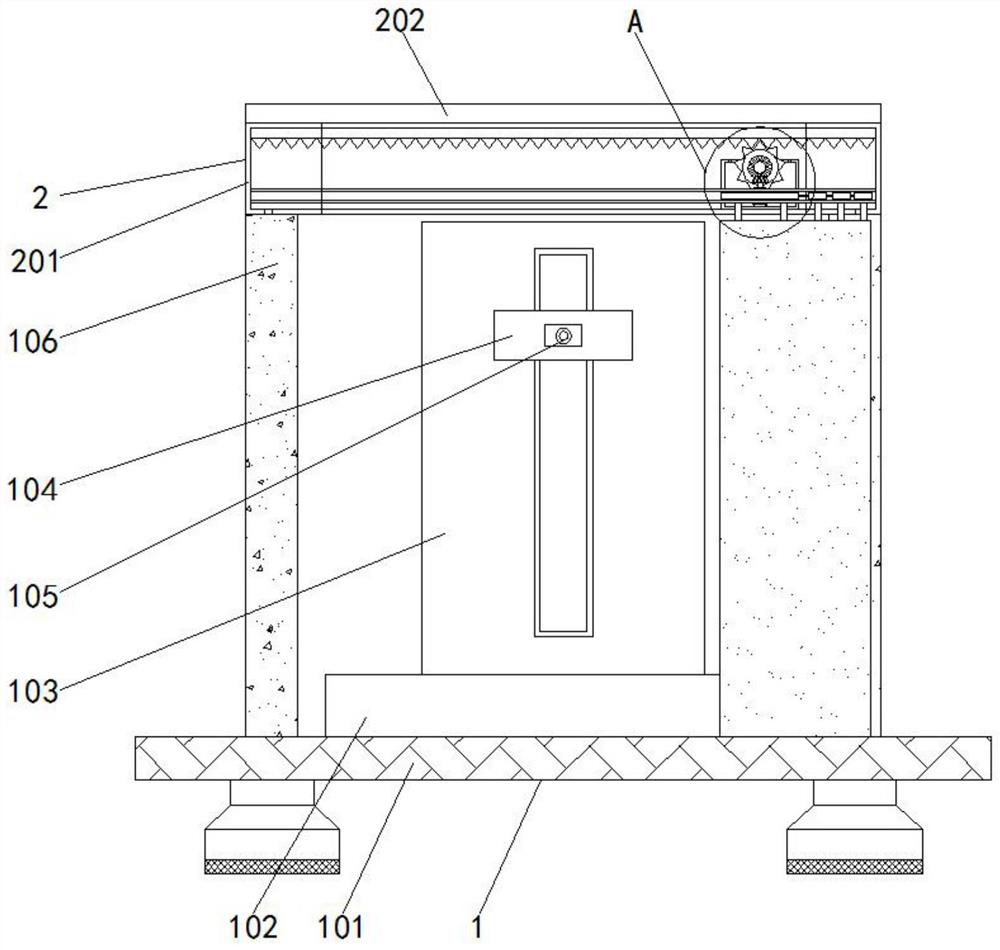

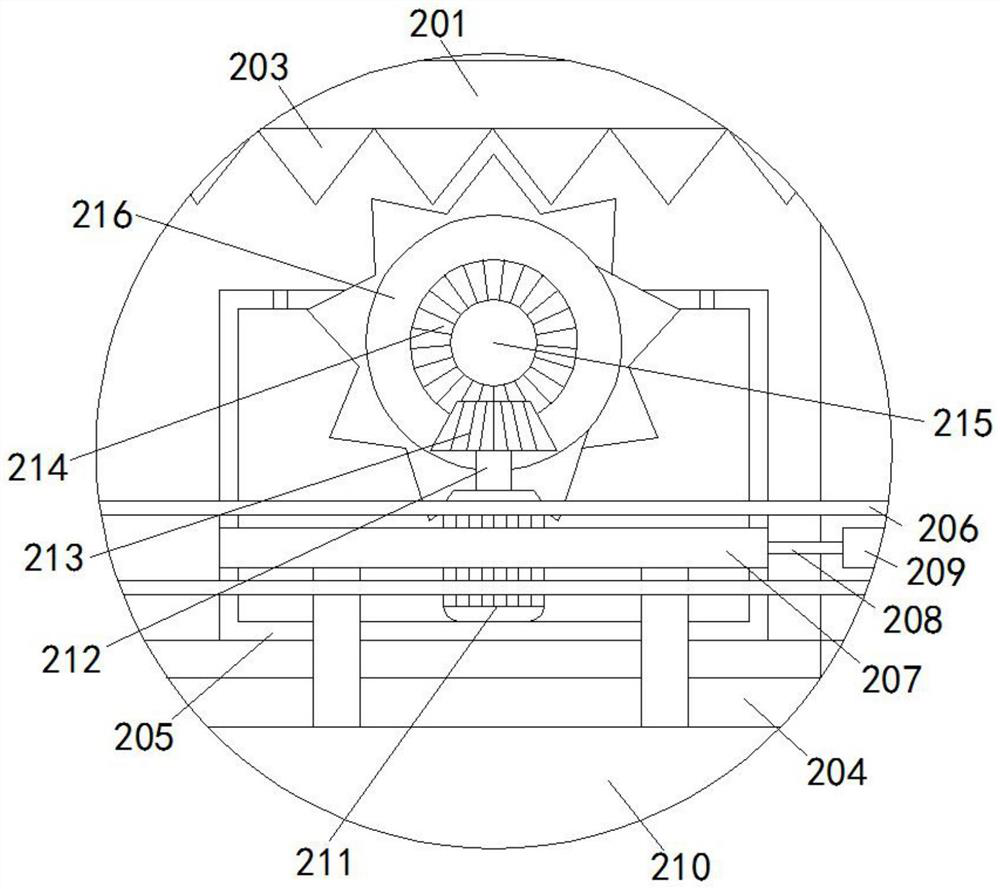

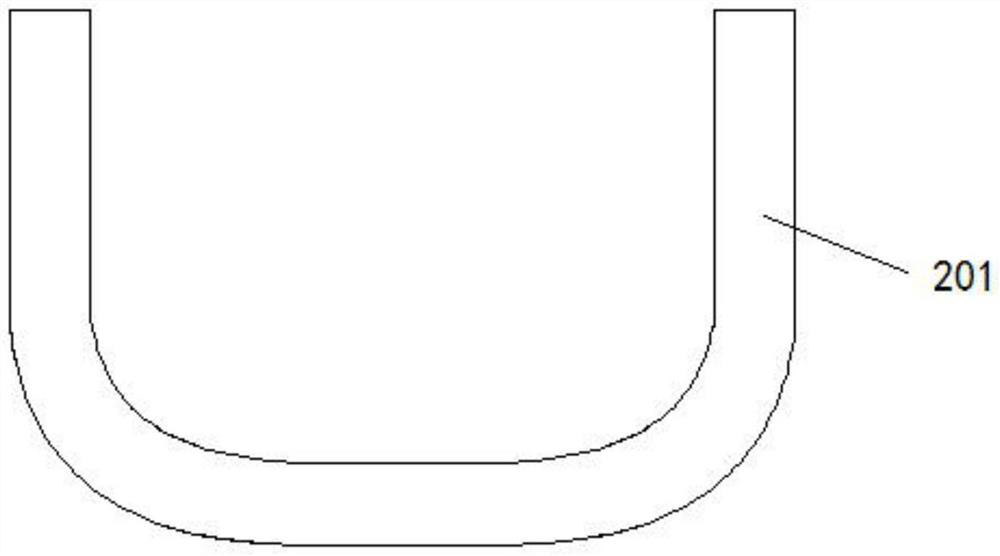

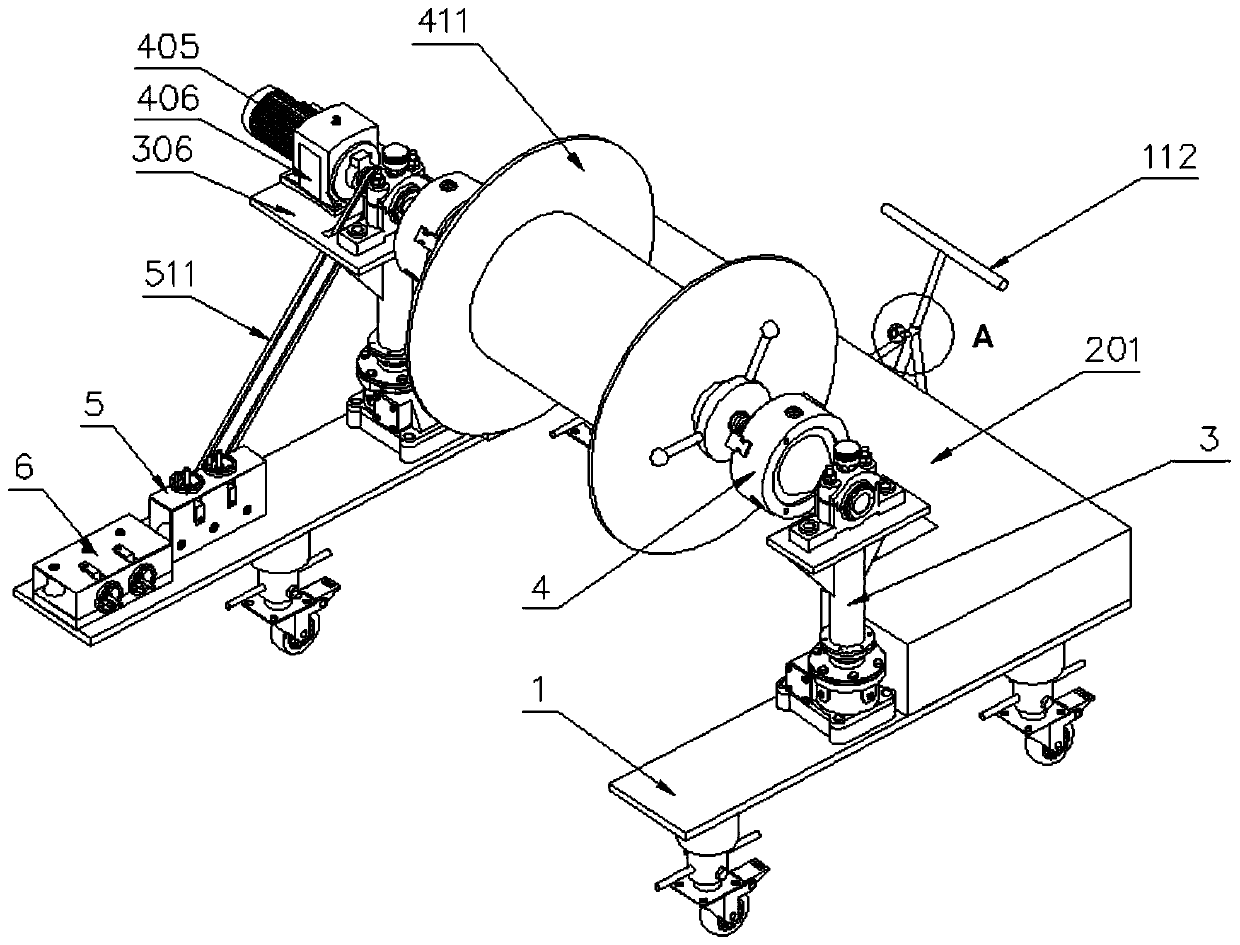

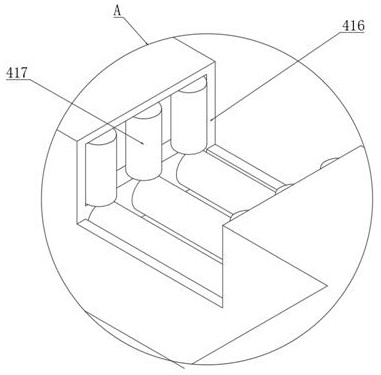

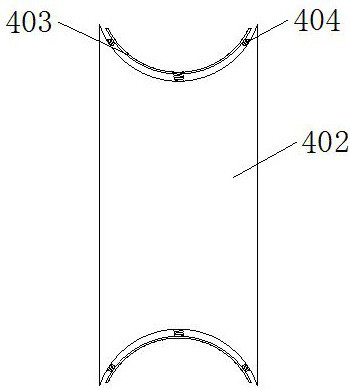

Annular wire winding machine

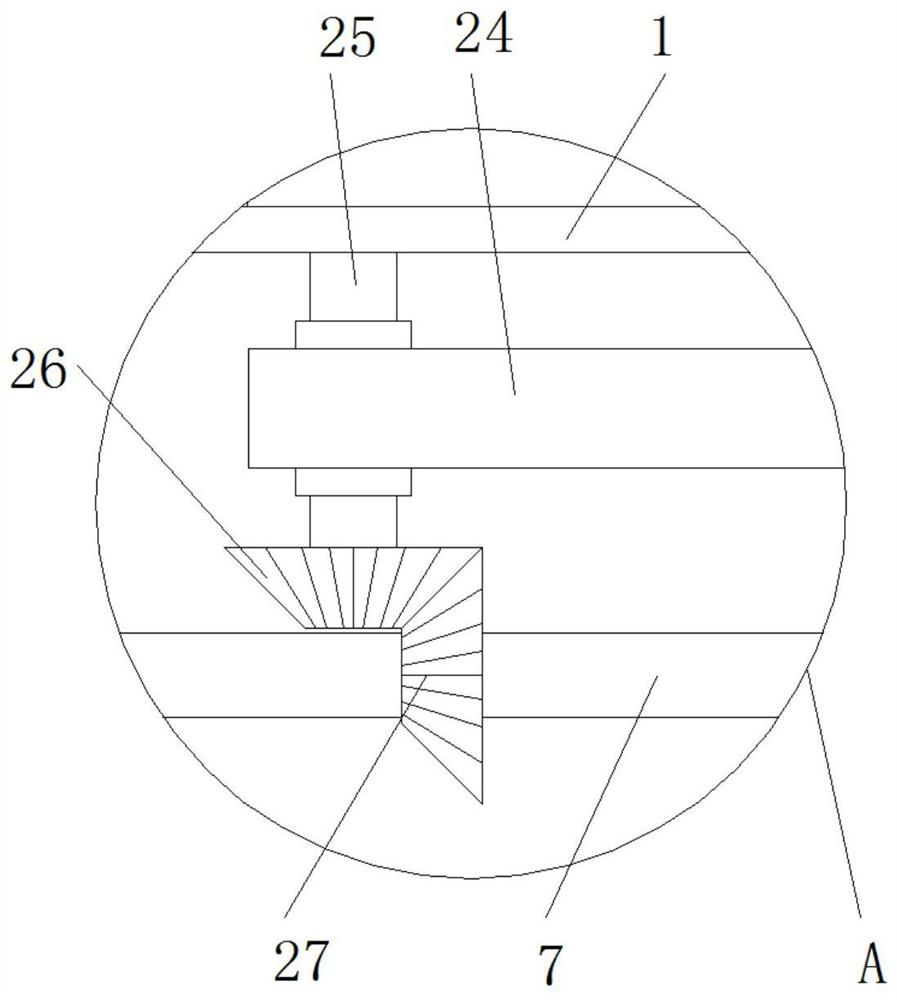

ActiveCN109509633ARotation does not affectPrevent jumpingCoils manufactureWinding machineDrive wheel

The invention discloses an annular wire winding machine, which comprises a machine frame, an assembly machine head, an electric control box, a transmission mechanism, a wire storage ring and a magnetic core clamping mechanism, wherein the magnetic core clamping mechanism comprises a supporting base arranged on the machine frame, and a supporting plate horizontally arranged on the supporting base;a C-shaped groove is formed in one end of the supporting plate, and a central angle of the C-shaped groove is greater than 180 degrees; the wire storage ring is matched with an opening position of theC-shaped groove of the supporting plate, and the plane of the supporting plate is perpendicular to the annular surface of the wire storage ring; the supporting plate is evenly provided with at leastthree roller columns and a driving roller which are perpendicular to the supporting plate, on the outer edge of the C-shaped groove, the roller columns are provided with rollers used for clamping a magnetic core, the driving roller is provided with a driving wheel used for clamping the magnetic core, and the driving wheel is connected with the transmission mechanism by means of the driving roller;and a magnetic core positioning assembly is arranged on the supporting plate. According to the annular wire winding machine, the magnetic core positioning assembly is arranged on the supporting plate, the magnetic core is prevented from moving upwards due to the rotation and traction of the wire storage ring in the wire winding process of the magnetic core, the wire winding evenness of the magnetic core is ensured, and the wire winding quality of the magnetic core is improved.

