Patents

Literature

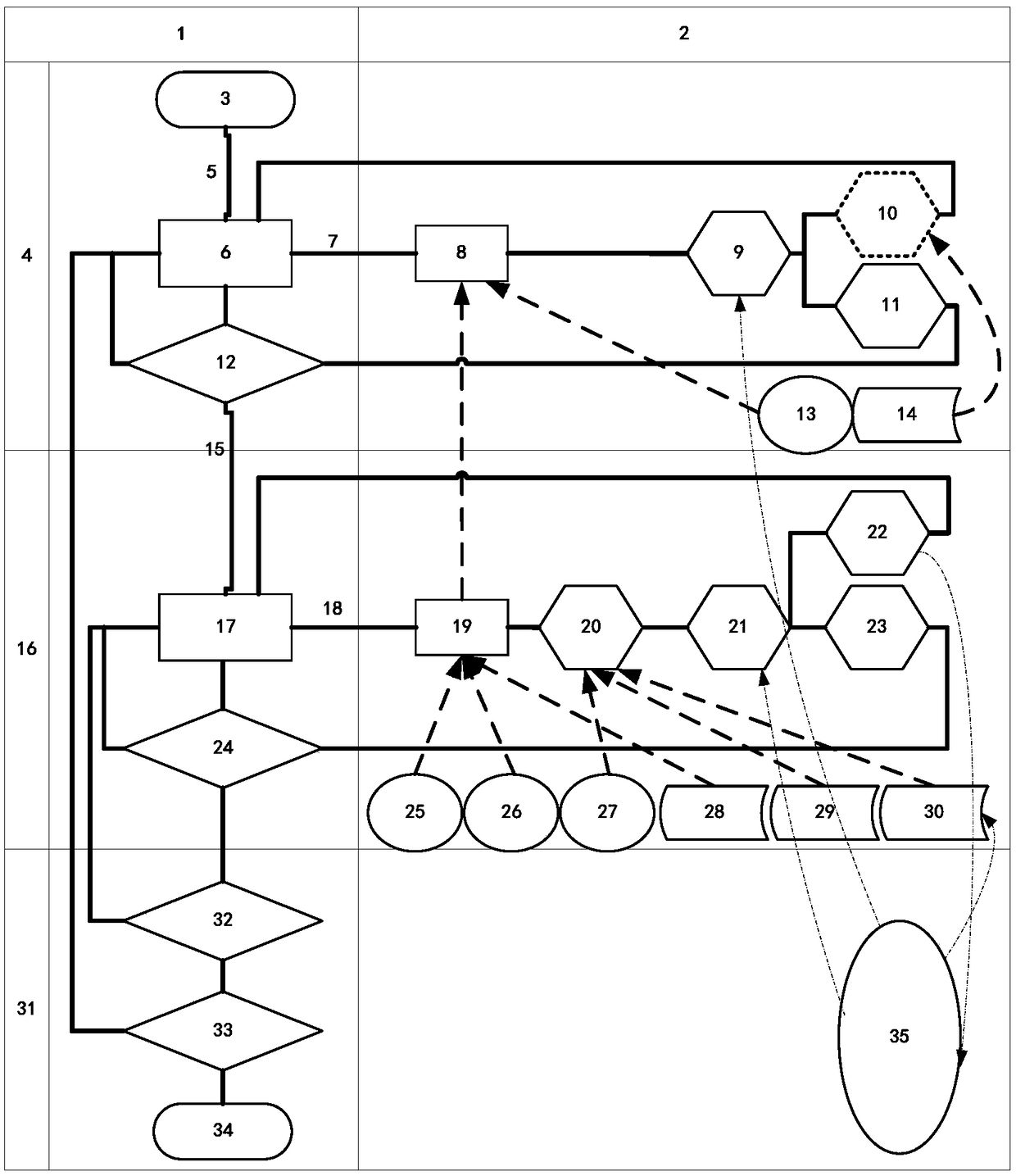

330 results about "Design process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A design process generates a conceptual solution for a problem stated in the form of requirements. ICONIX provides a complete software development process which incorporates a design process. Pure design methodologies can be plugged into software development processes like extreme programming and Rational Unified Process. A design process is usually followed by an implementation process which provides a concrete solution based on the design.

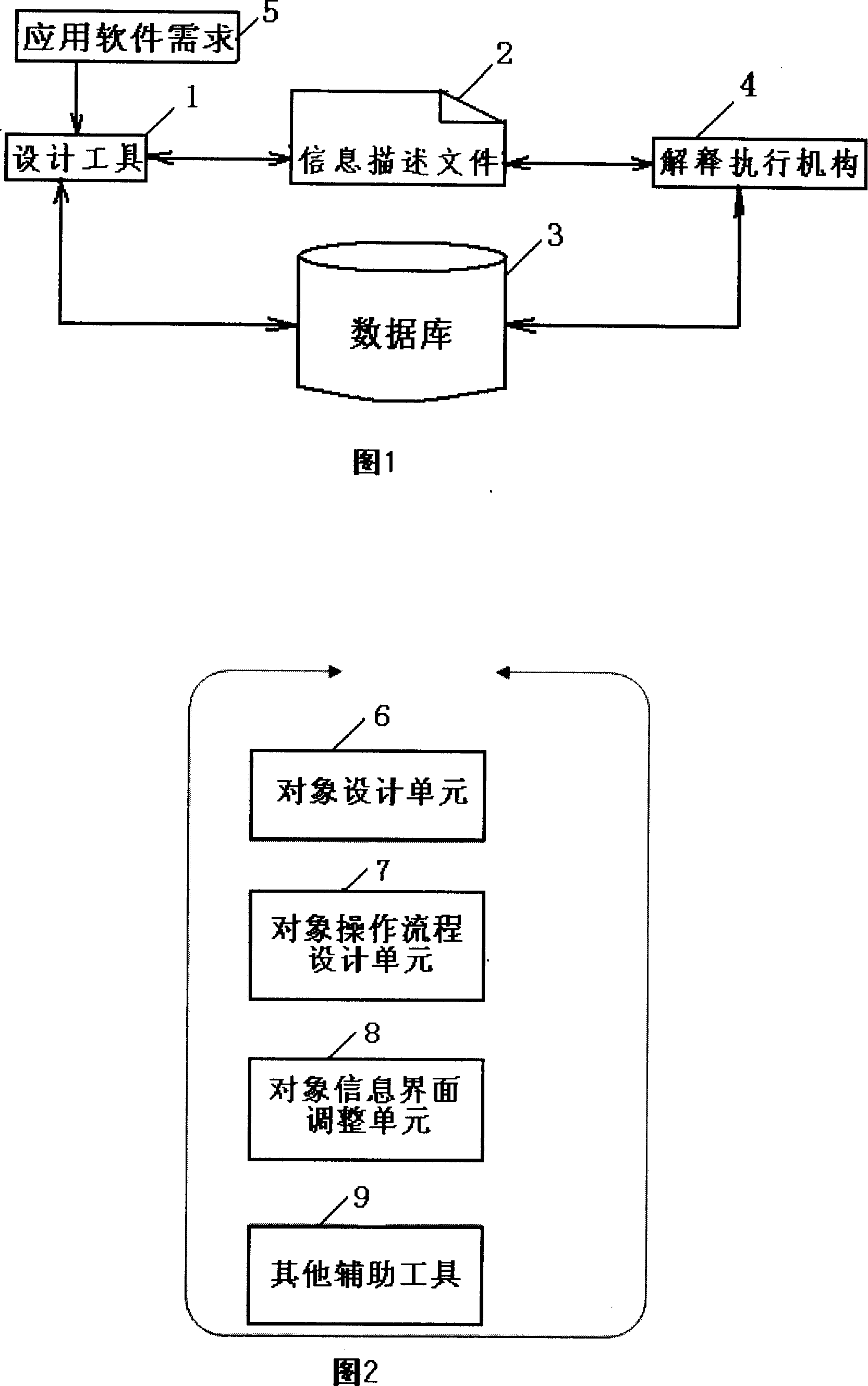

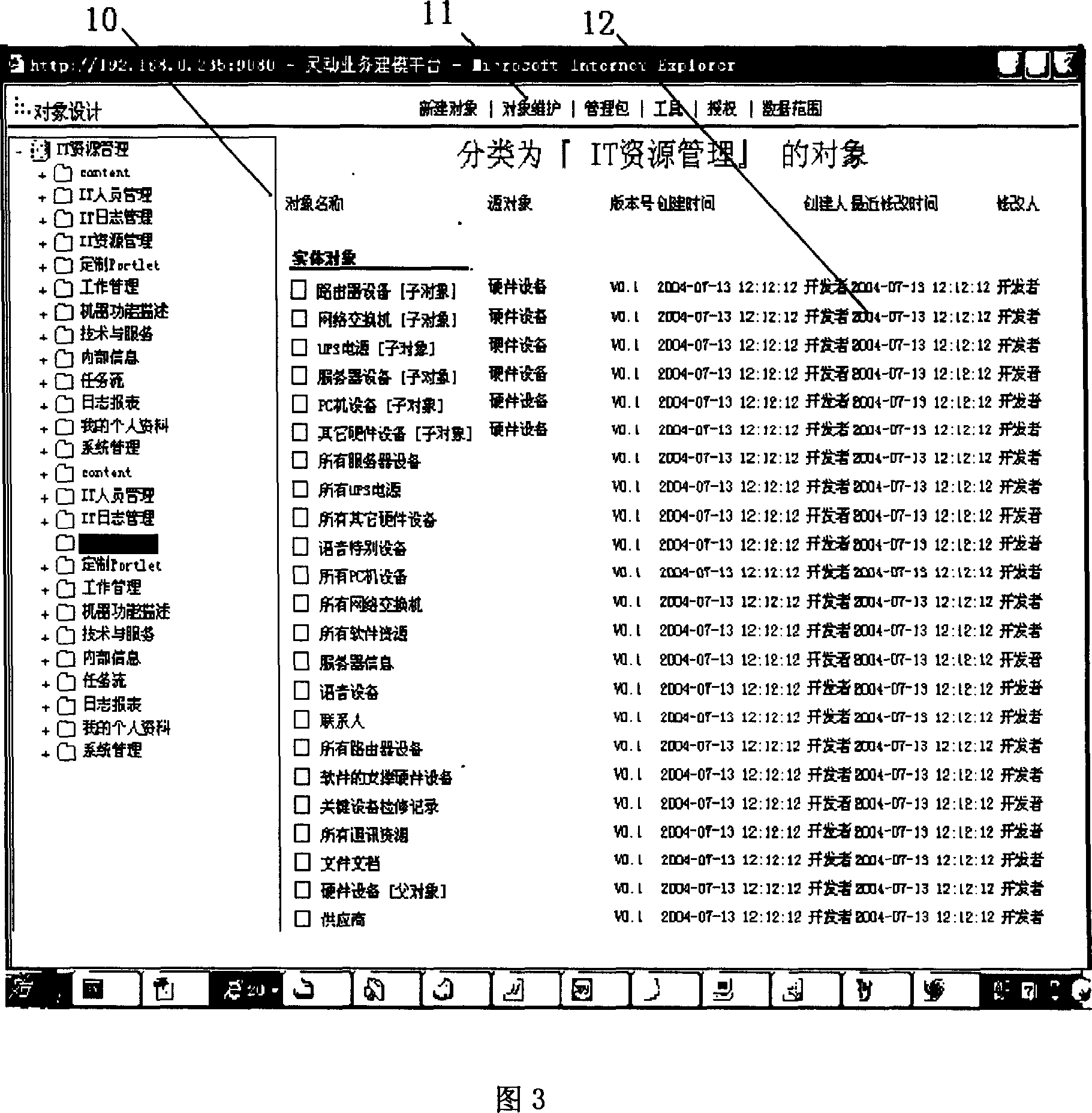

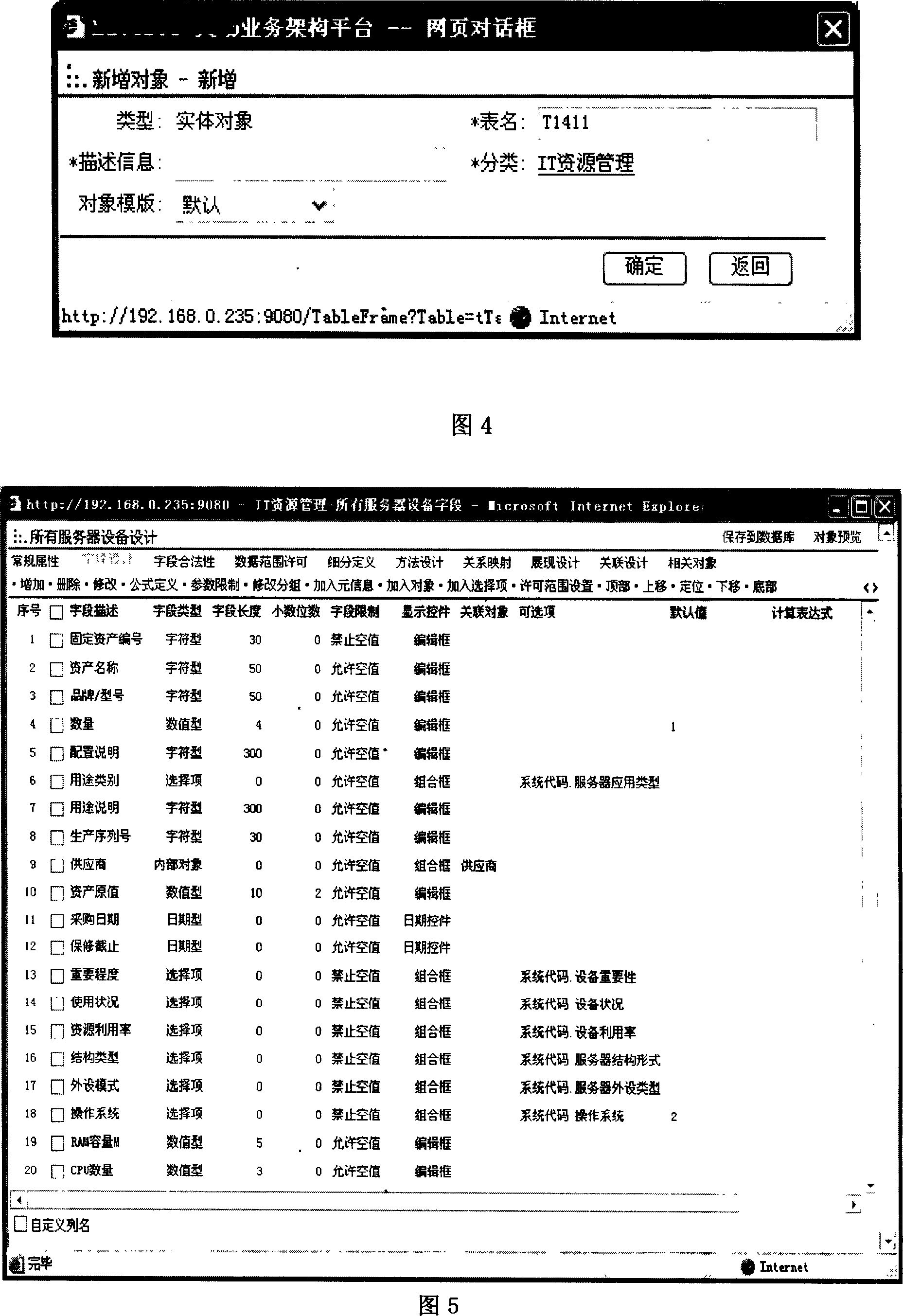

Flexible, fast software development method and support system by using kernels of direct operation object model definition

ActiveCN101004680ASimplify the development cycleEasy to maintain and expandSpecific program execution arrangementsRequirements analysisObject model

A method for quickly developing software by directly defining service object mode to be kernel includes using design tool to generate operation information description file of application software as per service requirement and simultaneously generating databank design process and application software function design process, modifying normal software development process to be design process of requirement analysis - generating information description file and databank-explaining and executing information description file for realizing application software function.

Owner:DINGDIAN SOFTWARE FUJIAN

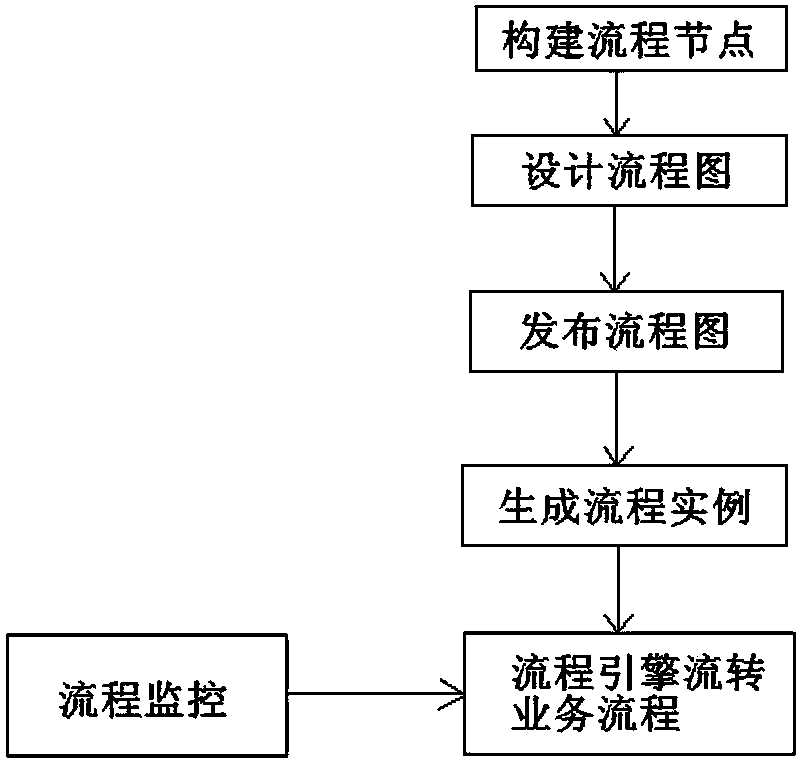

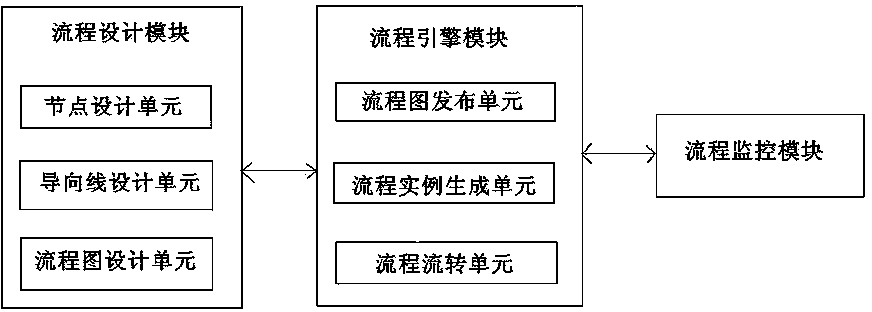

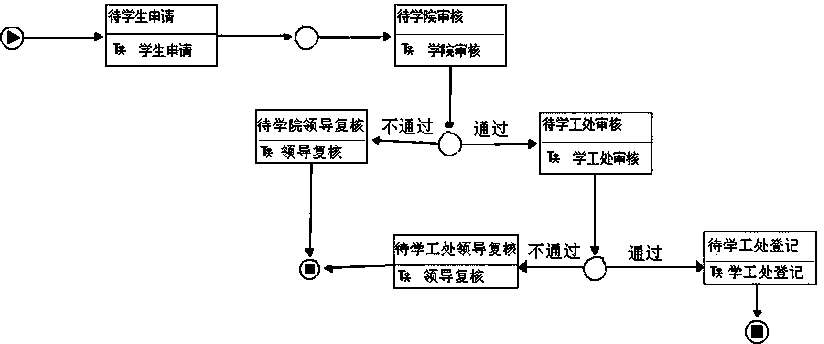

Process engine achieving method and system in service process

InactiveCN104281906ARapid deploymentEasy to createResourcesSpecific program execution arrangementsDesign flowProcess engineering

The invention discloses a process engine achieving method in a service process and belongs to the technical field of dynamic process control of the computer technology. The method includes the following steps that firstly, imaging process nodes are constructed; secondly, a process graph is designed, the process nodes are connected through a guiding line with a condition and a direction according to the service requirement, and the service process graph is formed; thirdly, the designed process graph is stored and issued to a process engine; fourthly, the process engine automatically circulates tasks to the corresponding nodes according to the operation of a service system. The invention further discloses a process engine system in the service process, and the process engine system comprises a process design module and a process engine module. The service process design and changing processes are simplified, the implementation cost is saved, and the process issuing time is shortened.

Owner:JIANGSU DATATECH INFORMATION TECH

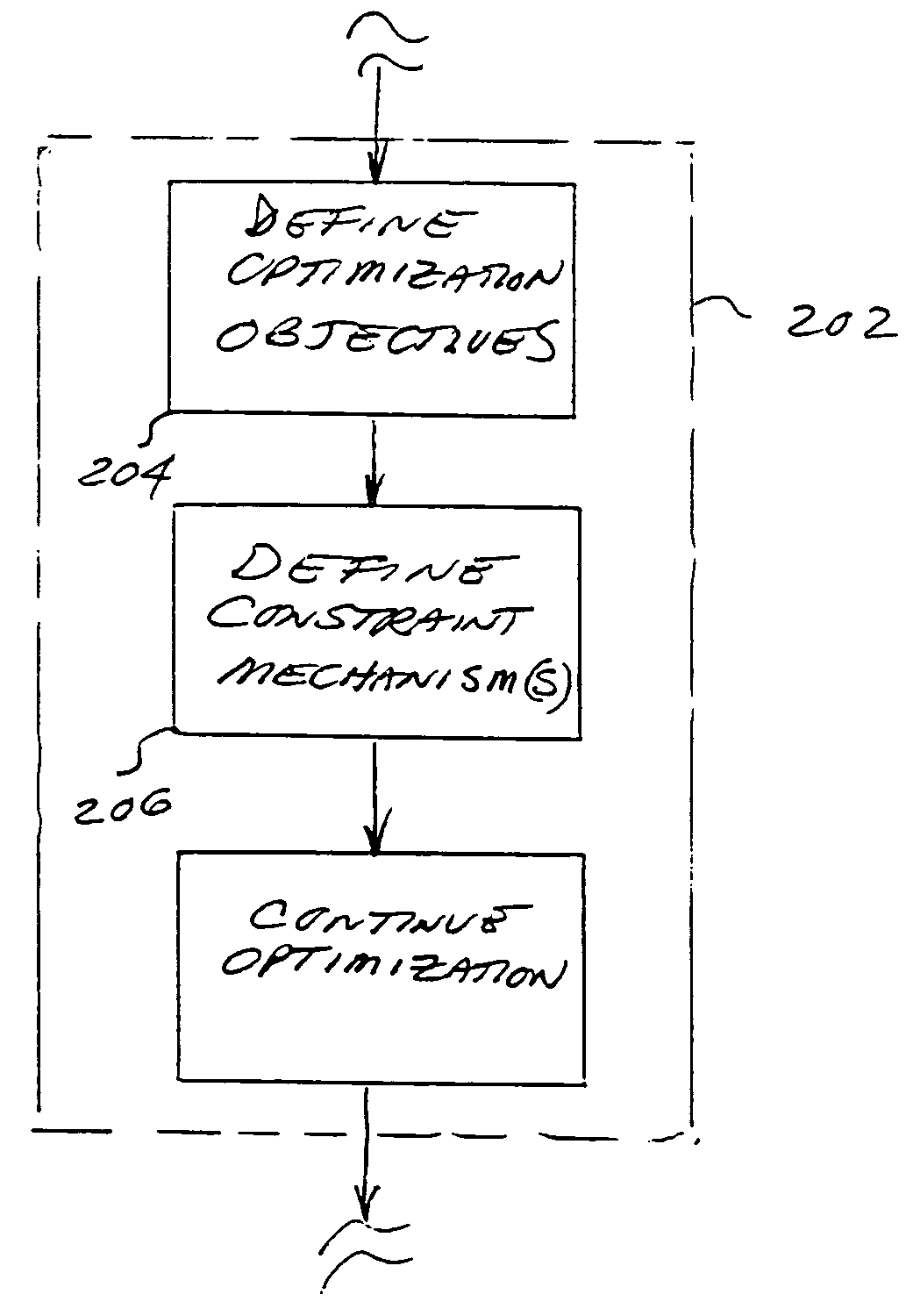

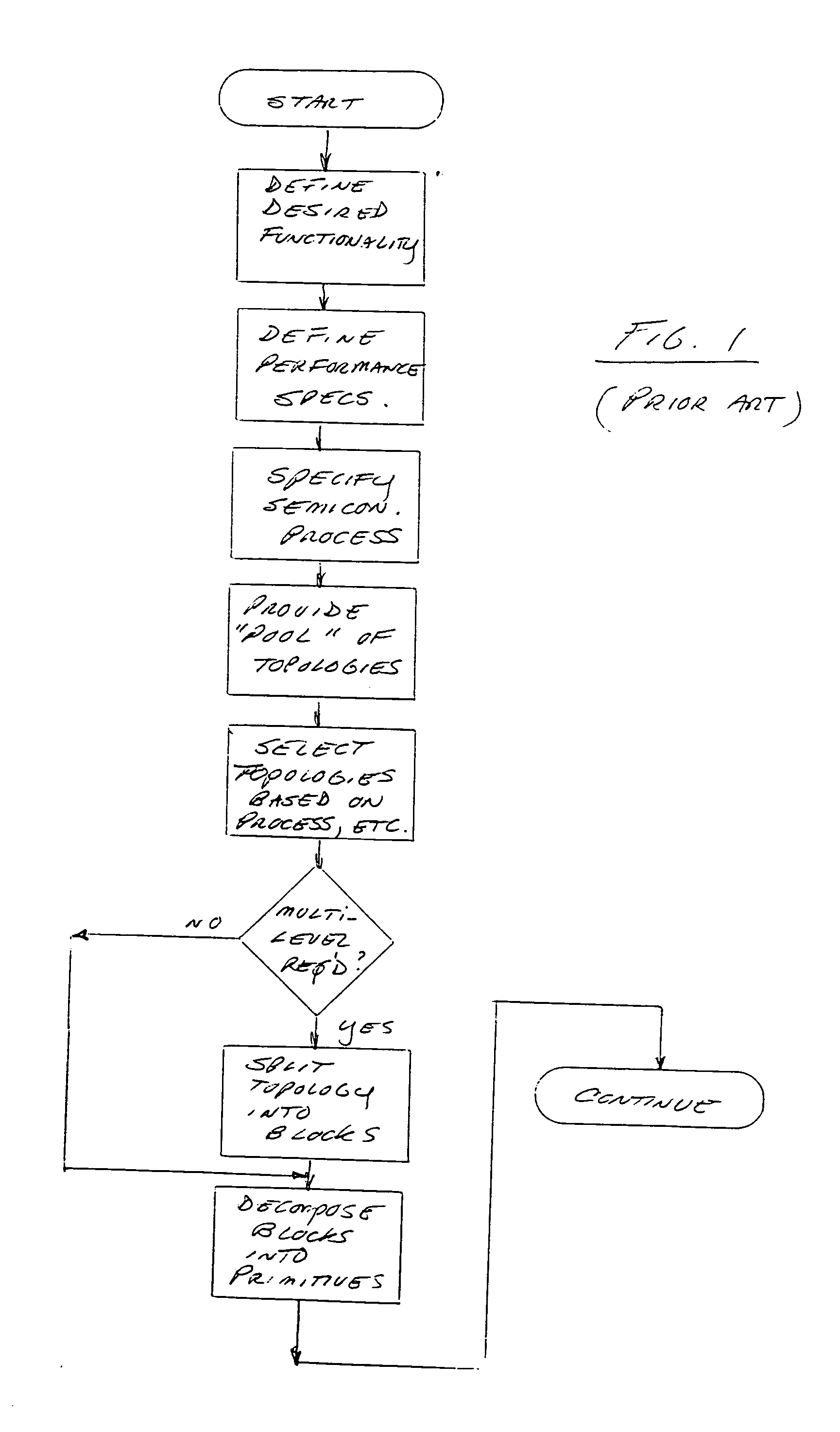

Method and apparatus for designing electronic circuits using optimization

InactiveUS20060015829A1Analogue computers for electric apparatusGenetic modelsOptimal designElectronic circuit

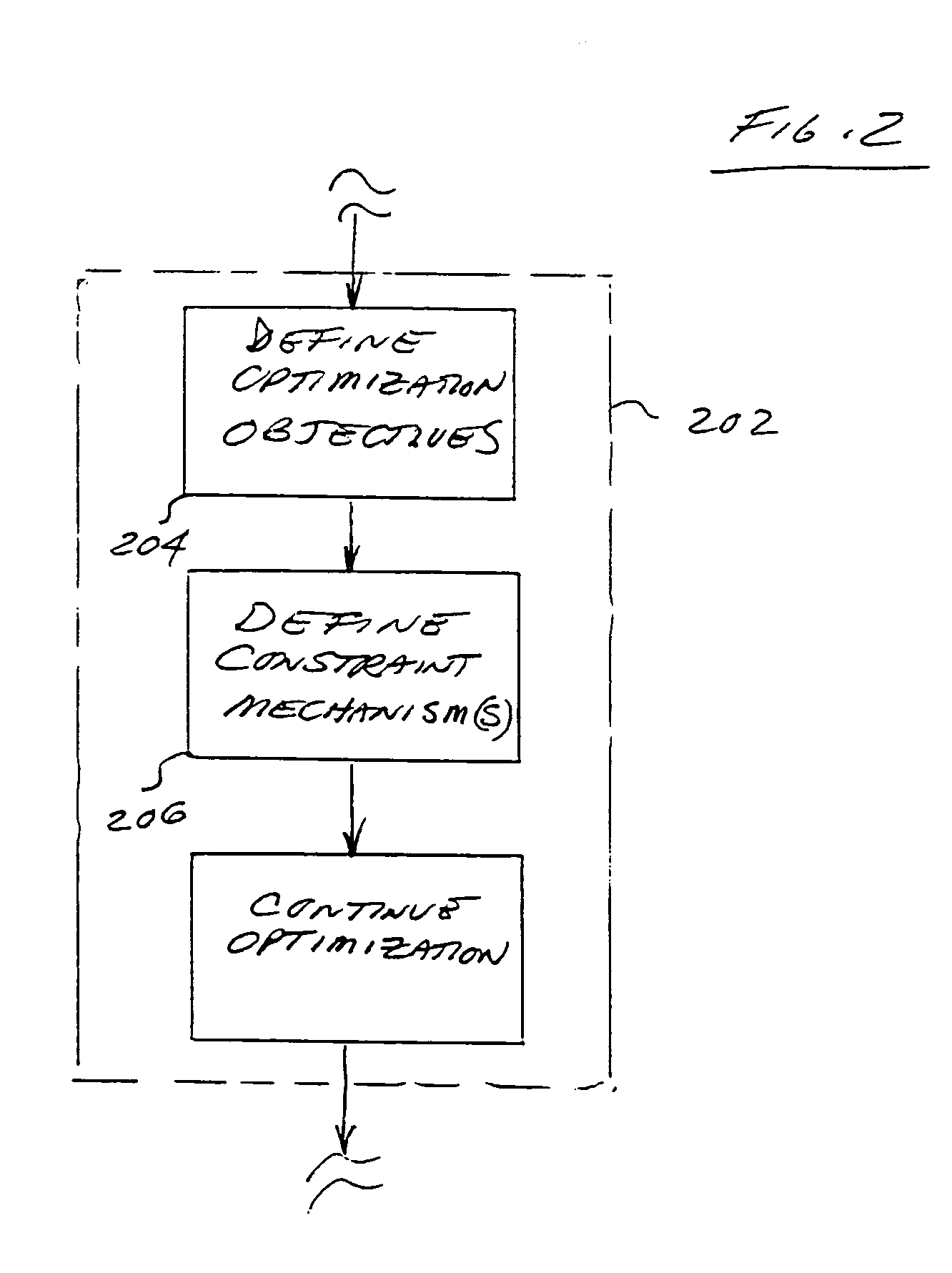

Methods and apparatus for designing electronic circuits, including analog and mixed signal (AMS) circuits, based on an evolutionary optimization approach. In one exemplary embodiment, the optimization approach is implemented using a computer program running on one or more computers. The optimization program receives inputs from the designer regarding (i) optimization objectives for the design process, and (ii) the constraint mechanisms to be applied. Both constrained and unconstrained optimization formulations can be addressed by the program. Various objective function evaluation mechanisms are implemented. The program also advantageously allows for continuously encoded variables, which are particularly useful for solving AMS design problems.

