Patents

Literature

5119results about How to "Scientific and reasonable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

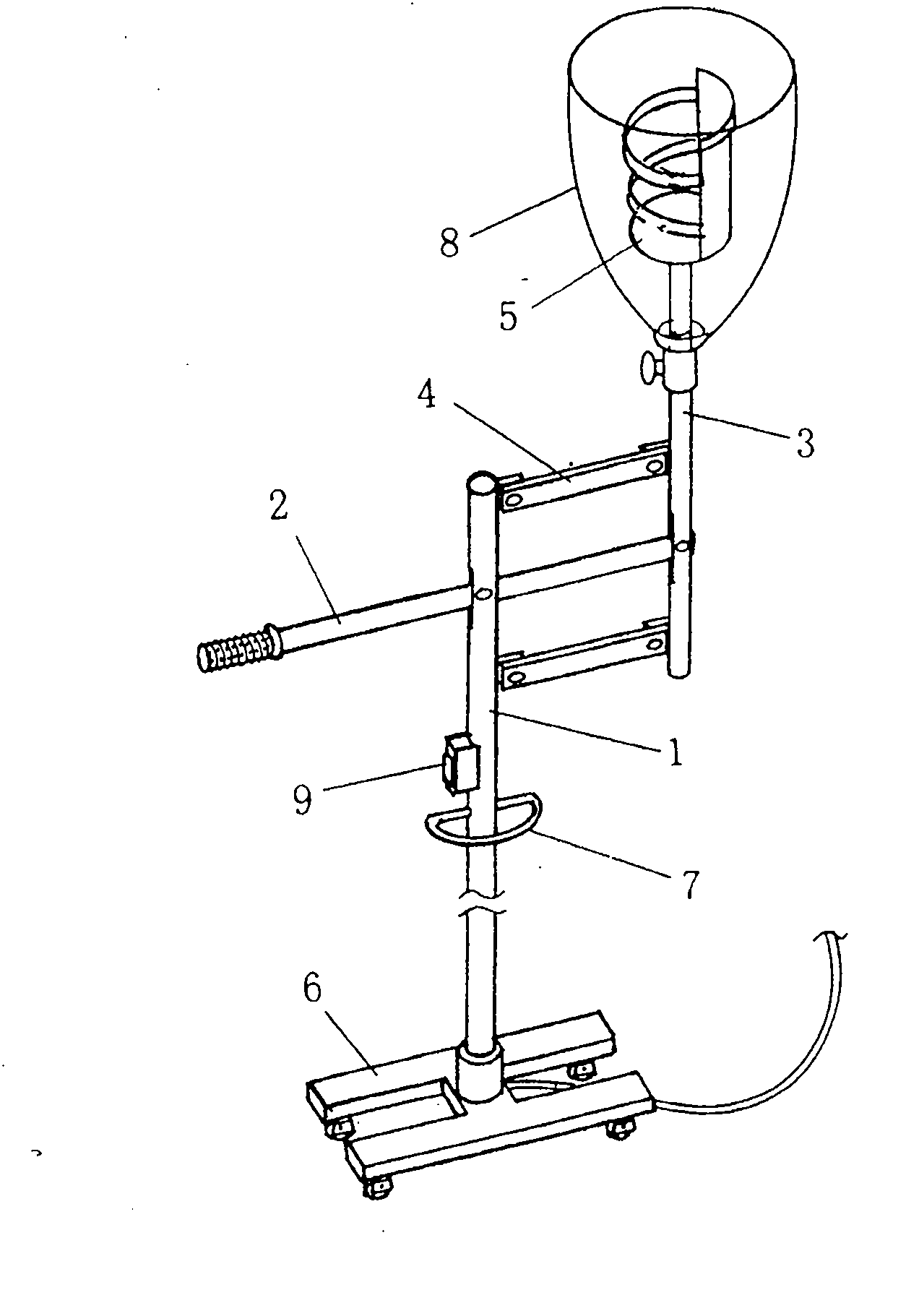

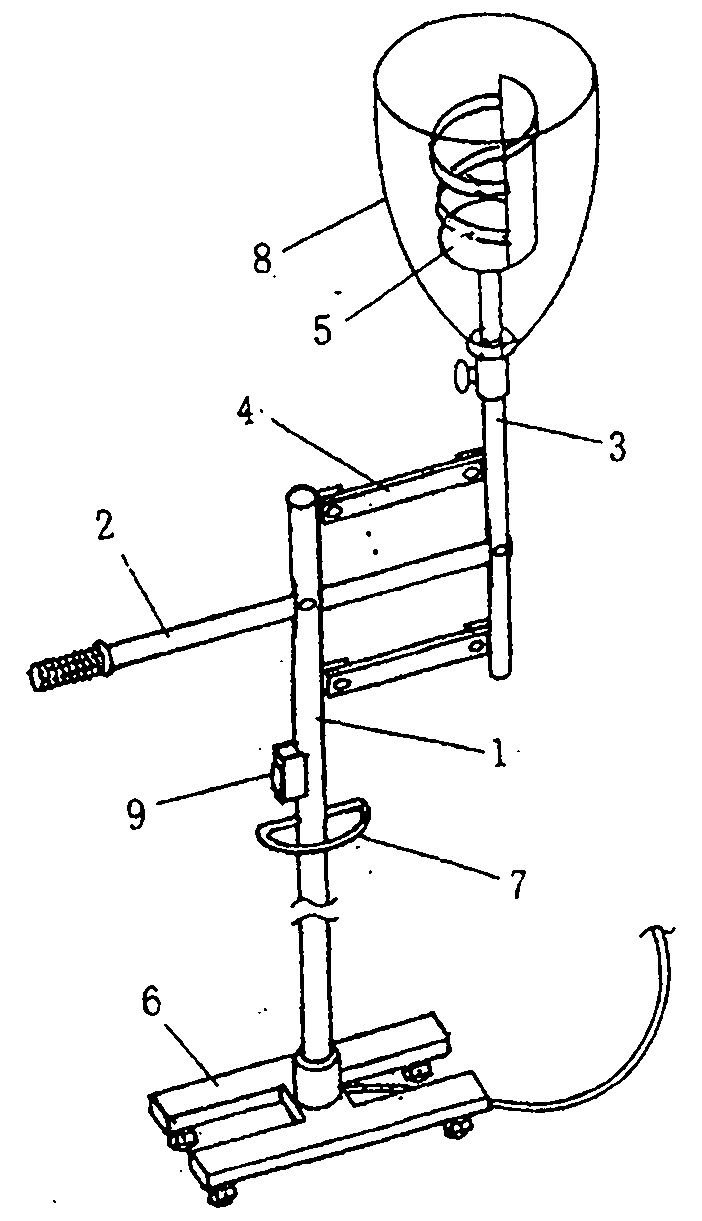

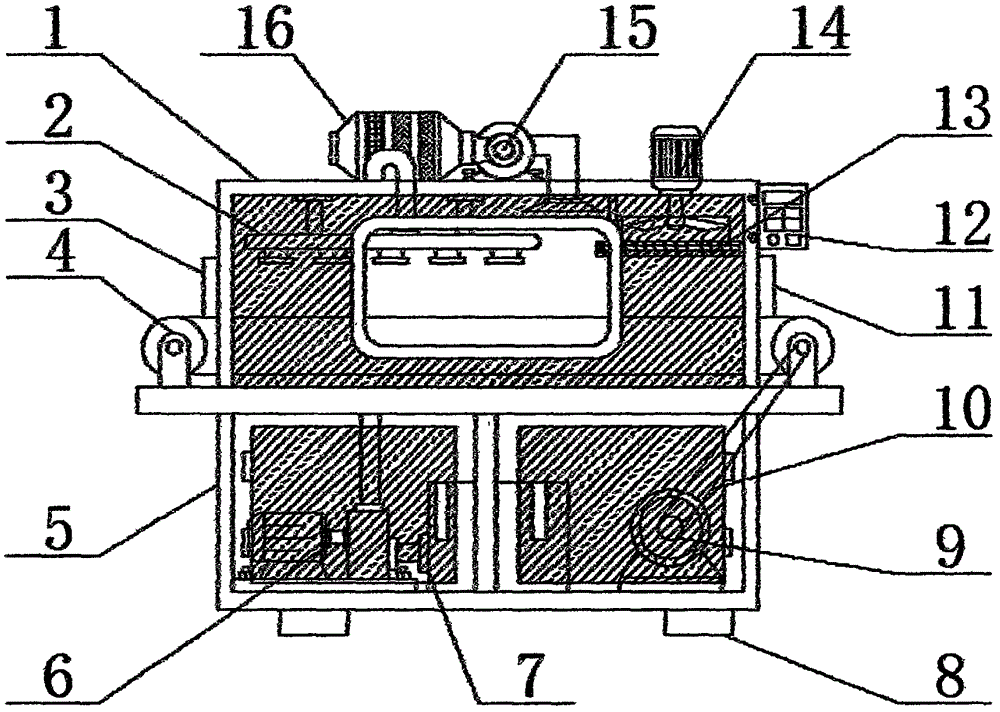

Mobile support frame for electric drill

InactiveCN102145398AGood for healthScientific and reasonable structurePortable drilling machinesPunchingPower switching

The invention provides a mobile support frame for an electric drill. An ejector rod is connected above a mobile support rod through a movable operating lever, the upper end of the ejector rod is provided with an electric drill fixing frame and a dust collecting cover, the lower end of the support rod is provided with a sliding base, a movable support rod used for positioning and reinforcing is arranged at the connecting part of the movable operating lever and the ejector rod, and the support rod is provided with a mobile operating handle and a power switch or a power socket with a switch. When the mobile support frame is used, the electric drill can be fixed on the electric drill fixing frame, the flat top of the ceiling above can be punched through pressing the movable operating lever, and the whole device can move as required, therefore, the trouble and fatigue of difficult operation of ceiling punching by the handheld electric drill can be solved, the labor intensity of workers is reduced, and the mobile support frame has the obvious characteristics that the construction and operation are convenient, and the working efficiency is improved.

Owner:XIANGFAN UNIVERSITY

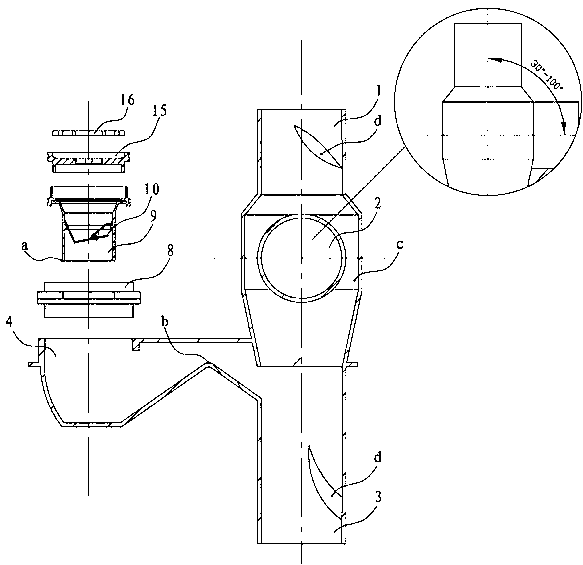

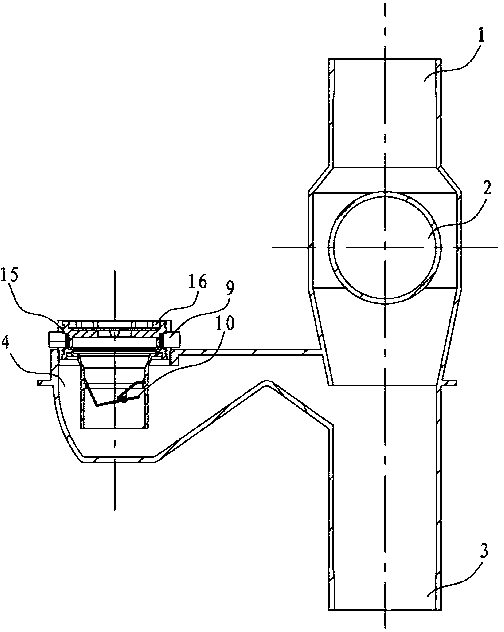

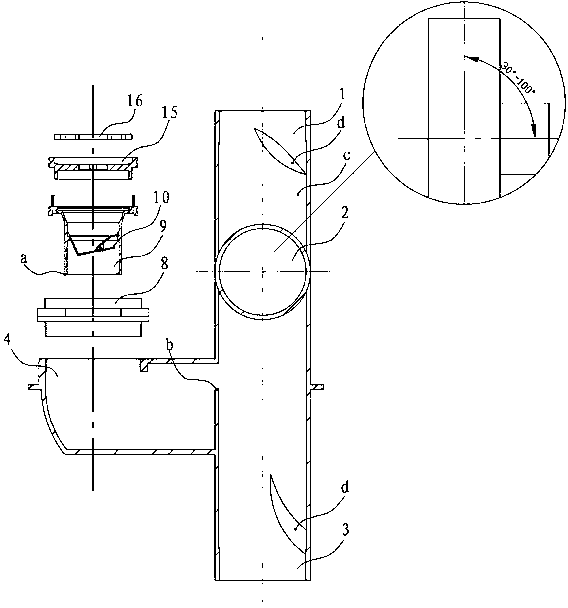

Same floor draining joint for building

InactiveCN102839724AIncrease drainage flowTo achieve the separation effectDomestic plumbingToiletCivil engineering

The invention relates to a same floor draining joint for a building, in particular to a same floor draining joint for a toilet, which consists of an upper vertical pipe draining port, a lower vertical pipe draining port and at least two transverse pipe draining ports; the upper vertical pipe draining port is communicated with the upper end and the lower end of the lower vertical pipe draining port; the at least two transverse pipe draining ports are staggered in position and are arranged between the upper vertical pipe draining port and the lower vertical pipe draining port; the orientation of the inlet of at least one of the transverse pipe draining ports is equal to or nearly equal to the orientation of the upper vertical pipe draining port, and the orientation of the inlet of at least one of the transverse pipe draining ports forms an included angle of 30-100 degrees with the orientation of the upper vertical pipe draining port. The same floor draining joint is rational and scientific in structure, and is capable of realizing the same floor draining and the same floor maintenance when the draining joint is adopted in the same floor draining of the non-falling plate or falling plate; the draining is more safe; the water is not easy to accumulate in the falling plate layer even the way of the falling plate is adopted, and the accumulated water is safely and completely discharged, so as to avoid the foreign smell in the room.

