Patents

Literature

8538 results about "Seed crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A seed crystal is a small piece of single crystal or polycrystal material from which a large crystal of typically the same material is to be grown in a laboratory. Used to replicate material, the use of seed crystal to promote growth avoids the otherwise slow randomness of natural crystal growth and allows manufacture on a scale suitable for industry.

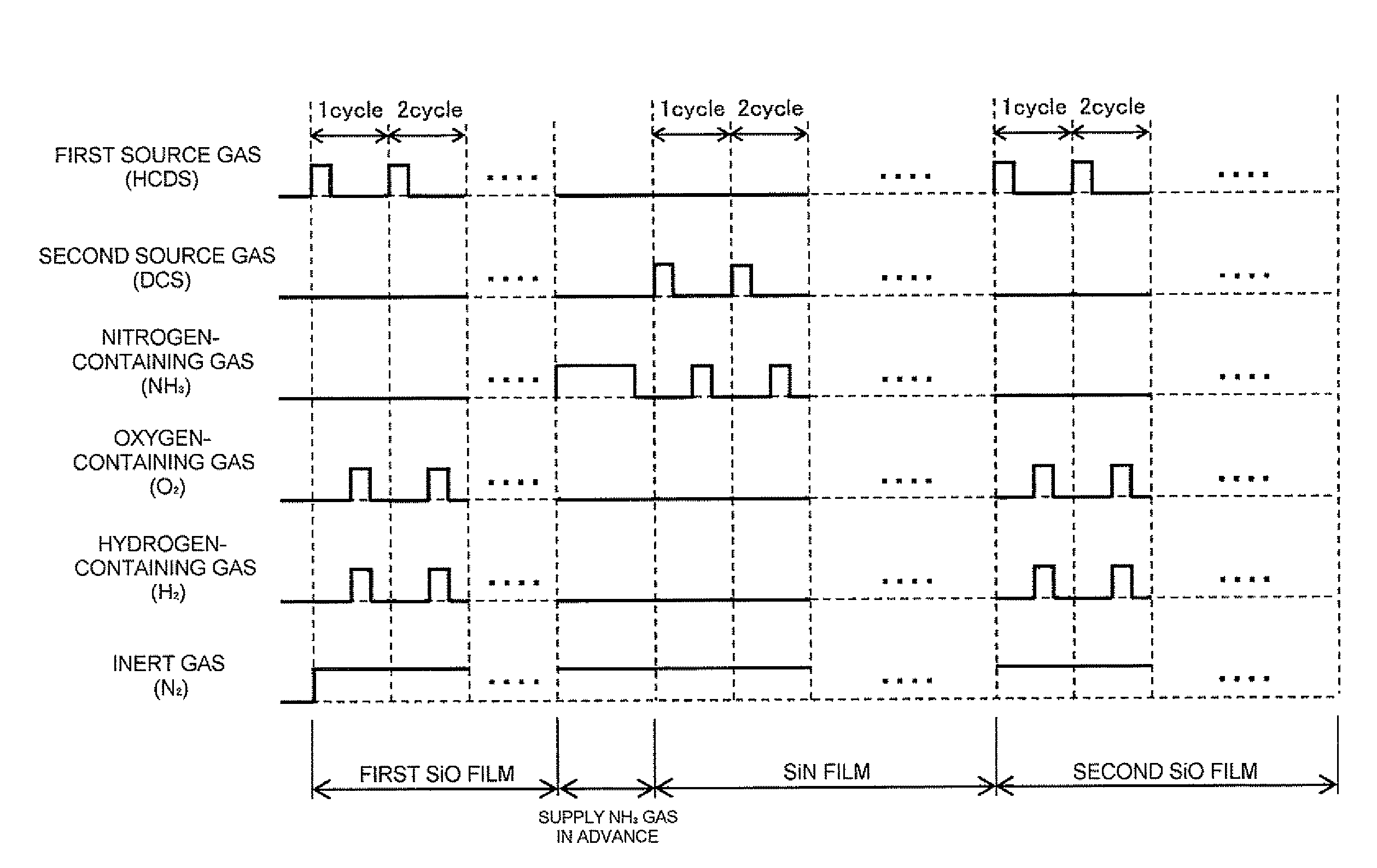

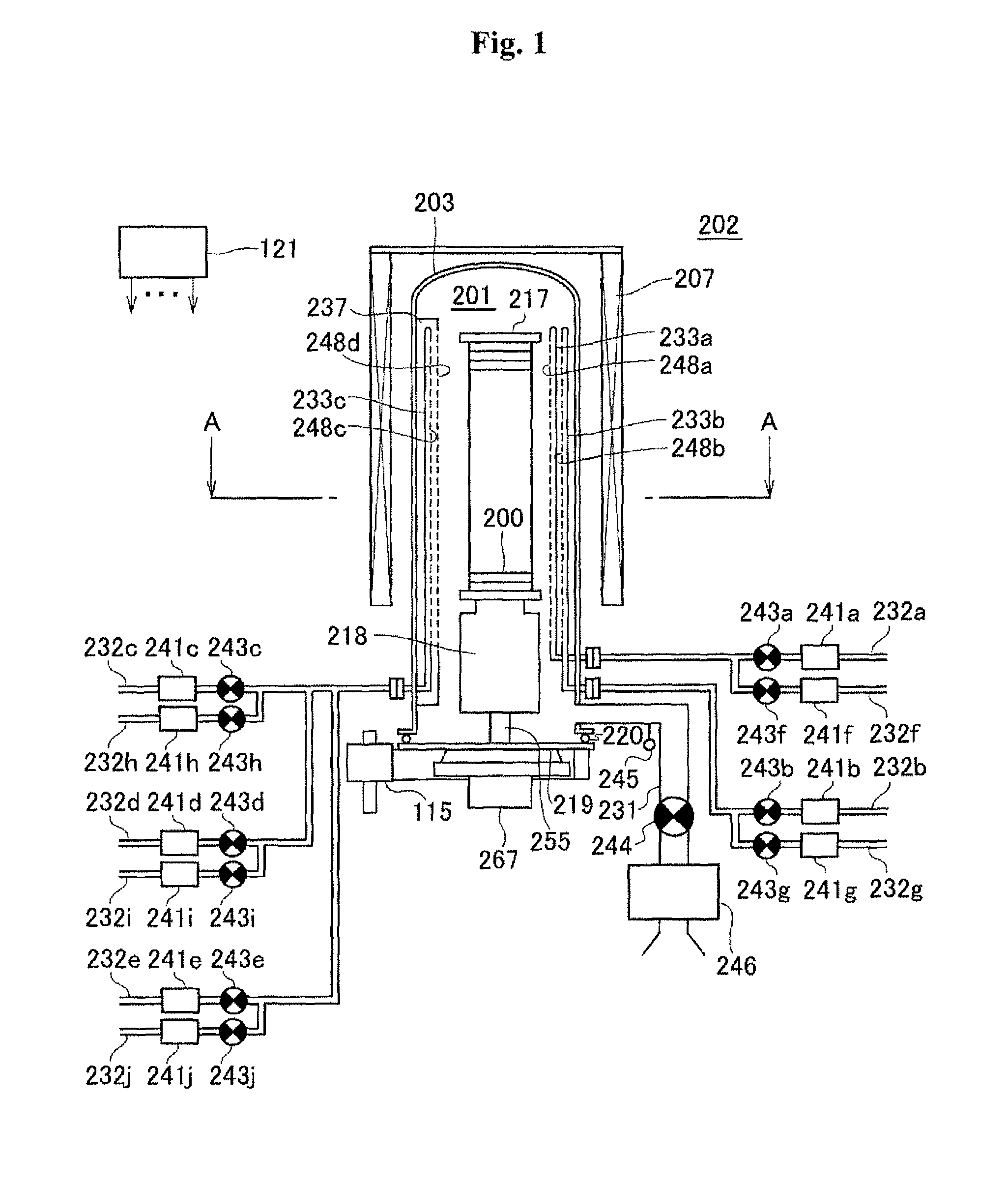

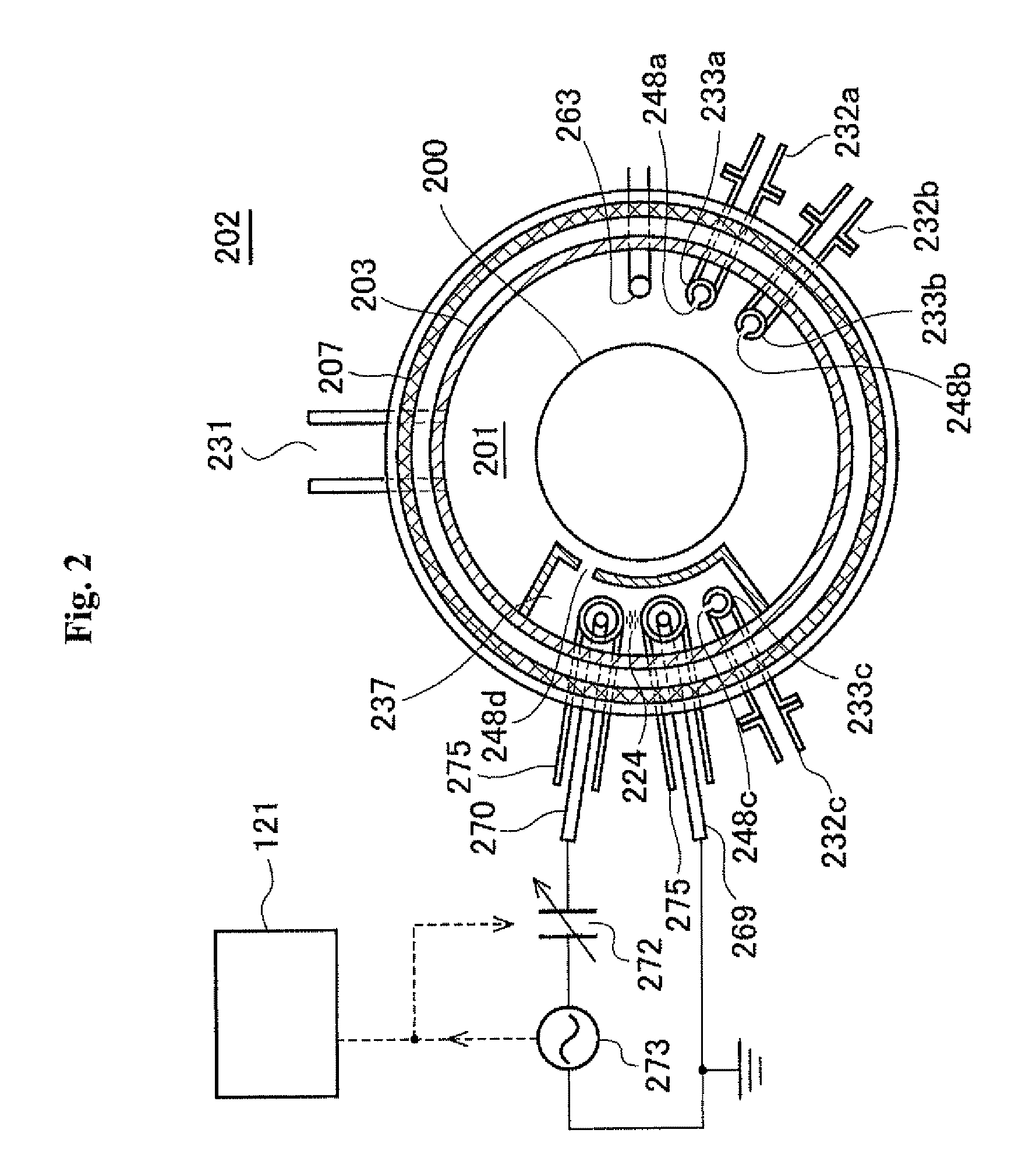

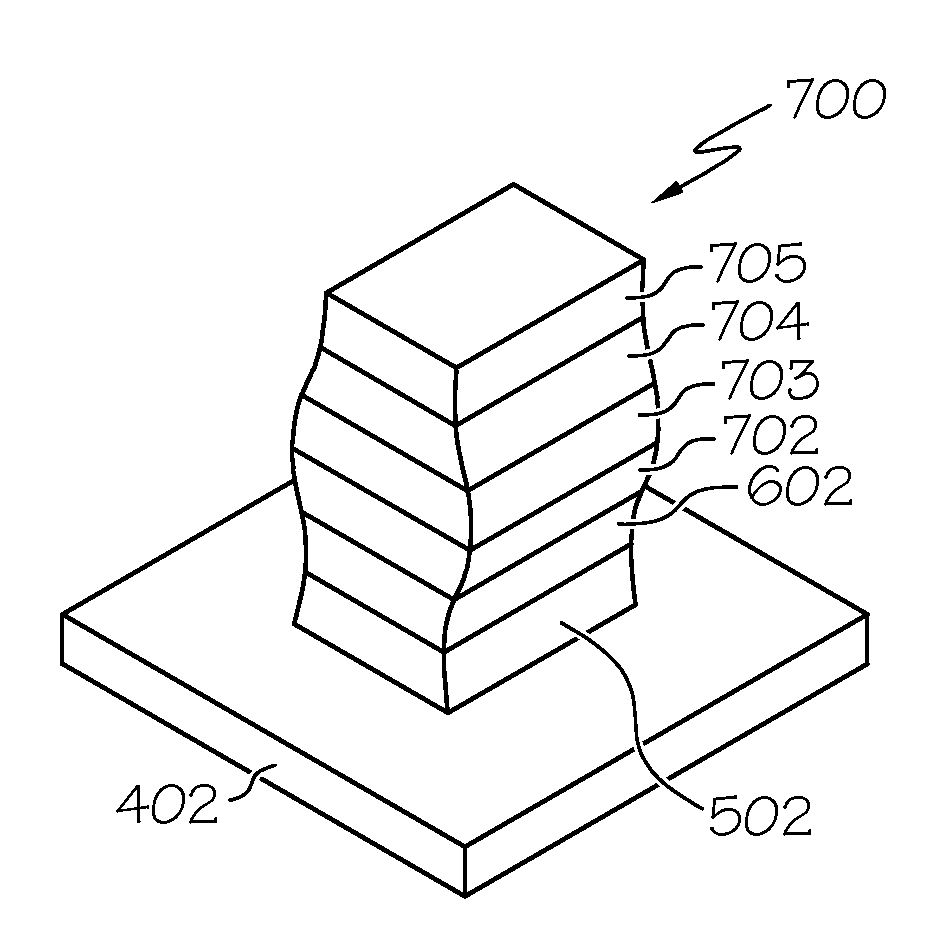

Method of manufacturing semiconductor device, method of processing substrate and non-transitory computer readable recording medium

ActiveUS9190264B2Increase productionEasy to operateLiquid surface applicatorsSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

A semiconductor manufacturing method includes forming an oxide film on a substrate by performing a first cycle a predetermined number of times, including supplying a first source gas, an oxidizing gas and a reducing gas to the substrate heated to a first temperature in a process container under a sub-atmospheric pressure; forming a seed layer on a surface of the oxide film by supplying a nitriding gas to the substrate in the process container, the substrate being heated to a temperature equal to or higher than the first temperature and equal to or lower than a second temperature; and forming a nitride film on the seed layer formed on the surface of the oxide film by performing a second cycle a predetermined number of times, including supplying a second source gas and the nitriding gas to the substrate heated to the second temperature in the process container.

Owner:KOKUSA ELECTRIC CO LTD

Non-polar and semi-polar GaN substrates, devices, and methods for making them

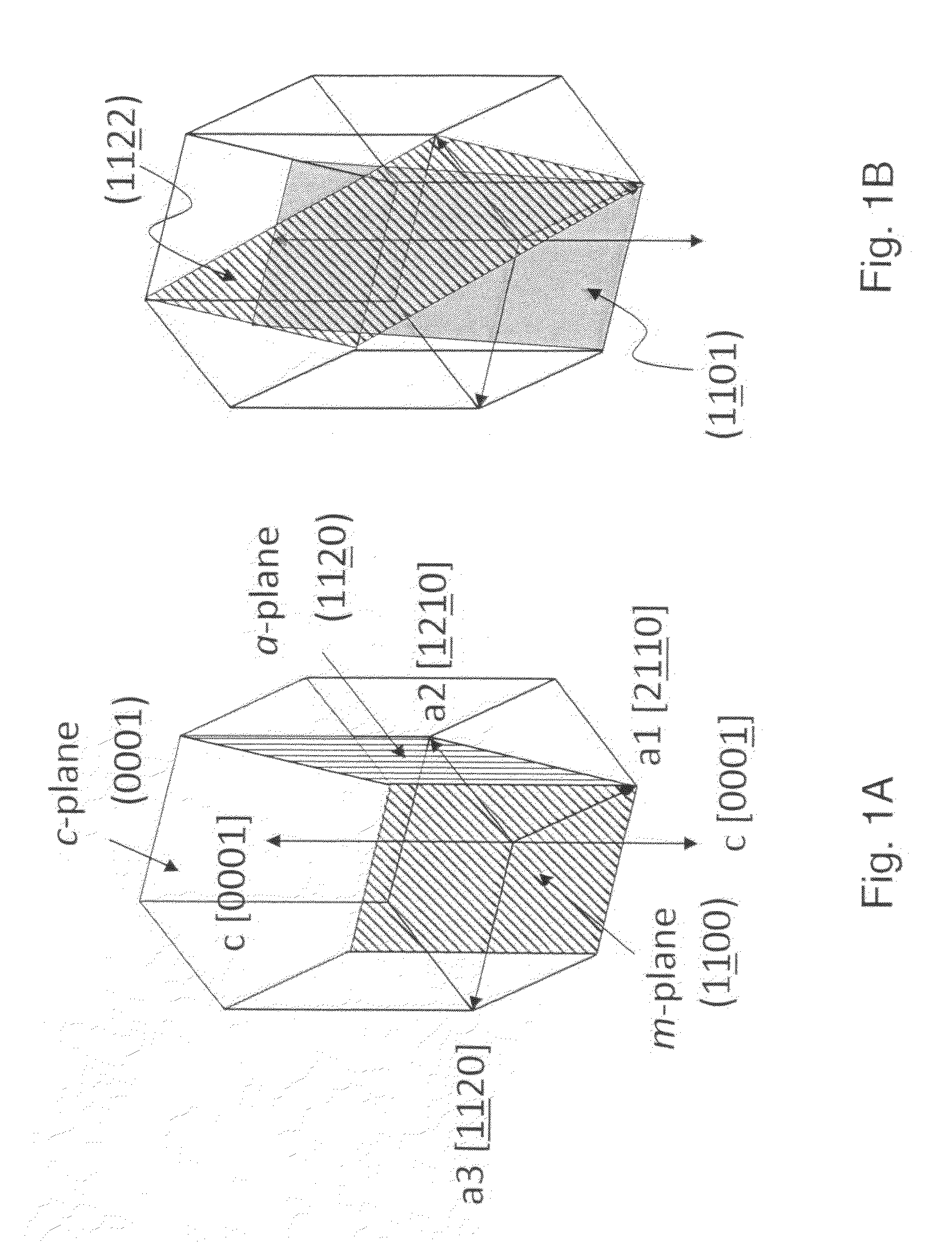

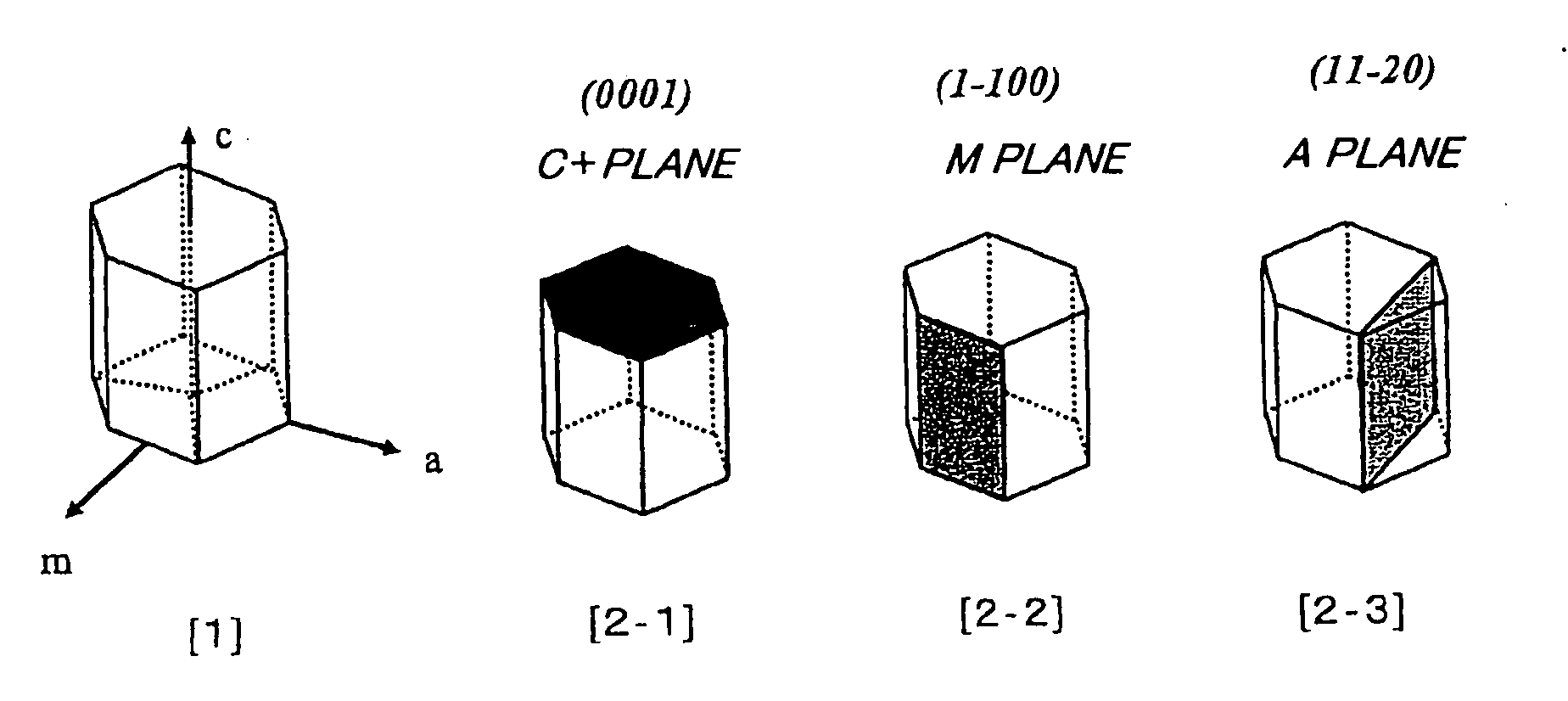

Non-polar or semi-polar (Al, Ga, In)N substrates are fabricated by re-growth of (Al, Ga, In)N crystal on (Al, Ga, In)N seed crystals, wherein the size of the seed crystal expands or is increased in the lateral and vertical directions, resulting in larger sizes of non-polar and semi-polar substrates useful for optoelectronic and microelectronic devices. One or more non-polar or semi-polar substrates may be sliced from the re-grown crystal. The lateral growth rate may be greater than the vertical growth rate. The seed crystal may be a non-polar seed crystal. The seed crystal may have crystalline edges of equivalent crystallographic orientation

Owner:KYMA TECH

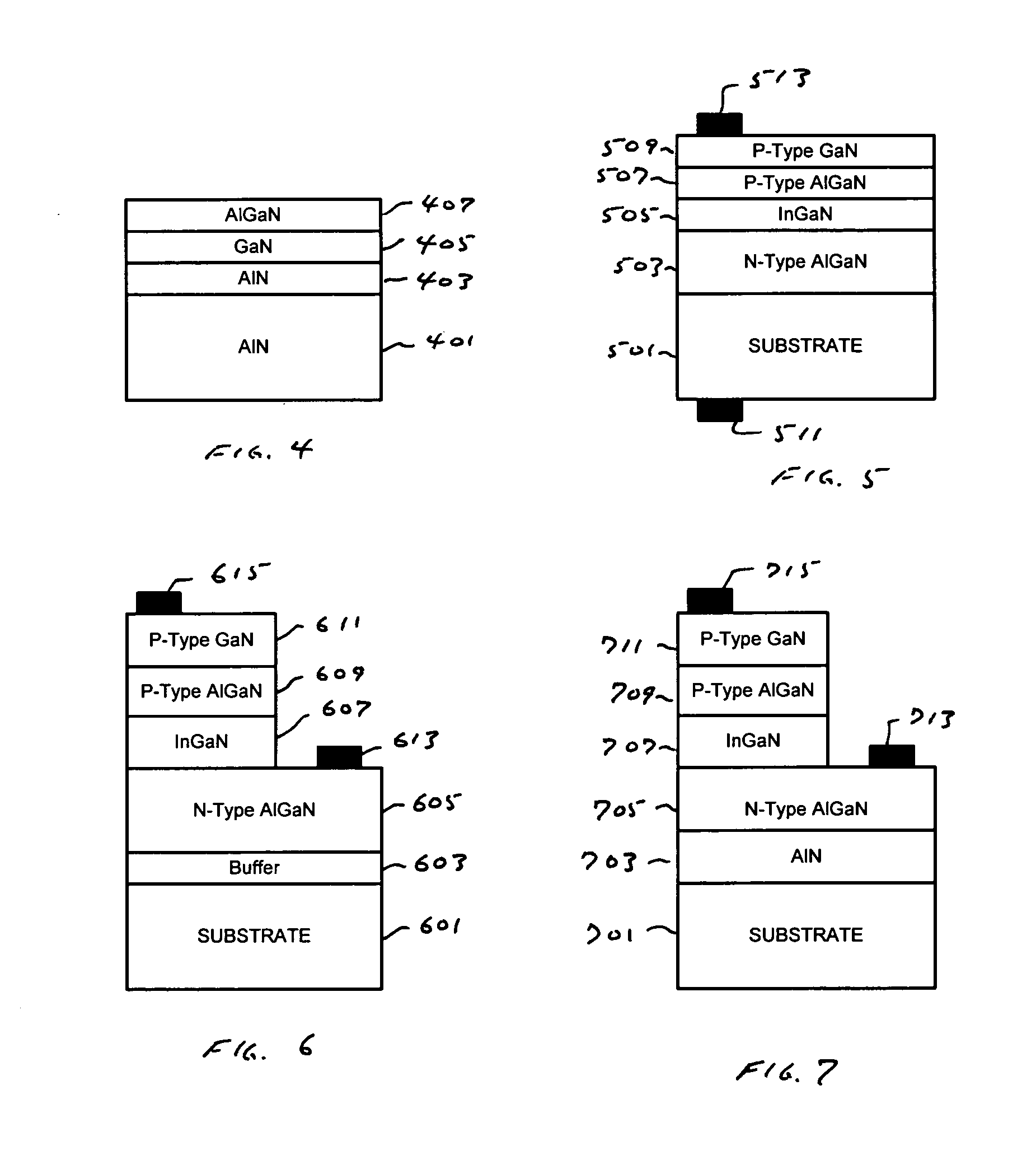

Resonant cavity light emitting devices and associated method

InactiveUS20060118799A1Increase probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingResonant cavitySource material

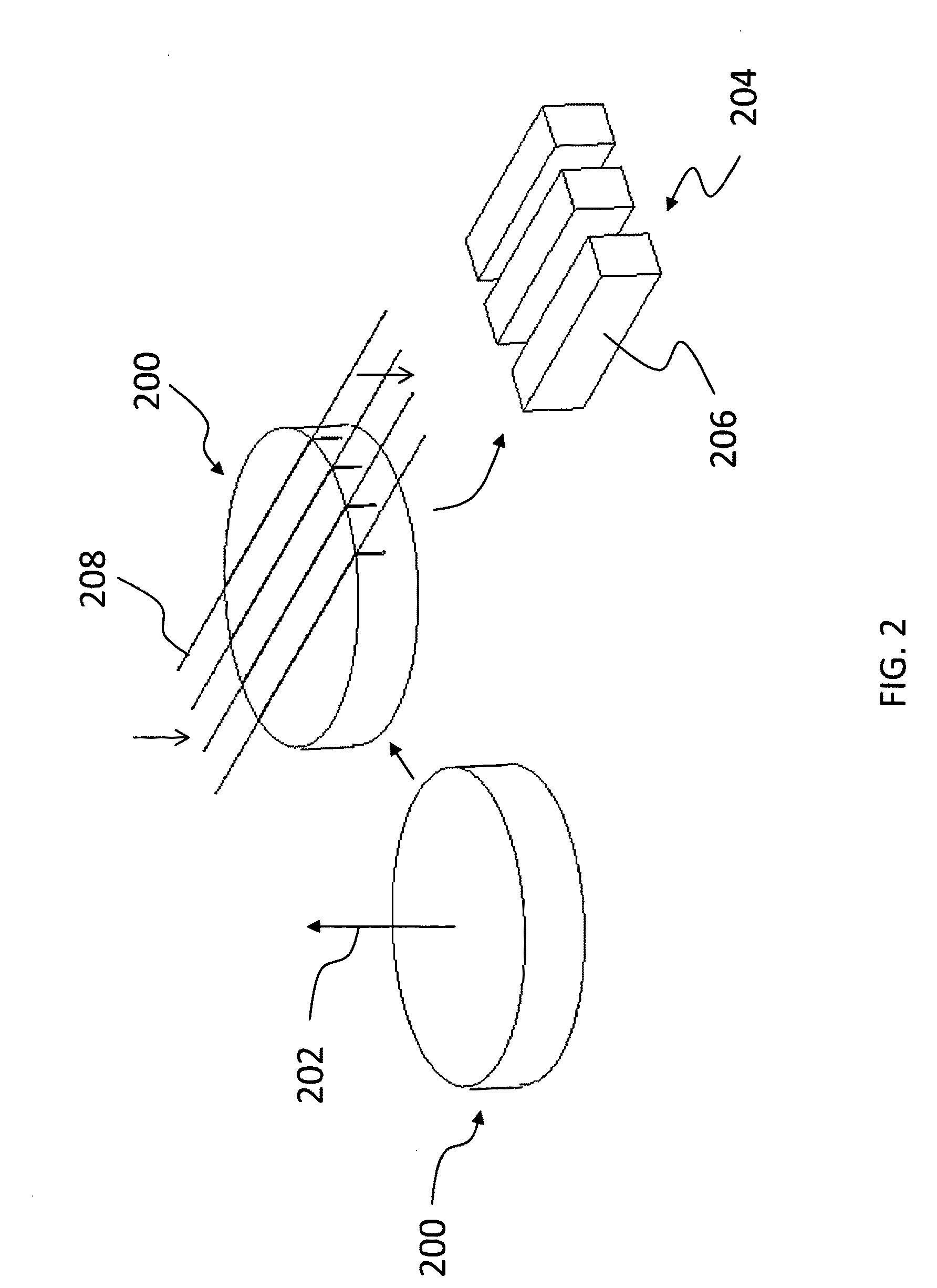

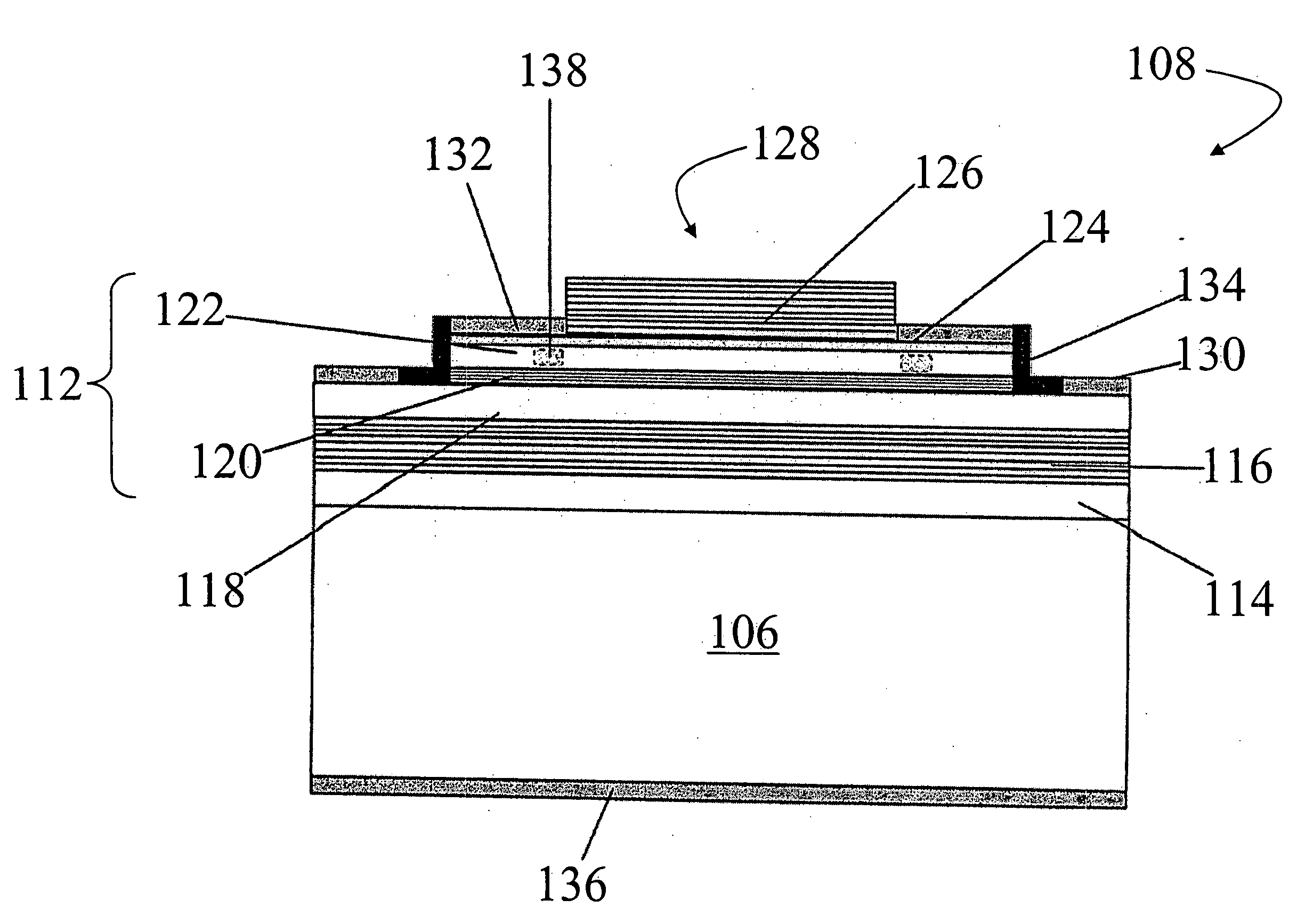

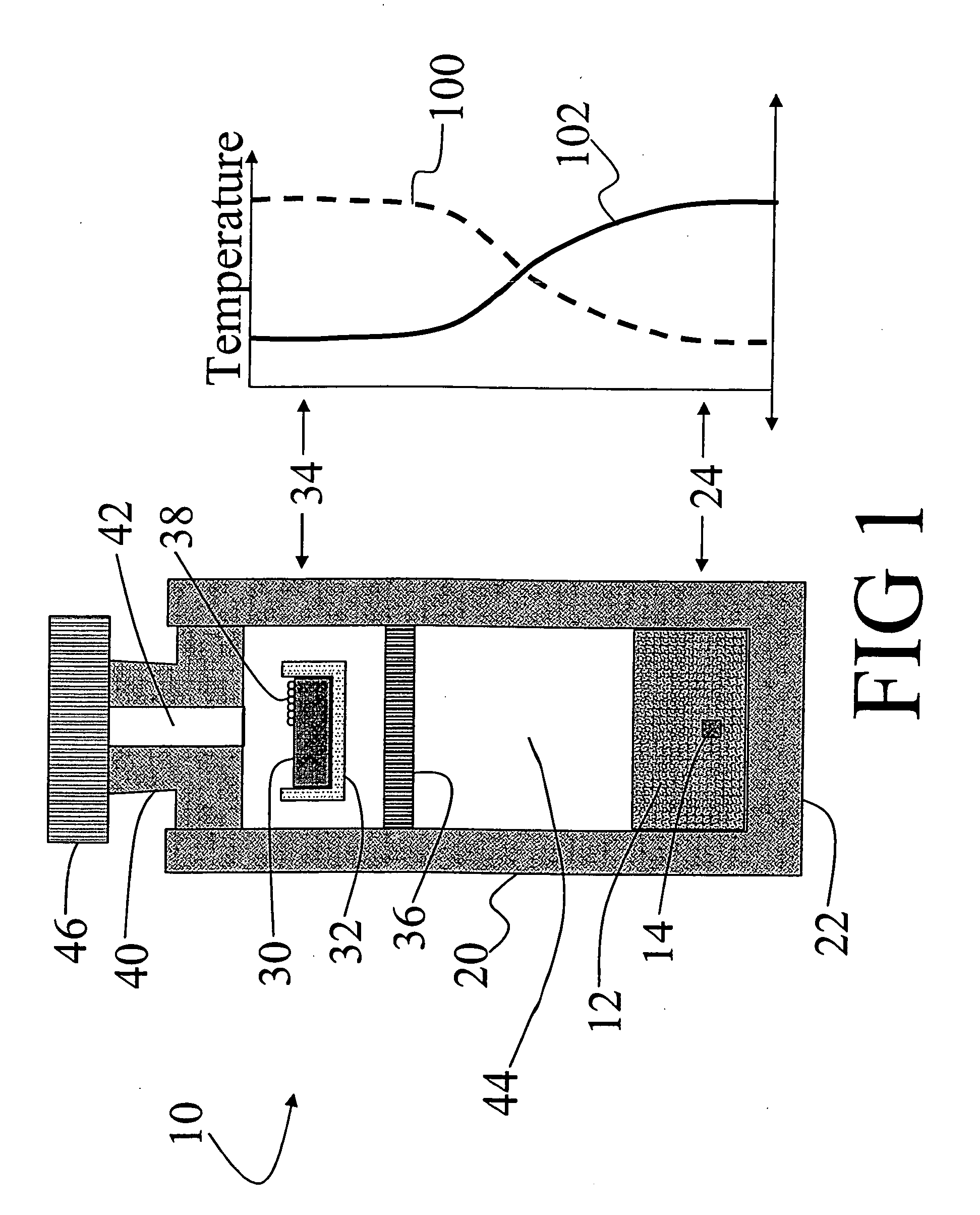

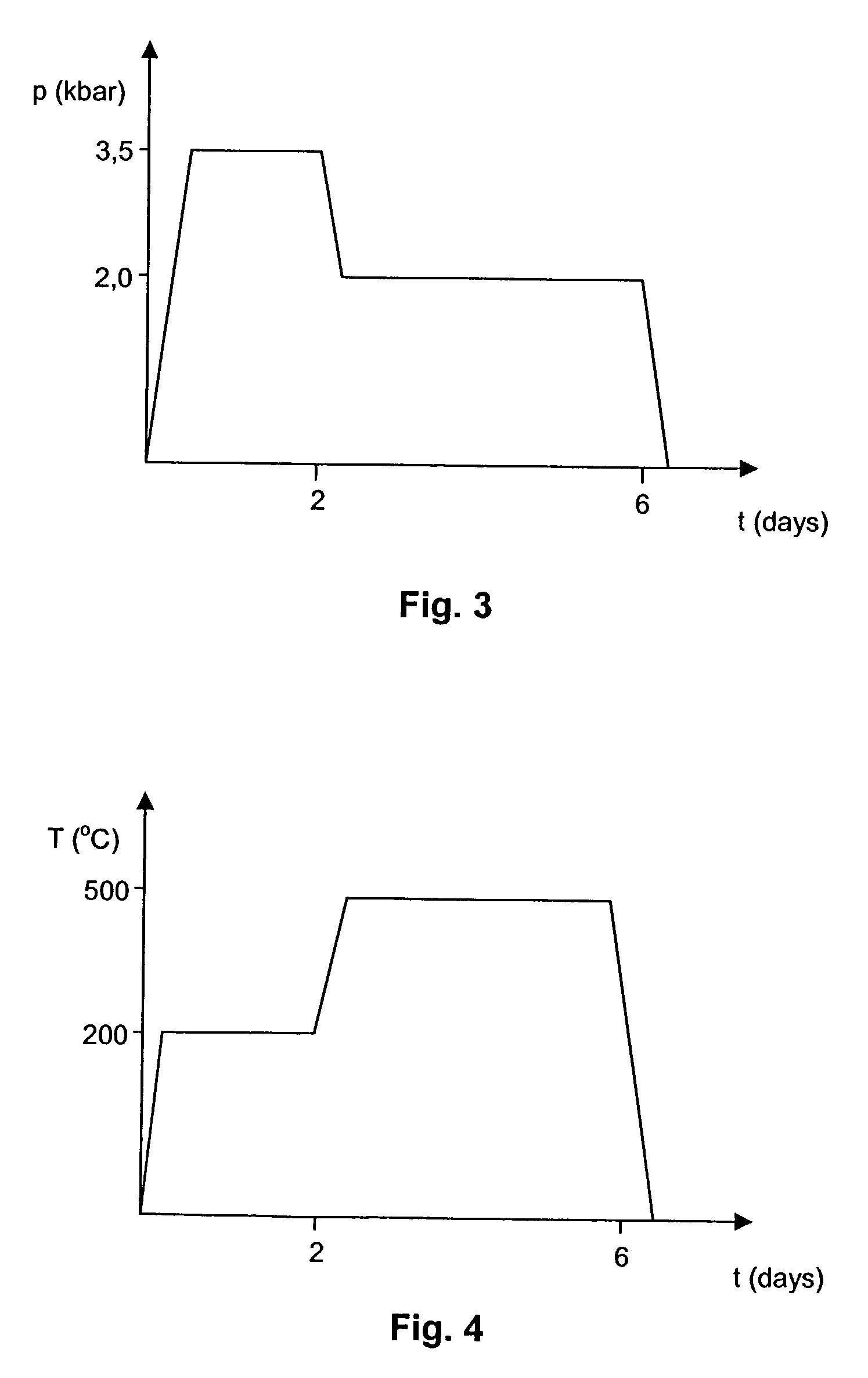

A method may produce a resonant cavity light emitting device. A seed gallium nitride crystal and a source material in a nitrogen-containing superheated fluid may provide a medium for mass transport of gallium nitride precursors therebetween. A seed crystal surface may be prepared by applying a first thermal profile between the seed gallium nitride crystal and the source material. Gallium nitride material may be grown on the prepared surface of the seed gallium nitride crystal by applying a second thermal profile between the seed gallium nitride crystal and the source material while the seed gallium nitride crystal and the source material are in the nitrogen-containing superheated fluid. A stack of group III-nitride layers may be deposited on the single-crystal gallium nitride substrate. The stack may include a first mirror sub-stack and an active region adaptable for fabrication into one or more resonant cavity light emitting devices.

