Catalyst for aromatics alkyl transferring and dealkylation to synthesis benzene and xylene

A technology of xylene catalyst and aromatic hydrocarbon alkyl, which is applied in the direction of molecular sieve catalyst, physical/chemical process catalyst, organic chemistry, etc., can solve the problems of poor quality of benzene products, achieve high quality of benzene products, increase transalkylation and dealkylation Catalytic activity of base reaction, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

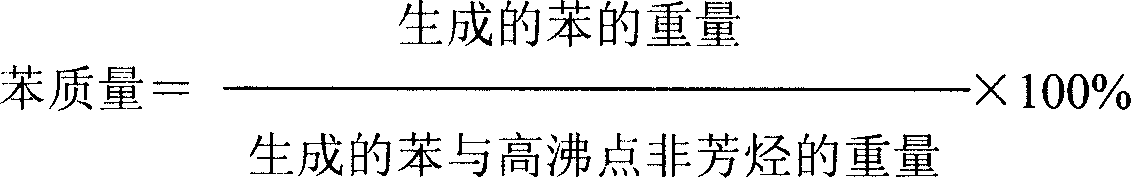

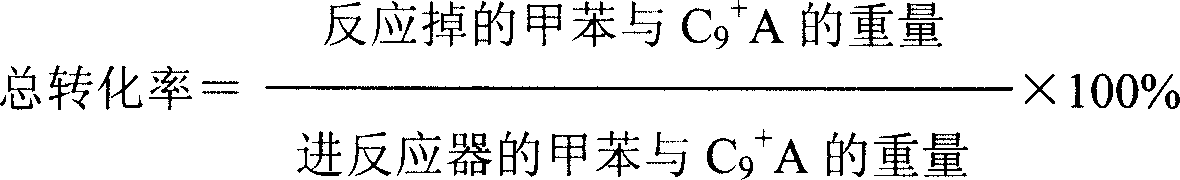

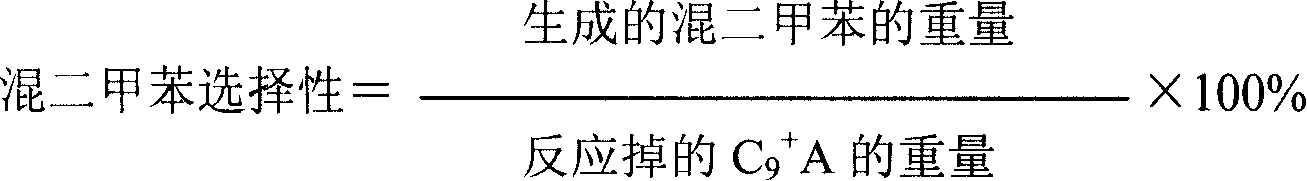

Method used

Image

Examples

Embodiment 1

[0028] Using Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 37 grams of ammonium type beta zeolite with a molecular ratio of 23 and Na 2 O content less than 0.10% (weight), SiO 2 / Al 2 o 3 26 grams of ammonium ZSM-5 zeolite with a molecular ratio of 72 and Na 2 Al with an O content of less than 0.1% by weight 2 o 3 Mix 40 grams evenly, and then impregnate with ammonium molybdate as an aqueous solution; then add a certain amount of dilute nitric acid solution, tetraammonium platinum chloride, stannous chloride and cerium nitrate solution, fully knead evenly, and carry out extrusion molding, 500 ℃ roasting to make catalyst A.

Embodiment 2

[0030] Using Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 Ammonium ZSM-5 zeolite with a molecular ratio of 26 and 15 grams of Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 65 grams of ammonium zeolite beta with a molecular ratio of 31 and Na 2 Al with an O content of less than 0.1% by weight 2 o 3 34 grams were uniformly mixed, then a certain amount of dilute nitric acid solution, nickel nitrate and lanthanum nitrate were added, fully kneaded, extruded and calcined at 500°C to make Catalyst B.

Embodiment 3

[0032] Using Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 10 grams of ammonium mordenite with a molecular ratio of 23 and Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 42 grams of ammonium β zeolite with a molecular ratio of 24 and Na 2 Al with an O content of less than 0.1% by weight 2 o 3 Mix 40 grams evenly, and then impregnate with ammonium molybdate to form an aqueous solution; add dilute nitric acid solution of bismuth nitrate and cerium nitrate to the impregnated powder, fully knead evenly, carry out extrusion molding, and roast at 500°C to make catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com