Owner:KUNMING QUNZHIYING TECH

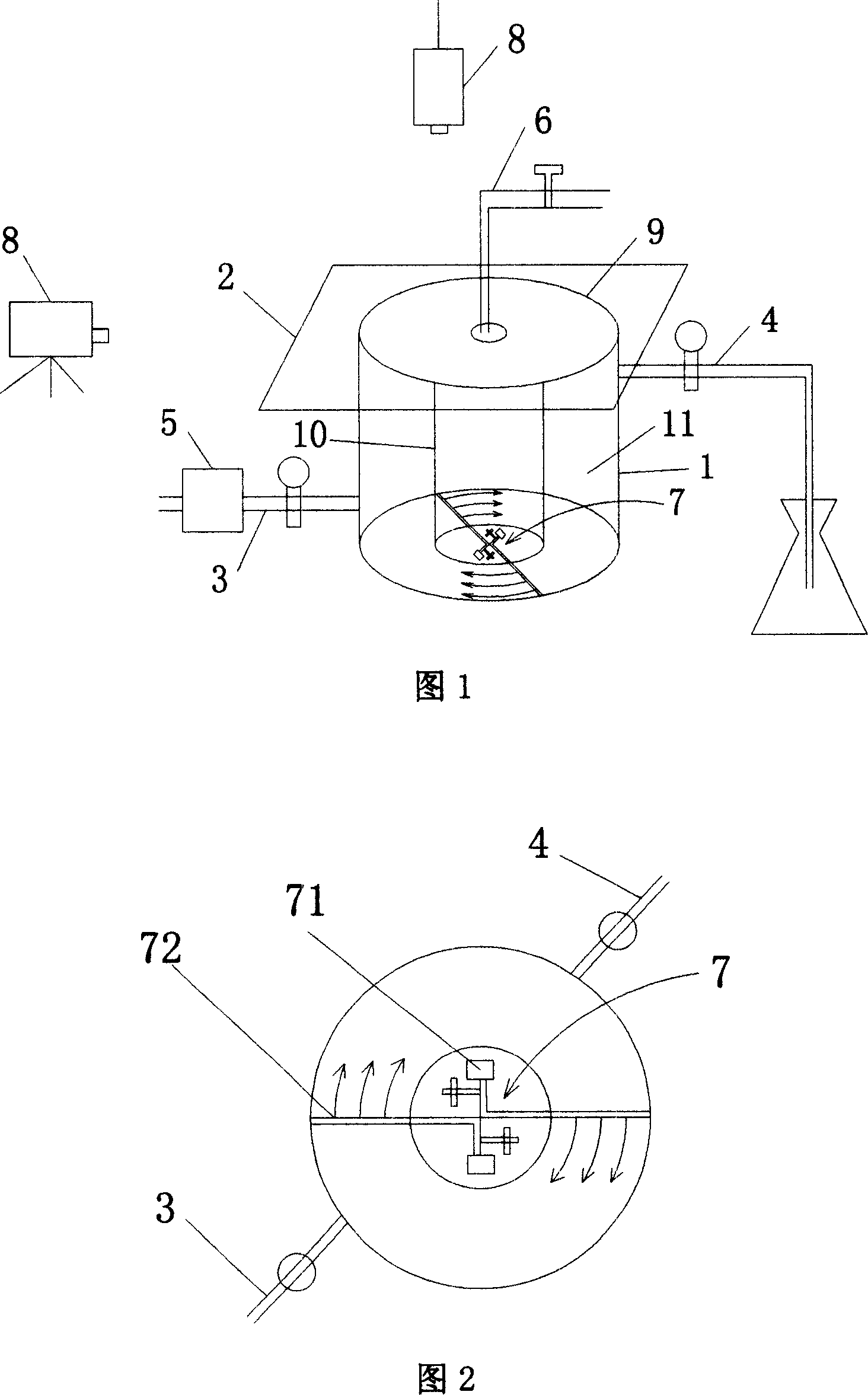

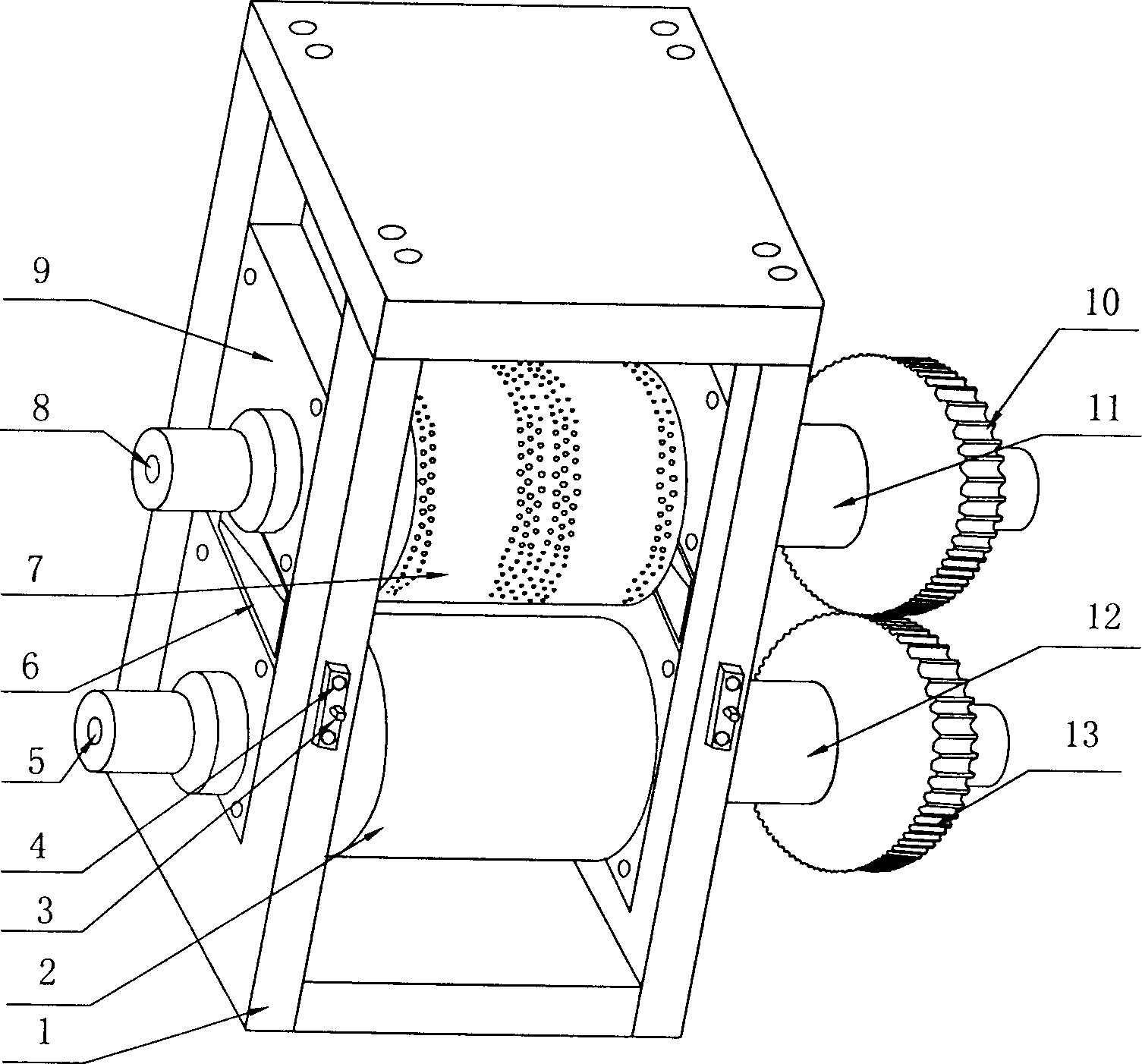

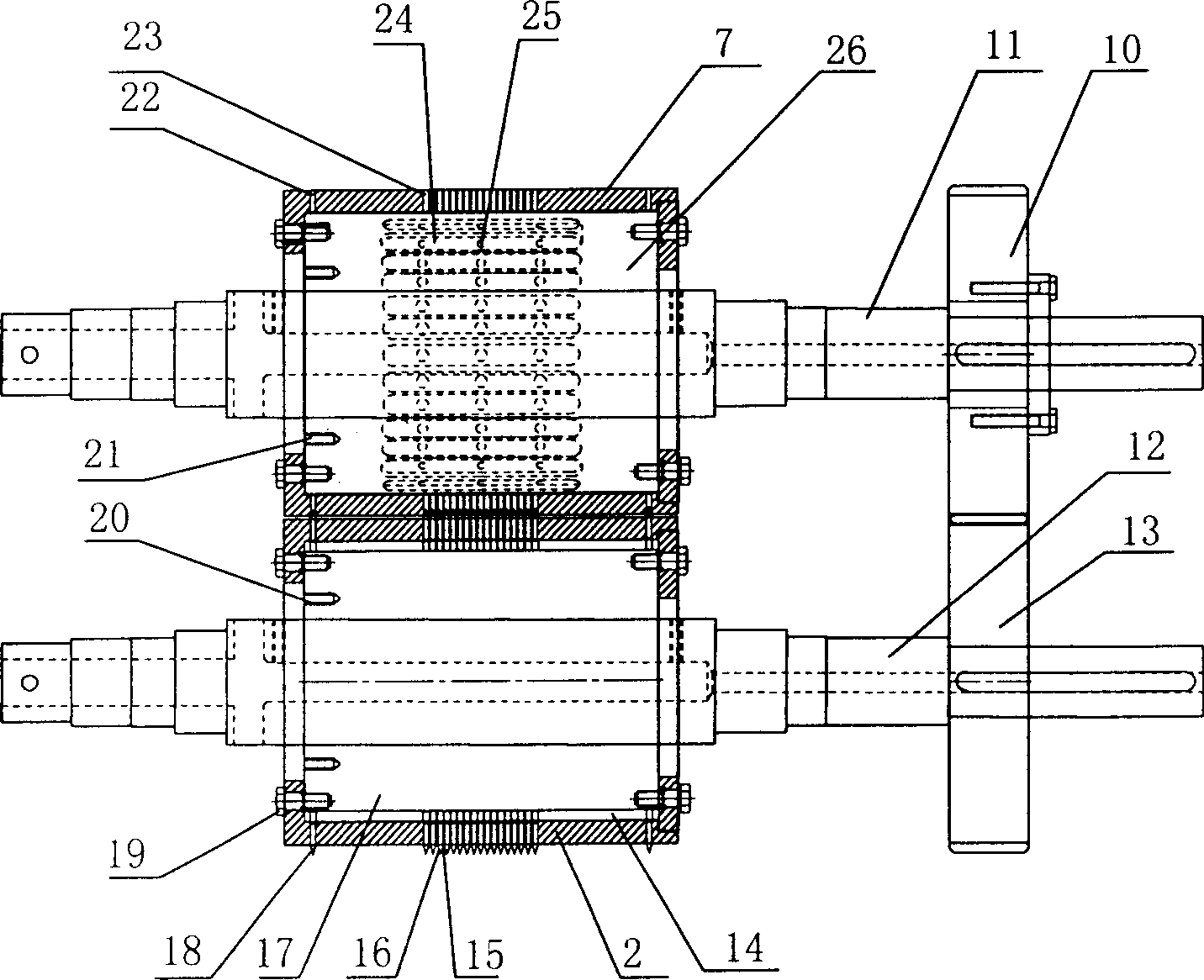

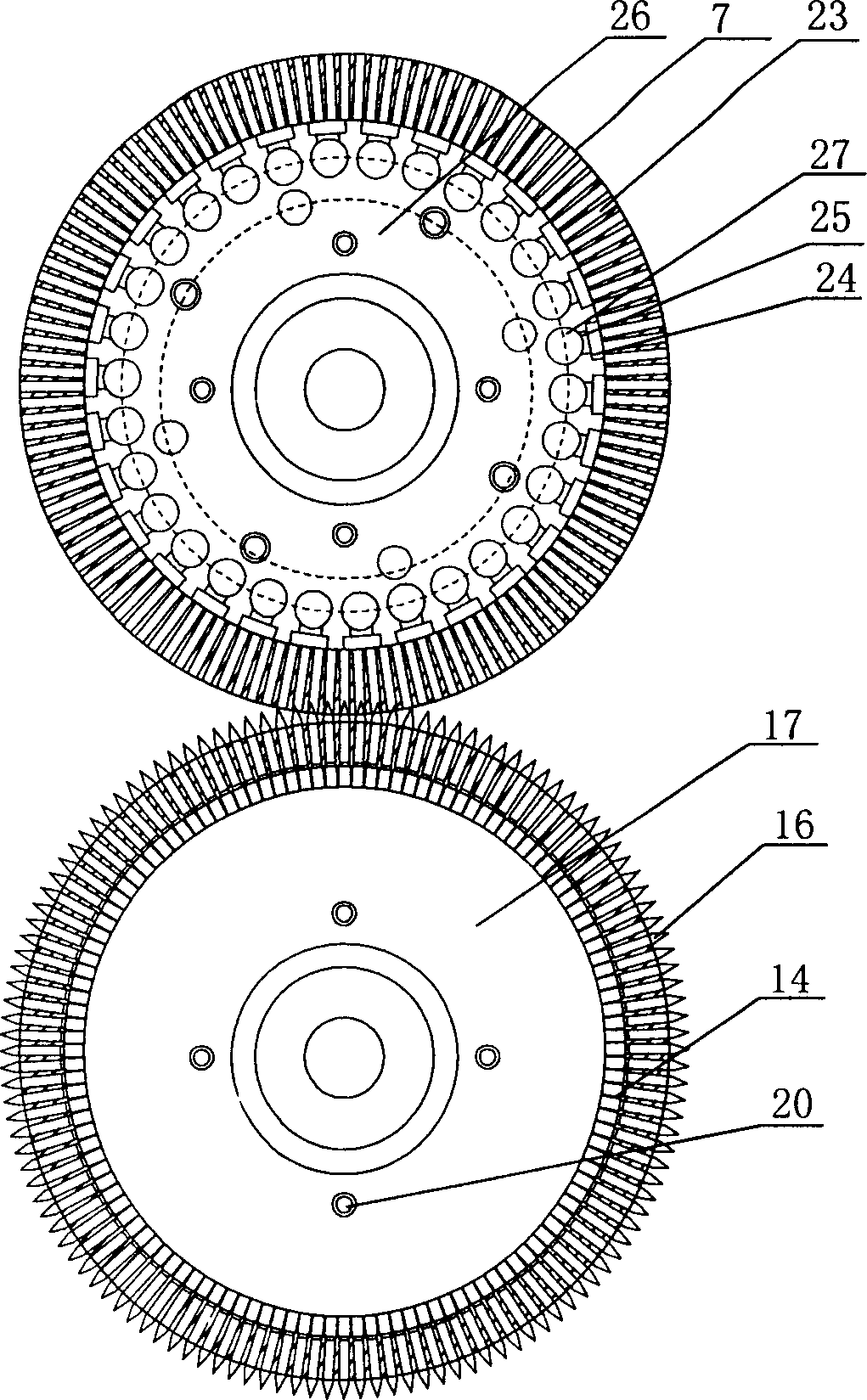

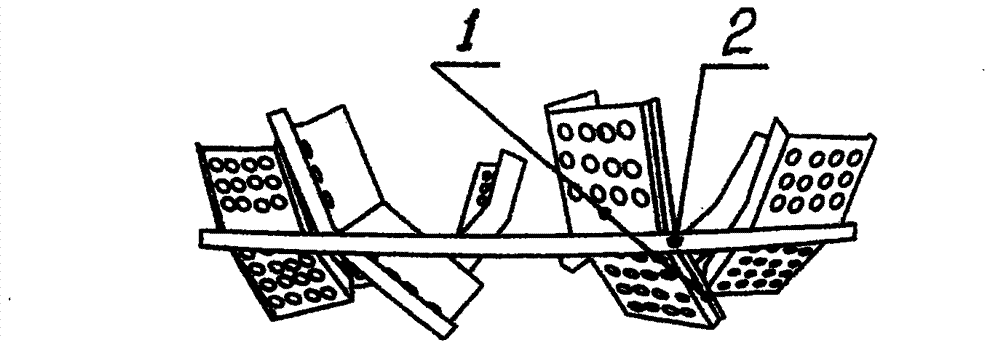

Synchronous recording and detecting apparatus for fish movement metabolism

InactiveCN101011042AFlow rate does not affectSimultaneous determination of activityClimate change adaptationPisciculture and aquariaRespiration chamberWater channel

The invention relates to a device for synchronously recording the metabolism and swimming motion of fish, comprising a sealed water groove, which is connected with a water inlet tube and a water outlet tube, and a flux adjuster mounted on the water inlet tube. The water groove has annular water channel, and a water-flow generating adjusting device for controlling the water flow to flow along the annular water channel in one direction. The sealed water groove is made from transparent material. The camera device is mounted above / beside the sealed breath room. The invention can measure the basic or general metabolism, at different strengths, and record the swimming motion.

