Patents

Literature

619results about How to "Improve winding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

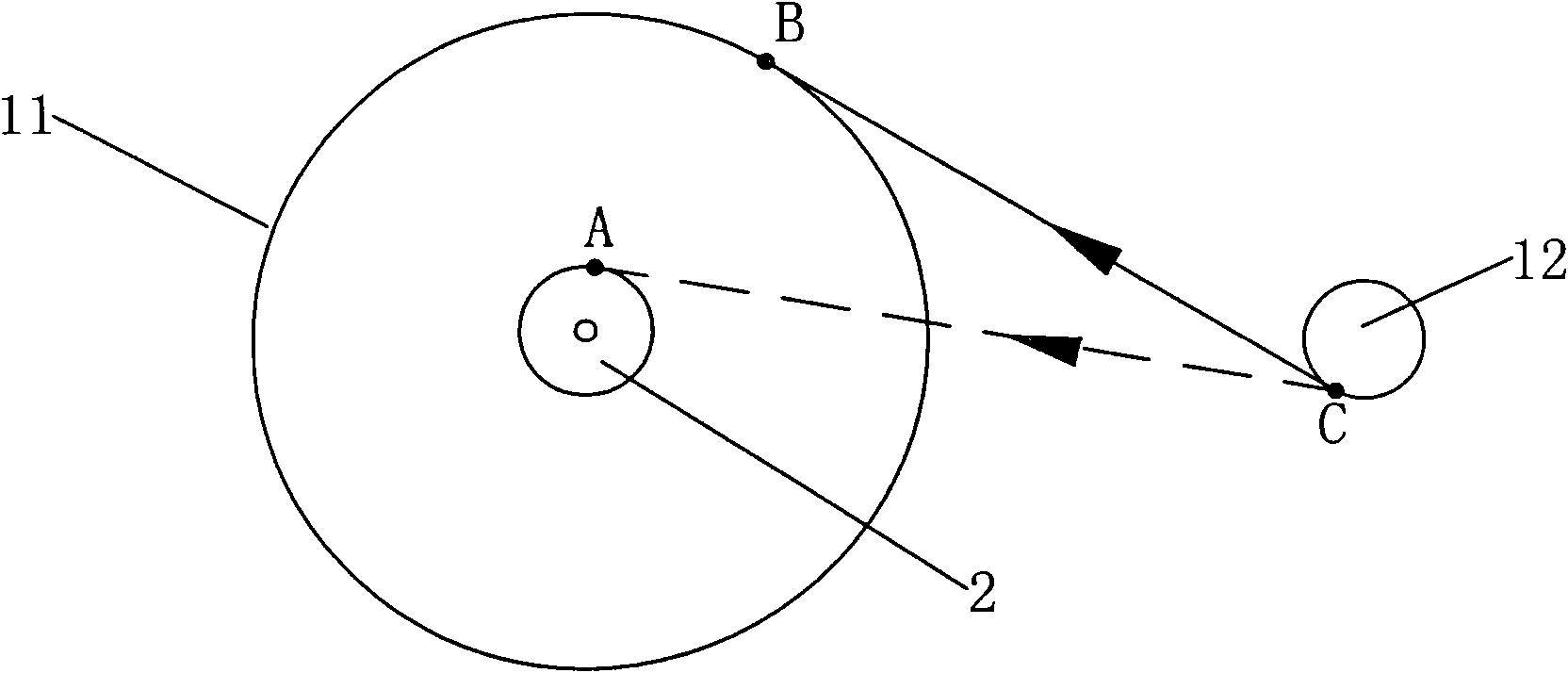

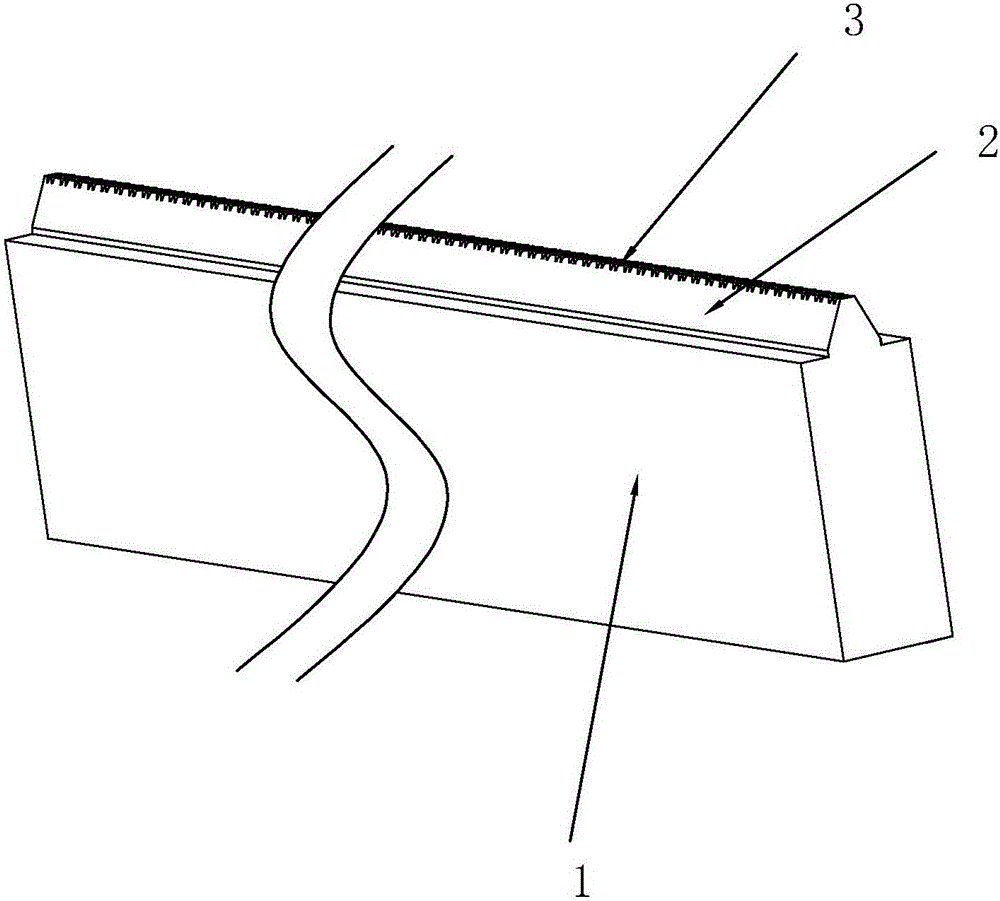

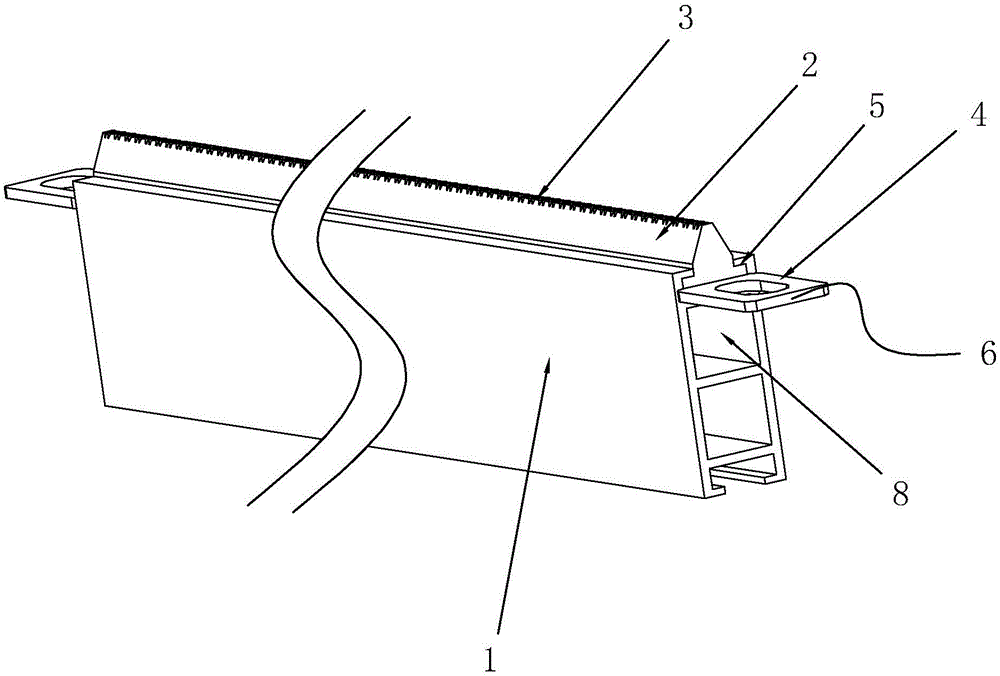

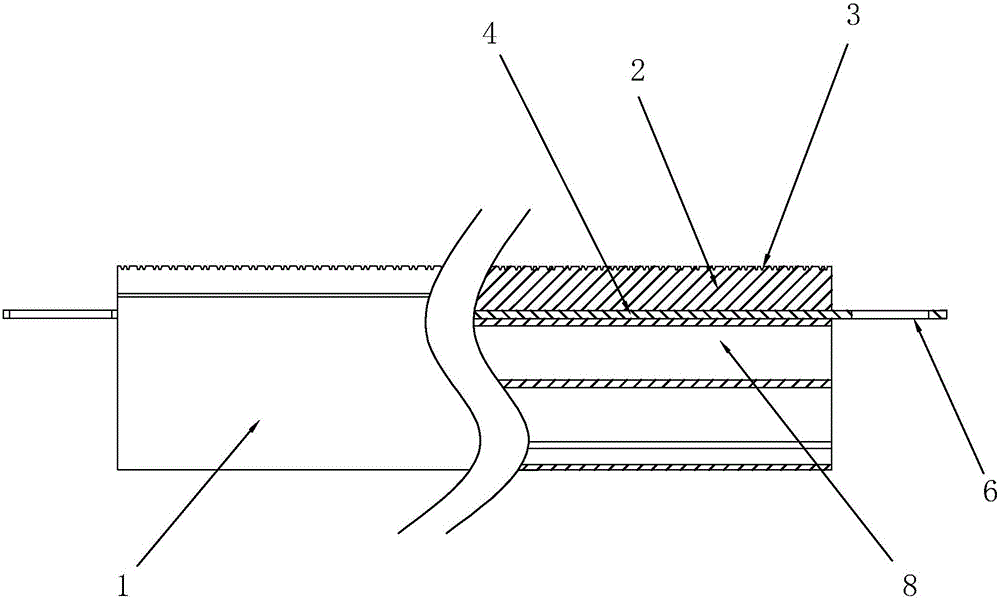

Copper wire winding device with cleaning function

InactiveCN108059032AGood dust removal effectImprove winding qualityFilament handlingCopper wireEngineering

