Patents

Literature

100 results about "Mechanical screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.

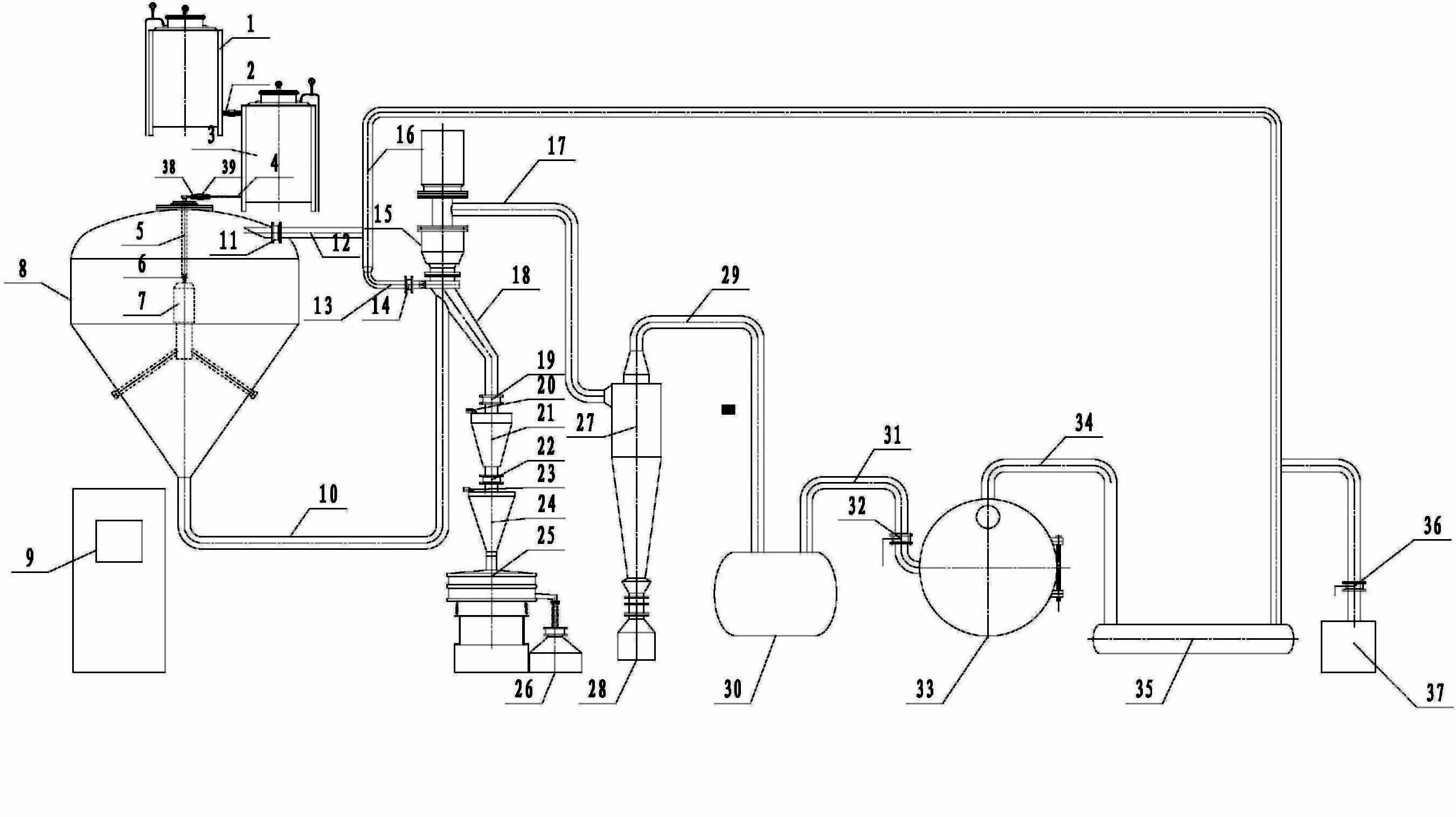

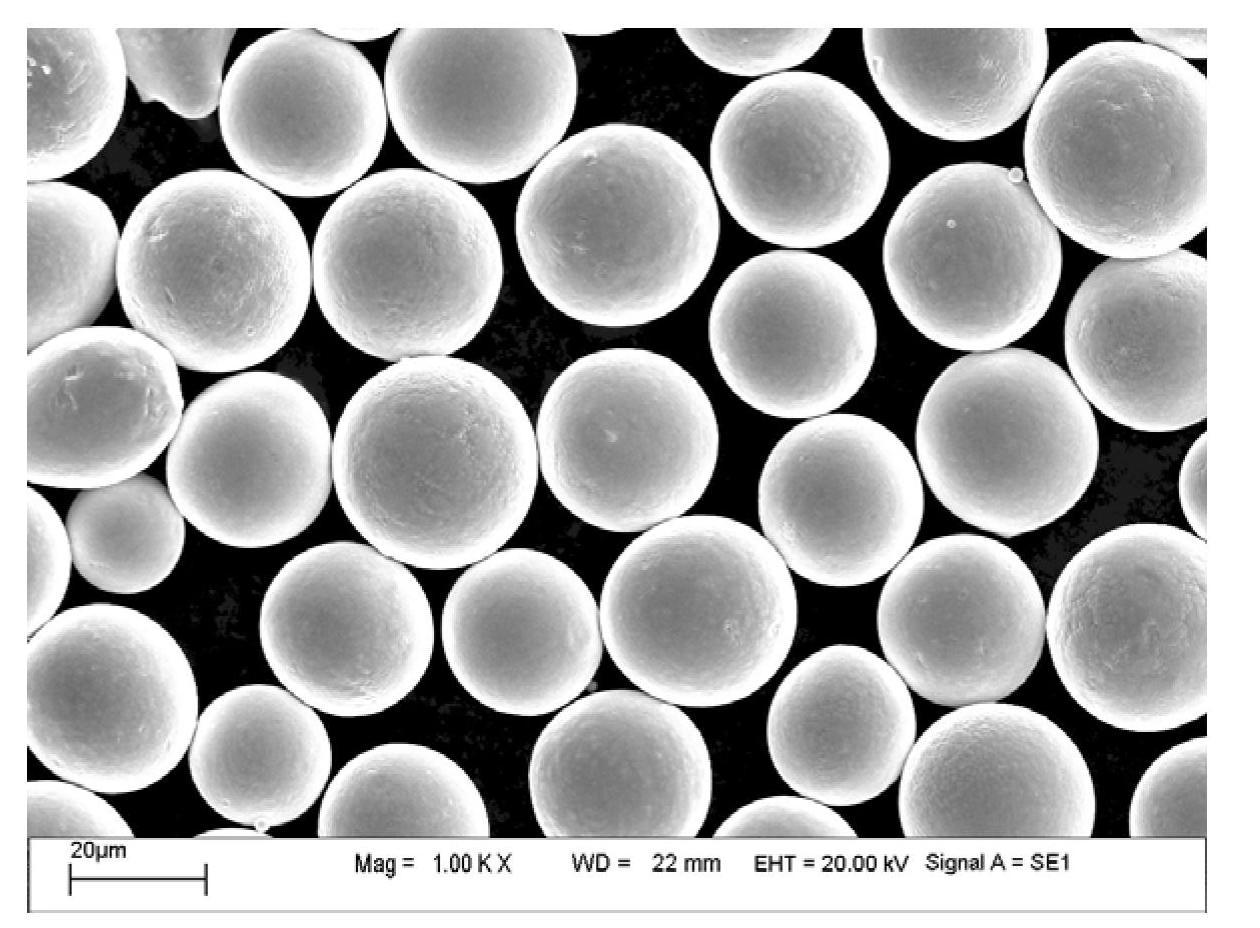

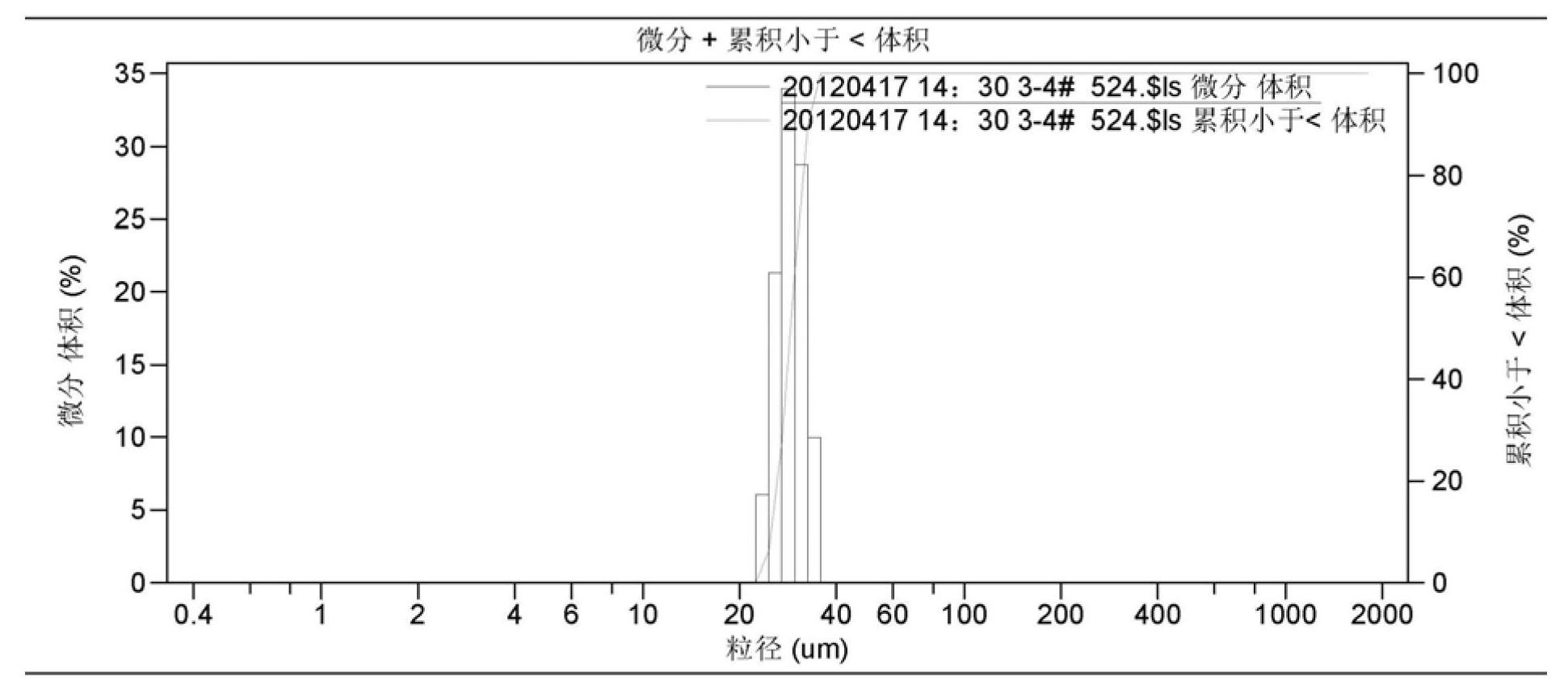

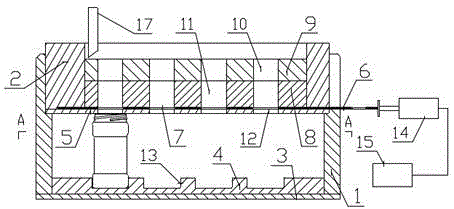

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

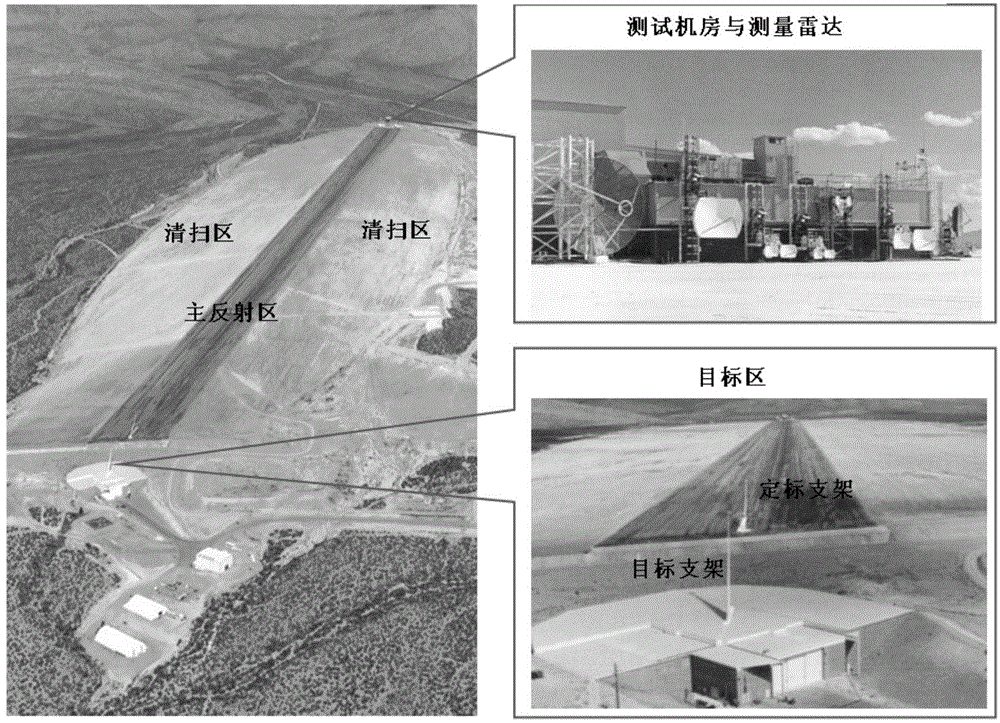

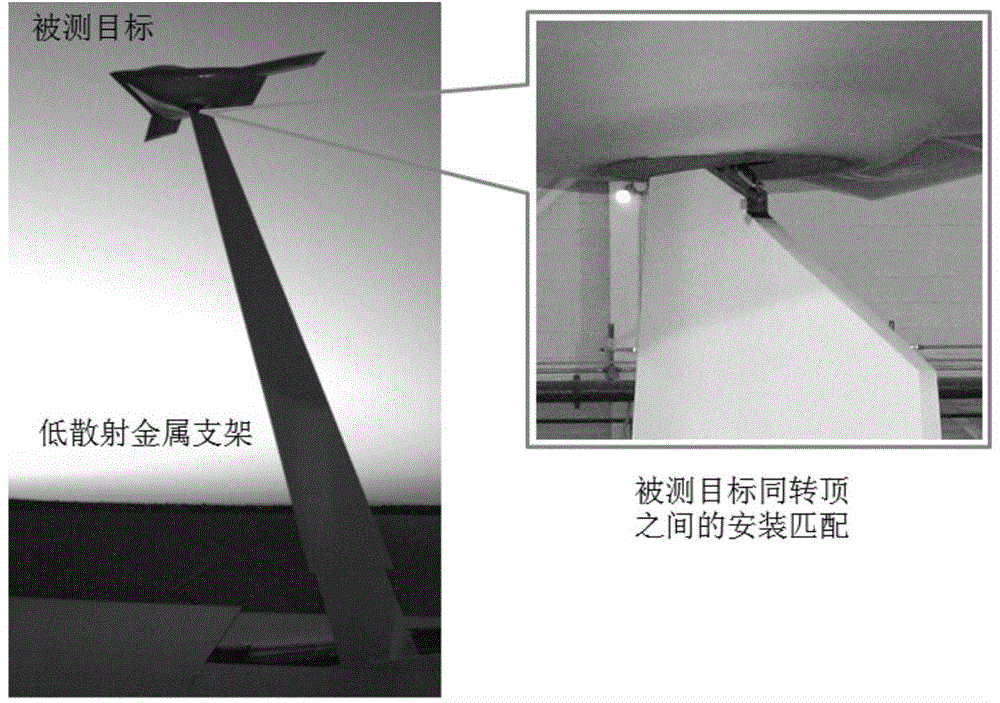

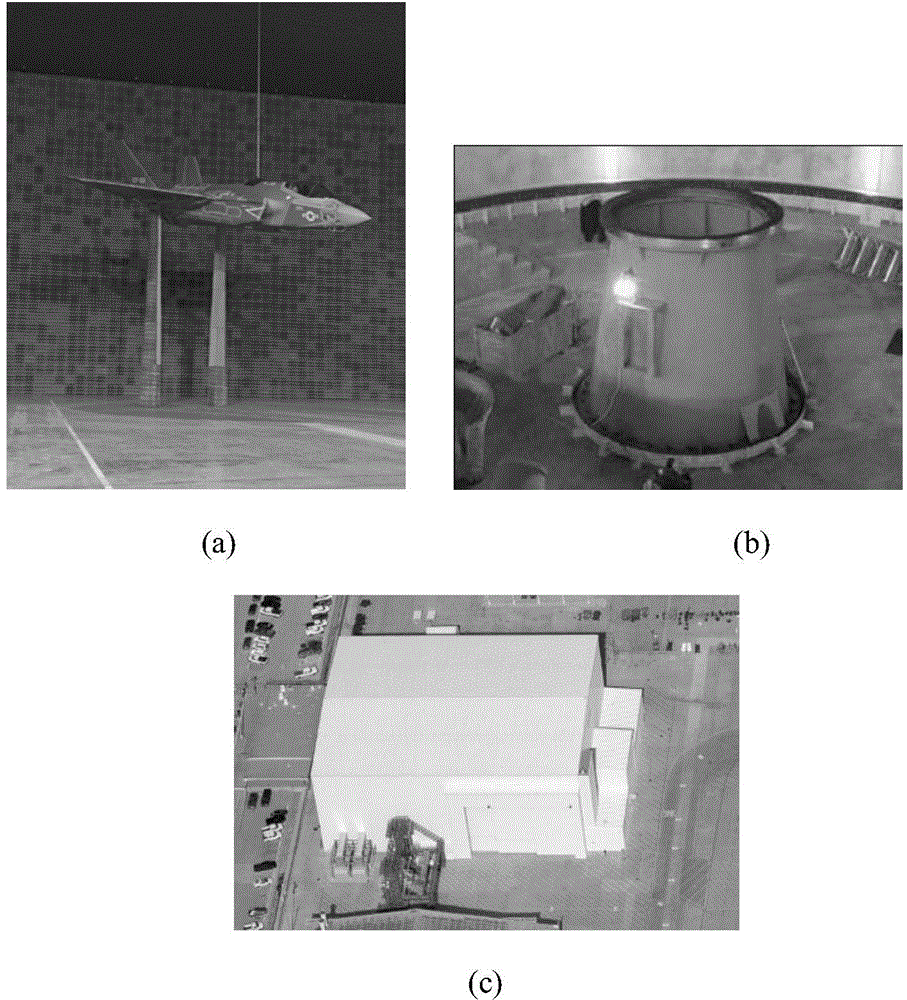

Telescopic array type portable MIMO-SAR (multiple-input multiple-output synthetic aperture radar) measurement radar system and imaging method thereof

ActiveCN104614726AQuick checkRapid positioningRadio wave reradiation/reflectionRadar systemsSynthetic aperture radar

The invention discloses a telescopic array type portable MIMO-SAR (multiple-input multiple-output synthetic aperture radar) measurement radar system and an imaging method thereof. The system comprises a telescopic MIMO antenna array, a radar transmitting / receiving machine, a control and processing computer, a liftable antenna frame and the like. The system has the advantages in an aspect of meeting field diagnosis and measurement of scattering properties in using and maintenance processes of a low detectable target that firstly, quick detection, positioning and imaging diagnosis of an abnormal scattering part of the low detectable target can be realized, that is, an MIMO-SAR different from a linear guiderail SAR in mechanical scanning imaging can finish high-resolution two-dimensional imaging of a measured target through one-time or two-time 'snapshot' electric scanning imaging; secondly, the requirement on a target test site environment is lowered, that is, guide rails for precision mechanical screening measurement do not need to be mounted in a target test site, so that the requirement on the site test environment in imaging diagnosis and measurement operation processes is greatly lowered; thirdly, the antenna array is telescopic, so that miniaturization, quick unfolding and folding as well as portability of the measurement radar system can be easily realized.

