Patents

Literature

202 results about "Process development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process Development is the setup and design of a process under specific requirements (quality, cost) and within certain time-frames through defining and describing a sequence of activities that need to be performed to meet the process’s objectives and to produce the process’s desired outcome. Development is one of the phases in process lifecycle.

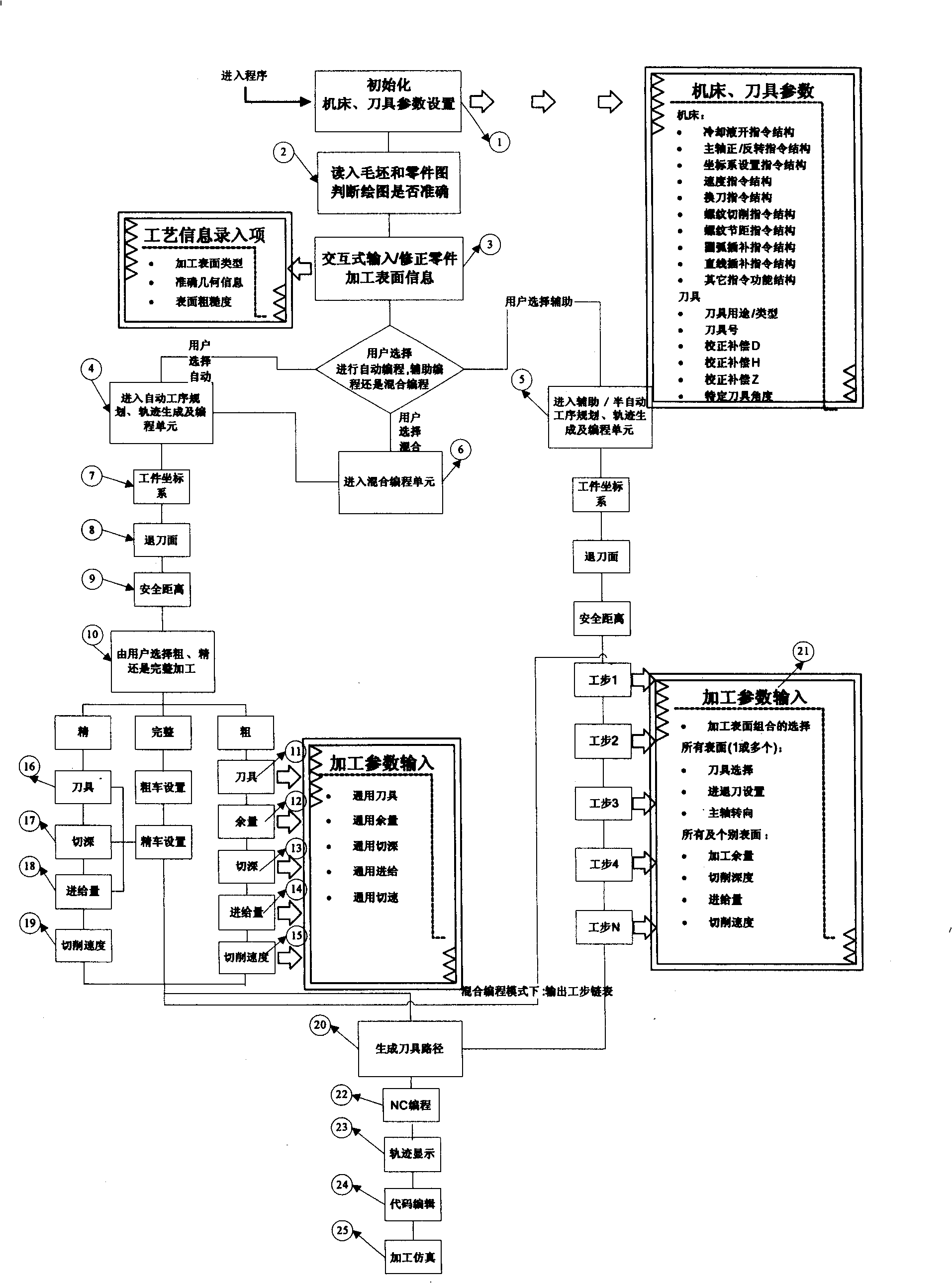

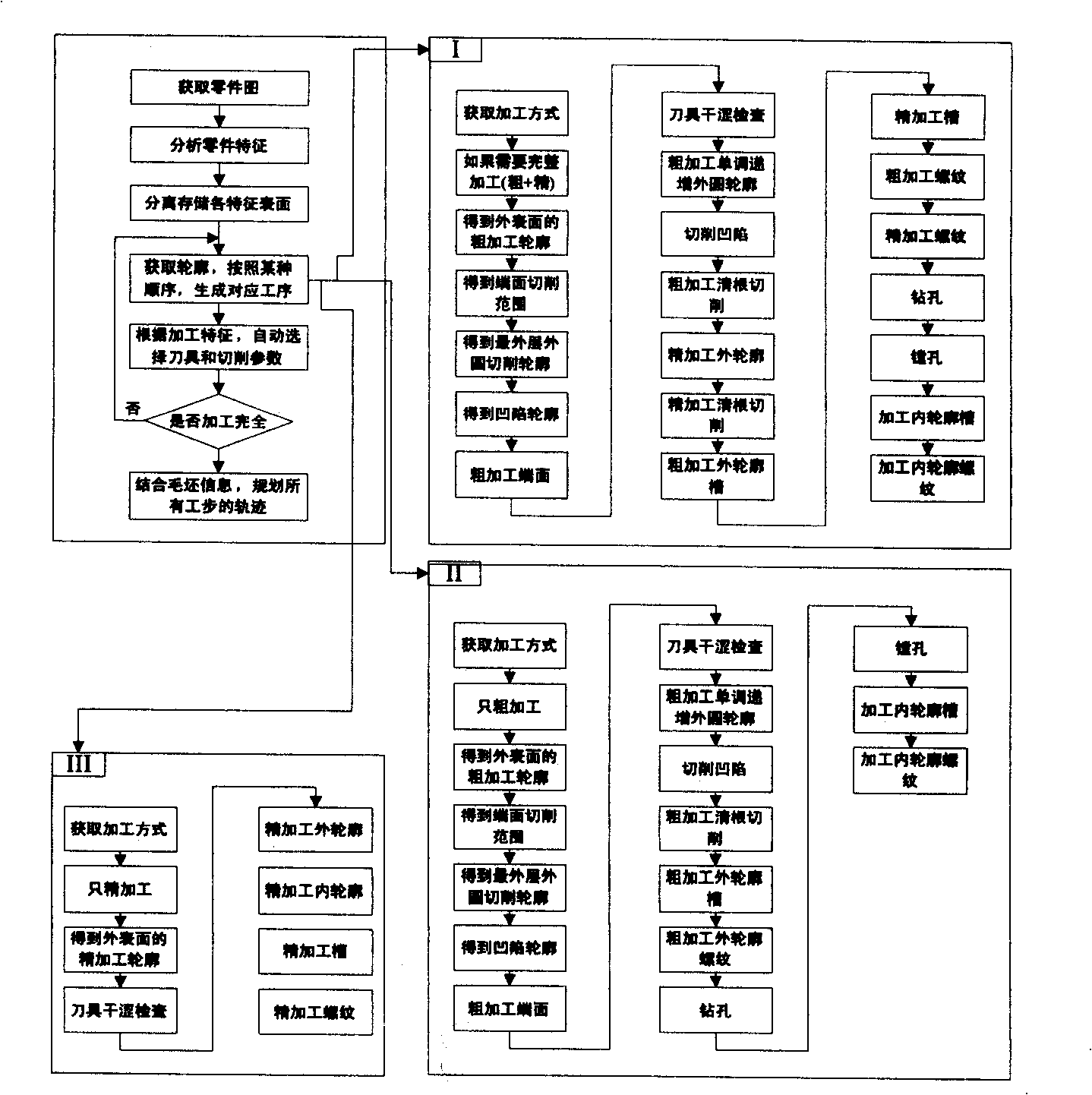

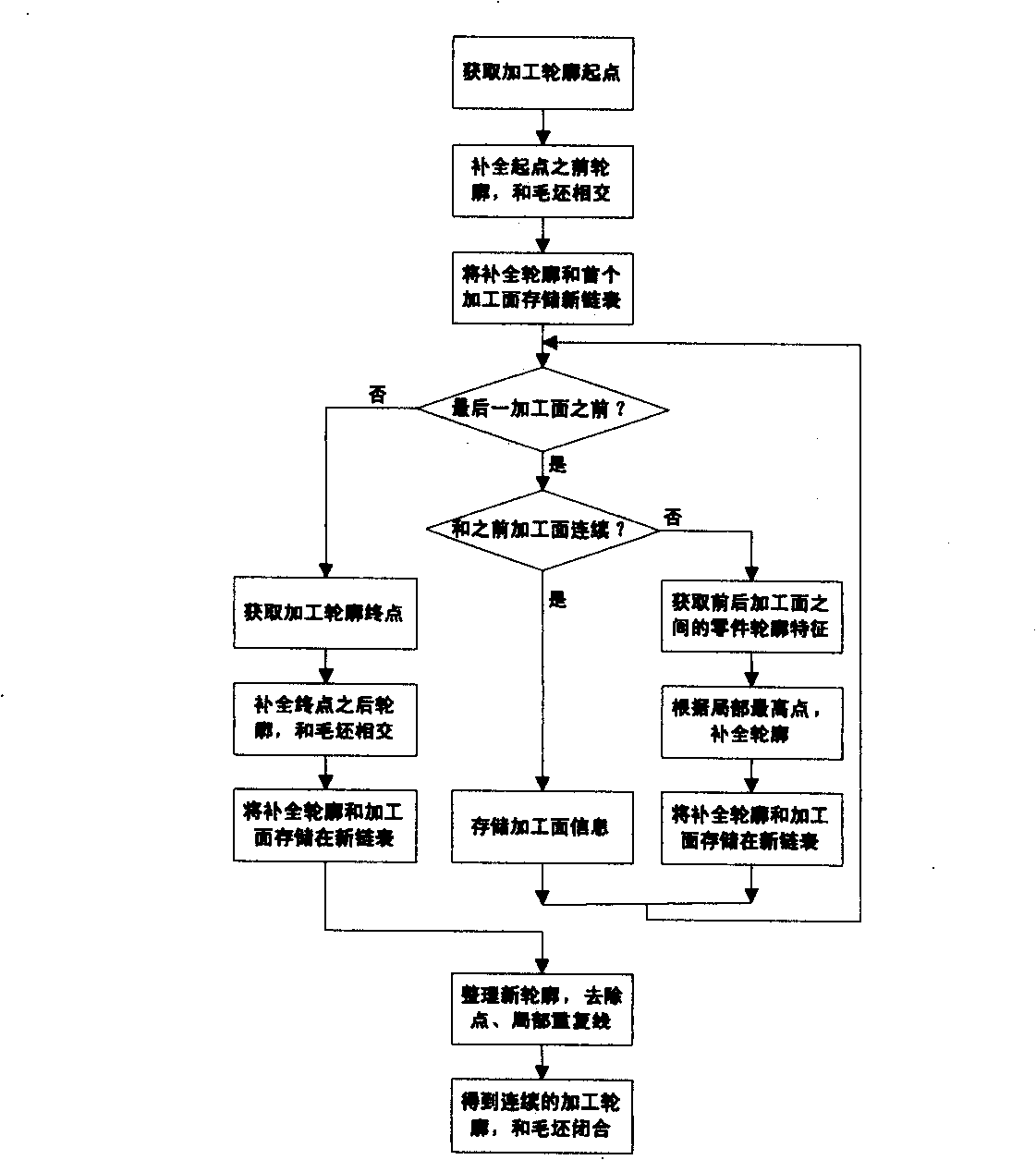

Imaging interactive numerical control turning automatic programming method and system

The invention provides an automatic graphical interaction-typed numerical control (NC) turning programming method and system used for improving programming efficiency and NC code quality, prompting quick product process realization (RPPR) and integrated product process development (IPPD). The technical proposal of the invention is that the automatic graphical interaction-typed numerical control turning programming method is characterized in that the method comprises the steps of: reading in blank and part drawing, removing redundant information, and judging whether the graphics are exact; leading the graphics to have real-time interaction function and be capable of correcting the information of the part processing surface, including processing surface type, exact geometrical information and surface roughness; determining whether to execute the corresponding system function modules by carrying out automatic programming or auxiliary programming or mixed programming according to the selection of the user. The automatic graphical interaction-typed numerical control turning control system is characterized in that the automatic graphical interaction-typed NC turning control system comprises a CAD data reading-in module which is respectively connected with an automatic programming module, an auxiliary programming module and a mixed programming module which are respectively connected with an automatic track layout module which is connected with an NC code generation module.

Owner:TSINGHUA UNIV

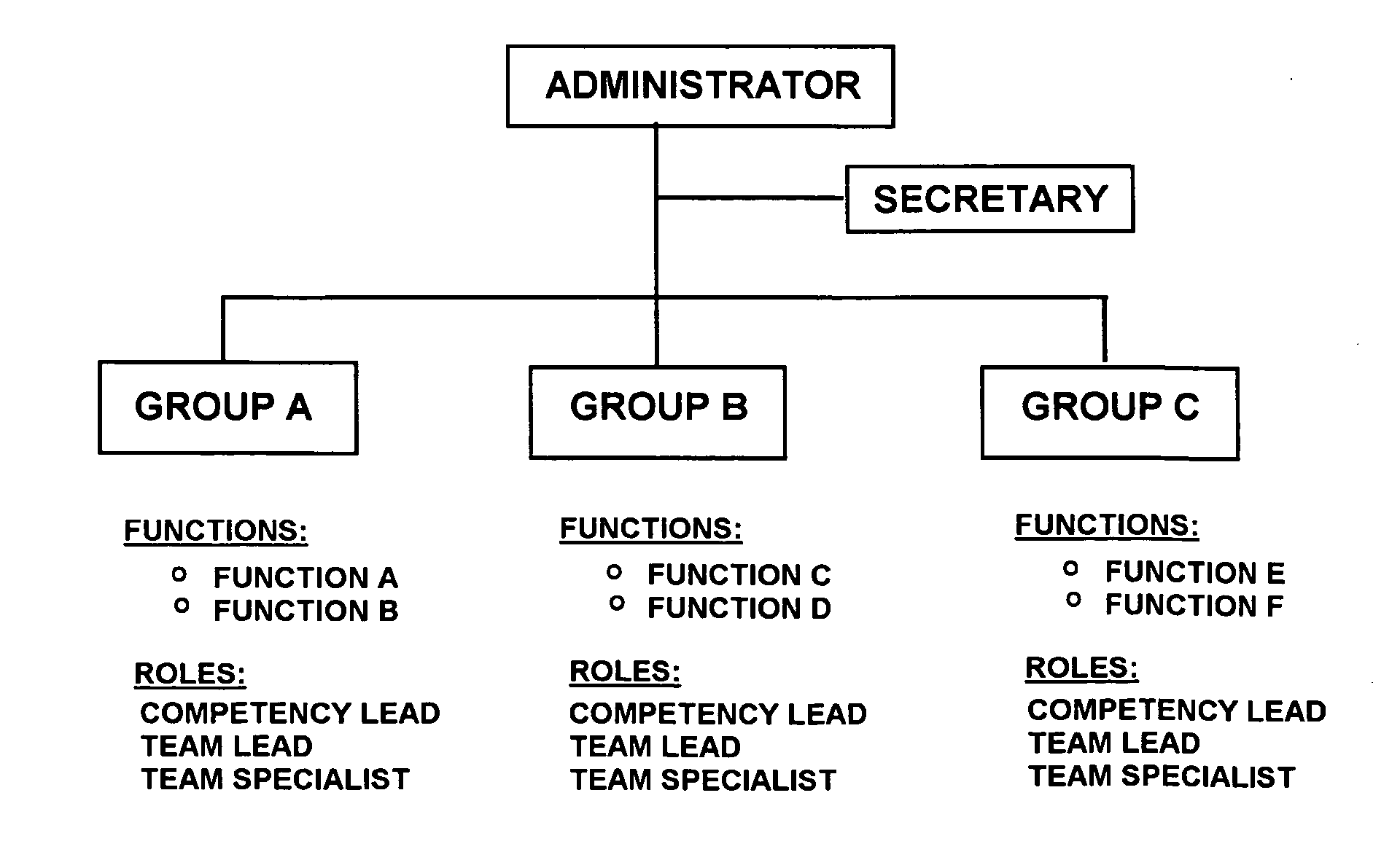

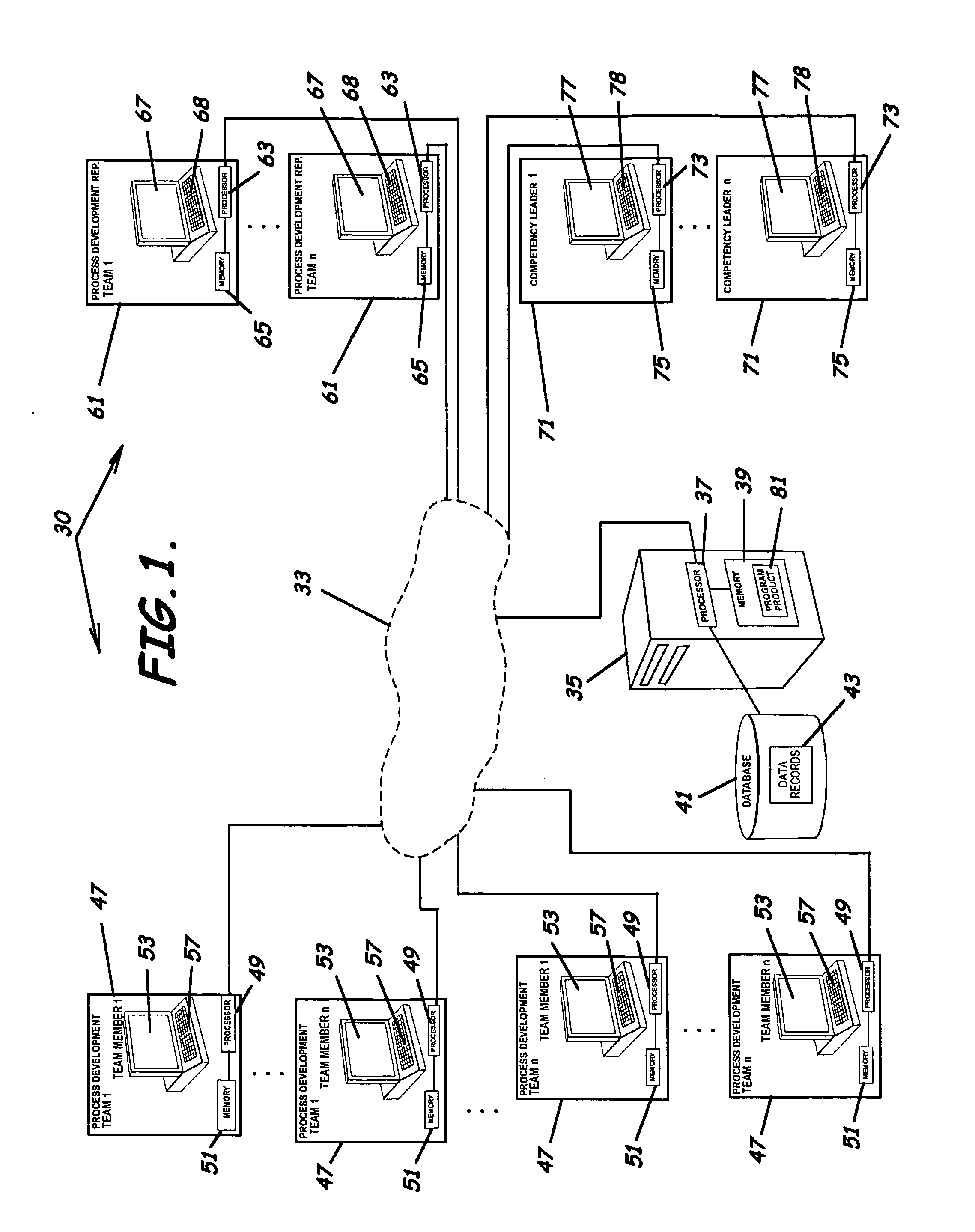

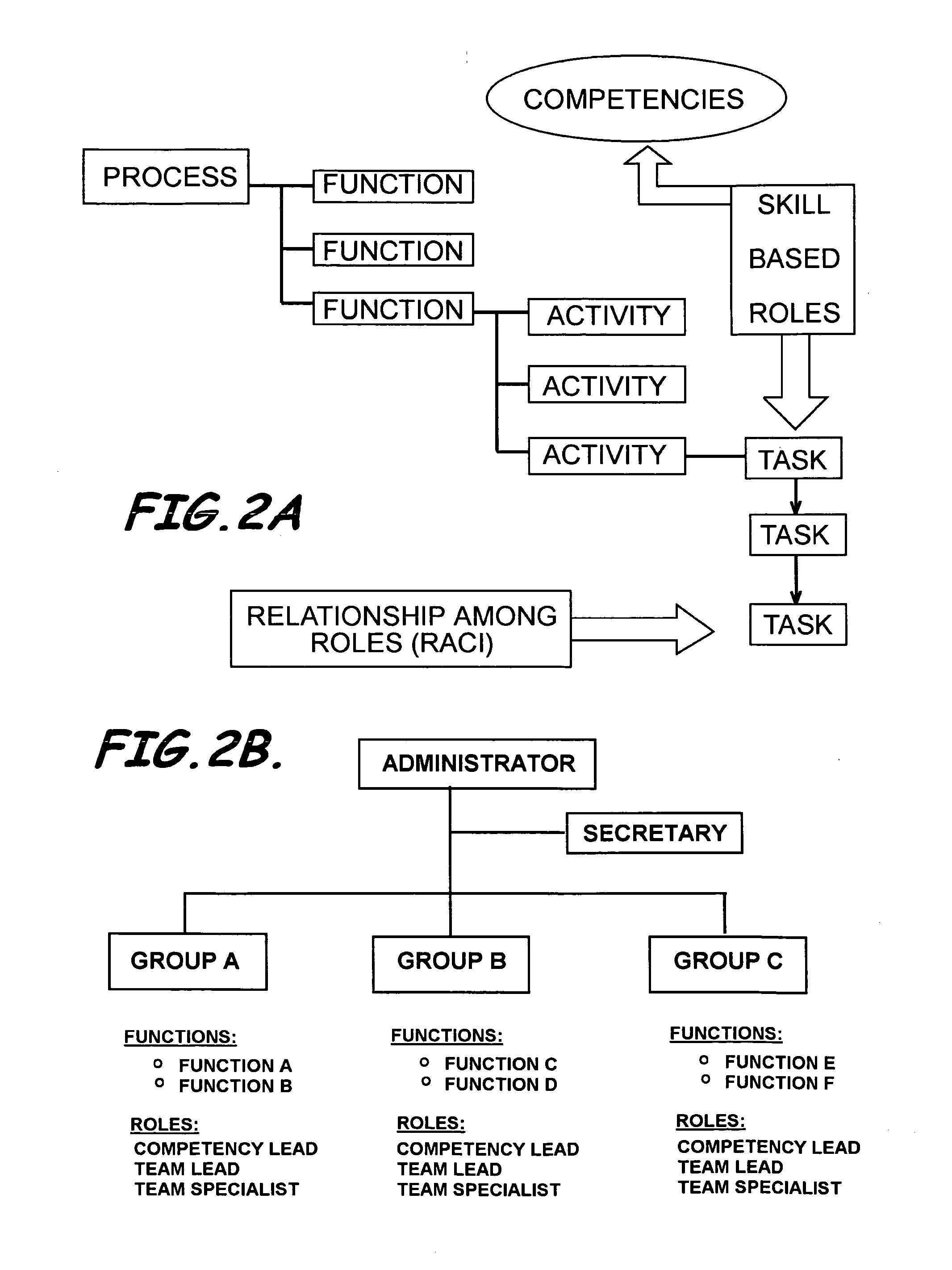

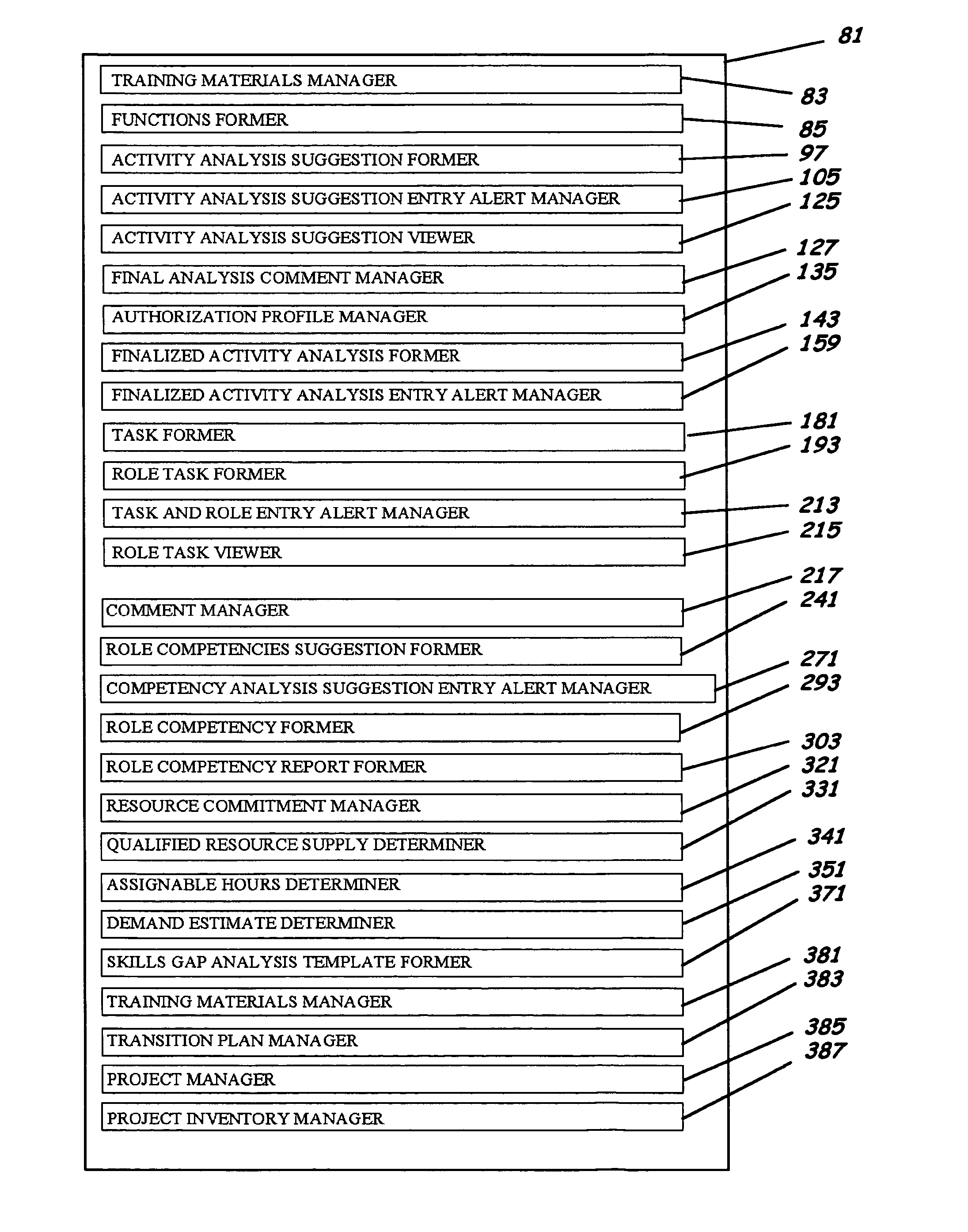

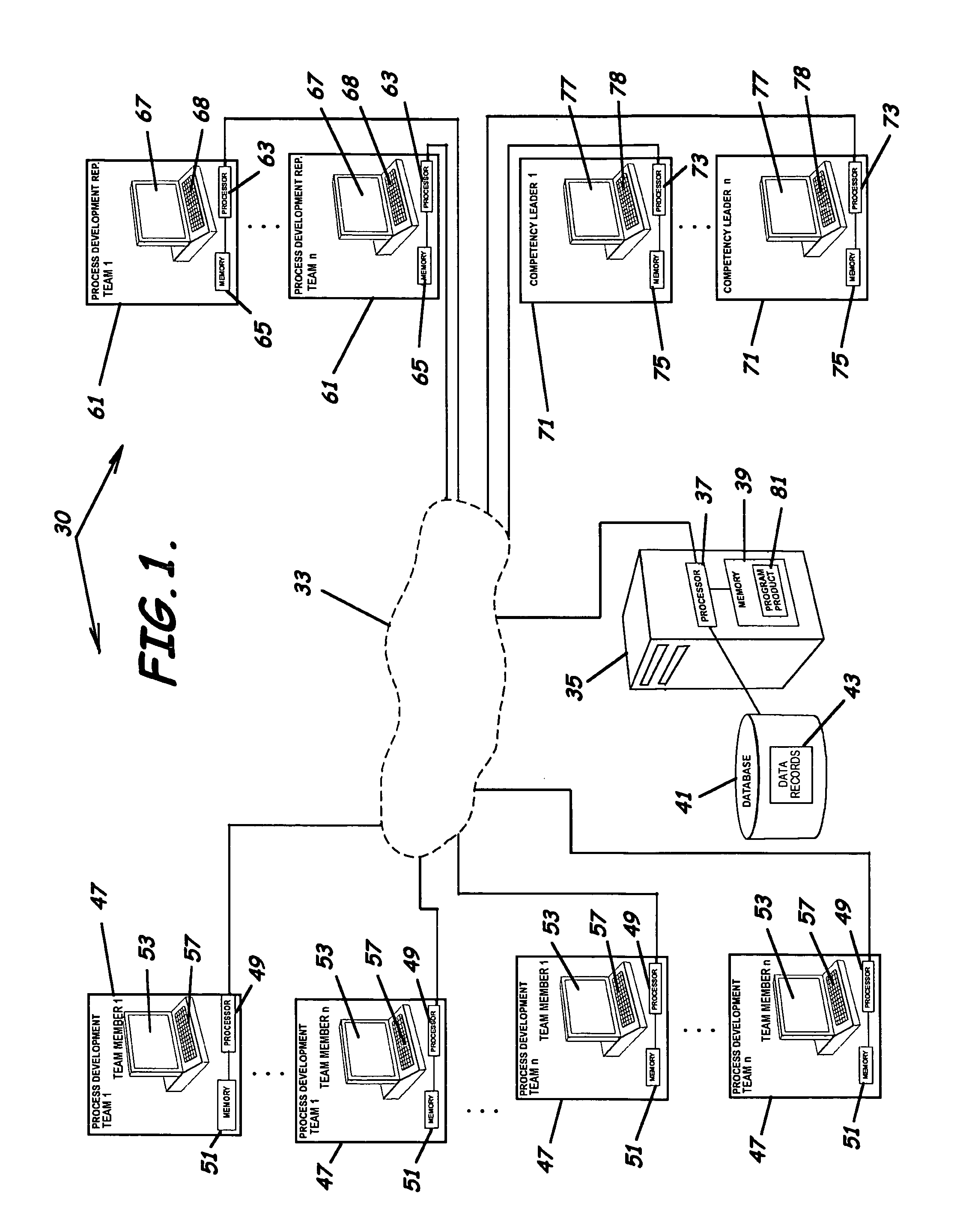

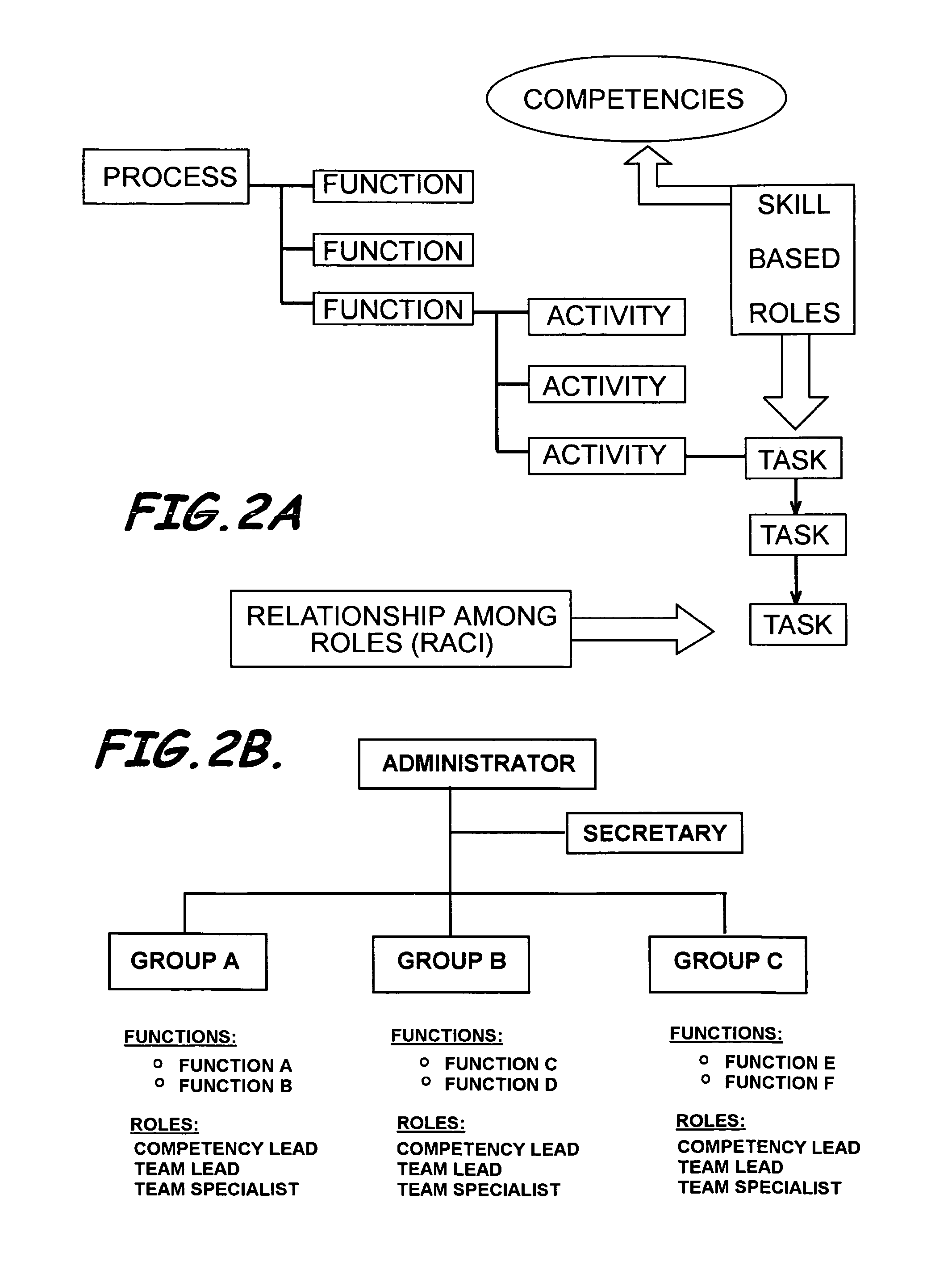

Systems, program product, and methods for organization realignment

InactiveUS20070198317A1Reduce resistanceImprove efficiencyOffice automationResourcesOrganizational analysisProcess development

A system to realign an organization structure, program product, and associated methods are provided. The system includes an organization realignment program server, a database accessible to the organization realignment program server, a plurality of process development team member computers, a plurality of process development representative computers, and an organization realignment program product stored in the memory of the organization realignment program server to facilitate reorganization program development through online access to the plurality of data records. The organization realignment program product can provide organization analysis web pages to capture data used to analyze and define functions, activities, tasks, and roles, forming a new organization structure, and can provide resource determination web pages to determine a qualified supply of resources available to the new organization structure to thereby determine a skills gap and a resource gap between resources demanded by the new organization structure and the qualified supply of resources.

