Patents

Literature

405 results about "Batch Number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A batch number is a designation that is printed on the drug label that allows the history of its production to be traced. This includes not only identification of the specific batch produced, but all relevant issues of control and manufacturing particulars should also be traceable from the batch number.

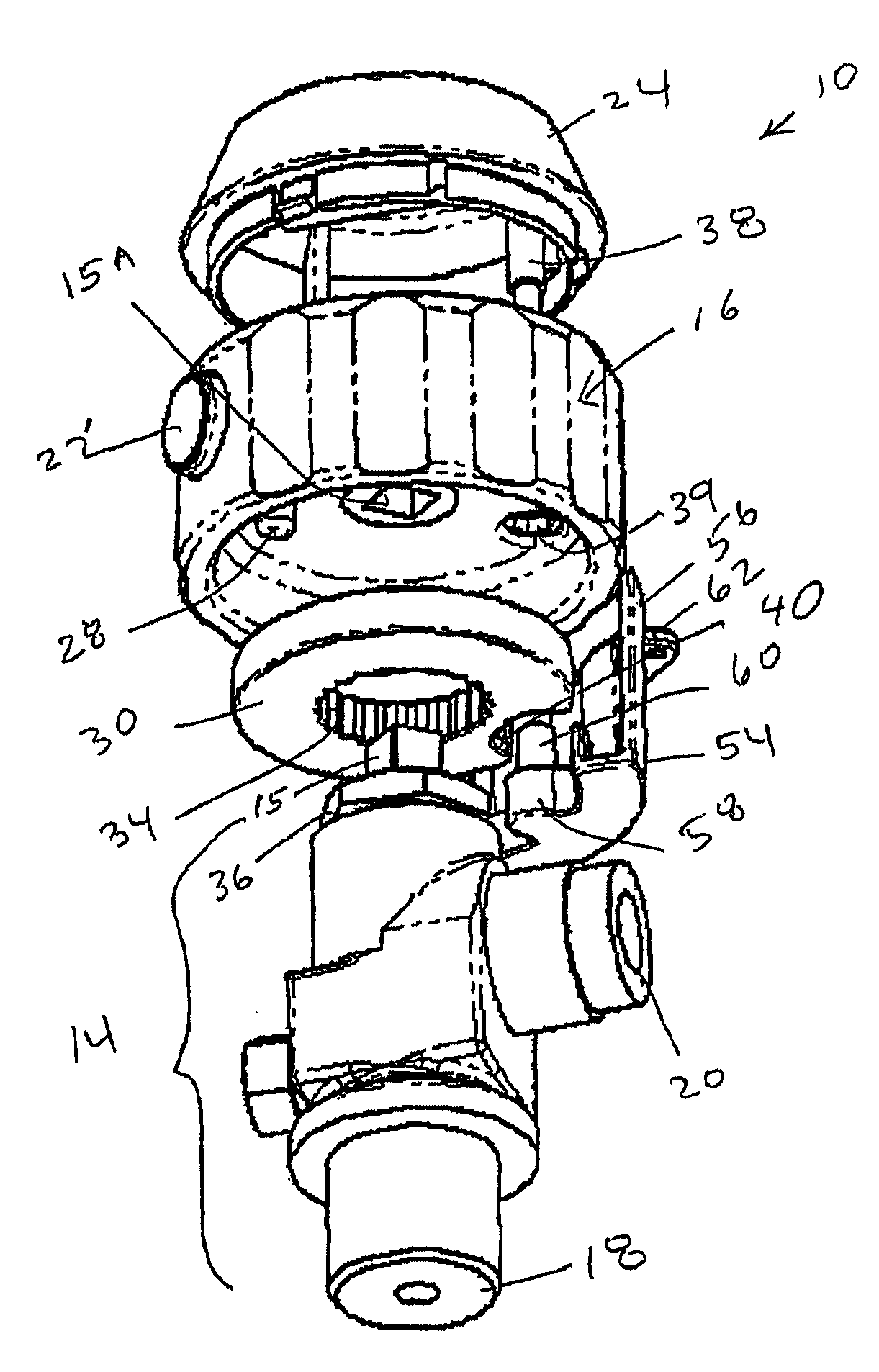

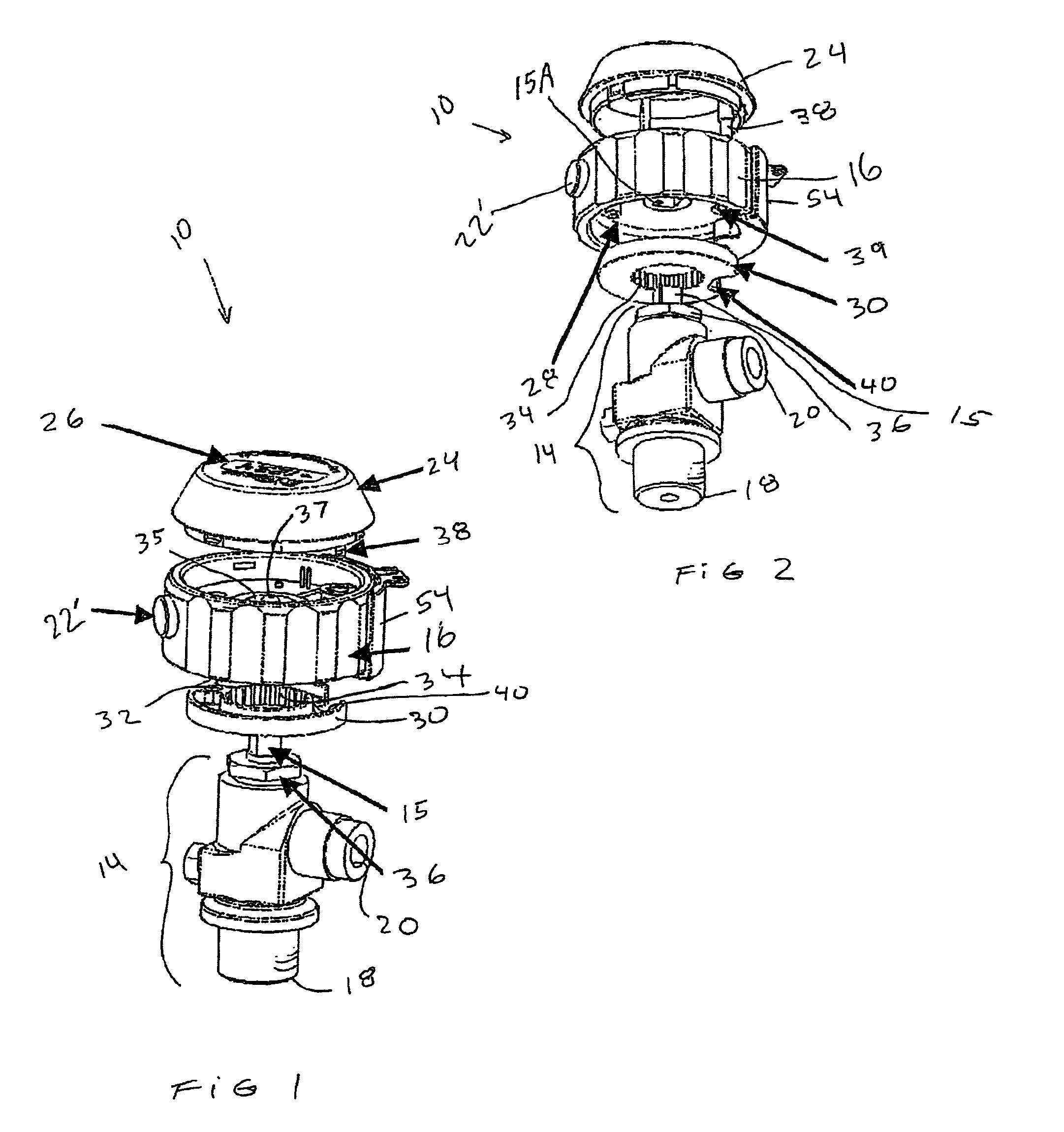

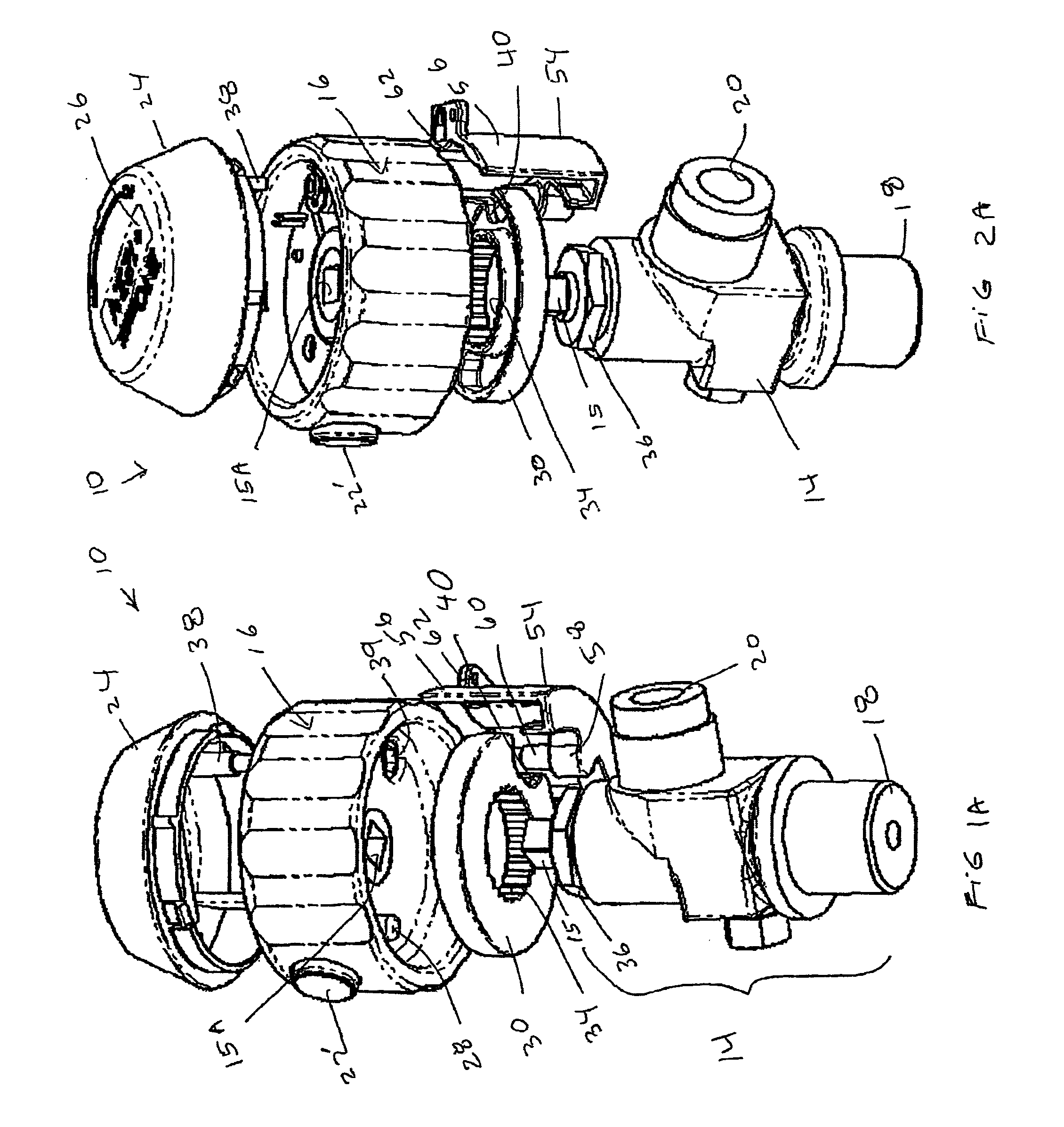

Valve with smart handle

A valve with a smart handle including a memory module to log relevant data. A sensor on the handle determines when the valve is open, and this triggers the start of timers and recording of the “open” event in a log in the memory module. When the valve is closed, the sensor triggers stopping of the timers and recording of the “closed” event in the log. The timer information is used to calculate the duration of the time “open” event, and this, together with the actual date and time of the opening and closing of the valve are recorded in the log. Other relevant information, such as cylinder fill date, cylinder I.D. number, batch number, and patient name or account number may also be logged in the memory module. The log of the events and the corresponding dates and times may be used to prepare invoices for billing gas treatments, for inventory control, and for other record-keeping and control functions.

Owner:VENTEK +1

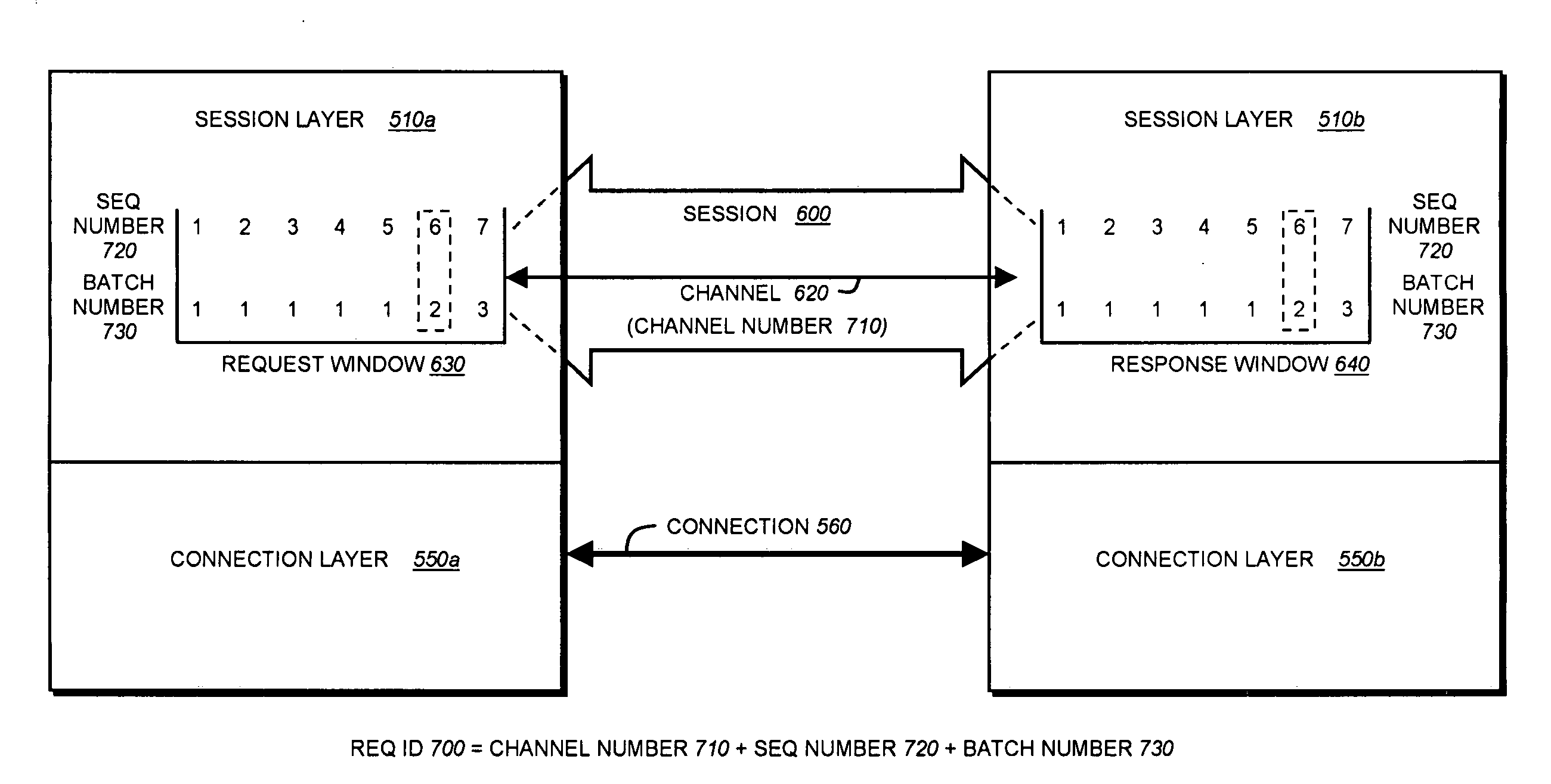

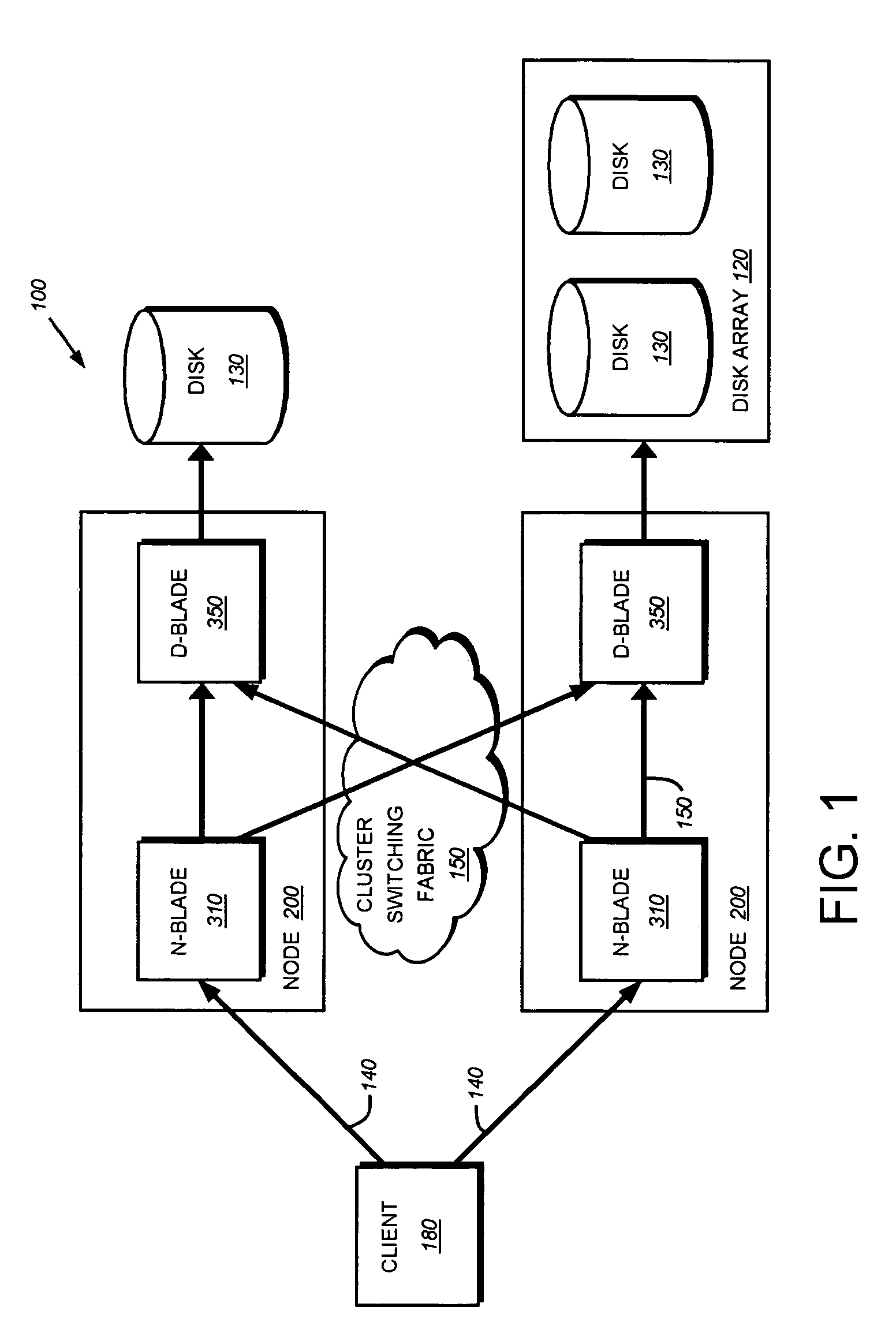

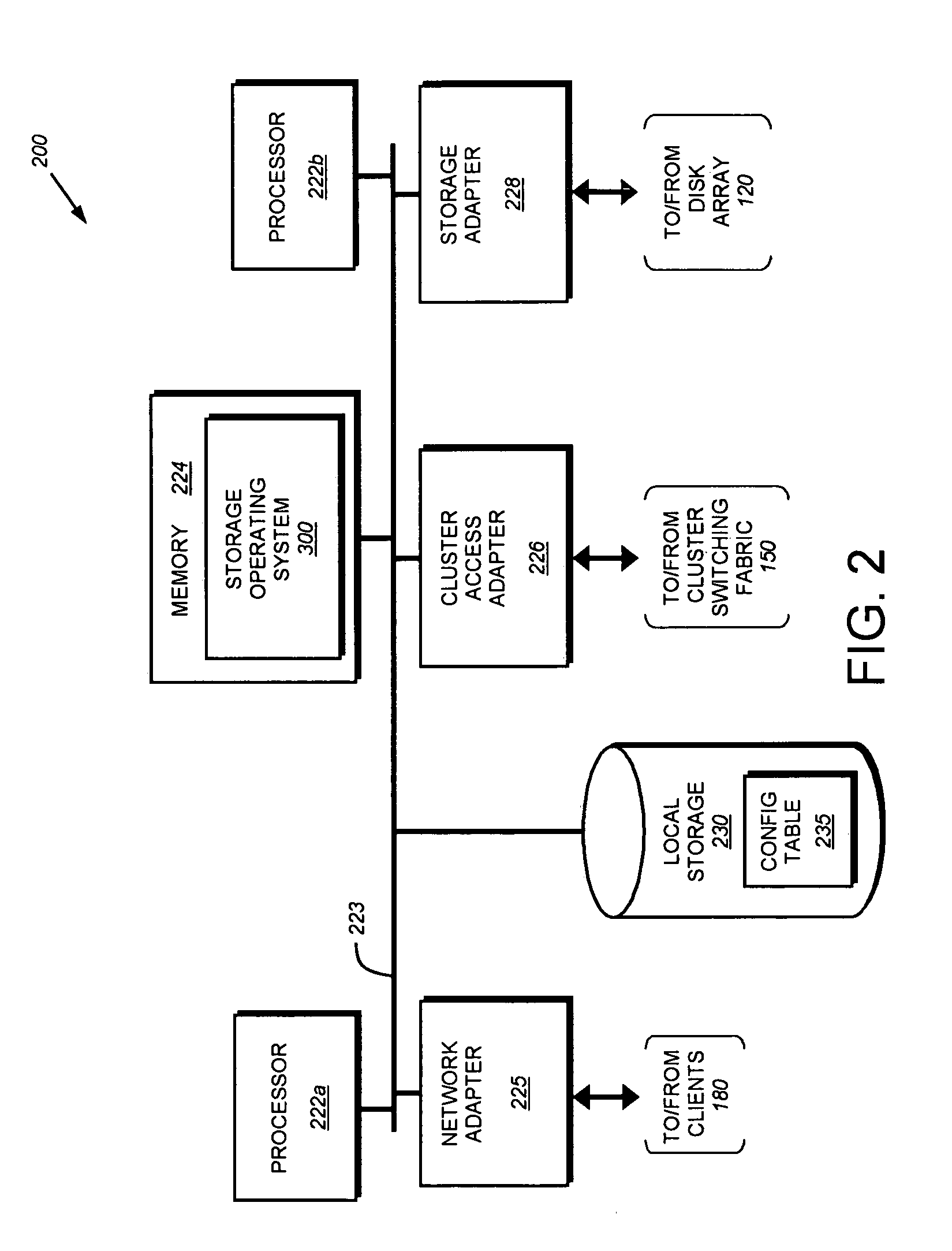

System and method for specifying batch execution ordering of requests in a storage system cluster

ActiveUS7657537B1Digital data processing detailsDigital computer detailsUnique identifierSerial code

A system and method specifies batch execution ordering of requests in a cluster of storage systems or nodes. Each node is generally organized as a network element and a disk element. One or more sessions are established between the elements in the cluster. Each session comprises a plurality of channels disposed over connections, wherein each channel enables multiple requests to be sent over a connection. Each request is identified by a unique identifier (“request id”) that is generally defined as the combination of a channel number and a sequence number. The request id is extended to include a batch number that provides an execution ordering directive within a channel. All requests with the same batch number in a channel can be executed in arbitrary order or concurrently. Ordering is imposed only when the batch number changes, e.g., increases. Although more than one request in a channel can have the same batch number, all requests with the same batch number are executed before any request with a higher batch number.

