Patents

Literature

20973results about "Manufacturing computing systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

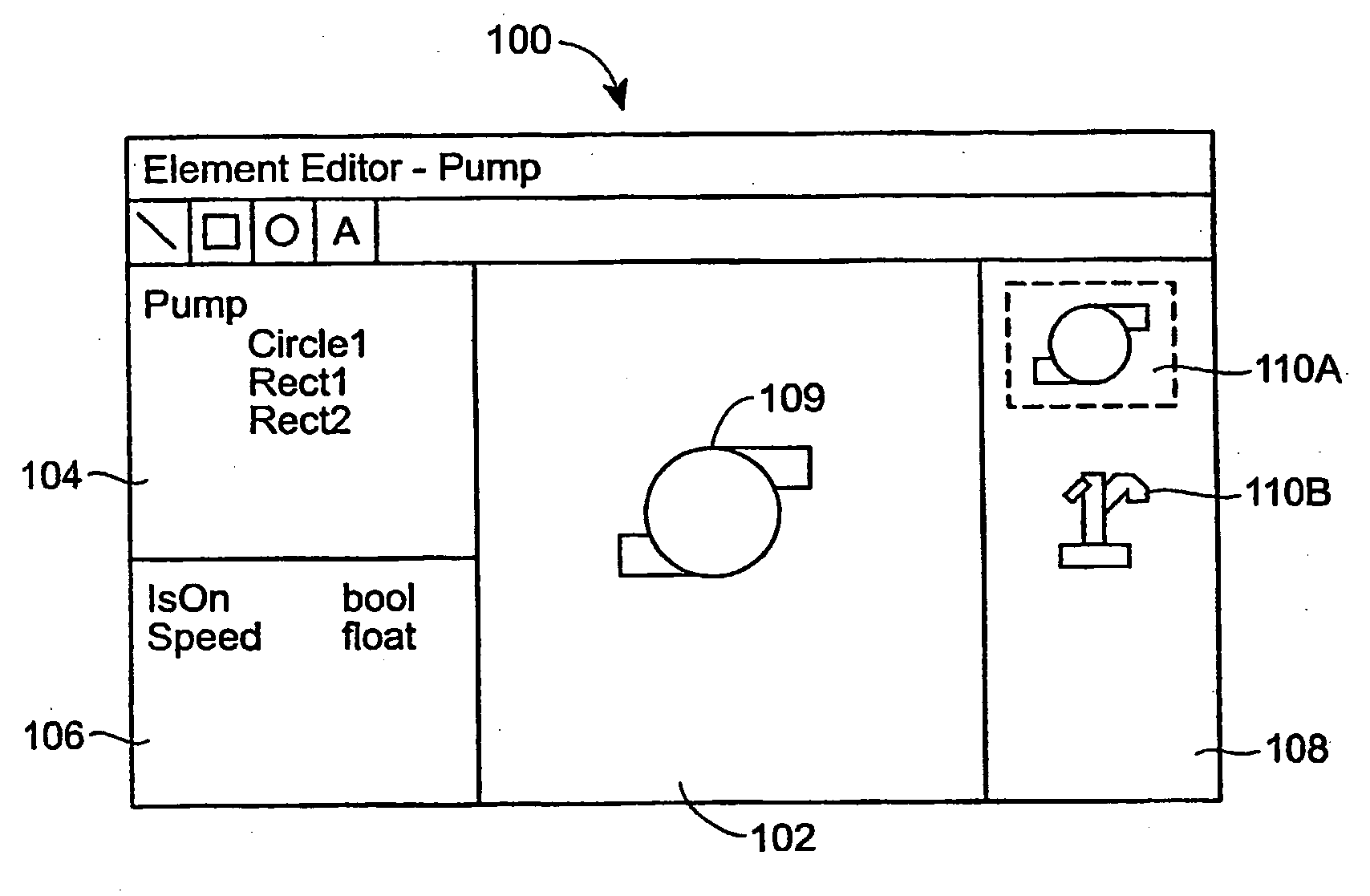

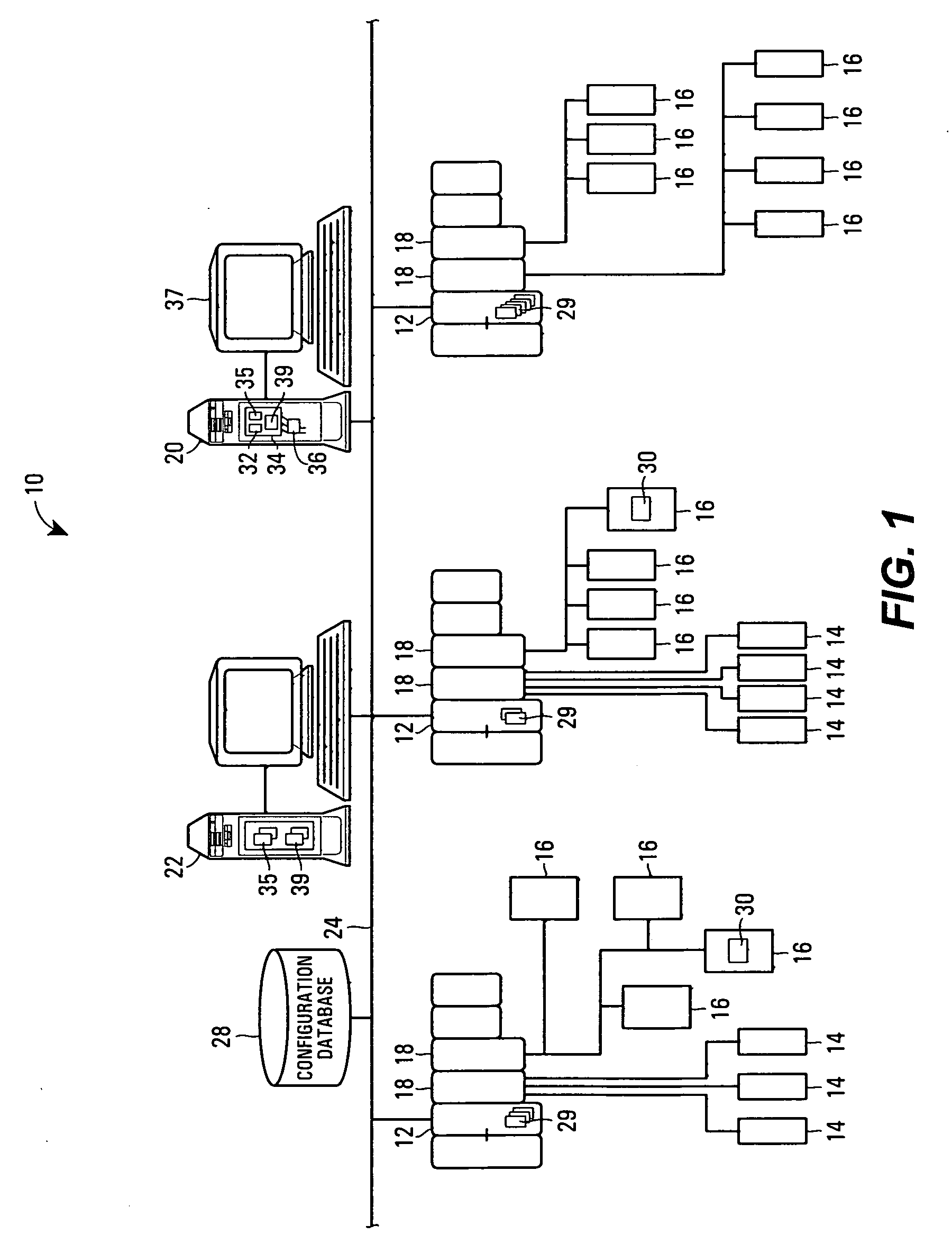

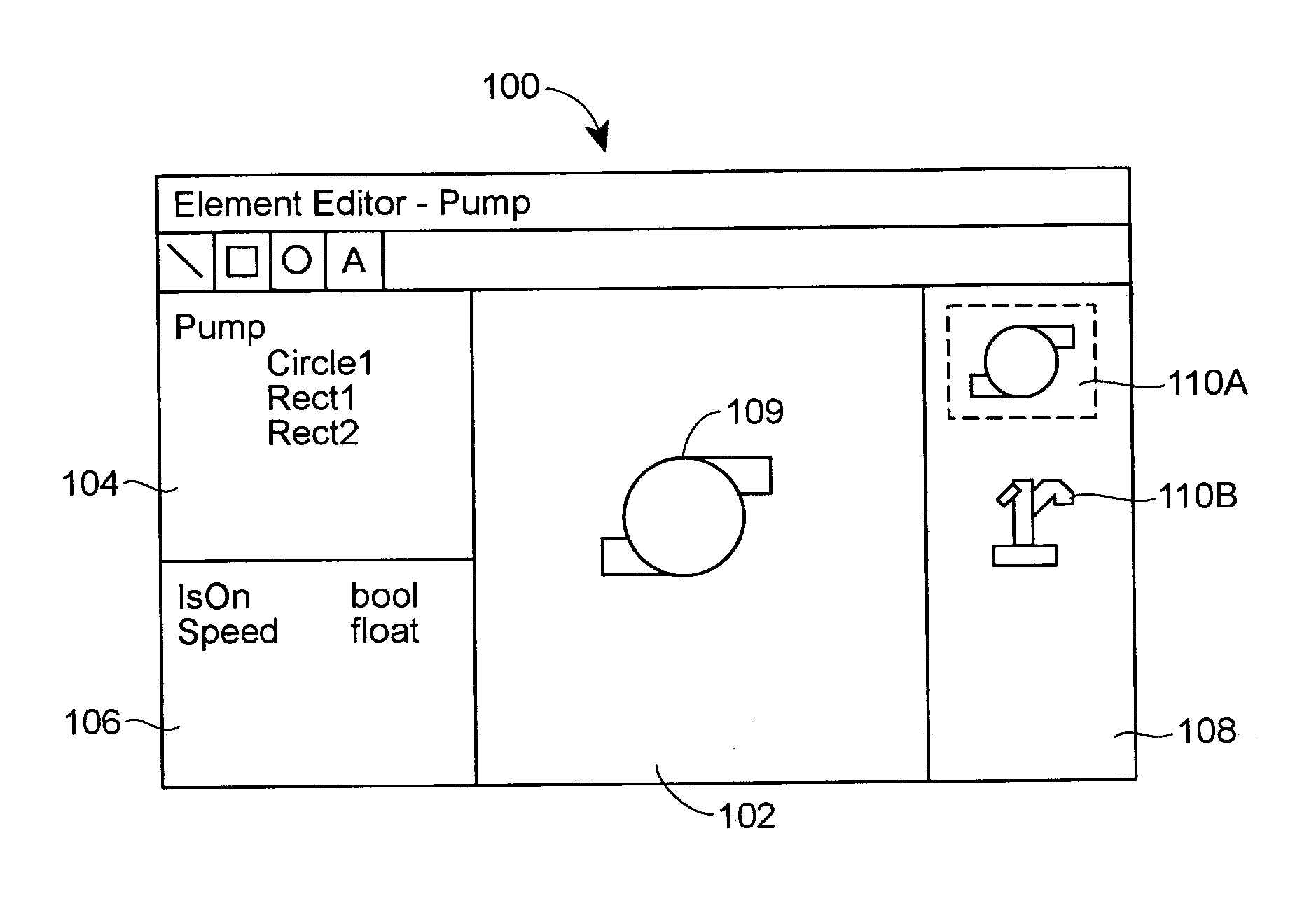

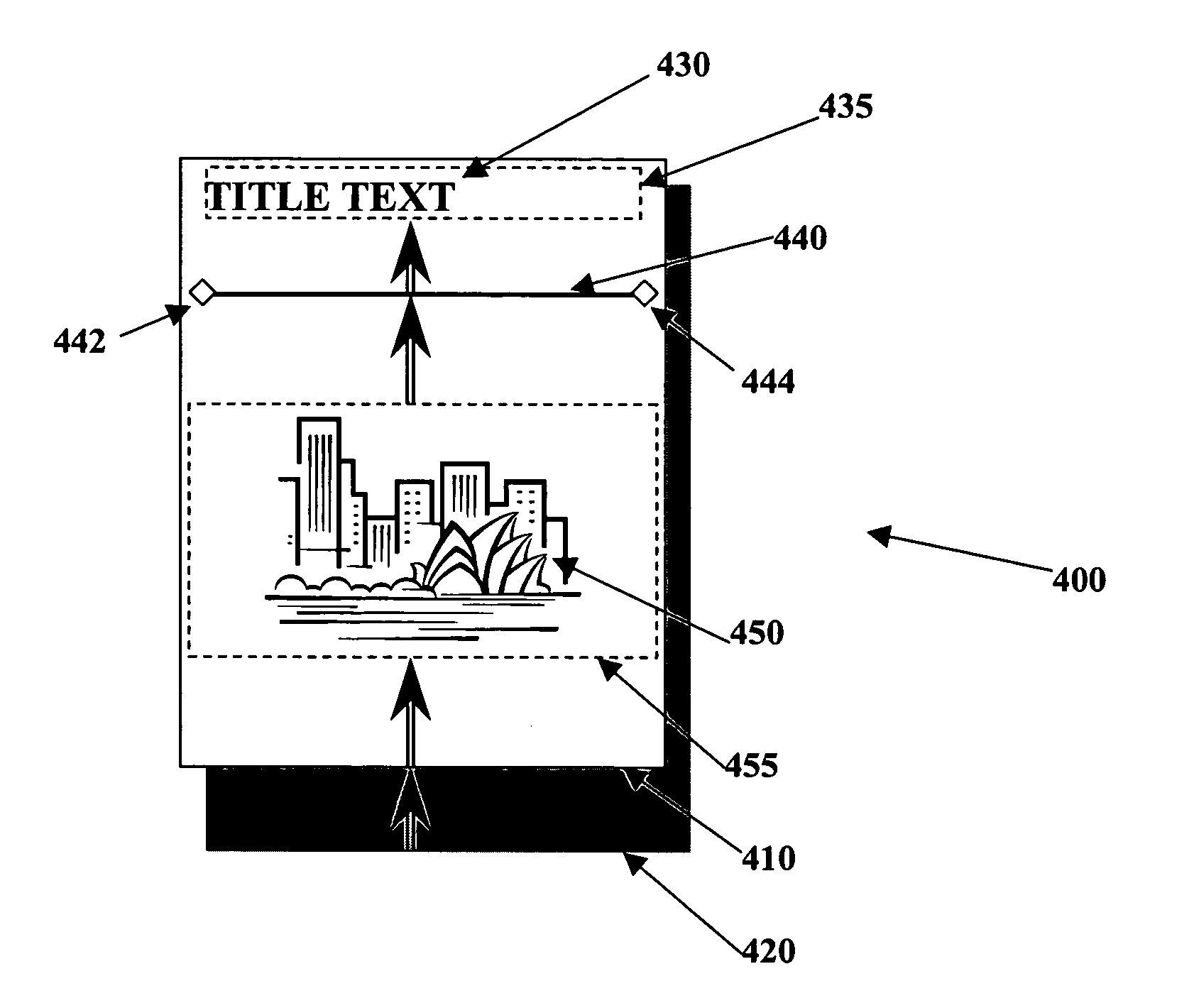

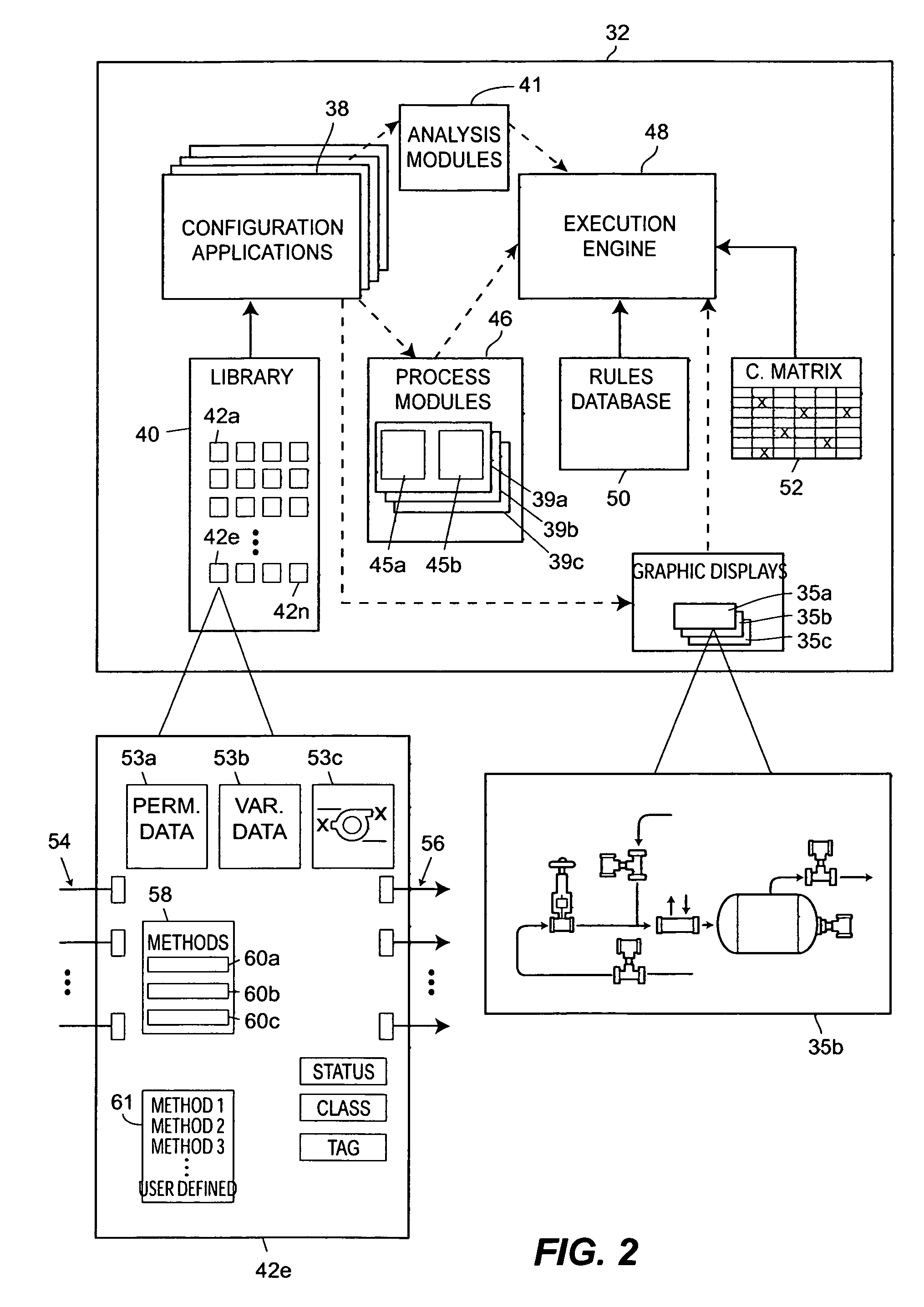

Graphic element with multiple visualizations in a process environment

ActiveUS20070132779A1Graphic element more versatileTechnology managementProgram controlGraphicsDisplay design

Smart graphic elements are provided for use as portions or components of one or more graphic displays, which may be executed in a process plant to display information to users about the process plant environment, such as the current state of devices within the process plant. Each of the graphic elements is an executable object that includes a property or a variable that may be bound to an associated process entity, like a field device, and that includes multiple visualizations, each of which may be used to graphically depict the associated process entity on a user interface when the graphic element is executed as part of the graphic display. Any of the graphic element visualizations may be used in any particular graphic display and the same graphic display may use different ones of the visualizations at different times. The different visualizations associated with a graphic element make the graphic element more versatile, at they allow the same graphic element to be used in different displays using different graphical styles or norms. These visualizations also enable the same graphic element to be used in displays designed for different types of display devices, such as display devices having large display screens, standard computer screens and very small display screens, such as PDA and telephone display screens.

Owner:FISHER-ROSEMOUNT SYST INC

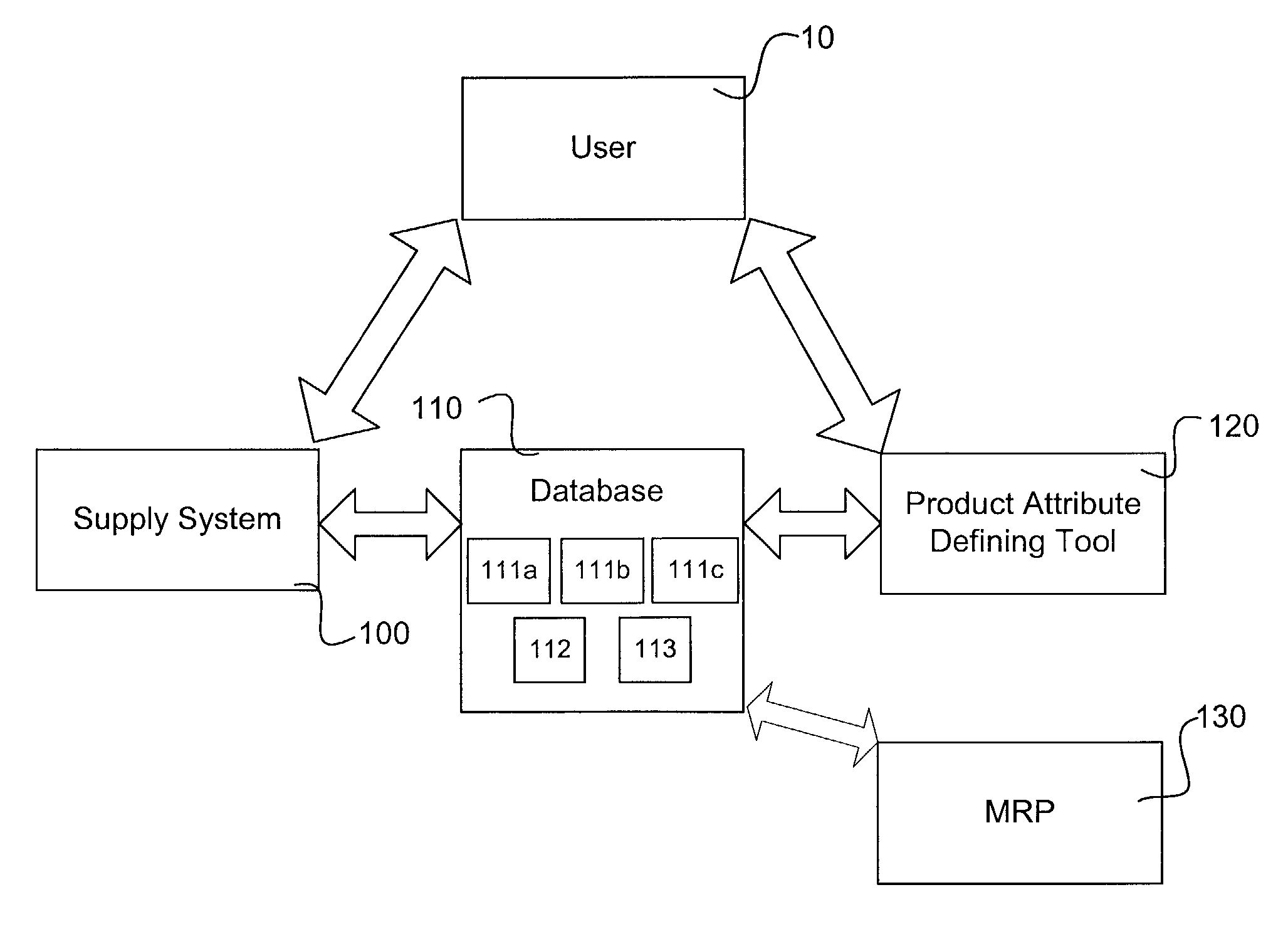

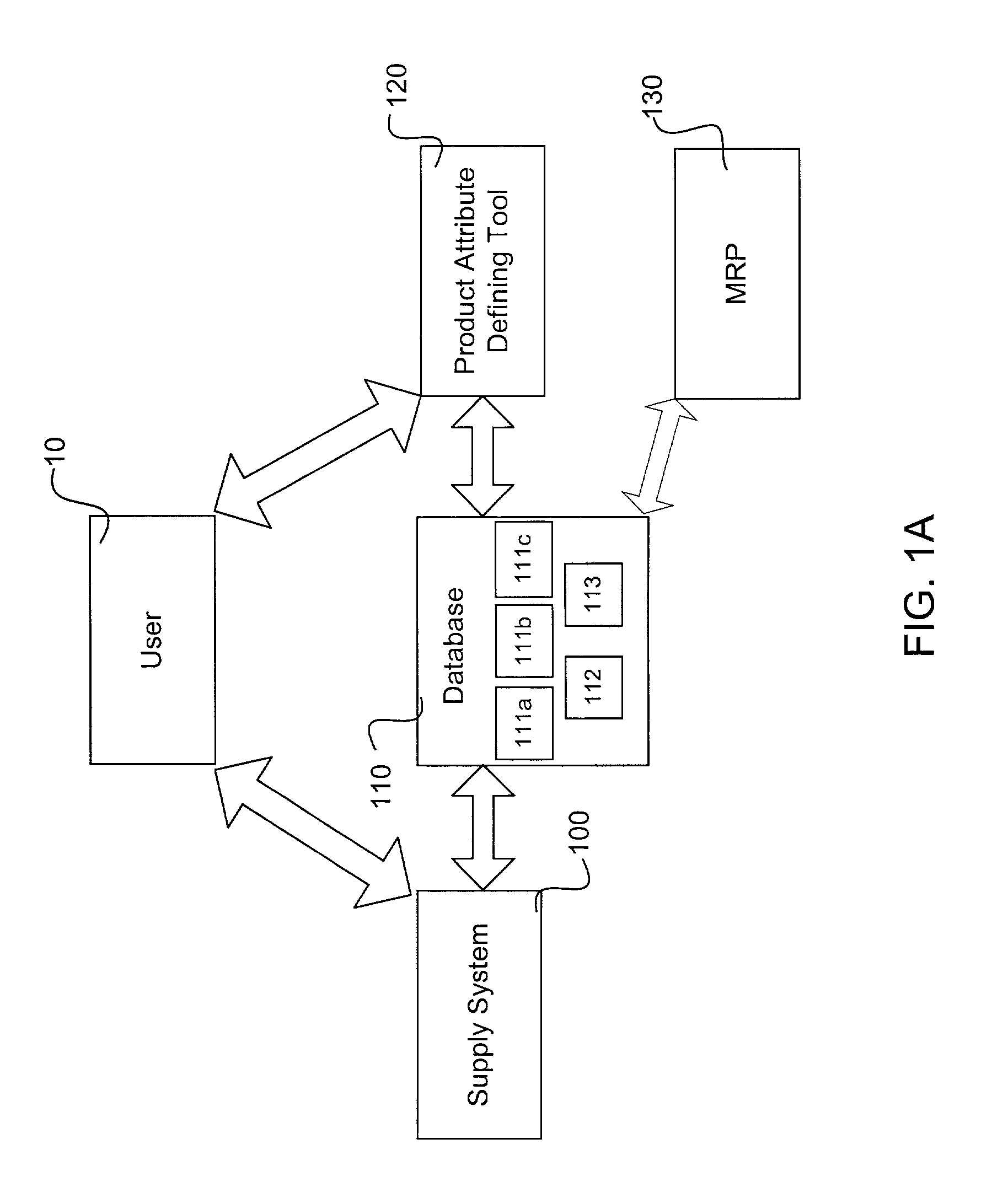

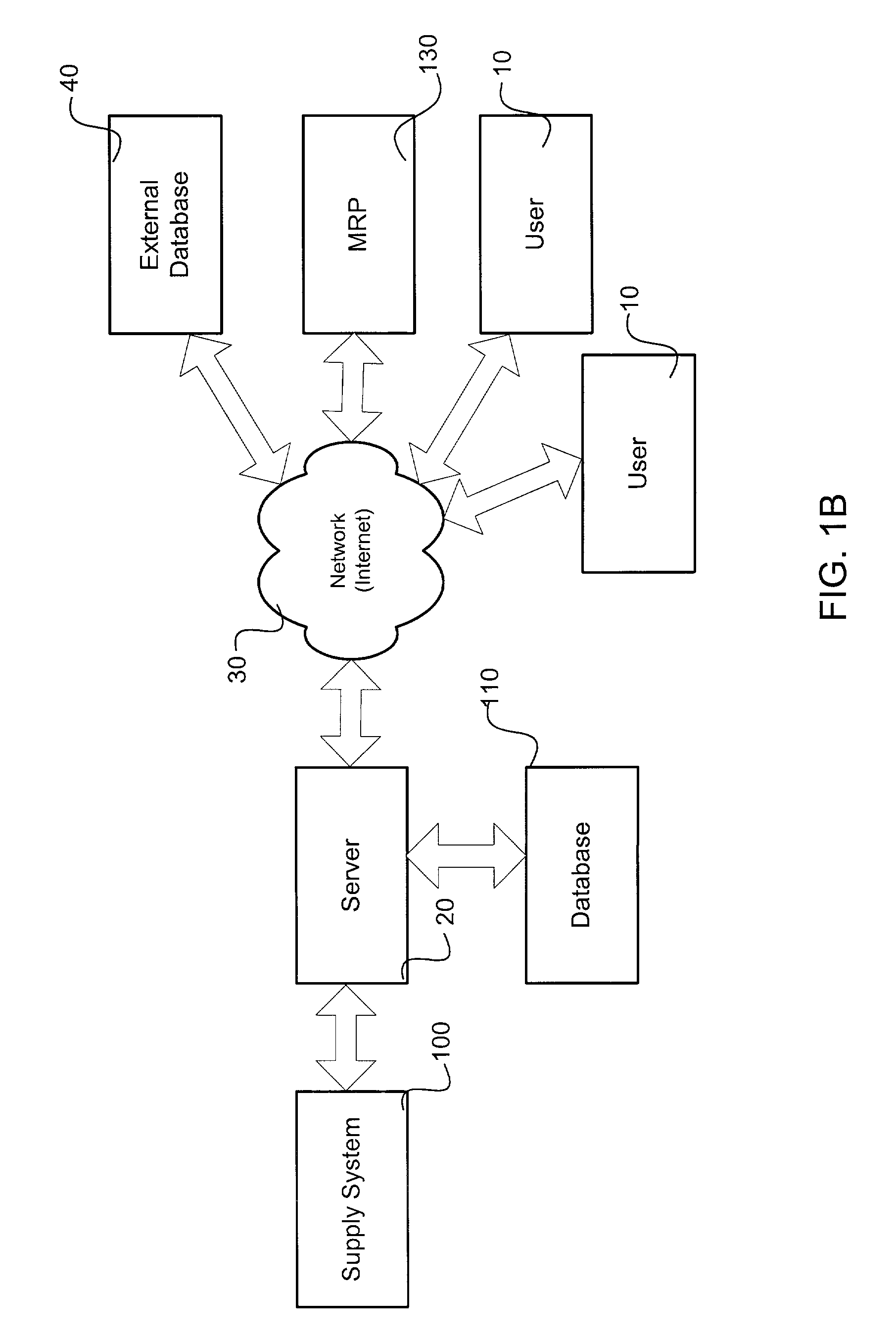

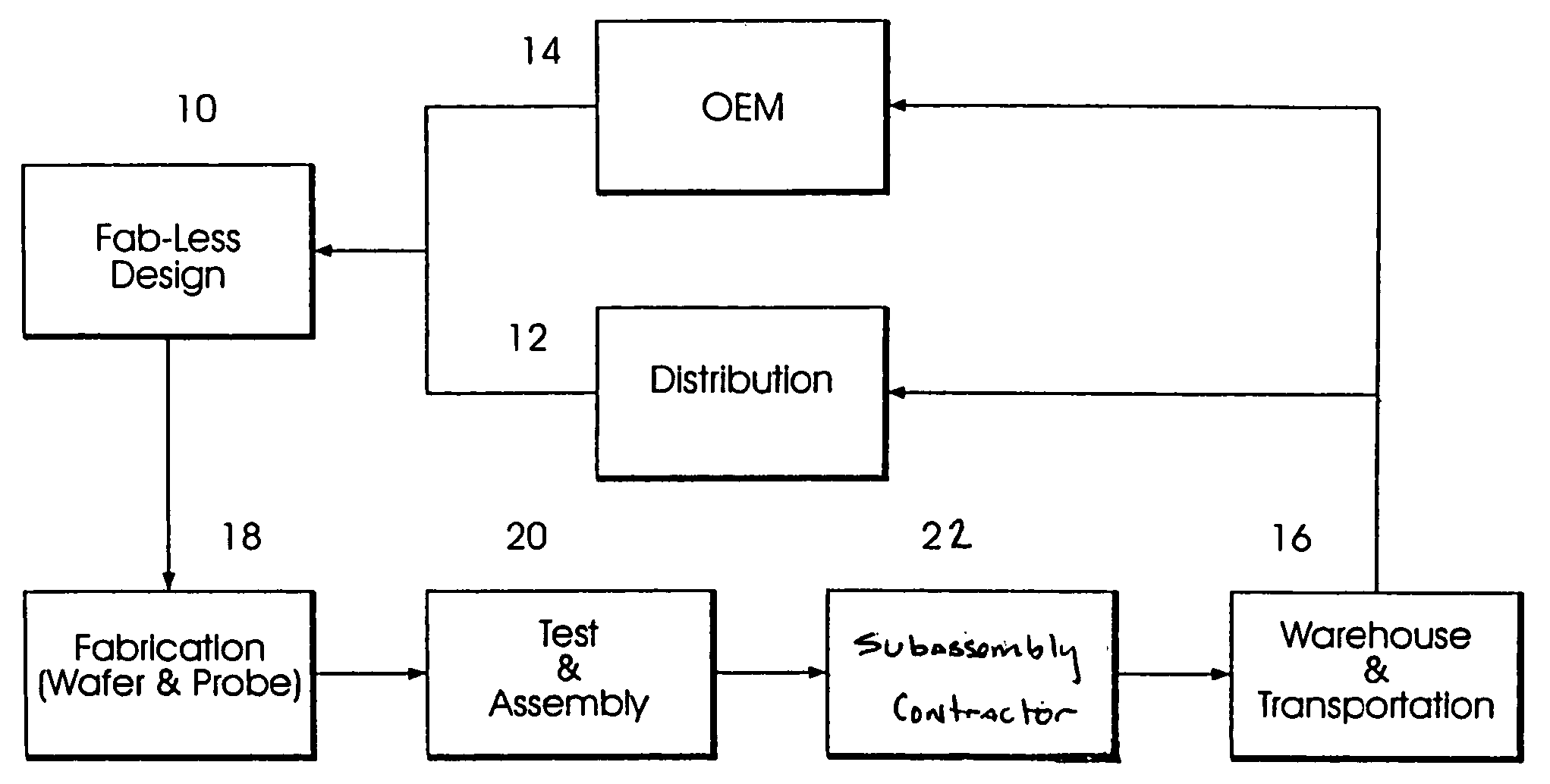

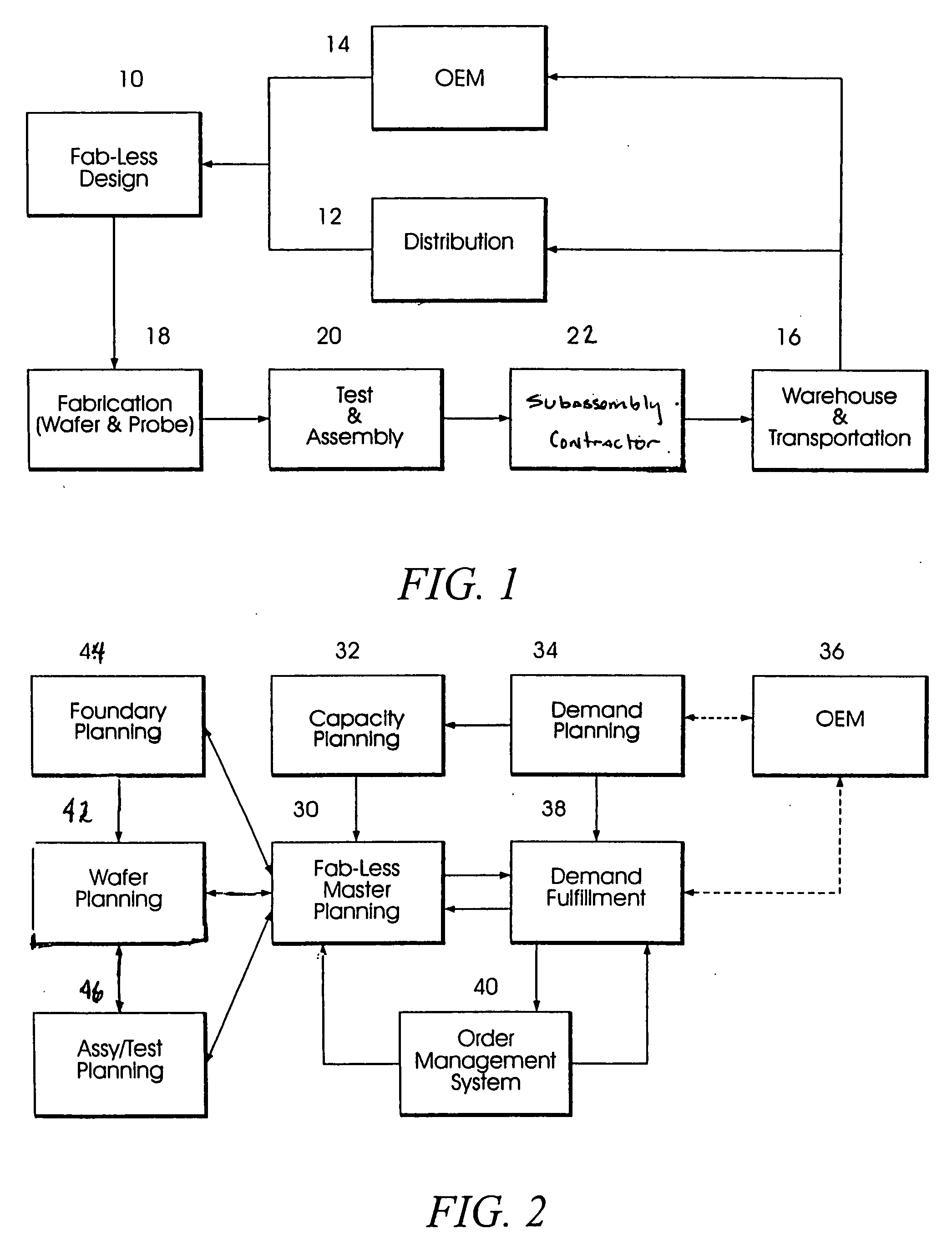

System and method for allocating the supply of critical material components and manufacturing capacity

InactiveUS7058587B1Improve responsivenessMaximize inventory useResourcesSpecific program execution arrangementsProgram planningChange analysis

The present invention allocates the supply of critical components and manufacturing capacity by optimizing critical material planning decisions and dynamically allocating constrained materials using advanced substitution logic that considers alternate suppliers and supports product life cycle from design through end-of-life. The present invention may utilize unique synchronized allocations and matched sets logic. The synchronized allocations ensure that all materials necessary for production are available in the appropriate time-phased allocation before beginning production to minimize wasted production capacity and materials. The supply system may include various combination of components, including a Supply Planner, a Resource Optimizer, a Constraint Based Master Planner, a Product Change Analyzer, a Comparer, a Resource Requirements Planner, a Finite Resource Planner, a Customer Promiser, and an Interactive Master Scheduler. Another embodiment of the supply system includes a tool that allows users to define products using engineering specifications.

Owner:BLUE YONDER GRP INC

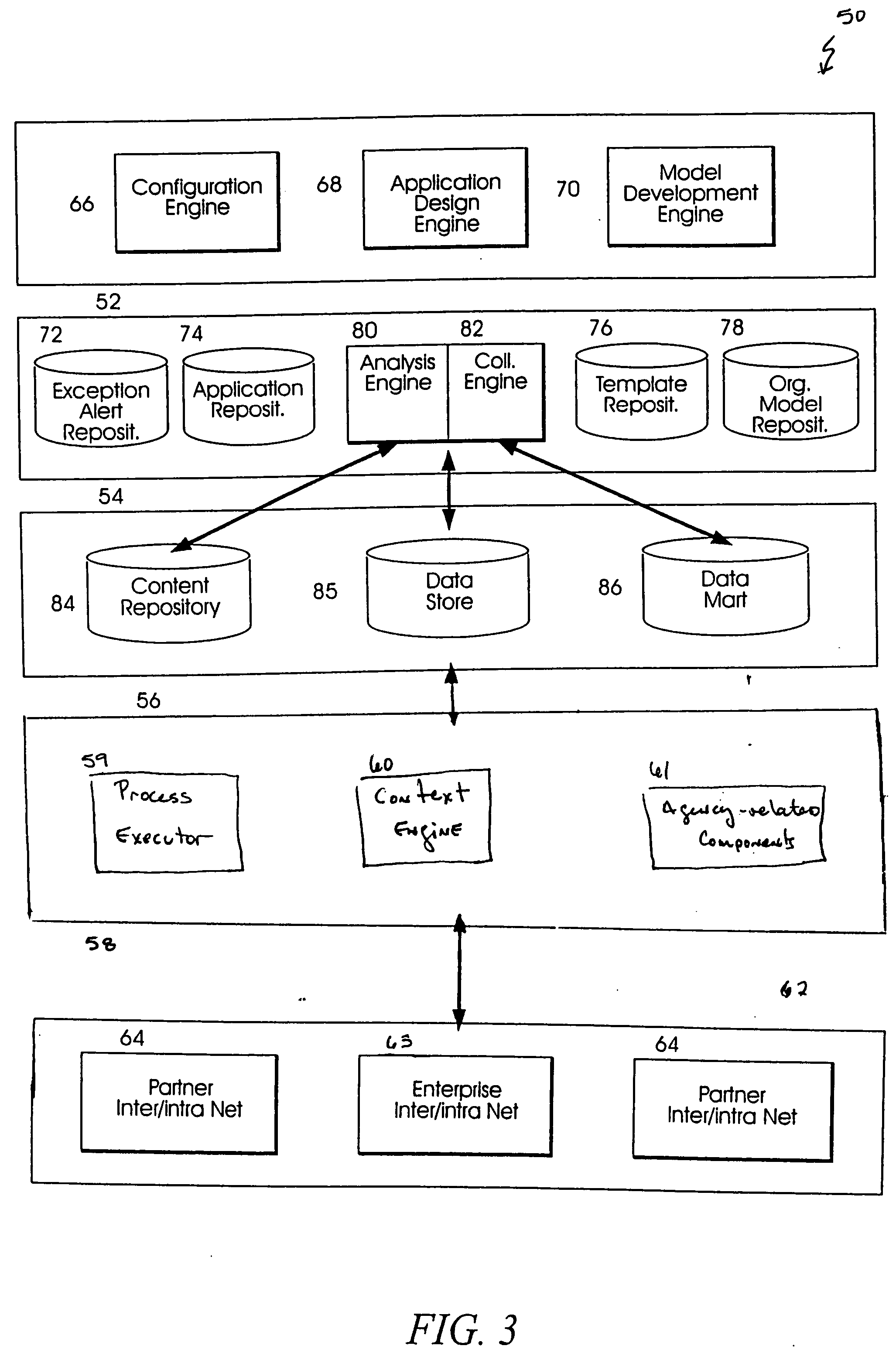

Decision support system for supply chain management

InactiveUS20050209732A1Eliminates and reduces disadvantageEliminates and reduces and problemHand manipulated computer devicesDigital data processing detailsGranularityEngineering

A decision support system for supply chain management is disclosed. In one embodiment, an organizational structure of an enterprise value chain is mock-constructed as a framework model and solutions are logically distributed through the organization in accordance with the model. Product management, demand management and inventory management are performed on an exception basis and these processes are implemented incrementally and organizationally such that enterprise activities may be tracked and monitored, by exception, at multiple levels of granularity. In a general aspect, the invention enables collaborative ordering, forecasting, inventory and replenishment management by implementing such systems through an enterprise organizational model.