Owner:BEIHANG UNIV

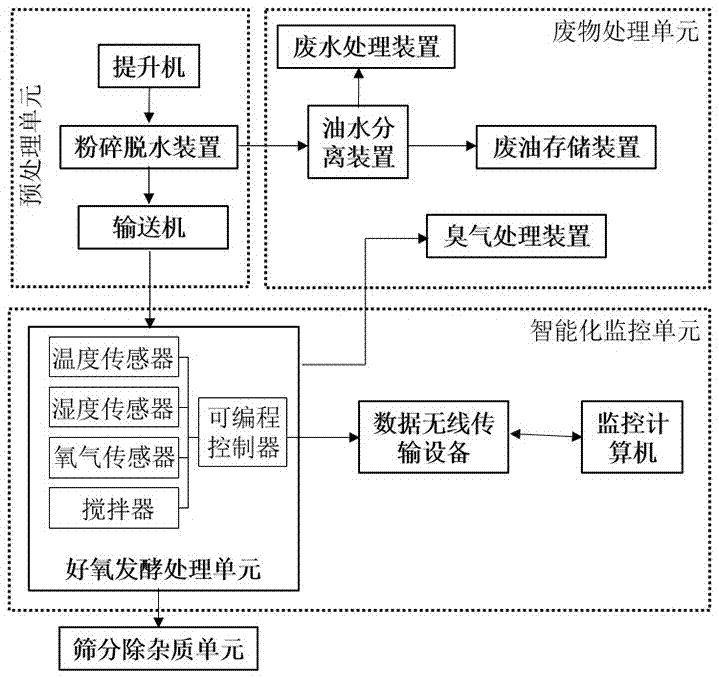

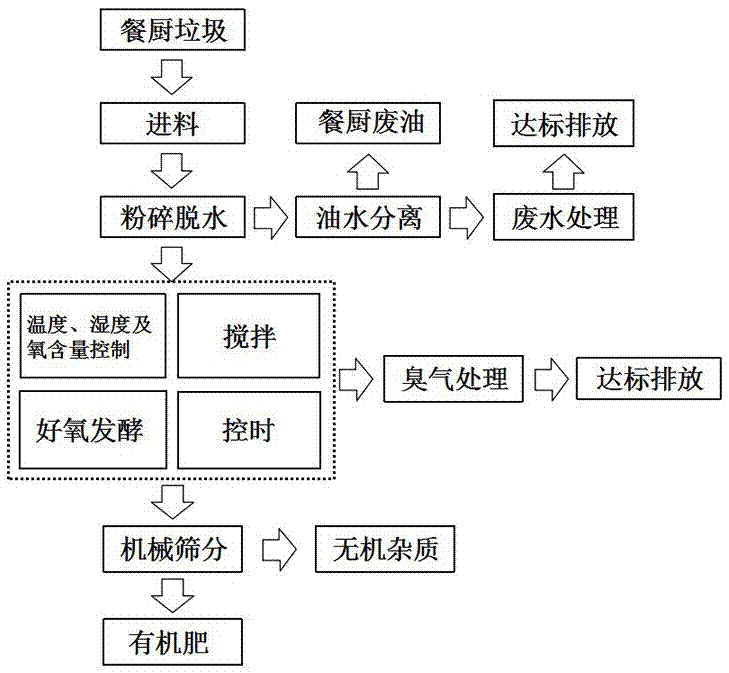

Novel kitchen waste treatment system and technology based on intelligent monitoring

InactiveCN106975645AImprove work efficiencyImprove biological activitySolid waste disposalIntelligent lightingOxygen

The invention discloses a novel food waste treatment system based on intelligent monitoring and a process thereof. The food waste treatment system based on intelligent monitoring of the present invention is characterized in that: the system comprises a pretreatment unit, an aerobic Fermentation processing unit, screening and removing impurities unit, waste processing unit and intelligent monitoring unit. The present invention also provides a kitchen waste treatment process, which is characterized by comprising the following steps: firstly, the collected kitchen waste is pulverized and dehydrated to obtain oil-water mixed liquid and residue particles; then the residue particles enter the aerobic state through a conveyor. The fermentation tank is mixed and stirred with fermentation strains, and aerobic fermentation is carried out at the same time to generate odor and organic materials; finally, the organic materials are mechanically screened by the screening and removal unit to separate organic materials and inorganic impurities to obtain high-quality organic materials. The fertilizer is used for recycling; the waste water obtained from dehydration and the odor generated during the aerobic fermentation process will be properly treated and disposed of by the waste treatment unit and then discharged up to the standard.

Owner:杭州科瑞特环境技术有限公司

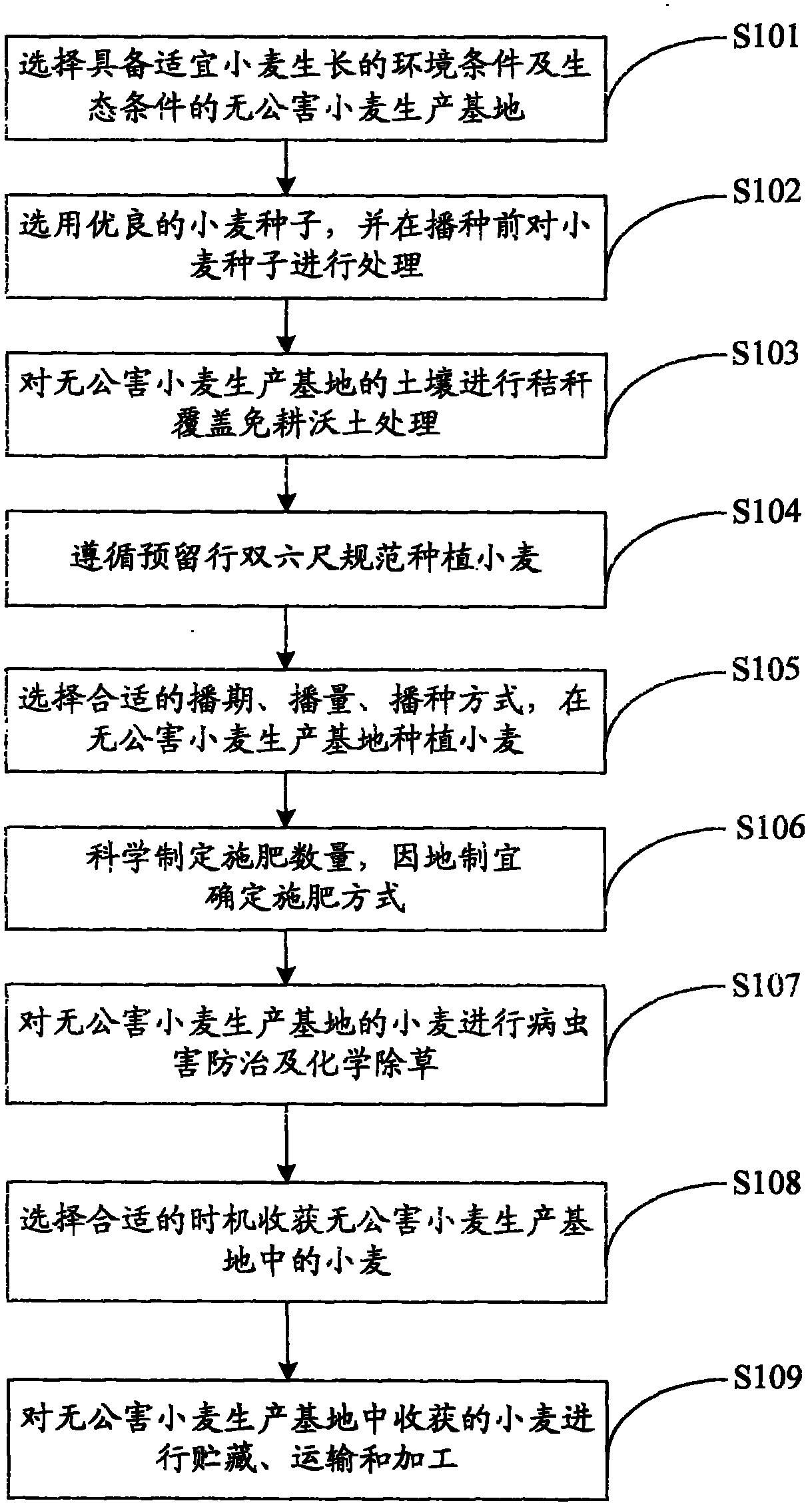

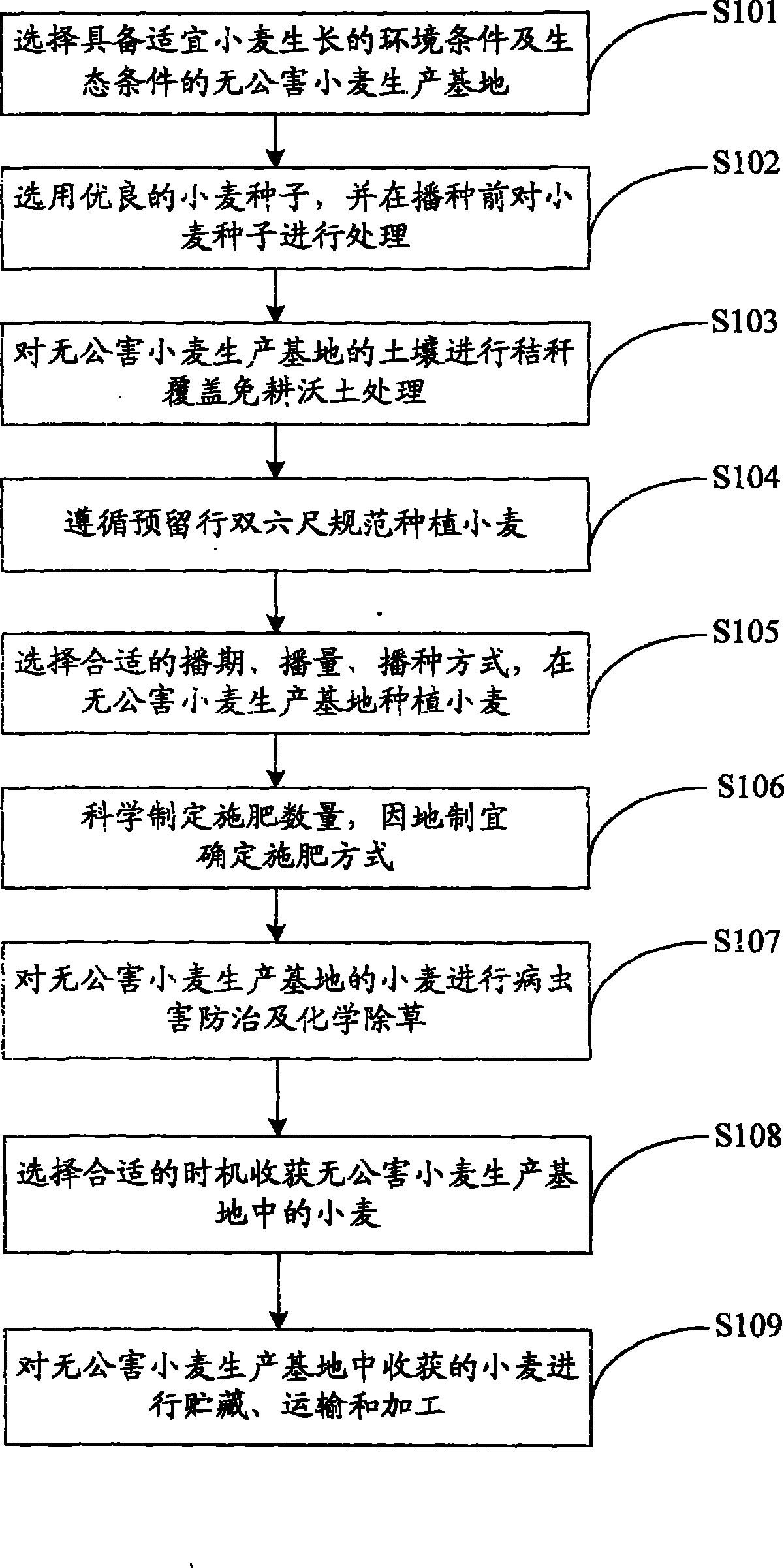

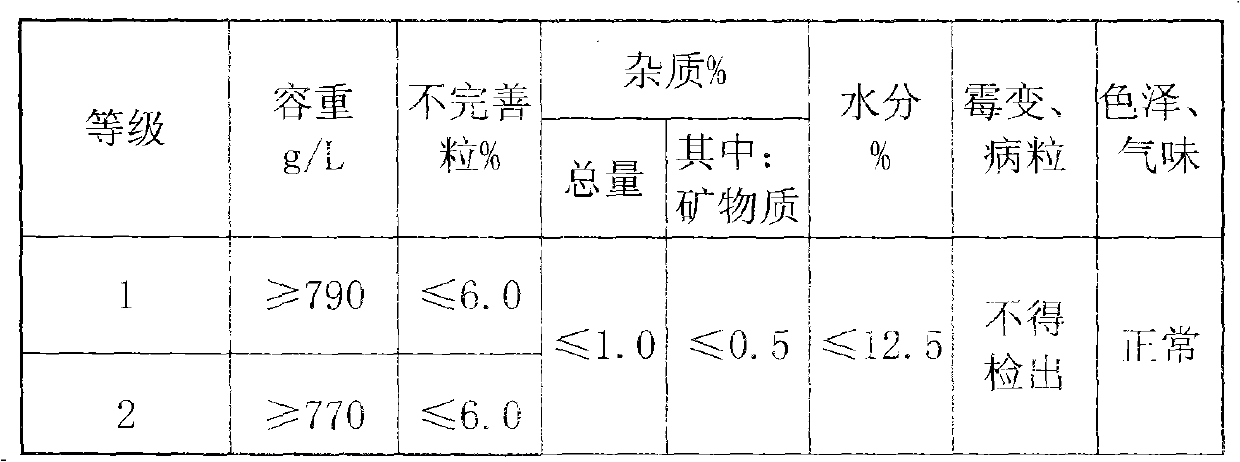

Wheat pollution-free high yield cultivation method

InactiveCN102668857AReduce investmentAvoid compromising qualityBiocideFertilising methodsEcological environmentInsect pest

The invention provides a wheat pollution-free high yield cultivation method and belongs to the technical field of agricultural production. The method includes reasonably selecting a production base with appropriate environmental conditions and ecological conditions, selecting and using fine breeds and carefully choosing seeds and seed coatings by methods of mechanical screening and the like, fertilizing soil fertility by using straw covering no-tillage soil fertilizing technology to improve soil, utilizing a planted model of double six-feet reserved rows to improve yield per unit area, selecting an appropriate seeding time, seeding rate and seeding method, scientifically fertilizing, utilizing a disease, insect pest and weed damage comprehensive control technology, harvesting wheat timely, and storing, transporting and processing harvested wheat. According to the method, the hygienic quality standard of the wheat can be effectively improved, rural incomes are increased, the market competitiveness is enhanced, and also the method has a fundamentally realistic significance for improving farmland ecological environment and quality safety of the pollution-free wheat production and guarantying agricultural sustainable development and customer fitness, and the method has good popularizing and applying values.

Owner:SICHUAN CANGXI AGRI TECH EXTENSION STATION

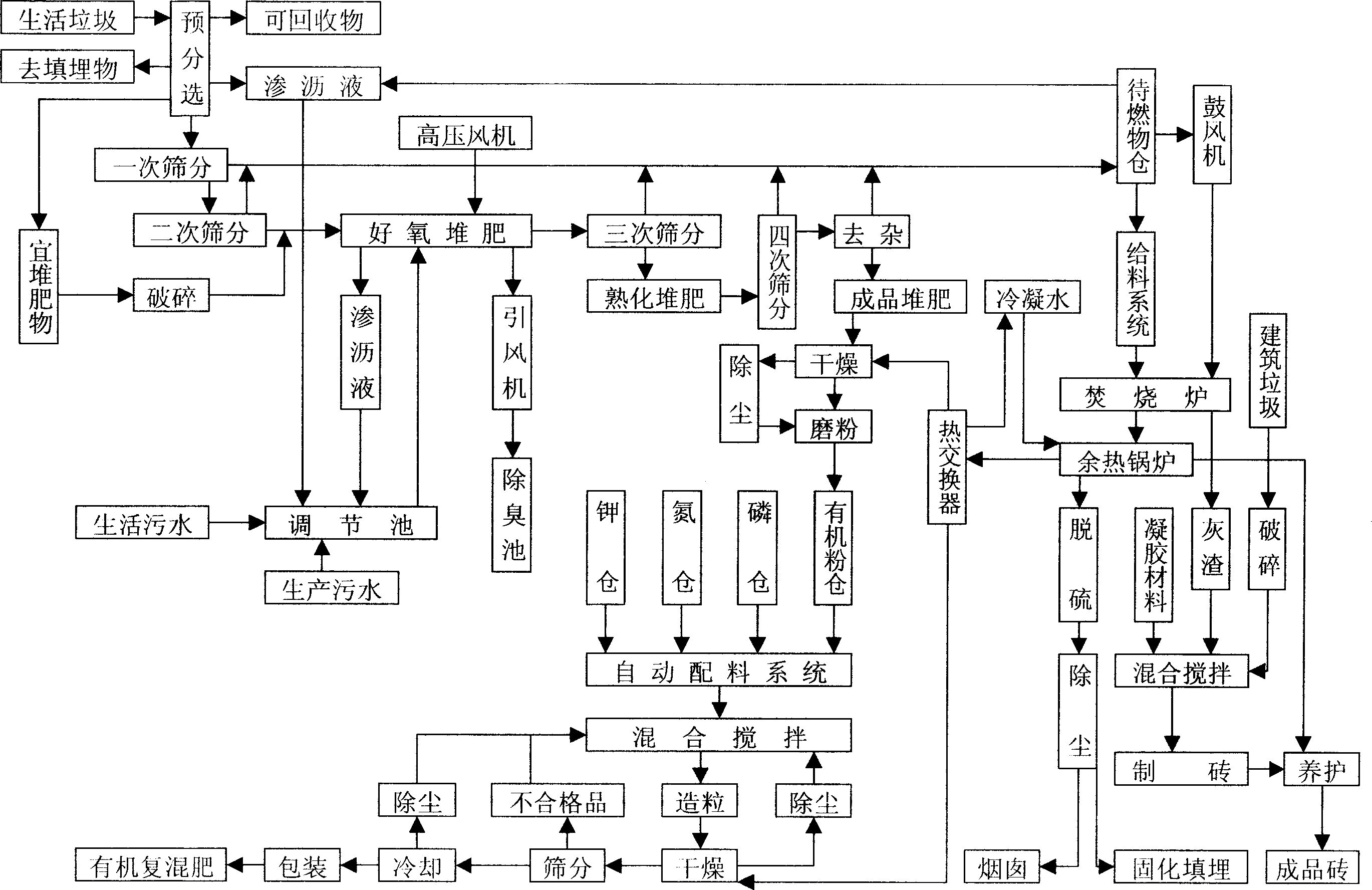

Urban domestic garbage comprehensive treatment technology

InactiveCN1654434ARealize processingFully resourcedSolid waste managementSolid waste disposalBrickEngineering

The technological process of treating domestic garbage comprehensively includes artificially pre-sorting to separate recovered matter, mechanical sorting to separate organic matter for making fertilizer and percolate for fertilizer humidity regulation, producing compost with organic matter, incinerating useless matter, making brick, heat energy utilizing for producing fertilizer and brick, etc. The fume is desulfurized and dedusted before exhaust via chimney, and the compost may be further processed to for different composite organic fertilizer products.

