Patents

Literature

60results about How to "Cutting synchronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

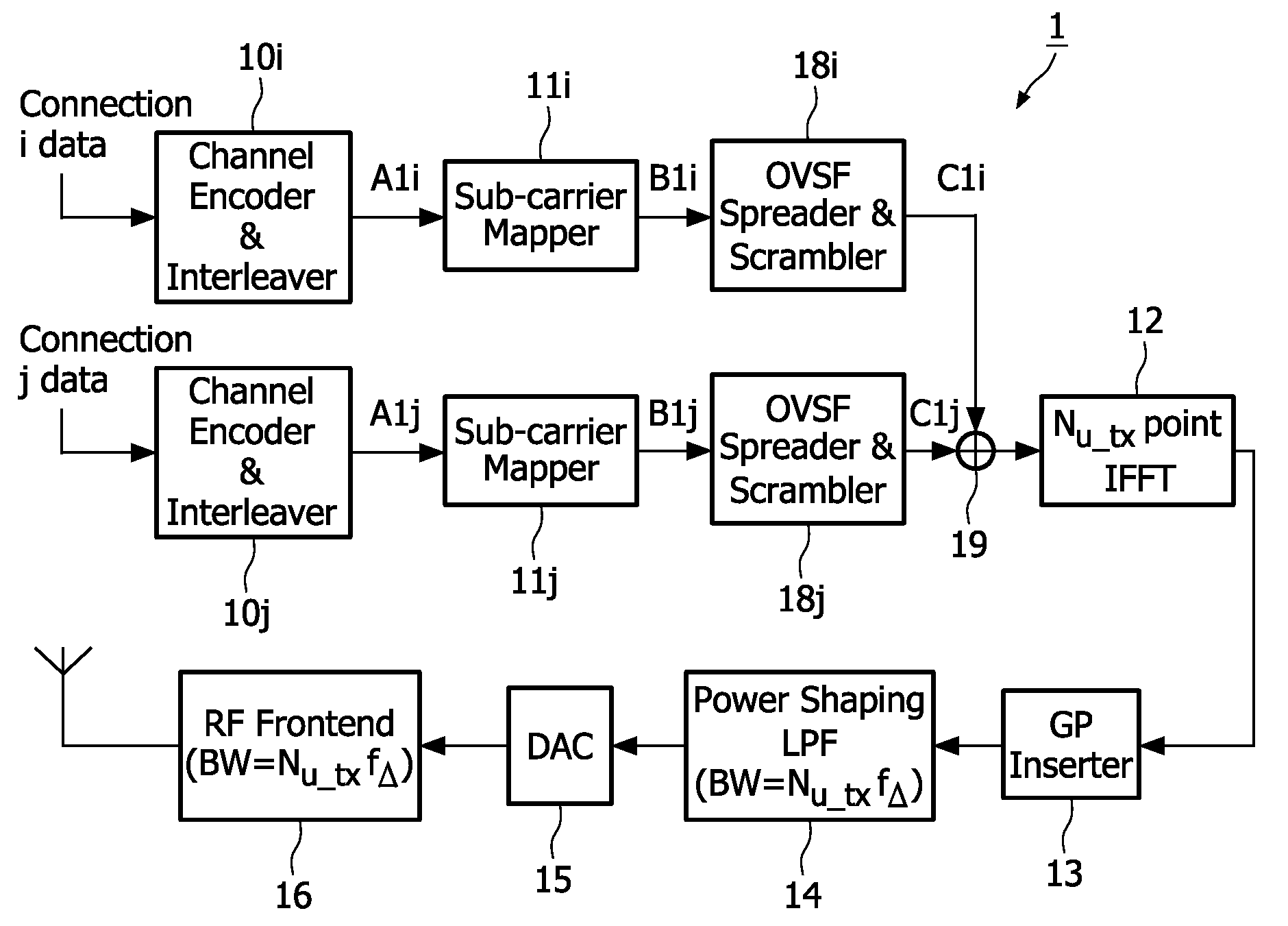

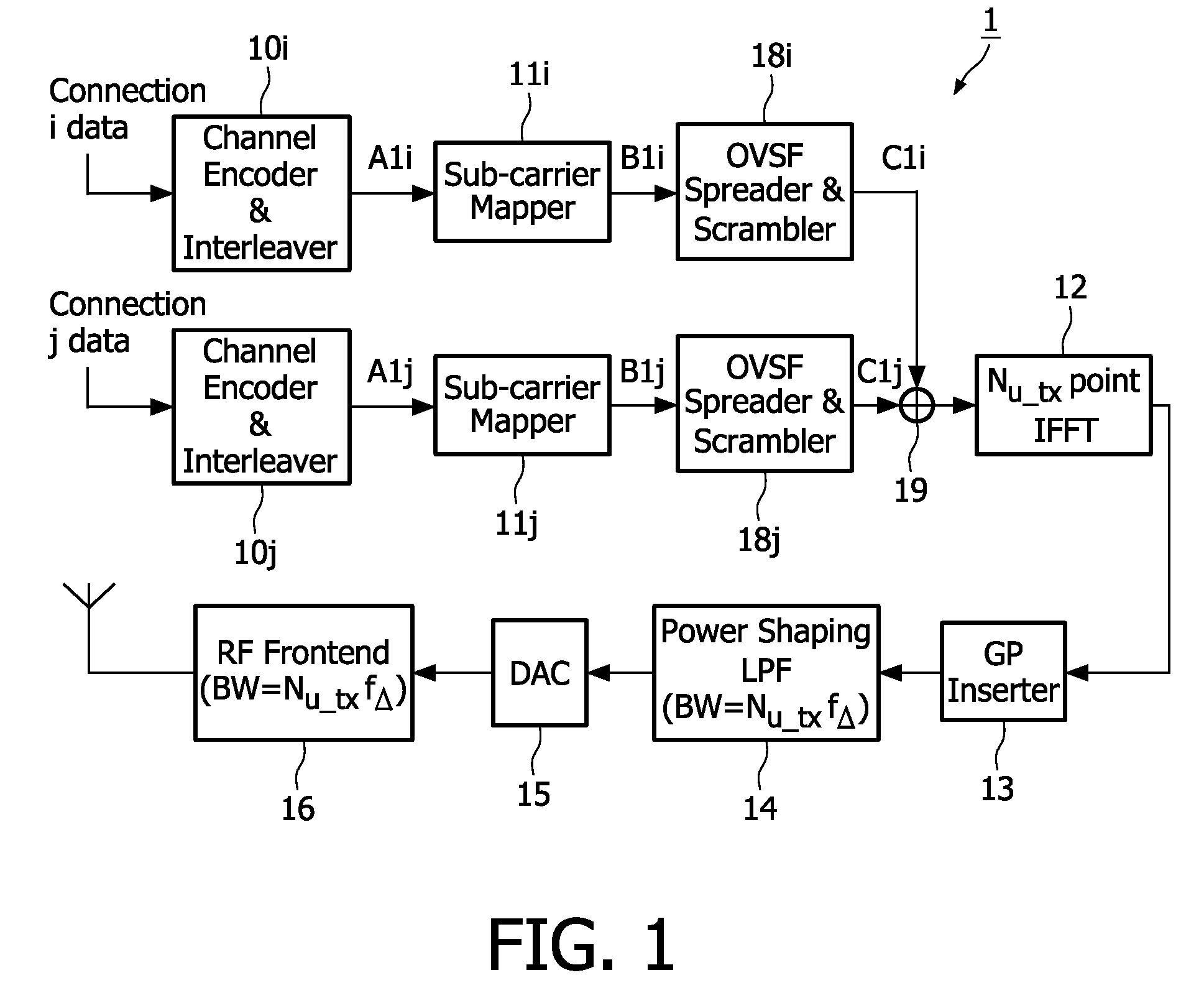

Bandwidth asymmetric communication system based on OFDM and TDMA

InactiveUS20090196163A1Reduce complexityCutting synchronizationTransmission path divisionSecret communicationCommunications systemUplink transmission

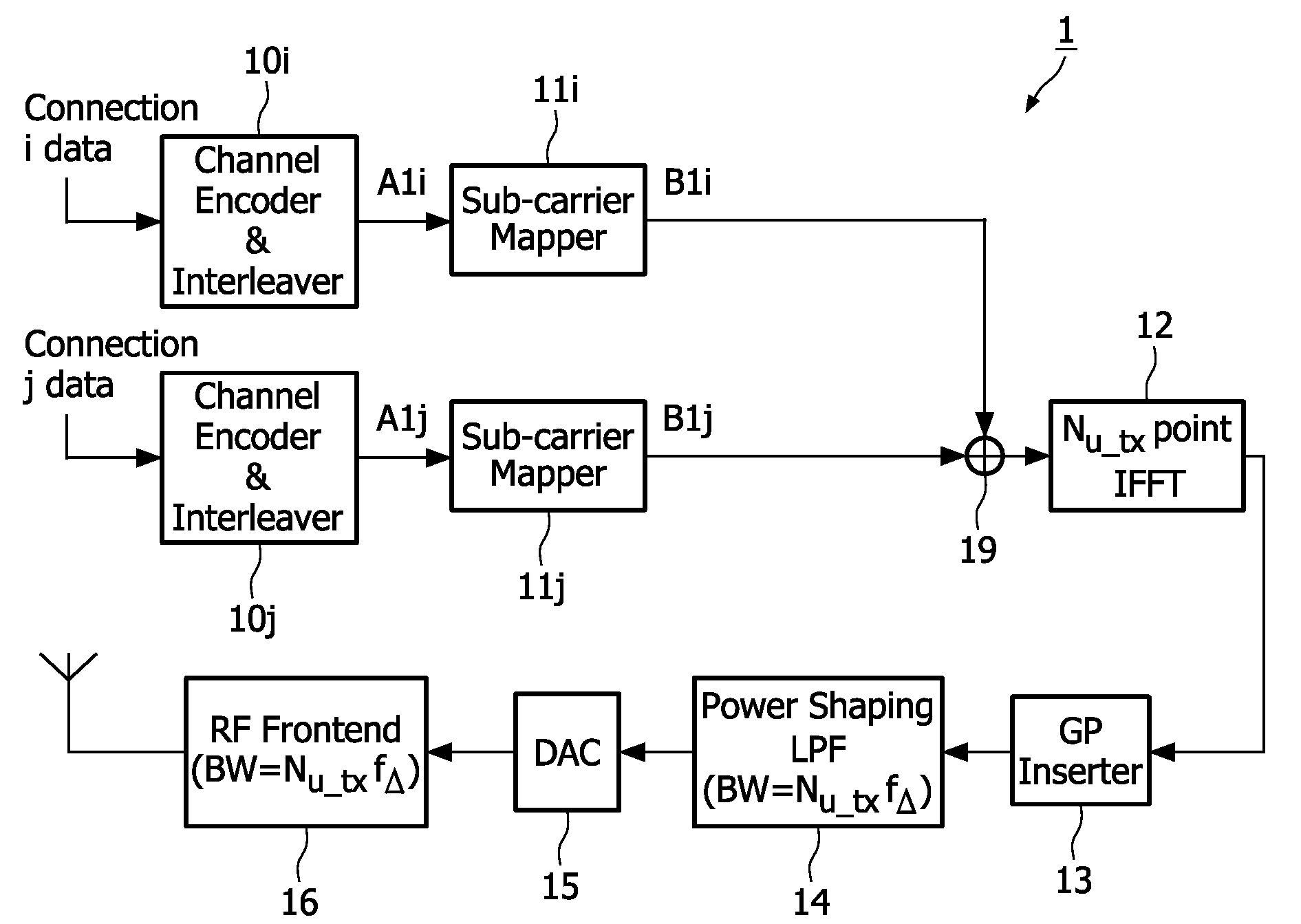

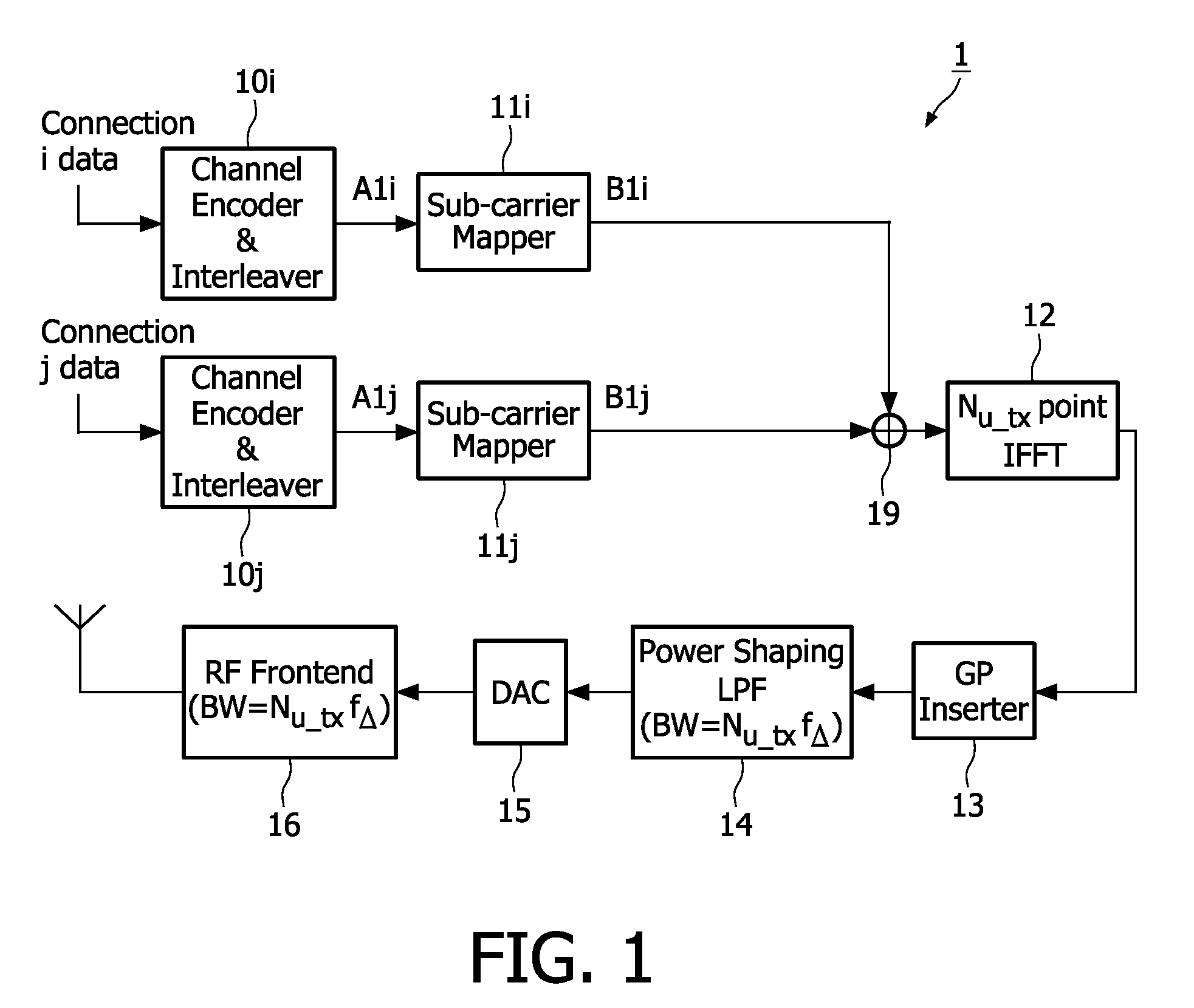

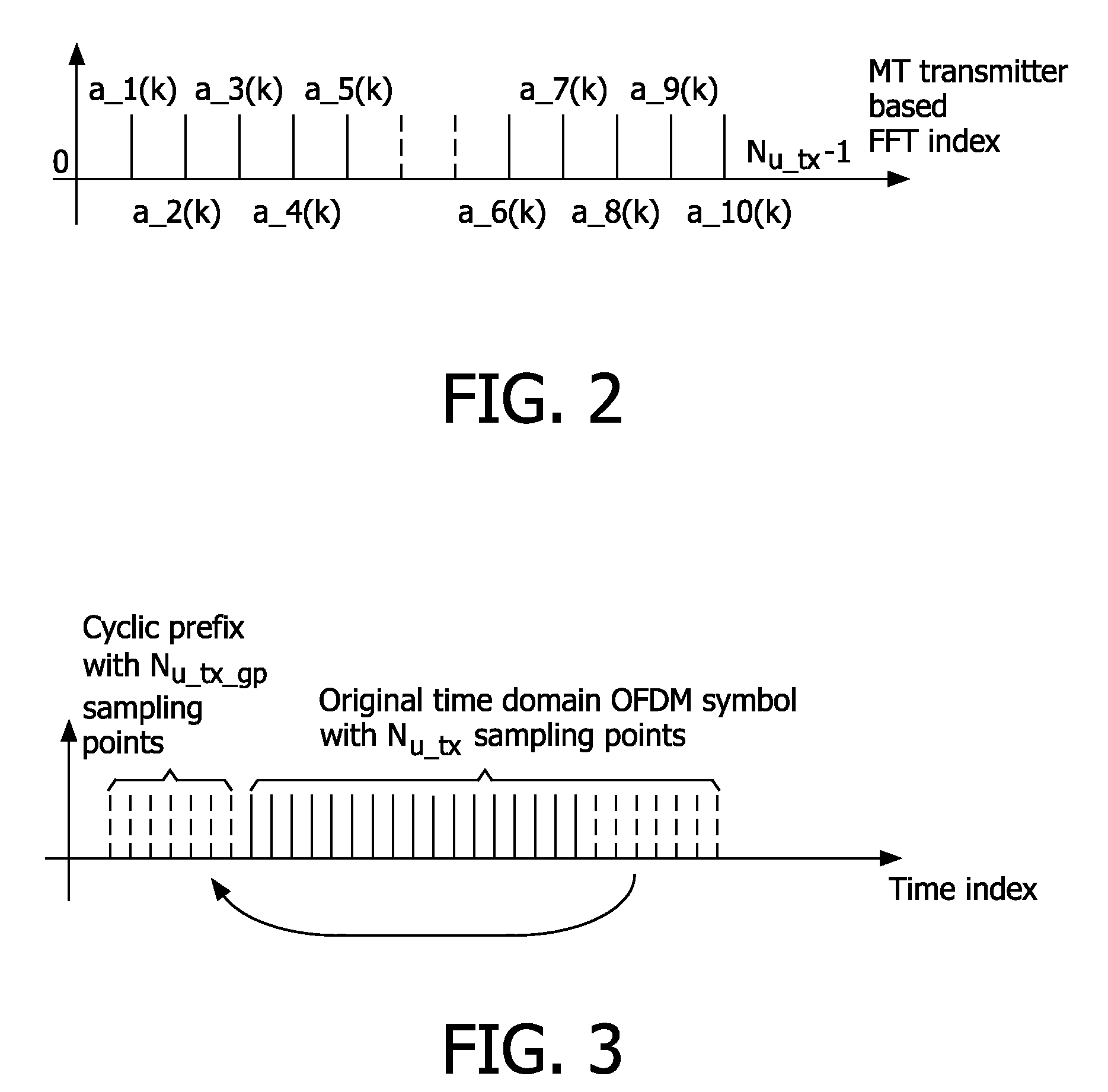

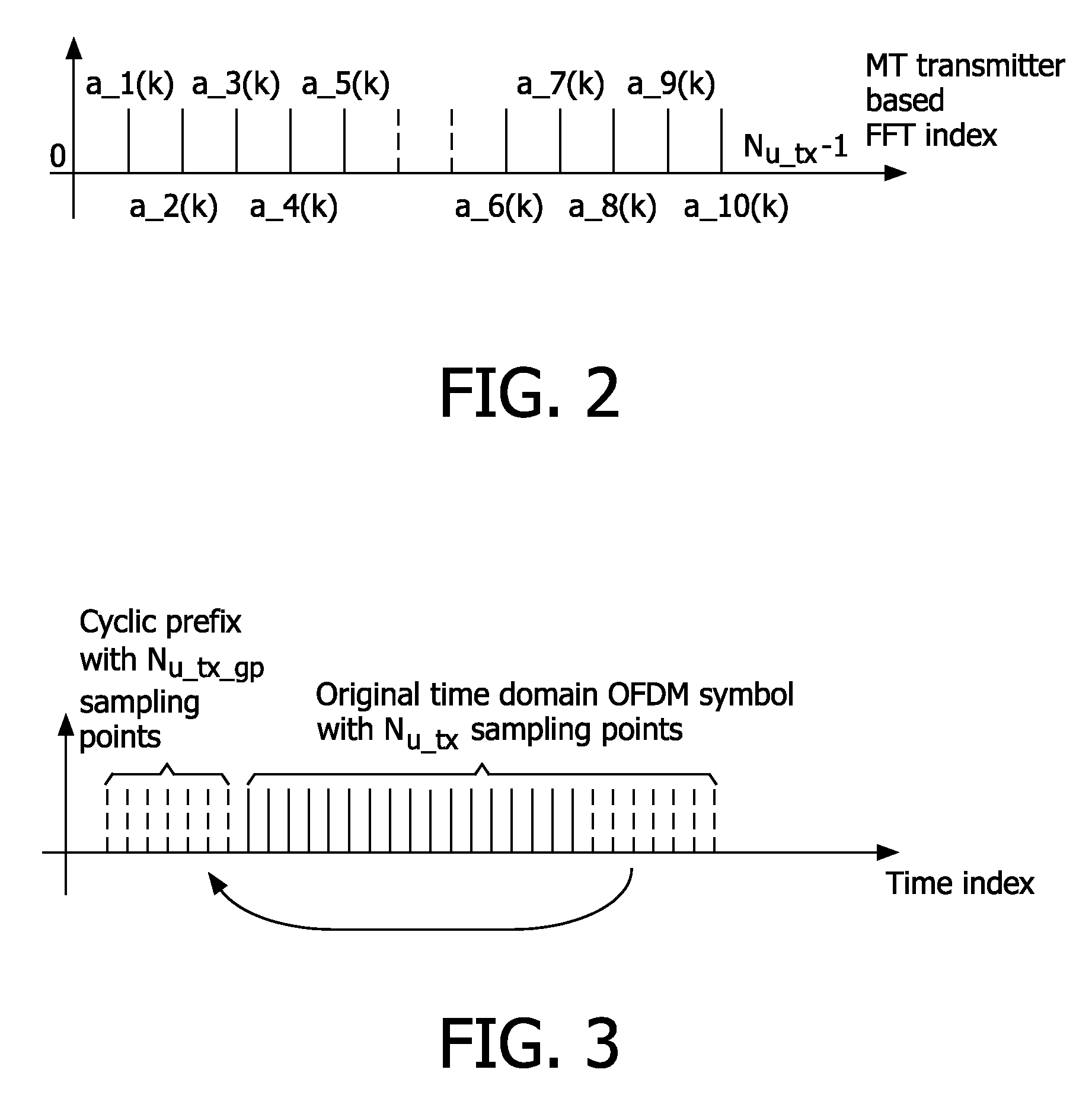

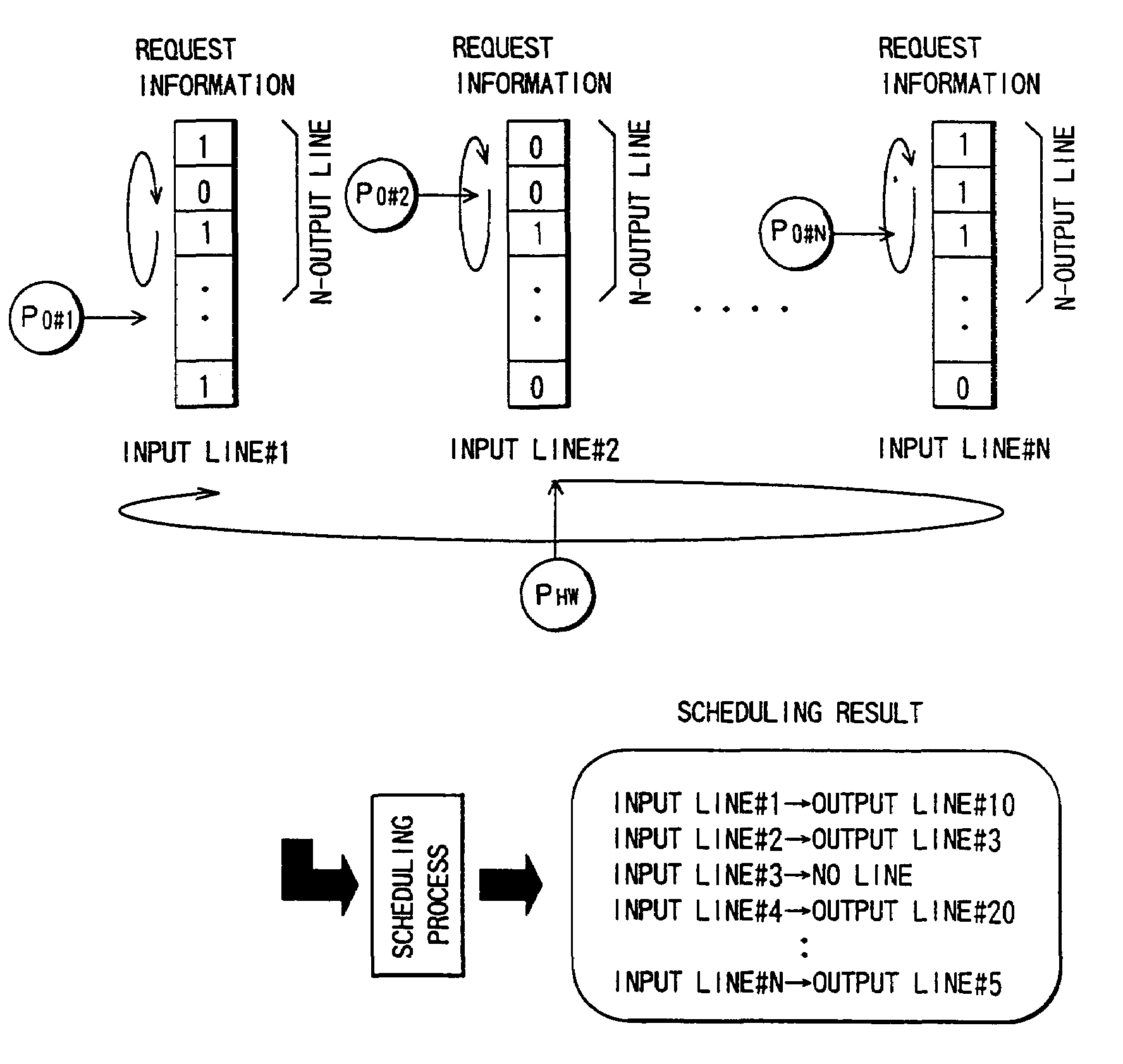

The present invention relates to a communication system comprising a plurality of terminals each having an uplink transmission unit (1) for transmitting radio frequency OFDM signals at a radio frequency and an access point having an uplink receiving unit (4) for concurrently receiving said radio frequency OFDM signals from at least two terminals, said OFDM signals being Orthogonal Frequency Division Multiplex (OFDM) modulated, wherein the bandwidth of said uplink transmission units and of the transmitted radio frequency OFDM signals is smaller than the bandwidth of said uplink receiving unit, that the bandwidth of at least two uplink transmission units and of their transmitted radio frequency OFDM signals is different and that the uplink transmission unit is adapted to assign different connections for concurrently transmitting radio frequency OFDM signals to different sub-carriers in the same time slots or to the same or different sub-carriers in different time slots.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