Owner:AUDIMOOLAM SRINIVASARAGAVAN +1

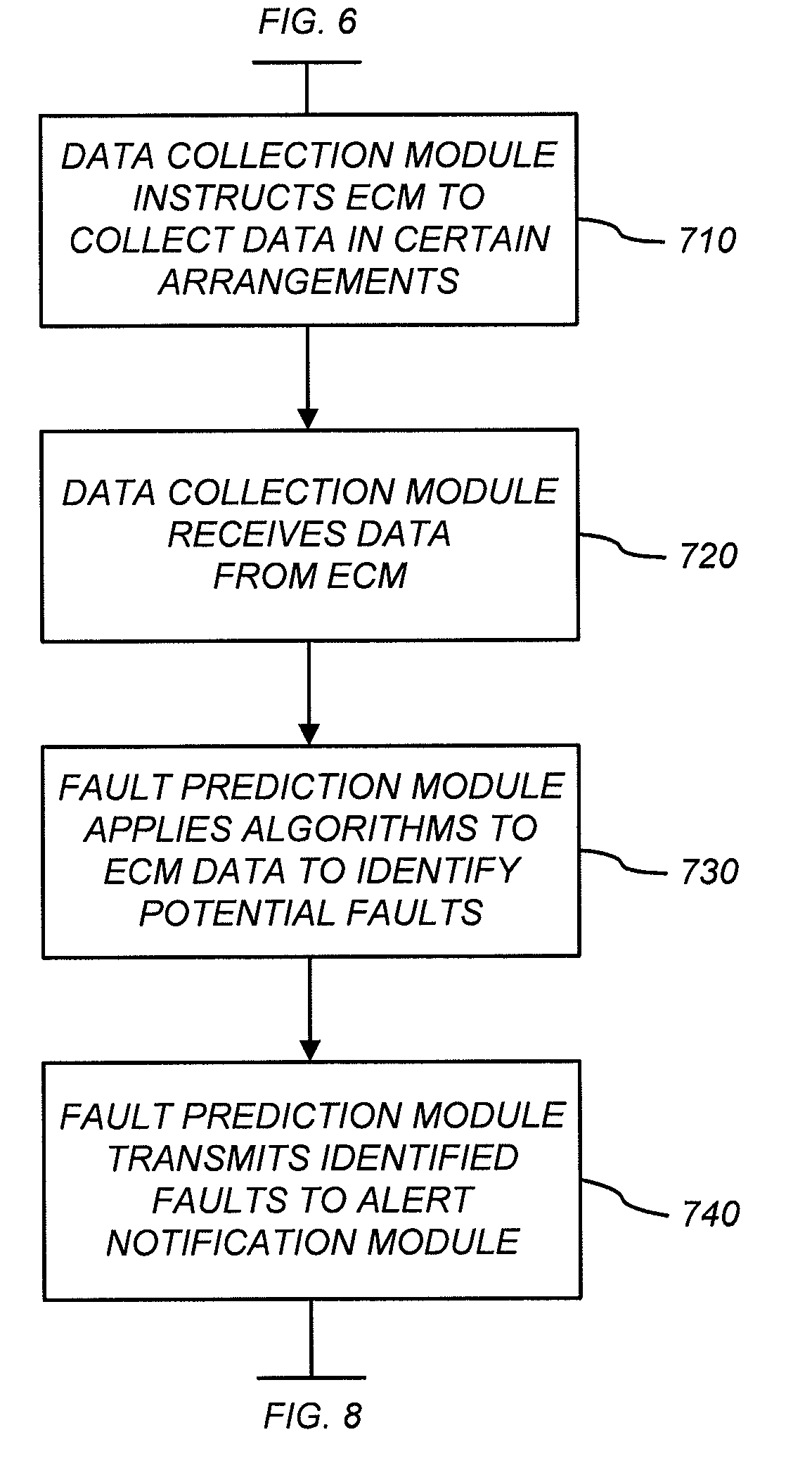

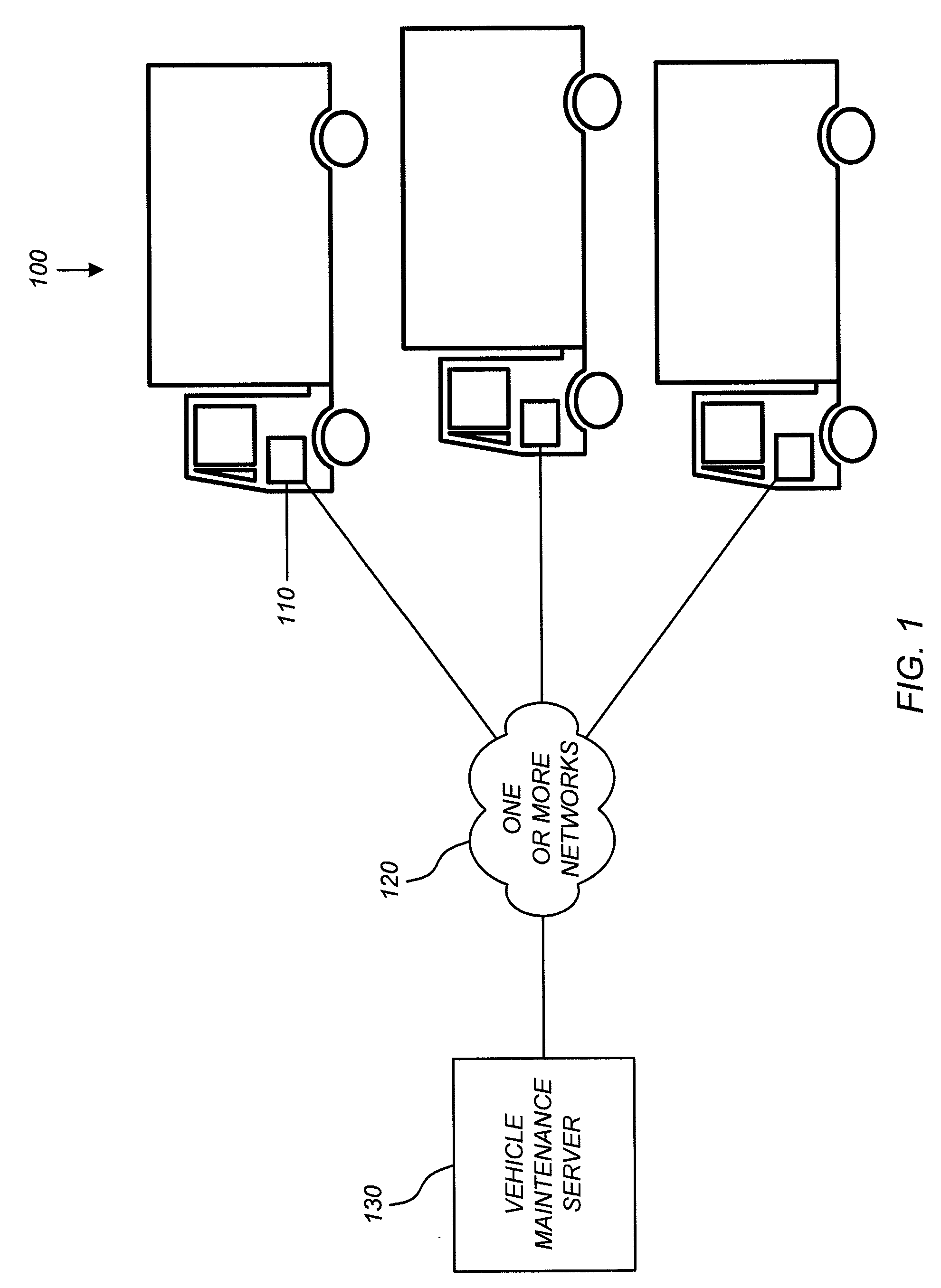

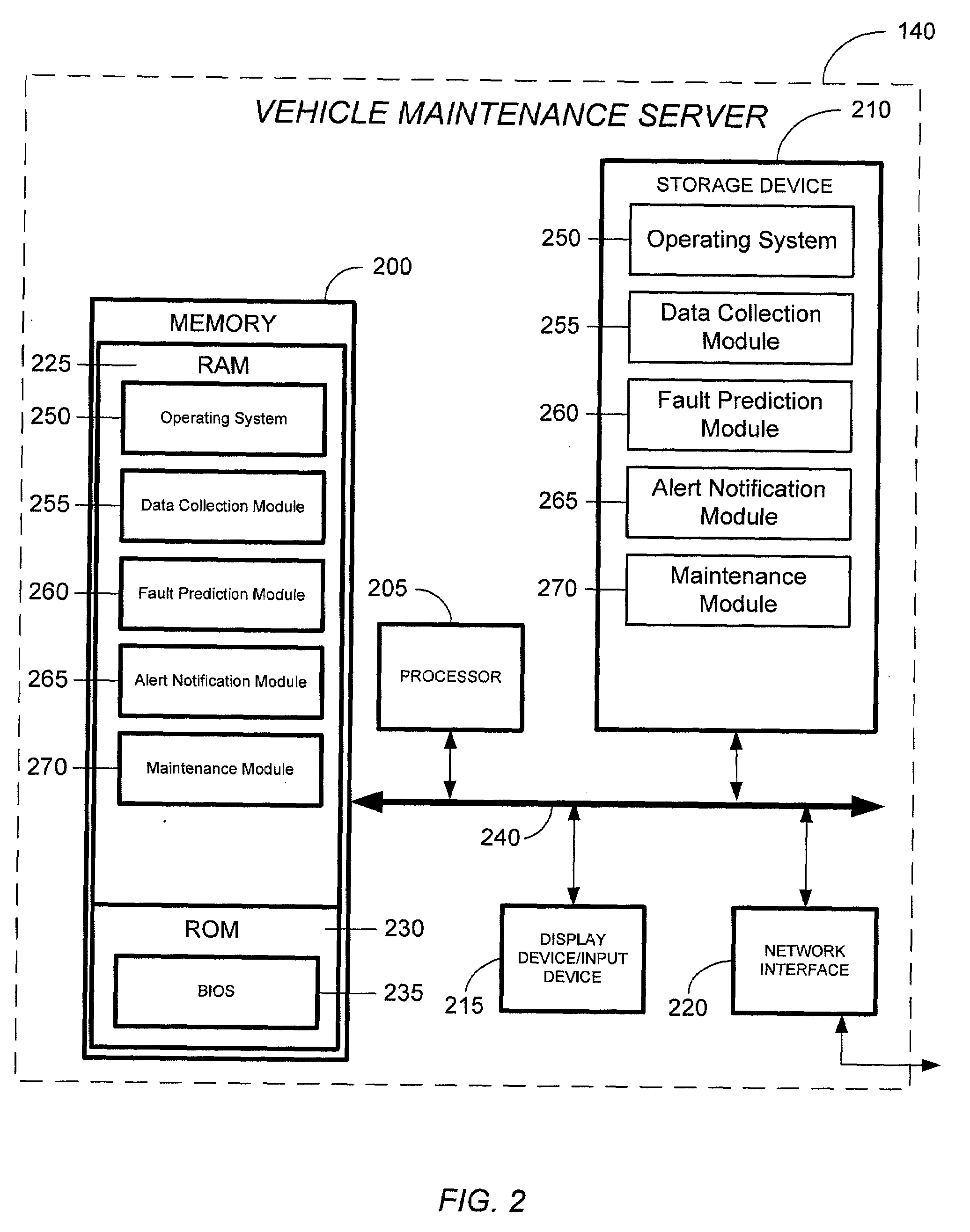

Vehicle maintenance systems and methods

ActiveUS20090254240A1Reduce in quantityImprove performanceVehicle testingRegistering/indicating working of vehiclesDriver/operatorIn vehicle

A system that enables a fleet of vehicles to be maintained is provided. The disclosed system allows a fleet operator to review the history of the vehicles in the fleet along with vehicle sensor data to identify earmarks in the vehicle sensor data that are predictive of faults that the vehicles have experienced. The operator develops statistical algorithms that can detect an earmark in vehicle sensor data. The system then collects vehicle sensor data and applies the statistical algorithms the vehicle data to determine if a potential fault is going to occur in a vehicle. In response to determining that a potential fault is going to occur, the disclosed system automatically alerts the vehicle driver, automatically schedule a maintenance visit, automatically check the fleet inventory for components required for a maintenance visit and order unavailable components, and automatically dispatch the components to the mechanic.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

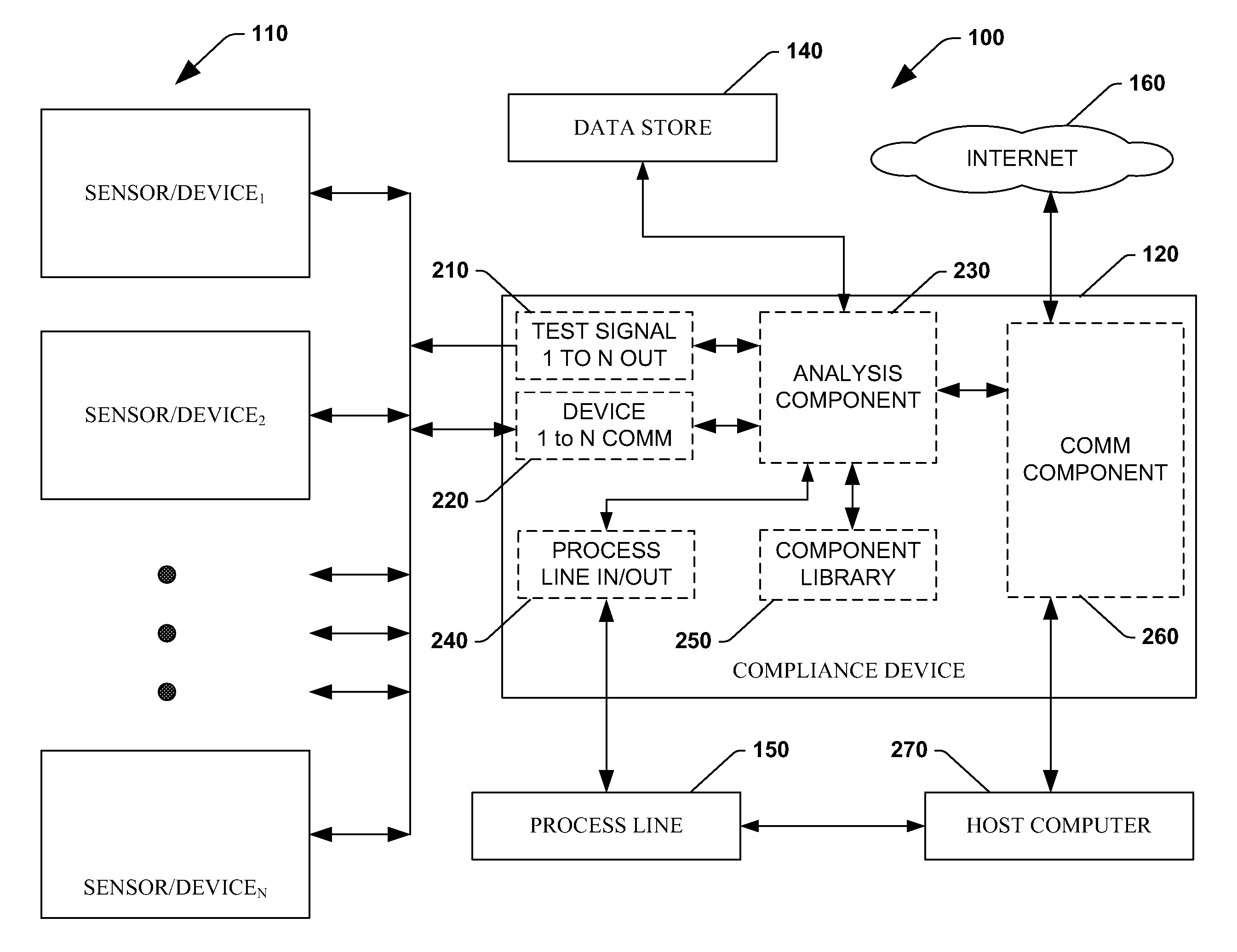

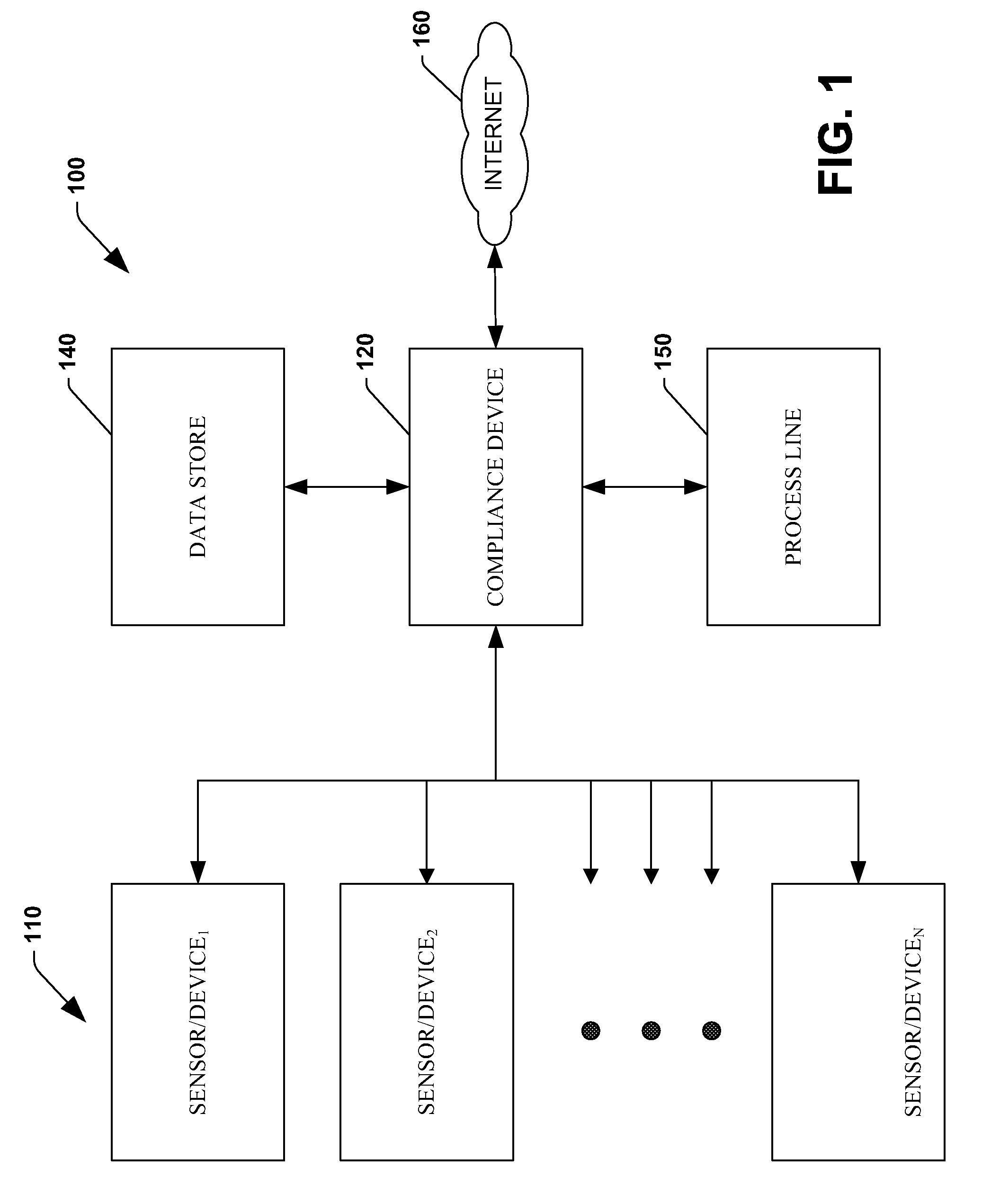

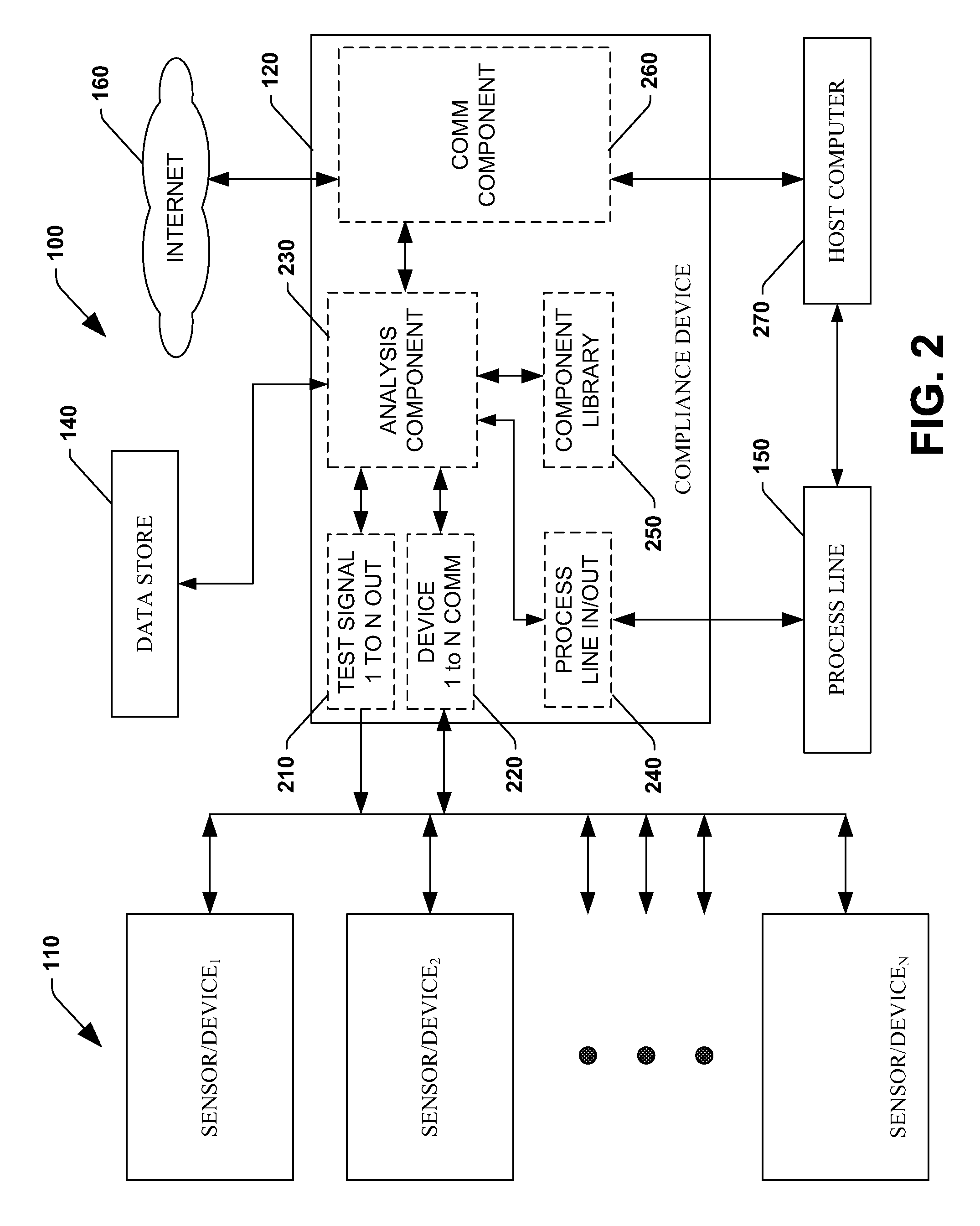

Self sensing component interface system

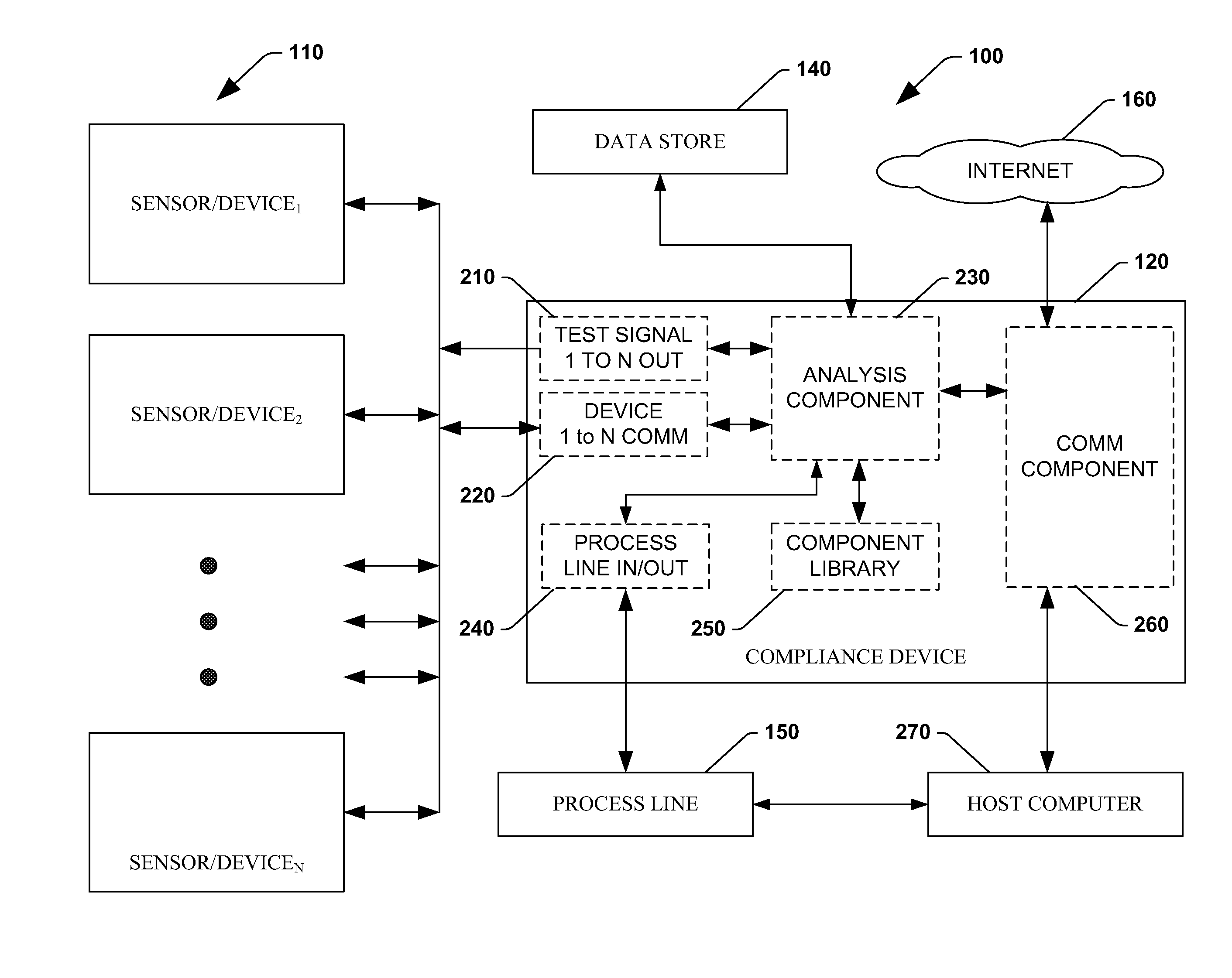

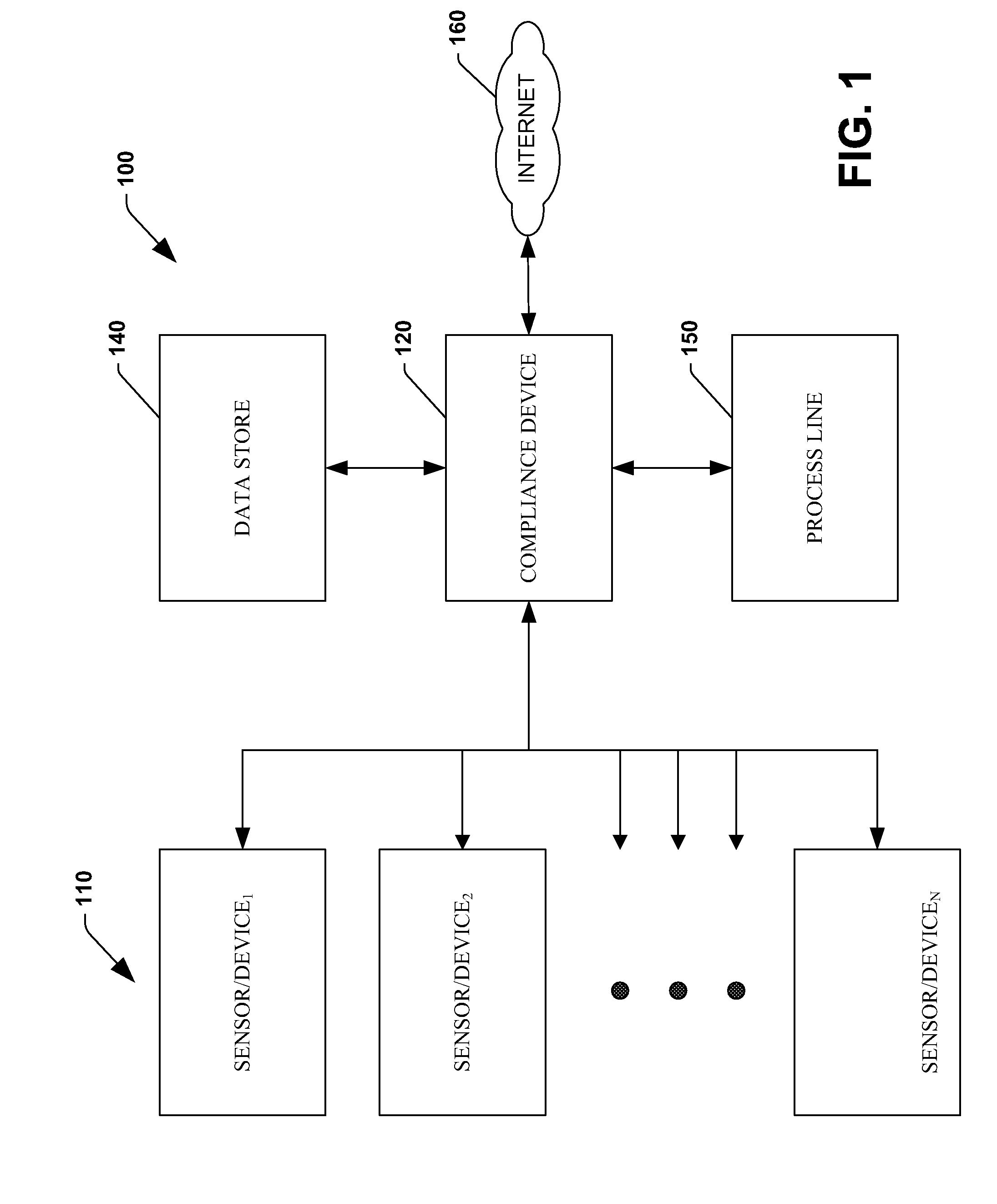

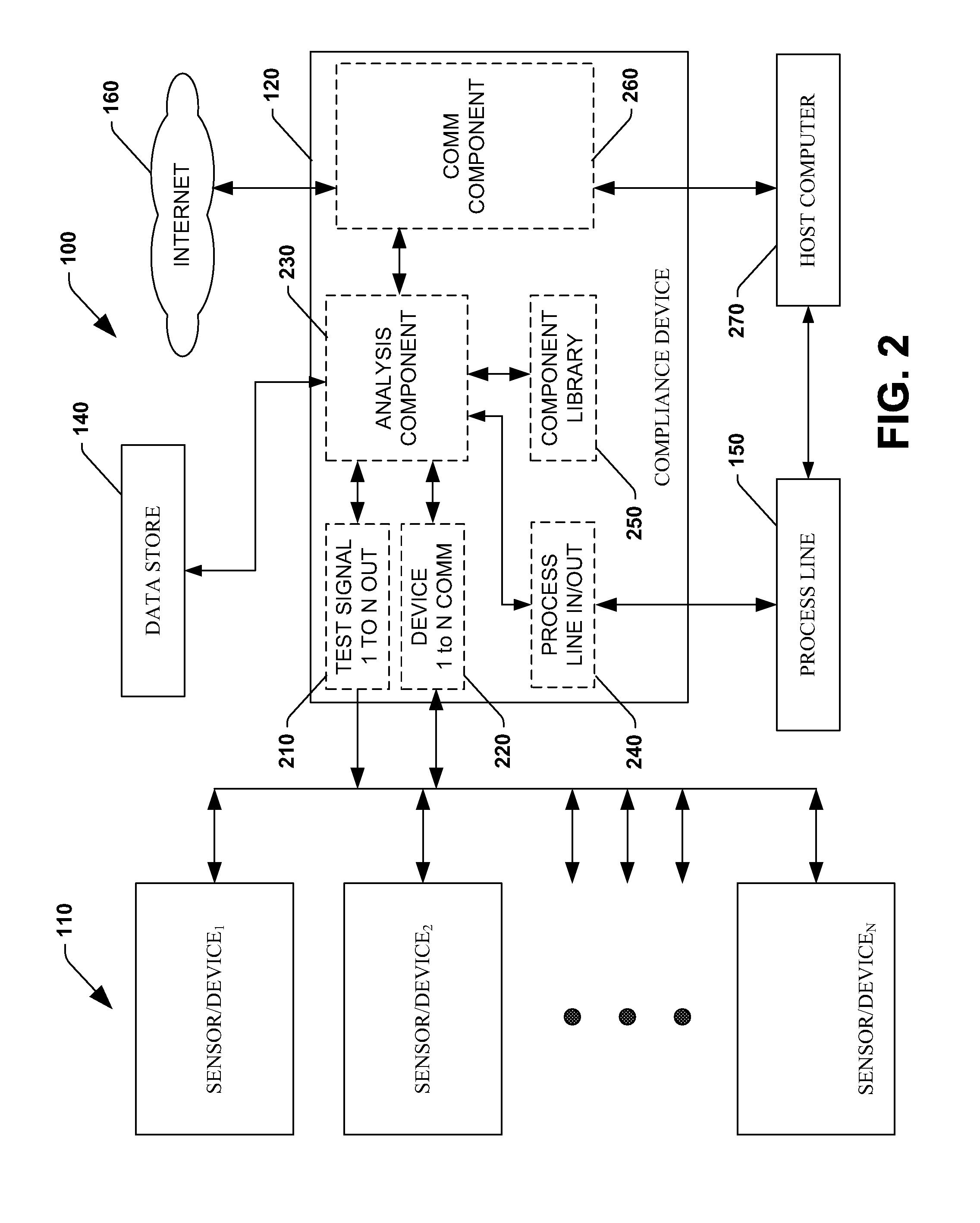

ActiveUS20090204232A1Easy to handleLow costDigital data processing detailsTechnology managementLogistics managementControl system

The subject innovation provides for systems and methods to optimize control systems for networked industrial sensors or devices and methods for self sensing, communicating with, monitoring of, controlling and optimizing utilization of networked industrial sensors and related control systems primarily in an industrial automation environment. The invention provides self-sensing and communication with sensors, and integration of control methods and strategies with decision support and logistics systems, to optimize specifically defined operational and performance objectives.

Owner:ROCKWELL AUTOMATION TECH

Process plant monitoring based on multivariate statistical analysis and on-line process simulation

ActiveUS20070005266A1Electric testing/monitoringTechnology managementMultivariate statisticalProcess measurement

Disclosed are systems and methods for on-line monitoring of operation of a process in connection with process measurements indicative of the operation of the process. In some cases, the operation of the process is simulated to generate model data indicative of a simulated representation of the operation of the process and based on the process measurements. A multivariate statistical analysis of the operation of the process is implemented based on the model data and the process measurements. The output data from the multivariate statistical analysis may then be evaluated during the operation of the process to enable the on-line monitoring of the process involving, for instance, fault detection via classification analysis of the output data.

Owner:FISHER-ROSEMOUNT SYST INC

Markup language-based, dynamic process graphics in a process plant user interface

A user interface system for a process plant includes a graphic display editor to configure a process graphic display having a graphic display element representative of a process plant element of the process plant. The process graphic display is specified via configuration information set forth in a declarative language. A graphics rendering engine generates a depiction of the process graphic display during runtime based on commands derived from the configuration information set forth in the declarative language. The configuration information for the process graphic display may be stored as an object, which, for instance, may include first and second portions to define a graphical parameter and identify a data source, respectively. The graphical parameter may be directed to defining a graphical depiction of the process plant element and, to this end, may be set forth in a formal in accordance with the declarative language. The data source may specify a location or path for data indicative of on-line operation of the process plant element to be displayed via the graphical depiction.

Owner:FISHER-ROSEMOUNT SYST INC

Self sensing component interface system

ActiveUS8571904B2Compliance of a sensor or device can be more easily assessedEasy to handleComputer controlSimulator controlLogistics managementControl system

The subject innovation provides for systems and methods to optimize control systems for networked industrial sensors or devices and methods for self sensing, communicating with, monitoring of, controlling and optimizing utilization of networked industrial sensors and related control systems primarily in an industrial automation environment. The invention provides self-sensing and communication with sensors, and integration of control methods and strategies with decision support and logistics systems, to optimize specifically defined operational and performance objectives.

