Patents

Literature

134results about How to "Isotropic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepreg applied for multi-layer board of printed electronic circuit

ActiveCN101220160ALow dielectricReduce residual stressSynthetic resin layered productsCircuit susbtrate materialsSolventFilling materials

The invention pertains to the technical field of the copper clad laminate, which more particularly relates to a prepreg applied to a printing circuit multilayer board. The prepreg comprises reinforced materials and resin composite, wherein, the reinforced materials is glass fiber paper, and according to part by weight, the formulation of the resin composite is as follows: 20 to 84 portions of resin, 0 to 35 portions of filling materials, 0.01 to 0.3 portions of curing accelerator and 10 to 45 portions of solvent; the resin composite solvent is soaked in the glass fiber paper for 1 to 5 minutes, and is put in a 140 to 200 DEG C oven for baking for 2 to 10 minutes; after the solvent is removed, the prepreg applied to multilayer PCB processing materials is obtained; white flake and spot problems of base materials during the manufacturing procedures of the multilayer PCB are prevented, problems of de-lamination, shrink resin, holes and crack of the resin and white flake, etc. that come up after the multilayer PCB goes through cold and hot impact are improved, and the prepreg has good reliability and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

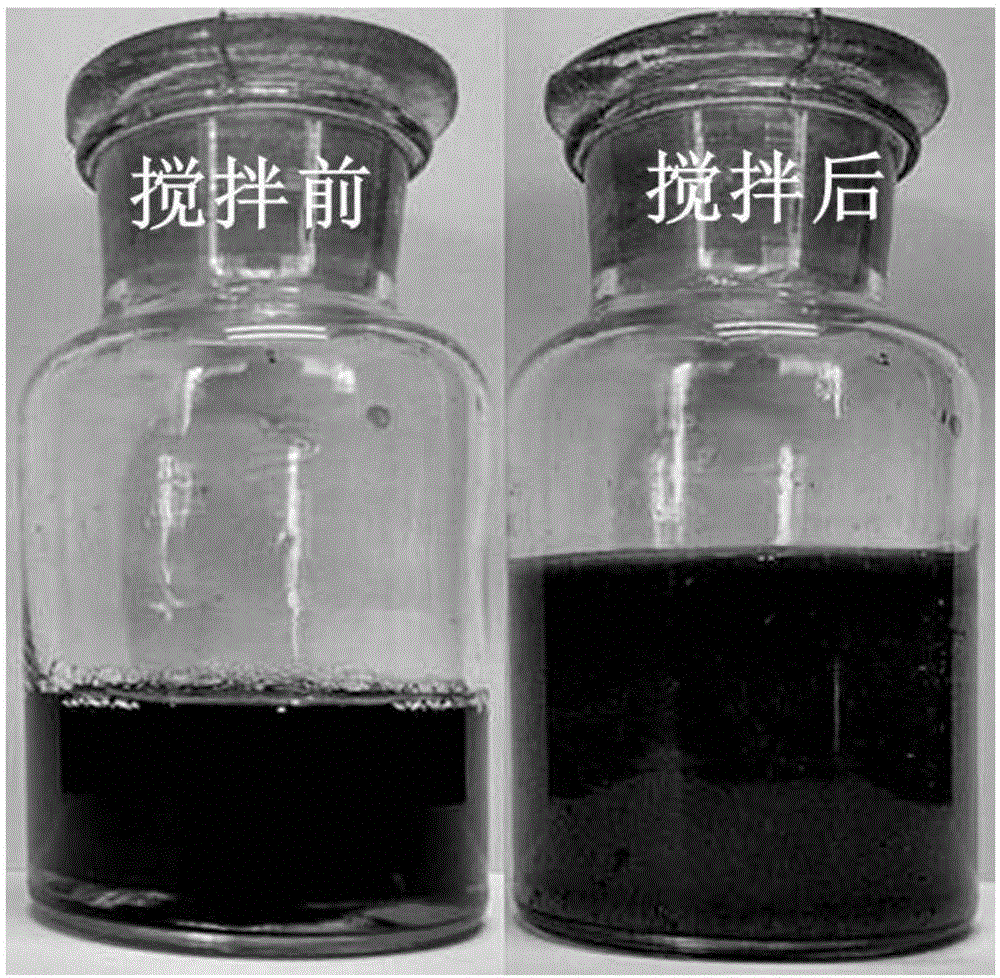

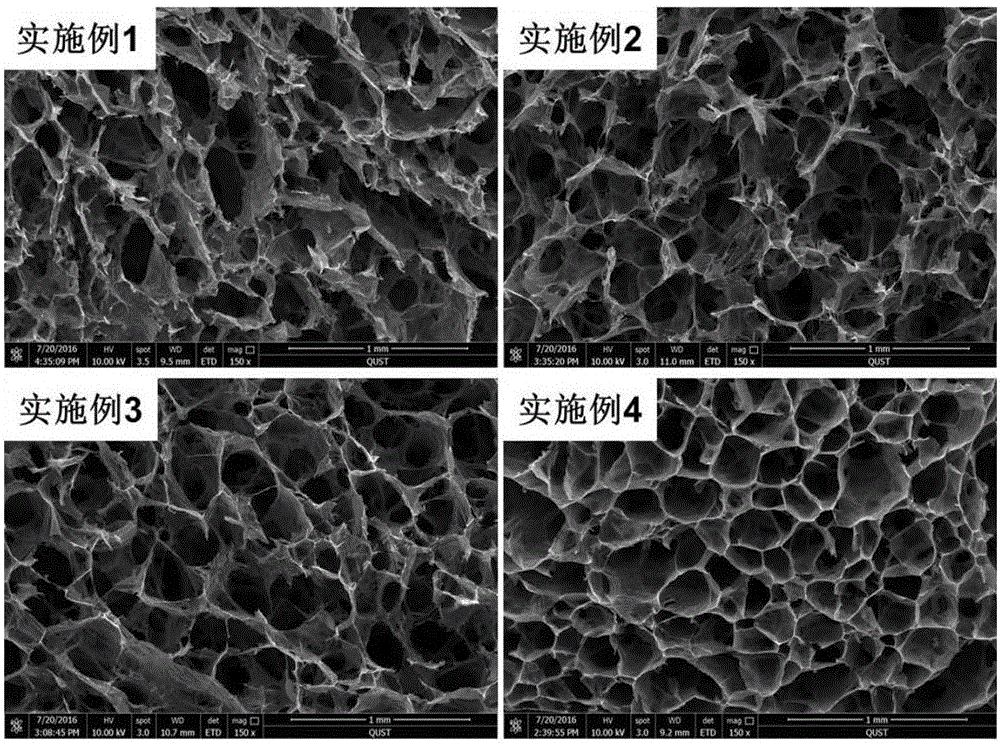

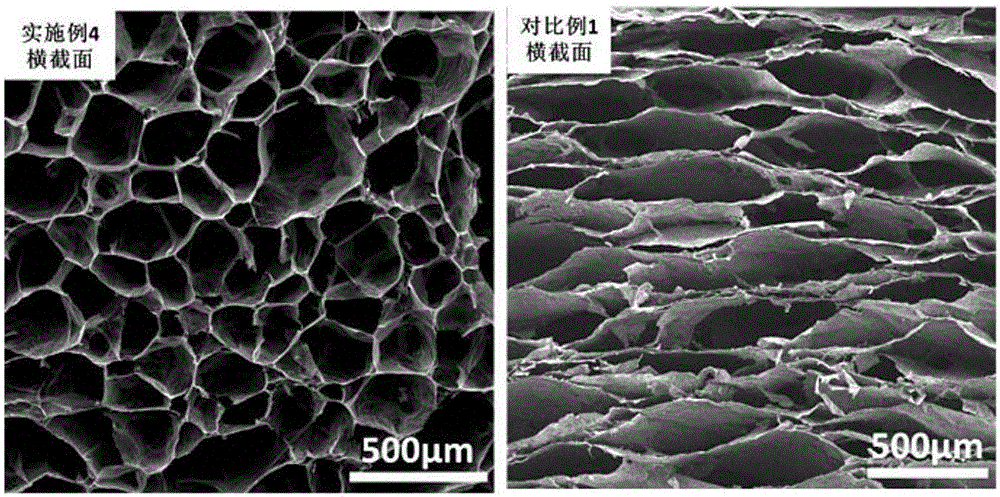

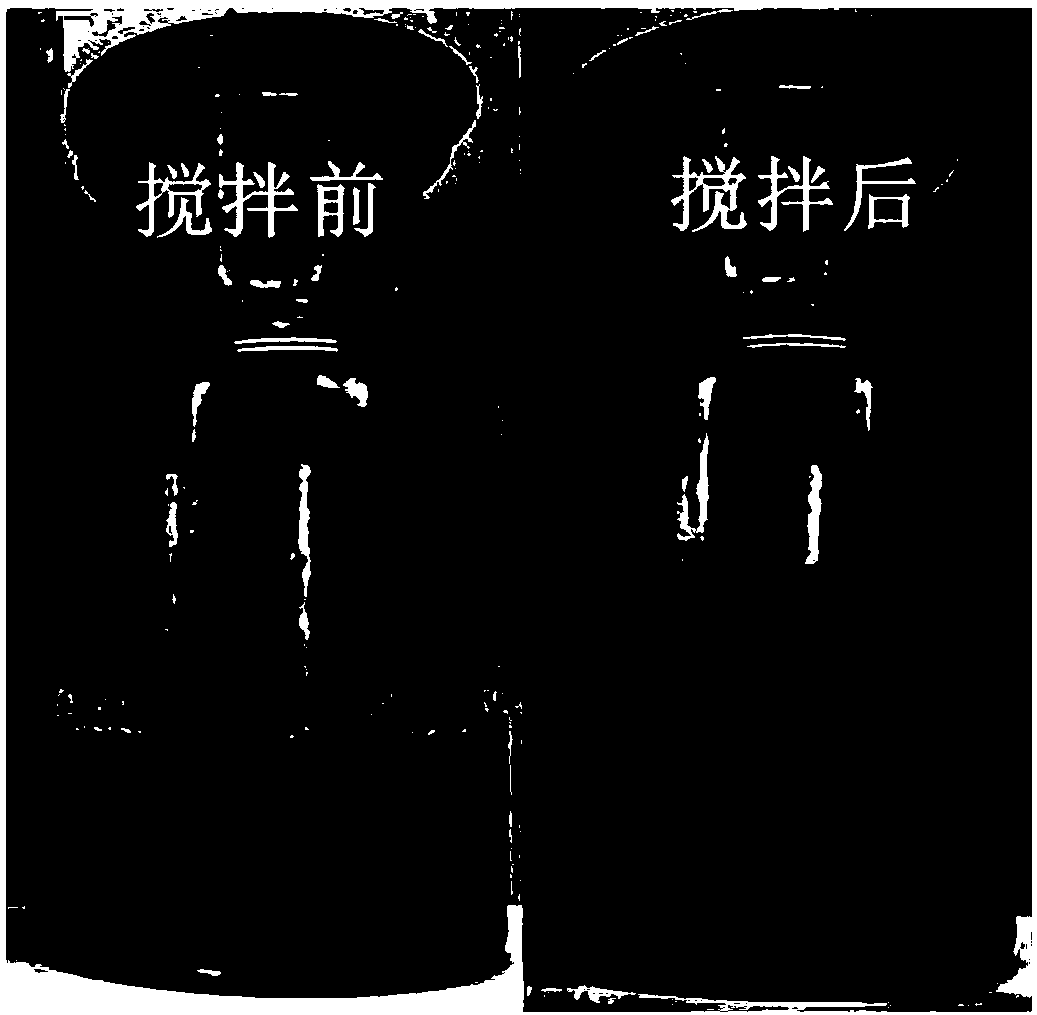

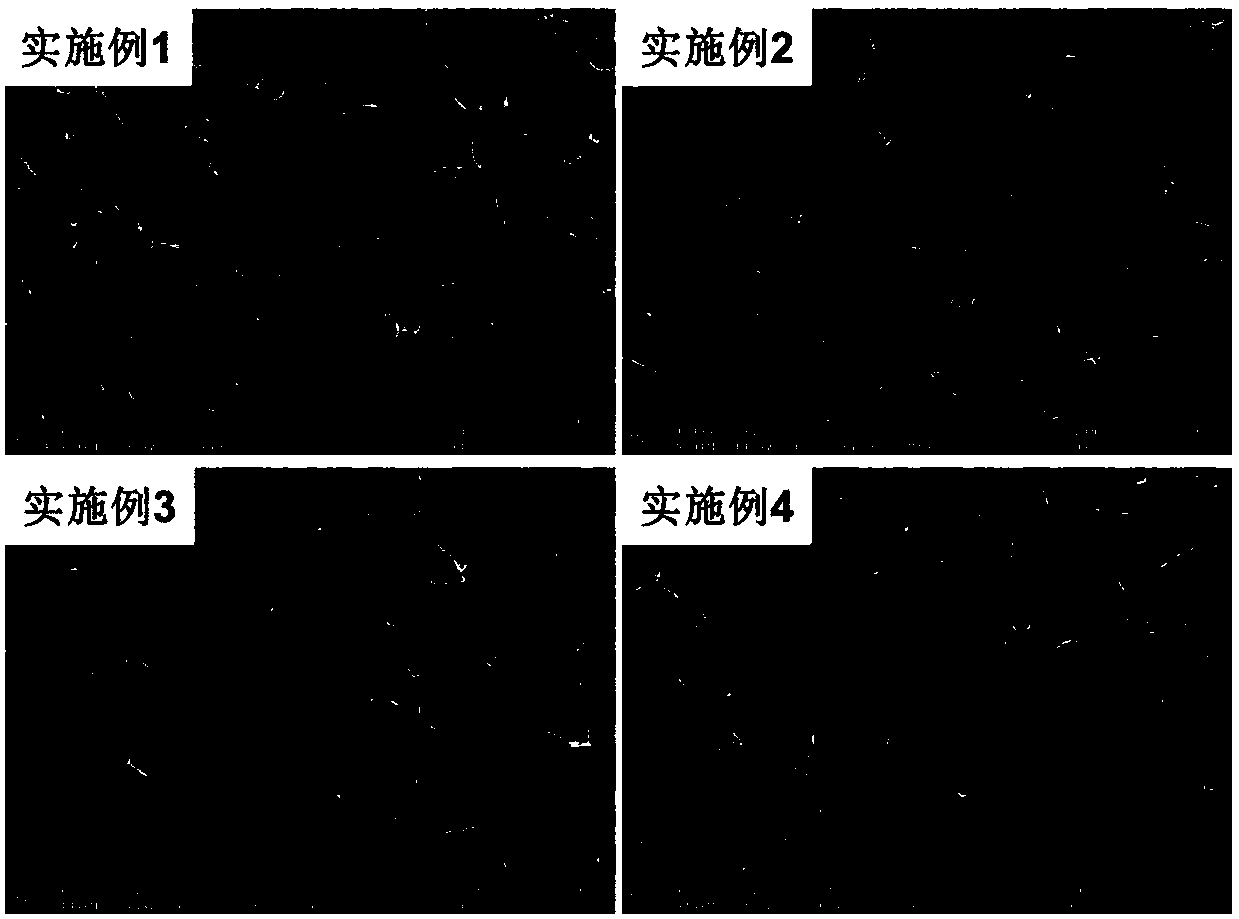

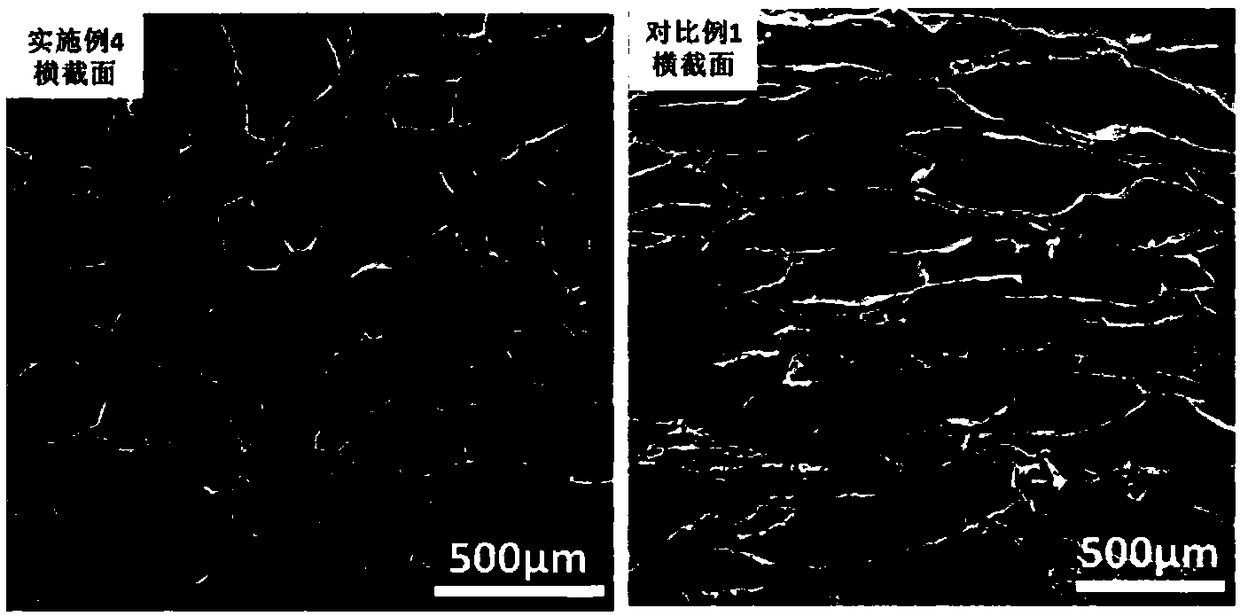

Method for preparing isotropic superelastic graphene aerogel

The invention provides a method for preparing isotropic superelastic graphene gasgel. The method comprises the following steps: firstly, stirring and mixing an oxidized graphene aqueous dispersion, a reducing agent and sodium dodecyl sulfate (SDS) at low speed, and then stirring at high speed; heating, freezing, melting at room temperature, washing with ethanol and drying at atmospheric pressure to obtain the isotropic superelastic graphene aerogel. The method provided by the invention has the advantages of simple process and is suitable for industrial production, and the obtained graphene aerogel is isotropic, has uniform cell size, and has excellent compression recovery and good electrochemical performance.

