Patents

Literature

1640 results about "ZSM-5" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ZSM-5, Zeolite Socony Mobil–5 (framework type MFI from ZSM-5 (five)), is an aluminosilicate zeolite belonging to the pentasil family of zeolites. Its chemical formula is NaₙAlₙSi96–nO₁₉₂·16H₂O (0<n<27). Patented by Mobil Oil Company in 1975, it is widely used in the petroleum industry as a heterogeneous catalyst for hydrocarbon isomerization reactions.

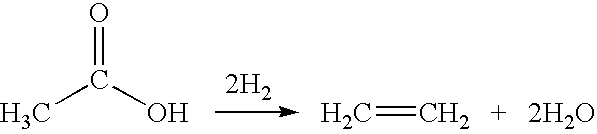

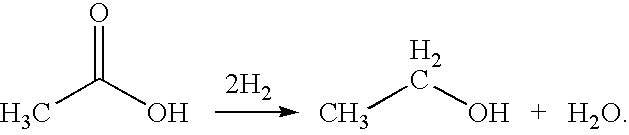

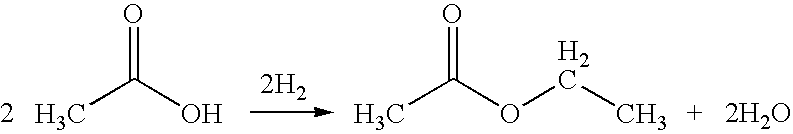

Process for catalytically producing ethylene directly from acetic acid in a single reaction zone

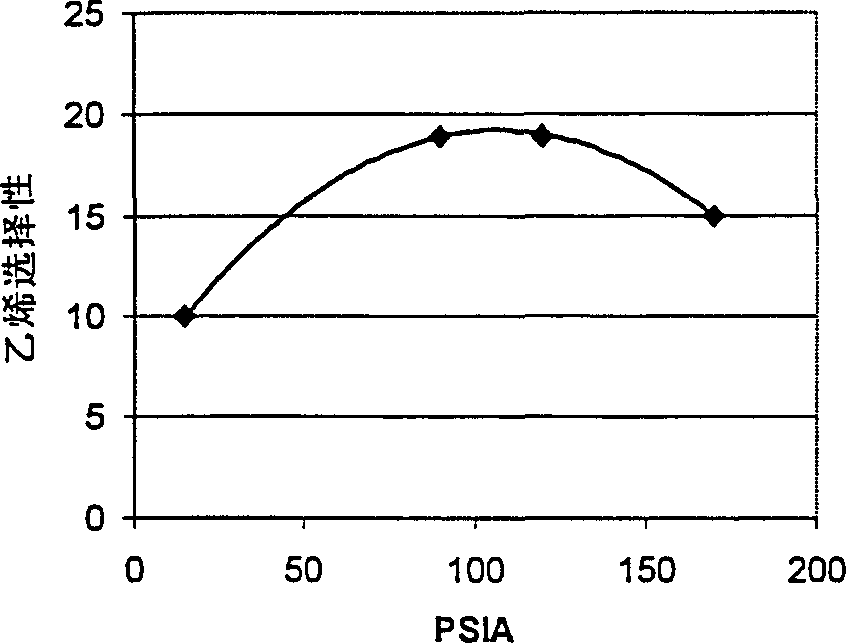

InactiveUS20100030001A1High selectivityHigh yieldHydrocarbonsBulk chemical productionAcetic acidHydrogen

A process for the selective production of ethylene by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethylene in a single reaction zone is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either a copper supported on iron oxide, copper-aluminum catalyst, cobalt supported on H-ZSM-5, ruthenium-cobalt supported on silica or cobalt supported on carbon selectively produces ethylene in a vapor phase at a temperature in the range of about 250° C. to 350° C.

Owner:CELANESE INT CORP

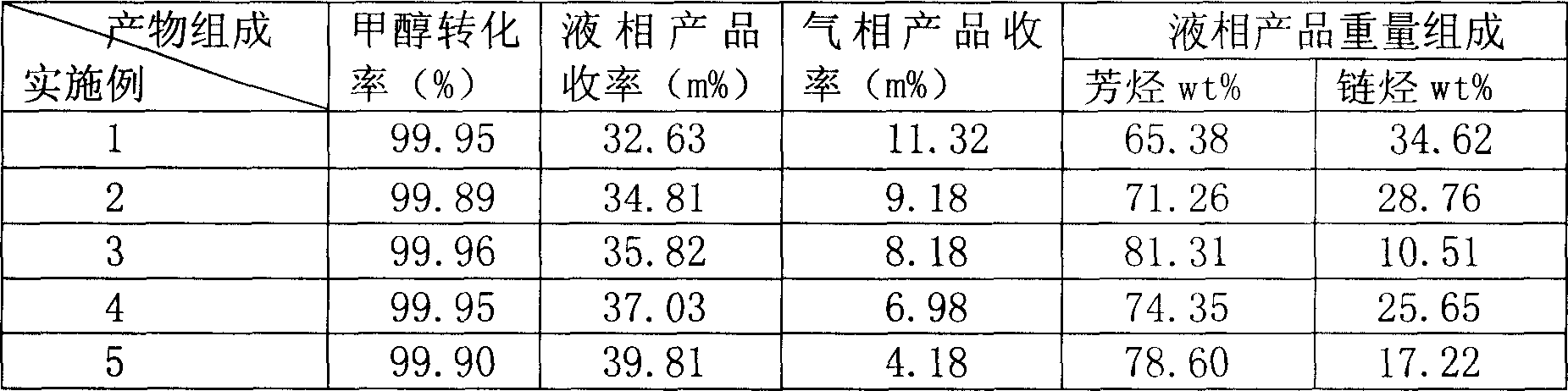

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

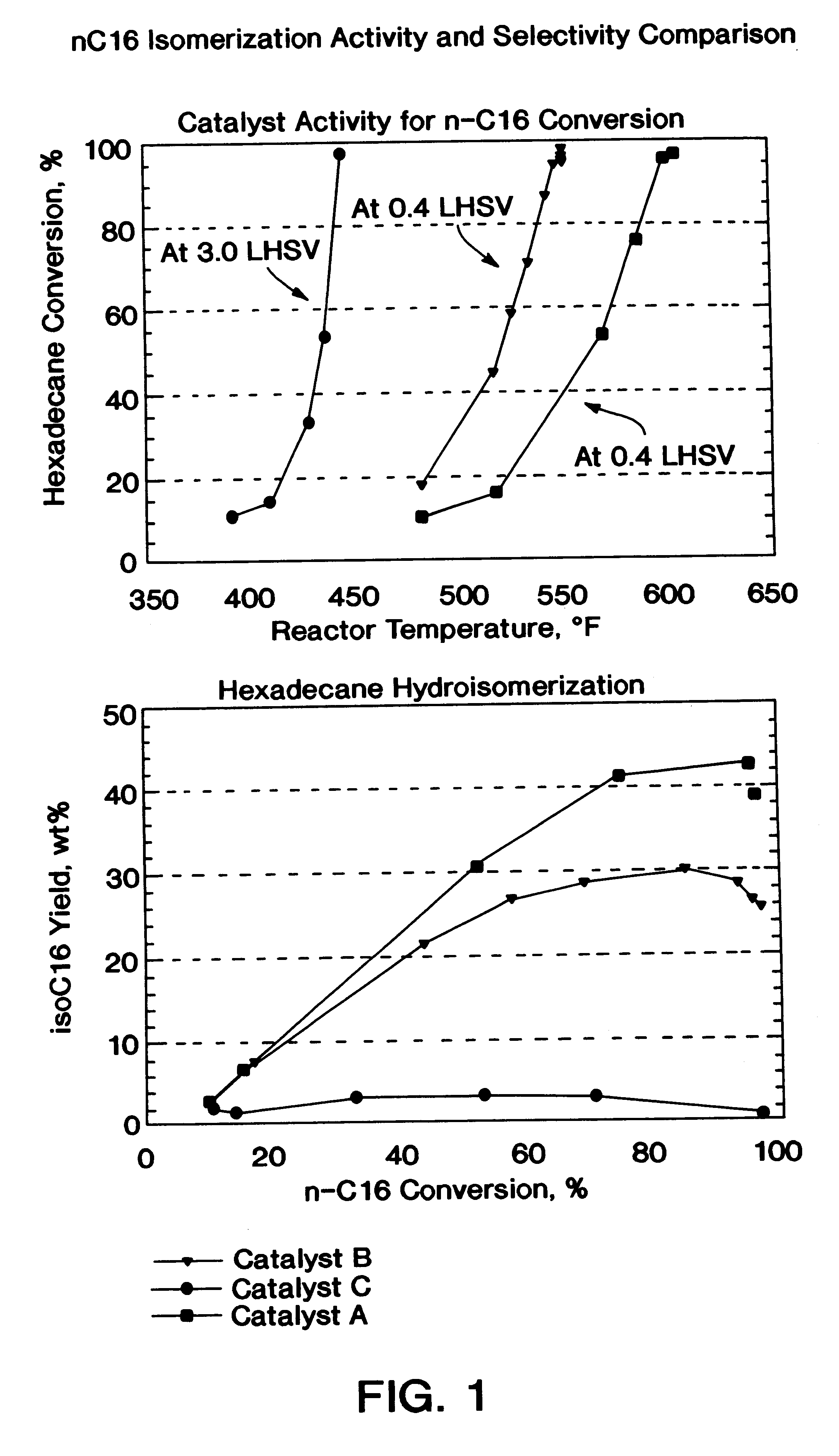

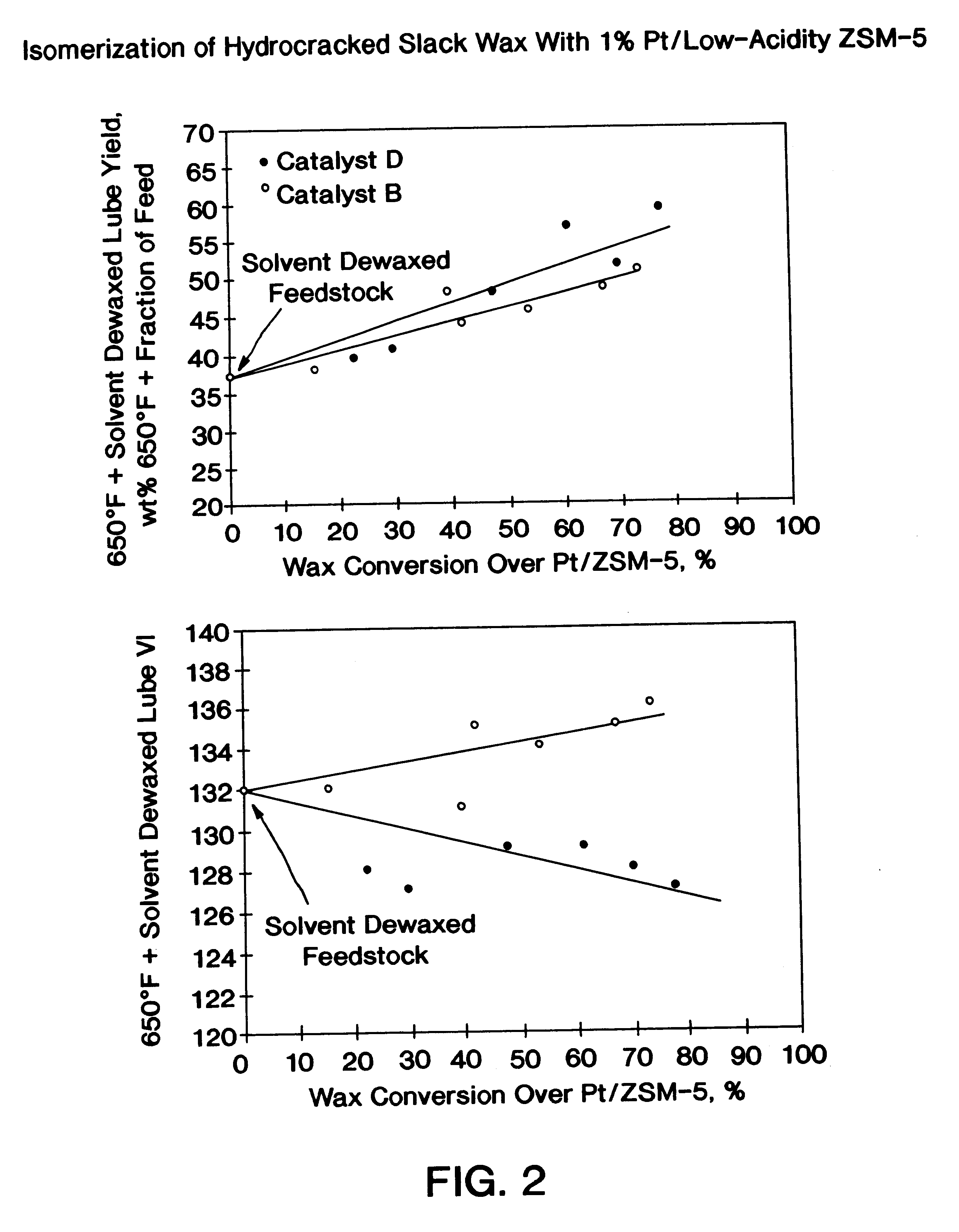

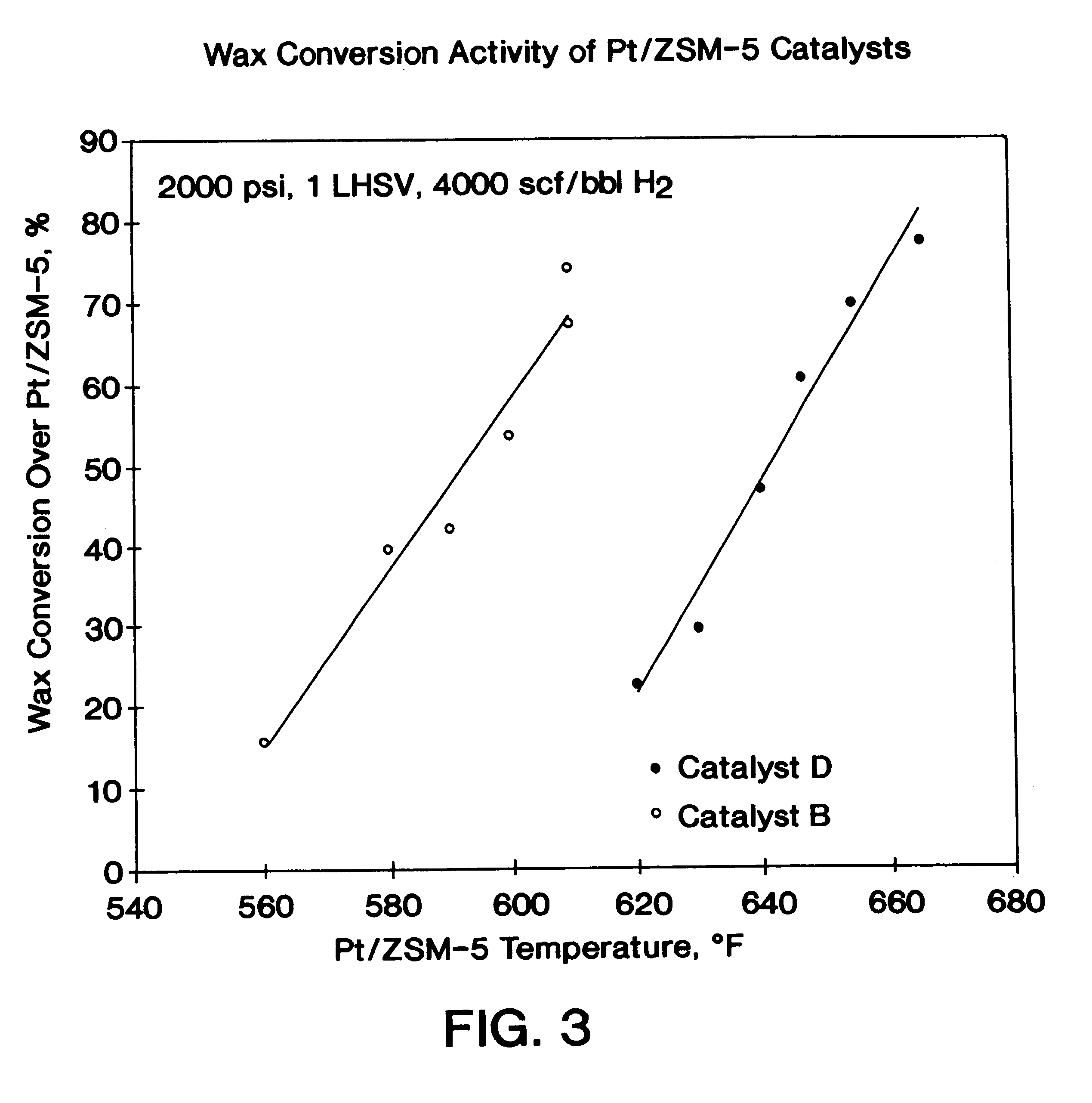

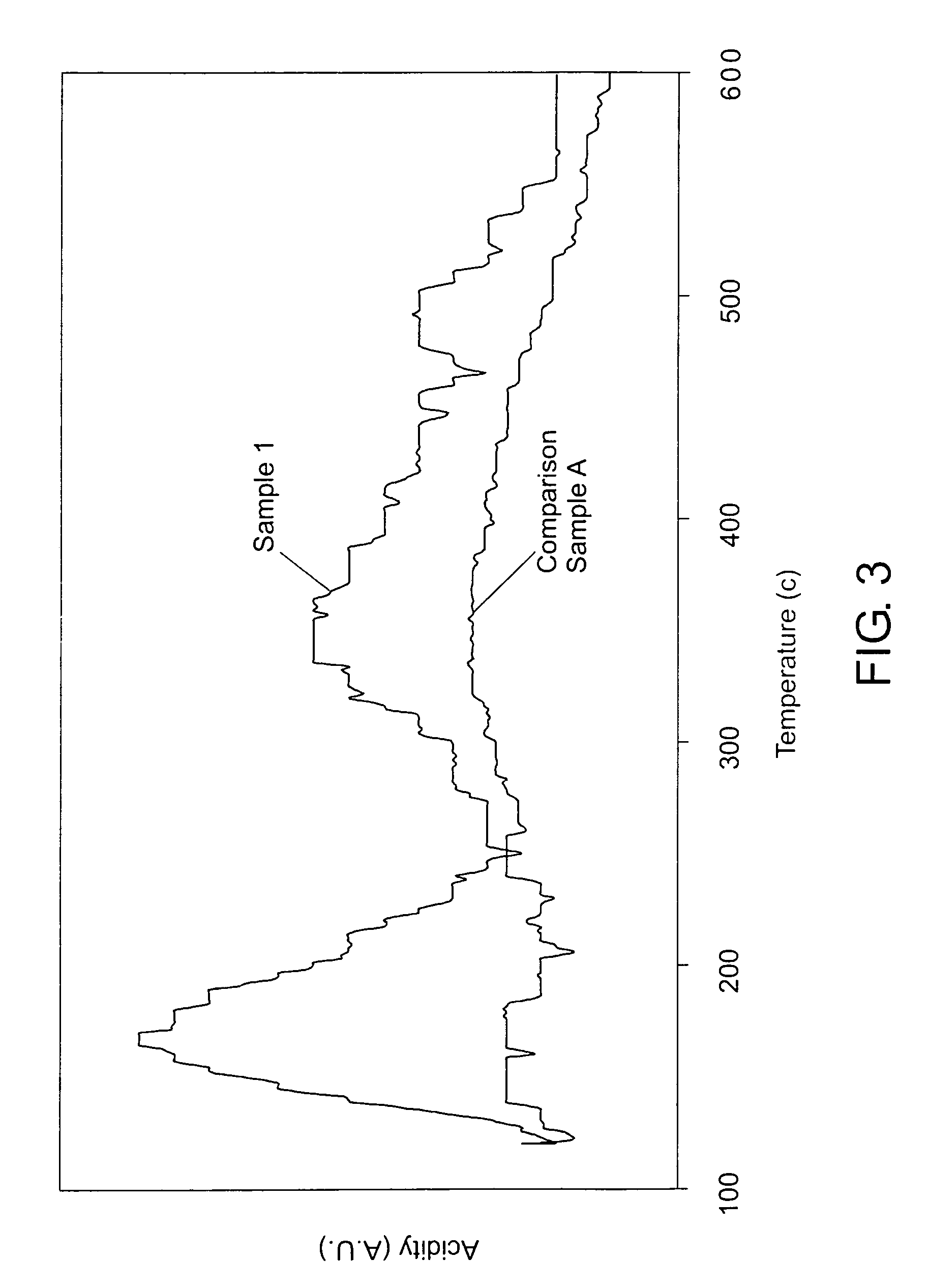

Production of high viscosity lubricating oil stock with improved ZSM-5 catalyst

InactiveUS6294077B1Low pour pointHigh viscosity indexMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenParaffin oils

The present invention is a process for producing a high viscosity index and low pour point lubricating oil base stock which comprises catalytically converting a hydrotreated hydrocarbon lube oil feedstock containing waxy paraffins in the presence of hydrogen and in the presence of a low acidity ZSM-5 catalyst having a highly dispersed noble metal component. The ZSM-5 catalyst is subjected to controlled acidity reduction to an alpha value below 15 prior to incorporation of the noble metal component.