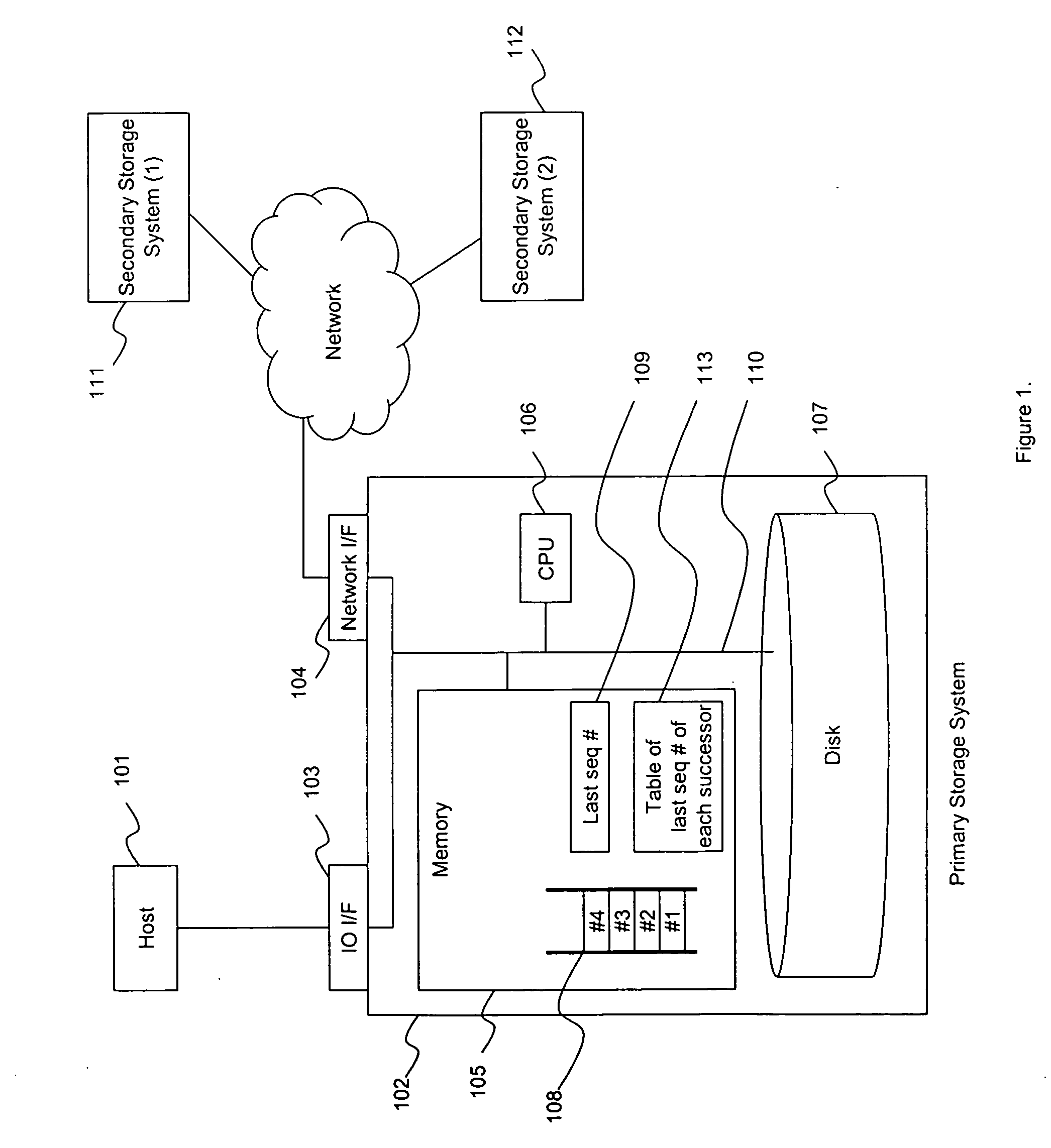

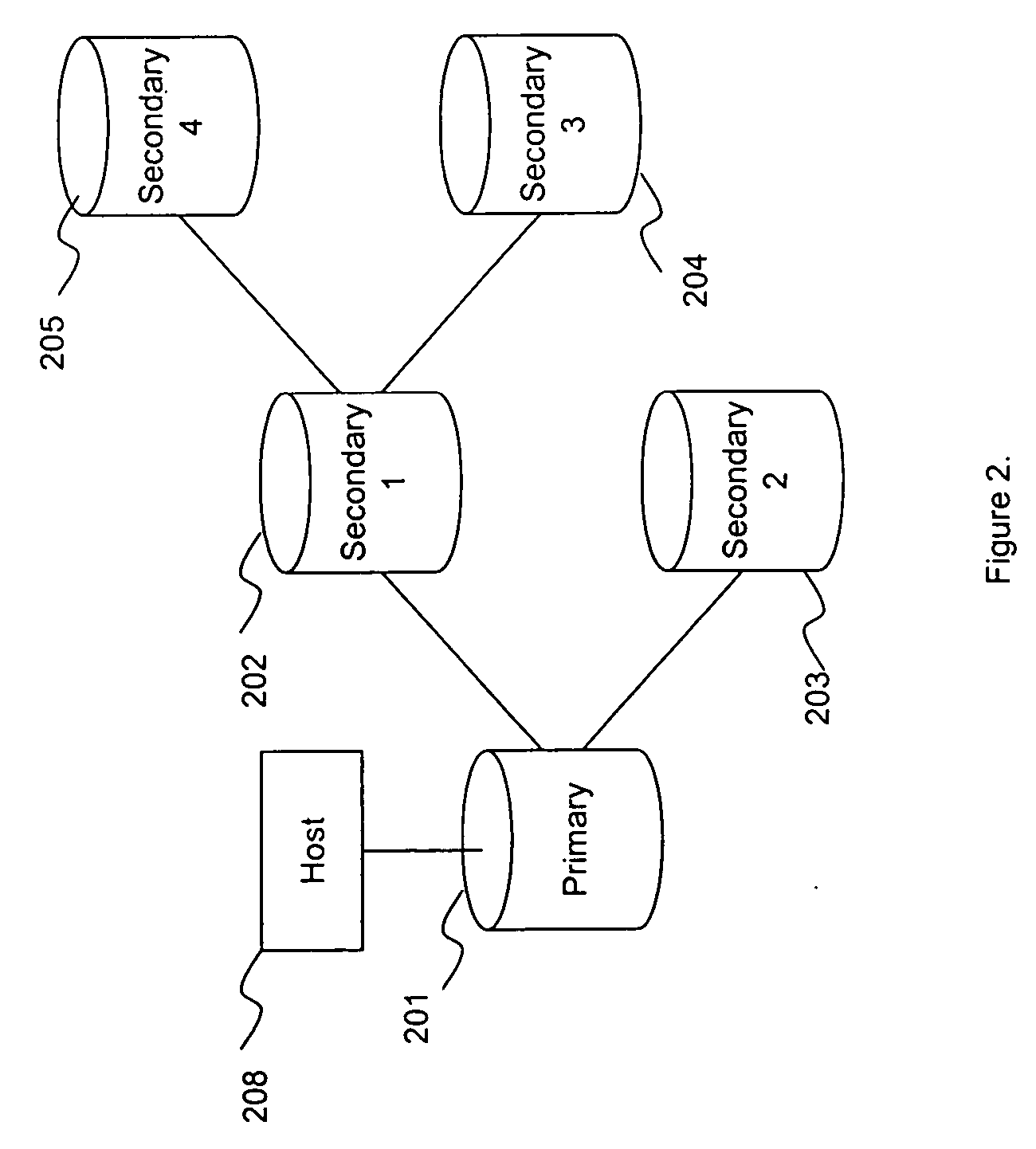

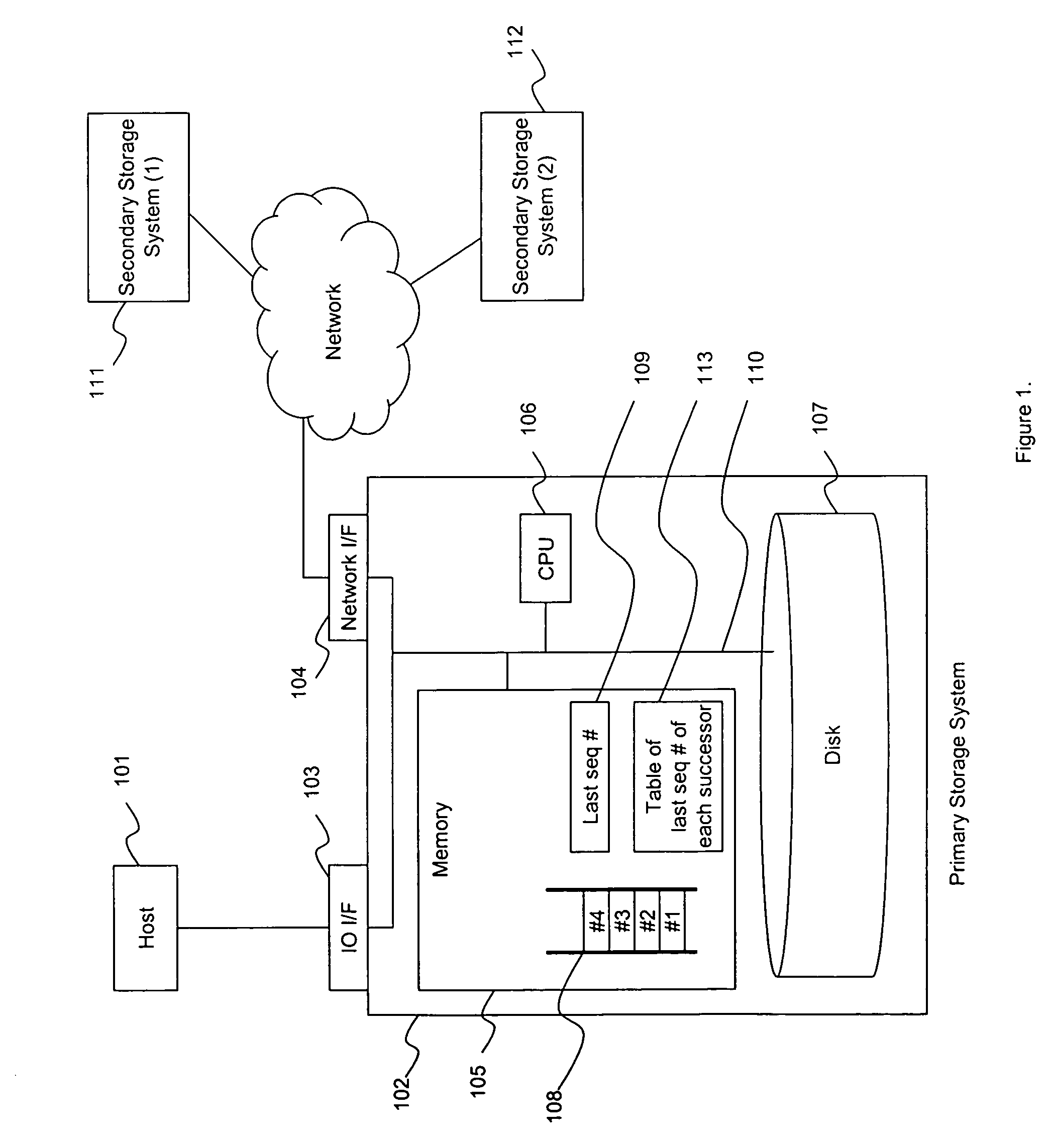

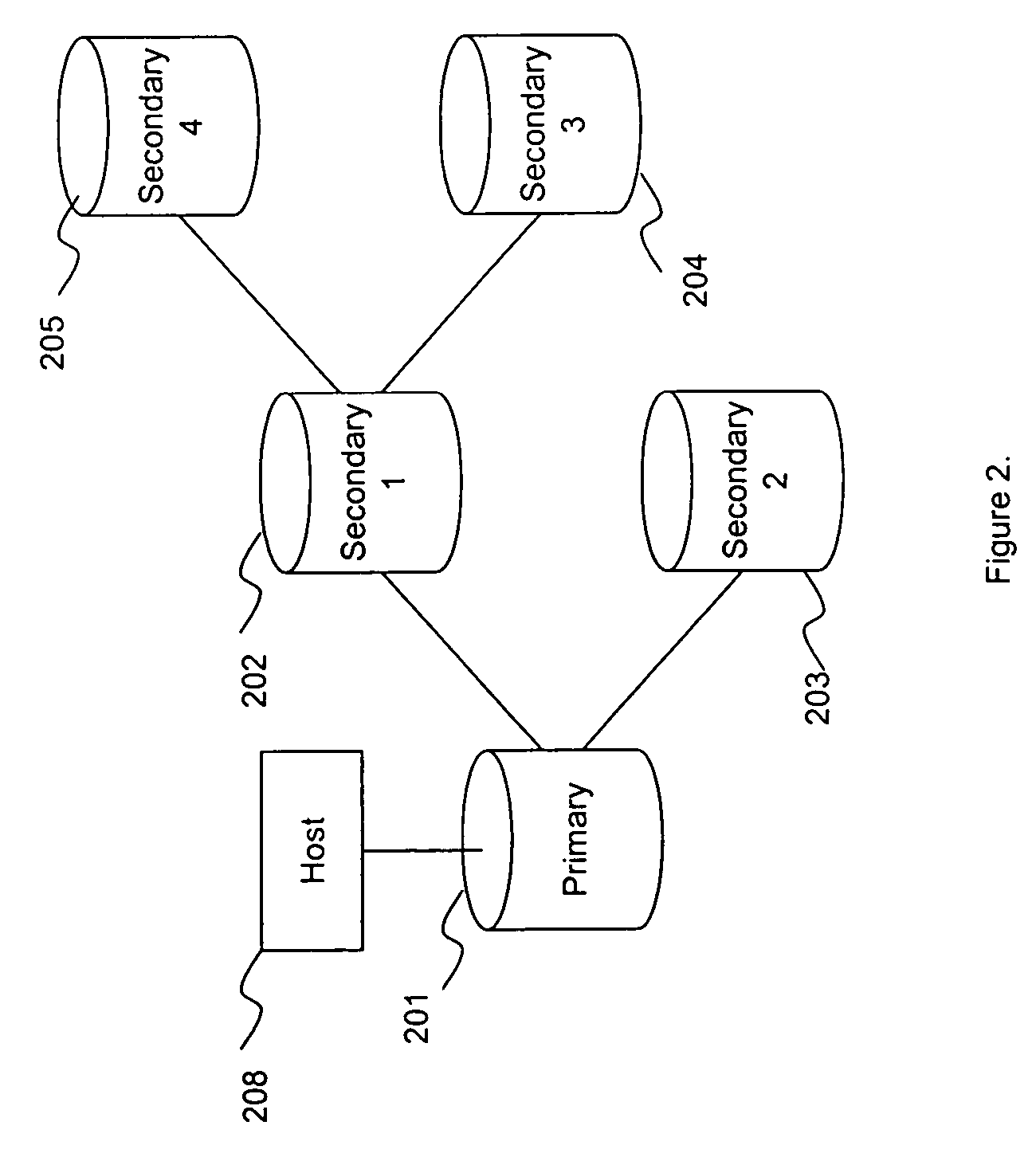

Data synchronization of multiple remote storage

InactiveUS20050198453A1Data synchronization is reducedMinimal amountData processing applicationsInput/output to record carriersComputer hardwareData synchronization

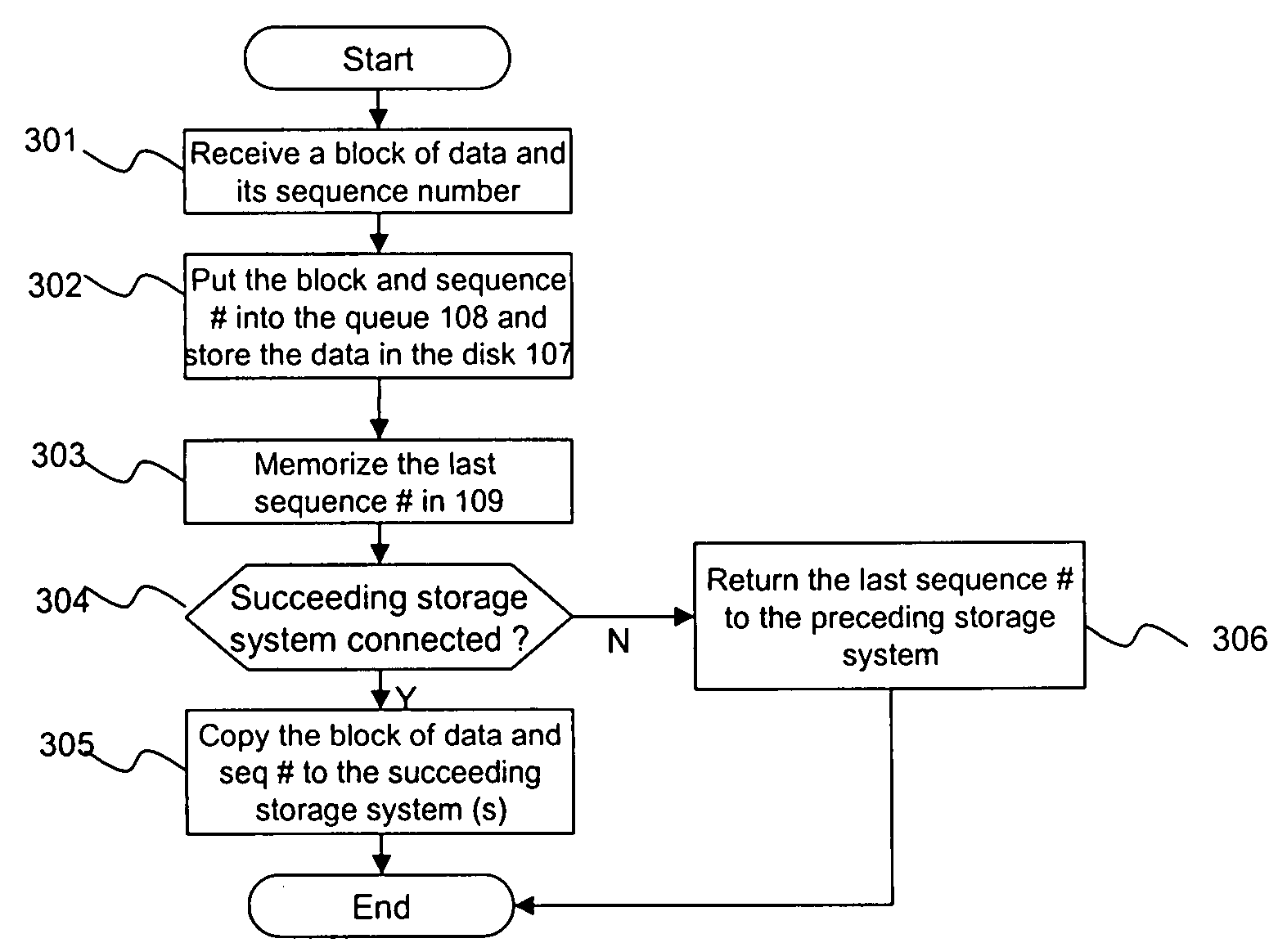

A storage system comprises a plurality of storage subsystems. One storage subsystem as a succeeding subsystem is configured to receive and store one or more blocks of data from another storage subsystem as a preceding subsystem. Each block of data has an associated sequence number in ascending order. The memory in each storage subsystem includes a queue to store the blocks of data and a sequence number associated with each block of data, a record to store a last sequence number associated with a last block of data received by the queue, and a table to store last sequence numbers stored in the last sequence number record gathered from each succeeding storage system. In some embodiments, a smallest last sequence number is determined from the last sequence numbers associated with the blocks of data in the storage subsystems. Blocks of data in the queue of each storage subsystem having associated sequence numbers less than or equal to the determined smallest last sequence number are deleted. In case of a failure of one or more storage subsystems, blocks of data are copied from the surviving storage subsystem having associated sequence numbers higher than the last sequence number of other surviving storage subsystems.

