Patents

Literature

520 results about "Mordenite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mordenite is a zeolite mineral with the chemical formula, (Ca, Na₂, K₂)Al₂Si₁₀O₂₄·7H₂O. and it is one of the six most abundant zeolites and is used commercially. It was first described in 1864 by Henry How. He named it after the small community of Morden, Nova Scotia, Canada, along the Bay of Fundy, where it was first found.

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly cumene, comprising the step of contacting a polyalkylated aromatic compound with an alkylatable aromatic compound under at least partial liquid phase conditions and in the presence of a transalkylation catalyst to produce the monoalkylated aromatic compound, wherein the transalkylation catalyst comprises a mixture of at least two different crystalline molecular sieves, wherein each of said molecular sieves is selected from zeolite beta, zeolite Y, mordenite and a material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom.

Owner:EXXONMOBIL CHEM PAT INC

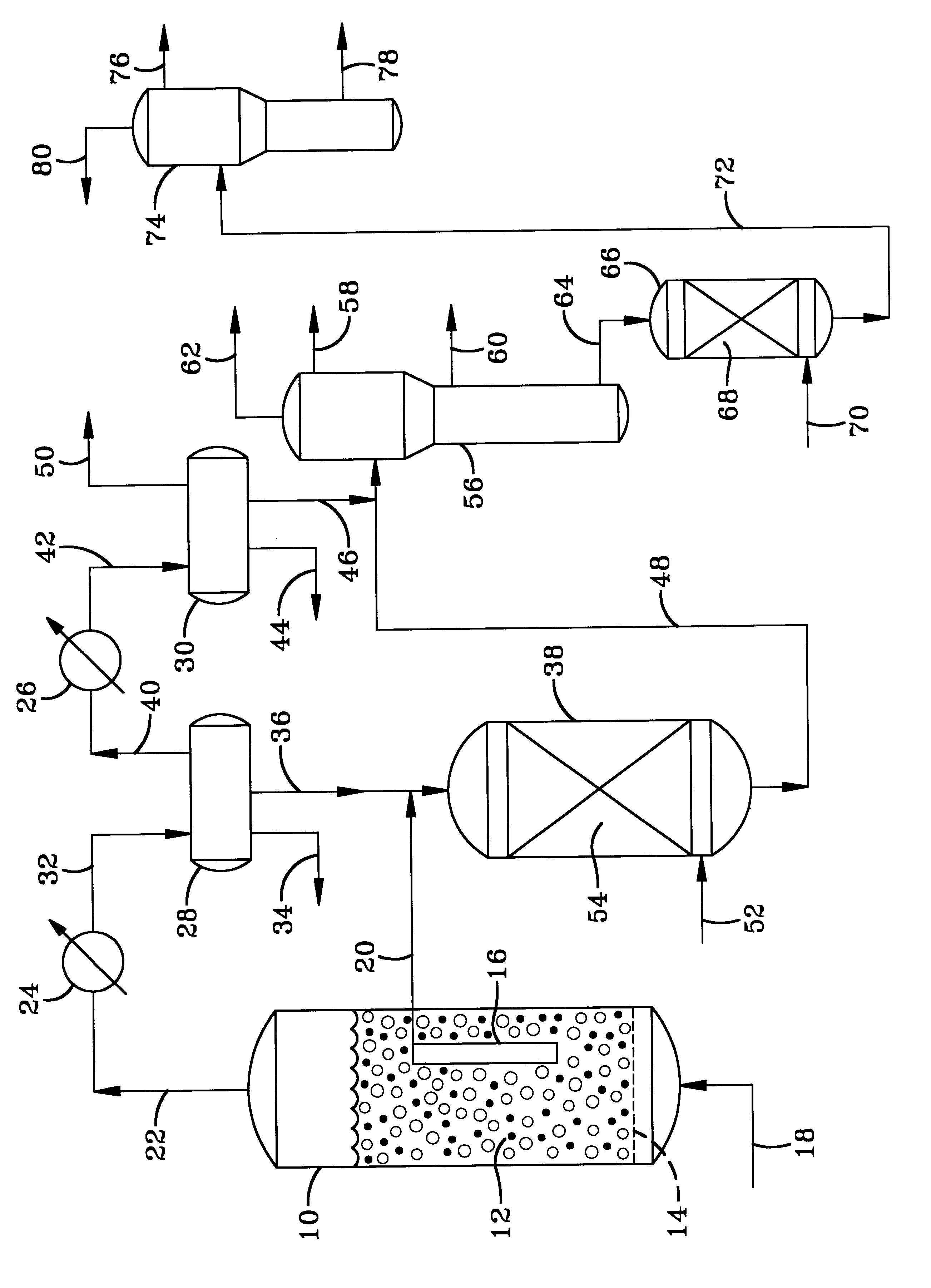

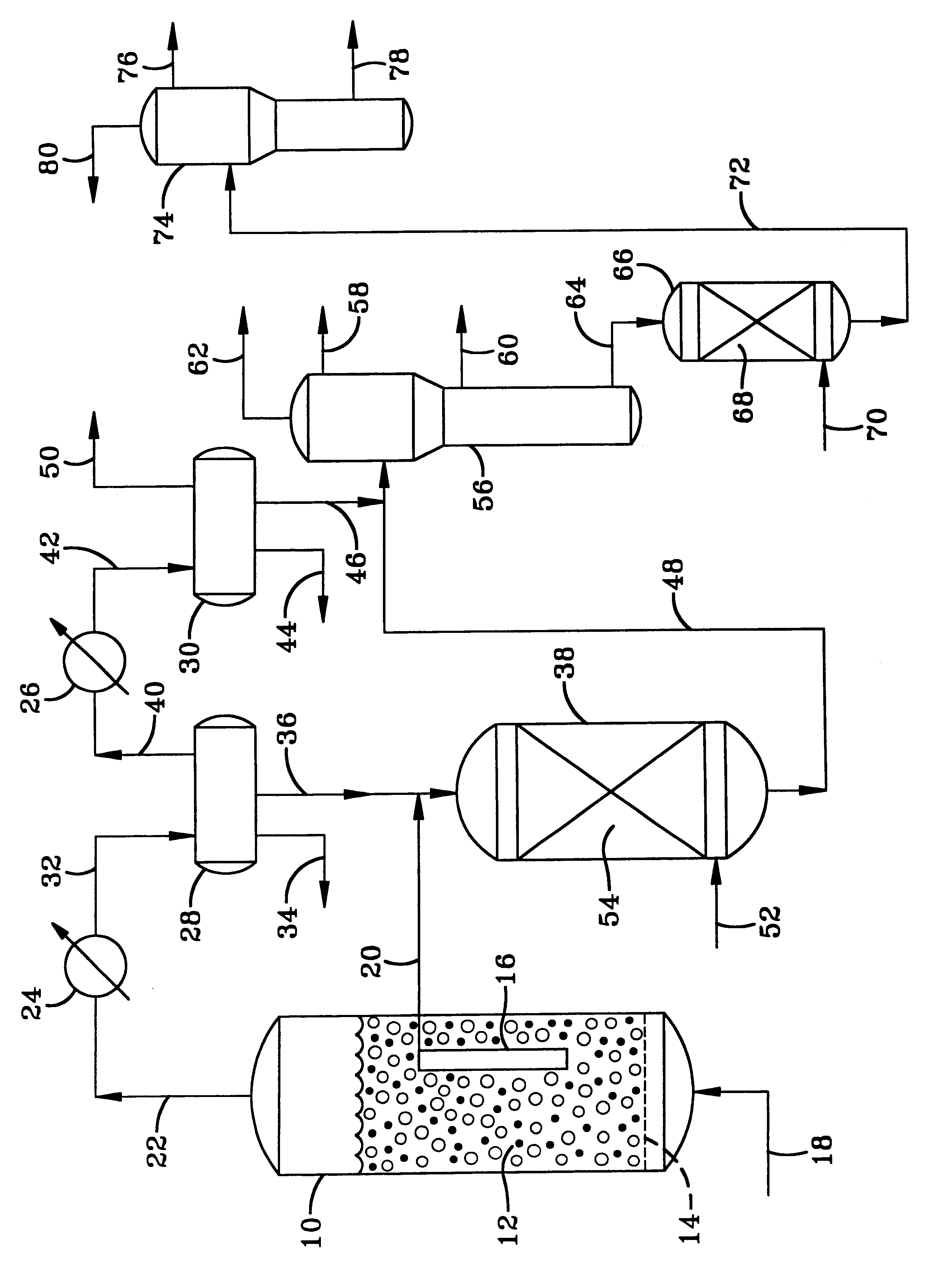

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly ethylbenzene or cumene, in which a polyalkylated aromatic compound is contacted with an alkylatable aromatic compound in the liquid phase and in the presence of a transalkylation catalyst comprising TEA-mordenite having an average crystal size of less than 0.5 micron.

Owner:EXXONMOBIL CORP (US)