Owner:ROCKWELL AUTOMATION TECH

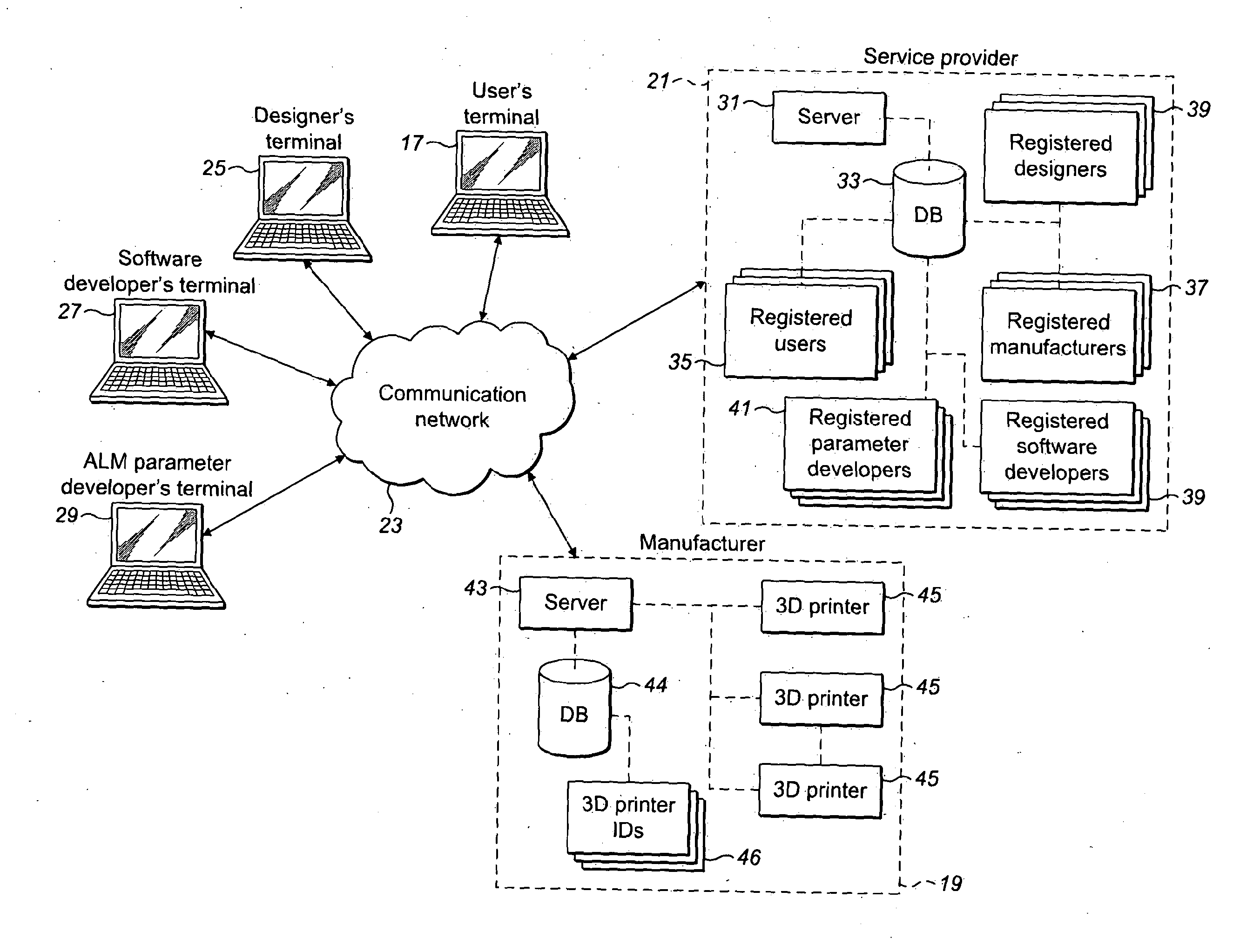

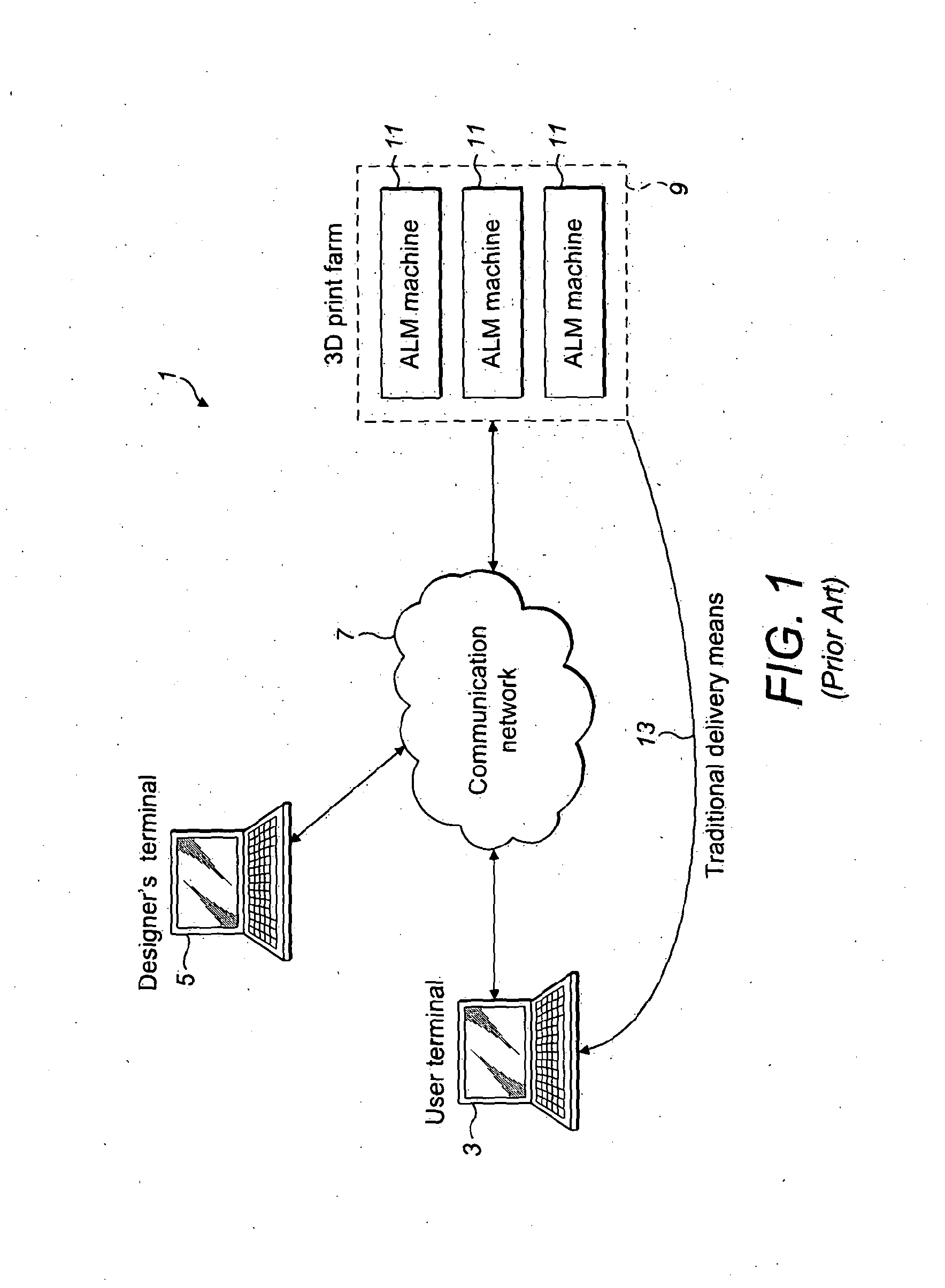

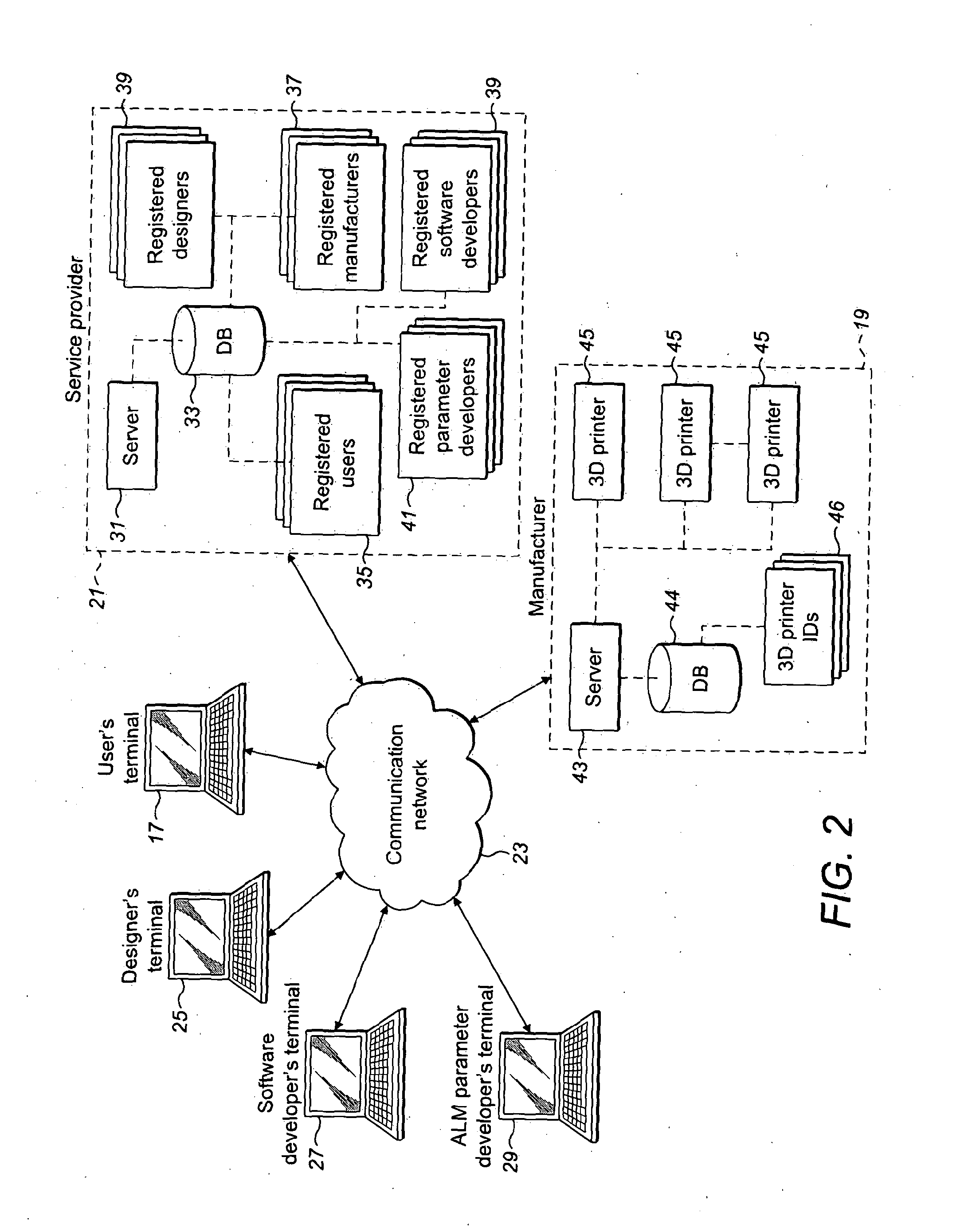

Three-dimensional design and manufacturing systems

ActiveUS20140156053A1Use directlyMinimize amount of processingAdditive manufacturing apparatusData processing applications3d print3d design

A method of authenticating the printing of a three-dimensional (3D) article at a 3D printer according to a 3D print file describing a three-dimensional design is described. The method comprises: receiving an authentication request from a 3D print server that is associated with the 3D printer, the request comprising a unique design identifier associated with a 3D design file and a unique 3D printer identifier associated with a 3D printer, the received unique 3D design identifier being related to the received 3D printer ter identifier in accordance with a first relationship; using at least one of the received unique identifiers to access a verifying 3D design identifier and a verifying 3D printer identifier, the verifying identifiers being related to each other in accordance with a second relationship; comparing the first and second relationships between the received and verifying identifiers; generating an authentication signal if the first relationship corresponds with the second relationship; obtaining a decryption key associated with the received identifiers in response to the authentication signal; and transferring the decryption key to the 3D print server to authenticate and enable the printing of the 3D article on the 3D printer.

