Skeleton for special-shaped high-temperature superconducting racetrack coil and winding method

A racetrack-shaped coil and high-temperature superconducting technology, which is applied in the direction of superconducting magnet/coil, inductor/transformer/magnet manufacturing, magnetic objects, etc., to achieve the effects of improving current carrying capacity, simple operation, and improving winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

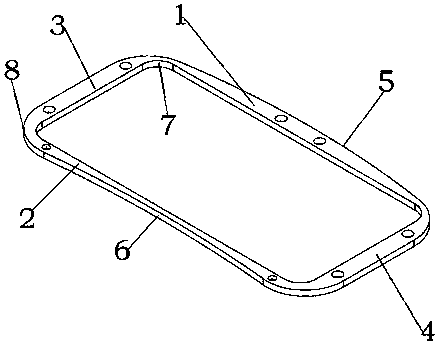

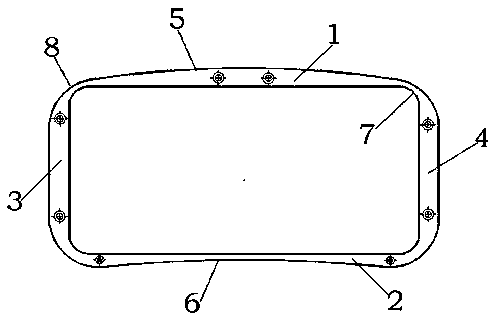

[0023] see figure 1 , 2 , shown in 3, a skeleton for special-shaped high-temperature superconducting racetrack coils, including a winding skeleton similar in shape to a racetrack coil, the long side 1 of the winding skeleton has an upper arc (5), and the length of the winding skeleton Side 2 has a lower arc of 16; the left side is short side 13, the right side is short side 2 (4), and the thickness of the winding skeleton is T; the long side 1 and short side 1 are excessively connected by an arc, and the arc Including inner radian-7 and outer radian-8.

[0024] The arc of the upper radian-5>0, the radian of the lower radian-60, the outer radian-8>0; skeleton Thickness T remains constant.

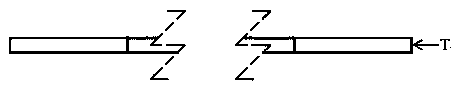

[0025] see figure 2 , 4 A method for winding a superconducting magnet with a framework for a special-shaped high-temperature superconducting racetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com