Metal powder preparation device and method therefor

A technology of metal powder and preparation equipment, which is applied in the field of metal powder preparation equipment, can solve the problems of difficulty in ensuring the control of ultrafine powder content, difficulty in continuous powder preparation for a long time, and unfavorable guarantee of powder quality, so as to improve the production environment and improve the quality of the powder. The degree of equipment automation and the effect of ensuring the screening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

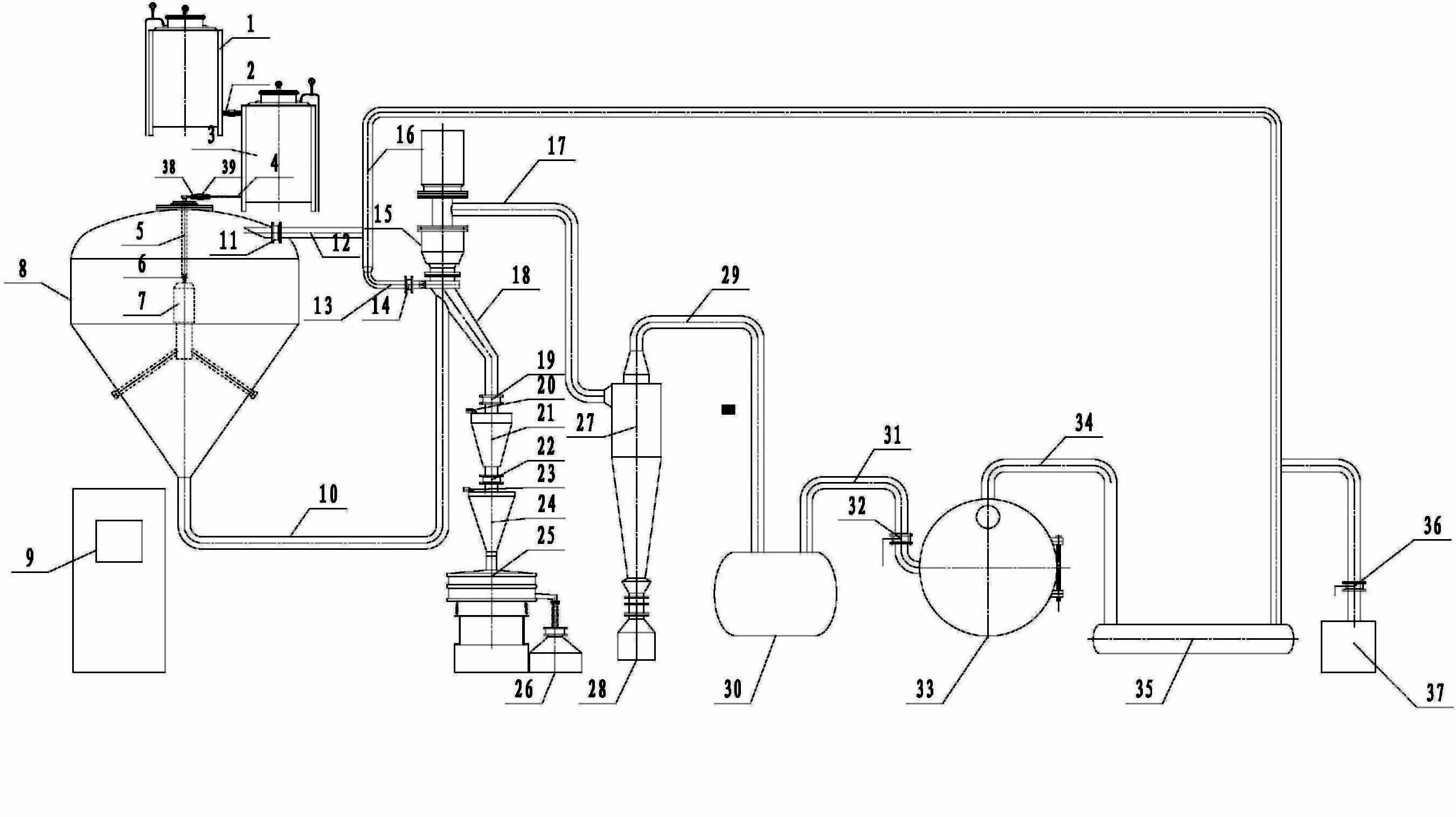

[0054] The preparation method of the metal powder of the present invention includes atmosphere preparation, metal smelting, melt transportation, atomization, floating powder settlement, pneumatic classification, mechanical screening, gas purification, gas driving, gas cooling and other links. Before entering the atomization, the system atmosphere preparation and metal smelting must be completed. First, the atomization chamber is evacuated and inflated to prepare the atmosphere; after the metal is melted and processed in the smelting furnace 1, it is connected to the atomization furnace 3 through the infusion tube 2, and then through the infusion The tube 4 and the conduit 5 pour the molten metal onto the atomizer 6, which forms a mist through the action of the atomizer 6, and the mist droplets fly, cool, and solidify in the atomization chamber 8 to form a powder. Under the action of the air, it is sent to the pneumatic classifier 15 for classification, and the coarse powder aft...