Owner:DNA AM LTD

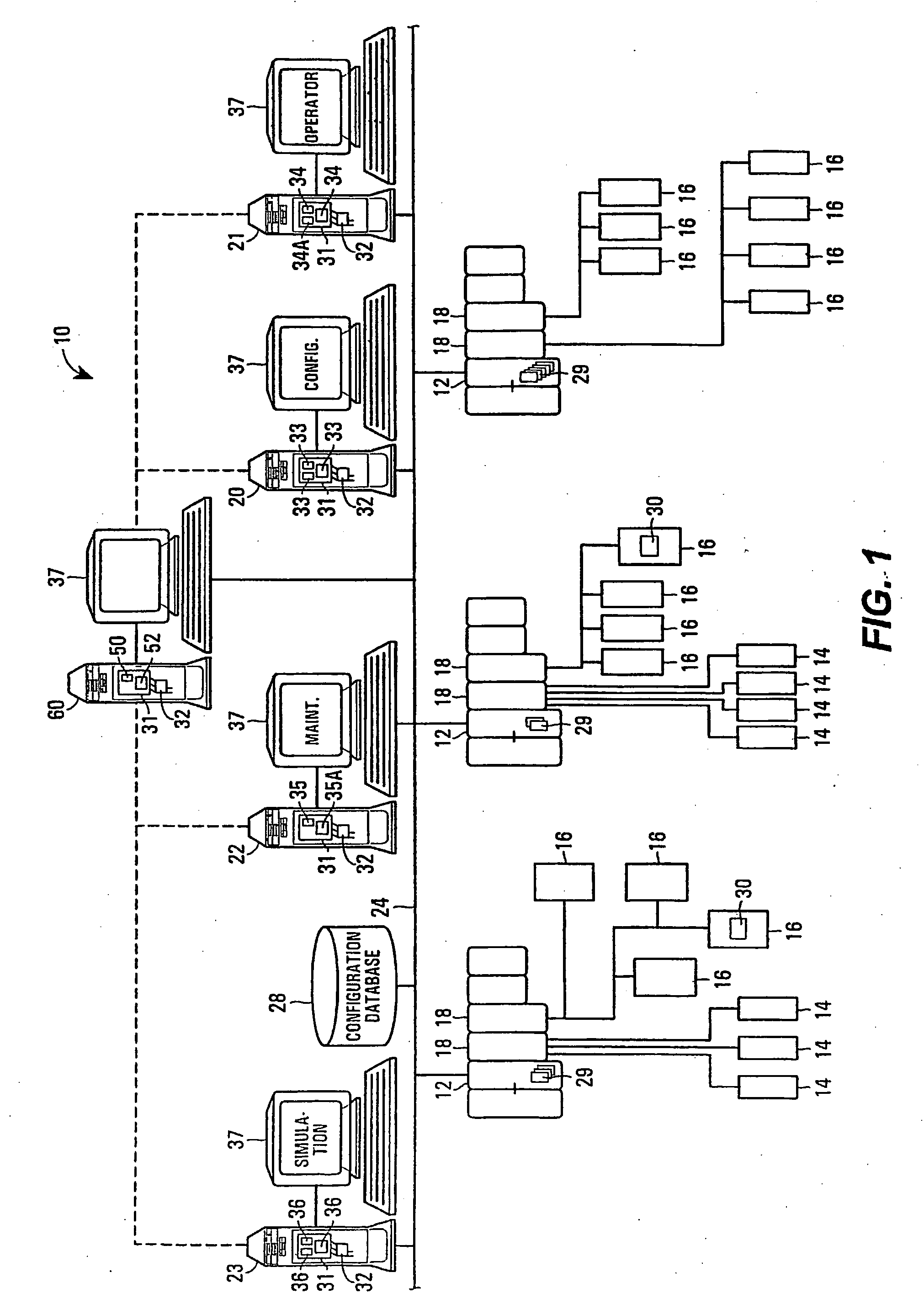

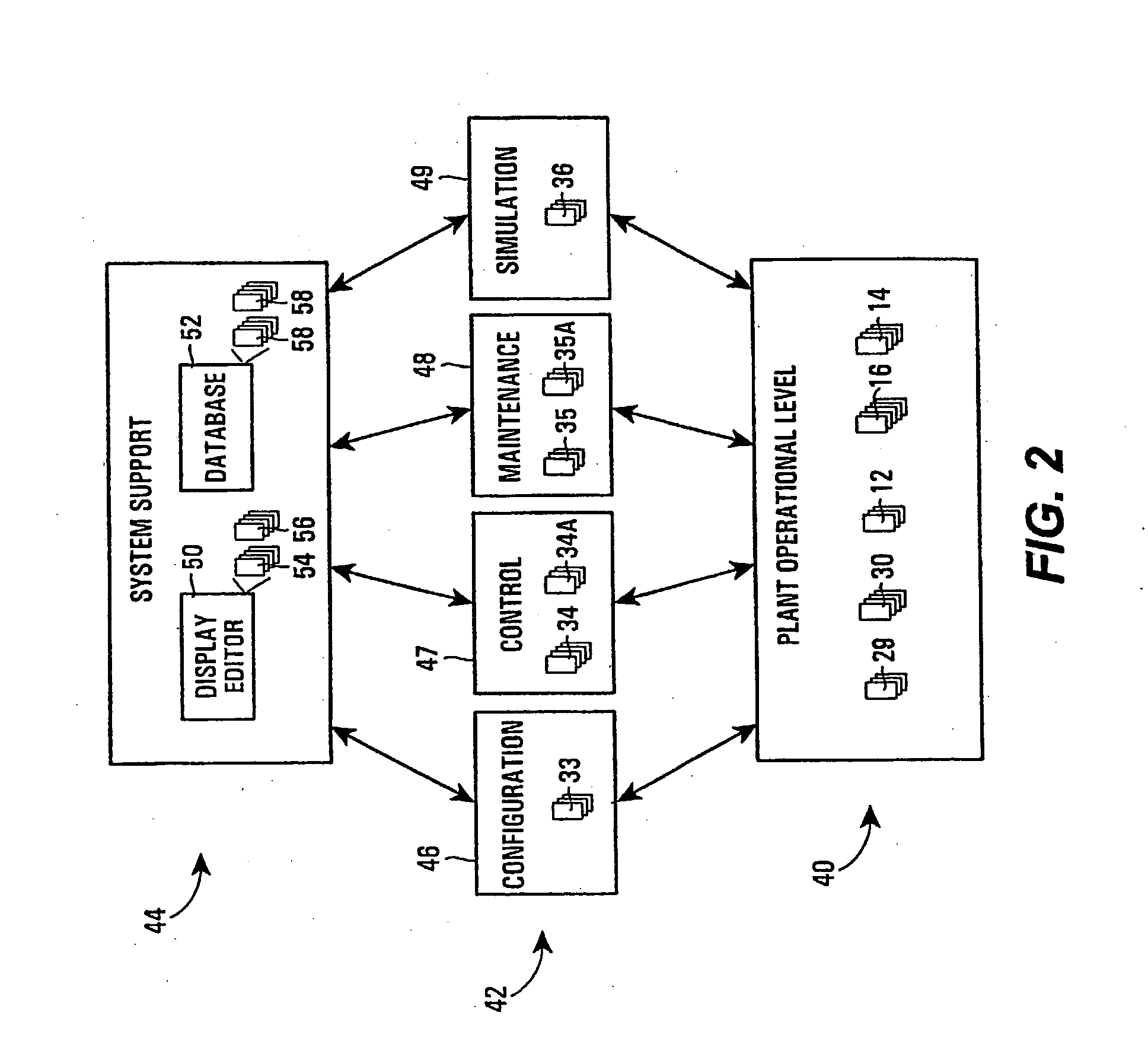

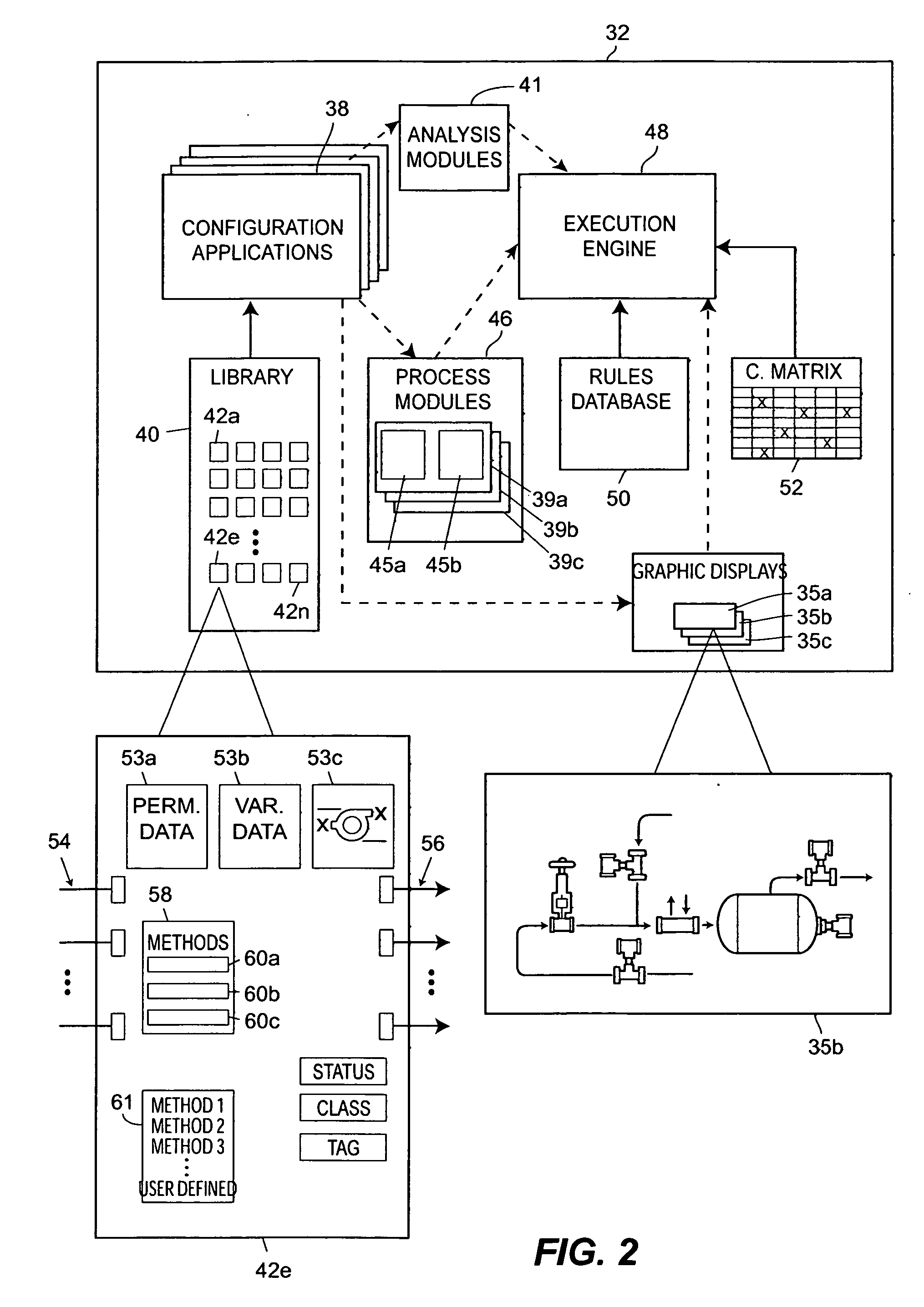

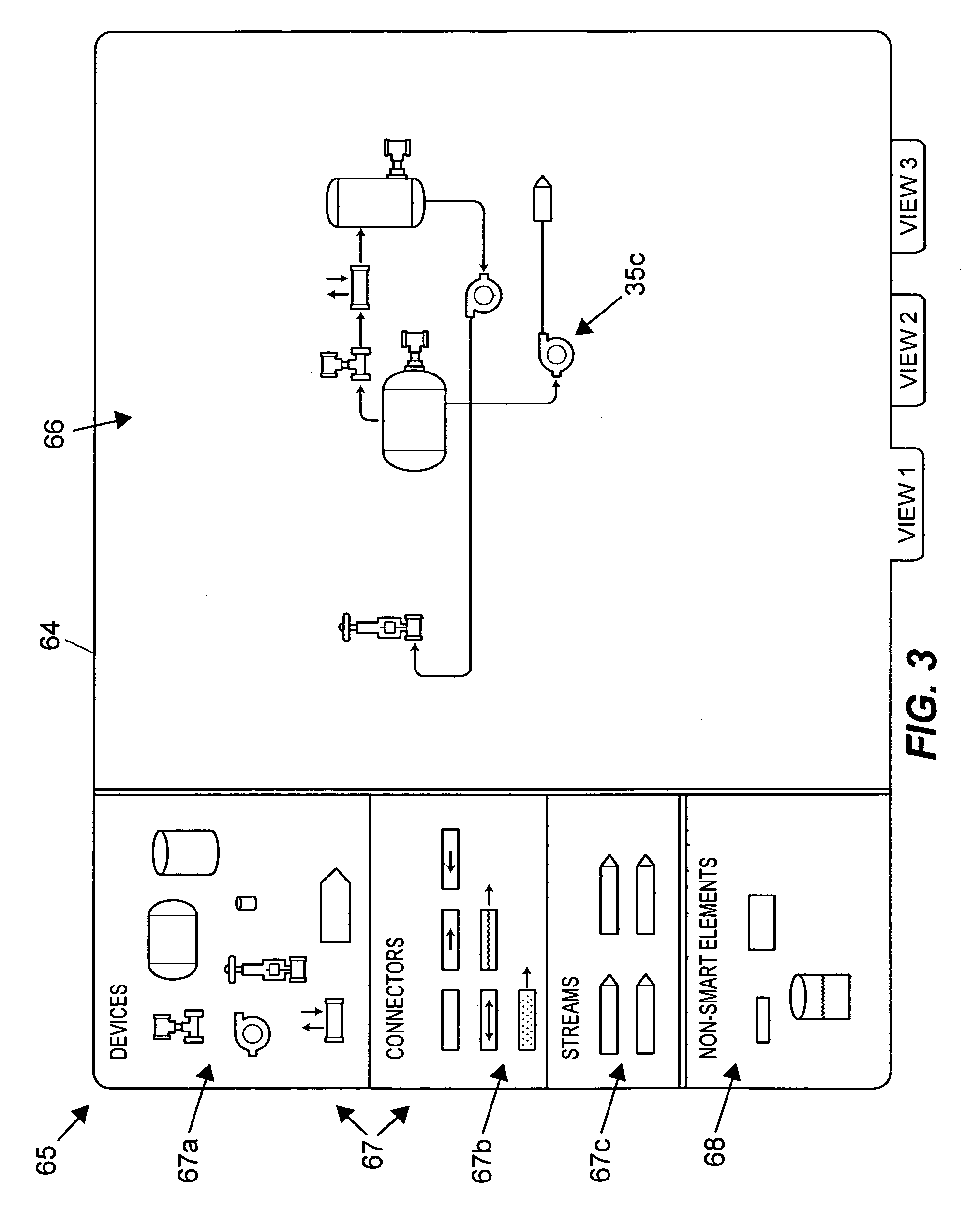

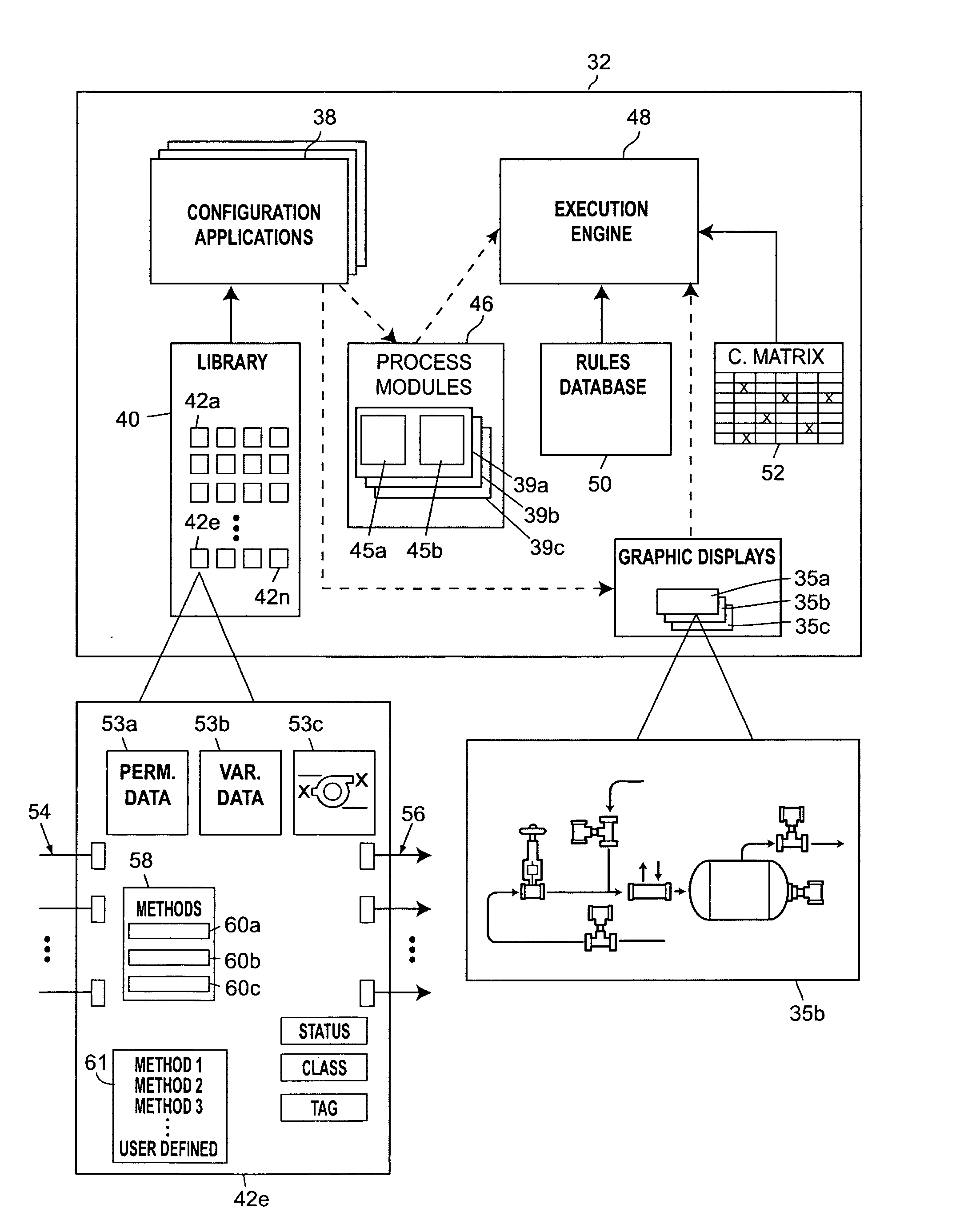

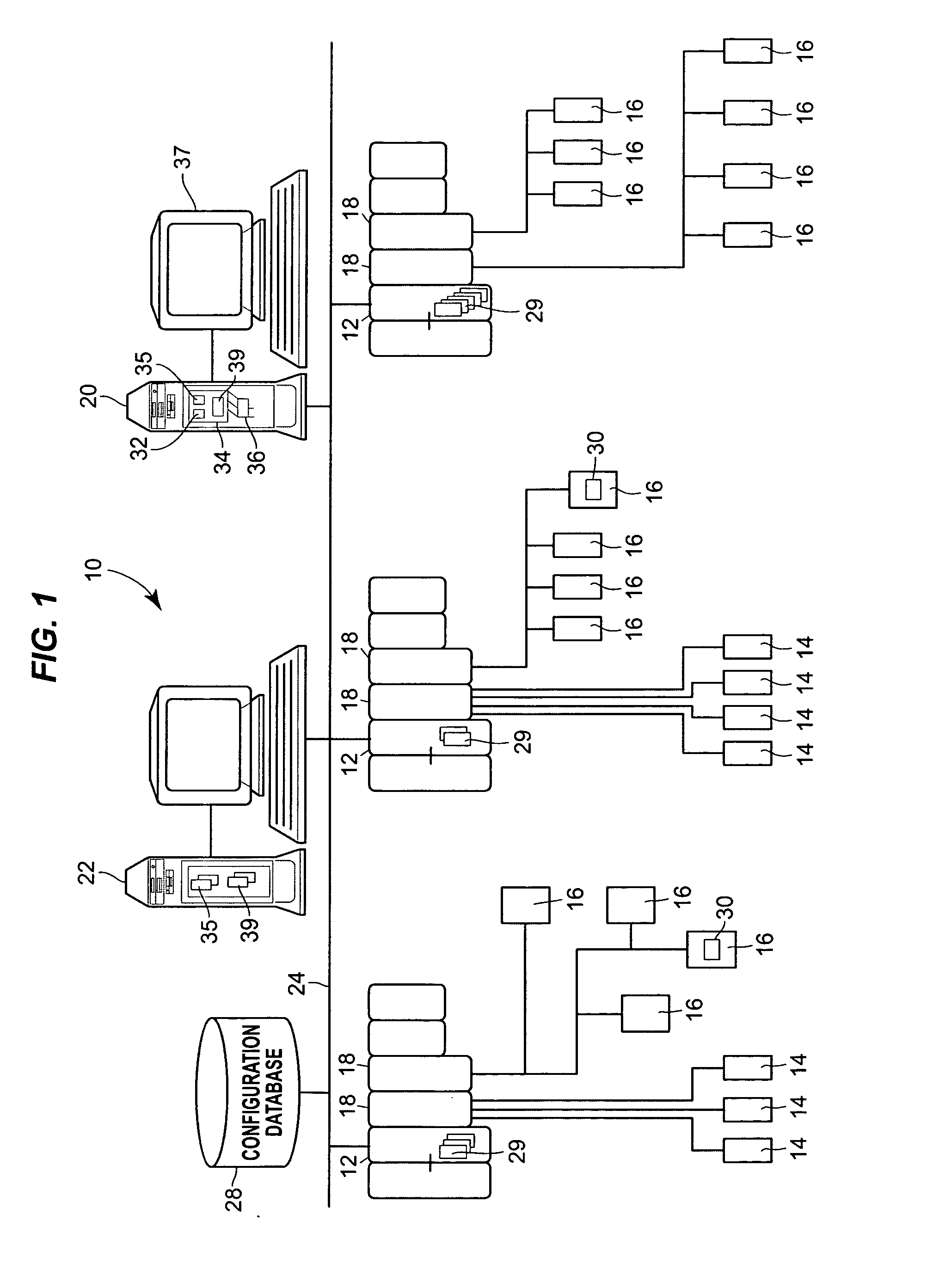

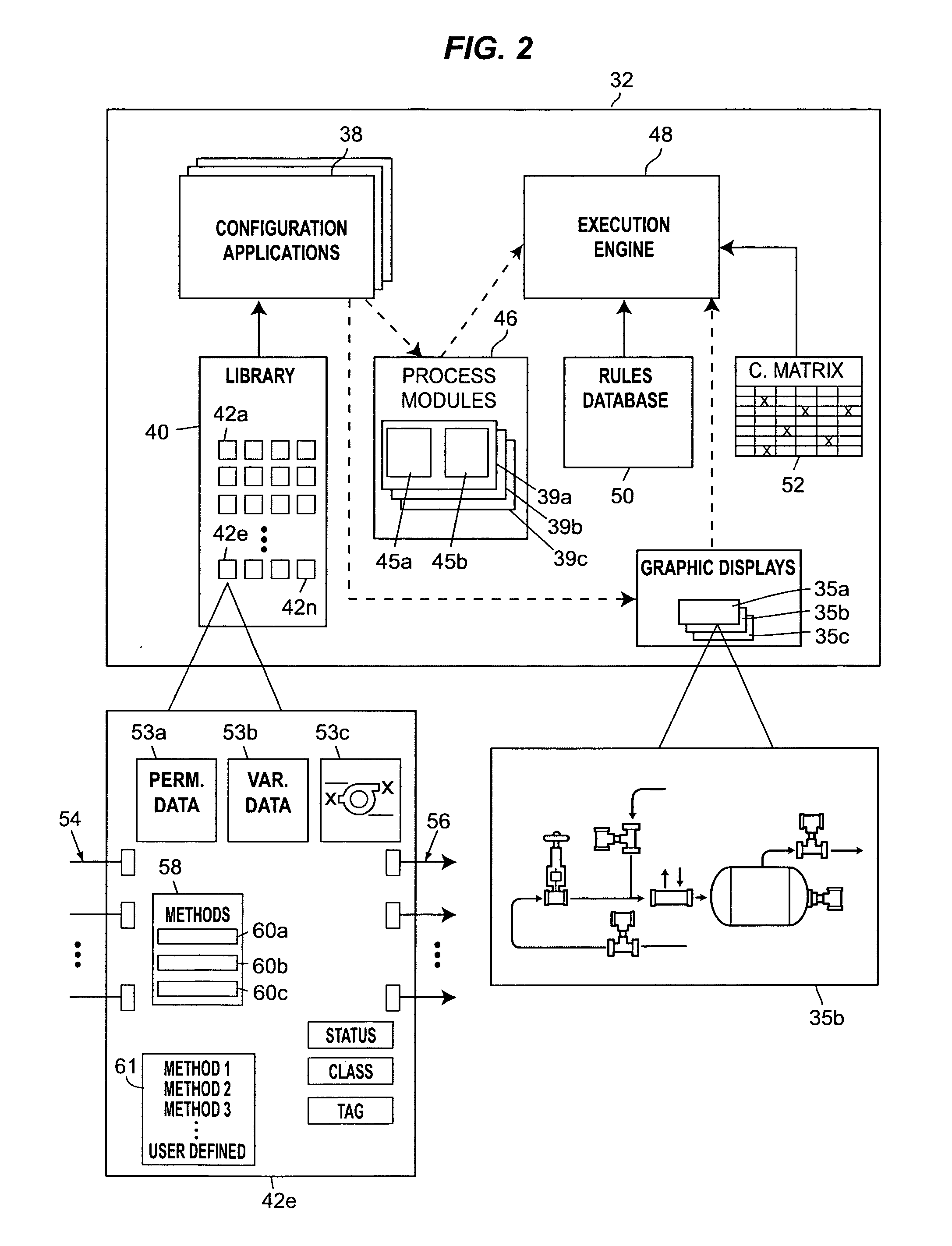

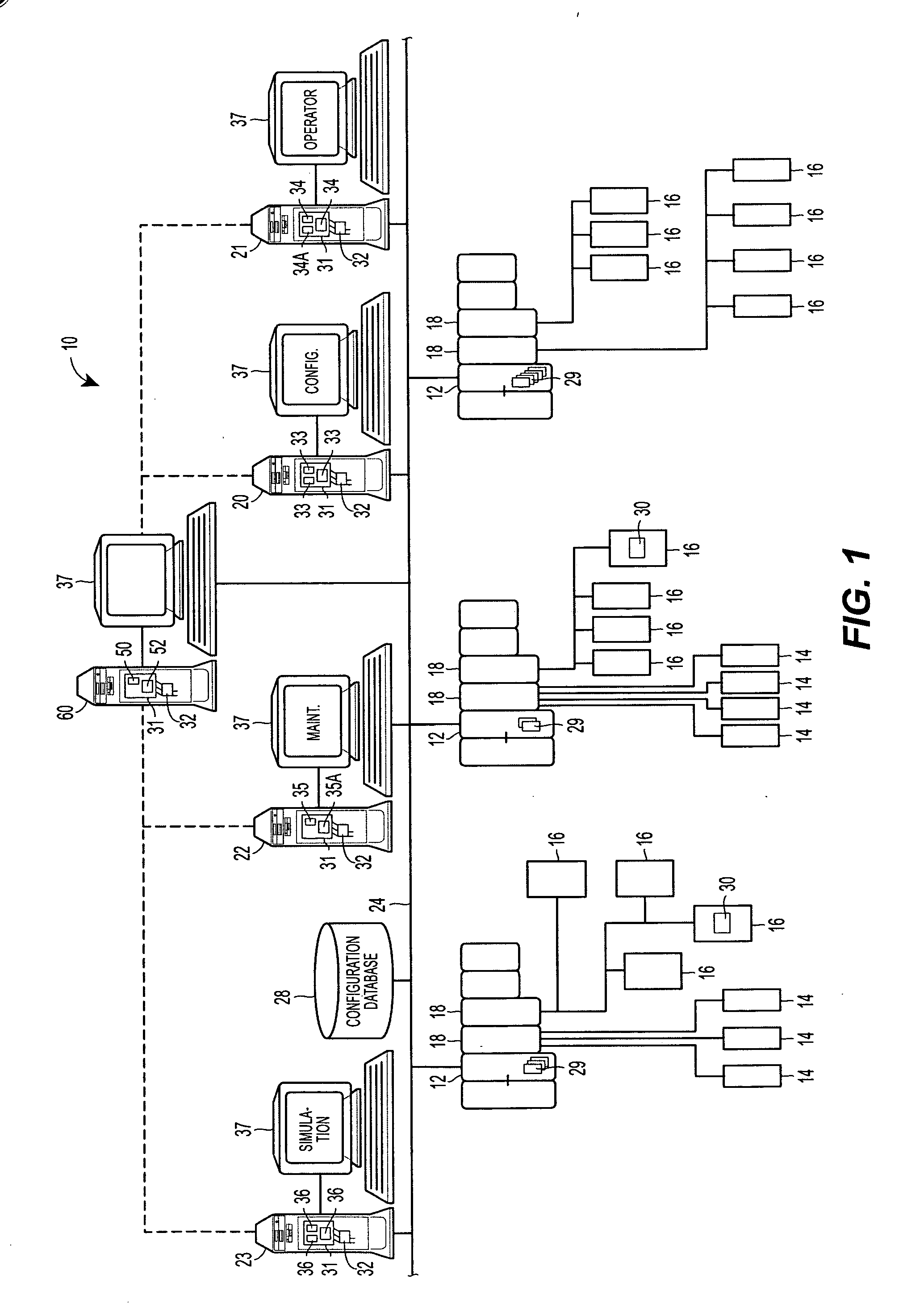

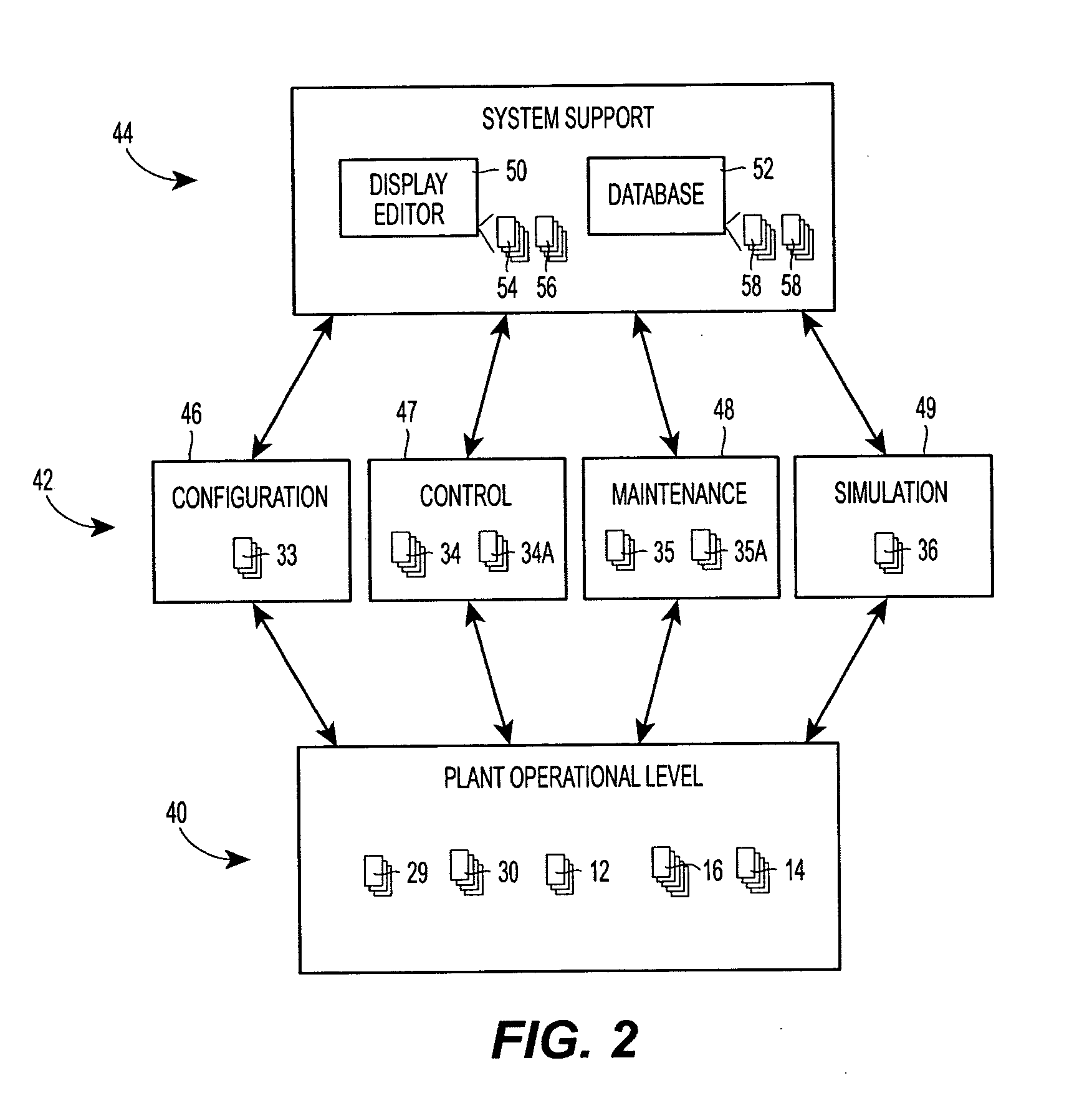

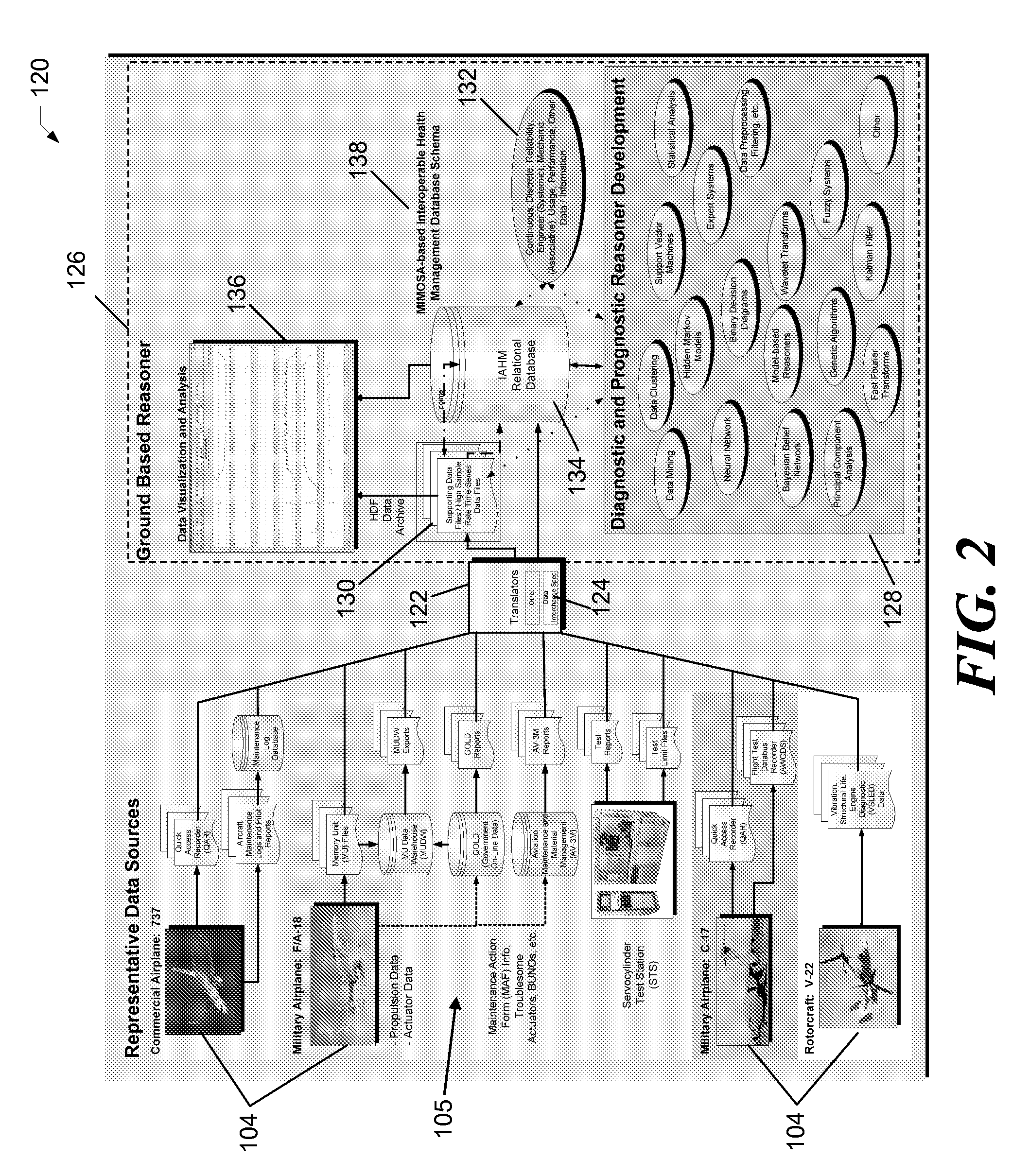

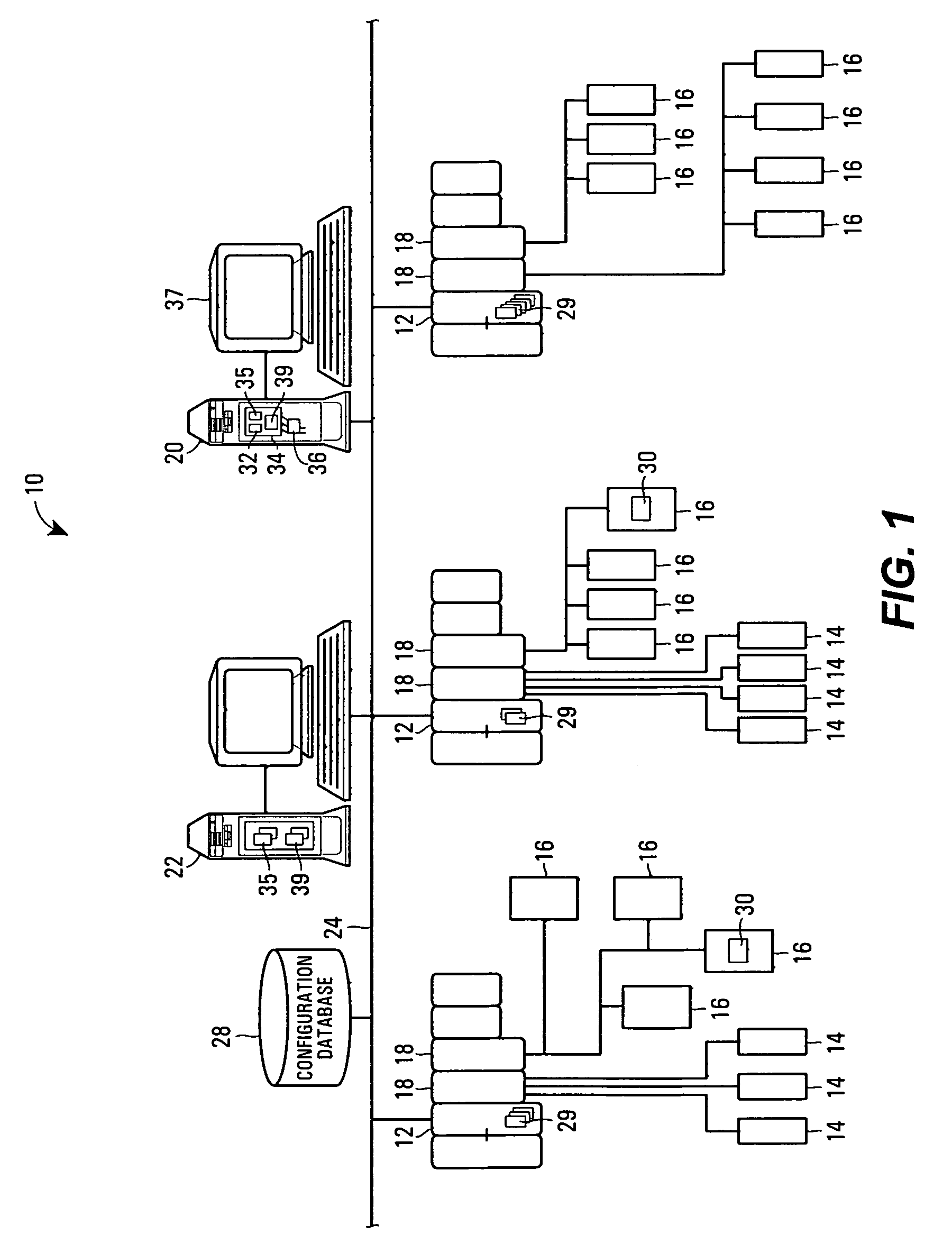

Graphics integration into a process configuration and control environment

ActiveUS20070139441A1Tedious and time-consumeGeometric CADElectric testing/monitoringGraphicsConfiguration item

Graphic elements and graphic displays are provided for use in a process environment to display information to one or more users about the process environment, such as the current state of device within a process plant. The graphic elements and display may be associated with various logical and physical elements within the process plant during configuration of the process plant, and may be configured and downloaded to the hardware within the process plant along with other configuration items, such as control routines. In particular, the graphic elements and graphic displays may be created and stored in a library, and may then be configured by being associated with various logical or physical entities within the plant. During the configuration process, the graphic elements and graphic displays may be associated with areas, equipment, process modules, control routines or control strategies of the plant as defined elsewhere in the plant configuration, or may be associated with interfaces or display devices, to define the hardware on which the graphic displays will execute during runtime, as well as to define the process entities to which these displays will be bound for display purposes. Still further, each of the graphic displays may be defined with a role or a functional use, such as an operator view, a maintenance view, etc., and these roles may be used to defined the proper access and use of the graphic displays within the runtime environment.

Owner:FISHER-ROSEMOUNT SYST INC

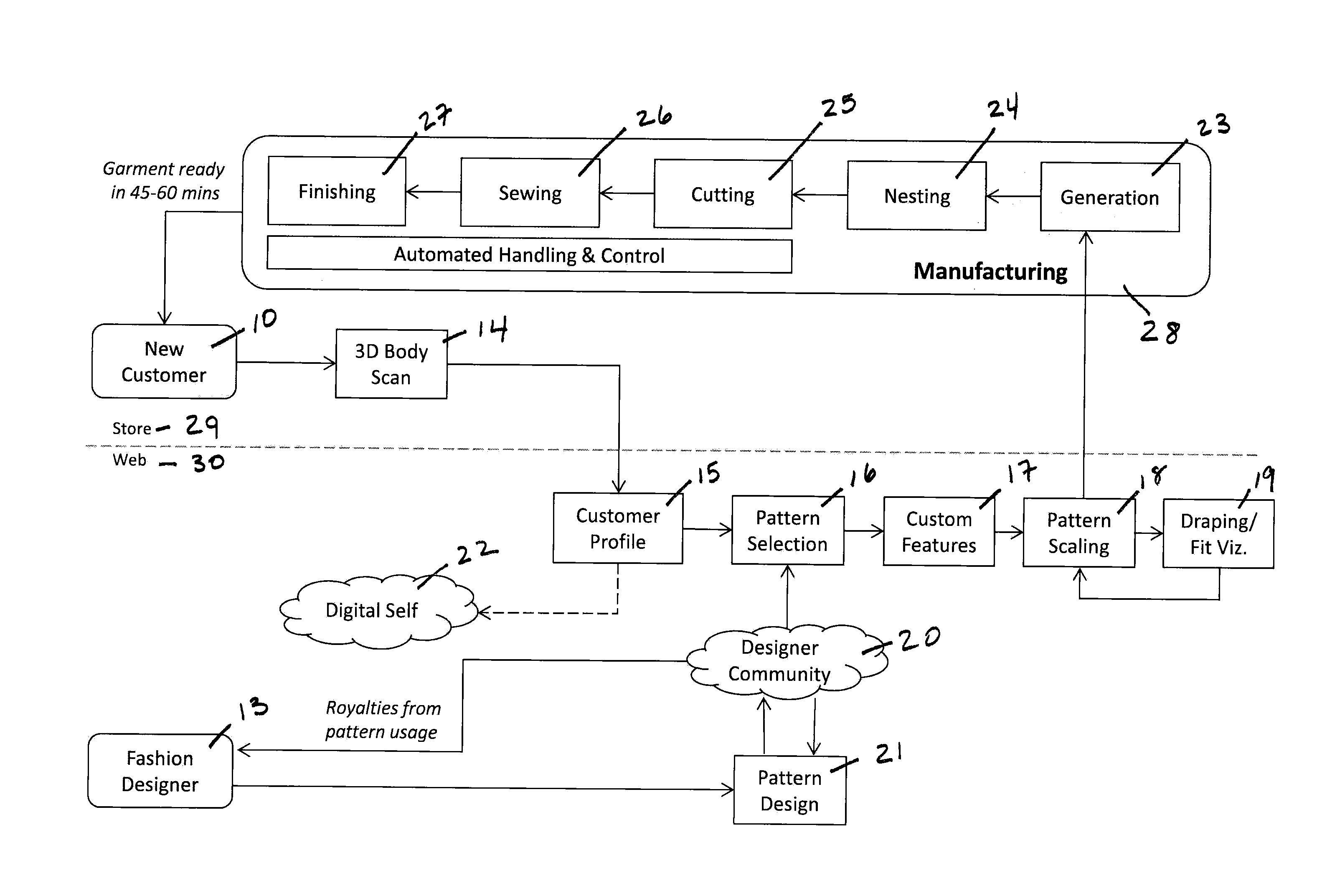

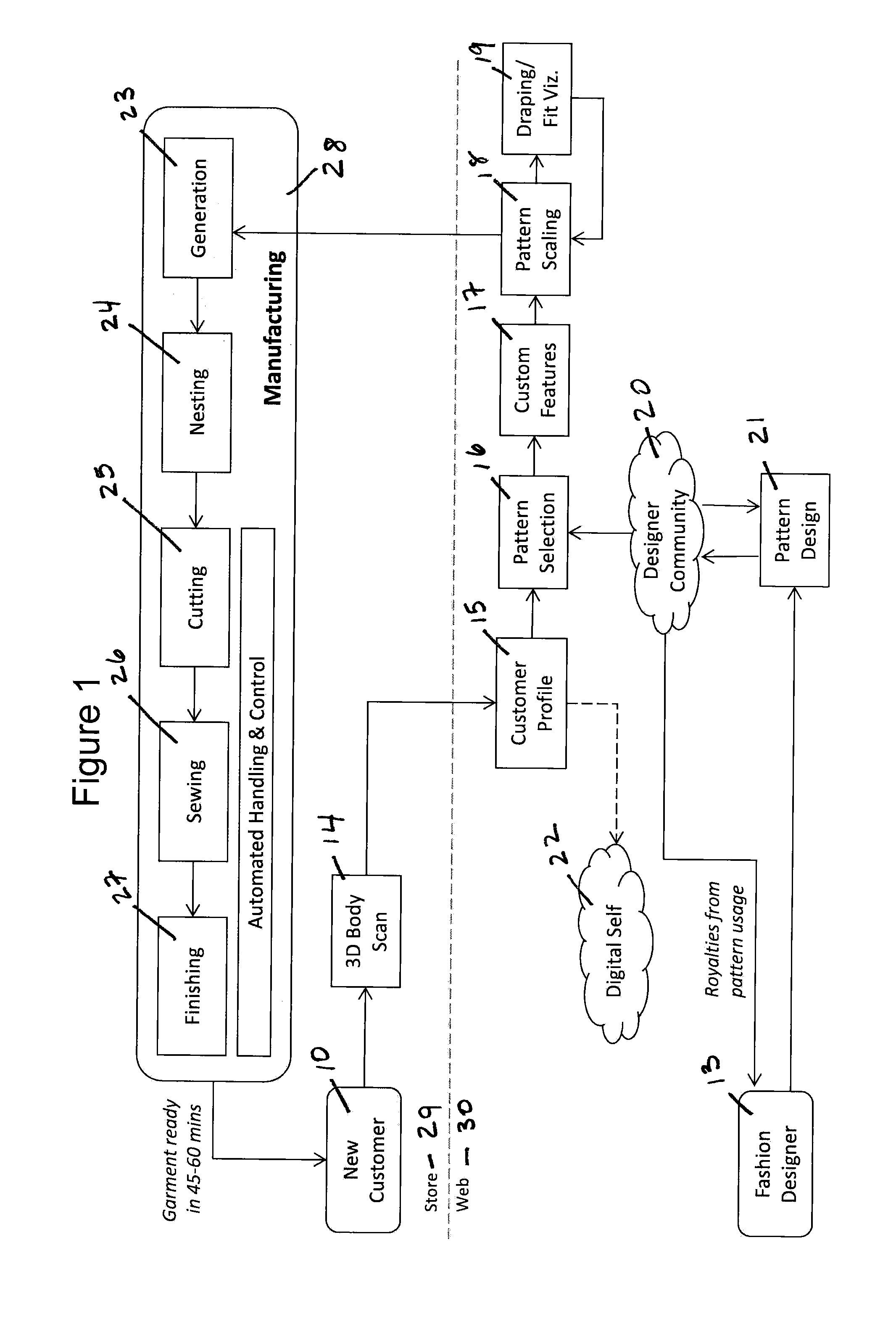

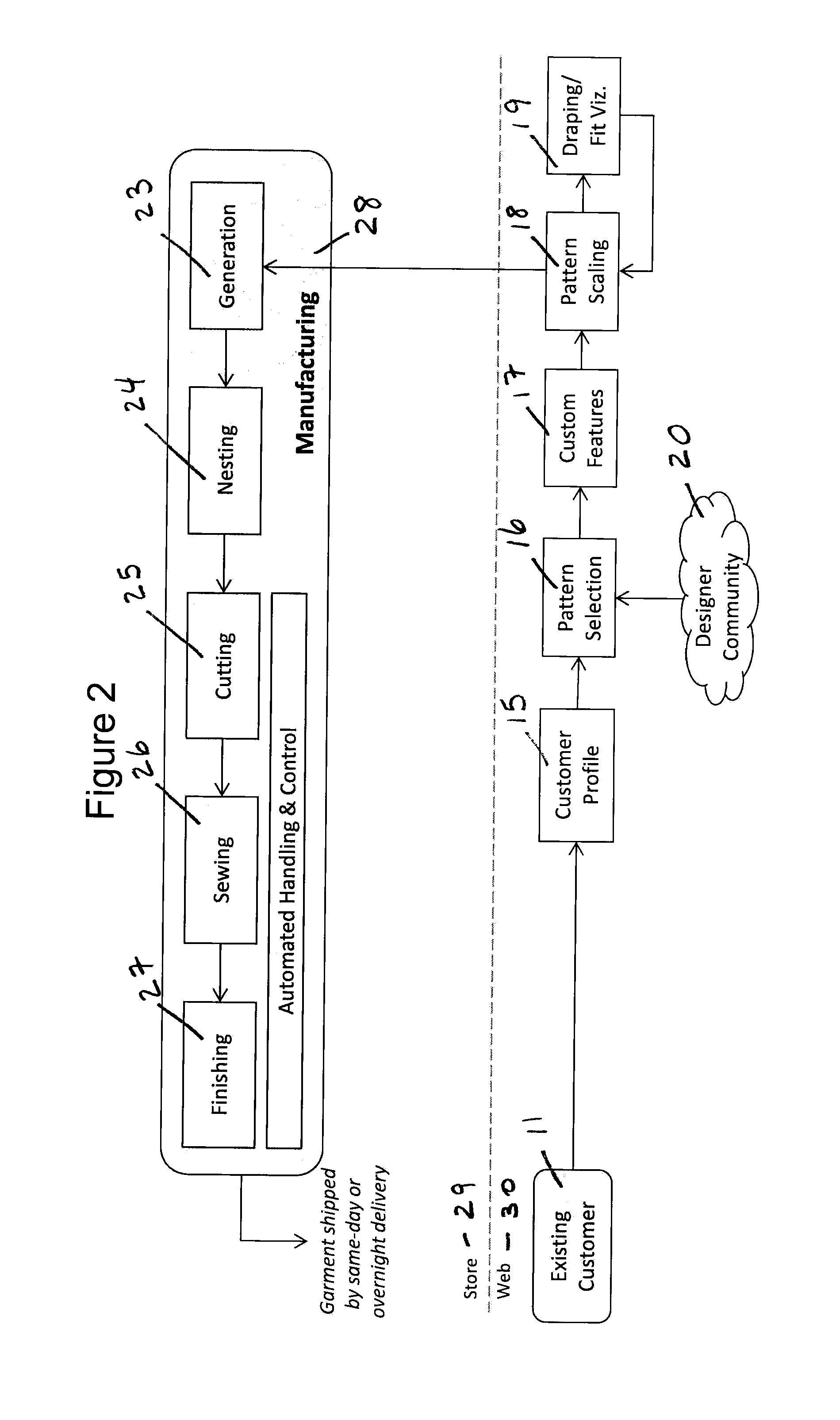

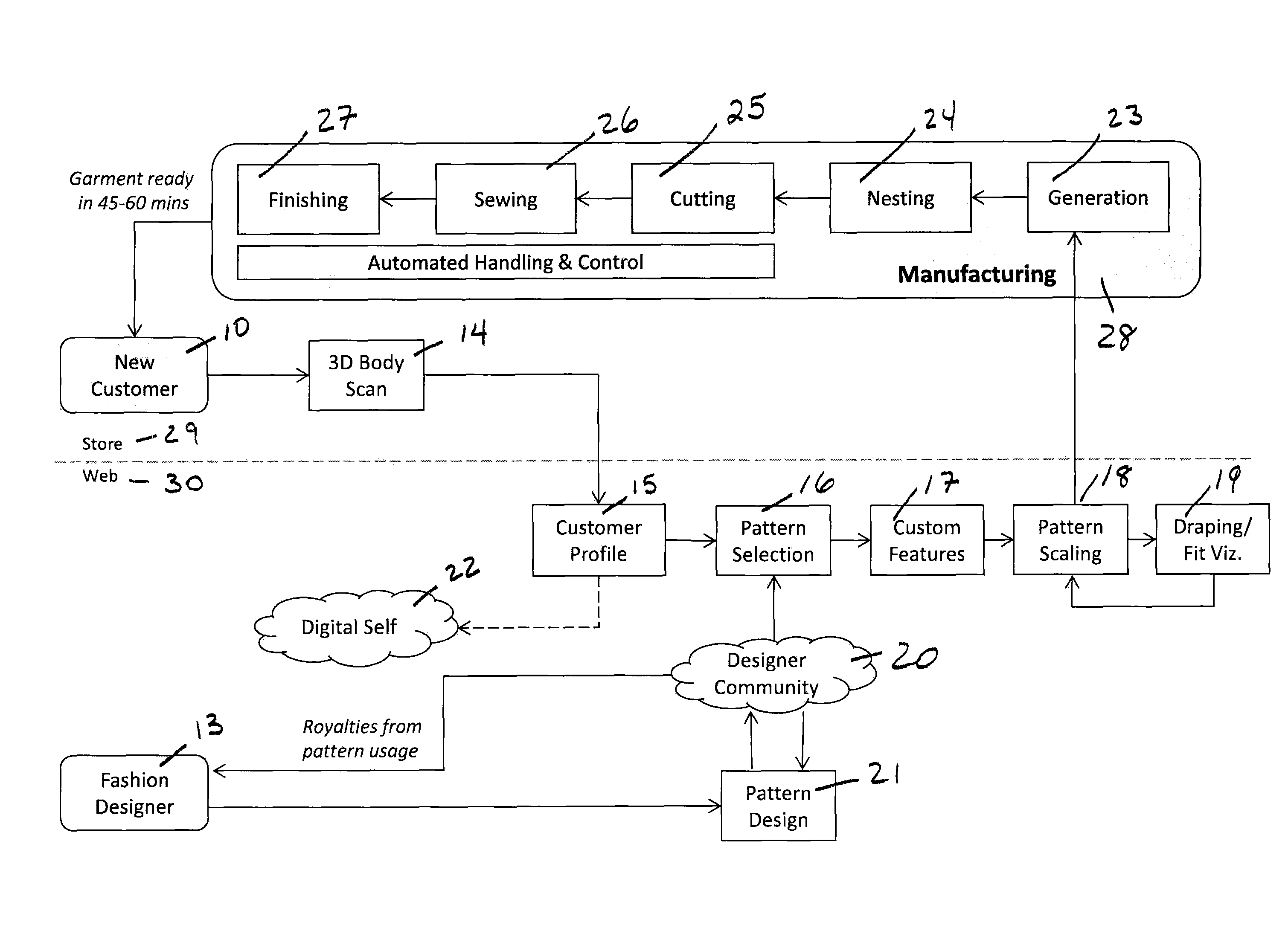

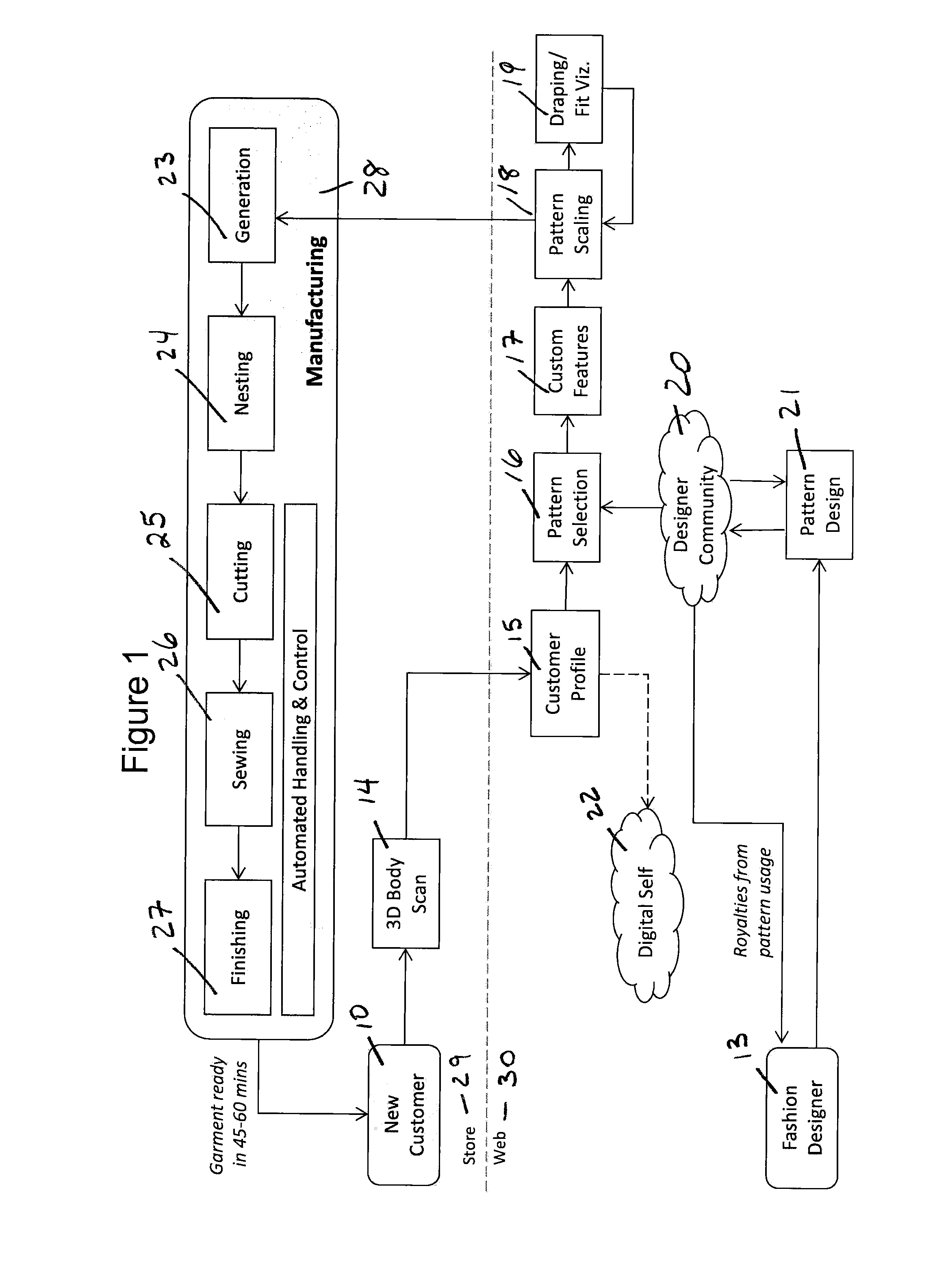

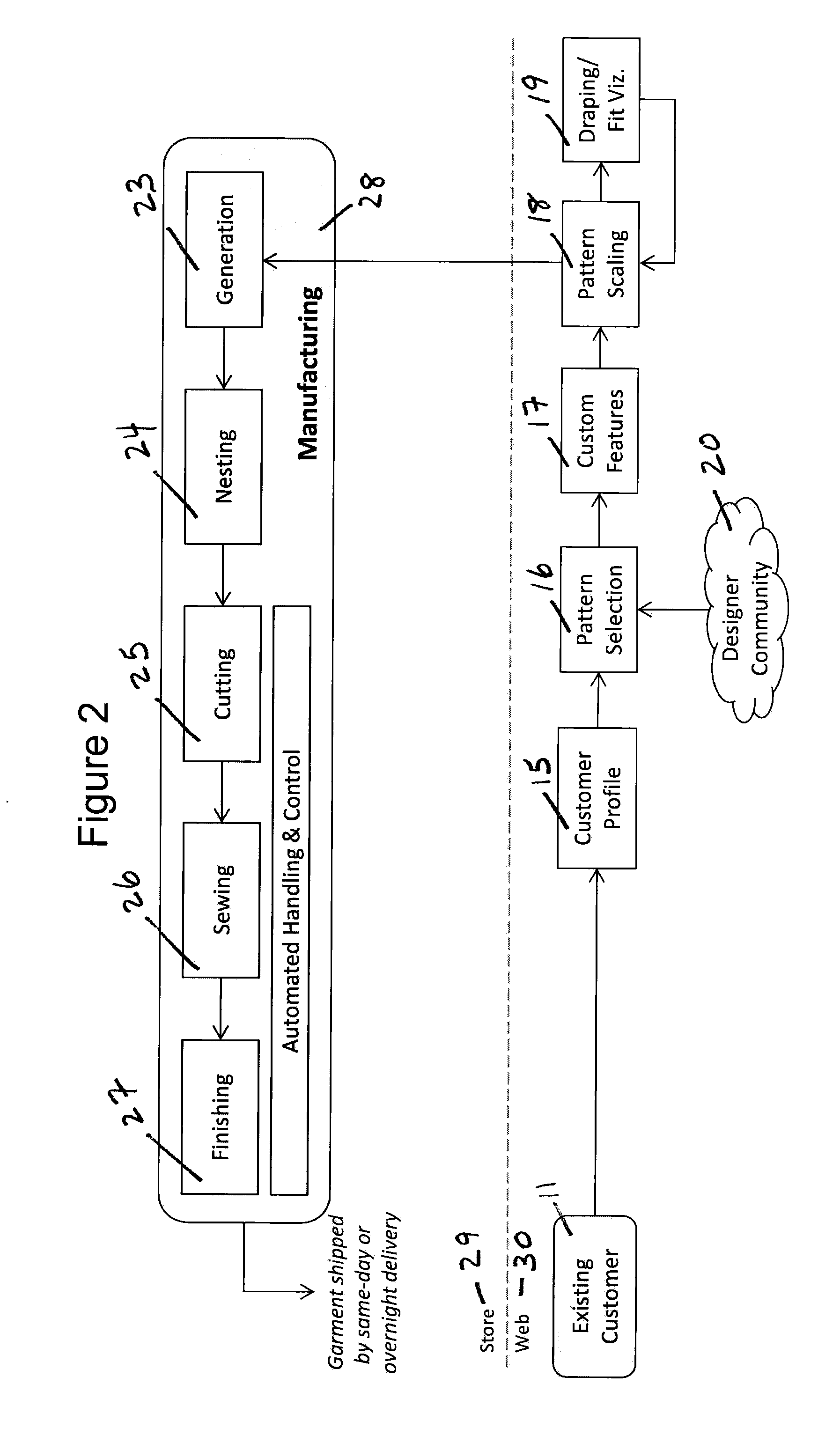

System and Method for Creating Custom-Fit Apparel Designs

InactiveUS20140277663A1Rapid visualizationShort amount of timeCommerceComputer aided designBody shapePersonalization

An automated system for the production of a personalized custom-fit garment comprises a scanner for obtaining a three-dimensional model of a customer's body shape; a computer having non-transitory computer algorithms for scaling a digital design to the customer's body shape, customizing the digital pattern with the customer's fit and style preferences, and visualizing the drape and fit of the garment; a database comprising a set of digital design patterns; and an automated garment manufacturing system networked to a central controller. A method for creating a personalized custom-fit garment comprises obtaining three-dimensional body measurements of a customer, having the customer select and customize a particular garment design, and manufacturing the personalized garment using an automated manufacturing process. The system and method can be used to prepare any kind of garments without substantive manual intervention or touch labor.

