System and Method for Creating Custom-Fit Apparel Designs

a technology of custom-fit apparel and system, applied in the field of system and method for creating custom-fit apparel designs, can solve problems such as parts of the process which cannot be readily automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

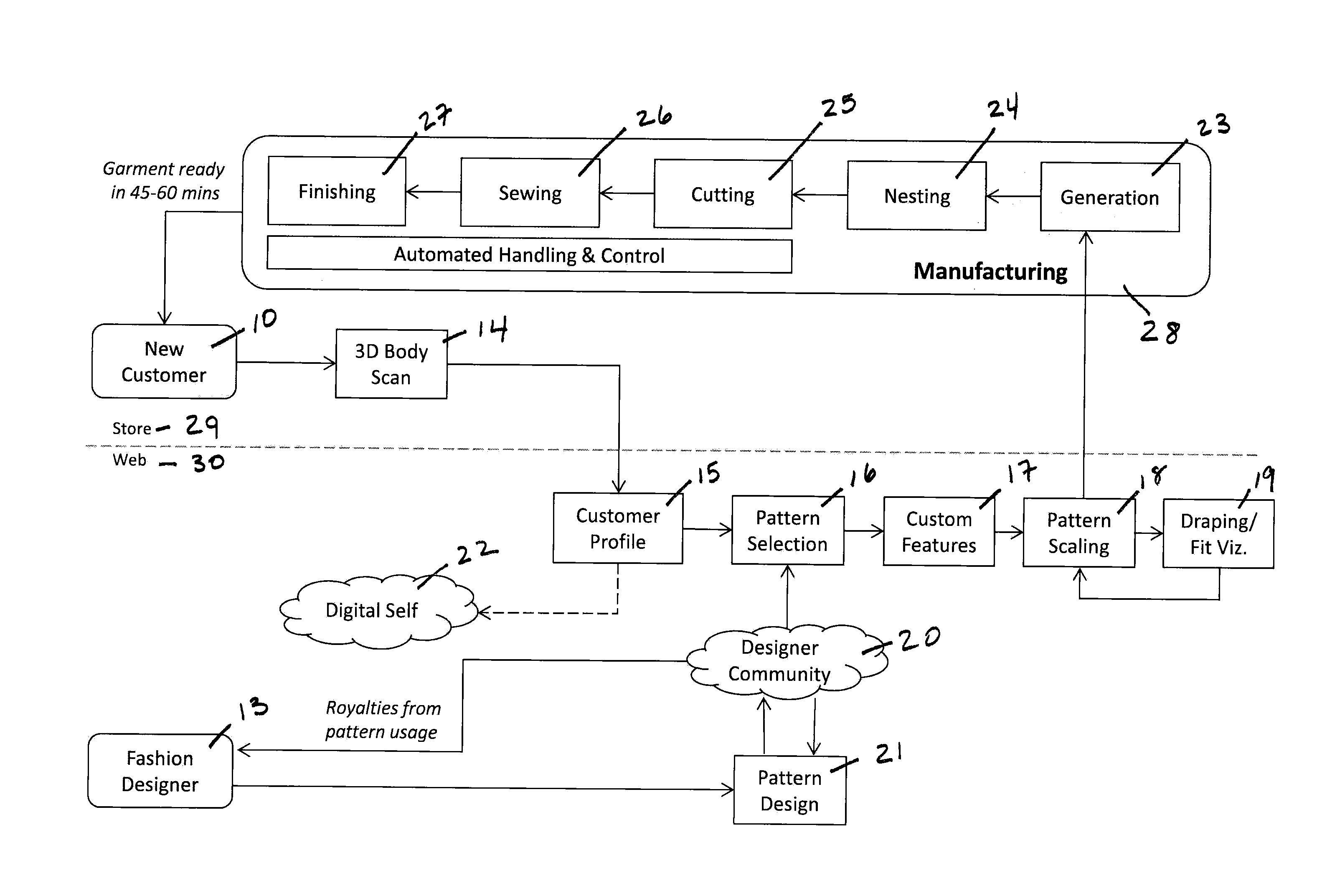

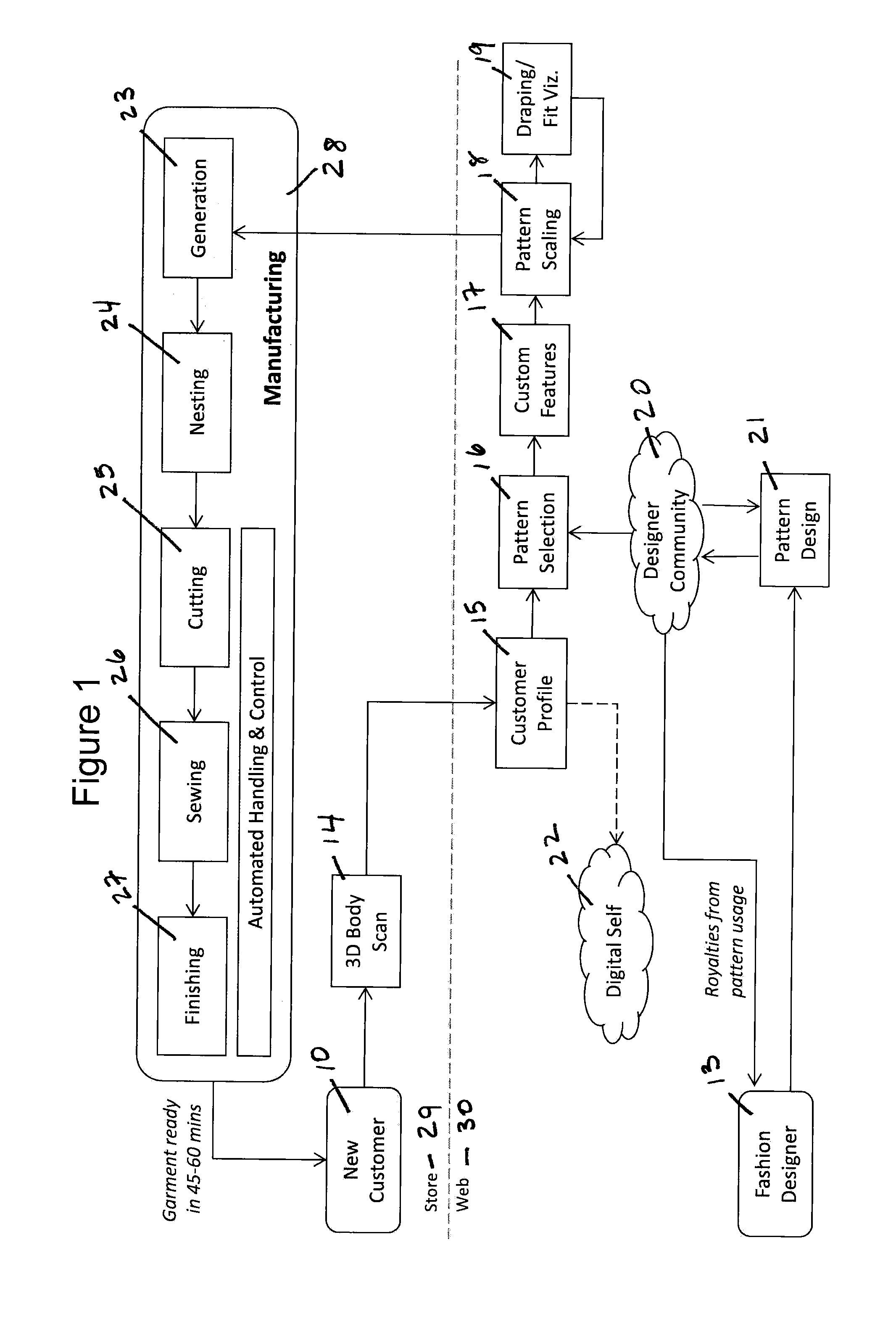

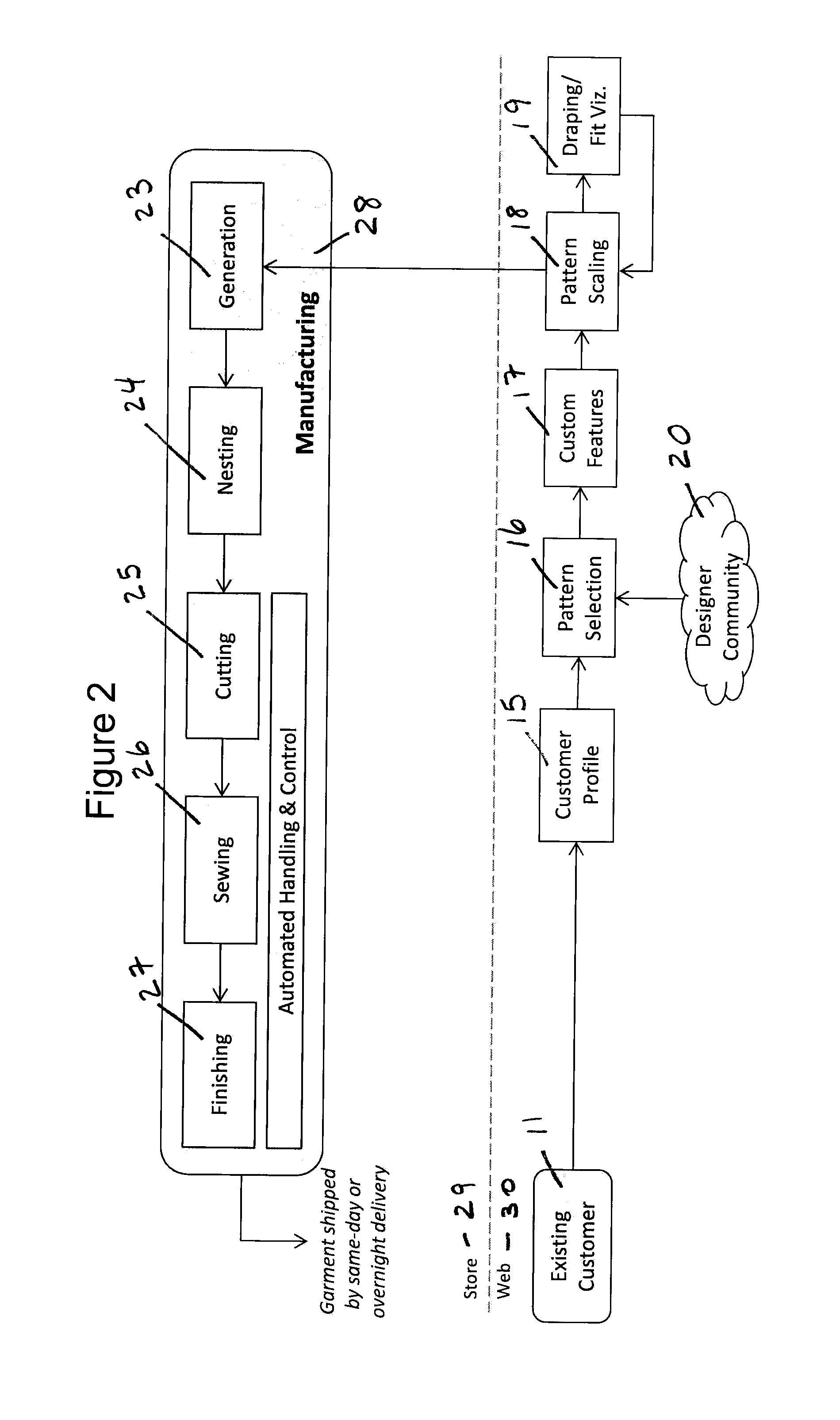

[0086]An object of the present invention is to enable the fabrication of apparel tailored to particular customer preferences with a high level of flexibility and customization, comparable to that of conventional hand tailoring, with the ability to utilize a wide range of digitally-represented clothing patterns to manufacture the personalized custom-fit garments on significantly shorter timelines.

[0087]A further object of the invention is to improve upon the level of automation that is customarily present in high-volume production facilities by automating material handling among manufacturing work steps and by providing a centralized control system for the manufacturing and material handling equipment. The invention is aimed principally at low- to medium-volume production and consequently is geared toward maximizing the flexibility and range of customization rather than production rate.

[0088]The automated manufacturing of apparel in accordance with the principles of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com