Patents

Literature

1077 results about "Screening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is described as a decrease in shielding effort between the nucleus and last orbital due to electrons present between them i.e., greater the screening effect, easier the removal of electron. In solids, especially in metals and semiconductors, the electrostatic screening or screening effect reduces the electrostatic field and Coulomb potential of an ion inside the solid. Like the electric field of the nucleus is reduced inside an atom or ion due to the shielding effect, the electric fields of ions in conducting solids are further reduced by the cloud of conduction electrons. The screened Coulomb potential is expressed as where Z is the atomic number, e is the elementary unit charge, r is the distance to the nucleus of the embedded ion, and q is the screening parameter that determines the range of the potential. The screening parameter q plays an important role in theoretical models in solid-state physics. The screened electrostatic potential, like the Yukawa potential, has a simple Fourier transform, expressed as The screened potential determines the inter atomic force and the phonon dispersion relation in metals.

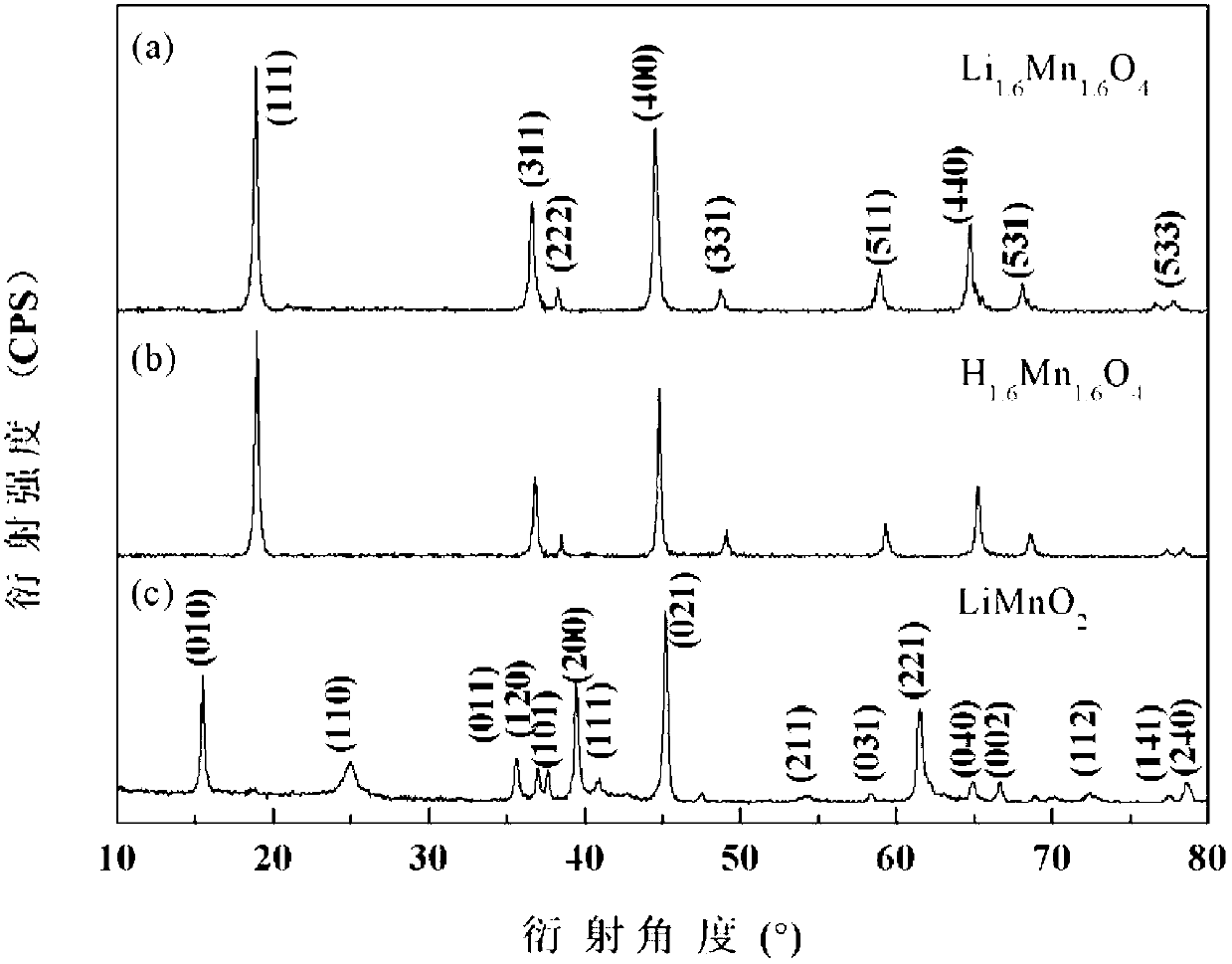

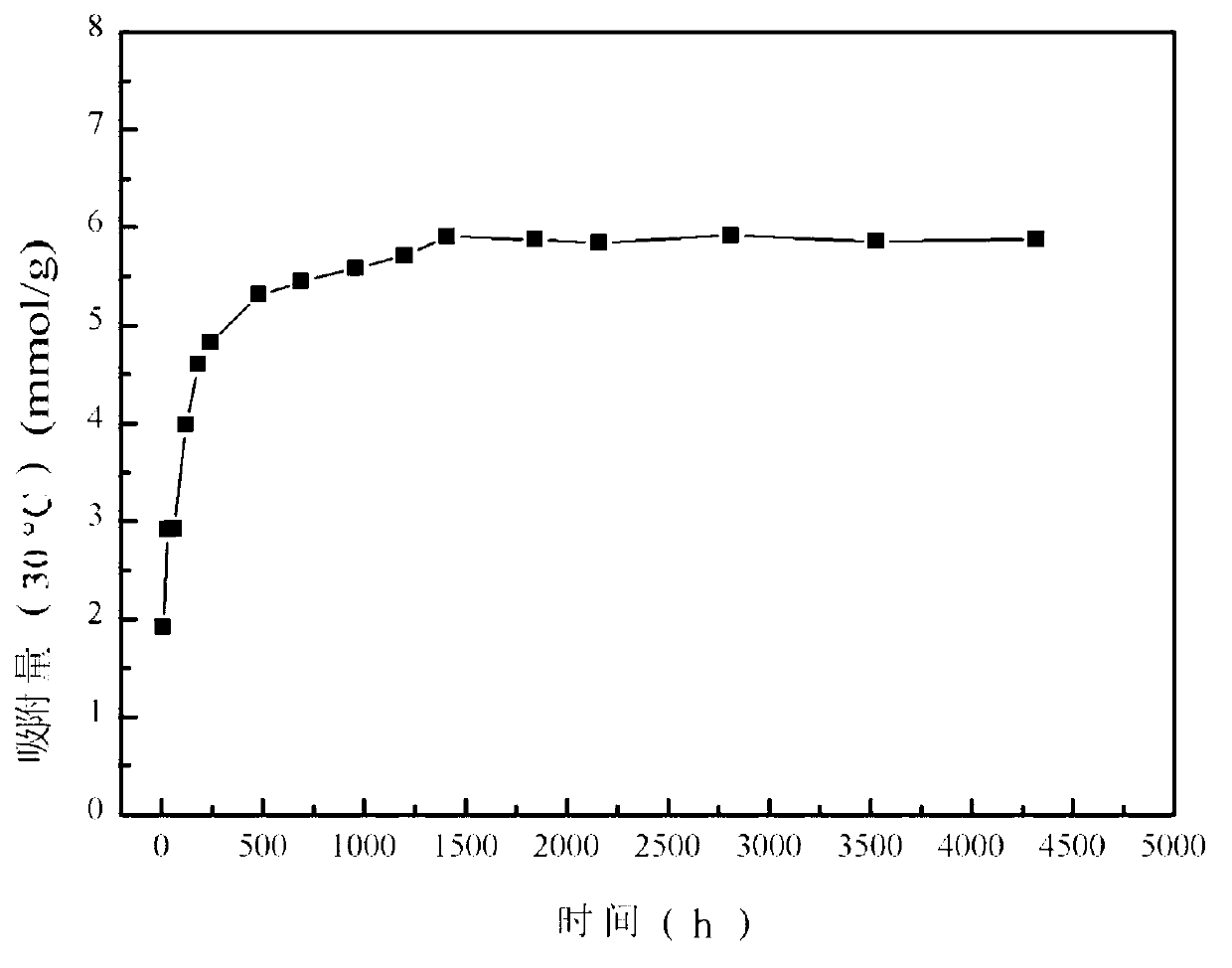

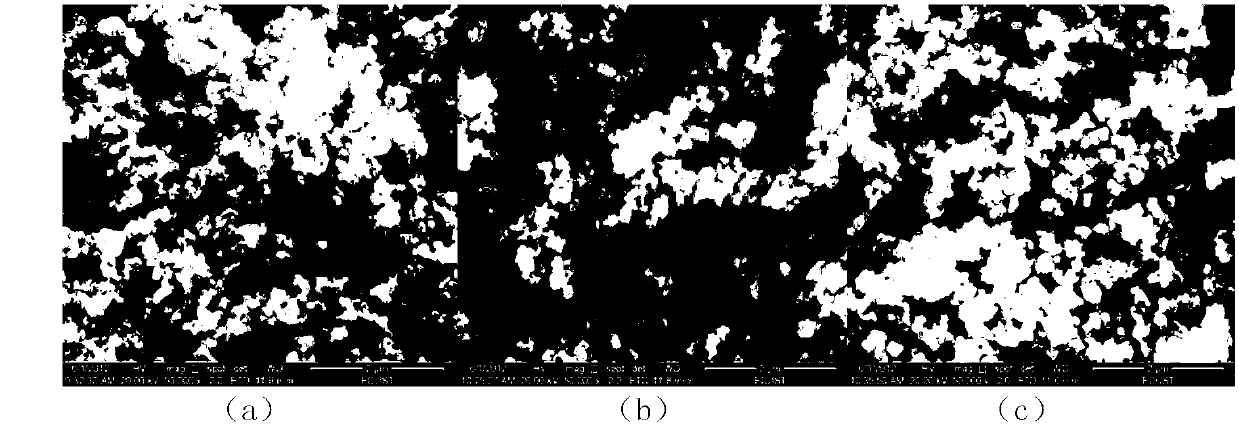

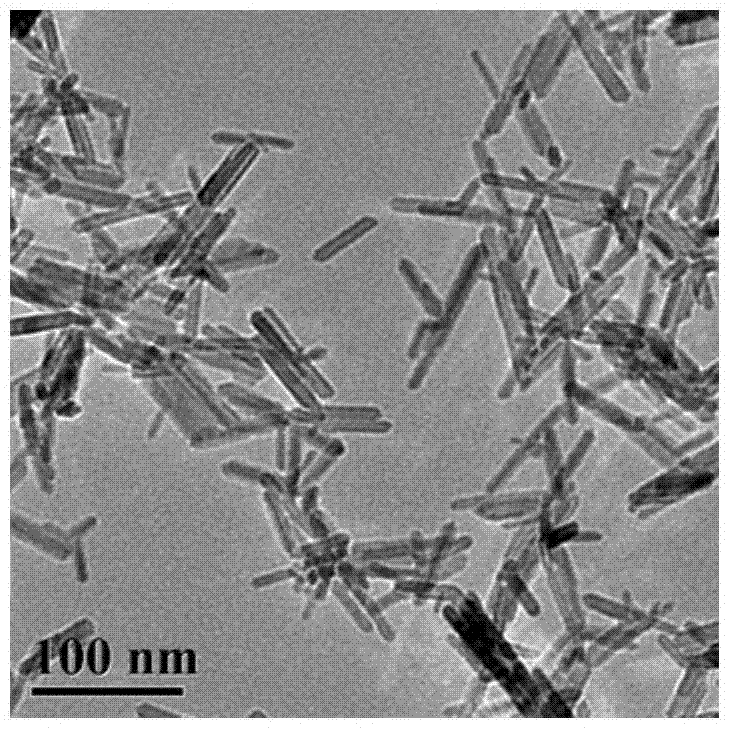

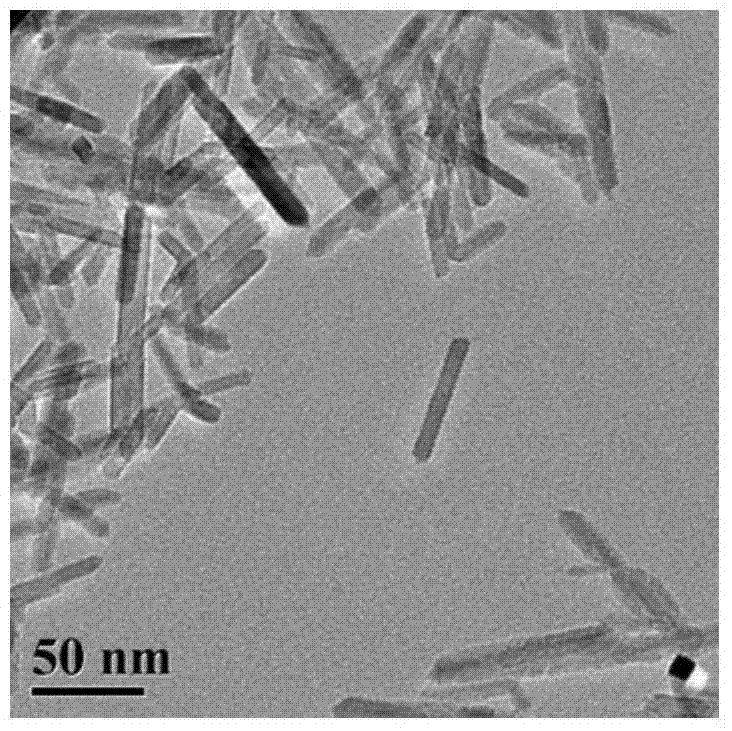

Method for preparing lithium ion sieve MnO2.0.5H2O and precursor thereof Li1.6Mn1.6O4

ActiveCN103121724AMole lowReduce wasteOther chemical processesManganese oxides/hydroxidesScreening effectPhysical chemistry

The invention discloses a method for preparing a lithium ion sieve adsorbent MnO2.0.5H2O and a precursor thereof Li1.6Mn1.6O4. The method comprises the following steps: carrying out one-step hydrothermal synthesis on raw materials inorganic manganese salt and lithium salt to obtain an intermediate, and roasting at low temperature to obtain the required precursor Li1.6Mn1.6O4; and carrying out acid treatment on the precursor to extract Li so as to obtain an H-type ion sieve, washing with water, filtering, and drying to obtain the ion sieve adsorbent MnO2.0.5H2O which has a screening effect on lithium ions. The invention has the advantages of simple process route and mild preparation conditions; and the obtained ion sieve has the advantages of low solution loss, high adsorption rate and high adsorption capacity.