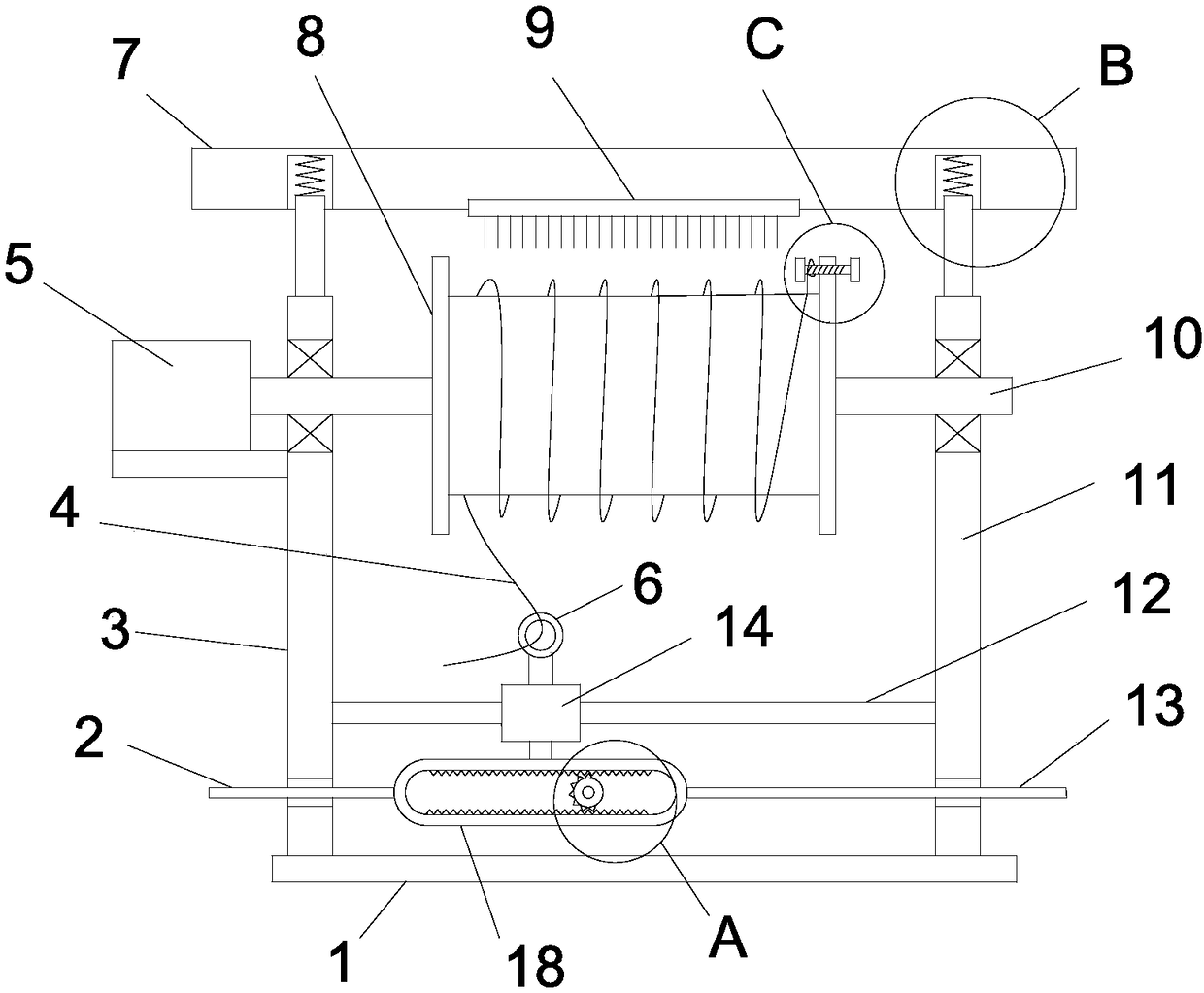

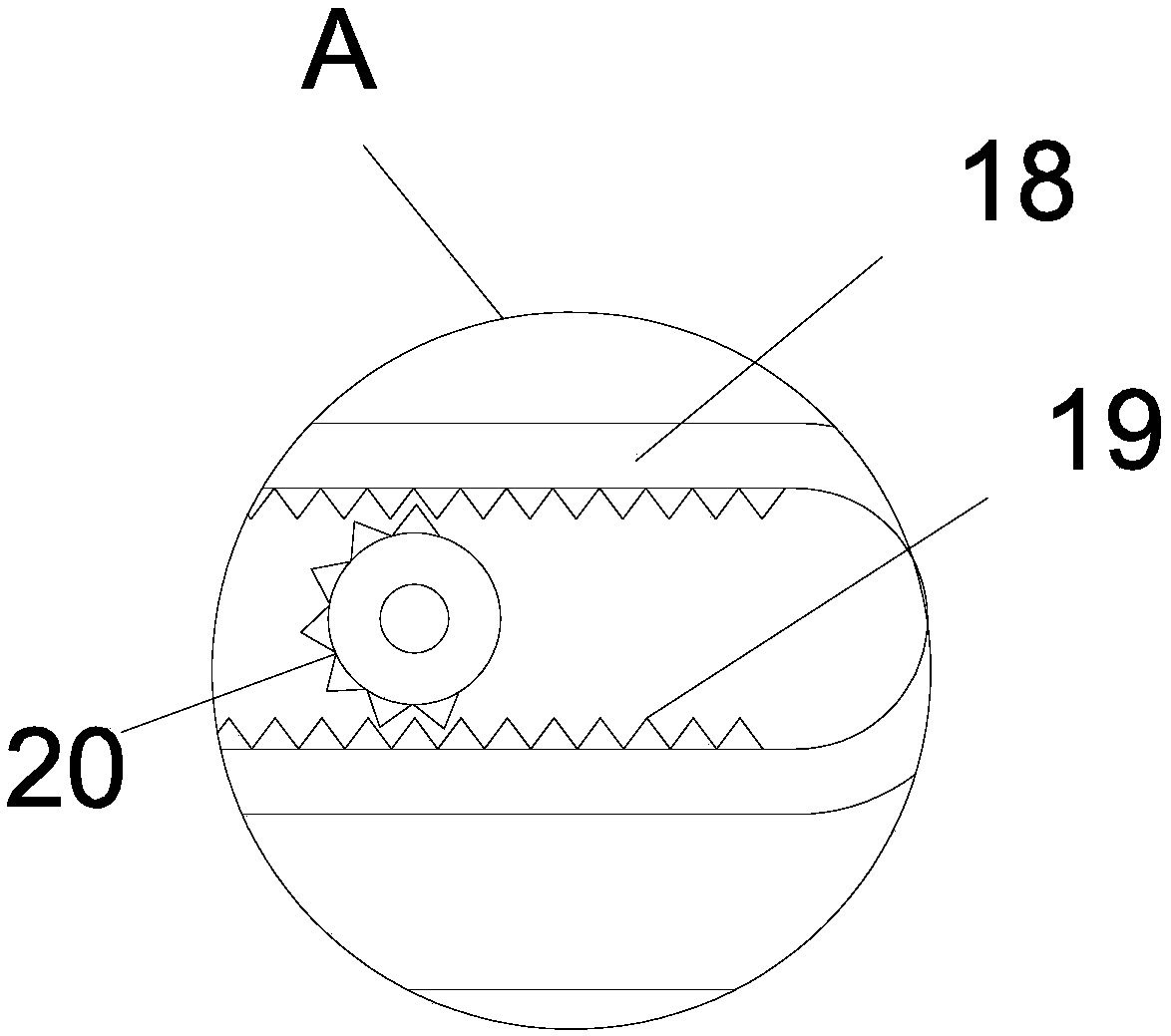

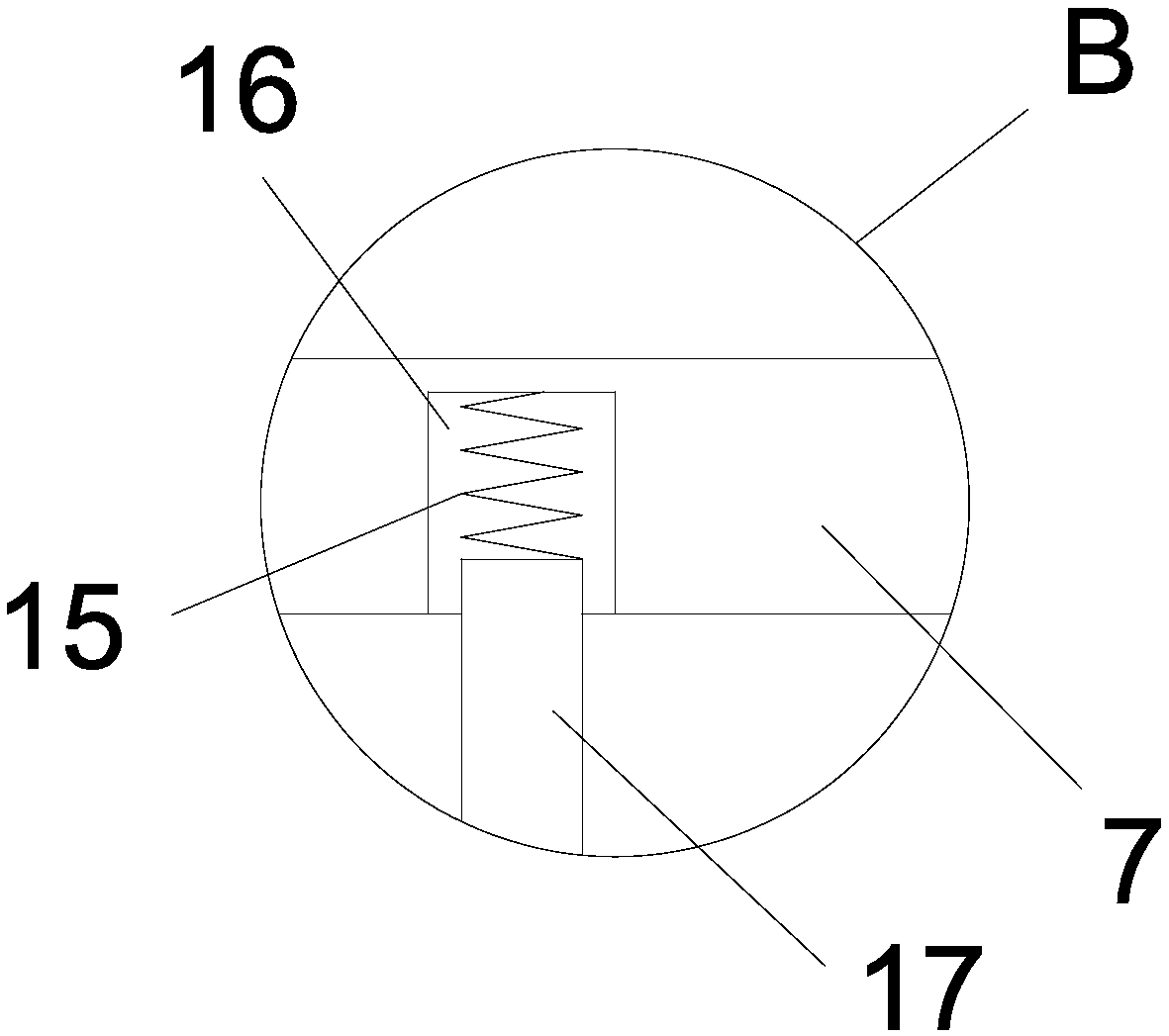

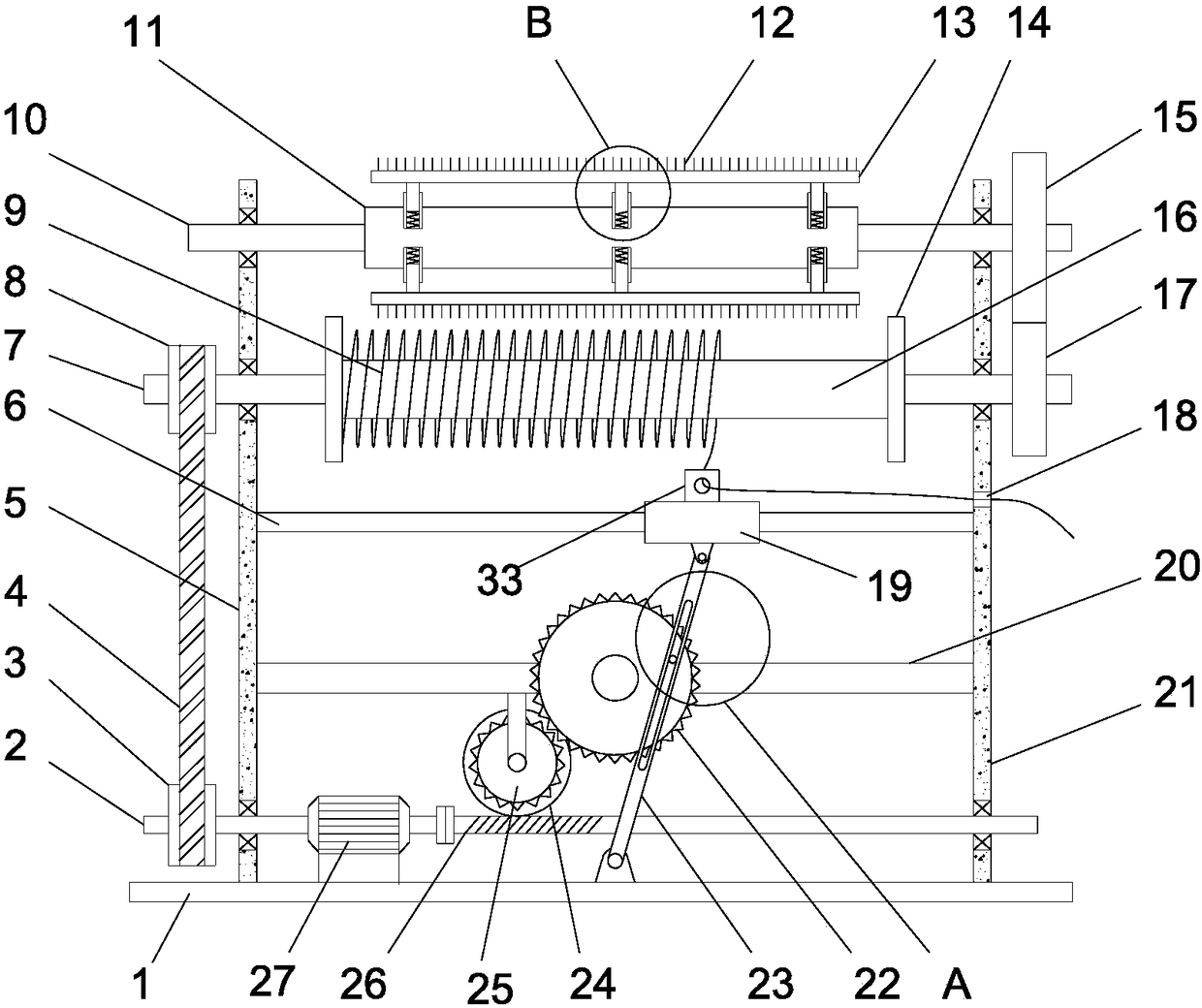

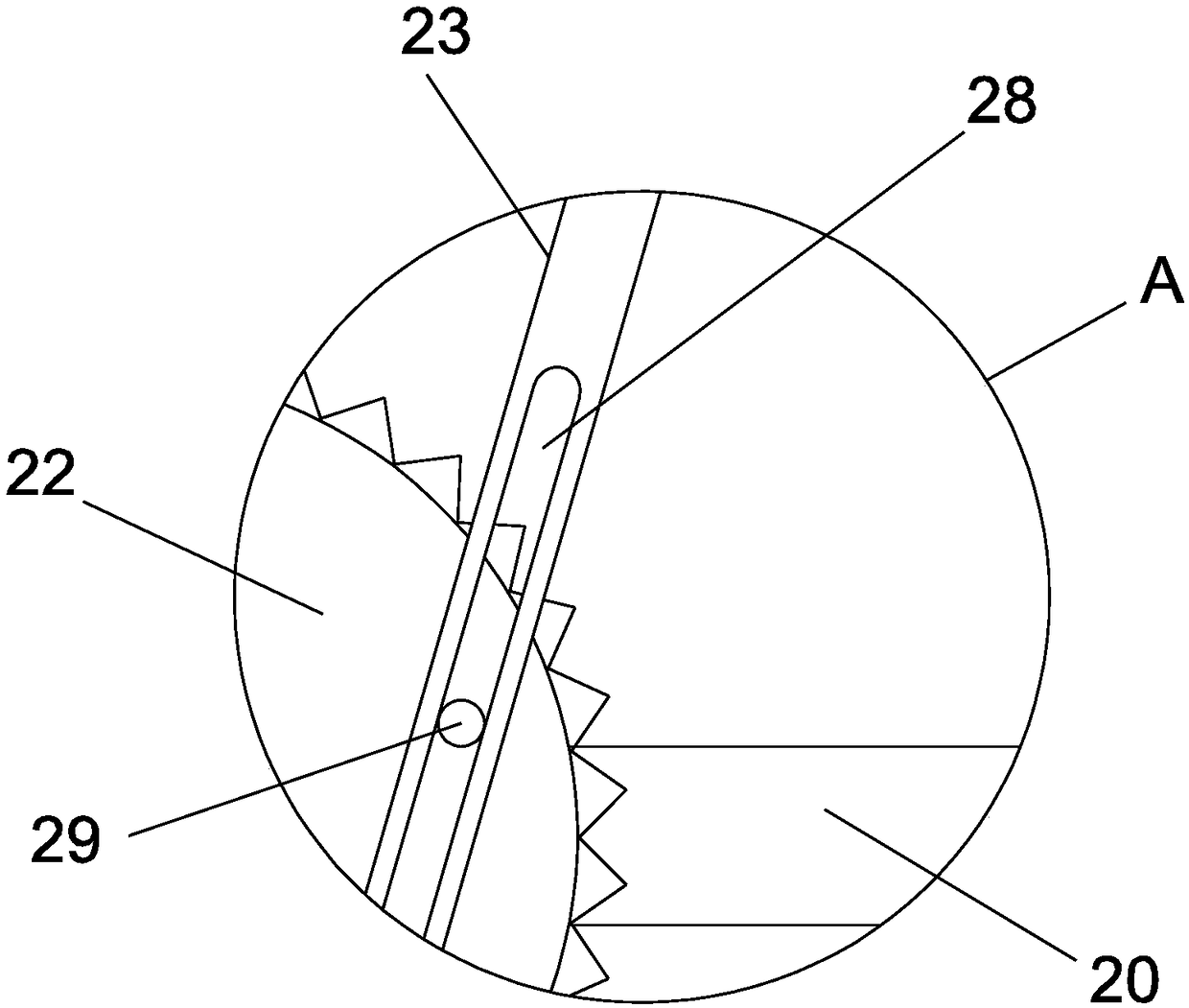

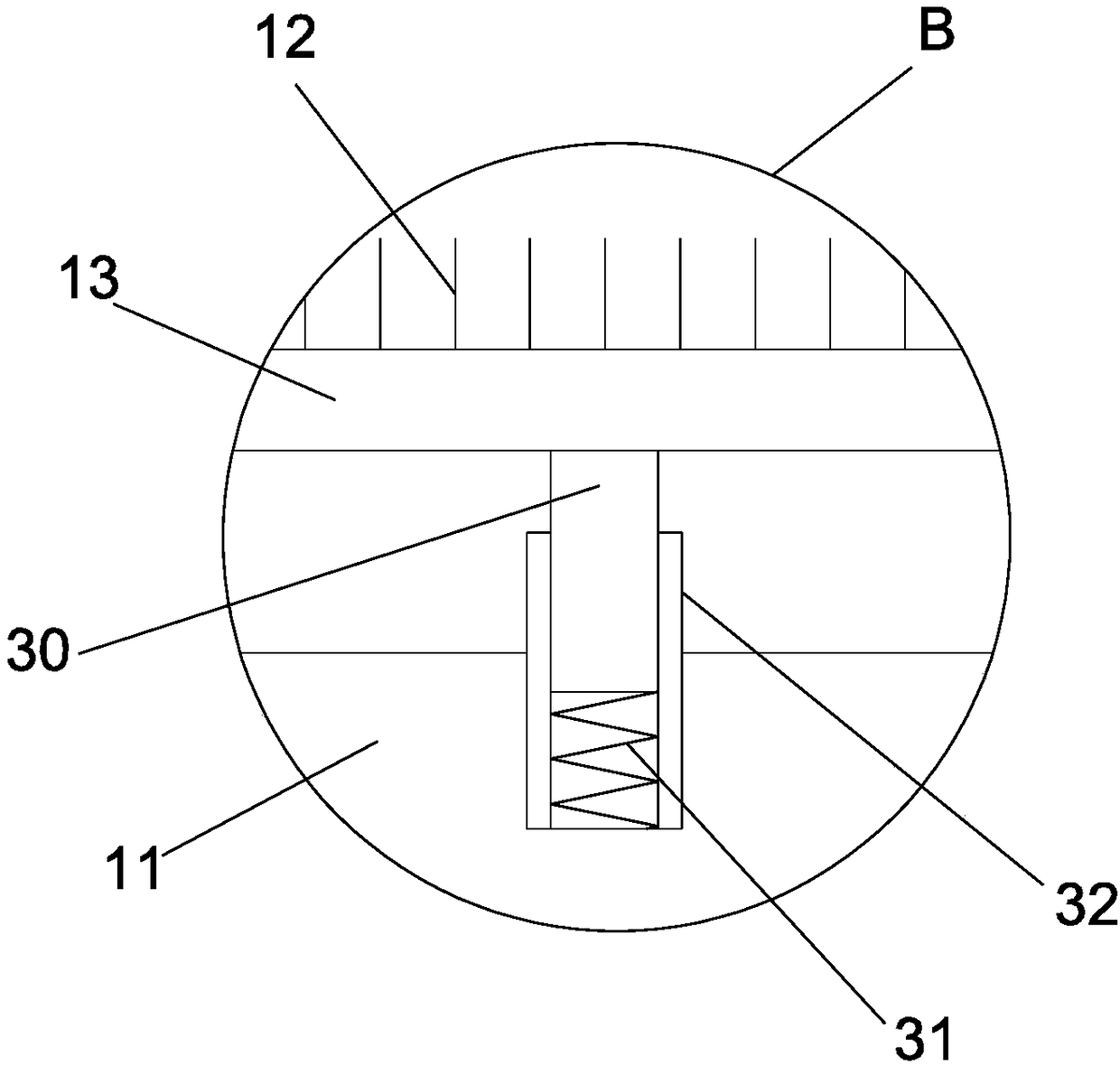

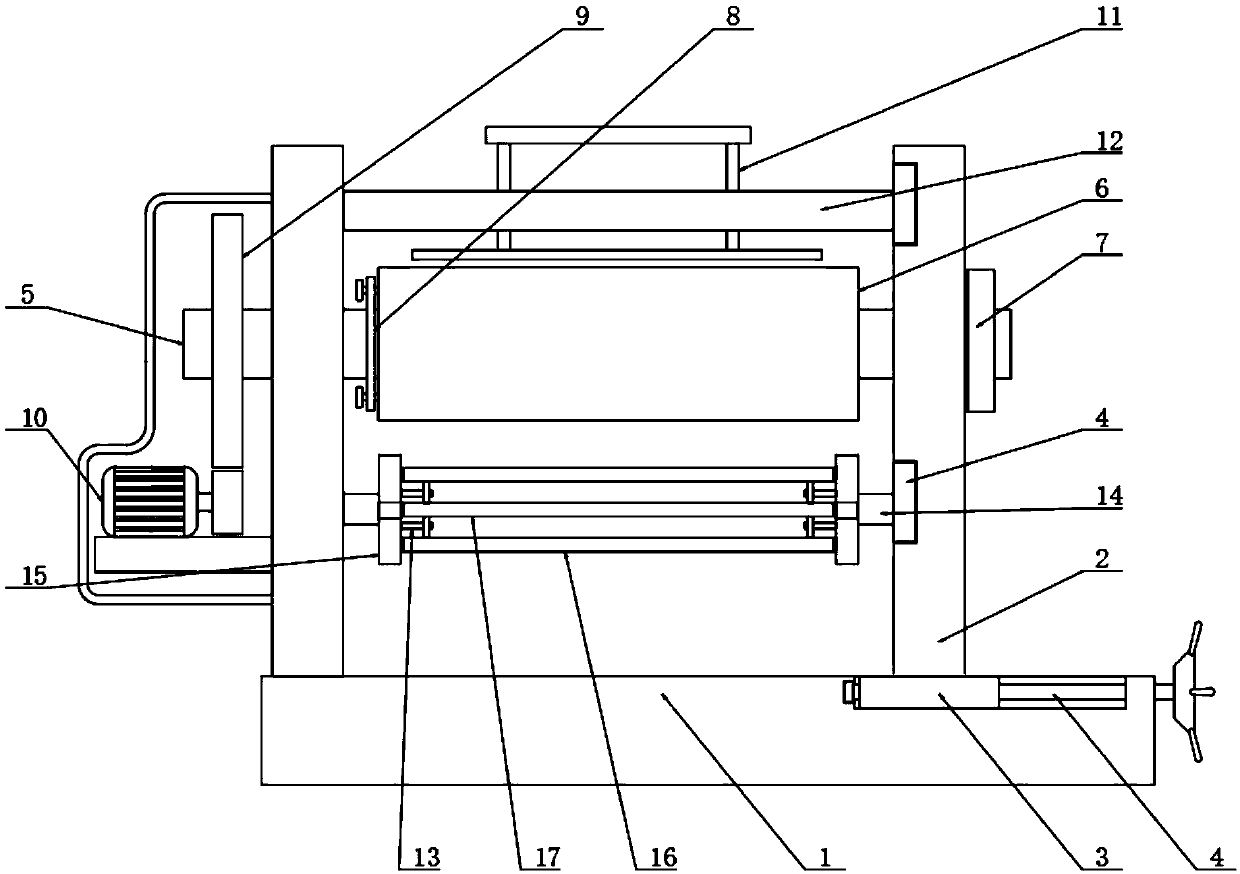

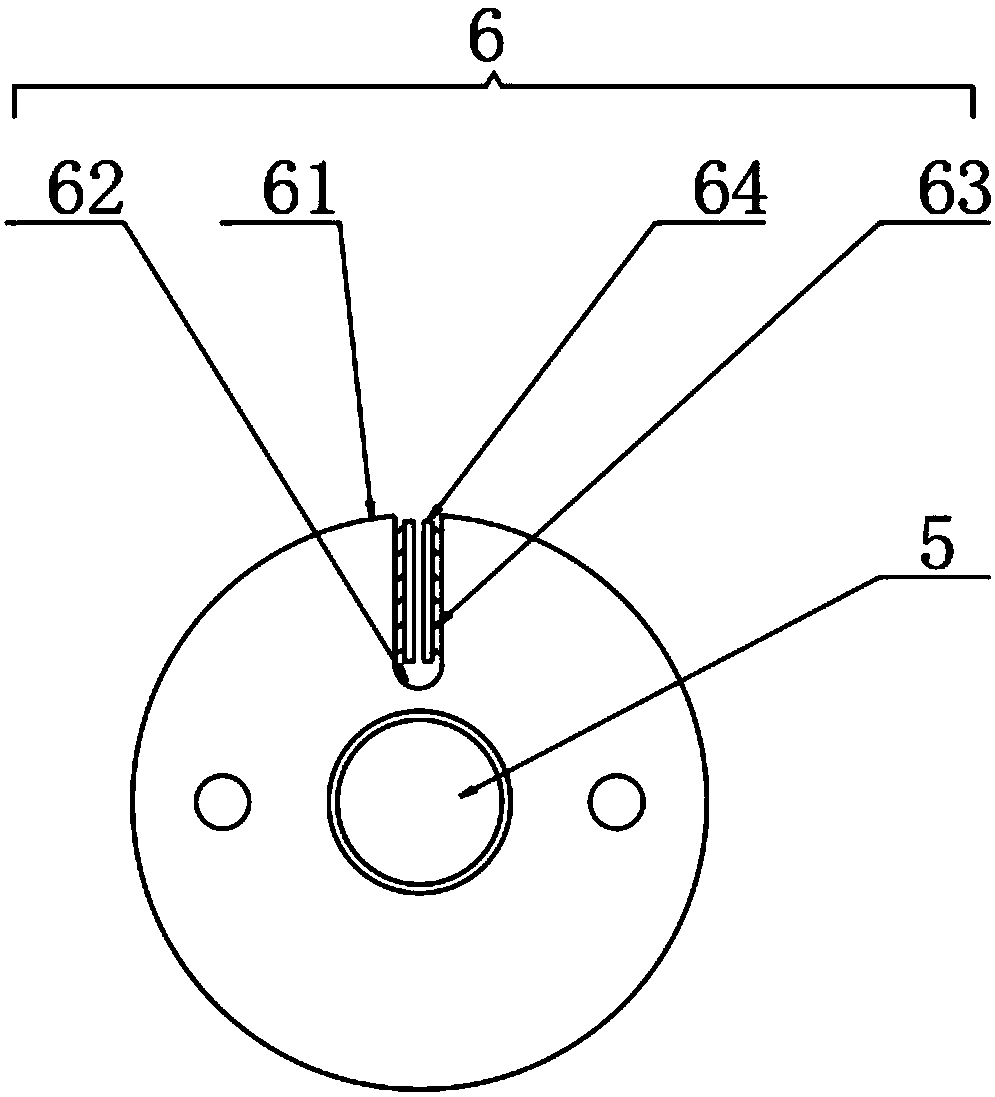

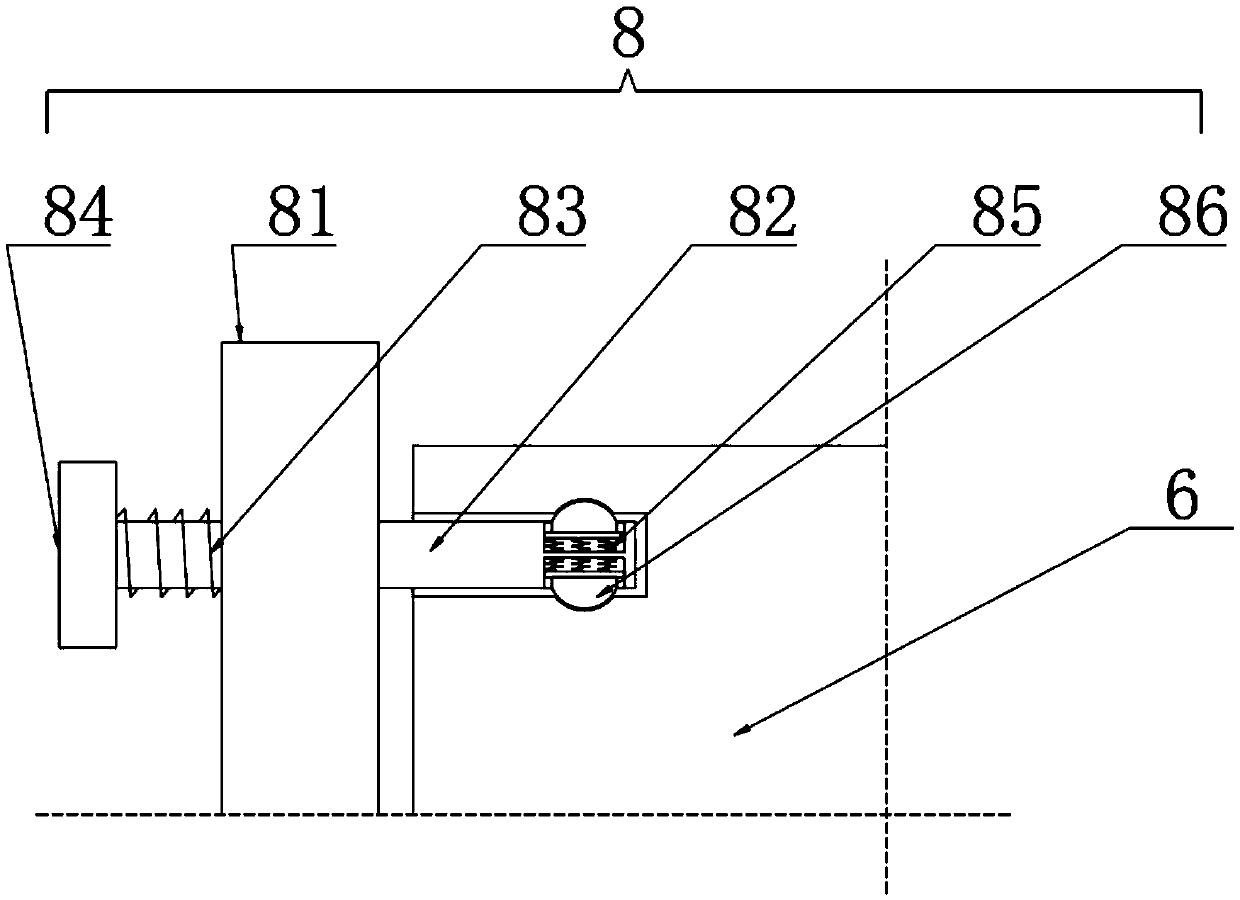

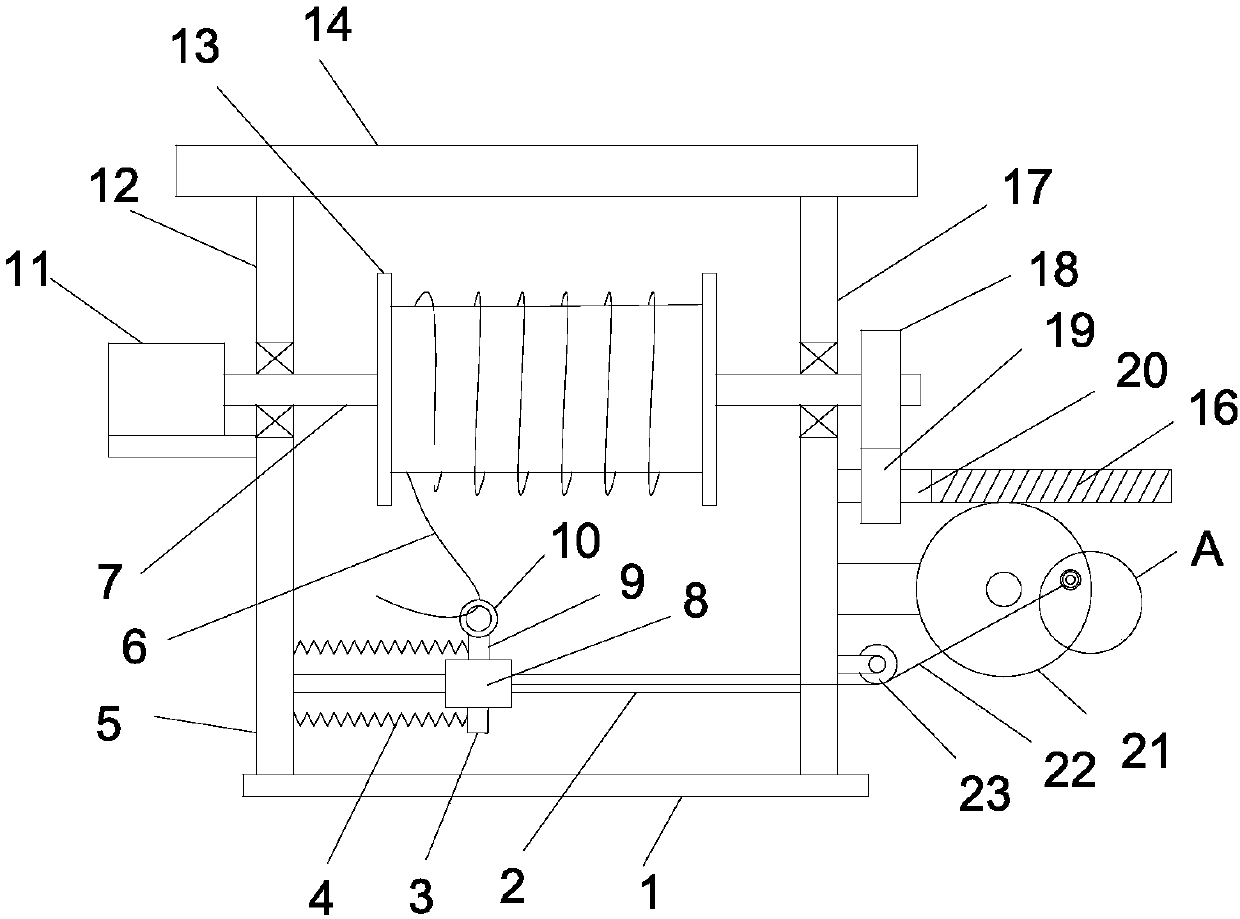

The invention discloses a copper wire winding device with a cleaning function. The copper wire winding device comprises a bottom plate. A left vertical plate and a right vertical plate are verticallyand fixedly arranged on the bottom plate. The upper end of each of the left vertical plate and the right vertical plate is vertically and fixedly provided with a vertical shaft. A pressing plate is horizontally arranged above the left vertical plate and the right vertical plate. The outer surface of a driving shaft is sleeved with and fixedly provided with a winding roller. A horizontal rod is horizontally and fixedly arranged between the left vertical plate and the right vertical plate. A sliding sleeve is fixedly provided with a limiting ring, and a copper wire penetrates the limiting ring.Straight racks are horizontally and fixedly arranged on the upper inner side wall and the lower inner side wall of a concentric-square-shaped frame. The copper wire is wound through the winding roller, the sliding sleeve is driven by the concentric-square-shaped frame to reciprocate left and right along the horizontal rod, accordingly, the limiting ring is used for driving the copper wire to reciprocate left and right, the copper wire is prevented from being excessively centralized at one position of the winding roller, and the copper wire is evenly wound around the winding roller; and a brushand the copper wire relatively rotate in the copper wire winding process, a very good dust removing effect is achieved, and the winding quality is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

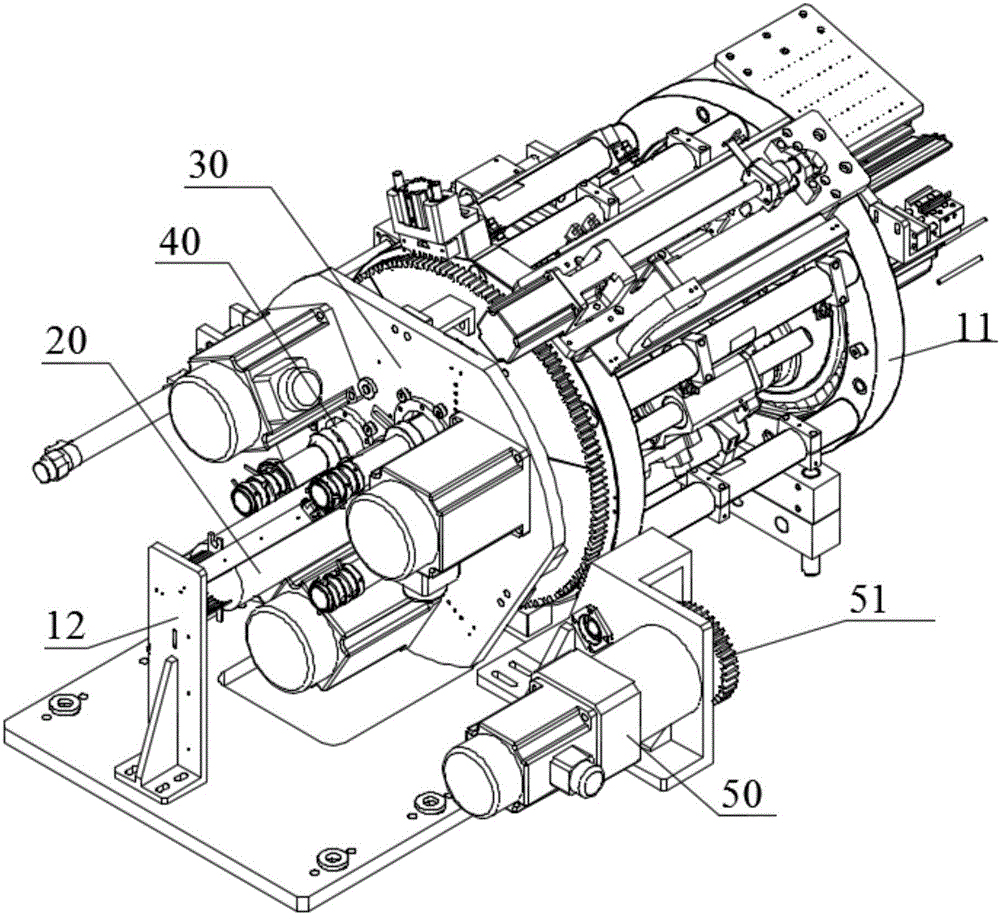

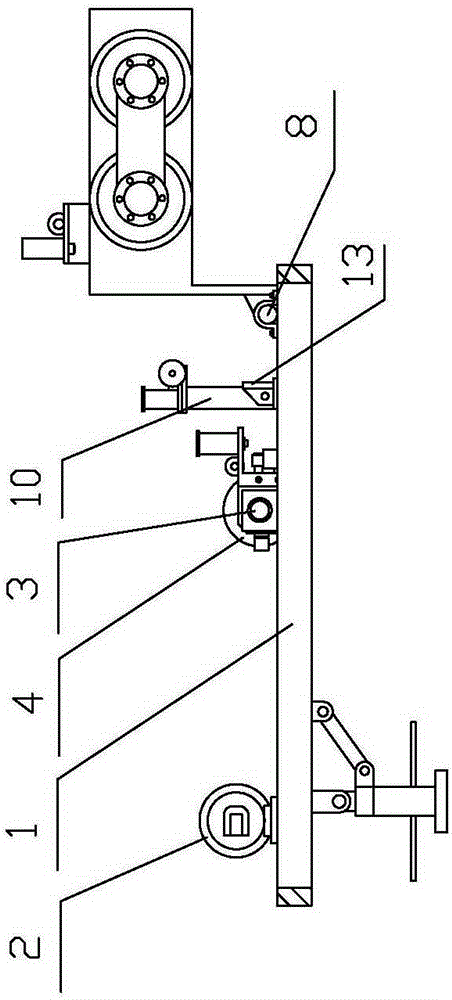

Coil winding machine with parallel winding of multiple coils

ActiveCN102497067AAvoid fluencyAvoid problems such as easy damage to the surface of the wireManufacturing dynamo-electric machinesWinding machineConductor Coil

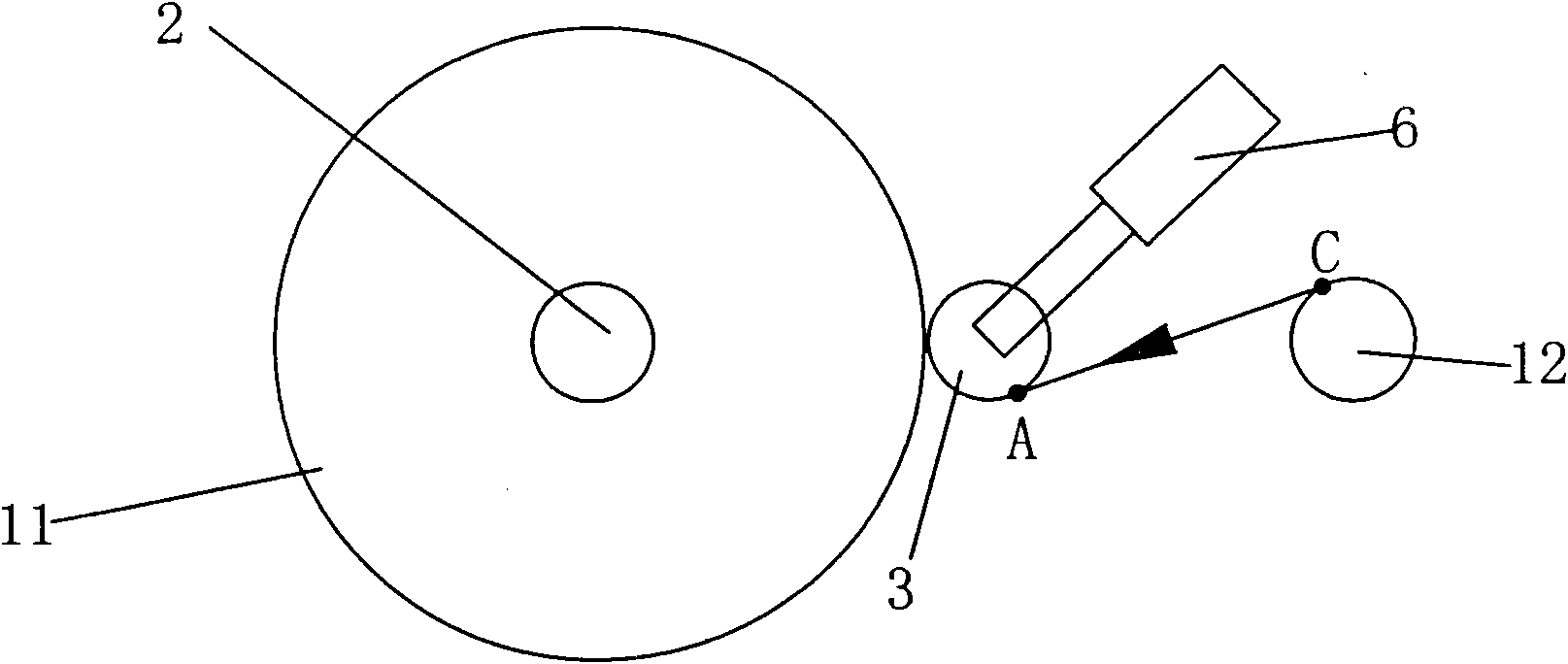

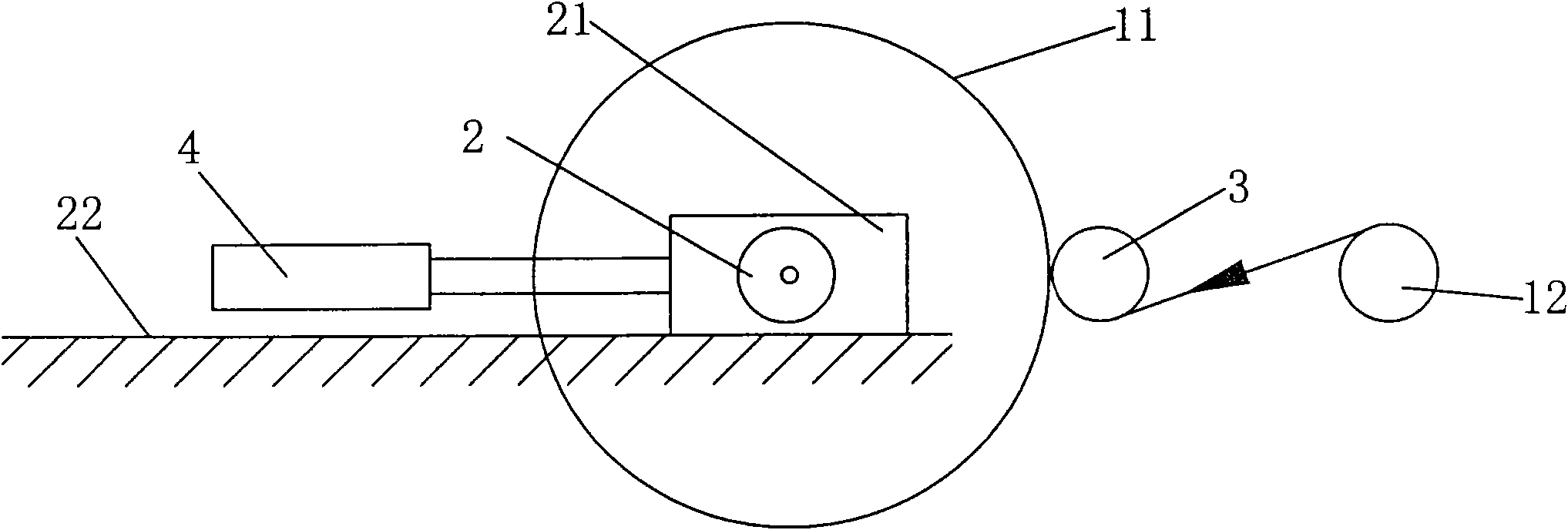

The invention discloses a coil winding machine with parallel winding of multiple coils. The coil winding machine comprises a rotation coil transmission holder, a rotation tension force apparatus and a flying fork mechanism, wherein, the rotation coil transmission holder is a holder for providing a plurality of coils, the rotation tension force apparatus comprises tension force mechanisms with corresponding quantity and is used for adjusting a tightness degree of each coil in a coiling process, the flying fork mechanism has one or more nozzles for traversing a plurality of coils, and each coilis wound into a stator notch in order. Rotation direction and speed of the rotation coil transmission holder and the rotation tension force apparatus are synchronous with the flying fork so as to avoid that coils are possibly intertwined together in the coiling process. The coil winding machine has the advantages of reasonable structure, smooth coil entry, high coiling efficiency and the like.