Owner:GOOGLE LLC

Bandwidth asymmetric communication system

InactiveUS20090232234A1Reduce complexityCutting synchronizationSignal allocationSynchronisation signal speed/phase controlCommunications systemUplink transmission

The present invention relates to a communication system comprising a plurality of terminals each having an uplink transmission unit (1) for transmitting radio frequency OFDM signals at a radio frequency and an access point having an uplink receiving unit (4) for concurrently receiving said radio frequency OFDM signals from at least two terminals, said OFDM signals being Orthogonal Frequency Division Multiplex (OFDM) modulated, wherein the bandwidth of said uplink transmission units and of the transmitted radio frequency OFDM signals is smaller than the bandwidth of said uplink receiving unit and that the bandwidth of at least two uplink transmission units and of their transmitted radio frequency OFDM signals is different. The present invention relates further to a communication system wherein the access point has a downlink transmission unit (7) for transmitting radio frequency OFDM signals at a radio frequency and that the at least two terminals each have a downlink receiving unit (11) for receiving said radio frequency OFDM signals, wherein the bandwidth of said downlink transmission unit is larger than the bandwidth of said downlink receiving units and that the downlink transmission unit is adapted to generate and transmit radio frequency OFDM signals having a bandwidth that is smaller than or equal to the bandwidth of the downlink transmission unit and that is equal to the bandwidth of the downlink receiving unit by which the radio frequency OFDM signals shall be received. Still further, the present invention relates to a communication method, to a terminal and to an access point for use in such a communication system.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

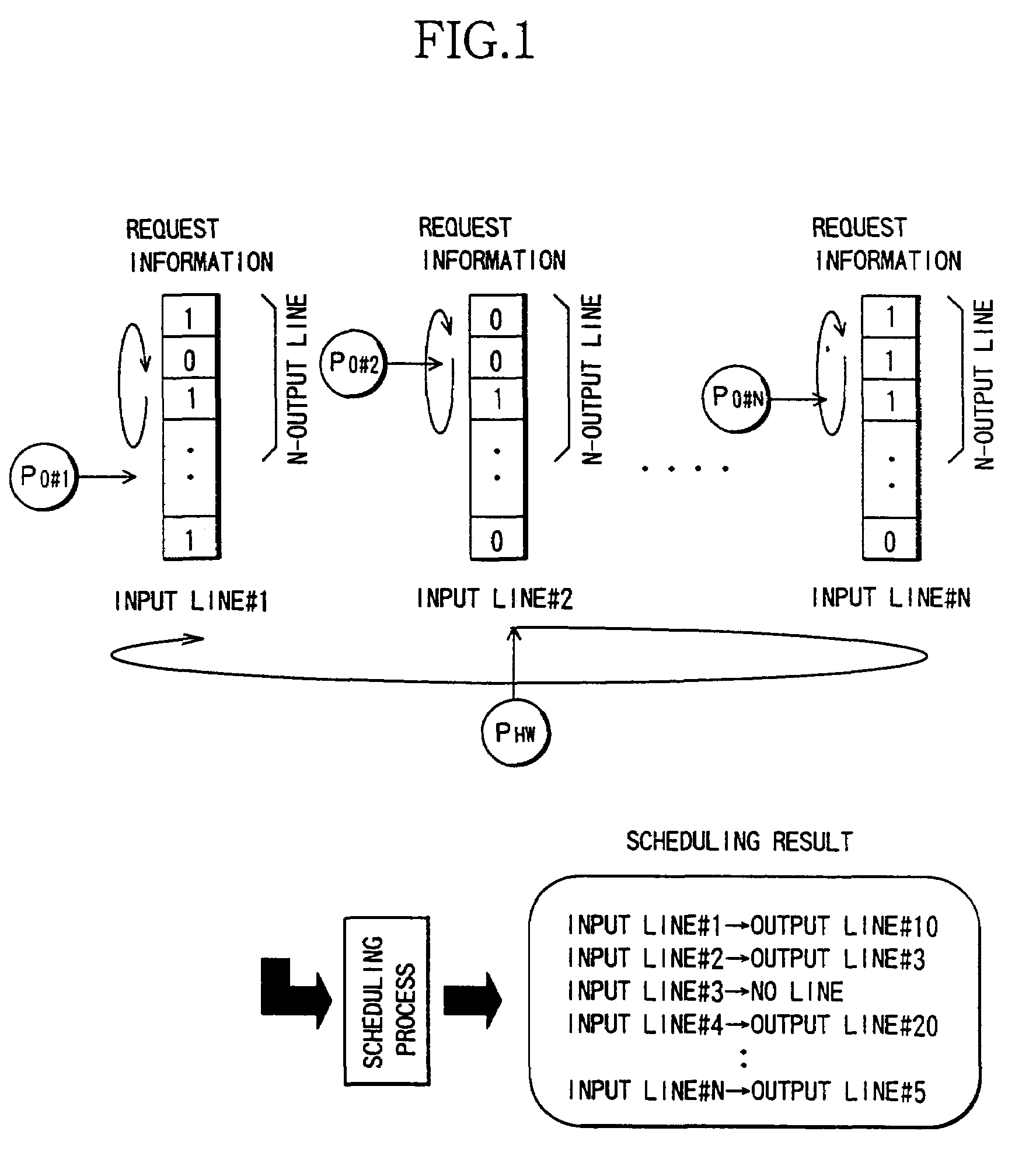

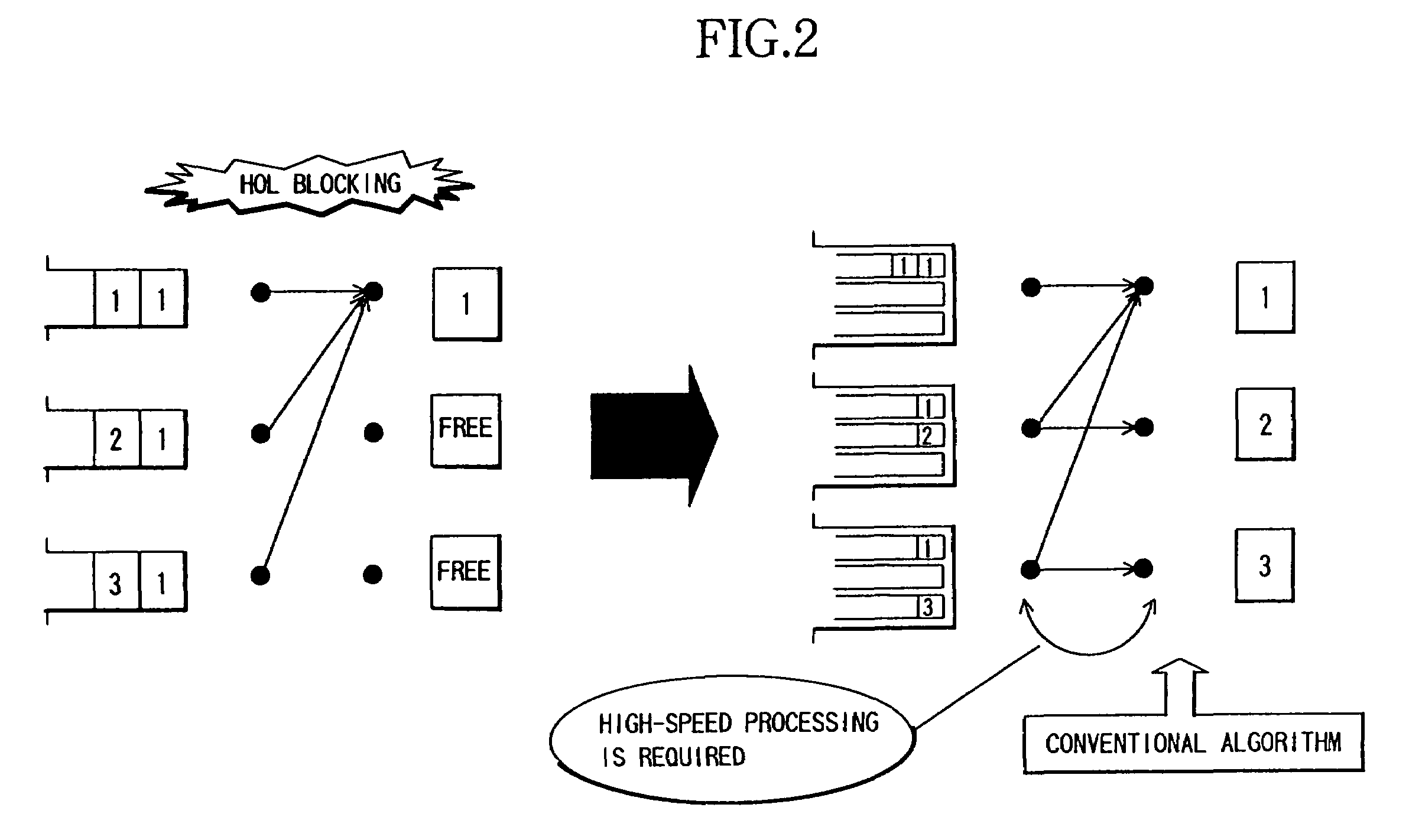

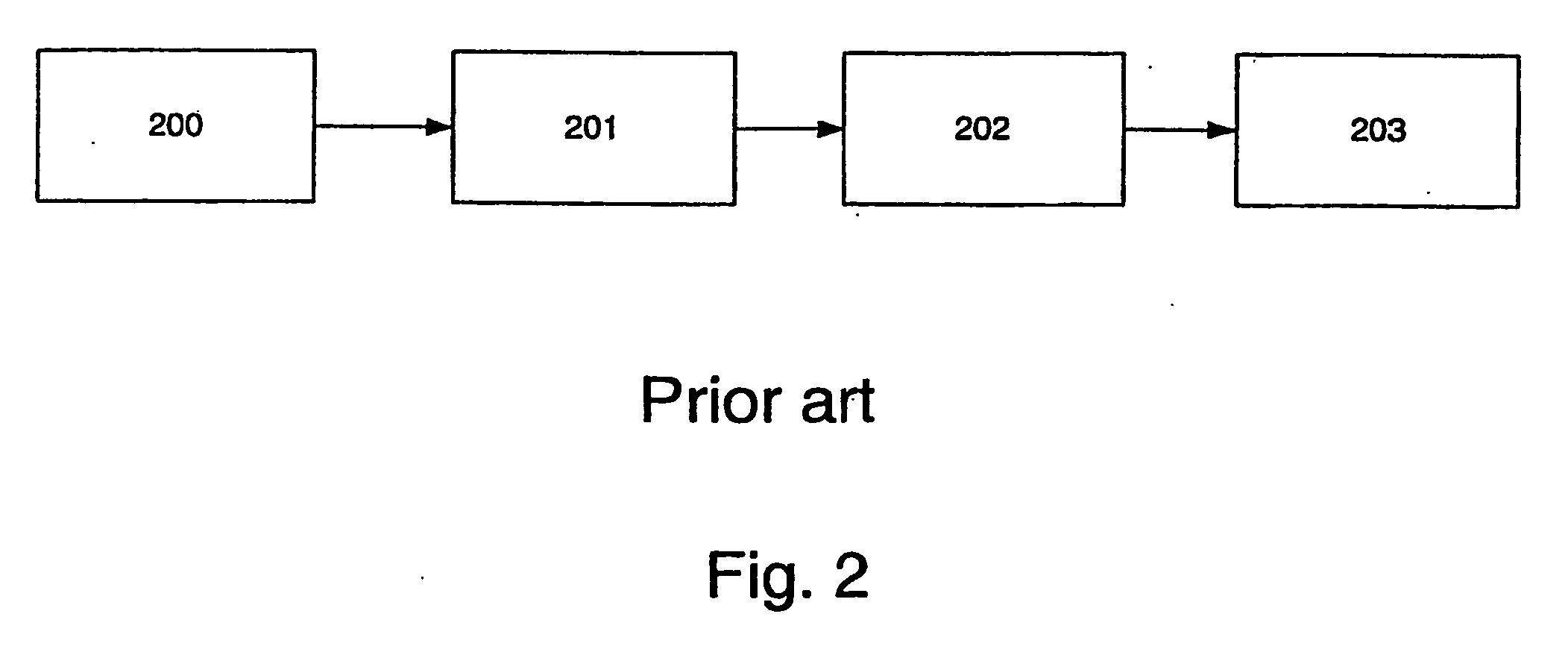

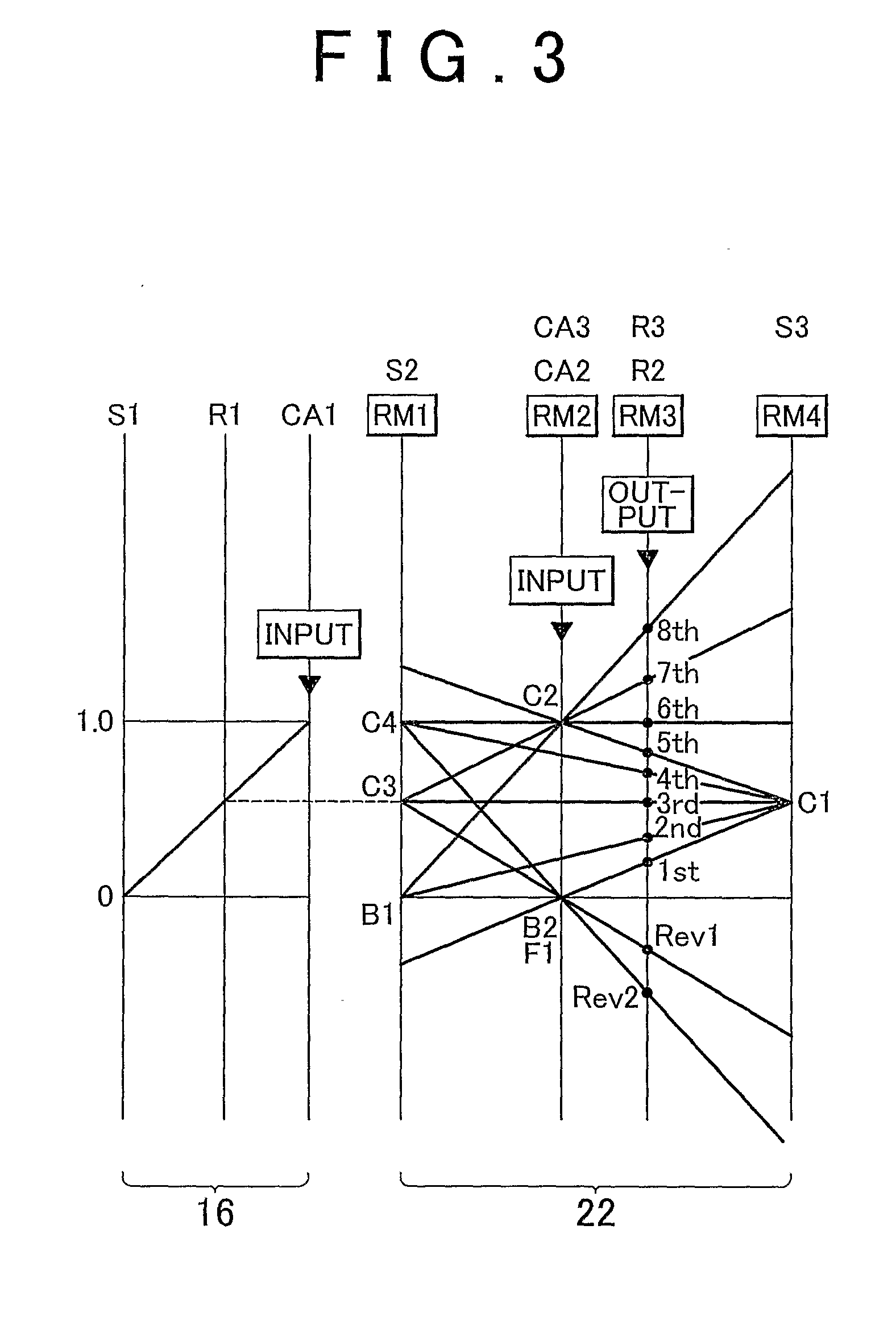

Scheduling control system and switch

InactiveUS7046685B1Shorten the timeCutting synchronizationMultiplex communicationDigital computer detailsControl systemClockwise

A scheduling system is capable of causing no deterioration of characteristics even under equal and unequal loads, eliminating the necessity for high-speed repetitive scheduling and complicated arithmetic processes, simplifying its architecture and having its processing speed which does not depend upon a device capability. For attaining this system, an inter-highway pointer is updated to an adjacent line (rightward) when the scheduling for all the lines are finished. If the inter-highway pointer is updated N-times in the same direction (clockwise), the same pointer is updated to an adjacent line in a reverse direction (counterclockwise) in next N-processes of scheduling.

Owner:FUJITSU LTD

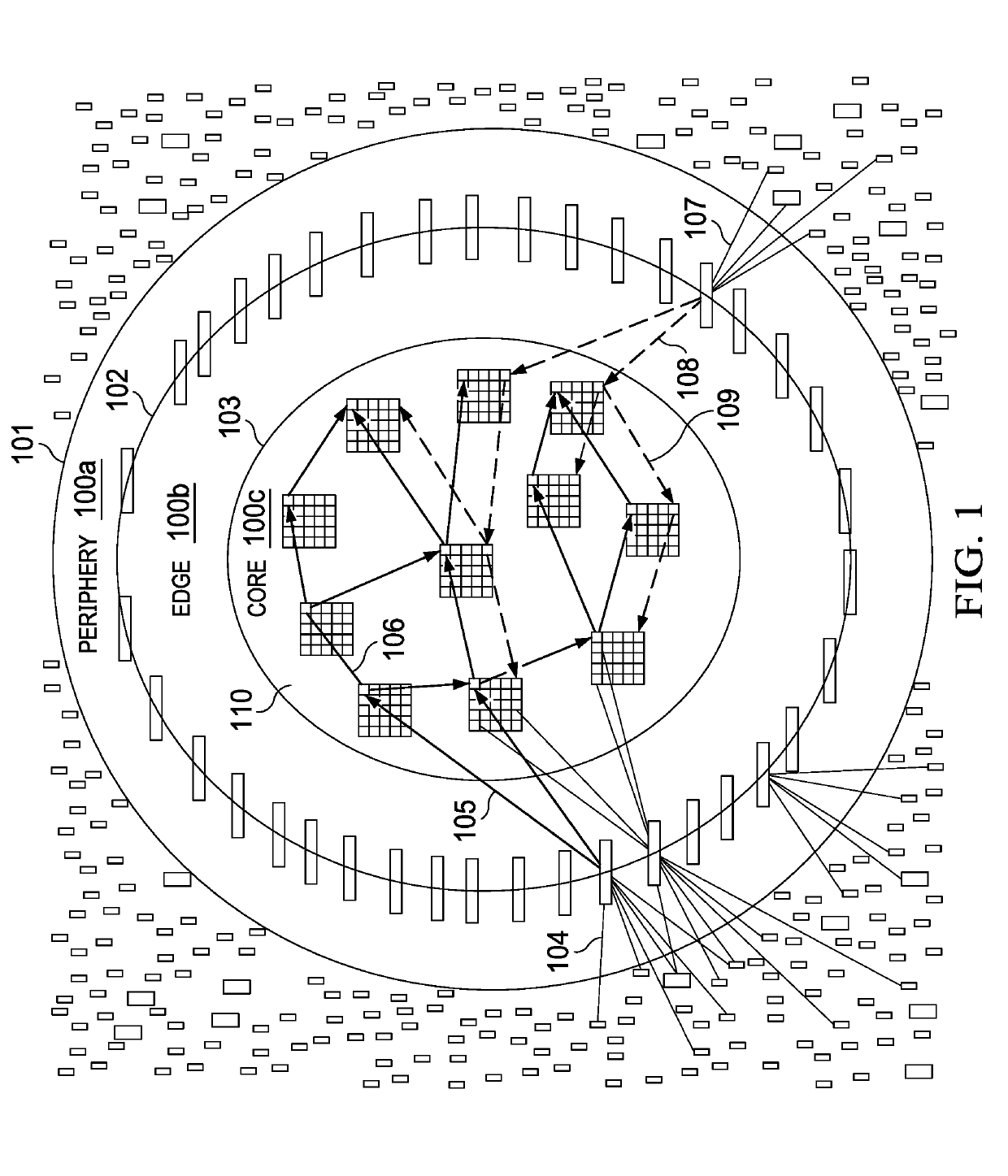

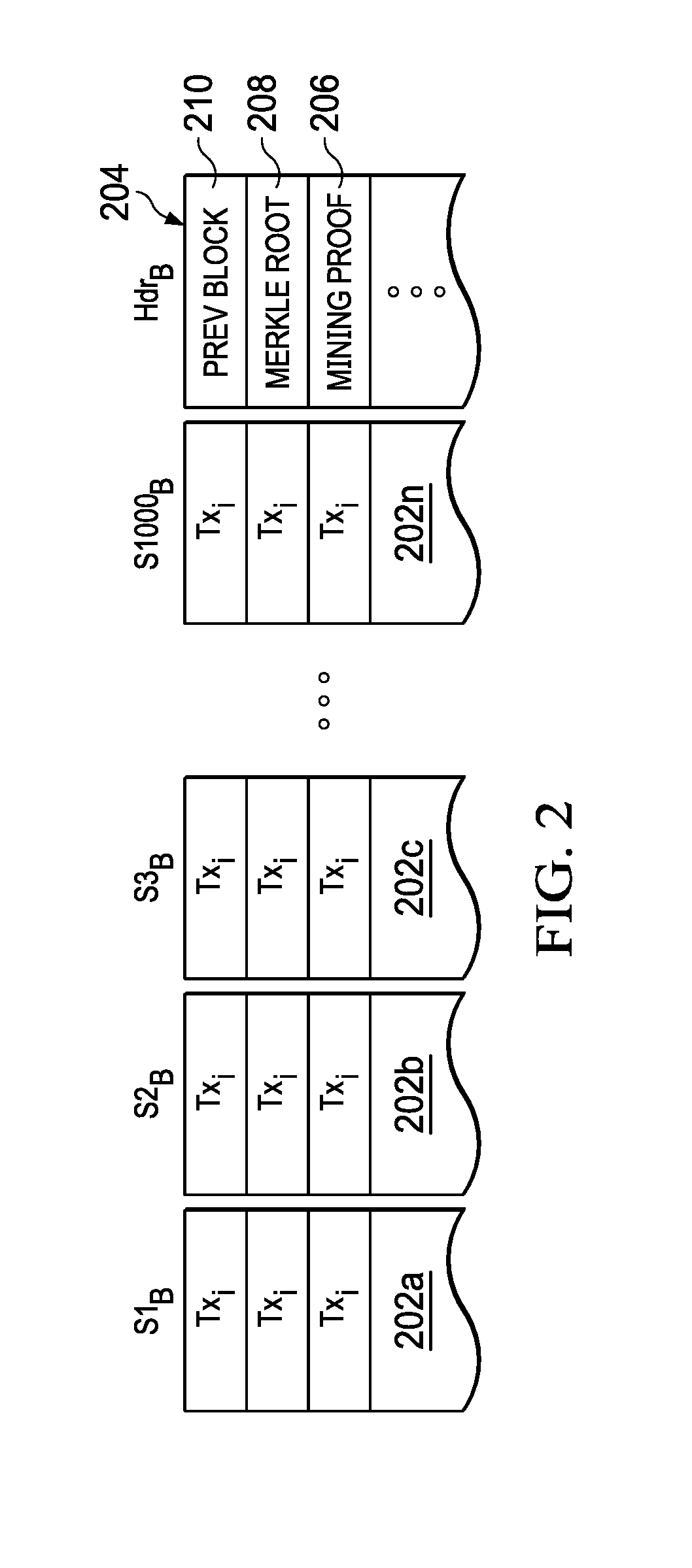

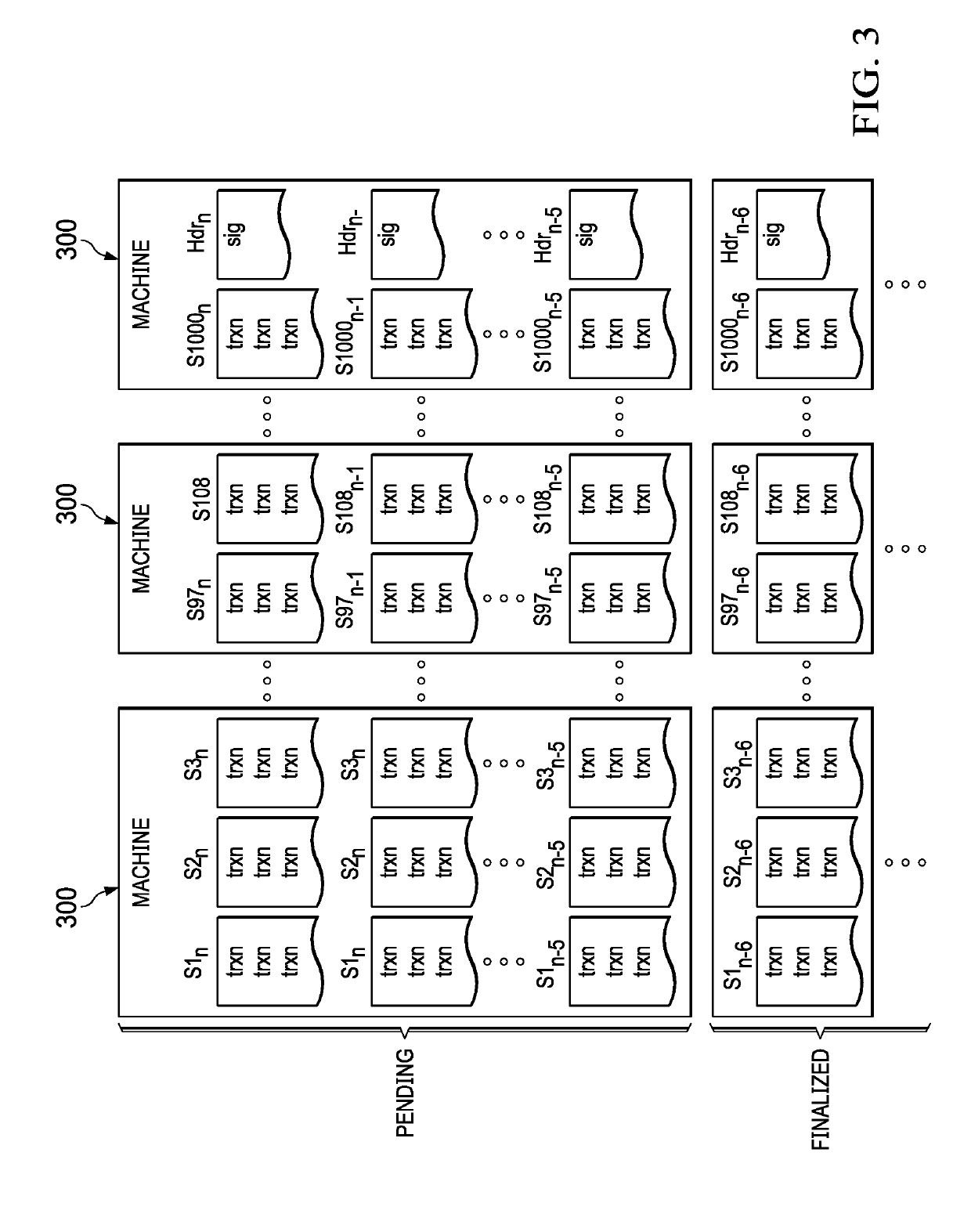

Concurrent transaction processing in a high performance distributed system of record

ActiveUS20190199515A1Little synchronizationImprove performanceEncryption apparatus with shift registers/memoriesCryptography processingCollision detectionStructure of Management Information

A high-performance distributed ledger and transaction computing network fabric over which large numbers of transactions (involving the transformation, conversion or transfer of information or value) are processed concurrently in a scalable, reliable, secure and efficient manner. In one embodiment, the computing network fabric or “core” is configured to support a distributed blockchain network that organizes data in a manner that allows communication, processing and storage of blocks of the chain to be performed concurrently, with little synchronization, at very high performance and low latency, even when the transactions themselves originate from distant sources. This data organization relies on segmenting a transaction space within autonomous but cooperating computing nodes that are configured as a processing mesh. Each computing node typically is functionally-equivalent to all other nodes in the core. The nodes operate on blocks independently from one another while still maintaining a consistent and logically-complete view of the blockchain as a whole. According to another feature, safe and performant transaction processing is provided using an optimistic concurrently control that includes a collision detection and undo mechanism.