Owner:EAST CHINA UNIV OF SCI & TECH

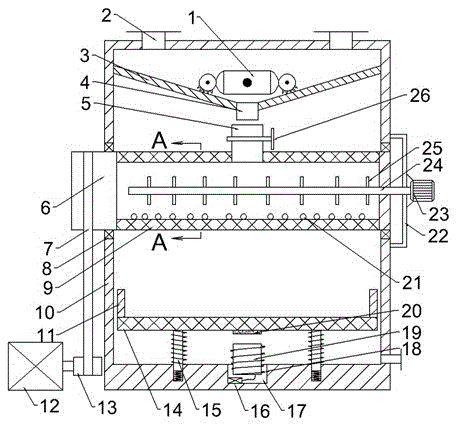

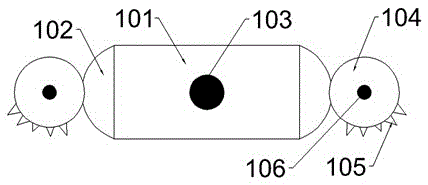

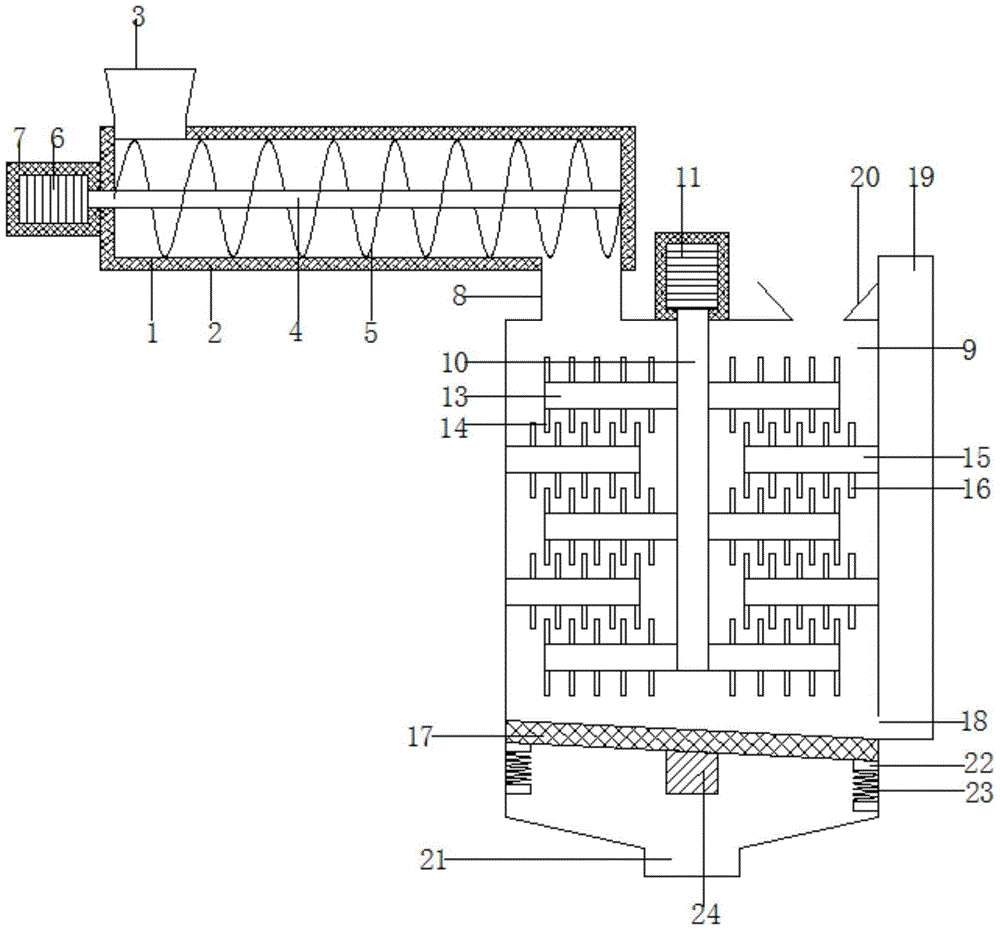

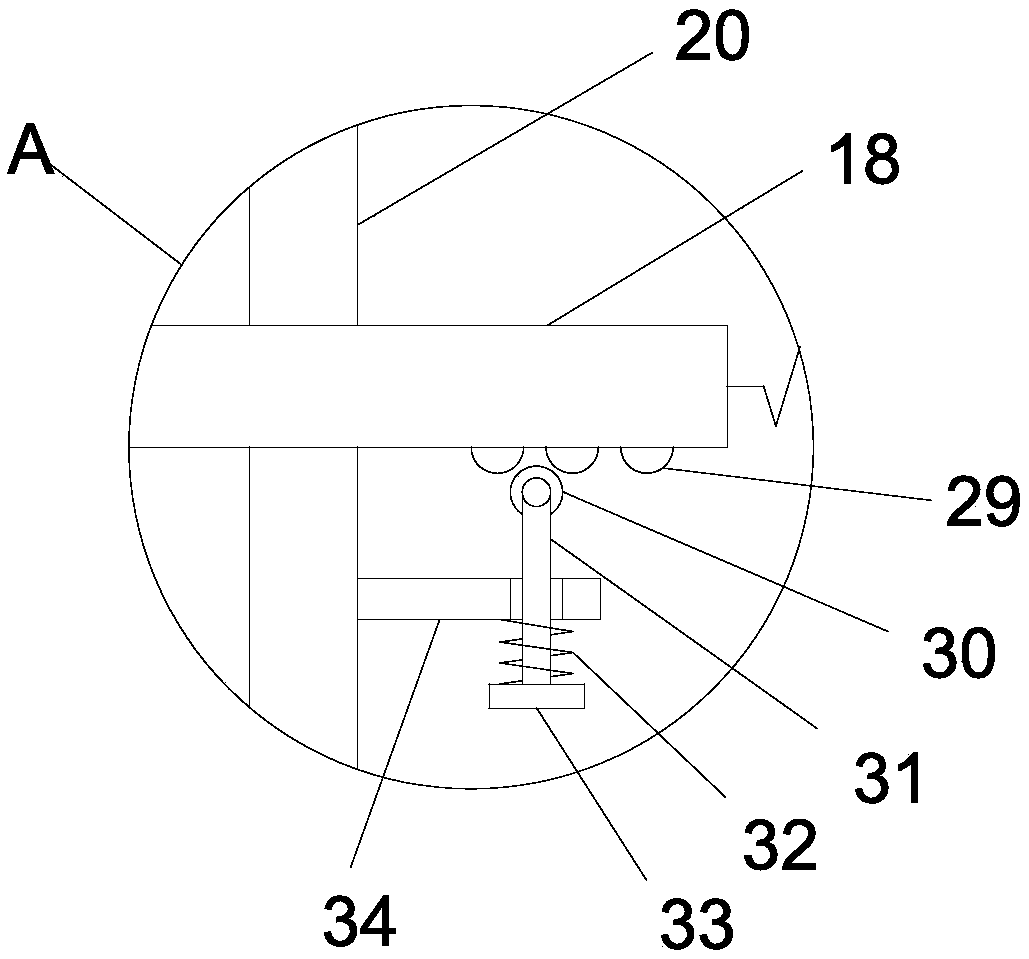

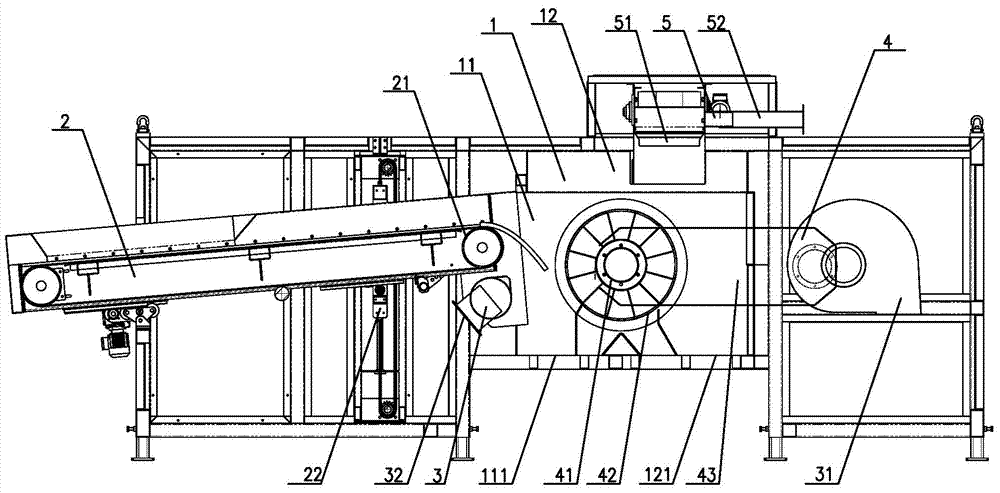

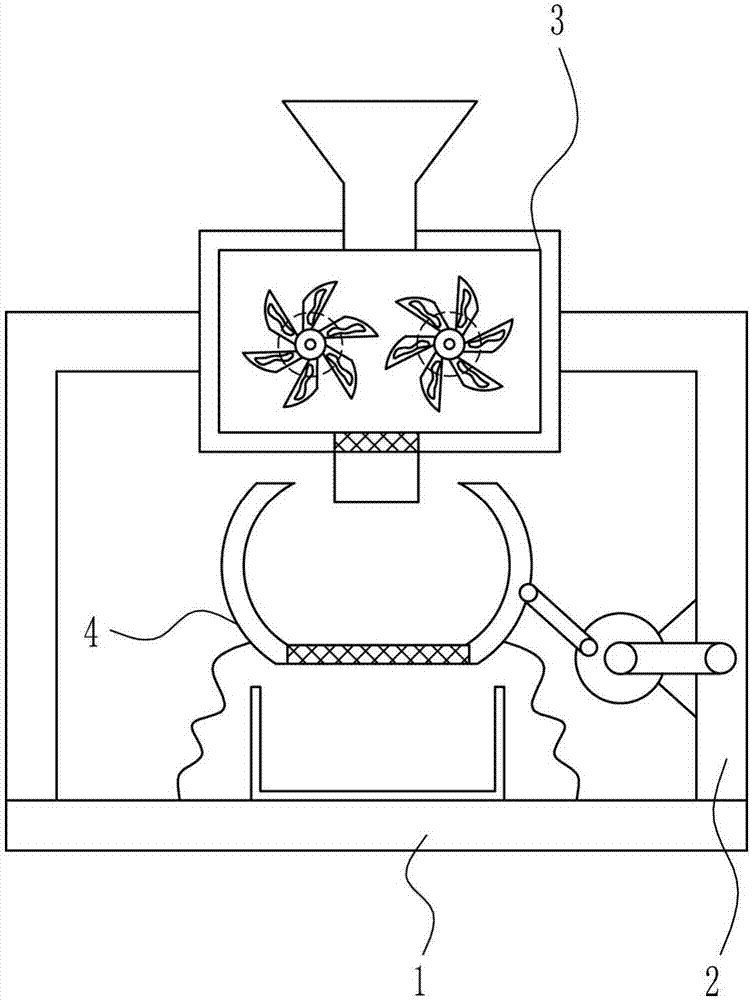

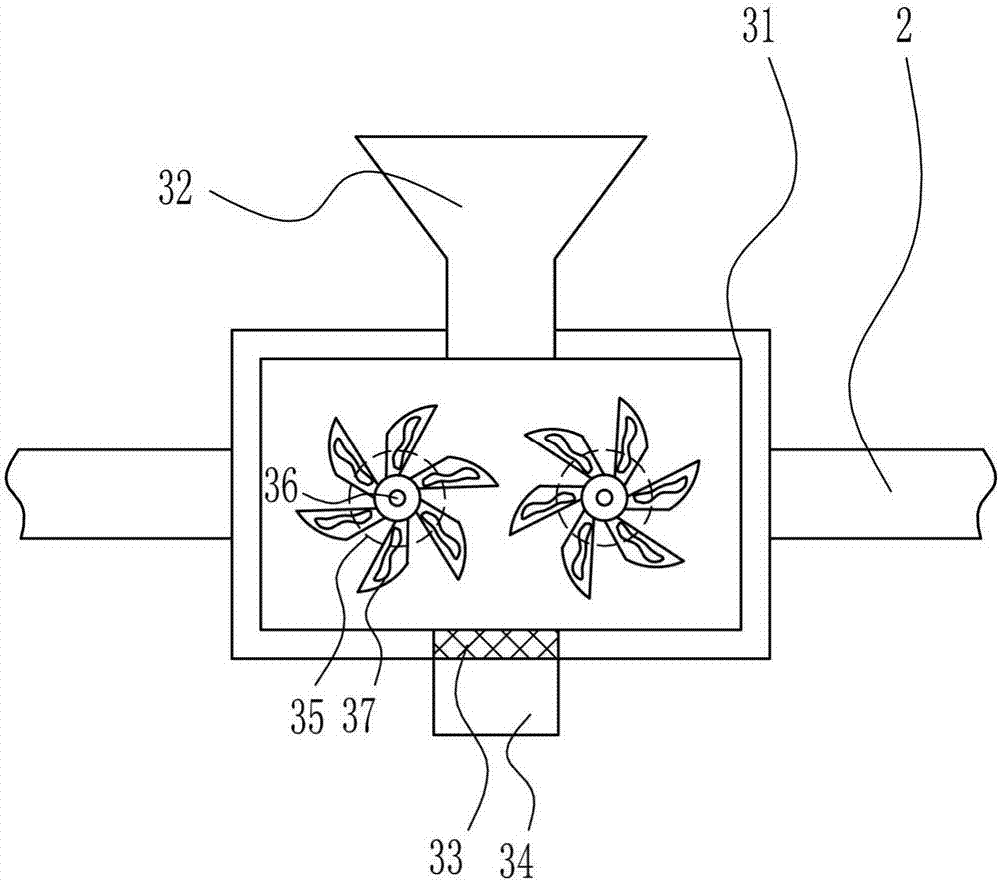

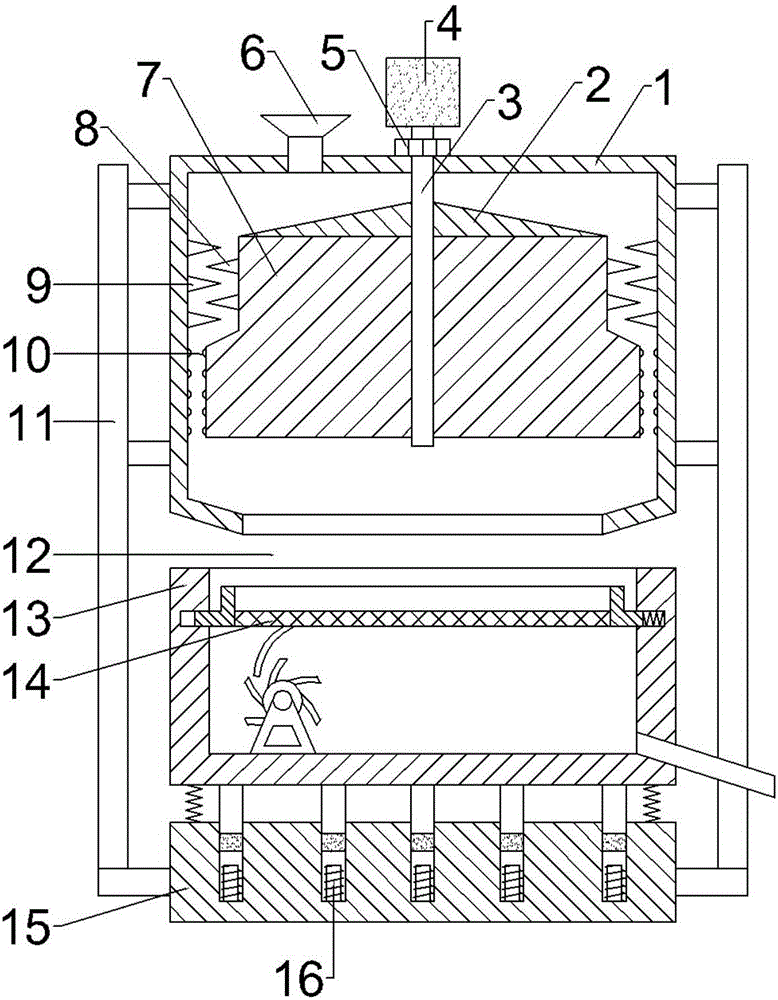

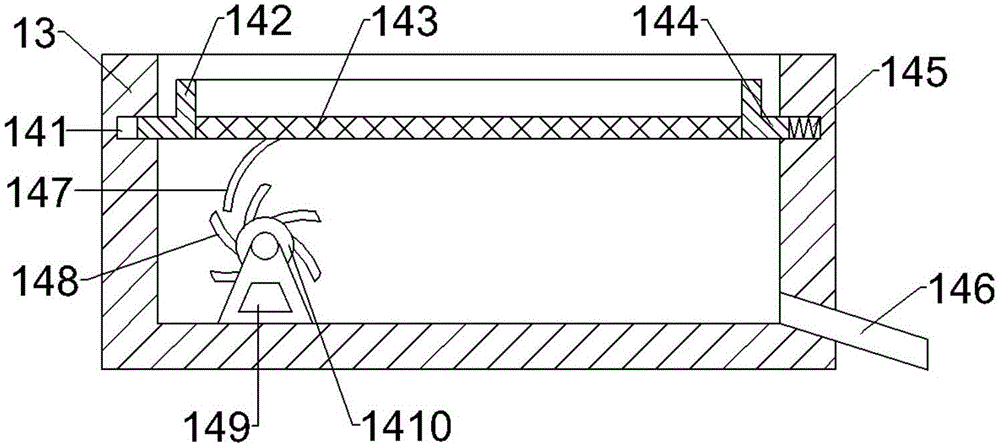

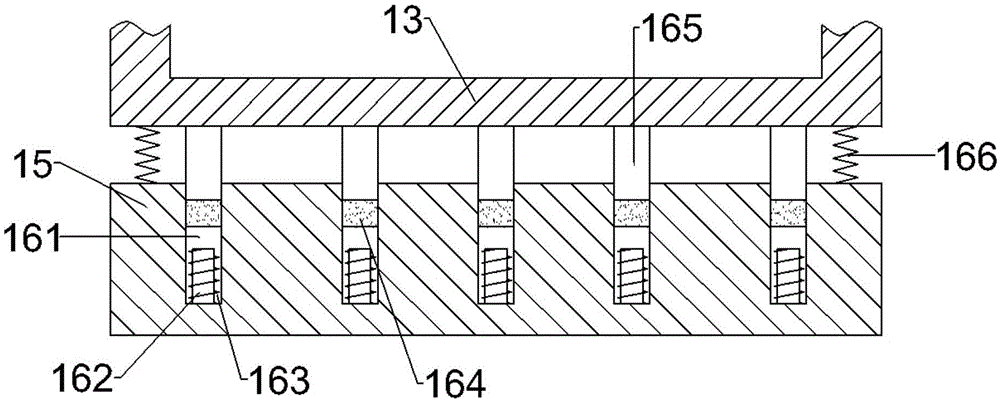

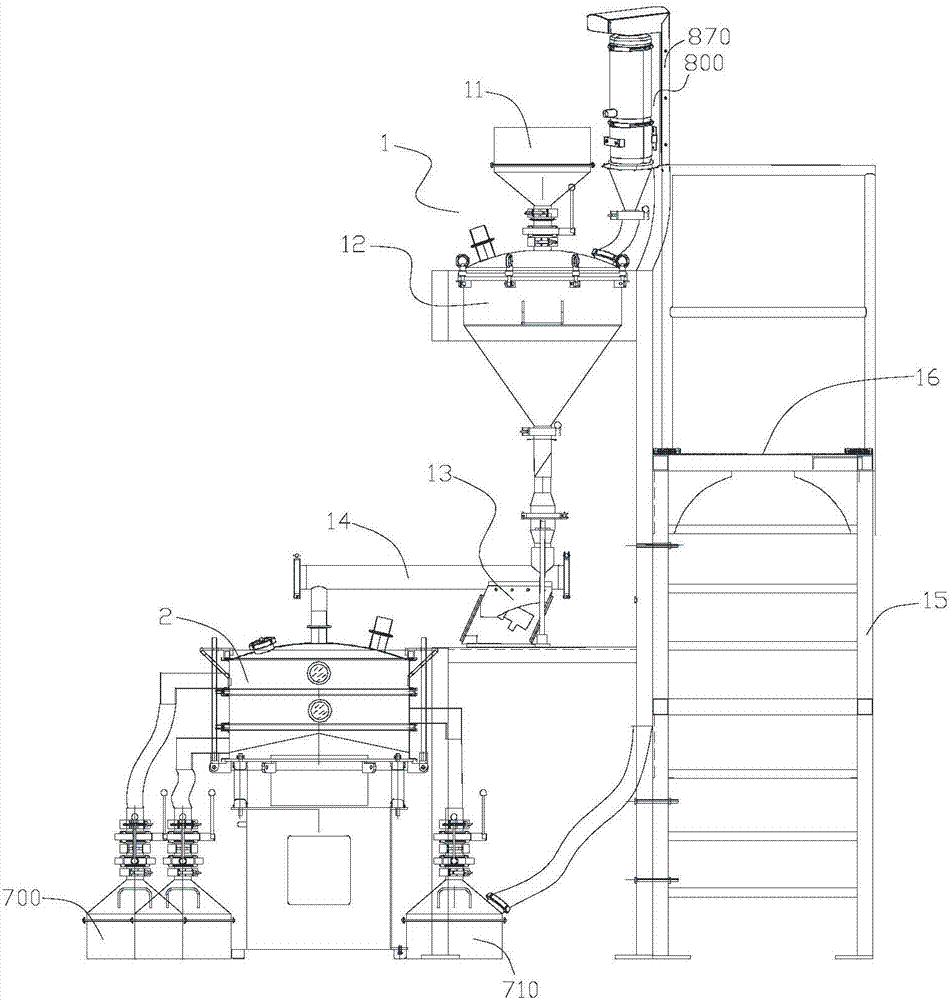

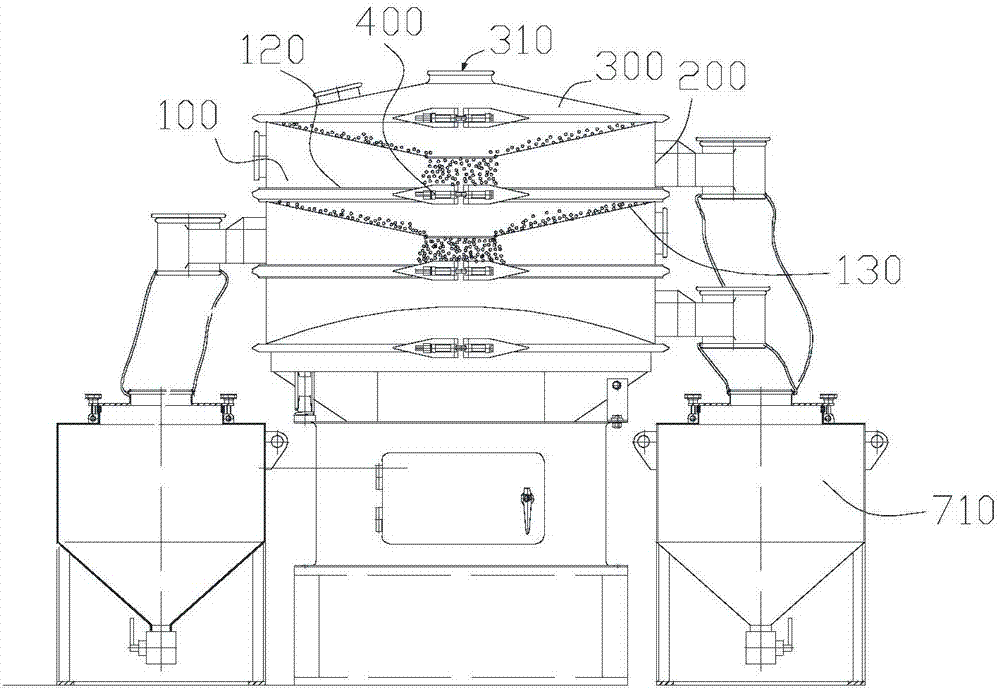

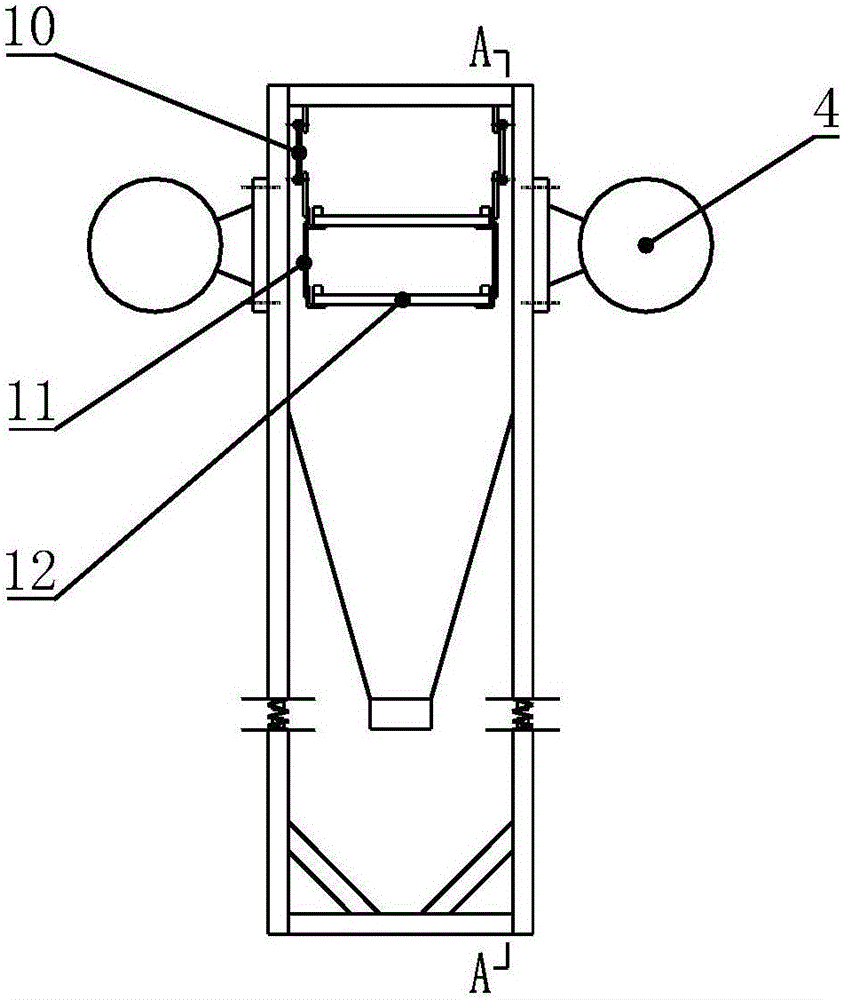

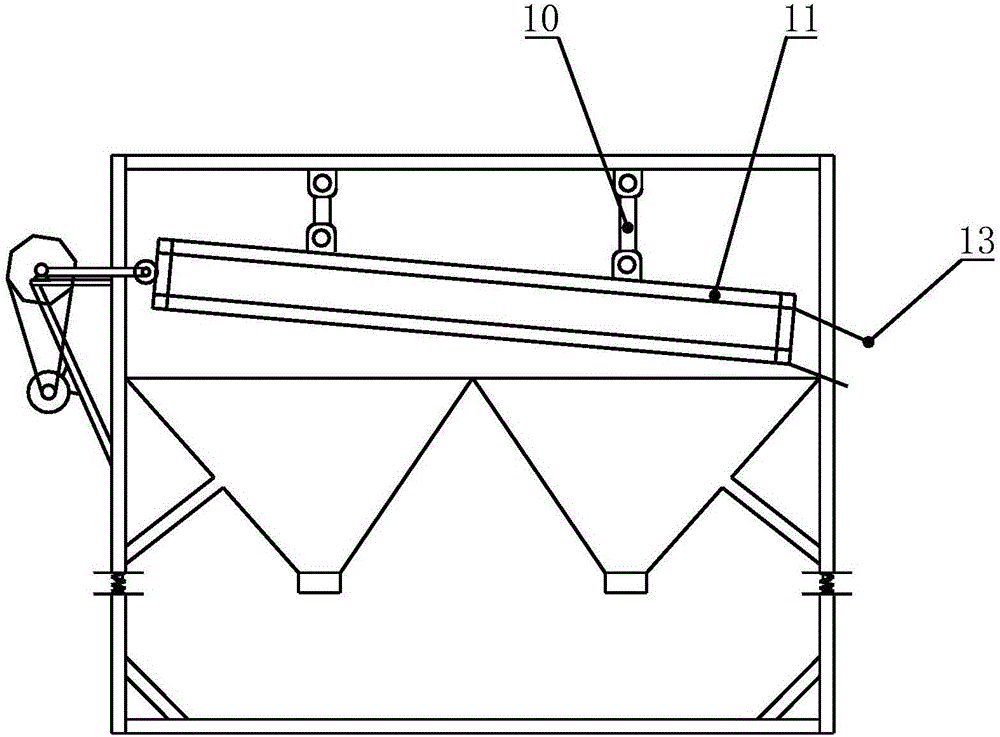

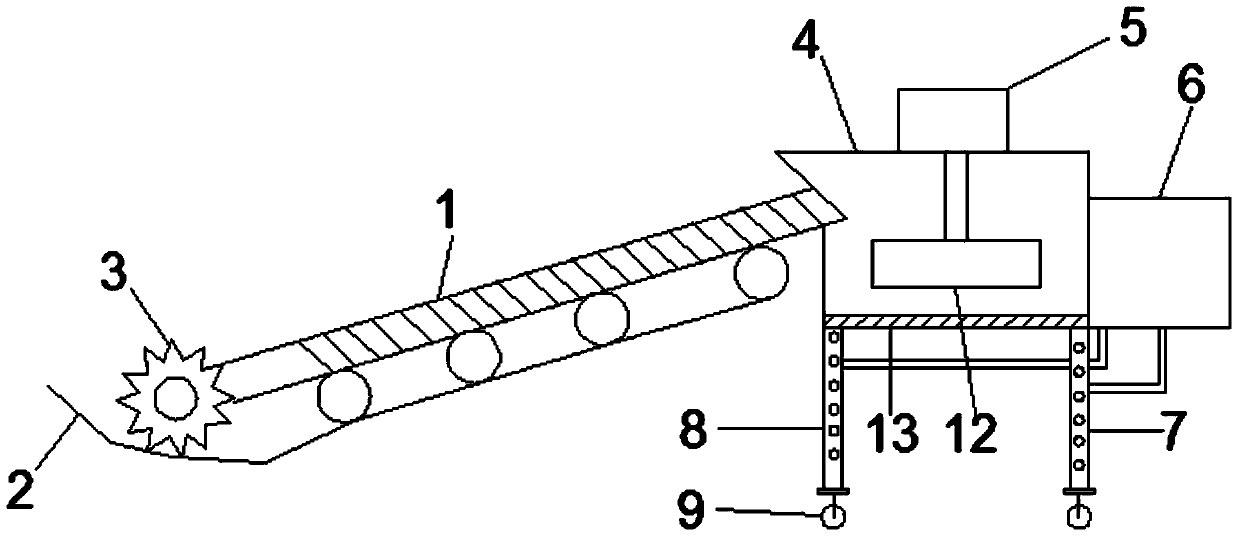

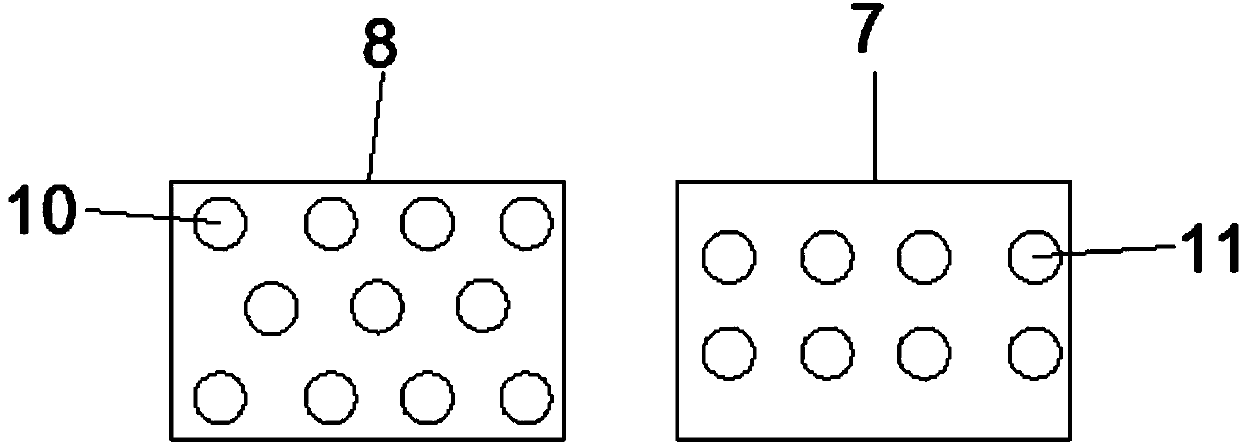

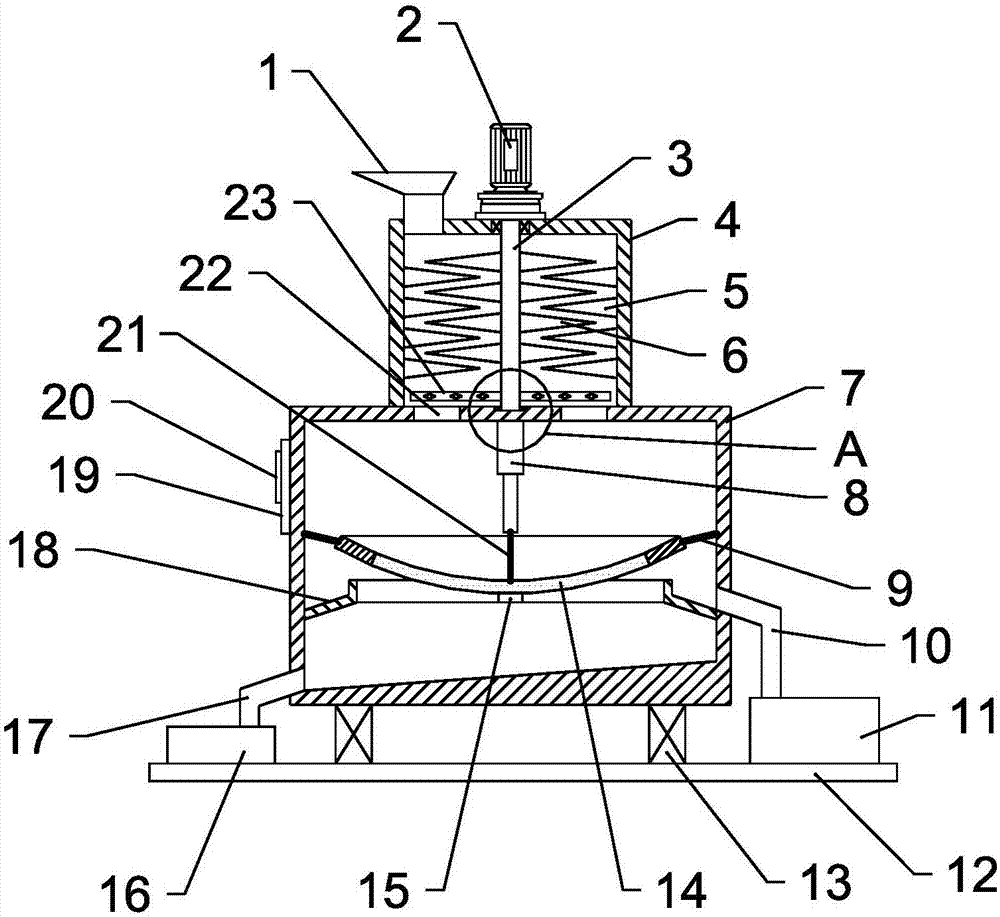

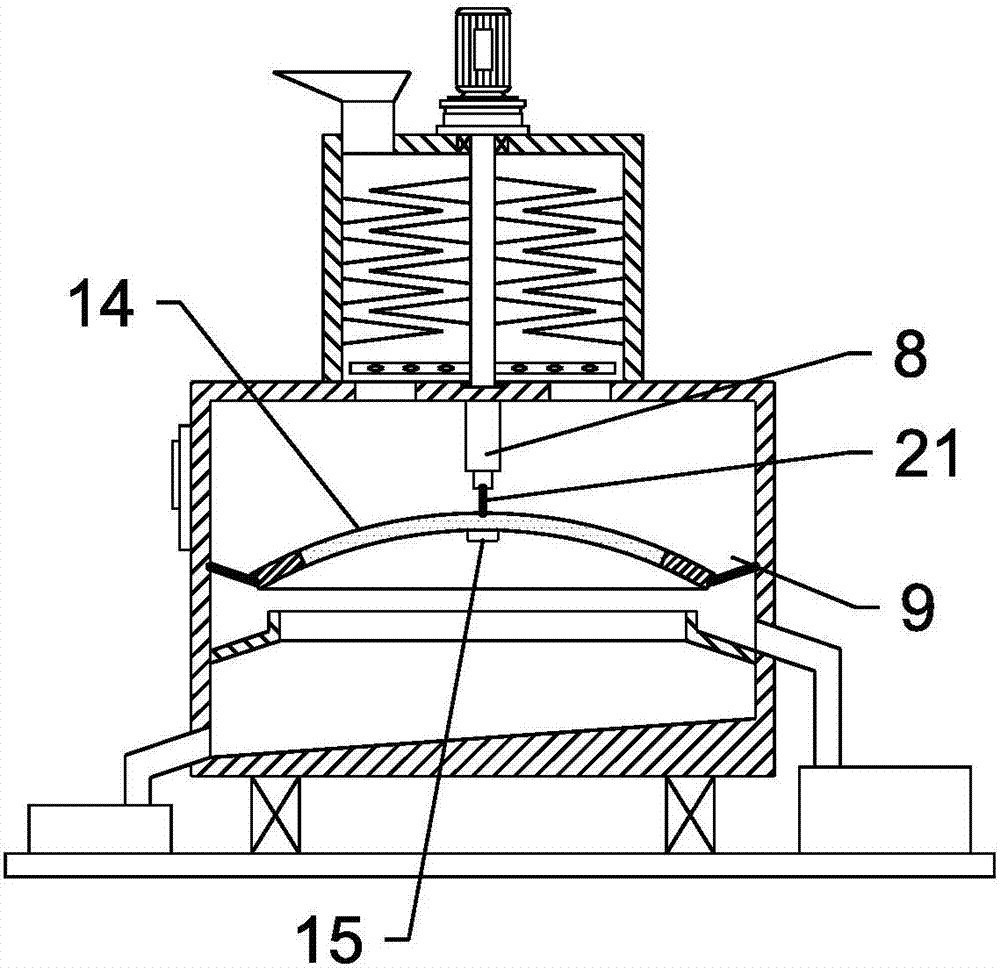

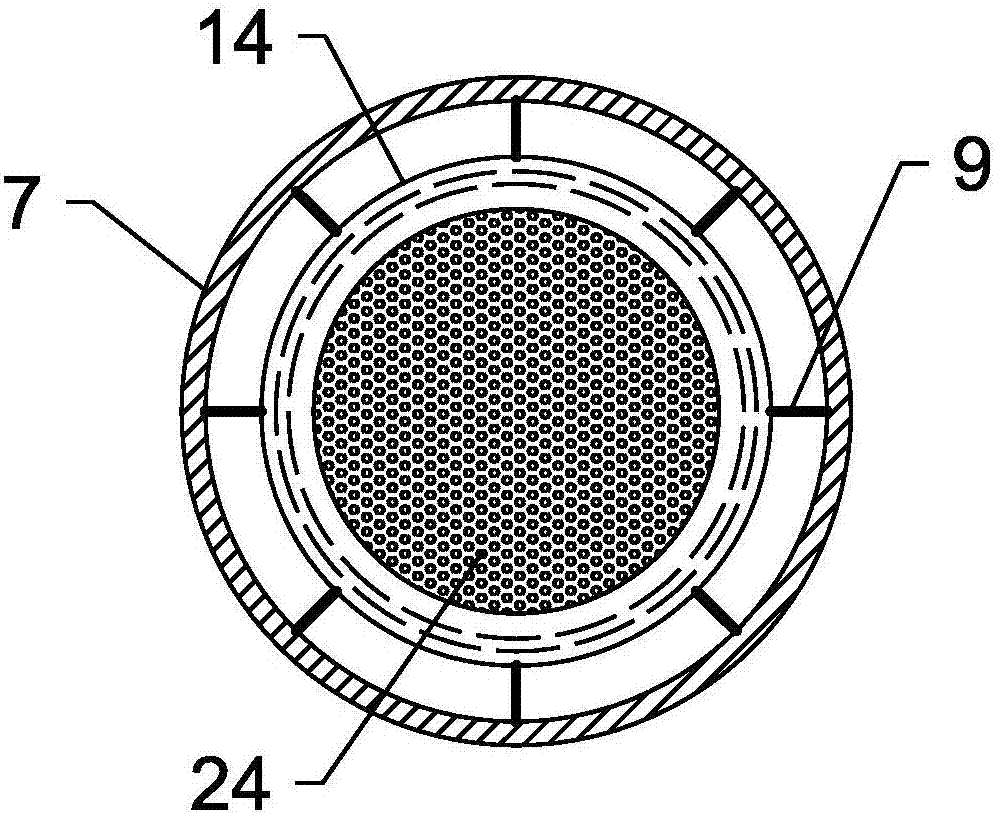

Screening integrated device for material production raw material crushing and based on ball milling principle