Owner:NETWORK APPLIANCE INC

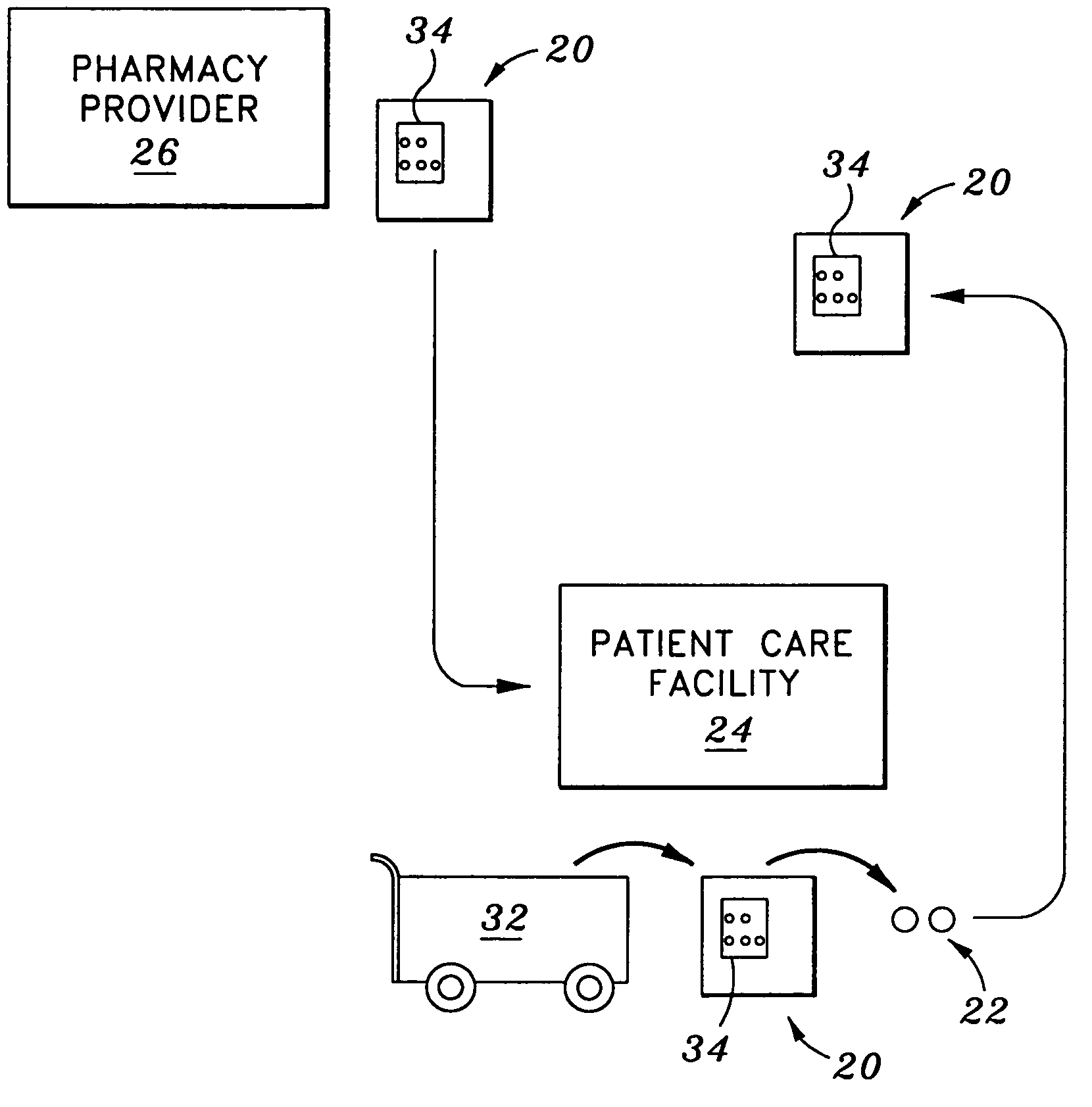

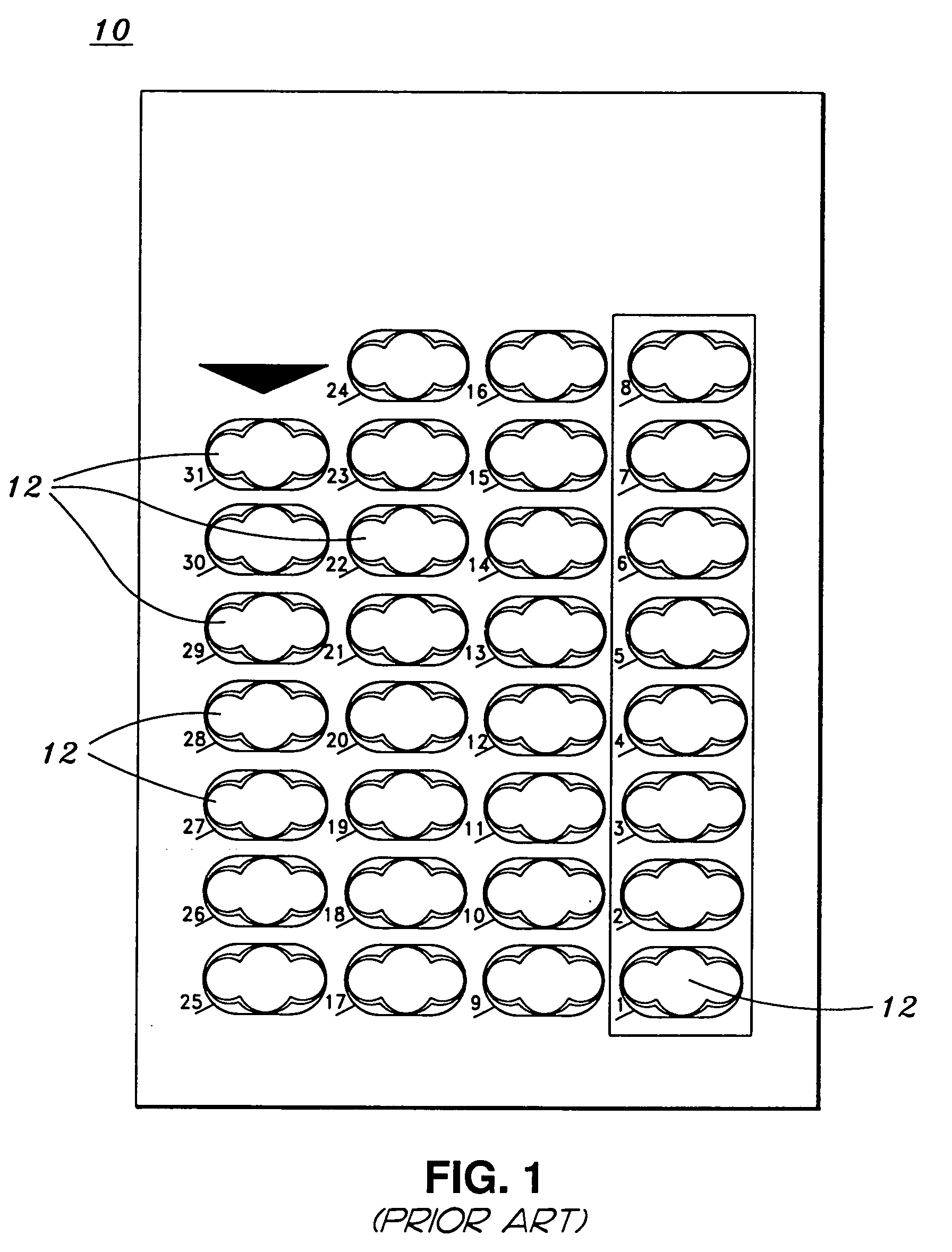

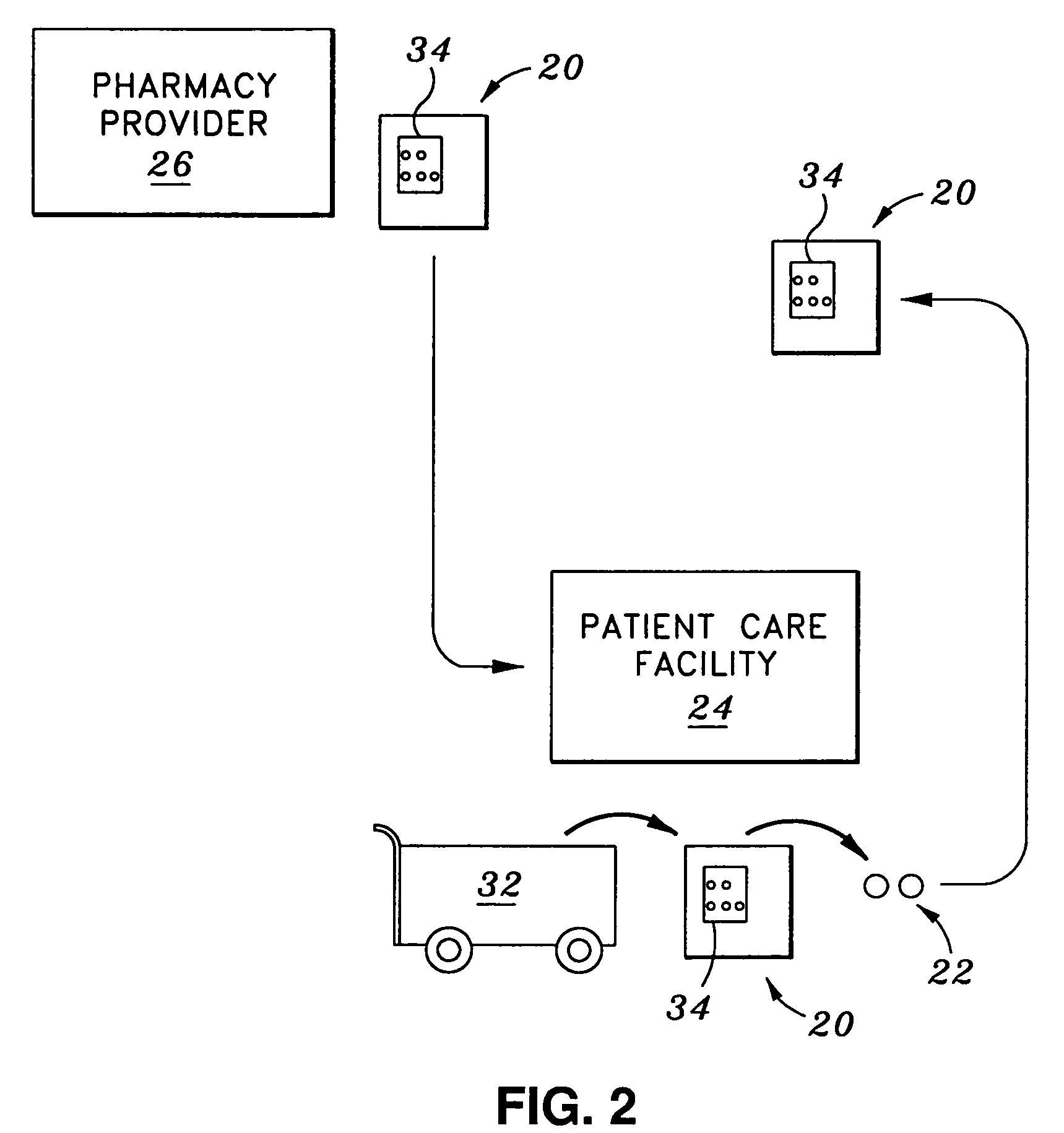

Method for saving medication costs by redistributing unused medications

InactiveUS20050096941A1Saving medication costLow costData processing applicationsDrug and medicationsMedical prescriptionMedication cost

There is provided a method of saving medication costs by redistributing unused medications. The method first features the step of receiving a request to fill a prescription for the medication of a patient serviced by a patient care facility. Thereafter, unit doses of the medication are assembled based upon the prescription. Each of the unit doses are individually identified with a lot number and an expiration date. The method further features the step of distributing the assembled unit doses to the patient care facility. Then, an unused portion of the unit doses is received from the patient care facility. An amount of such unused portion is identified and credited to the patient care facility. The identified unused portion of the unit doses are stored and later redistributed so as to mitigate the cost of the medication.

Owner:BROADCOM CORP

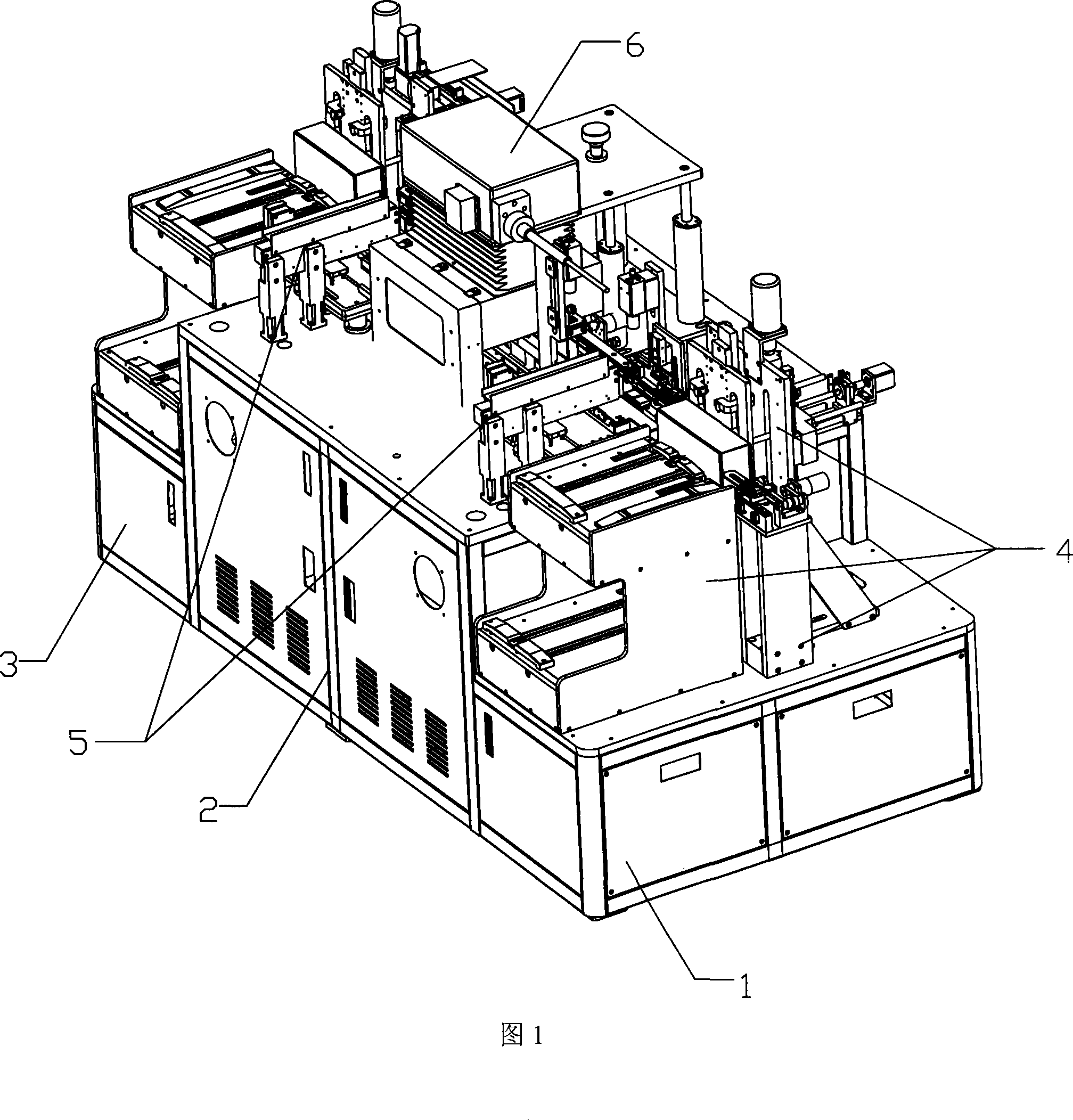

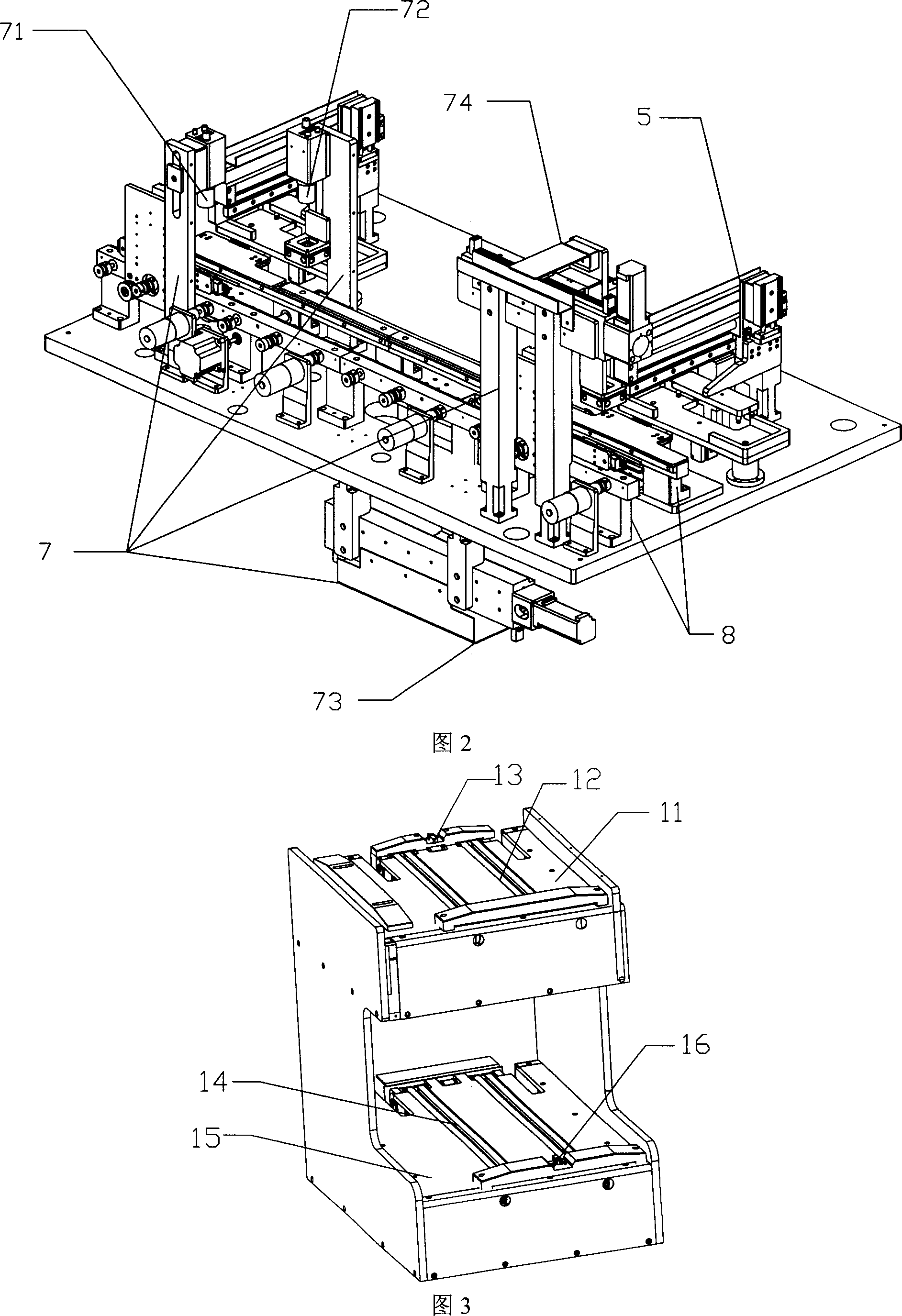

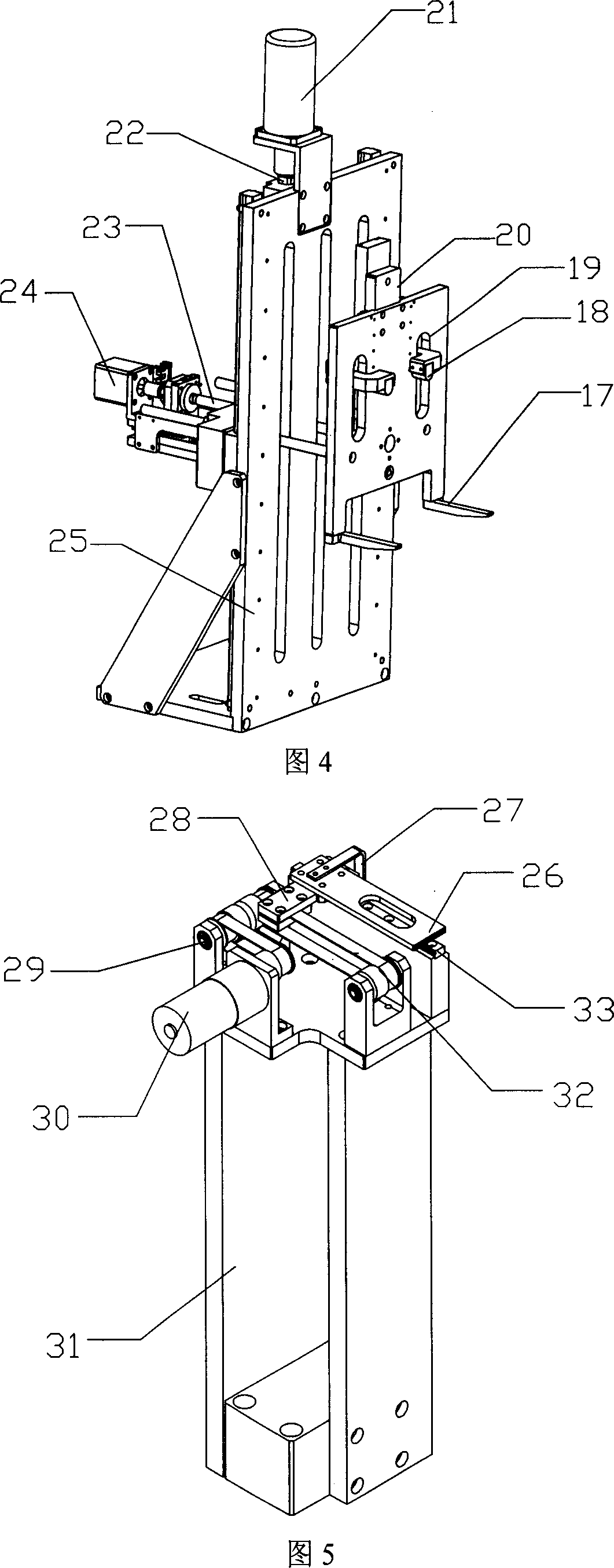

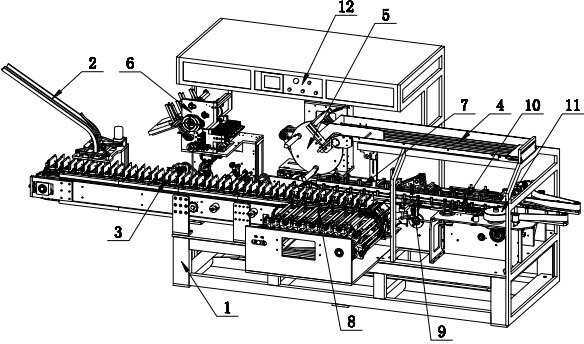

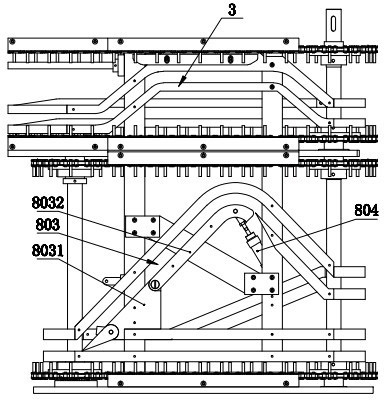

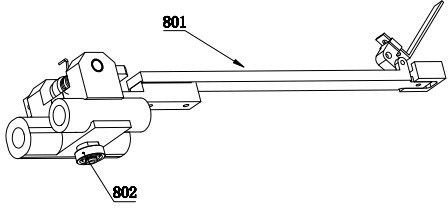

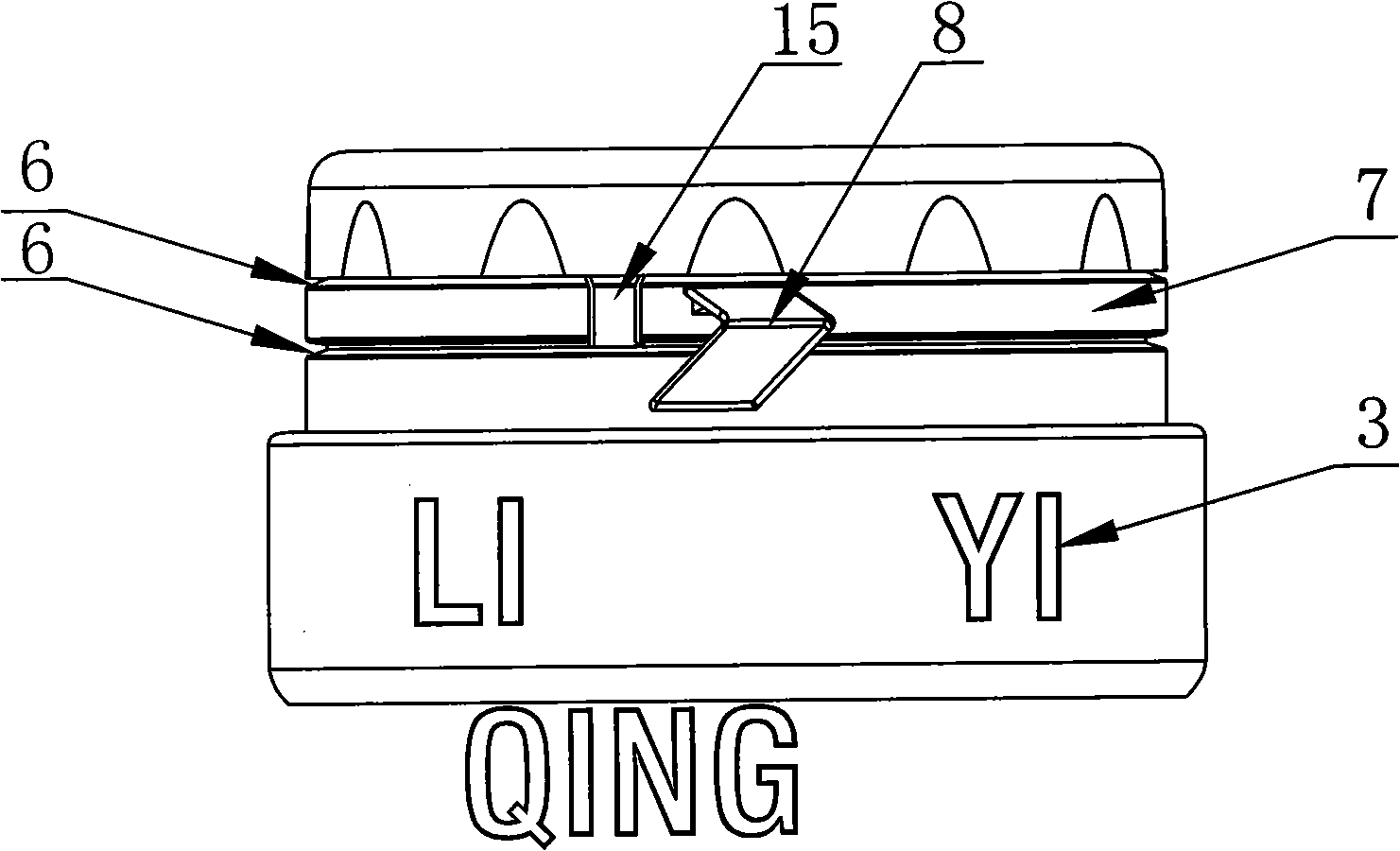

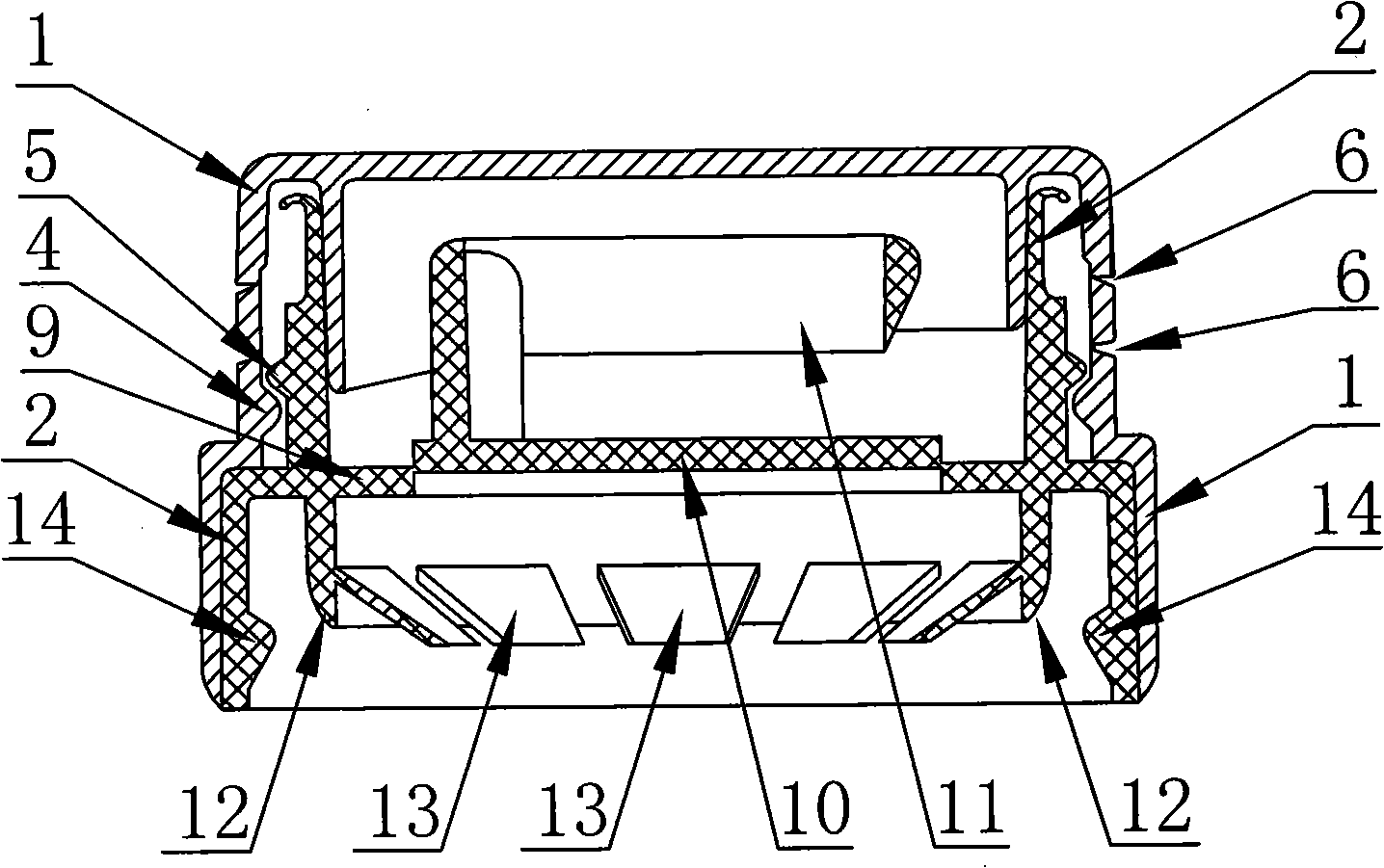

Laser marker for fully automatic IC material bar

InactiveCN101127301AReduce labor intensityPrecise and rational marking processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLocation detectionEngineering

The utility model relates to a full automatic IC strip laser marking machine, comprising a body; wherein, a PC device and an electric control system are arranged in the body; a loading-unloading outlet device, a strip conveying device, a laser marking device, a detection system and a removing device which are controlled by the PC device are arranged on the body; the loading outlet device and the unloading outlet device are arranged on both sides of the body, and the strip conveying device is arranged between the two devices. Besides, a direction detection device, a batch number detection device, a pre-marking removing device, a laser marking device, a post-marking quality detection device and a post-marking removing device are arranged on two conveying lines of the both sides of the strip conveying device in sequence, and a marking position detection device is arranged under the laser marking device. Because the loading, conveying, detecting, removing and marking devices which are controlled by the PC device are arranged on the marking machine, the whole marking process is accurate and reasonable; meanwhile, the labor intensity can be reduced.