Owner:AKAMAI TECH INC

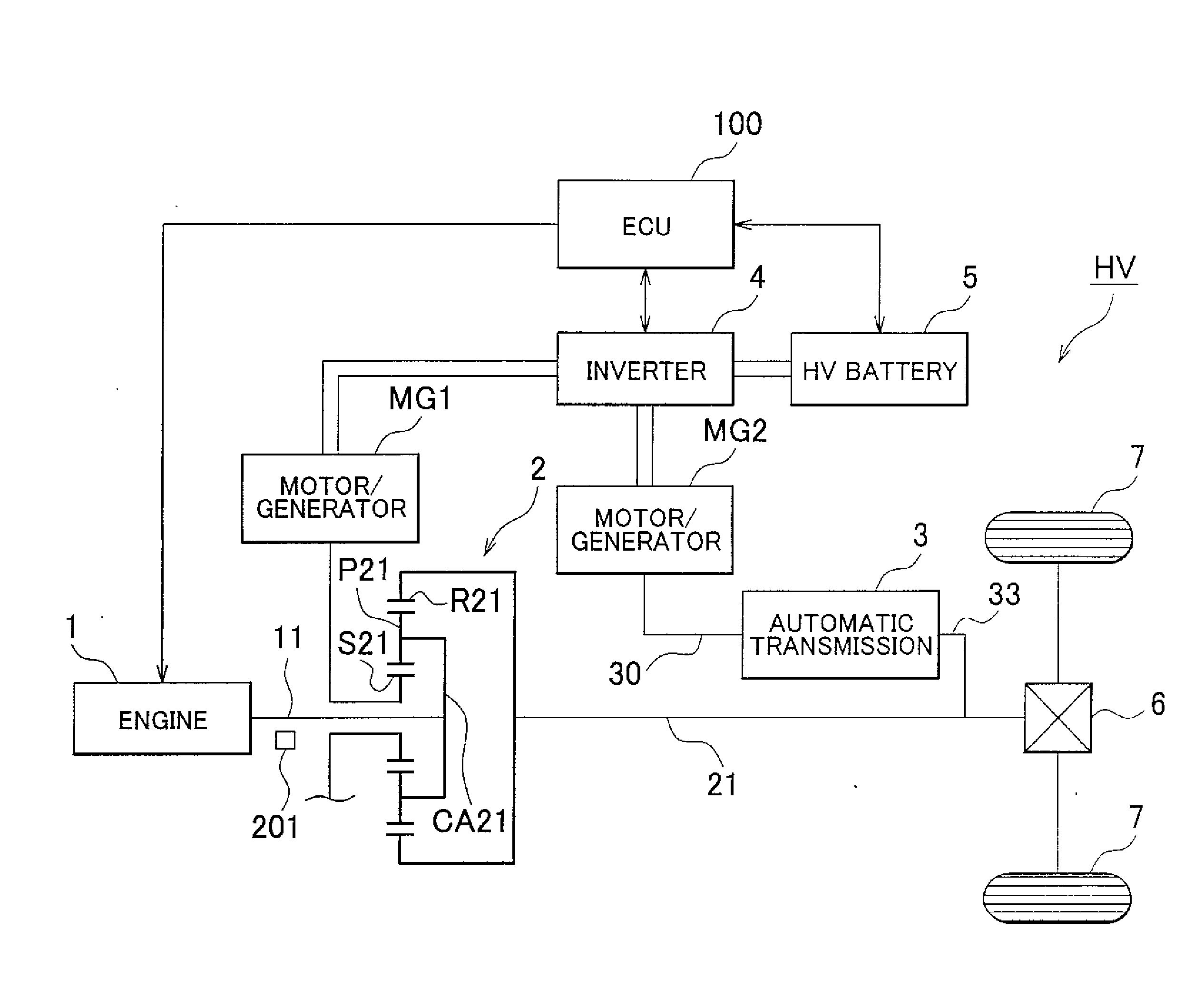

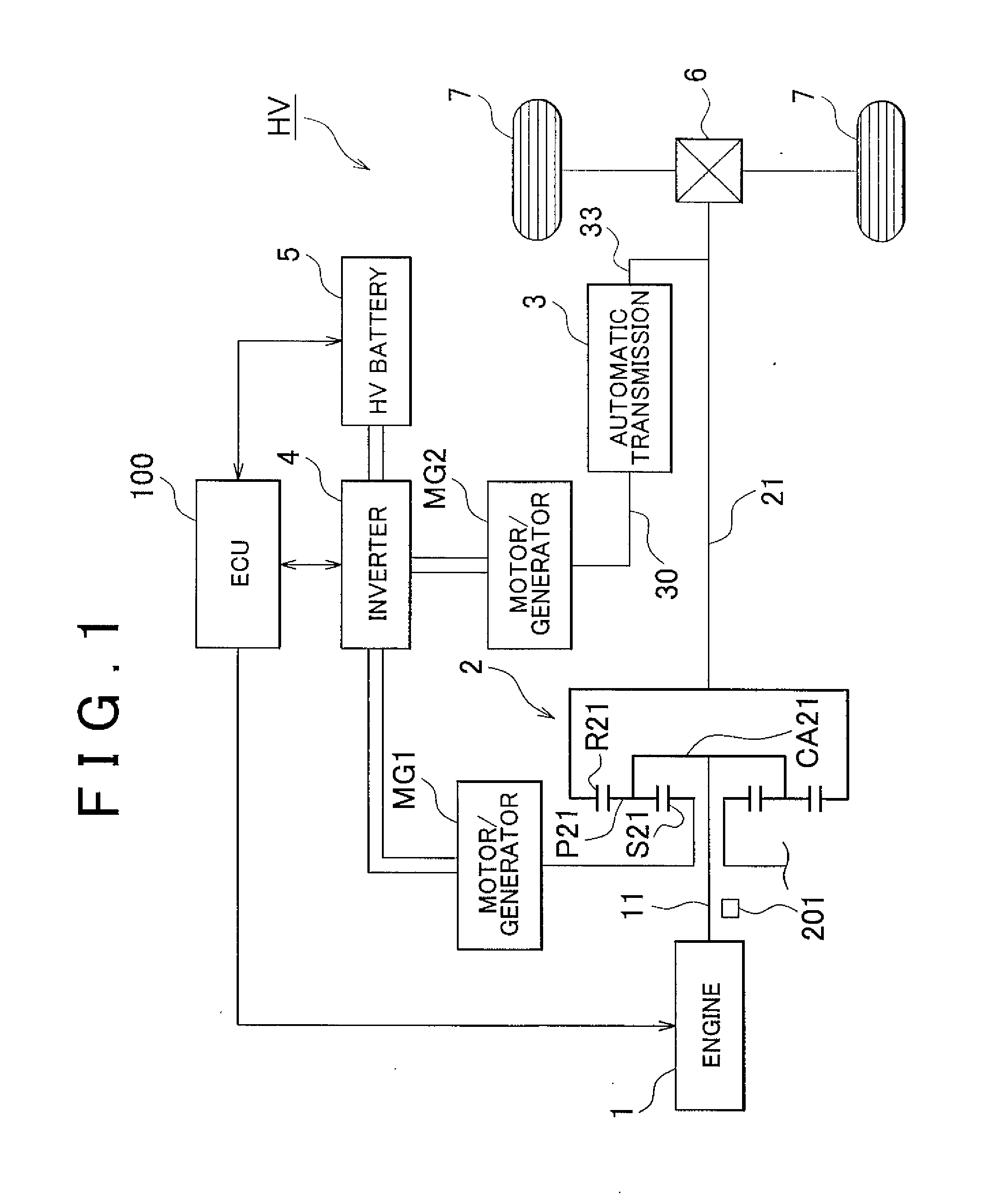

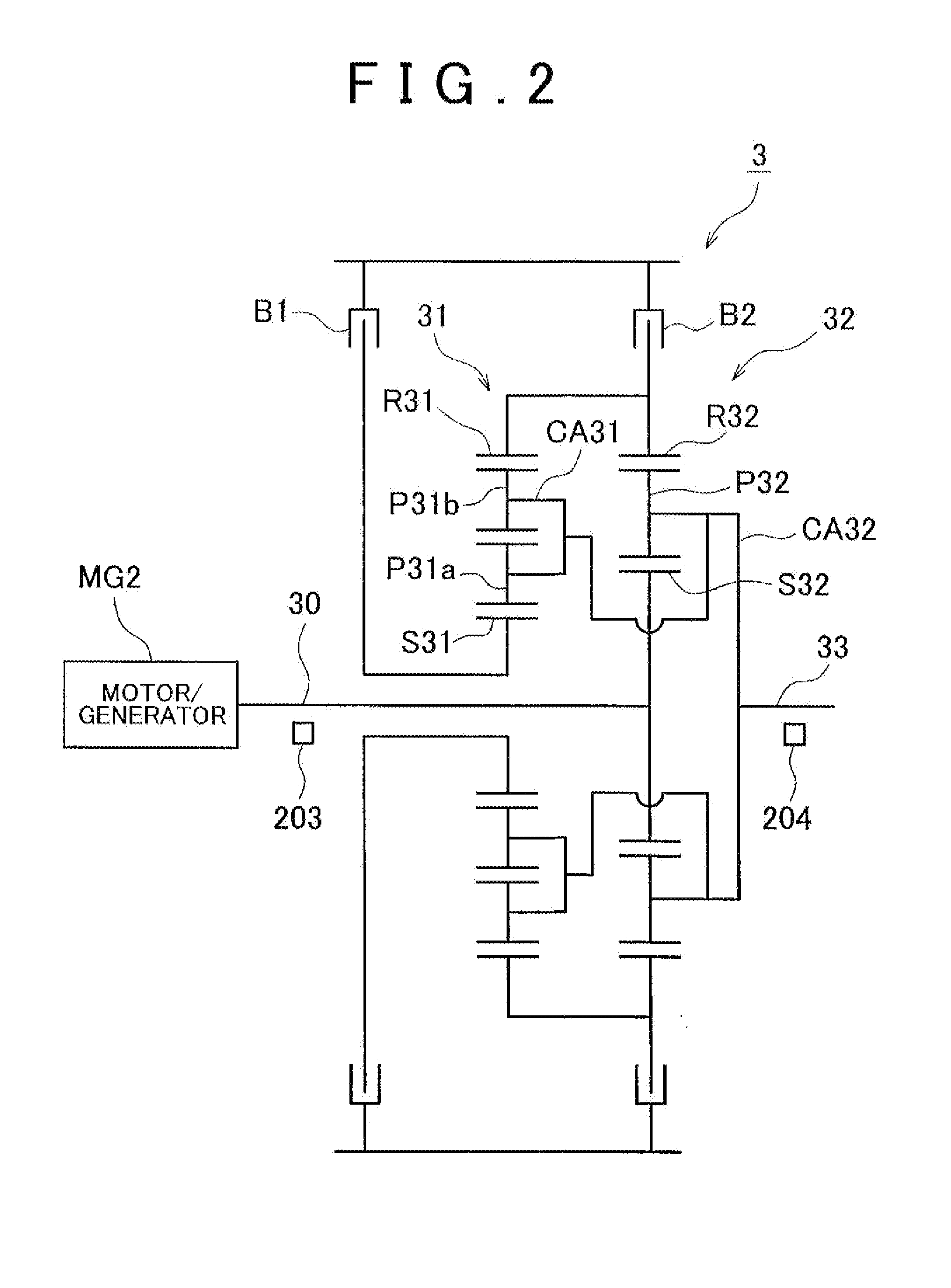

Vehicular control apparatus and control system

InactiveUS20080220933A1Reduce shockCutting synchronizationHybrid vehiclesSpeed controllerAutomatic transmissionTransmitted power

A control apparatus for a vehicle is provided with an electric motor that outputs driving force for running the vehicle; an automatic transmission that establishes a plurality of gears by selectively applying and releasing a plurality of friction apply elements in a predetermined combination for each gear among the plurality of gears, and transmits power from the electric motor to an output shaft of the vehicle; and a torque controlling portion which, when there is a demand for a power-off downshift, controls output torque of the electric motor such that input torque of the automatic transmission becomes constant torque during an inertia phase of that shift, and controls the output torque of the electric motor such that the output torque of the automatic transmission comes to match the torque required after the shift, after rotation synchronization by an apply-side friction apply element is complete.

