Graphene aqueous slurry, and preparation method thereof

A graphene water-based and graphene technology, applied in the field of graphene water-based slurry and its preparation, can solve the problems of light density of graphene powder, difficult to control graphene size, difficult packaging and transportation, etc., to avoid accumulation and agglomeration, solve the It is difficult to control the size and the effect of improving the dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Correspondingly, the embodiment of the present invention is also a kind of preparation method of graphene water-based slurry comprising the following steps:

[0021] S01. Using graphite oxide solid or expandable graphite solid as raw material, carry out expansion treatment to prepare expanded graphite;

[0022] S02. soaking the expanded graphite in an aqueous stripping solution to obtain a mixture containing expanded graphite;

[0023] S03. The mixture containing expanded graphite is subjected to high-speed shearing or ultrasonic treatment, and the stripping liquid is removed to obtain a graphene wet material;

[0024] S04. The graphene wet material is placed in an aqueous dispersion, and subjected to high-speed shearing treatment to obtain an aqueous graphene slurry.

[0025] Specifically, in the above step S01, the embodiment of the present invention uses graphite oxide solid or expandable graphite solid as a raw material. The selection of the graphite oxide solid o...

experiment example 1

[0047] A kind of graphene aqueous slurry and preparation method thereof, comprises the following steps:

[0048] S11. Take 14g of expandable graphite with a particle size of 80 mesh and an oxygen content of 10%, and carry out expansion treatment in a high-temperature expansion furnace at 1000°C to prepare 10g of expanded graphite;

[0049] S12. Soak the expanded graphite in 3L deionized water with a volume percentage of 15% ammonia and a mass concentration of 4×10 -4 kg / kg of n-octanol in the mixed stripping solution, stirred and wetted for 1 hour to obtain a mixture containing expanded graphite;

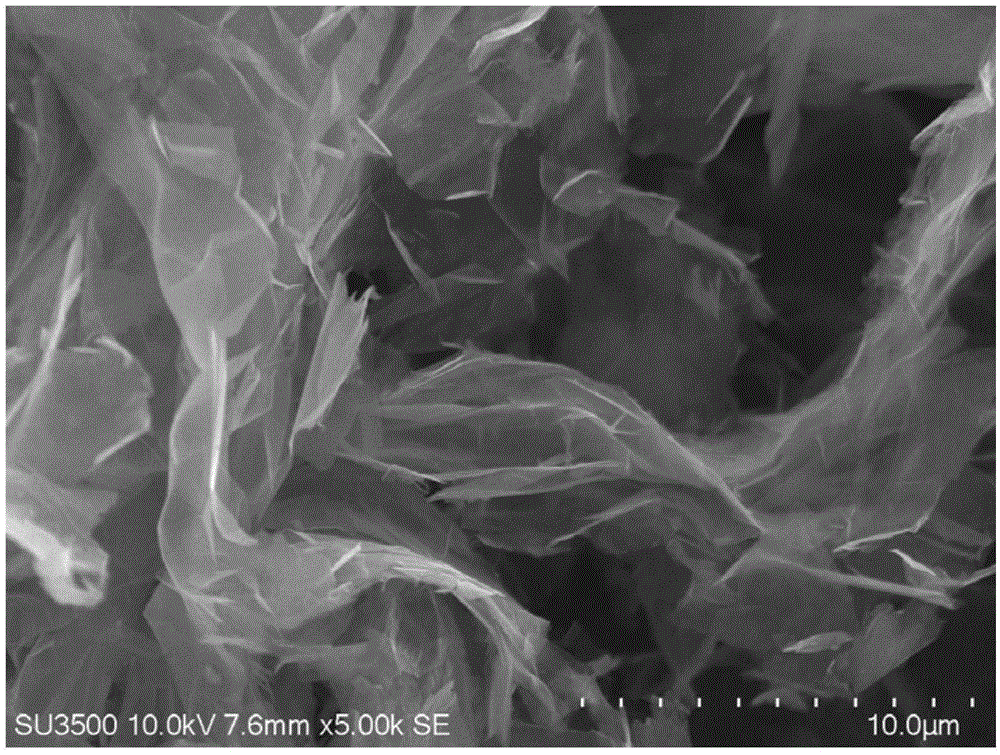

[0050] S13. The mixture containing expanded graphite is subjected to 800W ultrasonic action for 4h, and after centrifugal filtration, a graphene filter cake is obtained;

[0051] S14. Dispersing the graphene filter cake in 190g deionized water, adding PVP to adjust the surface tension within the range of 40-50mN / m, and sanding it in a nano sand mill for 6h to obtain graphite with a...

experiment example 2

[0053] A kind of graphene aqueous slurry and preparation method thereof, comprises the following steps:

[0054] S21. Get 14g of expandable graphite with a particle size of 150 mesh and 10% oxygen content, and carry out expansion treatment in an industrial microwave oven to prepare 10g of expanded graphite;

[0055] S22. Soak the expanded graphite in 1L volume percentage of 15% ammonia water and a mass concentration of 4×10 -4 kg / kg of n-octanol in the mixed stripping solution, stirred and wetted for 1 hour to obtain a mixture containing expanded graphite;

[0056] S23. The mixture containing expanded graphite is subjected to 1000W ultrasonic action for 3h, and after vacuum filtration, a graphene filter cake is obtained;

[0057] S24. Disperse the graphene filter cake in 90g of absolute ethanol, add sodium citrate to adjust the surface tension within the range of 40-50mN / m, and shear and disperse for 3h to obtain graphene with a weight percentage of about 10%. Ethanol slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com