Owner:薛占何 +1

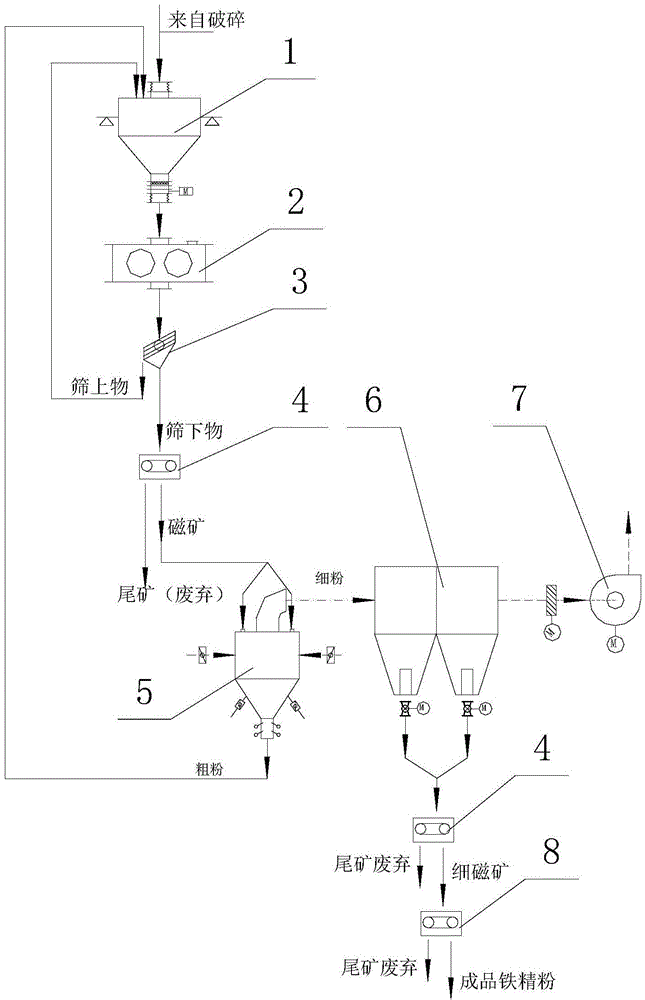

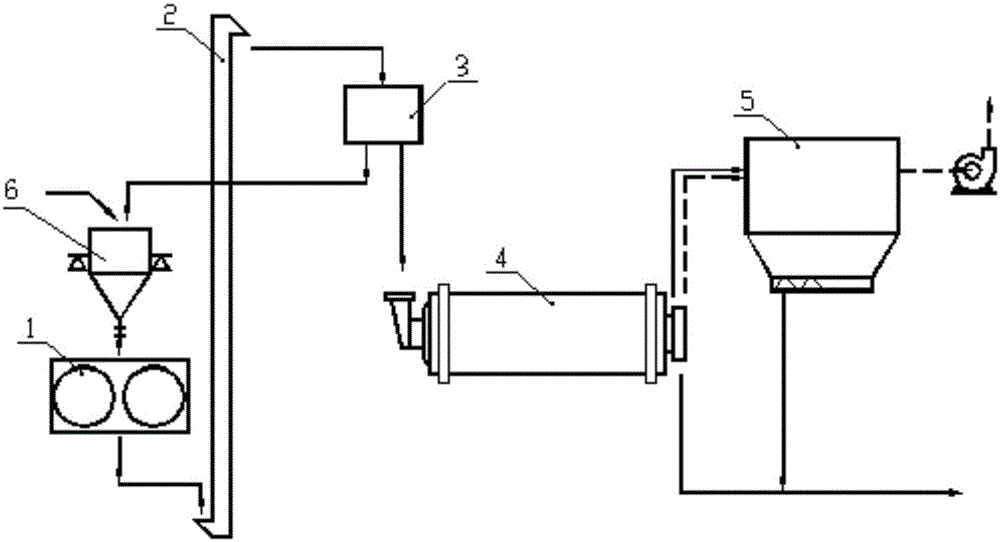

Magnetite dry grinding and dry separation method and device

ActiveCN104815739AReach granularity requirementsReduce power consumptionMagnetic separationGrain treatmentsHigh pressureMechanical screening

The invention discloses a magnetite dry grinding and dry separation method and a magnetite dry grinding and dry separation device, and belongs to the technical field of iron ore selection and grinding. The method comprises the steps of mixing secondarily crushed ore with particle size less than 80mm and coarse-grain return scrap to obtain a mixture I, extruding the mixture I by virtue of a high pressure roller, and mechanically screening the mixture I, wherein the screening granularity is 3mm; returning an oversize product adopted as the coarse-grain return scrap to the high pressure roller to be continuously extruded, separating screen underflow in a dry-type magnetic separator, grading rough concentrate separated by the dry-type magnetic separator by virtue of a wind power powder separation machine, returning coarse powder graded by the wind power powder separation machine and adopted as coarse-grain return scrap to the high pressure roller to be continuously extruded, collecting fine powder meeting the fineness requirement of iron fine powder after the grading of the wind power powder separation machine, separating the fine powder by virtue of the dry-type magnetic separator, and finally carrying out the wet-type magnetic separation for fine magnetic minerals meeting the fineness requirement of the iron fine powder after the separation of the dry-type magnetic separator. By adopting the magnetite dry grinding and dry separation method, the crushing grinding and the magnetic separation of the ore are reasonably matched, so that the system energy consumption is reduced, consumption of steel and water is reduced, and the environmental pollution is alleviated.

Owner:成都建筑材料工业设计研究院有限公司

Method for preparing lime for calcium carbide by utilizing carbide slag

The invention relates to a method for preparing lime for calcium carbide by utilizing carbide slag, which comprises the following steps of: S1: adding water into the carbide slag and stirring to obtain carbide slag slurry of which mass concentration is 12 to 20%; S2: removing large-particle impurities in the carbide slag slurry by mechanical sieving, enabling the carbide slag slurry of which large-particles are removed to flow into a mill to carry out fine milling processing, and controlling a particle size of carbide slag particles into a range of not over 40mu m; S3: carrying out separation on the fine-milled carbide slag slurry by a cyclone hydraulic separator, enabling the purified carbide slag slurry to flow out via an overflow pipe, enabling the purified carbide slag slurry to enter a vacuum belt dehydrator to carry out dehydration so as to obtain carbide slag with water content of not over 15%; S4: adding a pelletizing agent into the dehydrated carbide slag, stirring, pelletizing into balls and drying; S5: calcining the dried carbide slag at a temperature of 900 to 1,000 DEG C to obtain the lime for the calcium carbide. The lime prepared by the method disclosed by the invention is low in impurity content, uniform in particle size, high in strength and good in activity, and can meet requirements of the lime for the calcium carbide.

Owner:王光建

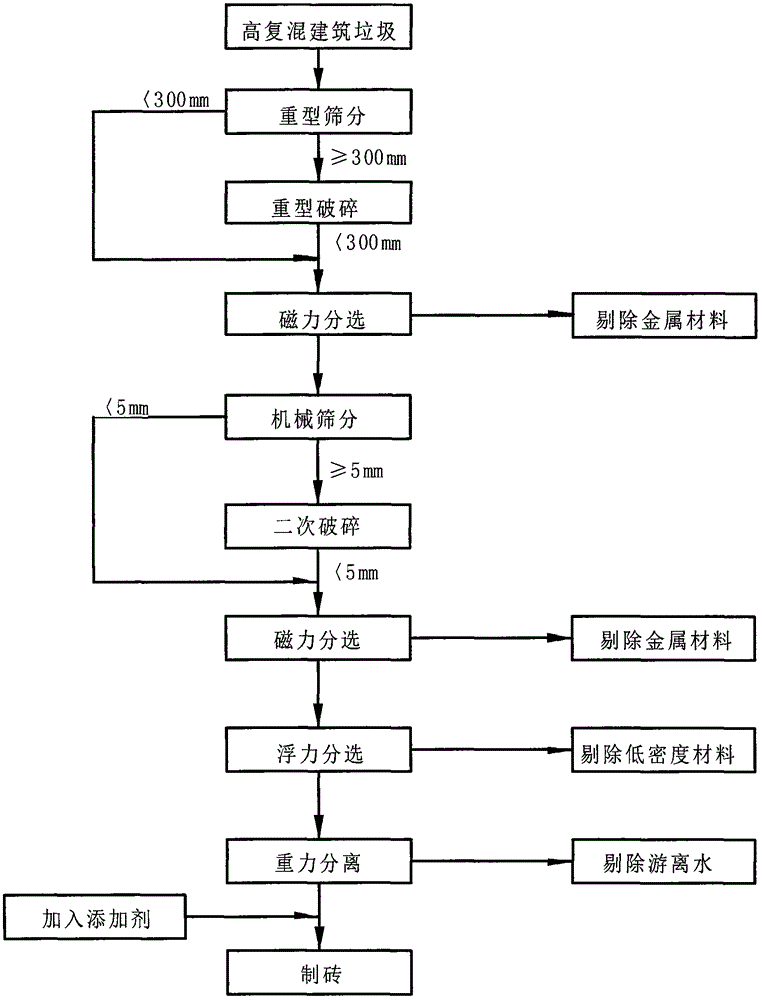

Disposal method for reusing highly-compound construction waste

The invention relates to the field of construction waste disposal, in particular to a disposal method for reusing highly-compound construction waste. According to the technical scheme, the disposal method comprises the following steps: (1) heavy-duty sieve sorting; (2) heavy-duty crushing; (3) magnetic separation; (4) mechanical sieving; (5) secondary crushing; (6) magnetic separation; (7) flotation separation; (8) gravitational separation; (9) conventional brick making. By utilizing a process for combining heavy-duty hydraulic crushing with conventional crushing, sieving, magnetic separation and flotation separation, the method can clear out metal materials and low-density organic materials such as wood, plastic and pitch from the highly-compound stacked construction waste such as concrete, walls, ceramics, muck, steel bars, wood, pitch and plastics of dismantled buildings with different sources, types, ingredients, shapes and natures under the condition without manual sorting. The method has the advantages of being low in cost and wide in adaptability.

Owner:魏云峰 +2

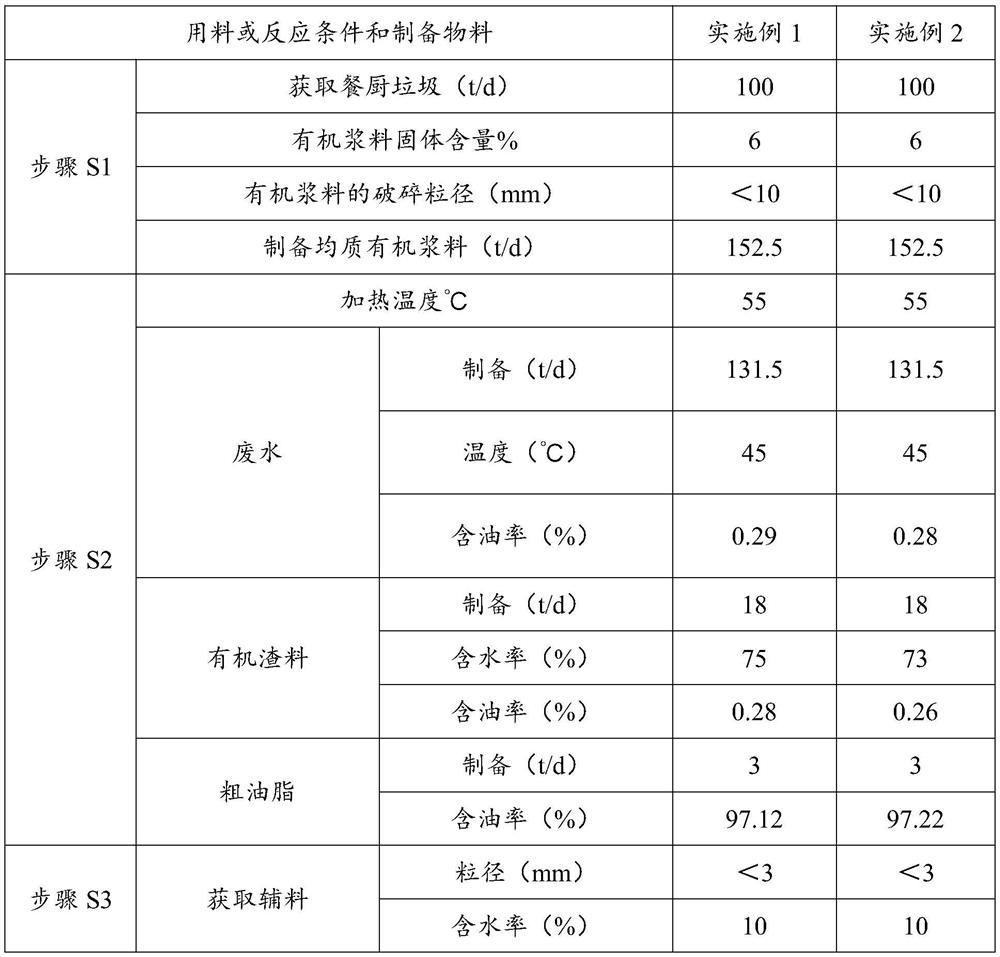

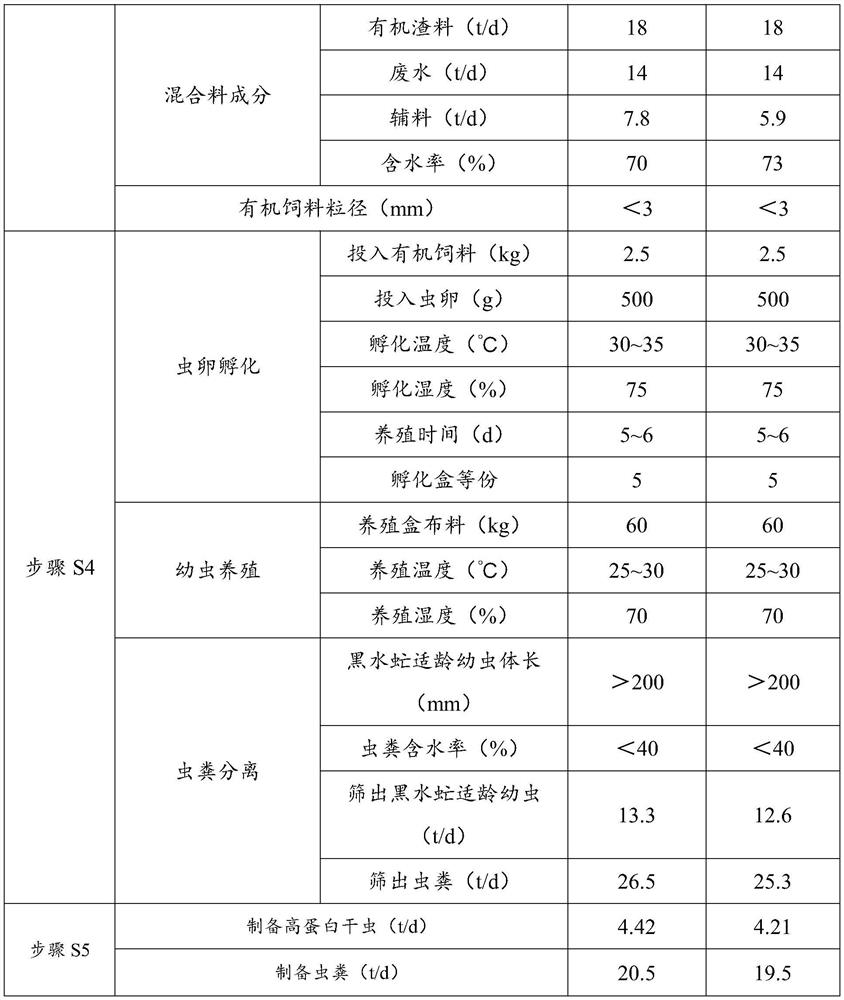

Kitchen waste deep recycling treatment method

InactiveCN112741047AHigh recovery rateHigh oil contentFood processingSolid waste disposalOil and greaseHermetia

The invention relates to the technical field of kitchen waste treatment, in particular to a kitchen waste deep recycling treatment method. The kitchen waste deep recycling treatment method comprises the steps of deep pretreatment, three-phase separation treatment, organic feed preparation, hermetia illucens breeding and hermetia illucens recycling treatment. According to the kitchen waste deep recycling treatment method, the recovery rate of the crude oil in the kitchen waste is increased, and the oil content of the produced crude oil is up to 97%; wastewater generated in the treatment process can directly enter a sewage treatment station without anaerobic digestion, meanwhile, part of the wastewater can be used for preparing the hermetia illucens breeding feed, so that the pressure of the sewage treatment station is relieved, and the investment cost is reduced; the prepared organic feed is high and uniform in nutrition density, the breeding period of the hermetia illucens is shortened, and mechanical screening of larvae and fecula of the hermetia illucens is achieved; and the hermetia illucens are bred by adopting automatic equipment such as an automatic guide transport vehicle, so that automatic and large-scale breeding of the hermetia illucens is realized, the labor cost is saved, and the production efficiency is improved.

Owner:DONGJIANG ENVIRONMENTAL

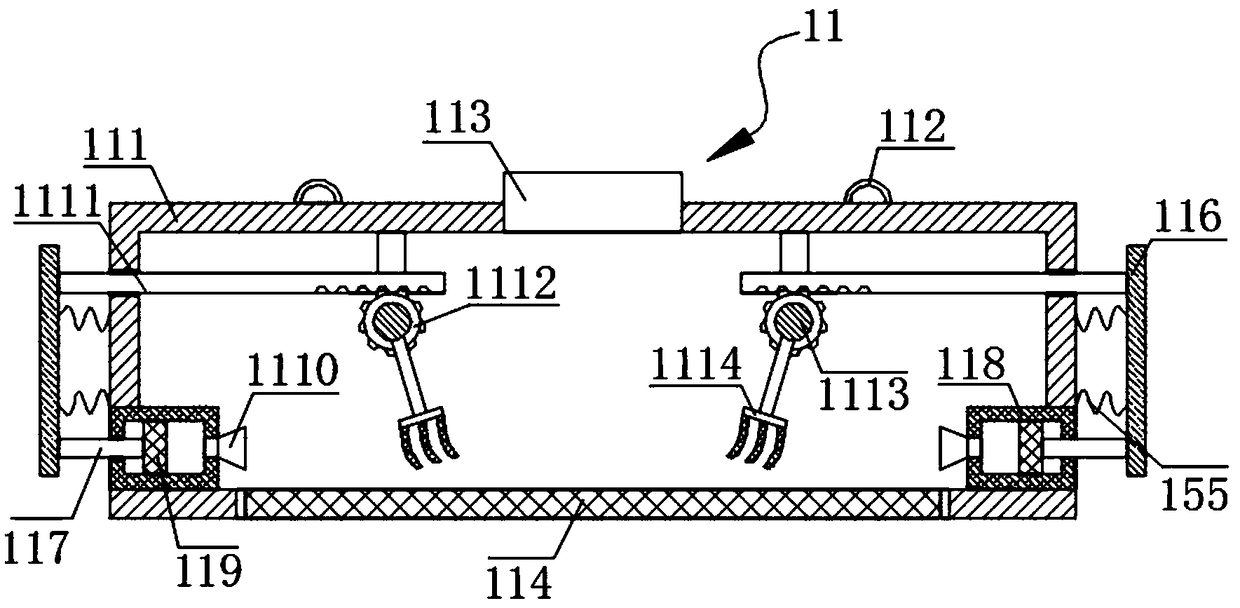

Grinding and screening integrated traditional Chinese medicine processing device

ActiveCN110935543ASimplify the process stepsImprove work efficiencySievingScreeningReciprocating motionElectric machinery

The invention relates to the technical field of traditional Chinese medicine processing, and particularly relates to a grinding and screening integrated traditional Chinese medicine processing device.The grinding and screening integrated traditional Chinese medicine processing device comprises a processing box body, wherein the processing box body comprises a grinding box body and a screening boxbody, a filter screen is mounted between the grinding box body and the screening box body, and a material distributing device, a grinding device and a rolling device are arranged in the grinding boxbody. According to the grinding and screening integrated traditional Chinese medicine processing device, the filter screen is arranged in the processing box body, the processing box body is divided into the grinding box body and the screening box body, so that grinding and screening are carried out in the same process, the process steps are simplified, and the working efficiency is improved; an electric push rod pushes a grinding block to do up-down reciprocating motion, meanwhile, a connecting shaft drives the electric push rod to rotate, so that the mechanical grinding work of traditional Chinese medicines is realized; and a working motor drives a rotating shaft to rotate, so that two elliptical teeth rotate synchronously, the two elliptical teeth are attached to a fixed pulley to slide,and the two elliptical teeth are different in height, so that a screening box can shake up and down, and the mechanical screening work is completed.