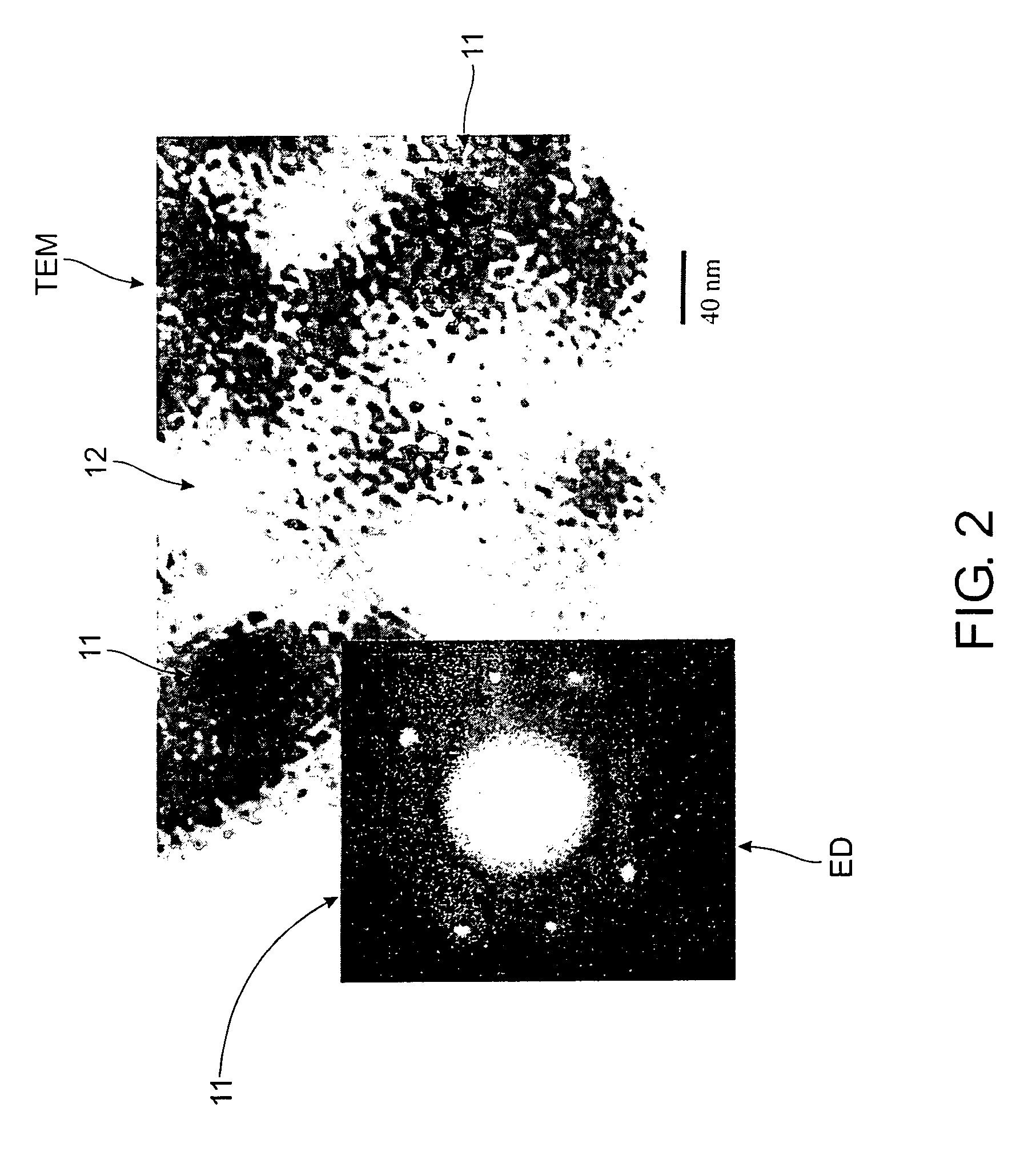

Micropore mesopore composite molecular sieve and its preparation method

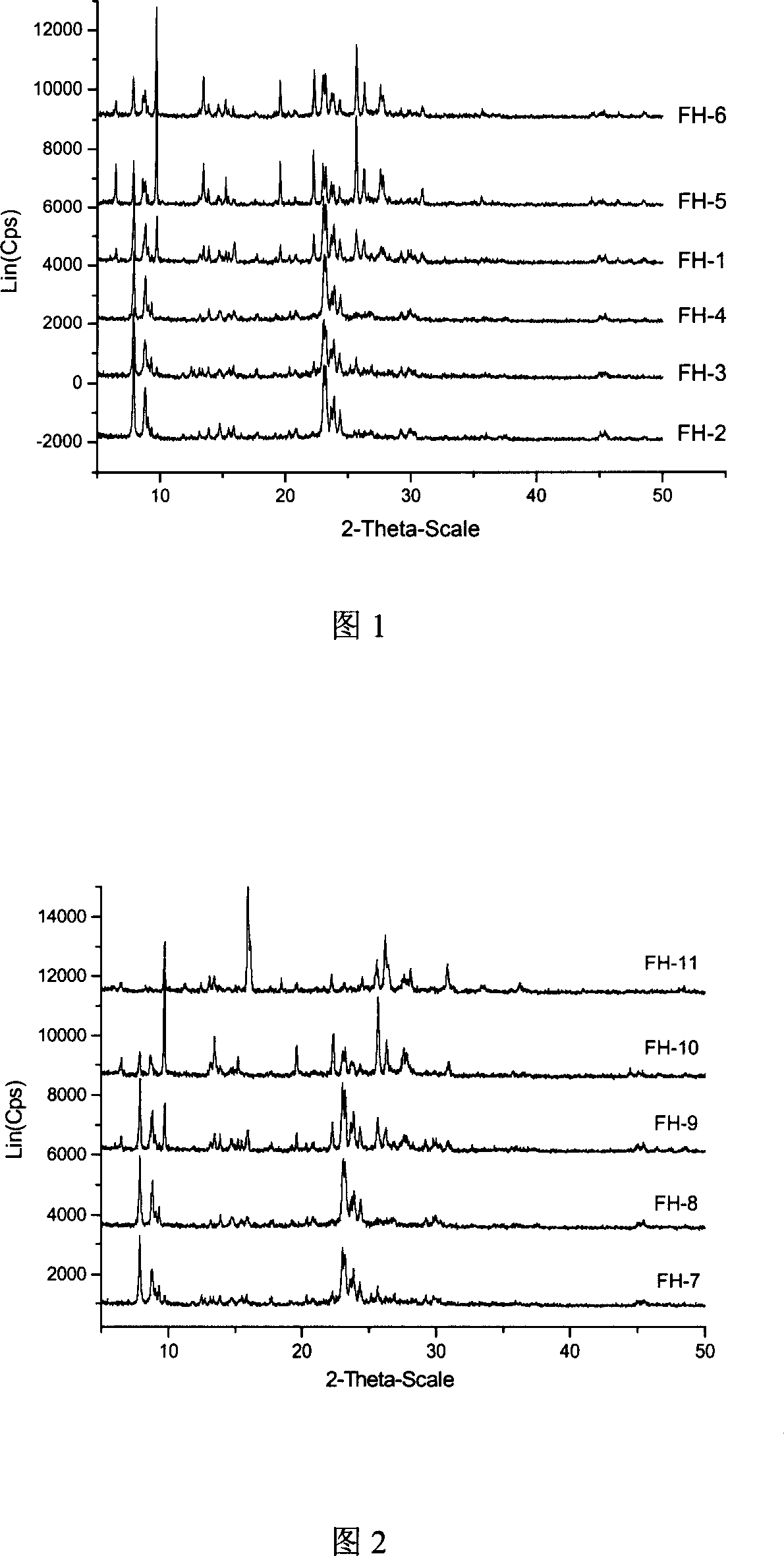

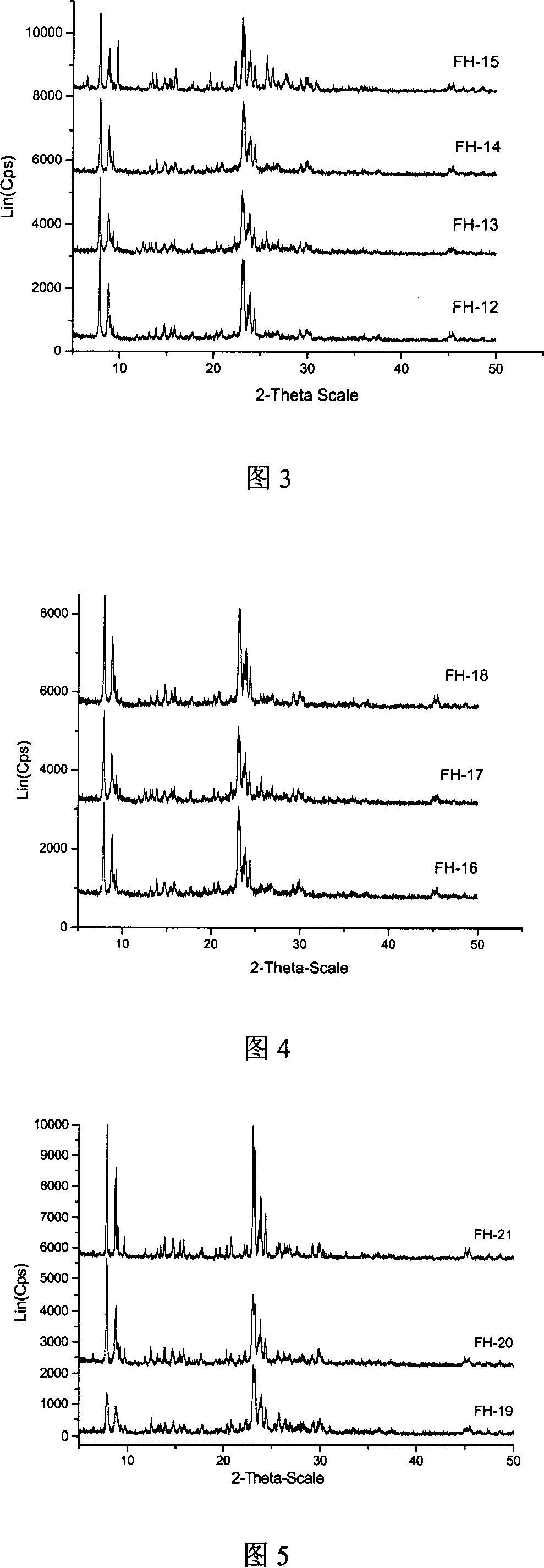

InactiveCN1597516AAdjustable silicon-aluminum ratioAdjustable aperture sizeCrystalline aluminosilicate zeolitesMordeniteSodium hydroxide

A composite millipore-mesopore molecular sieve is prepared through proportionally adding millipore Zeolite molecular sieve ZSM-5, beta-zeolite, mordenite, L-zeolite, MCM-22 and ZSM-35 to the solution of sodium hydroxide, stirring, adding the template agent of mesopore molecular sieve, crystallizing at 90-120 deg.C for 22-26 hr, regulating pH=7.5-7.9, and static crystallizing at 90-120 deg.c for 24-168 hr.

Owner:TAIYUAN UNIV OF TECH

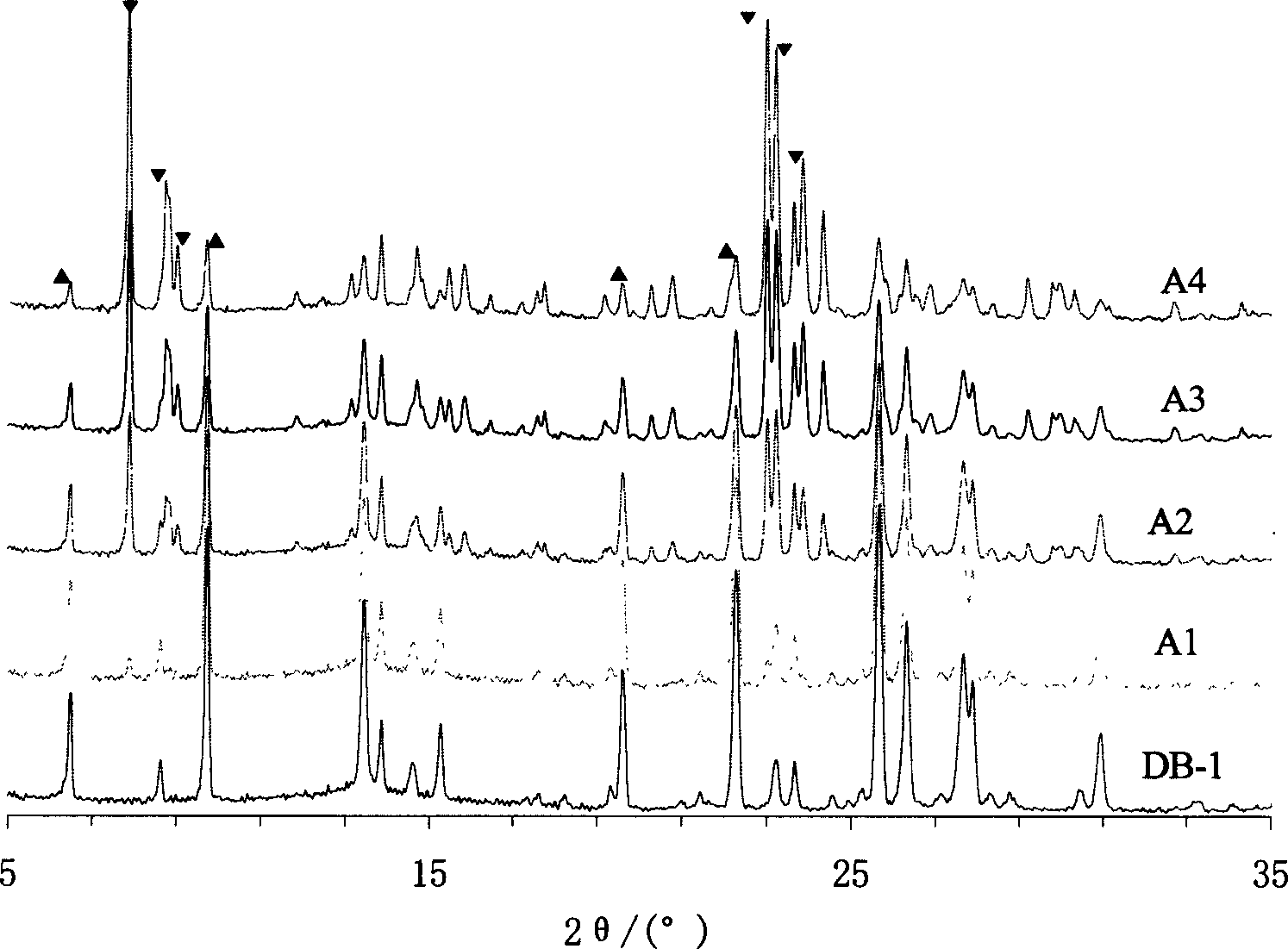

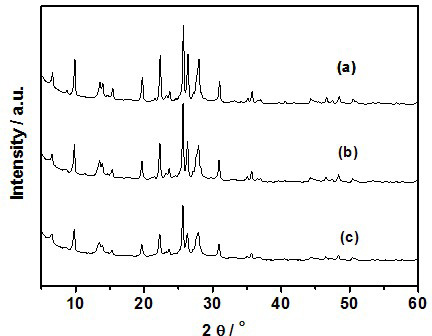

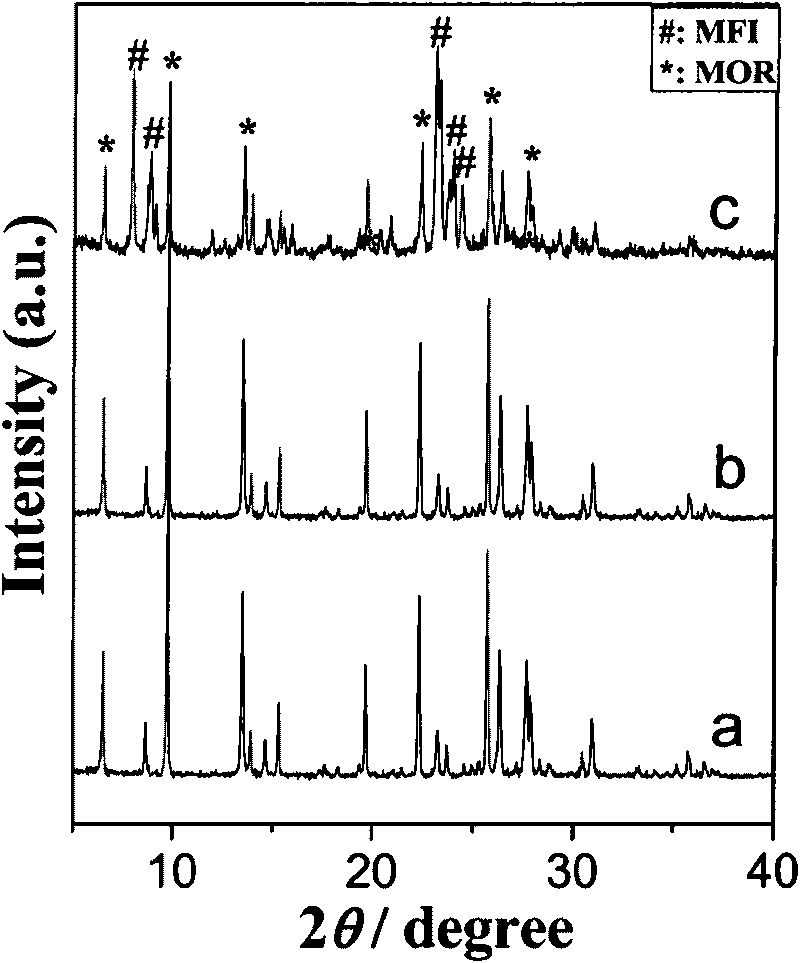

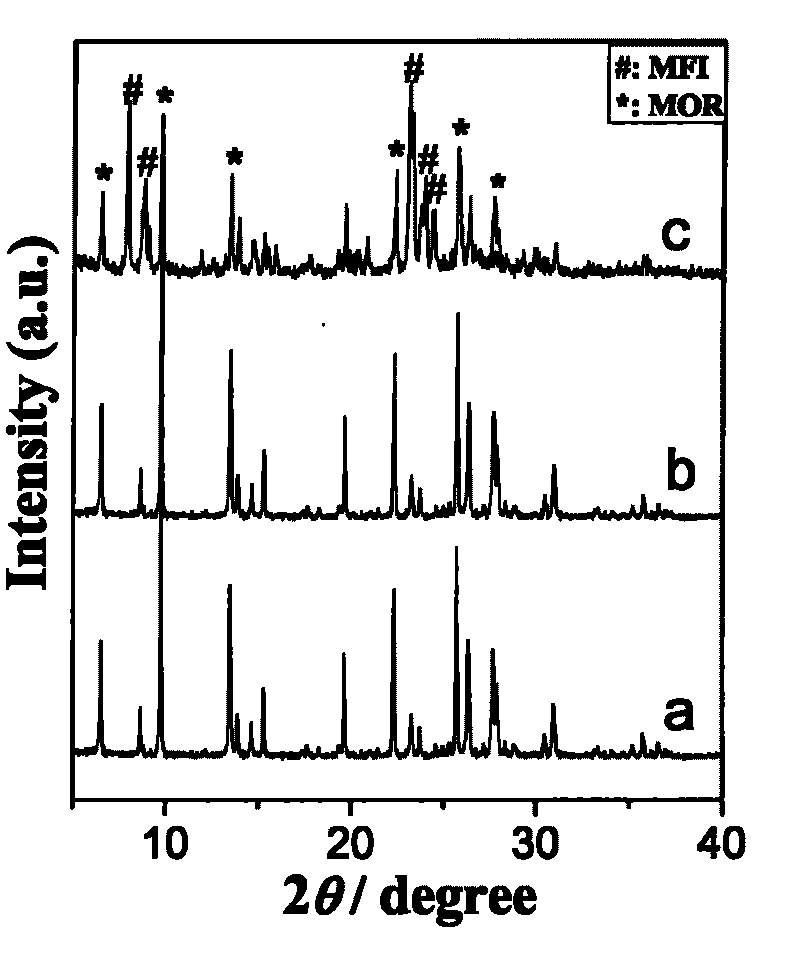

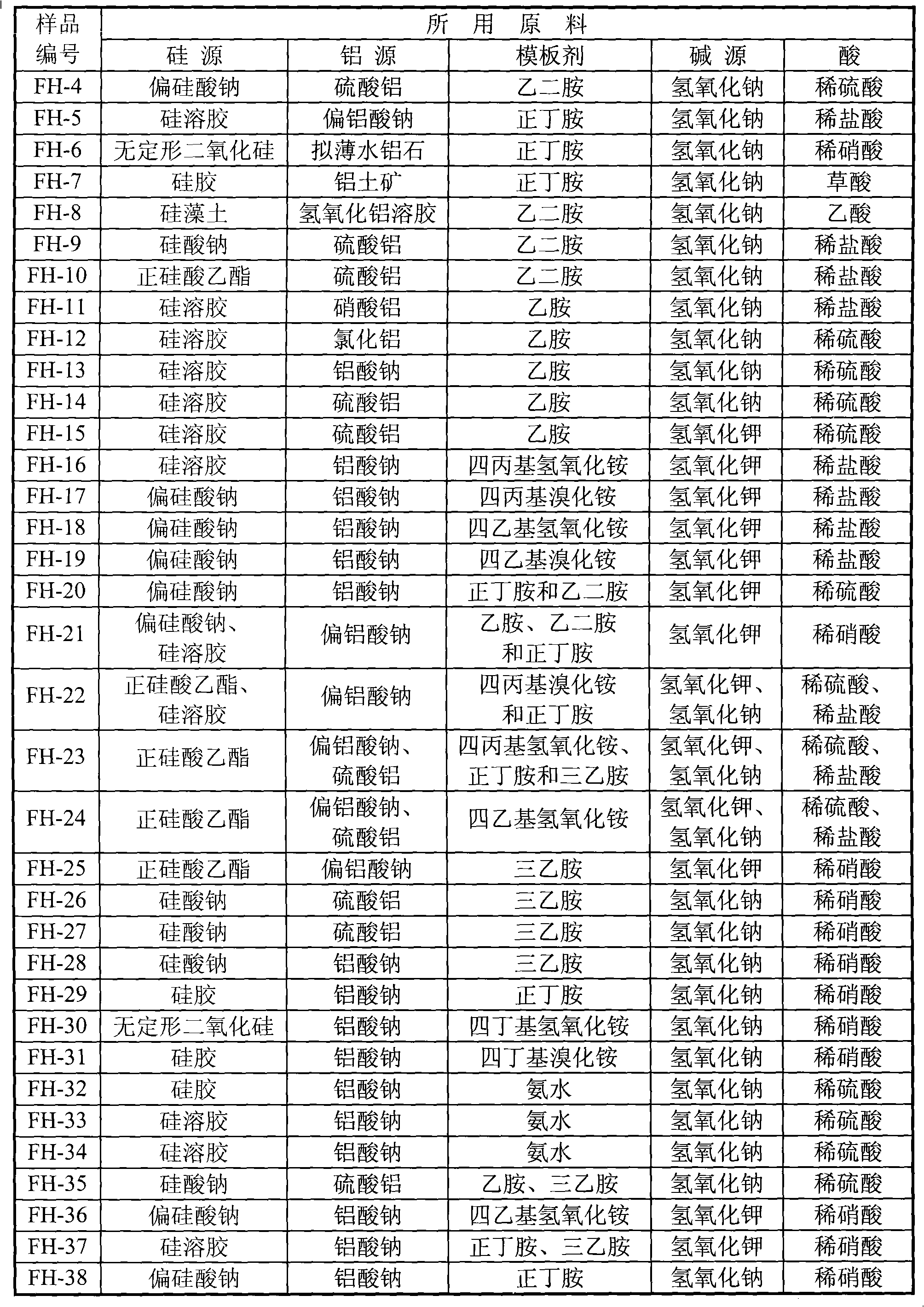

Synthetic method for ZSM-5/mordenite mixed crystal material

InactiveCN1565970ALower synthesis costEasy to adjustMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteThermal crystallization

The invention discloses a synthetic method for ZSM-5 / mordenite mixed crystal material, wherein ZSM-5 molecular sieve is charged into the synthesized reaction mixture of mordenite as seed crystal, and said material is prepared through water thermal crystallization. The invention realizes low making cost and more ideal catalyzing performance.