Owner:SAUDI ARABIAN OIL CO

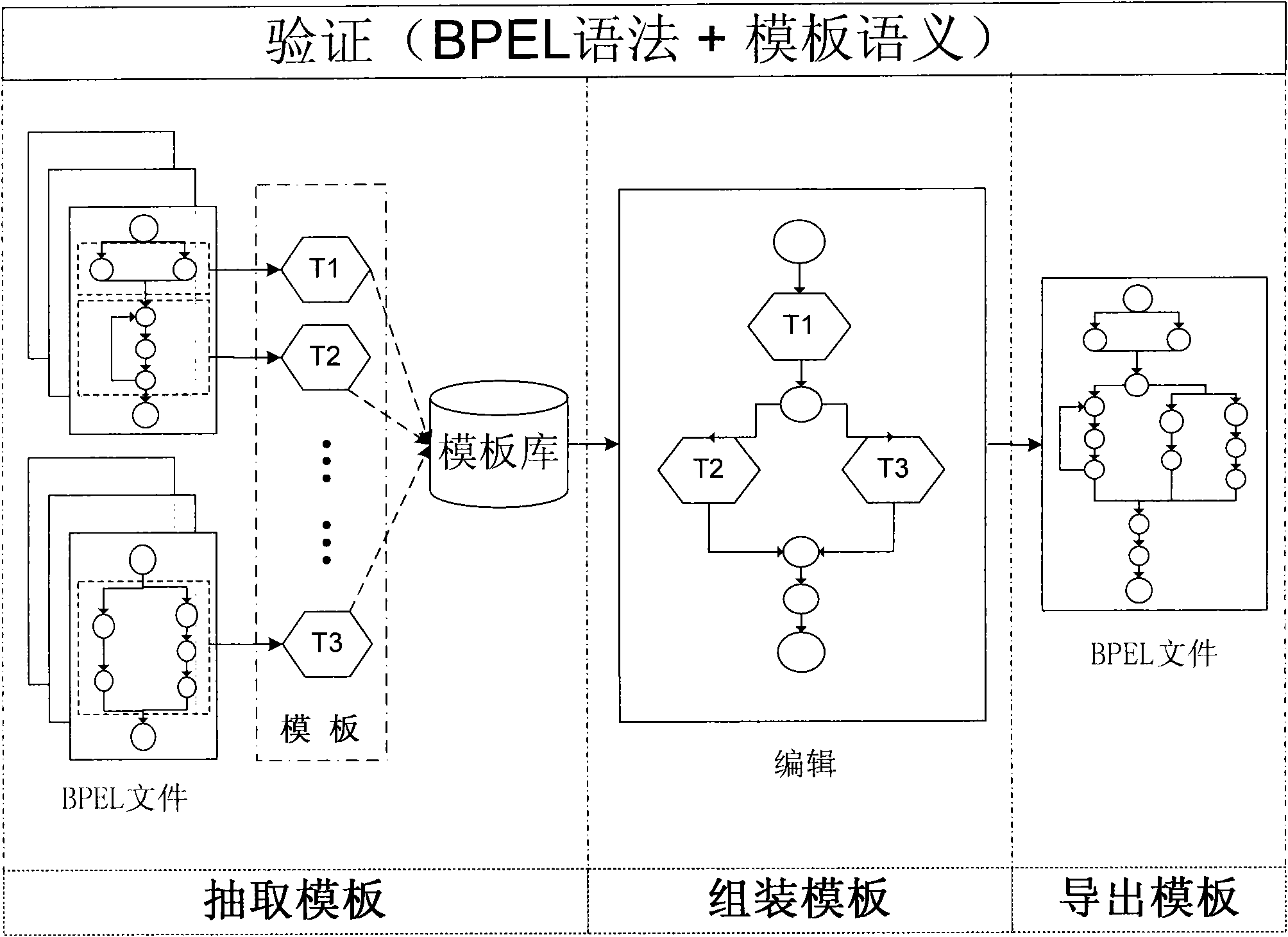

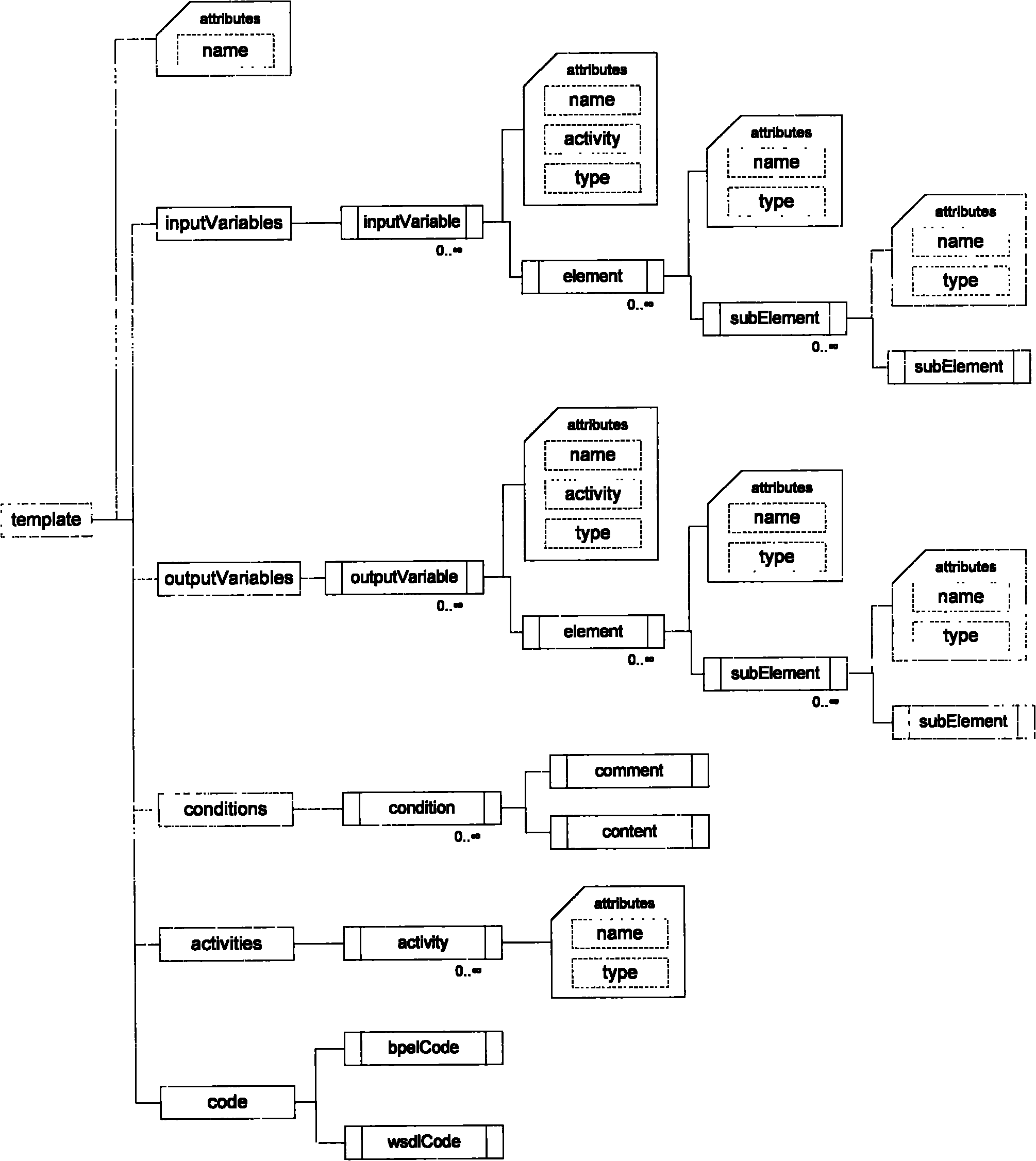

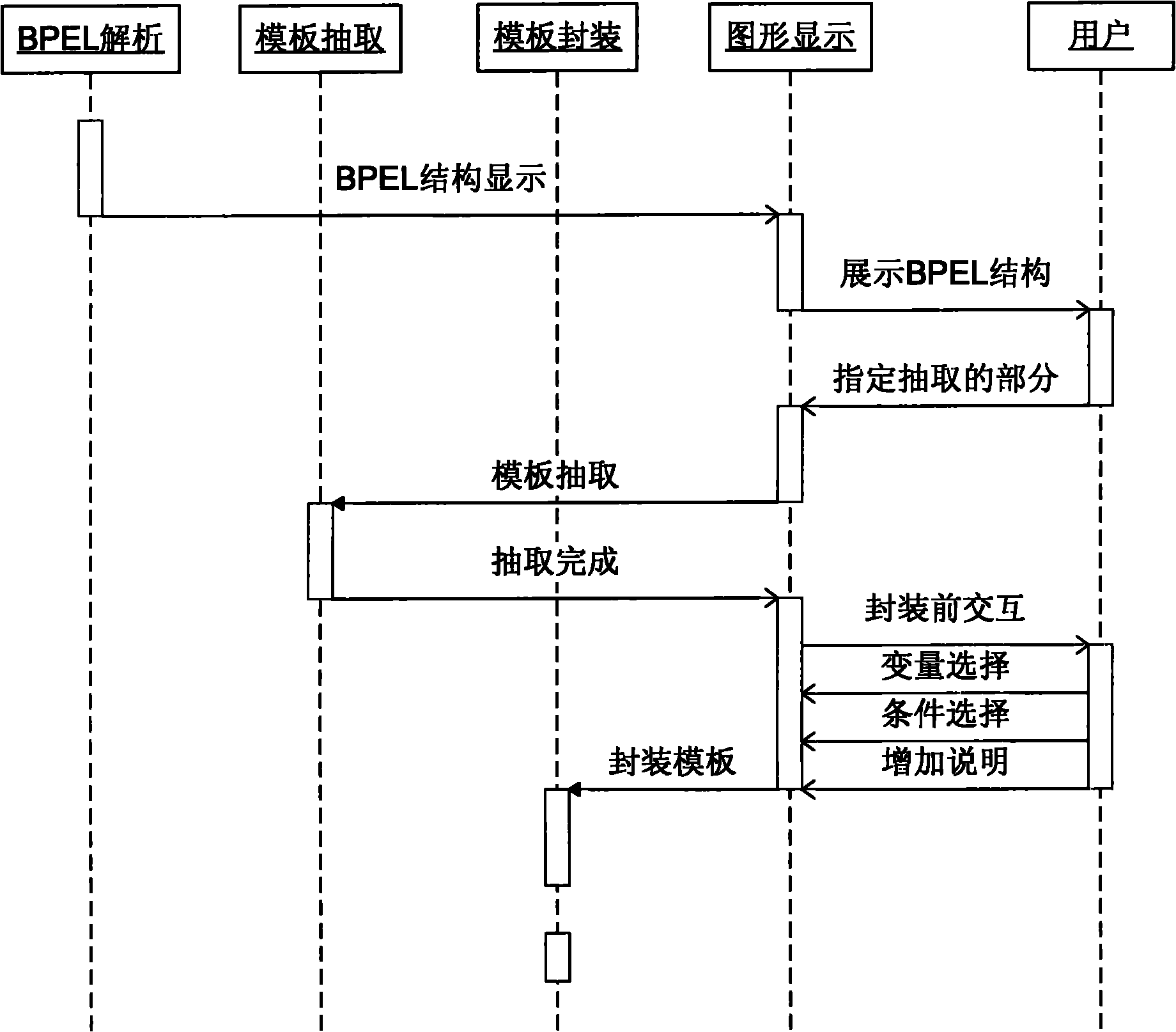

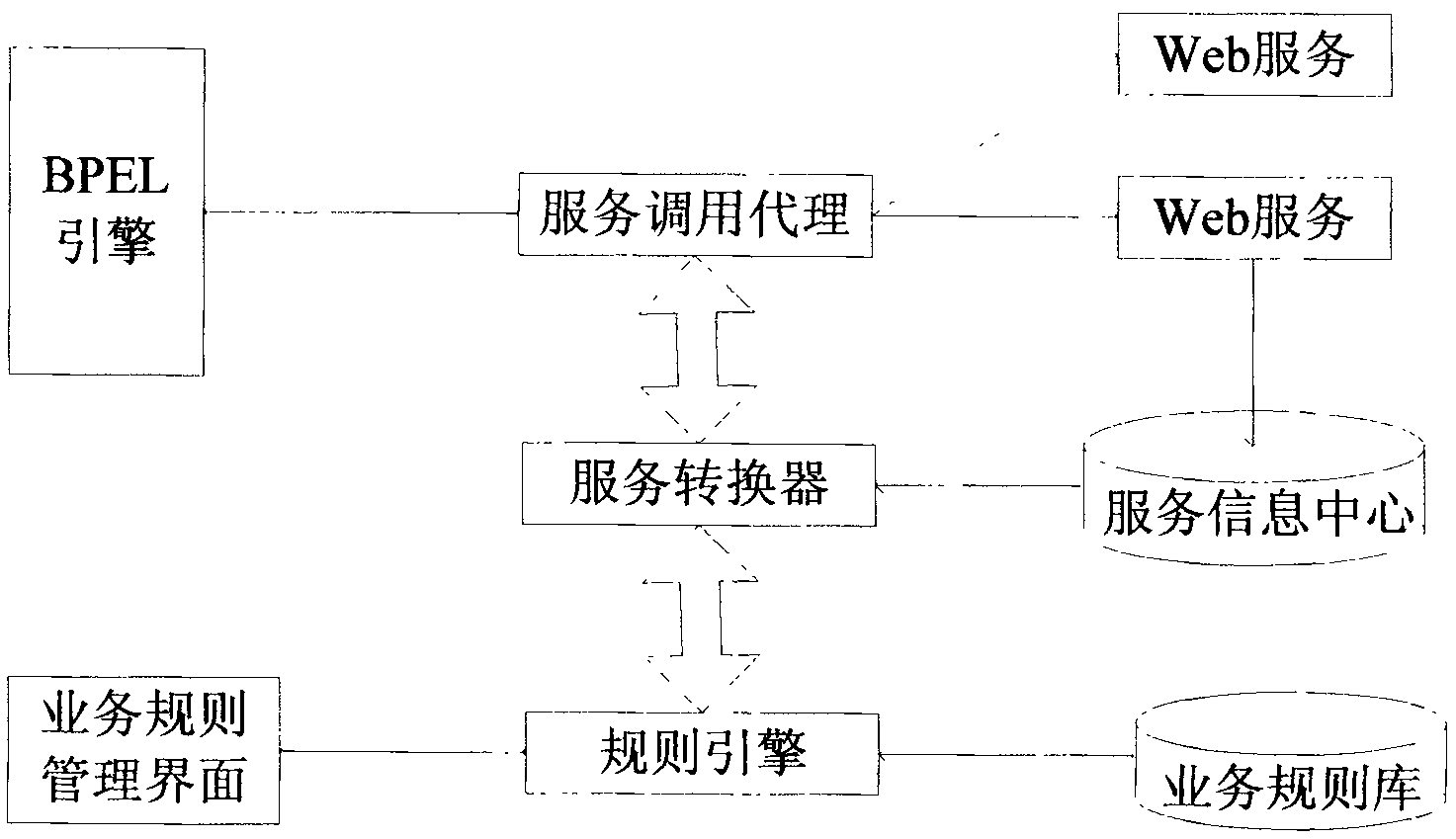

Method and system for realizing BPEL sub-process multiplexing based on template in service-oriented environment

InactiveCN101777004AReduce the work of secondary developmentIncrease flexibilityProgram controlMemory systemsService compositionMultiplexing

The invention discloses a method and a system for realizing BPEL sub-process multiplexing based on a template in a service-oriented environment. The method comprises the following steps of: performing model definition on the template to store related information which is needed when a BPEL sub-process is extracted for multiplexing; resolving an existing BPEL file and a related WSDL file, establishing a BPEL model and a WSDL model, extracting the needed BPEL sub-process from the existing BPEL file according to the established models, and encapsulating the extracted sub-process into the template and storing the template into a template base; and reading template information from the template base during development and calling the template to a BPEL process visualized development window to ensure that a user also can call the template to assist process design and development when developing the BPEL process, and the unification of a template mechanism and the BPEL process development can be realized. The method can realize the BPEL sub-process multiplexing, can greatly reduce work load of developers, improves the development efficiency of service combination, and shortens the development cycle by a pre-designed intra-industry common process template or a user-defined multiplexing template.

Owner:BEIJING UNIV OF POSTS & TELECOMM

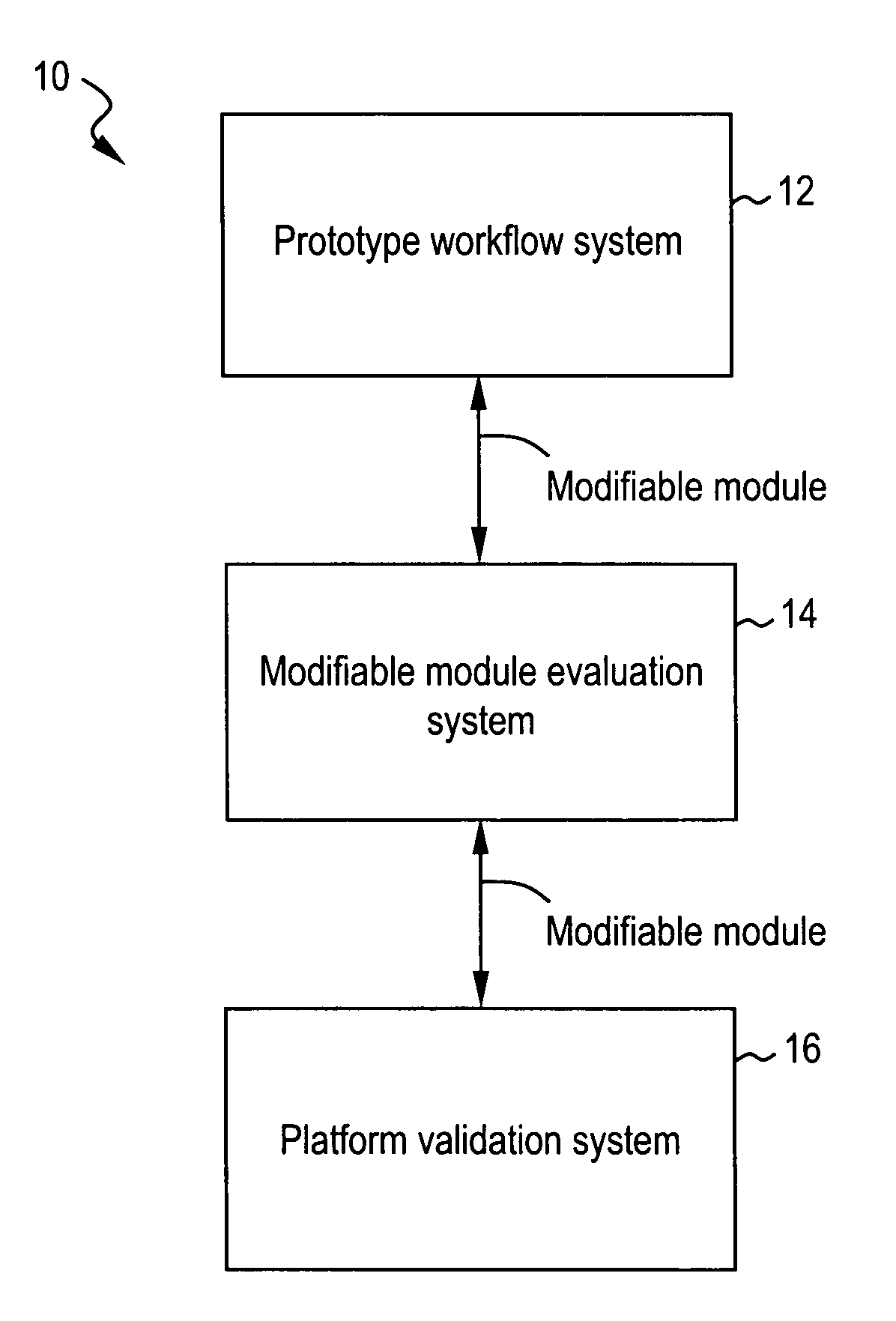

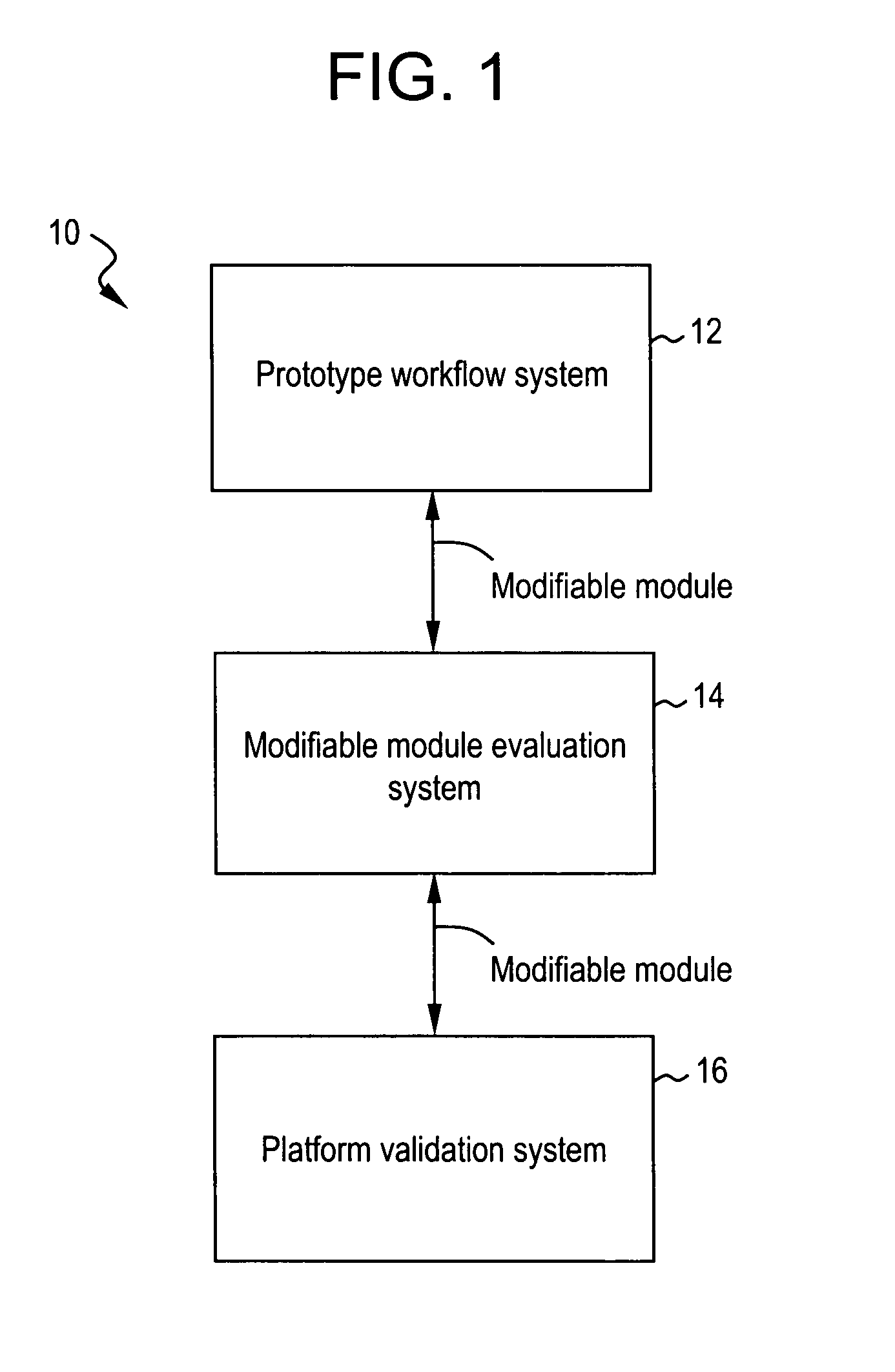

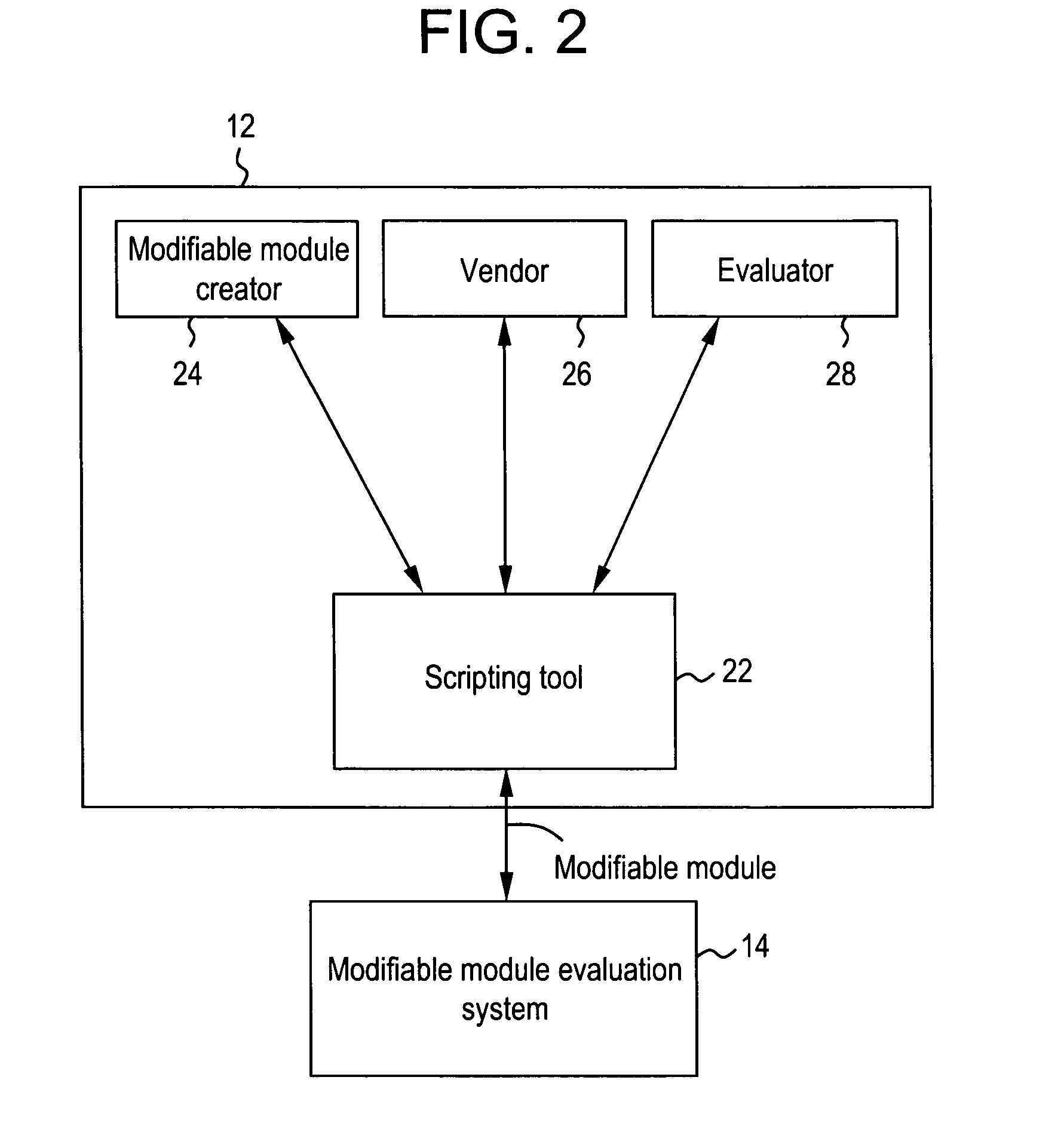

System and method for improved surgical workflow development

ActiveUS7371068B2Mechanical/radiation/invasive therapiesOffice automationResearch evaluationProcess development