Owner:JIANGYIN SPARK ELECTRONICS TECH

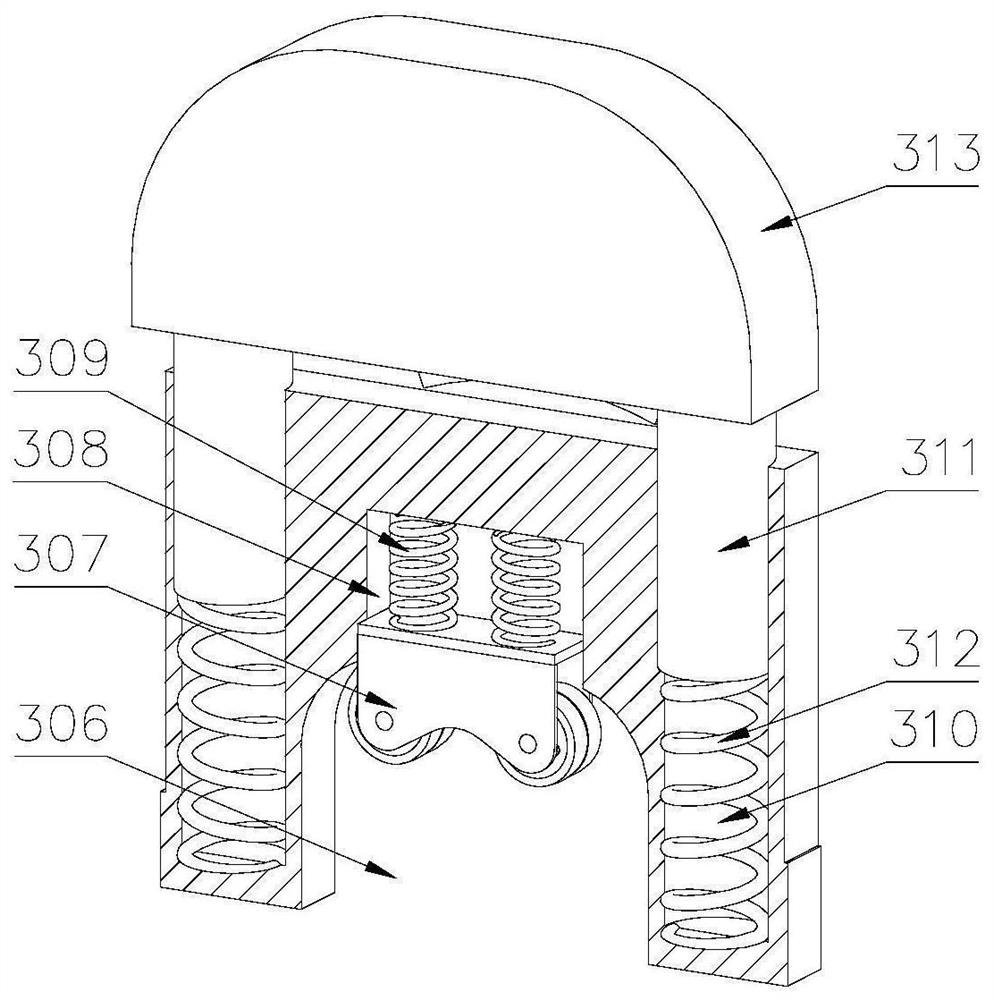

Sand screening equipment for construction

InactiveCN107185791APrevent disengagementAvoid Manual PullingSievingScreeningElectric machineryConductor Coil

The invention relates to screening equipment, in particular to sand screening equipment for construction. The sand screening equipment for construction is easy to operate, capable of saving time and labor and ideal in screening and comprises a network plate, an L-shaped connecting rod, a motor, a supporting rod, a lifting device and the like. The network plate is arranged at the top of the ground; the L-shaped connecting rod is arranged at the top of the network plate; the motor is arranged on the left side of the top of the L-shaped connecting rod; the supporting rod is connected on an output shaft of the motor; a connecting rod is connected at the bottom end of the supporting rod through the lifting device; a shovel is connected at the bottom end of the connecting rod; and a sand pushing device is arranged on the front side of the right portion of the connecting rod. According to the sand screening equipment, through a blocking block, the situation that a pushing plate excessively downwards moves, and thus the pushing plate is completely separated from a hollow mounting plate can be effectively avoided, and labor is replaced by a rotating winding wheel to pull the hollow mounting plate, so that equipment operation is easy.

Owner:汪永清

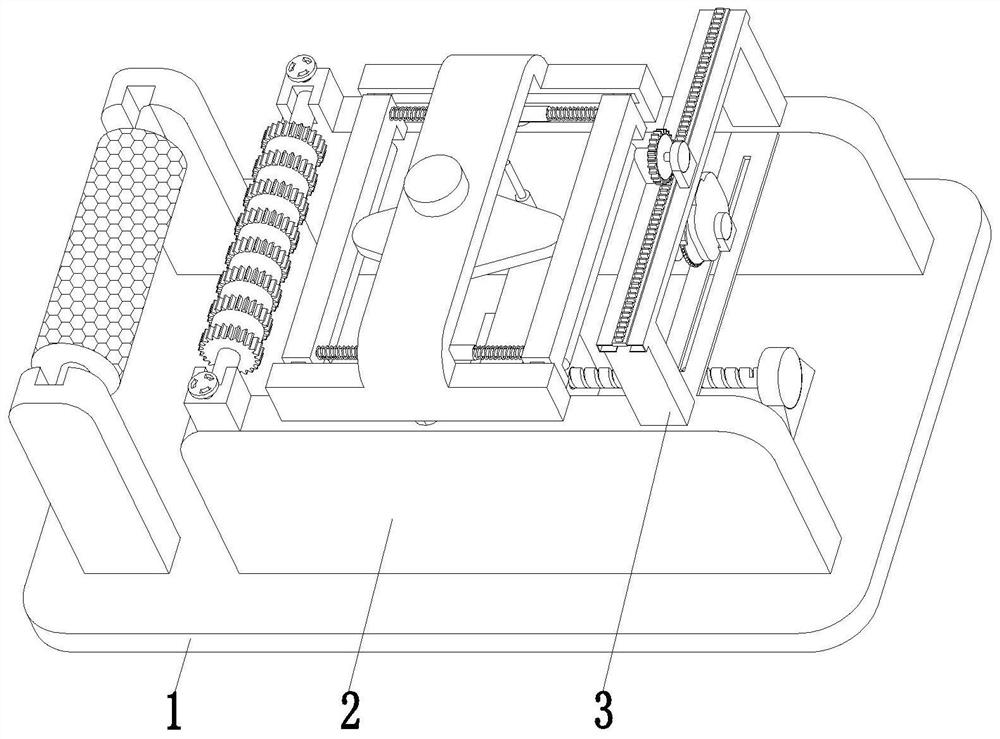

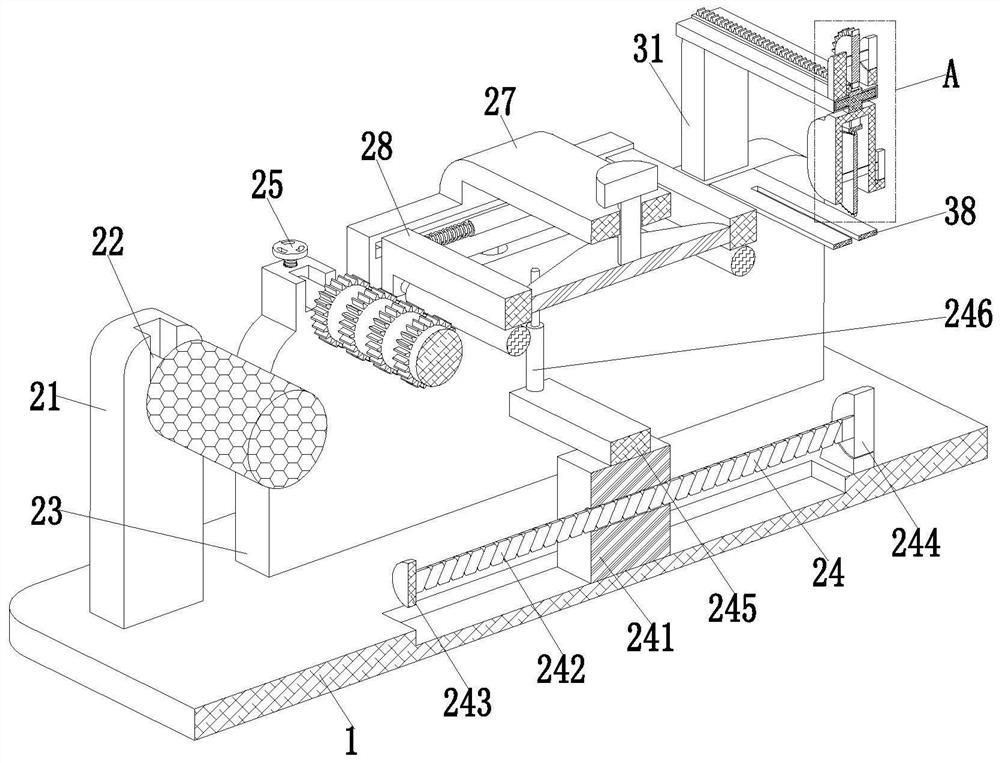

Production, manufacturing and processing technology for aluminum mesh oil fume filter screen

InactiveCN113210545ASolve the problem of uneven level and poor flatnessAvoid manual pullingMetal-working apparatusProcess engineeringMachining process

The invention relates to a production, manufacturing and processing technology for an aluminum mesh oil fume filter screen. A production, manufacturing and processing device for the aluminum mesh oil fume filter screen is used, the production, manufacturing and processing device for the aluminum mesh oil fume filter screen comprises a bottom plate, a flattening treatment mechanism and a filter screen cutting mechanism, the flattening treatment mechanism is installed in the middle of the upper end face of the bottom plate, and the filter screen cutting mechanism is installed on the flattening treatment mechanism. By means of the production, manufacturing and processing technology, the problems that an existing aluminum mesh filter screen processing device cannot flatten and limit an aluminum mesh before the aluminum mesh is cut, the rolled aluminum mesh curls up when being pulled out, the surface of the cut aluminum mesh is uneven, the aluminum mesh curls up again to be of a cylindrical structure, and the actual requirement cannot be met can be solved; and the problems that when the existing aluminum mesh filter screen processing device is used for cutting the aluminum mesh, linear cutting of a cutting knife cannot be guaranteed, deviation is prone to occurring, the surface of a notch is uneven, and the flatness is poor can be solved.