Owner:JINAN UNIVERSITY

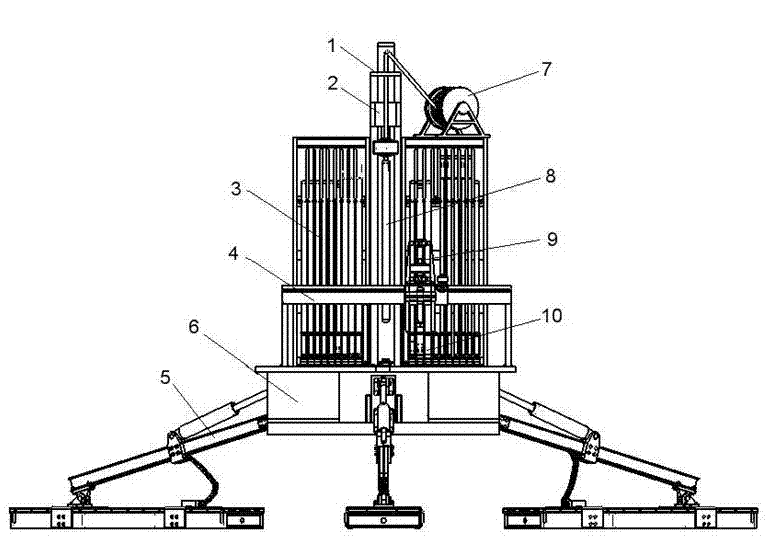

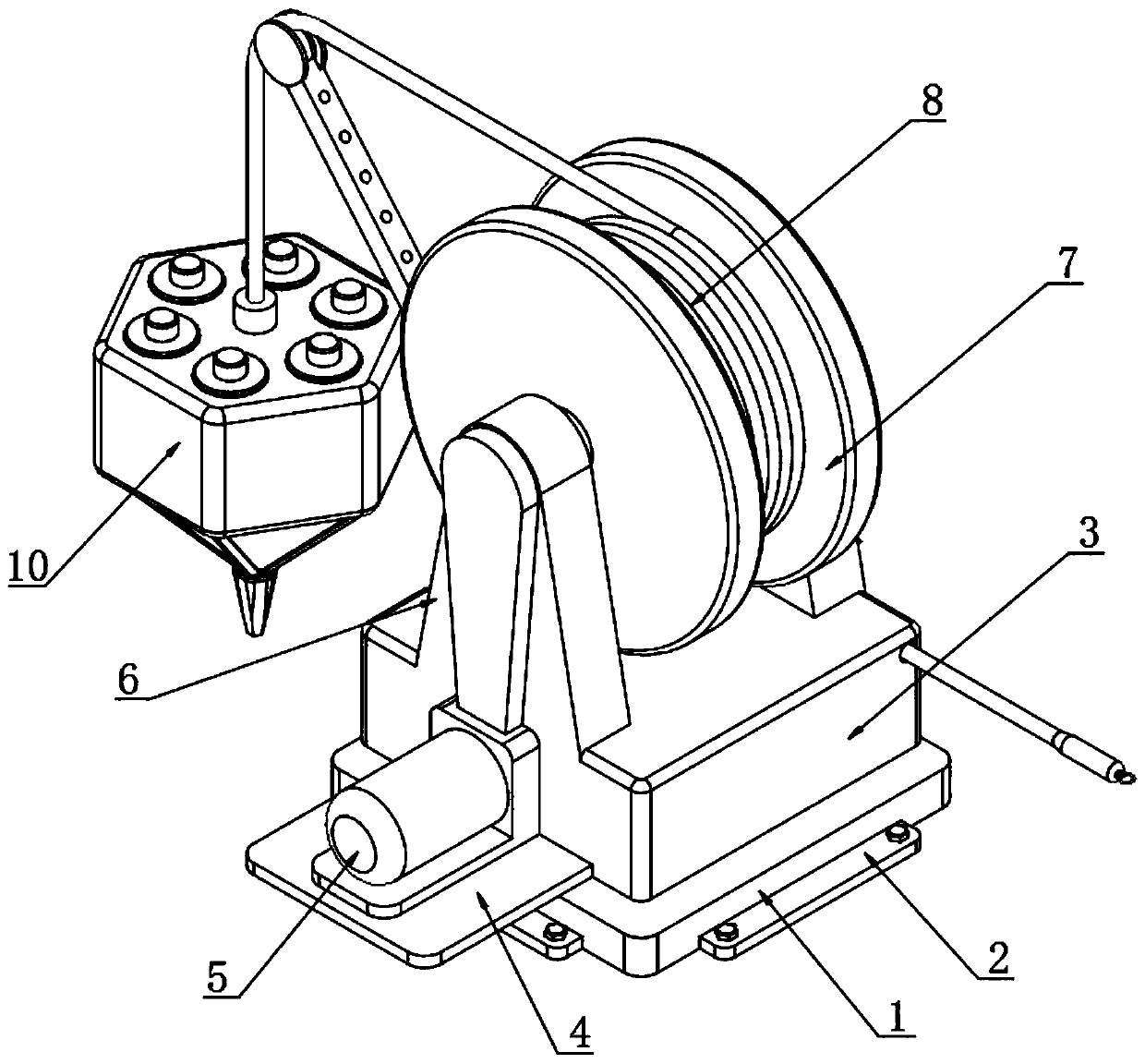

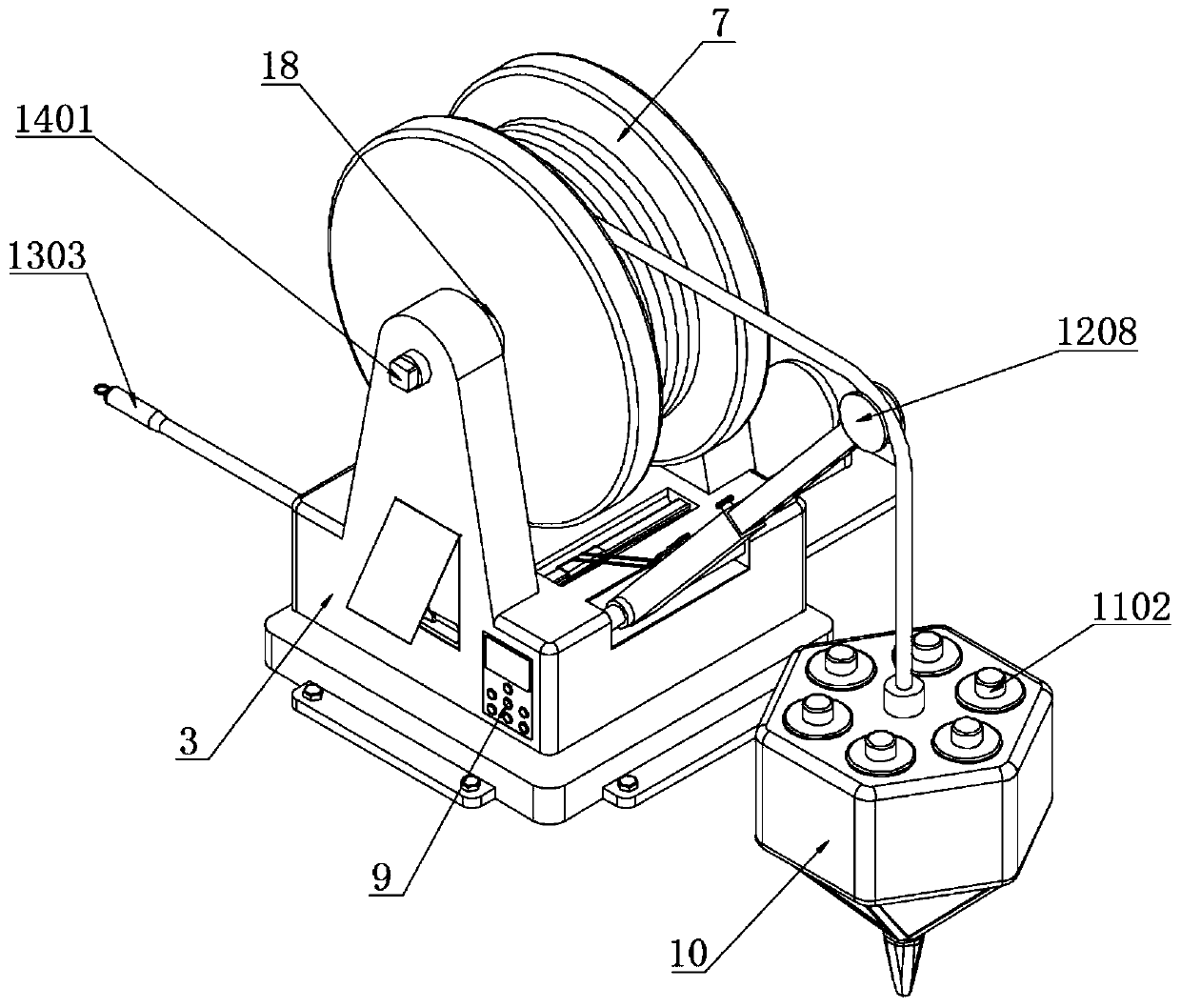

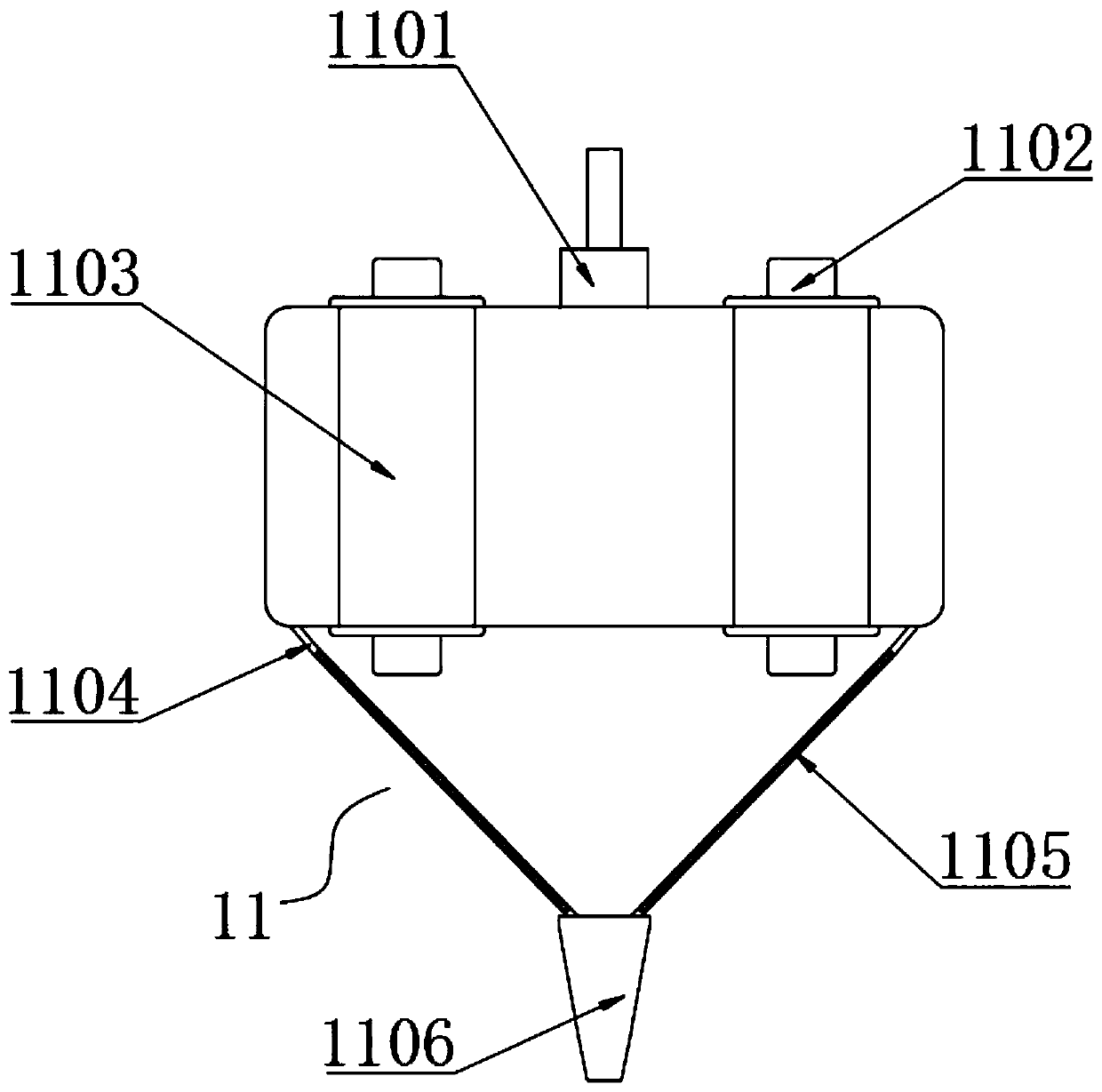

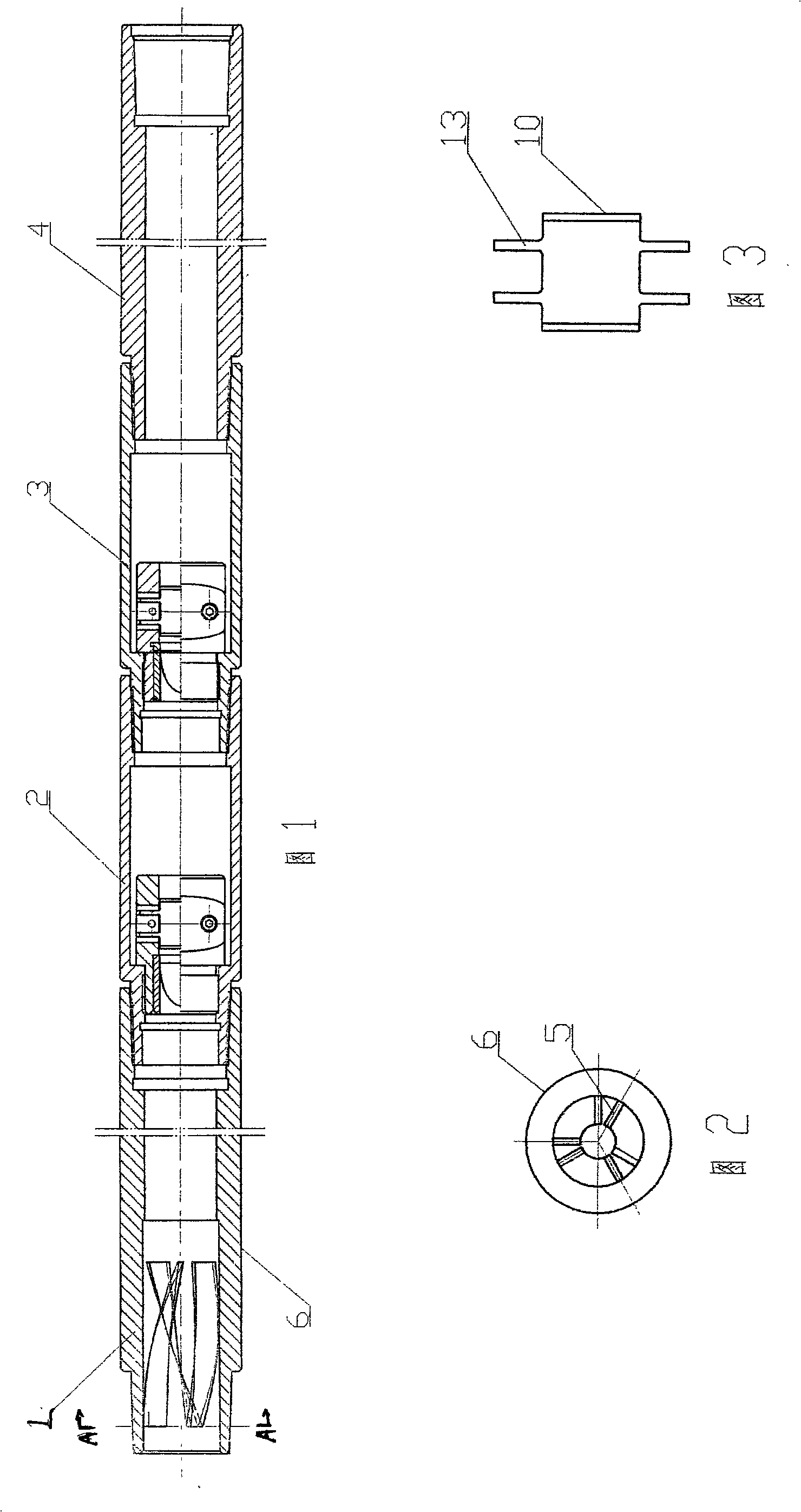

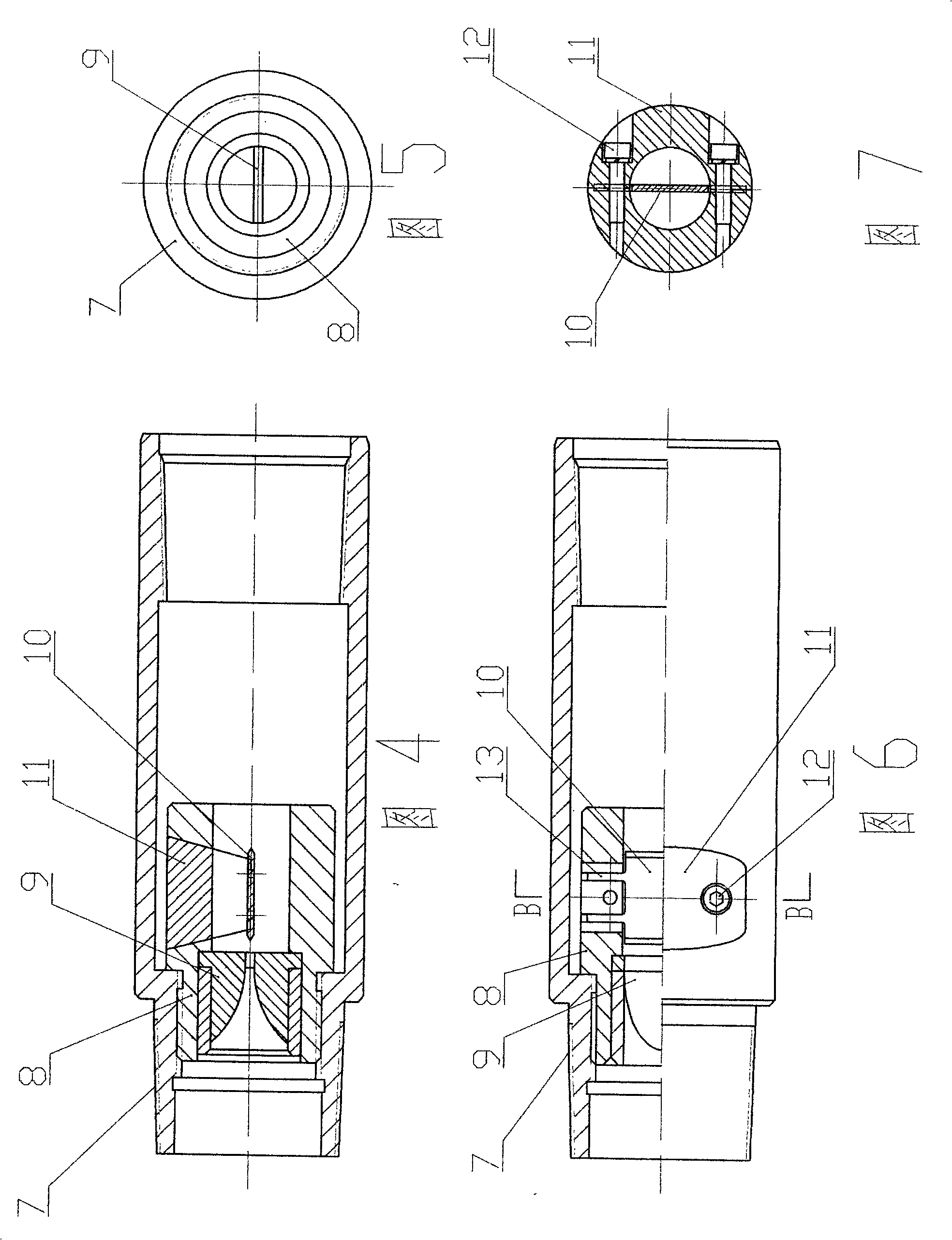

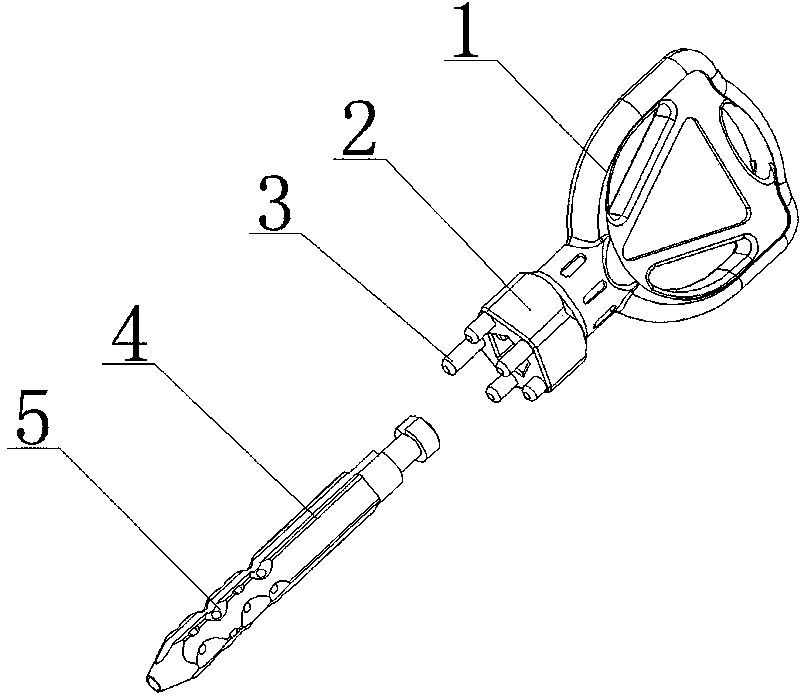

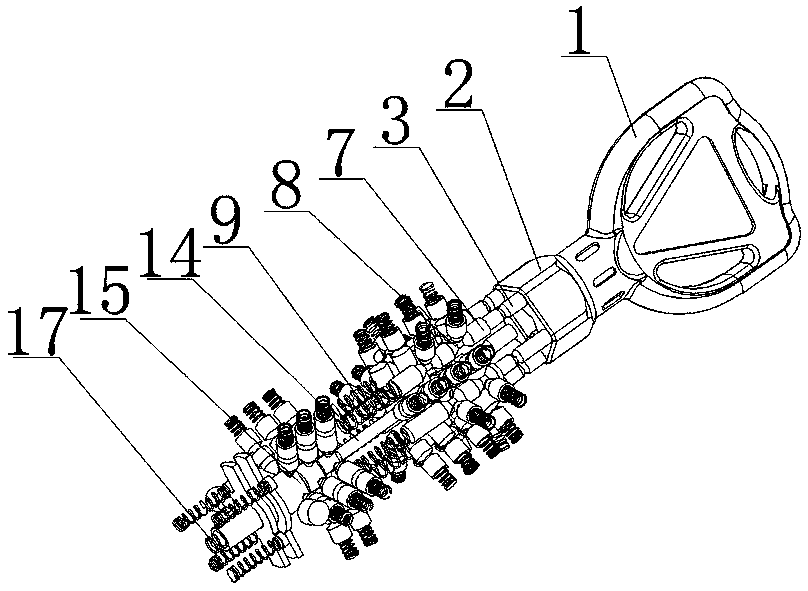

Seabed type conical investigating and drilling integrated machine

InactiveCN102383723AIncrease coefficient of frictionImprove securityDrilling rodsConstructionsManipulatorEngineering

The invention relates to a seabed type conical investigating and drilling integrated machine which comprises a tower, a power head, a drilling tool storeroom, a manipulator mechanism, a leveling mechanism, an instrument box, a winch, a drilling tool, a clamp holder and a hydraulic pump. According to the drilling process of a seabed drilling machine, the power head provides the rotation power and realizes the feeding and recycling of the drilling tool through a tower guide rail on the tower; the drilling tool storeroom is arranged on the two sides of the power head and used for storing variousdrilling tools; the drilling tools are automatically stored and fetched through the manipulator mechanism, and the leveling mechanism keeps the drilling tool vertical to the seafloor when the integrated machine works; a core barrel for wire line coring is released and recycled by the winch; and the drilling tool is clamped and removed by the clamp holder. The integrated machine provided by the invention has a scientific and reasonable structure, is simple and convenient to control and safe and reliable to use and is suitable for the large-depth deep hole core sampling on seabed and also for operation on land.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

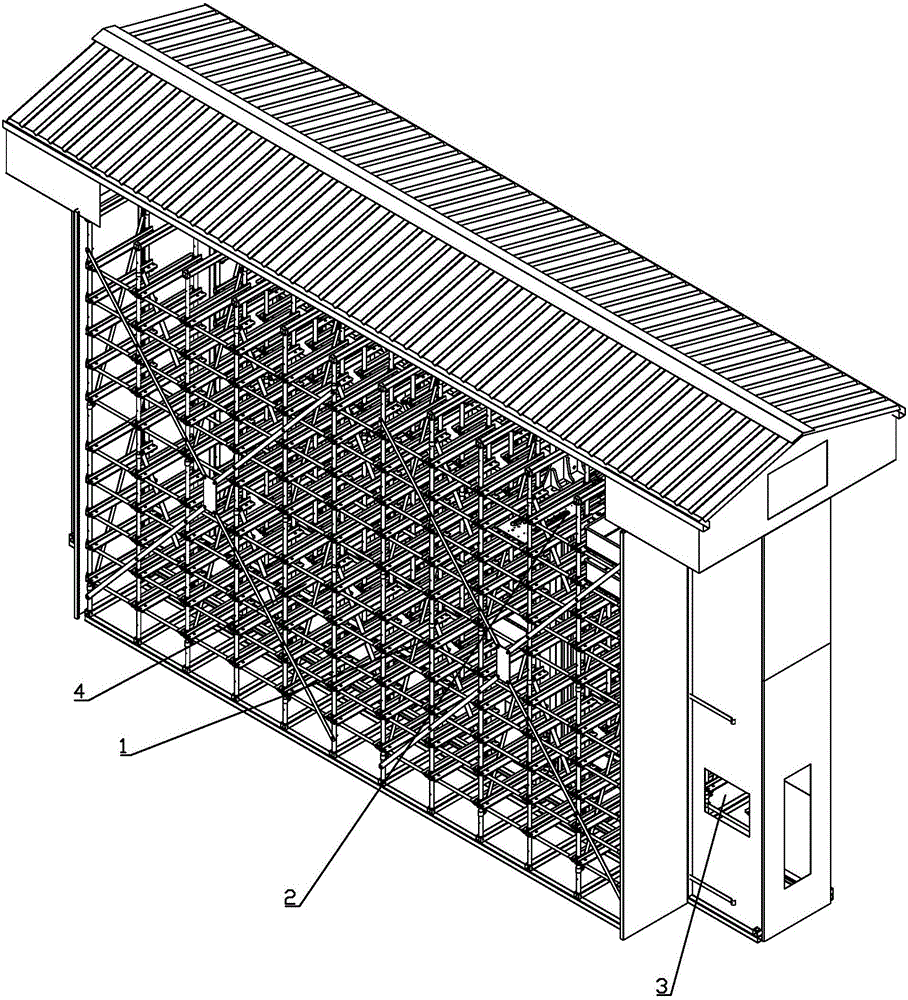

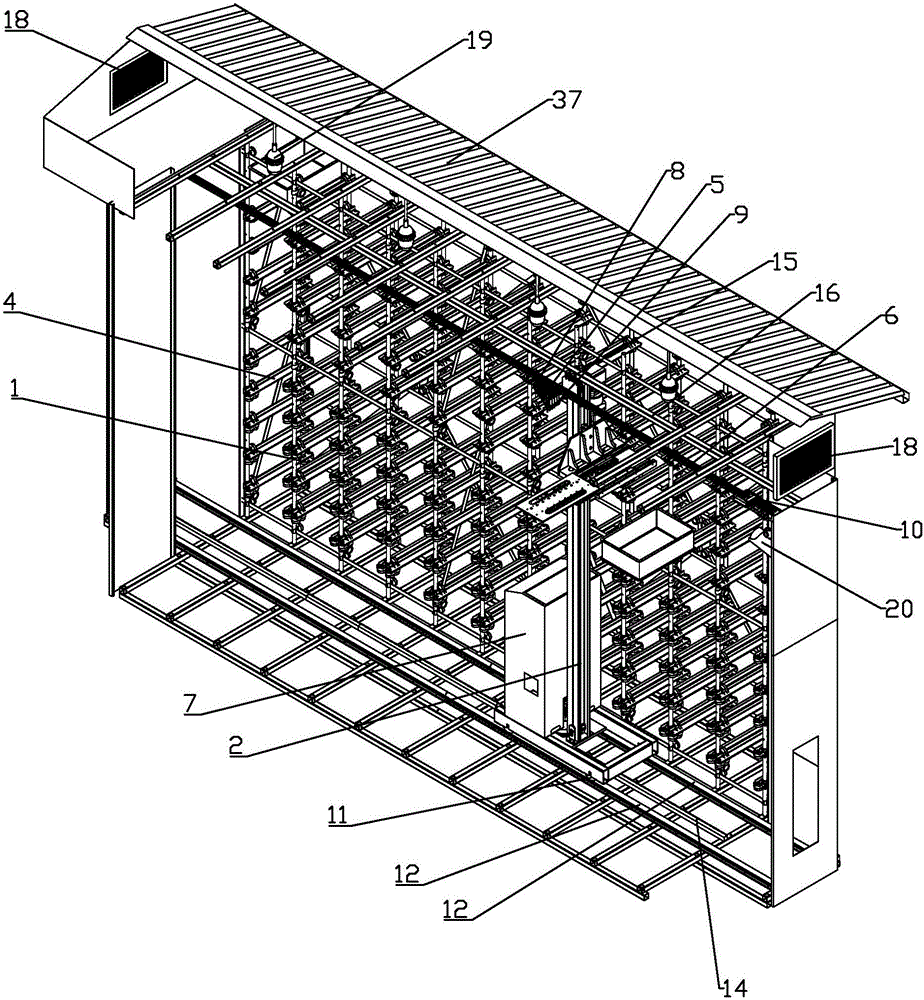

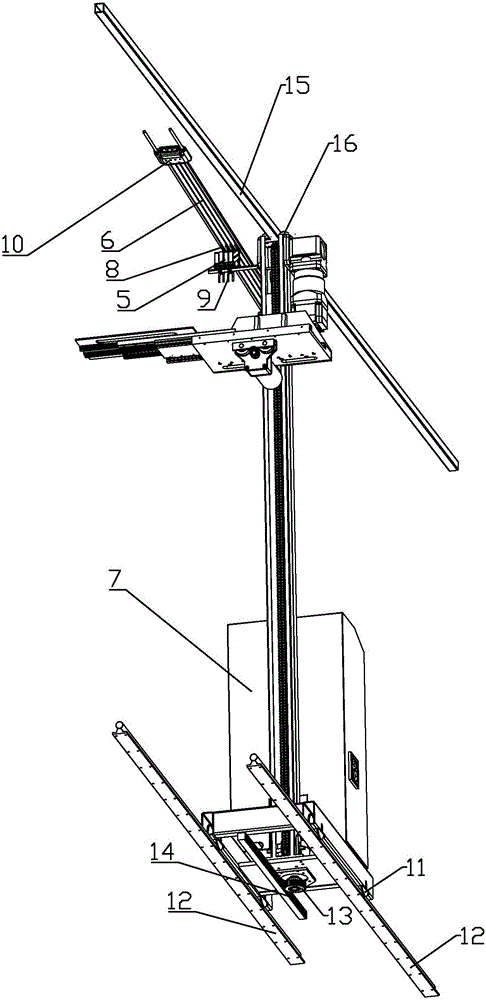

Intelligent storage equipment and control method thereof

InactiveCN106081464AScientific and reasonable structureIncrease running distanceStorage devicesNumerical controlControl engineering

The invention discloses intelligent storage equipment which comprises a storage shelf and a roadway robot. The storage shelf is provided with a plurality of storage sites and a space allowing the roadway robot to act. The intelligent storage equipment is characterized in that the roadway robot is provided with a chute current collector, the storage shelf is provided with a power supply chute wire for being connected with commercial power, and the chute current collector and the power supply chute wire are in coupling contact so as to supply power to the roadway robot. The roadway robot of the intelligent storage equipment corresponds to the power supply chute wire through a contact of the chute current collector, so that contact power supply is conducted, dragging of power supply cables is avoided, the operation distance is longer, and the operation speed is higher. The invention further discloses a control method for the intelligent storage equipment. The storage shelf is standardized, so that numerical control coordinate positioning of all the storage sites can be achieved, and the roadway robot can store and fetch goods automatically; and besides, the goods storage and fetching information can be recorded, so that docking and correlation between the storage equipment and an enterprise resource planning (ERP) administration system are achieved, and intelligent storage is achieved.

Owner:广东易库智能仓储设备科技有限公司

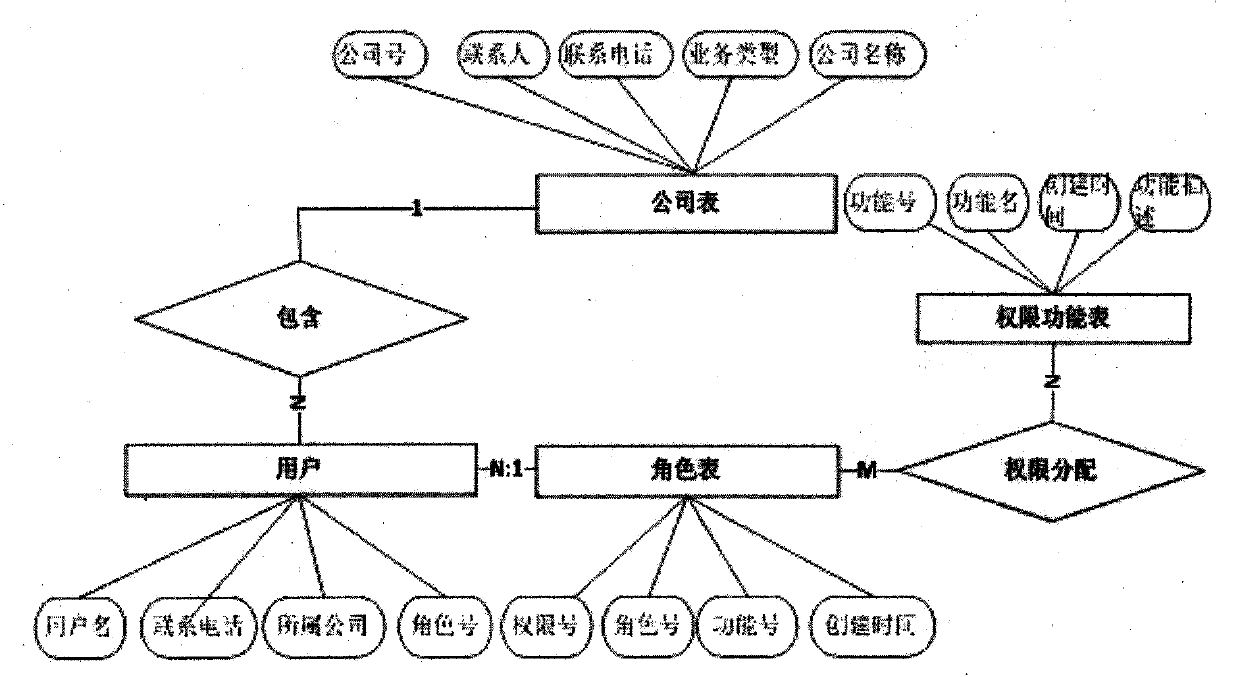

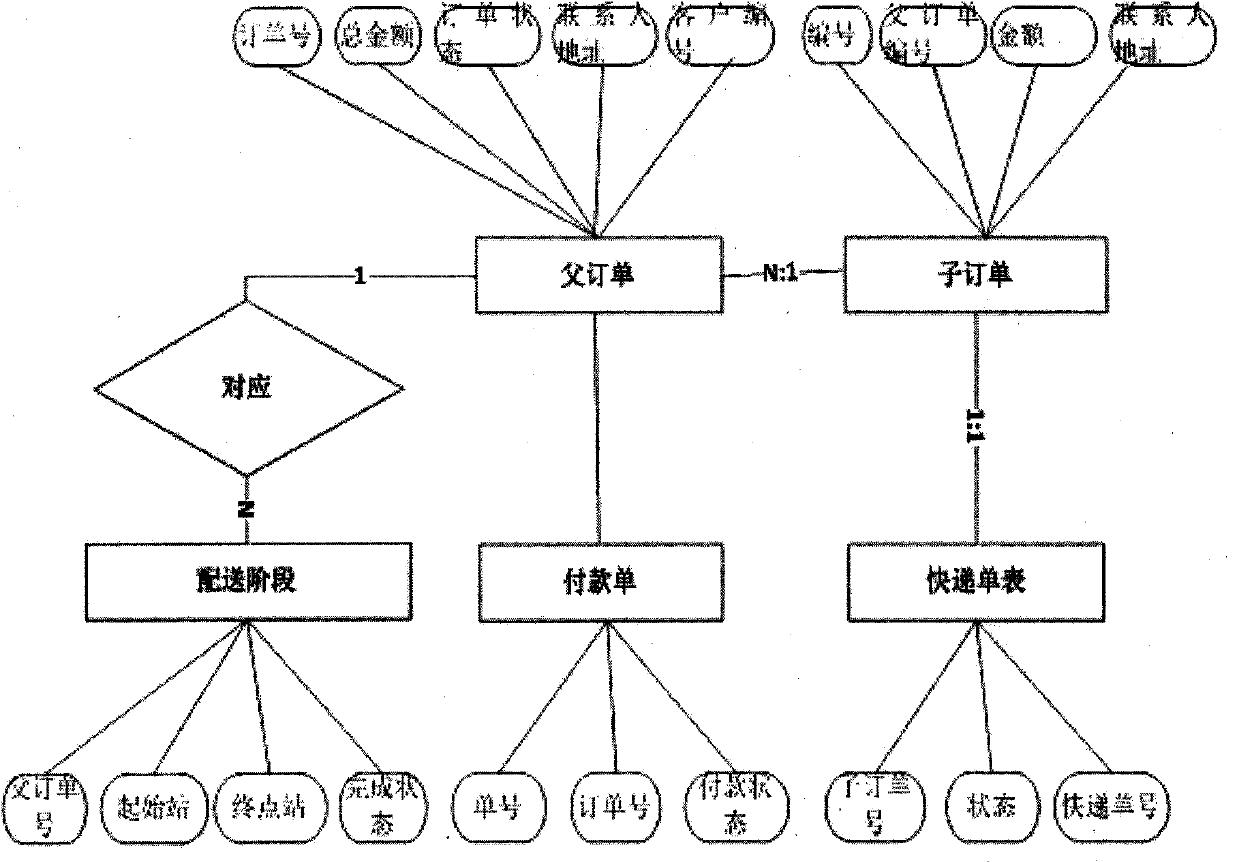

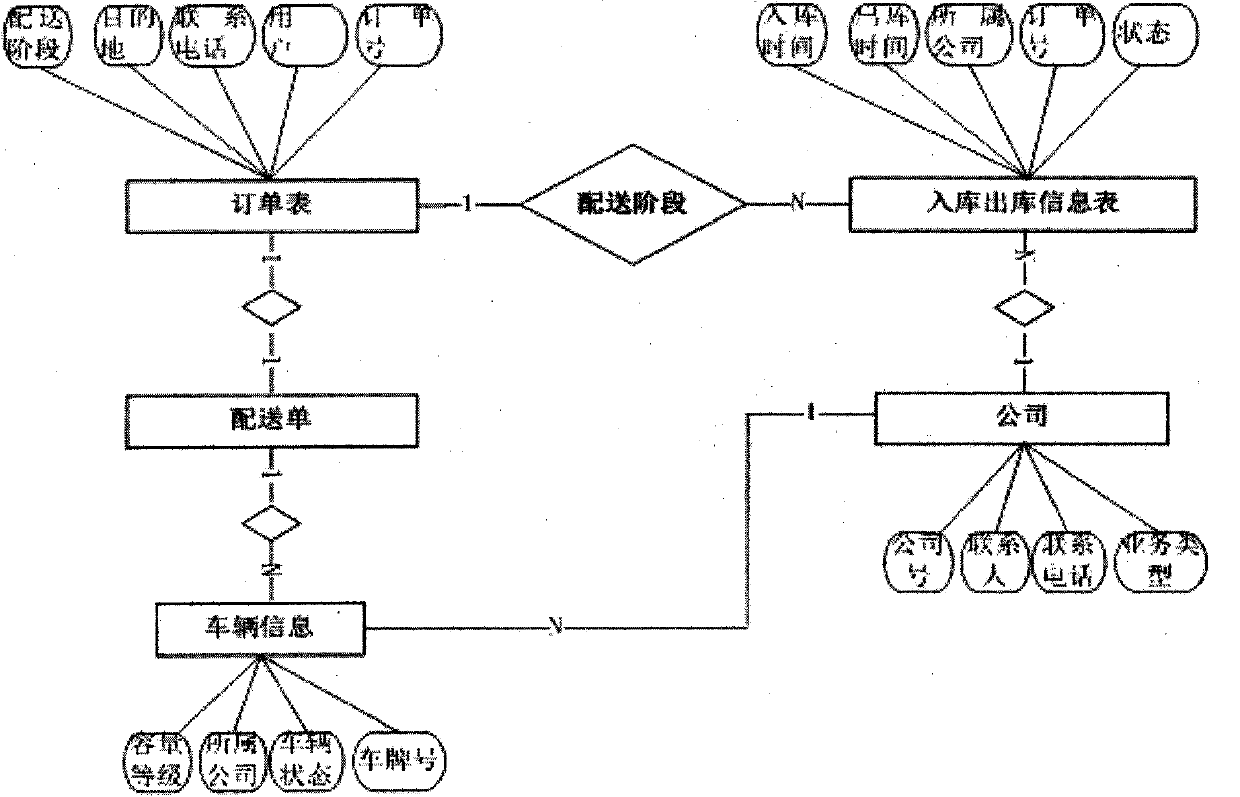

Inventory and distribution management system based on cloud computing

InactiveCN104050553AImprove securityDynamic Load BalancingLogisticsReal-time dataLogistics management