Owner:STRYKER EURO OPERATIONS HLDG LLC

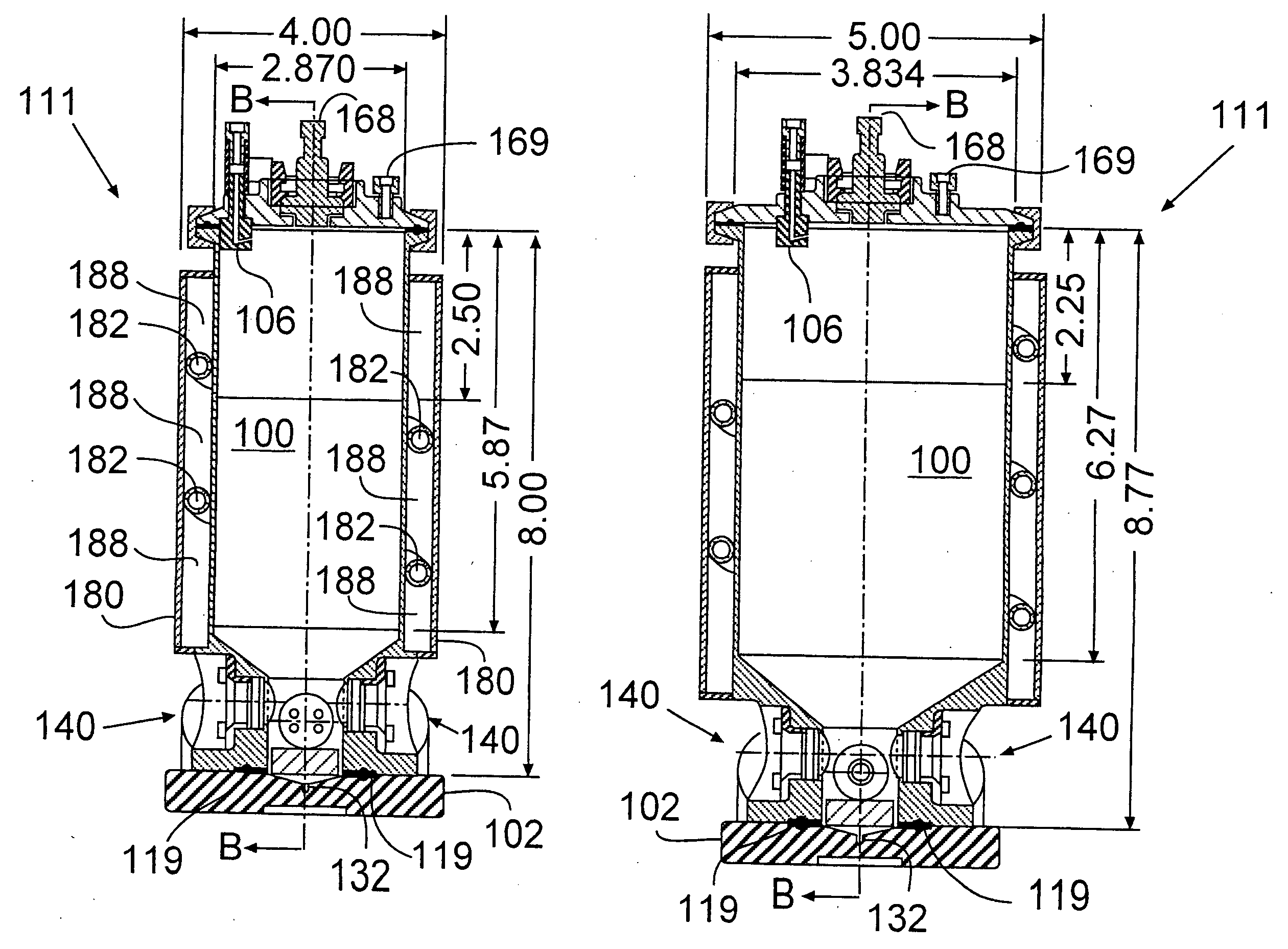

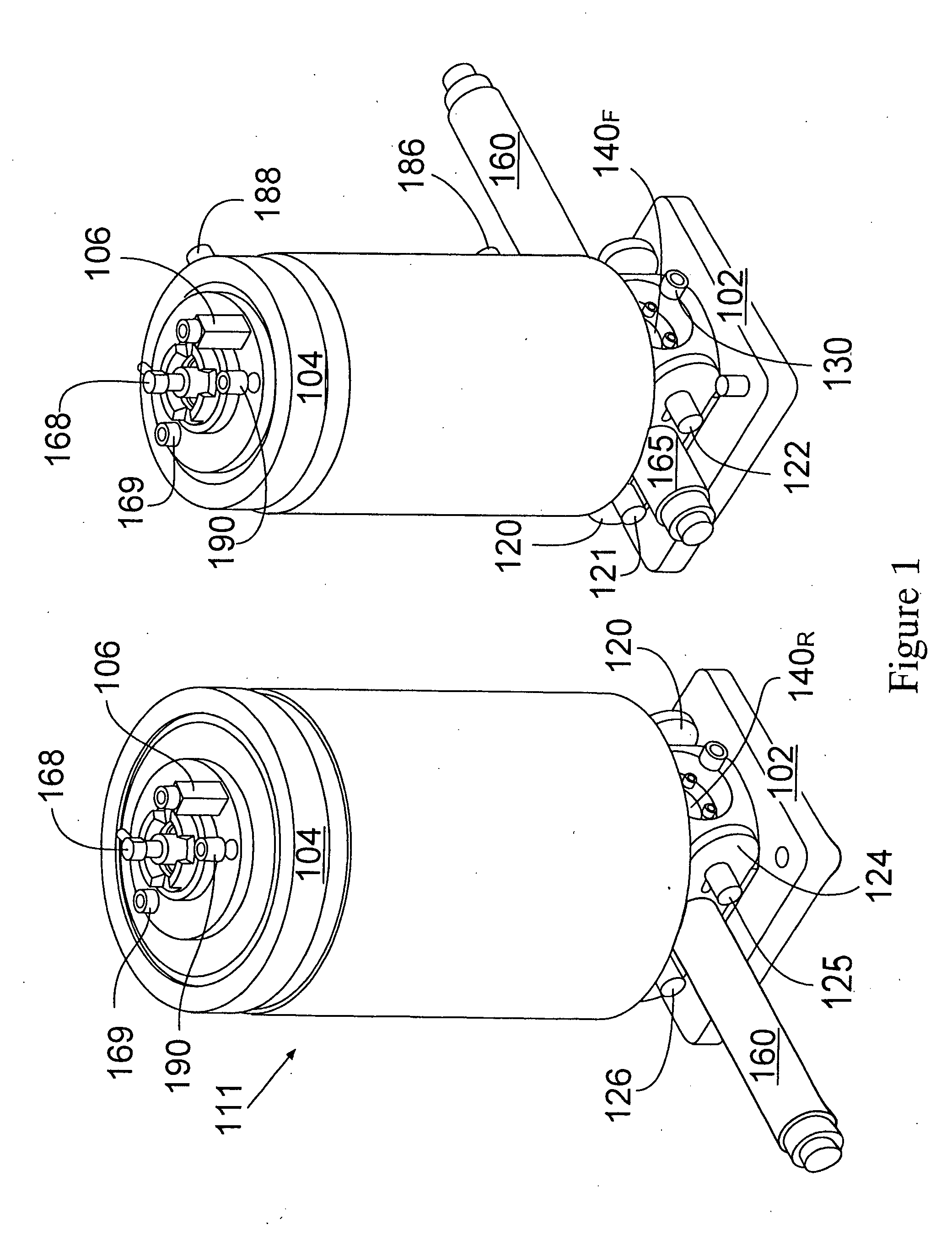

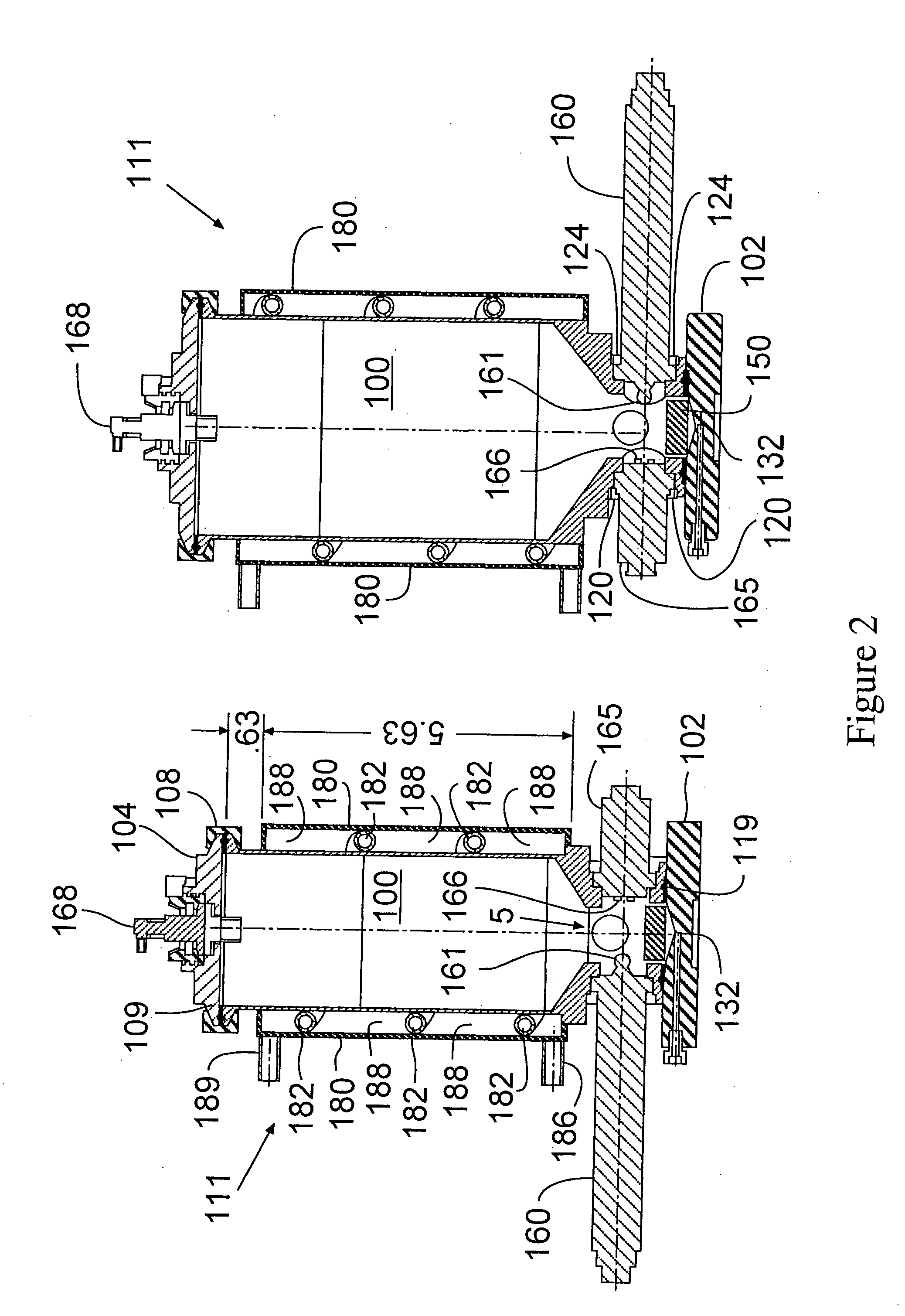

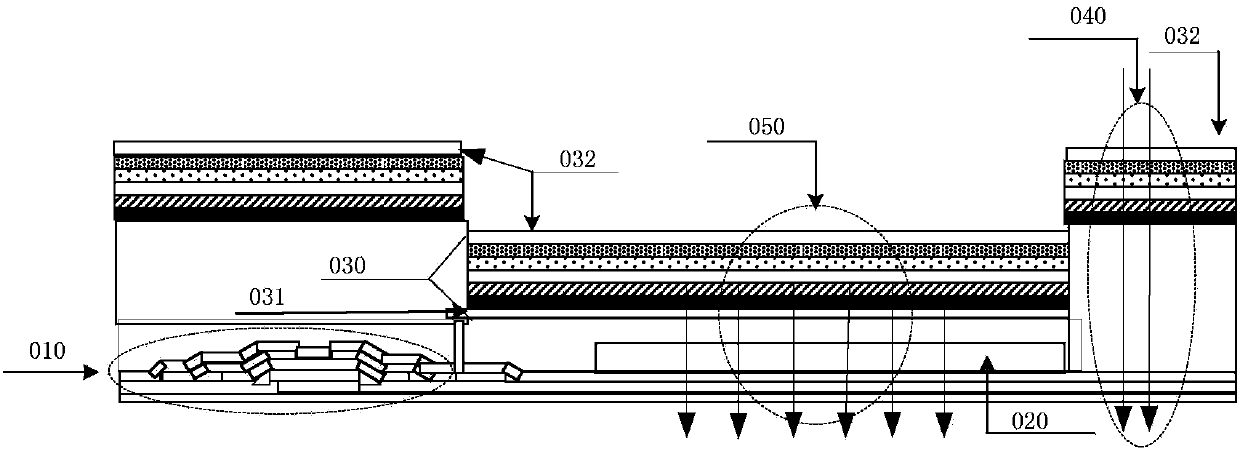

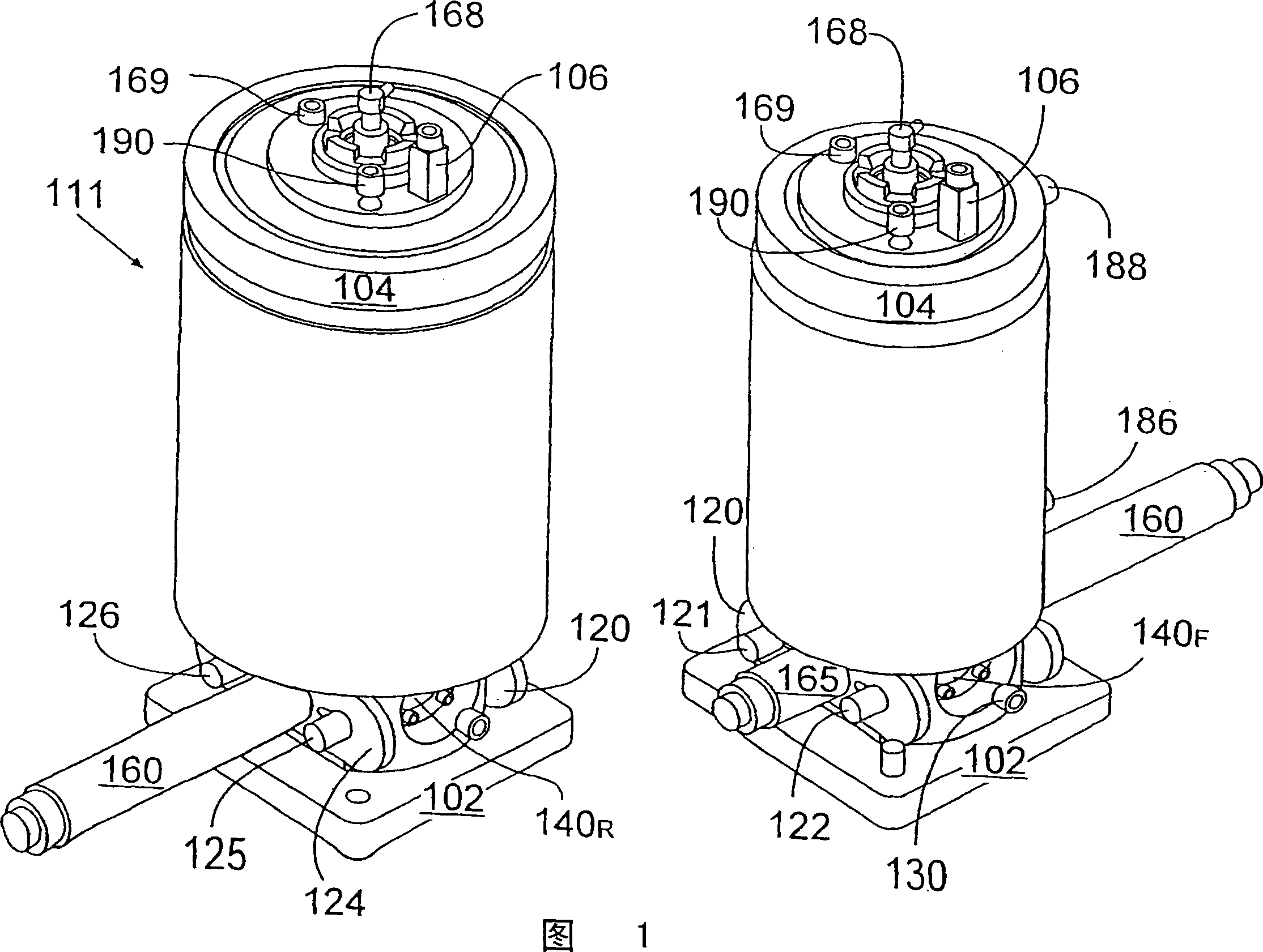

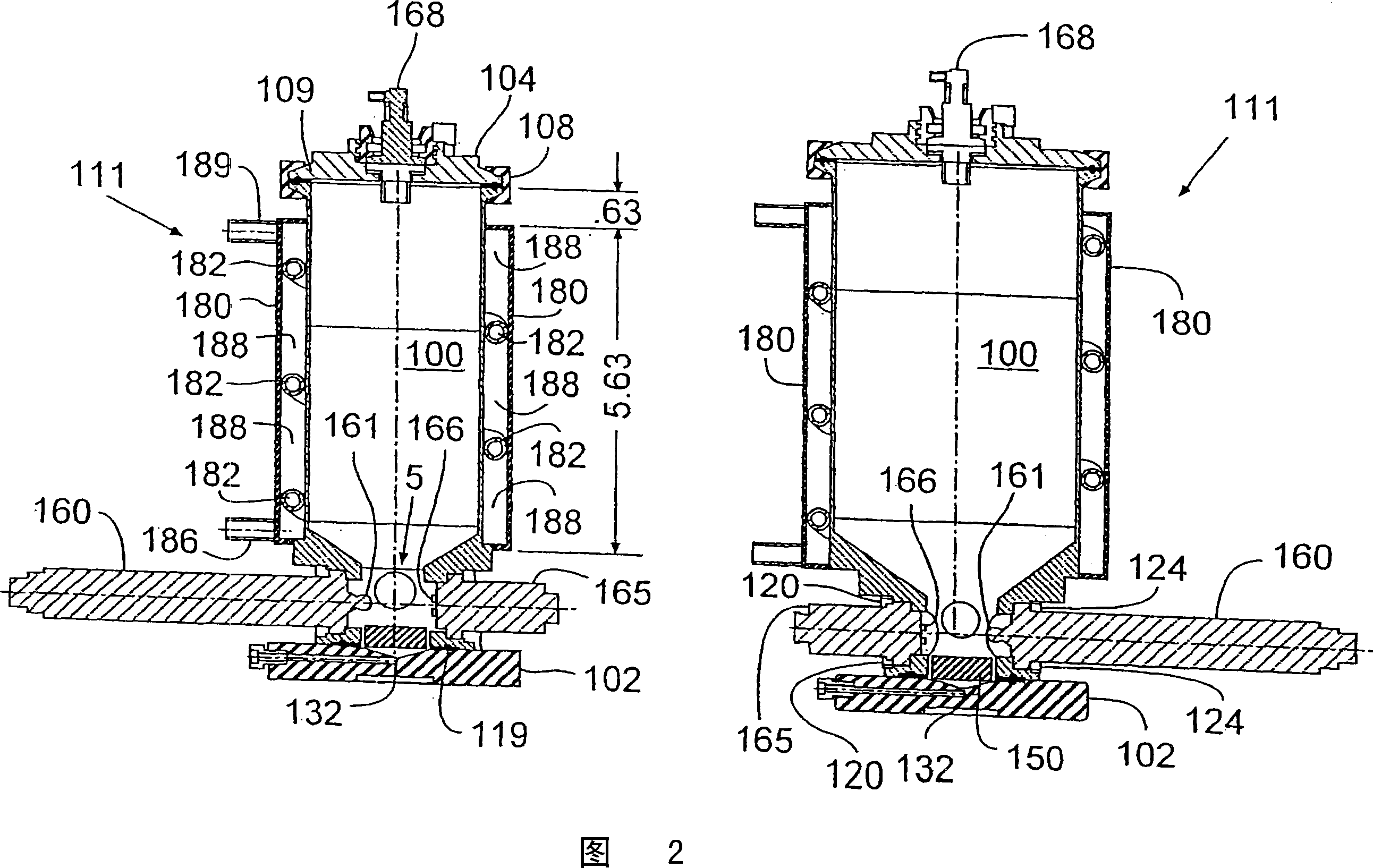

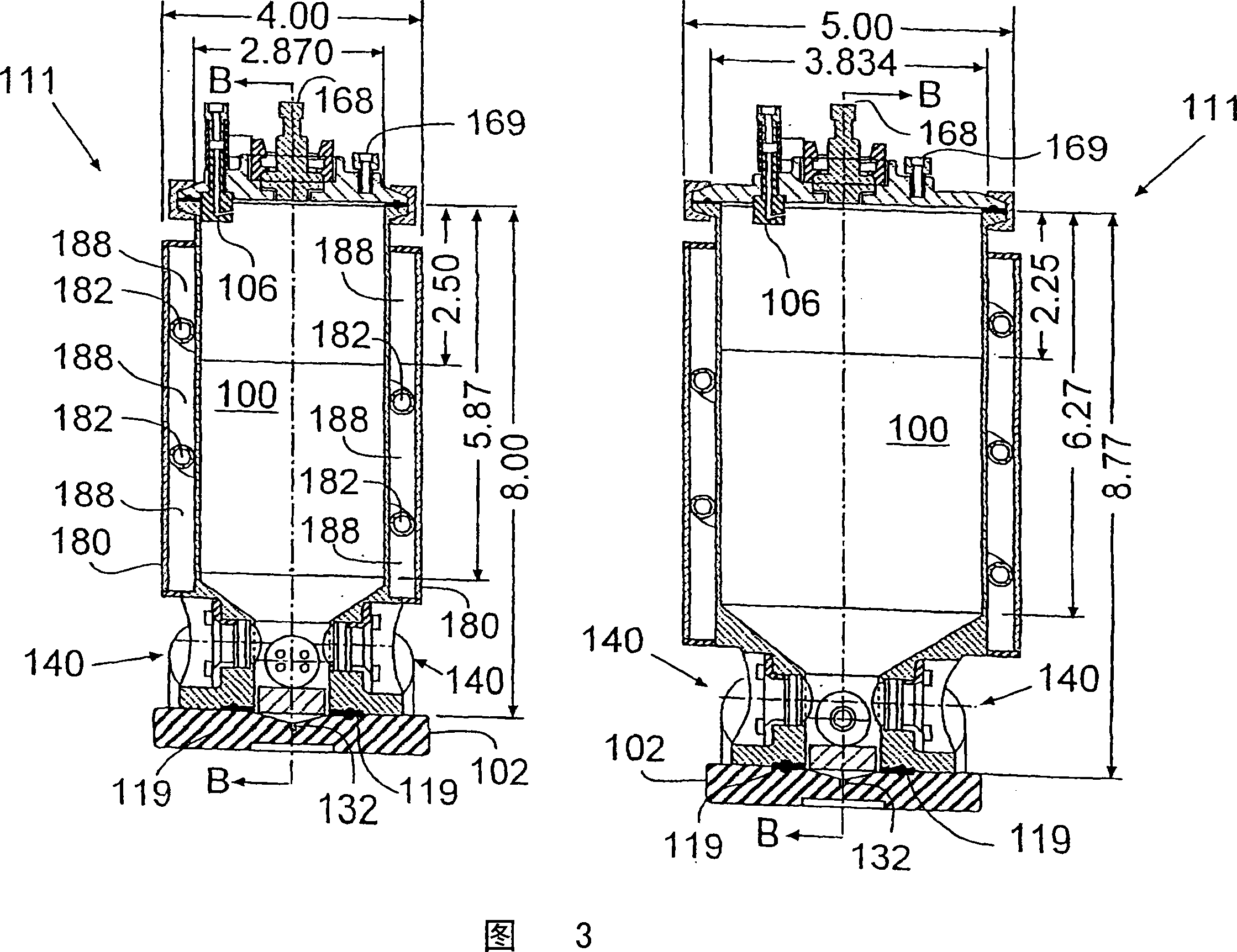

Automated low-volume tangential flow filtration process development device

InactiveUS20050023194A1Economical and fastEasy to disassembleIon-exchanger regenerationUltrafiltrationProcess developmentLaboratory scale

An automated process development device providing flexibility and accuracy for the investigative development of tangential flow filtration processes. The development device is used for evaluating the process parameters of a laboratory scale tangential flow filtration process with an eye towards developing a larger, commercial scale process. The process development device—operable to an unprecedented minimum reliable recirculation volume of less than approximately 20 milliliters—includes: (a) a reservoir having a distinct mixing zone; (b) a tangential flow filtration module; (c) conduits defining, together with the distinct mixing zone and the tangential flow filtration module, a fluid process stream through which a liquid sample is recirculated; (d) pumps for driving the flow of the liquid sample through the fluid process stream; (e) valves for regulating the flow of the liquid sample through the fluid process stream; (f) sensors for acquiring data about the liquid sample as it flows through the fluid process stream; and (g) an electronic data processing network capable of receiving, transmitting, processing, and recording data associated with the operation of the pumps, valves, and sensors, the recorded data being sufficiently comprehensive to determine the conduct of the tangential flow filtration process at a substantially larger scale.

Owner:MILLIPORE CORP

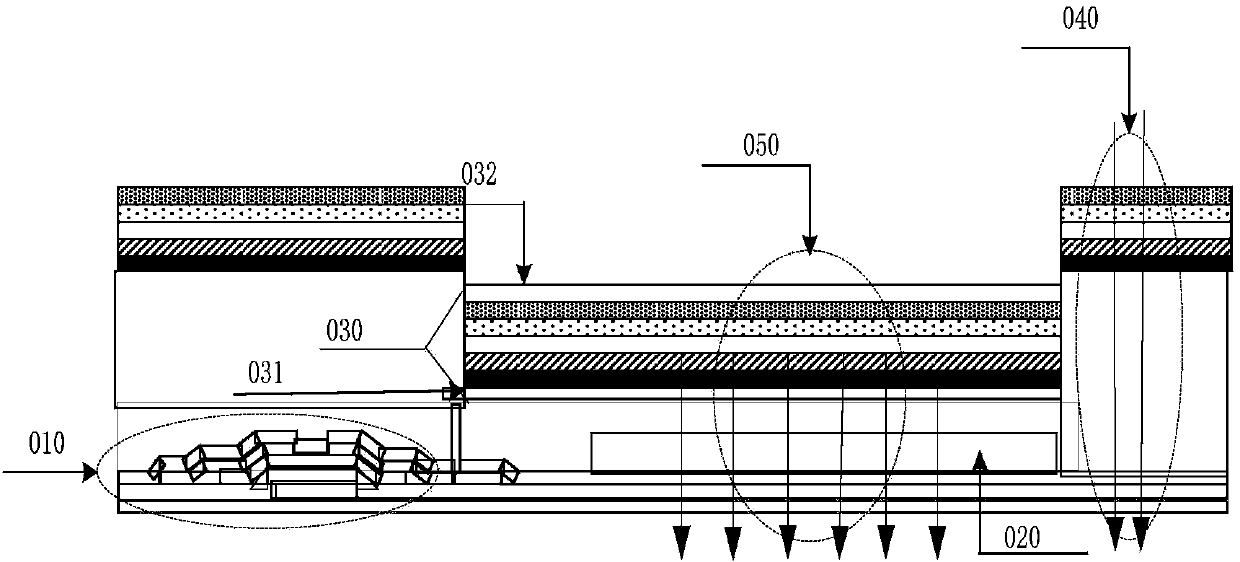

OLED (organic light emitting diode) display panel and production method thereof

InactiveCN103700692AImprove transmittanceRealize transparent displaySolid-state devicesSemiconductor/solid-state device manufacturingProcess developmentTransmittance

The invention provides an OLED (organic light emitting diode) display panel and a production method thereof. The OLED display panel comprises a plurality of pixel units, wherein each pixel unit comprises a light emitting area and a light transmitting area, each light emitting area is provided with a white light organic transmitting device and a light filter layer; each light transmitting area is not provided with the light filter layer. The light filter layers are additionally provided with the special light transmitting areas, so that the transmittance is increased, the transparent display is realized, no additional process development is needed, and the transparent display can be realized only by appropriately adjusting the design.

Owner:BOE TECH GRP CO LTD

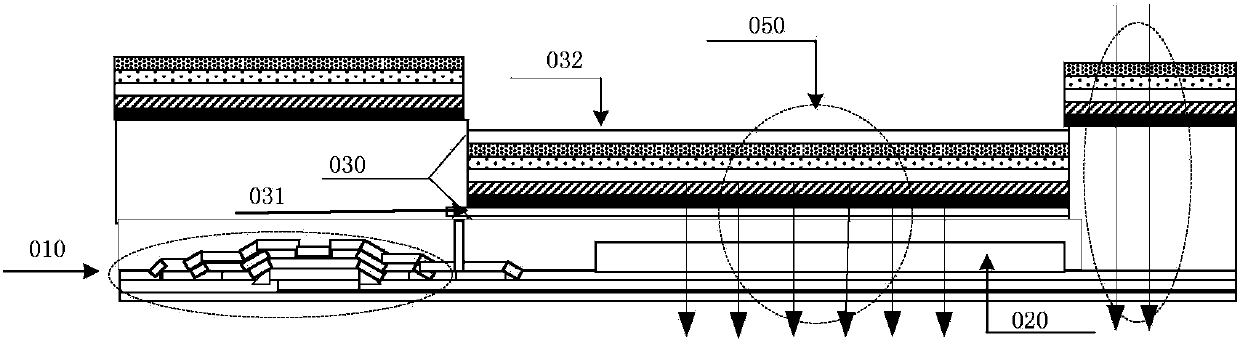

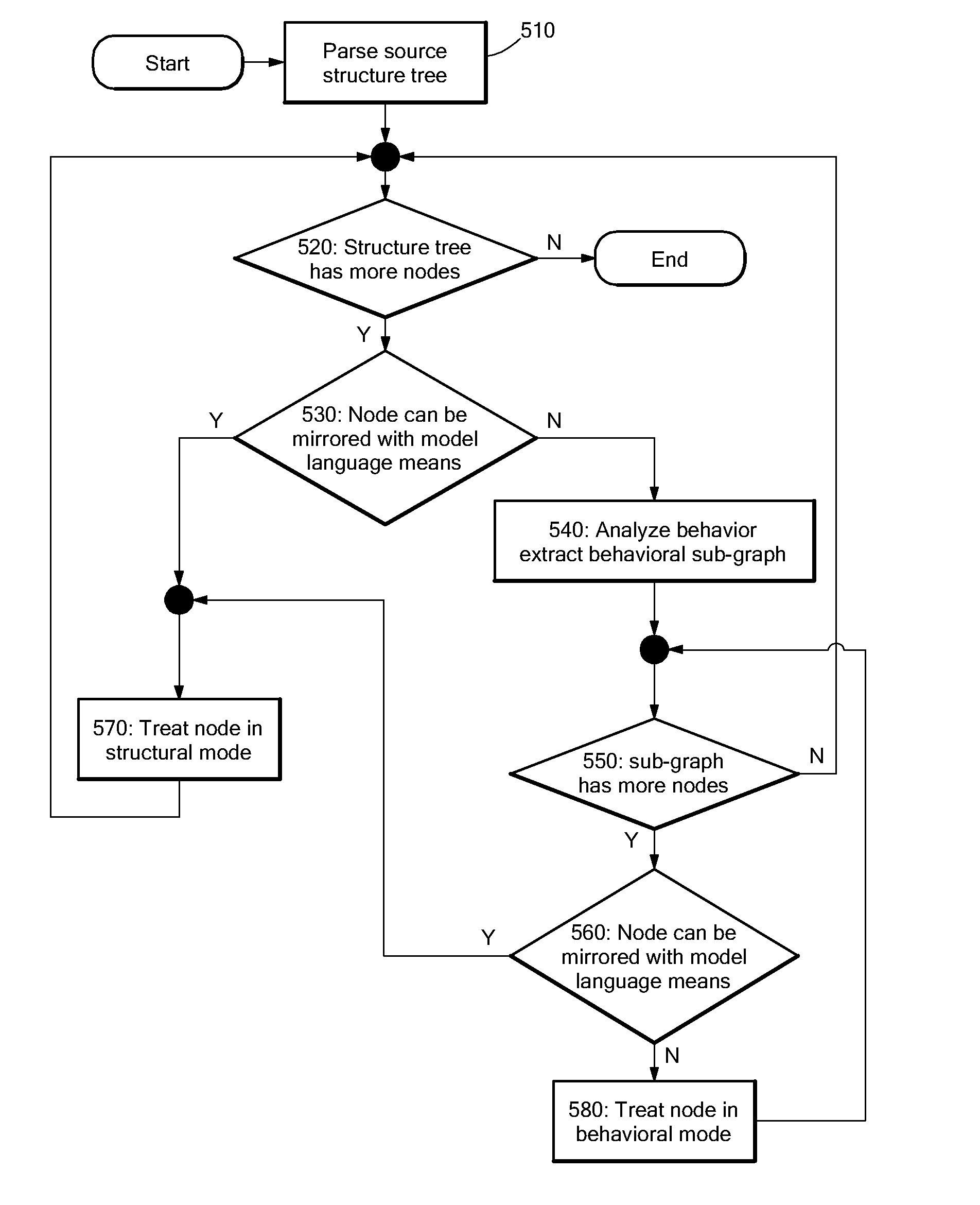

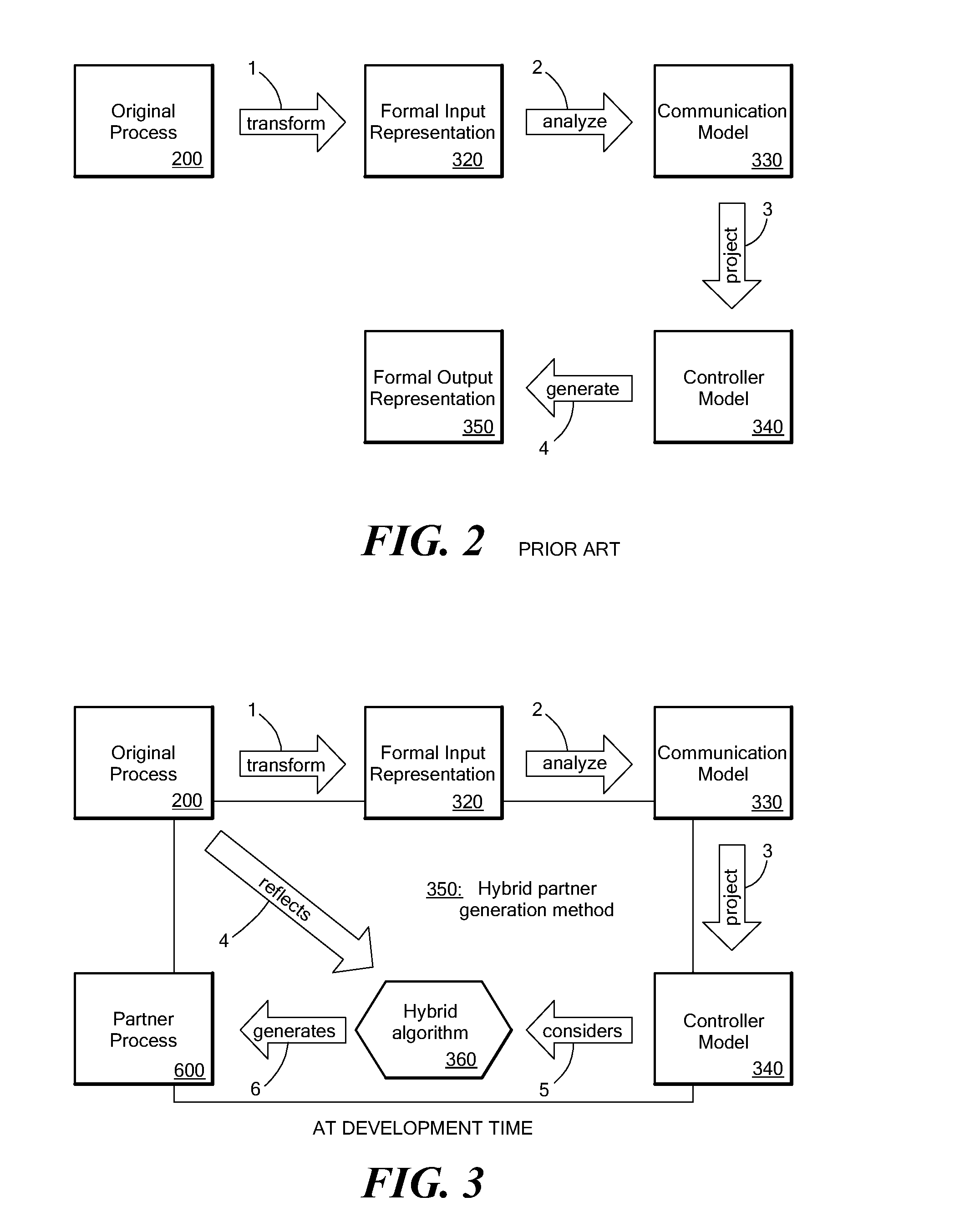

Method for generating compatible partner processes in BPEL

InactiveUS20070174822A1Simple procedureProgramming languages/paradigmsModel driven codeWorkflow management systemProcess development

The present invention relates to a Workflow Management System or a computer system with comparable functionality (WFMS). More particularly the invention relates to a method or means for generating a runtime compliant partner process for a given original process, wherein both processes are dedicated to interact with each other. In order to provide a method for generating a runtime compliant partner process for a given original process, which is easier understandable for a process developer, it is proposed to perform the steps of:Step 1: Identifying all activities of the original process interacting with the partner process,Step 2: Determining if an activity is able to be mirrored by a mechanism supported by the business process language, e.g. BPEL,Step 2.1: If yes, generating the mirrored activity and creating a respective activity name,Step 2.1: If not, using a predetermined mathematical method for dissecting such an activity that into a set of sub-activities, which can be mirrored,Step 2.2.1: Generating a respective mirrored sub-activity and creating a respective activity name for each sub-activity,Step 2.2.2: Arranging the mirrored sub-activities according to the outcome of the predetermined mathematical method.