Owner:QINGDAO UNIV OF SCI & TECH

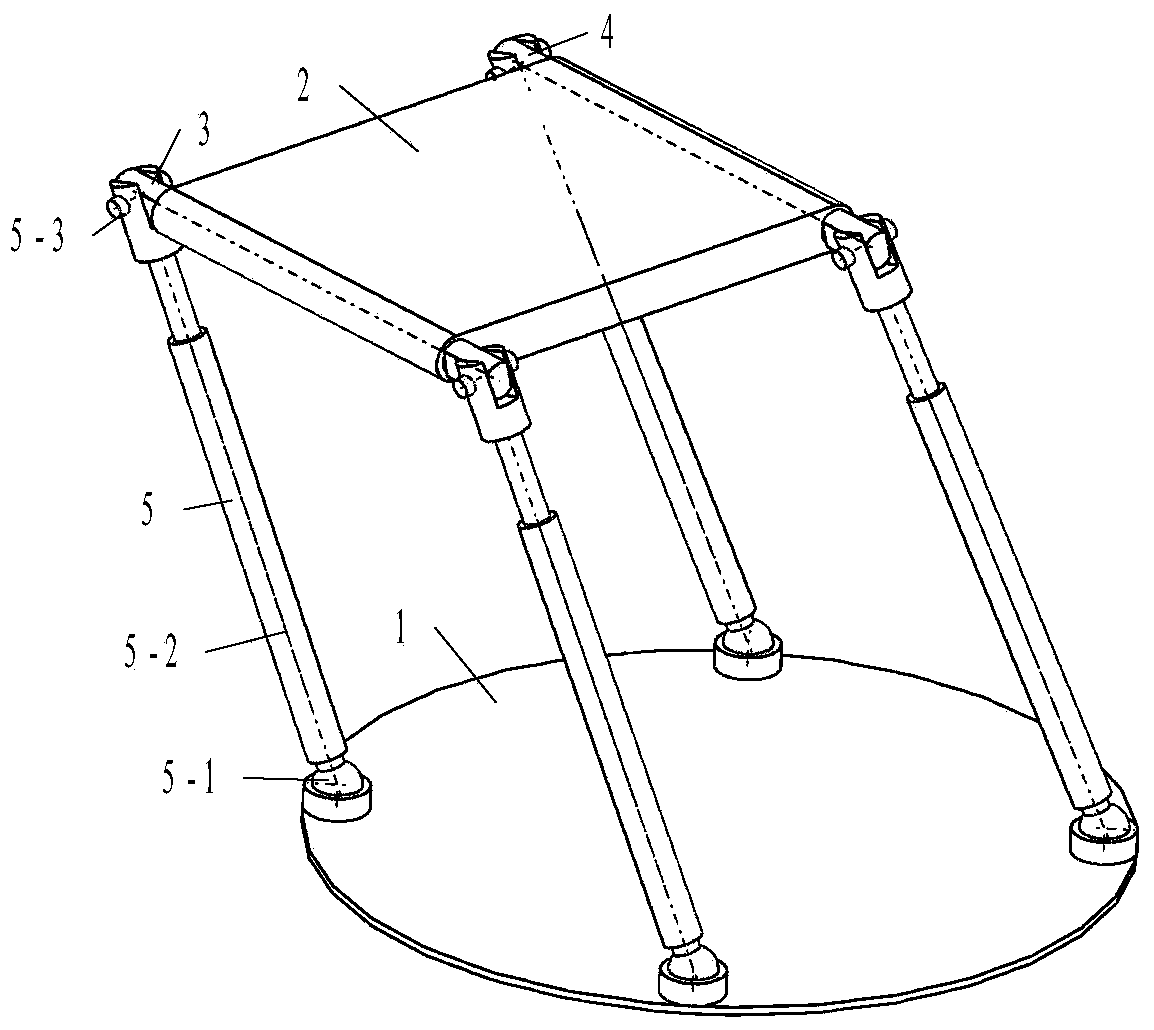

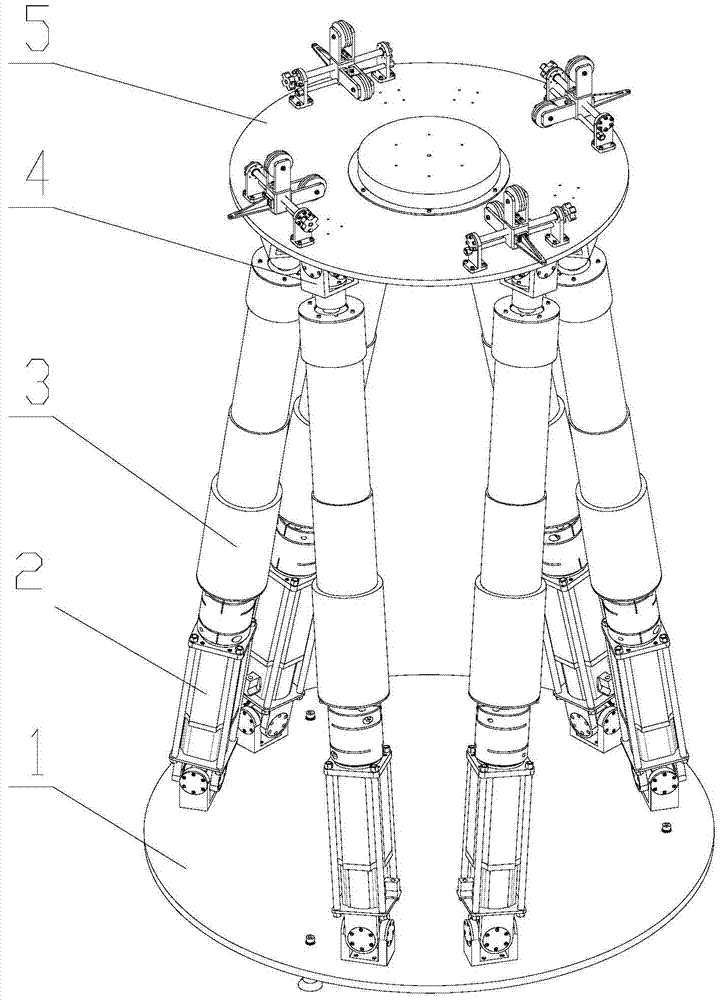

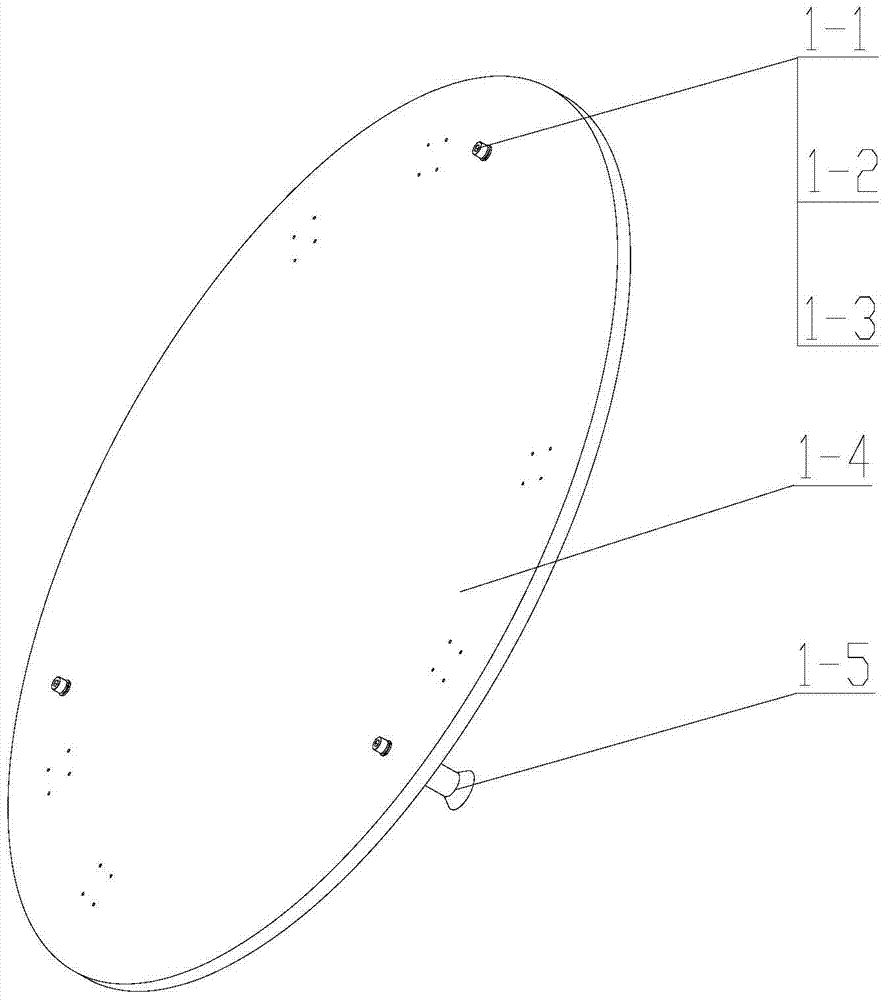

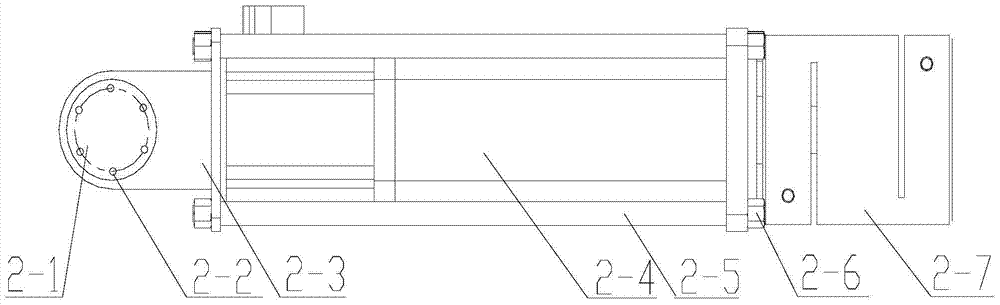

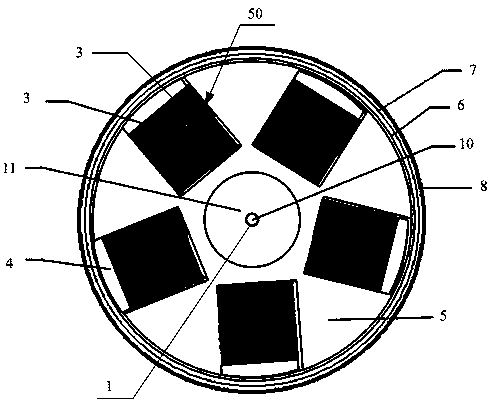

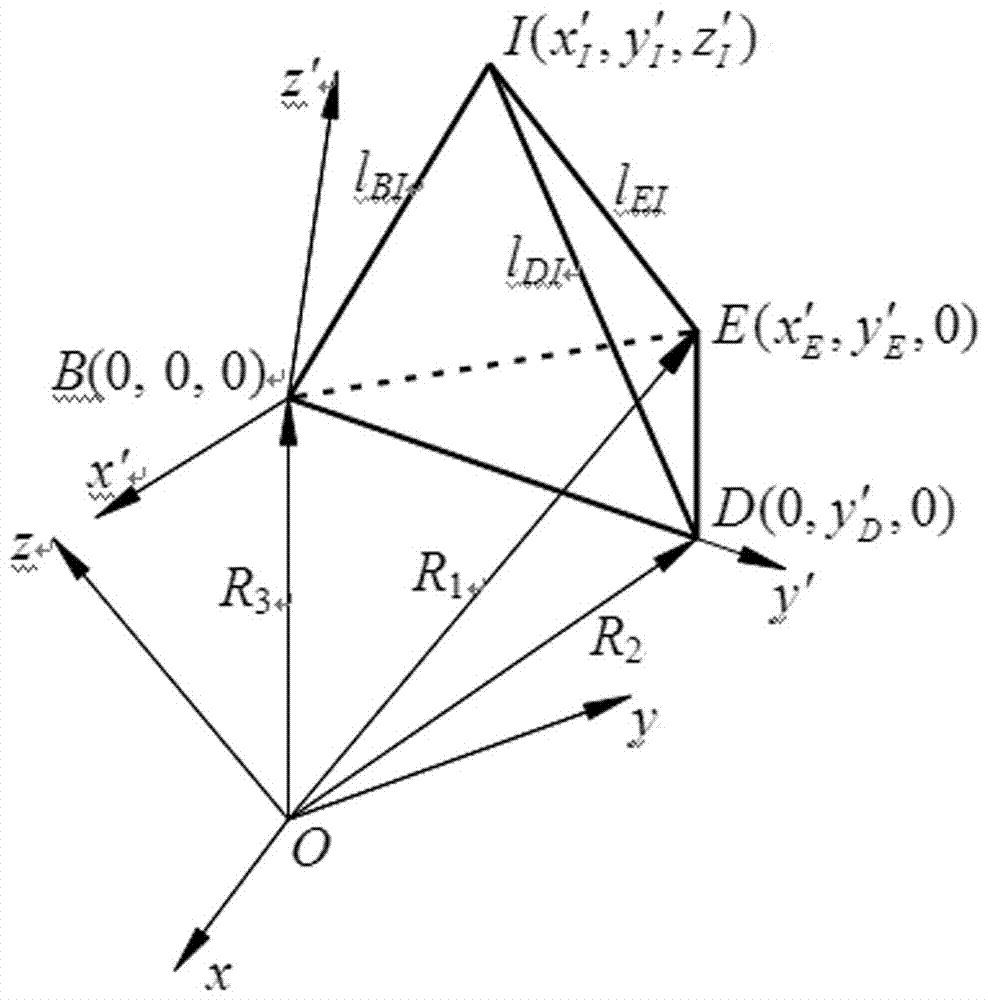

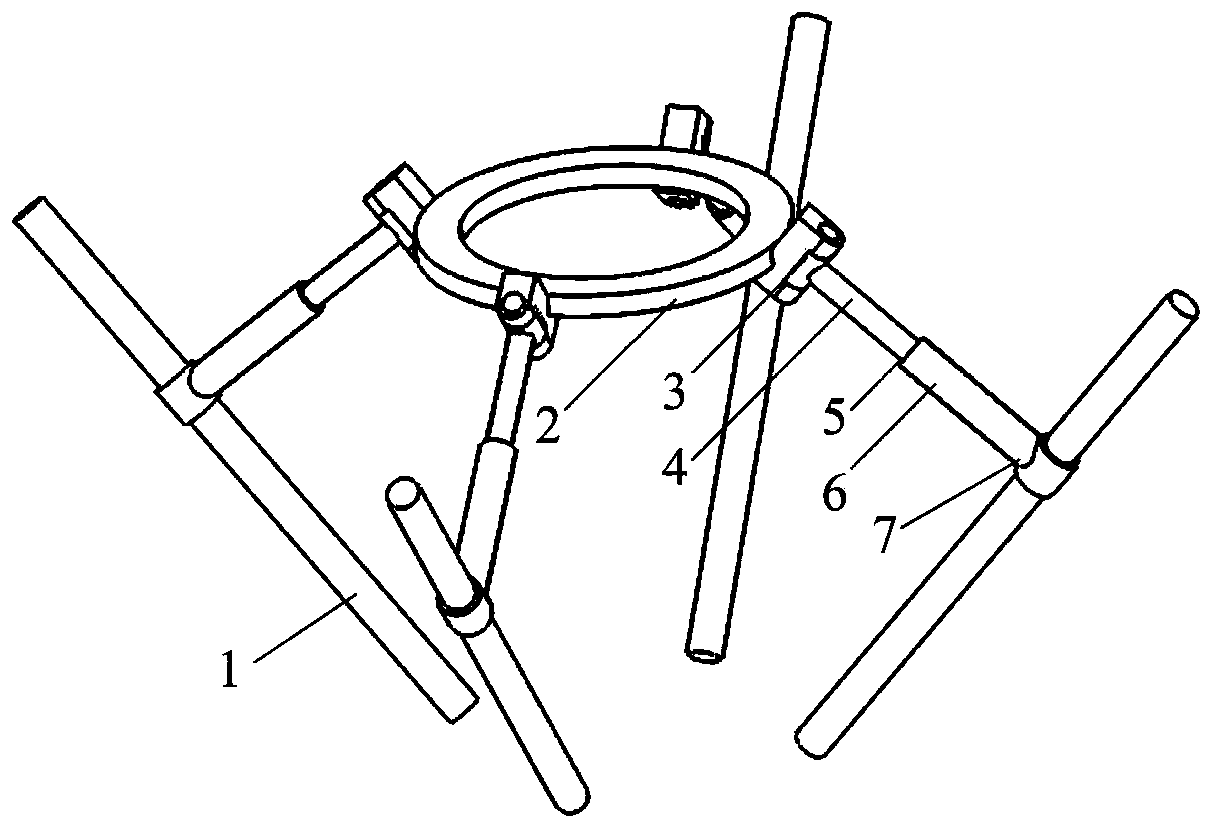

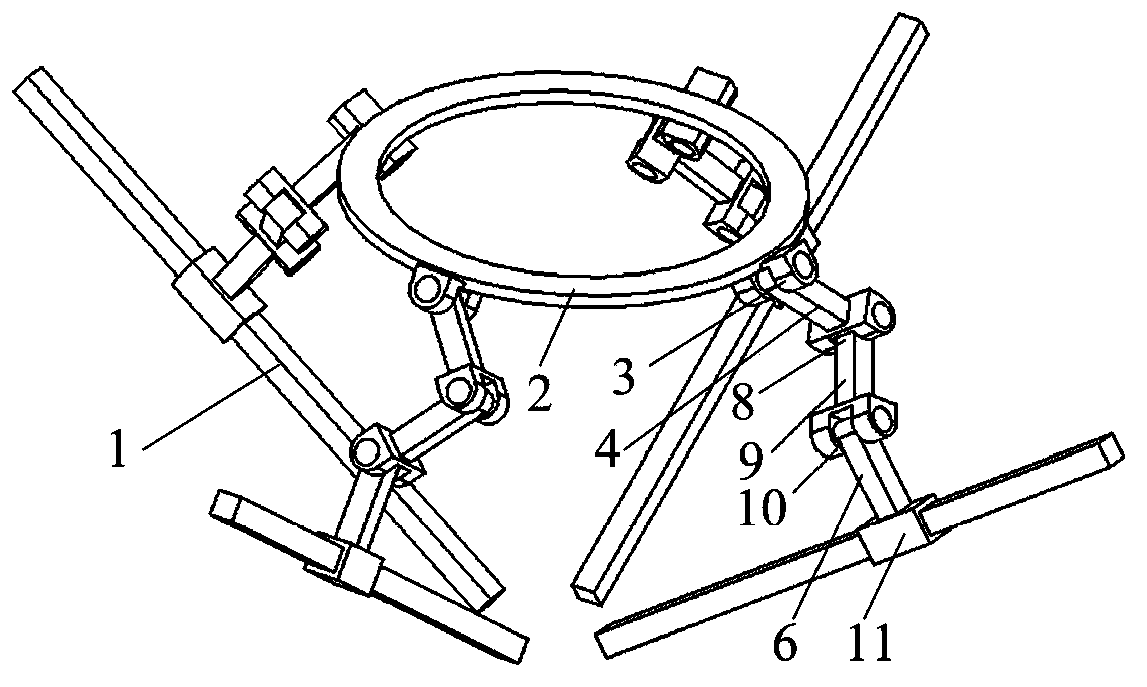

4SPR+2R type four-freedom-degree parallel mechanism

InactiveCN104369182AIsotropicStructural symmetryProgramme-controlled manipulatorTransverse axisEngineering