Owner:SORAA

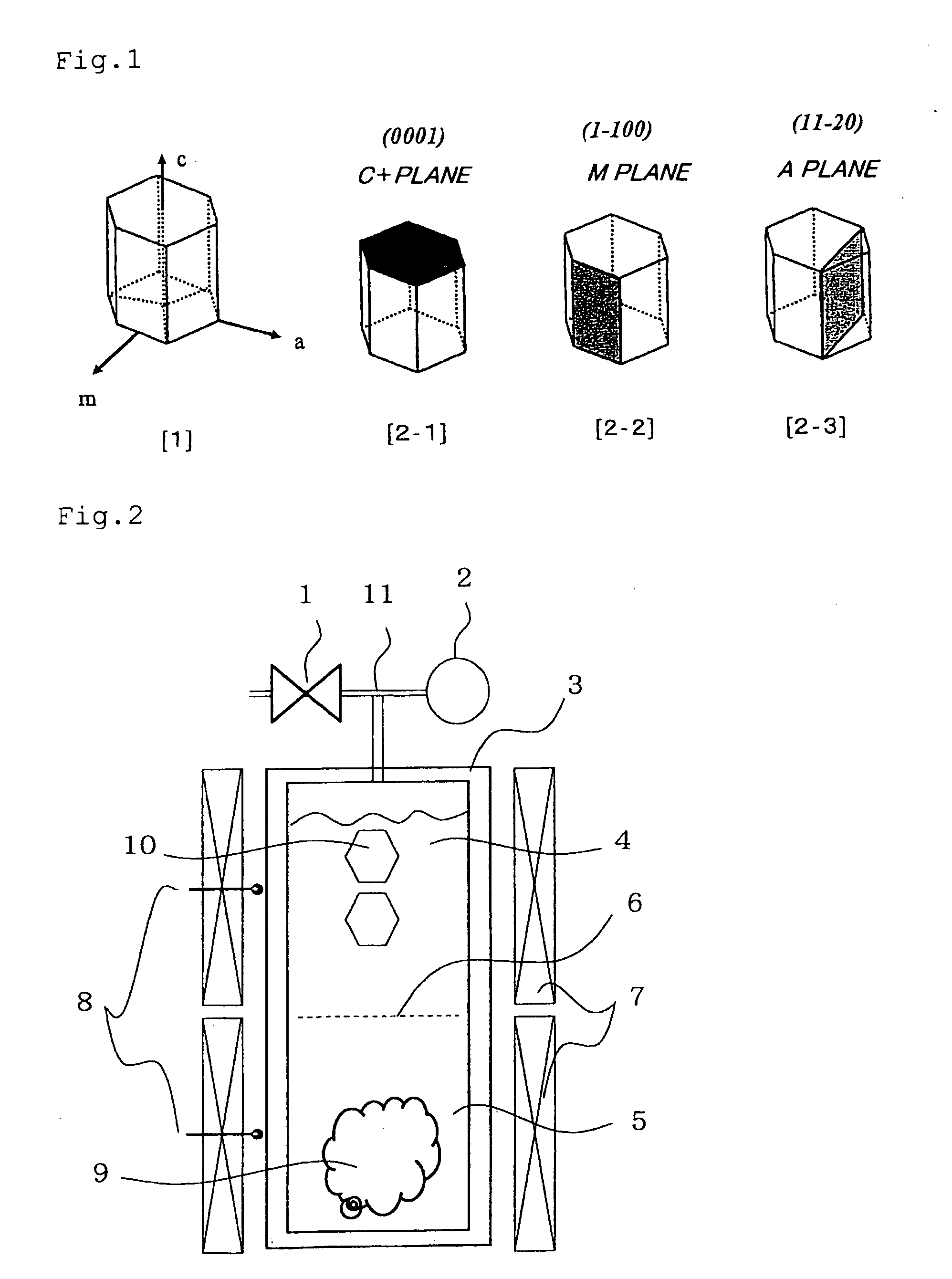

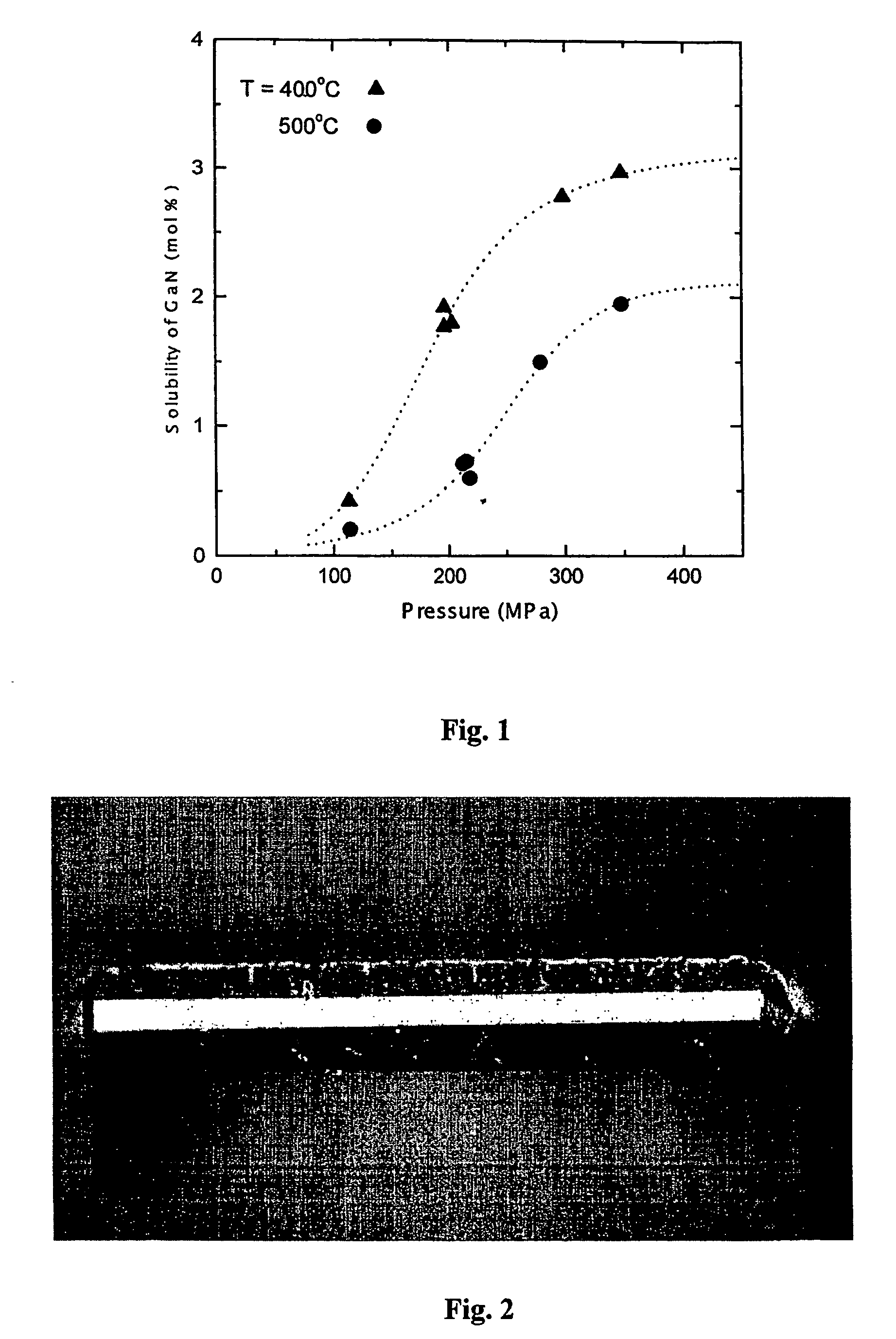

Method for producing nitride semiconductor, crystal growth rate increasing agent, single crystal nitride, wafer and device

InactiveUS20100104495A1Improve performanceIncrease probabilityPolycrystalline material growthFrom normal temperature solutionsNitrogenCrystal structure

A method for producing a nitride semiconductor, comprising controlling temperature and pressure in a autoclave containing a seed having a hexagonal crystal structure, a nitrogen element-containing solvent, a raw material substance containing a metal element of Group 13 of the Periodic Table, and a mineralizer so as to put said solvent into a supercritical state and / or a subcritical state and thereby ammonothermally grow a nitride semiconductor crystal on the surface of said seed, wherein the crystal growth rate in the m-axis direction on said seed is 1.5 times or more the crystal growth rate in the c-axis direction on said seed. By the method, a nitride semiconductor having a large-diameter C plane or a nitride semiconductor thick in the m-axis direction can be efficiently and simply produced.

Owner:MITSUBISHI CHEM CORP +1

Method and apparatus for fabricating crack-free Group III nitride semiconductor materials

InactiveUS20050142391A1Polycrystalline material growthFrom chemically reactive gasesWaferingCrack free

A method and apparatus for growing low defect, optically transparent, colorless, crack-free, substantially flat, single crystal Group III nitride epitaxial layers with a thickness of at least 10 microns is provided. These layers can be grown on large area substrates comprised of Si, SiC, sapphire, GaN, AlN, GaAs, AlGaN and others. In one aspect, the crack-free Group III nitride layers are grown using a modified HVPE technique. If desired, the shape and the stress of Group III nitride layers can be controlled, thus allowing concave, convex and flat layers to be controllably grown. After the growth of the Group III nitride layer is complete, the substrate can be removed and the freestanding Group III nitride layer used as a seed for the growth of a boule of Group III nitride material. The boule can be sliced into individual wafers for use in the fabrication of a variety of semiconductor structures (e.g., HEMTs, LEDs, etc.).

Owner:FREIBERGER COMPOUND MATERIALS

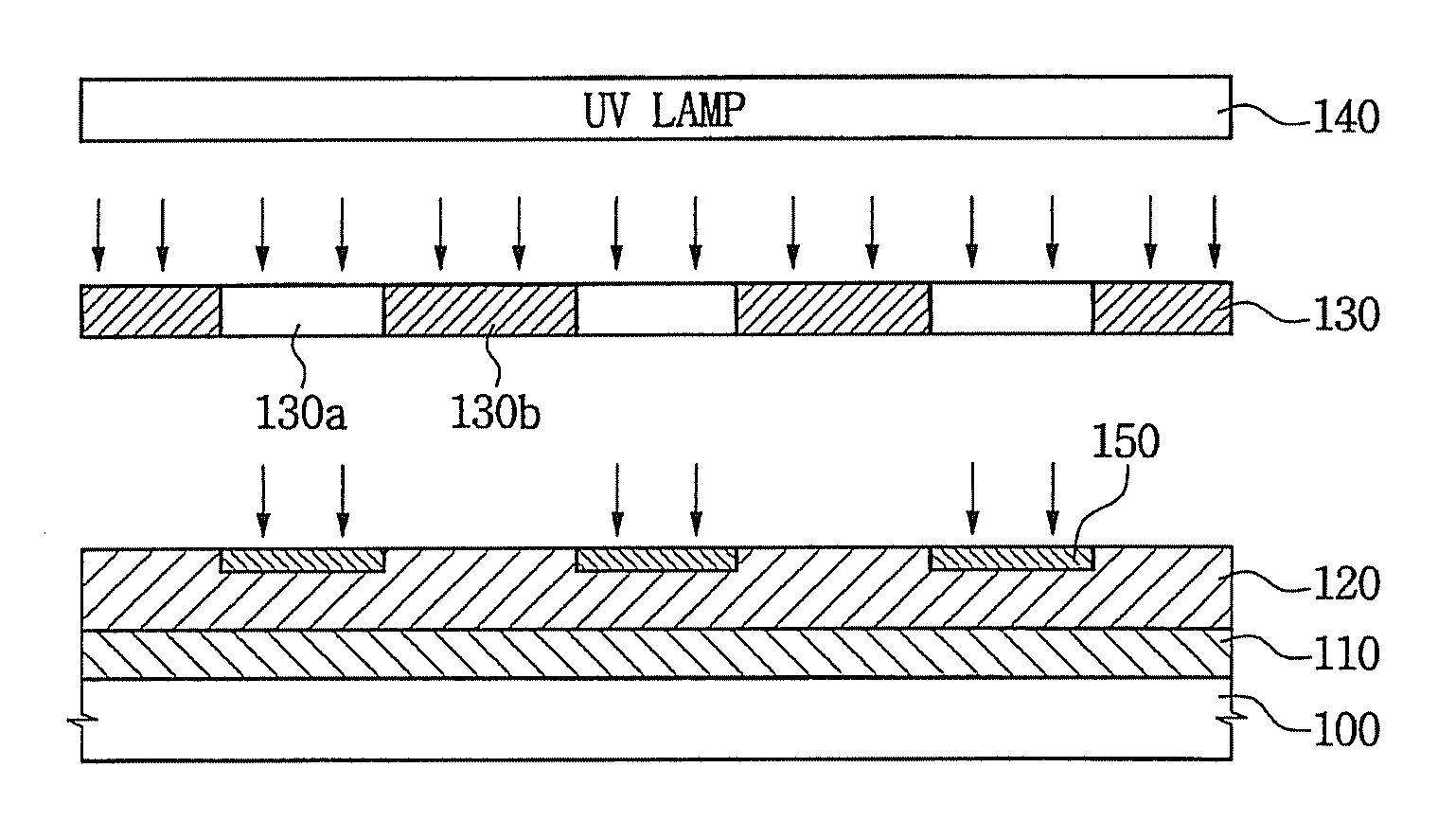

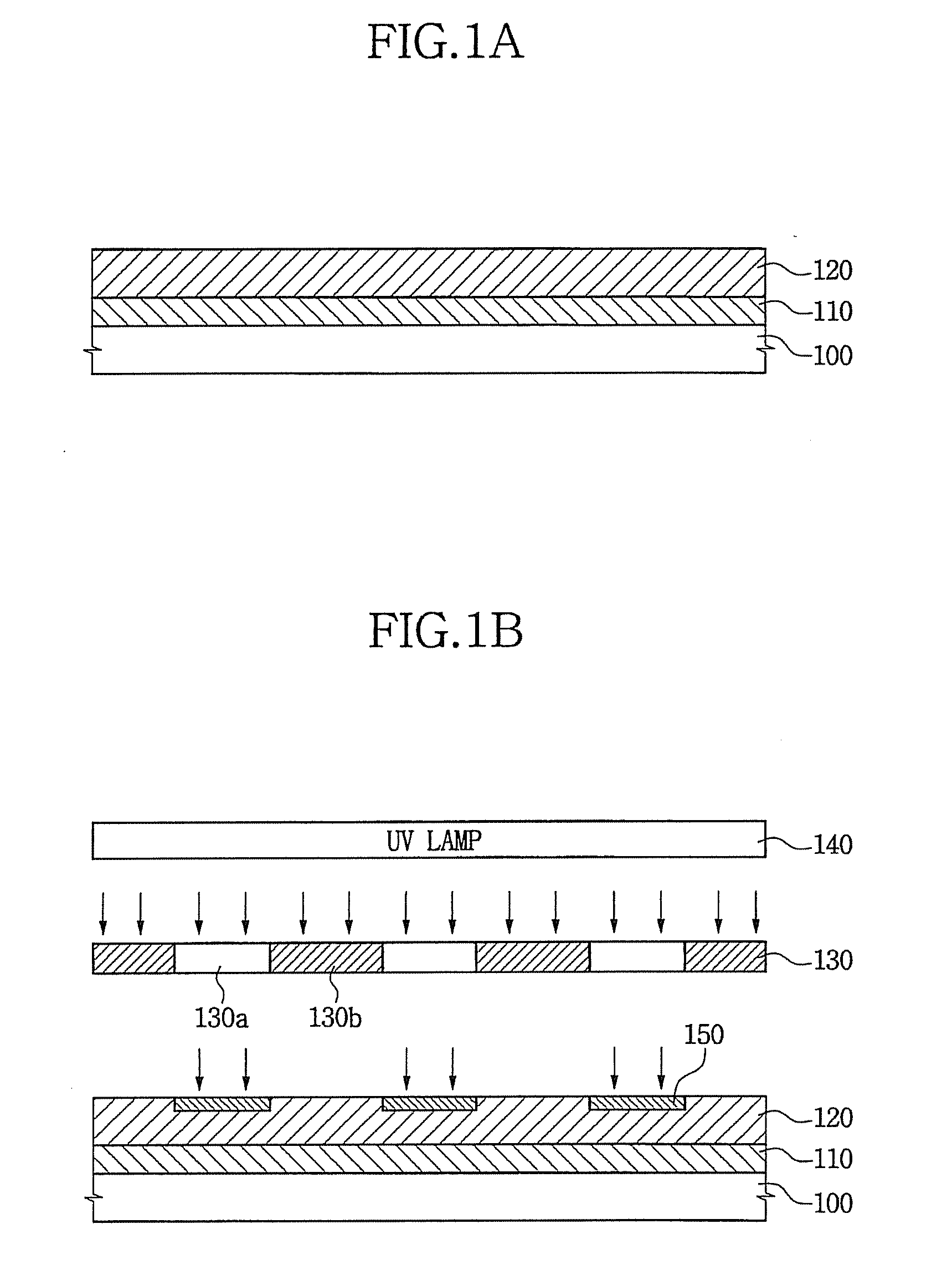

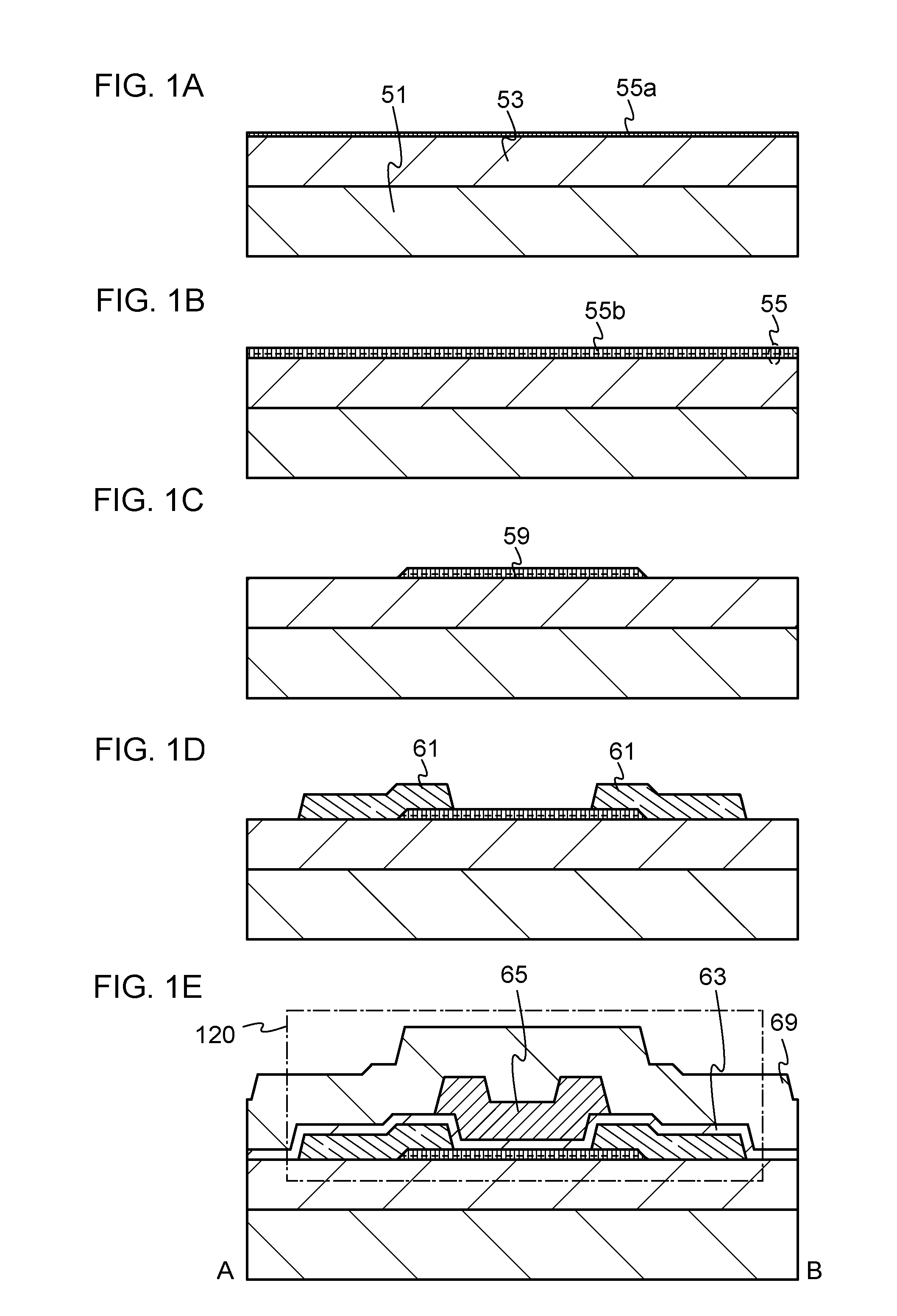

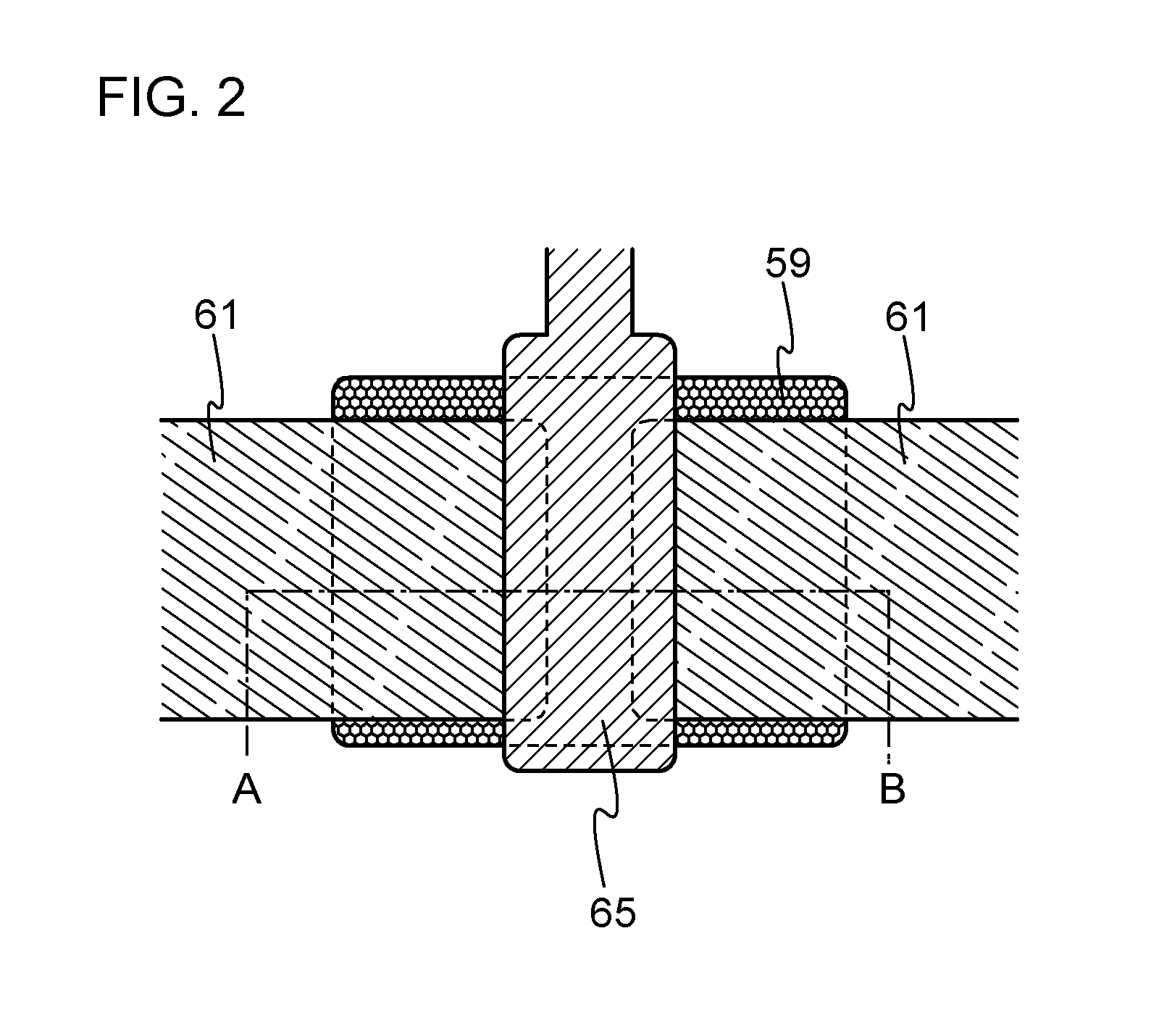

Method of forming polycrystalline silicon layer and atomic layer deposition apparatus used for the same

A method of forming a polycrystalline silicon layer and an atomic layer deposition apparatus used for the same. The method includes forming an amorphous silicon layer on a substrate, exposing the substrate having the amorphous silicon layer to a hydrophilic or hydrophobic gas atmosphere, placing a mask having at least one open and at least one closed portion over the amorphous silicon layer, irradiating UV light toward the amorphous silicon layer and the mask using a UV lamp, depositing a crystallization-inducing metal on the amorphous silicon layer, and annealing the substrate to crystallize the amorphous silicon layer into a polycrystalline silicon layer. This method and apparatus provide for controlling the seed position and grain size in the formation of a polycrystalline silicon layer.