Owner:GRAND TECH SHENZHEN

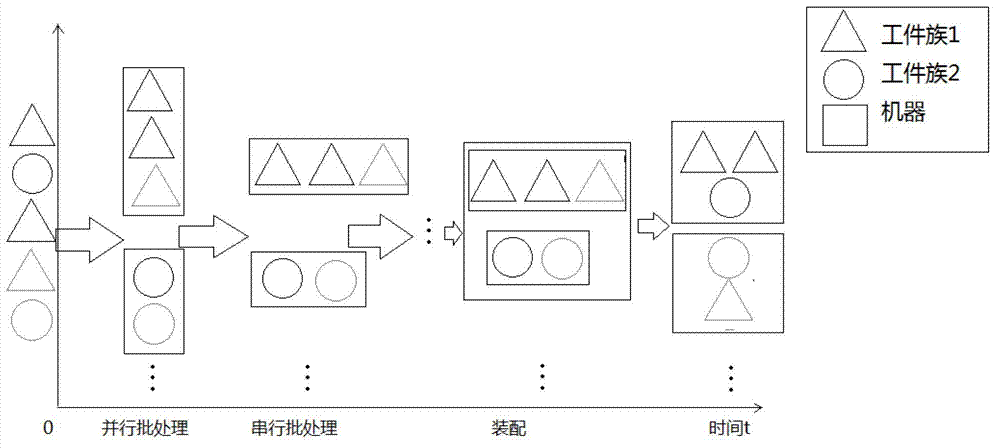

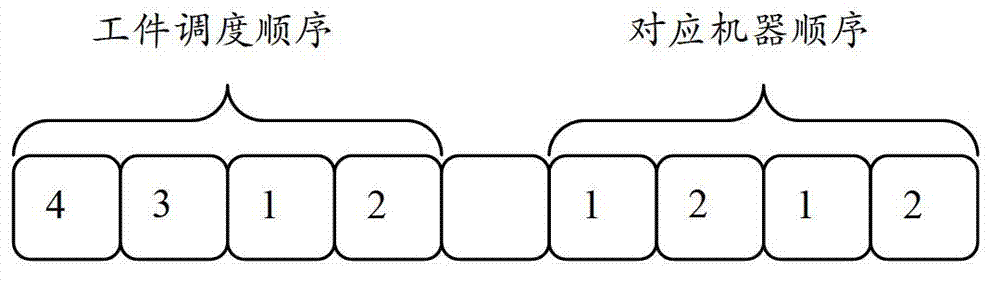

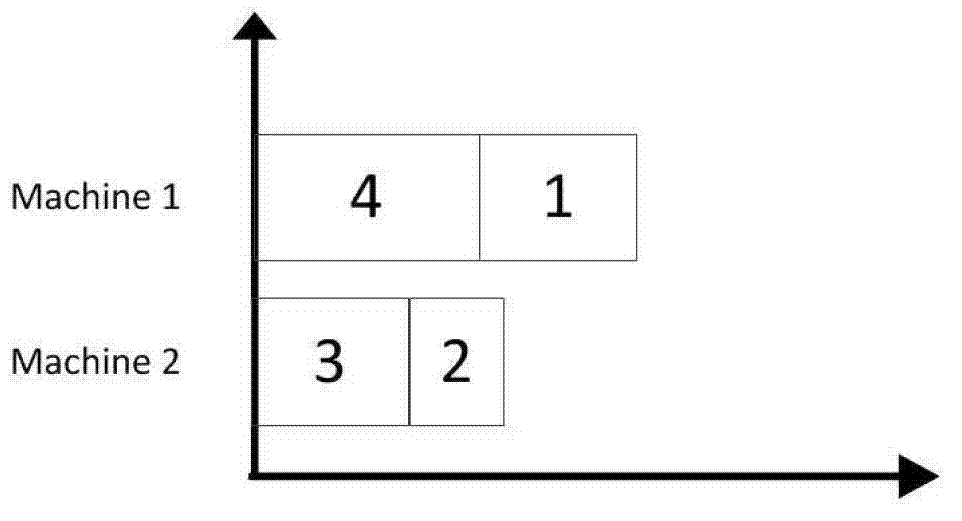

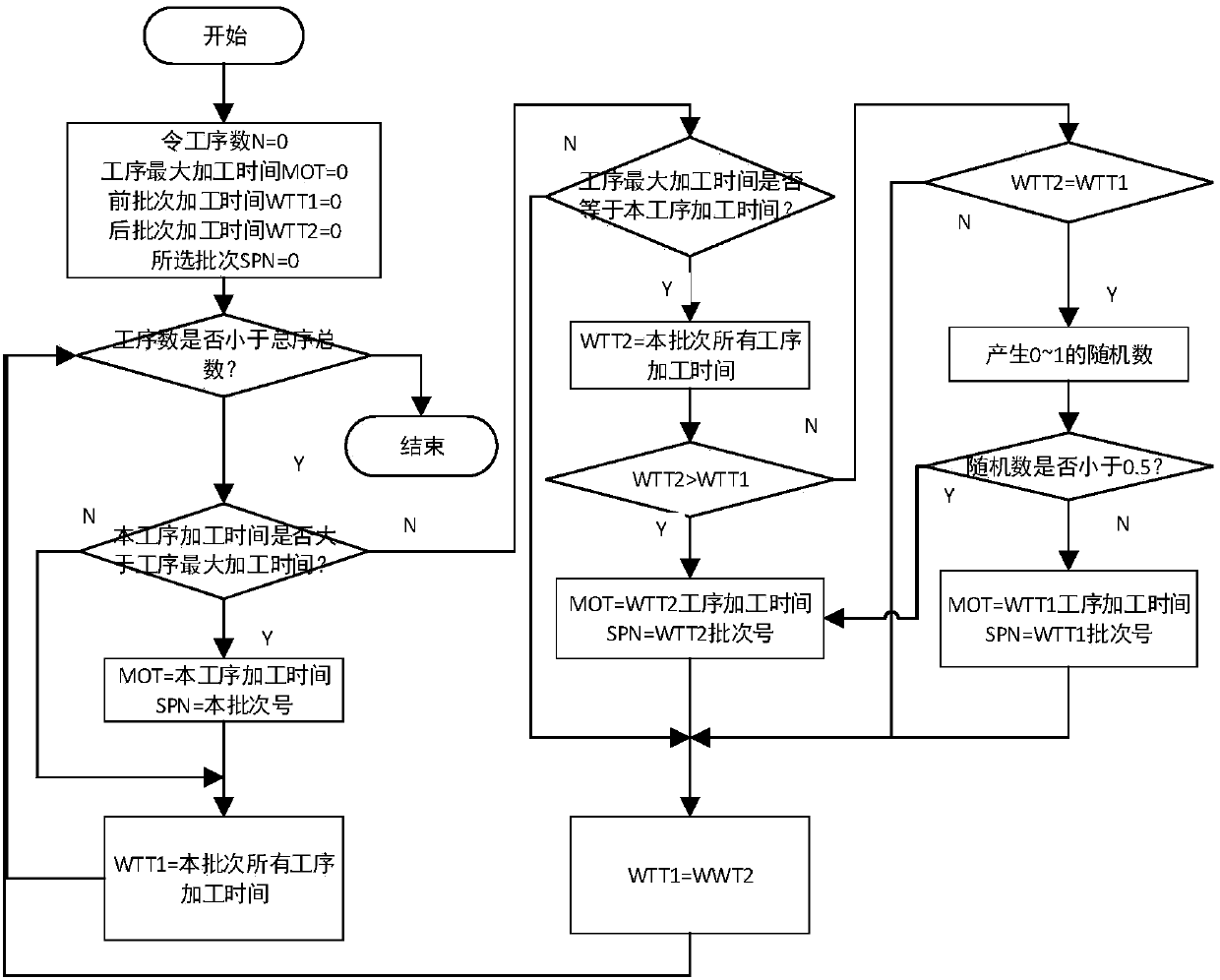

Hybrid flow shop scheduling method

InactiveCN102929263ASolving Scheduling Optimization ProblemsSolve the real problemProgramme total factory controlBatch processingBatch phase

The invention relates to a hybrid flow shop scheduling method, which comprises the following steps of: dividing parts into multiple part sets based on different part families of the required parts; establishing a new batch for each part and performing batching based on the volume of a thermal treating funnel; after the batching, making a serial number for each batch and a machine, and encoding at each stage, wherein each stage comprises two sections of chromosomes, the first section of chromosome is a batch number, and the second chromosome is a machine serial number corresponding to the batch number; generating chromosomes at random when a user meets the conditions restricted by the machines; selecting N chromosomes, carrying out a pairwise cross operation on N selected chromosomes, carrying out a mutation operation on each chromosome, and then repairing the chromosomes; and repeating the steps of selection, cross operation, mutation and repairing till the maximum number of iterations is reached. With the method, the problem of a hybrid flow shop where the assembling affects the batching in the parallel batch processing phase can be solved, and the algorithm operation efficiency can be ensured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method of replacing lime with limestone for slagging and producing steel in oxygen top blown converter

The present invention belongs to the field of steel production, and relates to a method of replacing lime with limestone for slagging and producing steel in an oxygen top blown converter. The invention is characterized in that the limestone is directly added during slagging in the steel production process. The added batch number is increased and the amount of each batch of material is reduced. Namely the lime is added by 1-3 times for slagging formerly, and when the limestone is added for slagging, the limestone is added by 4-8 times. The adding amount of each time, calculated according to the CaO therein, is 1 / 2-1 / 3 of lime added formerly and is for preventing the condensing and incrusting at the metal surface in the furnace in the early period of converting. The adding amount of limestone, calculated according to CaO therein, accounts for 30%-100% of adding amount of lime in the batch. The method of the invention has the main advantages of elimination of lime calcining procedure or reduction of production scale, reduction of cost required for operating the calcining device and reducing the discharged pollution, prevention of heat waste caused by cooling the lime after calcining, low sulfur content in the lime generated in the oxygen top blown converter, and benefit for restraining resulfurization of melted iron in the steel production process.

Owner:UNIV OF SCI & TECH BEIJING

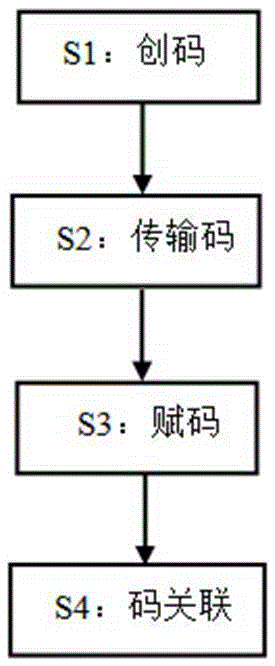

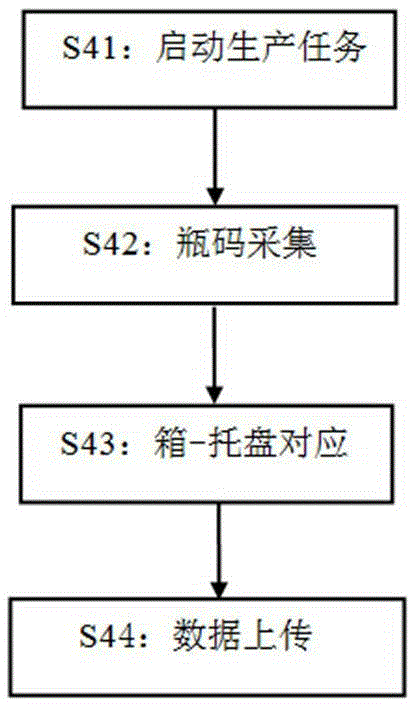

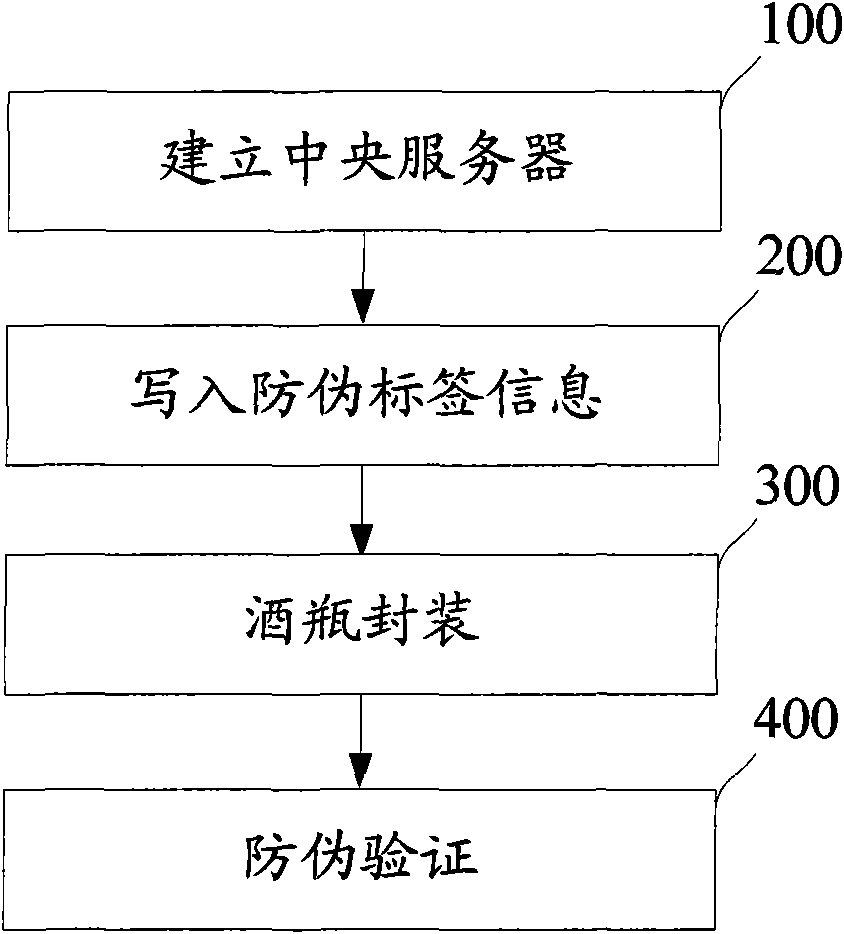

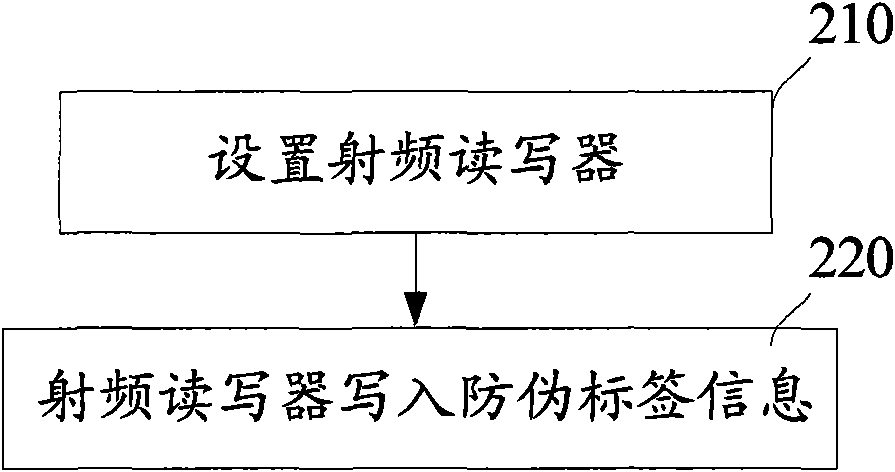

Two-dimensional code production method for wine bottle

ActiveCN105303220AEasy to participateUniqueness guaranteedCo-operative working arrangementsRecord carriers used with machinesThree levelLogistics management

The invention discloses a two-dimensional code production method for a wine bottle, and belongs to the field of bar code production, for solving the problems of logistics node management, fake and inferior products, out-zone sale and the like in the industry of liquor. Two-dimensional codes are generated by an encryption algorithm and are obtained through secondary encryption, verification and checking through a system, two-dimensional code pictures are generated, each product is endowed with a code, according to a three-level association sequence of bottles, boxes and pallets, the unique two-dimensional code of each wine bottle is acquired on a liquor filling streamline through a gatherer for association, and then the two-dimensional codes are enabled to be associated with such information as product specifications, production time, production batch numbers, groups, dealers, sale orders, delivery orders and the like through production scheduling and delivery, such that tracing of the quality of products in the whole life period, counterfeiting prevention, out-zone sale prevention, logistics monitoring, sale data monitoring, product stock monitoring and establishment of a basis of consumer group terminal client data can be realized, and vast users can rapidly and conveniently participate in quality tracing supervision.

Owner:泸州益和纸品包装有限公司

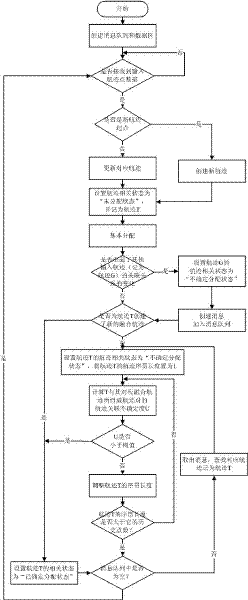

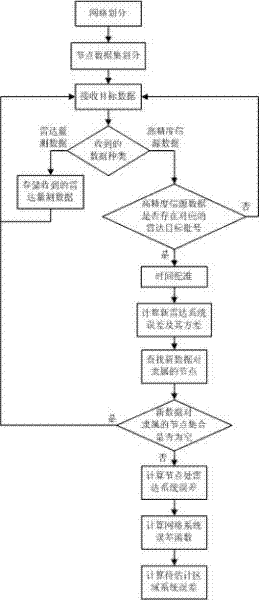

Self-adaptation flight path data correlation method

InactiveCN102194332AEliminate adverse effects of fusionGuaranteed accuracyMarine craft traffic controlMessage queueTarget distribution

The invention discloses a self-adaptation flight path data correlation method comprising the following steps: establishing and maintaining a public data flight path table and a message queue, wherein the flight path table is mainly used for maintaining flight path data and comprises attribute information of flight paths per se, information of flight path points, information of sequential lengths, state information of an affiliated flight path, information of an affiliated fused flight path and the like, and the message queue comprises flight path batch numbers used for searching corresponding flight paths; and distinguishing correlation states of an input flight path into three states, namely undistributed state, undetermined distribution state and determined distribution state by automatically updating a flight path correlation sequential length M, thus enabling a flight path correlation algorithm to automatically adapt to different target distribution, different target motion states, and different tracking dimensions, tracking accuracy and tracking stability of different sensors and overcome adverse influences of the differences on correlation judgments. By applying the method, data synthesis is carried out only on input flight paths in the determined distribution state, so that the precision of the fused flight path is favorably maintained.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

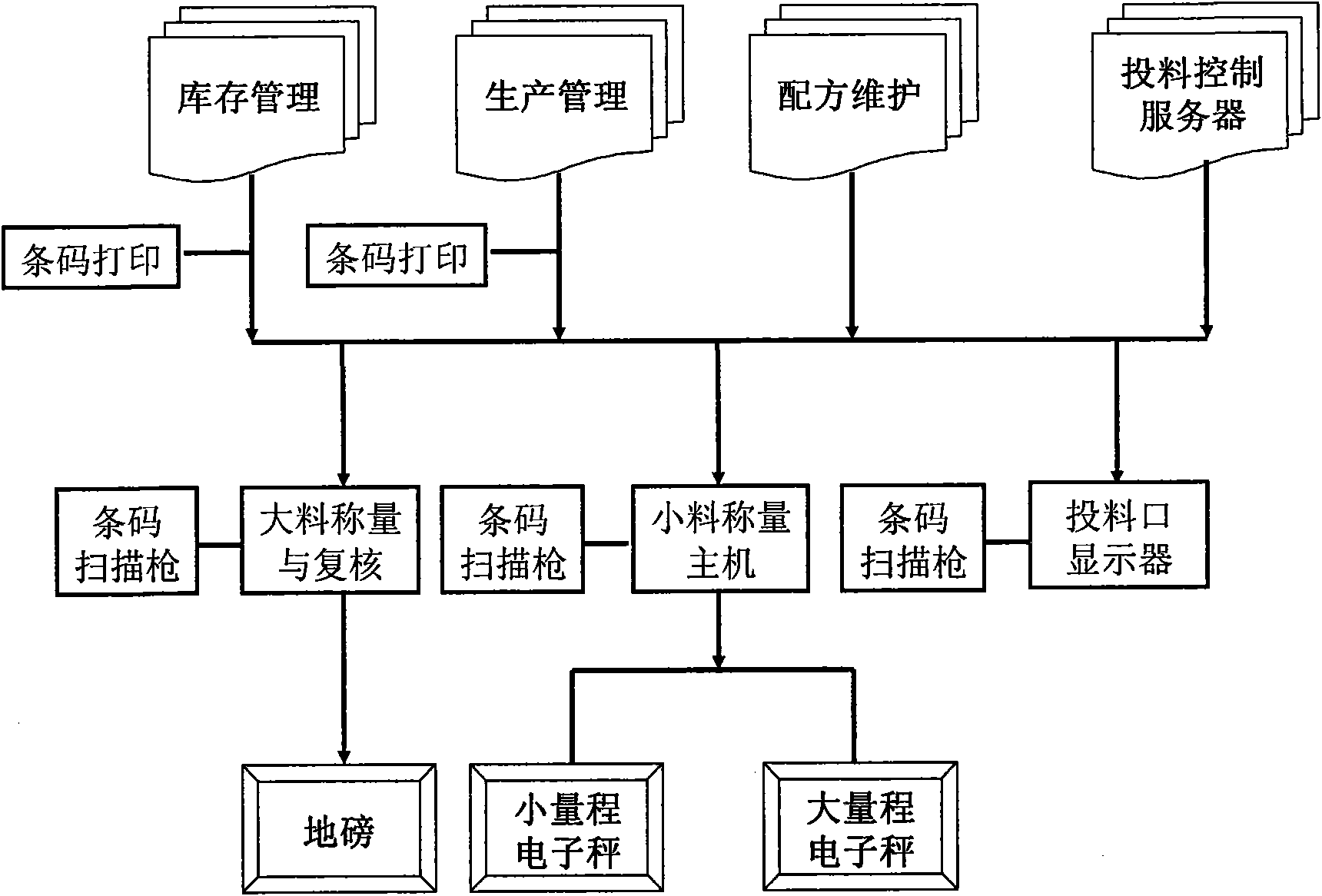

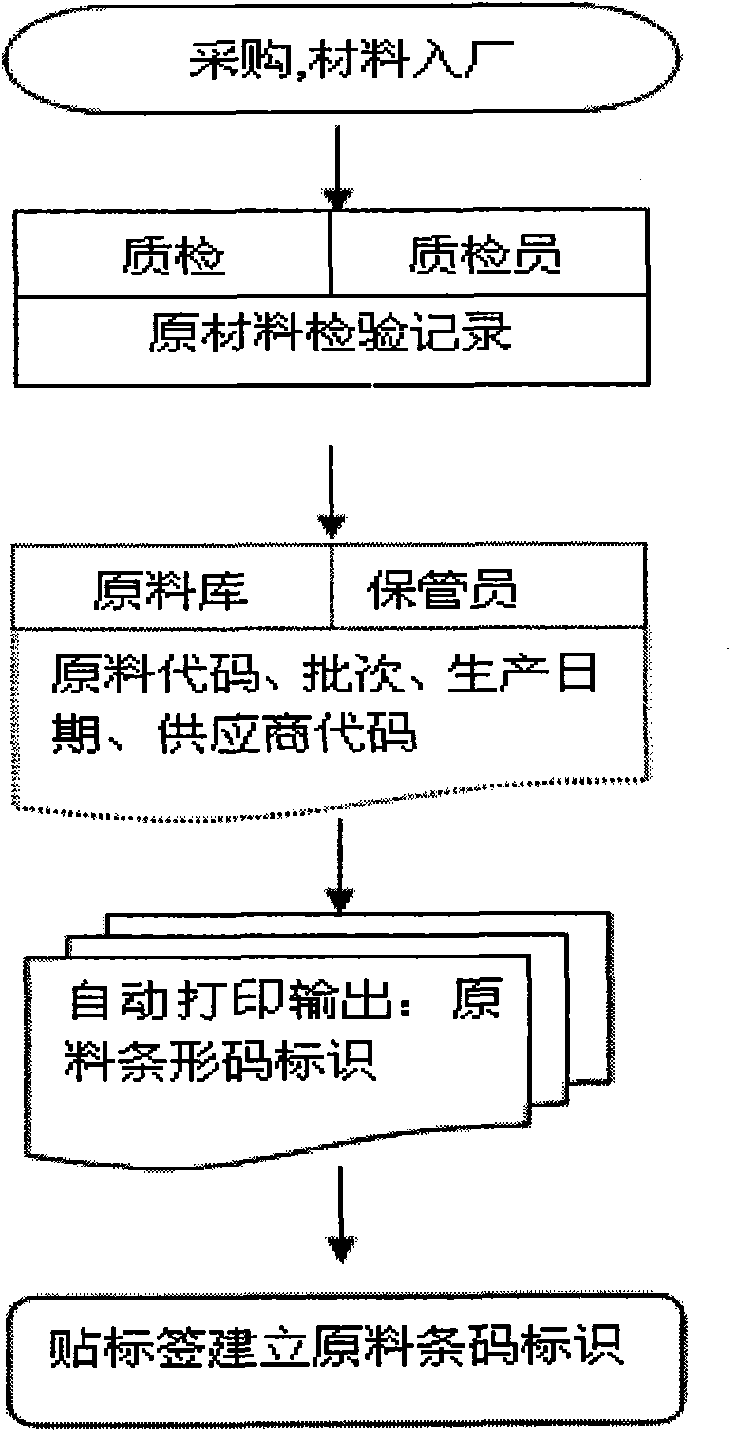

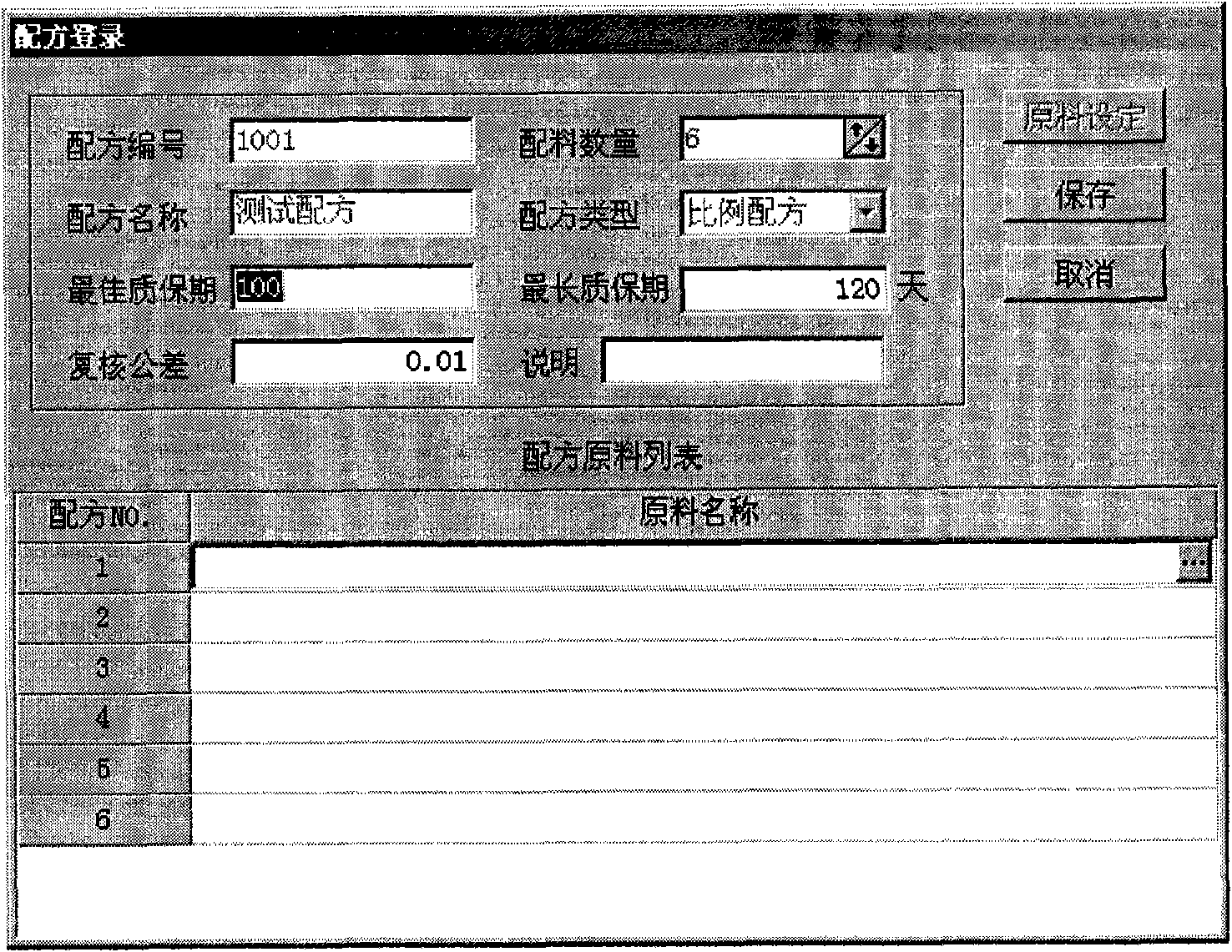

Feed production quality tracking system

InactiveCN101593323AFully transparent management capabilitiesGuaranteed visual controlResourcesAdditive ingredientAccess management

The invention provides a feed production quality tracking system, which comprises a bar code printer, a bar code scanner and a computer software system, wherein the computer software system realizes the following functions for tracking feed production quality together with a bar code technique: (1) raw material labeling and warehouse access management; (2) formula code management and maintenance limitation; (3) production control and production information recording; (4) minor ingredient mixing control; (5) batch feeding control; and (6) finished product batch number control. The system can track back to all production steps and raw materials from the batch number of finished feed to find out problems and provide bases for quality improvement.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES +1