The invention provides a 4SPR+2R type four-freedom-degree parallel mechanism. A base is composed of four auxiliary rods, four ball pair seats evenly distributed on the circumferential side are arranged on a round plate of the base, a movable platform is composed of two auxiliary rods, parallel through holes are formed in the two opposite sides of a square plate of the movable platform respectively, a first cross shaft and a second cross shaft penetrate through the through holes of the movable platform respectively, through holes are formed in the two ends of the first cross shaft and the two ends of the second cross shaft, and the axes of the two through holes of each cross shaft are parallel and perpendicular to the cross shaft. Four SPR type linear drive branches with the same structure are evenly distributed circumferentially between the movable platform and the base, each SPR type linear drive branch is composed of a rotating pair at the upper end, a movable pair electric cylinder in the middle and a ball pair at the lower end, the ball pairs at the lower ends of the branches are connected with the ball pair seats of the base, the upper ends of two branches are connected with the two ends of the first cross shaft through the rotating pairs, and the upper ends of the other two branches are connected with the two ends of the second cross shaft through the rotating pairs respectively. The 4SPR+2R type four-freedom-degree parallel mechanism has the advantages of being simple in structure, large in work space, high in rigidity, good in translational motion characteristic in all directions and the like.

Owner:YANSHAN UNIV

Composite material toughened ceramisite concrete and preparation method thereof

ActiveCN105541212AImprove toughnessImprove isotropic performanceSolid waste managementFiberAggregate (composite)

The invention belongs to the field of preparation of concrete, and in particular relates to composite material toughened ceramisite concrete and a preparation method thereof. The composite material toughened ceramisite concrete comprises the following components in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slagpowder, 20-40 parts of silica fume, 700-900 parts of recycled coarse aggregates, 500-800 parts of ceramisites, 3-4 parts of a water reducing agent, 100-200 parts of water, 10-20 parts of polyacrylate, 20-30 parts of a toughening composite material, 0.05-0.1 part of sodium gluconate, and 10-15 parts of triethanolamine, wherein the toughening composite material is prepared from the following raw materials in parts by weight: 1.2-1.8 parts of modified silicon dioxide nanotubes, 22-28 parts of a styrene-butadiene-styrene block copolymer, 46-50 parts of activated wood powder fibers, 3.5-5 parts of a silane coupling agent, 3.0-3.5 parts of a solubilizing agent, 4-6 parts of a filler and 180-220 parts of water. The concrete has good toughness, isotropy, fatigue resistance, compactness, crack resistance, shock resistance and permeability resistance, and is a high-performance concrete toughening material, and the 28-day compression strength of the prepared concrete can reach 30-60MPa, so that the concrete is suitable for building bearing structures.

Owner:福建省东霖建设工程有限公司

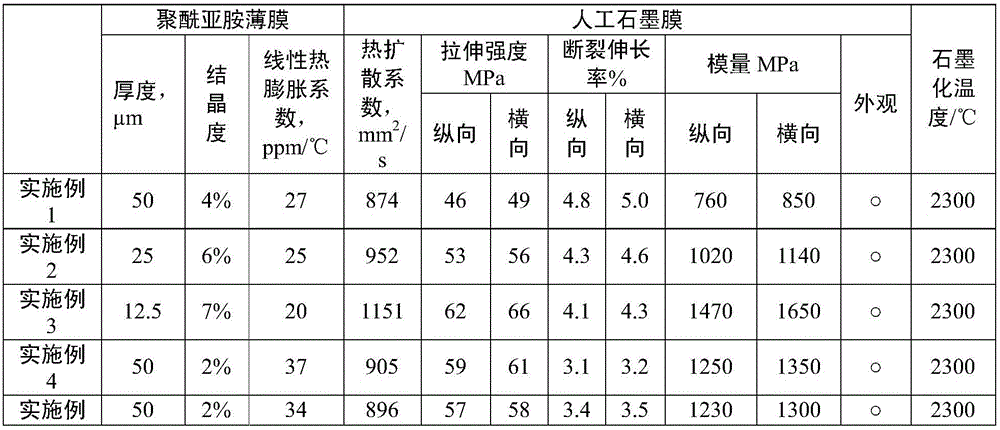

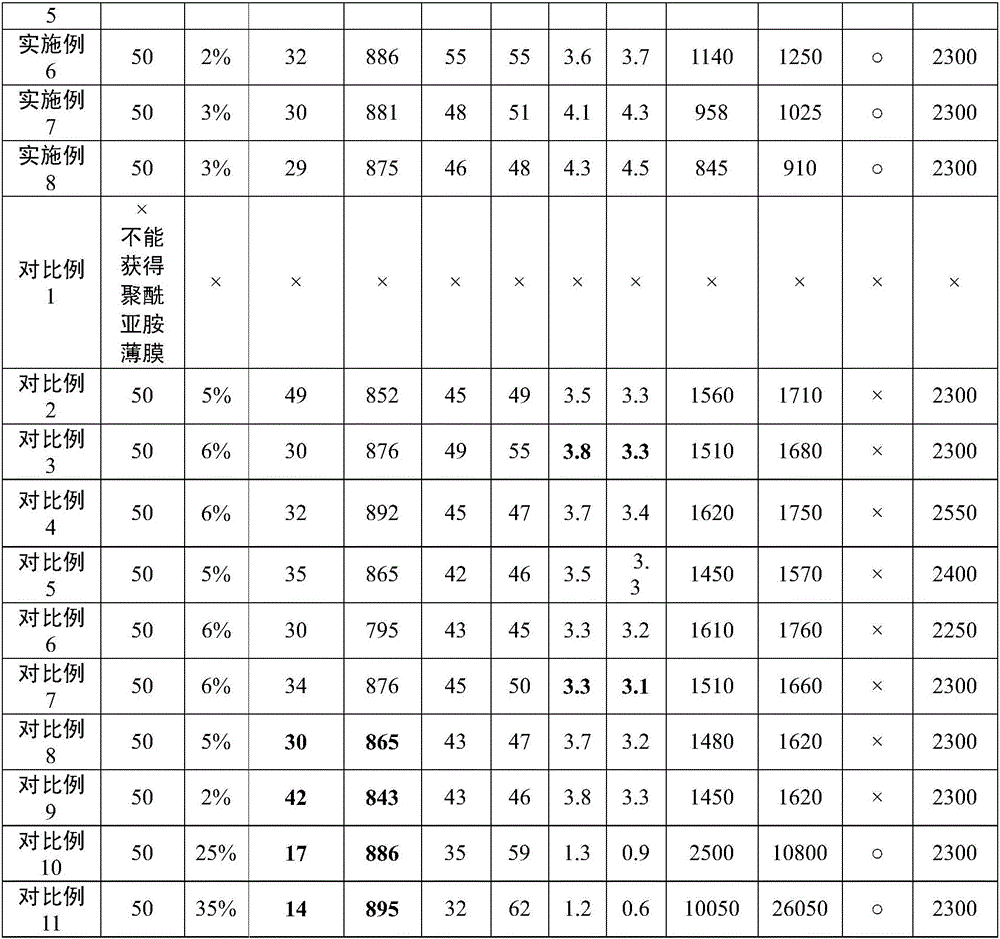

Polyimide thin film for preparing artificial graphite film and preparation method of polyimide thin film

The invention provides a polyimide thin film for preparing an artificial graphite film with excellent mechanical properties and a preparation method of the polyimide thin film. The polyimide thin film is prepared from a raw material diamine monomer which comprises 0 to 75 mol ratio of p-phenylenediamine; the raw material dianhydride monomer, comprises 40 percent to 100 mol ratio of of pyromellitic dianhydride; two types of inorganic fillers, including a calcium-containing compound and transition metal oxide, are uniformly dispersed in the polyimide thin film. The polyimide thin film provided by the invention is applicable to a graphitization process of single-sheet, multilayered stacking and continuous coiled materials and can be used for carrying out graphitization at temperature of 2300 DEG C; the crystallization degree is less than 10 percent. The graphite film prepared from the polyimide thin film has an excellent heat conducting property and has excellent mechanical properties in longitudinal and lateral directions of the thin film; the modulus is less than or equal to 2000MPa, the elongation at break is more than or equal to 3 percent, the tensile strength is more than or equal to 40MPa and the difference of the longitudinal and lateral directions is less than 15 percent.

Owner:RAYITEK HI TECH FILM CO LTD

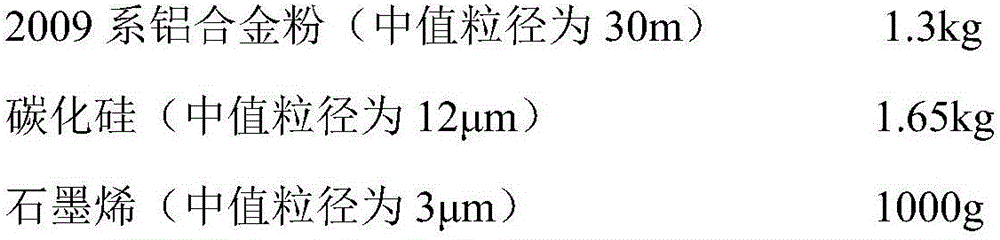

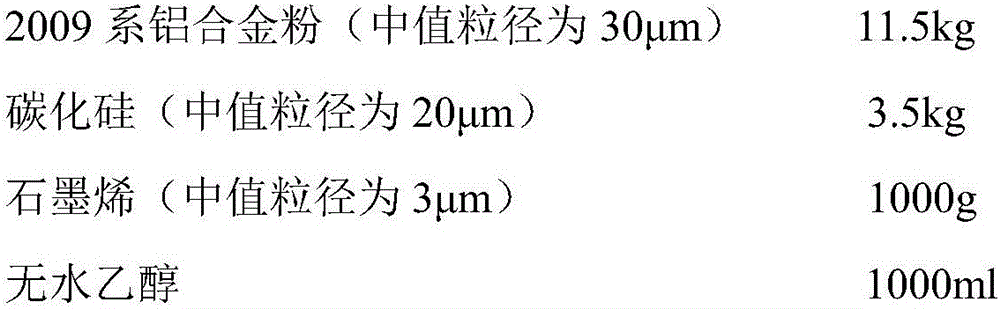

Graphene enhanced aluminium-based silicon carbide composite, preparation method and application thereof

ActiveCN106591666AImprove reliabilityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal diffusivityElectronic packaging

The invention relates to a graphene enhanced aluminium-based silicon carbide composite and a preparation method thereof. The composite comprises the following substances by volume percent: 40% to 70% of silicon carbide and 0.5% to 5% of graphene, and the balance being aluminium alloy. The composite is prepared through the powder metallurgy method and is obtained through the steps of blending, powder mixing, bagging, vacuum degassing and hot iso-hydrostatic forming treatment. The composite has the advantages of high thermal conductivity, high strength, high plasticity, light weight, good thermal diffusivity, isotropy, and the like, and becomes a second-generation electronic packaging material with wide application.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

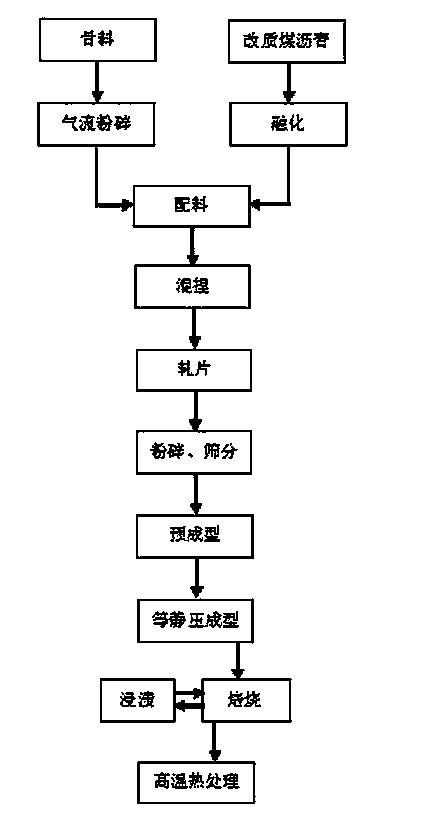

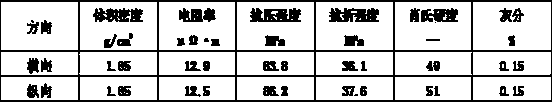

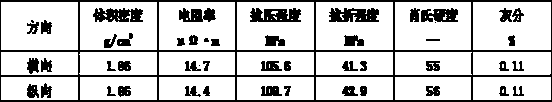

Preparation method of isostatic pressing microcrystalline graphite product

The invention relates to a preparation method of an isostatic pressing microcrystalline graphite product. The isostatic pressing microcrystalline graphite product comprises the following components by weight: 35-50% of microcrystalline graphite, 10-25% of artificial graphite, 10-25% of electrically calcined pitch coke and 30-40% of modified coal tar pitch. The isostatic pressing microcrystalline graphite product is obtained by the steps of pretreating raw material, burdening, kneading, rolling, fragmenting and pulverizing, preforming, performing isostatic compaction, roasting, dipping, performing heat treatment under high temperature and the like. The unique part in the method is the usage of the natural microcrystalline graphite as a main aggregate, the resource can be used in a reasonable mode, high temperature graphitization heat treatment at more than 2500 DEG C on the product is not required, so that preparation period can be shortened, and the energy consumption is greatly reduced. The prepared isostatic pressing microcrystalline graphite has the advantages of high volume density, mechanical strength, low resistivity, fine and compact structure, and isotropy.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

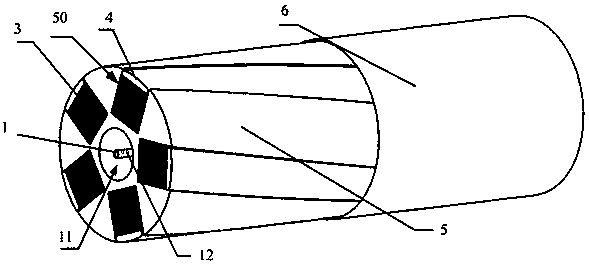

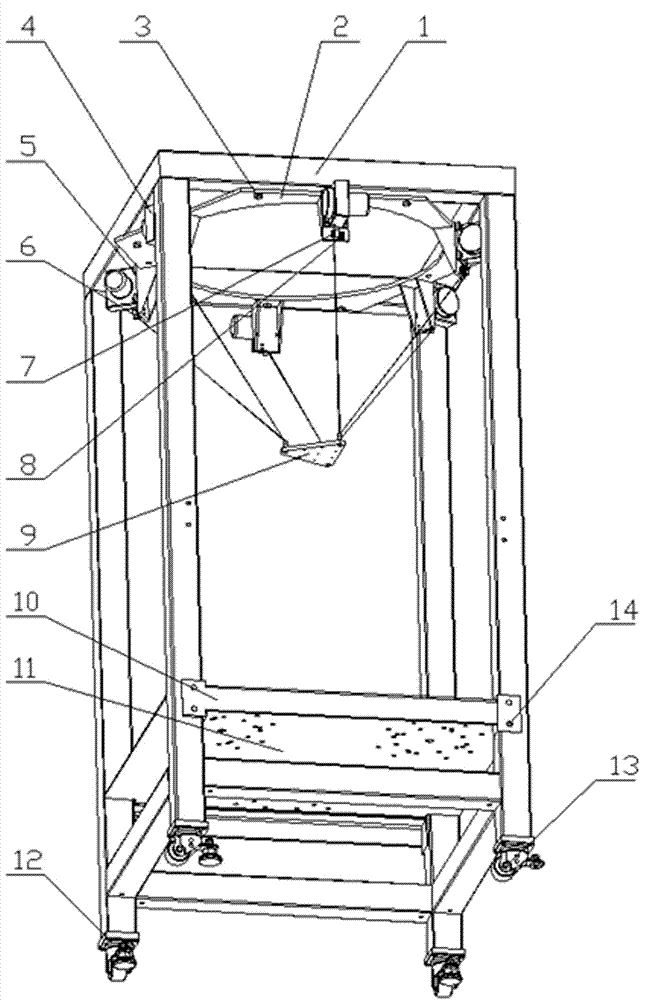

Multi-dimensional force sensor calibration device with controllable poses

InactiveCN103926038ARealize dynamic calibrationRealize functionForce/torque/work measurement apparatus calibration/testingChinese charactersEngineering

The invention provides a multi-dimensional force sensor calibration device with controllable poses. The multi-dimensional force sensor calibration device comprises a fixing platform, drive mechanisms, connecting rod mechanisms and a moving platform. The upper ends of the drive mechanisms and the lower ends of the connecting rod mechanisms are connected to form drive connecting rod mechanisms. The upper ends of the six drive connecting rod mechanisms are hinged to the moving platform through universal hinges, and the lower ends of the six drive connecting rod mechanisms are hinged to a fixed platform to form a six-freedom-degree parallel mechanism. The six drive connecting rod mechanisms are divided into three groups. Every two adjacent drive connecting rod mechanisms form one group and are arranged in the mode shaped like a Chinese character 'ba'. The poses of a calibration platform can be controlled and changed, and the calibration device has the function of calibrating a sensor dynamically and statically, and is complete in function, convenient to operate, high in calibration precision and capable of being well applied to practical engineering.