Owner:厦门义胜自动化设备有限公司

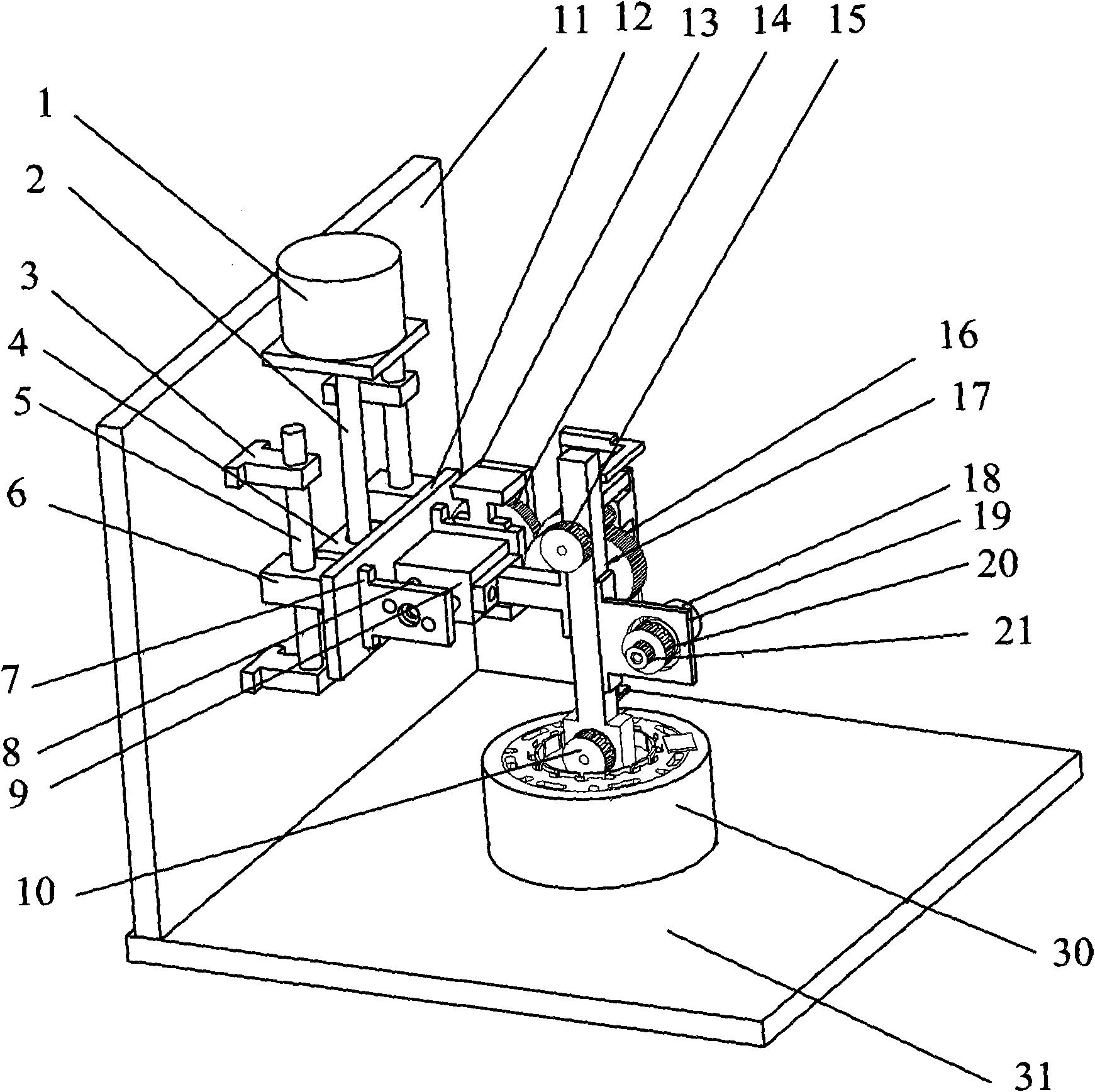

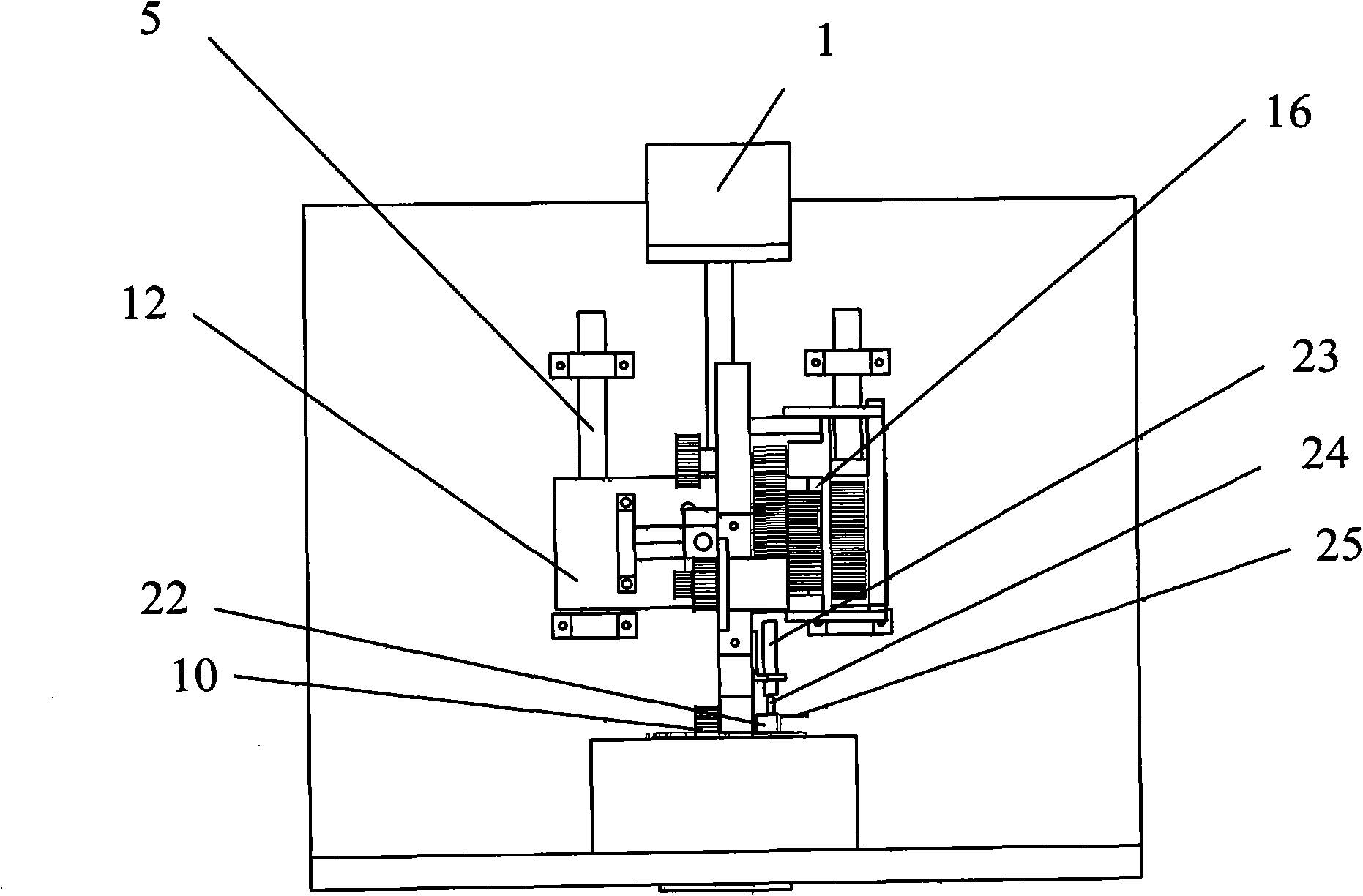

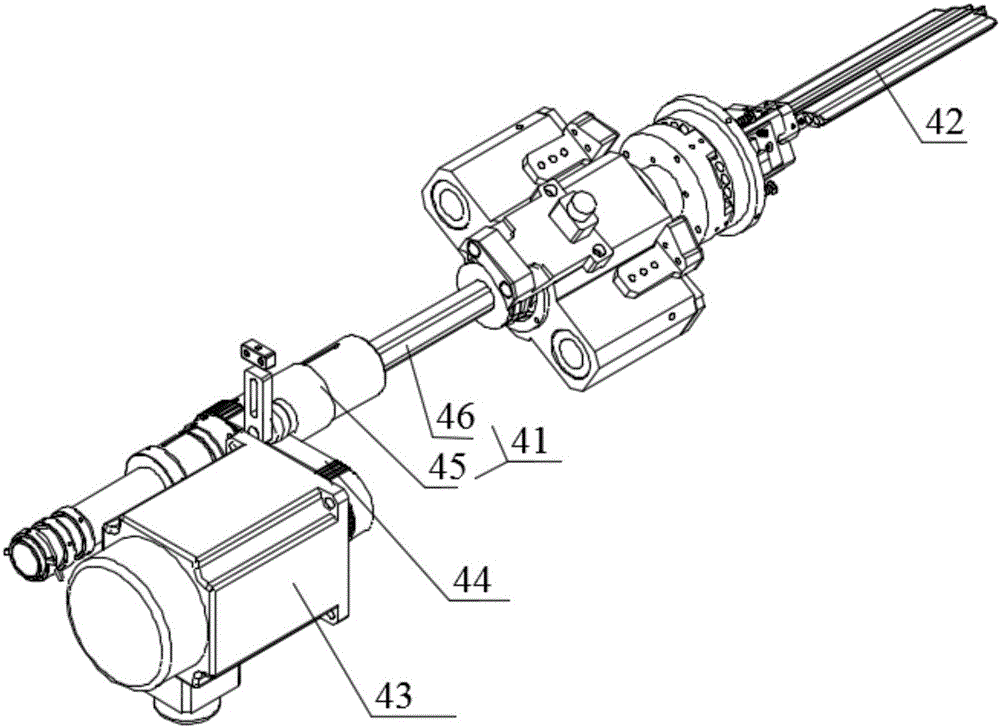

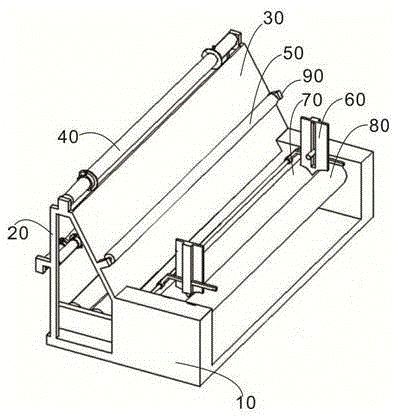

Winding device and winding machine with same

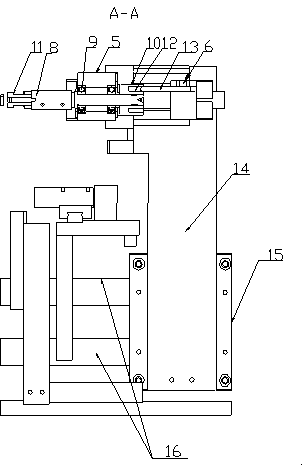

InactiveCN102117697AHigh positioning accuracyRealize automatic operationTransformersManufacturing dynamo-electric machinesWinding machineStator coil

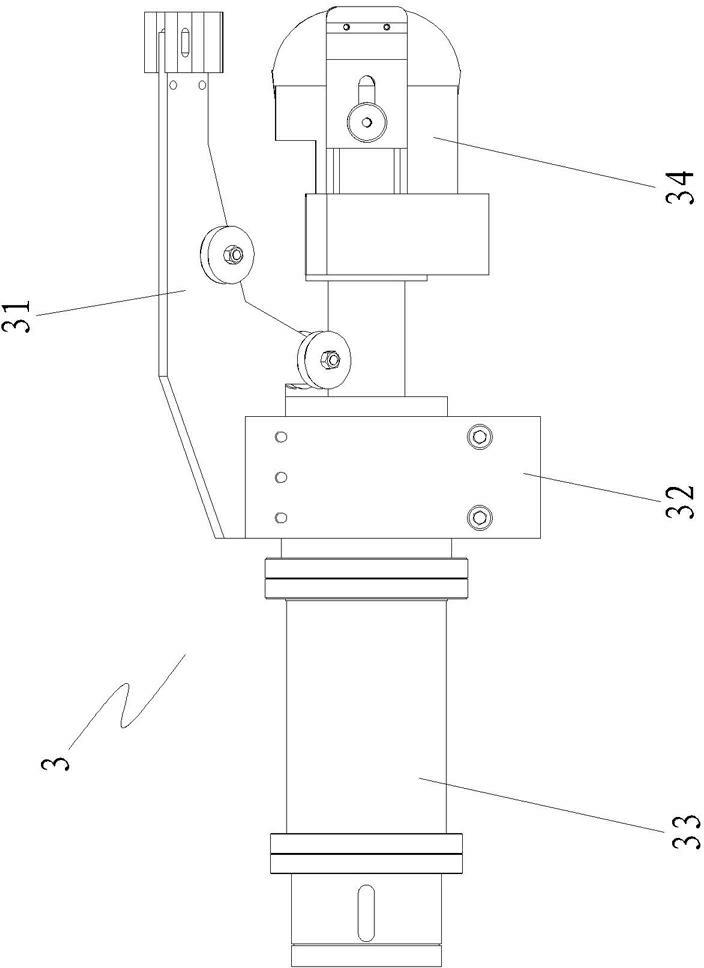

The invention provides a winding device. The device comprises a winding unit, a drive unit, a fixing unit and a control unit, wherein the fixing unit comprises a fixed first mounting plate; the drive unit comprises a first motor fixed on the first mounting plate and a lift rack driven by the first motor, and the winding unit is fixed on the lift rack; the winding unit comprises a winding needle, a winding motor and a traversing module, the winding motor is used for driving the winding need to wind wires and drive the traversing module to drive the winding unit to traverse wires; and the control unit is used for controlling the drive unit to drive positioning of the winding unit and controlling the winding unit to wind wires. The invention also provides a winding machine comprising the winding device. By adopting the winding unit, the drive unit, the fixing unit and the control unit which work cooperatively, so that automatic operation of stator coil winding can be realized; and the drive unit drives positioning of the winding unit, so the positioning accuracy of winding can be improved, and the winding quality of the stator coil can be improved.

Owner:BYD CO LTD

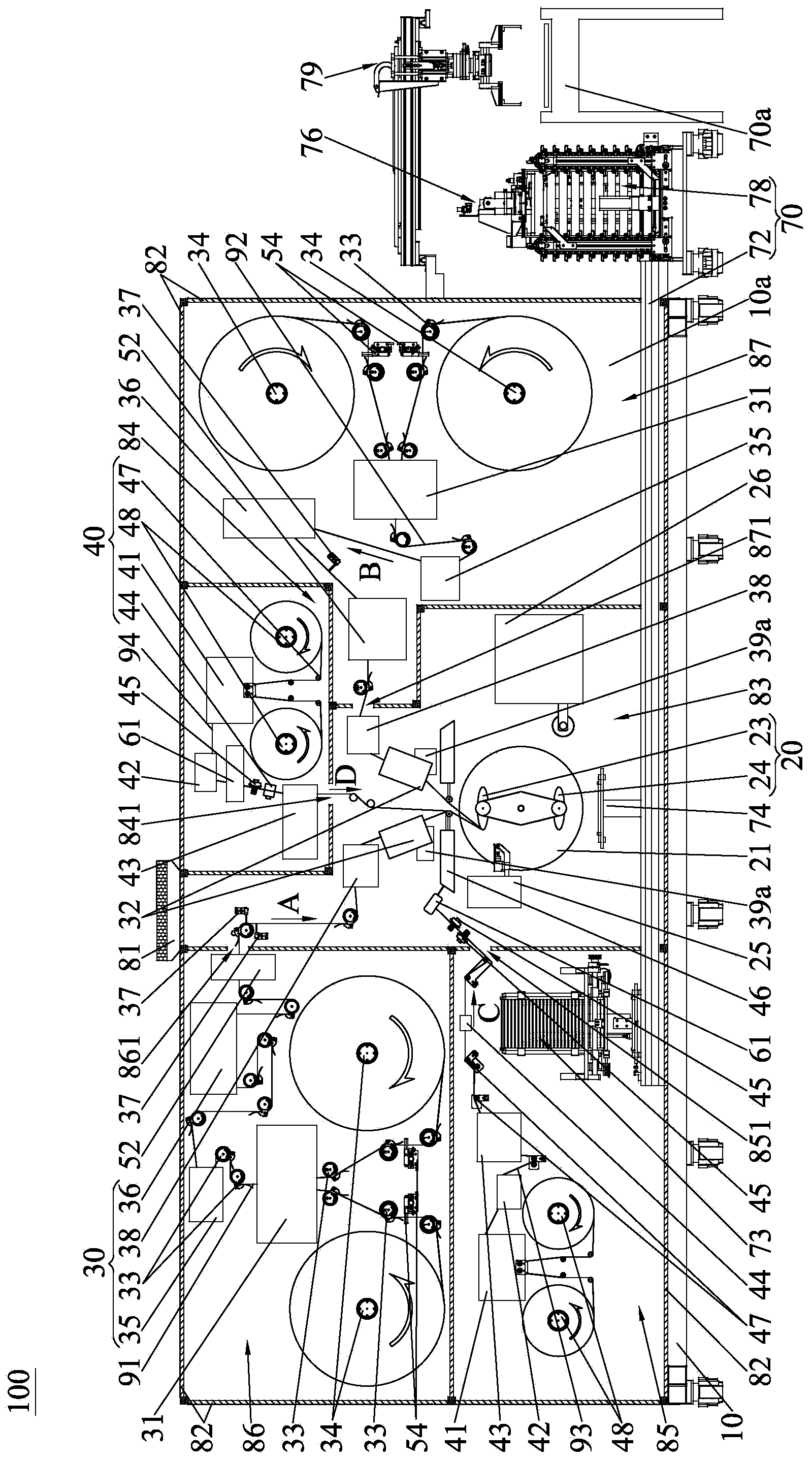

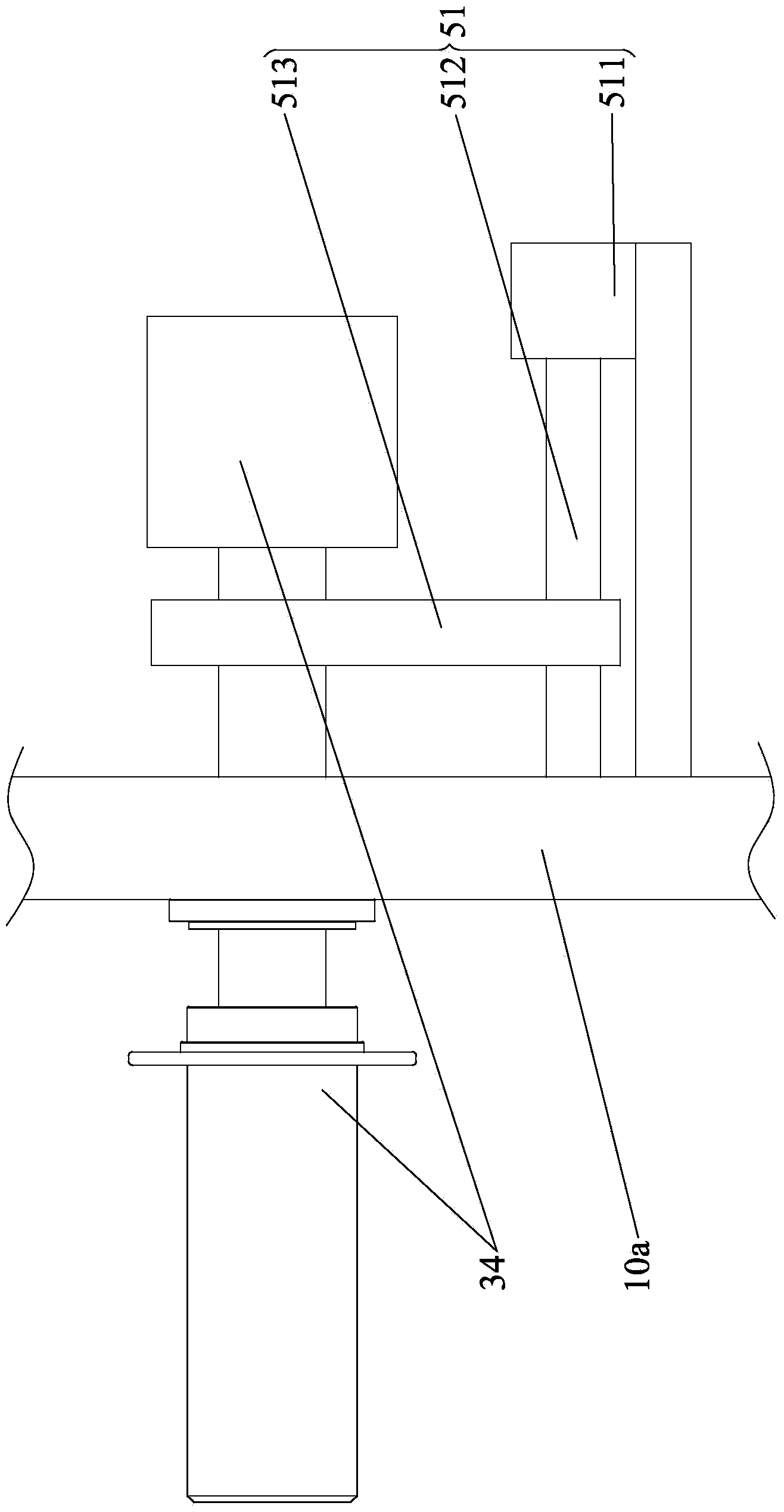

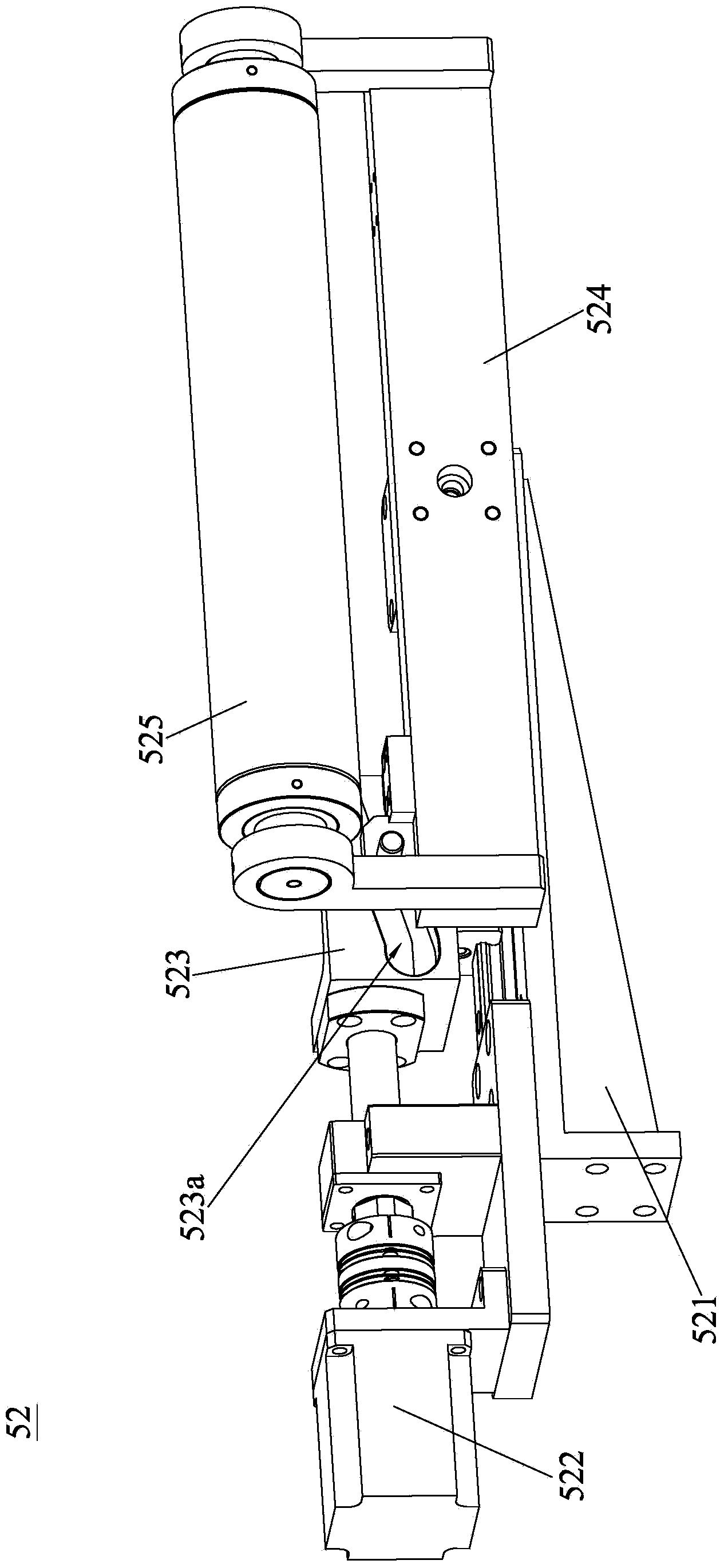

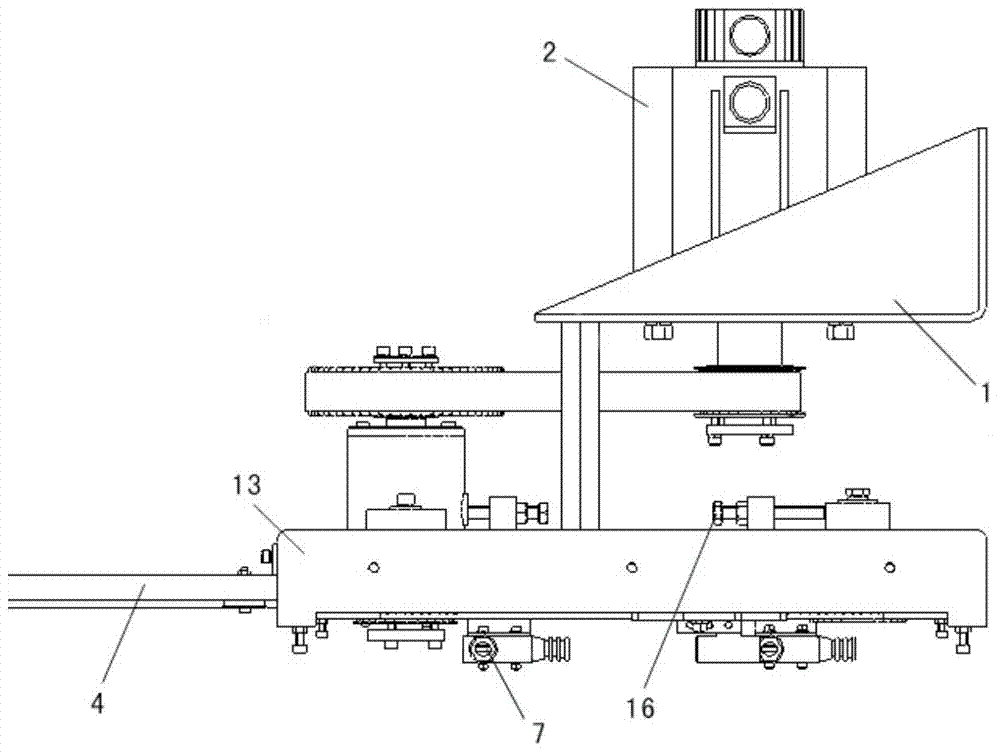

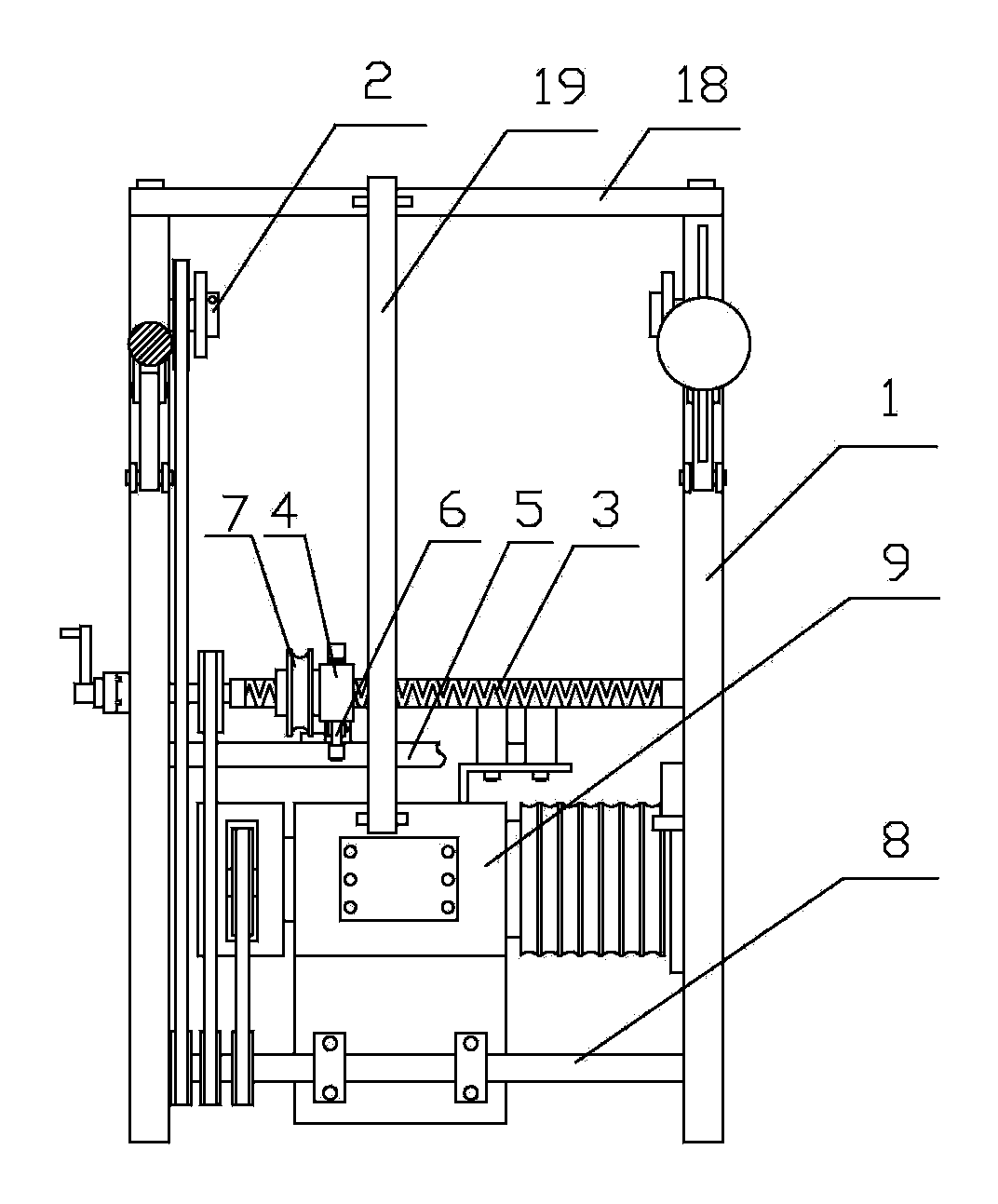

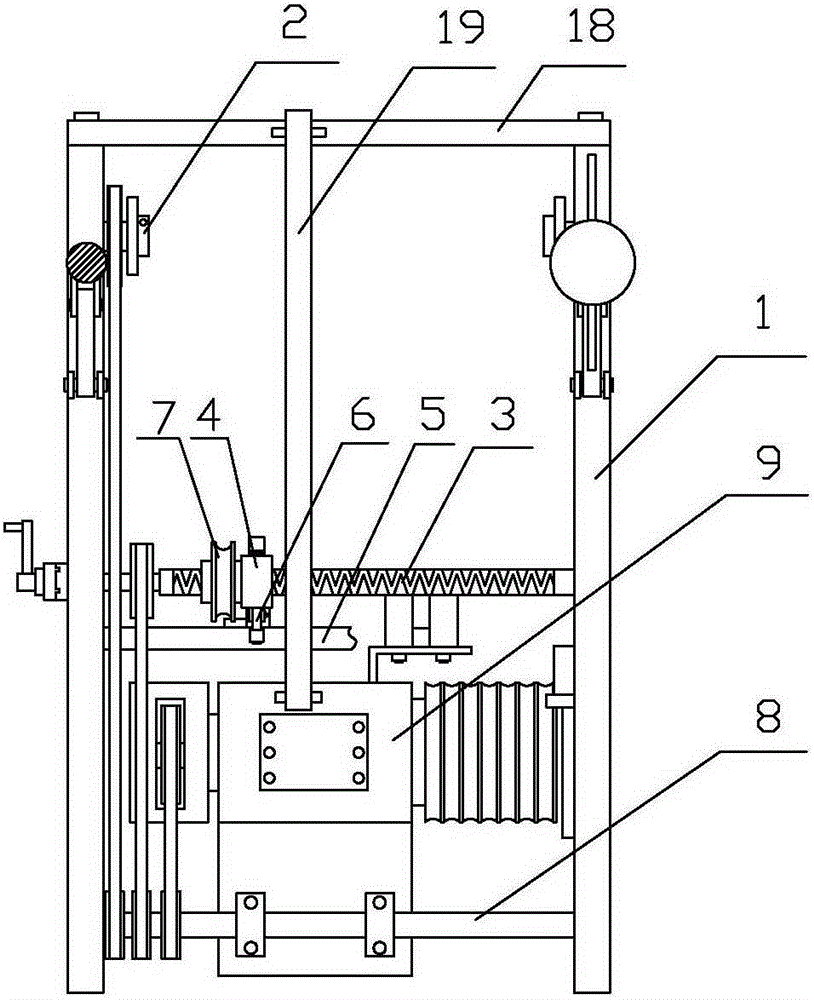

Battery winder

ActiveCN103915654ASimple structureImprove job stabilityMeasurement devicesAssembling battery machinesEngineeringPole piece

The invention discloses a battery winder which comprises a rack, an installation base board, a winding device, a delivery mechanism of two pole pieces and a delivery mechanism of two membranes, wherein the installation base board is arranged on the rack along the vertical direction, the winding device is arranged on the installation base board, a positive pole piece and a negative pole piece are respectively delivered to the winding device by virtue of the delivery mechanism of the two pole piece, a left membrane and a right membrane are respectively delivered to the winding device by the delivery mechanism of the two membranes, the left membrane, the positive pole piece, the right membrane and the negative pole piece which are successively superposed are wound and formed, so as to obtain a cell, a pole piece edge detection device and a pole piece centring device are arranged on the pole piece delivery mechanism, the pole piece edge detection device is used for detecting the edge of the positive pole piece or the negative pole piece in real time, the pole piece centring device is used for rectifying a deviation for the positive pole piece or the negative pole piece in real time according to the detection data of the pole piece edge detection device, a membrane edge detection device and a membrane centring device are arranged on the membrane delivery mechanism, the membrane edge detection device is used for detecting the edge of the left membrane or the right membrane in real time, and the membrane centring device is used for rectifying a deviation for the left membrane or the right membrane in real time according to the detection data of the membrane edge detection device.