Owner:MOBIL OIL CORP

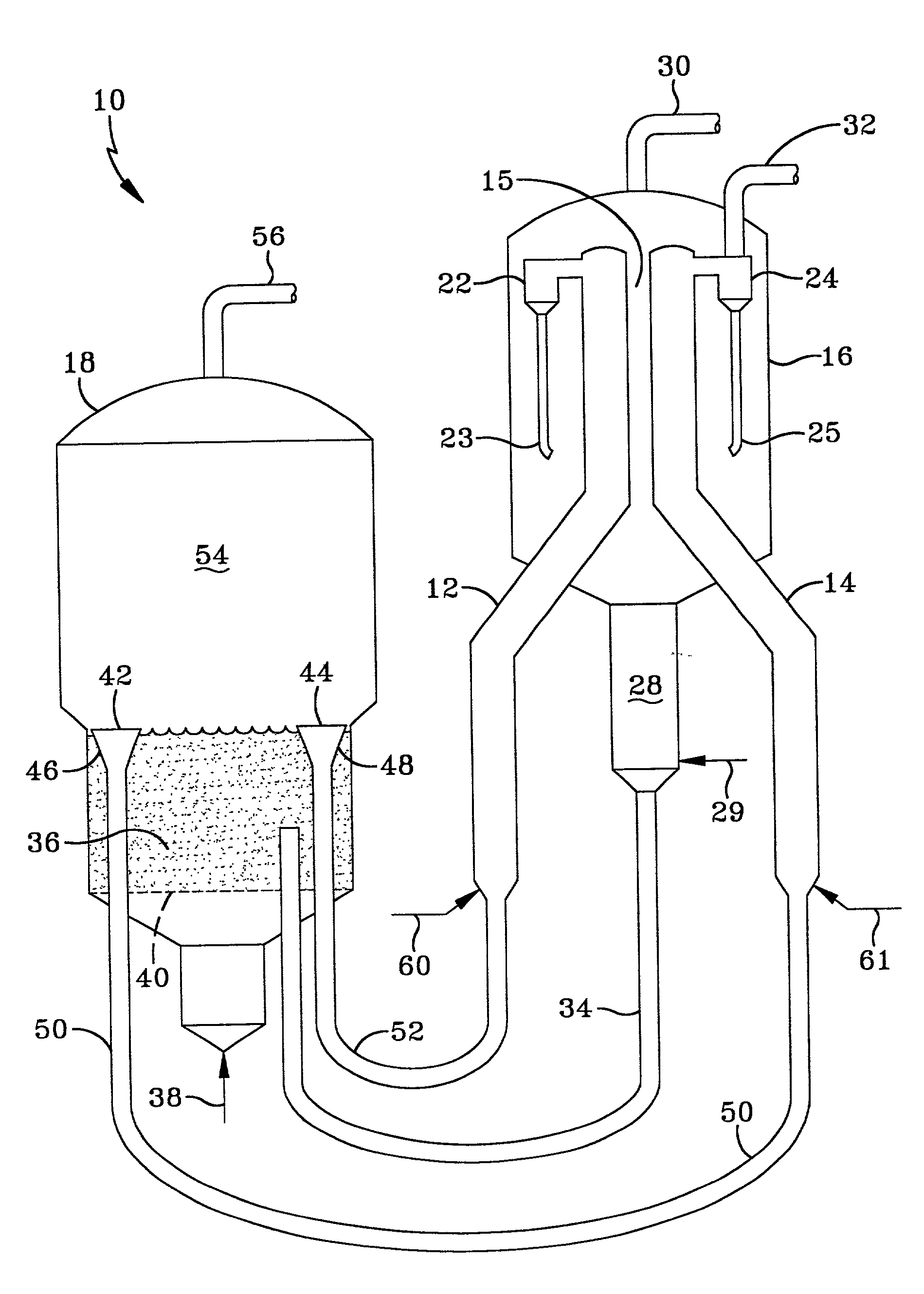

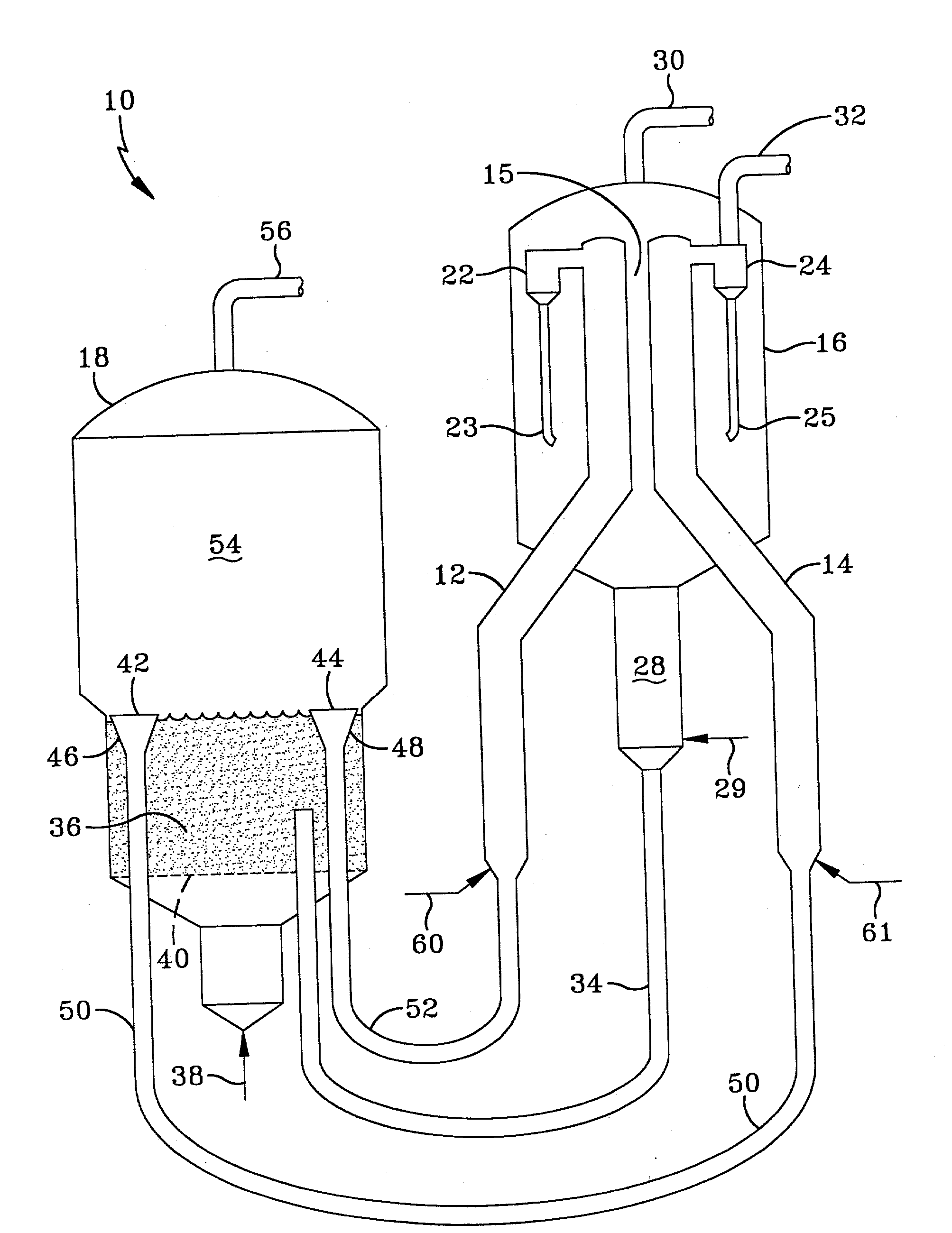

Fluid cat cracking with high olefins prouduction

InactiveUS20020003103A1Increase productionMaximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300.degree. F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

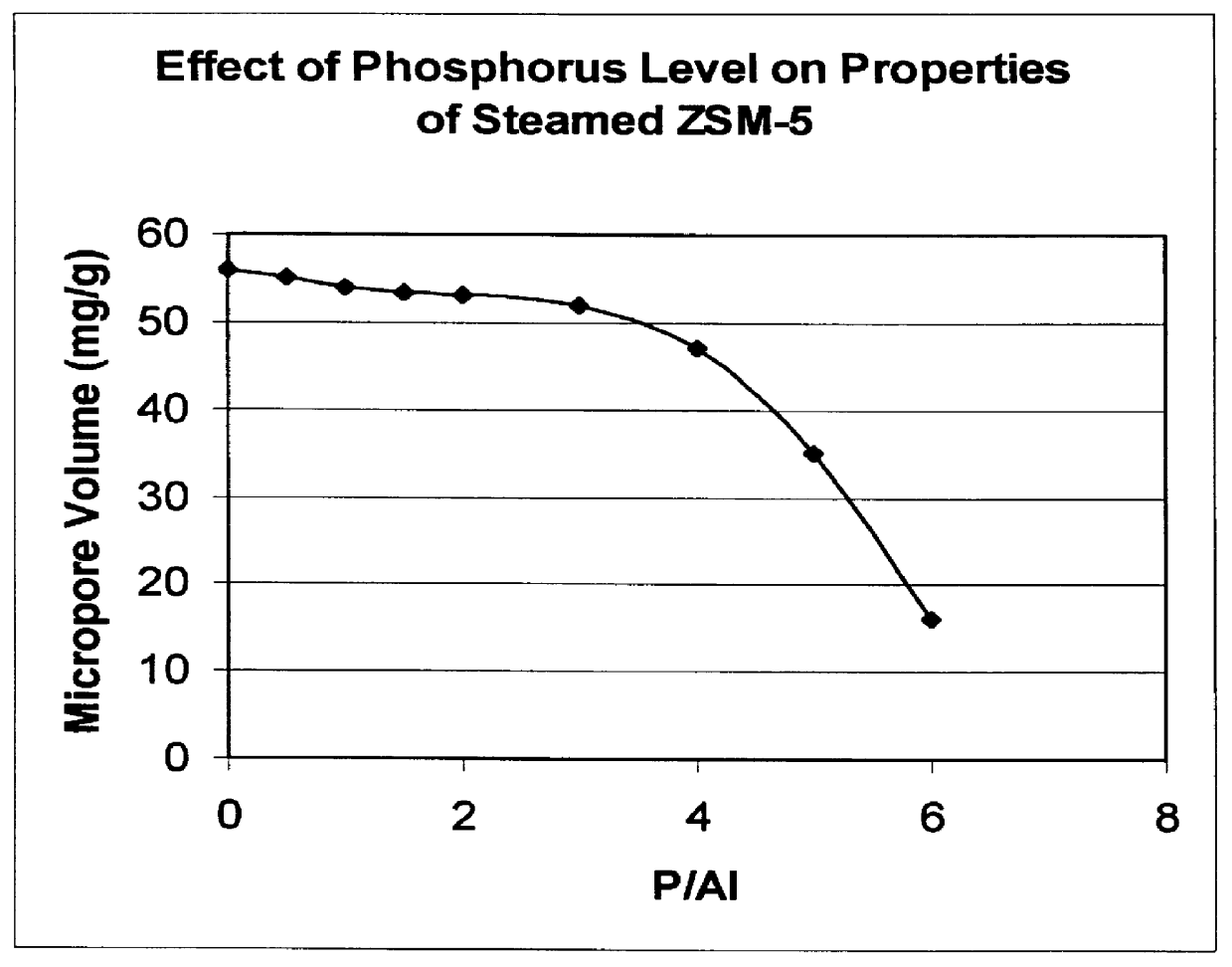

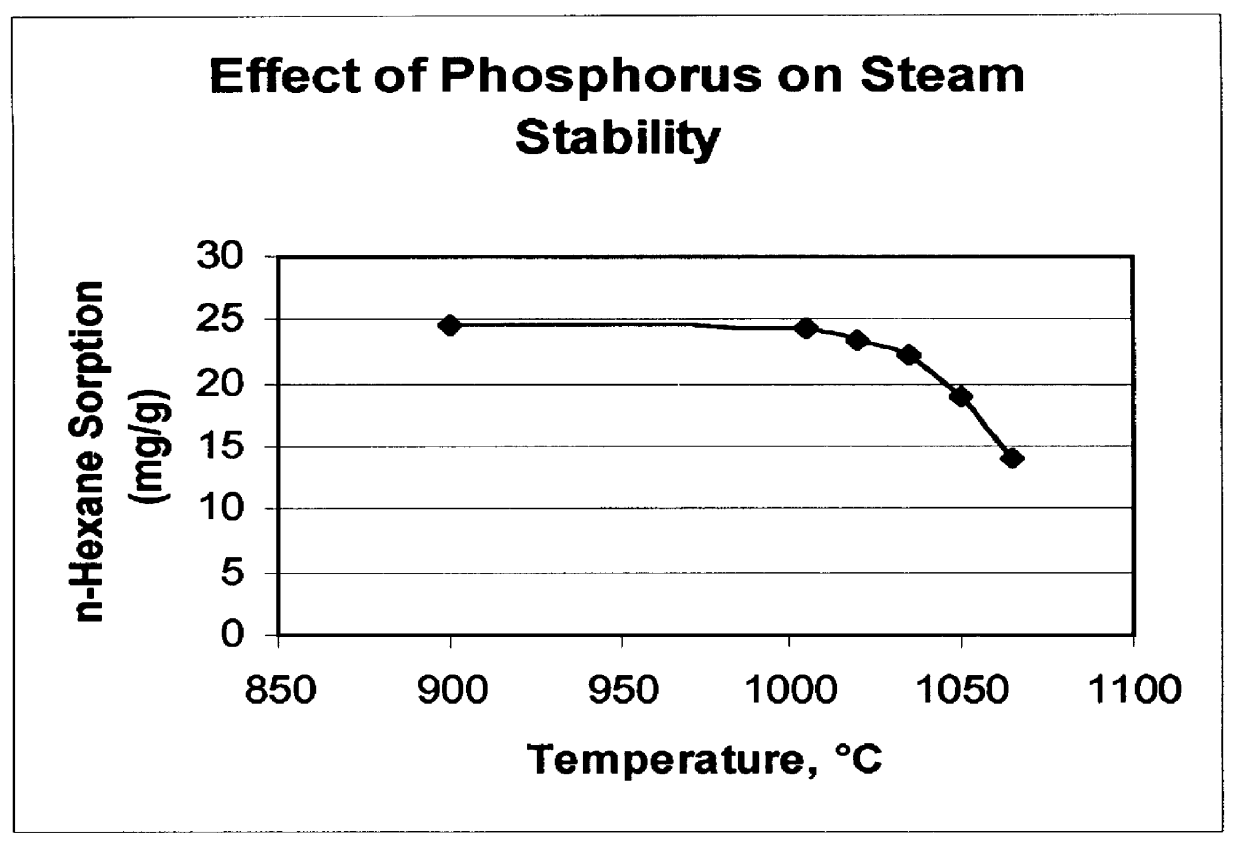

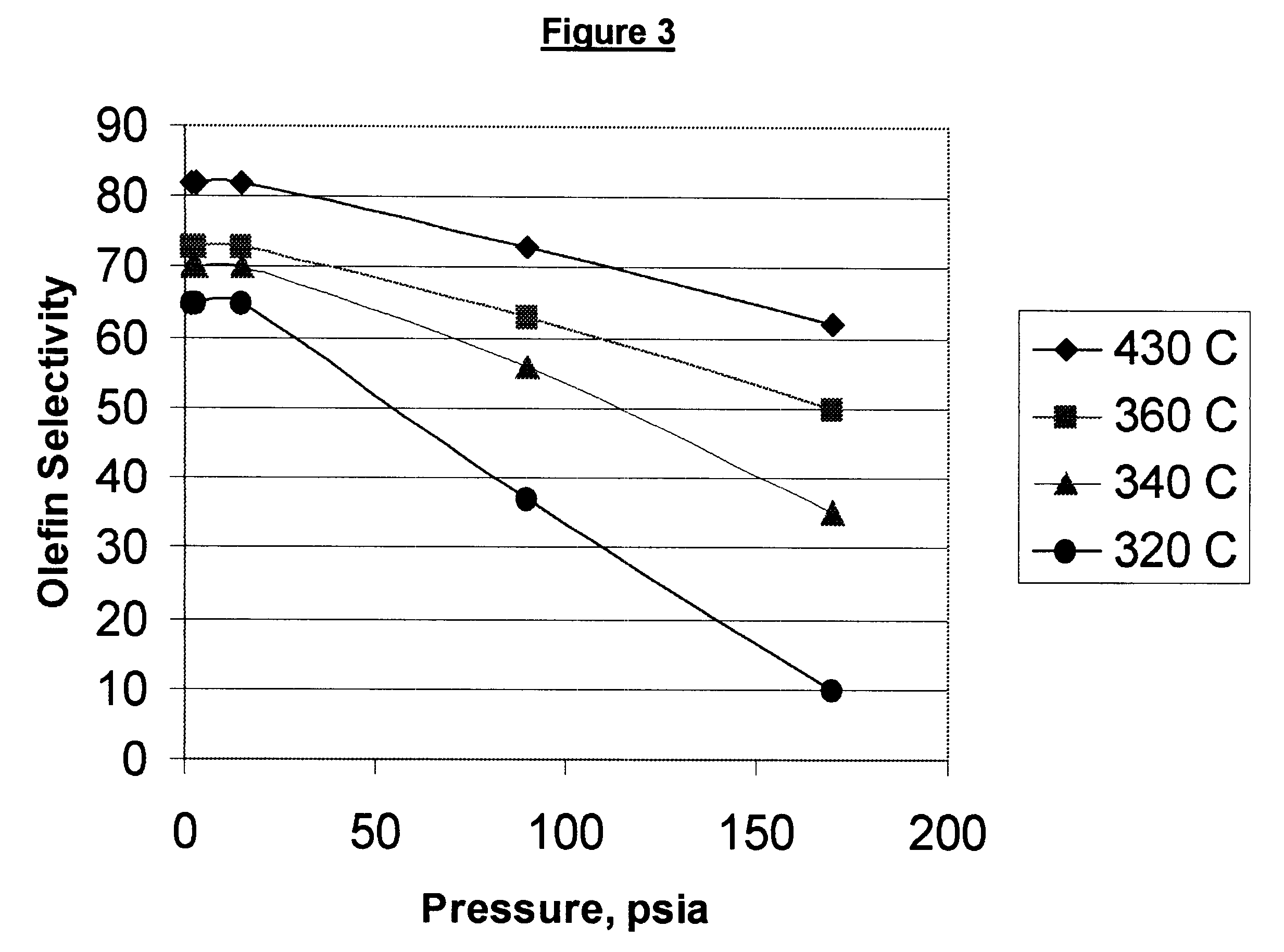

Catalyst and process for converting methanol to hydrocarbons

InactiveUS6048816AMolecular sieve catalystsMolecular sieve catalystCrystalline materialsDimethyl ether

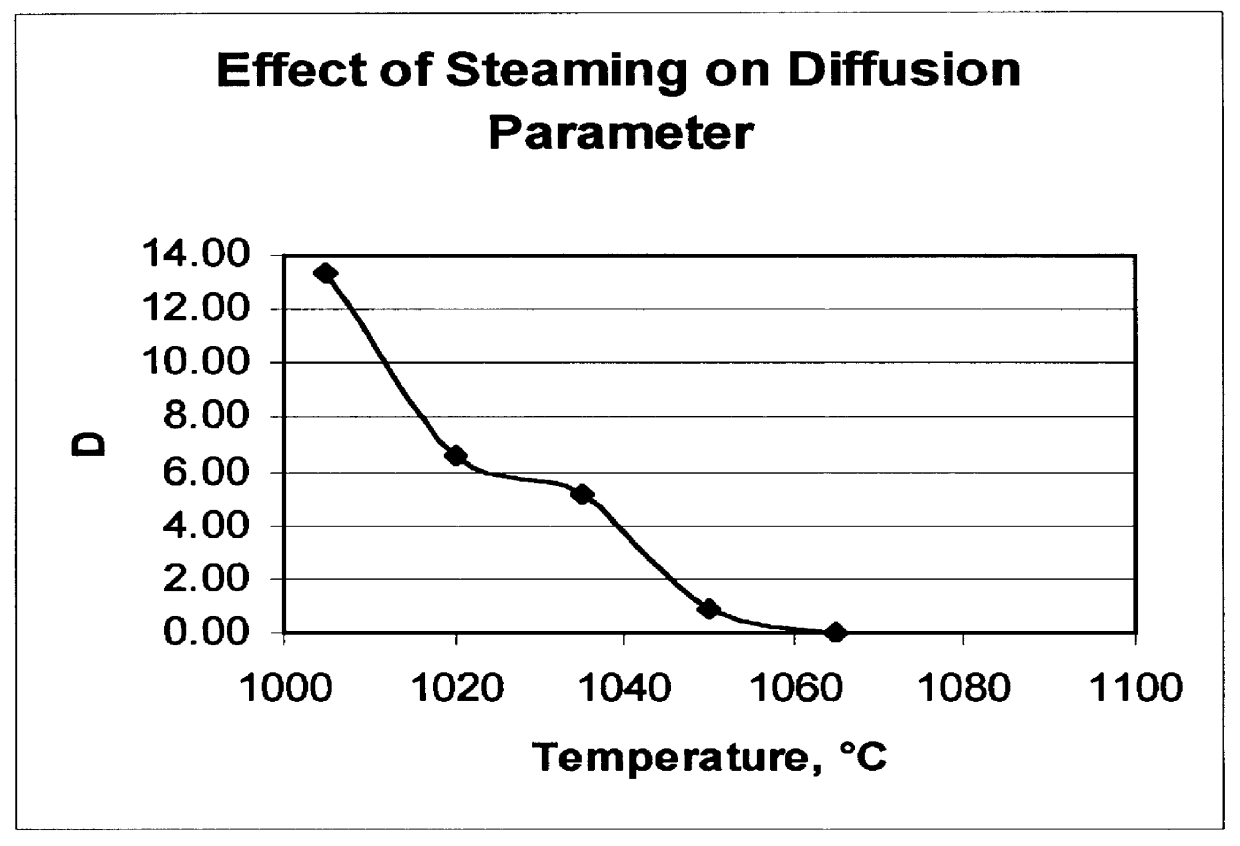

There is provided a catalyst and a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins. The catalyst comprises a porous crystalline material having a Diffusion Parameter for 2,2-dimethylbutane of about 0.1-20 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). In addition, the catalyst is characterized by a hydrothermal stability such that, after steaming the catalyst at 1025 DEG C. for 45 minutes in 1 atmosphere steam, the catalyst exhibits a methanol conversion activity of at least 50% when contacted with methanol at a methanol partial pressure of 1 atmosphere, a temperature of 430 DEG C. and 0.5 WHSV. The porous crystalline material is preferably a medium-pore zeolite, particularly ZSM-5, which contains phosphorus and has been severely steamed at a temperature of at least 950 DEG C.