Owner:TOYOTA JIDOSHA KK

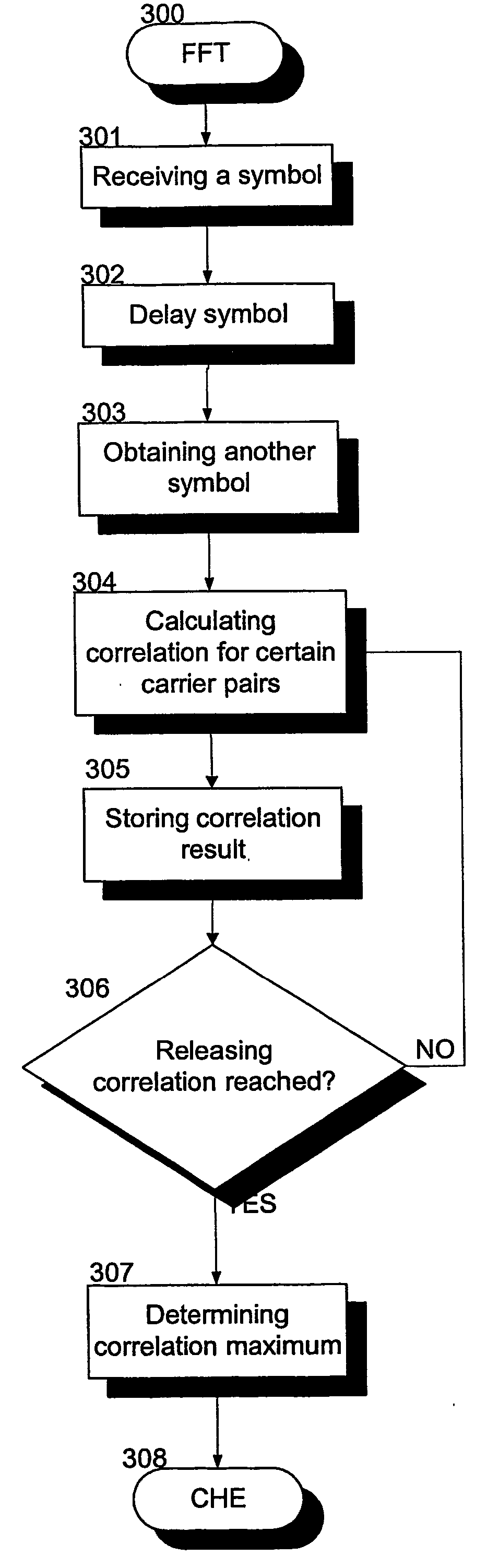

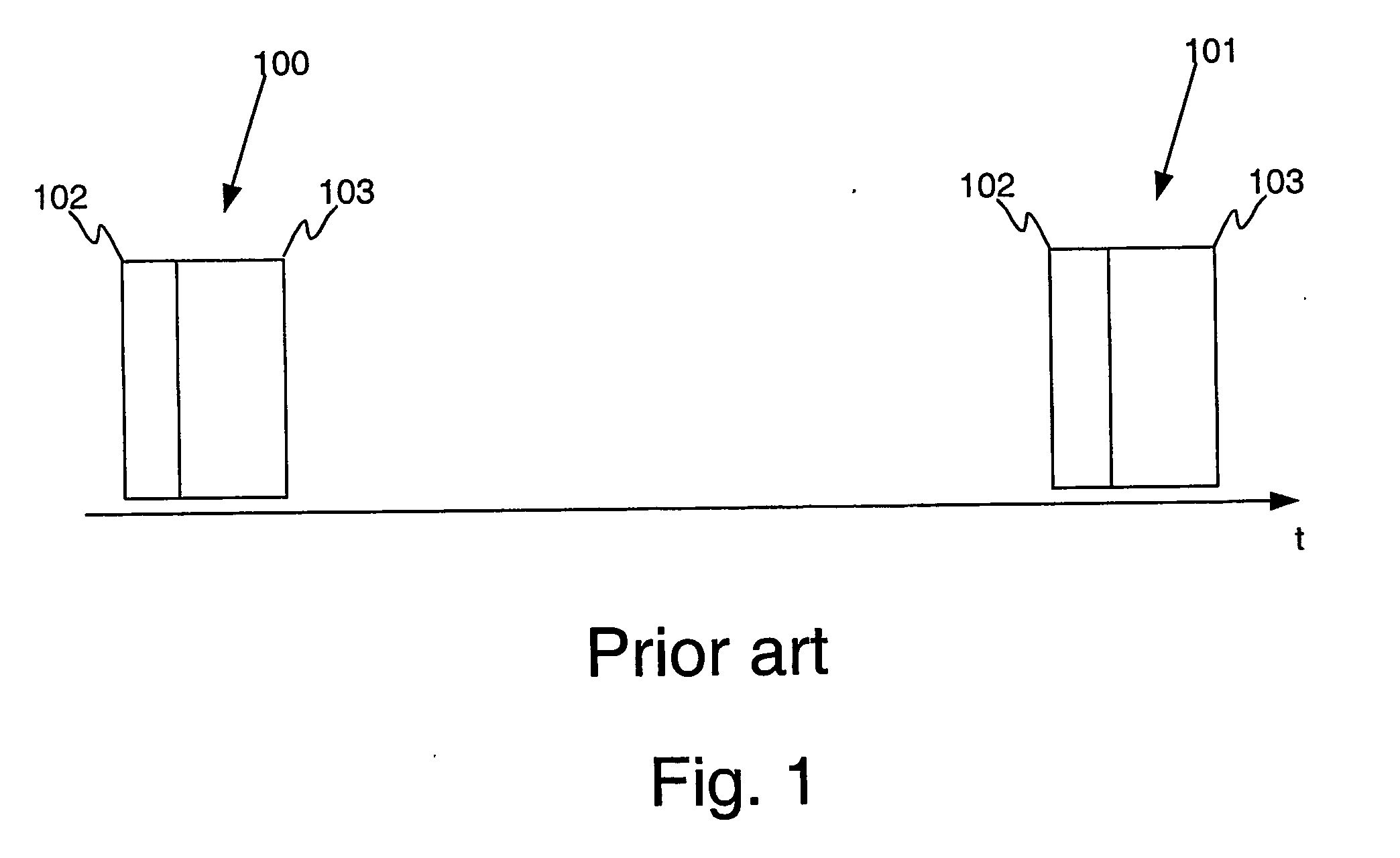

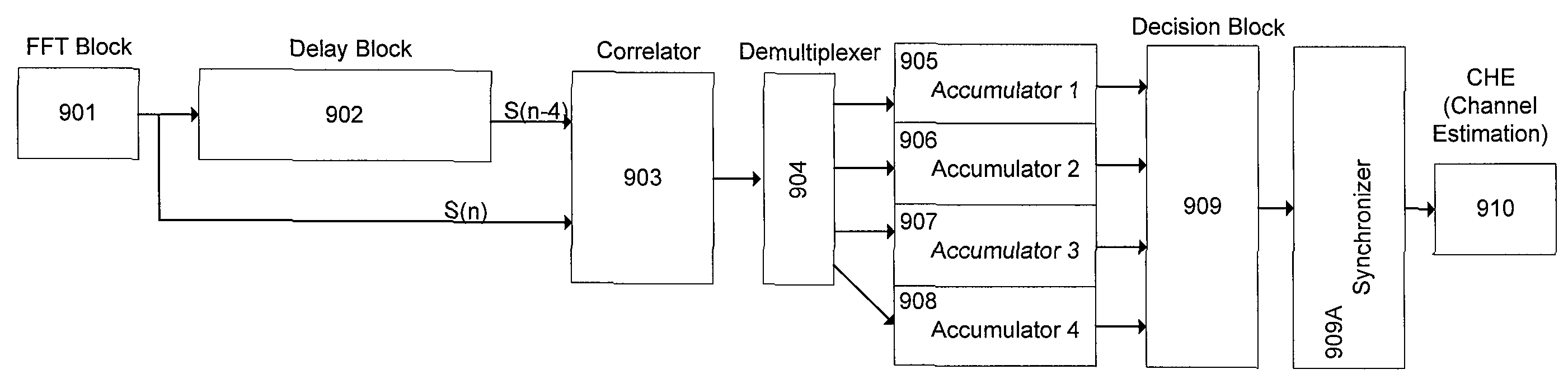

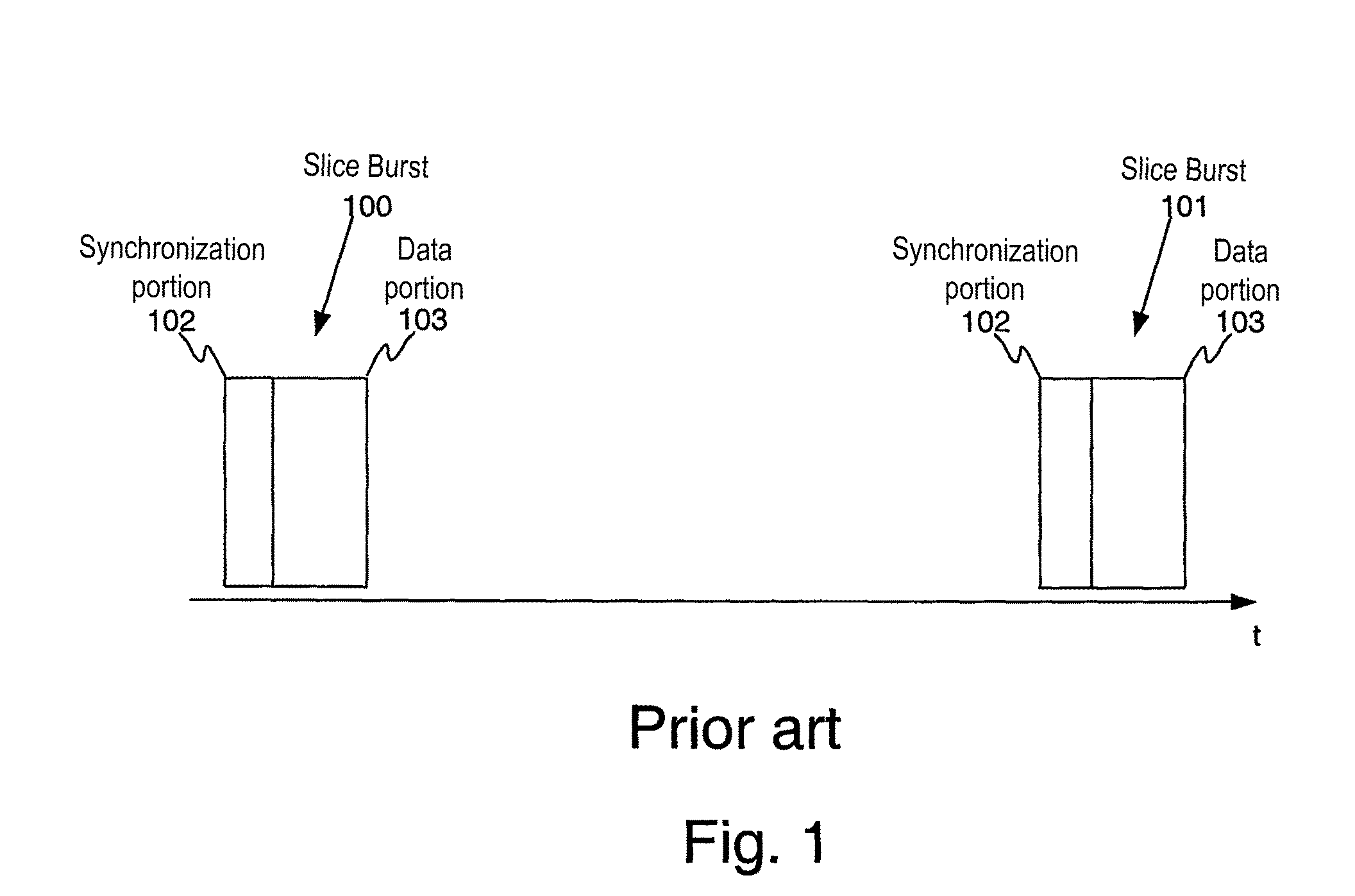

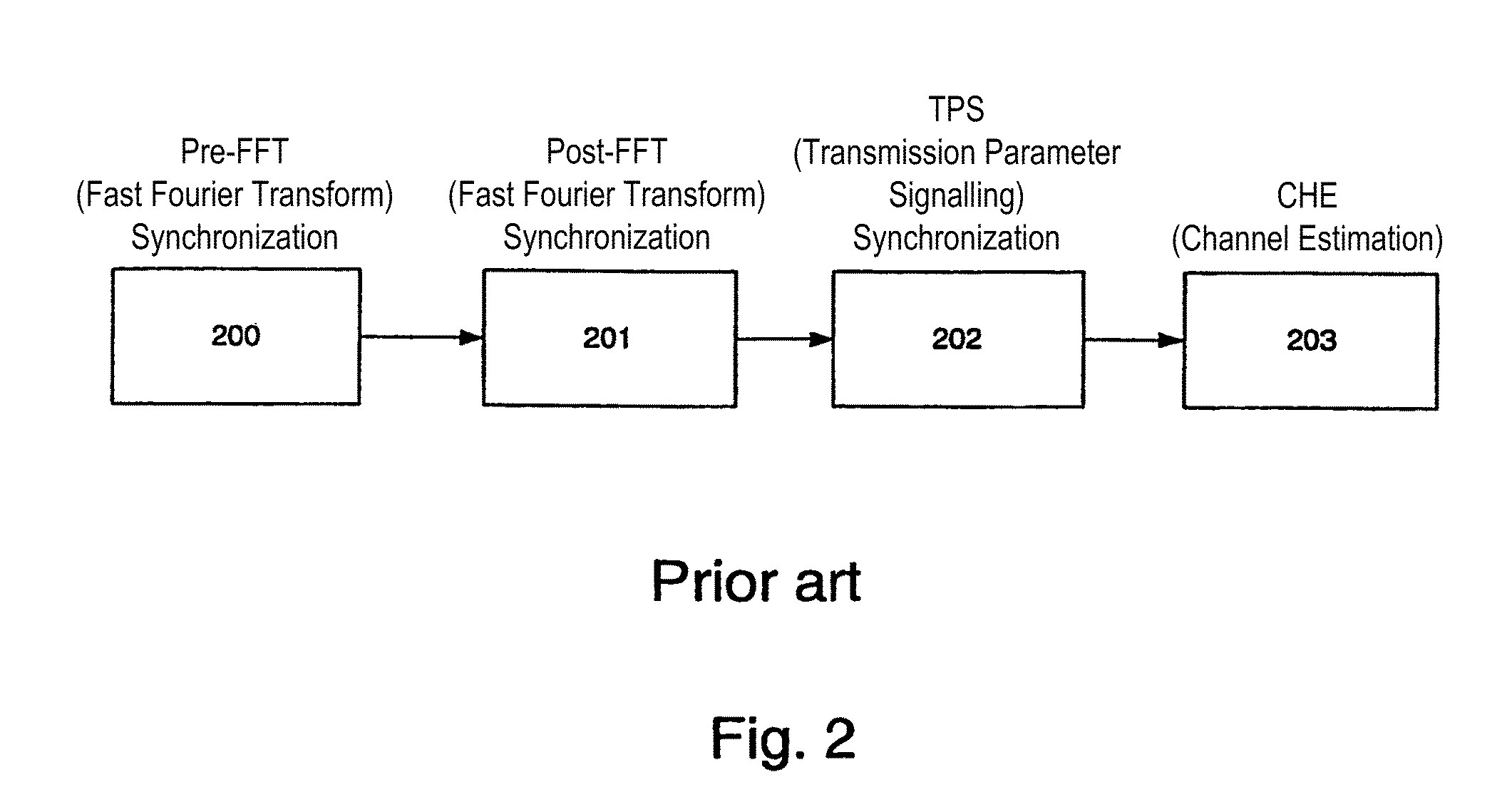

Method, system and receiver in receiving a multi-carrier transmission

InactiveUS20070053448A1Fast wayCutting synchronizationTransmission control/equlisationTime-division multiplexCarrier signalEngineering

Mobile handheld terminals receiving DVB transmission require relatively low power consumption and TDM based transmission can be used to reduce power of the terminals. In order find pilot carrier position at least two symbols are accessed which are adapted to establish a correspondence pattern for pilot carriers in a matrix of the at least two symbols. Carriers of the first symbol are correlated with the corresponding carriers of the second symbol within the matrix for determining a correlation maximum for indicating a pilot carrier position.