InactiveCN105521867AImprove filtering effectIncrease productivityGrain treatmentsScreening effectSteel ball

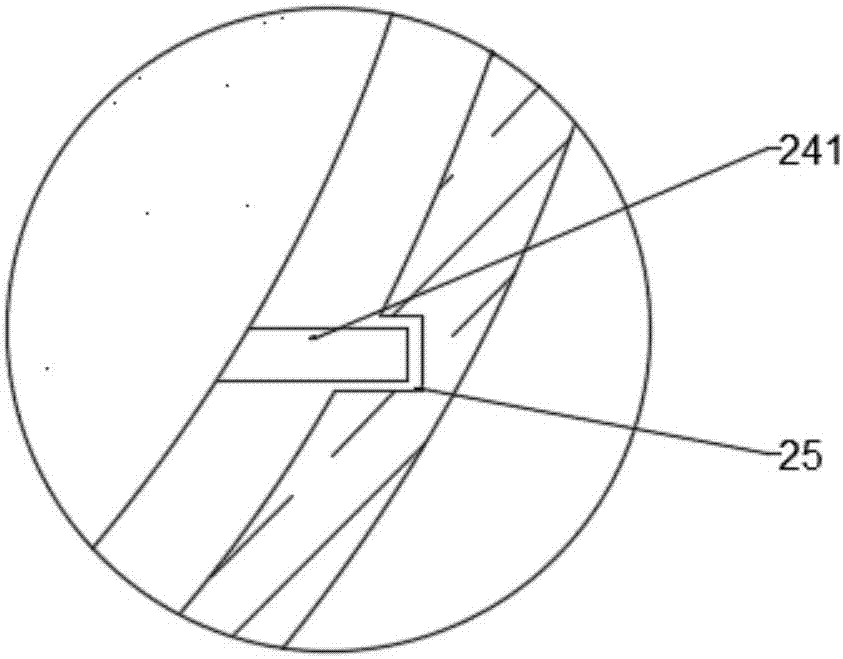

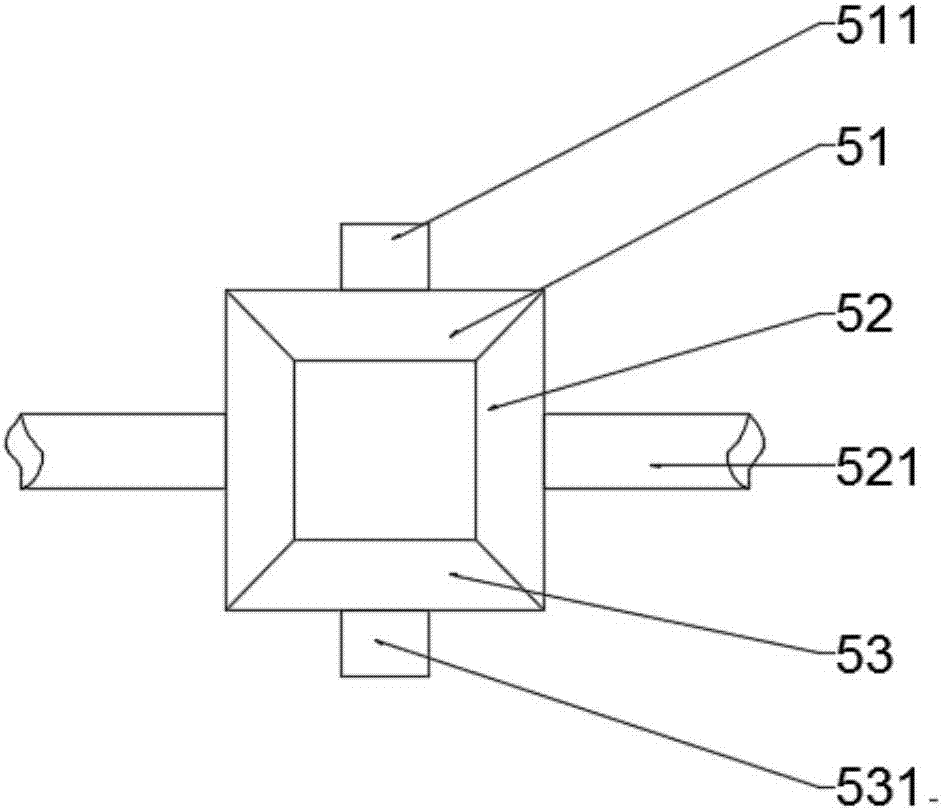

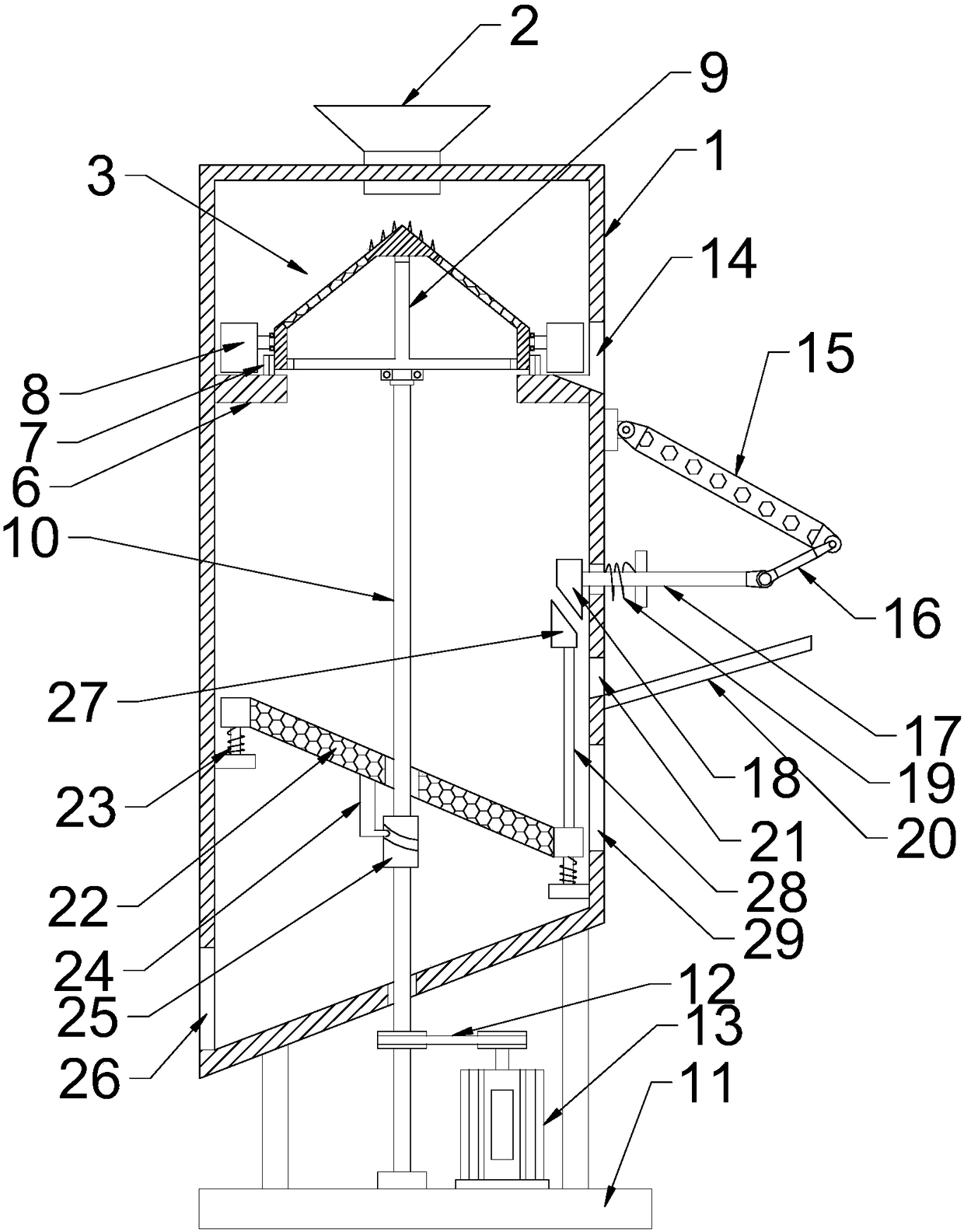

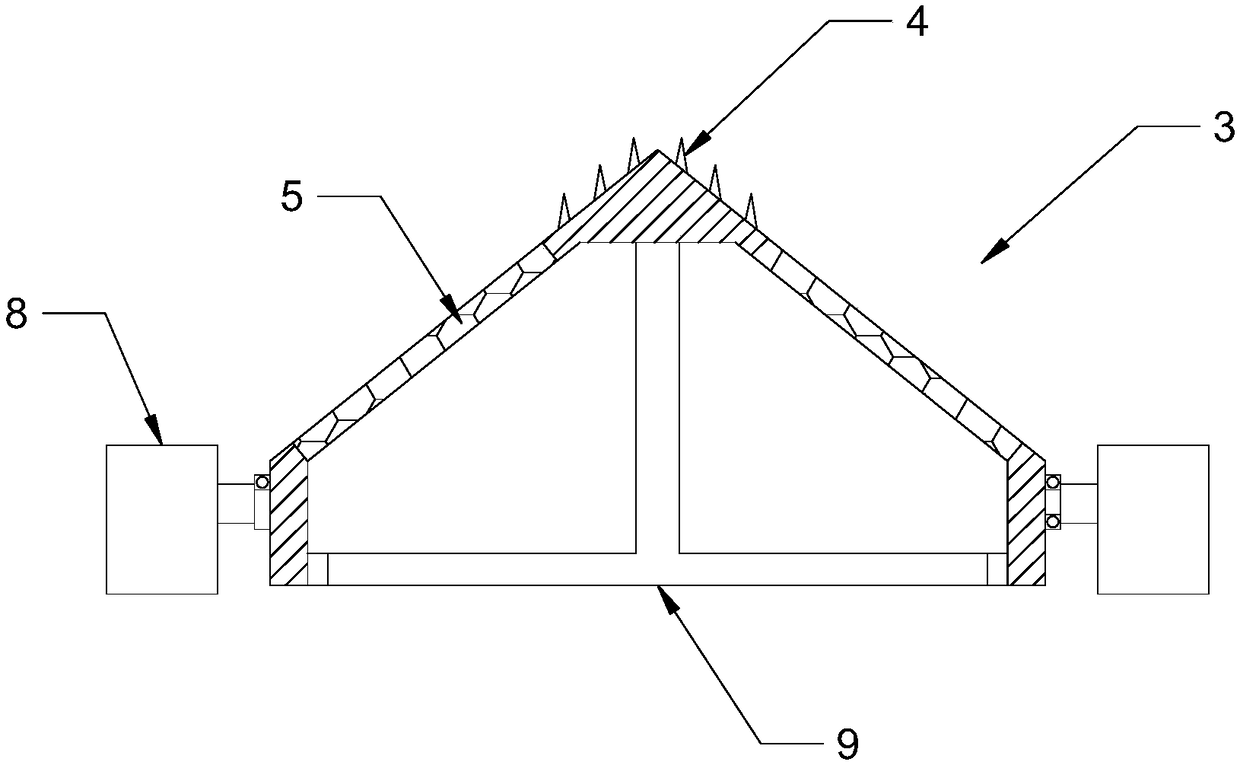

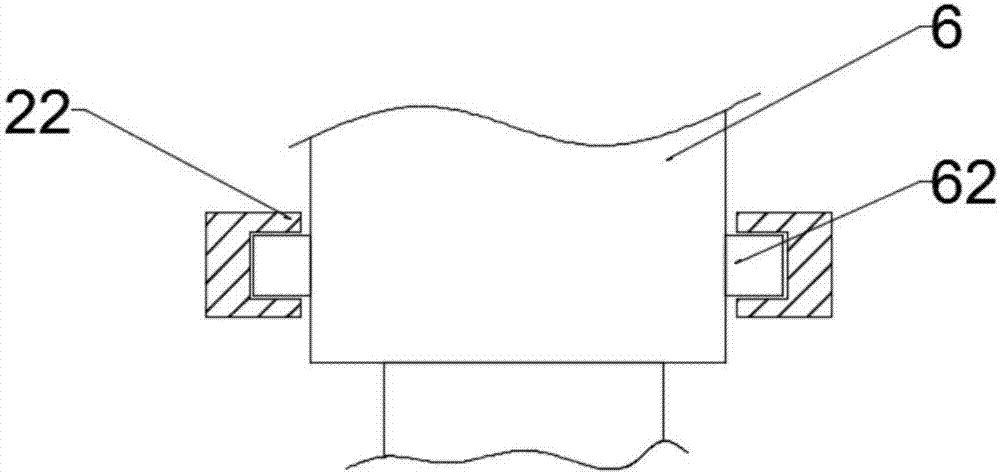

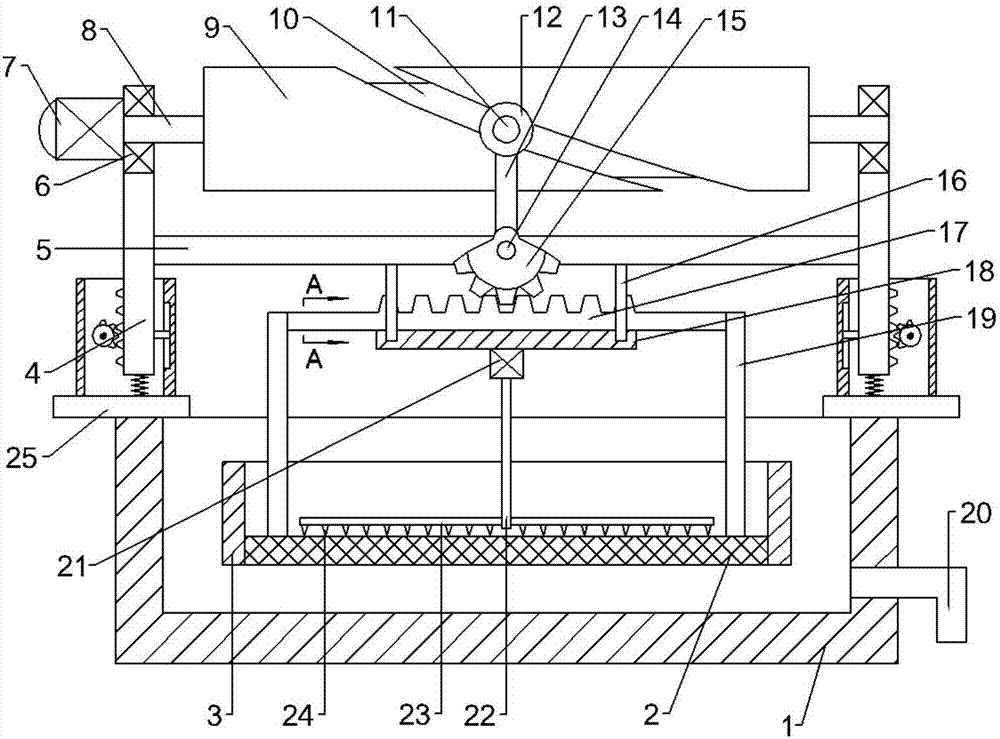

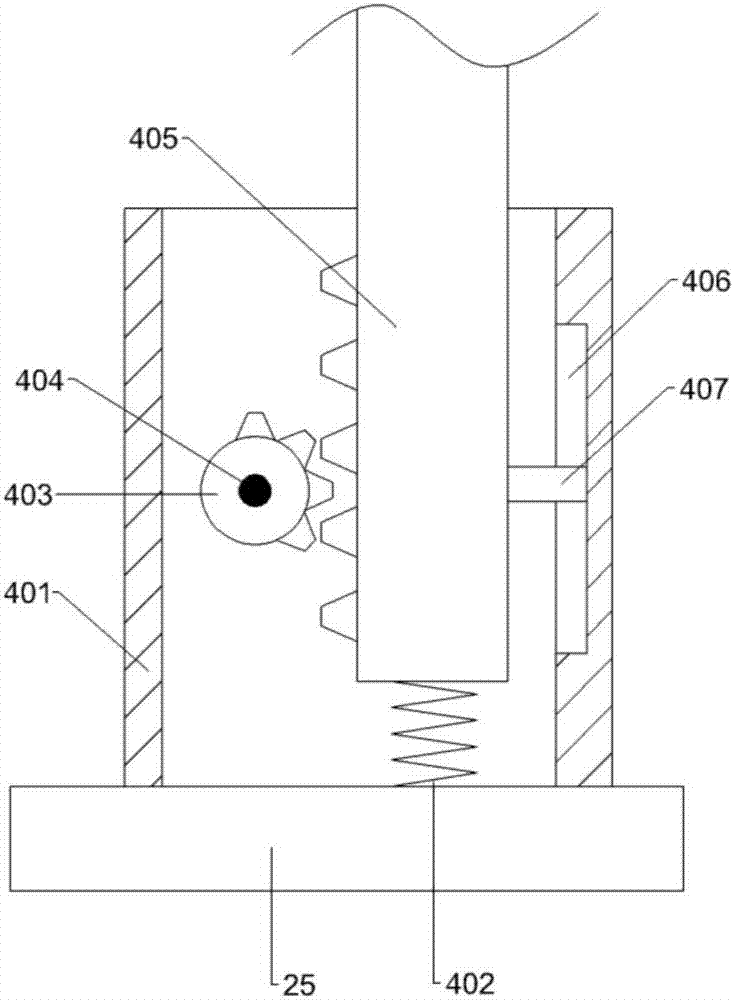

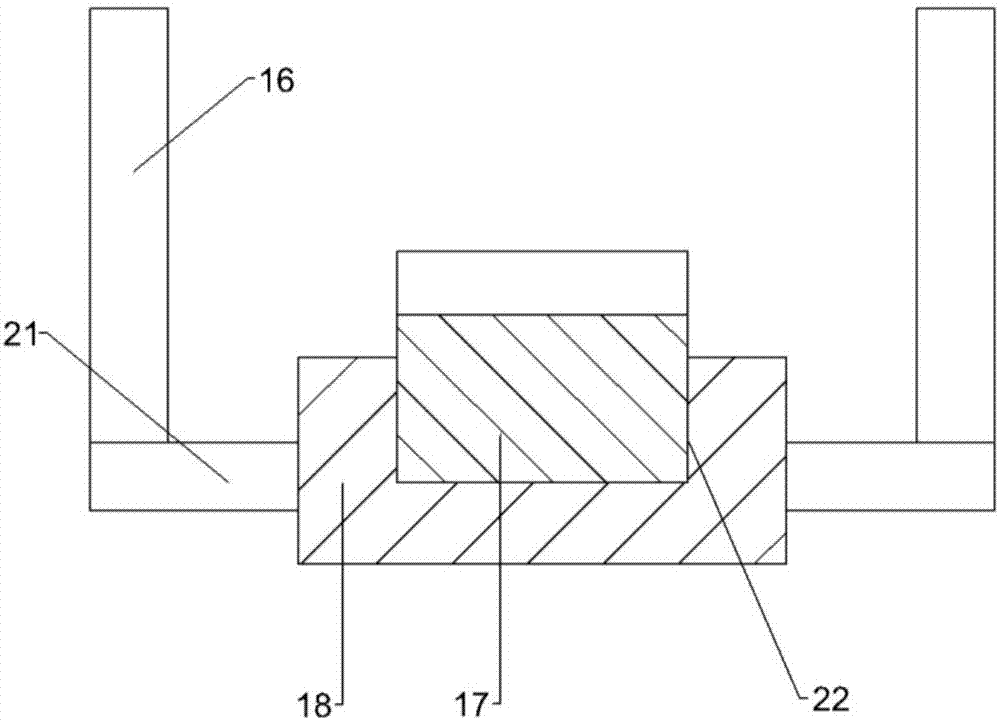

The invention discloses a screening integrated device for material production raw material crushing and based on a ball milling principle. The device comprises a shell; a guide plate is arranged at the upper part of the shell, and is funnel-shaped; a material outlet is formed in the center place of the guide plate; a crushing device is arranged above the material outlet, and includes a mounting part; the left and right two sides of the mounting part are fixedly connected with fan-shaped gears; one edges of the fan-shaped gears are engaged with driven gears; multiple crushing teeth are arranged on the lower sides of the driven gears; a rotating drum is arranged below the material outlet; a material inlet corresponding to the material outlet is formed in the middle place of the upper part of the rotating drum; and an electric control valve is arranged in the material inlet. The device has the following beneficial effects: in the process of filtering by a first screen, steel balls are used for further crushing materials to improve the productivity; and an electromagnetic coil and a vibration device are used for realizing vibration of a second screen up and down to effectively improve the screening effect of the second screen.

Owner:梁小利

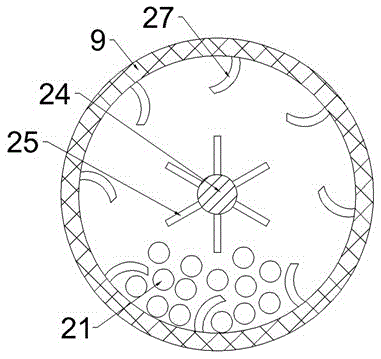

Roller type macadam screening jet flow ore washing equipment

The invention discloses a jet ore washing equipment for drum-type crushed stone screening, which comprises a water storage tank, an ore washing shell, an ore washing net cylinder, a spiral blade, a high-pressure jet hole and a hollow rotating shaft. The bottom of the ore washing shell is welded There is a water storage tank, the bottom of the water storage tank is welded on the support frame, the inner bottom of the water storage tank is set as a water storage tank, and the filter residue net is installed on both sides above the water storage tank, and the upper end of the filter residue net is connected to the separator, and the two ends of the separator are equipped with Slag drop hole; the ore washing shell is equipped with an ore washing net cylinder, and the ore washing net cylinder is respectively connected to the feeding cover and the discharge cover through the rotating guide sleeve, so that the hollow rotating shaft and the ore washing net cylinder can be driven to rotate at the same time. The hollow rotating shaft is opposite to the rotation direction of the ore washing net cylinder and is combined with the flushing of the high-pressure jet hole, which has a good cleaning efficiency and effect on the ore; after cleaning, the water flows into the water storage tank to realize water recycling; the ore washing net cylinder effectively filters out the ore The slag in the filter can improve the screening effect of the crushed stone.