Owner:MOBIL OIL CORP

Method for preparing polyoxymethylene dimethyl ether

ActiveCN101768058ANot corrosiveStrong acidOrganic chemistryMolecular sieve catalystsEnergy consumptionReagent

The invention relates to a method for preparing polyoxymethylene dimethyl ether. The invention mainly solves the problems of the prior art that: catalyst is corrosive, and is complexly separated from reactant, and energy consumption is high. The method adopts methanol and trioxymethylene as materials, the materials react with catalyst by way of contact under mild conditions, so that the polyoxymethylene dimethyl ether is produced, wherein the catalyst is selected from Beta zeolite, ZSM-5 molecular sieve, MCM-22 and MCM-56 zeolite molecular sieve. The method effectively solves the problems, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Micropore mesopore composite molecular sieve and its preparation method

InactiveCN1597516AAdjustable silicon-aluminum ratioAdjustable aperture sizeCrystalline aluminosilicate zeolitesMordeniteSodium hydroxide

A composite millipore-mesopore molecular sieve is prepared through proportionally adding millipore Zeolite molecular sieve ZSM-5, beta-zeolite, mordenite, L-zeolite, MCM-22 and ZSM-35 to the solution of sodium hydroxide, stirring, adding the template agent of mesopore molecular sieve, crystallizing at 90-120 deg.C for 22-26 hr, regulating pH=7.5-7.9, and static crystallizing at 90-120 deg.c for 24-168 hr.

Owner:TAIYUAN UNIV OF TECH

Molecular sieve based catalysts, preparation method and application thereof in crylic acid preparation by lactic acid dehydration

InactiveCN101602010AExtended service lifeReduce energy consumptionMolecular sieve catalystsOrganic compound preparationPhosphateAcid preparations

The invention discloses a molecular sieve based catalyst, a preparation method and an application thereof in crylic acid preparation by lactic acid dehydration. The method comprises the following steps: processing the ZSM-5 molecular sieve in aqueous alkali, or adopting an impregnation method to support phosphate, drying, roasting and finally obtaining the modified molecular sieve based catalyst. The catalyst realizes the reaction of crylic acid preparation by lactic acid dehydration in low temperature and has the advantages of high lactic acid conversion rate and crylic acid selectivity, and long-life of catalyst, the conversion rate of lactic acid dehydration reaction is 100%, and crylic acid selectivity can reach as high as 83.9%, thus having good industrial application prospect.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

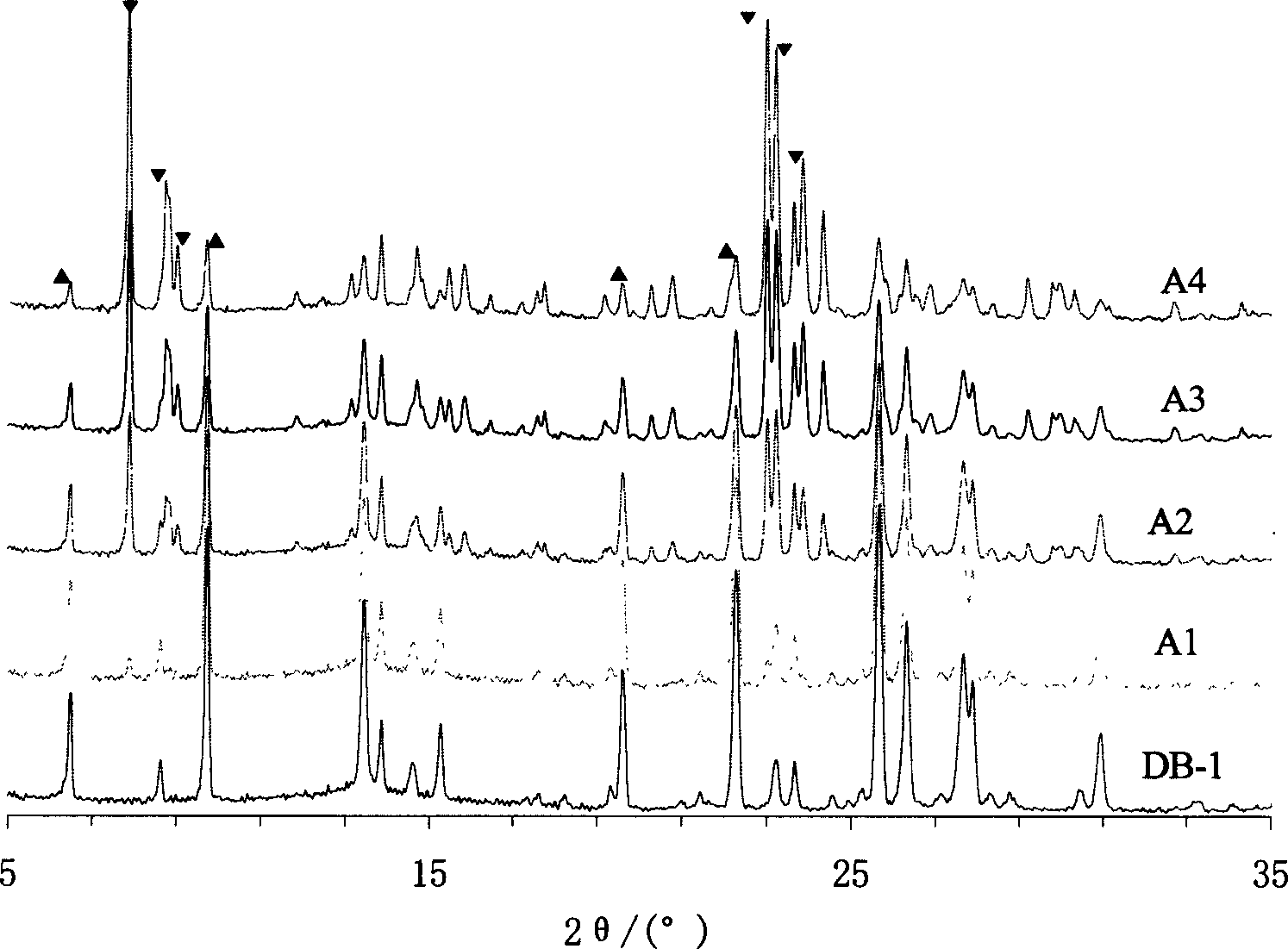

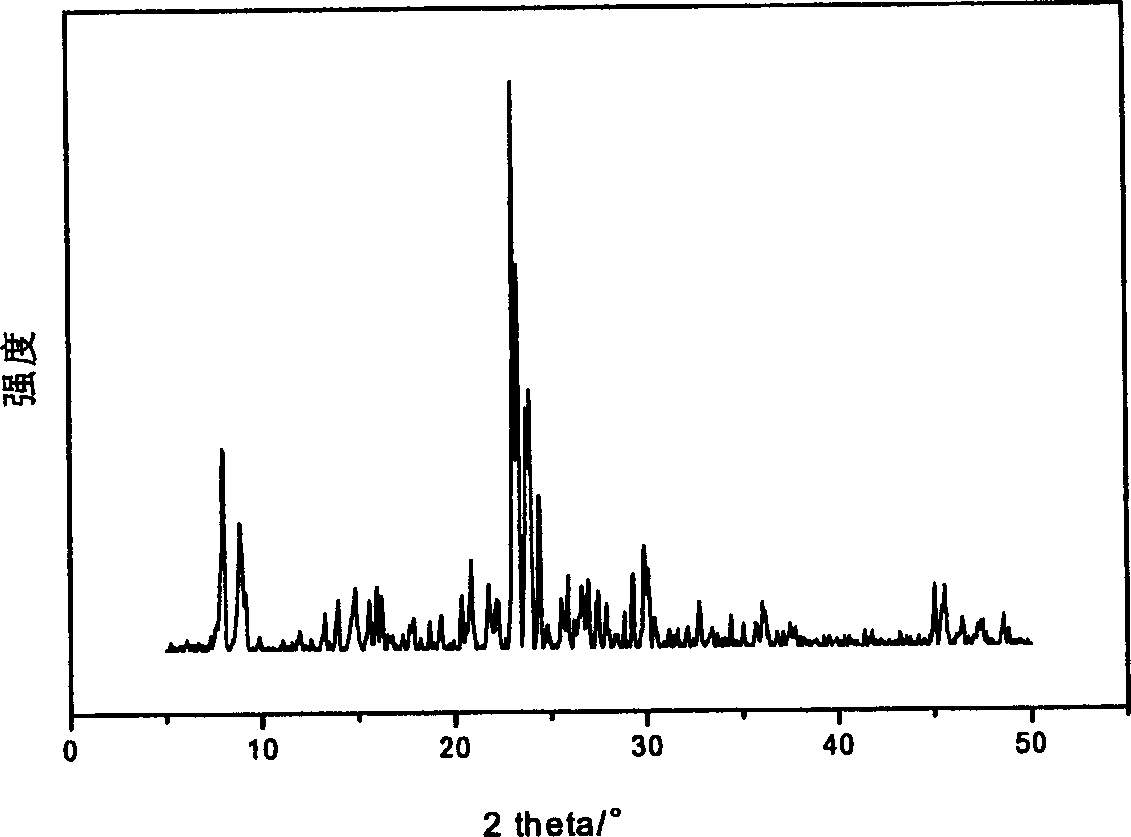

Synthetic method for ZSM-5/mordenite mixed crystal material

InactiveCN1565970ALower synthesis costEasy to adjustMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteThermal crystallization

The invention discloses a synthetic method for ZSM-5 / mordenite mixed crystal material, wherein ZSM-5 molecular sieve is charged into the synthesized reaction mixture of mordenite as seed crystal, and said material is prepared through water thermal crystallization. The invention realizes low making cost and more ideal catalyzing performance.

Owner:CHINA PETROLEUM & CHEM CORP +2

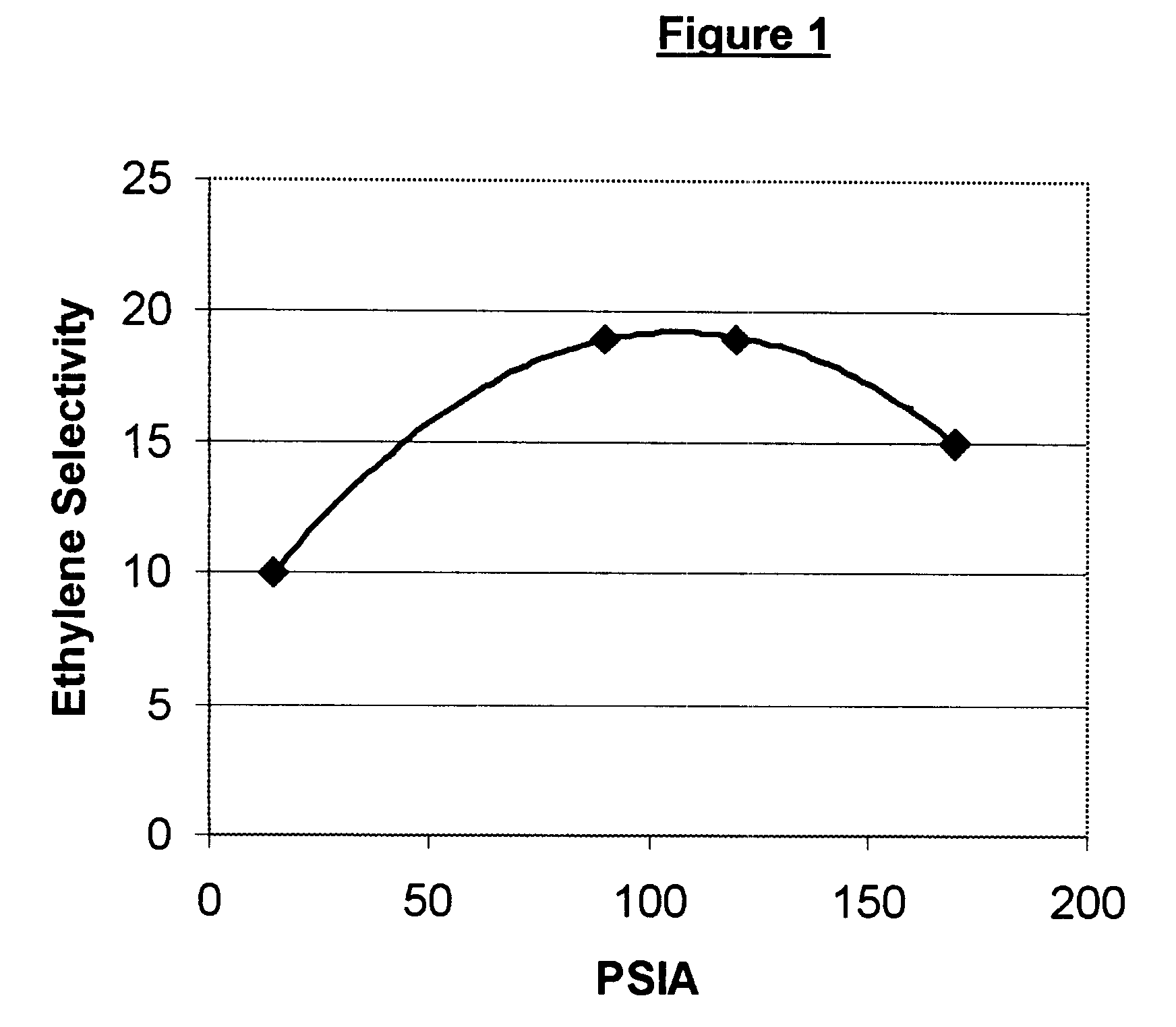

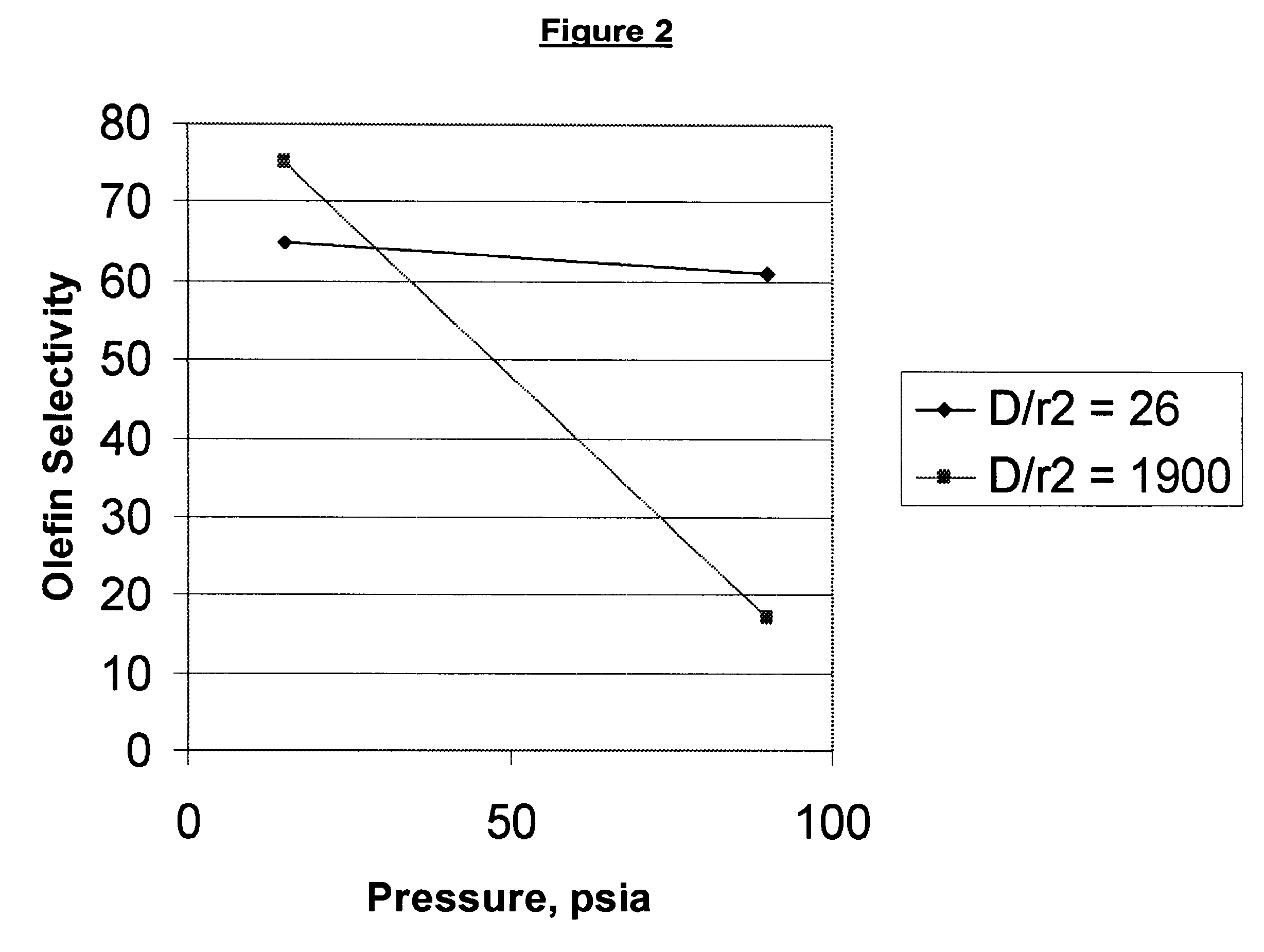

Process for converting methanol or dimethyl ether to olefins

There is provided a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins, which comprises the step of contacting a feed containing methanol or dimethyl ether with a catalyst which comprises a zeolite having 10-ring intersecting channels, such as ZSM-5, and which has a Diffusion Parameter for 2,2-dimethylbutane of less than 100 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). The contacting step is conducted at a temperature of 370 to 480 DEG C., a methanol partial pressure of 30 to 150 psia and a methanol conversion per pass of less than 95%.

