Patents

Literature

1142results about How to "Improve screening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

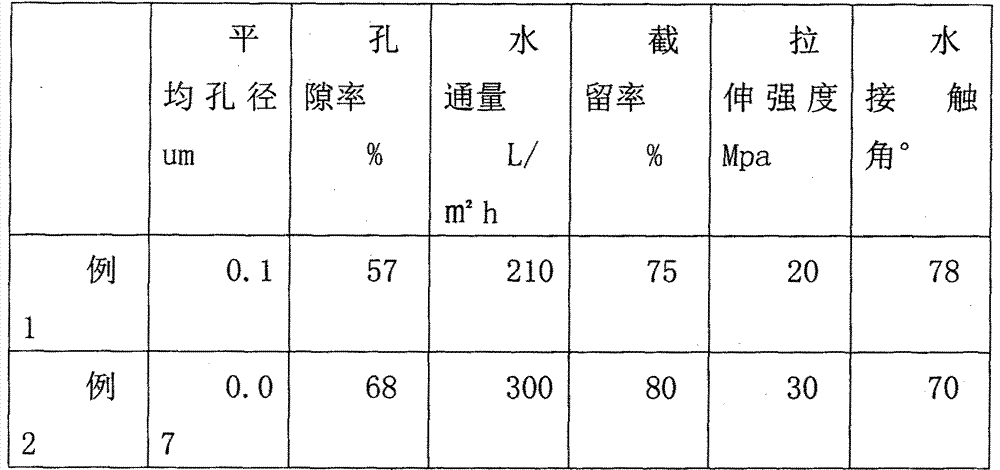

Preparation method of novel MOFs-PVDF (Metal-Organic Frameworks-Polyvinylidene Fluoride) composite film

InactiveCN107020020AAchieve stabilitySmall membrane poresMembranesSemi-permeable membranesPorosityComposite film

The invention discloses a preparation method of a novel MOFs-PVDF (Metal-Organic Frameworks-Polyvinylidene Fluoride) composite film. The preparation method is mainly characterized in that a synthesizing environment of MOFs is controlled to be consistent with a casting solution preparation condition, an organic ligand and metal ions are added into a casting solution by a simple one-step synthetic method, intermolecular acting force between the organic ligand and PVDF is regulated and controlled, the PVDF is chemically combined with the MOFs through a hydrogen bond of an 'F' atom, chemical bonding of a PVDF polymer and the MOFs is realized, and an MOFs-PVDF polymer is synthesized in the casting solution, so that the formation of a chemical bonding hole and the formation of an MOFs-PVDF novel film are performed simultaneously in a spinning process. The method is easy and efficient; moreover, the prepared film combines the advantages of an MOFs and PVDF composite film; the prepared novel MOFs-PVDF composite film has the advantages of high chemical stability, high mechanical strength, controllable aperture, large surface specific area and high porosity.

Owner:TIANJIN POLYTECHNIC UNIV

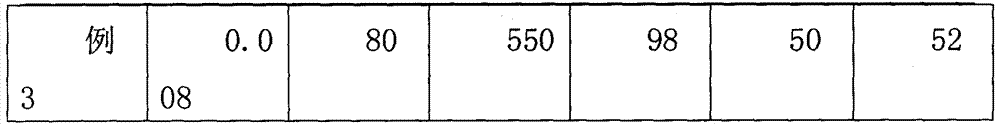

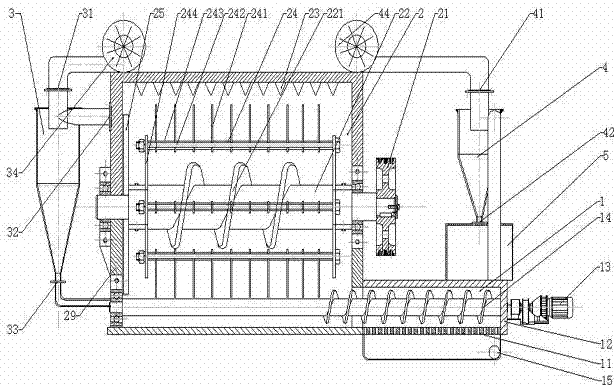

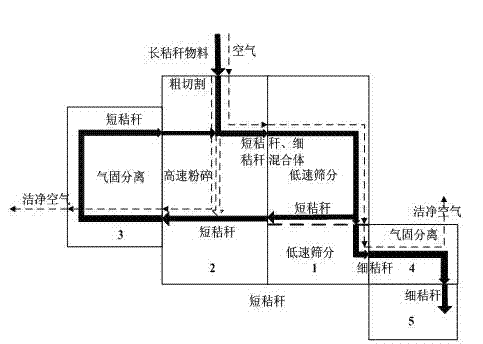

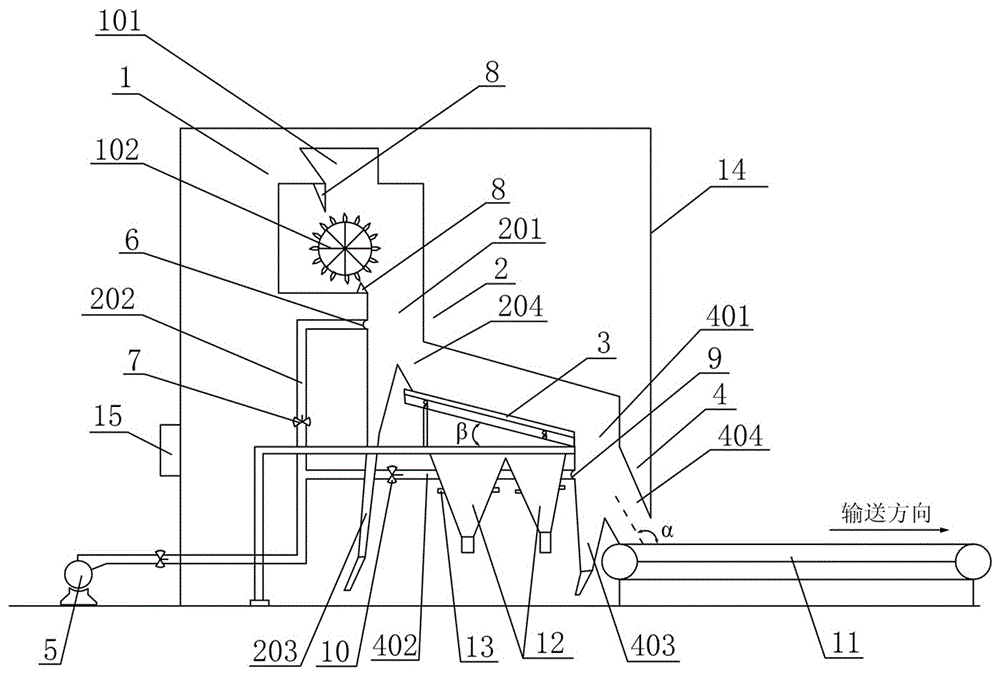

Straw cutting, crashing and sieving integrated device and method

ActiveCN103084286AIncrease production capacityPromote sustainable developmentVortex flow apparatusCuttersCycloneAgricultural engineering

The invention discloses a straw cutting, crashing and sieving integrated device and a method and belongs to the technical field of agricultural machines. The straw cutting, crashing and sieving integrated device comprises a sieving chamber, a cutting and crashing chamber, a first cyclone separator, a second cyclone separator and a storage bin. According to the straw cutting, crashing and sieving integrated device provided by the invention, low-speed sieving is distinguished from high-speed cutting and crashing, and the sieving capacity of a material is enhanced due to the agitation effect of sieving blades, so that a thin material can be sufficiently sieved, and a coarse and short material can be returned back to the cutting and crashing chamber again for secondary crashing; and meanwhile, the crashing efficiency is improved. The straw cutting, crashing and sieving integrated device provided by the invention has the advantages of compact structure and small occupied area due to the integrated design of the sieving chamber and the cutting and crashing chamber. The straw cutting, crashing and sieving integrated device provided by the invention is applicable to straw resourceful treatment of small-size facility horticulture planting enterprises and individual farmers; the machining environment is improved; the labor intensity is reduced; the machining efficiency is improved; the production cost is reduced; and the high-efficiency production and the sustainable development of facility horticulture cleaning can be promoted.

Owner:万华禾香板业(公安县)有限责任公司

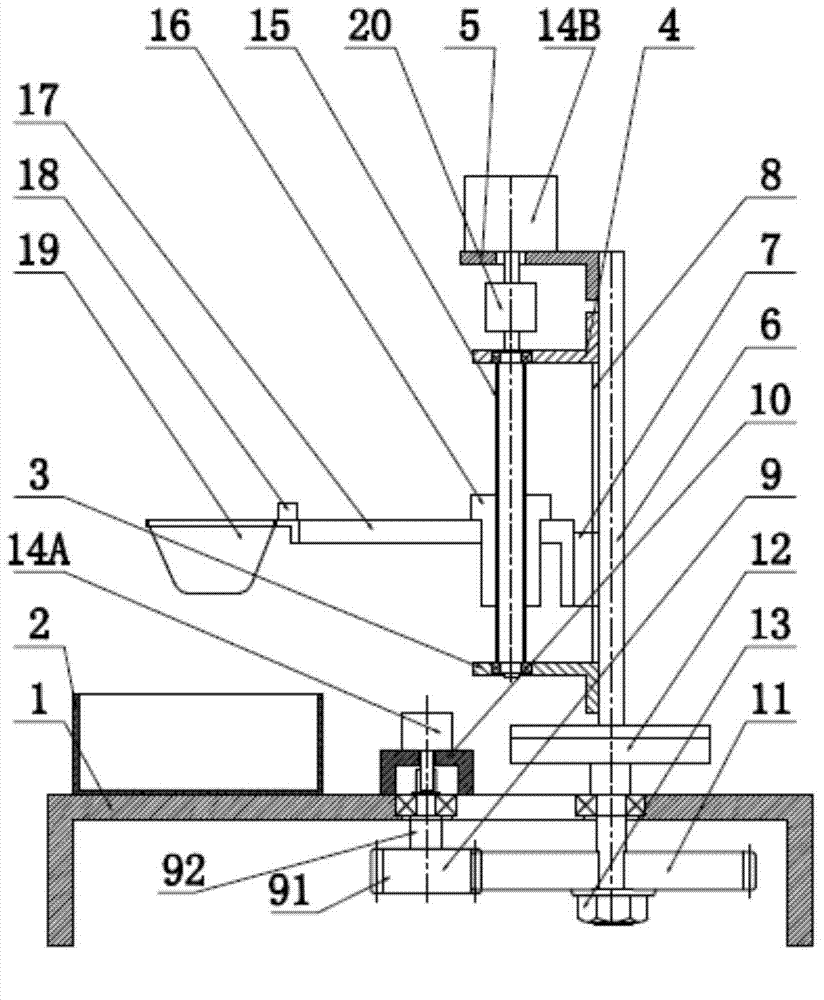

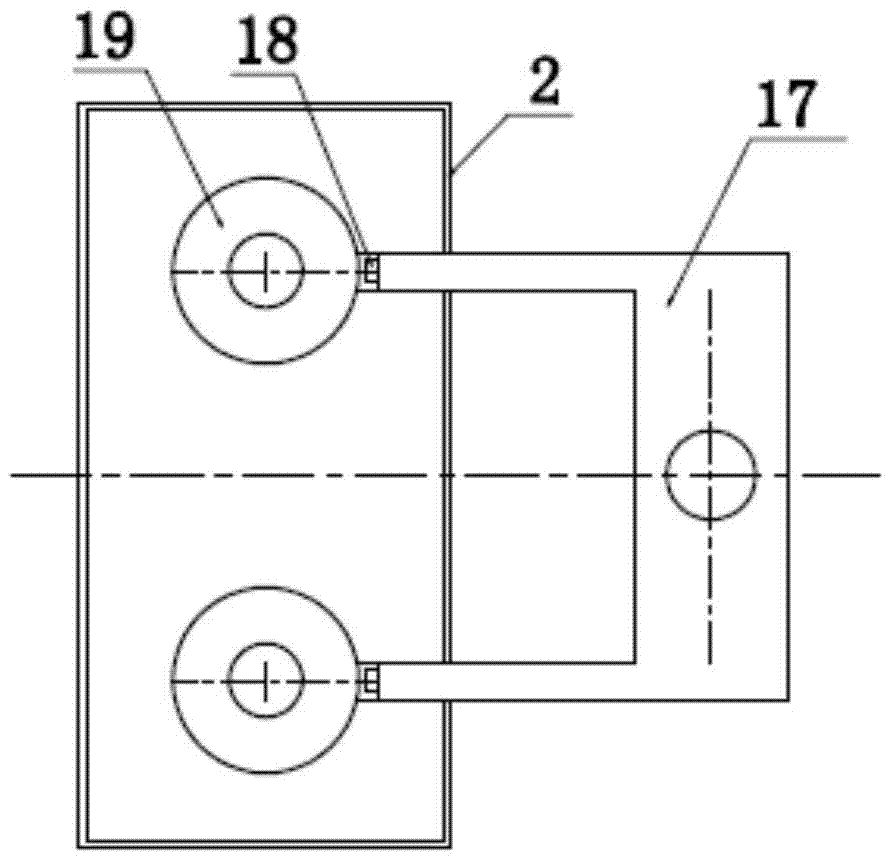

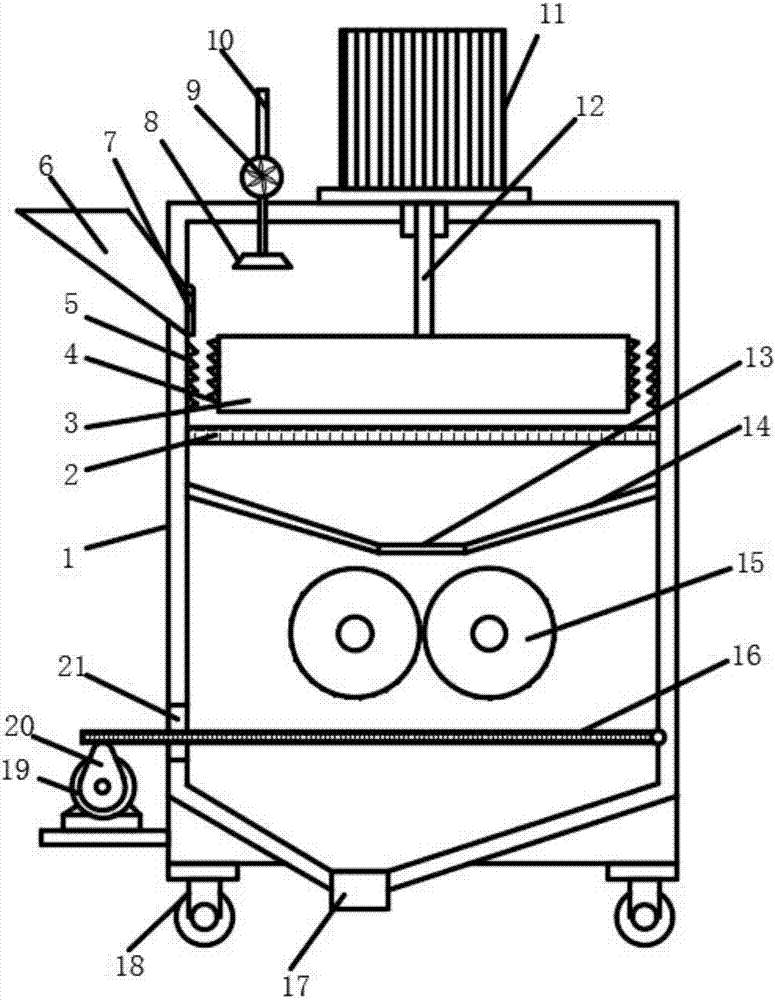

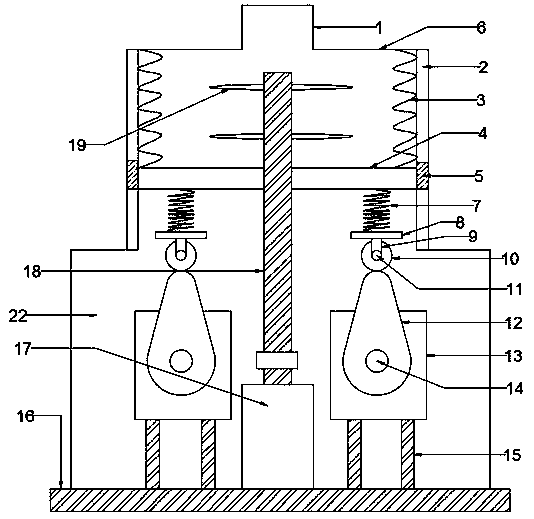

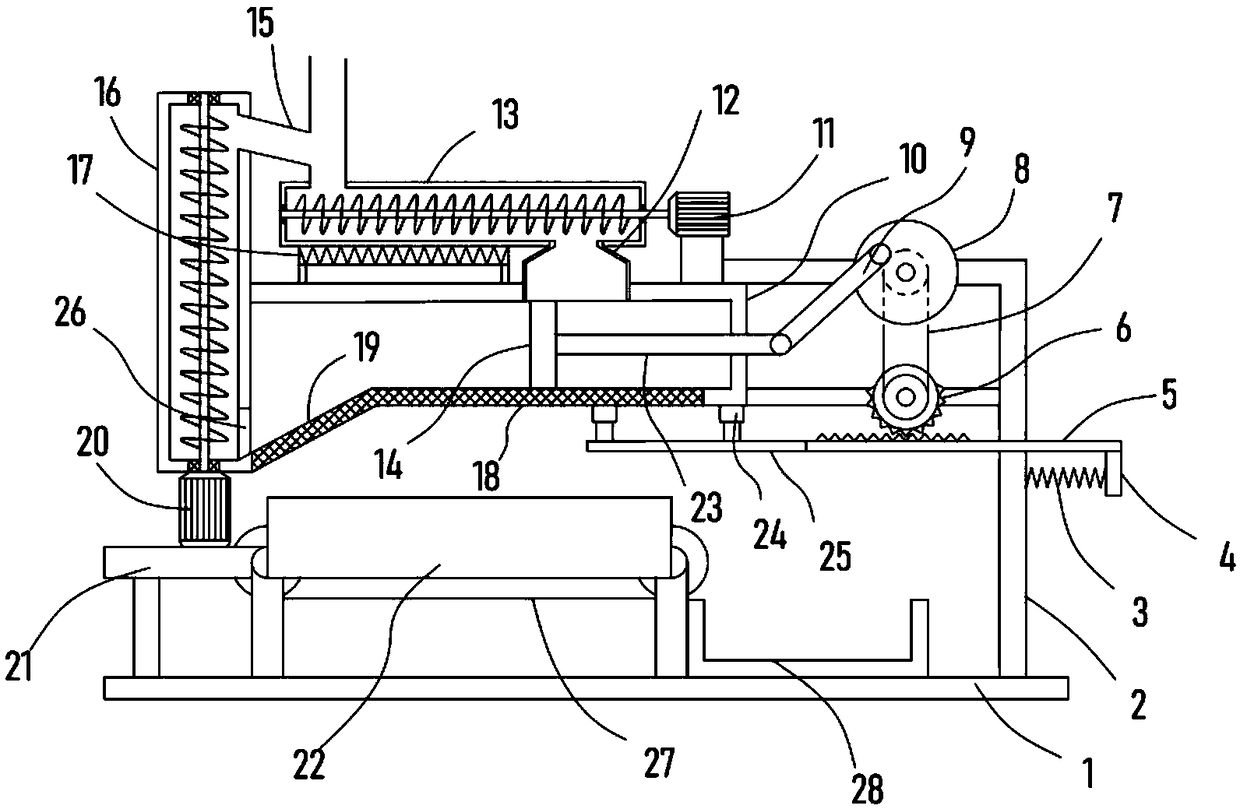

Automatic bituminous coal screening device

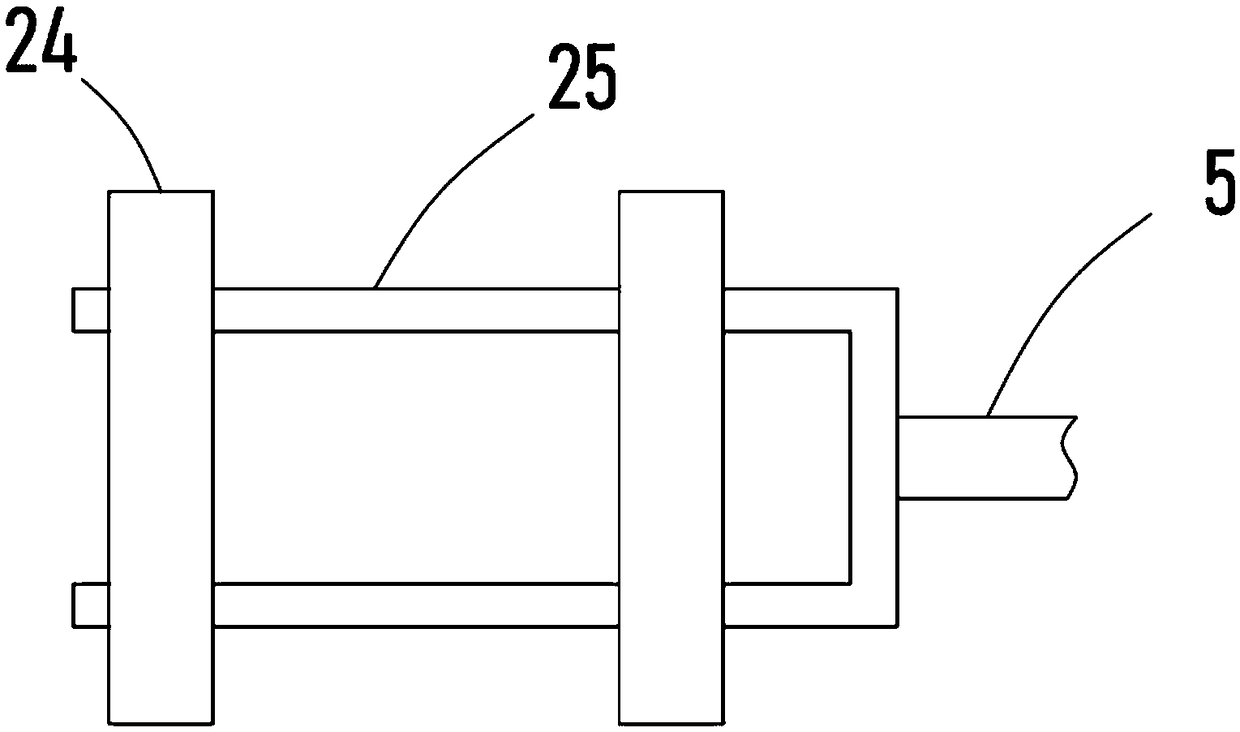

ActiveCN104741313AChanging the method of manually screening bituminous coalImprove screening effectSievingScreeningEngineeringTwo step

The invention discloses an automatic bituminous coal screening device. The automatic bituminous coal screening device comprises a waste box, a U-shaped motor rack, a composite gear shaft, a transmission shaft, a driven gear, a T-shaped elevator, a lower bearing bracket, a guide rail, an upper bearing bracket, an L-shaped motor rack, a sieve rack, two fine-mesh sieves symmetrically mounted on the sieve rack, two eccentric motors, two stepping motors and a rolling lead screw. The lifting motor is used for lifting the fine-mesh sieves; a vibrating motor rotates to drive the fine-mesh sieves to vibrate left and right; the two eccentric motors are capable of driving the fine-mesh sieves to vibrate up and down. The automatic bituminous coal screening device is an automatic instrument reasonable in structure, simple to operate, and capable of screening two parts of bituminous coal particles in a vibrating manner.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