Owner:安徽豪门国药股份有限公司

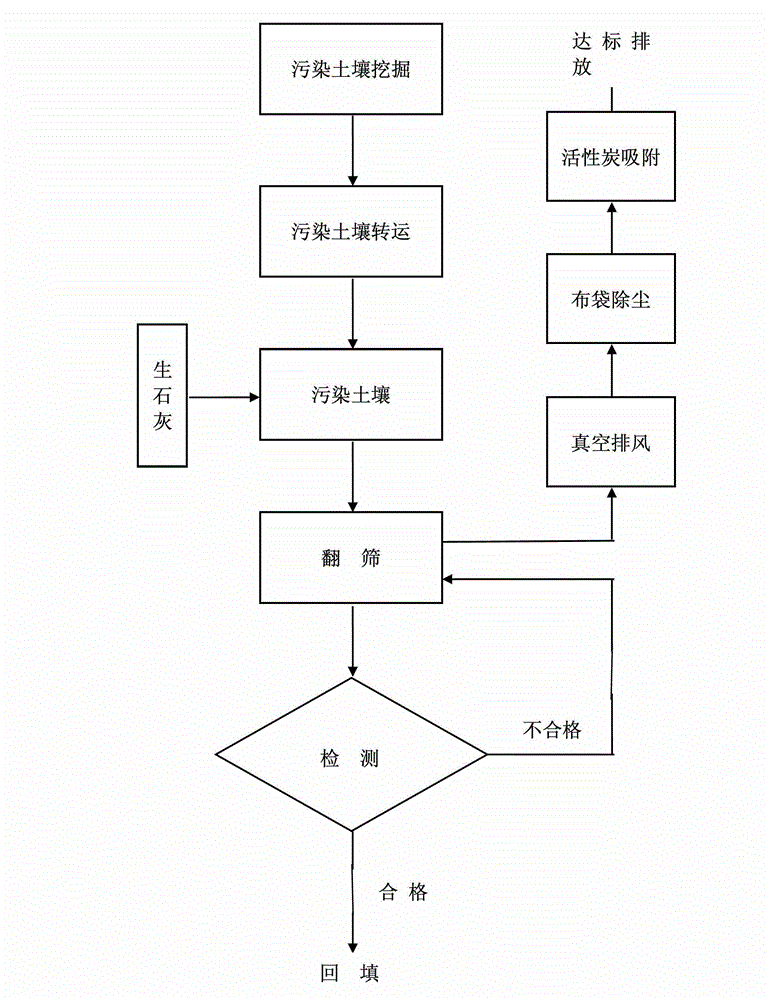

Chemical enhanced remediation method for organic contaminated soil

InactiveCN102974608AAccelerate evaporationContaminated soil reclamationActivated carbonChemical reaction

The invention discloses a chemical enhanced remediation method for organic contaminated soil. The chemical enhanced remediation method comprises the following steps of: (1) centralized storage and transportation process of the contaminated soil; (2) a chemical enhanced treating process; (3) a polluting tail gas treatment process; and (4) soil checking and transportation processes. The chemical enhanced remediation method provided by the invention adopts a method combining chemistry and physics, accelerates volatilizing of pollutants by jointly utilizing heat emitted through chemical reaction and the mechanical screening effect and by utilizing the characteristic that the organic pollutants in the soil easily volatilize after being heated, and enables gas containing the pollutants to be subjected to cloth-bag dust removal and activated carbon adsorption treatment by utilizing forced extraction of a vacuum fan, so that the tail gas can be discharged with the standard level, and finally, the aim of remediating the contaminated soil is achieved. Compared with other remediation methods, the project implementation result shows that the process of the method provided by the invention can achieve an expected governance objective with relatively small equipment investment, thus having broad application prospects.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION

Reed particle board and preparation method thereof

ActiveCN107243975AGood mechanical propertiesPromote environmental protectionLaminationWood working apparatusEnvironmental resistanceAdhesive

The invention relates to a reed particle board and a preparation method thereof and belongs to the technical field of production of novel straw artificial boards. According to the reed particle board and the preparation method thereof, according to the physical characteristics of reeds, wood shavings of the reed particle board are sorted according to different specifications, and by means of optimized configuration of surface layer wood shavings and core layer wood shavings, the board excellent in mechanical performance is obtained; and by adding an environment-friendly adhesive of poly-phenyl poly-methylene isocyanate or derivatives of the poly-phenyl poly-methylene isocyanate, the environment friendliness and the anti-moisture performance of the board are made to be substantially improved, and the board can be well applied in the fields of furniture production, indoor and outdoor decoration, packaging materials and the like. According to the reed particle board and the preparation method thereof, waste materials generated in the mechanical screening process of the reeds, the airflow impurity separating process and the production process, and rough reed particle board sanding powder serve as fuel to be combusted so as to be used as reed wood shaving drying and board blank hot pressing energy, the production cost is substantially reduced, solid-waste-free emission is achieved, and clean production is facilitated.

Owner:盘锦积葭生态板业有限公司

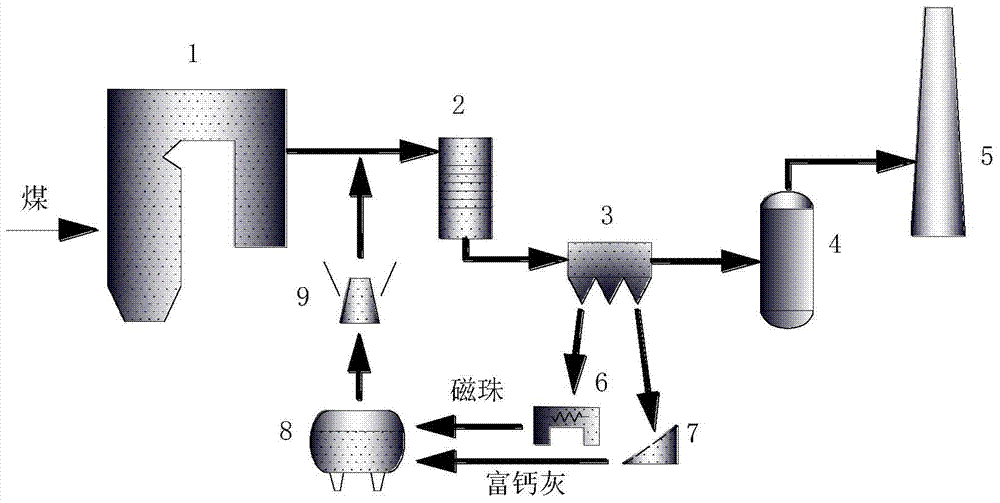

Device of removing arsenic and mercury in flue gas and method of removing arsenic and mercury

ActiveCN103657408ADoes not affect reuseEfficient removalDispersed particle separationMagnetic beadCatalytic oxidation

The invention discloses a device of removing arsenic and mercury in flue gas. The device comprises a denitration system, a dust remover, a magnetic separator, a mechanical screening machine and an injection system, wherein the denitration system is connected to a hearth, the outlet of the denitration system is connected to the inlet of the dust remover, the dust remover is connected to the magnetic separator and the mechanical screening machine, and the magnetic separator and the mechanical screening machine are connected to a pipeline at the front of the inlet of the denitration system through the injection system. The invention further discloses a method of recycling magnetic beads and calcium-rich ash in fly ash, and simultaneously removing the arsenic and the mercury in the flue gas by utilizing the device. According to the method provided by the invention, the gaseous arsenic in the flue gas is effectively removed, the elemental mercury in the flue gas is subjected to catalytic oxidation, and the method and the device of simultaneously removing two heavy metal pollutants containing the arsenic and the mercury in the flue gas can be provided; the magnetic beads and the calcium-rich ash are recycled.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

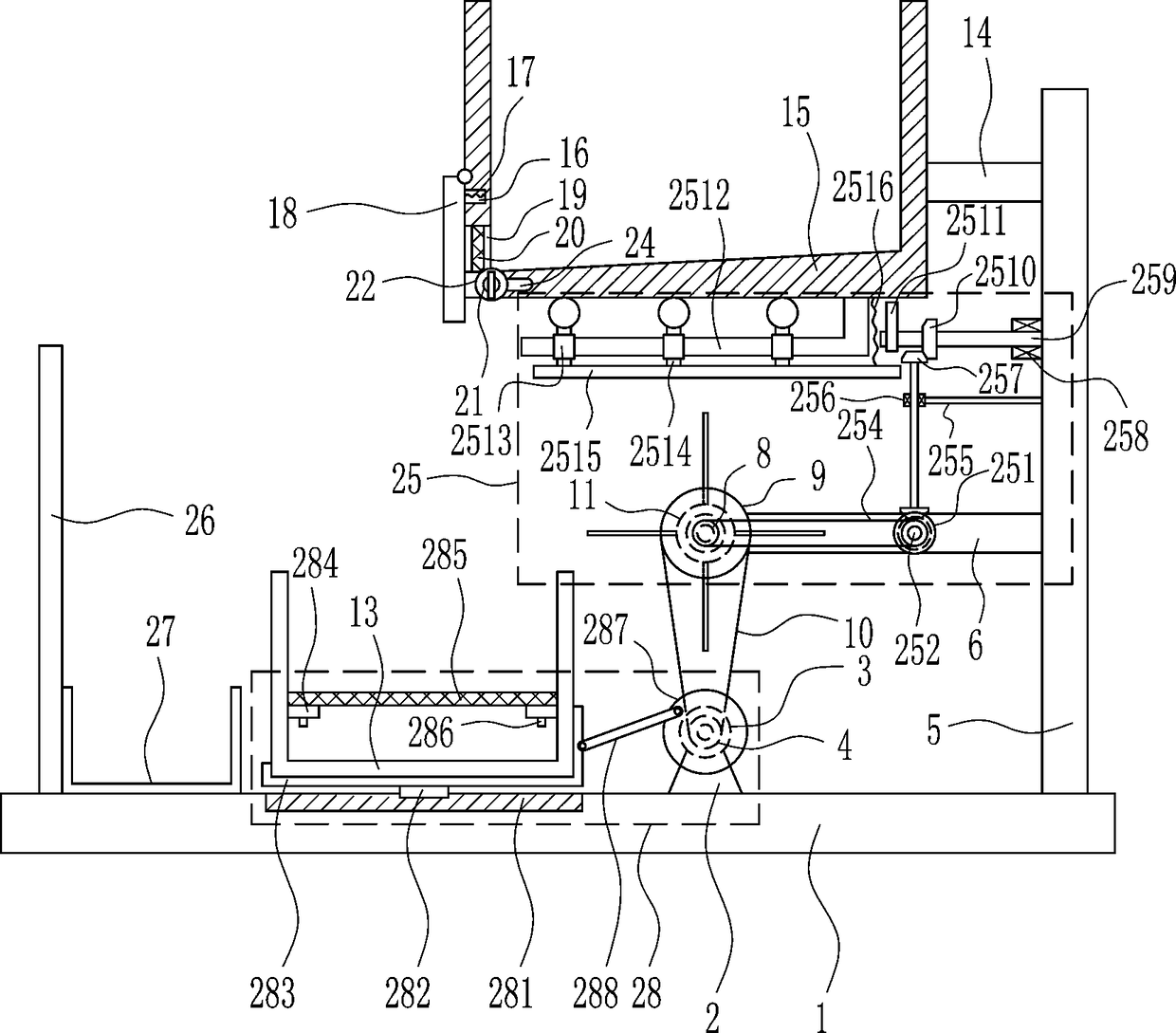

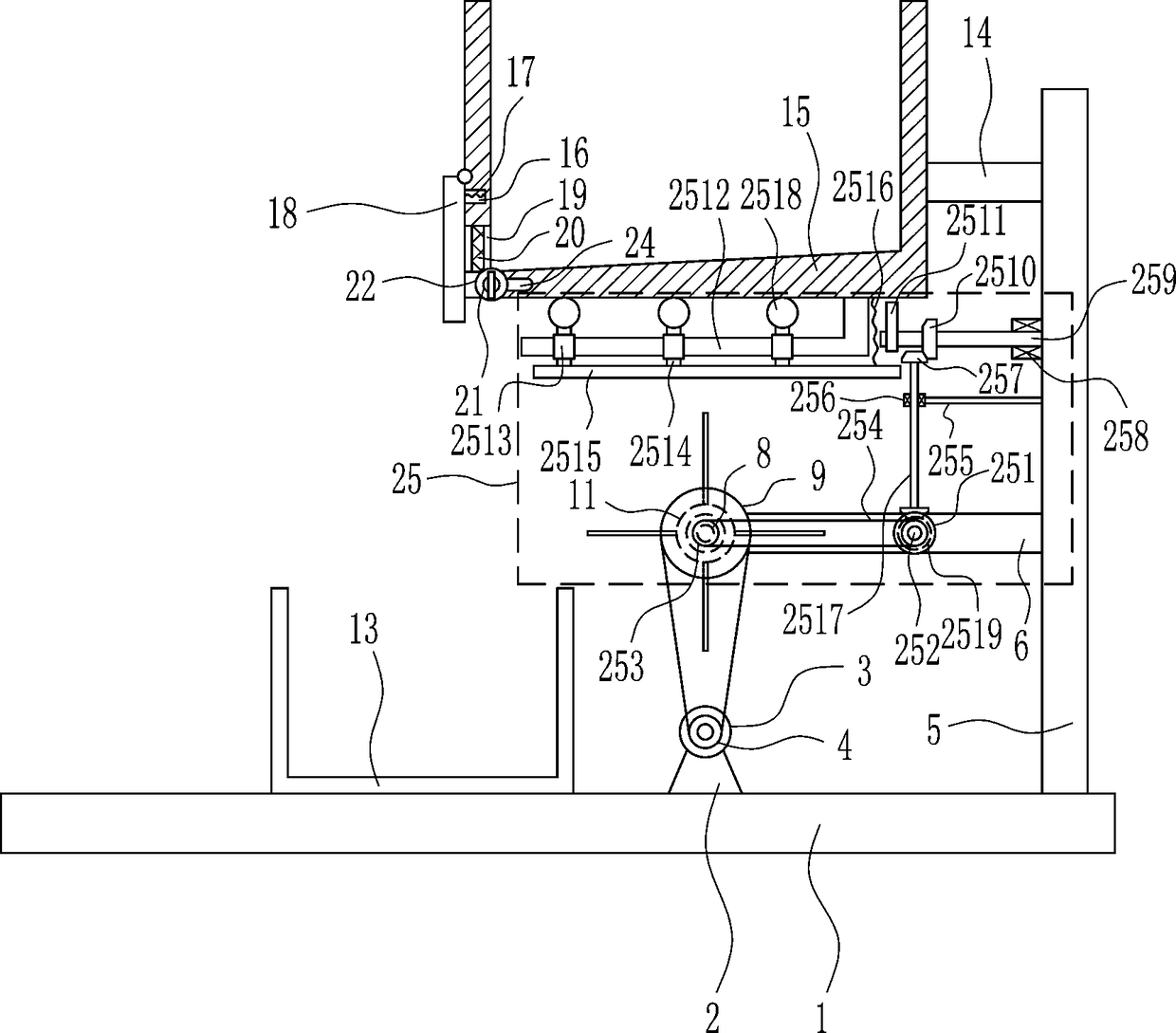

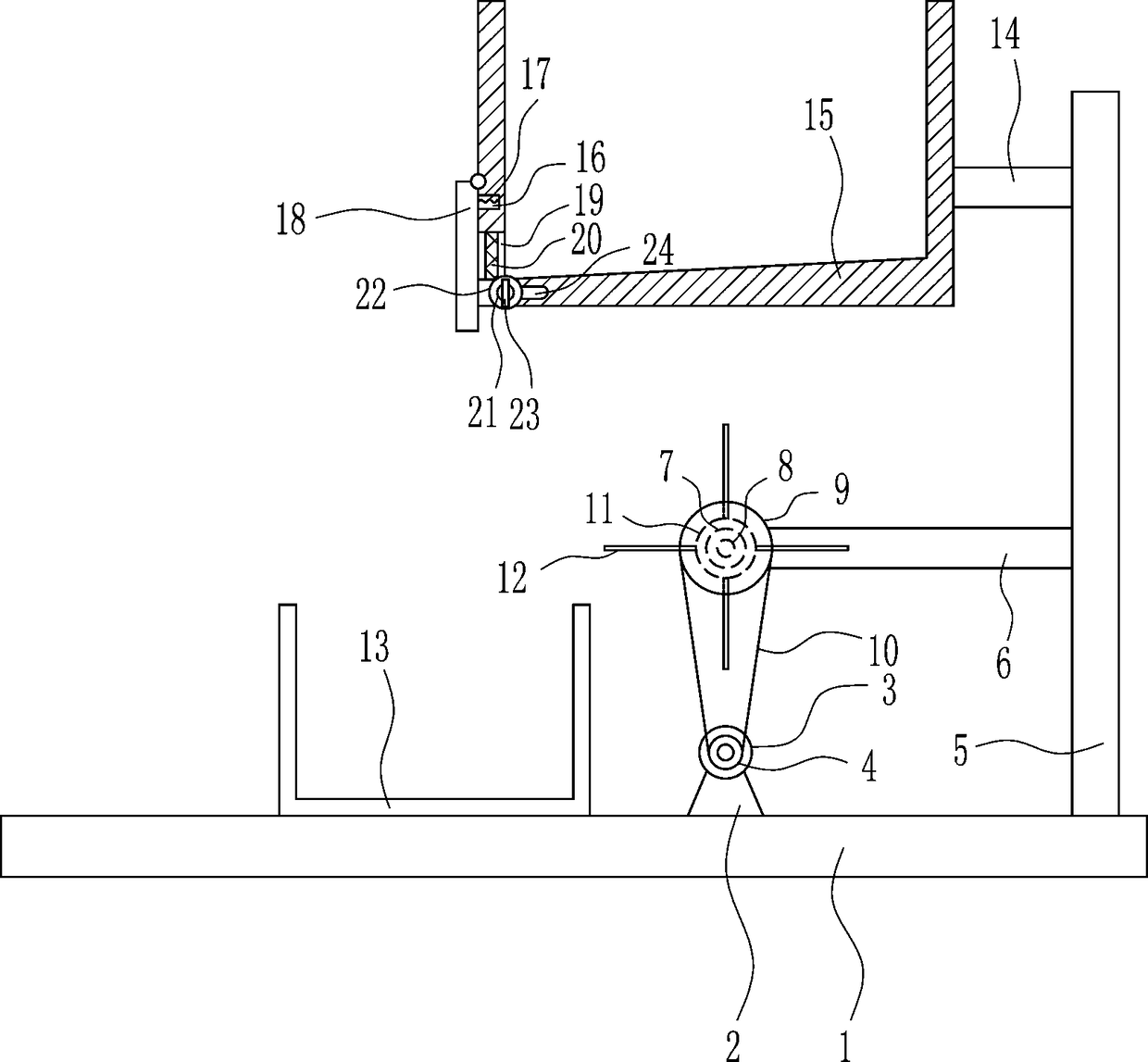

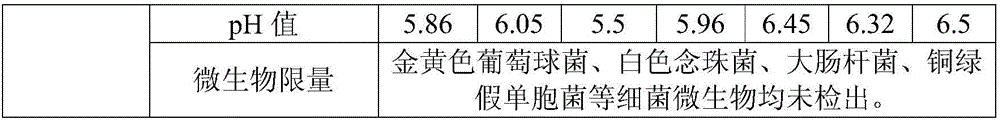

Rapeseed mechanical screening facility

The invention relates to a screening facility, in particular to a rapeseed mechanical screening facility. Consequently, according to the technical problem, the rapeseed mechanical screening facility which can easily screen rapeseeds and accurately screen the rapeseeds is provided. According to the technical implementation scheme, the rapeseed mechanical screening facility comprises a base plate, amounting base, a motor, a small belt pulley, a support, a first mounting plate, a first bearing pedestal and the like. The mounting base is arranged on the right side of the top of the base plate, the motor is arranged on the mounting base, the small belt pulley is arranged on an output shaft which is located on the front side of the motor, and the support is arranged on the right side of the topof the base plate. Due to the cooperation of a frame body and thin plates, good rapeseeds and bad rapeseeds in the falling rapeseeds can be easily distinguished in the process of rotation of the thinplates. By means of the arrangement of a large net plate, large particles and small particles of the rapeseeds which fall on the large net plate can be distinguished in the process that the motor drives a placement frame to move left and right, and therefore the rapeseeds are more accurately screened.

Owner:王乐明

Method for rapid measuring aluminum oxide abrasion index

InactiveCN101109682AReduce pollutionHigh degree of automationParticle size analysisInvestigating abrasion/wear resistanceSieveMechanical screening

The invention relates to a method for rapidly measuring the wear index of alumina, which is characterized in that a laser hondrometer is used to replace a grading way for measuring the grain size distribution; first the contents in percentage of grades are measured for the sample before wearing; then a wear index tester is used to wear the sample, the worn sample is collected, the fine powder lost during wearing is collected by a dust-collecting bag, the fine powder collected by the dust-collecting bag is used to sample the worn sample, which are mixed evenly, then the contents in percentage of grades are measured by a laser way; the wear index of the sample is calculated by the contents in percentage of grades before and after the wearing. The method measures the grain size distribution before and after wearing by a highly automatic laser hondrometer, reduces the influence of any artificial factors on the test results e.g. collecting specimen, weighing and choking test sieve, etc. for a mechanical sieving method; and for the method here, the working efficiency is greatly improved because it is not necessary to take a long time for cleaning and drying the test sieves.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

High-pressure and high-efficiency roller press grinding system with screening device

InactiveCN105057067AGive full play to the crushing efficiencyUnique processGrain treatmentsEngineeringHigh pressure

The invention discloses a high-pressure and high-efficiency roller press grinding system with a screening device. The high-pressure and high-efficiency roller press grinding system comprises a roller press and a ball mill. A weighing bin is arranged above the roller press. Fed materials are squeezed and crushed through pressure of a hydraulic system of the roller press. Fine powder discharged from a discharging port of the roller press enters the mechanical screening device through a lifter. Particles smaller than the aperture of a screen of the mechanical screening device enter the ball mill and then are ground in a fine mode and shaped so that finished products are obtained. The high-pressure and high-efficiency roller press grinding system with the screening device adopts a mechanical screening and classification mode instead of a traditional winnowing classification mode to reduce system energy consumption. The yield of the fine powder is increased through high pressure operation of the roller press. Adaptability to mechanically screened materials of the ball mill is realized through control over materials leaking from the edge of the roller press. According to the high-pressure and high-efficiency roller press grinding system with the screening device, the system yield is increased entirely, and system energy consumption is lowered.