Owner:武汉地朴商贸有限公司

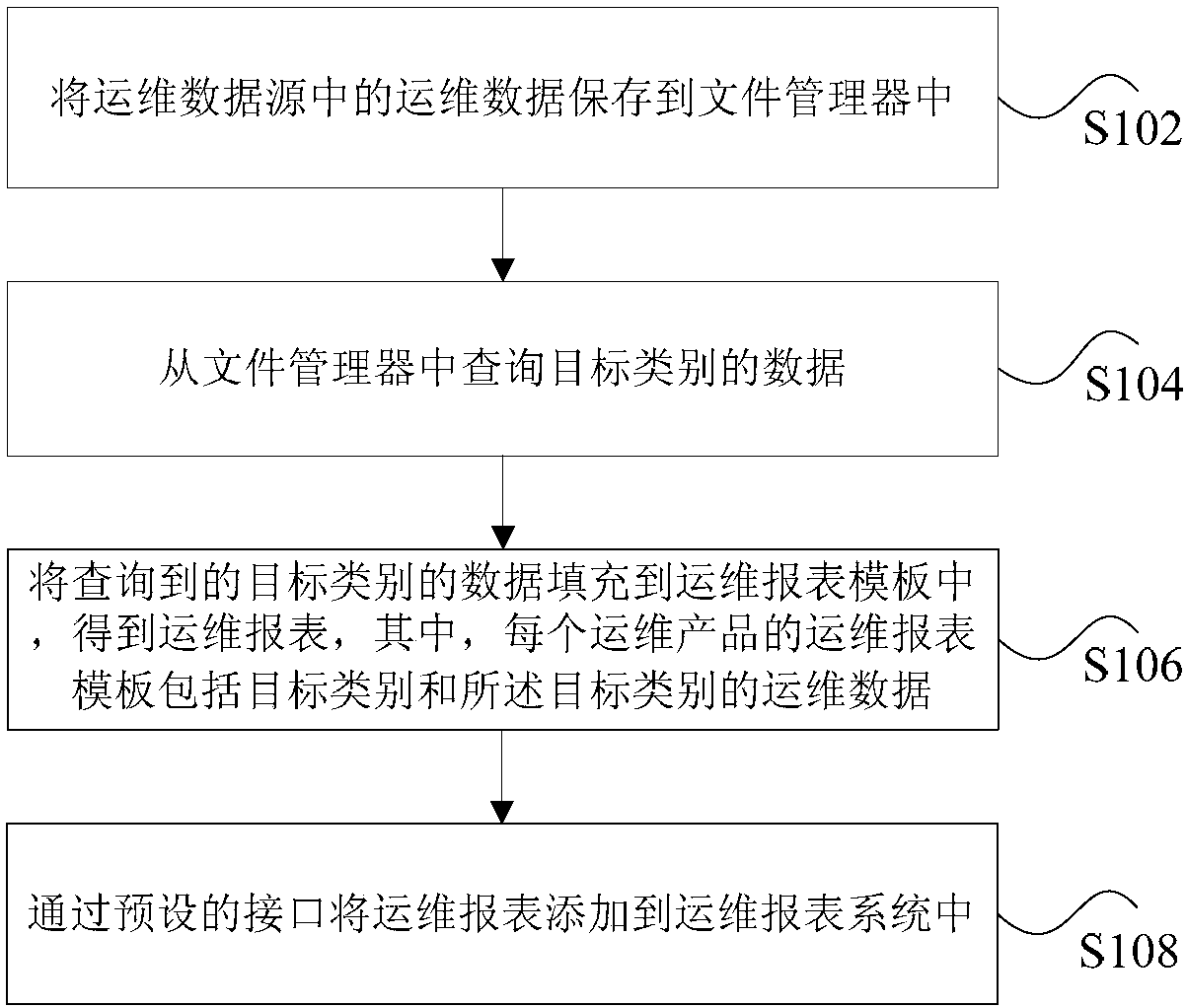

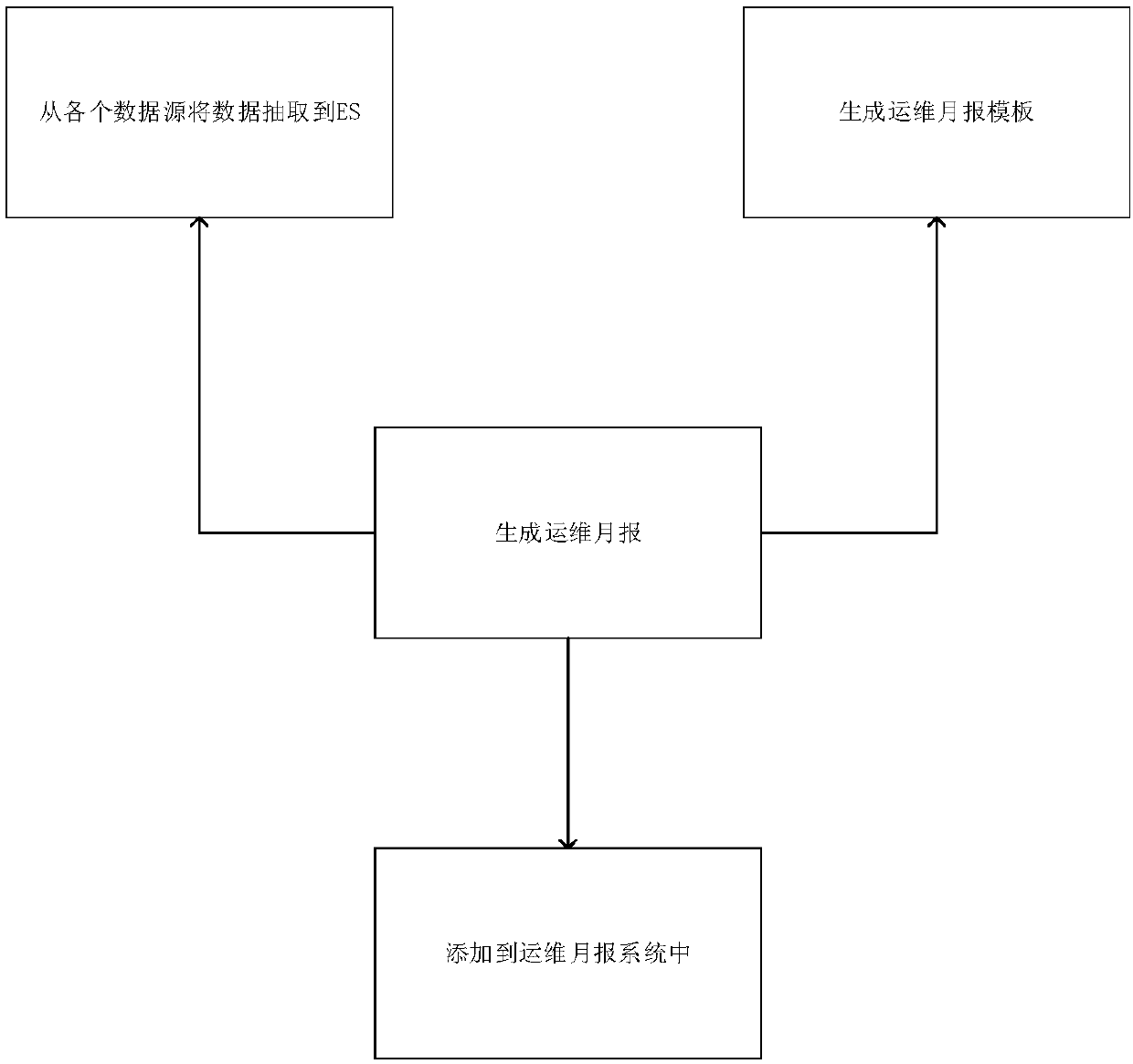

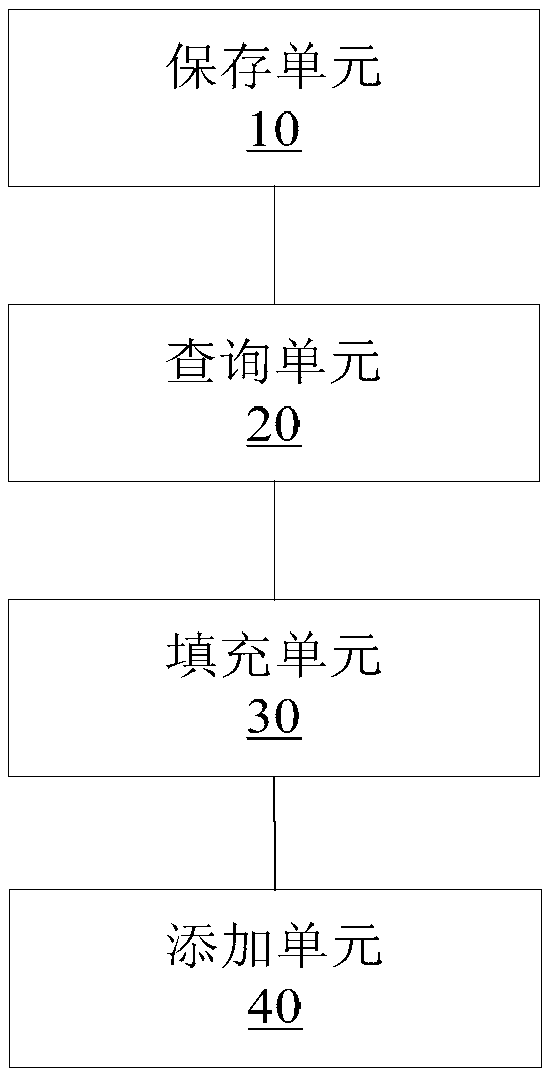

Operation and maintenance data processing method and device

InactiveCN110069453AAvoid Manual PullingSolve the low generation efficiencyFile access structuresFile metadata searchingData sourceFile manager

The invention discloses an operation and maintenance data processing method and device. The method comprises the following steps of storing the operation and maintenance data in an operation and maintenance data source into a file manager; querying the data of a target category from a file manager; filling the inquired data of the target category into an operation and maintenance report template,and obtaining an operation and maintenance report, wherein the operation and maintenance report template of each operation and maintenance product comprises the target category and the operation and maintenance data of the target category; and adding the operation and maintenance report to an operation and maintenance report system through a preset interface. According to the invention, the effectof improving the generation efficiency of the operation and maintenance report is achieved.

Owner:BEIJING GRIDSUM TECH CO LTD

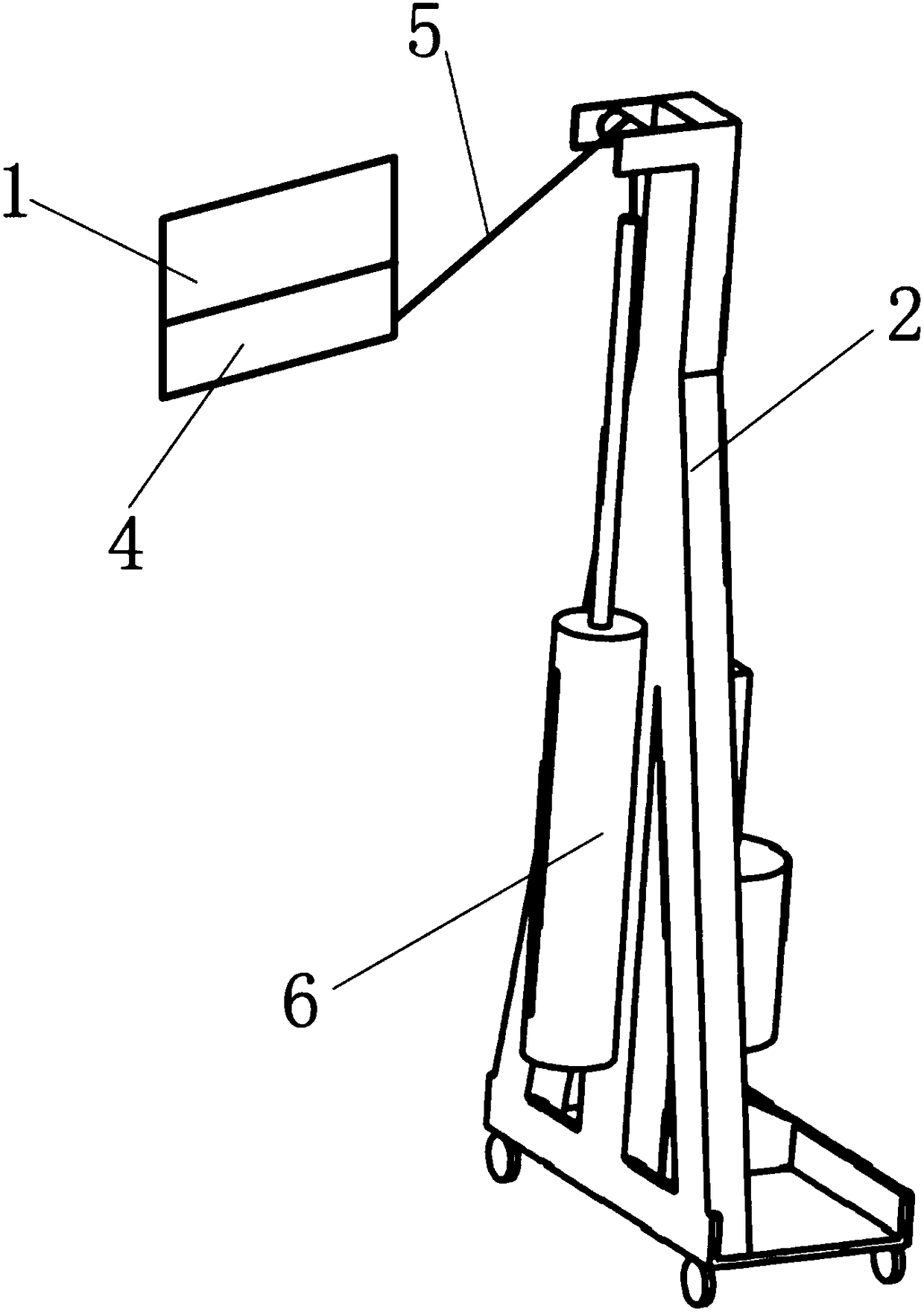

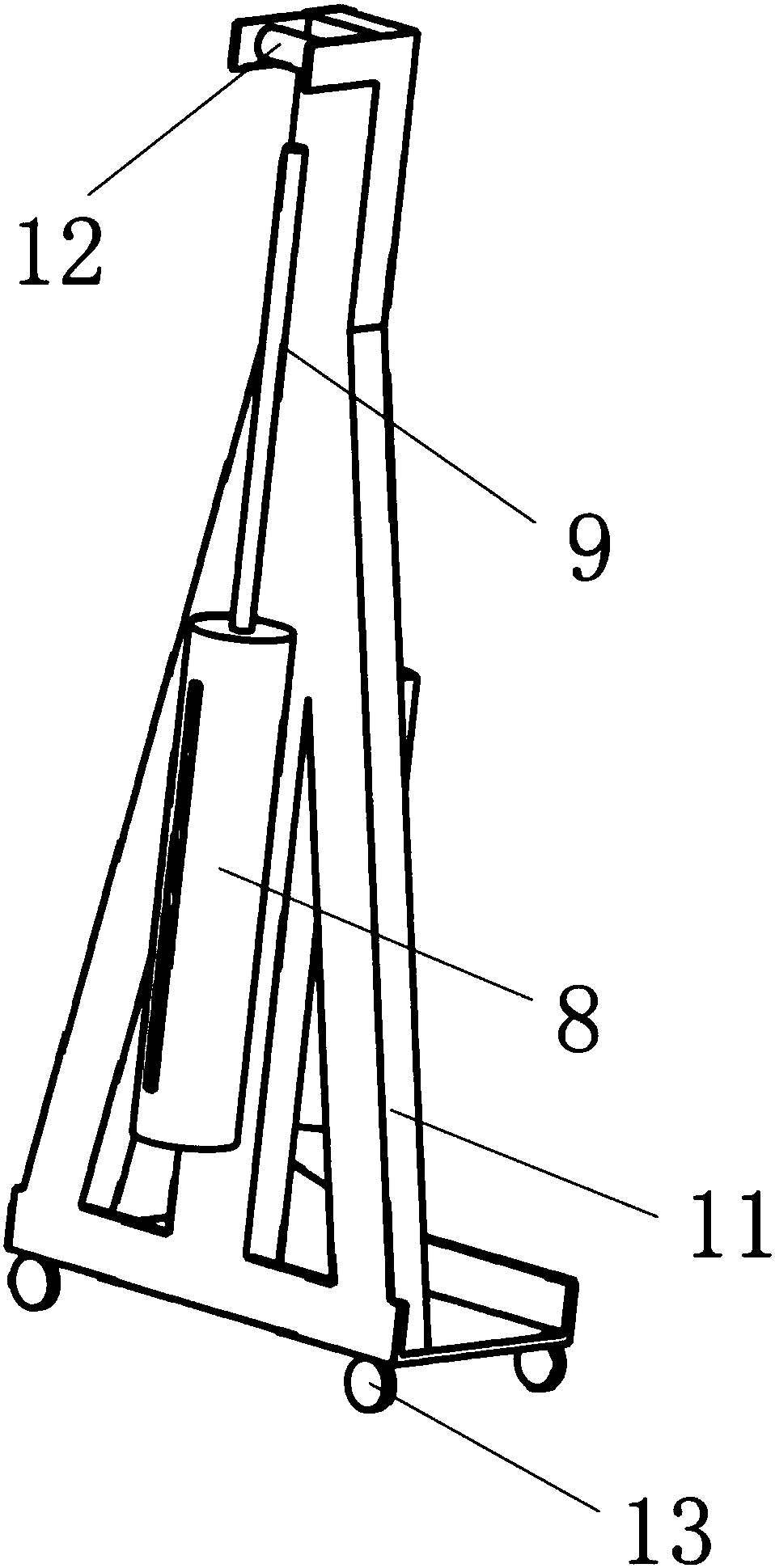

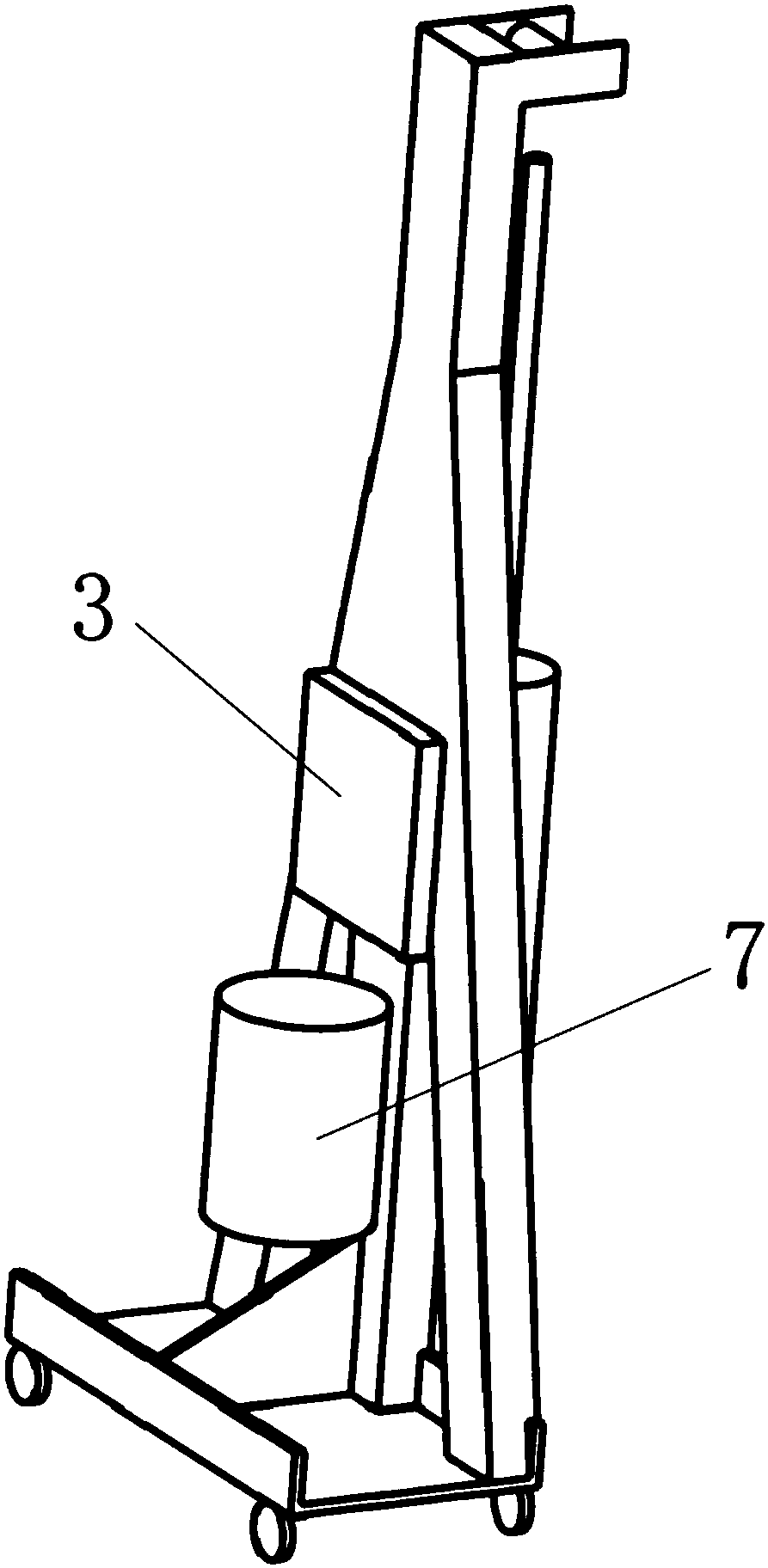

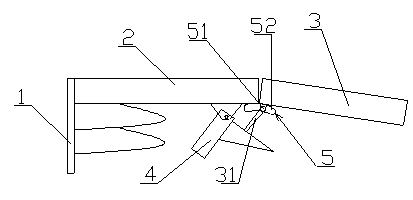

Pedestrian body model handling device

The invention discloses a pedestrian body model handling device, which comprises a launching device and a recovery device, wherein the recovery device comprises an execution device and a controller; the launching device is provided with a pedestrian body model, the execution device comprises a bracket, a cylinder, an energy storage device and a rope, one end of the rope is fixedly connected with the pedestrian body model, and the other end of the rope is connected with the cylinder. The pedestrian body model handling device disclosed by the invention adopts the movable execution device, is convenient to move the recovery device to a designated position so as to recover the pedestrian body model, adopts the controller to control a gating to trigger a piston rod so as to recover the pedestrian body model, realizes automatic recovery of the pedestrian body model, avoids manual pulling of the rope, reduces labor intensity and improves safety.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