Owner:陈鹏

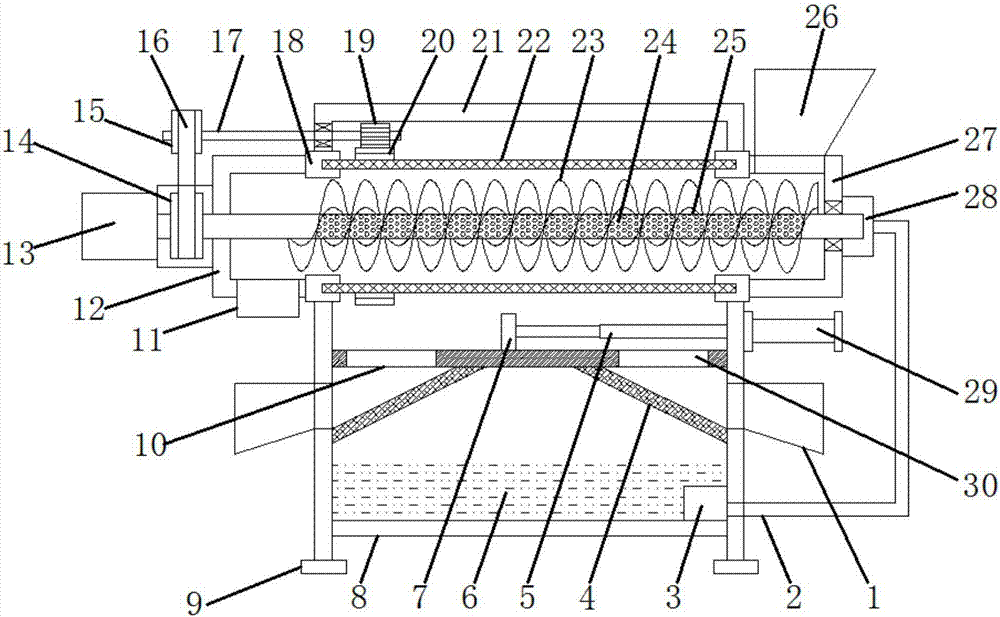

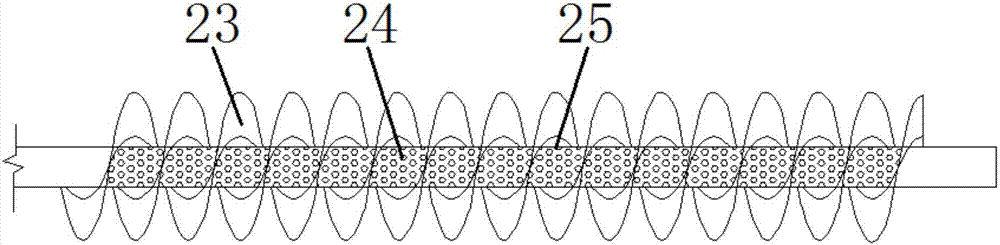

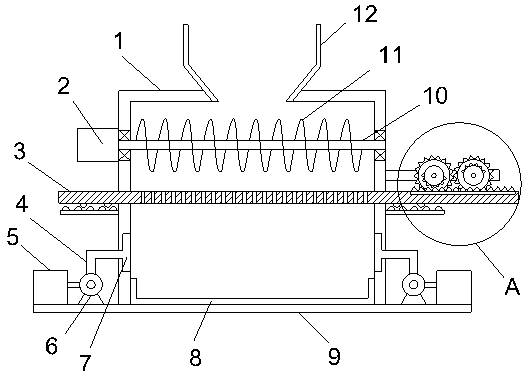

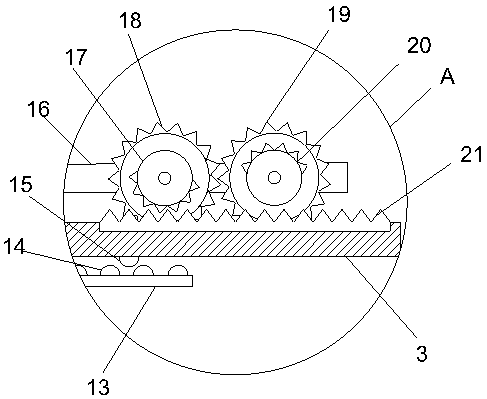

Efficient automatic conveying crusher for ceramic production

InactiveCN104923361AIncreased crush strengthAvoid accumulationSievingScreeningScreening effectHelical blade

The invention discloses an efficient automatic conveying crusher for ceramic production. The efficient automatic conveying crusher for ceramic production comprises a conveying barrel, a crusher body and a vibration motor, the outer wall of the conveying barrel is covered with an electric heating layer, a feeding hopper is arranged on the upper side of the left end of the conveying barrel, a first rotating shaft is arranged at the inner axis of the conveying barrel horizontally, and a plurality of helical blades are evenly arranged on the first rotating shaft from left to right. The efficient automatic conveying crusher for ceramic production has the advantages that the conveying barrel realizes automatic conveying, materials can be pre-crushed and dried in the conveying process, a rotary crushing rod, a rotary short beating rod, a fixed crushing rod and a fixed short eating rod jointly beat and crush the materials, beating force is strong, crushing strength is high, working efficiency of the crusher is increased, the vibration motor drives a screen to vibrate vertically to screen the materials, screening effect and efficiency is increased, the materials are avoided being accumulated on the screen, the materials not meeting requirements on size can be crushed cyclically, and crushing effect of the crusher is guaranteed.

Owner:苏晓玲

Multi-level sand screening device for municipal administration construction

InactiveCN107597543AIncrease loosenessImprove filtering effectSievingScreeningThree levelScreening effect

The invention discloses a multi-level sand screening device for municipal administration construction. The multi-level sand screening device comprises a box. A collecting basket is fixedly arranged atthe bottom of the inner side of the box. Reset springs are connected between the right end of an upper sieve plate and the inner side wall of the box and between a lower sieve plate and the inner side wall of the box. Sliding rods vertically penetrate extension plates in a sliding manner. Wheels are rotationally arranged at the top ends of the sliding rods. A rotation shaft is provided with a screening barrel. A plurality of comb teeth are arranged on the surface of the rotation shaft at equal intervals. The surface of the screening barrel is of a net-shaped structure. A first driven shaft isprovided with a first fan-shaped gear matched with a first outer gear ring, and a second driven shaft is provided with a second fan-shaped gear matched with a second outer gear ring. The multi-levelsand screening device is reasonable in design, sand sequentially passes through the screening barrel, the upper sieve plate and the lower sieve plate, finally, three-level screening of sand is achieved, and accordingly three kinds of sand different in particle size can be obtained. The comb teeth comb the sand in the screening barrel through rotation of the rotation shaft, the sand loose degree isimproved, the screening effect is improved, and the sand screening efficiency is higher.

Owner:郑州味觉信息技术有限公司

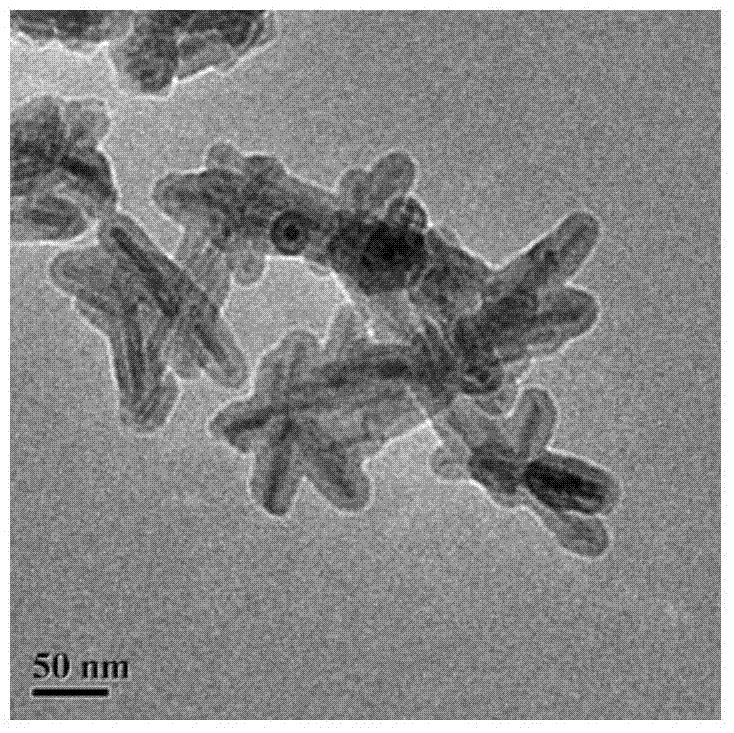

Ultraviolet screening agent, preparation method thereof, polylactic acid film containing ultraviolet screening agent and preparation method of polylactic acid film

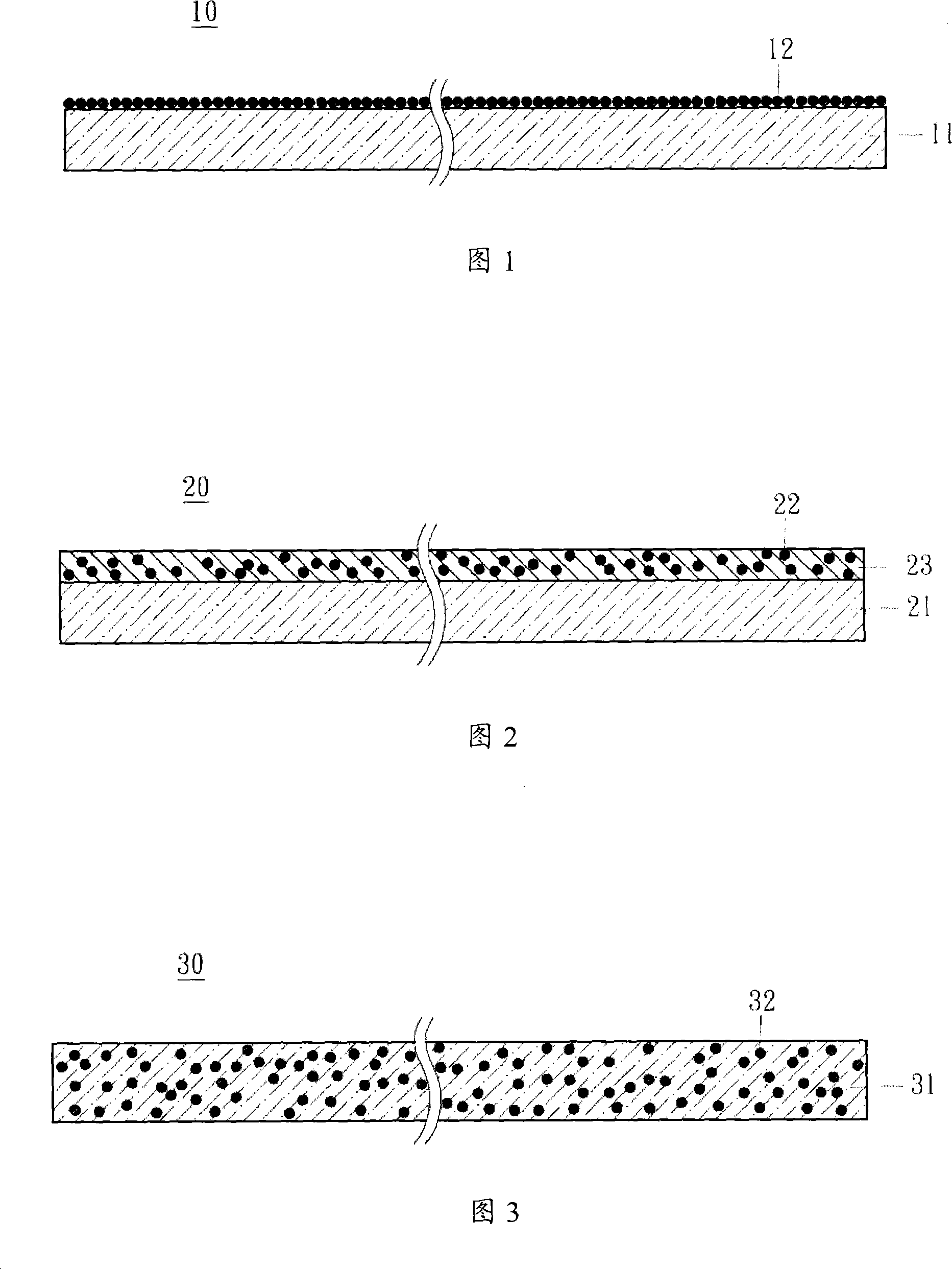

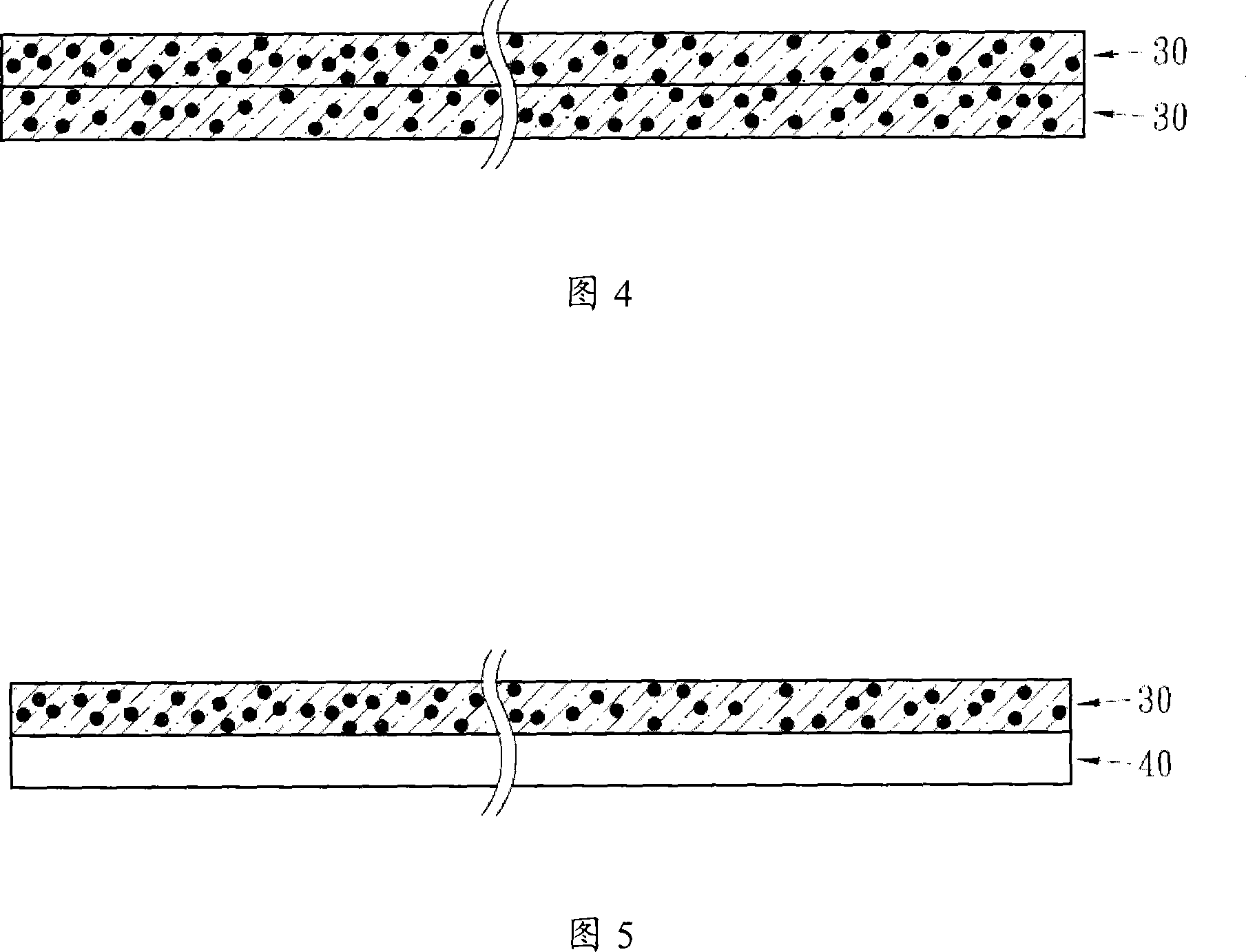

ActiveCN104845301ANo effect on mechanical propertiesAdd lessFlat articlesPigment treatment with organosilicon compoundsScreening effectUltraviolet

The invention provides an ultraviolet screening agent, a preparation method thereof, a polylactic acid film containing the ultraviolet screening agent and a preparation method of the polylactic acid film. The ultraviolet screening agent prepared by taking nanometer titanium dioxide as a nuclear material and n-silicate ester as a nanometer silicon dioxide raw material and coating a nanometer silicon dioxide layer on the surface of nanometer titanium dioxide simultaneously has favorable ultraviolet screening effect and visible light permeating effect; the polylactic acid film prepared by preparing masterbatches through adding the ultraviolet screening agent and a thermal stabilizer into polylactic resin and then carrying out film pressing on the prepared masterbatches has favorable transparency and ultraviolet screening property; and the ultraviolet screening agent is nontoxic and strong in stability and is not easy to seep.

Owner:BEIJING INST OF CLOTHING TECH +1

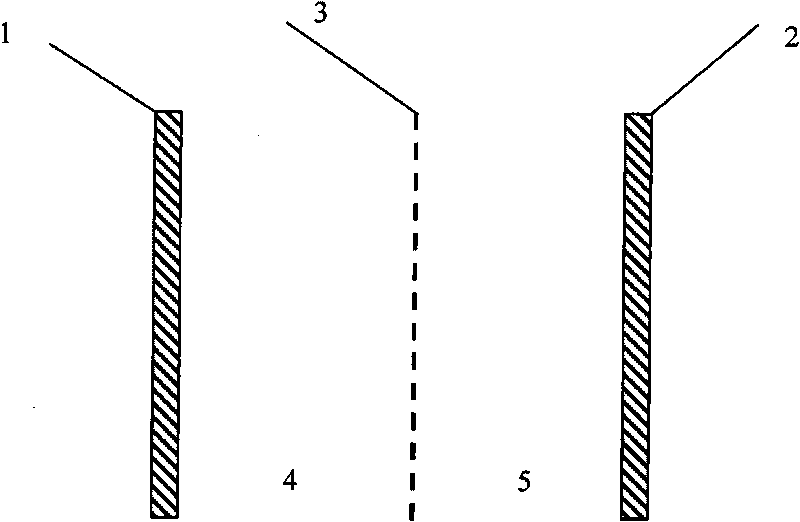

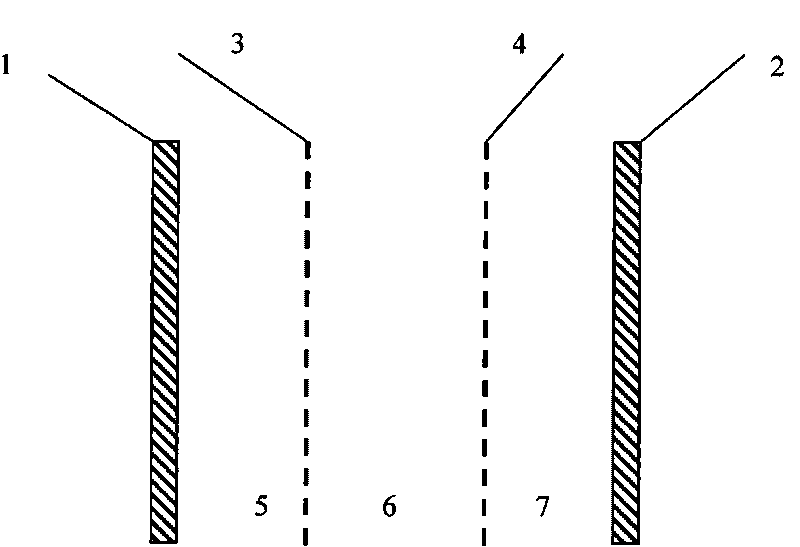

Method and device for separating electric field-separation membrane coupling

InactiveCN101716465AReduced activityReduce riskSemi-permeable membranesDispersed particle separationSeparation factorScreening effect

The invention discloses a method and a device for separating electric field-separation membrane coupling, which are characterized in that: separation membranes with different natures are parallelly arranged, and the outmost sides are provided with electrodes so as to form a plurality of layers of runners formed between the separation membranes and between the separation membranes and the electrodes; and fluid to be separated flows through the runners in a staggered way, and a DC electric field is applied in the direction vertical to the runners, so that electriferous molecules or microparticles generate deviation or dialytic electrophoretic behavior under the condition of the electric field, and an aperture screening effect of the separation membranes is combined so as to realize the process of quick and high-efficiency separation. The process can be performed only under the driving of the electric field, and also can be performed under the driving of the electric field and pressure. Compared with the conventional membrane process and electrophoresis process, the method and the device can greatly improve concentration and separation efficiency, improve separation factors, realize the separation which cannot be realized by the conventional membrane process, obviously reduce membrane fouling and improve the service life of the membranes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

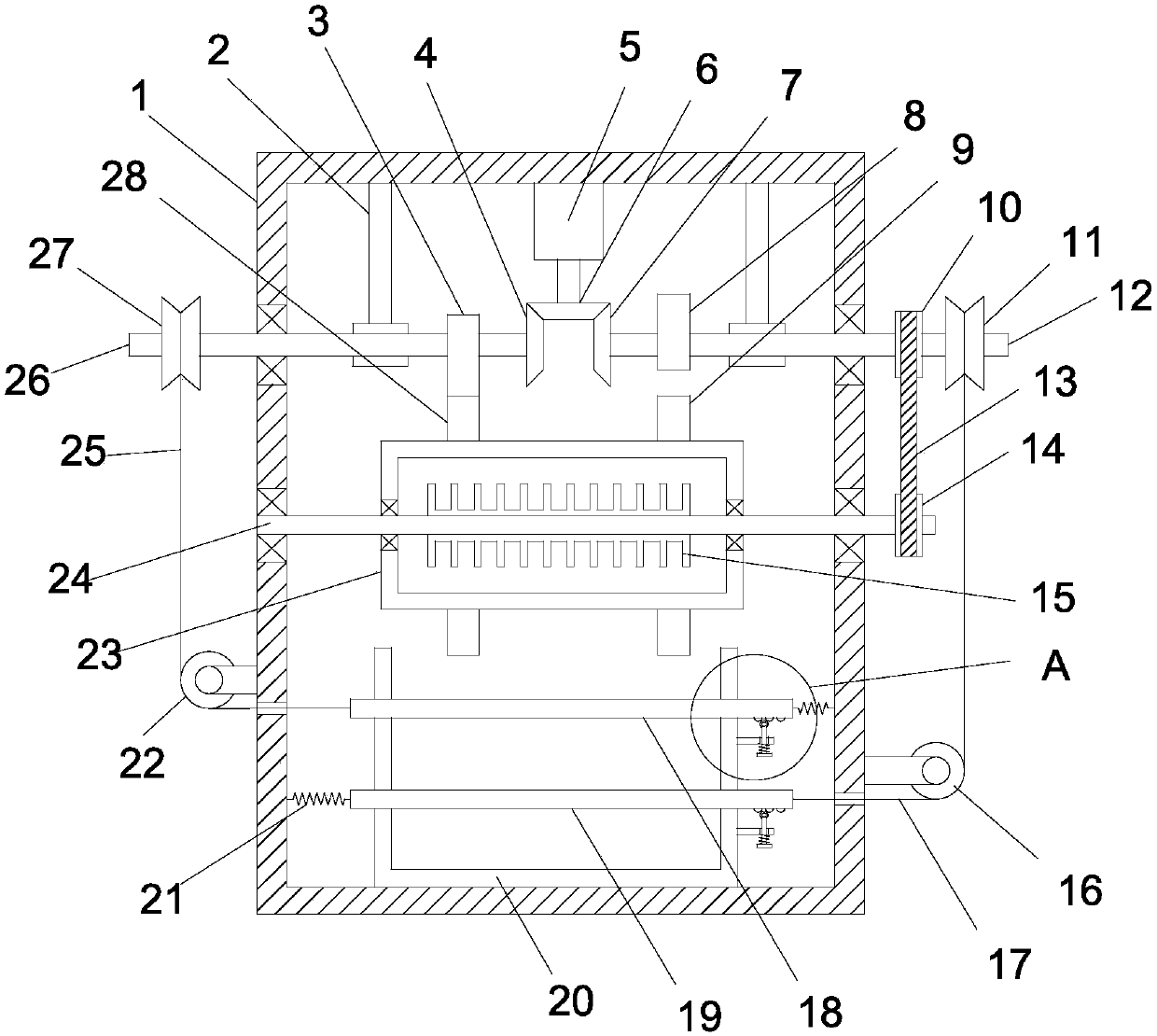

Efficient Chinese medicinal material grinding and screening integrated machine

InactiveCN107486315AAvoid affecting screening efficiencyGrind fullySievingScreeningBevel gearScreening effect

The invention discloses an efficient all-in-one machine for grinding and screening traditional Chinese medicinal materials, which comprises a base, a spherical shell, an outer frame and an inner frame. In the present invention, the reverse rotation of the upper grinding block and the lower grinding block is realized through the bevel gear set, so that the Chinese herbal medicines are successively ground in two directions during the falling process, so that the grinding is more sufficient and the grinding effect is guaranteed; The driving mechanism drives the outer frame to move left and right, so that the medicinal materials falling from the feeding pipe evenly fall onto the sieve plate, so as to avoid the accumulation of medicinal materials on the sieve plate, which will affect the screening efficiency. At the same time, the inner frame follows the outer frame to reciprocate left and right The movement makes the pulley move left and right on the raised surface, thereby driving the connecting frame to move up and down, and then making the inner frame drive the sieve plate to vibrate up and down, resulting in a vibrating sieve effect and improving the screening efficiency.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

Multi-stage sand screening equipment for building

InactiveCN108405340ARealize screeningAchieve recyclingSievingGas current separationScreening effectPrimary screening

The invention discloses multi-stage sand screening equipment for a building. The multi-stage sand screening equipment comprises a box body, a primary screening mechanism, a secondary screening mechanism and a tertiary screening mechanism, wherein the secondary screening mechanism is arranged on the right side of the box body, the secondary screening mechanism comprises a first screen plate and a material guide plate, the material guide plate is arranged below the first screen plate, and a backflow hole is formed in the position, located at the lower end of the material guide plate, of the boxbody. According to the multi-stage sand screening equipment for the building, a screen drum, scraping plates, an annular supporting plate, a second screen plate and a rotating shaft linkage mechanismare arranged, so that screening and recovery of fine sand in waste residues are achieved by swinging of the second screen plate, the screening effect is improved, repeated sand screening is avoided, and the screening efficiency is improved; the conical screen drum is arranged, and crushing cones arranged on the screen drum and screen holes formed in the screen drum are arranged, so that sand blocks in coarse sand are crushed, meanwhile, the waste residues in the coarse sand are separated efficiently, and follow-up treatment is facilitated; and the screen drum and the second screen plate are arranged, so that the secondary screening is carried out on the coarse sand, and the screening effect is improved.