Owner:WSOU INVESTMENTS LLC

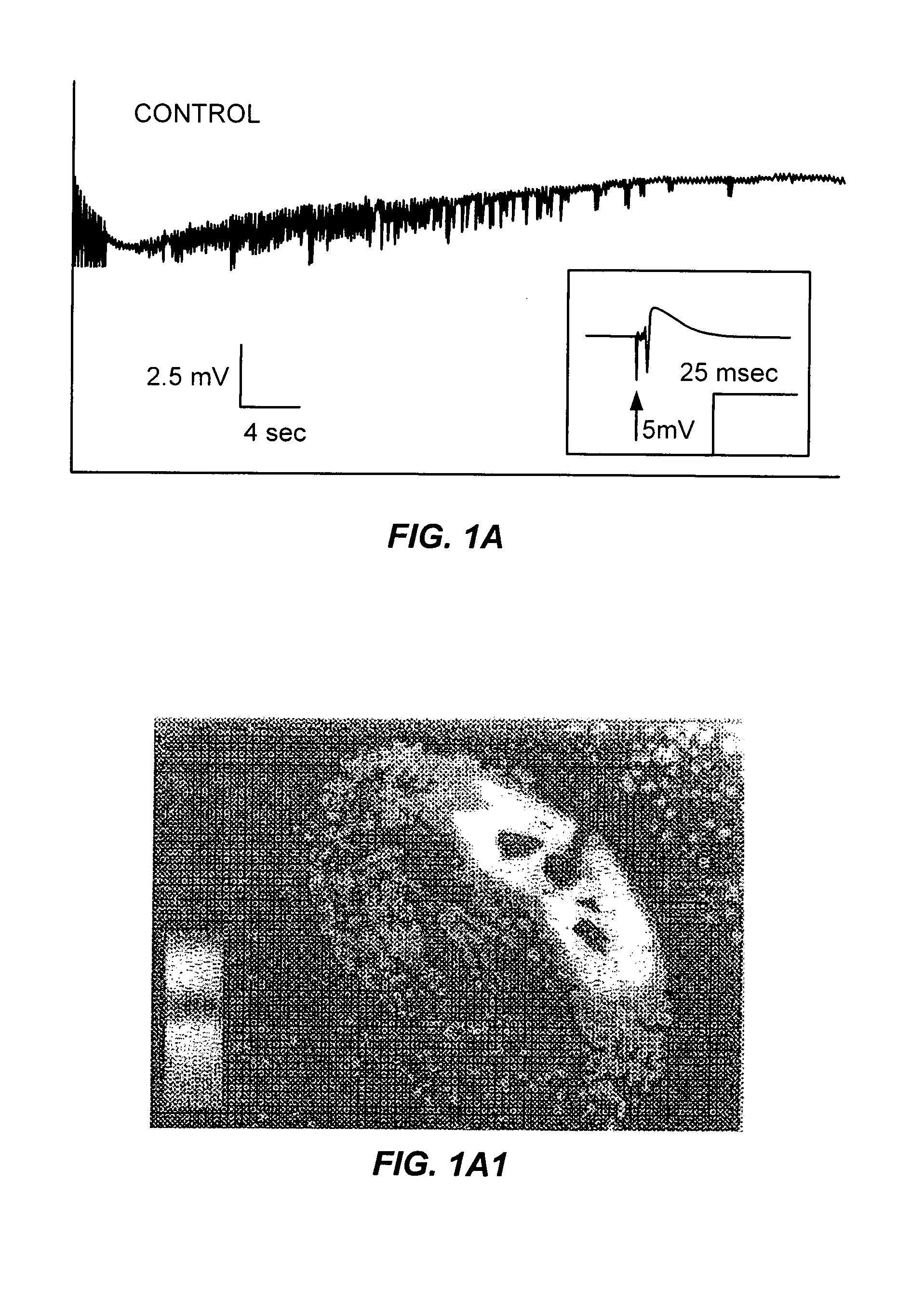

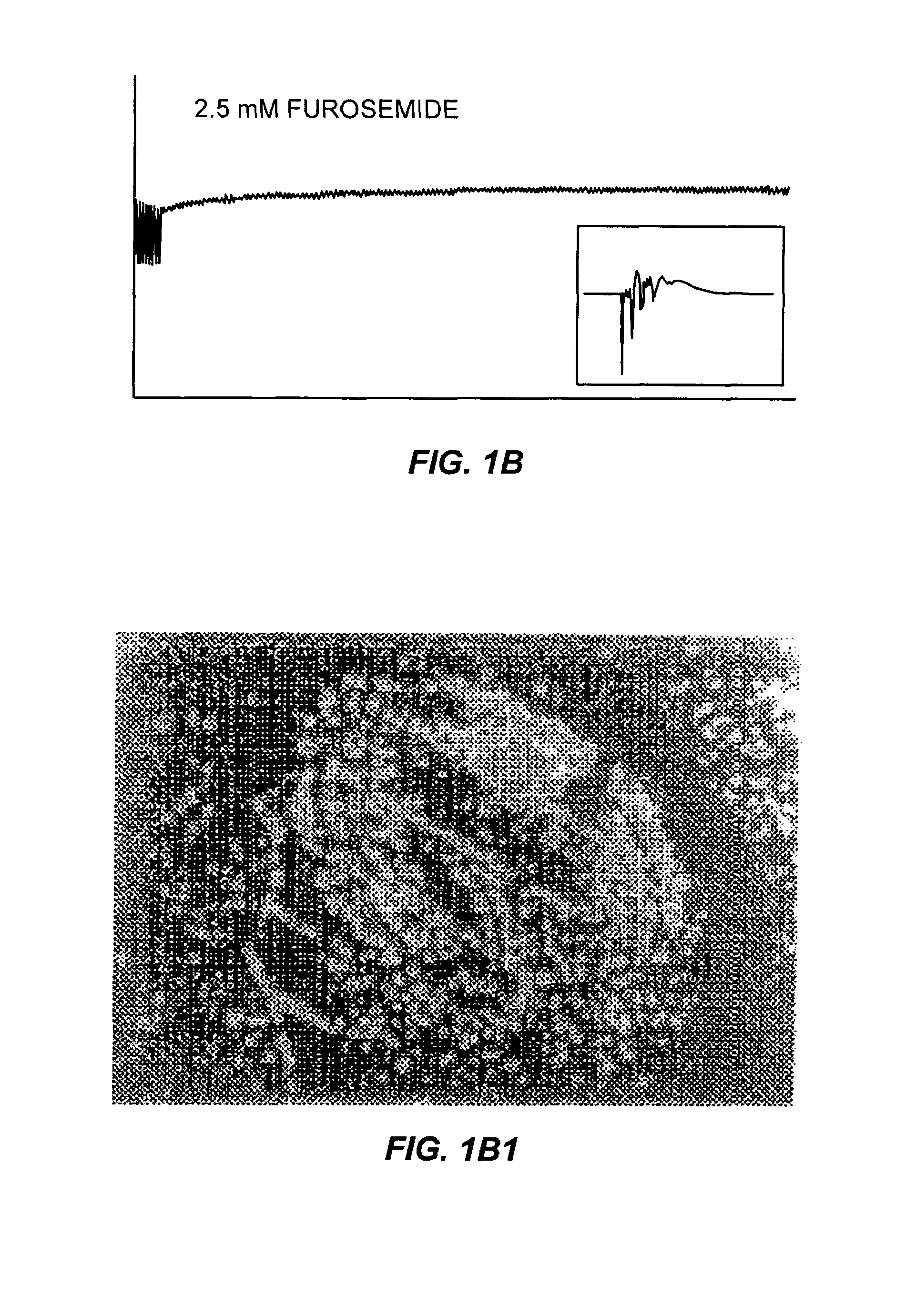

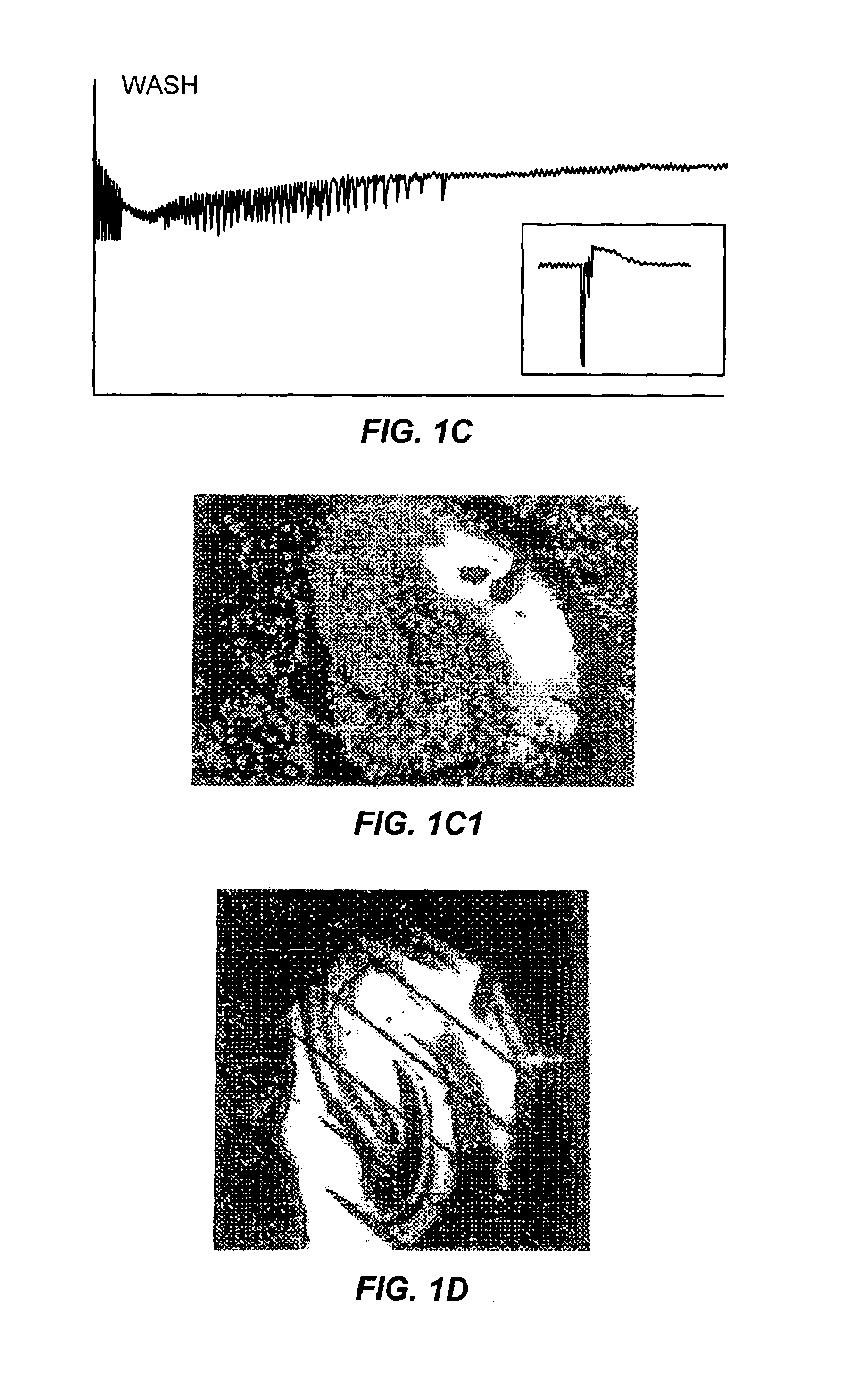

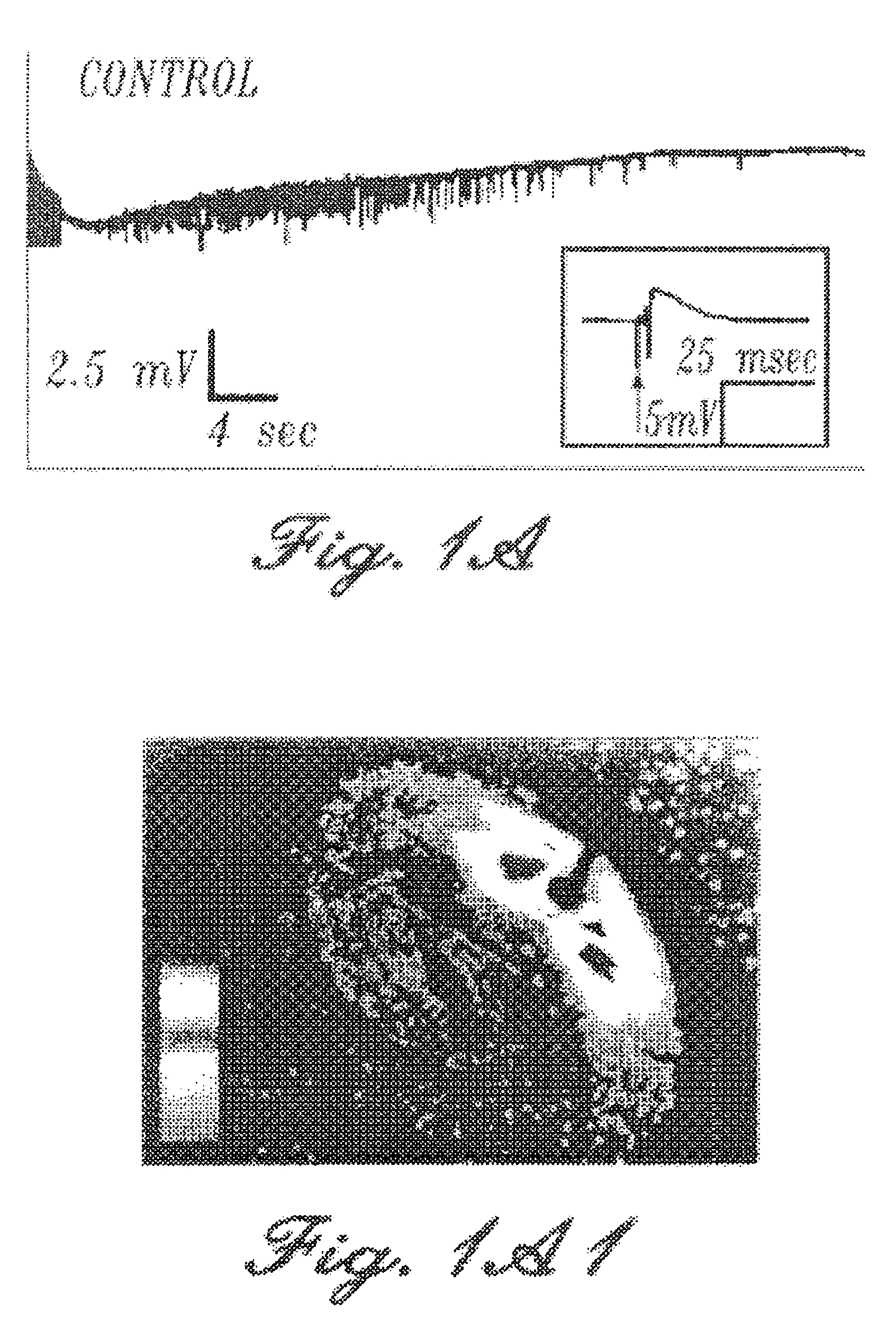

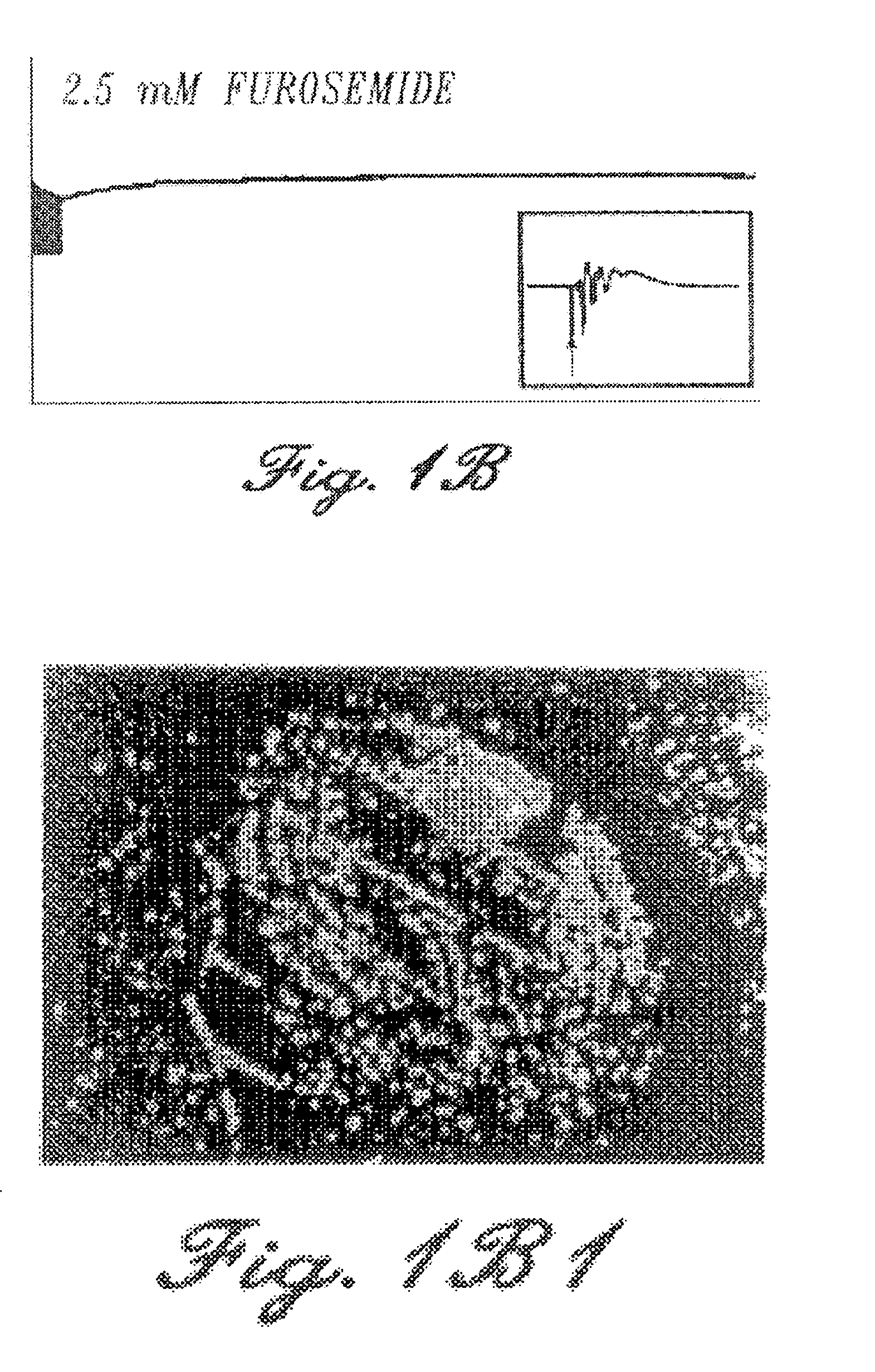

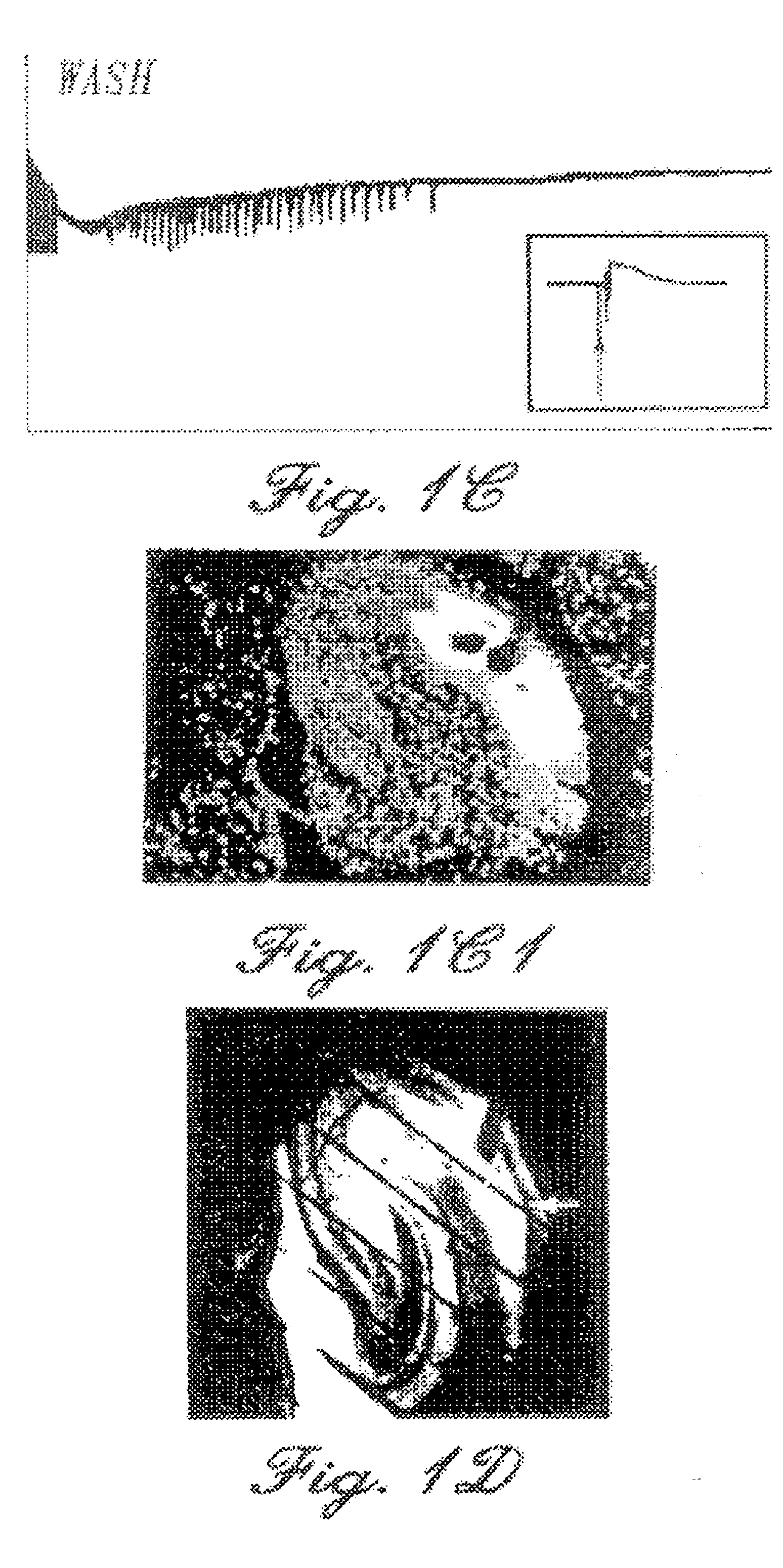

Method of treating migraine headache without aura

InactiveUS7214711B2Function increaseUseful in treatmentBiocideNervous disorderNervous systemTreatment pain

The present invention relates to methods and compositions for treating selected conditions of the central and peripheral nervous systems employing non-synaptic mechanisms. More specifically, one aspect of the present invention relates to methods and materials for treating seizure and seizure disorders, epilepsy, status epilepticus, migraine, spreading depression, intracranial hypertension; for treating the pathophysiological effects of head trauma, stroke, ischemia and hypoxia; for treating or protecting from the pathophysiological effects of neurotoxic agents such as ethanol; and for treating neurophsyciatric disorders and central nervous system edema by administering agents that modulate ionic concentrations and / or ionic gradients in the brain, particularly ion-dependent or cation-chloride cotransporter antagonists. Electrolyte cotransport antagonists and combinations of such compositions with other agents for treating various conditions are disclosed. The present invention also relates to methods and compositions for treating pain by administering ion-dependent cotransporter antagonists. Methods and compositions for enhancing cortical function, for example, in centers of cognition, learning and memory, by administering ion-dependent cotransporter agonists are disclosed.

Owner:NEUROTHERAPEUTICS PHARMA

Compositions and methods for the treatment of disorders of the central and peripheral nervous systems

InactiveUS20060035914A1Reducing neurodegenerative effectReduced activitySalicyclic acid active ingredientsBiocideDiseaseNervous system

The present invention relates to methods and compositions for treating selected conditions of the central and peripheral nervous systems employing non-synaptic mechanisms. More specifically, one aspect of the present invention relates to methods and materials for treating seizure and seizure disorders, epilepsy, status epilepticus, migraine, spreading depression, intracranial hypertension; for treating the pathophysiological effects of head trauma, stroke, ischemia and hypoxia; for treating or protecting from the pathophysiological effects of neurotoxic agents such as ethanol; and for treating neuropsychiatric disorders and central nervous system edema by administering agents that modulate ionic concentrations and / or ionic gradients in the brain, particularly ion-dependent or cation-chloride cotransporter antagonists. Electrolyte cotransport antagonists and combinations of such compositions with other agents for treating various conditions are disclosed.