Owner:CHINA PETROLEUM & CHEM CORP +2

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

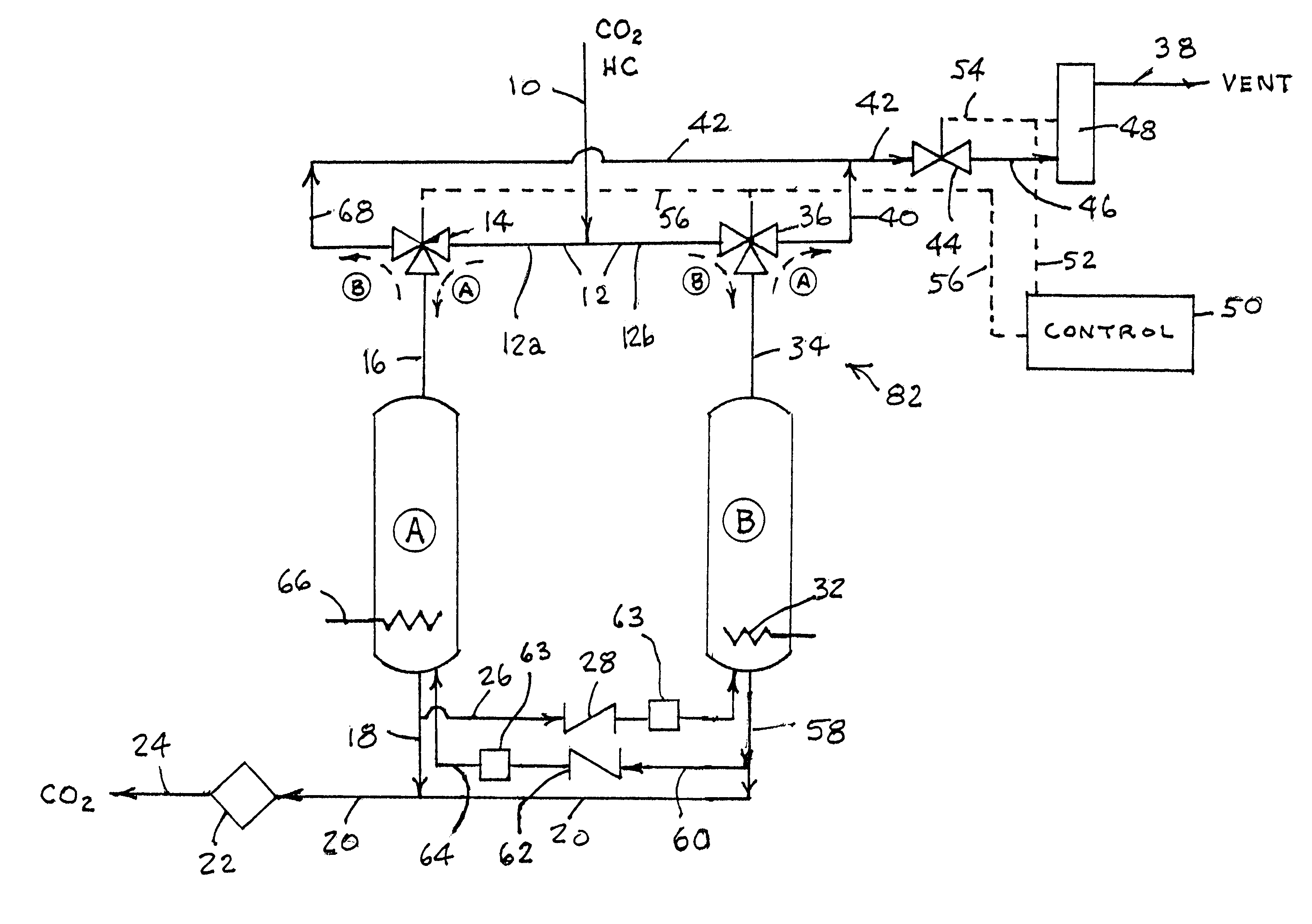

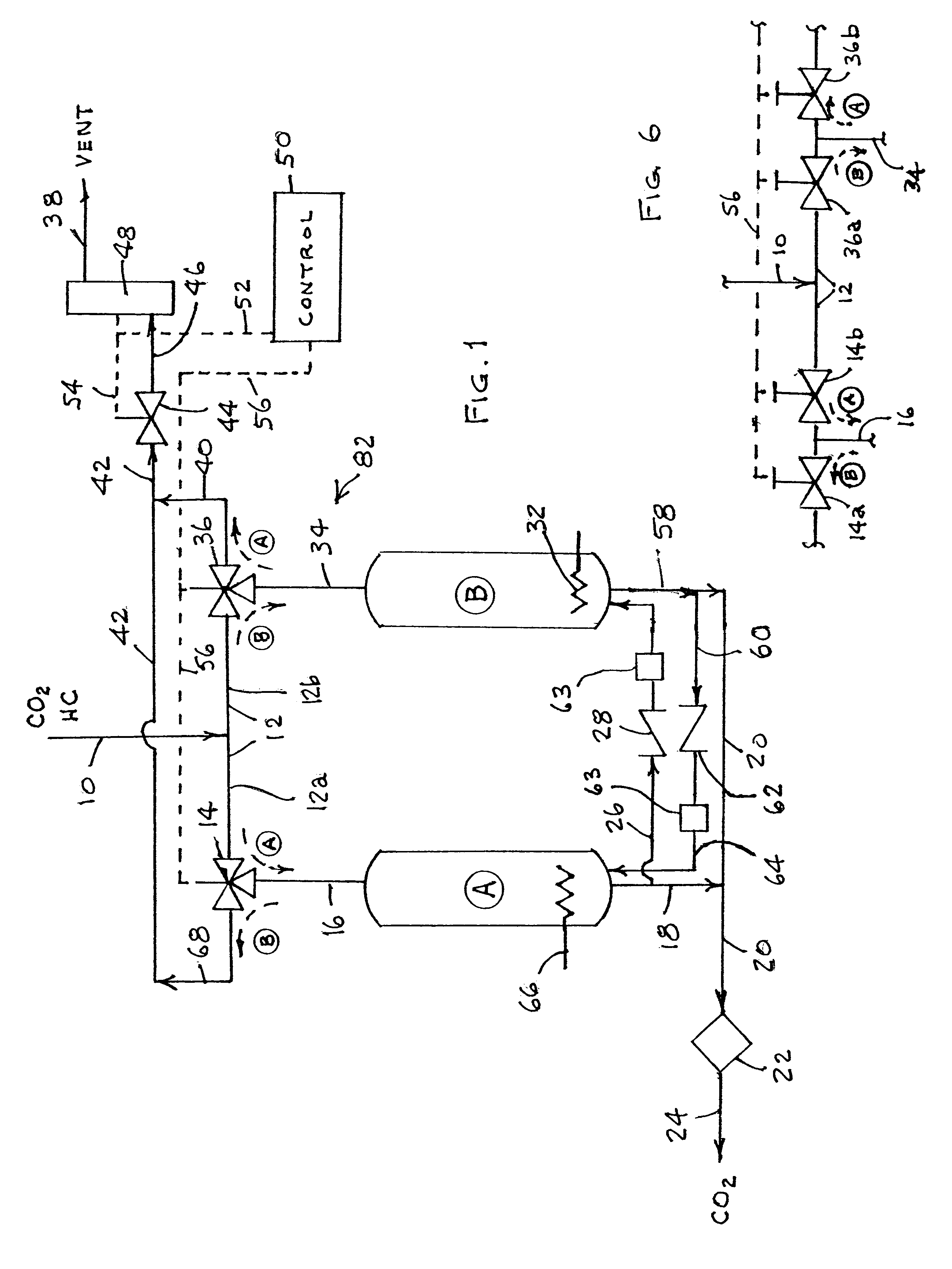

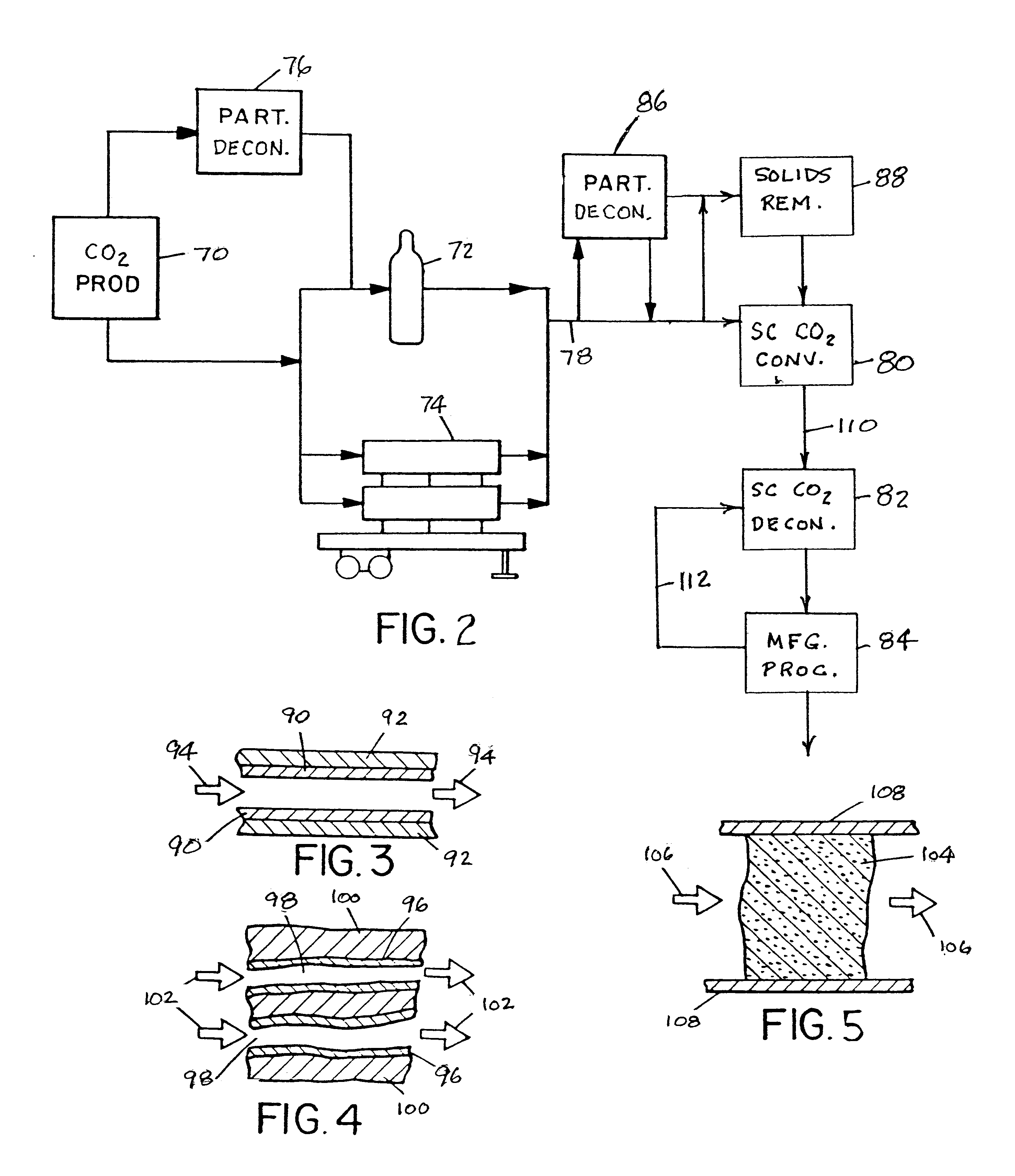

Self-regenerative process for contaminant removal from liquid and supercritical CO2 fluid streams

A method for the decontamination of fluid (liquid or supercritical) carbon dioxide fluid, especially of hydrocarbon contaminants, down to <=100 ppb concentration are described. The critical component is a high silica zeolite, preferably a high silica Y-type zeolite, ZSM-5 or a high silica mordenite, which in a variety of physical forms is capable of decontaminating such fluid CO2 to <=100 ppb, <=10-50 ppb, or ~1 ppb, without being detrimentally affected by the supercritical operating environment. The high silica zeolite may be produced by the removal of alumina from a natural or synthetic zeolite while retaining the desirable zeolite structure, to a silica:alumina ratio of from 20-2000:1. Preferably the zeolite is disposed in separate quantities in at least two vessels, which operate alternately. A portion of the purified product from the operating vessel is directed to the other vessel and there used to remove accumulated contaminants from that vessel's zeolite. The process thus provides self-regeneration, in that regeneration of one vessel occurs while the other vessel decontaminates contaminated fluid carbon dioxide, so that use of the two can be alternated for substantially continual production of purified fluid carbon dioxide. The invention provides purified fluid carbon dioxide used in manufacture of such products as high purity electronic, optical, prosthetic or similar products or polymers or pharmaceuticals or in beverages.

Owner:ENTEGRIS INC

Zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:ABB LUMMUS GLOBAL INC

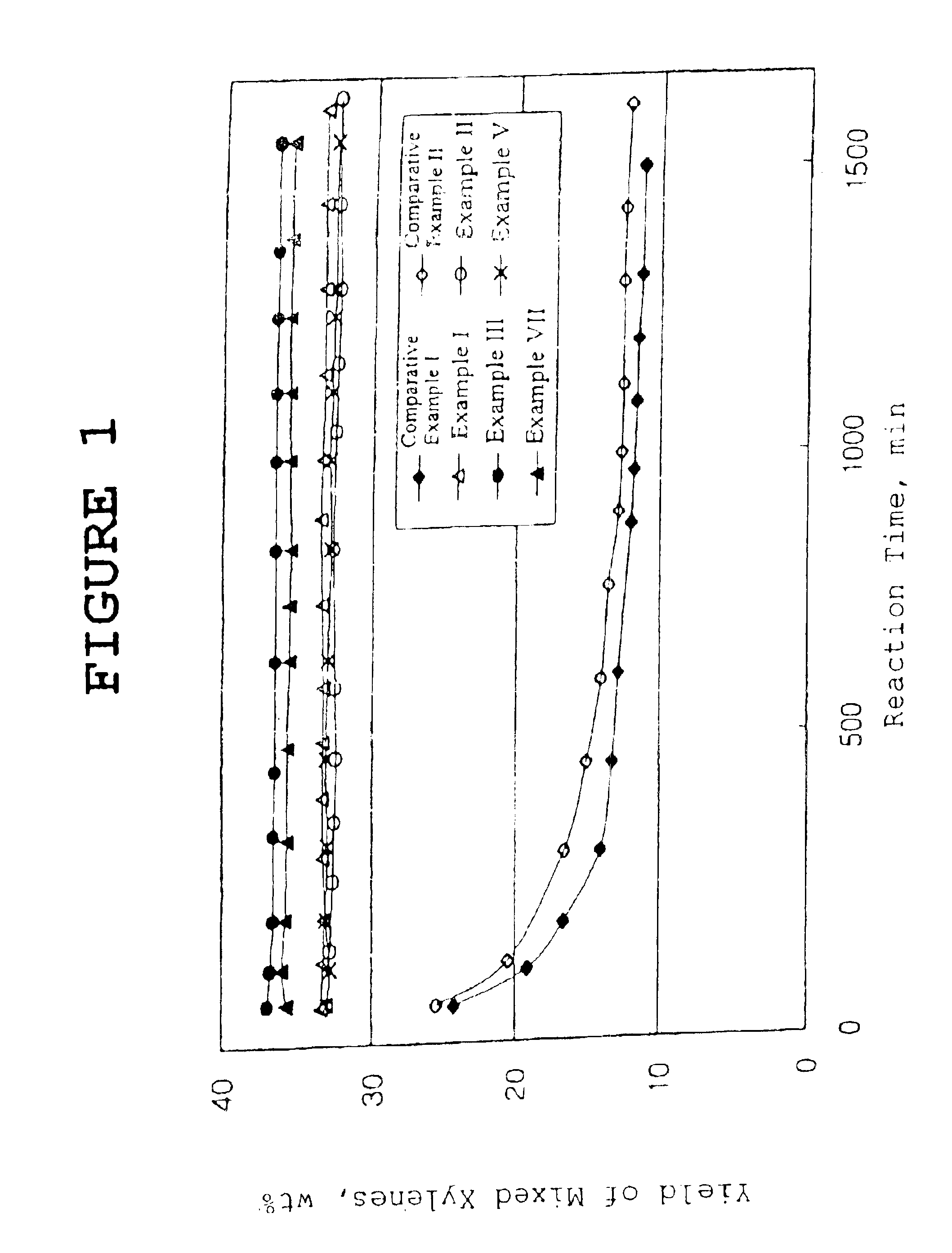

Disproportionation/transalkylation of aromatic hydrocarbons

InactiveUS6867340B2Prevents deactivationHigh yieldHydrocarbon by isomerisationMolecular sieve catalystsChemistryPectolite

A catalyst for the disproportionation / transalkylation of various hydrocarbons consists of a carrier and a metal component supported on the carrier. The carrier comprises 10 to 80 wt % of mordenite and / or beta type zeolite with a mole ratio of silica / alumina ranging from 10 to 200; 0 to 70 wt % of ZSM-5 type zeolite with a mole ratio of silica / alumina ranging from 30 to 500; and 5 to 90 wt % of at least one inorganic binder selected from the group consisting of gamma-alumina, silica, silica alumina, bentonite, kaolin, clinoptilolite, and montmorillonite. The metal component comprises platinum and either tin or lead. The catalyst enables mixed xylenes to be produced at remarkably high yields from benzene, toluene and C9 or higher aromatic compounds through disproportionation / transalkylation with a great reduction in aromatic loss. In addition, the catalyst can maintain its catalytic activity for a long period of time without deactivation.

