Patents

Literature

151results about How to "Fully dissociated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

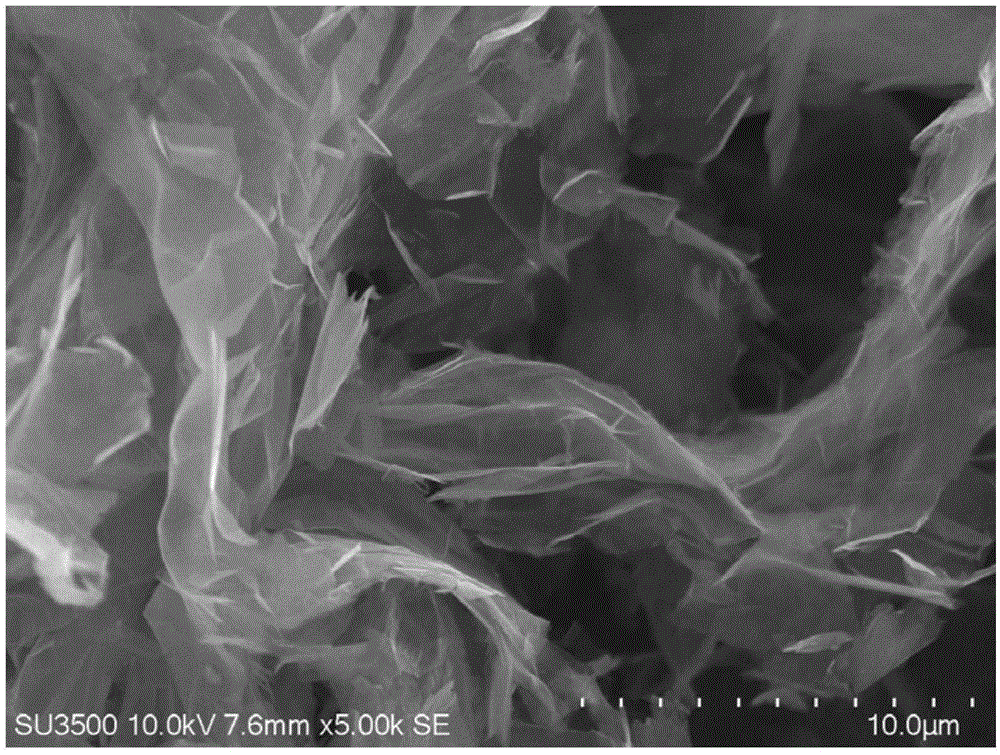

Graphene aqueous slurry, and preparation method thereof

The invention belongs to the field of graphene material, and provides a graphene aqueous slurry, and a preparation method thereof. The graphene aqueous slurry comprises an aqueous dispersion liquid and a graphene material dispersed in the aqueous dispersion liquid, wherein the aqueous dispersion liquid contains a surfactant. The preparation method comprises following steps: graphite oxide solid or expansible graphite solid is taken as a raw material, and expansion treatment is carried out so as to prepare expanded graphite; the expanded graphite is immersed into an aqueous stripping liquid for infiltration treatment so as to obtain a mixture containing the expanded graphite; the mixture containing the expanded graphite is subjected to high-speed shearing or ultrasonic treatment so as to remove the aqueous stripping liquid so as to obtain a graphene wet material; the graphene wet material is added into the aqueous dispersion liquid, and high-speed shearing is carried out so as to obtain the graphene aqueous slurry.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

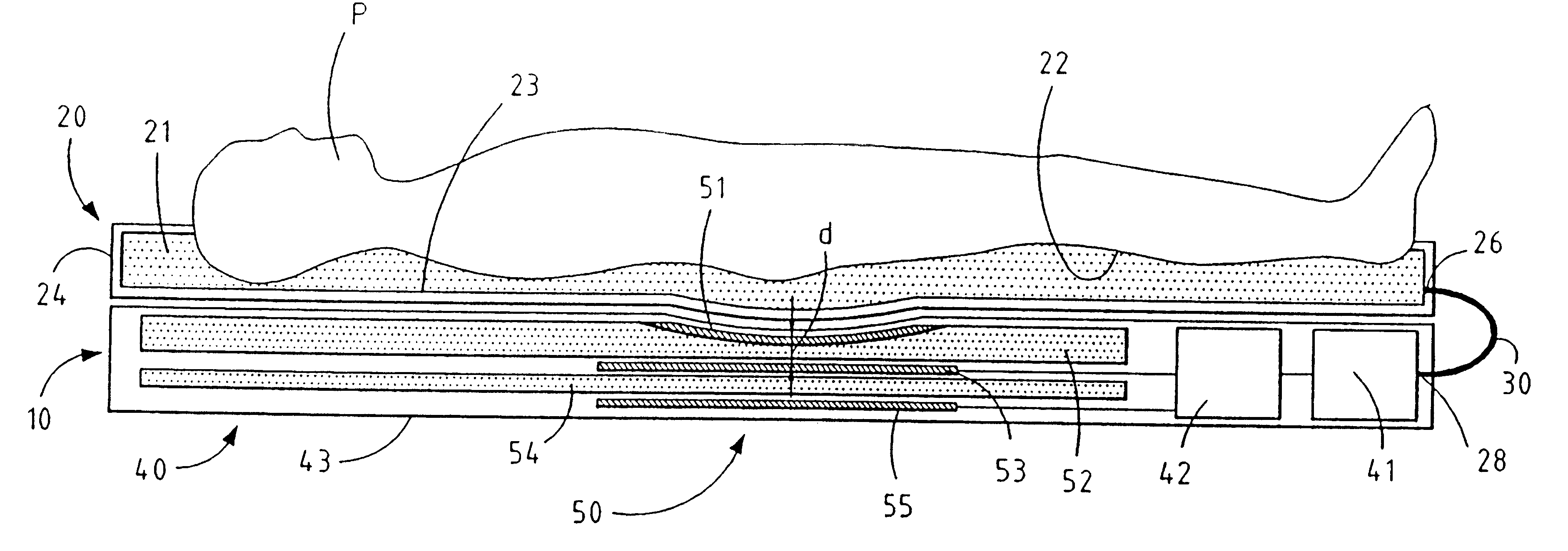

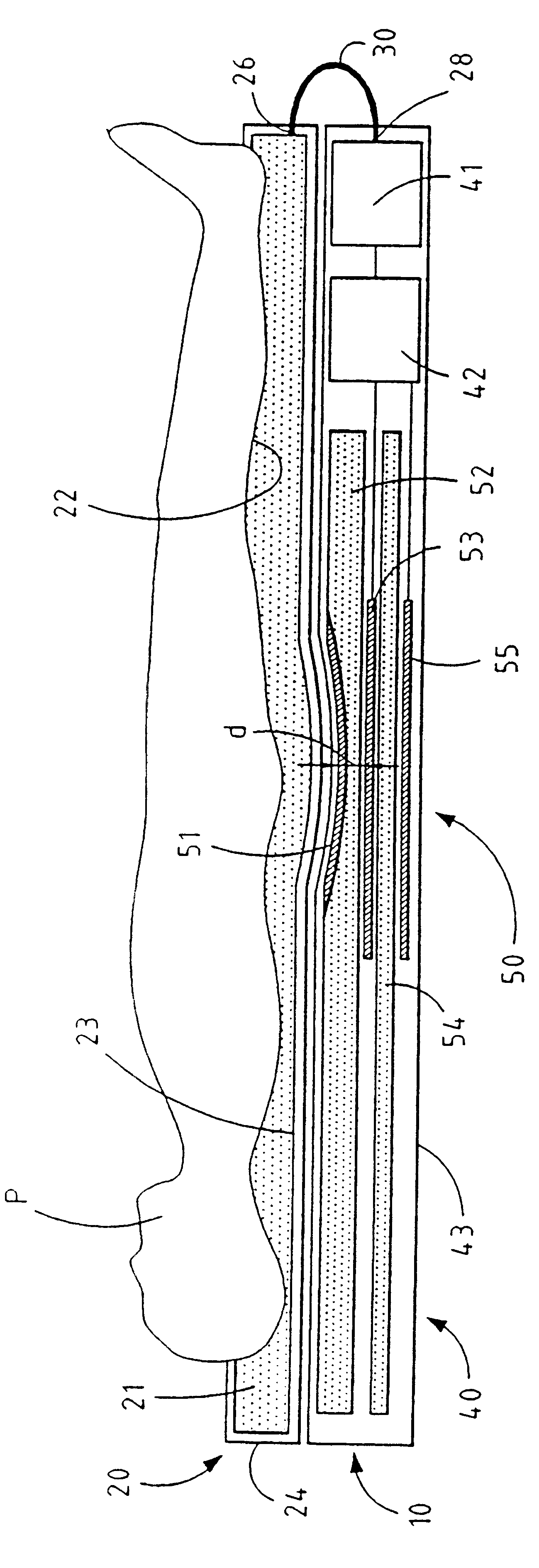

Method and apparatus for supporting an element to be support, in particular the body of a patient, the apparatus having a support device independent from the control device

InactiveUS6385803B1Fully dissociatedReduce manufacturing costStuffed mattressesSpring mattressesControl releaseBiomedical engineering

Owner:HILL ROM INDS

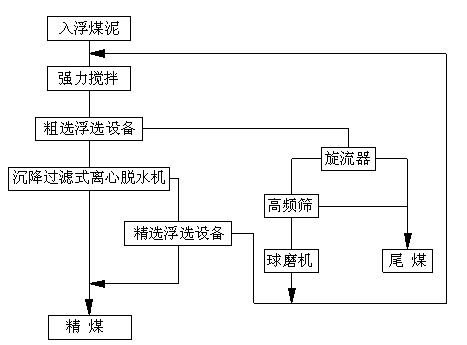

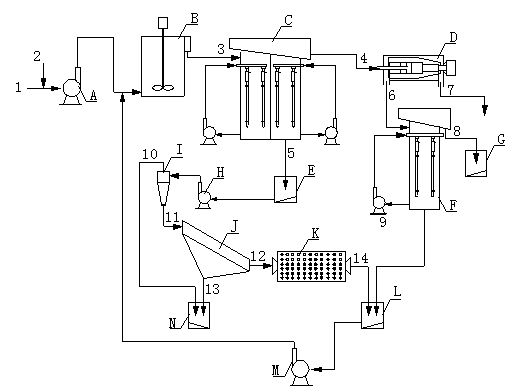

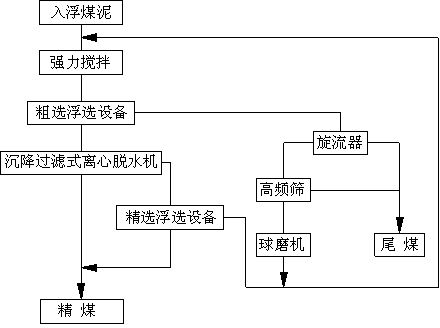

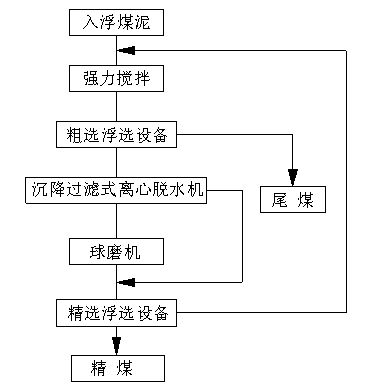

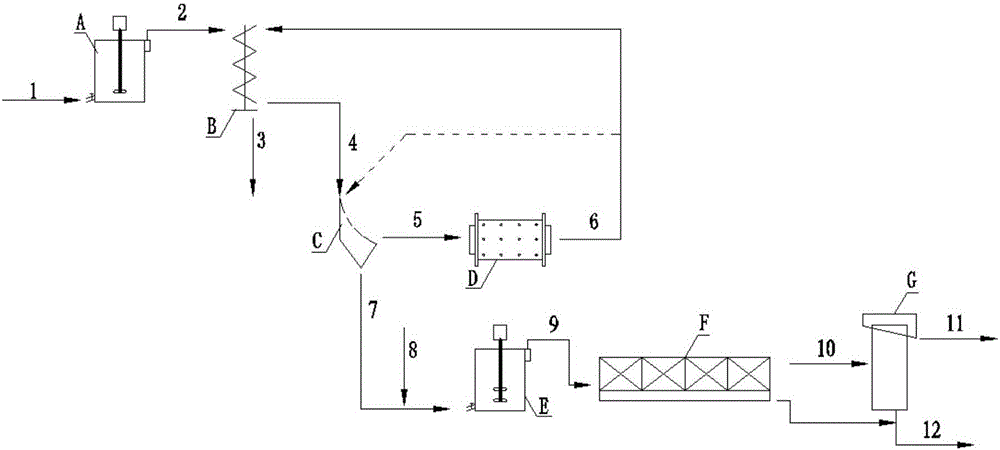

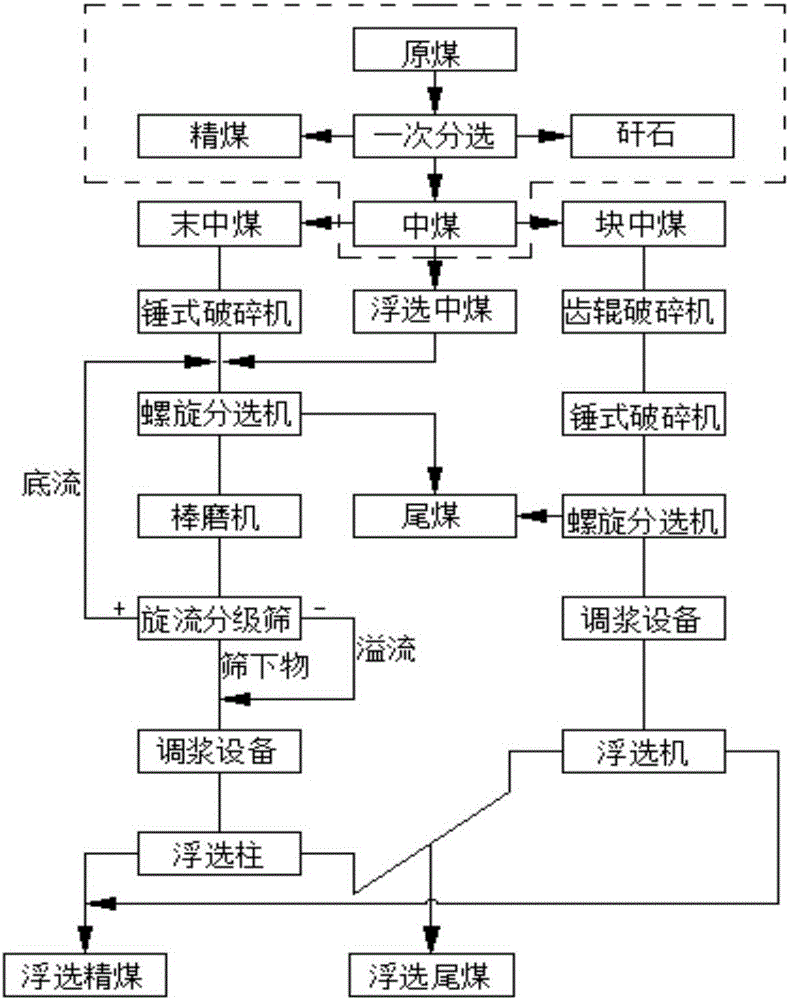

Sorting process for high-ash and difficult-separation coal slime

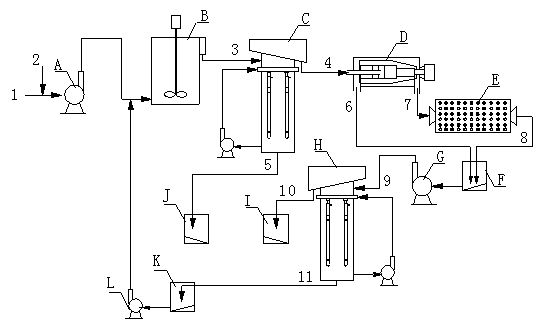

Disclosed is sorting process for high-ash and difficult-separation coal slime. Floatation coal slime is fed into a stirring barrel to be prepared into ore pulp with percentage concentration of 80g / L-120g / L, the ore pulp automatically flows to roughing and floatation equipment to be sorted, roughing tail coal enters a cyclone to be concentrated in a classified manner, concentrated bottom flow products enter a high-frequency screen to be dewatered, dewatered substances on the high-frequency screen return to roughing pulp mixing operation to be sorted again after being finely ground via a ball mill, floatation rough and fine ores are fed to a precipitation perforated basket centrifuge to be dewatered, after being dewatered via the precipitation perforated basket centrifuge, fine ore filter liquor is fed into concentration flotation equipment to be concentrated, and concentration tail coal and overflow of the ball mill return to roughing pulp mixing operation together via a pipeline to besorted again. Accordingly, low-ash and high-recovery-rate flotation clean coal is obtained. The sorting process not only avoids influence of high-ash content and fine particle slime and integrated ore to a floatation process, but also avoids contradiction between the quality and the recovery rate of a high-ash difficult-separation coal slime sorted product.