Owner:IBM CORP

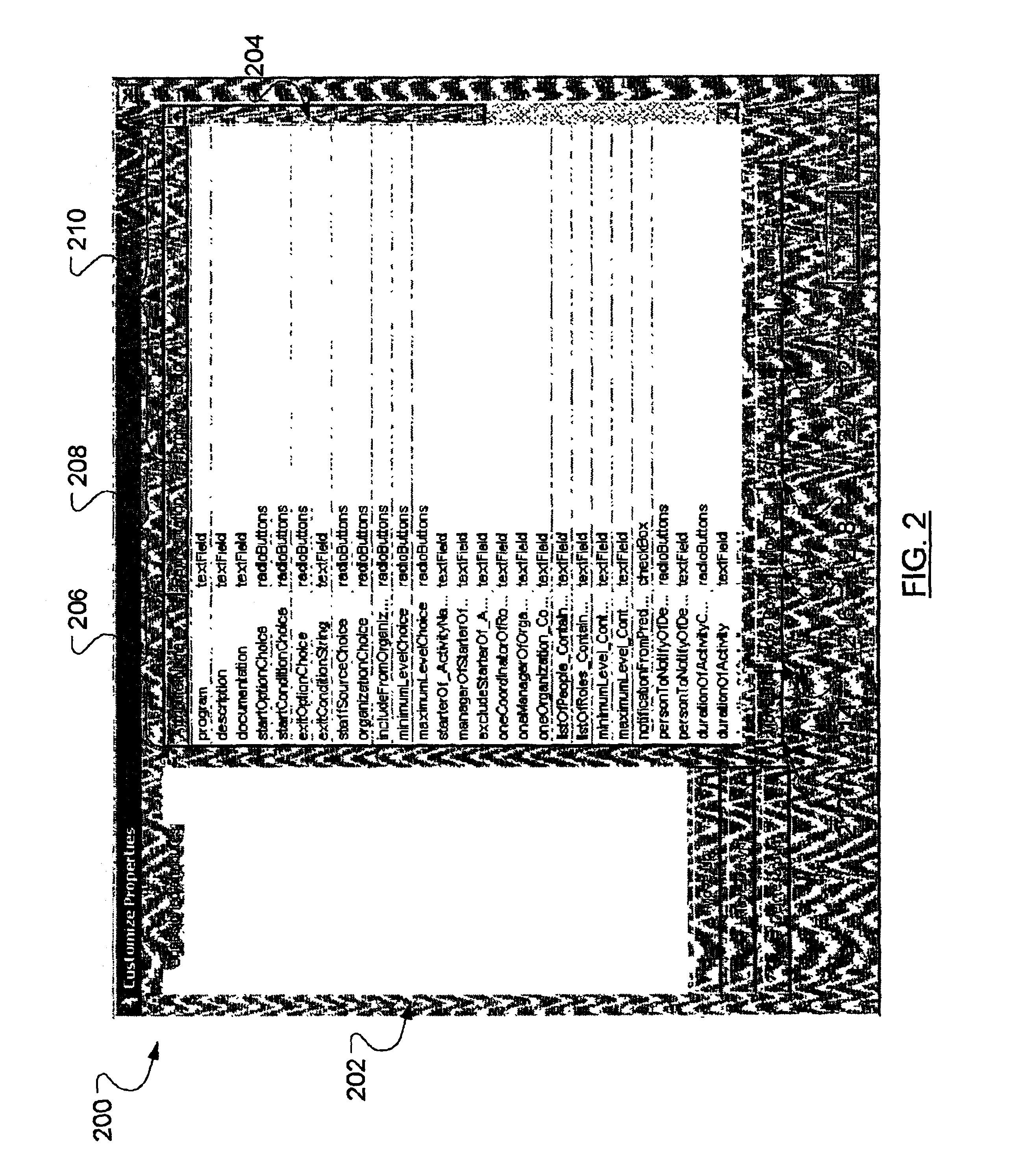

Customization of object property layout for a user interface

InactiveUS6925598B2Software engineeringSpecial data processing applicationsProcess developmentUser interface

A process flow development tool is given a capability of determining the properties corresponding to a particular type of object and allowing a user to decide how and where the properties will be shown in a Properties dialog for individual objects of the particular type. The capability allows the tool to present a dialog that allows the user to customize, for the particular type of object, the layout for the properties in the Properties dialog. This layout may then be stored in an organizer object associated with the particular type of object.

Owner:IBM CORP

Systems program product, and methods for organization realignment

InactiveUS8073724B2Minimize impactTime durationOffice automationResourcesOrganizational analysisProcess development

A system to realign an organization structure, program product, and associated methods are provided. The system includes an organization realignment program server, a database accessible to the organization realignment program server, a plurality of process development team member computers, a plurality of process development representative computers, and an organization realignment program product stored in the memory of the organization realignment program server to facilitate reorganization program development through online access to the plurality of data records. The organization realignment program product can provide organization analysis web pages to capture data used to analyze and define functions, activities, tasks, and roles, forming a new organization structure, and can provide resource determination web pages to determine a qualified supply of resources available to the new organization structure to thereby determine a skills gap and a resource gap between resources demanded by the new organization structure and the qualified supply of resources.

Owner:SAUDI ARABIAN OIL CO

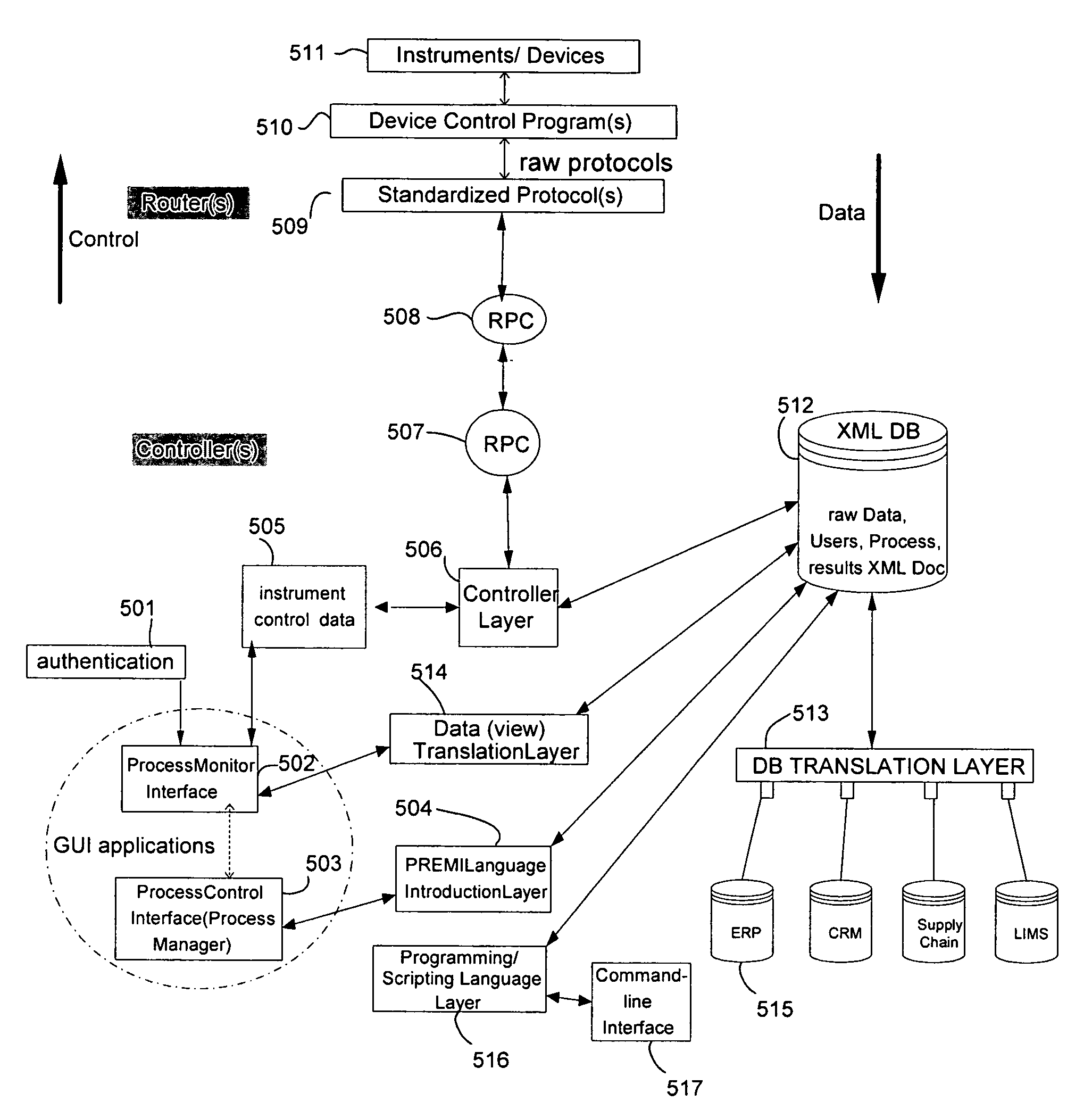

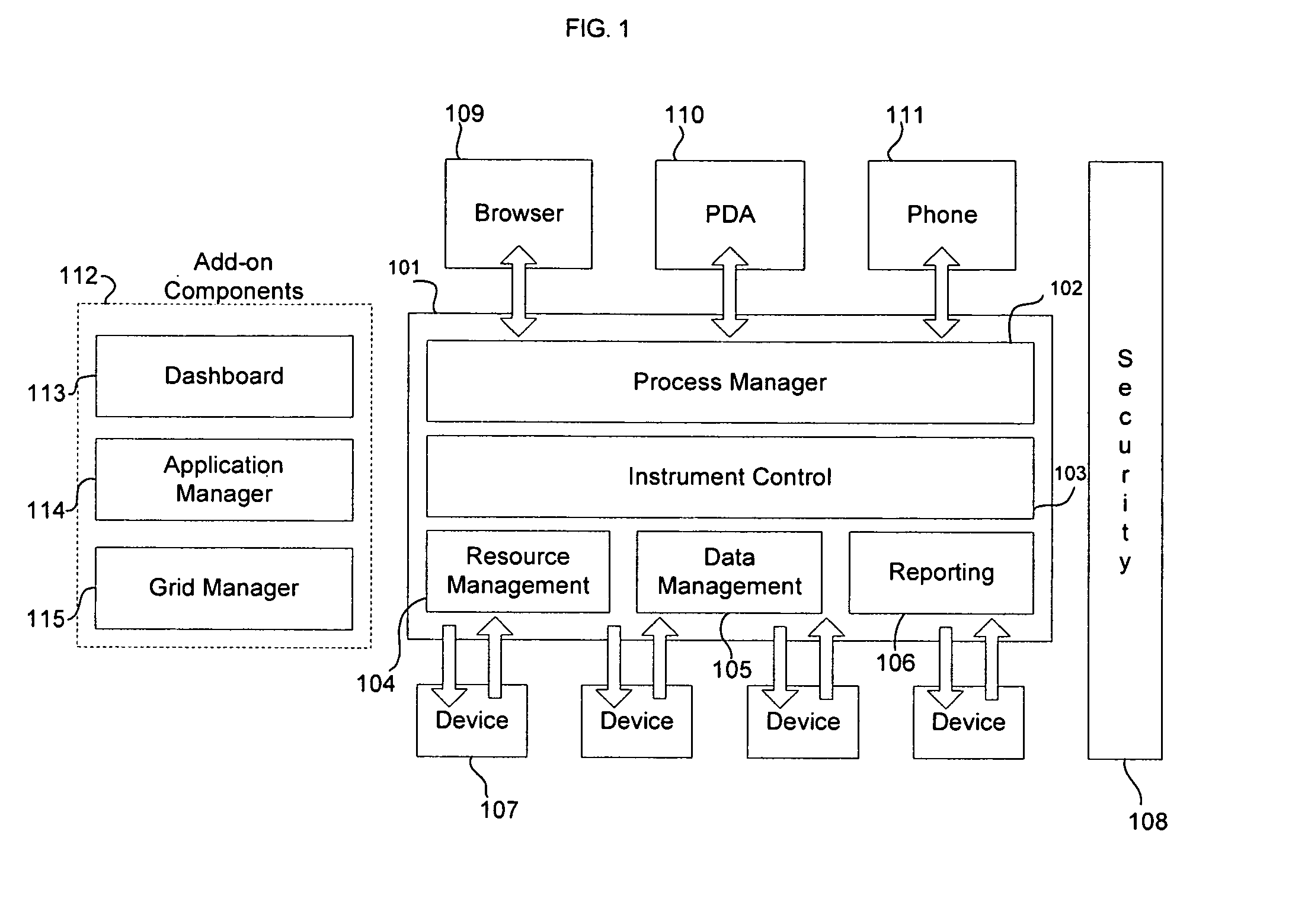

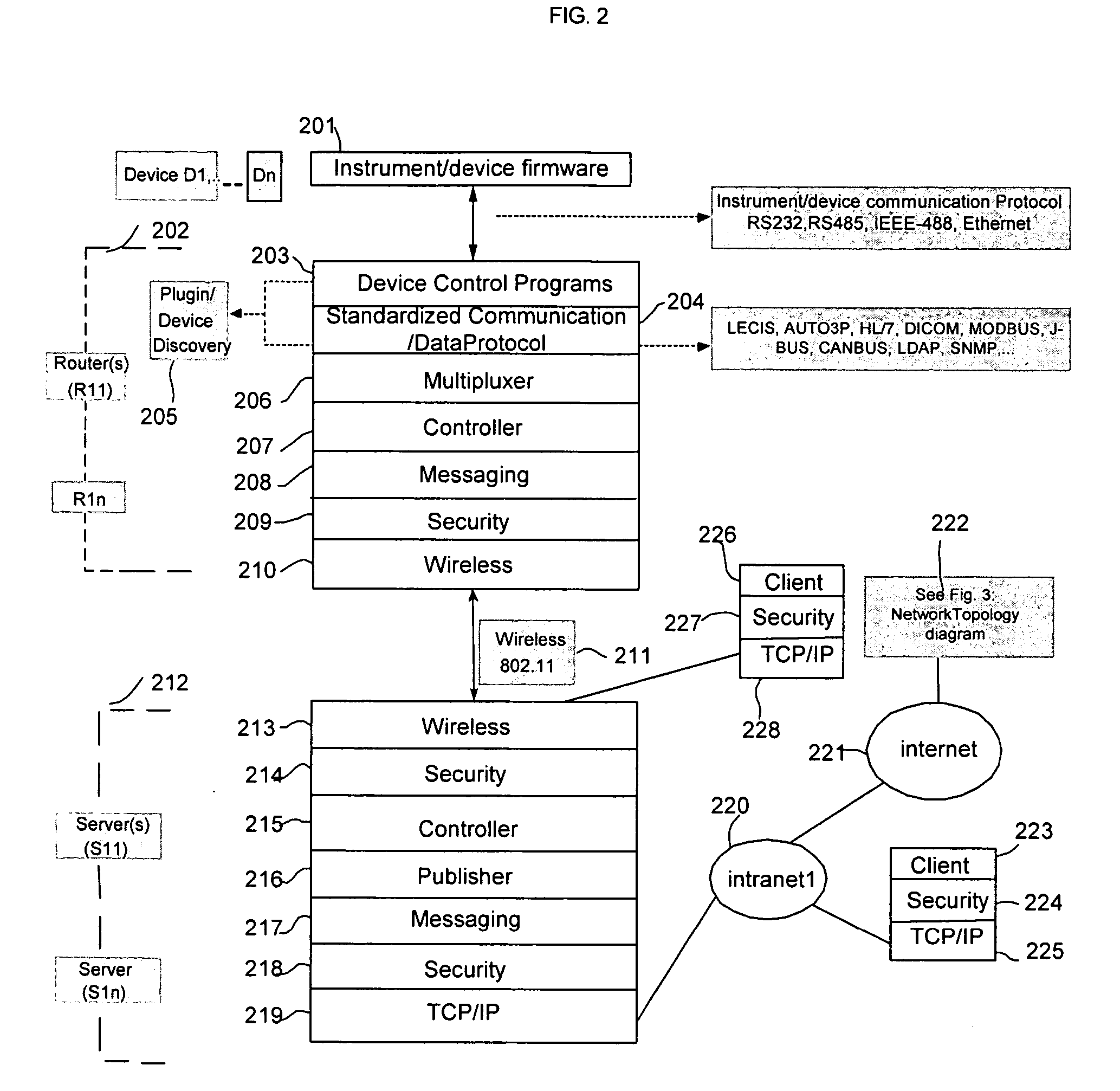

Embedded system and method for controlling, monitoring of instruments or devices and processing their data via control and data protocols that can be combined or interchanged

A system is described herein where an embedded computer method for (‘router’) is provided for full-duplex (two-way) communication between devices and / or instruments and TCP / IP-based networking. This system uses a process development component, which configures the router to communicate with a range of devices. A controller is described that can manage a collection of routers. This controller layer can reside inside the hardware or within the data-publishing layer. Each router is physically connected to devices using physical communication ports. This method offers significant improvements over prior art with respect to open architecture process, control protocols, graphical icon usage, process development, validation, execution, monitoring and messaging. The result data from the device control protocol functions are available for named complex processes and / or inter-device communication in real-time based on data decision algorithms in various formats. This method also describes a secure distributed method of using private networks for the devices.

Owner:USERSPACE CORP

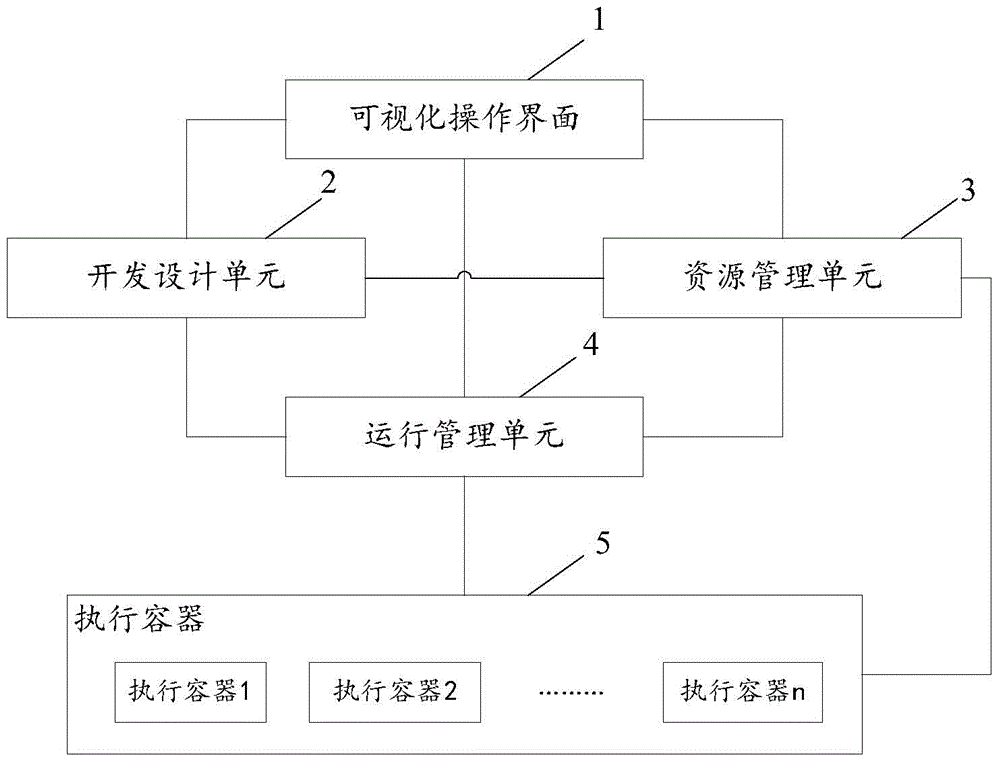

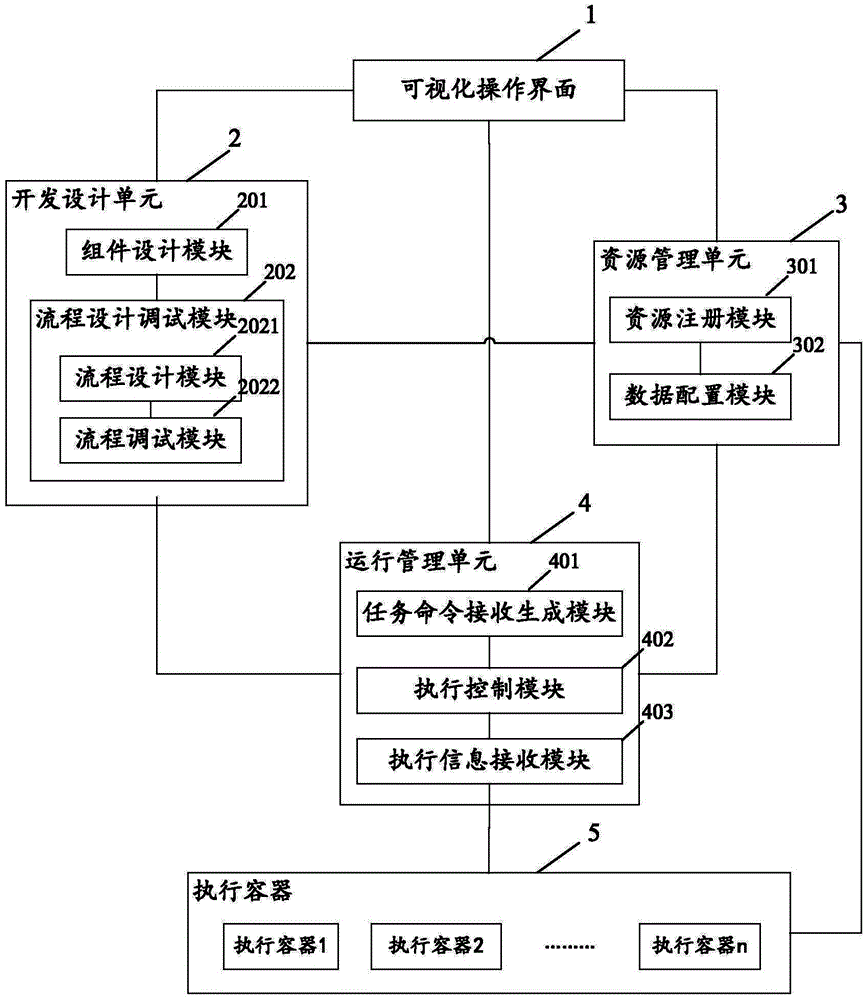

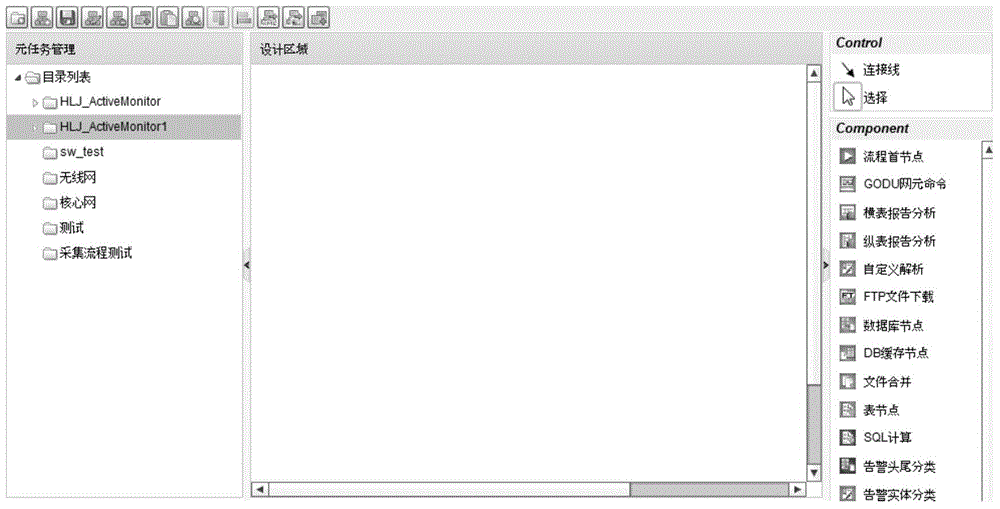

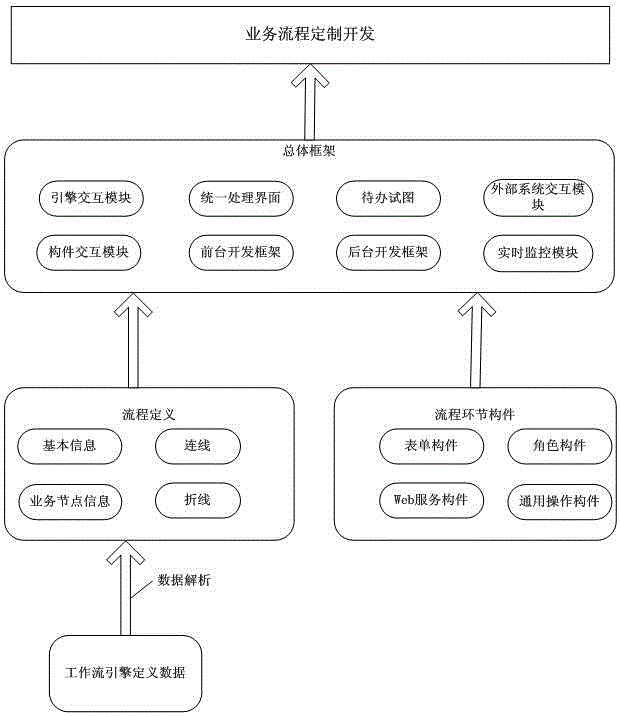

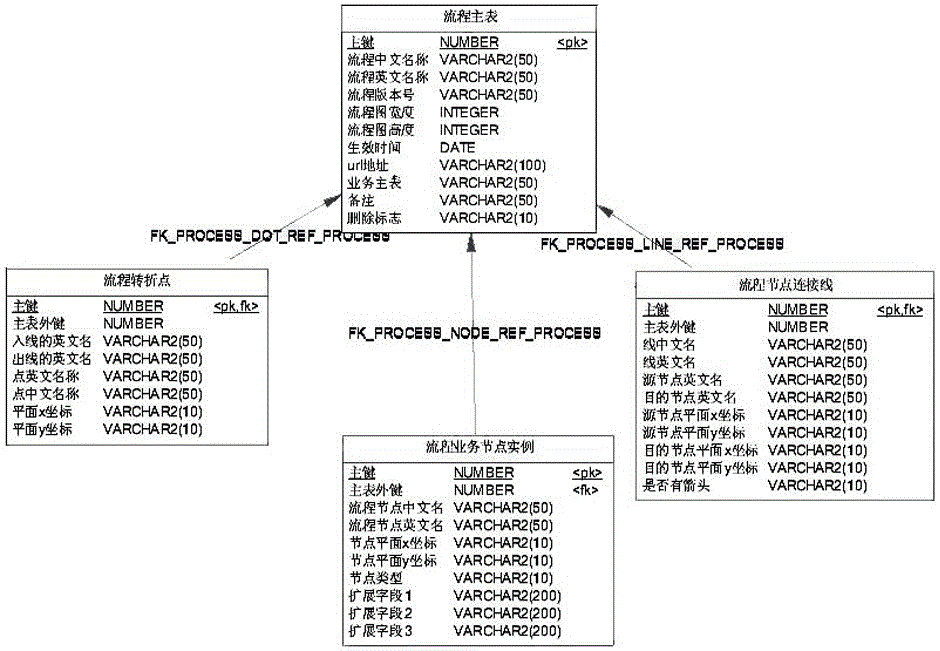

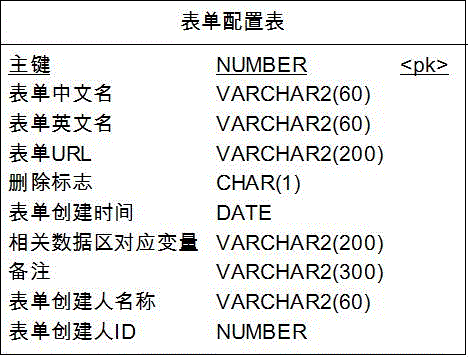

Flow path customized development platform and method

ActiveCN104679488AImprove visibility accuracyImprove efficiencyResourcesSpecific program execution arrangementsVisibilityManagement unit

The invention discloses a flow path customized development platform. The flow path customized development platform comprises a visual operation interface, a development design unit, a resource management unit, an operation management unit and an execution vessel. The flow path customized development platform can achieve customized development and online debugging of a flow path. The flow path customized development platform improves visibility and accuracy of flow path development, and is simple and easy to operate. When the flow path needs to be modified, a user only needs to modify the flow path in a development design module through the visual operation interface, and does not need to repeatedly compile development codes, and therefore manpower resources and cost of hardware and software are saved. The invention further discloses a flow path customized development method.

Owner:BEIJING BOCO COMM TECH

Automated low-volume tangential flow filtration process development device

An automated process development device providing flexibility and accuracy for the investigative development of tangential flow filtration processes. The development device is used for evaluating the process parameters of a laboratory scale tangential flow filtration process with an eye towards developing a larger, commercial scale process. The process development device - operable to an unprecedented minimum reliable recirculation volume of less than approximately 20 milliliters - includes: (a) a reservoir having a distinct mixing zone; (b) a tangential flow filtration module; (c) conduits defining, together with the distinct mixing zone and the tangential flow filtration module, a fluid process stream through which a liquid sample is recirculated; (d) pumps for driving the flow of the liquid sample through the fluid process stream; (e) valves for regulating the flow of the liquid sample through the fluid process stream; (f) sensors for acquiring data about the liquid sample as it flows through the fluid process stream; and (g) an electronic data processing network capable of receiving, transmitting, processing, and recording data associated with the operation of the pumps, valves, and sensors, the recorded data being sufficiently comprehensive to determine the conduct of the tangential flow filtration process at a substantially larger scale.