Owner:张翔

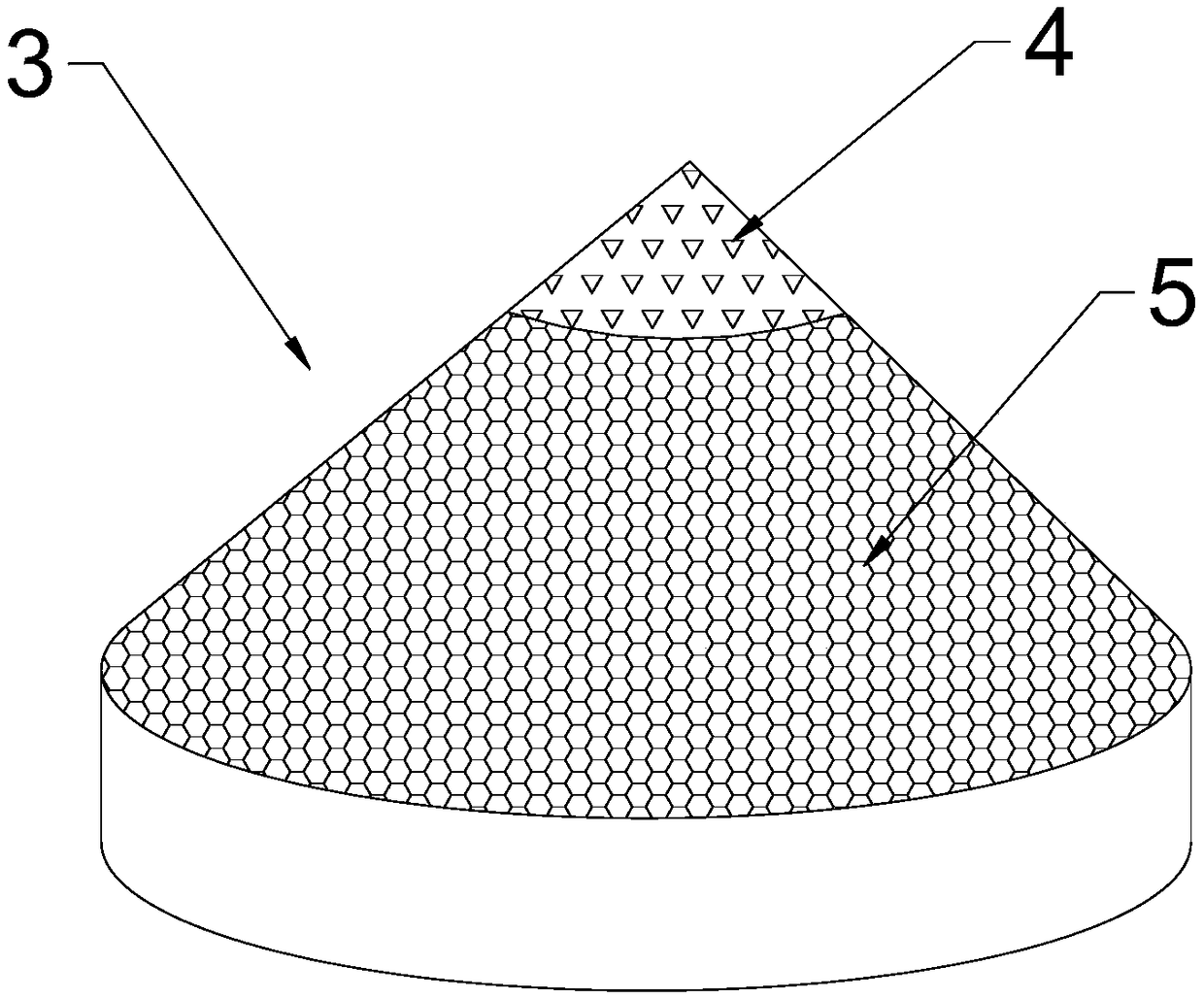

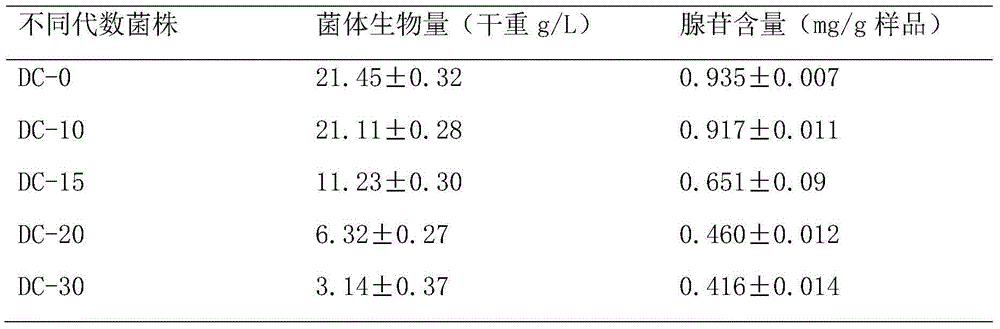

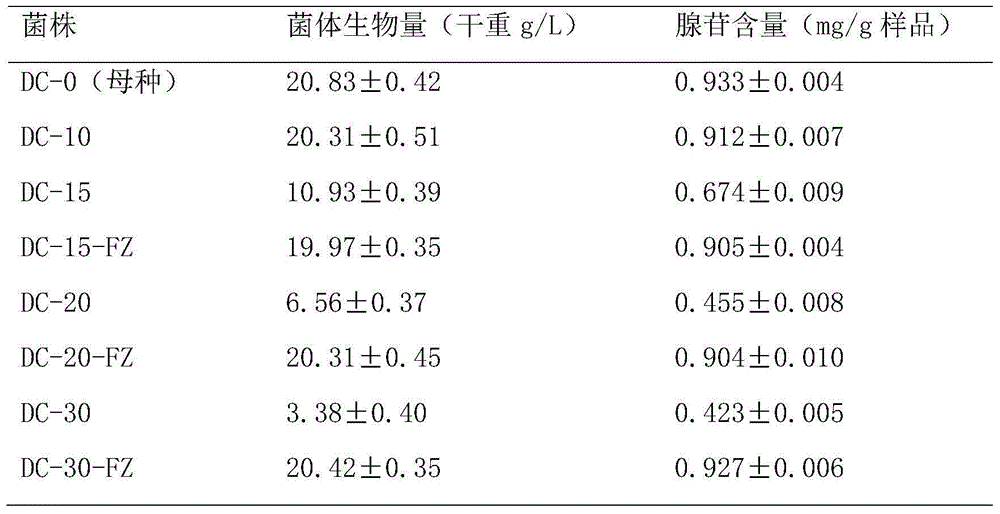

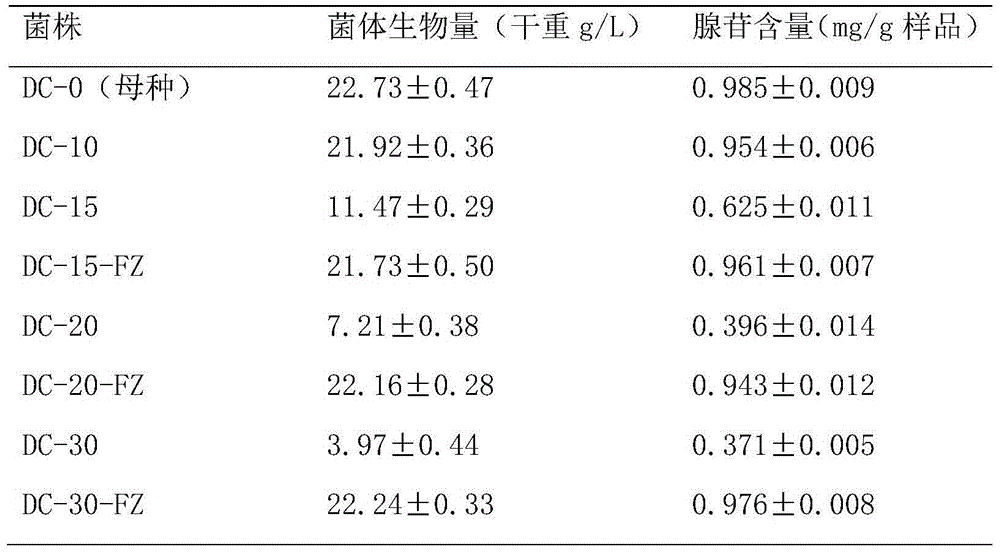

Cordyceps sinensis mycelium fermentation production method

ActiveCN104145719AGood filtering effectSolve the problem of caste declineHorticultureBiotechnologyScreening effect

The invention provides a cordyceps sinensis mycelium fermentation production method. The method includes the steps of preparation of a special culture medium for cordyceps sinensis mycelium liquid state fermentation, optimization of a mycelium provenance, fermentation of a strain in the culture medium and the like, wherein optimization of the mycelium provenance includes the procedures that cordyceps sinensis strain mycelia obtained after more than ten times of artificial passage are inoculated to the artificial solid culture medium, superior fruit bodies are selected, and a preferred China hirsutella rhossiliensis strain is separated from the fruit bodies. The cordyceps sinensis mycelium fermentation production method has the advantages that through strain selection, the cordyceps sinensis strain with strain character advantages is obtained, the screening effect is good, the problem of strain character recession can be effectively solved, and meanwhile the method also can serve as a China hirsutella rhossiliensis strain passage preservation method.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

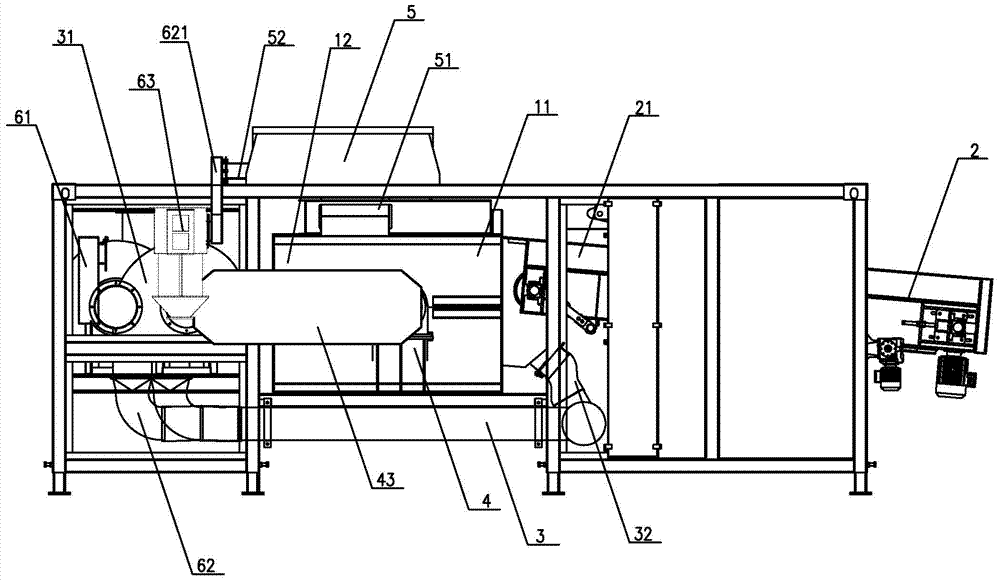

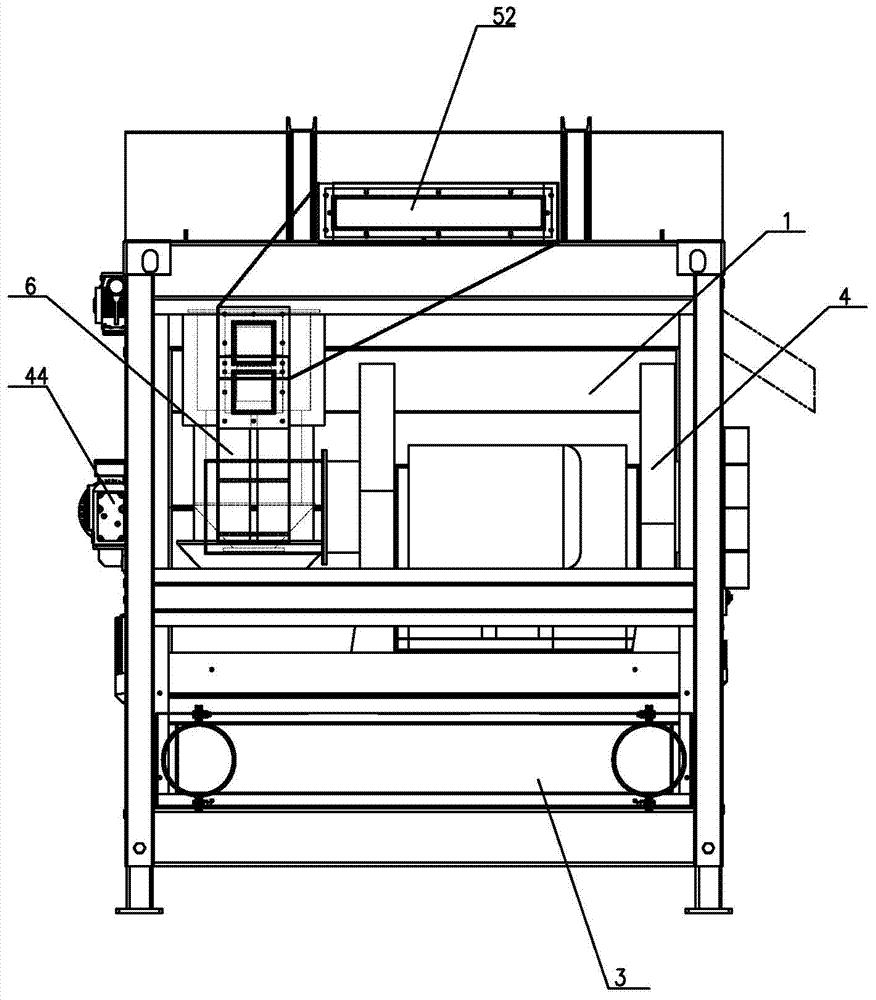

Building rubbish screening equipment and screening method

ActiveCN104759413AExtended service lifeImprove screening effectGas current separationScreening effectScreening method

The invention relates to the field of building rubbish recycling, in particular to building rubbish screening equipment and screening method. The building rubbish screening equipment comprises a sorting chamber, a throwing device, a wind power device and a medium-heavy object sorting device, and a first separation region and a second separation region are arranged in the sorting chamber; the throwing device conveys material to the first separation region; the wind power device uses the wind power to lift the material thrown from the first separation region; the medium-heavy object sorting device comprises a double-layer sorting barrel, a negative pressure mechanism, a fan and a barrel body drive mechanism. The building rubbish screening equipment can separate the building rubbish into heavy substance, medium-heavy substance and light substance according to the need, and the screening effect is good; the heavy material does not collide with the double-layer sorting barrel in the screening process, and the service life of the double-layer sorting barrel is prolonged; the material throwing angle and power of the throwing device can be regulated according to the need in the screening process, and the adaptive capacity of the equipment is greatly improved; the building rubbish screening equipment is capable of effectively lowering the equipment load and improving the winnowing efficiency.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

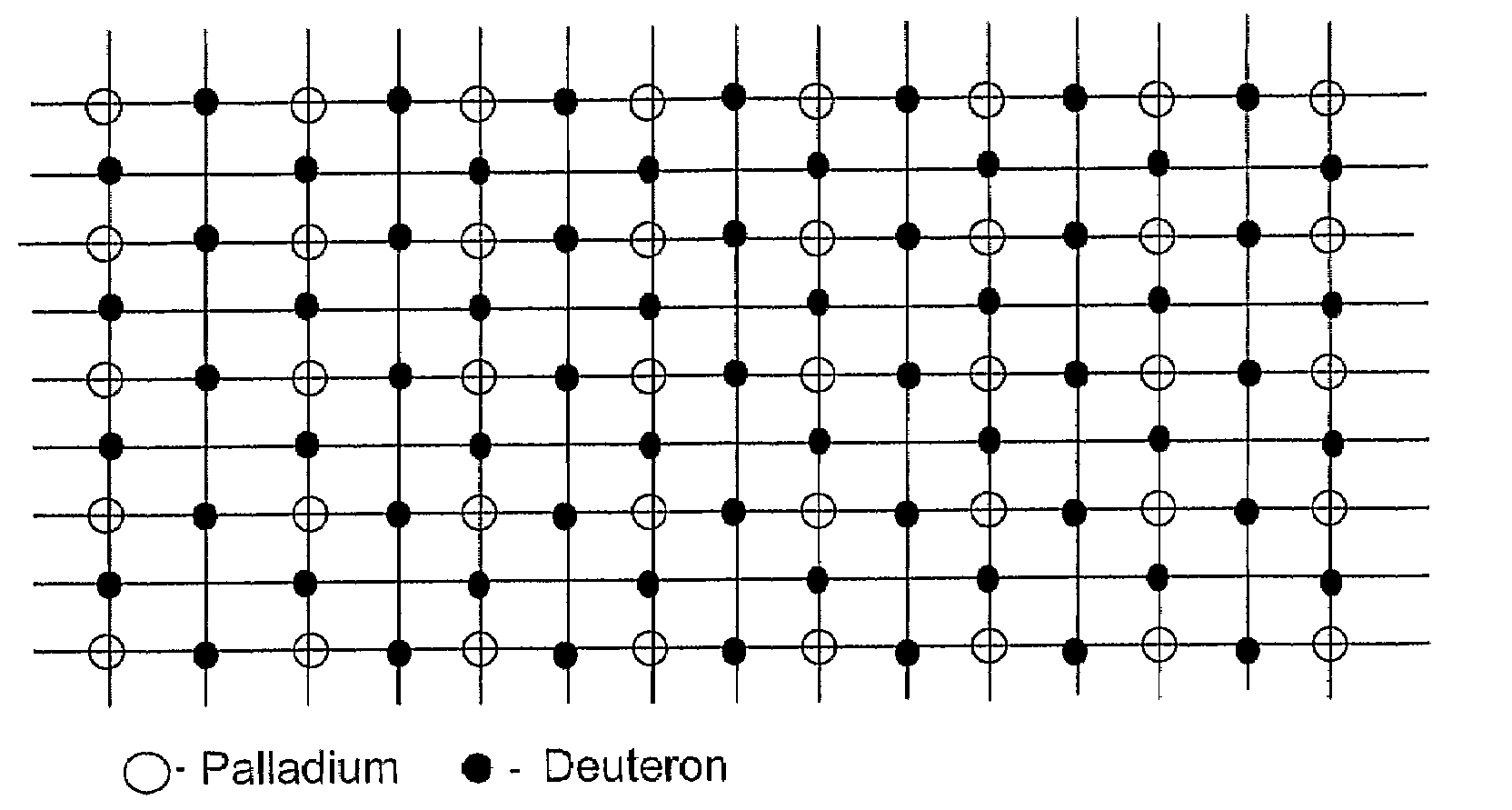

Low temperature fusion

InactiveUS20090122940A1Nuclear energy generationLow temperature fusion reactorOptical radiationScreening effect

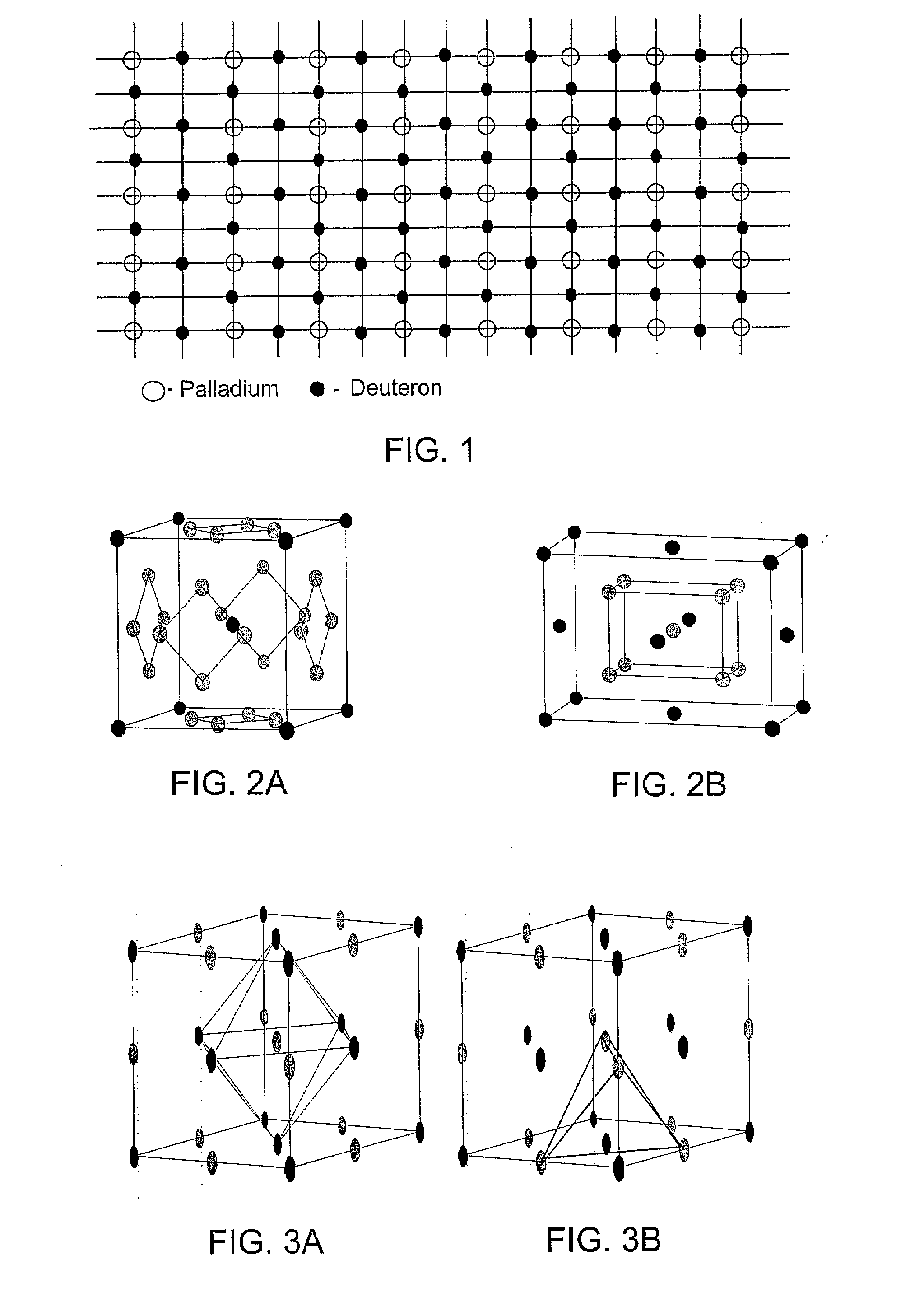

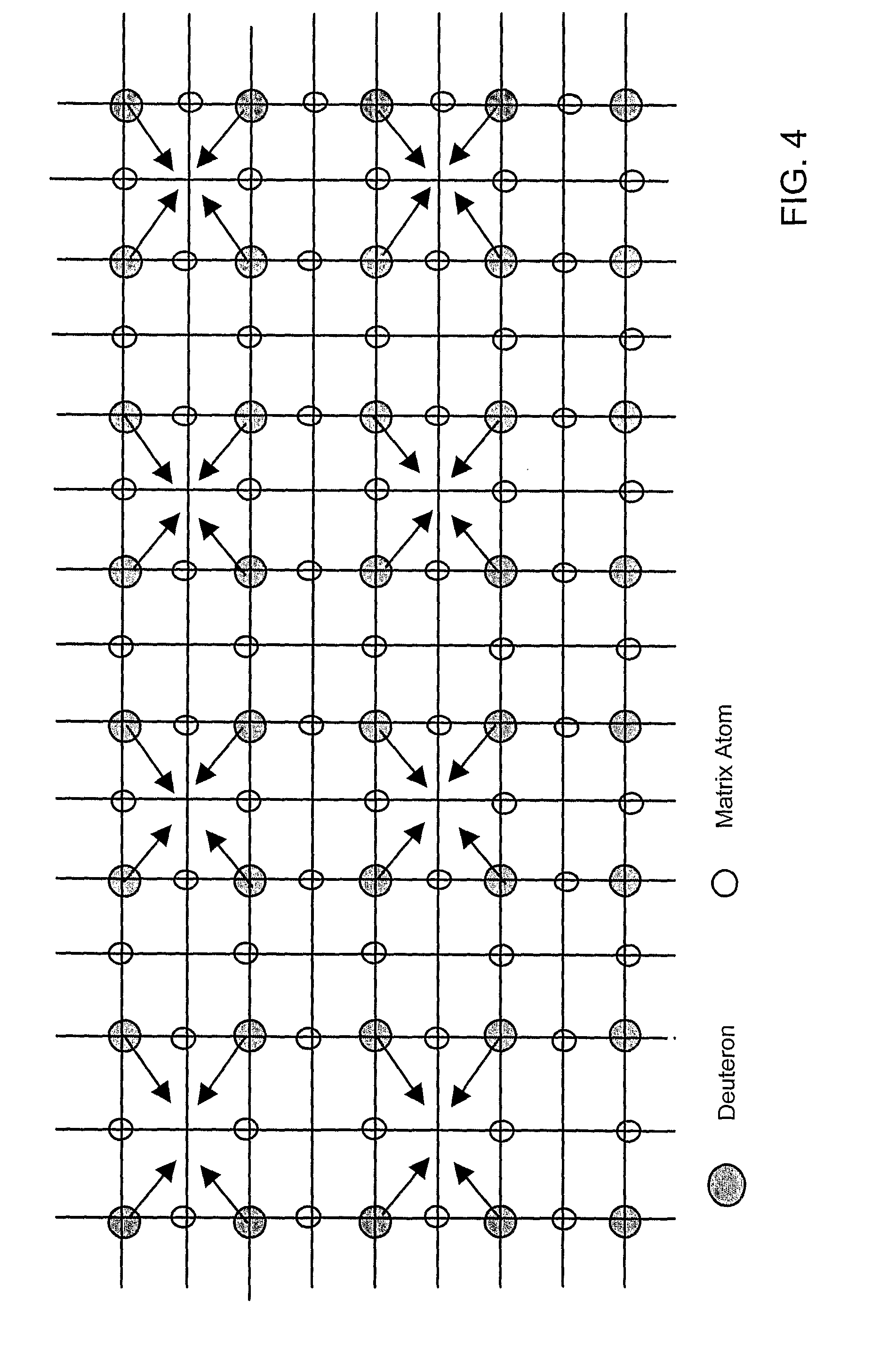

Methods for low-temperature fusion are disclosed. In one embodiment, a symmetrical crystal lattice including a plurality of deuterons either absorbed or embedded in a heavy-electron material is selected. The method provides alternatives for initiating a vibration mode involving the deuterons on the crystal lattice that induces them to converge. The oscillating convergence of the deuterons is enhanced by the charge screening effect of electrons. The electron screening effect is in turn enhanced by the high effective-mass associated with the selected materials. The vibration modes are excited, for example, by applying an electrical stress, a uniform magnetic field, mechanical stress, non-uniform stress, acoustic waves, the de Haas van Alphen effect, electrical resistivity, infrared optical radiation, Raman scattering, or any combination thereof to the crystal lattice.