Owner:CHINA UNIV OF MINING & TECH

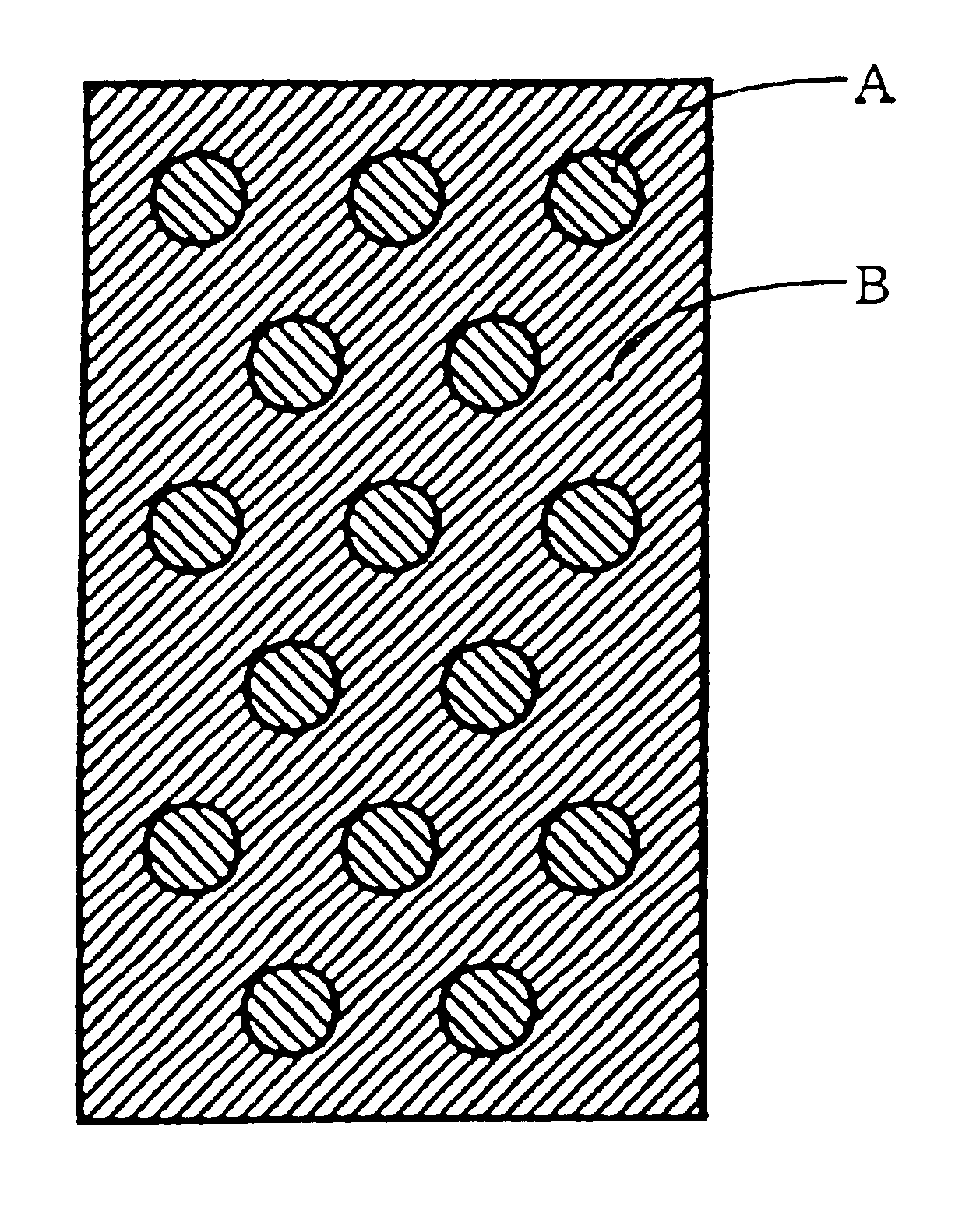

Apparatus for producing deionized water

InactiveUS6334941B1Improve the level ofReduce movement distanceSludge treatmentMachines/enginesIon-exchange membranesPolymer chemistry

An apparatus for producing deionized water, which has an ion exchanger accommodated in demineralizing compartments of an electrodialyzer having cation exchange membranes and anion exchange membranes alternately arranged between an anode and a cathode, wherein the ion exchanger is a composite ion exchanger comprising a first porous ion exchanger having a mixture of 60 to 95 wt % of cation exchange resin particles and 5 to 40 wt % of anion exchange resin particles bonded to each other and a second porous ion exchanger having a mixture of 60 to 95 wt % of anion exchange resin particles and 5 to 40 wt % of cation exchange resin particles bonded to each other.