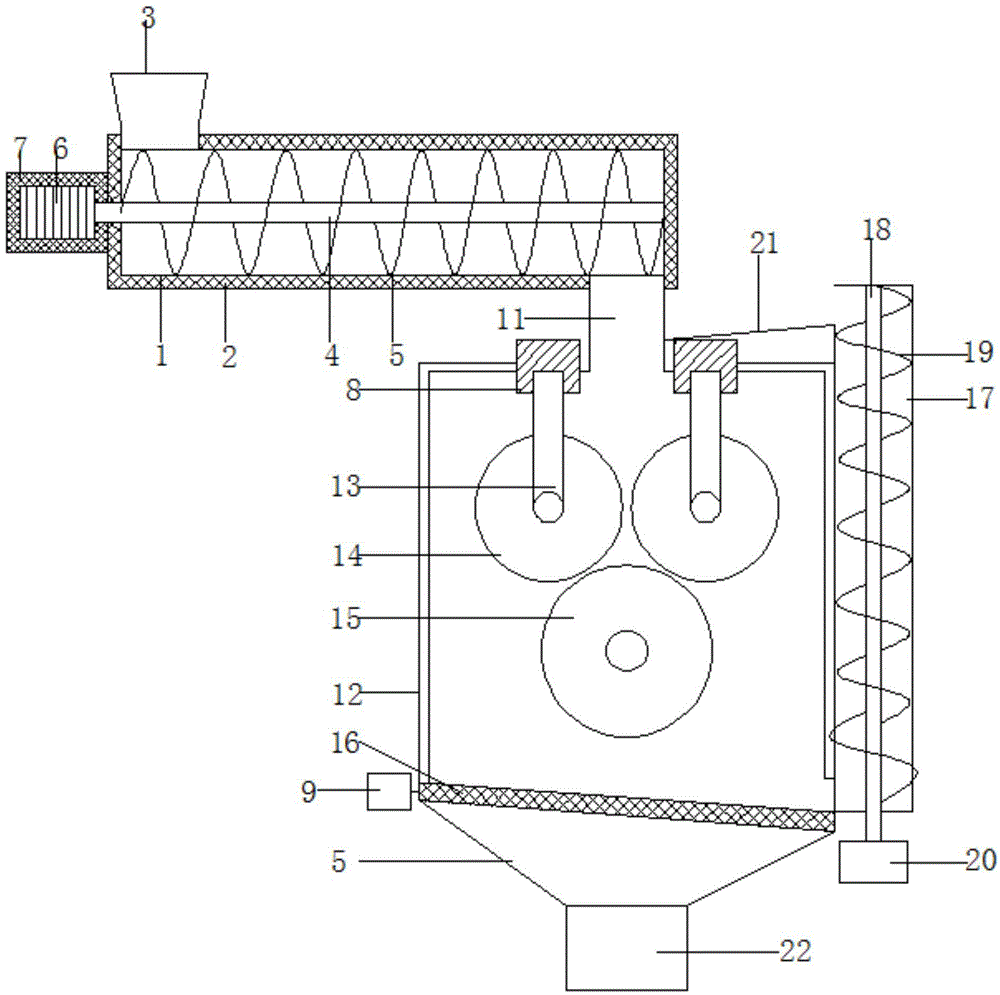

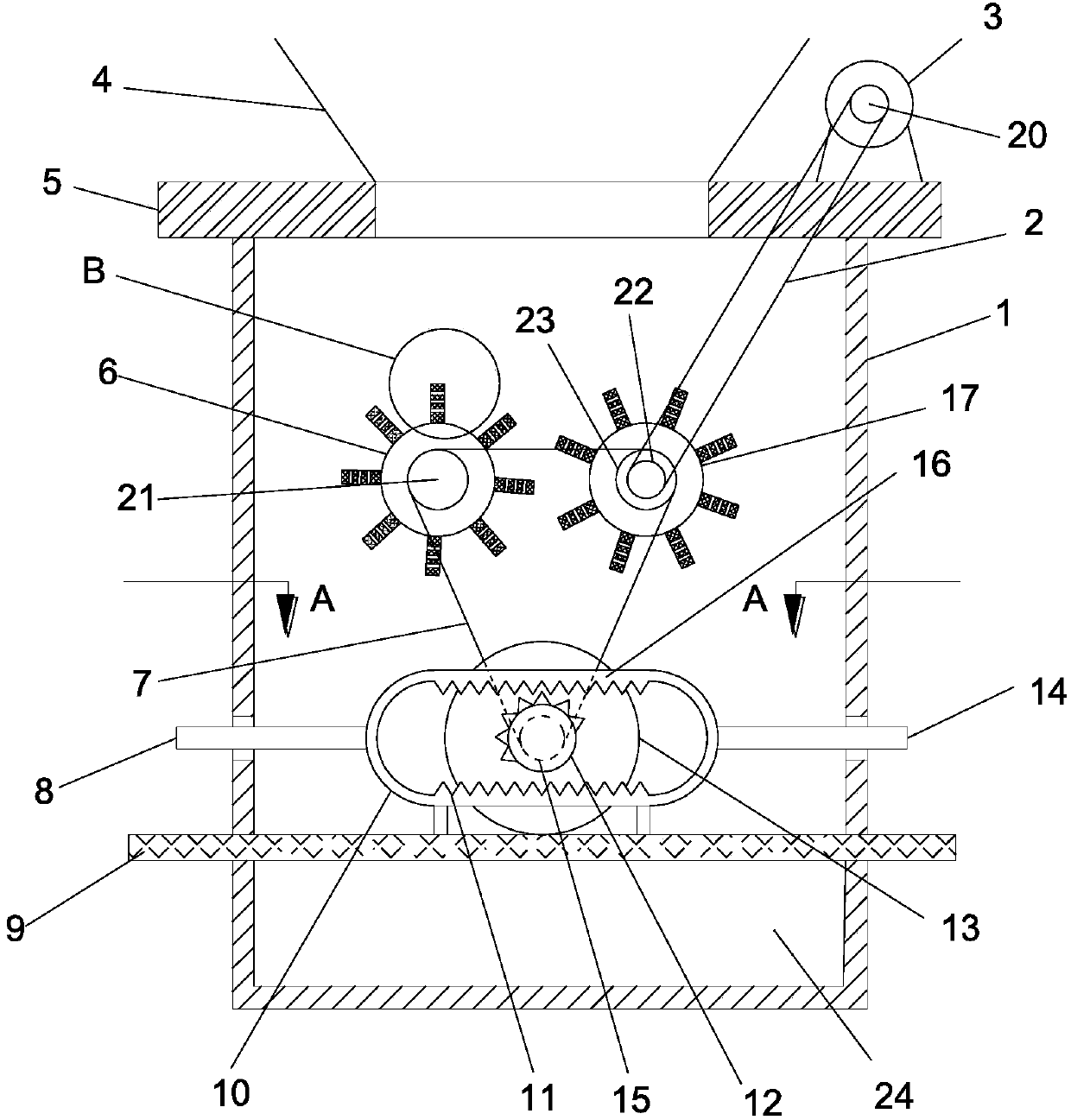

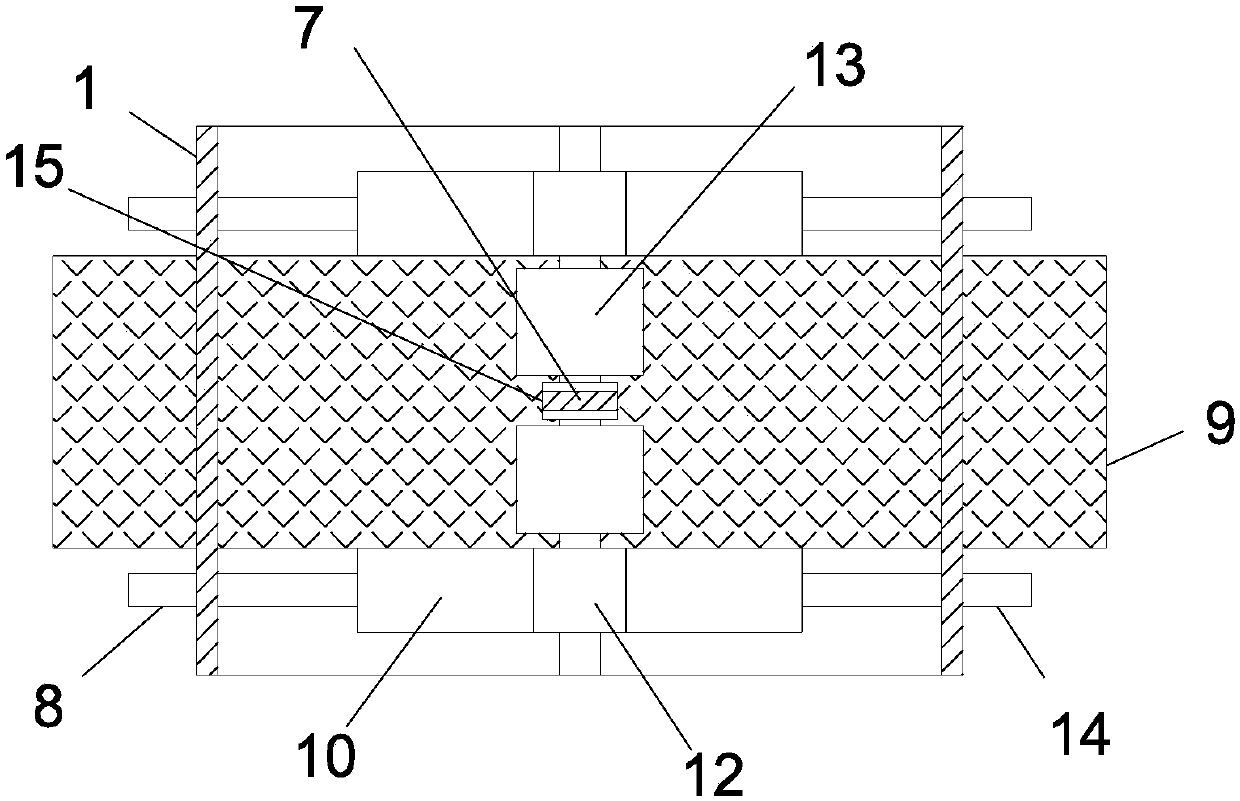

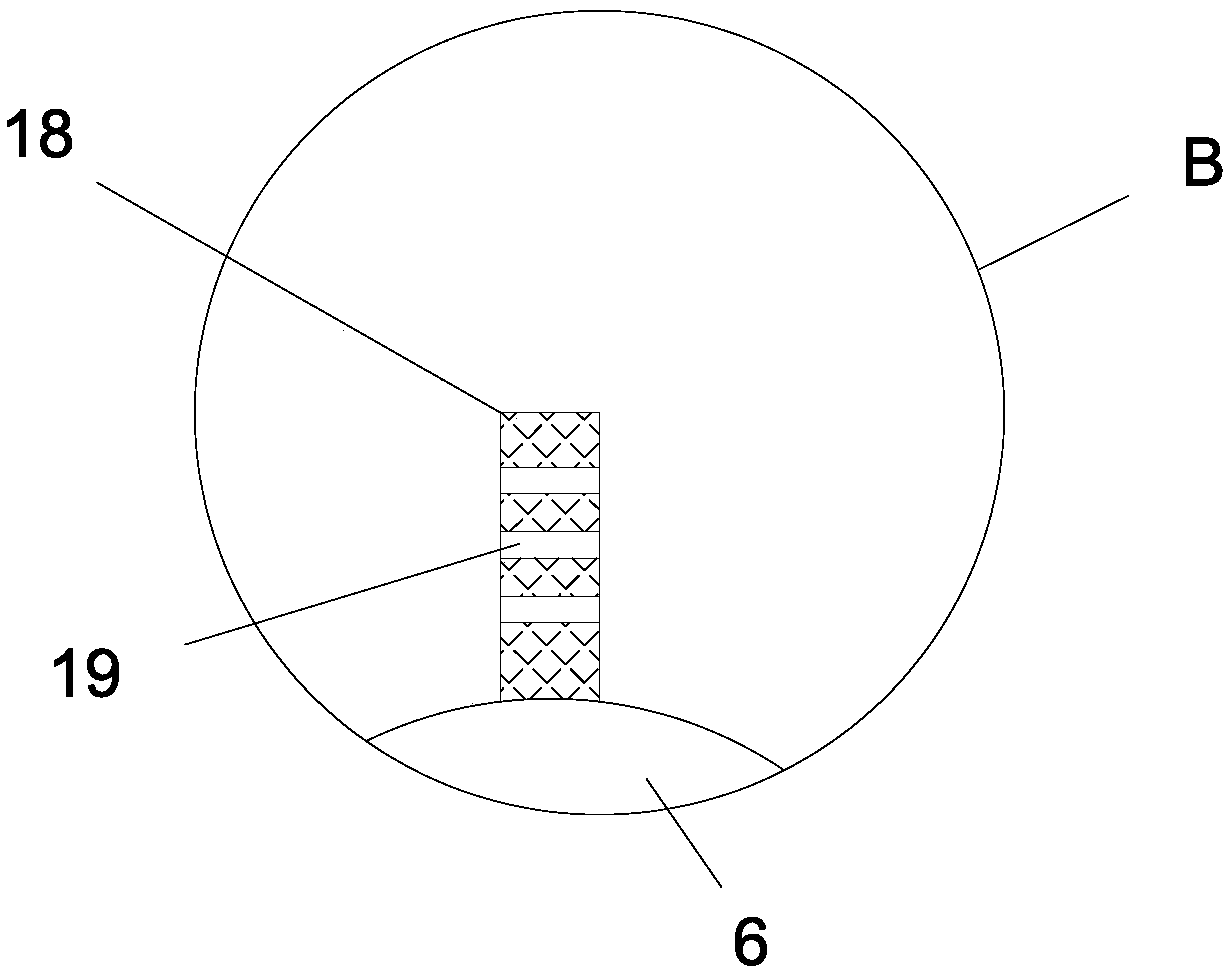

High-efficiency crusher for ceramic production

The invention discloses a high-efficiency crusher for ceramic production. The crusher comprises a conveying cylinder, a hydraulic cylinder and a vibrating motor, wherein the outer wall of the conveying cylinder is covered with an electric heating layer; a feed funnel is arranged at the upper side of the left end of the conveying cylinder; a first rotating shaft is horizontally arranged in the internal axes place of the conveying cylinder; and multiple spiral blades are uniformly arranged on the first rotating shaft from left to right. The high-efficiency crusher for ceramic production can crush and dry raw materials for ceramic production, adopts two crushing modes of the spiral blades and crushing rollers to greatly improve the crushing efficiency, can screen materials with unqualified particle size to convey into a crushing cavity for circularly crushing, adopts the vibrating motor to drive a screen to vibrate so as to improve the screening efficiency and effect, guarantees the crushing effect and the finished product quality, improves the adjustment of a gap between the upper and lower crushing rollers to realize the particle size adjustment of the crushed materials, and improves the practicability.

Owner:顾广才

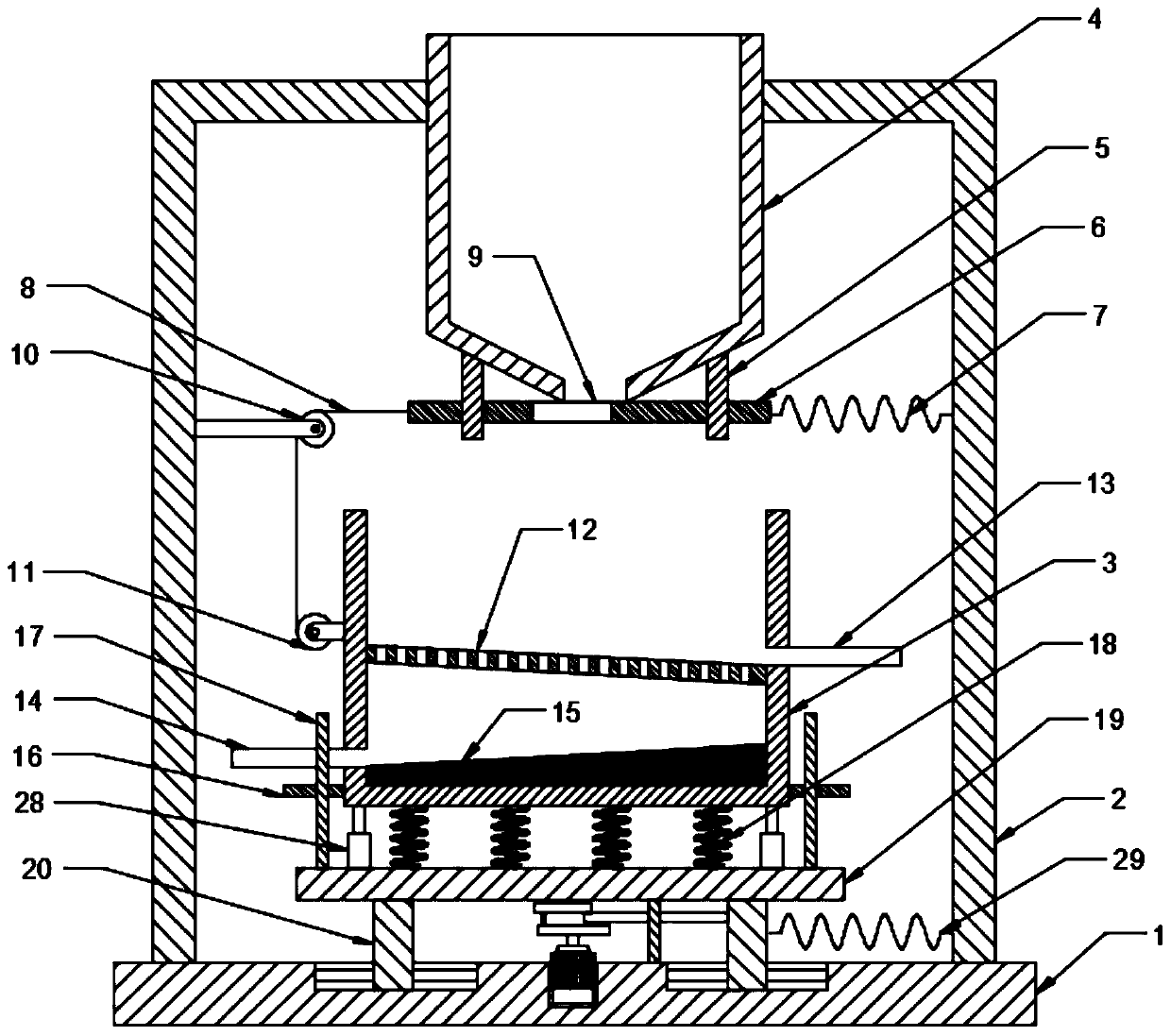

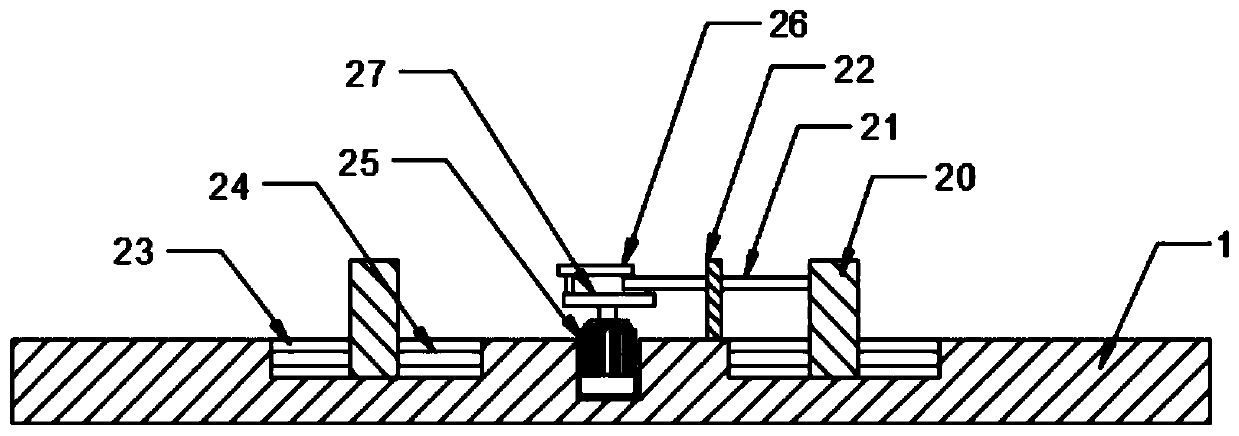

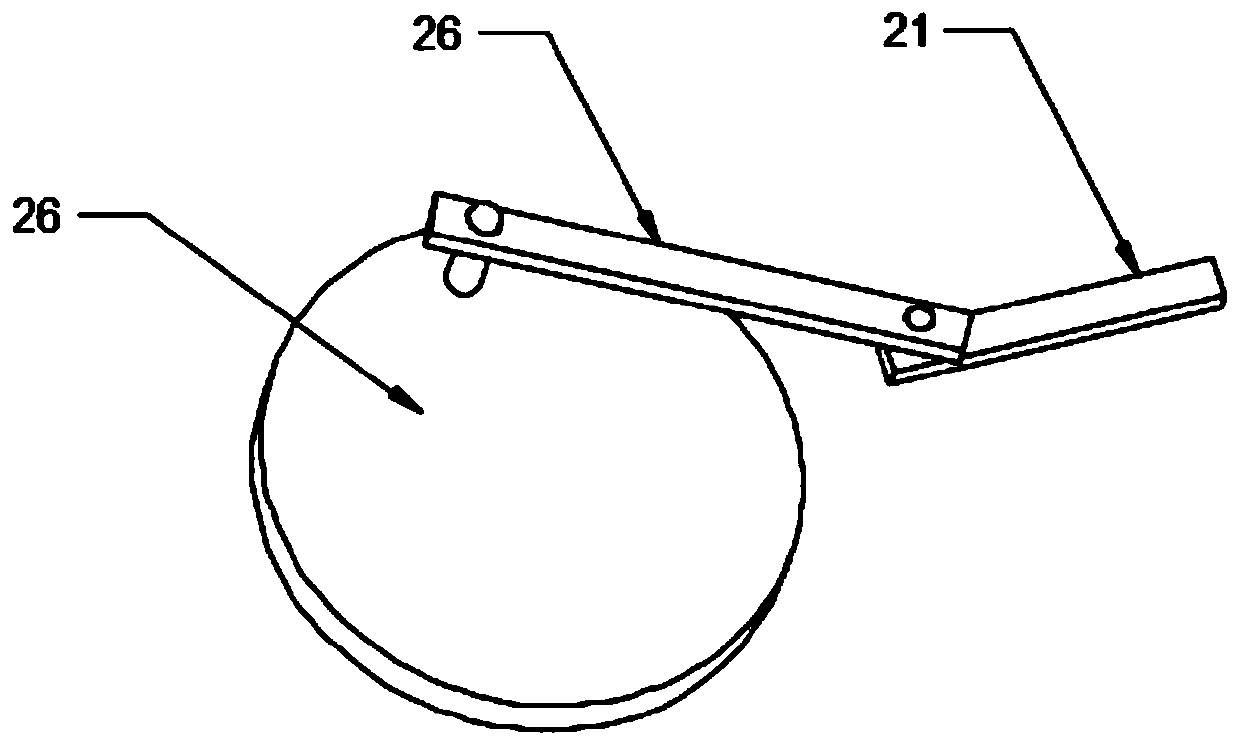

Construction solid waste multistage treatment device

The invention discloses a construction solid waste multistage treatment device. The construction solid waste multistage treatment device comprises a treatment box, wherein a servo motor is arranged onone side of the treatment box, an output shaft of the servo motor is fixedly provided with a first rotating shaft, the first rotating shaft is fixedly provided with a first belt wheel, the first beltwheel is in transmission connection with a second belt wheel, the second belt wheel is fixedly provided with a second rotating shaft, a smashing rod is fixed on the second rotating shaft, the smashing rod is located in the treatment box, a first gear is fixed to the first rotating shaft, the first gear is in transmission connection with a second gear, the second gear is fixed on a third rotatingshaft, a first grinding roller and a second grinding roller are fixed on the first rotating shaft and the third rotating shaft respectively, the first grinding roller and the second grinding roller are located in the treatment box, a screen is arranged below the smashing rod, and a vibrating mechanism is arranged on one side of the screen. According to the structure, waste crushing, screening andgrinding multistage treatment are realized, the working efficiency is high, and the treatment quality is good.

Owner:上海达人建设科技集团有限公司

Preparation method for Inconel718 alloy powder used for 3D printing technology

InactiveCN107716934AImprove liquidityHigh sphericitySievingAdditive manufacturing apparatusManufacturing technologyCoupling

The invention relates to a preparation method for Inconel718 alloy powder used for a 3D printing technology. The preparation method is characterized in that a vacuum induction melting technology and atight coupling gas atomization technology are adopted, an ultrasonic vibrating method and an airflow classifying method are applied to perform particle size distribution on powder, and a vacuum degassing technology is adopted to prepare Inconel718 alloy powder used for a laser selective melting technology. Compared with the prior art, the prepared Inconel718 alloy powder has performance featuressuch as high degree of sphericity, uniform particle size distribution, low oxygen content and low impurity content, meets performance requirements, on a powdered material, of the laser selective melting technology, and promotes development of the metal additive manufacturing technology.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Coal mine pulverizing and screening device

InactiveCN106964471AQuality assurancePrevent escapeSievingScreeningWorking environmentArchitectural engineering

The invention discloses a coal mine crushing and screening device, which comprises a tank body, and a feeding hopper is arranged on the left side of the tank body; The upper crushing disc is connected, the outer periphery of the crushing disc is provided with rotating teeth, and the inner wall of the tank is provided with fixed teeth adapted to the rotating teeth; the lower end of the crushing disc is provided with a coarse filter, and the coarse filter is below A guide hopper is provided, and the guide hopper is funnel-shaped and its lower end is provided with a material guide port; two adapted crushing rollers are arranged below the guide hopper, and the material guide port is facing the contact of the two crushing rollers ; A fine filter screen is arranged below the pulverizing roller. The new structure is reasonable in design and easy to use. It is screened twice by the pulverizer twice, which greatly improves the crushing quality, ensures the quality of coal mines discharged from the discharge port, and improves work efficiency; avoids dust from escaping from the feeding hopper, Ensure the surrounding working environment.

Owner:陈鹏

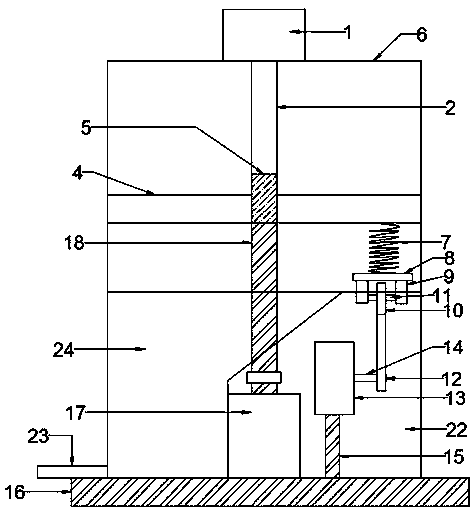

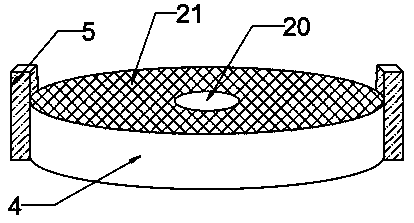

Seed screening and drying device for forestry planting

InactiveCN108816726AGood dispersionImprove screening effectSievingSeed and root treatmentAgricultural engineeringDrive motor

The invention discloses a seed screening and drying device for forestry planting. The seed screening and drying device comprises a bearing bottom plate. A left vertical plate and a right vertical plate are fixedly installed on the bearing bottom plate vertically. A top plate is fixedly installed at the upper end of the left vertical plate and the upper end of the right vertical plate horizontally.A drive motor is fixedly installed on the left side of the left vertical plate. A cylinder spur gear is fixedly installed on the surface of a rotating shaft in a sleeving manner and connected with asecond rack in an engaged manner. A screening net basket located in a collecting tank is fixedly installed at the upper end of the rotating shaft. According to the seed screening and drying device, arotating pipe drives stirring blades to rotate to screen forestry seeds in the screening net basket, the screening net basket rotates clockwise and anticlockwise in an alternating manner under drivingof the rotating shaft, dispersing of seeds is promoted, and the seed screening function of the screening net basket is accelerated; and in the screening process, hot air sprayed out by air outlets inthe rotating pipe and the dispersed seeds can be mixed fully, the seeds can be dried fully and fast, screening and drying of the seeds are carried out synchronously, and the working efficiency is improved greatly.

Owner:王丽萍 +4

Heavy metal contaminated soil remediation device

ActiveCN110153164AAvoid repairsPromote repairSoil lifting machinesContaminated soil reclamationSoil remediationEngineering

The invention discloses a heavy metal contaminated soil remediation device which comprises a storage barrel, a conveyor belt, a treatment seat, a connecting plate and a bucket, wherein two pairs of first traveling wheels are symmetrically arranged on two sides of the bottom end of an outer side wall of the treatment seat; and the connecting plate is welded on one side of the bottom end of the outer side wall of the treatment seat. A pulley matched with a guide seat is arranged on a connecting rod at one end of the screening bucket, and a movable sleeve is arranged on the outer side of a guiderod in a sleeving manner on the outer side wall of the screening bucket. On one hand, by utilizing guide of a bevel end of the guide seat, the screening bucket is matched with a reset spring at the other end of the screening bucket in a process of driving the screening bucket to rotate by a motor, so that the screening bucket can sway from side to side in the rotating and screening process, and the screening efficiency and the screening effect are improved; on the other hand, a second magnetic block having the same magnetism as a first magnetic block is arranged on the top of the movable sleeve, so that the movable sleeve enabling the screening bucket to rotate to a position just under the first magnetic block has a vibratory cleaning effect on the screening bucket, and blockage of sieve pores is avoided.