Owner:CONE PARTNERS

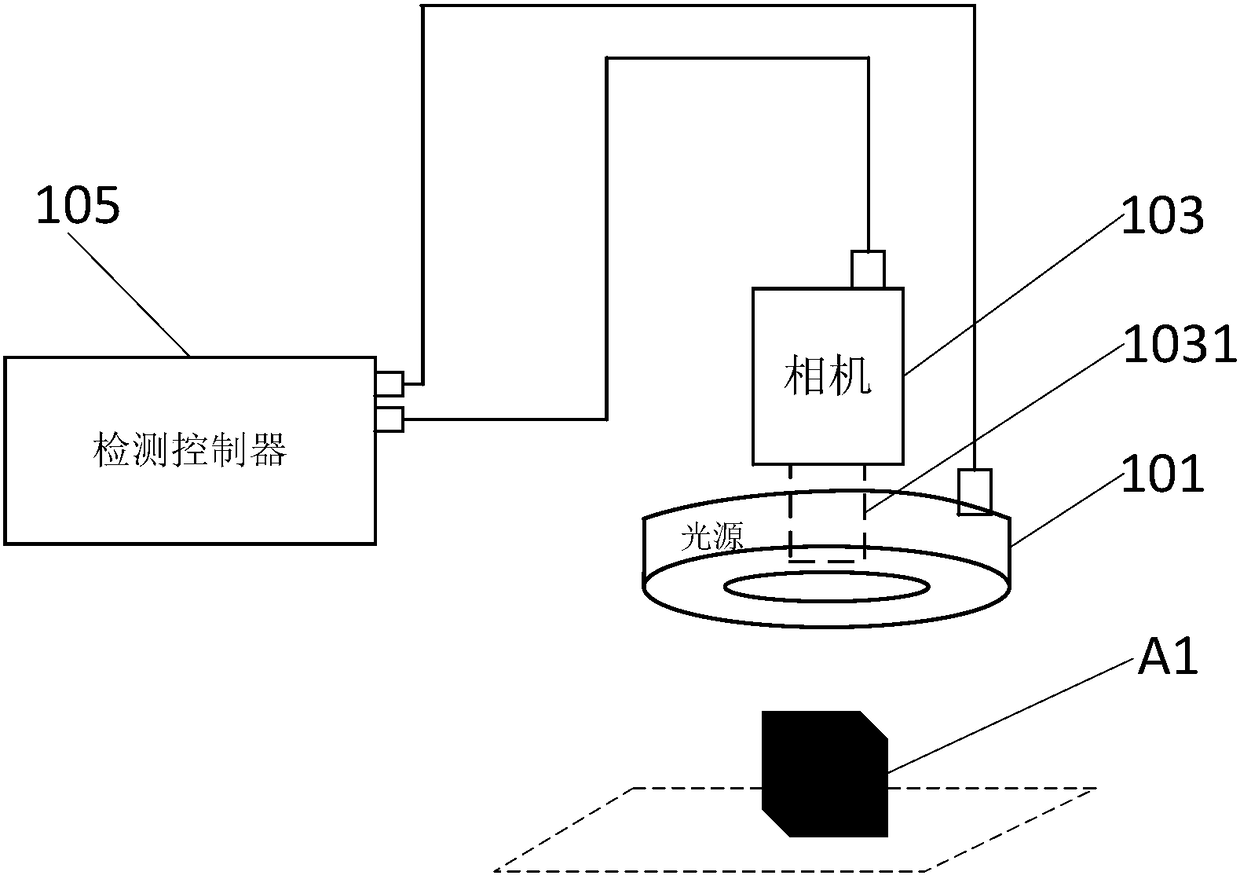

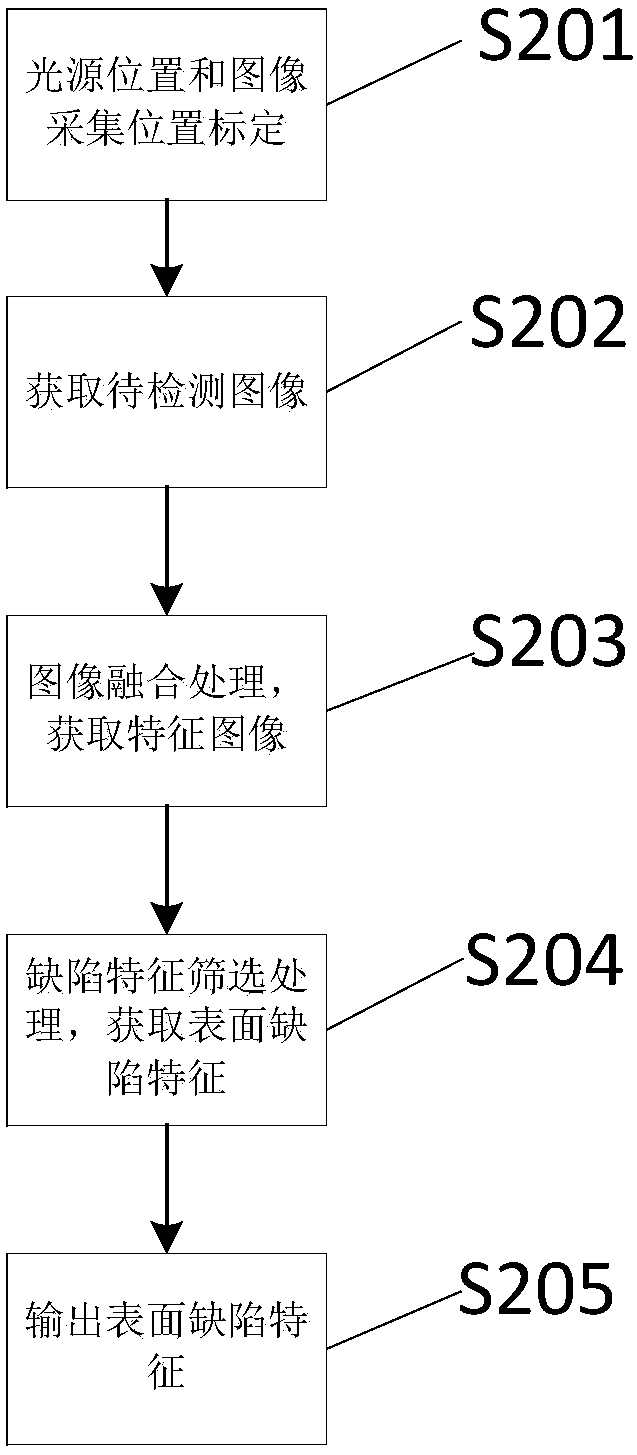

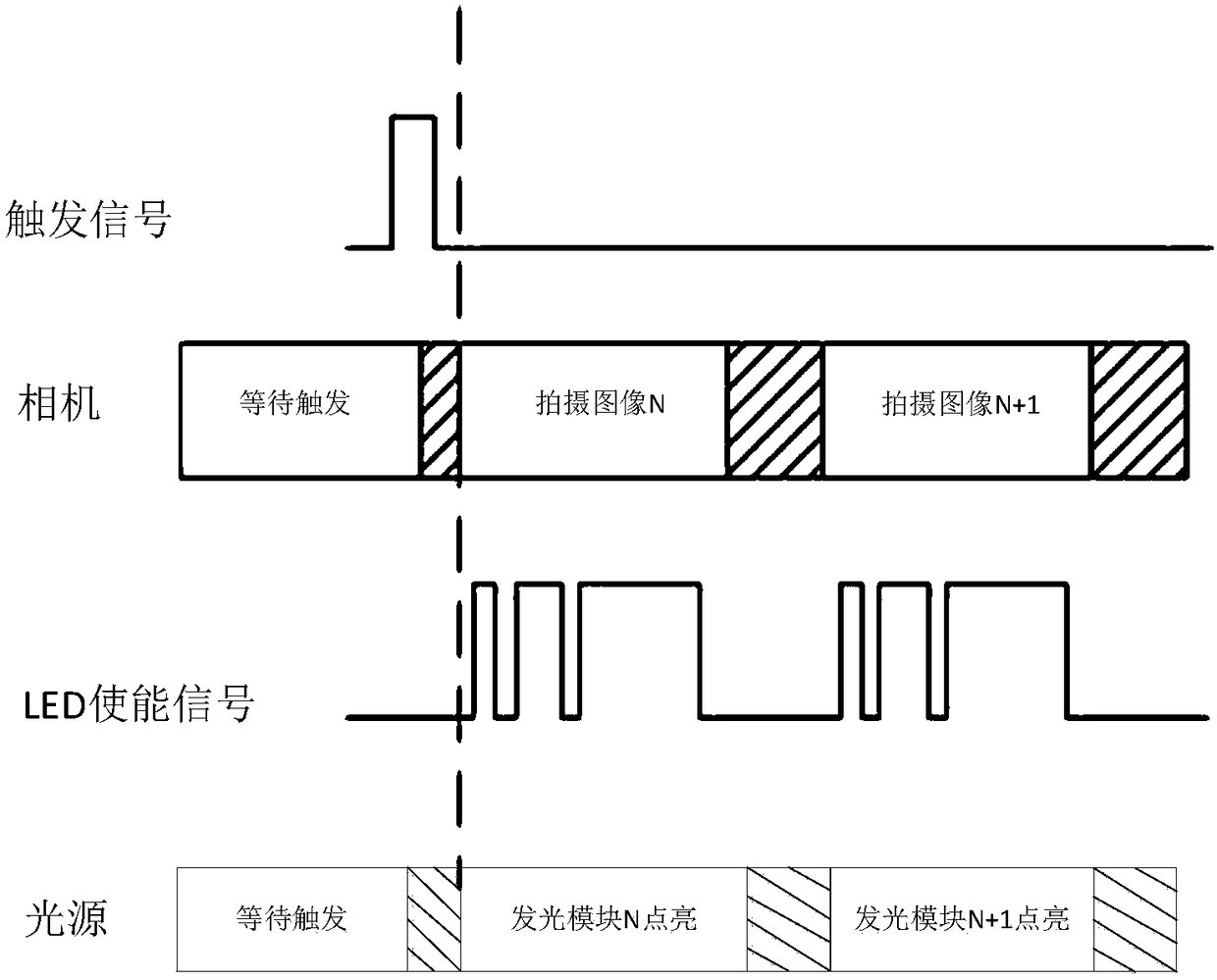

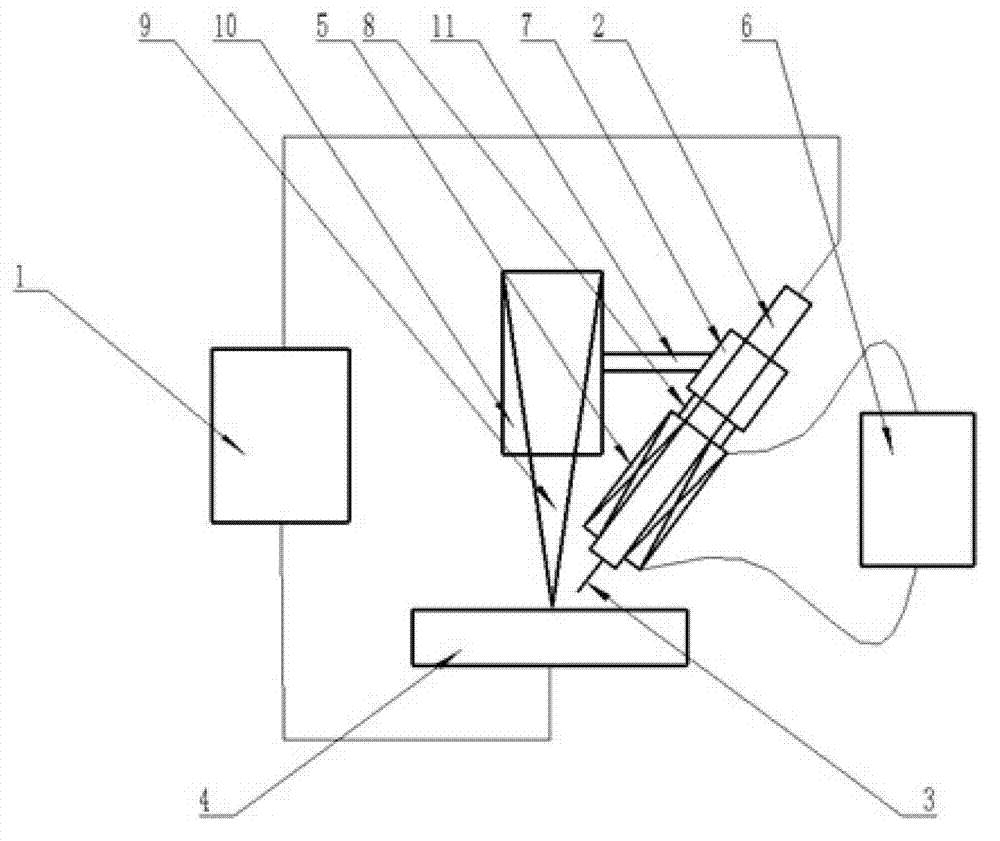

Detection method based on image fusion and detection apparatus therefor

ActiveCN108445007AIncrease contrastImprove filtering effectImage enhancementImage analysisScreening effectImage fusion

A detection method based on image fusion comprises the steps of: irradiating a to-be-detected object with a plurality of illuminating modules in different directions in order to obtain a plurality frames of to-be-detected images; performing image fusion treatment to the to-be-detected images; and performing feature screening to an obtained a texture image or a height image. The method not only canreduce influence due to poor image collection quality under low-contrast but also can provide complete surface feature information, which has advantages of fusing the surface feature information in each frame of the to-be-detected images into the texture image or height image and recognizing and screening the surface defect features from the distinguishing characteristics of the images. An apparatus, with combination of the surface defect detection method, can maximumly eliminate influence due to environmental factors during the detection on the to-be-detected object, and can synthesize and obtain the feature image, comprising the surface defect features from a large number of images. The method and apparatus enhance screening effect on the surface defect features and complete the surfacedefect detection operation under the low-contrast condition.

Owner:SHENZHEN HUAHAN WEIYE TECH

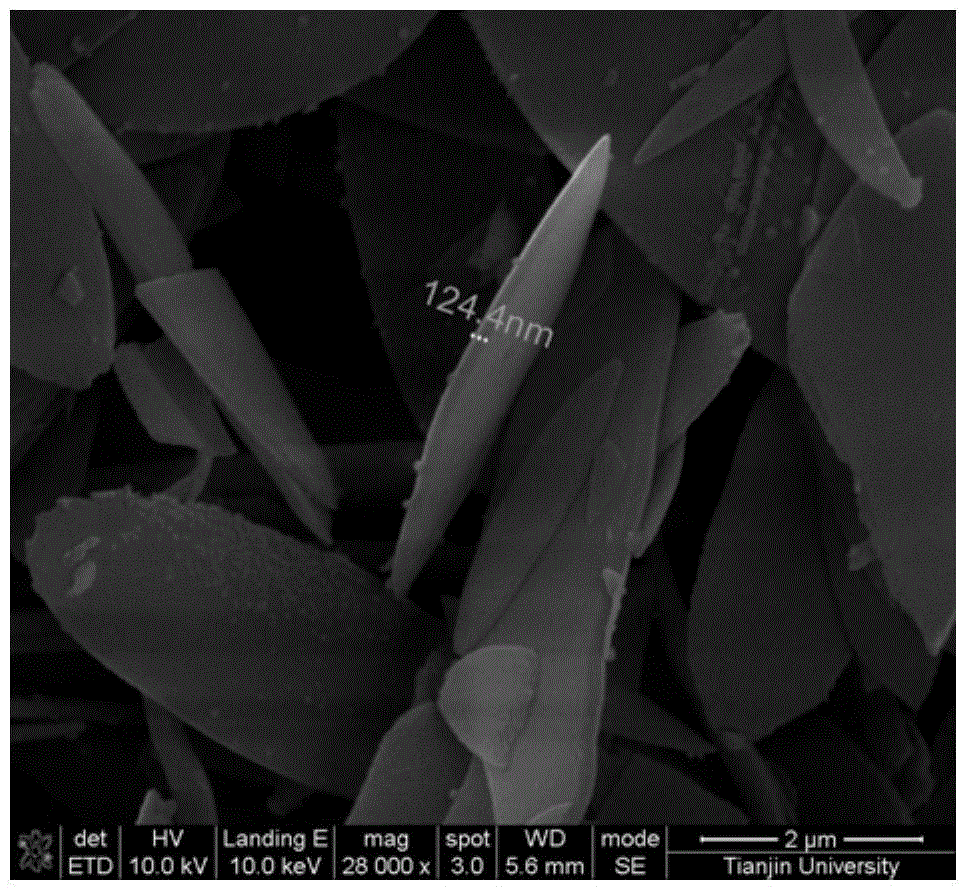

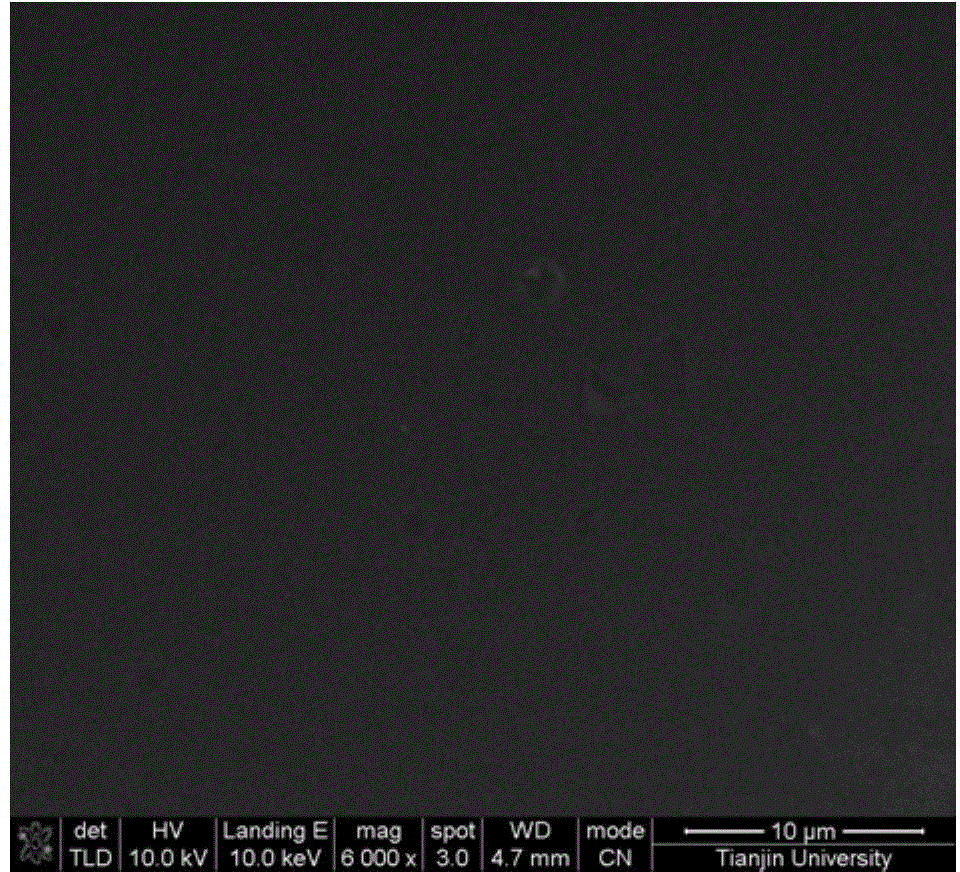

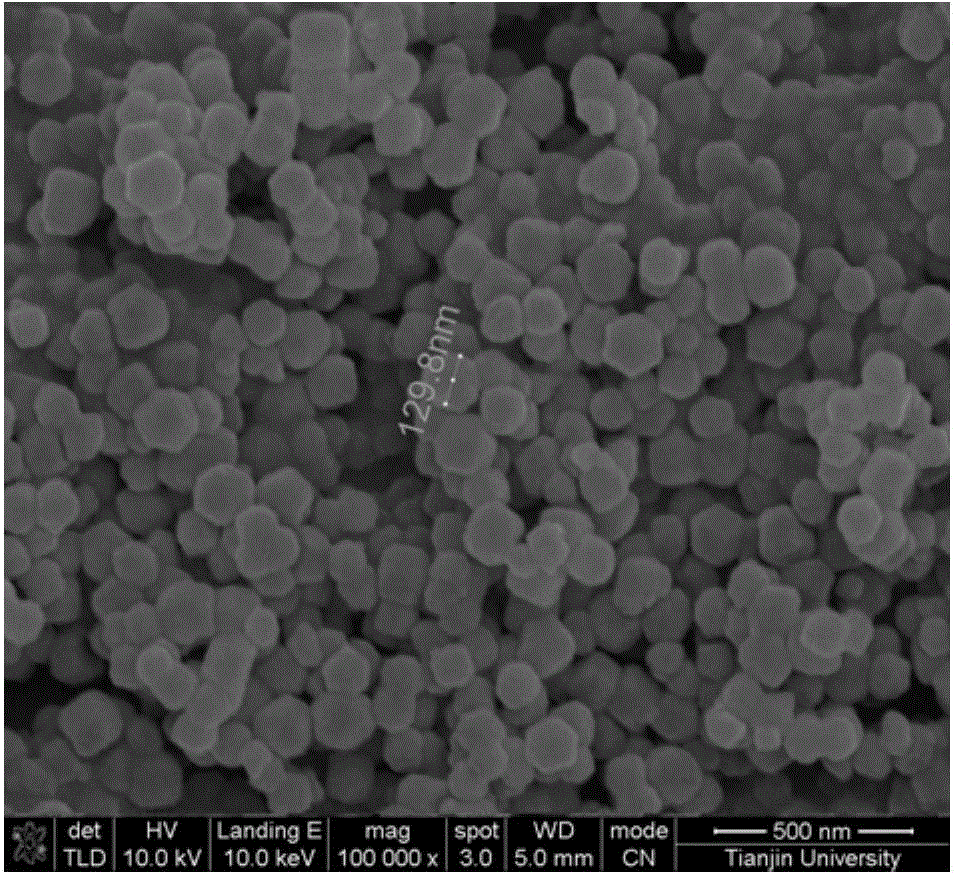

Sodium alginate-flaky ZIF-8 hybrid composite membrane, and preparation and application thereof

Owner:TIANJIN UNIV

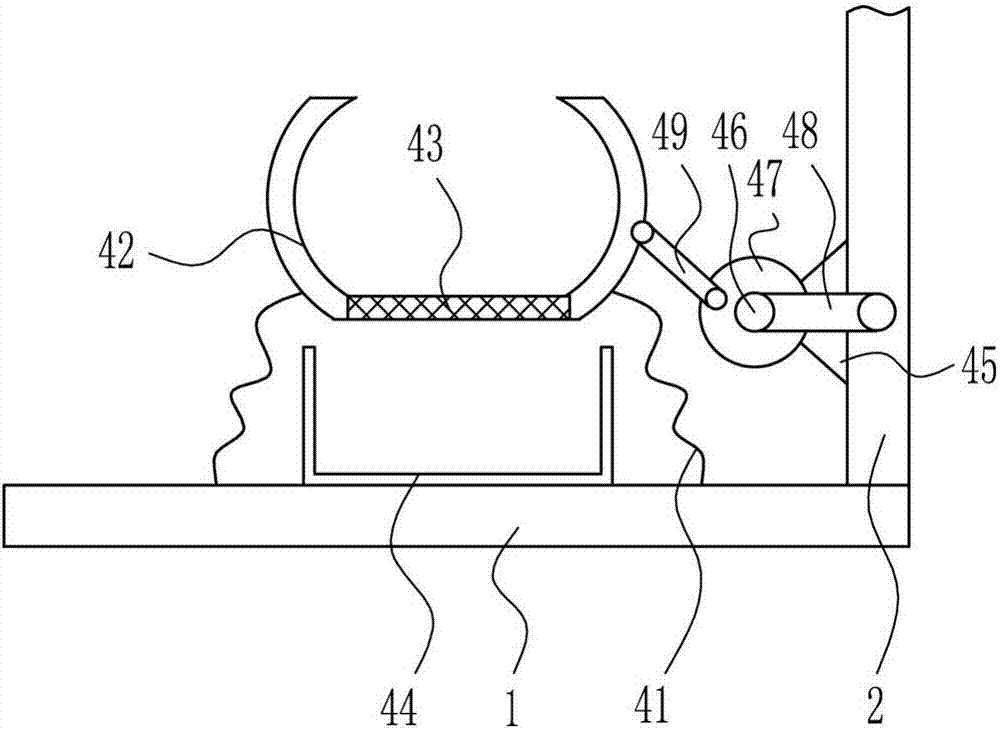

Crushing and screening equipment for automobile tire recycling

ActiveCN107009550AAvoid incomplete crushingTo achieve the screening effectSievingScreeningScreening effectTire recycling

The invention relates to crushing and screening equipment, in particular to crushing and screening equipment for automobile tire recycling. The technical problem to be solved is to provide the crushing and screening equipment which is used for automobile tire recycling and convenient to screen and controllable in feeding rate. To solve the technical problem, the crushing and screening equipment for automobile tire recycling is provided. The crushing and screening equipment comprises a bottom plate, L-shaped supports, a crushing device, a screening device and the like. The L-shaped supports are symmetrically arranged on the top of the bottom plate in a left-right manner. The crushing device is arranged between the two L-shaped supports. The screening device is arranged below the crushing device. According to the crushing and screening equipment for automobile tire recycling, a first operating crank is rocked to drive a screening frame to swing left and right, the screening effect is achieved, the feeding amount is adjusted by rocking a second operating crank, and it is avoided that crushing is not thorough due to the too large feeding amount.