Owner:CNBM HEFEI POWDER TECH EQUIP CO LTD

Size grading control method for coke at blast-furnace tuyere

ActiveCN106154868AAvoid blindnessBreak through the technical bottleneck of precise particle size classificationProgramme control in sequence/logic controllersSlagCoke

The invention discloses a size grading control method for coke at a blast-furnace tuyere and mainly solves technical a problem in precise control of size of coke at the blast-furnace tuyere during quality control of coke at the blast-furnace tuyere in the prior art. The technical scheme provided by the invention includes steps of removing iron particles in coke at the blast-furnace tuyere by using magnets; grading the coke at the blast-furnace tuyere with a mechanical sieve and measuring the percentage of the coke of different size grades in the total mass of the coke; crushing coke of different grades at the blast-furnace tuyere and detecting the mass ratio of iron slag in the coke of different grades at the blast-furnace tuyere through coke microscopic structure detection after sampling; and calculating the proportions of the coke of different grades at the blast-furnace tuyere in the total mass of the coke. According to the invention, correct evaluation of the degradation condition of the coke in the blast-furnace is realized and a guarantee is provided for smooth production operation control of the blast-furnace.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

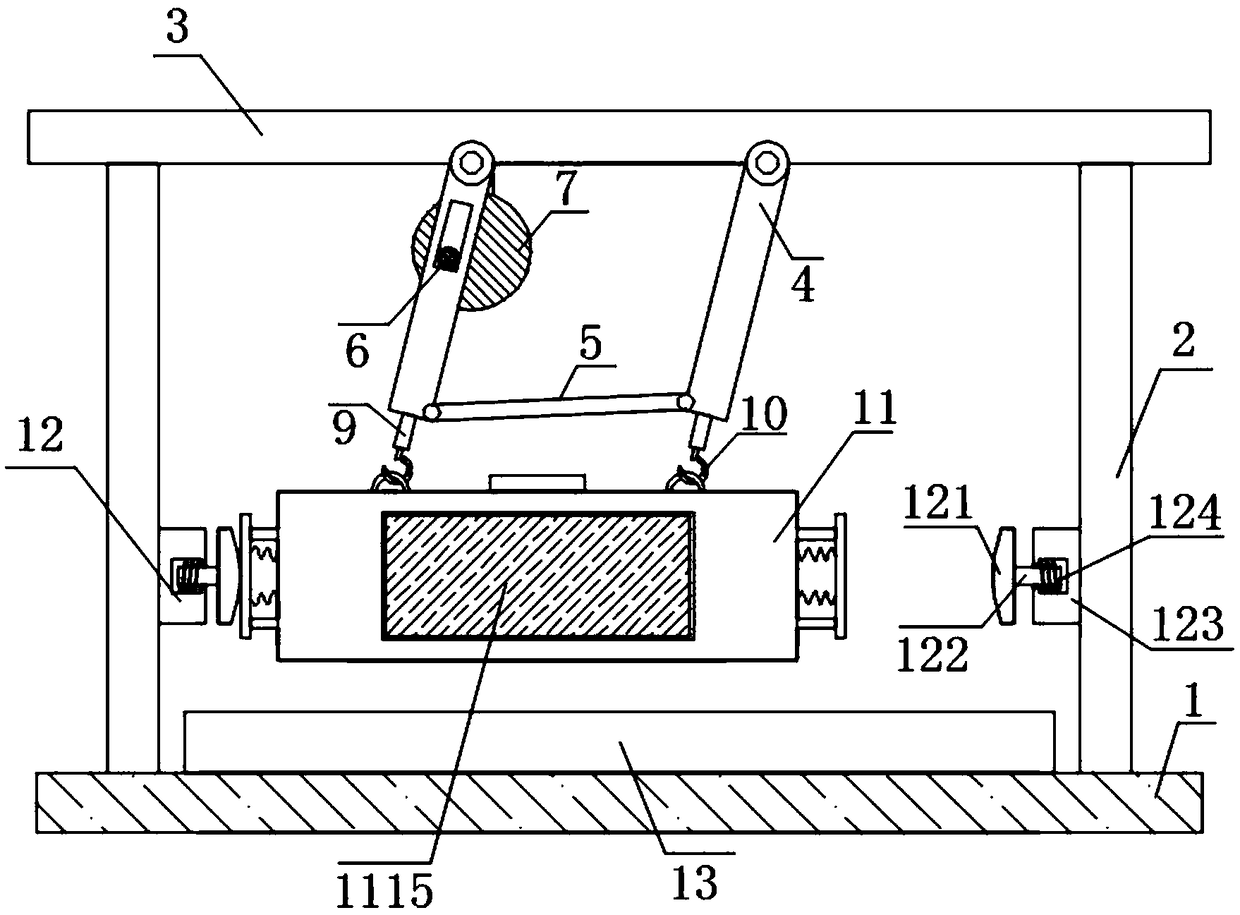

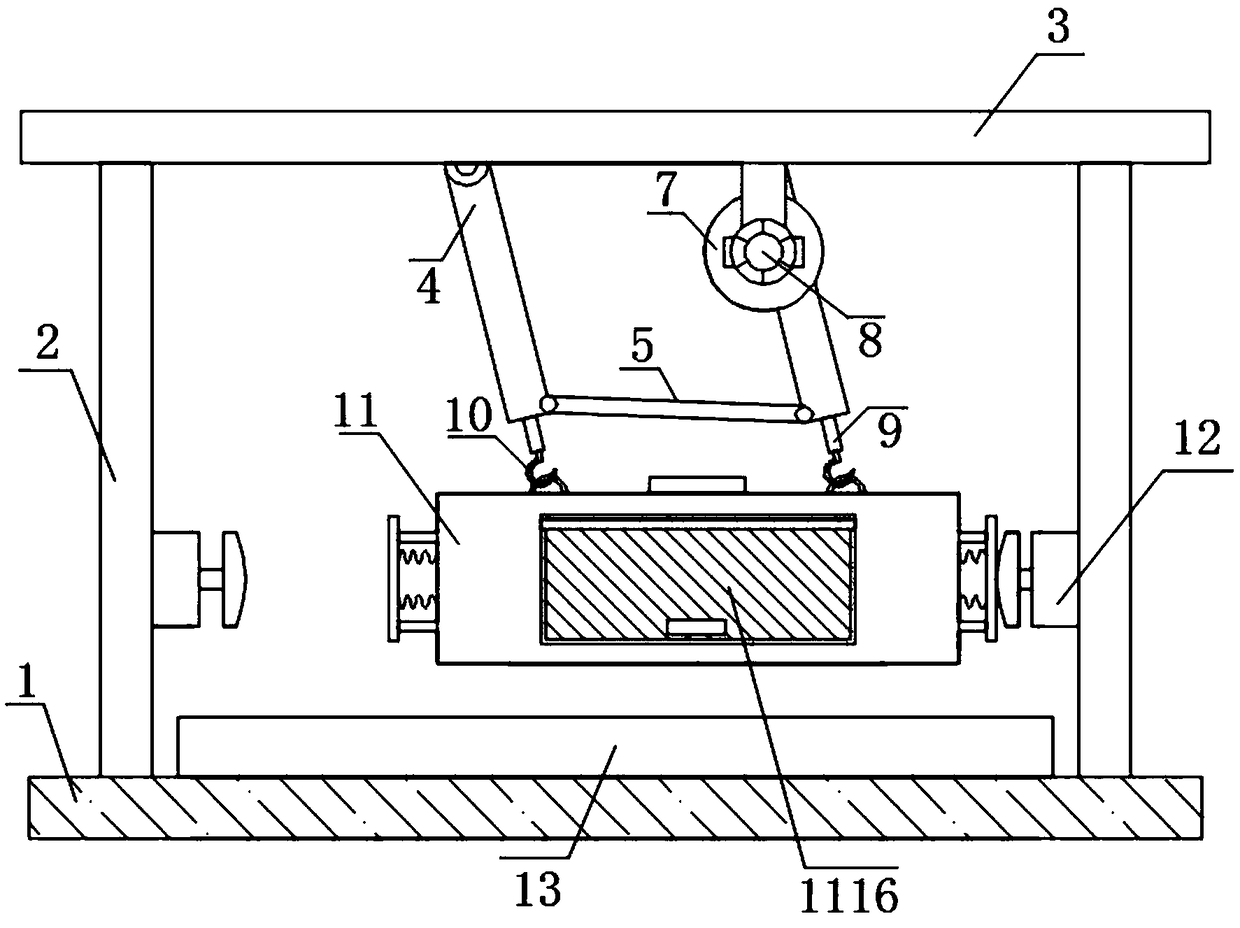

Screening apparatus for tea leaf processing

ActiveCN109261491ALabor savingImprove screening efficiencySievingScreeningScreening effectEngineering

The invention provides a screening apparatus for tea leaf processing, comprising a base, two supports connected symmetrically to the upper end of the base, a top plate connected to the upper ends of the two supports, and two rotary arms hinged to the lower end of the top plate; a same connection rod is hinged to the side walls of the opposing ends of the two rotary arms; the rotary arm on the leftis provided with a first rectangular through hole; a slider is slidably connected in the first rectangular through hole and is connected to a turnplate; a spindle of a motor is connected to the center of the rear wall of the turnplate; the motor is connected to the top plate; the lower ends of the two rotary arms are both connected with a powerful rope; the lower end of each powerful rope is connected with a hook; the hooks are connected with a screening device. The defects of the prior art are overcome; the screening apparatus for tea leaf processing is reasonable in design and compact in structure; the problem that the existing manual screening has low efficiency and requires high labor intensity is solved; it is avoided that the single mechanical screening mode affects screening efficiency; tea leaves are stirred in multiple modes, so that screening effect is improved.

Owner:潜山市槎水茶桑专业合作社

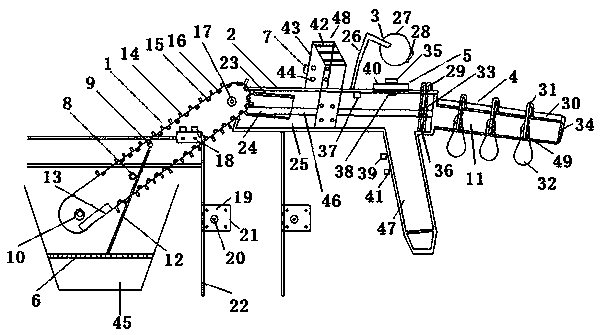

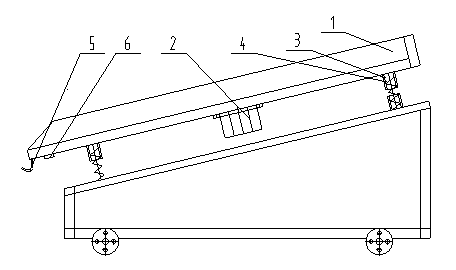

Sterilization, disinfection and sorting device for strawberries

The invention relates to a sterilization, disinfection and sorting device for strawberries, and belongs to the technical field of mechanical screening equipment. The sterilization, disinfection and sorting device for strawberries comprises a lifting mechanism, a conveying mechanism, a sterilization and disinfection mechanism, a maturity identification mechanism, a drip-washing mechanism, a strawberry size screening mechanism and a control mechanism which are sequentially connected, wherein a buffer plate in the conveying mechanism is connected with the lifting mechanism, the sterilization anddisinfection mechanism and the maturity identification mechanism are sequentially arranged on a conveying belt II in the conveying mechanism, one end of the conveying belt II in the conveying mechanism is connected with the strawberry size screening mechanism, the buffer plate is arranged above the other end of the conveying belt II, the drip-washing mechanism mutually communicating with the conveying mechanism through a pipeline is arranged on the conveying mechanism, and a conveying belt III is further arranged in the conveying mechanism; and the control mechanism is connected with the maturity identification mechanism. The sterilization, disinfection and sorting device for strawberries has the characteristics of being fully-automatic, capable of carrying out sterilization and pesticideremoval, and compact in structure, has the advantages of being high in working efficiency and good in working performance, can be widely applied to maturity identification and size screening for strawberry fruits, and meets the need of actual production.

Owner:KUNMING UNIV OF SCI & TECH

Fruit screening device

The invention discloses a fruit screening device which comprises a conveyer belt, a driven wheel, a driving wheel, a conveyer belt, a screening belt, a thin hose, a medium hose, a large hose, pins, a fruit tank, a motor, a wire, a storage battery and a rack. The fruit screening device is characterized in that the conveyer belt is mounted on the driven wheel and the driving wheel; the driven wheel is mounted on the rack; the driving wheel is mounted on the rack and is connected with the motor through the conveyer belt; the screening belt 5 is fixed on the bolts; the upper end of the thin hose is fixed on the screening belt; the lower end of the thin hose extends into the fruit tank; the upper end of the medium hose is fixed on the screening belt; the lower end of the medium hose extends into the fruit tank; the upper end of the large hose is fixed on the screening belt; the lower end of the large hose extends into the fruit tank; the pins are mounted on the rack; the motor is fixed on the rack through bolts; the storage battery is mounted on the rack; the wire is connected with the motor and the storage battery. By adopting the fruit screening device, mechanical screening can be achieved according to sizes of fruits, the labor can be effectively saved, the cost can be lowered, the working efficiency can be improved, and moreover the fruit screening device is simple in structure and convenient to operate.

Owner:NORTHWEST A & F UNIV

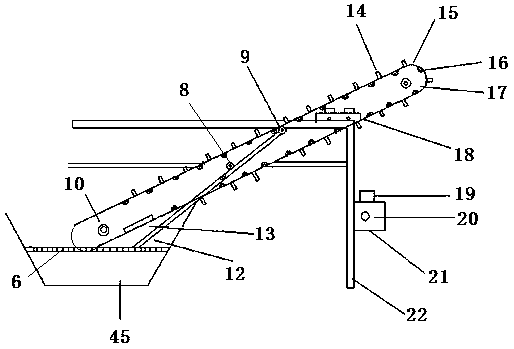

Blueberry screening machine capable of automatic feeding

InactiveCN105312242AAchieve mechanical screeningImprove screening efficiencyGradingEngineeringConveyor belt

The invention discloses a blueberry screening machine capable of automatic feeding. The blueberry screening machine comprises a screening machine body and a feeding device; a screen plate is arranged in an inclined manner; a plurality of inclined grooves are transversely arranged formed on in the screen plate; the width of each groove is arranged to be 8-15 mm, and increases gradually from the higher end to the lower end of the screen plate; a first baffle and a second baffle are vertically arranged at the upper parts of the both sides of the screen plate; receiver plates are arranged on one side of the screen plate; the feed inlets of the receiver plates are corresponding to the lower ends of the grooves; a third baffle is arranged on the lower-end side of the screen plate; the feed inlets of the receiver plates are larger than the discharge openings of the receiver plates; baffles are arranged on both sides of each receiver plate; a plurality of receiver plates are sequentially arranged on one side of the screen plate; blueberries enter the screen plate through a conveyor belt and are enabled to roll towards the lower end of the screen plate through the cooperation of the screen plate and the grooves; meanwhile, after the blueberries roll in the grooves with the sizes matched with the blueberries, the blueberries move towards the lower ends of the grooves and finally enter the receiver plates; the mechanical screening and cleaning of the blueberries are is realized, and the screening efficiency is improved.