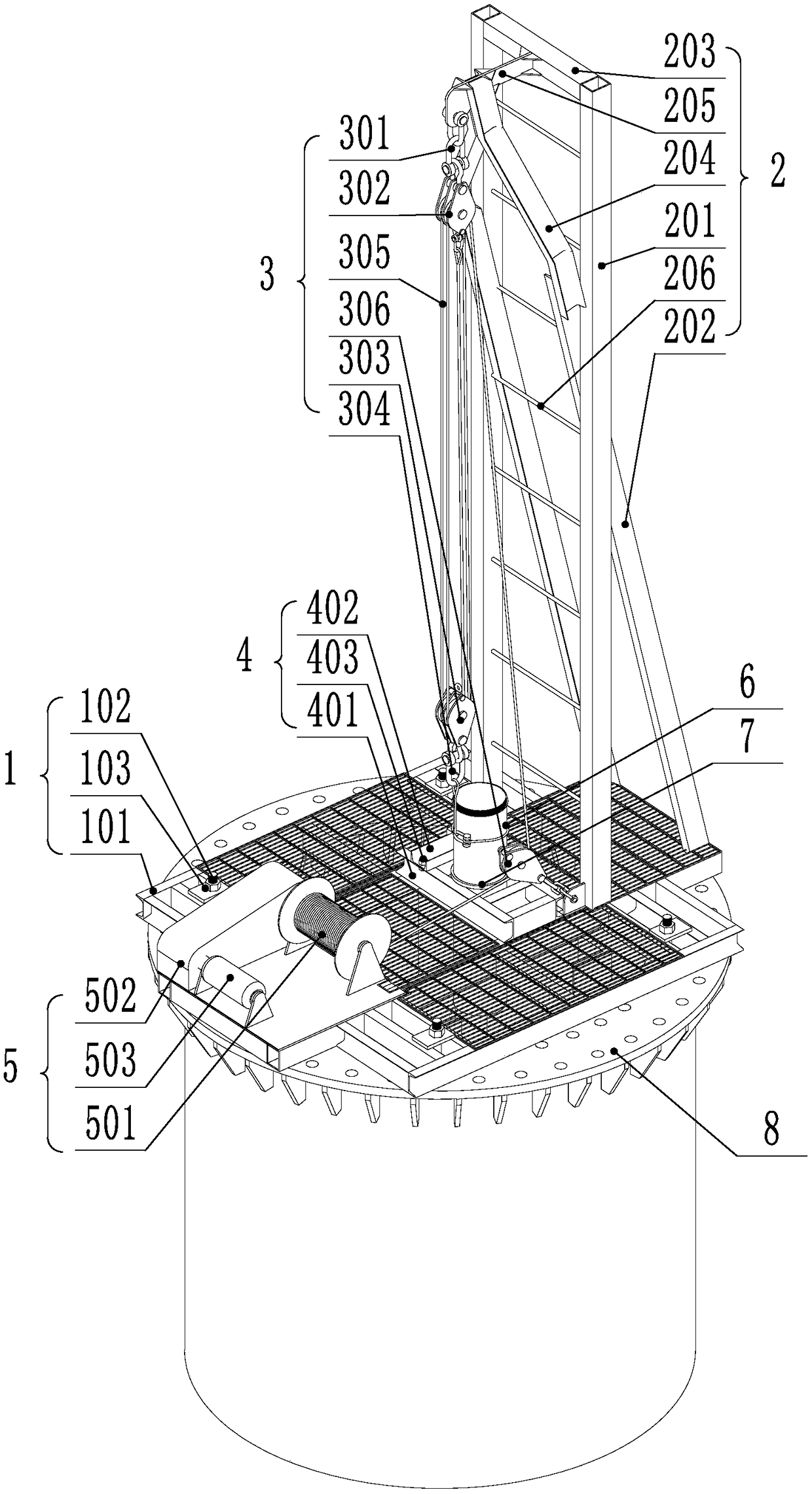

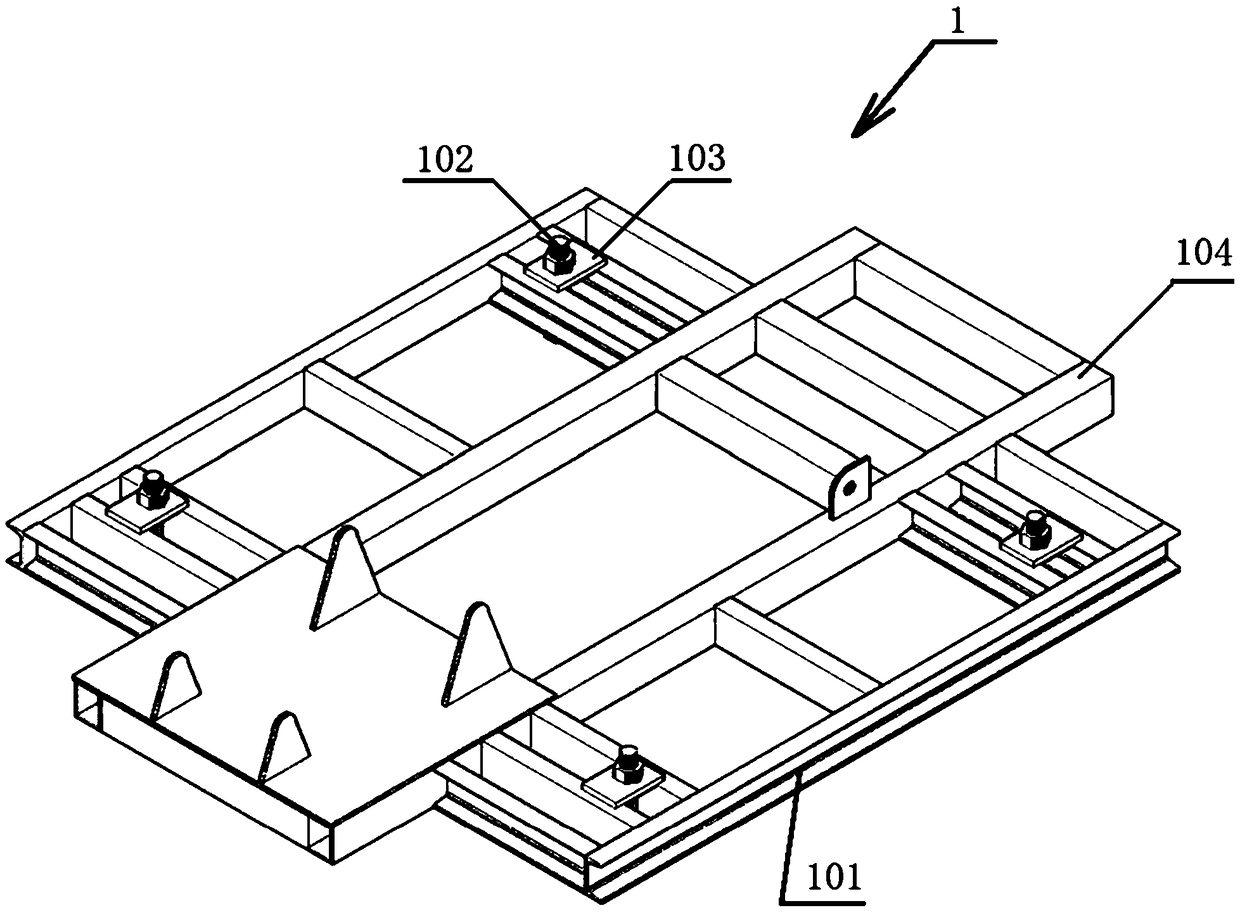

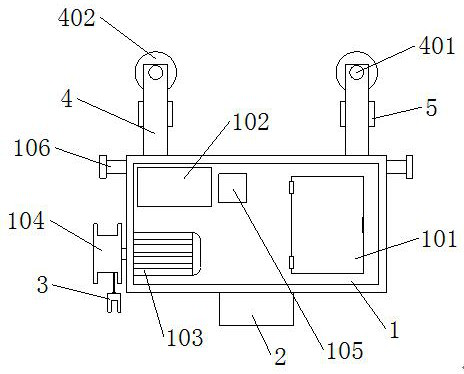

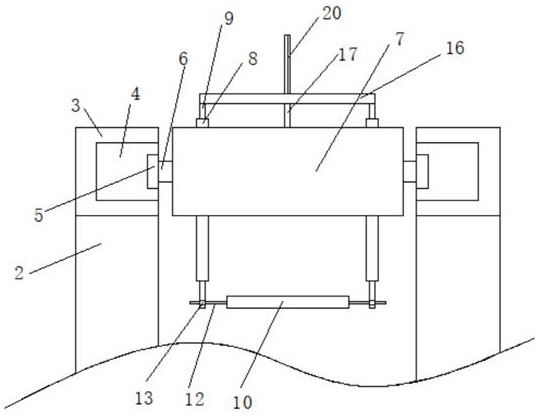

Conduit lifting device and method used for injection of concrete into steel tubes of power transmission tower in upper air

PendingCN108775153AImprove sub-sections for decentralized installationImprove securityTowersBuilding material handlingFixed frameArchitectural engineering

The invention relates to a conduit lifting device and method, in particular to a conduit lifting device and method used for injection of concrete into steel tubes of a power transmission tower in theupper air. At present, conduits are sleeved, wound, tied and fixed by steel wires, lifting operation is carried out on flange openings of the steel tubes, the operation efficiency is low, and the safety is low. The device includes a base, a bracket, a steel wire rope pulley group, a conduit fixing support and a hoisting mechanism; the base includes a bottom frame, long grooves are formed in four corners of the bottom frame respectively, the bottom frame is fixed to flanges crossing the steel tubes of a tower body through connectors, and the bracket is vertically arranged on the bottom frame and provided with the steel wire rope pulley group. The conduit fixing support includes a fixing frame and connecting rods, the connecting rods are detachably connected to the fixing frame through connectors, and the fixing frame is provided with conduit holes matched with the conduits. According to the technical scheme, the operation efficiency is improved, and the operation safety of the conduitsis improved. The long grooves are formed to provide convenience for inserting the connectors, and the connection reliability of the bottom frame is improved.

Owner:浙江省送变电工程有限公司 +2

Stapler device and application method thereof

InactiveCN108858067AEasy loadingConvenient bindingStapling toolsNailing toolsArchitectural engineering

Owner:朱晓燕

Steam drying treatment equipment for textiles

InactiveCN111394900AImprove molding shapeImprove processing efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingProcess engineeringWoven fabric

The invention relates to steam drying treatment equipment for textiles. The steam drying treatment equipment comprises fixed plates which are symmetrical from front to back, and a traction device is arranged between the fixed plates. A first steam shaft sleeve extending forwards is rotationally matched on the end face of the front side of the fixed plate positioned on the back side, and a steam device is arranged on the first steam shaft sleeve. A bottom connection plate is fixedly arranged between the fixed plates and is positioned on the lower side of the first steam shaft sleeve. The equipment adopts a way of high-temperature steam treatment, high-temperature steam can have the effects of drying and sterilization. The equipment is provided with the traction mechanism to complete the traction of the textiles affected by moisture, and therefore manual traction is avoided, and the working efficiency is improved. Meanwhile, the equipment is also provided with a position limiting mechanism to improve the forming shape of cloth. The equipment has the advantages of simple design and high treatment efficiency and is suitable for promotion in textile enterprises.

Owner:佛山市合昇纺织实业有限公司

Height adjusting plate

InactiveCN103253530AAvoid Manual PullingImprove work efficiencyLoading/unloadingEngineering managementSurface plate

The invention relates to a height adjusting plate. The height adjusting plate comprises a machine frame, a main panel, a lapping plate, a supporting foot and a connecting mechanism, wherein one side edge of the main panel is hinged to the machine frame, the other side edge of the main panel is hinged to one side edge of the lapping plate through the connecting mechanism, the supporting foot is hinged to a position, on one side of the joint of the main panel and the lapping plate, of the lower side face of the main panel, and the lapping plate is fixedly connected with a flexible plate which is in contacting connection with the supporting foot. When the lapping plate is rotated to a horizontal position, the flexible plate will be rotated along with the lapping plate and jack the supporting foot up to the horizontal position. According to the height adjusting plate, through the structure of the flexible plate, the supporting foot is jacked up to the horizontal position automatically when the lapping plate of the height adjusting plate is raised, manual drawing is omitted, and work efficiency is improved.