The invention discloses an inventory and distribution management system based on cloud computing. A Hadoop software architecture is applied for achieving distributed processing of mass Web data of the inventory and distribution management system, so that the safety of the inventory and distribution management system with respect to mass data storage is improved; in the cloud computing technology, distributed data storage can achieve dynamic load balance and automatic takeover of a failure node, so that high reliability, high performance, high availability and high extendibility are achieved; the inventory and distribution management system is established on a cloud computing public technology service platform so that abundant enterprises on a supply chain can conduct inventory management and logistics distribution in a finer and dynamic mode, and informationized running cost of export-oriented enterprises is reduced; the system can be applied to intelligent terminals; by the adoption of a Redis database, the functions of cluster deployment dynamic expansion, real-time data analysis, real-time data query, real-time data collection, real-time uploading, real-time communication and the like can be achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

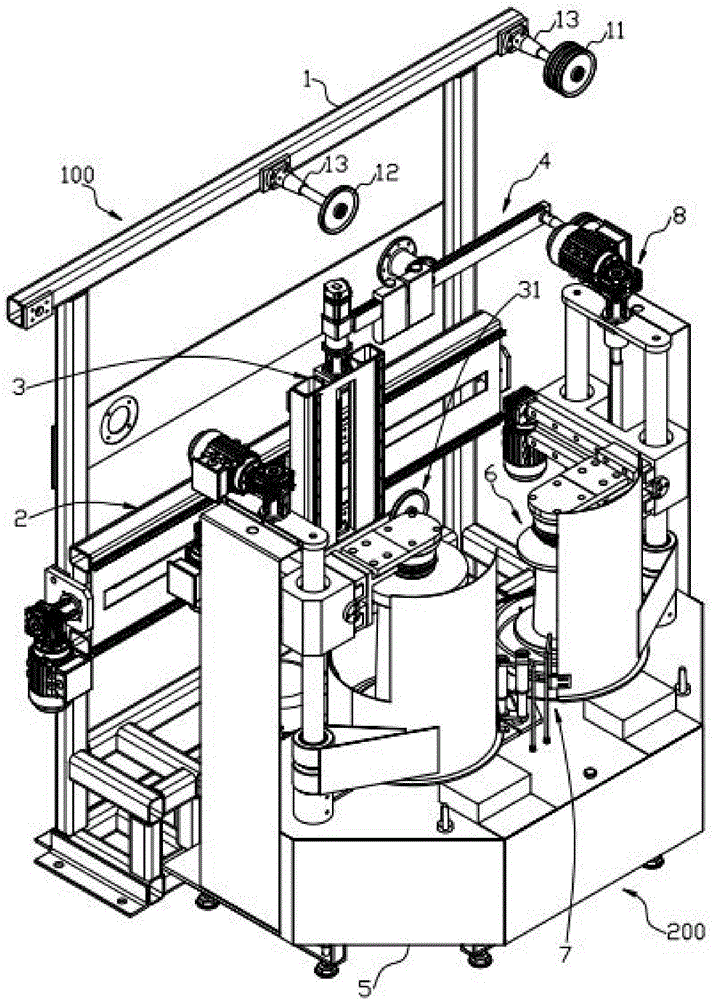

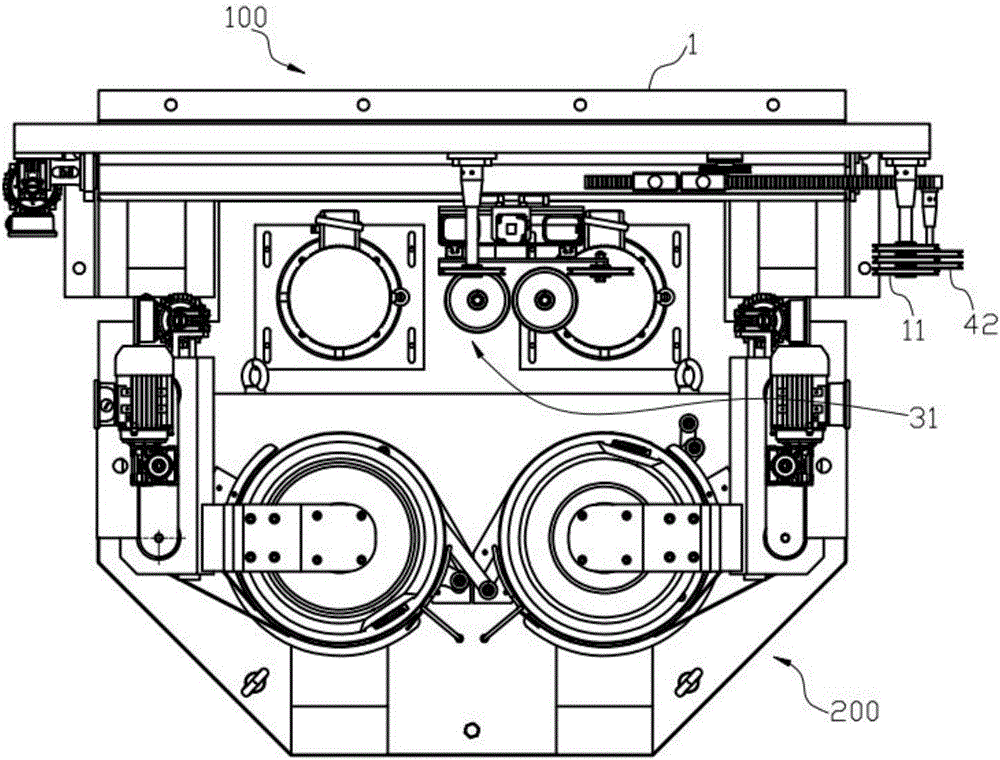

Automatic wire collecting and arranging machine

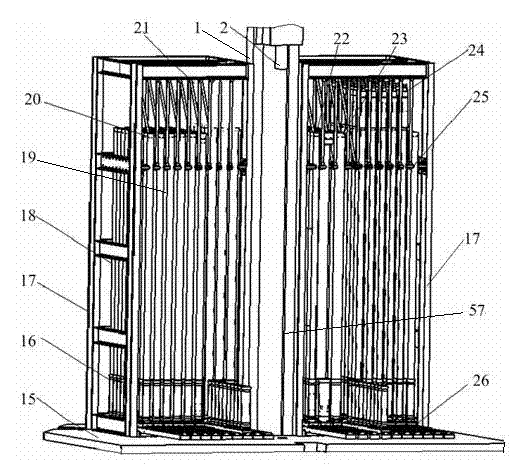

ActiveCN106276404ARealize automatic switchingAvoid scratchesFilament handlingEngineeringWire breakage

The invention discloses an automatic wire collecting and arranging machine. The machine comprises an XY type wire arranging device and a wire collecting device; the XY type wire arranging device includes a wire arranging frame, a transverse wire arranging frame, a longitudinal wire arranging frame, a first wire passing guide wheel, a second wire passing guide wheel and a wire collecting tension system; the transverse wire arranging frame is mounted on the wire arranging frame; the longitudinal wire arranging frame is movably mounted on the transverse wire arranging frame; the first wire passing guide wheel and the second wire passing guide wheel are both mounted on the wire arranging frame; the wire collecting tension system is horizontally arranged on the wire arranging frame; the longitudinal wire arranging frame is provided with a wire arranging guide wheel device capable of moving up and down; the wire collecting device includes a wire collecting frame, a wire collecting disc device, an automatic disc replacing device and a wire pressing disc device; the automatic disc replacing device is mounted at the bottom of the wire collecting disc device; the automatic disc replacing device is mounted on the wire collecting frame; and the wire collecting disc device is pressed and positioned through the wire pressing disc device in the wire collecting process. The wire arranging guide wheel device can move; and the automatic disc replacing device realizes automatic switching and wire breakage of empty and full discs without scratching product surfaces.

Owner:WUXI JUYI TONGCHUANG TECH CO LTD

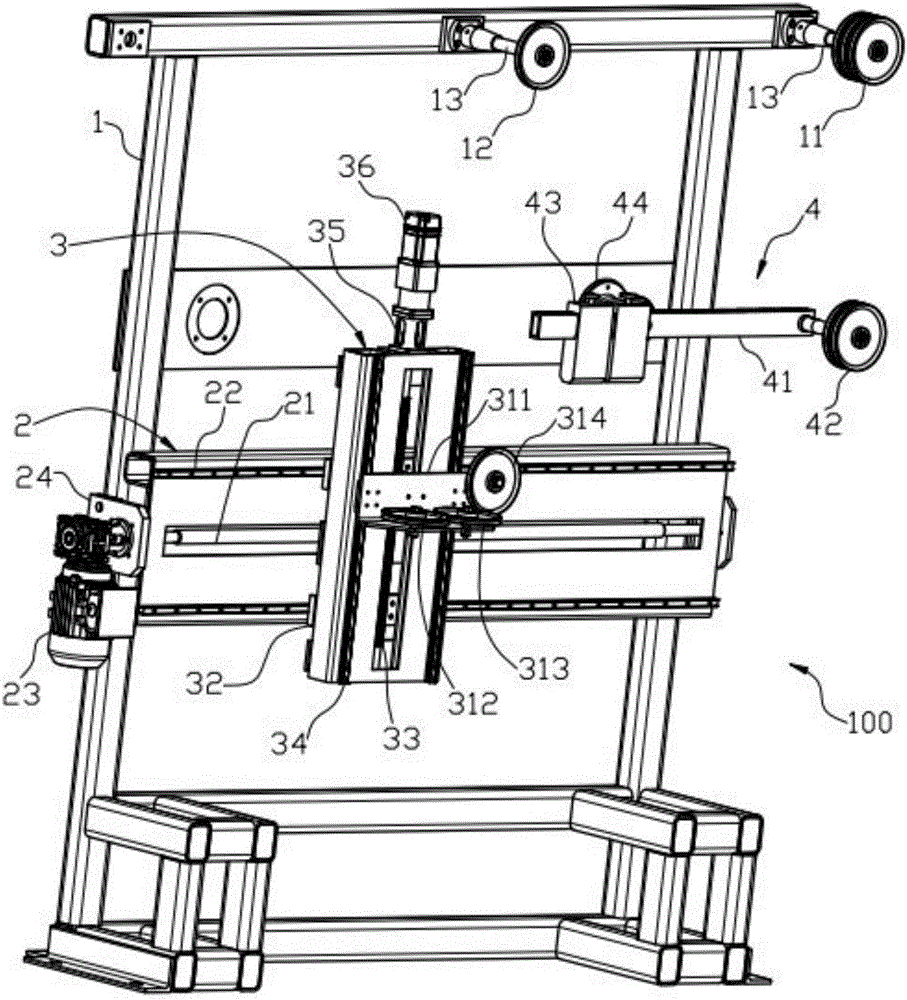

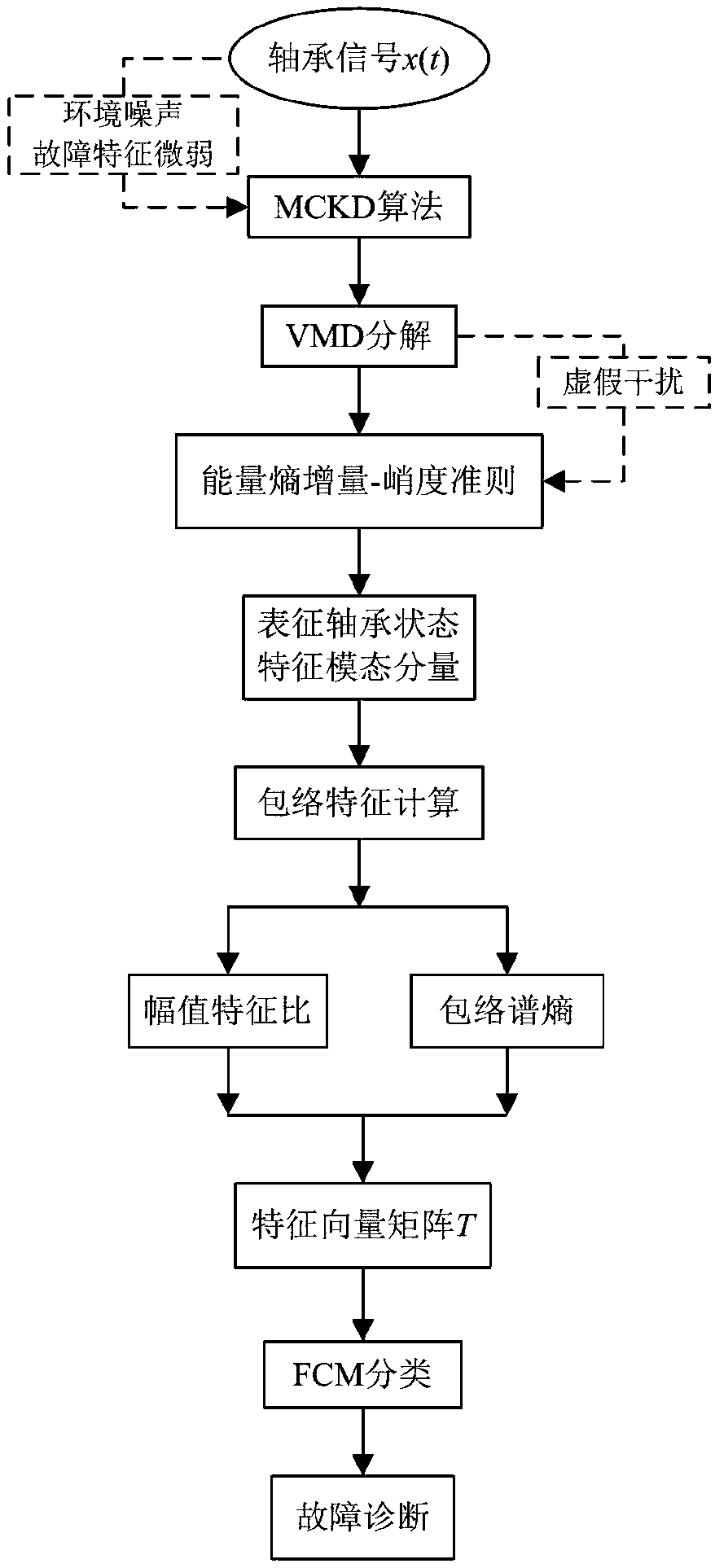

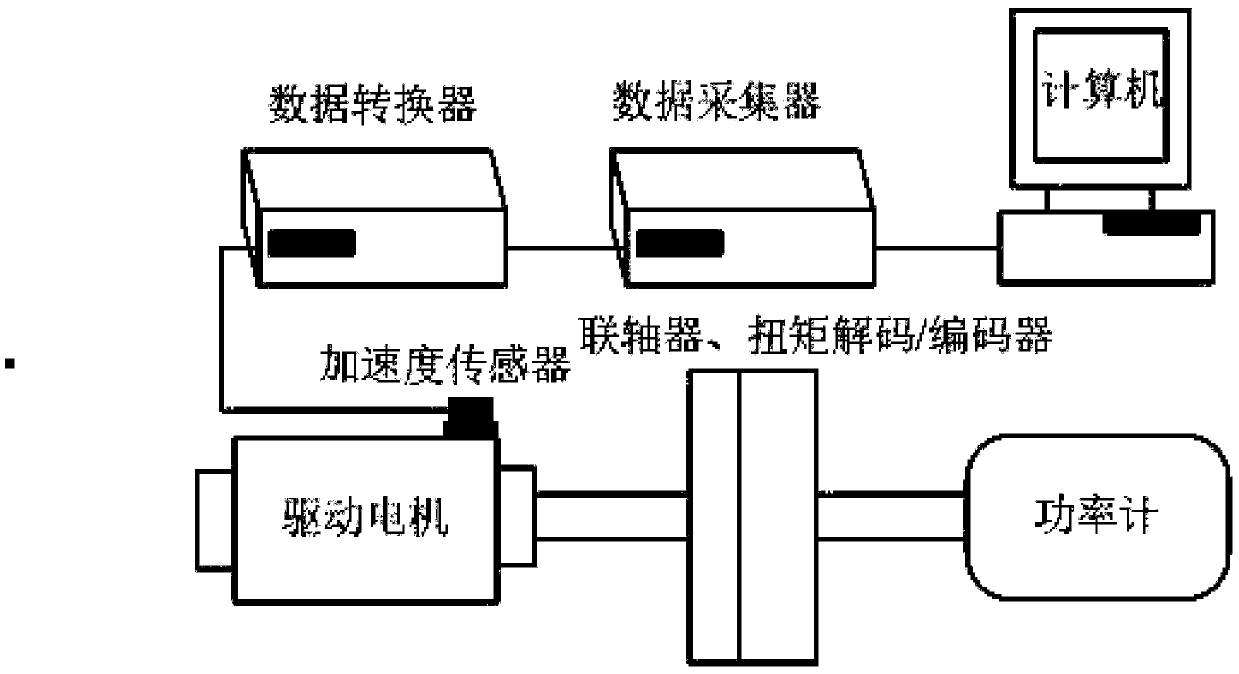

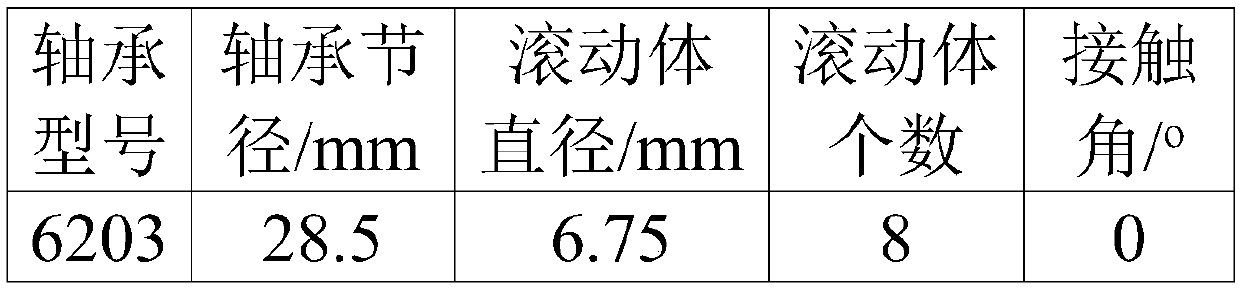

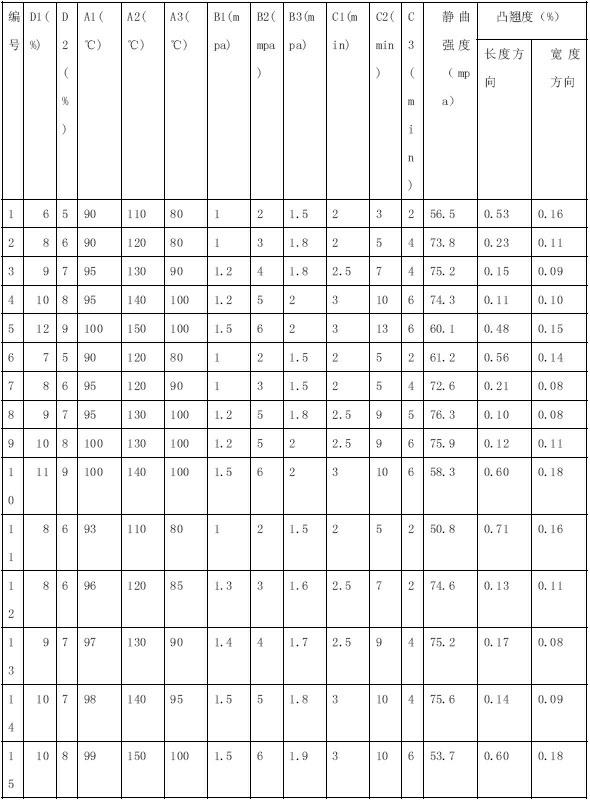

Rolling bearing fault diagnosis method based on deconvolution and envelope spectrum

InactiveCN109612732AEffectively distinguish working statusEffectively distinguish fault typesMachine part testingCluster algorithmDiagnosis methods

The invention discloses a rolling bearing fault diagnosis method based on deconvolution and an envelope spectrum. In order to study influence on classification and identification results of rolling bearing working states under different damage degrees, rolling bearing rolling body fault signals are analyzed, the rotating speed of a rotating shaft is 1800r / min, the sampling frequency is 12000Hz, and the damage degrees are divided into a mild degree, a moderate degree and a severe degree according to diameters of damage points. According to the rolling bearing fault diagnosis method based on thedeconvolution and the envelope spectrum, the structure is scientific and reasonable, and the usage is safe and convenient. The rolling bearing fault diagnosis method based on the deconvolution and the envelope spectrum comprises the steps that firstly, a fault feature of a rolling bearing vibration signal is enhanced by using MCKD algorithm; the enhanced signal is carried out VMD decomposing; IMFcomponents containing main fault feature information are selected based on energy entropy increment and a kurtosis criterion; an envelope spectrum feature amplitude ratio and envelope spectrum entropy of each sensitive IMF component are extracted to better reflect and quantify the fault feature information; and a fault state is identified by using fuzzy C-means clustering algorithm to realize thediagnosis of a working state and a fault type of a rolling bearing.

Owner:BEIHUA UNIV

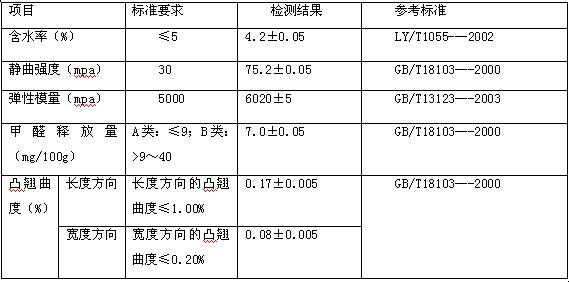

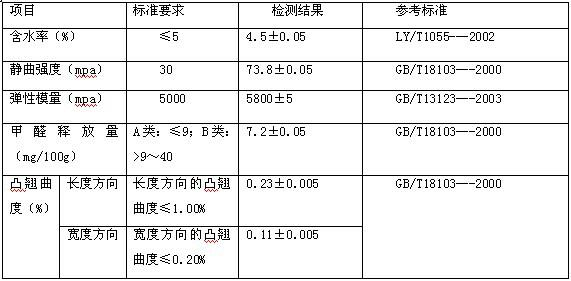

Method for producing bamboo-wood composite board

ActiveCN102398287AAchieve sustainable developmentShorten the growth cycleWood veneer joiningMaterials scienceStatic bending

The invention relates to a method for producing a building composite rubber plate, in particular to a method for producing a bamboo-wood composite board. The method for producing the bamboo-wood composite board is implemented by the following technical scheme that the method for producing the bamboo-wood composite board comprises the following steps of: (1) preparation of a core board and a surface board; and (2) compounding process of the core board and the surface board. The bamboo-wood composite board prepared by implementing the method disclosed by the invention has the advantages of low buckling deformation and high static bending strength.