Owner:HARBIN ENG UNIV

Quasi-isotropic high-current-carrying superconducting cable power-on conductor

PendingCN109637739AIsotropicEasy to fixSuperconductors/hyperconductorsSuperconductor devicesElectrical conductorCooling effect

The embodiment of the invention discloses a quasi-isotropic high-current-carrying superconducting cable power-on conductor, which comprises a skeleton, superconductors, metal covering layers, an insulating layer, a shielding layer and a protective shell arranged from inside to outside. The skeleton is a hollow metal skeleton, and an inner cooling channel and an outer cooling channel are formed along the axis of the hollow part of the skeleton. Multiple channel grooves which are longitudinally spiral on the whole are arranged uniformly and at intervals along the circumference of the outer surface of the skeleton. Superconductors are stacked in the channel grooves. The superconductor in each channel groove is covered with a metal covering layer. The insulating layer is wound on the outer surface of the skeleton covered with the metal covering layers. The shielding layer is arranged on the outer surface of the insulating layer. The shielding layer is grounded at a single end or at both ends. The protective shell is arranged outside the shielding layer. According to the embodiment of the invention, the superconductor has good isotropy, large carrying capacity, good fixing effect and good cooling effect.

Owner:SHENZHEN POWER SUPPLY BUREAU

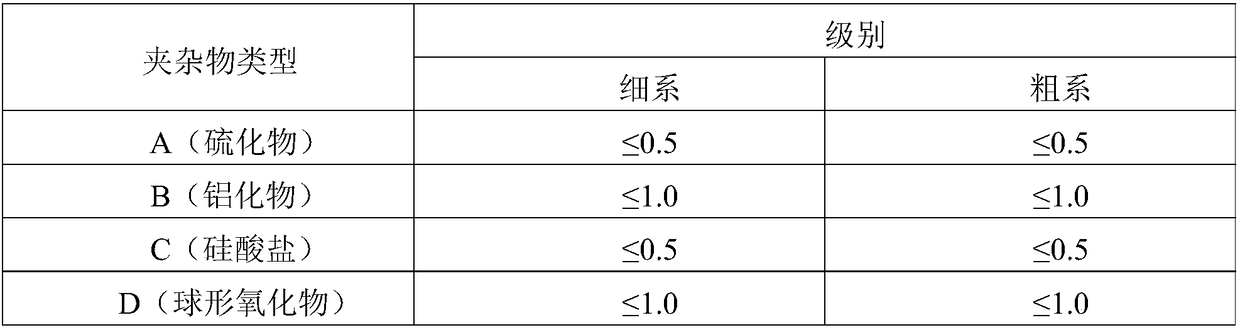

Production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates

InactiveCN102732674AReduce the process of forging billet openingReduce processProcess efficiency improvementElectric furnaceElectro-slag remeltingHeat treated

The invention provides a production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates. The method comprises the steps of smelting, casting, electroslag remelting, electroslag ingot cleaning, heating, rolling, water cooling, hydrogen diffusion treatment, supersonic wave flaw detection, normalization, examination and warehousing. The largest thickness of the steel plates produced through the method of the invention can reach 410mm. The method allows the isotropy, the impact toughness and the Z-directional performances of the heavy-gauge steel plates to be realized through adopting large slab electroslag remelting treatment and a reasonable controlled rolling and heat treatment technology, the production cost to be reduced, the time of delivery to be substantially shortened and the specification range to be wide, and is used for satisfying continuously increased market application amount demands; and the steel plates can completely substitute import products to satisfy various requirements of heavy-gauge large-single-weight steel plates applied to water power, wind power and large building structures.

Owner:WUYANG IRON & STEEL +1

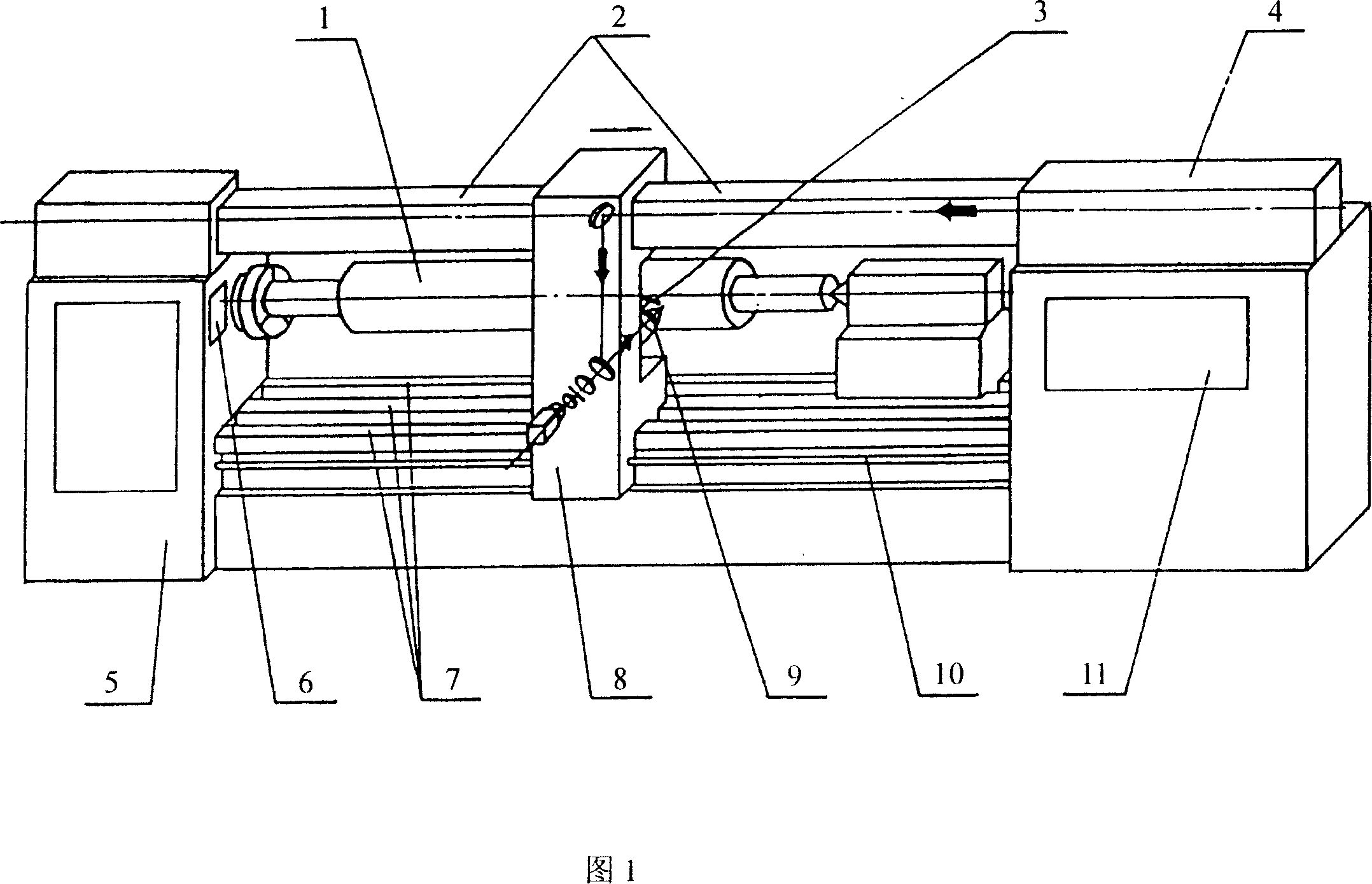

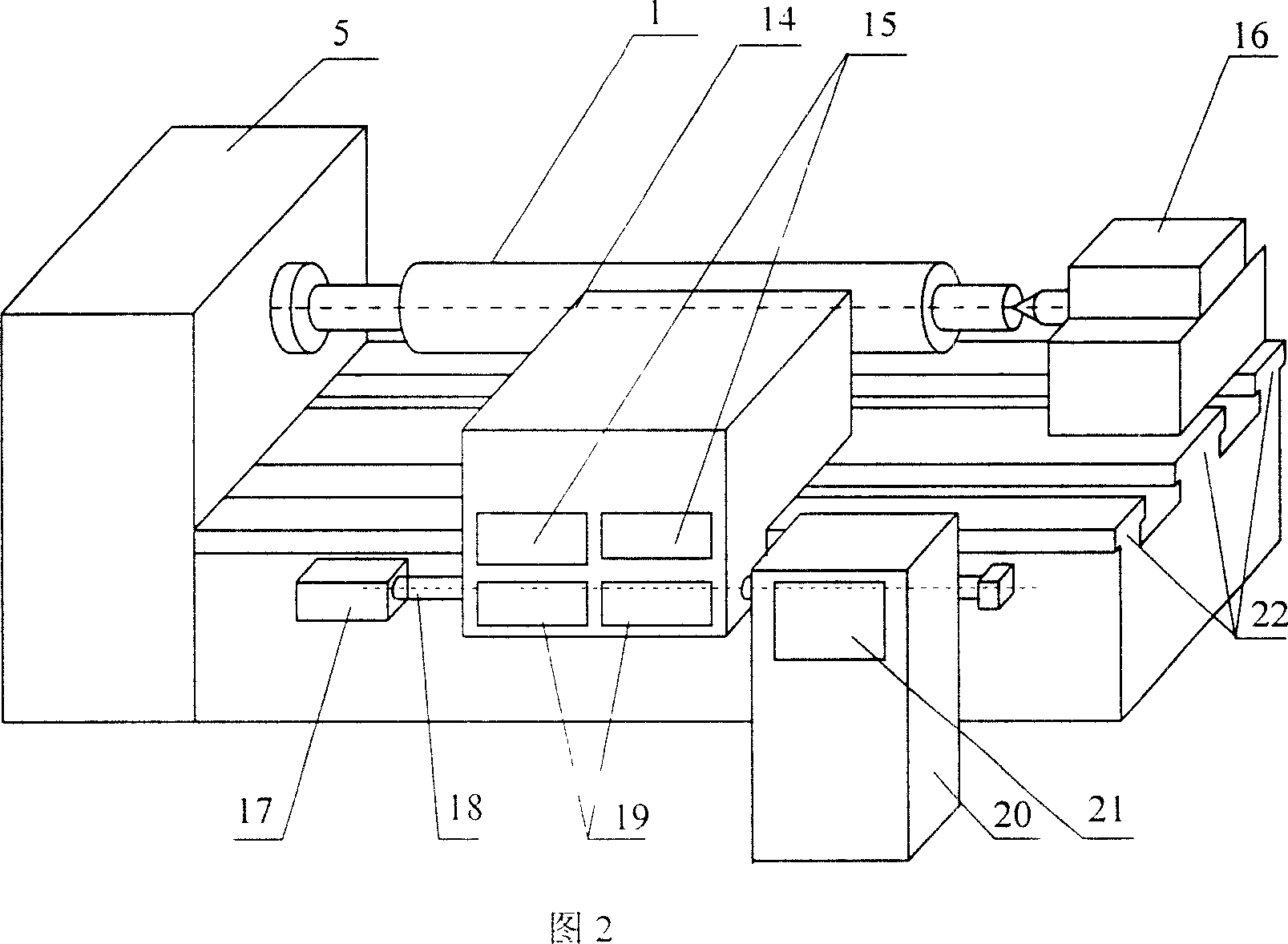

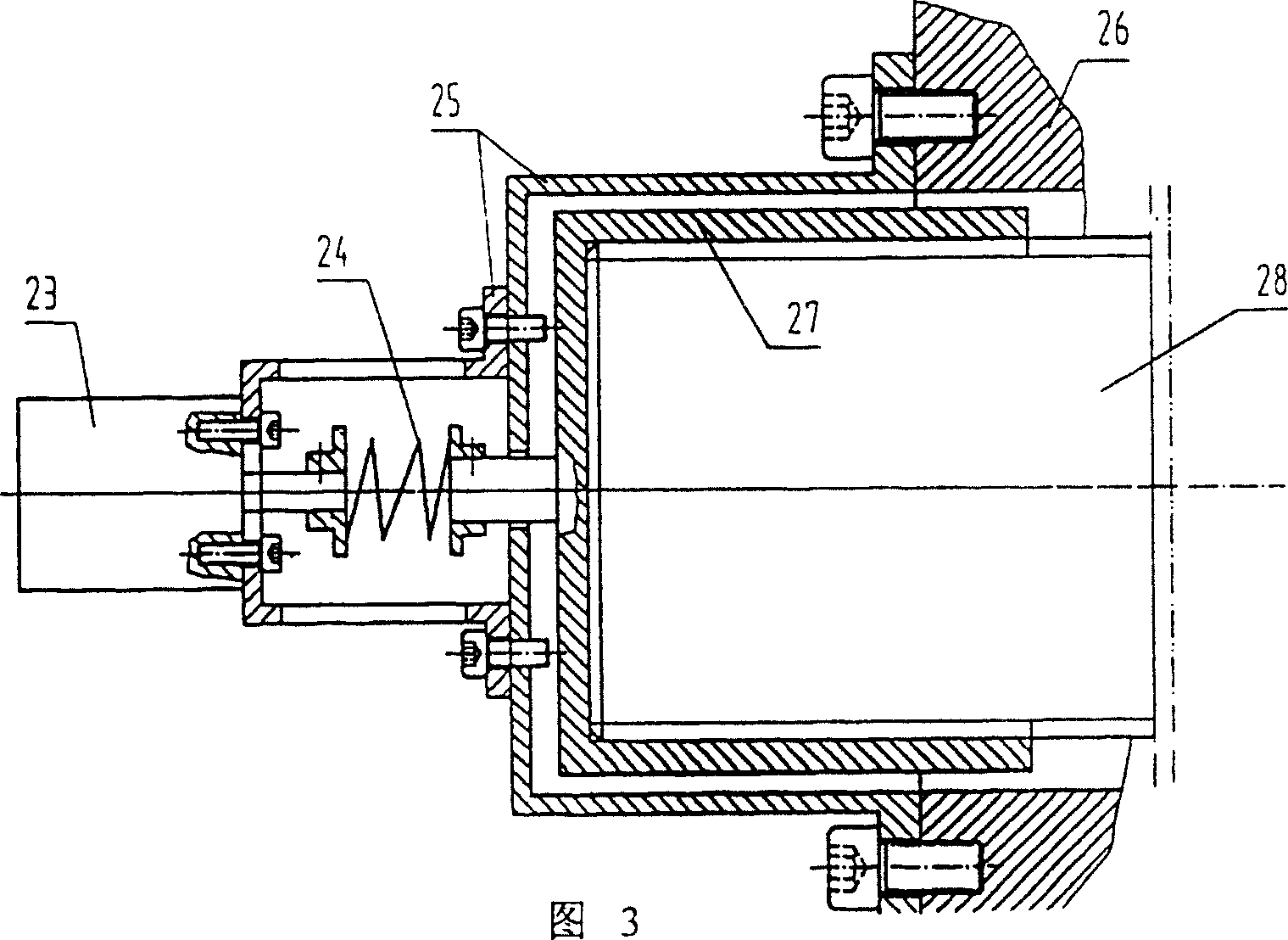

Coarsening laser processing system and method for surface of roller with circumferential irregular coarsening dots

A laser system for generating the roughened dots with irregular circumference on the surface of a roller is composed of a machine-tool system, a laser processing system and a pseudo-random delay unit for randomly delaying the laser output signals. Its method features that the laser output signals emitted to the surface of roller are randomly delayed in a defined time range.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

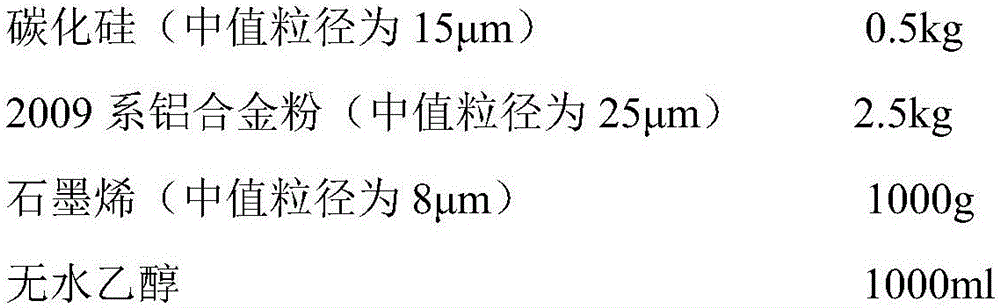

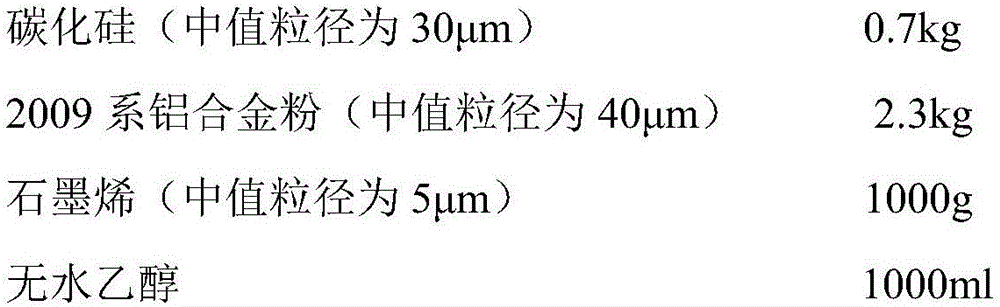

Graphene, aluminum and silicon carbide composite material and preparation method and application thereof

The invention relates to a graphene, aluminum and silicon carbide composite material and a preparation method thereof. The composite material is prepared from of constituents of 10-40 vol% of silicon carbide, 0.5-2 wt% of graphene, and the balance aluminum alloy. The composite material is prepared through a powder metallurgic method and can be obtained through proportioning, powder mixing, packaging, vacuum degassing and hot isostatic forming. The composite material has the advantages of low density, low weight, high hardness, high tensile strength and the like, the strength, fatigue resistance and toughness of the material are remarkably improved through addition of a proper amount of graphene, and thus the composite material has broader application prospects in the field of structural pieces.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