Owner:MILLIPORE CORP

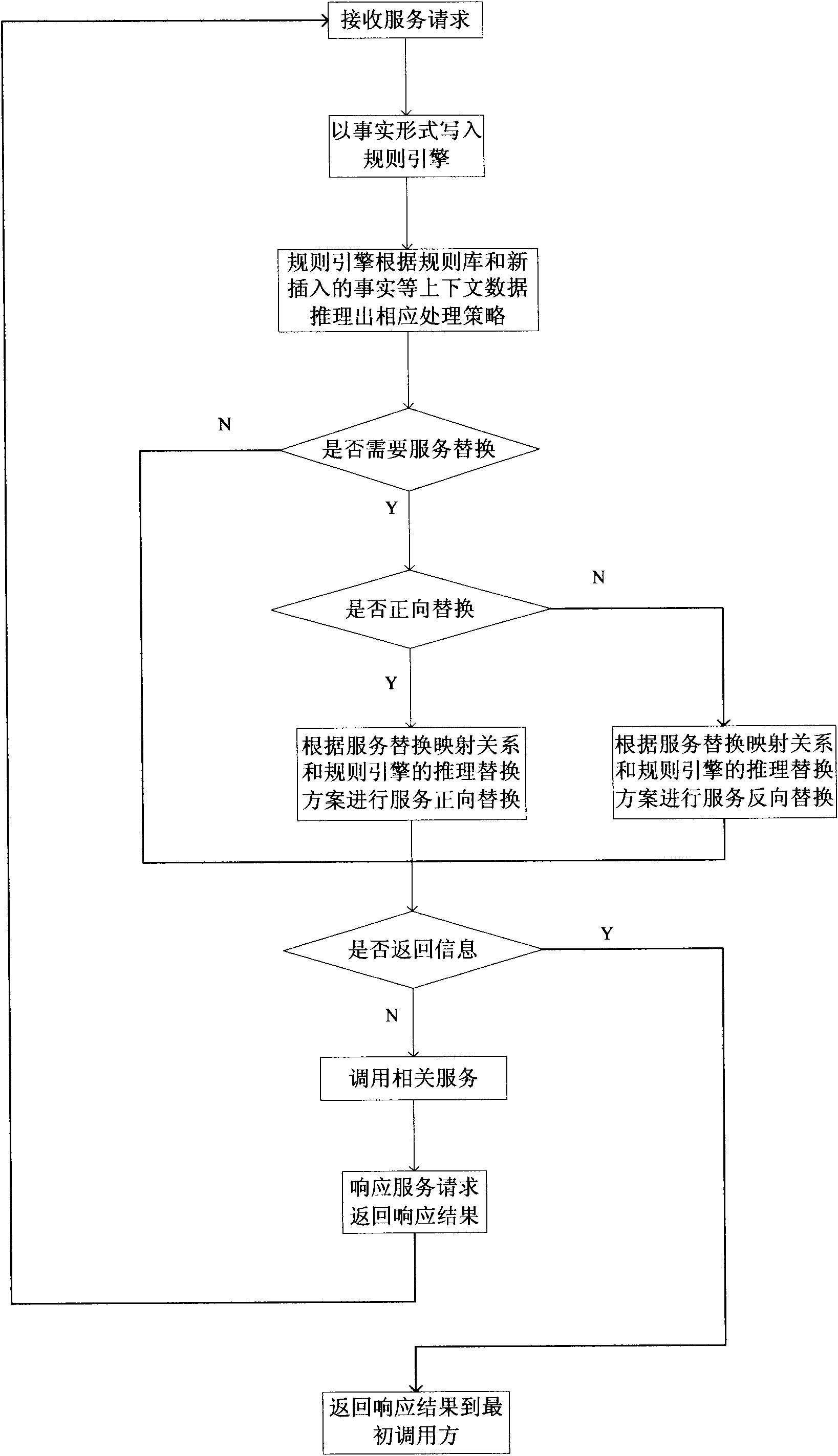

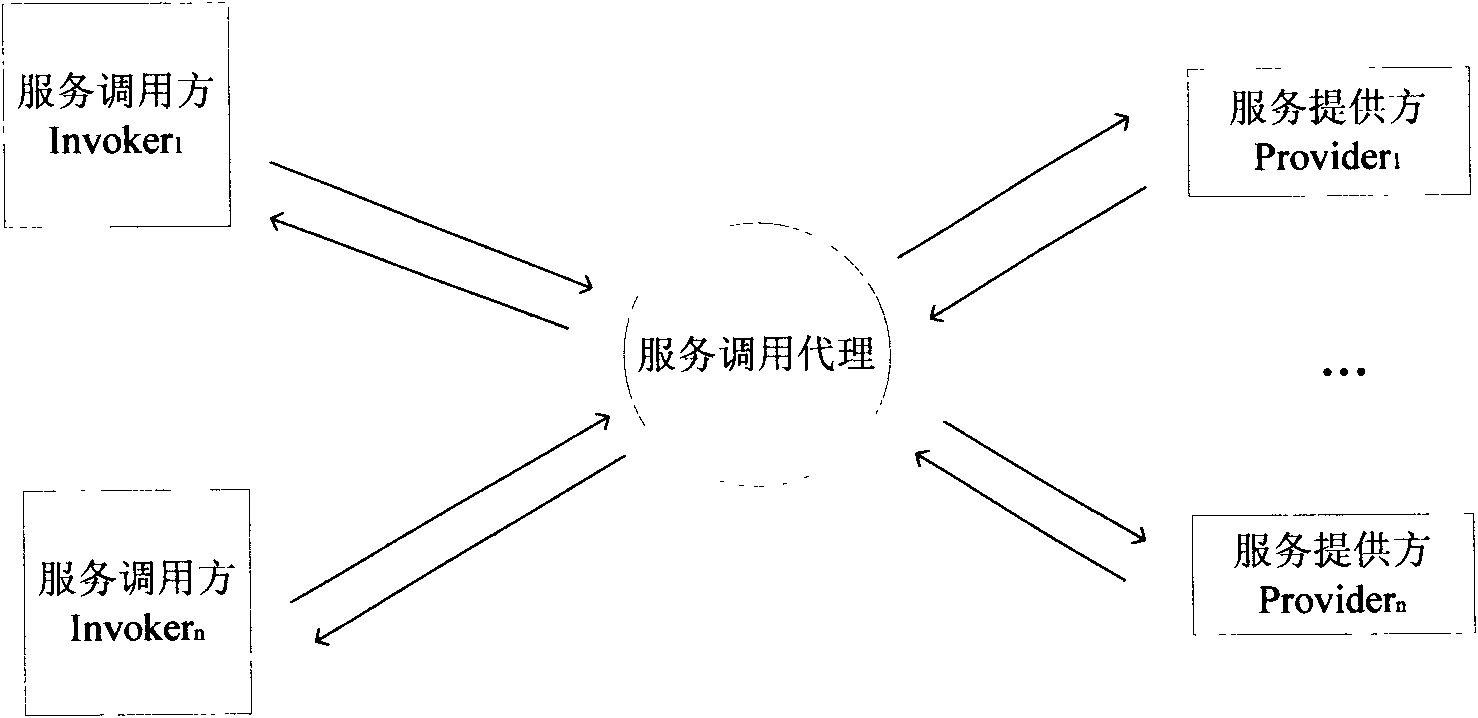

Method and system for dynamically combining services based on rule engine

InactiveCN102130965AImprove flexibilityImprove agilityData switching networksSpecial data processing applicationsProcess developmentWeb service

The invention discloses a method and system for dynamically combining services based on a rule engine. The method comprises the following steps of: intercepting web service calling request information and service response return information; distributing a unique identifier for the intercepted service calling request information and interpolating the request information into the rule engine; interpolating the intercepted service response return information into the rule engine; reasoning a service processing strategy of a service according to a service rule and context data needed by rule execution; and replacing the service calling information and re-orientating the service according to a service replacing scheme reasoned by the rule engine and service transition mapping information provided by a service information center. By adopting the method and the system, the flexibility and the sensitivity of the system in the aspects of development and maintenance of a new flow and modification of an old system service rule can be enhanced.

Owner:BEIJING UNIV OF POSTS & TELECOMM

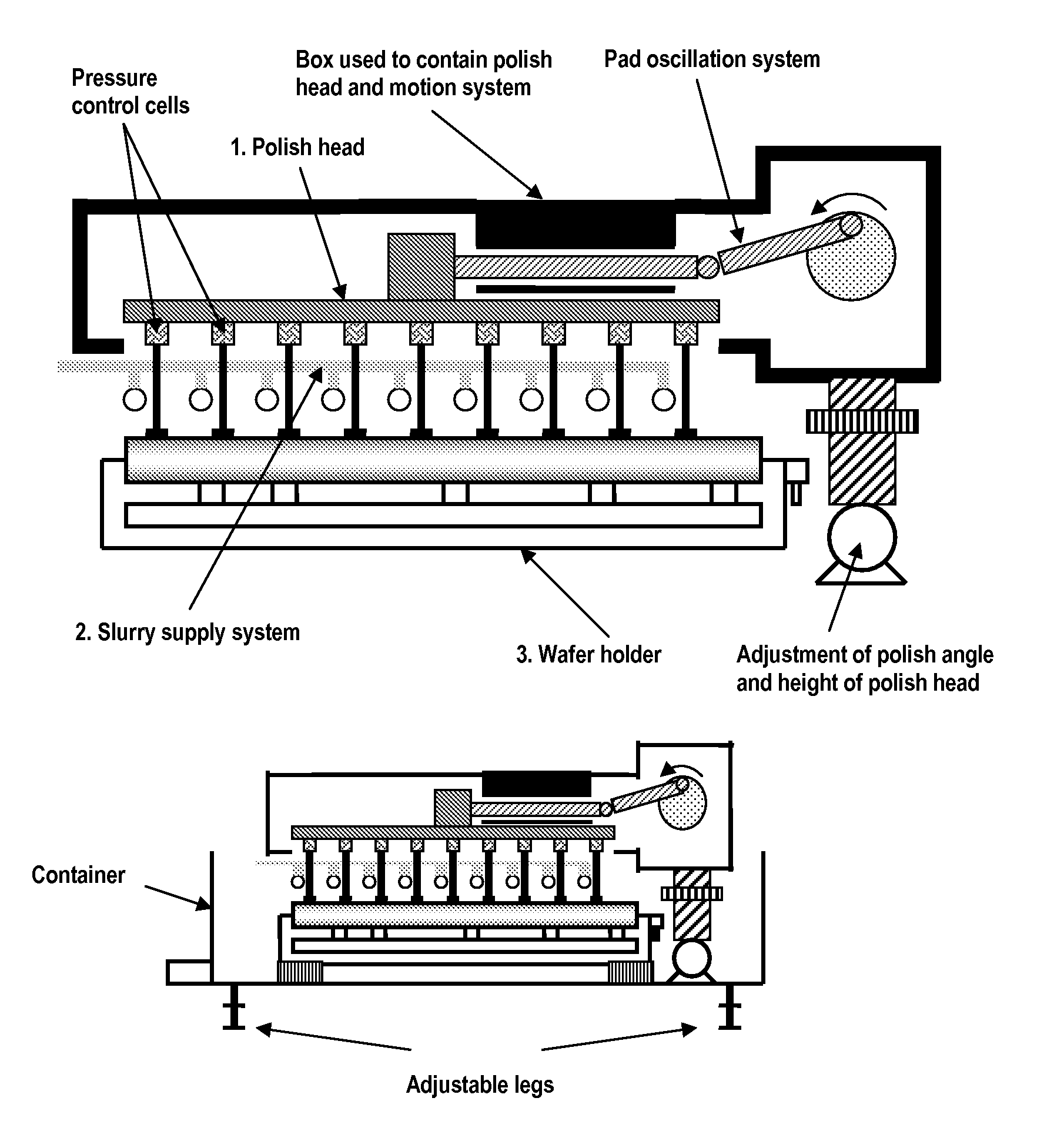

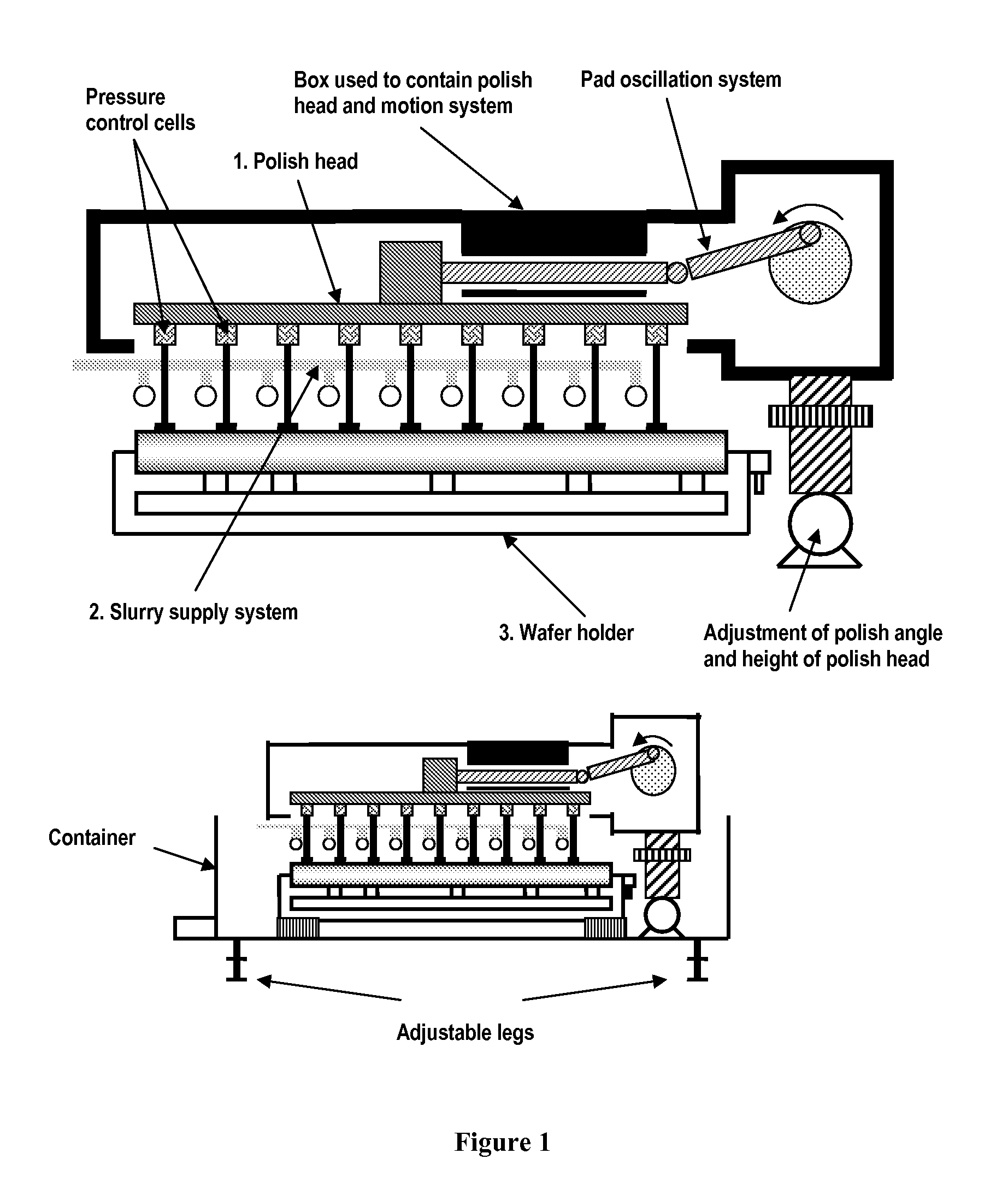

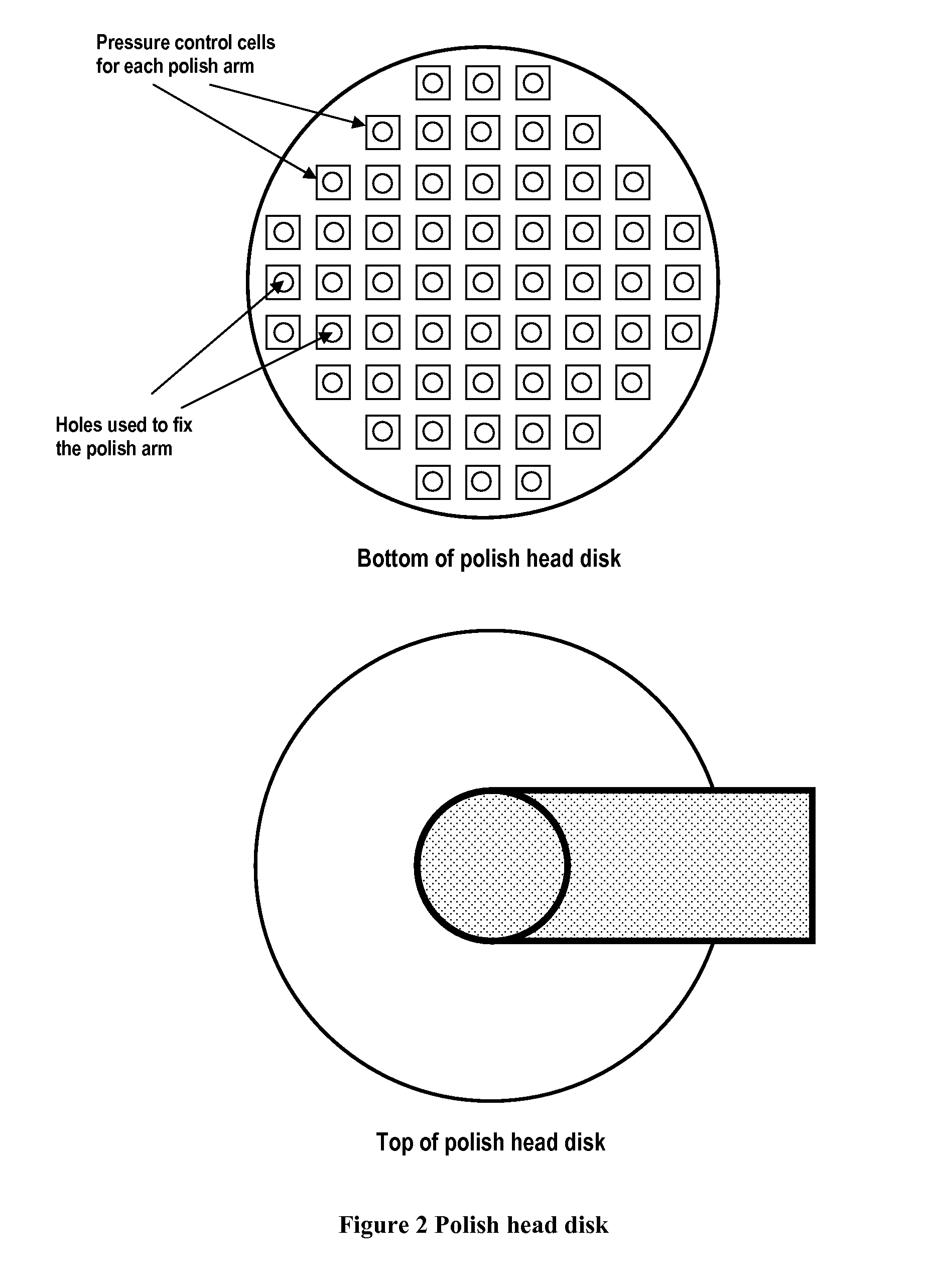

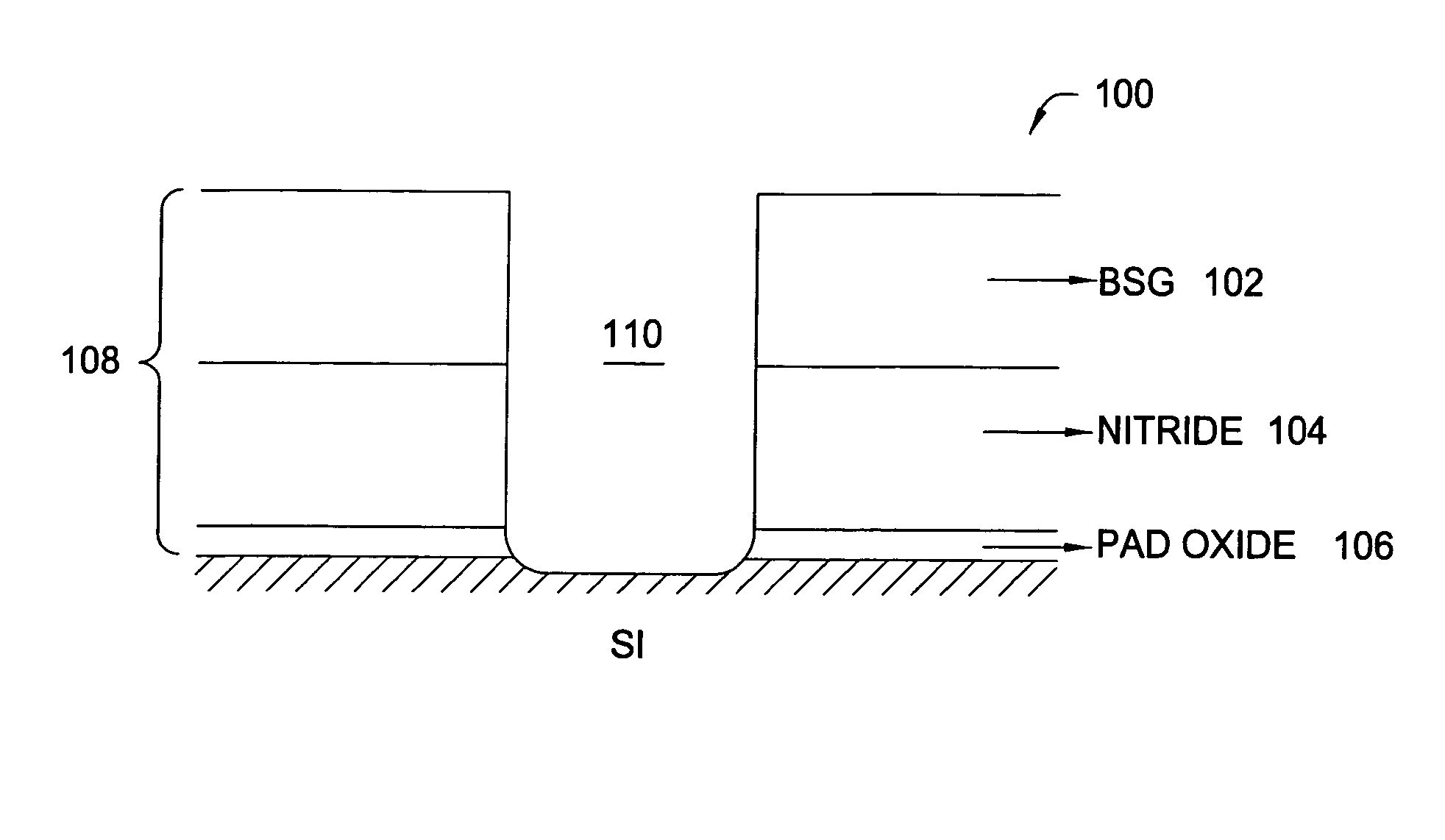

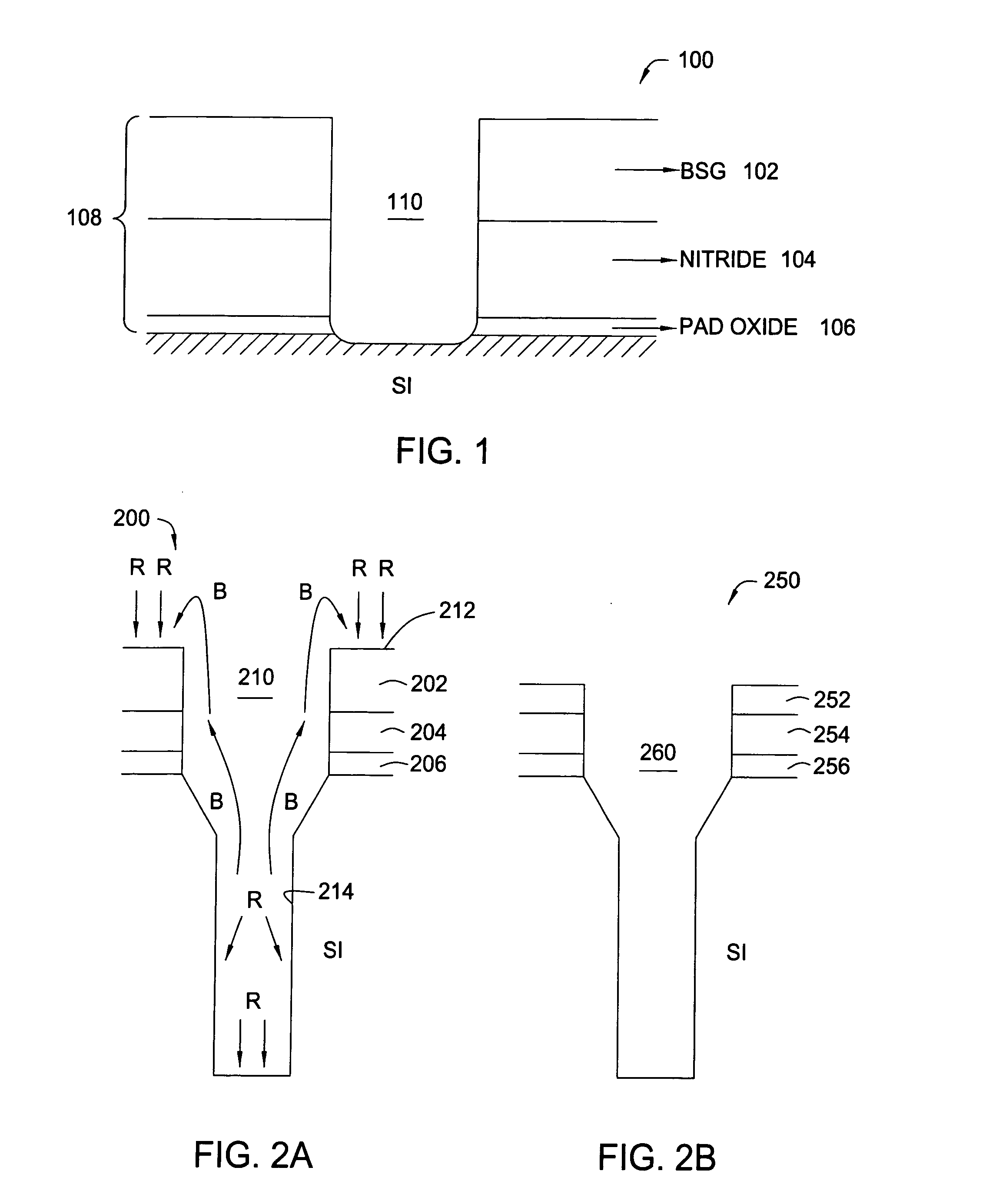

Method and apparatus for chemical mechanical polishing of large size wafer with capability of polishing individual die

InactiveUS20090298388A1Efficient and effectiveAchieve planarizationEdge grinding machinesBelt grinding machinesMaterial removalProcess development

A novel polisher for chemical mechanical planarization process is described. The polisher design can have many variations. For process development and consumable evaluation, the CMP process can be performed on a single die or a section of the wafer. The size of testing wafer can be as small as 2″ and as large as 18″. Furthermore, several variations can characterize the slurry for their static etch rate, dynamic etch rate, material removal rate, and viscosity in a single experiment. For production level wafer processing, Chemical Mechanical Polishing of all dies on the wafer surface is achieved by using multi-armed polishing heads or a single polishing head with small piece of a pad at the bottom of the head. The within wafer uniformity can be easily controlled and the equipment can be easily scaled up or down. This inventive design may translate to significant cost reduction for wafer processing at production level as well as evaluation of consumables at research and development level.

Owner:ST LAWRENCE NANOTECH

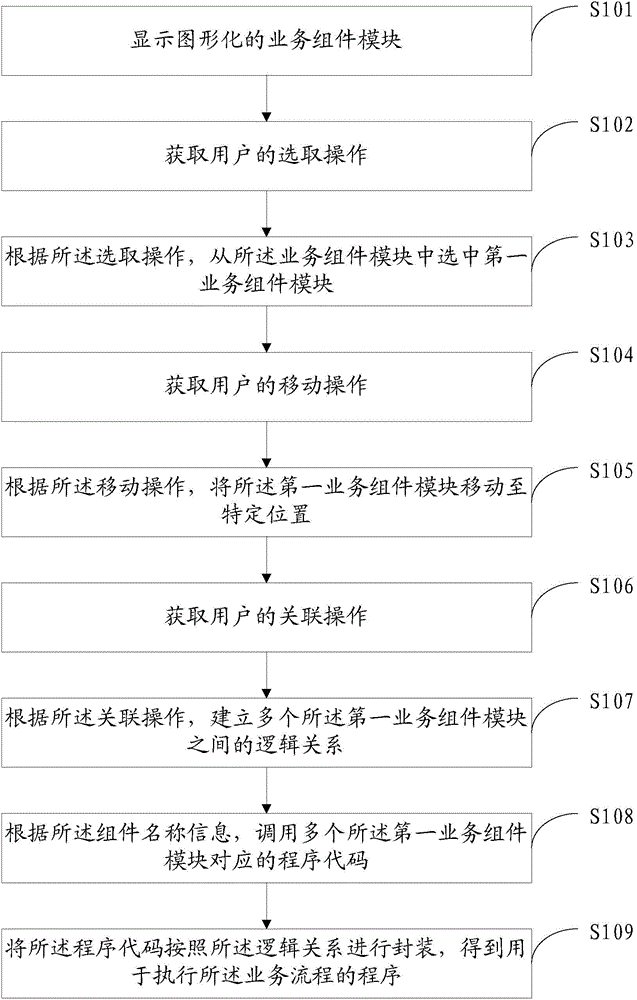

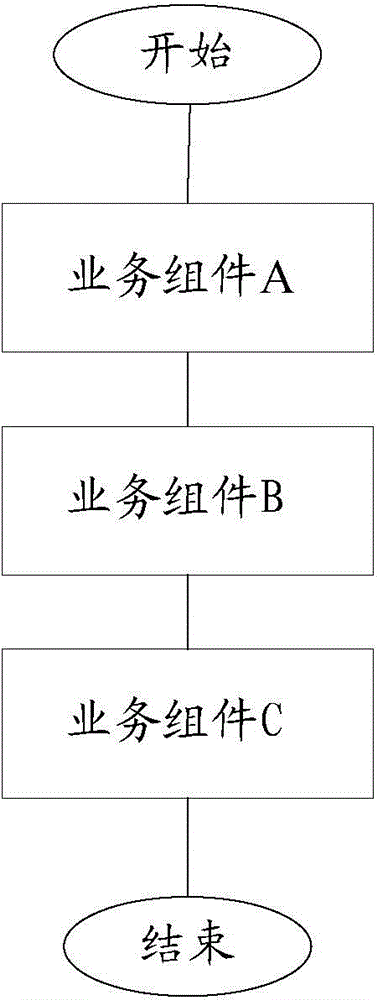

Business process development method and system

InactiveCN105988815ARealize visual developmentClear logicSpecific program execution arrangementsProcess developmentComputer module

The invention discloses a business process development method and system. The method comprises the steps of displaying graphic business component modules; selecting a first business component module from the business component modules according to a selection operation of a user; moving the first business component module to a specific position according to a moving operation of the user; establishing a logic relationship among a plurality of the first business component modules according to an associative operation of the user, wherein the logic relationship is used for representing an executive sequence of program codes corresponding to a plurality of the first business component modules when a business process is executed; calling the program codes corresponding to a plurality of the first business component modules according to component name information of the business component modules; and packaging the program codes according to the logic relationship to obtain a program used for executing the business process. Through the method and system, the graphic interface-based visual development of the business process is realized, the logic is clear, the development efficiency is high, and relatively high reusability and relatively low development cost are achieved.