Owner:浙江安吉双虎竹木业有限公司

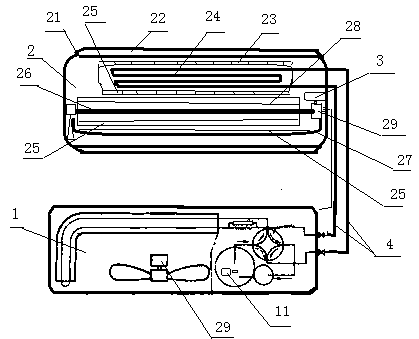

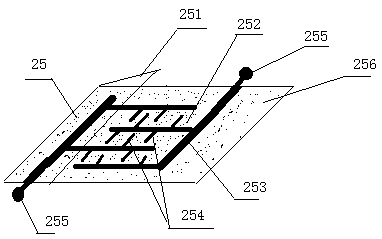

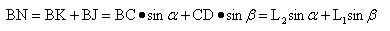

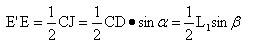

Direct current air temperature adjusting device based on composite graphene film auxiliary heat and manufacturing method

InactiveCN108931006AEasy to prepareImprove heating performanceMechanical apparatusLighting and heating apparatusMotor driveEngineering

Provided is a direct current air temperature adjusting device based on composite graphene film auxiliary heat. An outdoor machine unit only has a one-way refrigerating mode; an air conditioner outdoormachine communicates with an indoor machine unit through a refrigerant pipe; according to the air conditioner indoor machine unit, the upper end of a machine shell of the air conditioner indoor machine unit is provided with an air inlet, and the two ends of the machine shell of the air conditioner indoor machine unit are provided with clamping pieces to be fixedly connected with an evaporator; the evaporator is located on the lower portion of the air inlet; an inlet and an outlet of the refrigerant pipe of the evaporator are connected with an outdoor machine condenser; a copper pipe of the evaporator is provided with a composite graphene heating film; the lower portion of the evaporator is equipped with a cross flow fan which is installed in an air duct; the inner wall of the air duct isprovided with a composite graphene heating film; blades of fan blades of the cross flow fan are equipped with composite graphene heating films; and during heating of an air conditioner, a composite graphene heating film circuit is connected, the composite graphene heating films start heating, and a fan motor feeds hot air in the air duct into a room due to the fact that the motor drives the fan blades to rotate.

Owner:王子韩

Hydraulic automatic leveling system and leveling method of seabed drilling rig

InactiveCN102278072AScientific and reasonable structureControl altitudeDerricks/mastsServomotorsOcean bottomFiltration

The invention relates to a hydraulic automatic leveling system and a hydraulic automatic leveling method for a seabed drilling machine. The leveling system comprises support plates, large arms, chains, hydraulic cylinder legs, a base and a hydraulic system, wherein the base supports the drilling machine, and is connected with the hydraulic cylinder legs; the large arms are connected with the hydraulic cylinder legs, the base and the support plates; and the support plates are in contact with a seabed surface. The leveling method comprises the following steps of: selecting mutually vertical axes X and Y on the base, arranging double-axis tilt sensors along the axis X or Y, measuring inclination angles in two coordinate axis directions by using the double-axis tilt sensors, performing amplification, filtration and isolation by using a signal conditioning module, transmitting conditioned signals to data acquisition equipment and a computer, performing digital-to-analogue conversion and amplification after the signals pass through a signal analysis module, and outputting three paths of current to drive the motions of valve elements of three proportional reversing valves, control the flow of the system and drive the three hydraulic cylinder legs to ascend by y1, y2 and y3 to realize leveling. The system and the method are applied to kinds of offshore drilling equipment, and are highin leveling speed and accuracy.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

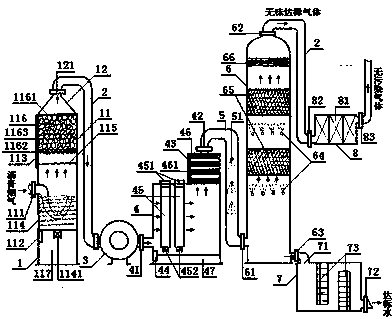

Multifunctional environment-friendly asphalt flue gas purification system

The invention relates to a multifunctional environment-friendly asphalt flue gas purification system, which comprises a dust treatment tower, a filtered oil odor removing box, a main gas spray pipeline, a turbulent power-wave water film washing tank, a sedimentation oil-separation circulation pool and a plasma oil-smoke purification and waste-gas purification device. The multifunctional environment-friendly asphalt flue gas purification system integrates a physical purification technology for automatically separating waste gas, greasy dirt, dust and smoke with a plasma oil-smoke purification and high-pressure plasma waste gas purification technology, effectively overcomes the defect that the current treatment equipment cannot completely treat waste gas, greasy dirt, dust and smoke, eliminate odor in gas and decompose harmful macromolecular compounds at the same time, realizes automatic separation, recovery and reusing of various solid wastes during comprehensive waste gas treatment of one system, and ensures emission of gas reaching the standard without odor and pollution. The system has the advantages of scientific and reasonable structure, reliable work and stable performance, the wastes cannot product secondary pollution, and the exhausted gas cannot harm the human health. The system has strong practicality.

Owner:上海北新月皇新材料集团有限公司

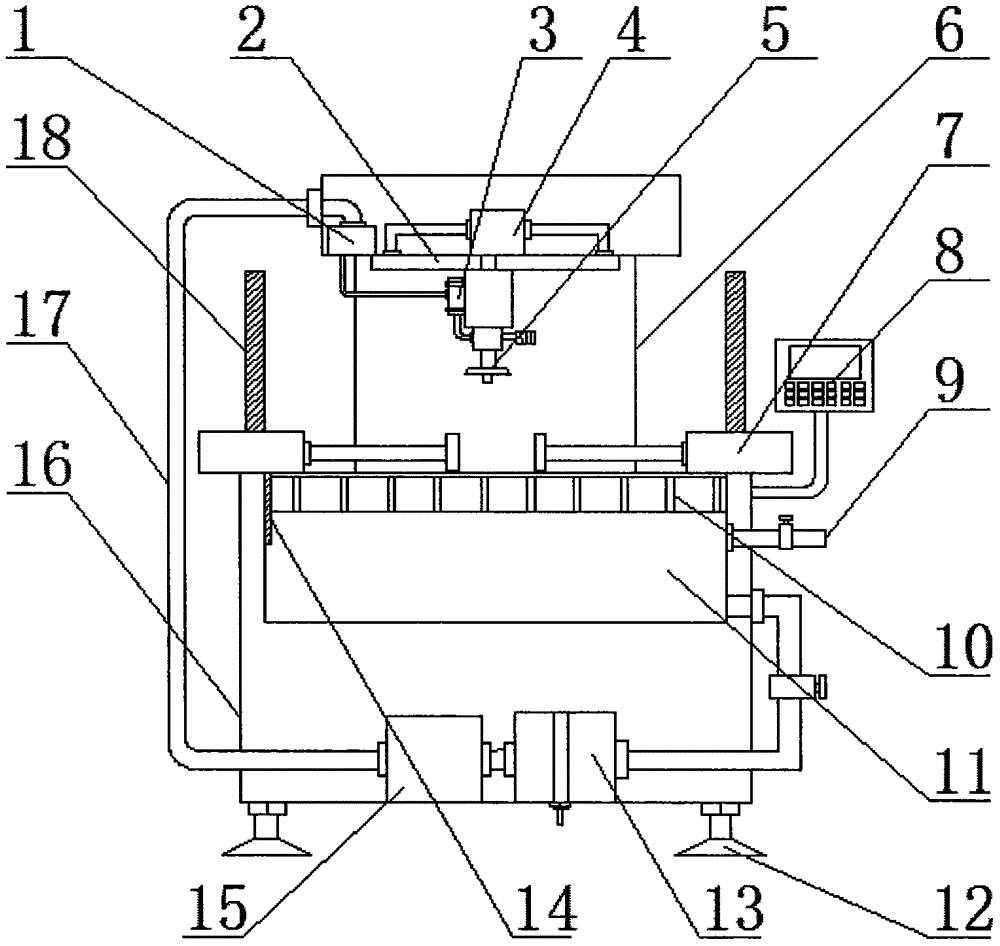

Water-saving water jet cutter special for mechanical part cutting

InactiveCN105856328AEasy to recycleReal-time detection of recyclingWorking accessoriesMetal working apparatusWater savingMachine parts

The invention discloses a water-saving water jet specially used for cutting mechanical parts, which comprises a hydraulic pipe, a control panel, a water tank and a main machine shell. A supporting column is arranged above the main machine shell, and the hydraulic tube is installed on the supporting column. In addition, a hydraulic pump is provided above the hydraulic pipe, a water pressure control device is provided on the left side of the hydraulic pump, a water pressure detection device is provided on the left side of the water jet cutting head, and the water tank is embedded and installed in the shell of the main engine. Above, the upper two ends of the hollow baffle are provided with hydraulic fixing devices. The invention has a scientific and reasonable structure, safe and convenient use, the water mist baffle can effectively prevent water splashing, and reduces unnecessary waste of resources, and the liquid level detection device can detect the liquid level in the water tank in real time to avoid damage to the hollow baffle due to too low water level The hydraulic fixing device can fix the parts during cutting, and the filtering device facilitates the recycling of water resources and prevents debris from clogging the cutter head.

Owner:XINCHANG COUNTY YULIN STREET SHANGDA BEARING PLANT

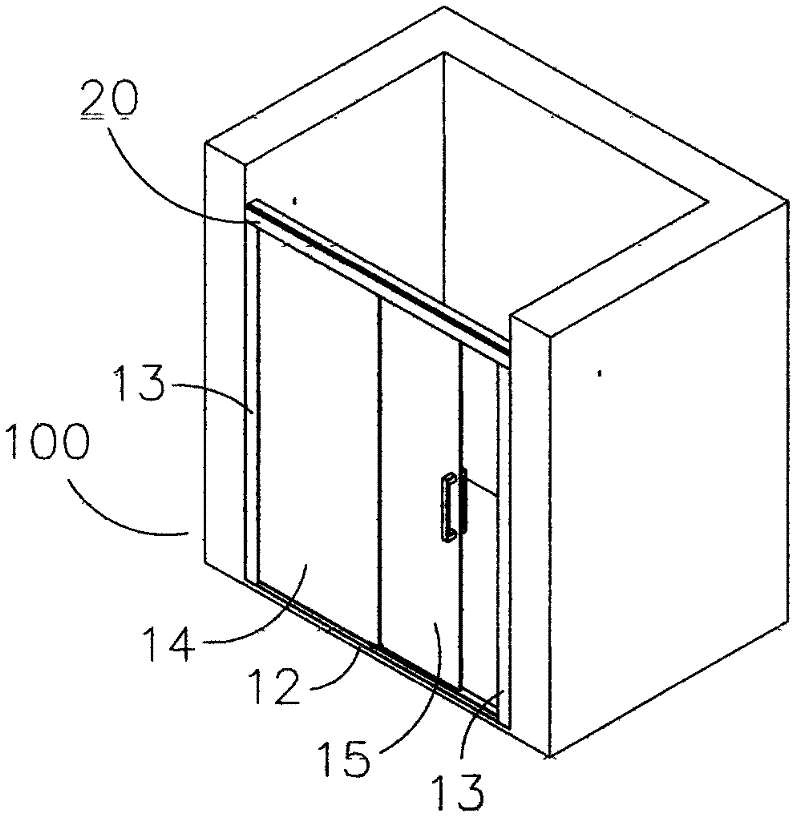

Intelligent induction shower cabin

The invention relates to an intelligent induction shower cabin, which comprises a shower cabin and an inductive control unit, wherein the inductive control unit is used for inducing the position of a human body so as to control the opening or the closing of the shower cabin, and comprises a driving motor, a microcomputer and an infrared inductive probe; when the shower cabin is in practical operation, firstly, the infrared inductive probe detects the existence of the human body and at this time sends a signal to the microcomputer, and the microcomputer commands a driver therein so as to drive the driving motor to work according to a compiled program and to drive a movable door to be opened or closed through the driving motor.

Owner:ZHONGSHAN LENS HOME CO LTD

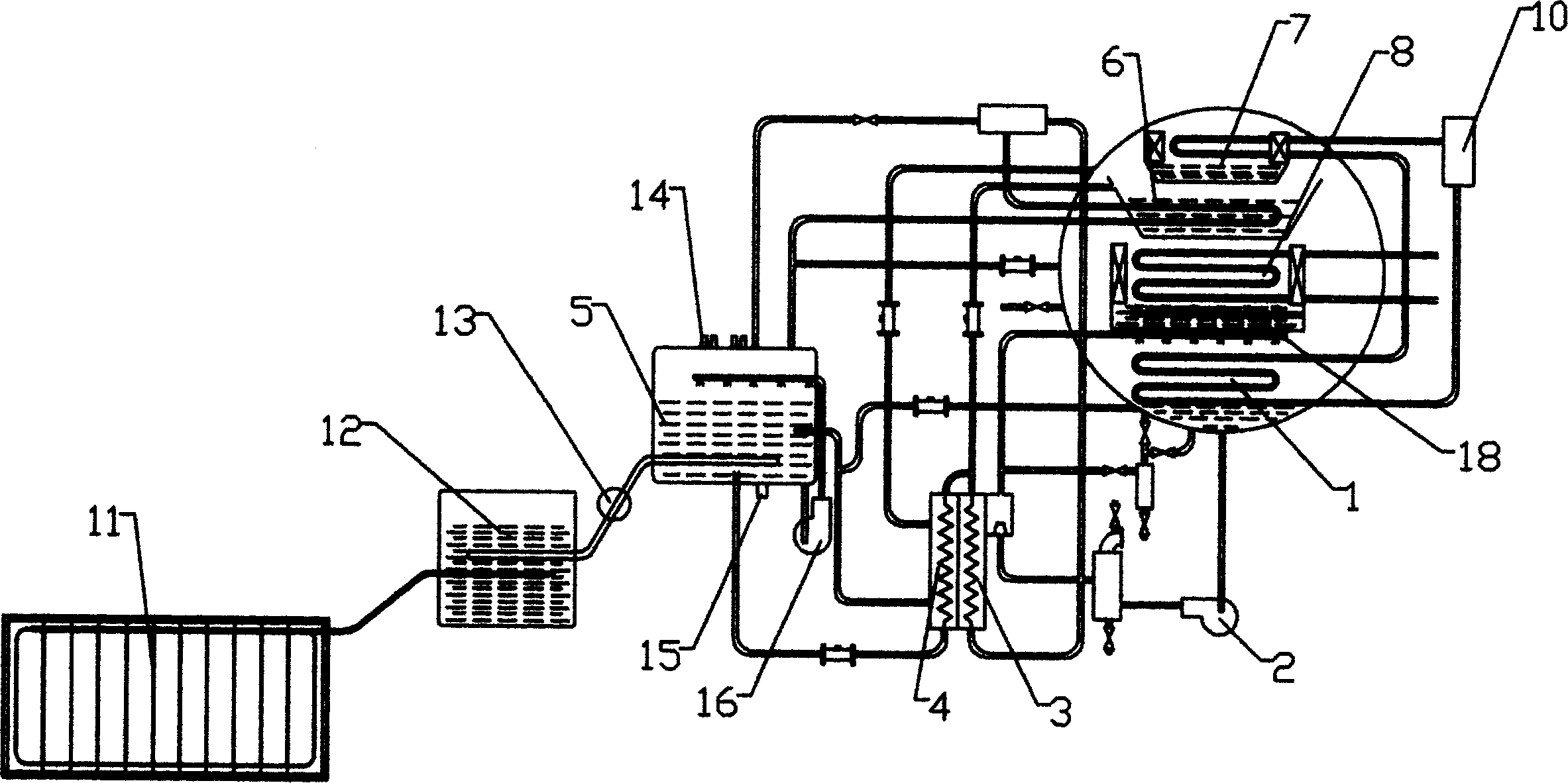

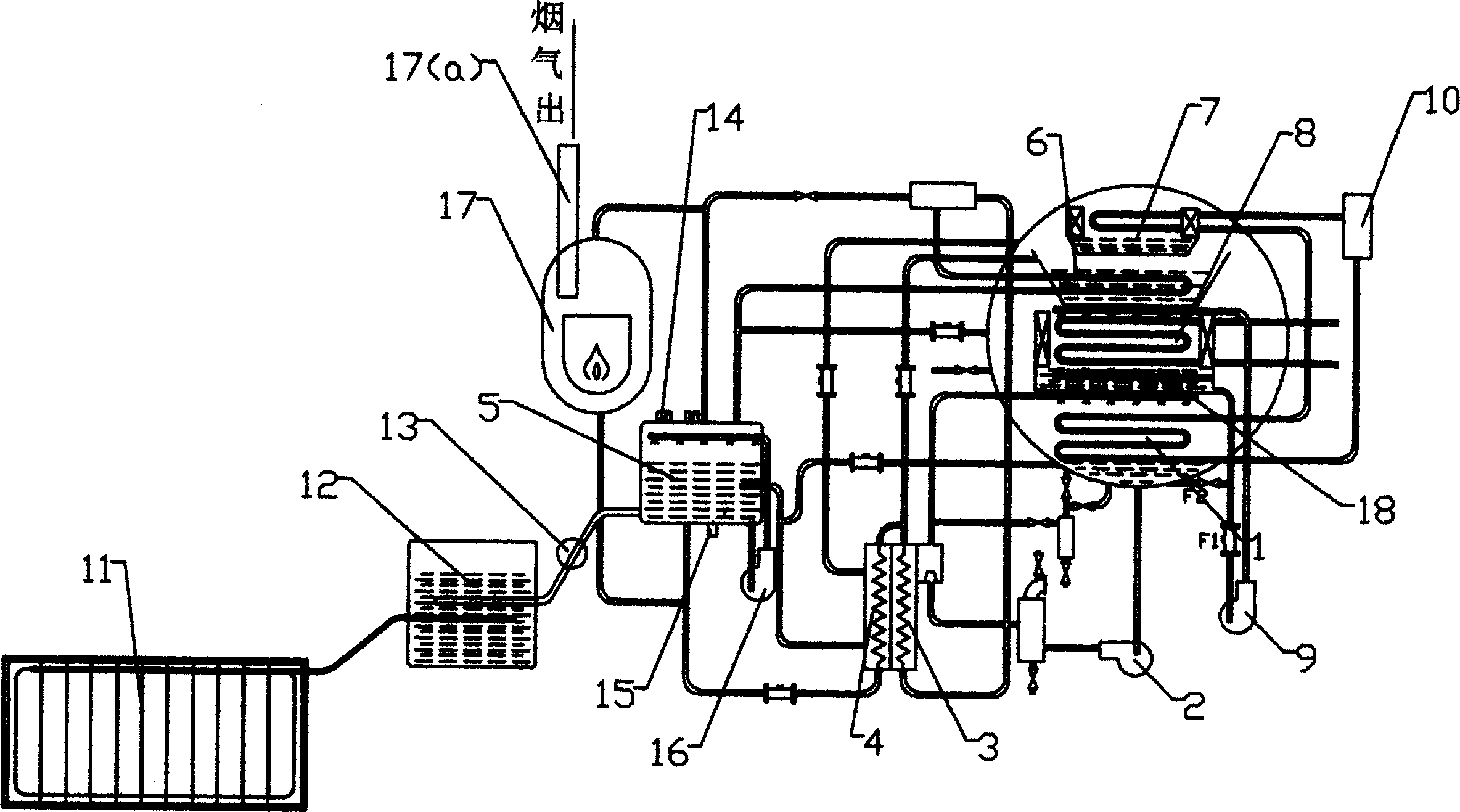

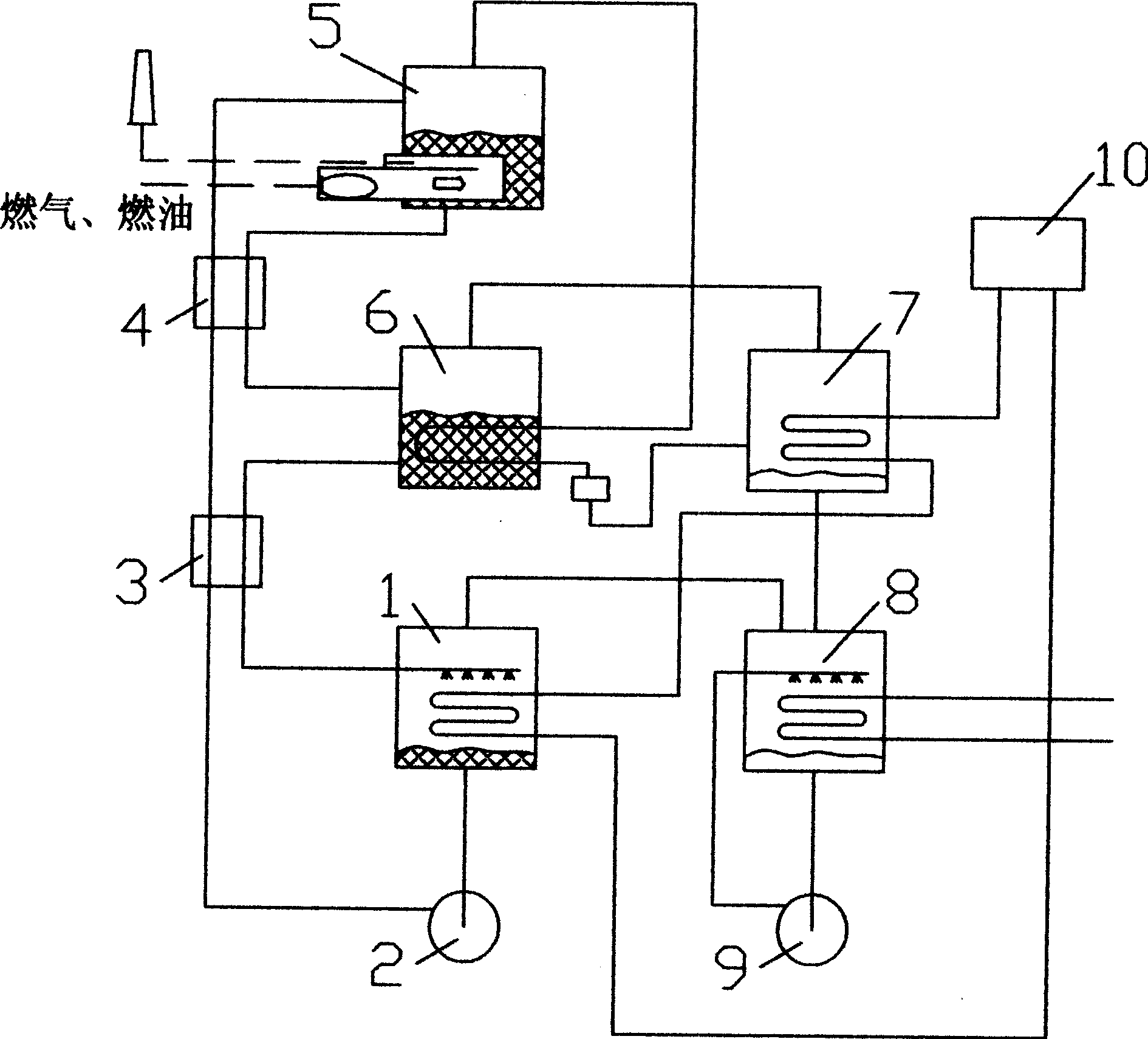

Multiple energy sources driven lithium bromide refrigerating air conditioner

InactiveCN1731035AScientific and reasonable structureLow investment costEnergy efficient heating/coolingClimate change adaptationThermal energyCooling tower

The multiple energy source driven lithium bromide cooling air conditioner makes it possible to select different kind of energy source for cooling with the identical lithium bromide cooling set. It contains absorber, solution pump, low temperature heat exchanger, high temperature heat exchanger, high pressure generator, low pressure generator, condenser, evaporator and cooling tower. It features the high pressure generator connected to the solar energy driving assembly comprising solar heat collector, solar heat accumulator and heat pump, and the microwave energy driving assembly comprising magnetron set on the high pressure generator, ultrasonic solid-liquid separator capable of realizing ultrasonic spraying and microwave heating and spraying pump; and the evaporator with ultrasonic evaporator for normal pressure evaporation.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