Embodiment 1

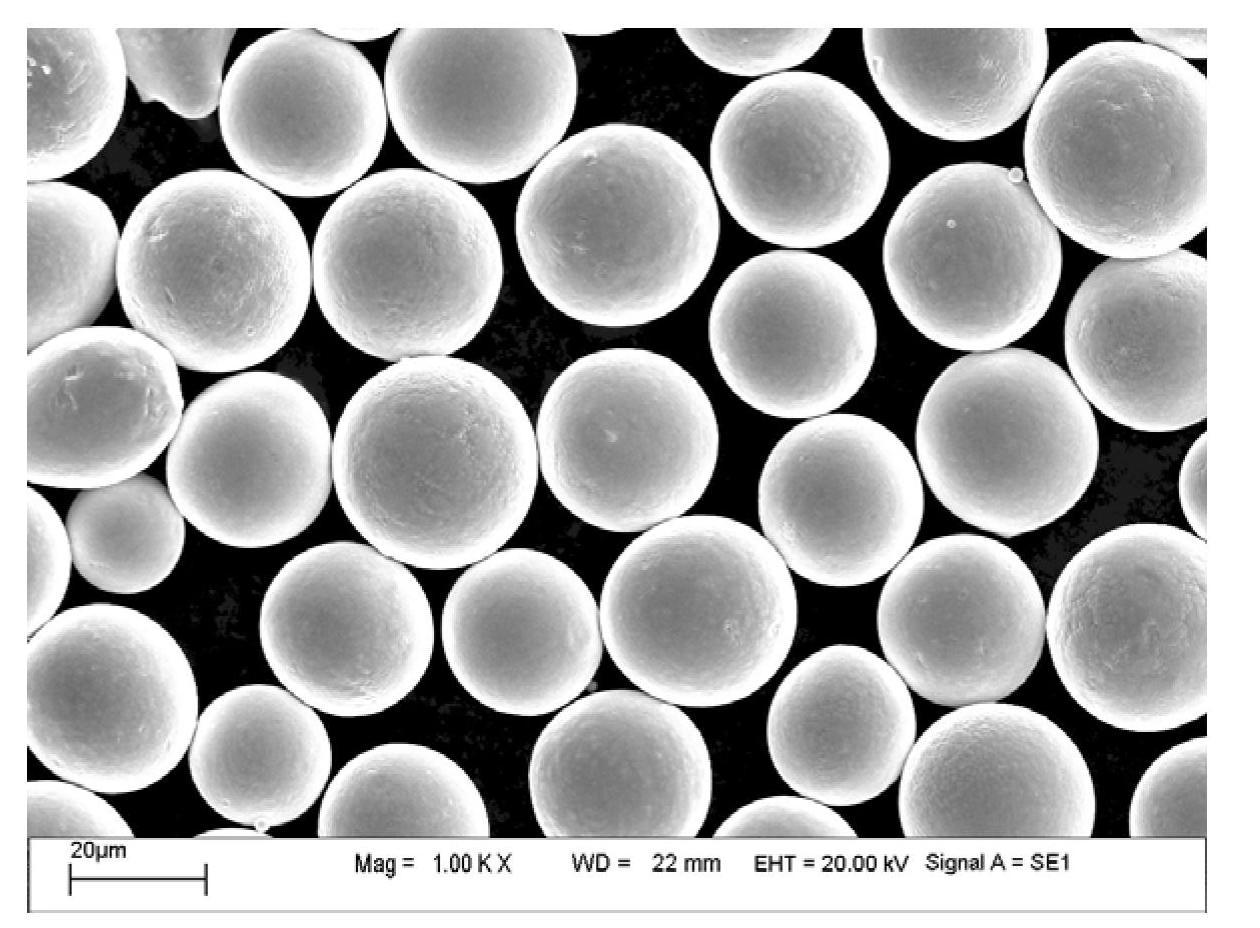

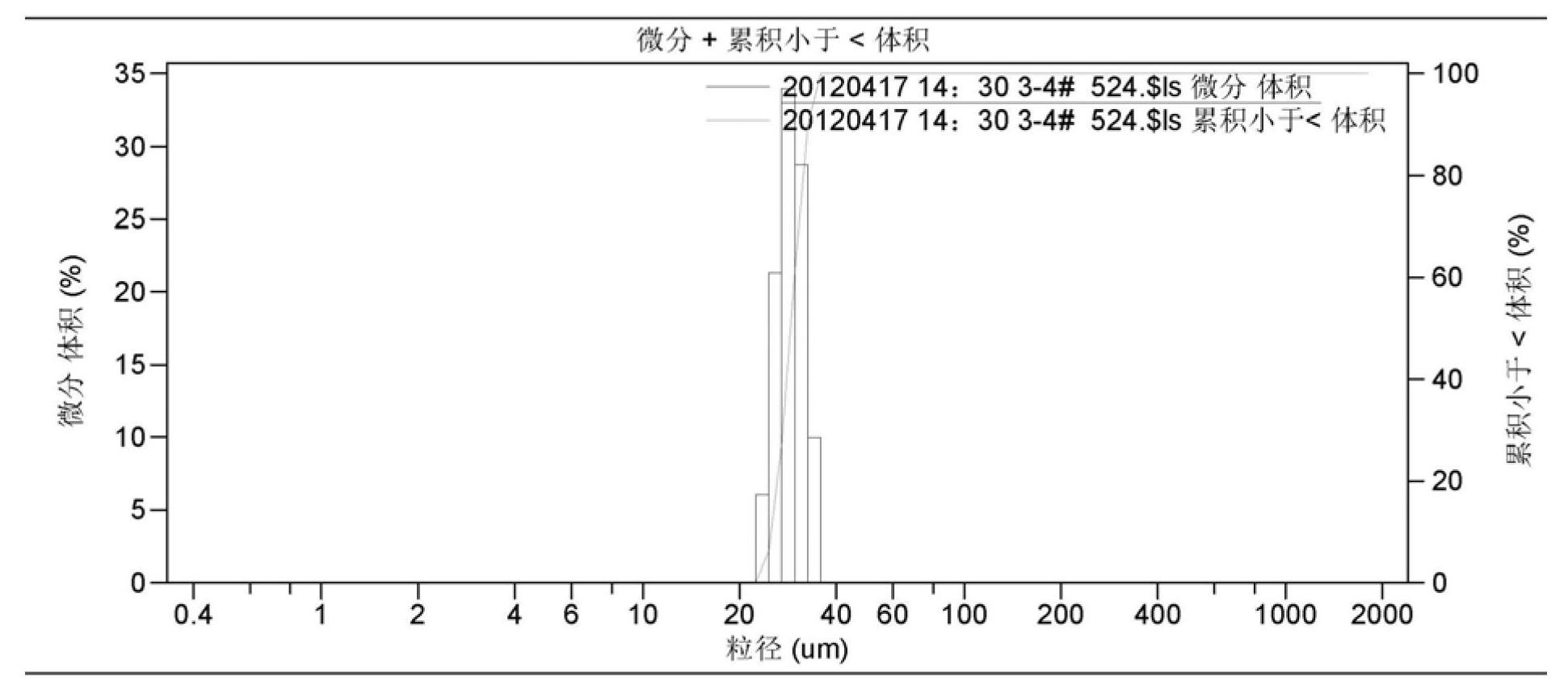

[0060] Atomized SnAg 3 Cu 0.5 . The system is evacuated to 50Pa, filled with nitrogen and 100ppm oxygen to 40KPa to prepare for atomization. Add Sn, Ag, and Cu into the vacuum melting furnace 1 according to the designed ratio, and then smelt at 330°C after vacuuming and inflating. The turntable is driven to rotate at a speed of 50000rpm for atomization, and the oxygen content in the atomization chamber 8 is stabilized at 100ppm. Under the action of gravity and airflow, the powder enters the centrifugal classifier for classification, and the centrifugal classifier cage rotates at 750rpm. The coarse powder separated by the centrifugal classifier passes through the transfer of the intermediate bin 21, and is transferred out from the closed system to the screening funnel 24, and then sieved by the rotary vibrating screen to obtain the finished powder (see the photo of the powder appearance figure 2 , the particle size distribution see image 3 ). The ultra-fine powder enter...

Embodiment 2

[0062] Nebulized SnBi58. The system is evacuated to 50Pa, filled with nitrogen and 80ppm oxygen to 30KPa to prepare for atomization. Add Sn and Bi into the vacuum melting furnace 1 according to the designed ratio, smelt at 200°C after vacuuming and inflating, and pour the melt into the atomizing furnace 3 after purification treatment, and then supply the atomizer through the infusion channel, the mist The atomizer adopts an ultrasonic atomizer with a vibration frequency of 60KHz to atomize the melt, and the oxygen content in the atomization chamber 8 is stabilized at 80ppm. The powder enters the centrifugal classifier 15 under the action of gravity and airflow for classification, and the centrifugal classifier cage rotates at a speed of 500 rpm. The coarse powder separated by the centrifugal classifier passes through the transfer of the intermediate bin 21, and is transferred out from the closed system to the screening funnel 24, and then sieved by the rotary vibrating screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com