Owner:江苏沃克物流设备制造有限公司

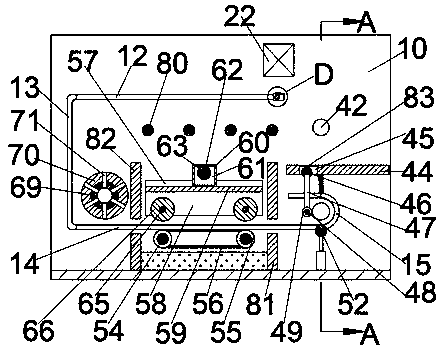

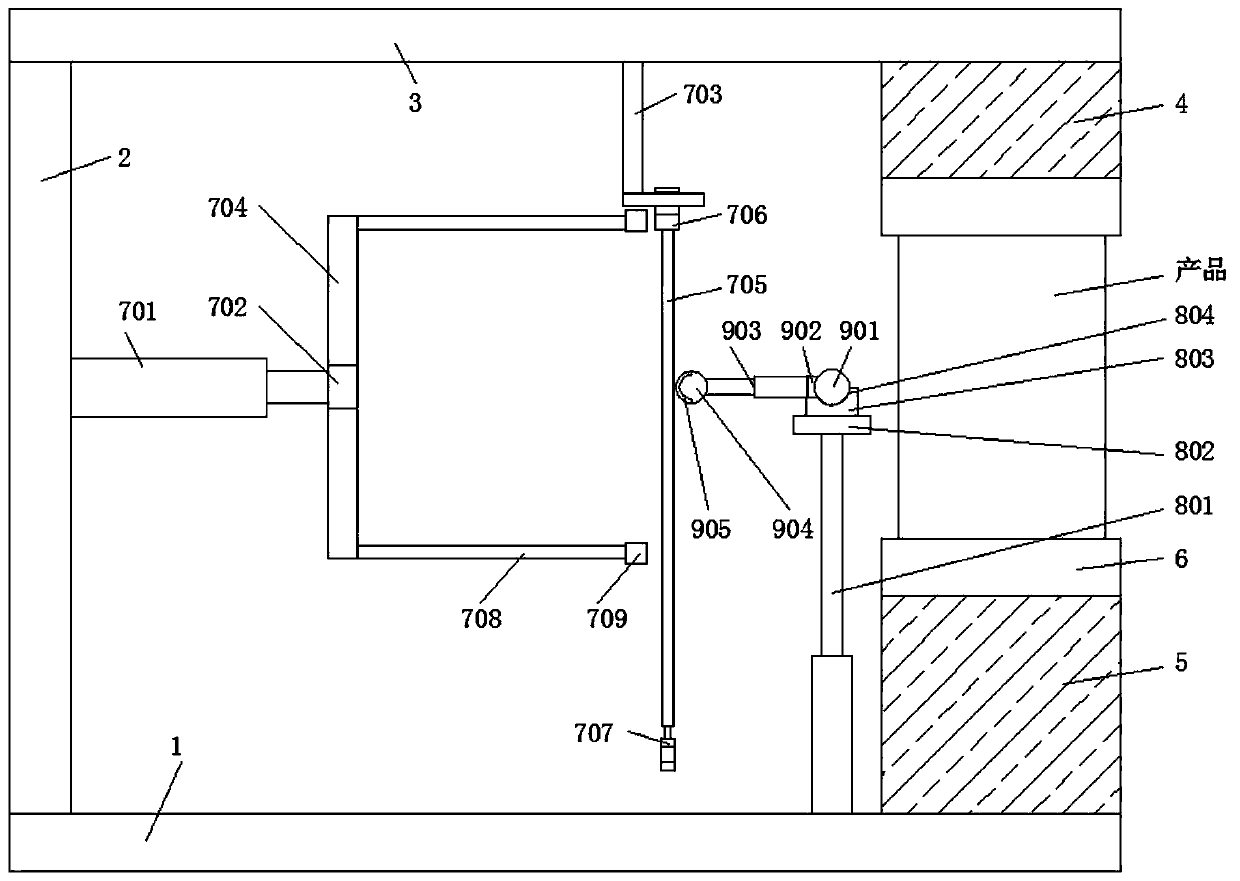

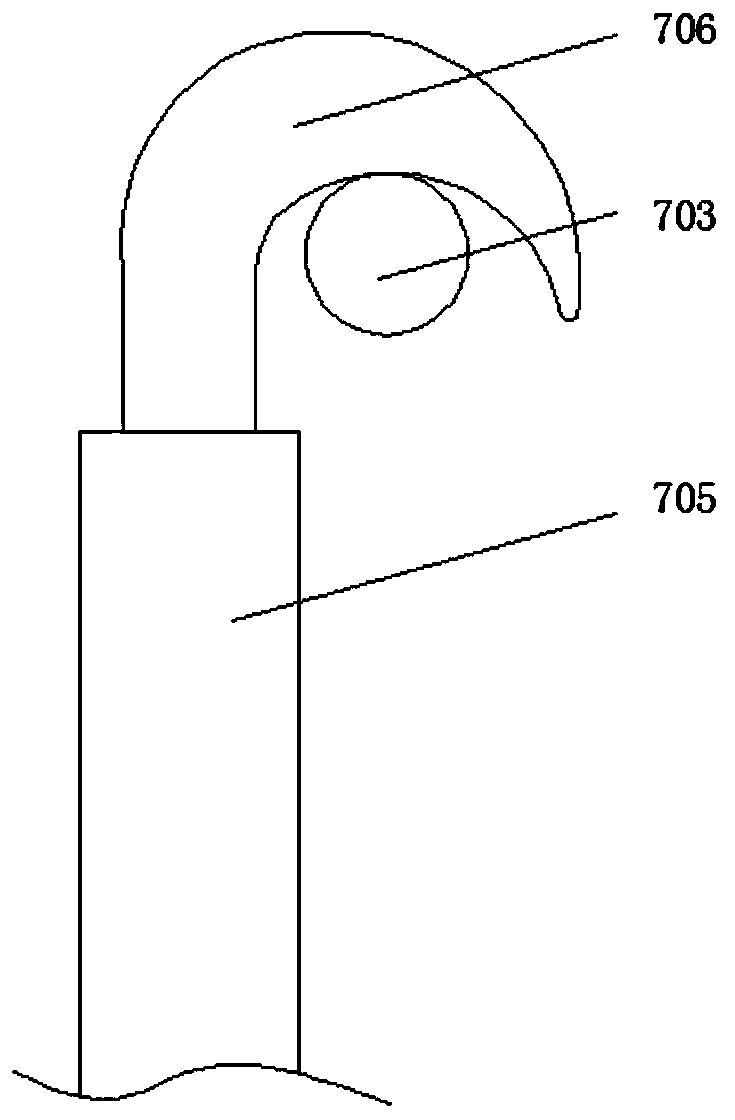

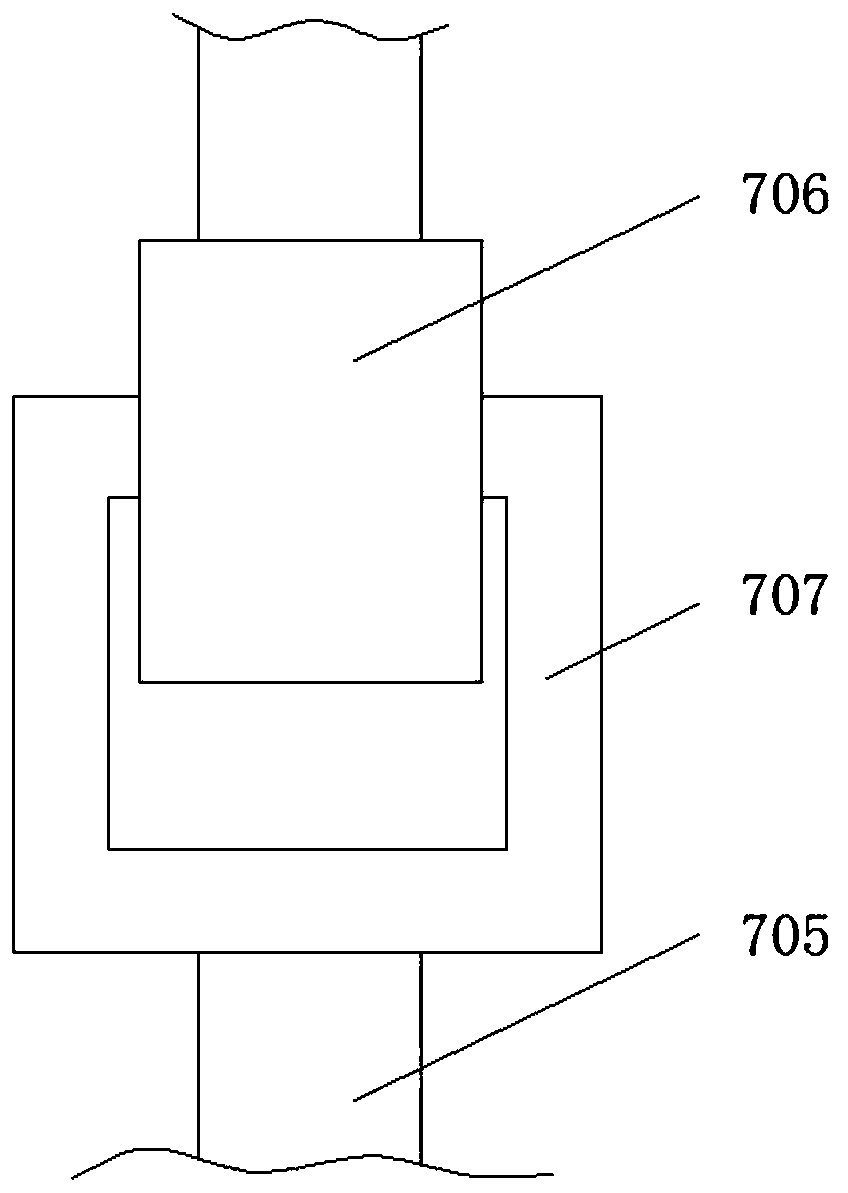

Automatic product packer

InactiveCN111056061AStrapping is easy to implementImprove work efficiencyBundling machine detailsStrappingIndustrial engineering

The invention relates to the technical field of product packaging, and particularly discloses an automatic product packer. The automatic product packer comprises a bottom plate. A support plate is fixedly connected to the left side of the top of the bottom plate, and a top plate is fixedly connected to the top of the support plate. A top support block is fixedly connected to the top plate, and a bottom support block is fixedly connected to the bottom plate. Long grooves uniformly distributed are formed in the top support block and the bottom support block. The automatic product packer also comprises a horizontal moving mechanism, a support mechanism and a strapping tape supporting mechanism. The horizontal moving mechanism is arranged on the right side of the support plate, and comprises afirst telescopic rod which is fixedly connected to the support plate. The support mechanism is arranged on the top of the bottom plate. According to the automatic product packer, a long plate and a horizontal rod can be driven to move to the right by the horizontal moving mechanism, and a strapping tape is fixed by a magnet at the same time so as to be driven to move to the right, and a hook anda hanging ring are both moved to the right sides of the long grooves, so that product binding is convenient to realize, and the working efficiency is improved.

Owner:柏晓珏

Cloth unfolding and hanging device for spinning

The invention discloses a cloth unfolding and hanging device for spinning. The cloth unfolding and hanging device comprises an upper transverse frame and two side supports arranged at the ends of theupper transverse frame, wherein an upper rotating rod shaft and a transmission rod shaft which are rotationally connected with the upper transverse frame are arranged at the two ends of the upper transverse frame correspondingly; the top of the upper rotating rod shaft penetrates the upper transverse frame and is provided with a cloth winding and unwinding roller; a pushing lead screw is arrangedat the upper portion of the upper transverse frame, wherein the two ends of the pushing lead screw are installed through bearing pedestals, and the pushing lead screw is rotationally connected with the top of the upper transverse frame; the pushing lead screw is provided with a spiral sliding base, wherein the bottom of the spiral sliding base slides on the upper end face of the upper transverse frame, and the spiral sliding base is in spiral fit with the pushing lead screw; a clamping assembly used for clamping the ends of cloth is arranged at the bottom end of the spiral sliding base; and the end of the pushing lead screw is connected to the output end of a pushing motor arranged on the upper transverse frame. The cloth unfolding and hanging device is simple in structure, the cloth winding and unwinding roller is driven to rotate through movement of a clamping piece and cooperation of a transmission piece so that the cloth can be unfolded and wound in order, operation is convenient and fast, cloth processing operation is convenient, and practicability is high.