Owner:SK INNOVATION CO LTD

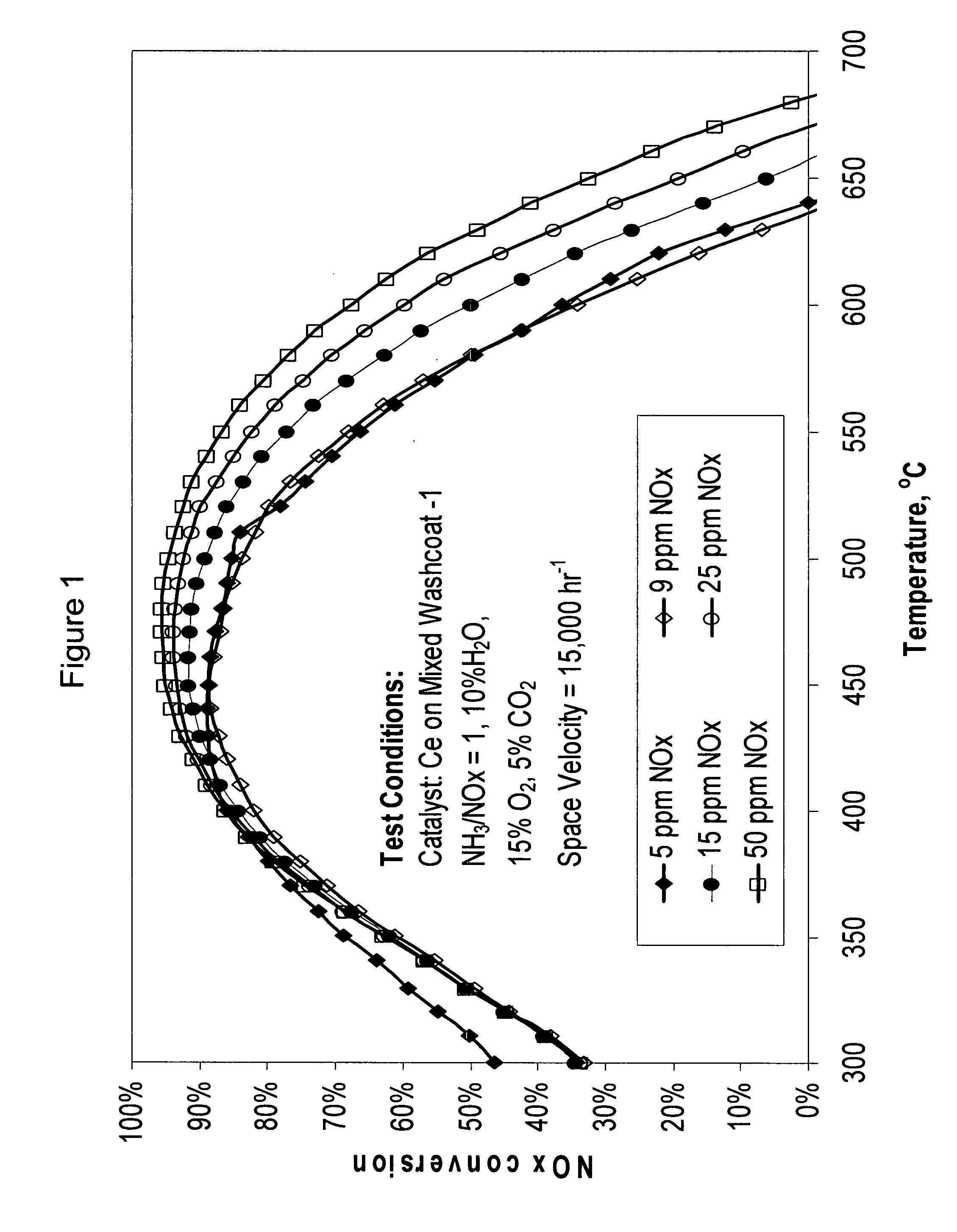

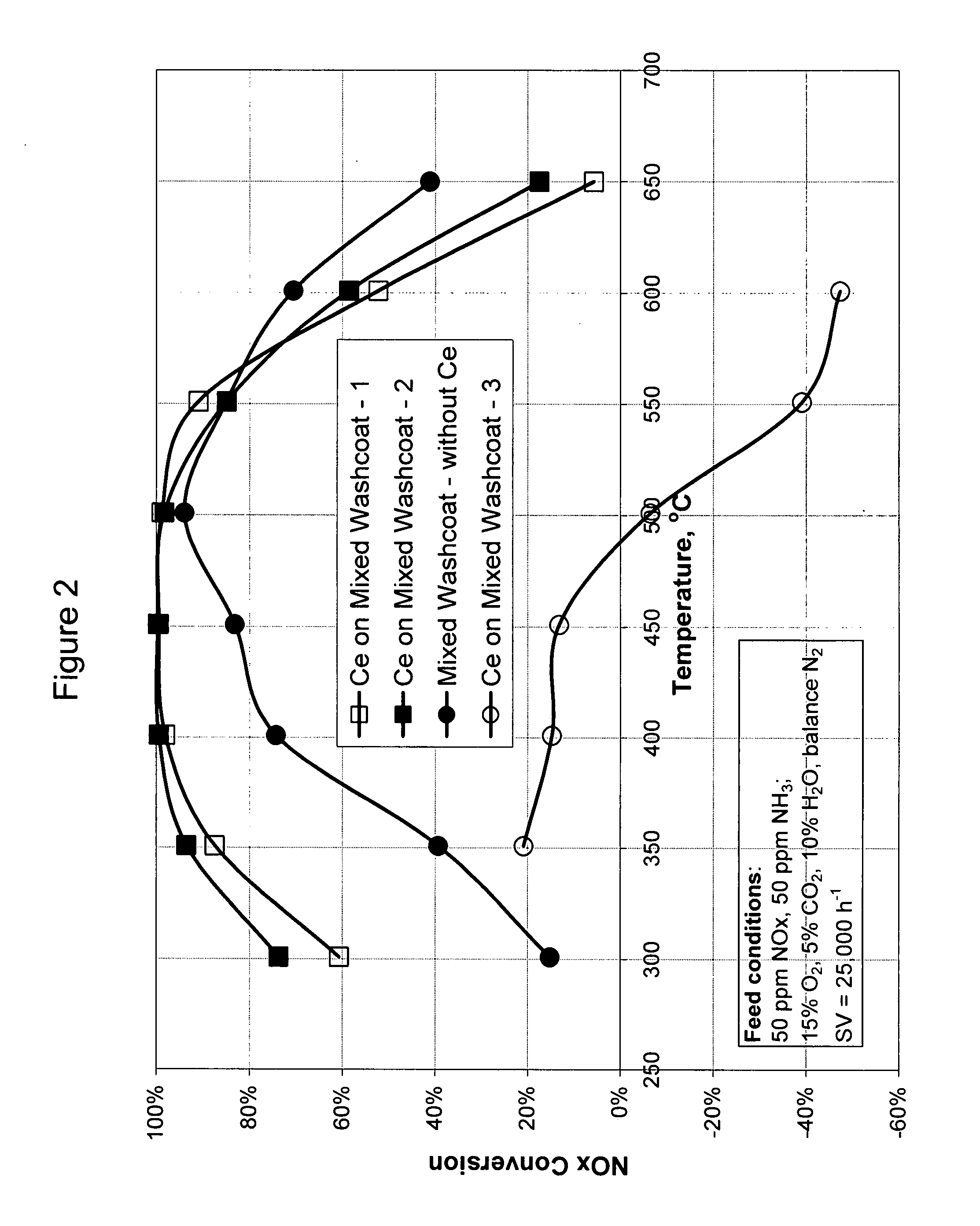

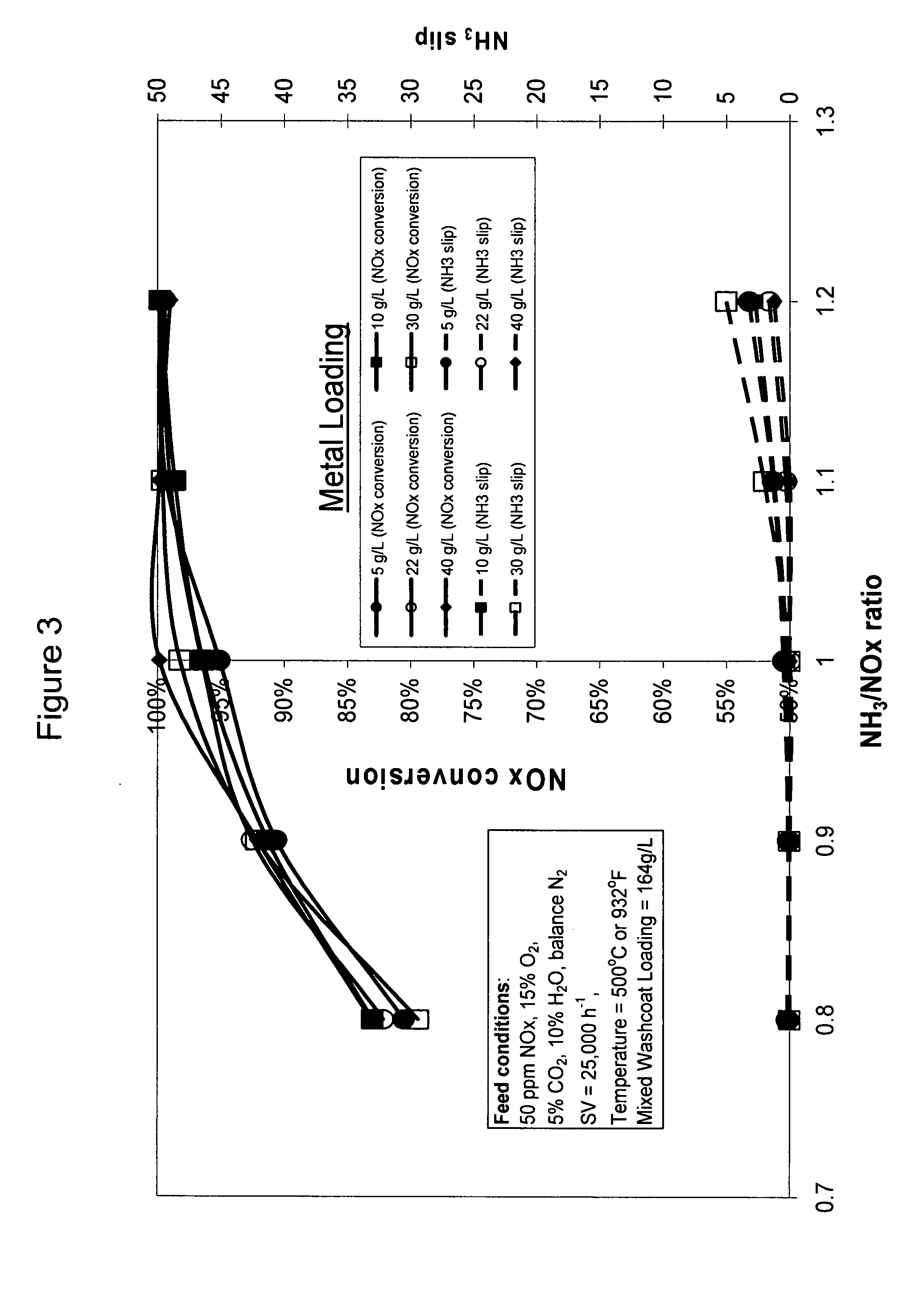

High temperature ammonia SCR catalyst and method of using the catalyst

ActiveUS20080167178A1Reduce selection requirementsMolecular sieve catalystsInternal combustion piston enginesCeriumMordenite

A catalyst and a method for selectively reducing nitrogen oxides (“NOx”) with ammonia are provided. The catalyst includes a first component comprising a zeolite or mixture of zeolites selected from the group consisting of ZSM-5, ZSM-11, ZSM-12, ZSM-18, ZSM-23, MCM-zeolites, mordenite, faujasite, ferrierite, zeolite beta, and mixtures thereof; a second component comprising at least one member selected from the group consisting of cerium, iron, copper, gallium, manganese, chromium, cobalt, molybdenum, tin, rhenium, tantalum, osmium, barium, boron, calcium, strontium, potassium, vanadium, nickel, tungsten, an actinide, mixtures of actinides, a lanthanide, mixtures of lanthanides, and mixtures thereof; optionally an oxygen storage material and optionally an inorganic oxide. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia at high temperatures. The catalyst has high hydrothermal stability. The catalyst has high activity for conversion of low levels of nitrogen oxides in exhaust streams. The catalyst and the method may have special application to selective reduction of nitrogen oxides in exhaust gas from gas turbines and gas engines, although the catalyst and the method have broad application to a wide range of gas streams that have excess oxygen and high temperatures. The temperature of exhaust gas from gas turbines and gas engines is high. Both the high temperature and the low levels of inlet NOx are challenging for selective catalytic reduction (SCR) catalysts.