Owner:ASAHI GLASS CO LTD

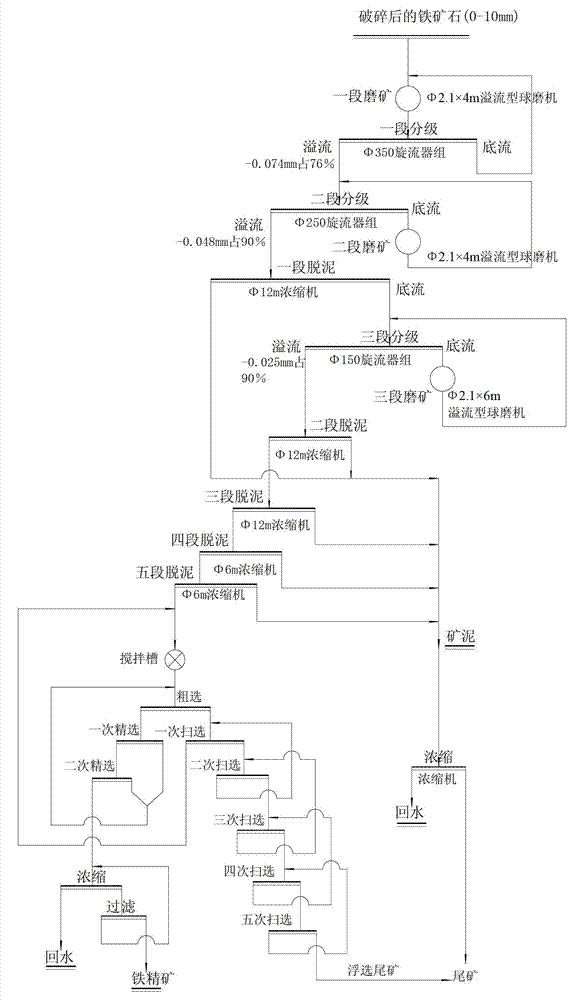

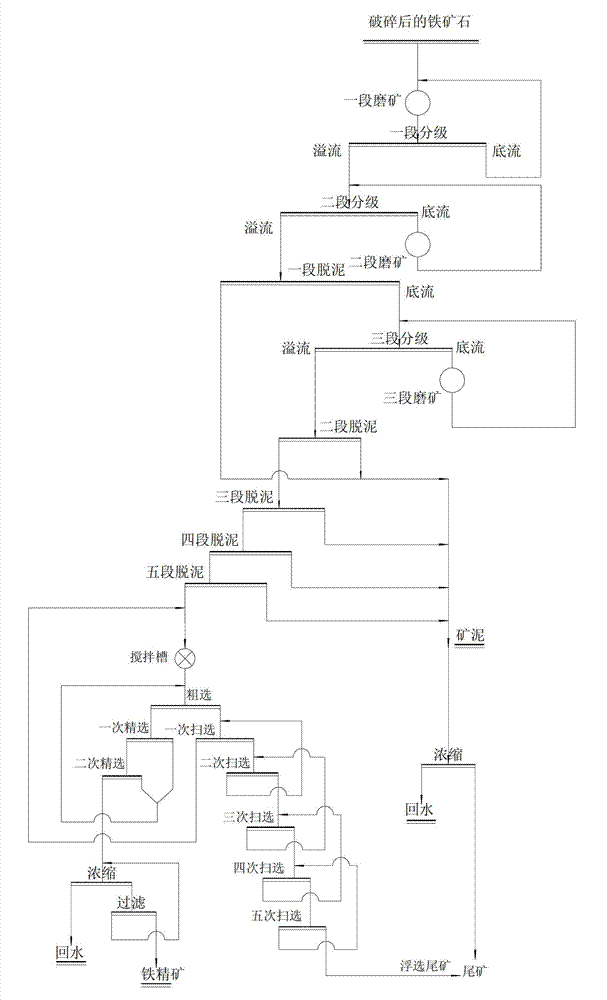

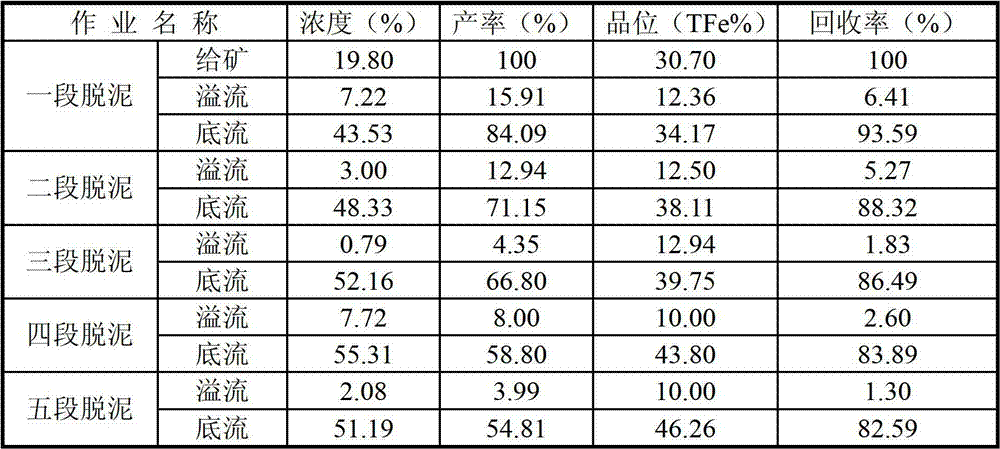

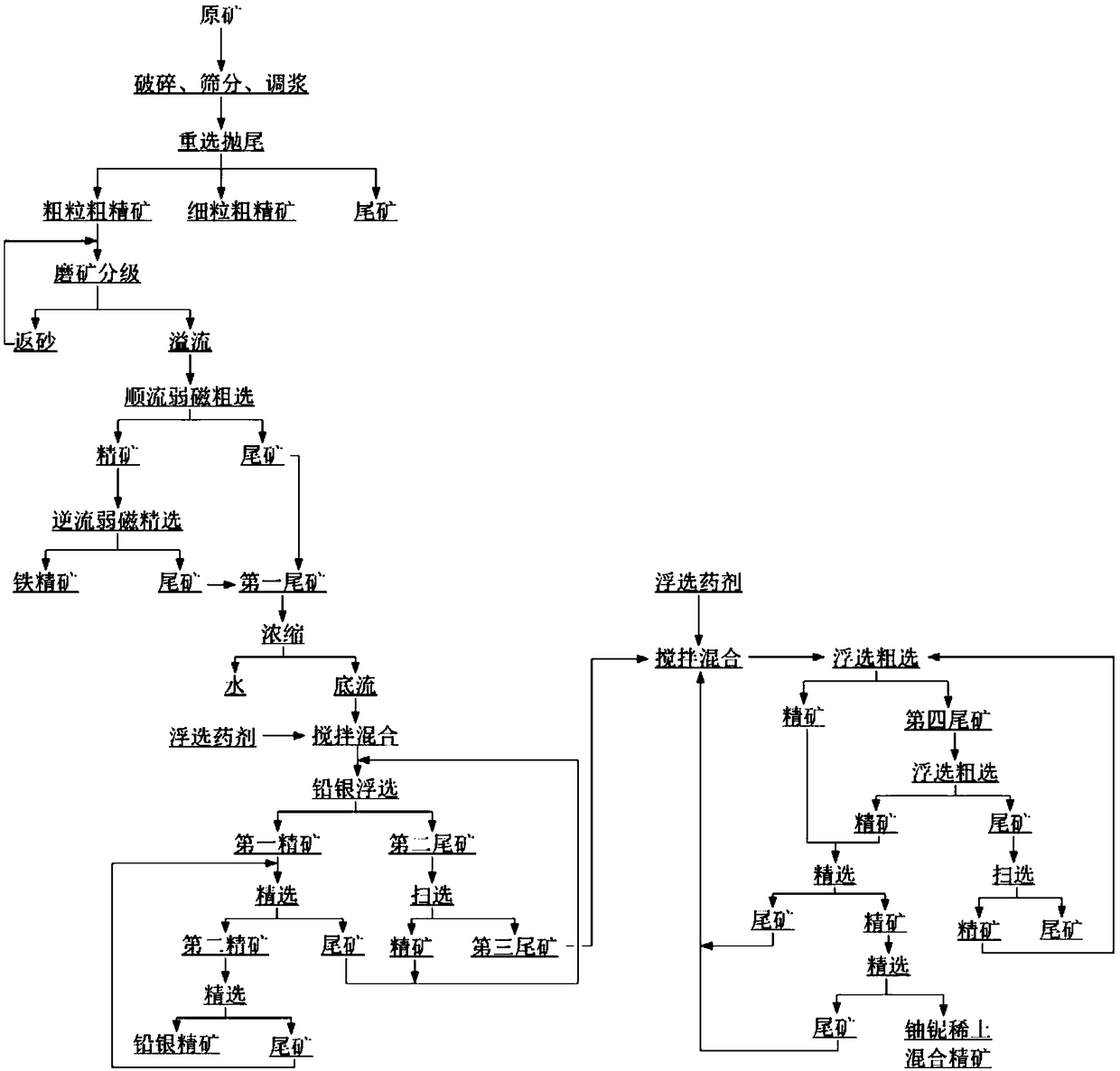

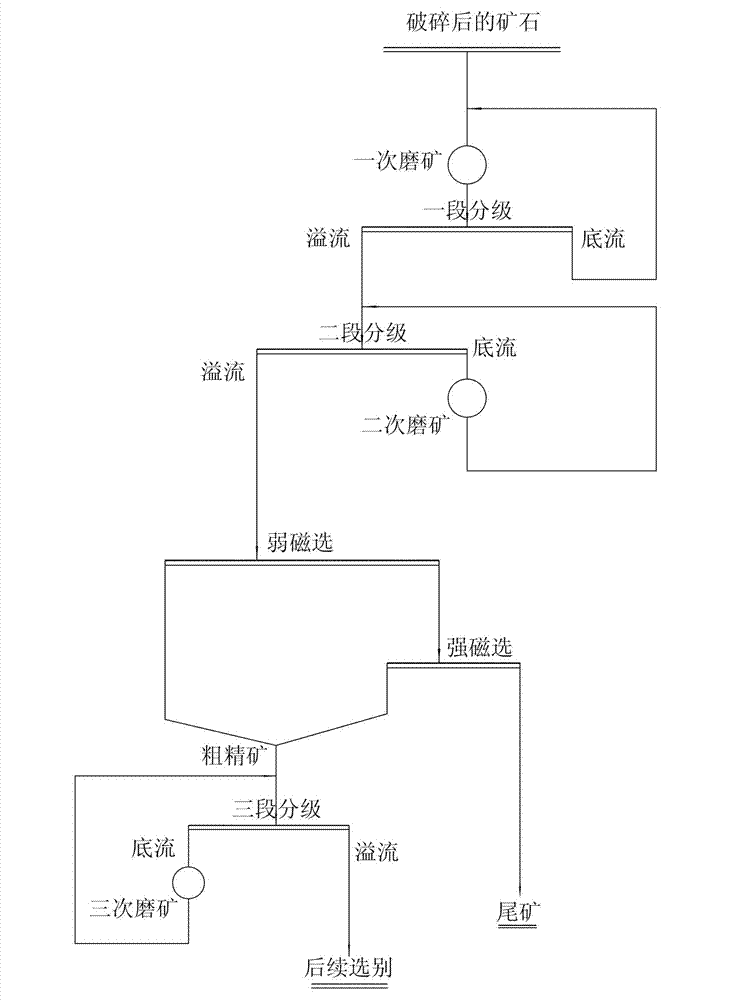

Ore benefication process for low-grade fine particle grade embedded distribution refractory iron ore

ActiveCN102806139AEliminate the effects ofGood desliming effectDifferential sedimentationGrain treatmentsFlocculationThree stage

The invention discloses an ore benefication process for low-grade fine particle grade embedded distribution refractory iron ore. The process comprises the following steps that crushed ore products are firstly subjected to one-stage ore grinding and one-stage grading, underflow after the grading is returned for re-grinding, and overflow is subjected to two-stage grading; underflow after the second-stage grading is subjected to second-stage ore grinding, ore grinding discharge materials are returned to the second-stage grading, and overflow is subjected to one-stage desliming; underflow after the desliming is subjected to three-stage grading and three-stage ore grinding, ore grading discharge materials are returned to three-stage grading, and overflow is subjected to second-stage desliming; next, three-section, four-section or five-section or more-section desliming is sequentially carried out; underflow after the desliming starts to be subjected to reverse flotation after the stirring, rougher flotation is firstly carried out, products in a groove after the rougher flotation are subjected to fine selection, foam products after the fine selection are returned to a rougher flotation groove, and products in a groove after the fine selection are concentrated and filtered to obtain ore concrete; and concentration machines and selective flocculation desliming processes are respectively adopted for each stage of desliming. The process provided by the invention has the advantages that the investment cost is low, the occupied area is small, the production and the maintenance are simple and convenient, the adaptability is high, the fine grinding desliming effect is good, and the like.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

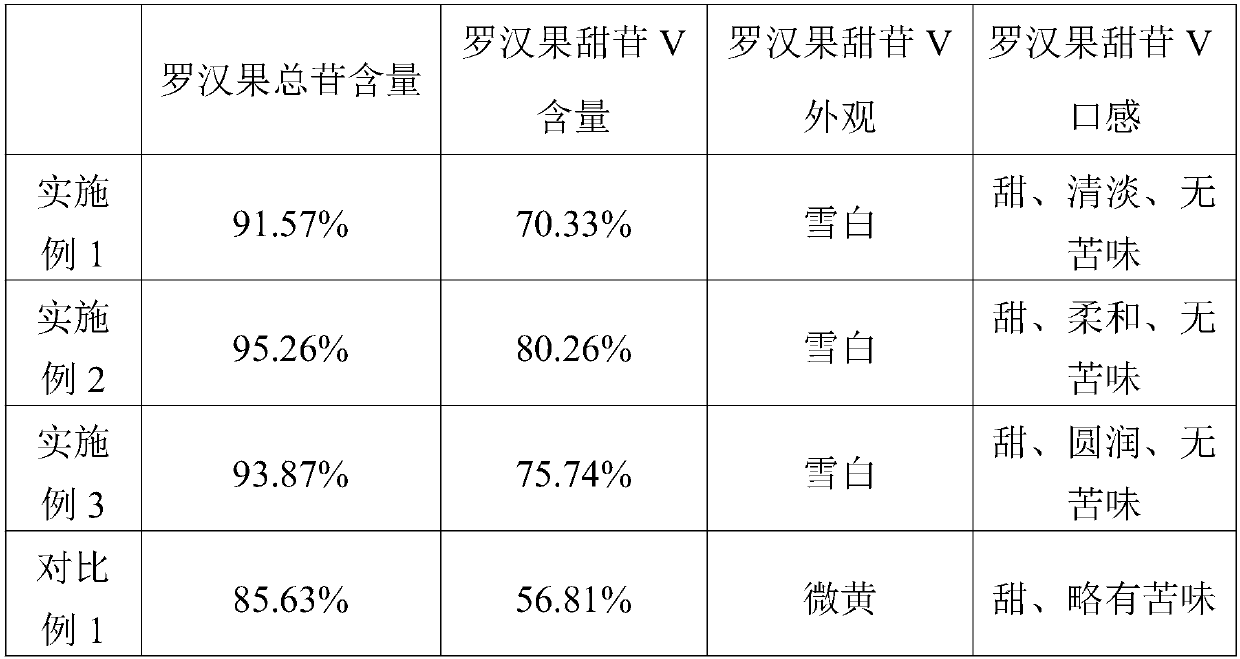

Method for separating mogroside V

The invention relates to the field of extraction and purification of plant effective components, and especially provides a method for separating mogroside V from grosvenor momordica fruits. The methodfor separating mogroside V comprises the following steps: addition of water to grosvenor momordica fruits, pulping, phytoenzyme enzymatic hydrolysis, biological enzyme hydrolysis, collection of the obtained enzymatic hydrolysate, enzyme deactivation, yeast fermentation, composite anion-cation exchange resin purification, and concentration drying for preparing the mogroside V. The product preparedthrough the production method has the advantages of snowy white color, no bitterness, small solvent residual, no pesticide residue and stable quality; and the content of the mogroside V in the product is greater than 60%, and total glycoside content of the product is greater than 90%.

Owner:GUILIN NATURAL INGREDIENTS CORP

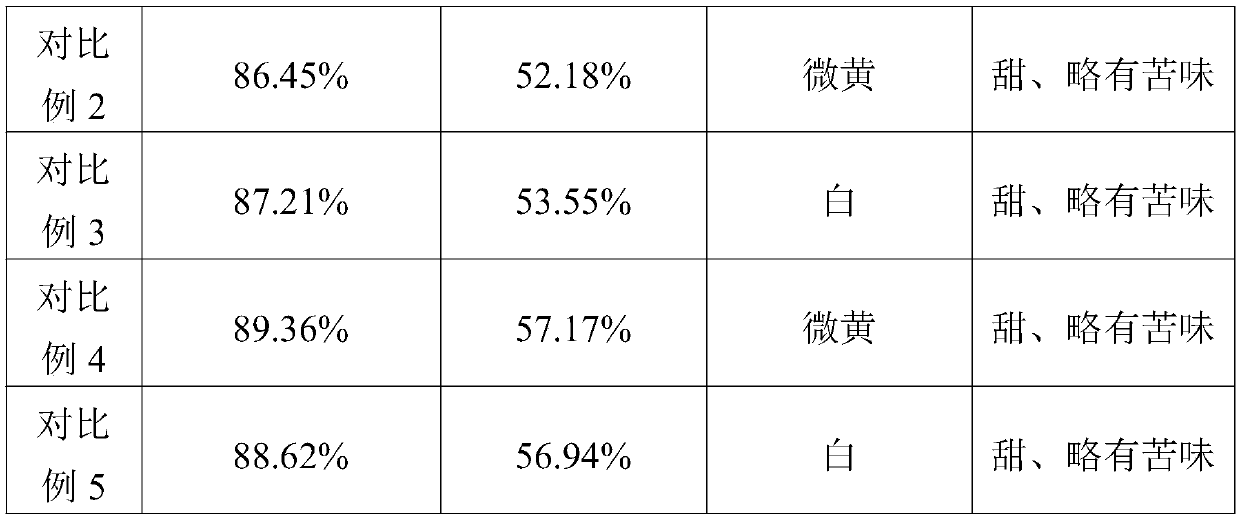

Comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore

The invention provides a comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore. The comprehensive recovery and beneficiation method comprises the followingsteps that (1) overflow products obtained by grinding the uranium-containing polymetallic ore are subjected to direct flow magnetic separation roughing operation and reverse flow magnetic separation concentration operation in sequence, and iron concentrate and first tailings are obtained; (2) the tailings are subjected to condensation and flotation to obtain first concentrate and second tailings,the first concentrate is subjected to concentration to obtain lead silver concentrate, and the second tailings are subjected to scavenging to obtain third tailings; and (3) the third tailings are subjected to flotation roughing and condensation, and then uranium, niobium and rare earth mixed concentrate is obtained. The beneficiation index is good, the purpose of fully recovering all useful components in coarse-grain coarse concentrate subjected to tailing discarding through gravity concentration under the coarse grinding condition is achieved, an efficient beneficiation separation and enrichment technology is provided for large-scale development and utilization of the low-grade complex polymetallic hard rock uranium ore in China, and the subsequent cost of extracting uranium, niobium andrare earth in the uranium ore through hydrometallurgy is greatly lowered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Fine grinding process for micro fine grain ore

ActiveCN102773155ALow investment costSmall footprintGrain treatmentsWet separationBall millSmall footprint

The invention discloses a fine grinding process for micro fine grain ore. The fine grinding process comprises first-stage ore grinding, second-stage ore grinding and a third-stage ore grinding in sequence, wherein ball mills are adopted in the first-stage ore grinding, the second-stage ore grinding and the third-stage ore grinding for ore grinding, and swirlers are adopted for grading; the draw ratio of the ball mills adopted in the three stages of ore grinding is 2.5-3.0; a ore grinding medium adopted in the three stages of ore grinding is preferably a steel section, and the filling quantity of the steel section is 20%-40% of the volume of a barrel body of the ball mills. The process provided by the invention has the advantages of being low in investment cost, small in space area, simple and convenient to produce and maintain, efficient and low in consumption, easy to implement, produce and operate and the like.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

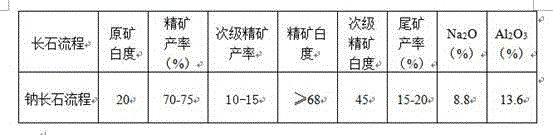

Method for efficiently preparing feldspar glazes for ceramics

The invention discloses a method for efficiently preparing feldspar glazes for ceramics. The method comprises the following specific steps: after raw feldspar ores are crushed, grinding the raw feldspar ores by a high-alumina ball grinding mill, classifying the raw feldspar ores in a spiral manner by a spiral classifier, and screening the raw feldspar ores by a high-frequency classifying screen, so that the sufficient dissociation of feldspar mines and the controlling the granularity can be ensured, the feeding granularity of the fed feldspar mines can be ensured, and conditions for the following magnetic separation and the classifying processes of a cyclone are created; separating and effectively removing magnetic impurities of the raw feldspar ores by the magnetic separation with various intensity in a classifying and multi-section manner of the granularity, increasing the kinds of products, and increasing the recovery of resources. Through the use of the technologies, such as the classification of the cyclone, the permanent magnet iron removal of a drum magnetic separator, the iron removal of a vertical ring pulsating high-gradient strong magnetic separator and the like, the adaptability and the reliability are greatly improved, the quality of the concentrates is effectively ensured and stabilized, the risk due to fluctuation of the impurity content is reduced, the separating efficiency and the comprehensive utilization of resources are improved, and the efficiently comprehensive utilization of the feldspar resources is realized.