Owner:东莞市博拓锂电科技有限公司

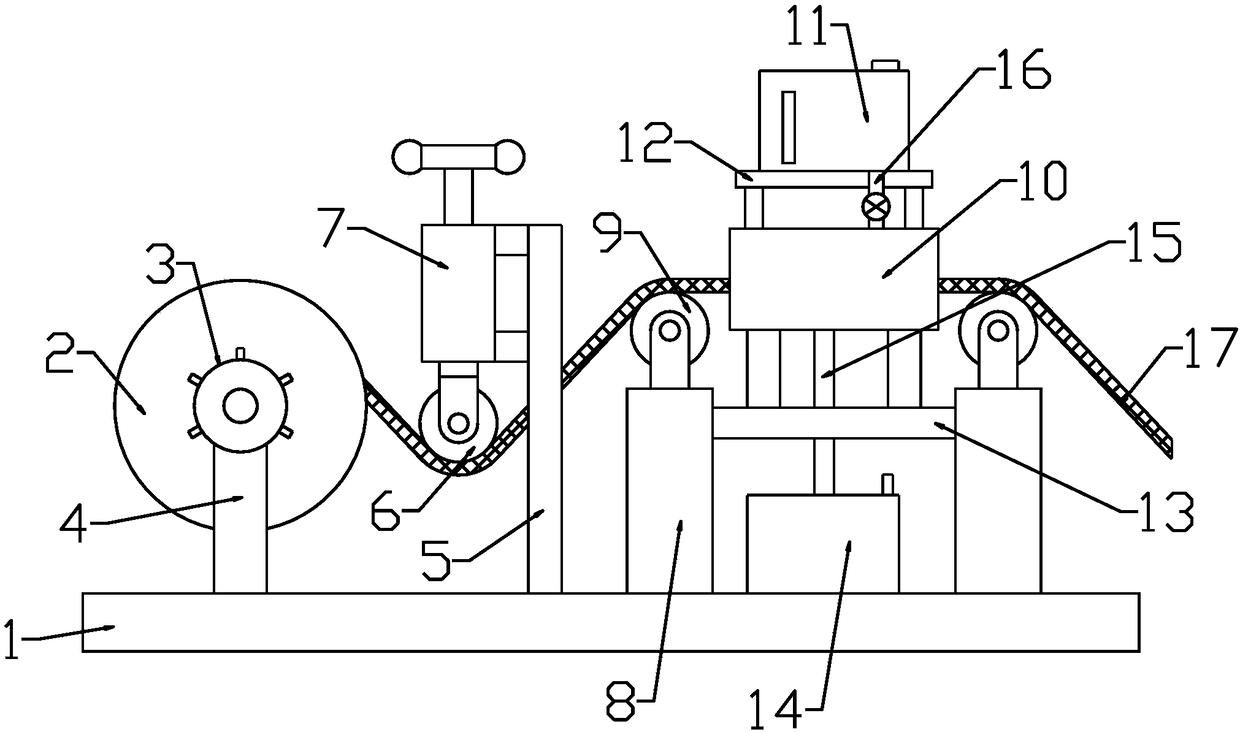

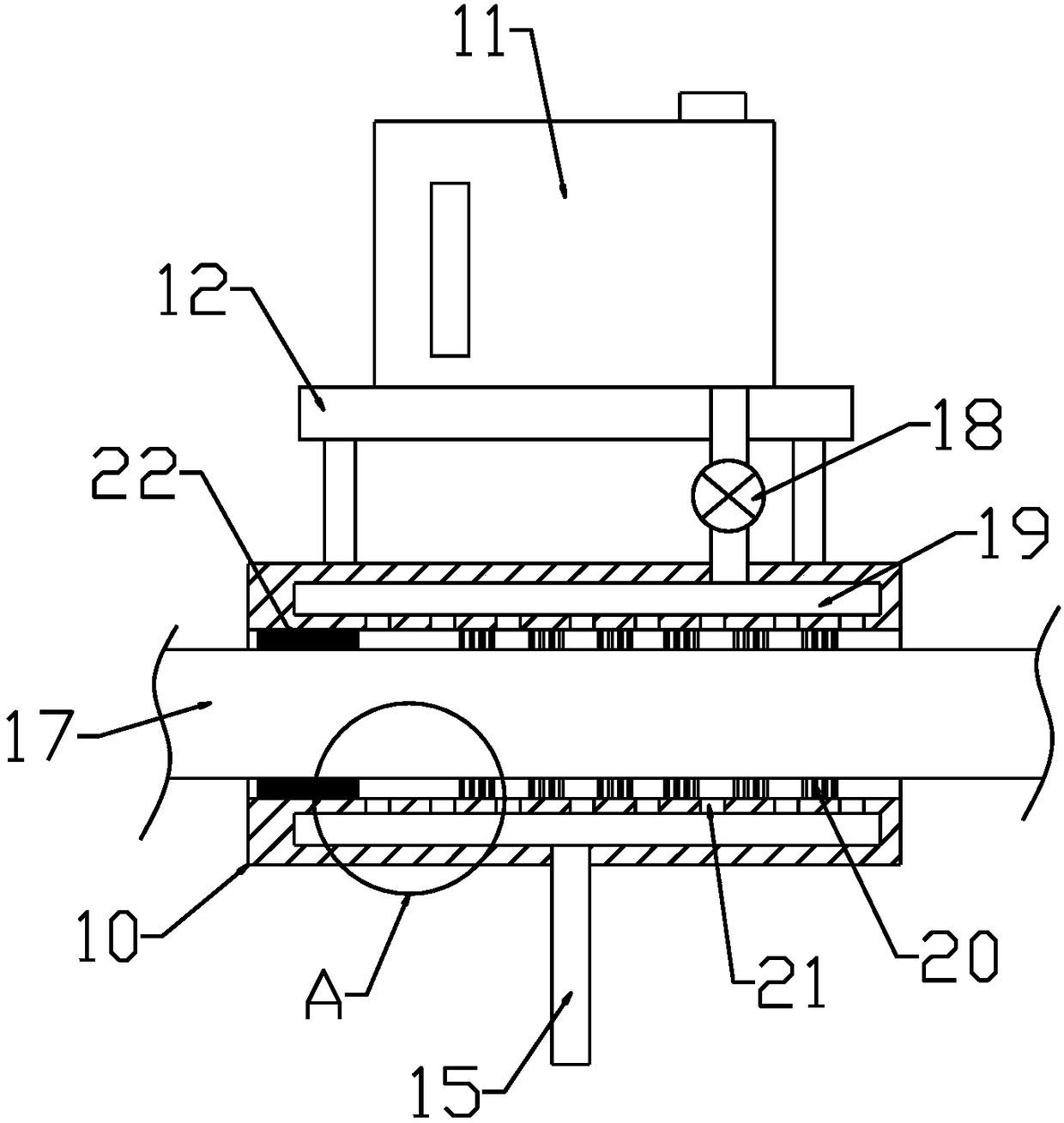

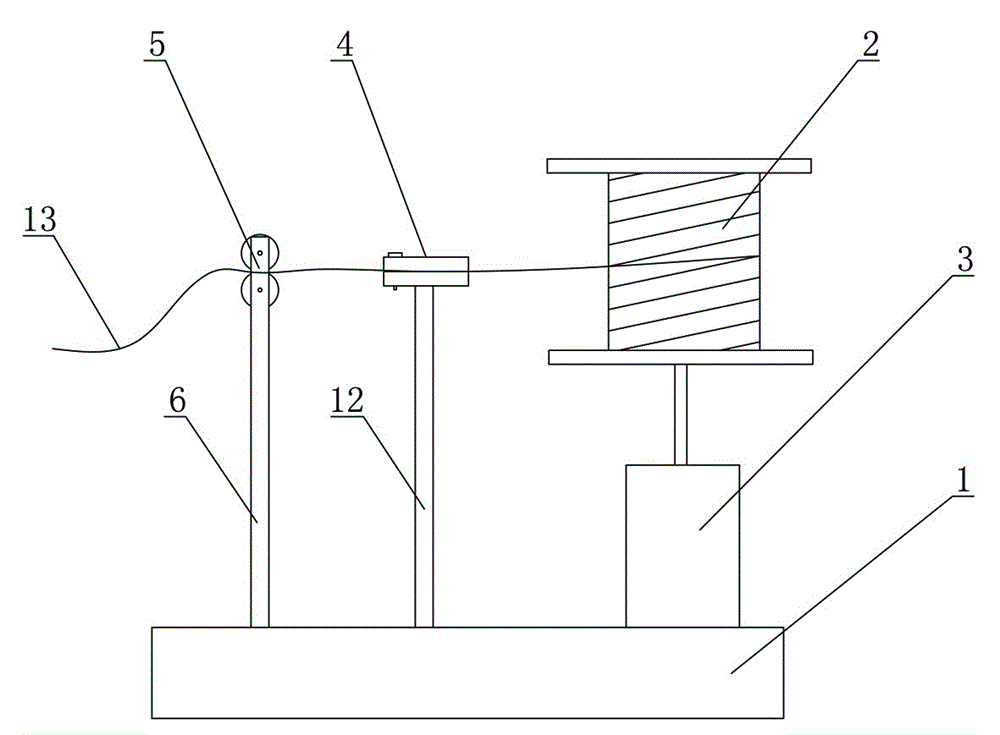

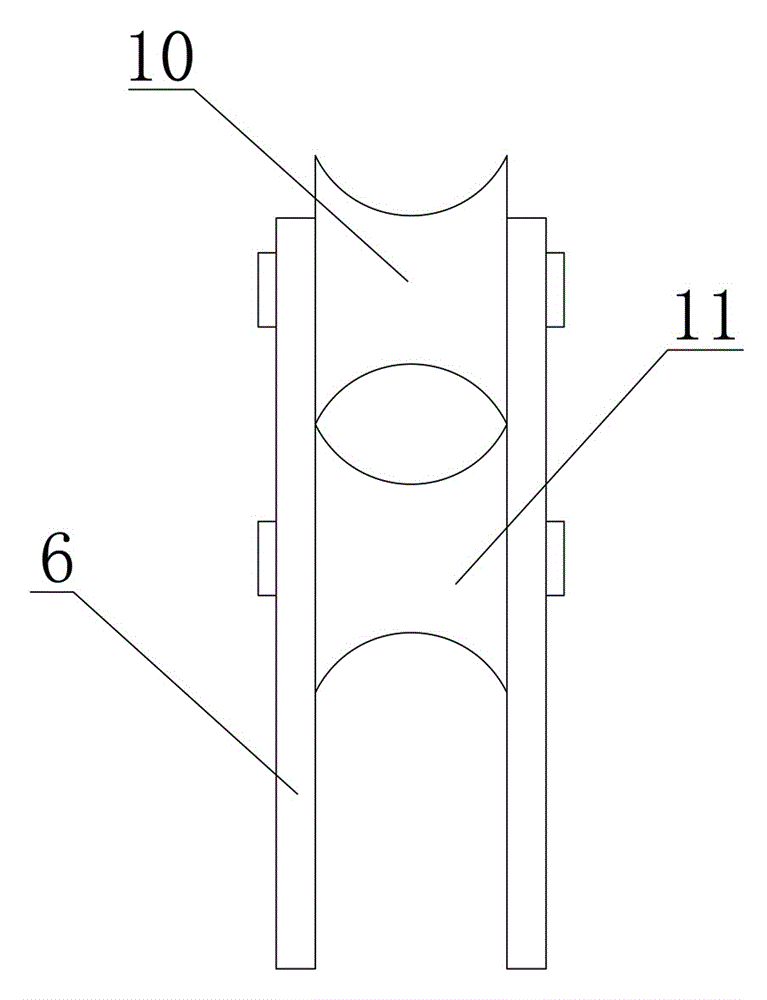

Cleaning type cable winding device

The invention discloses a cleaning type cable winding device. The cleaning type cable winding device comprises a base, a winding roller, a guide movable pulley, an elastic supporting piece, guide fixed pulleys and a cleaning box; supporting stand columns are fixedly arranged at the top of the left end of the base, the winding roller is rotationally arranged at the top end of the supporting stand columns, and supporting stand columns are symmetrically and fixedly welded to the top end of the right portion of the base; an annular cavity is formed in the inner portion of a shell of the cleaning box, a plurality of through holes communicating with the inner cavity of the cleaning box are formed in the inner wall of the annular cavity, and a plurality of cleaning brushes are uniformly distributed on the inner wall of the right portion of the cleaning box; and the left portion of the cleaning box is provided with a rubber sleeve, a support is fixedly arranged at the top end of the cleaning box, a cleaning fluid box is fixedly arranged on the support, and the bottom of the inner cavity of the cleaning fluid box is in communication with the annular cavity through an infusion tube. According to the cleaning type cable winding device, the structure is simple and reasonable, the labor intensity of workers is greatly reduced, and the winding effect of the cable is good, the cleaning of thesurface of the cable is guaranteed, and the device is suitable for popularization and use.

Owner:NANTONG MILANTE ELECTRIC

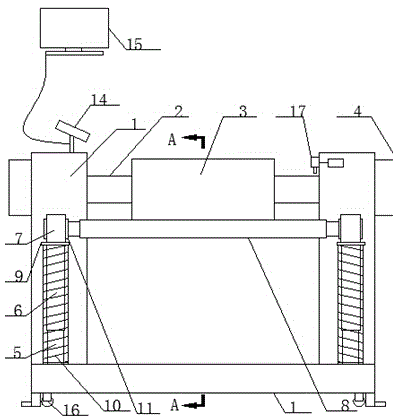

Translational rolling mechanism

InactiveCN101837901AStable winding pressureConstant volumeWebs handlingEngineeringMechanical engineering

The invention relates to a translational rolling mechanism. The translational rolling mechanism comprises a rack, a rolling shaft and a contact compression roller; a rolling shaft support is arranged on a horizontal rail in a mode of being capable of moving back and forth, and is provided with an oil cylinder capable of pushing the rolling shaft support to move back and forth; a contact compression roller support is arranged on the rack in a mode of being capable of moving back and forth, and is provided with an air cylinder which applies pushing force on the contact compression roller support, and the piston rod of the air cylinder is connected with the contact compression roller support; and the translational rolling mechanism also comprises a central control processor, a sensing air cylinder piston rod or a linear displacement sensor for the displacement of the contact compression roller support, wherein the linear displacement sensor is connected to the central control processor, the central control processor is connected with the drive circuit of the oil cylinder, and the central control processor controls the oil cylinder to operate according to the signal of the linear displacement sensor. The invention ensures that the pressure between a finished scroll and the contact compression roller is stable; the transmission path and clipped corner for a rolled material to entering into a finished roll remain unchanged all the time; and the rolling quality is ensured, thus the translational rolling mechanism is suitable for high-grade rolled material rolling, large-diameter rolled material rolling and high-speed rolling.

Owner:汕头市双丰机械有限公司

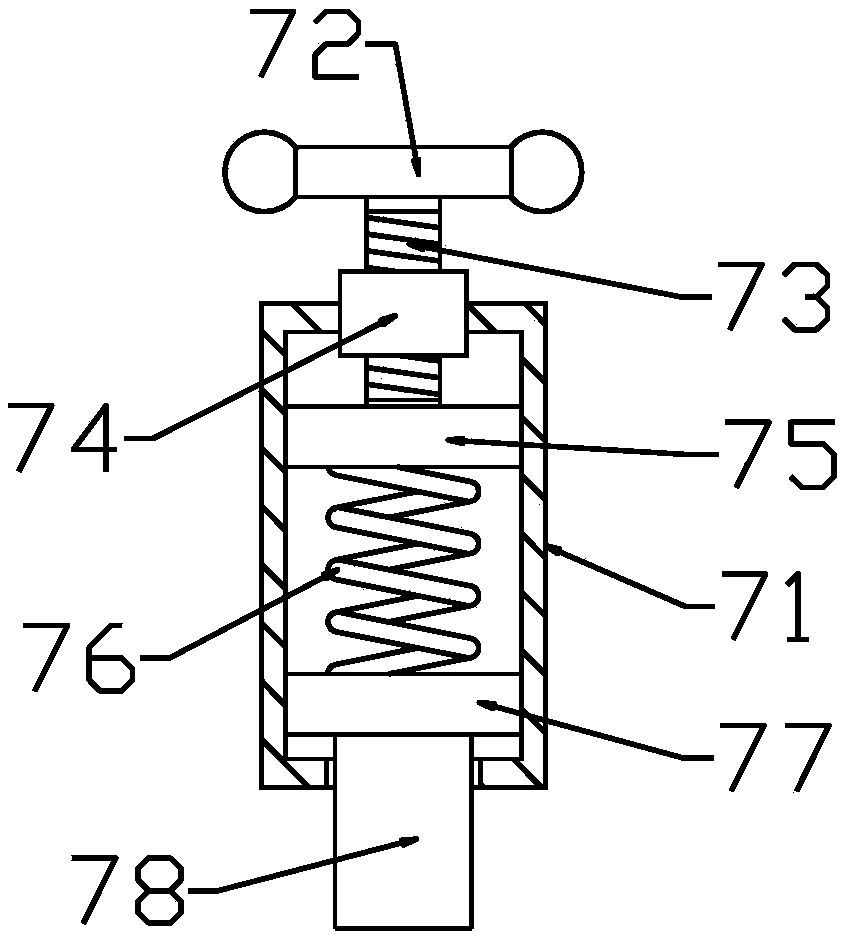

Uniform spinning silk yarn winding device

InactiveCN108516403AAvoid concentrated windingAchieve regulationFilament handlingFibre cleaning/openingYarnDrive shaft

The invention discloses a uniform spinning silk yarn winding device. The uniform spinning silk yarn winding device comprises a bearing plate. A supporting plate I and a supporting rod II are vertically fixedly arranged on the bearing plate, and a double-shaft motor is fixedly arranged on the bearing plate. A first drive shaft is fixedly arranged on an output shaft of the double-shaft motor. A swinging strip plate is provided with a guiding groove, and the surface of a second driven shaft is sleeved with and fixedly provided with a cleaning rotation roller. The end, away from the cleaning rotation roller, of a sliding rod is horizontally and fixedly provided with a brush plate, and a soft brush is fixedly arranged on the surface of the brush plate. Through rotation of a winding rotation roller, silk yarn winding is achieved; through the left-right reciprocating motion of a sliding casing pipe along a guiding rod, the silk yarn position is adjusted through a silk yarn limiting block, theuniform silk yarn winding effect is achieved, the silk yarn is prevented from being wound around one position of the winding rotation roller in a centralized manner, and the winding quality is improved; and meanwhile, through rotation of the soft brush, rotating cleaning is conducted on dust attached to the silk yarn, and the cleanliness of the silk yarn is guaranteed.

Owner:绍兴柯桥涵雷服饰科技有限公司

Winding drum used for textile machinery and facilitating winding

The invention discloses a winding drum used for textile machinery and facilitating winding, and belongs to the technical field of textile machinery. The winding drum comprises a base, wherein verticalplates are symmetrically arranged on the left side and the right side of the top of the base, an assembling rotating rod is arranged at the position, close to the position, between the two groups ofvertical plates, the outer wall of the assembling rotating rod is connected with a winding drum assembly in an interference fit mode, a limiting ring fixing part which fixedly sleeves the outer wall of the assembling rotating rod is arranged on the left of the winding drum assembly, a compaction part matched with the winding drum assembly is arranged at the top of a connecting block, three sets oflimiting rollers are evenly and movably arranged on the outer wall of the opposite side of the two sets of V-shaped plates. According to the winding drum, a groove is formed in a cylinder body, and meanwhile a stress spring and a pressing plate are arranged in the groove, so that before winding is carried out, one end of cloth can be clamped and fixed through the matching of the pressing plate and the spring, the winding can be rapidly carried out without manual winding of a plurality of circles, the working efficiency is greatly improved, and the winding drum is rapid and convenient to use.

Owner:连云港祥美机械有限公司

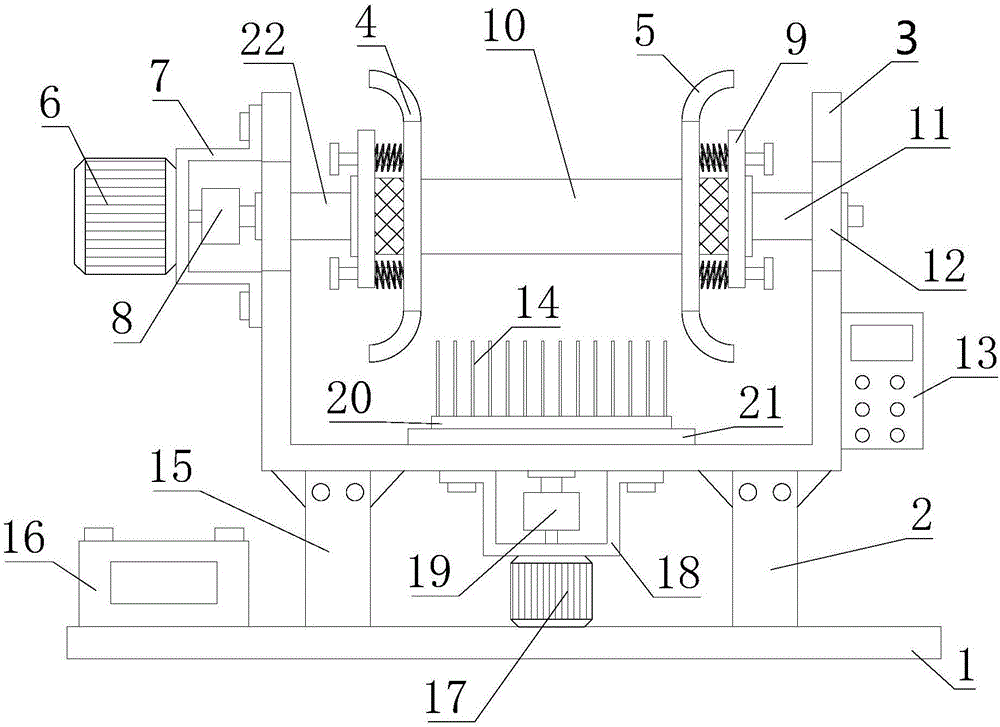

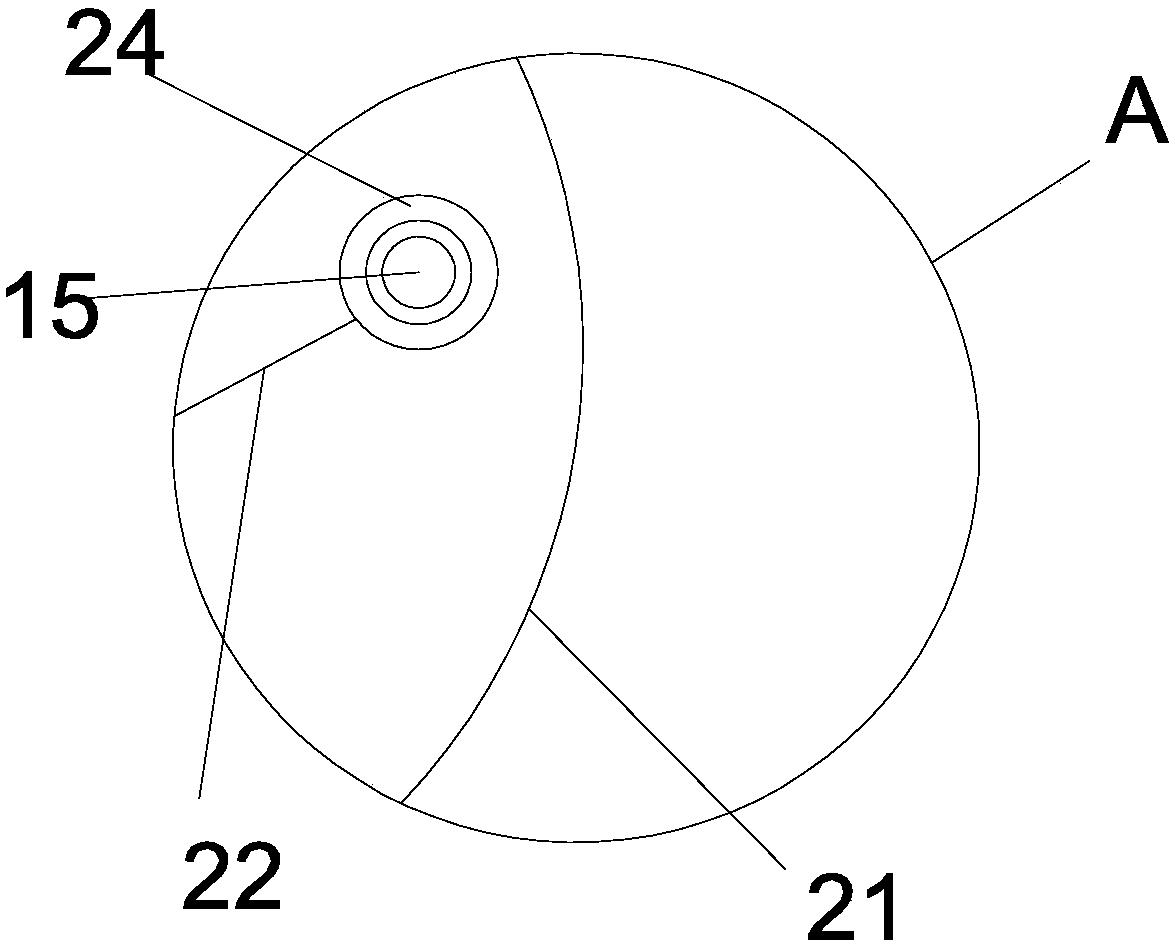

Automatic compression rewinding machine for rubber belt

InactiveCN104310096AAvoid affecting the winding qualityAvoid affecting unified packagingWebs handlingAgricultural engineeringCompression device

The invention discloses an automatic compression rewinding machine for a rubber belt and relates to the field of rubber belt production equipment. The automatic compression rewinding machine comprises a frame, a rotating shaft, a rubber belt roller and an electric motor, wherein the rotating shaft is arranged on the frame, the rubber belt roller is fixed on the rotating shaft, the electric motor is arranged on the frame and is connected to the rotating shaft, a compression device is arranged on the frame and comprises a fixed guide pillar, a movable guide sleeve, a shaft seat and a compression rotating shaft, the guide sleeve sleeves the fixed pillar, a flange is arranged at the top of the guide sleeve, a spring sleeves the guide pillar and the guide sleeve, the shaft seat is arranged on the upper part of the flange, the compression rotating shaft is connected to the shaft seat through a rolling bearing and is in contact connection with the rubber belt roller, and rectangular holes capable of allowing the compression rotating shaft to move vertically are formed in two sides of the frame. According to the automatic compression rewinding machine, the compression device is arranged on the frame, so that a rubber belt can be compressed in a winding process and becomes compact without the corrugated phenomenon, and the automatic compression rewinding machine has the advantages of simple structure, firmness and good working stability.

