Annular wire winding machine

A winding machine and ring-shaped technology, which is applied in the field of ring-shaped winding machines, can solve the problems of magnetic core jumping upwards, affecting the uniformity of magnetic core winding and winding quality, so as to ensure uniformity, avoid manual pulling, and improve The effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

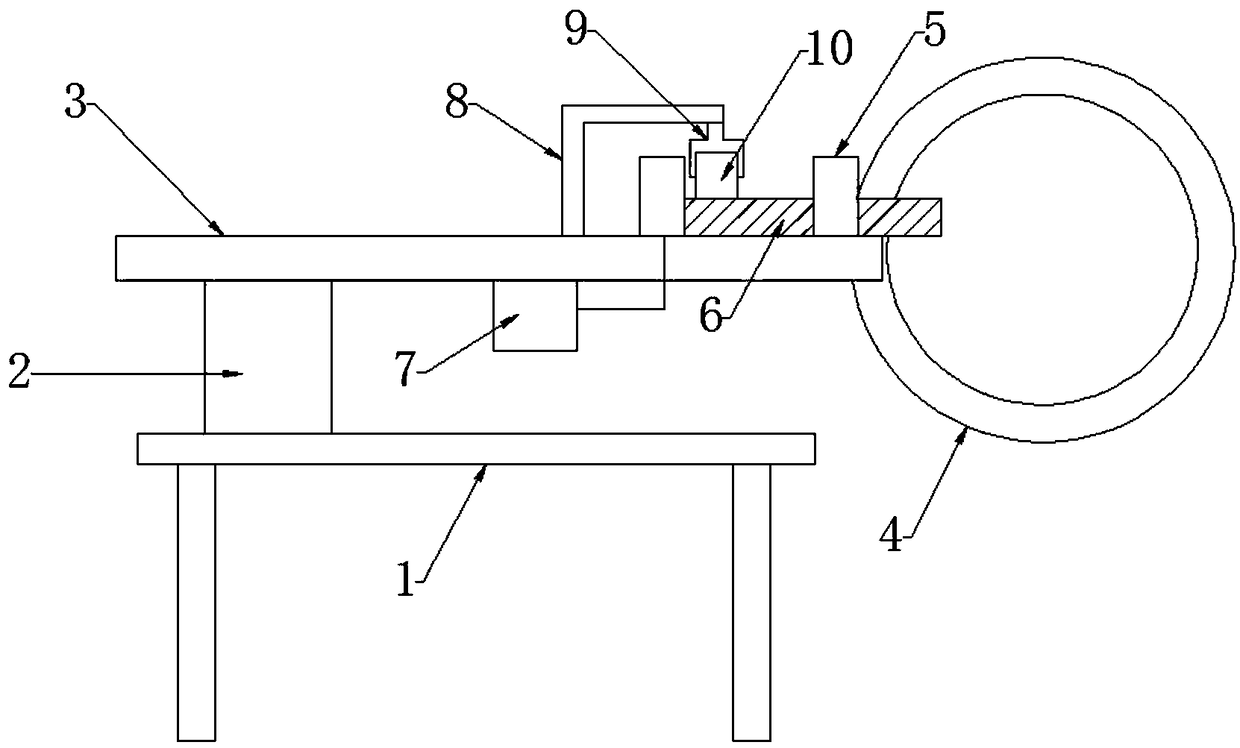

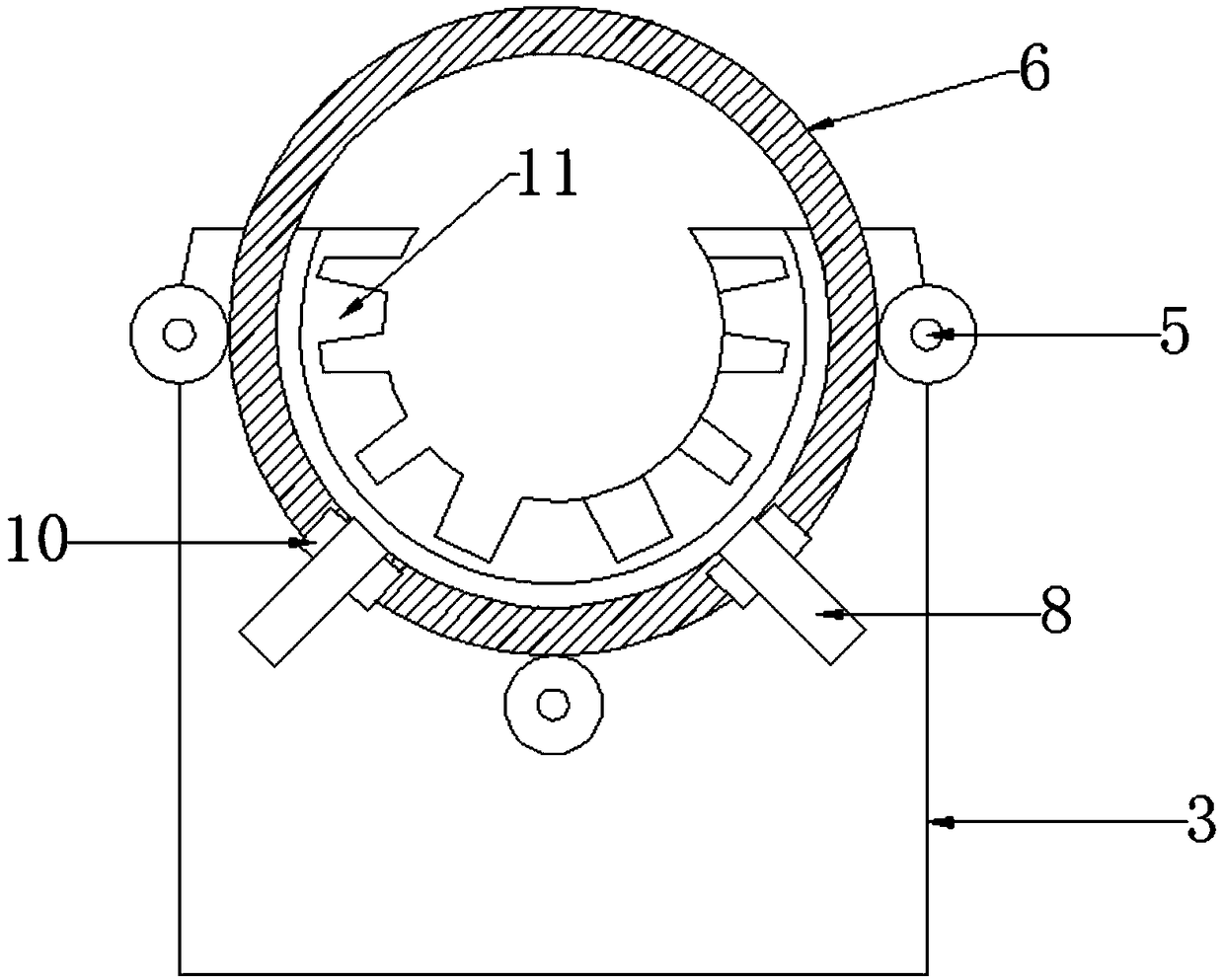

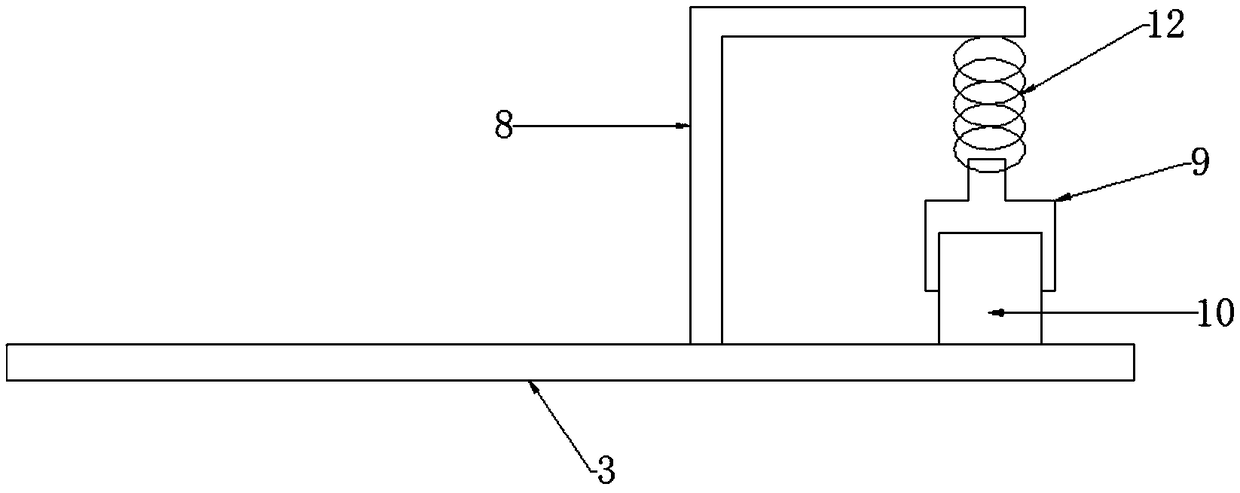

[0023] Such as Figure 1-3 As shown, the present invention is a ring winding machine, including a frame, an assembly head, an electric control box, a transmission mechanism, a wire storage ring, and a magnetic core clamping mechanism. The magnetic core clamping mechanism includes a The support seat 2 on the frame 1, the support plate 3 horizontally arranged on the support seat, one end of the support plate is provided with a C-shaped groove, the central angle of the C-shaped groove is greater than 180 degrees; the wire storage ring 4 and the support plate The opening position of the C-shaped groove matches, and the plane of the support plate is perpendicular to the annulus of the wire storage ring; the support plate is evenly provided with at least three roller columns 5 perpendicular to the support plate on the outer edge of the C-shaped groove and drives Roller, the roller column and the driving roller are provided with a roller and a driving wheel for clamping the magnetic ...

Embodiment 2

[0026] Such as Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the magnetic core positioning component is a groove 15 provided on the support plate 3 for embedding the magnetic core, and the opening direction of the groove is C-shaped with the support plate. The opening directions of the grooves are consistent, and the bottom surface of the grooves is provided with notches 16 for accommodating rollers.

[0027] Such as Figure 5 As shown, the ring winding machine of the present invention also includes a wire fixing assembly, and the wire fixing assembly includes a fixing rod 13 arranged on the bottom surface of the support plate 3, and the end of the fixing rod is provided with a hook passing through the ring hole of the magnetic core 6 Bar 14, the hook bar is rotatably connected with the fixed bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com