Graphene, aluminum and silicon carbide composite material and preparation method and application thereof

A graphene-aluminum-silicon carbide and composite material technology is applied to graphene-aluminum-silicon carbide composite materials and their preparation and application fields, and can solve the problems of control difficulty, safety, material property anisotropy, and insufficient mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1 Preparation of graphene-aluminum-silicon carbide composites

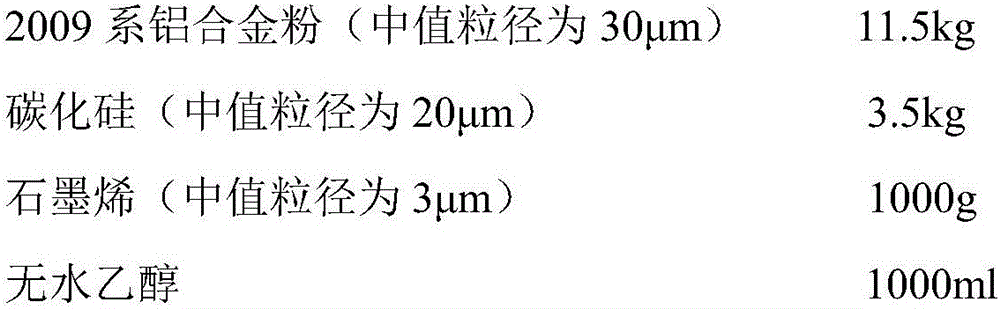

[0066] The composition of the graphene aluminum silicon carbide composite material is:

[0067]

[0068] The preparation method of graphene aluminum silicon carbide composite material may further comprise the steps:

[0069] 1. Uniformly disperse 1000g graphene ultrasonically (frequency 50Hz, ultrasonic 40min) into 1000ml absolute ethanol to prepare graphene ethanol dispersion;

[0070] 2. Weigh 11.5kg of aluminum alloy powder and 3.5kg of silicon carbide, put them into the mixer in turn, and mix them at 500rpm for 30 minutes; after mixing at 850rpm for 1 hour, the aluminum-silicon carbide mixed powder is obtained and divided into five grades share;

[0071] 3. Measure 0ml, 15ml, 30ml, 45ml, and 60ml of graphene ethanol dispersion, respectively, at 900rpm, atomize and spray the graphene ethanol dispersion into five equal parts of aluminum silicon carbide mixed powder, and mix again at 900rpm ...

Embodiment 2

[0075] Example 2 Preparation of graphene-aluminum-silicon carbide composites

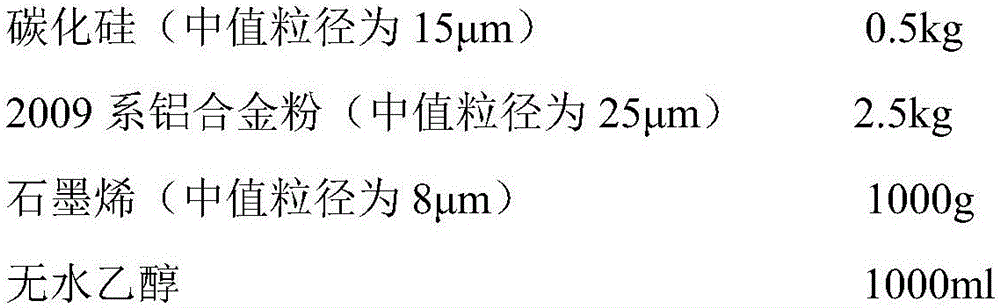

[0076] The composition of the graphene aluminum silicon carbide composite material is:

[0077]

[0078] The preparation method of graphene aluminum silicon carbide composite material may further comprise the steps:

[0079] 1. Uniformly disperse 1000g of graphene into 1000ml of absolute ethanol by ultrasonic (frequency 60Hz, ultrasonic 45min) to obtain graphene ethanol dispersion;

[0080] 2. Weigh 2.5kg of aluminum alloy powder and 0.5kg of silicon carbide, put them into the mixer in turn, mix at 600rpm for 30min; mix at 950rpm for another 1h, and prepare aluminum-silicon carbide mixed powder;

[0081] 3. Under the condition of 950rpm, atomize and spray 30ml of graphene ethanol dispersion into the aluminum silicon carbide mixed powder, and then mix at 950rpm for 2 hours to prepare the graphene aluminum silicon carbide mixed dispersion;

[0082] 4. After collecting the graphene-aluminum-silico...

Embodiment 3

[0085] Example 3 Preparation of graphene-aluminum-silicon carbide composites

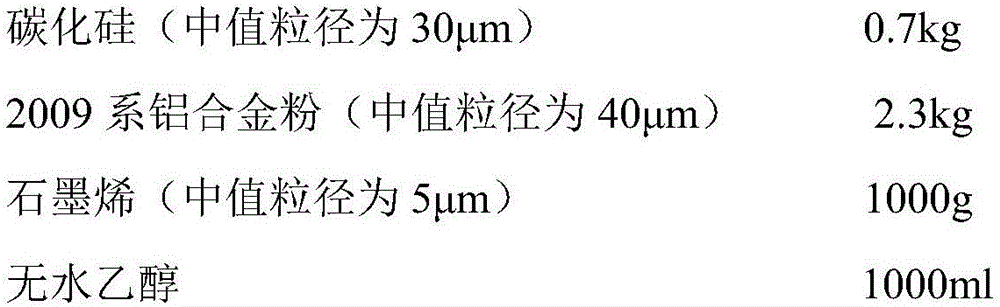

[0086] The composition of the graphene aluminum silicon carbide composite material is:

[0087]

[0088] The preparation method of graphene aluminum silicon carbide composite material may further comprise the steps:

[0089] 1. Uniformly disperse 1000g of graphene into 1000ml of absolute ethanol by ultrasonic (ultrasonic frequency 70Hz, ultrasonic 30min) to prepare graphene ethanol dispersion;

[0090] 2. Weigh 2.3kg of aluminum alloy powder and 0.7kg of silicon carbide, put them into the mixer in turn, mix at 650rpm for 30min; after mixing at 1000rpm for 1h, the aluminum-silicon carbide mixed powder is obtained;

[0091] 3. Under the condition of 1000rpm, atomize and spray 30ml of graphene ethanol dispersion into the aluminum silicon carbide mixed powder, and then mix at 1000rpm for 2 hours to obtain the graphene aluminum silicon carbide mixed dispersion;

[0092] 4. After collecting the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com