Owner:SAMSUNG DISPLAY CO LTD

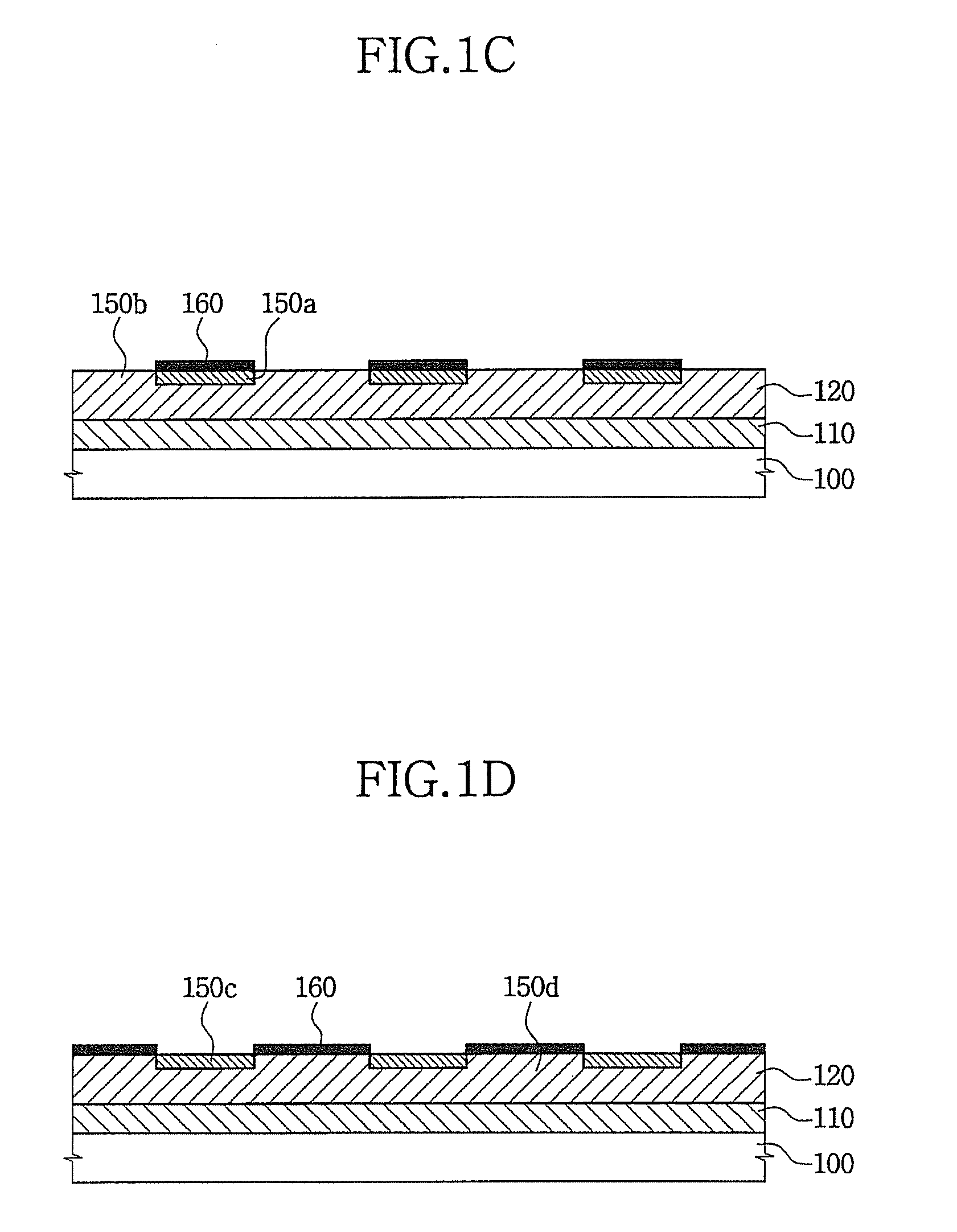

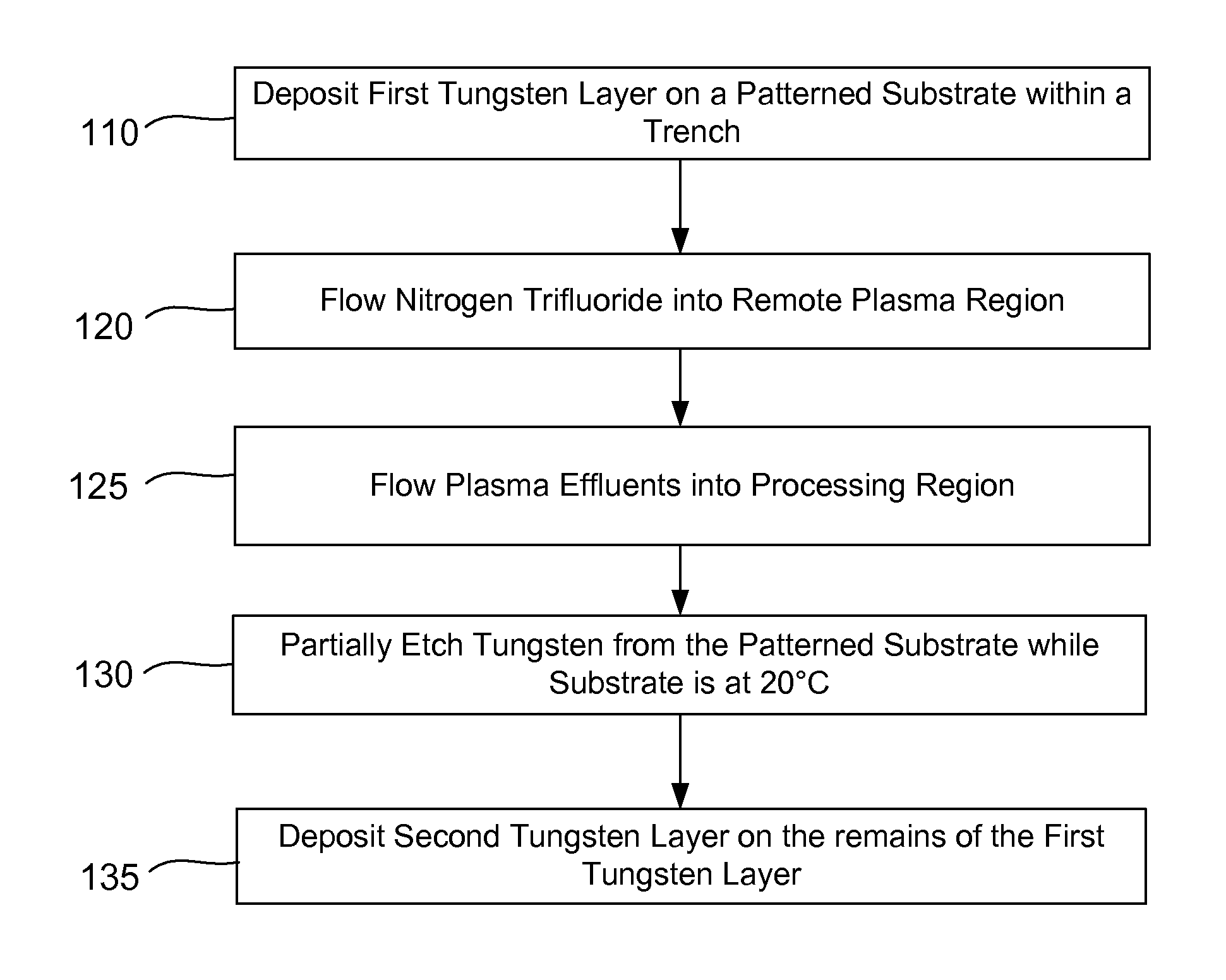

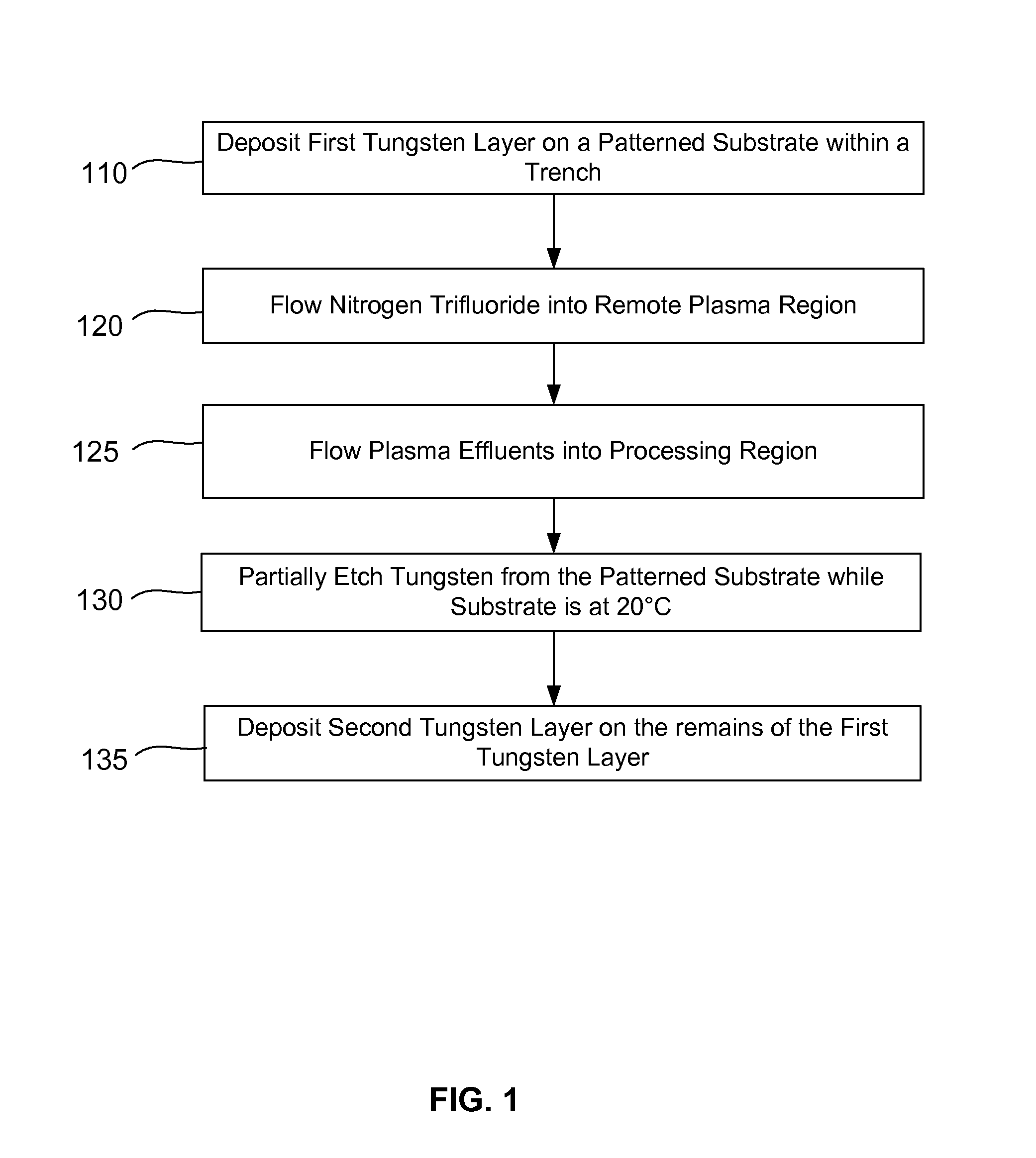

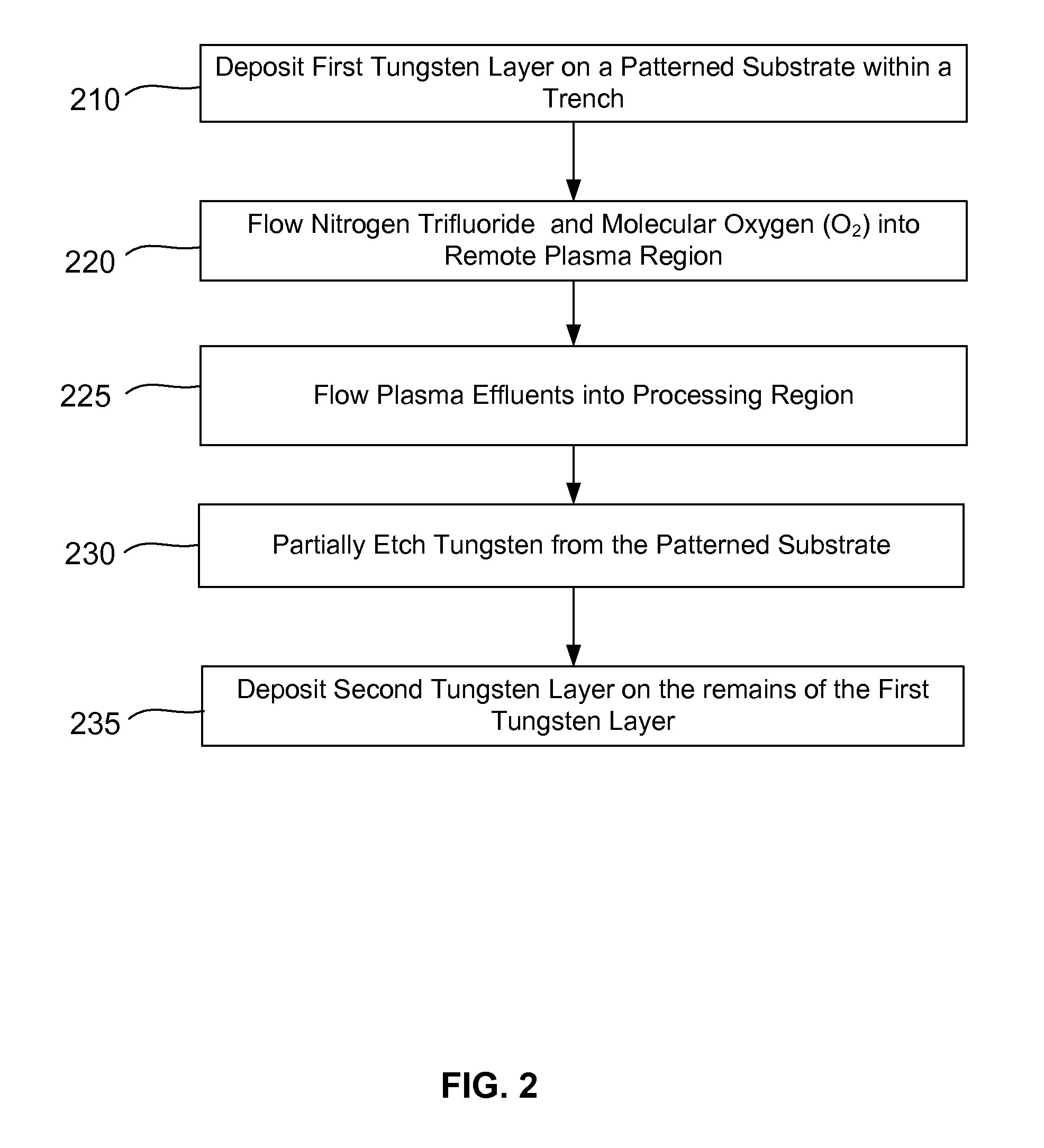

Tungsten deposition sequence

InactiveUS20140273451A1Enhance gapfillingAvoid difficultySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHalogenRoom temperature

Methods of filling gaps with tungsten are described. The methods include a tungsten dep-etch-dep sequence to enhance gapfilling yet avoid difficulty in restarting deposition after the intervening etch. The first tungsten deposition may have a nucleation layer or seeding layer to assist growth of the first tungsten deposition. Restarting deposition with a less-than-conductive nucleation layer would impact function of an integrated circuit, and therefore avoiding tungsten “poisoning” during the etch is desirable. The etching step may be performed using a plasma to excite a halogen-containing precursor while the substrate at relatively low temperature (near room temperature or less). The plasma may be local or remote. Another method may be used in combination or separately and involves the introduction of a source of oxygen into the plasma in combination with the halogen-containing precursor.

Owner:APPLIED MATERIALS INC

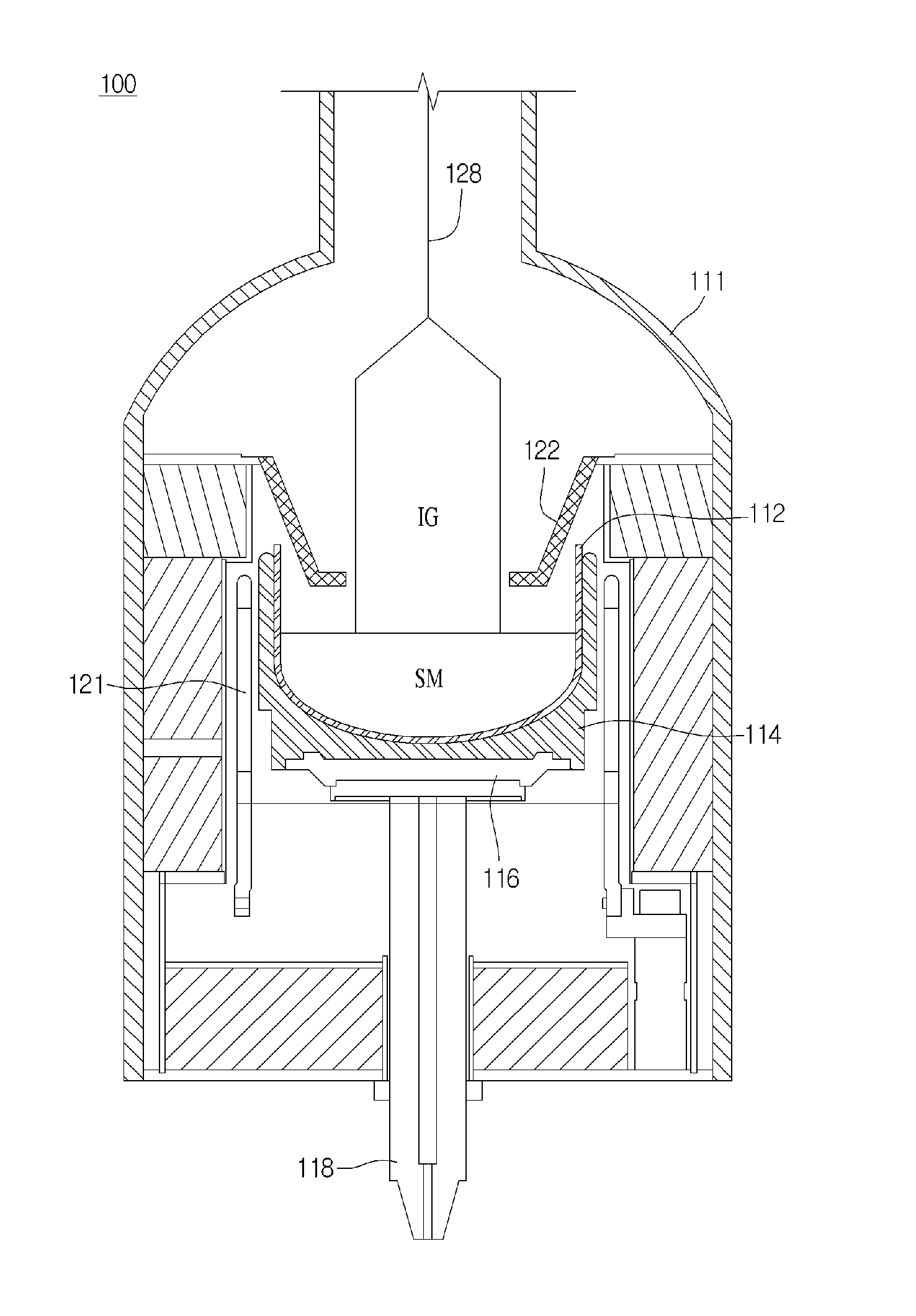

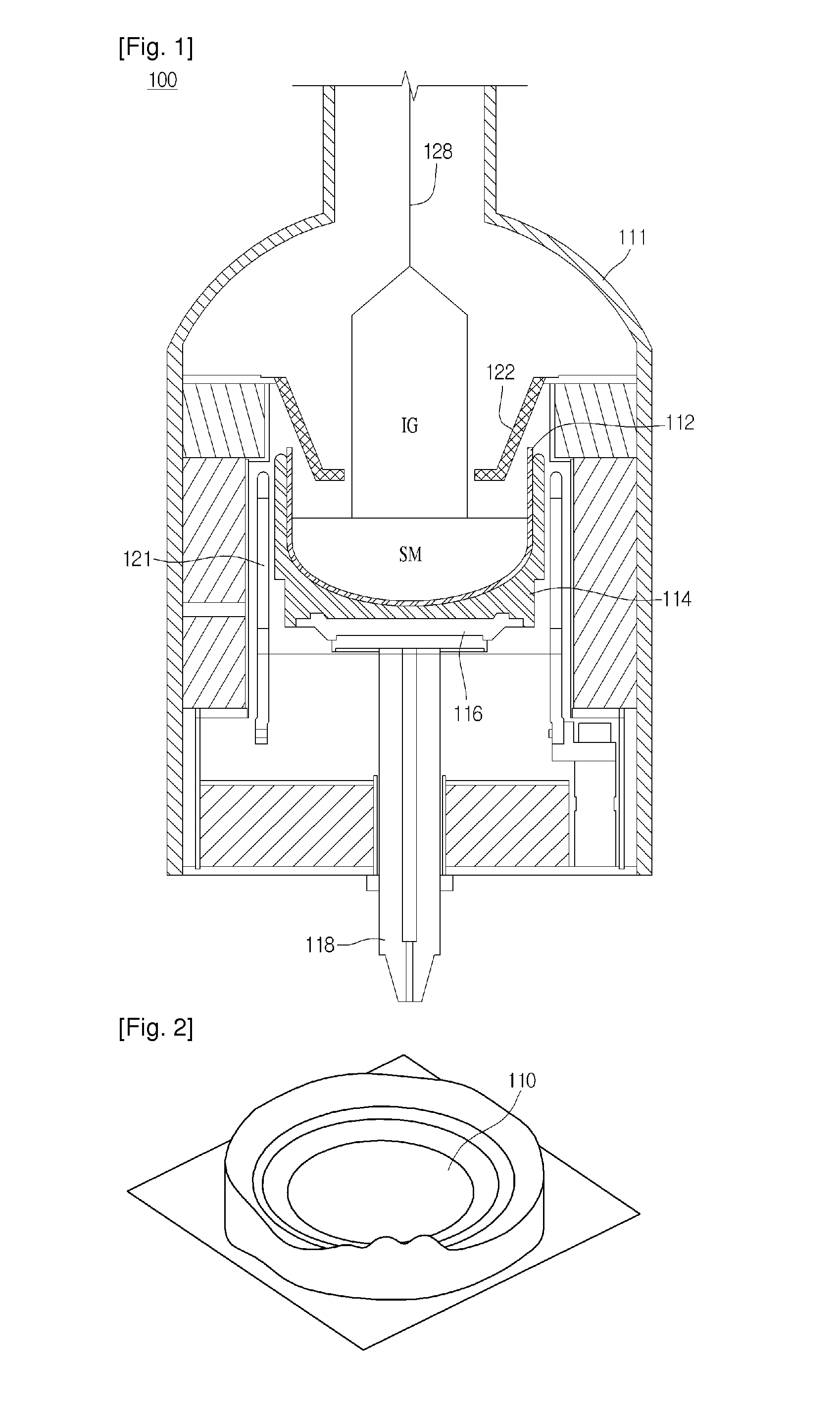

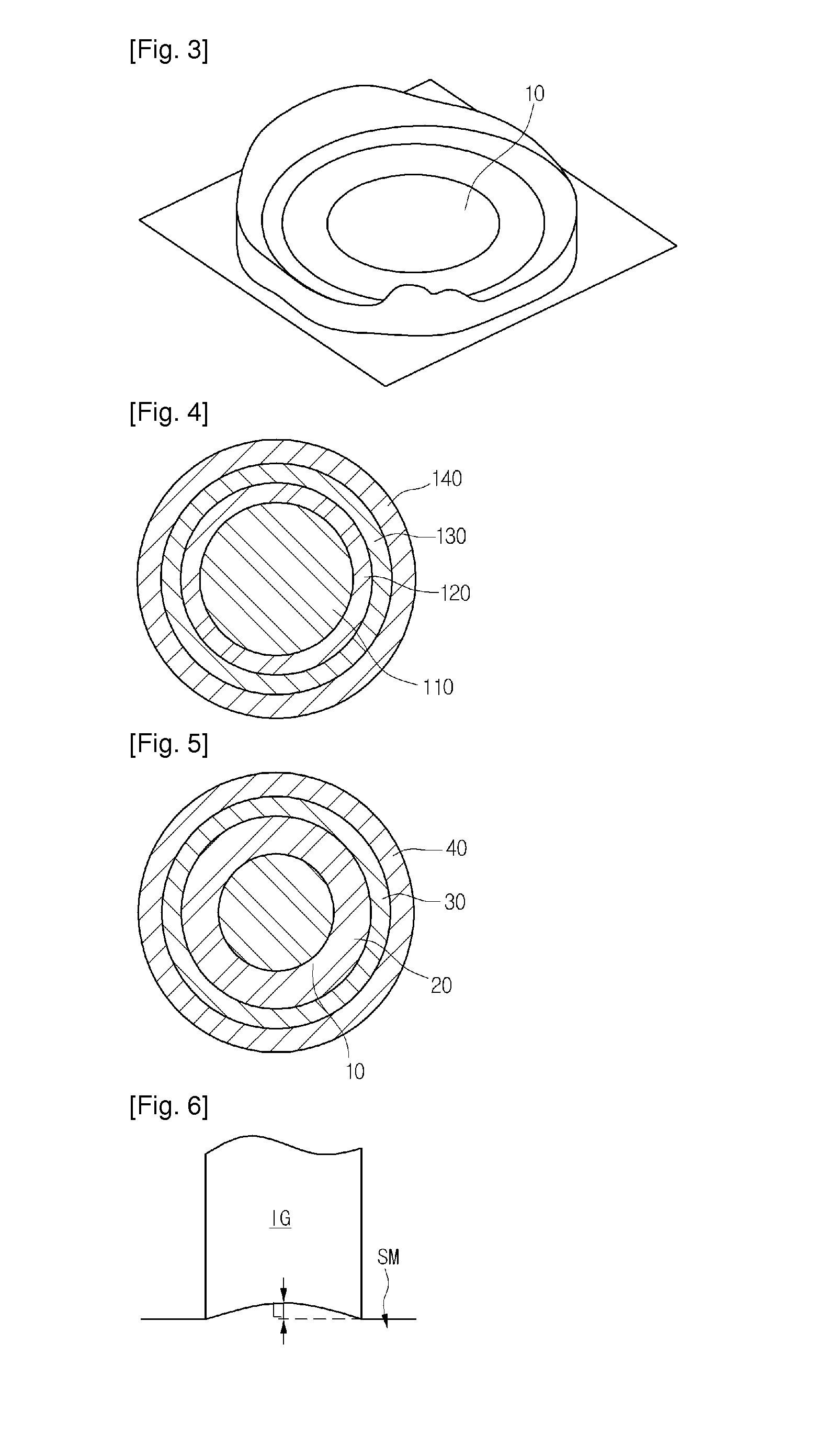

Method of manufacturing single crystal ingot, and single crystal ingot and wafer manufactured thereby

InactiveUS20140015108A1Increase productionPolycrystalline material growthSemiconductor/solid-state device manufacturingCrucibleIngot

A method of manufacturing a single crystal ingot, and a single crystal ingot and a wafer manufactured thereby are provided. The method of manufacturing a single crystal ingot according to an embodiment includes forming a silicon melt in a crucible inside a chamber, preparing a seed crystal on the silicon melt, and growing a single crystal ingot from the silicon melt, and pressure of the chamber may be controlled in a range of 90 Torr to 500 Torr.

Owner:LG SILTRON

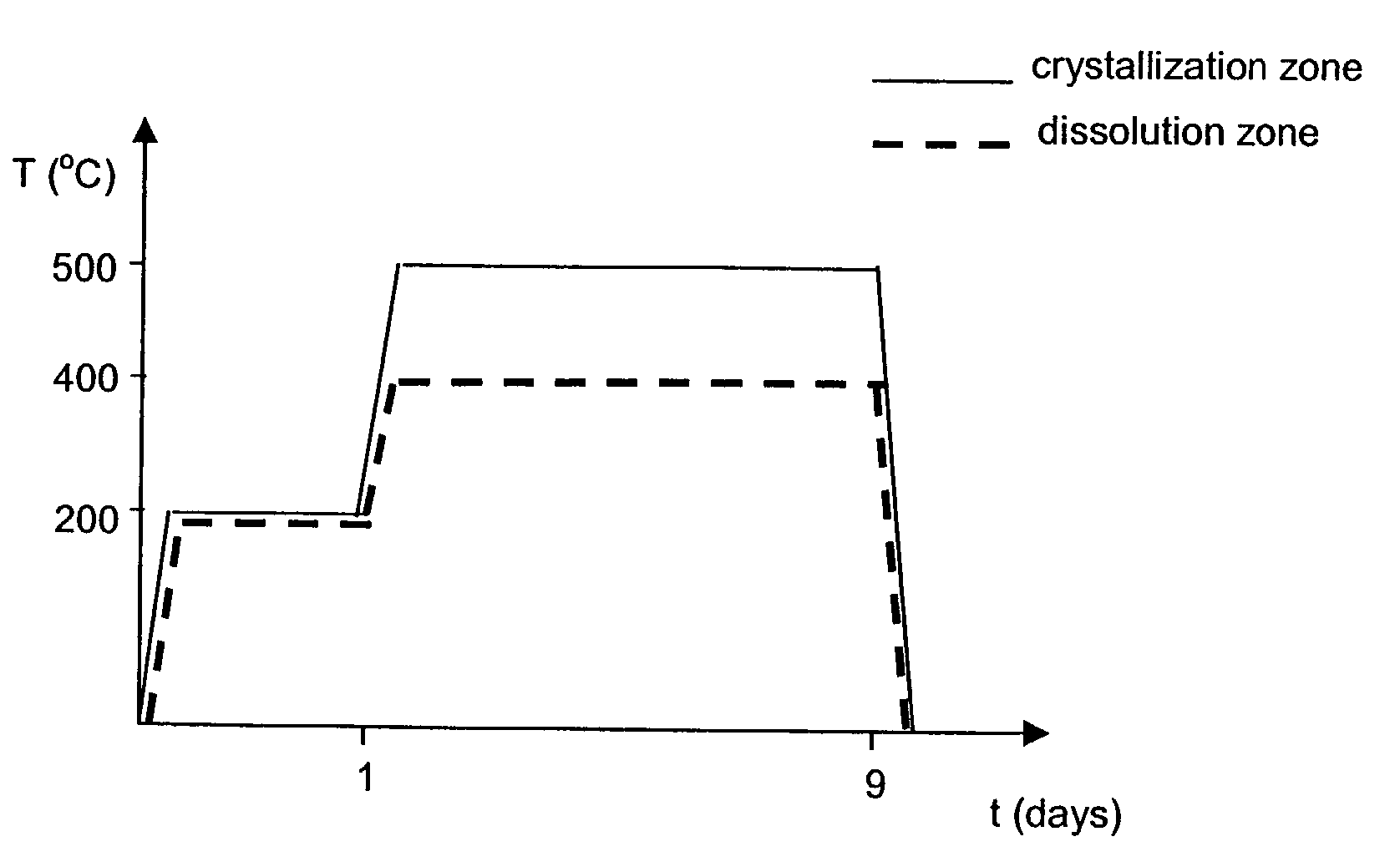

Process and apparatus for obtaining bulk monocrystalline gallium-containing nitride

Owner:AMMONO SP Z O O (PL) +1

Method for assembling nano objects

InactiveUS7147894B2Orientation can be controlledEfficient assemblyMaterial nanotechnologyNanostructure manufactureEvaporationSolvent

A method for the self assembly of a macroscopic structure with a pre-formed nano object is provided. The method includes processing a nano object to a desired aspect ratio and chemical functionality and mixing the processed nano object with a solvent to form a suspension. Upon formation of the suspension, a substrate is inserted into the suspension. By either evaporation of the solvent, changing the pH value of the suspension, or changing the temperature of the suspension, the nano objects within the suspension deposit onto the substrate in an orientational order. In addition, a seed crystal may be used in place of the substrate thereby forming single-crystals and free-standing membranes of the nano-objects.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Nitride semiconductor crystal and its production method

InactiveUS20110129669A1Easy to produceEfficient productionSemiconductor/solid-state device manufacturingGlass/slag layered productsCrystal growthSeed crystal

A method for efficiently producing a plate-like nitride semiconductor crystal having the desired principal plane in a simple method is provided. A raw material gas is fed to a seed crystal in which a ratio (L / W) of length L in a longitudinal direction and maximum width W, of a plane of projection obtained by projecting a crystal growth face on the seed crystal in a growth direction is from 2 to 400, and the maximum width W is 5 mm or less, thereby growing a plate-like semiconductor crystal on the seed crystal.

Owner:MITSUBISHI CHEM CORP

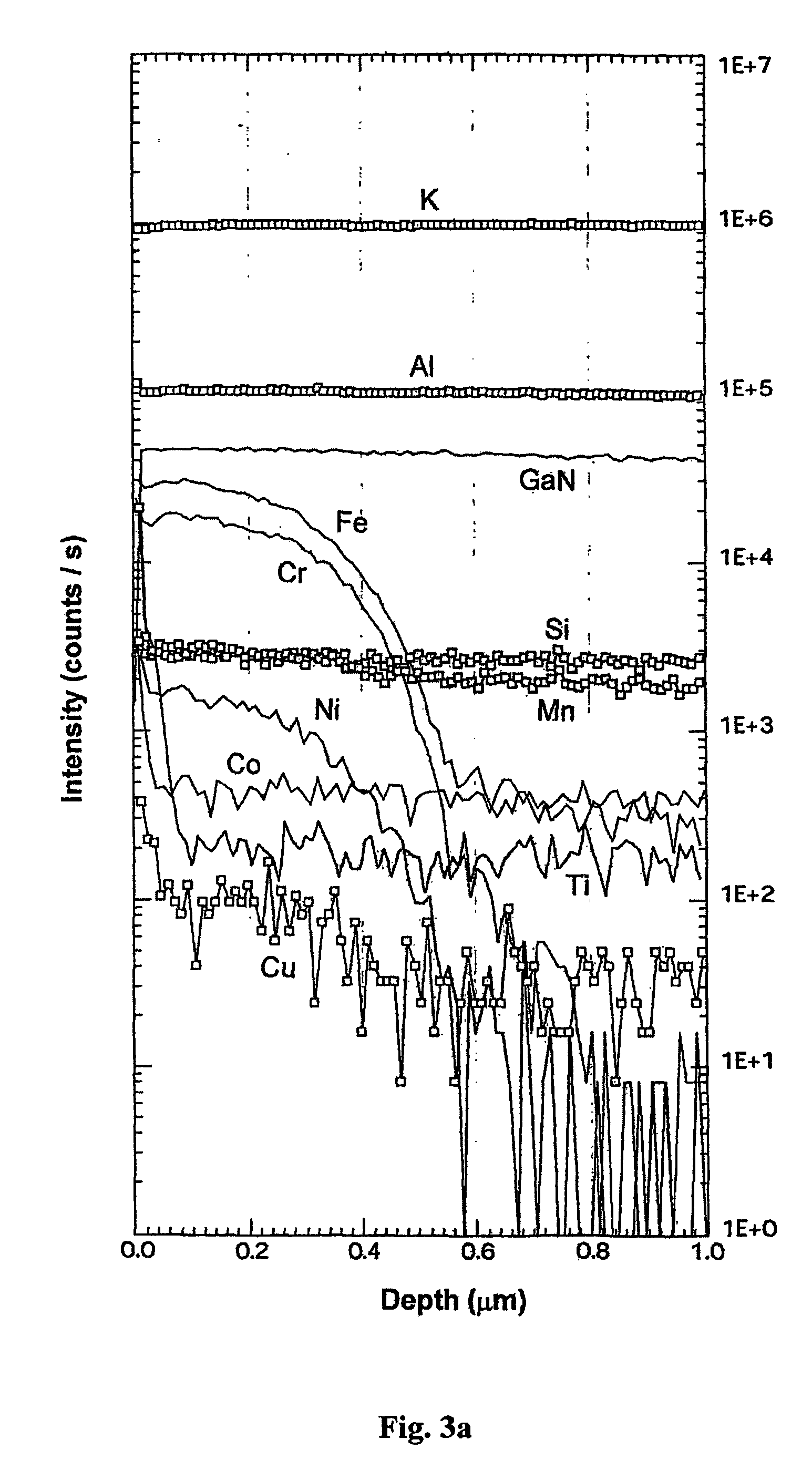

Bulk nitride mono-crystal including substrate for epitaxy

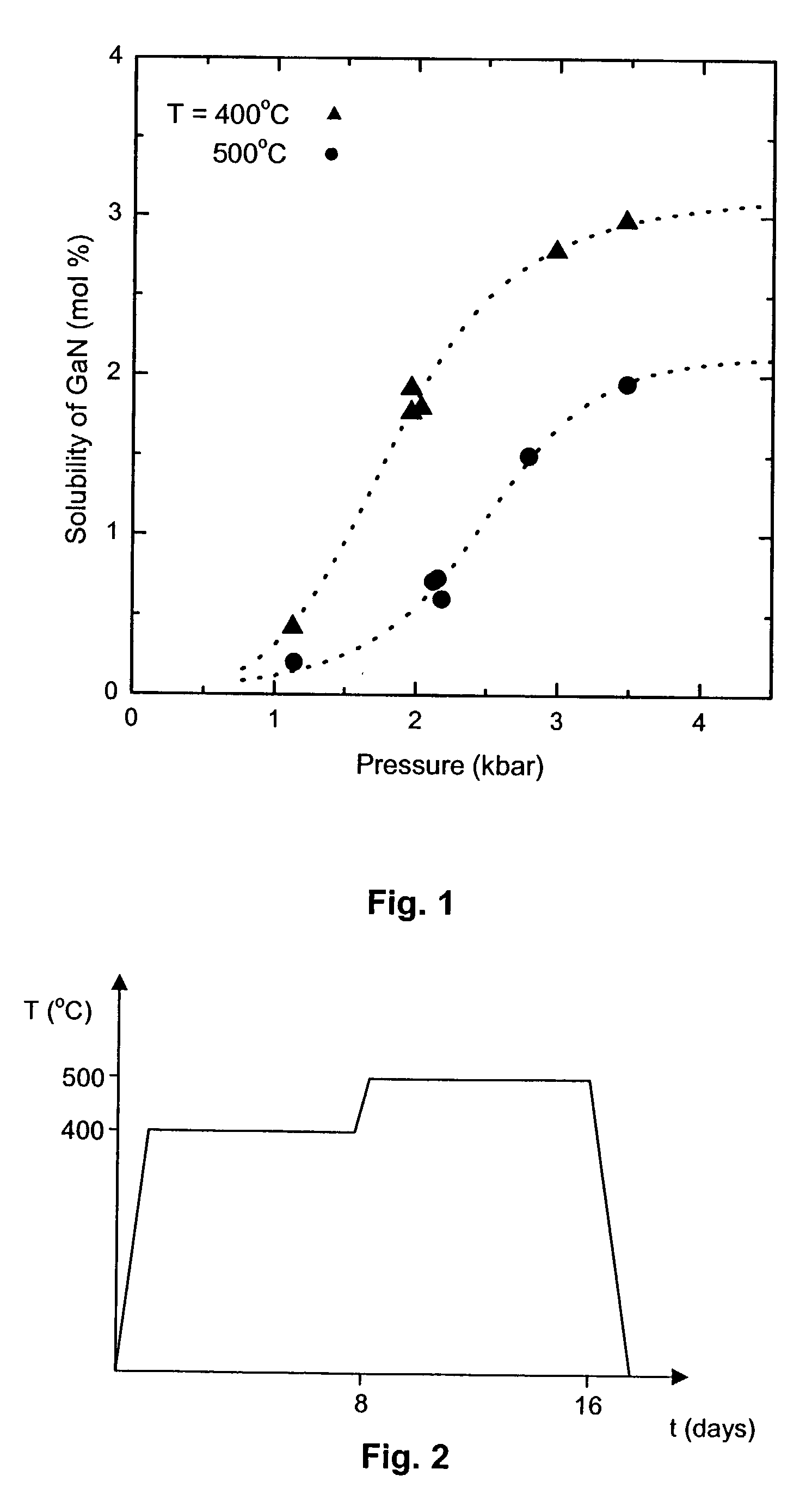

InactiveUS7132730B2Reduced life-timeLaser detailsFrom normal temperature solutionsDissolutionSolvent

The invention relates to a substrate for epitaxy, especially for preparation of nitride semiconductor layers. Invention covers a bulk nitride mono-crystal characterized in that it is a mono-crystal of gallium nitride and its cross-section in a plane perpendicular to c-axis of hexagonal lattice of gallium nitride has a surface area greater than 100 mm2, it is more than 1.0 μm thick and its C-plane surface dislocation density is less than 106 / cm2, while its volume is sufficient to produce at least one further-processable non-polar A-plane or M-plane plate having a surface area at least 100 mm2. More generally, the present invention covers a bulk nitride mono-crystal which is characterized in that it is a mono-crystal of gallium-containing nitride and its cross-section in a plane perpendicular to c-axis of hexagonal lattice of gallium-containing nitride has a surface area greater than 100 mm2, it is more 1.0 μm thick and its surface dislocation density is less than 106 / cm2. Mono-crystals according to the present invention are suitable for epitaxial growth of nitride semiconductor layers. Due to their good crystalline quality they are suitable for use in opto-electronics for manufacturing opto-electronic semiconductor devices based on nitrides, in particular for manufacturing semiconductor laser diodes and laser devices. The a.m bulk mono-crystals of gallium-containing nitride are crystallized on seed crystals. Various seed crystals may be used. The bulk mono-crystals of gallium-containing nitride are crystallized by a method involving dissolution of a gallium-containing feedstock in a supercritical solvent and crystallization of a gallium nitride on a surface of seed crystal, at temperature higher and / or pressure lower than in the dissolution process.