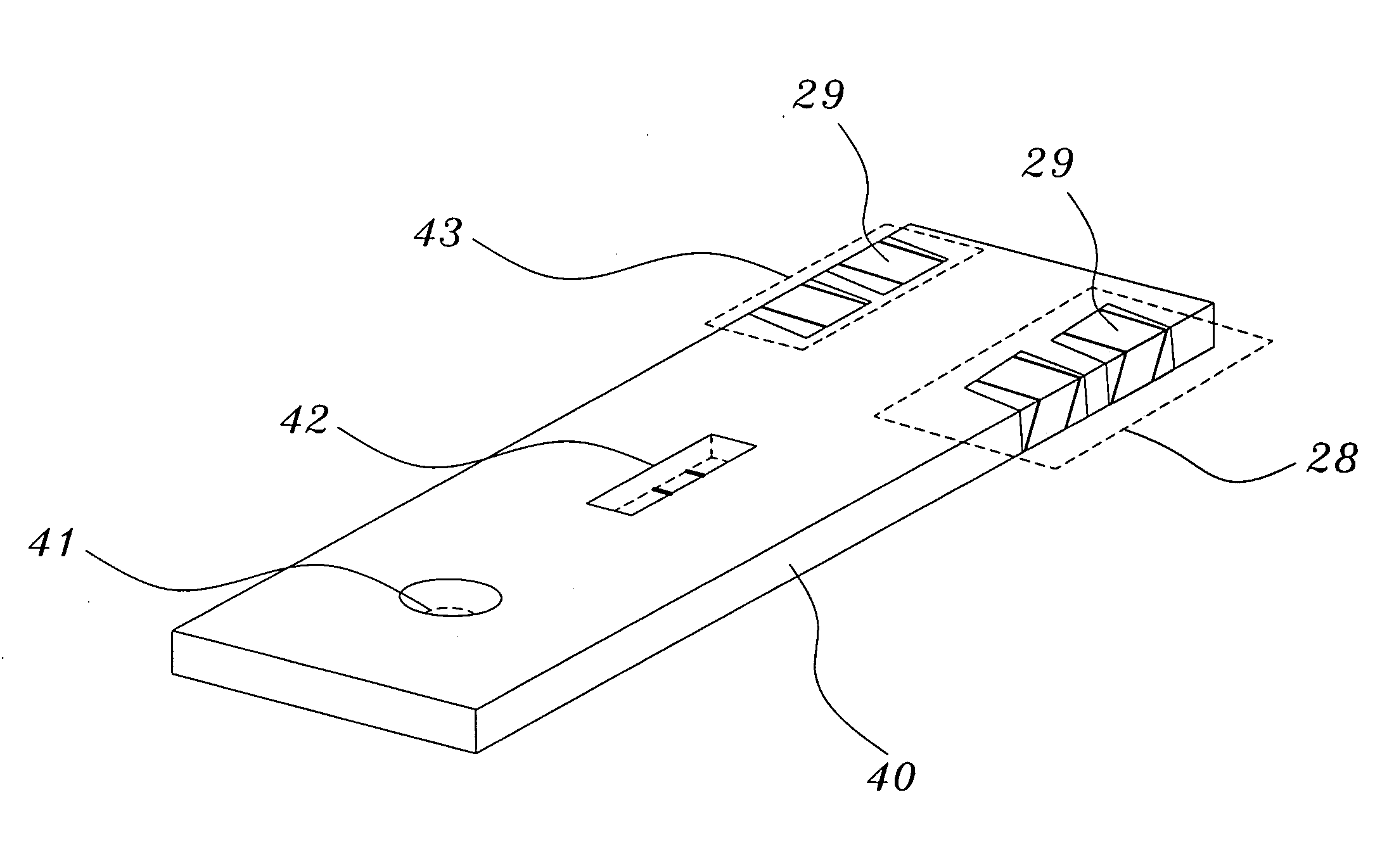

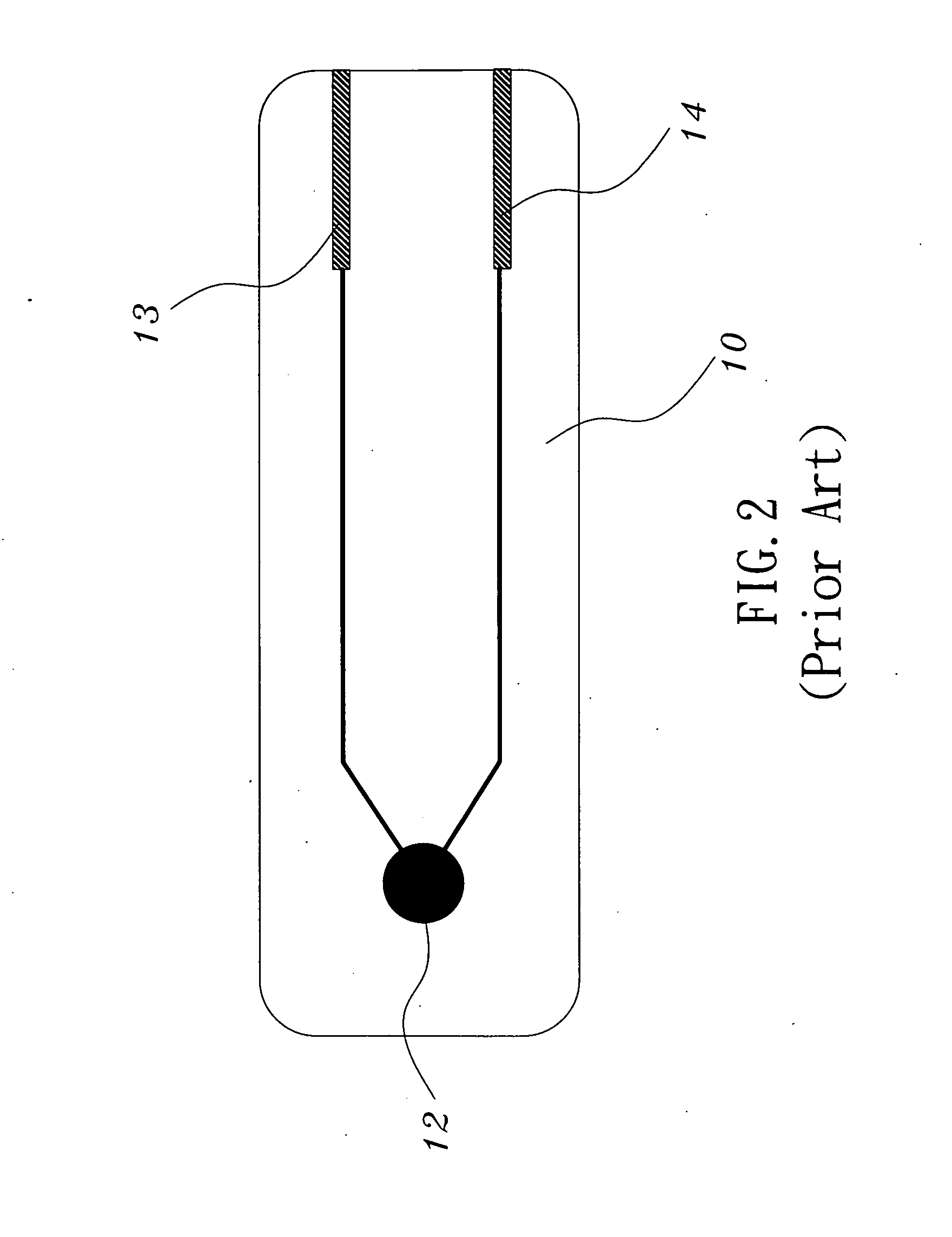

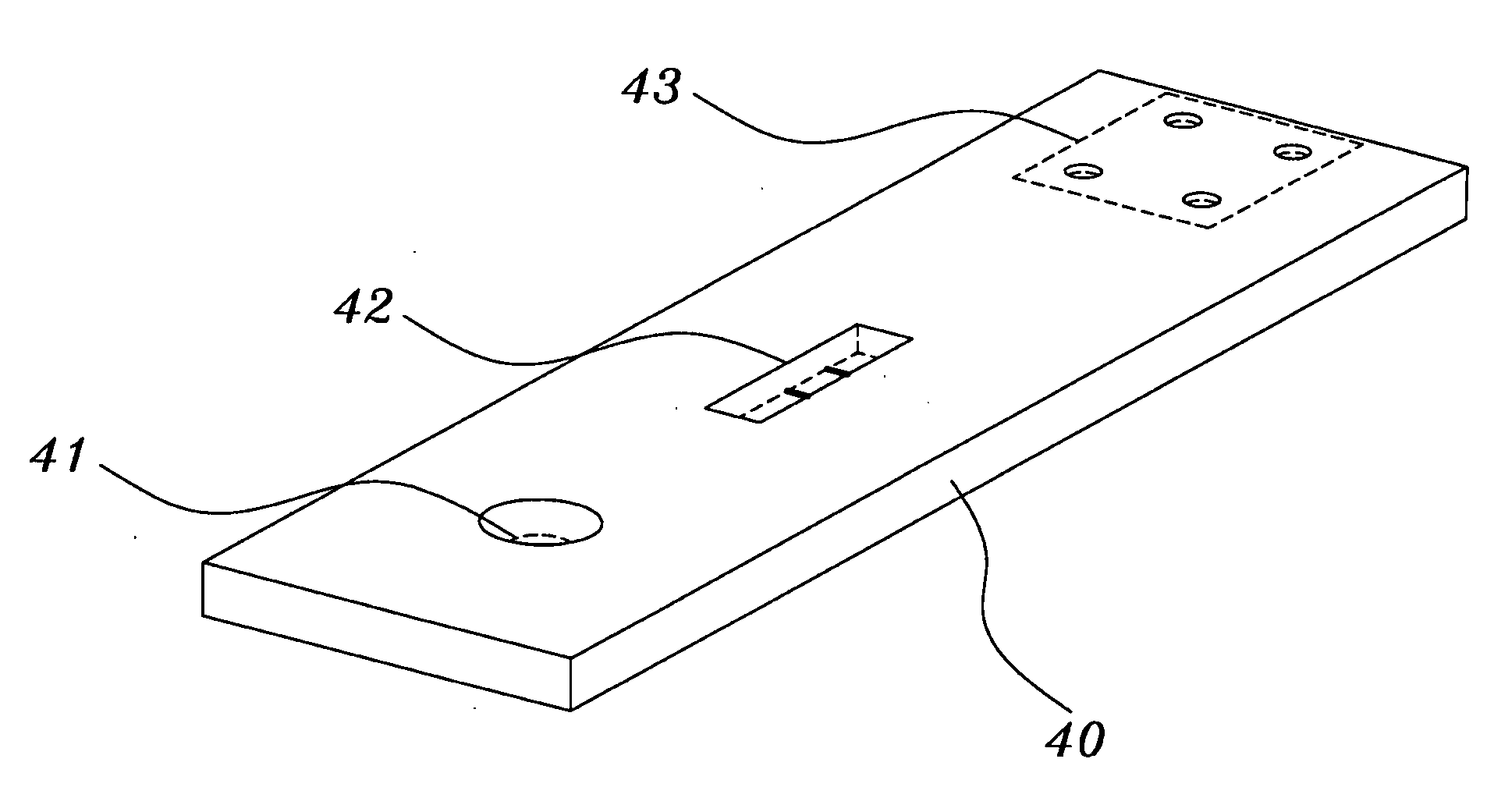

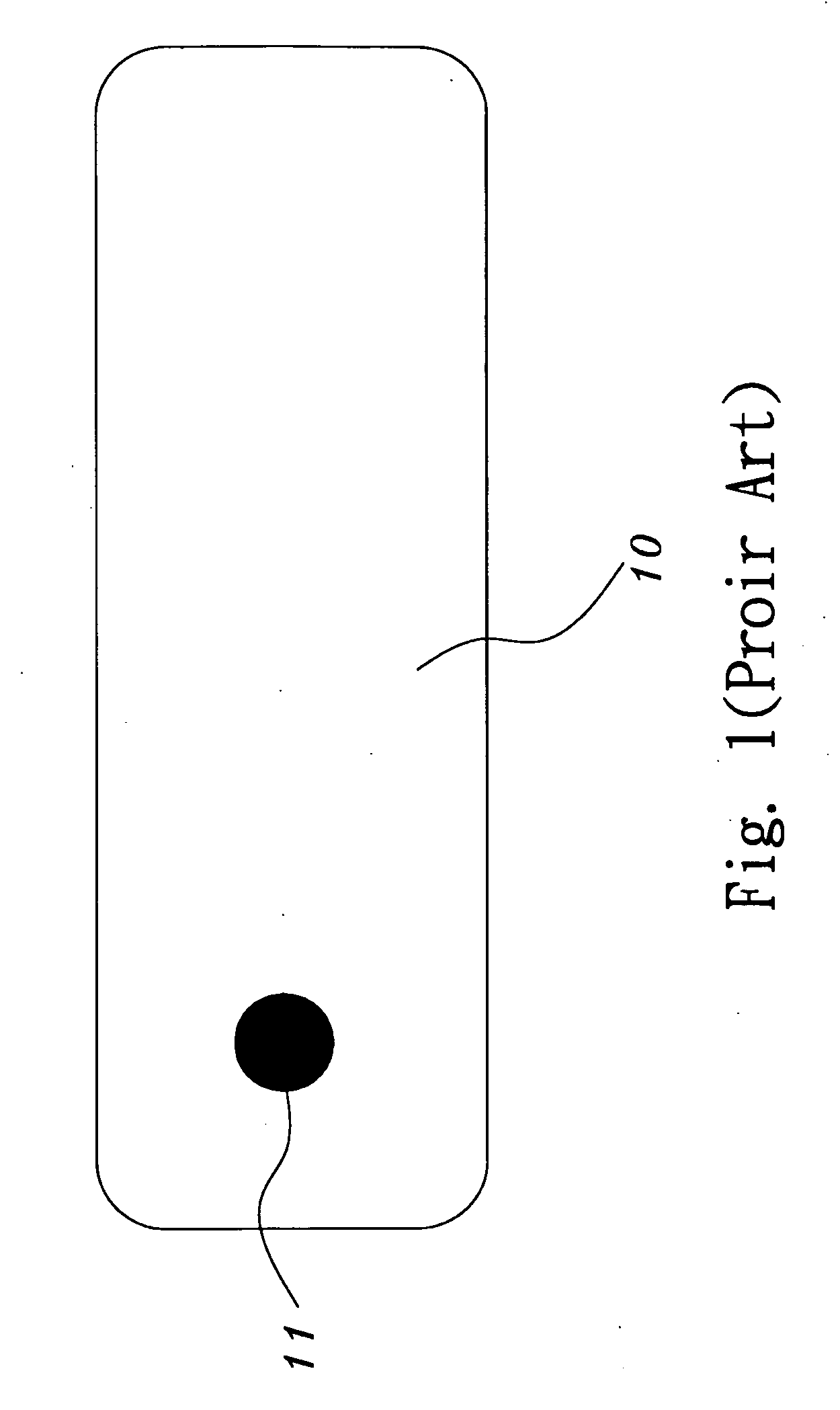

Test strip with optical identification patterns and test instrument using the same

InactiveUS20100012490A1Automatically calibratingEffectively prevent a user from forgettingAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorTester deviceEngineering

The present invention discloses a test strip with optical identification patterns and a test instrument using the same characterized in that the test strip incorporates an identification area. Different combinations of optical identification patterns on the identification area create different digital identification signals. After the test strip is inserted into the test instrument, the test instrument will obtain the digital identification signal and learn the test code, analysis parameters, expiry date and batch number of the test strip. Thereby, the test instrument can verify the batch number and expiry date of the test strip, perform calibration according to the analysis parameters, and provide a correct test result. The present invention can provide many sets of digital identification signals to differentiate test strips. Therefore, the present invention can be operated fast, conveniently and correctly and can prevent a user from forgetting to calibrate the test instrument.

Owner:HMD BIOMEDICAL

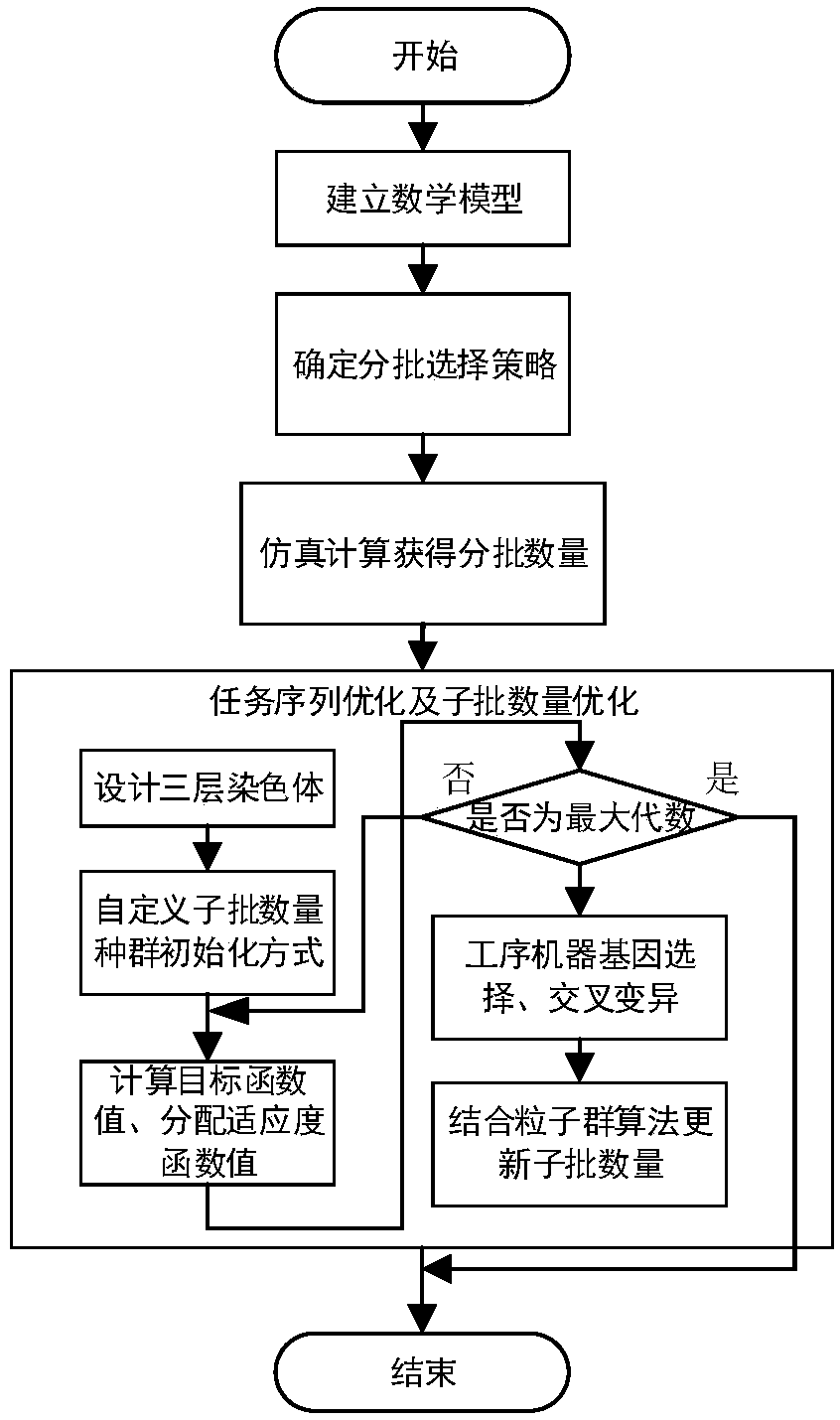

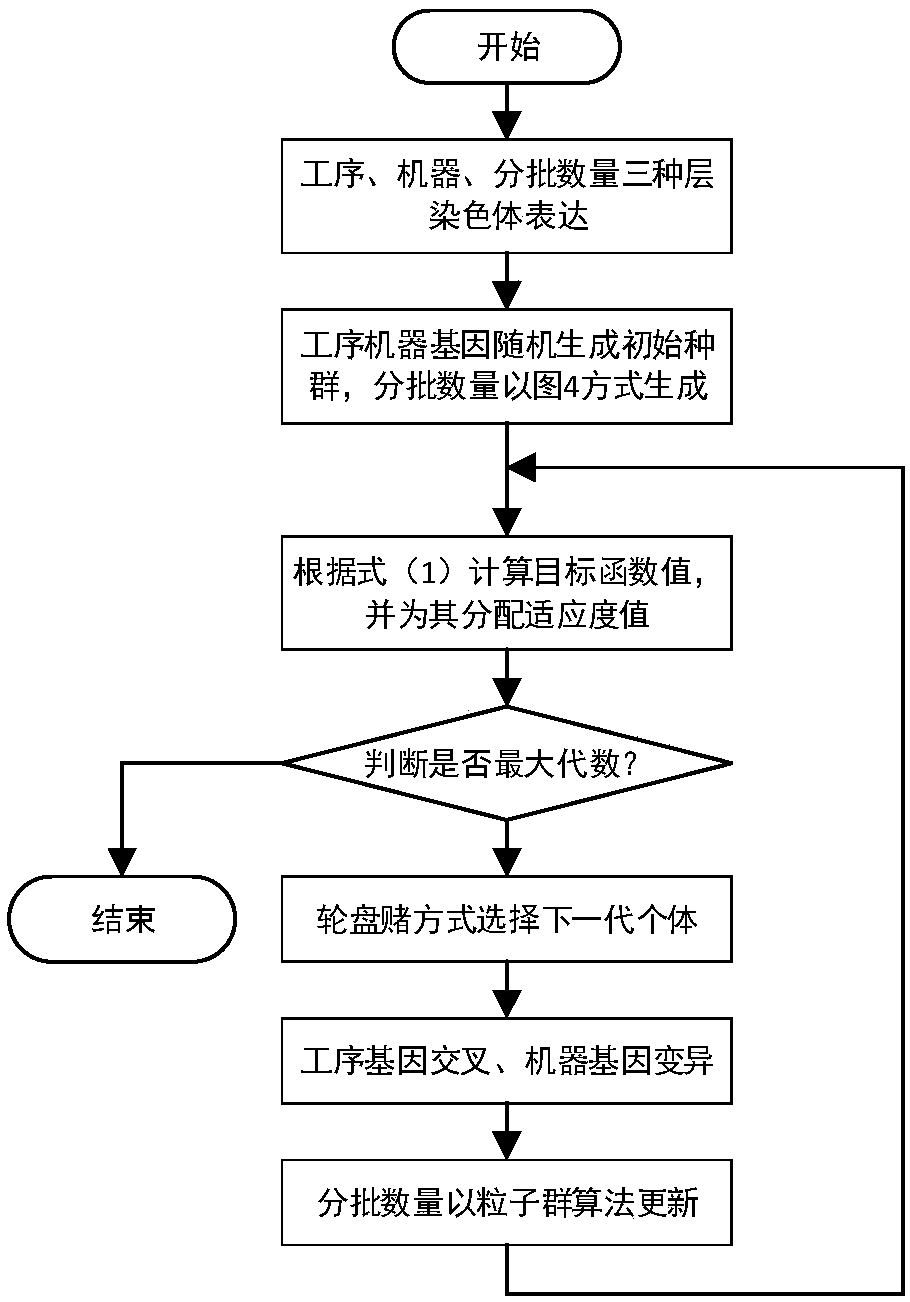

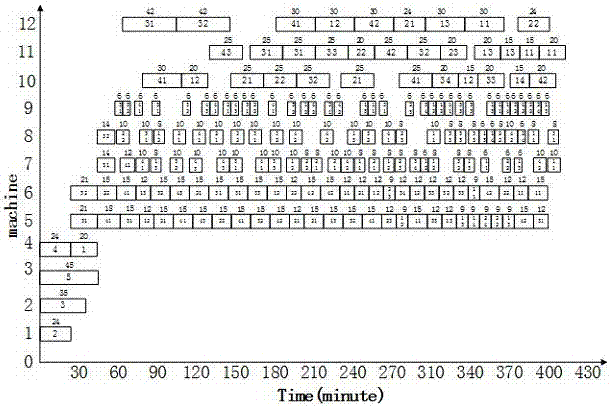

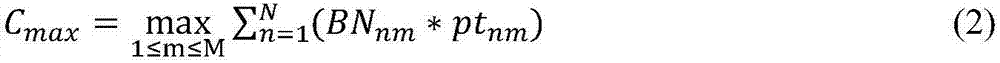

Flexible job shop order insertion dynamic scheduling optimization method

ActiveCN107831745AReduced delay periodImprove the individual population update methodInternal combustion piston enginesProgramme total factory controlMathematical modelParticle swarm algorithm

A flexible job shop order insertion dynamic scheduling optimization method is a solution method aiming at the delay problems caused by the order insertion in the job shop batch dynamic scheduling, andcomprises the steps of on the basis of establishing a mathematical model of the task sequence optimization and the order batch distribution, researching a batch selection strategy, adopting an example simulation mode to obtain the reasonable sub-batch number, at the same time, according to the simulation and calculation of the typical examples, giving a recommending value of the batch number; secondly, based on the three-layer gene chromosomes of the processes, the machines and the order distribution number, taking the minimum maximum time of completion and the delay period as the optimization targets; and finally, adopting a mixed algorithm of a particle swarm optimization algorithm and a genetic algorithm to improve the speed of evolution of the sub-batch number towards an optimal direction, thereby effectively reducing the tardiness quantity. The method is good at reducing the delay period in the job shop dynamic scheduling, and for the conventional genetic algorithm, enables the convergence speed and the stability to be improved substantially, at the same time, fully combines the actual production statuses of the intelligent job shops, greatly promotes the dynamic scheduling solution, and has the great application value in the engineering.

Owner:SOUTHWEST JIAOTONG UNIV

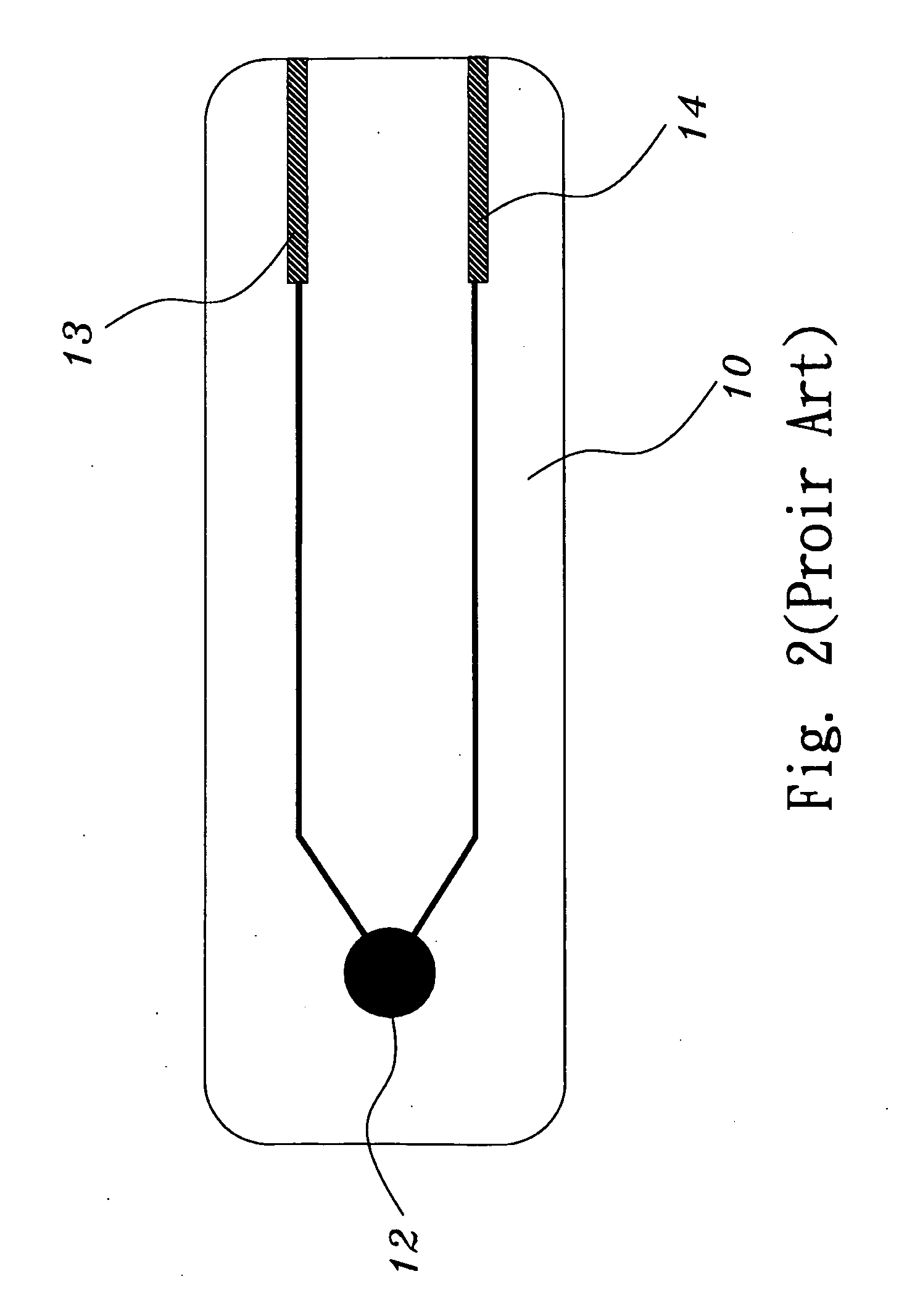

Test strip with identification openings and test instrument using the same

InactiveUS20100015006A1Automatically calibratingEffectively prevent a user from forgettingAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorTester deviceCalibration test

The present invention discloses a test strip with identification openings and a test instrument using the same, which are characterized in that the test strip incorporates an identification area. Different combinations of the notched and unnotched positions, or the holed and unholed positions, on the identification area create different digital identification signals. After the test strip is inserted into the test instrument, the test instrument will obtain the digital identification signal and learn the test code, analysis parameters, expiry date and batch number of the test strip. Thereby, the test instrument can verify the batch number and expiry date of the test strip, perform calibration according to the analysis parameters, and provide a correct test result. The present invention can provide many sets of digital identification signals to differentiate test strips. Therefore, the present invention can be operated fast, conveniently and correctly and can prevent a user from forgetting to calibrate the test instrument.