Owner:赣州金环磁选科技装备股份有限公司

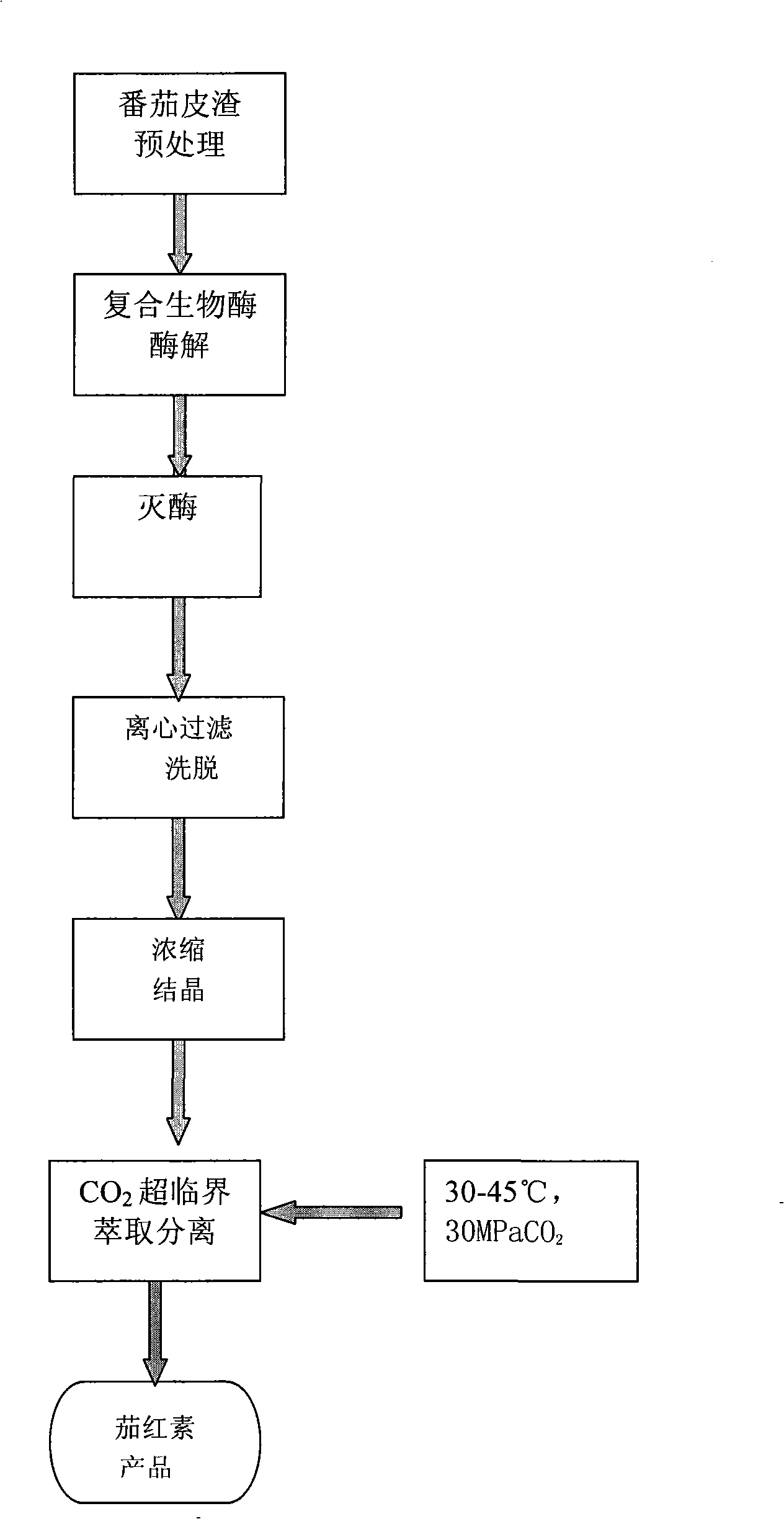

Method for extracting lycopene from tomato pomace

The invention relates to a method for extracting lycopin with tomato skins and marcs and belongs to the field of the extraction of native compounds. By utilizing the composition of three kinds of neutral and alkalic bio-enzymes under neutral and alkalinity leaning condition, the method realizes complete enzymolysis of the tomato skins and marcs and complete dissociation of the lycopin, and by combining with the extraction technique that is combined with CO2 supercritical technique, the method for extracting the lycopin leads wastes to be reclaimed and recycled, greatly improves the utilization rate and the added value of agricultural resources, and simultaneously reduces environmental pollution; the method for extracting the lycopin from the tomato skins and marcs achieves that the lycopin extraction rate is larger than 80 percent and the purity of the obtained product is larger than 95 percent, does not have solvent residue, and holds a lead in the world concerning the research. A bio-enzymatic method of the method for extracting the lycopin from the tomato skins and marcs adopts the three kinds of enzymes that have similar enzymolysis conditions, implements the enzymolysis under the same condition, and does not need to adjust the pH value of an enzymolysis solution for multiple times, thus having simple technique and easy operation, the production cost of the lycopin can be greatly reduced by adopting the production technique of the invention, and the method for extracting the lycopin from the tomato skins and marcs has remarkable economical benefits and important social meanings.

Owner:上海博翼有机农业技术发展有限公司

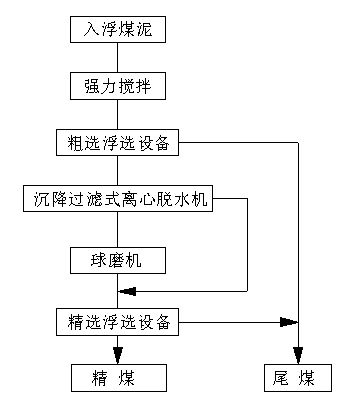

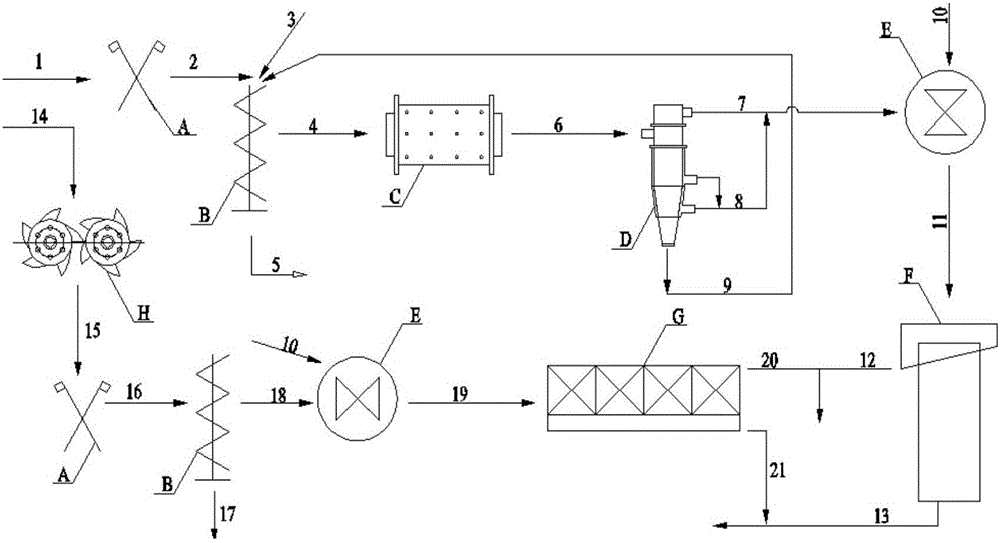

Coarse clean coal regrinding recleaning separation technique

The invention discloses a coarse clean coal regrinding recleaning separation technique, comprising the following steps of: firstly taking a floating agent and coal floatation into a stirring barrel; stirring, pulping, and automatically flowing to a roughing floatation column or a floatation machine; obtaining floated coarse clean coal and roughing floatation tailing coal after roughing floatation through the floatation column or the floatation machine; taking the floated coarse clean coal into a precipitation filter type centrifugal dehydrator to carry out dehydration operation so as to obtain coarse clean coal products and clean coal filter liquor; directly taking the clean coal filter liquor into the clean floatation column or the floatation machine to carry out cleaning operation; taking the coarse clean coal into a ball grinder to carry out ore grinding operation; and taking the grinded coarse clean coal products to the clean floatation column or the floatation machine to carry out cleaning operation so as to obtain final clean coal and cleaned tailing coal. According to different coal quality conditions, the cleaned tailing coal can be used as final tailing coal, or returned to an ore pulp preparation operation for re-separation, therefore the recovery rate of the floatation clean coal is improved. The coarse clean coal regrinding recleaning separation technique has the advantages of simple technique, less investment, low power consumption, low operation cost, high separation efficiency and obvious economic benefits.

Owner:CHINA UNIV OF MINING & TECH

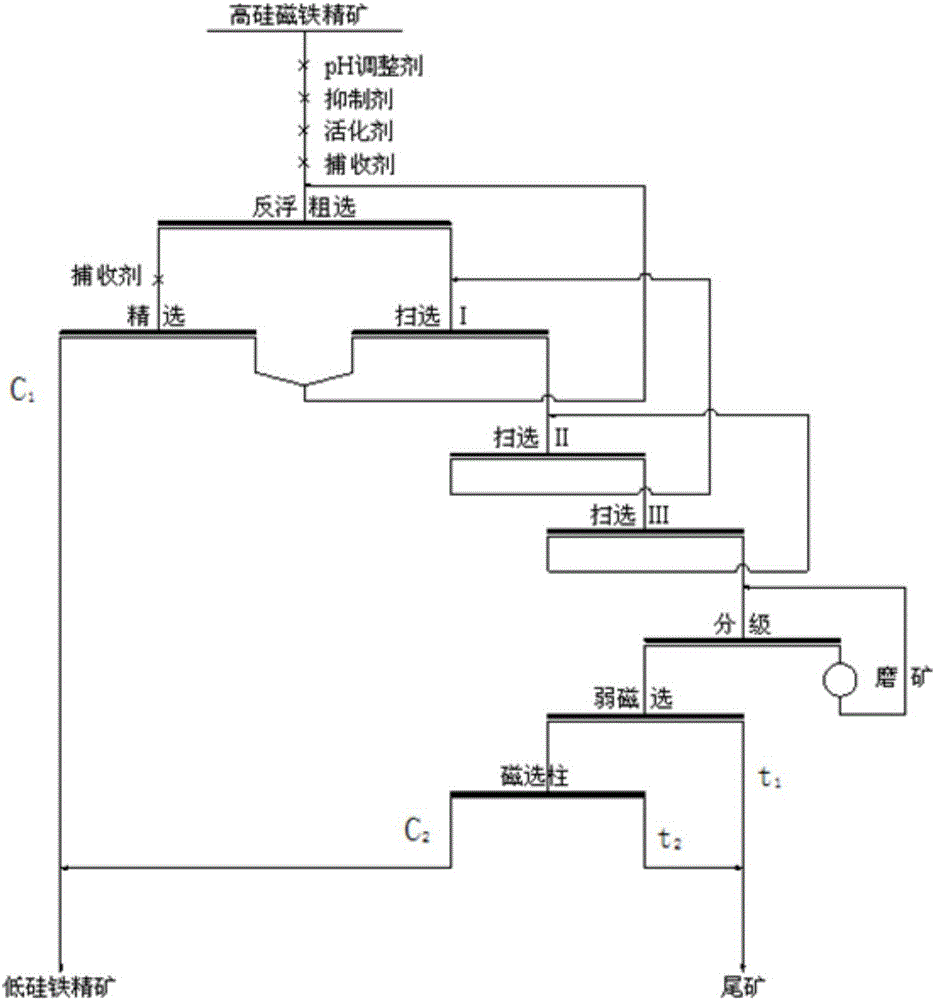

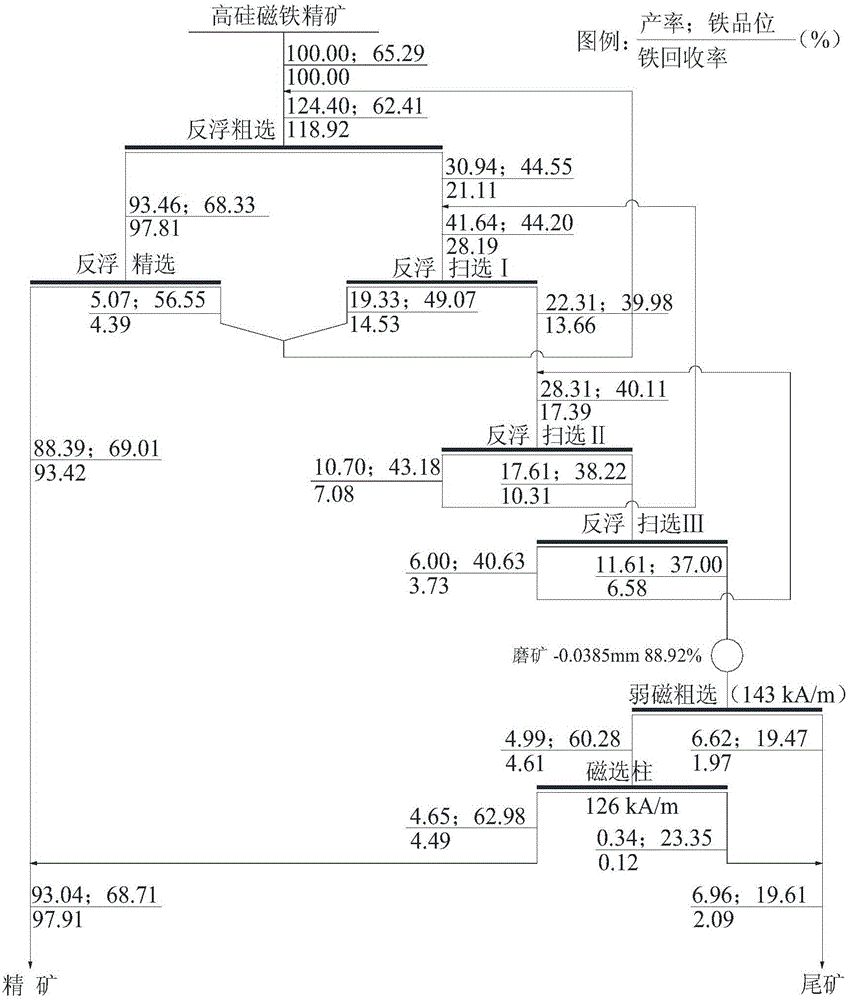

Beneficiation method for reducing content of SiO2 in magnetite concentrate

InactiveCN105728176AReduce SiO <sub>2</sub> contentSiO <sub>2</sub> Low contentDifferential sedimentationFlotationMagnetiteReverse flotation

The invention discloses a method for reducing SiO in magnetite concentrate 2 The beneficiation method adopts the following process: 1) Anion reverse flotation of high-silicon magnetite concentrate to obtain TFe≥68.75%, SiO 2 High-quality low-silicon ferrosilicon concentrate C with content <3.0% 1 , and discharge anion reverse flotation tailings; 2) anion reverse flotation tailings pre-classification-regrinding-weak magnetic separation to obtain weak magnetic separation concentrates; 3) weak magnetic separation magnetic re-separation concentrates to further obtain TFe≥ 62.5%% Magnetic Gravity Separation Iron Concentrate C 2 . The invention has the advantages of high grade iron concentrate, SiO 2 It has the advantages of low content, high iron recovery rate, small loss of fine-grained iron minerals, low energy consumption for beneficiation, stable indicators, and easy operation and management on site.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

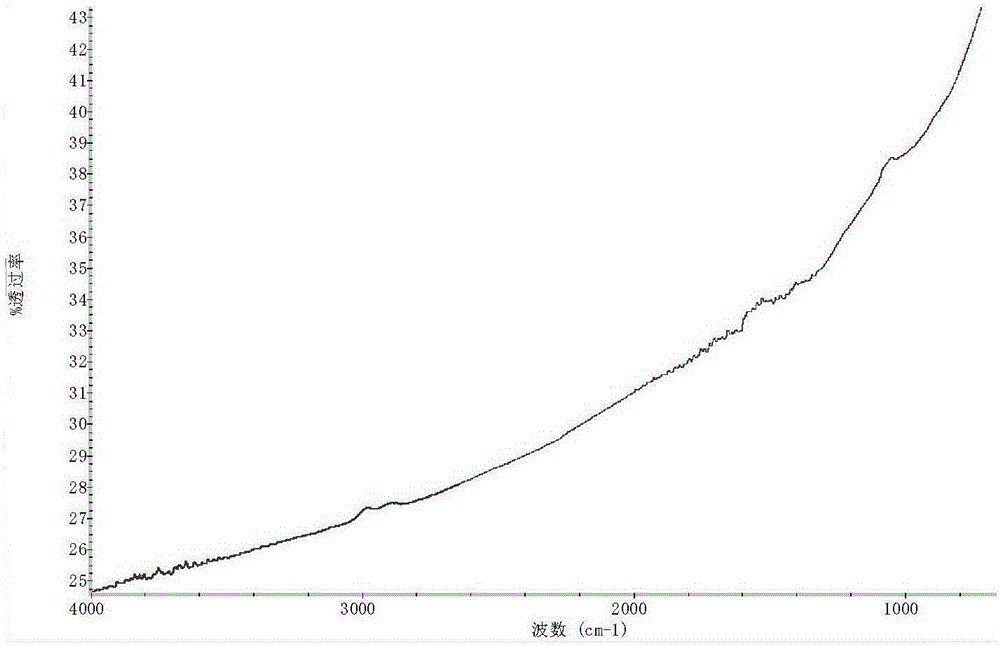

Aqueous graphene slurry and preparation method thereof

InactiveCN108455584AGood size controlRealize mass productionGrapheneConductive coatingSupercapacitor

The invention discloses aqueous graphene slurry and a preparation method thereof. The aqueous graphene slurry comprises aqueous dispersion liquid and a graphene material dispersed in the aqueous dispersion liquid, wherein the aqueous dispersion liquid contains a surfactant, and the mass content of graphene is 0.2 to 12%. The preparation method for the aqueous graphene slurry comprises the following steps: with a graphite oxide solid or an expandable graphite solid as a raw material, performing expansion treatment to prepare expanded graphite; immersing the expanded graphite in an aqueous stripping solution for infiltration treatment to obtain a mixture containing the expanded graphite; subjecting the mixture containing the expanded graphite to high-speed shearing or ultrasonic treatment toremove the aqueous stripping solution and obtain a wet graphene material; and adding the wet graphene material in aqueous dispersion liquid, and carrying out high-speed shearing to obtain aqueous graphene slurry. The aqueous graphene slurry prepared by using the method of the invention can be applied to the fields of electroconductive and heat-conductive coatings, anticorrosive coatings, batteries / supercapacitors and the like.