Owner:ANHUI LANDING ENVIRONMENTAL PROTECTION ENERGY TECH

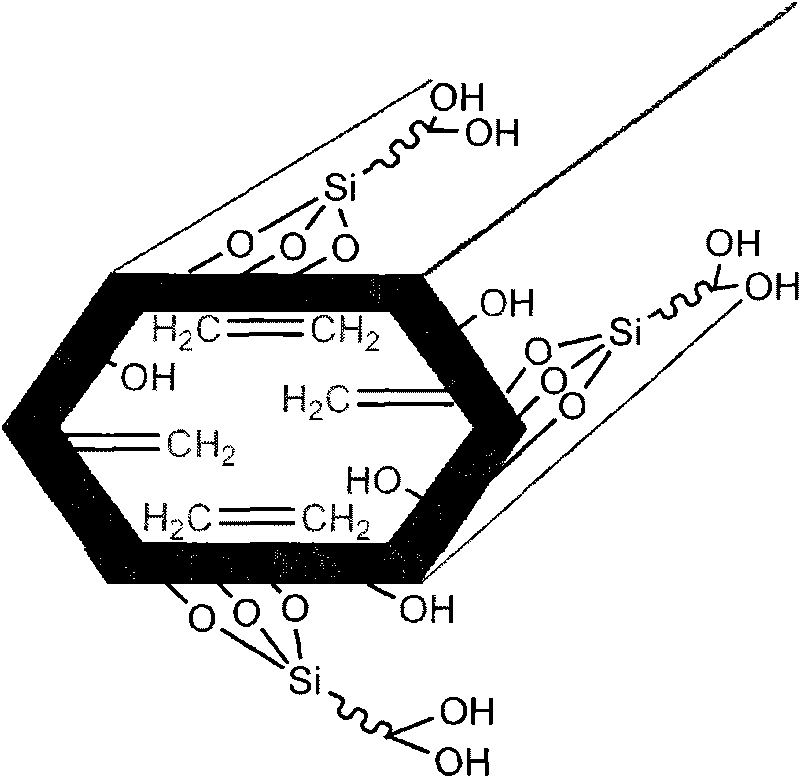

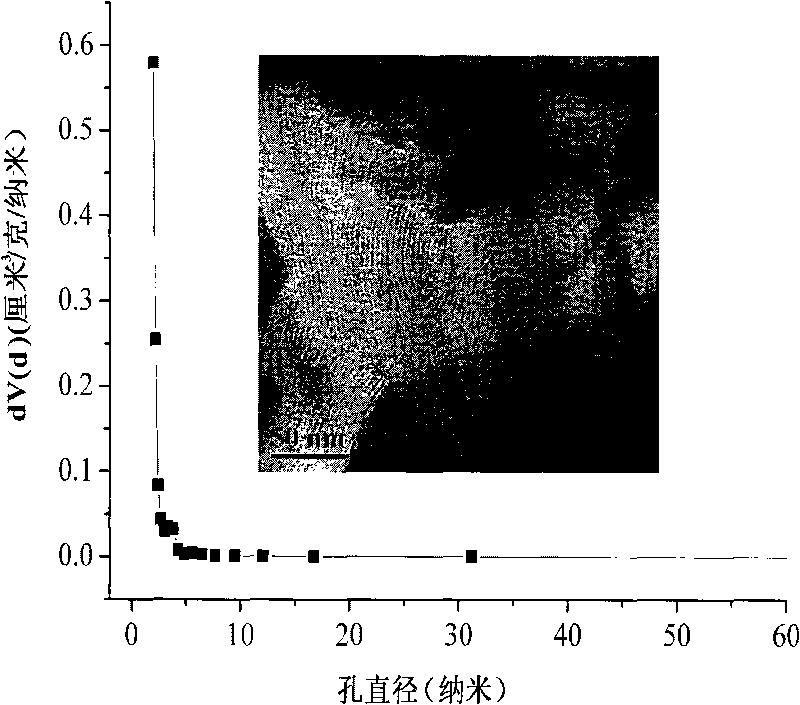

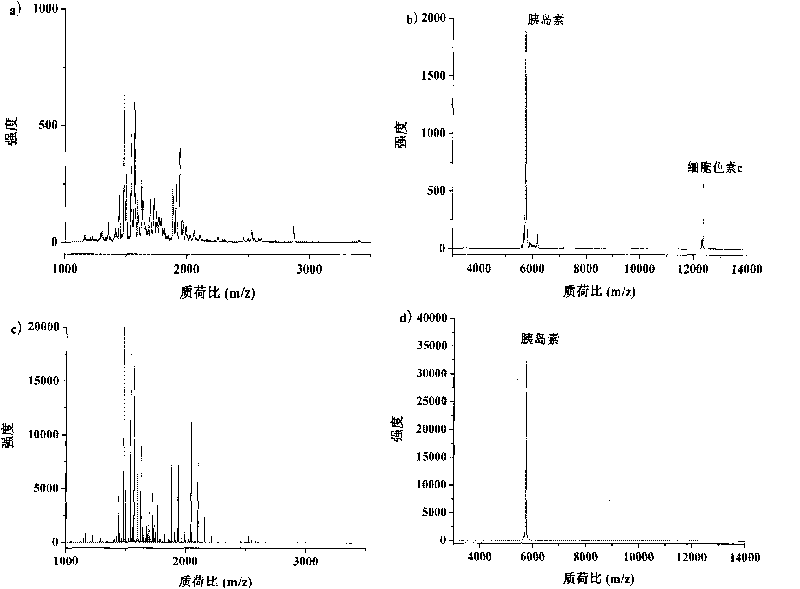

Method for preparing mesoporous material with hydrophobic inner surface and hydrophilic outer surface

InactiveCN101733066AImprove sieving capacity and extraction efficiencyReduce cloggingOther chemical processesSilicon compoundsPeptideSurface modification

The invention relates to a method for preparing mesoporous material with the hydrophobic inner surface and the hydrophilic outer surface, comprising the steps of coprecipitating and synthesizing the mesoporous material, modifying the outer surface of the mesoporous material and removing the pore-forming agent. Tetra-alkoxy silicane and siloxane containing hydrophobic functional groups are used as mixed silicon source, the mixed silicon source is hydrolyzed and synthesized into hydrophobic mesoporous material which contains pore forming agent under the alkaline condition, the hydrophobic mesoporous material reacts with the siloxane which contains or can generate the hydrophilic functional groups in methylbenzene under the protection of nitrogen, the products of reaction are extracted by acidified alcohol, and the pore-forming agent is removed. The mesoporous material with the hydrophobic inner surface and the hydrophilic outer surface can greatly reduce the interference of high molecular weight biological matrix in the process of pretreating the sample, improve the protein or peptide screening ability and highly elute and recover the small molecule protein or the small molecule peptide and is suitable for selectively extracting the medicament and the low molecular weight protein in the complex biological matrix.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

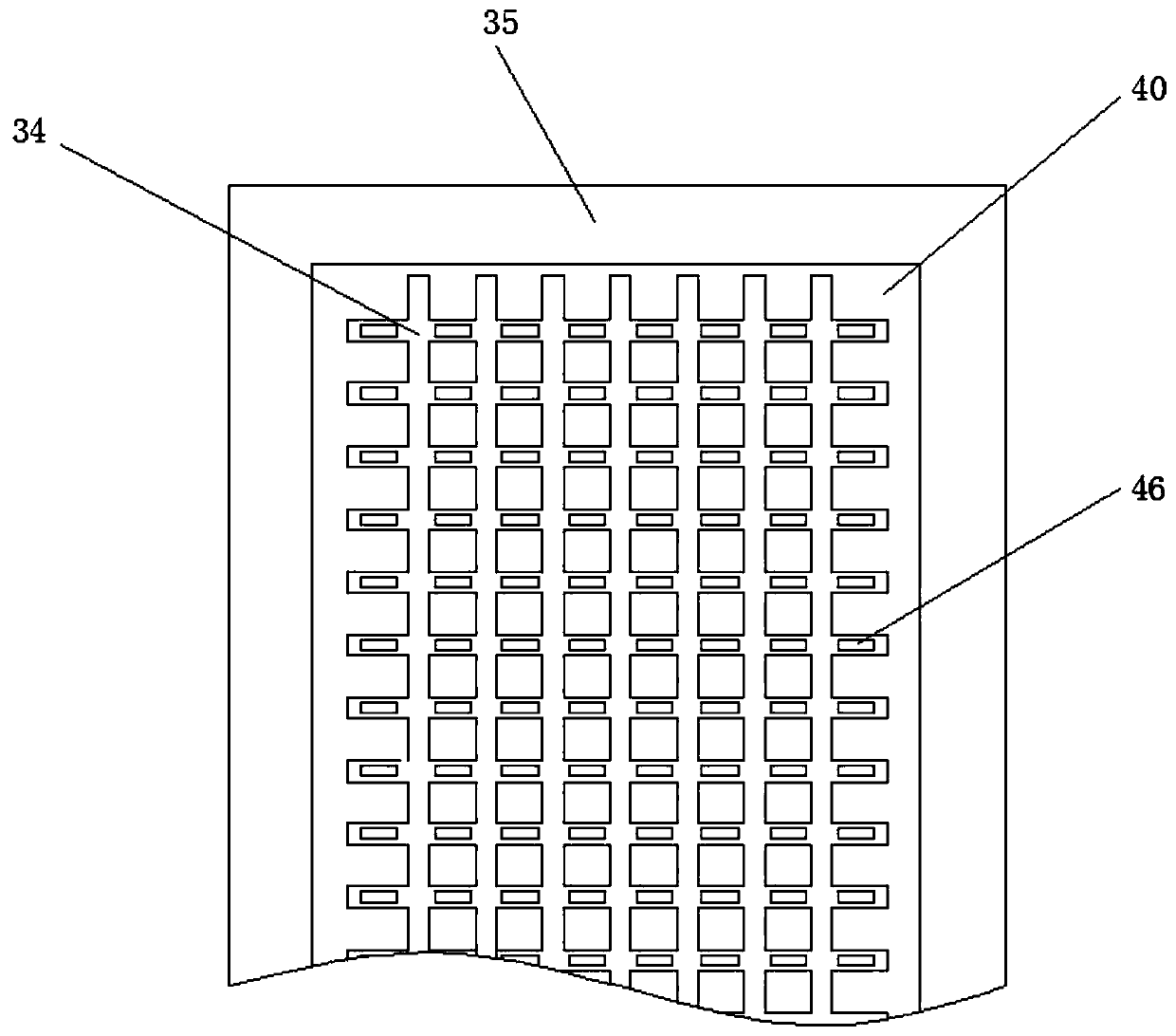

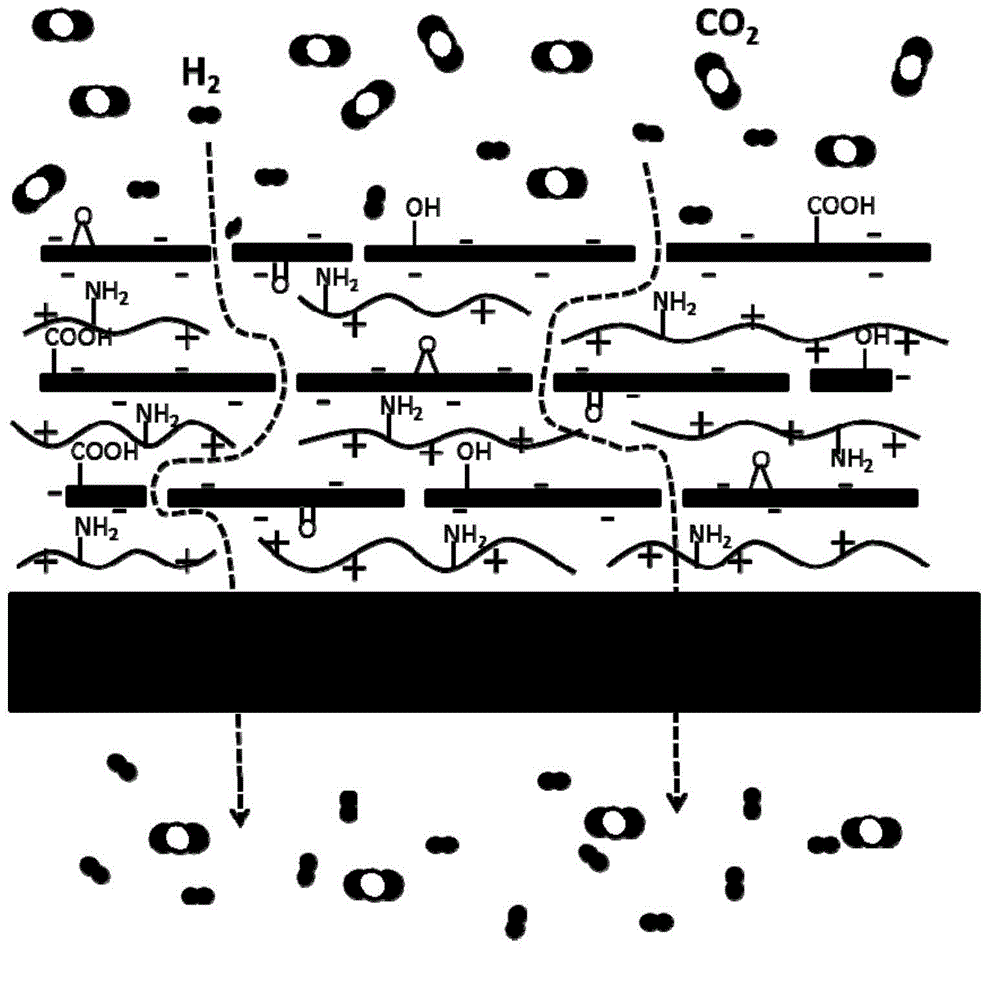

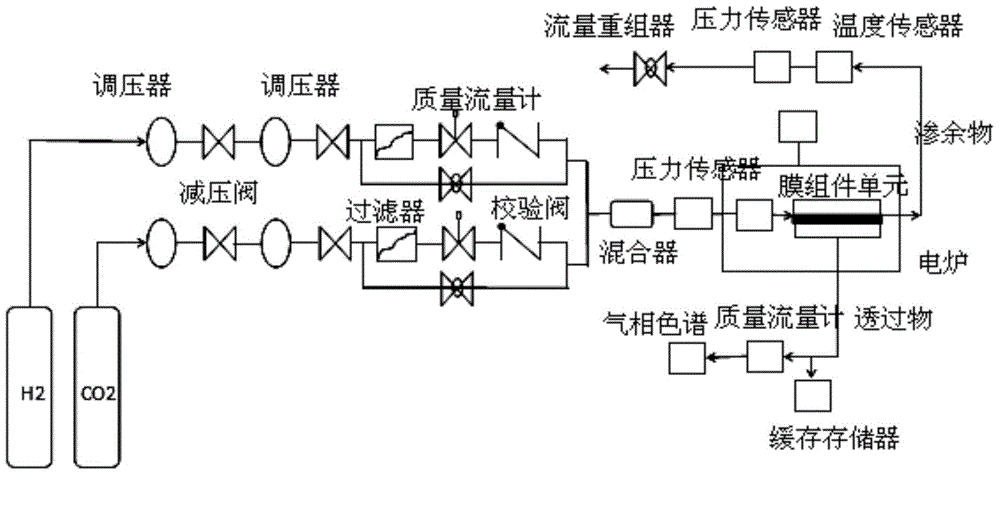

Gas separation membrane, preparation method thereof, and membrane type gas separation device

InactiveCN104524990AQuality improvementIncrease the areaSemi-permeable membranesDispersed particle separationPorous substrateChemical physics

The invention discloses a gas separation membrane and a preparation method thereof and belongs to the technical field of membrane separation. The gas separation membrane comprises a porous substrate, wherein a composite membrane which is prepared by mixing oxidized graphene and polymeric branched polyethyleneimine is attached to at least one surface of the porous substrate. The preparation method of the gas separation membrane disclosed by the invention comprises the following steps: dispersing a flaky oxidized graphene material in an aqueous solution; and then preparing a single-layered or a multi-layered composite membrane on the porous substrate with a polymeric branched polyethyleneimine solution by a coating method of overlaying layer by layer. The invention further discloses a membrane assembly unit, namely a membrane type gas separation device which uses the gas separation membrane. By means of a special molecular transmission characteristic of a layered graphene material, a limiting relationship between the permeability and selectivity in the gas separation membrane is broken and an excellent gas separating performance is exhibited. The method disclosed by the invention is simple and economic in process, wide in application range and suitable for scaled preparation.

Owner:NANJING UNIV OF TECH +1

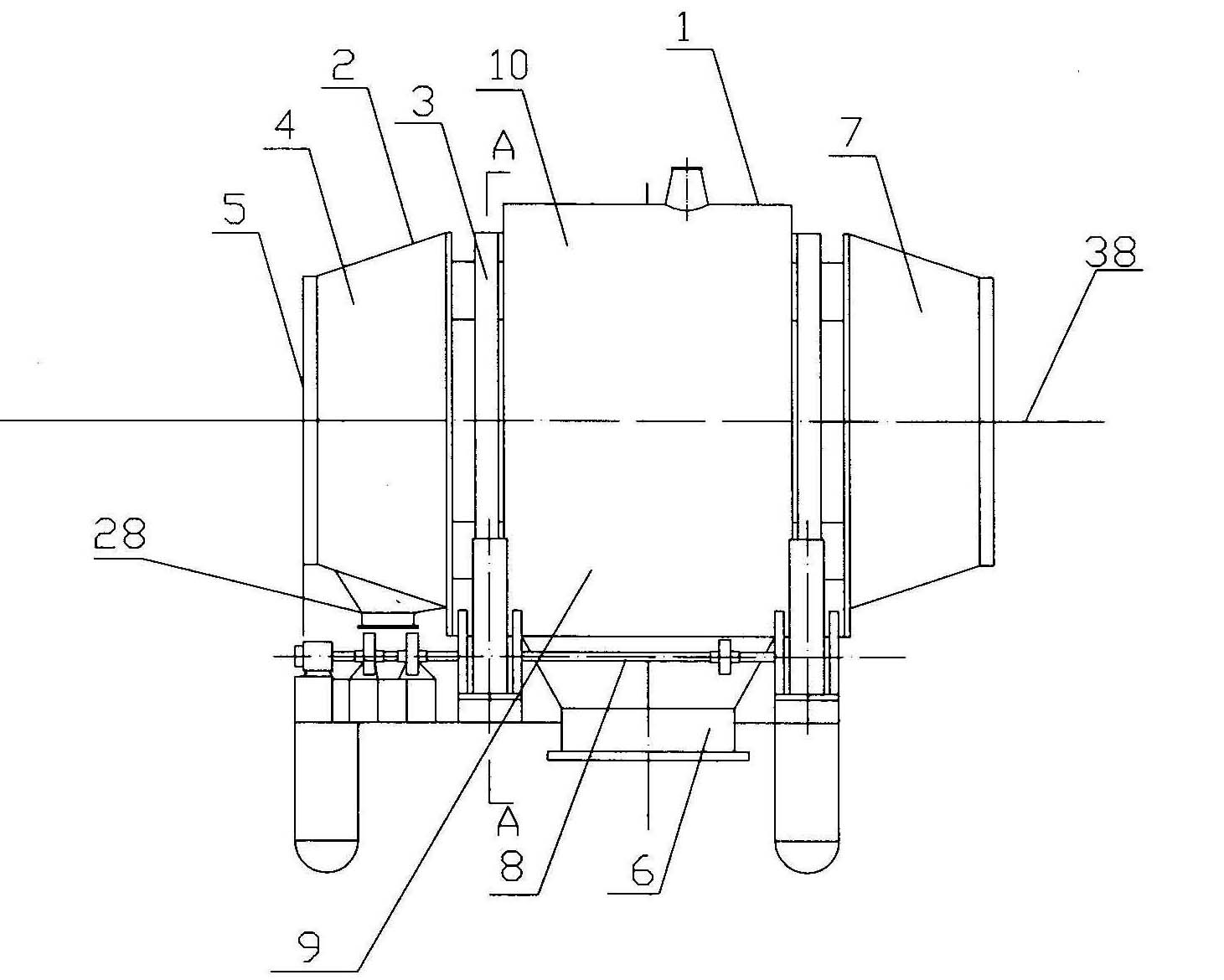

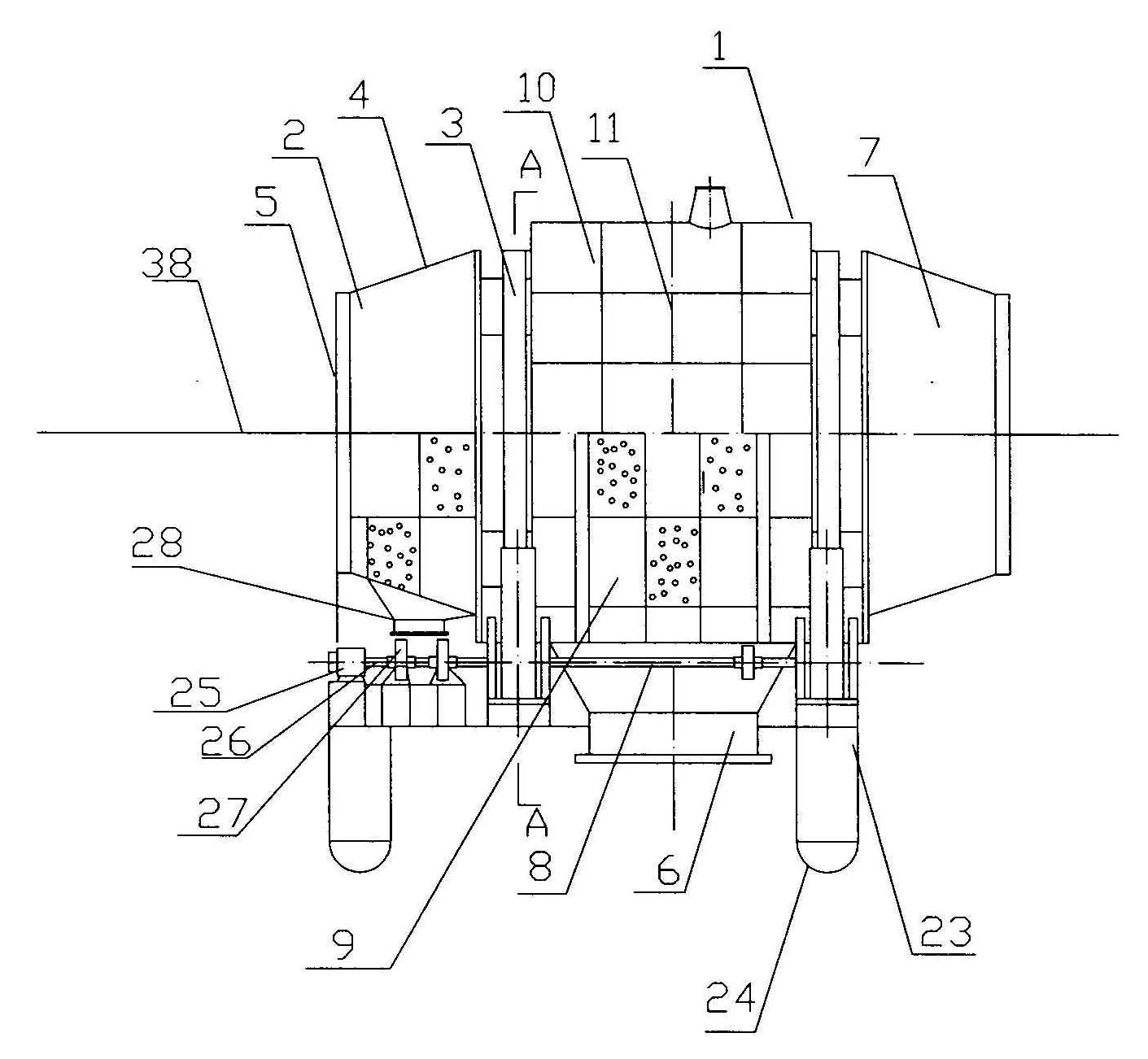

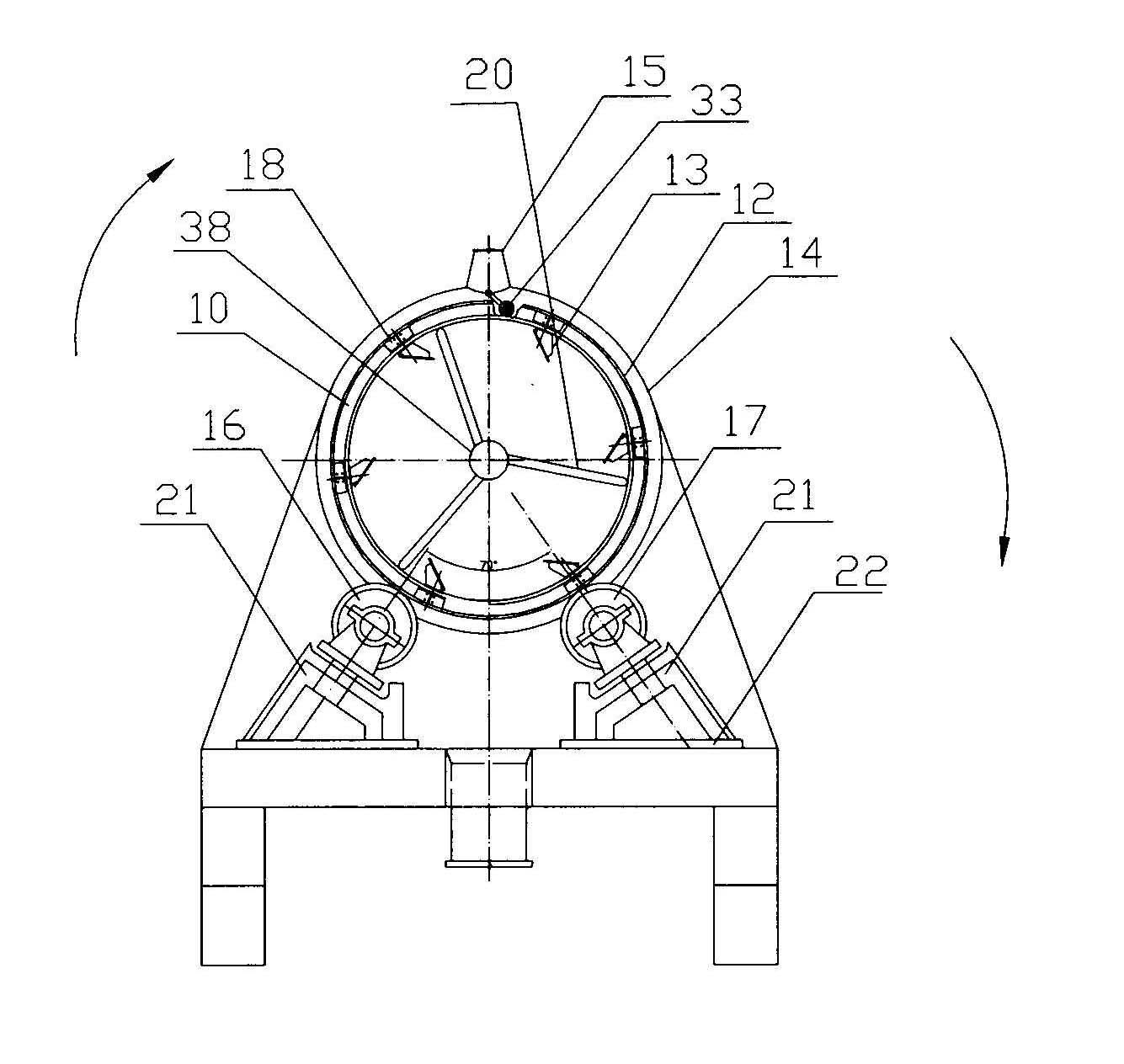

Selective crusher for underground use

The invention relates to a selective crusher for underground use, which comprises a supporting stand, a supporting roller mechanism and a revolving drum body, wherein the supporting roller mechanism is arranged on the supporting stand, and the revolving drum body is horizontally installed on the supporting roller mechanism through a rolling ring which is arranged around the drum body and is matched with a supporting roller in the supporting roller mechanism; the inner cavity of the roller is provided with a pre-screening section, a pushing and screening section, a crushing and screening section and a discharge section sequentially backwards from the feed end, wherein a pre-screening section discharge opening is arranged below the pre-screening section, and a discharge chute is arranged below the crushing and screening section; a center shaft which is coaxial with the roller and is driven by a power source to rotate is installed in the roller, a beater plate is arranged on the shaft body of the center shaft at the section matched with the pre-screening section, a rotor in the shape of an oblique tooth is arranged on the shaft body of the center shaft at the section matched with the crushing and screening section, and a spiral discharge auger is arranged on the shaft body of the center shaft at the section matched with the discharge section; and a plurality of axially arranged lifting plates and nail plates are installed on the inner wall of the screening drum of the crushing and screening section at intervals.