Owner:CATALYTIC SOLUTIONS INC

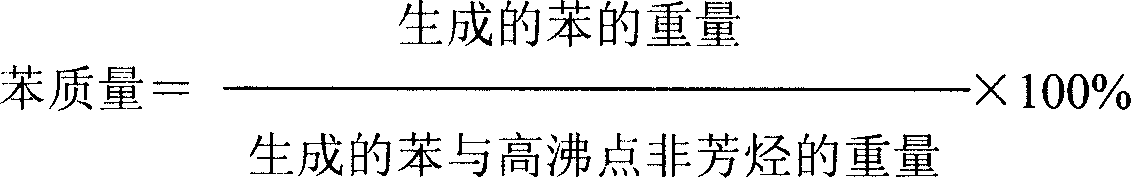

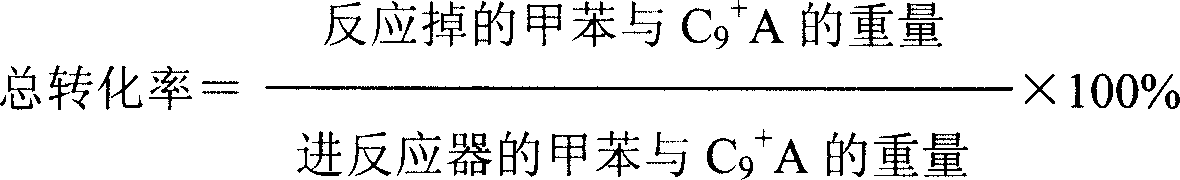

Catalyst for aromatics alkyl transferring and dealkylation to synthesis benzene and xylene

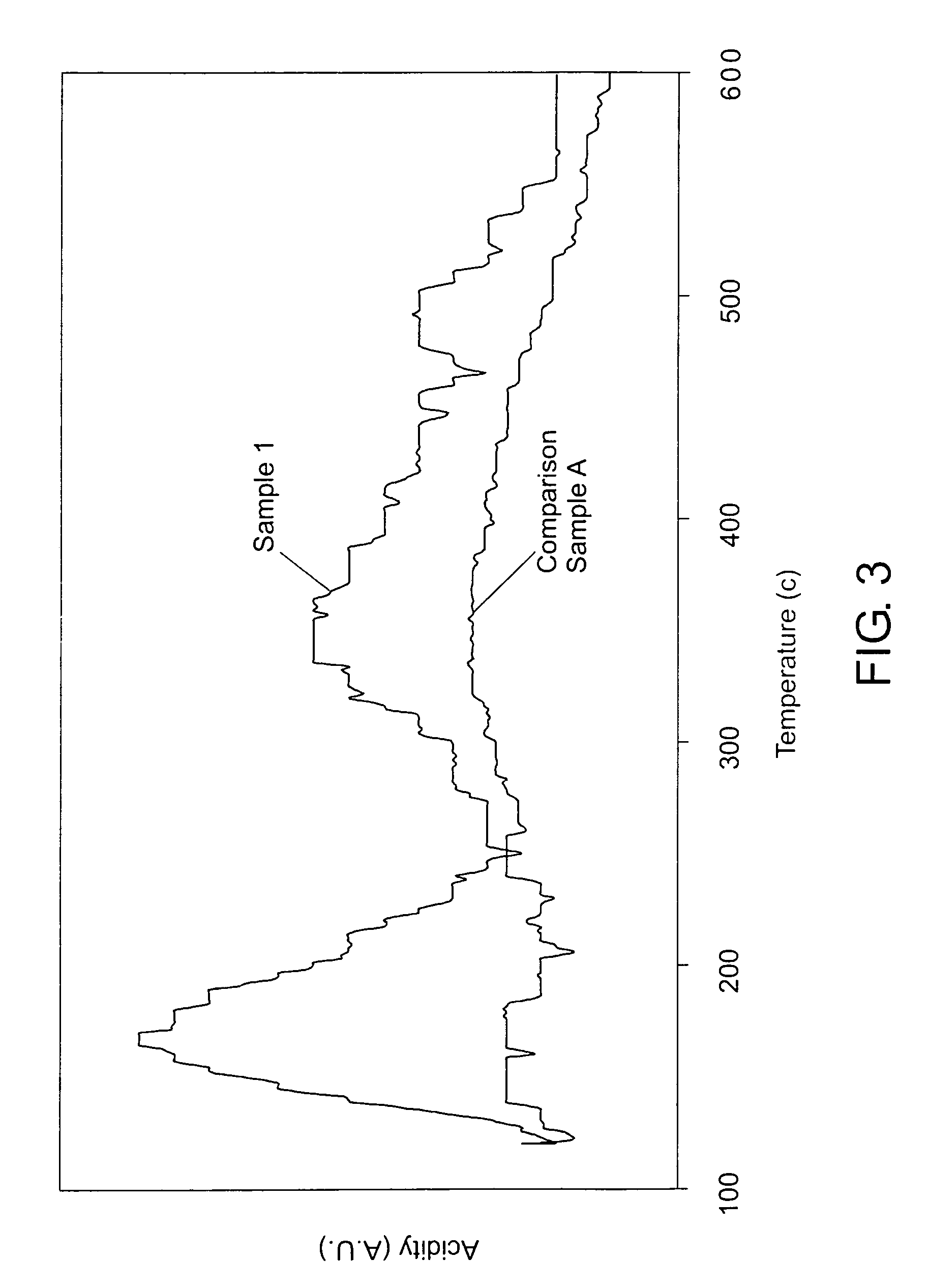

ActiveCN101121144AAdjust acid strengthIncreased transalkylationMolecular sieve catalystsHydrocarbonsCeriumMordenite

The present invention relates to a benzene and xylene catalyst, which is synthesized by aromatics transalkylation and dealkylation. The present invention mainly solves the problem in the prior art that a high by-product content in a benzene product of the reaction products causes bad quality of the benzene product. The present invention solves the problem well by a technical proposal that a catalyst consists of 40 to 130 portions of a mixture of a beta zeolite, SiO2 / Al2O3, Beta zeolite, the molar ratio of which is 10 to 100 and at least one zeolite which is selected from a mordenite, a Y zeolite, ZSM-12 or ZSM-5, 10 to 60 portions of binder, and 0.1 to 20 portions of at least one oxide of which is selected from molybdenum, palladium, fe, bismuth, cerium, lanthanum, nickel, tin or platinum, and all components are accounted by weight portions. The catalyst can be used for the technologies of a transfer of a heavy aromatic hydrocarbon of carbon-nine or above with toluene alkyl and the dealkylation and used for the industrial production of the xylene products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and process for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock

InactiveUS20090023968A1Large acid densityModerate activityMolecular sieve catalystsCatalyst activation/preparationPolycyclic aromatic hydrocarbonAlkane

The present invention provides a catalyst comprising metallic Pt and / or Pd supported on a binder-free zeolite for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock, wherein the amount of metallic Pt and / or Pd is of 0.01-0.8 wt %, preferably 0.01-0.5 wt % on the basis of the total weight of the catalyst, and the binder-free zeolite is selected from the group consisting of mordenite, beta zeolite, Y zeolite, ZSM-5, ZSM-11 and composite or cocrystal zeolite thereof. The present invention also provides a process for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock using said catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

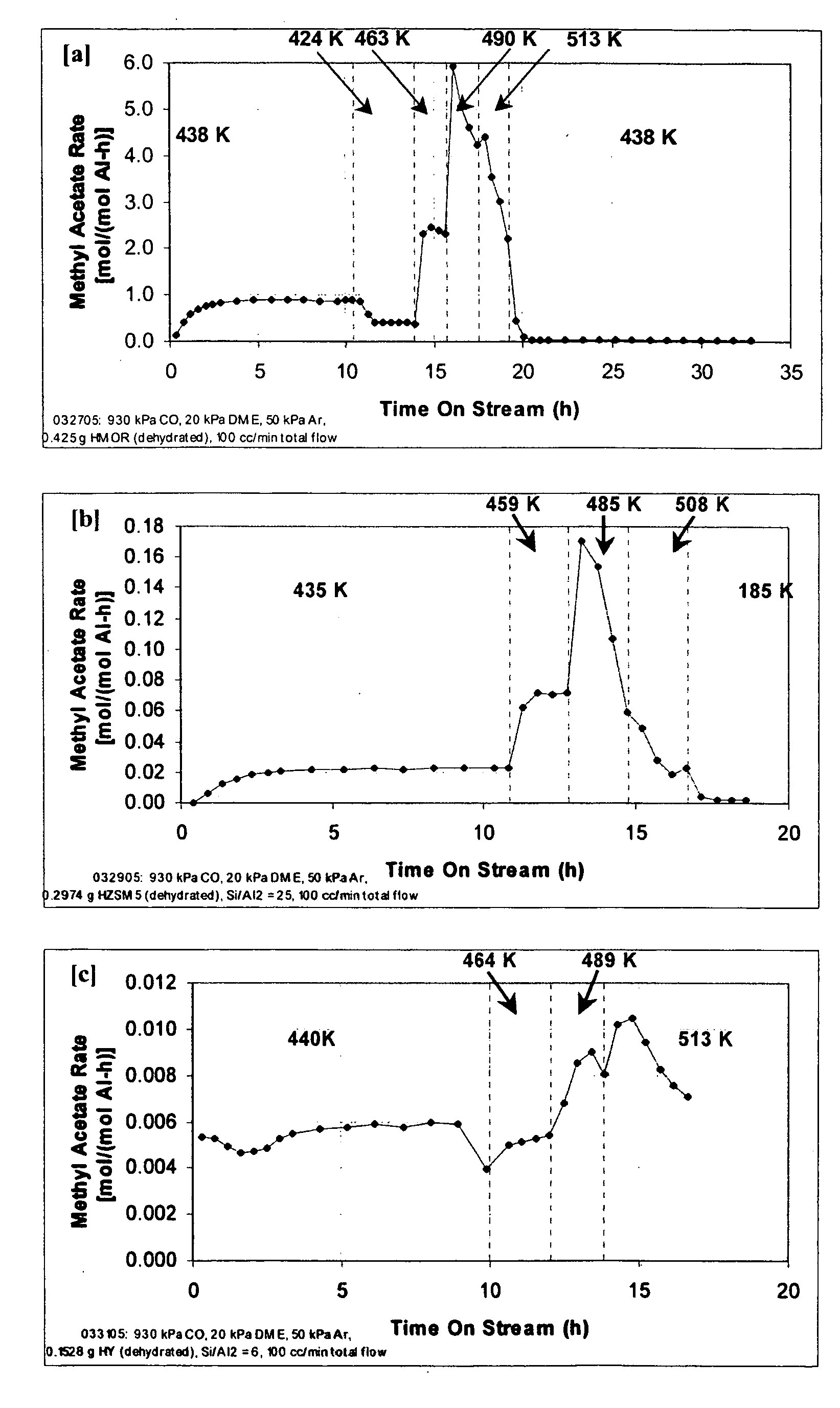

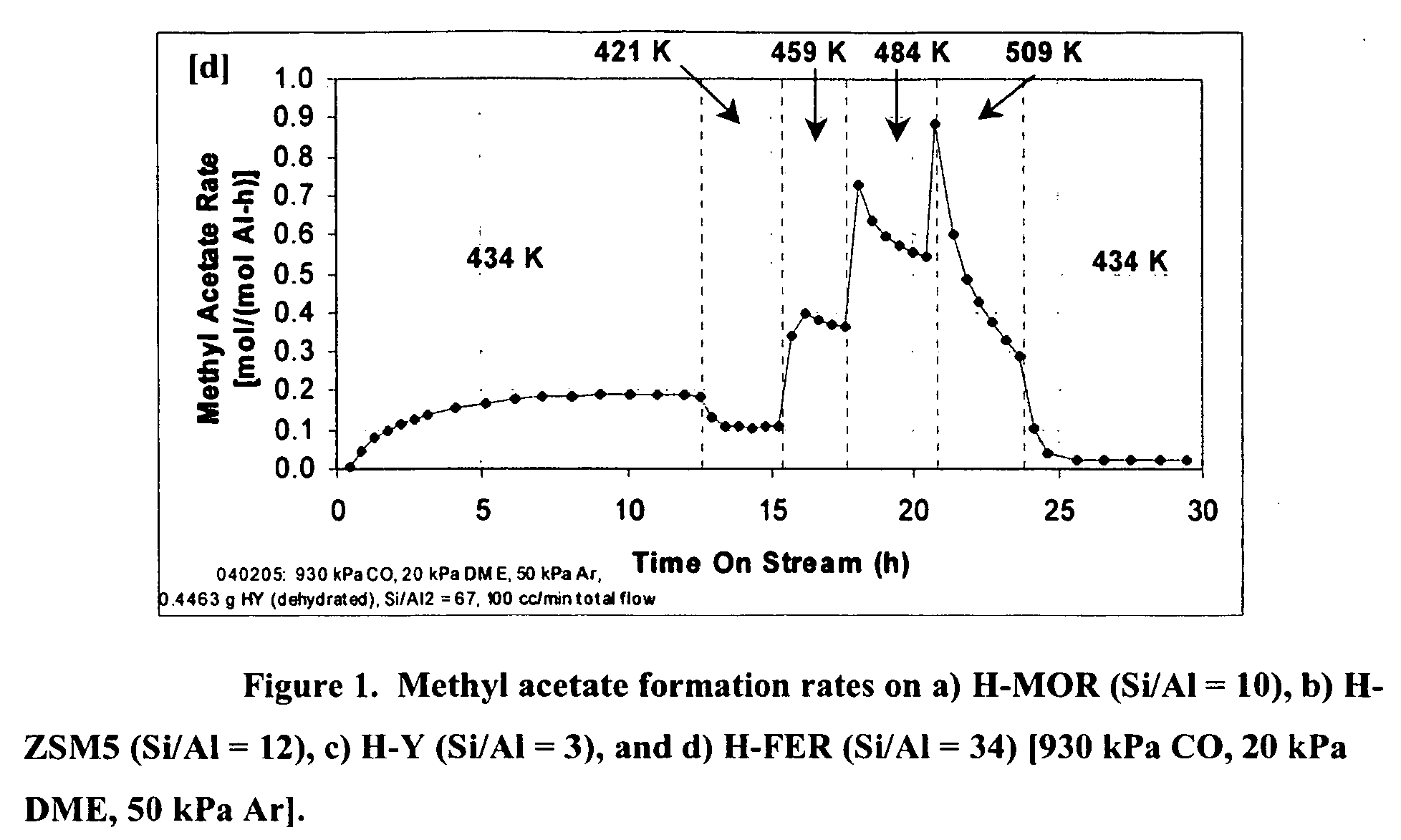

Process for carbonylation of alkyl ethers

InactiveUS20060252959A1Organic compound preparationPreparation from carboxylic acid esters/lactonesMordeniteMethyl acetate

A product comprising a lower alkyl ester of a lower aliphatic carboxylic acid is produced by a process comprising reacting a lower alkyl ether with carbon monoxide in the presence of a catalyst comprising mordenite and / or ferrierite, under substantially anhydrous conditions. More specifically, methyl acetate is selectively produced by reaction of dimethyl ether with carbon monoxide in the presence of a catalyst comprising mordenite or ferrierite, under substantially anhydrous conditions.

Owner:RGT UNIV OF CALIFORNIA +1

Method for preparing composite molecular sieve of ZSM 5/ mordenite

ActiveCN101091920AImprove catalytic performanceImprove technical effectMolecular sieve catalystsCatalytic pyrolysisNaphtha

The invention relates to a preparation method of the ZSM-5 / mordenite compound molecular sieve, mainly solves the complex question which needs to add the seed crystal or subsect the crystallization in the existing compound molecular sieve synthesize process. Through controls the certain silicon aluminum ratio and the pH value in the molecular sieve synthesize process, the invention prepares the compound molecular sieve with the adjustable ZSM-5 and the mordenite proportion, the technical program solves the problem preferably. The molecular sieve which is prepared by the invention can be used in the industrial production of the naphtha catalytic pyrolysis system ethylene propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy arenes lightening catalyst and preparing method thereof

InactiveCN1472181AImprove activity stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsMordeniteCarbon deposit