Owner:3D TECH LLC

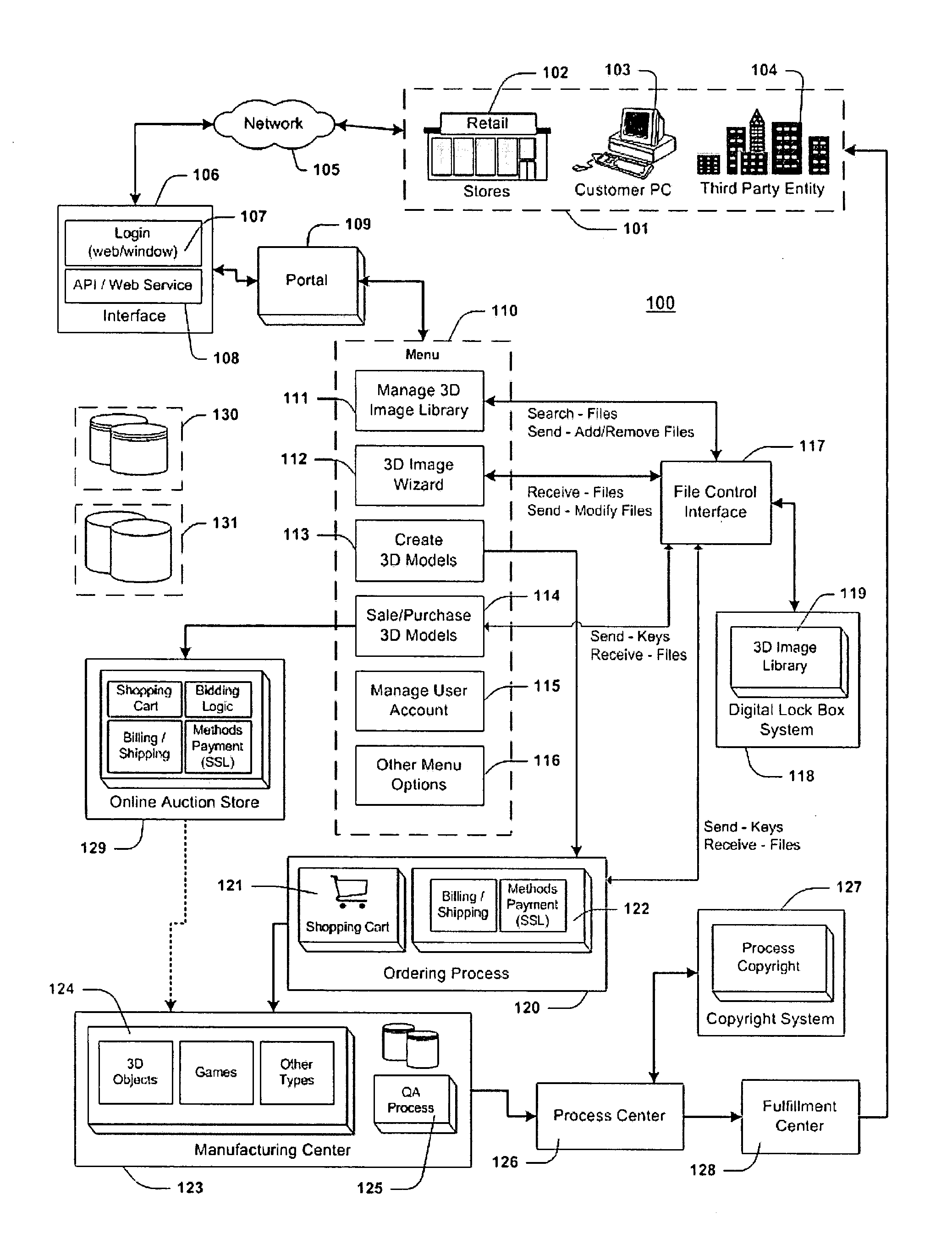

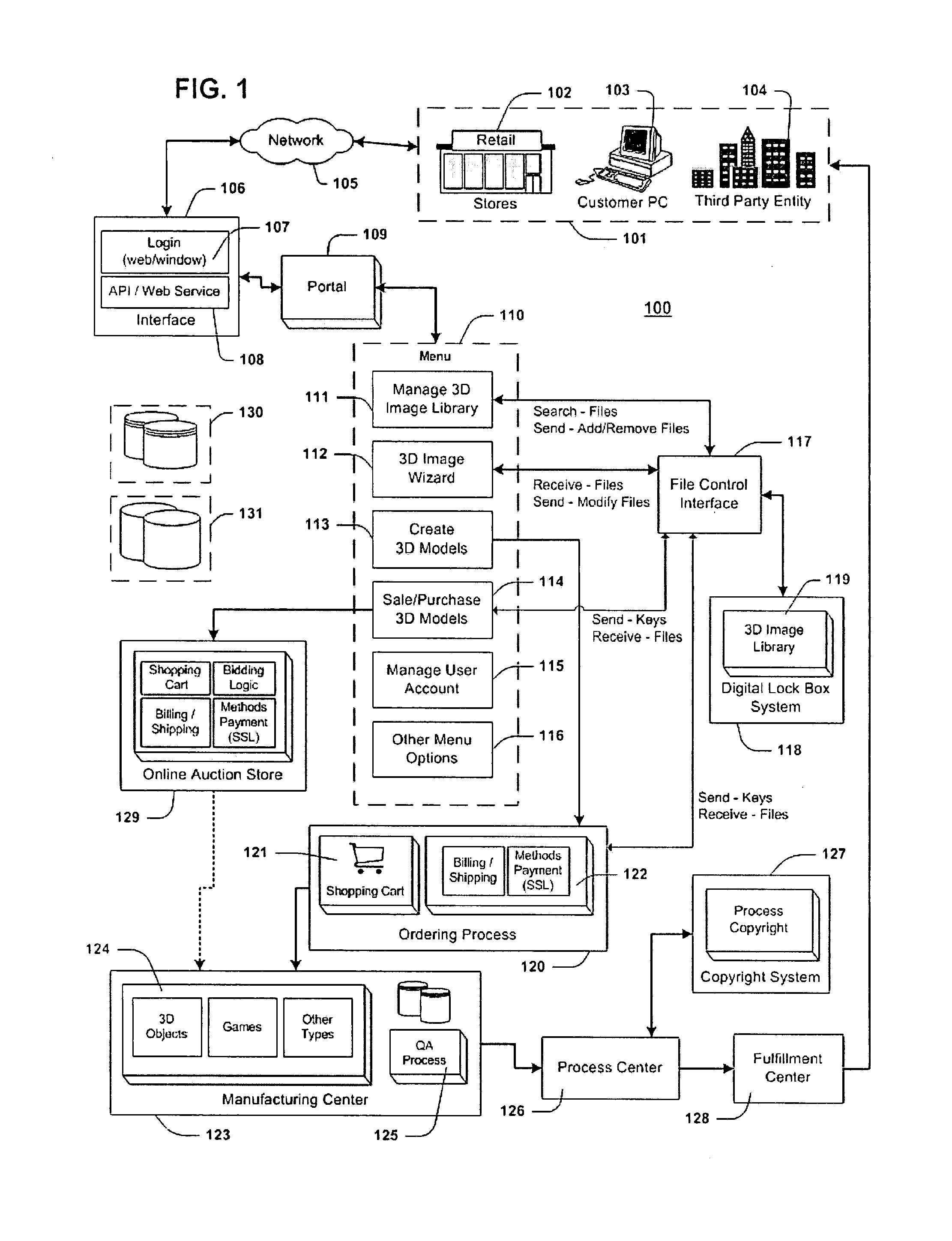

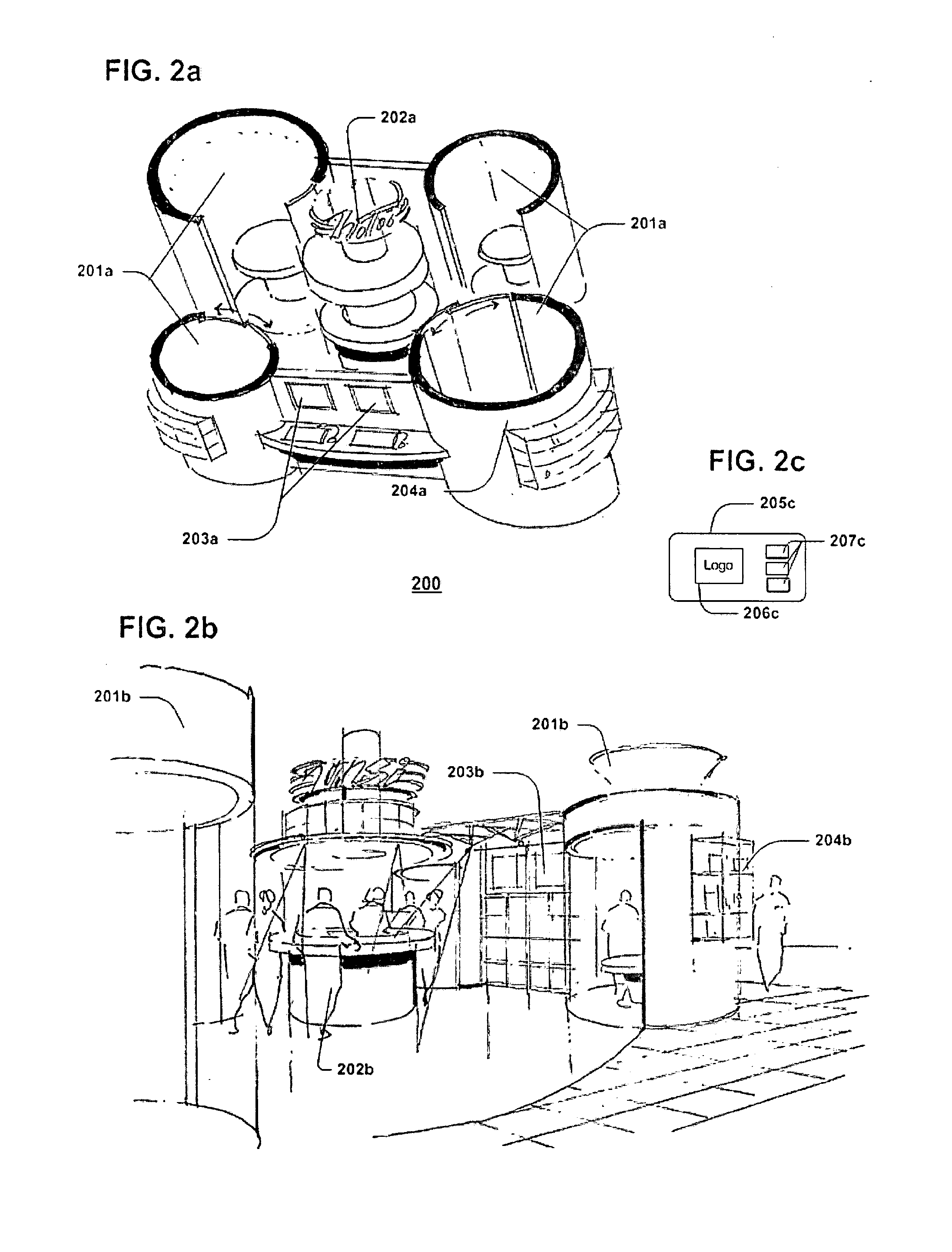

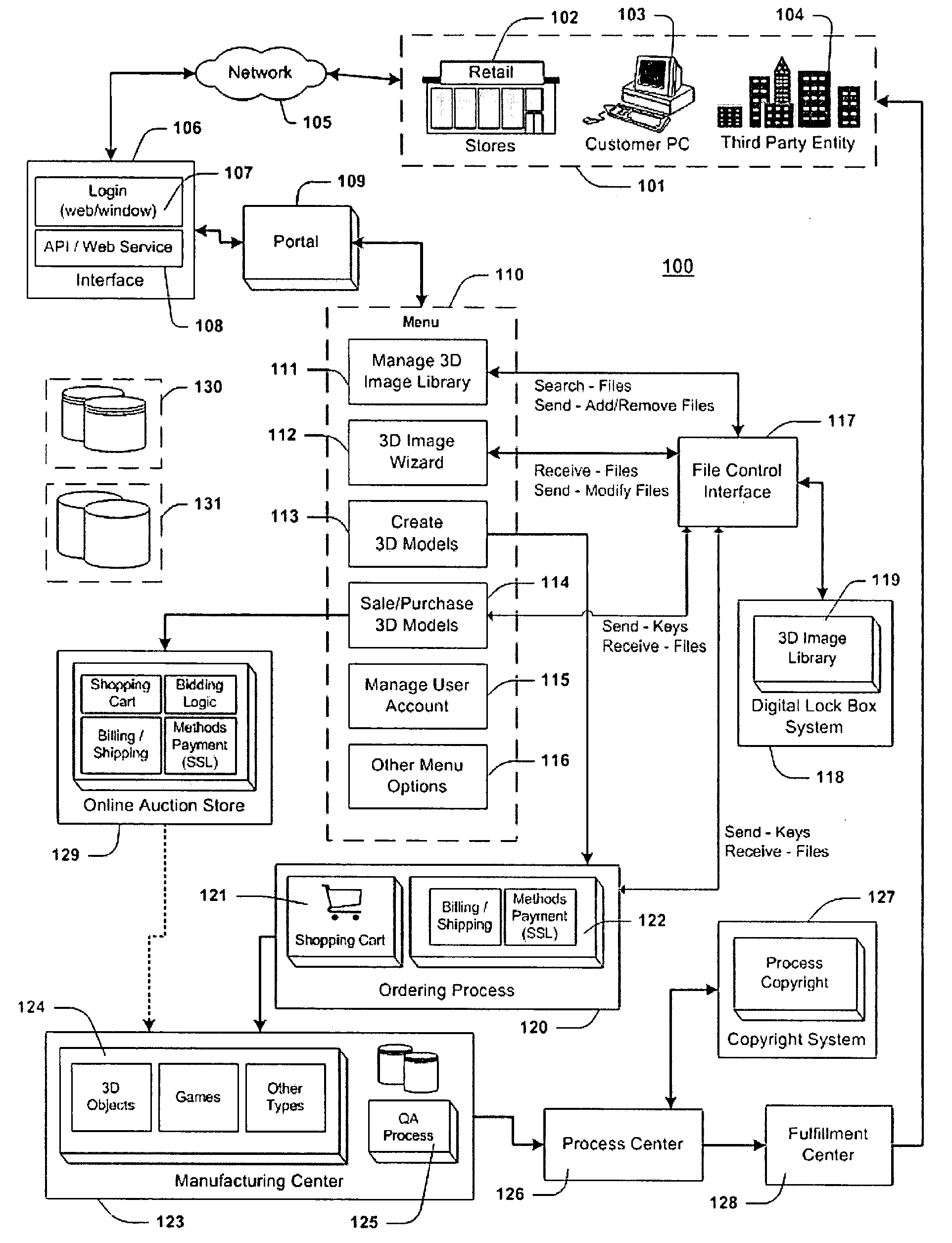

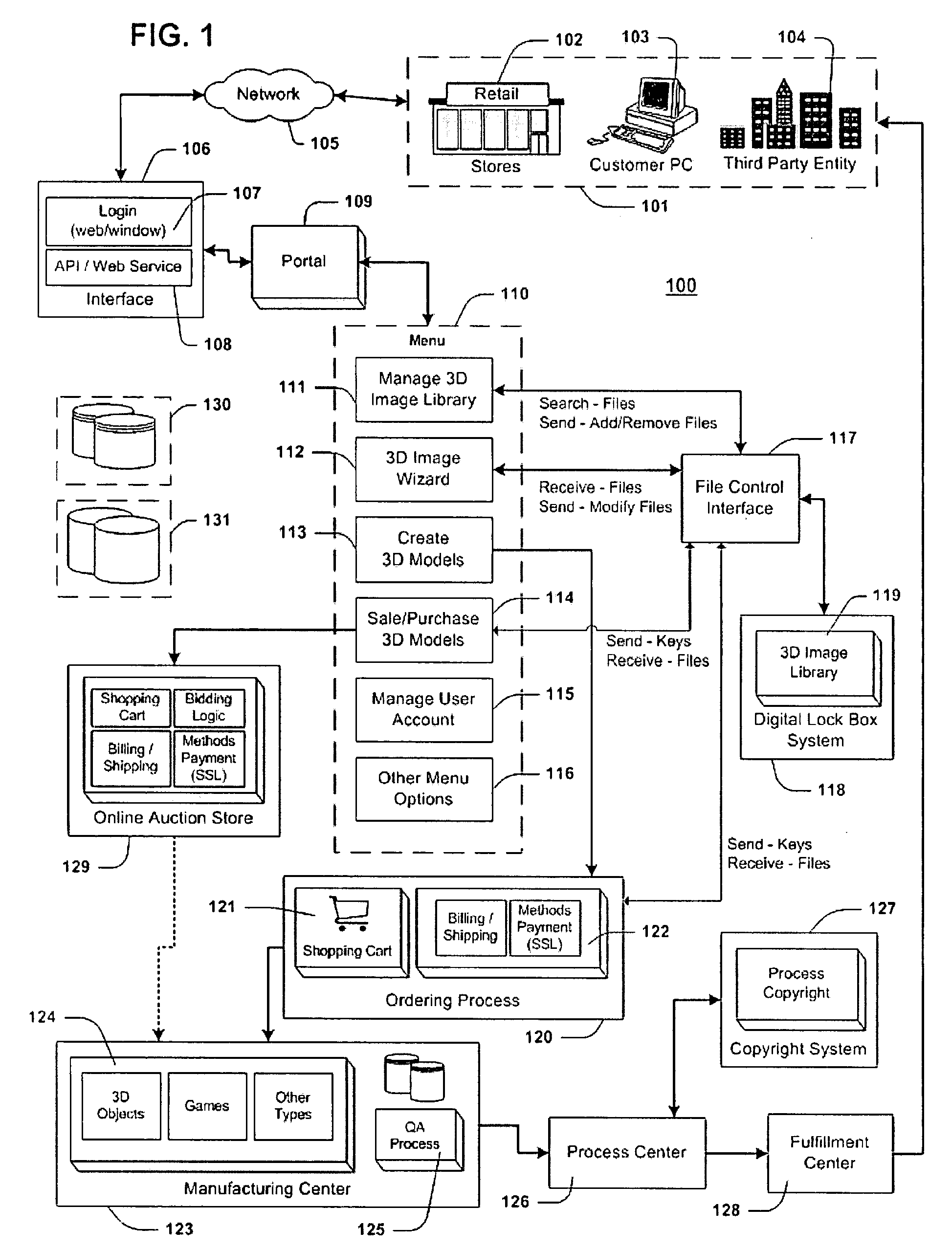

Method for creating, manufacturing, and distributing three-dimensional models

InactiveUS20080111816A1Ensure uniquenessMedical simulationAdditive manufacturing apparatusThird party3d image

A method is provided for producing three-dimensional (3D) models. The invention will take any sculpture, character, or model from artwork, still life models, images of human beings, characters from a computer game, or any other 3D digital image or model that is scanned, and turn the digital image into 3D models. The method is comprised of the following steps: creating a user account in a computer storage area; storing 3D images under the user account; allowing the user to select the 3D image(s) he or she wants to create as 3D models; manufacturing the 3D models; and delivering the models to the user or to a specified third-party. An online storefront and / or auction system may allow each user the opportunity to sell their 3D models or purchase other users' 3D models. The system may also create 3D models for a mobile phone and portable media player while transferring the models to either of these devices.

Owner:TAG LLC (US)

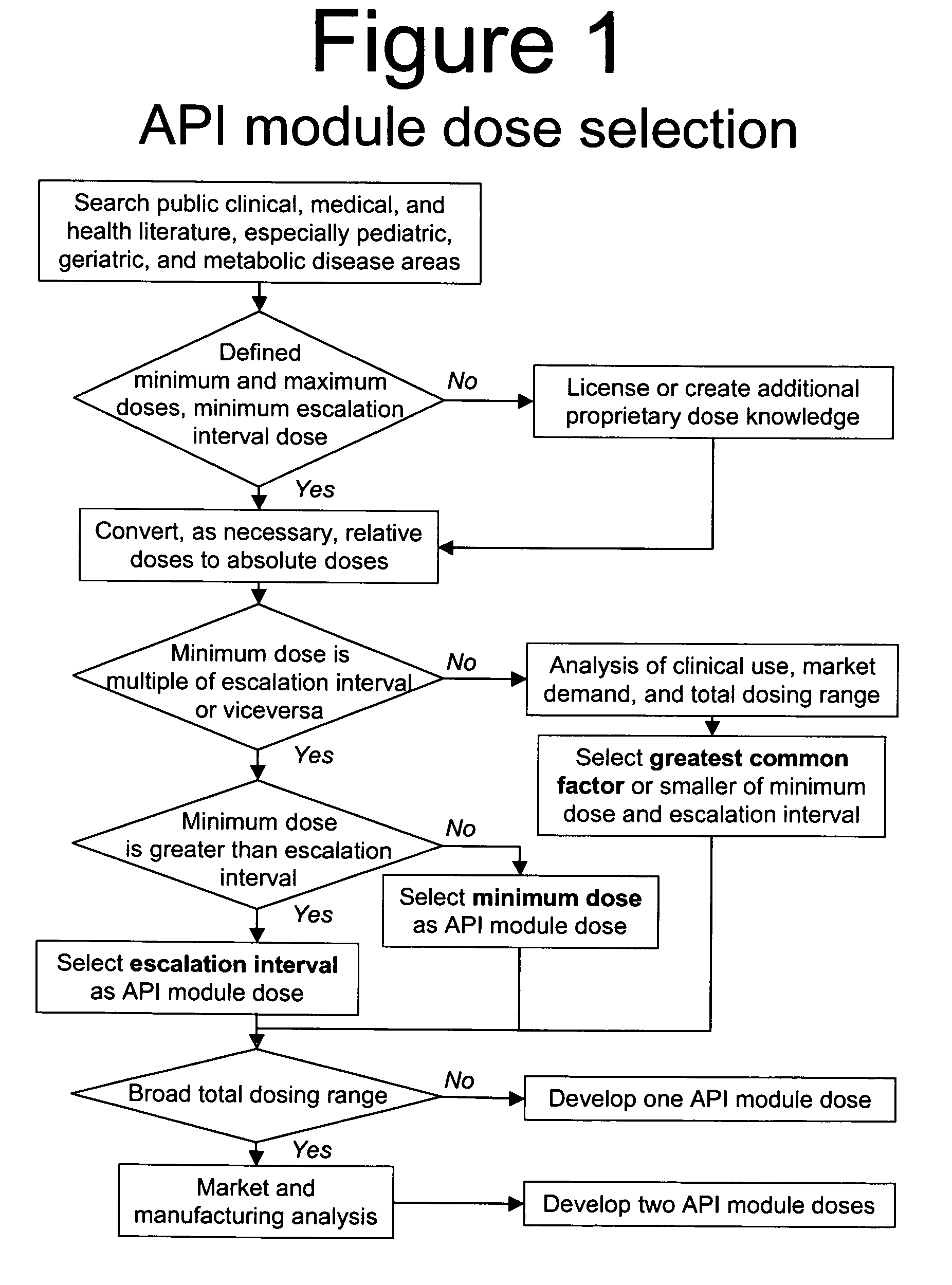

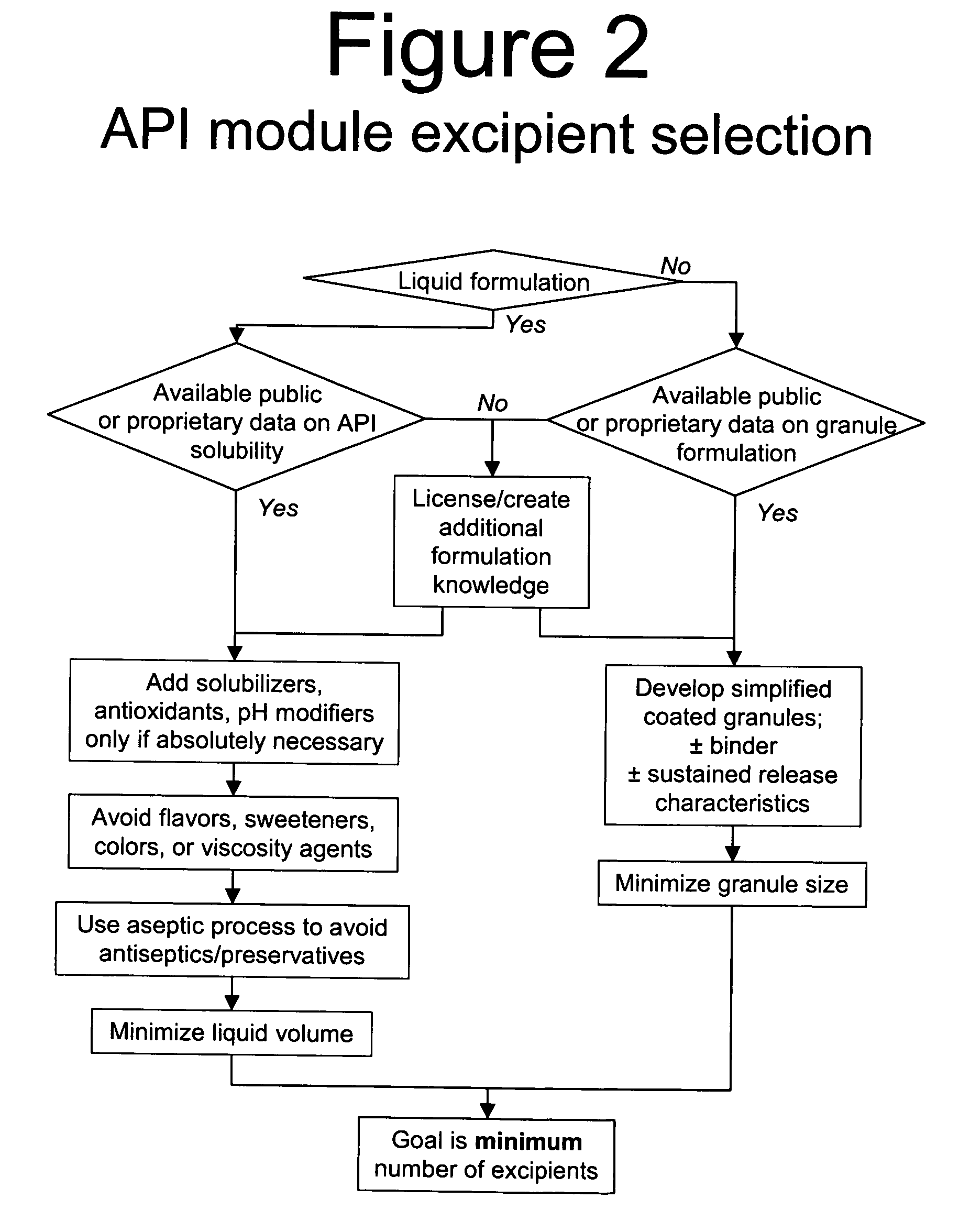

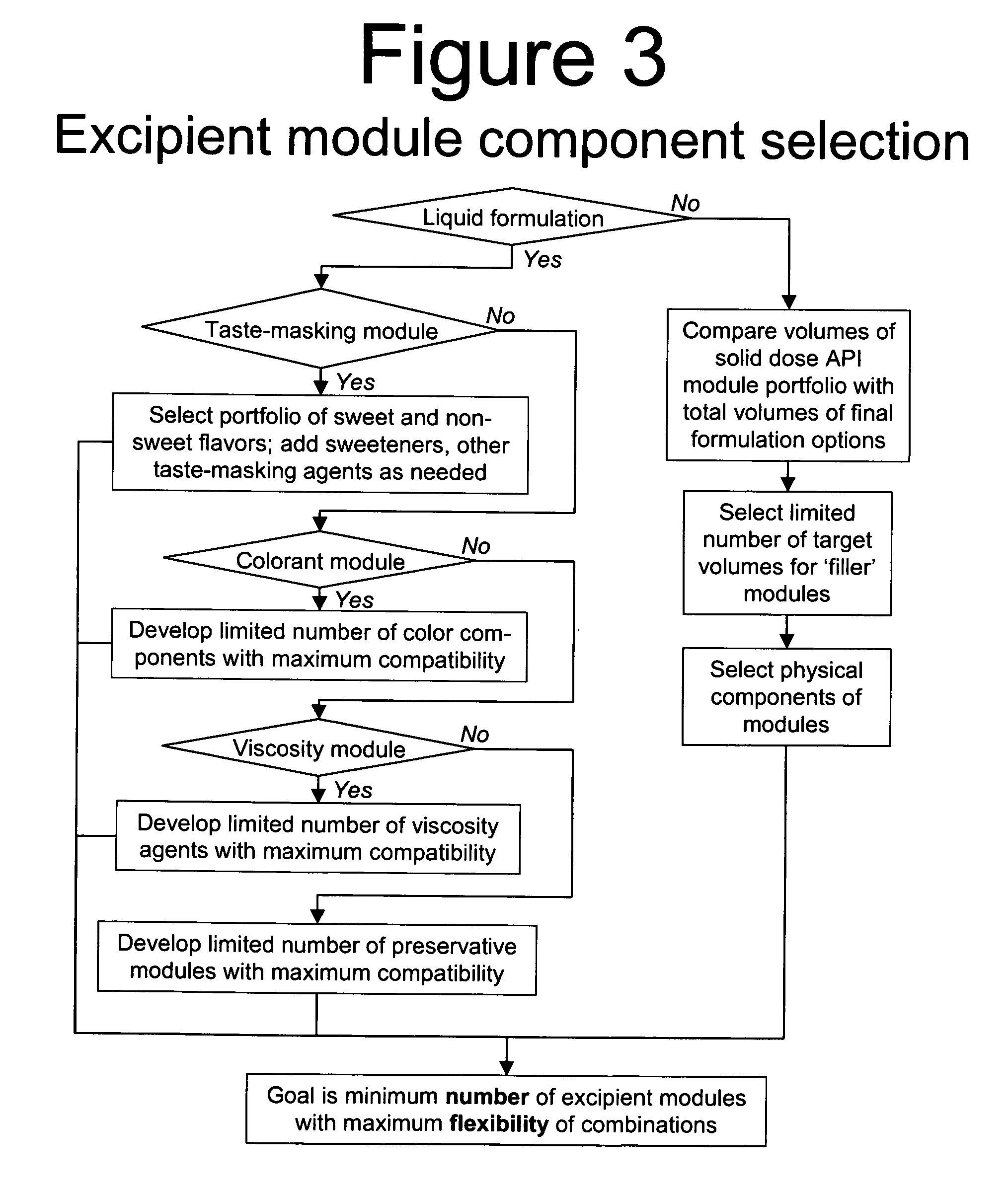

Methods of Making Pharmaceutical Components for Customized Drug Products

InactiveUS20100015184A1Maximize desired pharmaceutical characteristicLow costDrug and medicationsPharmaceutical product form changeFlavorAdditive ingredient

Methods and systems for developing and manufacturing componentized drug product precursor modules that can be simply assembled to create customized drug products are disclosed. Each module contains components of a final drug product (e.g., active pharmaceutical ingredients, nutritional ingredients, and / or excipients) in a fixed mixture selected to maximize desired pharmaceutical characteristics (e.g., stability, manufacturing efficiency) and minimize cost. The modules can be extensively tested for quality and assembled immediately, or at a later time, in multiple combinations to customize the final drug product characteristics (e.g., multiple active ingredients, doses, flavor, viscosity, etc.) to meet individual patient / consumer needs and / or preferences while assuring high quality. Permitted combinations may be maintained in a database to enable networked drug product selection, prescribing, and ordering. Each resulting customized drug product dose can be labeled to facilitate compliance and reduce the number of drug products administered per day.

Owner:TUEL STEPHEN M

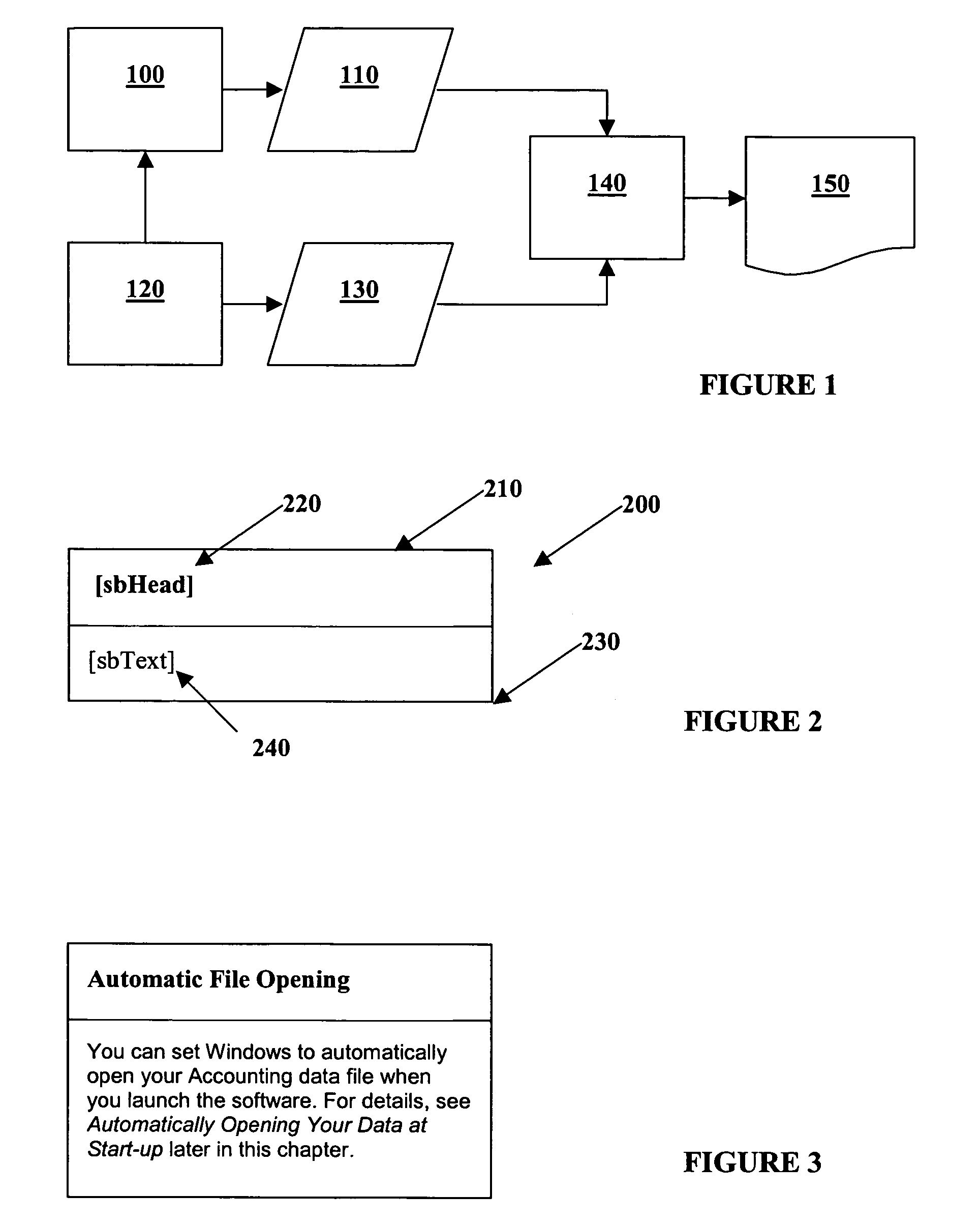

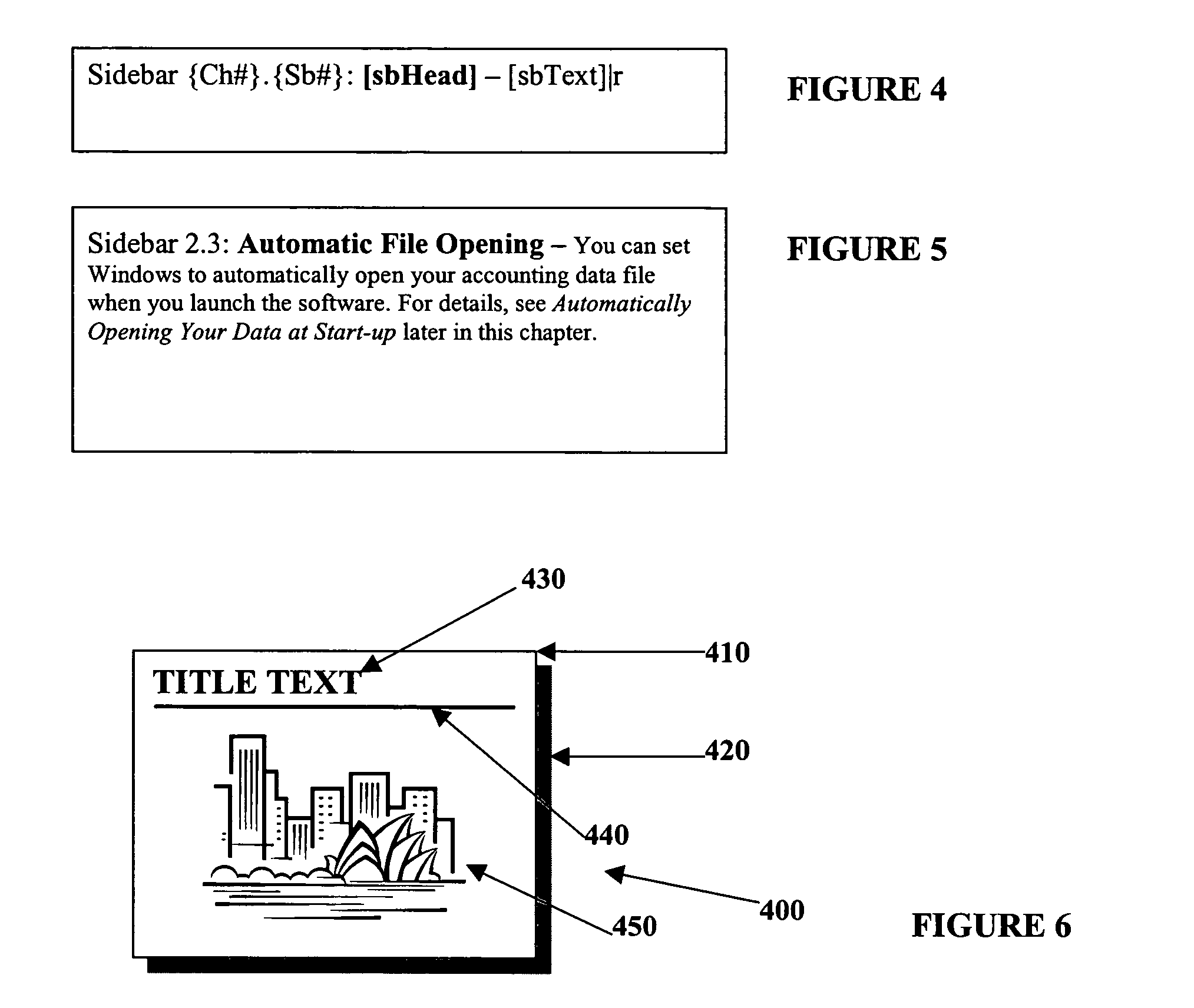

Method of formatting documents

ActiveUS7272789B2Flexible designFlexible presentationNatural language data processingSpecial data processing applicationsGraphicsRating system

Owner:TYPEFI SYST PTY LTD

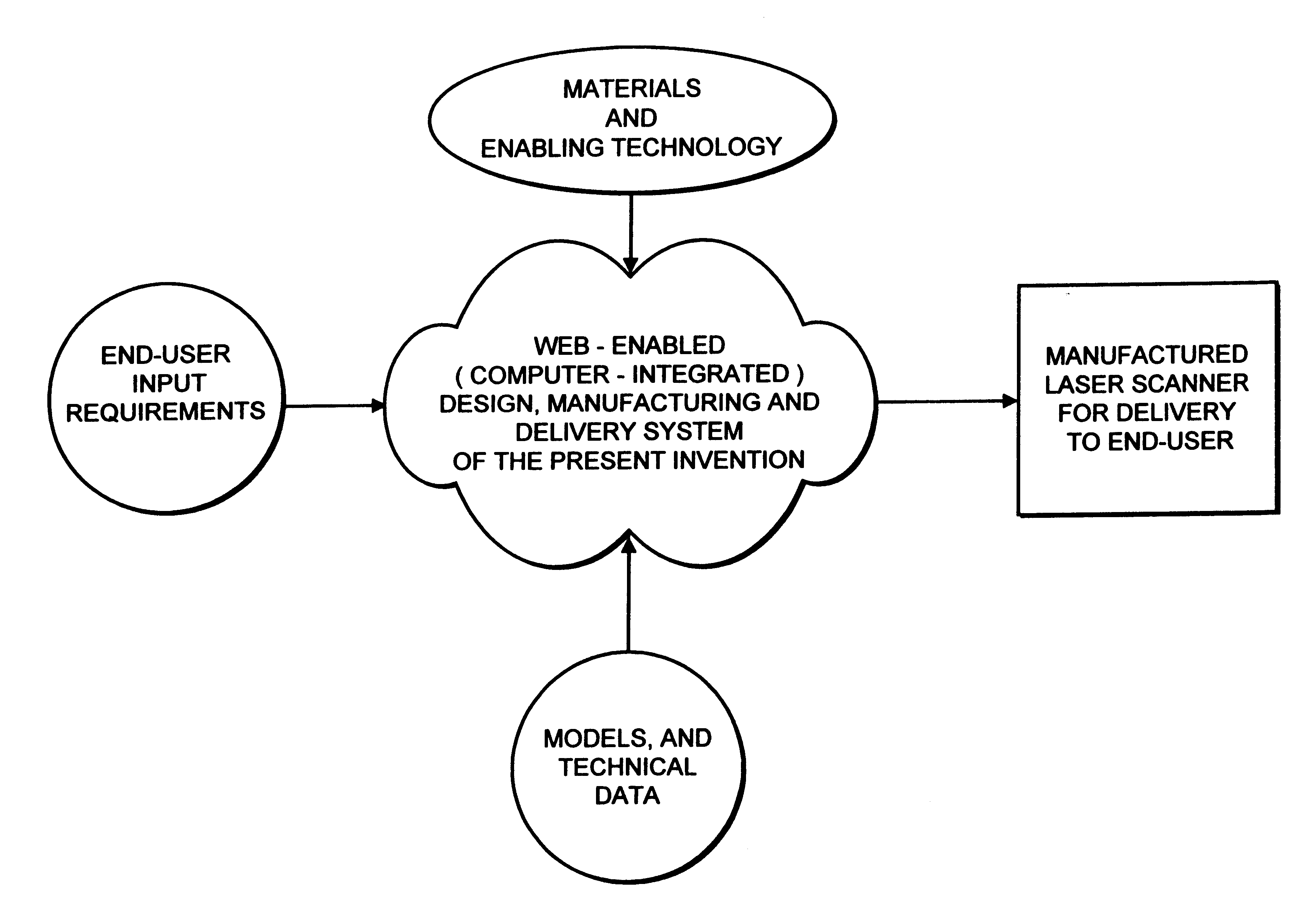

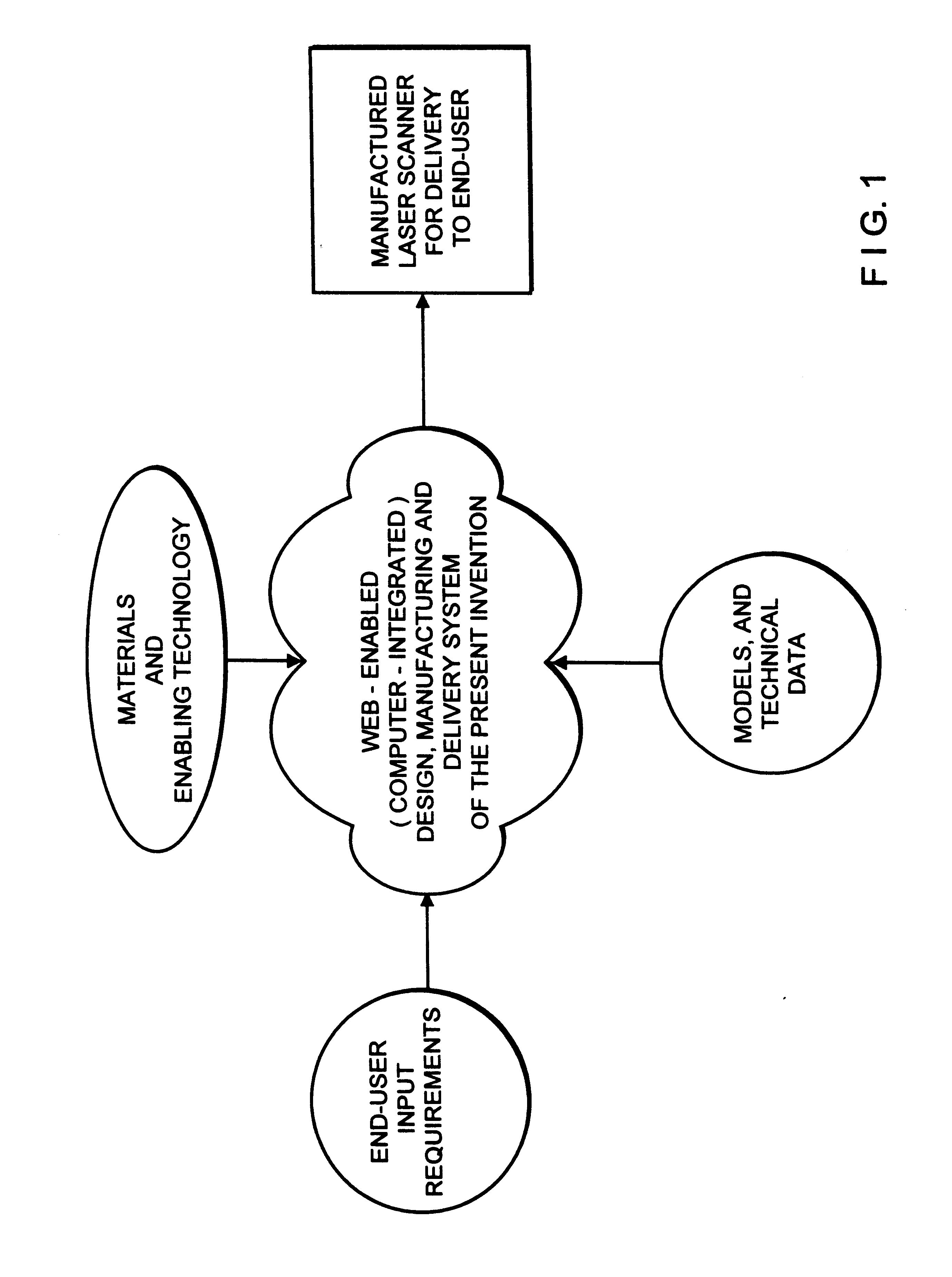

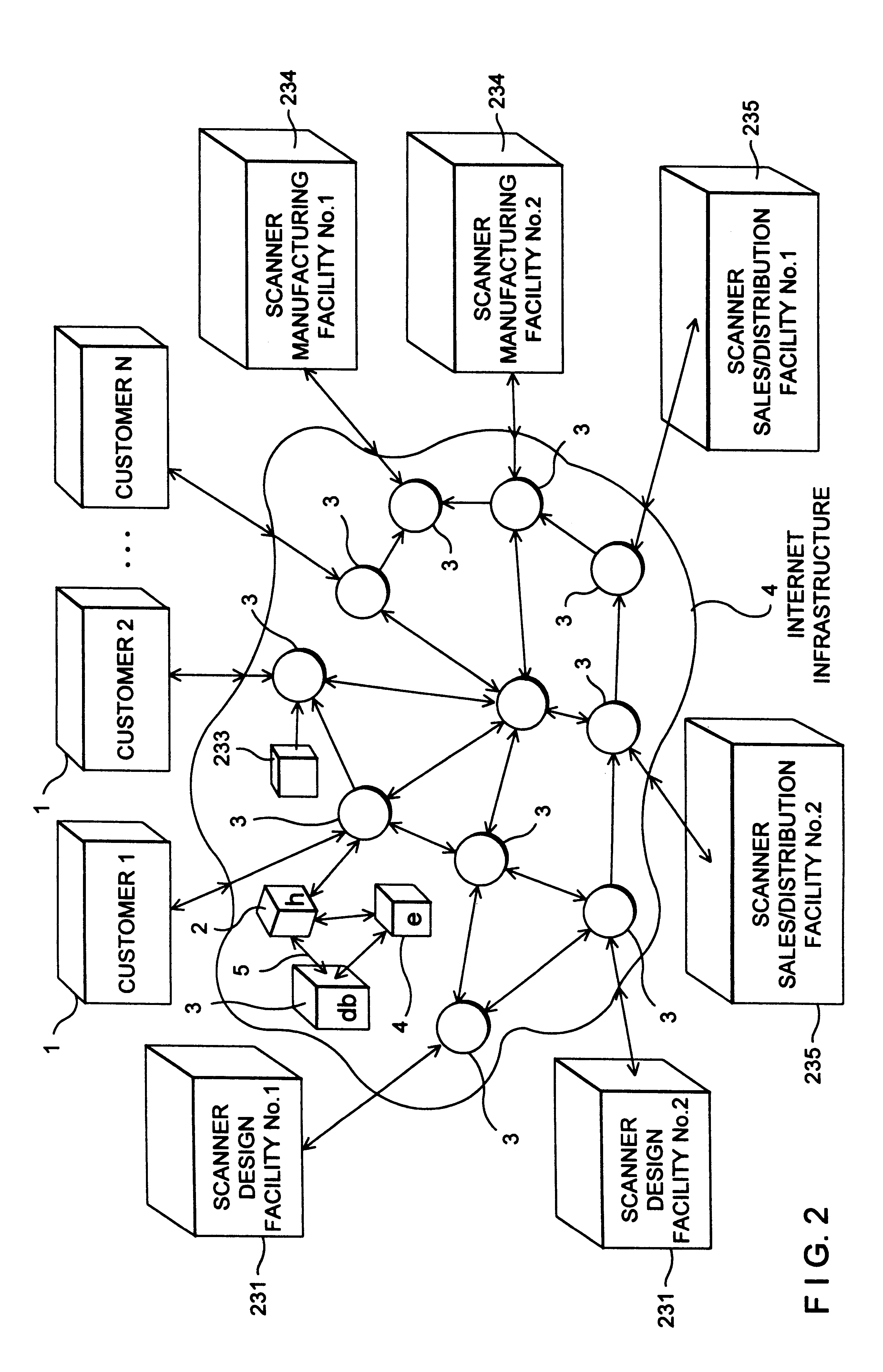

Web-enabled system and method for designing and manufacturing laser scanners

InactiveUS6182897B1Coin-freed apparatus detailsCo-operative working arrangementsInformation networksModular design

An Internet enabled method and system (1) for designing, and manufacturing laser scanners of modular design and construction (231) using globally based information networks (3), such as the Internet, supporting the World Wide Web (WWW).

