ZSM-5/SAPO-11 composite zeolite and catalytically cracked gasoline hydrogenation quality-improved catalyzer and the methoer for preparing the same

A SAPO-11, composite zeolite technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of poor catalytic stability and poor comprehensive performance, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, sodium ZSM-5 / SAPO-11 composite zeolite I was synthesized.

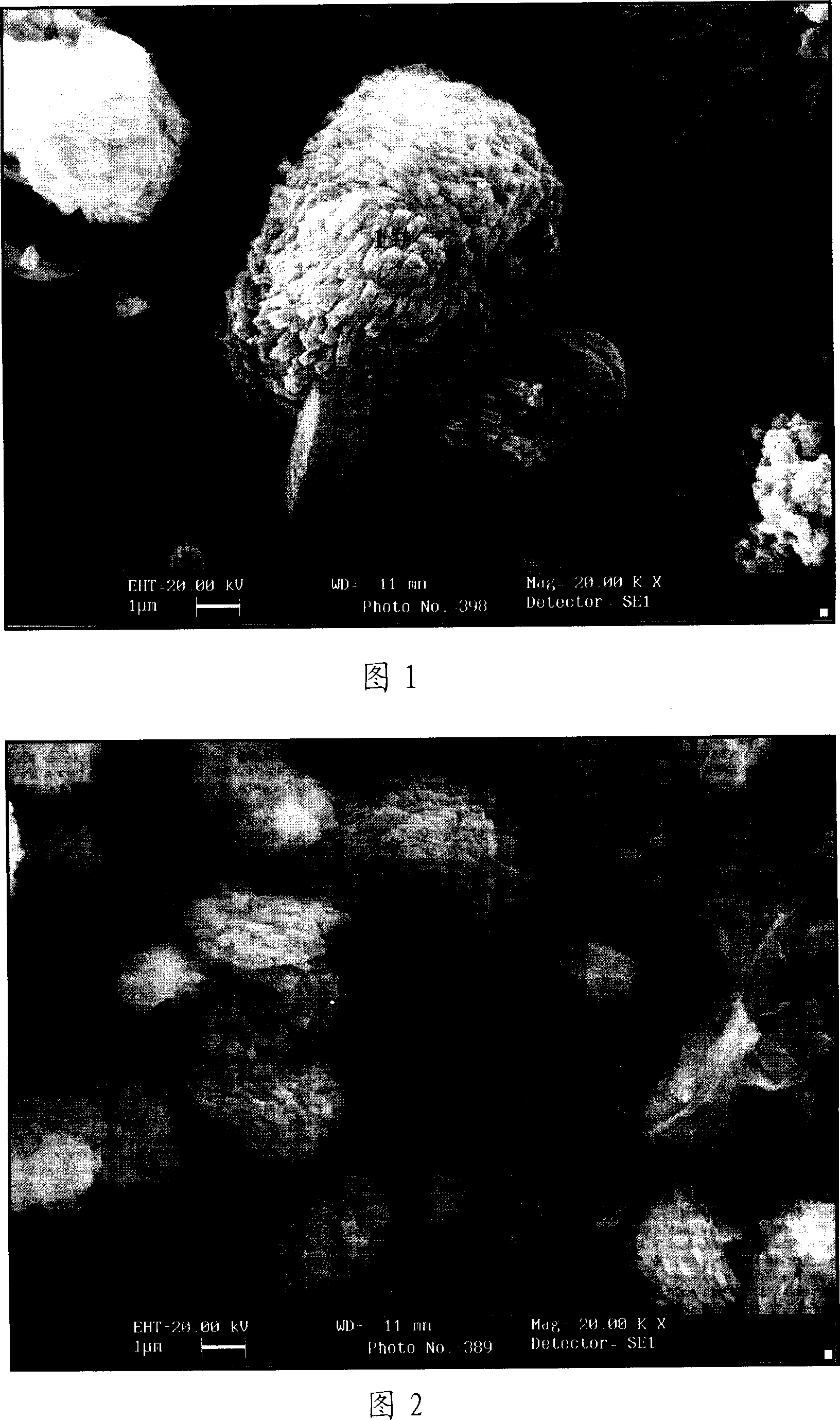

[0034] According to chemical composition (molar ratio) 9.7 Na 2 O: 1Al 2 o 3 : 55SiO 2 : 10TEAOH (tetraethylammonium hydroxide): 3500H 2 O Prepare the initial gel of ZSM-5, put it into a 500ml reactor, and crystallize it at 175°C for 48 hours to obtain the crystallized product of ZSM-5. In the crystallized product, according to the chemical composition (molar ratio) 1DPA (di-n-propylamine): 1 Al 2 o 3 : 1P 2 o 5 : 0.4SiO2 2 :50H 2 O sequentially quantitatively add phosphorus source, aluminum source, silicon source and organic amine, and crystallize the reaction mixture gel at 185°C for 24 hours. The composition of the obtained sodium-type composite zeolite I is: sodium-type ZSM-5 silicon-alumina The ratio is 50, and the weight percentage is 30%; the silicon-aluminum ratio of the sodium type SAPO-11 is 0.3, and the weight percentage is 70%. Its scanning electron microscope photo is sh...

Embodiment 2

[0036] In this example, sodium ZSM-5 / SAPO-11 composite zeolite II was synthesized.

[0037] According to chemical composition (molar ratio) 8.5 Na 2 O:Al 2 o 3 : 68SiO 2 : 15TEAOH (tetraethylammonium hydroxide): 3000H 2 O Prepare the initial gel of ZSM-5, put it into a 500ml reaction kettle, and crystallize it at 175°C for 48 hours to obtain the crystallized product of ZSM-5. In this crystallized product, according to the chemical composition (molar ratio) DPA (di-n-propylamine): Al 2 o 3 :P 2 o 5 : 0.8SiO2 2 :50H 2 O sequentially quantitatively added phosphorus source, aluminum source, silicon source and organic amine, and crystallized the reaction mixture gel at 190°C for 24 hours to obtain sodium ZSM-5 / SAPO-11 composite zeolite II, in which: ZSM-5 The silicon-aluminum ratio is 62, and the weight percentage is 20%; the silicon-aluminum ratio of SAPO-11 is 0.6, and the weight percentage is 80%.

Embodiment 3

[0039] In this example, sodium ZSM-5 / SAPO-11 composite zeolite III was synthesized.

[0040] According to chemical composition (molar ratio) 10.6 Na 2 O:Al 2 o 3 : 79SiO 2 : 20TEAOH (tetraethylammonium hydroxide): 3600H 2 O Prepare the initial gel of ZSM-5, put it into a 500ml reaction kettle, and crystallize it at 175°C for 48 hours to obtain the crystallized product of ZSM-5. In this crystallized product, according to the chemical composition (molar ratio) DPA (di-n-propylamine): Al 2 o 3 :P 2 o 5 : 1.0 SiO 2 :50H 2 O sequentially quantitatively added phosphorus source, aluminum source, silicon source and organic amine, and crystallized the reaction mixture gel at 190°C for 24 hours to obtain sodium-type ZSM-5 / SAPO-11 composite zeolite III, in which: ZSM-5 The silicon-aluminum ratio is 70, and the weight percentage is 40%; the silicon-aluminum ratio of SAPO-11 is 0.8, and the weight percentage is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com