Owner:CHINA PETROLEUM & CHEM CORP +1

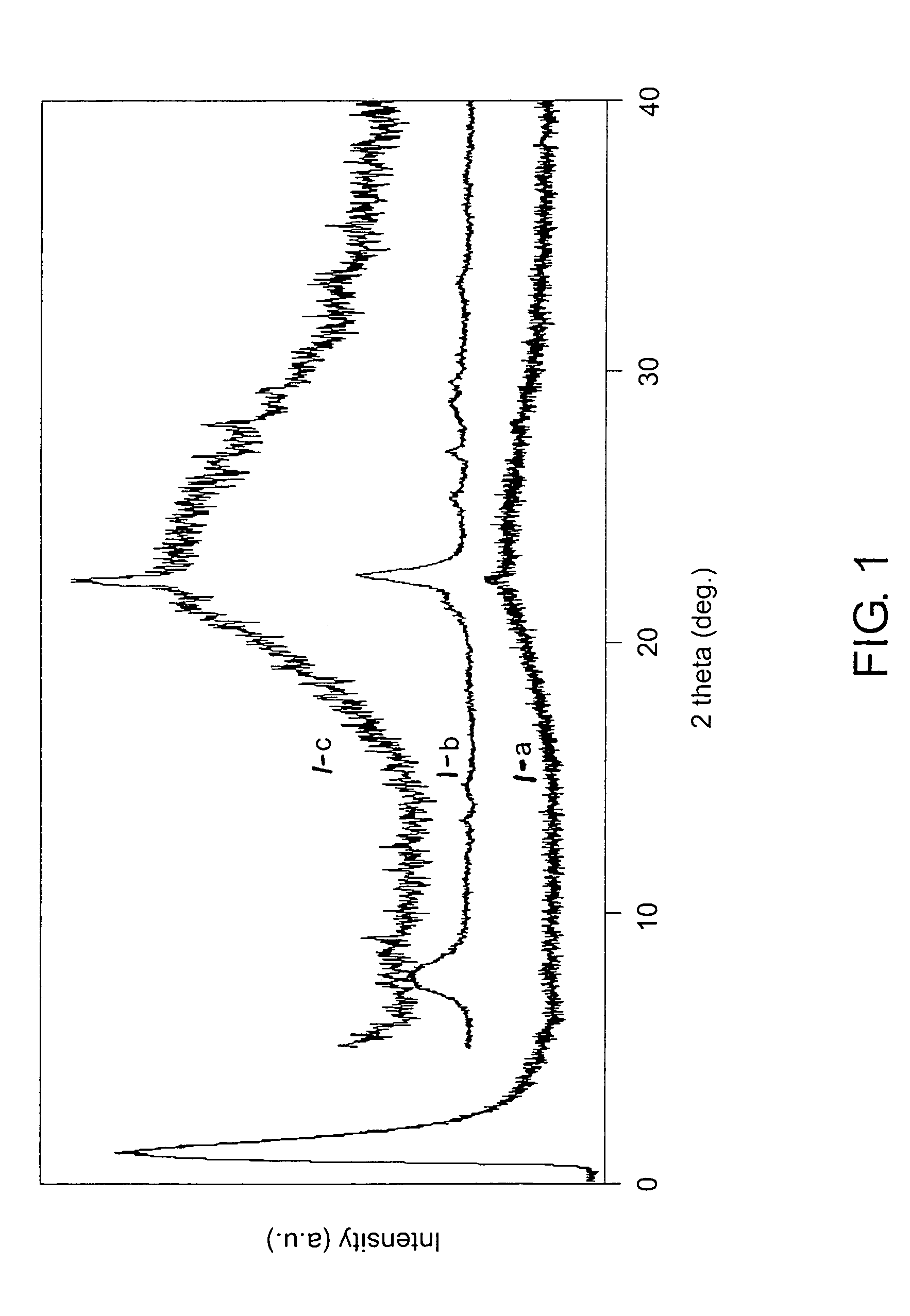

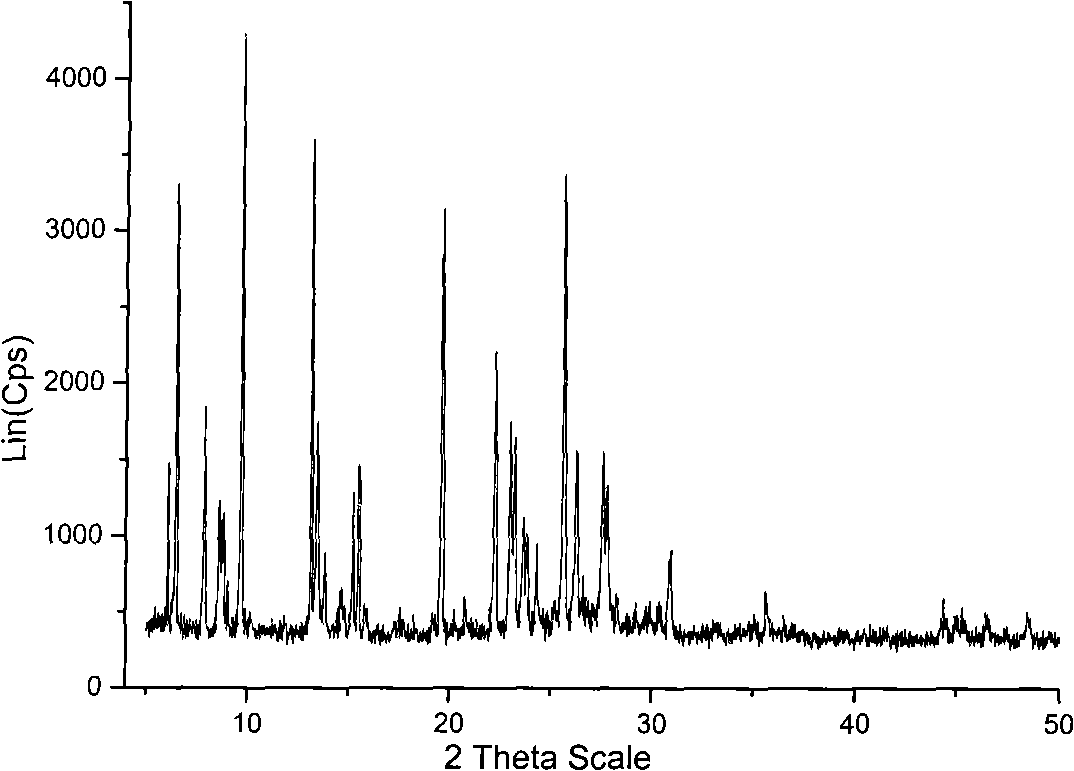

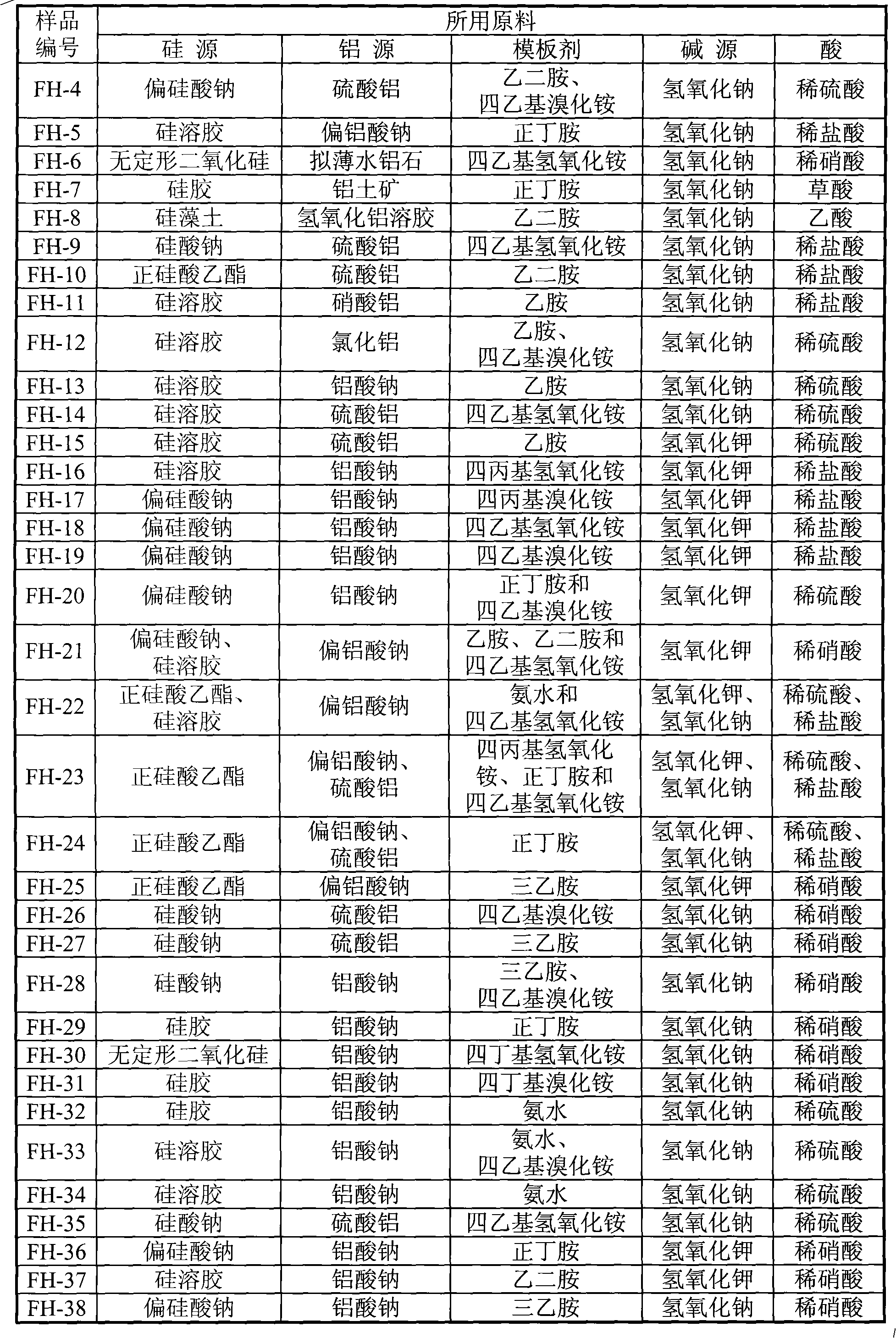

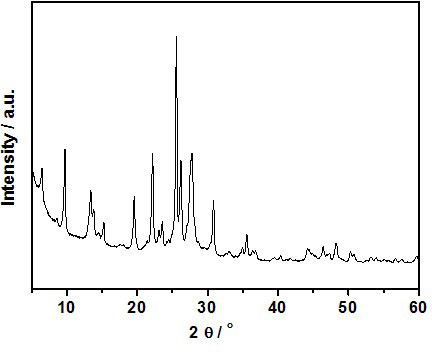

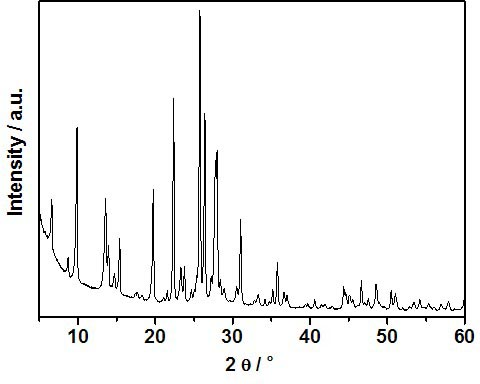

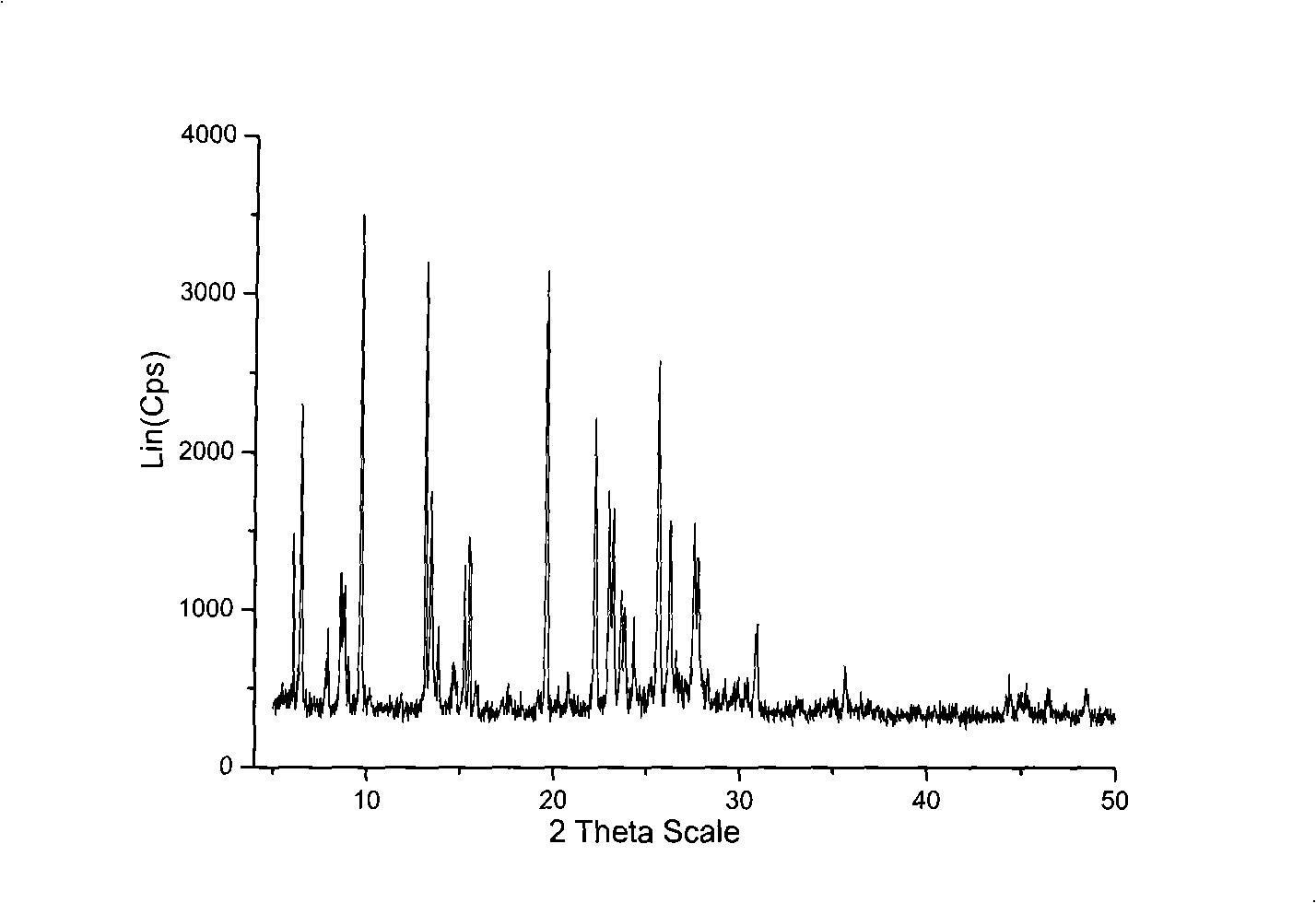

Mordenite/beta zeolite/Y zeolite coexisting material and method for synthesizing same

ActiveCN101514009AStrong acidImprove catalytic performanceFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteCatalytic pyrolysisNaphtha

The invention relates to a mordenite / beta zeolite / Y zeolite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / beta zeolite / Y zeolite coexisting material by adding a seed crystal containing a Y zeolite precursor during a synthesis process of mordenite / beta zeolite / Y zeolite coexisting material. A mole relation of the components of the synthesized mordenite / beta zeolite / Y zeolite coexisting material is nSiO2 :Al2O3, wherein n is between 4 and 400; the XRD diffraction pattern of the mordenite / beta zeolite / Y zeolite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.1 and 14.52+0.1 A, 13.52-0.1 and 13.52+0.1 A,11.32-0.1 and 11.32+0.1 A, 8.96-0.1 and 8.96+0.1 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71+0.1 A, 4.51-0.05 and 4.51+0.05 A, 4.15-0.05 and 4.15+0.05 A, 3.97-0.05 and 3.97+0.05 A, 3.78-0.05 and 3.78 +0.05 A, 3.51-0.05 and 3.51+0.05 A, 3.02-0.05 and 3.02+0.05 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The mordenite / beta zeolite / Y zeolite coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