Owner:李琦

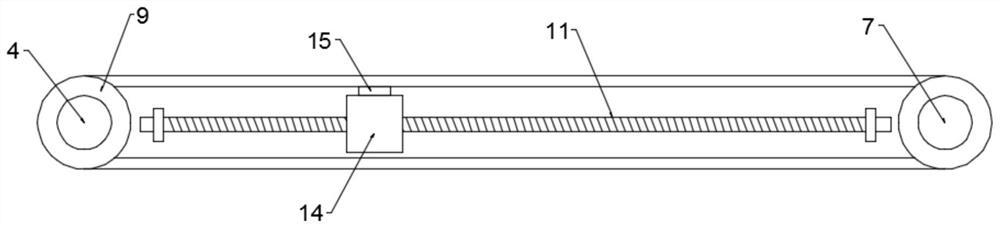

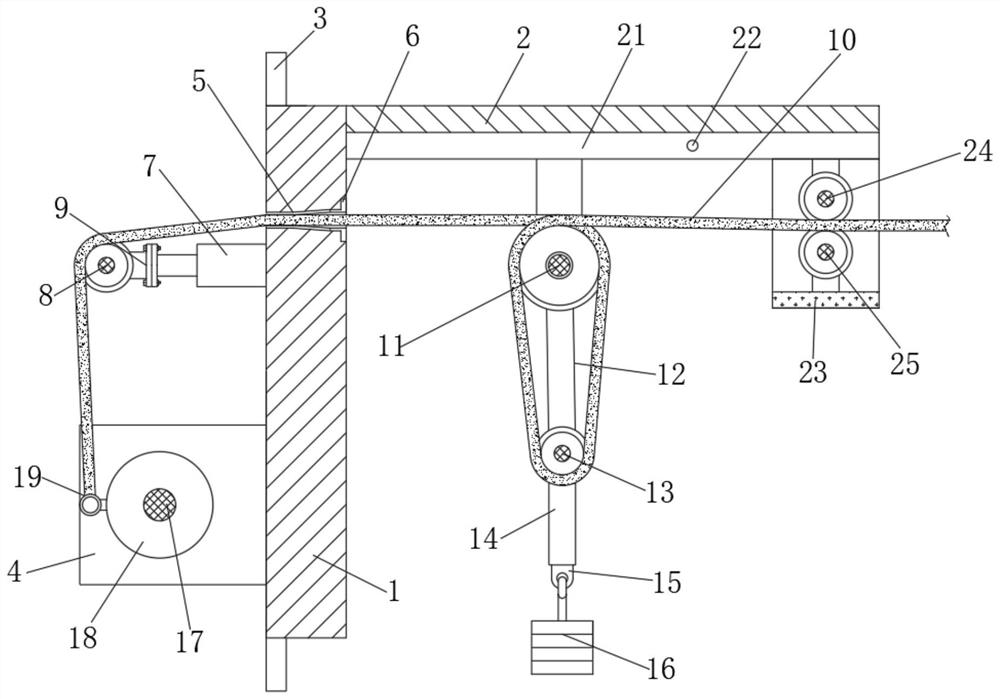

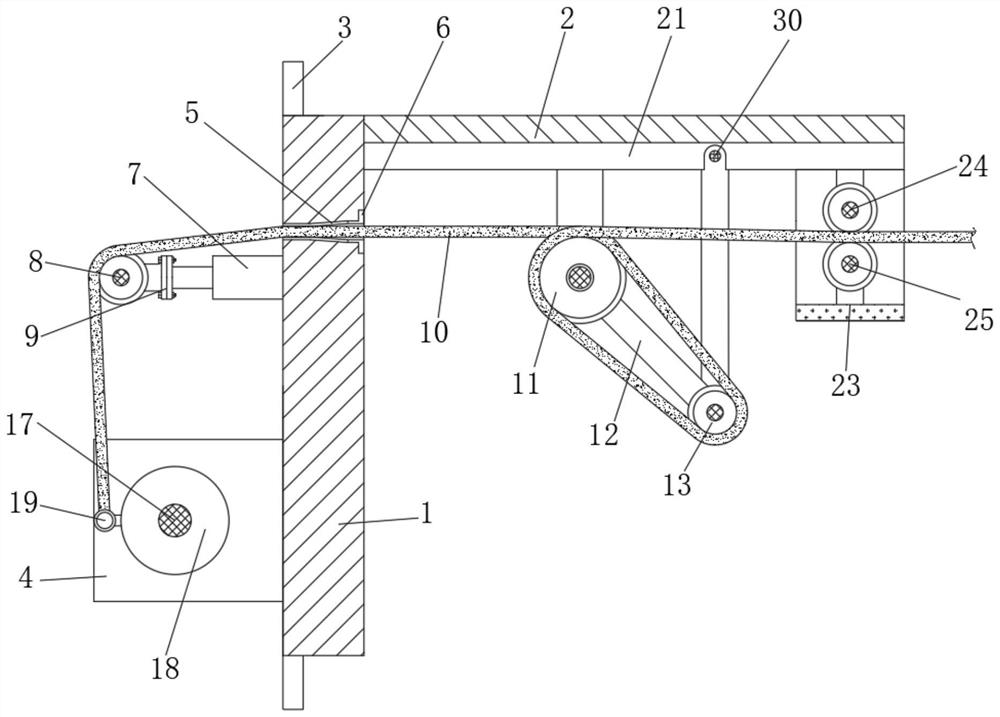

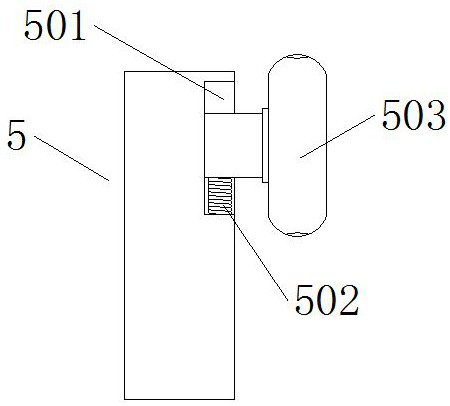

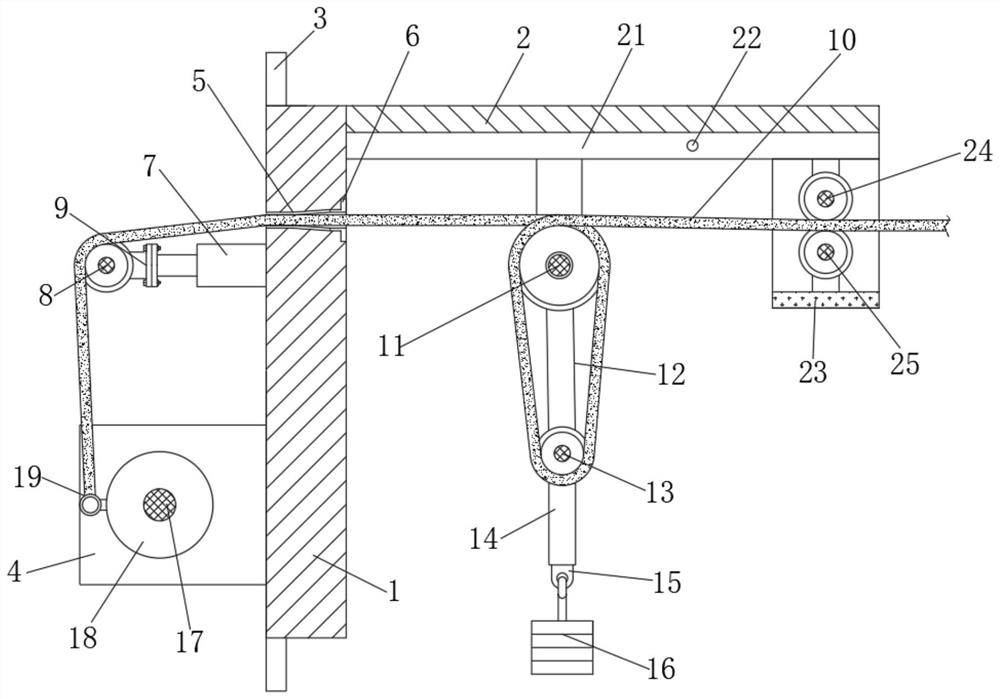

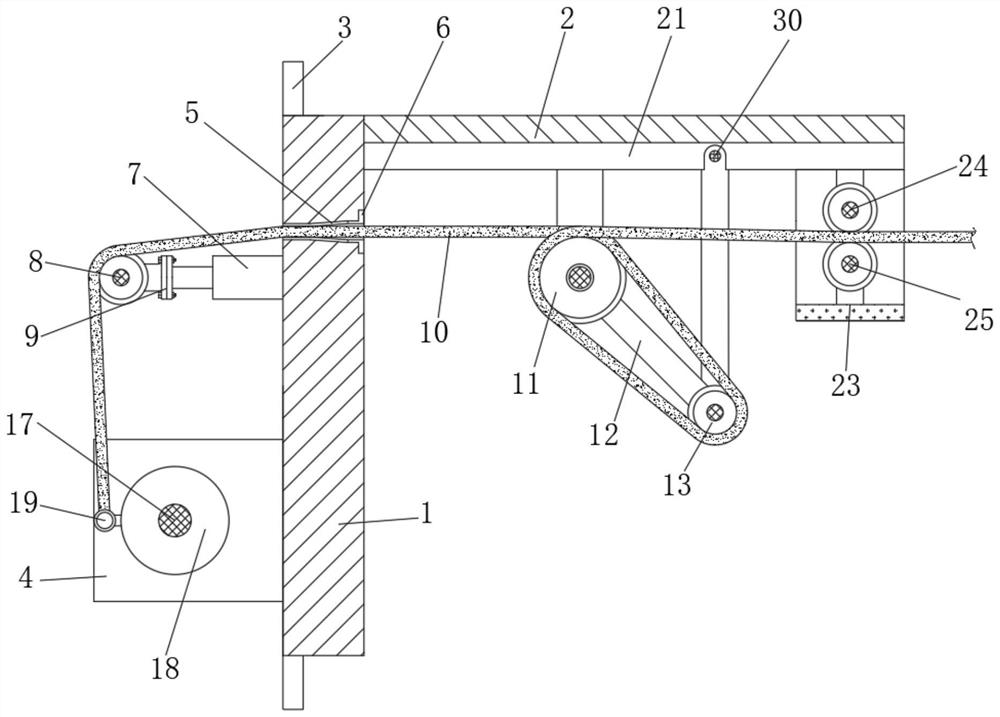

Electric power iron tower high-voltage line pre-tightening device

ActiveCN111697492AAchieve winding fixationImprove securityApparatus for overhead lines/cablesElectric machineDrive motor

The invention relates to the technical field of a high-voltage line laying device and particularly relates to an electric power iron tower high-voltage line pre-tightening device. The high-voltage line pre-tightening device of an electric power iron tower comprises a vertical plate, wherein a cross beam plate is transversely welded at an upper end of the right side of the vertical plate, a throughhole penetrating left and right is formed in an upper end of the vertical plate, and an electric telescopic rod and a side support are vertically welded at upper and lower ends of the left side of the vertical plate. The high-voltage line laying device is advantaged in that winding and fixing of a high-voltage cable are achieved through cooperation of a driving motor and a pulley, so stretching and laying of the high-voltage cable are achieved through rotation of a motor, manual pulling is avoided, operation safety and convenience are greatly improved, and high-altitude operation is more convenient, three-stage pre-tightening is realized through motor driving, extension of a telescopic rod and stretching of a balancing weight, so adjustment of pre-tightening force is refined, the magnitude of the pre-tightening force on the high-voltage cable is convenient to control, excessive stretching is avoided, and a purpose of fine adjustment is realized.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

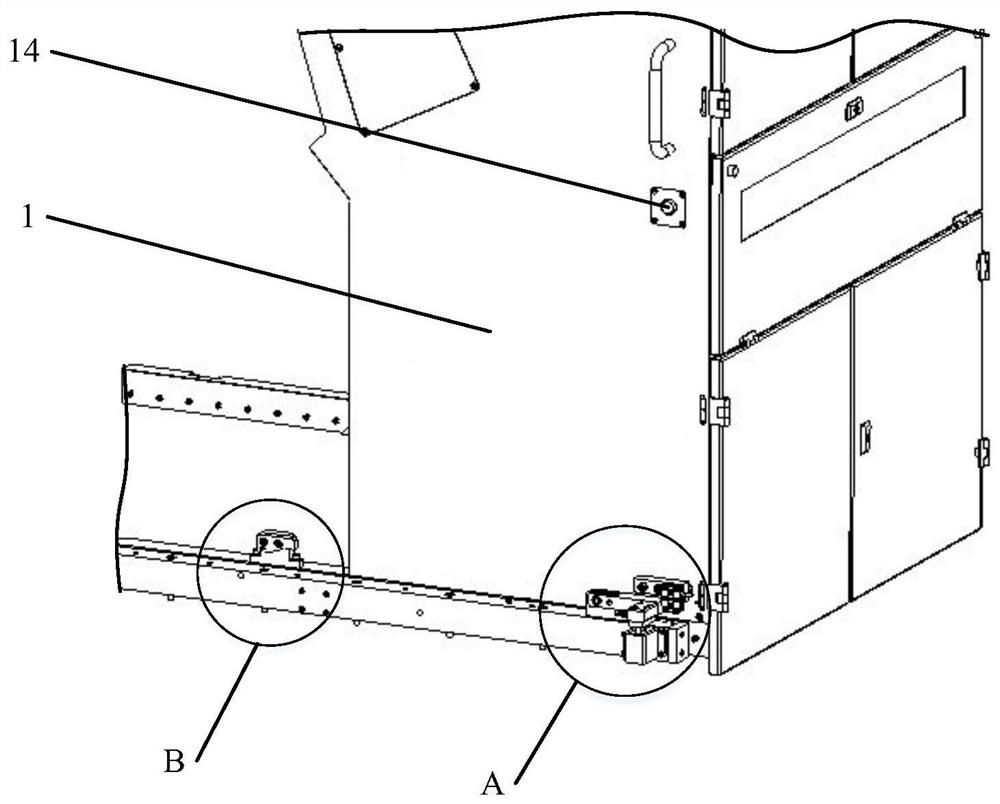

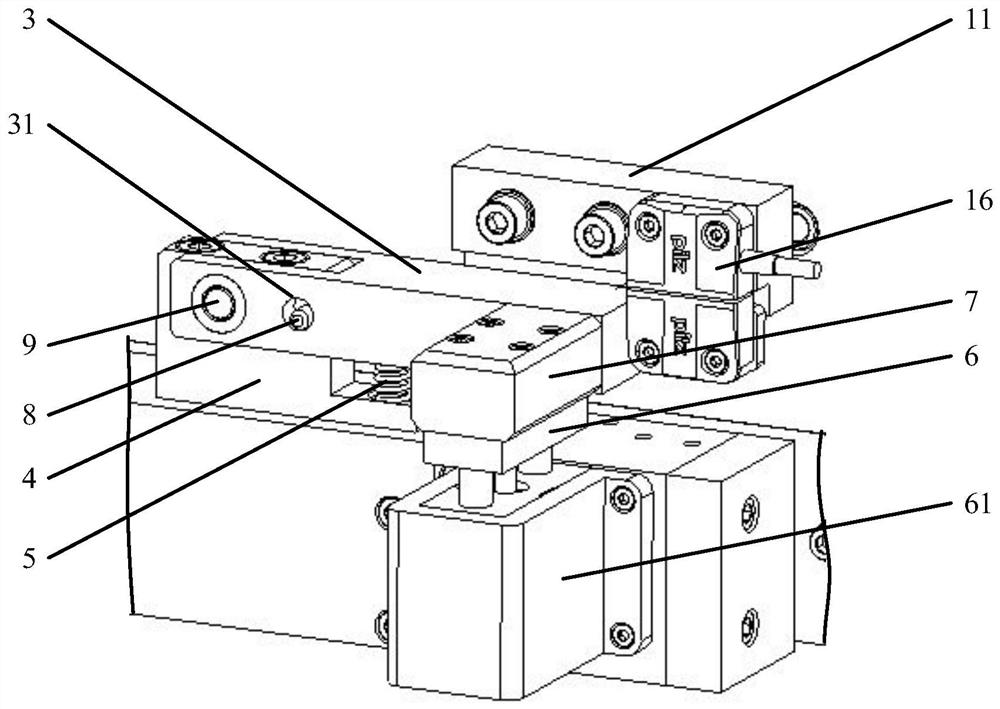

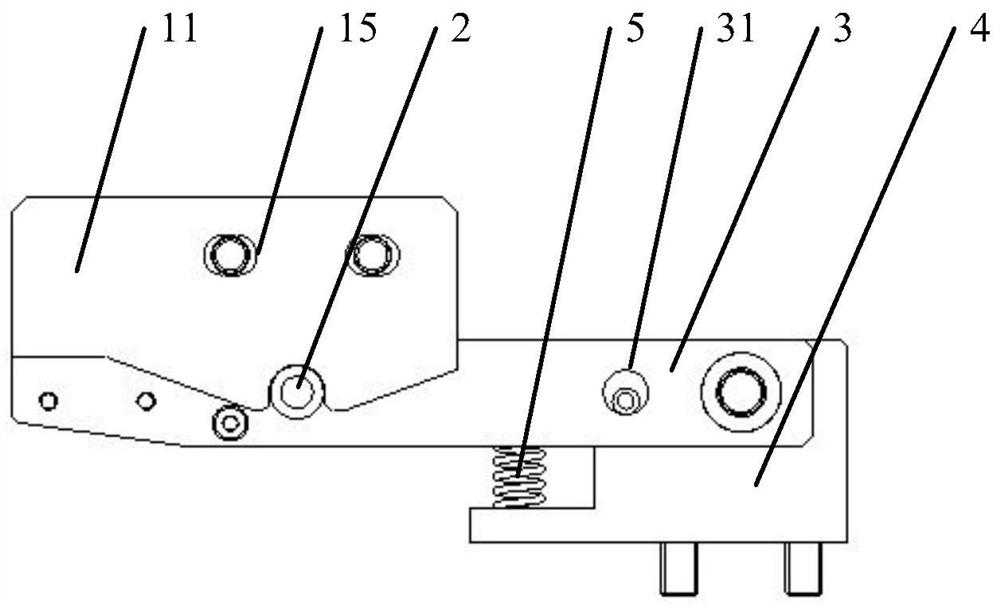

A limiting device for pre-supplied filaments and a coiling machine with the limiting device

ActiveCN108244695BRealize automatic limitSimple and convenient limit operationCigarette manufactureControl engineeringControl theory

The invention discloses a limiting device of a tobacco shred body to be supplied. The limiting device comprises two preset positions arranged at the tobacco shred body to be supplied, a first limitingblock, a second limiting block and limiting pins, wherein the first limiting block and the second limiting block limit a working position and an overhaul position of the tobacco shred body to be supplied respectively; limiting pin holes are formed in the first limiting block and the second limiting block; the limiting pins are selectably matched with the limiting pin holes of the first limiting block and the second limiting block for limiting; and the limiting pins are connected with a driving device and driven by the driving device to be capable of being clamped into and separated from the limiting pin holes. According to the limiting device, the limiting pins are driven by the driving device to be clamped into or separated from the limiting pin holes, so that the limiting pins are matched with the first limiting block and the second limiting block for limiting or separated from the first limiting block and the second limiting block; manual pulling of the limiting pins are avoided; the limiting device achieves automatic limiting of the tobacco shred body to be supplied; the limiting of the tobacco shred body to be supplies is simple and convenient to operate and saves time and labor; and the production efficiency is improved. The invention further discloses a cigarette making and plug assembling machine comprising the limiting device.