Owner:HMD BIOMEDICAL

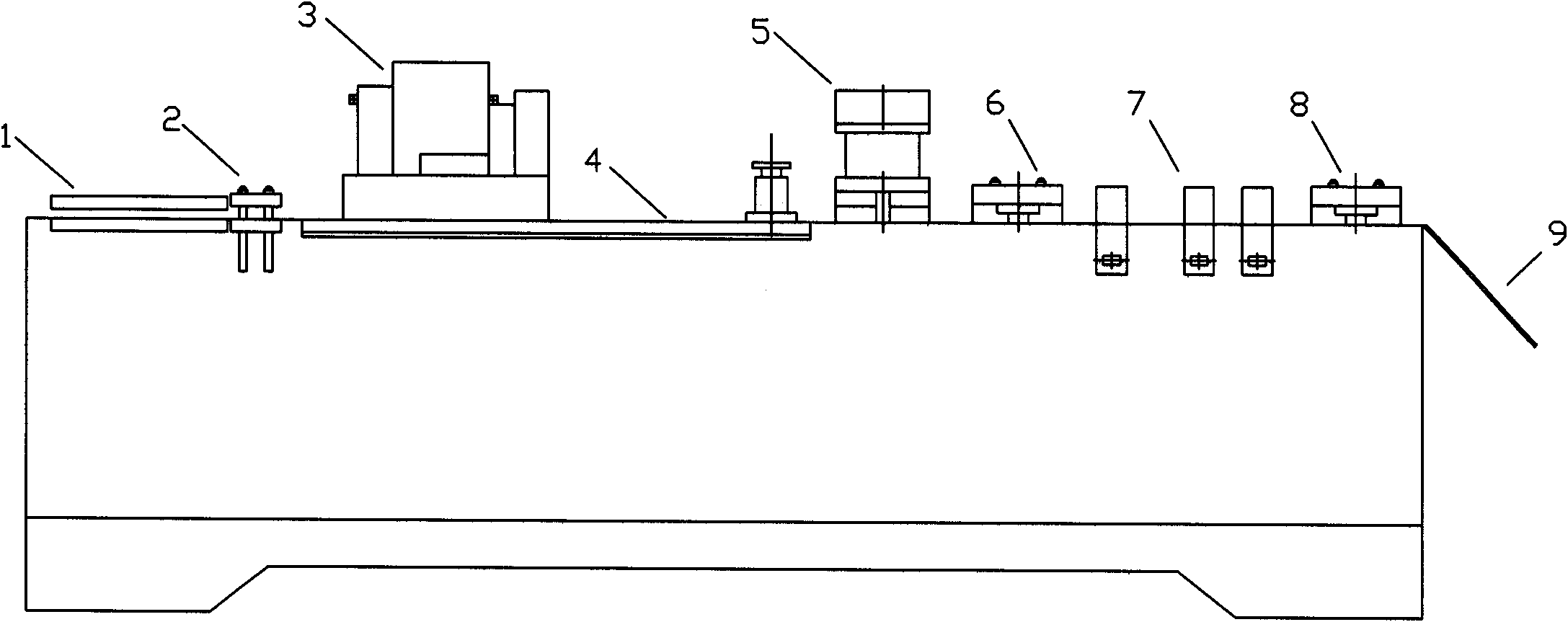

Multifunctional high-speed boxing machine

ActiveCN102556387ALow costImprove efficiencyWrapper twisting/gatheringIndividual articlesMachine controlControl system

The invention discloses a multifunctional high-speed boxing machine, which comprises a frame. A feeding device, a material conveying chain, a paper box storage, a box sucking device, a paper folding device, a paper box conveying chain, a pushing and feeding device, a batch number printing device, a box sealing device, a reject removing device and a complete machine control system, wherein the feeding device is arranged at the left end of the material conveying chain, the pushing and feeding device is arranged at the right end of the material conveying chain and parallel to the left end of thepaper box conveying chain, the pushing and feeding device and the left end of the paper box conveying chain are fixedly mounted on the inner side and the outer side of the right end of the material conveying chain respectively, the paper folding device is arranged at the left end of the paper box conveying chain, the paper box storage is arranged above the paper box conveying chain and is connected with the paper folding device through the box sucking device, and the batch number printing device, the box sealing device and the reject removing device are sequentially arranged at the right end of the paper box conveying chain from left to right. The multifunctional high-speed boxing machine is full-automatic in the whole process, low in packaging cost, high in packaging efficiency and particularly applicable to batch or mass packaging production of products.

Owner:RUIAN HAOTENG MACHINERY

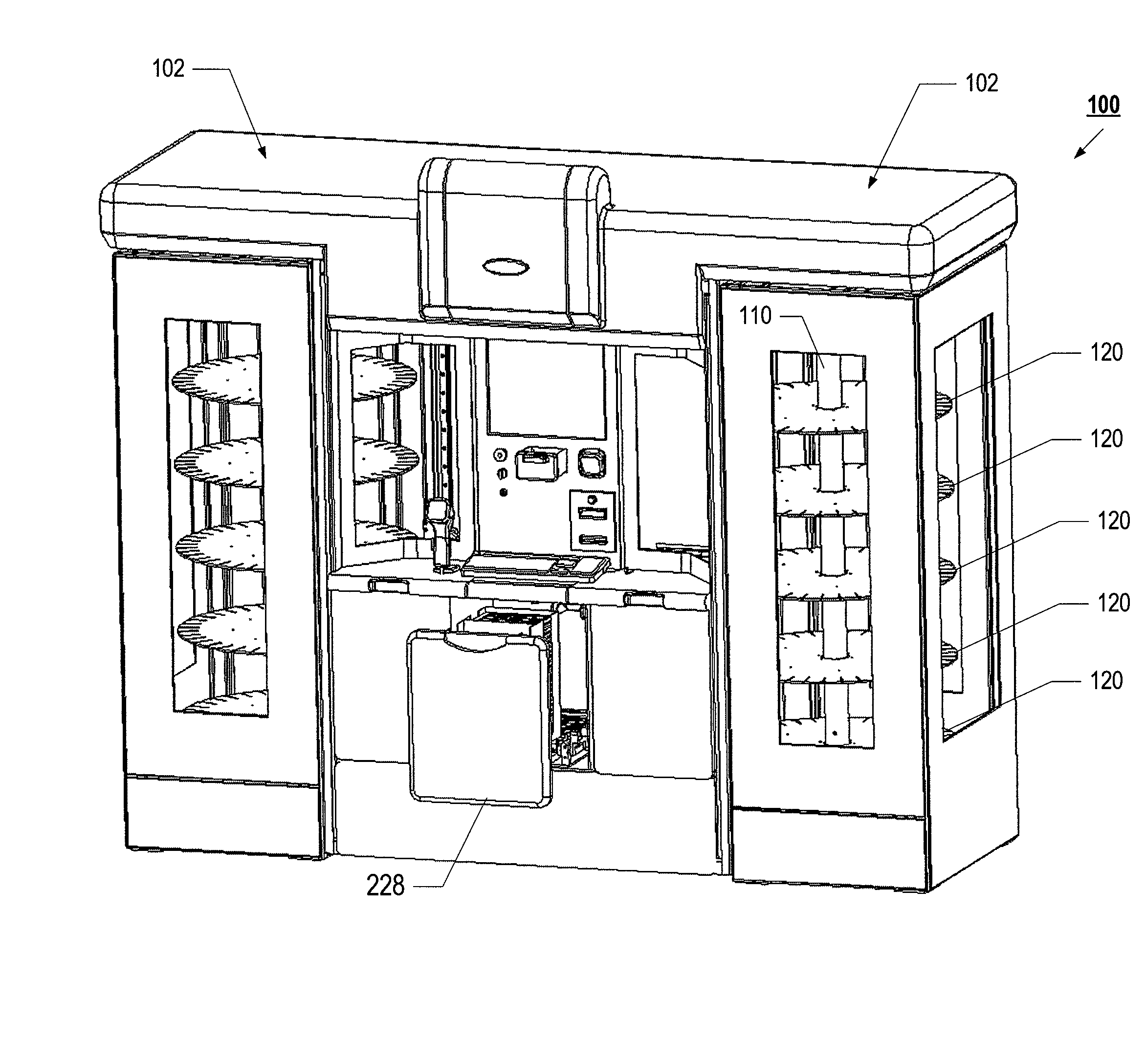

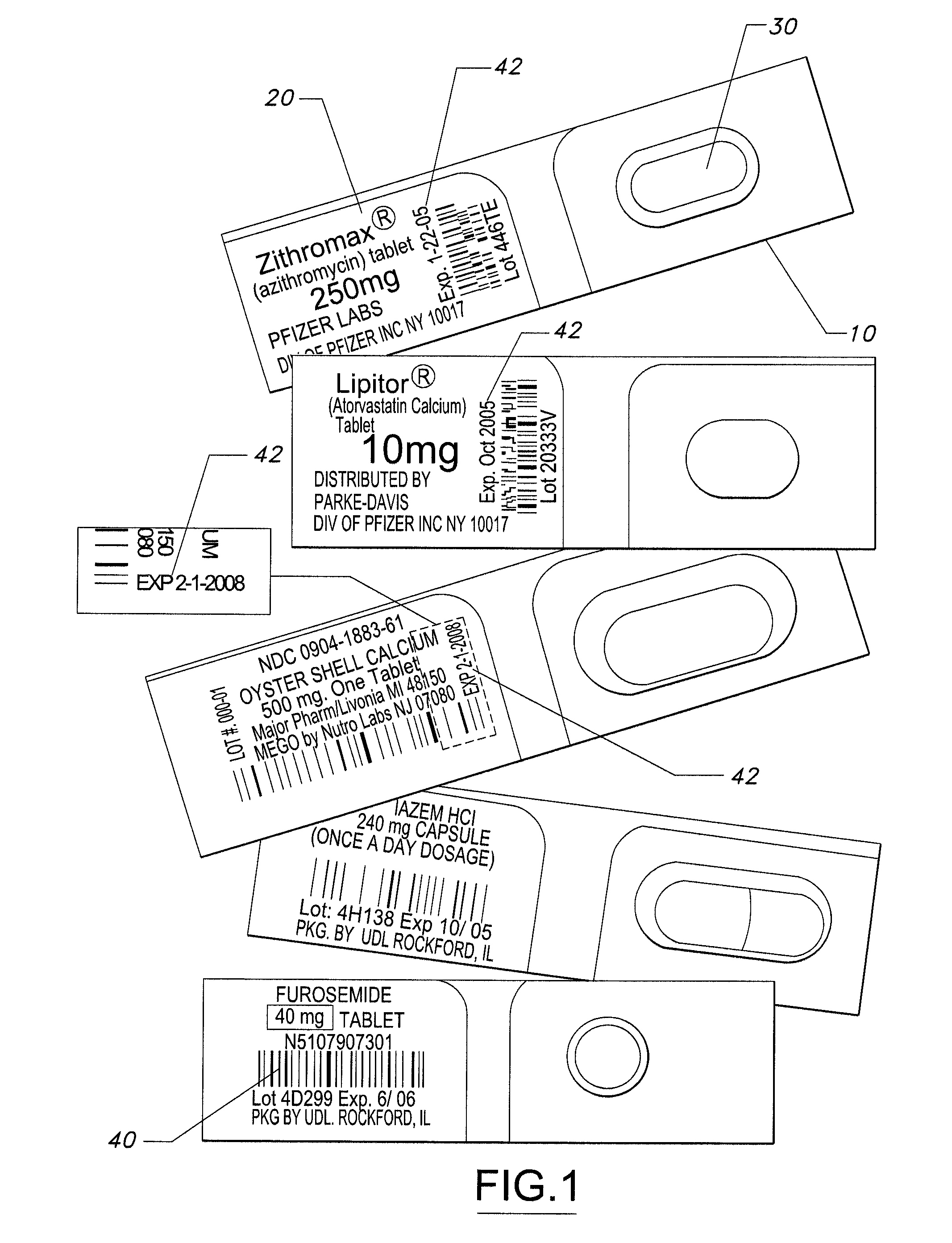

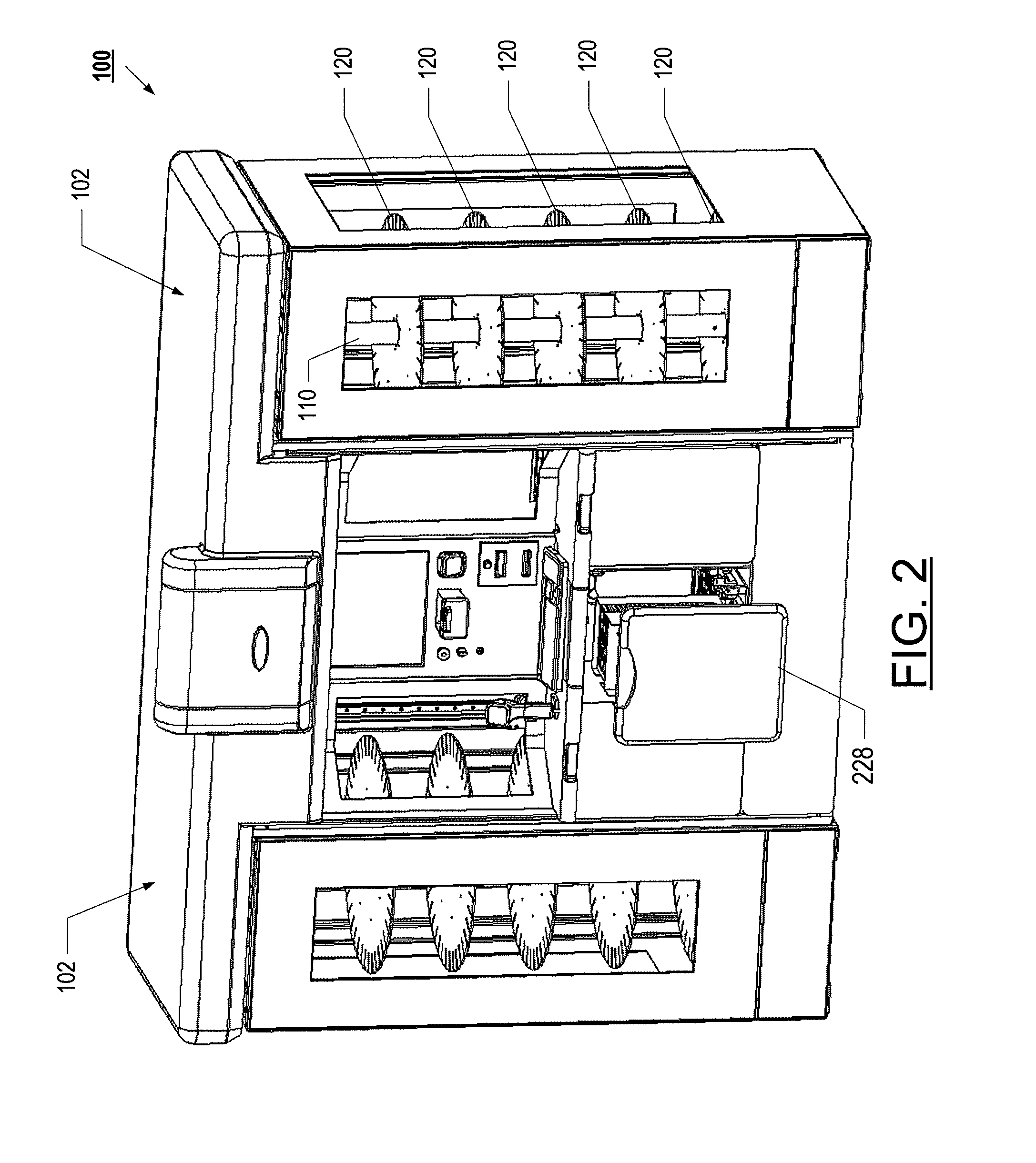

System, method, apparatus and computer program product for capturing human-readable text displayed on a unit dose package

ActiveUS8009913B2Character and pattern recognitionVerifying markings correctnessText displayComputer science

A system, method, apparatus and computer program product are provided for capturing human-readable text displayed on a unit dose package. In particular, identification information associated with a unit dose package may be used to determine a location and / or a format in which human-readable text, such as an expiration date or lot number associated with the corresponding unit dose medication, is displayed on the unit dose package. Once the location and / or format of the human-readable text has been determined, this information can be used in order to scan the unit dose medication and translate the human-readable text into machine-readable text using, for example, optical character recognition.

Owner:OMNICELL

Method and device for cargo sorting under conditions of large cargo amount and large cargo owner amount

ActiveCN104174599ASave on shippingImprove sorting efficiencySortingIndustrial engineeringBatch Number

The invention discloses a method and a device for cargo sorting and especially relates to a method and a device for cargo sorting under conditions of a large cargo amount and a large cargo owner amount. The method for cargo sorting adopts a receiving-type sorting method and a distribution-type sorting method. In receiving-type sorting, cargoes supplied by all suppliers are orderly arranged according to cargo owner numbers so that a rule of cargo arrangement based on the cargo owner numbers is formed; then a sorting process round is carried out several times, wherein in the each sorting process round, a sorting process is carried out several times so that the cargoes belonging to the same service station are sorted, then the cargoes sorted by the sorting process rounds are orderly arranged according to service station numbers, a part of the cargoes belonging to a service station in a corresponding-level region are sorted in each sorting process and the rest of the cargoes are stayed in original positions; and the sorted cargoes are arranged in a type number order and the same type of the cargoes are orderly arranged according to the cargo owner numbers so that a rule of cargo arrangement based on cargo types is formed. In distribution-type sorting, batch numbers are used as main sorting basis and city numbers are used as minor sorting basis.

Owner:吴宁飞

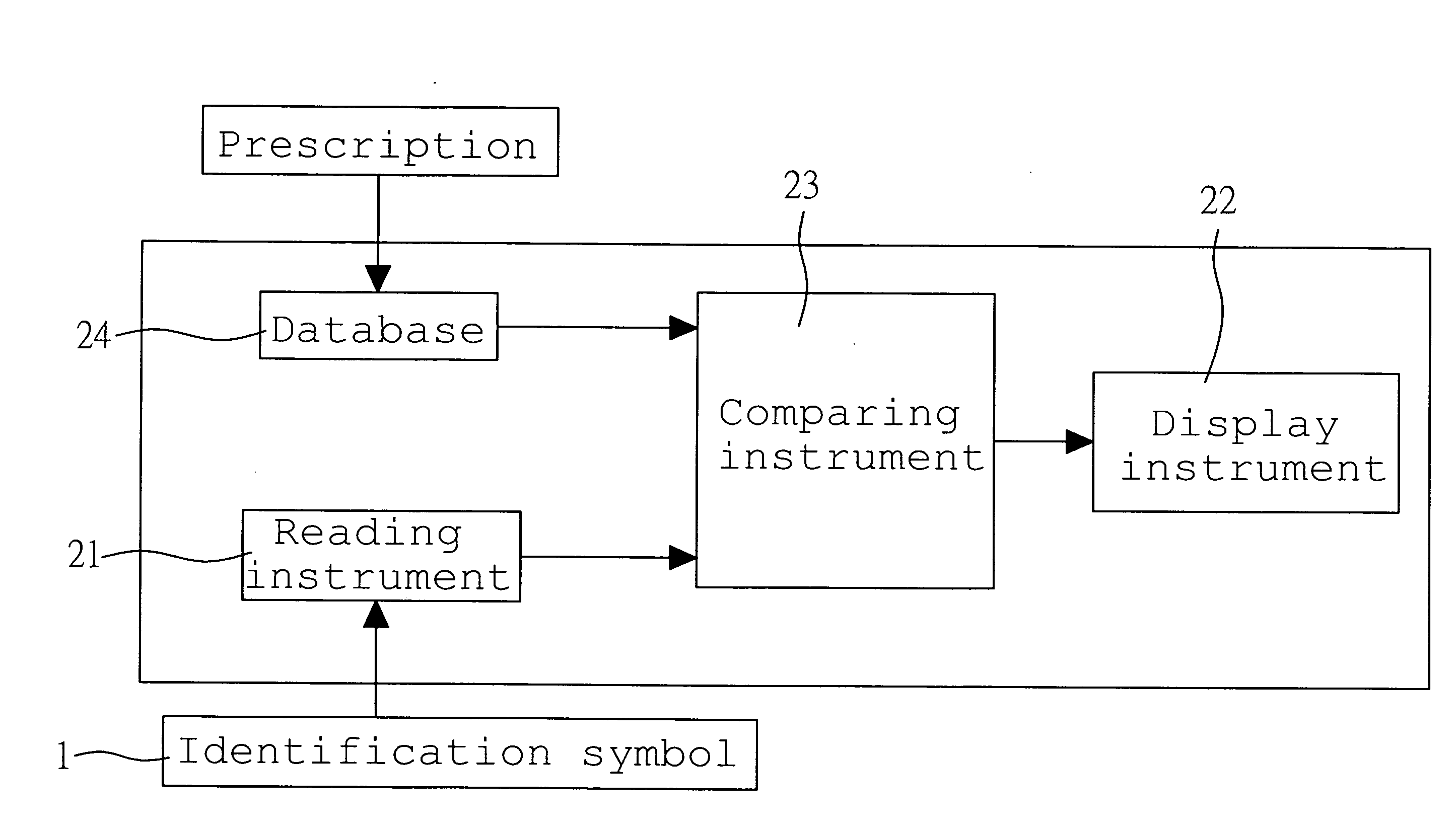

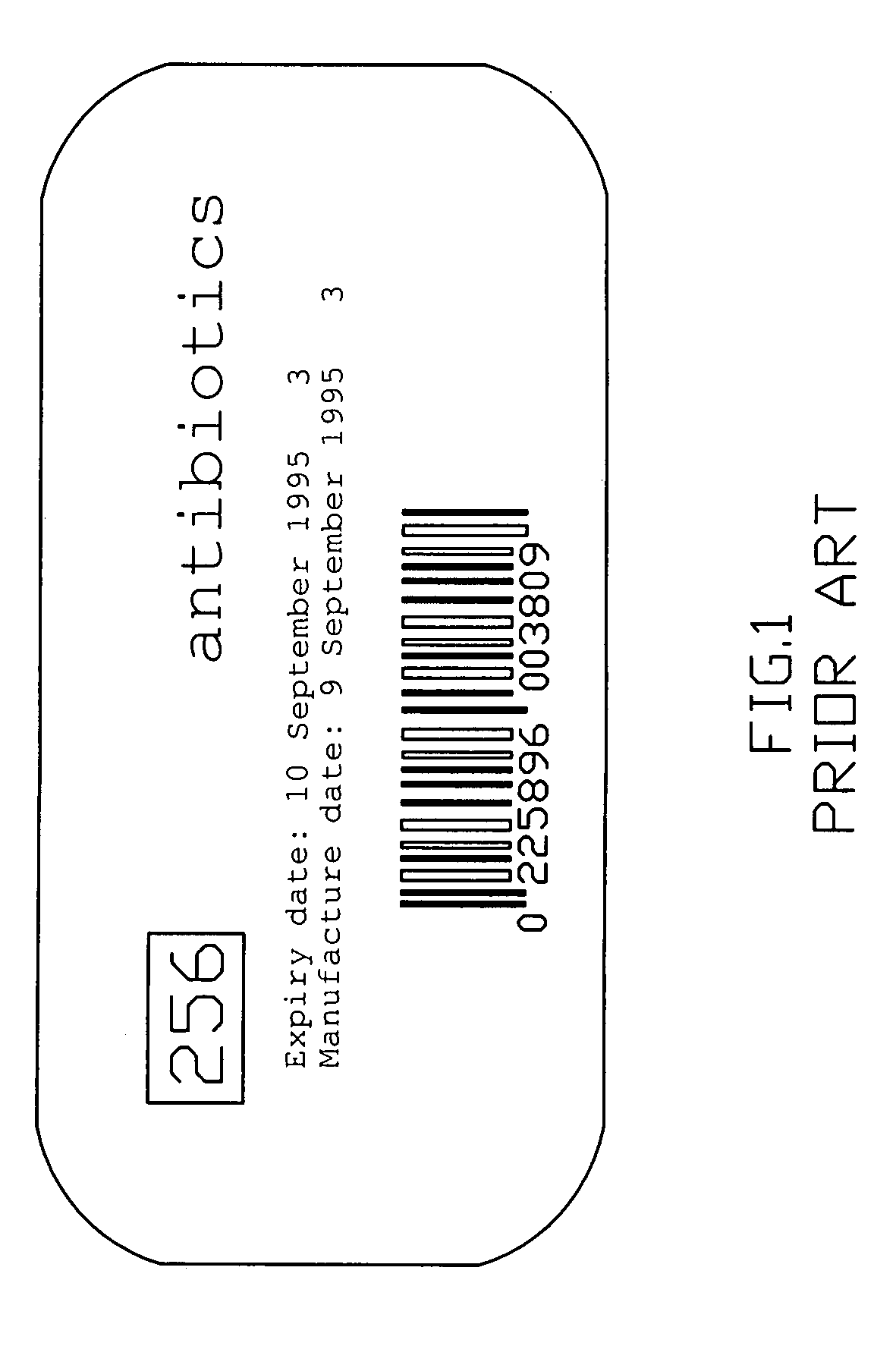

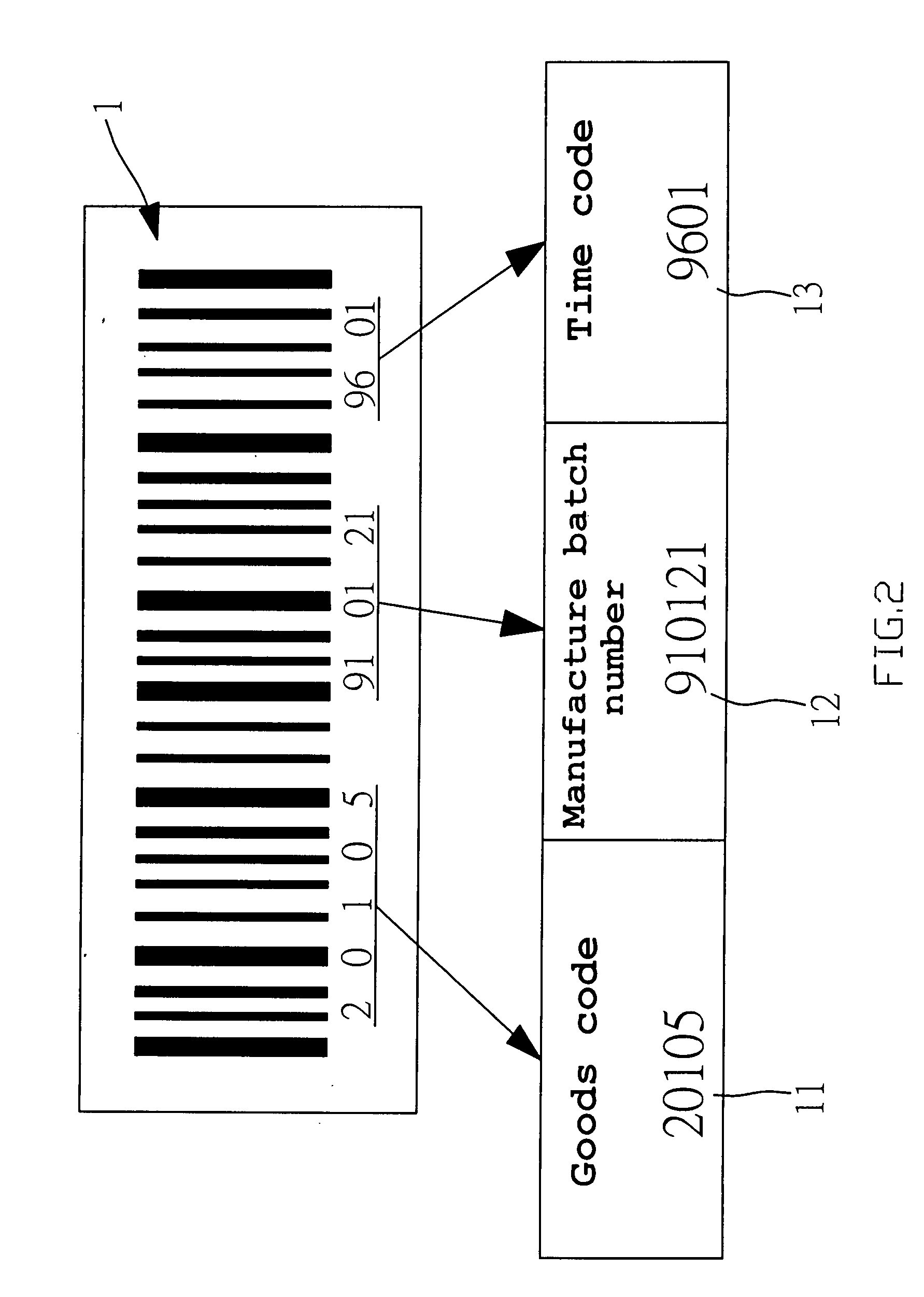

Drug dispense, identification, labeling and the system of inspection

InactiveUS20080128482A1Effectively control qualityEffectively control conservationStampsRecord carriers used with machinesMedicineDrug identification

This system of identification and labeling is set on the container or package of drugs and contains drug identification units for the identification of the drug name, including identification units of manufacturing batch number and time. The identification unit of manufacturing batch number is used for the identification of the batch number of the drug while the time identification unit for the identification of the expiry date of the drug, quickly making the consumers understanding the manufacturing batch number and the expiry date of the drug through reading the identification labels so as to effectively control the quality and conservation of drugs.