Owner:EXXONMOBIL CORP (US)

Integral supported carbon molecular sieve catalyst, preparing method and applications thereof

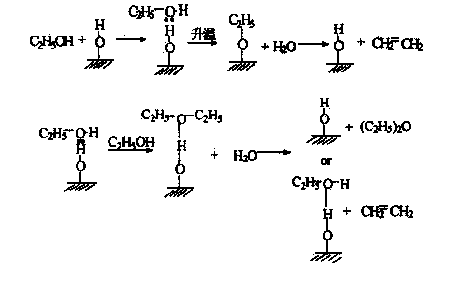

InactiveCN101224432AReduce the number of growthSave raw materialsMolecular sieve catalystsEther preparation by compound dehydrationGas phaseCarbon nanotube

A catalyst for an integrated supported carbon modular sieve comprises an integrated beehive cordierite, a carbon-nano tube and an HZSM-5 modular sieve, wherein the carbon-nano tube takes 7-20 proportions, HZSM-5 takes 10-30 proportions, and cordierite tales 60-80 proportions. The preparation method is that: carbon-nano tube is produced in situ on the integrated beehive cordierite by using chemical vapor deposition firstly, and the carbon-nano tube is taken as carrier, then the ZSM-5 modular sieve is developed on the carrier by using a secondary growth method. The catalyst for an integrated supported carbon-modular sieve can be used for the gas-phase synthesis of dimethyl ether DME by the dehydration of methanol.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

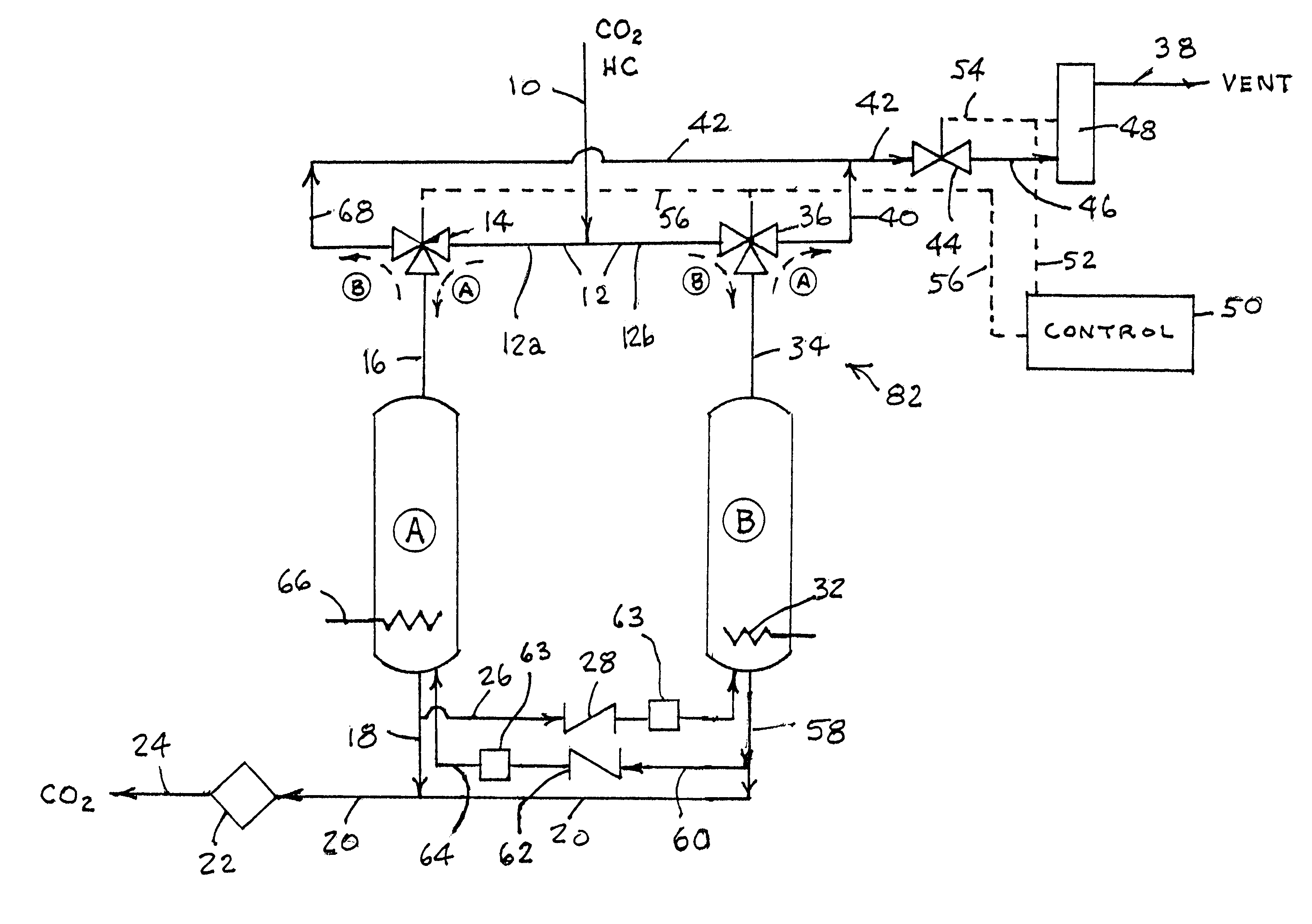

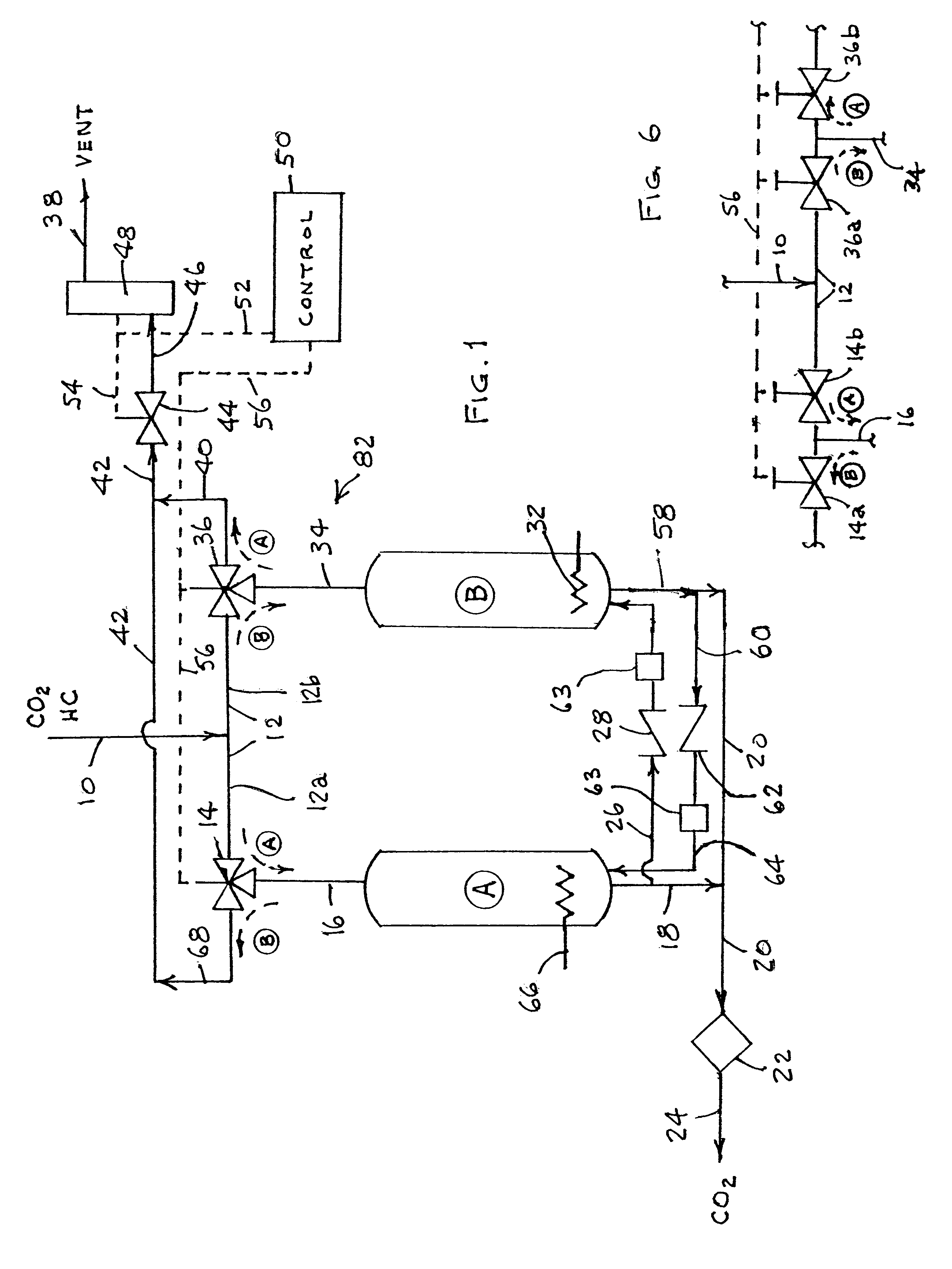

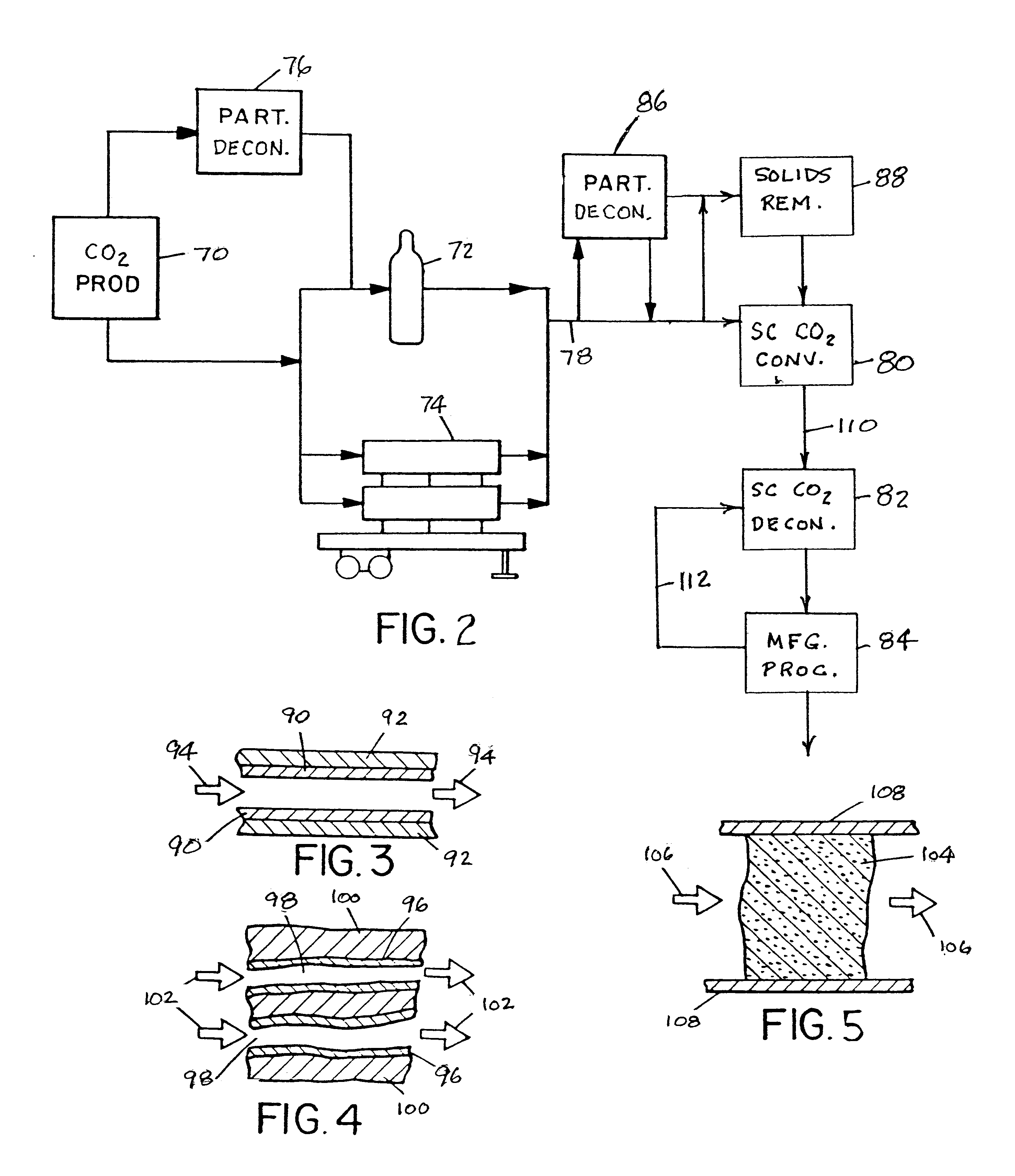

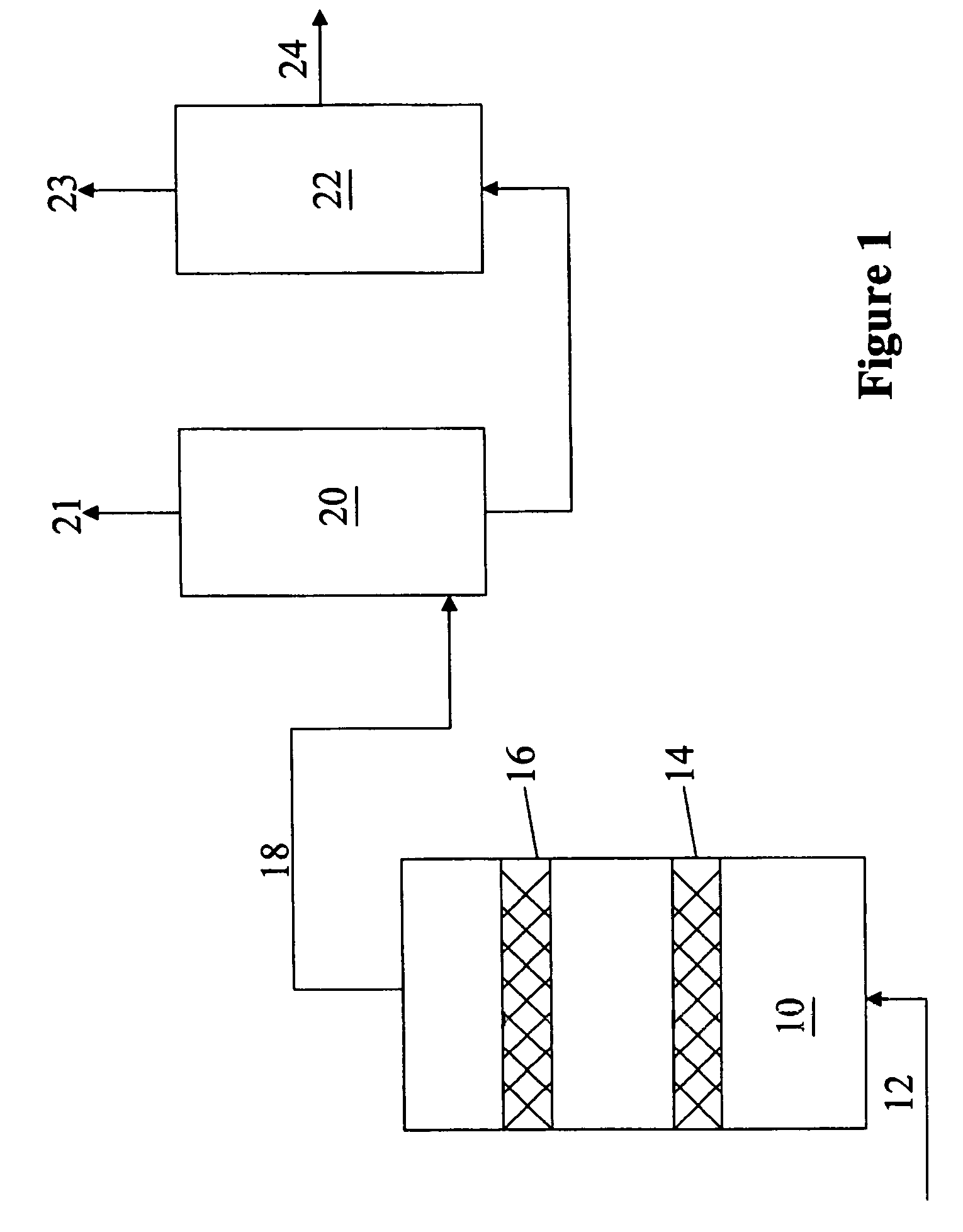

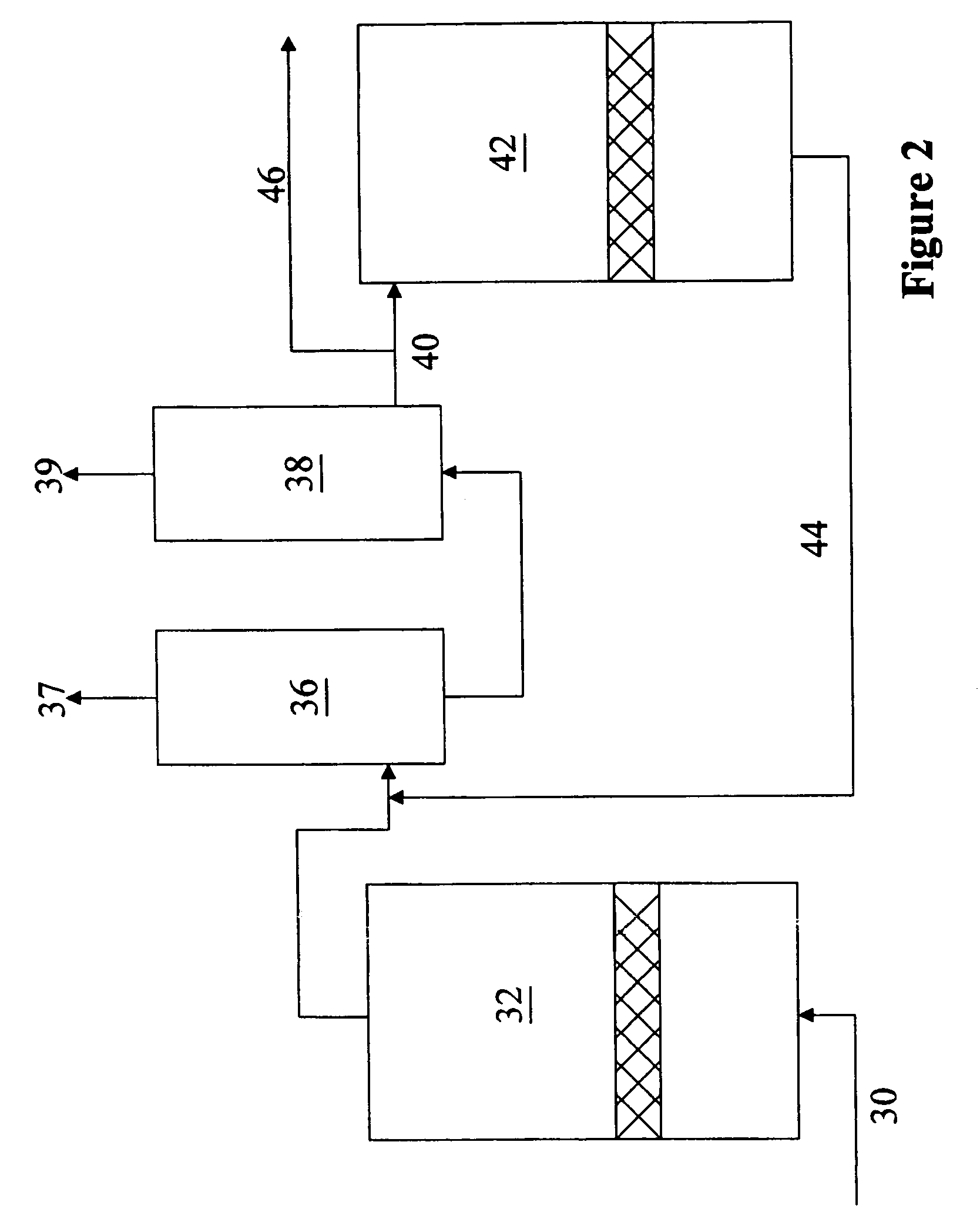

Self-regenerative process for contaminant removal from liquid and supercritical CO2 fluid streams

A method for the decontamination of fluid (liquid or supercritical) carbon dioxide fluid, especially of hydrocarbon contaminants, down to <=100 ppb concentration are described. The critical component is a high silica zeolite, preferably a high silica Y-type zeolite, ZSM-5 or a high silica mordenite, which in a variety of physical forms is capable of decontaminating such fluid CO2 to <=100 ppb, <=10-50 ppb, or ~1 ppb, without being detrimentally affected by the supercritical operating environment. The high silica zeolite may be produced by the removal of alumina from a natural or synthetic zeolite while retaining the desirable zeolite structure, to a silica:alumina ratio of from 20-2000:1. Preferably the zeolite is disposed in separate quantities in at least two vessels, which operate alternately. A portion of the purified product from the operating vessel is directed to the other vessel and there used to remove accumulated contaminants from that vessel's zeolite. The process thus provides self-regeneration, in that regeneration of one vessel occurs while the other vessel decontaminates contaminated fluid carbon dioxide, so that use of the two can be alternated for substantially continual production of purified fluid carbon dioxide. The invention provides purified fluid carbon dioxide used in manufacture of such products as high purity electronic, optical, prosthetic or similar products or polymers or pharmaceuticals or in beverages.

Owner:ENTEGRIS INC

Process for alkane aromatization using platinum-zeolite catalyst

InactiveUS20050143610A1Formation is suppressedHigh selectivityMolecular sieve catalystsMolecular sieve catalystAlkanePlatinum

Aromatization of alkanes having one to four carbon atoms per molecule to aromatics, such as benzene, toluene and xylenes (BTX), uses a catalyst of a crystalline zeolite on which platinum has been deposited, specifically a platinum-containing ZSM-5. A byproduct of the process is a light gas fraction of methane and ethane. The use of a platinum-containing ZSM-5 catalyst in an alkane aromatization process, such as the Cyclar process, suppresses the formation of methane and increases selectivity to BTX. The high content of ethane relative to methane in the light gas fraction allows this process effluent to be a feedstream for a cracker.