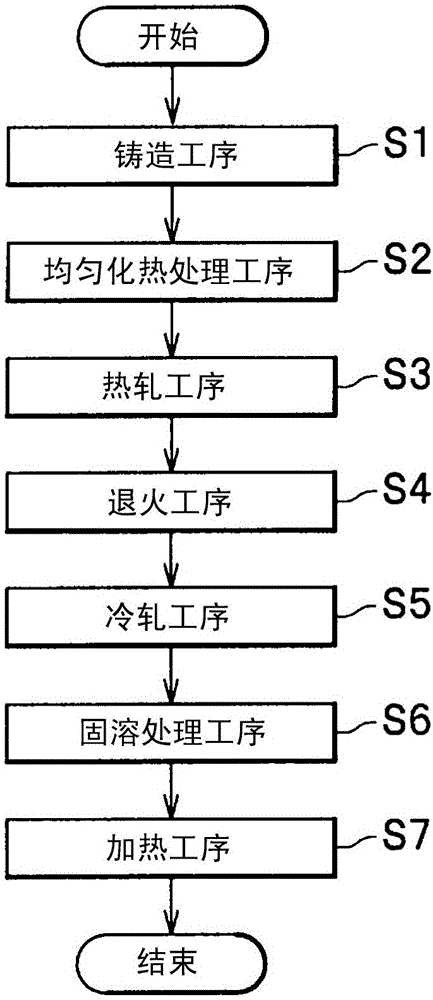

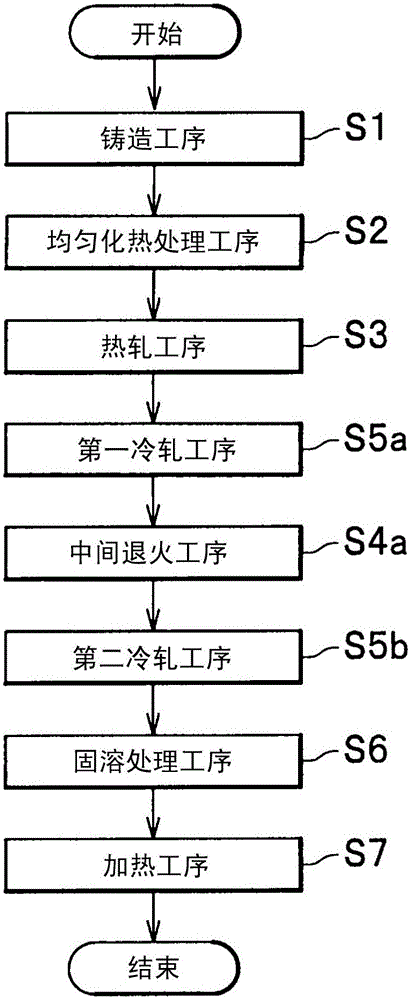

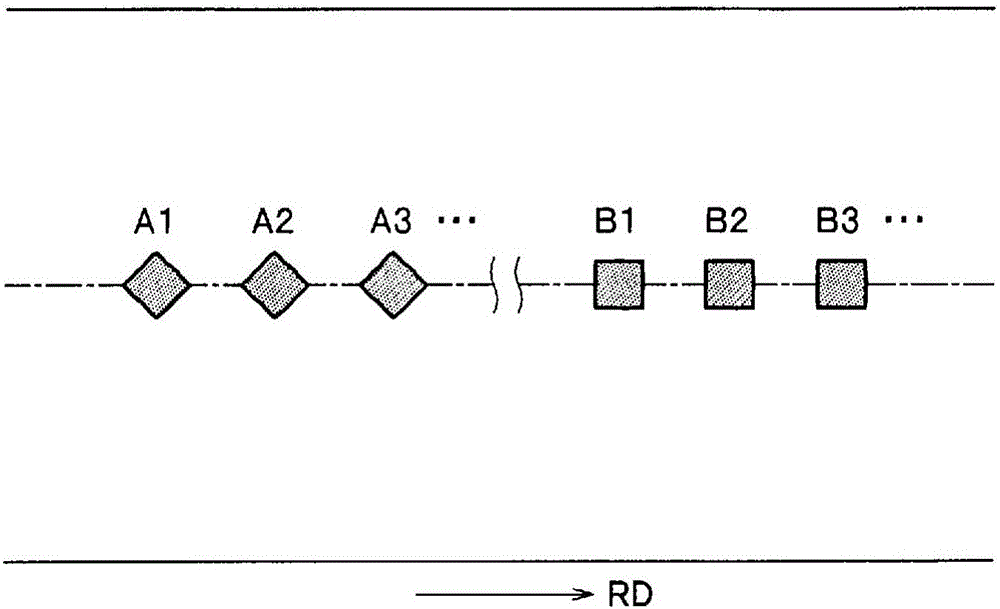

Aluminum alloy sheet for press forming, process for manufacturing same, and press-formed product thereof

The present invention provides an aluminum alloy sheet for press forming, said aluminum alloy sheet being made of an aluminum alloy that contains 0.4 to 1.5 mass% of Si and 0.3 to 1.0 mass% of Mg with the balance being Al and unavoidable impurities and exhibiting a ratio (P(%)) of ΔL to L0 of 2.0% or less [wherein: L0 is the length of a diagonal line lying at an angle of 0º to the rolling direction in an indentation formed by a Vickers hardness tester; and ΔL is a difference between L0 and the length (L45) of a diagonal line lying at an angle of 45º to the rolling direction therein]. Further, the present invention provides a process for manufacturing the aluminum alloy sheet and a press-formed product thereof.

Owner:KOBE STEEL LTD

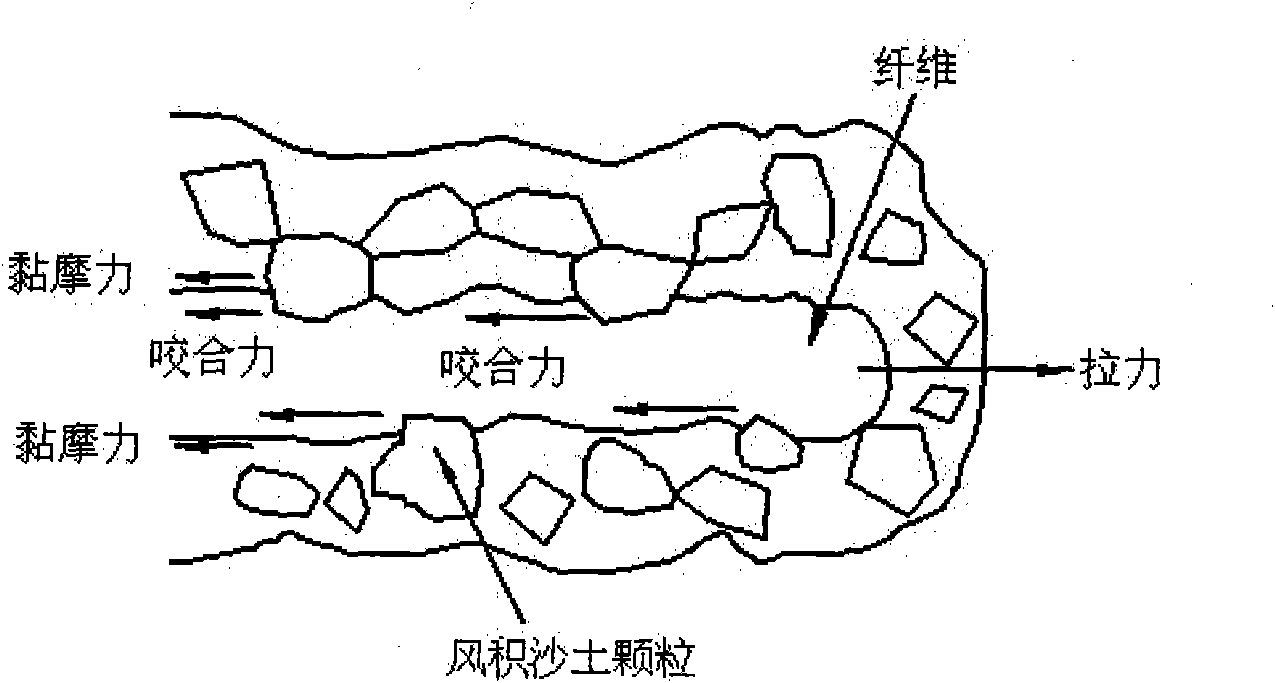

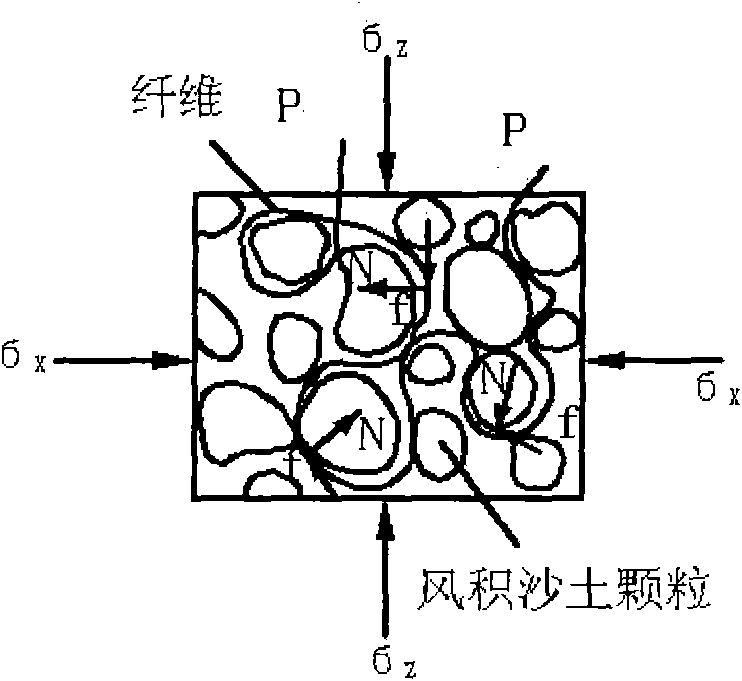

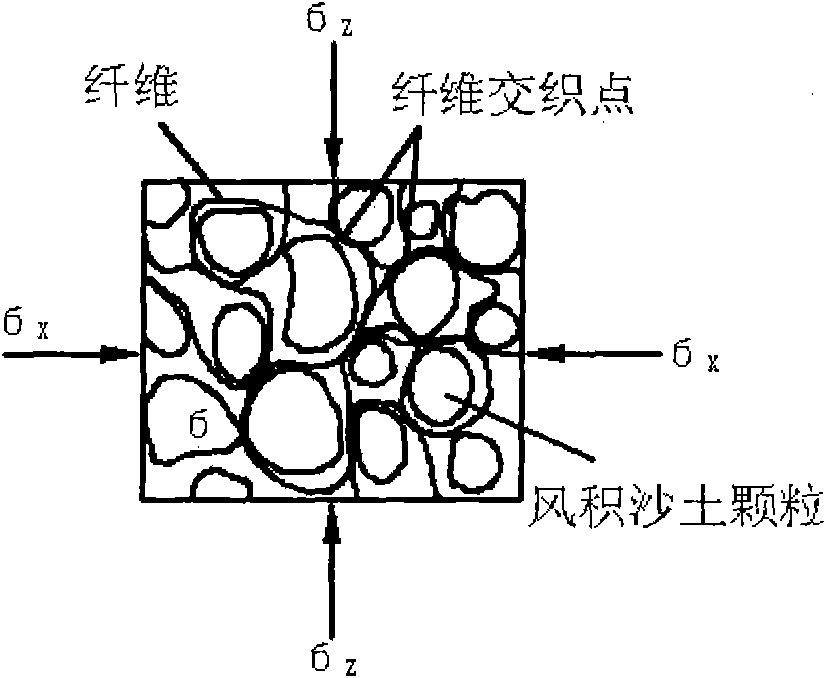

Method for reinforcing aeolian sandy soil by polypropylene fibers

The invention discloses a method for reinforcing aeolian sandy soil by polypropylene fibers. The method comprises the following steps: selecting materials for preparing fiber aeolian sandy soil, wherein the length of the polypropylene fiber is 18mm, the mix ratio of the fiber is 0.3 percent, and the aeolian sandy soil materials are air-dried aeolian sand or aeolian sandy soil (the moisture content accounts for 11.2wt%); according to the proportioning scheme, closely and completely mixing fine TEXSOL with aeolian sandy soil particles by way of spraying, so that a composite three-dimensional spatial structure is formed by the TEXSOL and the aeolian sandy soil; and carrying out mechanical compaction on the composite fiber aeolian sandy soil subjected to spraying, wherein the compaction method and standard of the composite fiber aeolian sandy soil are same as those of common soil, so that the compaction density of the aeolian sandy soil reaches 100 percent of the standard compaction density, and the fiber aeolian sandy soil is compacted closely. By utilizing the method in earth-filled dams, retaining walls and the drainage works of the earth-filled dams, the water stability of the interior of the soil body can be effectively improved, the shearing strength and tensile strength of the soil body can be obviously improved, and the construction process is simple; and because the fiber content of the fiber aeolian sandy soil is very low, the method has the advantages of cheapness and environmental protection.

Owner:HARBIN INST OF TECH

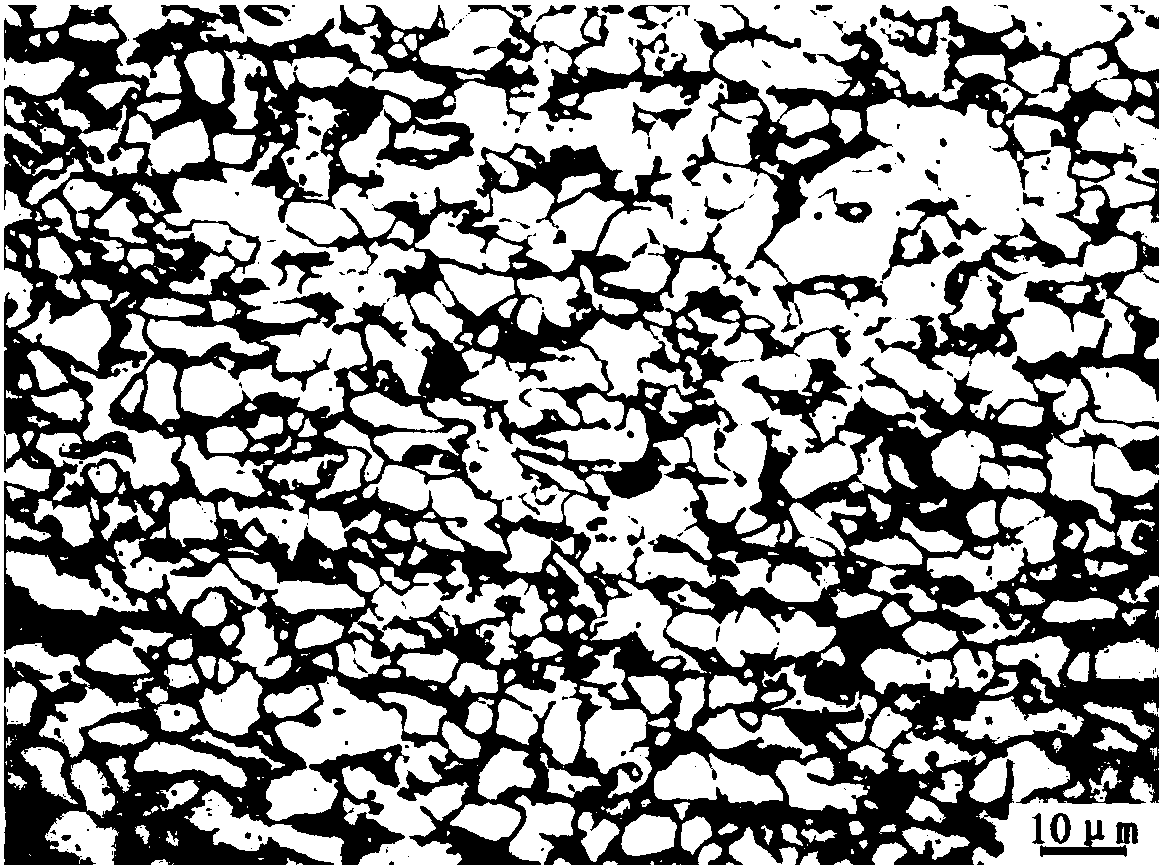

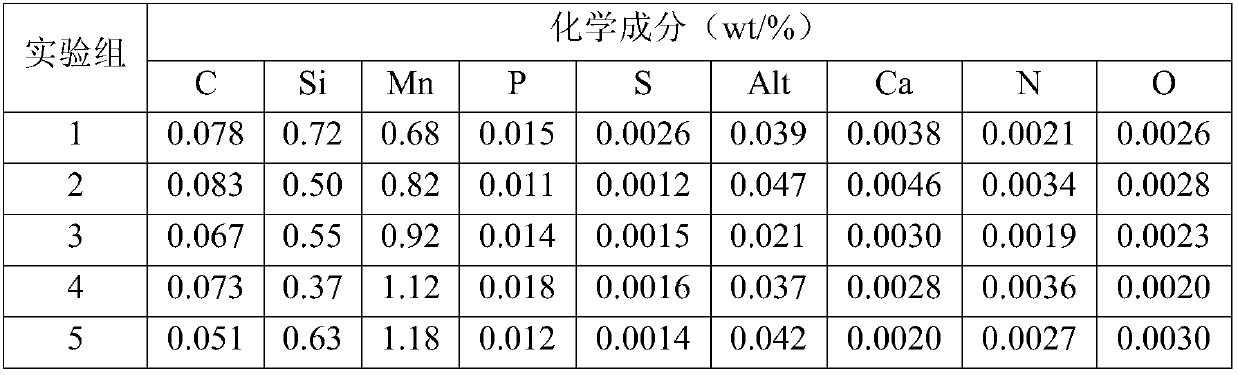

450MPa economical type high-surface-quality highly-reamed steel and preparation method thereof