Owner:WUJIANG OUCHENG PACKAGING MATERIALS

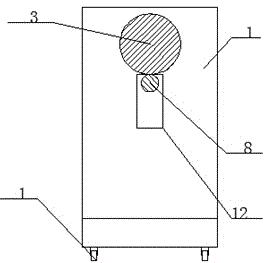

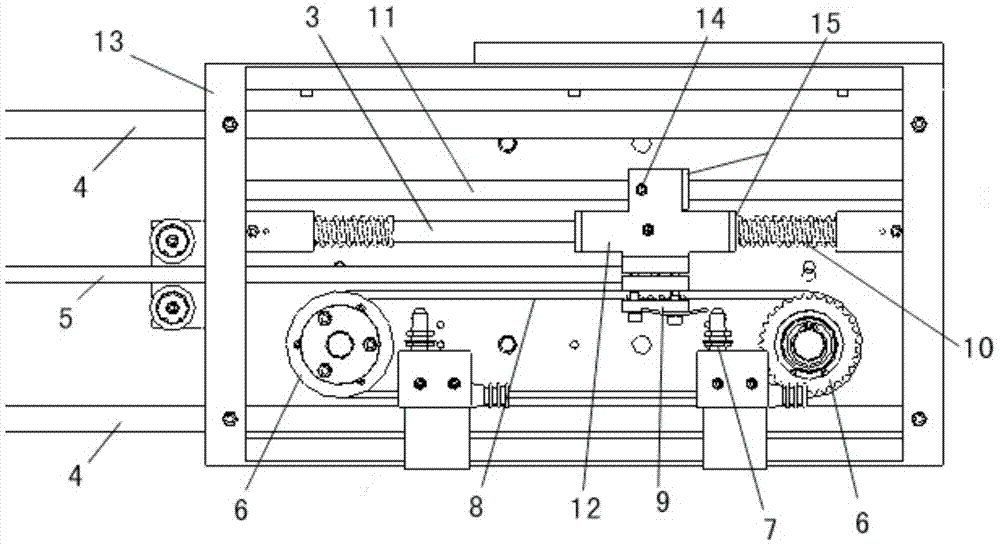

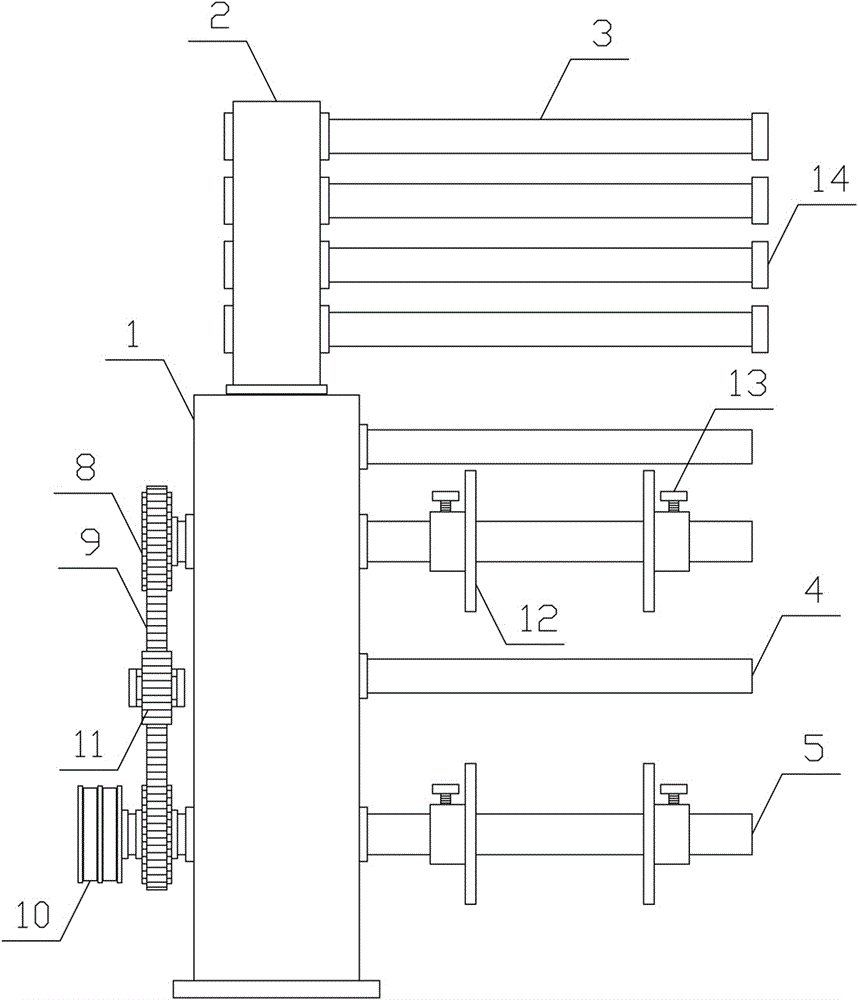

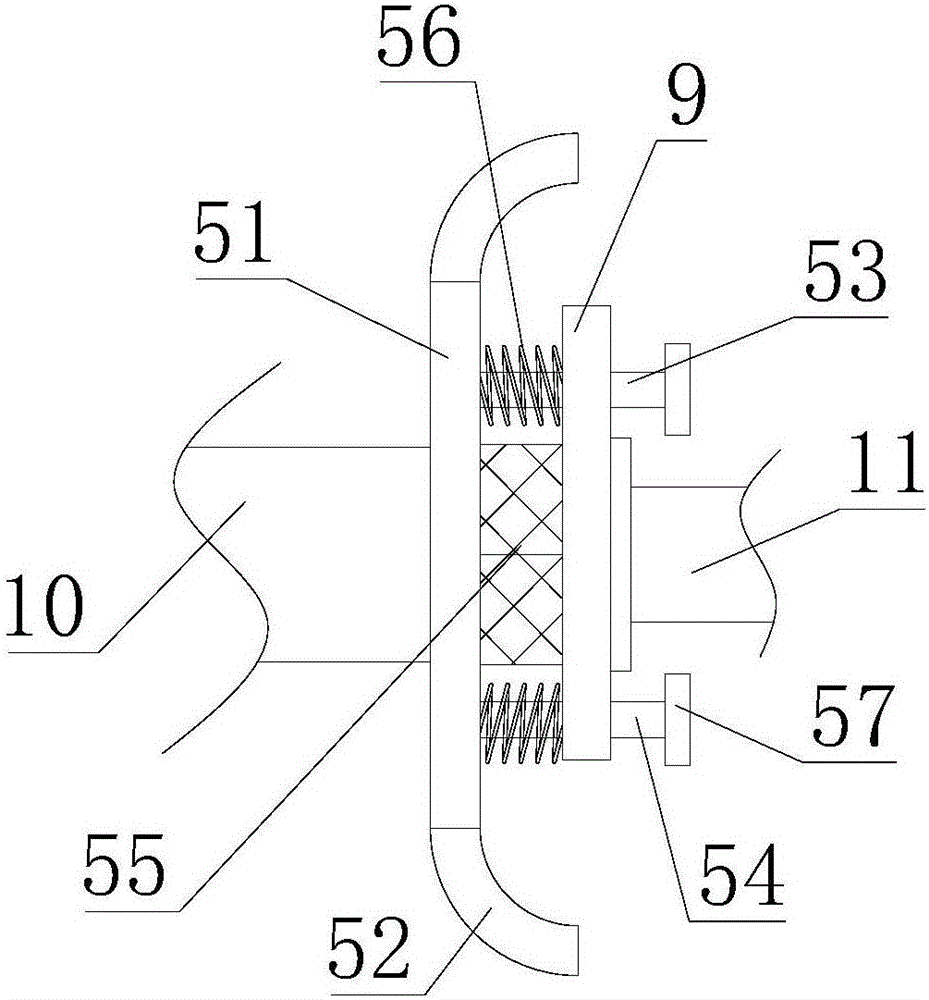

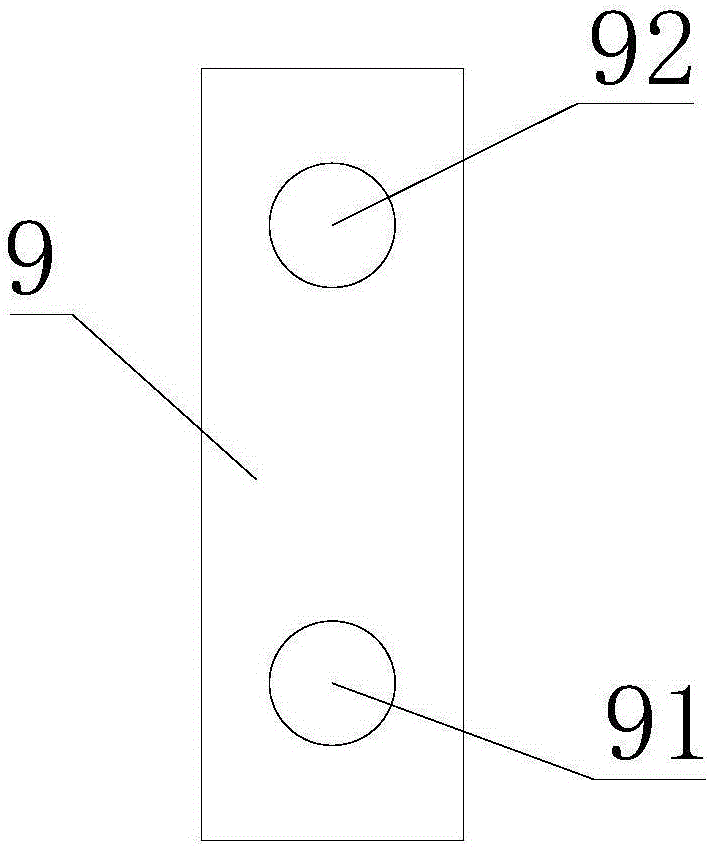

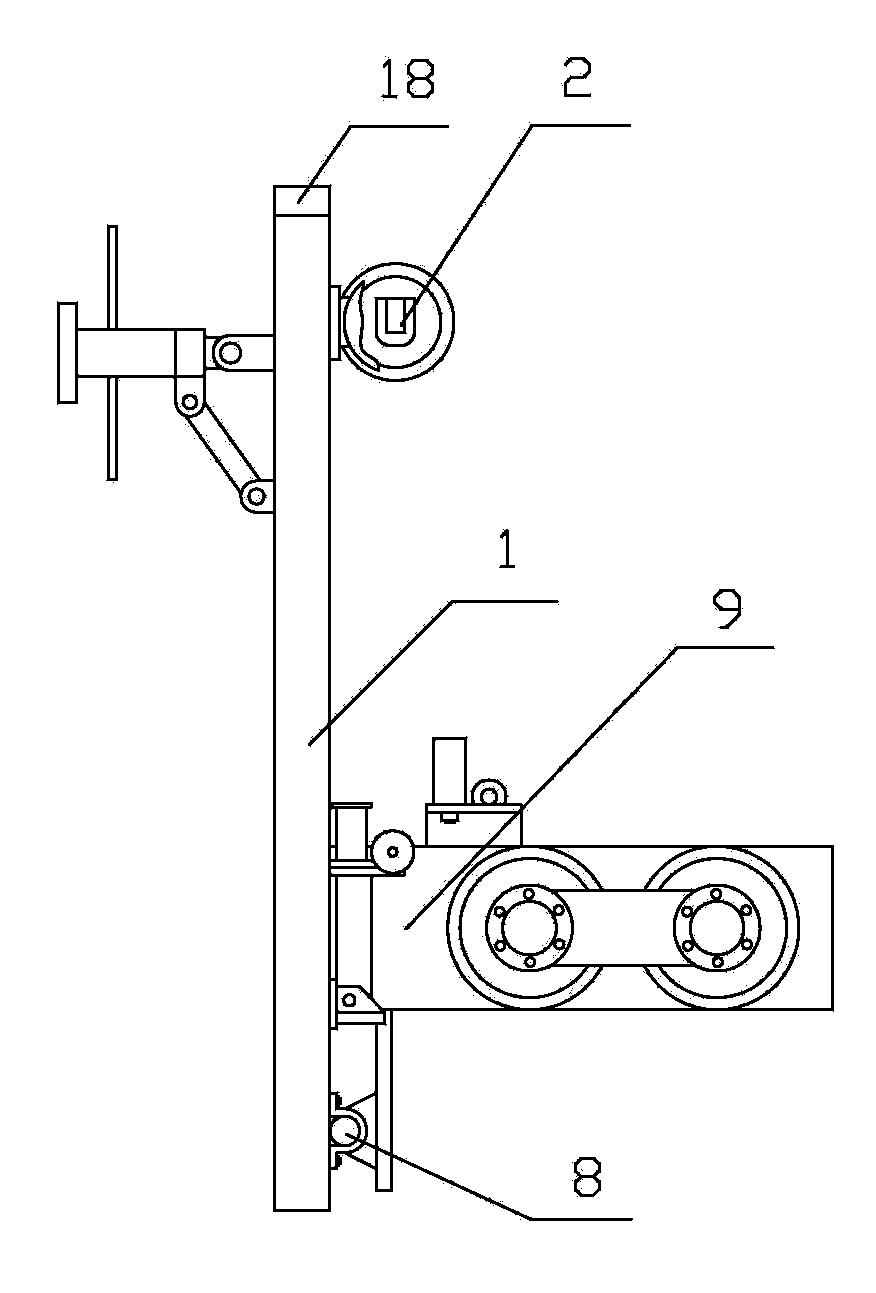

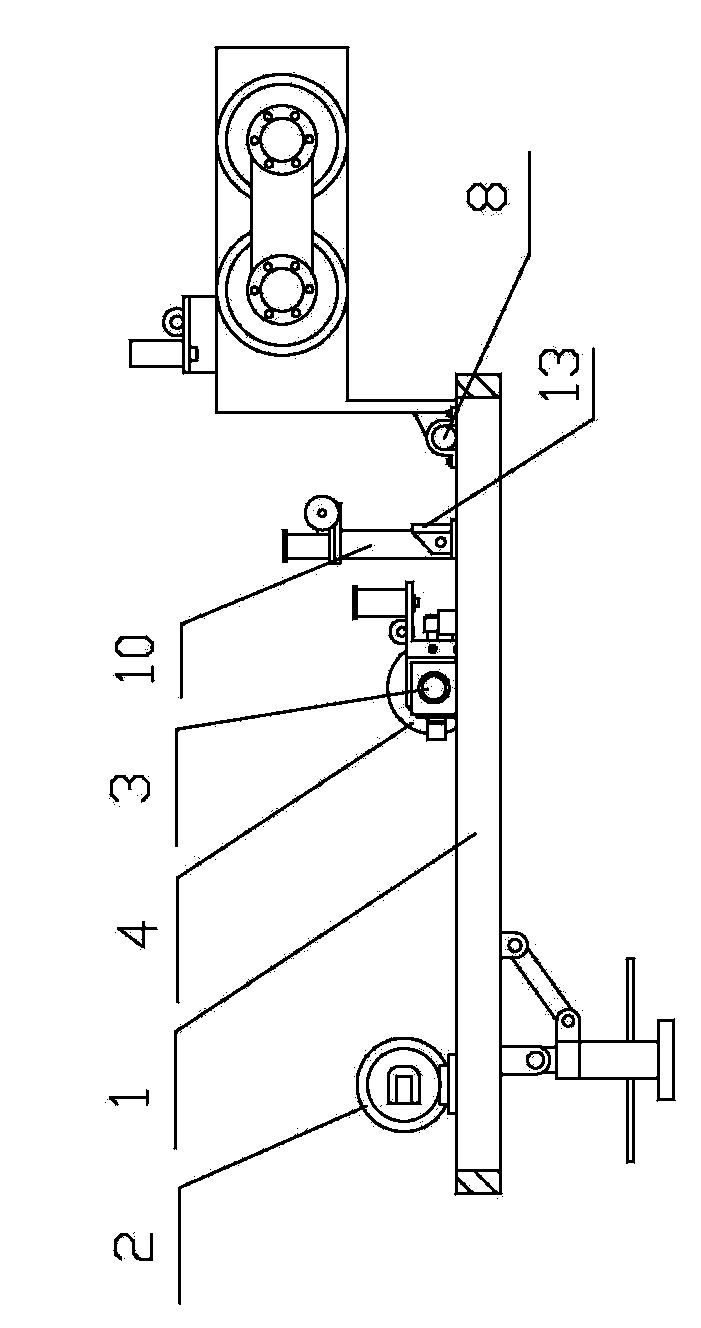

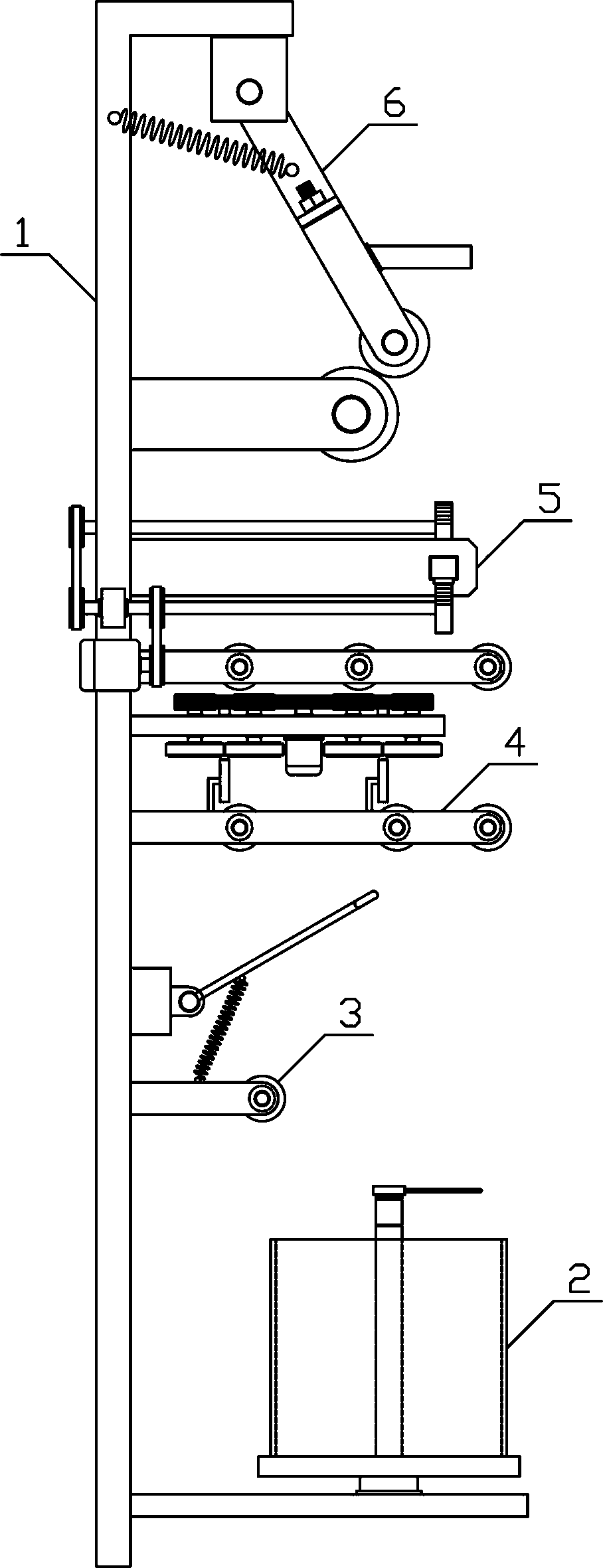

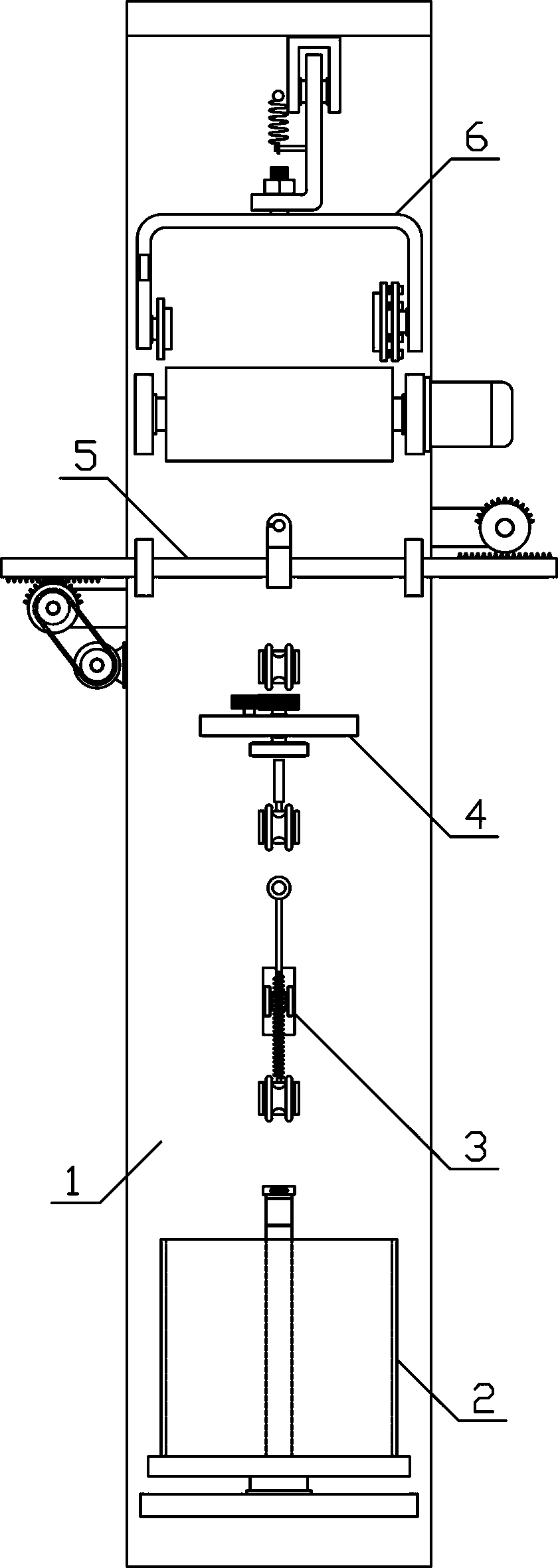

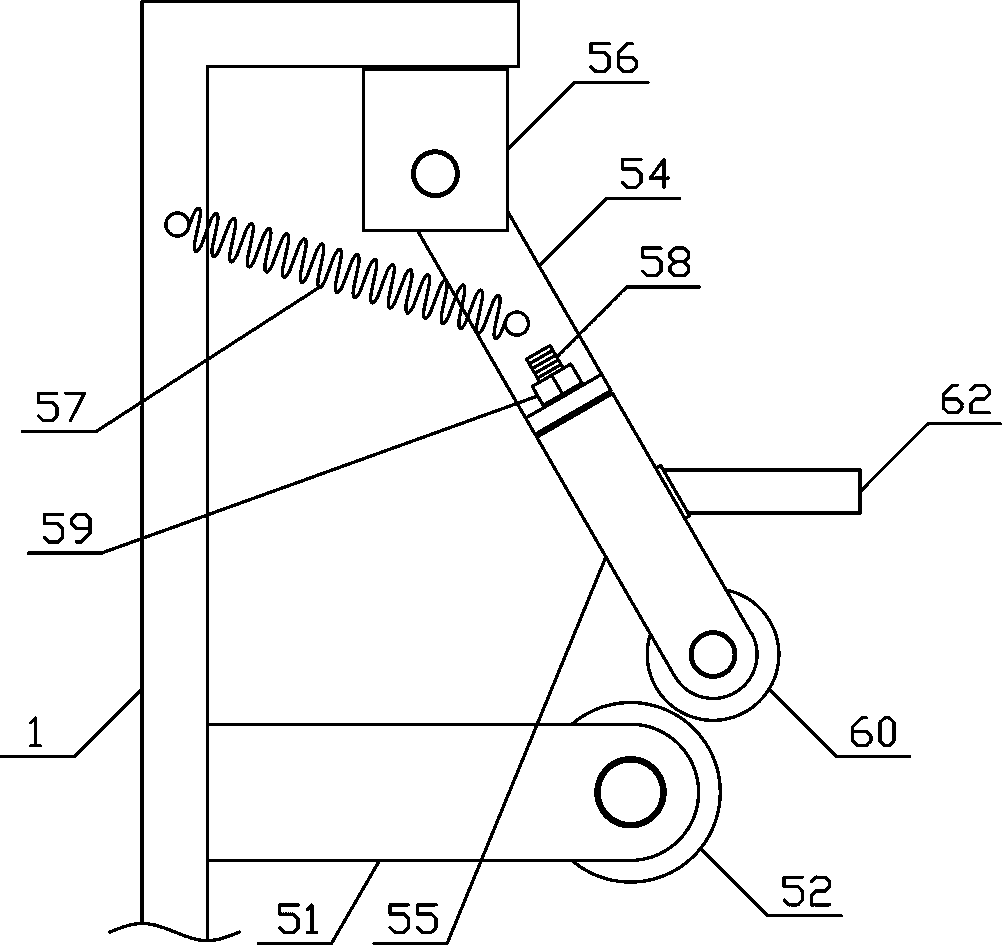

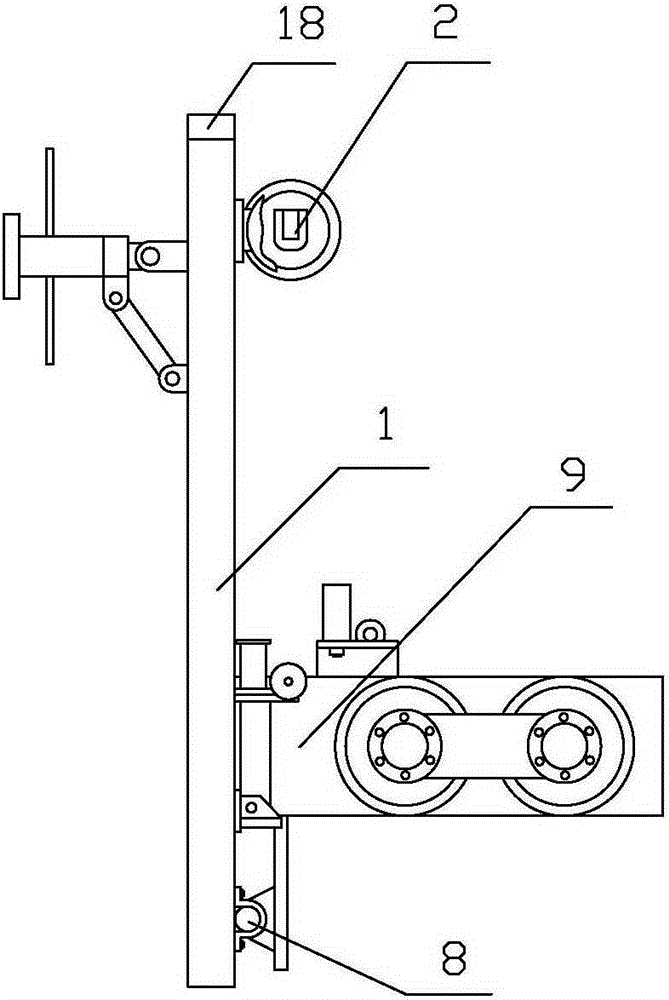

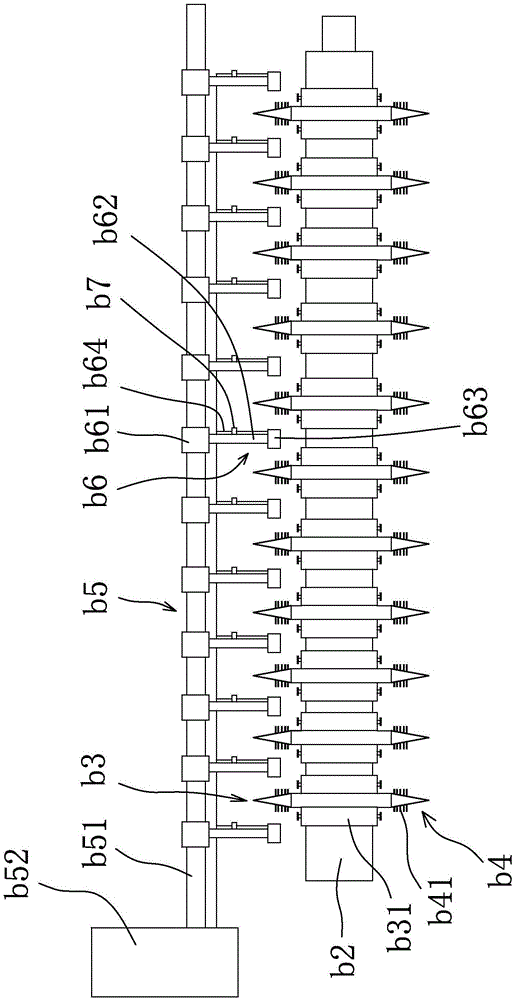

Spinning machine servo drive winding transversing gear

The invention relates to a spinning machine servo drive winding transversing gear, belongs to the technical field of textile machinery parts, and overcomes the defects that the existing yarn guide transversing gears are complex in structure and cannot satisfy the requirements of multi-variety spinning. A yarn guide rod transversing drive mechanism on each set of yarn guide rods drives the yarn guide rods to horizontally reciprocate left and right. Each yarn guide rod transversing drive mechanism comprises a base plate, a servo motor, a transmission mechanism, a sensing mechanism and an energy accumulation mechanism. The transmission mechanism comprises a slider part, a slide rod, a synchronous belt and two synchronous belt pulleys. The energy accumulation mechanism comprises two spiral springs and one spring guide rod. The axial direction of the spring guide rod is same with that of the slide rod. The spring guide rod and the slide rod are fixedly mounted on the base plate. One spiral spring is sleeved at each of the two ends of the spring guide rod. The slider part is located between the adjacent ends of the two spiral springs. The distance between the adjacent ends of the two spiral springs is smaller than the transversing travel of each guide rod. The sensing mechanism comprises two sensing switches. The sensing mechanism senses the slider part through the sensing switches and feeds back a signal to a control system.