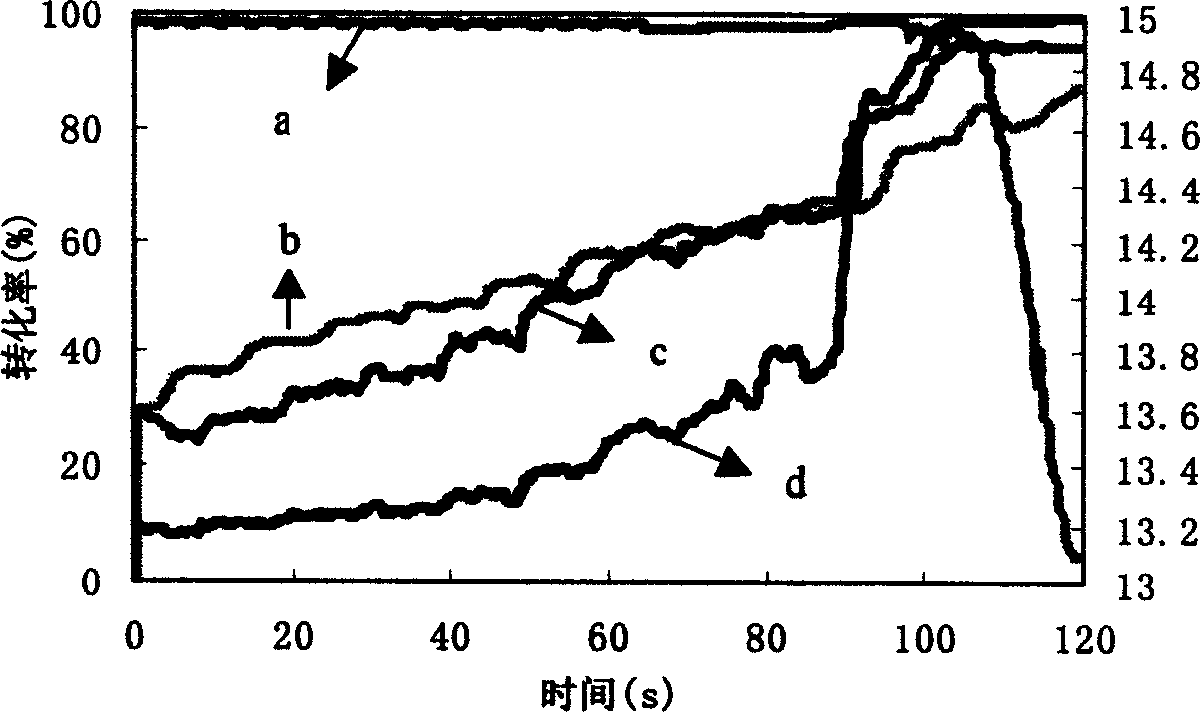

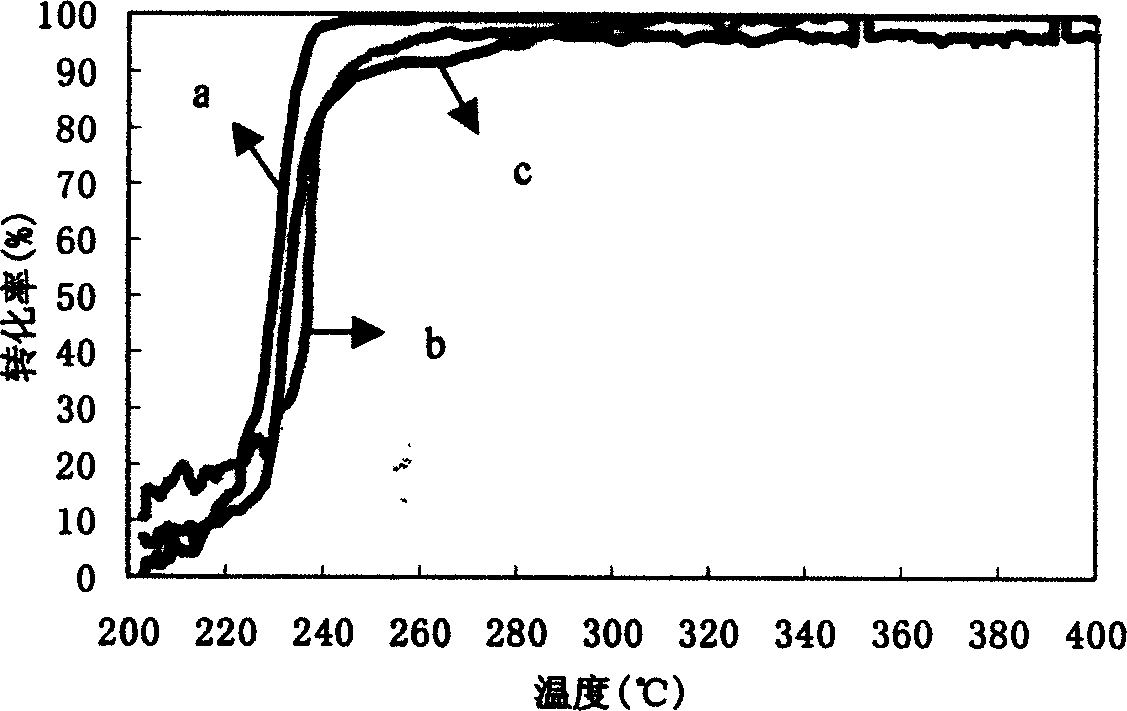

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

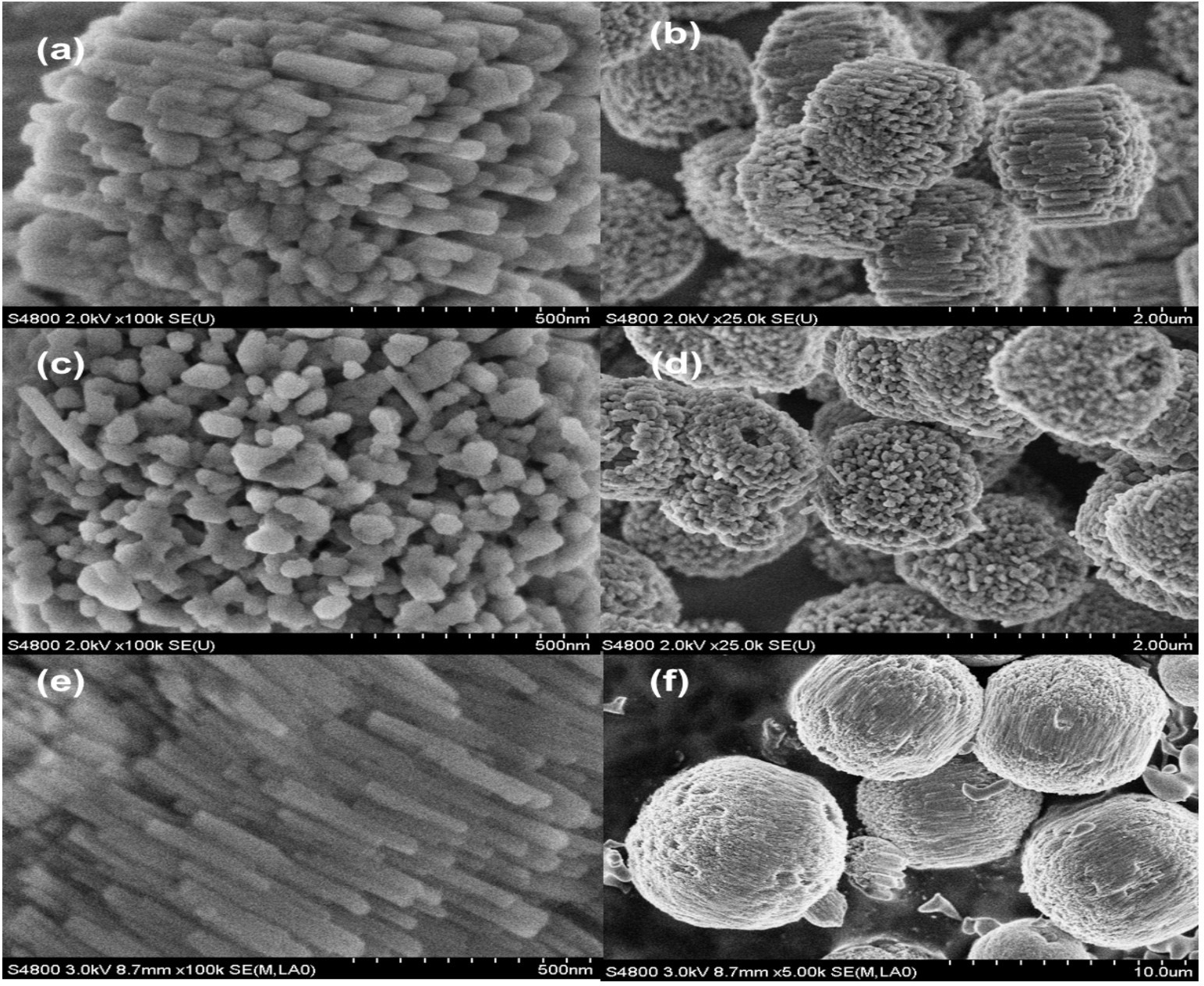

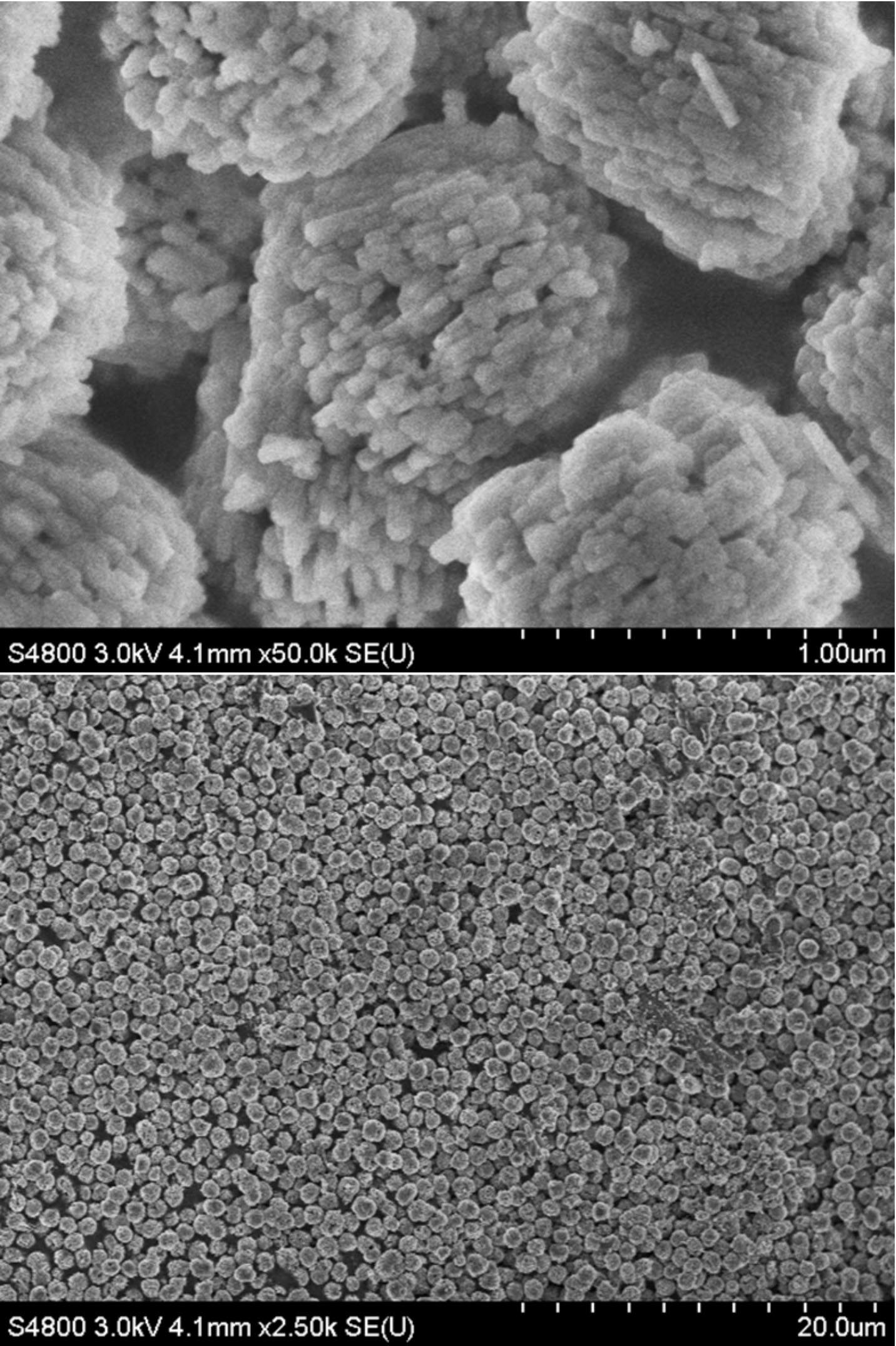

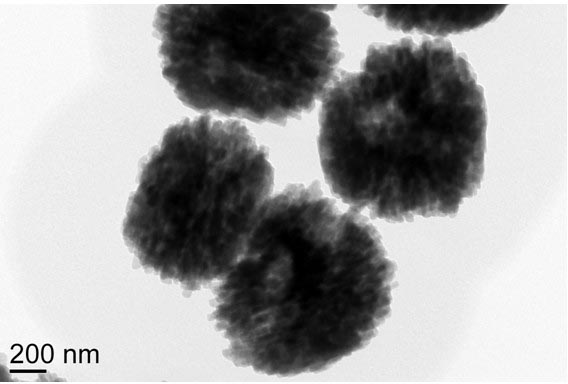

Preparation method for mordenite with high Si/Al ratio and small crystal particle

ActiveCN102602957ANovel Crystal MorphologyIncrease surface areaNanotechnologyMordenite aluminosilicate zeoliteSynthesis methodsFiltration

The invention discloses a preparation method for mordenite with a high Si / Al ratio and a small crystal particle, which comprises the following steps of: firstly, dissolving an Al source in sodium oxide solution; after an Si source is added, stirring and dispersing for certain time at room temperature and under strong magnetic force; mixing the Al source solution and the Si source solution which are evenly dispersed into glue at the room temperature; adding inorganic lamellar precursors, such as lamellar zeolite molecular sieves, lamellar silicate and the like to serve as seed crystal; after mixture is stirred and mixed evenly at the room temperature and under the strong magnetic force, transferring into a reaction crystallization kettle; at the temperature of 150-170DEG C, carrying out crystallization reaction for 0.5-3 days; and obtaining a solid product after common suction filtration, washing and drying. The synthesis method disclosed by the invention has the characteristics that expensive organic amine template is not used as structure-directing agent, and instead, the easily-obtained inorganic lamellar precursors with abundant source and low price are used as the seed crystal to directly synthesize a mordenite molecular sieve with the high Si / Al ratio. The prepared nanometer mordenite molecular sieve has the advantages of high degree of crystallinity and purity, controllable particle size and morphology, low cost and small environment pollution, and is convenient for industrially producing on a large scale.

Owner:EAST CHINA NORMAL UNIV

Alkylated aromatic compositions, zeolite catalyst compositions and processes for making the same

ActiveUS6977319B2Prolong lifeReduce inactivation rateMolecular sieve catalystsOrganic chemistry methodsAlkyl transferMordenite

Owner:CHEVRON ORONITE CO LLC +1

Preparation method of mordenite/ZSM-5 core-shell type molecular sieve material

InactiveCN101722034APromote growthLower synthesis costMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteCore shell

The invention relates to a preparation method of a mordenite / ZSM-5 core-shell type molecular sieve material, mainly solving the problems that mordenite and ZSM-5 zeolite molecular sieve are difficult for compound growth in the prior art. The method comprises the following steps of: (1) treating mordenite crystal grains in a modified agent solution; (2) adding the mordenite crystal grains treated by a modified agent into a ZSM-5 synthetic system comprising a template agent R, a silicon source, an aluminum source and water, wherein the mol ratio of R2O to SiO2 is 0.05-0.5, the mol ratio of SiO2 to Al2O3 is 50-infinity, the mol ratio of SiO2 to Na2O is 2-10 and the mol ratio of H2O to SiO2 is 20-100; and (3) hydrothermally crystallizing, filtering, washing and roasting to obtain the mordenite / ZSM-5 core-shell type molecular sieve material, thus the problems are better solved. The invention can be used for industrial production of the mordenite / ZSM-5 core-shell type molecular sieve materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for decontaminating tail gas of motorcar and preparation method

A catalyst for cleaning the tail gas of car is prepared from the cordierite ceramics as carrier, the Al gel and mordinate as basic layer of coated layer, the La-Ce-Zr sosoloid or one or more oxides of La, Ce, Zr and Mn as assistant and the Pt, Pd and Rh as active components through mixing Al gel, mordenite, assistant and distilled water to obtain slurry, immersing carrier in it, drying, calcining, immersing in the solution of noble metal precursor, drying and calcining.

Owner:昆明贵研催化剂有限责任公司 +1

Preparation method of mesoporous mordenite

ActiveCN102602958ANovel Crystal MorphologyAbundant secondary stacking poresNanotechnologyMordenite aluminosilicate zeoliteFiltrationSynthesis methods

The invention discloses a method for synthesizing a mesoporous mordenite molecular sieve. The method comprises the following steps of: dissolving an aluminum source in a sodium hydroxide solution; adding a silicon source and stirring to disperse for a certain period of time at room temperature under strong magnetic force, wherein the uniformly dispersed solution of silicon source and aluminum source is mixed into glue at room temperature; adding a dealuminated mordenite molecular sieve as seed crystal; stirring and uniformly mixing at room temperature under strong magnetic force, and transferring the product into a reaction crystallization kettle; performing crystallization reaction at 150-170 DEG C for 0.5-3 days; and performing conventional suction filtration, washing and drying to obtain a solid product. The synthesis method disclosed by the invention has the characteristics that the expensive organic amine template agent is not used as a structure directing agent, and the cheap and easily-available inorganic layered precursor with wide source is used as the seed crystal to directly synthesize a mordenite molecular sieve with high silica-alumina ratio; and the prepared nano mordenite molecular sieve has the advantages of high crystallinity and purity, abundant accumulation meso pores, controllable particle size, form and low cost, less environment pollution and convenience for industrial large-scale production.