Owner:AMMONO SP Z O O (PL) +1

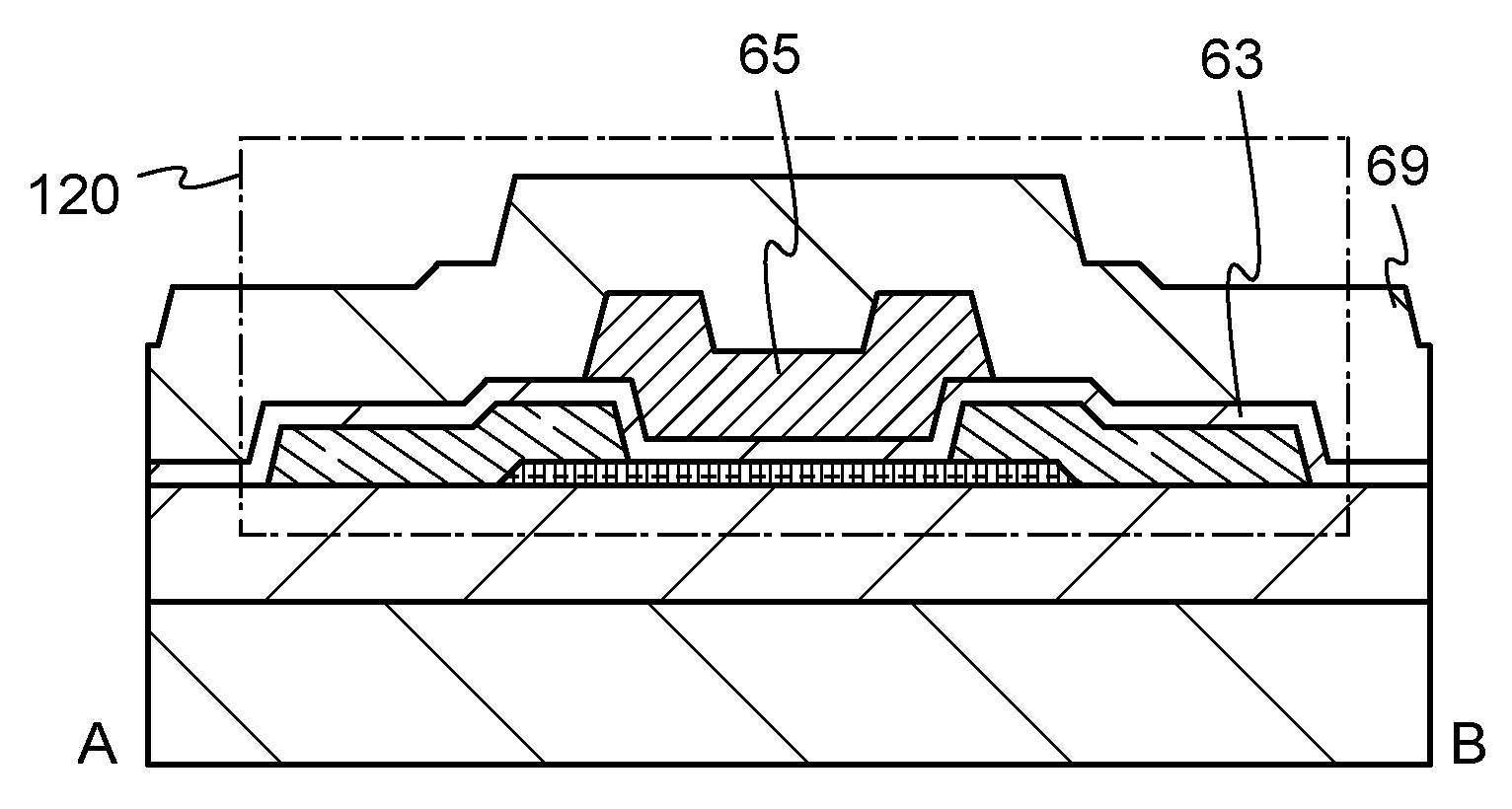

Method for manufacturing semiconductor device

ActiveUS20120064664A1Stable electrical characteristicsReduce the amount of variationSemiconductor/solid-state device detailsElectroluminescent light sourcesCrystalline oxidePower semiconductor device

An object is to manufacture a semiconductor device including an oxide semiconductor film, which has stable electric characteristics and high reliability. A crystalline oxide semiconductor film is formed, without performing a plurality of steps, as follows: by utilizing a difference in atomic weight of plural kinds of atoms included in an oxide semiconductor target, zinc with low atomic weight is preferentially deposited on an oxide insulating film to form a seed crystal including zinc; and tin, indium, or the like with high atomic weight is deposited on the seed crystal while causing crystal growth. Further, a crystalline oxide semiconductor film is formed by causing crystal growth using a seed crystal with a hexagonal crystal structure including zinc as a nucleus, whereby a single crystal oxide semiconductor film or a substantially single crystal oxide semiconductor film is formed.

Owner:SEMICON ENERGY LAB CO LTD

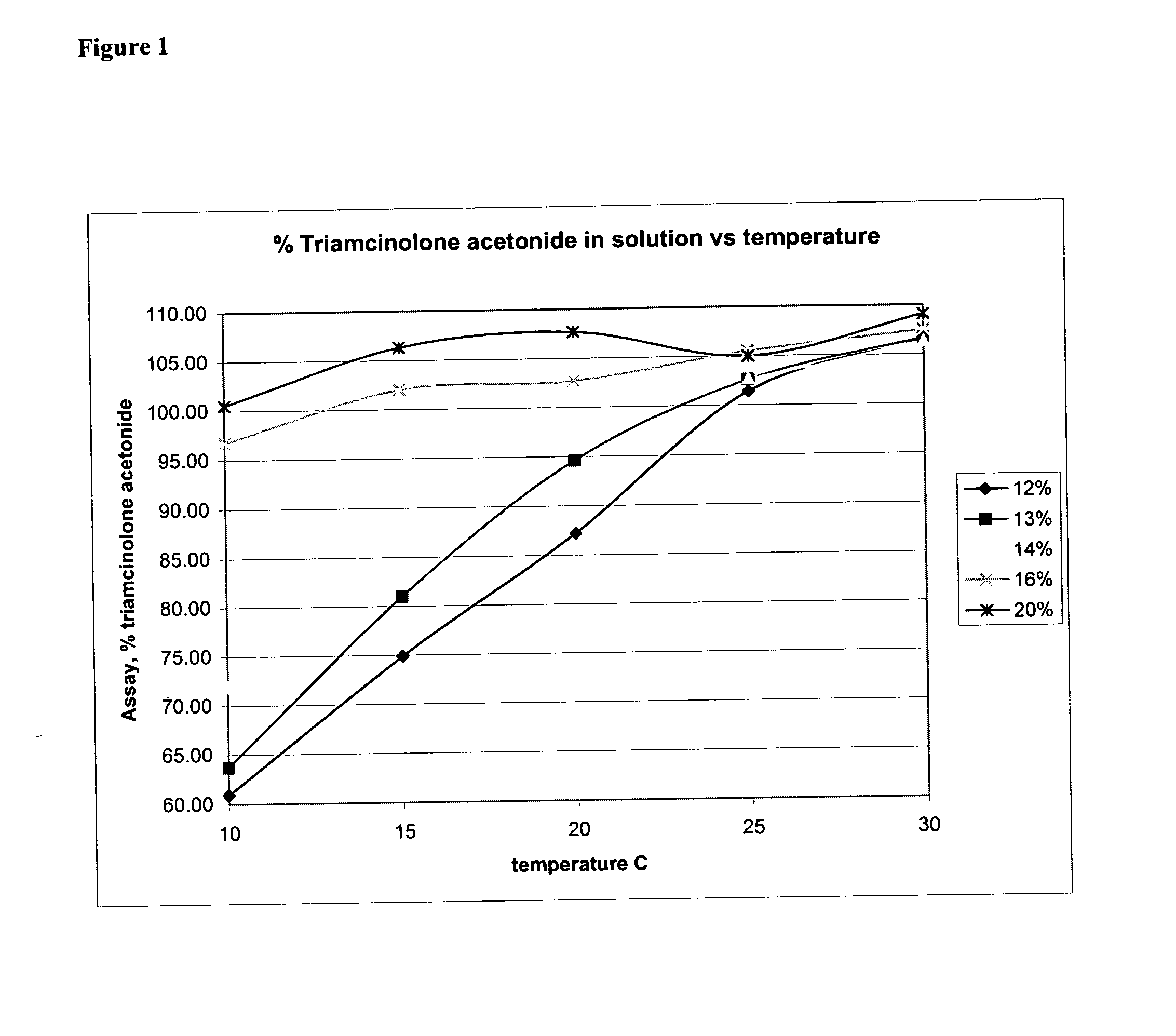

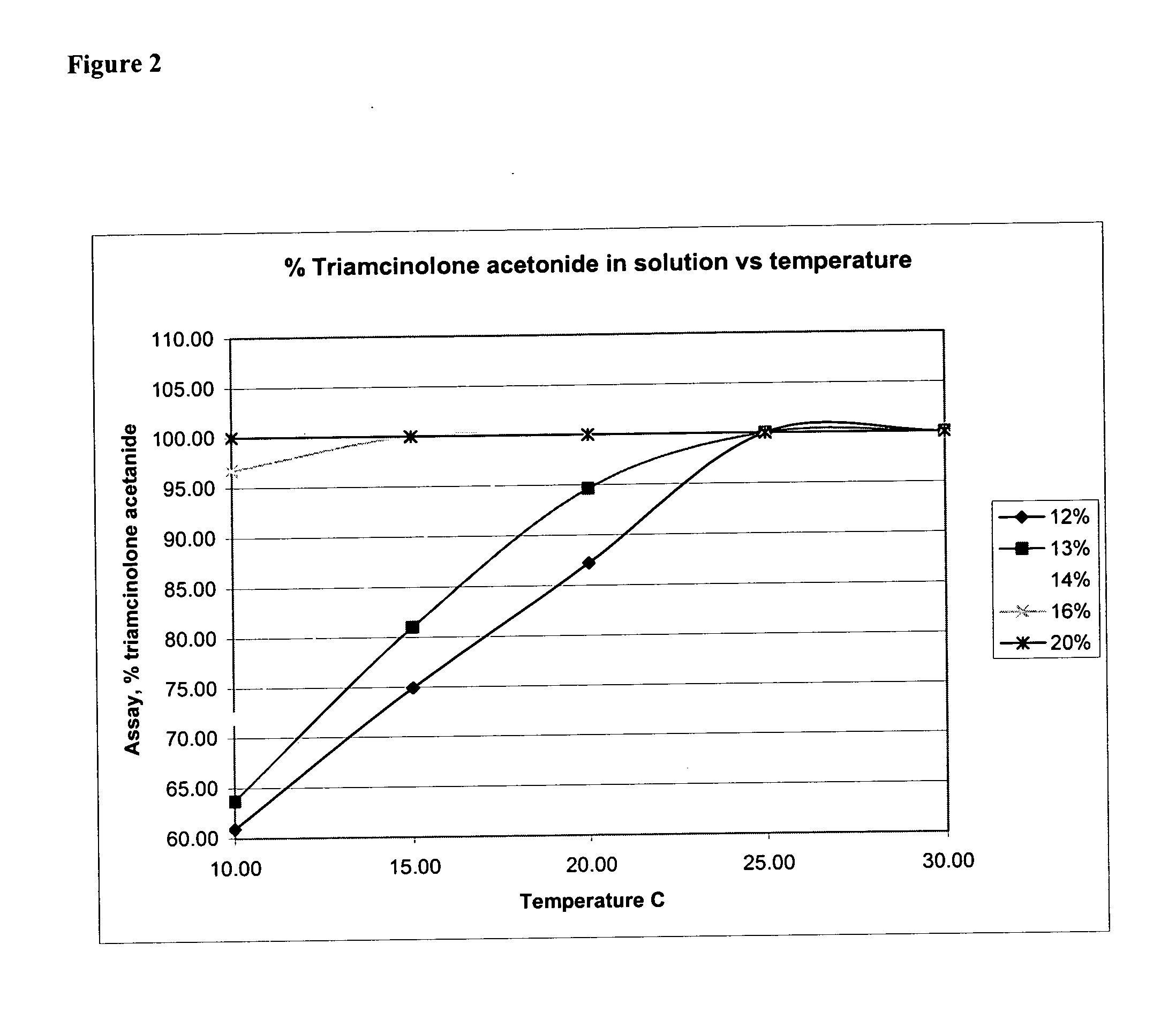

Temperature-stable formulations, and methods of development thereof

One embodiment of the present invention relates to a method of preparing a concentrated pharmaceutical formulation, comprising the steps of: combining in a container a therapeutic agent, a solvent and at least one pharmaceutically acceptable excipient to give a solution; adding to said solution a seed crystal of said compound to give a heterogeneous mixture; and observing the stability of said heterogeneous mixture.

Owner:LUPIN ATLANTIS HLDG

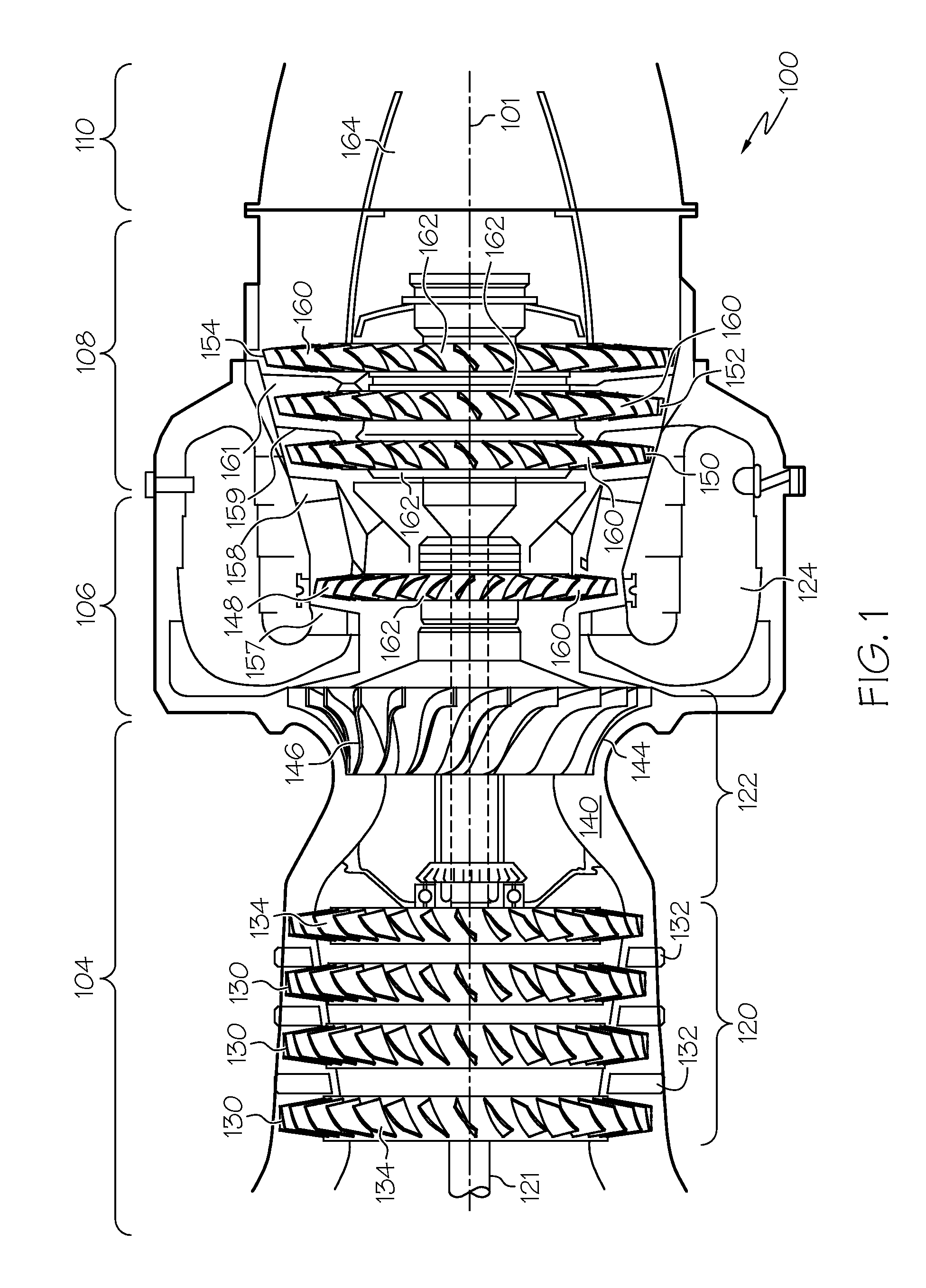

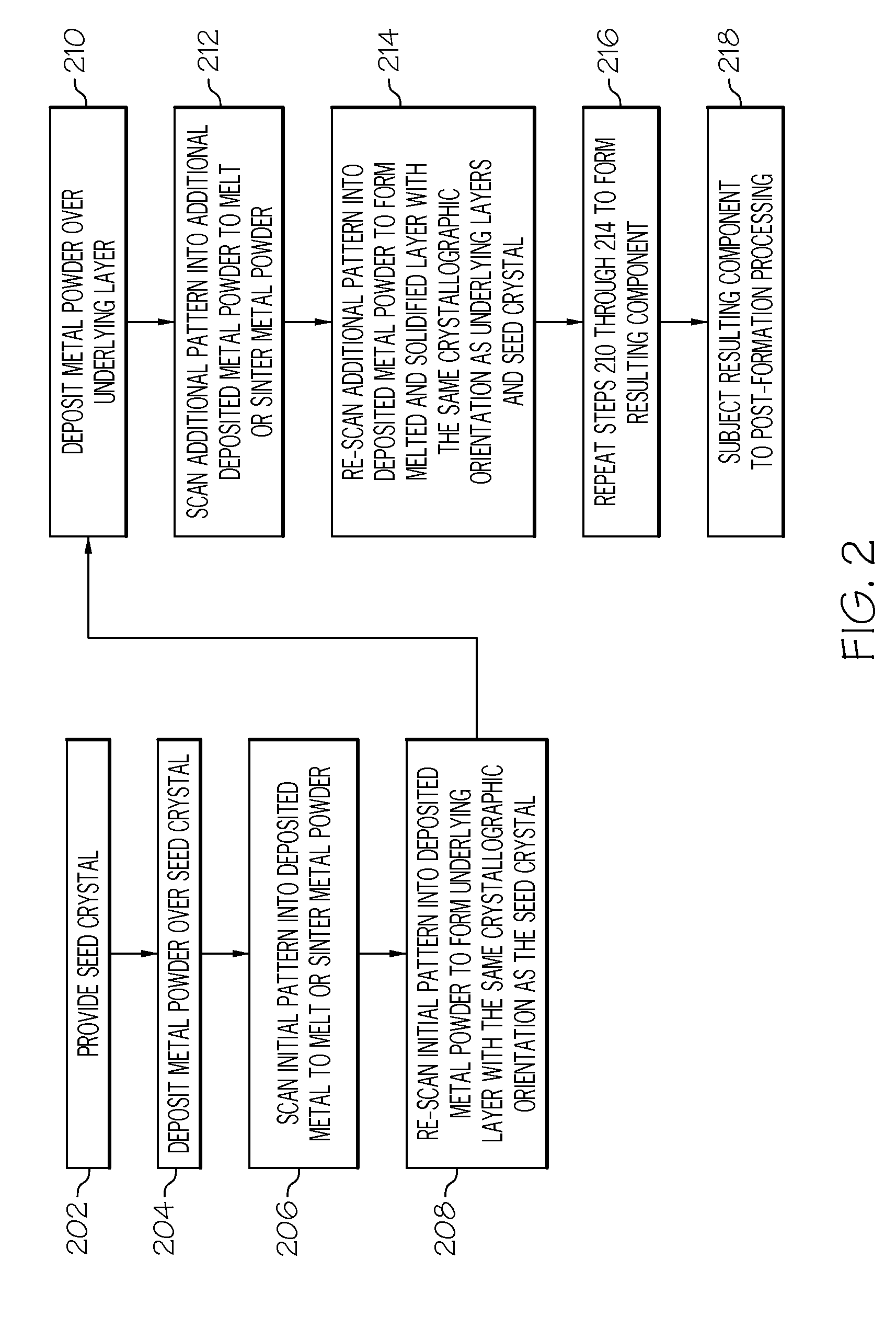

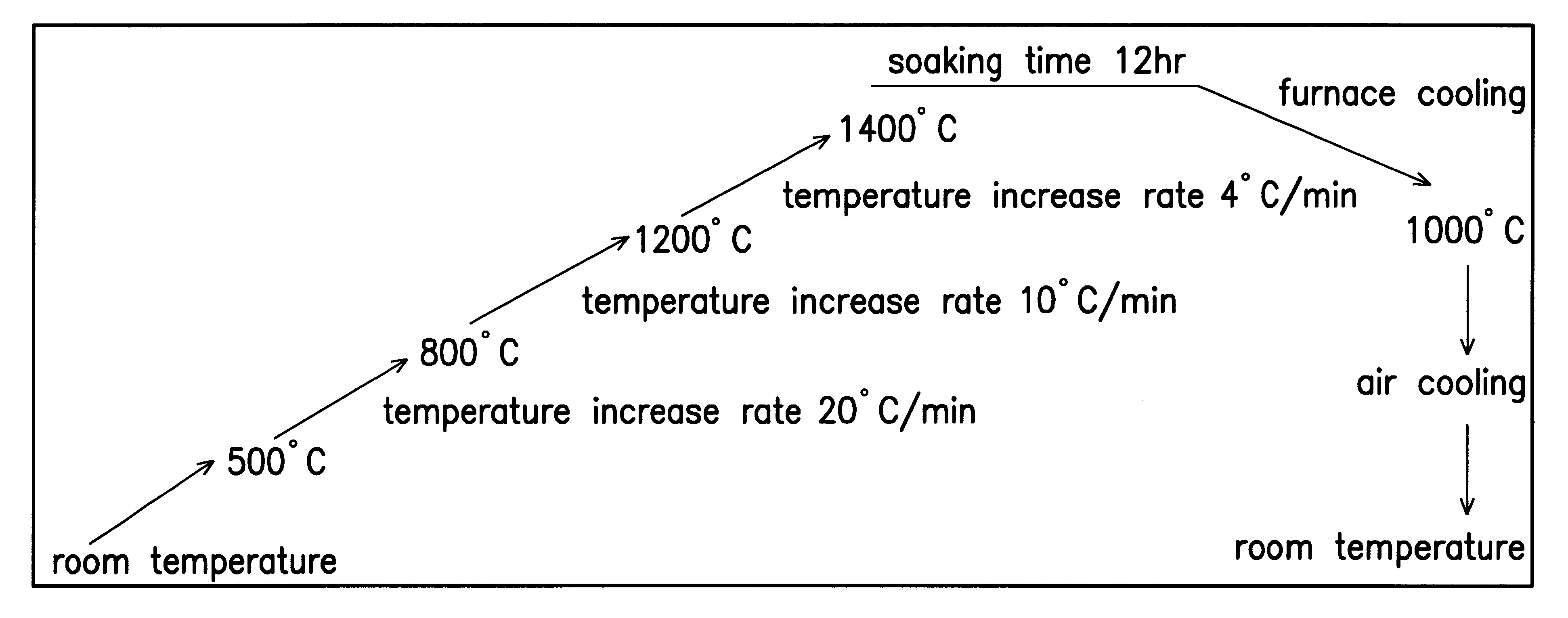

Turbine components for engines and methods of fabricating the same

A method is provided that includes depositing metal powder over a seed crystal having a predetermined primary orientation, scanning an initial pattern into the metal powder to melt or sinter the deposited metal powder, and re-scanning the initial pattern to re-melt the scanned metal powder and form an initial layer having the predetermined primary orientation. The method further includes depositing additional metal powder over the initial layer, scanning an additional pattern into the additional metal powder to melt or sinter at least a portion of the additional metal powder, re-scanning the additional pattern to re-melt a portion of the initial layer and the scanned deposited additional metal powder to form a successive layer having the predetermined primary orientation, and repeating the steps of depositing additional metal powder, scanning the additional pattern, and re-scanning the additional pattern, until a final shape of the component is achieved.

Owner:HONEYWELL INT INC

Process for producing fast-setting, bioresorbable calcium phosphate cements

InactiveUS6379453B1Improve biological activityOther chemical processesDentistry preparationsSeed crystalCalcium phosphate cement

Owner:CALCITEC

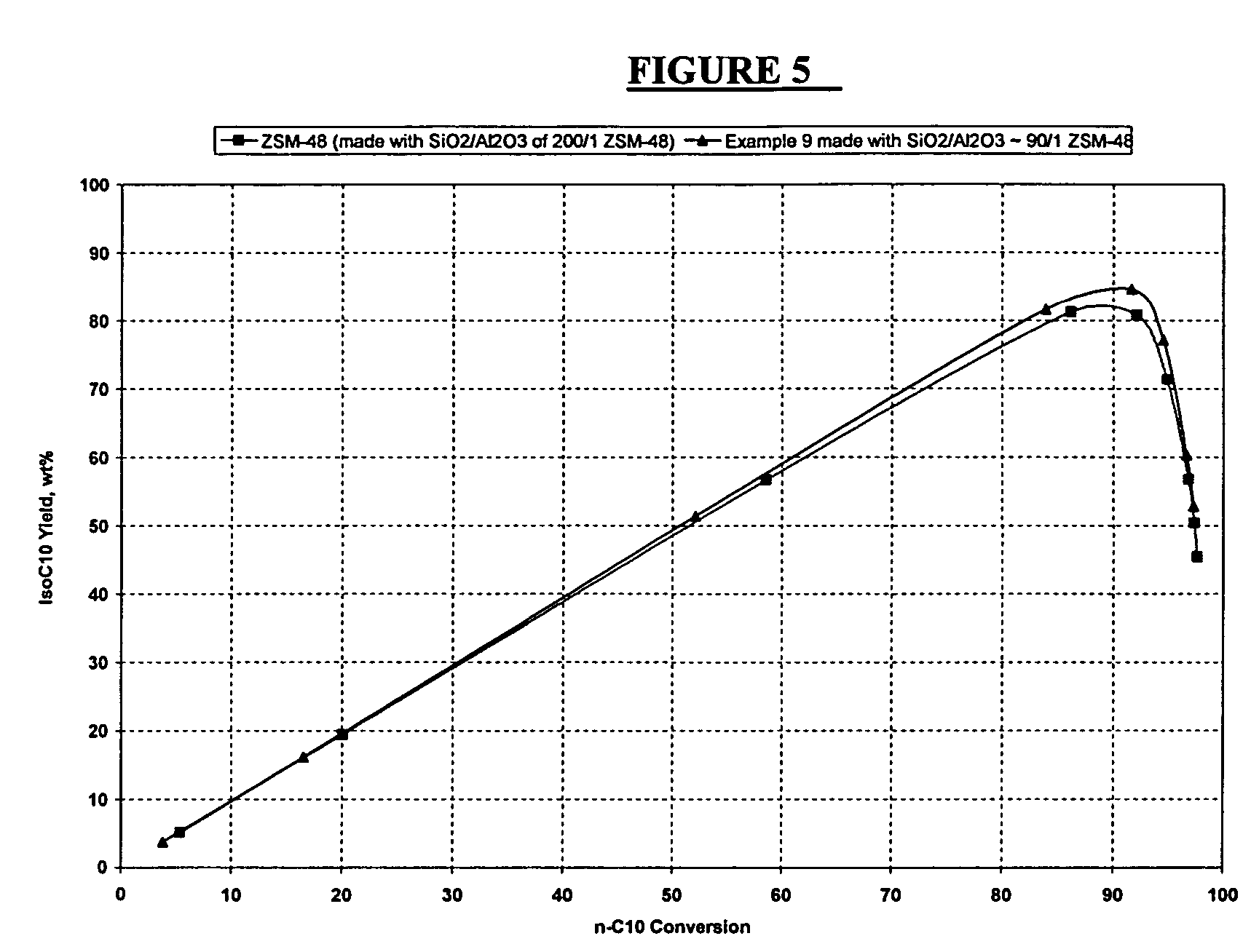

High activity ZSM-48 and methods for dewaxing

Owner:EXXON RES & ENG CO

Semiconductor laser, semiconductor device, and their manufacture methods

A substrate is made of SiC. A plurality of AlxGa1-xN patterns (0<=x<=1) is formed on a surface of the substrate and dispersively distributed in an in-plane of the substrate. An AlyGa1-yN buffer layer (0<=y<=1) covers the surface of the substrate and the AlxGa1-xN patterns. A laser structure is formed on the AlyGa1-yN buffer layer. Since the AlGaN buffer layer is grown by using the AlGaN patterns as seed crystals, a dislocation density of a predetermined region in the AlGaN buffer layer can be lowered. The characteristics of a laser structure can be improved by forming the laser structure above the region having a low dislocation density. Since the AlGaN pattern has electric conductivity, the device resistance can be suppressed from being increased.

Owner:FUJITSU LTD

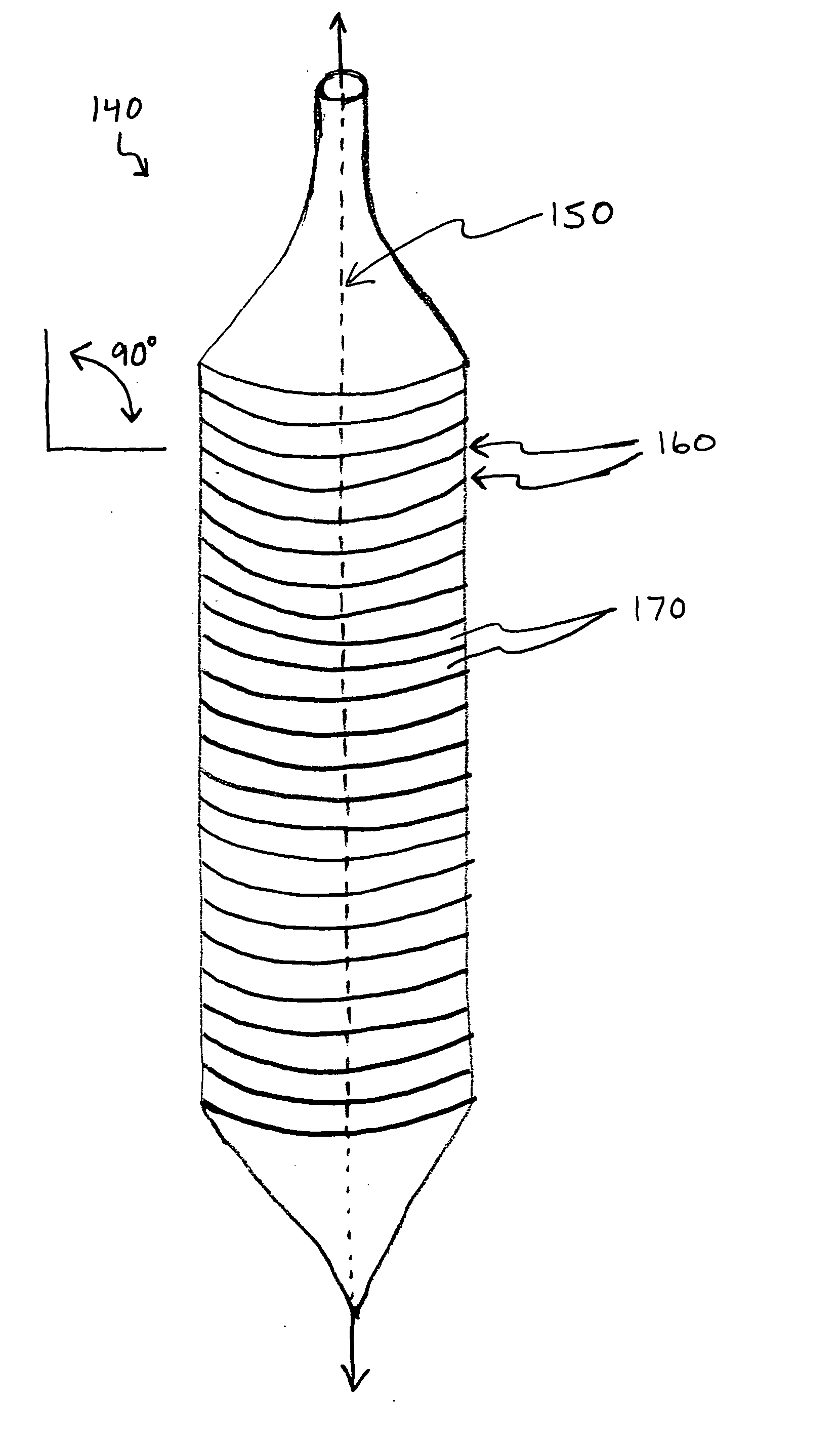

Semiconductor wafers with non-standard crystal orientations and methods of manufacturing the same

The crystal orientations of monocrystalline semiconductor wafers may be varied by four parameters. The first parameter is the type of crystal seed used to grow the monocrystalline semiconductor ingot from which the wafers are cut. The second parameter is the angle at which the wafer is sliced from the ingot. The third parameter is the crystal plane towards which the wafer is cut. And, the fourth parameter is the position of the orientation indication feature that is used to align the wafer during processing. Different combinations of these parameters provide variations of non-standard crystal orientations of monocrystalline semiconductor wafers and semiconductor-on-insulator substrates such as silicon-on-insulator.