Owner:重庆金徽林业发展有限公司

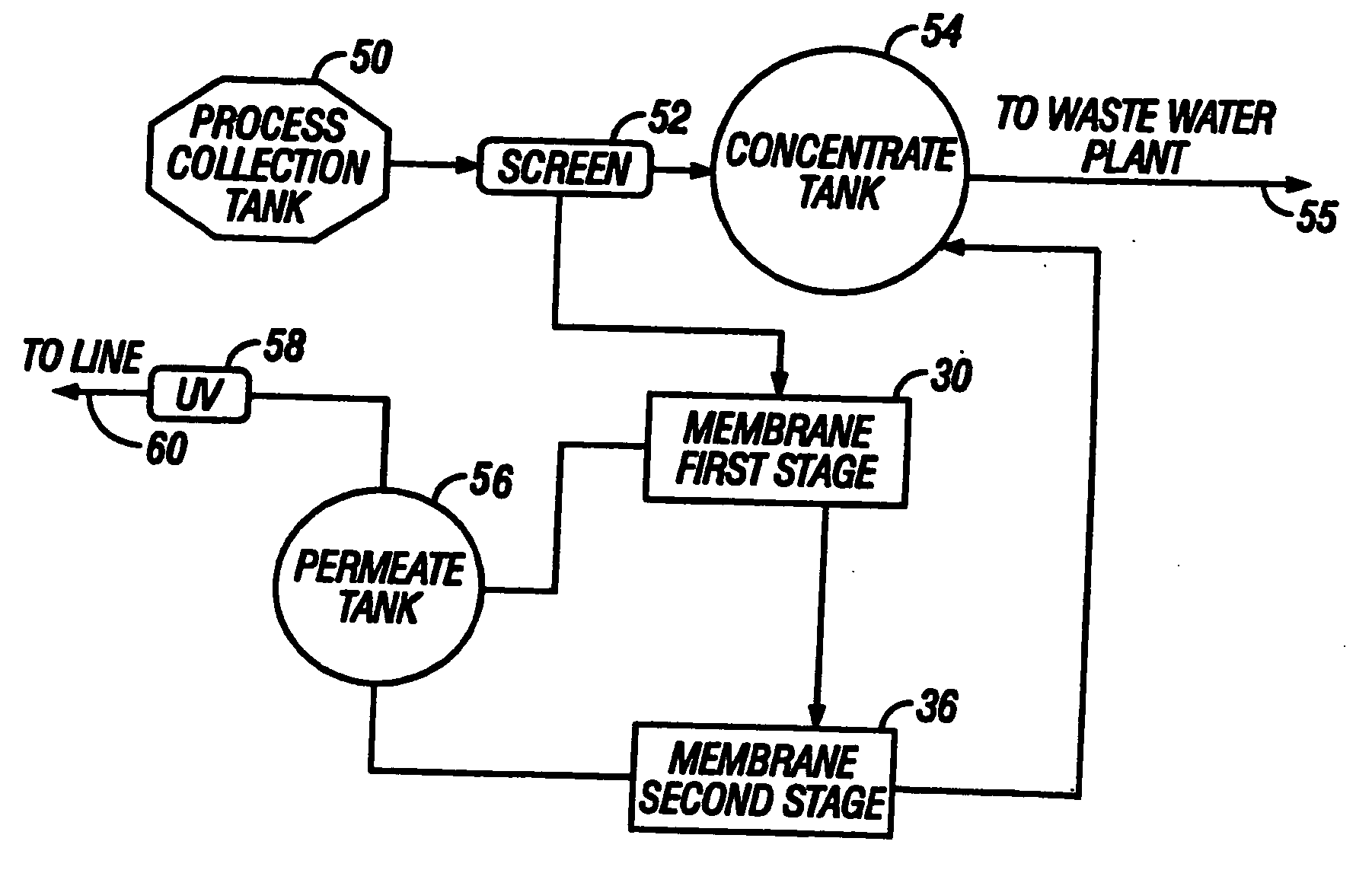

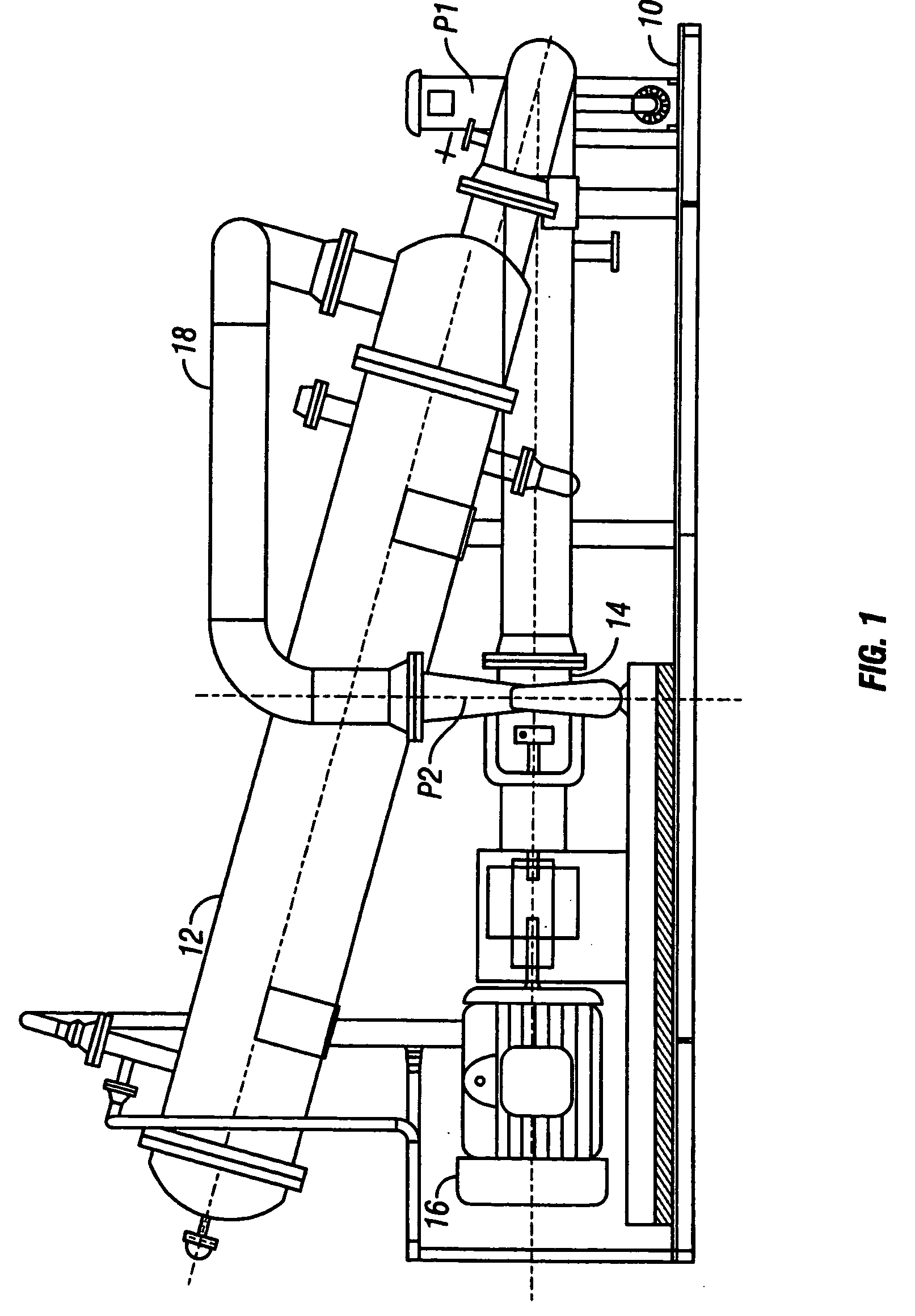

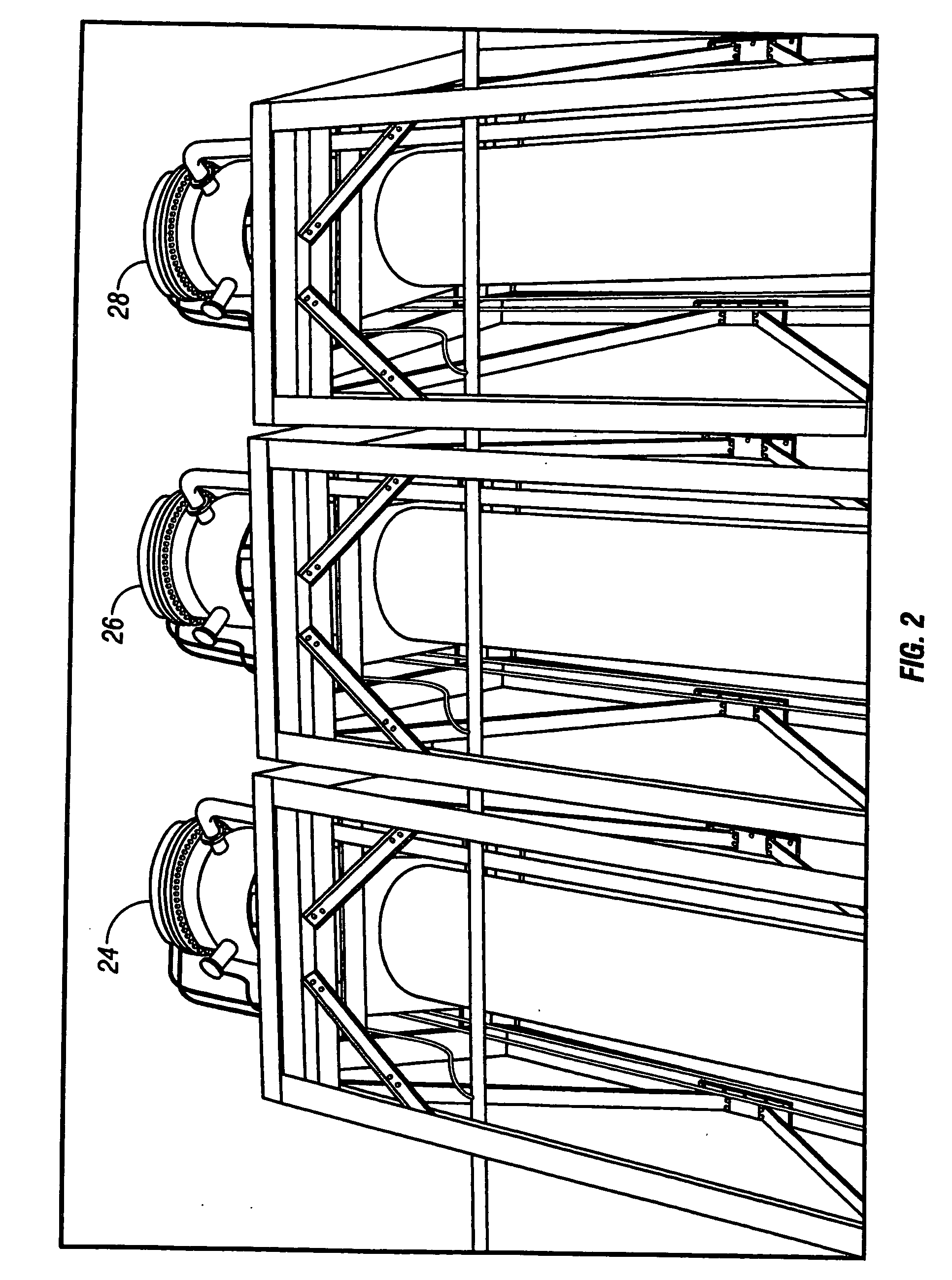

Water filtration system for food processing line

InactiveUS20050051470A1Improve concentrationMinimized volumeUltrafiltrationLoose filtering material filtersFiltrationCompound (substance)

A process water treatment and recycling system clarifies and purifies the process water in a food processing or similar system wherein the treated water may used in the fresh water stream of the system. Removal of useful byproducts in the process water stream is also facilitated. The system is a mechanical filter system and does not use any chemicals. The system is a multiple step filter process. Additional steps may added where further clarification is required and fewer steps are contemplated in certain applications. The system incorporates multiple mechanical screening to remove the solid waste from the water stream. Experimental results have established that up to 100% of TSS, 79% of BOD and 86% of COD are removed. This brings the water to acceptable recycling purity ranges and reduces the amount of fresh water required to be added to the system by as much as 75%. It also increases the recovery level of useful byproducts such as starch. The mechanical filtration system of the subject invention eliminates the need for various chemicals, defoamers and process water treatment chemicals. No additional process water treatment is required for water released into the public waste water system.

Owner:POTTER J LEON +2

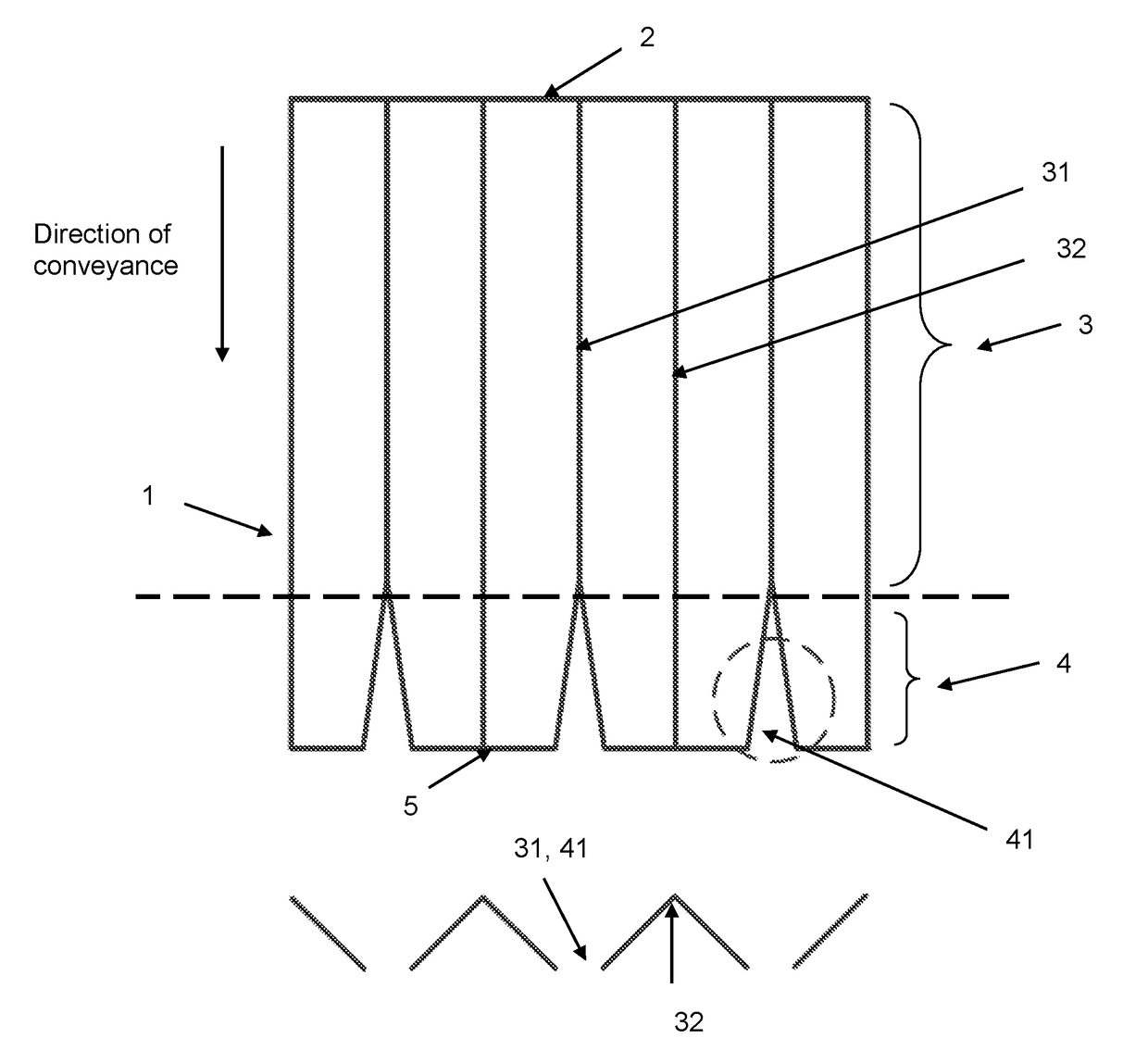

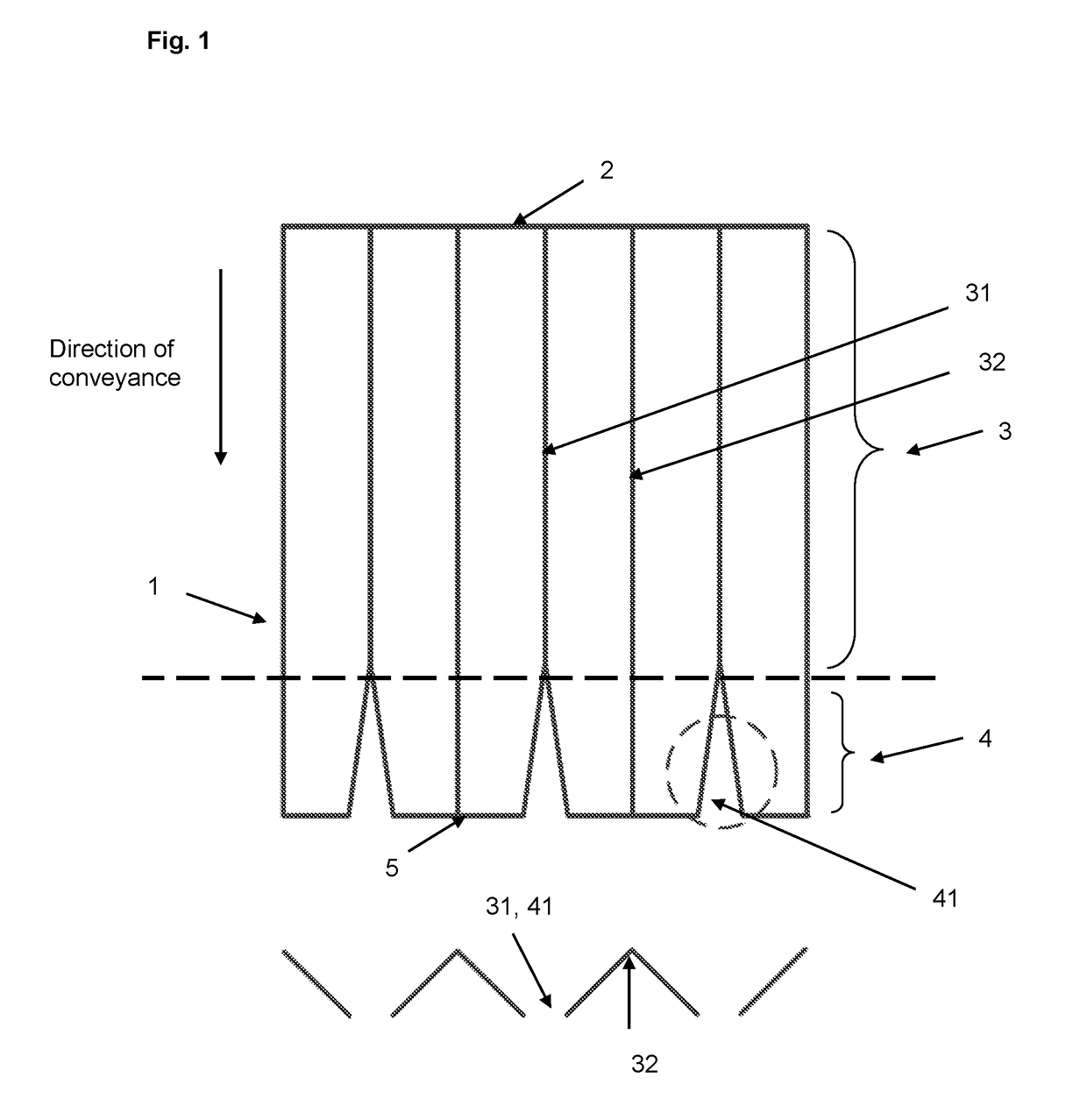

Screen plate for screening plants for mechanical classification of polysilicon

ActiveUS20180185882A1Avoid cloggingHigh level of costSievingScreeningEngineeringMechanical screening

Polysilicon chunks or granules are classified into size fractions using a mechanical screen having a profiled surface having peaks and valleys, and terminating in widening slots through which a polysilicon size fraction falls. The device is effective and the slots are resistant to clogging.

Owner:SILTRONIC AG +1

Method for separating waste polyphenylene sulfide from polytetrafluoroethylene blended dust removal bag

InactiveCN105397935AEfficient separationBeneficial technical effectPlastic recyclingFiberPre treatment

The invention relates to a method for separating waste polyphenylene sulfide from a polytetrafluoroethylene blended dust removal bag, and belongs to the technical field of industrial dust removal. The method comprises the following steps: step, pre-processing; step II, freezing and crushing; and step III, screening and separating. According to the technical scheme, by utilizing difference between brittleness of the frozen polyphenylene sulfide fibers and brittleness of frozen polytetrafluoroethylene fibers, the polyphenylene sulfide fibers are embrittled into powder within a temperature interval of (-)100 DEG C to (-)200 DEG C while the polytetrafluoroethylene fibers are not changed, so that the polyphenylene sulfide fibers and the polytetrafluoroethylene fibers are effectively separated by virtue of mechanical screening means. The method has the beneficial effects that the operation process is simple, the separation process is free from secondary pollution, and industrial popularization and application can be realized.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