Owner:HAIMEN CITY RUITAI TEXTILE TECH CO LTD

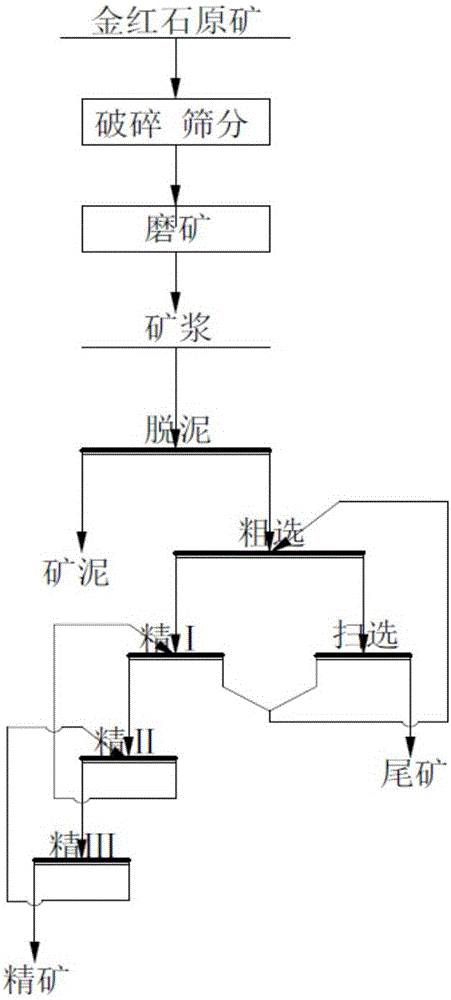

Method for improving rate of recovery of floatation of rutile

The invention discloses a method for improving rate of recovery of floatation of rutile. The method comprises the following steps: after pulverizing and grinding primary minerals of the rutile, pulping to obtain pulp; carrying out gravity concentration on the pulp to remove slime; and carrying out flotation separation by taking H2SO4 as a pH regulator, ethylenediamine tetraacetic acid as an ion complexing agent, Al2(SO4)3 as a rutile activating agent, sodium fluosilicate as a gangue mineral inhibitor, and styryl phosphonic acid and n-octanol as compound collectors to obtain rough concentrate of the rutile. By the method, relatively high rate of recovery of flotation and grade of the rutile can be guaranteed, chemical costs in a flotation process can be reduced, and the problem of low rate of recovery of flotation of low-grade primary rutile is solved.

Owner:CENT SOUTH UNIV

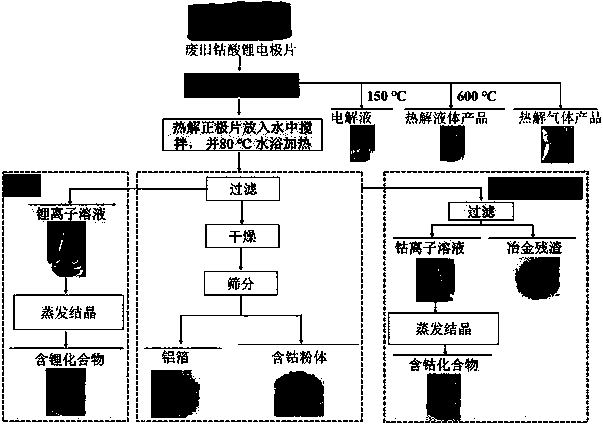

Method for recycling valuable components from waste lithium cobalt oxide battery positive electrode sheet

ActiveCN110541077AImprove metallurgical efficiencyEfficient dissociationWaste accumulators reclaimingProcess efficiency improvementScreening methodLithium compound

The invention discloses a method for recycling valuable components from a waste lithium cobalt oxide battery positive electrode sheet, and belongs to the field of waste lithium battery recycling. According to the method, residual electrolyte and an organic binding agent in the positive electrode sheet are removed by using a pyrolysis method, and the thermal reduction of the positive electrode sheet lithium cobalt oxide is synchronously realized; efficient dissociation of the positive electrode sheet material particles and the aluminum foil is realized through hydraulic stirring and water bathheating, and the purposes of ion formation of the water-soluble lithium-containing compound and separation of the lithium element and the cobalt element are achieved synchronously; separating and purifying of the electrode material and the aluminum foil are achieved by adopting a screening method; and purifying of the cobalt element is achieved through an acid leaching method by means of an acid without a reducing agent. According to the technical scheme of the method, the purposes of removing organic matters in the electrode sheet and performing metal ion thermal reduction are achieved synchronously.

Owner:CHINA UNIV OF MINING & TECH

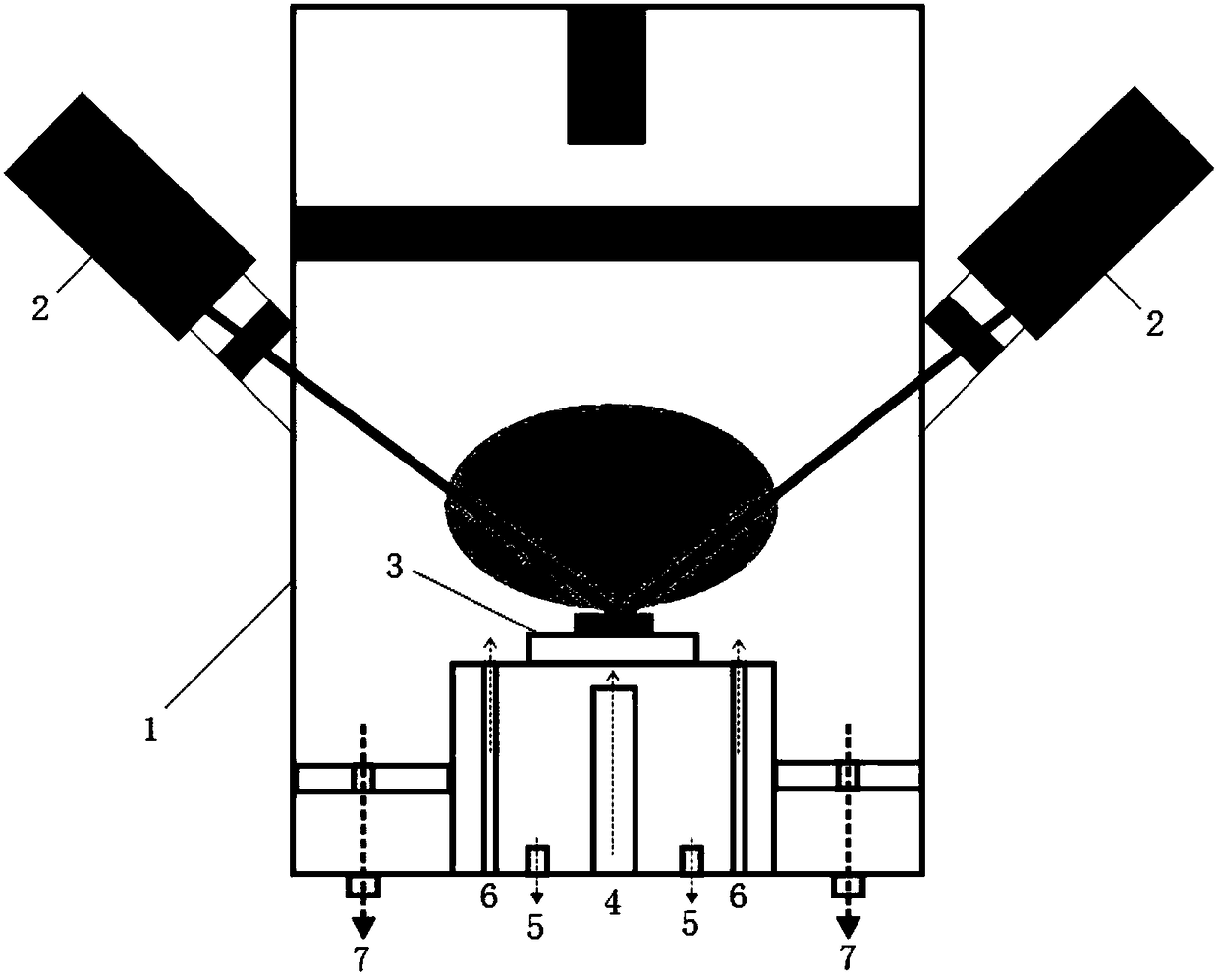

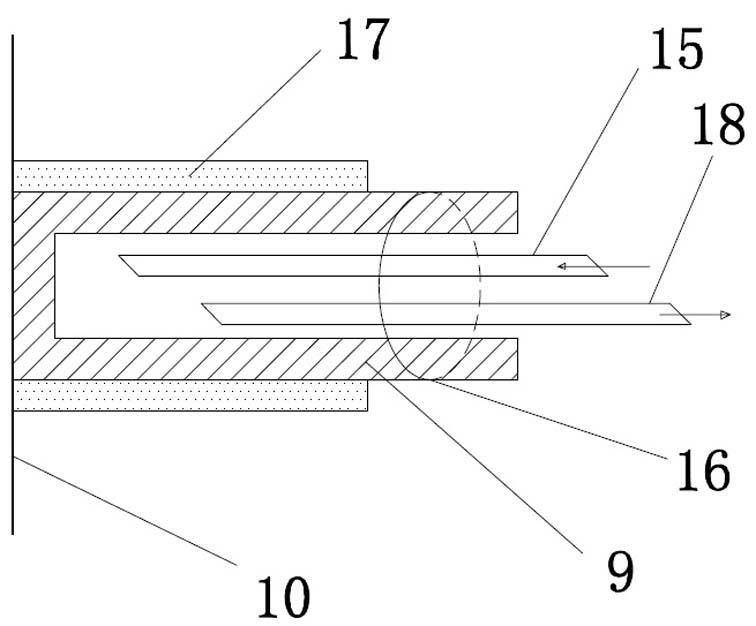

Device and method for preparing single crystal diamonds by laser enhanced plasma CVD

ActiveCN108251892AHigh densityIncrease dissociation ratePolycrystalline material growthFrom chemically reactive gasesMicrowaveSingle crystal

The invention discloses a device and method for preparing single crystal diamonds by laser enhanced plasma CVD. The device comprises plasma CVD equipment and laser equipment, wherein more than 1 set of laser equipment is respectively positioned on the outside of a cylindrical cavity of the plasma CVD equipment, laser emitted by the laser equipment can irradiate onto a substrate table positioned inthe cavity of the plasma CVD equipment; the substrate table is positioned in the middle of the cavity of the plasma CVD equipment, a cooling water circulation system is arranged at the lower part ofthe substrate table and comprises a cooling water inlet and a cooling water outlet; and a raw material gas inlet and an extraction opening are formed in the bottom of the cavity of the plasma CVD equipment. The method combines microwave energy (or electric energy) with laser energy and improves the energy of plasma and the gas dissociation rate in a diamond synthesizing process by using low-cost high-energy laser, thereby improving the synthetic rate of the diamonds and effectively solving the problem of high-speed mass preparation of diamonds.

Owner:湖北碳六科技有限公司

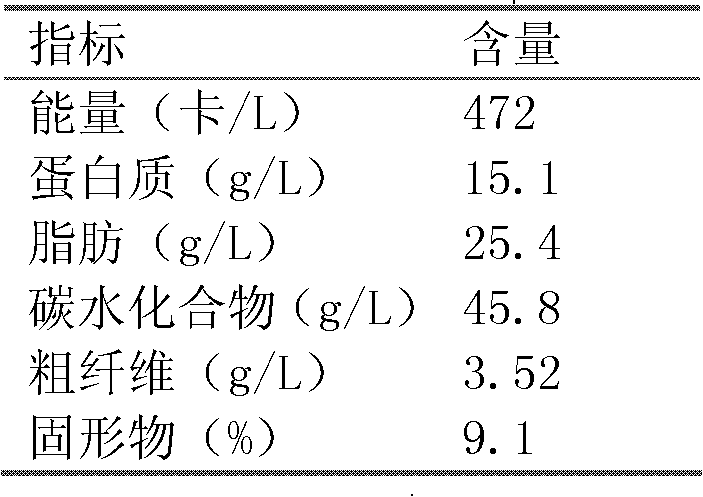

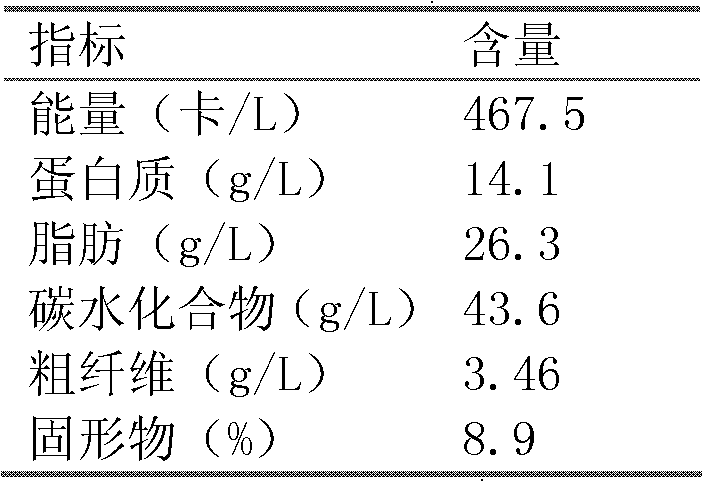

Production method of natural rice bran beverage

InactiveCN102224967ARetain functional nutrientsImprove EdibilityFood preparationCelluloseHigh pressure

The invention relates to a production method of a natural rice bran beverage. The method is mainly characterized by taking rice bran as a raw material and comprising the following steps: adding a certain amount of water into the rice bran; crushing with a colloid mill; sequentially adding protease, tannase, amylase and glucoamylase to perform composite enzymolysis; filtering the enzymolysis liquid; and performing the processes of seasoning, homogenizing, instantaneously sterilizing at a high temperature, canning and the like to obtain the finished product. By adopting the technology such as biological compound enzyme, high-pressure homogenizing and the like to process the rice bran, the method provided by the invention increases the content of soluble cellulose in rice bran, reduces the starch content and improves the edibility of rice bran on one hand, and on the other hand, sufficiently enables the nutrient components and functional substances in rice bran to be free and change intosubstances that can be directly absorbed by a human body and become a novel grain beverage integrating nutrition and functions.