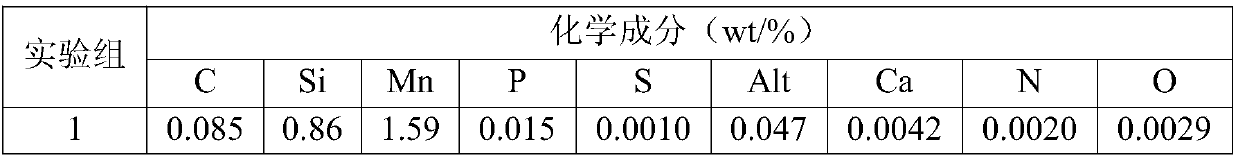

The invention discloses 450MPa economical type high-surface-quality highly-reamed steel and a preparation method thereof, and belongs to the technical field of ferrous metallurgy and calendaring. The450MPa economical type high-surface-quality highly-reamed steel comprises, by weight, 0.045-0.085% of C, 0.30-0.80% of Si, 0.60-1.30% of Mn, 0.010-0.020% of P, 0-0.003% of S, 0.010-0.050% of Alt, 0.0010-0.0050% of Ca, 0-0.0050% of N, 0-0.0040% of O, and the balance Fe and inevitable impurities, wherein C*Mn*104 is smaller than or equal to 0.10, {P+10*S}*102 is smaller than or equal to 0.04, and Ca / S is greater than or equal to 0.3. The preparation method comprises the following steps of smelting, continuous casting, heating, rough rolling, hot box coiling, finish rolling, laminar cooling, coiling, slow cooling, acid pickling and coiling. The 450MPa economical type high-surface-quality highly-reamed steel has the characteristics of being low in cost and excellent in performance, and can meet the requirements of steel for car chassis and complex stamping parts.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

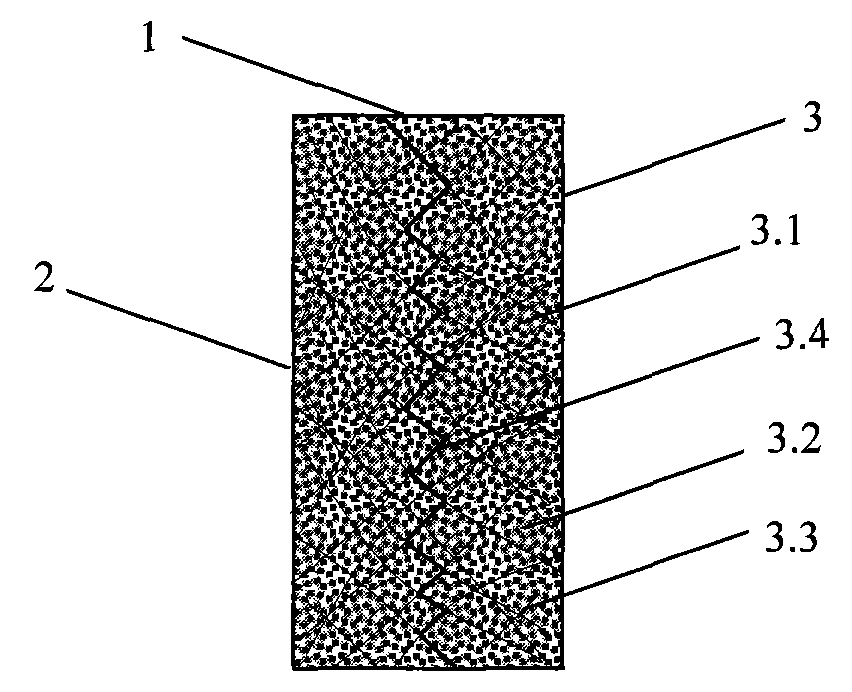

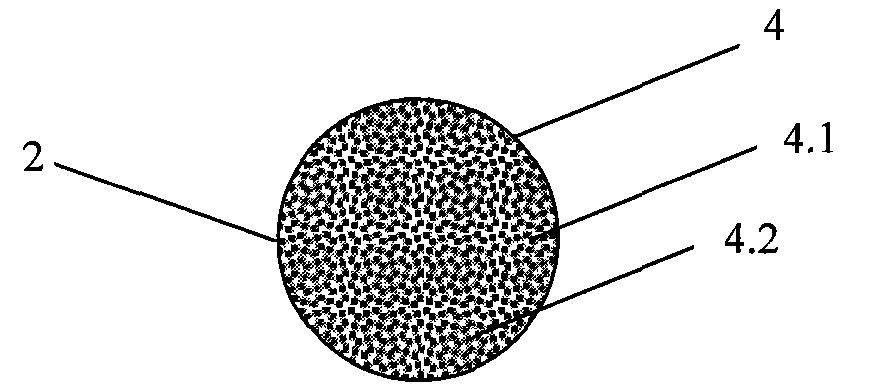

Standard test piece based on calibration permeability test

InactiveCN101587055ASolve the problem of changing permeability coefficientPrecise specification of permeabilitySurface/boundary effectPermeability/surface area analysisHeat resistanceOsmotic coefficient

The invention discloses a standard test piece based on a calibration permeability test. The standard test piece is in the shape of a solid cylinder and composed of a solid framework, gaps and pore canals. The solid framework has a firm structure and stably material properties. The material has high rigidity, good toughness, corrosion resistance, rust resistance, heat resistance and pressure resistance. The gaps are near-spherical, the aperture sizes are uniform, and the apertures are controlled in the range of 1-50 microns, the gaps are uniformly distributed inside the test piece and on surface thereof. The pore canals are intersected and the average pore opening extent of the interconnected pore canals passing through two end faces is controlled in the range of 0.1-5% on the cross section. The invention is detected by permeation for a long time, has constant permeability parameters, high efficiency, high reliability and strong practicality. By using the permeation coefficients of the invention as a reference standard, the invention provides a detection method and tool as reference for global permeability test technique. The standard test piece based on a calibration permeability test is applicable to all permeability tests and in particular to the precision and measuring range of a calibration low-permeability testing method and device.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Image edge detection method based on neighbourhood dispersion

ActiveCN105741281AAvoid Image Outline BreaksIsotropicImage analysisComputer visionDispersion coefficient

The invention discloses an image edge detection method based on neighbourhood dispersion. The image edge detection method comprises the following steps: 1) transforming an original colorful image into a single-channel eight-bit gray level image; 2) obtaining the dispersion coefficient matrix M of the eight-bit gray level image; 3) executing a horizontal direction refining operation for the dispersion coefficient matrix M to obtain a matrix Mh; 4) executing a vertical direction refining operation for the dispersion coefficient matrix M to obtain a matrix Mv; 5) combining the matrix Mh with the matrix Mv, and combining all points which are equal to 1 in the two matrixes to obtain a rough refining edge matrix O; and 6) carrying out precise processing and redundant information filtering on an image outline by the rough refining edge matrix O according to an orientation gradient to obtain an outline matrix, and finally, carrying out transformation through the outline matrix to obtain a binary edge image. The method disclosed in the invention is simple and easy in implementation and guarantees the accuracy of the outline.

Owner:西安深信科创信息技术有限公司

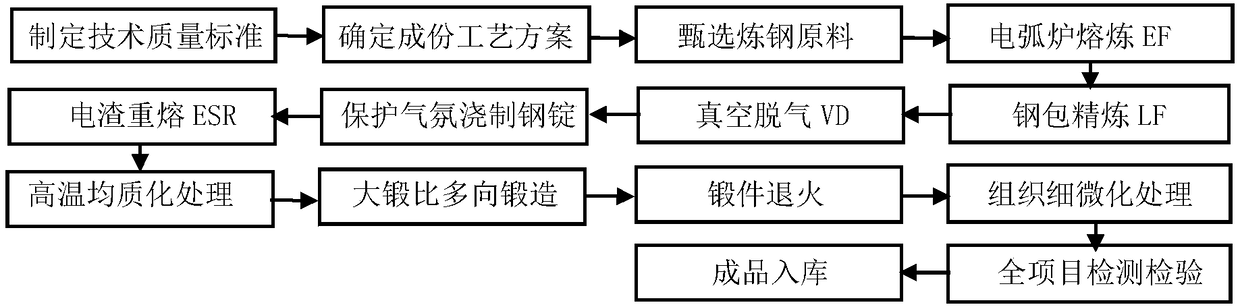

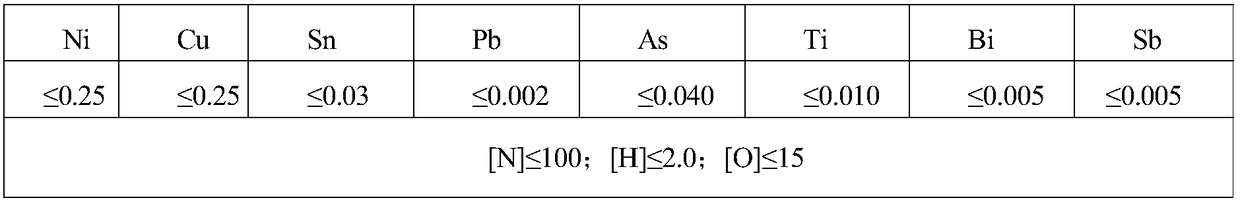

Special hot-stamping die steel HS7 and preparation method thereof

InactiveCN109402514AExcellent toughness and ductilityImprove performanceProcess efficiency improvementHot stampingCrack resistance

The invention discloses novel special hot-stamping die steel HS7 and relates to the technical field of die steel component formulas and manufacturing. The chemical components of the special hot-stamping die steel include, by weight, 0.41-0.45% of C, 0.45-0.55% of Si, 0.35-0.45% of Mn, 6.4-6.80% of Cr, 1.20-1.40% of Mo, 0.75-0.85% of V, 015% or below of P, 0.003% or below of S and the balance Fe and inevitable impurities and residual trace elements. The die steel adopts unique optimized alloy element proportion, the organization level of and purity degree of materials are greatly improved through refined smelting and multidirectional forging and combination with high temperature homogenizing, ultrafine processing and other processes, the key indicators of the hot-stamping die steel are obviously improved, including abrasion resistance, high temperature abrasion resistance, thermal fatigue cracking resistance, resistance to plastic deformation and the like. Therefore, improve the qualityof hot stamping dies can be obviously improved, the service life of the dies can be prolonged, and better economic benefits can be obtained.

Owner:上海合毓模具技术有限公司

Method for producing large-thickness lamination-crack-resistant tempered high-strength steel plate

The invention discloses a method for producing a large-thickness lamination-crack-resistant tempered high-strength steel plate. The method is characterized by comprising the steps: smelting, performing continuous casting, performing electroslag remelting, heating, rolling, annealing and performing heat treatment. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.18 percent of C, 0.20-0.50 percent of Si, 0.95-1.25 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.80-1.15 percent of Ni, 0.40-0.60 percent of Cr, 0.40-0.60 percent of Mo, 0.020-0.050 percent of Nb, 0.010-0.030 percent of Ti, 0.020-0.045 percent of TAl, and the balance of Fe and inevitable impurities. According to the method, electroslag remelting treatment is adopted, good overall performance of the large-thickness steel plate with the diameter of 30mm can be met due to the reasonable controlled rolling and heat treatment process, and the production cost is reduced; and the specification range is wide. The method adopts the steps of electric furnace smelting, continuous casting and electroslag remelting smelting, the contents of P and S in the obtained tempered high-strength steel plate are low, and the steel is pure; and moreover, a large-slab electroslag remelting technology is adopted, the round ingot hammer cogging process during electroslag remelting is reduced, the production period is shortened, and the cost is obviously reduced.

Owner:WUYANG IRON & STEEL

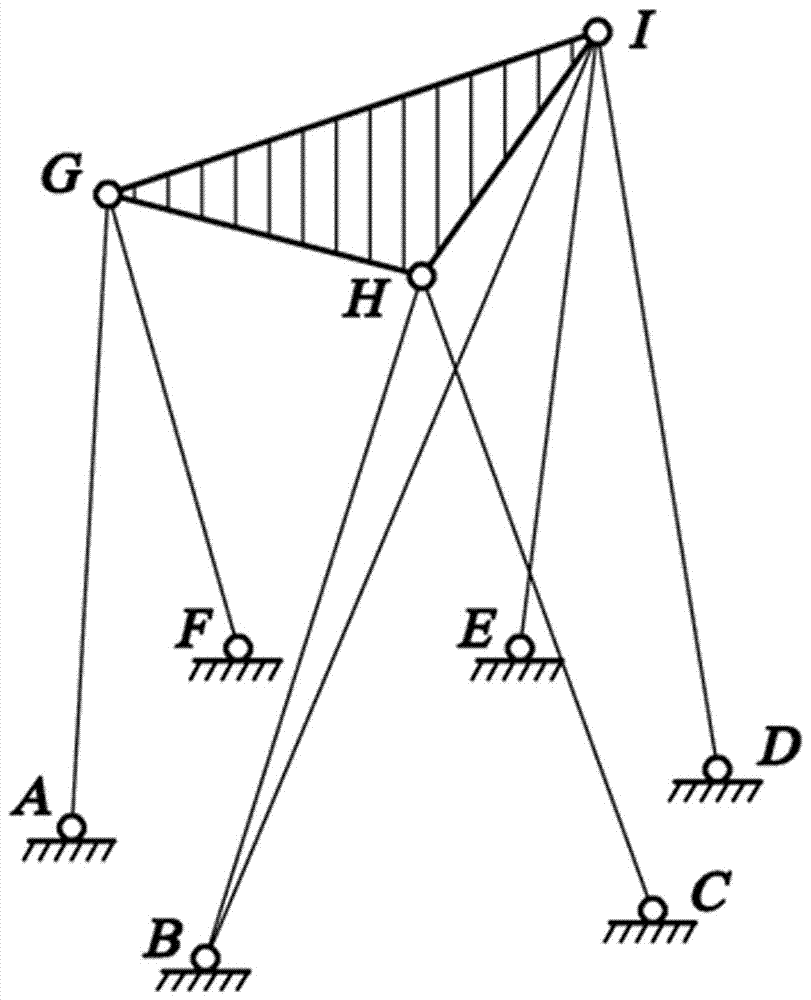

Parallel/series-parallel mechanism and robot performance parameter test system

InactiveCN107030732AAccurately map motion locationsAccurately draw attitude trajectoriesProgramme-controlled manipulatorRoboticsEngineering

The invention belongs to the field of mechanisms and robotics, and aiming at the deficiencies of existing test technologies, the invention provides a performance parameter test system suitable for parallel / series-parallel mechanisms and robots to overcome the defects that existing test devices are unstable in parameter and prone to being affected by environment factors. The performance parameter test system comprises a supporting platform, a test device, an upper computer and a servo control system. The test device is detachably mounted on the supporting platform and comprises pull rope encoders, a pulley base, a rolling bearing and a test platform. The middles of all the edges of a hexagonal platform are separately connected with the pull rope encoders. The pull rope tail ends of all the pull rope encoders are fixed to the edge of the test platform. The test platform and an end effector of a tested mechanism are fixed together. The test platform moves along with the end effector of the tested mechanism and pulls pull ropes of the pull rope encoders. According to the performance parameter test system, through the six pull rope encoders, the movement positions and the posture track of a tested part can be accurately drawn on the basis of unawareness of mechanism kinematic models.

Owner:ZHONGBEI UNIV

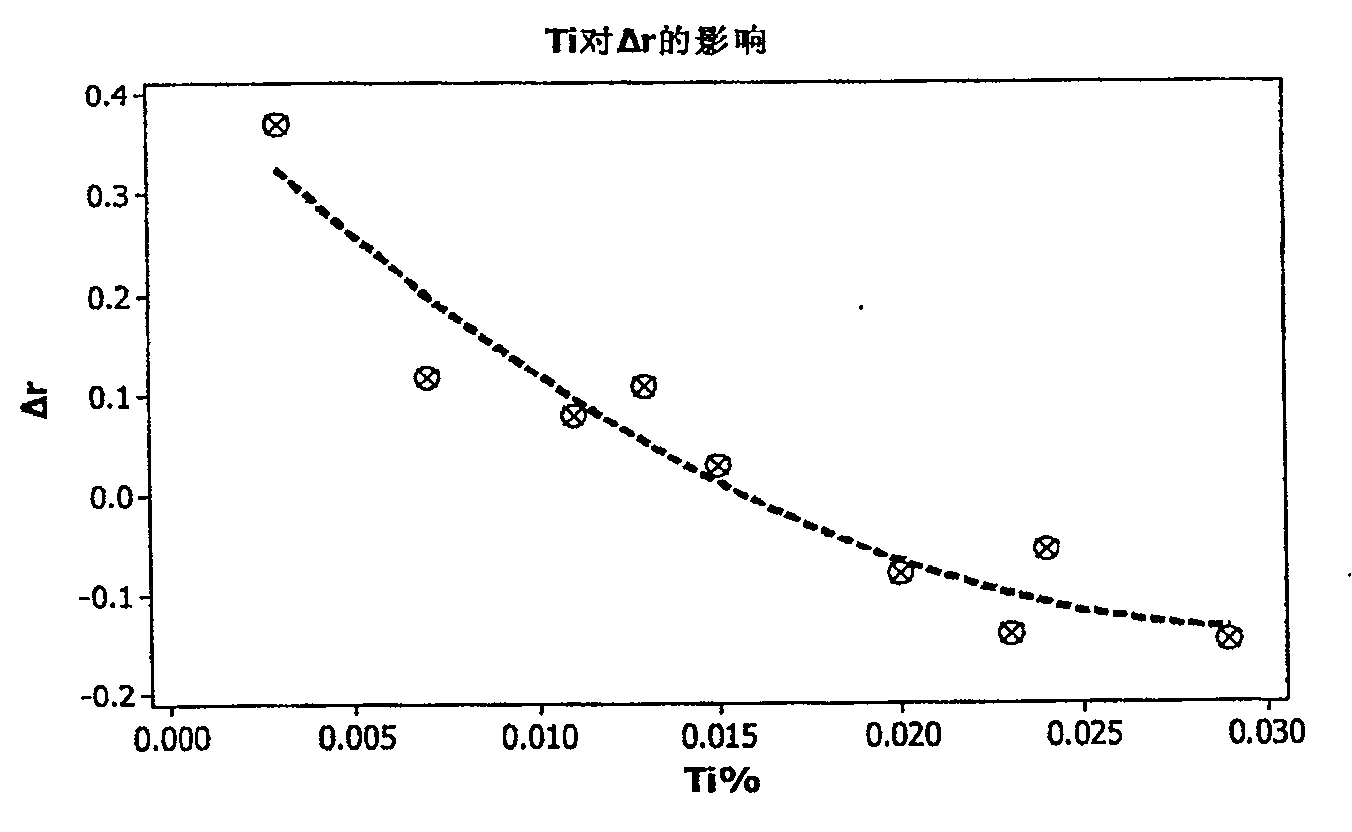

Steel for battery shell with excellent planar isotropism and its production

ActiveCN100560770CIsotropicImprove deep drawing performanceHeat treatment process controlPre treatmentHeating temperature

The invention relates to steel for battery steel shells and a manufacturing method thereof. The invention mainly solves the defects of large plane anisotropy, poor secondary processing embrittlement resistance, high production cost and the like existing in the existing steel for battery shells. The steel for battery case with excellent planar isotropy of the present invention has the following chemical element components by weight percentage: C: ≤0.01-0.05%, Si: ≤0.03%, Mn: 0.10-0.50%, P: ≤0.02%, S: ≤0.015%, Al: 0.01-0.10%, N: 0.002-0.007%, Ti: 0.005-0.02%, and the rest are iron and inevitable inclusions. The manufacturing method includes the following steps: molten iron pretreatment, converter smelting, post-furnace refining, hot rolling, pickling, cold rolling, bell annealing, leveling, finishing into finished coils, and is characterized by: heating temperature: ≤1270°C , Finish rolling temperature: 860~930℃, coiling temperature: ≤640℃; cold rolling deformation is controlled at 75%~90%, bell furnace annealing temperature: 650~800℃; others are carried out according to conventional processes. The product is used for stamping after electroplating nickel or directly stamping into battery case.