Owner:HENAN POLYTECHNIC UNIV

Process for screening and refining wheat starch

The invention discloses a process for screening and refining wheat starch. The process comprises the following steps: screening starch slurry material by a 250-mesh primary centrifugal screen at the rotation speed of 900r / min, screening oversize materials by a 200-mesh secondary centrifugal screen at a rotation speed of 900r / min, collecting the undersized materials screened out by the primary and the secondary centrifugal screen and feeding into a primary horizontal-spiral decanter centrifuge for separation treatment, wherein obtained light-phase substances such as soluble proteins and sugar can be treated in other ways, the obtained starch phase is concentrated by a secondary horizontal-spiral decanter centrifuge to obtain the finished starch slurry; and drying the finished starch slurry to obtain the standard finished starch product. Compared with the prior art, the process has the advantages of simple technology and reduction of energy consumption due to the use of the horizontal-spiral decanter centrifuge instead of the cyclone separator unit used in the conventional processes.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

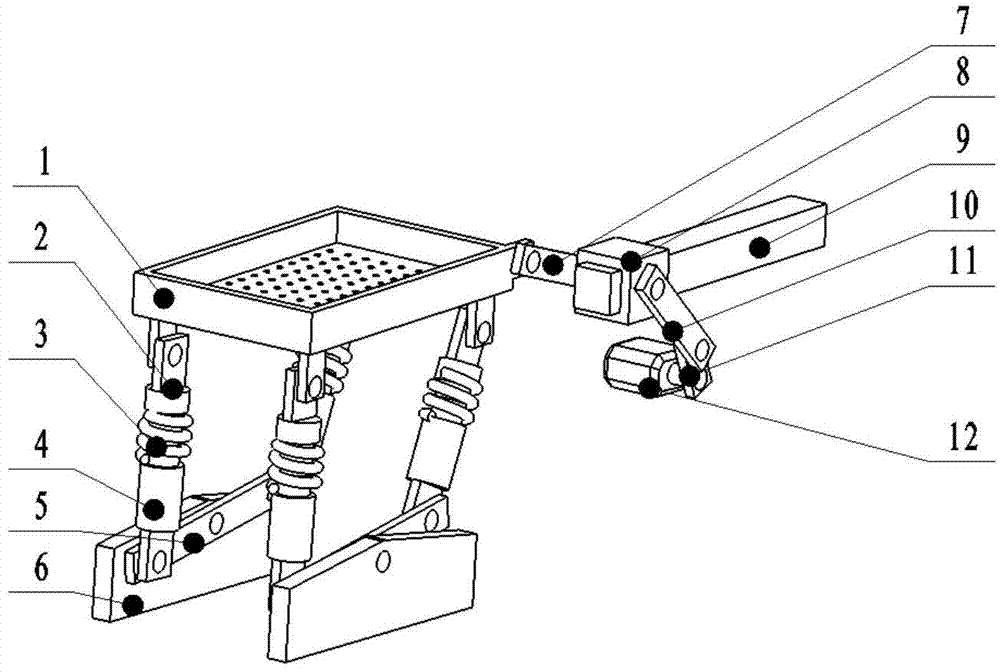

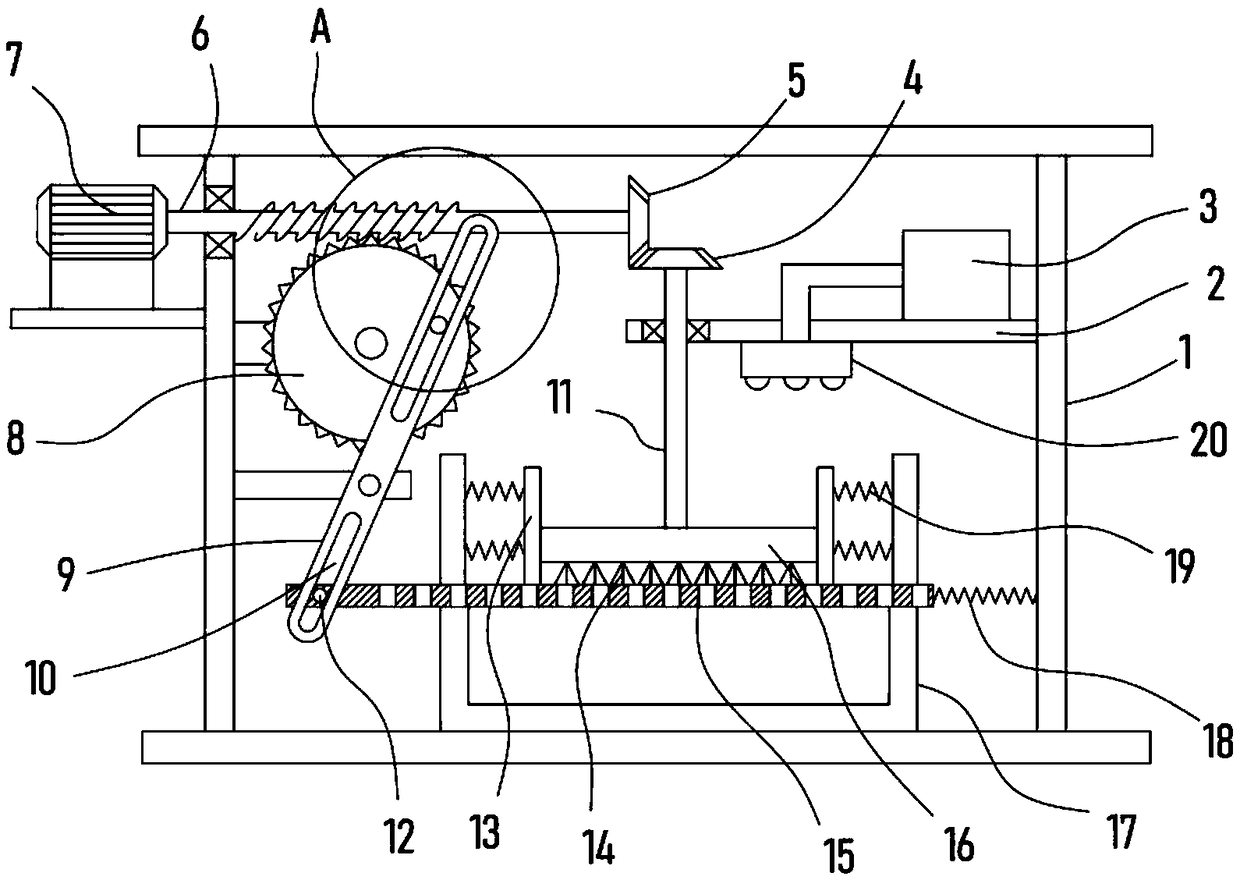

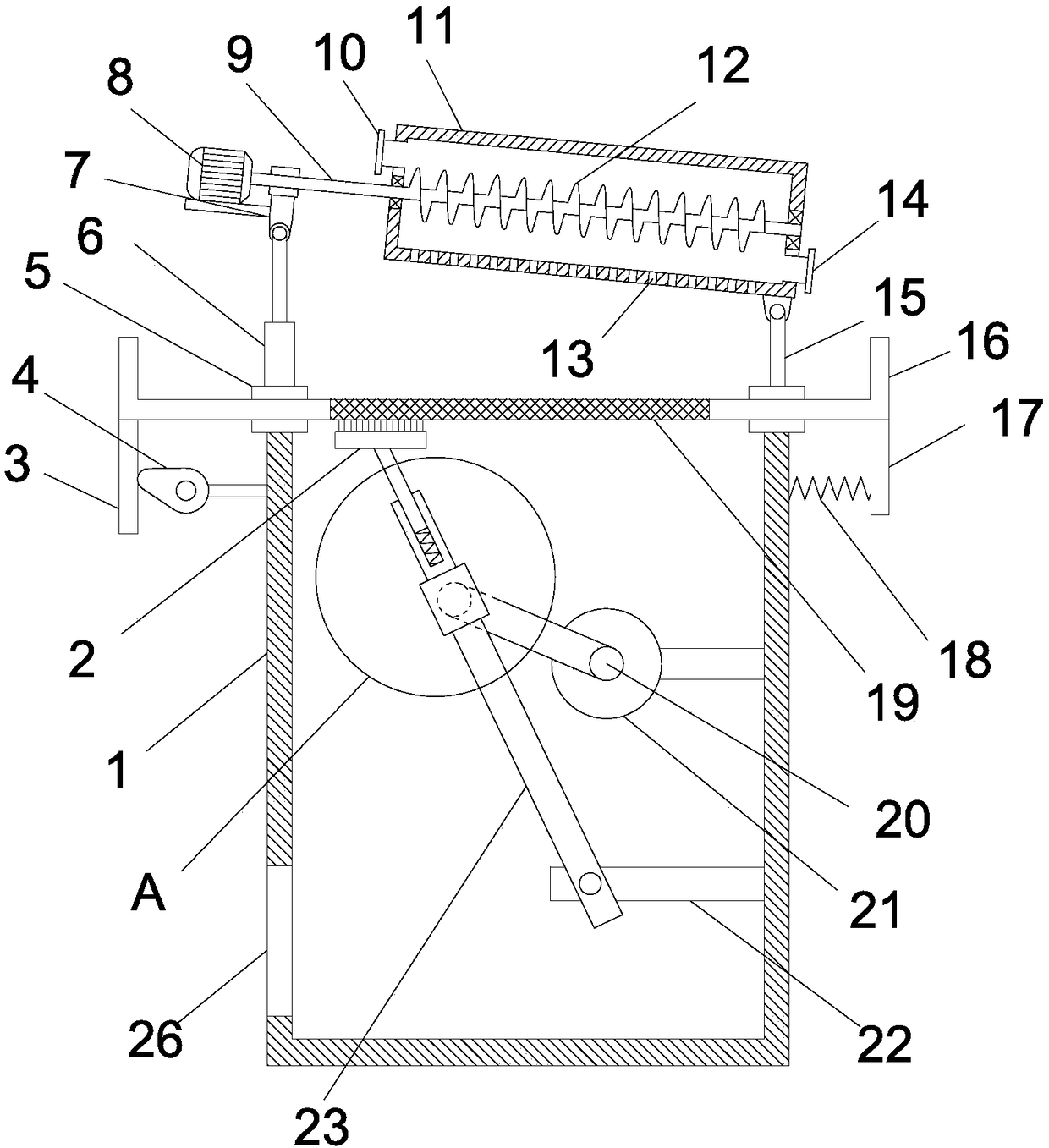

Elastic vibration sieving device

The invention discloses an elastic vibration sieving device, and belongs to the field of production equipment. The elastic vibration sieving device is composed of an alternating-current motor, crank rockers, a sliding block, a fixed guide rail, a carrying sieving platform, a swing rod, a fixing support, upper supporting frames, lower supporting frames and springs. The alternating-current motor is fixed onto the ground and is connected together with the corresponding crank rocker, the crank rocker is connected together with the sliding block through another crank rocker, the sliding block is installed on the fixed guide rail, the carrying sieving platform is connected with the sliding block through the corresponding crank rocker, the four upper supporting frames and the carrying sieving platform are hinged under the carrying sieving platform, the four lower supporting frames and the swing rod are hinged respectively above the fixing support, the swing rod is hinged to the fixing support, the four springs are connected between the four lower supporting frames and the four upper supporting frames, and the upper supporting frames, the lower supporting frames and the springs form a whole. The elastic vibration sieving device has the advantage that swing of the swing rod and vibration of the springs can be used for conducting complex movement to realize evener sieving.

Owner:XUZHOU LIFANG MECHANICAL & ELECTRICAL EQUIP MFG CO LTD

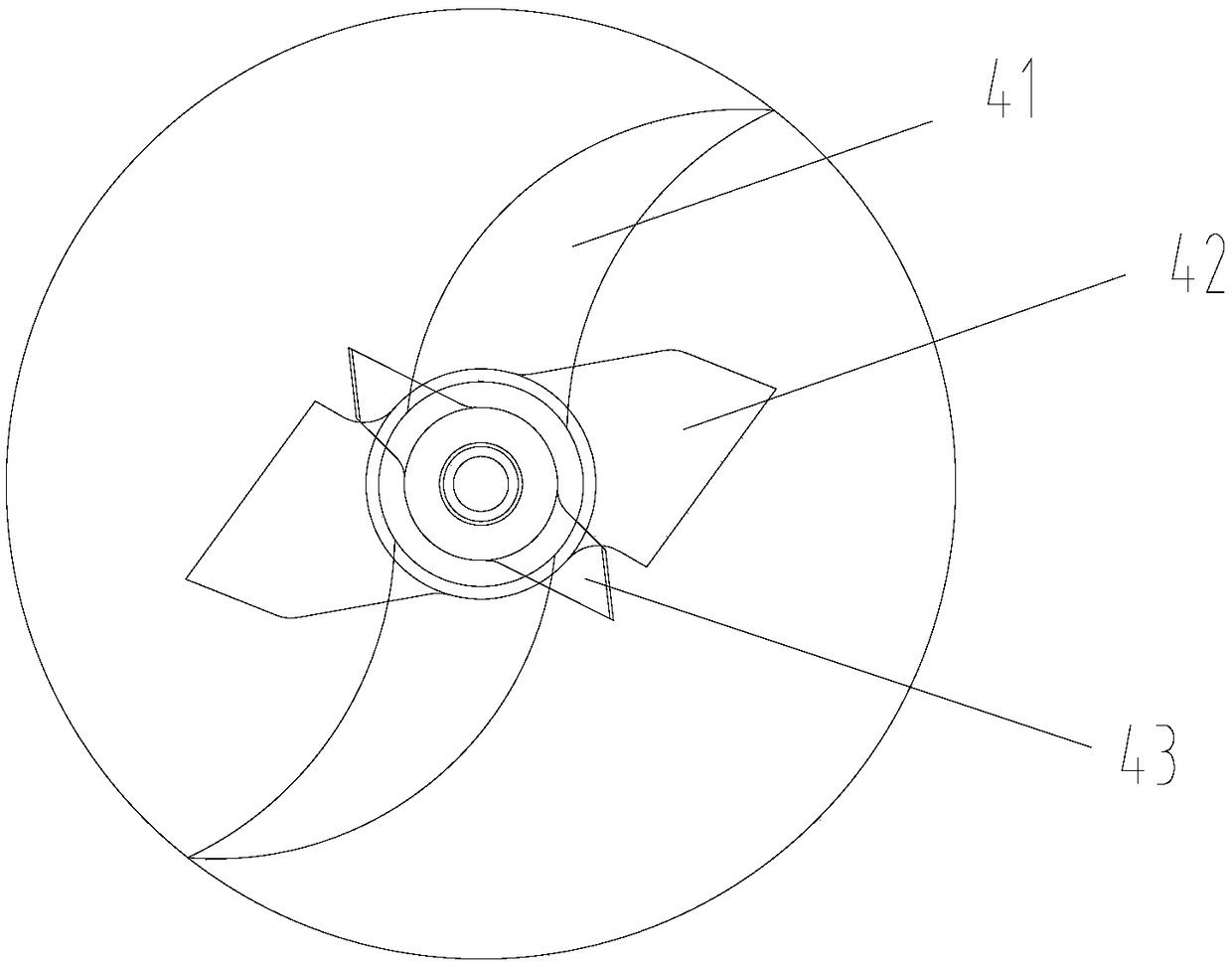

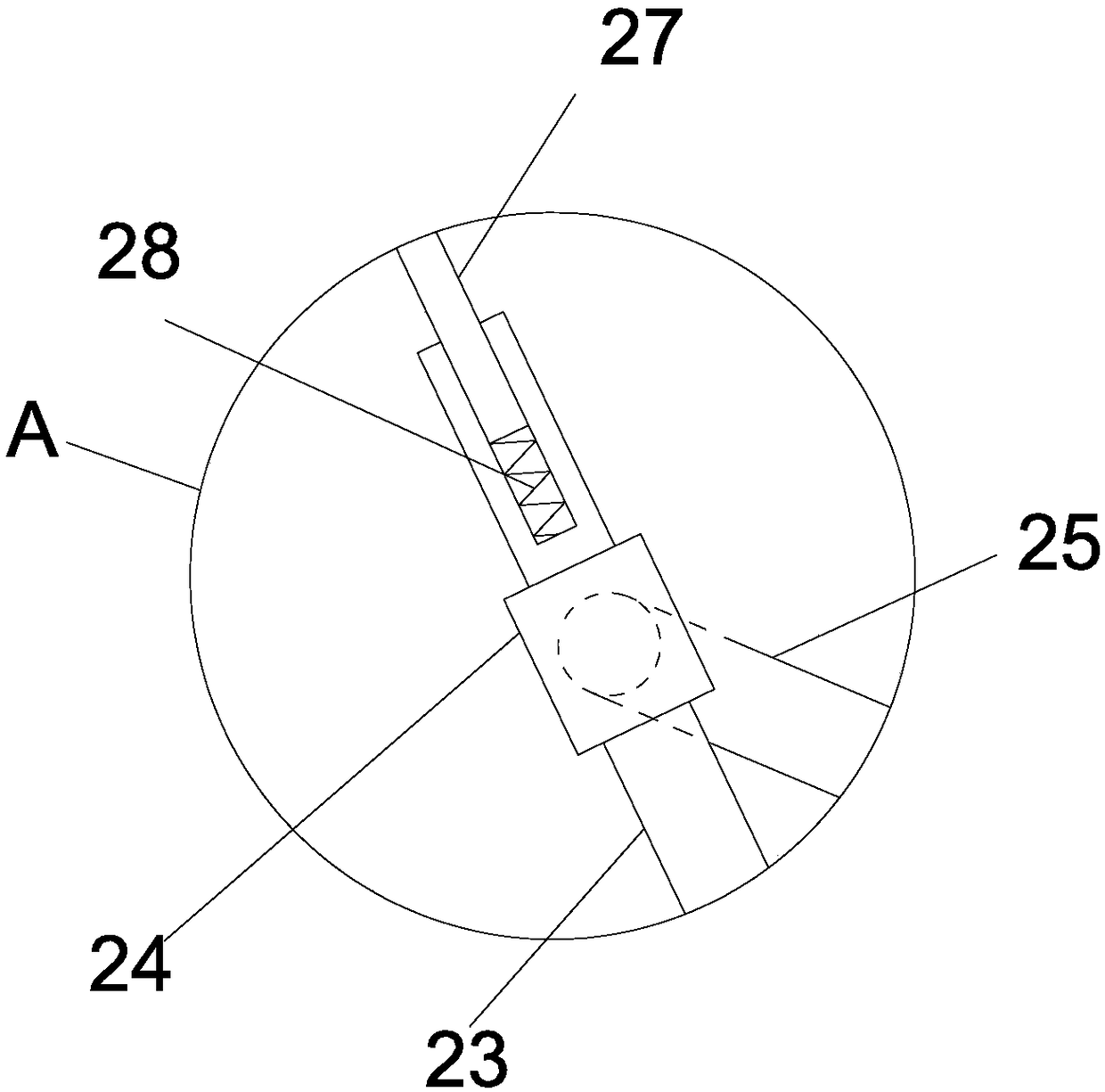

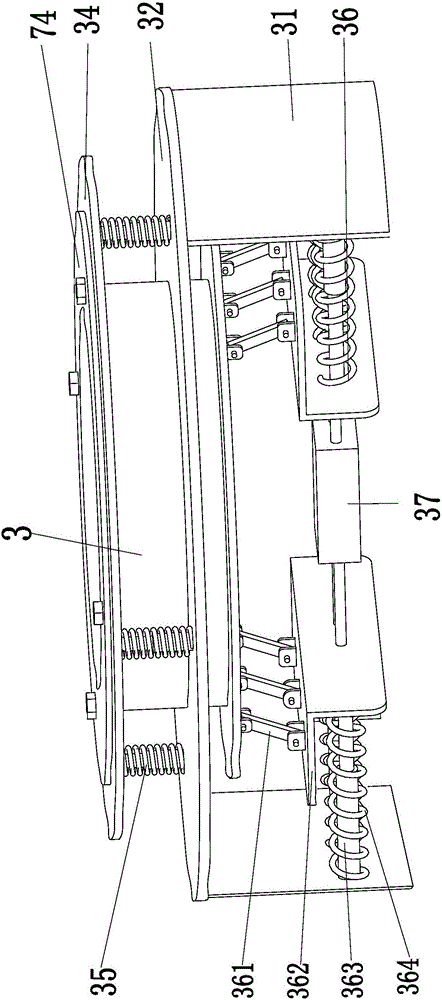

Vibratory screening mechanism for vertical sand making machine

The invention discloses a vibratory screening mechanism for a vertical sand making machine. The vibratory screening mechanism comprises a vibratory screening box, two vibration mechanisms, a rotatingmechanism and a base, wherein a screening plate and a first spring are arranged in the vibratory screening box, the vibration mechanism comprises a first motor, a cam, a driven wheel and a second spring, the rotating mechanism comprises a second motor, a rotating shaft and an impeller, the vibration mechanisms and the rotating mechanism are arranged below the vibratory screening box, the rotatingmechanism is arranged between the two vibration mechanisms, and the base is arranged below the vibration mechanisms and the rotating mechanism. The vibratory screening mechanism has the advantages ofbeing simple in structure and better in vibratory screening effect, and the vertical sand making machine using the vibratory screening mechanism is high in crushing efficiency and good in crushing quality.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