Owner:INTEL CORP

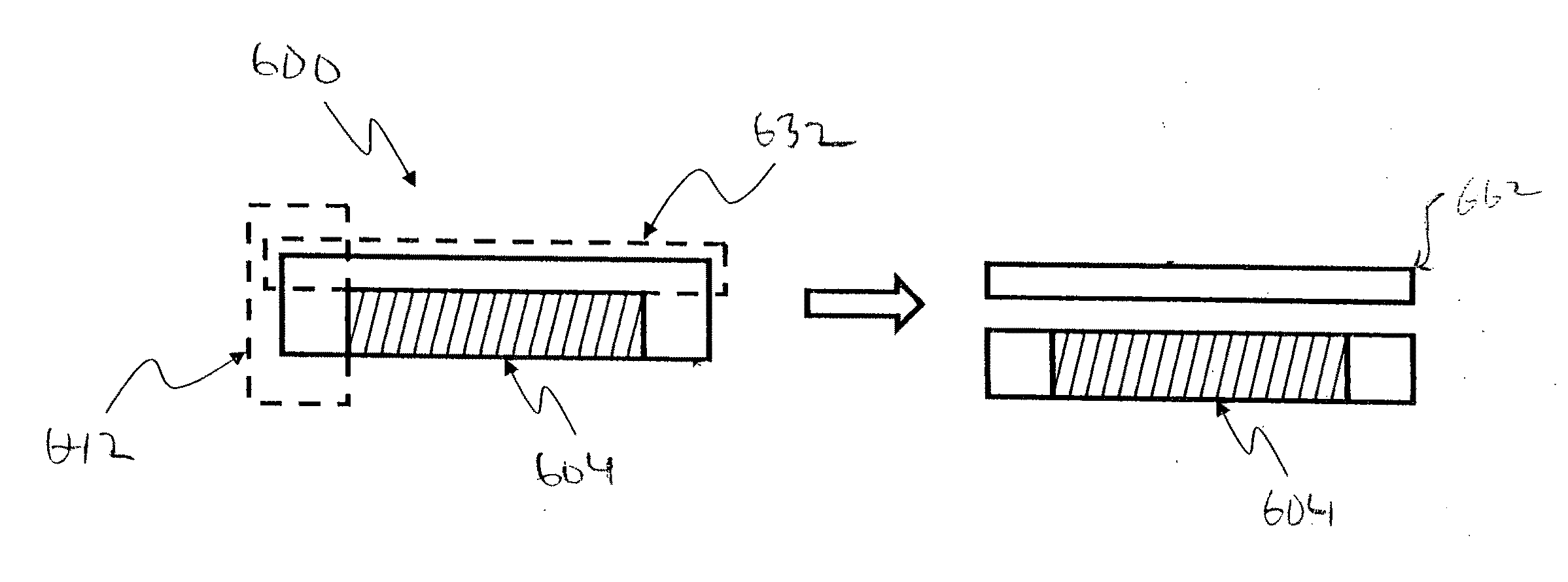

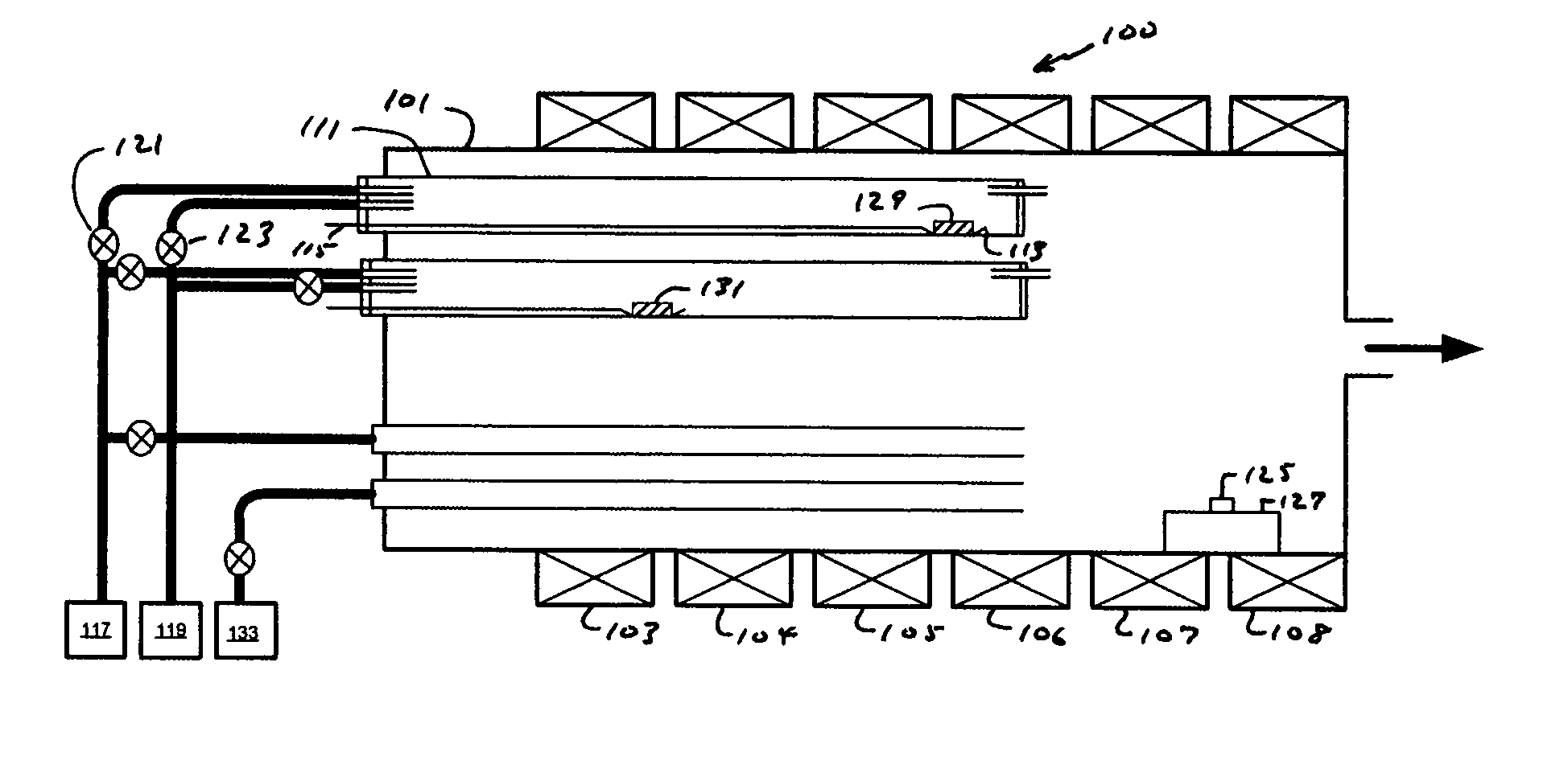

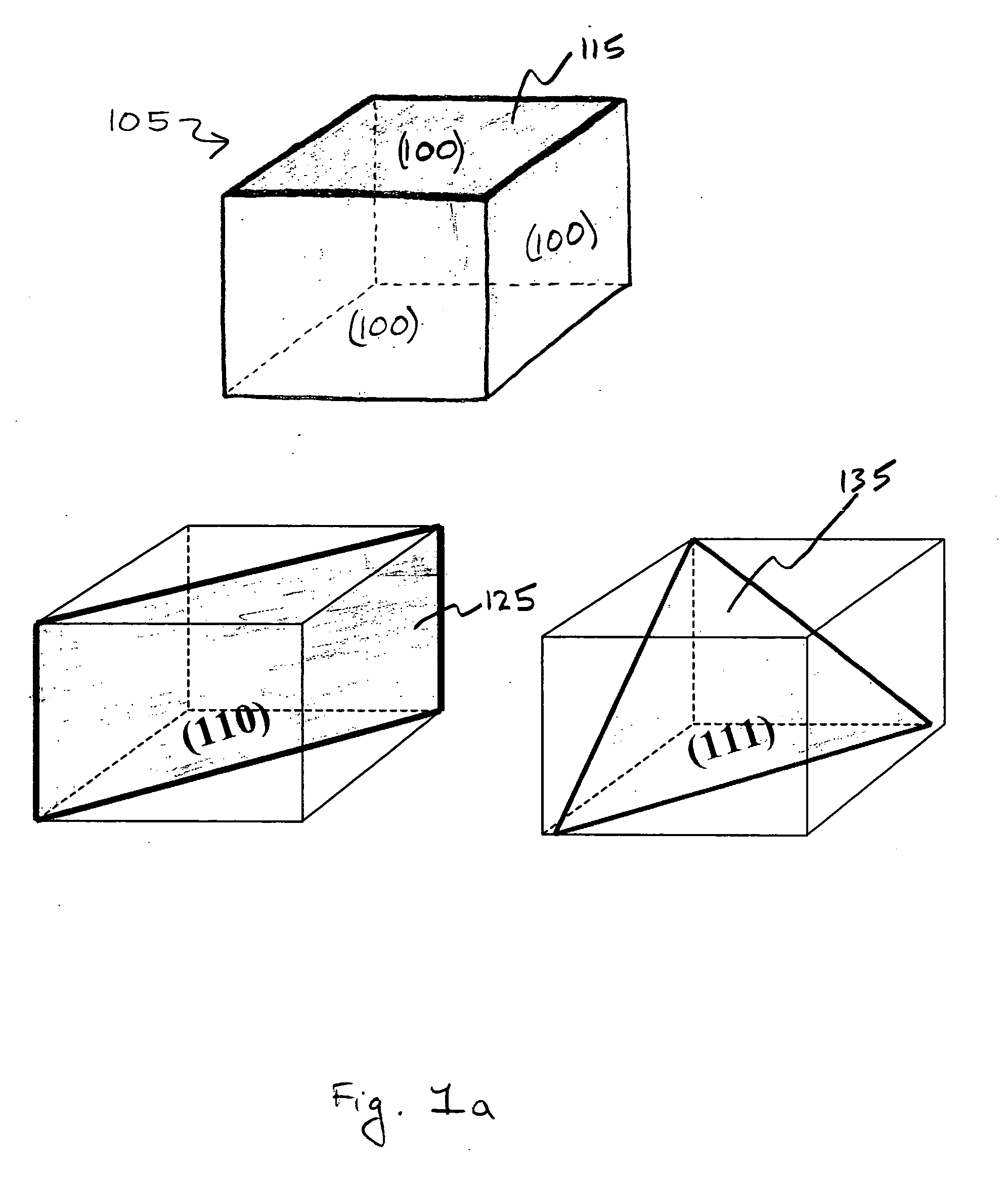

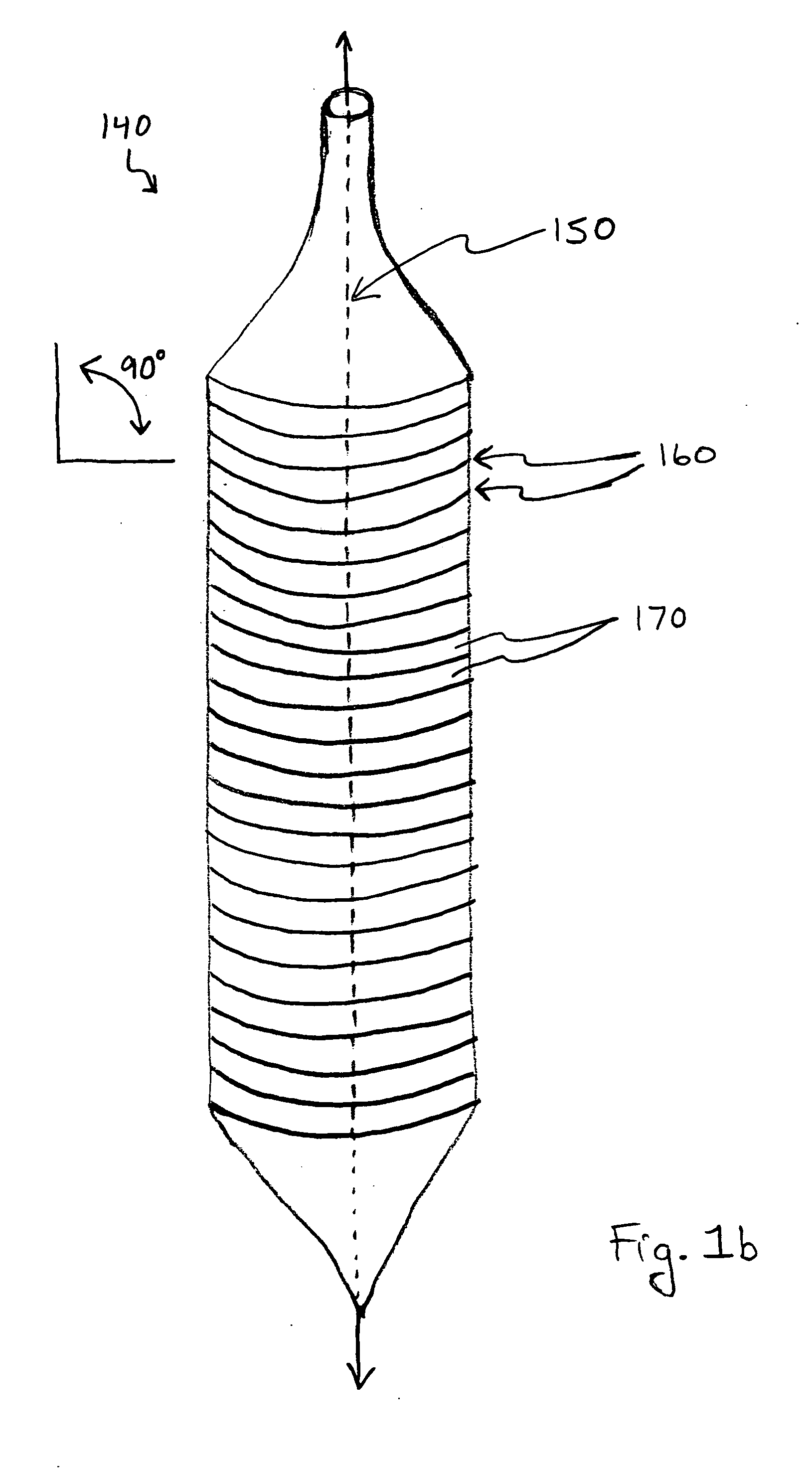

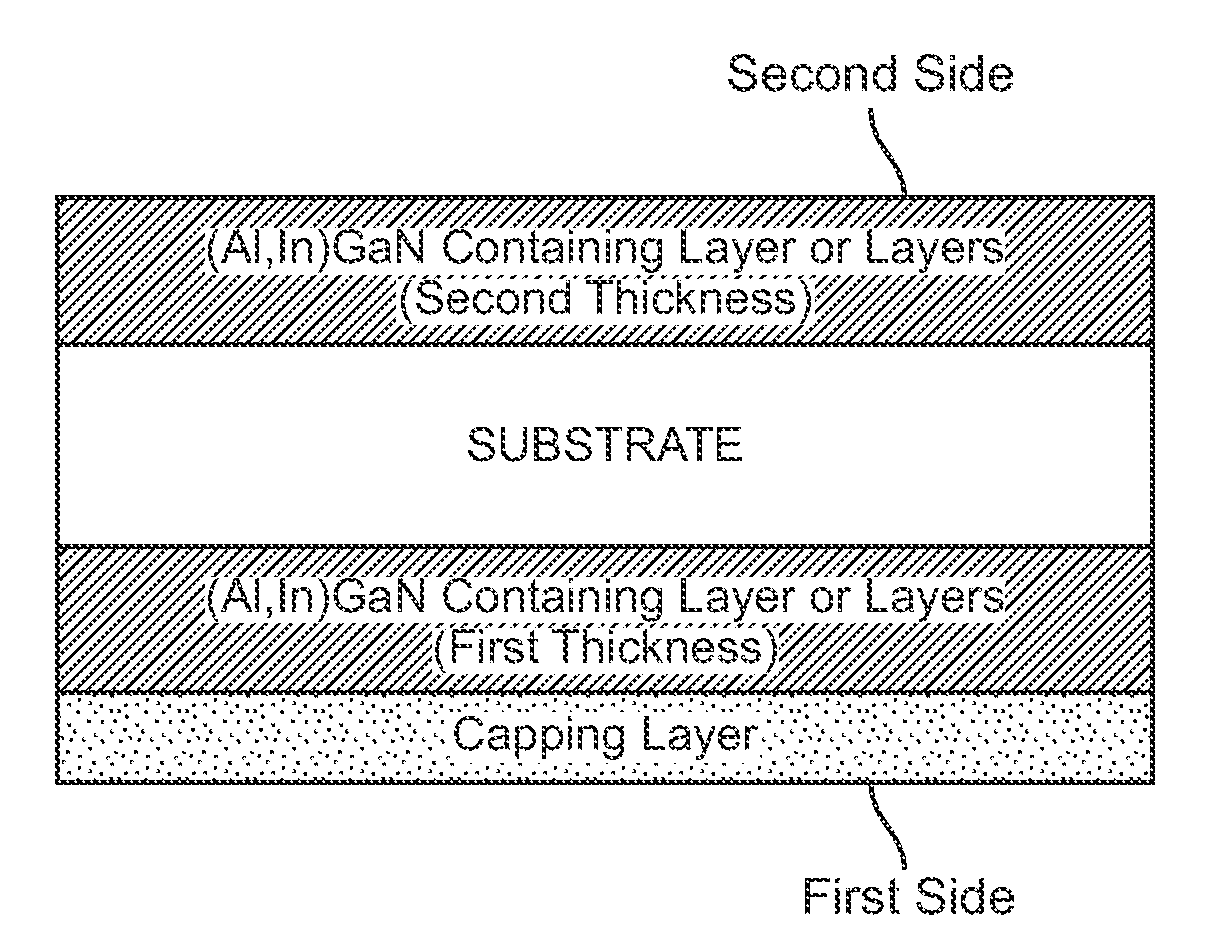

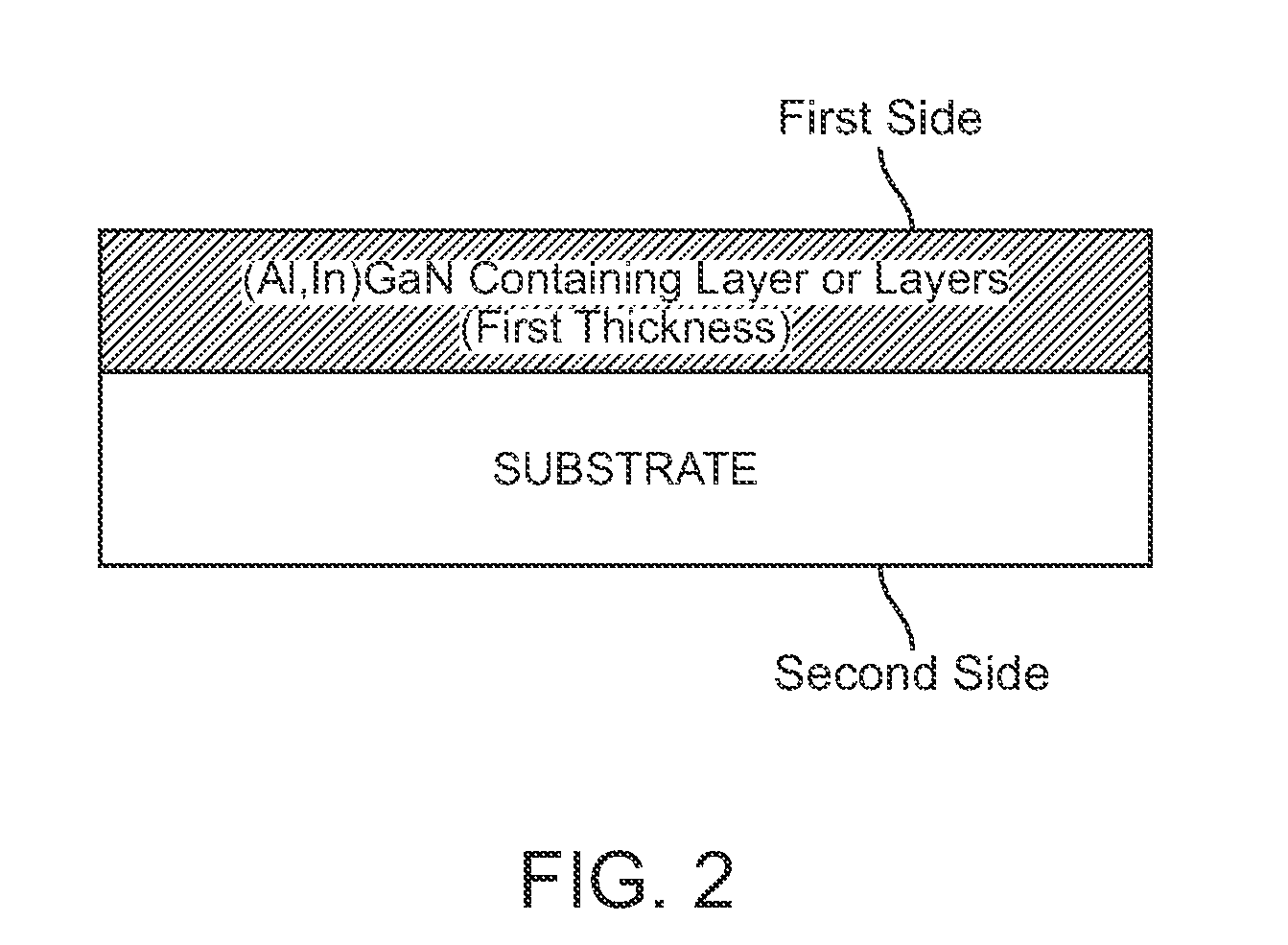

Large-area seed for ammonothermal growth of bulk gallium nitride and method of manufacture

ActiveUS20100075175A1Quality improvementLow costPolycrystalline material growthFrom normal temperature solutionsWaferingGallium nitride

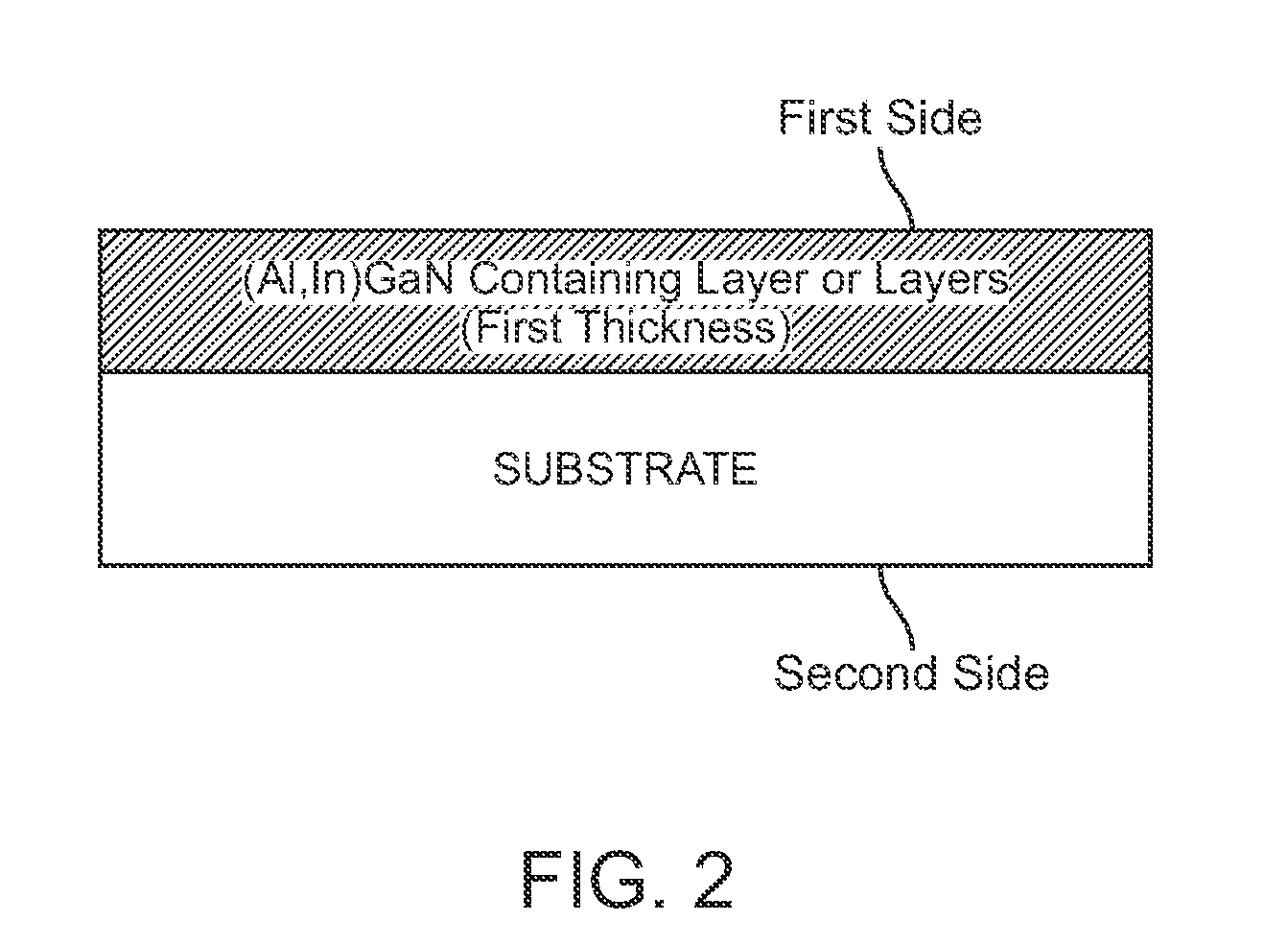

A high-quality, large-area seed crystal for ammonothermal GaN growth and method for fabricating. The seed crystal comprises double-side GaN growth on a large-area substrate. The seed crystal is of relatively low defect density and has flat surfaces free of bowing. The seed crystal is useful for producing large-volume, high-quality bulk GaN crystals by ammonothermal growth methods for eventual wafering into large-area GaN substrates for device fabrication.

Owner:SLT TECH

ß-Ga2o3 single crystal growing method, thin-film single crystal growing method, Ga2o3 light-emitting device, and its manufacturing method

InactiveUS20060150891A1Trend downHigh crystallinityPolycrystalline material growthBy zone-melting liquidsDopantInfrared

Owner:WASEDA UNIV

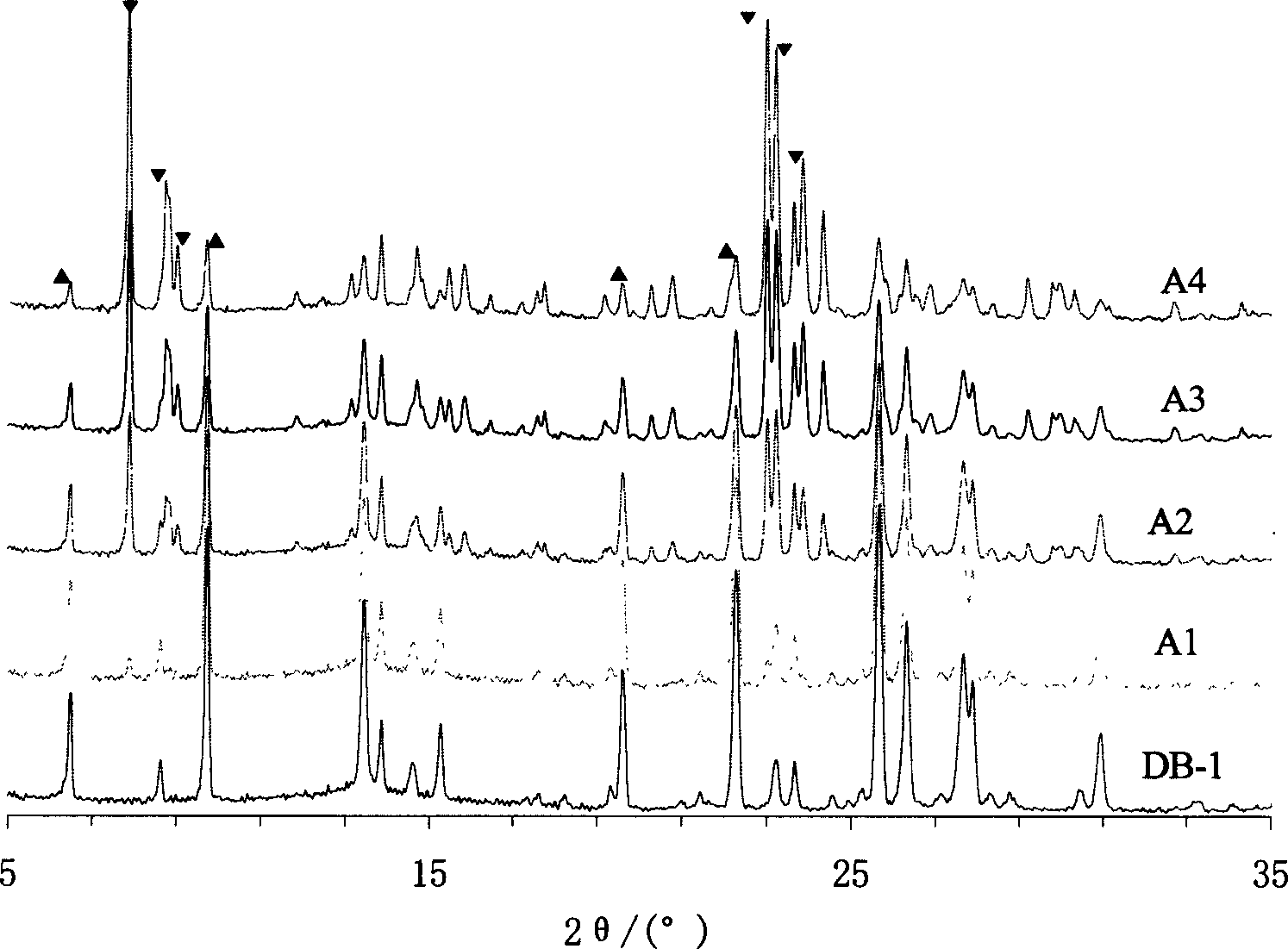

Synthetic method for ZSM-5/mordenite mixed crystal material

InactiveCN1565970ALower synthesis costEasy to adjustMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteThermal crystallization

The invention discloses a synthetic method for ZSM-5 / mordenite mixed crystal material, wherein ZSM-5 molecular sieve is charged into the synthesized reaction mixture of mordenite as seed crystal, and said material is prepared through water thermal crystallization. The invention realizes low making cost and more ideal catalyzing performance.

Owner:CHINA PETROLEUM & CHEM CORP +2

Large-area seed for ammonothermal growth of bulk gallium nitride and method of manufacture

ActiveUS7976630B2Polycrystalline material growthFrom normal temperature solutionsWaferingGallium nitride

A high-quality, large-area seed crystal for ammonothermal GaN growth and method for fabricating. The seed crystal comprises double-side GaN growth on a large-area substrate. The seed crystal is of relatively low defect density and has flat surfaces free of bowing. The seed crystal is useful for producing large-volume, high-quality bulk GaN crystals by ammonothermal growth methods for eventual wafering into large-area GaN substrates for device fabrication.

Owner:SLT TECH

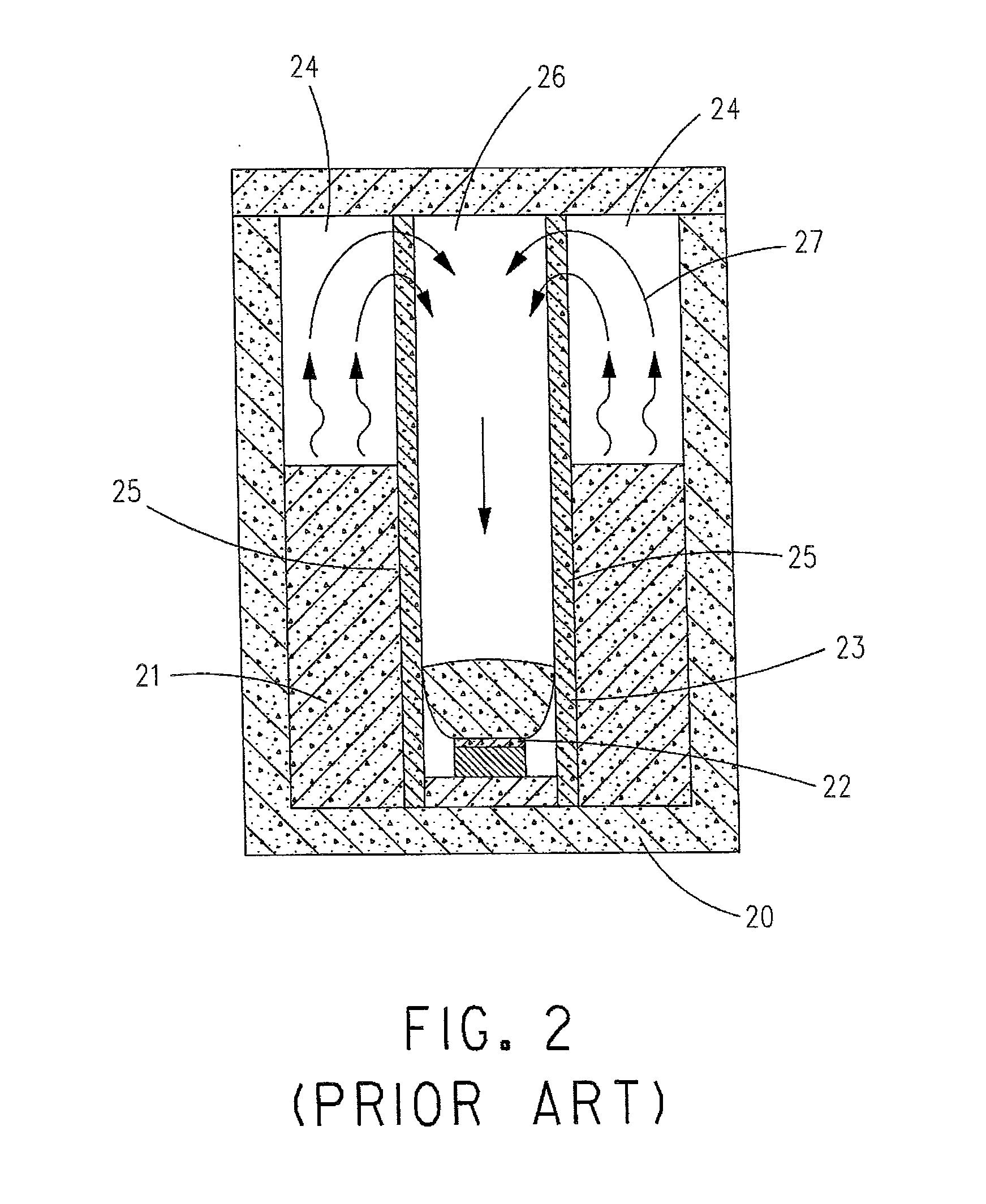

Sic single crystal sublimation growth method and apparatus

ActiveUS20120103249A1Polycrystalline material growthFrom chemically reactive gasesSource materialGas phase

A physical vapor transport growth system includes a growth chamber charged with SiC source material and a SiC seed crystal in spaced relation and an envelope that is at least partially gas-permeable disposed in the growth chamber. The envelope separates the growth chamber into a source compartment that includes the SiC source material and a crystallization compartment that includes the SiC seed crystal. The envelope is formed of a material that is reactive to vapor generated during sublimation growth of a SiC single crystal on the SiC seed crystal in the crystallization compartment to produce C-bearing vapor that acts as an additional source of C during the growth of the SiC single crystal on the SiC seed crystal.