Owner:SAUDI BASIC IND CORP SA

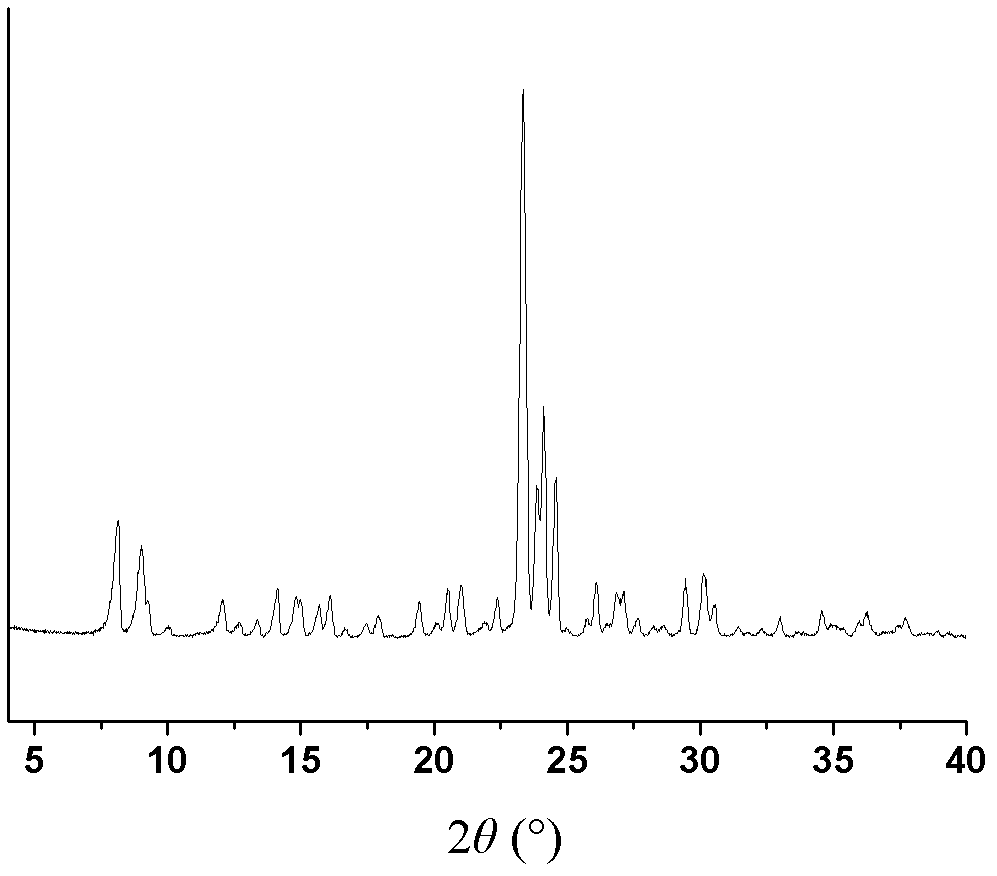

Method for synthesizing molecular sieve under solvent-free condition through grinding solid phase raw materials

ActiveCN102627287AHigh crystallinityThe synthesis steps are simplePentasil aluminosilicate zeoliteSolvent freeSolvent

The invention relates to a method for preparing a molecular sieve, aiming to provide a method for synthesizing a molecular sieve under a solvent-free condition through grinding solid phase raw materials. The method comprises the following steps of: grinding and mixing the pre-weighed solid raw materials which include silicon sources, metal atom sources, an organic template agent, and an alkalinity regulator, putting the grinded material into a reactor, and performing a crystallization reaction for 1-8 days at a temperature ranged from 80 DEG C to 180 DEG C; and drying for over 12 hours at a temperature of 80 DEG C after washing the reaction product thoroughly by using deionized water to obtain a final product. A ZSM-5 molecular sieve, a Beta molecular sieve, a ZSM-39 molecular sieve, and a SOD molecular sieve, which have a good crystallinity and a controllable silicon-aluminum ratio, can be prepared through the method provided by the invention. The synthetic route only involves a mixture of the raw materials without a use of any solvents, which simplifies the synthetic process compared to the traditional method, improves the yield rate and the single reactor utilization rate greatly, reduces the production cost greatly, saves energy and reduces emission, and has a wide industrial application prospect.

Owner:淮安六元环新材料有限公司

Gasoline sulfur reduction in fluid catalytic cracking

InactiveUS6852214B1Reduce sulfur contentLow sulfurCatalytic crackingMolecular sieve catalystsOxidation stateGasoline

The sulfur content of liquid cracking products, especially the cracked gasoline, of the catalytic cracking process is reduced by the use of a sulfur reduction additive comprising a porous molecular sieve which contains a metal in an oxidation state above zero within the interior of the pore structure of the sieve. The molecular sieve is normally a large pore size zeolite such as USY or zeolite beta or an intermediate pore size zeolite such as ZSM-5. The metal is normally a metal of Period 4 of the Periodic Table, preferably zinc or vanadium. The sulfur reduction catalyst may be used in the form of a separate particle additive or as a component of an integrated cracking / sulfur reduction catalyst.

Owner:MOBIL OIL CORP +1

Zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:ABB LUMMUS GLOBAL INC

Two catalyst process for making olefin

This invention is to a process of making olefin, particularly ethylene and propylene, from an oxygenate feed. The invention uses two or more zeolite catalysts. Examples of zeolite catalysts include a first catalyst containing of ZSM-5, and a second catalyst containing a 10-ring molecular sieve, including but not limited to, ZSM-22, ZSM-23, ZSM35, ZSM-48, and mixtures thereof. The ZSM-5 can be unmodified, phosphorous modified, steam modified having a micropore volume reduced to not less than 50% of that of the unsteamed ZSM-5, or various mixtures thereof.

Owner:EXXONMOBIL CHEM PAT INC

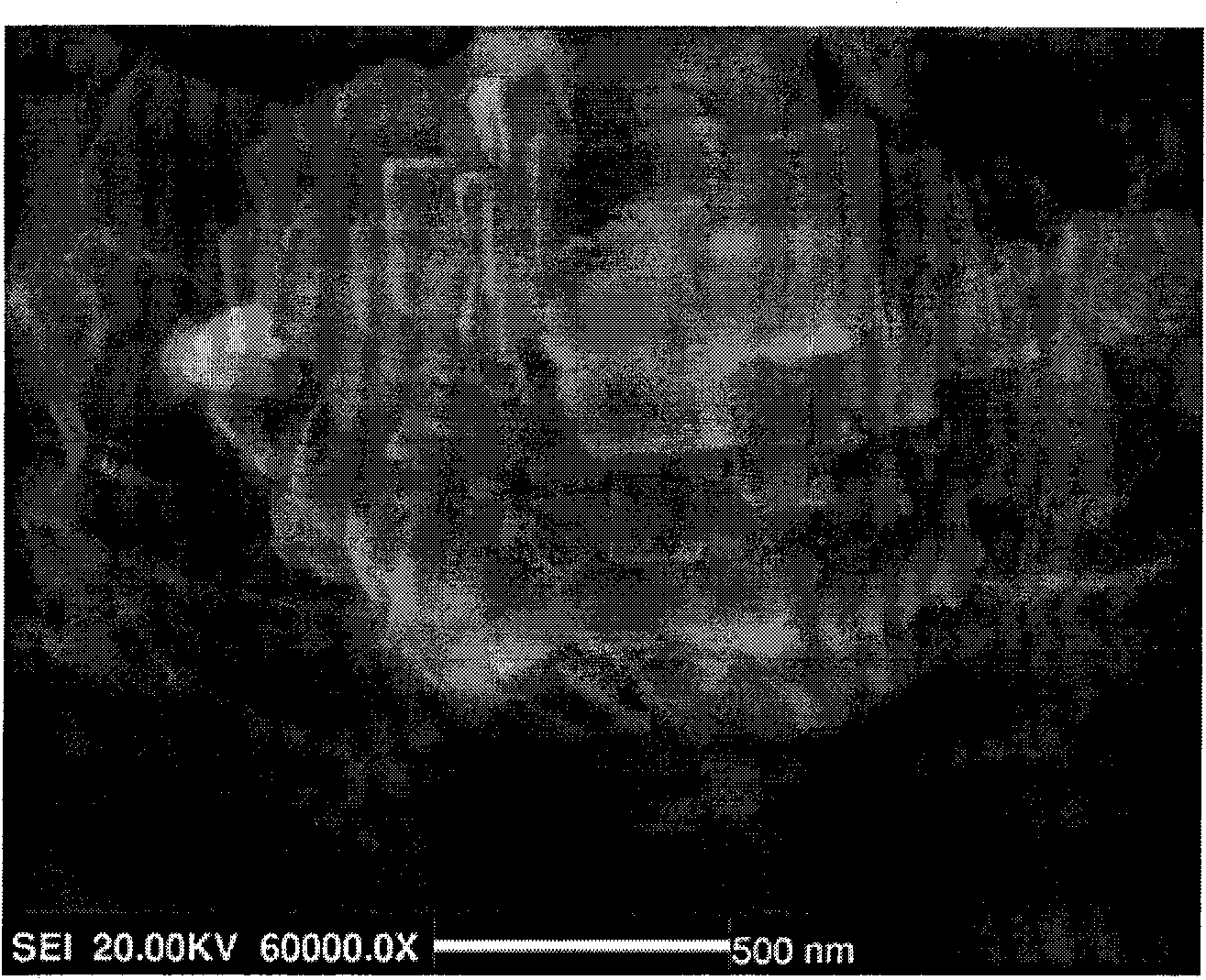

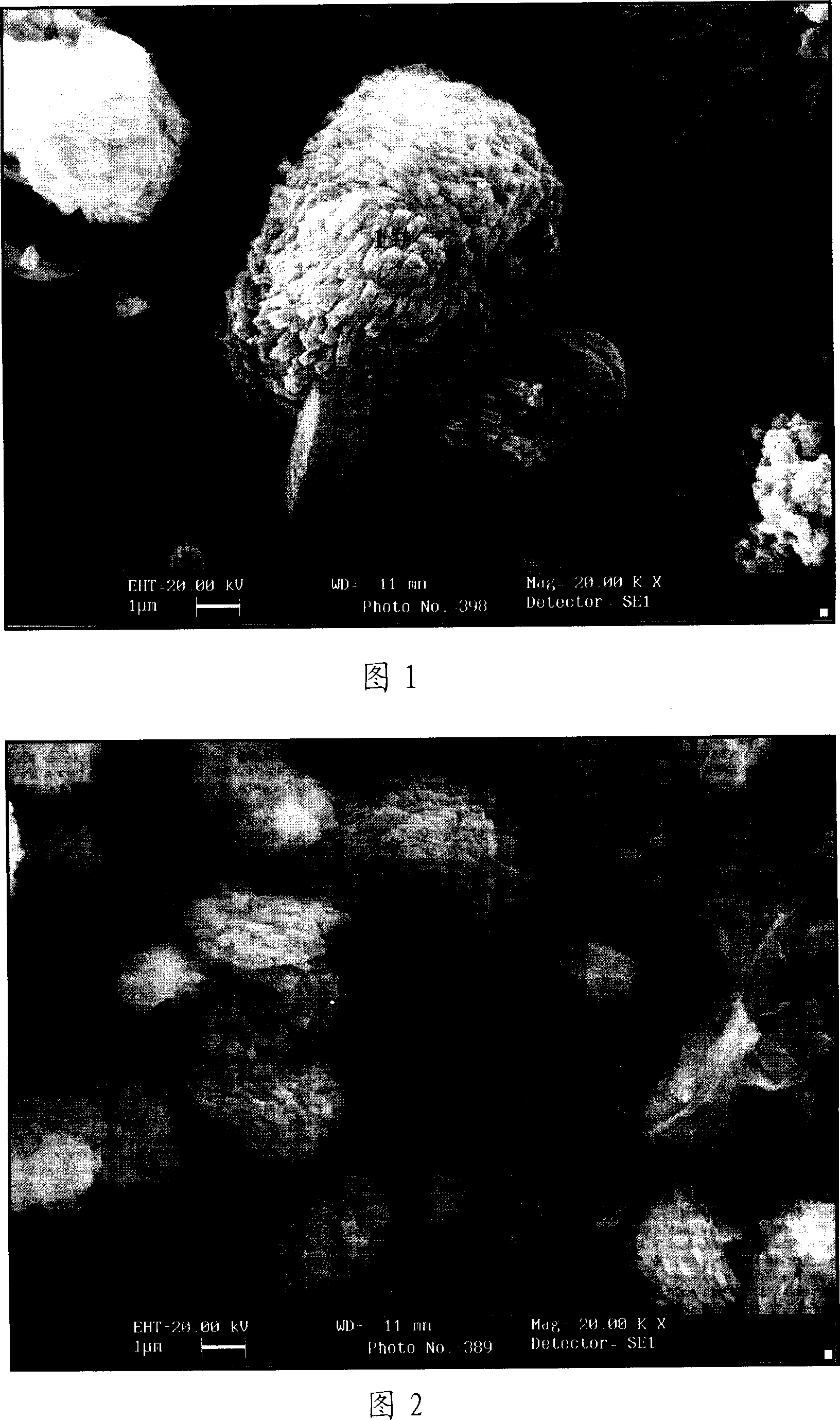

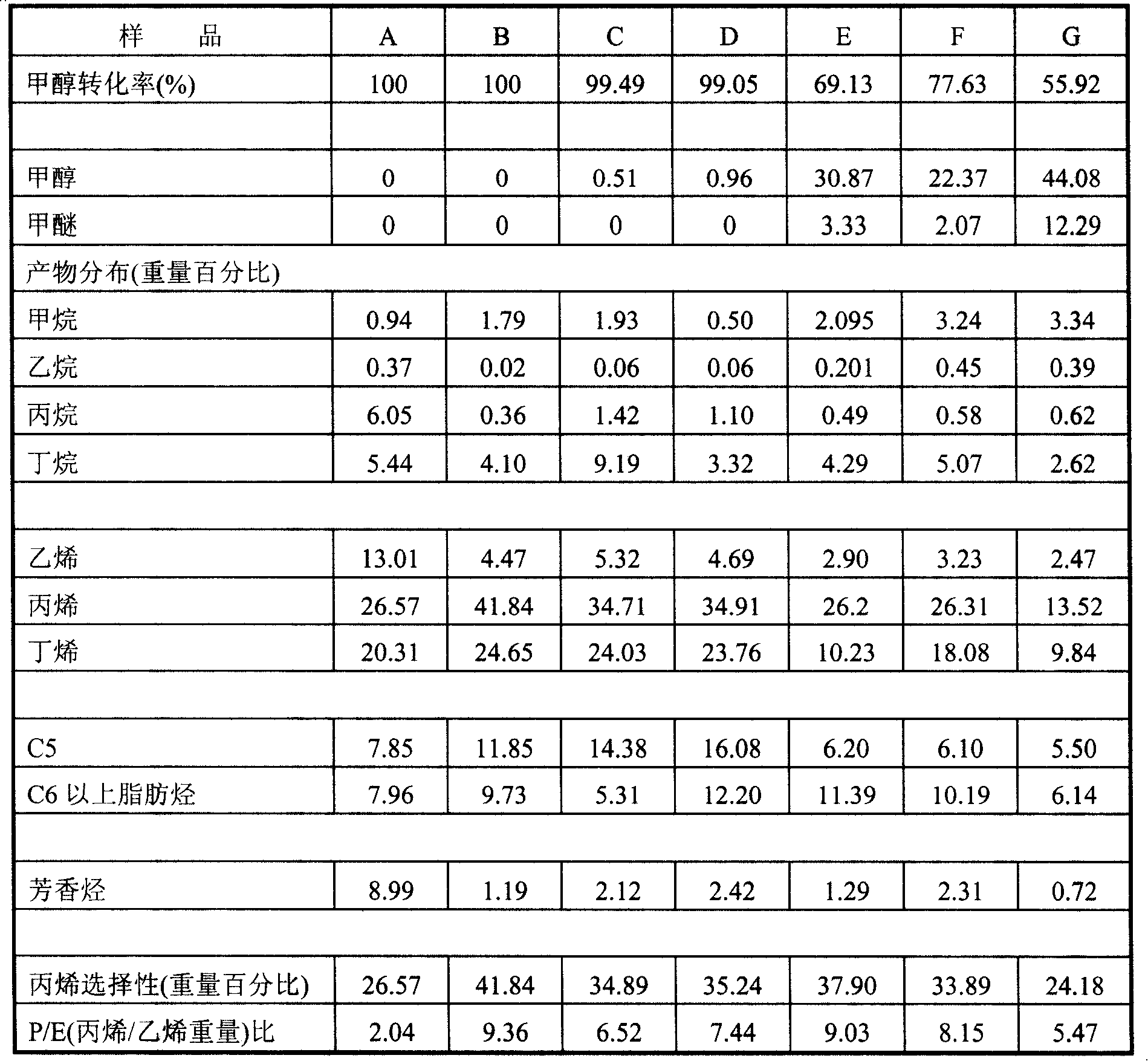

Preparation method of nano-ZSM-5 molecular sieve

InactiveCN101643219ASolve the costSolve pollutionPentasil aluminosilicate zeoliteRoom temperatureNanoscopic scale

The invention relates to a preparation method of a nano-ZSM-5 molecular sieve, which belongs to the field of preparation of zeolite molecular sieve catalysts. The preparation method can solve the problem that the existing synthesis technology has the defects of easy emergence of mixed crystal phase, high cost, environmental pollution and easy loss of features of nanomaterials. The method is as follows: adding pre-crystallized crystal seeds into a gel system of the template-free synthetic nano-ZSM-5 molecular sieve, carrying out crystallization for 24 hours at the temperature of 160-180 DEG C,cooling to room temperature, carrying out centrifugal filtration on products, washing, drying and baking. The prepared nano-ZSM-5 molecular sieve is highly concentrated nanoscale crystals without themixed crystal phase; and the method has the advantages of low cost and environmental protection.