Owner:KIMOTION TECH (BE)

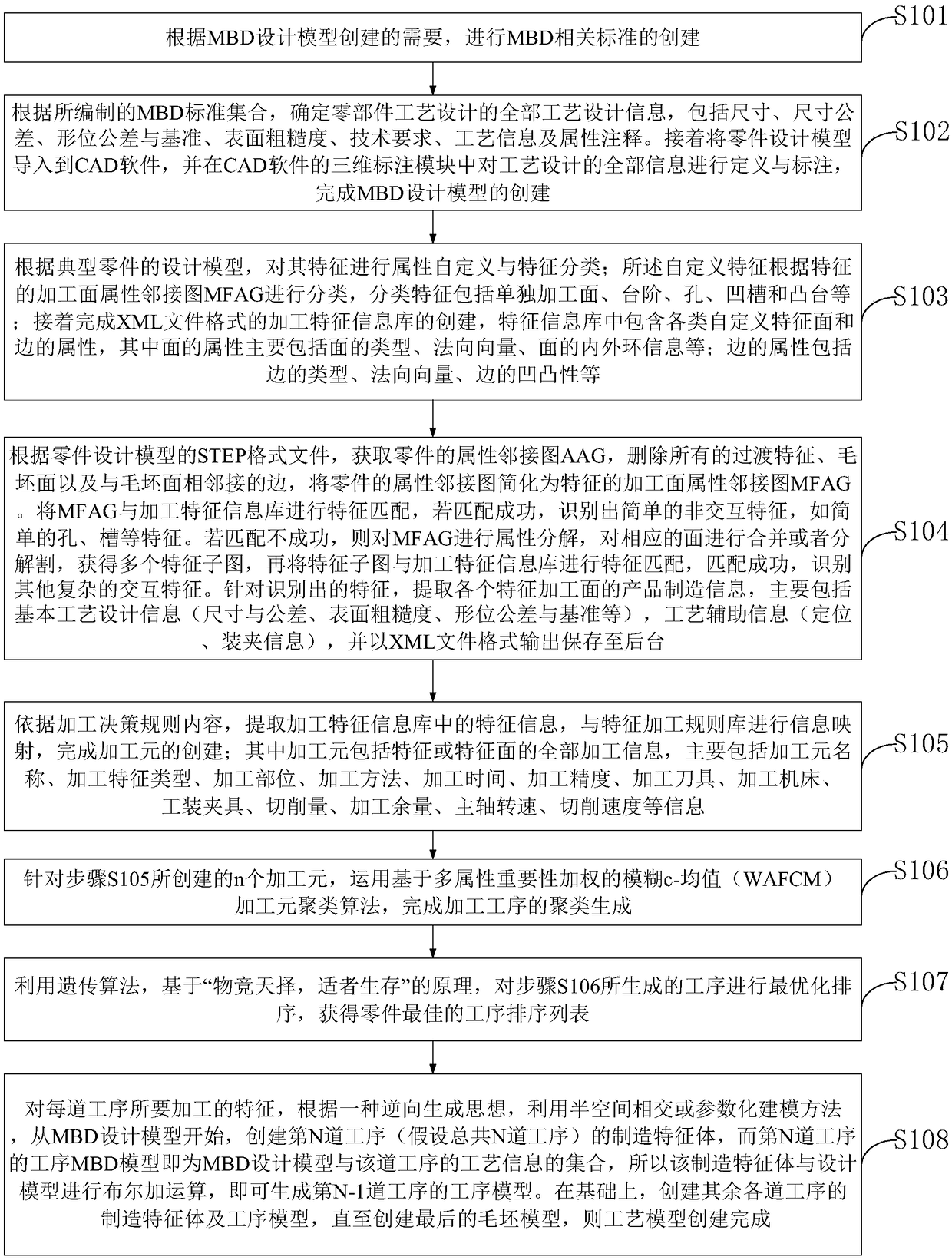

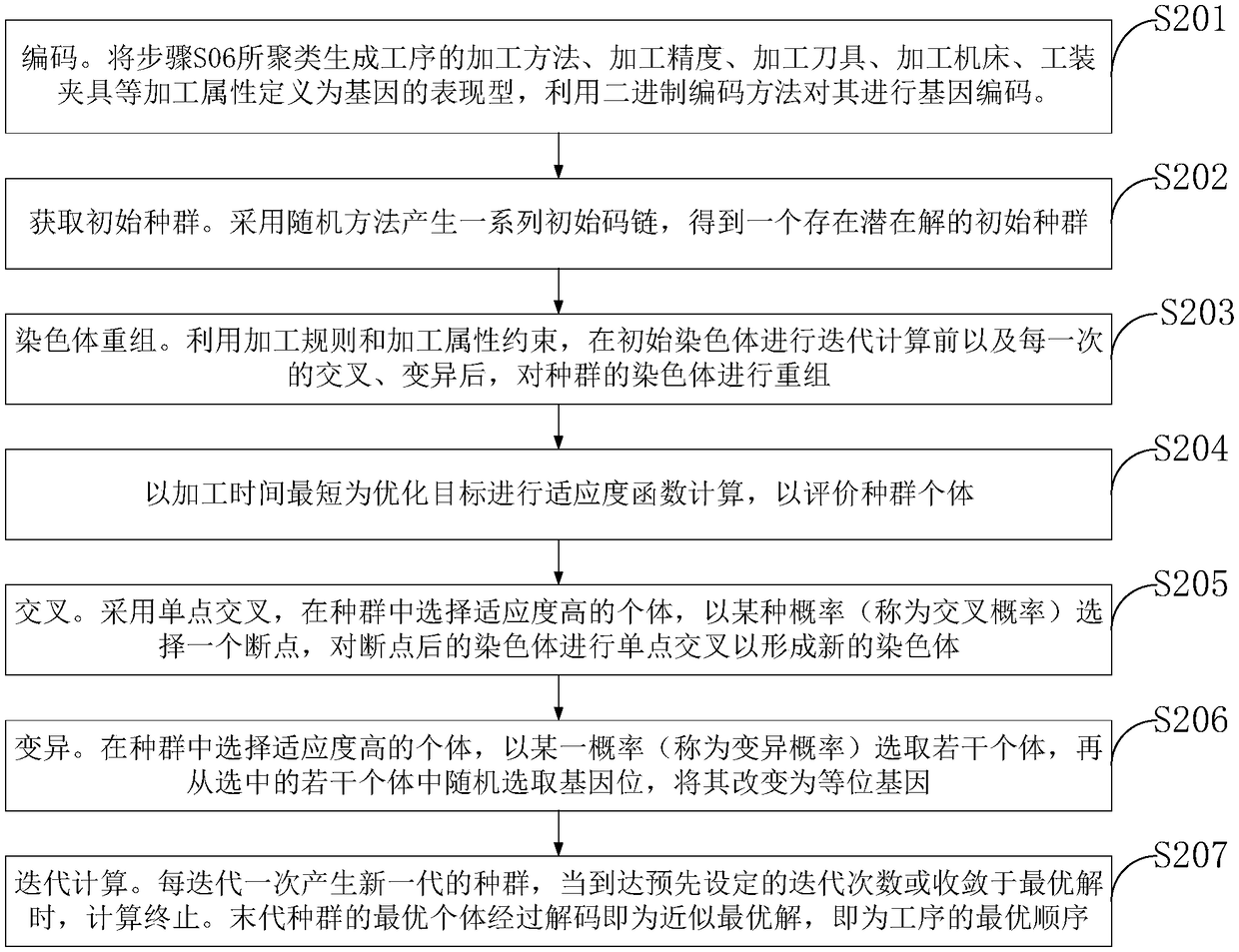

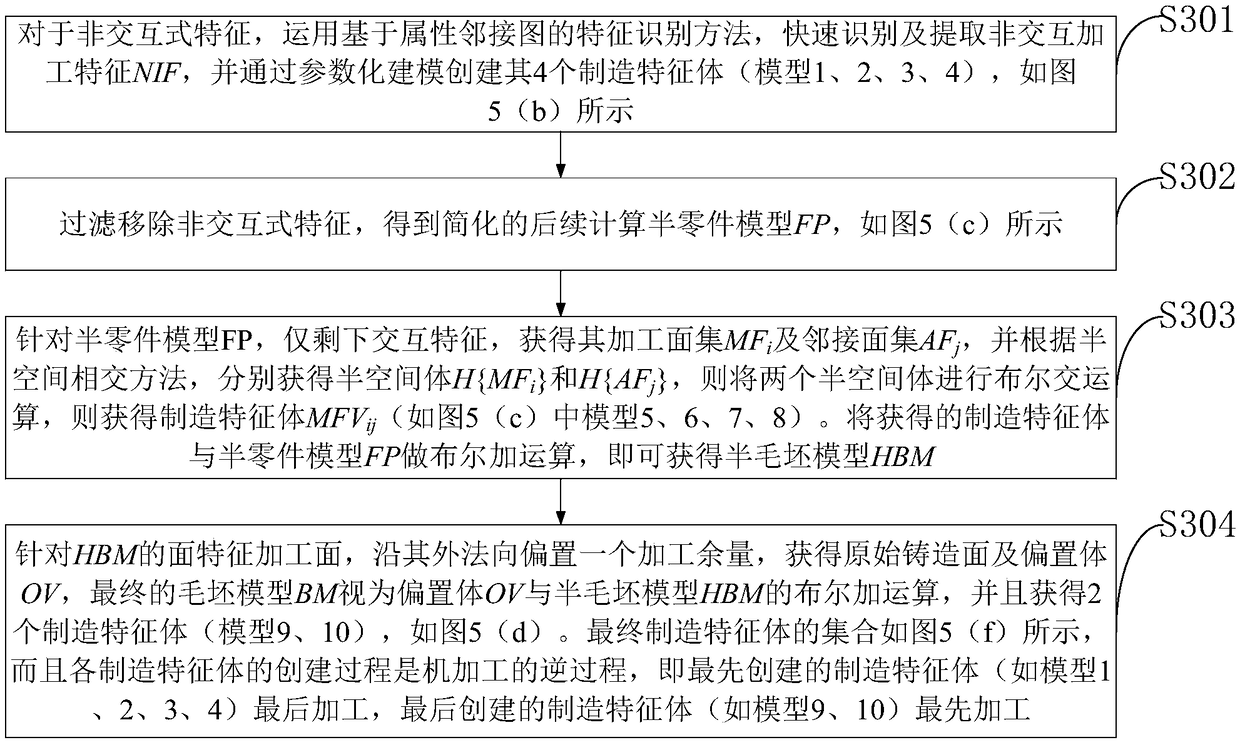

Three-dimensional process planning method and platform for typical automobile machined parts based on MBD

ActiveCN109117560ADesign specificationGuaranteed accuracyGeometric CADDesign optimisation/simulationMachine partsComputer-aided

The invention belongs to the technical field of computer-aided process planning, the invention discloses a three-dimensional process planning method and a platform for typical automobile machined parts based on MBD, based on 3D CAD software, with the MBD design model as the sole data input, the process MBD model is used as the data output, and the design process includes the establishment of MBD related standards, the creation of MBD design model, feature classification and feature database, feature recognition and information extraction, the generation of machining elements, the generation ofmachining elements clustering process, process sequencing, manufacturing features, the creation of process model and so on. The final application example of the present invention is in the case whereNX is used as a carrier, C + + and NXopen language, the invention can quickly generate a process MBD model which integrates a process model and a manufacturing feature body, can realize the visualization of the process design flow, improve the process design efficiency, and lays a foundation for the integration of CAD / CAPP / CAM. The invention can be used in the three-dimensional CAPP system developed by C + + and NXopen language.

Owner:WUHAN UNIV OF TECH

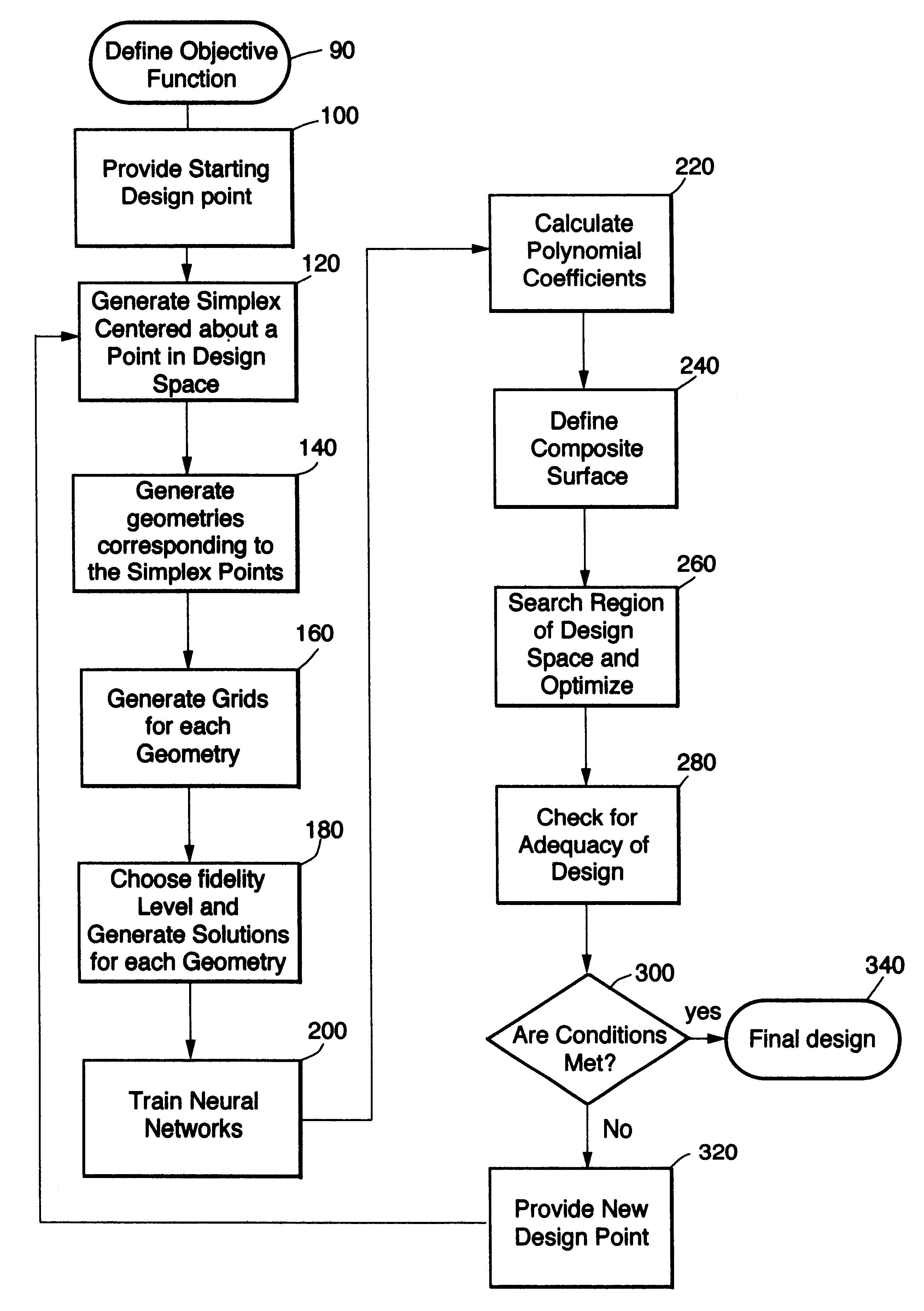

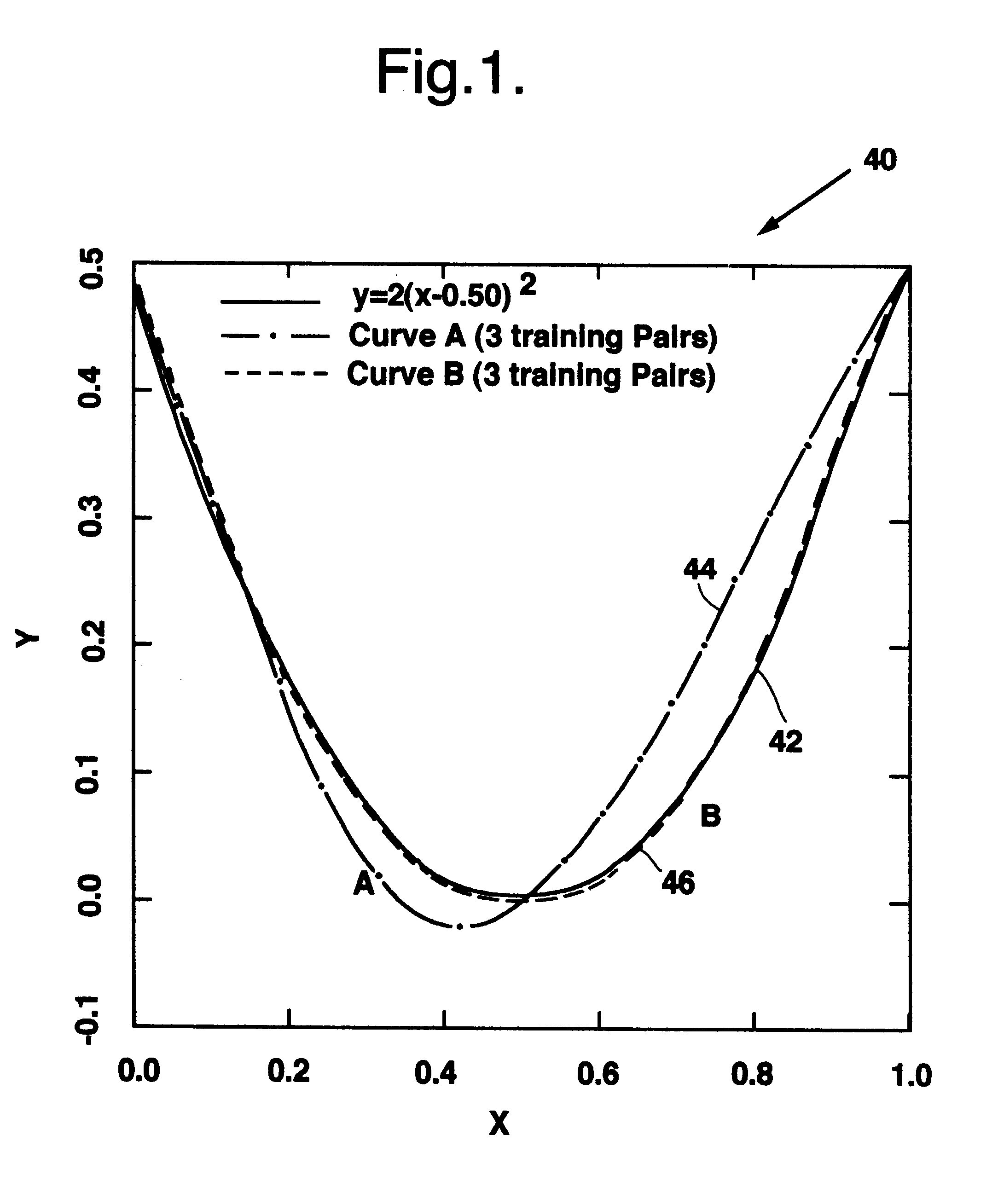

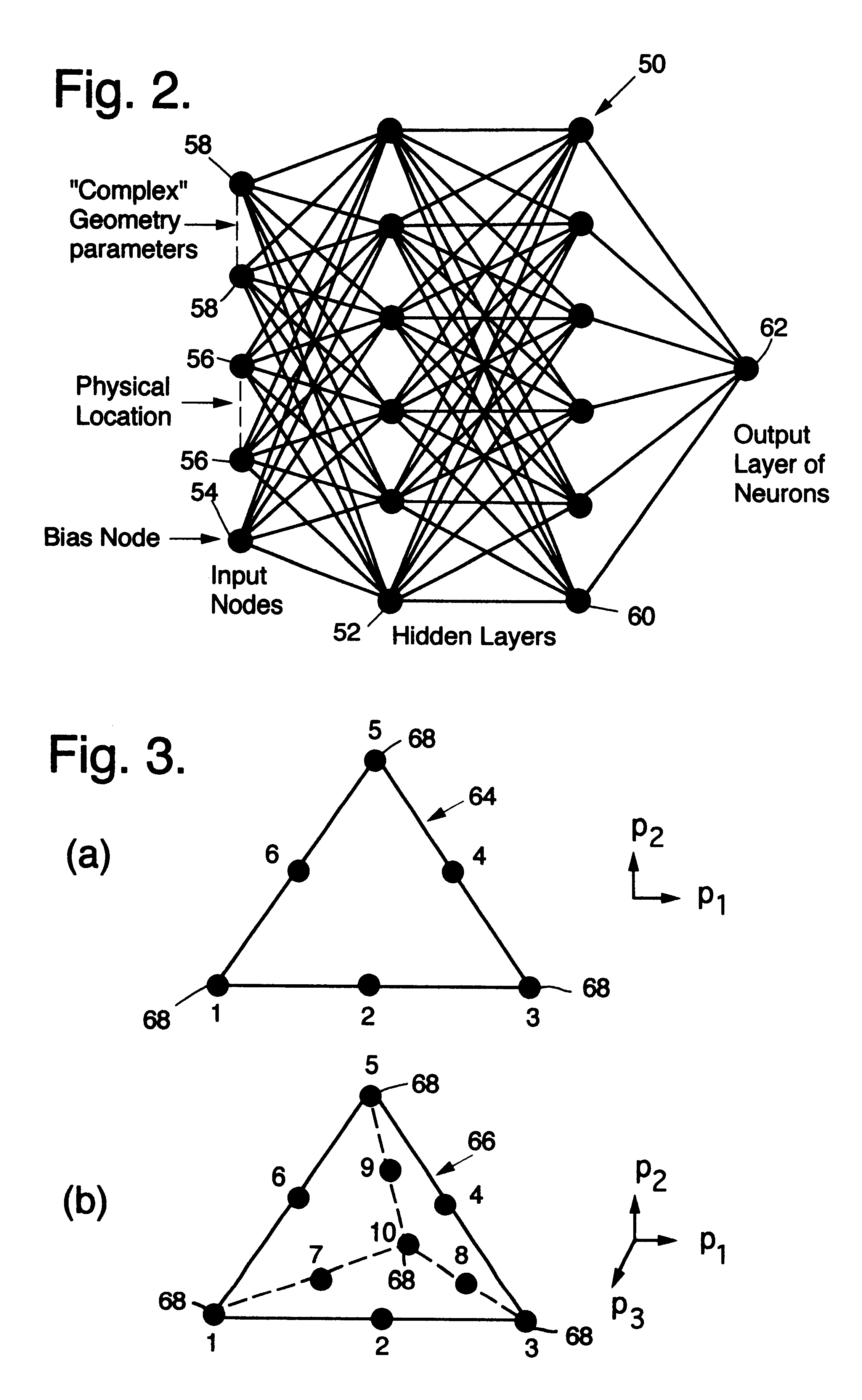

Method for constructing composite response surfaces by combining neural networks with other interpolation or estimation techniques

InactiveUS6606612B1Small amountReduce amountGeometric CADDigital computer detailsAlgorithmEngineering

A method and system for design optimization that incorporates the advantages of both traditional response surface methodology (RSM) and neural networks is disclosed. The present invention employs a unique strategy called parameter-based partitioning of the given design space. In the design procedure, a sequence of composite response surfaces based on both neural networks and polynomial fits is used to traverse the design space to identify an optimal solution. The composite response surface has both the power of neural networks and the economy of low-order polynomials (in terms of the number of simulations needed and the network training requirements). The present invention handles design problems with many more parameters than would be possible using neural networks alone and permits a designer to rapidly perform a variety of trade-off studies before arriving at the final design.

Owner:NASA

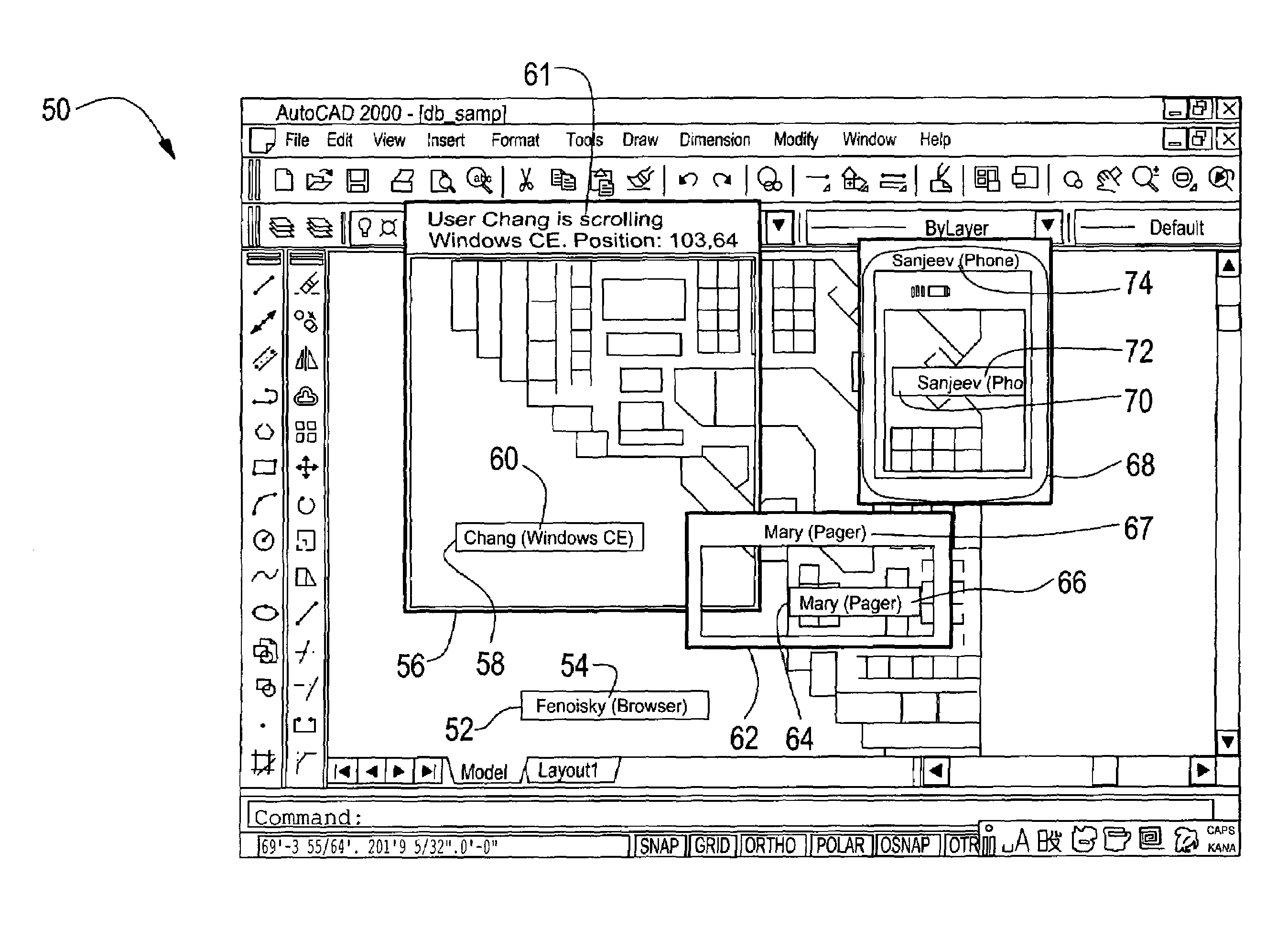

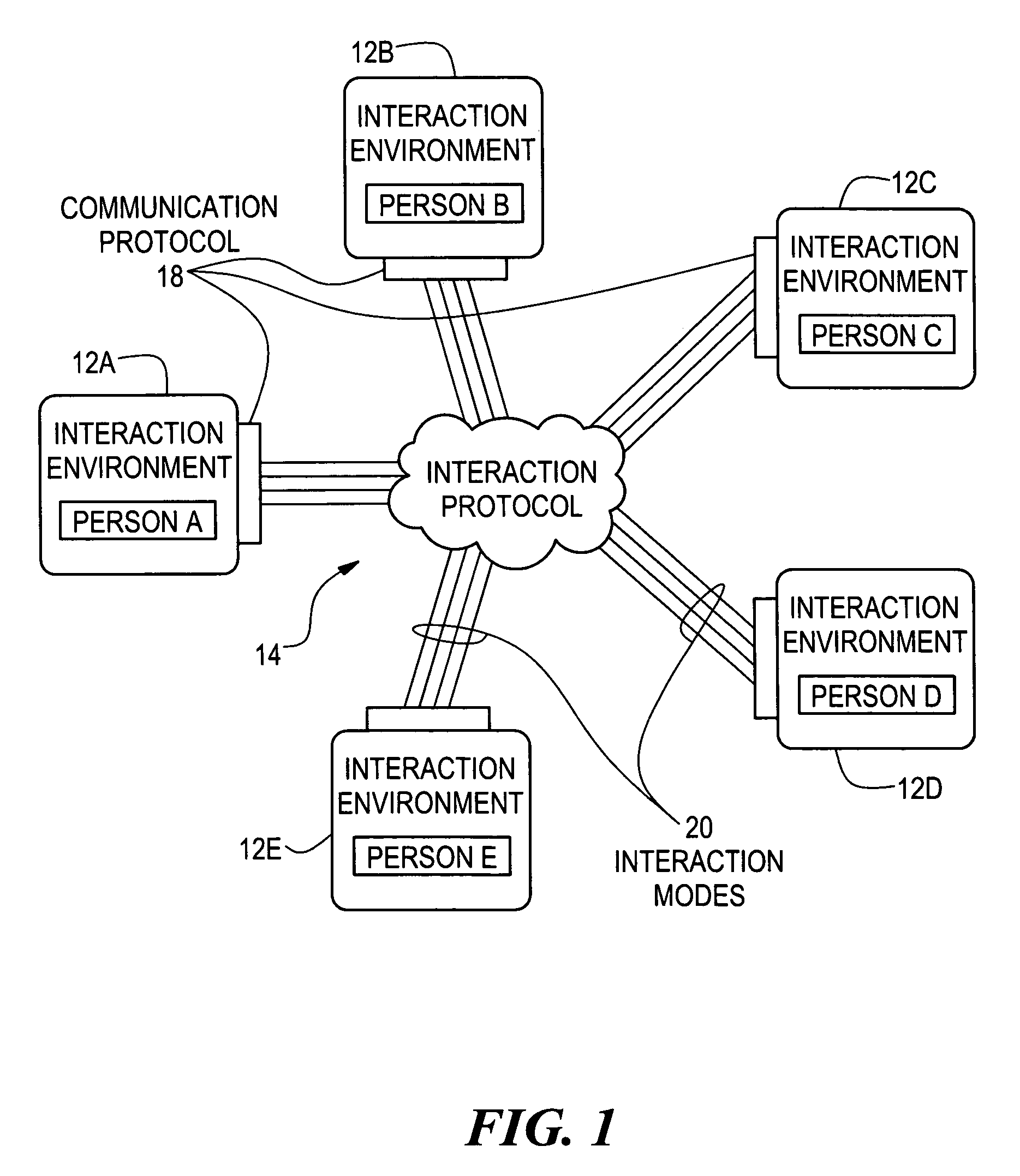

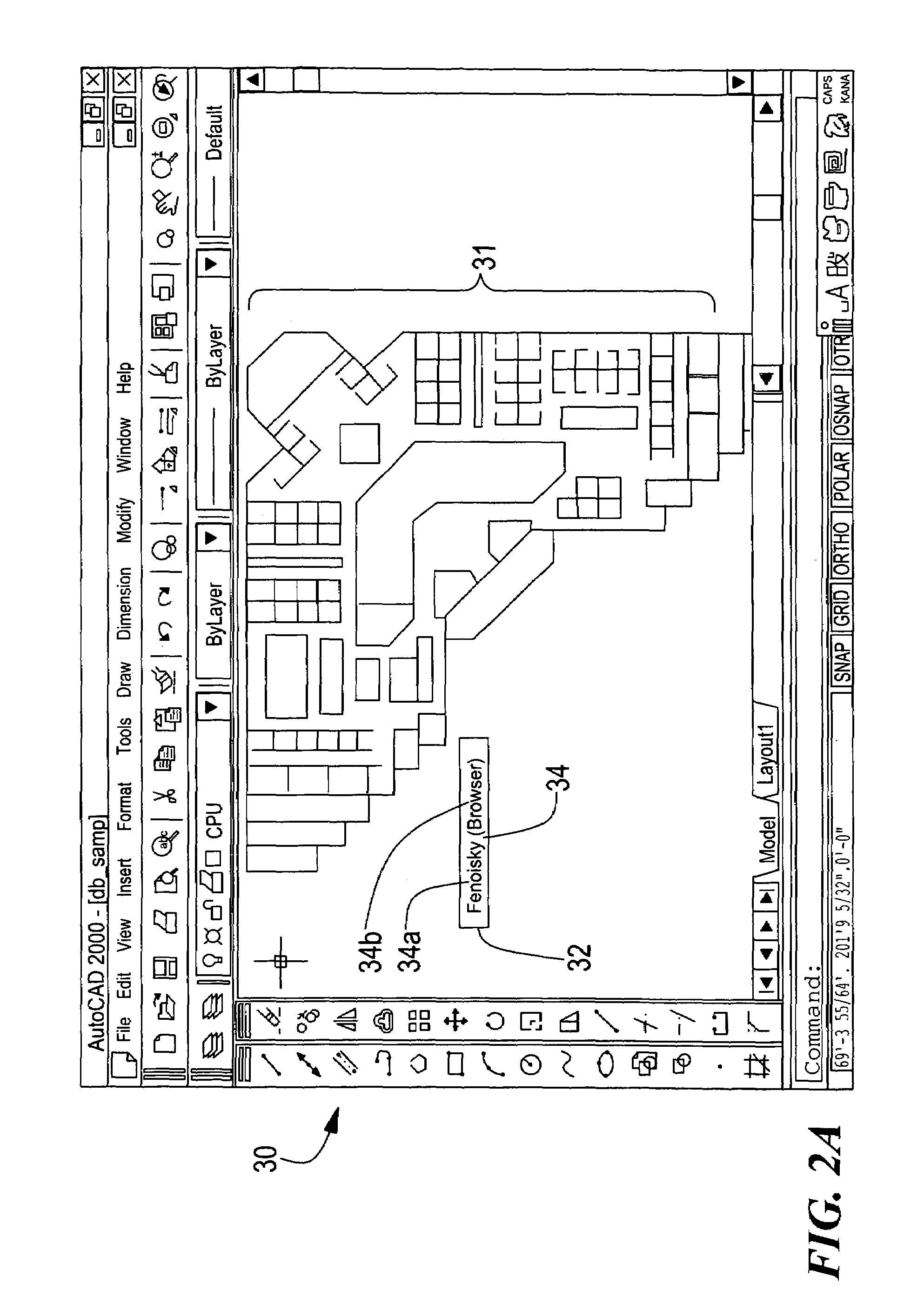

Mechanisms and artifacts to manage heterogeneous platform interfaces in a collaboration system

InactiveUS7162699B1Multiple digital computer combinationsOffice automationImage resolutionControl participant

A collaboration system including a coordinated distributed design process and which allows individuals to hold interactions over a network and work together in a coordinated fashion on shared problems, wherein a controlling participant in control of the floor of a collaboration interaction and in control of certain aspects of the user interfaces of one or more collaboration participants is described. Furthermore, a user interface is described that can minimize confusion that can otherwise result from collaboration participants having user interfaces with different sizes and resolutions.