Owner:METROLOGIC INSTR INC

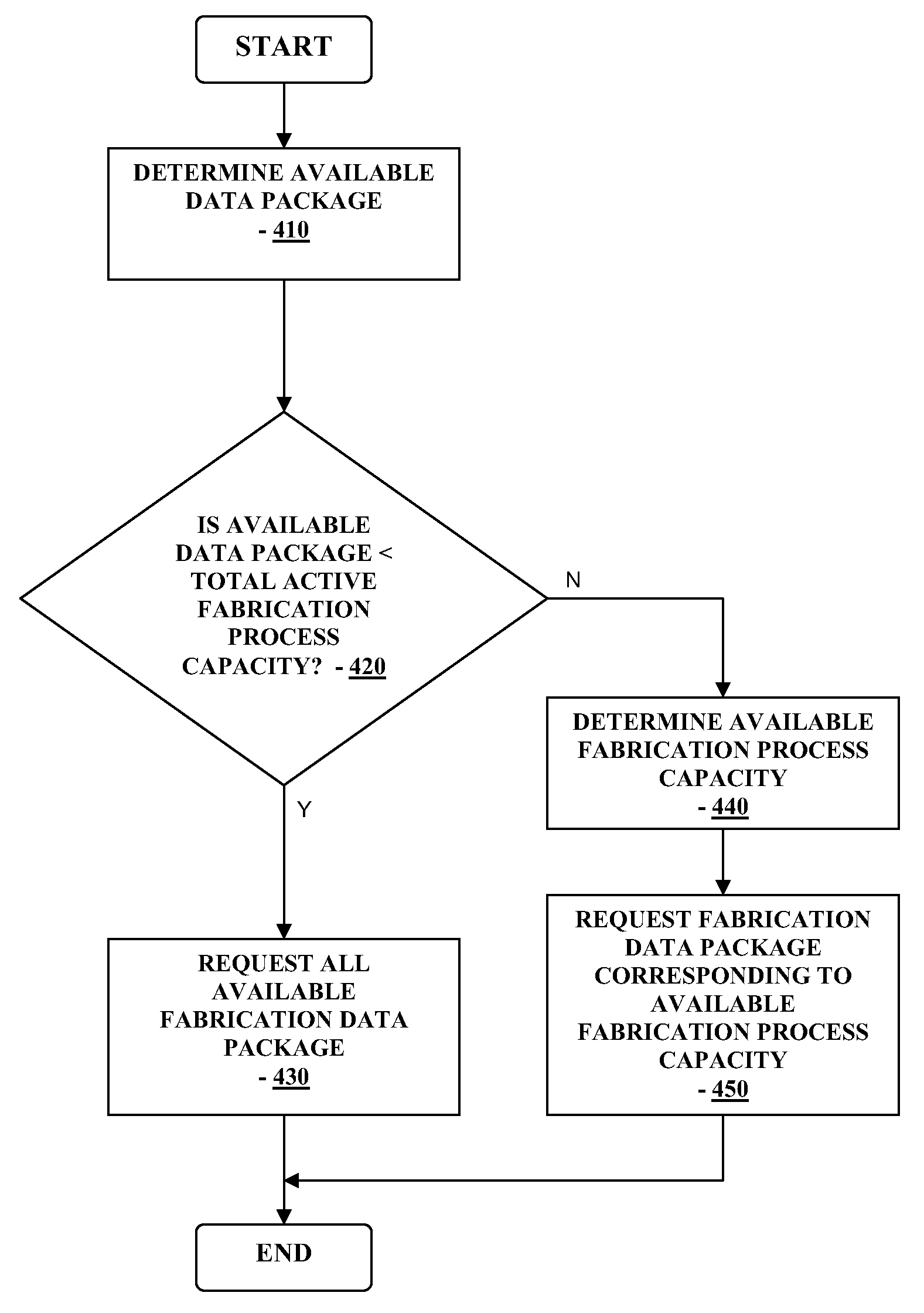

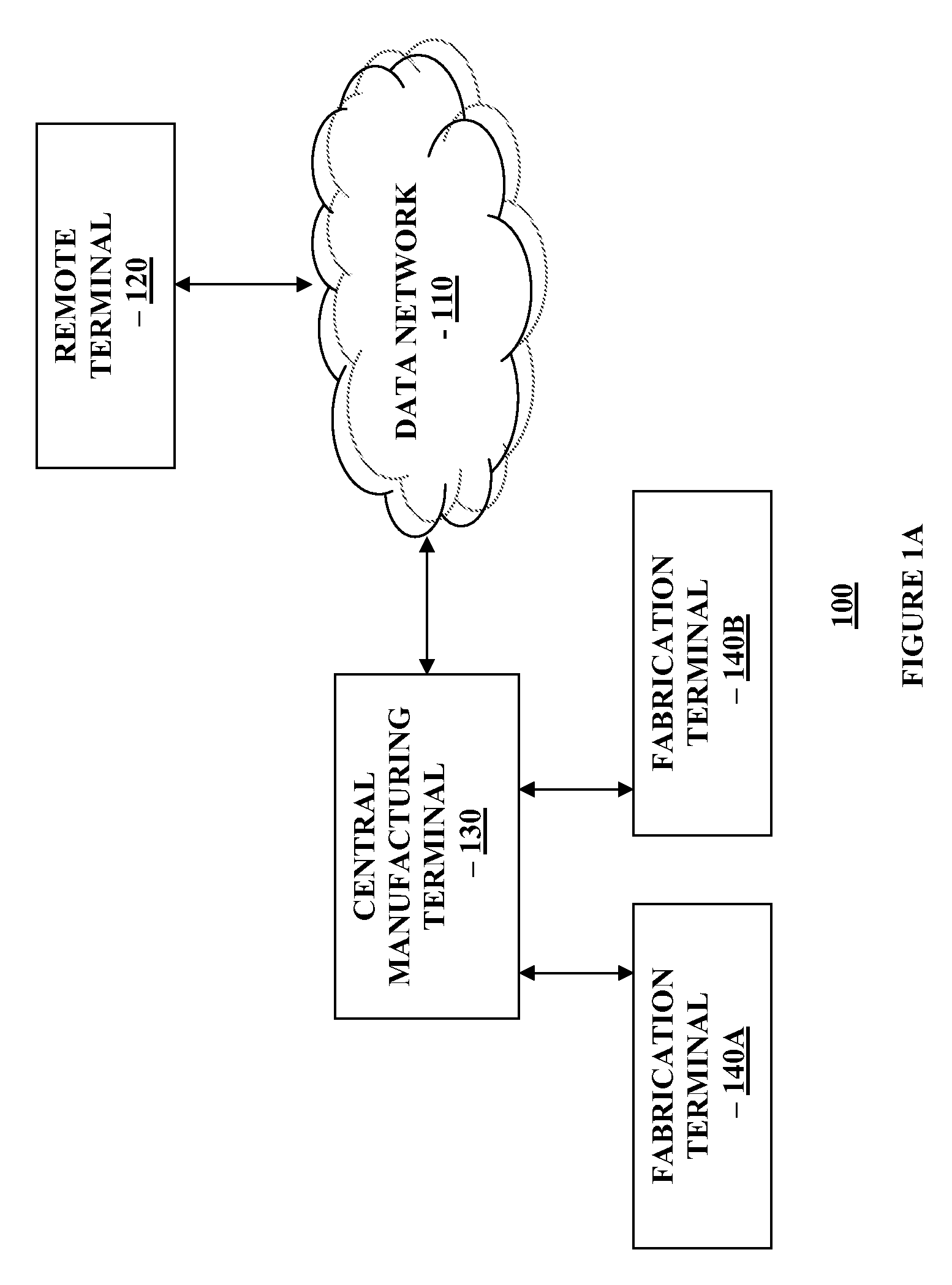

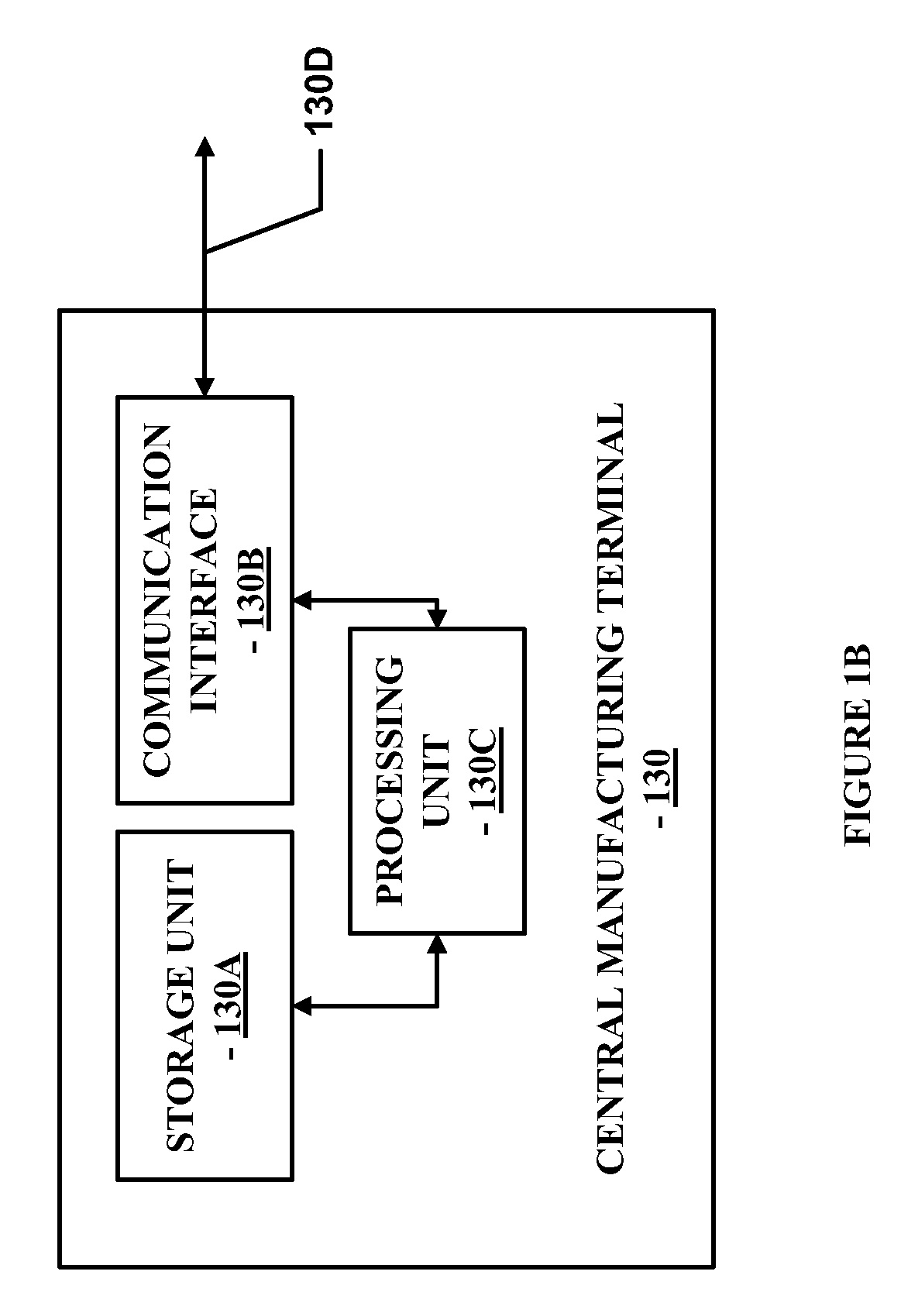

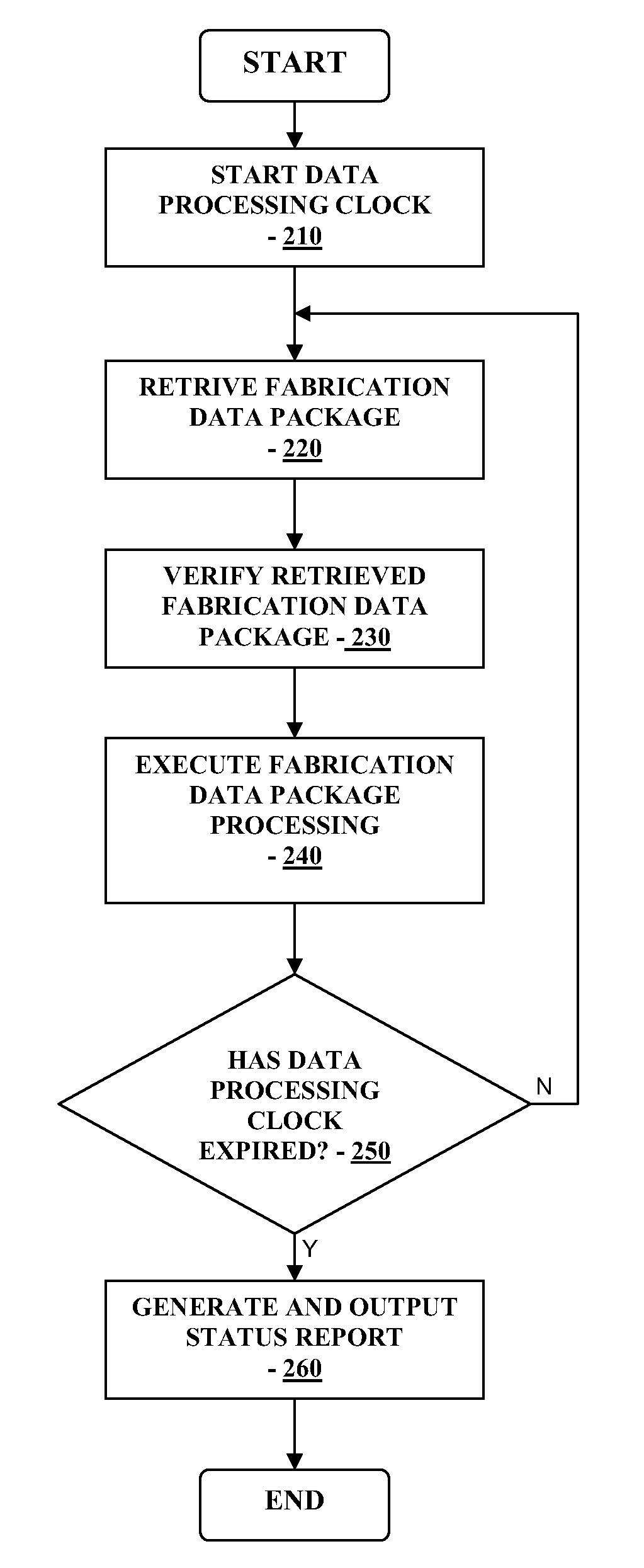

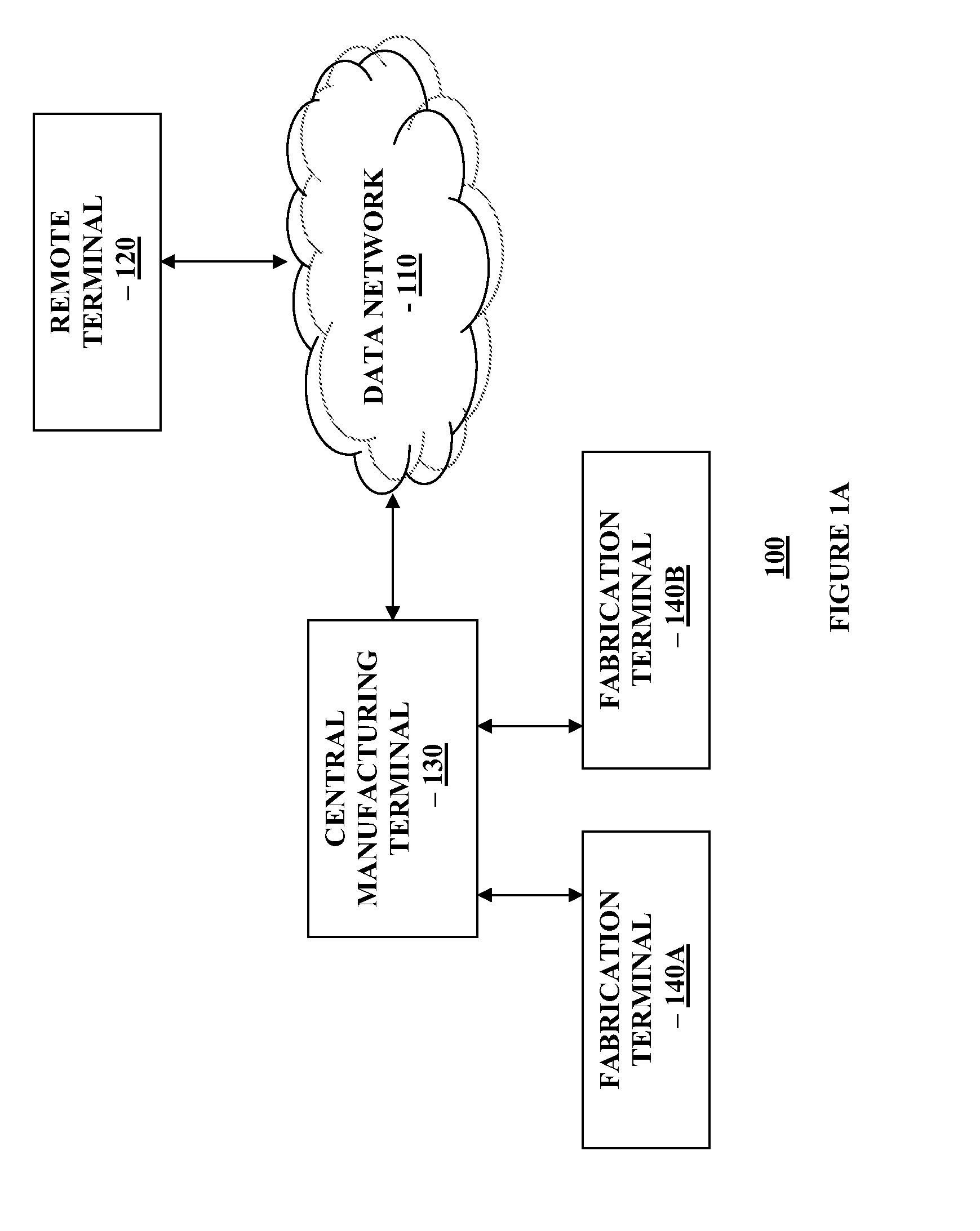

Method and system for providing automated high scale fabrication of custom items

Method and system for providing volume manufacturing of customizable items including receiving a data package including a plurality of manufacturing parameters, each of the plurality of manufacturing parameters associated with a unique item, verifying the received data package, and implementing a manufacturing process associated with the received data package is provided.

Owner:ALIGN TECH

System

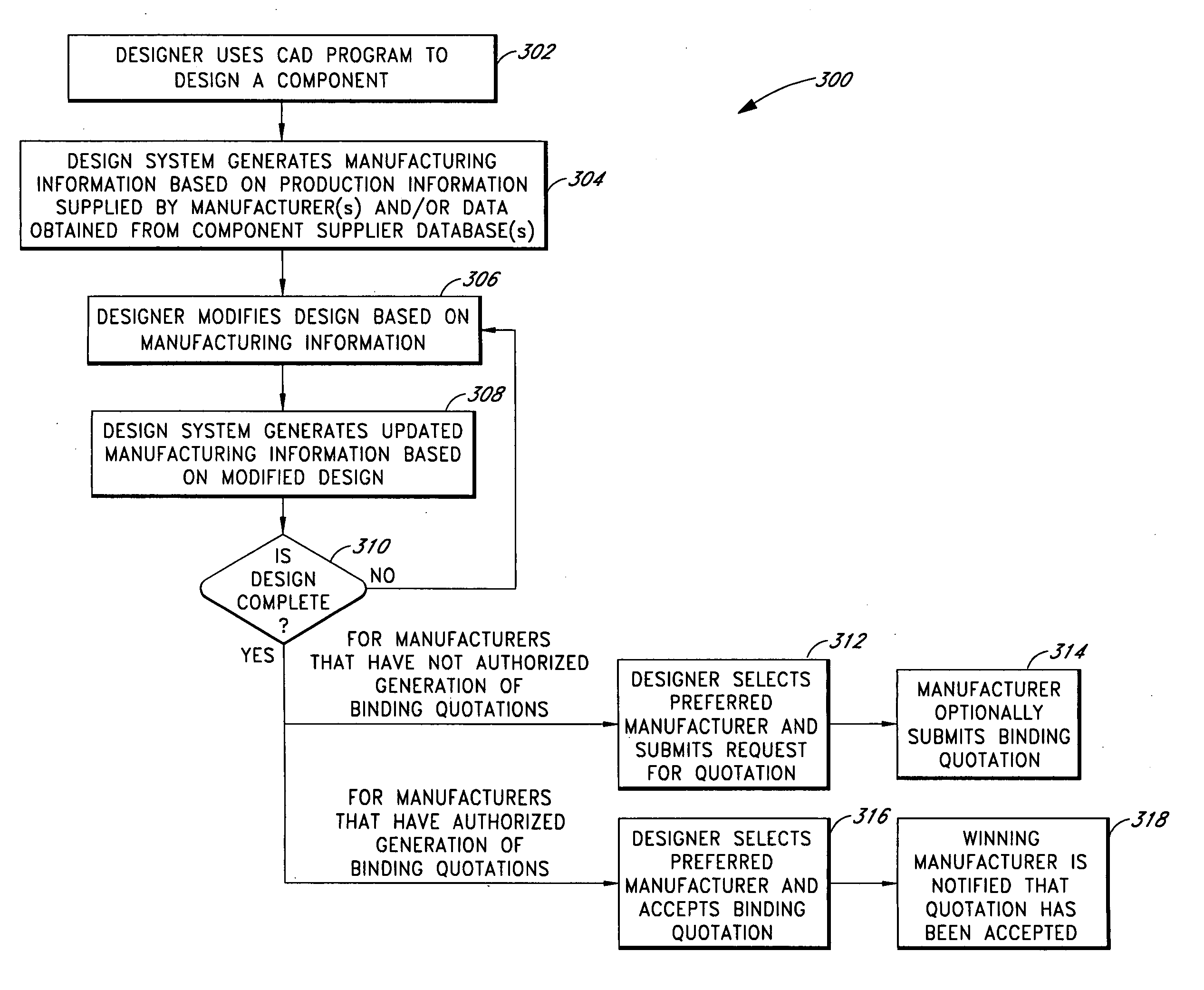

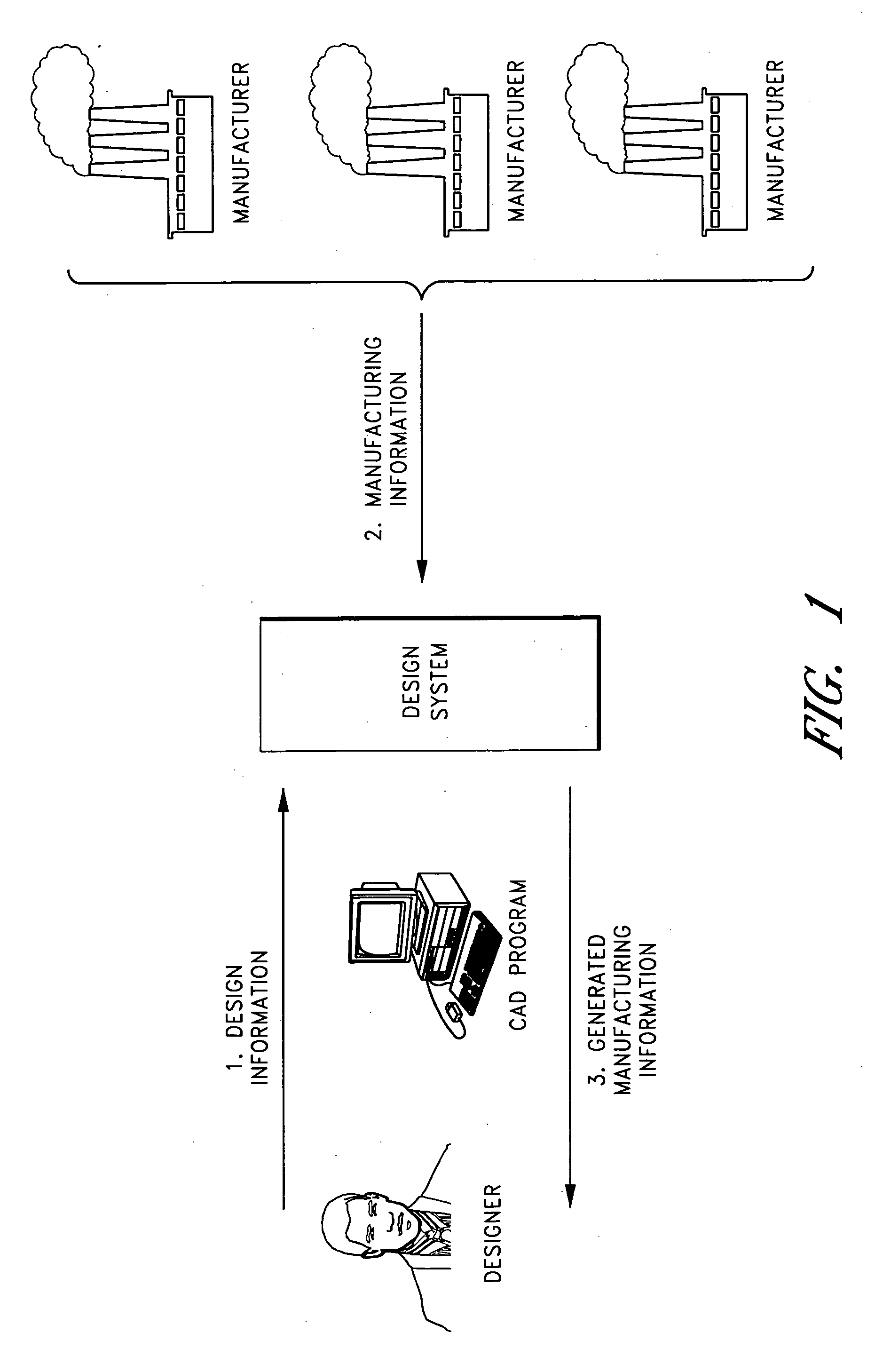

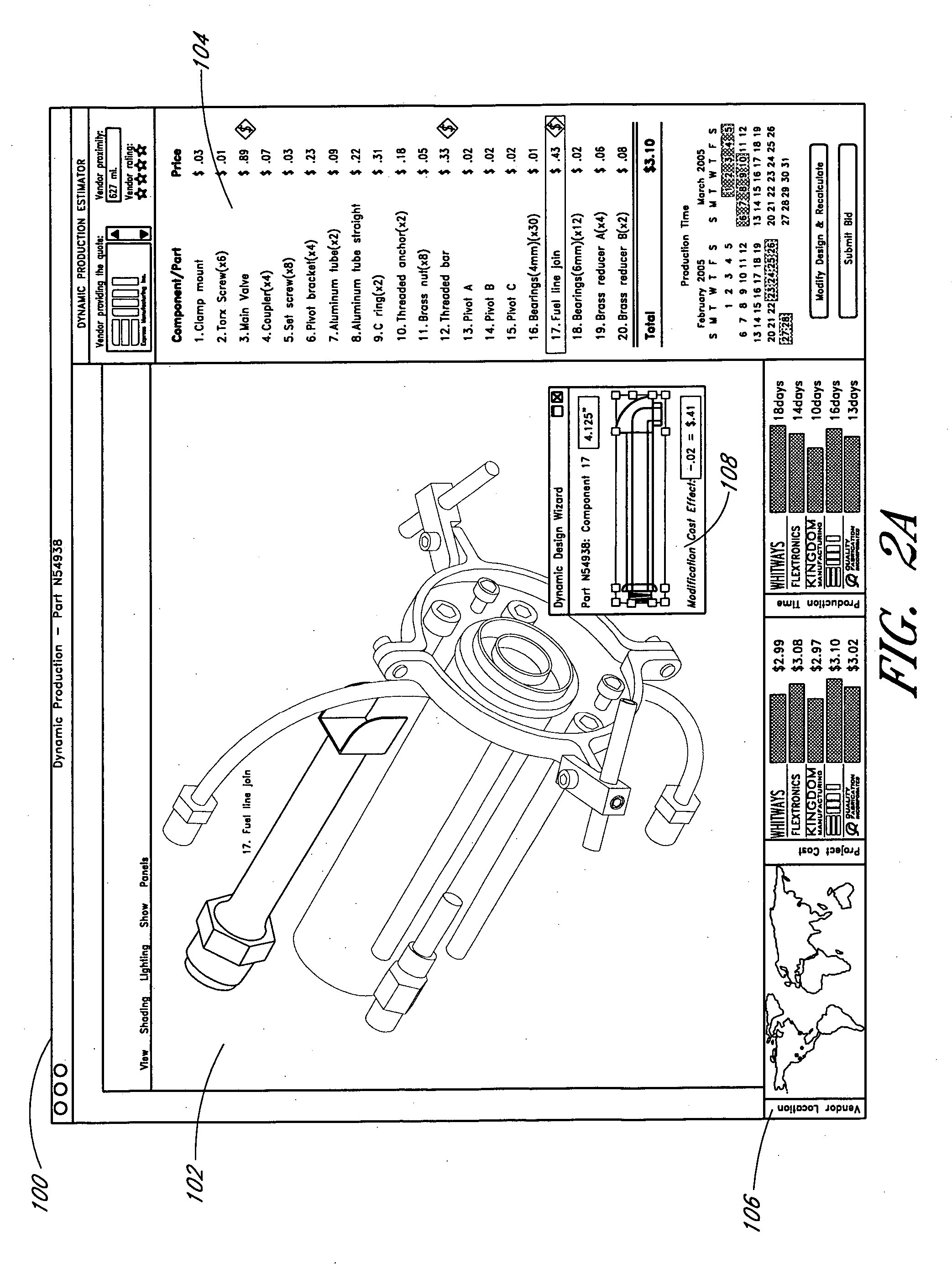

ActiveUS20060253214A1Address rising pricesSimple designResourcesComputer aided designDesign informationUser interface

A design system is accessible to a designer and a plurality of manufacturers. The design system comprises a first user interface configured to receive design information for a component from the designer. The design system further comprises a second user interface configured to receive manufacturing information from the plurality of manufacturers. The manufacturing information comprises at least process cost information. The design system further comprises a database comprising the manufacturing information associated with each of the plurality of manufacturers. The design system further comprises a cost estimation module. The cost estimation module is configured to generate a cost estimate for producing the component for each of the plurality of manufacturers. The cost estimate is at least partially based on the process cost information. The cost estimation module is further configured to output the cost estimate for one or more of the plurality of manufacturers to the first user interface.

