Flexible job shop batch optimization scheduling method having intermediate storage constraint

A flexible operation, optimized scheduling technology, applied in the fields of instruments, manufacturing computing systems, data processing applications, etc., can solve the problem of no batch division plan research and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

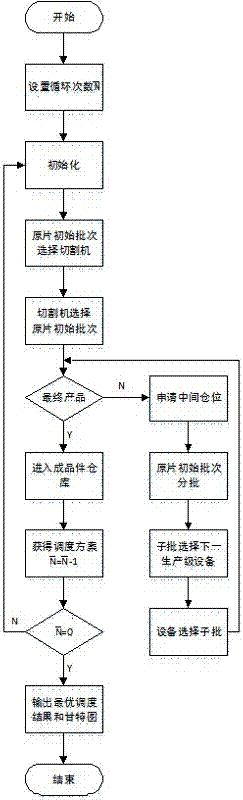

Method used

Image

Examples

Embodiment

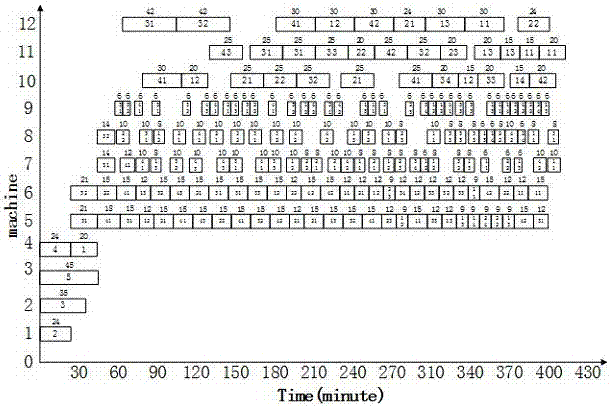

[0096] A glass deep processing and manufacturing workshop undertakes 1 order task, including 5 initial batches of original films. There are four cutting machines on production level 1, and the processing capacity and processing time of each cutting machine are shown in Table 1 and Table 2.

[0097] Table 1 Cutting machine processing capacity table (mm)

[0098]

[0099] Table 2 Cutting machine processing time (single batch processing time)

[0100]

[0101] —Indicating that the cutting machine cannot process this kind of original film

[0102] In this example, four types of monoliths are generated after the initial batch cutting of each raw film. Different processing machines represent different processing procedures, and each procedure has one or more parallel machines. The glass deep processing process mainly includes edging, cleaning, tempering, coating and hollowing. The workshop has two edging machines, two washing machines, two coating machines, one tempering f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com