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

Screening device for producing refractory material

ActiveCN106076823AMeet the needs of useImprove filtering effectSievingScreeningScreening effectRefractory

The invention discloses a screening device for producing a refractory material. The screening device comprises a shell. A storage bin is arranged at the top end of the shell. A first screen frame is arranged at the top end in the shell, a coarse screen is fixedly installed at the upper end of the inner side of the first screen frame, and a fine screen is fixedly installed at the lower end of the inner side of the first screen frame. A second screen frame is arranged at the bottom end in the shell, an efficient screen is arranged on the inner side of the second screen frame, and a rotary cam is arranged at the bottom end of a drive motor. According to the screening device for producing the refractory material, through cooperation of the coarse screen, the fine screen and the efficient screen, an exciter works to drive the first screen frame to vibrate through a first vibrating spring and a first telescopic supporting rod; through cooperation of the coarse screen and the fine screen, the material is screened twice, and the screening effect is improved; and the drive motor works to drive a propelling ring groove through the rotary cam to drive the second screen frame to work in a reciprocating manner so that the efficient screen can finely screen the material, the screening effect is improved, and the use requirements of the refractory material are met.

Owner:新疆天山建材集团耐火材料有限责任公司

Magnetic signal measurement apparatus

InactiveCN1877354AShorten the lengthReduce deformation effectsMagnetic/electric field screeningMagnetic sensor packagingMagnetic measurementsScreening effect

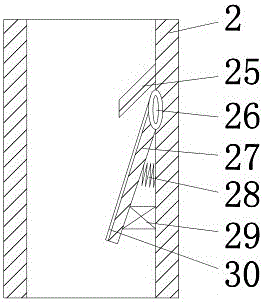

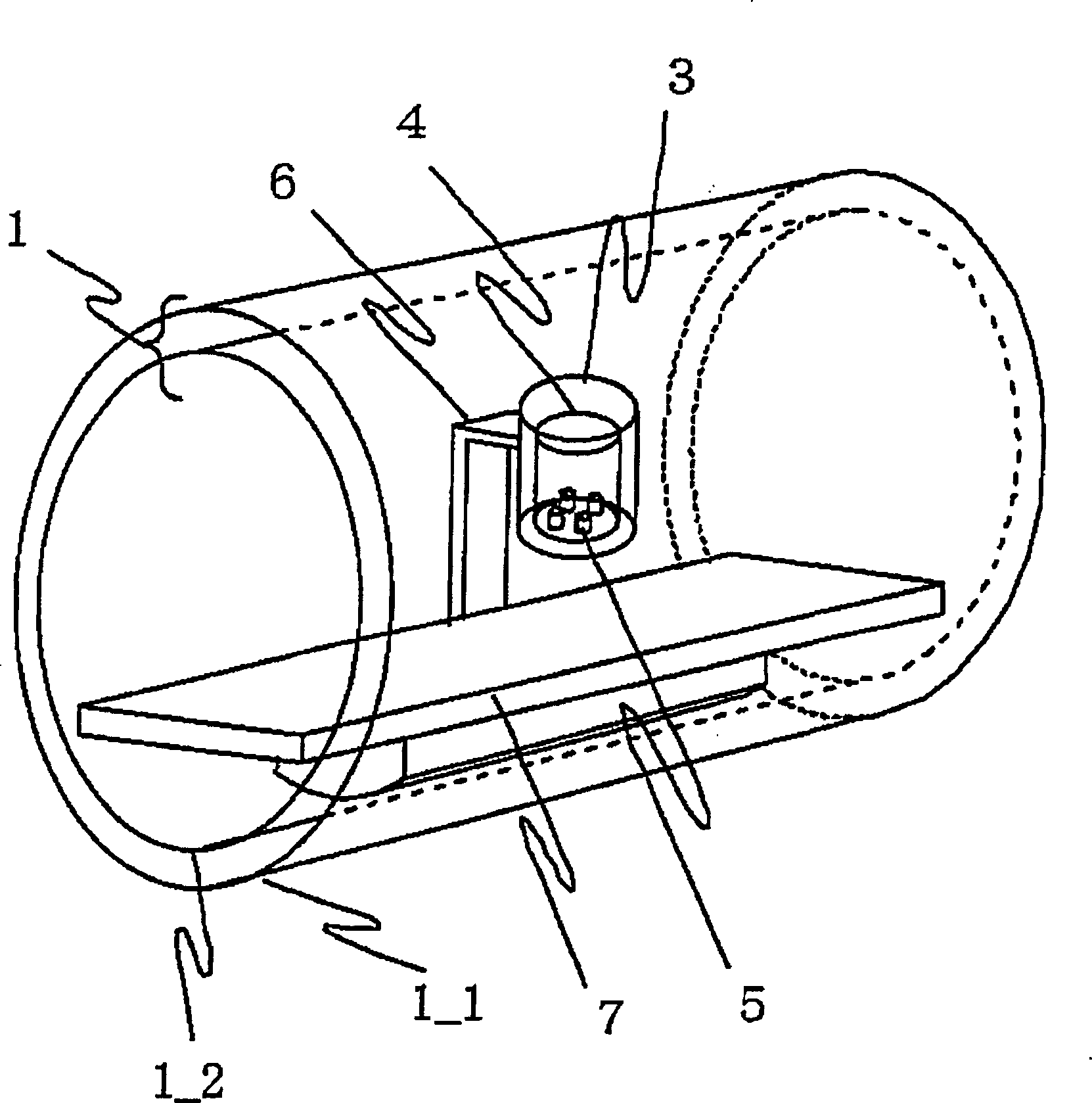

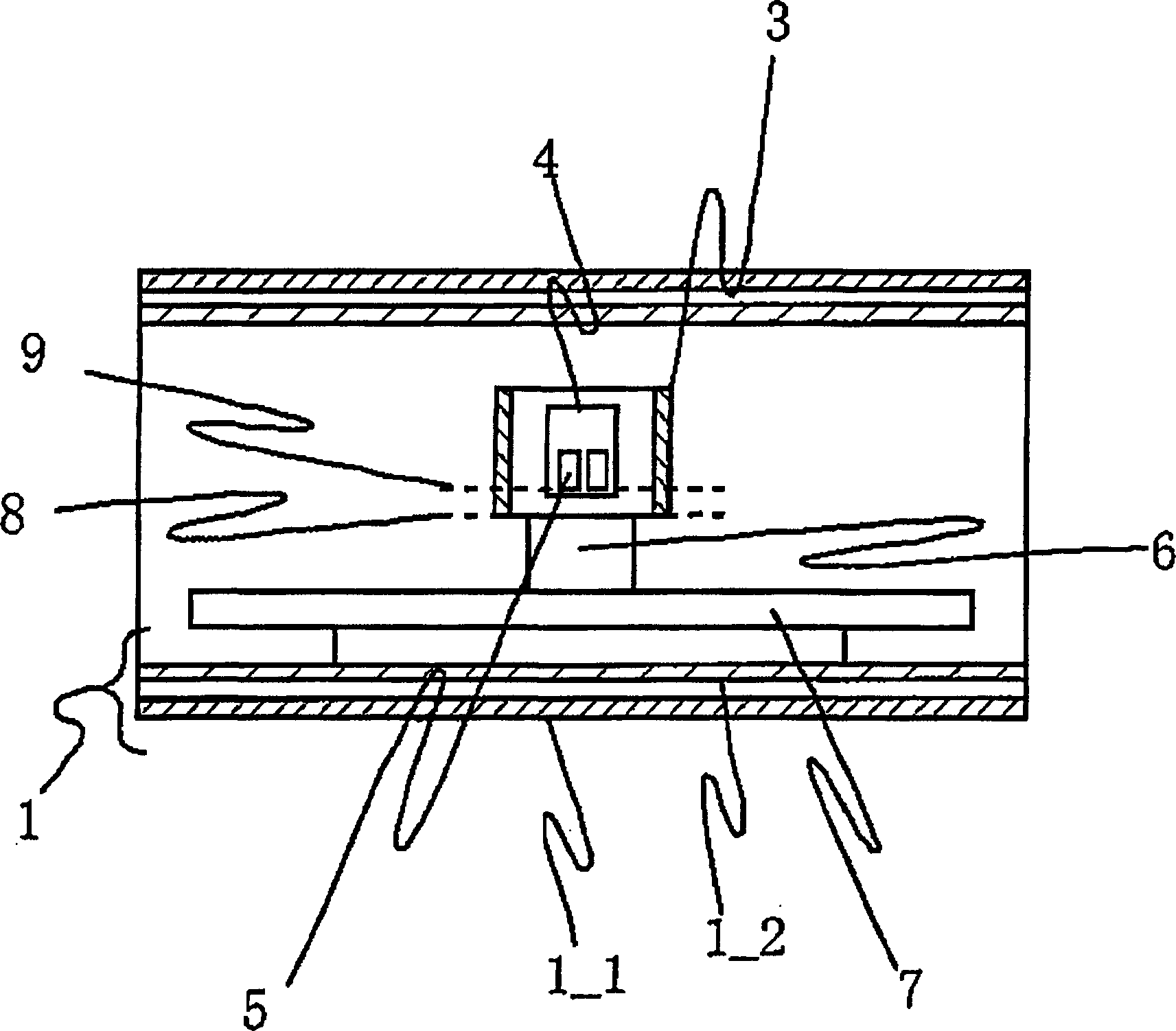

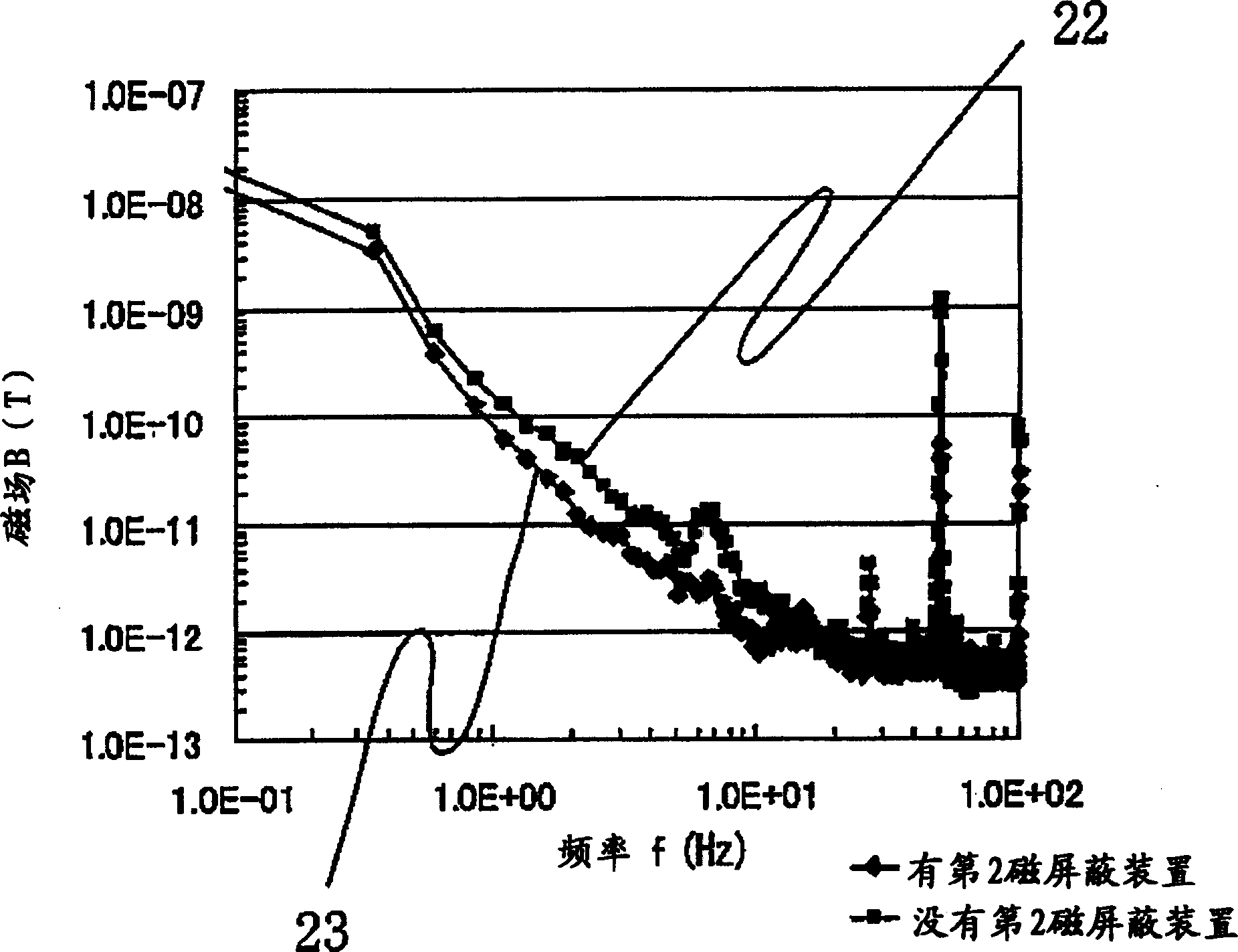

If the length of cylinder of magnetic screening arrangement is shorter, the magnetic screening effect is reduced. At the two ends of magnetic-measurement, there is the second magnetic screening arrangement, which is in the first magnetic screening arrangement. The second magnetic screening arrangement can shield the magnetic-field component which the first magnetic screening arrangement can't shield.

Owner:HITACHI HIGH-TECH CORP

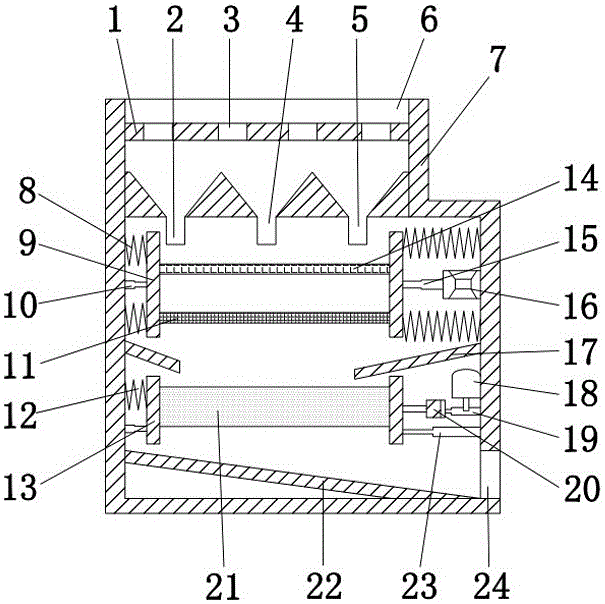

Integrated material crushing and screening device with all-directional vibration functions

ActiveCN106423446AImprove filtering effectIncrease vibration amplitudeSievingScreeningVertical vibrationVibration amplitude

Owner:ZHEJIANG JIANGSHAN HENGLIANG BEE PRODS

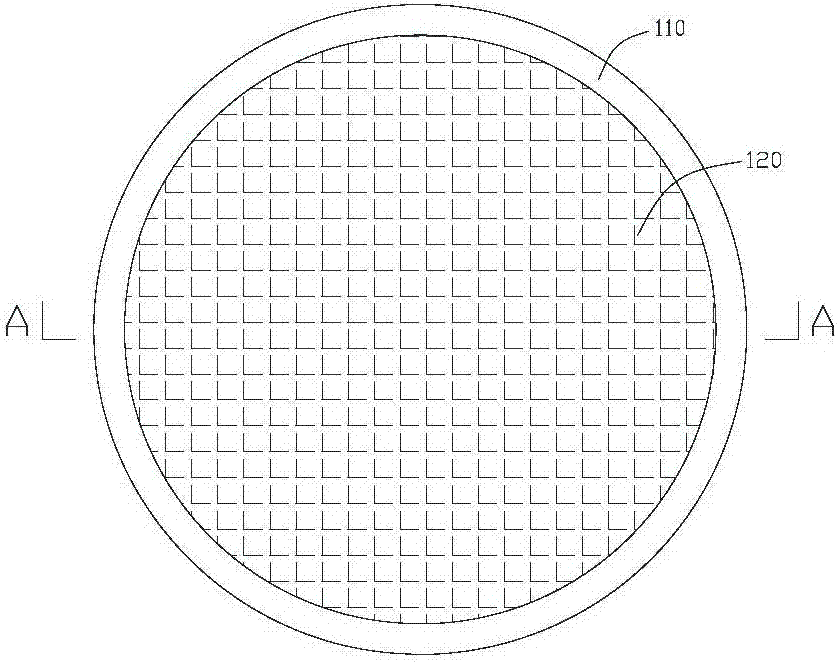

Screening device and titanium alloy powder screening system

PendingCN107159562ASimple structureEasy to processSievingAdditive manufacturing apparatusScreening effectEngineering

The invention provides a screening device and a titanium alloy powder screening system and belongs to the technical field of 3D printing powder screening and production. The screening device comprises a feeding assembly, a screening assembly and a vacuum feeding assembly. The screening assembly comprises a screen frame, a screen body and a guide piece. The guide piece is provided with a first opening, a second opening and a guide wall by which a guide channel is defined. The guide piece is mounted on the screen frame. The first opening is configured to receive materials falling off from the screen body. The guide wall is configured to receive materials falling off from the first opening and guide the materials to the second opening. The vacuum feeding assembly is configured to collect the materials screened from the screen body and put the materials to the feeding assembly. In the use process of the screening device, the screened materials falling off from the screen body can be gathered and fall into the next stage of screen to be screened; and the materials do a involute helicoid motion along with the swing of the screening machine, the screening effect is good, the screen body is not likely to be blocked, multiple times of screening can be conducted, and the yield is increased.

Owner:苏州三峰激光科技有限公司

Efficient sand screening device with conveying frame

InactiveCN107457044AAchieve vibrationAvoid affecting screening efficiencySievingScreeningScreening effectMechanical engineering

The invention discloses a high-efficiency sand screening device with a conveying frame, which comprises a conveying frame, a sand screening frame and a base arranged from top to bottom; Lifting rollers are provided; the conveying frame is connected to the base through a bracket, a feeding frame is embedded on the top plate of the conveying frame, and a breaking hammer is arranged in the feeding frame; U-shaped Guide rails, a hollow movable block is arranged between the U-shaped guide rails on both sides, and a left and right reciprocating mechanism is arranged on the inner side of the movable block to drive it to move; High drive mechanism. The sand screening device of the present invention can effectively solve the problems of sand agglomeration and concentrated accumulation, and improve the sand screening efficiency; meanwhile, the setting of multi-directional vibration can effectively improve the sand screening effect.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Multidirectional gravel classifying equipment for building operations

InactiveCN106984536AEasy to filterIncrease vibration amplitudeSievingScreeningScreening effectMulti directional

A multi-directional sand and gravel grading equipment for building construction, comprising a shell, two bases are symmetrically and fixedly connected to the upper side of the shell, the base is provided with an up and down reciprocating device, and the tops of the two up and down reciprocating devices are jointly fixedly connected with a A left and right reciprocating device, the left and right reciprocating device includes two rotating rods, one end of one of which is connected to the output shaft of the motor, and a rotating body is fixedly connected between the two rotating rods, and the rotating body is horizontally cylindrical. A spiral groove is provided on the side wall of the rotating body, and the spiral groove is arranged around the rotating body; a first connecting column is arranged in the spiral groove, and the diameter of the first connecting column is equal to the width of the spiral groove, and the outside of the first connecting column An installation sleeve is fixedly connected, the lower end of the installation sleeve is fixedly connected with a swing rod, and the lower end of the swing rod is fixedly connected with a sector gear. The invention realizes the back and forth movement of the sieve net, and the vibration amplitude is relatively large, thereby realizing a better screening effect.

Owner:合肥蔚然花绿化工程有限公司

Switch cabinet fault feature selection method and apparatus

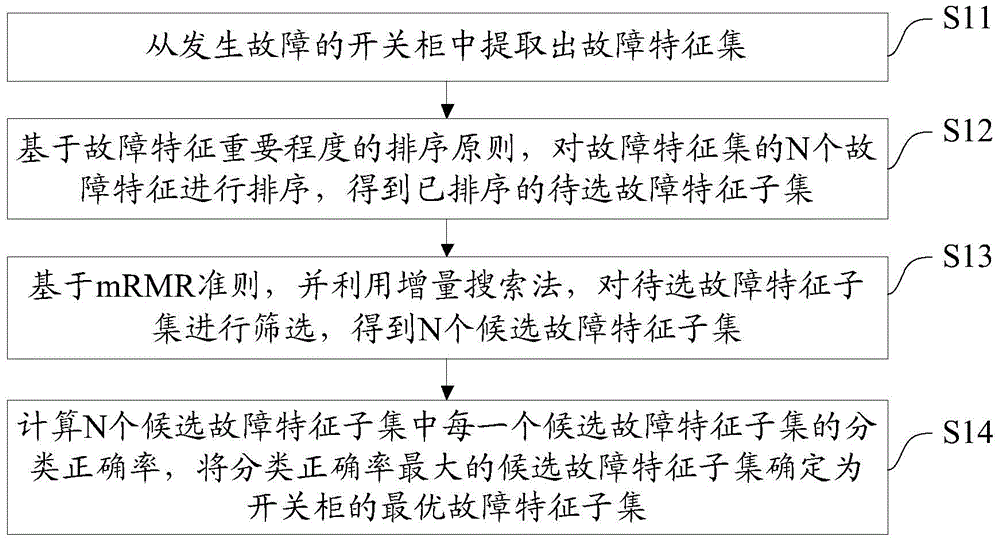

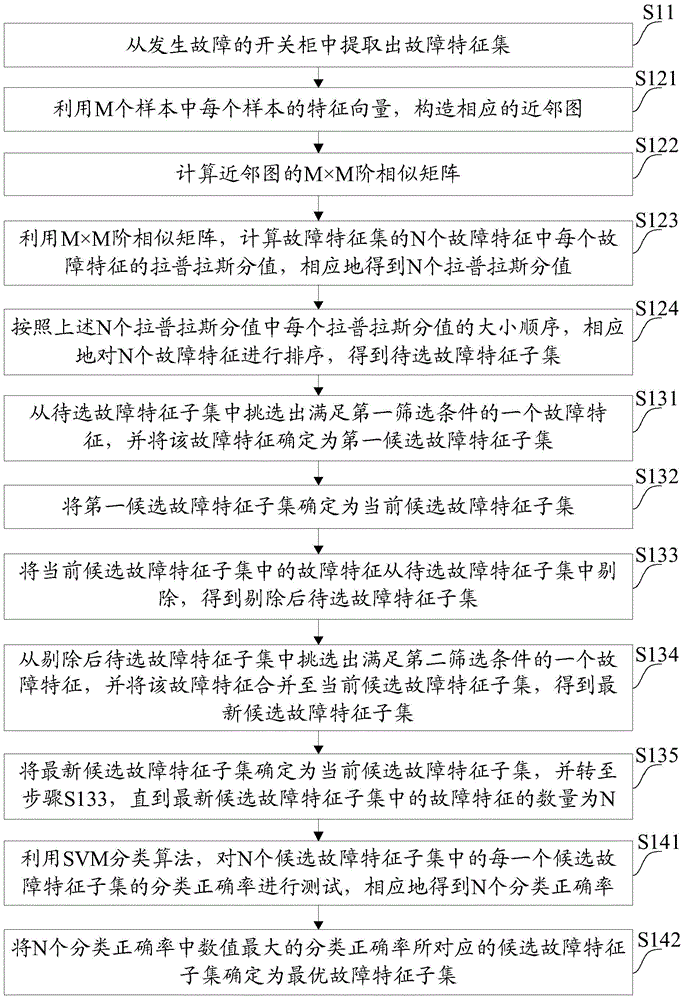

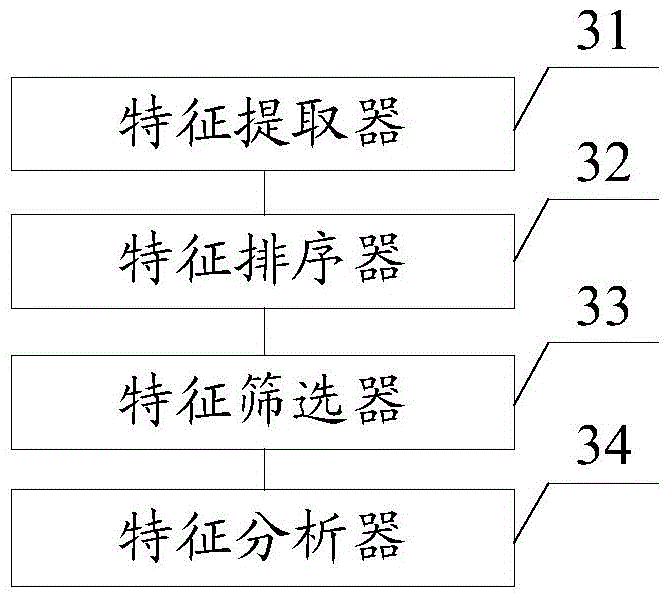

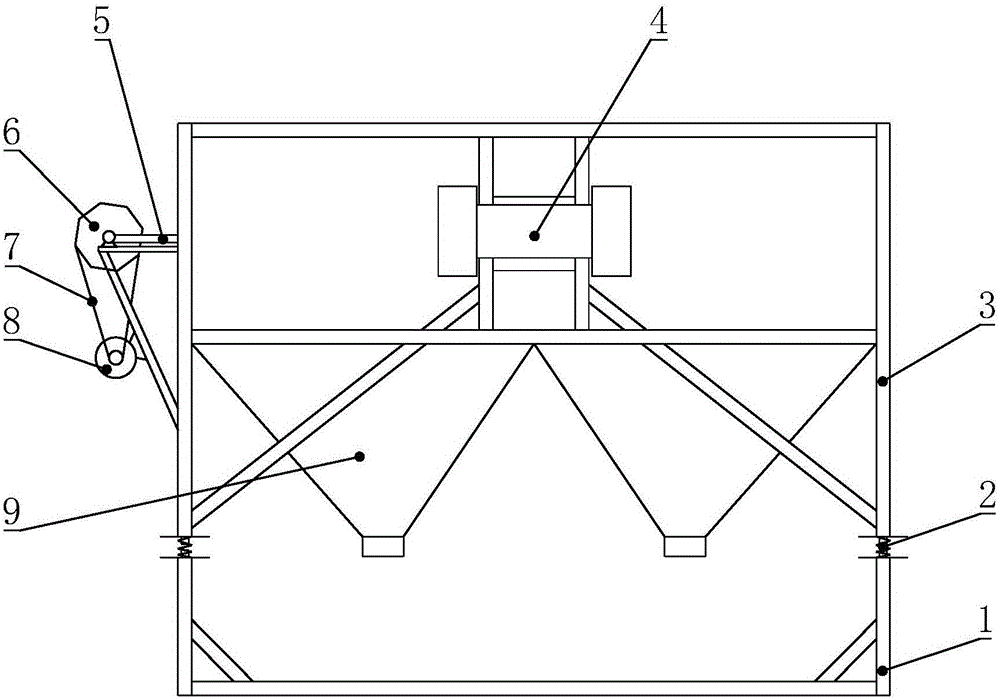

ActiveCN105095675AReduce noise componentsAchieve dimensionality reductionSpecial data processing applicationsFeature DimensionFeature set

The application discloses a switch cabinet fault feature selection method and apparatus. The method comprises: based on a sorting principle of importance degree of fault features, performing sorting on N fault features of a fault feature set to obtain to-be-selected fault feature subsets; based on mRMR criterions, performing screening on the to-be-selected fault feature subsets with an increment search method; and calculating the classification accuracy of each candidate fault feature subset in N candidate fault feature subsets obtained after screening, and determining the candidate fault feature subset with highest classification accuracy as an optimal candidate fault feature subset. According to the switch cabinet fault feature selection method and apparatus, the fault features in the fault feature set are sorted in advance, so that the dimension reduction of the fault features is realized; and then the screening is performed based on the mRNR criterions, so that noise components in a fault feature sample are effectively reduced, the feature dimensions are further reduced, the screening effect is improved, and the degree of matching between the subsequently obtained optimal fault feature subset and an actual fault reason is increased.