Owner:MASSACHUSETTS INST OF TECH

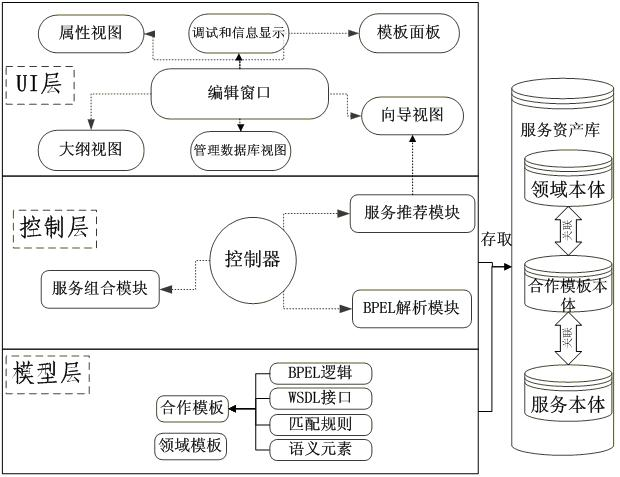

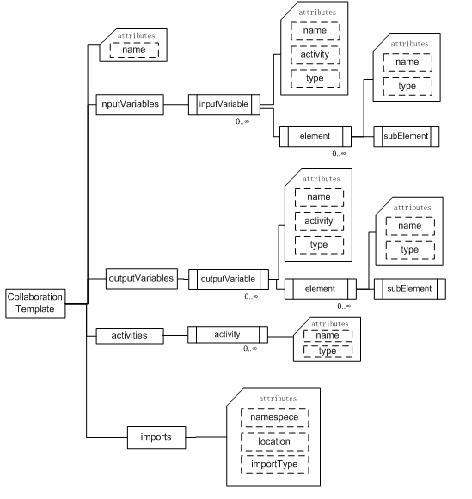

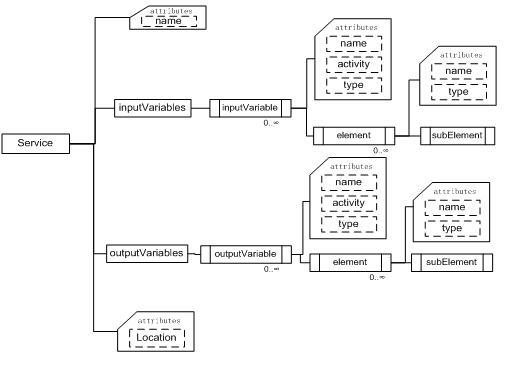

Linked data-based multiplexing method of business process execution language (BPEL) templates and services and system thereof

InactiveCN102426519AReduce the work of secondary developmentImprove development efficiencySpecific program execution arrangementsService compositionMultiplexing

The invention discloses a linked data-based multiplexing method of business process execution language (BPEL) templates and services and a system thereof. The system comprises a model layer, a control layer, a user interface (UI) layer and a service asset library, wherein the model layer is used for providing models required by graphing and various functions of the whole system; the control layer is used for carrying out a control operation on a visualization process in the whole system, and further, realizing functions of script parsing of BPEL, template extracting and packaging, service combining and business exporting; the UI layer is mainly used for the functions of a palette, an editing window, an attribute view, an outline view and a guide view; and the service asset library specifically consists of field bodies, template bodies and service bodies. With the adoption of the linked data-based multiplexing method of the BPEL templates and services and the system thereof, the multi-granularity service asset multiplexing which includes the multiplexing by taking a BPEL subprocess as a template and the atomic Web service multiplexing can be realized; and the development efficiency for service combinations can be increased so as to shorten a development cycle through a pre-designed process template or a user-defined multiplexing template.

Owner:BEIJING UNIV OF POSTS & TELECOMM

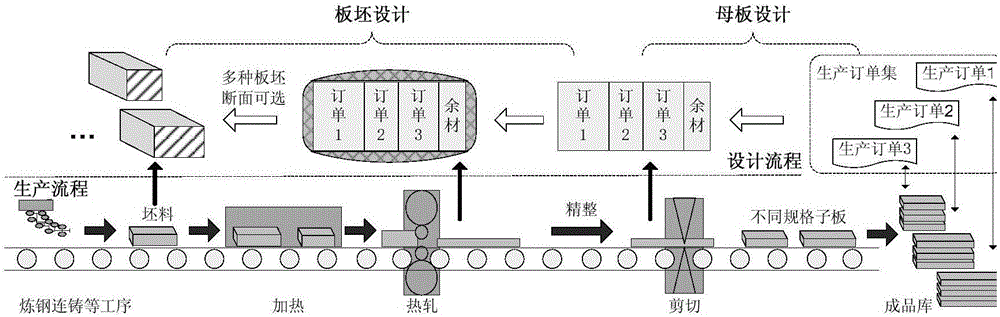

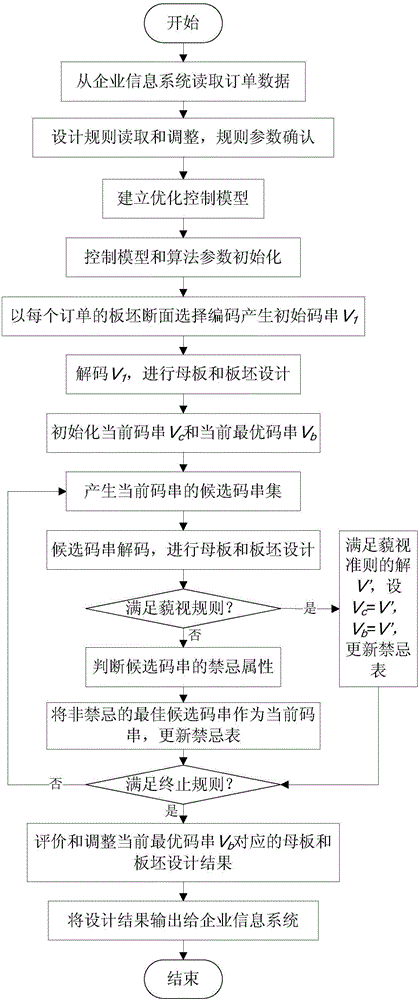

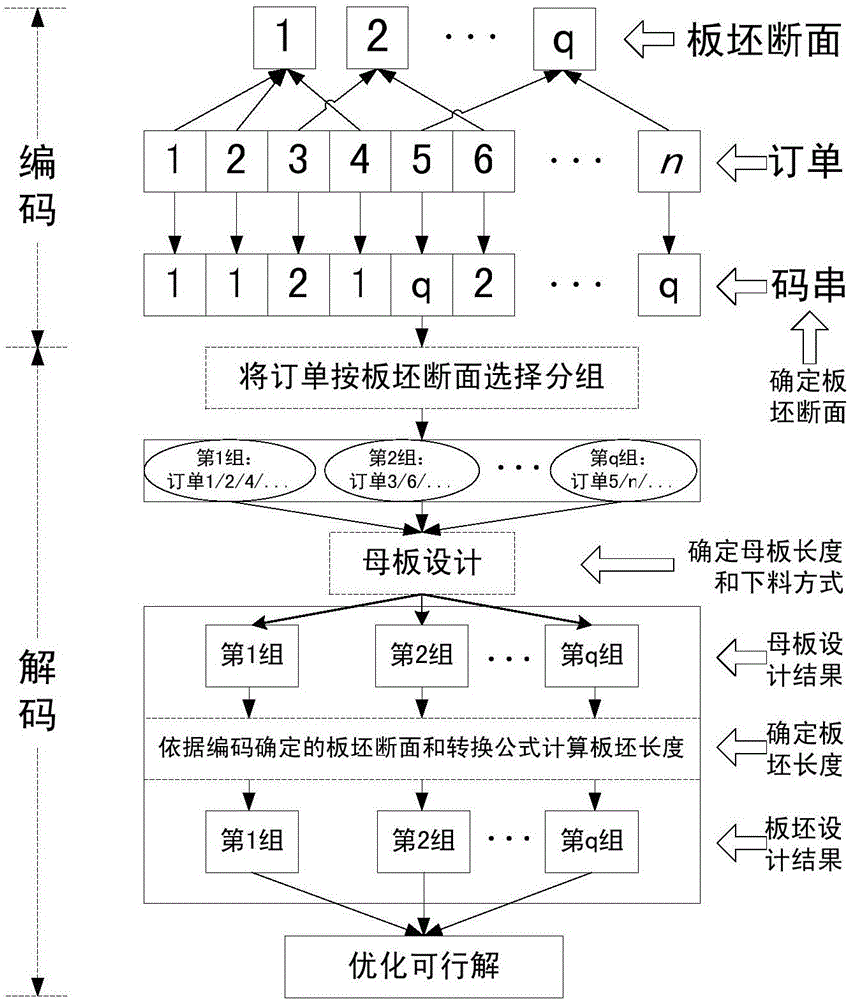

Collaborative design method and system for parent plate and plate blank of medium plate oriented to production order combined optimization

ActiveCN106599519AEase of tuning design rulesEasy parameter adjustmentDesign optimisation/simulationResourcesDecoding methodsOn column

The invention provides a collaborative design method and system for a parent plate and a plate blank of a medium plate oriented to production order combined optimization. The method comprises the following steps: specific to a sub-plate one-dimensional combined optimization design in a medium plate production order, building an optimized control model under the consideration of the constraints of complicated production processes, equipment and the like specific to the aim of minimizing residual materials and material loss, deciding a sub-plate combination way, the length of the parent plate and the length of the plate blank, selectively coding the plate blank section of each order after orders are received, designing a decoding method based on column generation, and generating plate blank and parent plate design schemes; then, searching for a better code string in neighborhood through repeated iterations based on tabu search; and when an end condition is satisfied, selecting a current optimal code string for evaluation and adjustment, and outputting corresponding plate blank and parent plate design results lastly. A system controller controls the design processes of the parent plate and the plate blank of the medium plate according to the method. Through adoption of the collaborative design method and system, residual parent plates and material loss are reduced, and the production demand can be met better.

Owner:CHONGQING UNIV

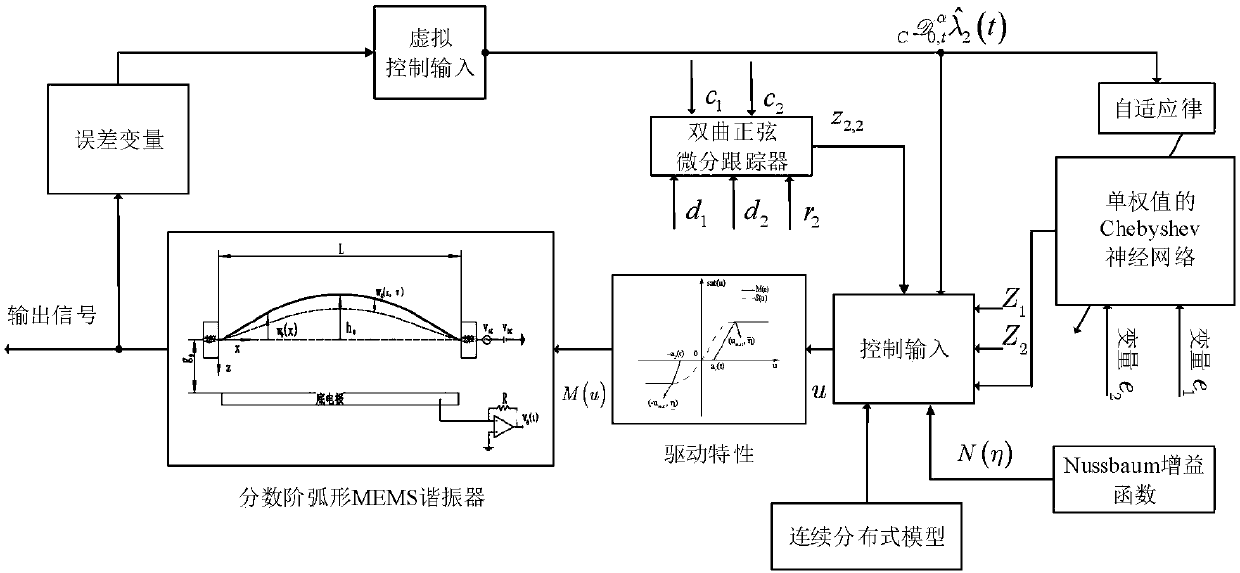

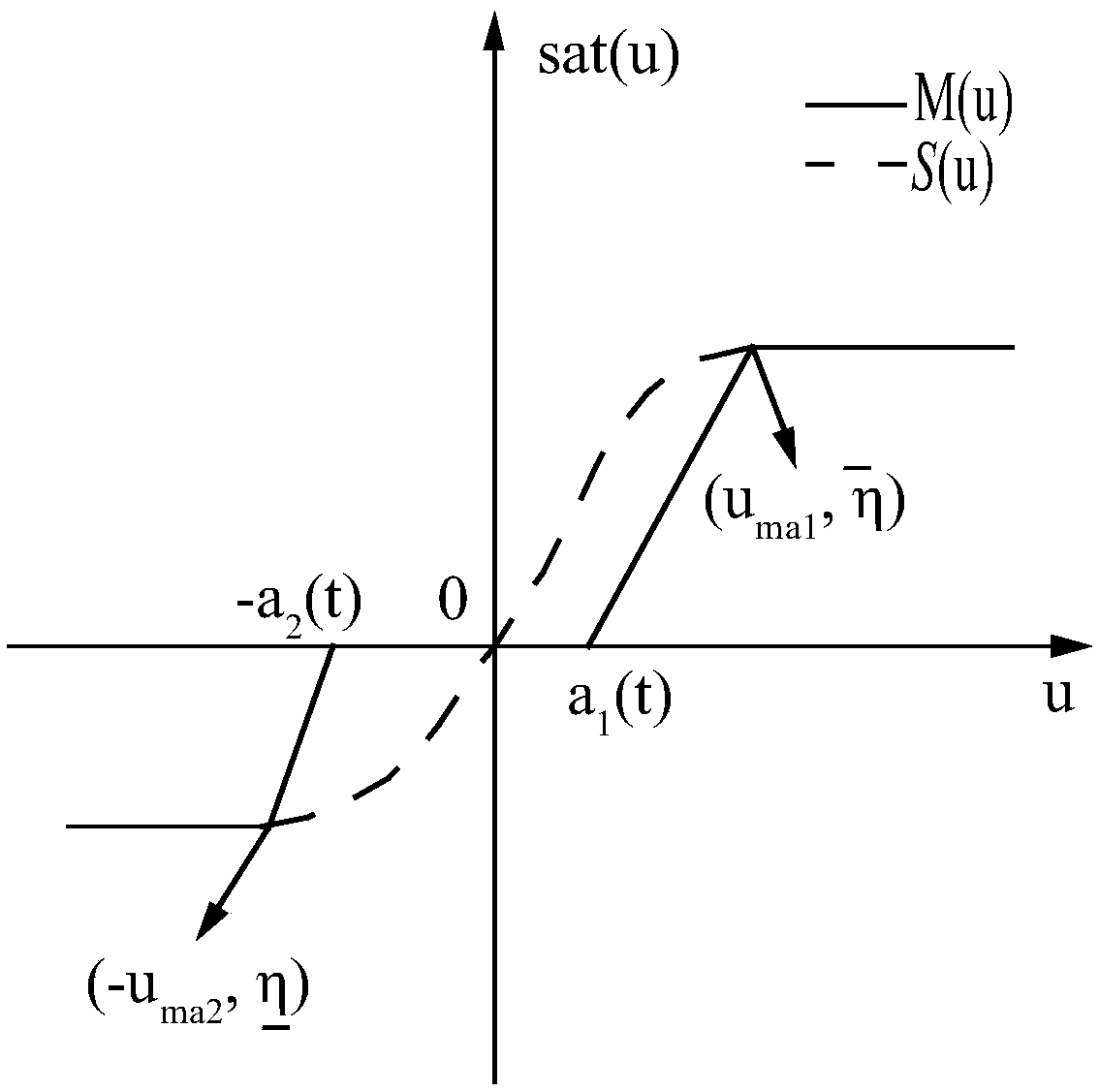

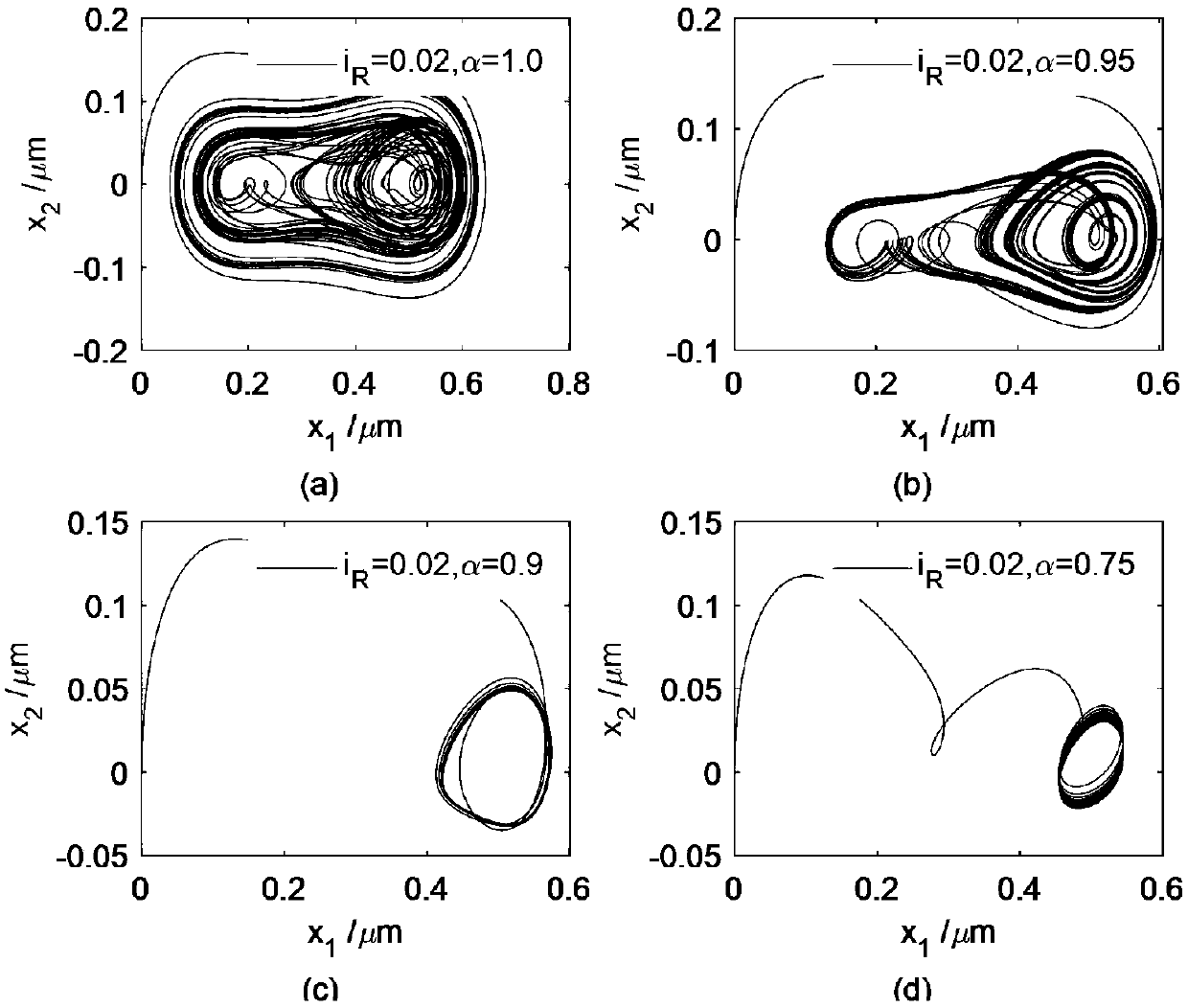

Inverse oscillation adaptive control method of fractional-order arched MEMS resonator

The invention relates to an inverse oscillation adaptive control method of a fractional-order arched MEMS resonator, and belongs to the field of inverse oscillation control. In the design process, uncertain items are compensated through a Chebyshev neural network with updated single weights, and the problem of the unknown control direction caused by the excitation characteristic in Caputo fractional-order calculus is solved through the Nussbaum function; meanwhile, a tracking differentiator based on the hyperbolic sine function is designed, and the problem of repeated differential with complexfractional-order calculation in virtual control is solved; then under an adaptive backstepping control frame, through a continuous frequency distribution model, an inverse oscillation adaptive control scheme integrated with the Nussbaum function, the neural network and the tracking differentiator is invented; on the basis of the criterion of the fractional-order Lyapunov stability, the asymptoticstability of a closed-loop system is proven; and finally, the validity of the proposed scheme is verified through numerical simulation.

Owner:CHONGQING AEROSPACE POLYTECHNIC COLLEGE

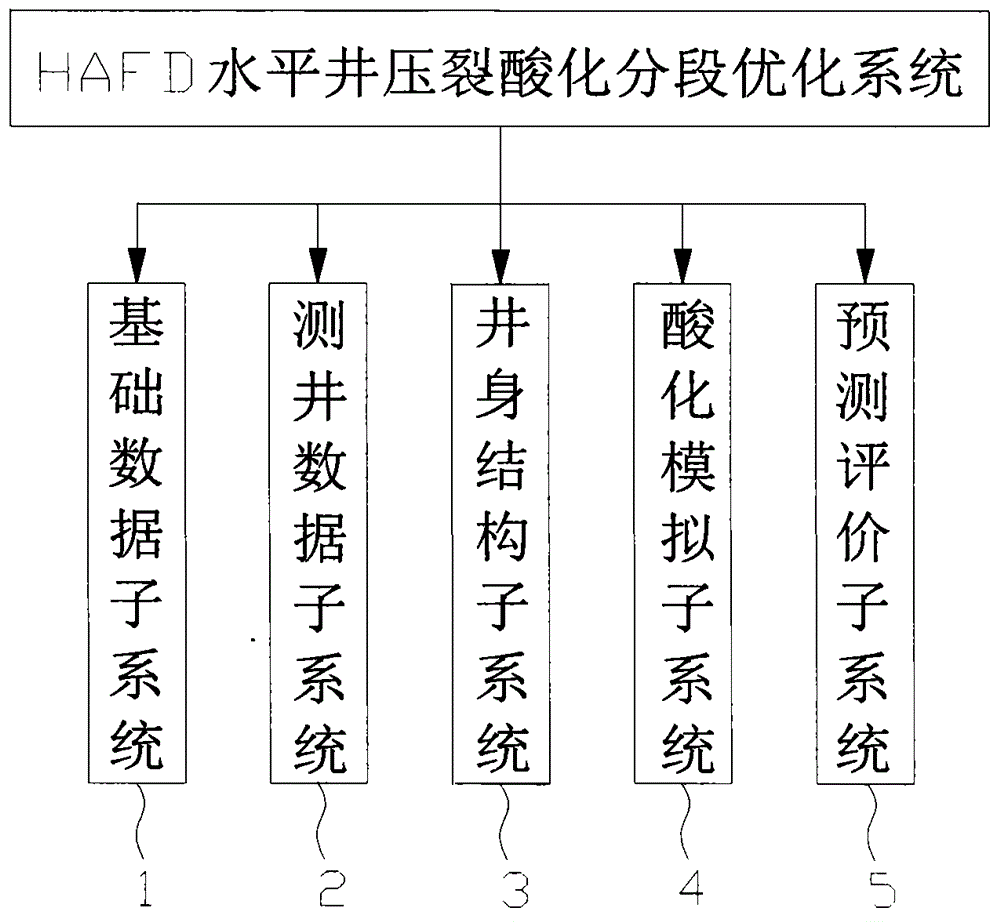

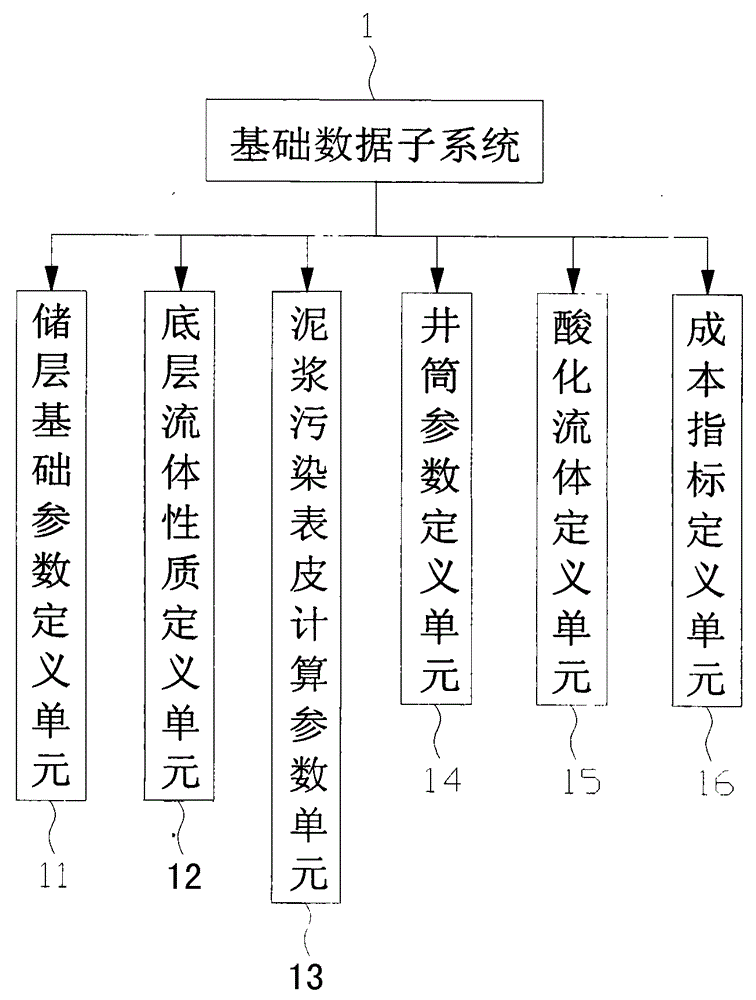

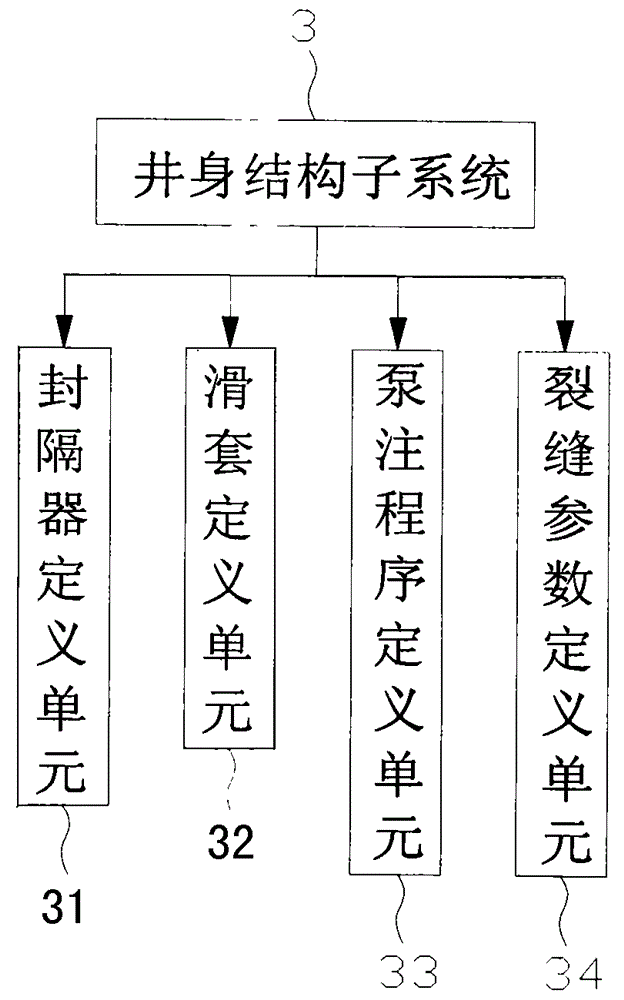

HAFD segmented optimization method and system

The invention relates to an HAFD (Horizontal-well Acid Fracturing) segmented optimization method and system. The optimization method comprises the following optimization flow: simulating a horizontal well segmented matrix acidization, predicting acidizing capacity for forming the horizontal well segmented matrix, predicting the capacity of the segmented acid fracturing horizontal well, optimizing segmented acidizing and acid fracturing for the horizontal well, realizing digitalization of well logging drawings, and combining the segmented matrix acidizing technology with the acid fracturing technology. The optimization system comprises a basic data subsystem, a log data subsystem, a well bore configuration definition subsystem, an acidizing simulation subsystem and a prediction evaluation subsystem. The optimization method disclosed by the invention is ingenious and reasonable in conception, simple in steps, and capable of avoiding the problems that the carbonatite reaction kinetic model is complicated and difficult to apply and estimating the acid absorption content of the stratum segment more accurately. The optimization system disclosed by the invention is simple and reasonable in structure, and capable of realizing integrated design process of the parameter design of the acidizing and acid fracturing technologies, effect prediction and economic evaluation, and brings convenience for field engineers to carry out optimization design on the acidizing scheme.

Owner:BEIJING GOODLUCK PETROLEUM TECH CO LTD

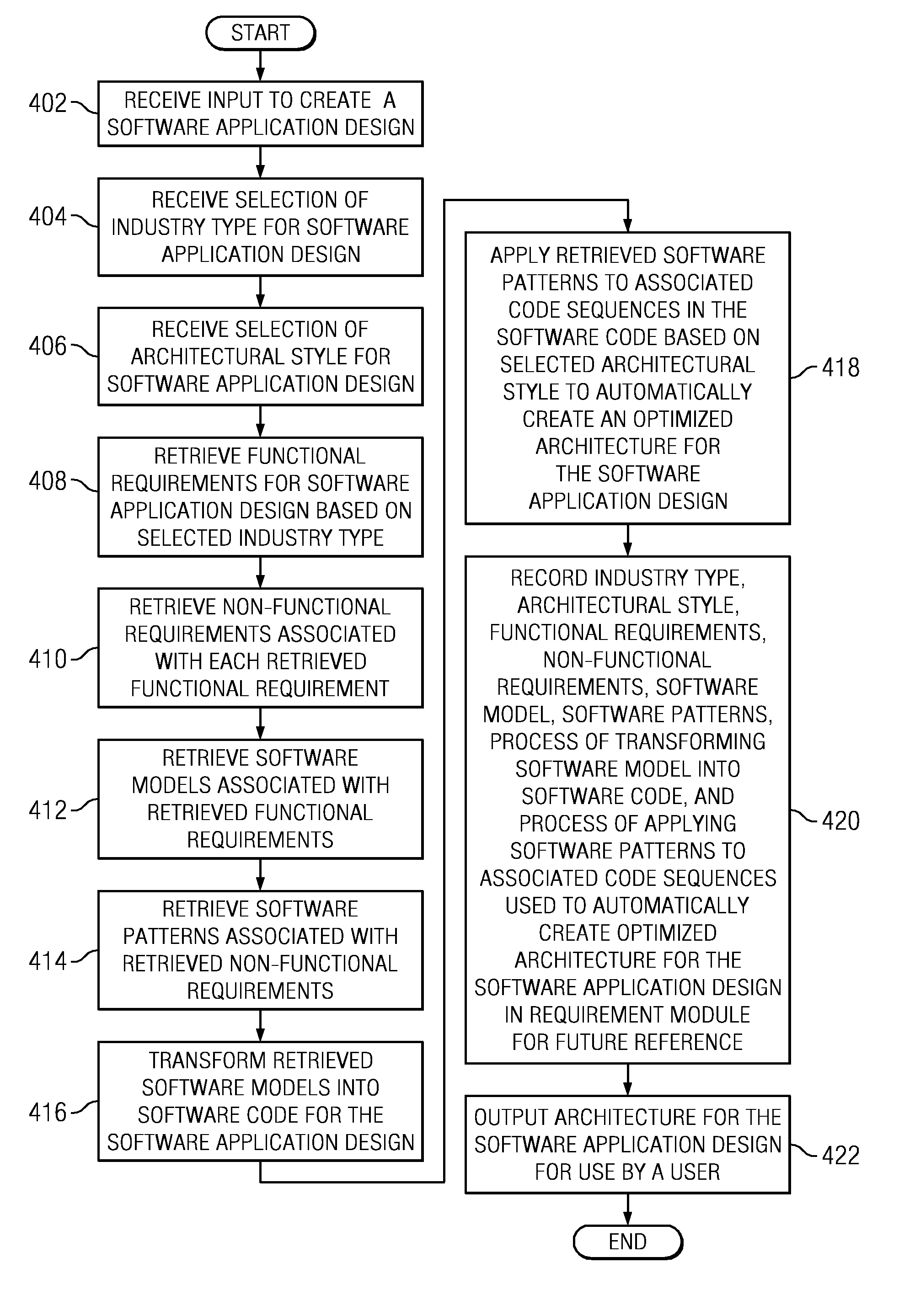

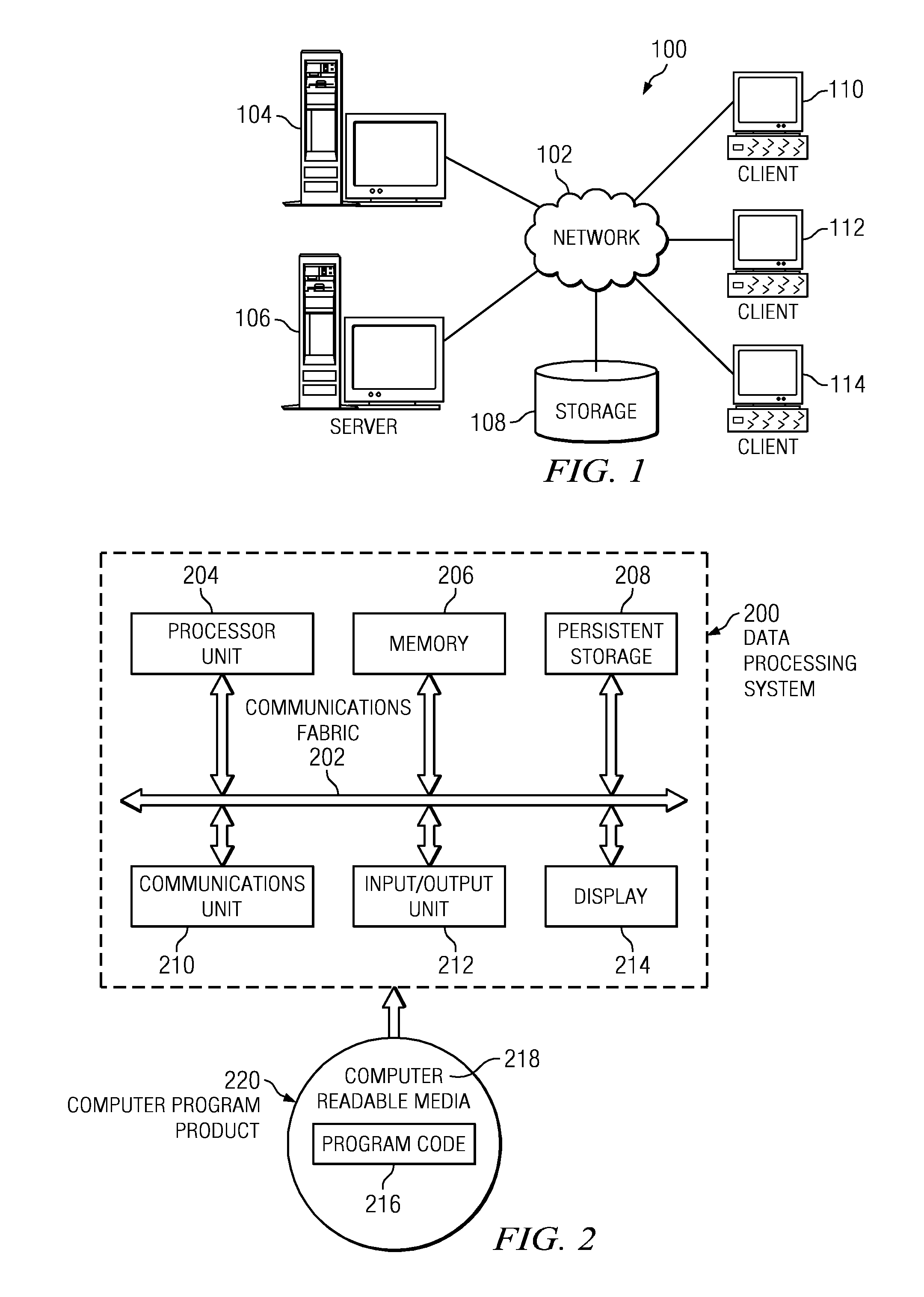

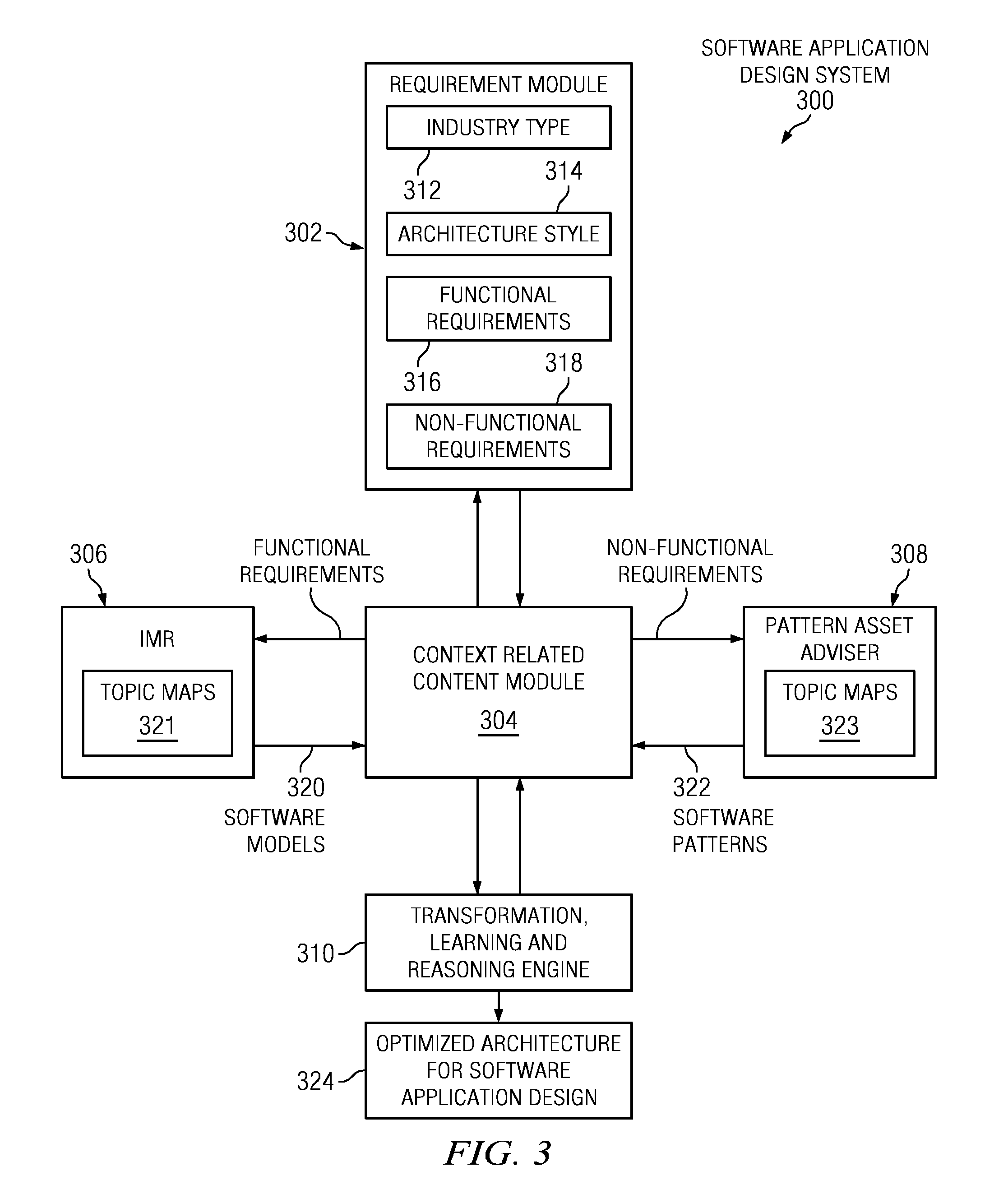

Automation of software application engineering using machine learning and reasoning

InactiveUS8607190B2Digital data processing detailsDigital computer detailsComputer architectureNon-functional requirement

A system for automatically creating a desired software application design. In response to an input to create a desired software application design, functional requirements for the desired software application design are retrieved. Then, non-functional requirements associated with each retrieved functional requirement are retrieved. In addition, software models associated with the retrieved functional requirements are retrieved. Further, software patterns associated with the retrieved non-functional requirements are retrieved. Then, the retrieved software models are transformed into software code for the desired software application design. Also, the retrieved software patterns are applied to associated code sequences in the software code to automatically create an architecture for the desired software application design. Finally, the architecture for the desired software application design is outputted for use by a user. The decisions made during the software application design process are also captured for analysis for future improvement of the desired software application design.

