Semiconductor-type gas sensor with A1N heat isolation panel double-side micro structure and manufacturing method thereof

A gas sensor and thermal isolation technology, applied in the field of sensing, can solve problems such as poor thermal conductivity, high process development costs, and complex processes, and achieve the effects of reducing heating power loss, low process development costs, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

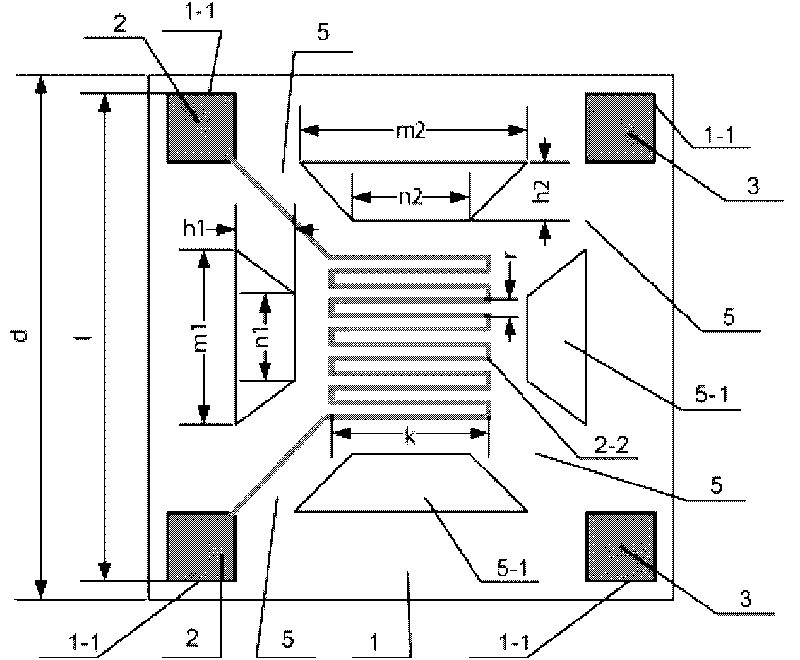

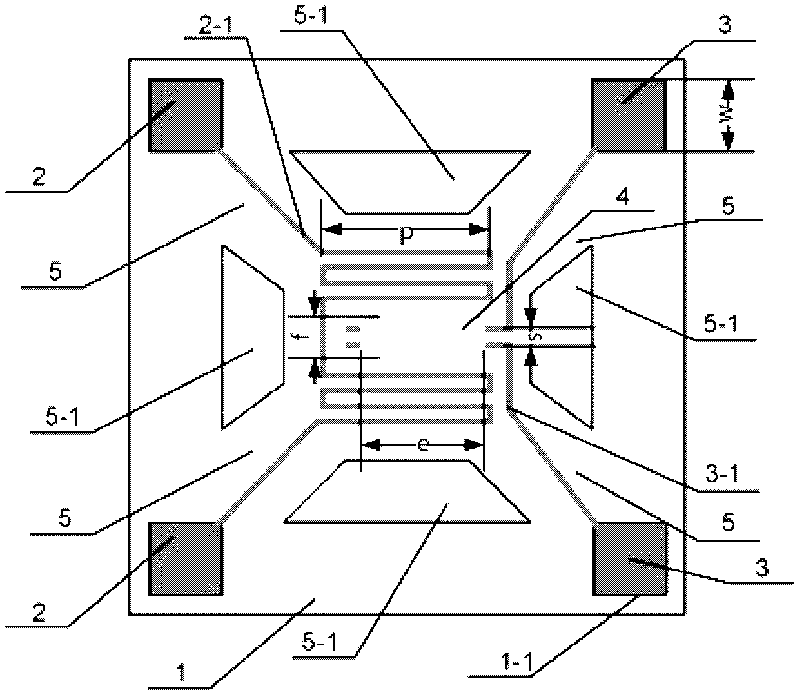

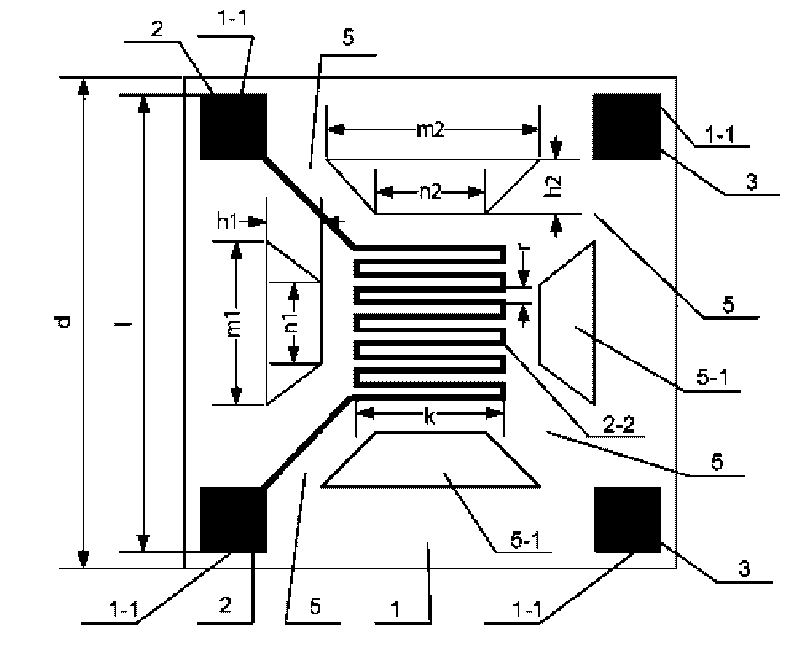

[0023] Specific implementation mode 1. Combination figure 1 and figure 2 Description of this embodiment, AlN heat isolation plate double-sided microstructure semiconductor gas sensor, it includes AlN ceramic substrate 1, two heating electrodes 2, front heater 2-1, back heater 2-2, two signal Electrode 3, two signal acquisition pieces 3-1, sensitive film 4 and thermal isolation groove 5, are etched with thermal isolation groove 5 on four directions of the diagonal line of described AlN ceramic substrate 1, and thermal isolation groove 5 makes Four island protrusions 51 are respectively formed on the front and back of the AlN ceramic substrate 1, four through holes 1-1 are etched along the edges of the thermal isolation groove 5 in four directions, and the front of the AlN ceramic substrate 1 is provided with a heating electrode 2 , a front heater 2-1, a signal electrode 3 and a signal collecting sheet 3-1, the heating electrode 2 runs through the two through holes 1-1 on one ...

specific Embodiment approach 2

[0024] Specific embodiment two, combine figure 1 and figure 2This embodiment is described. The difference between this embodiment and the first embodiment is that the AlN ceramic substrate 1 is square.

specific Embodiment approach 3

[0025] Specific embodiment three, combine figure 1 and figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is that the side length d of the AlN ceramic substrate 1 is 3.1-3.3 mm, and the distance between the outer boundaries of two adjacent through holes 1-1 l is 2.9-3.1mm, the island protrusions 5-1 formed by the thermal isolation groove 5 are four isosceles trapezoids, wherein every two opposite isosceles trapezoids are congruent, and a pair of island protrusions 5-1 are isosceles trapezoids The upper bottom n1 is 0.45-0.55mm, the lower bottom m1 is 1.35-1.45mm, the height h1 is 0.25-0.35mm, and the upper bottom n2 of another pair of island protrusions 51 isosceles trapezoid is 0.85-0.95mm, and the lower bottom m2 is 1.55-1.65mm, height h2 is 0.45-0.55mm, the length k of the serpentine arrangement structure of the rear heater 2-2 is 0.95-1.05mm, the spacing r is 0.045-0.055mm, and the length e of the sensitive film 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com