Owner:ZHEJIANG RIFA TEXTILE MASCH CO LTD

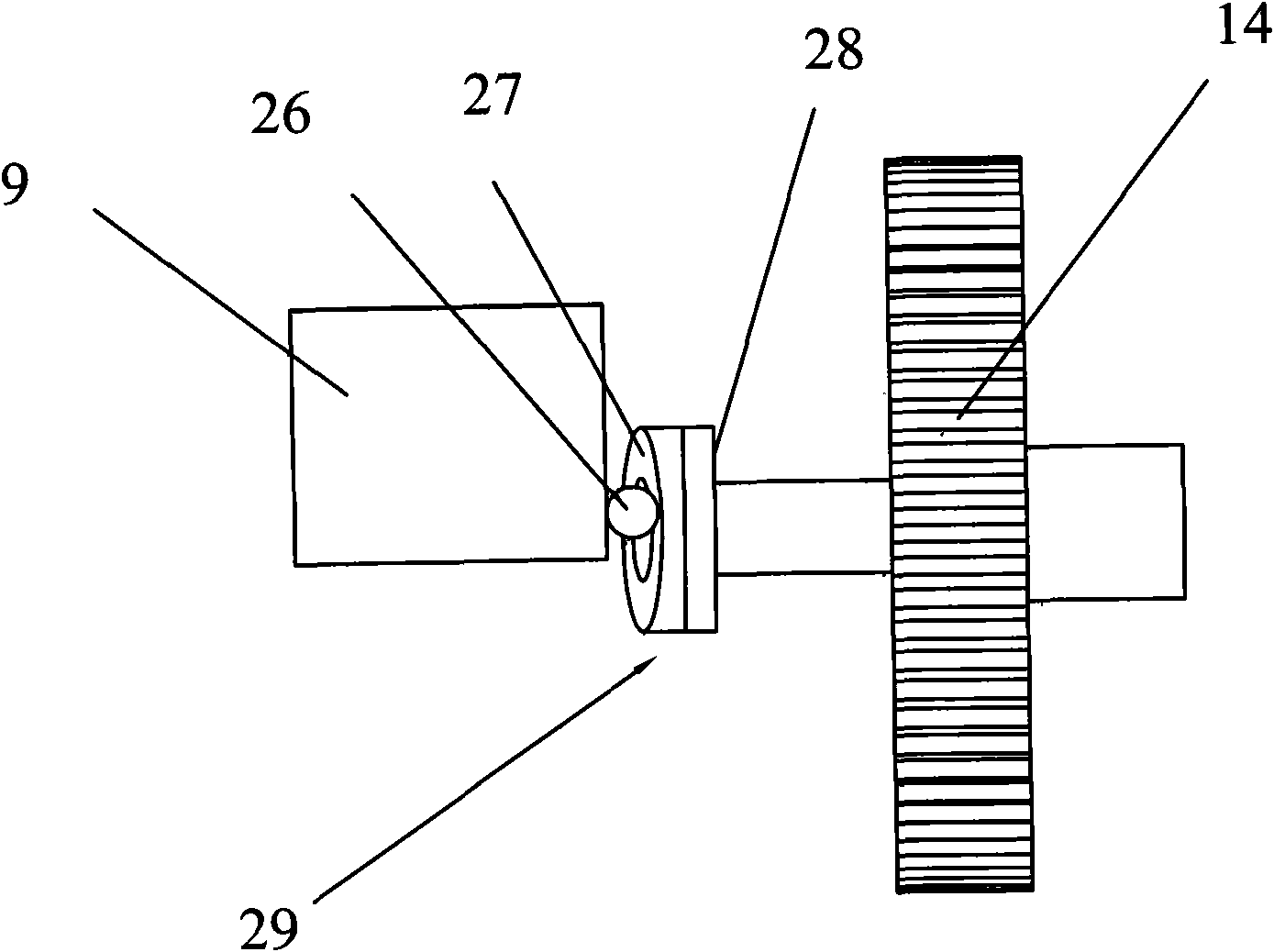

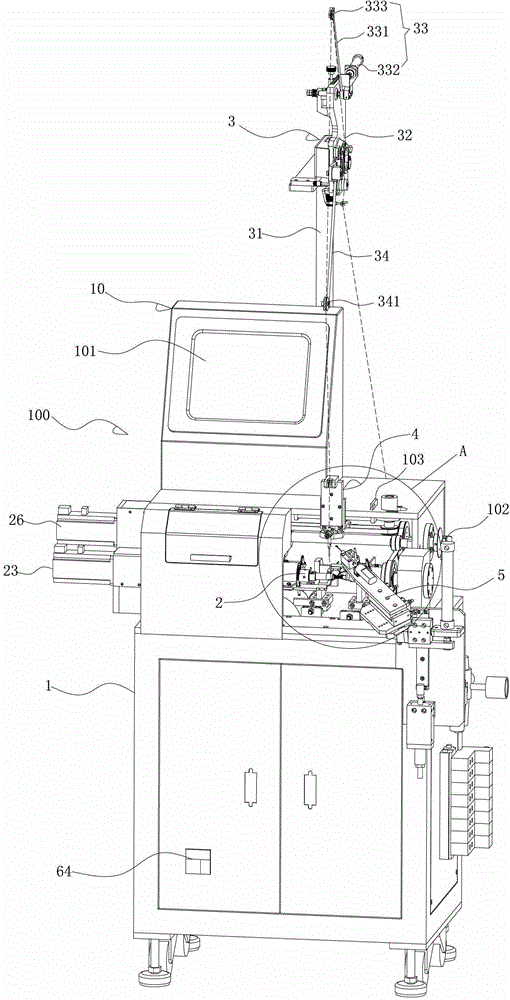

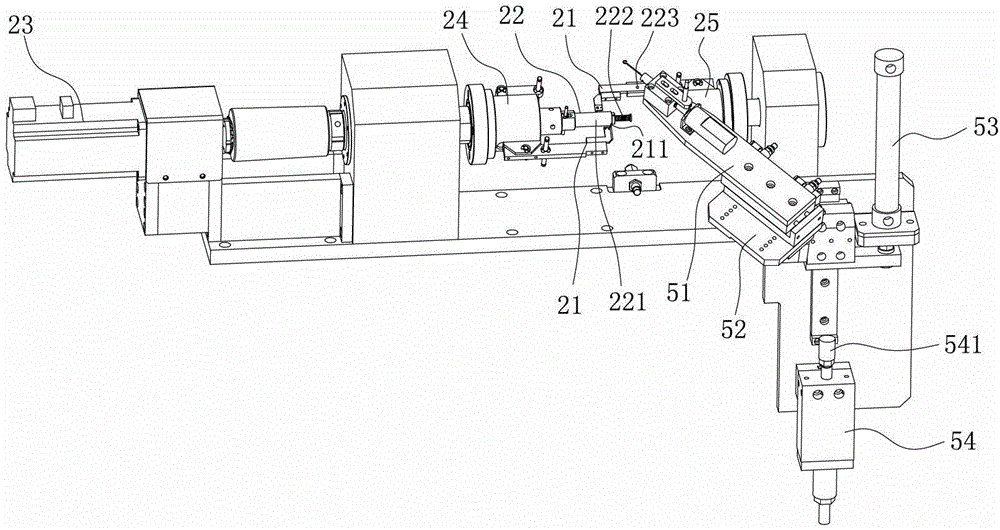

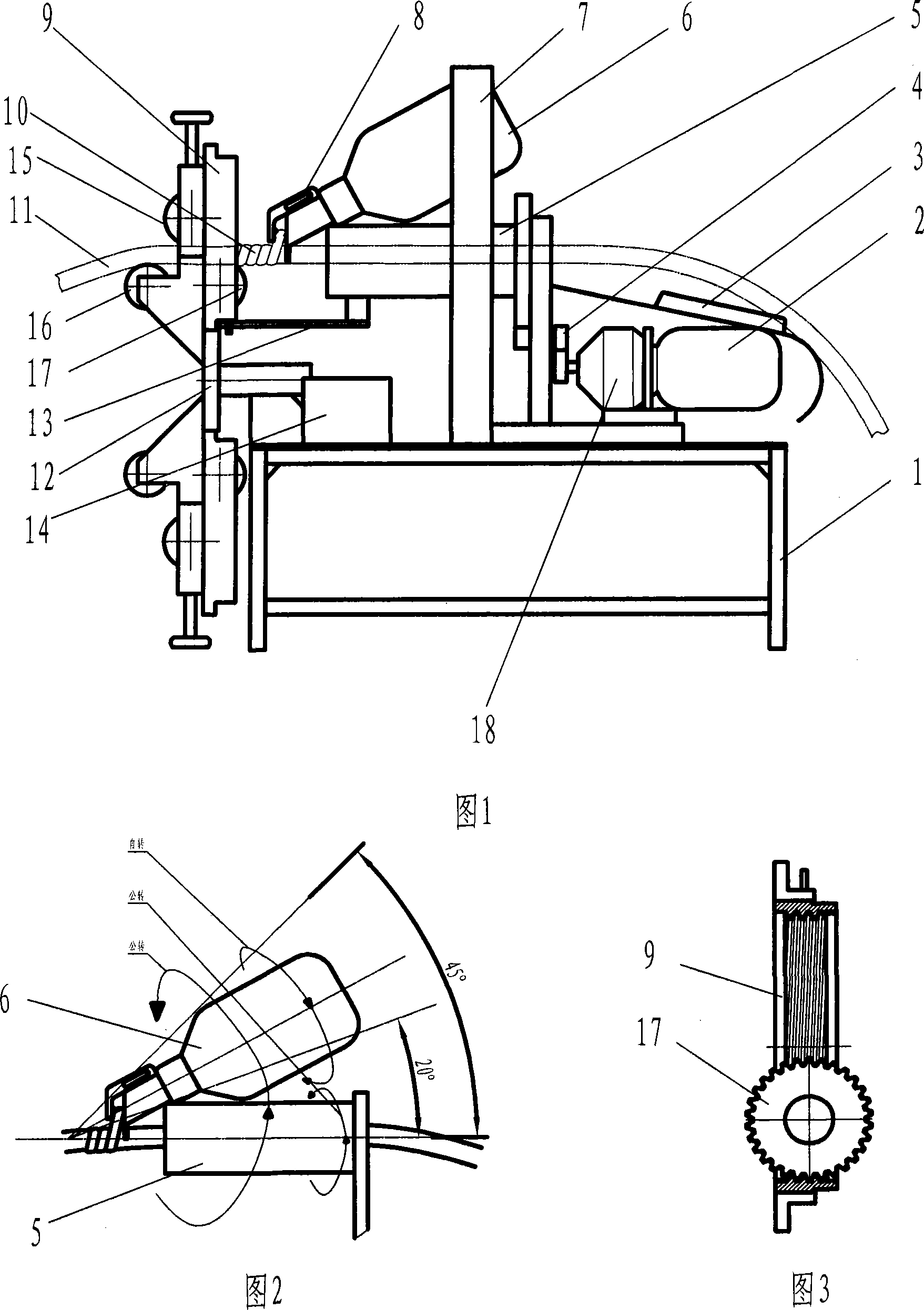

Inclined winding type coreless coil winding device

InactiveCN102983689AAvoid the "can't find the line" phenomenonAccurate hookManufacturing dynamo-electric machinesCopper wireDrive motor

The invention discloses an inclined winding type coreless coil winding device which comprises a winding device, wherein the winding device comprises a machine box, a wire winding mechanism, a wire feeding mechanism, a wire arranging mechanism, a stranded wire integrating mechanism and a first heater. The stranded wire integrating mechanism comprises a universal manipulator and a wire cutting mechanism, wherein the universal manipulator has the wire hooking, wire pulling and wire stranding functions, and the wire cutting mechanism is used for cutting copper wires which are stranded by the universal manipulator. The universal manipulator is arranged in an inclined mode, and the inclined angle of the universal manipulator is in accordance with the inclined angle of a winding dial needle in the wire winding mechanism. The wire arranging mechanism comprises a wire guide needle, a first cylinder and a first drive motor, wherein the first cylinder is used for driving the wire guide needle to move up and down, and left and right. A wire hole for a copper needle to penetrate is formed in the wire guide needle. The inclined winding type coreless coil winding device has the advantages of being simple in structure, small in size, high in work quality and efficiency, and the like.

Owner:倪林木

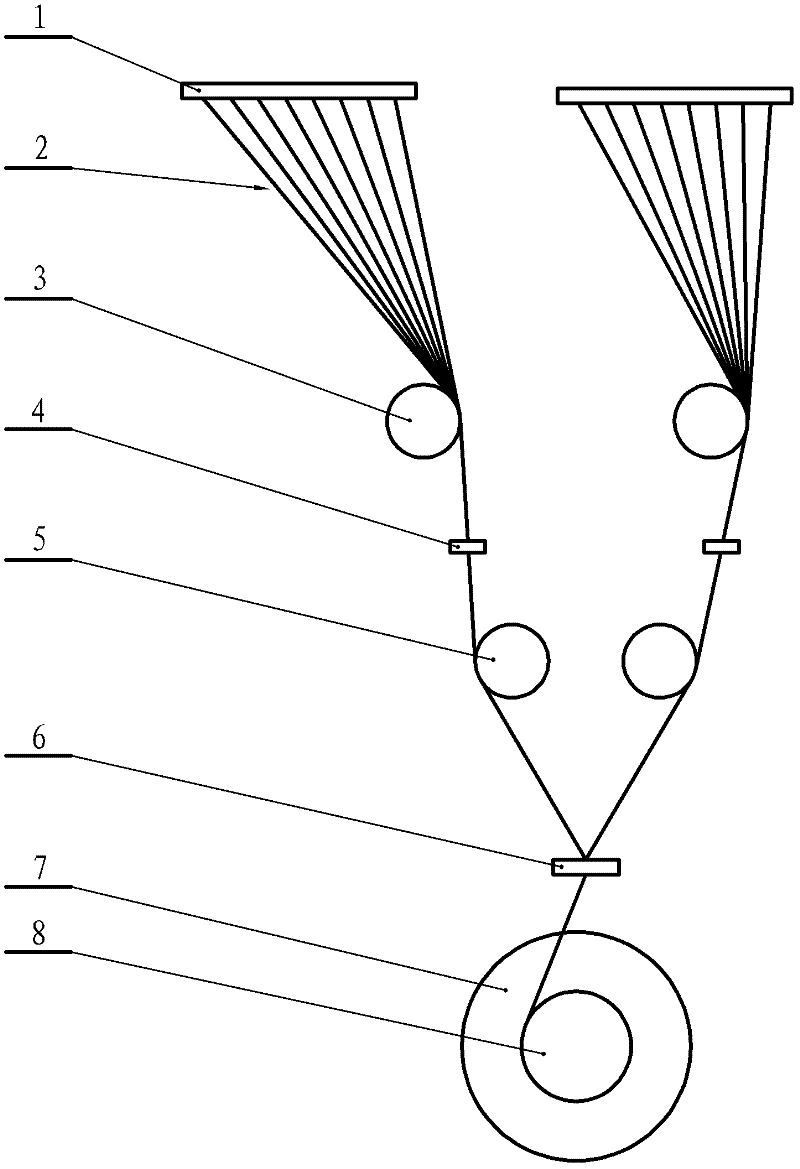

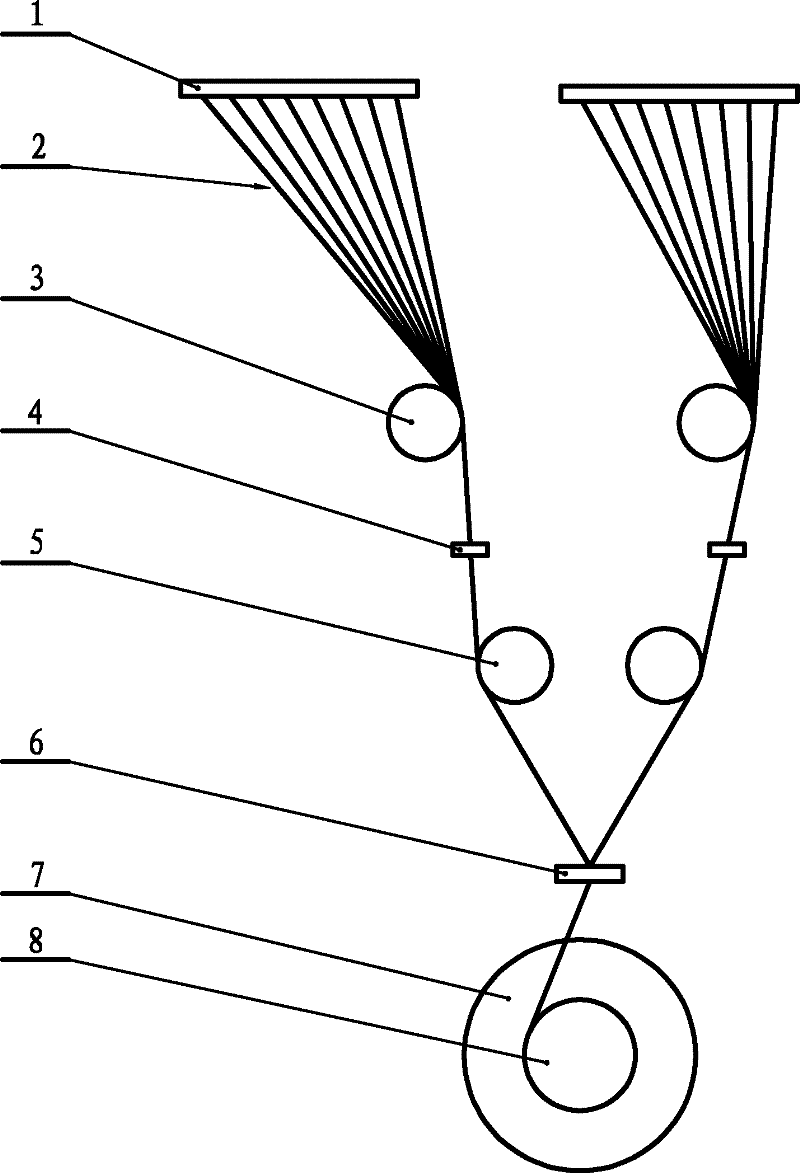

Multi-bushing plate merging wiredrawing technology and multi-bushing plate wiredrawing device employing it

ActiveCN102515504ASimplify temperature controlReduce manufacturing costGlass making apparatusGlass fiberEngineering

The invention provides a multi-bushing plate merging wiredrawing technology. Specifically, 2 or more bushing plates are employed, and each bushing plate is provided with a plurality of leaks. Molten glass flows through each leak of each bushing plate and is cooled, and then a plurality of glass fibers can be obtained through wiredrawing molding respectively. Pulled by a wiredrawing machine driven wire cylinder, the glass fibers respectively pass through multiple upper bunchers and are neatened and gathered into glass fiber bundles, which are then neatened and gathered by a gathering buncher into a complete glass fiber bundle that is then wound on the wire cylinder into a finished glass fiber bundle. A multi-bushing plate wiredrawing device is provided with 2 or more bushing plates, each of which is equipped with a plurality of leaks. An upper buncher is installed behind each bushing plate respectively, a gathering buncher is arranged behind each upper buncher, the wiredrawing machine is disposed behind the gathering buncher, the wire cylinder is positioned on the gathering buncher, and the wire cylinder and the wiredrawing machine are in driving rotary connection. With the technology and device provided in the invention, the manufacturing cost of a bushing plate for a glass fiber bundle with a great weight of per unit length can be reduced, the band forming property of the glass fiber bundle can be improved, and the effect can be obvious.