Owner:INT BUSINESS MASCH CORP

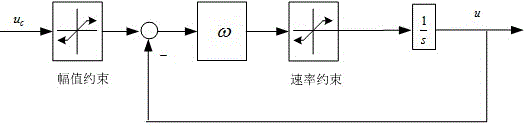

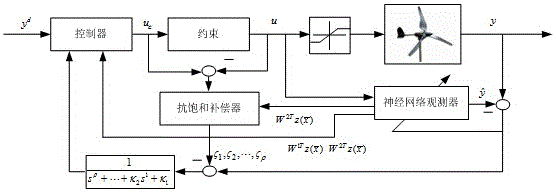

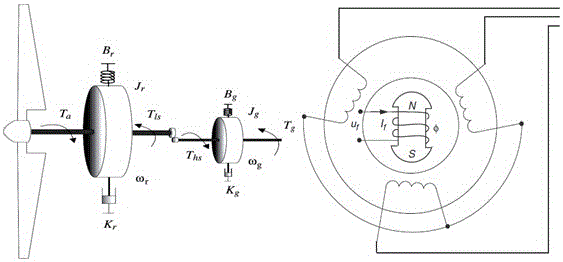

Model-free adaptive control method based on control input saturation

ActiveCN106054594ARealize speed tracking controlGood effectAdaptive controlSystems designConstraint control

The invention provides a model-free adaptive control method based on control input saturation. Under the condition of considering control input has position and rate saturation, the invention designs an adaptive neural network constraint controller based on observer technology; and in the design process, a dynamic anti-saturation compensator is provided for adjusting reference preset value in real time to ensure control input does not enter a saturation region. The method is characterized by, to begin with, carrying out model transformation on a common affine nonlinear system through a feedback linearization method; and then, designing a neural network observer and a constraint controller for the transformed system, and providing a dynamic anti-saturation algorithm to adjust a reference set value online to enable the input of the controller to be always within a constraint range.

Owner:南京杰峰实业有限公司

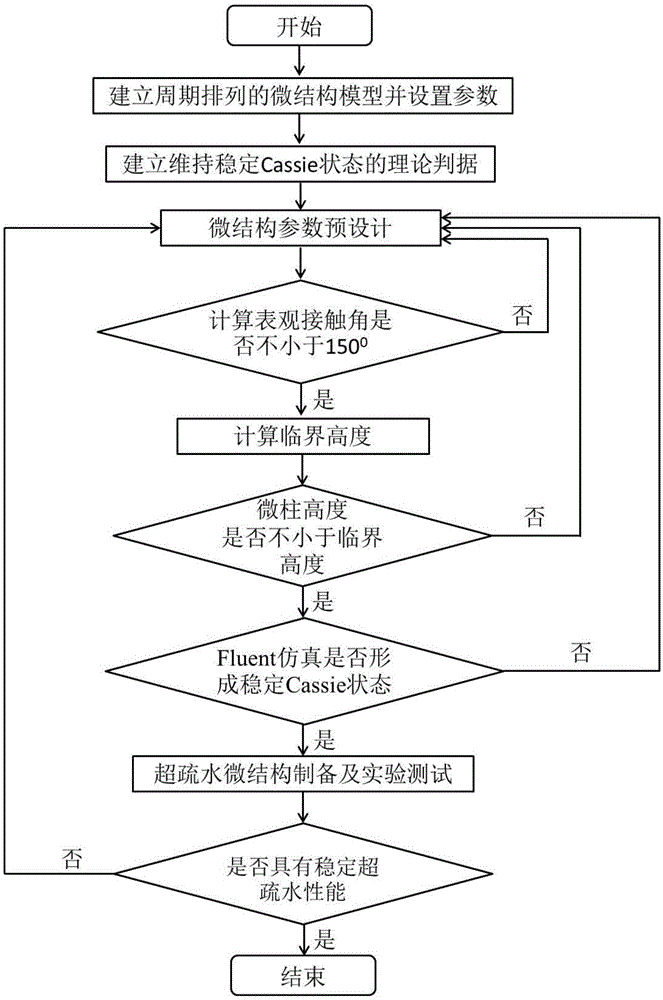

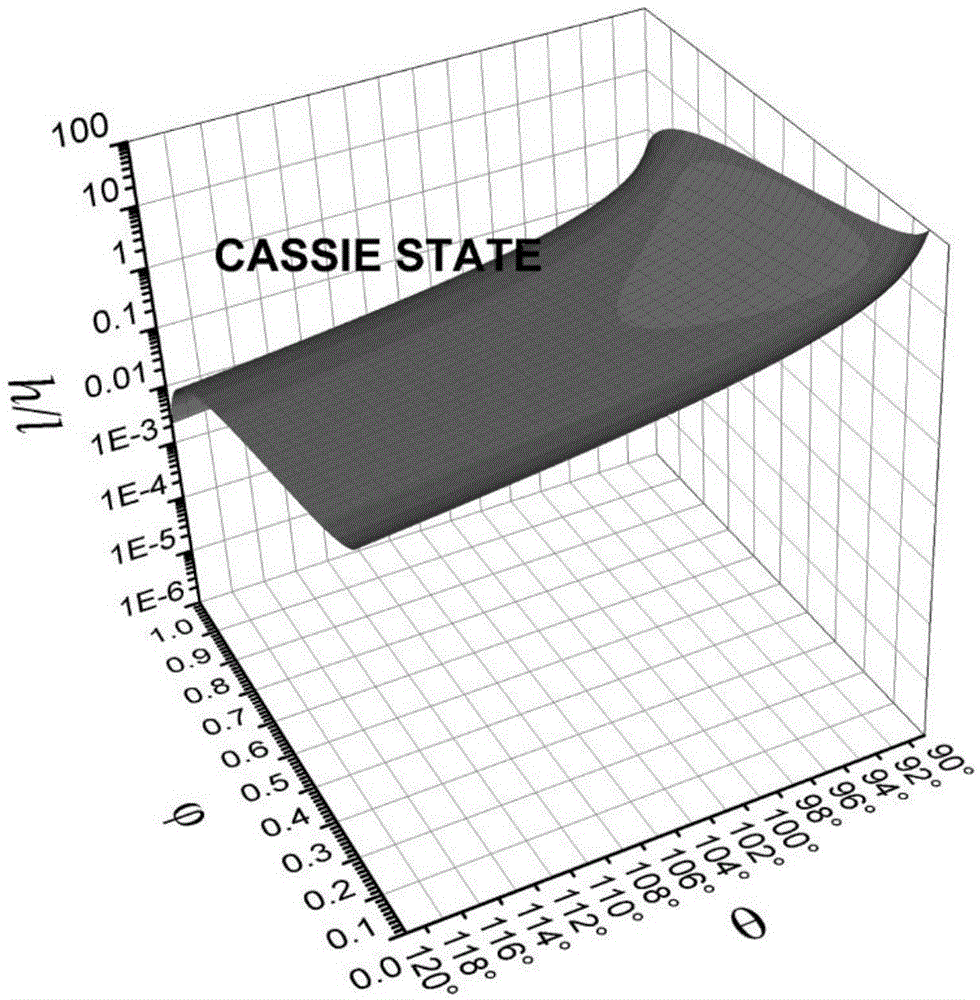

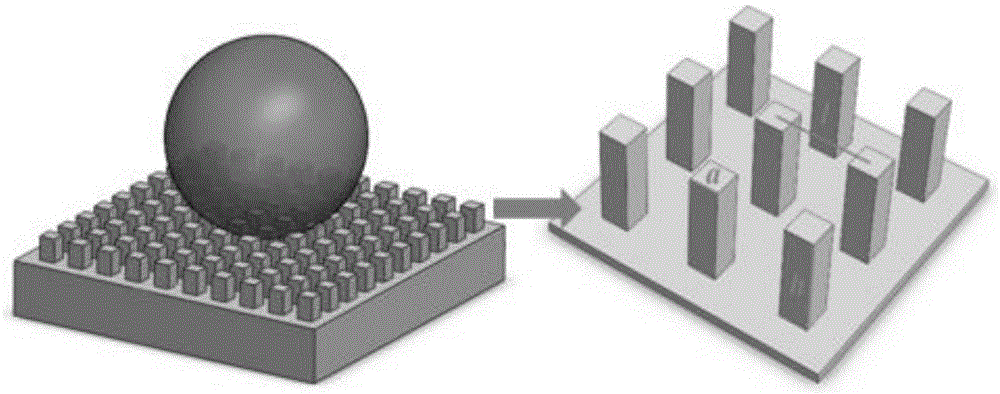

Stable superhydrophobic surface design method for periodically arranged microcolumn structure

ActiveCN105550476AStable and controllable designSimple designGeometric CADVolume meteringResidenceMicro column

The invention provides a controllable design method for a stable superhydrophobic surface of a microcolumn structure. A critical height criterion for a liquid drop to form a stable Cassie state is proposed from the perspective of a minimum energy principle and can serve as a theoretical criterion for the preparation of a stable superhydrophobic microstructure. The critical height is calculated to perform theoretical prediction on whether the stable Cassie state can be formed or not, so that the controllable design of the stable superhydrophobic surface is realized. The surface soaking performance of the designed microcolumn structure is verified through Fluent software numerical simulation of static sessile drops and dynamic residence of the designed microcolumn structure. The superhydrophobic surface design method for the periodically arranged microcolumn structure, proposed by the invention, considers the influences of the microcolumn height, the microcolumn spacing, the microcolumn bottom surface edge length and an intrinsic contact angle on the surface hydrophobic performance of the microcolumn structure at the same time, and relates to the fields of superhydrophobic design, material simulation and the like; a design process is convenient and quick; and the design method is easy to master.

Owner:DALIAN UNIV OF TECH

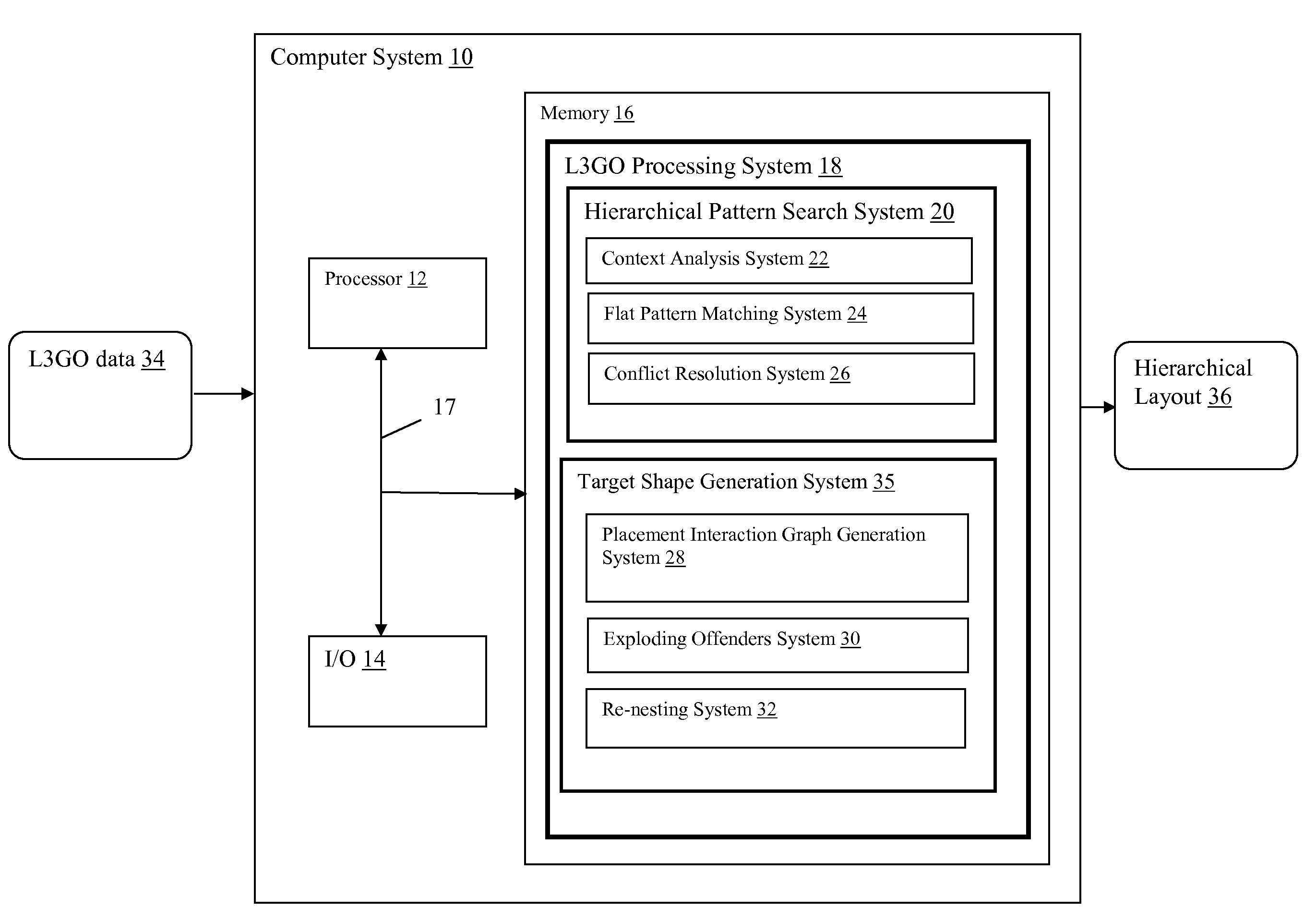

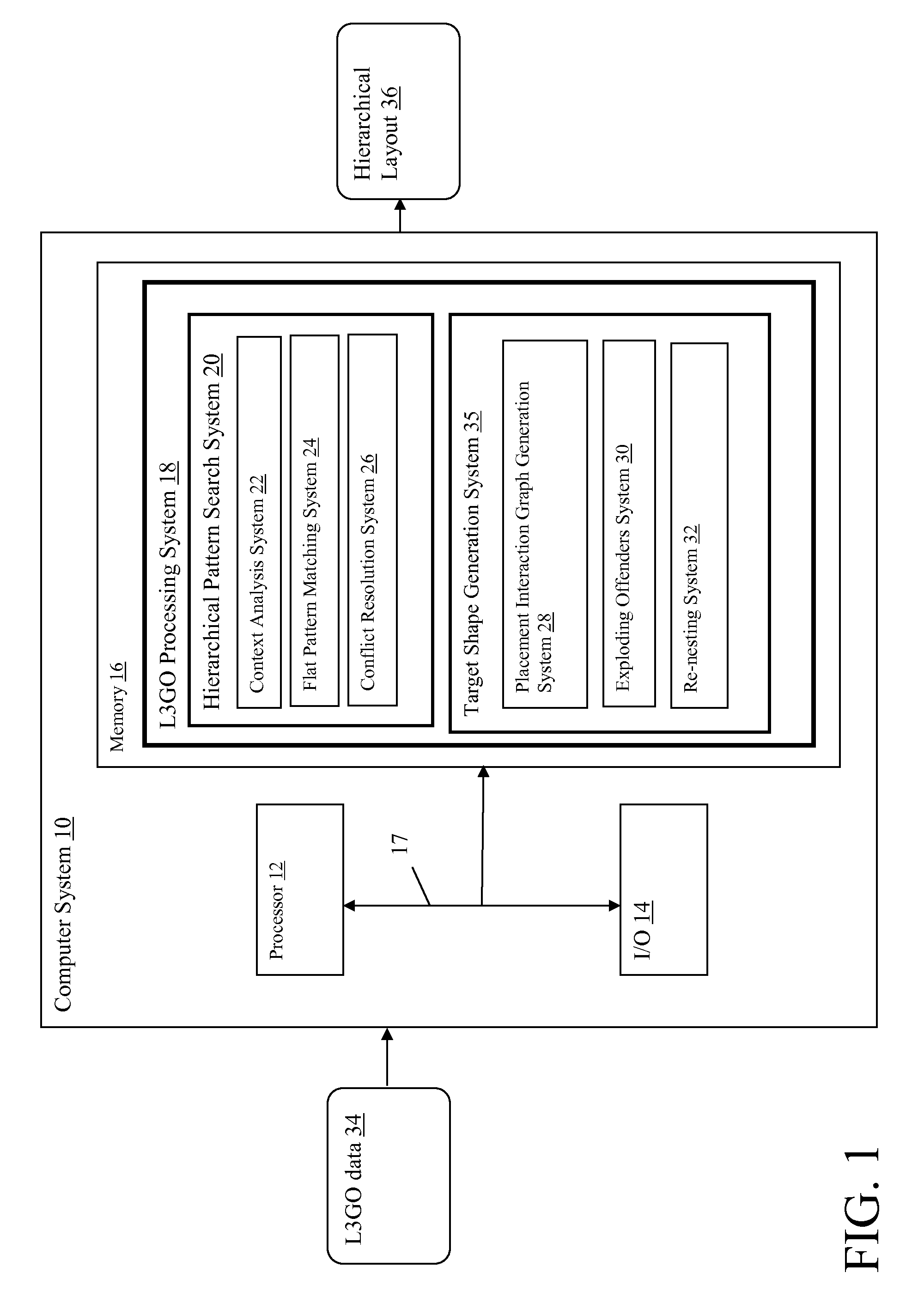

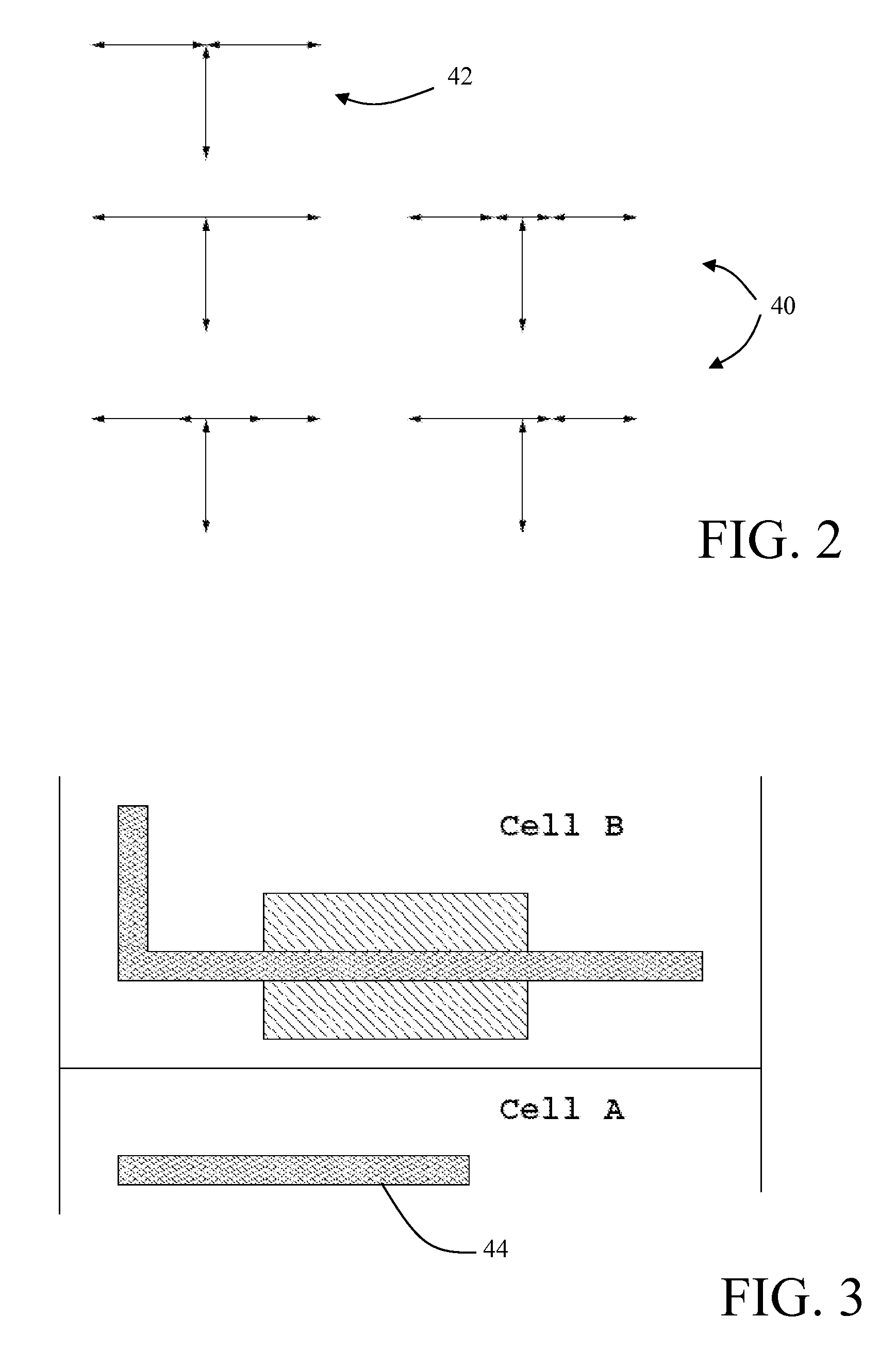

Pattern based elaboration of hierarchical l3go designs

InactiveUS20080244493A1The result is accurateCAD circuit designRecord carriers used with machinesGlyphHierarchical design

A system, method and program product that utilizes flat pattern based L3GO elaboration in a hierarchical environment to create a nested conventional layout. A system is provide for processing a glyph layout to generate shapes for use in a VLSI (very large scale integrated circuit) design process, including: a hierarchical pattern search system that matches patterns from a pattern library to a set of glyph data, wherein the patterns have dependencies that cross hierarchical design boundaries; and a target shape generation system that selects patterns from a set of matching patterns and generates associated shapes.

Owner:IBM CORP

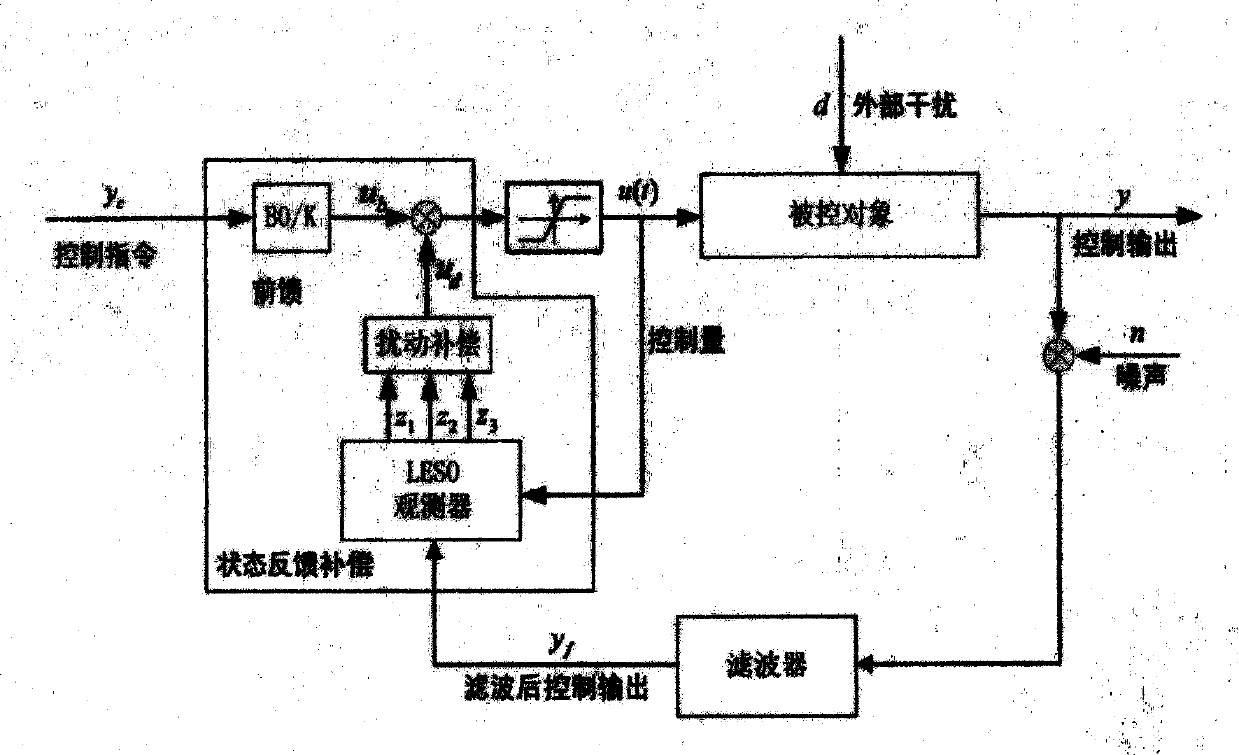

Linear extended state observer-based composite control system and design method thereof

The invention provides a linear extended state observer-based composite control system and a design method thereof. The method includes the following steps that: the nominal design model of a controlled object is established; closed-loop poles expected to be configured are designed; a feedback measurement channel low-pass filter GLP is designed; a linear extended state observer is designed; a state compensation feedback control law is designed; and a feedforward control law and composite control output are designed. According to the linear extended state observer-based composite control systemand the design method thereof of the invention, each design link does not require complicated parameter setting; the physical meaning of a design process is clear; and a requirement for the robust performance of a closed-loop system and the robust stability of the closed-loop system can be satisfied simultaneously through linear extended state observer-based composite control.