Owner:CHINAUMS

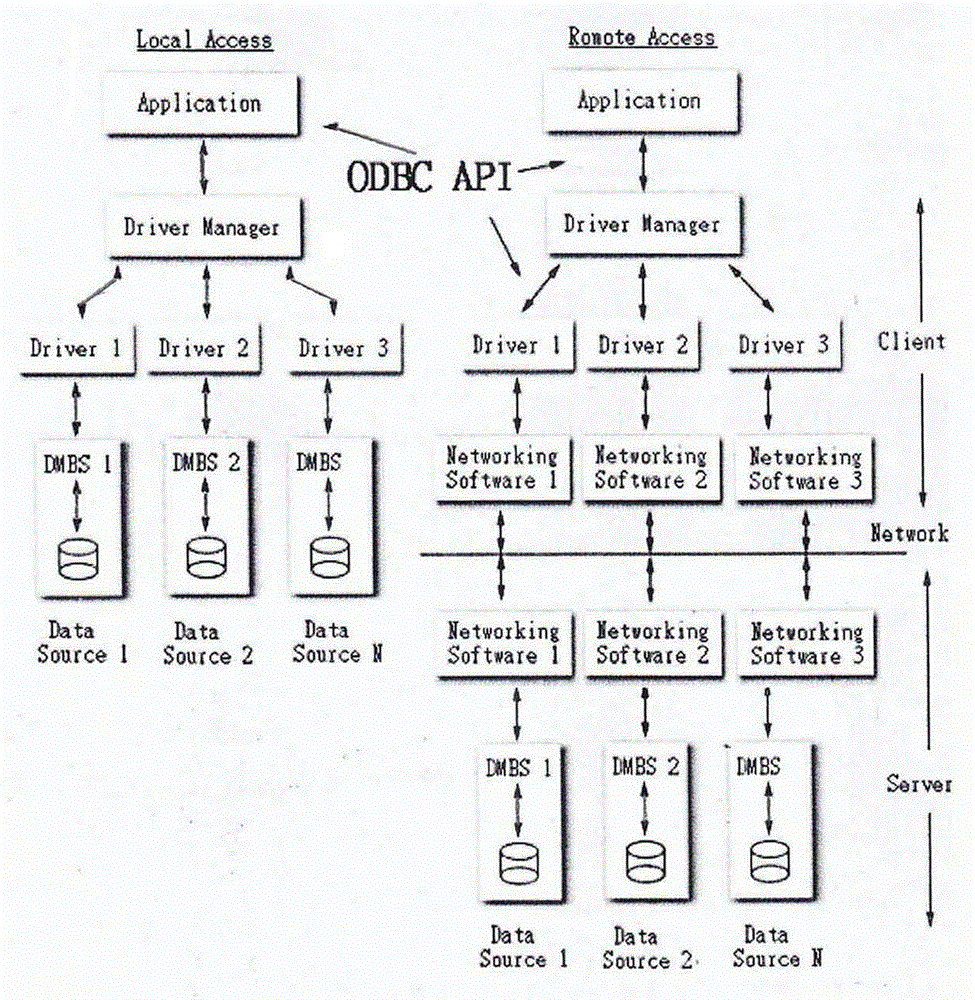

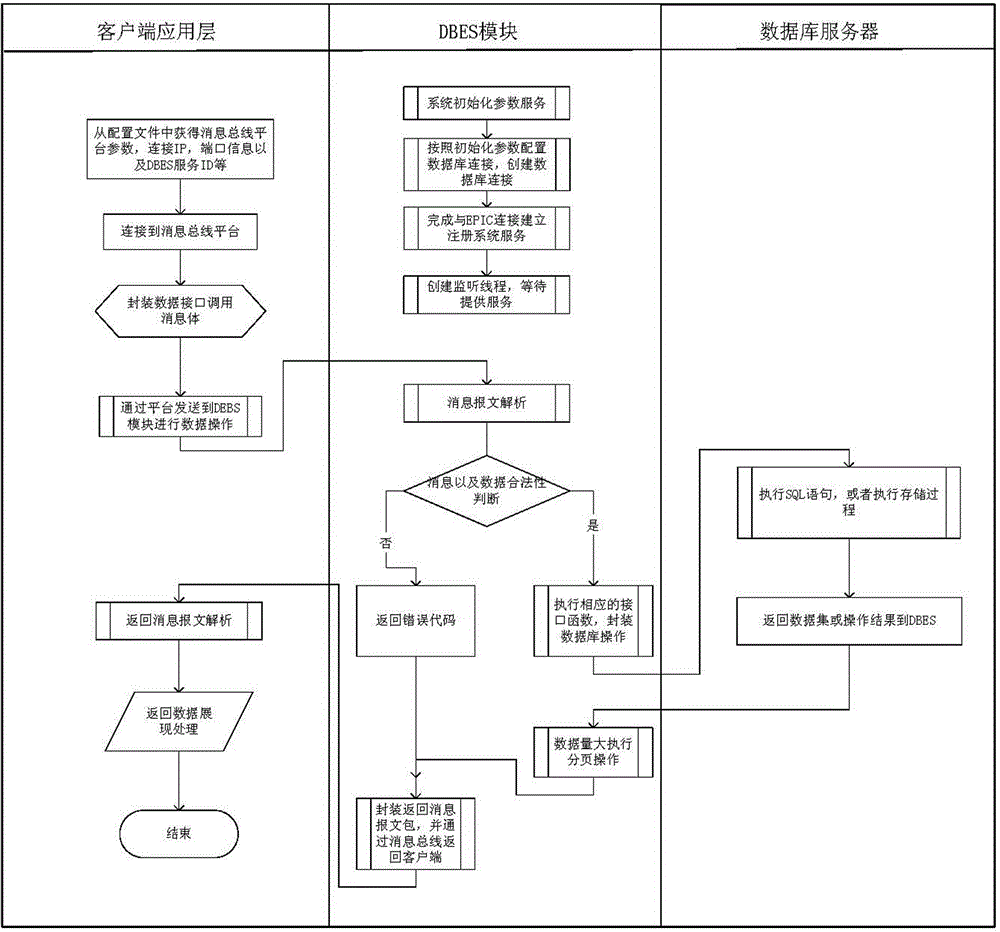

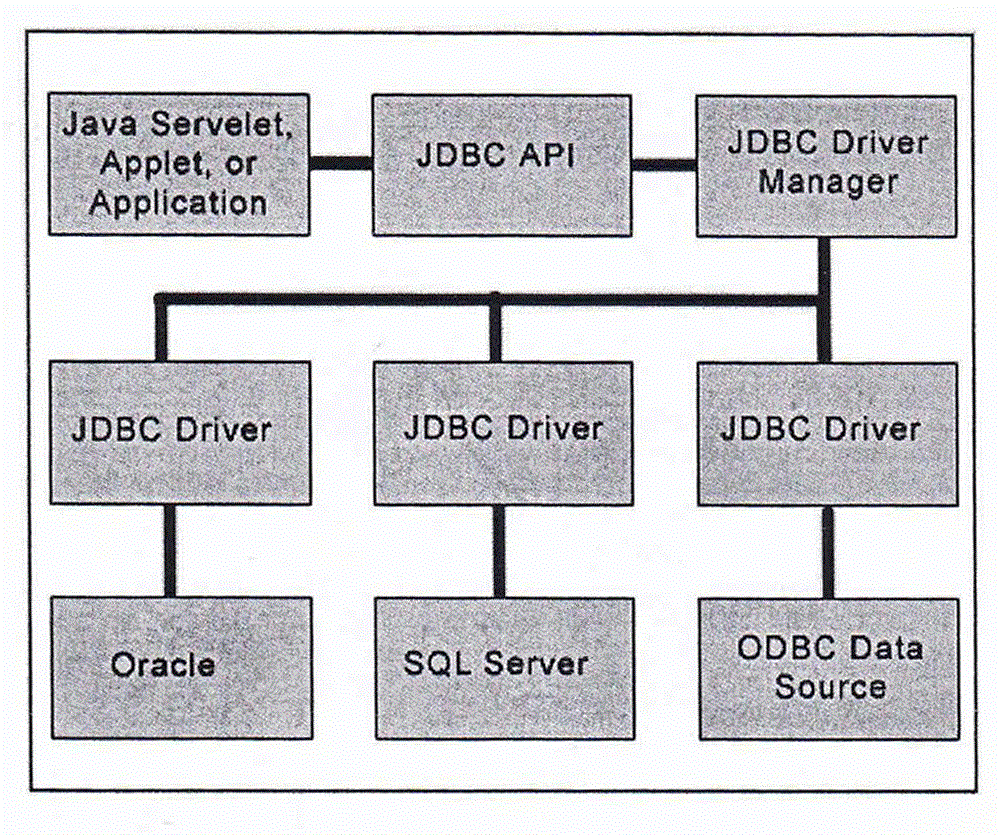

Heterogeneous database access method

InactiveCN104794147AAchieve accessAddress cross-platform featuresSpecial data processing applicationsProcess developmentData access

The invention provides a heterogeneous database access method. According to the JDBC technology, the ODBC technology, the ADO technology and the BDE technology, the problems existing in the data access cross-platform characteristic, the data access cross-development-language characteristic and the data access cross-development-environment characteristic are solved, data access efficiency is fully considered, access modes of different data types and large-capacity data types are achieved through a specific method, developers of an application layer abandon the complex SQL, database storage process development work focuses on achievement of application service logic, and the database developers can focus on the characteristics of different database servers, organize service data formats and improve data access efficiency. For the developers, a mature system structure model and professional development work division are adopted, and application system development reliability can be improved.

Owner:JIANQIAO COMM TECH SHENZHEN

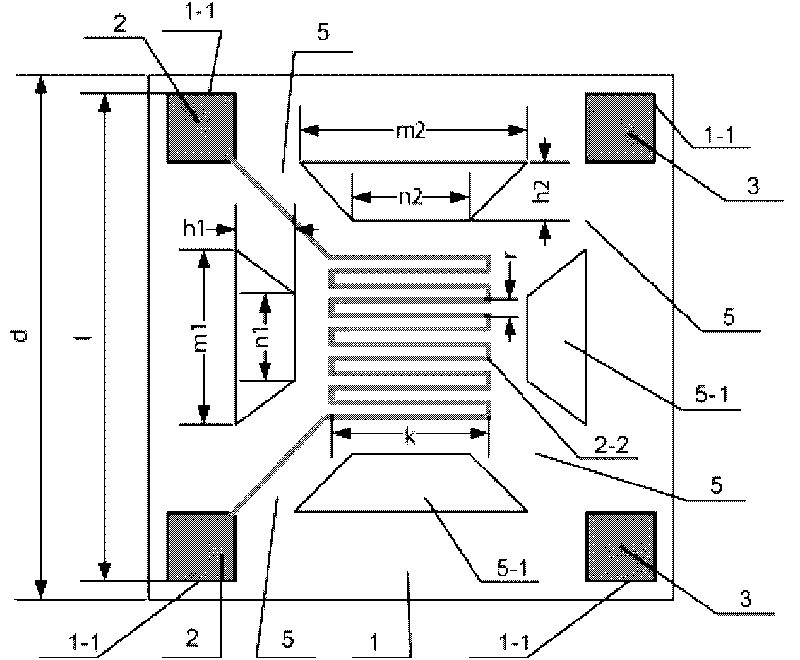

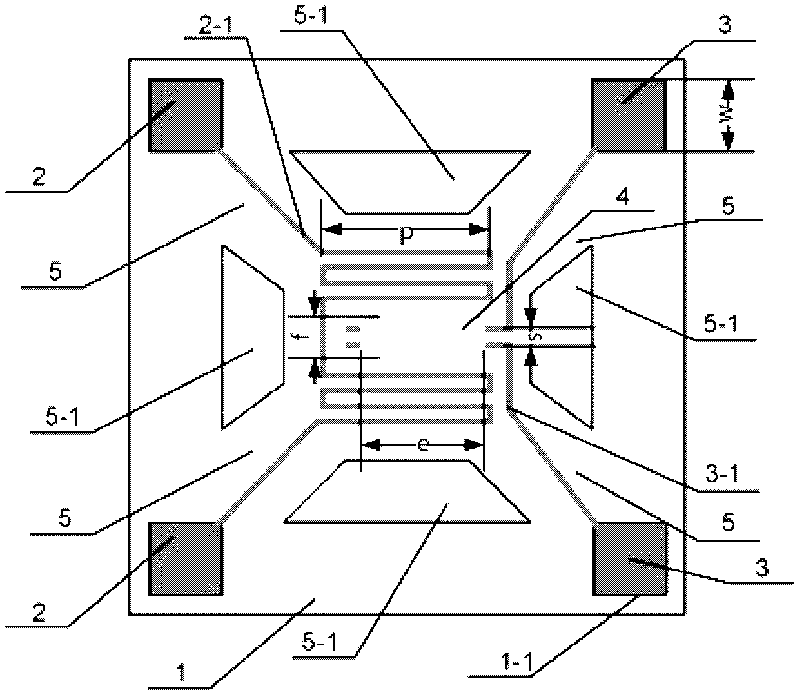

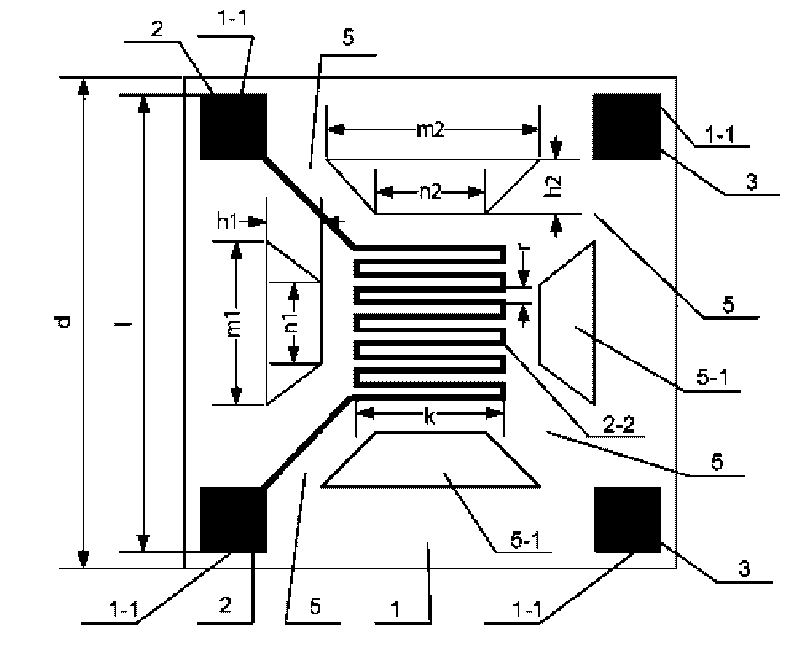

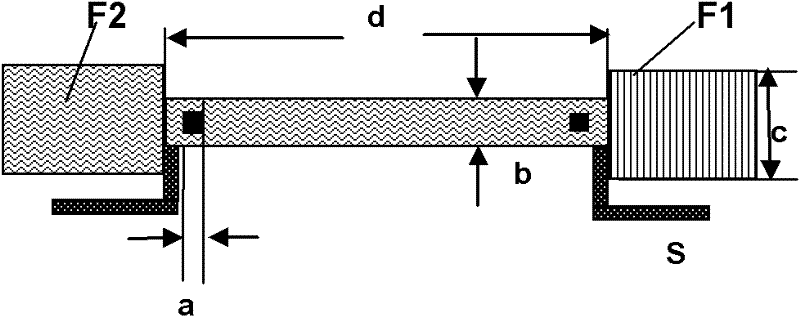

Semiconductor-type gas sensor with A1N heat isolation panel double-side micro structure and manufacturing method thereof

InactiveCN101762623AReduce power consumptionLow process development costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMicro structureProcess development

A semiconductor-type gas sensor with an A1N heat isolation panel double-side micro structure and a manufacturing method thereof relate to a self-heat isolation panel double-side micro structural gas sensor and a manufacturing method thereof. The invention solves the problems that the existing Si-material gas sensor has high cost of process development, complex process and the like, and is characterized in that four positions of the diagonal line of a substrate are etched with heat isolation grooves; the back of the substrate is provided with heating electrodes and signal electrodes; the heating electrodes of the front and the back of the substrate are communicated by a through hole; the heating electrodes are arranged in a snakelike structure, and a sensitive film is attached on the signal electrode. The manufacturing method is as follows: 1. selecting the substrate; 2. preparing the Pt metal film signal electrode of the sensor: photoetching, coating film and stripping the metal film; 3. preparing the antarafacial heating electrodes: firstly, coating film, and then etching with laser; 4. isolating heat; 5. annealing; and 6. attaching the sensitive film. The invention can be used as a sensor for semiconductor-type C12, NOX, CO and the like.

Owner:HARBIN UNIV OF SCI & TECH +1

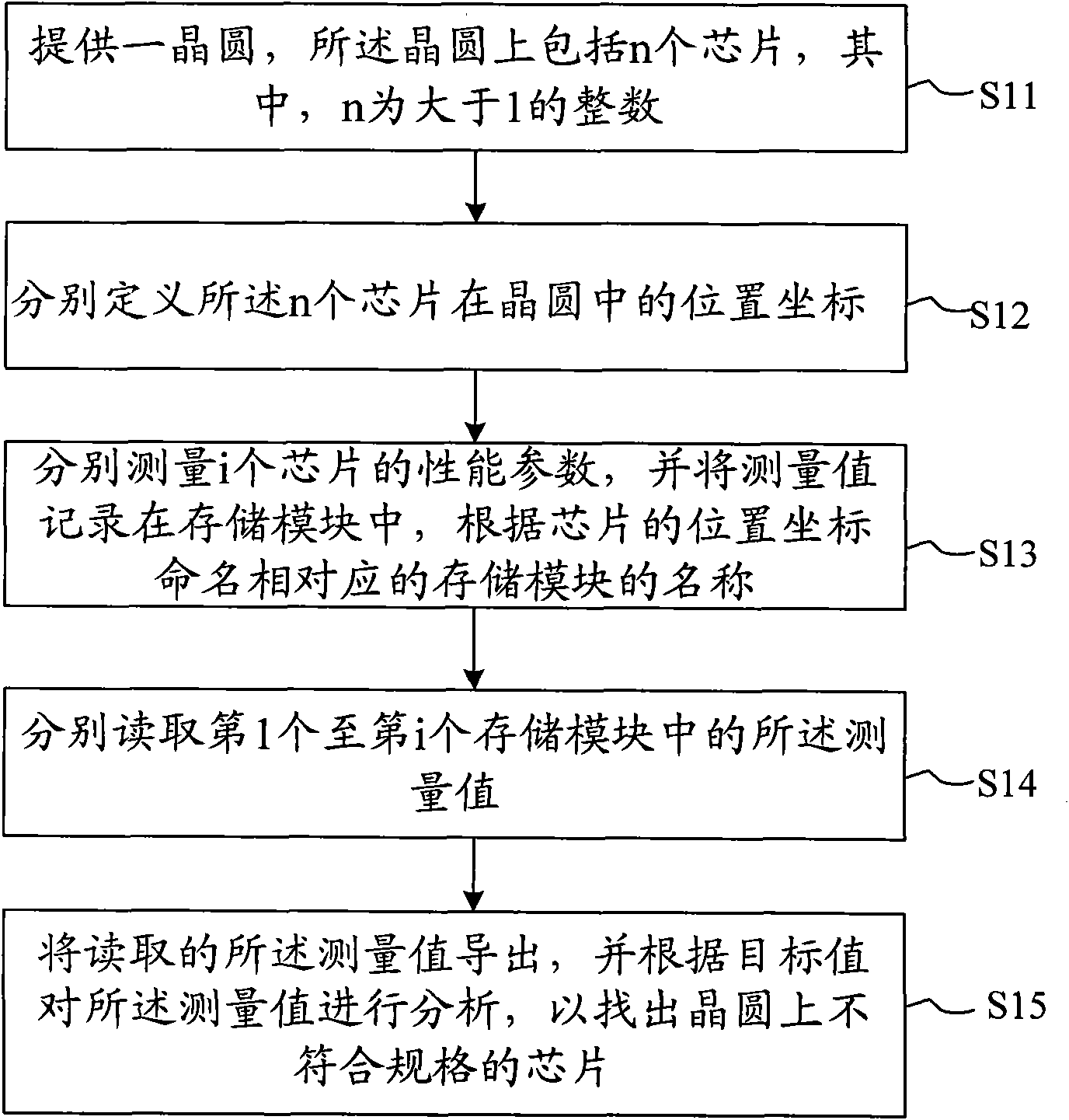

Data processing method for testing parameters of chips

InactiveCN102135597AImprove developmentHigh speedElectronic circuit testingIndividual semiconductor device testingProcess developmentComputer module

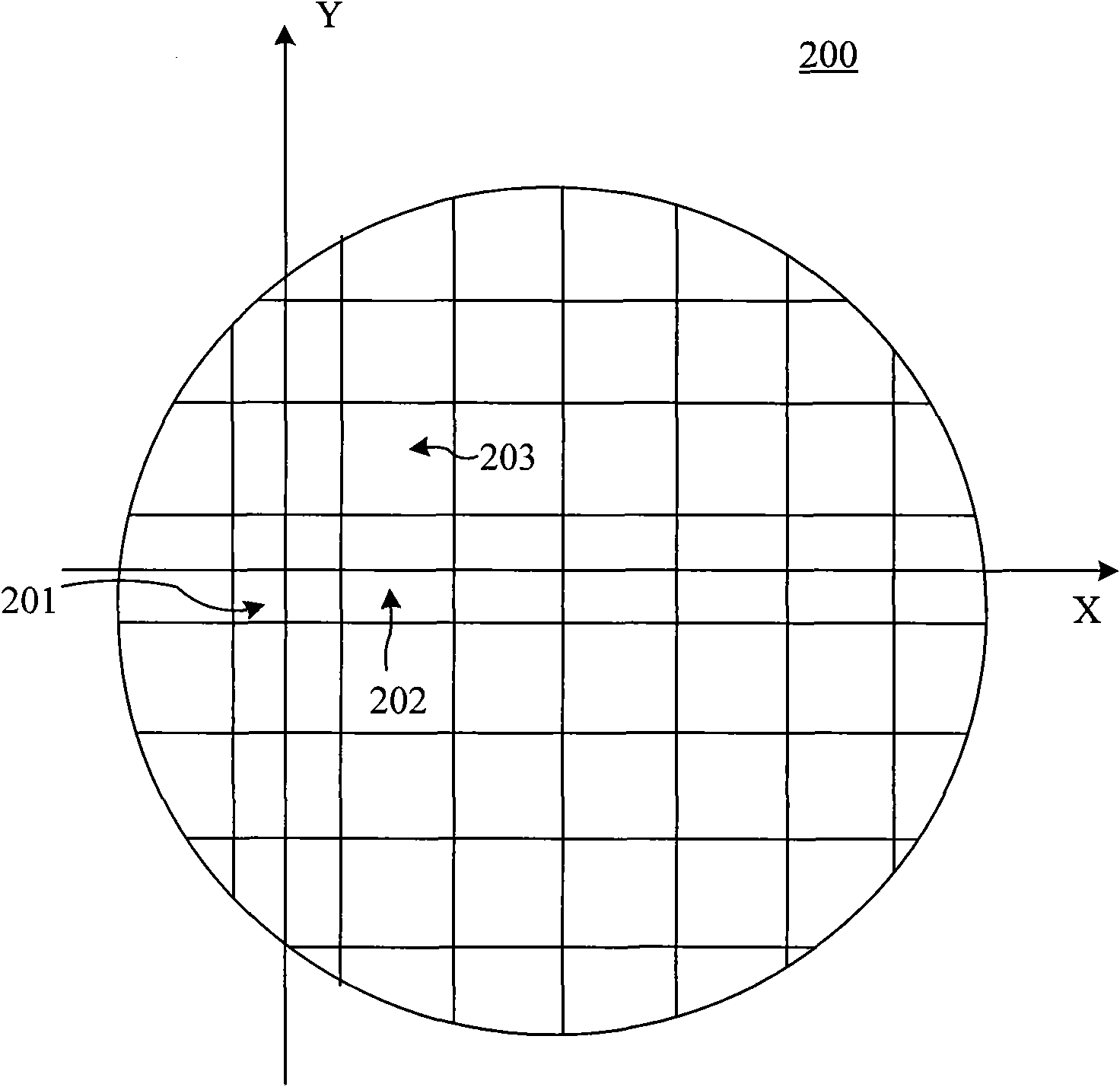

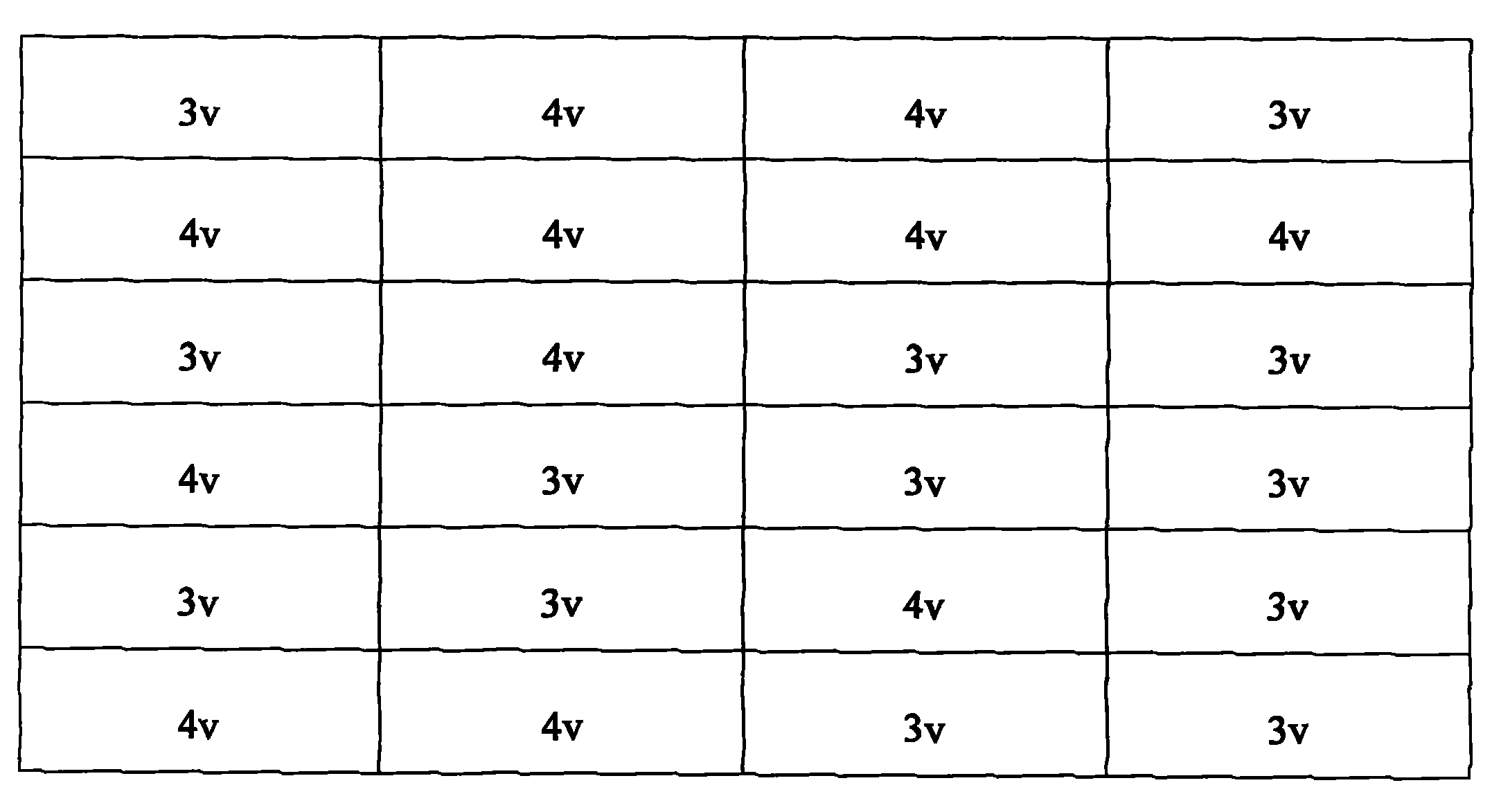

The invention provides a data processing method for testing parameters of chips, which comprises the following steps: providing a wafer, wherein the wafer comprises n chips, and n is an integer which is greater than 1; defining position coordinates of the n chips in the wafer respectively; measuring the performance parameters of i chips respectively, and recording measured values in memory modules, wherein i is the integer which is greater than 1, i is not more than n, each chip corresponds to one memory module, and names of the corresponding memory modules are named according to the position coordinates of the chips; reading the measured values from the first module to the ith memory module respectively; and exporting the read measured values, and analyzing the measured values according to a target value so as to find the chips which do not meet the specification on the wafer. By adopting the data processing method for testing the parameters of the chips, the extraction period of a chip parameter measurer can be greatly shortened, and the chip development speed and the process development speed can be accelerated.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

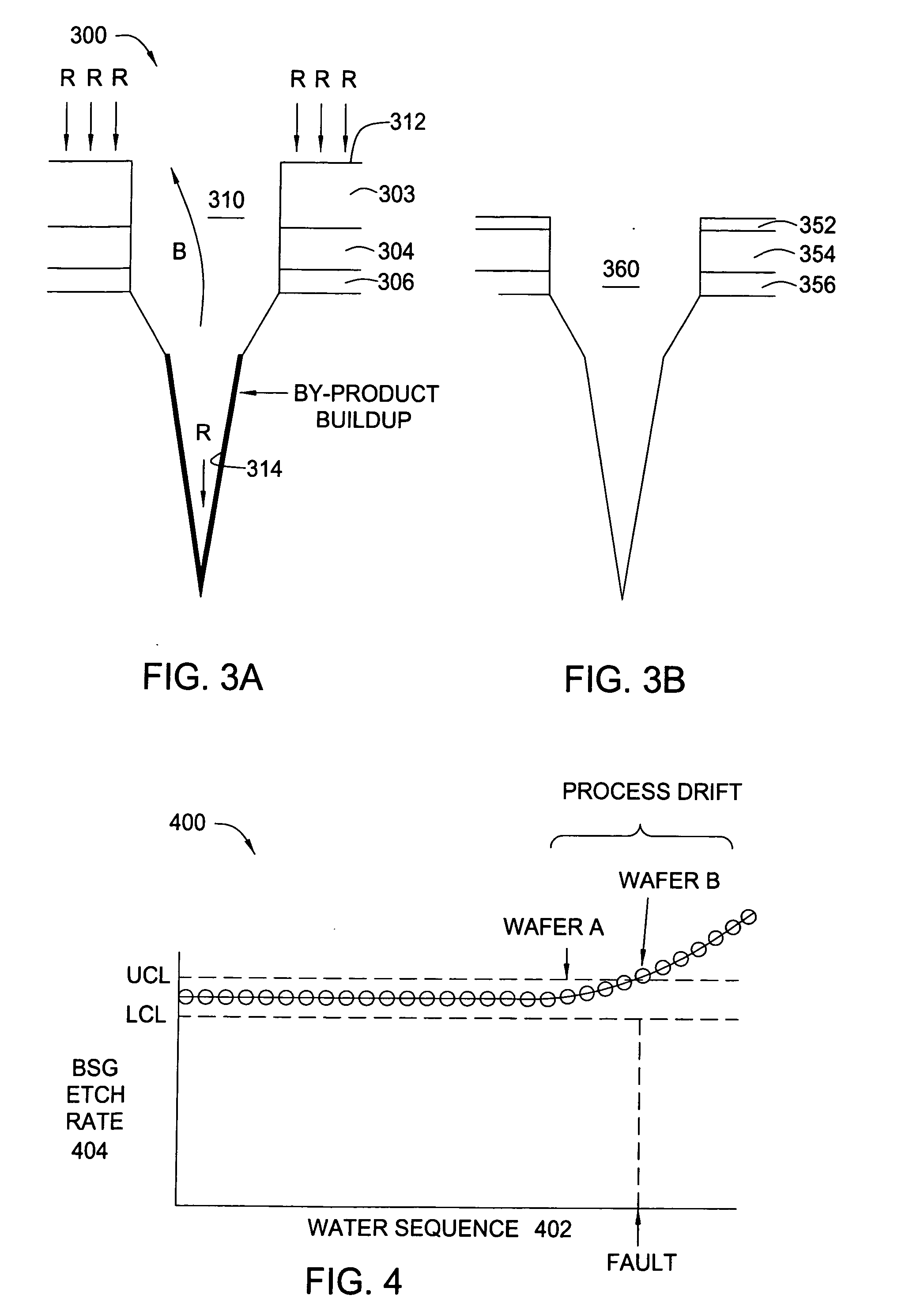

Chamber stability monitoring using an integrated metrology tool

InactiveUS20050032250A1Shorten cycle timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyProcess development

A method and apparatus for monitoring the stability of a substrate processing chamber and for adjusting the process recipe. Thickness and CD measurement data are collected before wafer processing and after wafer processing by an integrated or an in-situ metrology tool to monitor process chamber stability and to adjust the process recipe. The real time chamber stability monitoring enabled by the integrated metrology tool reduces the risk and cost of wafer mis-processing. The real time process recipe adjustment allows tightening of the process recipe. Process development cycle can also be reduced by the method and apparatus.