Owner:IDEA LAB SRL

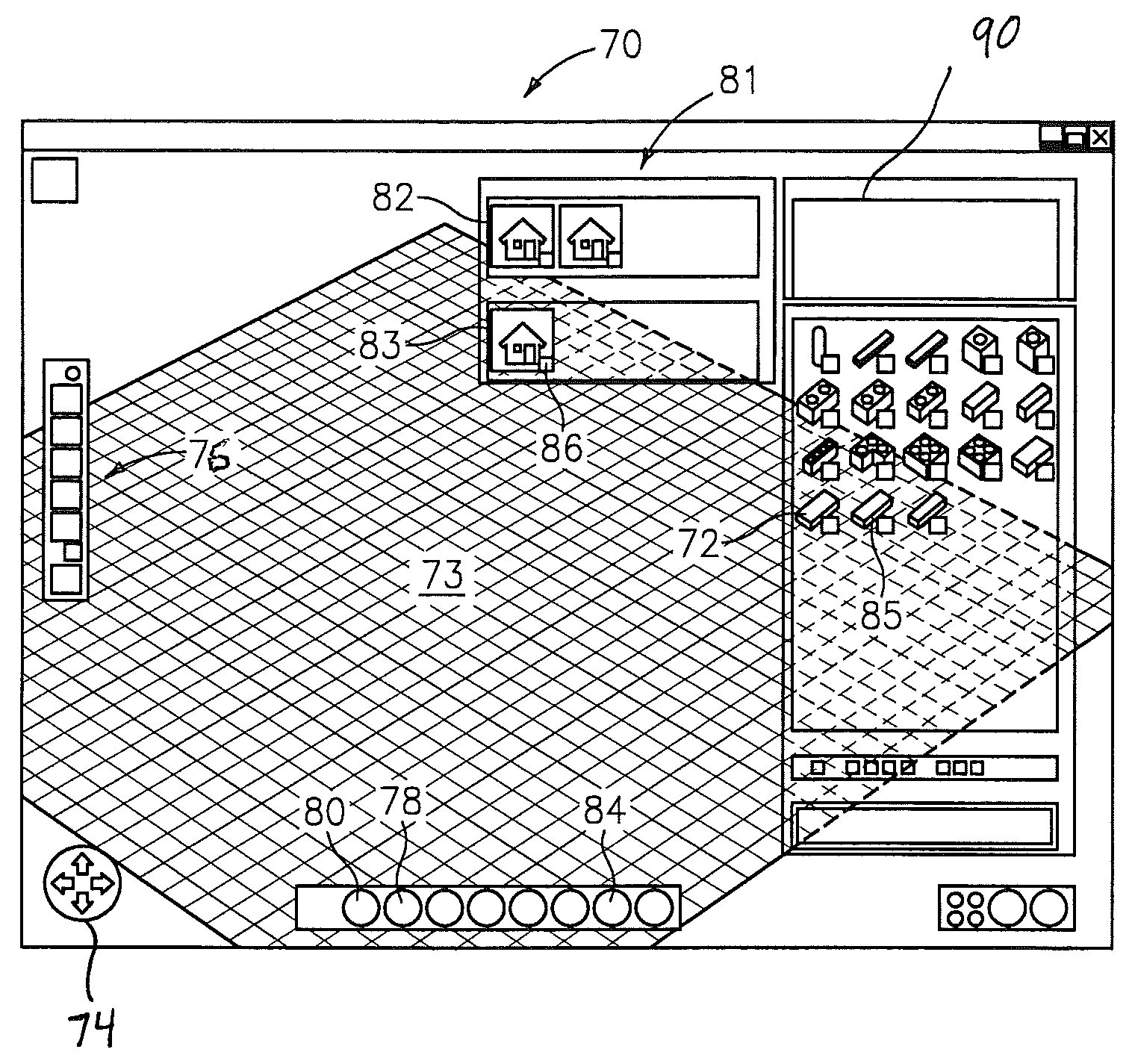

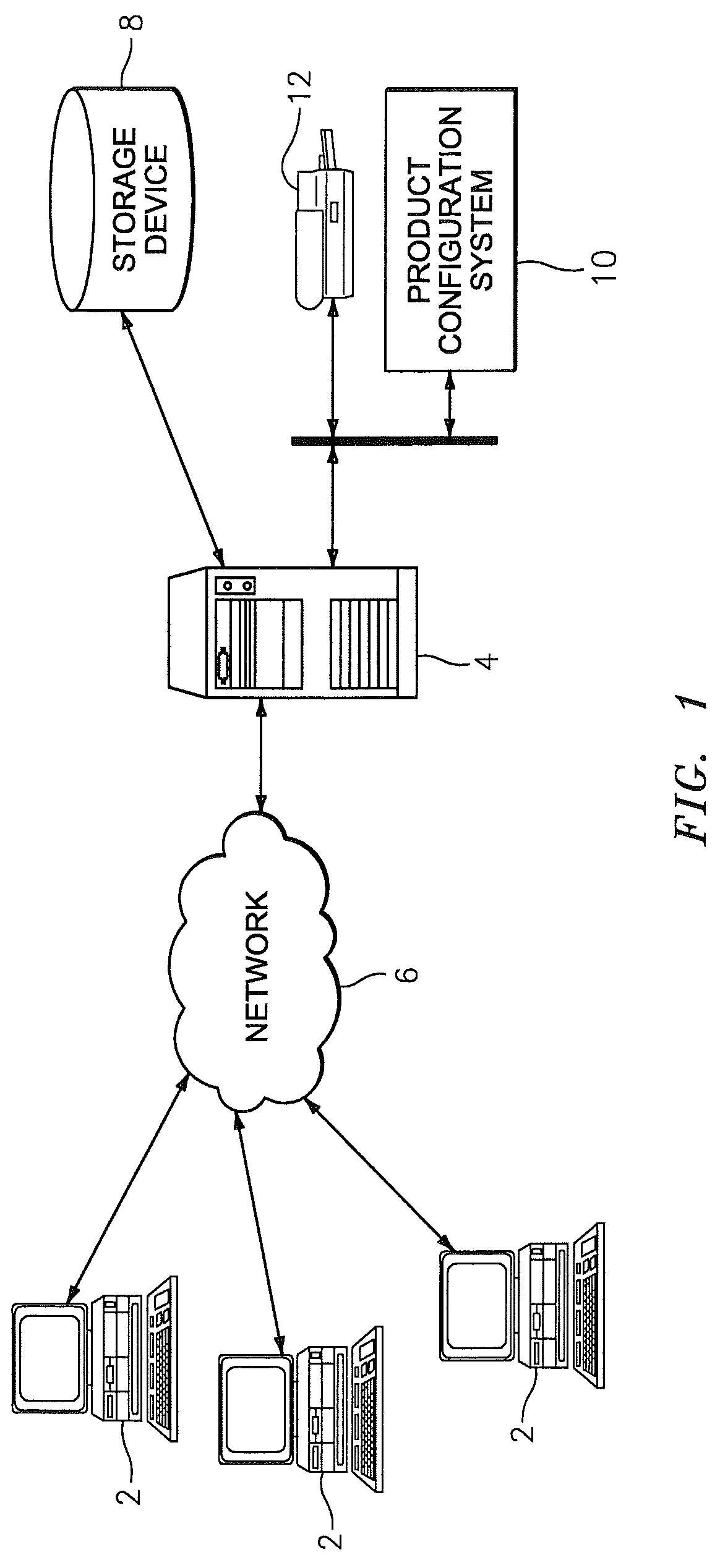

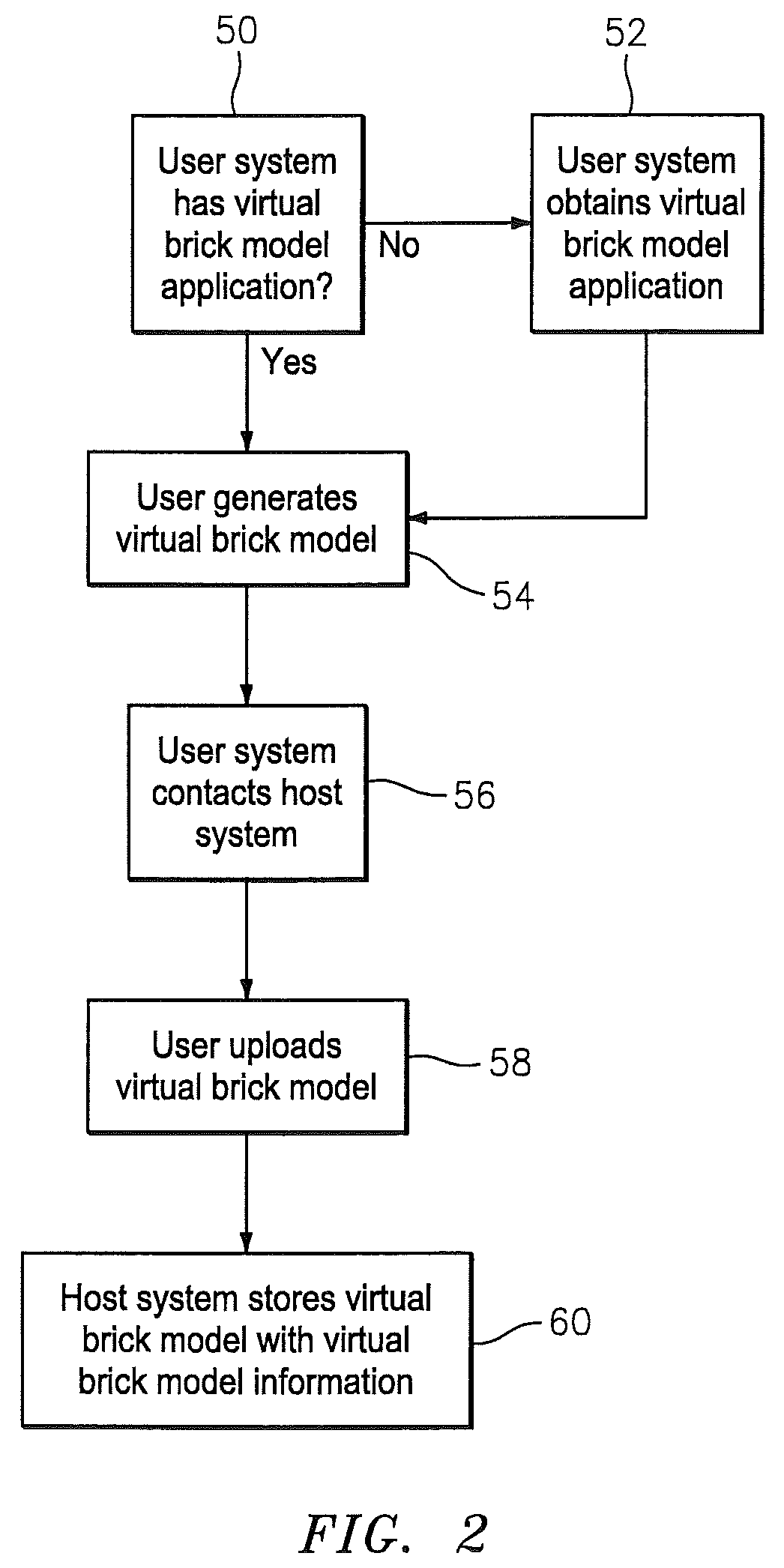

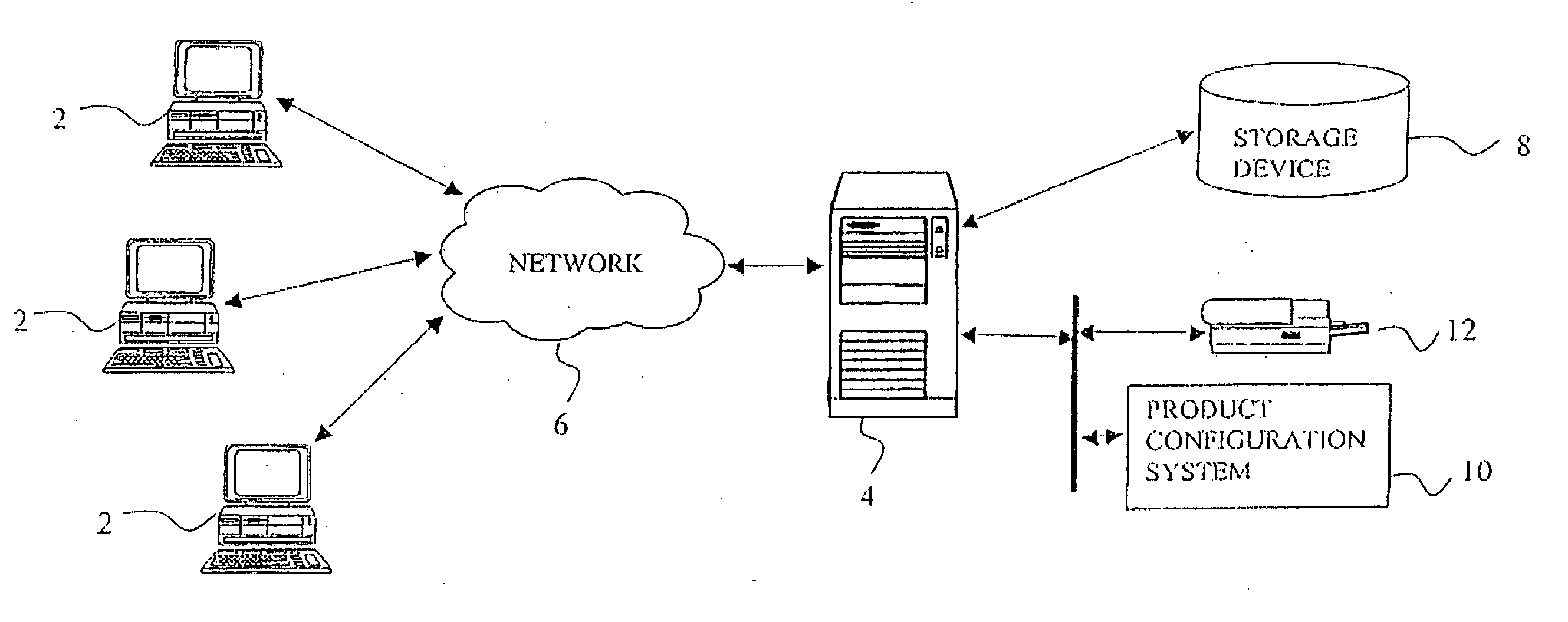

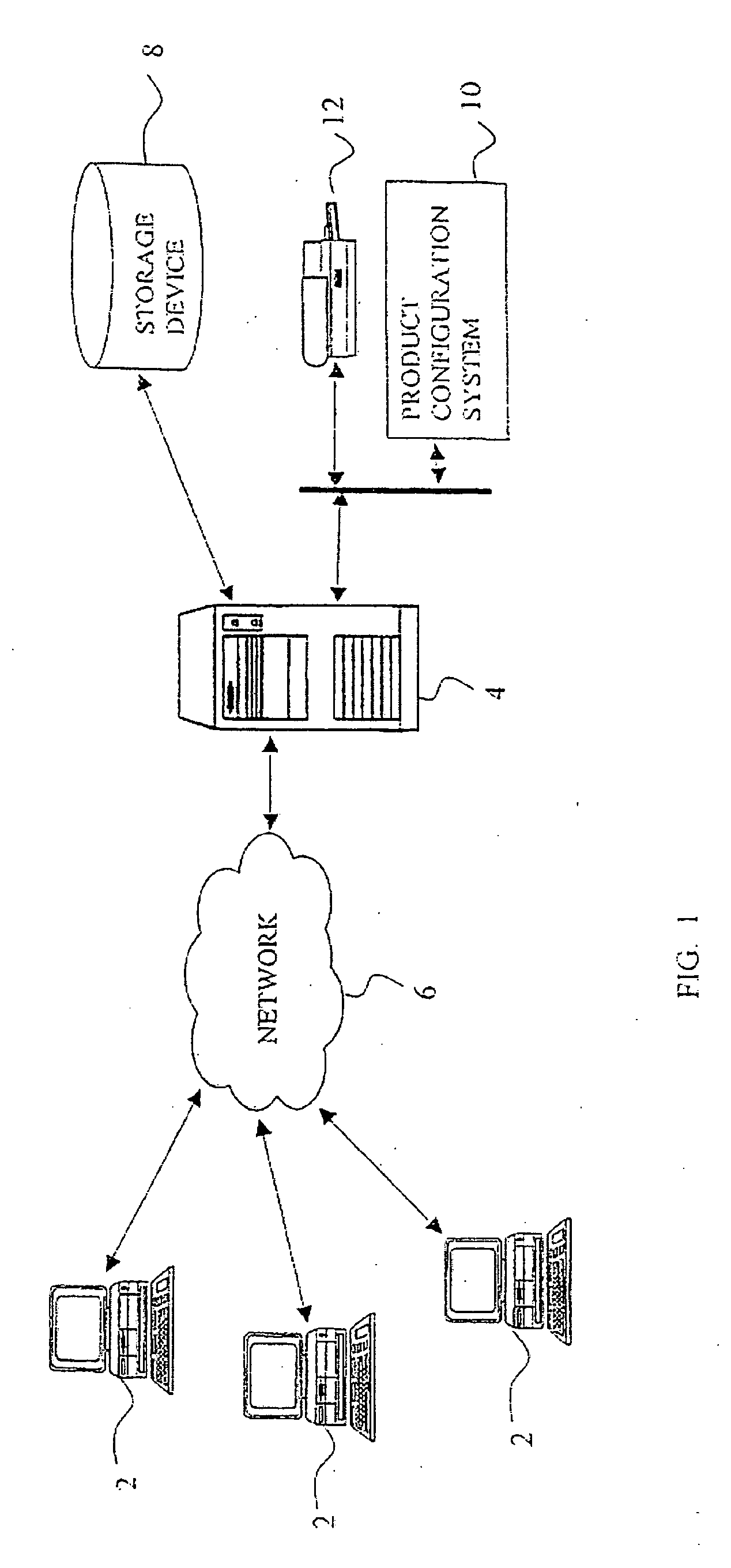

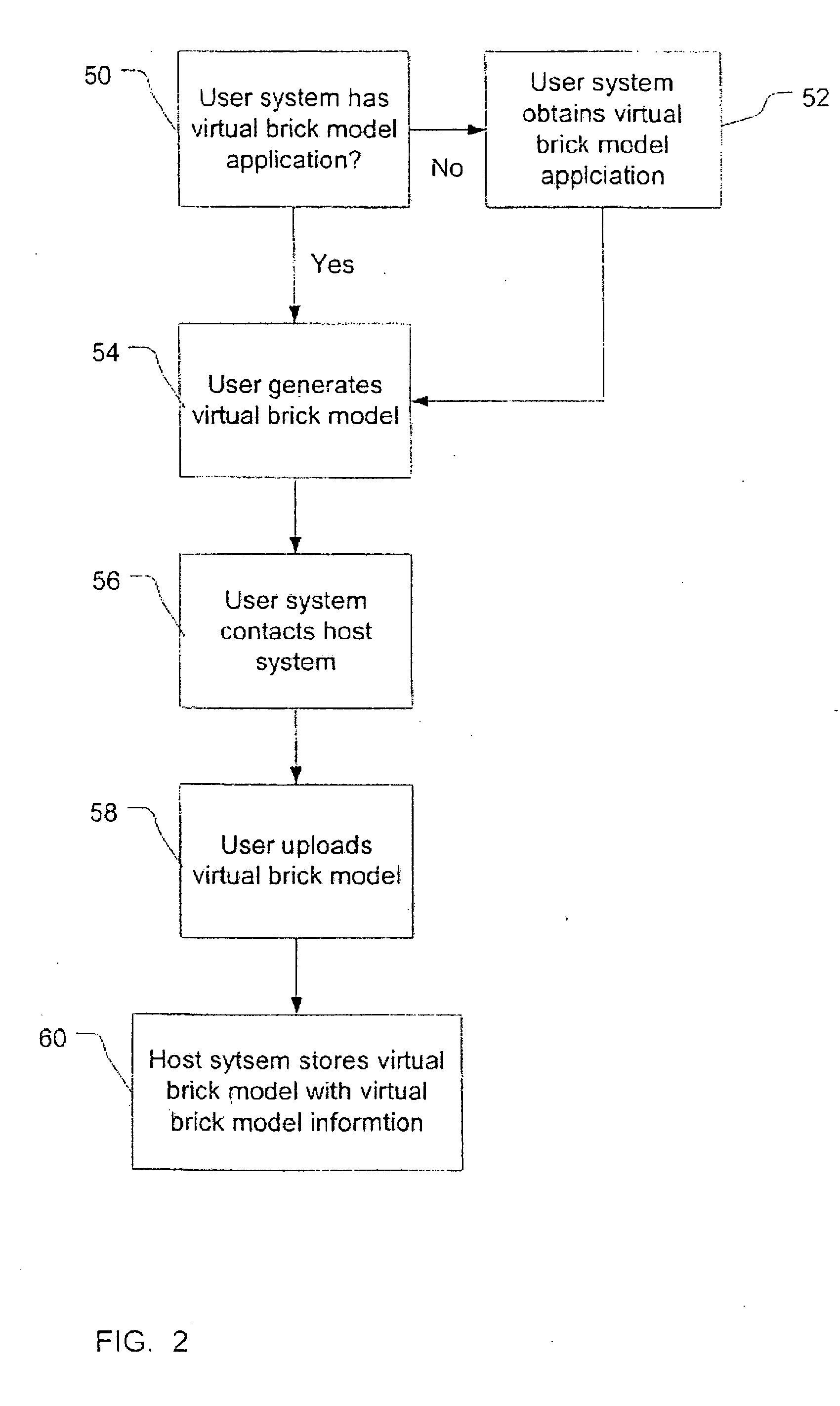

Method of constructing a virtual construction model

InactiveUS7596473B2Reduce usageAvoid buyingToysCAD network environmentArchitectural engineeringBuilding model

Owner:LEGO AS

Selecting virtual brick models

A method of selecting a virtual toy construction model, the method comprising: receiving by a host computer system a digital representation of an input toy construction model, the input toy construction model including a plurality of construction elements; generating a bill-of-materials that includes at least all construction elements of the received input construction model; performing a search in a repository of respective digital representations of a plurality of virtual toy construction models for one or more construction models that can be constructed from the set of construction elements included in the bill of materials; presenting on a client computer system at least one of the construction models identified in the search.

Owner:LEGO AS

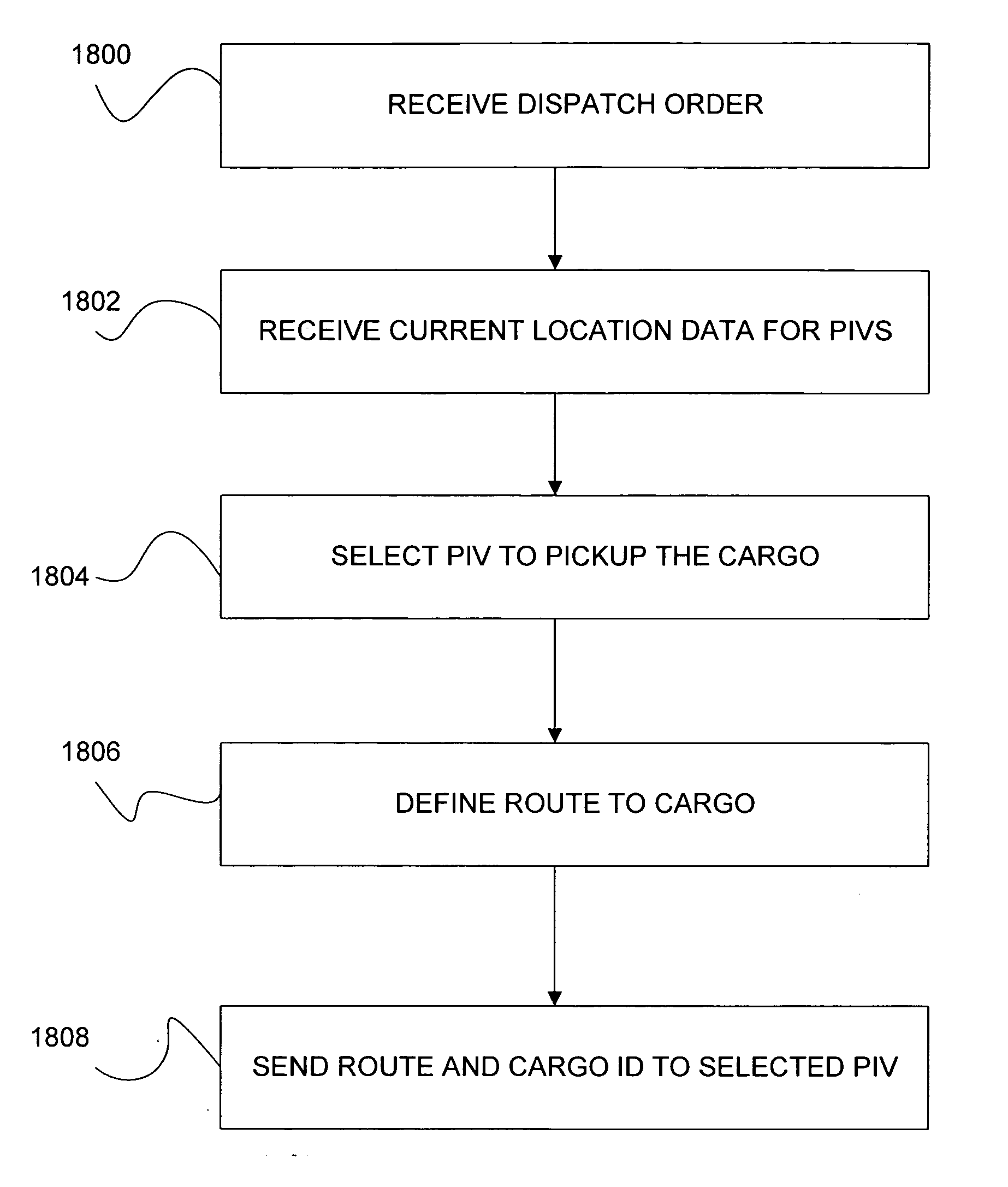

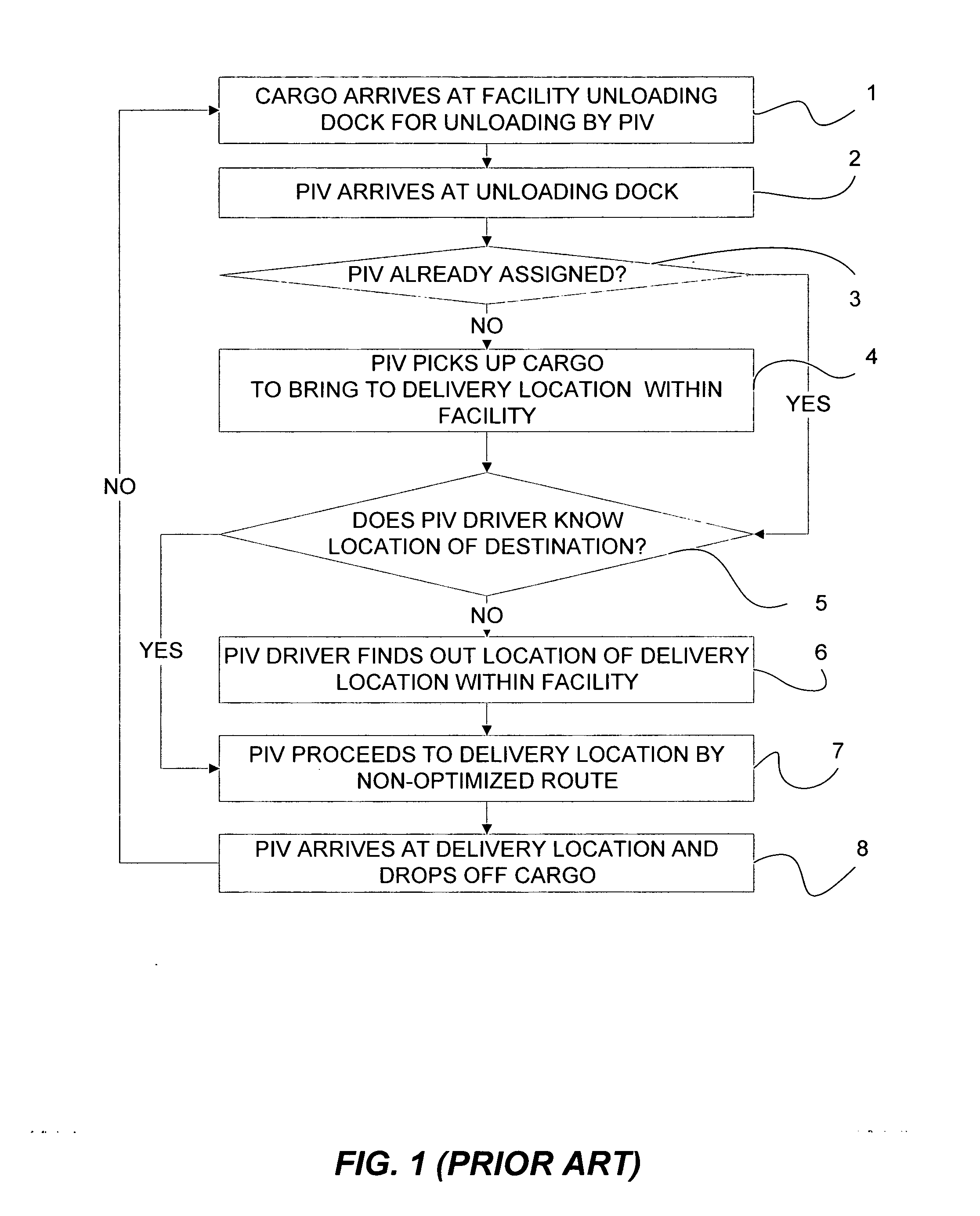

Systems and methods for creating on-demand routes for powered industrial vehicles

Systems and methods for creating in a facility on-demand routes for powered industrial vehicles to transport cargo efficiently. In one embodiment, an on-demand route generation module receives receiving a request to move cargo. The module analyzes data about the current location, the current tasking, and the driver availability of PIVs in operation. Based on the information, the module creates an on-demand route through the facility and sends a notification to an assigned PIV to pick up the cargo and carry it on the defined on-demand route.

Owner:US POSTAL SERVICE

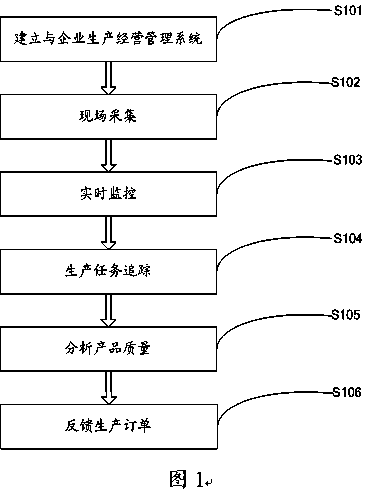

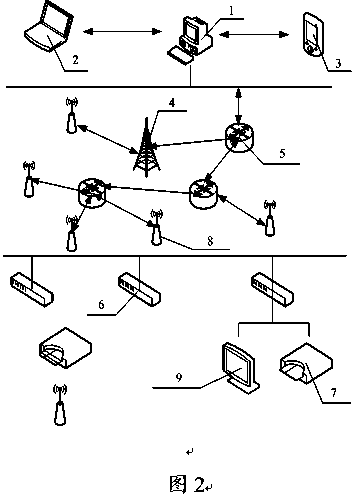

Workshop production management method and system based on Internet of Things

InactiveCN103810576AAchieve integrationAchieve sharingCo-operative working arrangementsResourcesData informationManufacturing execution system

The invention discloses a workshop production management method and system based on Internet of Things. The management method includes the steps of establishment of an enterprise production and operation management system, on-site acquisition, real time monitoring, productive task tracking, product quality analyzing and production order feeding back. The workshop production management system based on Internet of Things comprises a terminal management server, a receiving computer, a mobile phone with bluetooth or wireless fidelity (WiFi), a ZigBee coordinator, a ZigBee router, a station controller, a radio frequency identification (RFID) reader-writer, an electronic tag and a process displayer. According to the workshop production management method and system based on Internet of Things, workshop site is connected with an upper decision system by the aid of the RFID reader-writer and electronic tag manufacturing execution system (MES), integration and sharing of various data information of workshops can be achieved, thereby, the 'fault' phenomenon caused by incomplete sharing and exchange of enterprise data information in enterprises can be avoided, the management process is simplified, and the management efficiency is increased.

Owner:XIAN TECHNOLOGICAL UNIV

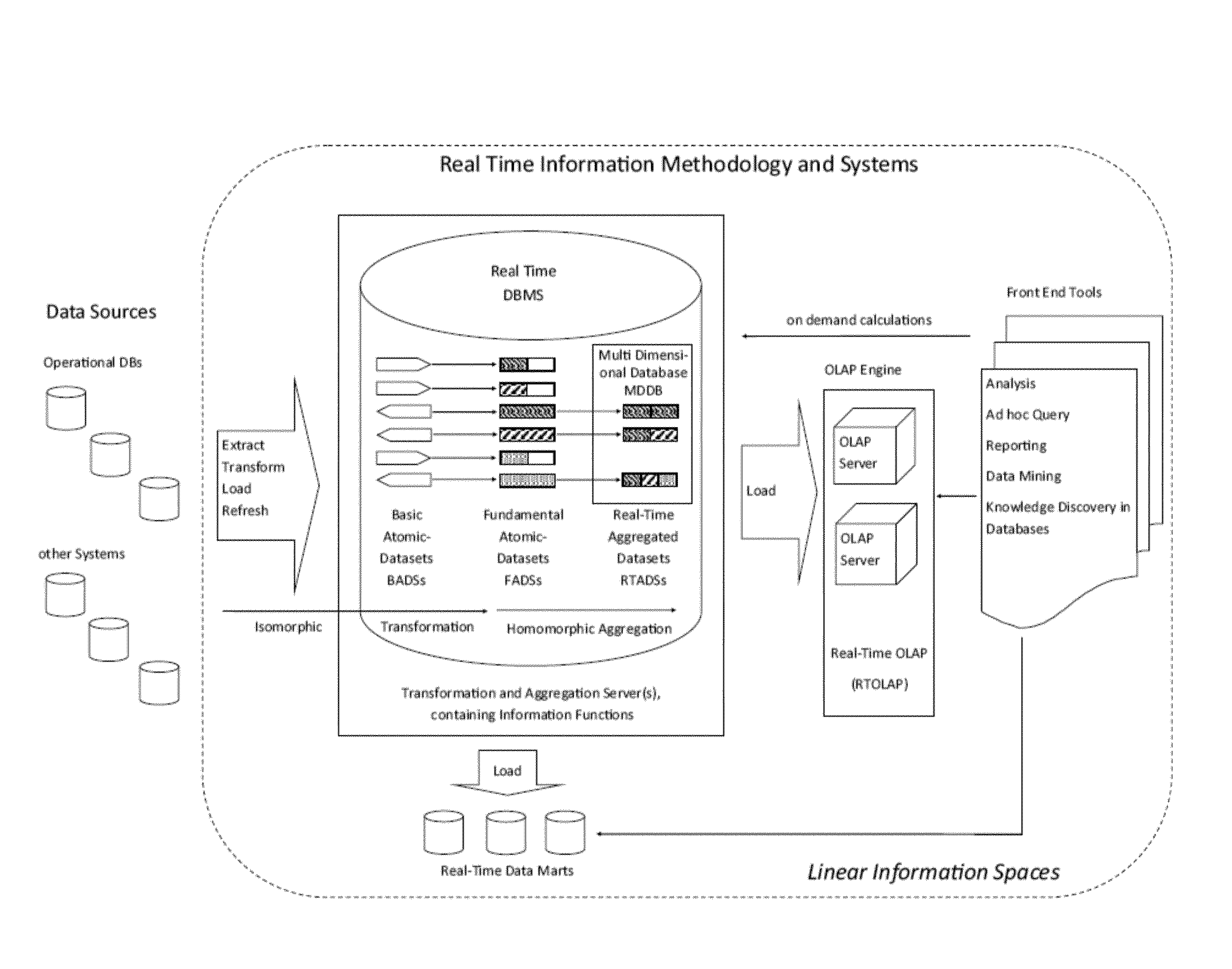

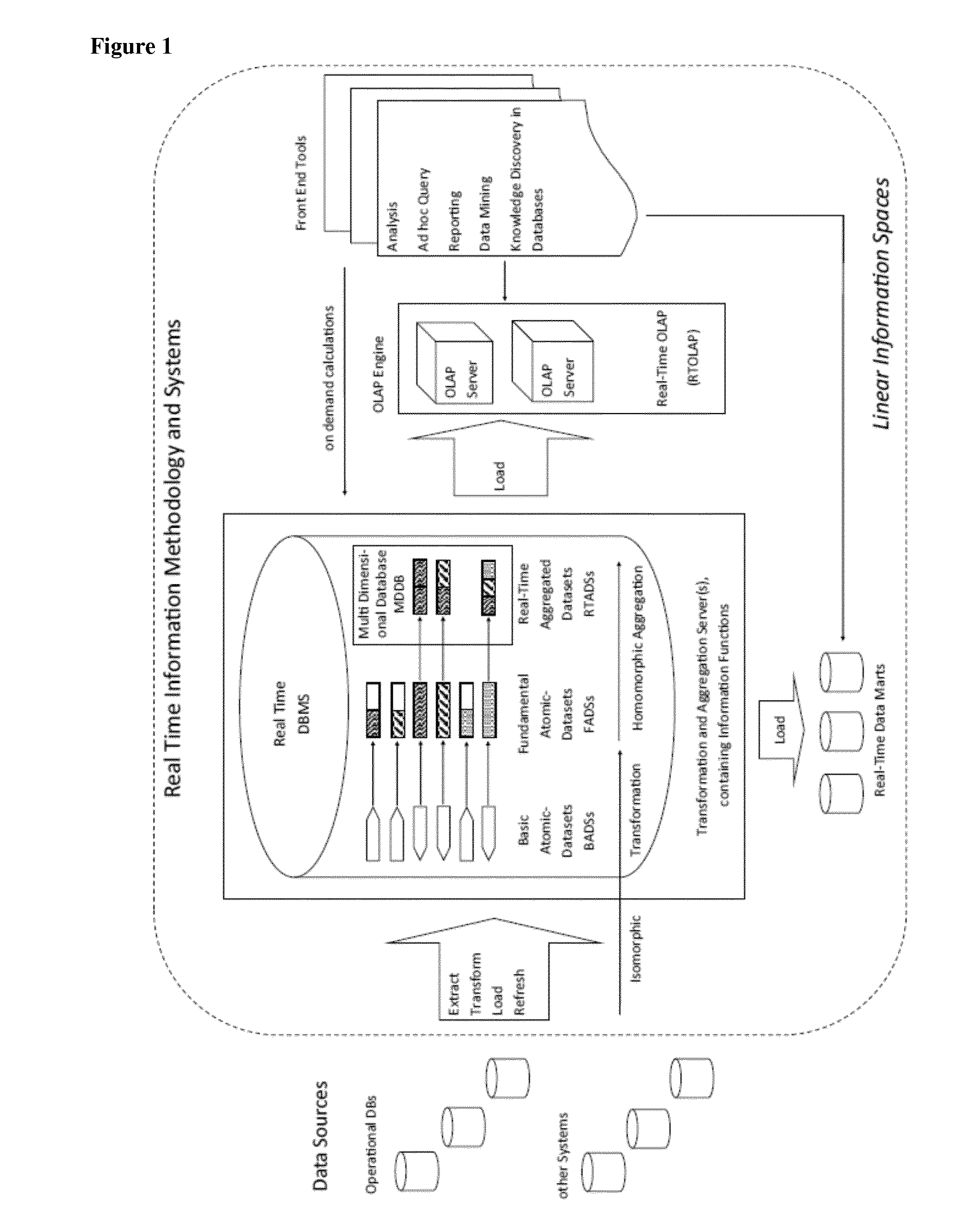

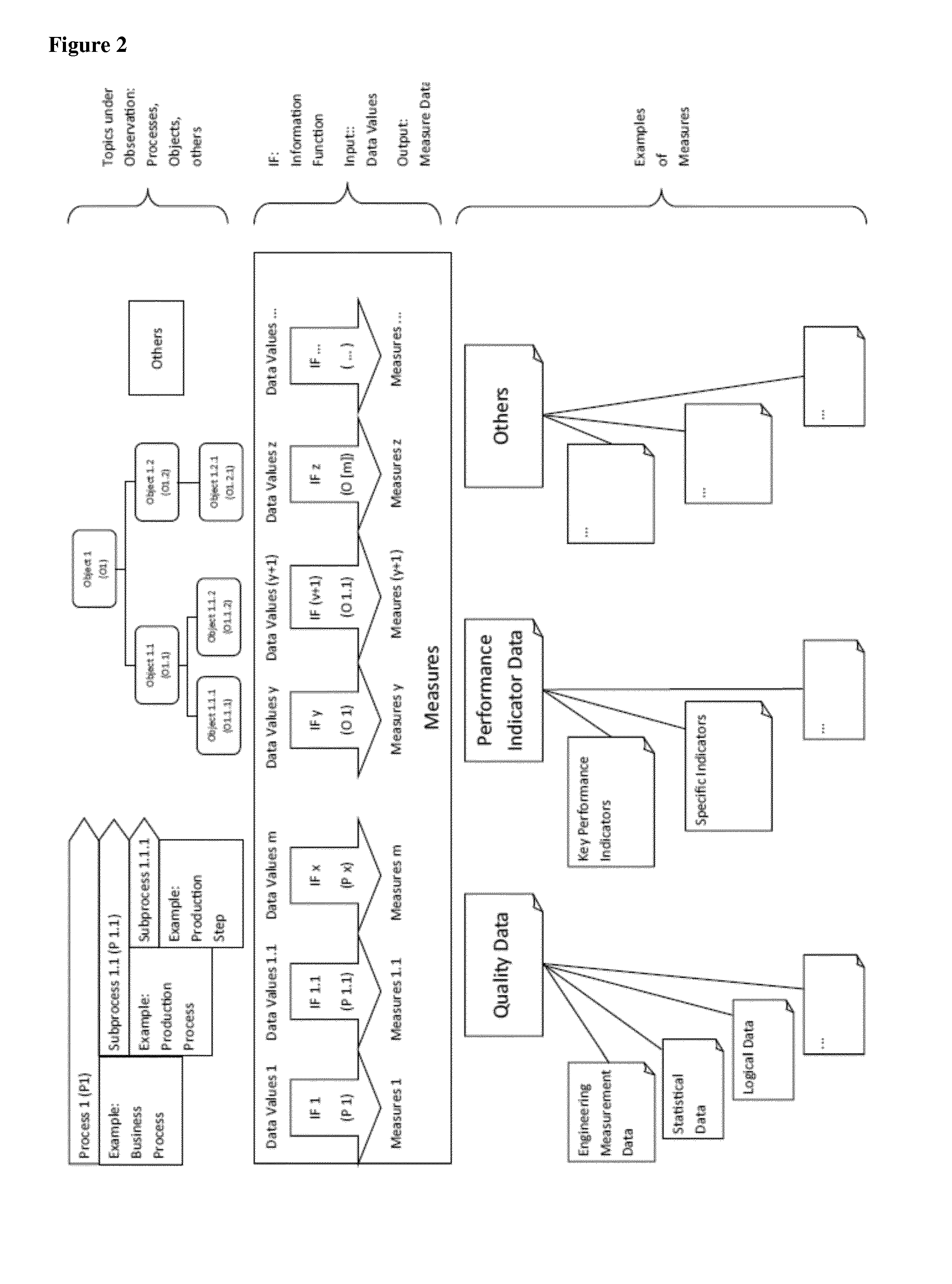

Real-time information systems and methodology based on continuous homomorphic processing in linear information spaces

InactiveUS20170032016A1Keep linearMulti-dimensional databasesResourcesTime informationInformation space

The present invention relates to the field of information system technology. More particularly, the present invention relates to methods and systems for Real-Time information processing, including Real-Time Data Warehousing, using Real-Time in-formation aggregation (including calculation of the performance indicators and the like) based on continuous homomorphic processing, thus preserving the linearity of the underlying structures. The present invention further relates to a computer program product adapted to perform the method of the invention, to a computer-readable storage medium comprising said computer program product and a data processing system, which enables Real-Time information processing according to the methods of the invention.

Owner:SYST SYSTNTWICKLUNG DIP INF MANFRED AUSTEN

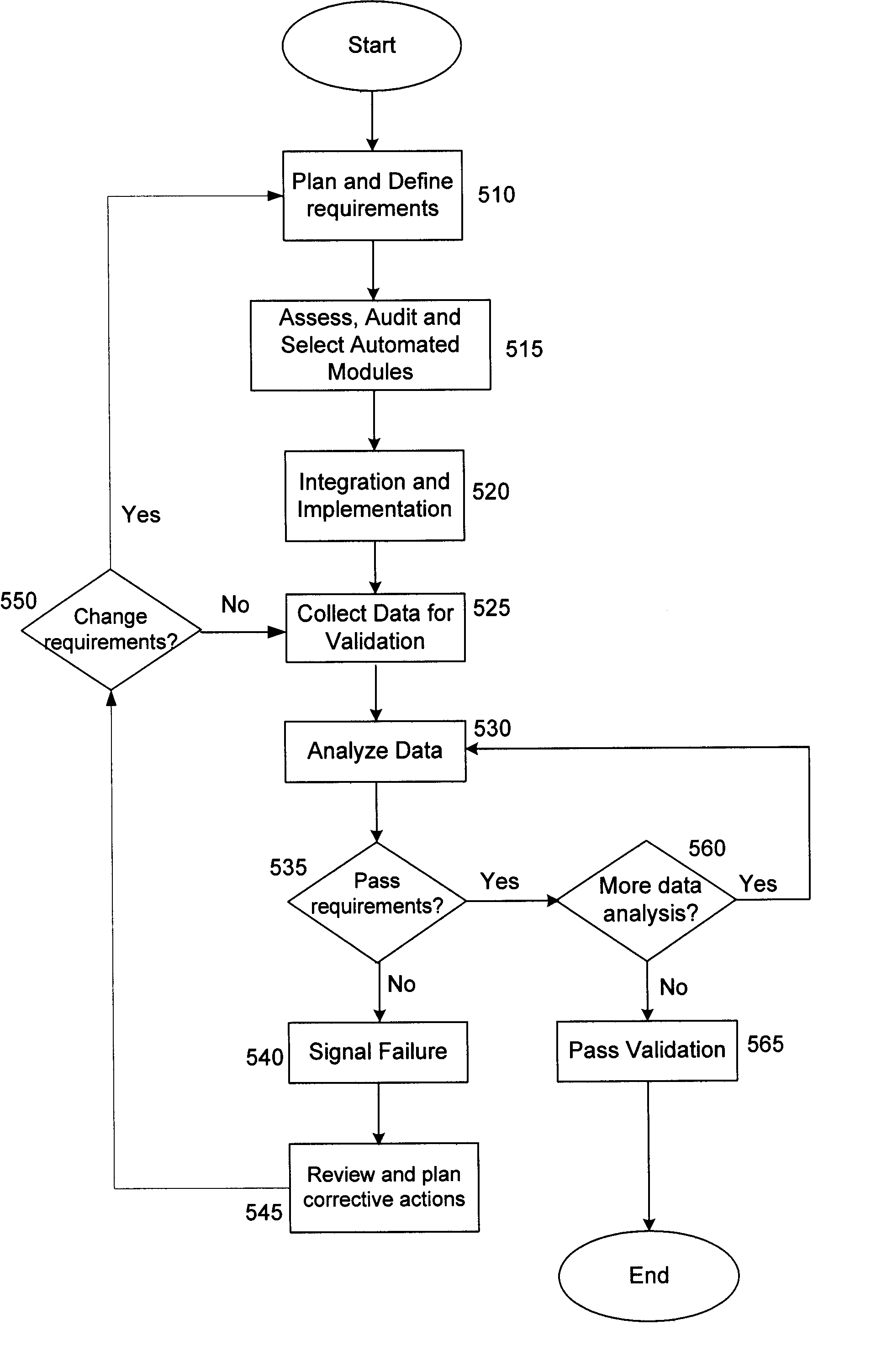

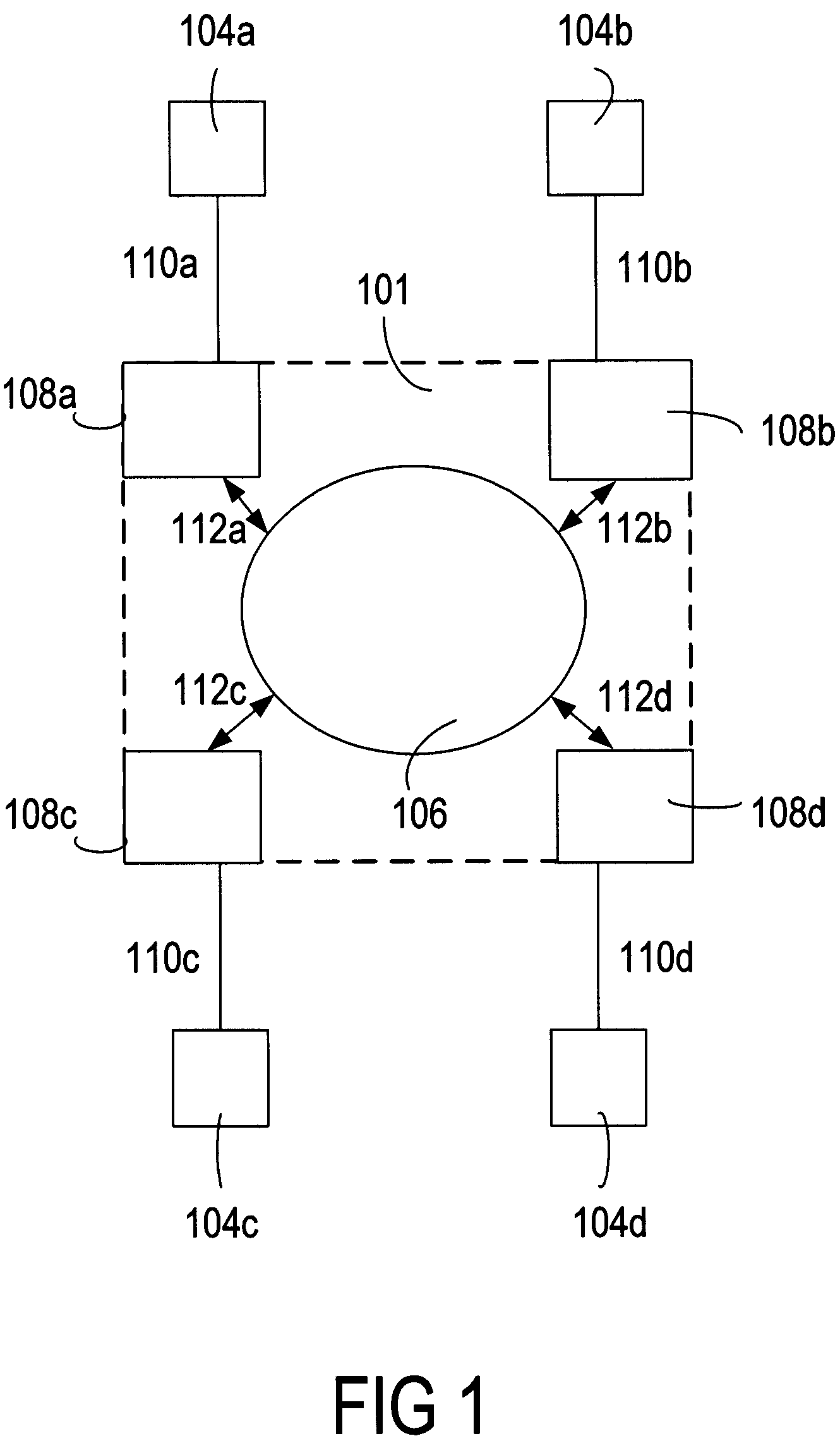

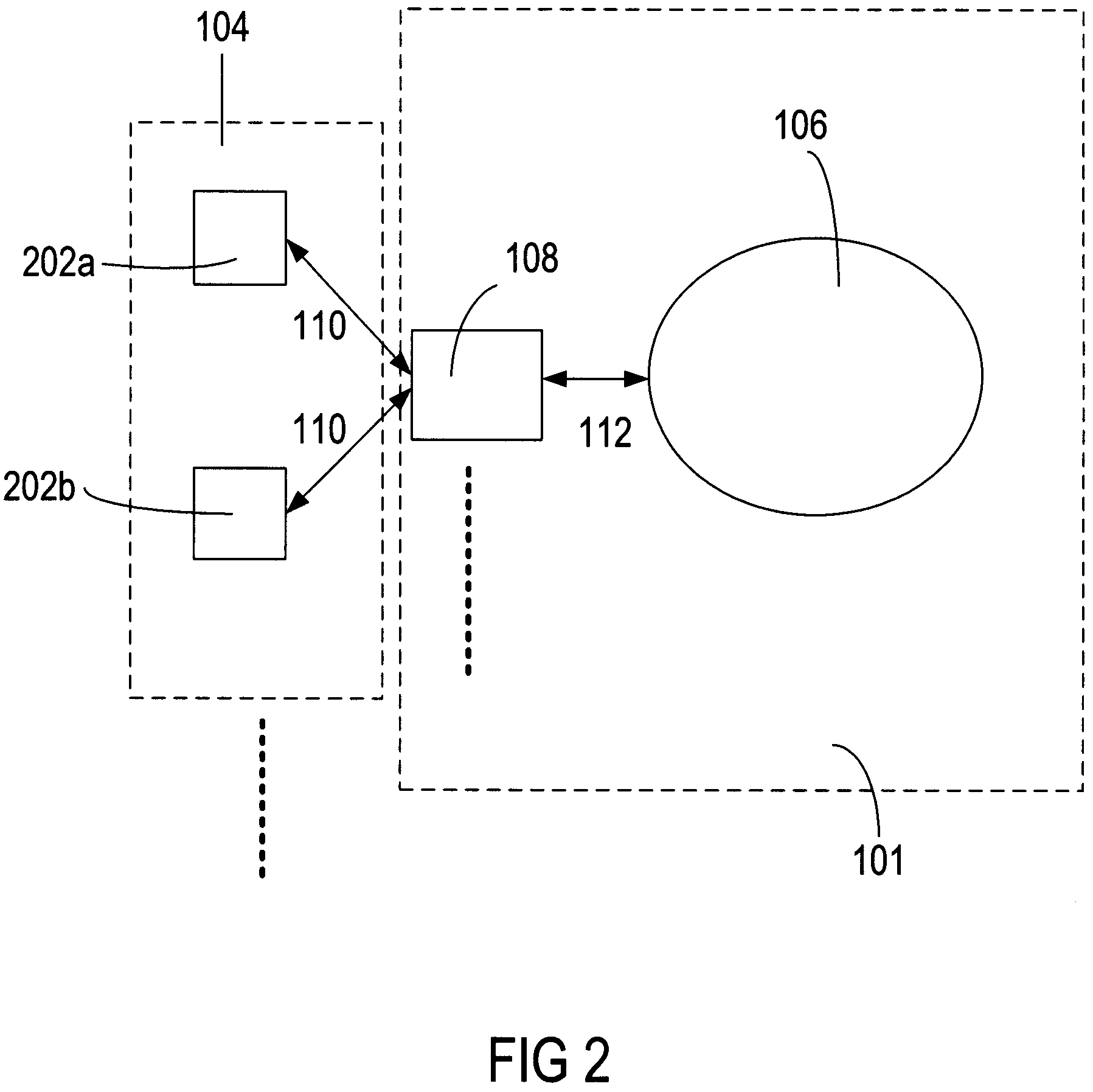

Virtual platform to facilitate automated production

InactiveUS20050137735A1Facilitate communicationSatisfies requirementData processing applicationsTotal factory controlTelecommunications linkCommunication link

A method of automating validation in a manufacturing facility is disclosed. The method comprises defining requirements, selecting and integrating automated devices for manufacturing. A hub-box with communication links is used to integrate the automated devices. The hub-box controls and facilitates communication between automated devices. The hub-box further collects and analyzes processing data for validation of the process. By interconnecting the automated devices to a hub-box, processing data may be collected substantially real-time and accessed remotely, facilitating continuous process validation.