Owner:BAOSHAN IRON & STEEL CO LTD

Redundant drive symmetric three degree-of-freedom mobile parallel mechanism

InactiveCN103358302AAvoid singularitiesIncrease stiffnessProgramme-controlled manipulatorKinematic pairEngineering

The invention discloses a redundant drive symmetric three degree-of-freedom mobile parallel mechanism, which mainly comprises four fixed guide rails, a moving platform and four branched chains with the identical structure and for connecting the moving platform and the fixed guide rails, wherein the four fixed guide rails are uniformly distributed on the same conical surface, one ends of upper connecting rods of the branched chains are connected with the moving platform through revolute pairs, the other ends of the upper connecting rods are connected with one ends of lower connecting rods through sliding pairs, the other ends of the lower connecting rods are connected with the fixed guide rails through cylindrical pairs, the mobile parts of the cylindrical pairs are input kinematic pairs, the axial lines of the cylindrical pairs coincide with the axial directions of the fixed guide rails, the four revolute pairs on the four branched chains are uniformly distributed on the moving platform, the axial lines of the revolute pairs are parallel to the axial lines of the cylindrical pairs, and the axial lines of the sliding pairs are perpendicular to the axial lines of the cylindrical pairs. The mechanism has the advantages of large bearing capacity and excellent isotropy.

Owner:YANSHAN UNIV

Method for preparing aluminum-based composite material subjected to enhanced particle-copper alloy interface compatibility treatment

The invention discloses a method for preparing an aluminum-based composite material subjected to enhanced particle-copper alloy interface compatibility treatment. The preparation raw materials comprise 100 weight parts of matrix alloy, 8-10 weight parts of enhanced particles and 0.05-0.08 weight part of refining agent, wherein the matrix alloy selects 75-80 weight parts of cast aluminum alloy ZAlSi8MgBe, 15-20 weight parts of copper alloy Cu20Ni20Mn and 5-8 weight parts of copper alloy Cu20Ni35Mn; the enhanced particles refer to combinations of tungsten carbide, tetrapod-like zinc oxide whiskers, silicon carbide and nanometer titania; and the weight ratio of the four enhanced particles is (4-4.5):(3-3.5):(1-1.5):(2-2.5). The aluminum-copper-based composite material prepared by the method disclosed by the invention is light in weight, high in specific strength, high in specific stiffness and low in thermal expansion coefficient and has high thermal conductivity and high wear and corrosion resistance. Moreover, the preparation is simple, the cost is low, the enhanced phase is in dispersed distribution in the matrix and has isotropy, and the composite material is applied to various complex stress states.

Owner:福铂斯(天津)科技有限公司

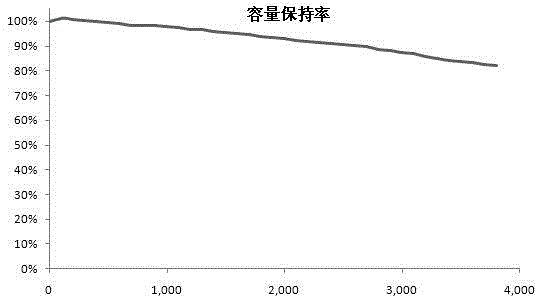

A kind of preparation method of isotropic superelastic graphene airgel

The invention provides a method for preparing isotropic superelastic graphene gasgel. The method comprises the following steps: firstly, stirring and mixing an oxidized graphene aqueous dispersion, a reducing agent and sodium dodecyl sulfate (SDS) at low speed, and then stirring at high speed; heating, freezing, melting at room temperature, washing with ethanol and drying at atmospheric pressure to obtain the isotropic superelastic graphene aerogel. The method provided by the invention has the advantages of simple process and is suitable for industrial production, and the obtained graphene aerogel is isotropic, has uniform cell size, and has excellent compression recovery and good electrochemical performance.

Owner:QINGDAO UNIV OF SCI & TECH

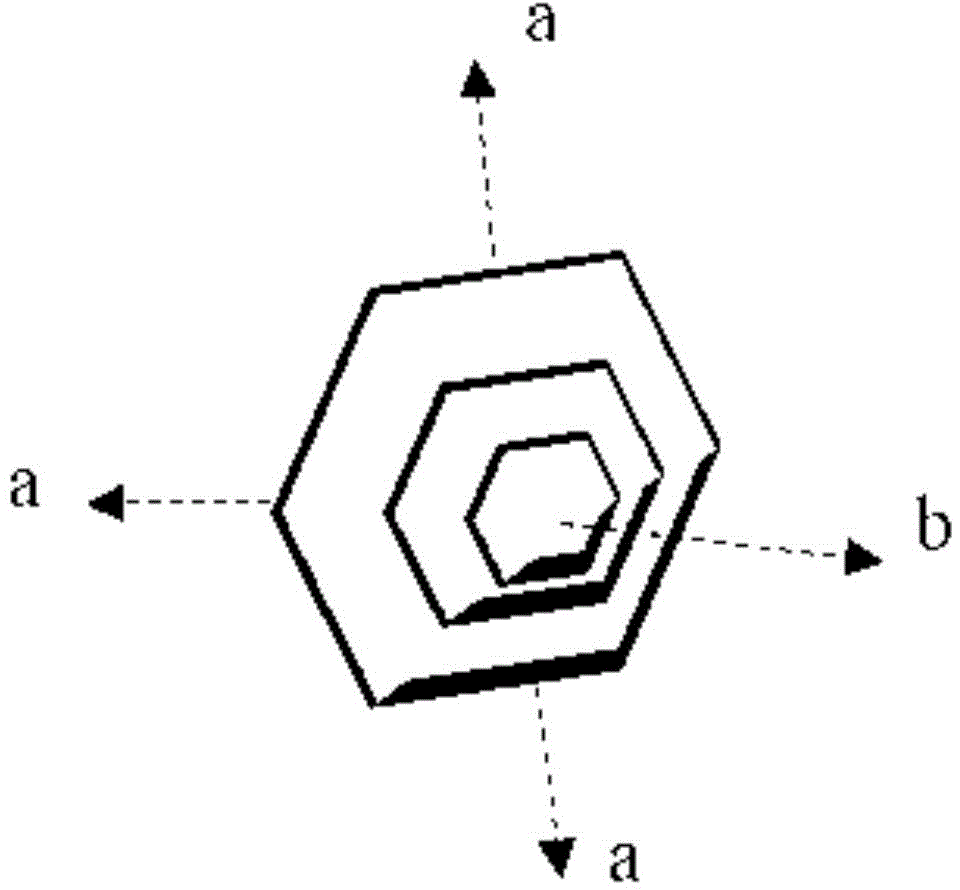

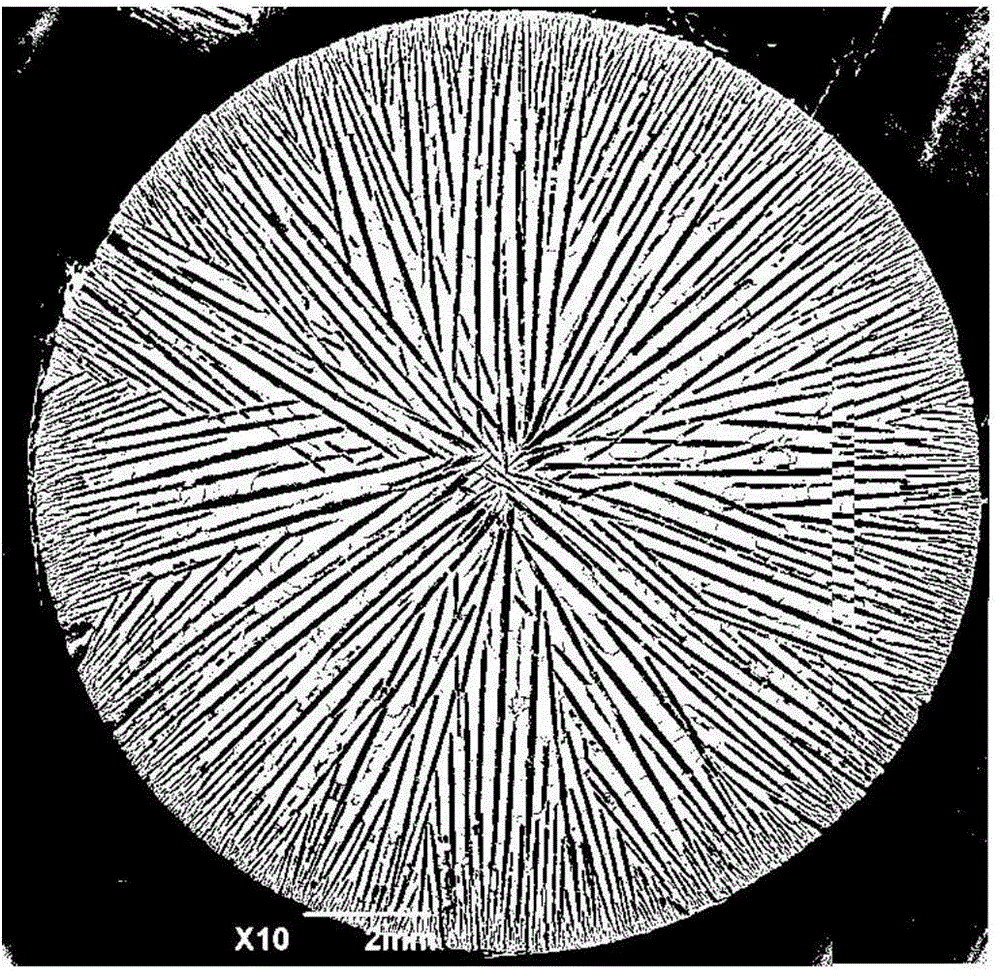

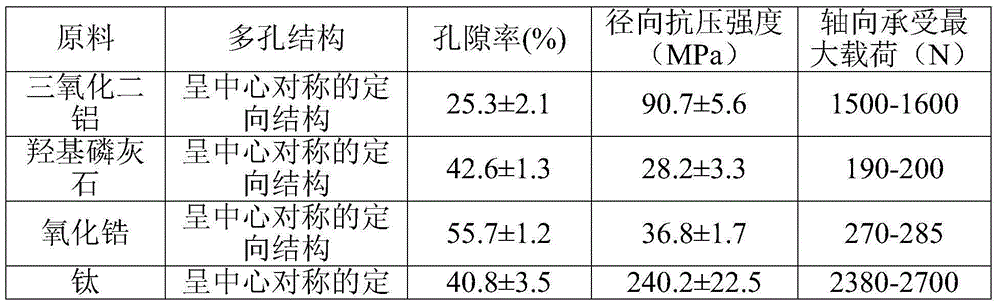

Porous material with central symmetry structure and method for preparing the same

ActiveCN104945005AGood uniformityGood stability and mechanical propertiesCeramicwareBall millAdhesive

The invention discloses a porous material with a central symmetry structure. Layered holes of the porous material are of a central symmetry oriented structure along the radial cross section. A method for preparing the porous material with the central symmetry structure comprises adding a dispersing agent and adhesives in water, adding ceramic powder after uniform mixing, using a zirconia ball or an alumina ball as a ball milling medium to perform ball milling, obtaining slurry with the volume concentration of 20%-40%; injecting the slurry in a cylindrical die with the side face and the bottom surface provided with a heat transfer material, placing the die on a freezing partition plate of a freezing dryer to freeze the slurry for 2-4 h, causing the freezing temperature to be -50 DEG C to -30 DEG C; completely freezing the slurry and then taking the slurry out of the die, placing the frozen slurry in the environment with the pressure of 0-600 Pa to perform low pressure drying for 20-24 h, so as to obtain a porous material prefabricated body; and finally sintering the porous material prefabricated body in the air or in the atmosphere of vacuum at 800-1700 DEG C for 2-3 h to obtain the porous material.

Owner:XIAN UNIV OF TECH

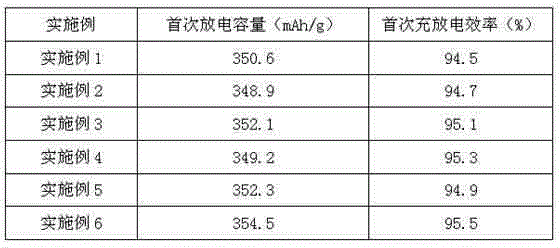

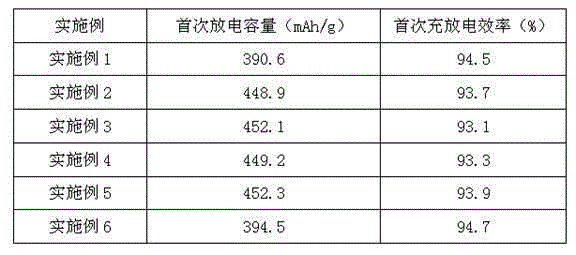

Preparation method of carbon/graphite composite anode material

InactiveCN105047931AReduce capacityLarge irreversible capacity loss for the first timeCell electrodesSecondary cellsFiberCarbon fibers

The invention relates to a preparation method of a carbon / graphite composite anode material. The carbon / graphite composite anode material is prepared from the following raw materials with following grain sizes and weight percent: 1.5%-2.5% of carbon black, 5%-8% of natural graphite with the grain size being not greater than 1mm, 25%-30% of calcined petrol coke powder with the grain size being not greater than 0.075mm, 15%-20% of calcined petroleum coke with the grain size being 1-4mm, 10%-15% of electrically calcined anthracite with the grain size being 4-10mm, 5%-10% of electrically calcined anthracite with the grain size being 10-16mm, 5%-15% of calcined pitch coke with the grain size being 10-16mm, 18%-20% of coal pitch, and short carbon fibers, the weight of which is 1%-3% of the total weight of the aforementioned raw materials. The carbon / graphite composite material is prepared by the following steps: burdening, mixing kneading, roasting, graphitizing, crushing and balling. By combination of respective advantages of carbon materials and graphite materials as the anode materials, the prepared composite material has the characteristics of high first capacity, high first charge and discharge efficiency, electrolyte solvent resistance, isotropy and the like.