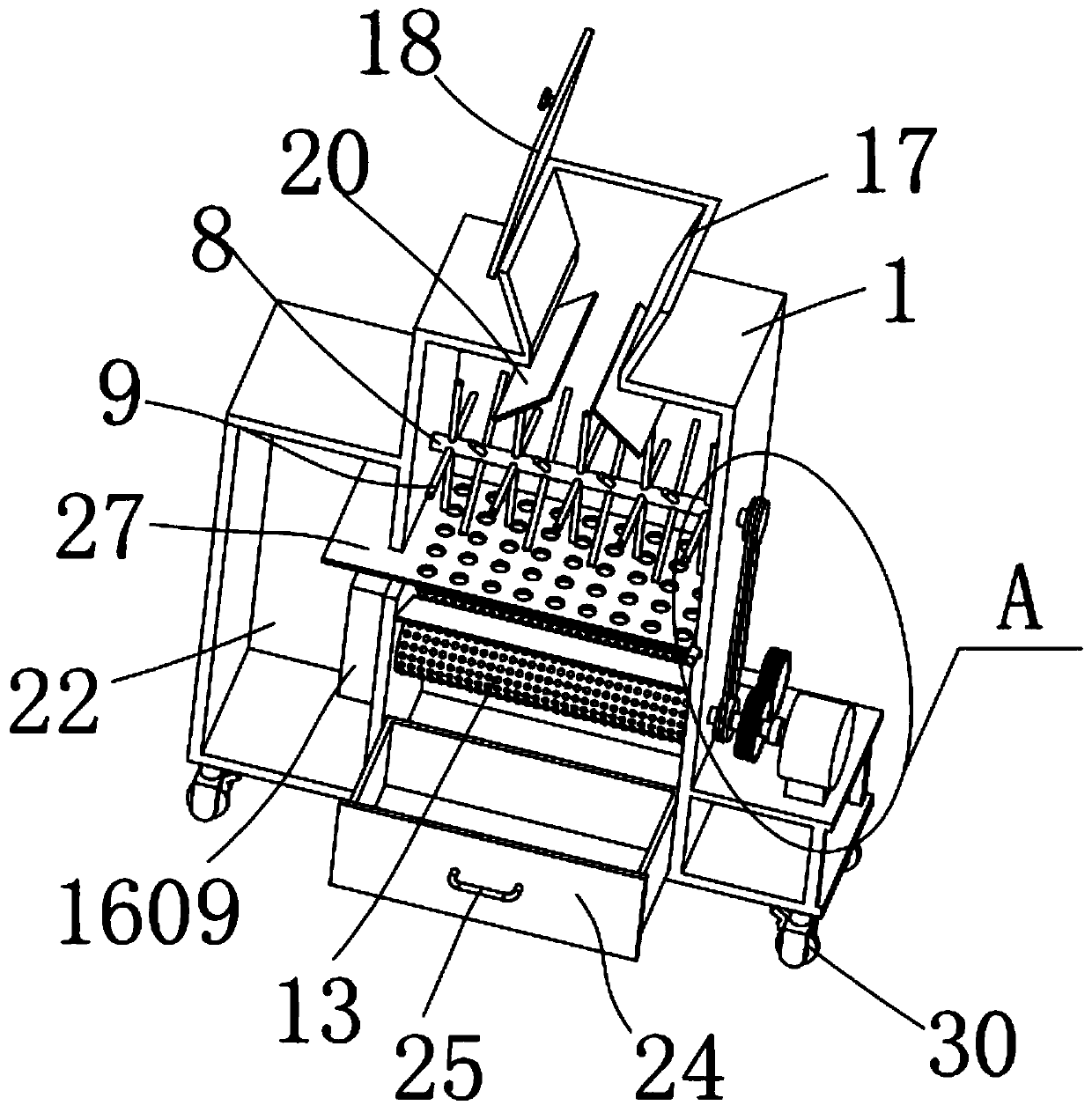

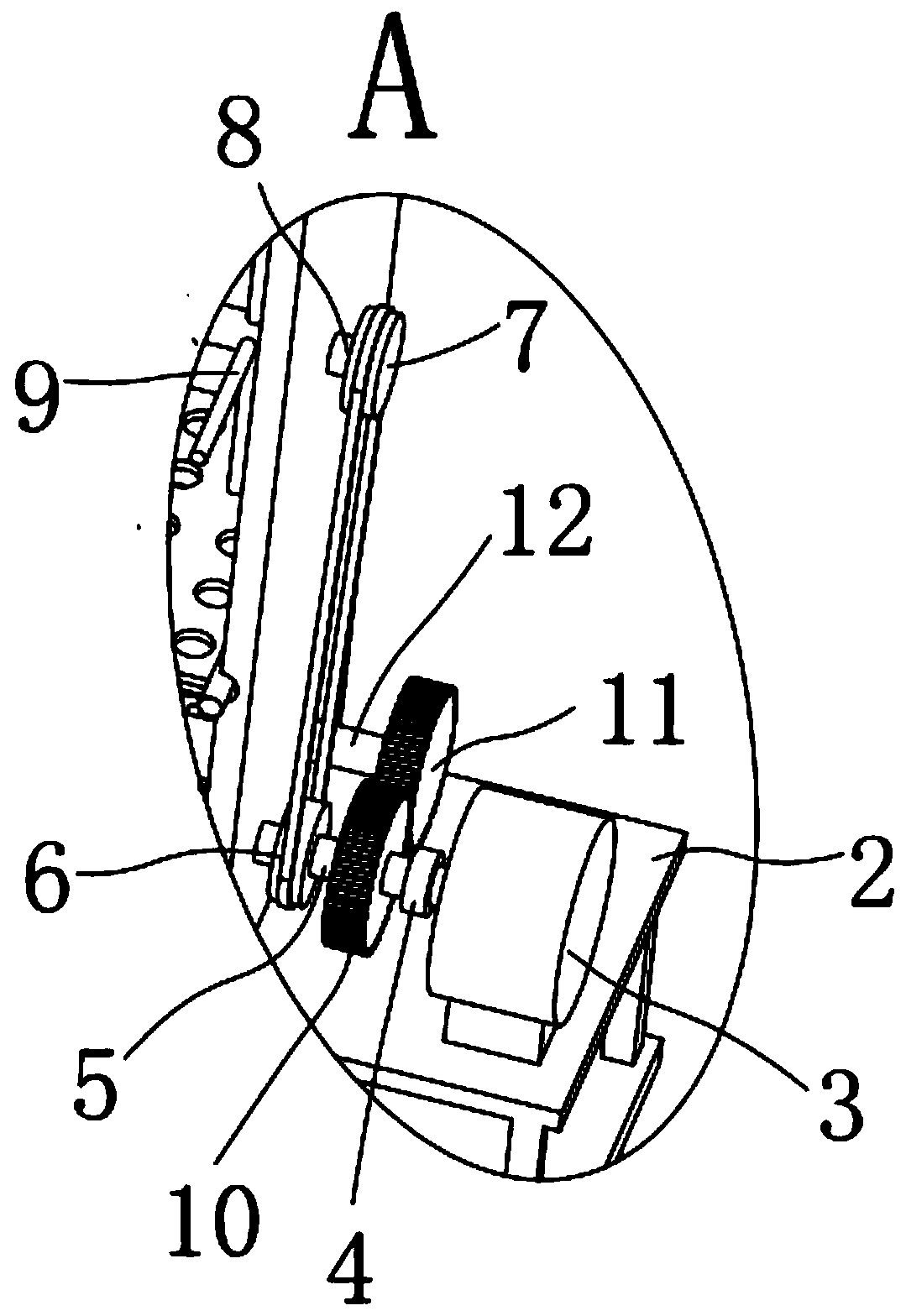

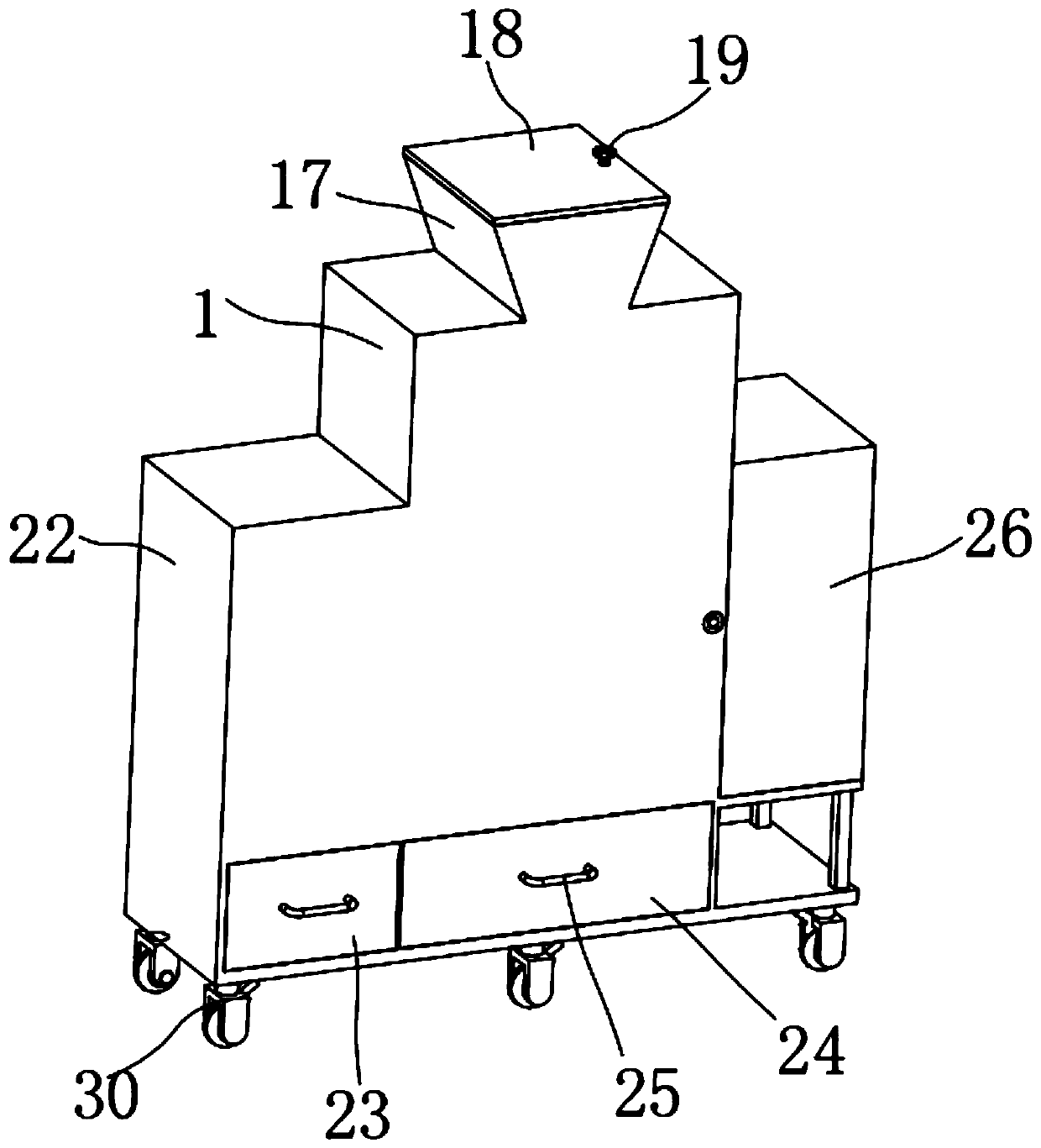

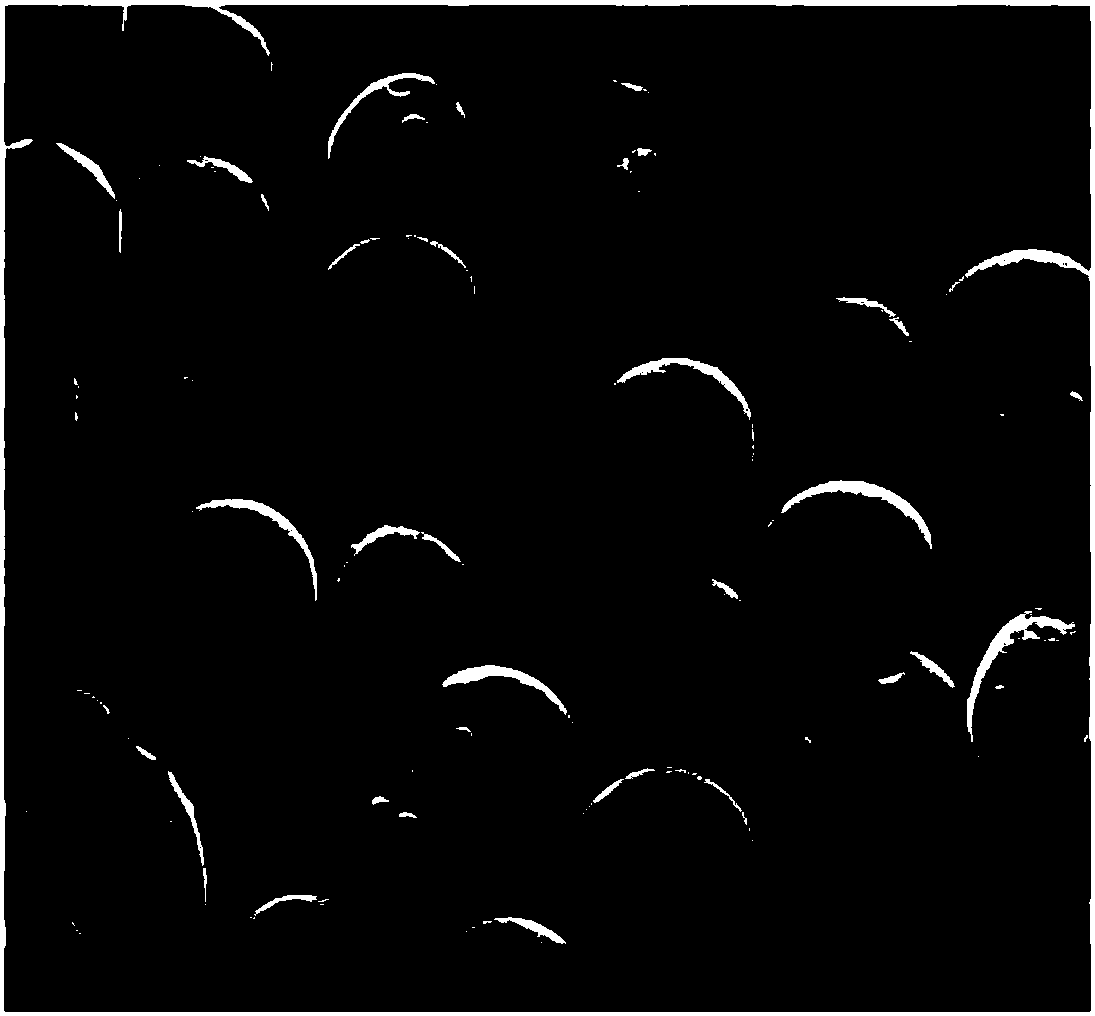

Living garbage drum screening machine

InactiveCN104084370ASimple structureEasy to operateSievingScreeningEngineeringMechanical engineering

The invention provides a living garbage screen drum screening machine. The living garbage screen drum screening machine comprises a rack, a screen drum and a screen drum hood, wherein the screen drum is mounted on the rack, and the screen drum hood is mounted on the rack and covers the screen drum; the screen drum comprises a screen drum frame and a screen sheet, the screen sheet is mounted on the side part of the screen drum frame in a detachable way, the screen drum frame is enclosed by the screen sheet for one circle, a plurality of screen holes are formed in the screen sheet, one end of the screen drum frame is high, the other end of the screen drum frame is low and obliquely arranged, a feeding opening is formed in the screen drum hood at the high end of the screen drum frame, a large material outlet is formed in the screen drum hood at the low end of the screen drum frame, a fine material outlet is formed in the screen drum hood below the screen sheet, an odor extracting opening is formed in the screen drum hood, the screen drum hood is communicated with an air extractor through the odor extracting opening, and a driving device which is in transmission connection with the screen drum and used for driving the screen drum to axially rotate is mounted on the rack. The living garbage screen drum screening machine is simple in structure and easy to operate, the operation environment can be greatly improved, and the damaged screen can be changed.

Owner:ZHEJIANG ZOKSEN ENVIRO ENERGY EQUIP

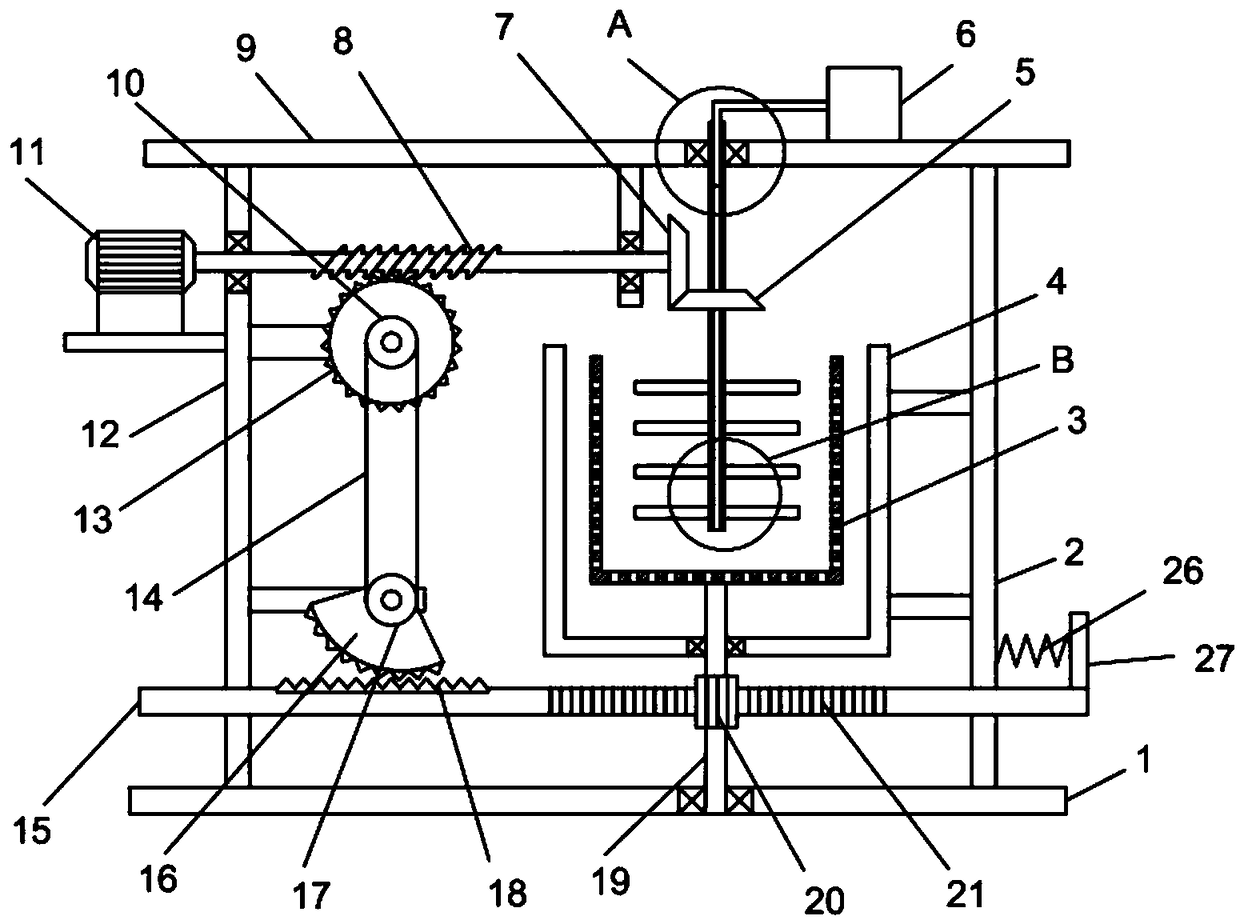

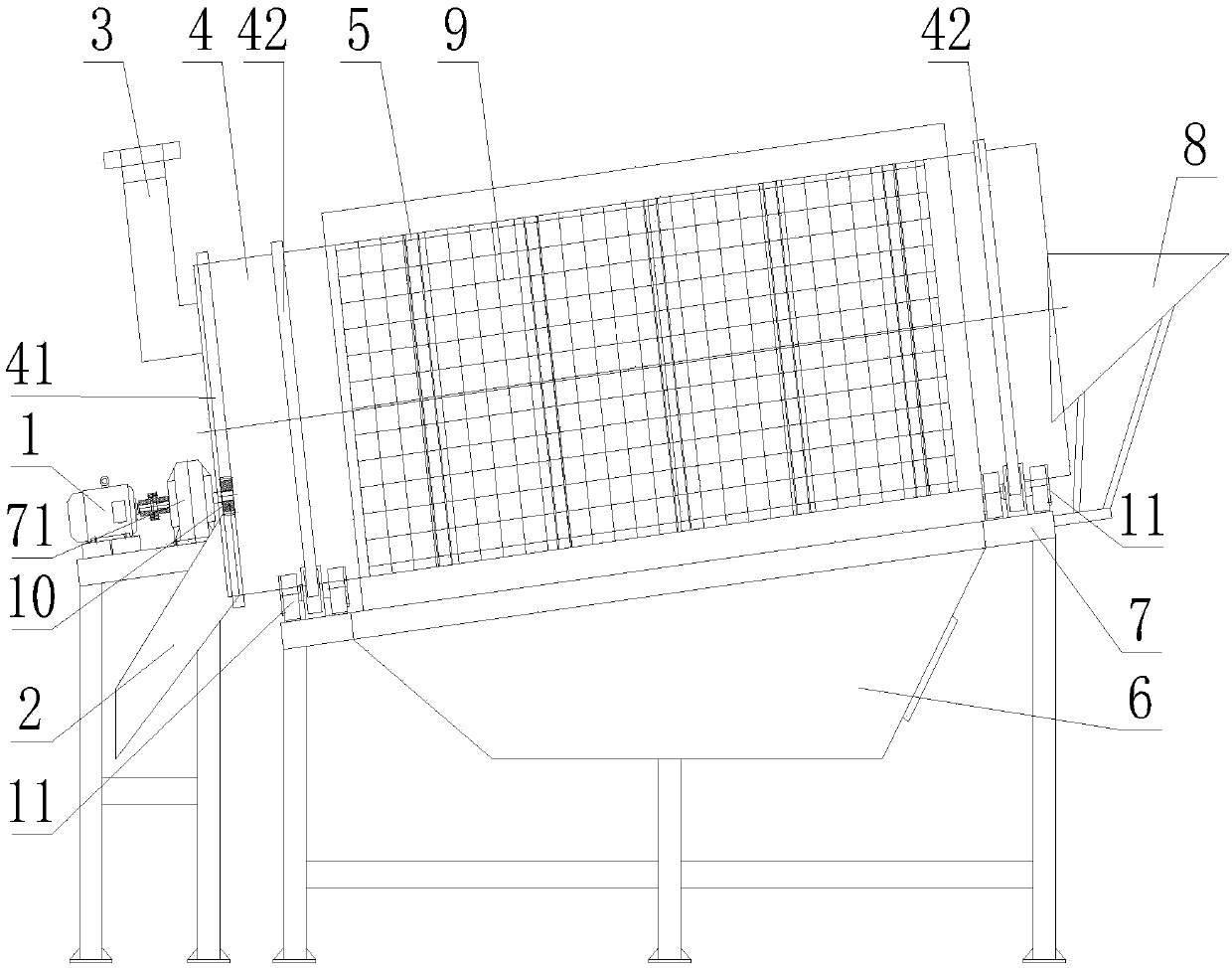

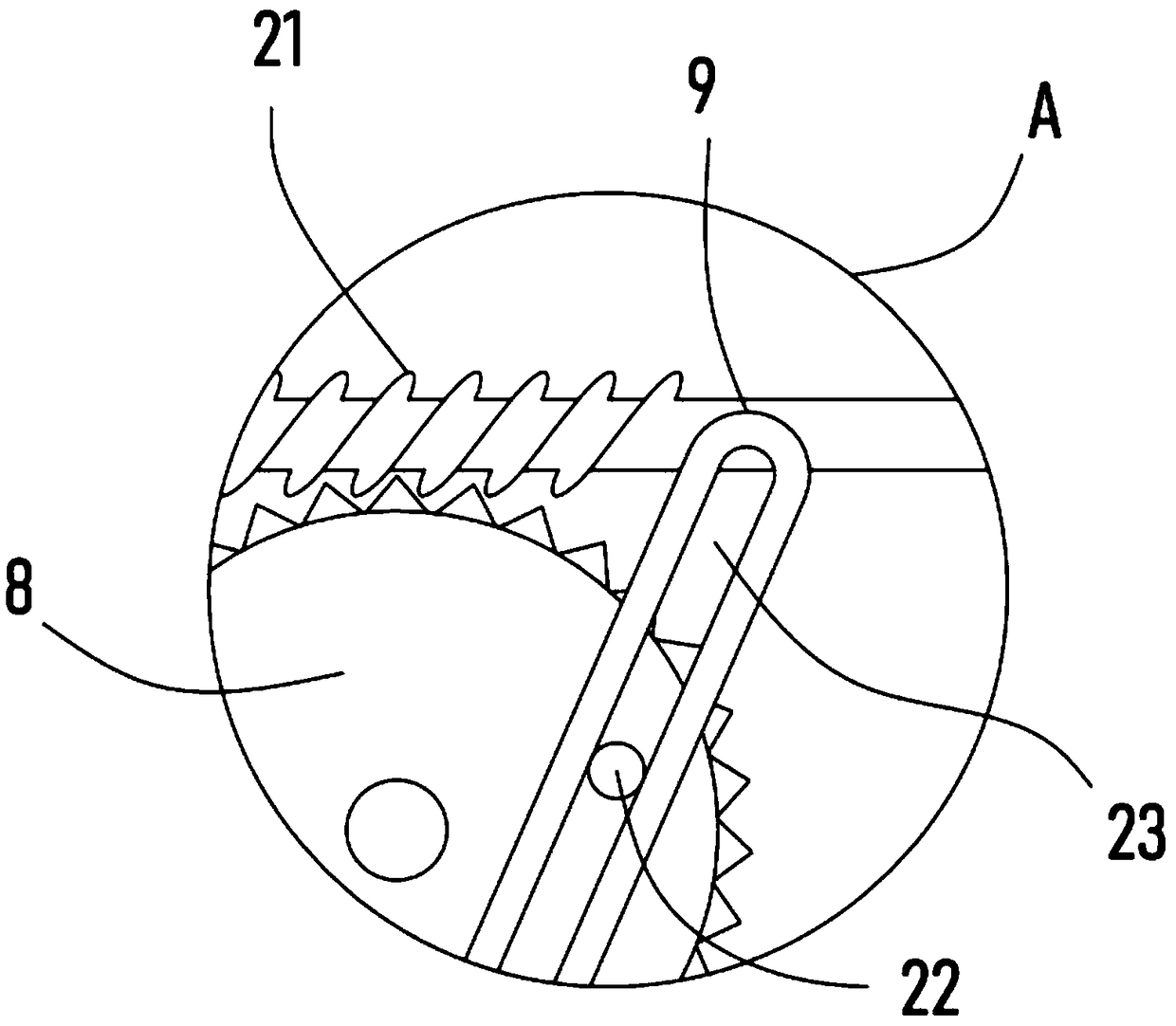

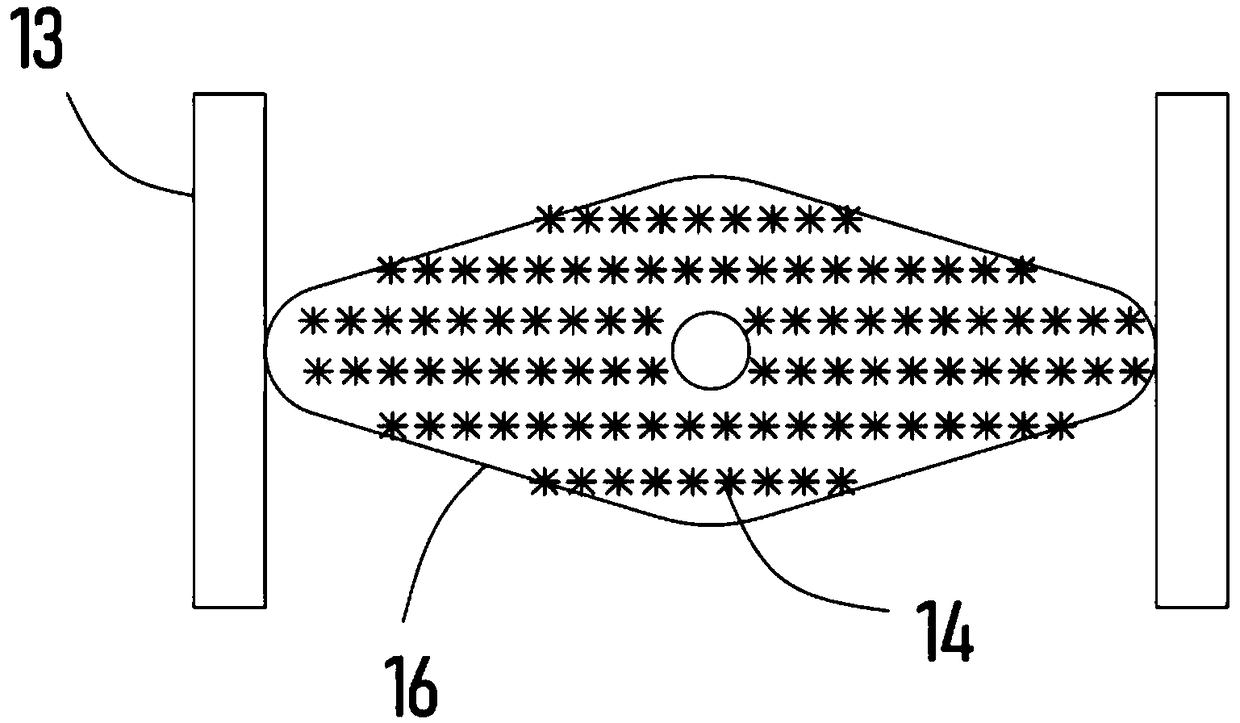

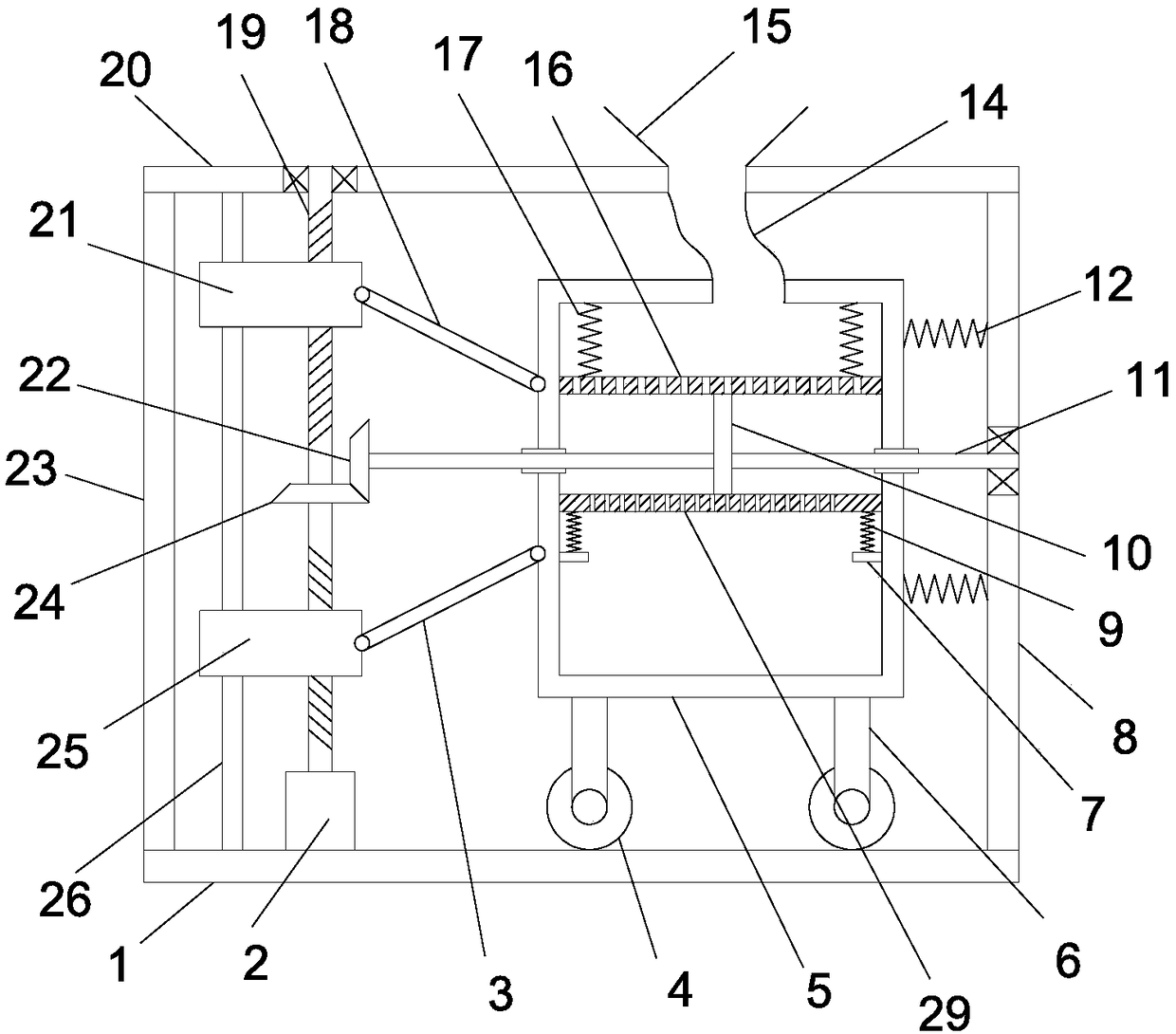

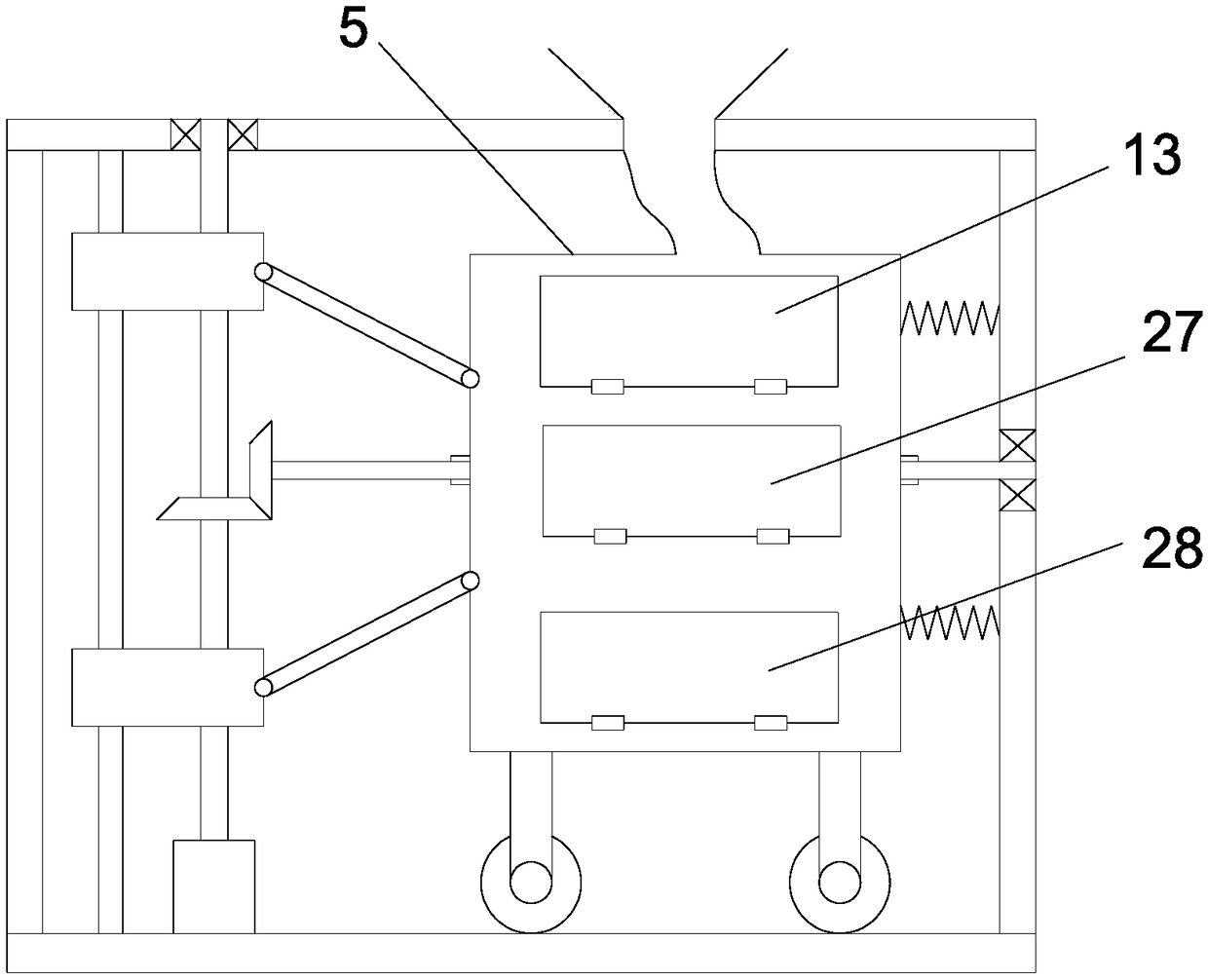

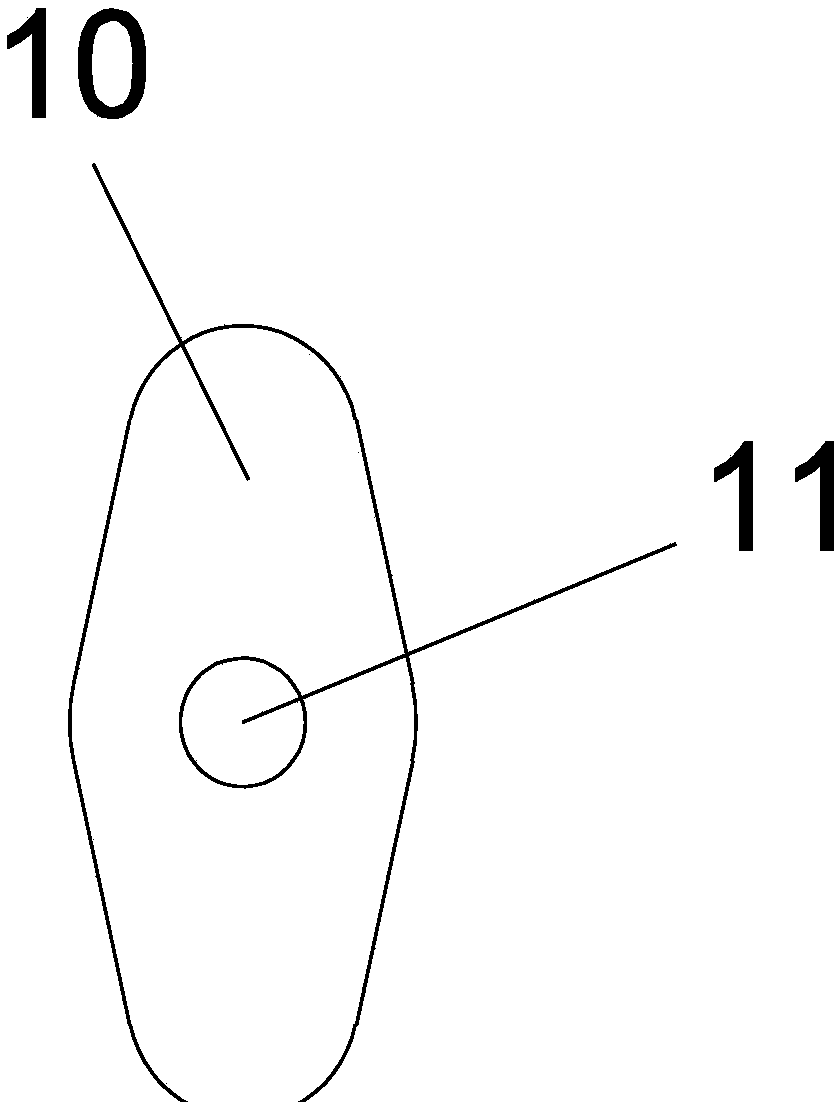

Seed screening device for agricultural seed breeding

InactiveCN108855896AImprove screening effectGood dispersionSievingScreeningScreening effectDrive shaft