Owner:EAST CHINA NORMAL UNIV

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

Catalyst for purifying diesel engine exhaust emissions

InactiveUS20060035780A1Emission reductionMolecular sieve catalystsInternal combustion piston enginesMordeniteVanadium oxide

A diesel oxidation catalyst comprising a honeycomb substrate washcoated with a mixture of clay, a refractory oxide and a zeolite is disclosed. The washcoated substrate is subsequently deposited with a precious metal catalyst and a sulfur oxidation suppressant. In a preferred embodiment, the clay is acid-leached bentonite, the refractory oxide is zirconia or titania, the zeolite is beta-zeolite or Y-zeolite or ZSM-5 or mordenite, the precious metal catalyst is preferably platinum, and the sulfur oxidation suppressant is vanadium or vanadium oxide or a combination thereof

Owner:SUD CHEM INC

Sulfur-tolerance deoxidation catalyst and preparation and use thereof

InactiveCN101301611ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsAluminum silicateMordenite

The invention discloses a sulfur-tolerant deoxidizing catalyst, preparation method and application thereof. The catalyst of the invention is composed of active components and porous carriers, the active components are one or more of compound of iron and / or copper, the porous carriers are selected from one or more of aluminium oxide, titanium oxide, zirconium oxide, zinc oxide, magnesium oxide, calcium oxide, silicon dioxide, aluminophosphate molecular sieves, A type molecular sieves, X type molecular sieves, Y type molecular sieves, mordenite, ZSM-5 zeolite, kieselguhr, kaoline, natural clay, aluminum silicate and magnesium silicate. Based on the oxide content, the active components loading amount is 1-95% by weight, the rest are porous carriers. The catalyst of the invention has definite sulfur-tolerant performance, is suitable for deoxidation treatment of coal seam gas with oxygen content of 3-6% (V / V), and can deoxidize the coal seam gas to make the oxygen content less than 0.5%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Amination catalyst and preparation method thereof

ActiveCN101406845AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationDodecaneMordenite

The invention discloses an amination catalyst and a preparation method thereof, which aims to solve the problem that the amination catalyst is not high in activity and selectivity. The compositions in weight percentage of the amination catalyst are: 15 to 25 percent of A, 5 to 10 percent of B, 1 to 3 percent of C, 0.1 to 1.5 percent of D, and the balance being h-type mordenite, wherein the A is alumina; the B is titanium oxide; the C is metallic ion W<6+>, Re<7+> or Bi<3+>; the D is metallic ion Cs<+>; and the metals exist in the form of elements or oxides. The preparation method comprises the following steps of loading the components C and D on the h-type mordenite, well mixing the components C and D with the alumina and ethanolamine titanate dodecane alcohol ester, molding, roasting and activating the mixture. The catalyst is used for synthesizing ethylene dimine under the conditions of ethanolamine and ammonia phase.

Owner:XIAN MODERN CHEM RES INST

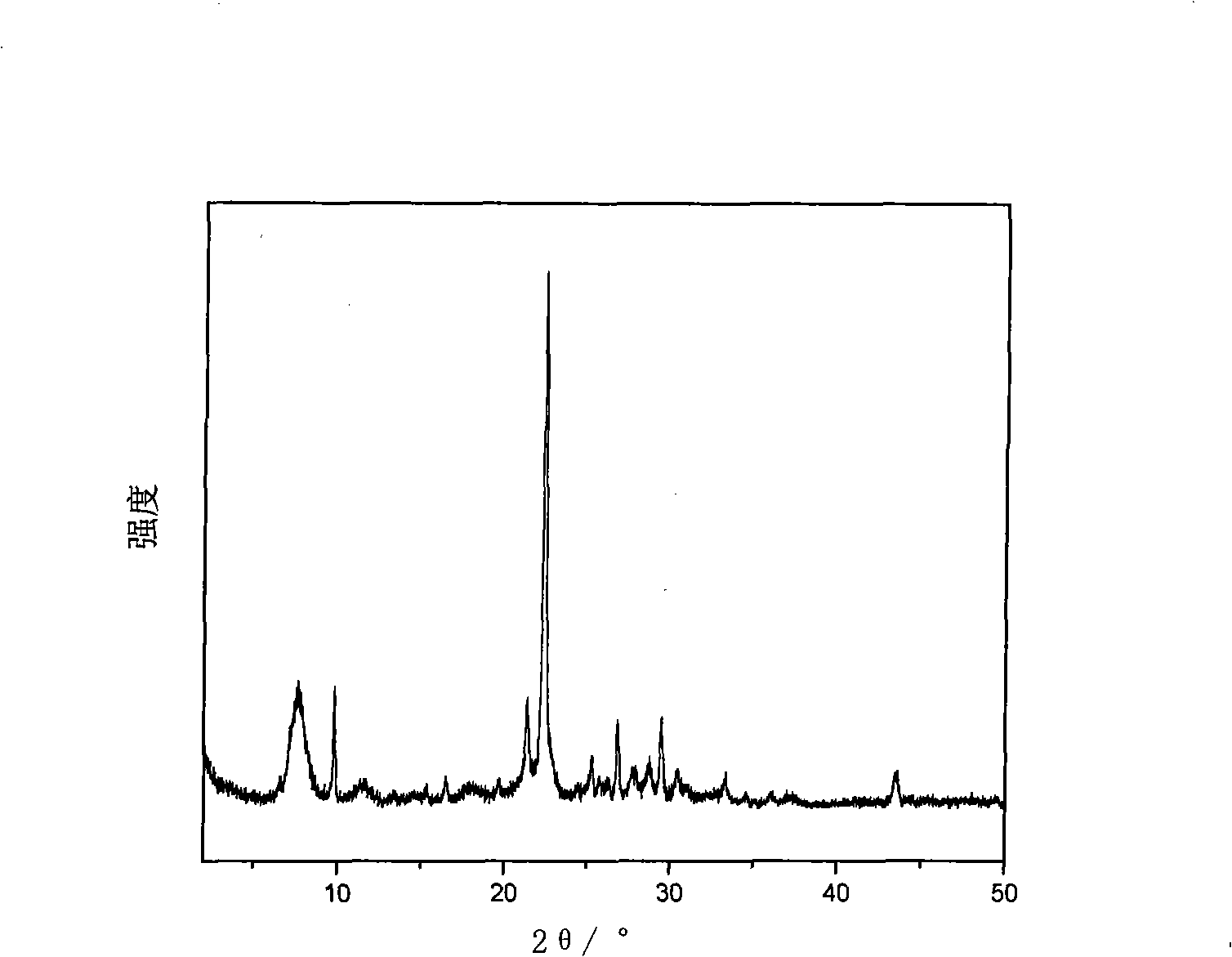

Mordenite/Y zeolite coexisting molecular sieve and method for synthesizing same

ActiveCN101514008AIncrease acidityStrong acidFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteMolecular sieveCatalytic pyrolysis

The invention relates to a mordenite / Y zeolite coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / Y zeolite coexisting molecular sieve by adding a seed crystal containing a Y zeolite precursor and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of mordenite. The coexistence phase ratio of the mordenite / Y zeolite coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 4 and 400; the coexisting molecular sieve has more than two phases, the XRD diffraction pattern of the coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.05 and 14.52+0.05 A, 13.52-0.05 and 13.52+0.05 A, 8.96-0.05 and 8.96+0.05 A, 8.83-0.05 and 8.83+0.05 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71 +0.1 A, 4.51-0.1 and 4.51+0.1 A, 3.98-0.1 and 3.98+0.1 A, 3.78-0.05 and 3.78+0.05 A, 3.47-0.1 and 3.47+0.1 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for gas phase synthesis of ethylenediamine and preparation method thereof

ActiveCN1962058AHigh catalytic activityImprove stabilityMolecular sieve catalystsOrganic compound preparationEthylenediamineHydrogen

The invention relates to a catalyst used to composite ethanediamine from gas phase and relative production, wherein it comprises 20-30% alumina, 5-15% metal ion, and left is hydrogen mordenite treated by acid, while metal ion can be one of Zr4+, Nb5+, Mo6+, Sn4+, Sb5+ with one of Zn2+, Fe3+, while their mol ratio is 1-10:1. And its production comprises loading the metal ion on the treated hydrogen mordenite, drying, and mixing with alumina, compressing, baking and activating. The invention is used to composite ethanediamine from ethanolamine and ammonia gas.

Owner:XIAN MODERN CHEM RES INST

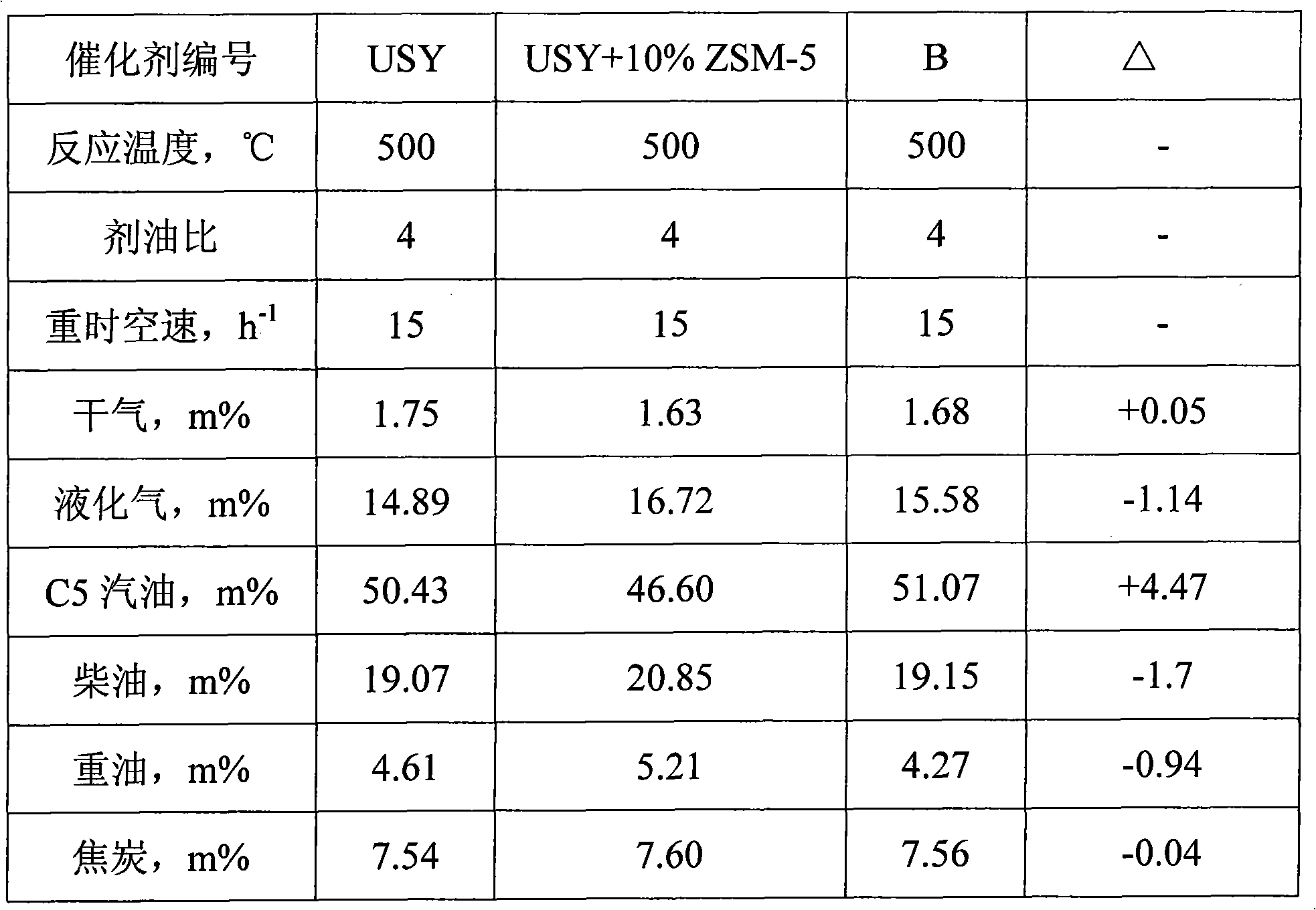

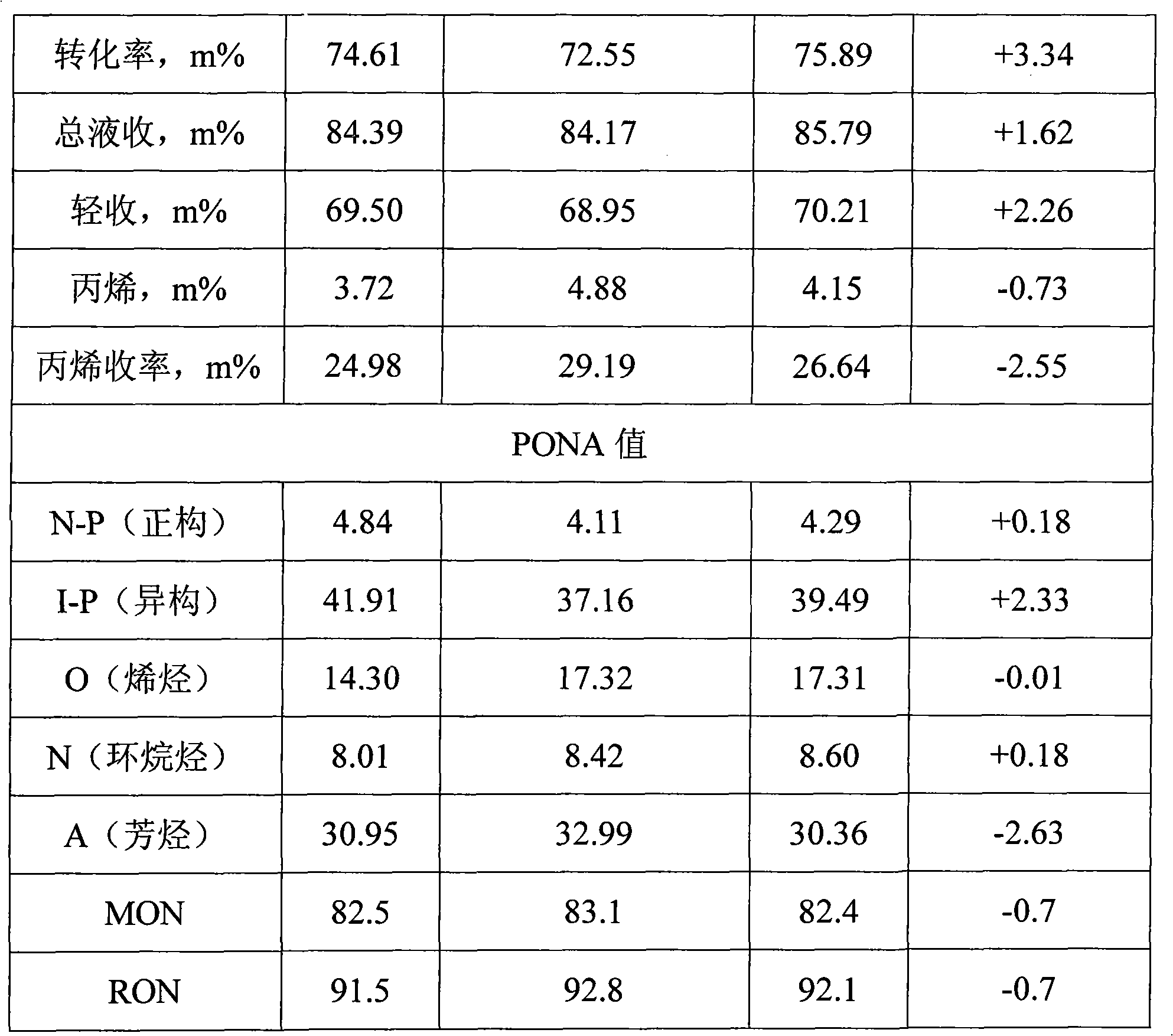

Heavy oil catalytic cracking catalyst

InactiveCN101310858AHigh yieldLow costCatalytic crackingMolecular sieve catalystsMordeniteStructural unit

The invention relates to an RFCC catalyst which mainly uses a USY-typed molecular sieve and then adds a beta-mercerized eutectic molecular sieve assistant. Based on the weight percentage of the catalyst, the content of the USY-typed molecular sieve is 10 percent to 50 percent and the content of the beta-mercerized eutectic molecular sieve is 10 percent to 20 percent, a binder accounts for 5 percent to 50 percent and clay accounts for 10 percent to 75 percent. The beta-mercerized eutectic molecular sieve is a molecular sieve provided with the structural units of beta zeolite and mordenite. Compared with ZSM-5 with the same quantity of the assistant, the catalyst of the invention has obvious improvement in conversion ratio and liquid yield while obtaining comparatively high yield of propylene, furthermore, when used for synthesizing a template, the beta-mercerized eutectic molecular sieve has low consumption, low cost, and a practical application prospect for industrialization.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst for purifying diesel engine exhaust emissions

InactiveUS7235507B2Emission reductionMolecular sieve catalystsInternal combustion piston enginesPlatinumSulfur

A diesel oxidation catalyst comprising a honeycomb substrate washcoated with a mixture of clay, a refractory oxide and a zeolite is disclosed. The washcoated substrate is subsequently deposited with a precious metal catalyst and a sulfur oxidation suppressant. In a preferred embodiment, the clay is acid-leached bentonite, the refractory oxide is zirconia or titania, the zeolite is beta-zeolite or Y-zeolite or ZSM-5 or mordenite, the precious metal catalyst is preferably platinum, and the sulfur oxidation suppressant is vanadium or vanadium oxide or a combination thereof

Owner:SUD CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com