Owner:NEUROTHERAPEUTICS PHARMA

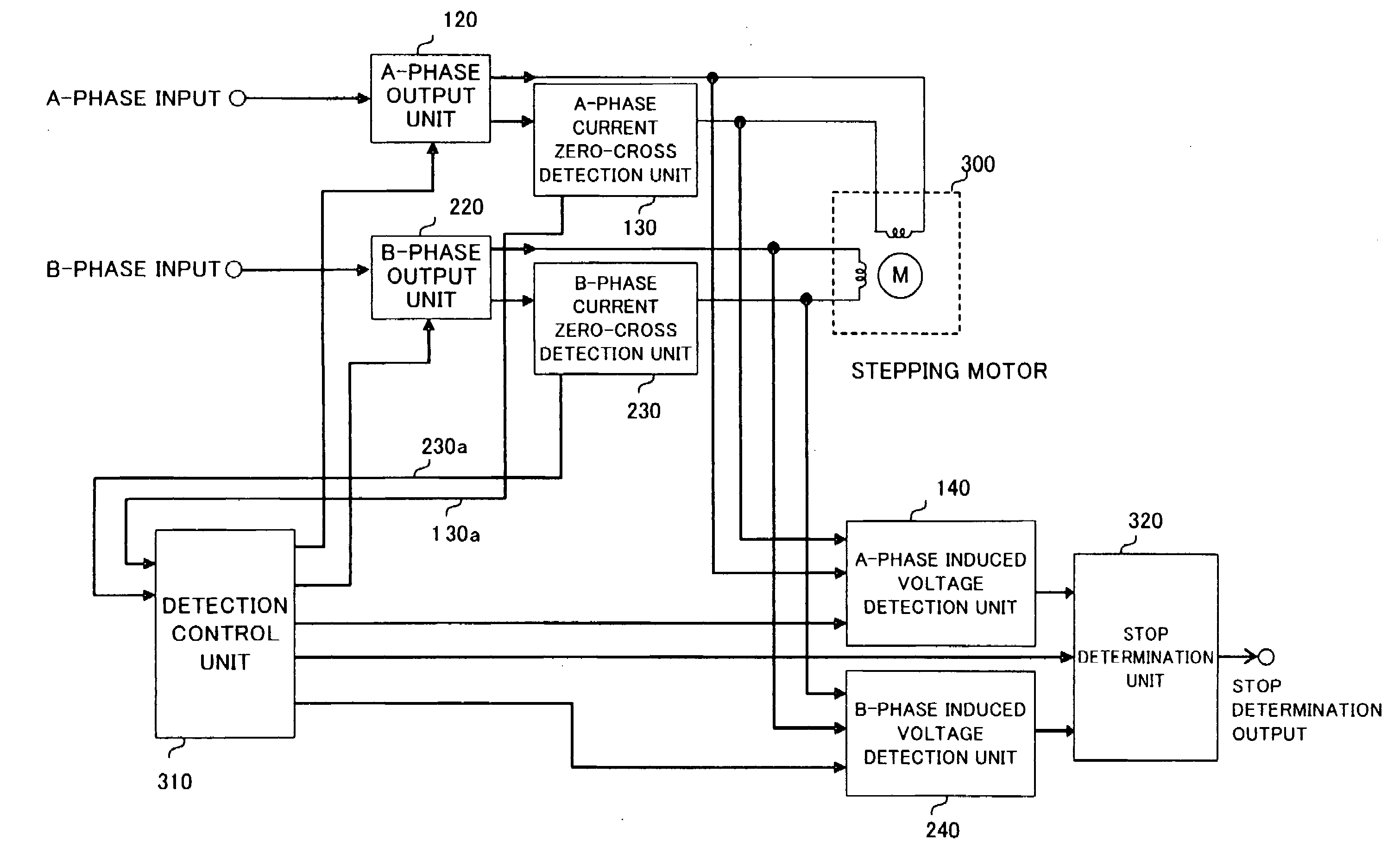

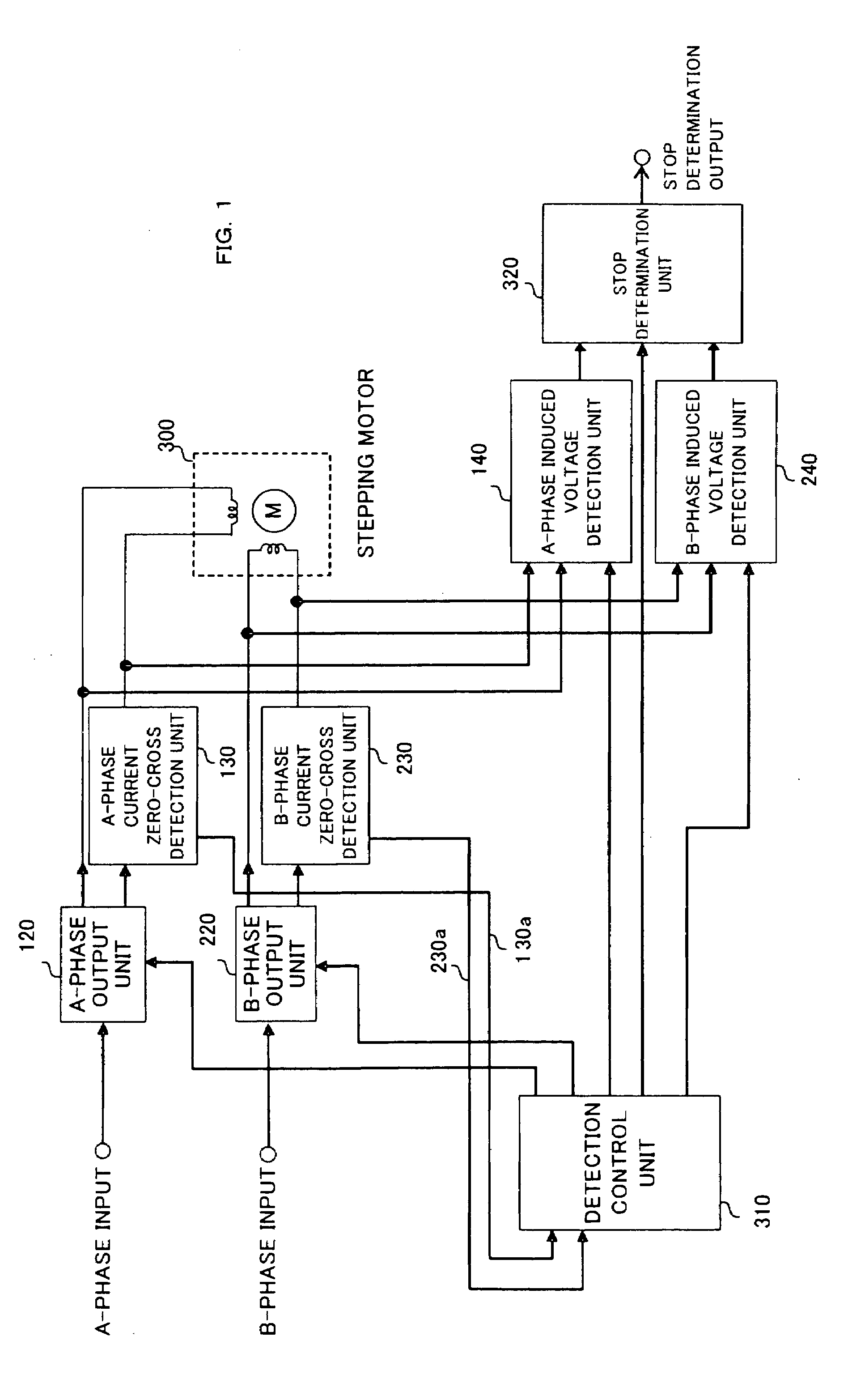

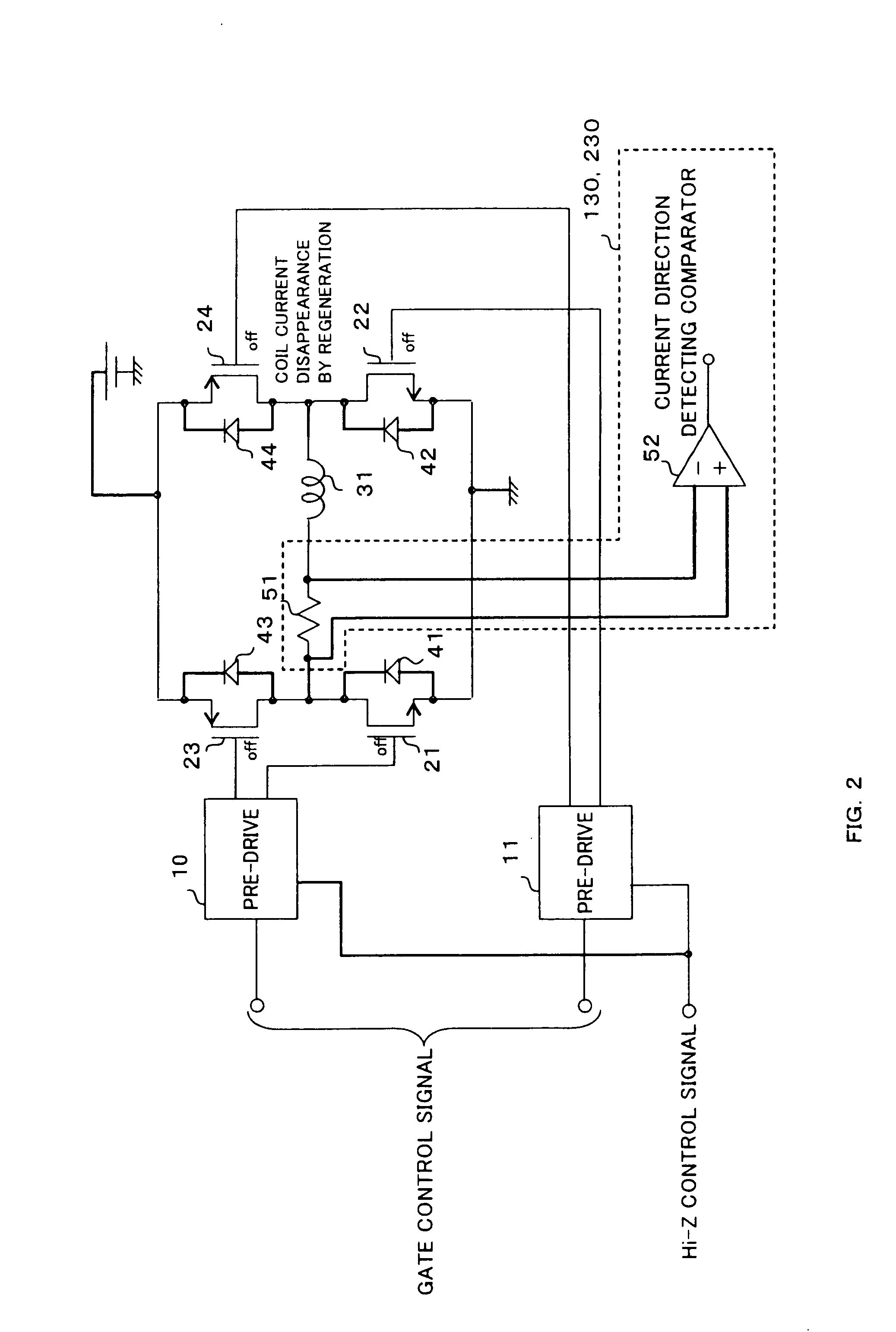

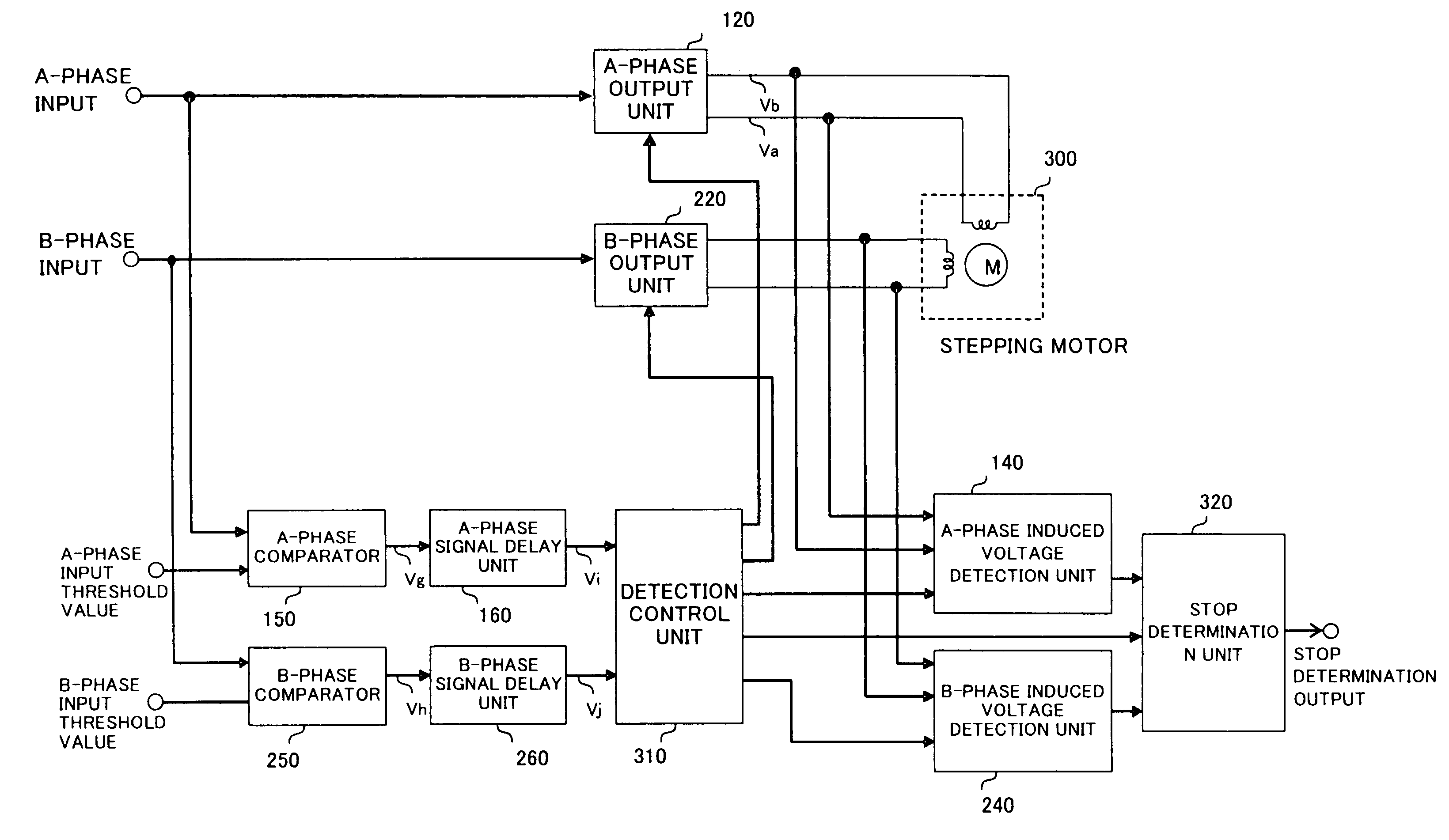

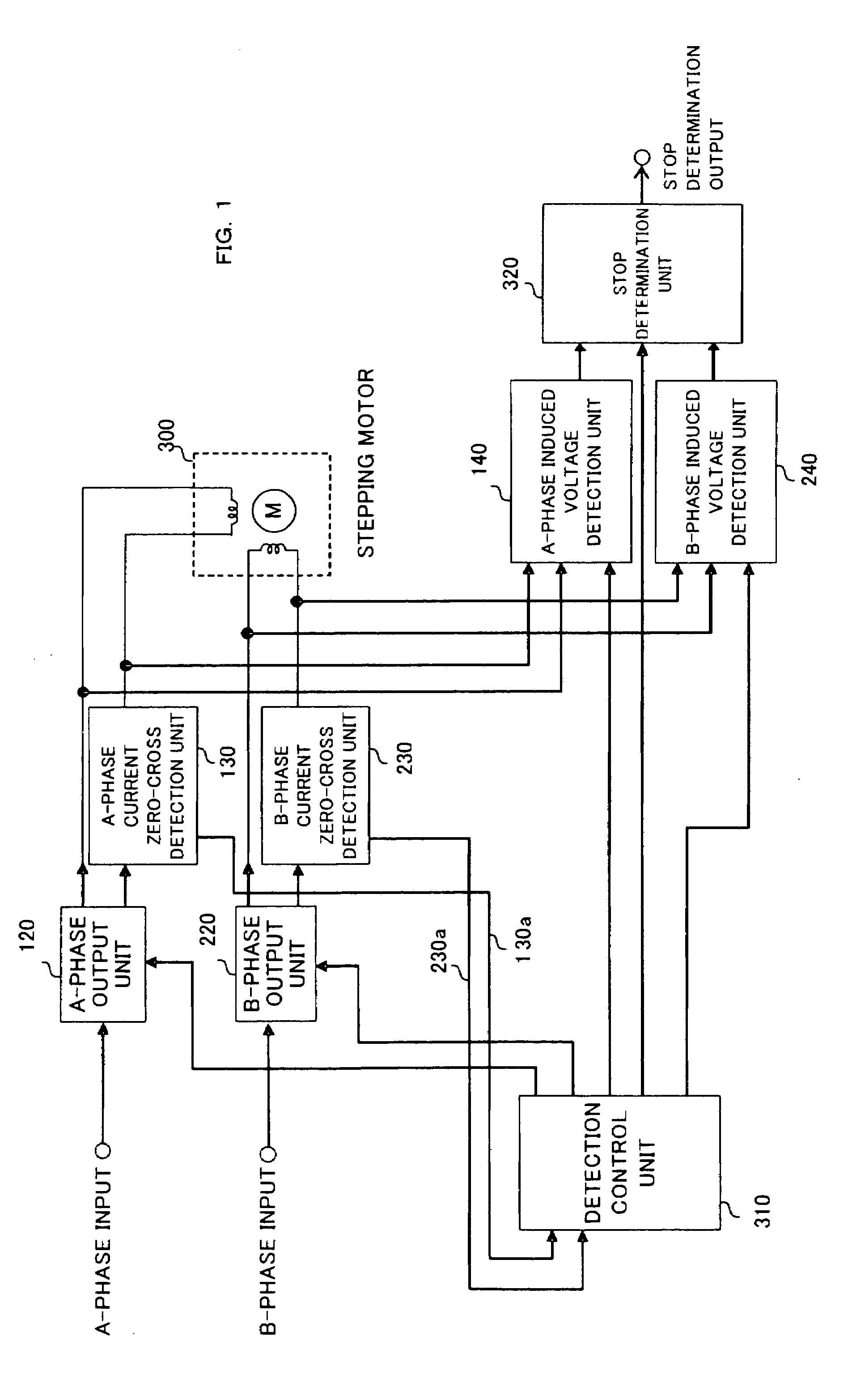

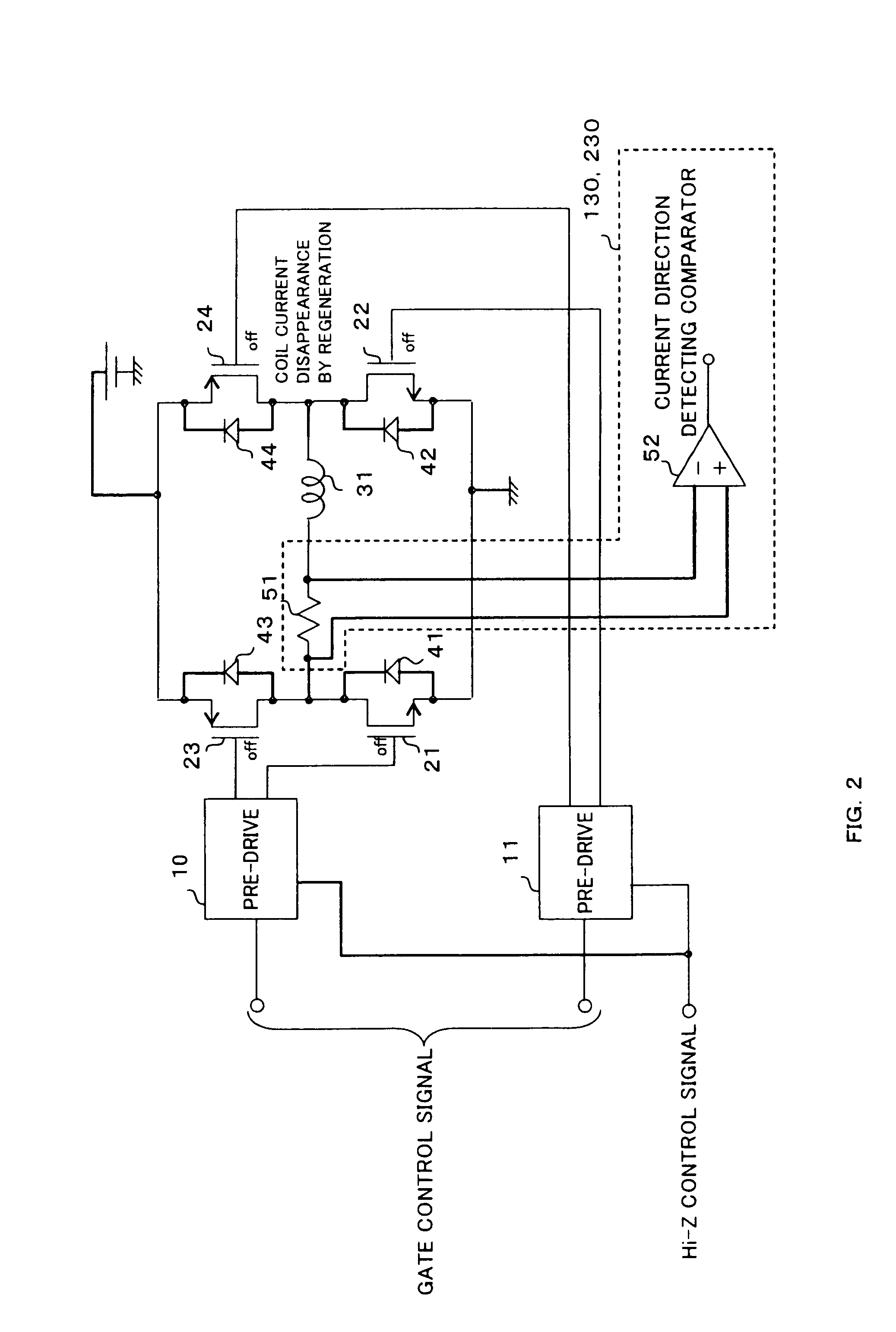

Stepping motor drive and stepping motor driving method

InactiveUS20090066278A1Suppression of distortionReduce distortion problemsMotor/generator/converter stoppersSynchronous motors startersDriving currentMotor drive

In a drive of a stepping motor, an electromotive force is generated on the coil of a motor with a sinusoidal wave having the same period as an energization period by smoothly rotating a rotor with microstep driving, and an induced power is stably detected by detecting the electromotive force at the zero cross of driving current. The detection around the current zero cross makes it possible to shorten a detection section, form a driving waveform with few distortions, and perform driving with a driving waveform as in an ordinary micro step. Thus a circuit is provided which is aimed at reducing noise, vibrations, and loss of synchronization, and increasing current consumption efficiency in the determination of stop.

Owner:PANASONIC CORP

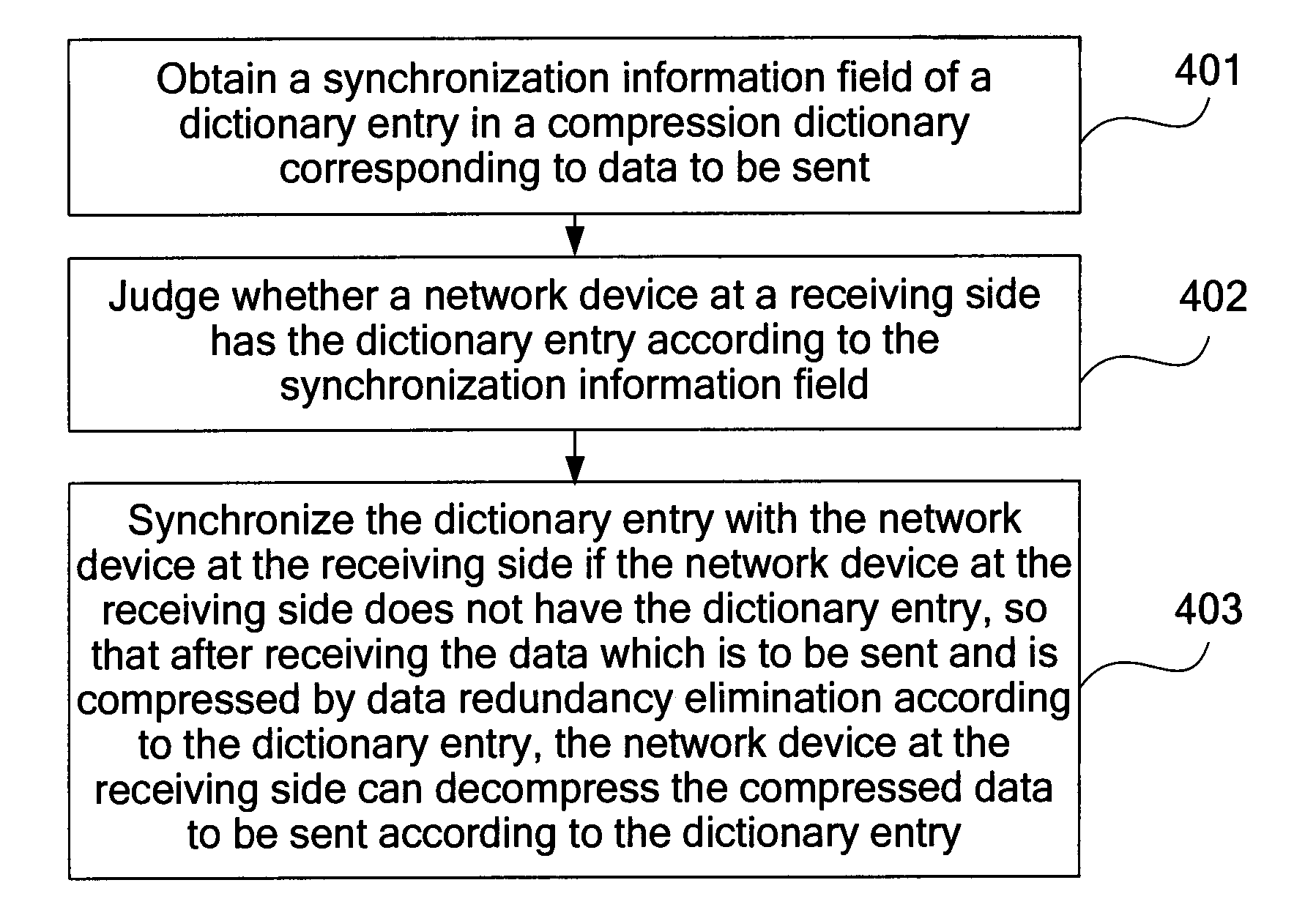

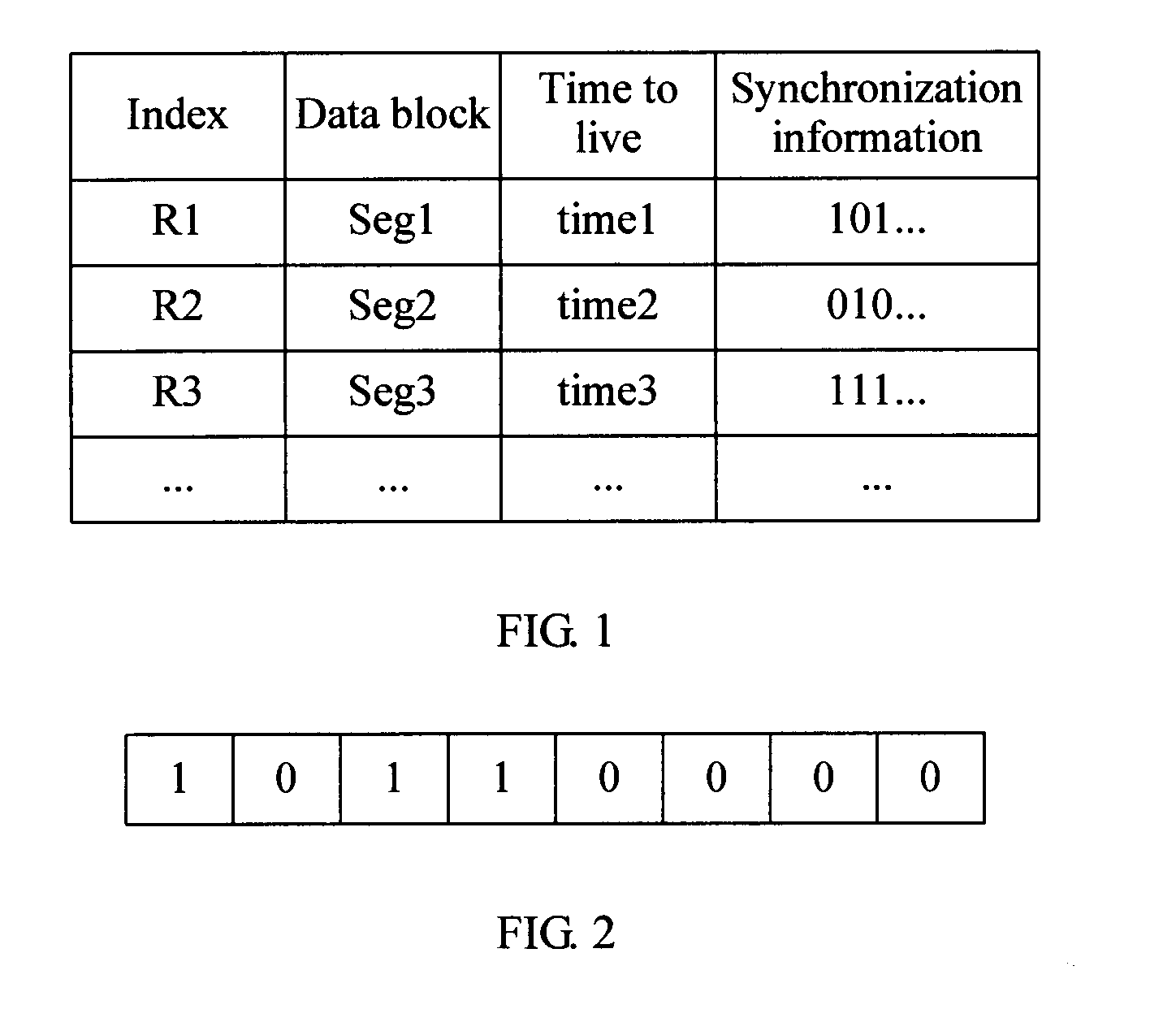

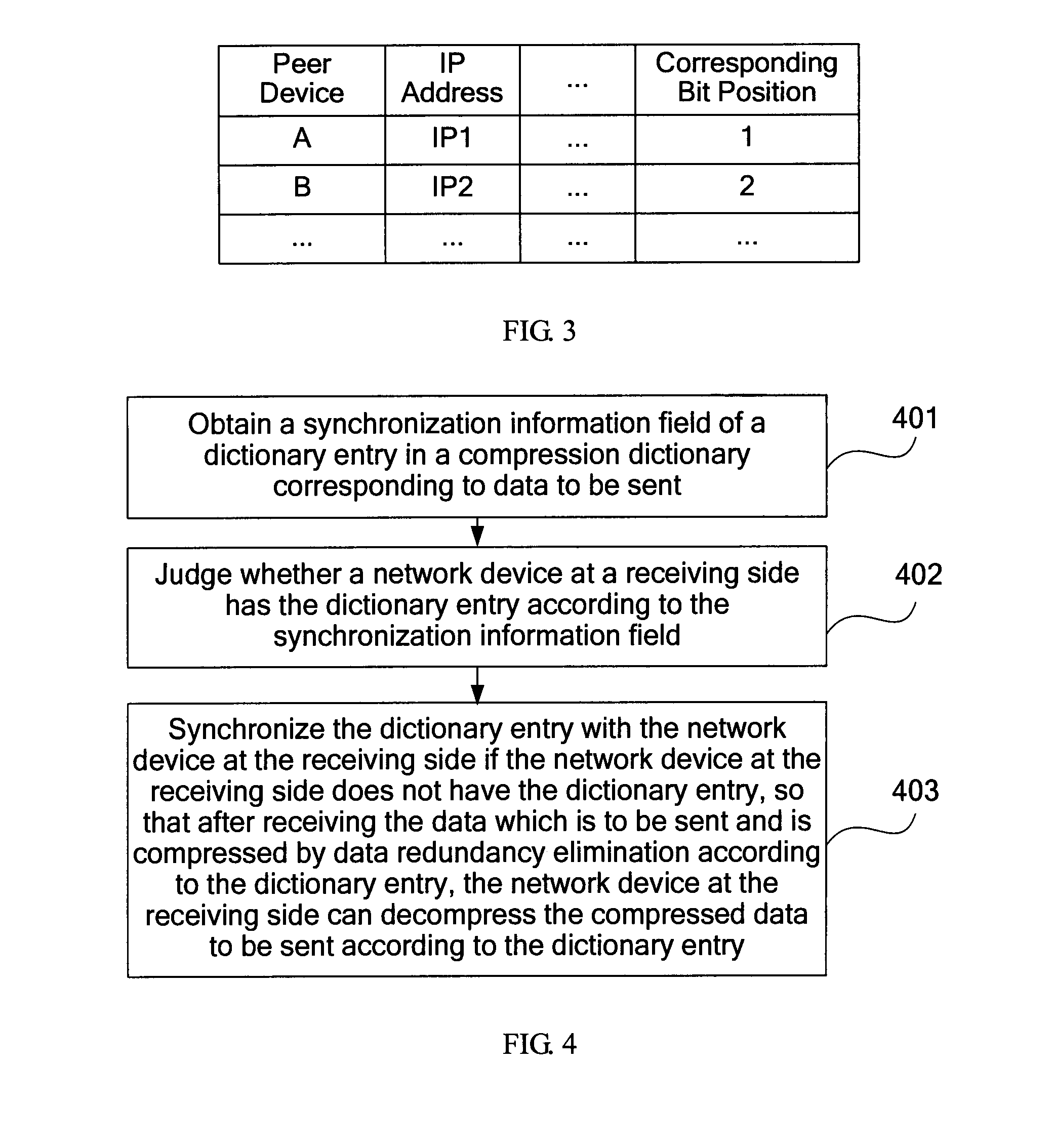

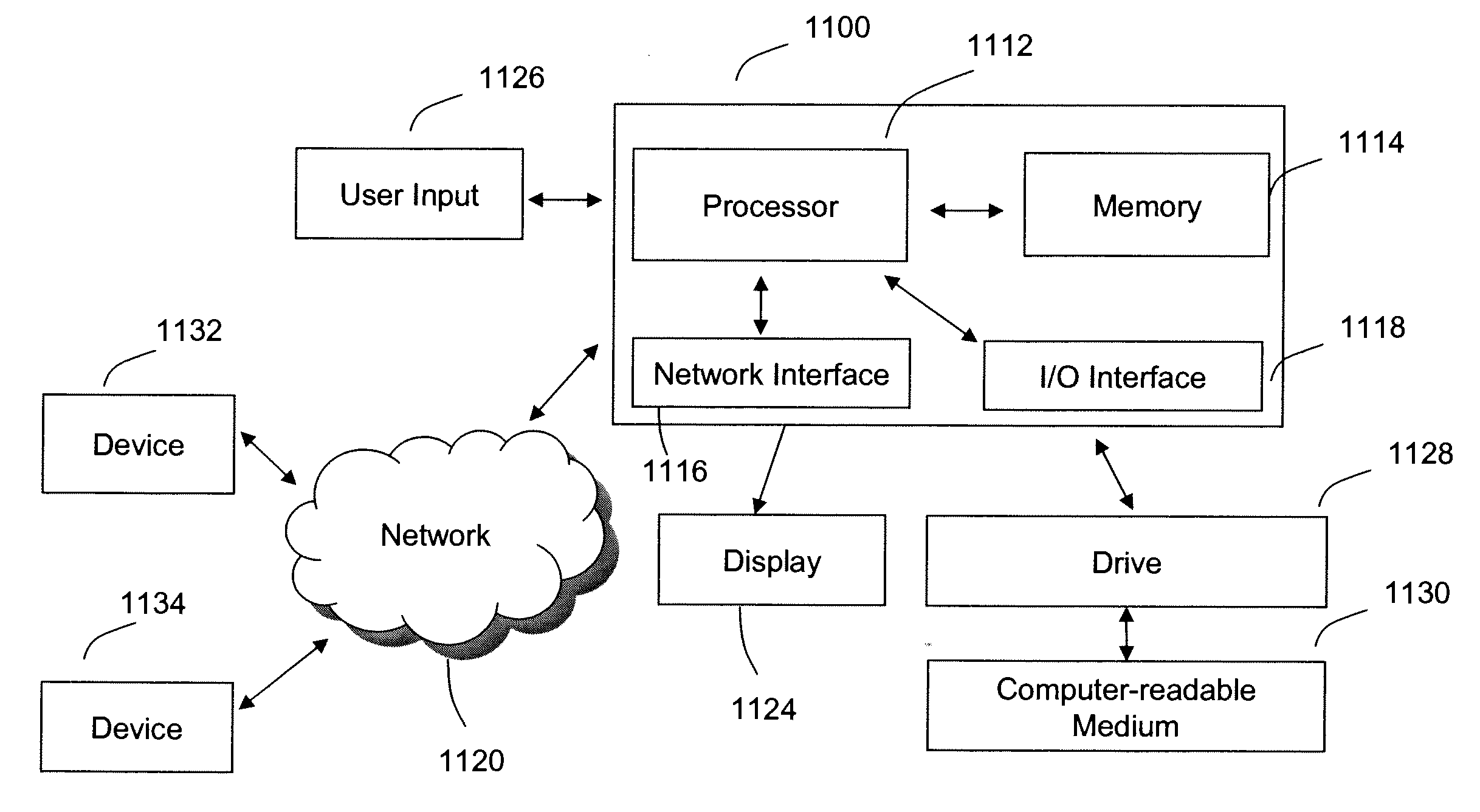

Compression dictionary synchronization method and device

InactiveUS20110222596A1Reduce data redundancyCutting synchronizationCode conversionTransmissionEngineeringElectrical and Electronics engineering

A compression dictionary synchronization method and device are provided. The method includes: obtaining a synchronization information field of a dictionary entry in a compression dictionary corresponding to data to be sent; judging, according to the synchronization information field, whether a network device at a receiving side has the dictionary entry; and synchronizing the dictionary entry with the network device at the receiving side if the network device at the receiving side does not have the dictionary entry, so that after receiving the data which is to be sent and is compressed by data redundancy elimination according to the dictionary entry, the network device at the receiving side can decompress the compressed data to be sent according to the dictionary entry. Data redundancy is decreased by reducing useless dictionary entry synchronization between devices.