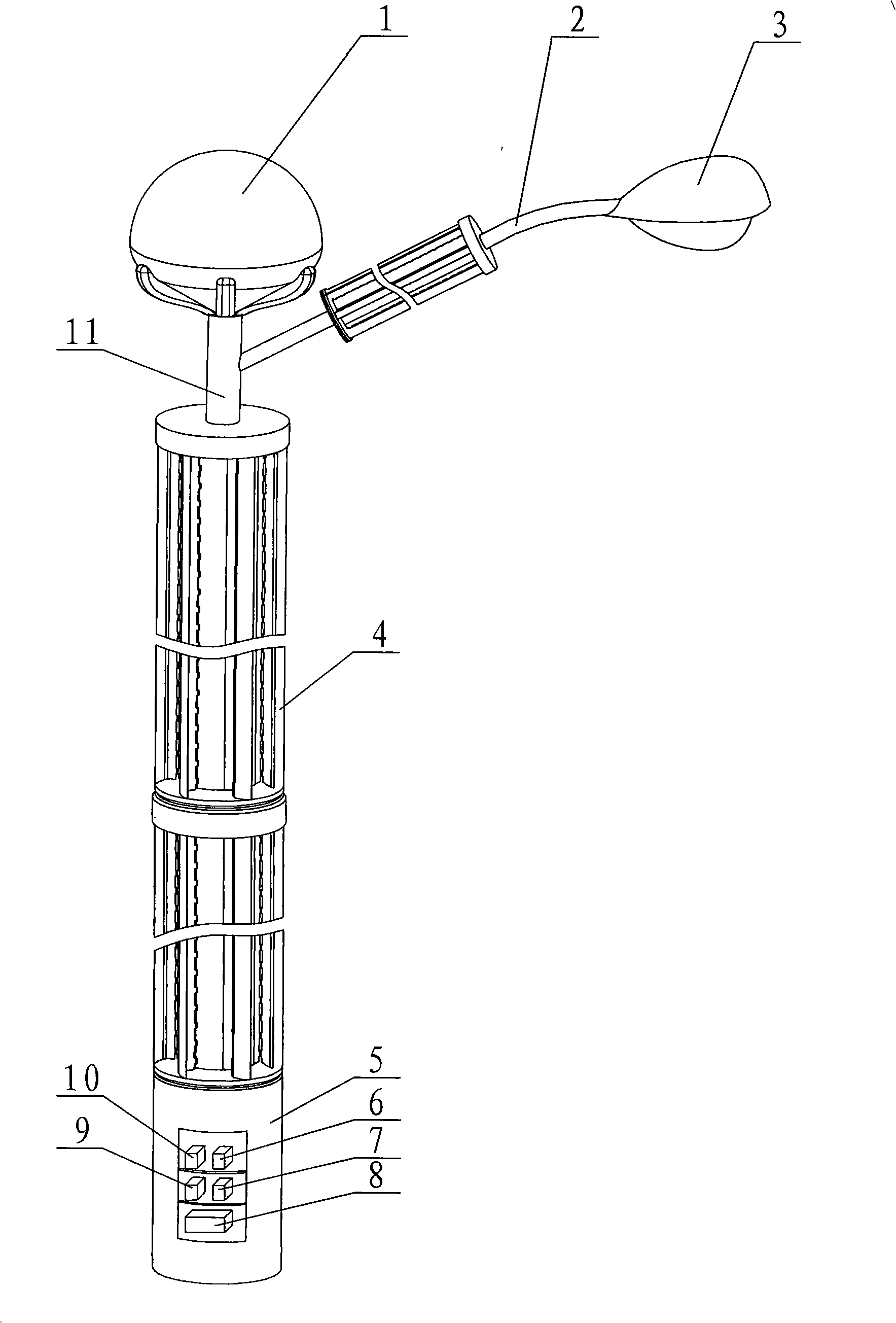

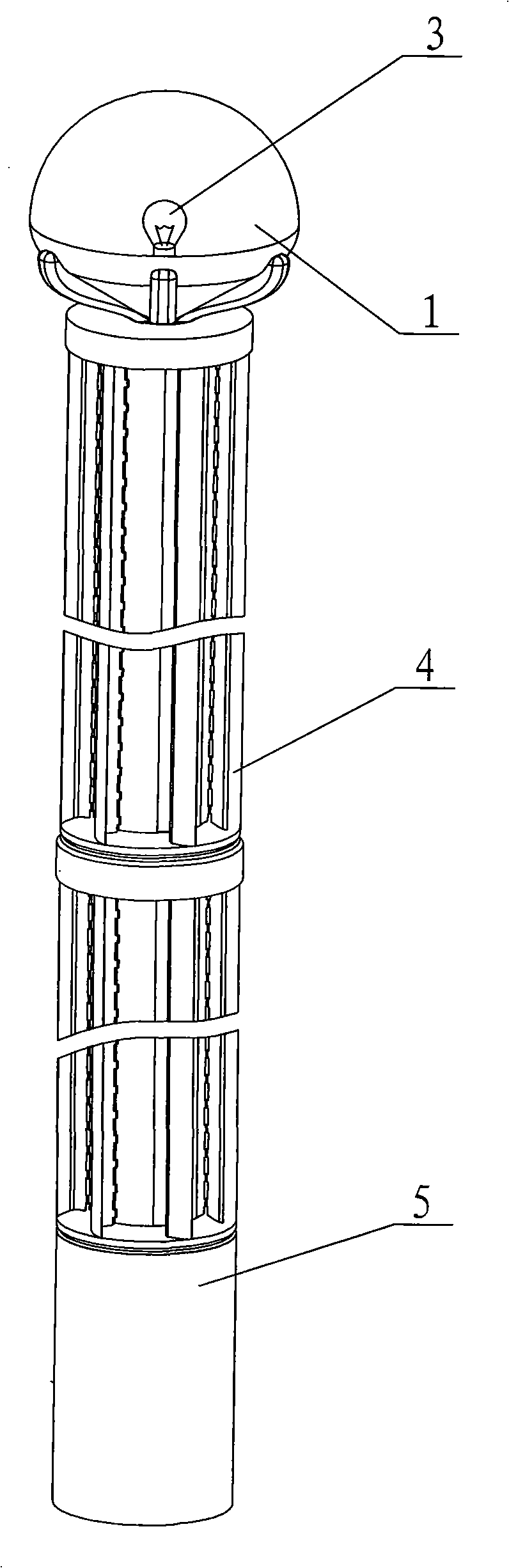

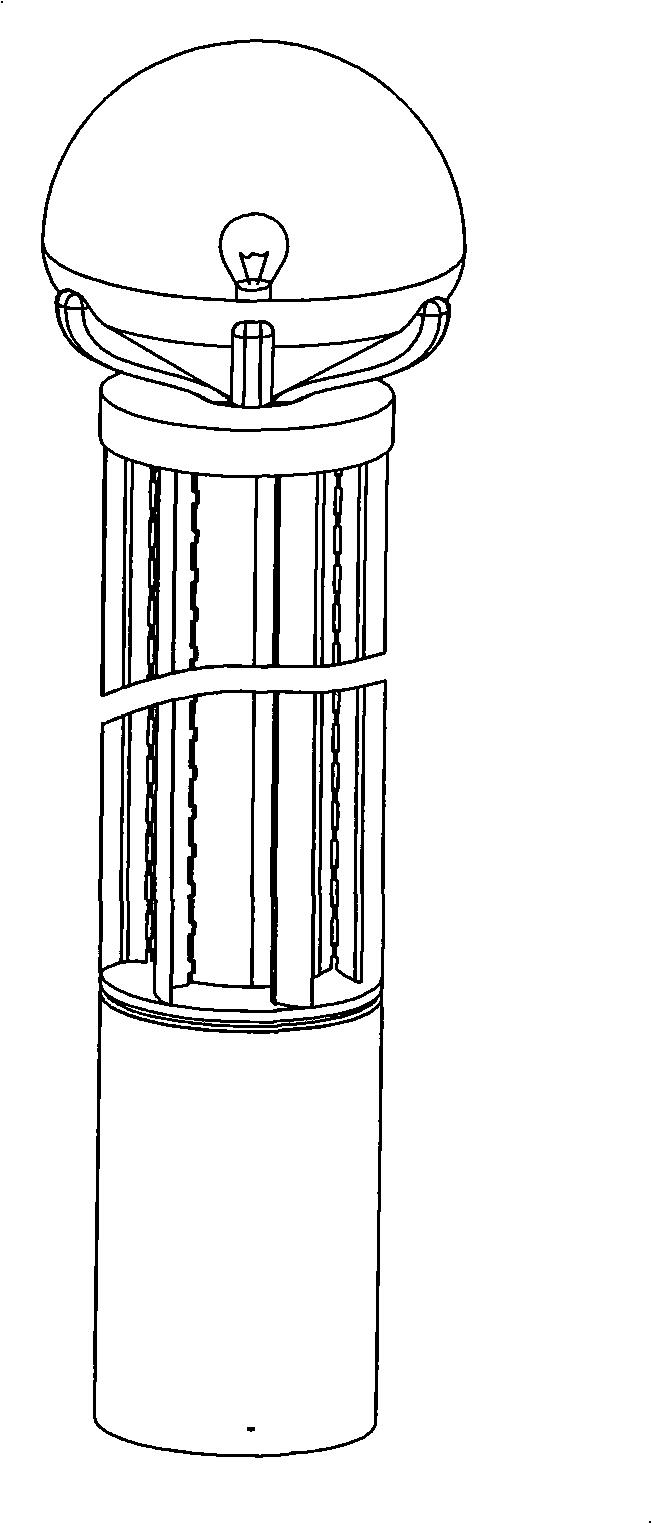

Wind-light complementation magnetic suspension slight breeze power generation road lamp

InactiveCN101403481ALarge torqueHigh inertiaWind energy with electric storageEnergy storageEngineeringFan blade

The invention relates to a magnetic suspension light wind generating street lamp with the complementation of wind and light, comprising a lamp rod, a junction box and a lamp head. The lamp rod body, or the pole support body connected with the lamp rod, or the bodies of the lamp rod and the pole support are provided with magnetic suspension generating devices; or one group or a plurality of groups of magnetic suspension generating devices are sequentially connected in series through an upper and a lower fixed flange as the street lamp rod, a spherical solar energy photospot generating device is installed on the top of the lamp rod or directly on the upper fixed flange of the magnetic suspension generating device and the lower fixed flange is installed and fixed on the junction box; the magnetic suspension generating device comprises a stator consisting of the inner shell of the lamp rod body, the pole support body or the generating device, a coil winding, a radial permanent-magnetic clamp and the upper and the lower fixed flange and a rotor consisting of a continuous permanent-magnetic clamp, a shell and a fan blade. The invention can directionally revolve the wind of any direction, with high reliability, small resolving noise, no mechanical abrasion, high power generation efficiency and long service life of the whole appliance. The street lamp can be widely used for various occasions.

Owner:杨晓莹 +3

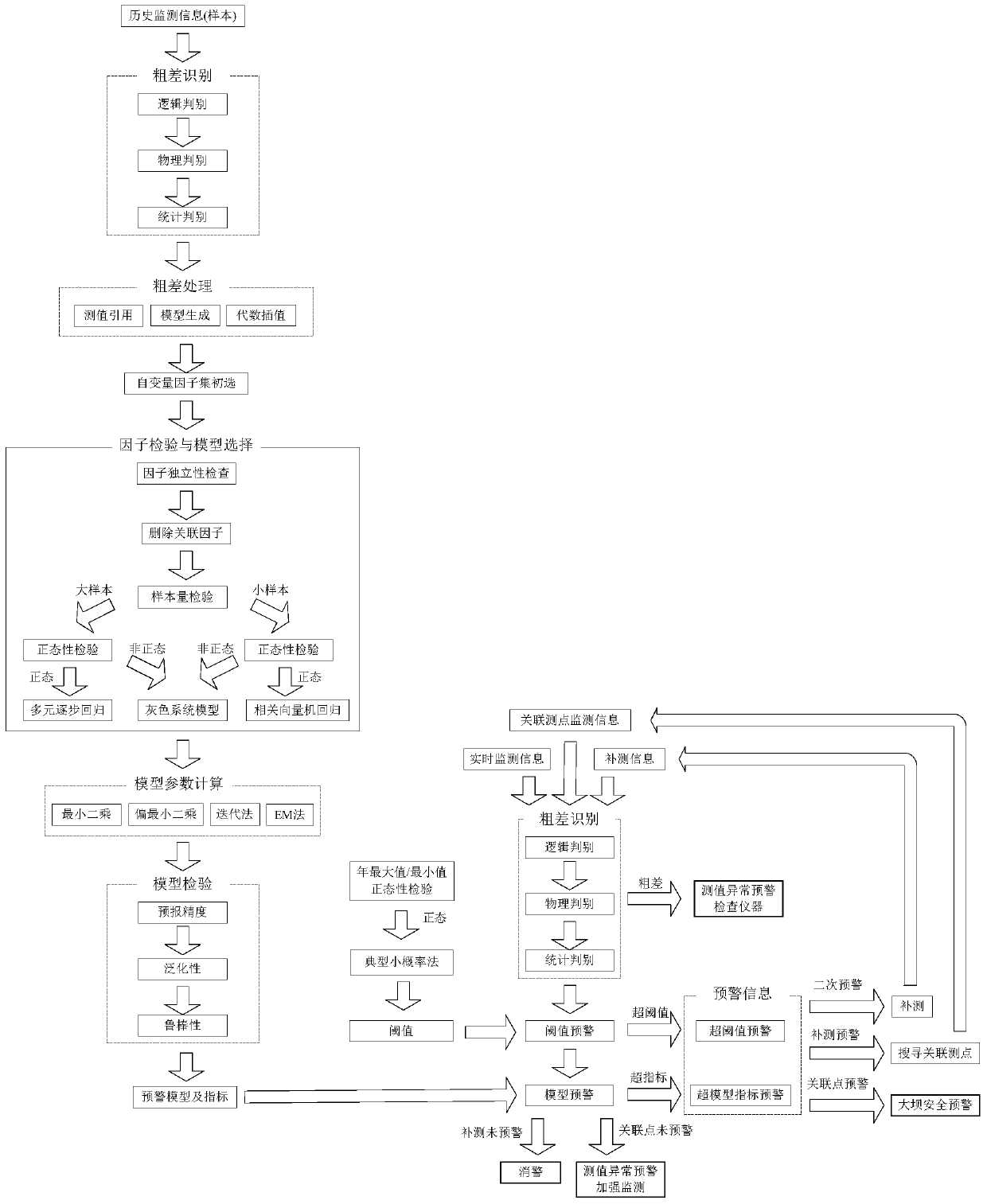

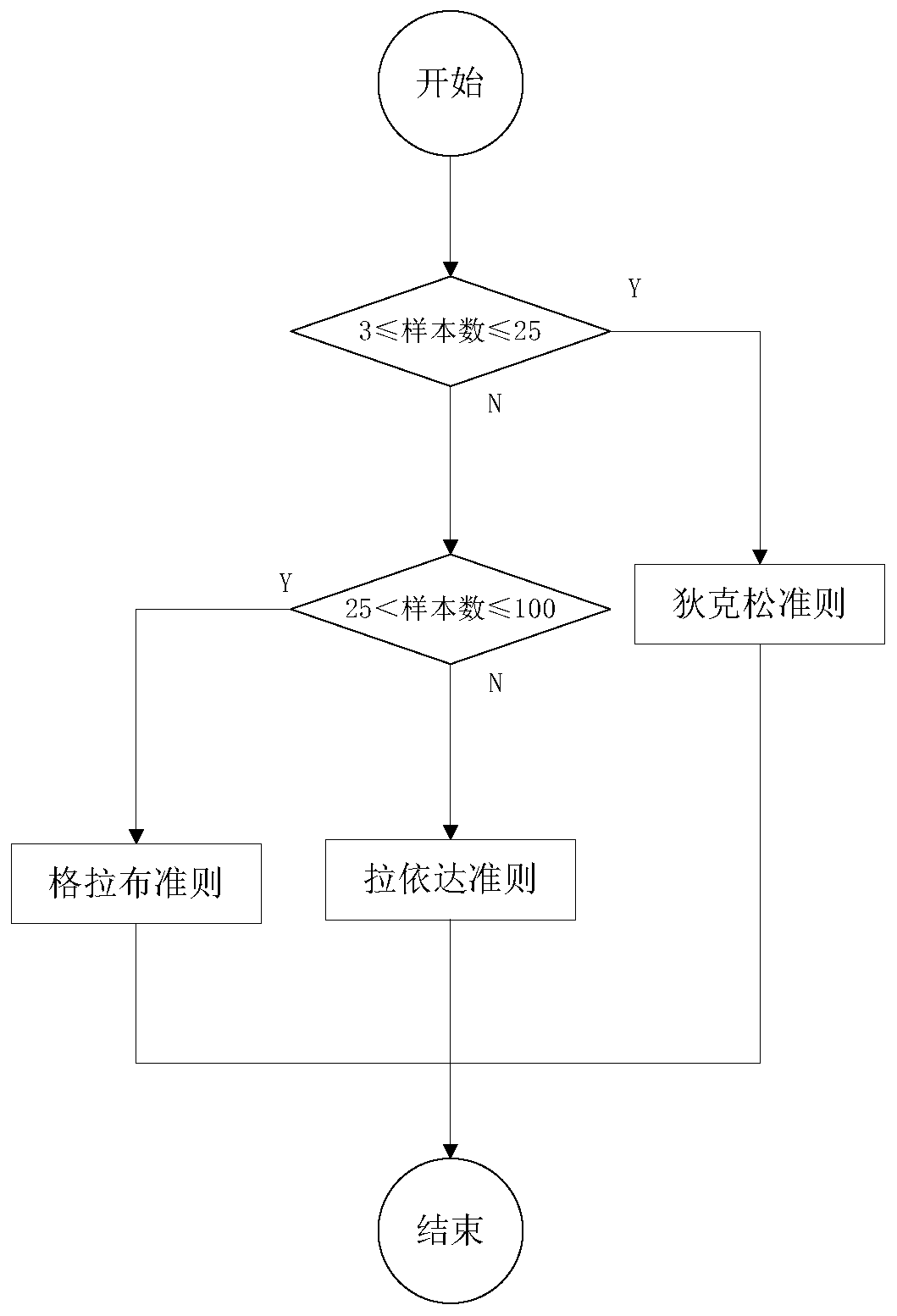

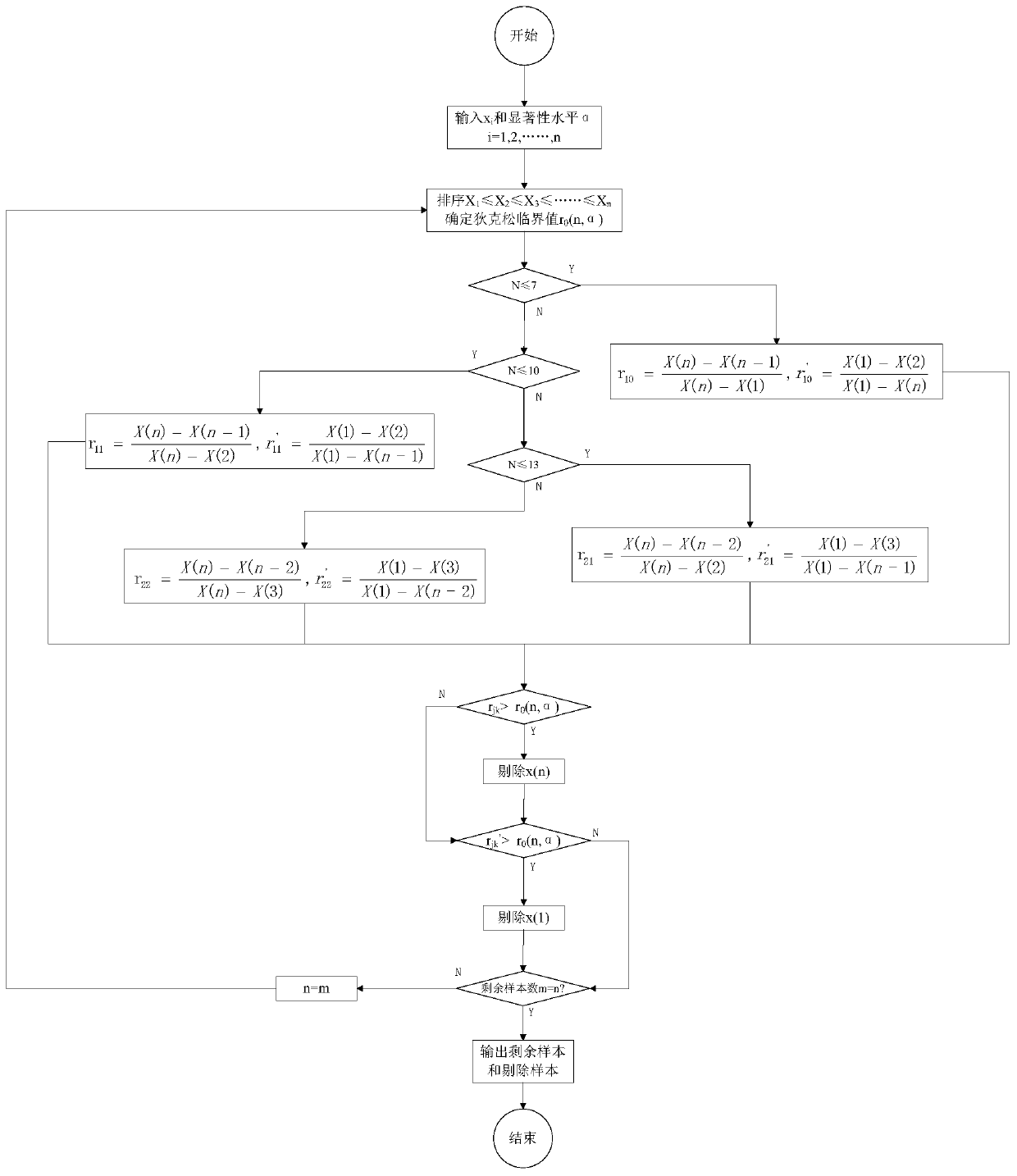

Intelligent early warning method for dam safety monitoring data

ActiveCN111508216AImprove sample data qualityAccurately reflectAlarmsModel sampleMeasuring instrument

The invention discloses an intelligent early warning method for dam safety monitoring data. The method comprises the steps of early warning model establishment, threshold value setting and mutual feedback type early warning. Gross error identification and gross error processing are carried out, model sample data quality is improved, according to the monitoring items, independent variable relevance, historical monitoring data quantity and historical monitoring data distribution, different early warning models and indexes are established, including a stepwise regression model, a correlation vector machine model and a gray system model; the established models can reflect the relationship between the independent variable and the dependent variable more truly and are wide in application range,according to a measuring instrument, measuring point attributes, a threshold value, an early warning model and indexes, real-time early warning is carried out on monitoring data, monitoring instrumentabnormity early warning is sent to monitoring personnel, or dam safety early warning is sent to dam safety management personnel, experts with professional knowledge and rich experience are not needed, the workload is small, the early warning speed is high, and the early warning result is more accurate and reliable.

Owner:NANJING HYDRAULIC RES INST

Construction waste recovering and powdering device

The invention discloses a construction waste recovering and powdering device. The construction waste recovering and powdering device comprises a machine frame outer shell, a hopper, a crushing roller,a permanent magnetic iron core, a grinding roller, a grinding barrel, filtering holes and a powder collection tank. The hopper is arranged on the upper portion of the machine frame outer shell. The crushing roller is arranged at the upper end of the interior of the machine frame outer shell. A first filtering screen is arranged at the bottom of the crushing roller and fixedly connected with the machine frame outer shell through nuts. The permanent magnetic iron core is arranged under the first filtering screen. The novel construction waste recovering and powdering device is provided with a crushing roller, construction waste is evenly crushed, the permanent magnetic iron core is arranged under the crushing roller and can be driven by rotation of a magnet motor to adsorb various metal irondoped in the construction waste, garbage and iron are separated, and the iron is recycled, resources are saved; and the construction waste recovering and powdering device is provided with the grinding roller, construction waste is further ground into powder, and the construction waste is recycled.