Owner:CHONGQING POLYCOMP INT

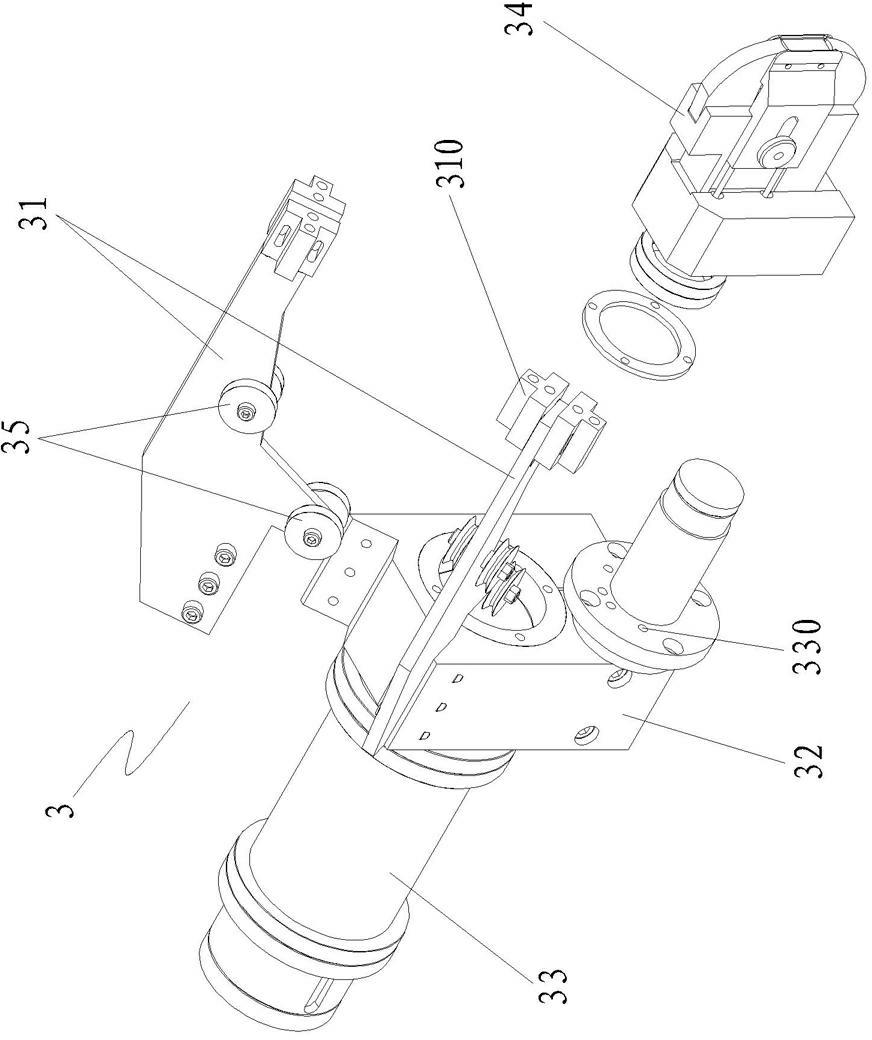

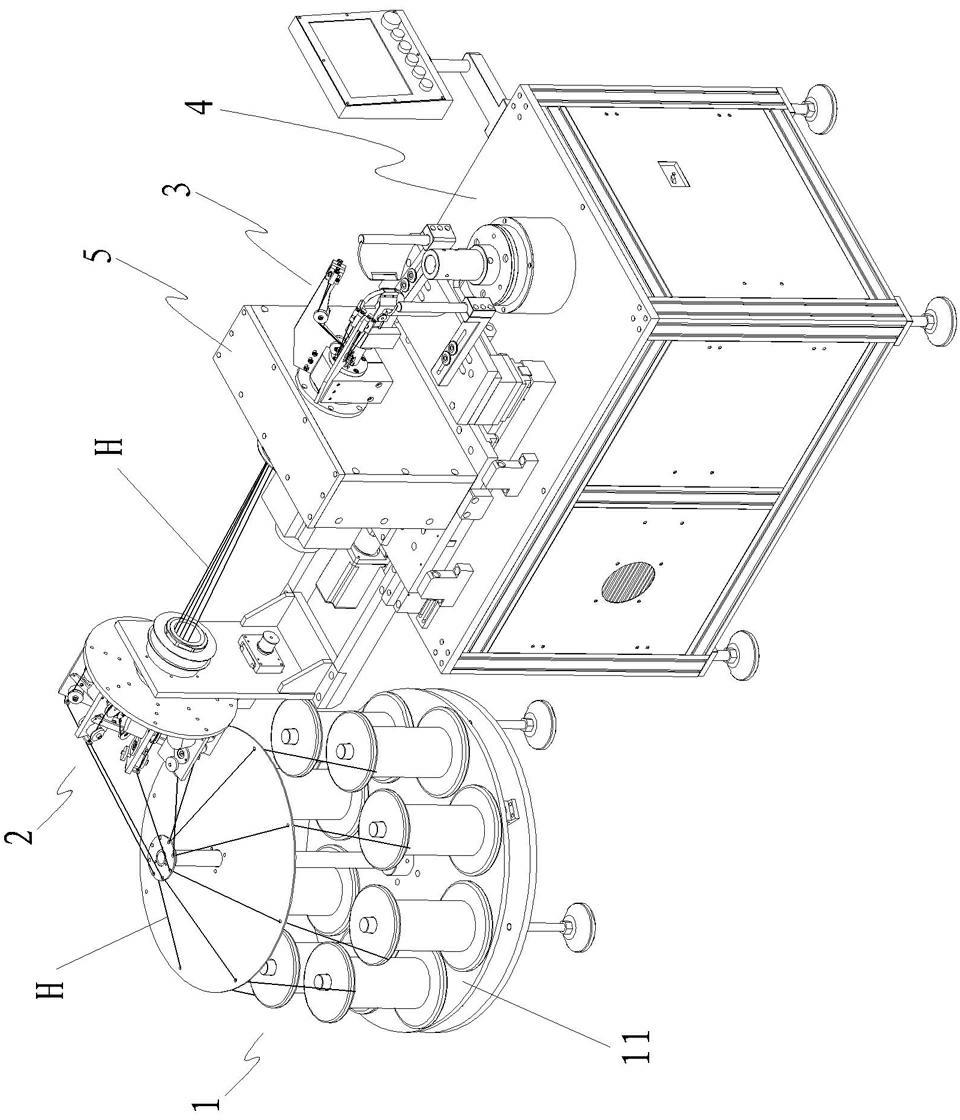

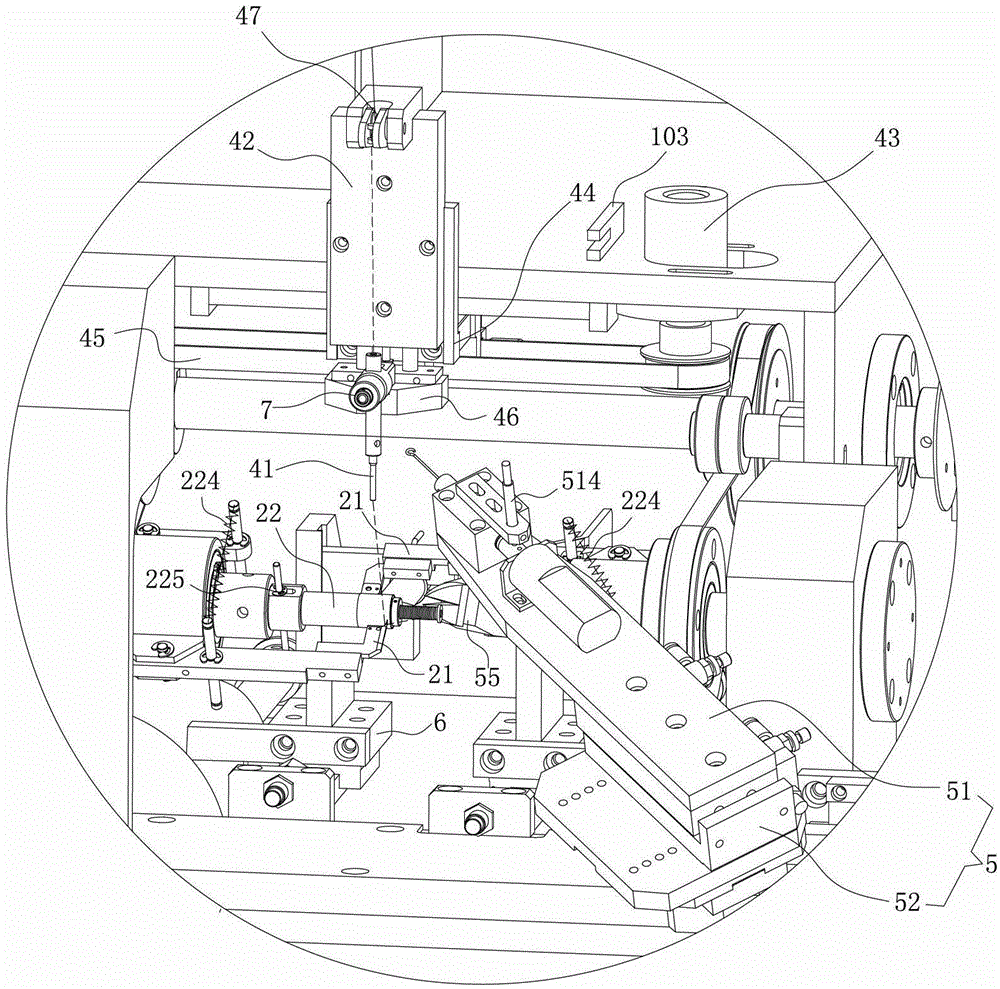

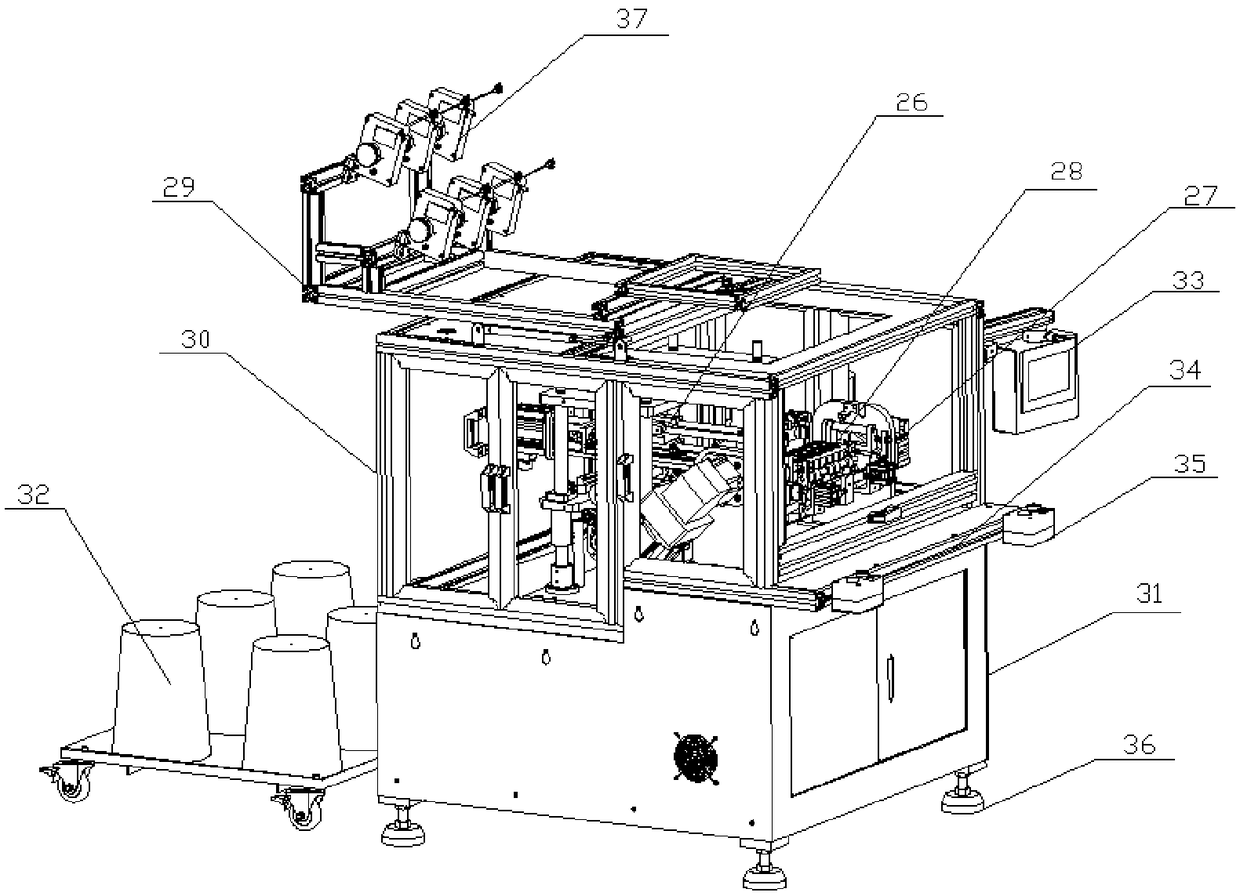

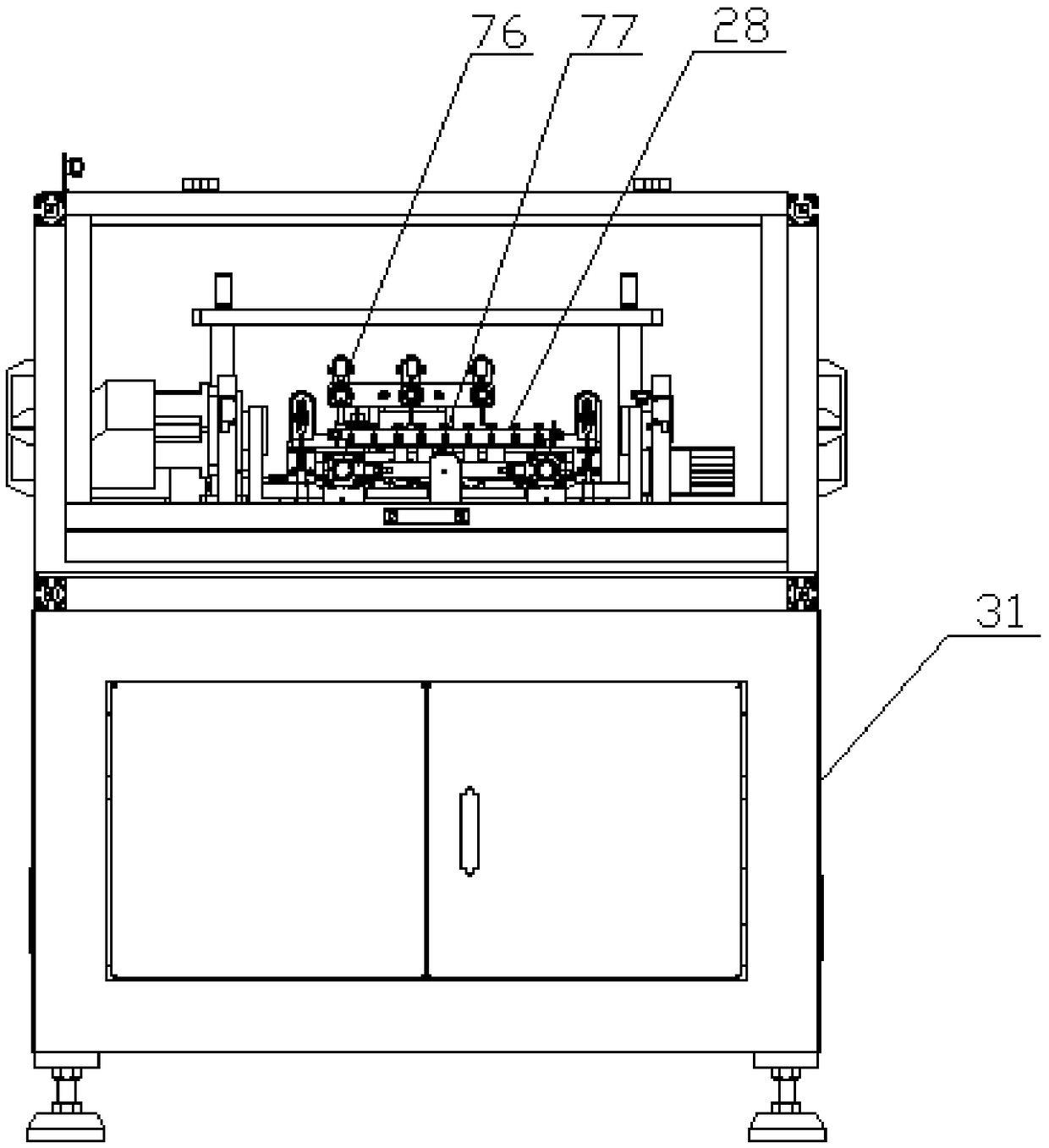

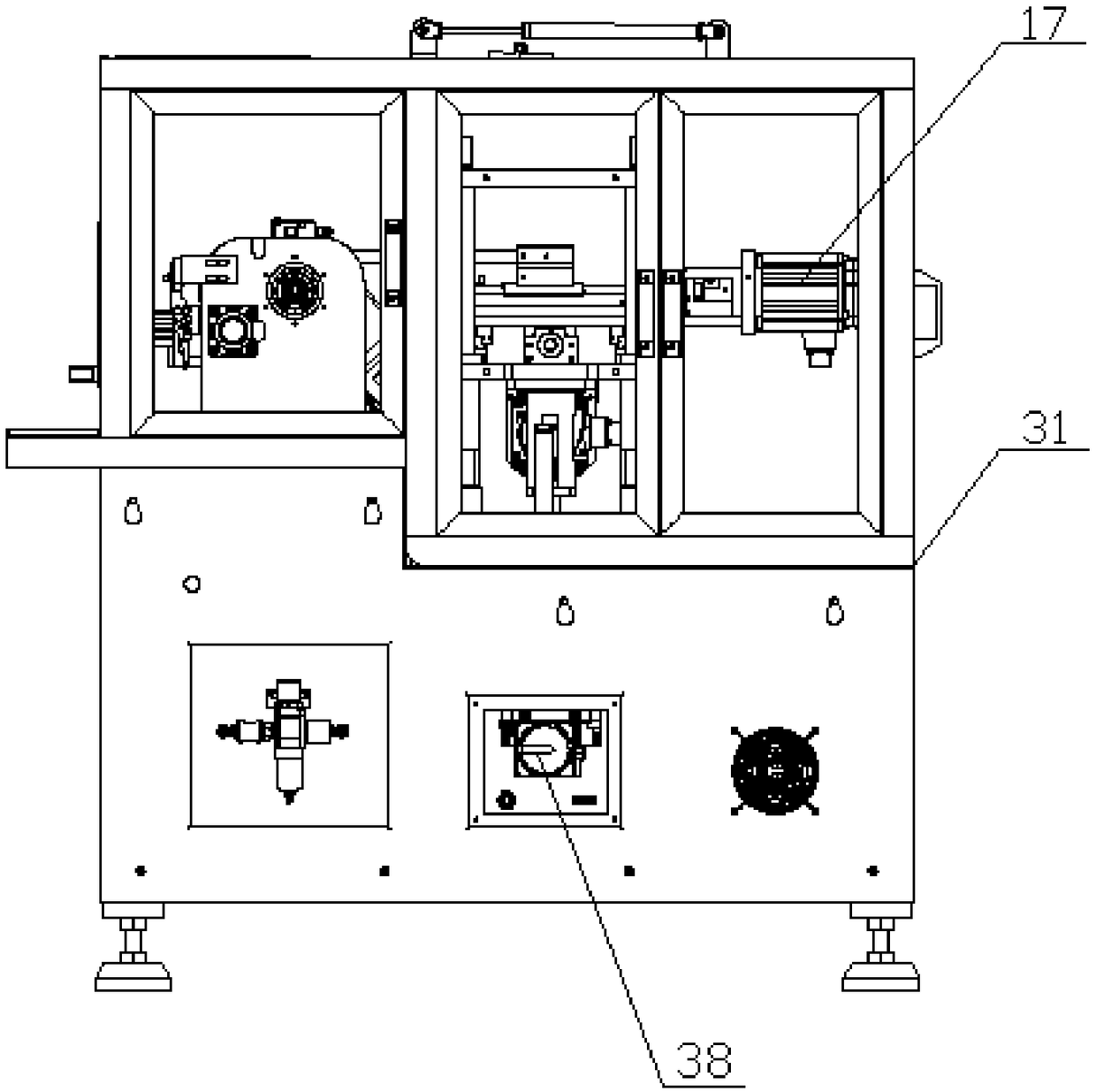

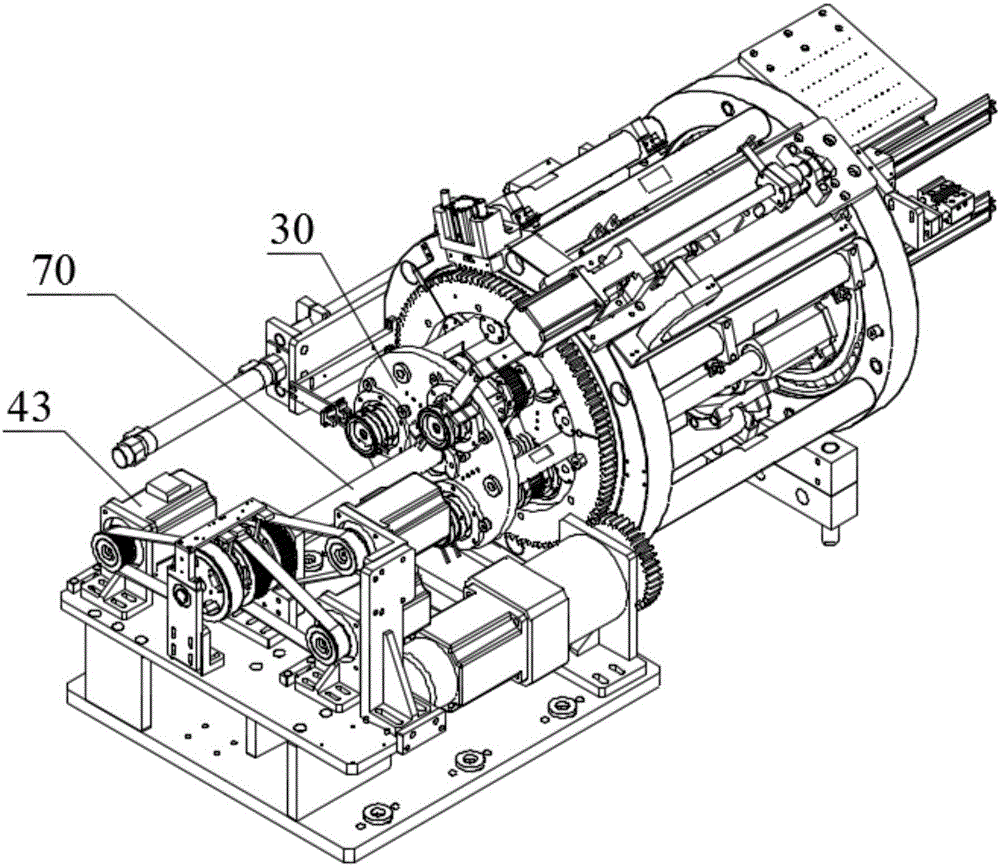

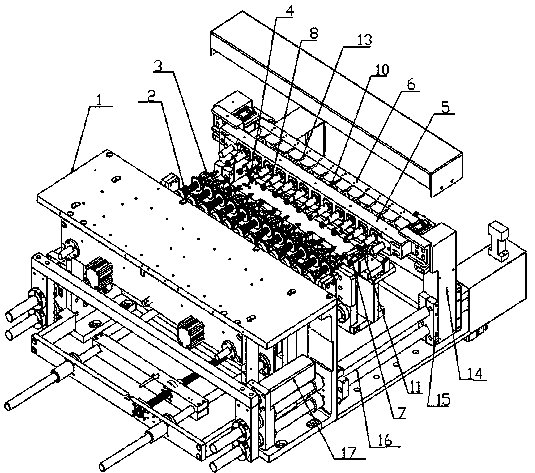

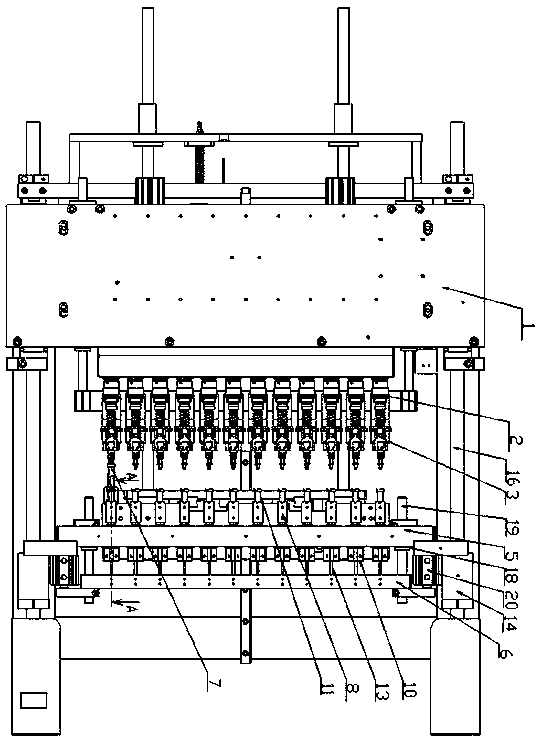

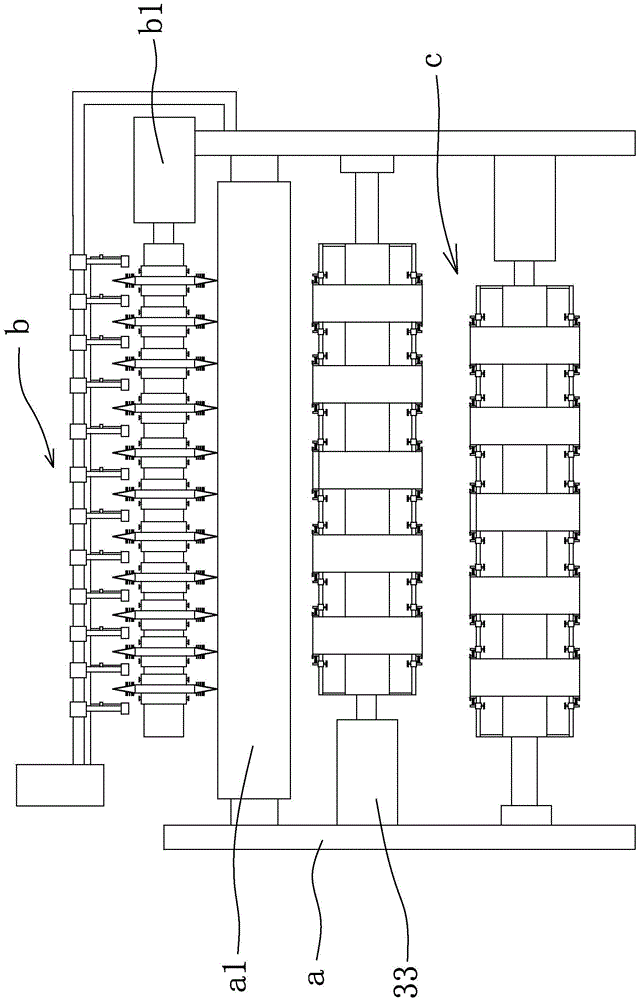

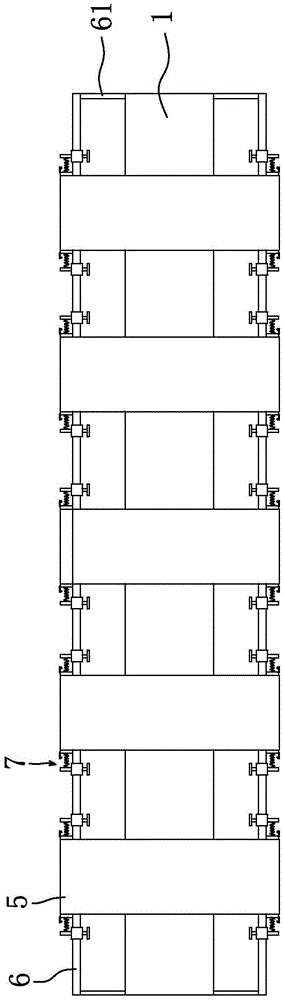

Three-needle parallel winding and blocked stator winding machine

ActiveCN108512377AReduce workloadFully automatedManufacturing dynamo-electric machinesWinding machineHuman–machine interface

The invention discloses a three-needle parallel winding and blocked stator winding machine. The three-needle parallel winding and blocked stator winding machine comprises an equipment bottom rack, a three-dimensional winding mechanism, a blocked stator placement jig, a tensioner main body, a safety protection cover, a trimming device, a clamping device, a turnover workbench, a winding device and ahuman-computer interface, wherein the three-dimensional winding mechanism is arranged at an upper end of the equipment bottom rack, the winding device is arranged in front of the three-dimensional winding mechanism, the turnover workbench is arranged at a position, arranged at a front surface of the three-dimensional winding mechanism, of an upper end of the equipment bottom rack, the trimming device and the blocked stator placement jig are arranged on the turnover workbench, the trimming device is arranged at a lower end of the blocked stator placement jig, the safety protection cover is arranged at an upper end of the equipment bottom rack, and the tensioner main body is arranged at an upper end of the safety protection cover. By matching, the function that a line passing through blocked motor stators is not broken is achieved, subsequent wire end trimming and wire end welding are greatly reduced, and the production efficiency is improved.

Owner:杭州直尚智能设备有限公司

Old wire recovery device

The invention provides an old wire recovery device comprising a frame, a take-up reel mounted on the frame, a motor driving the take-up reel to move, and a wire smoothing device. The old wire recovery device is scientific in design, convenient to use and high in recovery quality, and wires can be automatically smoothed.

Owner:STATE GRID CORP OF CHINA +1

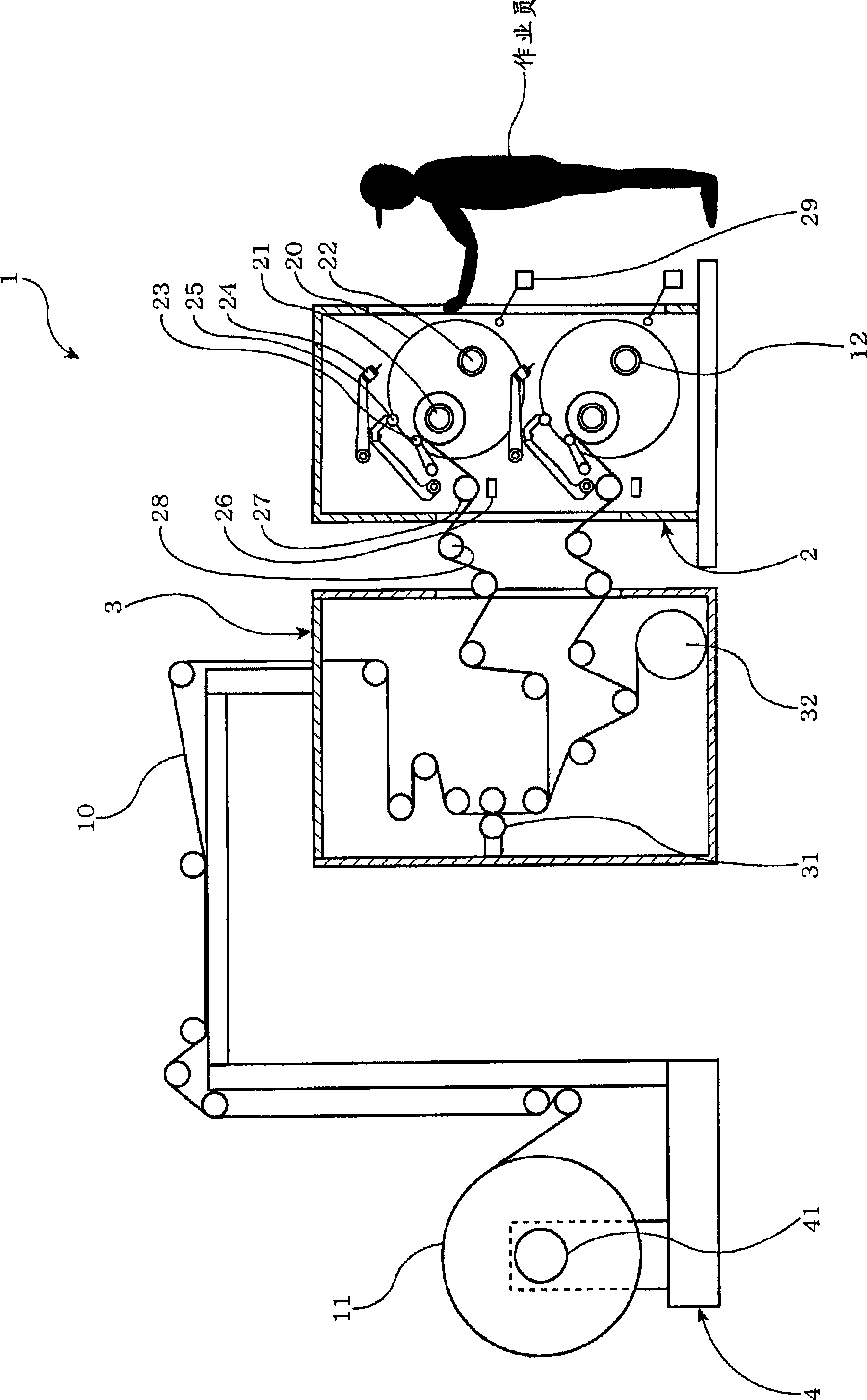

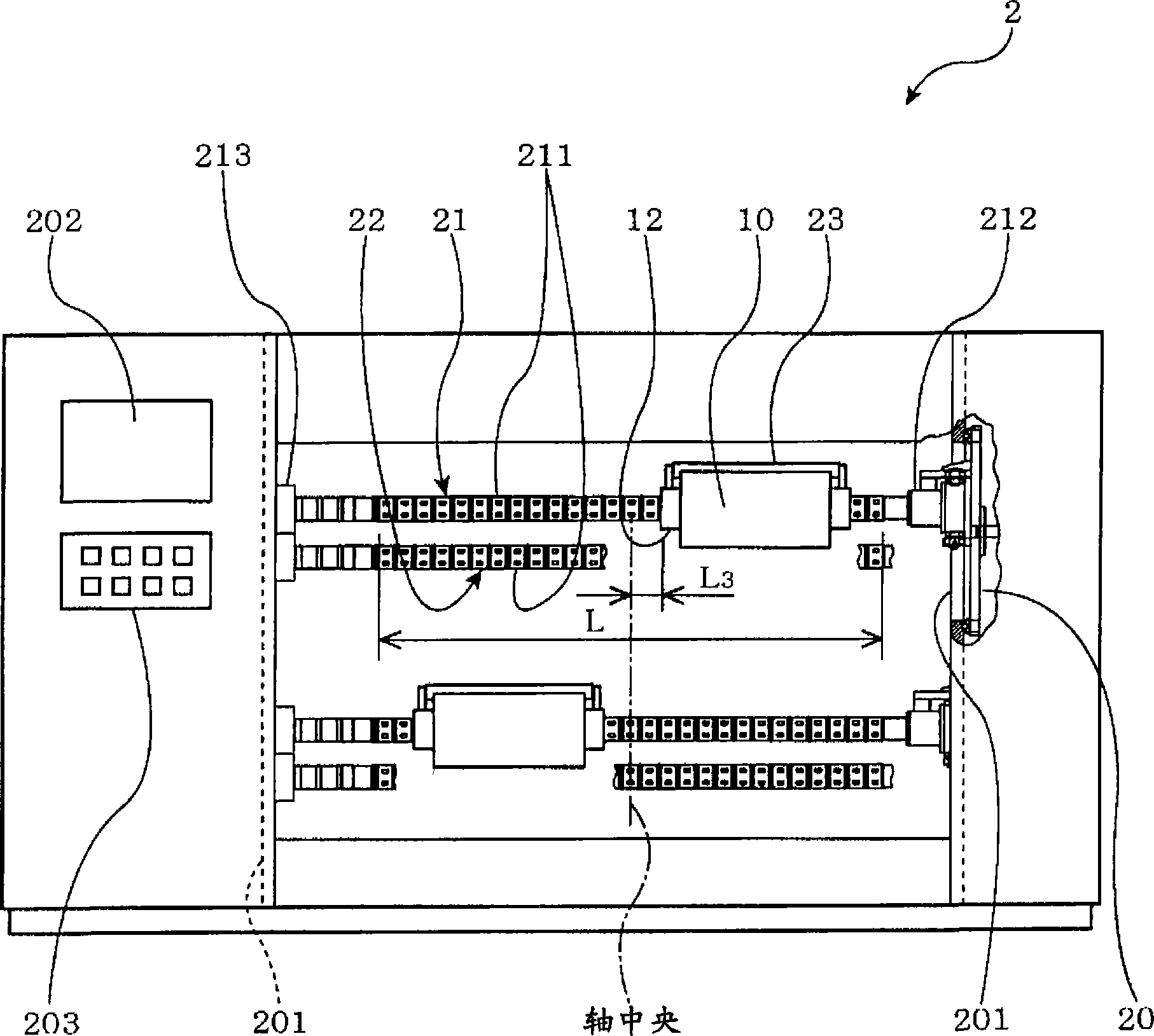

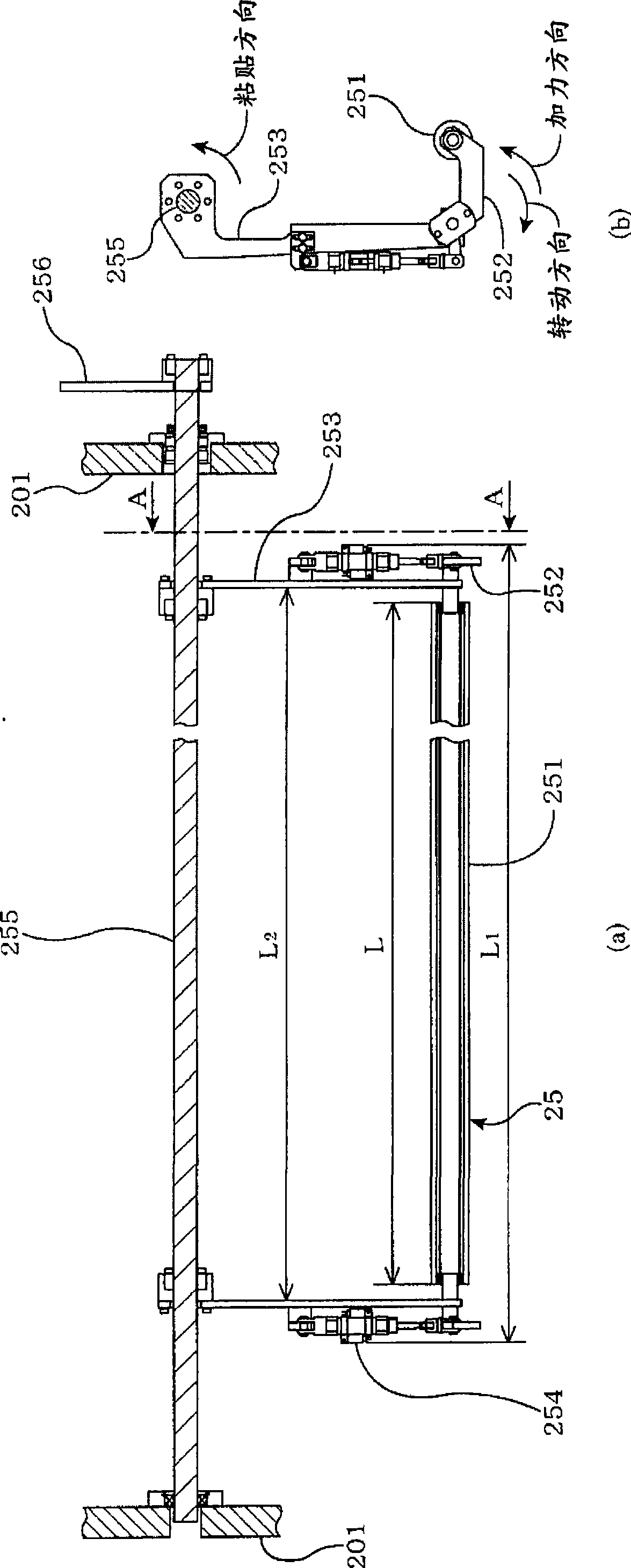

Automatic film winding device, slitting and winding system, and method of producing rolled film

To provide an automatic film winding apparatus, a slit winding system and a method for producing a rolled film which can improve winding quality, is reduced in size and enables winding mechanisms to be arranged in multiple stages. The automatic film winding apparatus includes winding shafts 21 and 22 for winding a film around a winding core 12, a turret 20 for pivotabaly supporting the winding shafts 21 and 22 in a rotatable manner, a touch roller 23 which presses the film to the winding shaft 22 when a predetermined amount of the film is wound by the winding shaft 21, and the turret 20 is rotated by a predetermined angle to allow the film to be hung on the winding shaft 22, a cutter 241 which cuts the film between the winding shaft 21 and the winding shaft 22, and a film affixing roller 25 which presses the film which has been cut to the winding shaft 22, and moves to the front end of the film while winding the film around the winding core 12 with the film being pressed.

Owner:RESONAC CORPORATION

Thin film strip conveying and winding device

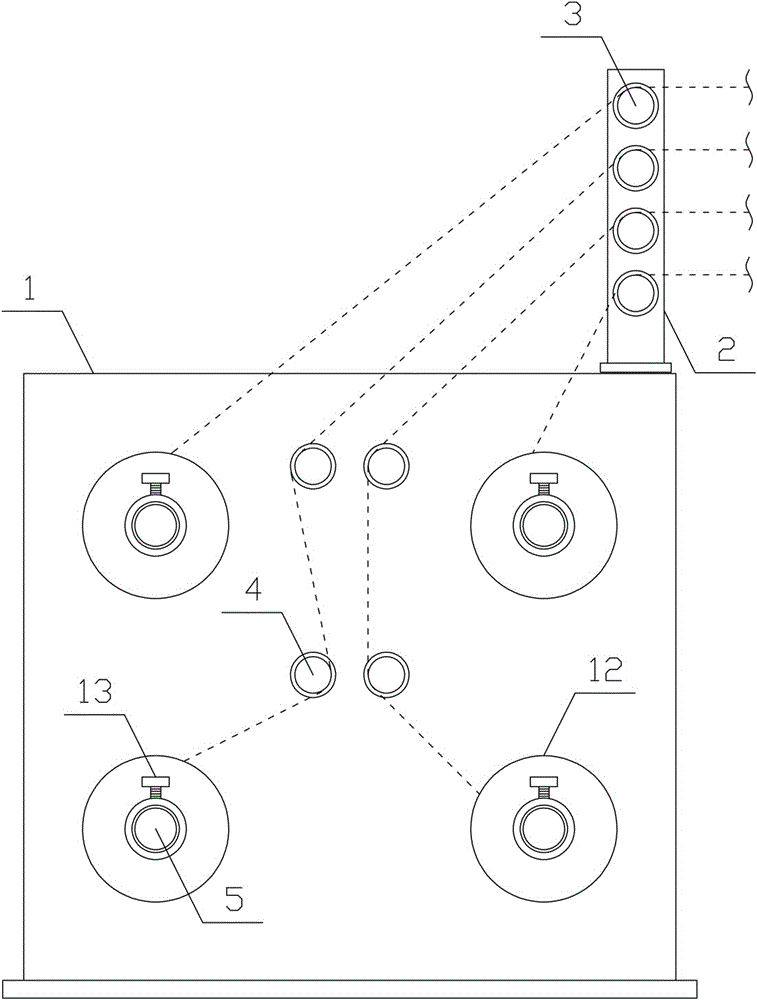

InactiveCN106081687ARotation synchronization is efficient and smoothThere are multiple film feeding rollers connected by rotation, and the winding is synchronously efficient and stableWebs handlingHydraulic cylinderSprocket

The invention discloses a thin film strip conveying and winding device and belongs to the field of packaging and machining mechanical equipment. The thin film strip conveying and winding device comprises a winding support, a film feeding support, film feeding rollers, film guiding rollers, winding rollers, a tensioning hydraulic cylinder and a winding motor; one side of the film feeding support is sequentially, horizontally, evenly and rotationally connected with the multiple film feeding rollers from top to bottom; the multiple winding rollers are horizontally, evenly and rotationally connected to the outer side of the winding support; the two sides of the middle portion of the winding support are sequentially, horizontally and rotationally connected with the film guiding rollers from top to bottom; one ends of the multiple winding rollers are each vertically provided with a winding chain wheel; a winding chain is connected to the winding chain wheels in an engaged manner; the winding motor and one winding chain wheel are in transmission connection through a conveying belt; the two ends of the tensioning hydraulic cylinder are vertically and rotationally connected with tensioning chain wheels correspondingly; and the winding chain is connected with the inner sides of the tensioning chain wheels in an engaged manner. The thin film strip conveying and winding device is reasonable in structural design and capable of fast and efficiently conveying and winding a plurality of thin film strips synchronously and steadily and meeting the production and use requirement.

Owner:浙江耀阳新材料科技有限公司

Winding device for cable production and machining

The invention discloses a winding device for cable production and machining. The winding device comprises a winding support, a reel, a cushioning device and a rotating device, wherein the cushioning device comprises a second cushioning device and a first cushioning device which are the same in structure; each of the second cushioning device and the first cushioning device comprises a buffer plate, a No. 1 guide rod, a No. 2 guide rod, an elastic rubber cushion and a spring; and the rotating device comprises a rotating motor, a rotating motor bracket, a rotating plate and a rotating seat. The winding device is reasonable in structural design; a cable is wound uniformly, is effectively prevented from being damaged during a winding process, and can be cleaned during the winding process, so that the quality of cable winding is improved, and the practicability is strong.