Owner:BEACONS PHARMA

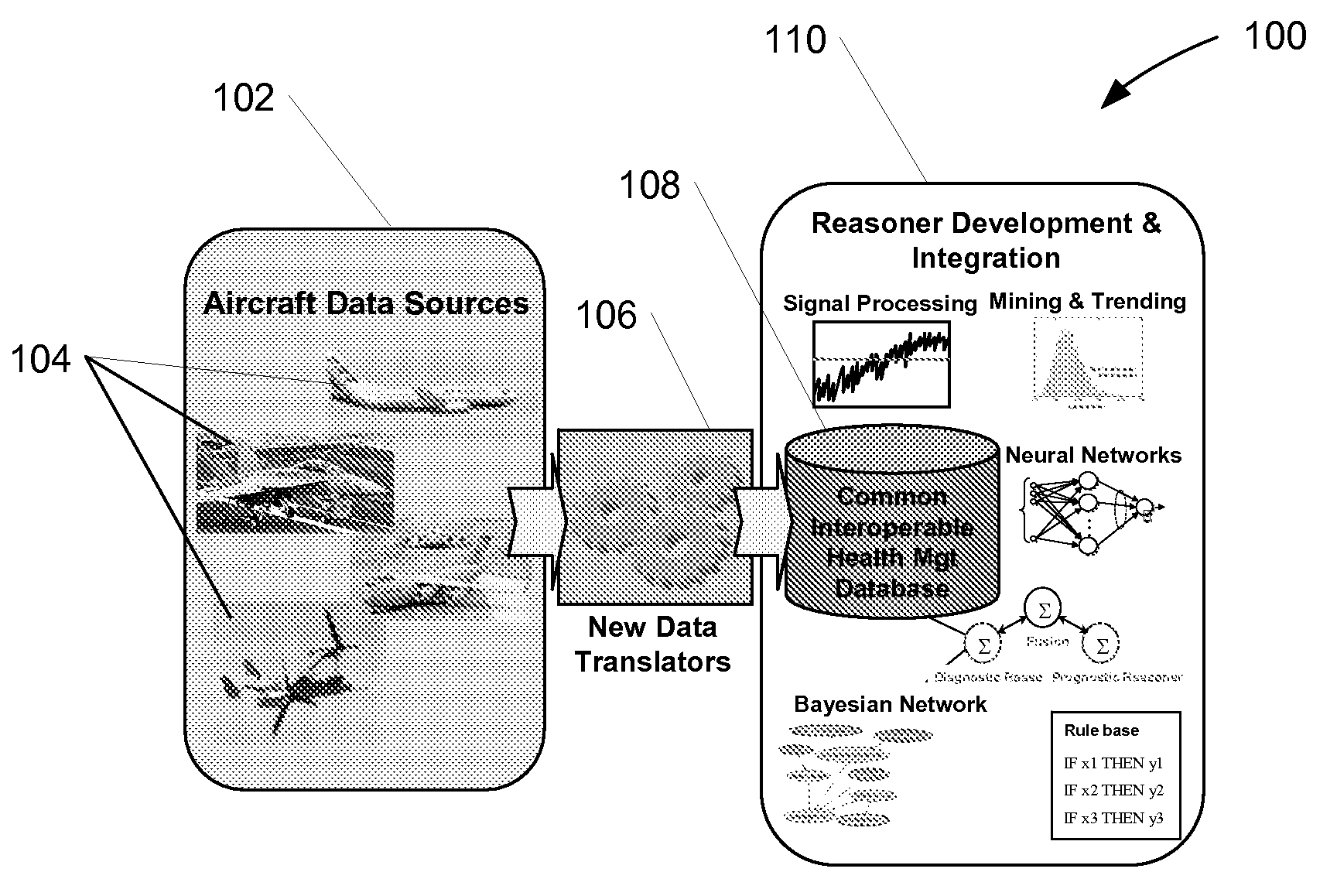

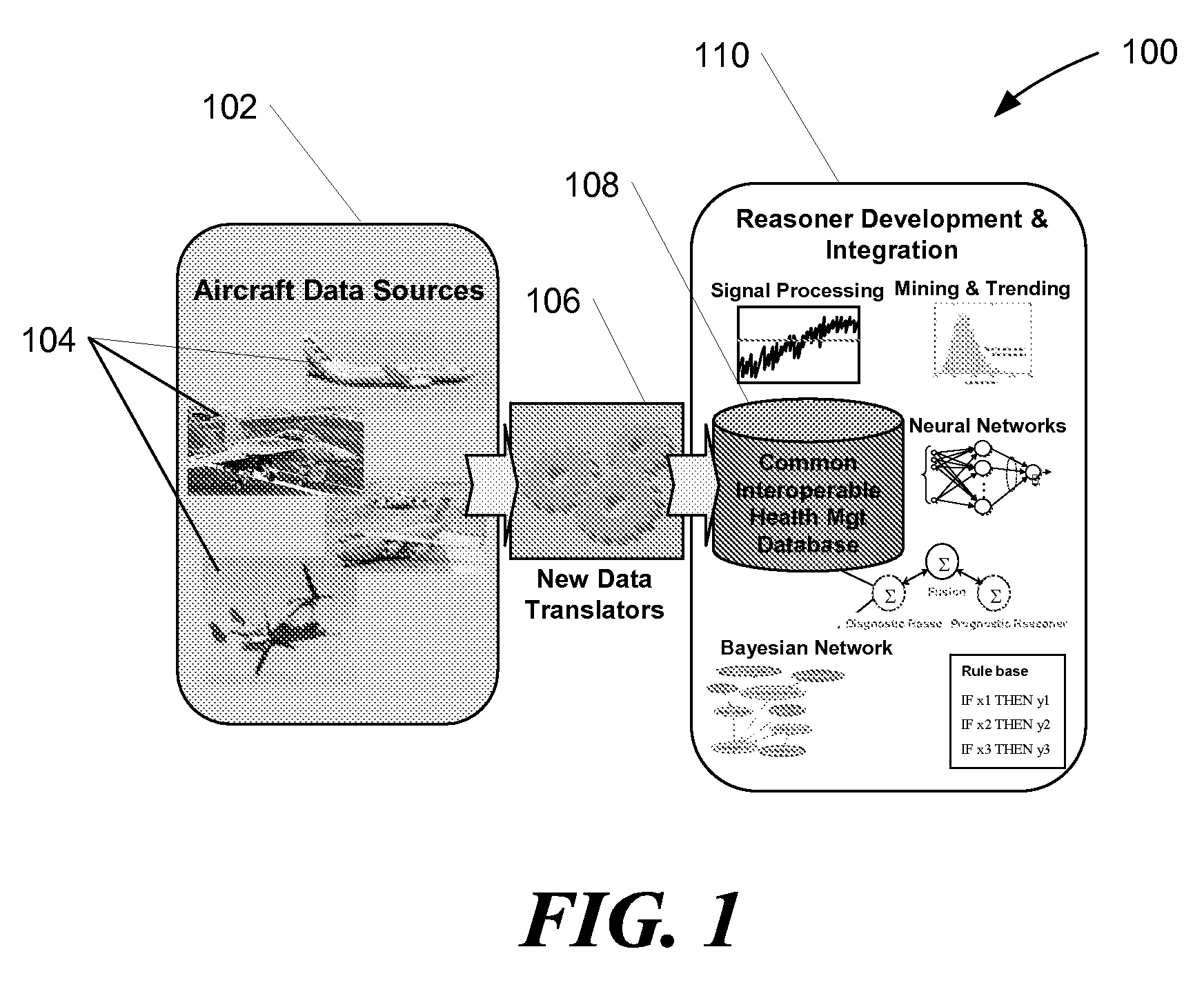

Systems and Methods for Health Management of Single or Multi-Platform Systems

InactiveUS20080040152A1Improve maintainabilityImprove securityData processing applicationsTesting/monitoring control systemsMulti platformAnalysis of algorithms

Systems and methods for health data management are disclosed. In one embodiment, a method of monitoring health information for a multi-platform system includes receiving health information from one or more subsystems of a plurality of platforms, and analyzing the health information using one or more reasoner algorithms configured to predict a potential failure of the one or more subsystems. Upon prediction of a potential failure, the method includes providing a prognostic characteristic of the one or more subsystems. In alternate embodiments, the method may further include translating at least some of the health information for each of the one or more subsystems into a common format, and storing the translated health information into a database for subsequent analysis.

Owner:THE BOEING CO

Process plant monitoring based on multivariate statistical analysis and on-line process simulation

Disclosed are systems and methods for on-line monitoring of operation of a process in connection with process measurements indicative of the operation of the process. In some cases, the operation of the process is simulated to generate model data indicative of a simulated representation of the operation of the process and based on the process measurements. A multivariate statistical analysis of the operation of the process is implemented based on the model data and the process measurements. The output data from the multivariate statistical analysis may then be evaluated during the operation of the process to enable the on-line monitoring of the process involving, for instance, fault detection via classification analysis of the output data.

Owner:FISHER-ROSEMOUNT SYST INC

Method for creating, manufacturing, and distributing three-dimensional models

InactiveUS7656402B2Ensure uniquenessMedical simulationAdditive manufacturing apparatusThird party3d image

A method is provided for producing three-dimensional (3D) models. The invention will take any sculpture, character, or model from artwork, still life models, images of human beings, characters from a computer game, or any other 3D digital image or model that is scanned, and turn the digital image into 3D models. The method is comprised of the following steps: creating a user account in a computer storage area; storing 3D images under the user account; allowing the user to select the 3D image(s) he or she wants to create as 3D models; manufacturing the 3D models; and delivering the models to the user or to a specified third-party. An online storefront and / or auction system may allow each user the opportunity to sell their 3D models or purchase other users' 3D models. The system may also create 3D models for a mobile phone and portable media player while transferring the models to either of these devices.

Owner:TAG LLC (US)

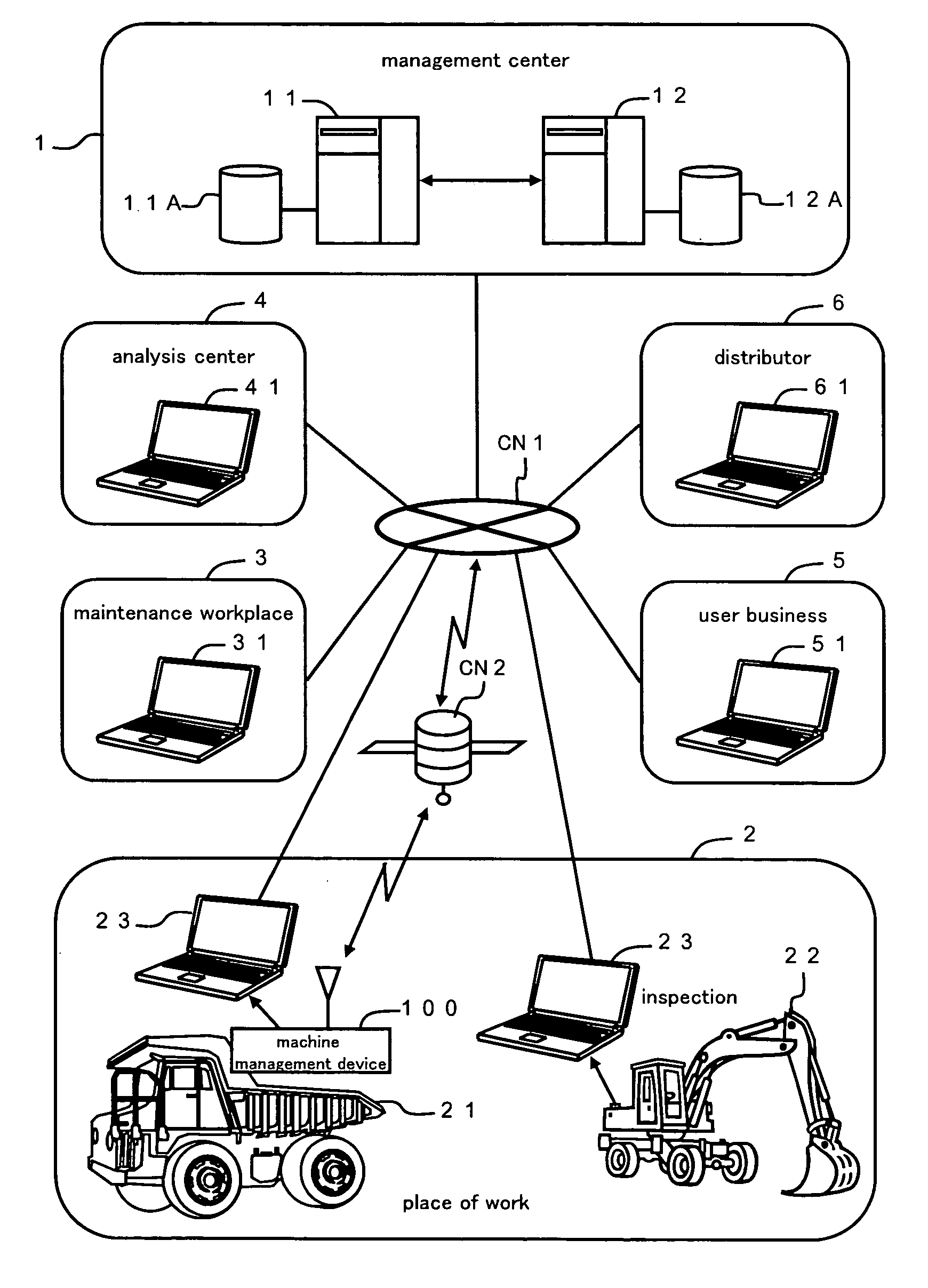

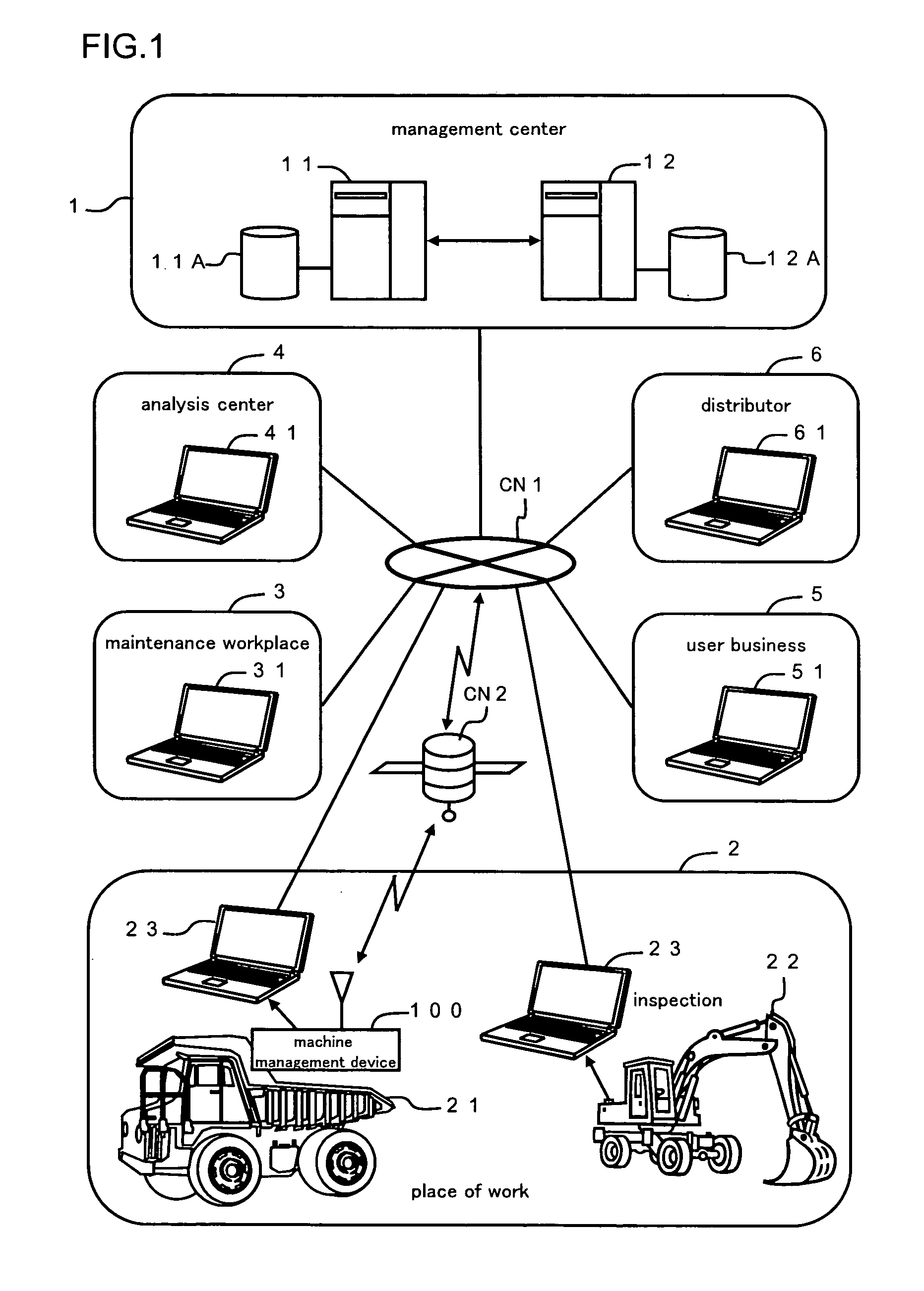

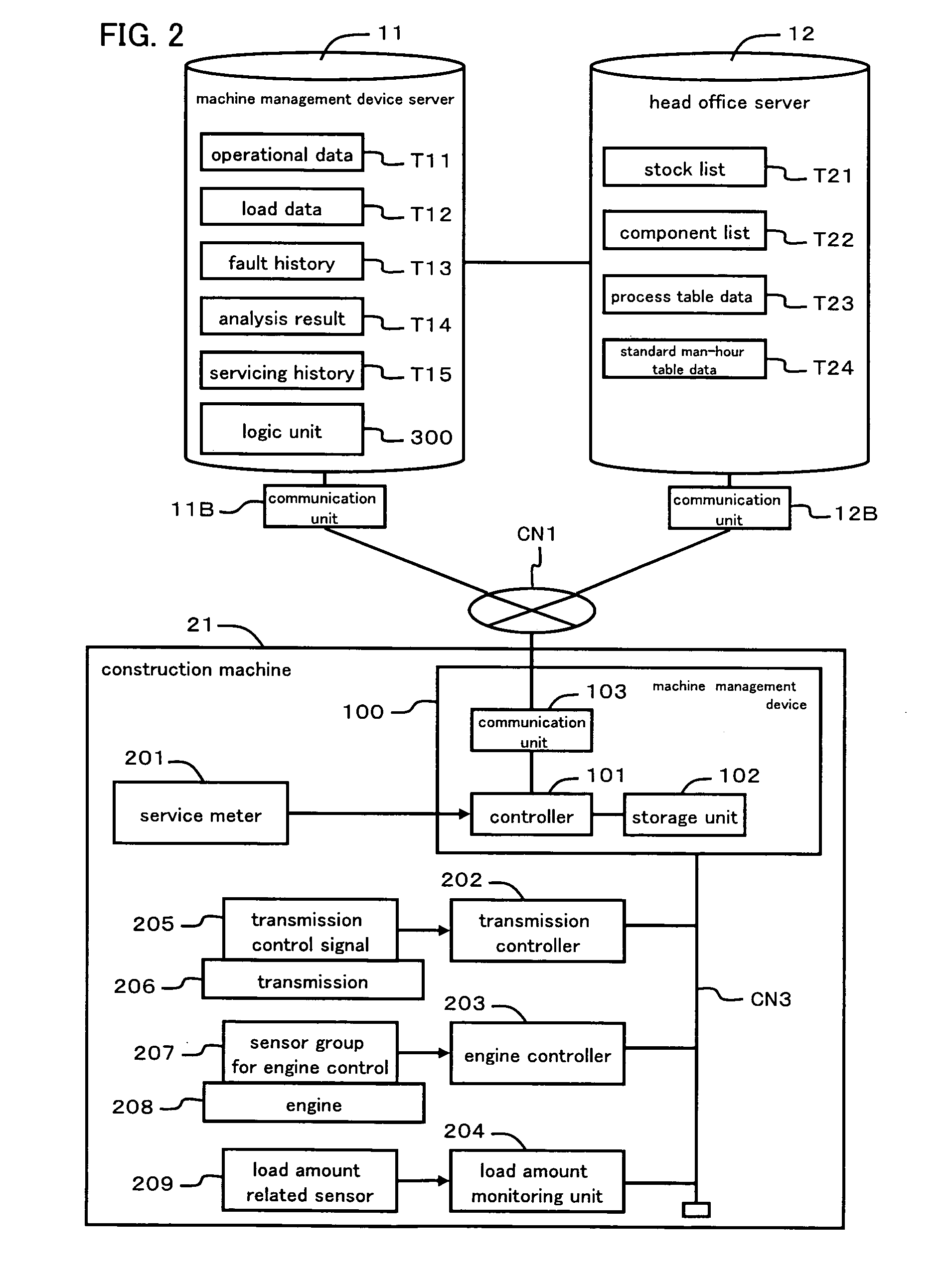

System for construction machine maintenance based on predicted service life

ActiveUS8533018B2Improve accuracyWorking capability of the maintenance workplace is exceededForecastingSoil-shifting machines/dredgersMachine maintenancePaper document

To predict the service life of a construction machine more accurately, and to make it possible to draw up an appropriate overhaul implementation plan at an early stage.A first service life prediction unit 311 predicts the service lives of main components such as an engine and the like, based upon their actual wear states. And a second service life prediction unit 312 predicts the service lives of the same components, based upon their cumulative load amounts. An order setting unit 320 selects the ones of these two predicted service lives which are the shorter, and sets a priority order for overhaul in order of shortness of predicted service life. An overhaul schedule table generation unit 330 creates a schedule table D1 based upon this priority order. The contents of this schedule table D1 are decided upon by a judgment unit 340, and, if necessary, are corrected by a correction unit 341. And a plan creation unit 350 creates an overhaul implementation plan document D2 and the like, based upon the corrected schedule table D1a. The result of the overhaul task and the present states of components are tested, and these test results are reflected by the service life prediction units 311 and 312.

Owner:KOMATSU LTD

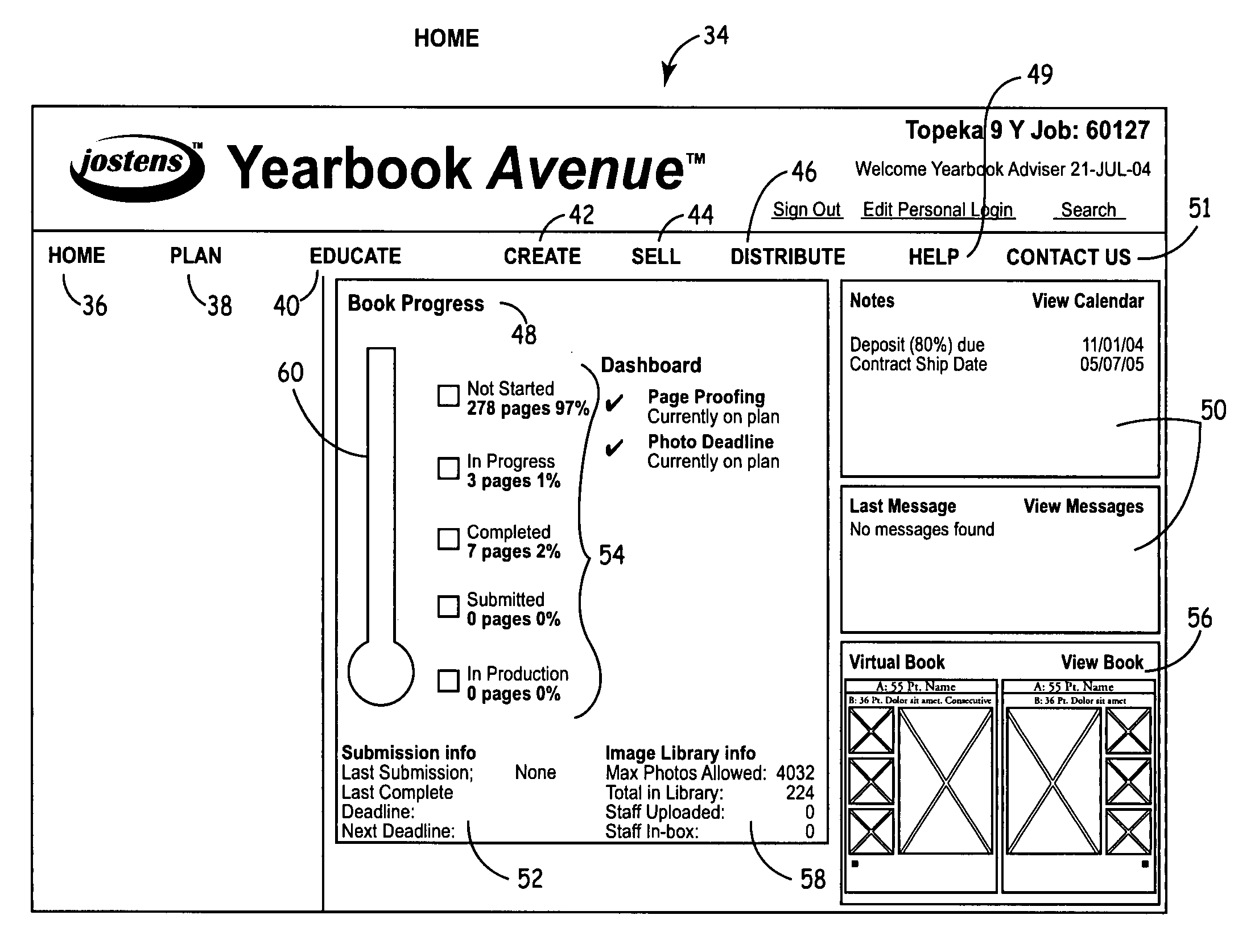

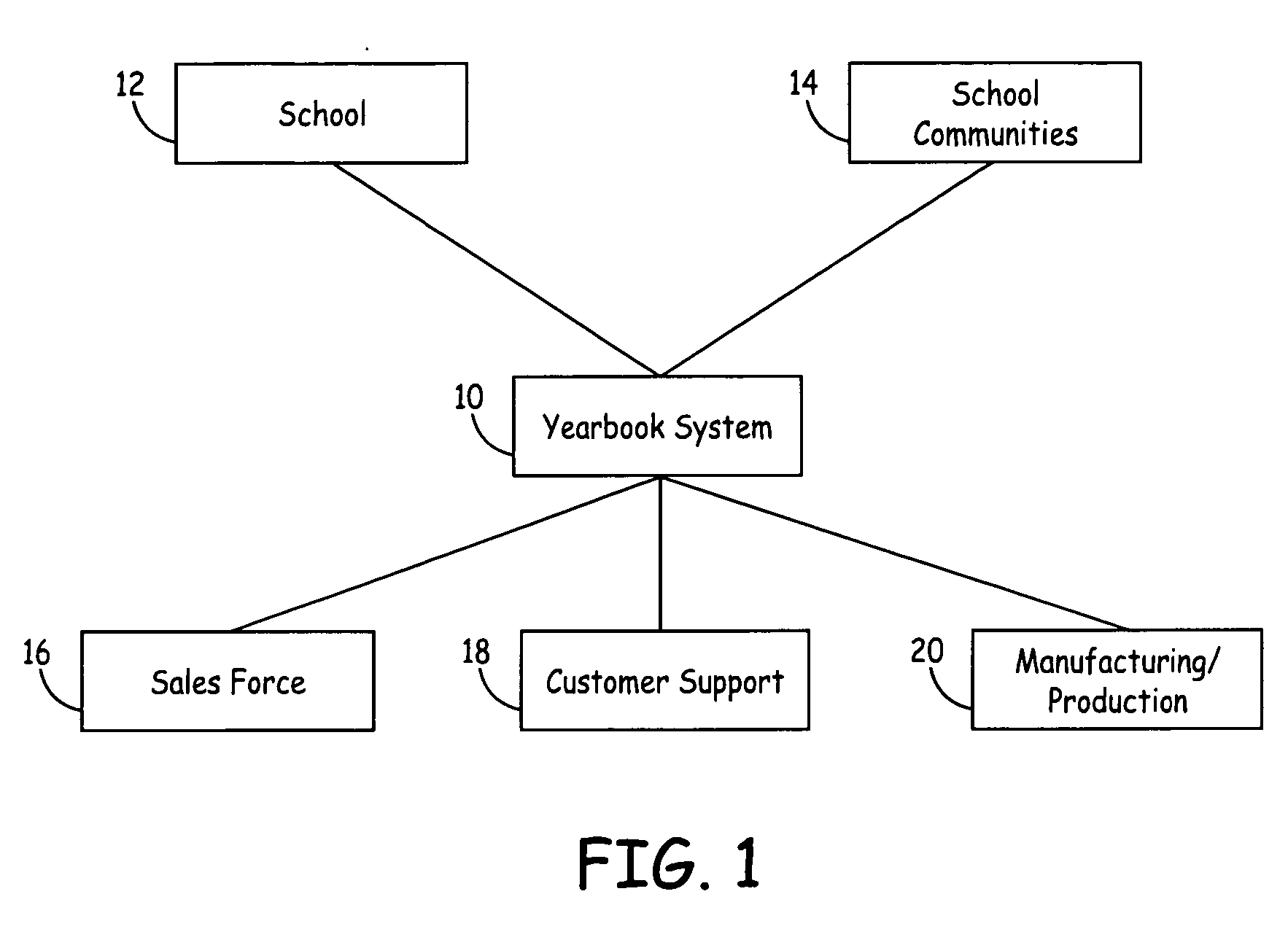

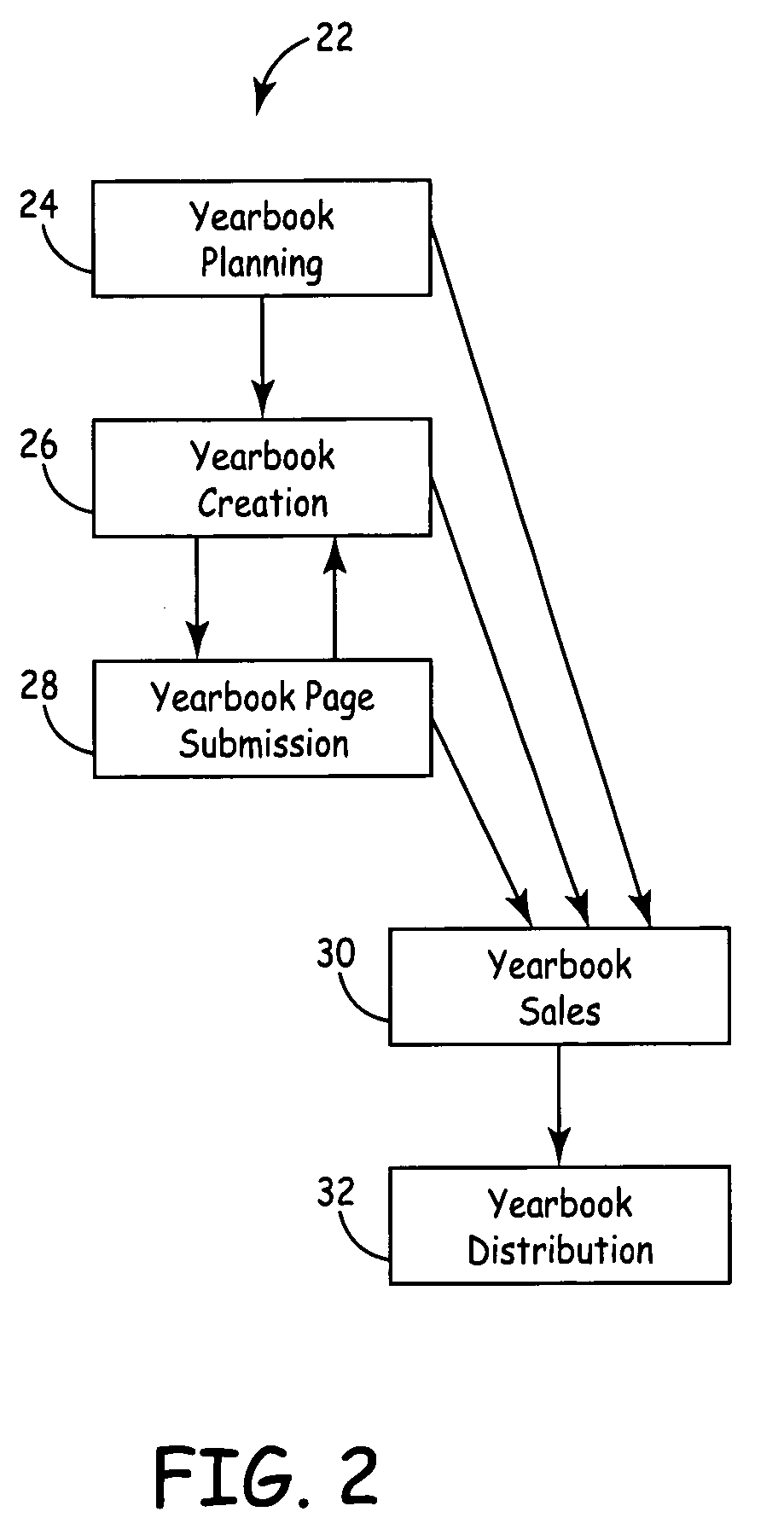

System and method for yearbook creation

A yearbook system is provided. The yearbook system provides a single, extensive resource to plan, create, educate about, sell, and distribute yearbooks. The system further provides an integrated yearbook system management and yearbook production system to enable the production of the yearbook to a printed output. A yearbook server hosts a client site and a client database. The client site is enables the school to plan, create, sell and distribute a yearbook. Further, they system may be used to create the yearbook online. A production server hosts a production database synchronizes with the yearbook server, providing images to the client for use in creating the yearbook, and accepting completed created pages submitted by the school from the yearbook server. The production server translates the created pages into the format to proceed through the regular preparation for production of the yearbook.

Owner:JOSTENS INC

Method and system for providing automated high scale fabrication of custom items

ActiveUS20080215176A1High scaleIncrease volumeProgramme controlAdditive manufacturing apparatusNetwork packetCustom-fit

Method and system for providing volume manufacturing of customizable items including receiving a data package including a plurality of manufacturing parameters, each of the plurality of manufacturing parameters associated with a unique item, verifying the received data package, and implementing a manufacturing process associated with the received data package is provided.

Owner:ALIGN TECH

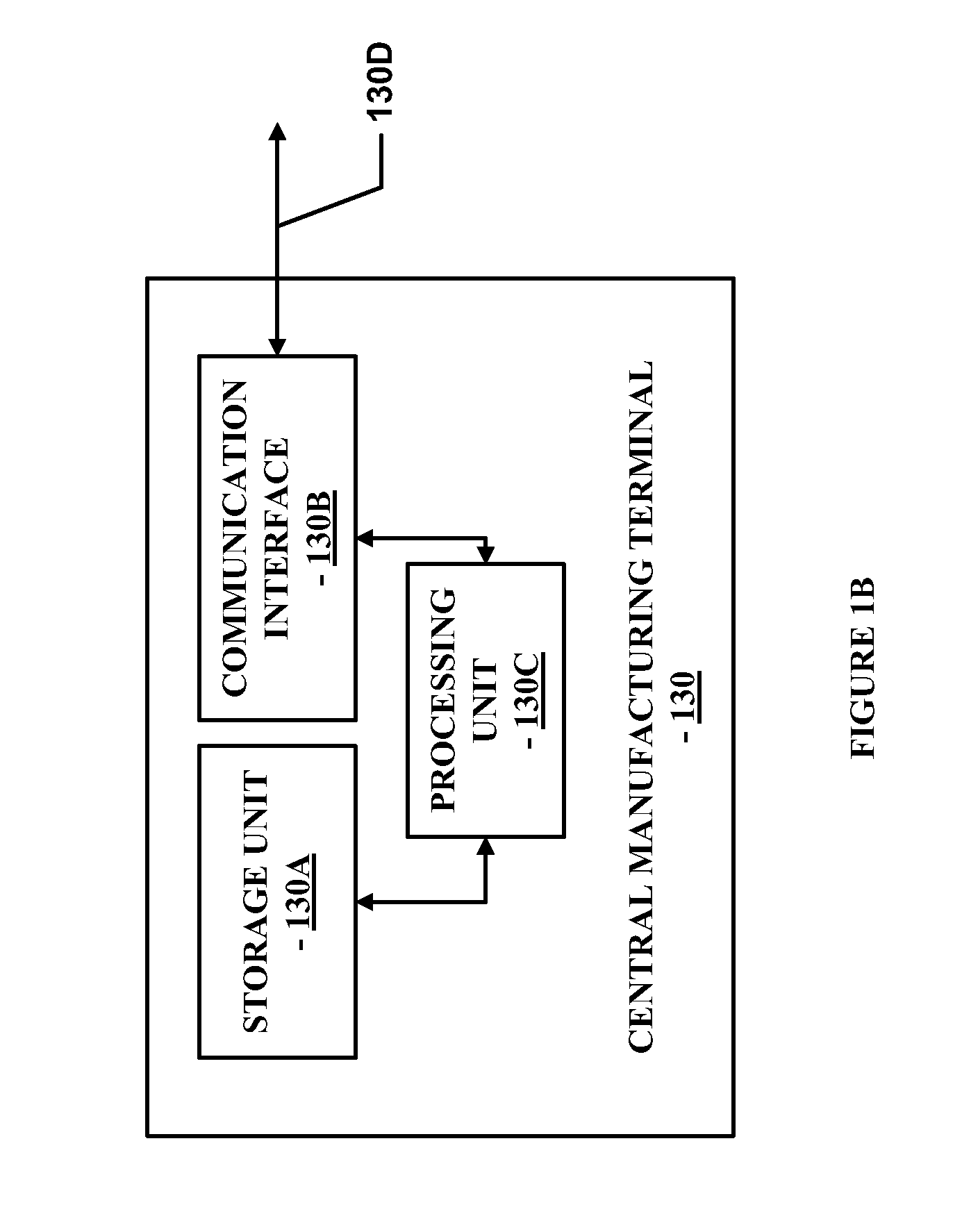

System and Method for Automated Manufacturing of Custom Apparel

A centralized command and control network system for the automated manufacture of a personalized custom-fit garment comprises a centralized control system; automated programmable manufacturing equipment configured for assembling and stitching the personalized custom-fit garment from a digital pattern; and automated programmable material handling equipment configured for transporting the personalized custom-fit garment or its components through each step of the manufacturing equipment. After the customer has had his or her body scanned, and selected and personalized a garment design, the inventive manufacturing system will then manufacture the garment upon receipt of the order in an automated manner without requiring further substantive manual intervention or touch labor. The resultant personalized custom-fit garment is based on the customer's three-dimensional body shape and style and fit preferences. The system can be used to prepare any kind of garments.

Owner:3D TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com