Owner:南京极佳物联网科技有限公司

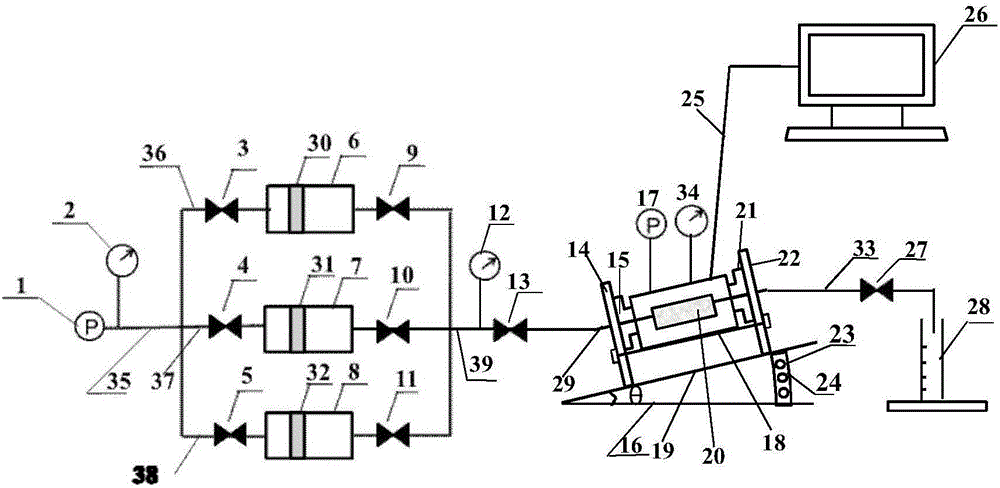

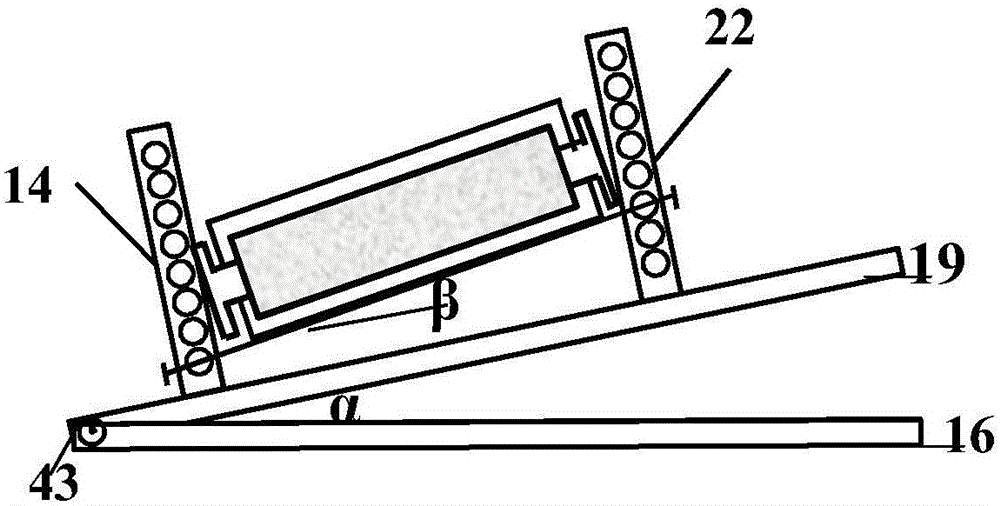

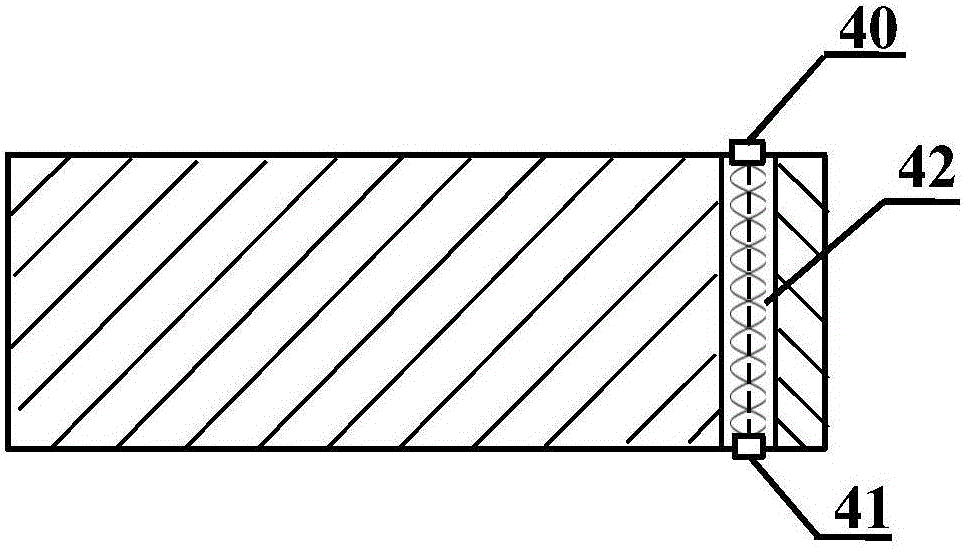

Device and method capable of simulating oil displacement efficiencies of oil layers with different dip angles

ActiveCN106121603ALarge angle change spaceChange inclinationFluid removalWater floodingConstant speed

The invention discloses a device and method capable of simulating oil displacement efficiencies of oil layers with different dip angles in order to explore oil displacement efficiencies generated when different displacing agents are applied to heterogeneity stratums with dip angles. The device is composed of a constant-speed displacement pump, pressure gages, three intermediate containers, a variable-dip-angle core holder, an image analyzer, a measuring cylinder, pipelines and valves, wherein the pipelines and the valves are used for connecting all the parts. The three intermediate containers contain stratum water, crude oil and a displacing agent correspondingly. A tracer agent is added into the displacing agent. By adoption of the device, the dip angle of a core can be changed by changing the dip angle of the core holder, so that the influence of the different dip angles on the oil displacement efficiency is studied, and a relation formula of the liquid production capacity and the dip angle is regressed. By use of the device and method, the flowing law of stratum crude oil in the water flooding or gas flooding process of the stratum with the dip angle can be simulated, so that an appropriate displacing agent is selected preferably and conveniently.

Owner:NORTHEAST GASOLINEEUM UNIV

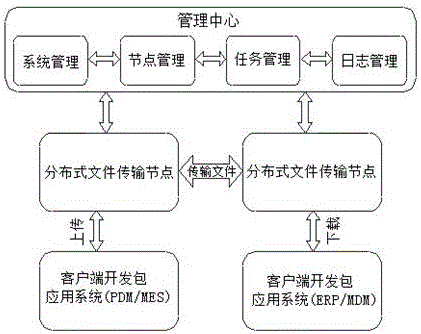

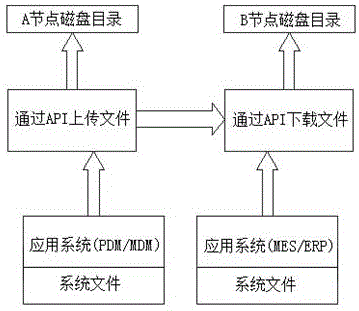

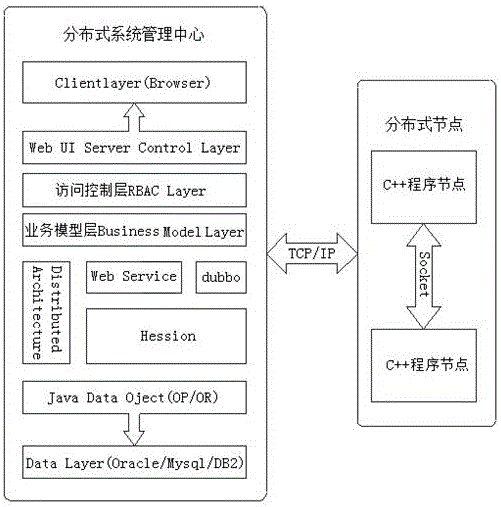

Distributed ERP and MES data synchronous connection system and data communication method

PendingCN106375481ASimple structureGuaranteed uptimeDatabase distribution/replicationTransmissionFile transmissionData management

A distributed ERP and MES data synchronous connection system and a data communication method are disclosed. The method comprises the following steps: in step S601, data and / or a file are uploaded onto one or more distributed file transmission platform source nodes by an ERP module via a first client end program; in step S602, a distributed file management and transmission platform generates a transmission task, and communication between the distributed file transmission platform source nodes and distributed file transmission platform object nodes; in step S603, an MES module is used for downloading a technical solution for data and / or files from the distributed file transmission platform object nodes; a defect that unstructured data larger than 10 M cannot be transmitted in special industries or enterprise groups can be overcome; the distributed ERP and MES data synchronous connection system and the data communication method are suitable for informationized data management and transmission within systems in the special industries, the enterprise groups and government administration organizations and the like; the distributed ERP and MES data synchronous connection system is scientific and reasonable in overall structure and is convenient to install and operate; via coordination and cooperation among all modules and software, stability and security of data transmission are improved.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

Special energy-saving and environment-friendly paint spraying machine capable of conducting drying and used for floor machining

PendingCN106733377AScientific and reasonable structureSafe to useLiquid surface applicatorsCoatingsElectric heatingEngineering

The invention discloses a special energy-saving and environment-friendly paint spraying machine capable of conducting drying and used for floor machining. The special energy-saving and environment-friendly paint spraying machine comprises a paint spraying box, a sprayer, a machine case, a paint pump and a suction fan. Supporting feet are arranged on the lower surface of the machine case. A case door is arranged on the front surface of the machine case. The part, close to the right end of the upper surface of the paint spraying box, of the right side of the suction fan is provided with an electric fan. The sprayer is arranged above the interior of the paint spraying box. The paint pump, a servo motor, an electric heating wire, the electric fan and the suction fan are electrically connected with a control panel. The special energy-saving environment-friendly paint spraying machine is scientific and reasonable in structure, safe and convenient to use, easy to operate and fast and convenient in work; a filter and the suction fan are arranged, smelly gases emitted by floor paint can be filtered and purified so that air cannot be polluted, and environment friendliness is achieved during using; meanwhile, the electric fan and the electric heating wire are arranged, integrated floor paint spraying and drying can be achieved, accordingly, time and labor force are saved, energy is saved during using accordingly, and the floor machining and producing efficiency is effectively improved.

Owner:天津浩华民生科技发展有限公司

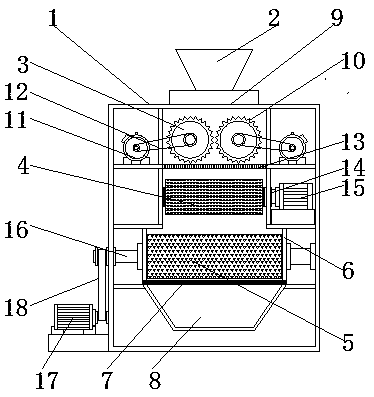

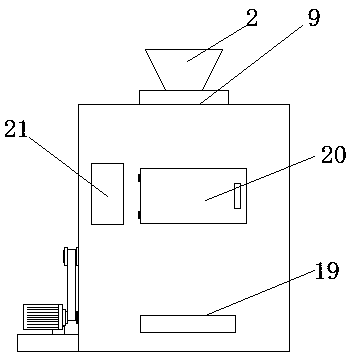

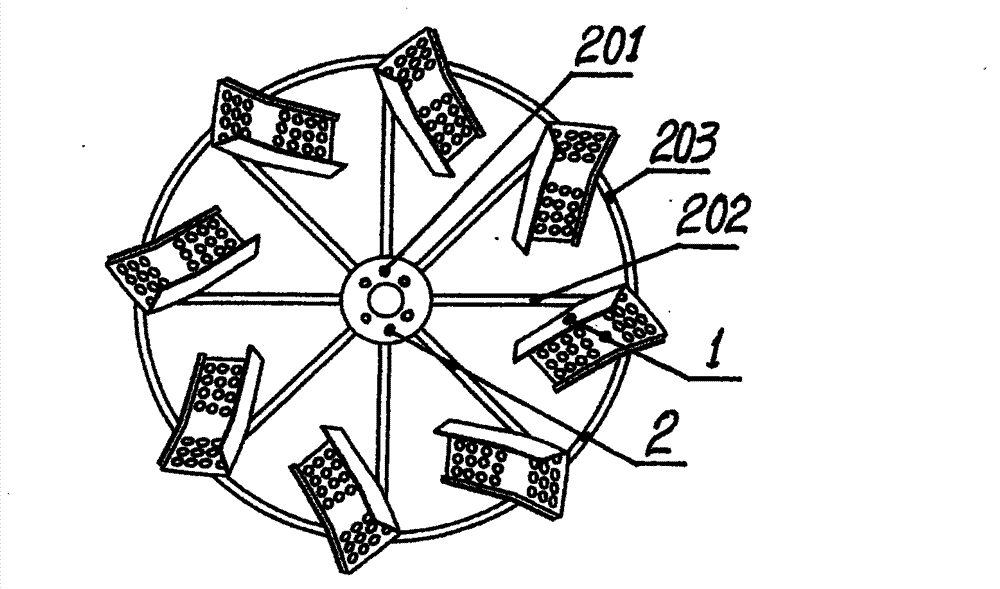

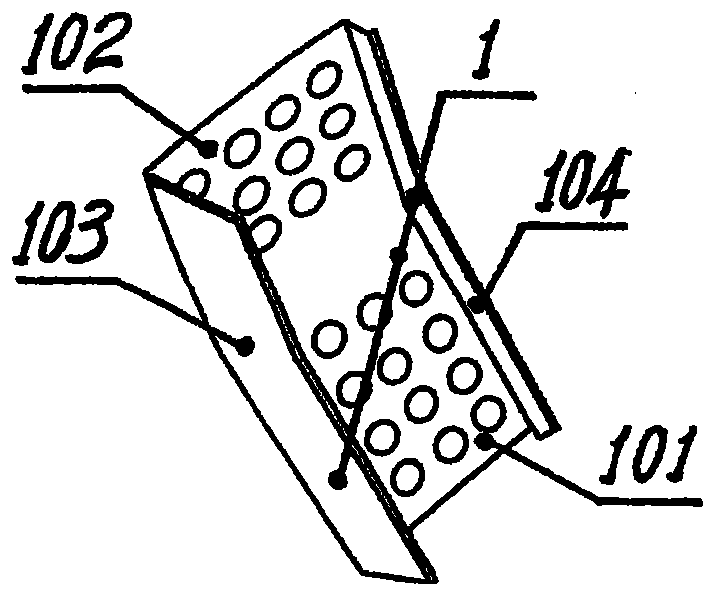

Frame type high efficiency impeller of impeller aerator

The invention relates to the machinery technical field and provides a frame type high efficiency impeller of an impeller aerator. A key technology that a circular ring frame is combined with angle set shovel-shaped or spoon-shaped blades with holes is adopted; angles which are formed between lower water shifting plates and upper water guiding plates are 90 to 160 degrees; the inner sides of the lower water shifting plates and the upper water guiding plates are provided with inner water guiding plates and the outer sides of the lower water shifting plates and the upper water guiding plates are provided with outer water guiding plates in a perpendicular mode to form the blades; the inner ends of radiation supports are fixed connected with a shaft disk and the outer ends of the radiation supports are fixedly connected with a circular ring to form a transmission connection plate; the plane which is formed by being close to the fixed joint of the outer ends of the radiation supports and the circular ring is fixedly connected with the lower water shifting plates to form 30 to 90 degrees of angles; meanwhile the radiation supports are fixedly connected with the inner water guiding plates to form 20 to 90 degrees of angles or angles in 90 to 135 degrees outward; shaft holes of the shaft disk are fixedly connected with power shafts. The frame type high efficiency impeller of the impeller aerator is used for performing aeration on a fish pond and is simple and reasonable in structure, long in service life, stable and reliable in effect, small in power, easy to manufacture and low in cost.

Owner:梁家明

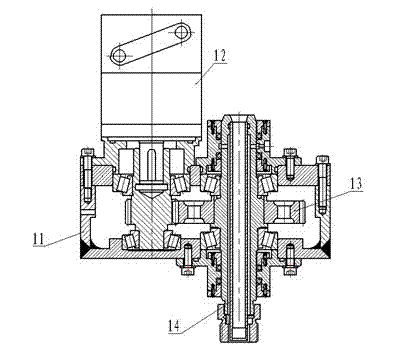

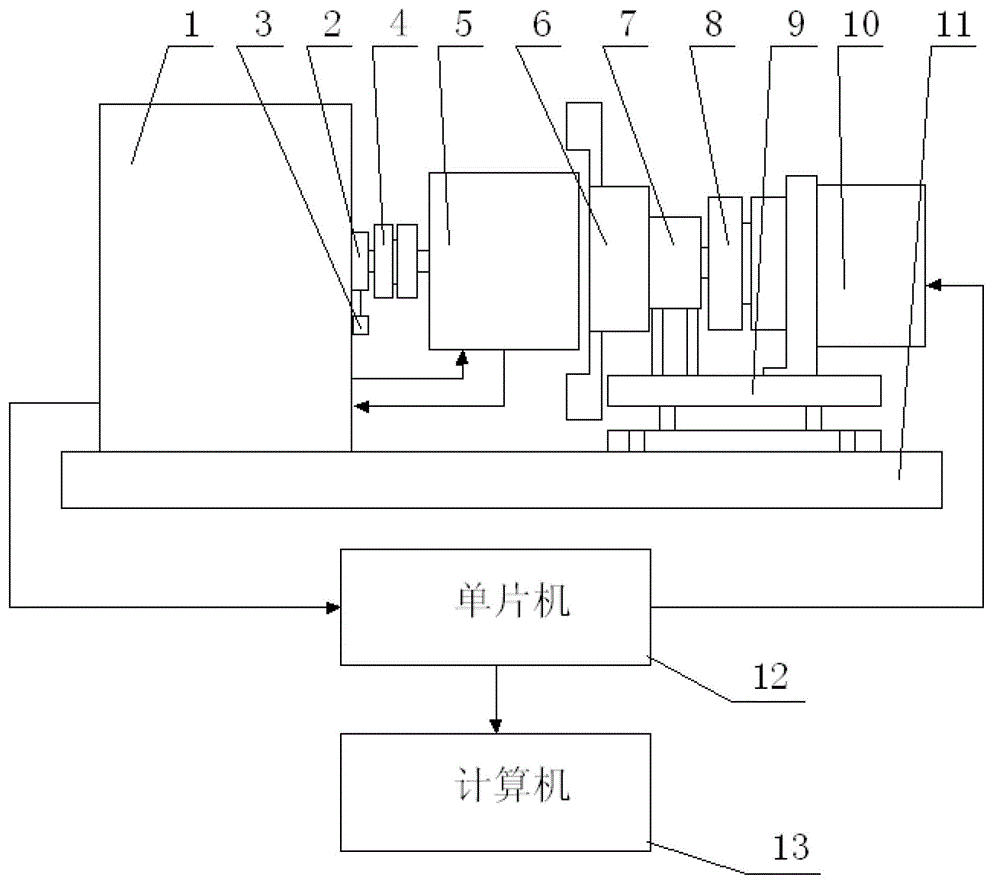

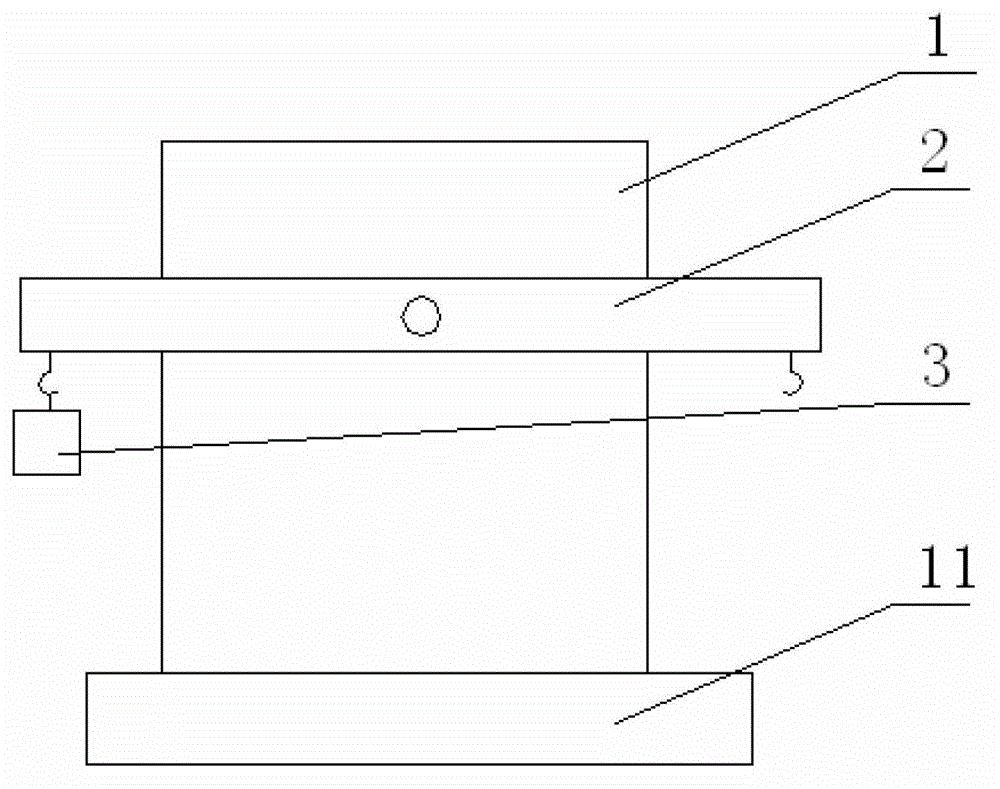

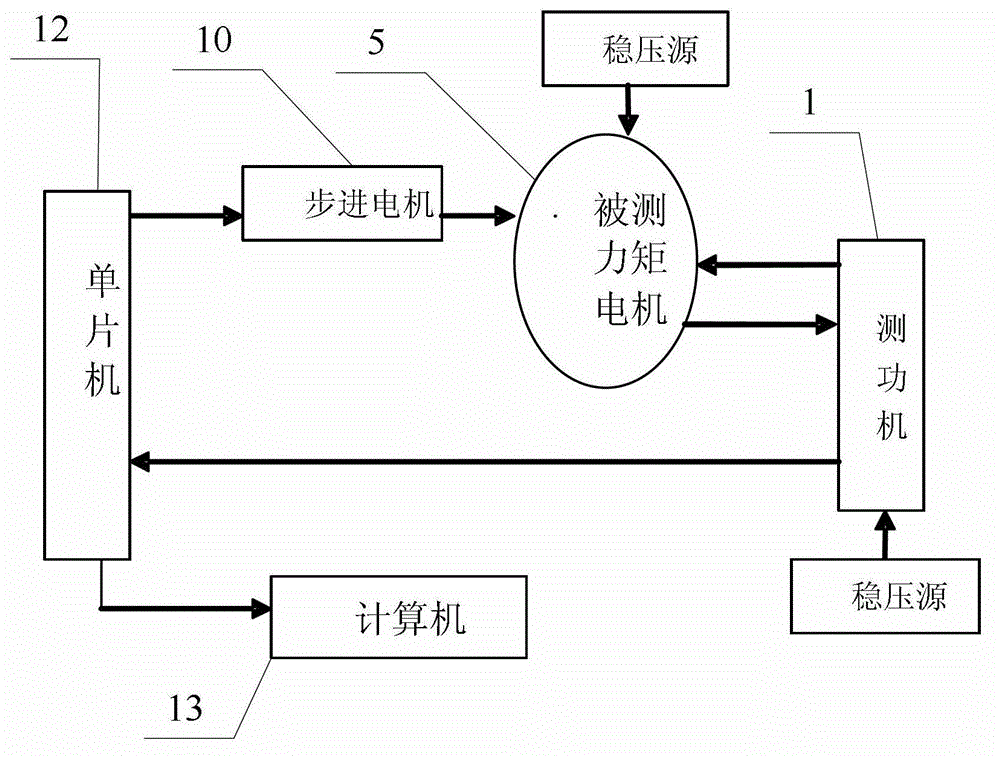

Torque motor torque fluctuation coefficient detector and detecting method

InactiveCN102944344AScientific and reasonable structureEasy to operateWork measurementTorque measurementMicrocontrollerElectric machine

The invention relates to a torque motor torque fluctuation coefficient detector and a detecting method and belongs to the technical field of torque motor torque fluctuation measurement. The torque motor torque fluctuation coefficient detector and the detecting method solve the problems that during the process of measuring force from a stator to a sensor, existing torque motor torque fluctuation coefficient detectors are unreliable in detected results due to gravity interference of the stator. The detector comprises a dynamometer, a calibration assembly, a first coupler, a torque motor to be measured, a chuck mechanical arm, a load bearing, a second coupler, a position adjusting base, a stepping motor, a stabilizing base, a singlechip and a computer. The detecting method comprises the steps of firstly performing initial calibration; then adjusting the chuck mechanical arm to firmly clamp a stator of the torque motor to be measured; powering up the torque motor to be measured to enable the torque motor to be measured to generate torque, then enabling the torque motor to be measured to be under a lock rotor state; and finally driving the stator of the torque motor to be measured by the stepping motor to rotate a circle, synchronously collecting torque signals, and outputting the torque signals to the computer. The torque motor torque fluctuation coefficient detector and the detecting method are suitable for detection of torque motor torque fluctuation coefficients.