Owner:合肥九州龙腾科技成果转化有限公司

Winding forming method for double-layer composite material of rotator

InactiveCN102941676ASolve the problem of slippageImprove winding qualityConductor CoilMaterials science

The invention relates to a winding forming method for a double-layer composite material of a rotator, belongs to the forming field of composite materials, solves the problems that an inner layer material is easy to shift in a conventional winding method of the double-layer composite material, aims to increase winding quality, and is suitable for the formation of rotators with the inner molded surface in a truncated cone shape or a revolution surface. The method comprises a preparation step, a winding forming step, a curing step, a processing step and a product protection step. The winding forming method changes a winding forming sequence of a conventional double-layer composite material, and immediately winds a part of external layer external layer prepreg cloth after a part of internal layer prepreg cloth is winded, so that a trend of slipping outward of the internal prepreg cloth can be prevented in time, and internal and external quality of the double-layer composite material can be effectively improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

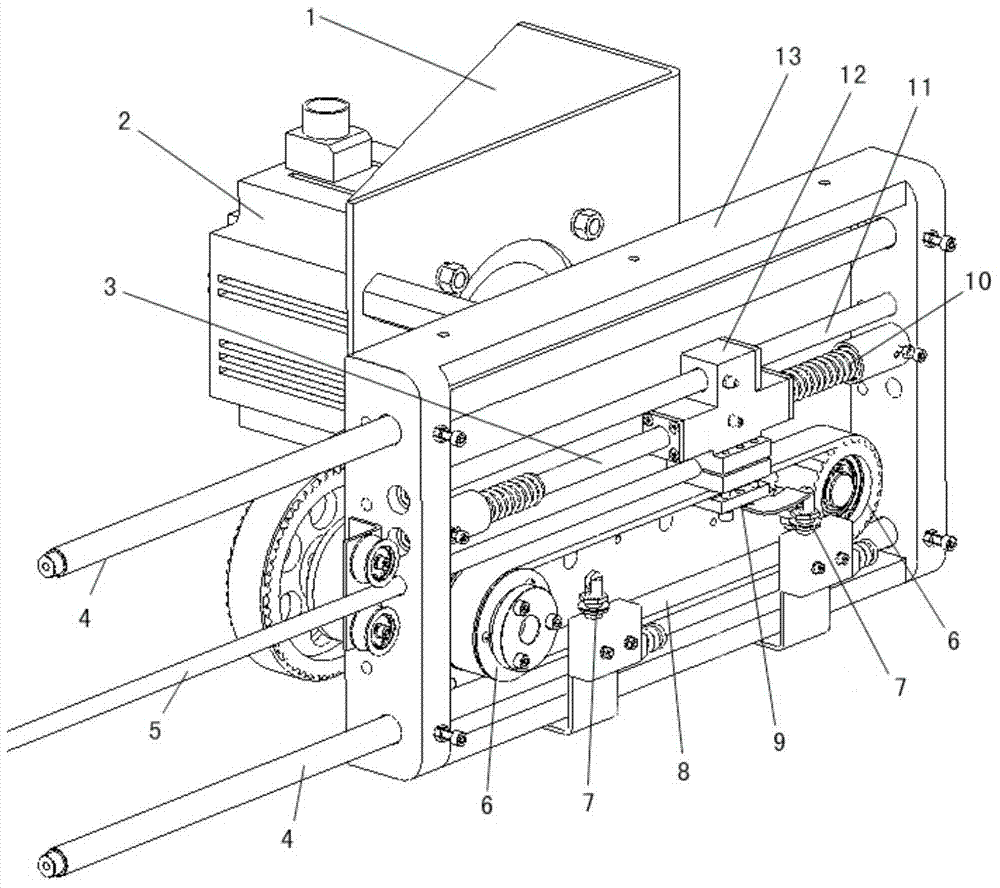

Winding head mechanism

ActiveCN106025326ASolve the knotSmall transmission clearanceAssembling battery machinesFinal product manufactureEngineeringConductor Coil

The invention provides a winding head mechanism which comprises a base, a sliding ring, a following plate, a station change motor and at least one winding main body, wherein the sliding ring comprises a rotor and a stator which can rotate relatively; the stator is fixed on a limiting bracket; the following plate is fixedly connected with the rotor of the sliding ring, and can rotate relative to a main supporting part. According to the winding head mechanism provided by the invention, due to the rotatable matching between the rotor and the stator in the sliding ring, the problem that a cable is knotted in the prior art is solved; meanwhile, a winding motor is mounted on the following plate to directly drive a winding driving shaft to rotate and further drive a winding needle to work, so that a transmission gap and an error can be reduced; furthermore, the response speed can be greatly increased, and the winding quality and the efficiency are improved; moreover, speeding up of variable rotating speed control is facilitated, so that the production efficiency is greatly improved, and the equipment cost and the production cost are reduced.

Owner:GEESUN AUTOMATION TECH

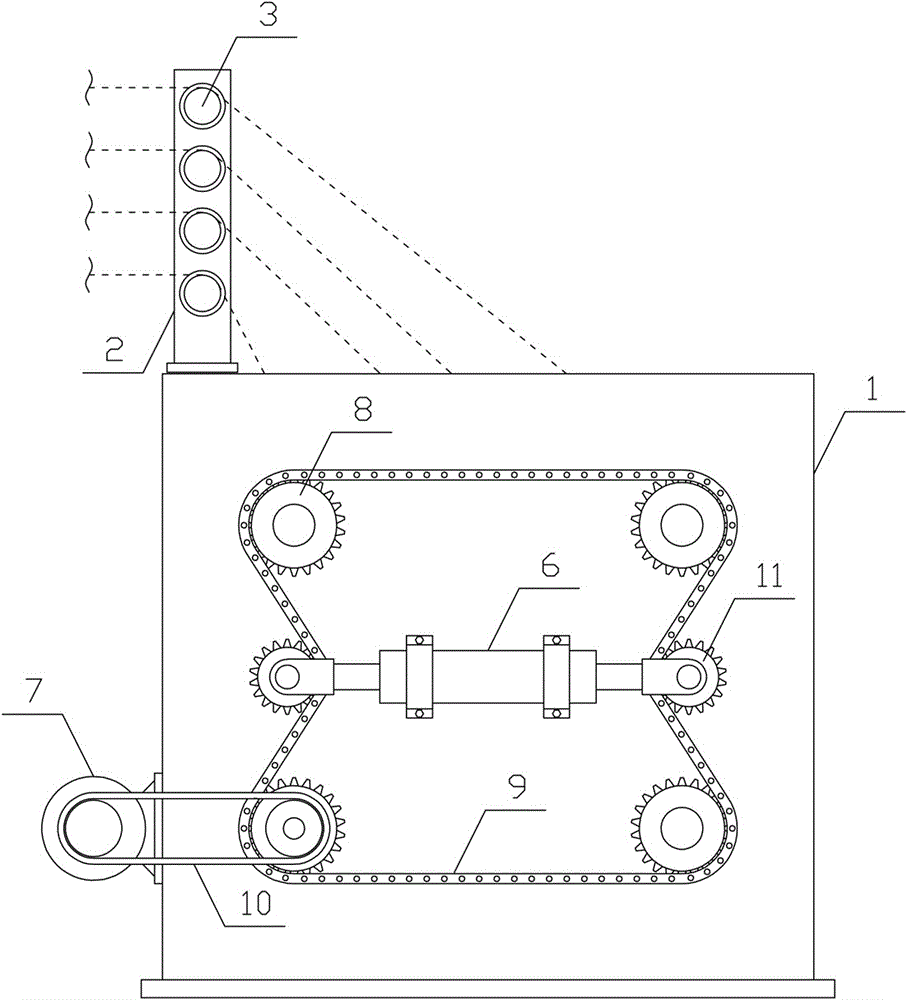

Electric cable winding machine

InactiveCN103640926AImprove work efficiencyImprove winding qualityFilament handlingWinding machineSprocket

The invention relates to electrical equipment, in particular to an electric cable winding machine. The electric cable winding machine comprises a bracket adopting a rectangular frame structure and a cable roll shaft seat mounted at the rear end of the bracket through a bearing, wherein a power input shaft is arranged at the front end of the bracket; a bidirectional screw rod is mounted in the middle of the bracket through a bearing; the power input shaft is in transmission connection with the cable roll shaft seat, the bidirectional screw rod and a power machine through a chain and chain wheel pair respectively; a flat cable tackle is nested on the bidirectional screw rod; a slide track is fixedly mounted on the bracket and is parallel to the bidirectional screw rod; and the flat cable tackle is fixedly connected with a supporting rod mounted in the slide track, and a flat cable pulley is mounted on the flat cable tackle through a bearing. The electric cable winding machine adopts the power machine such as a tractor and the like as drive mechanisms to replace manpower operation, the operation efficiency is high, a cable can be uniformly wound around a take-up reel by means of a cabling mechanism, the cable winding quality is high, and the cable winding effect is good; and the cable wound around the take-up reel can be conveniently detached, and the maintenance operation is facilitated.

Owner:国网山东省电力公司郯城县供电公司 +1

Device for evenly winding spinning yarn

The invention discloses a device for evenly winding spinning yarn. The device includes a base plate. A left vertical plate and a right vertical plate are vertically fixedly installed on the base plate, and top plates are vertically fixedly installed on the left vertical plate and the right vertical plate. The left side of the left vertical plate is provided with a driving motor, a driving shaft iscoaxially fixedly mounted on an output shaft of the driving motor, and a driving gear is coaxially fixedly mounted at the right end of the driving shaft. Returning springs are fixedly connected between the left vertical plate and a first fixed plate and between the left vertical plate and a second fixed plate respectively, the left end of each returning spring is fixed to the right side wall of the left vertical plate, and a pull rope extends rightwards horizontally and penetrates the right vertical plate. A limiting ring pulls the spinning yarn to move back and forth in the length directionof a winding roller, so that the spinning yarn can be evenly wound around the surface of the winding roller, which avoids the excessive concentration of the spinning yarn on a certain position on thewinding roller, achieves uniform winding of the spinning yarn and avoids the winding knotting of the spinning yarn. As a result, the winding quality is improved, the operation of the device can be achieved through the driving motor, and the device saves energy and is efficient.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

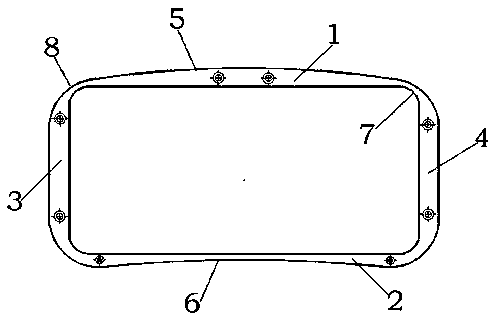

Skeleton for special-shaped high-temperature superconducting racetrack coil and winding method

InactiveCN108766708AImprove current carrying capacityImprove the current carrying capacity and improve the winding quality of the coilInductances/transformers/magnets manufactureSuperconducting magnets/coilsWinding machineHigh temperature superconducting

The invention discloses a skeleton for a special-shaped high-temperature superconducting racetrack coil. The skeleton comprises a winding skeleton for a racetrack coil, wherein a long edge I of the winding skeleton is provided with an upper arc I; a long edge II of the winding skeleton is provided with a lower arc I; a short edge I is arranged at the left side; a short edge II is arranged at the right side; the long edge I is connected with the short edge I in an arc transition manner; and a winding method comprises the following steps of (1) arranging the skeleton for a high-temperature superconducting racetrack coil on a horizontal winding machine; (2) winding a coil winding: introducing a high-temperature superconducting wire from the segment of the short edge I and fixing a wire inletend; fixing the coil by using a fixing clamp I and completing winding of the short edge II during winding through the long edge I; arranging a fixing clamp II, a fixing clamp III and a fixing clamp IVon the segment of the long edge II for fixing the coil, and slowly winding to complete winding of the long edge II; and (3) curing the winding: after winding the coil, taking down the fixing clamps and fixing a cutting tip matched with the coil at the outer side of the long side II during removal. The skeleton is simple in structure, easy to produce, simple in method and easy to operate.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

Double-group winding machine

The invention relates to a double-group winding machine. The machine comprises a first rack, a plurality of main winding shafts which are horizontally mounted at equal intervals on the front side of the rack, a double-group winding mechanism, a glue covering mechanism, and a feeding mechanism in the front of the rack, wherein the double-group winding mechanism and the glue covering mechanism are arranged above the rack; each main winding shaft is provided with a jig provided with a coil framework; the feeding mechanism, the double-group winding mechanism and the glue covering mechanism are respectively matched with the jigs on the main winding shafts to perform feeding, double-group winding and glue covering. The machine has the advantages that all mechanisms are reasonably arranged and matched, so that the structure is compact, the service life is long, and the production efficiency of a product is increased.

Owner:JIANGSU FEIER ELECTRICAL TECH

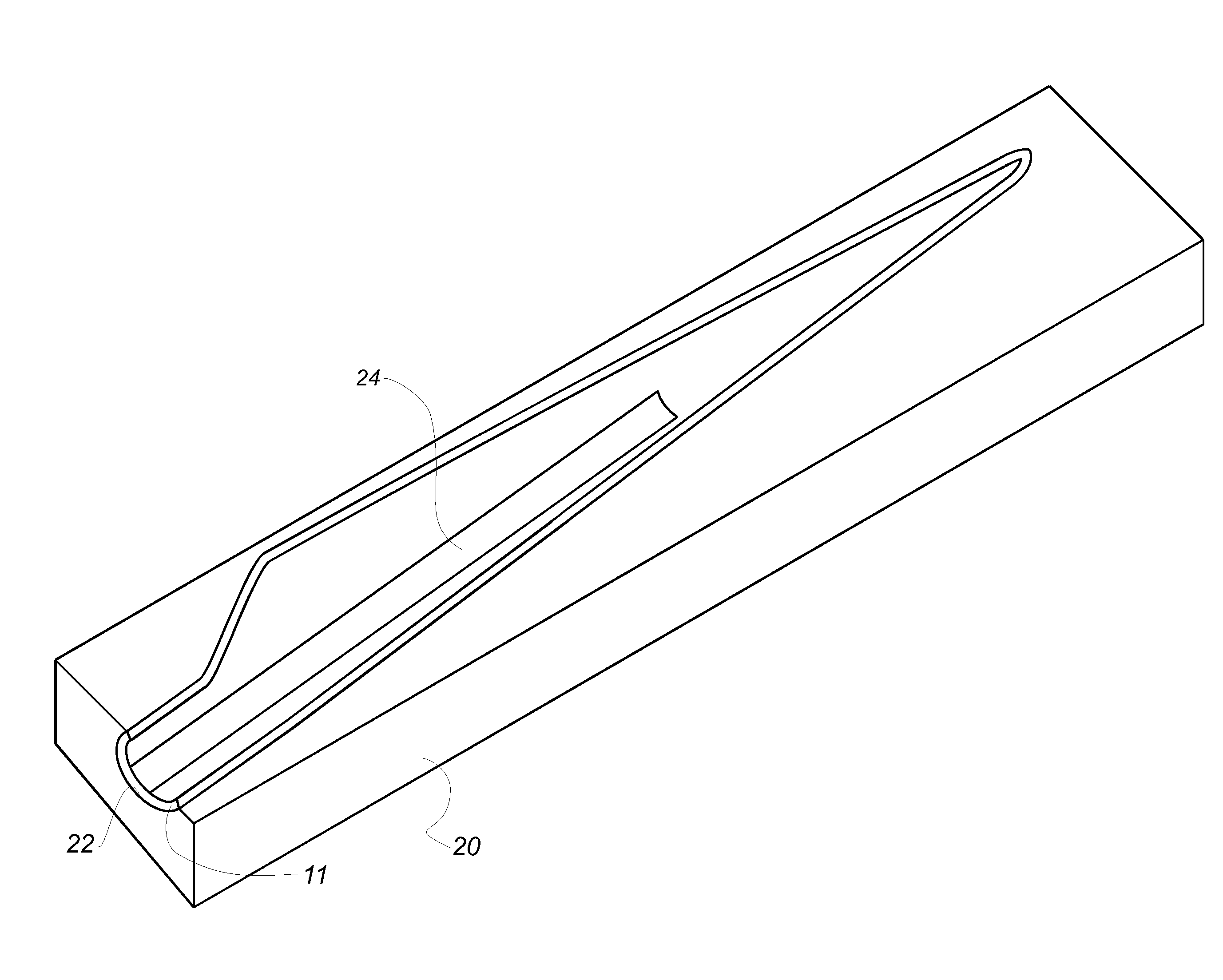

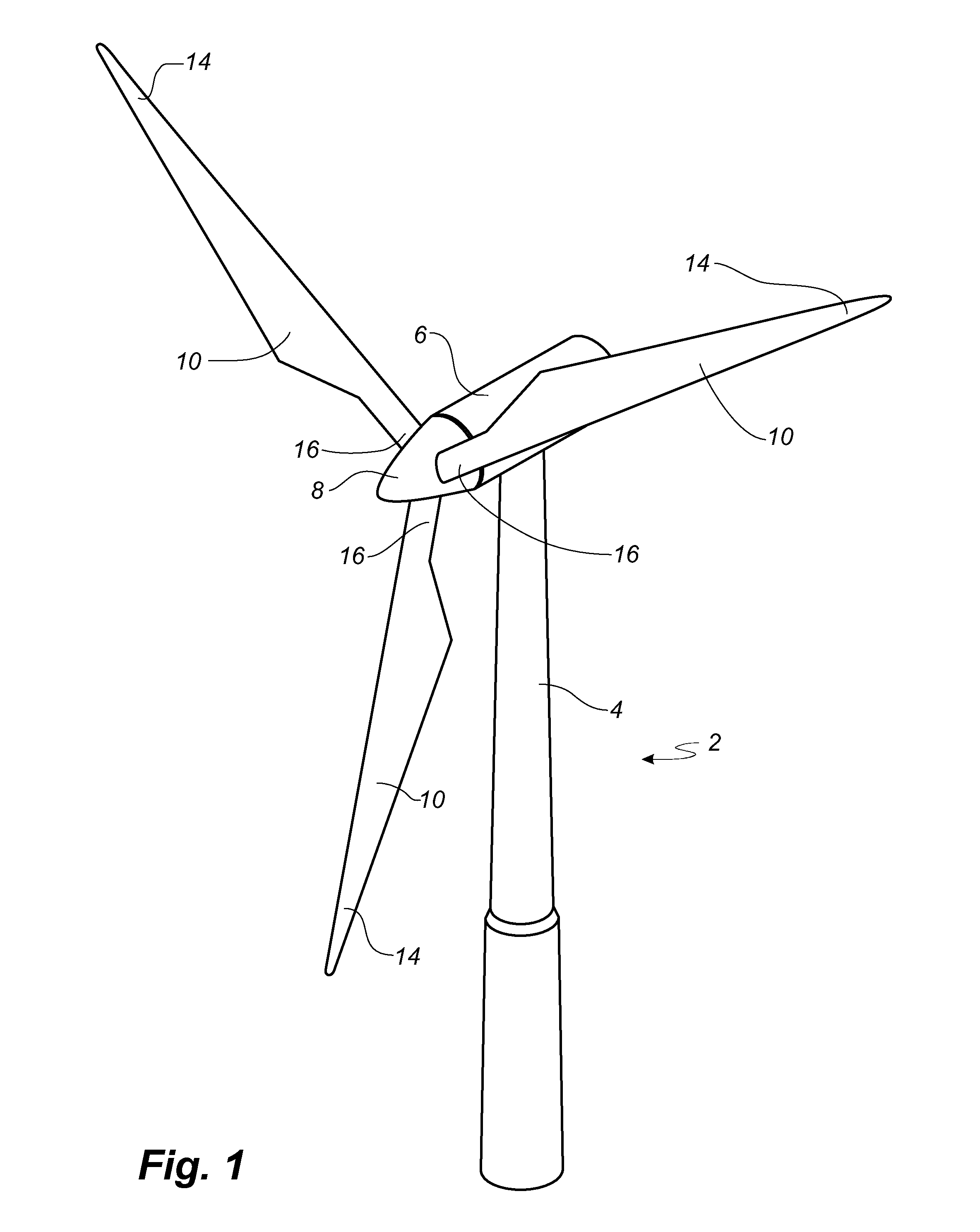

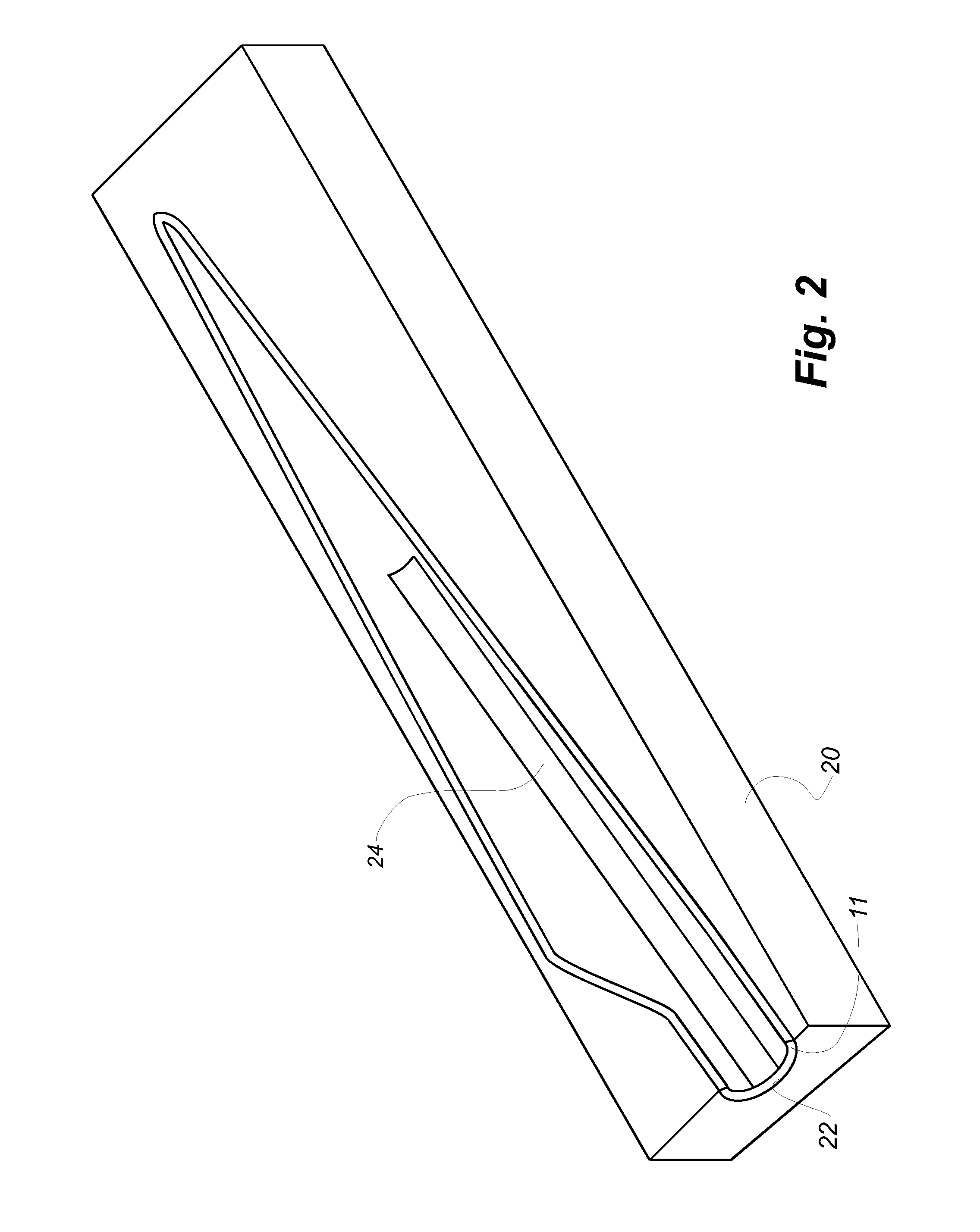

System and Method for Assisting in the Manufacture of a Wind Turbine Blade Shell

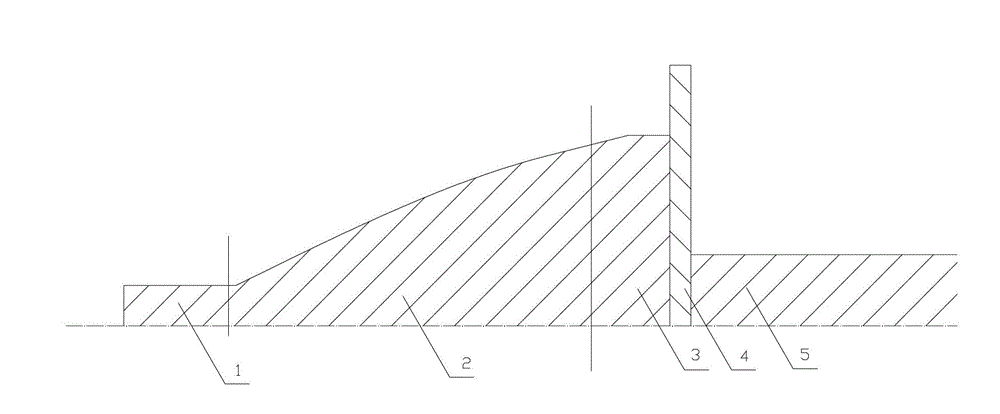

ActiveUS20160176127A1Improve winding qualityReduce riskEngine manufactureMouldsTurbine bladeEngineering

A method of manufacturing a wind turbine blade shell part is described. Fibre mats and a root end insert are laid up in a mould part in a layup procedure by use of an automated layup system. The fibre mats are laid up by use of a buffer so that the fibre mats may continuously be laid up on the mould surface, also during a cutting procedure. The root end insert is prepared in advance and mounted on a mounting plate. The root end insert is lowered onto the mould by use of the mounting plate and a lowering mechanism. After the wind turbine blade shell has been moulded, the mounting plate is removed.

Owner:LM WP PATENT HLDG

Rubber hose sheath winding machine

The present invention discloses a twister of a rubber tube jacket. A frame (1) is provided with a hollow feeding cylinder (5) driven by a drive mechanism to revolve round an axial line of the feeding cylinder and provided with a charging ladle (6), of which an outlet is corresponding to the outlet of the feeding cylinder (5). The charging ladle (6) can revolve round the axial line freely. The front ed of the charging ladle (6) is provided with a winding pulley component (8). An axial central line of the charging ladle (6) and the axial central line of the feeding cylinder (5) intersect to form an angle. The frame (1) is provided with a feeding component corresponding to the feeding cylinder (5). The present invention has the advantages of high production efficiency, small labor intension, stable twisting quality, simple structure, convenient operation, reliable performance, applicable to twisting the rubber tube jackets of different sizes and the jacket twisting equipment in manufacturers of different sizes.

Owner:CENT SOUTH UNIV +1

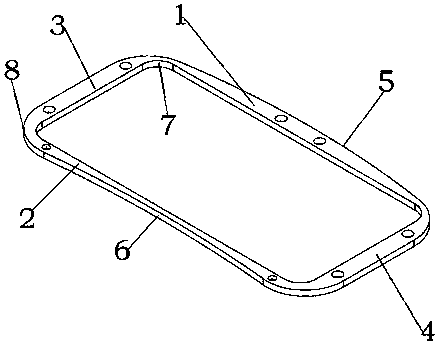

Mold special for wire harness winding, winding device and lamp manufacturing process

ActiveCN106115372AImprove the degree of adaptationReduce manufacturing costFilament handlingLight fasteningsEngineeringConductor Coil

The invention discloses a mold special for wire harness winding, a winding device and a lamp manufacturing process. According to the technical scheme, the mold special for wire harness winding comprises a main mold plate and an auxiliary mold plate; the outer plate wall of the auxiliary mold plate is provided with a plurality of inserting line grooves distributed along a straight line; and the distance between the adjacent inserting line grooves is kept to be consistent; the mold special for wire harness winding further comprises inserting-connection plates; the main mold plate is provided with a slide groove, and the auxiliary mold plate is slidably arranged in the slide groove; the edge of the auxiliary mold plate with the inserting line grooves is protruded out of the main mold plate; and the production cost of the mold special for wire harness winding can be substantially reduced; the winding device has the characteristic of being capable of enabling a tandem connection wire to be efficiently wound on the mold special for wire harness winding; and the lamp manufacturing process can improve the lamp manufacturing quality.

Owner:TAIZHOU WANLI LIGHTING MFG CO LTD

Yarn continuous twisting device

ActiveCN109137153AEfficient and accurate twisting processingEasy accessTextile disintegration and recoveryContinuous wound-up machinesYarnEngineering

The invention discloses a yarn continuous twisting device and belongs to the weaving processing machinery equipment field. A yarn winding mechanism, a yarn guiding mechanism, a twisting mechanism, a yarn drawing mechanism, and a yarn releasing mechanism of the invention are successively and fixedly arranged on one side of a fixing support from top to bottom. The central section of the lower side of a rotation disc is rotatably connected to a yarn bearing support. A drawing spring is arranged between a yarn drawing pull rod and a yarn wheel support. The upper yarn guide support, the twisting support and the lower yarn guide support of the twisting mechanism are successively, horizontally and fixedly arranged on one side of the fixing support from top to bottom. A reciprocating connection rod is slidably arranged on a reciprocating support along a horizontal direction. A yarn winding roller is horizontally and rotatably connected to a yarn winding support. A yarn winding spring is arranged between a rotation support and the fixing support in an inclined mode. A locking screw rod is arranged between the central section of the upper side of a yarn winding placing rack and the rotationsupport. The structure is designed reasonably, yarns can be high-efficiently and accurately twisted and processed continuously, the twisting degree of the yarns can be increased and a production and usage demand is satisfied.

Owner:浙江新景和纺织科技有限公司

Power cable take-up machine

The invention relates to electrical equipment, in particular to a power cable take-up machine. The power cable take-up machine comprises a support of a rectangular frame structure, and a cable roller shaft base installed at the rear end of the support through a bearing. A power input shaft is arranged at the front end of the support. A both-way lead screw is installed in the middle of the support through a bearing. The power input shaft is in transmission connection with the cable roller shaft base, the both-way lead screw and a power machine through a chain and chain wheel pair. The both-way lead screw is sleeved with a winding displacement tackle. A sliding rail is fixedly installed on the support and is parallel to the both-way lead screw. A supporting rod installed in the sliding rail is fixedly connected to the winding displacement tackle. A winding displacement pulley is installed on the winding displacement tackle through a bearing. According to the power cable take-up mechanism, a tractor and other power machines are adopted as drive mechanisms to replace manual operation, operation efficiency is high, a cable can be evenly wound on a take-up reel through a cable arranging mechanism, the winding quality is high, and the winding effect is good. The cable wound on the take-up reel can be conveniently dismounted, and maintaining operation is facilitated.

Owner:郯城县明珠发展有限公司

Double-surface ironing winding machine

InactiveCN105417259AImprove ironing effectAvoid wrinklesIroning apparatusTextiles and paperWinding machineEngineering

The invention provides a double-surface ironing winding machine. The machine comprises a base which is fixedly arranged, wherein a rack is arranged at one side of the base; a supporting plate which is obliquely arranged in a preset angle is arranged between the rack and the base; a fabric winding roller is mounted at the upper end of the rack; a guide roller is arranged on the supporting plate; a driving device, a limiting mechanism, a first heating roller and a second heating roller are arranged on the base; the driving device is used for driving the first heating roller and the second heating roller to rotate in opposite directions; the limiting mechanism is used for limiting the moving route of a nonwoven fabric. According to the machine, the first heating roller and the second heating roller which are rotated in the opposite directions are arranged on the winding machine and can be used for performing double-surface ironing for the nonwoven fabric to be wound, so that the nonwoven fabric can be flat, and the ironing effect is improved; meanwhile, the nonwoven fabric can be prevented from wrinkling due to the surface flatness during winding. With the adoption of the machine, the nonwoven fabric can be wound regularly and accurately, so that the winding quality can be improved, and the operation is simplified.

Owner:YANGZHOU XIANGBEI MACHINERY

Efficient thin film slitting machine

InactiveCN105600565AQuality improvementGuaranteed stabilityArticle deliveryWebs handlingEngineeringLocking mechanism

The invention provides an efficient thin film slitting machine. The efficient thin film slitting machine comprises a rack, wherein a feeding roller is arranged on the rack; a slitting blade mechanism for slitting a thin film wound on the feeding roller is arranged above the feeding roller; the thin film, which is slit by the slitting blade mechanism, is wound on a winding mechanism; the winding mechanism comprises at least two rollers which are connected with a first driving mechanism; the two rollers are provided with tensioning mechanisms which are arranged in sequence in a staggered manner; each tensioning mechanism comprises at least one tensioning assembly; each tensioning assembly is connected with a tensioning part which sleeves a winding barrel; an elastic sealing assembly is arranged between each tensioning part and the corresponding roller; each tensioning part is provided with fastening devices which are located at the two sides of the corresponding winding barrel and can be used for tightly clamping the winding barrel; the position between the two fastening devices can be adjusted; locking mechanisms are arranged on the fastening devices. The efficient thin film slitting machine has the advantage of good slitting effect.

Owner:ZHEJIANG OUTE ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com