Owner:HIWING TECH ACAD OF CASIC

Method for optimizing an artificial neural network (ANN)

Owner:XILINX TECH BEIJING LTD

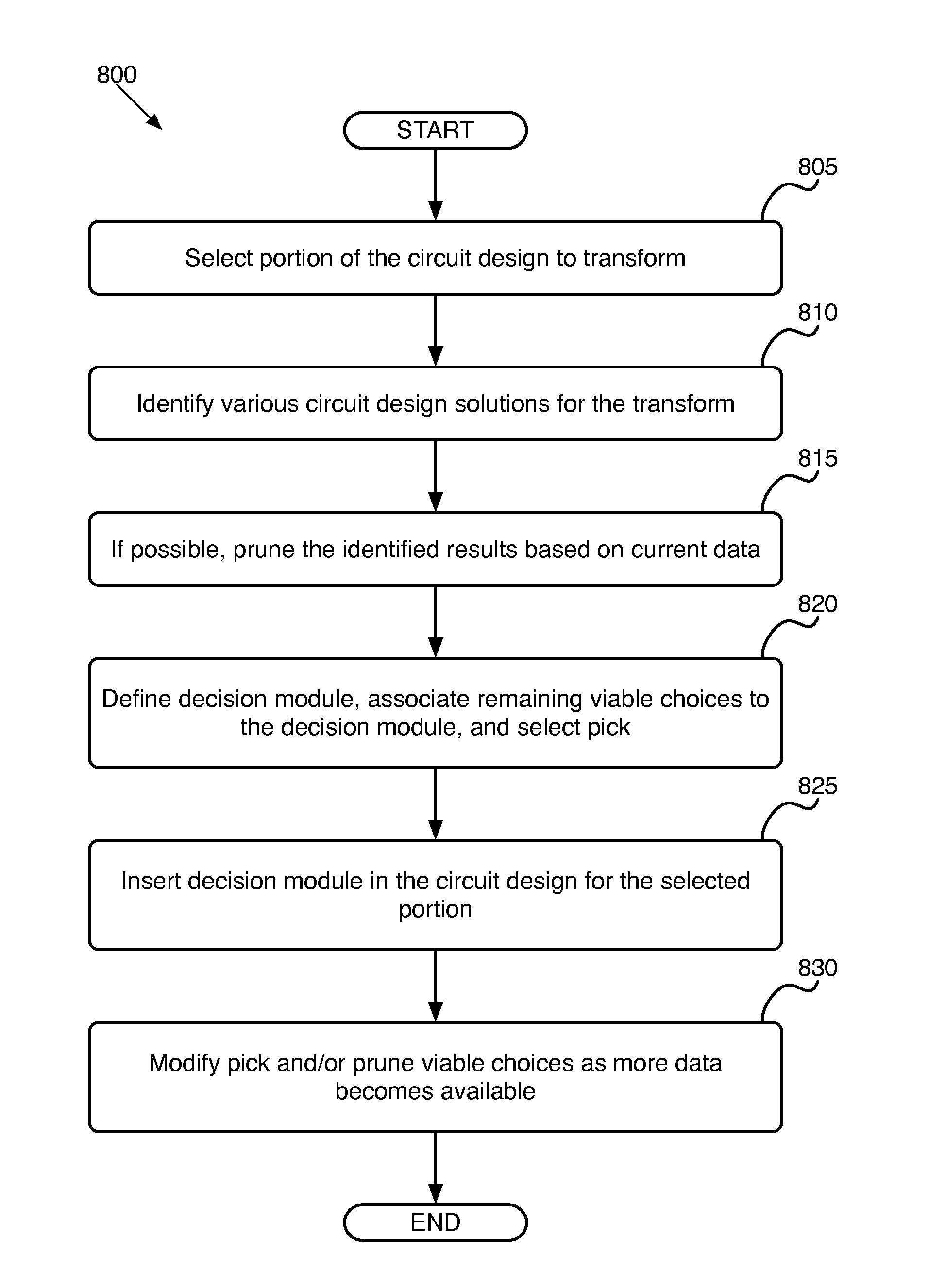

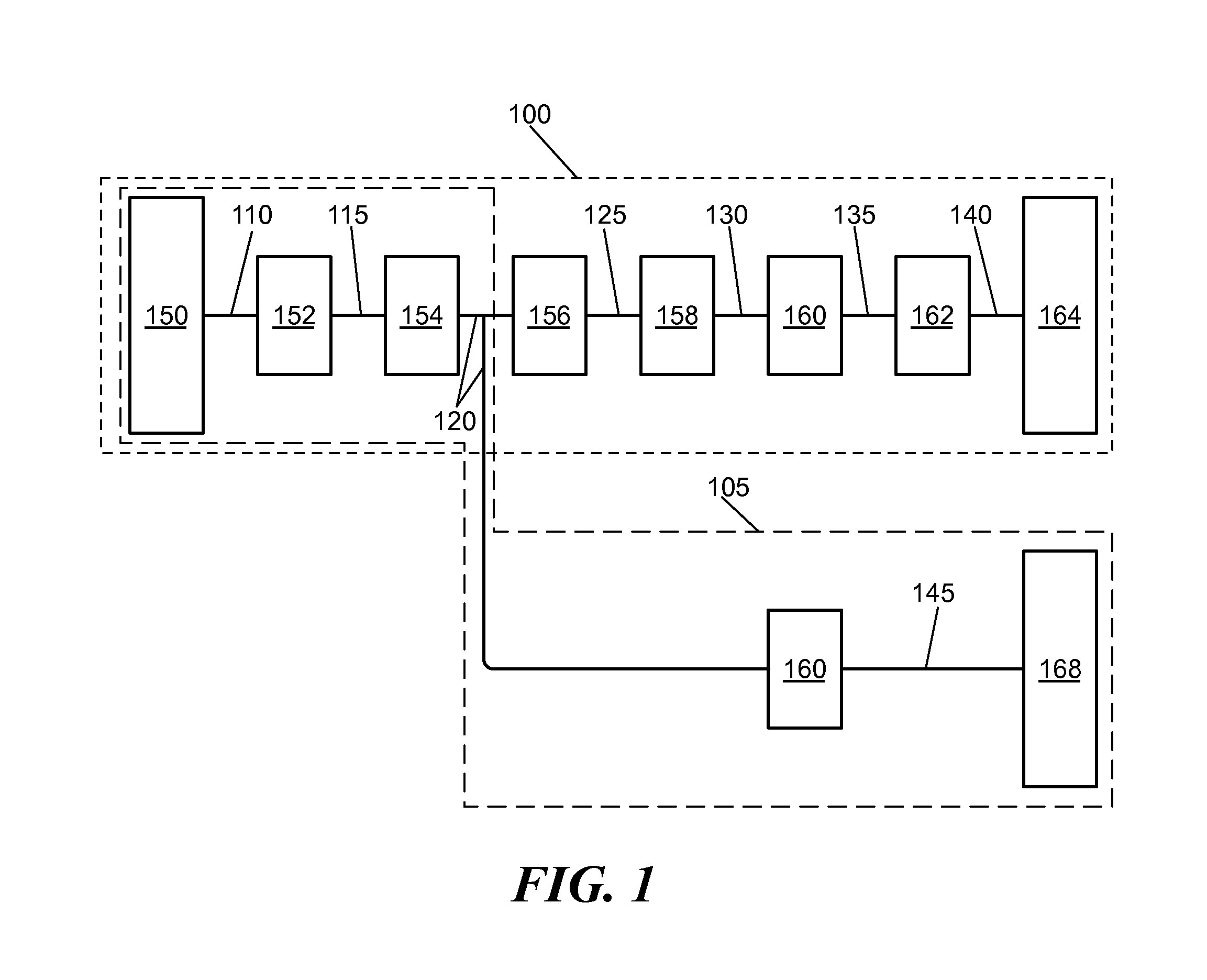

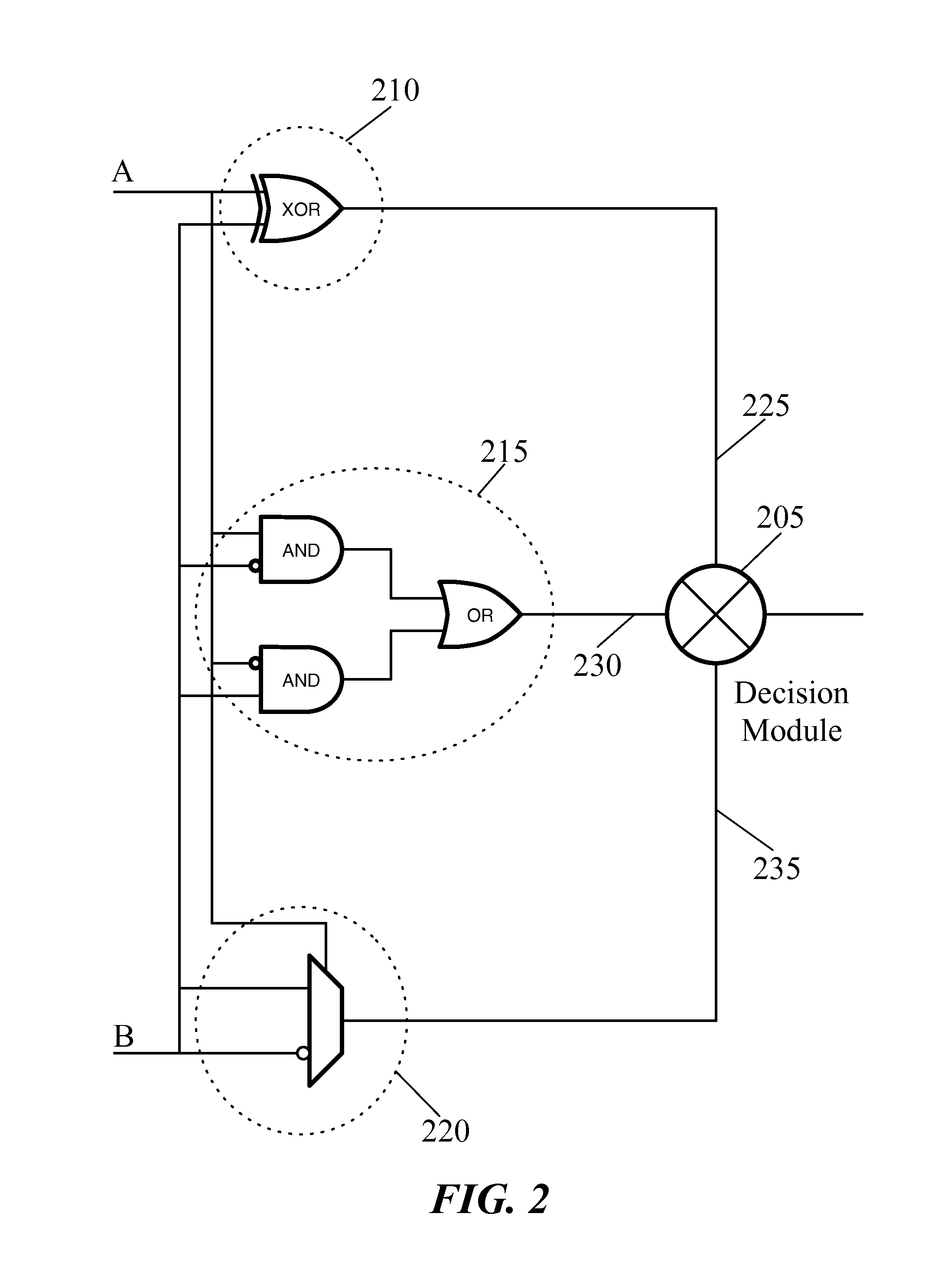

Decision modules in integrated circuit design

ActiveUS8458629B2Convenient post-operationEasy to installDetecting faulty computer hardwareCAD circuit designComputer moduleDecision taking

An abstract decision module primitive for placement within a logical representation (i.e., a netlist) of a circuit design is described. The decision module primitive receives as inputs alternative solutions for a given function or segment of a netlist. The alternative solutions include functionally equivalent, but structurally different implementations of the function or segment of the netlist. The decision module primitive alternatively selects between connecting one of the inputs to the netlist to provide a complete functional definition for the netlist based on constraint information. The selected input of the decision module may be updated as additional constraint information is determined throughout the various stages of the design process. In addition, alternative solutions for a given function or segment of the netlist may be added to and / or removed from the inputs of a decision module as additional constraint information is identified.

Owner:ALTERA CORP

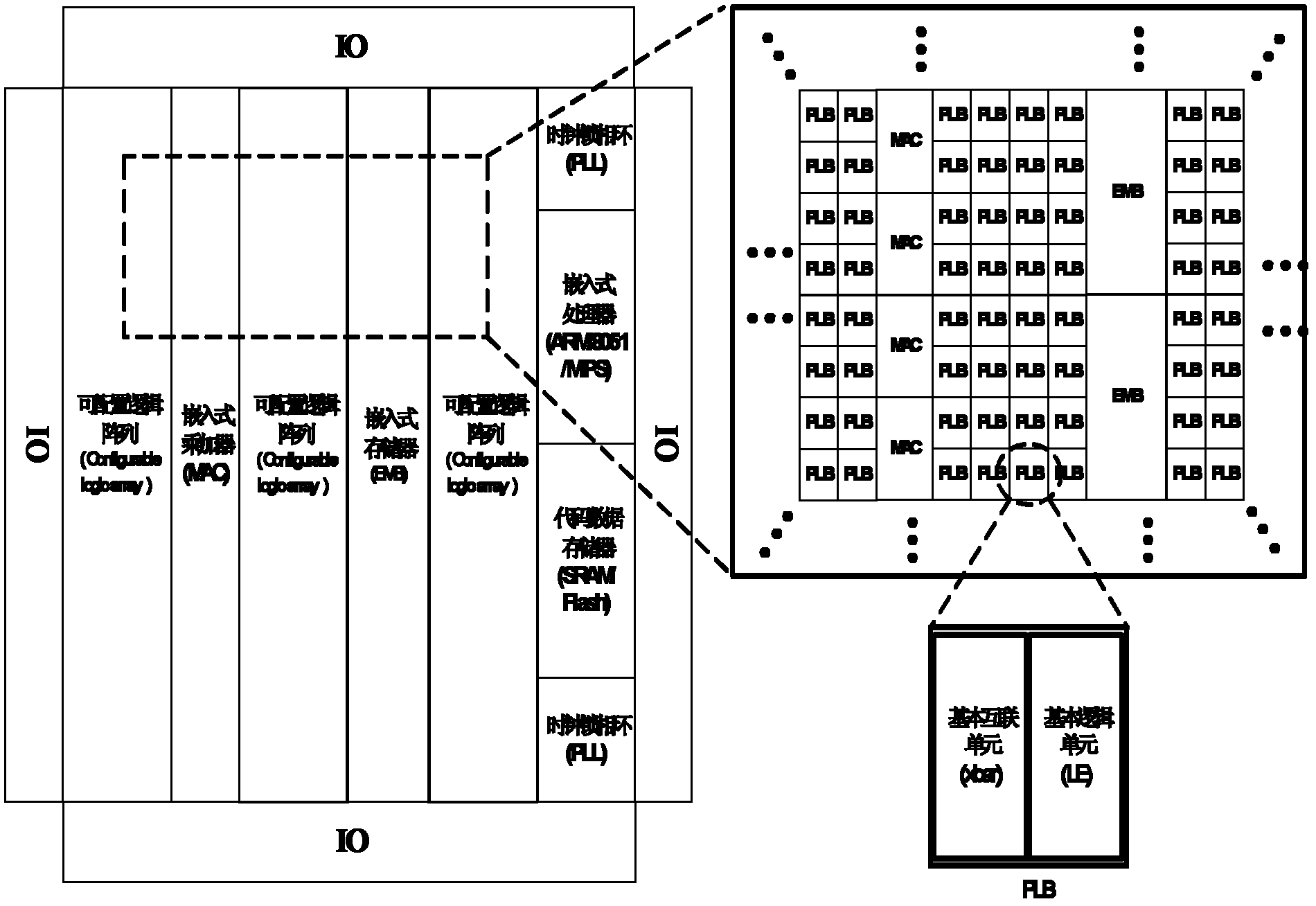

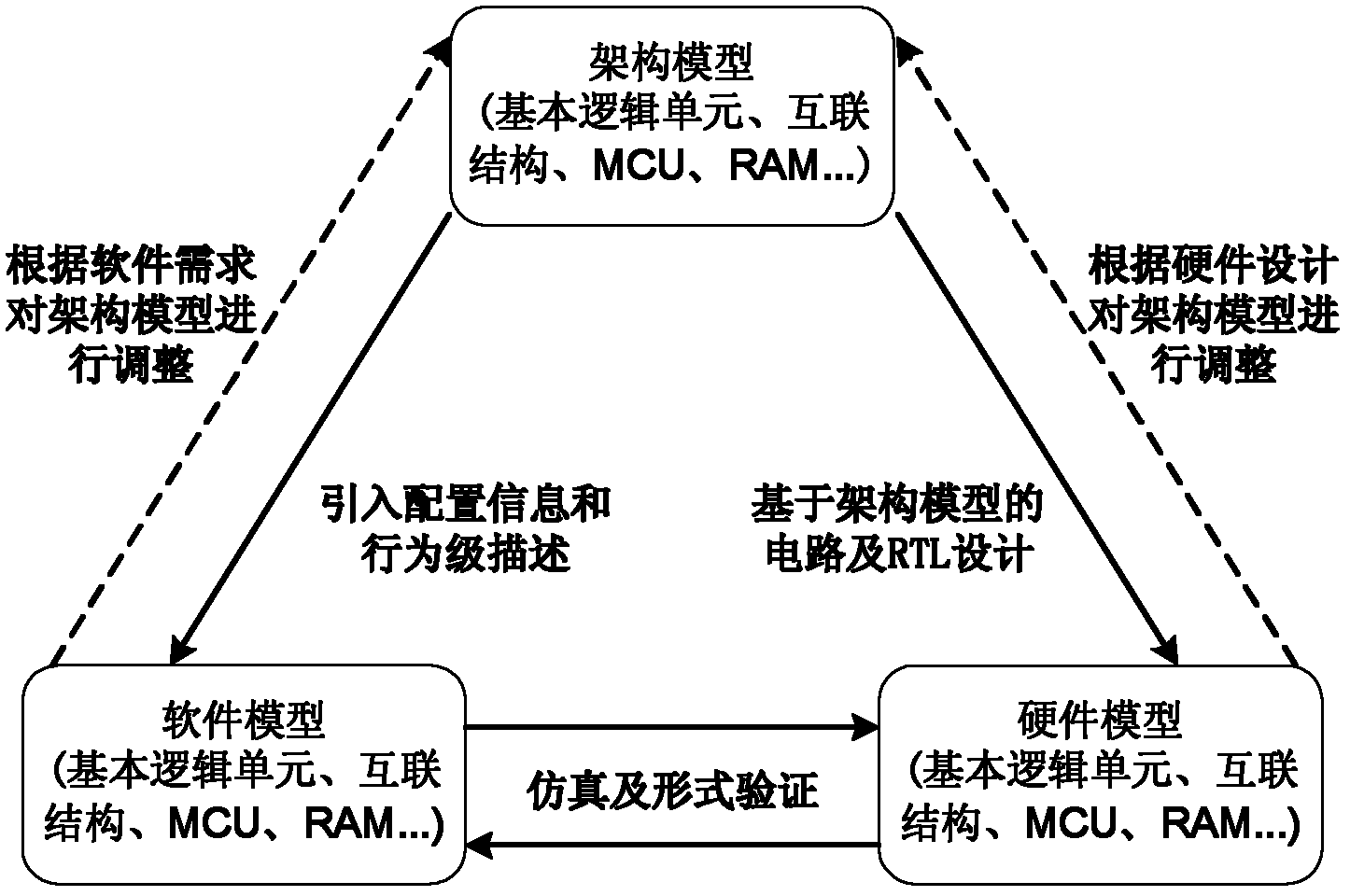

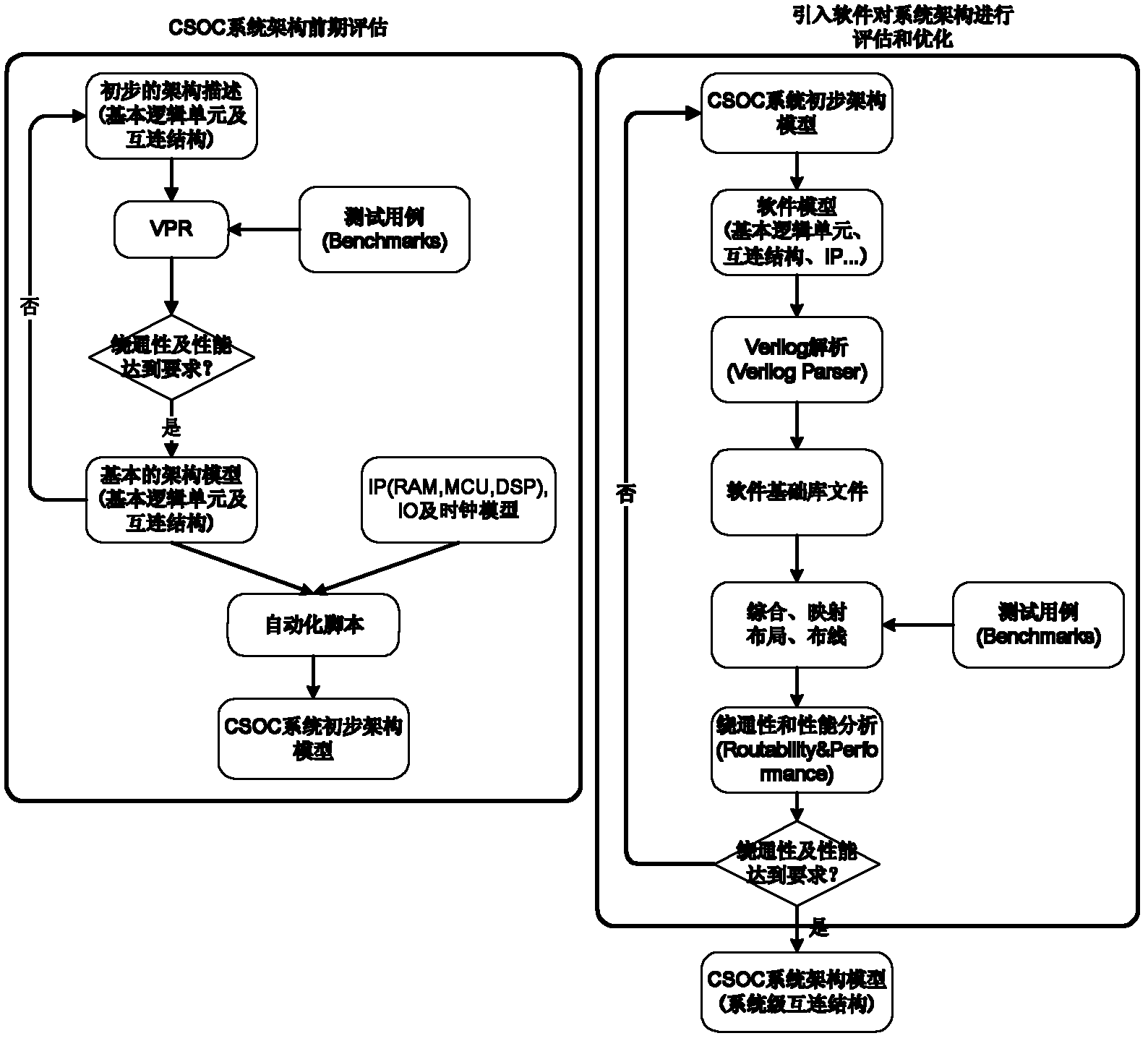

Method for keeping architecture, software and hardware conforming in configurable chip operating system

ActiveCN103258067AEnsure consistencySpecial data processing applicationsHardware description languageData architecture

The invention provides a method for keeping architecture, software and hardware conforming in a configurable chip operating system. The method includes steps of describing an architecture model of a CSOC (configurable system on chip) system by hardware description language; describing a software model on the basis of the architecture model through configuration parameters and behavioral level description by hardware description language; and describing a hardware model on the basis of the architecture model by the hardware description language. By the method for keeping architecture, software and hardware conforming in the configurable chip operating system, design process of the CSOC system can be greatly simplified, and a great quantity of repeated work can be reduced.

Owner:CAPITAL MICROELECTRONICS

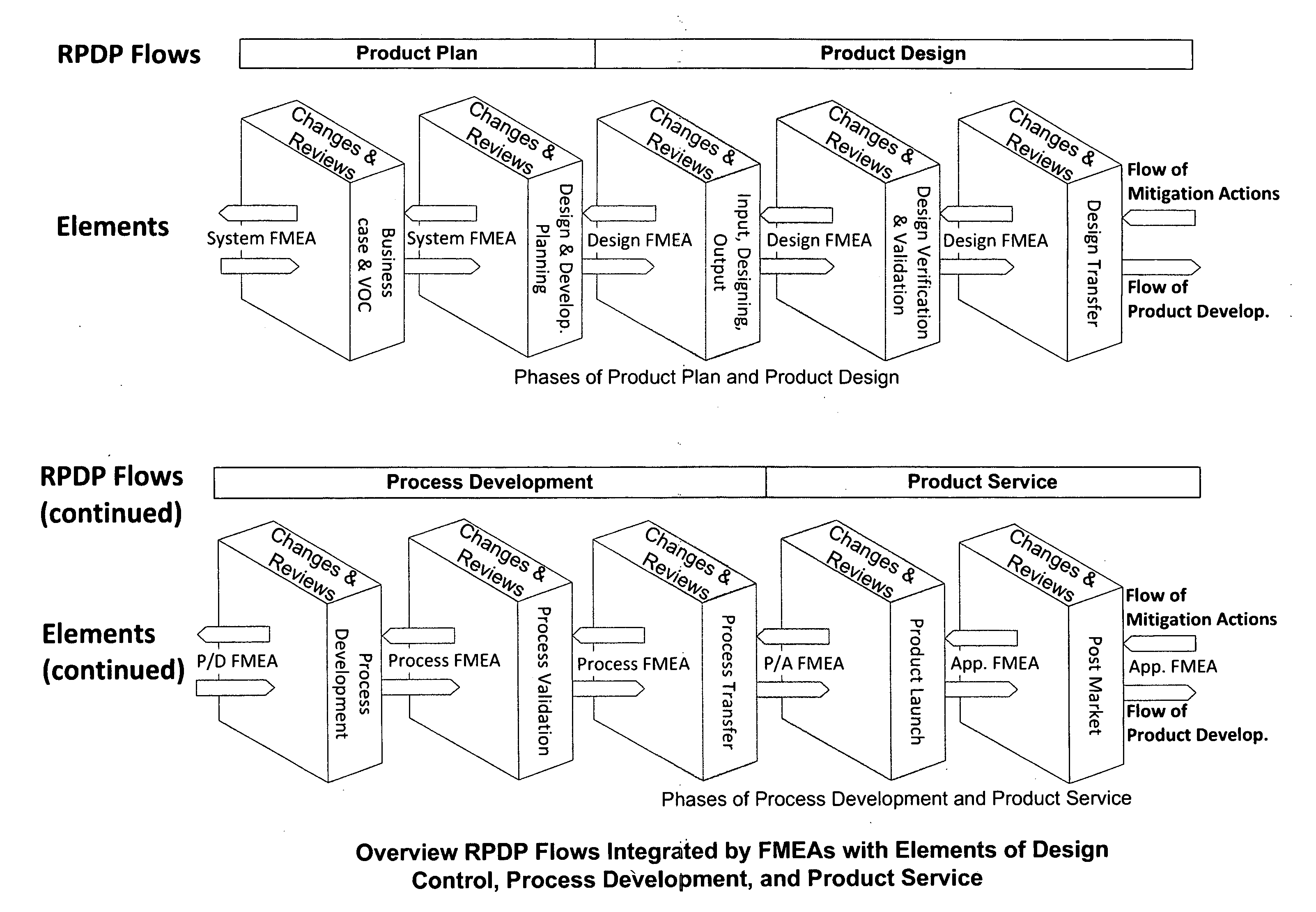

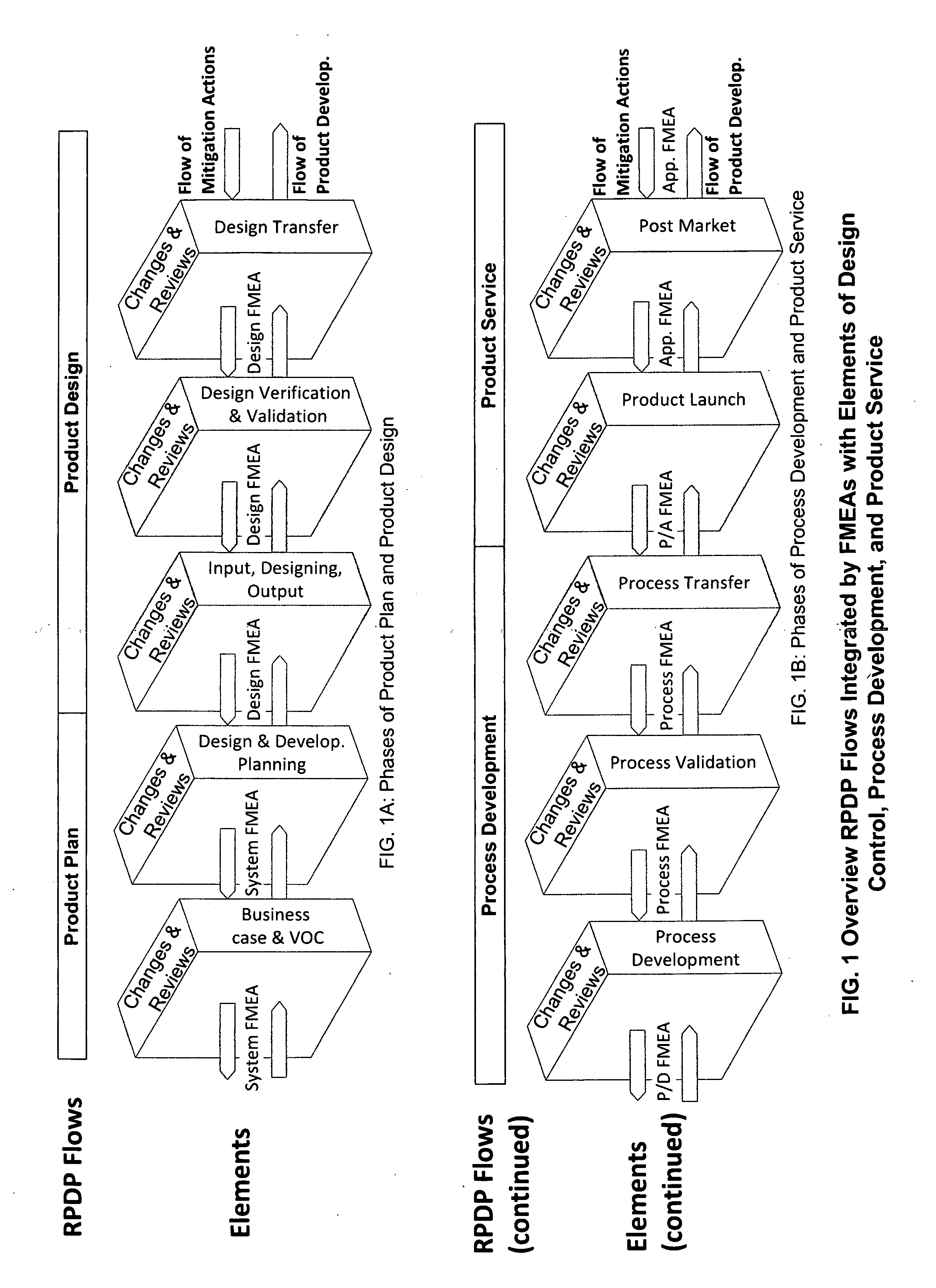

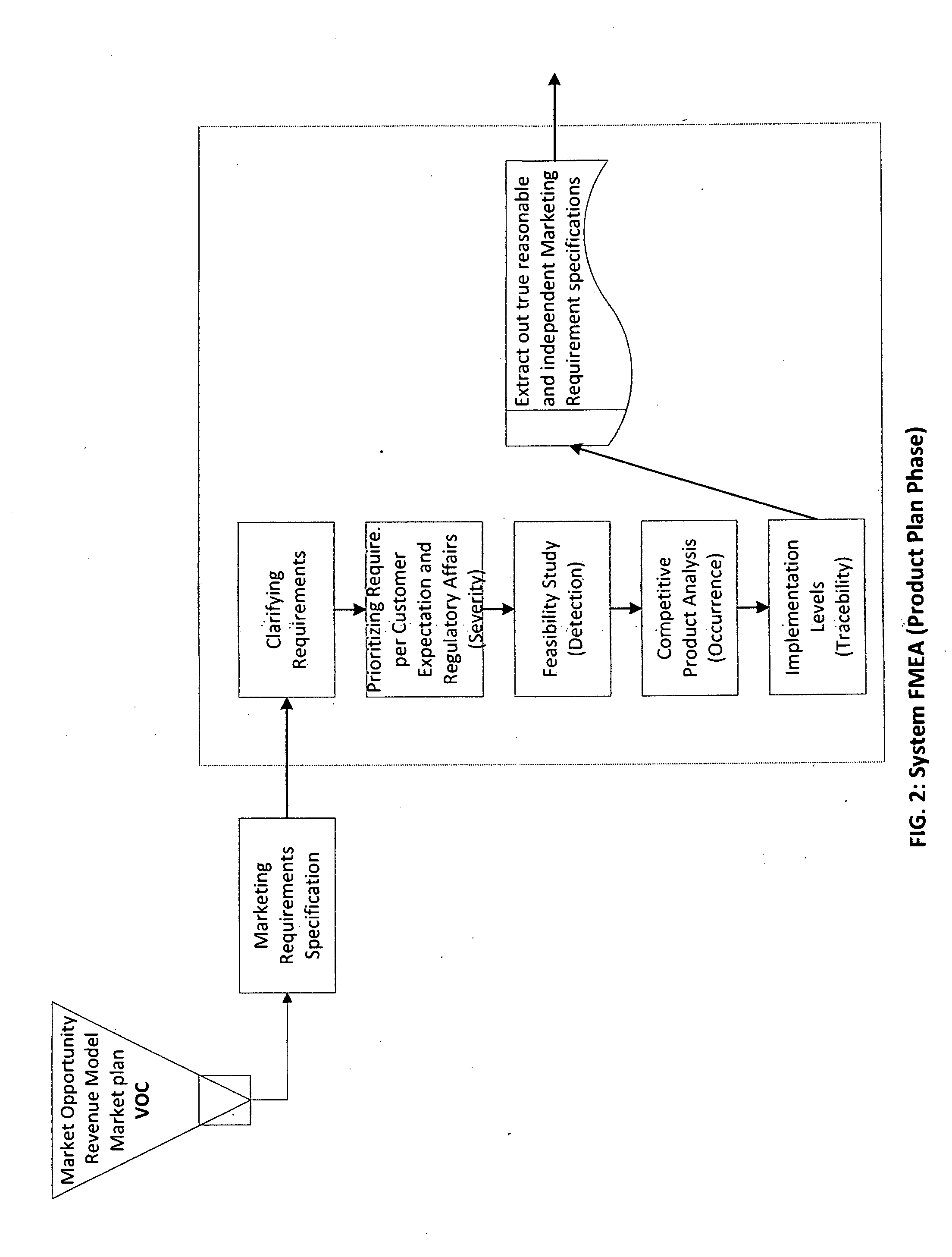

Risk driven product development process system

InactiveUS20150134398A1Less competitiveFinanceTechnology managementRequirements analysisProcess systems

New product developments are getting more and more risks due to the following uncertainties. The technology uncertainties are caused by the immaturity of components or system integration. The company-internal uncertainties are resulted from an inefficiency and unqualified Product Development Process (PDP). The customer requirement uncertainties are induced by levels of understanding of customer requirements or customer requirement changes. The market uncertainties are due to the actions of competitors or environmental influence.In order to comfortably deal with above uncertainties, a new Risk driven Product Development Process (RPDP) is invented to facilitate new product developments. This method has phases of Product Plan, Product Design, Process Development, and Product Service which are communicated by FMEA tools. Within each phase, specific FMEA tools are dominated to manage potential risks and initiate mitigated actions if their risk levels are unacceptable. Particularly, a new FMEA Frisbee uses to determine the optimal mitigated actions. Once all potential risks are controlled under the acceptance levels, the process is flowed to the next phase.The other new tools in this invention include Interaction Matrix, Integration Matrix, Spreadsheet of Market Requirement Analysis, and FMEAs Templates.