Owner:TIANJIN UNIV OF SCI & TECH

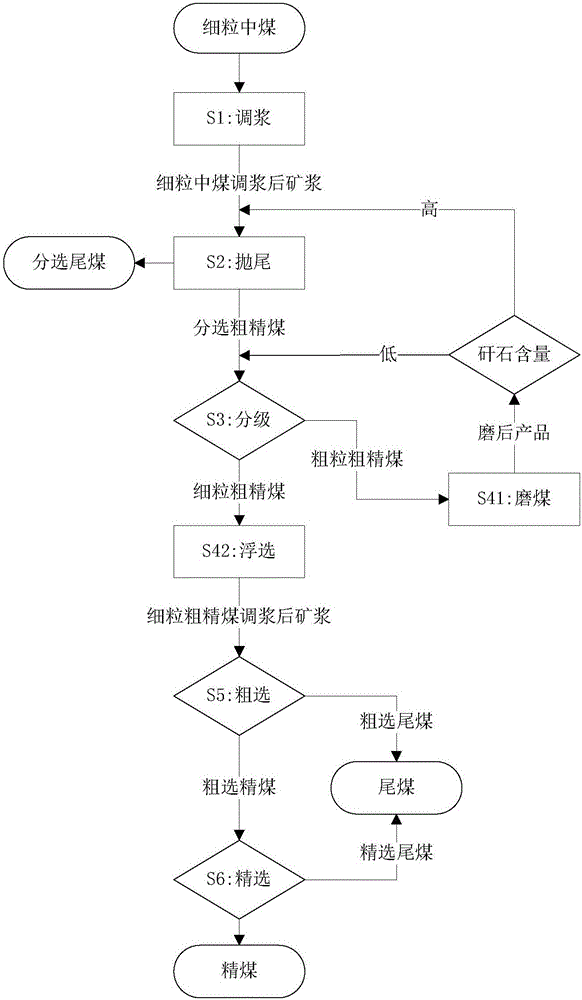

Dissociation and recleaning technology for coking fine grain middling coal

The invention relates to a dissociation and recleaning technology for coking fine grain middling coal. The technology comprises the processes that the size mixing operation is conducted on the fine grain middling coal; the operation of pretreating ore to remove tailings is conducted through coarse slime separation equipment; classification is conducted through classification equipment, and fine grain coarse clean coal and coarse grain coarse clean coal are produced; dissociation is conducted on the coarse grain coarse clean coal through coal grinding equipment; the flotation operation is conducted on fine grain coarse clean coal through size mixing equipment; after size mixing is conducted on the fine grain coarse clean goal through rough separation equipment, rough separation clean coal is produced; and concentrate is conducted on the rough separation clean coal through cleaning equipment, and the clean coal is produced. The dissociation and recleaning technology has the beneficial effects that the process is simple, the technology is mature, the investment is small, the operating cost is low, and the economic benefits are remarkable; the ash content of the tailings is guaranteed, and meanwhile the materials with the medium ash content and the low ash content are fully dissociated; and it is avoided that gangue enters a grinding machine, the load of the grinding machine is reduced greatly, the energy consumption is lowered, and the recovery rate of the tailings and the clean coal is increased.

Owner:CHINA UNIV OF MINING & TECH

Method for growing nanocrystalline silicon powder

The invention discloses a method for growing nanocrystalline silicon powder. The method comprises the following steps: introducing gas mixture into a reaction chamber from gas inlet pipelines; inputting radio frequency alternating current into electrodes which are vertically arranged by a radio frequency source to cause working gases to discharge to form a plasma zone between quartz plates; enabling reactive gases to be decomposed by plasmas in the plasma zone, and enabling fragments obtained after decomposition to form nanocrystalline silicon cores; controlling the time spent on flowing through the plasma zone by the reactive gases by adjusting the flow of the introduced gases and / or adjusting the pressure of the reaction chamber, and controlling the sizes of the grown nanocrystalline silicon particles by controlling the retention time; and enabling the nanocrystalline silicon particles to stop growing after flowing out of the plasma zone along with airflow, and carrying out collection on a connection net to obtain the nanocrystalline silicon powder with uniformly distributed particle sizes. The method disclosed by the invention is simple to operate, has lower requirements for temperature, dispenses with heating devices, can be used for producing nanocrystalline silicon powder with uniformly distributed and controllable particle sizes, and can realize industrial production.

Owner:HEBEI UNIVERSITY

Method for preparing fine water coal slurry by utilizing coal slime in coal preparation plant

InactiveCN102764702AReduce energy consumptionFine granularityDifferential sedimentationActivated carbonFuel oil

The invention relates to a method for preparing fine water coal slurry by utilizing coal slime in a coal preparation plant, solving the problems that a product bin can be easily blocked and unloading and quality accidents can be easily caused after washing cleaned coal is doped in the existing coal slime treatment. The method comprises the following steps of: a, firstly carrying out conventional floatation on the coal slime, and reselecting to further eliminate gangue after the coal slime at the density class of 1.8g / cm<3> is obtained; b, smashing the coal slime subjected to the floatation for 20min until average particle size is 7.26Mum; c, preparing the coal slime into water coal slurry with the concentration of 50g / l, and adding 120kg / t of flocculating agent No.2 for stirring and sorting, thus ultra-clean coal with yield of 82.06% and ash content of 1.94% is sorted; and d, adding naphthalene additive with the dosage of 1.0% to prepare the fine water coal slurry with the concentration of 56.15% and the viscosity of 980-1146mPa.s corresponding to shear rate of 100 / s. With the adoption of the method disclosed by the invention, the ultra-clean coal with the ash content being lower than 3% is sorted, the fine water coal slurry with the concentration being about 57% and the viscosity being about 1000mPa.s is prepared; a coarse crushing link is eliminated, energy consumption is saved; the fine water coal slurry can be taken as a raw material for carbon materials such as a carbon electrode and activated carbon; sulphur content of the ultra-clean coal is reduced; and heavy oil, diesel oil and natural gas can be replaced.

Owner:DATONG COAL MINE GRP

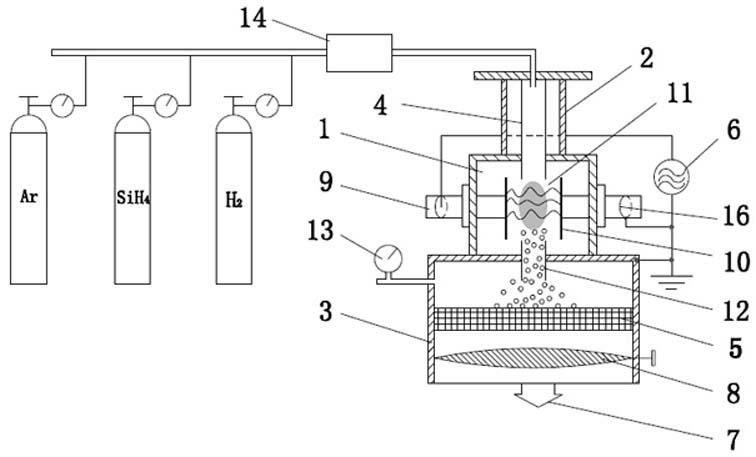

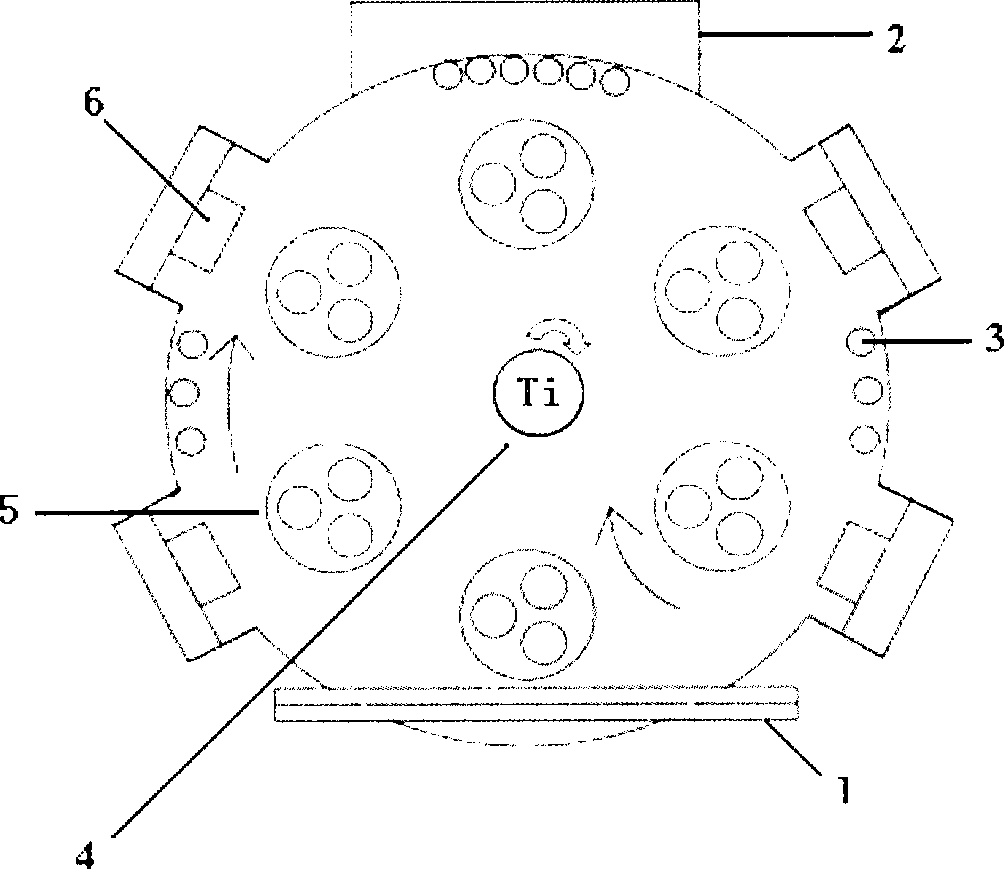

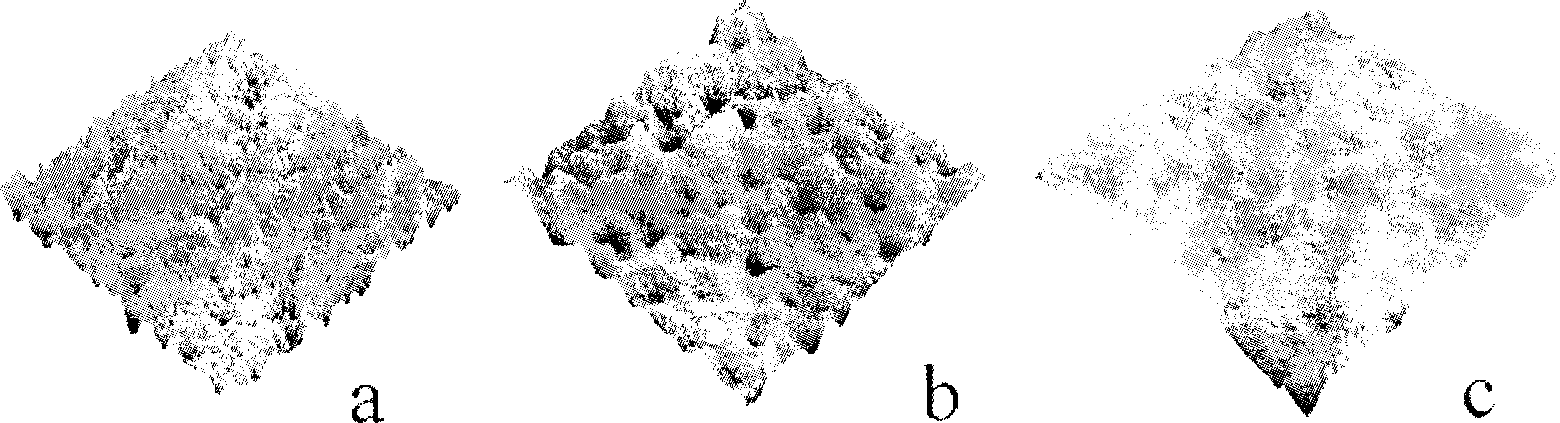

Method for preparing Ti-Si-N nanocrystalline-amorphous composite superhard coating

InactiveCN101457359AOvercome expensiveFast deposition rateVacuum evaporation coatingSputtering coatingCemented carbideIon

The invention discloses a method for preparing a Ti-Si-N nano-crystal-noncrystalline composite ultra-hard coating. The method employs high-density arc discharge controlled by a magnetic field to lead the Ti arc target to evaporate Ti; nitrogen and steam are ventilated so as to react with Ti to generate TiN; meanwhile, silane (SiH4) is inlet and decomposed to Si ions and H ions; the Si ions react with the nitrogen to generate Si3N4. Under bias pressure, the TiN crystal and the SiN4 competitively grow on the workpiece substrate simultaneously to form a film, thus generating the Ti-Si-N nano-crystal-noncrystalline composite coating. The prepared Ti-Si-N nano-crystal-noncrystalline composite coating has the advantages of high hardness, strong adhesion, fast growth speed of coating, high production efficiency, low production cost, simple structure of coating equipment, and the like; according to the use requirement, the preparation of the Ti-Si-N nano-crystal-noncrystalline composite coating of different thickness can be carried out on various workpieces such as hard alloy, stainless steel, carbon steel, and the like.

Owner:WUHAN UNIV

Method for recovering metal elements from waste and old ternary lithium-ion battery

ActiveCN108281730AEfficient removalEfficient decompositionWaste accumulators reclaimingBattery recyclingRecovery methodOrganic acid

The invention relates to a method for recovering metal elements from a waste and old ternary lithium-ion battery, belongs to the technical field of recovery of waste and old batteries, and aims at solving the problem that the conventional method is low in recovery rate of metal elements. The method comprises the following steps: disassembling the waste and old ternary lithium-ion battery, and collecting the powder of positive electrode materials of the battery; preprocessing the powder of the positive electrode materials with a mixed solution containing biogenic organic acid and bioflavonoid;filtering, and collecting the filtrate; selectively depositing the collected filtrate; recovering at least one metal element. According to the method, the adhesive component in the positive electrodematerial can be effectively removed and decomposed, so that the metal elements can be effectively separated and dissolved out, thus the dissolving rate is effectively increased, and the subsequent recovery effect of the metal elements can be ensured.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

Dissociation and recleaning process for coking middlings

ActiveCN105728155ALarge crushing ratioSmall amount of crushingSolid separationGrain treatmentsRefractoryEngineering

The invention discloses a dissociation and recleaning process for coking middlings which are high in ash content and refractory, and belongs to coal washing methods. The coking middlings are divided into lump middlings (+13 mm) and slack middlings (with the granularity of -13 mm, and including coarse granules in floatation tailings) according to the granularity. The dissociation and recleaning process for the lump middlings involves a crushing system, a spiral tailing discarding system and a floatation system according to the characteristics of the lump middlings. The dissociation and recleaning process for the slack middlings involves a crushing system, a coarse slime dissociation and recleaning system, a grading system and a floatation system. Full coverage is realized for recycling of the coking middling resources at different granularity grades, clean coal in the middlings is recycled to the maximum extent, and the process is simple, reliable, small in investment and remarkable in economical benefit.