Owner:KO PHARML

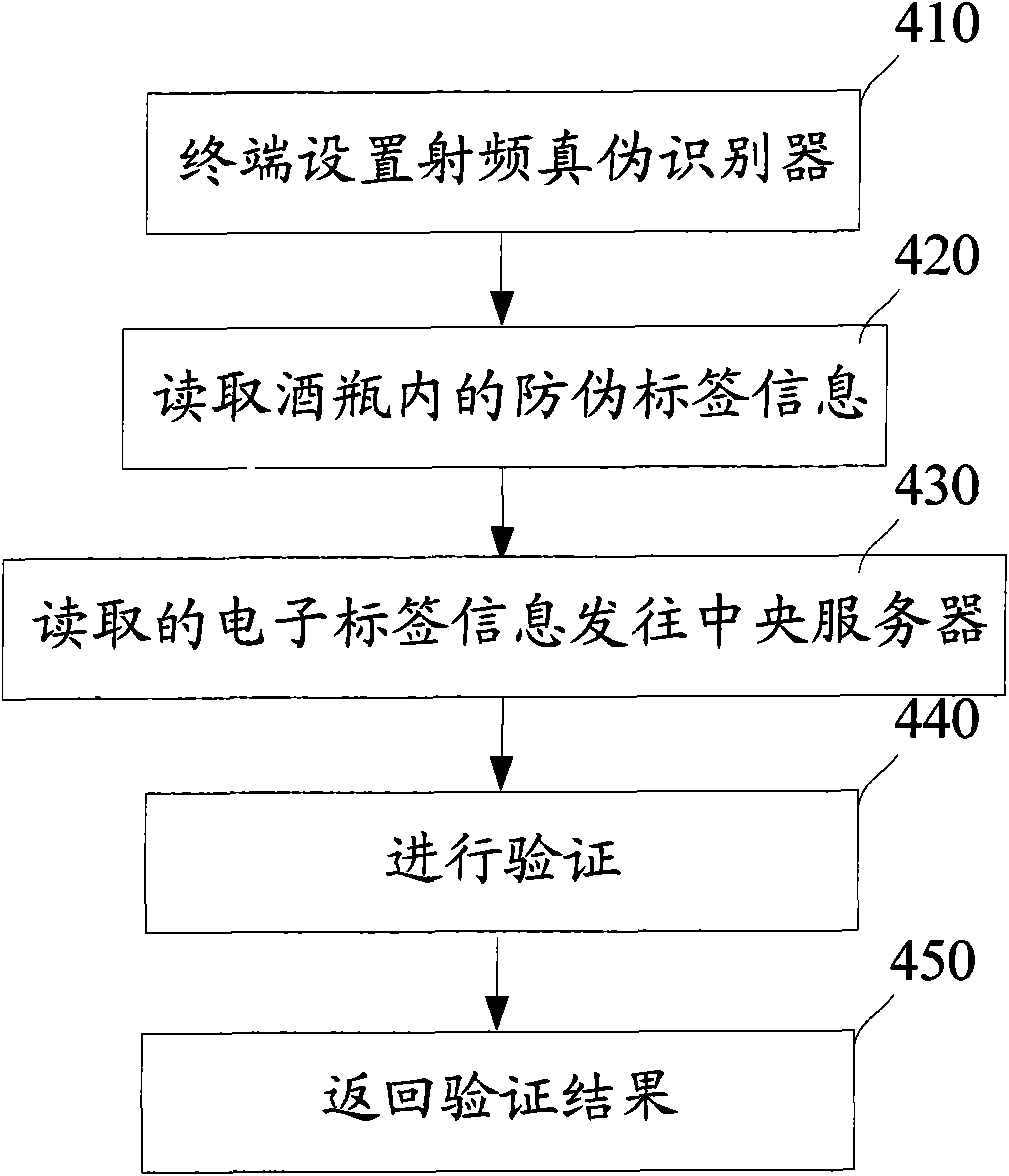

Wine anti-counterfeit method and system thereof

InactiveCN101882277ARealize the purpose of authenticity identificationCo-operative working arrangementsCommerceCarrier signalAuthentication

The invention relates to an anti-counterfeit method and a system thereof, in particular to the wine anti-counterfeit method and the system thereof. The anti-counterfeit method comprises the following steps: a recognizer sends outwards a low-frequency encrypted data carrier signal through a transmitting antenna; when an anti-counterfeit electronic tag on a wine bottle cover enters a transmitting antenna working area of a reader to be activated, encrypted information loaded with an ID number and a recognition code is transmitted through a high-frequency transmission module in the tag; after the receiving antenna of the recognizer receives the carrier signal sent from the electronic tag and the carrier signal passes password authentication, the recognizer extracts the ID number and the recognition code thereof through a network and then sends the ID number to an anti-counterfeit system server at an anti-counterfeit center; and the server checks the legality of the recognizer, and after passing authentication, a central server returns the corresponding production date, the batch number, the manufacturer and the inquiry times of the product, register information corresponding to a recognizer code and the like to a radio frequency identification reader-writer and displays on the display screen of the recognizer, thus achieving the purpose of authenticity identification.

Owner:SHENZHEN AIMTOP INTELLIGENT SYST

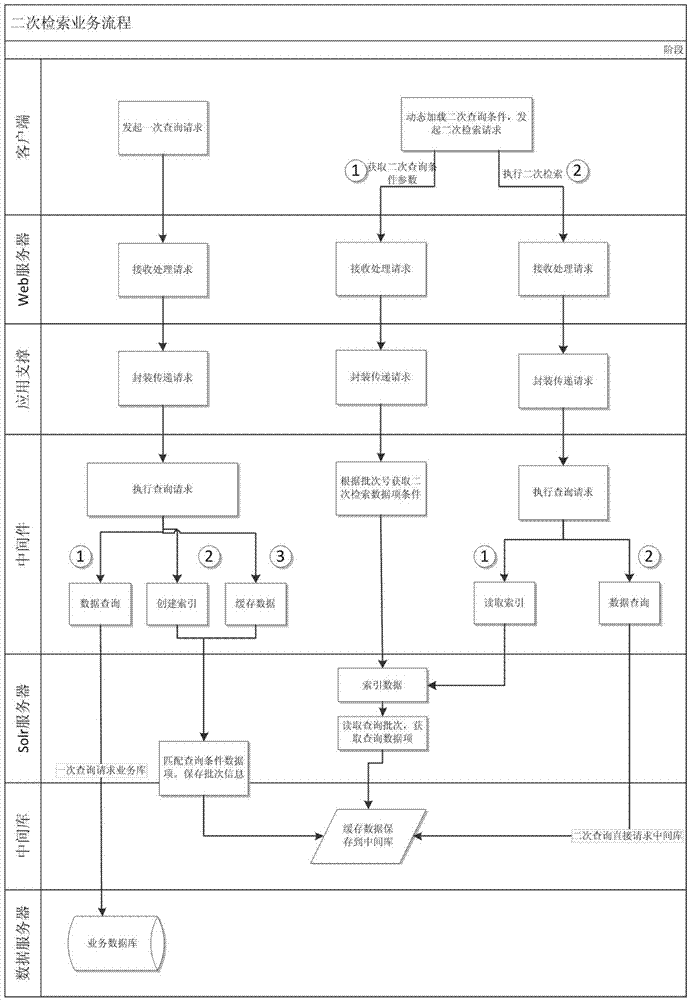

Data query method and data query system based on quadratic search

ActiveCN104516979AEfficient cache functionFlexible cache functionSpecial data processing applicationsIndexing ServiceClient-side

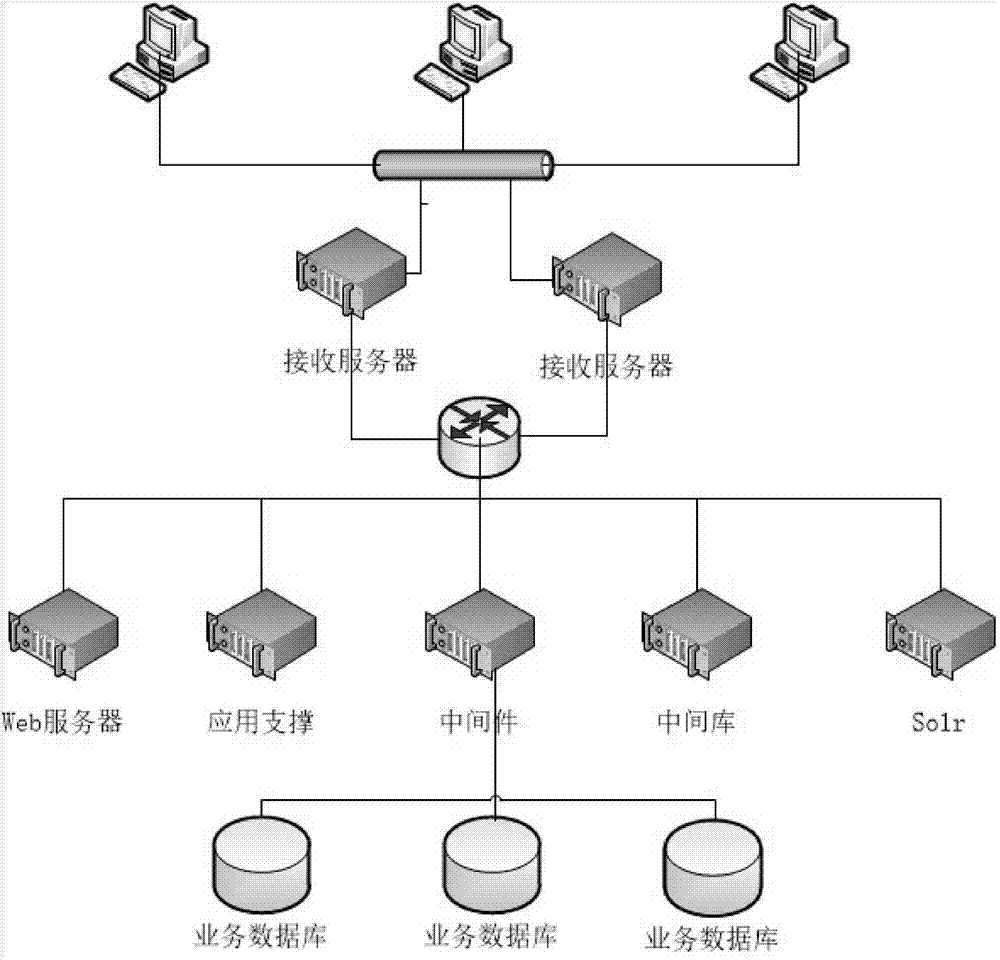

The invention discloses a data query method and a data query system based on quadratic search. The data query method comprises the following steps: (1) establishing an index template, when a user logs in a client for the first time of search, generating a bath number for the logging of the user, and storing the batch number and the first time of retrieved result in a middle base server; (2) an index server extracting all data items and splitting rules capable of serving as query conditions from the first time of retrieved result according to an index template, and establishing the index of the batch number; (3) when the user carries out quadratic search, reading all index data containing the conditions of the quadratic search input by the user from the index of the batch number, and then obtaining the retrieved result from the middle base server according to the index data. The query conditions of the quadratic search can be dynamically reconstructed, and the result of one-time query is cached through a middle base, so that the total data volume during the quadratic search is reduced, and the efficiency of quadratic search data is greatly improved.

Owner:RUN TECH CO LTD BEIJING

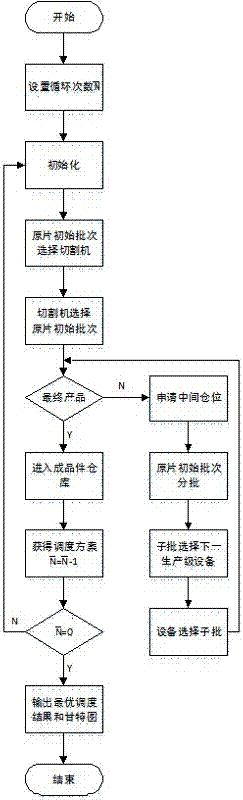

Flexible job shop batch optimization scheduling method having intermediate storage constraint

ActiveCN106971235AFast solutionImprove search abilityForecastingResourcesOptimal schedulingComputer science

The invention discloses a flexible job shop batch optimization scheduling method having intermediate storage constraint, and belongs to the technical field of shop scheduling. The method includes: establishing a flexible job shop optimization scheduling problem model and initializing parameters; considering a constrained condition of a limited storage amount of an intermediate storage warehouse; obtaining machining paths of any different types of workpiece batches; batching the different types of workpieces, and determining a batch dividing scheme thereof; selecting production equipment of each process for the workpiece batches in a random sequence according to the preference probabilities thereof; selecting proper workpiece sub-batches from a waiting batch queue thereof for machining by the equipment according to the preference probabilities thereof; obtaining the scheduling scheme until the number of accomplished batches is equal to the total batch number; and performing iterative operation, and outputting an optimal scheduling method. According to the method, the utilization rate of the equipment can be greatly increased, the whole production cycle is shortened, the production efficiency is improved, and flexile job shop batch optimization scheduling is realized.

Owner:SHANGHAI UNIV

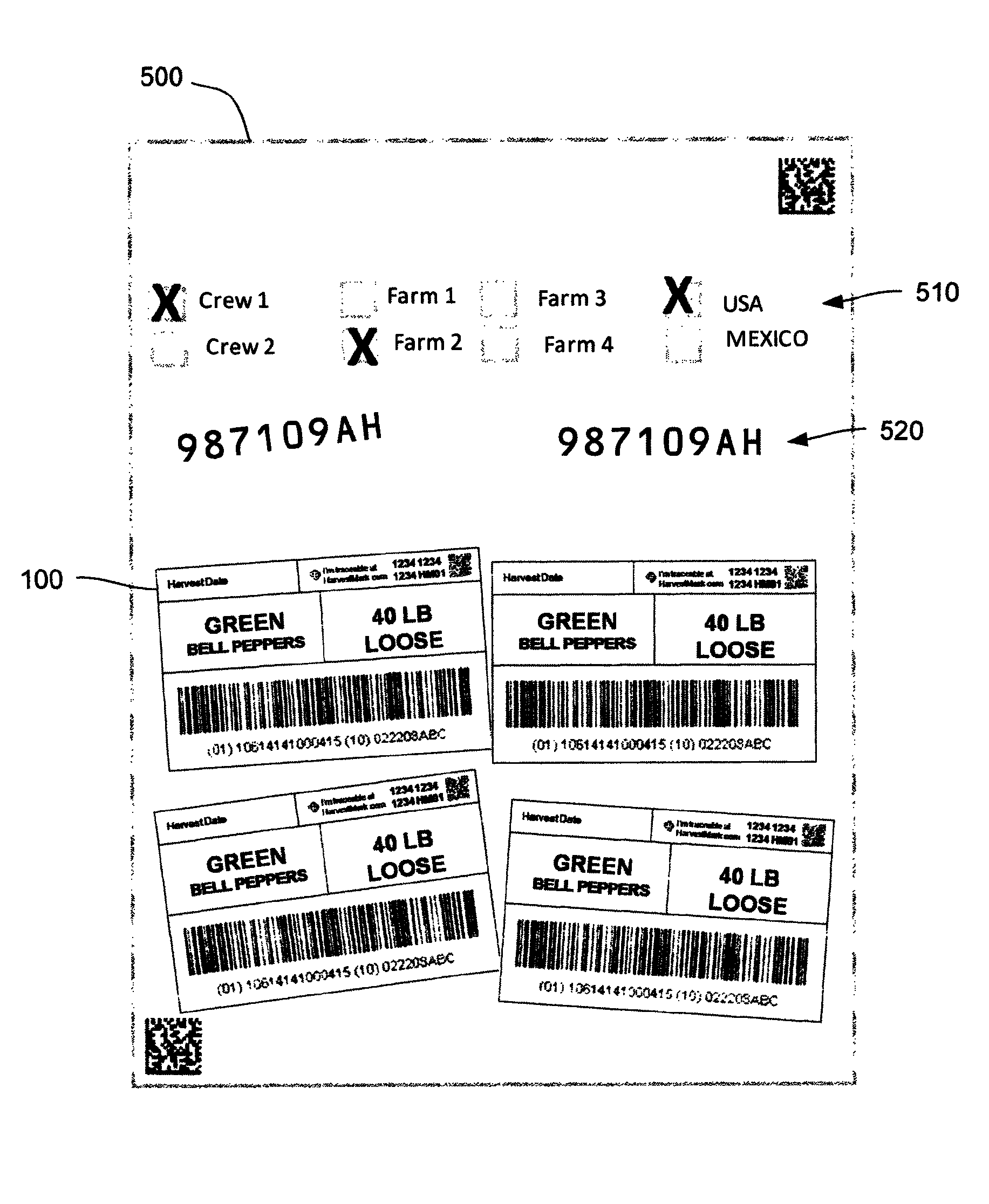

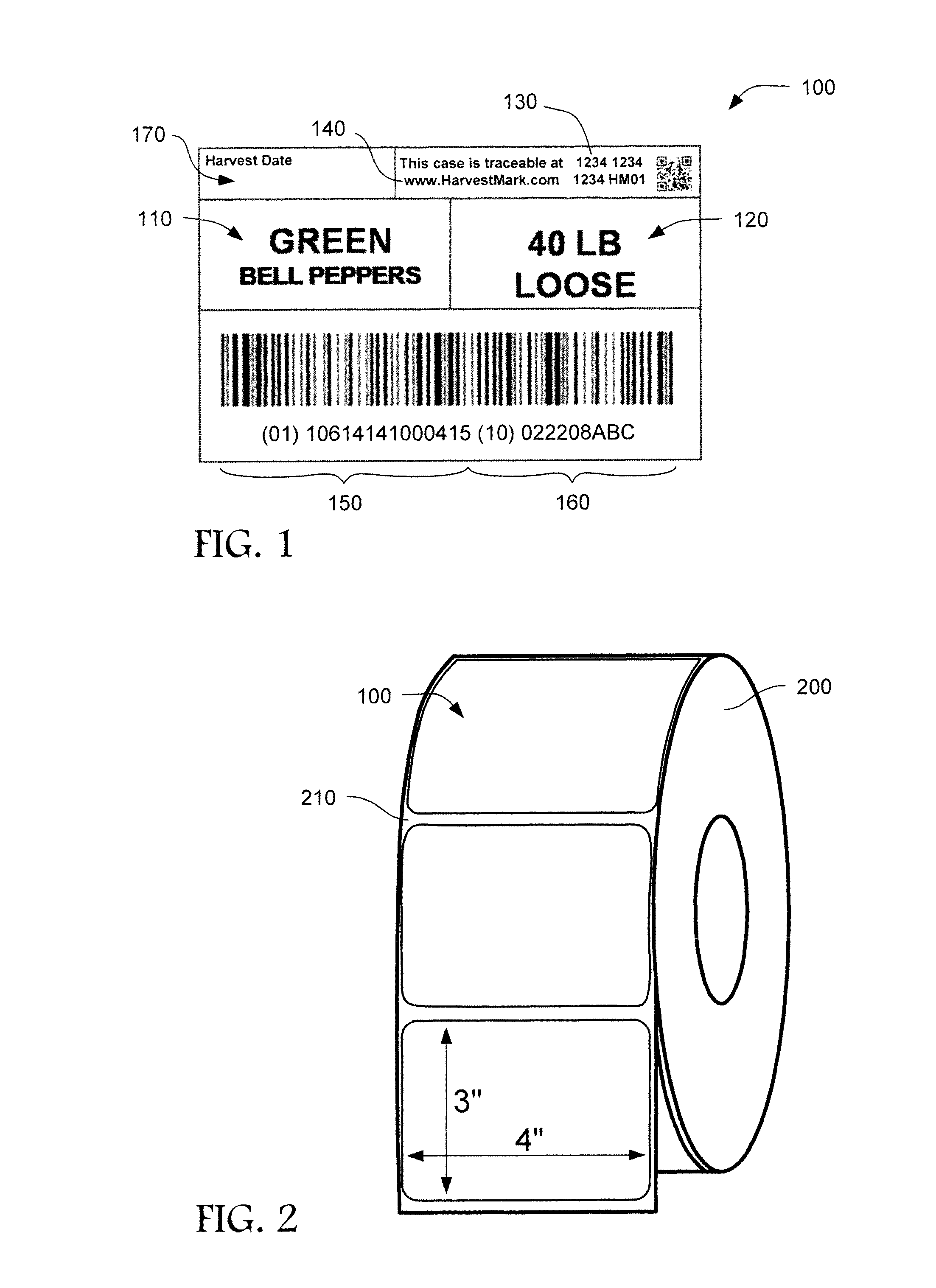

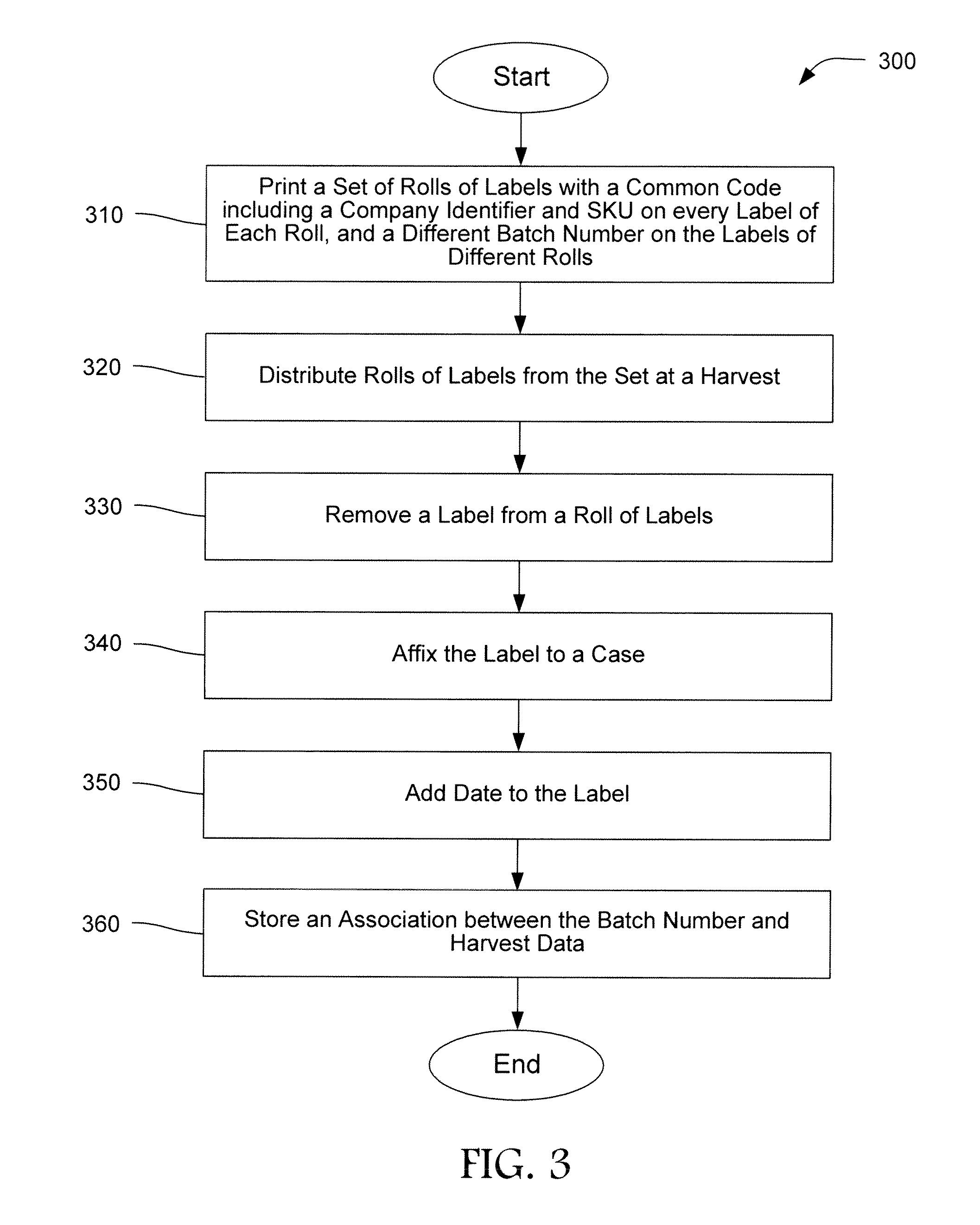

Case labeling for field-packed produce

Rolls of pre-printed case labels are distributed at a harvest for labeling the cases of packed produce. The labels on each roll include common information such as the type of produce, the packing configuration, the country of origin, the company identifier, and a SKU. Labels on the same roll include a common batch number, while labels on different rolls include different batch numbers. The company, SKU and batch numbers are subsequently associated in a database with harvest event data to provide traceability back to the harvest and forward from the harvest to those cases packed at that harvest. Optionally, each label can also include a unique code, a field to place a date stamp, and / or a field to place a ranch stamp.

Owner:TRIMBLE NAVIGATION LTD

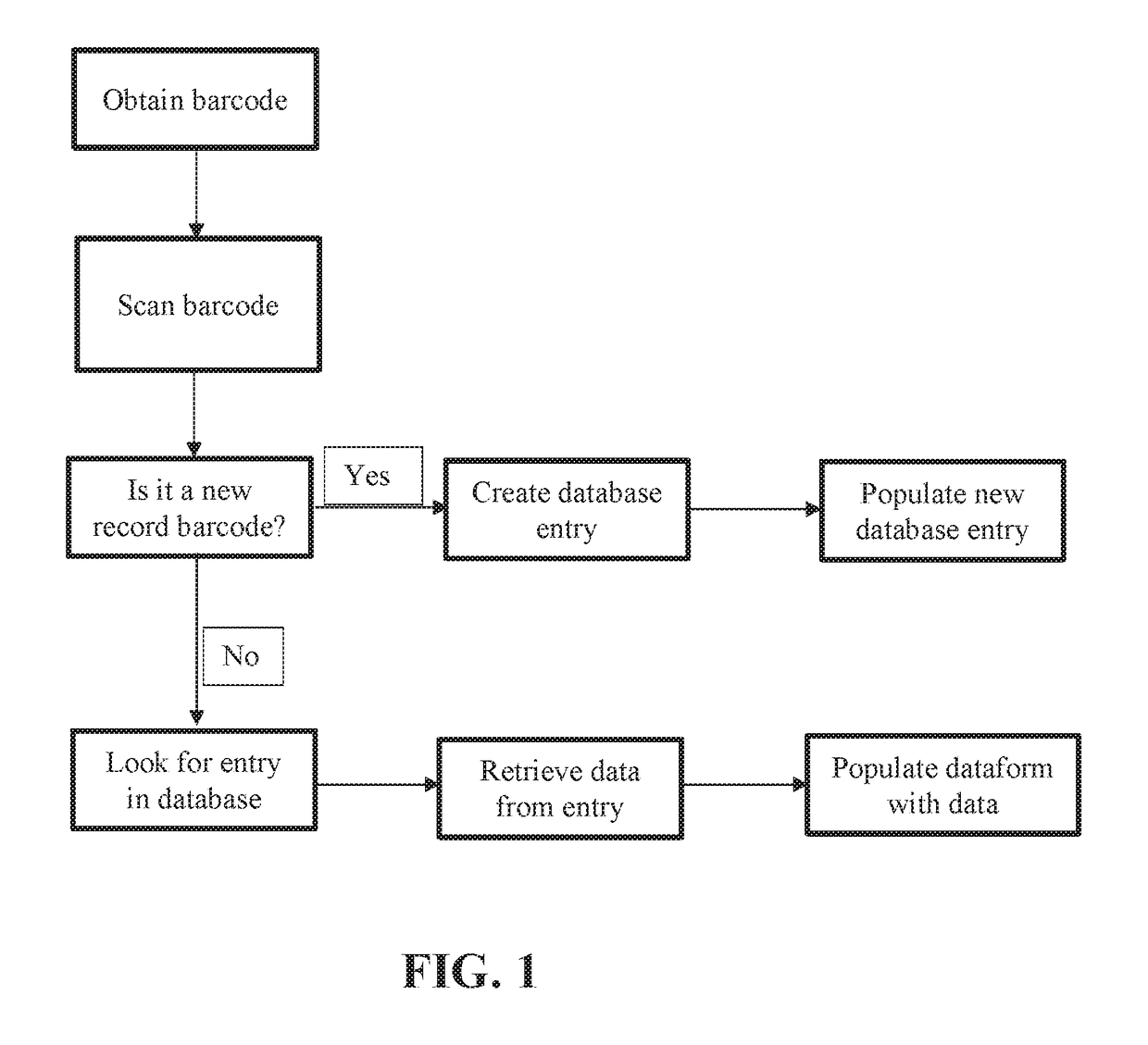

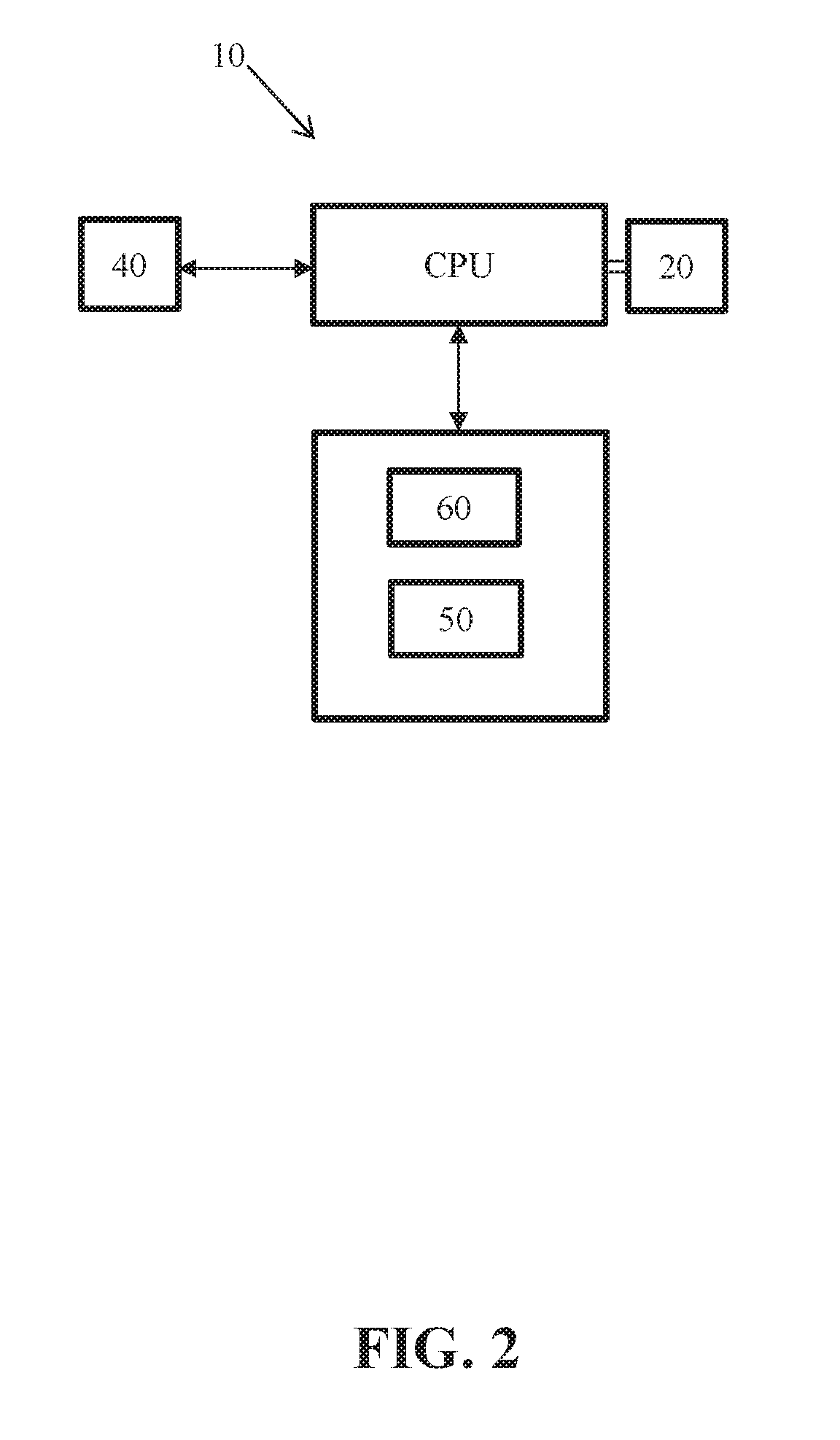

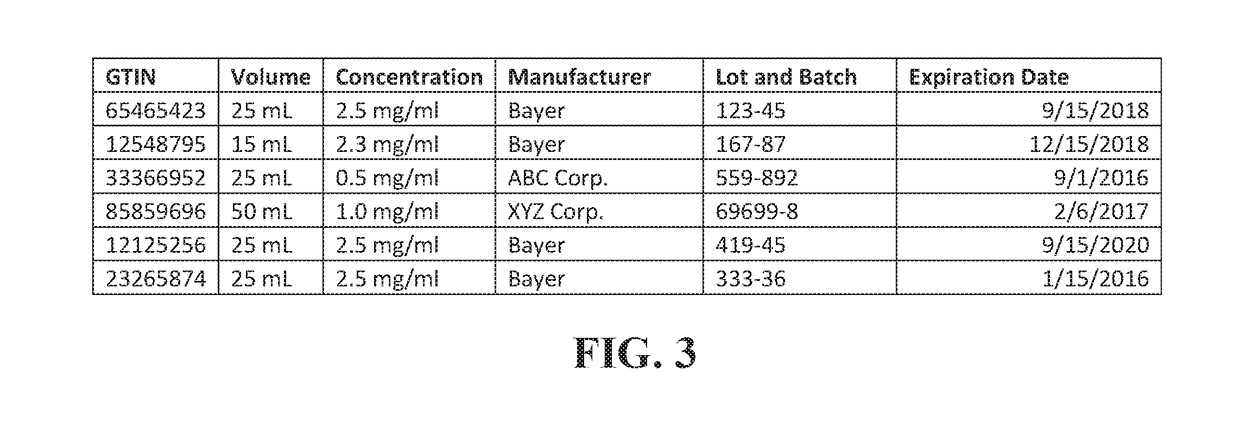

Barcode database and software update system

Provided is a method of creating a record in a reference table contained in a database associated with a medical system. The method includes obtaining a new record barcode which includes pharmaceutical information embedded therein. The pharmaceutical information may include a pharmaceutical identifier and at least one of a pharmaceutical concentration, a pharmaceutical volume, a pharmaceutical expiration date, and a pharmaceutical lot and batch number. The method further includes scanning the new record barcode using a barcode reader associated with the medical system. Upon scanning the new record barcode, a processor associated with the database creates a reference table record in the reference table and populates the reference table record with the pharmaceutical information. Also provided is a system for implementing the above-described method.