Owner:II VI DELAWARE INC

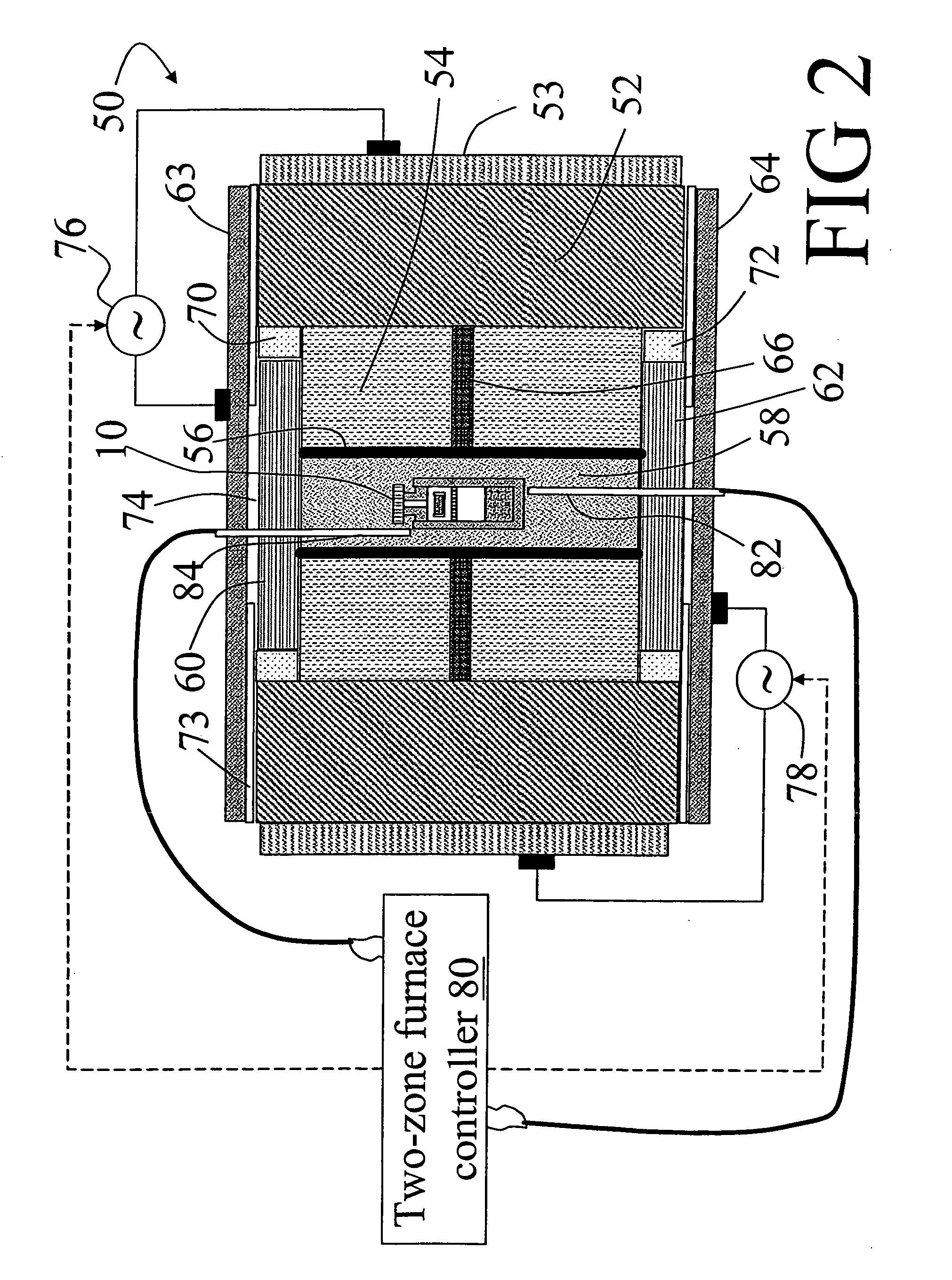

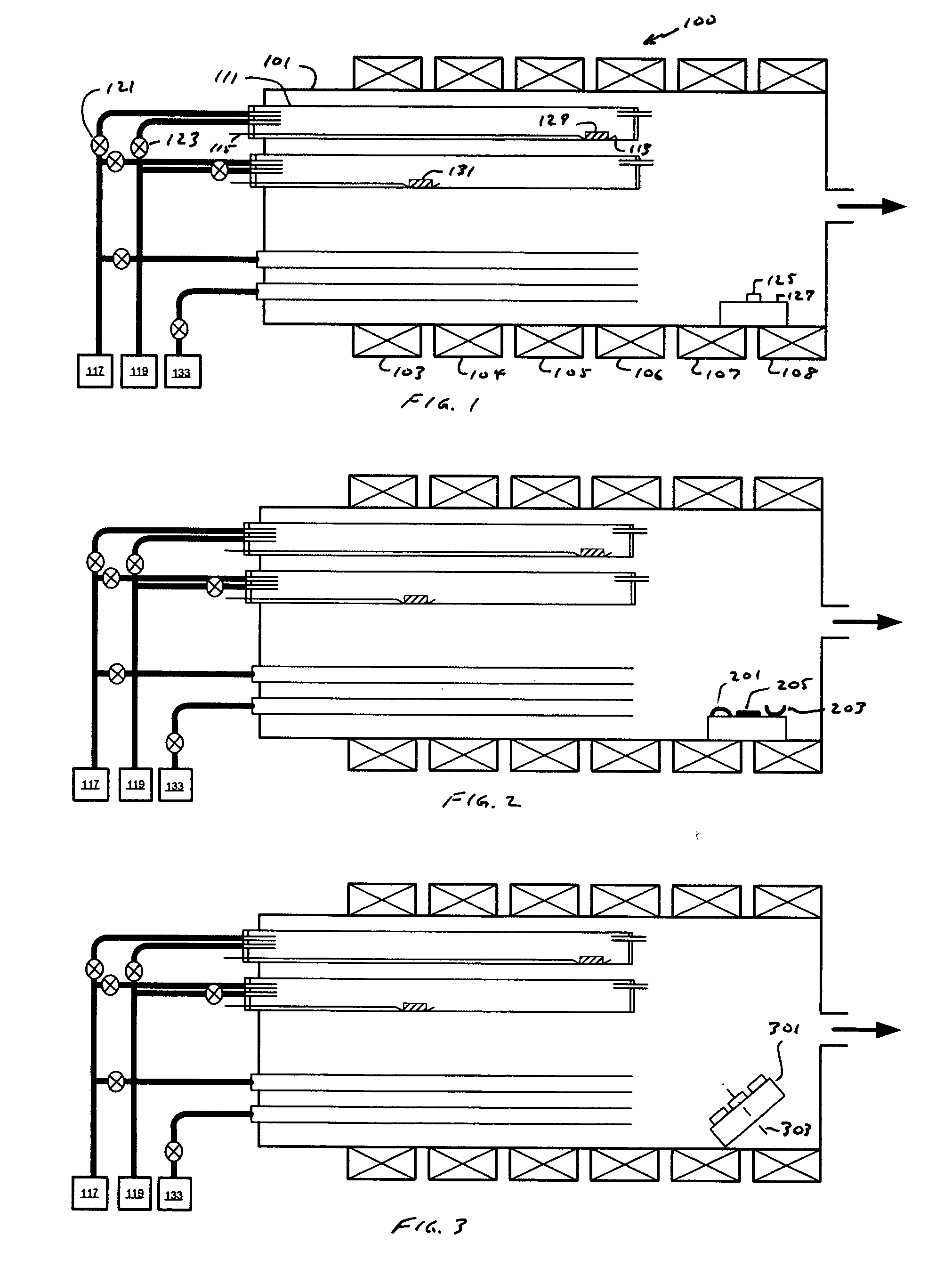

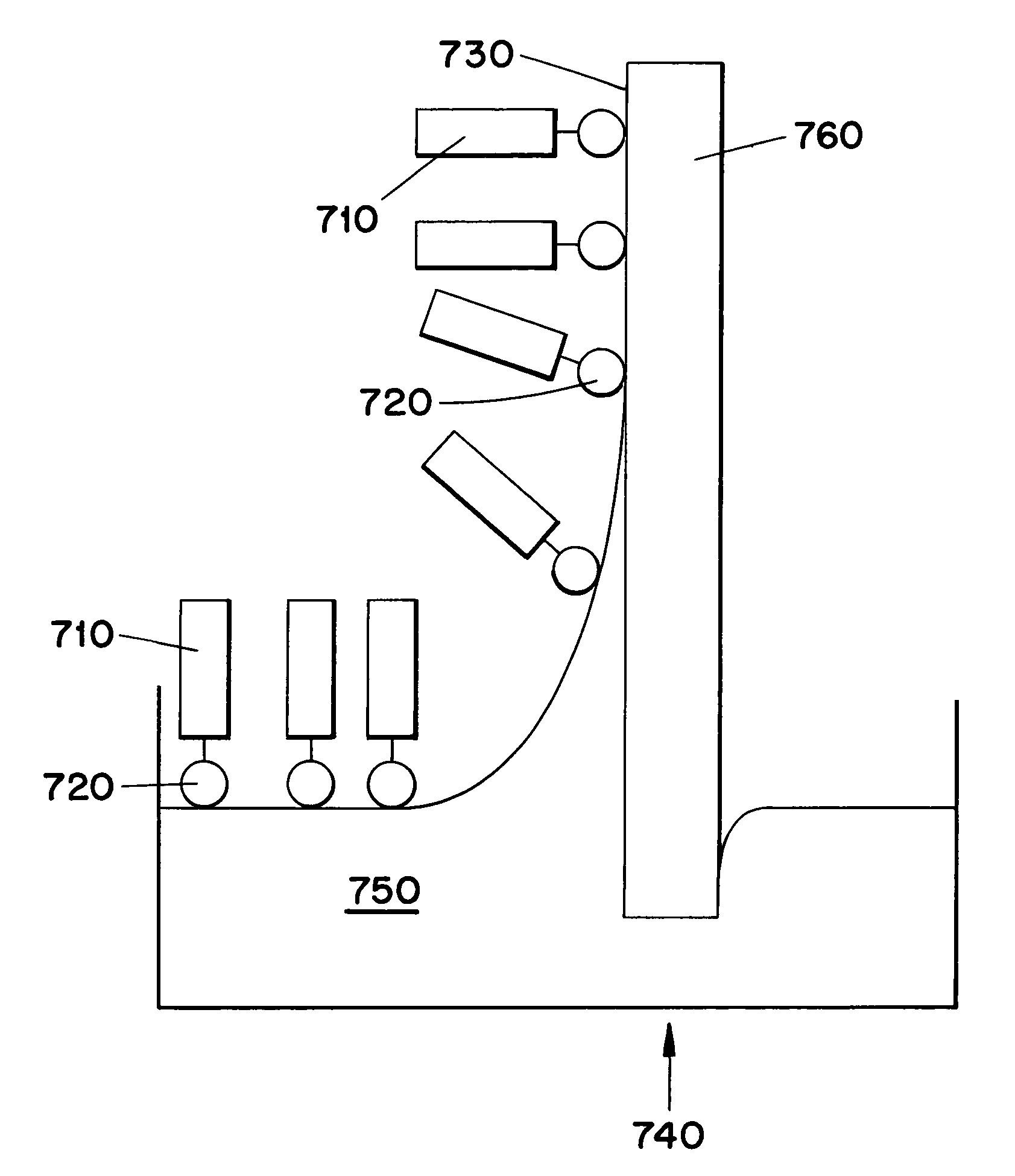

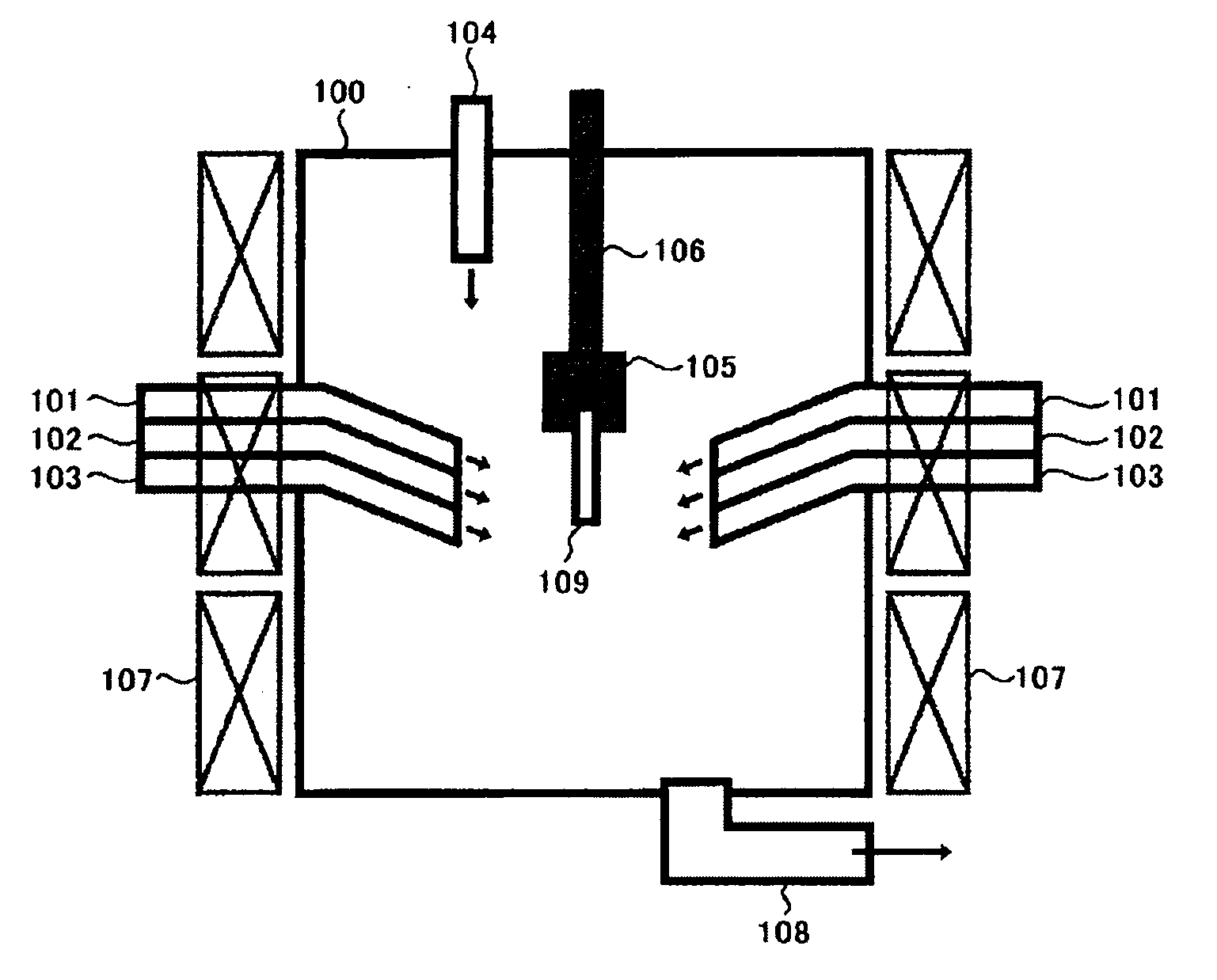

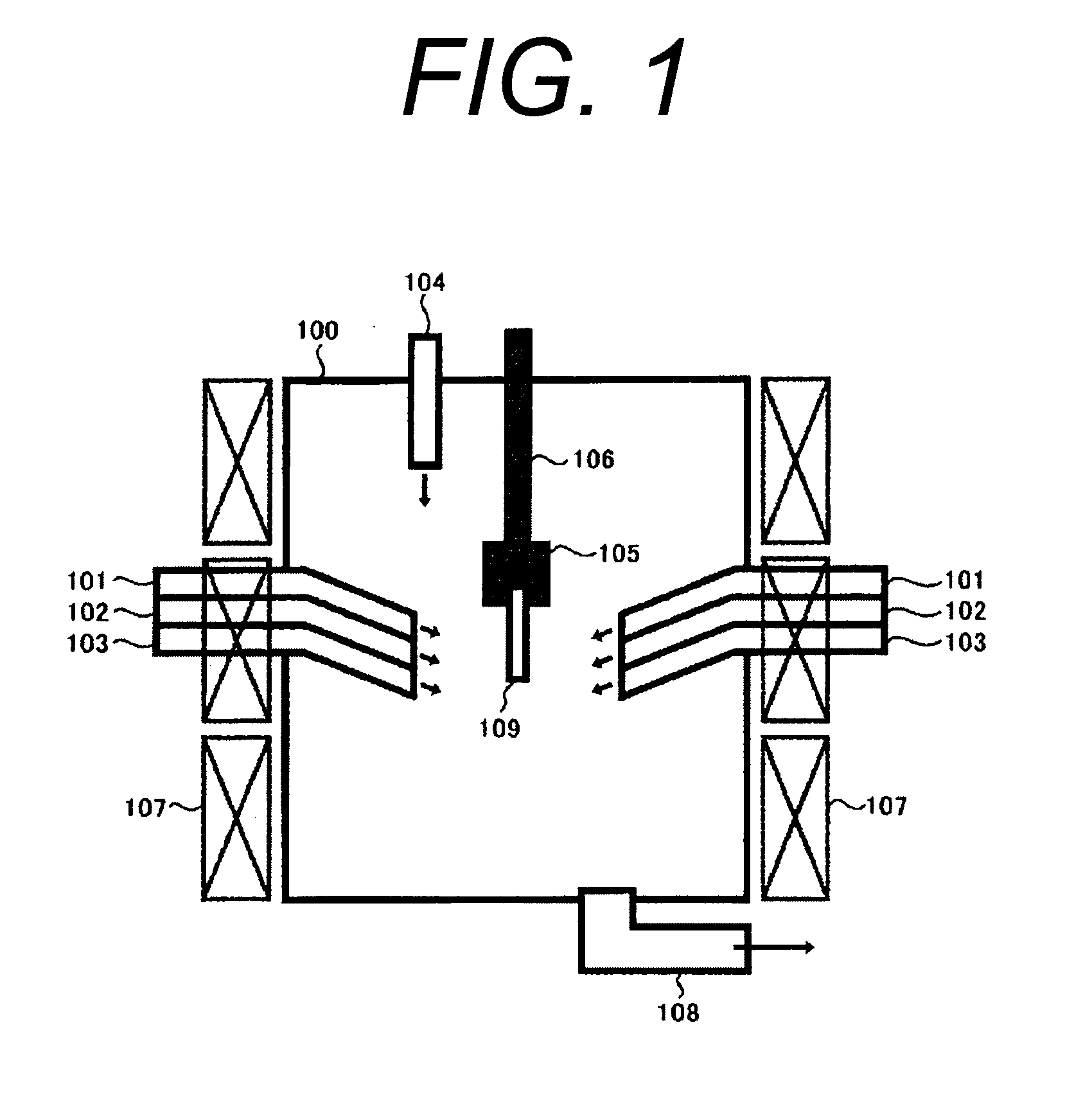

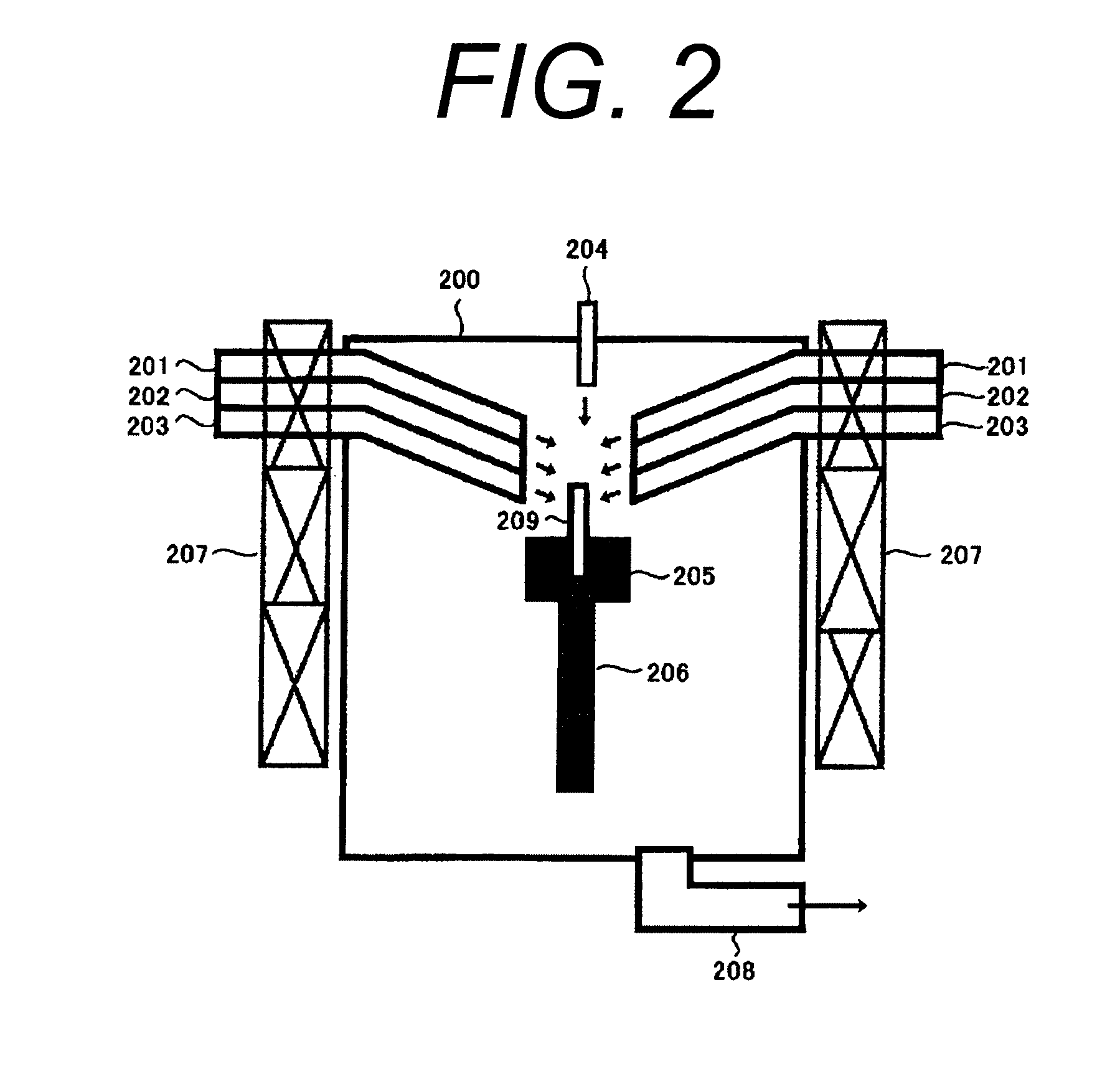

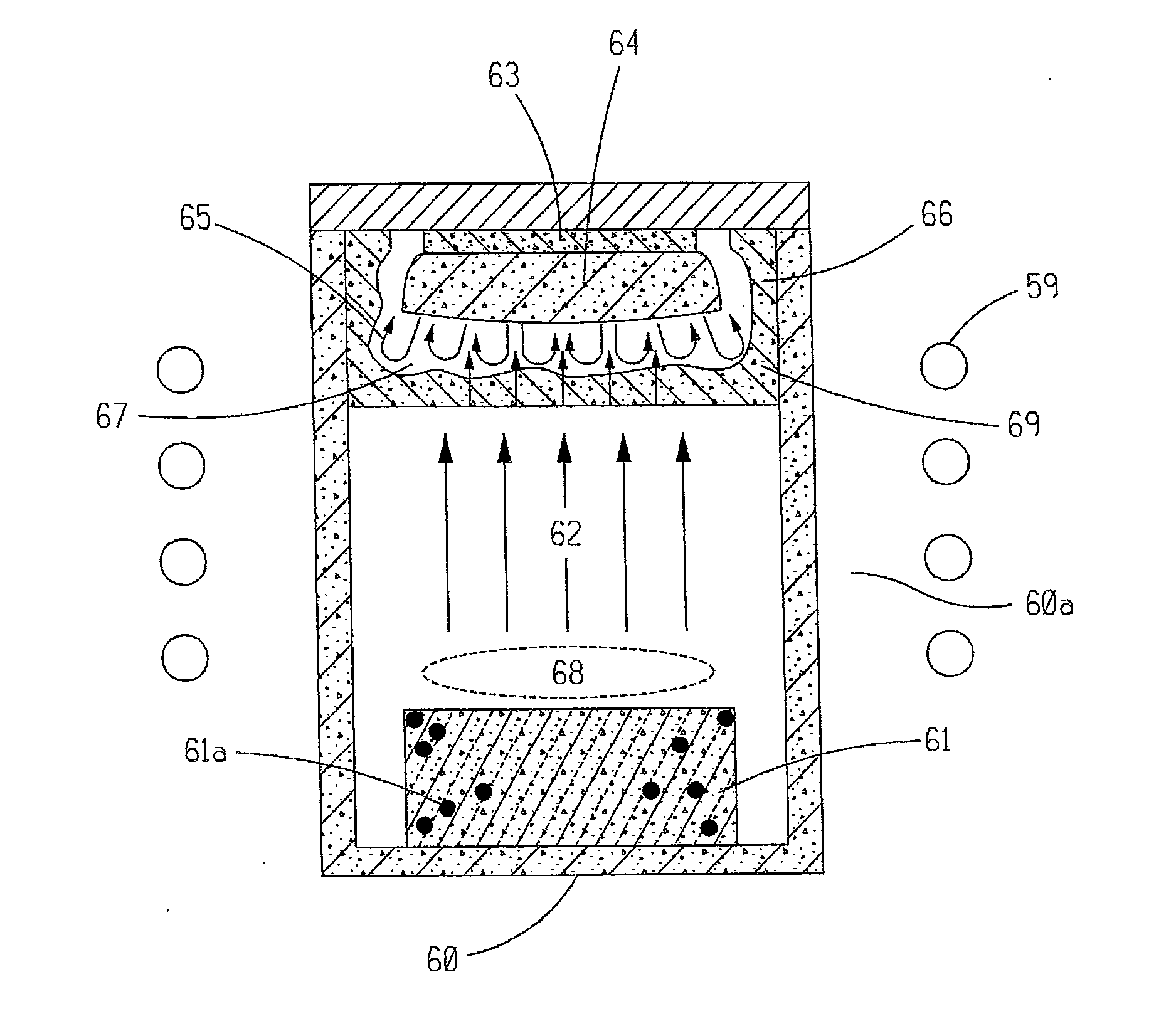

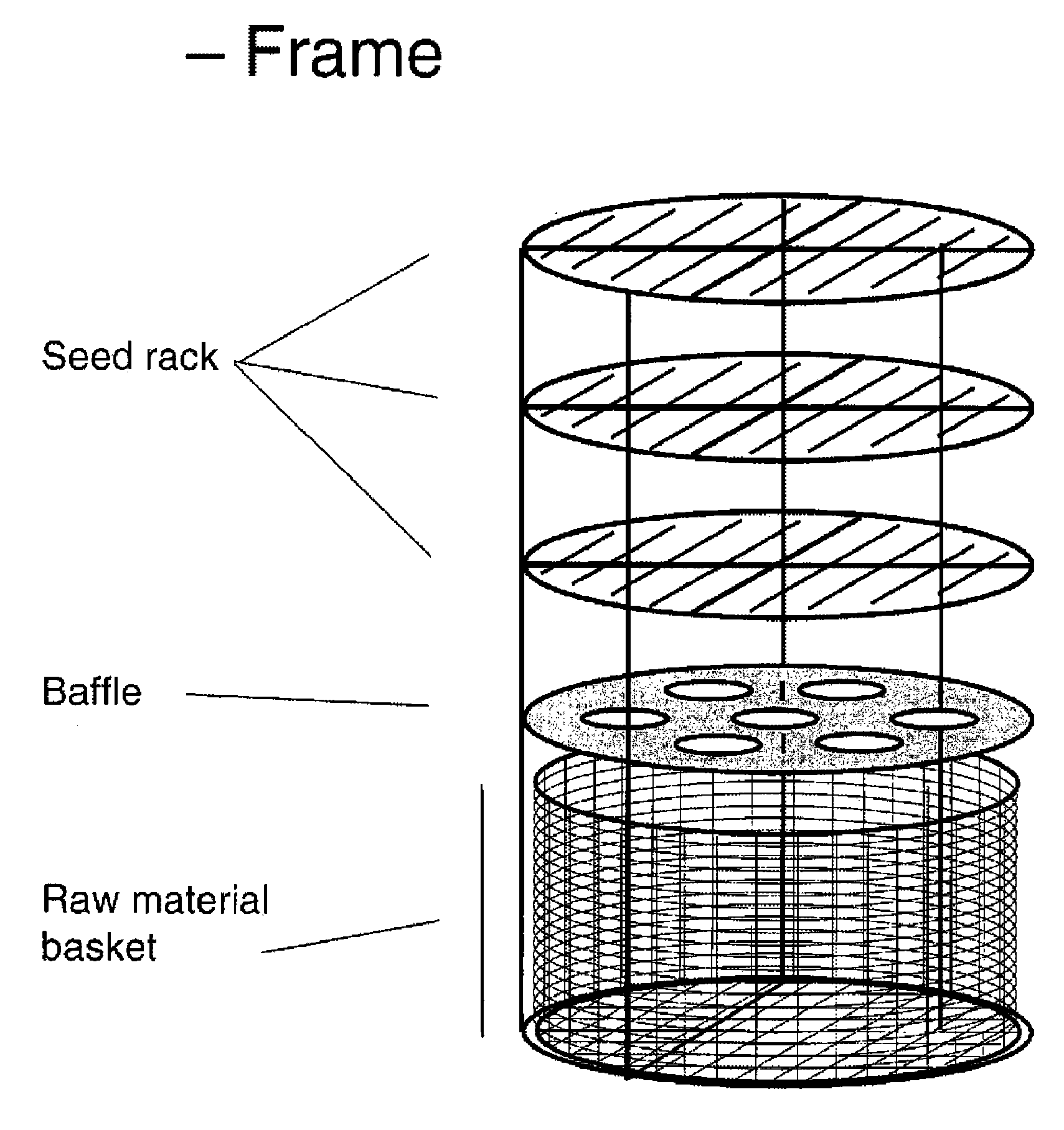

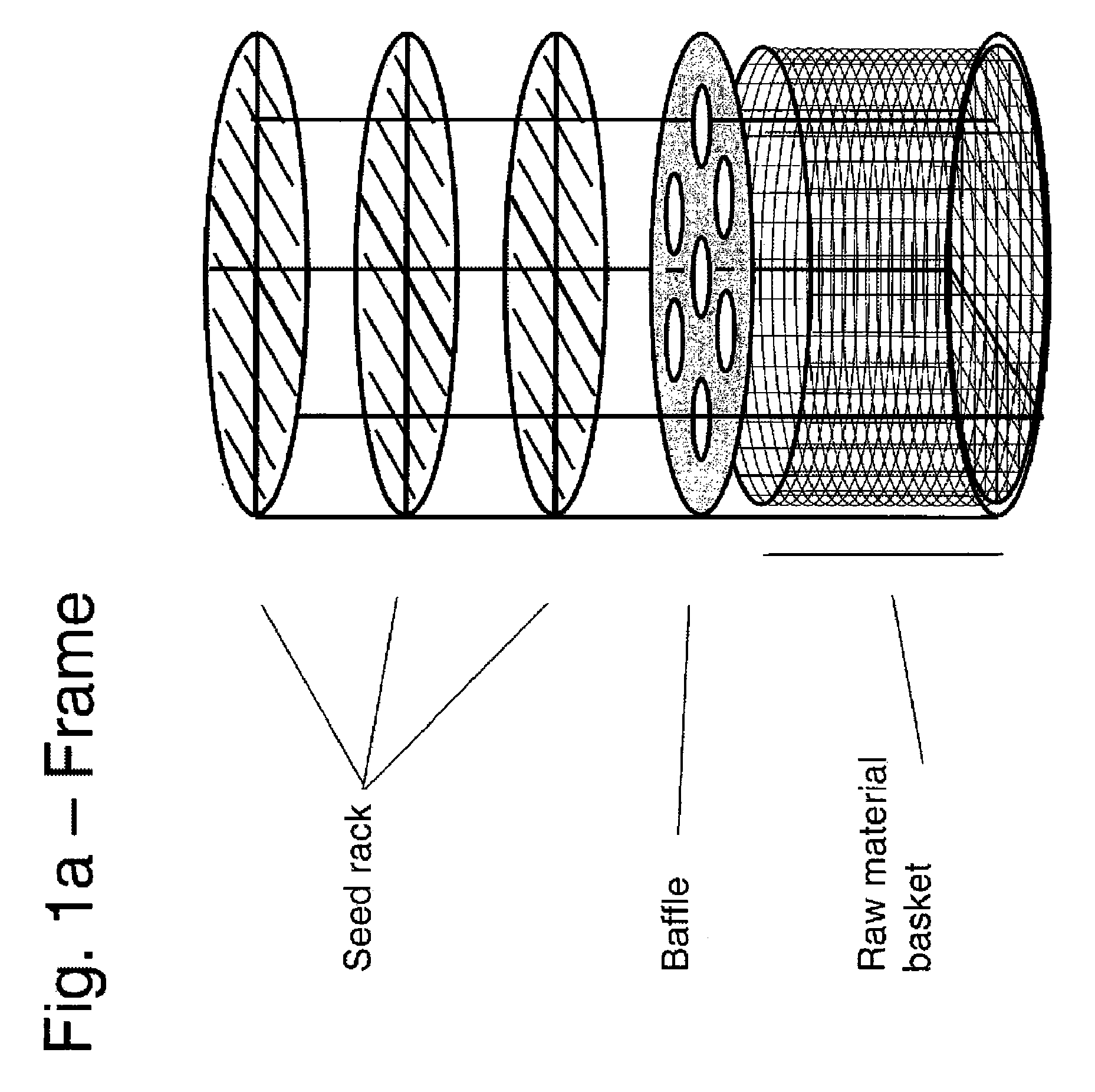

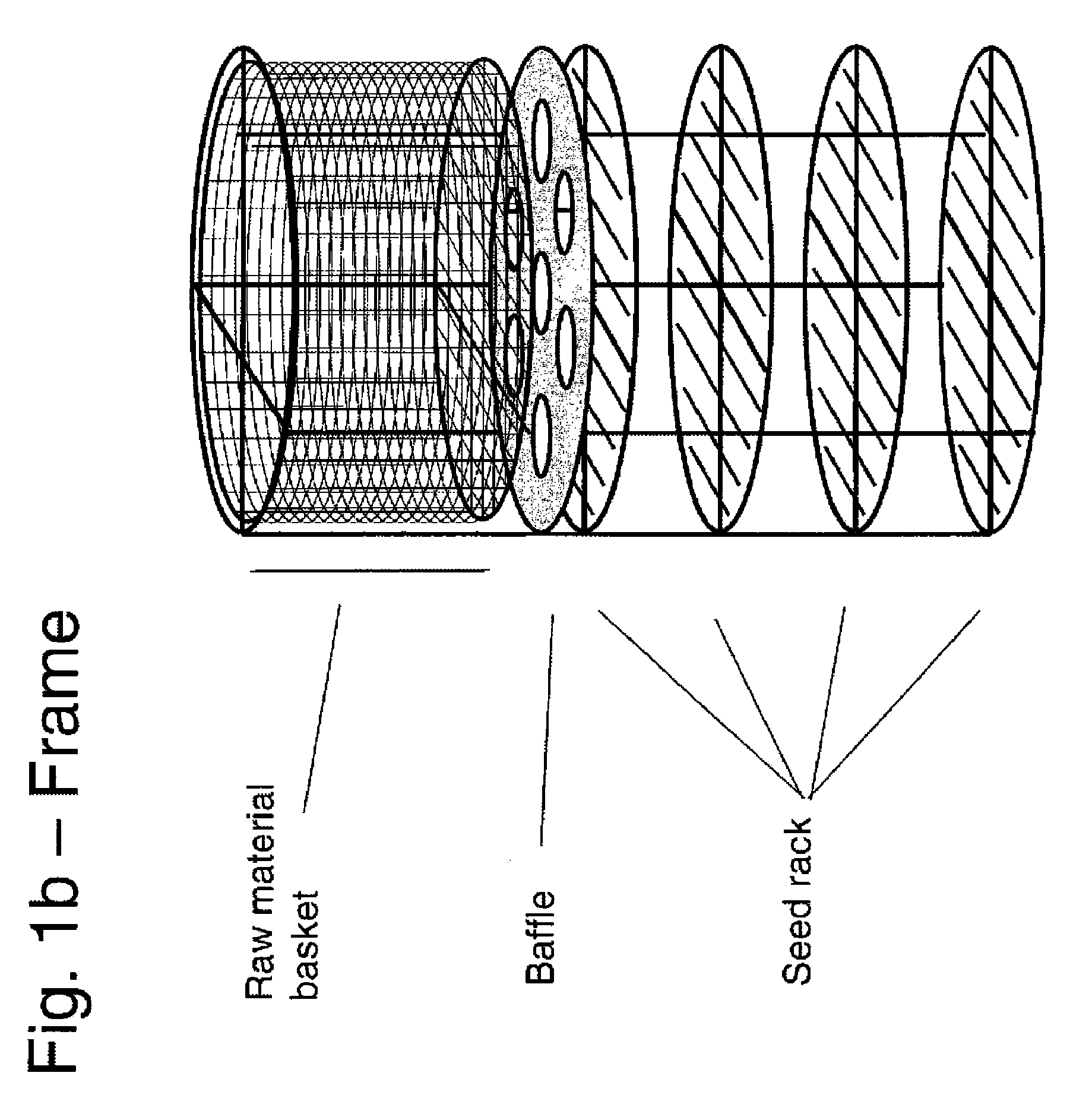

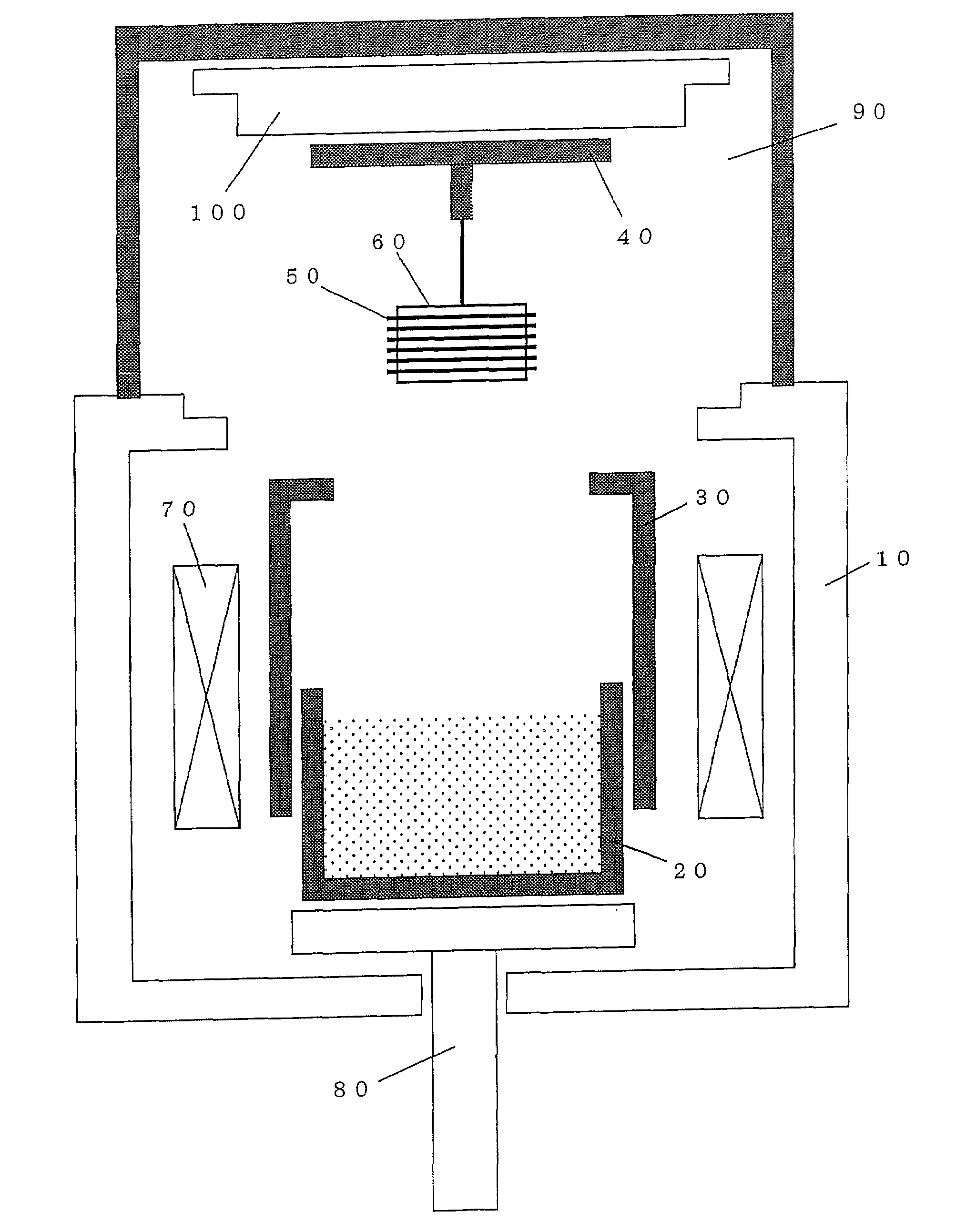

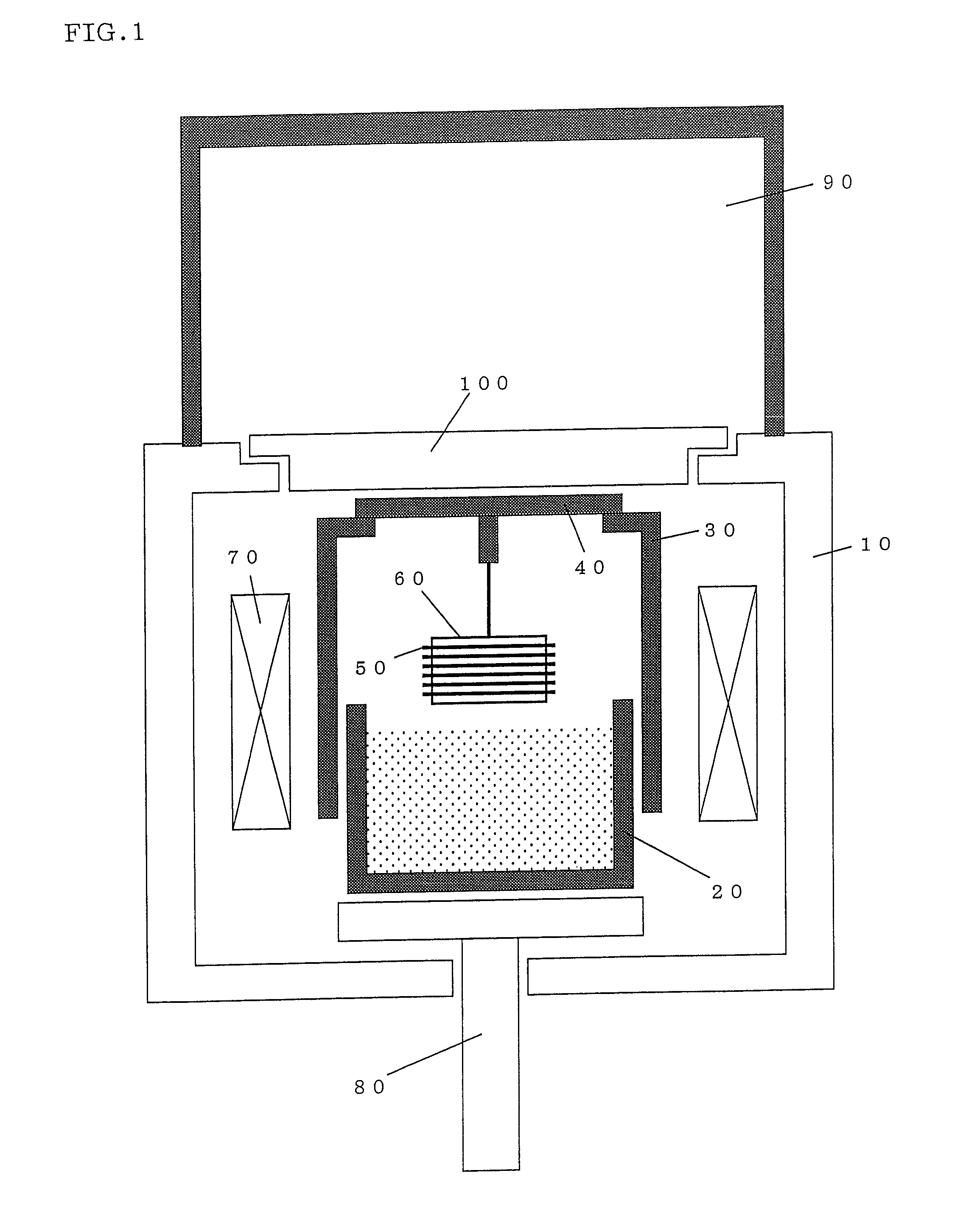

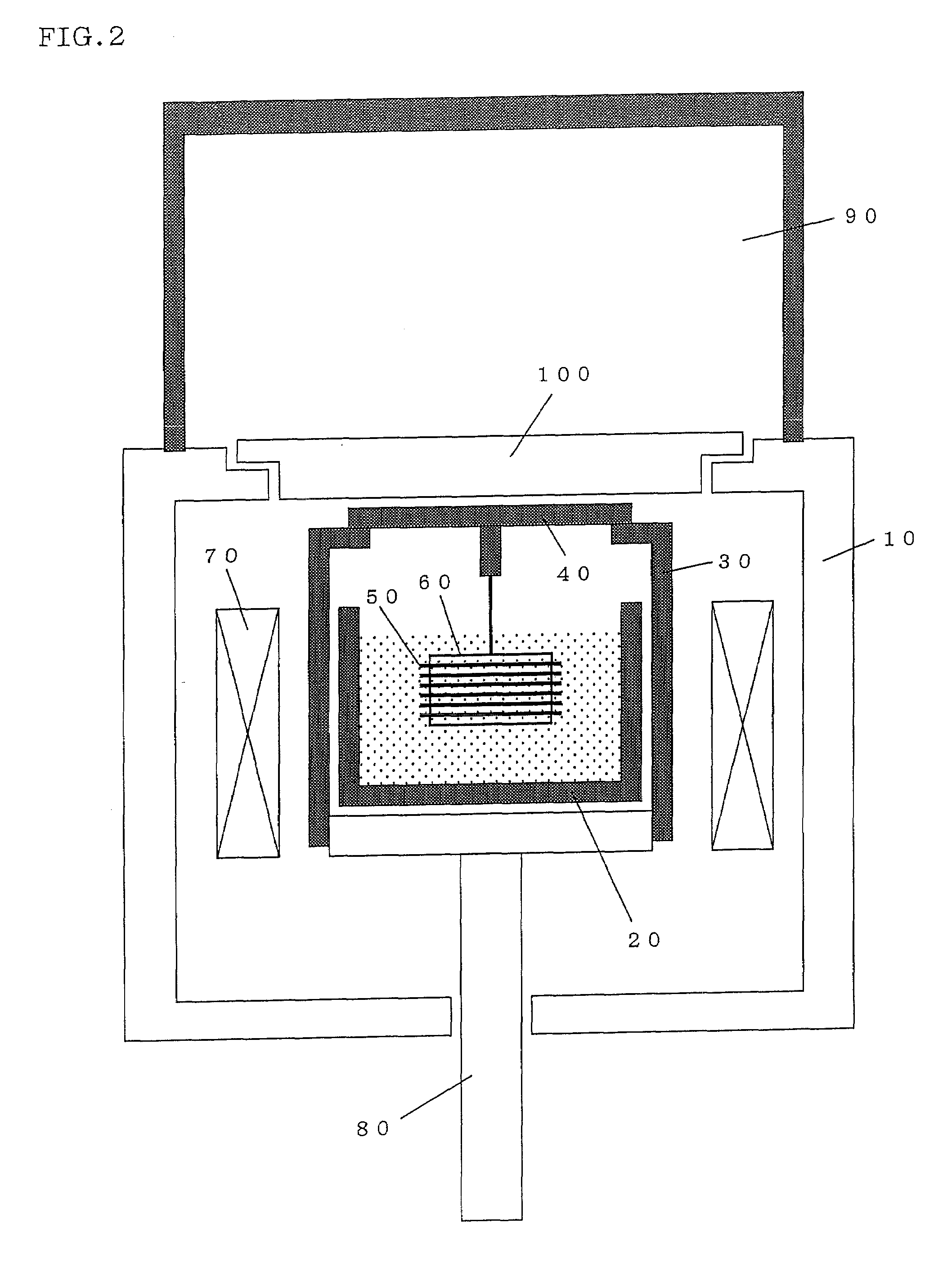

Apparatus and method for seed crystal utilization in large-scale manufacturing of gallium nitride