Owner:CHANGDE TOBACCO MACHINERY

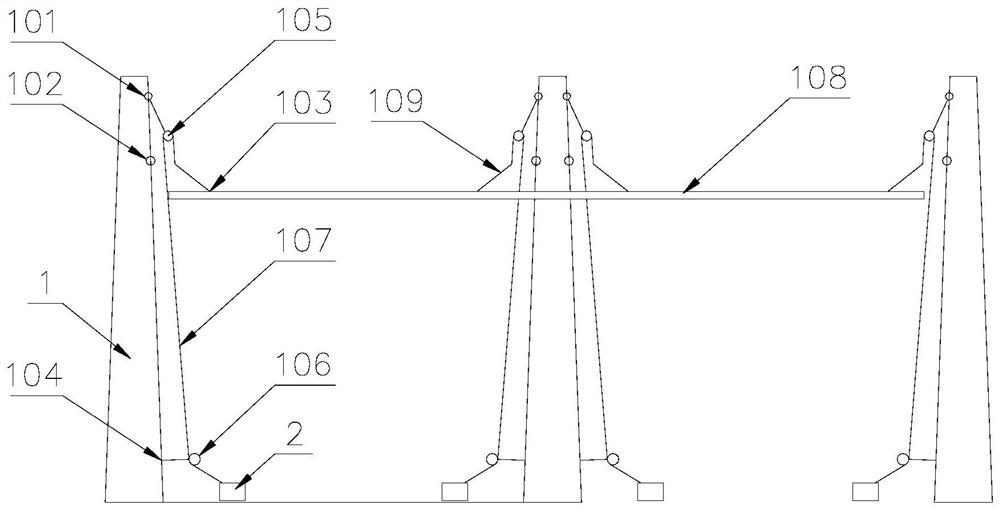

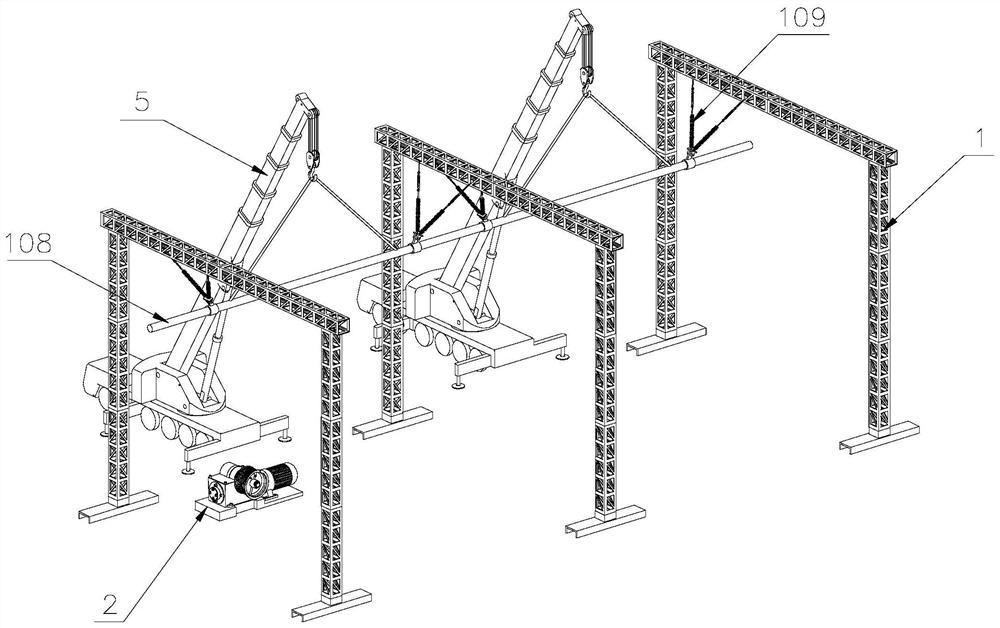

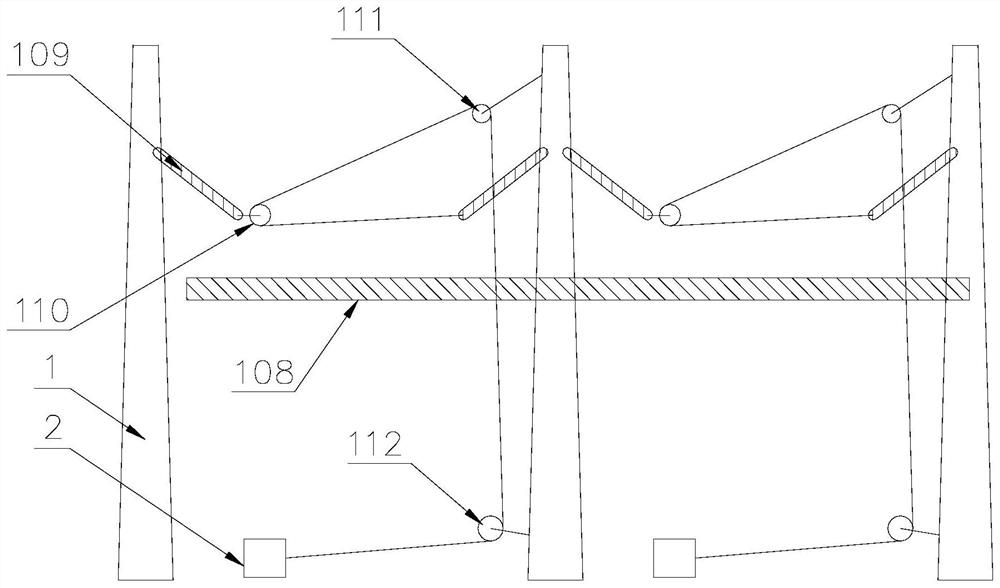

Hoisting method of obliquely-pulling type insulator string ultra-long tubular bus

ActiveCN112320650AImprove securityImprove construction efficiencyBus-bar installationPortable liftingBlock and tackleWinch

The invention discloses a hoisting method for a obliquely-pulling type insulator string ultra-long tubular bus. The hoisting method comprises the following steps of S1, hoisting a V-shaped insulator string, S2, installing a pulley block, S3, obliquely pulling an insulator string, S4, hoisting a tubular bus, S5, fitting connection and S6, fitting adjustment. The V-shaped insulator string is connected with a portal frame in advance by using a crane, the insulator string is obliquely pulled to a fixed angle in advance by using a winch, a steel wire rope and a pulley block, at the moment, the tubular bus is hoisted to an installation height and can be directly connected with the V-shaped insulator string, the whole tubular bus only has tension in the vertical direction, the safety coefficientis high, the overhead operation time of personnel is shortened, and the construction efficiency is obviously improved.

Owner:QINGHAI POWER TRANSMISSION & TRANSFORMATION ENG +2

High-voltage transmission line routing robot

ActiveCN111872952AAvoid falling easilyNot easy to slipManipulatorApparatus for overhead lines/cablesRubber ringElectric machinery

The invention discloses a high-voltage power transmission line routing robot, and relates to the technical field of high-voltage power transmission lines. The high-voltage power transmission line routing robot comprises a device main body, a fixing clamp and a clamping block, and a storage box is embedded in the right side of the interior of the device main body. According to the high-voltage power transmission line routing robot, rotating wheels are installed, when the device main body moves along the power transmission lines through the rotating wheels and when the rotating wheels are drivenby second motors to rotate, rubber rings always expand outwards through the elastic force of first springs, so that the rubber rings can be tightly attached to the power transmission lines of different sizes, the rotating wheels and the power transmission lines are not prone to slipping, and rolling wheels are always upwards tightly attached to the lower ends of the power transmission lines through the elastic force of second springs; and concave arc surfaces in the middles of the outer side surfaces of the rolling wheels can effectively fit the outer surfaces of the power transmission lines,so that the firmness between the rotating wheels and the power transmission lines through the rolling wheels is improved, and the rotating wheels are prevented from falling easily during movement along the power transmission lines.

Owner:QIXIA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

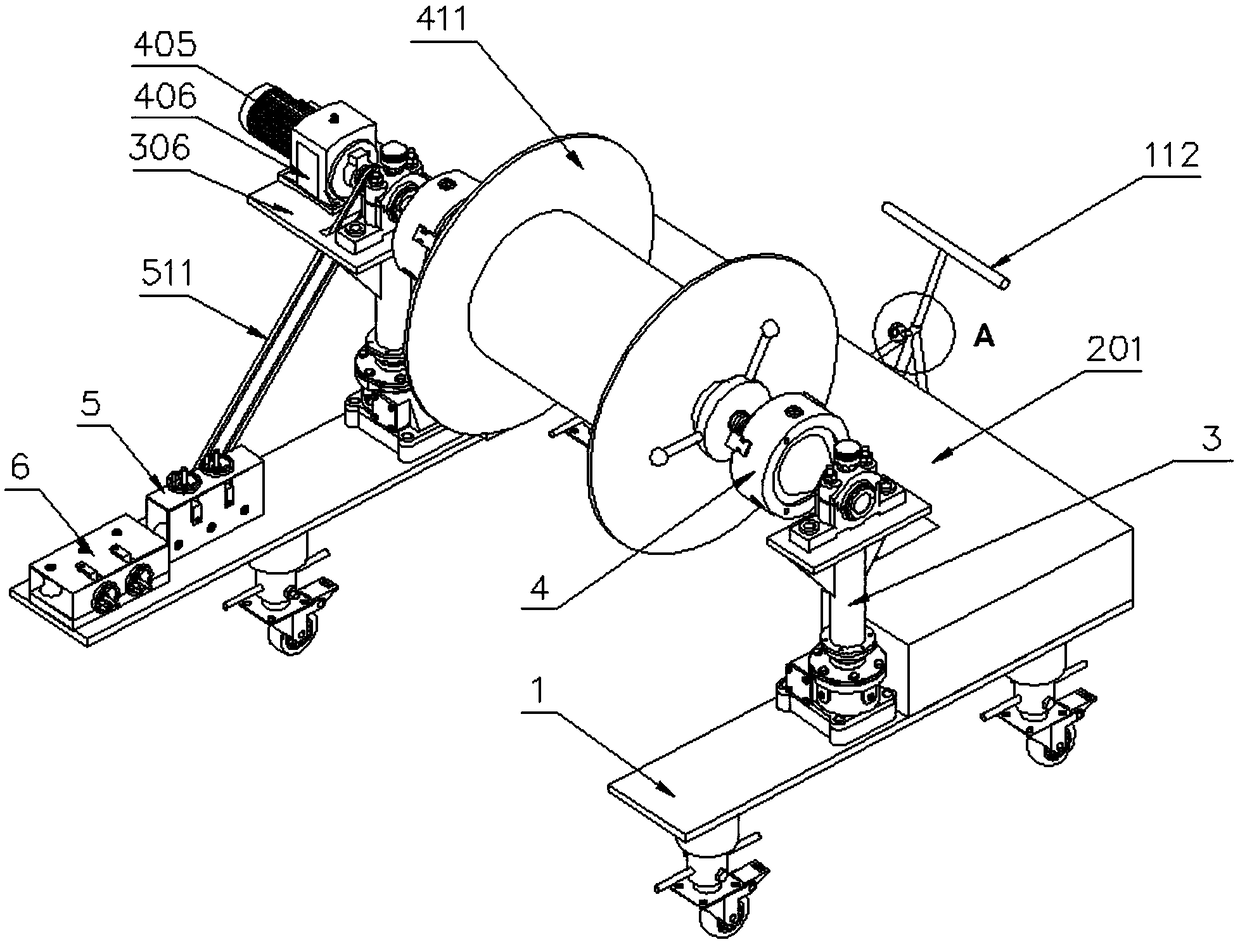

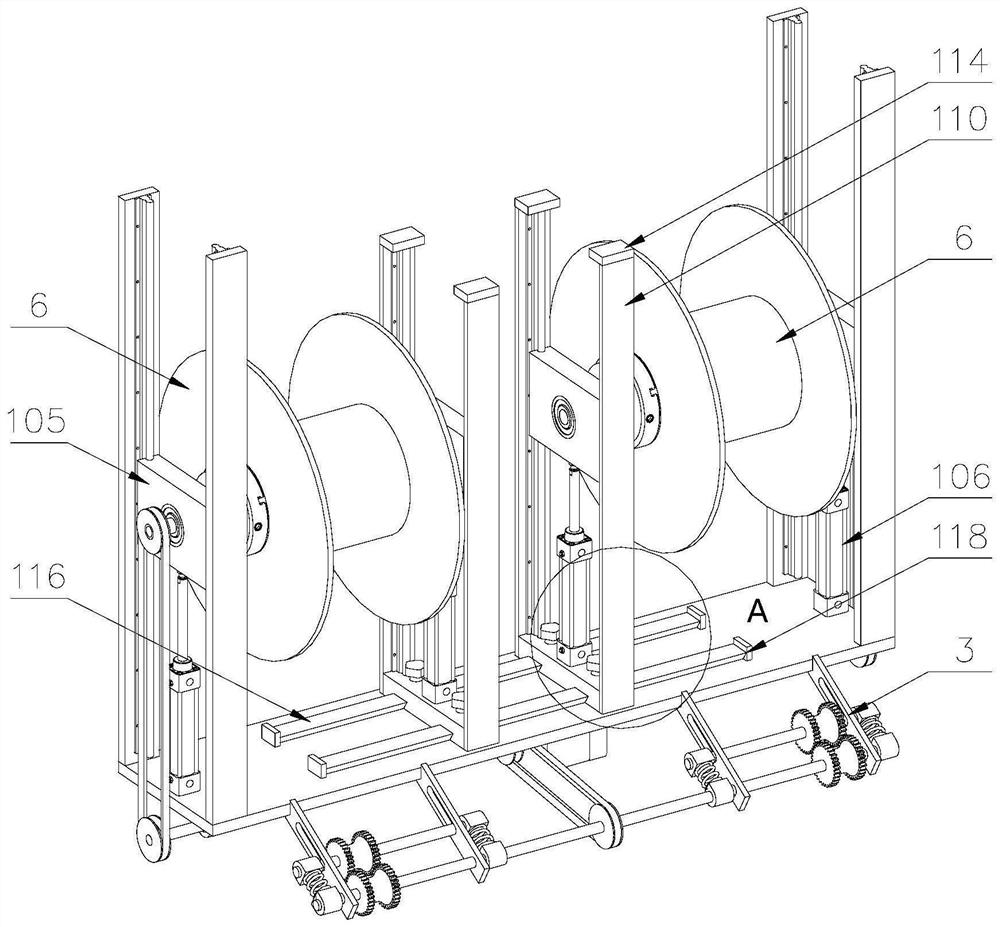

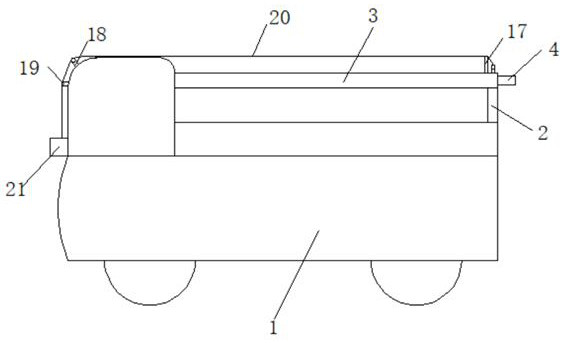

Multi-cable pay-off device for cable erection

ActiveCN110589602BGuaranteed stabilityPrevent disengagementFilament handlingApparatus for laying cablesVehicle frameElectric machinery

The invention discloses a multi-cable pay-off device for cable erection. A first slide block is provided on one side of a column, first slide rails are provided at both ends of the first slide block, and clamping claws are provided on one side of the first slide block; One end of the first rotating shaft is provided with a first pulley; the second slider is provided with a gripper; the upper end of the first slider is connected with the top plate through the first oil cylinder, and the upper end of the second slider is connected with the third slider through the second oil cylinder; The driving device includes a first double-headed motor arranged on the top of the top plate, a second rotating shaft connected to both ends of the output shaft of the first double-headed motor, a second pulley installed on the second rotating shaft, and the second pulley is connected to the first double-headed motor through a belt. One wheel connection. In the present invention, claws are arranged at both ends of the vehicle frame, and the claws are used to support the reel, which prevents the reel from being separated from the pulley when it rotates, and ensures the stability of the reel, and a driving device is arranged on the top of the top plate, and the driving device is used to drive The reel rotates, which avoids manual wire pulling, reduces the labor load of workers, and improves the efficiency of unwinding.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Hand-held stapler