Owner:APPLIED MATERIALS INC

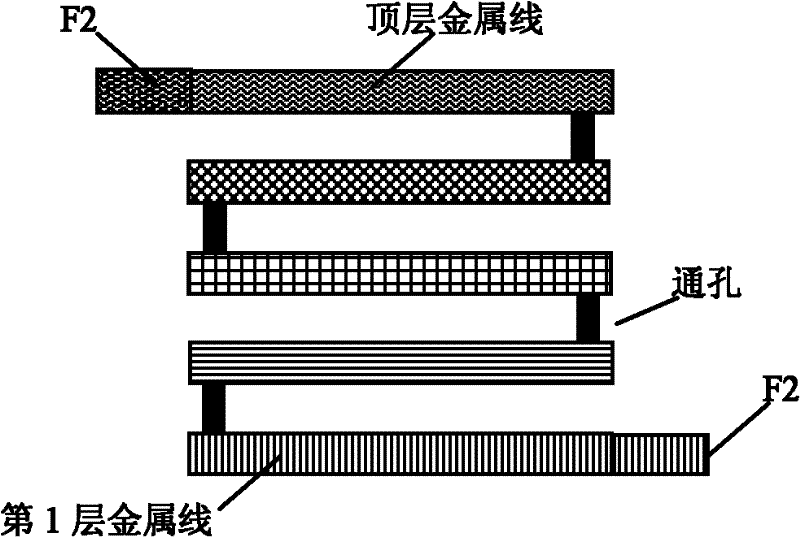

Electromigration reliability test structure and making method for multilayer of metal interconnected metal wires

ActiveCN102446900ARapid assessment of electromigration reliability riskShorten test timeResistance/reactance/impedenceSemiconductor/solid-state device detailsChinese charactersTest sample

The invention discloses an electromigration reliability test structure of multilayer of metal interconnected metal wires, comprising the multilayer of metal wires, the lengths of the metal wires are no less than 200 microns, other parameters of the metal wires meet the design requirements of a chip to be tested, and every two layers of metal wires are connected by a through hole so as to form a structure in shape of Chinese character GONG (arch), wherein one end of a first layer of metal wire far away from the through hole and one end of a top layer of metal wire far away from the through hole are respectively provided with a current input end; and both ends of each metal wire are respectively provided with a voltage measuring end. With the adoption of the electromigration reliability test structure disclosed by the invention, electromigration service life data of each layer of metal wire are obtained with the testing of a structure, thereby the test time can be greatly shortened, a process development period is shortened, test samples are reduced, and the test cost is reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

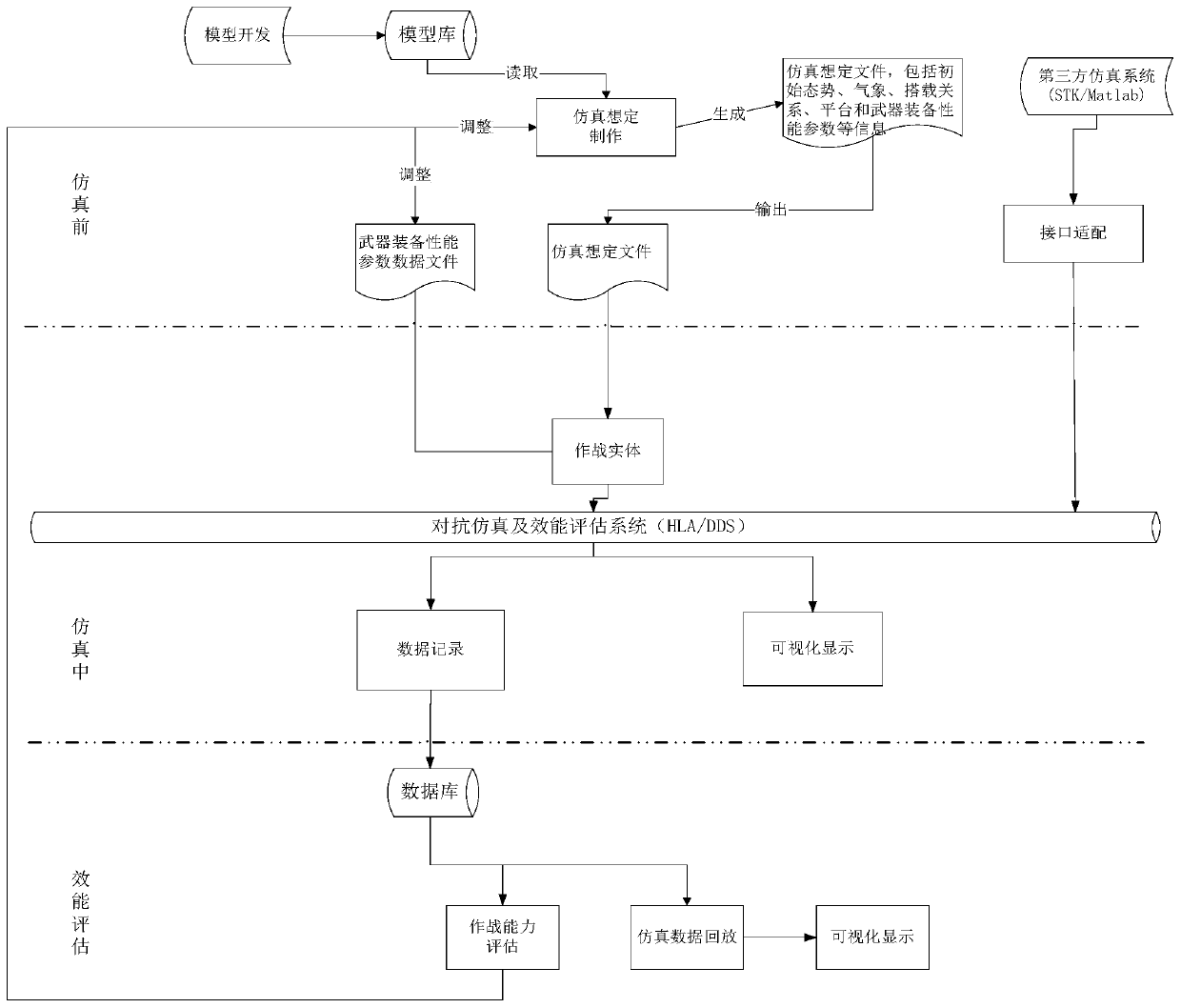

A confrontation simulation and efficiency evaluation system based on equipment parameterization

PendingCN109948228AImprove portabilityImprove reusabilitySpecial data processing applicationsFull life cycleService Component Architecture

The invention designs a confrontation simulation and efficiency evaluation system based on equipment parameterization. According to the system, a simulation model development module supports a simulation service component architecture, an engineering management and operation guide control module adopts a distributed simulation guide control technology, a simulation resource management tool is adopted to uniformly manage and deploy models, scenarios and parameter resources in a simulation resource library, and the models, scenarios and parameter resources are deployed on a target node in a distributed simulation network; the simulation platform loads and operates various simulation resources through the simulation execution engine, and the efficiency assessment module adopts custom data management and efficiency assessment technologies. The system is used for an equipment confrontation simulation and efficiency evaluation software system in a large-scale combined action scene, solves the problems of universalization, platformization and expandability of a confrontation simulation system, supports full-life-cycle whole-process development, and can process simulation and evaluation tasks related to multiple types of simulation objects and multiple action scenarios.

Owner:CHINA SHIP DEV & DESIGN CENT

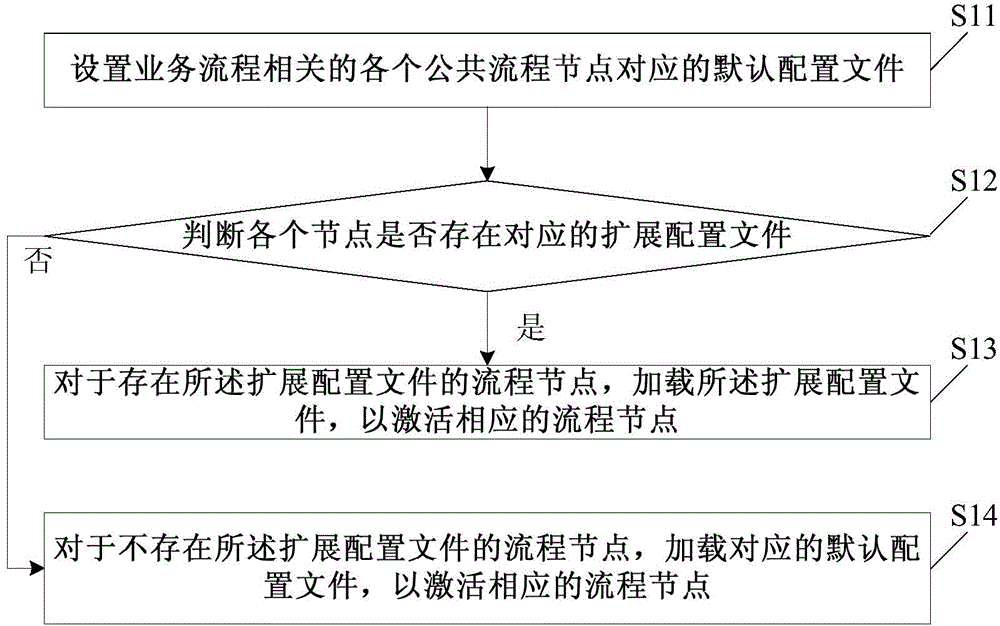

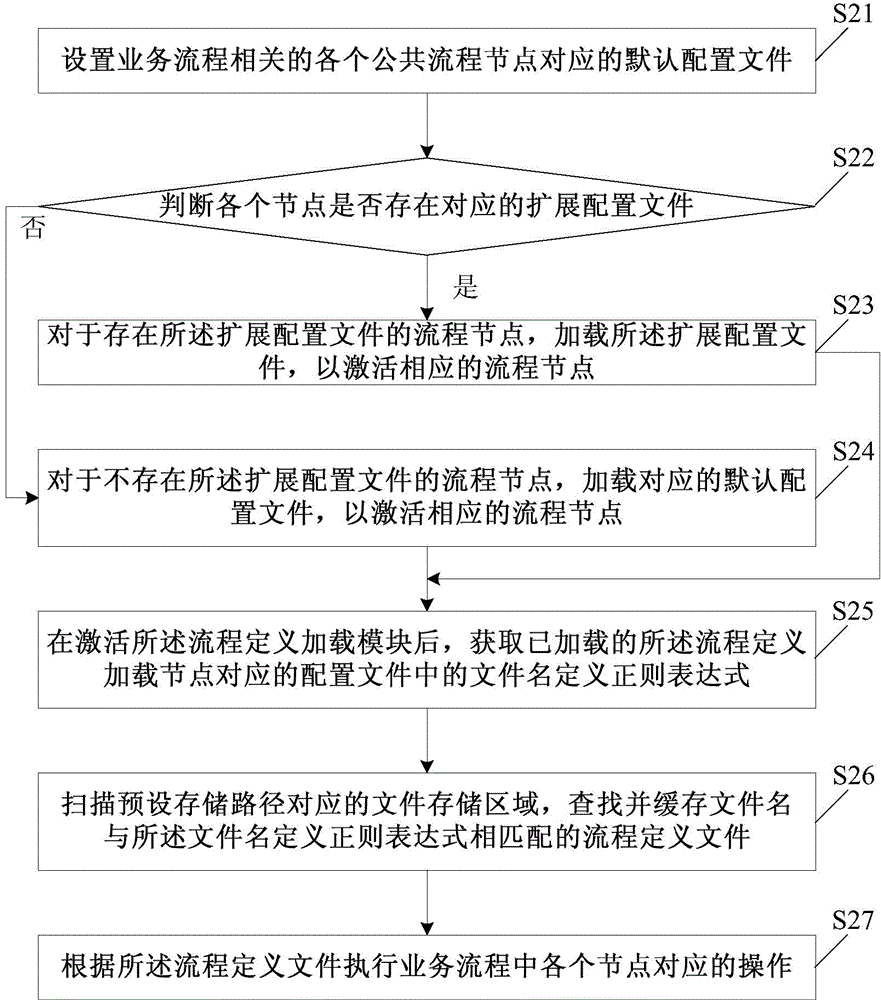

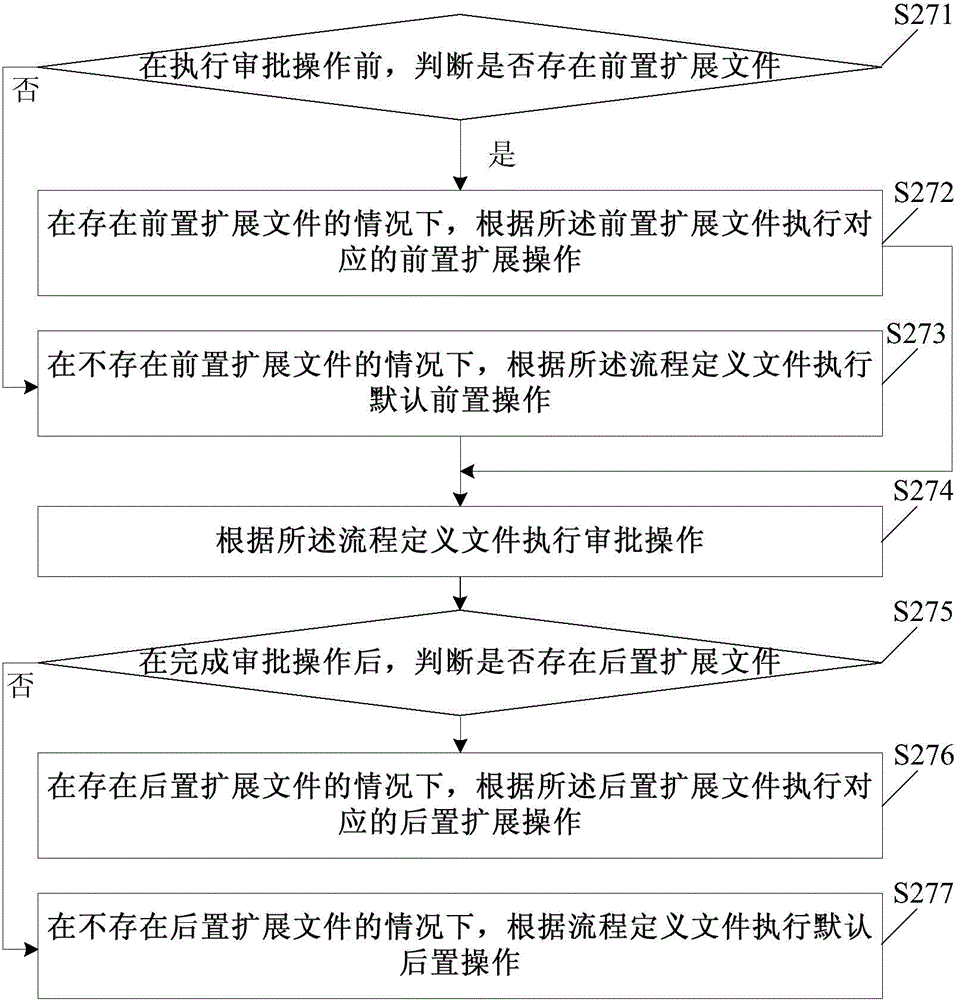

Process engine implementation method and process engine system

ActiveCN106155718AGuarantee the basic realizationReduce development costsProgram loading/initiatingProcess developmentBusiness process

The invention discloses a process engine implementation method and a process engine system. According to the process engine implementation method, default configuration files are set preliminarily for common process nodes; when the process engine system needs to be started to perform business process control, an extending configuration file of each process node is preferentially loaded, and the corresponding default configuration file is directly loaded on a common process node which does not have a corresponding extending configuration file, so that not only is basic implementation of a process engine guaranteed, but also the individuation of the process engine due to the extending configuration files, and specific requirements of different business processes are met. Therefore, the process engine implementation method and the process engine system, disclosed by the invention, have high expansibility, and can be compatible with business processes of different business systems, and the problem that different process engines are required to be developed for different business processes is solved, so that the development cost of process engines can be reduced, and the maintenance difficulty of the process engines is lowered.

Owner:ALIBABA GRP HLDG LTD

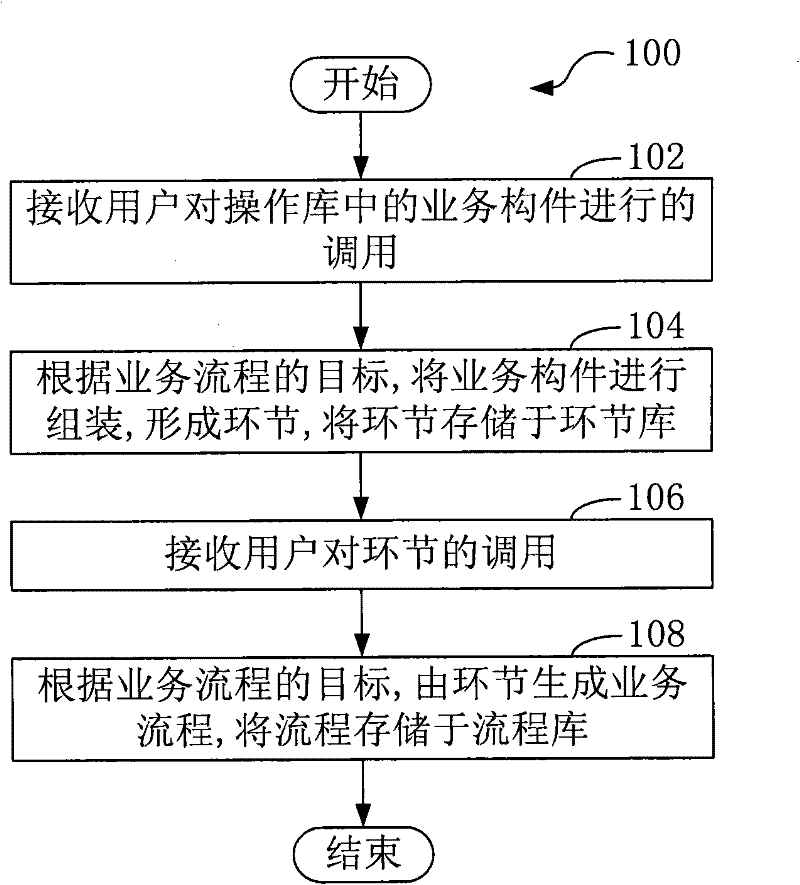

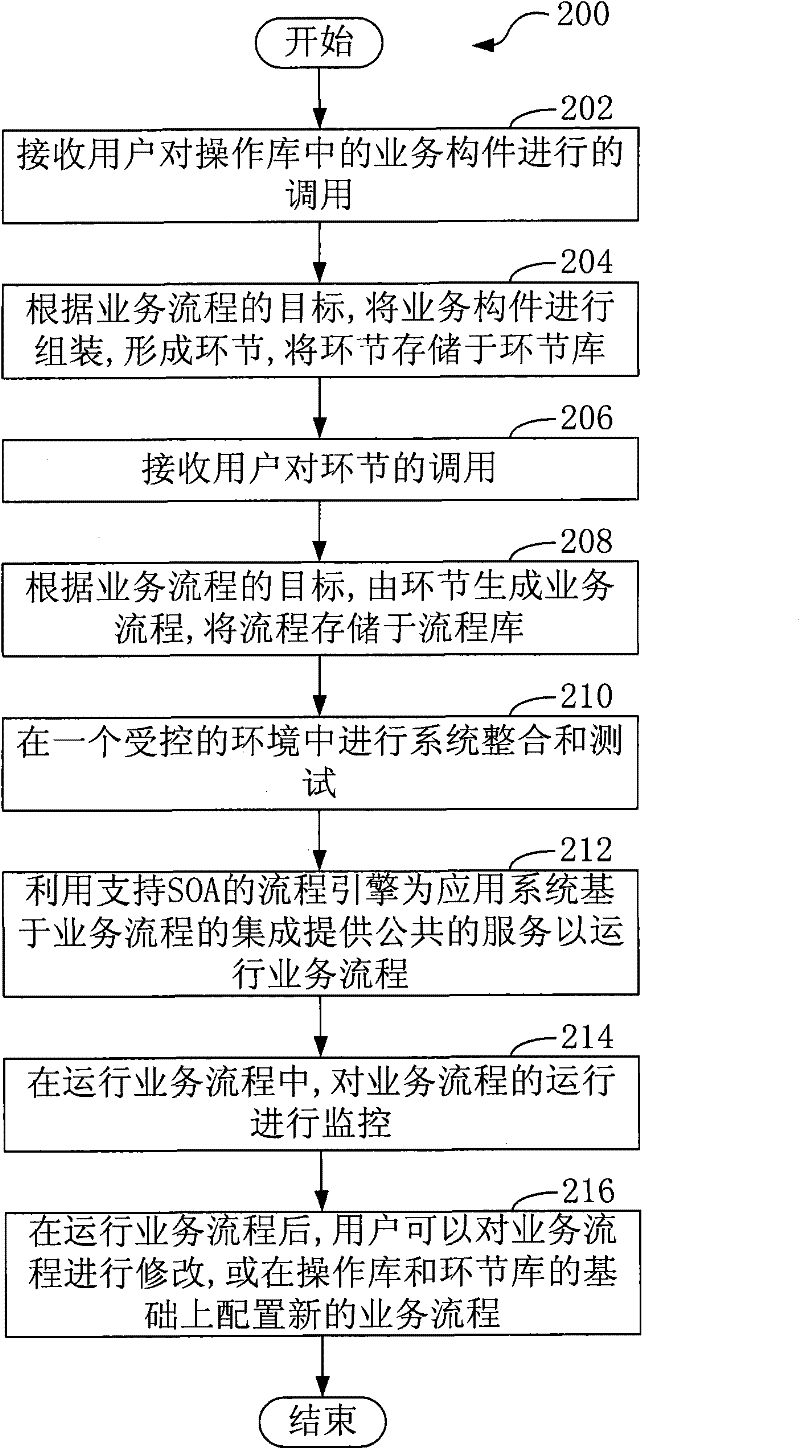

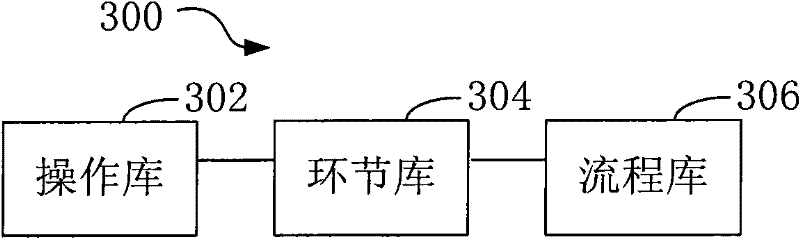

Soa-based business-level process customization platform and method

The invention provides a business-level process customizing platform and method based on an SOA (Business Oriented Architecture), relating to a computer technology, wherein the business-level process customizing method comprises the steps of: receiving a call of a user to a business member in an operating base, wherein the business member is formed by a workflow through abstraction; assembling the business member to form a link according to a target of a business process, storing the link in a link base; receiving a call of the user to the link; and generating the business process by the link according to the target of the business process, and storing the process in a process base. Therefore, businesses as a center are actually reflected during the development of the business-level business process, and business and technology separation is realized, so that the user and a developer can focus on respectively-skilled fields.

Owner:CHINA TELECOM CORP LTD

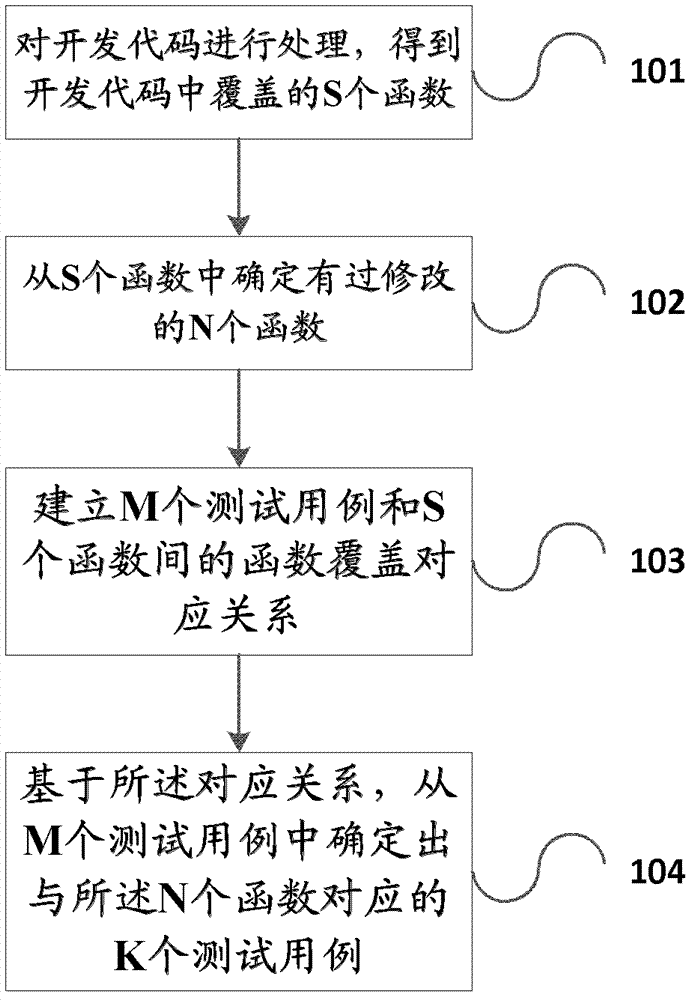

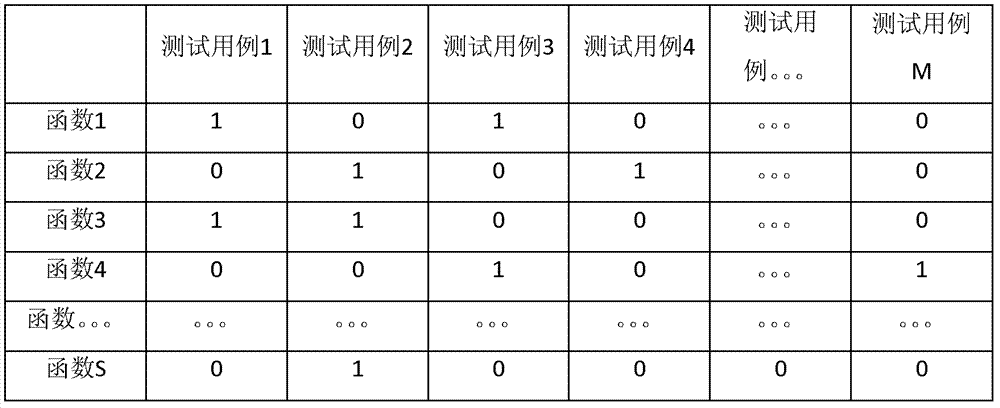

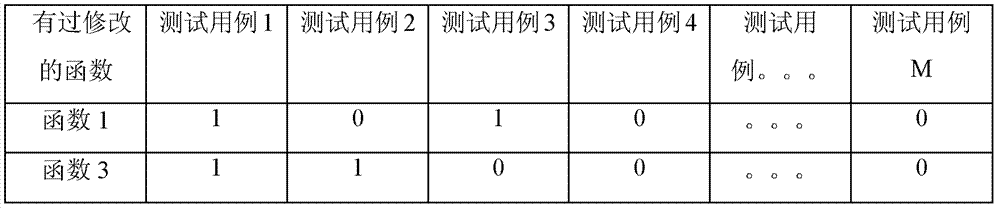

Method and system of test cases surely needing to perform regression testing

InactiveCN103092748AGuaranteed accuracyQuality assuranceSoftware testing/debuggingProgramming languageRegression testing

The invention discloses a method and system of test cases surely needing to perform regression testing. The method is used for determining K test cases needing the regression testing from M test cases and particularly includes: processing development codes to obtain S functions covered in the development codes; determining N modified functions from the S functions, wherein N is an integral smaller than or equal to S; building a function covering corresponding relation of the M test cases and the S functions; and determining K test cases corresponding to the N functions from the M test cases based on the corresponding relation. By means of the technical scheme, the testing range of the regression testing can be accurately determined, and the testing efficiency of the regression testing is further improved.

Owner:ALIBABA GRP HLDG LTD

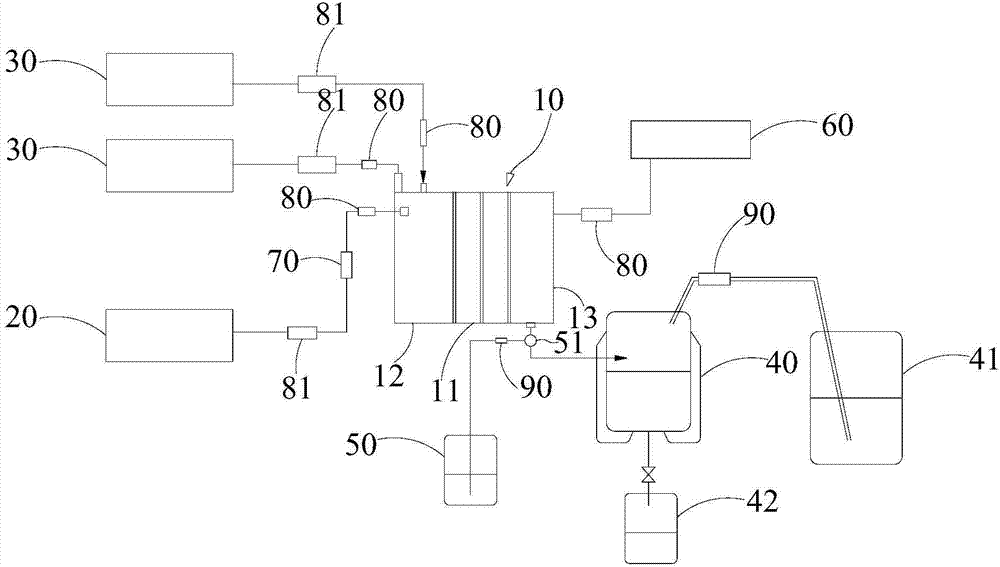

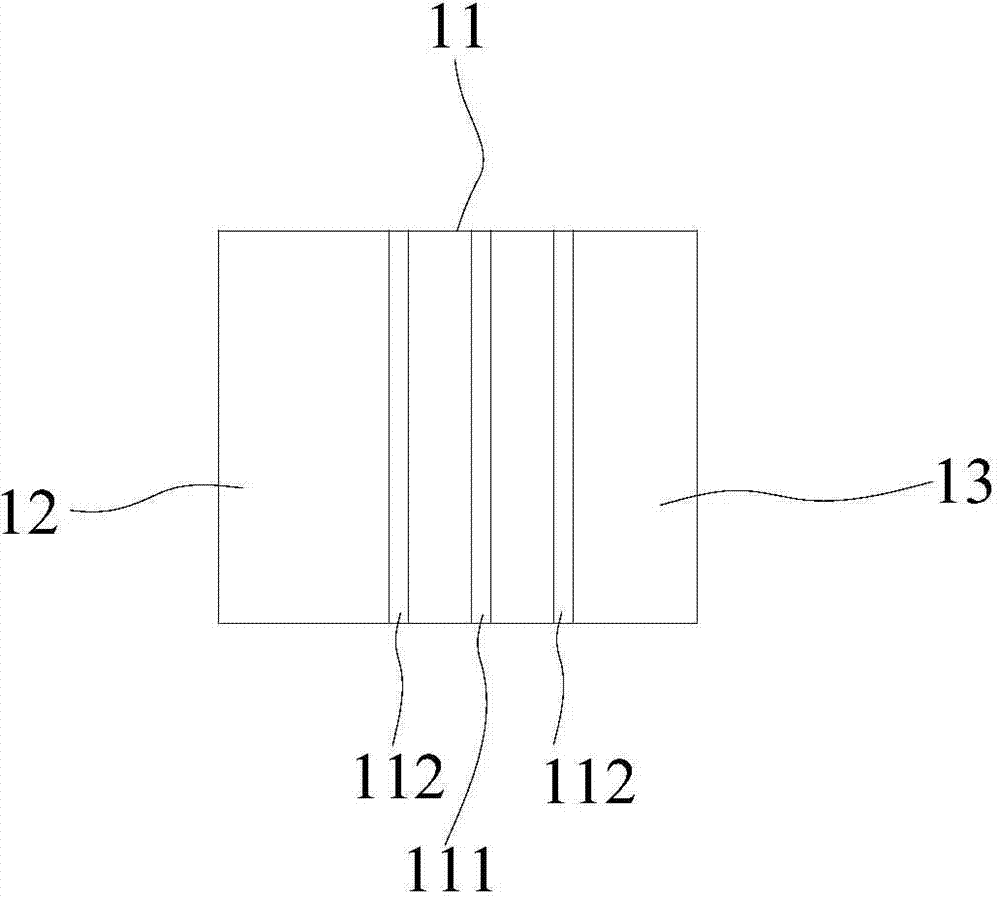

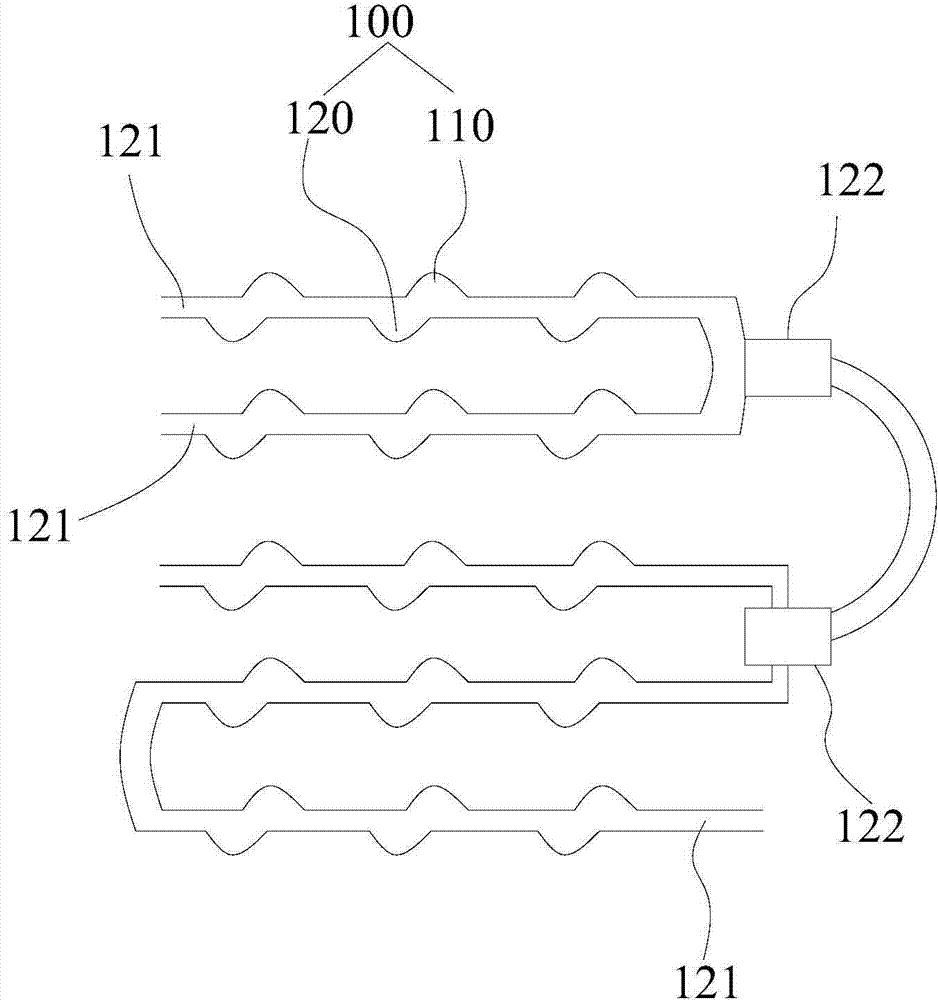

Micro-channel reaction system

ActiveCN104511264ASimple structureMeet the needs of the pilot testChemical/physical/physico-chemical microreactorsGas liquid reactionProcess development

The invention relates to the field of synthetic equipment and provides a micro-channel reaction system. The micro-channel reaction system comprises a micro-channel reaction device, a gas conveying device for introducing gas into the micro-channel reaction device, two or more liquid conveying devices for introducing liquid into the micro-channel reaction device, a gas-liquid separation device communicated with the micro-channel reaction device, and a sampling device. According to the micro-channel reaction device, different types of synthetic reactions such as gas-liquid reaction and liquid-liquid reaction can be produced; moreover, highly corrosive and strongly exothermal reactions of hydrogenation, oxidation, fluorination, bromination, nitration, sulfonation and the like can be produced by the micro-channel reaction device; in addition, the reaction system is simple in structure and easy to realize, and can meet the needs of small-amount process development research and pilot test.