ActiveUS20100031872A1Cost-effectiveSimple and cost-effective to manufactureAfter-treatment apparatusPolycrystalline material growthCost effectivenessAdemetionine

An apparatus and associated method for large-scale manufacturing of gallium nitride. The apparatus comprises a large diameter autoclave or internally-heated high pressure vessel, a seed rack, and a raw material basket. Methods include effective means for utilization of seed crystals. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

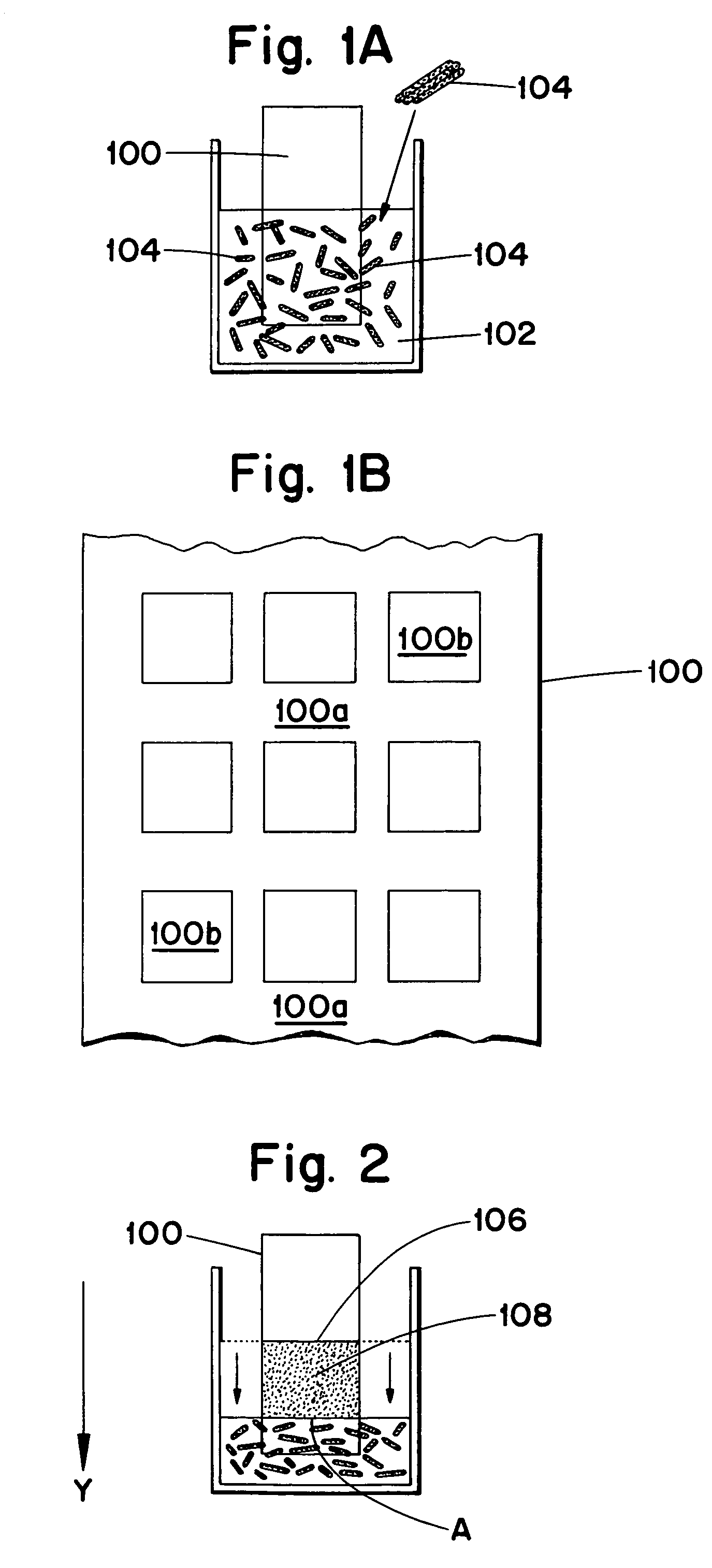

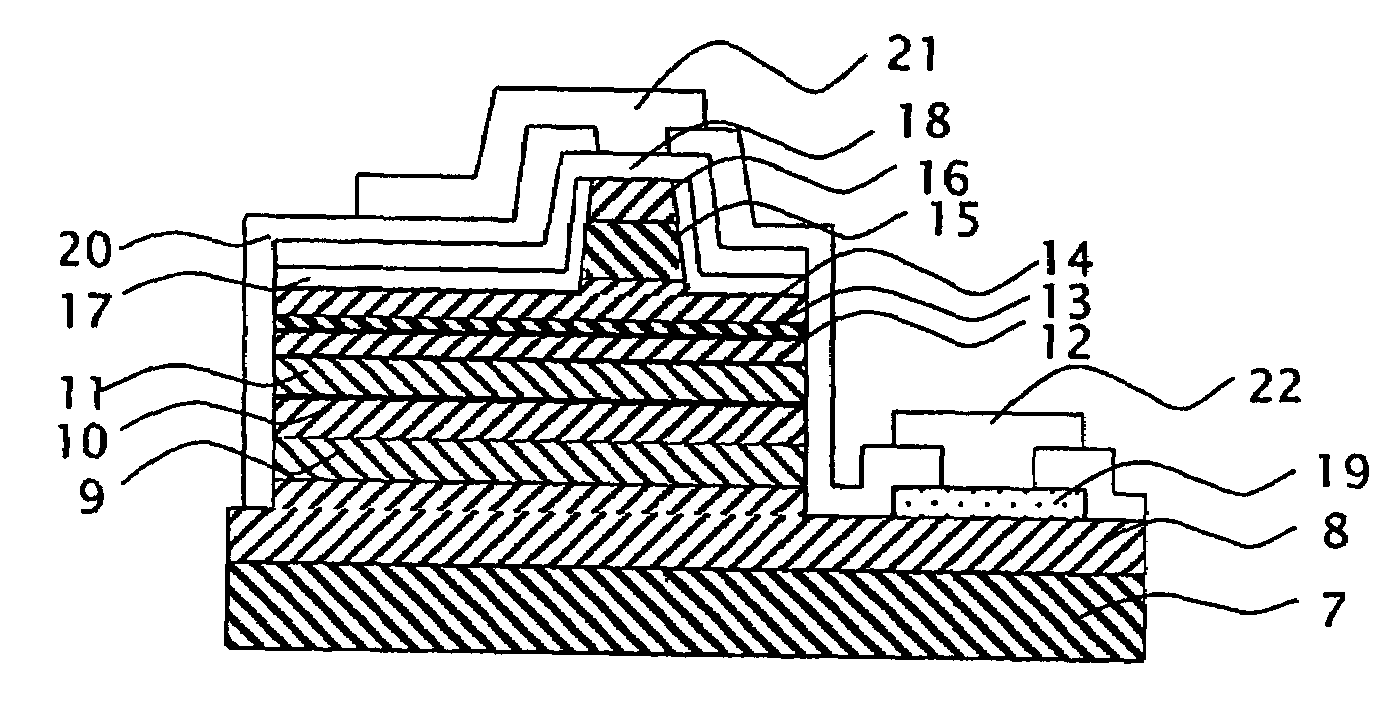

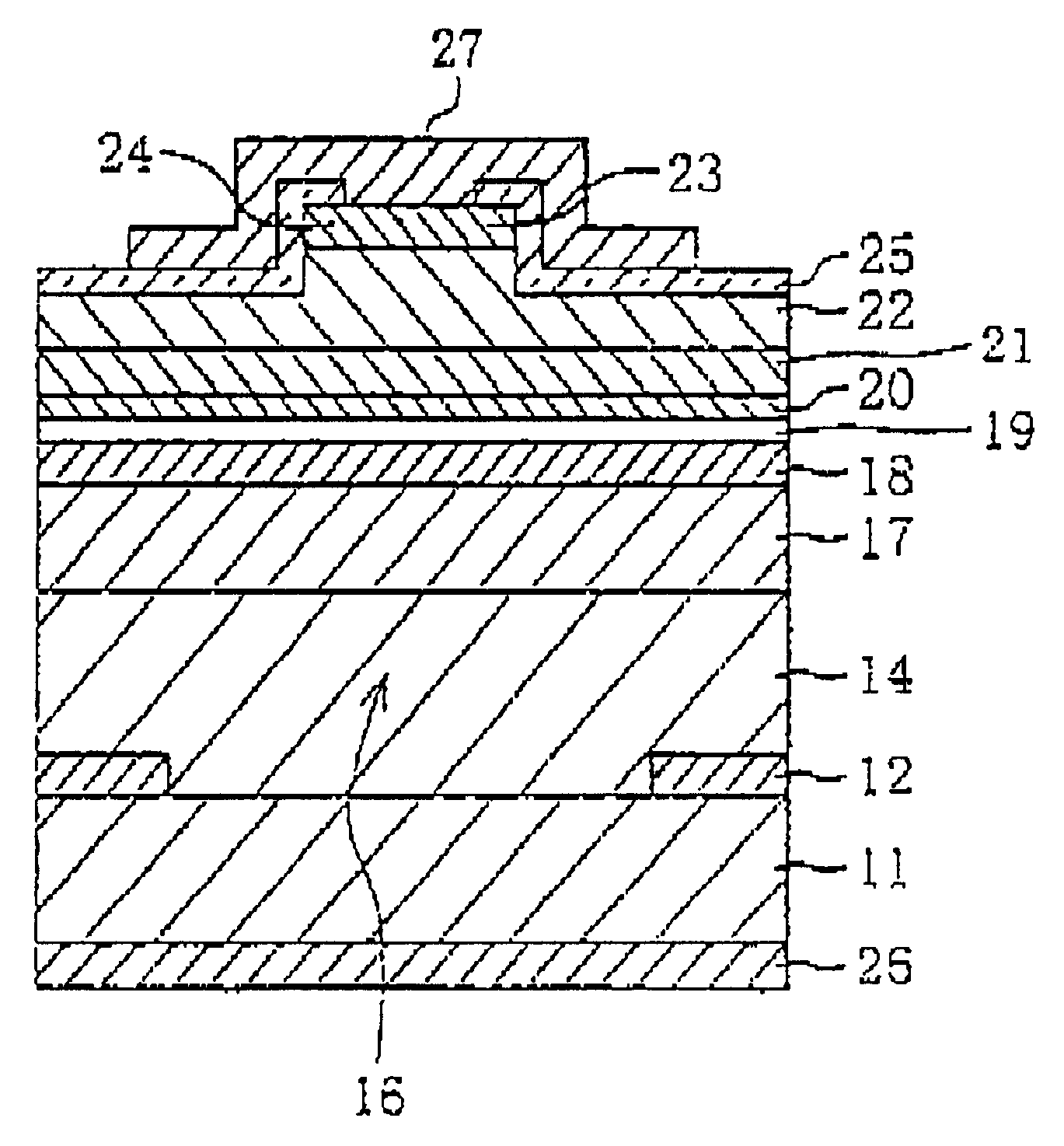

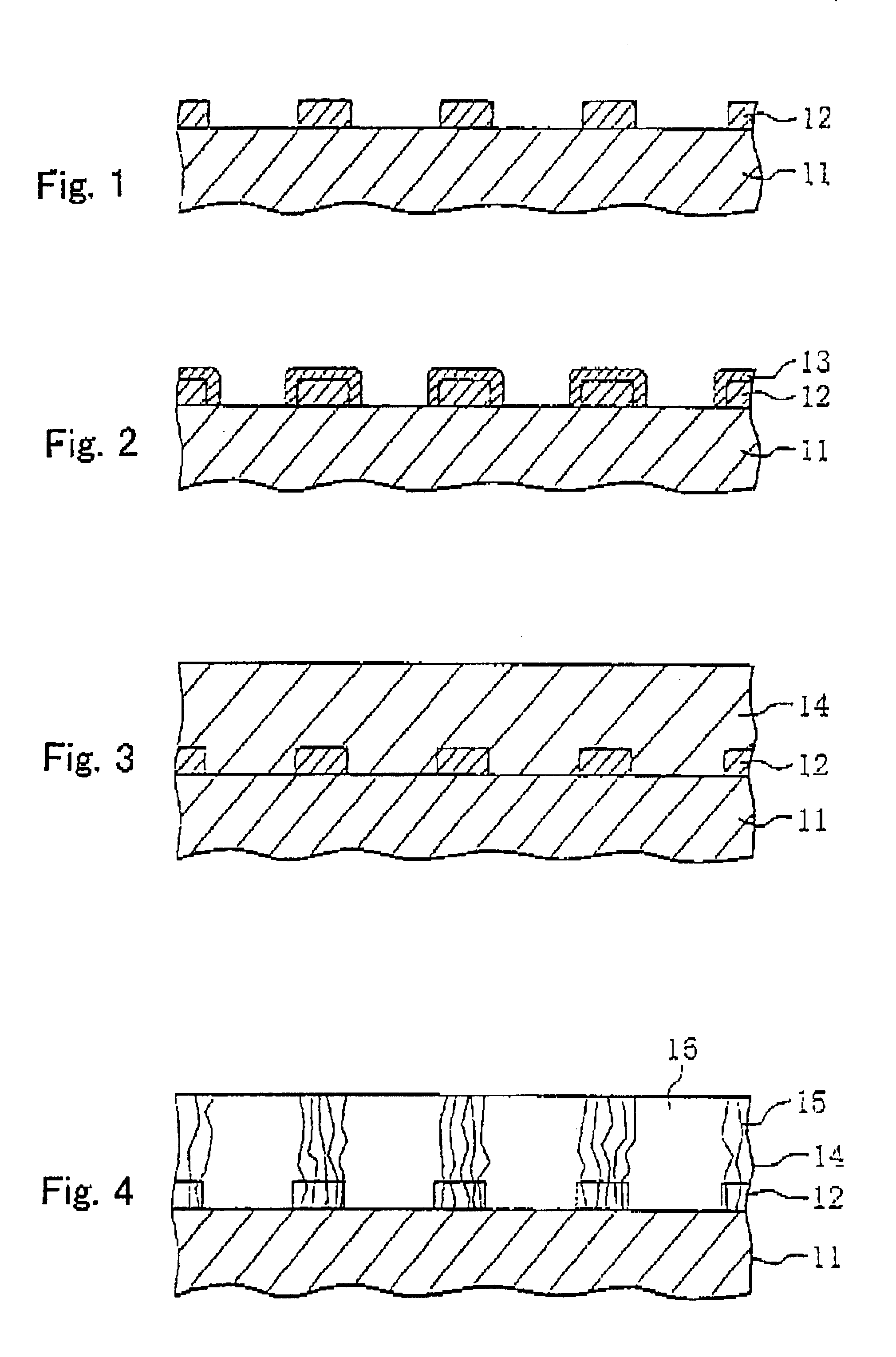

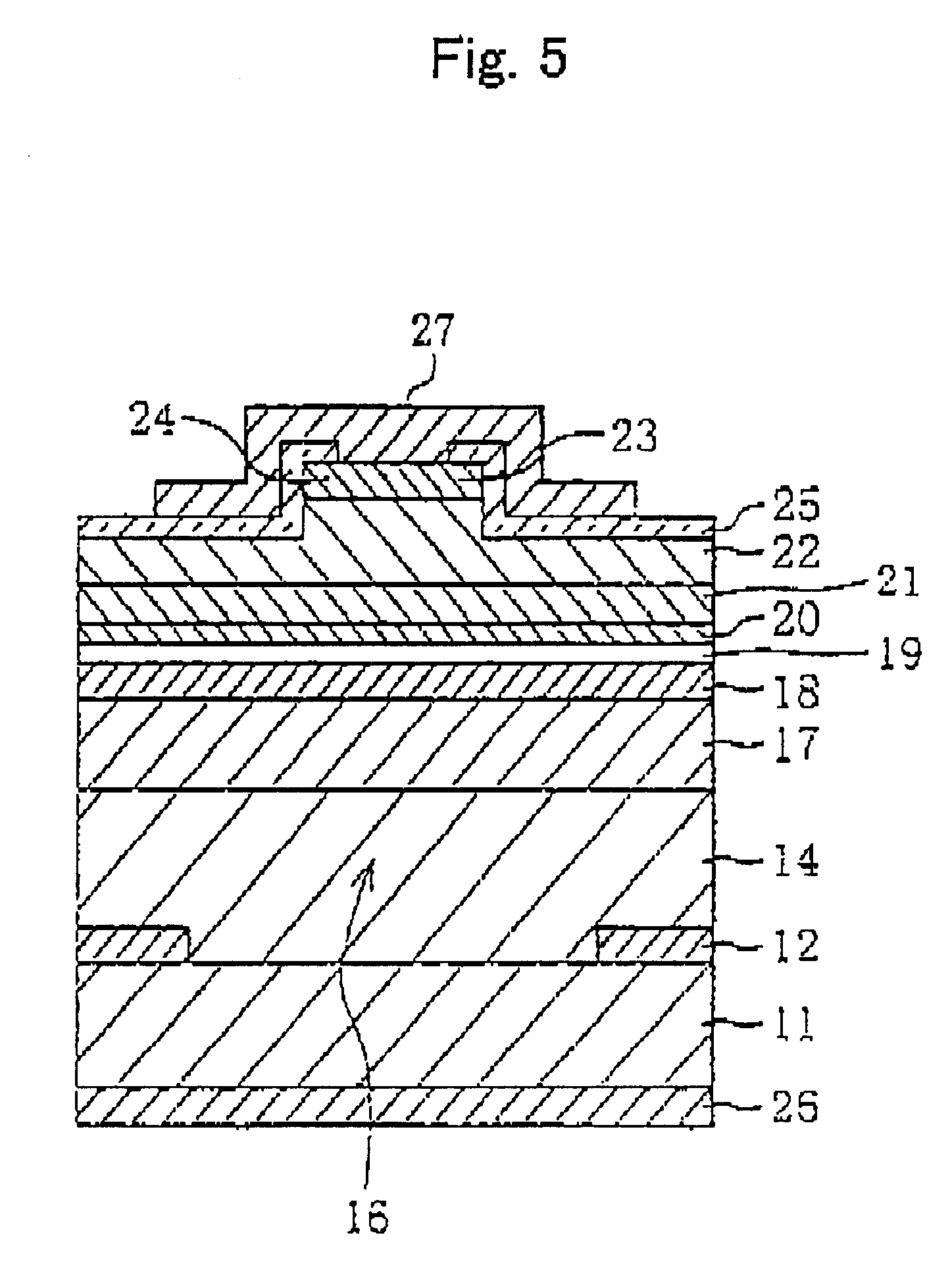

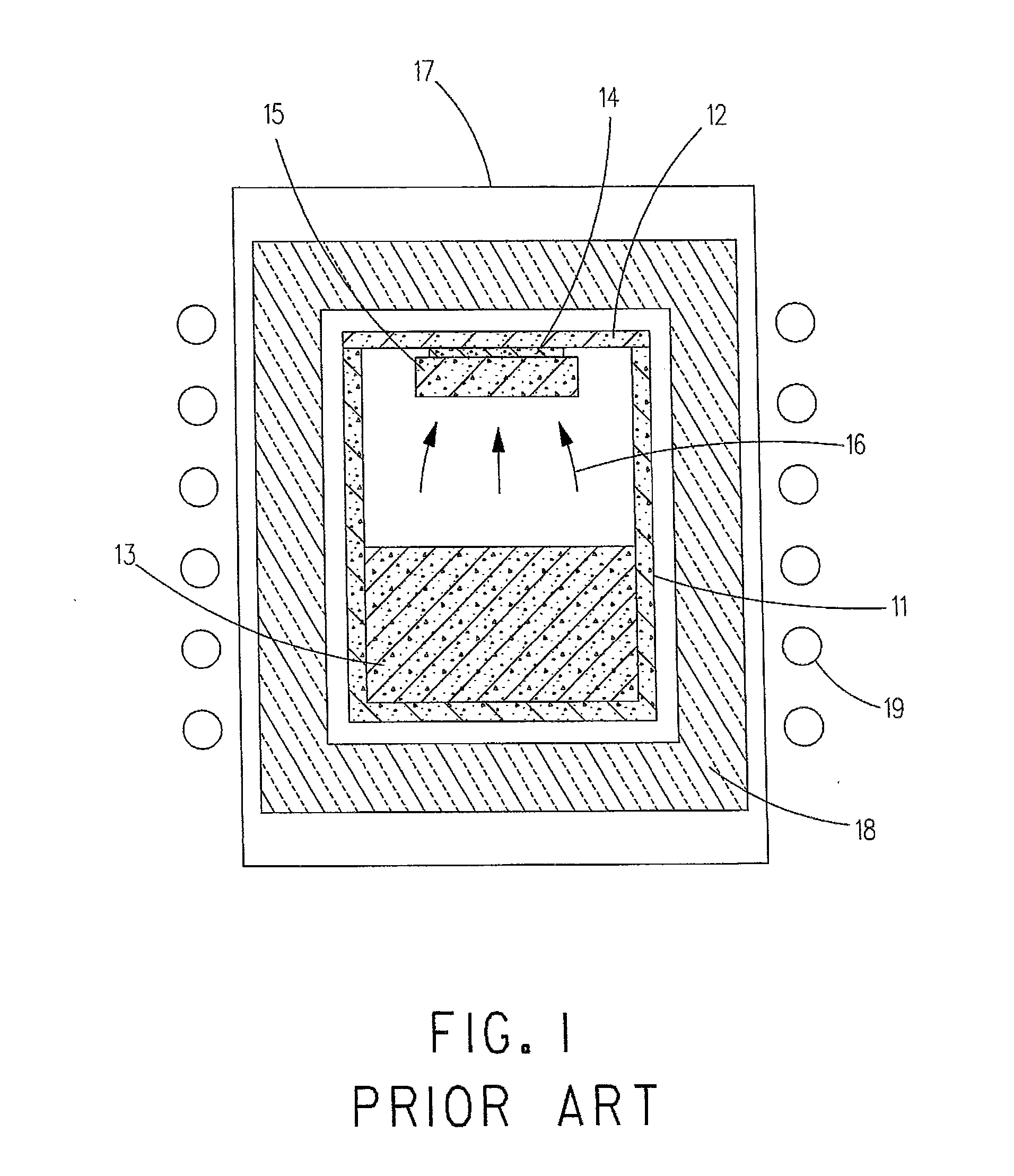

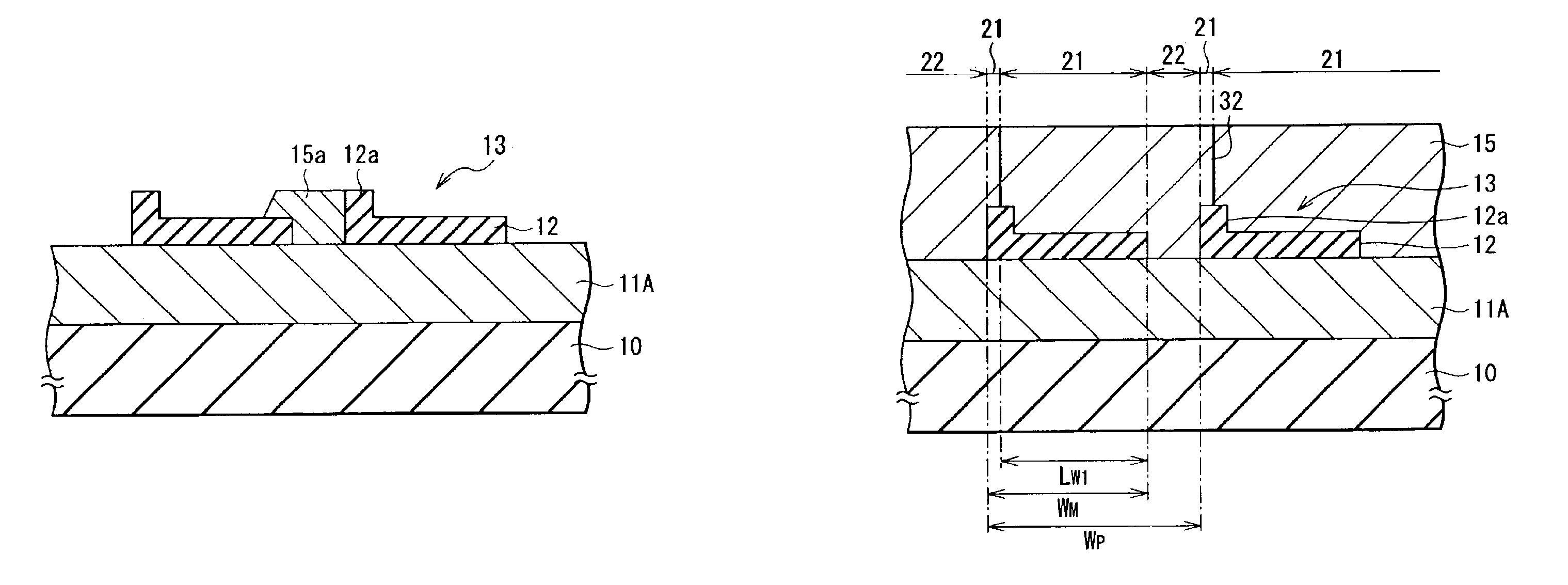

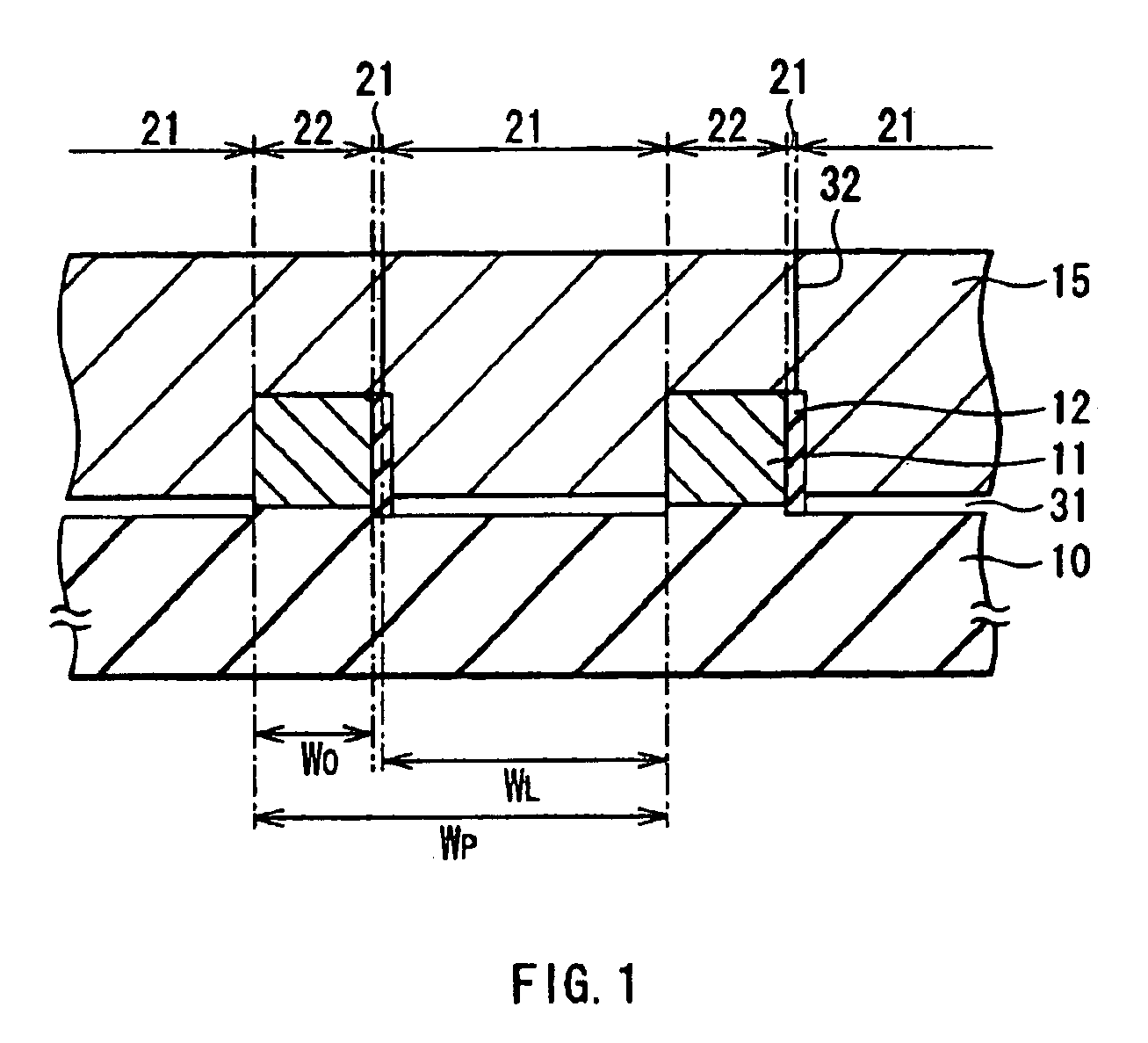

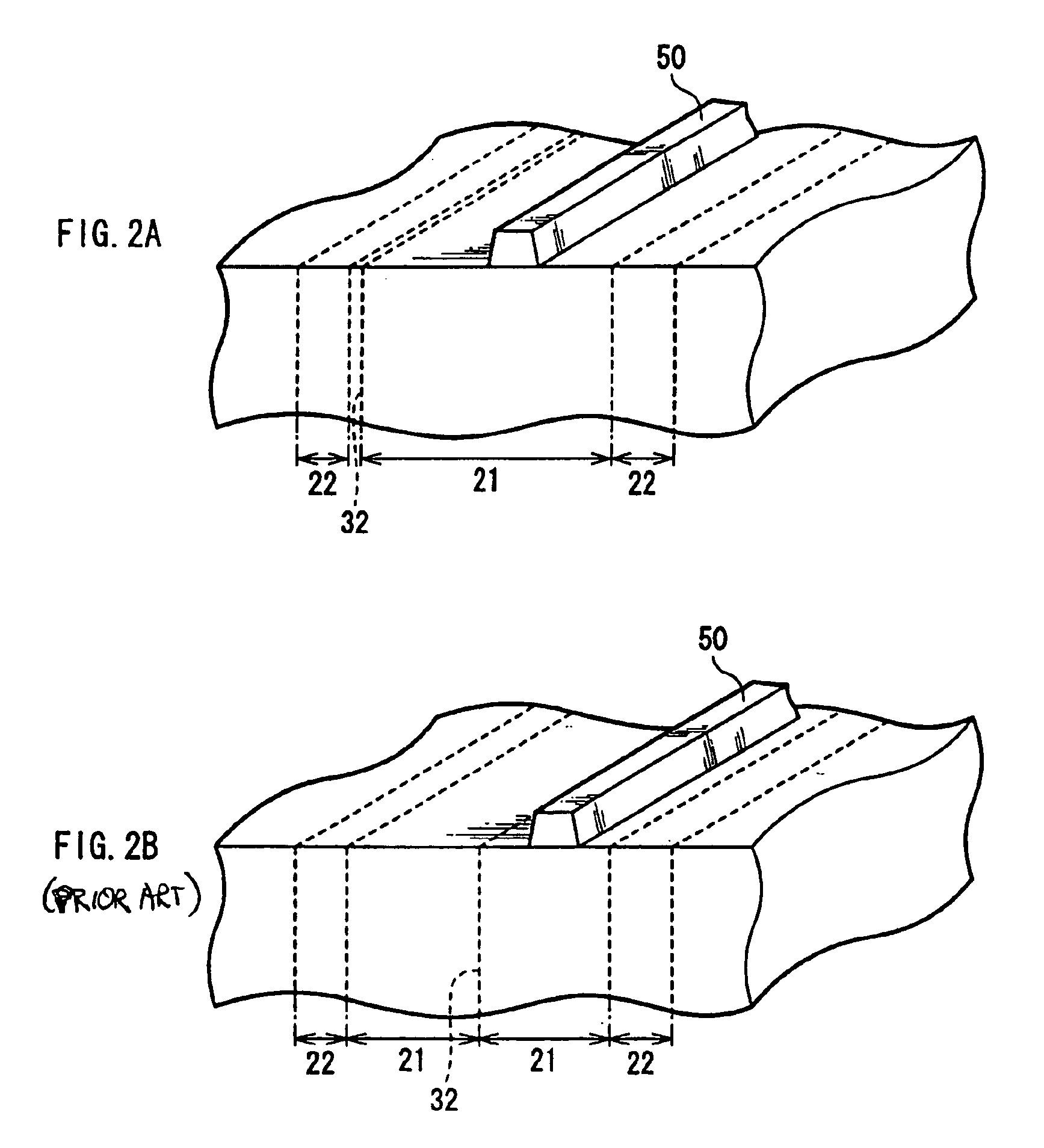

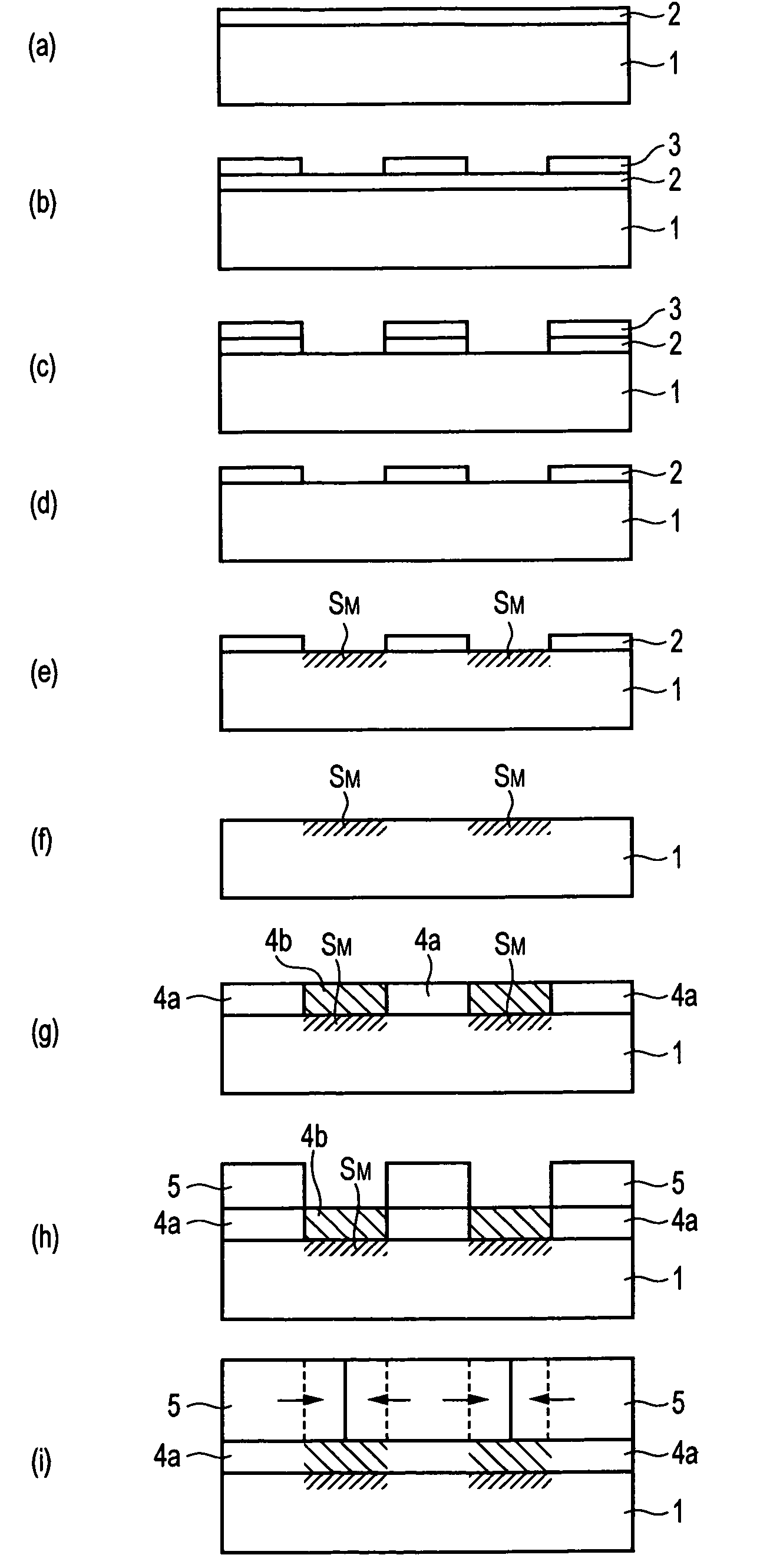

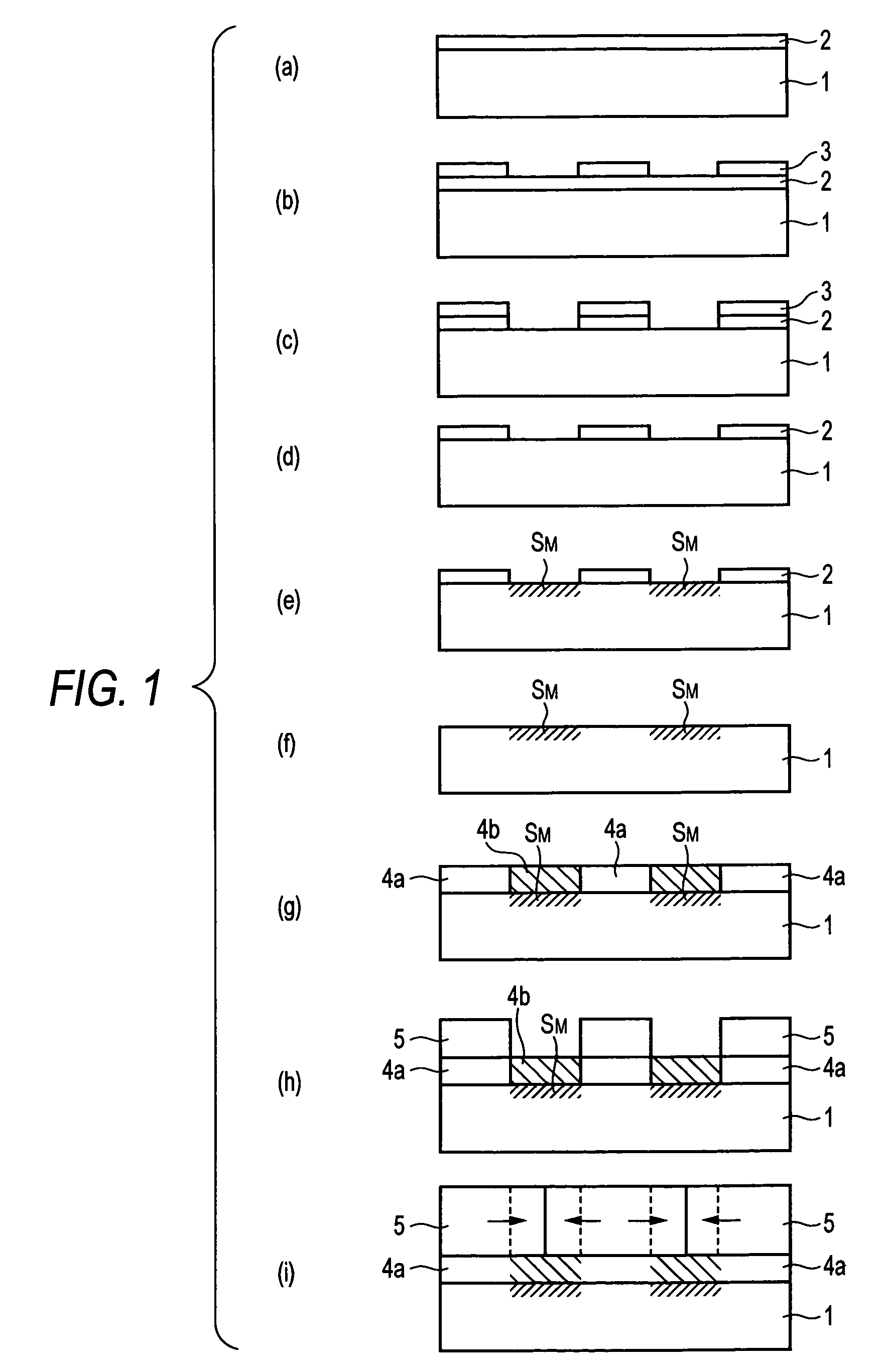

Nitride semiconductor device and method of manufacturing the same

InactiveUS6921673B2Increase horizontal widthIncrease widthOptical wave guidancePolycrystalline material growthLateral overgrowthEngineering

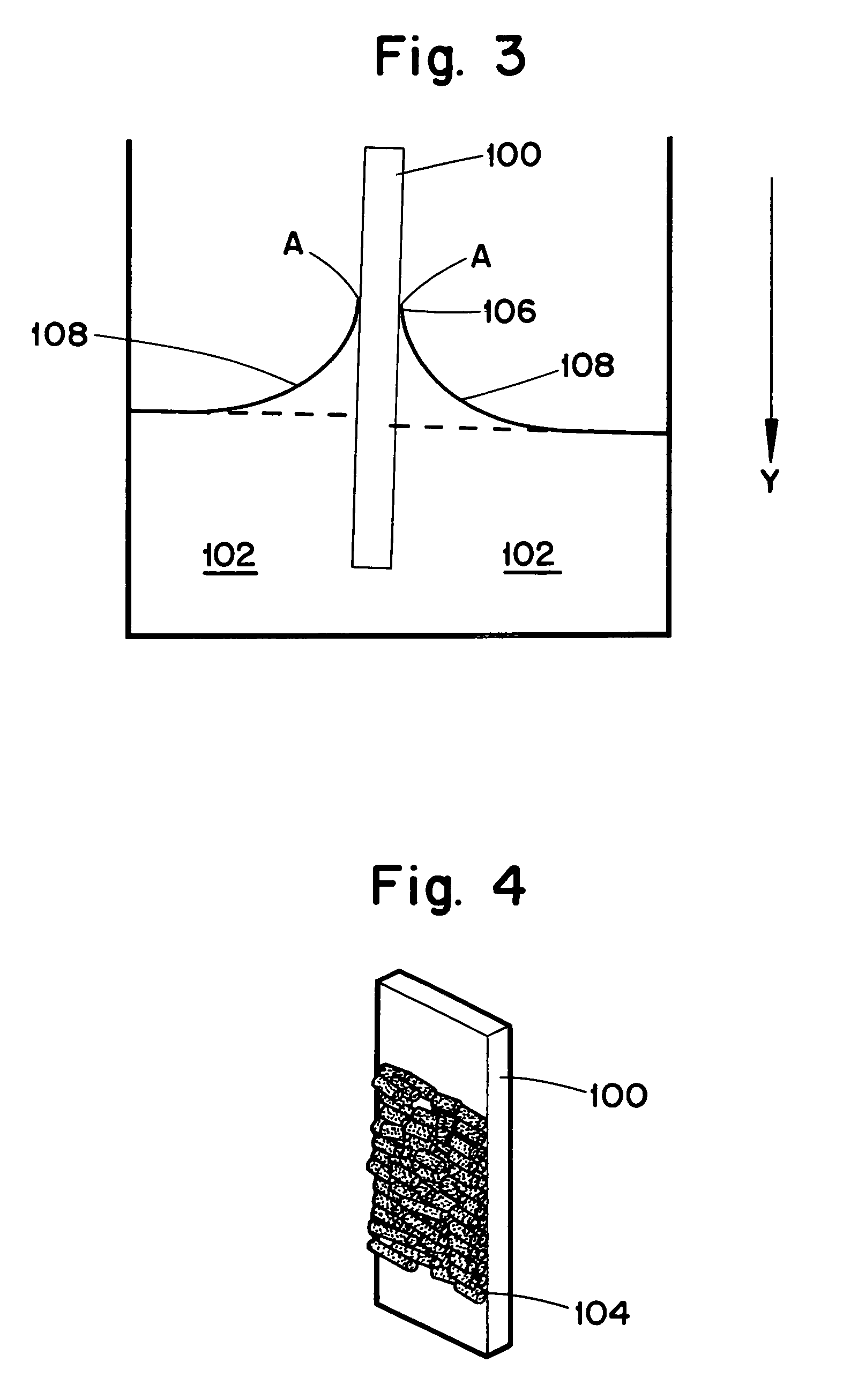

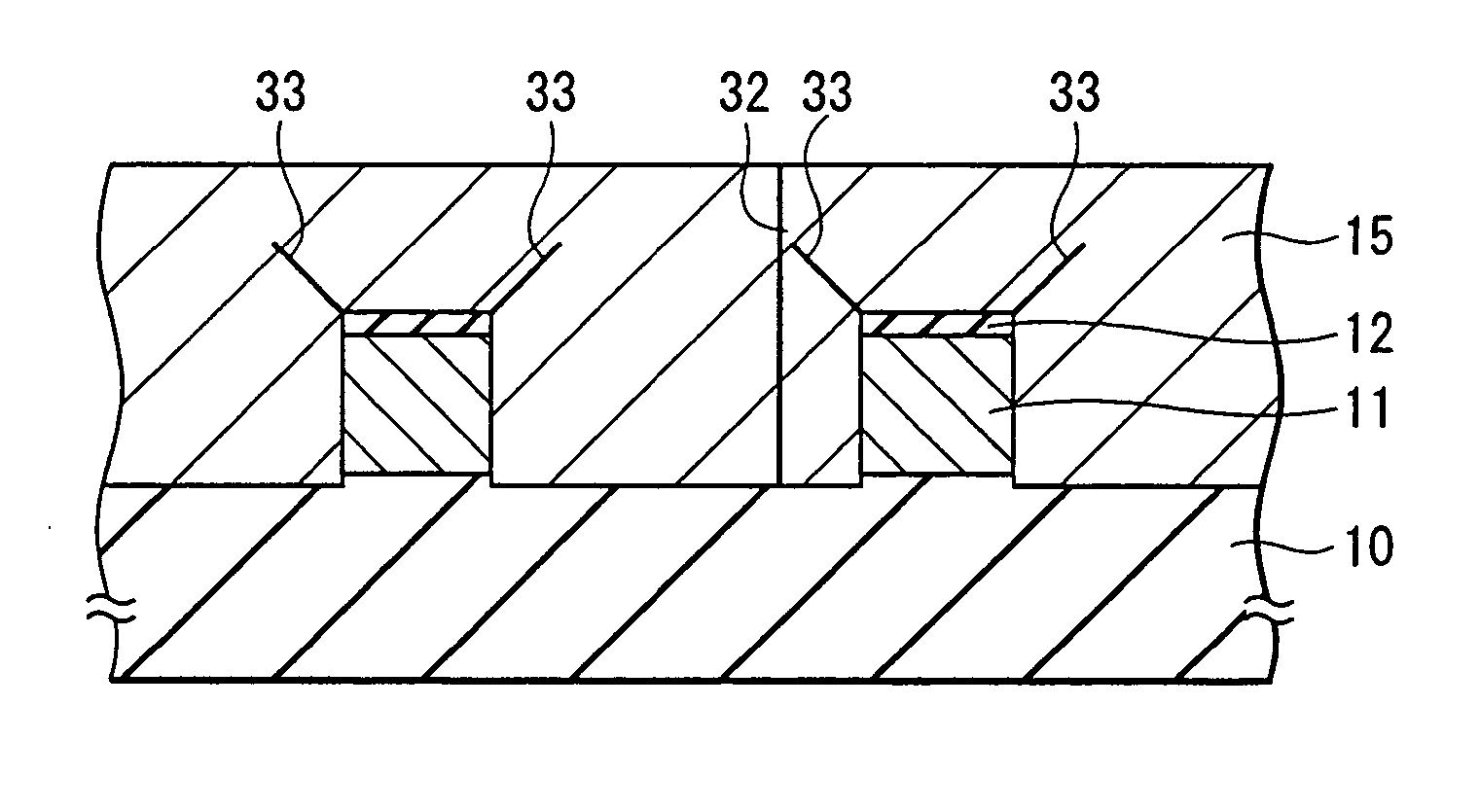

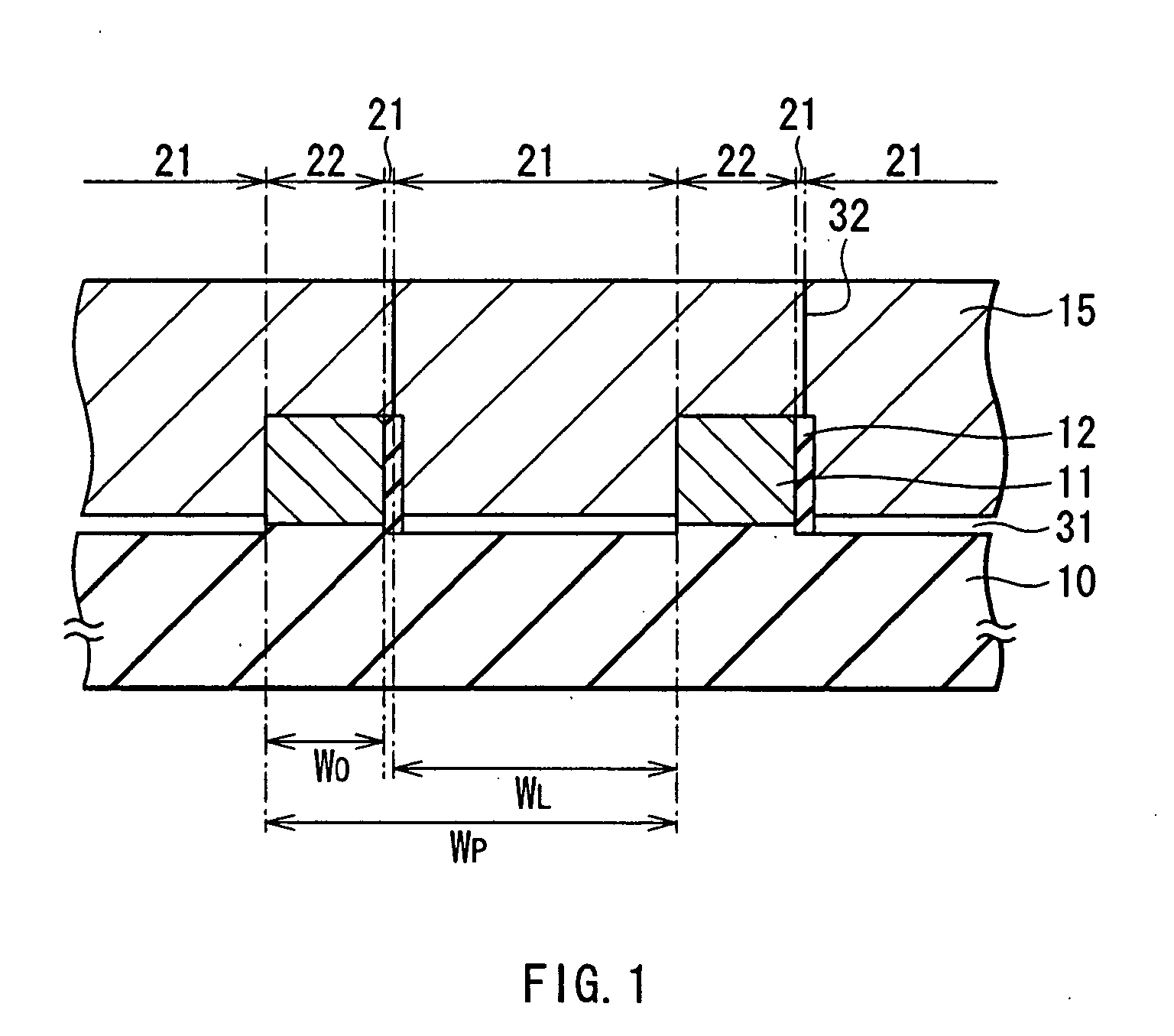

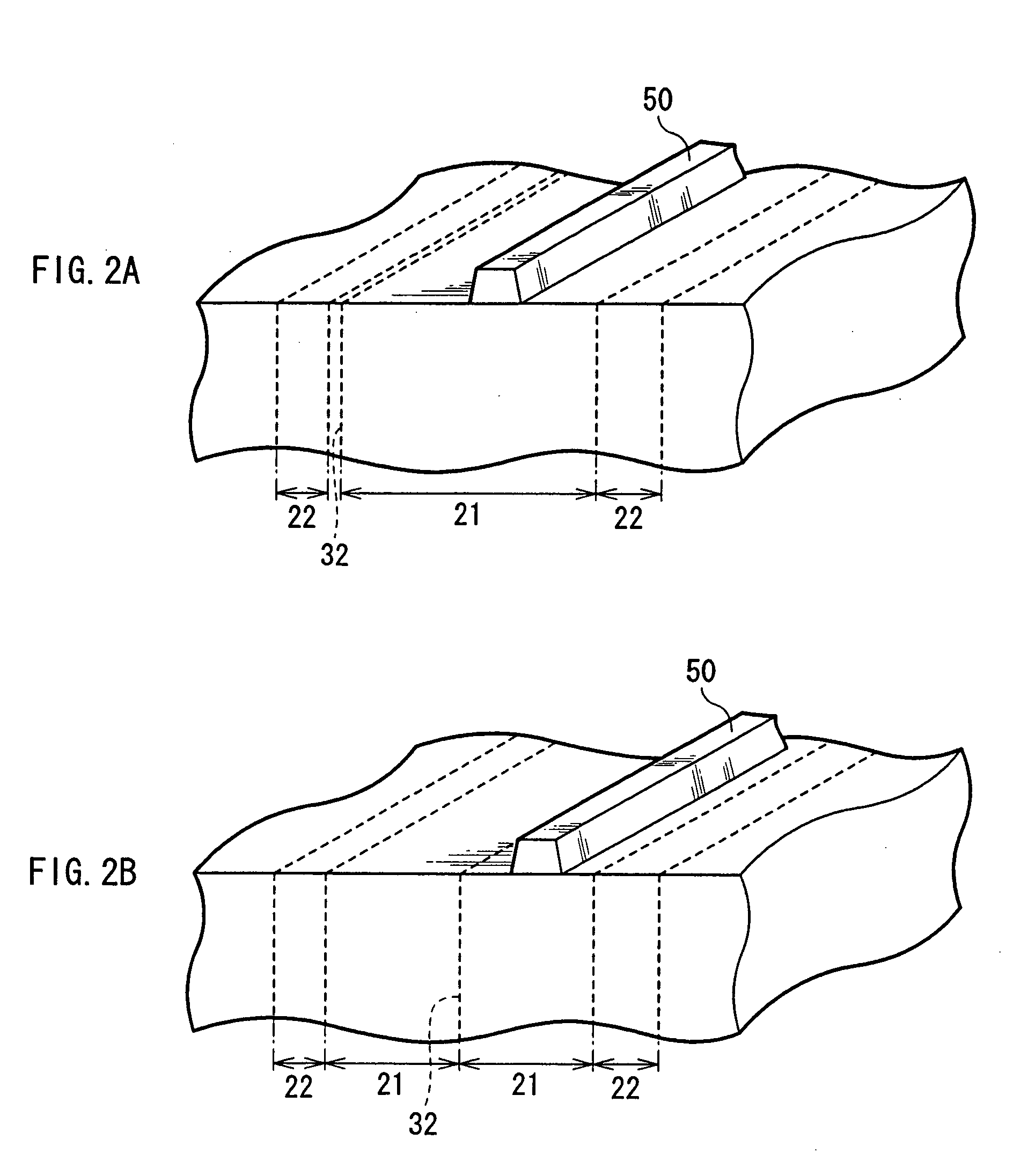

Provided is a nitride semiconductor device with high reliability and high flexibility in design and manufacture of the device. The nitride semiconductor device comprises a seed crystal portion (11) formed on a sapphire substrate (10) and having a mask (12) on one side surface thereof, and a GaN layer (15) grown on the sapphire substrate (10) and the seed crystal portion (11) through epitaxial lateral overgrowth. The GaN layer (15) is grown only from an exposed side surface of the seed crystal portion (11) which is not covered with the mask (12), so the lateral growth of the GaN layer (15) is asymmetrically carried out. Thereby, a meeting portion (32) is formed in the vicinity of a boundary between the seed crystal portion (11) and the mask (12) in a thickness direction of the GaN layer (15). Therefore, as the meeting portion (32) is formed in a position away from the center between the adjacent seed crystal portions (11) in a direction parallel to a surface of the substrate, a width WL of a lateral growth region is larger with respect to a pitch WP of the seed crystal potion (11), compared with conventional configurations.

Owner:SONY CORP

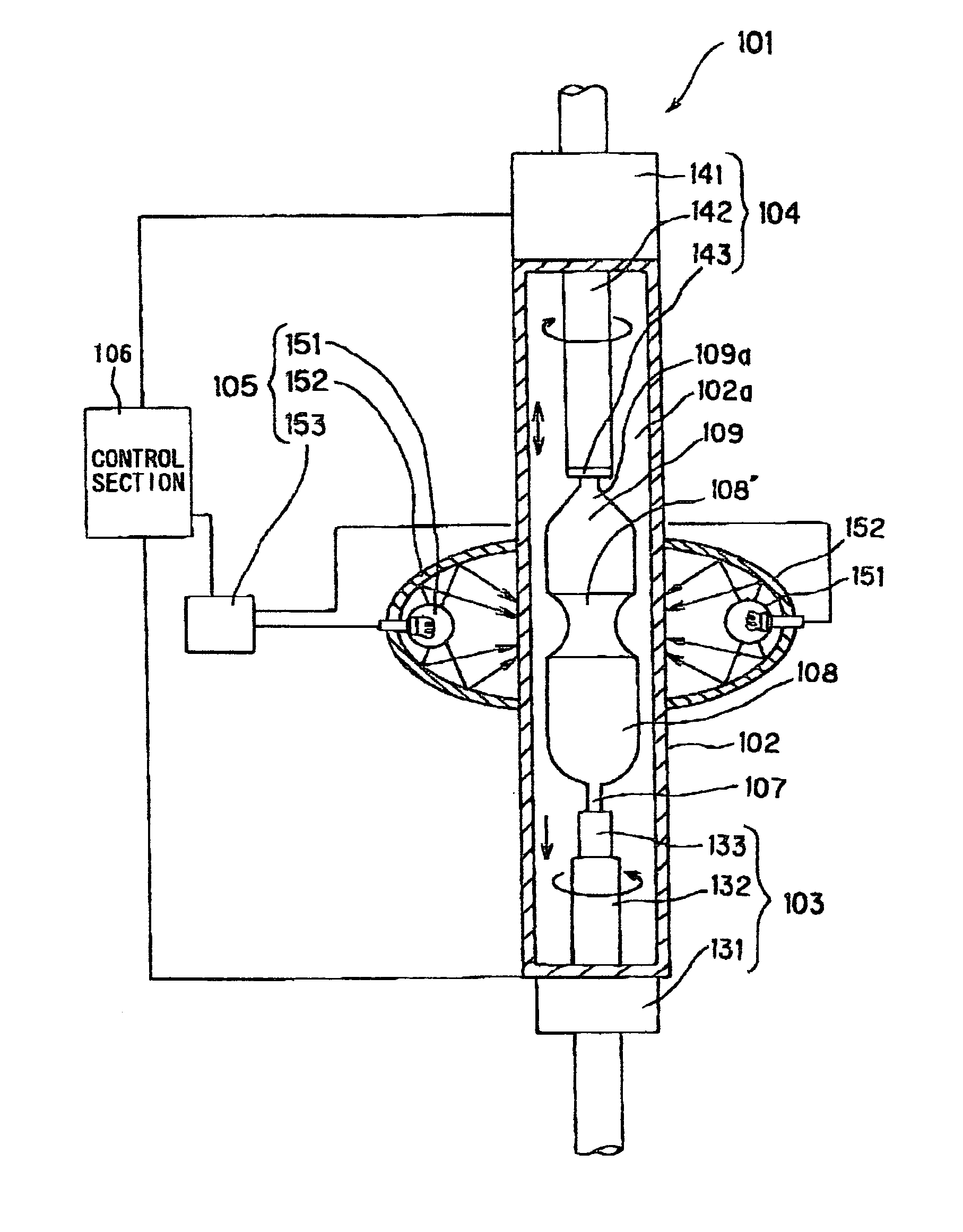

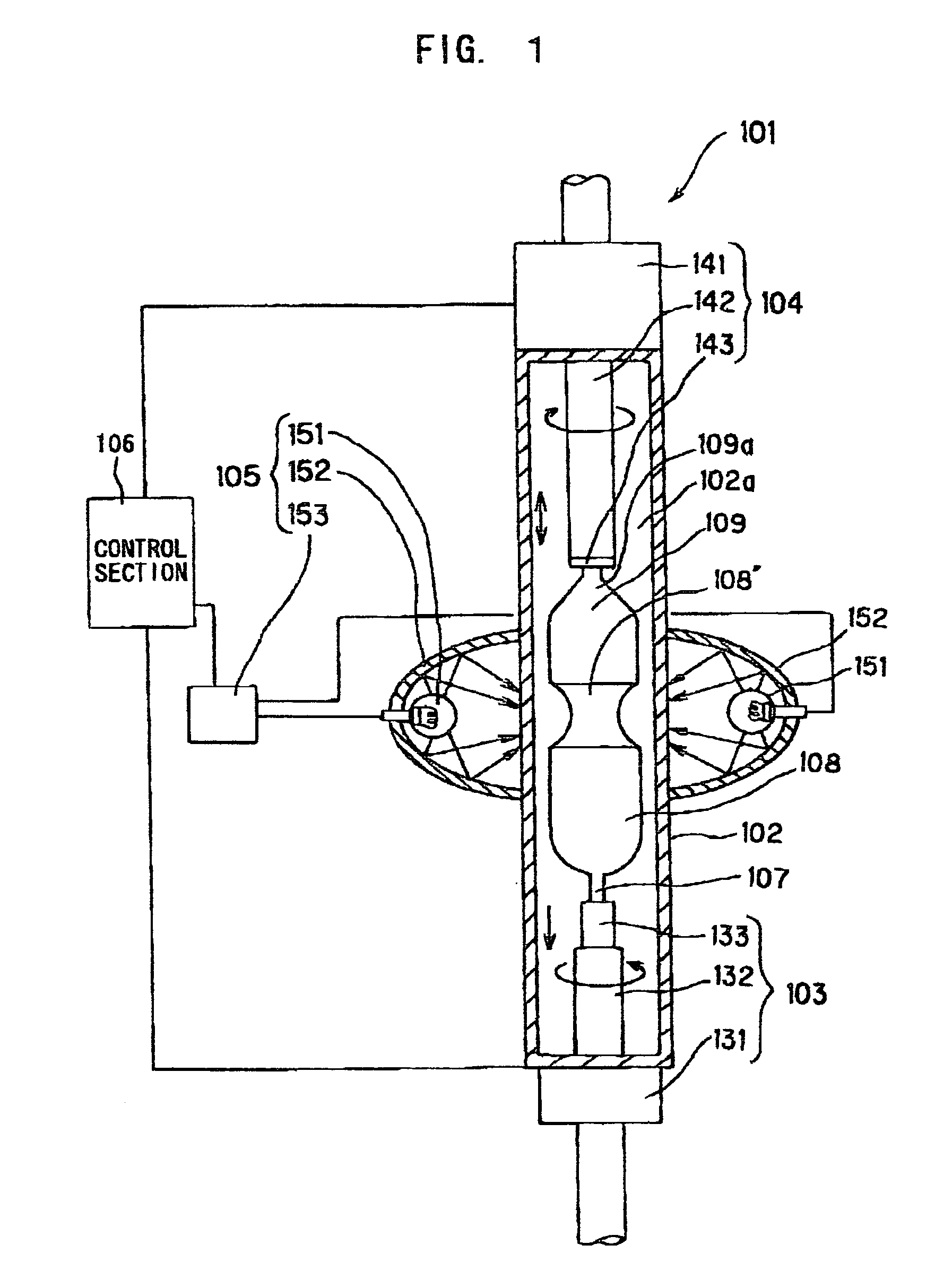

Method and apparatus for manufacturing group iii nitride crystals

InactiveUS20070215033A1Reduce defect densityAchieve mass productionPolycrystalline material growthFrom normal temperature solutionsAlkaline earth metalNitrogen