Owner:HEILONGJIANG UNIV

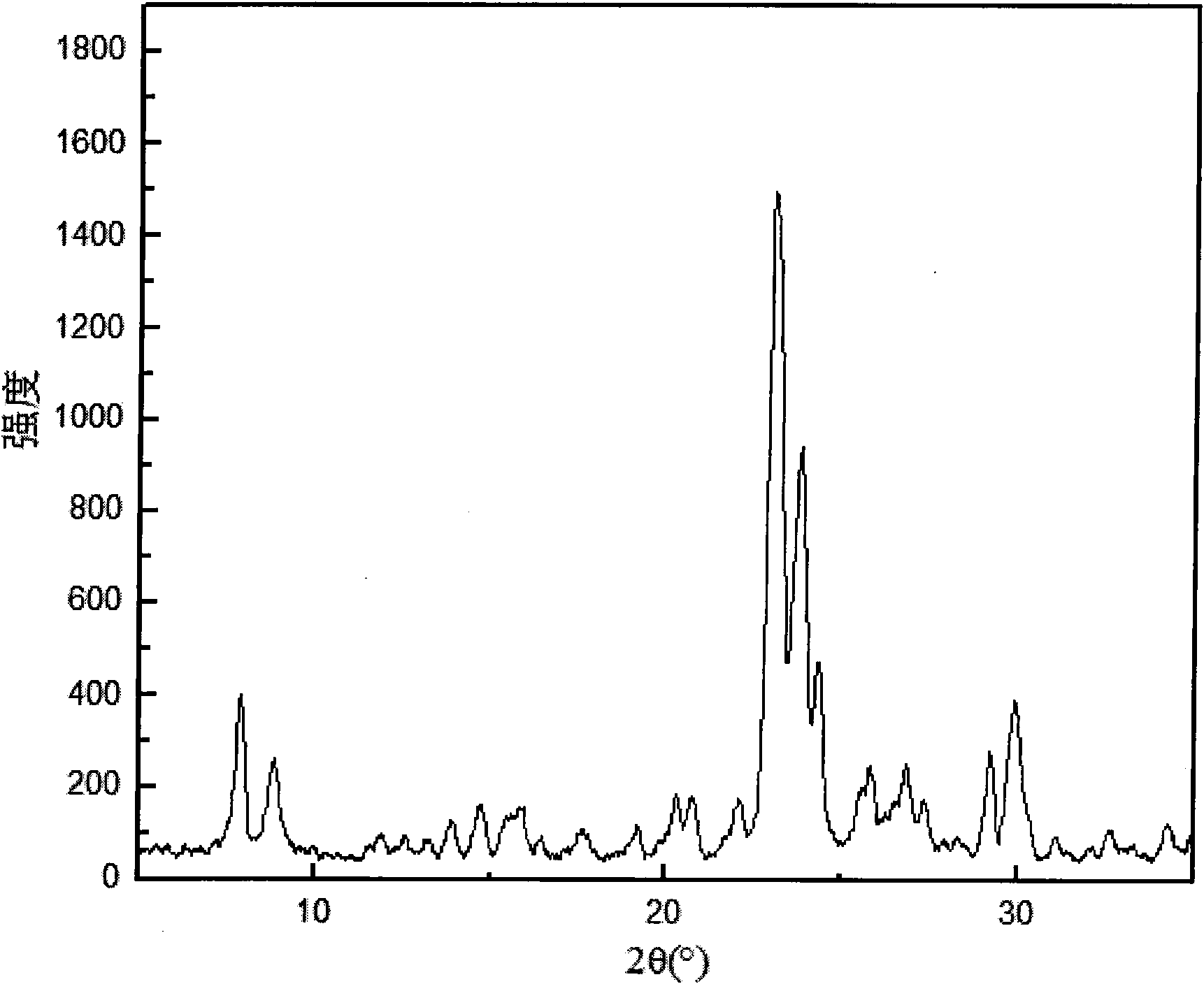

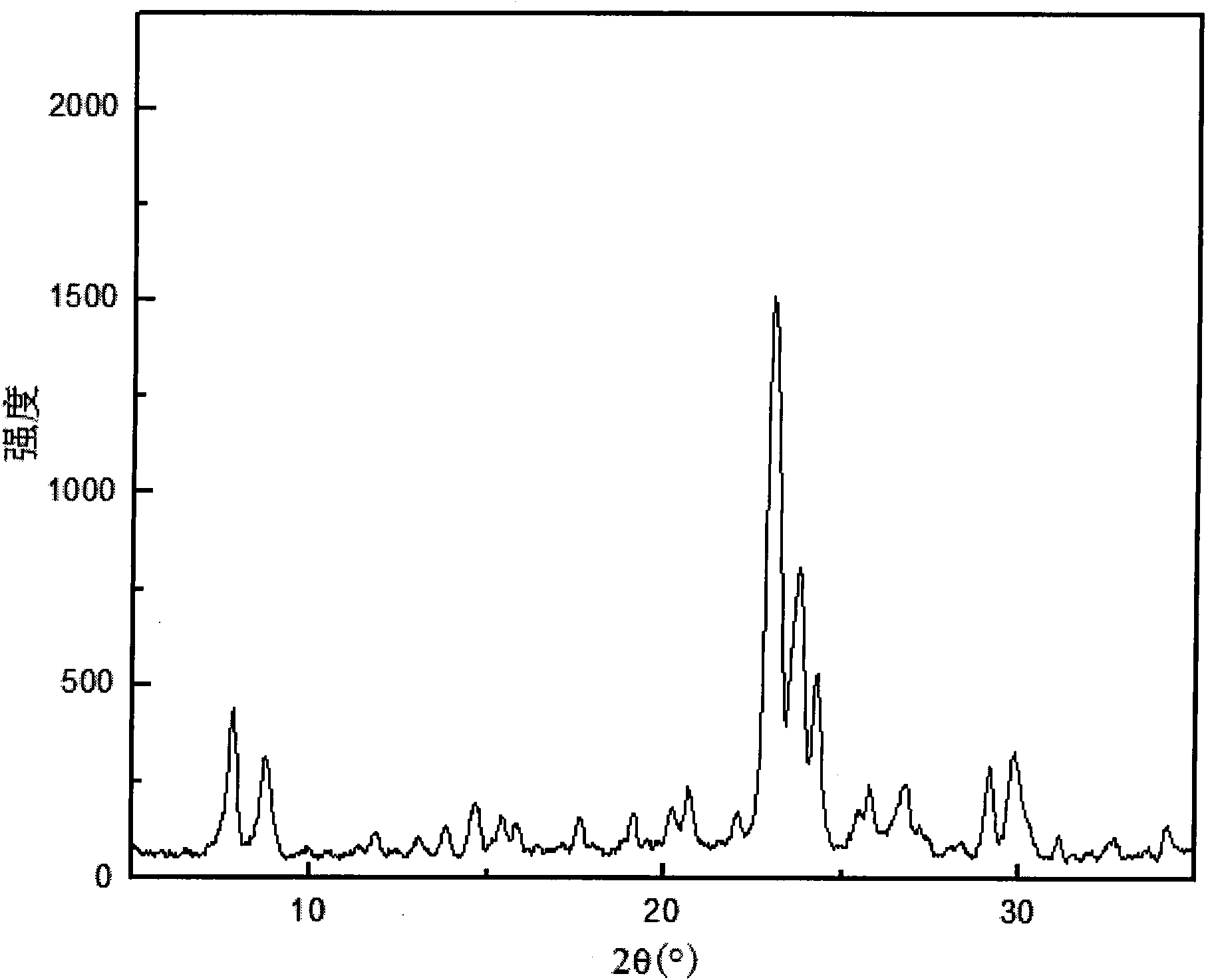

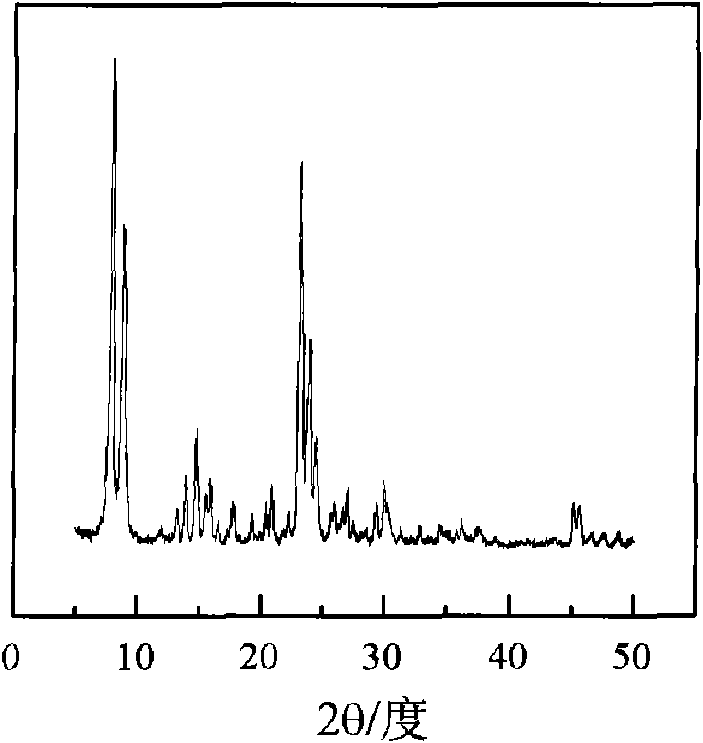

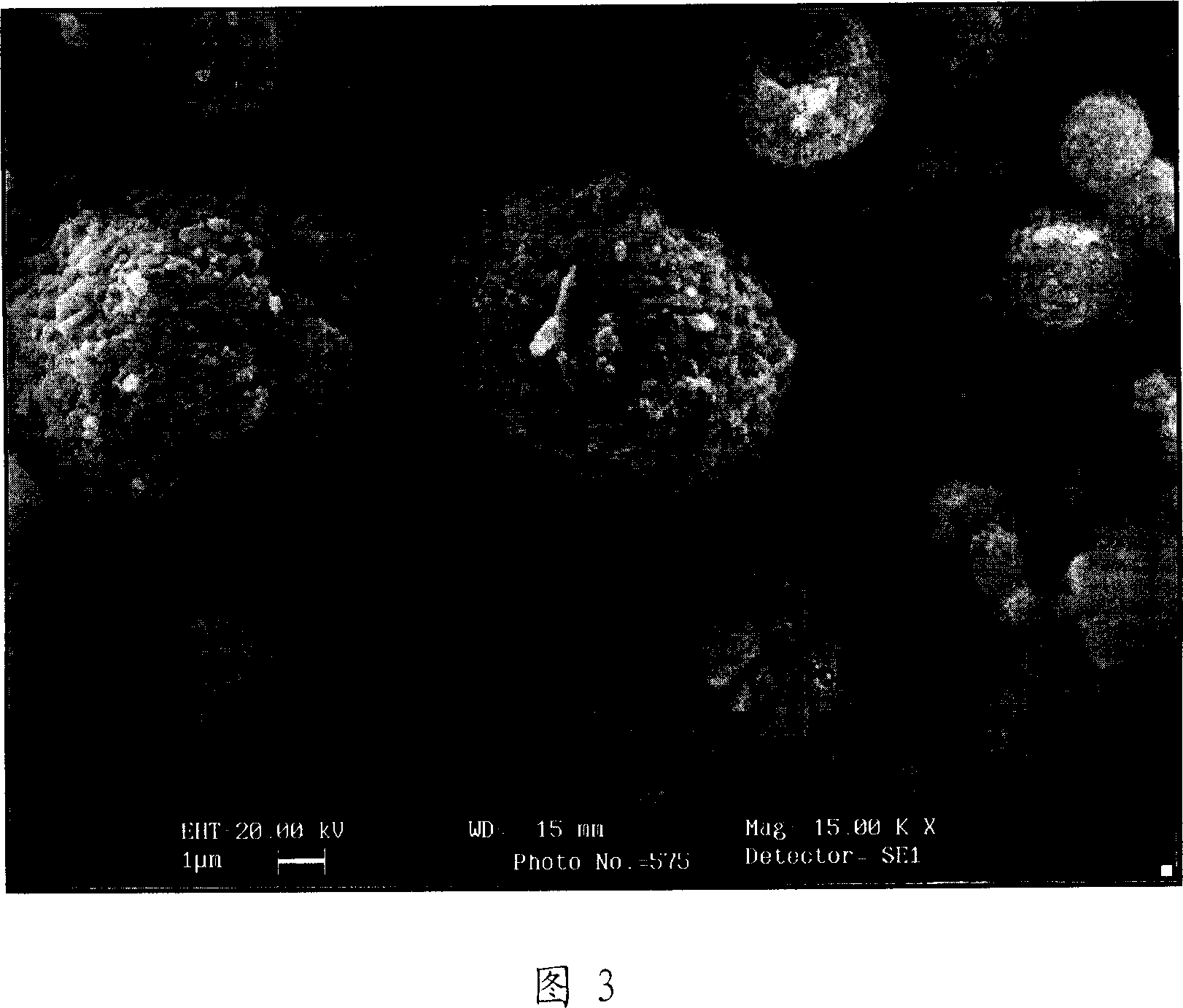

ZSM-5 type molecular sieve and method for preparing the same

ActiveCN1803613AReduce contentPerformance is not affectedMolecular sieve catalystsPentasil aluminosilicate zeolitePearliteZSM-5

The invention provides a preparation method for small-size ZSM-5 molecular sieve. Wherein, using pearlite and montmorillonite as material for aluminum, adding crystal seed for crystallization reaction on hydrothermal condition, and obtaining a small-size product with 5~95% ZSM-5 that can be used to prepare modified ZSM-5 molecular sieve by different post-treatment method or as the active intergradient or carrier for catalyst. This invention cuts the cost more.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Catalytic synthesis method for polyoxymethylene dimethyl ethers (PODE) by molecular sieves

ActiveCN102040491AStrong acidHigh yieldOrganic chemistryOrganic compound preparationSynthesis methodsReaction temperature

The invention relates to a catalytic synthesis method for polyoxymethylene dimethyl ethers (PODE) by molecular sieves, mainly solving the problem of relatively high cost in the conventional method which adopts trioxymethylene as a raw material. In the method, methanol, methylal and paraformaldehyde are adopted as raw materials based on the mass ratio of (0-10): (0-10):1, the raw materials contactwith a catalyst to react and generate PODE, wherein the dosages of the methanol and the methylal can not be zero at the same time; the reaction temperature is 70-200 DEG C; the reaction pressure is 0.1-6MPa; and the adopted catalyst is selected from at least one of beta zeolite, X zeolite, Y zeolite, ZSM-5 molecular sieve, MCM-22, MCM-56, UZM-8 or SAPO-34 molecular sieve. The technical scheme adopted by the invention solves the above problem preferably, thus being applicable to industrialized production of the PODE.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for alkane aromatization using platinum-zeolite catalyst

InactiveUS7186871B2Formation is suppressedHigh selectivityMolecular sieve catalystsMolecular sieve catalystAlkanePlatinum

Owner:SAUDI BASIC IND CORP SA

Process for converting methanol to olefins

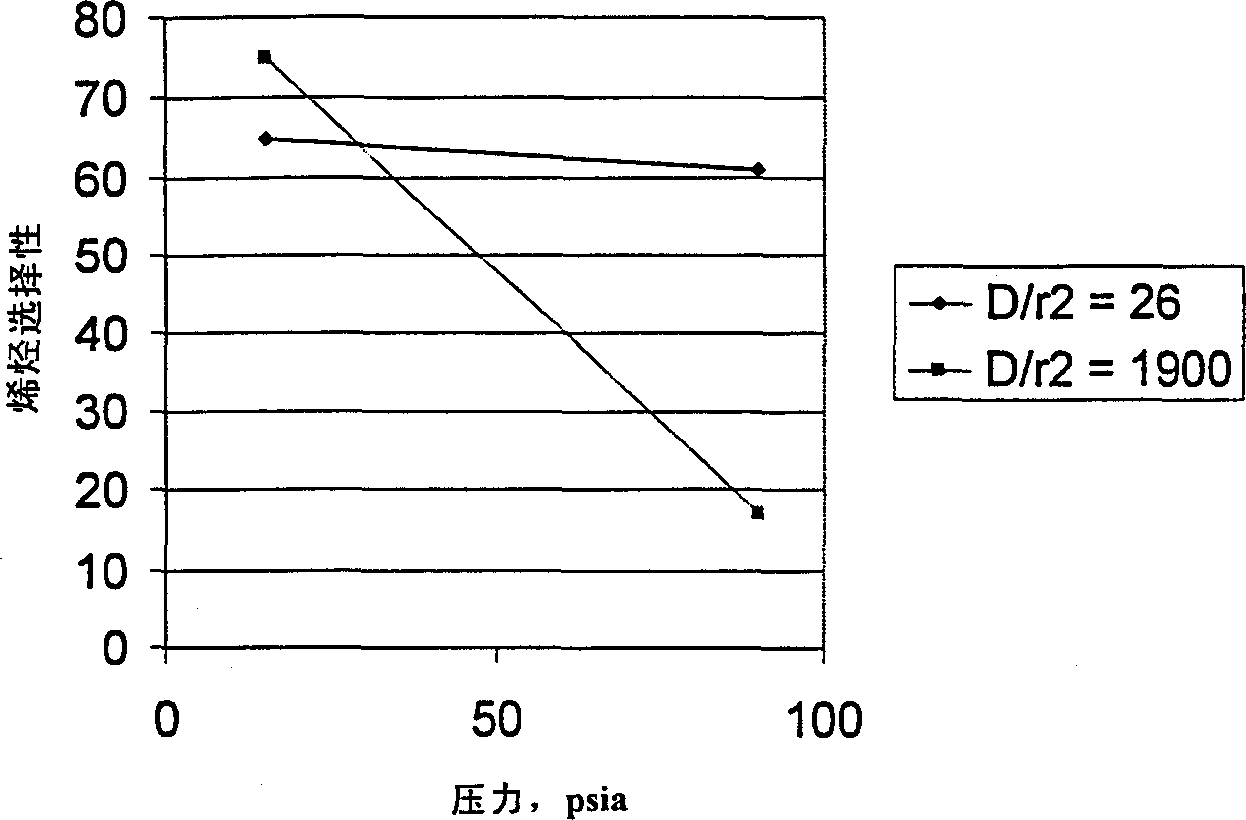

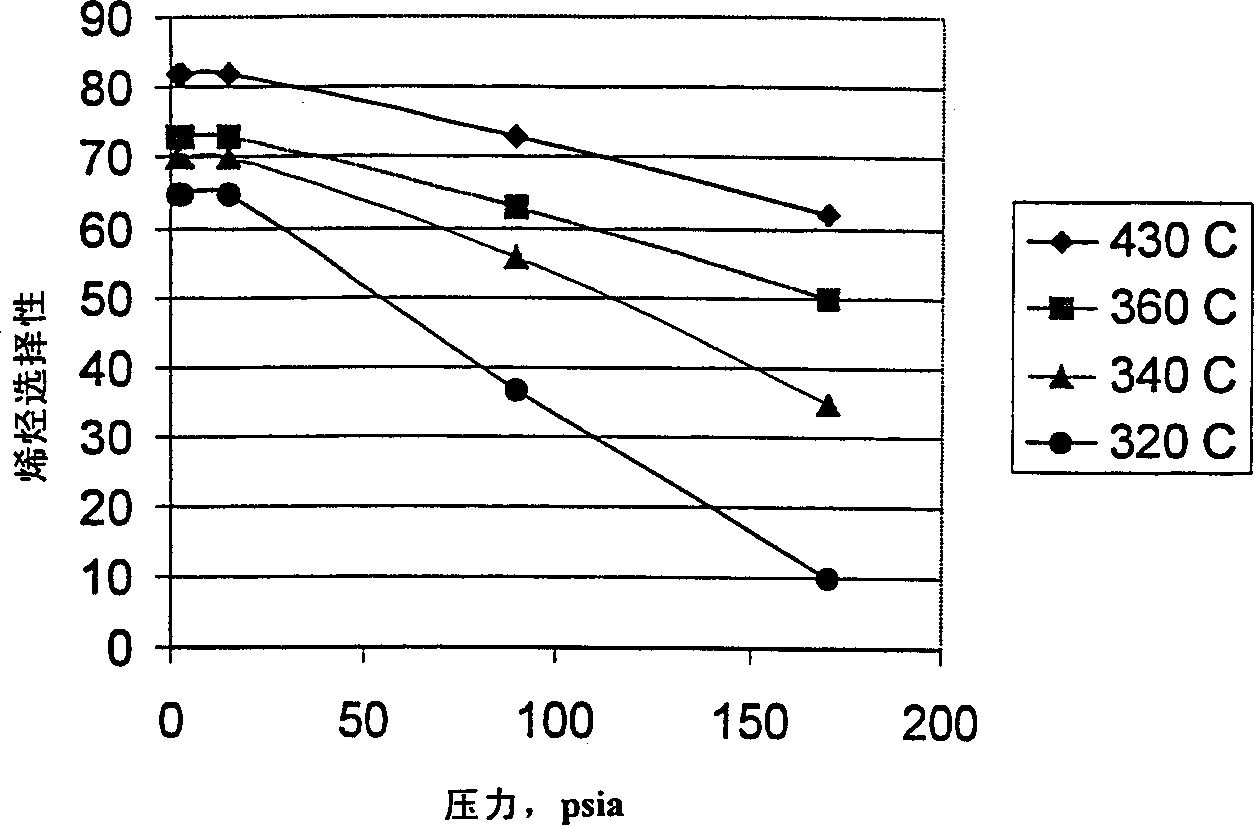

InactiveUS6613951B1No loss in ethylene+propylene selectivityLight olefin selectivityMolecular sieve catalystCatalystsAlkeneTorr

There is provided a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins, which comprises the step of contacting a feed containing methanol or dimethyl ether with a catalyst which comprises a zeolite having 10-ring intersecting channels, such as ZSM-5, and which has a Diffusion Parameter for 2,2-dimethylbutane of less than 100 sec-1 when measured at a temperature of 120° C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). The contacting step is conducted at a temperature of 370 to 480° C., a methanol partial pressure of 30 to 150 psia and a methanol conversion per pass of less than 95%.