Owner:XIAO JIN XING

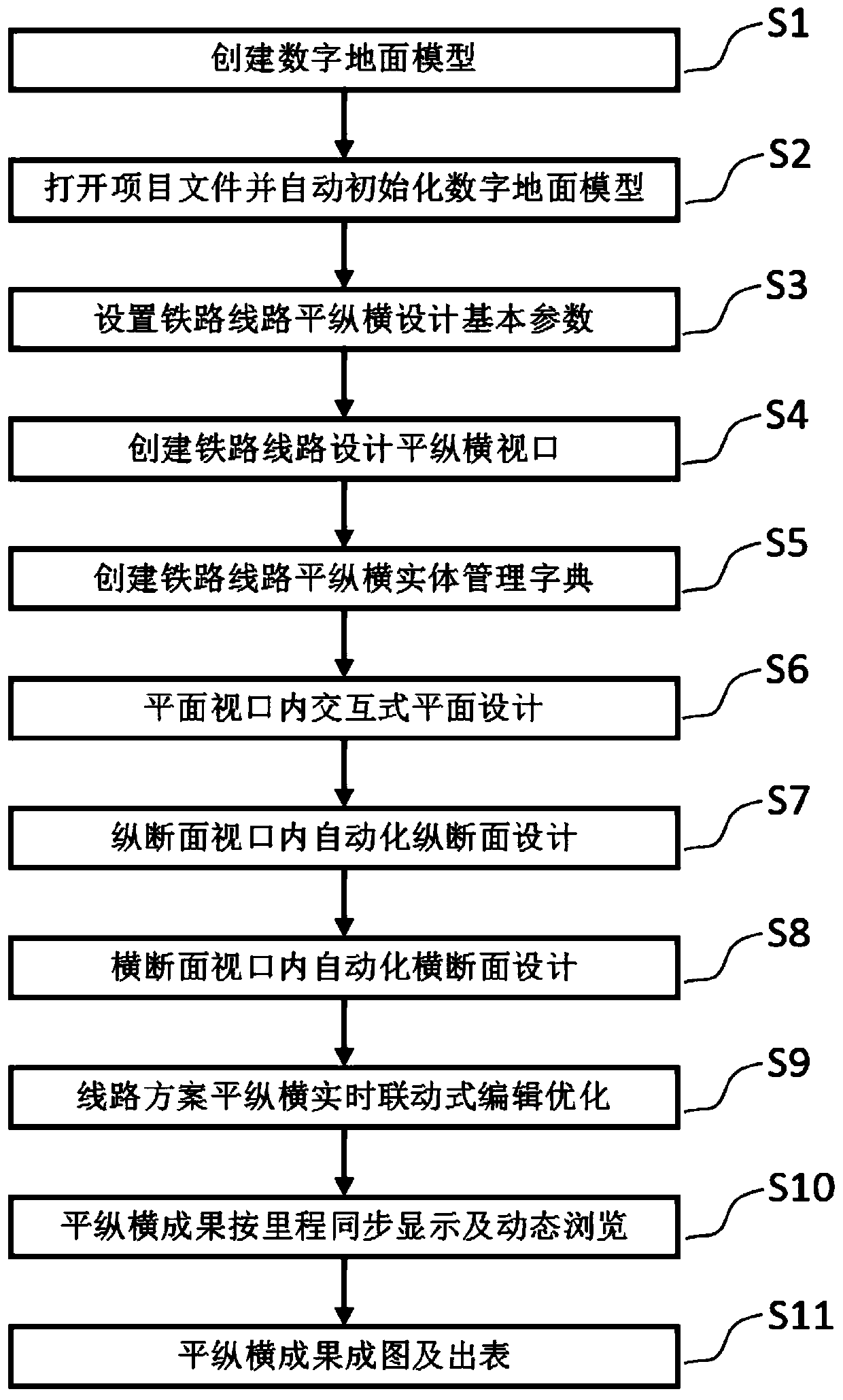

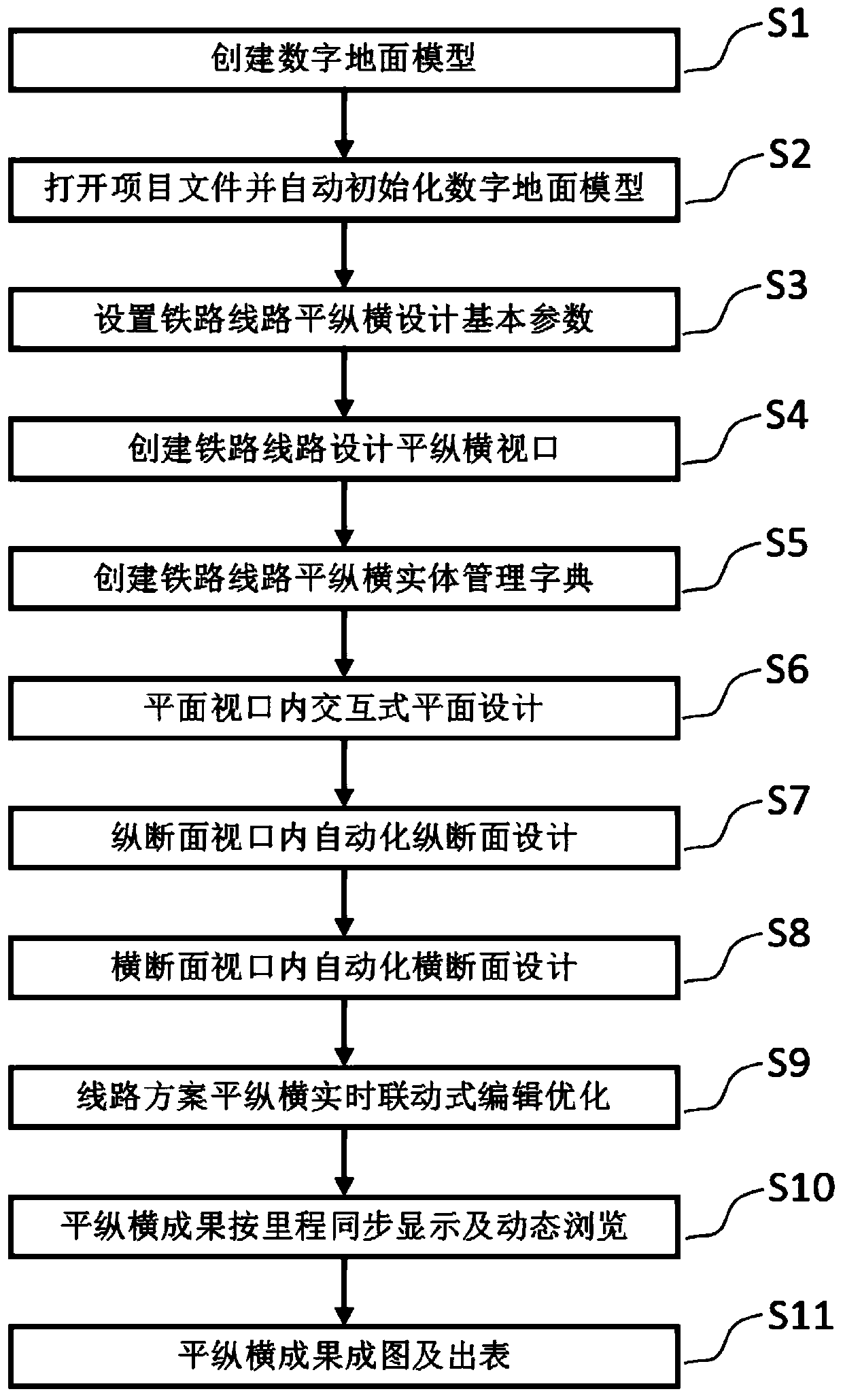

Railway line horizontal and vertical real-time linkage design method

PendingCN109918803AFast and convenient interactive designEasy accessSpecial data processing applicationsMechanical engineeringIndustrial engineering

The invention discloses a railway line horizontal and vertical and horizontal real-time linkage design method. Technical steps are included. creating a digital ground model (S1); opening the project file and automatically initializing a digital ground model (S2); (S3) setting railway line horizontal and vertical design basic parameters; creating railway line design flat vertical and horizontal viewports (S4); creating a railway line horizontal and vertical entity management dictionary (S5); carrying out interactive plane design (S6) in a plane viewport; (S7) carrying out automatic longitudinalsection design in a longitudinal section viewport; (S8) carrying out automatic cross section design in a cross section viewport; (S9) carrying out line scheme horizontal and horizontal real-time linkage type editing optimization; (S9) synchronously displaying and dynamically browsing horizontal and horizontal achievements according to mileage; According to the method, railway line plane interaction, longitudinal section and transverse section automatic design and a plane and transverse scheme real-time collaborative rapid adjustment function are achieved, the design process is high in automation degree and high in practicability, the design efficiency and the achievement quality can be greatly improved, and the obvious application and popularization value is achieved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

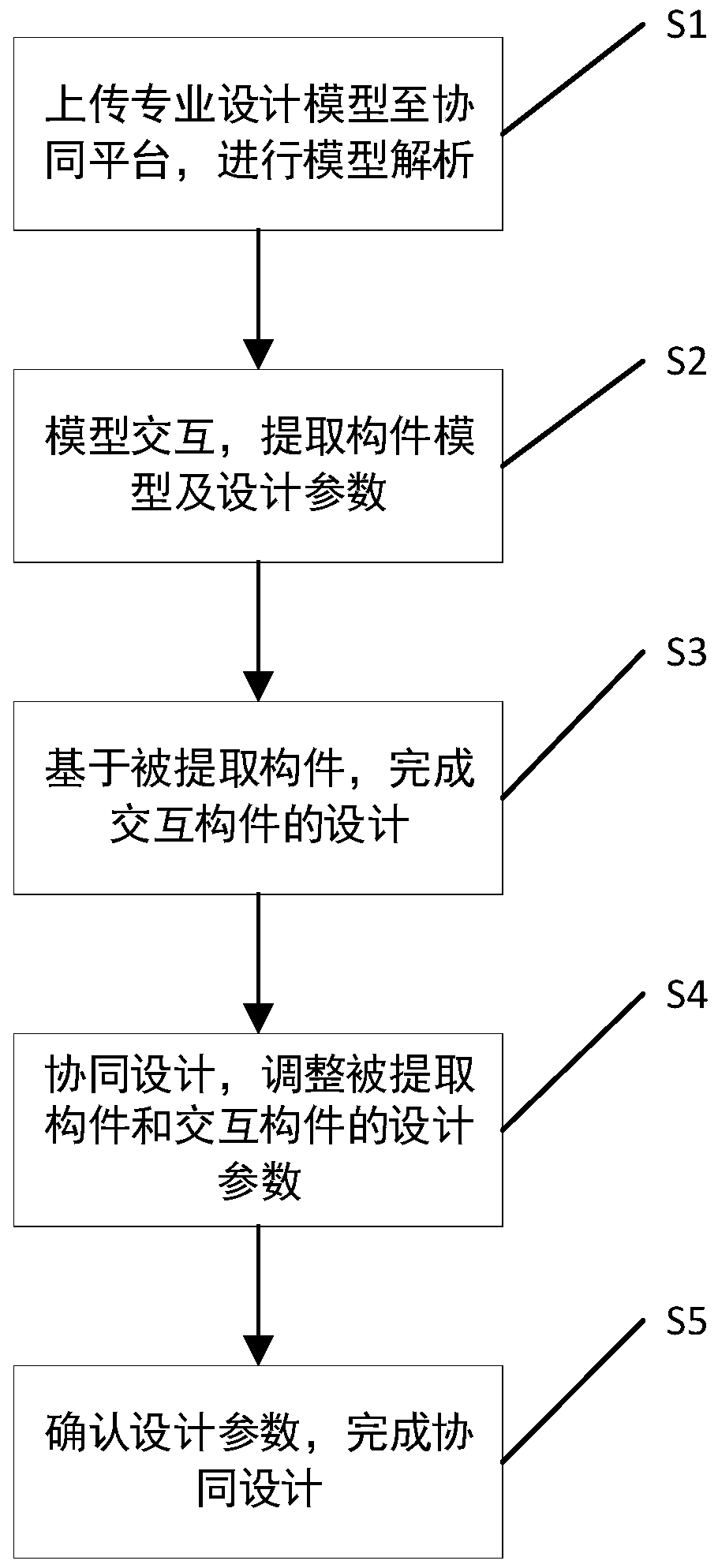

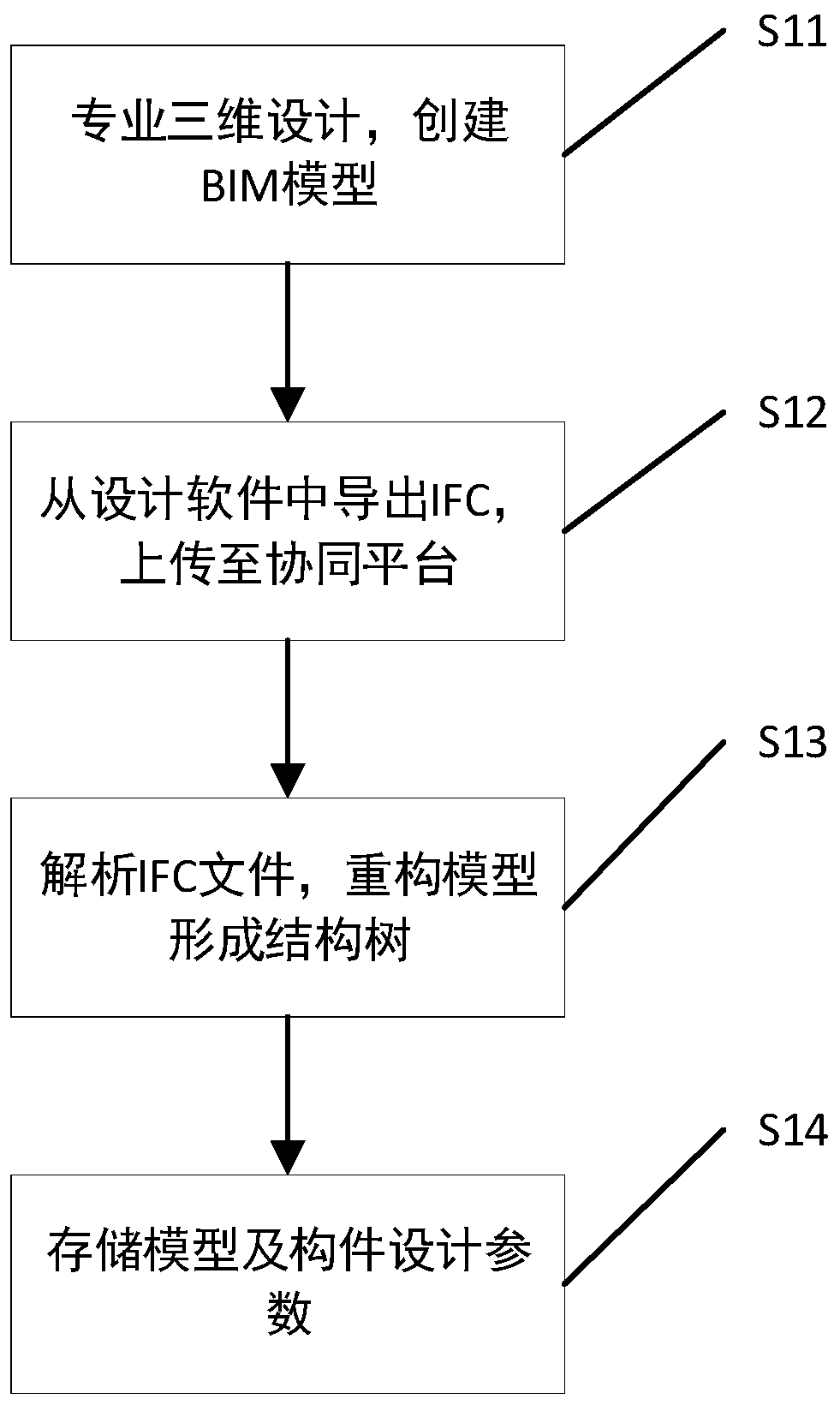

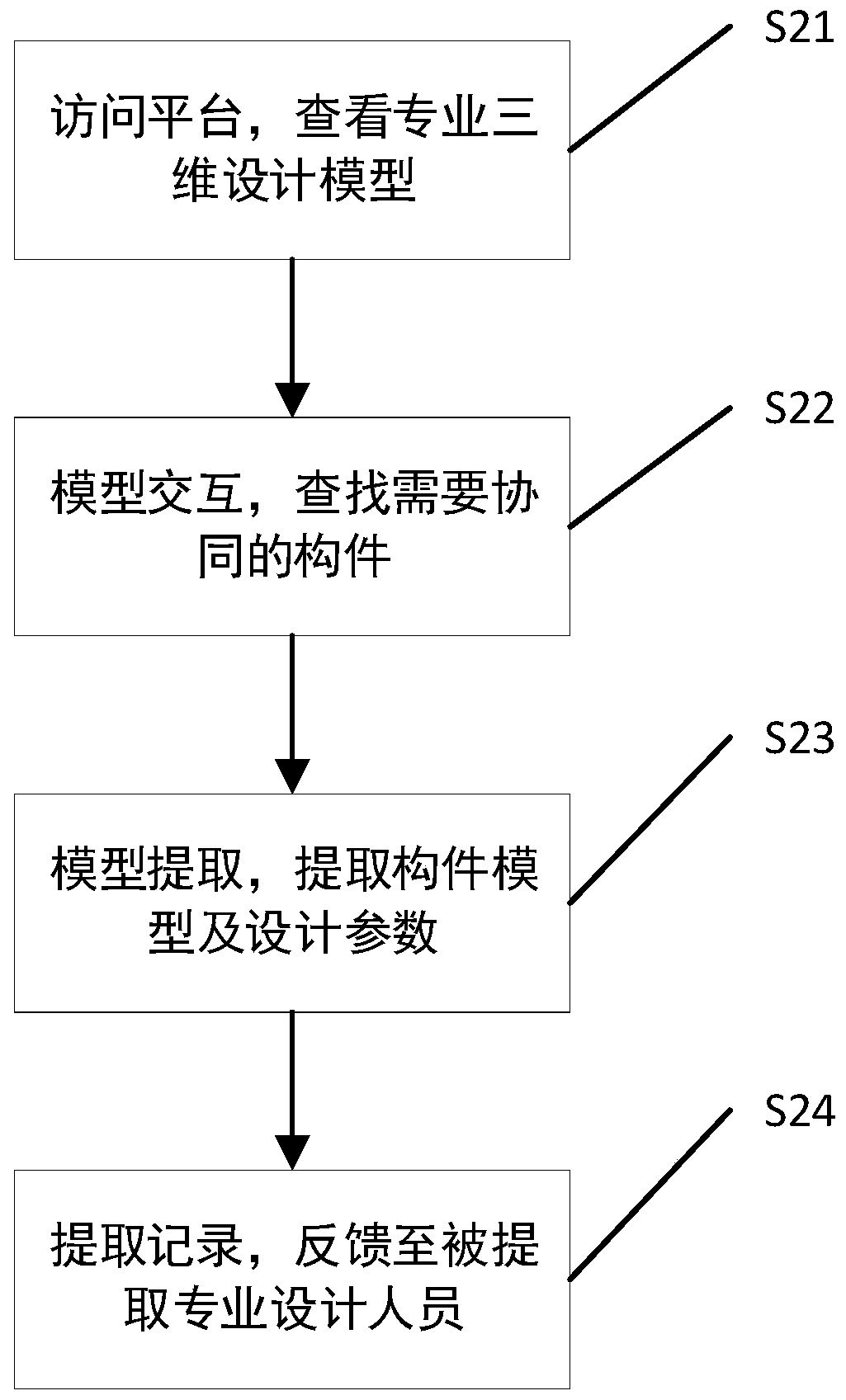

Multi-specialty forward collaborative design interaction method for urban rail transit

ActiveCN111311181AImprove collaboration efficiencyReduce Design ChangesDesign optimisation/simulationOffice automationDesign standardDimensional modeling

The invention provides a multi-specialty forward collaborative design interaction method for urban rail transit, and belongs to the technical field of urban rail transit engineering design. The methodincludes: carrying out three-dimensional design on each major of the involved urban rail transit, creating a BIM model, and uploading a model IFC file to a collaborative platform; analyzing the IFC file according to an IFC standard specification; a designer refers to the extracted component three-dimensional model and the design parameters to design specific parameters of the interaction component, and professional three-dimensional modeling is completed; the collaborative platform completes analysis of the three-dimensional model; a message management module of the platform sends a message uploaded by the interaction component three-dimensional model to a designer of the extracted specialty; the platform analyzes the parameter difference between the newly uploaded three-dimensional modeland the original three-dimensional model in a version comparison mode after analyzing the file; and a designer professionally confirms final design parameters of the extracted component and the interactive component according to design standards, design specifications and project technical requirements of the country or the industry, and a collaborative design process is completed.

Owner:GUANGZHOU METRO DESIGN & RES INST

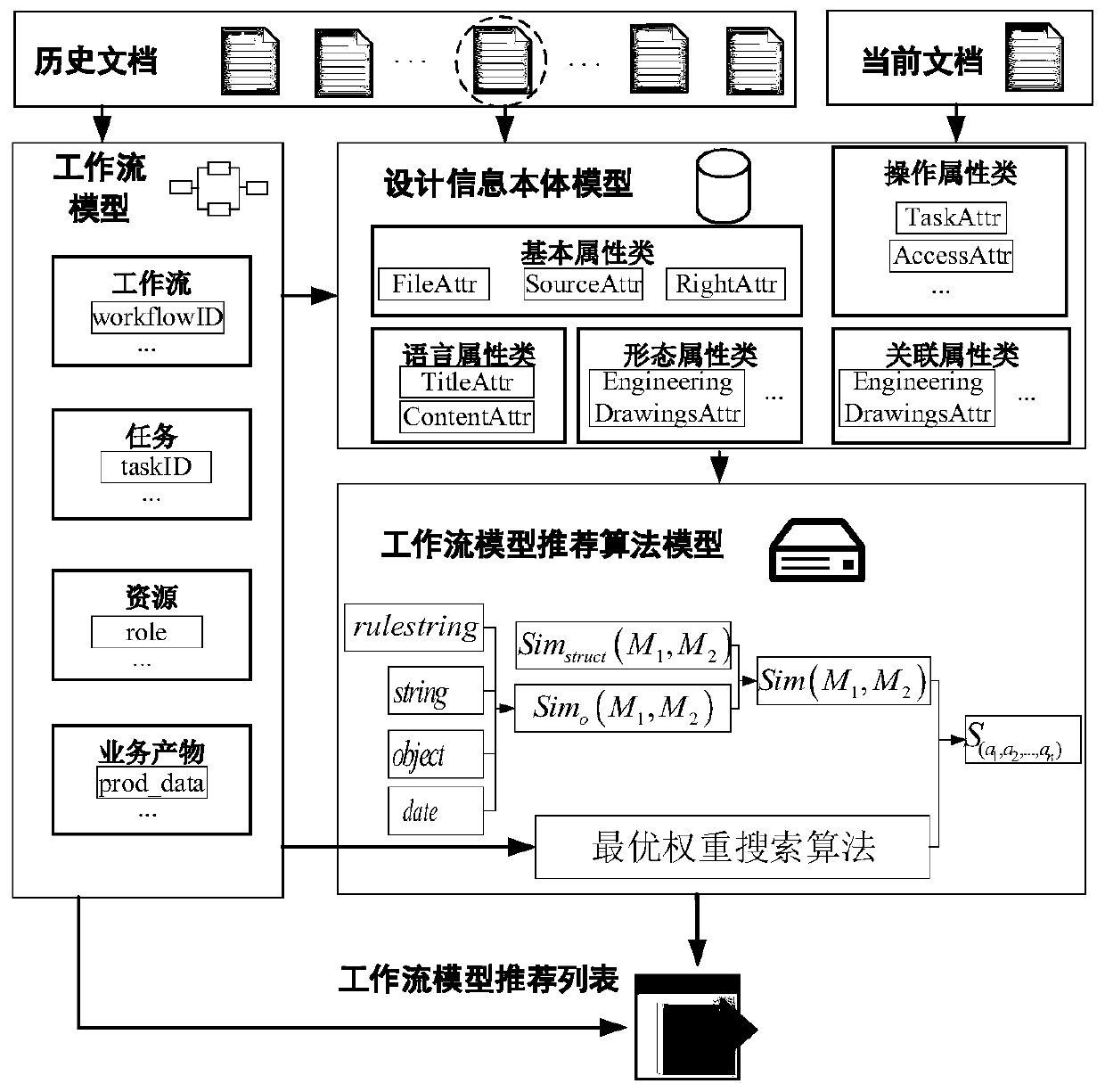

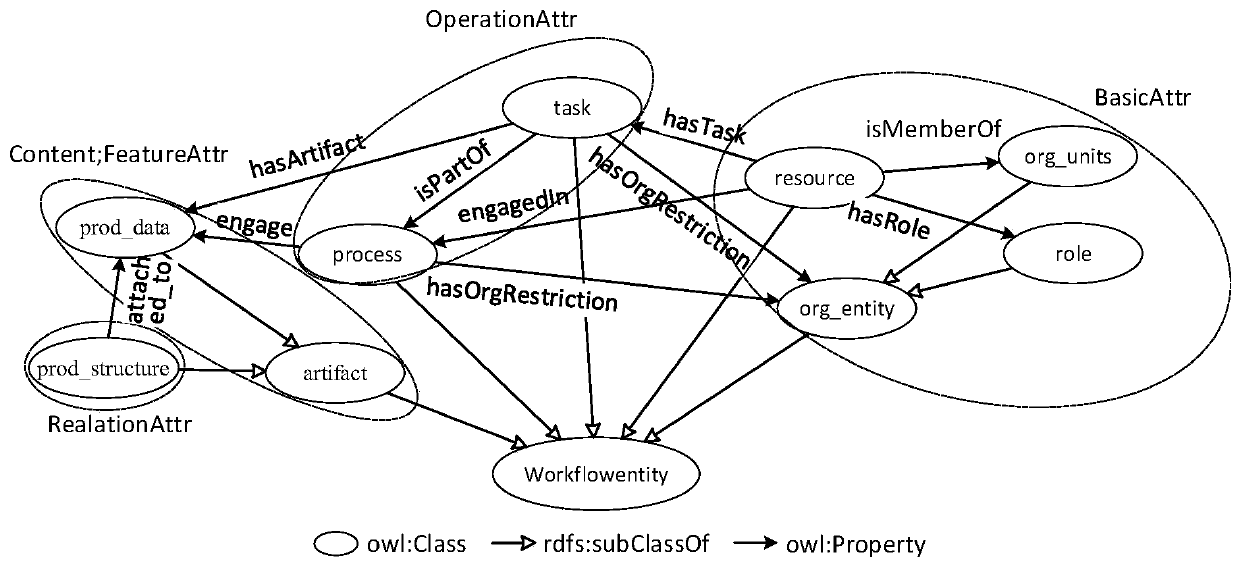

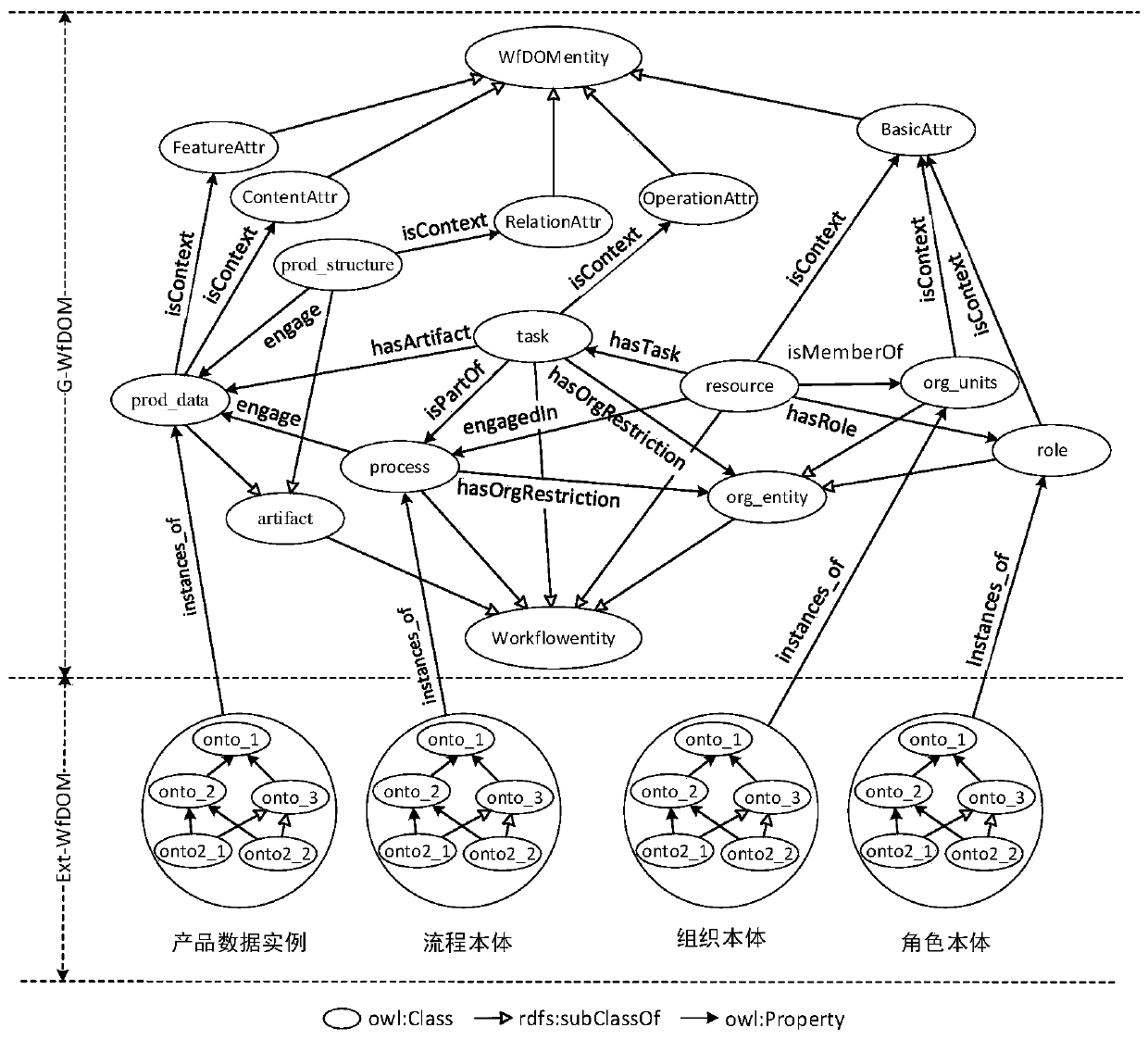

Workflow model recommendation method based on design information model

PendingCN111027189AIntegrity guaranteedGuaranteed normalizationDesign optimisation/simulationOther databases queryingInformatizationTheoretical computer science

The invention discloses a workflow model recommendation method based on a design information model, wherein a design document, design information, a design process and a recommendation algorithm are constructed into three models, and the three models jointly form a workflow model recommendation algorithm method. The three models are respectively mathematical models of a design information model, aworkflow model and a recommendation algorithm. The design information model body comprises various types of design information of a design document, such as basic attributes, operation attributes andsemantic attributes, and the design information can be obtained by mapping a workflow model. Basic entities contained in the workflow model are processes, tasks, resources, entity roles and organizations in the resources, and business products in the workflow. A mathematical model of the pushing algorithm is composed of an entity node similarity calculation method, an optimal weight vector searchmethod and an ontology matching similarity integration method. The method has important value significance for improving the working efficiency of engineers, shortening the product development life cycle and promoting the informatization development of enterprises.

Owner:WUHAN UNIV OF TECH

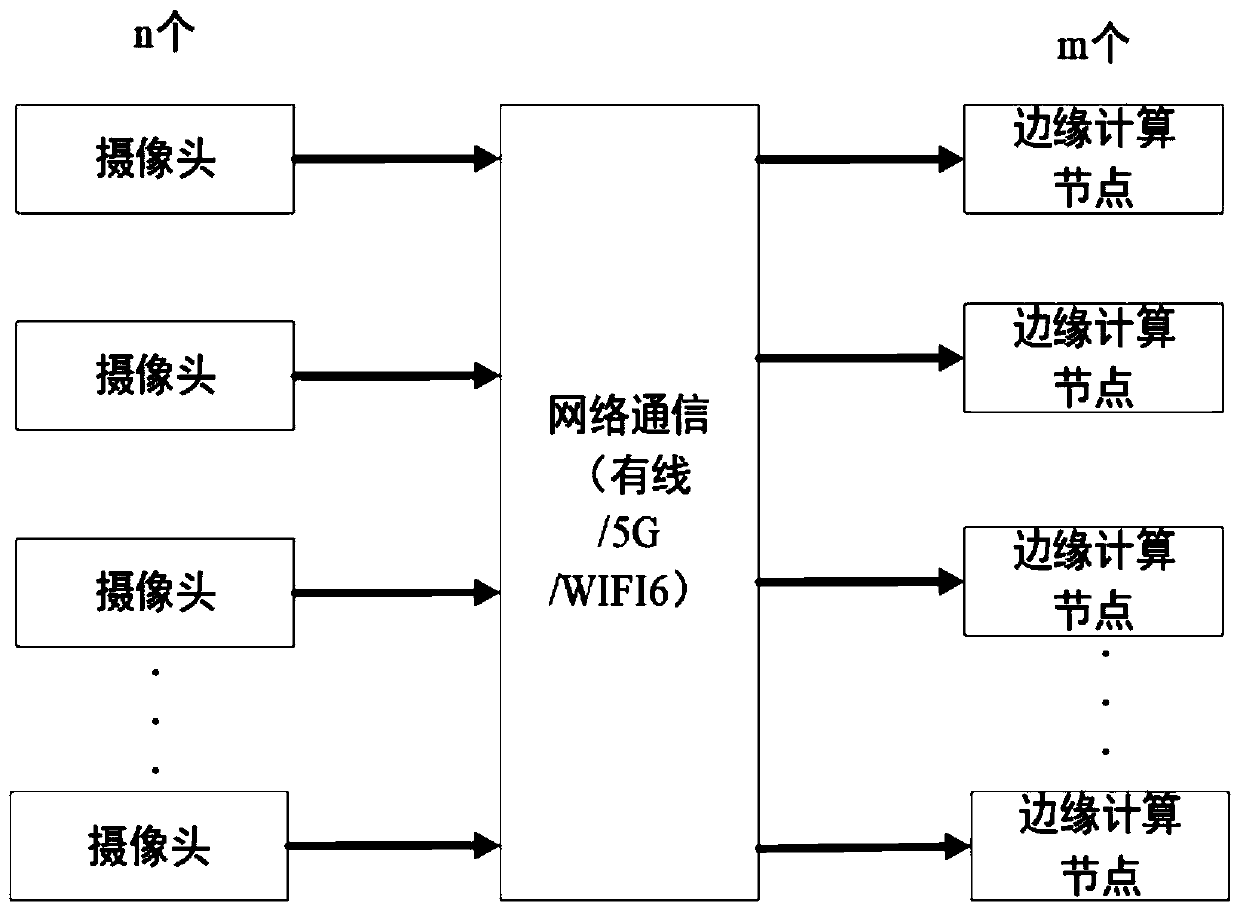

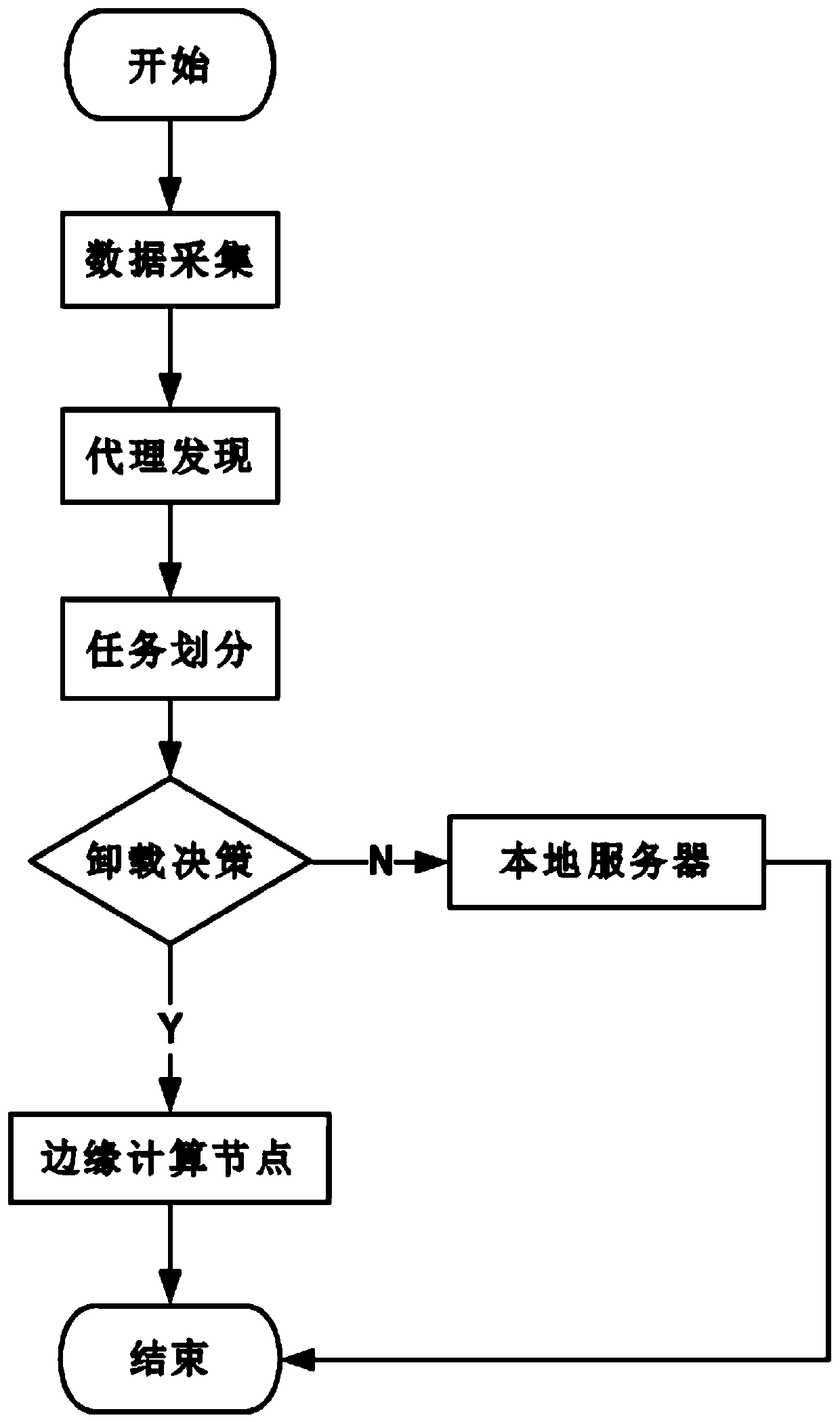

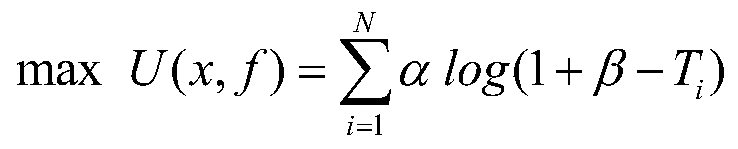

Traffic data-oriented end-edge cooperative computing unloading method

In order to solve the problem that a calculation computing algorithm in the prior art is not suitable for the field of intelligent transportation, the invention provides a traffic data-oriented end-edge cooperative computing unloading method, which comprises the following steps: firstly, establishing a system model for communication time delay and calculation time delay; then establishing a systemutility function taking time delay and resources as constraint conditions; and finally, designing an optimization strategy to obtain balance between the two. In the computing unloading process, calculation resources and time delay are comprehensively considered, and an optimization function is designed to obtain balance between the calculation resources and the time delay. The traffic data-oriented end-edge cooperative computing unloading method firstly establishes a total time delay system model according to a communication time system model, an edge side calculation time system model and alocal calculation time system model, then comprehensively considers the balance of resource allocation, designs a system utility function, finally, researches a system optimization strategy, and completes the design of a calculation unloading algorithm. According to the characteristics of intelligent transportation industry application, resource allocation and time delay are considered in the design process, and the performance is superior to that of a traditional algorithm.