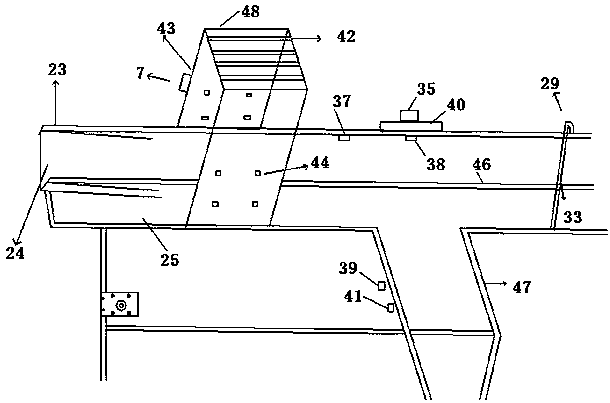

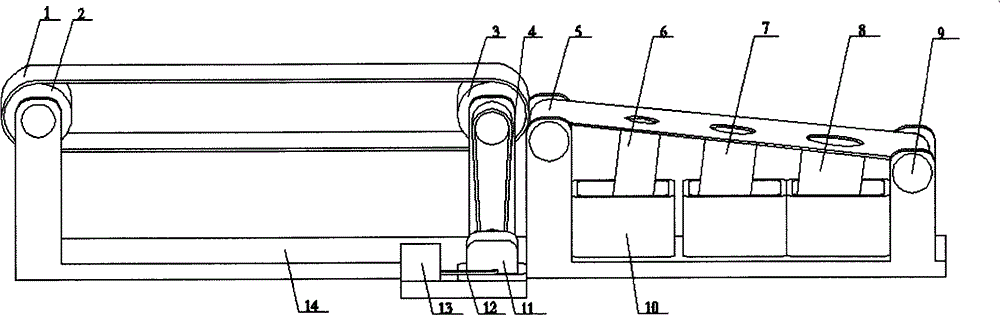

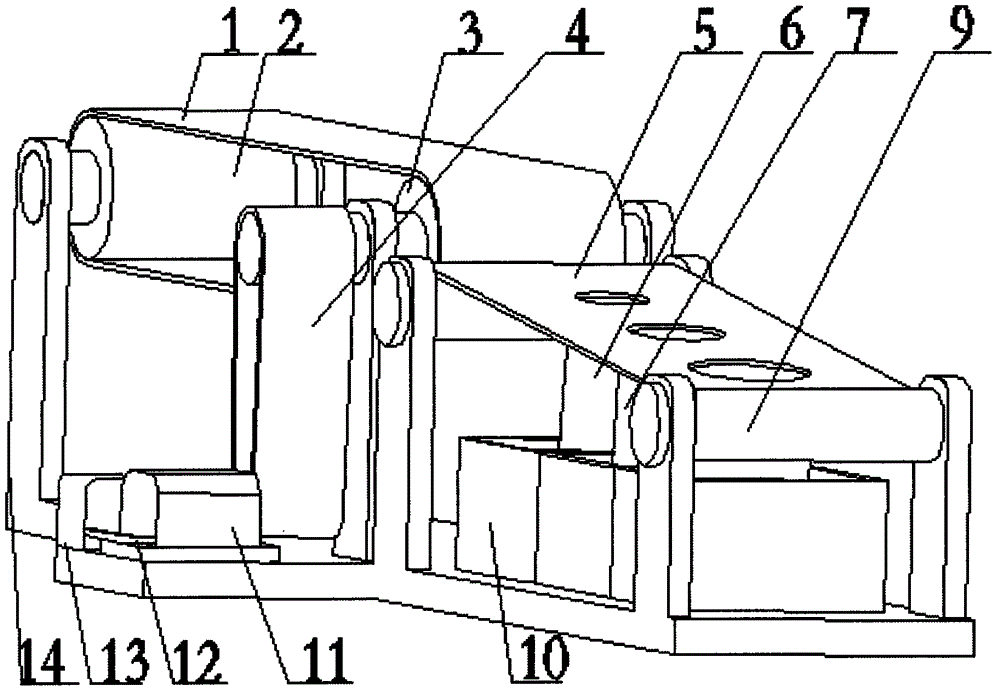

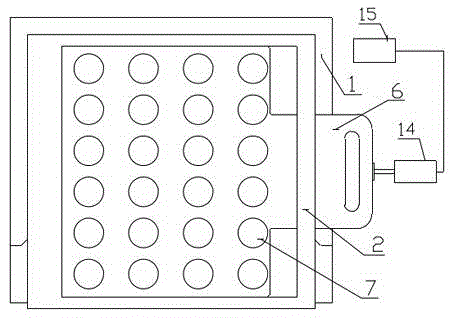

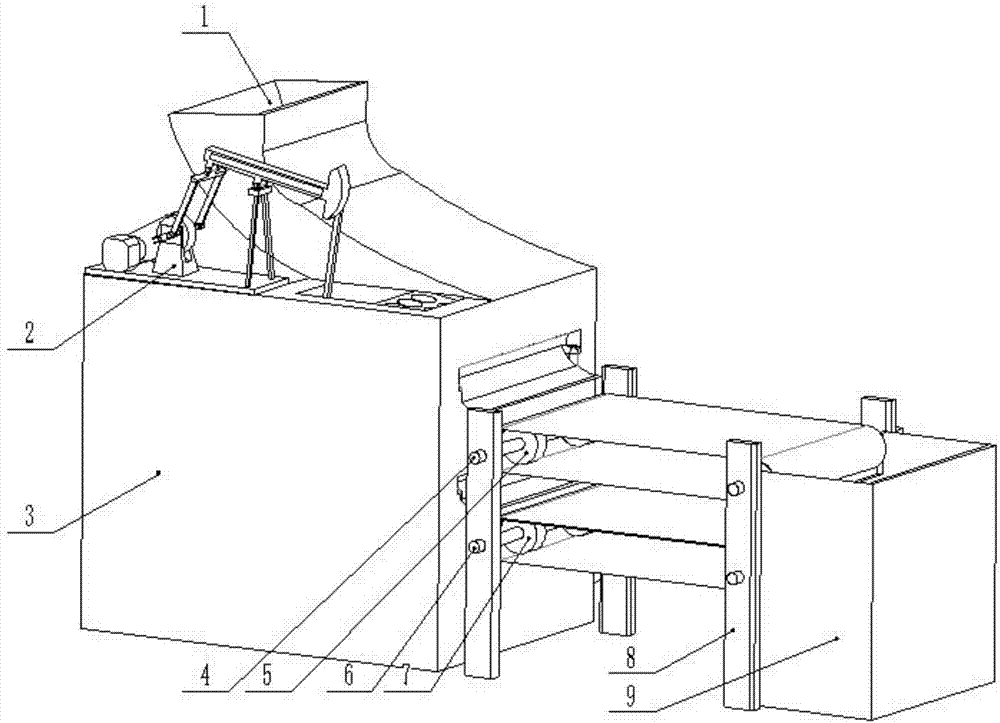

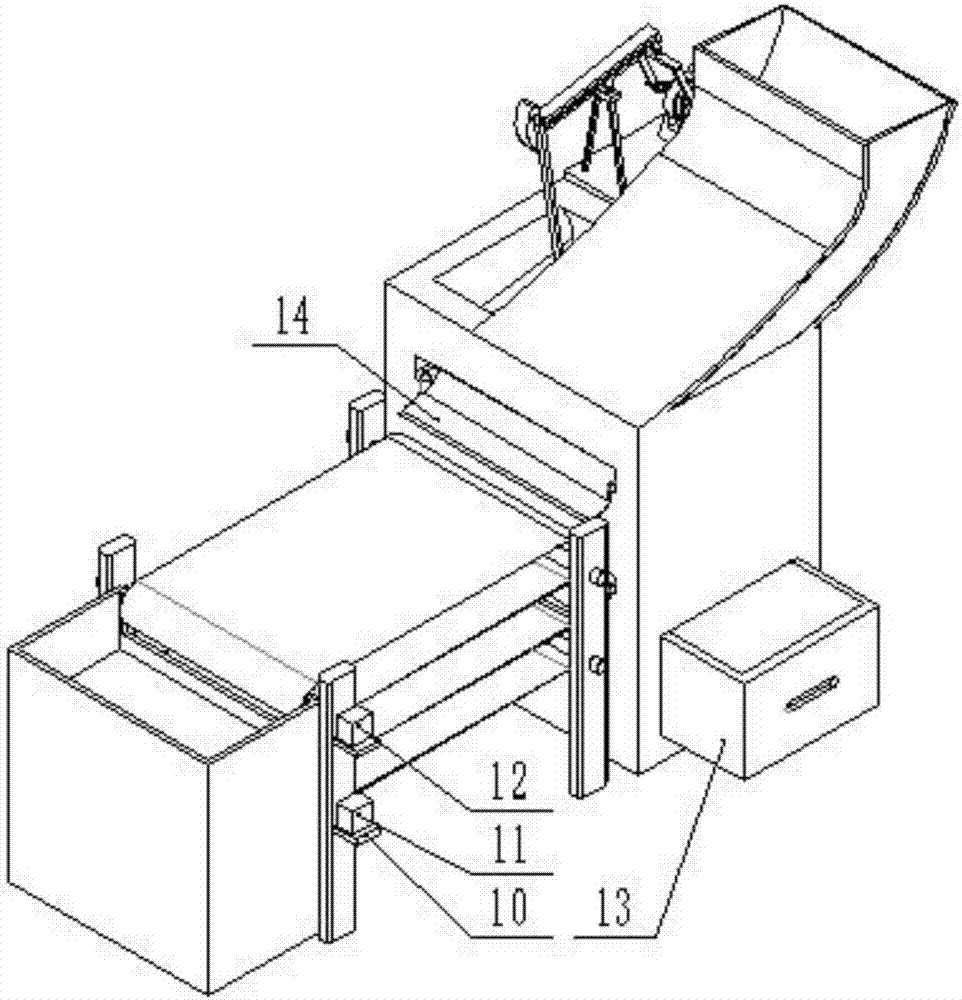

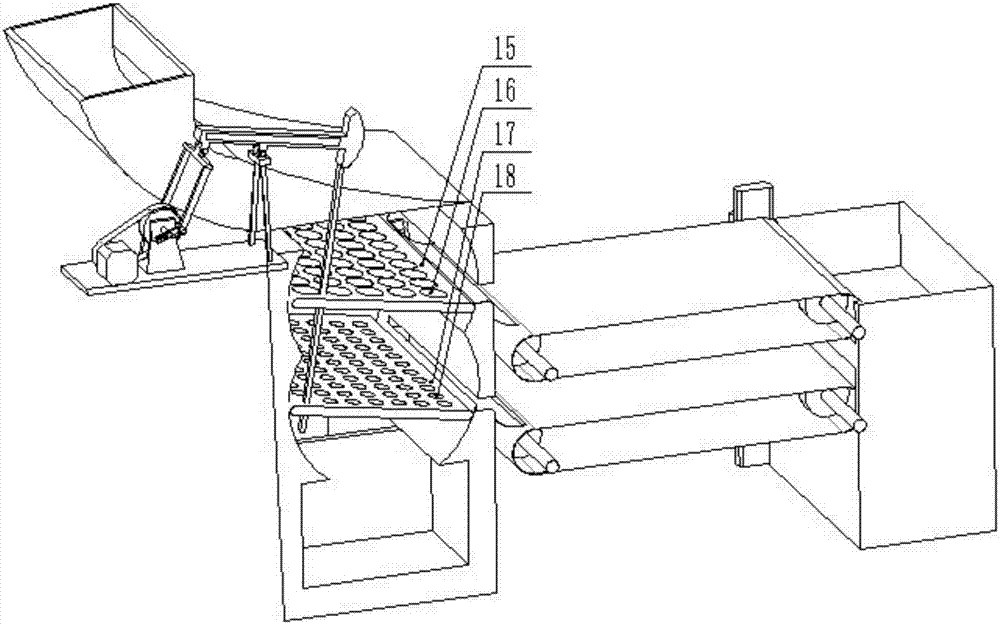

Mechanical screening type mixed material food racking machine and racking method thereof

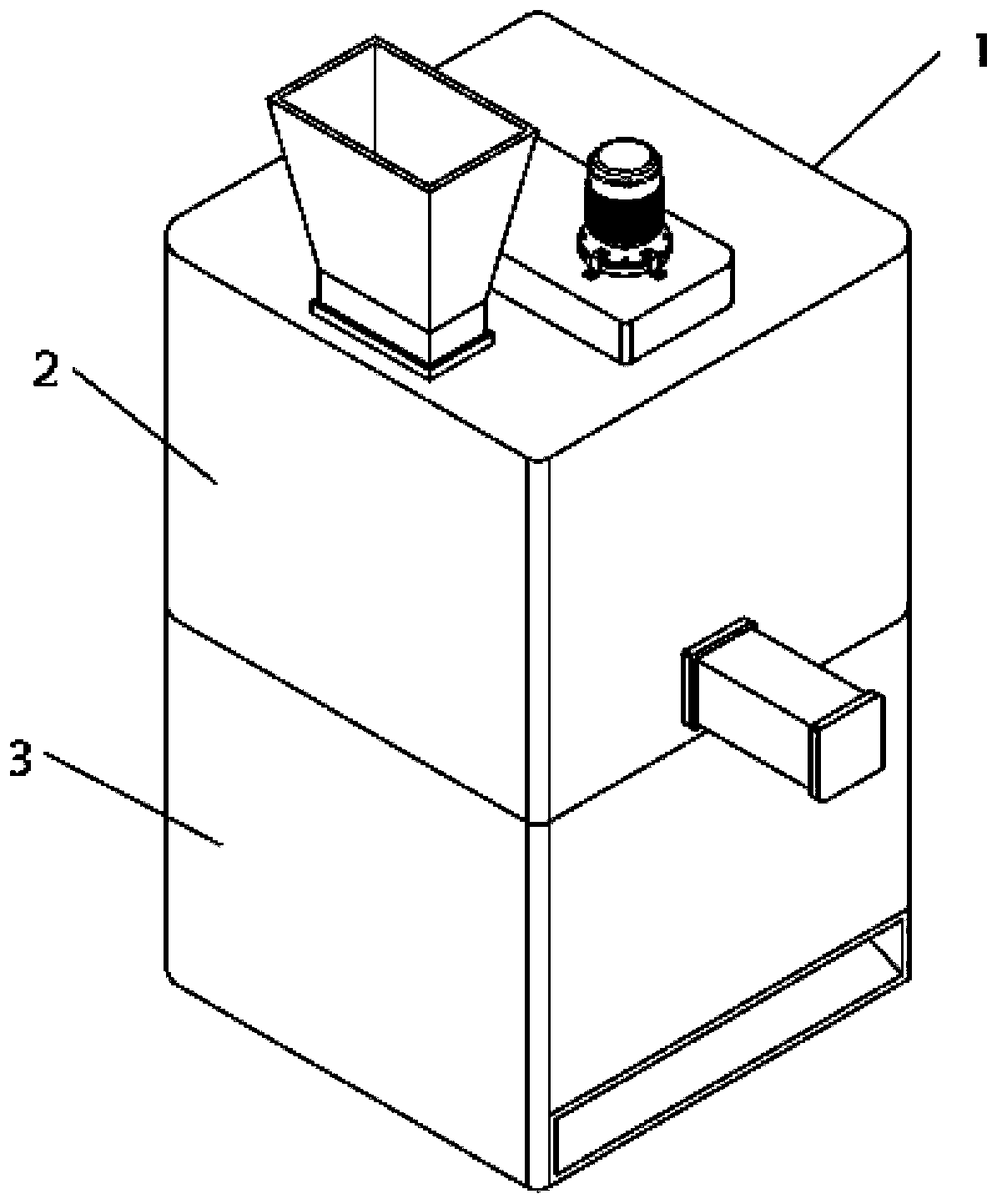

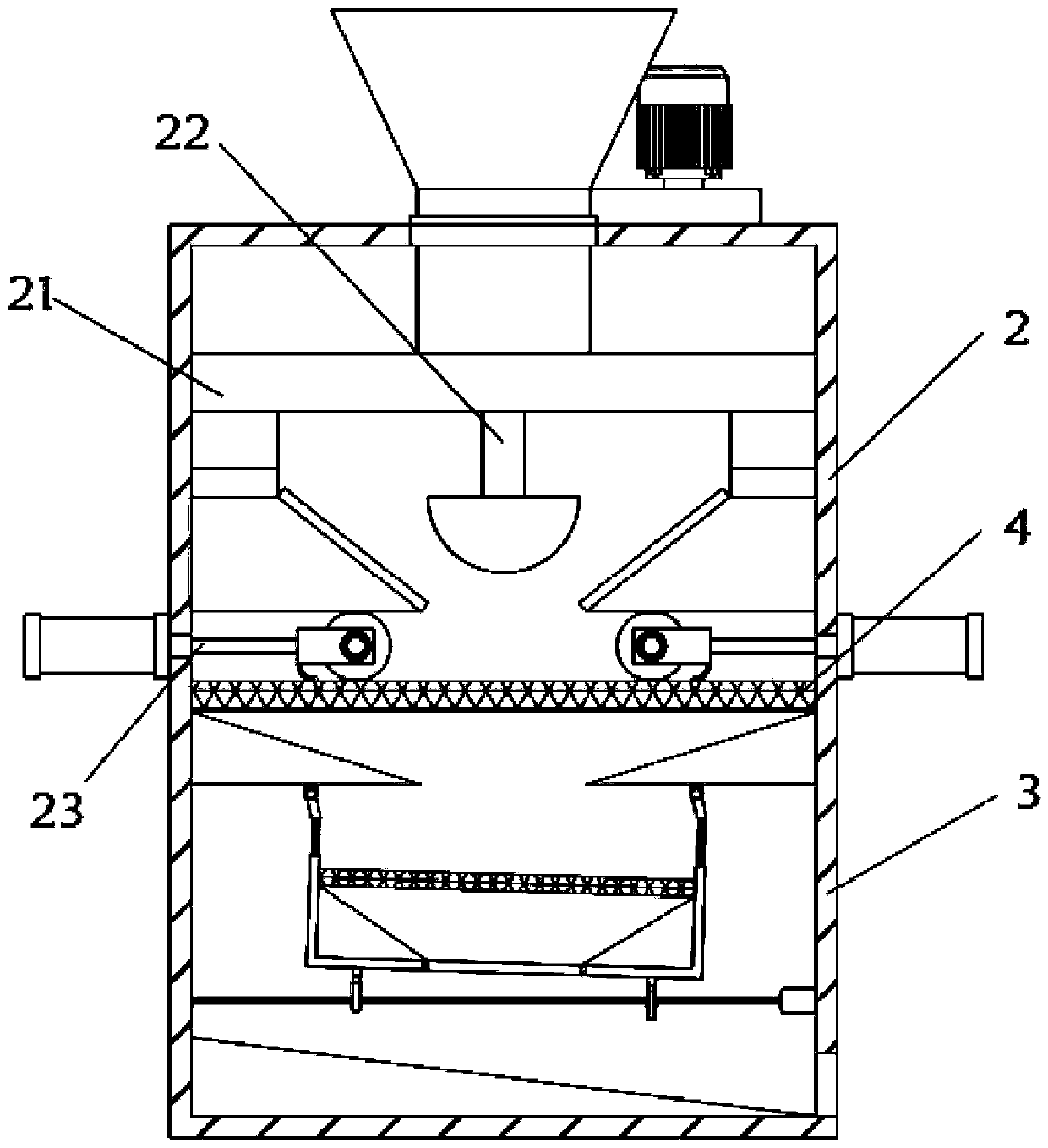

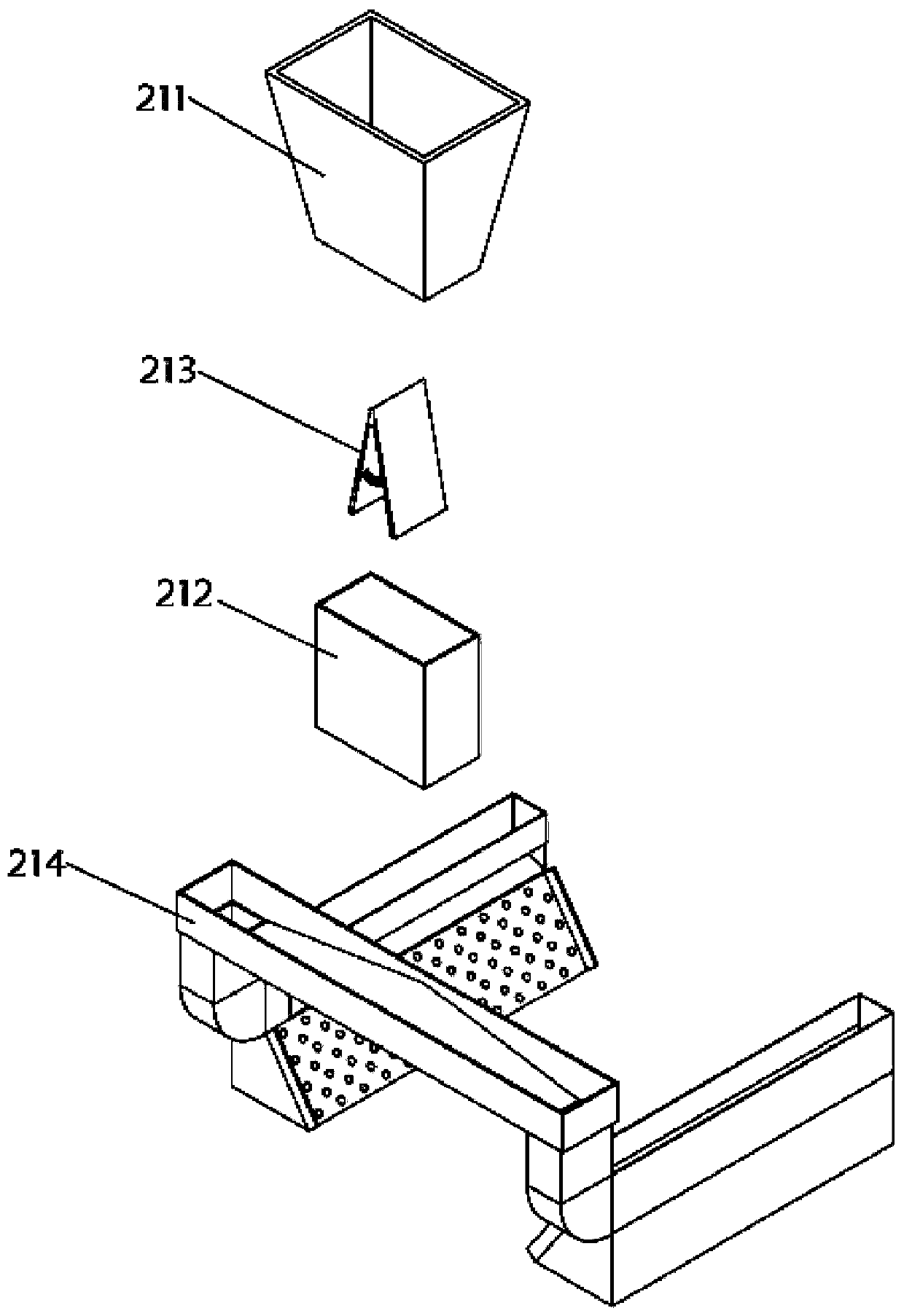

InactiveCN104627401AControlling the Mixing RatioThe controller controls the mixing ratioLiquid materialFood materialEngineering

The invention discloses a mechanical screening type mixed material food racking machine and a racking method thereof. The racking machine comprises a locating frame (1), and the upper portion of the locating frame (1) is connected with a material distribution frame (2); the material distribution frame (2) comprises a material distribution frame bottom plate (5), a switching plate (6) is arranged above the material distribution frame bottom plate (5), a material distribution hopper is arranged above the switching plate (6), the material distribution hopper is arranged inside the material distribution frame (2) and is provided with quantitative holes; the material distribution frame bottom plate (5) is provided with material passing holes (12); the switching plate (6) is provided with switching holes (7). The mechanical screening type mixed material food racking machine can improve production efficiency, accurately control the mixing proportion and weight of food materials and guarantee the attractiveness and taste of products; in addition, the mechanical screening type mixed material food racking machine is simple in principle and structure and low in equipment manufacturing cost and maintenance cost.