Owner:MOBIL OIL CORP

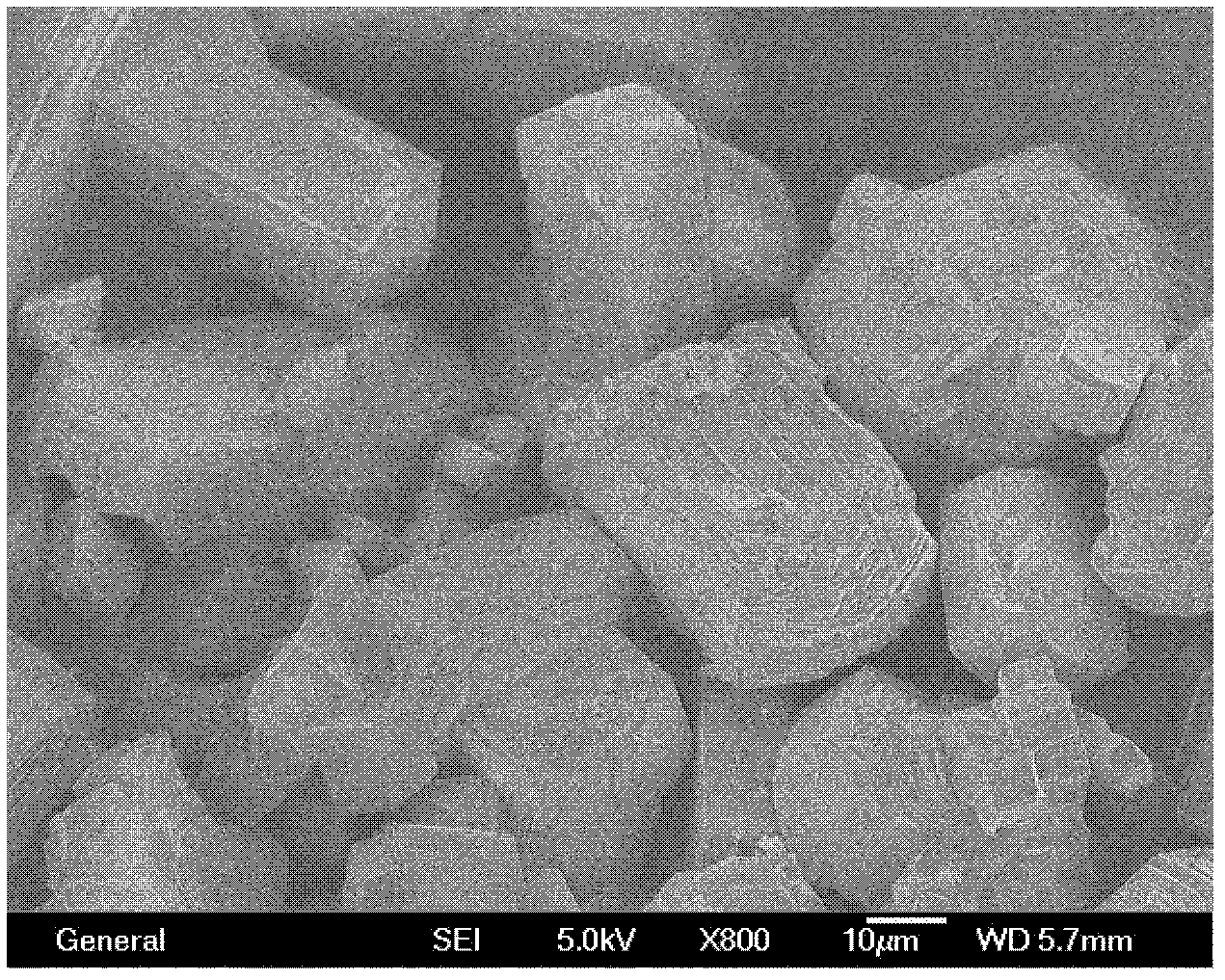

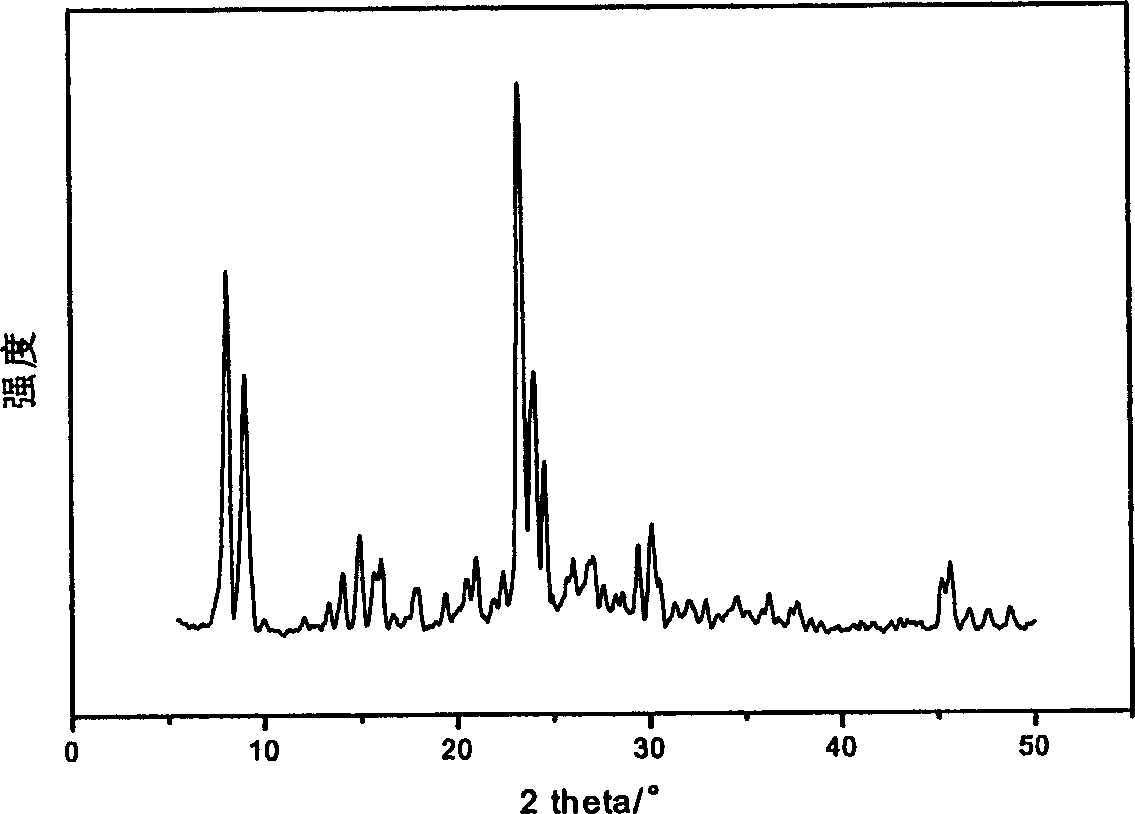

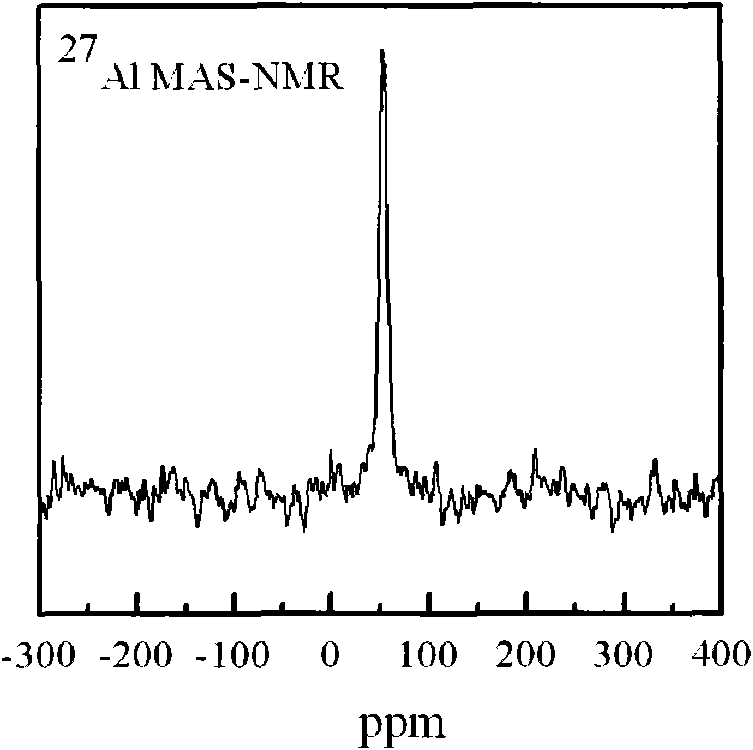

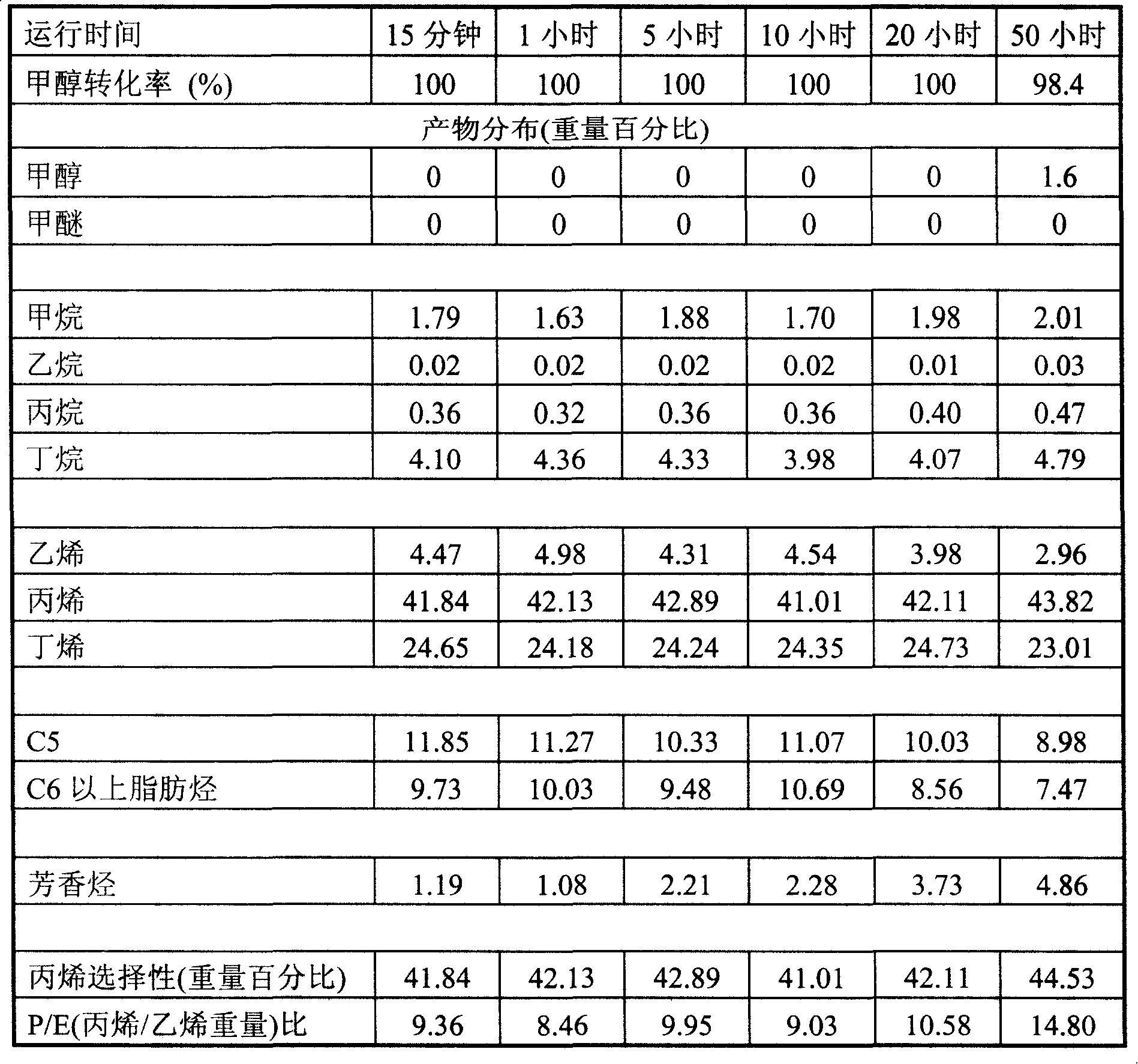

ZSM-5 type molecular sieve for catalyst for reaction for preparing propylene from methanol and/or dimethyl ether

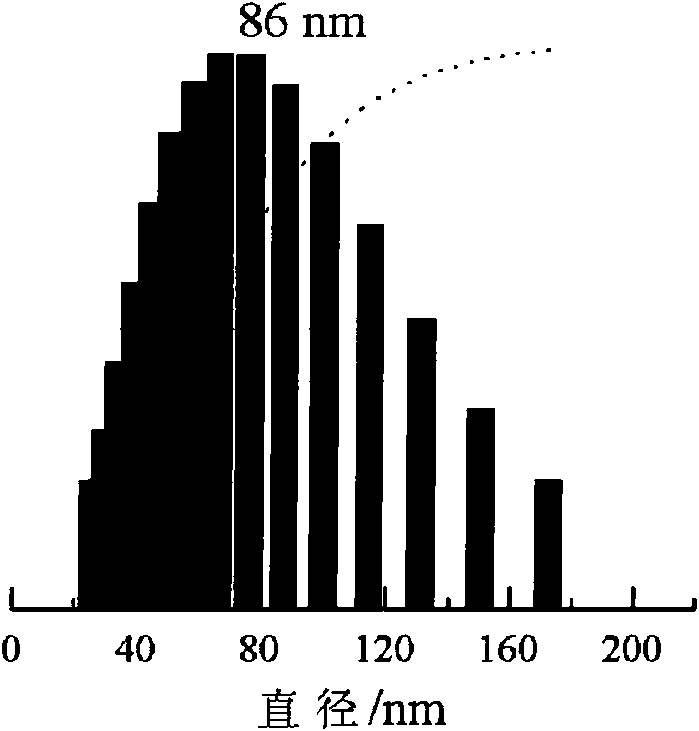

ActiveCN101624192AImprove diffusion abilityHigh P/E ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsDispersitySilicon

The invention provides a ZSM-5 type molecular sieve for a catalyst for a reaction for preparing propylene from methanol and / or dimethyl ether, which has a silica alumina ratio of 250-1,150 and a grain diameter of 65-250nm. A preparation method of the molecular sieve comprises the following steps: (1) mixing an aluminum source and an organic directing agent and stirring an obtained mixture at constant temperature of 0-30 DEG C for 2-24 hours; (2) adding a silicon source and an organic addition agent to the mixed solution obtained in the step (1) and continuing stirring the mixed solution to obtain gel; (3) stirring the gel obtained in the step (2) at 35-95 DEG C and then carrying out a crystallization reaction for 24-240 hours at 60-200 DEG C, wherein in the raw materials for synthesizing the molecular sieve, and the molar ratio of OH<-1> to SO2 to AL2O3 to H2O to the organic directing agent to the organic directing agent is (0.1-0.35):1:(0.0005-0.01):(10-25):(0.1-0.6):(0.5-8). The ZSM-5 type catalyst has the characteristics of controllable grain size, adjustable silica alumina ratio, high dispersity, and the like and has higher propylene selectivity and P / E ratio in the reaction for preparing low carbon olefin from the methanol and / or the dimethyl ether.

Owner:DATANG INT CHEM TECH RESINST

ZSM-5 molecular sieve with small crystal grains and application thereof

ActiveCN101733143AGuaranteed alkali concentrationGuaranteed crystallinityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsZSM-5Methanol

The invention relates to ZSM-5 molecular sieve with small crystal grains and application thereof, mainly solving the technical problems that the silica-alumina molar ratio (SiO2 / Al2O3) of ZSM-5 molecular sieves with small crystal grains is less than 200, and the traditional ZSM-5 molecular sieves have poor catalyst stability and short service life when used for reaction for preparing propylene from methanol in the prior art. The invention well solves the problems by the technical scheme that the ZSM-5 molecular sieve with small crystal grains, which has a crystal diameter less than 300 microns and a SiO2 / Al2O3 molar ratio not less than 200, is used for reaction for preparing the propylene from the methanol. The invention can be used in industrial production for preparing the propylene from the methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