The invention relates to the technical field of agricultural machinery and discloses a seed screening device for agricultural seed breeding. The seed screening device comprises a supporting frame, a driving motor is fixedly mounted on the left side wall of the supporting frame, a driving shaft extending into the supporting frame is coaxially fixedly mounted on an output shaft of the driving motor,a transmission pin II which slidably penetrates an elongated hole II is eccentrically and fixedly mounted on the front face of a worm gear, the lower half portion of a transmission swing rod is provided with an elongated hole I, and a transmission pin I which slidably penetrates an elongated hole I is fixedly mounted at the left end of a screen plate. The transmission swing rod swings to drive the screen plate to reciprocate transversely, and accordingly seed screening effects of the screen plate are improved; a driven shaft rotates to drive an elliptic cam to rotate, on the one hand, the elliptic cam drives a brush to rotationally sweep the screen plate to promote seed dispersion, and on the other hand, two abutting plates are driven to move face to face and back to back alternately, sothat seed dispersion is greatly improved, and seed screening rate of the screen plate is remarkably increased.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

Clay screening and crushing integrated equipment

InactiveCN109127026AGood sealingReasonable structural designDirt cleaningGrain treatmentsPre screeningEngineering

The invention clay screening and crushing integrated equipment. The clay screening and crushing integrated equipment comprises a sealed shell and is characterized in that the upper portion of the shell is provided with a feed inlet, the upper portion of the shell is provided with a discharge outlet, a pre-screen plate which connects the feed inlet and the inlet of a cyclone crushing device and isused for screening small-particle clay materials smaller than screen holes, a material conveying device used for conveying the screened and crushed materials into the discharge outlet is arranged under the pre-screen plate, and the outlet of the cyclone crushing device is arranged right above the material conveying device through a screen. The clay screening and crushing integrated equipment has the advantages that clay of different particle sizes can be crushed, high crushing efficiency, low energy consumption and small discharged material particle size can be achieved, and secondary pollution is reduced by an independent flying dust capturing and treating system.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Sand screening device for constructional engineering

InactiveCN111515117AImprove screening efficiencyImprove screening effectSievingScreeningElectric machineryStructural engineering

The invention discloses a sand screening device for constructional engineering. The sand screening device for constructional engineering comprises a pedestal, a mounting frame and a feeding hopper; the mounting frame is welded on the pedestal; the feeding hopper is fixedly mounted above the mounting frame; the sand screening device for constructional engineering further comprises a screening assembly for screening sand and an intermittent discharging assembly; the screening assembly comprises a screening frame, a screening plate, a first discharging channel, a second discharging channel and amovable plate; the bottom of the movable plate is connected to a driving assembly for driving the movable plate to waggle left and right; the driving assembly comprises a sliding block, a push rod, asliding groove, a guide rod, a motor and a connecting rod; the intermittent discharging assembly comprises an auxiliary plate, a blocking plate, a pull rope, a through hole, a first limiting rolling wheel, a second limiting rolling wheel, a buffering spring and a telescopic rod; and through the screening assembly, the intermittent discharging assembly and the driving assembly, a motor drives a turnplate to rotate, so that a push rod is driven by a connecting rod to move back and forth, the sliding block and the movable plate joggles along a sliding groove to a small extent, screening of sand on a screening plate is accelerated, and the screening efficiency is improved.

Owner:巴秀英

Seed screening device for garden breeding

InactiveCN108080247AAchieve repeated improvementAchieve repeated scrapingSievingScreeningScreening effectDrive shaft

The invention discloses a seed screening device for garden breeding. The device comprises a collection box. A limiting sleeve is fixedly installed at the upper end of the collection box. A screening groove is formed in the limiting sleeve in a sliding mode, a transmission rod is fixedly installed at the end of a rotating shaft, a swing rod is arranged in the collection box, a driving motor is fixedly installed on a supporting frame, and an output shaft of the driving motor is coaxially and fixedly provided with a driving shaft. Seeds are repeatedly lifted through rotation of spiral lifting blades, the seeds slide downwards along the inner side wall of a collection barrel to be subjected to the repeated screening effect, first-level screening of the seeds is promoted, a screen net is repeatedly scraped through transverse reciprocating movement of a brush scraper plate at the bottom of the screening groove, and the screening effect of the screen net on the seeds in the screening groove is promoted. A cam drives the screening groove through a first limiting baffle to swing back and forth under the elastic effect of a reset spring, the seeds can more rapidly penetrate through the screen net to fall into the bottom of the collection box, second-level screening of the seeds is achieved, the screening effect is good, and the screening efficiency is high.

Owner:储昭汉

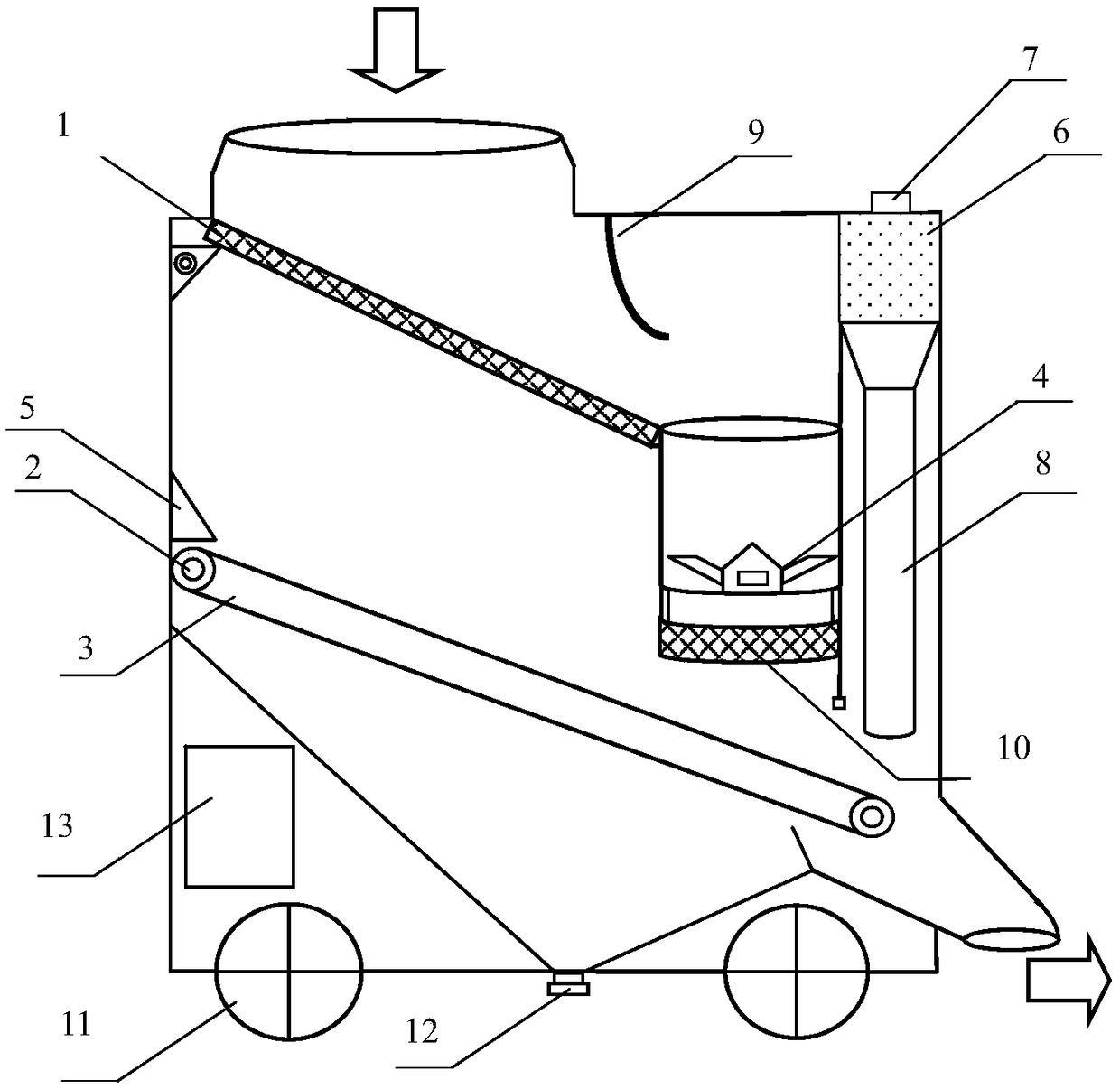

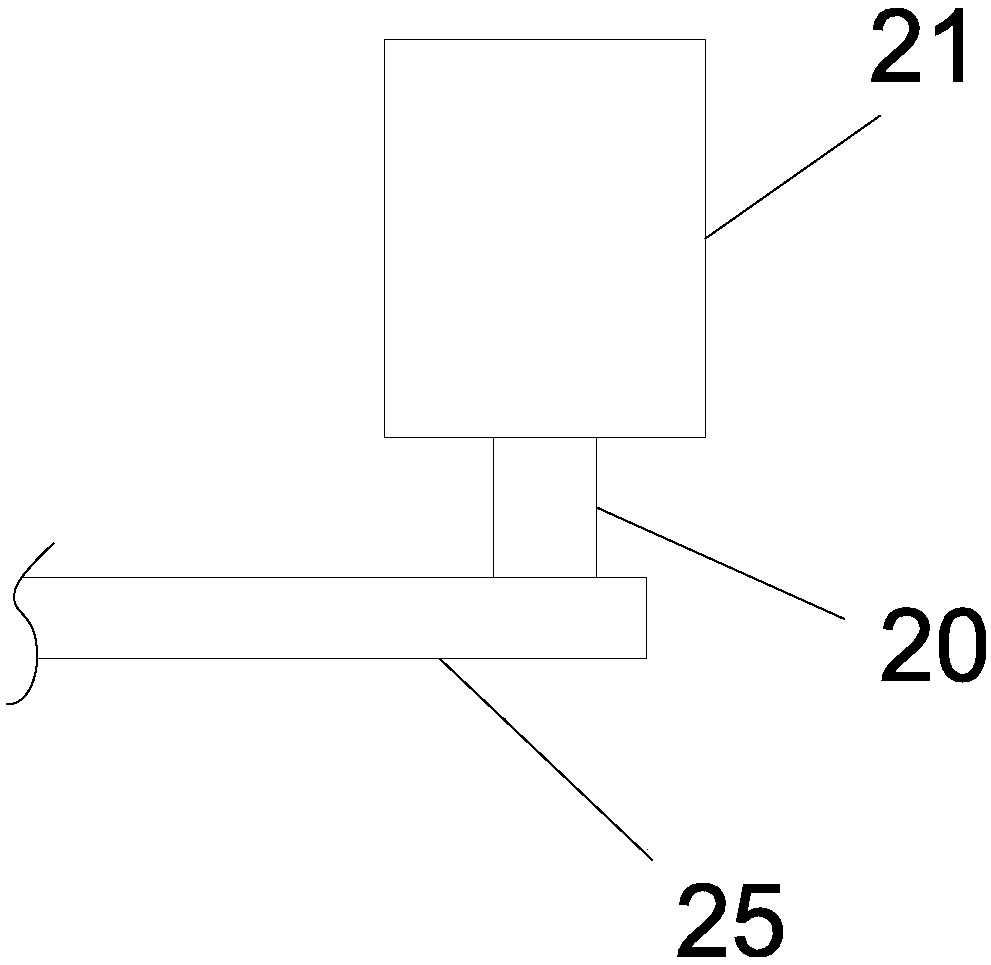

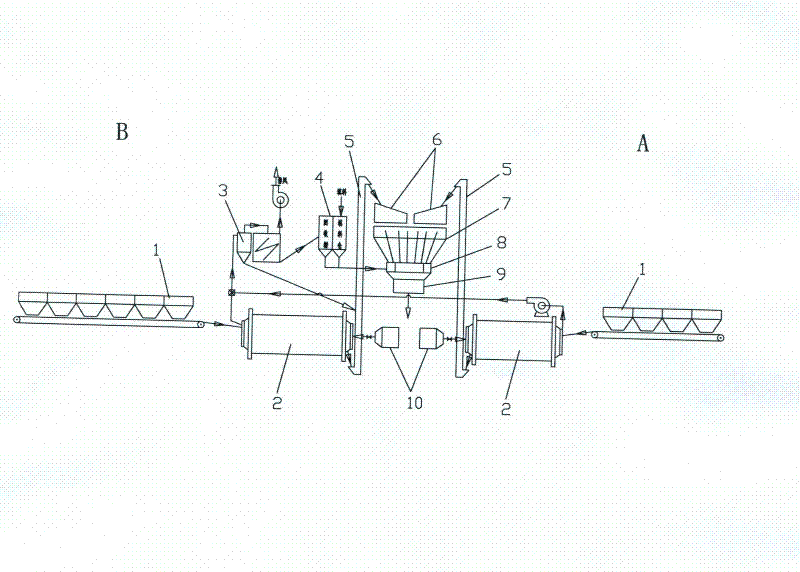

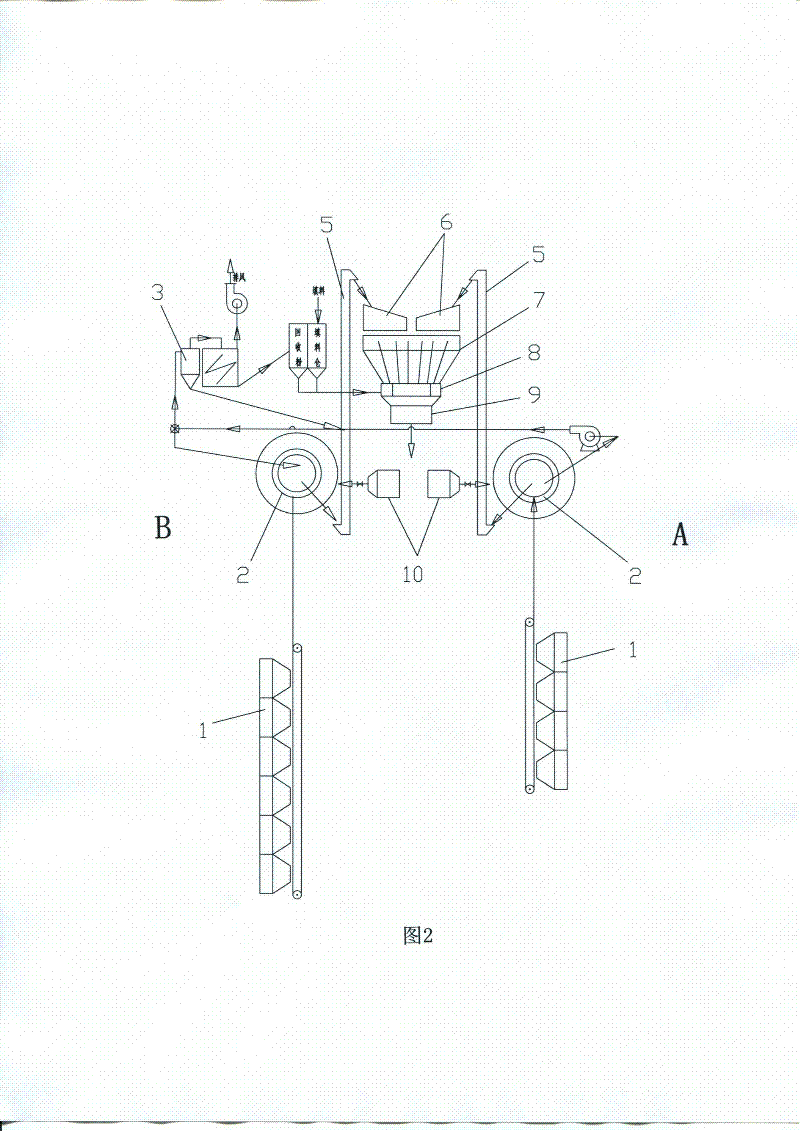

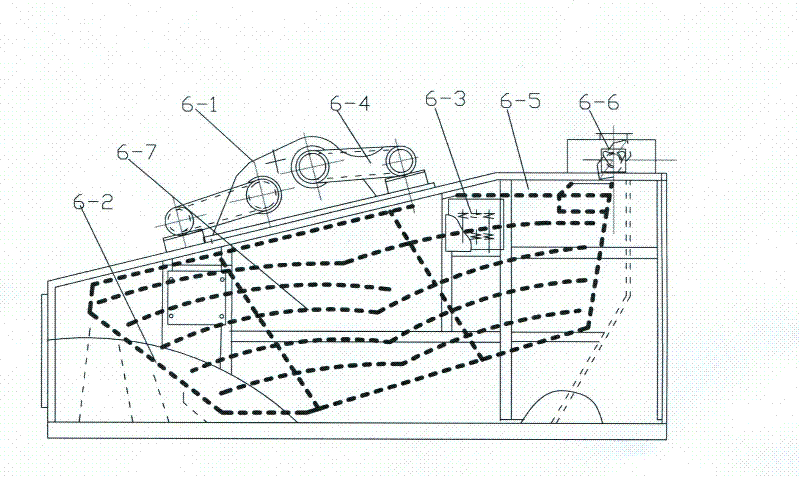

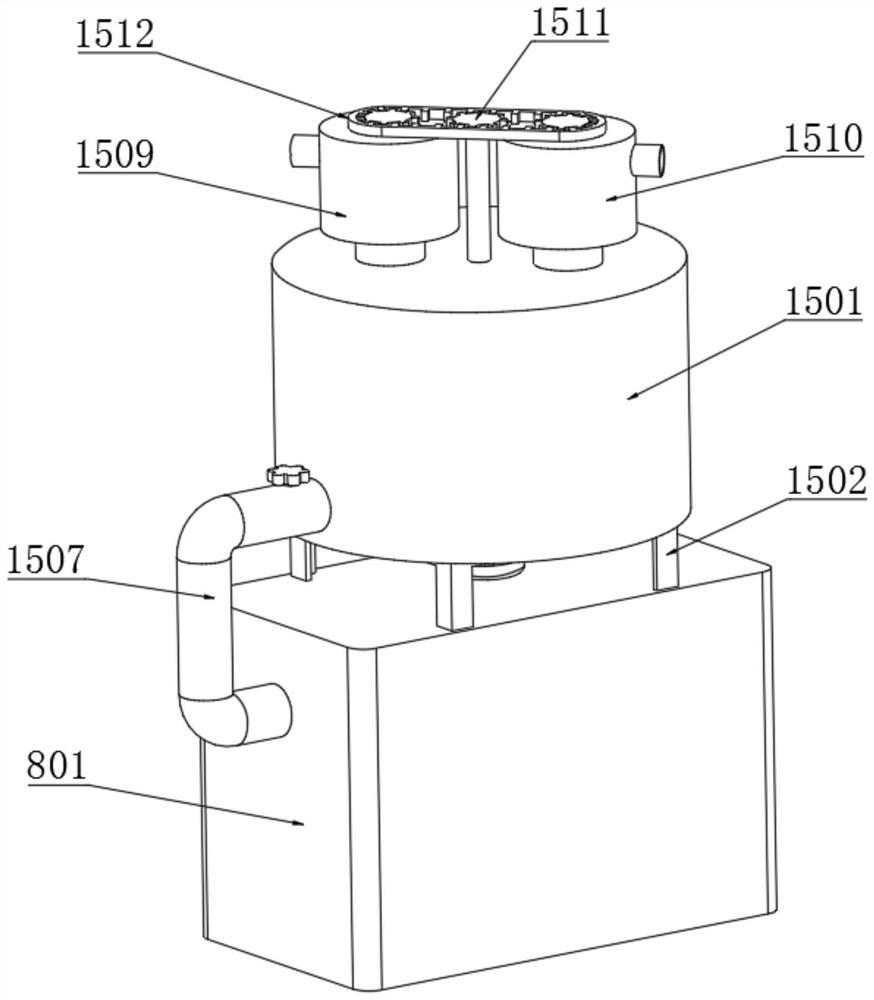

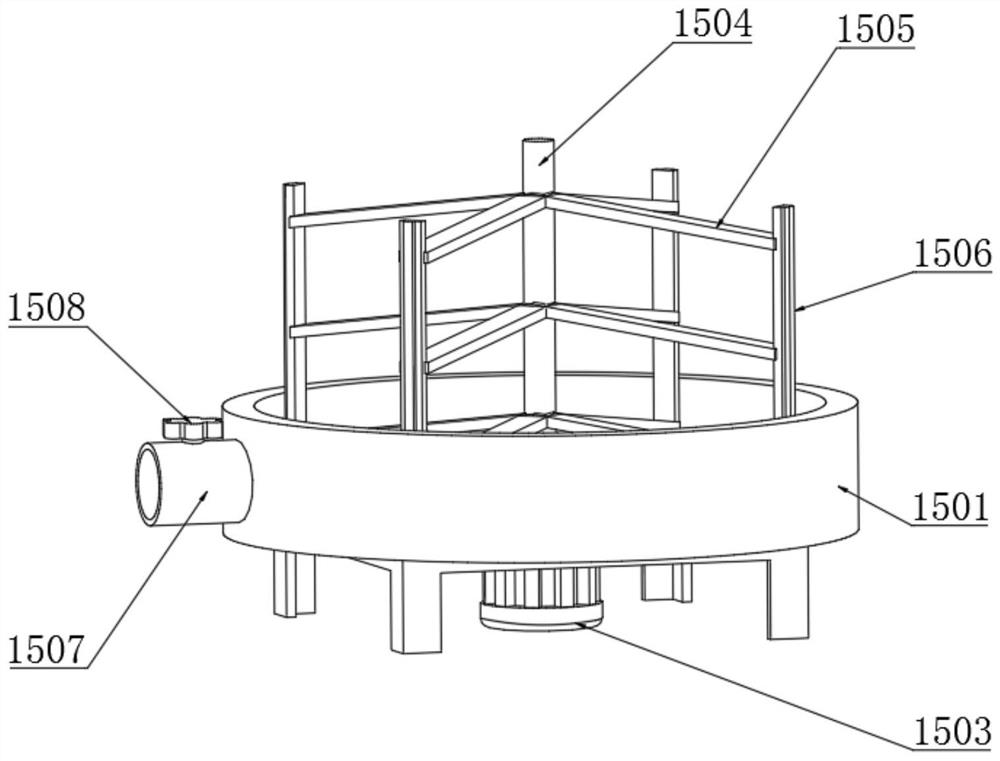

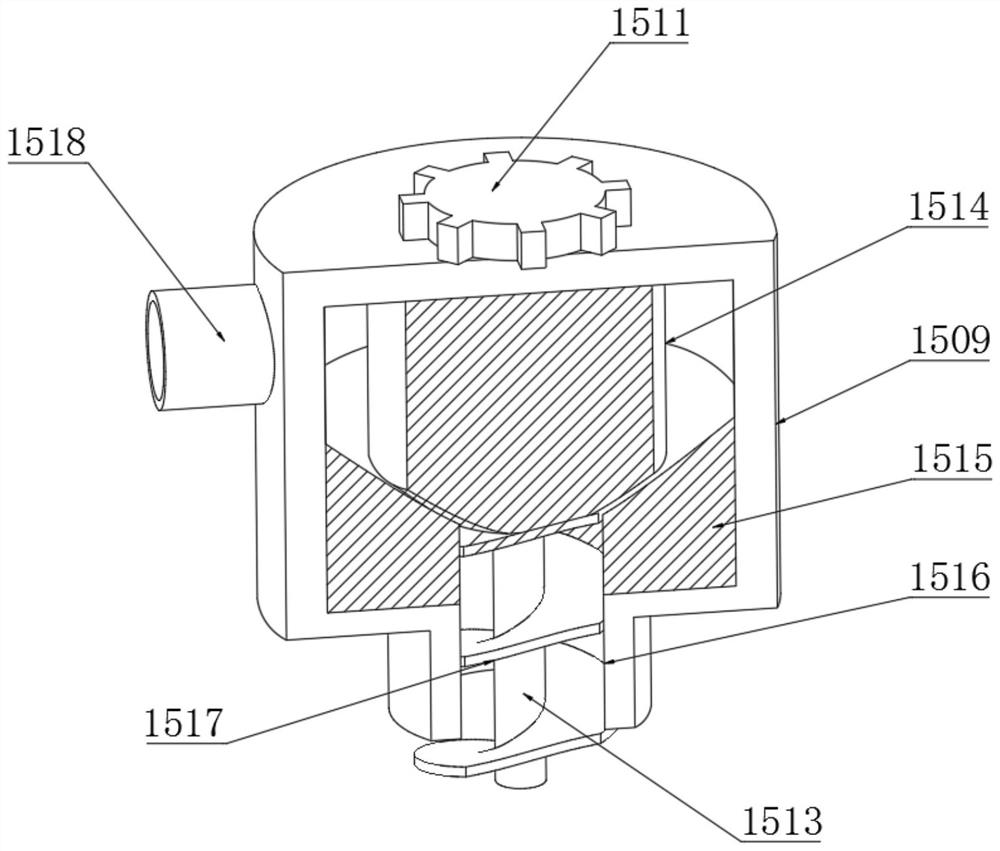

Separation feeding-type hot mix intermittent asphalt mixture blending machine and production technology therefor

ActiveCN102345265ATwice the drying speedDouble productionRoads maintainenceProcess engineeringAsphalt

The invention relates to a separation feeding-type hot mix intermittent asphalt mixture blending machine and a production technology therefor. The separation feeding-type hot mix intermittent asphalt mixture blending machine mainly comprises cold aggregate feeding systems, drying rollers, dedusting systems, powder systems, hot aggregate elevators, a hot aggregate screening machine, a hot aggregate storehouse, a metering system and a mixer. The separation feeding-type hot mix intermittent asphalt mixture blending machine is characterized in that the separation feeding-type hot mix intermittent asphalt mixture blending machine comprises the two cold aggregate feeding systems, the two drying rollers, the two dedusting systems, the two powder systems and the two hot aggregate elevators; the two cold aggregate feeding systems comprise a cold aggregate feeding system A and a cold aggregate feeding system B; cold aggregates are separated into two groups according to specifications, wherein one of the two groups comprise the best fine cold aggregates and is corresponding to the cold aggregate feeding system A and the other one comprises the coarse cold aggregates and is corresponding to the cold aggregate feeding system B; the hot aggregate screening machine is provided with two separation vibrating screens with separation sieve apertures; and the two separation vibrating screens are corresponding to the two groups of the cold aggregates separated according to the specifications. The separation feeding-type hot mix intermittent asphalt mixture blending machine can solve effectively the problem of shortage of a cold aggregate storage space of the existing intermittent blending machine, improve screening ability, reduce energy consumption, increase individual output and improve production efficiency.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

High-efficiency sand sieving device for municipal construction

The invention discloses a high-efficiency sand sieving device for municipal construction. The high-efficiency sand sieving device for municipal construction comprises a sieving box. The top of the sieving box is provided with a top plate. A driving motor is arranged on the top plate. An output shaft of the driving motor is coaxially and fixedly provided with a driving belt pulley. A second smashing rotary roller is coaxially and fixedly provided with a fourth driven belt pulley and a third driven belt pulley. A first driving bet is wound around the third driven belt pulley and the driving beltpulley. The right end of a concentric-square-shaped frame is horizontally and fixedly provided with a right guide slide rod which is slidably connected with the right sidewall of the sieving box. Sand entering the sieving box through a feed hopper is scattered by a first smashing rotary roller and the second smashing rotary roller in the rotating process, so that caking sand blocks in the sand are broken up and scattered. Rotary blades rotate to promote scattering of the sand. Meanwhile, wind generated by rotating of the rotary blades promotes flowing of air in the sieving box to play a rolein drying the sand. The fluidity of the sand is improved, and the subsequent sieving effect is improved accordingly.