Owner:GUANGDONG UNIV OF TECH

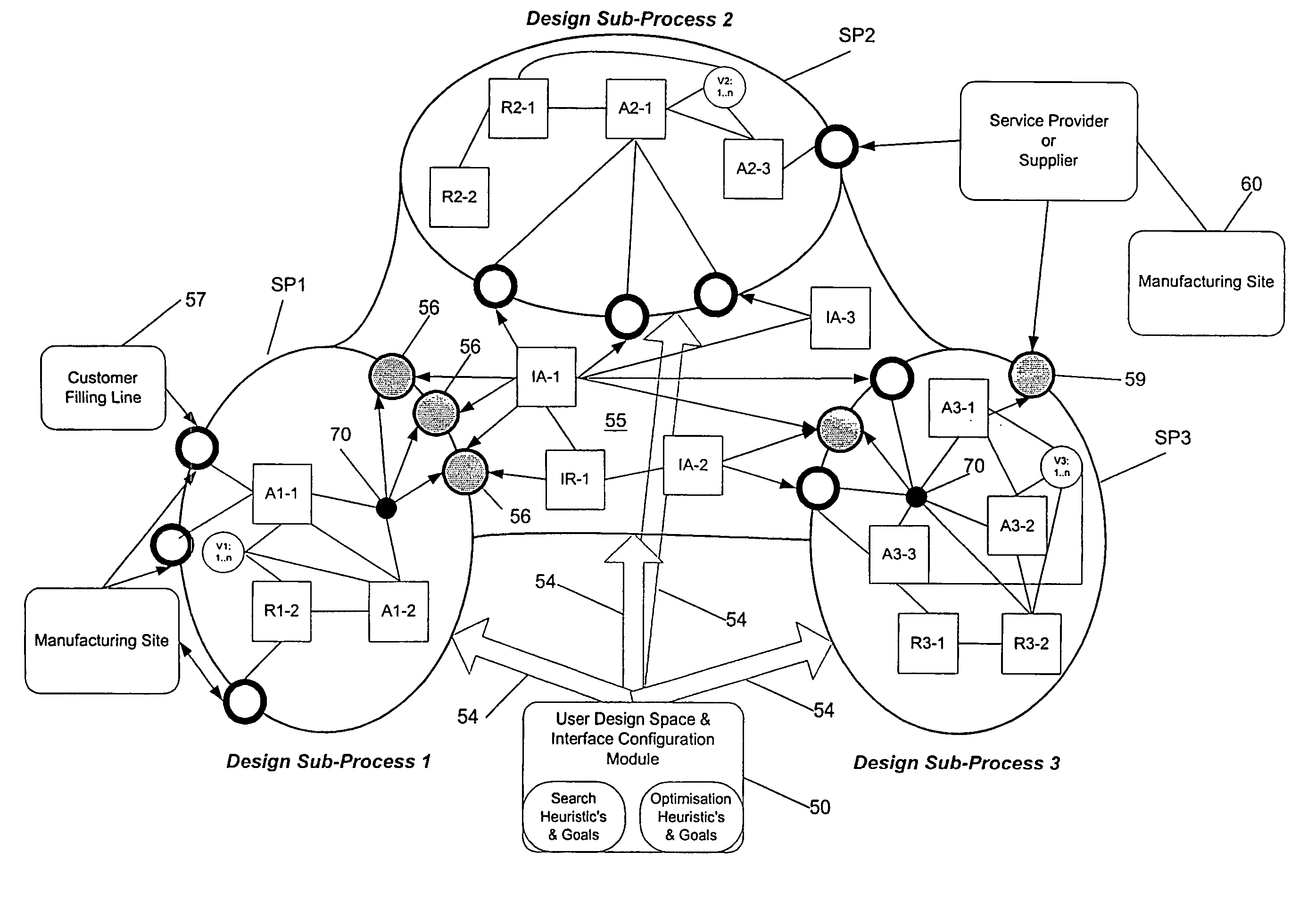

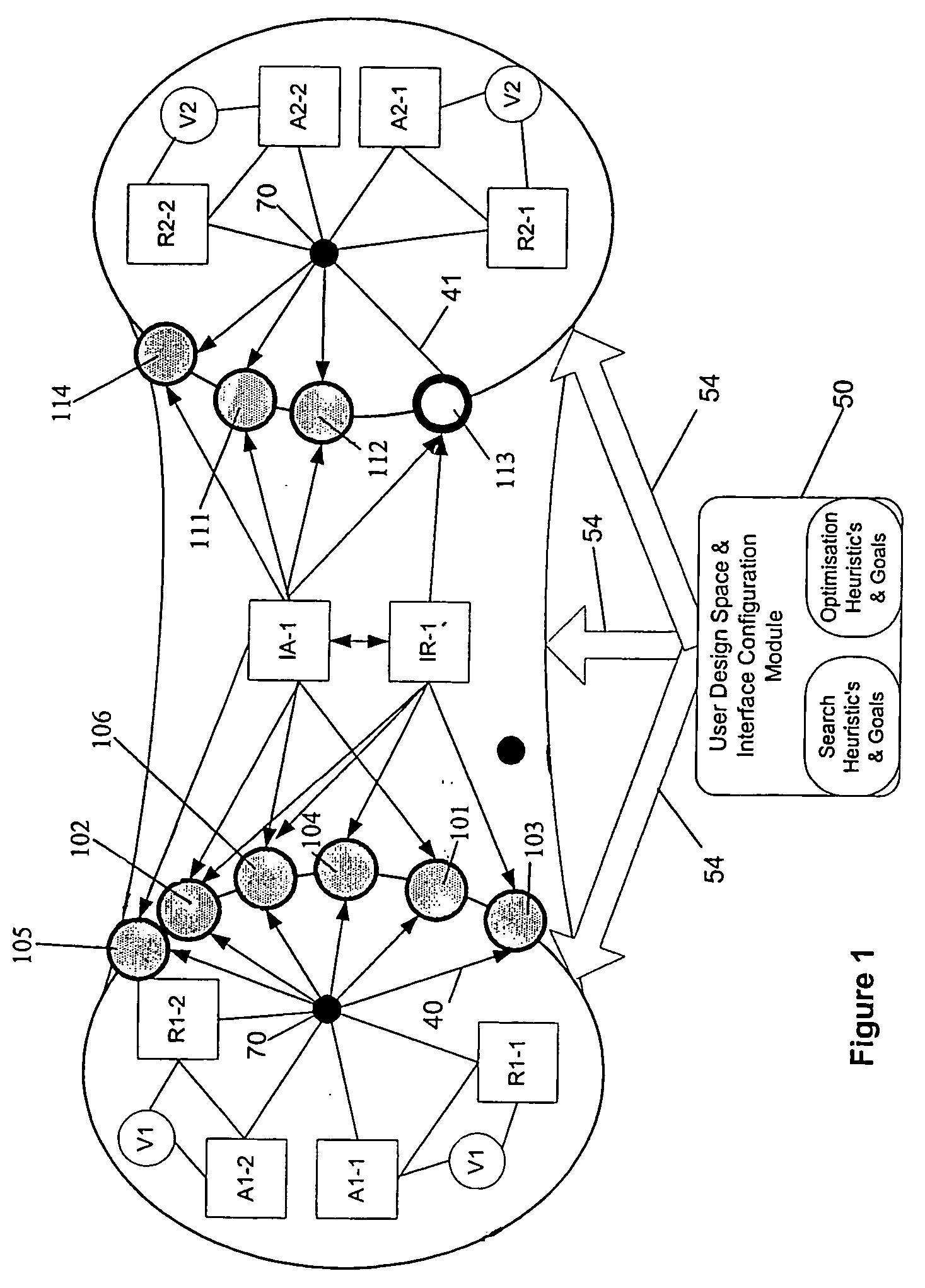

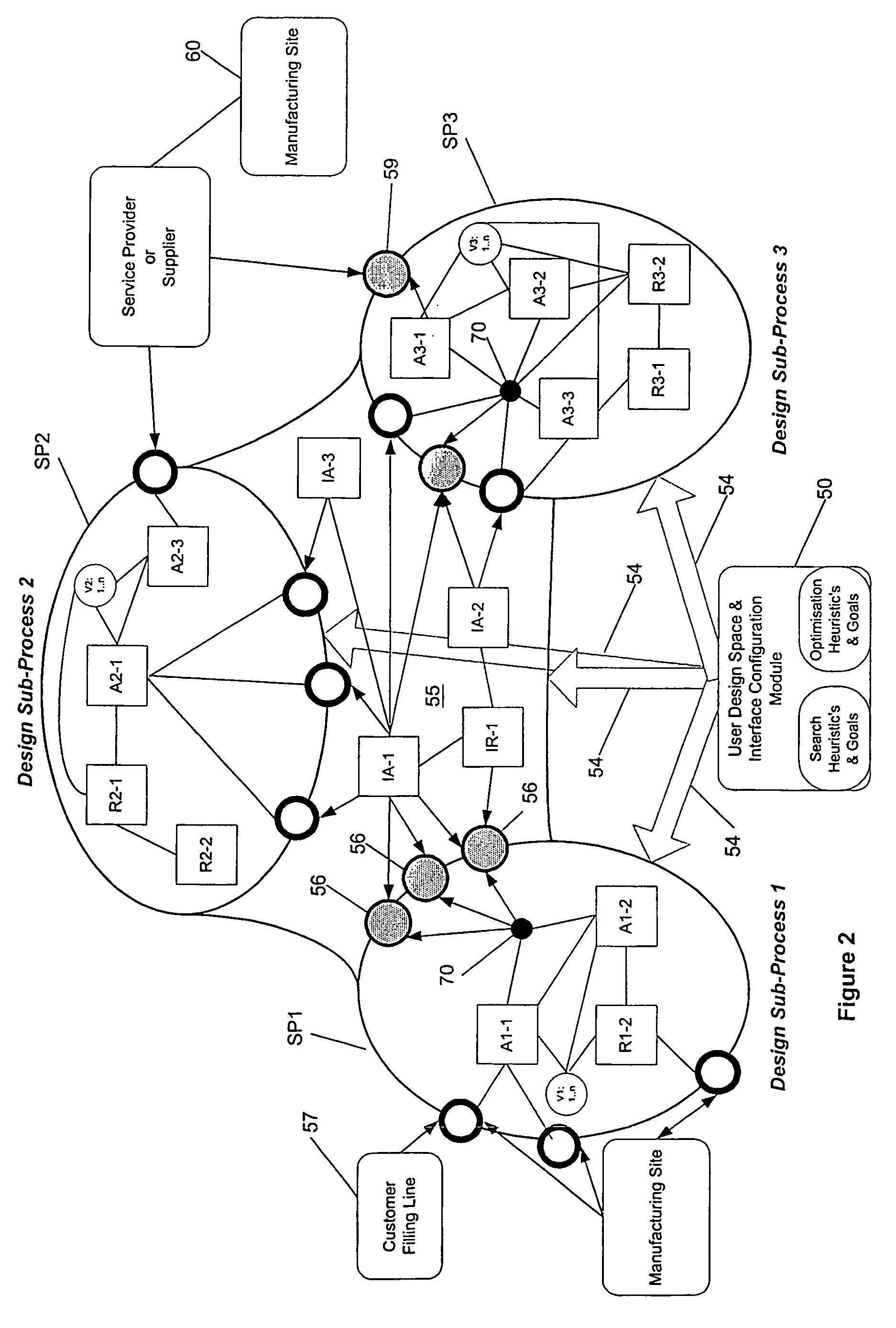

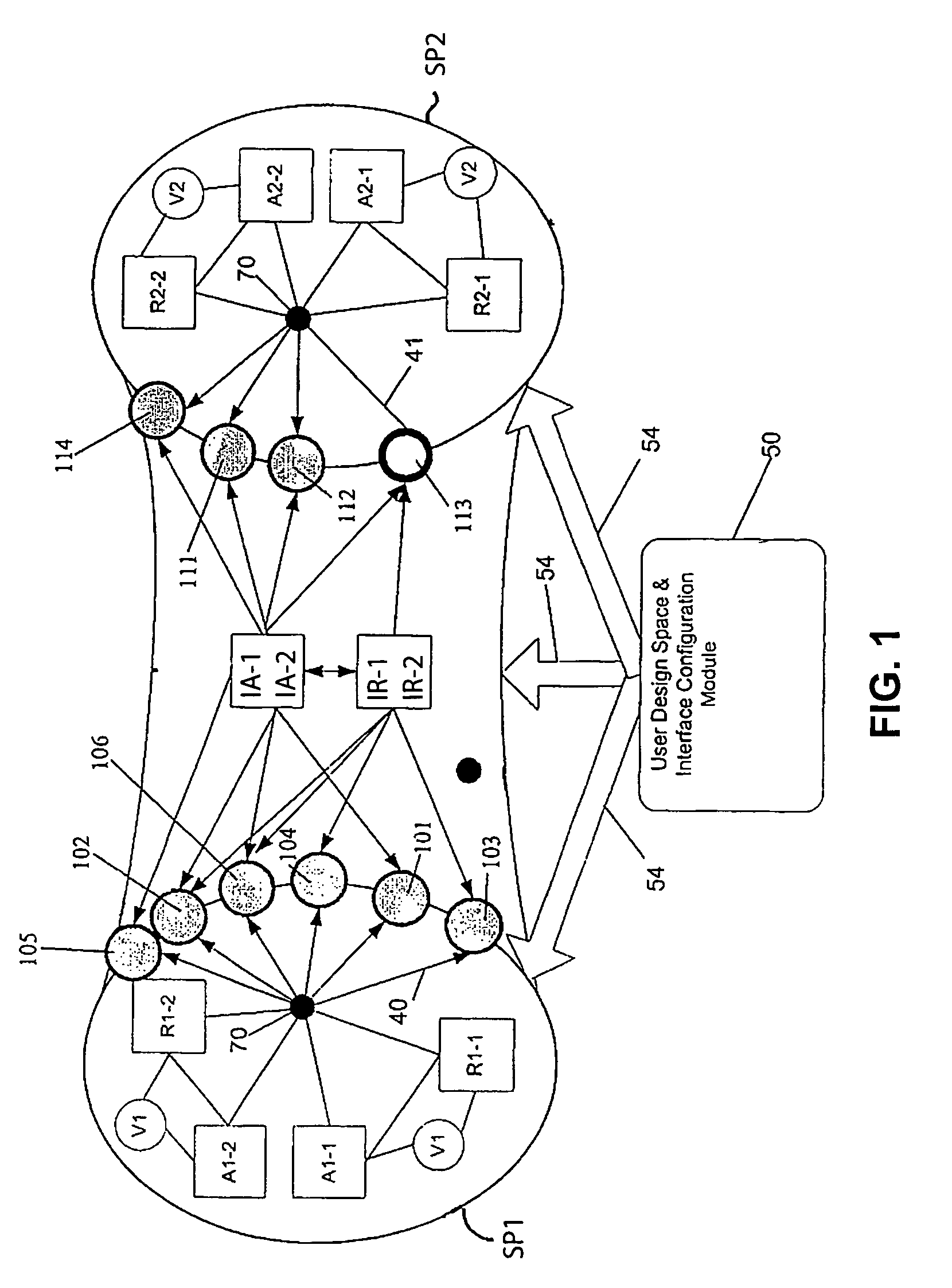

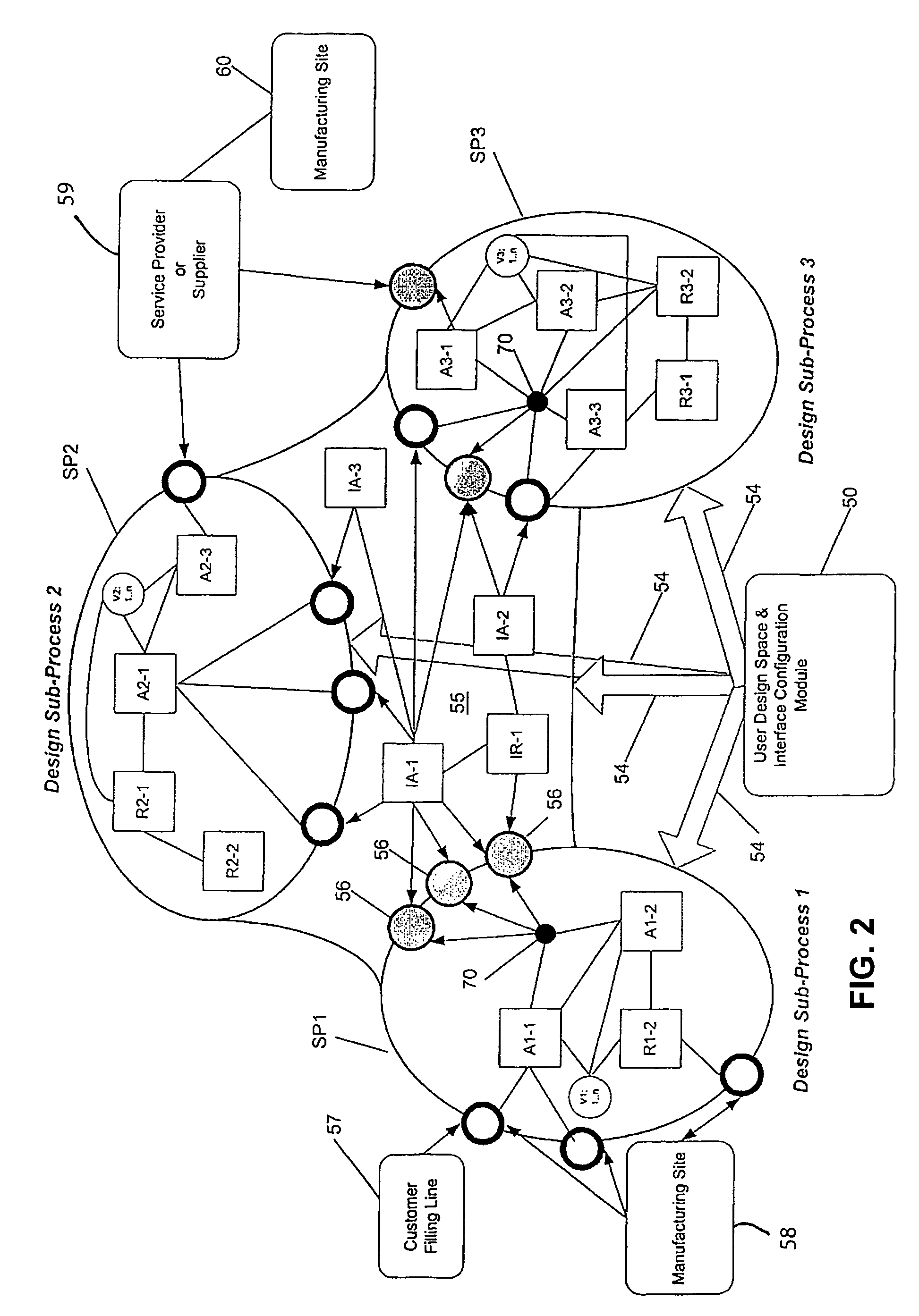

System and method for controlling a design process

InactiveUS20060052890A1Digital data processing detailsConstraint-based CADProcess engineeringIndustrial engineering

A system for controlling a design process having a first design sub-process (SP1) and a second design sub-process (SP2), outcomes of one of the first and second design sub-processes (SP1, SP2) being linked to outcomes of the other of the design sub-processes by a relationship between one or more first design sub-process variables (A) and one or more second design sub-process variables (B). The system comprises a user configurable interface (I) between the first and second design sub-processes (SP1, SP2), the interface allowing a user to the system to control the design process by specifying which of the one or more variables (A, B) (101-106, 111-114) are active variables which can have their domains modified by at least internal process within the sub-process to which the variable belongs and which of the one or more variables (A, B) are passive variables which have their domains determined within allowable values by the domains of the other variable(s) in the relationship.

Owner:ORORA PACKAGING AUSTRALIA

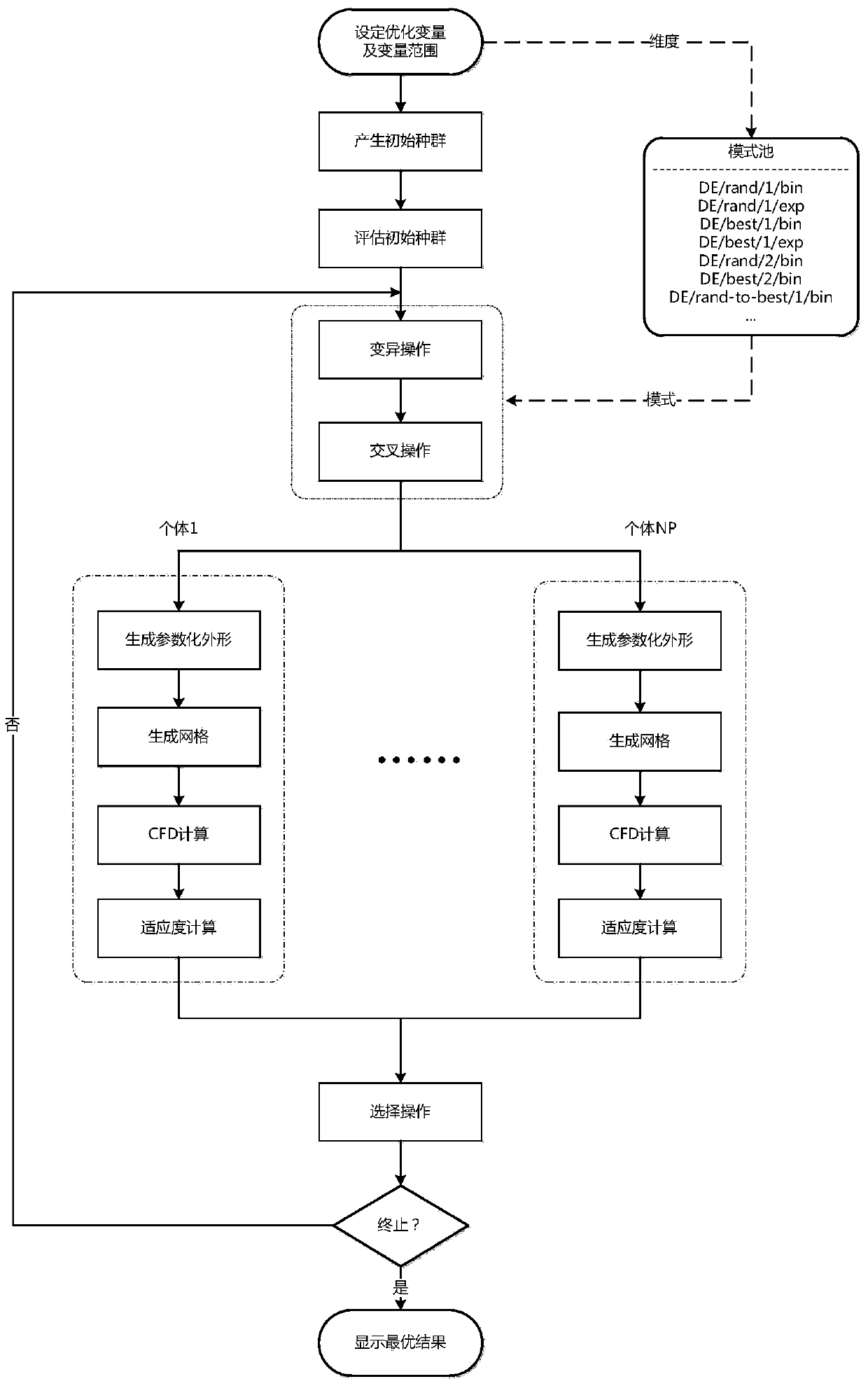

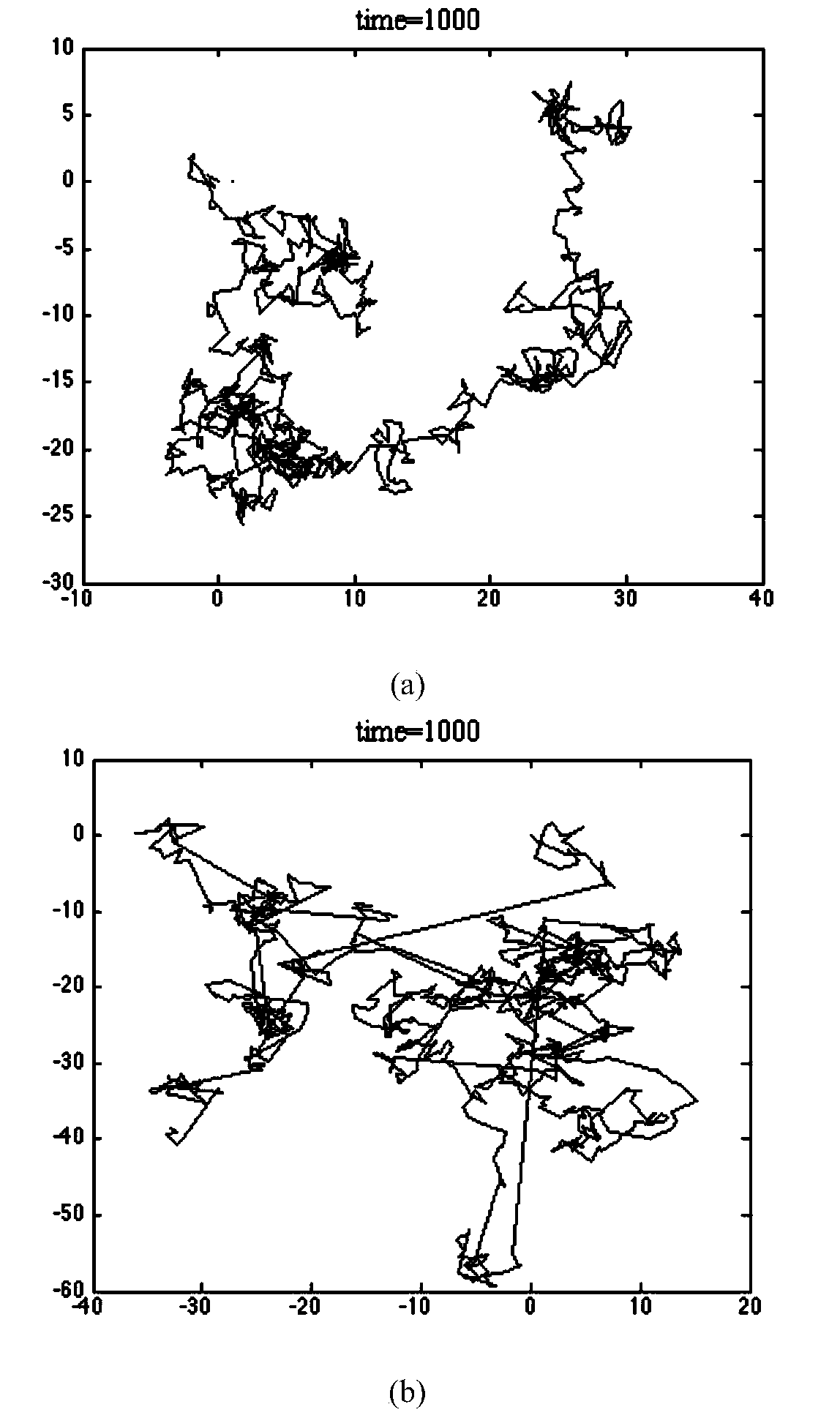

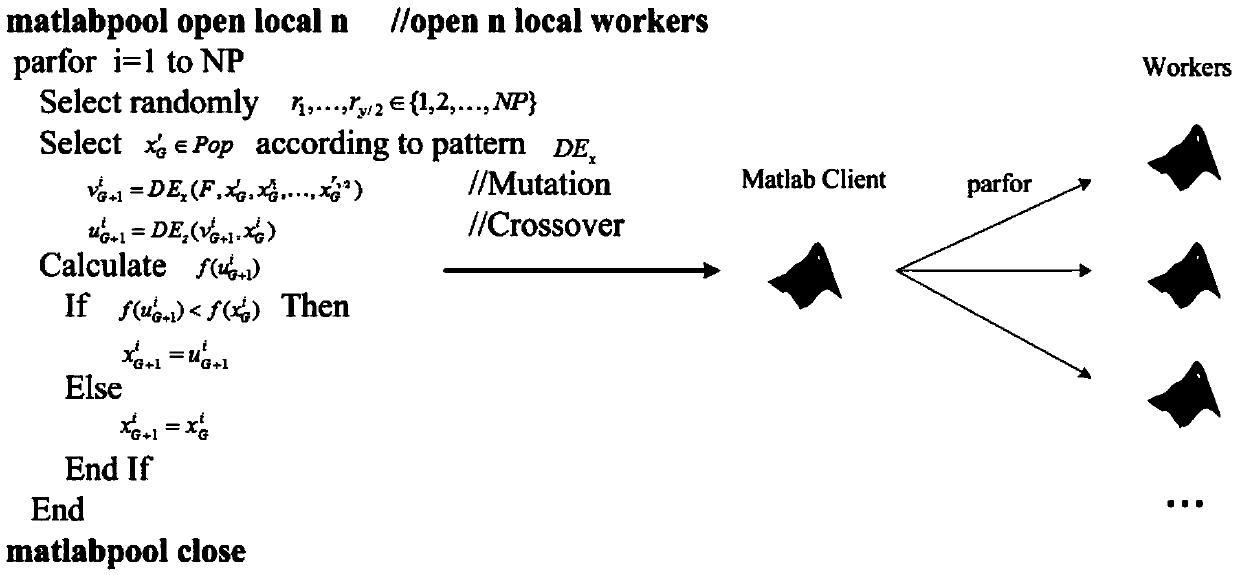

Aircraft aerodynamic configuration optimum design method based on improved parallel DE algorithm

ActiveCN103440377AImprove search efficiencyGood effectSpecial data processing applicationsConfiguration designParallel algorithm

The invention discloses an aircraft aerodynamic configuration optimum design method based on the improved parallel DE algorithm. The method is used for achieving aircraft aerodynamic configuration optimum design. According to the method, different DE algorithm patterns are integrated in a pattern pool, and therefore the DE pattern selection range is expanded; besides, a dynamic parameter pattern is newly adopted, and more effective research on a large area of unknown solution spaces can be achieved through the pattern. In the iteration process, test vectors are generated through mutation operation and interlace operation; individual codes in a species group are reduced to corresponding aircraft configurations, the CFD computational analysis process is introduced to an individual fitness evaluation stage and serves as a basis for selection on a new generation of individuals, therefore, the design result analysis process and the parameter modification process can be effectively combined, and the design cycle is shortened; offspring groups are generated through selection operation. In view of the characteristic that the computing amount in the aircraft aerodynamic configuration design process is large, the parallel computing mechanism is introduced into the method, and therefore the method greatly shortens algorithm running time and improves design efficiency.