Owner:BAYER HEALTHCARE LLC

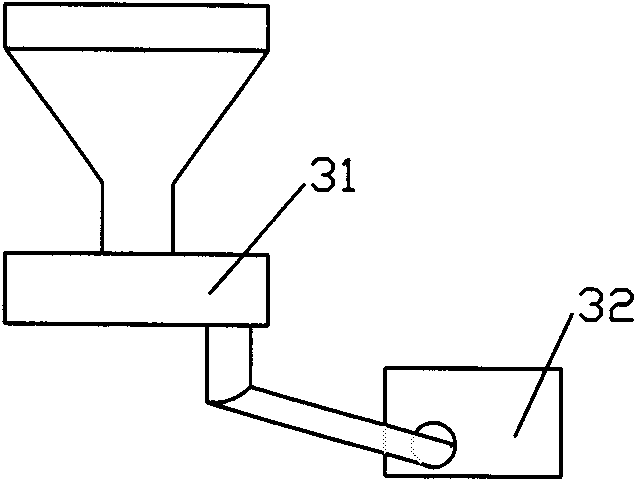

Aluminum-plastic blister packaging machine

ActiveCN101786509AReduced commissioning timeSave materialWrappingWrapper twisting/gatheringPunchingEngineering

The invention discloses an aluminum-plastic blister packaging machine, which at least comprises a plate negative preheating component, a blister forming component, a filler component, a track, a heat-seal component, a batch number indentation component, a manipulator pneumatic chuck traction component, a plate block blanking component and a blanking track component, wherein the filler component is formed by a filler with a vibration screen and a closed falling track; the lateral surface of a filler body is provided with a feeding opening; the track is an integrated track; two positioning devices for fixing the punching positions of batch numbers are arranged below the batch number indentation component; and the blanking track component is provided with a plurality of rows of pores capable of removing impurities. The invention can effectively reduce dust in the production, bring convenience to cleaning equipment, shorten the time for debugging the equipment, save consumed materials required for debugging large batch of equipment, effectively reduce the cost and improve the production efficiency.

Owner:杭州仟源保灵药业有限公司

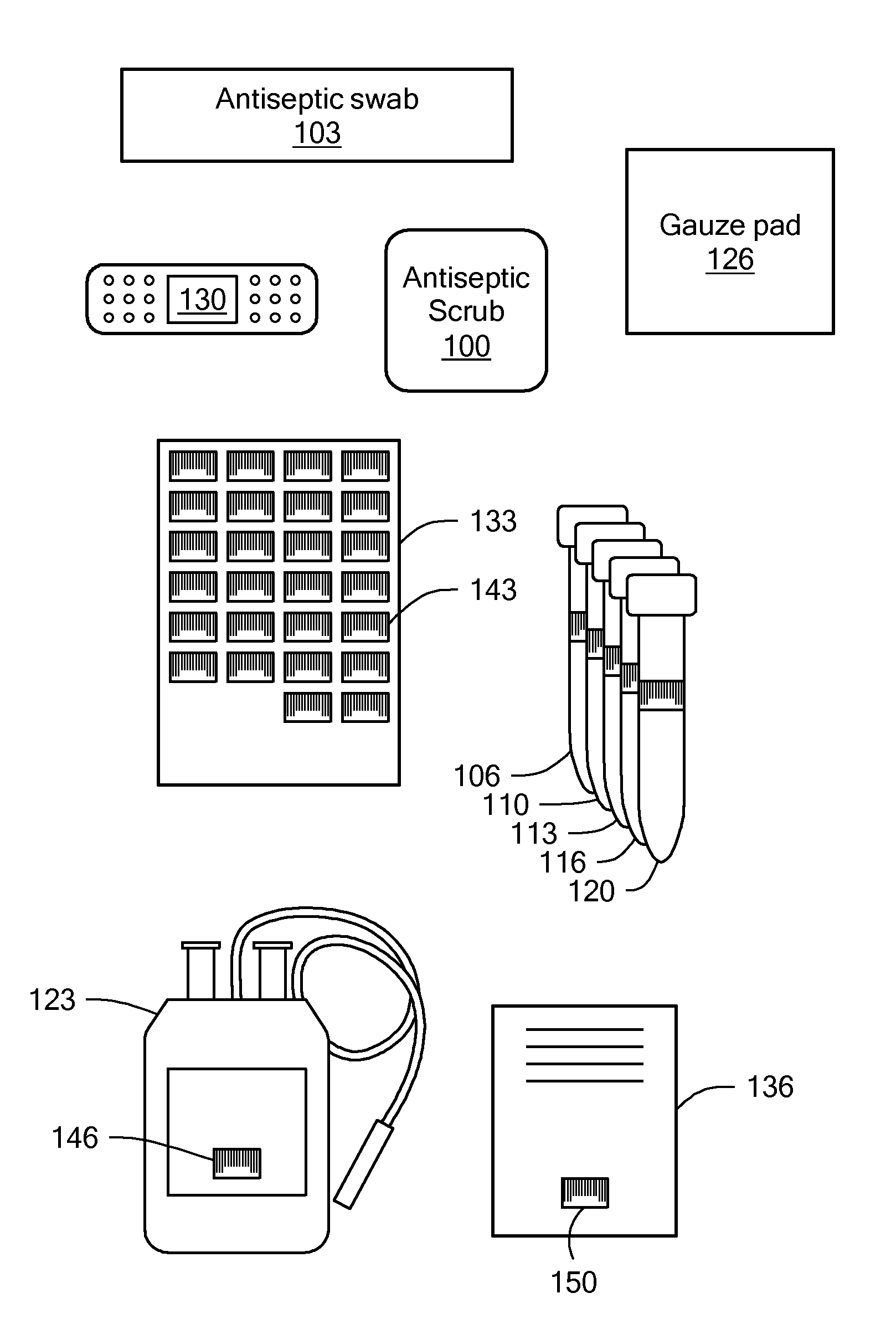

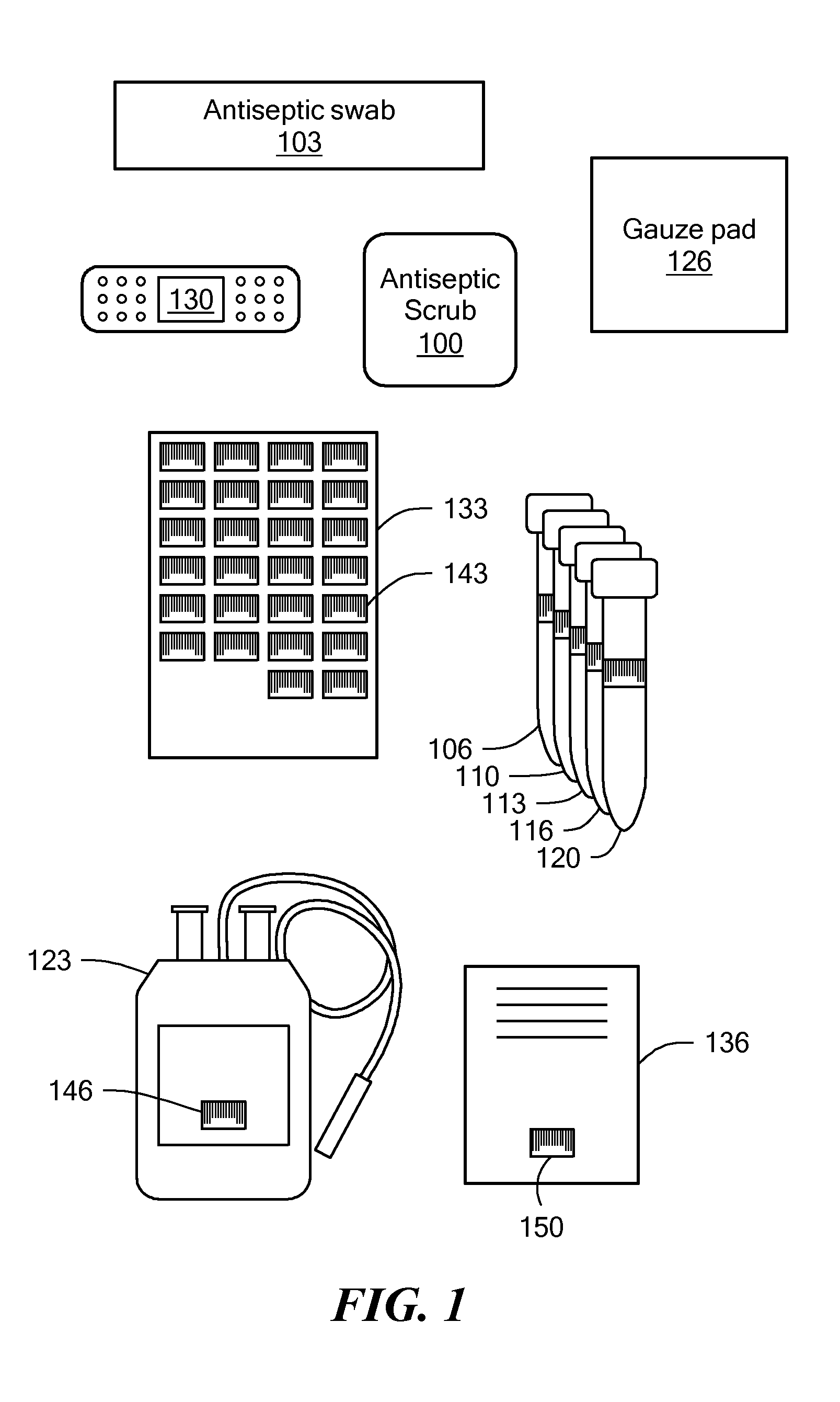

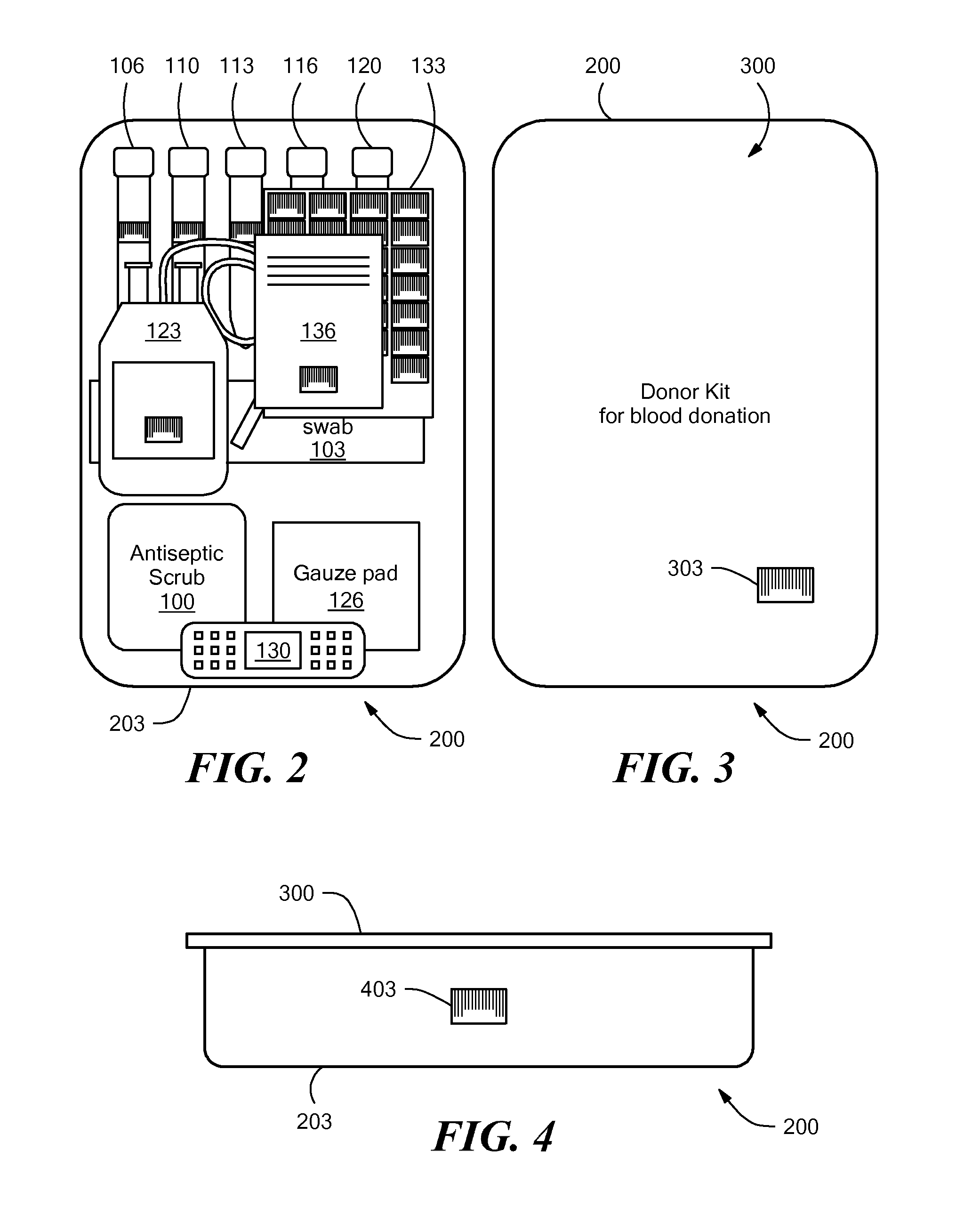

Donated Blood Collection Kit

InactiveUS20110281346A1Easy to collectBioreactor/fermenter combinationsBiological substance pretreatmentsBlood Collection TubeMedicine

A donated blood collection kit includes an easy-to-open closed container. Stored within the container are items necessary or useful for collecting donated blood, such as an antiseptic scrub, an antiseptic swab, test tubes, a blood collection container, a gauze pad and a sheet of pre-printed adhesive barcode labels. Each kit is assigned a unique identification when the kit is manufactured. The identification may eventually be used as the unique donor identification for a unit of donated blood that is collected using the items in the kit. The container is pre-labeled with the unique identification, such as by a barcode or an RF-ID tag. The test tubes and, if included, the blood collection container are pre-labeled with the same unique donor identification. The adhesive barcode labels in the container are pre-printed with the same unique donor identification and may be affixed to items that are not provided in the kit but, nonetheless, should be associated with the unit of blood that may be collected using the kit. Information about lot numbers and expiration dates for the items in the kit may be encoded in the kit's unique identification and / or stored in a database in association with the kit's identification.

Owner:HAEMONETICS

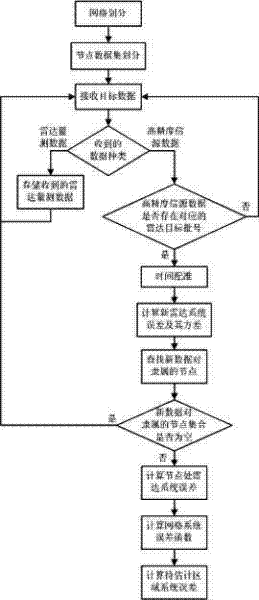

Method for estimating radar system error

InactiveCN102221688AImprove estimation accuracySmall amount of calculationWave based measurement systemsRadar systemsEstimation methods

Provided is a method for estimating radar system error. The method comprises: (1) dividing grids; (2) dividing node data sets; (3) receiving target data; (4) determining the kind of the data received; (5) storing radar measurement data received; (6) determining whether high precision source data has a corresponding radar object batch number or not; (7) registering time; (8) calculating the error and variance of the new radar system; (9) searching the nodes new data pairs subject to; (10) determining whether the node set the new data pairs subject to is empty or not; (11) calculating the radar system error at the node; (12) calculating a grid system error function; (13) calculating system error of an area to be estimated. The advantages are: according to the invention, a value method is adopted to obtain the area distribution the system error and the estimation precision is improved because the system error estimation method driven by data overcomes the difficulties that the radar system error model is complex and the radar system error model is hard to be established; a grid node iterative computation and a grid bilinear function interpolation are adopted, so the computational complexity is less and the engineering enforcement is convenient. The invention can be used for the radar system error calibration of a shore-based system.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

Anti-counterfeit bottle cap

The invention discloses an anti-fake bottle cap. The anti-fake bottle cap comprises a bottle cap anti-fake sleeve and a cap liner with one end nested in the bottle cap anti-fake sleeve and the other end connected with a bottle mouth, wherein the cap liner and the bottle cap anti-fake sleeve are arranged into two different colors, the bottle cap anti-fake sleeve is provided with a dent or a through-hole forming characters or design marks, the dent or the through-hole presents marks with special significance against the cap liner, such as anti-counterfeiting numbers, production date, quality guaranteed period, batch number, trademarks and other simple patterns with special significance, and the marks are clear and cannot fall off nor be erased. The anti-fake bottle cap has the advantages that the processing is simple, the marks are obvious, and the anti-fake bottle cap has good identification and anti-counterfeiting function, can be widely used for oil bottles and beverage bottles, etc., and brings great convenience for manufacturers and users.

Owner:李志彬

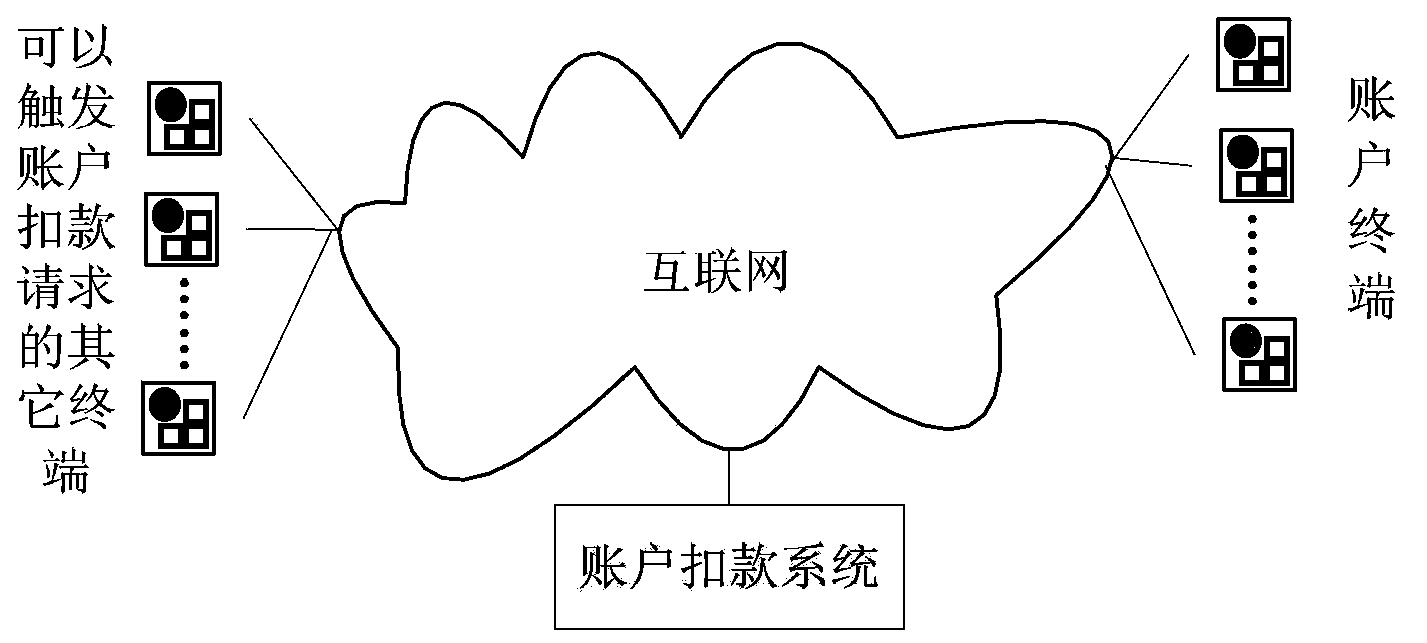

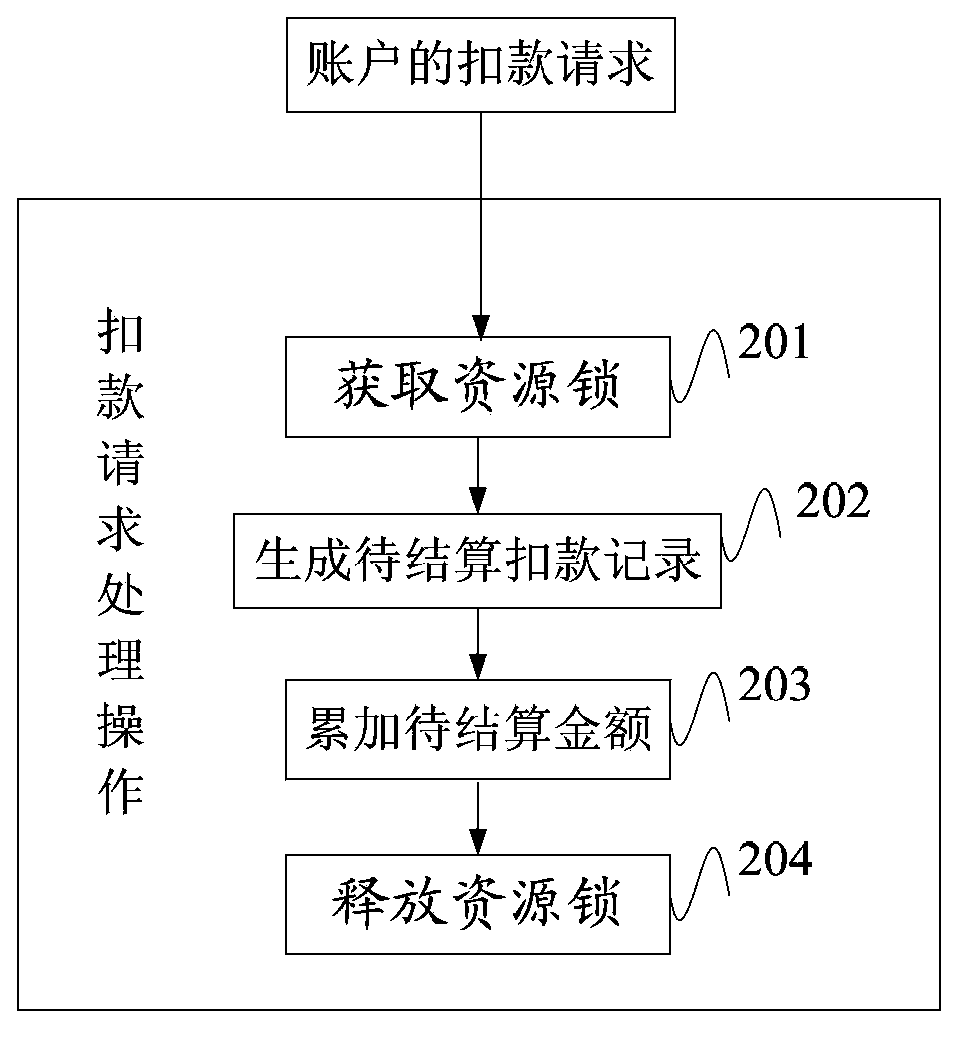

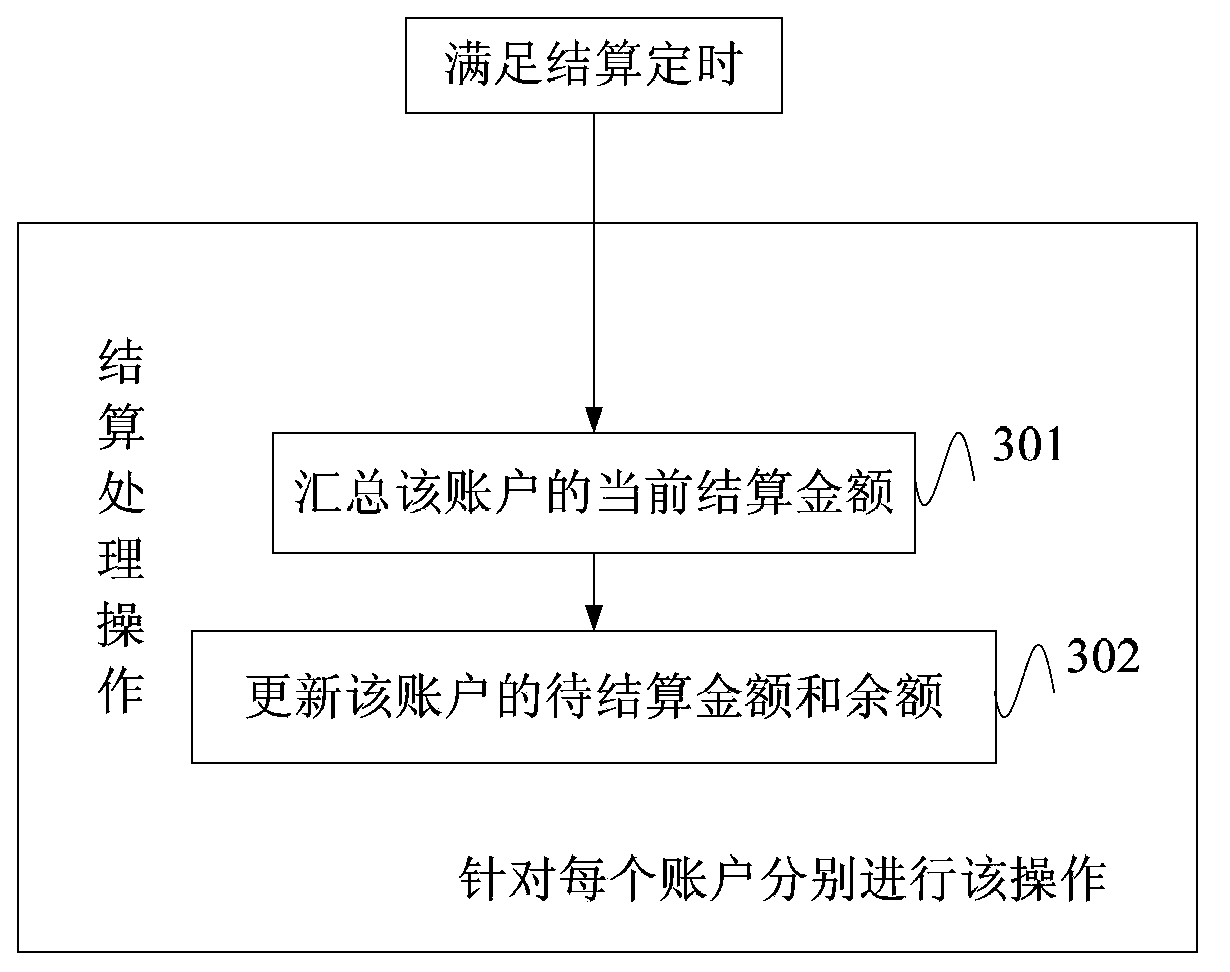

Account data processing method and device

The invention discloses an account data processing method. Corresponding settlement request processing operation is triggered for each received settlement request. The settlement request processing operation comprises that: a resource lock of an account corresponding to the settlement request is acquired; the amount of money to be settled of the account is locked, a batch number type corresponding to the settlement request is inquired and a current batch number of a corresponding type batch number is acquired; and the resource lock of the account corresponding to the settlement request is released.

