Device and method for preparing single crystal diamonds by laser enhanced plasma CVD

A single crystal diamond and plasma technology, applied in the field of diamond processing, can solve the problems of inability to obtain high-density plasma, limit diamond high-speed batch preparation, and low growth rate of single crystal diamond, so as to reduce differences and reduce energy consumption , increasing the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

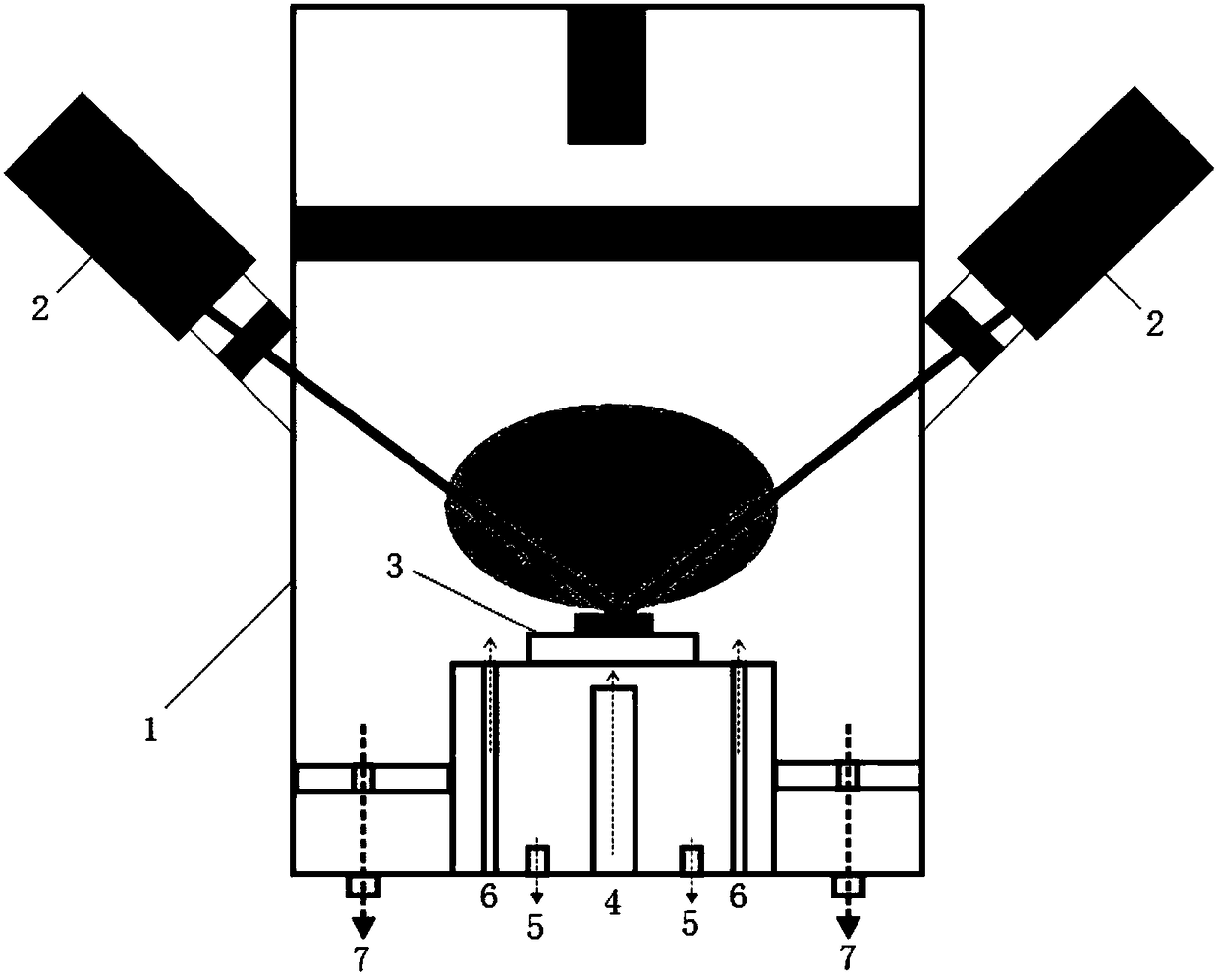

Method used

Image

Examples

Embodiment

[0033] A method for preparing single crystal diamond using the laser-enhanced plasma CVD device provided by the present invention to prepare single crystal diamond is as follows:

[0034] (1) Seed crystal cleaning treatment, using volatile liquids such as acetone and alcohol to clean impurities such as organic matter on the surface of the seed crystal; then drying at 60°C;

[0035] (2) Place the seed crystal into the cavity of plasma CVD equipment (hot wire CVD, microwave CVD, DC CVD, etc.), and then pump the background vacuum to 1*10 -4 Within Pa, open the cooling water circulation system, then pass in 1-1000sccm hydrogen and maintain the balance of intake and extraction to ensure a constant air pressure, input energy (including hot wire, microwave, direct current, etc.), generate discharge, and adjust the temperature of the seed crystal to 600-800°C, treatment for 1-120 minutes;

[0036] (3) Introduce carbon-containing gases such as methane, acetone, and carbon dioxide to g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com