Owner:BEIHANG UNIV

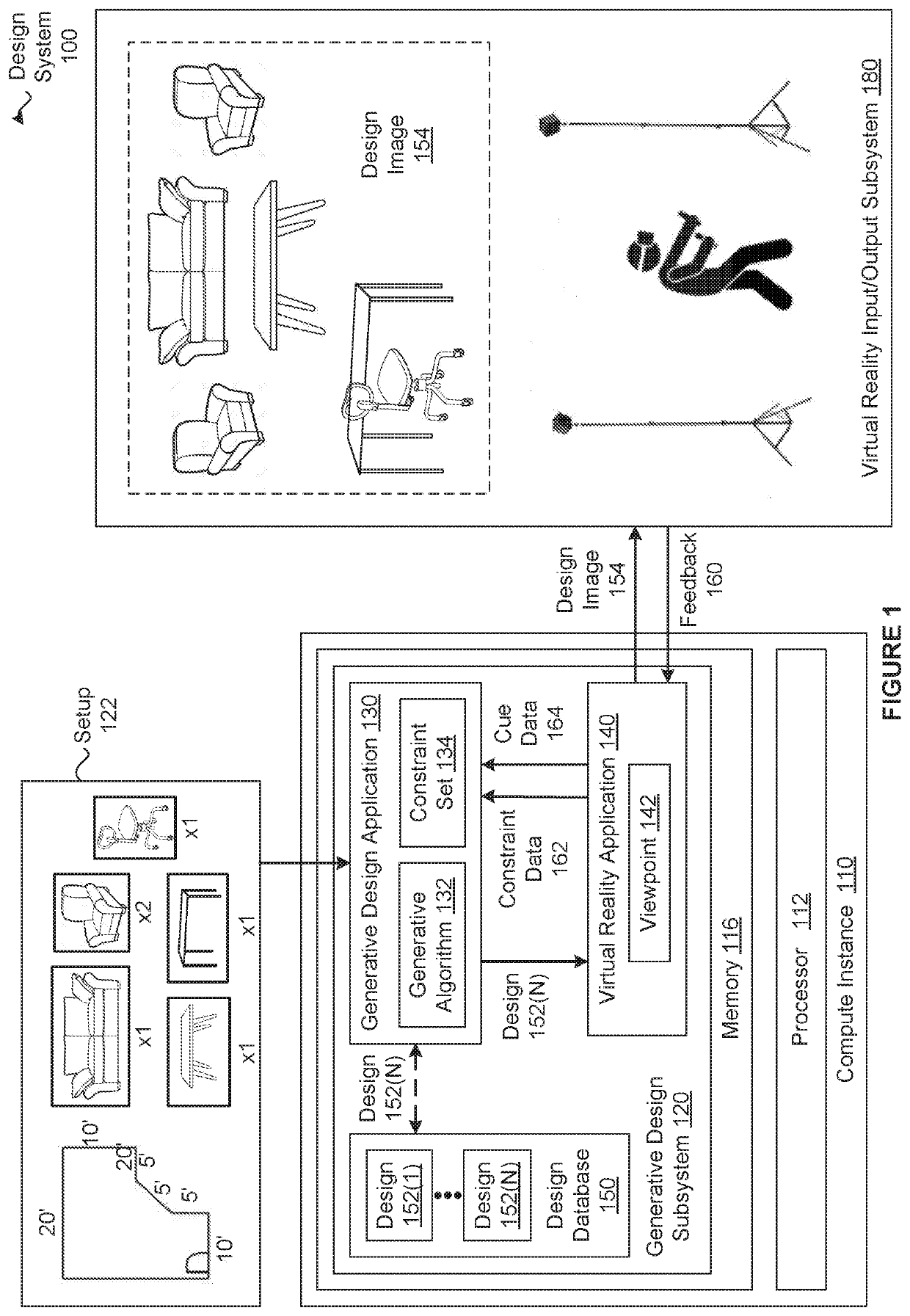

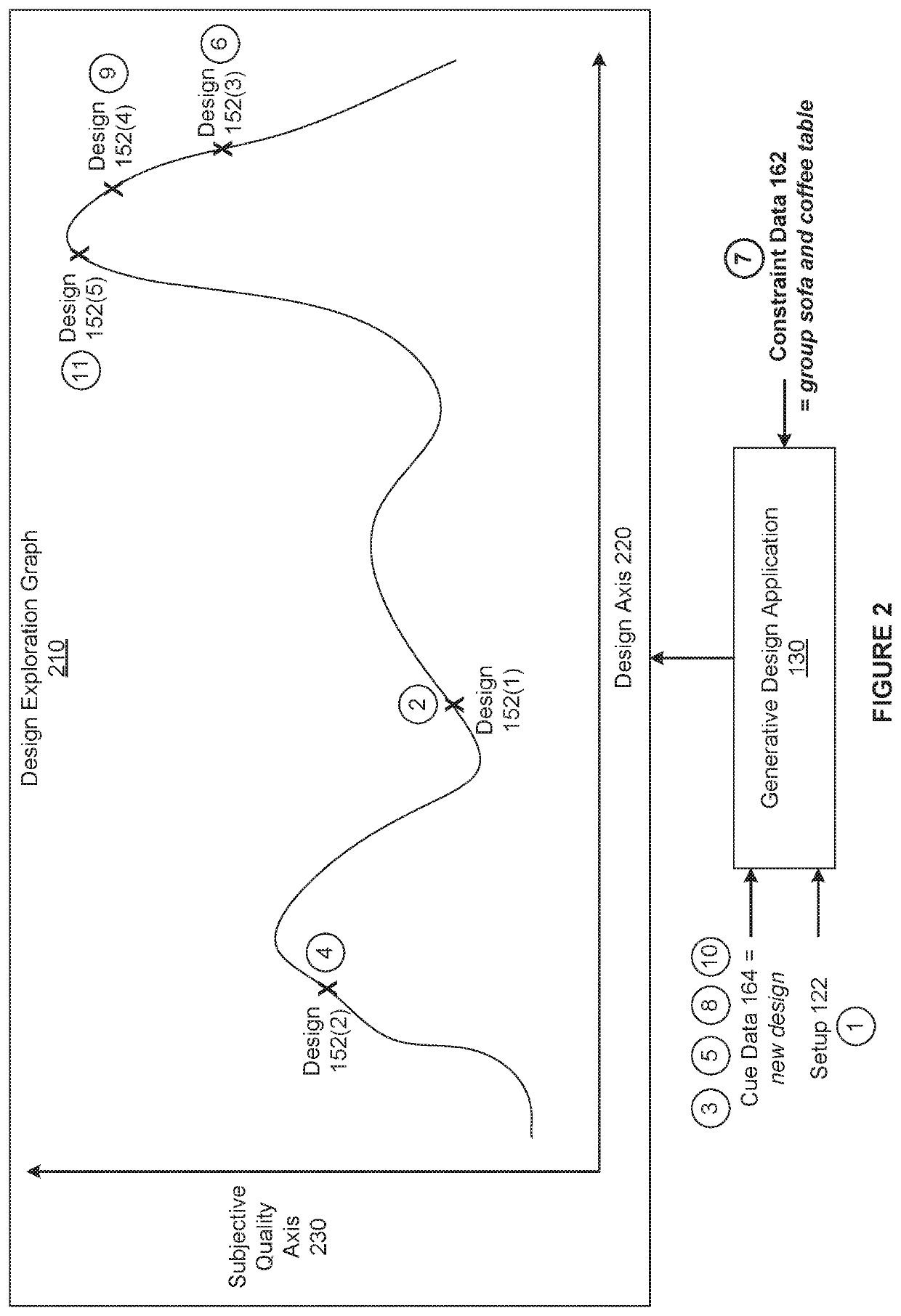

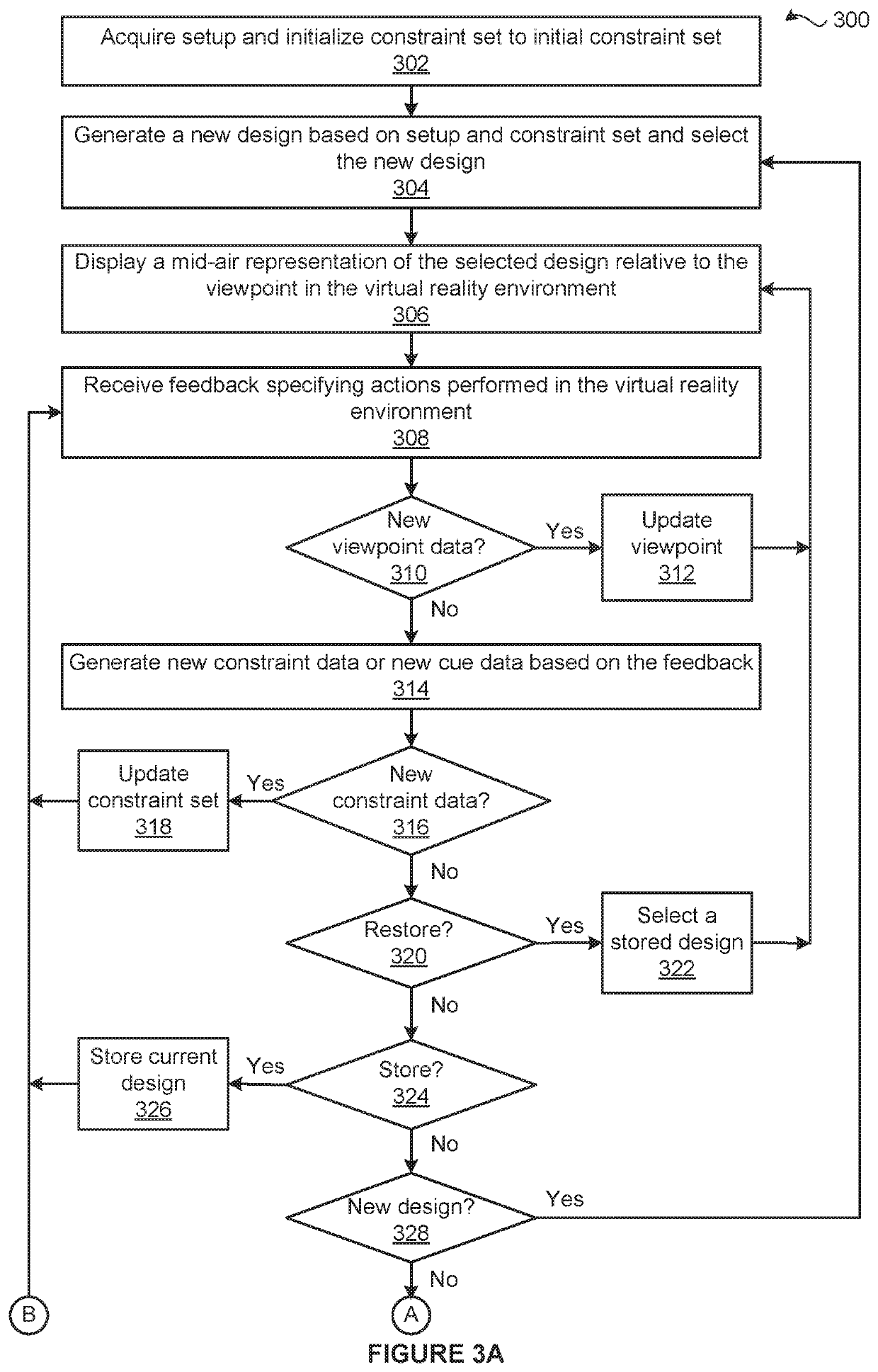

Computer-aided techniques for iteratively generating designs

ActiveUS20200242201A1Efficiently specifiedReduce effortGeometric CADSpecial data processing applicationsAlgorithmTheoretical computer science

In various embodiments, a generative design application iteratively generates designs via a generative design process. In operation, the generative design application performs one or more layout operations on virtual objects based on a first set of design constraints to generate a first design. The generative design application then modifies the first set of design constraints based on feedback associated with a mid-air representation of the first design displayed in a virtual reality environment to generate a second set of design constraints. Subsequently, the generative design application performs one or more layout operations on the virtual objects based on the second set of design constraints to generate a second design that achieves design goal(s). Advantageously, enabling a designer to incrementally indicate design goal(s) as constraints via a virtual reality environment instead of as a predetermined objective function reduces both the time and effort required to generate designs.

Owner:AUTODESK INC

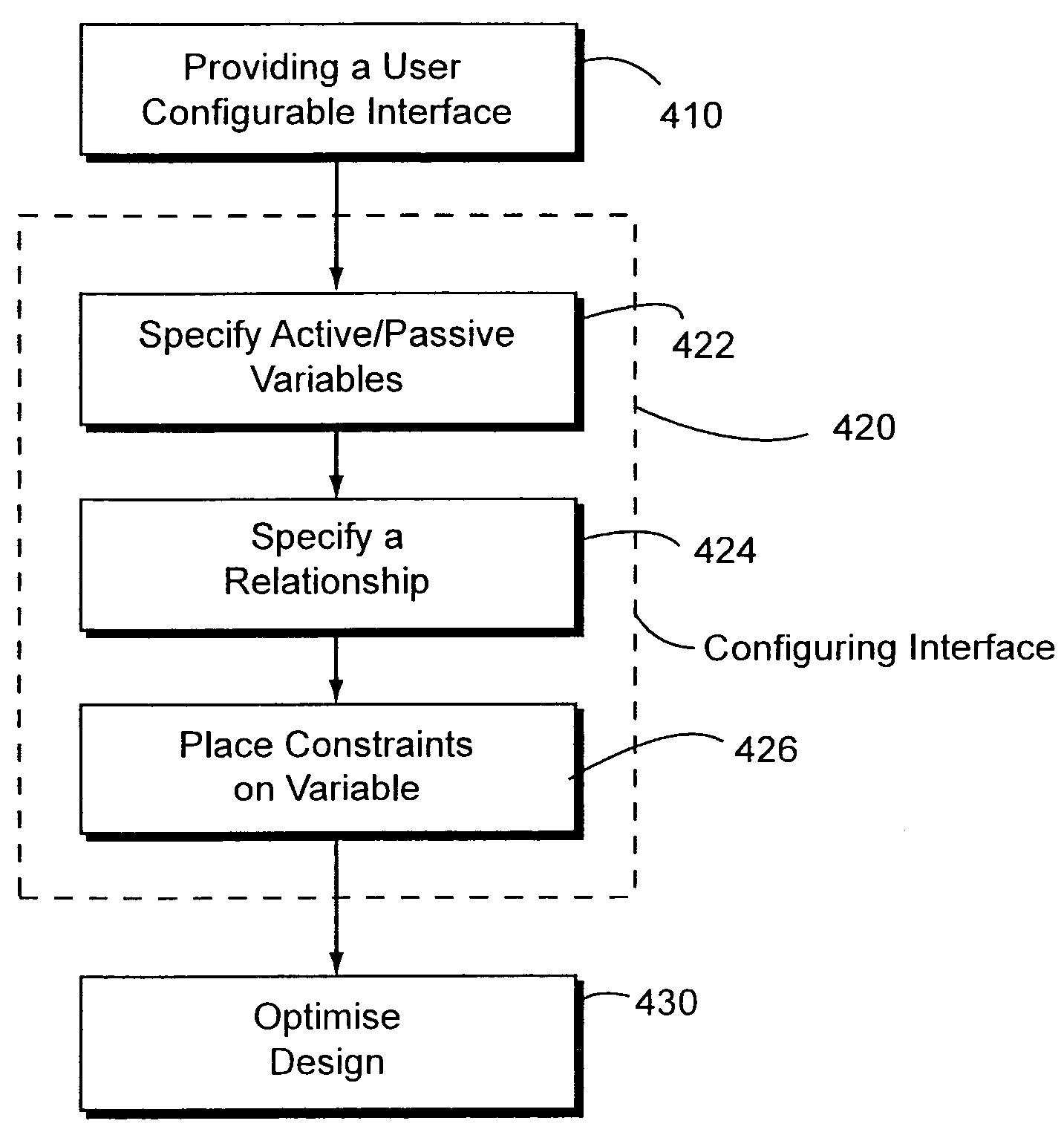

System and method for controlling a design process by specifying active variables and passive variables

InactiveUS7433748B2Constraint-based CADSpecial data processing applicationsProcess engineeringIndustrial engineering

A system for controlling a design process having a first design sub-process and a second design sub-process, outcomes of one of the first and second design sub-processes being linked to outcomes of the other of the design sub-processes by a relationship between one or more first design sub-process variables and one or more second design sub-process variables. The system comprises a user configurable interface between the first and second design sub-processes, the interface allowing a user to the system to control the design process by specifying which of the one or more variables are active variables which can have their domains modified by at least one process within the sub-process to which the variable belongs and which of the one or more variables are passive variables which have their domains determined within allowable values by the domains of the other variable(s) in the relationship.

Owner:ORORA PACKAGING AUSTRALIA

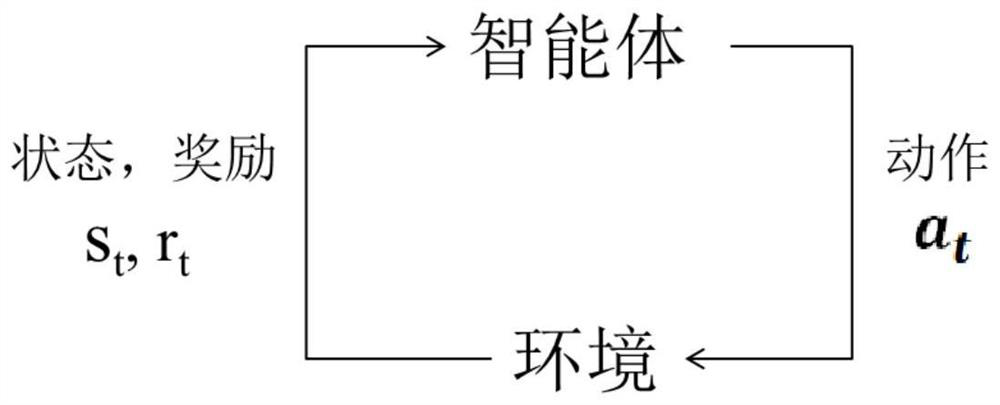

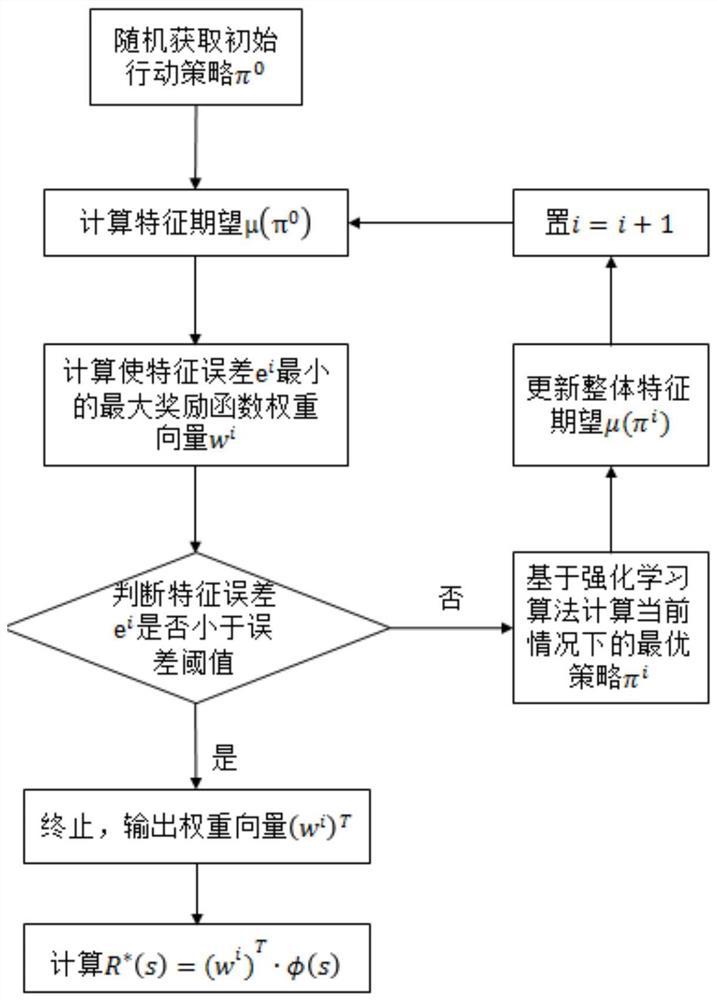

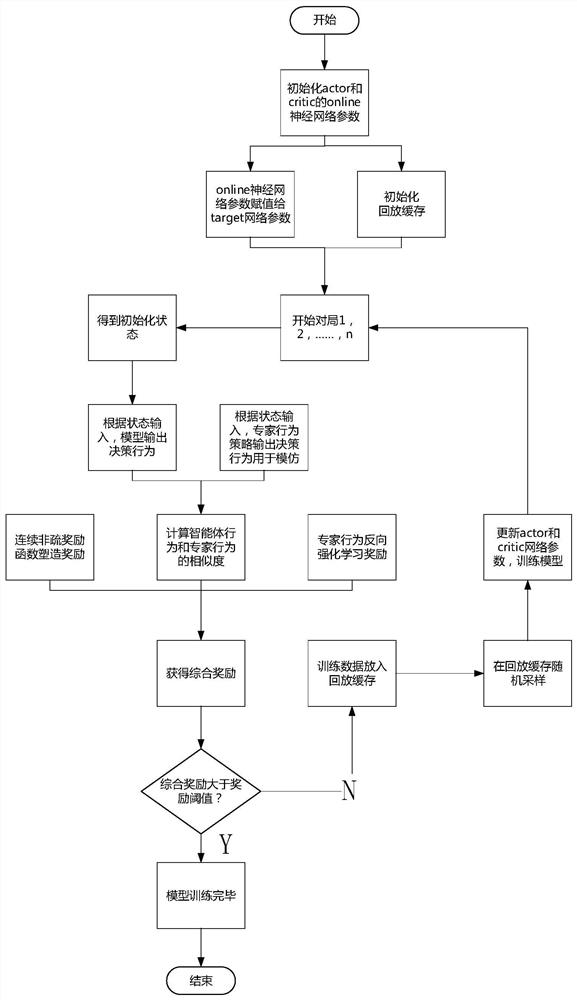

Behavior imitation training method for air intelligent game

ActiveCN113221444AClear designInterpretableDesign optimisation/simulationMachine learningDecision modelSimulation

The invention discloses a behavior simulation training method for an air intelligent game. The method comprises the following steps: S1, constructing an intelligent agent game decision model; S2, determining an environment state and an action space, and shaping a continuous non-sparse reward function of each action; S3, carrying out an air game in the model, and executing the following steps: S31, generating a next environment state according to an executed action, obtaining a reward, and carrying out loop iteration in sequence to realize maximum accumulated reward; S32, realizing reverse reinforcement learning based on expert behaviors, and obtaining a target reward function; S33, calculating the similarity between each agent behavior and the expert behavior; S34, obtaining a comprehensive reward; and S4, training the agent game decision model. According to the method, a traditional low-efficiency reward function design process and a model training random exploration process are improved, so that the reward function has interpretability and human intervention ability, the agent decision level and convergence speed are improved, and the cold start problem of model training is solved.

Owner:HANGZHOU EBOYLAMP ELECTRONICS CO LTD

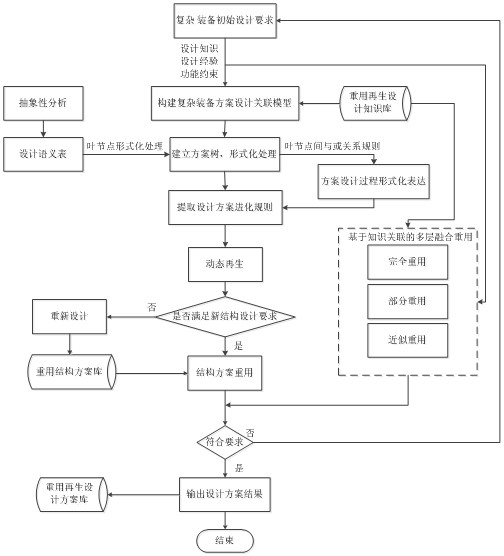

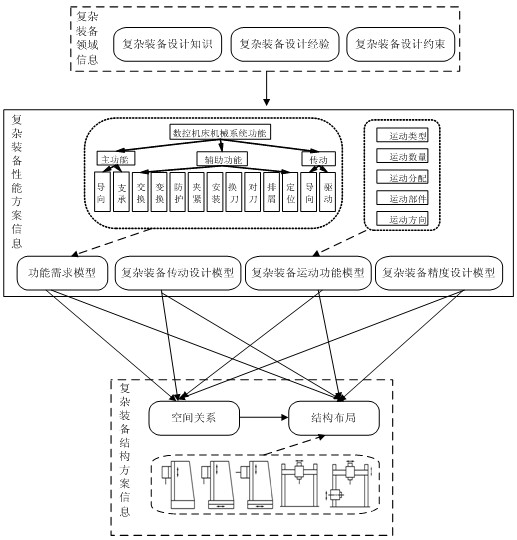

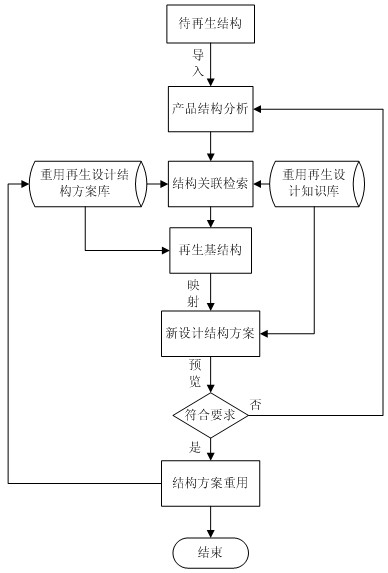

Reuse and regeneration design method of complex equipment scheme

InactiveCN102436528AAchieve structural reuseRealize automatic solutionSpecial data processing applicationsRegenerative designDesign plan

The invention discloses a reuse and regeneration design method of a complex equipment scheme. The method comprises the following steps of: according to the design requirement of the complex equipment scheme, structuring the association model of the product design scheme on the complex equipment function information, the design knowledge, the design restrict, dimension, space relationship and the structure arrangement; building a functional solution tree and / or the relationship element and performing the formal representation of the scheme design process according to the rule; extracting the product design scheme progression rule and dynamically regenerating according to the progression rule of the design scheme association model, performing the variable topology structural reuse on the association model of the product design scheme; realizing the multi-layered fuse reuse regeneration on the basis of the knowledge association, realizing the reuse of the product design scheme. The invention solves the problems that the manual experience design method is relied, the design process cannot be reused by only reusing the design result and the regenerative property of the complex equipment scheme is weak. The invention can self-adaptively realized on the basis of knowledge association according to the association model requirement of different complex equipment design scheme, thereby improving the design efficiency and the innovation of the complex equipment scheme.

Owner:ZHEJIANG UNIV

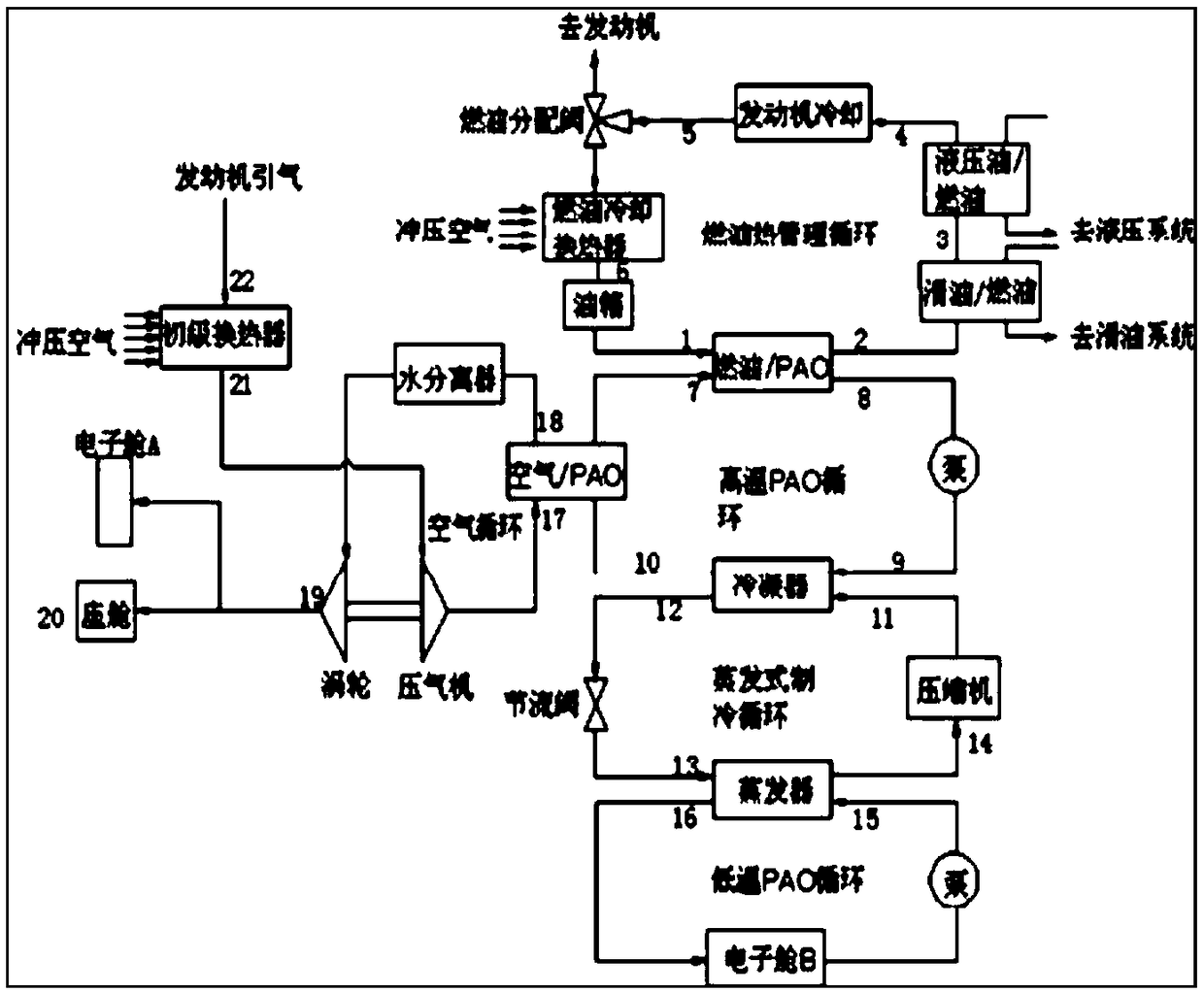

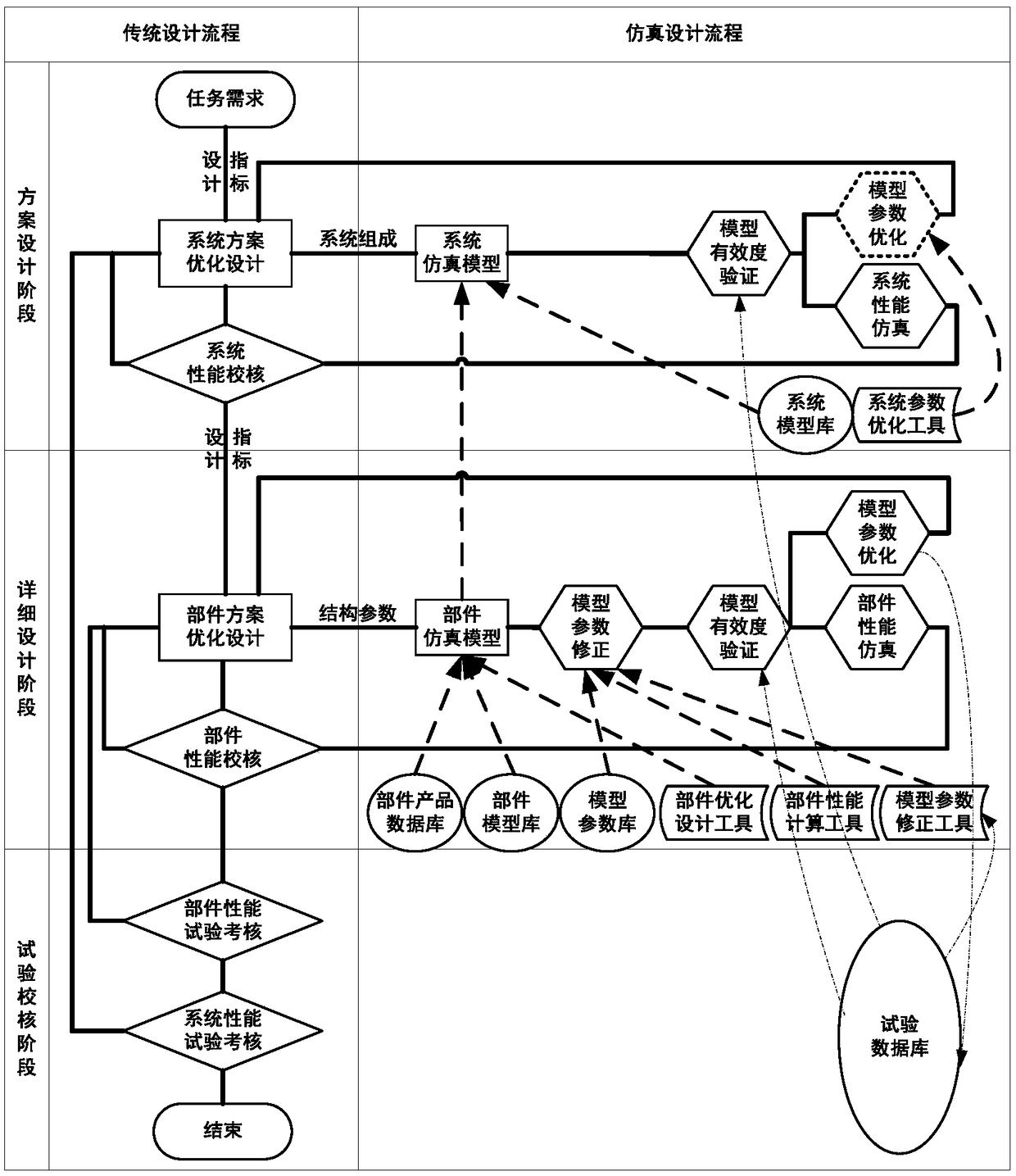

Method for model-based integrated design and simulation software architecture of airborne thermal management system

ActiveCN109446624ARealize evaluationEase of evaluationGeometric CADDesign optimisation/simulationDesign flowThermal management system

The invention belongs to the design field of airborne environmental control / heat management system, and a method for model-based integrated design and simulation software architecture of airborne thermal management system is proposed. The method comprises 1 normalizing the model-based integrated design process of the airborne thermal management system as a matrix of two columns and three rows, intersecting the columns and rows to determine the belonging of the design flow; 2 firstly building the architecture of the traditional design flow 1; 3 qualifying that scheme of the system performancecheck 12 and entering the second row of the first column of the matrix; 4 enabling the component qualified by the component performance check 24 to enter the third row of the first column of the matrix; 5 constructing the architecture of the second column simulation design flow 2 of the matrix; 6 entering that construction of the simulation design flow 2 of the second column and the second row; 7entering the third row of the second column to build the simulation design flow 2. The invention realizes the comprehensive evaluation and optimization from parameters to configurations.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com