There is provided a group III nitride crystal growth method capable of obtaining a material which is a GaN substrate of low defect density capable of being used as a power semiconductor substrate and in which characteristics of n-type and p-type requested for formation of transistor or the like. A growth method of group III nitride crystals includes: forming a mixed melt containing at least group III element and a flux formed of at least one selected from the group consisting of-alkaline metal and alkaline earth metal, in a reaction vessel; and growing group III nitride crystals from the mixed melt and a substance containing at least nitrogen, wherein after immersing a plurality of seed crystal substrates placed in an upper part of the reaction vessel in which the mixed melt is formed, into the mixed melt to cause crystal growth, the plurality of seed crystal substrates are pulled up above the mixed melt.

Owner:NGK INSULATORS LTD

Process for producing group III nitride compound semiconductor

InactiveUS20050118825A1Efficient productionPolycrystalline material growthDecorative surface effectsNitrogen atmosphereAdemetionine

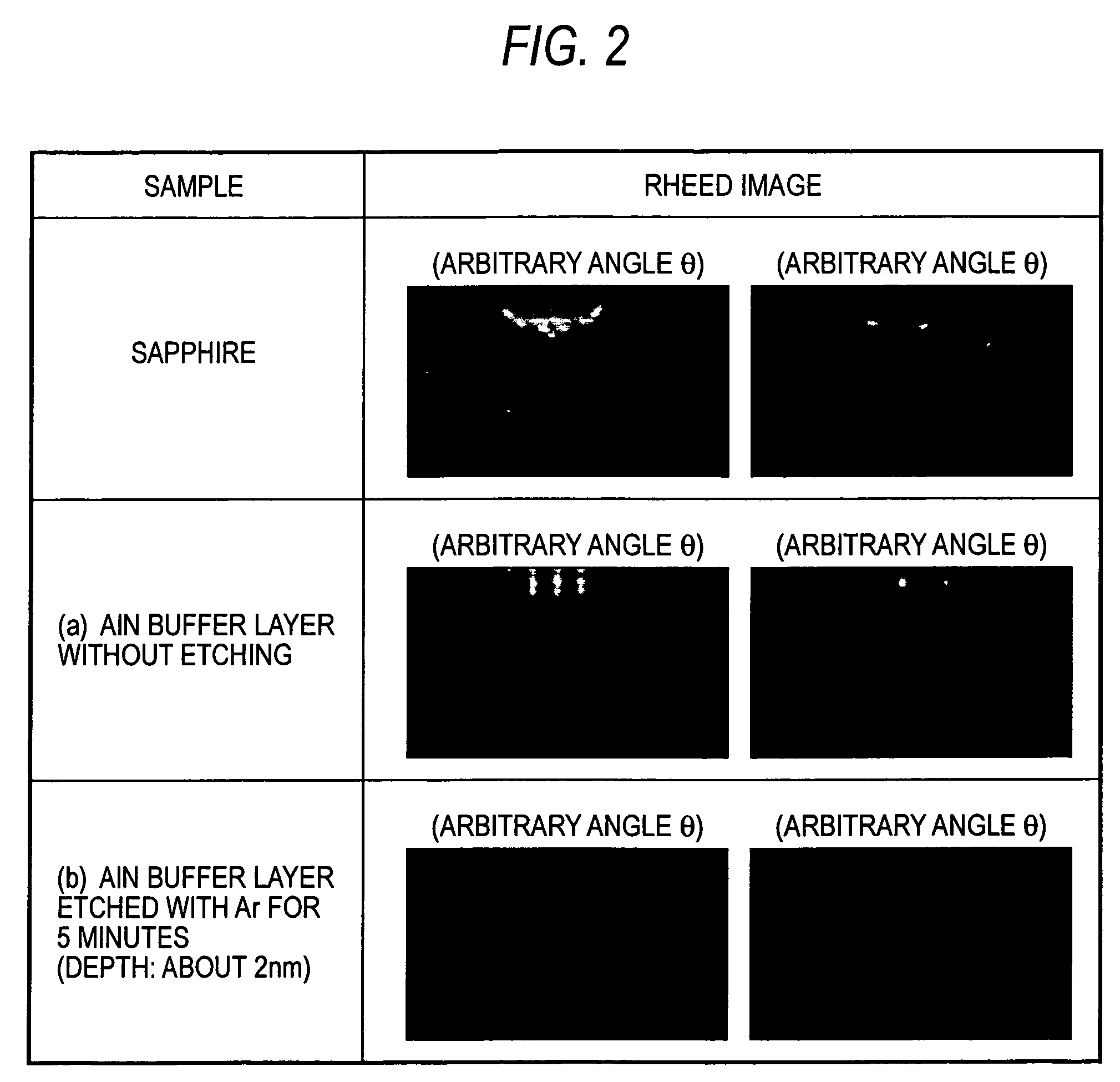

A method including the steps of: modifying at least one part of a sapphire substrate by dry etching to thereby form any one of a dot shape, a stripe shape, a lattice shape, etc. as an island shape on the sapphire substrate; forming an AlN buffer layer on the sapphire substrate; and epitaxially growing a desired Group III nitride compound semiconductor vertically and laterally so that the AlN layer formed on a modified portion of the surface of the sapphire substrate is covered with the desirably Group III nitride compound semiconductor without any gap while the AlN layer formed on a non-modified portion of the surface of the sapphire substrate is used as a seed, wherein the AlN buffer layer is formed by means of reactive sputtering with Al as a target in an nitrogen atmosphere.

Owner:TOYODA GOSEI CO LTD

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN1699173AUniform particle sizeHigh ratio of silicon to aluminumPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Nitride semiconductor device and method of manufacturing the same

InactiveUS20050184302A1Increase widthIncrease horizontal widthPolycrystalline material growthOrganic electrolyte cellsCrystallographyLateral overgrowth

Provided is a nitride semiconductor device with high reliability and high flexibility in design and manufacture of the device. The nitride semiconductor device comprises a seed crystal portion (11) formed on a sapphire substrate (10) and having a mask (12) on one side surface thereof, and a GaN layer (15) grown on the sapphire substrate (10) and the seed crystal portion (11) through epitaxial lateral overgrowth. The GaN layer (15) is grown only from an exposed side surface of the seed crystal portion (11) which is not covered with the mask (12), so the lateral growth of the GaN layer (15) is asymmetrically carried out. Thereby, a meeting portion (32) is formed in the vicinity of a boundary between the seed crystal portion (11) and the mask (12) in a thickness direction of the GaN layer (15). Therefore, as the meeting portion (32) is formed in a position away from the center between the adjacent seed crystal portions (11) in a direction parallel to a surface of the substrate, a width WL of a lateral growth region is larger with respect to a pitch WP of the seed crystal potion (11), compared with conventional configurations.

Owner:KOBAYASHI TOSHIMASA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com