Owner:朱晓燕

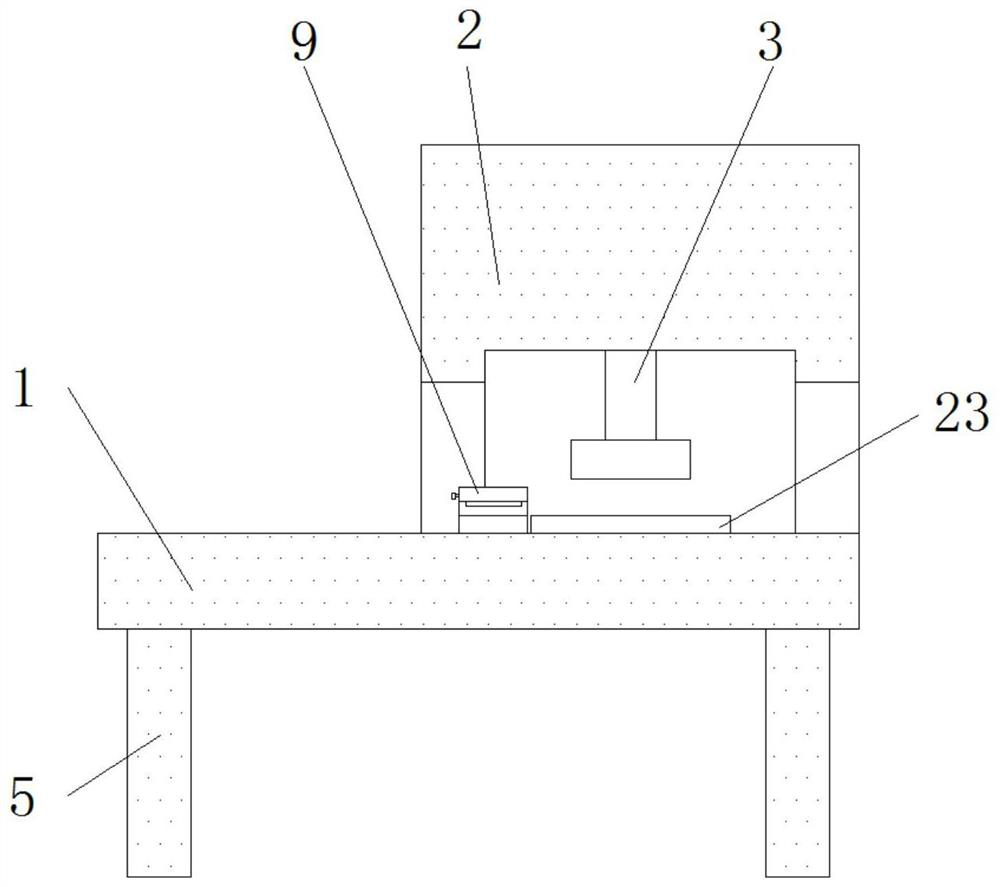

Automatic discharging and waste discharging device of open type fixed table press

InactiveCN112497825AAvoid manual pullingInhibit sheddingCleaning using toolsPressesElectric machineryProcess engineering

The invention discloses an automatic discharging and waste discharging device of an open type fixed table press. The automatic discharging and waste discharging device comprises a workbench; the pressis fixed on the upper surface of the workbench; a lifting rod is arranged on the lower surface of the press; an extrusion plate is fixed at the lower end of the lifting rod; a motor is fixed inside the workbench; a first screw rod is fixed on the motor; a base is fixed on the lower surface of the workbench; a connecting block is connected to the first screw rod in a threaded mode, slidably connected on the upper surface of the workbench, and slidably connected inside a second slideway; the second slideway is fixed inside the workbench; a clamp is fixed on the upper surface of the connecting block; and a placing groove is formed in the clamp. The automatic discharging and waste discharging device of the open type fixed table press can quickly move materials after pressing the materials, sothat the manual traction is avoided; and crushed waste generated after the materials are pressed can be collected, so that the waste discharging treatment is carried out.

Owner:芜湖博威机械制造有限公司

Lifting device for loading and unloading equipment for electric maintenance vehicle

ActiveCN111217275BAvoid collisionQuick releasePortable liftingStructural engineeringMechanical engineering

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

Protective device for radioactive source in radiology department, and use method

InactiveCN113892965AAvoid manual pullingAvoid harmRadiation safety meansStructural engineeringNuclear medicine

The invention relates to the technical field of the radiology department, and discloses a protective device for a radioactive source in the radiology department, and a use method. The protective device comprises a supporting mechanism, wherein the top of the supporting mechanism is fixedly connected with a protection mechanism; the protection mechanism comprises a sliding groove body, wherein the top of the sliding groove body is fixedly connected with a protection cover; the inner wall of the sliding groove body is fixedly connected with a rack; the bottom of the sliding groove body is provided with a fixing groove; the inner wall of the sliding groove body is movably connected with a box body; the inner wall of the sliding groove body is fixedly connected with a guide rail; a sliding body is fixedly connected to the outer wall of the box body; a pulling rope is fixedly connected to the right side of the sliding body; a sliding block is fixedly connected to one end, which is far away from the sliding body, of the pulling rope; a protective cover is fixedly connected to the bottom of the sliding body; and a motor is fixedly connected in the box body. The protection device for the radioactive source in the radiology department, and the use method have the advantages that automatic unfolding is facilitated, harm caused by entering of medical staff is reduced and the like.

Owner:青岛山大齐鲁医院(山东大学齐鲁医院(青岛))

A rolling shutter door safety lock

ActiveCN110259364BQuick closeSimple structureDoor/window protective devicesBuilding locksStructural engineeringMechanical engineering

The invention discloses a roller shutter door safety lock. The roller shutter door safety lock comprises a wall, a channel penetrating in the front-rear direction is formed in the wall, safety devices are arranged in the inner walls of the left side and the right side of the channel, each safety device comprises through grooves which are symmetrically formed in the inner walls of the left side and the right side of the channel, and fixing blocks are fixedly connected to the inner walls of the sides, close to the symmetrical center, of the through grooves; and rotating cavities with openings deviating from the symmetrical center are formed in the fixing blocks, and connecting shafts are rotatably connected between the upper inner walls and the lower inner walls of the rotating cavities. The roller shutter door safety lock is easy to operate and convenient to use, the winding speed during retracting of a roller shutter door can be automatically limited, manual traction is avoided, personal safety is ensured, meanwhile, the winding speed is not limited when the roller shutter door is expanded, convenience and quickness are achieved, and the channel can be quickly closed.

Owner:何永刚

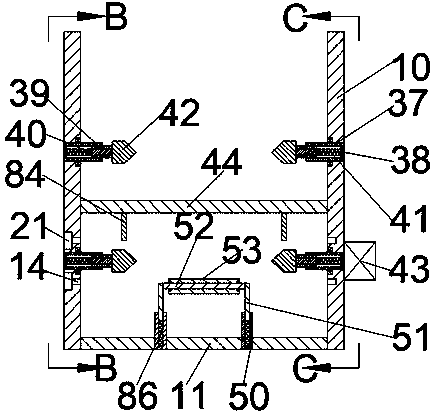

An auxiliary device for laying cables

The invention discloses a cable laying assisting device. One side of a transmission motor is provided with a double-headed reducer; one end of each first transmission shaft is provided with a drivinggear; one end of each second transmission shaft is provided with a driven gear that is engaged with the corresponding driving gear; one side of each second transmission shaft is provided with a lifting device; the input shaft of each screw jack is connected with the corresponding second transmission shaft through a coupling; the upper part of each screw sleeve I is provided with a screw sleeve III; the upper parts of the supporting plates is provided with a rotating device; the rotating device comprises bearing seats II, rotating shafts I, chucks, and a rotating shaft II; the bearing seats IIare fixedly mounted on the upper parts of the supporting plates respectively; the bearing seats II are internally provided with bearings respectively; the rotating shafts I are installed in bearing inner rings inside the bearing seats II respectively; one end of each rotating shaft I is fixedly connected with the corresponding chuck; and two ends of the rotating shaft II are respectively installedinside the chucks at two sides. The cable laying assisting device of the invention is of an integrated structure. With the cable laying assisting device adopted, operation can be completed by one person, so that work efficiency is high; and the lifting device adopts a linkage manner, and the lifting rate of the lifting device is uniform, and therefore, the inclination of a cable reel can be avoided.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

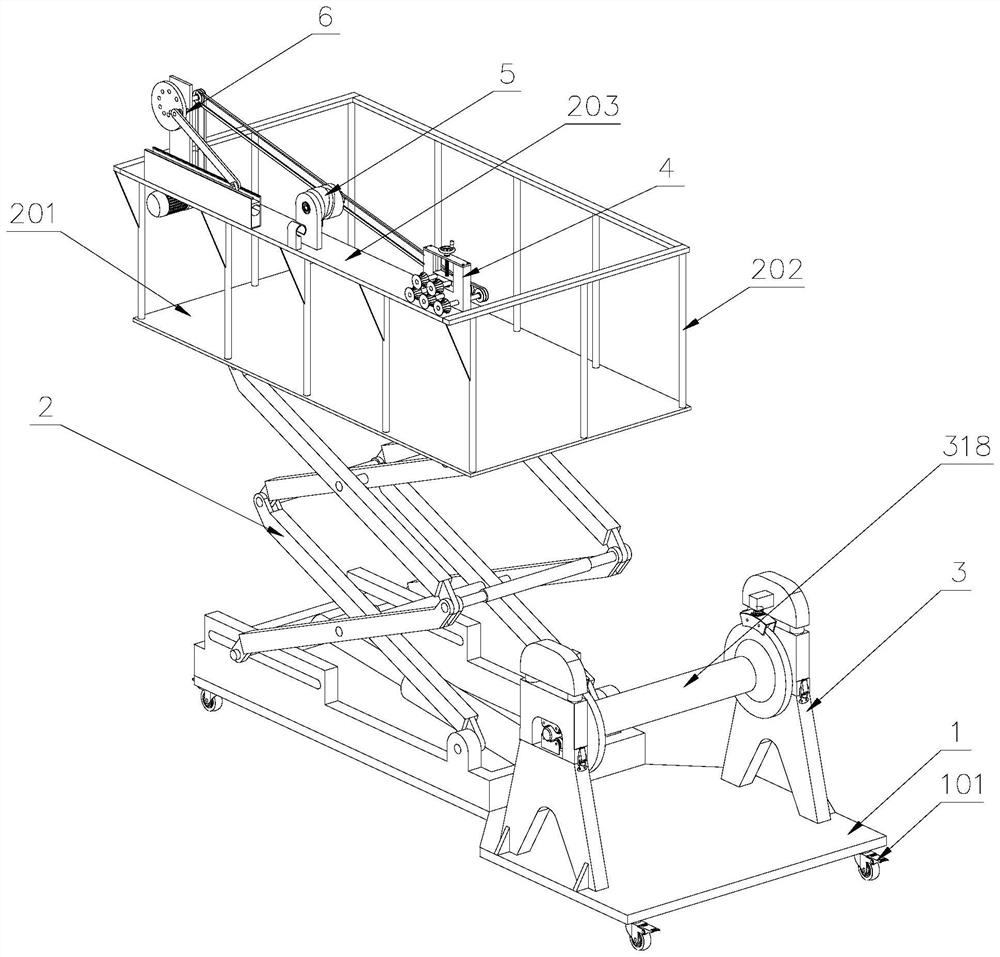

A kind of cable construction frame for electrician which is convenient for taking cables

InactiveCN111731928BControl pay-off lengthImprove construction efficiencyFilament handlingEngineeringElectric cables

The invention discloses a cable construction frame for electric power workers which is convenient for accessing cables. The idler roller on the upper part of the outrigger, the gland hinged on the upper side of the outrigger, the lower side of the gland is provided with a pressure groove, and the winding roller is arranged between the idler roller and the pressure groove on both sides; the lifting frame is a shear Cut-type lifting workbench, the wire management device includes a first vertical plate, a number of first rotating shafts movably installed on the first vertical plate, one end of the first rotating shaft is provided with a wire management roller, and one end of the second rotating shaft is movably installed with a crimping roller. In addition, the wire management rollers and the wire crimping rollers are alternately arranged, and the cables are arranged between the wire management rollers and the wire crimping rollers. The invention adopts a mobile structure, which integrates the cable placing frame and the lifting frame. The cable placing frame moves synchronously with the lifting frame, which is convenient to control the cable laying length according to the construction progress, improves the efficiency of cable construction, and reduces the labor force of workers. Labor intensity.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

Preparation system for deep processing of meat

ActiveCN114468014AScientific and reasonable structureEasy to useClimate change adaptationSausage filling/stuffing machinesWater storage tankEngineering

The preparation system comprises a processing machine body, and an extrusion moving mechanism is installed at the top position of one end of the processing machine body; and the extrusion moving mechanism comprises a discharging pipe, a water storage tank, a booster pump, a water outlet pipe, a connecting pipe, a connecting valve, an air bag, a guide pipe, a convergence cavity, a guide hole, a moving hole, a sliding plate, a placement hole, a storage hole, a connecting frame, a tensioning spring, a moving plate, a limiting plate, an extrusion plate, a clamping hole, a limiting rod and a water outlet valve. Water can be conveniently guided into the air bag and sprayed to the outer end of the connecting pipe from the guide hole through the air bag and the gathering cavity, so that a worker can conveniently sleeve the casing, the outer end of the casing can be conveniently extruded by an extrusion plate through a tensioning spring and a moving plate, and a sliding plate can be conveniently moved by matching with a limiting rod. Therefore, one end of the casing is stacked neatly, and the casing filling work is facilitated.

Owner:广东亚北农副产品有限公司

Production equipment and manufacturing method of antibacterial sound-insulation fabric

PendingCN113684628AImprove the effect of antibacterial and soundproof processingImprove product qualitySingeingLiquid/gas/vapor removal by squeezing rollersAnti bacterialConveyor belt

The invention discloses production equipment and a manufacturing method of antibacterial sound-insulation fabric, and belongs to the field of fabric production. The production equipment comprises an immersion cleaning box and four guide conveyor belts, four groups of immersion guide rollers are rotatably connected in the immersion cleaning box, the four groups of immersion guide rollers are distributed in a concave shape, a group of dewatering rollers is mounted in the immersion cleaning box, a drying mechanism is arranged on the right side of the immersion cleaning box, a fluff removing box is arranged on the right side of the drying mechanism, and two ironing plates are fixedly mounted in the fluff removing box. Fluff on the surface of the fabric is removed at a certain degree of high temperature, so that the antibacterial sound-insulation processing effect of the fabric is improved, the production quality of the antibacterial sound-insulation fabric is improved, the traction work of the fabric is improved, traditional manual traction is avoided, the automation degree is high, and the fabric inserting effect is better; and meanwhile, the use safety is high, and the production efficiency of the antibacterial sound-insulation fabric is improved.

Owner:深圳山而威医疗科技集团有限公司

A high-voltage transmission line routing robot

ActiveCN111872952BAvoid falling easilyNot easy to slipManipulatorApparatus for overhead lines/cablesRubber ringElectric machinery

The invention discloses a high-voltage transmission line routing robot, which relates to the technical field of high-voltage transmission lines, and includes a device main body, a fixing clip and a clamping block. A storage box is embedded in the right side of the main body. The invention installs a rotating wheel, When the main body of the device is moving along the transmission line through the rotating wheel, when the rotating wheel is driven by the second motor to rotate, the rubber ring will always expand outward through the elastic force of the first spring, so that the rubber ring can closely fit the power transmission lines of different sizes. line, so that it is not easy to slip between the rotating wheel and the transmission line, and the roller will always be tightly attached to the lower end of the transmission line through the elastic force of the second spring, and the concave arc surface in the middle of the outer surface of the roller can effectively fit the outer surface of the transmission line. The firmness between the rotating wheel and the transmission line can be improved through the roller, so as to avoid the easy falling of the rotating wheel when it rotates and moves along the transmission line.

Owner:QIXIA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

A pretensioning device for high-voltage wires of electric power towers

ActiveCN111697492BAchieve winding fixationImprove securityApparatus for overhead lines/cablesElectric machineDrive motor

The invention relates to the technical field of a high-voltage line laying device and particularly relates to an electric power iron tower high-voltage line pre-tightening device. The high-voltage line pre-tightening device of an electric power iron tower comprises a vertical plate, wherein a cross beam plate is transversely welded at an upper end of the right side of the vertical plate, a throughhole penetrating left and right is formed in an upper end of the vertical plate, and an electric telescopic rod and a side support are vertically welded at upper and lower ends of the left side of the vertical plate. The high-voltage line laying device is advantaged in that winding and fixing of a high-voltage cable are achieved through cooperation of a driving motor and a pulley, so stretching and laying of the high-voltage cable are achieved through rotation of a motor, manual pulling is avoided, operation safety and convenience are greatly improved, and high-altitude operation is more convenient, three-stage pre-tightening is realized through motor driving, extension of a telescopic rod and stretching of a balancing weight, so adjustment of pre-tightening force is refined, the magnitude of the pre-tightening force on the high-voltage cable is convenient to control, excessive stretching is avoided, and a purpose of fine adjustment is realized.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com