Owner:田东

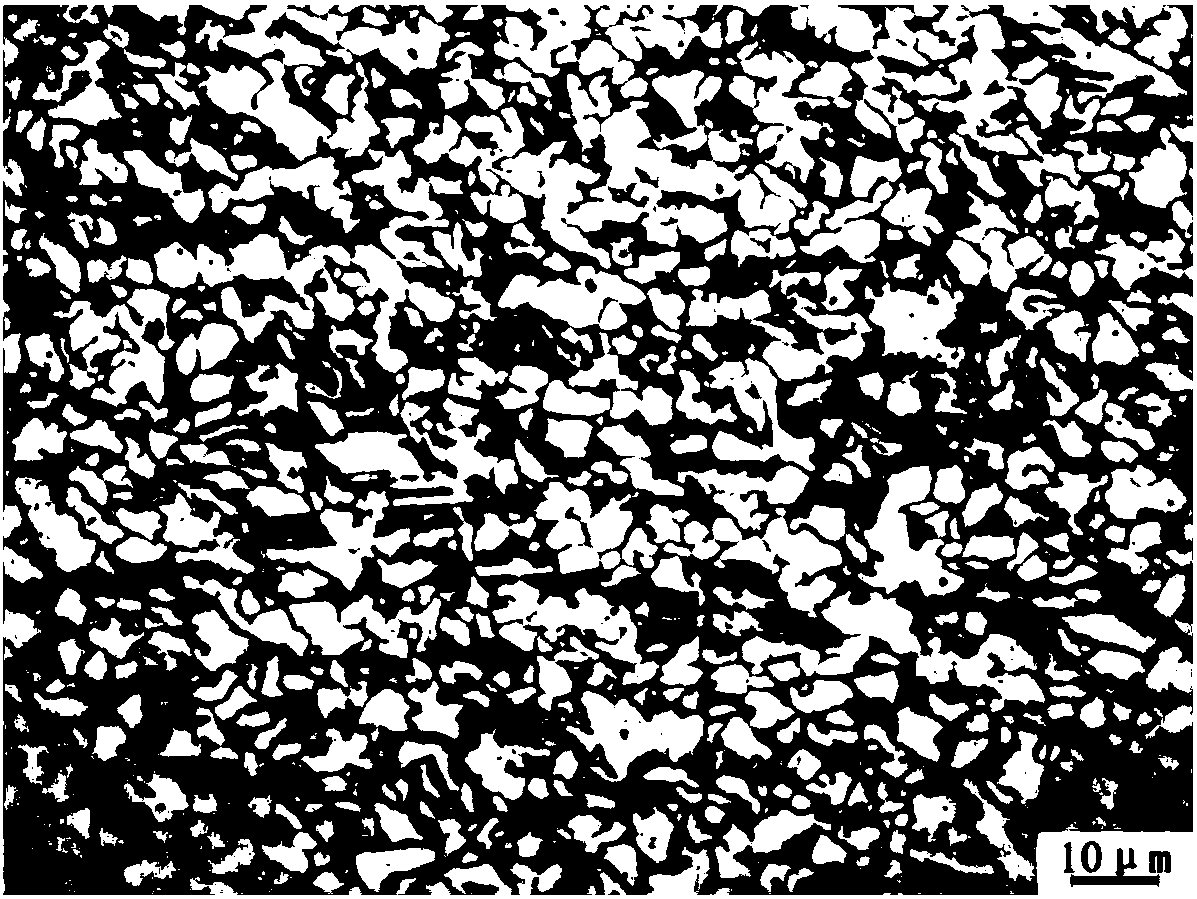

690 MPa grade economical high-surface-quality high-hole-expansion steel and preparation method thereof

InactiveCN107747042AIncrease manufacturing costReduce manufacturing costChemical compositionLaminar cooling

The invention discloses 690 MPa grade economical high-surface-quality high-hole-expansion steel and a preparation method thereof, and belongs to the technical field of iron and steel metallurgy and calendering. The 690 MPa grade economical high-surface-quality high-hole-expansion steel comprises, by weight percentage, C, Si, Mn, P , S, Alt , Ca, N, O and the balance Fe and unavoidable impurities.The preparation method comprises the following steps of smelting, continuous casting, heating, rough rolling, box hot coiling, finish rolling, laminar cooling, coiling, slow cooling, pickling and coiling for packaging. According to the 690 MPa grade economical high-surface-quality high-hole-expansion steel, by controlling the chemical composition and preparation method of the high-hole-expansion steel, the high-hole-expansion steel has the characteristics of being high in surface quality, low in cost and excellent in performance and can meet the demand of an automobile chassis and steel used for complex stamping parts.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

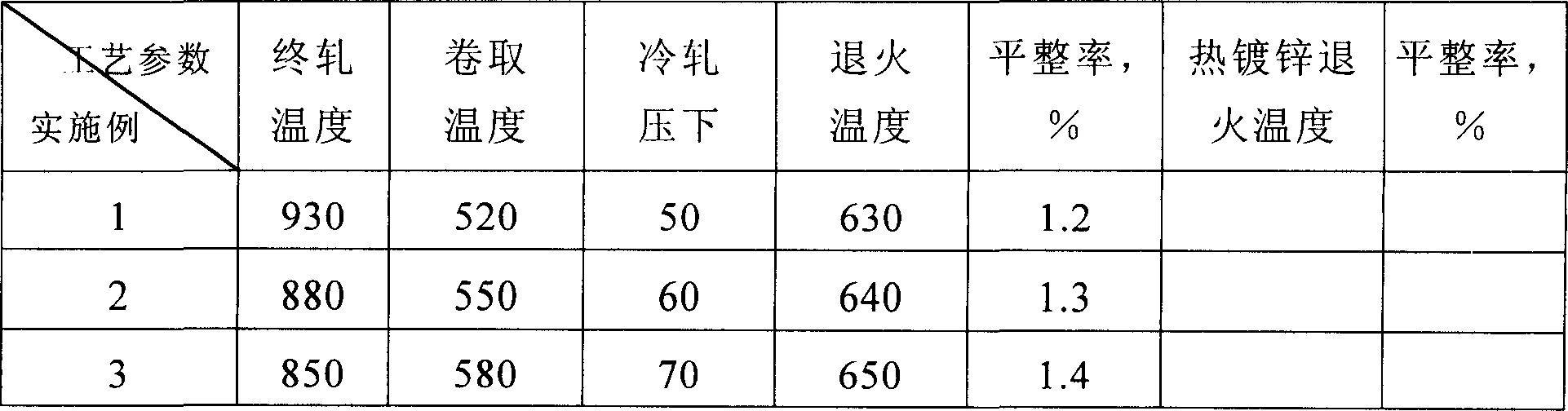

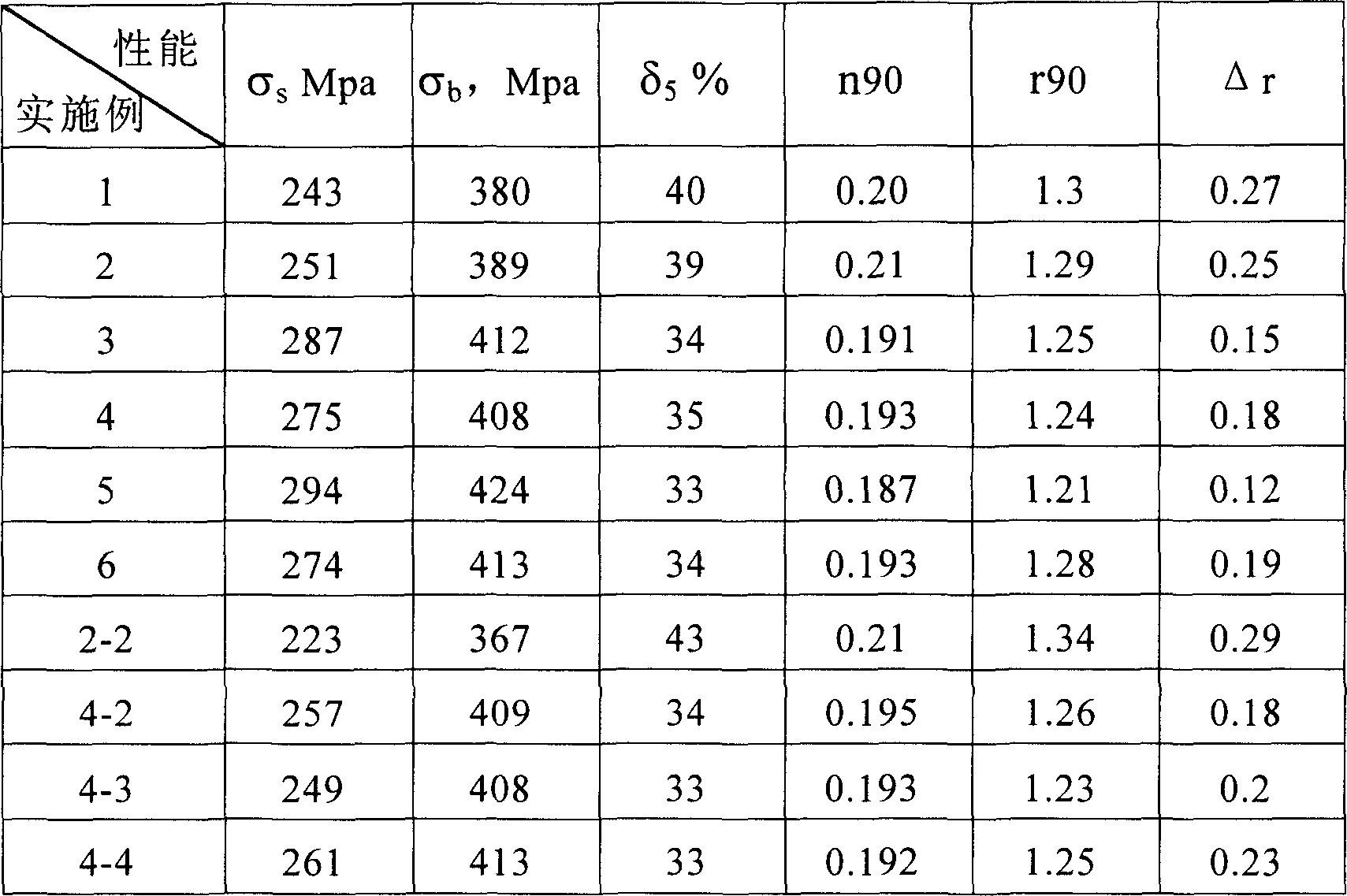

Solution strengthening isotropical steel and preparation method thereof

ActiveCN101078085AIsotropicHigh strengthRoll force/gap control deviceTemperature control deviceComing outSolid solution strengthening

Solid solution strengthening isotropy steel, the mass percent of it' s components is : C: 0.03-0.07,Si: <= 0.03, Mn: 0.4-1.0, P: 0.02-0.08, S: <=0.02, N: <=0.005, B: 0.002-0.005, Al: 0.015-0.05, the other is Fe and the impurity, which can be avoided. It' s manufacture method contains the following steps: 1) Smelting, to make billet by casting; 2) Hot reduction of billet, finishing temperature : 830-930deg.C, coiling temperature: 520-620deg.C, 3) Acidwashing, routine acidwashing technology. 4) Cold rolling, the draft is 50-80%, 5) Annealing, heat preserbation temperature: 630-720deg.C. Heat preservation time: 4-30h, to come out from stove when it has been cooled to lower than 200deg.C; 6) Leveling, the cold rolling product will be gained. The routine of solid solution strengthening is used in this patent, and it takes advantage of C and Mn to decrease the sum lever of r value, and adjusts the relative difference of r value on three directions by adding P, some proper technology is also be used to help it, and the ideal isotropy steel can be gained.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of carbon/graphite/tin composite anode material

InactiveCN104953100AAlleviate volume effectReduce capacityCell electrodesSecondary cellsFiberCarbon fibers

The invention relates to a preparation method of a carbon / graphite / tin composite anode material. The carbon / graphite / tin composite anode material adopts the following raw materials in percentage by weight and particle size: 1.5-2.5% of carbon black, 5-8% of natural graphite with the particle size being smaller than or equal to 1 mm, 3-10% of nanosized tin with the particle size being smaller than or equal to 100 nm, 25-30% of calcined petroleum coke powder with the particle size being smaller than or equal to 0.075 mm, 15-20% of calcined petroleum coke with the particle size being 1-4 mm, 10-15% of electric calcined anthracite with the particle size being 4-10 mm, 5-10% of electric calcined anthracite with the particle size being 10-16 mm, 5-15% of calcined pitch coke with the particle size being 10-16 mm, 18-20% of coal pitch, and short carbon fiber, wherein short carbon fiber accounts for 1-3% the total amount of the raw materials. The carbon / graphite / tin composite anode material is prepared by adopting the steps of burdening, mixing, kneading, roasting, graphitizing, smashing, and spheroidizing. The carbon / graphite / tin composite anode material prepared by adopting the preparation method provided by the invention combines respective advantages of carbon material, graphite material and tin powder when serving as anode materials, and the prepared carbon / graphite / tin composite anode material has the characteristics of high first-cycle capacity, high initial charge-discharge efficiency, electrolyte solvent resistance and isotropic homogeneity and the like.

Owner:田东

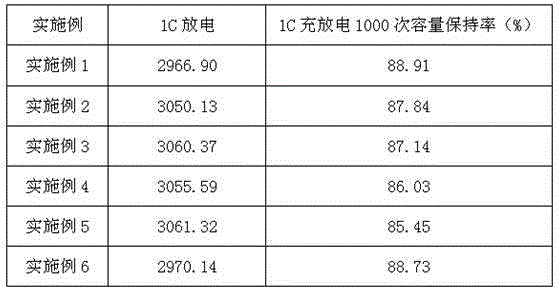

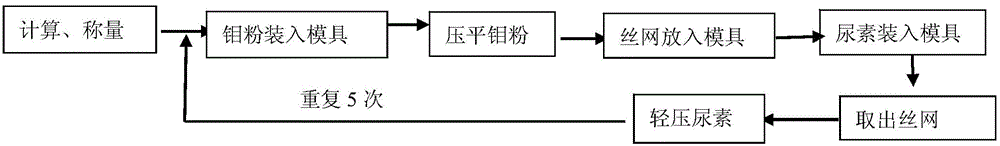

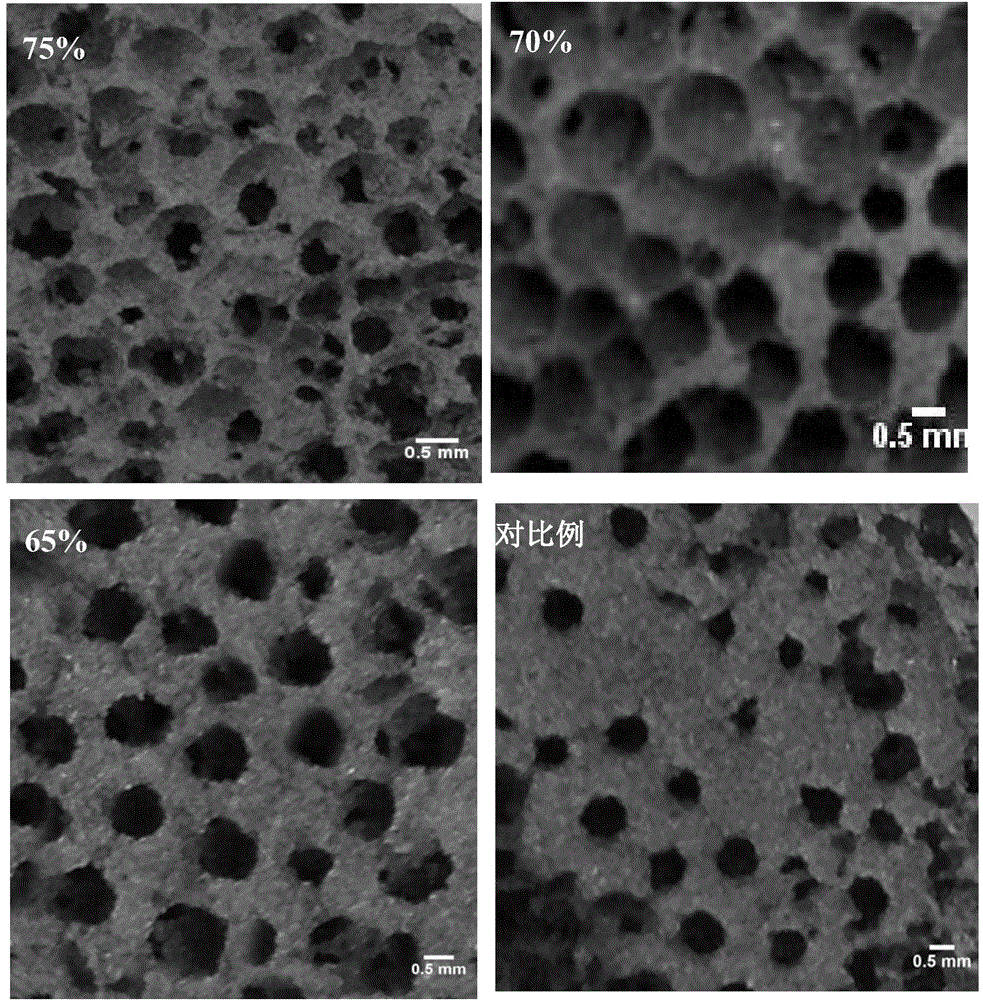

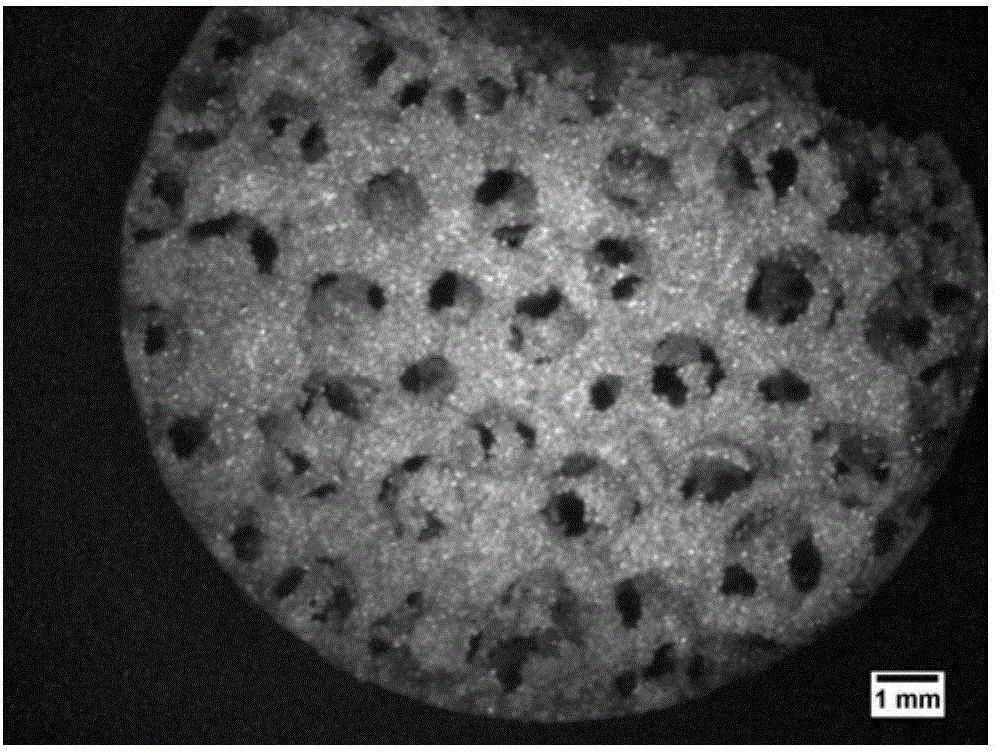

High-pore controllable three-dimensional through hole foam molybdenum and preparation method thereof

The invention discloses a high-pore controllable three-dimensional through hole foam molybdenum and a preparation method thereof. The molybdenum pore is in the shape of a three-dimensional sphere, and the pore is formed by mutually communicating generating holes with interstitial holes. The pore rate of the molybdenum structure is higher and is controllable, the pore is in the shape of a regular sphere, and the pore has isotropic mechanical characteristic. The preparation method is based on a traditional powder metallurgy method, a foaming method is combined, a novel layer spread method for material loading is adopted, and then, the foam molybdenum is obtained through pressing, dissolving and sintering. The preparation method provided by the invention is simple, the cost is low, the production cycle is short, pores are distributed uniformly, and the foam molybdenum has favorable mechanical and energy absorption properties.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com