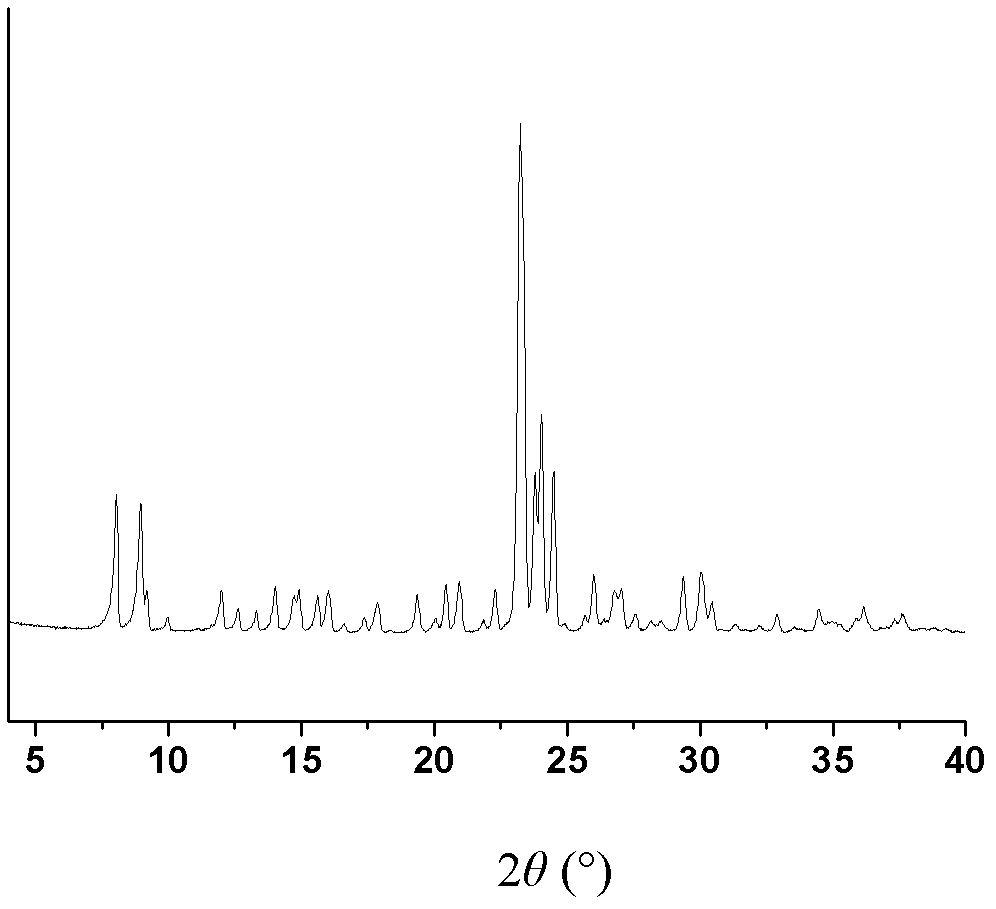

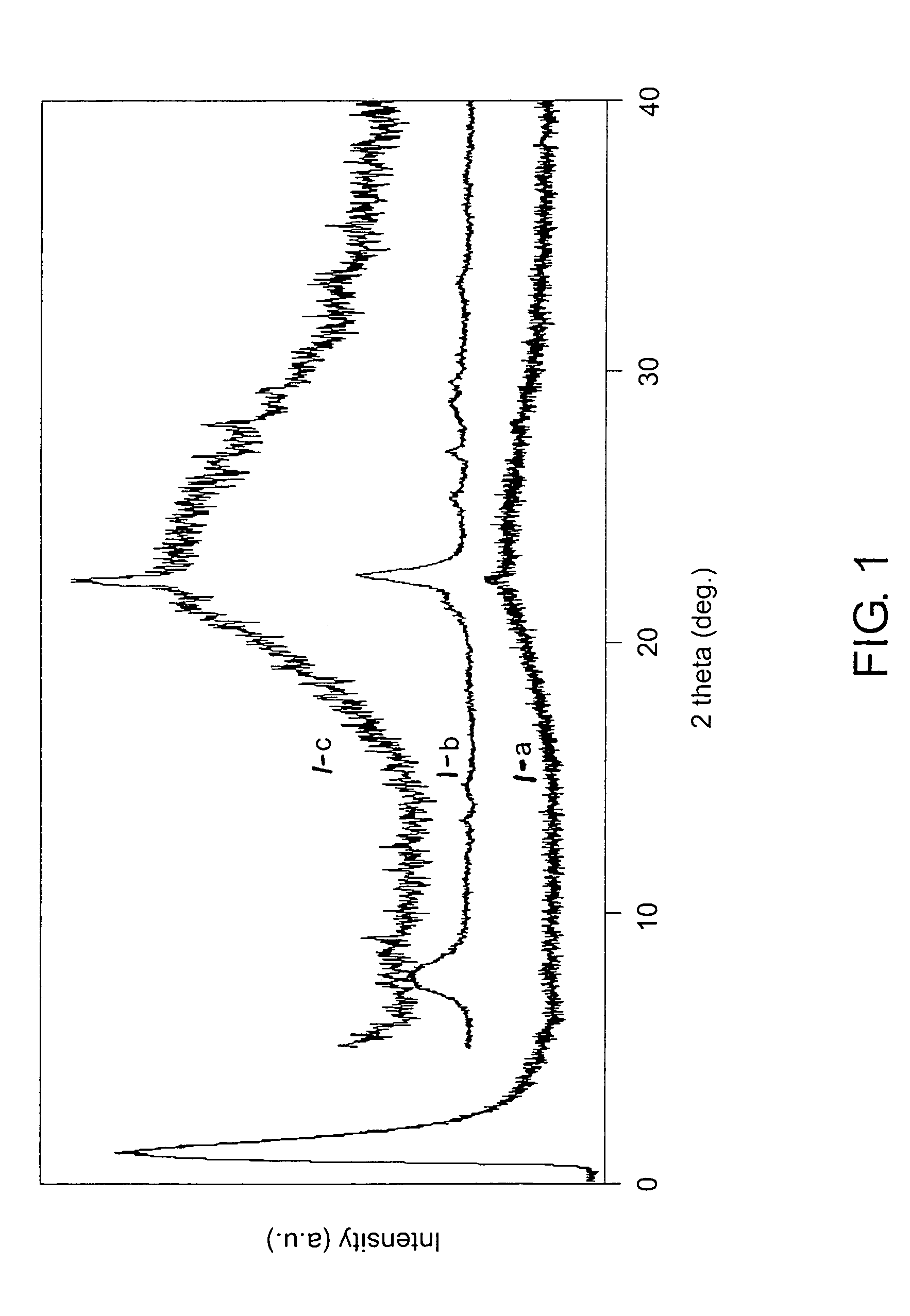

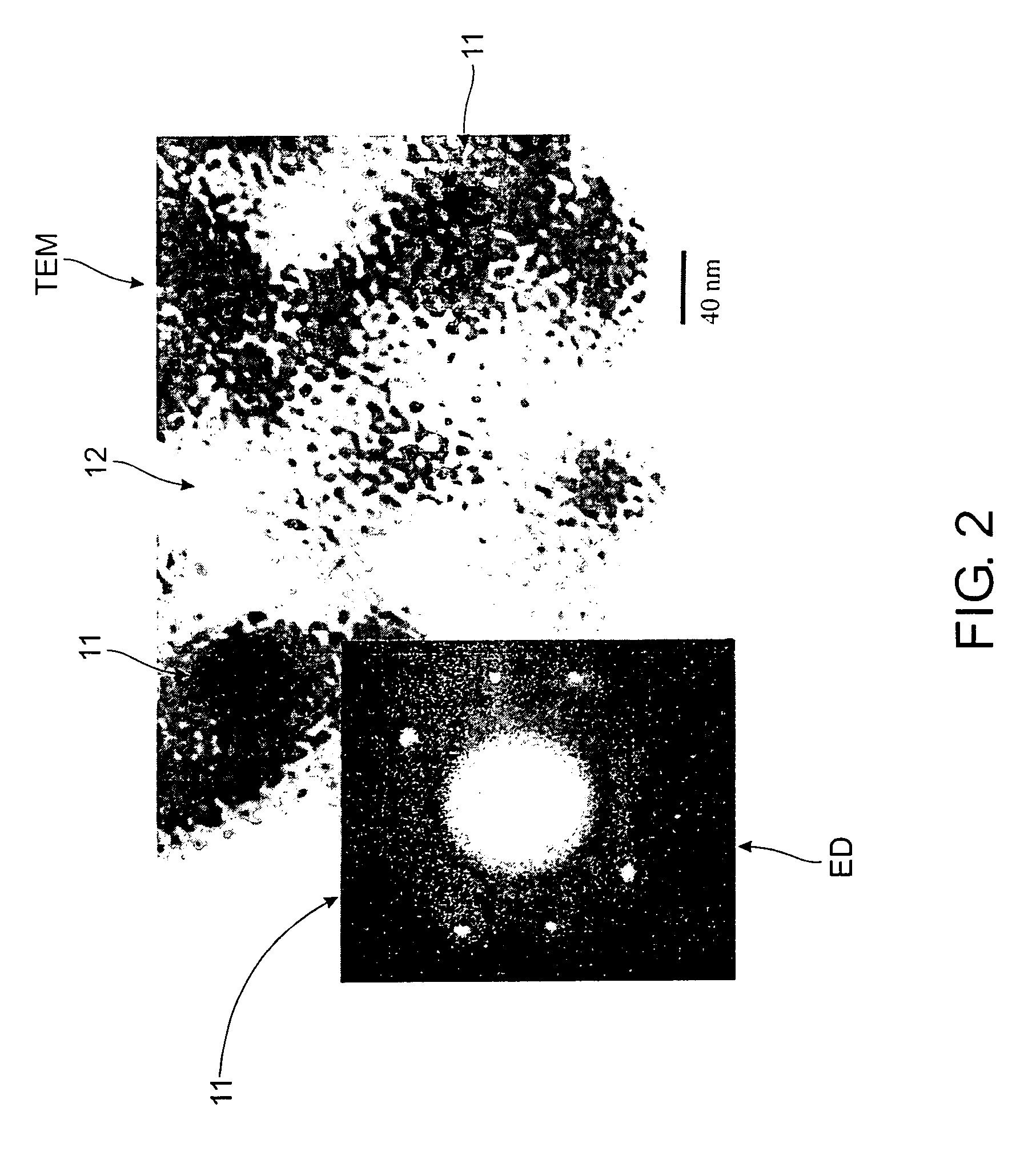

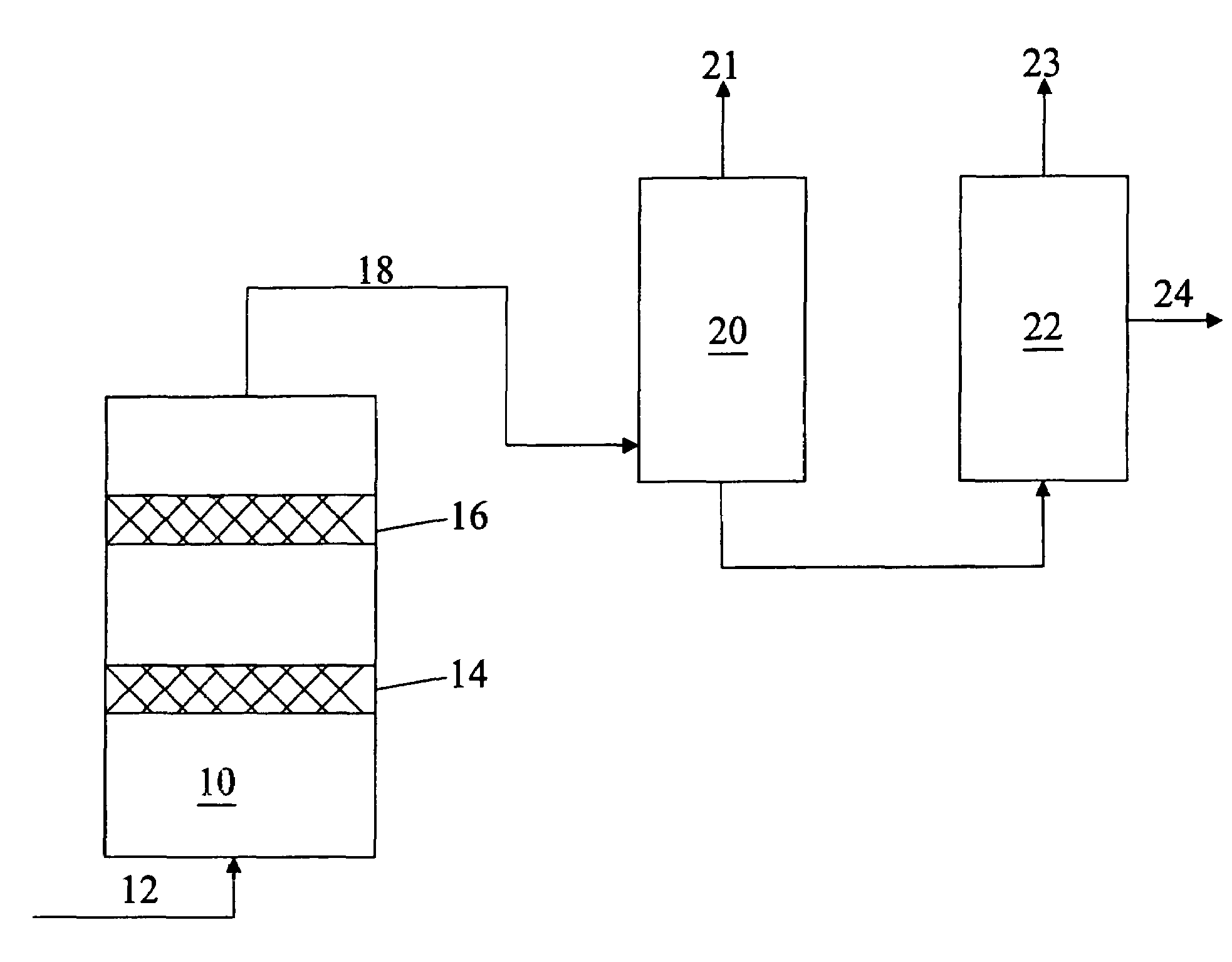

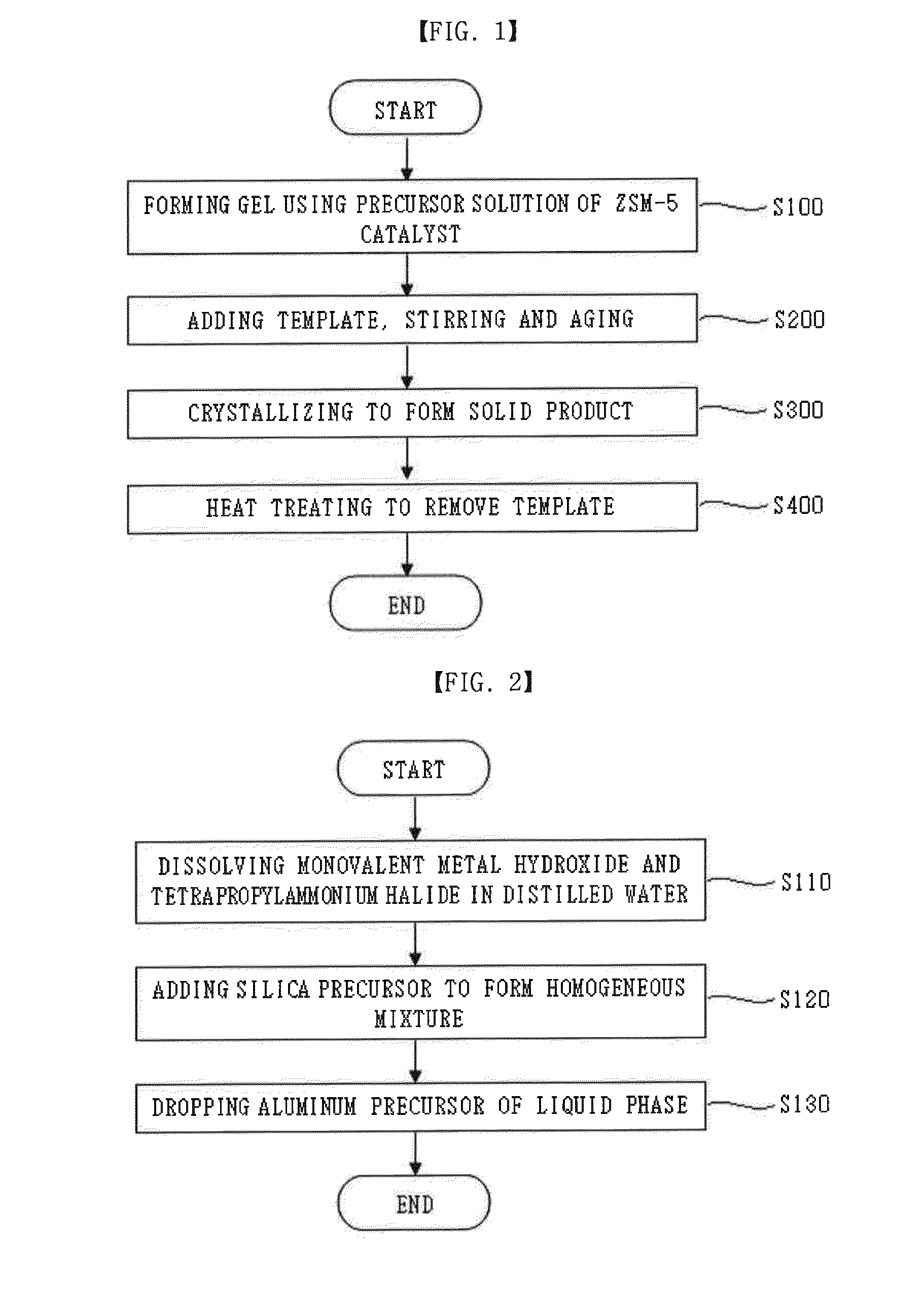

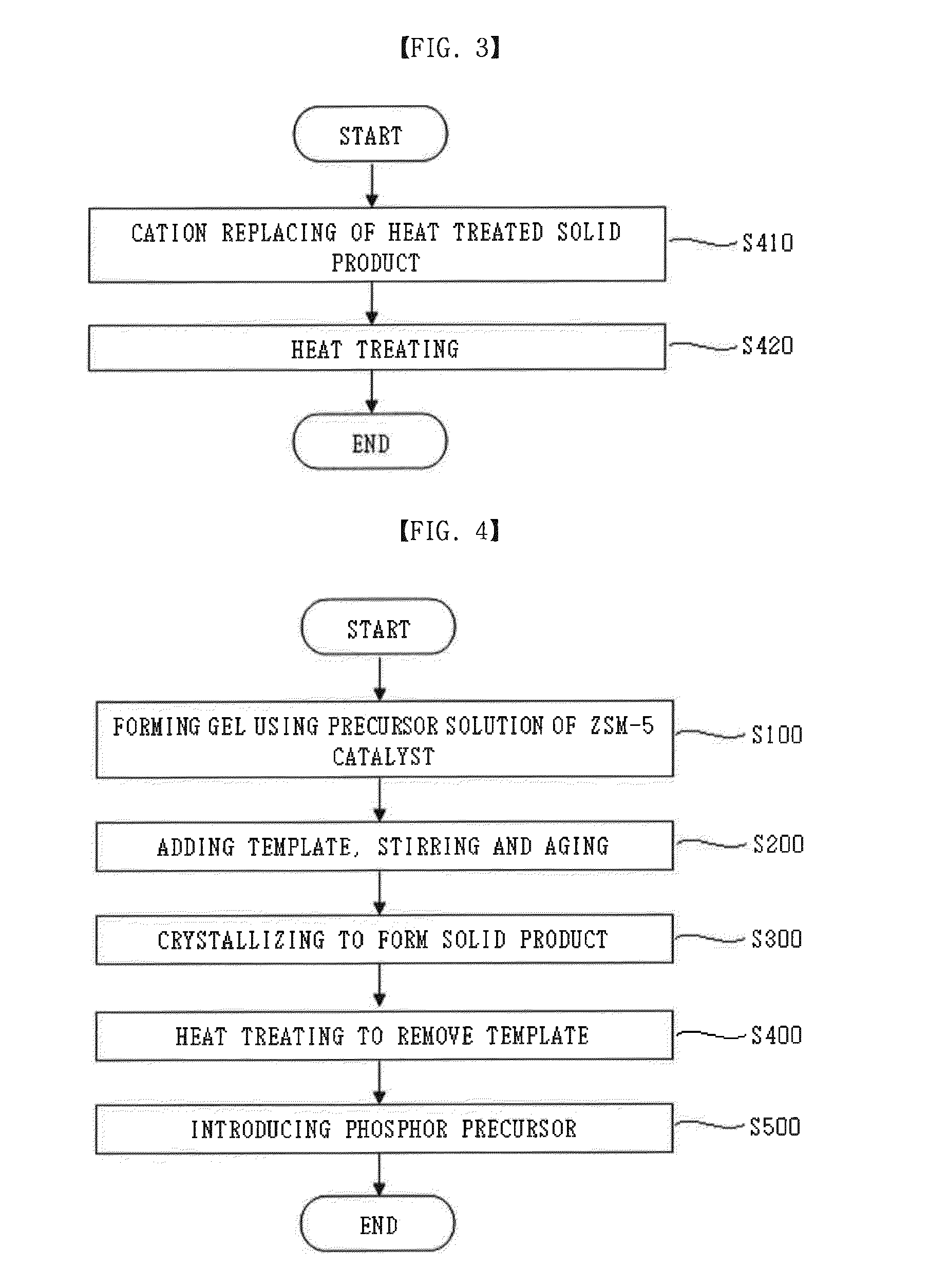

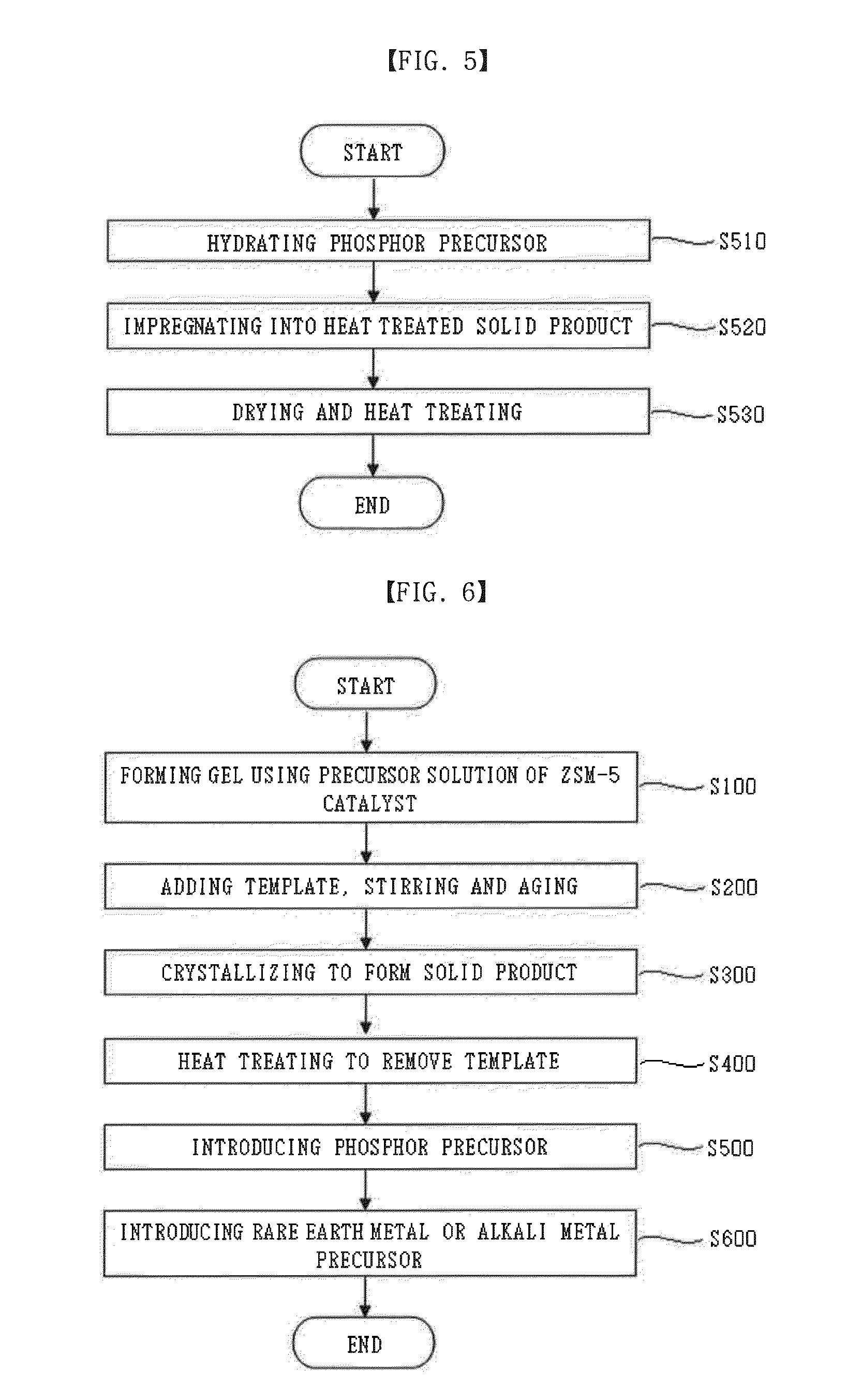

ZSM-5 catalyst with micropores and mesopores, preparation method thereof and production method of light olefins through catalytic cracking of hydrocarbons using the catalyst

InactiveUS20130085311A1Increase productionImprove featuresTreatment with plural serial cracking stages onlyCatalytic crackingHydrocarbon mixturesNaphtha

Provided is a method of preparing a ZSM-5 catalyst for preparing light olefins including ethylene and propylene through a catalytic cracking of a hydrocarbon mixture of C4 to C7 produced after a naphtha cracking. The method includes (a) forming a gel by aging a mixture solution including a silica precursor and an aluminum precursor; (b) adding a template possibly forming mesopores through a heat treatment, into the gel, stirring and then aging; (c) forming a solid product by crystallizing the aged mixture in step (b); and (d) heat treating the solid product to remove the template. The ZSM-5 catalyst may include micropores and mesopores and may have good physical and chemical properties along with a good pore property. The production yield of the light olefins may be increased.

Owner:HONAM PETROCHEM

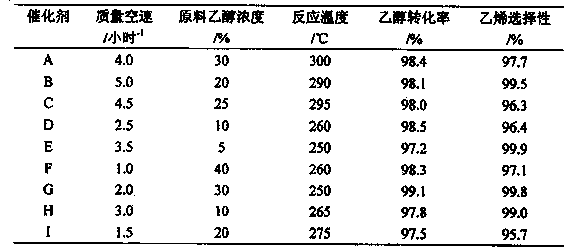

Catalyst for alkylation of toluene methanol

ActiveCN1915512AHigh activityImprove para-selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkyl transferHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

ZSM-5 molecular sieve modified catalyst as well as preparation method and application thereof

InactiveCN103521257AAchieve growthAchieve transformationMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureFixed bed

The invention relates to a ZSM-5 molecular sieve modified catalyst. The ZSM-5 molecular sieve modified catalyst comprises the following porous crystal materials in molar ratio: Al2O3 to nSiO2. The invention also relates to a preparation method of the ZSM-5 molecular sieve modified catalyst, a load modified catalyst which is used for low-concentration ethanol dehydration reaction and is specifically prepared performing radical grafting and surface modification by taking a ZSM-5 molecular sieve as a carrier and, and a preparation method for preparing ethylene through dehydration of low-concentration ethanol on a fixed bed reactor. In the preparation method, the low-concentration ethanol dehydration catalyst prepared by loading a modified ZSM-5 molecular sieve has the characteristics of high catalytic activity, high selectivity, easiness in regeneration and the like. Through long-term continuous running on the fixed bed reactor, the ZSM-5 molecular sieve modified catalyst shows the low reaction temperature and low energy consumption performances when used in a low-concentration ethanol dehydration process, the ethanol conversion ratio is high, the ethylene selectivity and yield are high, and the catalyst has the advantages of being stable in activity, convenient to regenerate, stable to operate and the like.

Owner:连云港阳方催化科技有限公司

ZSM-5/SAPO-11 composite zeolite and catalytically cracked gasoline hydrogenation quality-improved catalyzer and the methoer for preparing the same

ActiveCN101081370AImprove product qualityEquilibrium HydrodesulfurizationMolecular sieve catalystsHydrocarbon oils refiningIsomerizationHydrodesulfurization

The present invention is one kind of catalyst with ZSM-5 / SAPO-11 composite zeolite for hydrogenating and modifying catalytically cracked gasoline and its preparation process. The composite zeolite is prepared through compounding solution A with aluminum sulfate, sulfuric acid and water; compounding solution B with water glass, tetraethyl ammonium hydroxide and water; mixing solution A and solution B to form homogeneous colloid; crystallizing the colloid mixture at 150-180 deg.c for 24-72 hr; adding phosphoric acid, pseudoboehite, silica sol and SAPO-11 synthesizing template agent; and final crystallizing at 170-200 deg.c for 24-48 hr to obtain sodium type composite zeolite. The catalyst with the composite zeolite as carrier has excellent hydrogenating and desulfurizing performance, high stability, high gasoline yield, high isomerization activity and certain aromatization activity, and may be applied in producing high quality clean gasoline product.

Owner:BEIJING CUP GREEN CATALYTIC TECH

Method for preparing propylene catalyst from methanol conversion

ActiveCN101239326AHigh yieldWeight increaseMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPhosphoric acidZSM-5

The present invention provides a preparing method of propylene catalyst by converting methanol, mainly resolves the problem of lower yield of product propylene and lower P / E ratio present in the technology. ZSM-5 powder of the invention partly removes the template agent in air, ZSM-5 molecular sieve precursors I then is acid cleaned by at least one mineral acid from hydrochloric acid, nitric acid, sulphuric acid or phosphoric acid, molecular sieve precursors II is caustic washed by washing the molecular sieve precursors I by aqueous slkali; the catalyst is prepared by converting and baking the molecular sieve precursors I using at least one mineral acid from hydrochloric acid, nitric acid, sulphuric acid or phosphoric acid, the method can resolve the problem, and used for DMTP industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluid cat cracking with high olefins production

InactiveUS20020189973A1Maximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300° F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com