Owner:SHENZHEN E ZHENG TECH

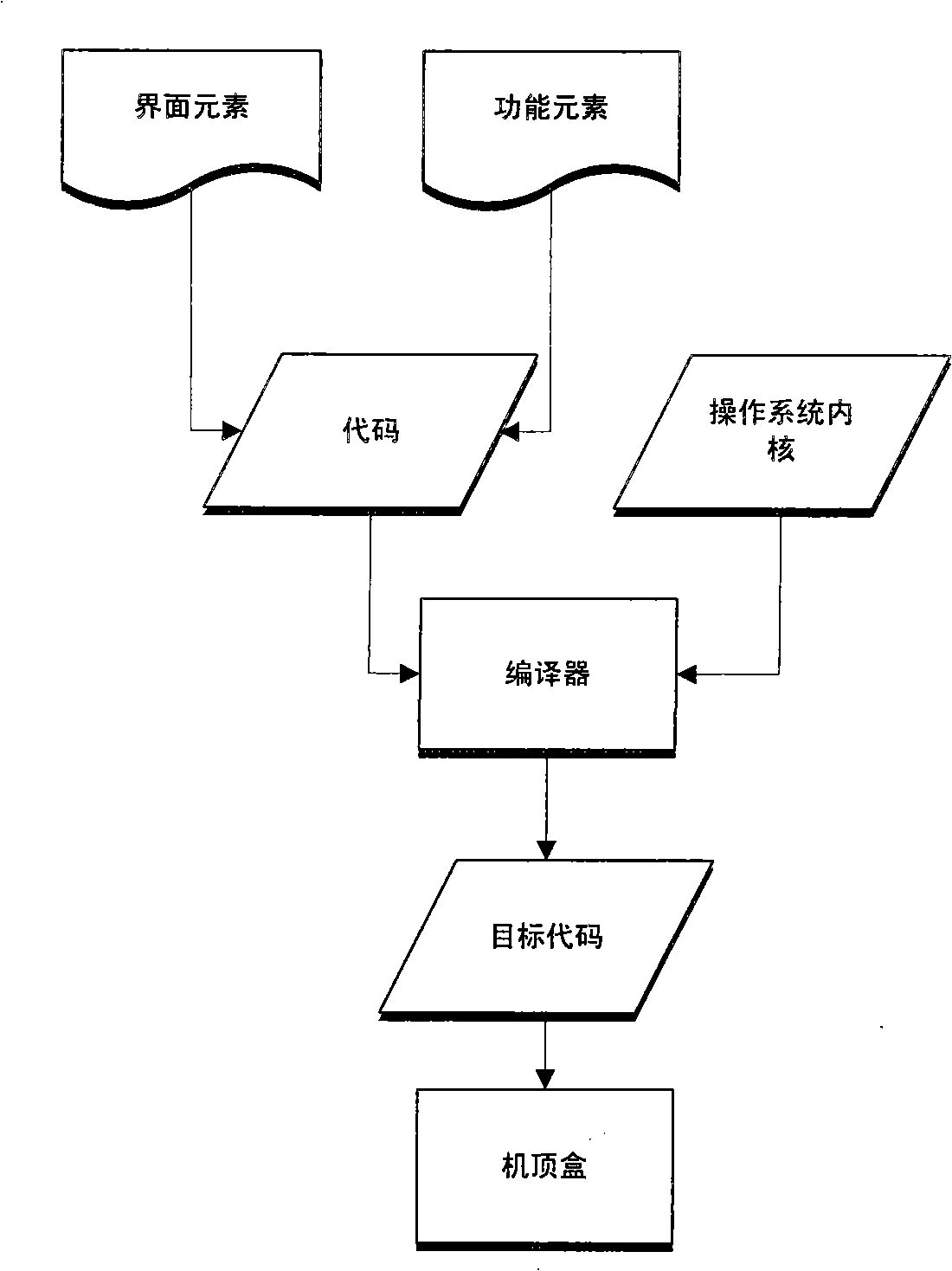

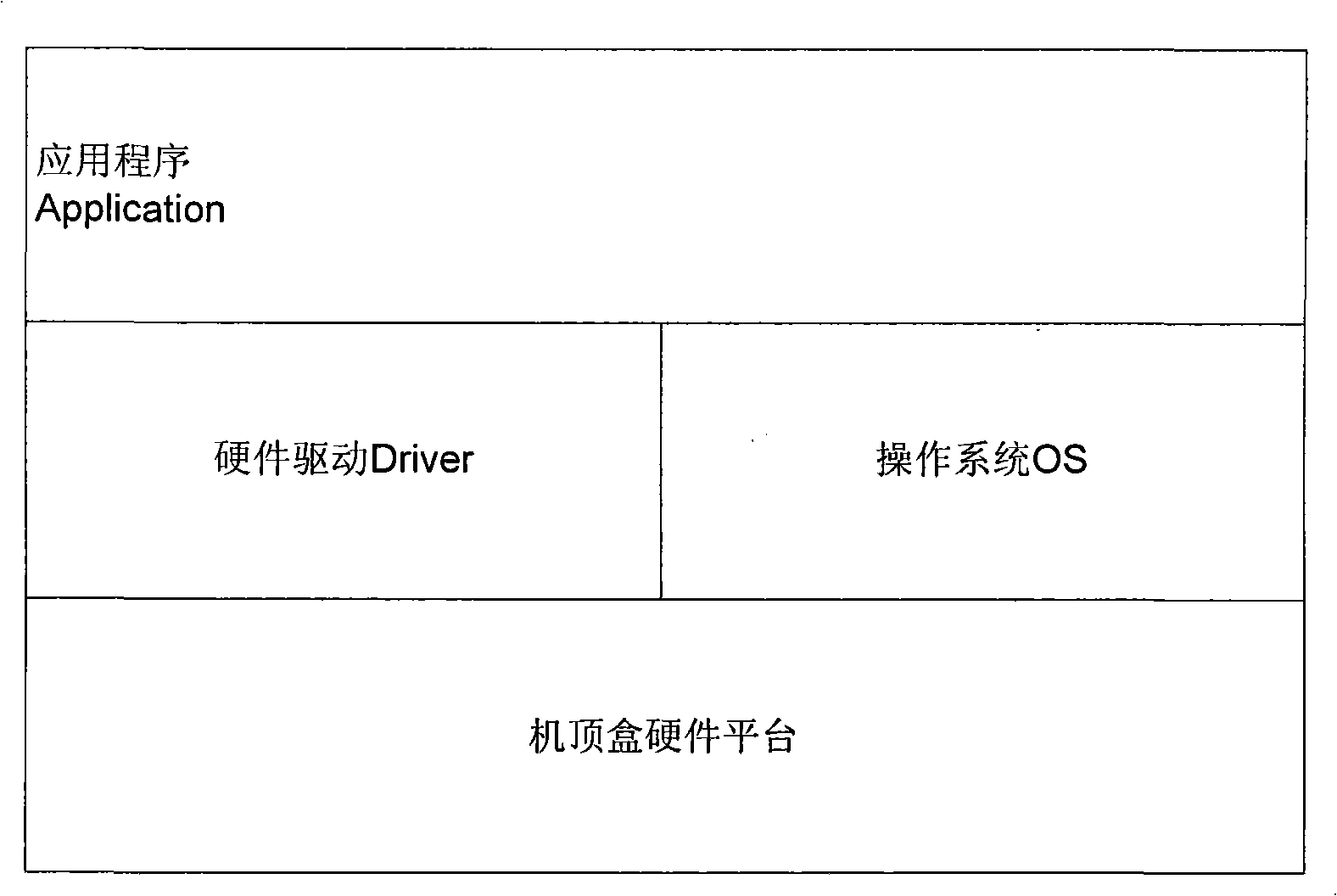

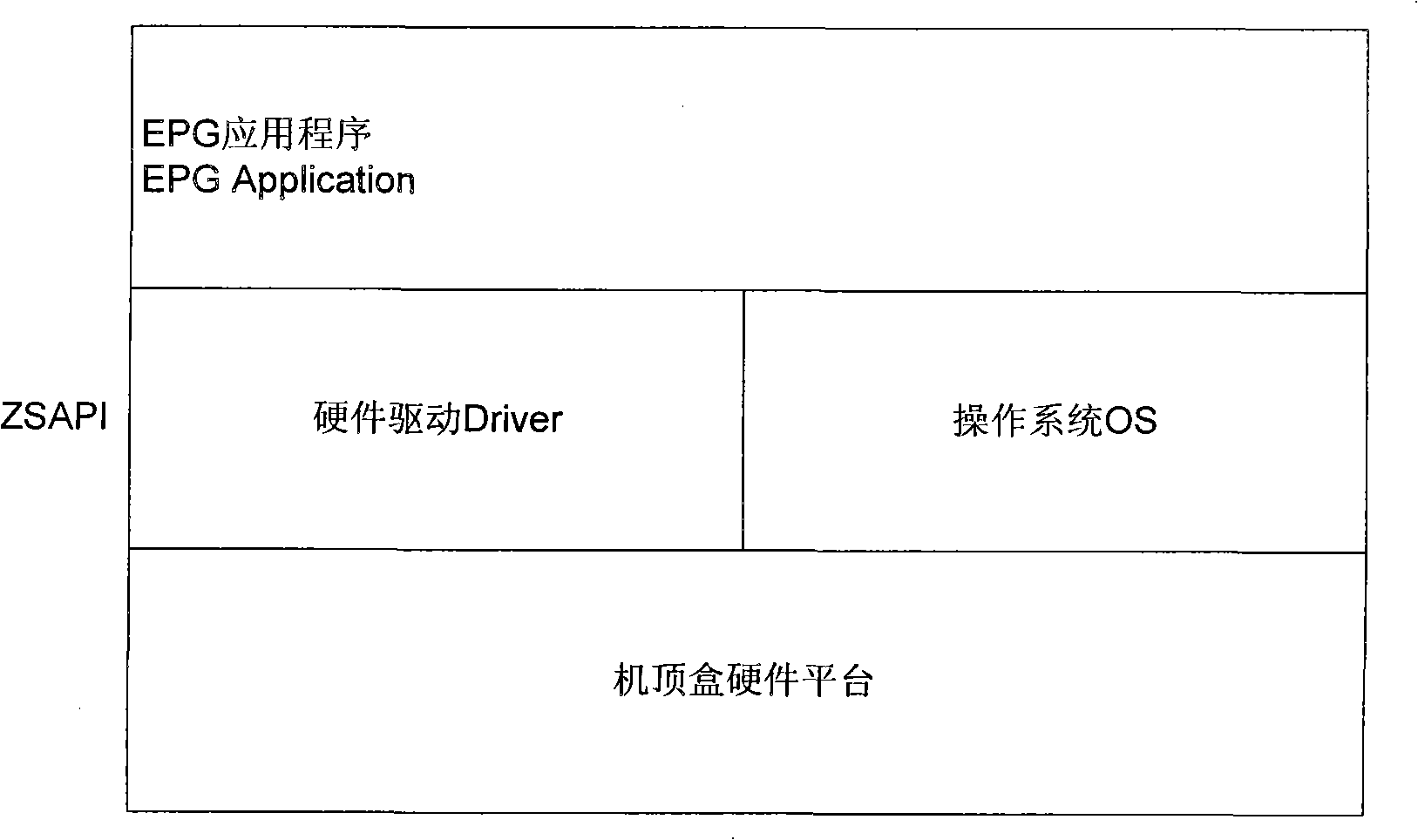

Software development visualizing editing method aiming at set top box

InactiveCN101276275AImprove development efficiencyShorten the development cycleTelevision system detailsColor television detailsSoftware development processProcess development

The present invention provides a software development visualization editing method aiming at the set-top box, adopting SDF application protocol, mainly including two parts: (1) a method of background service system operation SDF application program existing in the set-top box; (2) a preparation method of SDF application program. The invention adopts the SDF application program protocol, reading and explaining produced SDF application program by utilizing a background explanation program, capable of processing development by utilizing component mode, and realizing a cross-platform in real meaning, reducing the difficulty of the set-top box development, improving the develop efficiency and safety at the same time.

Owner:罗笑南

Extended development method of workflow engine

ActiveCN105760180AImprove the level of standardizationImprove development efficiencySoftware designSpecific program execution arrangementsGeneral functionWeb service

The invention provides an extended development method of a workflow engine, and belongs to the comprehensive resource management field of mobile operators. A desired business process can be quickly developed through the method. The method supports that various parts of business process development are standardized and componentized to dynamically customize business process link forms, WEB service, handling roles, general functions and the like under browser / server (B / S) architecture to simplify the development and maintenance of an actual process.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

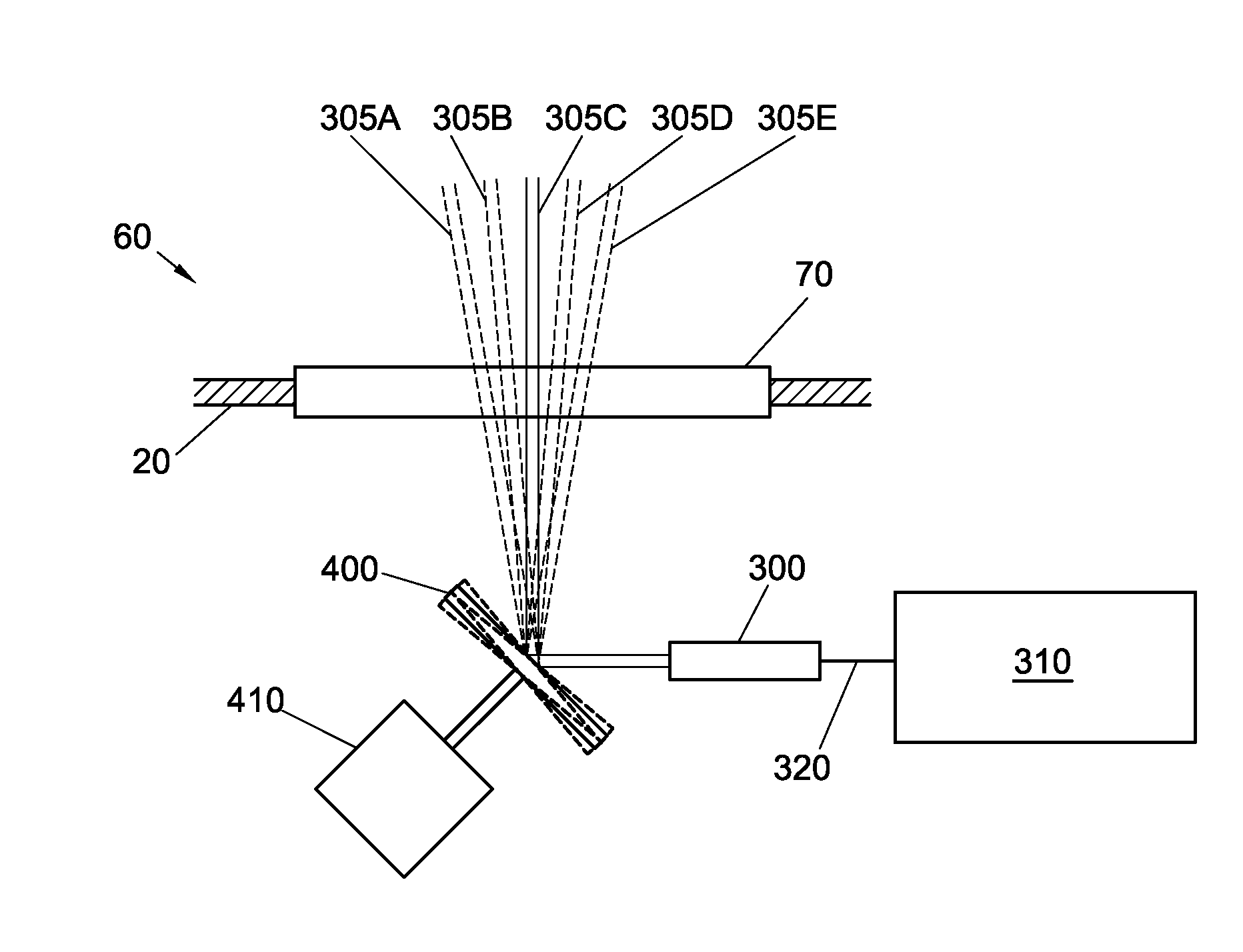

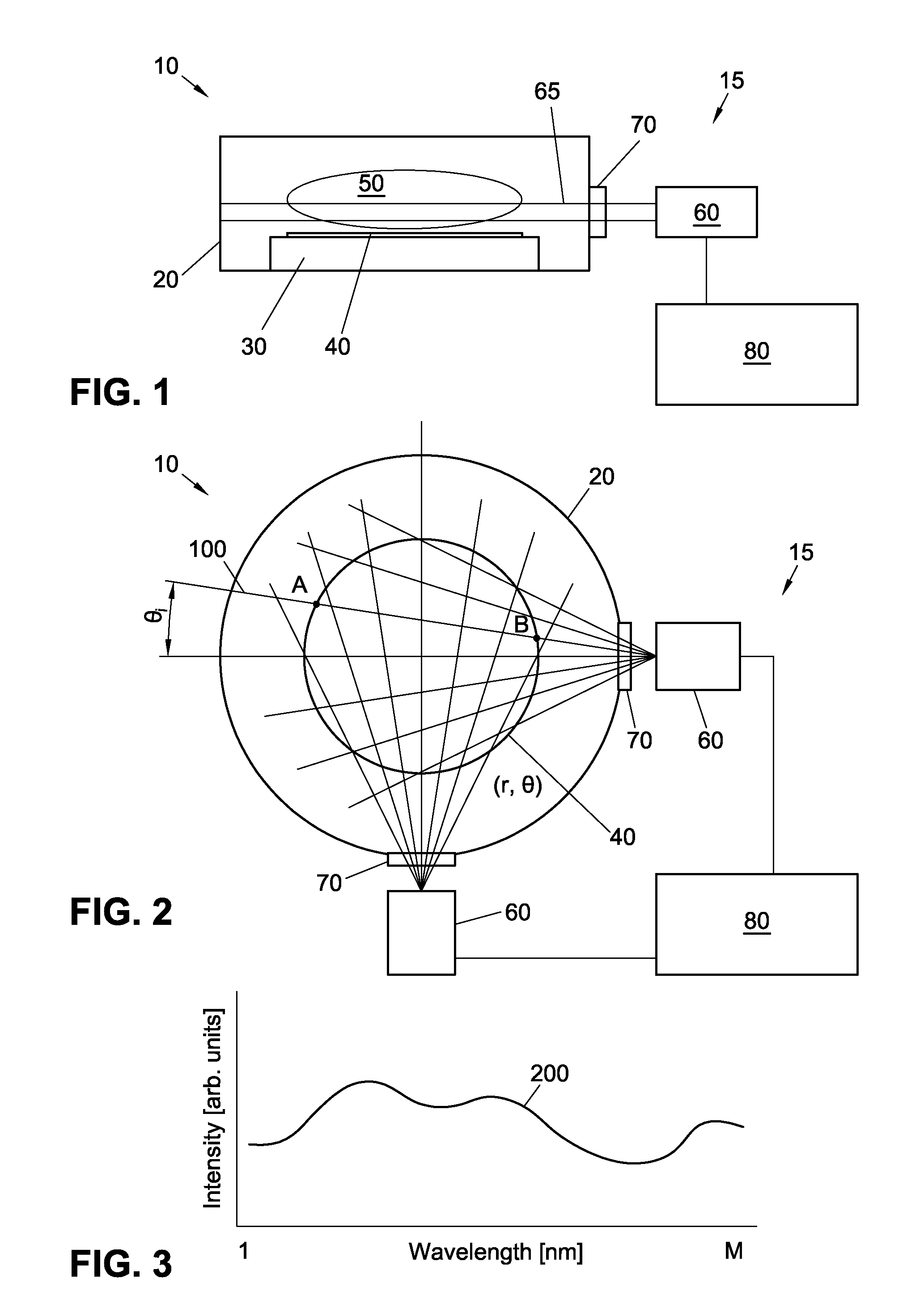

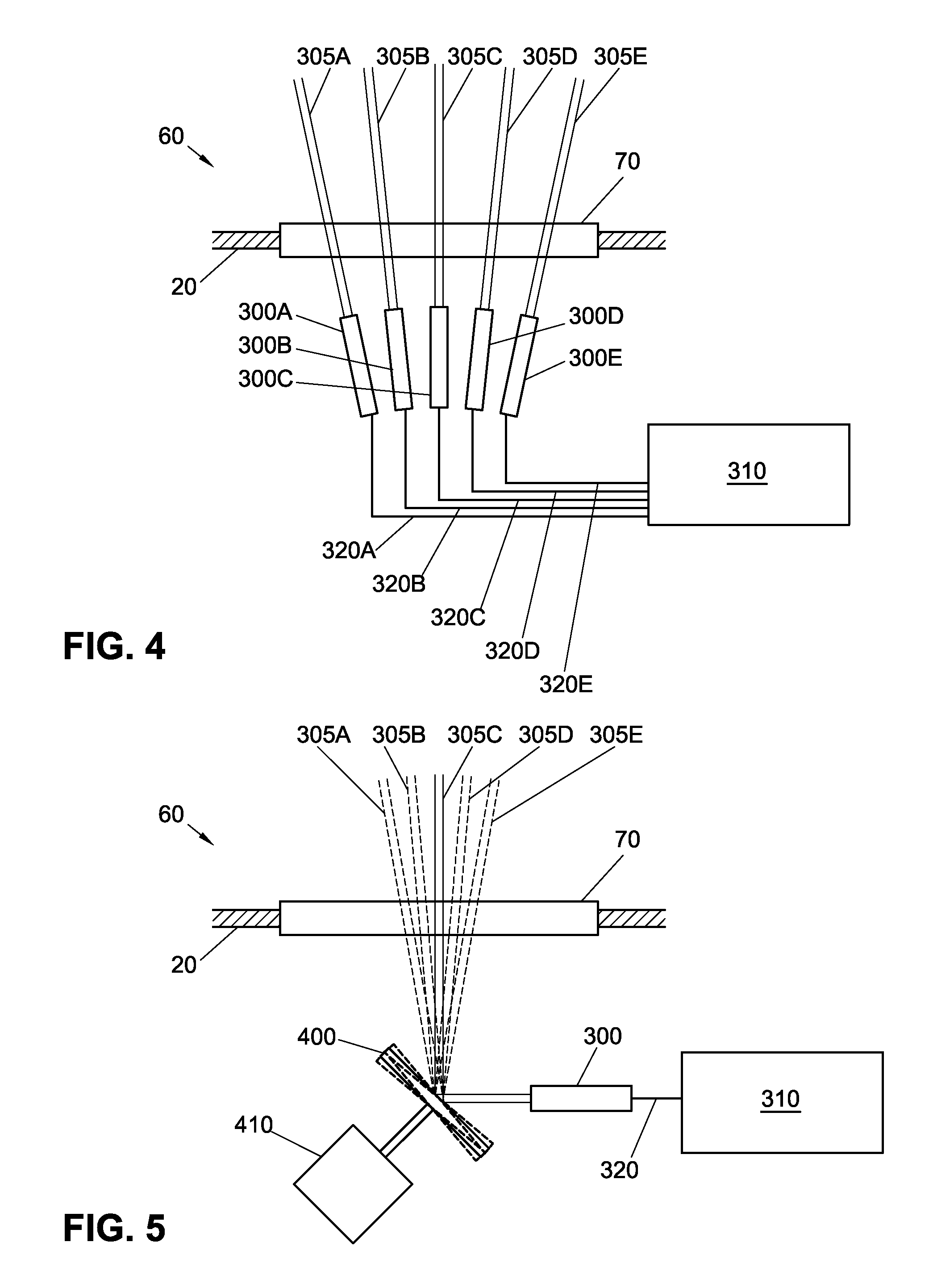

Spatially resolved optical emission spectroscopy (OES) in plasma processing

ActiveUS20150124250A1Emission spectroscopyRadiation pyrometryProcess developmentOptical emission spectrometry

Disclosed is a method, computer method, system, and apparatus for measuring two-dimensional distributions of optical emissions from a plasma in a semiconductor plasma processing chamber. The acquired two-dimensional distributions of plasma optical emissions can be used to infer the two-dimensional distributions of concentrations of certain chemical species of interest that are present in the plasma, and thus provide a useful tool for process development and also for new and improved processing tool development. The disclosed technique is computationally simple and inexpensive, and involves the use of an expansion of the assumed optical intensity distribution into a sum of basis functions that allow for circumferential variation of optical intensity. An example of suitable basis functions are Zernike polynomials.

Owner:TOKYO ELECTRON LTD

Heat treatment nitridation technology for metal

InactiveCN101886241AFast penetrationEasy to controlSolid state diffusion coatingSurface layerProcess development

The invention discloses a heat treatment nitridation technology for metal. The technology is characterized in that pre-oxidation is carried out before nitridation to form a uniform oxidation film on a metal surface. The technology comprises the following steps: 1) vacuumizing a furnace; 2) charging nitrogen and uniformly heating to 520-570 DEG C; and 3) charging oxygen in the nitrogen atmosphere. In the invention, pre-oxidation is carried out before nitridation so as to form an even active oxidation film on a metal surface layer. The active oxidation film on the metal surface is a core absorbed by initial active nitrogen atoms, so that active nitrogen can be absorbed on the metal surface more effectively to speed up nitridation. Therefore, after the active oxidation film is formed on the metal surface, the nitridation process development has high stability.

Owner:SHANGHAI GKN DRIVE SYST

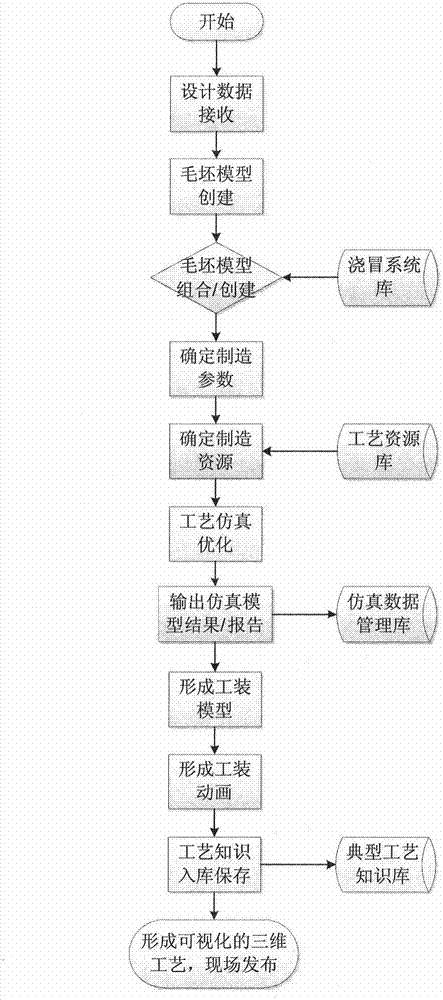

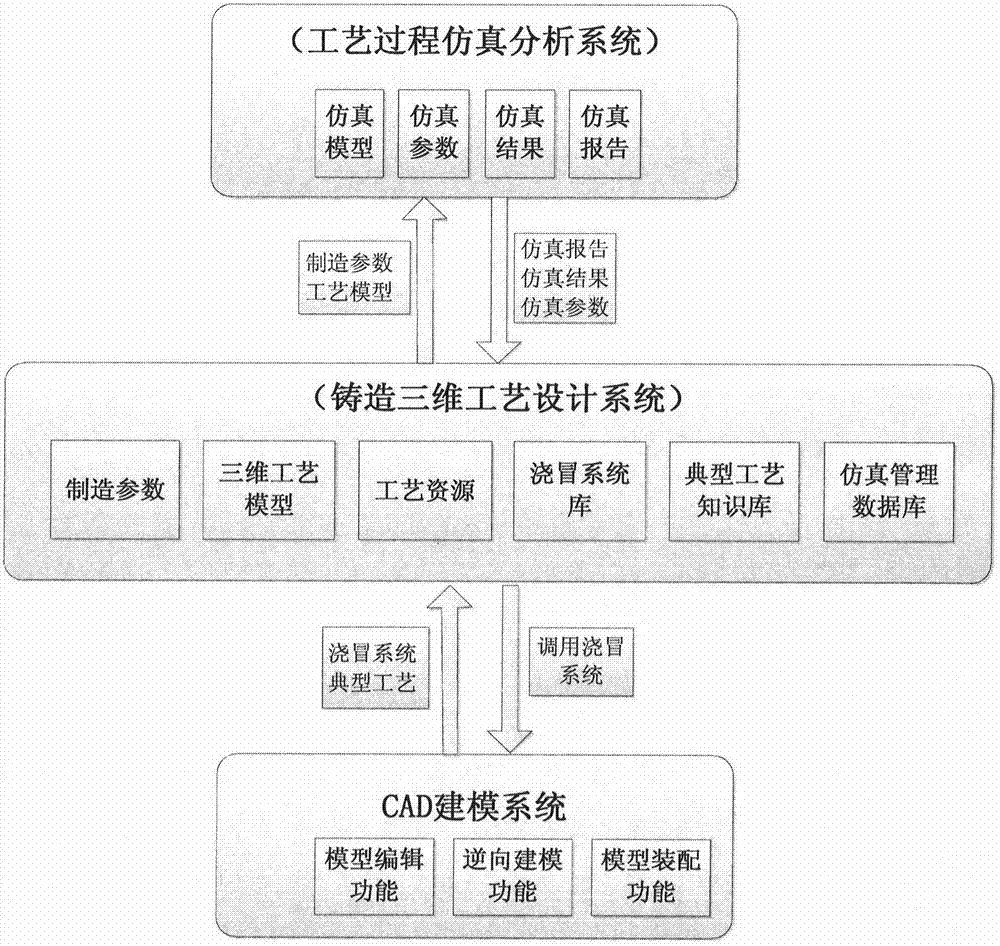

Casting three-dimensional process designing method

InactiveCN104239653AImprove pass rateHigh yieldSpecial data processing applicationsProcess developmentProcess efficiency

The invention relates to a casting three-dimensional process designing method which solves the problems caused when the two-dimensional mode is adopted for the existing casting process. Firstly, a casting three-dimensional process designing system which can have the three-dimensional manufacturing reception capacity is designed and is then integrated with a CAD modeling system and a process simulation analysis system; in a system formed through integration, three-dimensional design data issued by a design department are firstly received from a design data management system, compiling is conducted on the basis of the design data, a casting blank model is generated, an appropriate rigging system is selected from a rigging system library for assembling, a rigging system is recreated and kept into a knowledge base if no appropriate rigging system exists, manufacturing parameters, manufacturing process resources and the like are designed, simulation analysis is started on a simulation interface under the analogue simulation conditions, the simulation result is analyzed, the process and manufacturing parameters are optimized, the process is determined, and a visual three-dimensional process is formed. By means of the casting three-dimensional process designing method, the process design efficiency is improved, and the cycle of process development is shortened.

Owner:内蒙古第一机械集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com