Owner:CHINA UNIV OF MINING & TECH

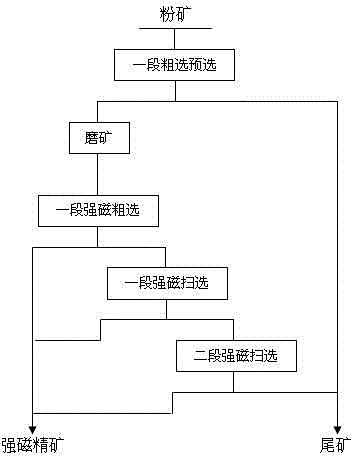

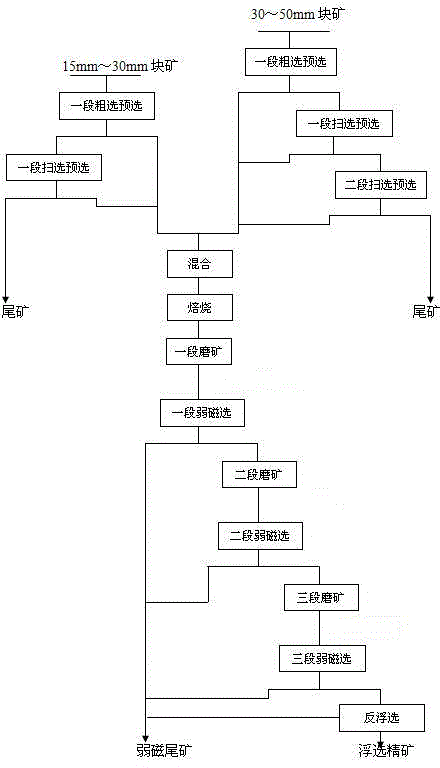

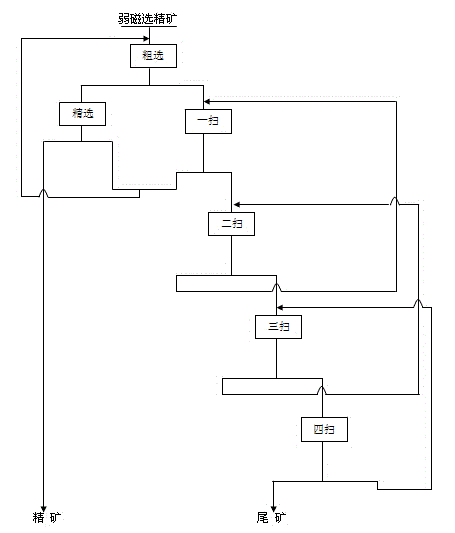

Separation method of high-silicon low-grade oxidized iron ore

ActiveCN104785347AAvoid inclusionsReduce subsequent beneficiation loadFlotationMagnetic separationBall millMaterials science

The invention provides a separation method of high-silicon low-grade oxidized iron ore. Raw ore is crushed and sieved, lump ore and powdery ore are obtained, and the lump ore is divided into two sizes of particles; the powdery ore and the lump ore with the two sizes of particles are pre-separated respectively, and powdery ore pre-separated concentrate and full-particle-size lump ore pre-separated concentrate are obtained; the powdery ore pre-separated concentrate is ground by a ball mill and then subjected to high-intensity magnetic separation including one-time roughing separation and two-time scavenging, and high-intensity magnetic concentrate is obtained; the full-particle-size lump ore pre-separated concentrate is subjected to three-section ore grinding and three-section low-intensity magnetic separation after sintering, and low-intensity magnetic concentrate is obtained; the low-intensity magnetic concentrate is subjected to reverse flotation, and flotation concentrate is obtained; the high-intensity magnetic concentrate and the flotation concentrate are mixed in the ratio being 1:1, and comprehensive concentrate is obtained. Different particle sizes of iron ore are deeply pre-separated through different processes, tailings are discarded in a grading manner, ore inclusions are avoided, waste stone is discarded to the greatest extent, and the follow-up ore separation load is reduced. Different means are adopted for purification in different links, the whole technology has high adaptability, finally, the iron grade is up to 53.58%, the content of SiO2 is reduced to 12%, and the metal recovery rate of the whole process is up to 70.9%.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

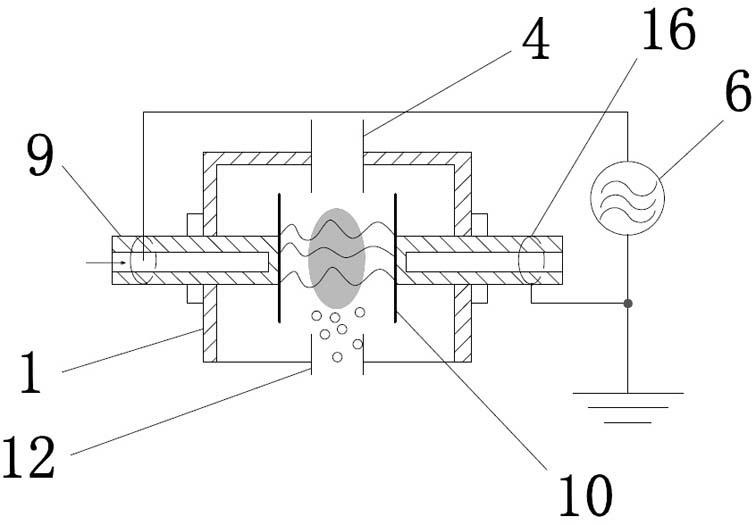

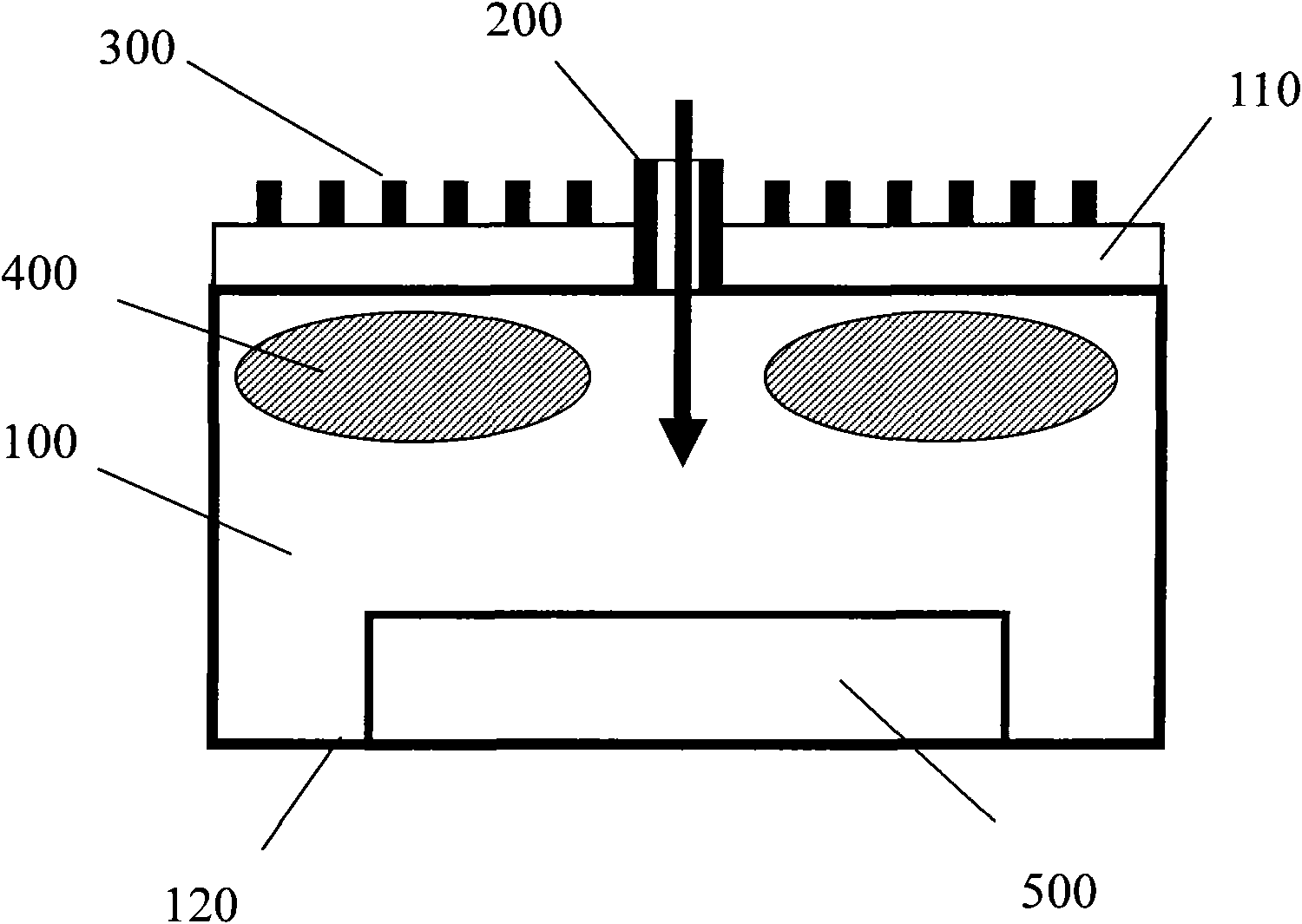

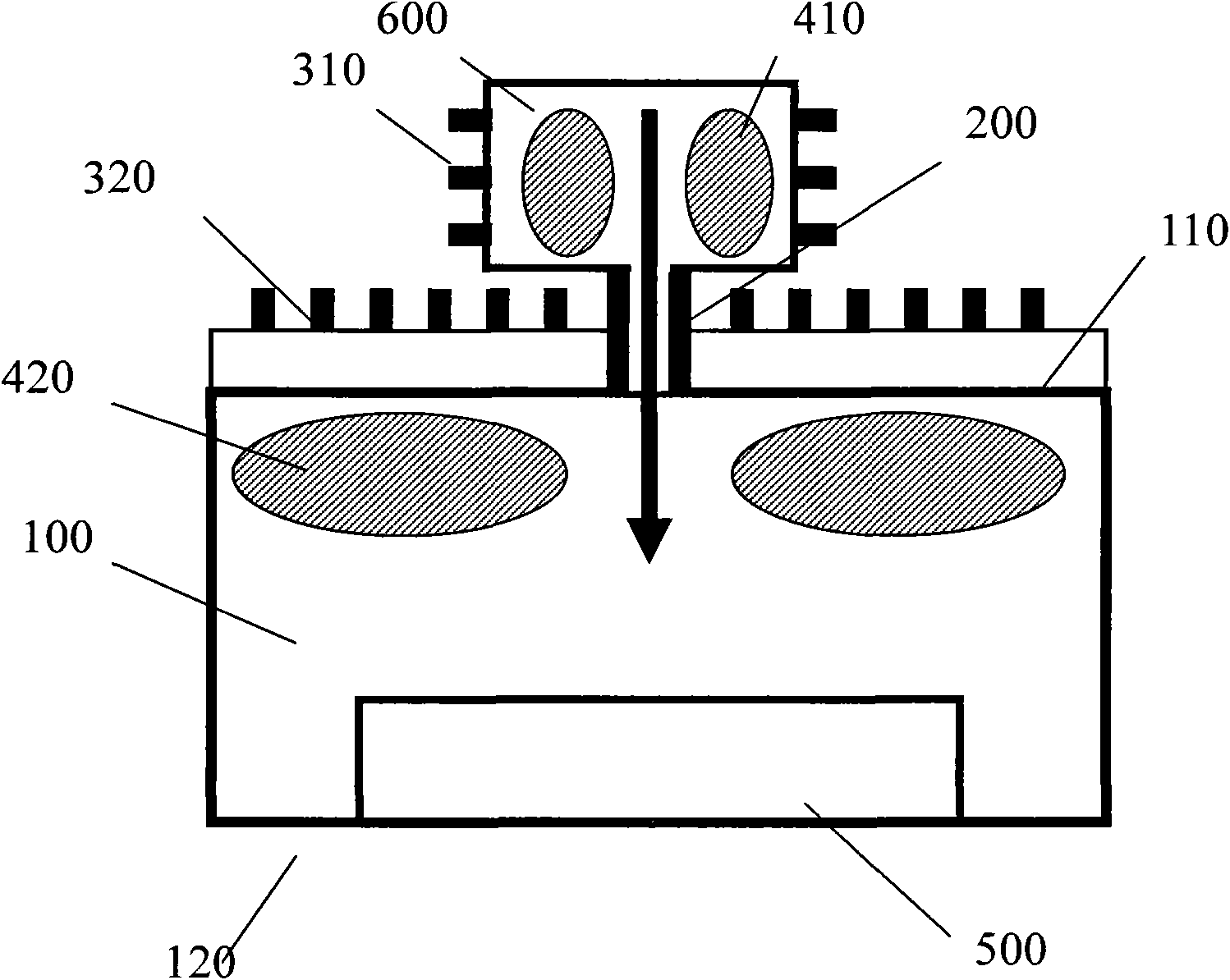

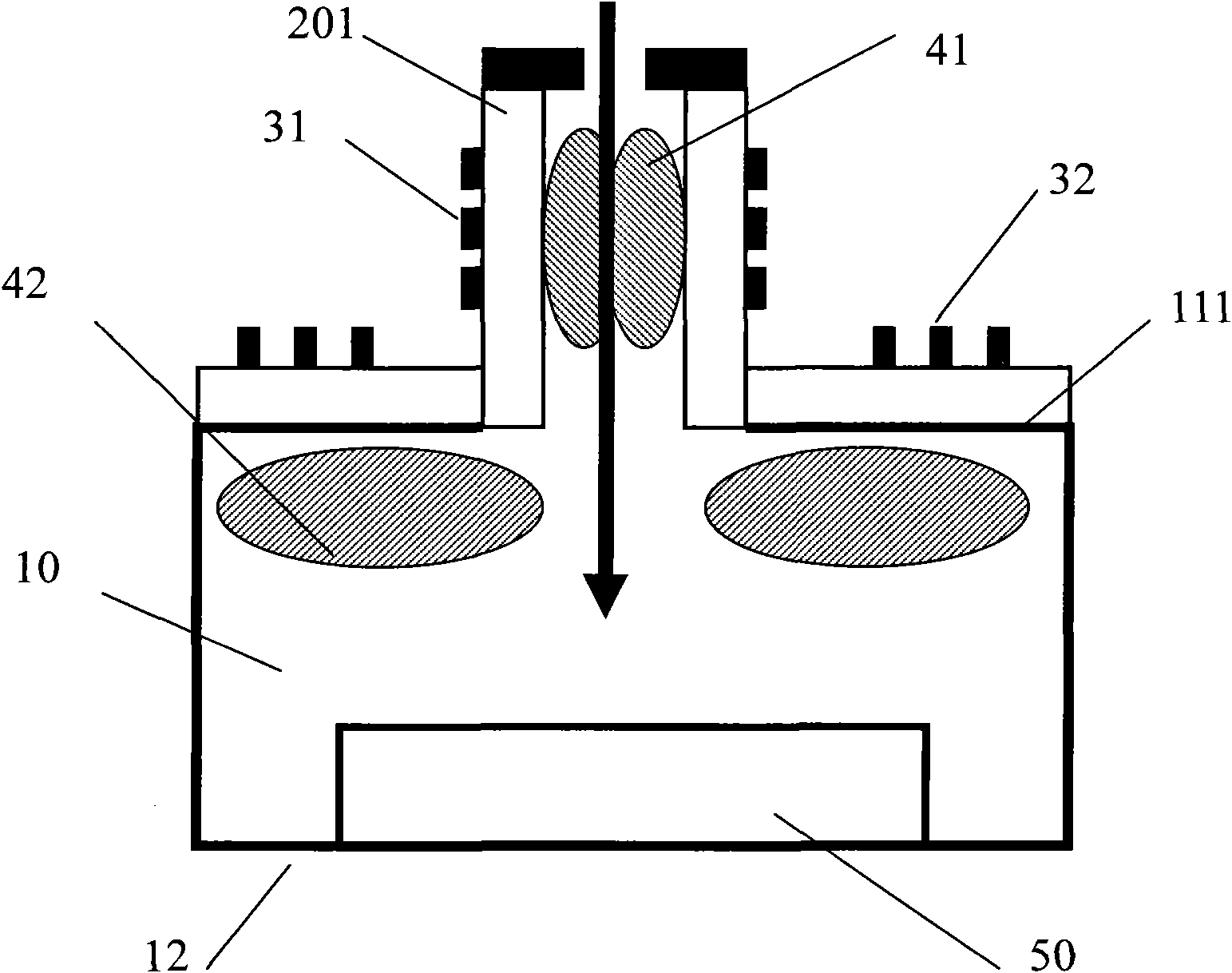

Plasma treatment device with diffused dissociation

ActiveCN101789354AHigh densityProcessing speedElectric discharge tubesEngineeringInductively coupled plasma