Owner:王书愚

Soil remediation ecological moisturizing method based on efficient stirring

ActiveCN111804724AScientific and reasonable structureEasy to useSievingDispersed particle filtrationSoil remediationElectric machine

The invention discloses a soil remediation ecological moisturizing method based on efficient stirring. A solution mixing and effect-improving mechanism comprises a mixing cylinder, a bracket, a secondrotating motor, a stirring rod, a stirring frame, a shovel plate, a discharge pipe, a water stop valve, a charging barrel, a filtering barrel, a chain wheel, a chain, a rotating rod, an upper grinding block, a lower grinding block, a channel, a spiral feeding plate, a feeding pipe, a rotary vane, a filtering barrel, a water outlet and a water inlet pipe, the bottom end of the mixing cylinder is fixedly connected with a bracket, safe and convenient use is realized, a solution mixing and efficiency improving mechanism is arranged, the second rotating motor drives the stirring rod to rotate, andthe two rotating rods are driven to move and rotate through transmission of the chain wheels and the chains, so that the repairing agent is crushed through cooperation of the upper grinding block andthe lower grinding block, the repairing agent can be rapidly mixed with water, meanwhile, the rotary vane and the filtering barrel are matched to filter the water, impurities in the water are reduced, and the effect of the mixed repairing liquid is prevented from being affected by too many impurities.

Owner:合肥润田规划设计有限公司

Circular building sand screening device

InactiveCN109127348AAchieve decentralizationImprove liquiditySievingScreeningScattering functionScreening effect

The invention discloses a circular building sand screening device, and relates to the technical field of building machines. The circular building sand screening device comprises a supporting bottom plate, and a transverse packing auger driven by a motor I is horizontally and fixedly mounted on the supporting frame. A dispersing barrel communicating with the transverse packing auger through a discharging pipe is arranged below the transverse packing auger. A conveying belt mounted on a supporting table is arranged below a horizontal screen, and a longitudinal packing auger driven by a motor IIis fixedly mounted on the supporting table. A lifting inlet communicating with the dispersing barrel is formed in the lower right side wall of the longitudinal packing auger, and a circulating pipe ismounted between the upper right side wall of the longitudinal packing auger and the transverse packing auger in a communicating manner. According to the circular building sand screening device, sandcan be screened through the horizontal screen and an inclined screen and passes. By means of conveying of the transverse packing auger and the longitudinal packing auger, on one hand, the scattering function on the sand is improved, the mobility of the sand during screening is improved, and the screening effect is improved; and on the other hand, repeated and circular screening of the sand can beachieved, screening can be more sufficient and thorough, and the screening quality of the sand is improved.

Owner:霸州市辉月网络技术有限公司

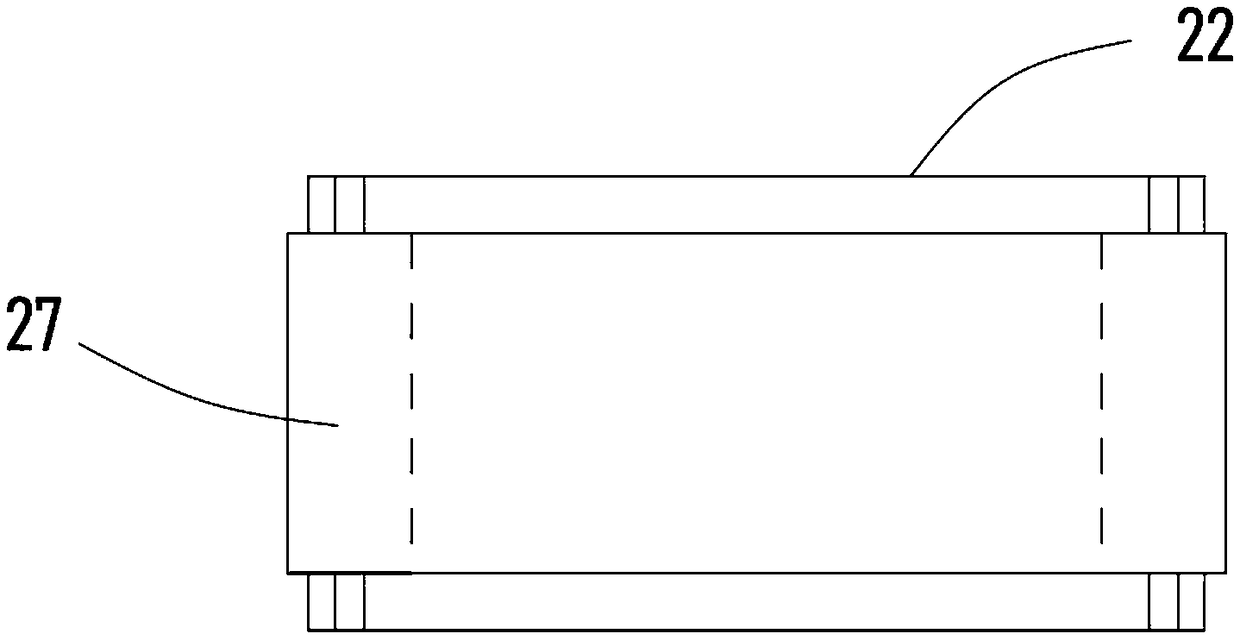

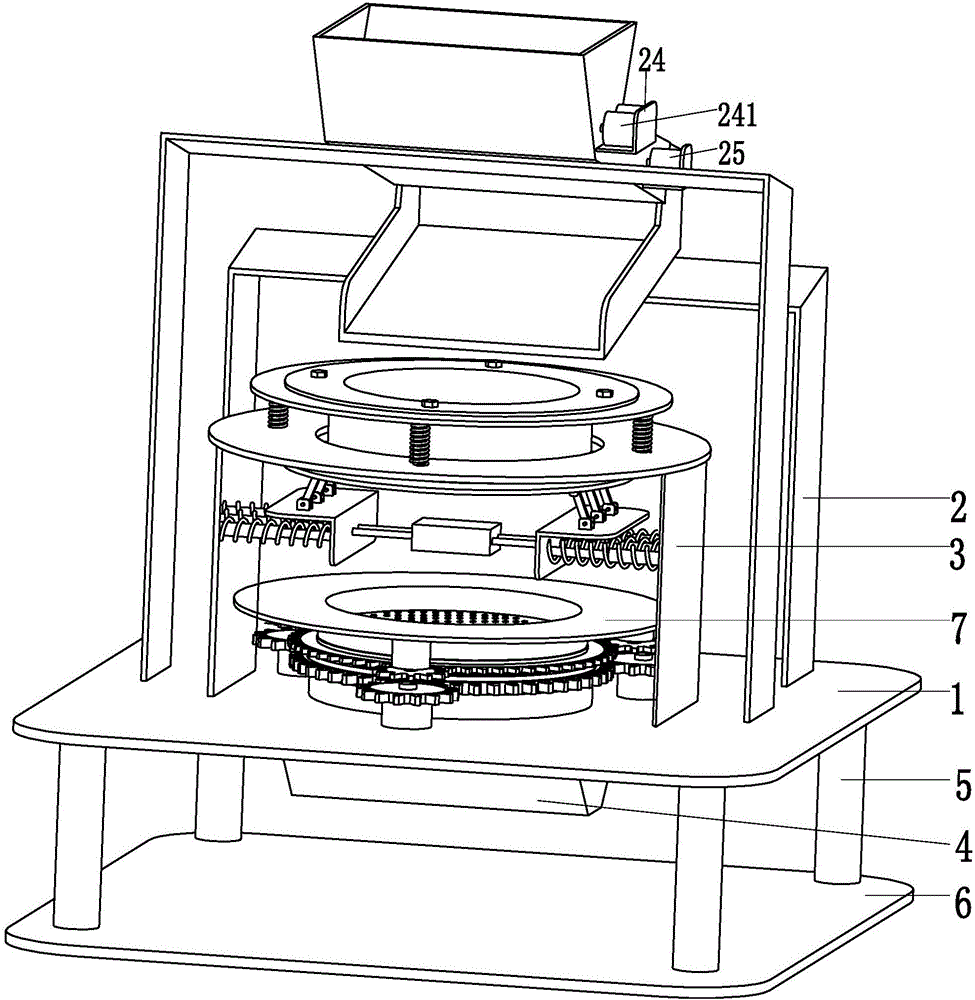

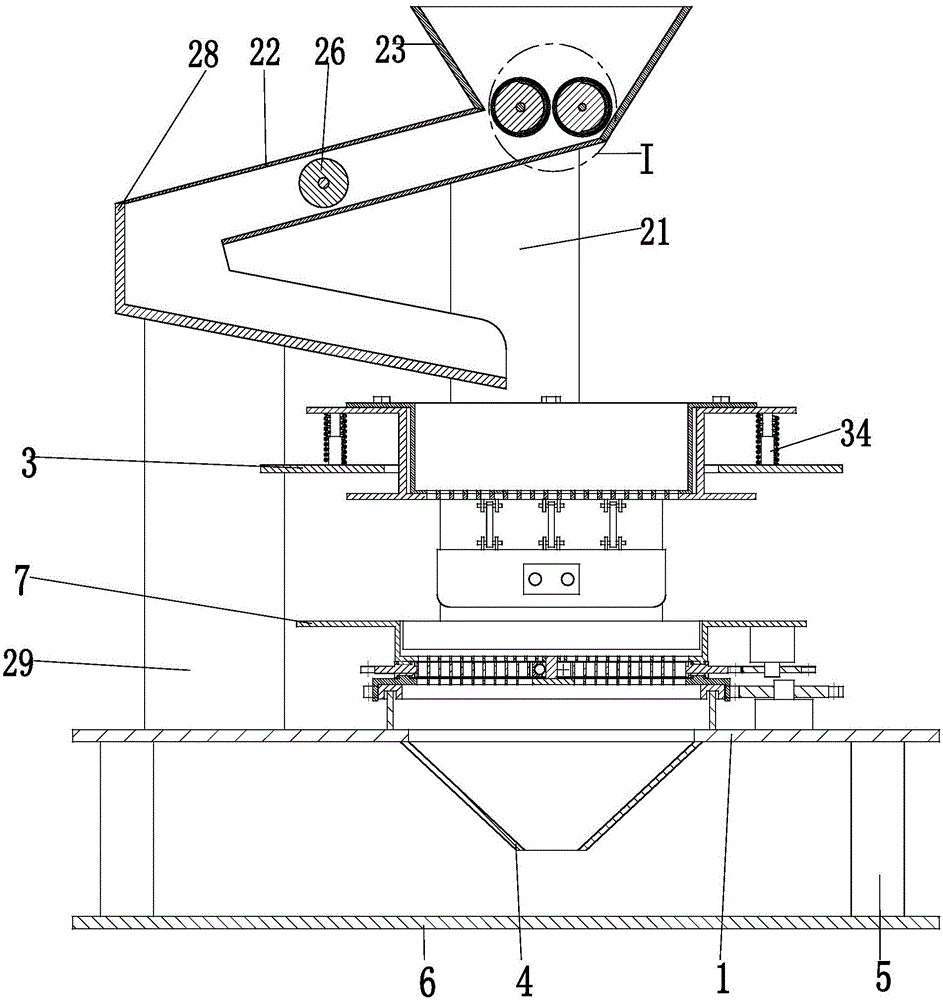

Powder coating quantifying and packing machine capable of achieving sort screening of particle sizes

The invention relates to a powder coating quantitative packaging machine that can classify and screen particle sizes, comprising a bottom plate, a conveying grinding mechanism, a screening mechanism and a quantitative mechanism are installed on the bottom plate; Above, the conveying and grinding mechanism is located above the screening mechanism, the lower end of the bottom plate is provided with a guide frame, the lower end of the bottom plate is provided with a support column, the support column is installed on the working plate, and the conveying and grinding mechanism, the screening mechanism, the quantitative mechanism, the guide The lead frame is matched to complete the quantitative packaging process of powder coating. The invention can solve the problems existing in the existing powder coating production process that need to be manually screened according to the particle size, long screening time, poor screening effect, manual packaging according to the specified weight, low quantitative packaging efficiency, and low screening efficiency. The problems of separate processing of quantitative packaging, low processing efficiency and low work efficiency can realize the functions of powder coating screening, quantitative and packaging integrated production.

Owner:谢秋晨

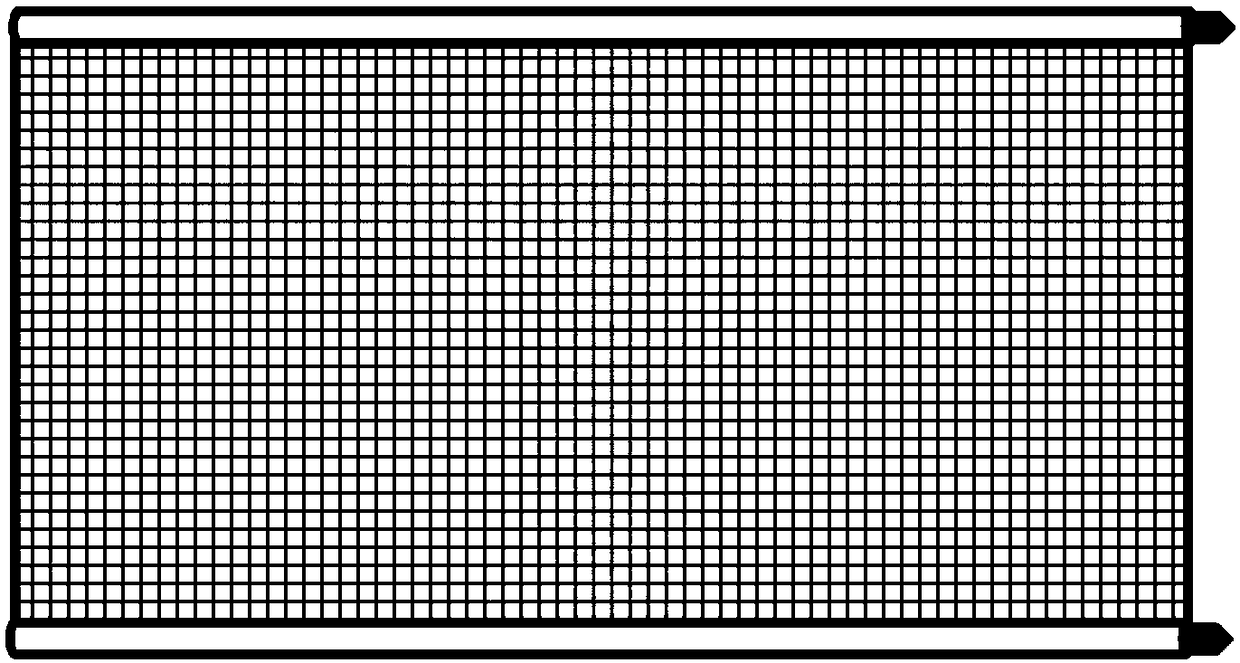

Sand screening device for construction

InactiveCN108421703AImprove screening effectIncrease screening speedSievingScreeningScreening effectReciprocating motion

The invention discloses a sand screening device for construction. The sand screening device comprises a bottom plate and a screening box. A left vertical plate and a right vertical plate are vertically and fixedly mounted on the bottom plate. A top plate is horizontally and fixedly mounted on the left vertical plate and the right vertical plate. Supporting legs are vertically and fixedly mounted at the bottom of the screening box. A feeding pipe is mounted on the top plate and communicates with the interior of the screening box through a flexible connecting pipe. Damping springs are fixedly connected between the screening box and the left side wall of the right vertical plate. The sand screening device has the obvious advantages that the screening effect on sand is good, and the screeningspeed is high; the screening box is driven through a second connecting rod and a first connecting rod to do left-and-right reciprocating motion under the elastic acting force of the damping springs,shaking of the sand in the screening box is promoted, and the sand screening rate is increased; and through rotation of an oval cam, a first screening plate and a second screening plate are driven tovibrate up and down under the elastic action of second limiting springs, and the screening speed of the first screening plate and a second screening plate on the sand is further increased.

Owner:重庆峰创科技有限公司

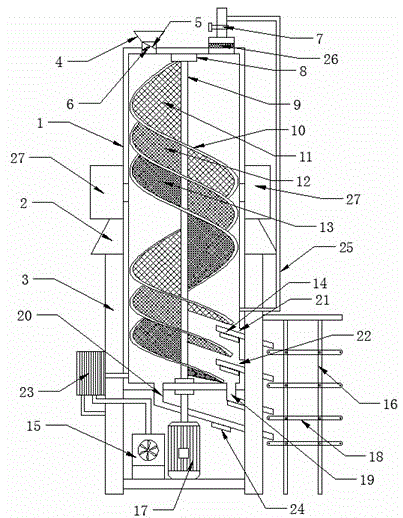

Multilevel energy-saving drying spiral sieve

The invention discloses a multilevel energy-saving drying spiral sieve. The multilevel energy-saving drying spiral sieve comprises a sealed barrel, a foundation column, an adjusting-controlling motor, a support and an air blower. A lug seat on the outer wall of the sealed barrel is installed on the foundation column. A microwave generator and an electric heater are installed on the outer wall of the sealed barrel. A rotary shaft connected with the adjusting-controlling motor is arranged between shaft seats in the sealed barrel. A feed hopper with a baffle, and an air outlet pipe with a filter screen are installed at the top end of the sealed barrel. A check valve on the air outlet pipe is connected in the middle of the side wall of the sealed barrel through a heat recovery pipe. A spiral sieve body is arranged between each of three layers of spiral frames and the rotary shaft. The side wall and the bottom end of the sealed barrel are provided with discharge plates and discharge pipes correspondingly, and the discharge plates and the discharge pipes are each provided with a vibrator. Four layers of conveyer belts are installed on the part, close to the foundation column, of the support. The air blower is communicated with the electric heater and the sealed barrel through pipelines. The multilevel energy-saving drying spiral sieve is simple in structure, reasonable in design, good in sealing effect, capable of screening out materials with different grain sizes and meeting the need of actual production, good in screening effect, high in work efficiency and good in energy-saving effect and has a drying function.