Owner:贵州省机电研究设计院

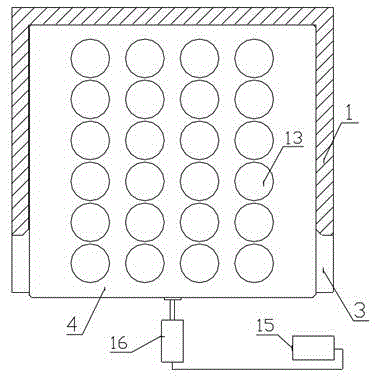

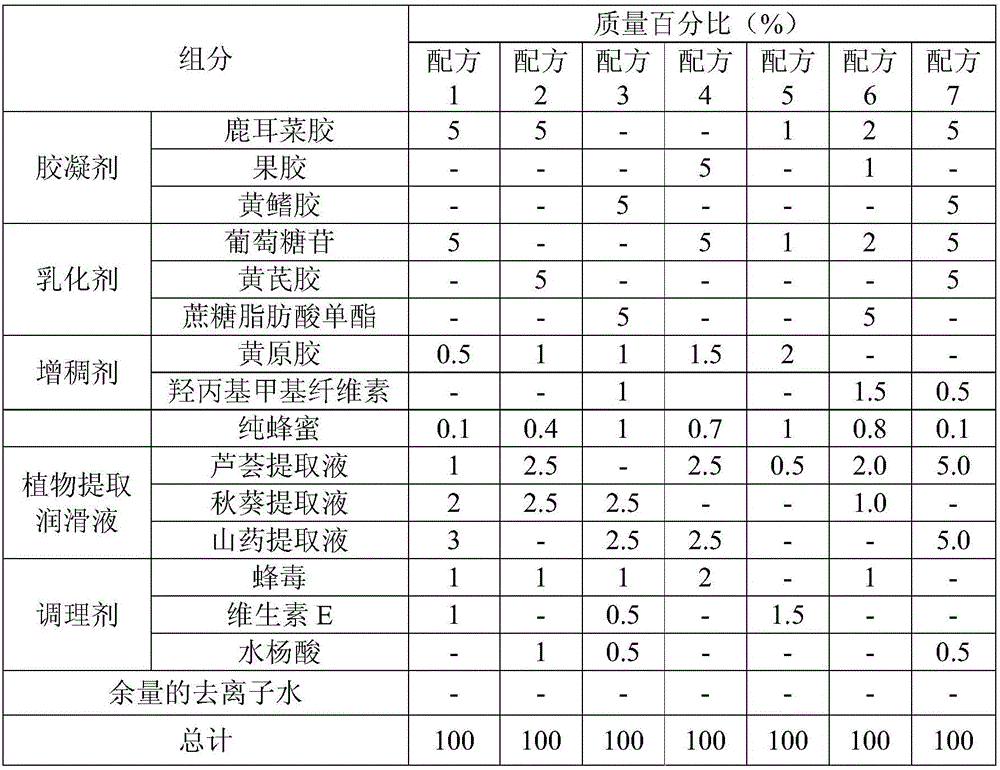

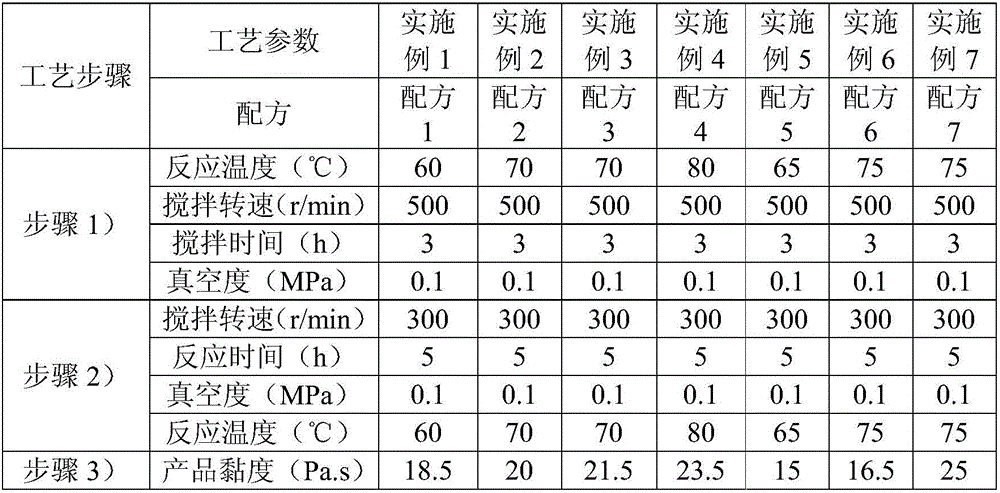

Pure natural water-soluble human bodfy lubricant, preparation method and application thereof

The invention provides a pure natural water-soluble human body lubricant which is prepared from the following components by weight percent: 1%-10% of gelatinizing agent, 1%-10% of emulgator, 0.5%-2% of thickening agent, 0.1-1% of pure honey, 0.5%-10% of plant extracted lubricating fluid, 0.5%-2% of conditioner and the balance of sterilized deionized water. The lubricant provided by the invention has excellent lubricating property, high stability, safety and environmental protection; the plant extracted lubricating fluid is prepared according to a three-level filtering technology of mechanical screening filtering, micro-filtration and reverse osmosis concentration purification, and the active component with the highest practical value is remained; the product performance is promoted in the manner of combining vacuumizing and heating; the pure natural water-soluble human body lubricant has multiple effects of sterilizing, diminishing inflammation, restraining inflammation diffusion, draining secreta, promoting local metabolism, converging wound, preventing lesion and tumor, and the like.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

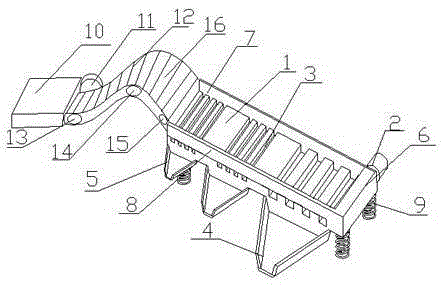

Vibration pump type vibration screening mechanism of vibration pump type peanut cleaner

InactiveCN103706557AImprove the efficiency of screening qualitySmooth vibrationSievingScreeningControl engineeringStructural engineering

The invention discloses a vibration pump type vibration screening mechanism of a vibration pump type peanut cleaner. The vibration pump type vibration screening mechanism of the vibration pump type peanut cleaner comprises a vibration screen, a vibration pump, springs, spring seats, a bagging pothook and an outlet for unqualified small peanuts, wherein the vibration pump is installed right in the middle of the lower surface of the vibration screen, the spring seats are arranged at two sides of the lower surface of the vibration screen, the springs are installed on the spring seats, the bagging pothook is arranged at the tail end of the vibration screen, the outlet for unqualified small peanuts is formed in the back surface of the bagging pothook, and the springs are fixed to the upper surface of a machine frame of the peanut cleaner at the same time. The vibration pump type vibration screening mechanism of the vibration pump type peanut cleaner achieves mechanical screening operation for peanuts, and has the advantages of being uniform in vibration, low in noise, good in screening effect and capable of automatically bagging the peanuts and obviously improving the screening quality and screening efficiency of the peanuts.

Owner:QINGDAO FEIERTE IND

Biological pesticide screening machine

The invention discloses a biological pesticide screening machine, and relates to the technical field of biological pesticides. The biological pesticide screening machine comprises a box. A heat dissipating fan is fixedly connected to the bottom of the inner wall of the left side of an inner cavity of the box, and the outer surface of a rotary shaft is fixedly connected with a driving gear; a driven belt pulley is fixedly connected to the position, in an inner cavity of a protecting support, of the outer surface of the rotary shaft; the output end of a screening motor is fixedly connected witha driving belt pulley through a coupling, and the positions, on the side, away from the heat dissipating fan, of a supporting support, of the bottom of the inner cavity of the box are fixedly connected with a first transferring device and a second transferring device correspondingly; and the top of the driving gear is provided with a screening tube in an engagement transmission mode, and the position, on the right side of a fixing top frame, of the top of the inner cavity of the box is fixedly connected with an adsorption device. According to the biological pesticide screening machine, mechanical screening can be carried out, manual screening is avoided, the labor intensity is lowered, the efficiency is improved, batch production and flow dividing conveying can be carried out, machining ofthe next step is facilitated, machining dust is adsorbed to be prevented from harming personal safety, and the environment is protected.

Owner:谭崴

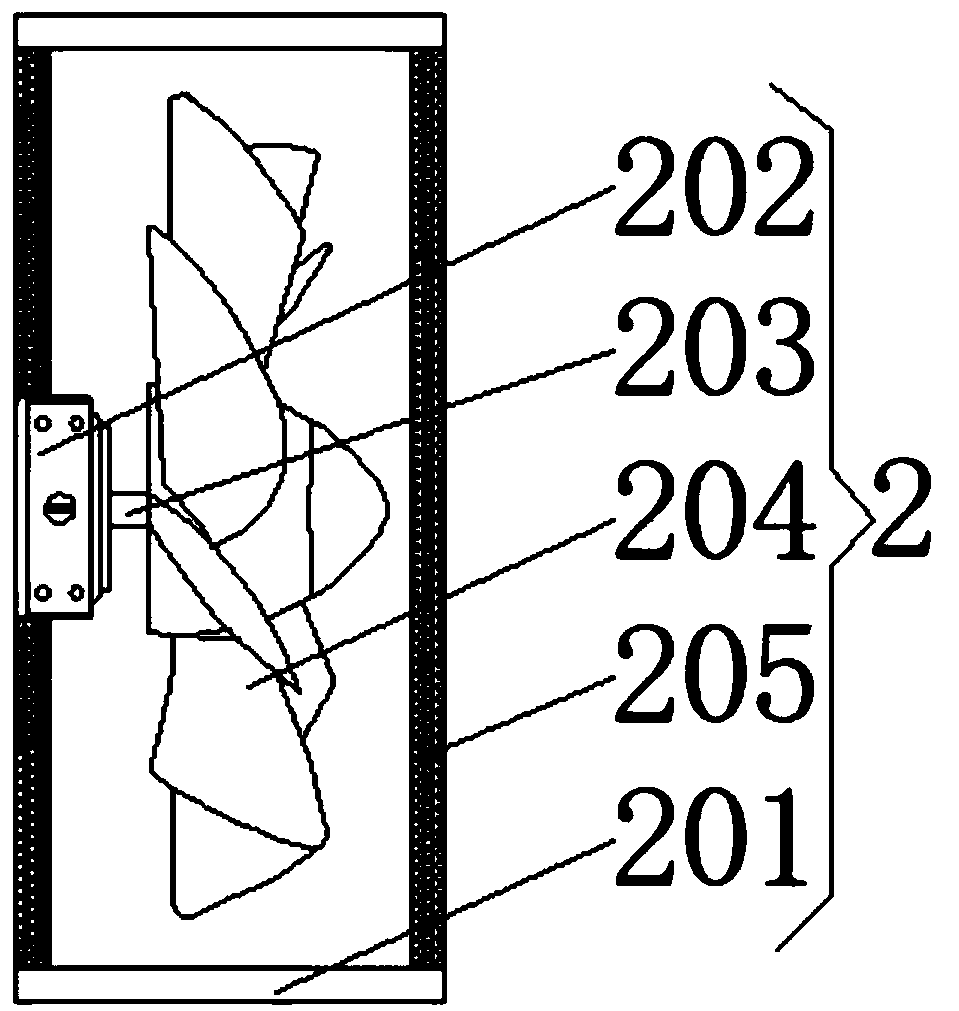

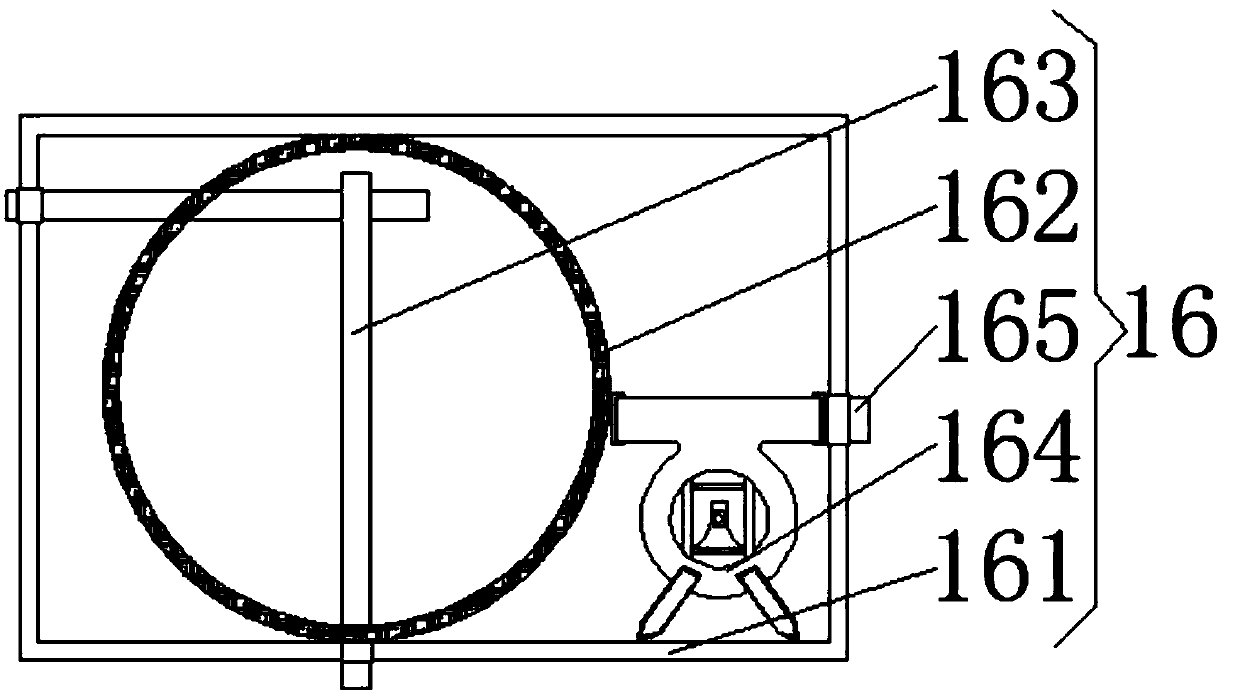

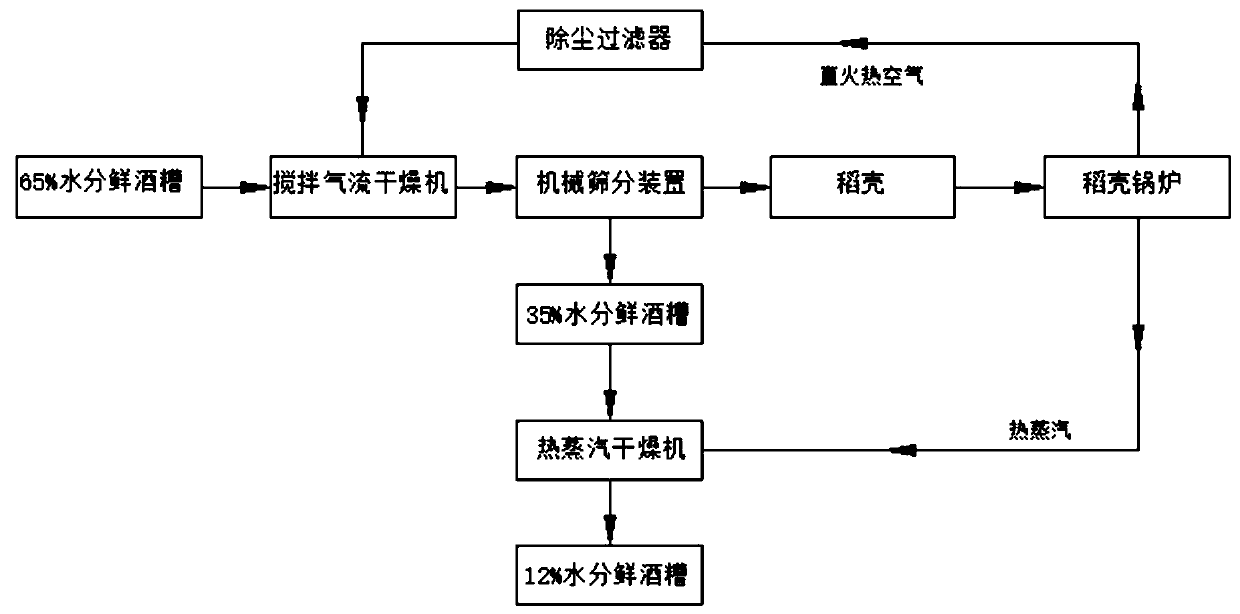

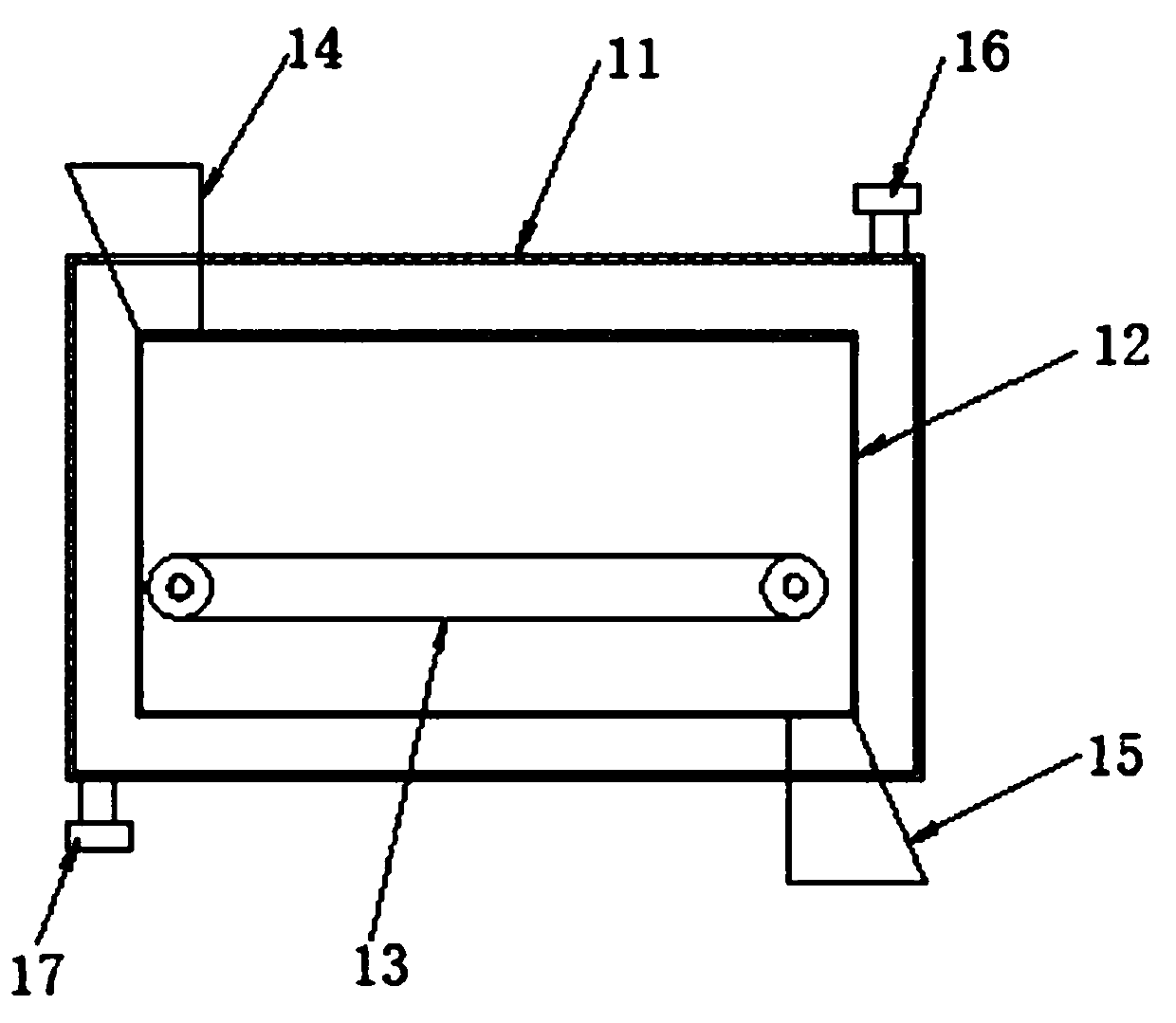

Drying technology for fresh vinasse to prepare feed

The invention discloses a drying technology for fresh vinasse to prepare feed. The technology specifically includes the following steps: performing primary drying treatment on fresh vinasse with 65% of moisture through a stirring airflow dryer to dehydrate into fresh vinasse with 35% of moisture; performing rice husk removing treatment on the obtained fresh vinasse with 35% of moisture through a mechanical screening device, the obtained rice husks being used for the combustion of a rice husk boiler to supply direct fire hot air to the stirring airflow dryer to work; and performing secondary drying treatment on the rice husk-removed fresh vinasse with 35% of moisture through a hot steam dryer to dehydrate into fresh vinasse with 12% of moisture, the obtained rice husks being used for the combustion of the rice husk boiler to supply hot steam to the stirring airflow dryer to work.

Owner:河南贾湖生物科技有限公司

Winter jujube sorting device

ActiveCN107029997ARealize sorting functionEasy accessSievingScreeningMechanical screeningEngineering

The invention relates to a winter jujube sorting device, and belongs to the field of mechanical screening equipment. A feeding opening is formed in the upper portion of a machine body and communicates with the interior of the machine body. A vibration device is mounted on the side face of the feeding opening. A first rotary shaft is mounted on supporting legs. Two first rotary shaft rolling wheels are distributed on the two sides of a first conveying belt and are mounted on the first rotary shaft. A second rotary shaft is mounted below the first rotary shaft. Two second rotary shaft rolling wheels are distributed on the two sides of a second conveying belt and are mounted on the second rotary shaft. A box body is fixed to the tail end of the first conveying belt and the tail end of the second conveying belt. A waste box is mounted at the bottom in the machine body. Two side plates are mounted at an opening in the front end of the machine body and are located at the upper end of the first conveying belt and the upper end of the second conveying belt correspondingly. According to the winter jujube sorting device, a first screening plate and a second screening plate are driven by the vibration device to do arc swinging in the machine body, the winter jujube sorting function is achieved, and manual labor force is relieved.

Owner:WENLING ZHIYING ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com