Owner:ZHEJIANG TRULY ELECTRIC +4

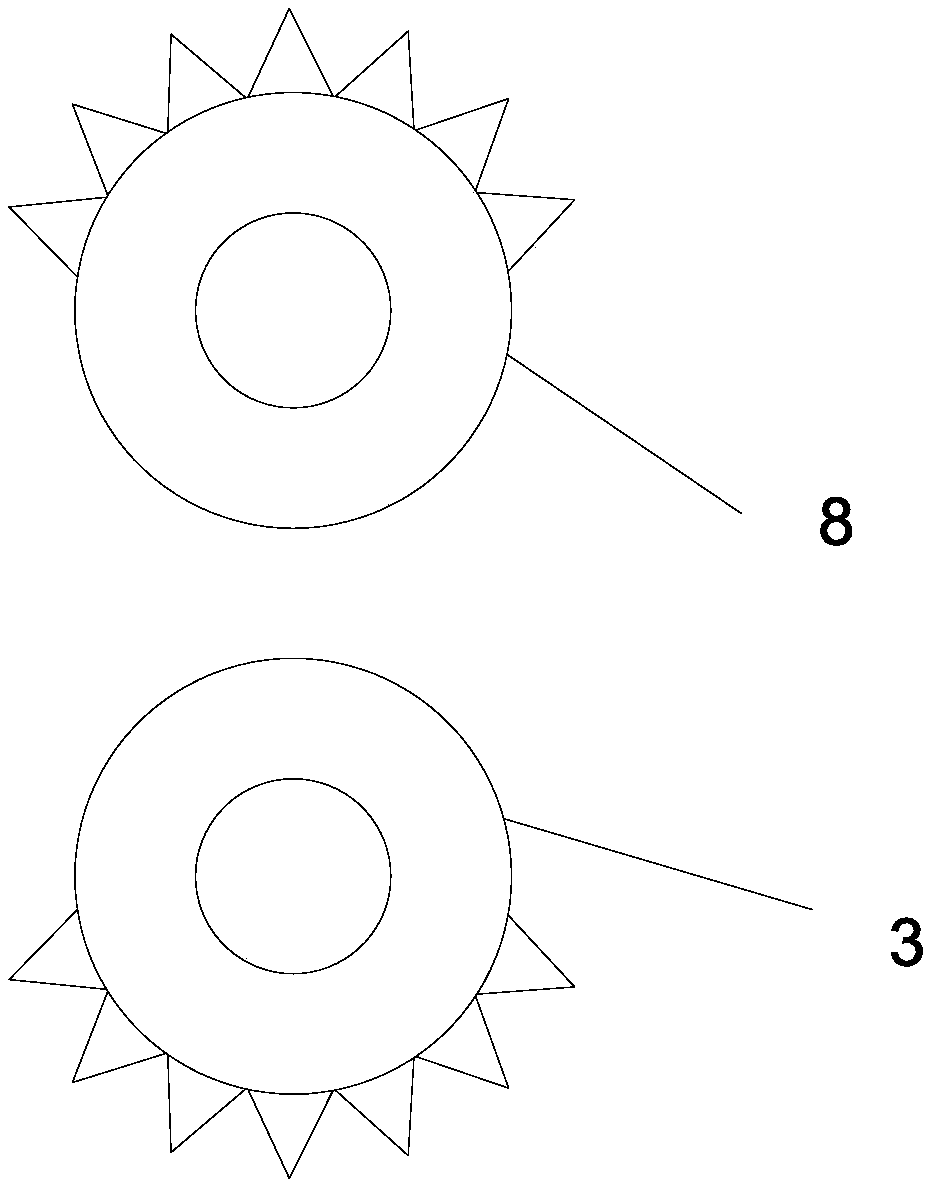

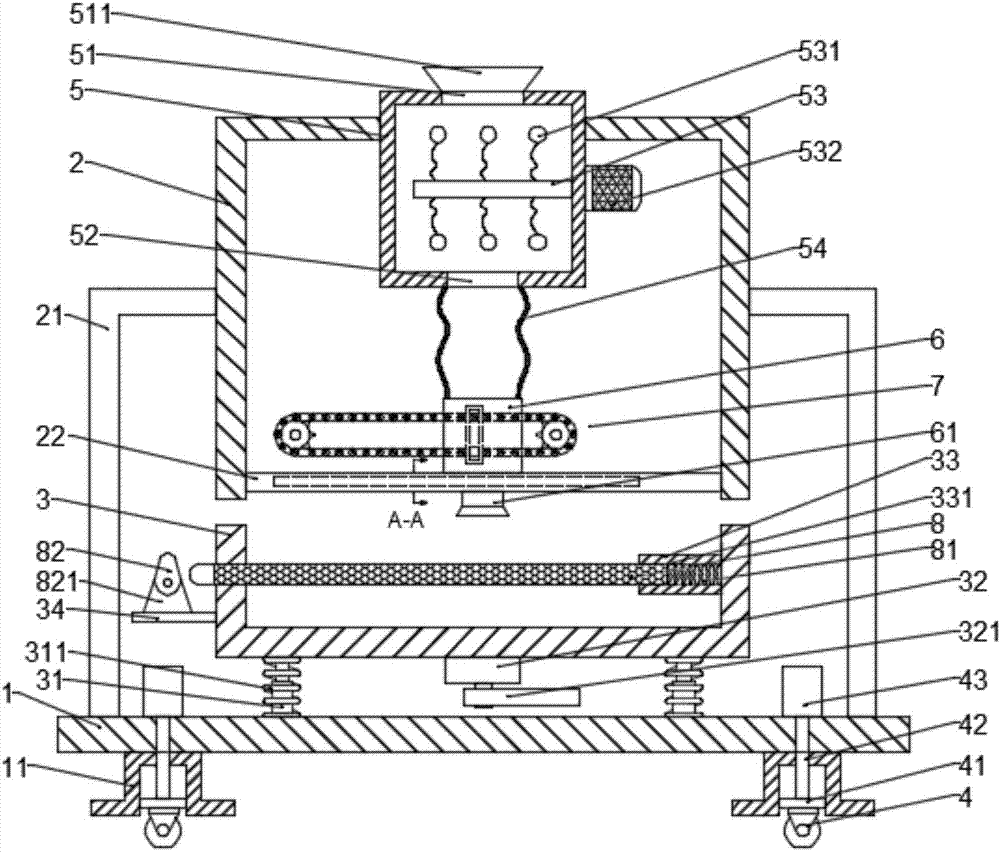

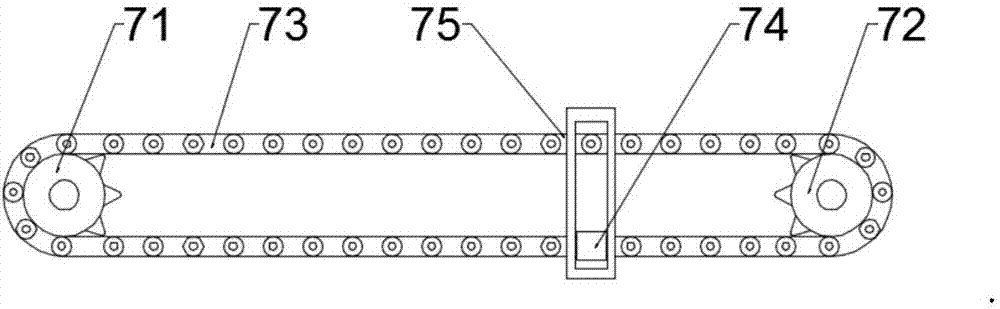

Reciprocating type vibrating screen

InactiveCN105149216AIncrease the usable areaImprove screening efficiencySievingScreeningScreening effectMotor vibration

The invention discloses a reciprocating type vibrating screen. The reciprocating type vibrating screen comprises a base, a spring, a rack, vibrating motors, reciprocating driving devices, a screen net frame and a combined screen net, wherein the rack is connected with the base through the spring; the vibrating motors are correspondingly mounted on two opposite side surfaces of the rack, and the reciprocating driving devices are mounted on one side surface, adjacent to the side surfaces equipped with the vibrating motors, of the rack; the reciprocating driving devices are connected with the screen net frame and can drive the screen net frame to reciprocate; the combined screen net is detachably positioned on the screen net frame; two discharging ports are formed in the lower part of the combined screen net. According to the reciprocating type vibrating screen, the vibrating motors perform vibrating while the reciprocating moving type screening is carried out, so that materials can be spread to the whole screen net, and as a result, the use area of the screen surface can be increased, and the screening efficiency can be improved; elastic balls are positioned in the combined screen net and can pump to strike the screen net to scatter the agglomerated materials, and as a result, the screening effect can be improved; meanwhile, the screen net can be greatly prevented from being blocked, so that the service life of the screen net can be prolonged.

Owner:JINAN JIGANG IRON ALLOY FACTORY

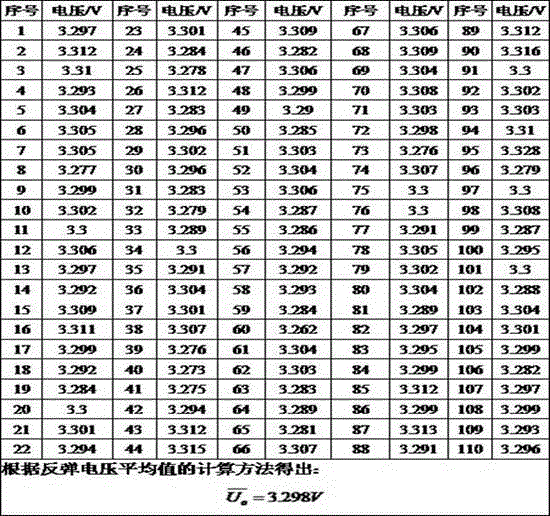

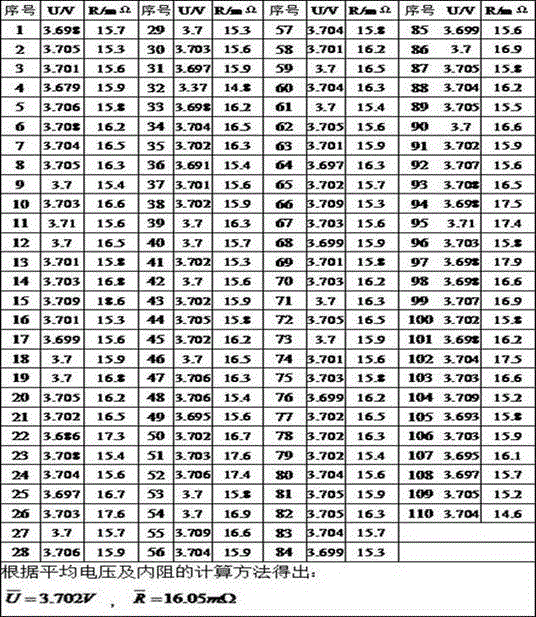

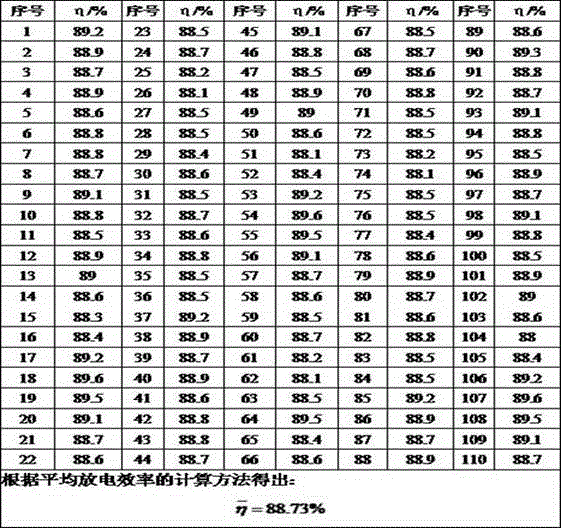

Lithium ion battery stepped formation and consistency screening method

ActiveCN106384853AFully infiltratedImprove stabilitySecondary cells charging/dischargingElectricityScreening effect

The invention relates to a lithium ion battery stepped formation and consistency screening method, which comprises the following steps of 1, pre-charging; 2, high-temperature standing; 3, second-time charging; 4, high-temperature standing; 5, voltage internal resistance screening; 6, third-time charging; 7, high-temperature standing; 8, discharging capacity screening; 9, high-temperature standing; 10, rebounding voltage screening test; 11, partial capacity group distribution. The formation process adopts three times of charging in different steps; in addition, corresponding temperature standing is performed after each time of charging, so that the infiltration of electrolyte is more thorough; the stability of an SEI film formed in the formation process is effectively improved; the battery circulation performance is improved. The discharging residue electricity quantity in the formation process is used for judging the self discharging condition of a battery; the conventional charging and discharging process is more accurately and efficiently reduced. The battery is screened through the rebounding voltage of the discharged battery, and the consistency screening effect is further improved.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

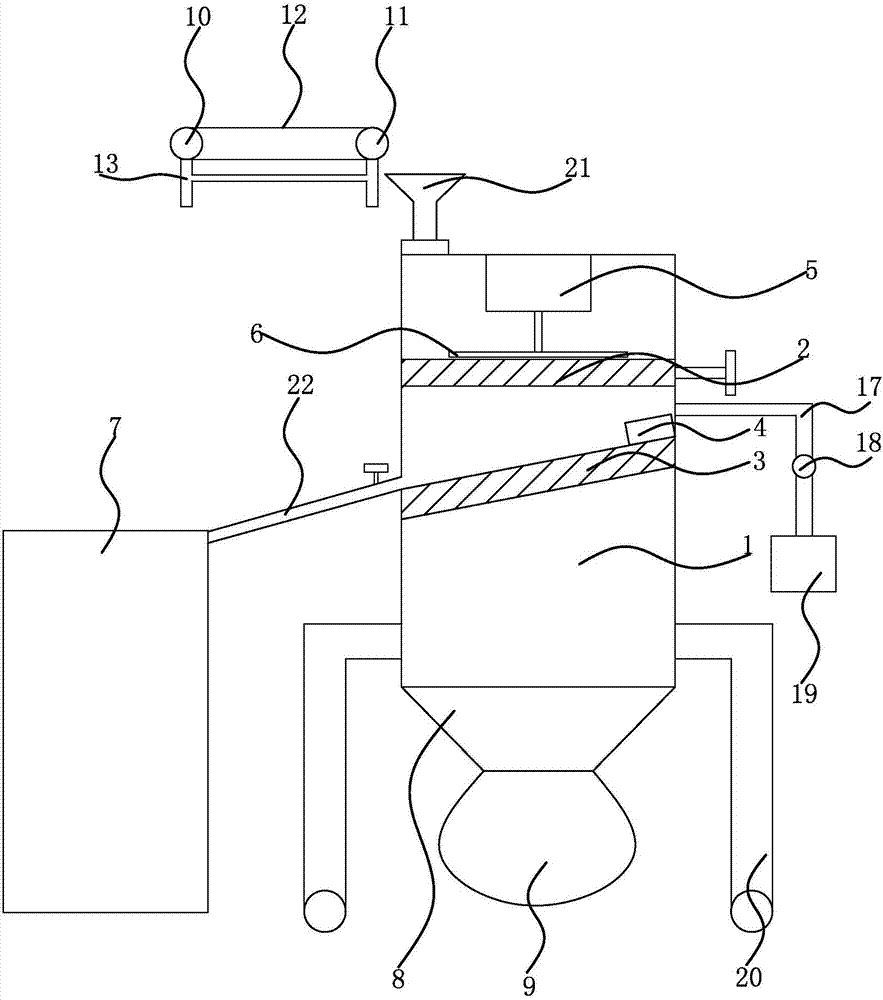

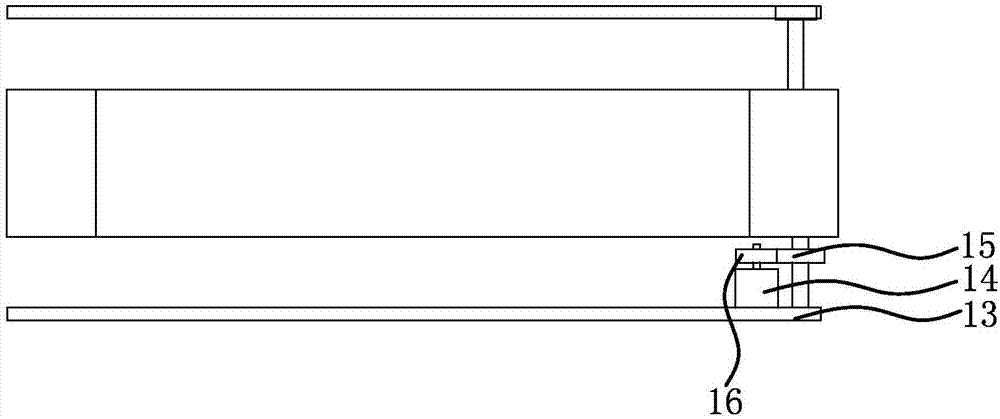

Arc paraxial welding device and method of laser consumable electrode additionally provided with high-frequency magnetic field

InactiveCN103170753AHigh densityImprove stiffnessLaser beam welding apparatusPorosityScreening effect

The invention relates to an arc paraxial welding device of a laser consumable electrode additionally provided with a high-frequency magnetic field. The arc paraxial welding device comprises a welding machine, a welding gun, a welding wire, a laser coil, an exciting coil, an exciting power source, a combined welding head-welding gun clamping mechanism, a connection piece, a laser head and a combined welding head type connection piece. Compared with the prior art, the arc paraxial welding device provided by the invention has the beneficial effects that: the arc paraxial welding device has the characteristics of small size, low cost and strong practical applicability; the exiting coil acts on photo-induced plasma generated by laser, so that the screening effect of the photo-induced plasma on laser can be reduced, the use rate of electromagnetism and the own stable burning capacity of arc can be improved, molten drops are prompted to smoothly transit and metal in a furnace hearth is prompted to sufficiently flow, and the defects of generation of splashing and vents in welding beams and the like in a welding process can be reduced; the electromagnetic stirring effect of the exiting coil is beneficial to the flow of the metal in the furnace hearth and the thinning of a grain structure of the welding beams, so that the porosity and the cracking rate of the welding beams can be reduced, the structure property of a welding joint is improved, an arc paraxial welding process of the laser consumable electrode can be optimized, and wide market prospect is realized.

Owner:鞍山煜宸科技有限公司

Screening machine

InactiveCN106862079AQuality assuranceExpedited screeningSievingGas current separationScreening effectBiochemical engineering

The invention provides a screening machine, belongs to the field of biochemical technique, and solves the problem in the prior art that the screening effect is poor. The screening machine comprises a box, wherein a feeding hole is formed in one side of the top end of the box; a feeding mechanism capable of conveying material in the box is arranged out of the feeding hole; a cavity is formed in the box; a filter screen I is horizontally arranged in the cavity; a filter screen II is obliquely arranged below the filter screen I; a vibration motor is fixed at the upper end of the filter screen II; the pore diameter of the filter screen I is greater than that of the filter screen II; the filter screen I and the filter screen II sequentially divide the cavity into a lower cavity, a middle cavity and an upper cavityfrom bottom up; a motor I is fixed at the top of the upper cavity; the output shaft of the motor I is vertically downwards; a stirring rod is fixed at the end part of the output shaft of the motor I; a discharging hole I is formed in the lower end of the filter screen II on the inner wall of the box; a storage box is arranged on one side of the box; and the discharging hole I communicates with the storage box through a discharging pipe. The screening machine has the advantage of an excellent screening effect.

Owner:ZHEJIANG LANBO BIOTECH CO LTD

Soil screening remediation device

InactiveCN104170550AImprove repair effectEfficient removalSoil lifting machinesGatherer machinesChemical storageSoil treatment

The invention relates to the technical field of agricultural devices, in particular to a soil screening remediation device. The soil screening remediation device comprises a soil conveying belt, a soil taking shovel is mounted at the front end of the soil conveying belt, the rear end of the soil conveying belt is connected with a soil treatment tank, a film adsorption mechanism is mounted in the soil treatment tank, a screening device is mounted under the film adsorption mechanism, and a chemical spraying device is mounted below the spraying device and connected with a chemical storage tank through a delivery pipe. Through the soil screening remediation device, processes of soil turning, crushing, screening, chemical spraying, remediation and the like can be performed simultaneously, screening effect is good, mulching films and solid impurities can be removed effectively, and separation efficiency is high; the soil screening remediation device is simple in structure, chemical spraying holes in the chemical spraying device are arranged alternatively, chemical and soil are mixed more uniformly, time for soil impurity removal and remediation is short, and the remedied soil can be kept soft and highly breathable within a long time.

Owner:DANYANG BAODE ECOLOGICAL AGRI & FORESTRYDEV

Rapid sand screening device for building construction

InactiveCN108097415ASpeed up sievingAchieve left and right shakingSievingScreeningScreening effectSpiral blade

The invention discloses a rapid sand screening device for building construction. The rapid sand screening device comprises a bottom plate and a screening box fixed on the bottom plate, and a feeding hopper is vertically and fixedly installed at the top part of the screening box; a sieve plate is horizontally arranged in the screening box in a sliding mode; a driving gear is connected to a horizontal support through a motor in a driving mode, and a first semicircular gear is coaxially and fixedly installed on the front side of the driving gear; and the bottom part of the bottom plate is fixedlyprovided with an air heater and a draught fan connected with the air heater through a pipeline. According to the rapid sand screening device, spiral blades are driven to rotate through forward and reverse rotation of a forward and reverse rotation motor, the spiral blades rotate and dissipate sand, sand can move back and forth in the left-right direction at the same time, so that screening of thesand is promoted; the sieve plate moves back and forth in the left-right direction, so that left and right shaking of the sand is realized; meanwhile, upper convex blocks and lower convex blocks arecoordinated with each other, so that small vibration of the sieve plate is realized, and the sand is accelerated to pass through the sieve plate; and hot air sprayed into the screening box by an air injection disc plays a role in drying the sand, so that the sand is more dispersed, and therefore the screening effect is better.

Owner:徐玲燕

Heat-proof polychloroethylene transparent adhesive tape

InactiveCN101157829AEasy to makeReduce processing costsFilm/foil adhesivesScreening effectThermal insulation

A transparent polyvinyl chloride coated fabric for heat insulation is made by the processing method of non-coating. The coated fabric has the function of shading infrared and ultraviolet. The preparation method is that polyvinyl chloride colophony containing special formula, plasticizer, inorganic thermal insulation particles and other mixtures of adding addition agent are used directly in the traditional process of making the polyvinyl chloride coated fabric, as a result, the transparent polyvinyl chloride coated fabric for thermal insulation not only has the existing physical properties of polyvinyl chloride, but also transparency, little fog, and excellent screening effect against infrared and ultraviolet.

Owner:NANYA PLASTICS CORP

Fodder grinder of improved screening structure

The invention discloses a fodder grinder of an improved screening structure. The fodder grinder comprises a grinding box, a screening box and a base; the grinding box is arranged on the top of the screening box, the base is arranged below the screening box, a grinding shaft is arranged in the middle of the inner side of the grinding box, a grinding motor connected with the grinding shaft is arranged on the top of the grinding box, a plurality of rotating tool teeth are mounted at the position, on the inner side of the grinding box, on the grinding shaft, a plurality of fixed tool teeth are arranged on the inner side wall of the grinding box, a scraping plate is arranged at the position, located at the bottom of the inner side of the grinding box, on the grinding shaft, a screening plate is arranged on the inner side of the screening box, the middle of the upper side of the screening plate is connected with an electric telescopic rod through a second supporting spring, a vibration motor is arranged in the middle of the lower side of the screening plate, multiple first supporting springs are arranged on the outer ring of the screening plate, and a receiving plate is arranged below the screening plate. The fodder grinder is good in fodder grinding and screening effect, and novel in structure and has the very high popularization and utilization value.

Owner:临沂正能量生物有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com