The invention relates to a plasma treatment device with a diffused dissociation areas, which is used for reacting inductive coupling plasmas for generating an introducing gas with a substrate. The plasma treatment device is characterized by comprising a vacuum treatment chamber, air inlet passages, first coils, first diffused dissociation areas and second coils, wherein the air inlet passages are arranged above top plates of the vacuum treatment chamber and are communicated and connected with the vacuum treatment chamber; the first coils are arranged on the air inlet passages; the first diffused dissociation areas are arranged inside the air inlet passages which are provided with the inductive coupling plasmas for generating the introducing gas; and the second coils are arranged on the top plates of the treatment chamber, since the first coils and the second coils are arranged, gas molecules of the plasma are subjected to electronic bombardment for two times in the first diffused dissociation areas and the second diffused dissociation areas in sequence and then fully dissociated; in addition, the vertical through air inlet pipeline is widened and lengthened, the bottom of the vertical through air inlet pipeline is set into an inverse funnel or a horn shape and the vertical through air inlet pipeline corresponds to the substrate, so that the plasma dissociated by the bombardment can be quickly introduced to the surface of the substrate; and the density uniformity of the plasma on the surface of the substrate can be improved to shorten the time of treating reaction.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

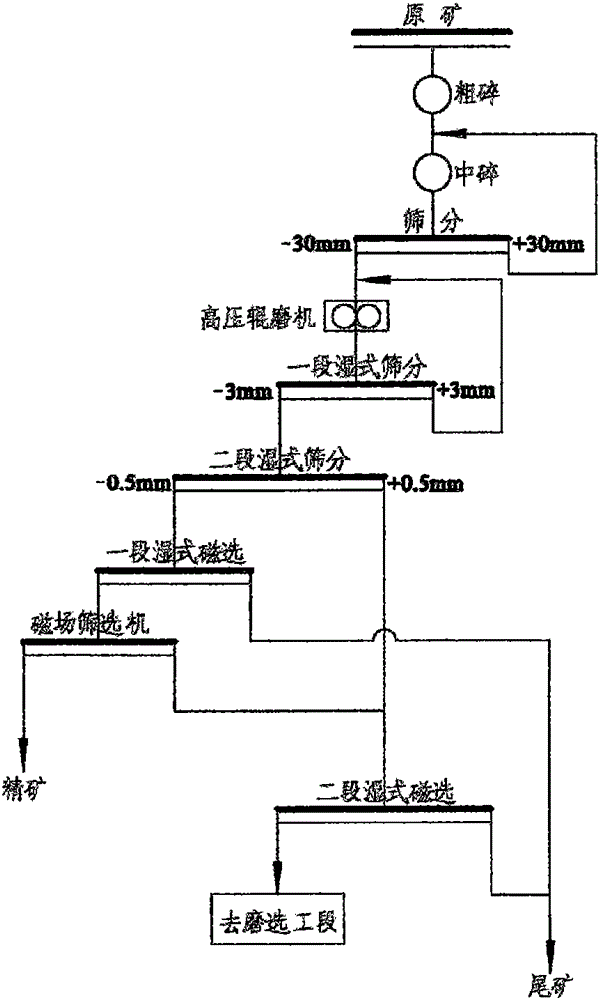

Efficient mineral processing technology achieved through cooperation of high-pressure grinding roller and magnetic field screening machine

InactiveCN105032582AEasy to handleFully dissociatedSolid separationGrain treatmentsOperational costsEconomic benefits

The invention discloses an efficient mineral processing technology achieved through cooperation of a high-pressure grinding roller and a magnetic field screening machine. The efficient mineral processing technology is scientific and simple in technological process and low in operating cost. The high-pressure grinding roller is high in reduction ration and small in product particle size, and therefore the iron mineral monomer separation degree is effectively improved during crushing operation, and the processing capacity of the grinding roller is greatly improved. For high-pressure roller fine fraction products, part of qualified iron core concentration where monomer separation is conducted is selected through the magnetic field screening machine, and therefore the excessive grinding amount and the grinding and separating operation ore quantity are effectively decreased, energy conservation and consumption reduction are achieved, and economic benefits are obvious.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

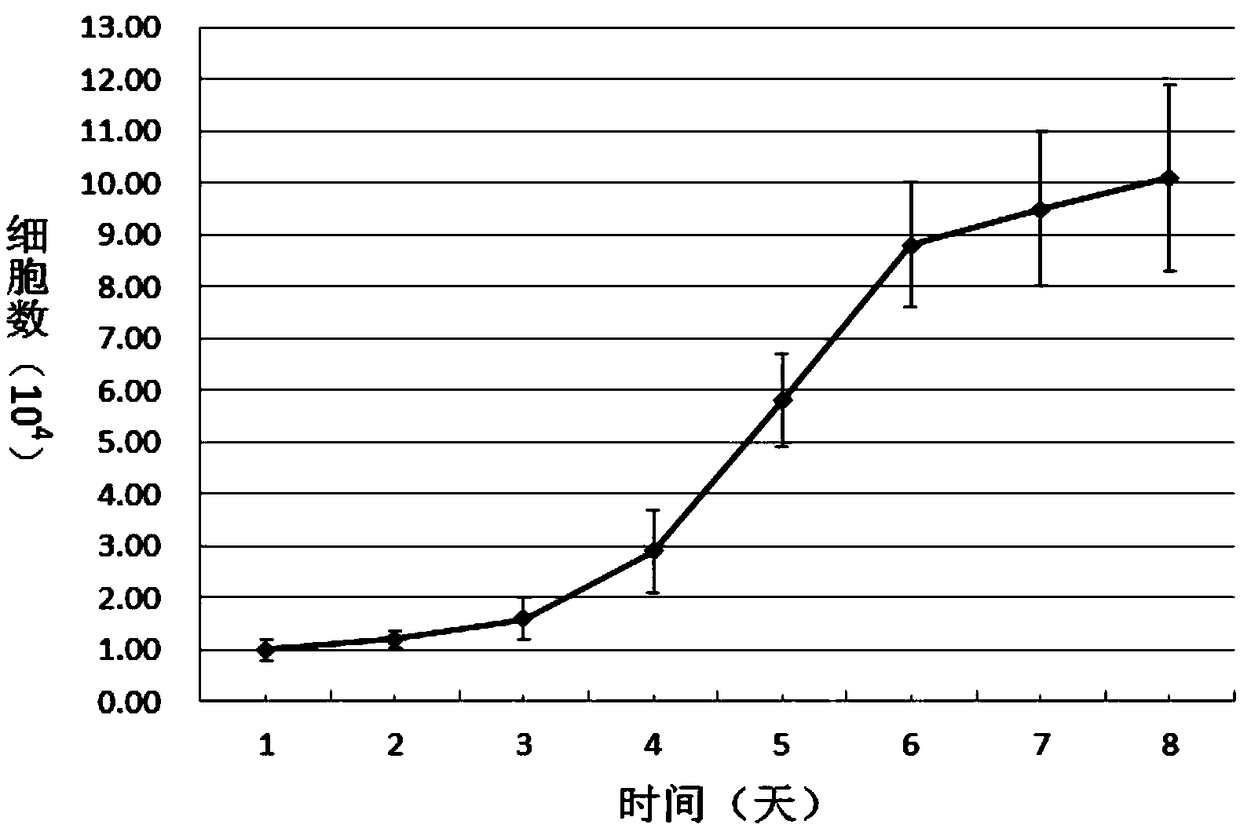

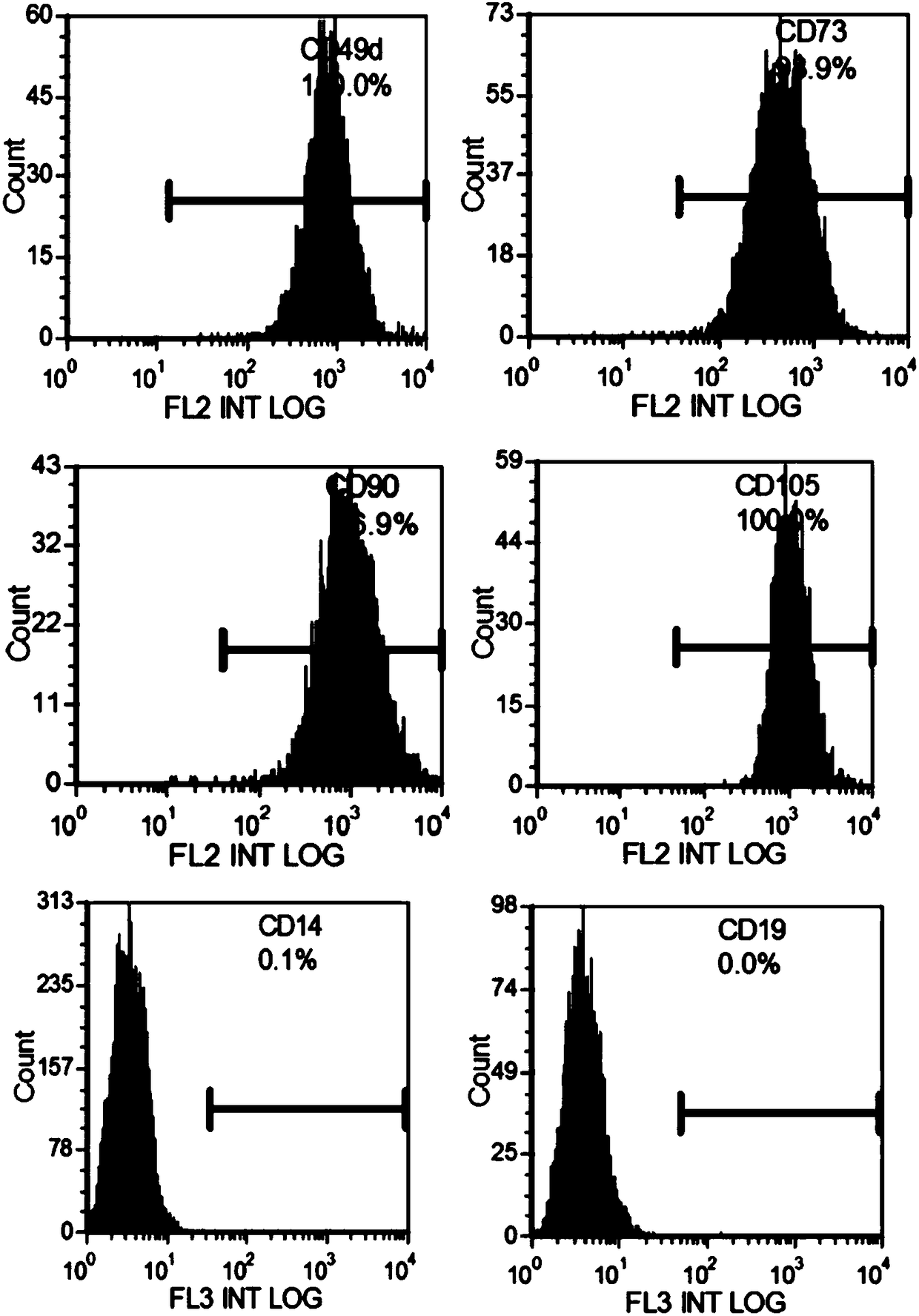

Preparation method for improving yield of umbilical cord derived mesenchymal stem cell primary cells

ActiveCN108220229AImprove utilizationIncrease the number ofCell dissociation methodsSkeletal/connective tissue cellsWharton's jellyPrimary cell

The invention relates to the technical field of cell culture and cell separation and in particular discloses a preparation method for improving the yield of umbilical cord derived mesenchymal stem cell primary cells. On the basis of culturing and separating mesenchymal stem cells on a traditional Wharton's jelly tissue block in a disposable adherence manner, Wharton's jelly tissue blocks are finely collected at different time of a later period of culture and are repeatedly adhered; P0 generation mesenchymal stem cells can be continuously collected at different time. According to the method provided by the invention, the utilization rate of Wharton's jelly is maximized through a property that the mesenchymal stem cells continuously move out from Wharton's jelly tissues to grow; compared with Wharton's jelly tissue block disposable adherence culture, the obtained quantity of the P0 generation mesenchymal stem cells can be increased by two times at least; the culture density of the mesenchymal stem cells, the concentration of serum replacements in a culture medium and the culture time are subsequently controlled; when the cells are sub-cultured to a P3 generation, the obtained cell quantity can completely meet the requirements of cell storage and clinical transplantation.

Owner:北京中科易微生物科技有限公司

Production method of pea starch

The invention discloses a production method of pea starch. Since the technical processes of cleaning-soaking, grinding and residue removing, pulp mixing and separating, and settling are adopted in the method, the purification rate of the starch is enhanced greatly, the color and the luster of the starch are very good, the original toughness can be kept, the nutritive value is high, and the starch is very suitable for processing cold noodles, bean jelly and bean vermicelli.

Owner:孟祥帅

Preparation method of nano hydroxyapatite powder with controllable morphology

ActiveCN103553013AMorphology regulationEffective control of morphologyMaterial nanotechnologyPhosphorus compoundsCoprecipitationNano hydroxyapatite

The invention relates to the technical field of a preparation method of nano hydroxyapatite powder with a controllable morphology, and belongs to the scope of preparing nano hydroxyapatite powder with different morphologies by regulating an additive amount of a morphology regulator sodium polyacrylate and controlling coprecipitation synthesis conditions.

Owner:NORTH CHINA INST OF AEROSPACE ENG

Method using steam explosion technique to prepare chicken bone soup-stock

InactiveCN106722647ASimple processEasy to operateFood ingredientsFood processesChicken boneEngineering

The invention provides a method using a steam explosion technique to prepare chicken bone soup-stock. The method comprises the following steps of (1) cleaning chicken bone, putting into a steam explosion machine, closing and sealing a material charging valve and a material charging valve of the steam explosion machine, setting the steam pressure of the steam explosion machine to 2.0 to 3.5MPa, and the pressure maintaining time to 200s to 900s, automatically opening the material discharging valve, enabling the chicken bone to instantaneously spray and explode from a sample chamber into a collection chamber, and converting the chicken bone into milky white slurry and bone residues; (2) centrifuging and separating the milky white slurry and the bone residues in step (1), and collecting a supernatant, so as to obtain a chicken bone steam explosion treatment raw soup liquid; (3) performing vacuum concentration on the chicken bone steam explosion treatment raw soup liquid obtained in step (2), so as to obtain the chicken bone soup-stock. The method has the advantages that the technology is simple, the operation is easy, and the production capacity of equipment is high; the raw material is thoroughly treated, the extracting rate is increased, the production cost is reduced, and the enterprise profit is improved.

Owner:HENAN YONGDA MEIJI FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com