Owner:ALIBABA GRP HLDG LTD

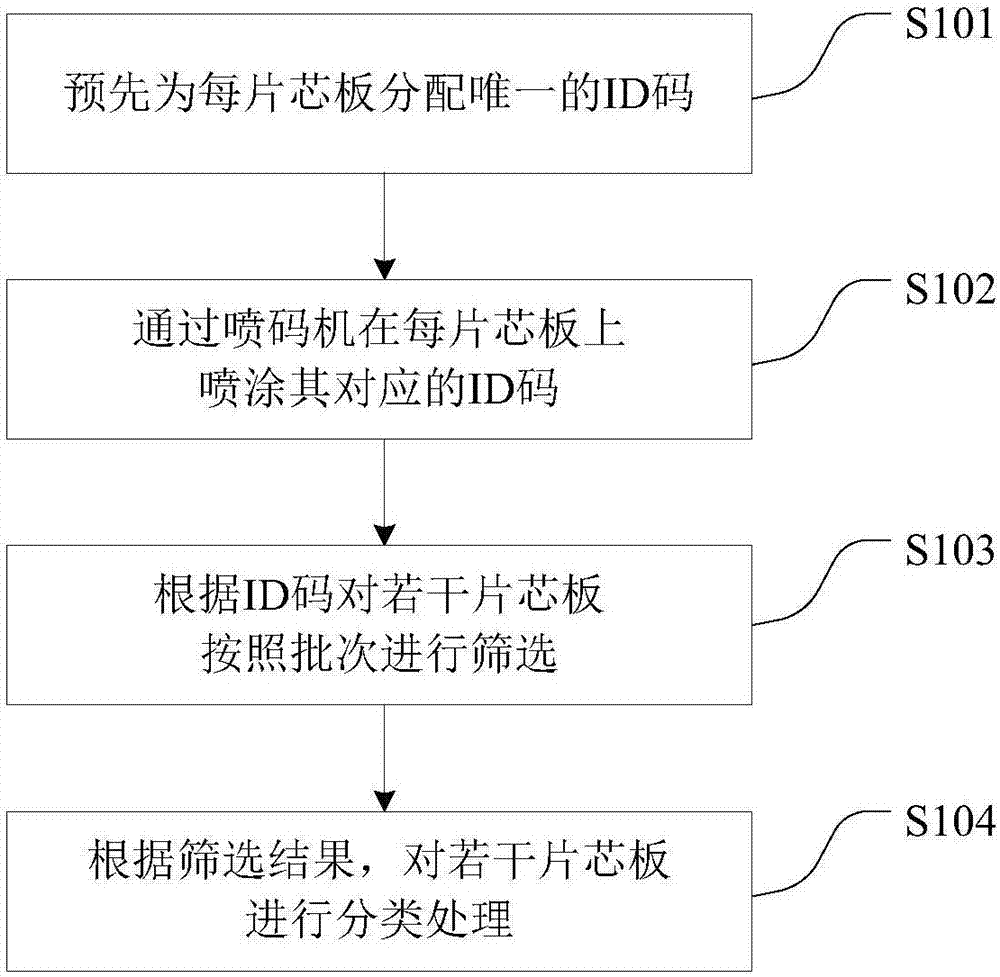

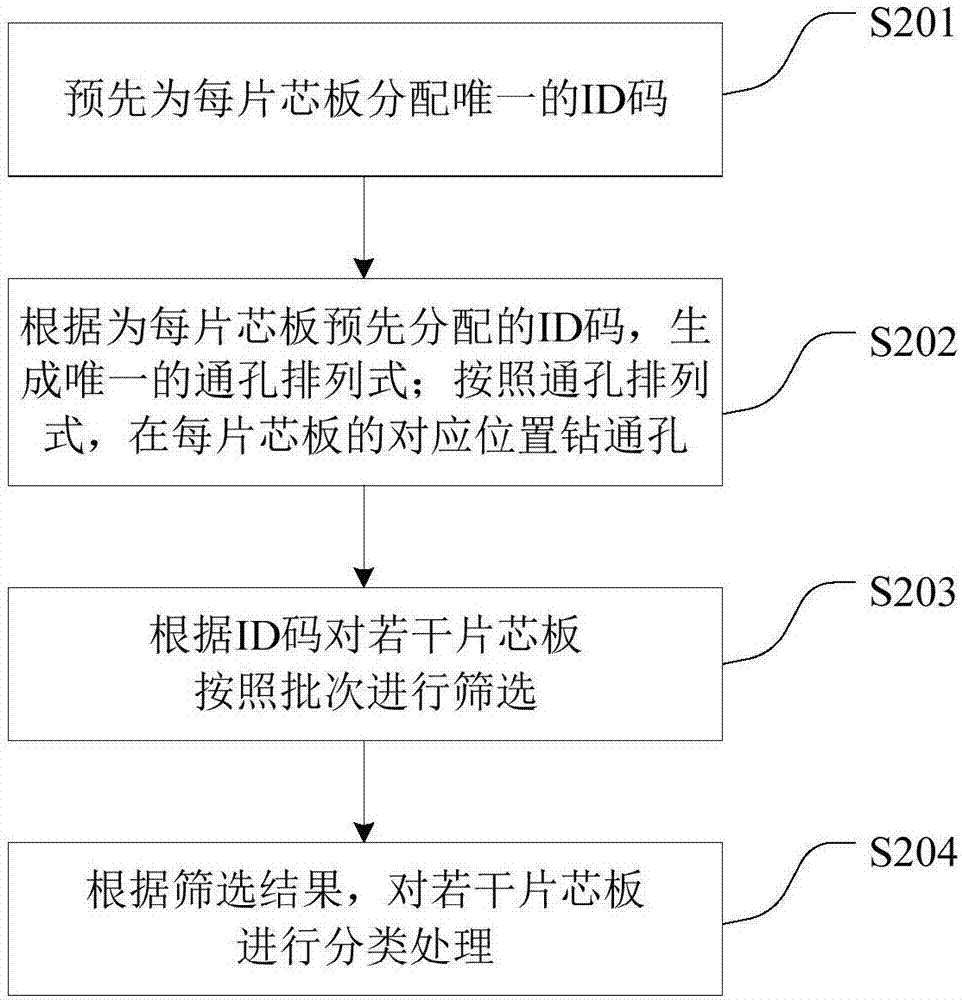

Control method and system against batch mix-up in PCB production process

InactiveCN107135618AFast readEliminate the phenomenon of mixed batchesPrinted circuit aspectsInspection/indentification of circuitsComputer scienceProduction quality

The invention discloses a control method and system against batch mix-up in a PCB production process. The method comprises that each core plate is distributed with a unique ID code and provided with the corresponding ID code, and information of the ID code includes the model, the batch number and the number of the core plate; and the core plates are screened according to the models and batch numbers of the ID codes. Thus, the core plates of different batches can be screened rapidly and accurately according to the ID codes, the phenomenon of batch mix-up is avoided, quality-related accidents are avoided, and the production quality and efficiency are improved; and the ID code arranged in the edge of the core plate in a hole row form can be read conveniently and rapidly, is effectively prevented from adverse influence and is durable.

Owner:东莞市五株电子科技有限公司

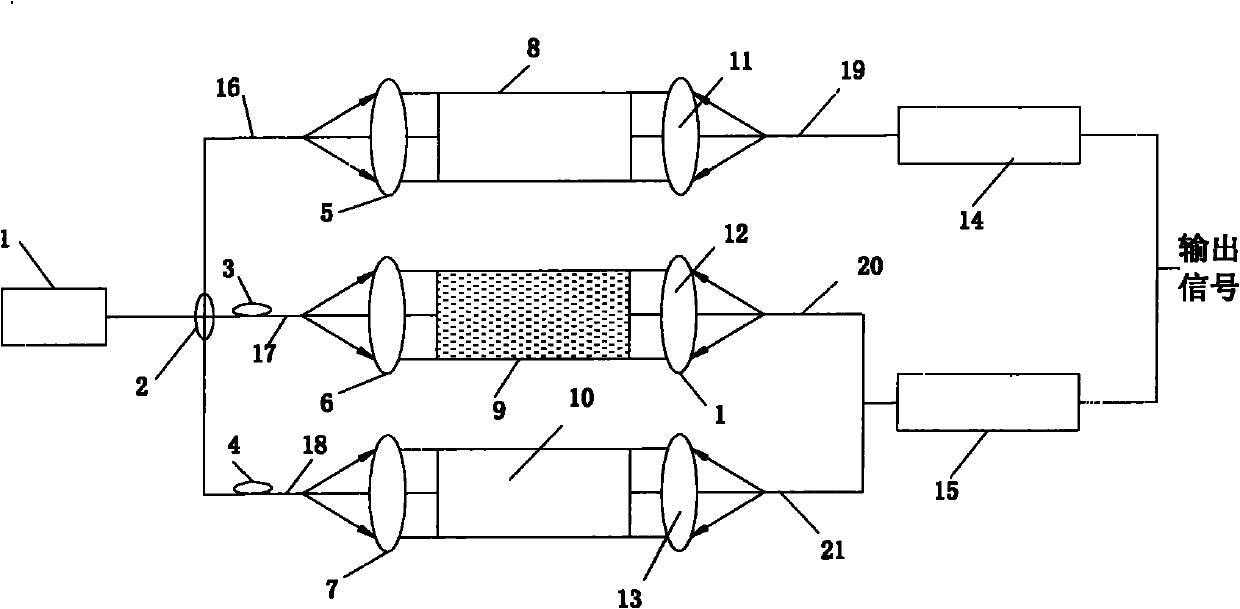

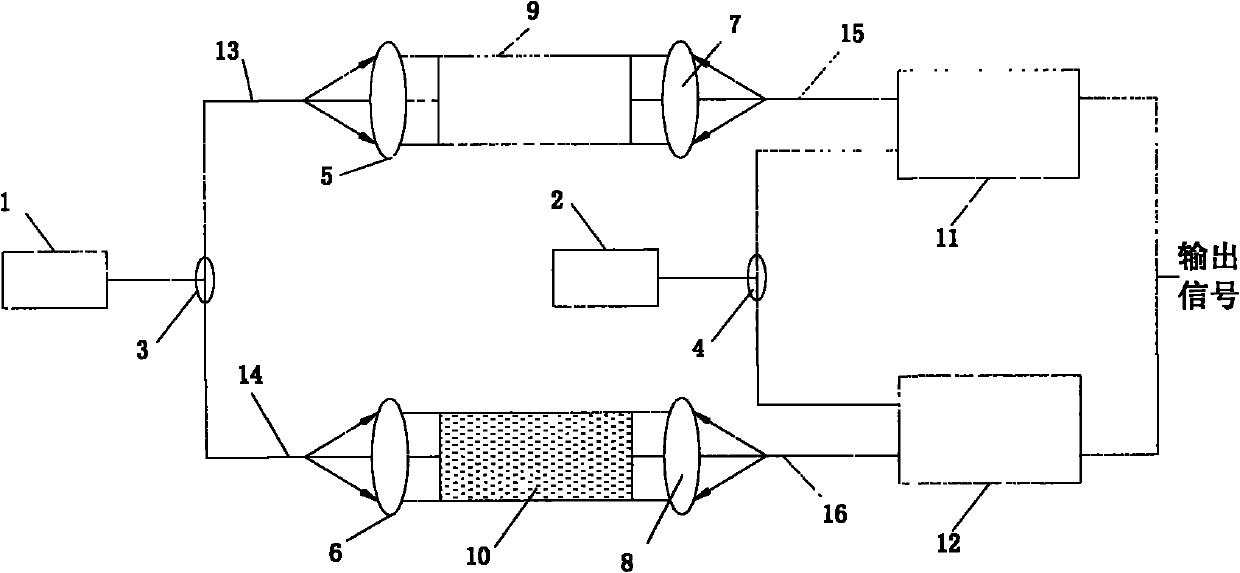

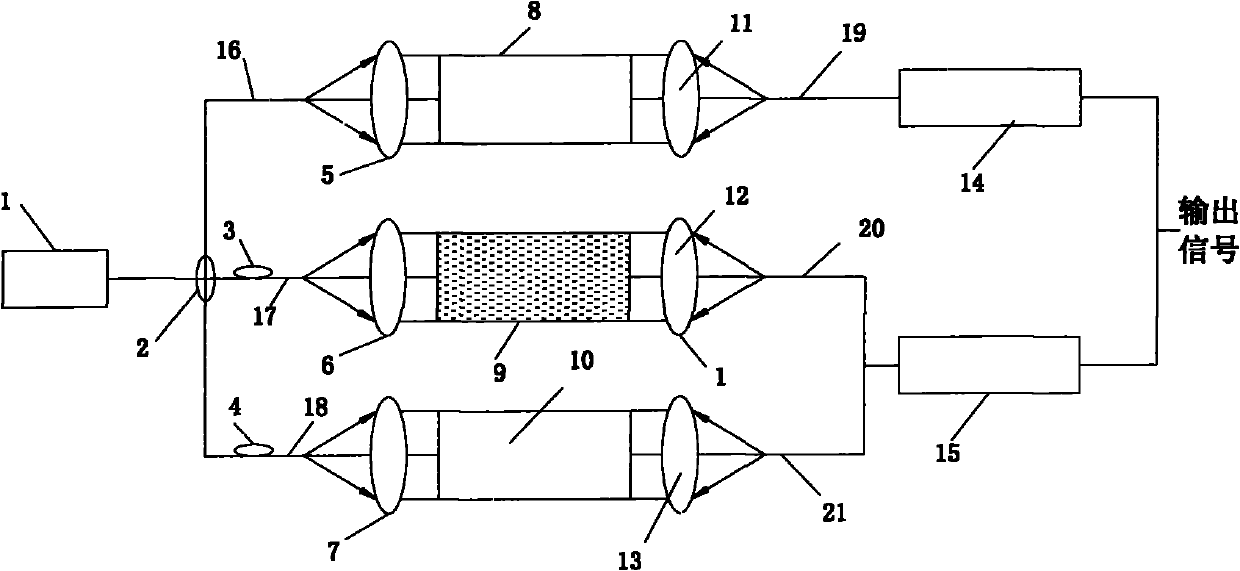

On-line oil particle pollution degree detection sensor based on optical sensing

InactiveCN102004079AImprove ease of useAccurate measurementColor/spectral properties measurementsOptical sensingOptical coupler

The invention discloses an on-line oil particle pollution degree detection sensor based on optical sensing. The input end of a 1*3 optical coupler of the sensor is connected with a light source through an optical fiber, the output end of the 1*3 optical coupler is divided into three paths, and the first path is sequentially connected with a first incidence optical fiber, a first self-focusing lens, a first reference optical path oil pool, a fourth self-focusing lens, a first emergence optical fiber and a first optical detector; or the input end of a first 1*2 optical coupler of the sensor is connected with a first light source through an optical fiber, the output end of the first 1*2 optical coupler is divided into two paths which are respectively connected with a first incidence optical fiber and a second incidence optical fiber, and the first path of first incidence optical fiber, first self-focusing lens, reference optical path air pool, third self-focusing lens, first emergence optical fiber and first optical detector are sequentially connected. By adopting a multi-channel system, different influences on colors of different trades and batch numbers of lubricating oil are corrected, and the influence on measurement light source and light path drift is modified.

Owner:SOUTH CHINA UNIV OF TECH

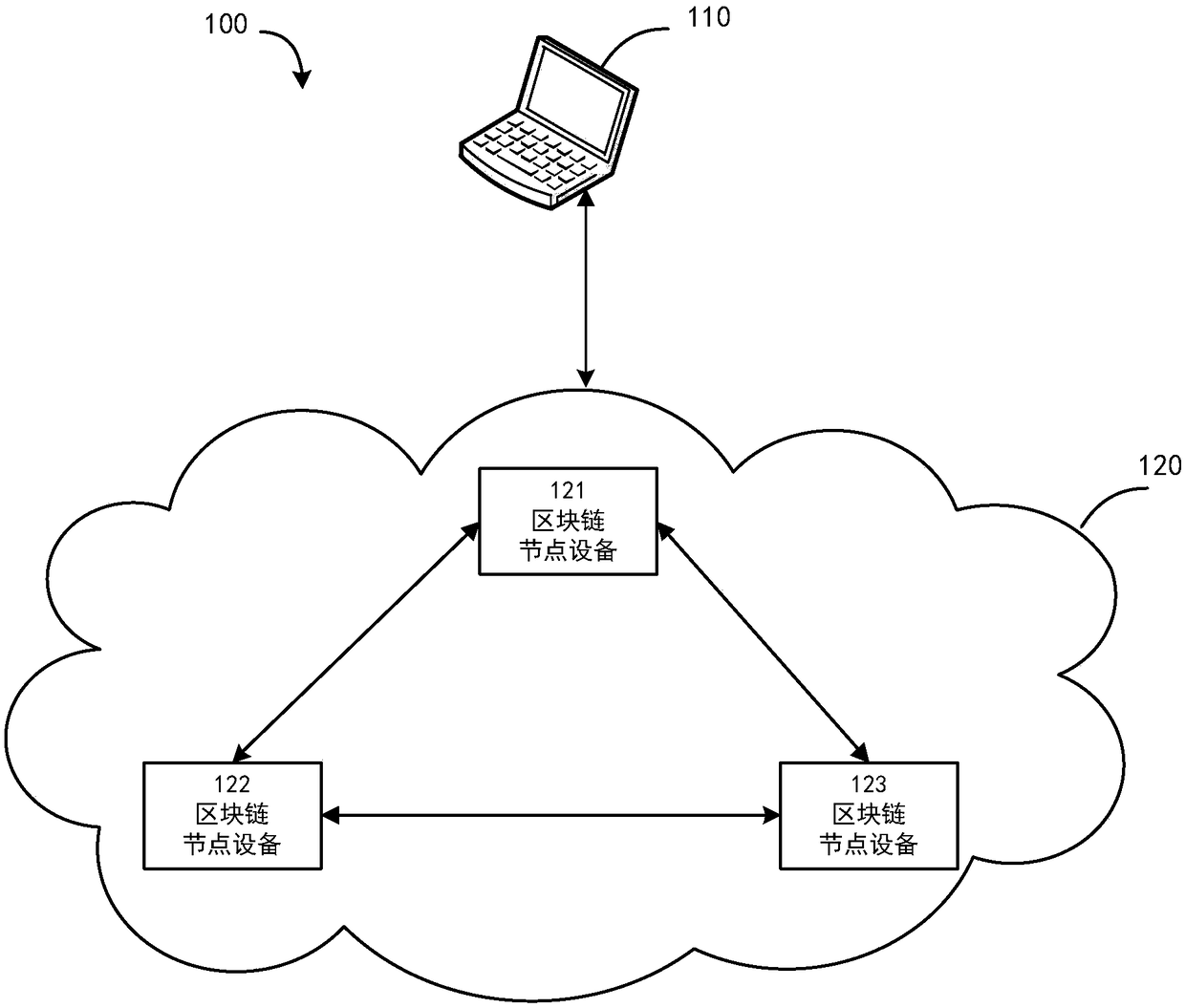

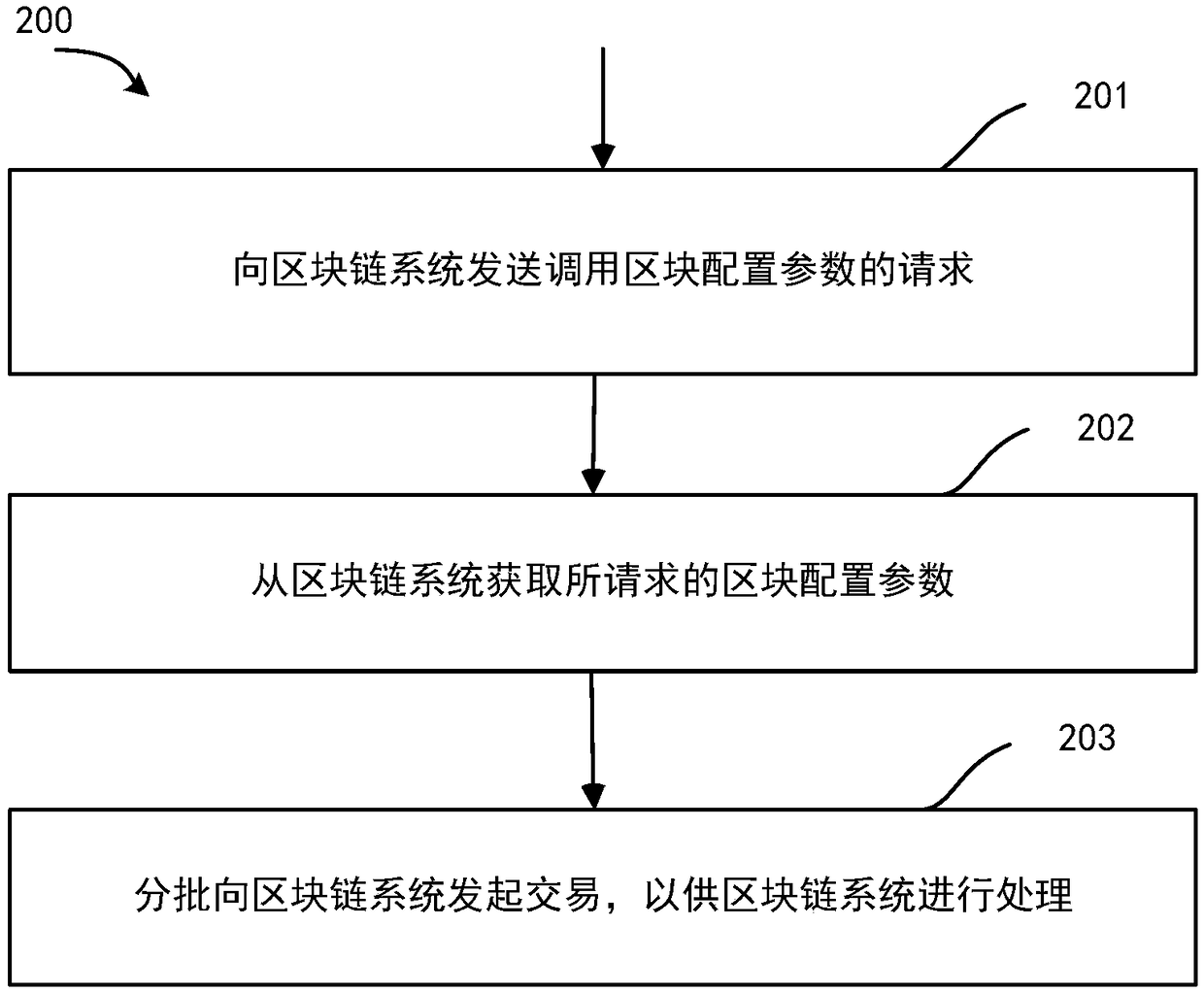

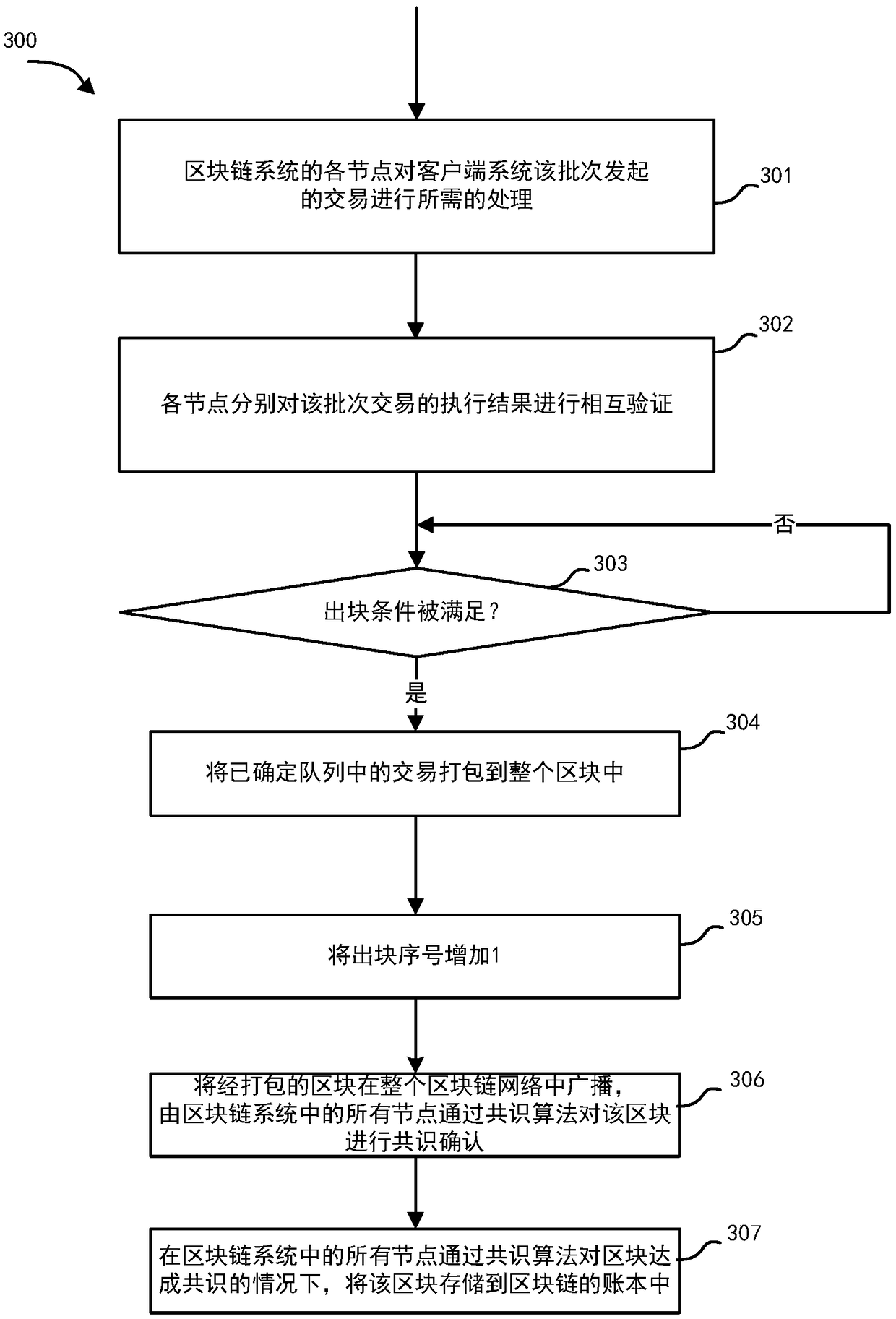

Transaction processing method and device based on block chain

ActiveCN109461079AReduce overheadImprove performanceFinanceOther databases indexingFinancial transactionChain system

Embodiments of the present disclosure disclose a block chain-based transaction processing method and apparatus. The method comprises the following steps of: sending a request for calling block configuration parameters to the block chain system, wherein the block configuration parameters at least comprise a batch number of transactions; Obtaining the requested block configuration parameter from theblock chain system; A transaction is initiated to the block chain system in batches for processing by the block chain system, wherein the number of transactions initiated to the block chain system ineach batch is equal to the number of batch transactions.

Owner:ZHONGAN INFORMATION TECH SERVICES CO LTD

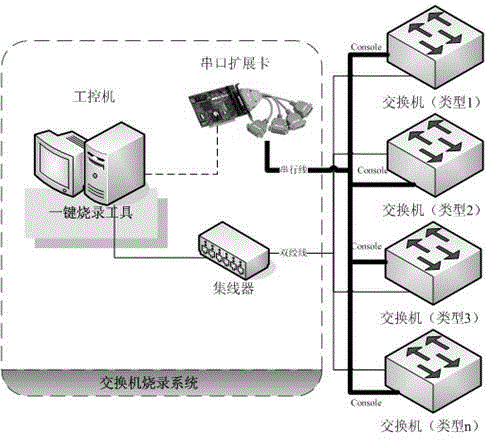

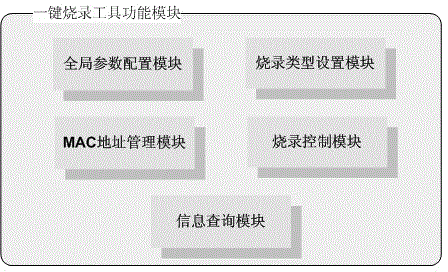

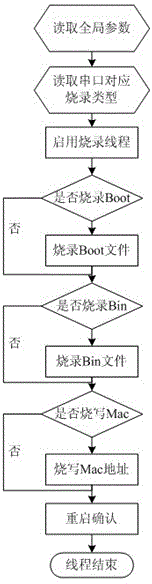

System for simultaneously burning multiple switches, method thereof and corresponding switches

InactiveCN104425001AImprove programming productivityReduce duplicationDigital storageData switching networksBack burnsThe Internet

The invention relates to a system for simultaneously realizing one-button burning on multiple switches, a method thereof and the corresponding switches. The system comprises a computer arranged with a one-button burning tool, at least a serial port expansion member and a bench common exchange apparatus. The system can simultaneously sent correlation operation instructions to multiple switches to be burned through the serial port expansion member and read the return content; and then is simultaneously connected to the internet access of multiple switches to be burned through the common exchange apparatus, and then simultaneously transmits the upgrade files to the multiple switches to be burned; the one-button burning tool arranged on the computer can be used for starting several tasks and control burning operation on multiple switches. The system can greatly increase the production efficiency of switch burning, by management of MAC address and batch number, faults such as repetition and omission due to artificial operation can be reduced.

Owner:TRANSCEND COMM BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com