Owner:GUIZHOU JIQIAN NETWORK CO LTD

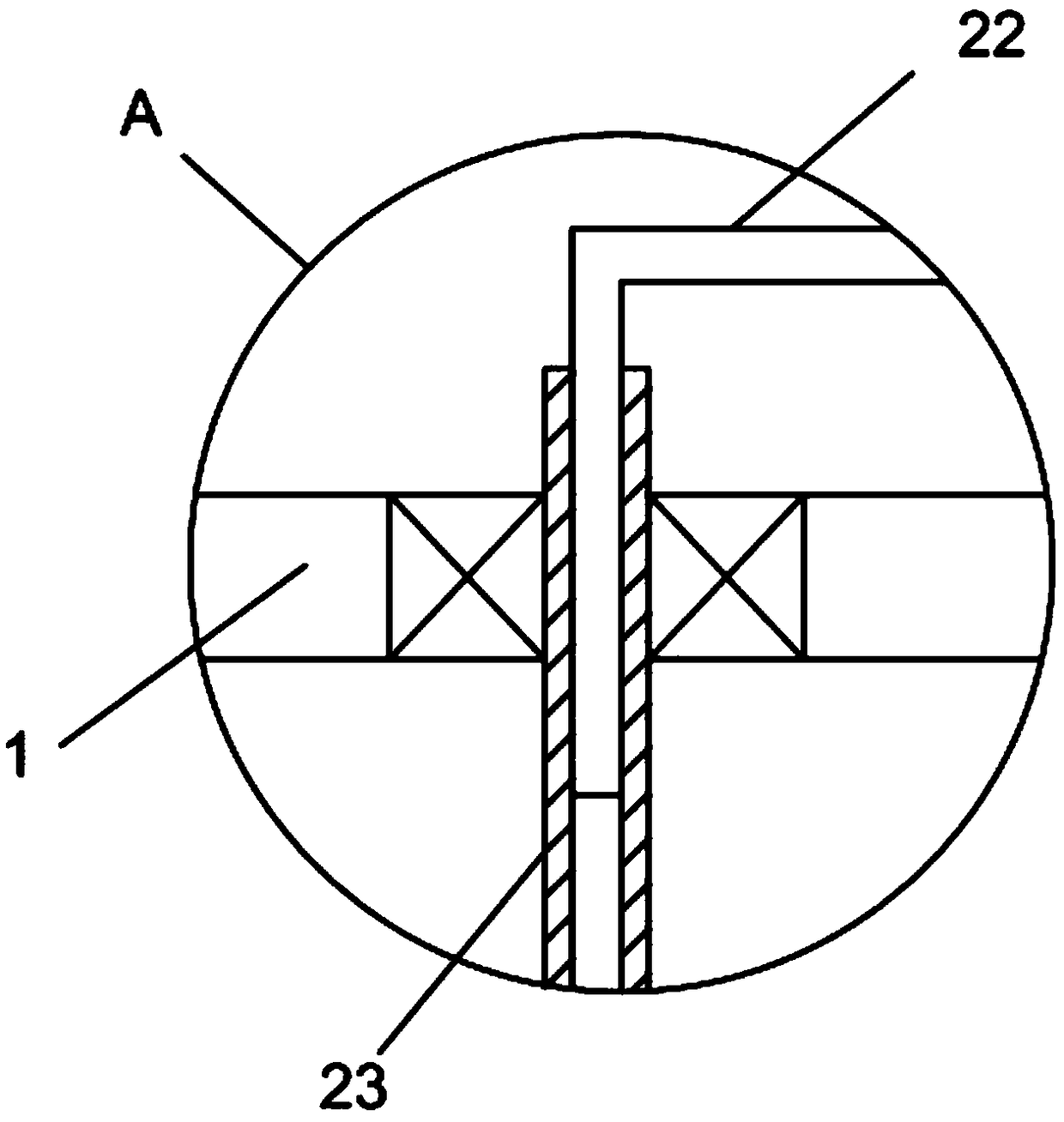

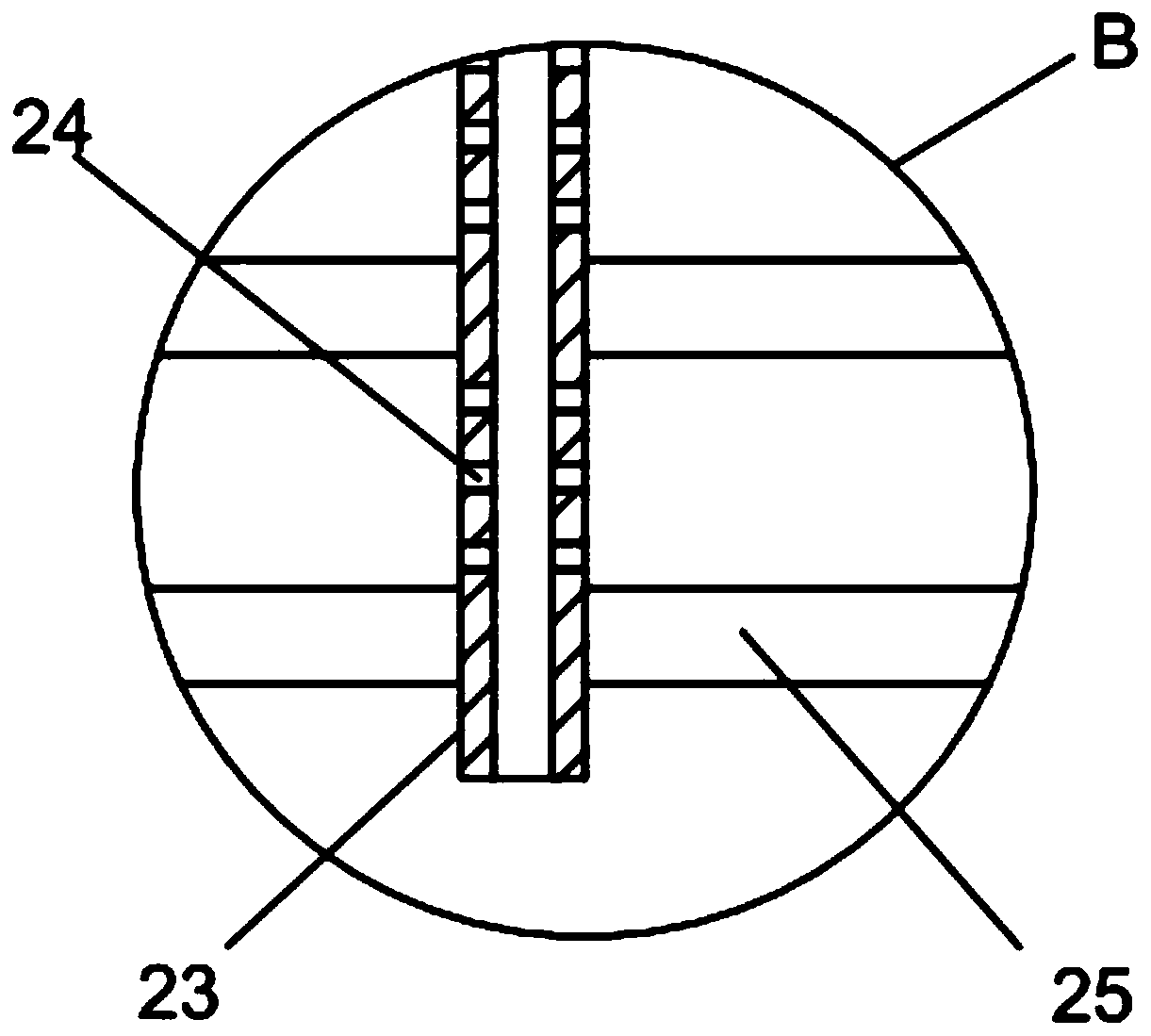

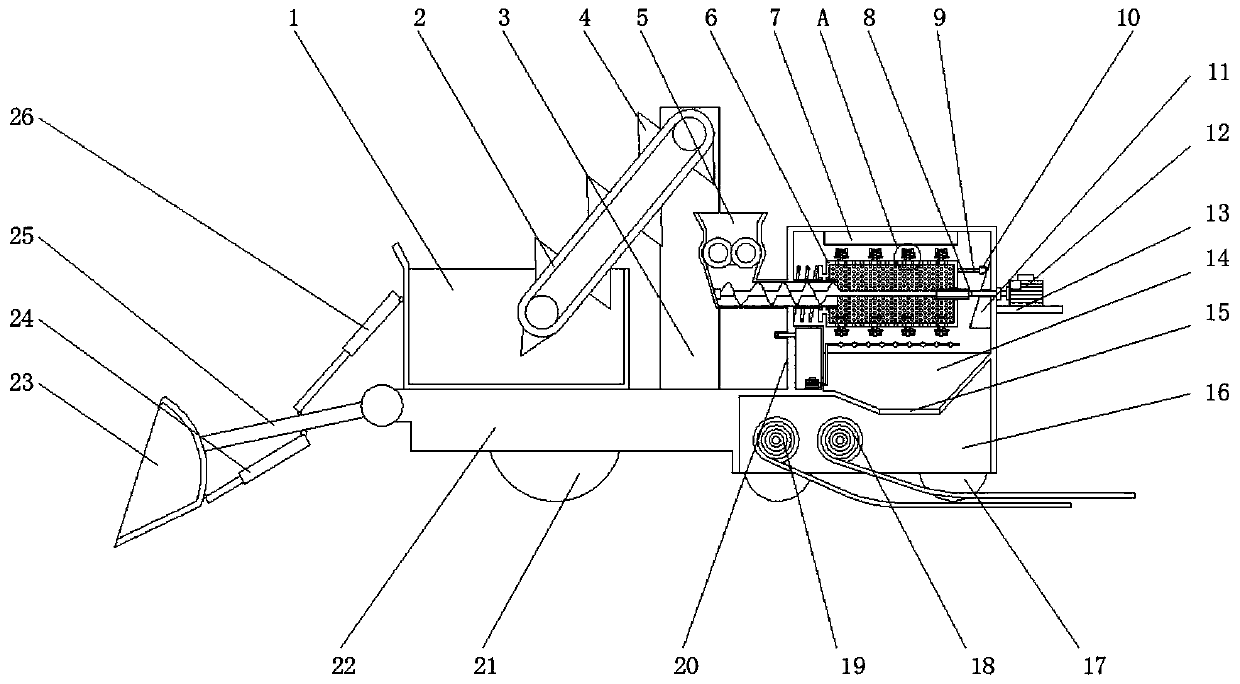

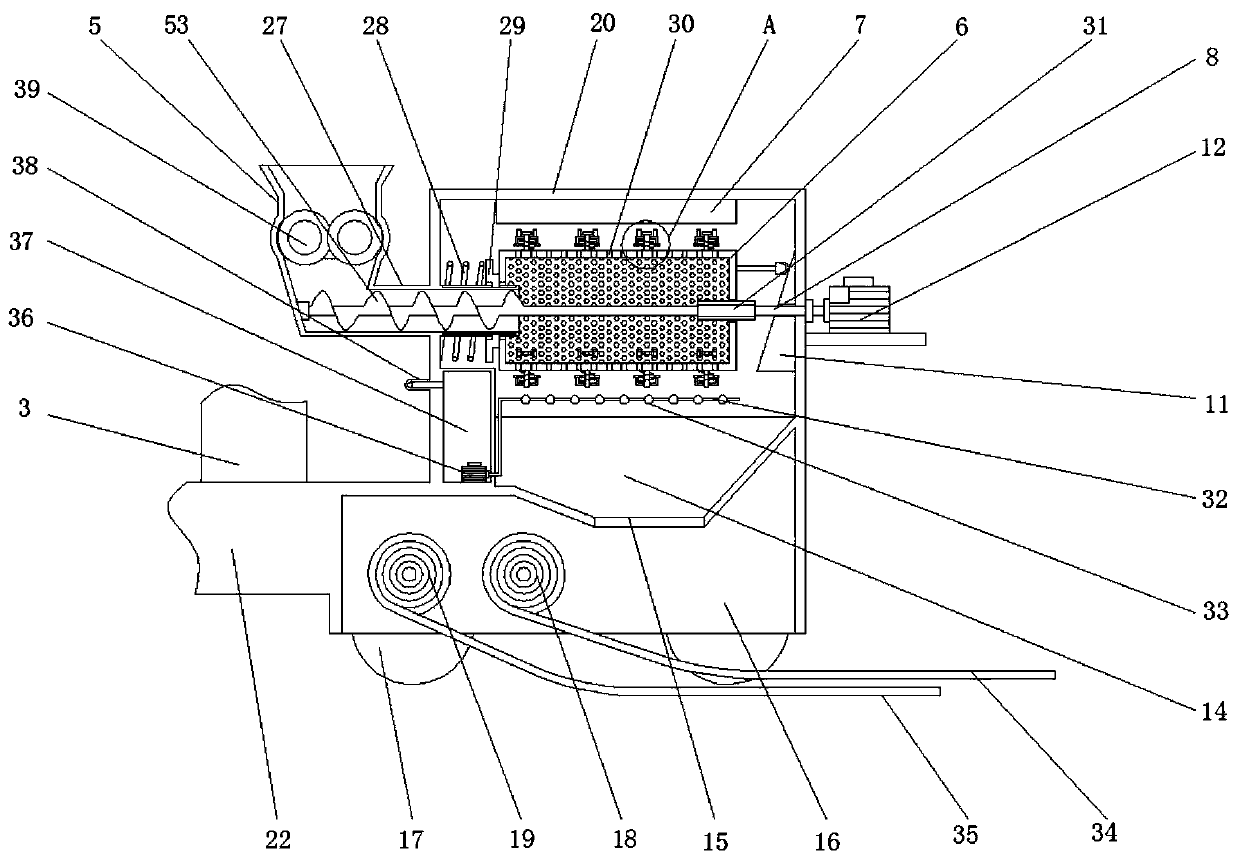

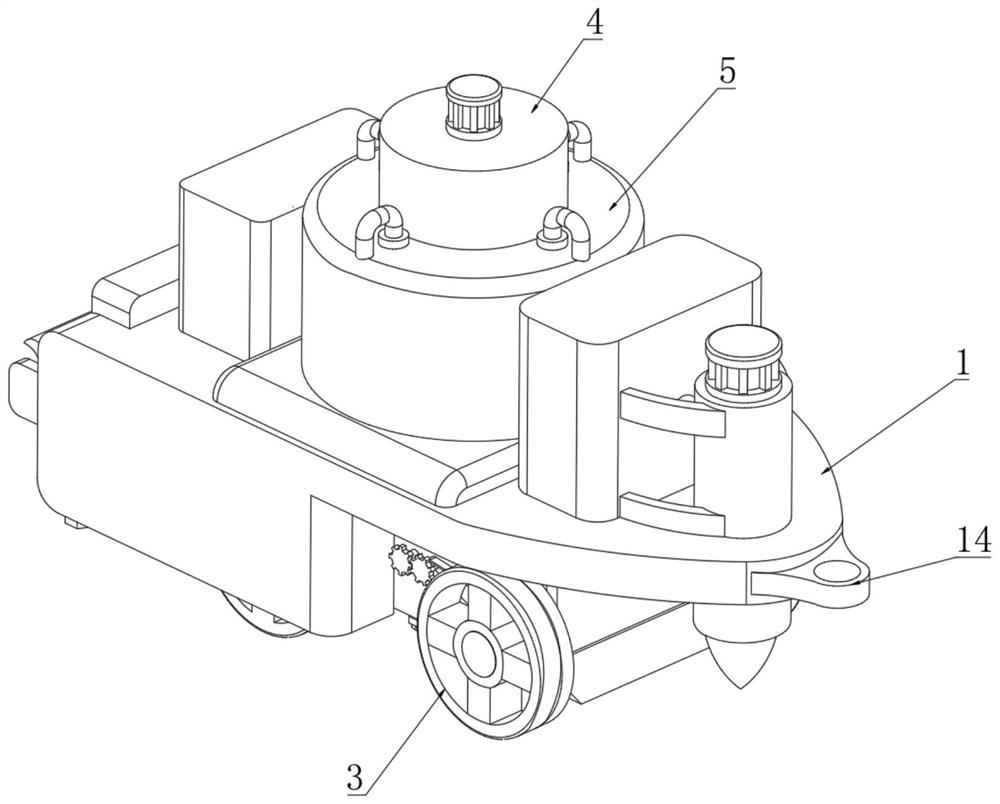

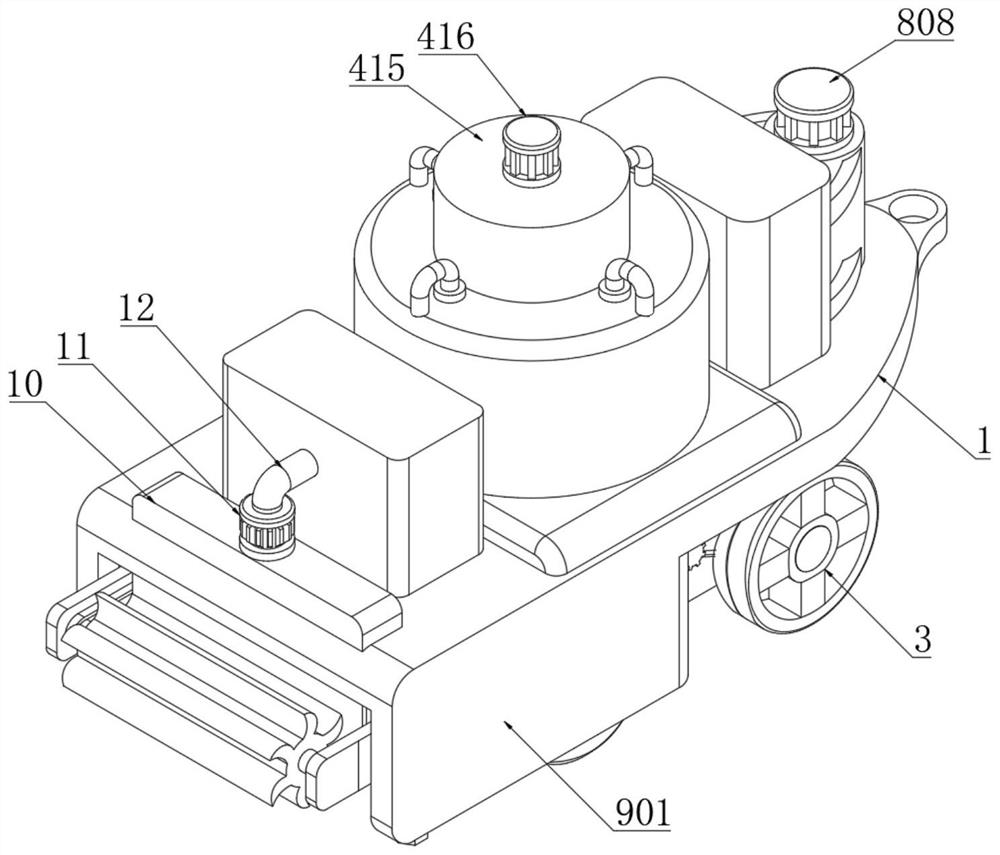

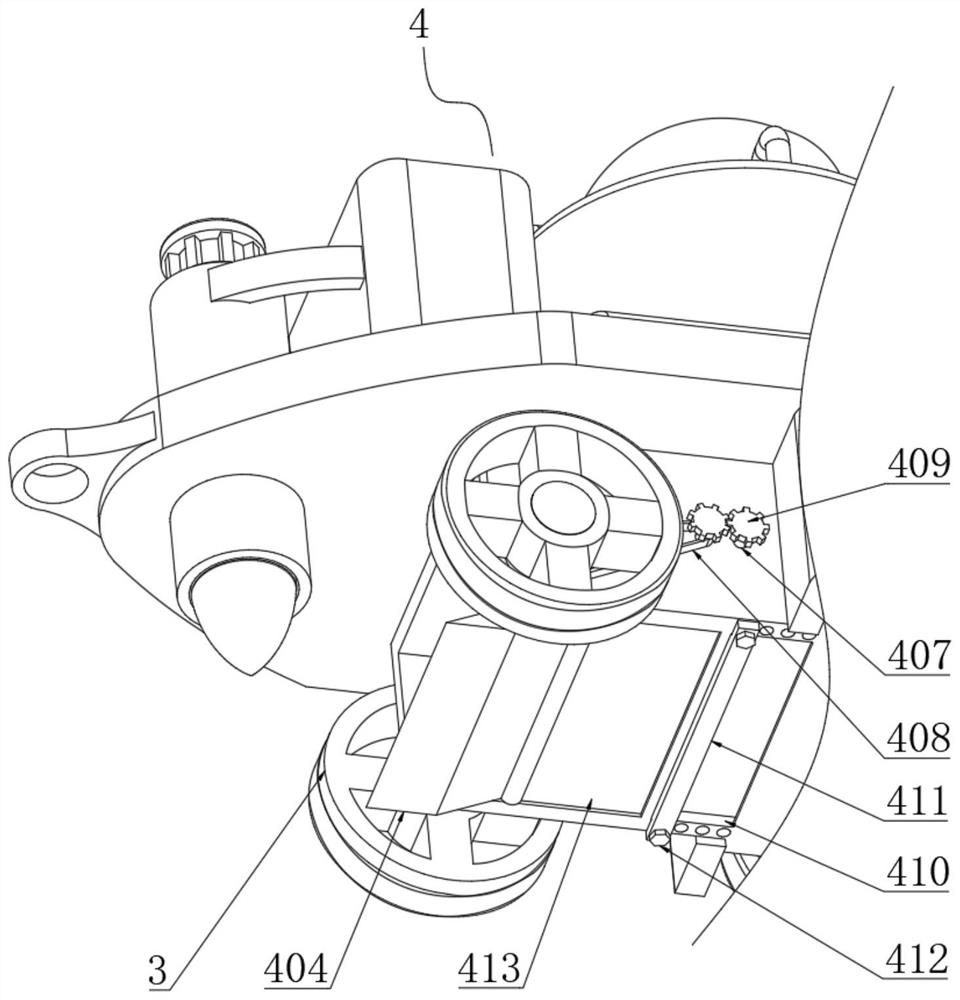

Soil remediation ecological moisturizing system

ActiveCN111842459AScientific and reasonable structureEasy to useSpadesSievingVehicle frameSoil remediation

The invention discloses a soil remediation ecological moisturizing system which comprises a vehicle frame, a hanging ring is fixedly connected to one end of the vehicle frame, fixing bases are fixedlyconnected to the bottom end of the vehicle frame, and rolling wheels are rotationally connected to the two ends of the two fixing bases. A soil collecting and crushing mechanism is installed in one fixing base, a heating cylinder is fixedly connected to the top end of the vehicle frame, a soil repairing and discharging mechanism is embedded in the heating cylinder, use is safe and convenient, thesoil collecting and crushing mechanism is arranged, and through cooperation of a positioning pin, a limiting block and a limiting groove, the angle of a shovel plate is conveniently adjusted, so thatthe angle of the shovel plate is adjusted according to the actual ground, the shovel plate is attached to the ground, severely polluted soil is conveniently shoveled up, the soil collection efficiency is improved, the soil remediation efficiency is improved, meanwhile, the labor pressure of workers is reduced, and a rotating shaft, a conveying belt, a rotating rod, a belt and a transmission gearare matched.

Owner:WUHU YUTIANRUN AGRI TECH CO LTD

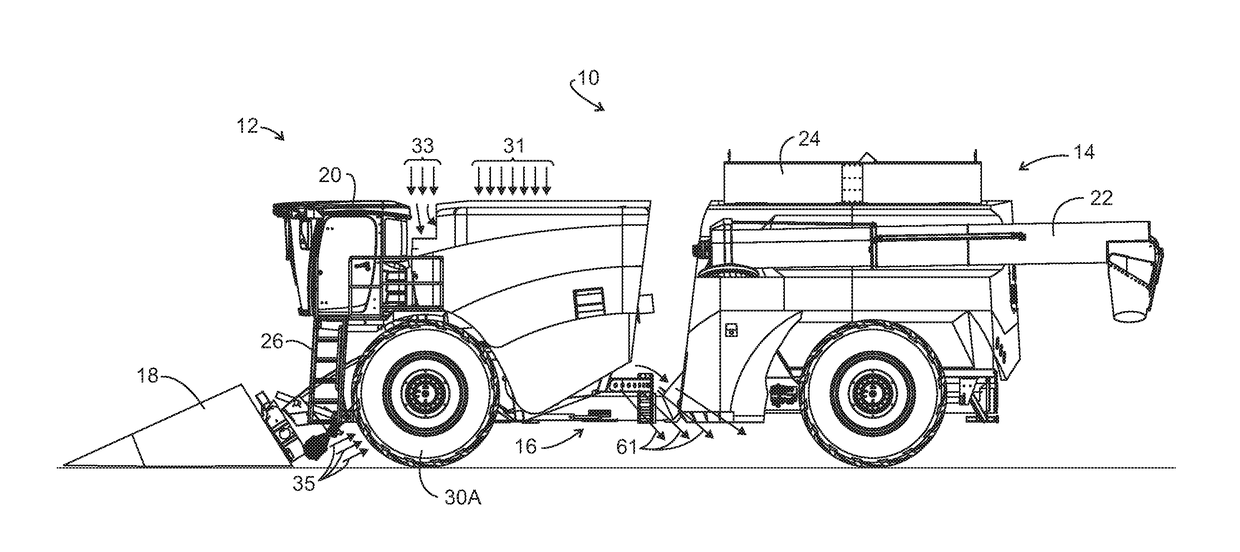

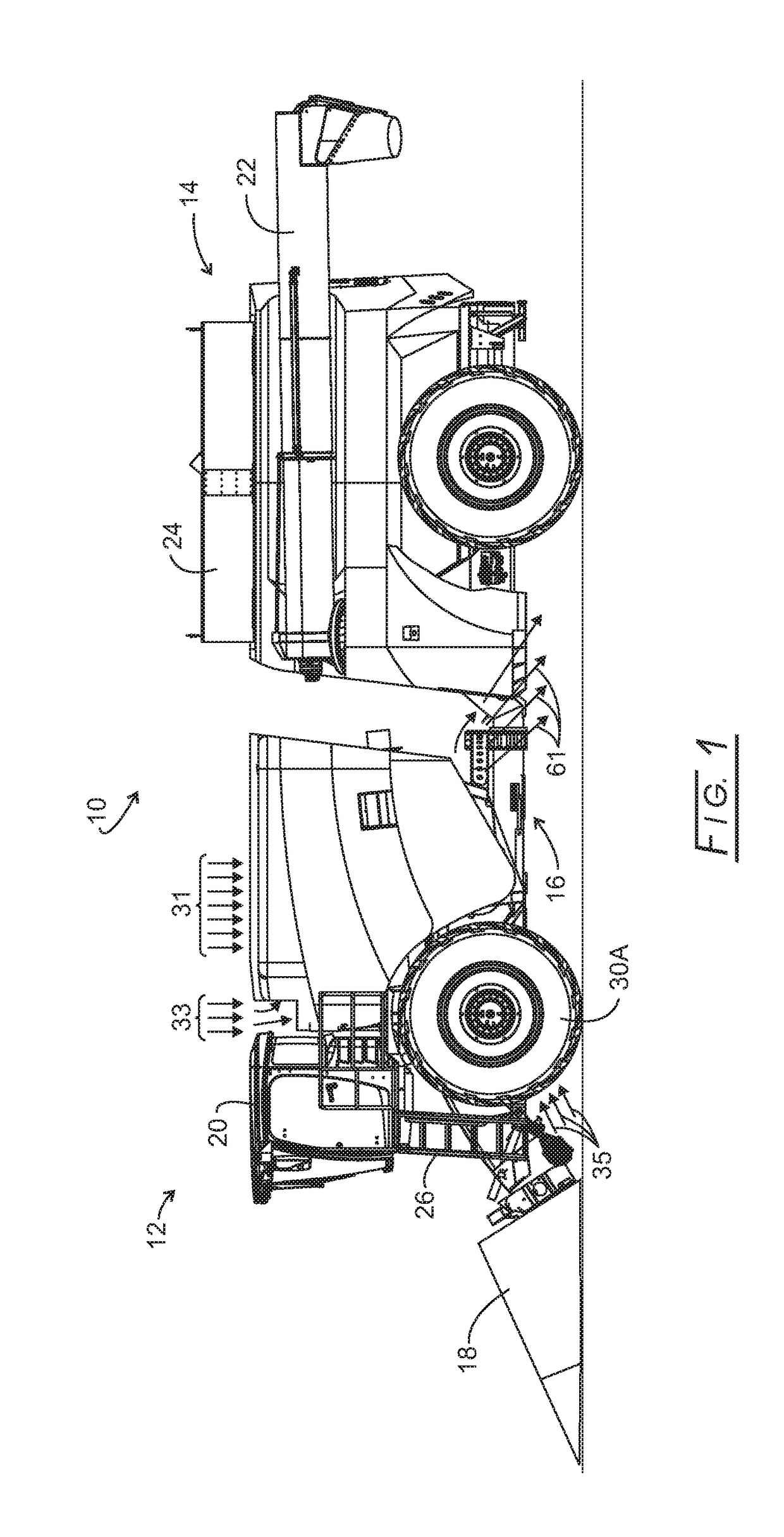

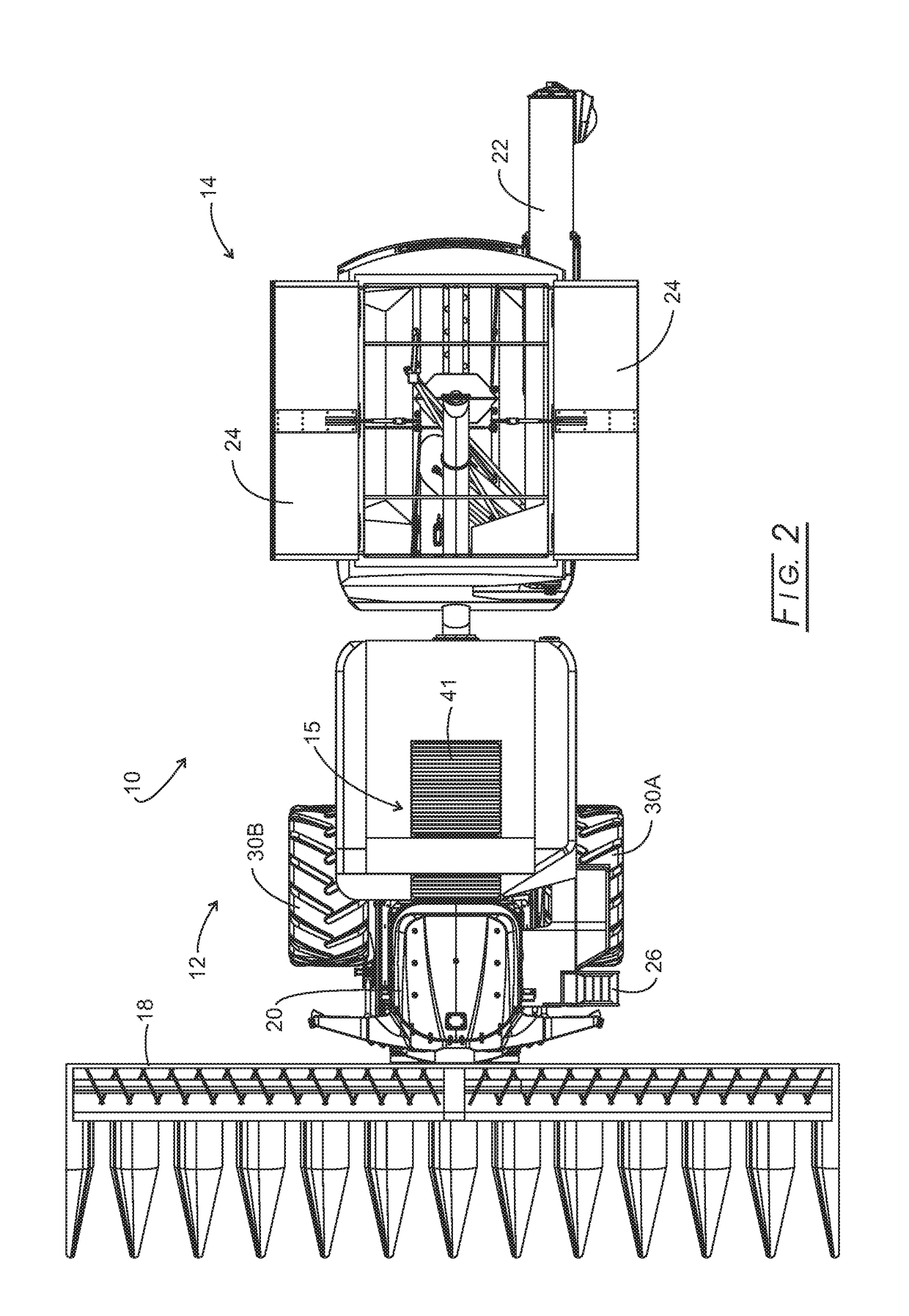

Airflow for an Agricultural Harvesting Combine

ActiveUS20180007830A1Enhance capacityEffectively pre-cleanMowersCombination enginesAirflowInternal combustion engine

Disclosed is a complete engine cooling system for an engine carried by a grain harvesting combine having an internal combustion engine and hot exhaust components, and having a front operator cab. The system includes a generally horizontal fan assembly located atop the harvesting combine for drawing in air, a radiator associated with the engine and over which air flows for engine cooling, and charge air coolers for combustion air cooling, and air conditioning and hydraulic coolers, a centrifugal scroll that takes the drawn in air and removes entrained particles to produce a clean exhaust air and dirty exhaust air; and a filter assembly through which the pre-cleaned exhaust air flows for producing filtered air for admittance into the engine for combustion.

Owner:TRIBINE IND

Integrative sorting machine for household garbage

PendingCN106391471AImprove sorting effectImprove sorting efficiencySievingGas current separationBrickEngineering

The invention discloses an integrative sorting machine for household garbage. The integrative sorting machine for the household garbage comprises a feeding device (1), a vibrating screen (3), a first-time winnowing device (2) and a second-time winnowing device (4). The feeding device (1) is arranged above the first-time winnowing device (2), the vibrating screen (3) is obliquely installed, the feeding end of the vibrating screen (3) is higher than the discharging end of the vibrating screen (3), the feeding end of the vibrating screen (3) is connected with the lower portion of the first-time winnowing device (2), and the discharging end of the vibrating screen (3) is connected with the second-time winnowing device (4). The integrative sorting machine for the household garbage is high in sorting efficiency, good in sorting effect, and capable of effectively relieving the manual labor intensity, and sorting, separating and recycling materials such as bricks, glass bottles, batteries, and iron blocks with the specific gravity being larger than 1.5, materials such as big block fruits with the specific gravity being about 0.8-1.5, and mud and sand.

Owner:高细平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com