Owner:HARBIN INST OF TECH

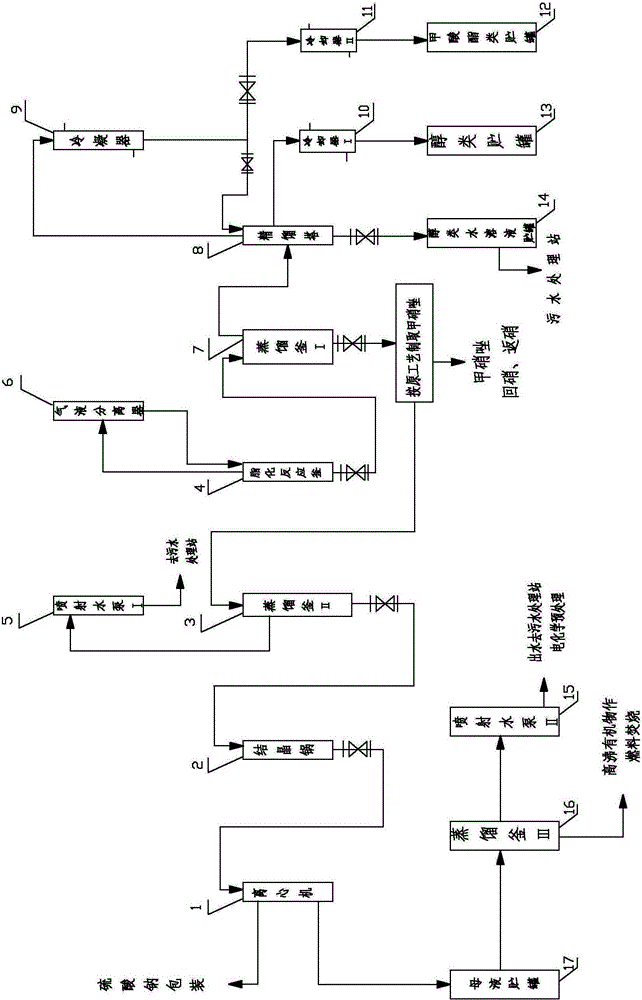

Method and apparatus for producing formic esters by comprehensively utilizing metronidazole hydroxylation synthesis wastewater

ActiveCN105001087AElimination of formic acid waste gasImprove working environmentOrganic compound preparationCarboxylic acid esters preparationMethyl formateChemistry

The invention discloses a method and an apparatus for producing methyl formate or ethyl formate by comprehensively utilizing metronidazole hydroxylation synthesis wastewater, and solves the problems of high formic acid waste, difficulty for mixed salt treatment, very high difficulty for hydroxylation synthesis wastewater treatment, serious environmental pollution due to direct discharge and the like in the prior art. According to the process, alcohols are added for producing an esterification reaction to recover formic acid in the wastewater; and technological processes of distillation, rectification, crystallization, centrifugation and the like are added for separating and recovering formic acid in the wastewater on the premise of not influencing metronidazole preparation by a product, so that the difficult problem of metronidazole production wastewater treatment is radically solved, the metronidazole production cost is reduced, and the metronidazole yield is increased. The method has very good environmental, social and economic benefits, can be widely applied to metronidazole enterprises and has important practical significance.

Owner:黄冈银河阿迪药业有限公司

Sampling device for ocean monitoring of quality of seawater at different depths

InactiveCN109916676AScientific and reasonable structureEasy to useWithdrawing sample devicesSolenoid valveOcean sea

The invention discloses a sampling device for ocean monitoring of the quality of seawater at different depths. The device includes a base, wherein bottom portions of four side surfaces of the base areequipped with mounting tabs, a top end of the base is connected with a rotation seat, and one end of the rotation seat is connected with a mounting plate. The device is advantaged in that the structure is scientific and reasonable and is safe and convenient to use, when a sampling bucket is lowered, all solenoid valves are opened by a control switch, the seawater passes through a seawater sampling bin, the seawater at the sampling position can be sampled; when the sampling bucket is lowered, the corresponding solenoid valves are closed by the control switch to sample at different depth positions, a rotating handle is taken out by opening a storage cover, one end of the rotating handle is mounted on a hexagonal rotating block, the rotating handle is turned to drive the hexagonal rotating block and a rotating shaft to rotate, a cable storage roller can be driven to rotate, when a driving motor fails, the cable storage roller can be manually driven to rotate, and the sampling bucket is pulled out of the sea.

Owner:NATIONAL MARINE ENVIRONMENTAL MONITORING CENTRE +1

Environment protection type wax-proof anti-scaling viscosity reduction machine

ActiveCN101328796AIncrease productionScientific and reasonable adjustmentCleaning apparatusFluid removalCycloneEnvironmental resistance

The invention relates to oil production equipment, in particular to an environment-friendly paraffin-scale preventive viscosity reducer for underground oil pumping, comprising a jet flow ultrasonator, an ultrasonic cavitation cavity and a cyclone. The viscosity reducer is characterized in that: the cyclone is an inlet end; the back end of the cyclone is butted against a jet flow ultrasonic signal emitter and then is butted orderly against the jet flow ultrasonator and the ultrasonic cavitation cavity; and the outer end of the ultrasonic cavitation cavity is an outlet. The viscosity reducer solves the problem that the prior similar products are not ideal in the effects of preventing paraffin and reducing viscosity, really has ultrastrong functions of preventing paraffin, reducing viscosity and preventing scale, greatly increases the liquidity of crude oil, raises pump efficiency, increases oil well yield, needs no additional power, is safe and environment-friendly, accords with oil production wells with different types, and is suitable for the oil wells with different paraffin content and water content as well.

Owner:SHANDONG QUNFENG PETROLEUM TECH DEV CO LTD

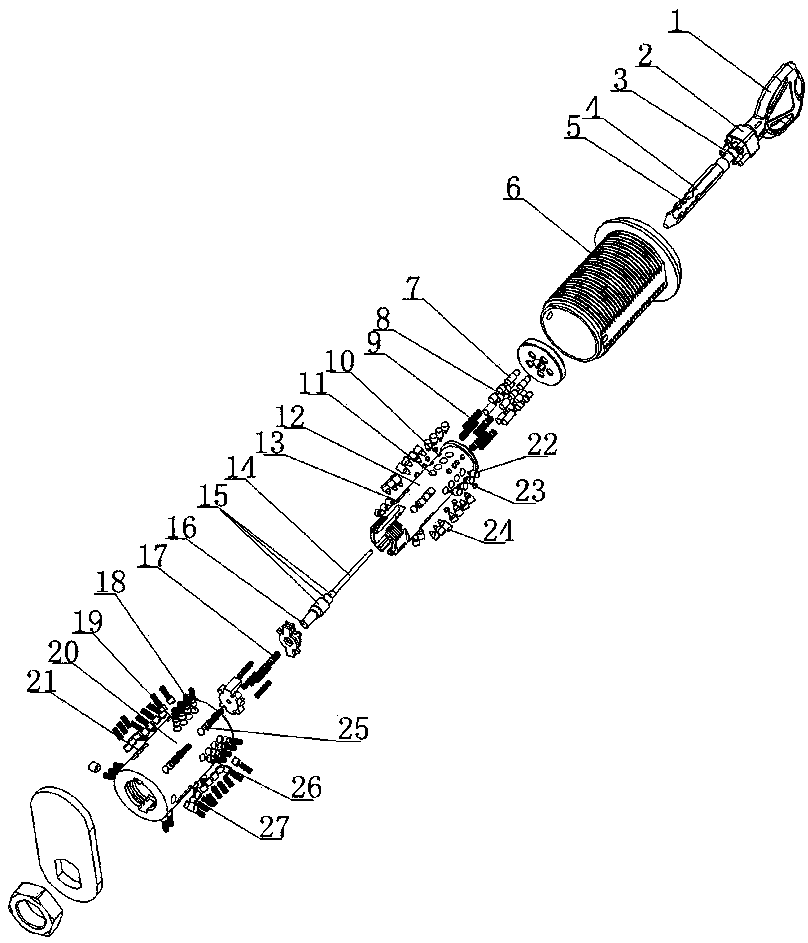

Anti-theft lock

InactiveCN103790441AScientific and reasonable structureStrong anti-theftKeysCylinder locksFlangeElectrical and Electronics engineering

The invention discloses an anti-theft lock, and belongs to the field of hardware. The anti-theft lock is mainly characterized in that a key comprises a key handle, a connecting portion and a key head; the key head is mounted on the connecting portion; the connecting portion is connected with the key handle; stand columns are arranged around a hole site, for mounting of the key head, of the connecting portion; a slot hole is formed in the key head; sliding cores corresponding to the stand columns are arranged in a lock cylinder; the sliding cores are provided with tapered sliding grooves or protrusions matched with pins in fourth pin holes; pins in third pin holes are matched with teeth on the key head; a sliding rod is arranged in the lock cylinder; a plurality of flanges with different outer diameters are arranged on the sliding rod; pins in sixth pin holes are abutted against the peripheral walls of the flanges; the sliding rod can extend into the slot hole of the key head; springs are arranged at the ends of the sliding cores and at the end of the sliding rod respectively. The anti-theft lock is scientific and reasonable in structure, has multiple-theft-prevention performance and is high in theft prevention performance, so that possibility of technical unlocking is completely eradicated.

Owner:RUIAN ZHENGQUAN LOCK IND

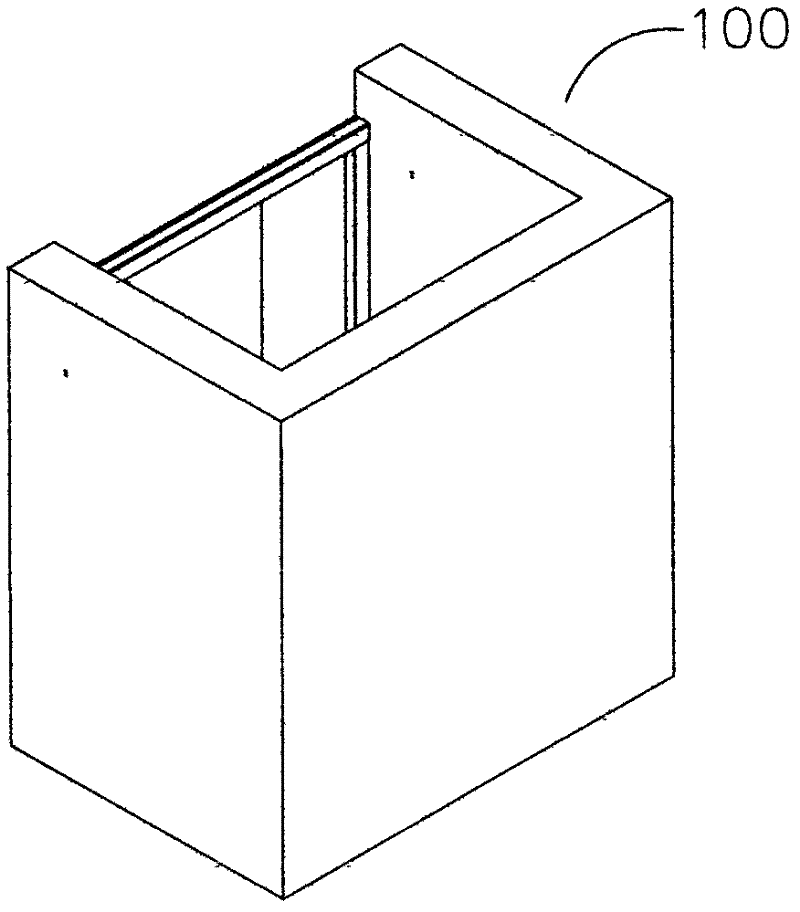

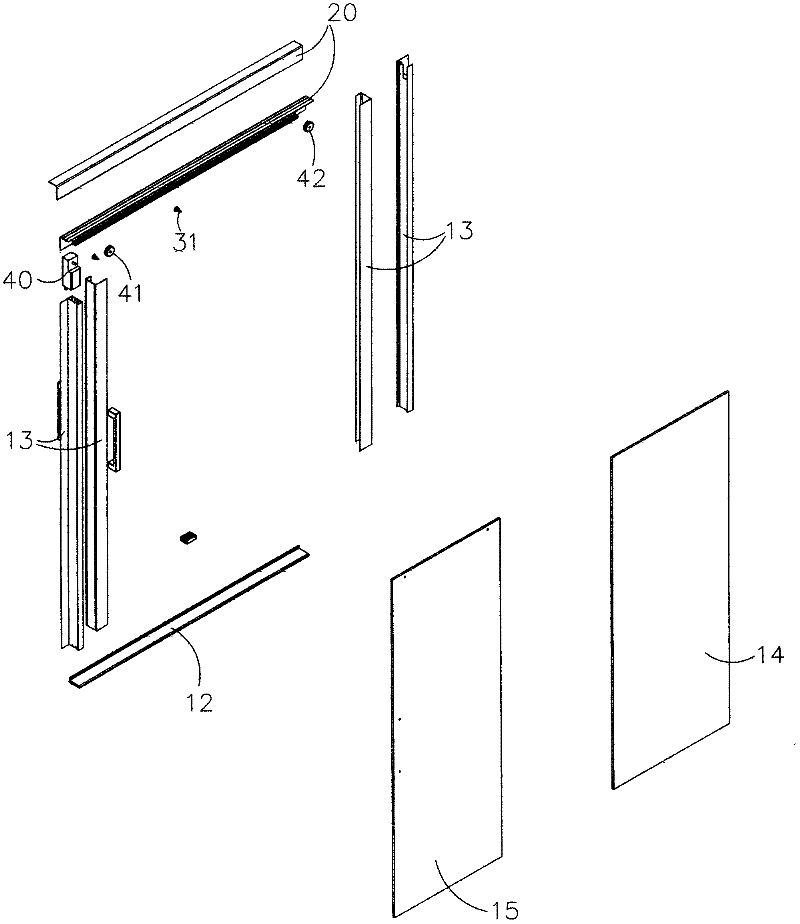

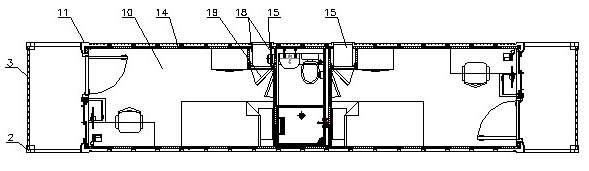

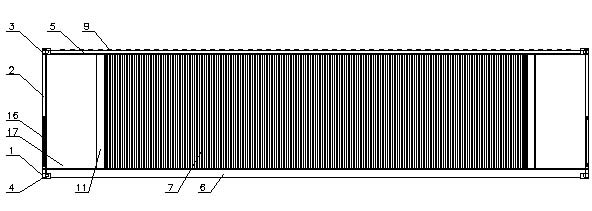

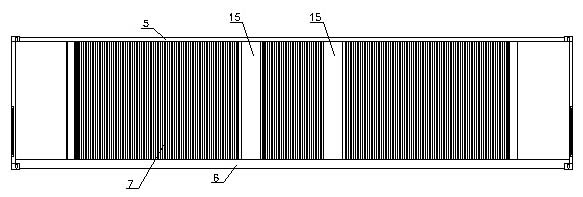

Container type house unit and modularized group building residential building

ActiveCN102304942AGuaranteed basic strengthScientific and reasonable structureBuilding constructionsDwelling buildingEngineeringOperability

The invention discloses a container type house unit, comprising a container house body, wherein the front end wall and the rear end wall of the container house body are respectively provided with a door (13) for entering the container house body; the front end and the rear end of the of the container house body are respectively provided with a balcony; the balcony and the container house body areformed into a whole; the left side and the right side of each balcony are respectively provided with an access used for the balcony; and side wall on one side of the container house body is provided with a piping shaft (15). In addition, the invention also provides a modularized group building residential building assembled by the container type house unit. According to the container type house unit and the modularized group building residential building formed by the container type house unit, the construction of the original container type residential building is kept, and the basic strength of the container type house is guaranteed. On the basis of the existing container type house, the reliability and the operability of the product can be perfected, the quality of the product is guaranteed, and the container type house unit is suitable for the requirement of industrial production.

Owner:YANGZHOU TONGLEE REEFER CONTAINER

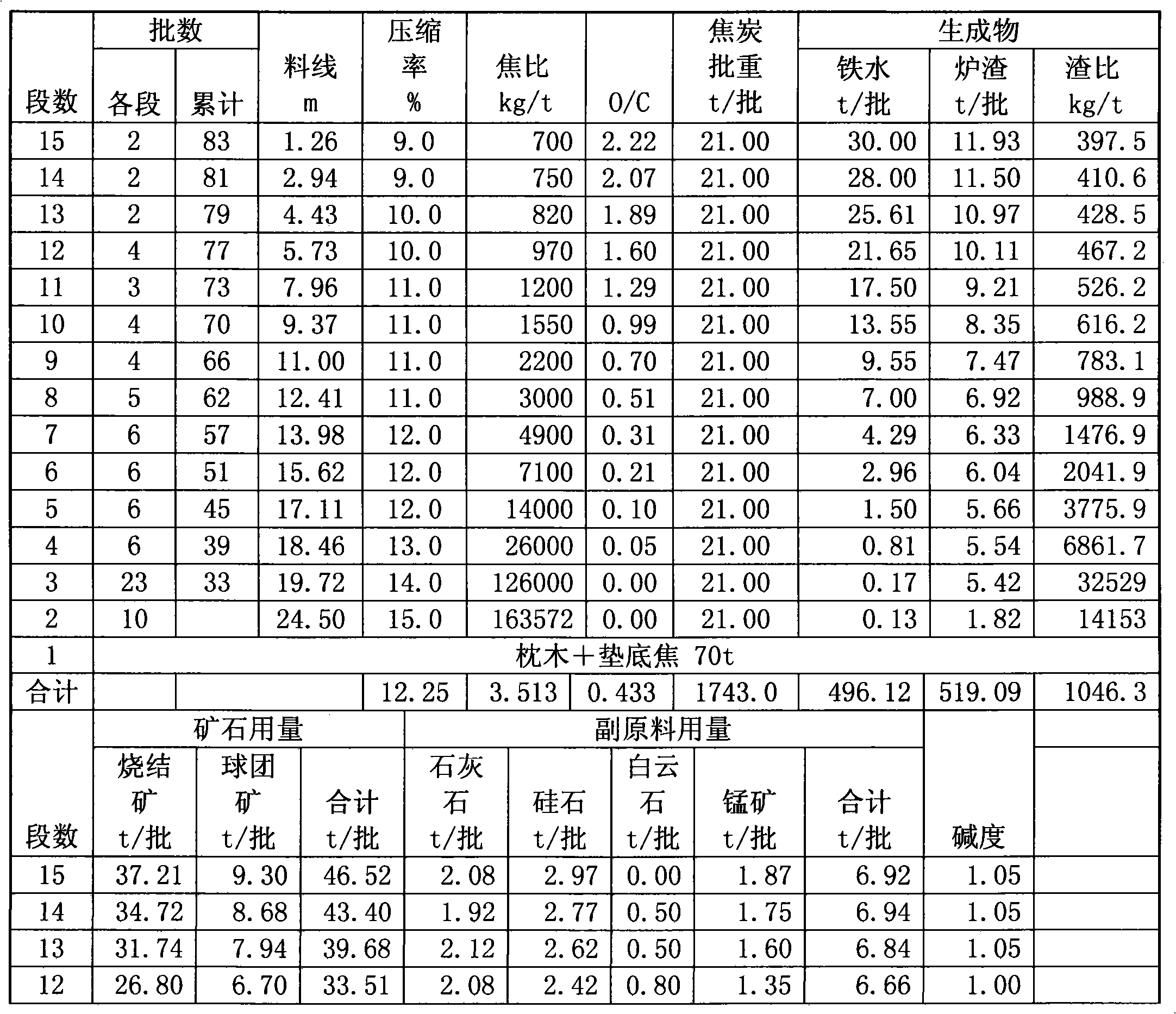

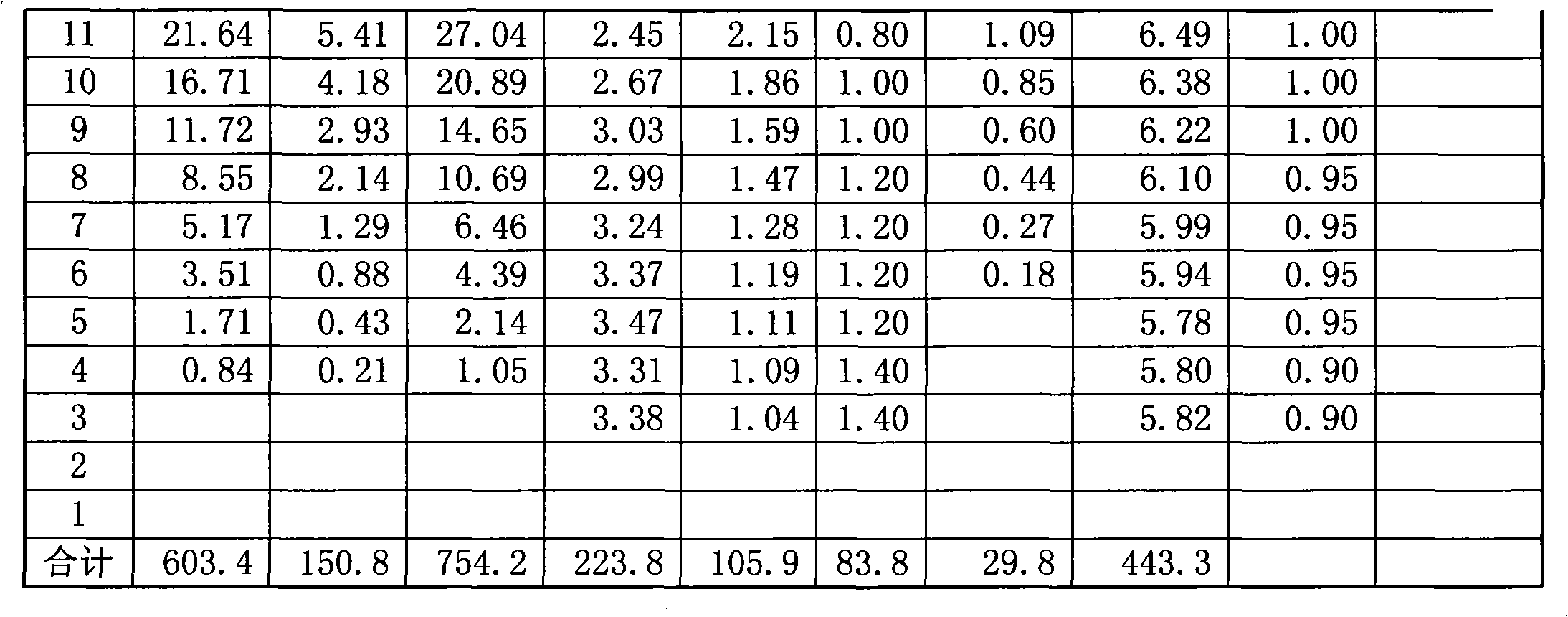

Blast furnace blowing-in burdening method

InactiveCN102399921ARefining the focal ratio gradientFlexible responseBlast furnace detailsSlagBatch Number

The invention provides a blast furnace blowing-in burdening method. A blast furnace normal material is divided into at least eight segments, and batch weights of ore at all the segments are unfixed but the batch weights of coke at all the segments are fixed on condition that alkalinities and Al2O3 balances of all the segments are guaranteed; the ratio between agglomerate and pellet ore in the ore is fixed as needed, different coke loads which are adopted by the coke ratio from the top down are determined according to a preset coke ratio of each segment, the content of mixed ore in each batch material is adjusted according to the content of MgO in slag, and the batch number of the material of each segment is adjusted according to the charging volume, the total coke ratio and the total final slag alkalinity. The practical charging stockline is guaranteed to be same as a stockline obtained through calculation, the coke ratio gradient is refined, and the ratio of all components in the slag is adjusted and controlled by the mixed ore, so the furnace man labor intensity is greatly reduced, the accident probability is reduced, the blast furnace production go smoothly, and the material slipping and hanging phenomenon is reduced, thereby the blast furnace blowing-in production target reaching time is greatly shortened, and the method has obvious economic benefits.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com