Owner:HUAWEI TECH CO LTD

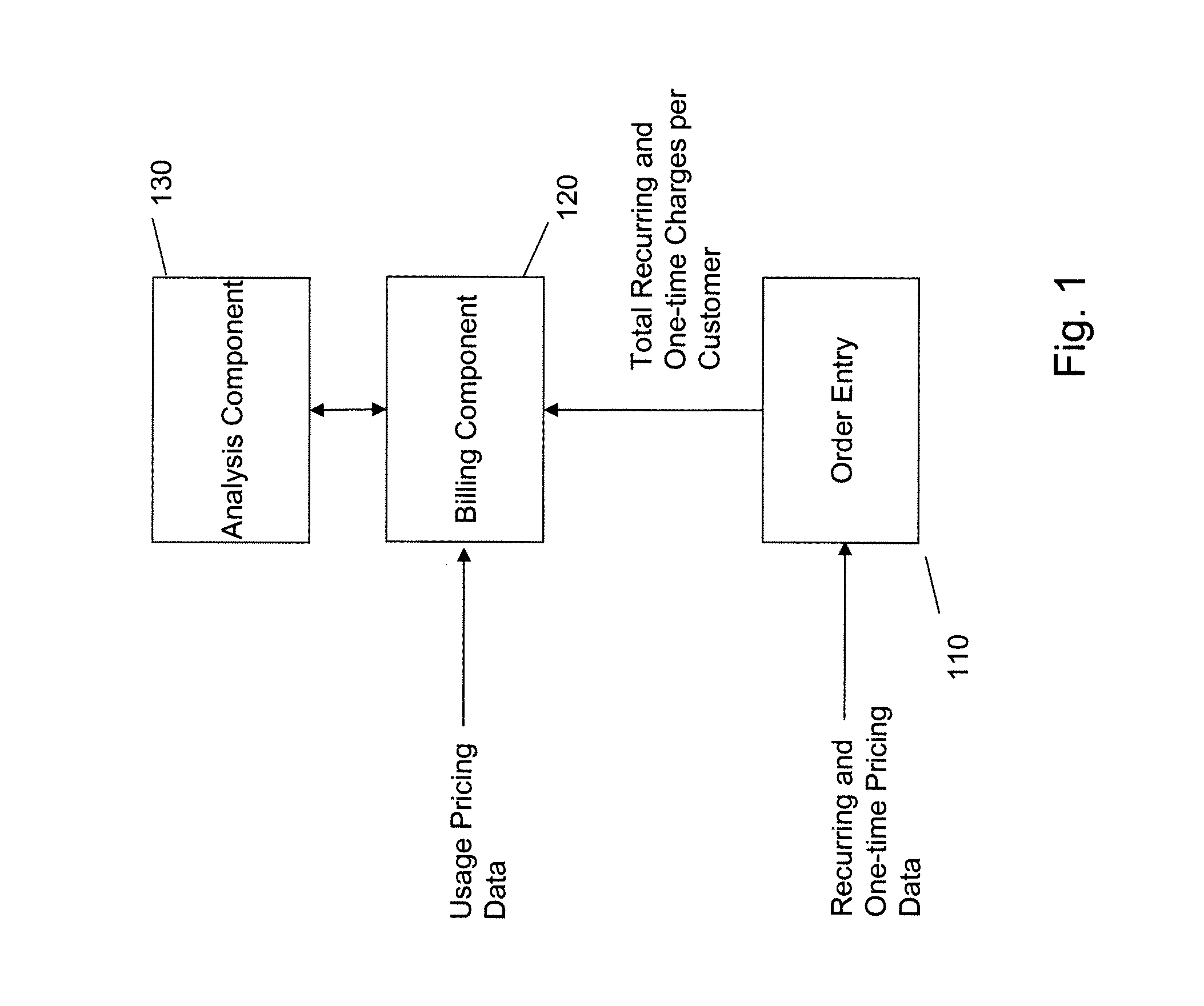

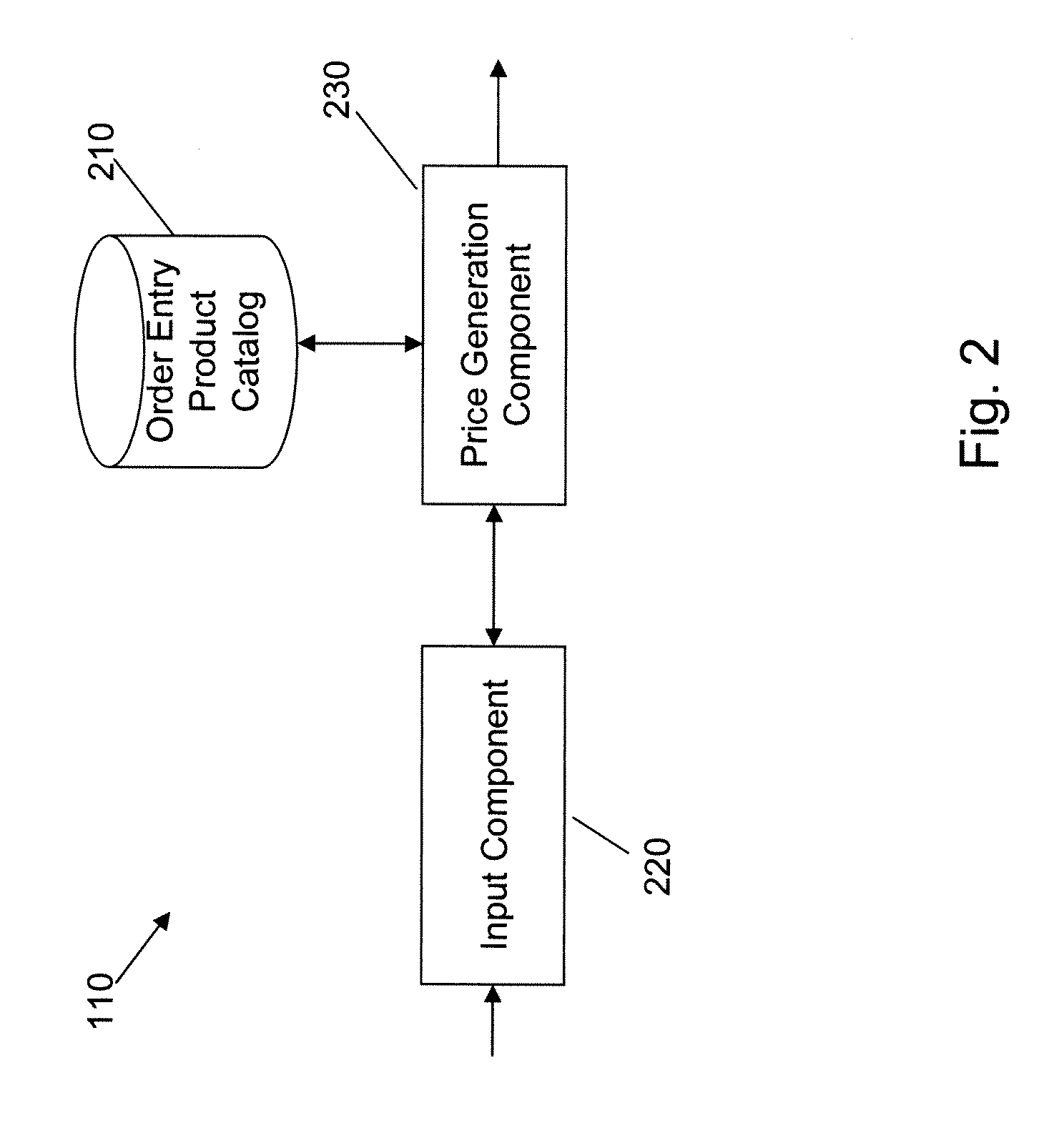

Systems and methods for improved billing and ordering

InactiveUS20120254000A1Reduces of informationCutting synchronizationComplete banking machinesMarket predictionsProgram planningTime cost

A price-generation system exemplary of the present invention reduces reliance on synchronization of rating and billing information, simplifies and speeds up commercial implementation of such systems, and reduces computational costs associated with real-time cost calculations by pre-computing rating data that can be automatically applied to subscriber usage. In one embodiment, a price-generation system comprises an analysis component configured to automatically generate at least one rate cube, wherein the at least one rate cube is configured to store rate plan information, an order entry component configured to pre-compute recurring charge information associated with at least one service based on at least a first set of rules, and a billing component configured to calculate total charges based on at least the pre-computed recurring charge information and usage charge information, wherein the usage charge information is calculated using the at least one rate cube.

Owner:NETCRACKER TECH CORP

Stepping motor driver

InactiveUS8072177B2Stable detectionReduce noiseMotor/generator/converter stoppersAC motor controlDriving currentWave shape

In a drive of a stepping motor, an electromotive force is generated on the coil of a motor with a sinusoidal wave having the same period as an energization period by smoothly rotating a rotor with microstep driving, and an induced power is stably detected by detecting the electromotive force at the zero cross of driving current. The detection around the current zero cross makes it possible to shorten a detection section, form a driving waveform with few distortions, and perform driving with a driving waveform as in an ordinary micro step. Thus a circuit is provided which is aimed at reducing noise, vibrations, and loss of synchronization, and increasing current consumption efficiency in the determination of stop.

Owner:PANASONIC CORP

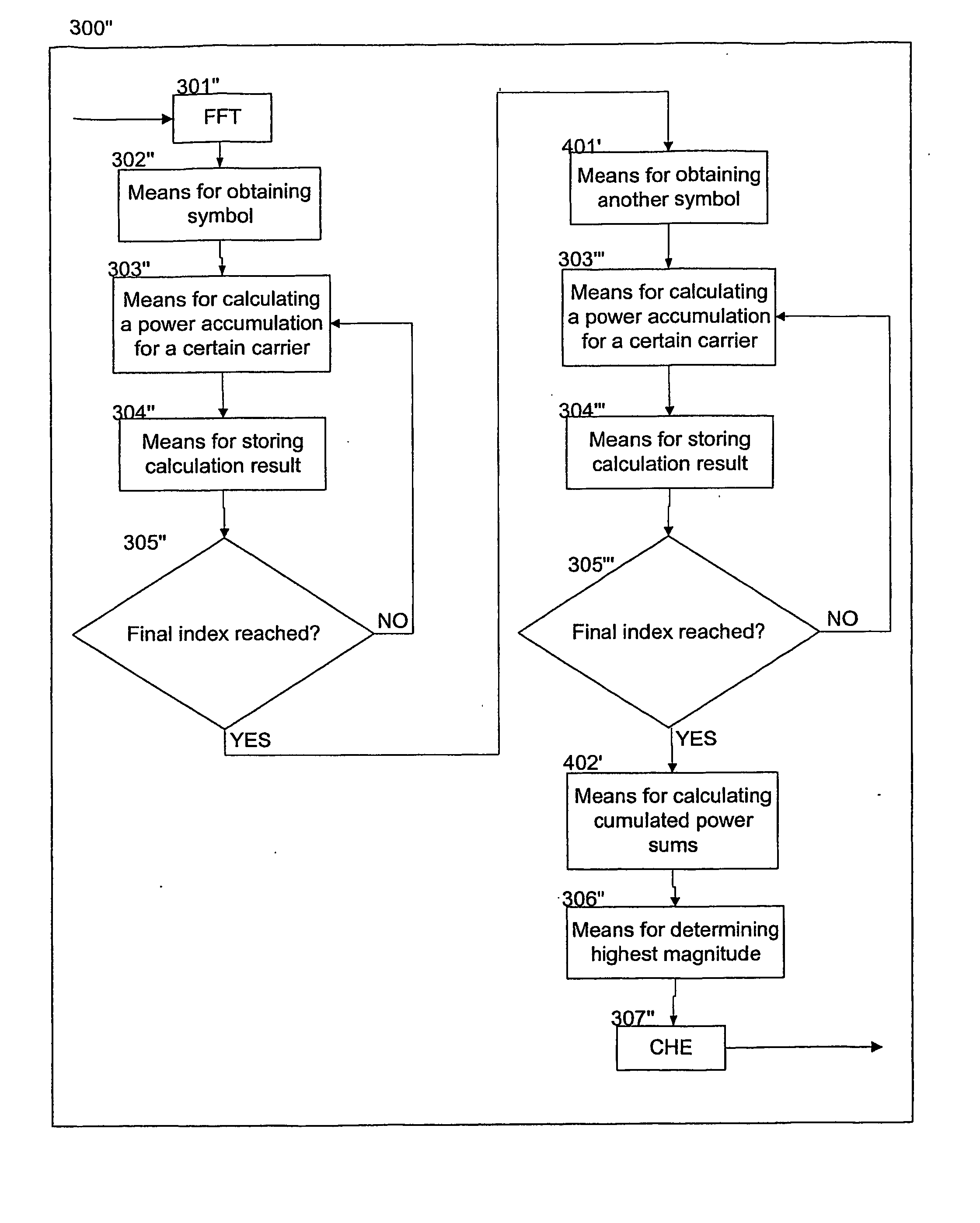

Method system and receiver for receiving a multi-carrier transmission

InactiveUS20070053281A1Cutting synchronizationEasy accessMulti-frequency code systemsOrthogonal multiplexCarrier signalMulti carrier

Mobile handheld terminals receiving DVB transmission require relatively low power consumption and TDM based transmission can be used to reduce power of the terminals. In order find pilot carrier position at least one symbol is accessed which is adapted to establish a correspondence pattern for pilot carriers in a matrix of the symbols. Carriers of the symbol are power accumulation summed within the matrix for determining a power accumulation sum maximum for indicating a pilot carrier position.

Owner:NOKIA CORP

Method, system and receiver in receiving a multi-carrier transmission

InactiveUS7751515B2Fast wayCutting synchronizationTransmission control/equlisationTime-division multiplexCarrier signalEngineering

Mobile handheld terminals receiving DVB transmission require relatively low power consumption and TDM based transmission can be used to reduce power of the terminals. In order find pilot carrier position at least two symbols are accessed which are adapted to establish a correspondence pattern for pilot carriers in a matrix of the at least two symbols. Carriers of the first symbol are correlated with the corresponding carriers of the second symbol within the matrix for determining a correlation maximum for indicating a pilot carrier position.

Owner:WSOU INVESTMENTS LLC

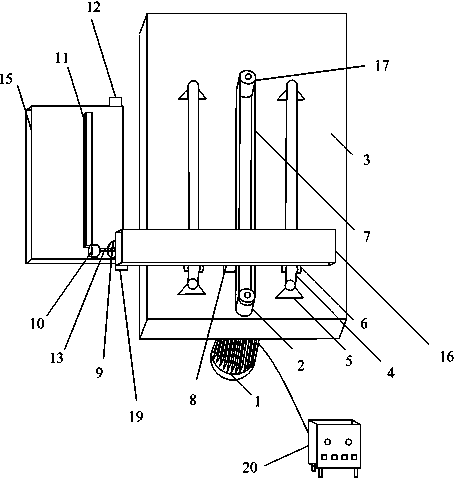

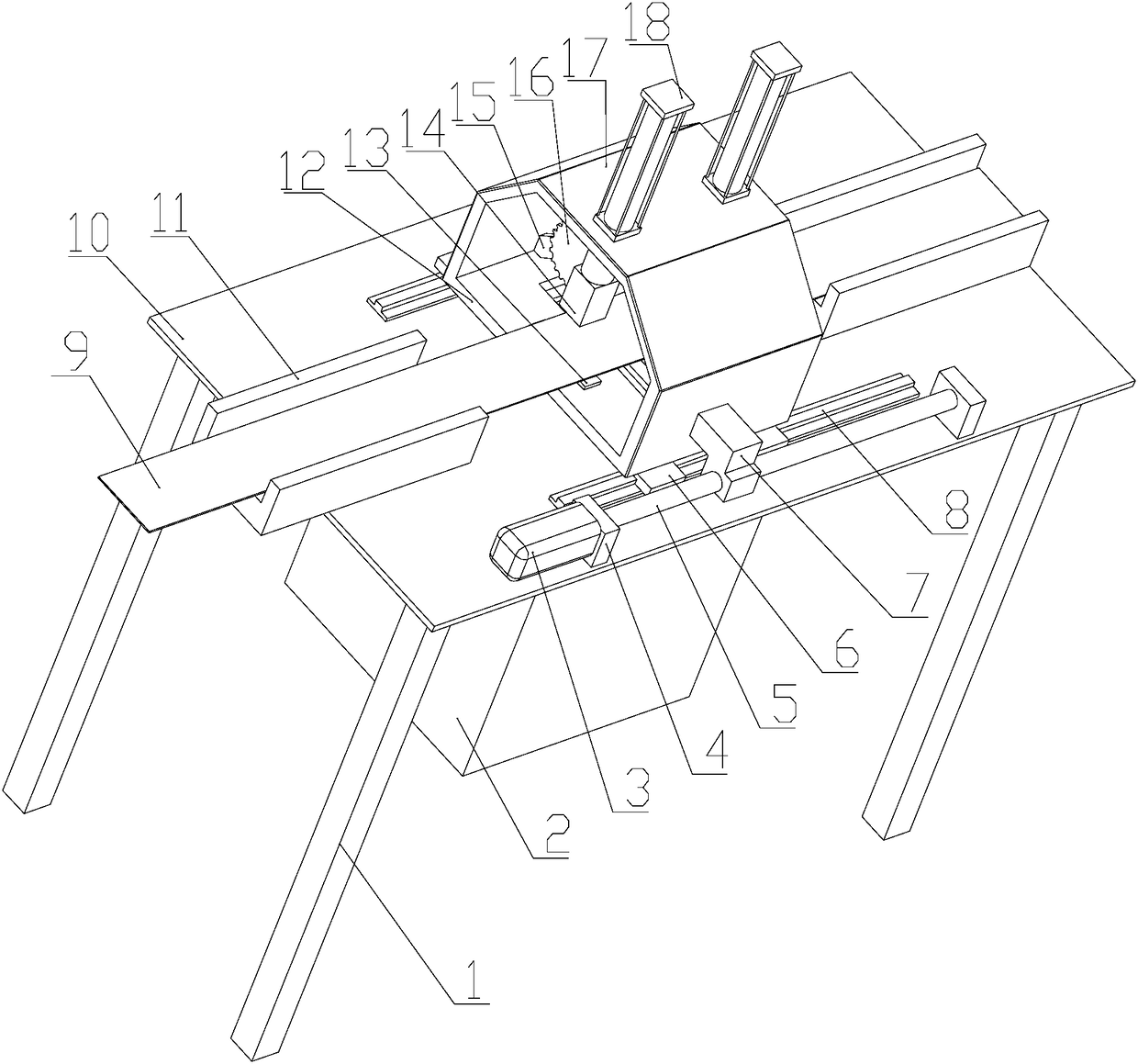

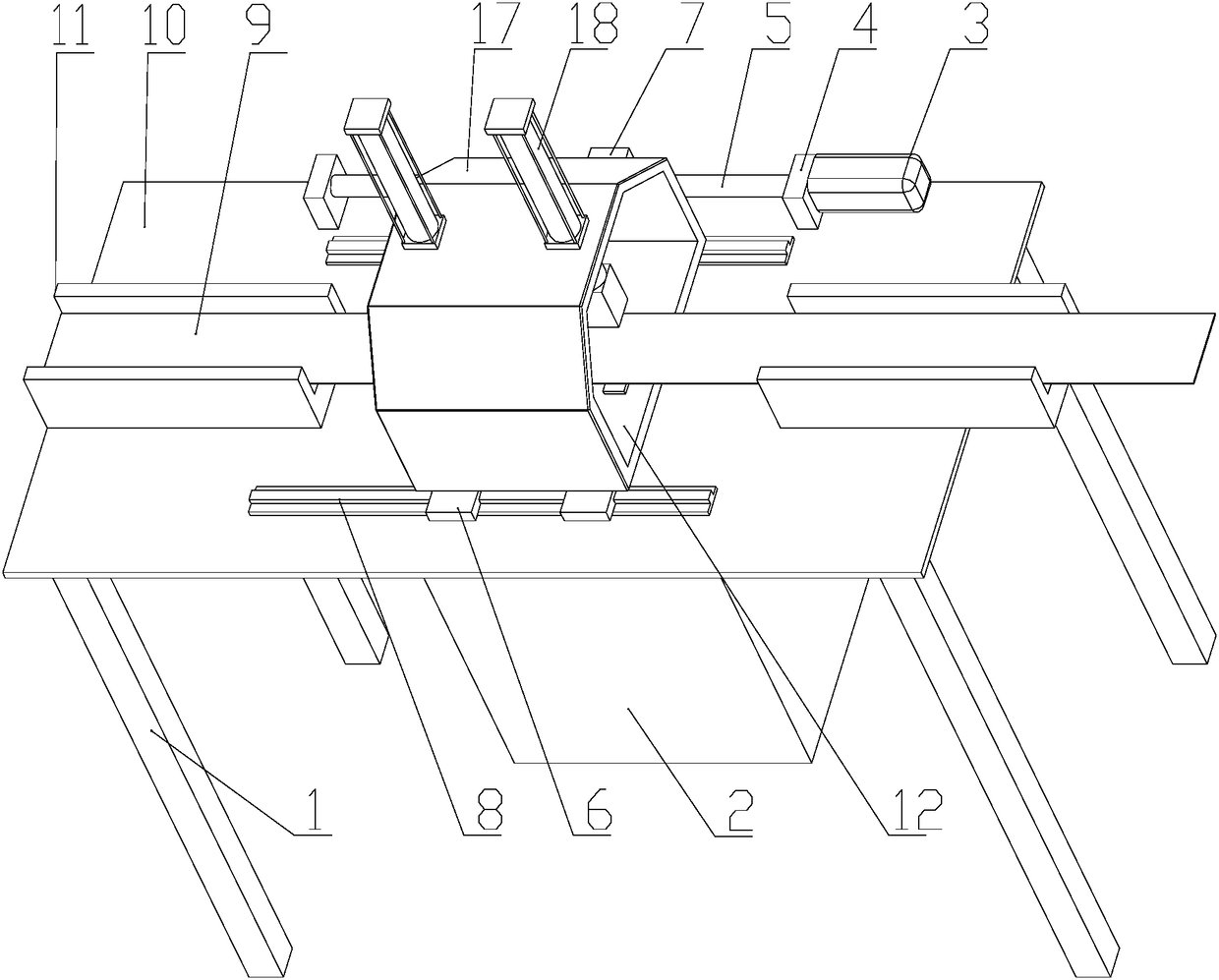

Cutting device integrating cutting and pressing

InactiveCN103419225ASimple structureHigh degree of automationShearing machinesMetal working apparatusElectric machineryMachine

The invention discloses a cutting device integrating cutting and pressing. The cutting device integrating cutting and pressing comprises a machine table, a feeding bed and a PLC. A guide rail is arranged on the machine table, and a guiding strip is arranged on the guide rail through a guide rail groove. A first revolving shaft and a second revolving shaft are further arranged on the machine table, a motor drives the first revolving shaft to rotate, a cutter is arranged on one side of the guiding strip, and the cutter is connected with a pressing roller through a third revolving shaft. Grooves are formed in the two sides of the sorting bed. The cutting device integrating cutting and pressing is simple in structure, capable of performing cutting repeatedly in a circulating mode, good in cutting quality, high in cutting efficiency, low in cost, and suitable for small-batch production and processing.

Owner:安徽省旌德县江南机电配件有限公司

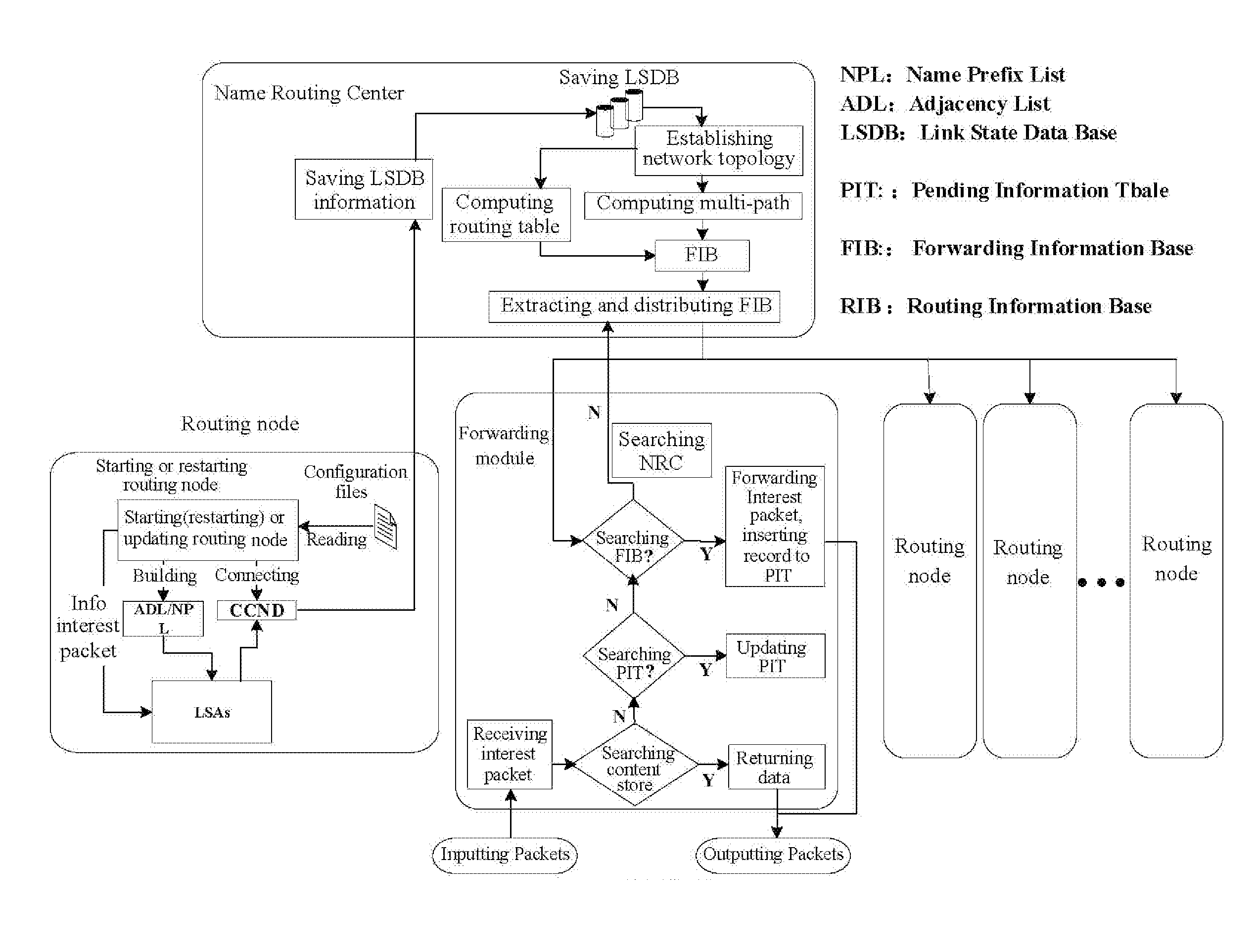

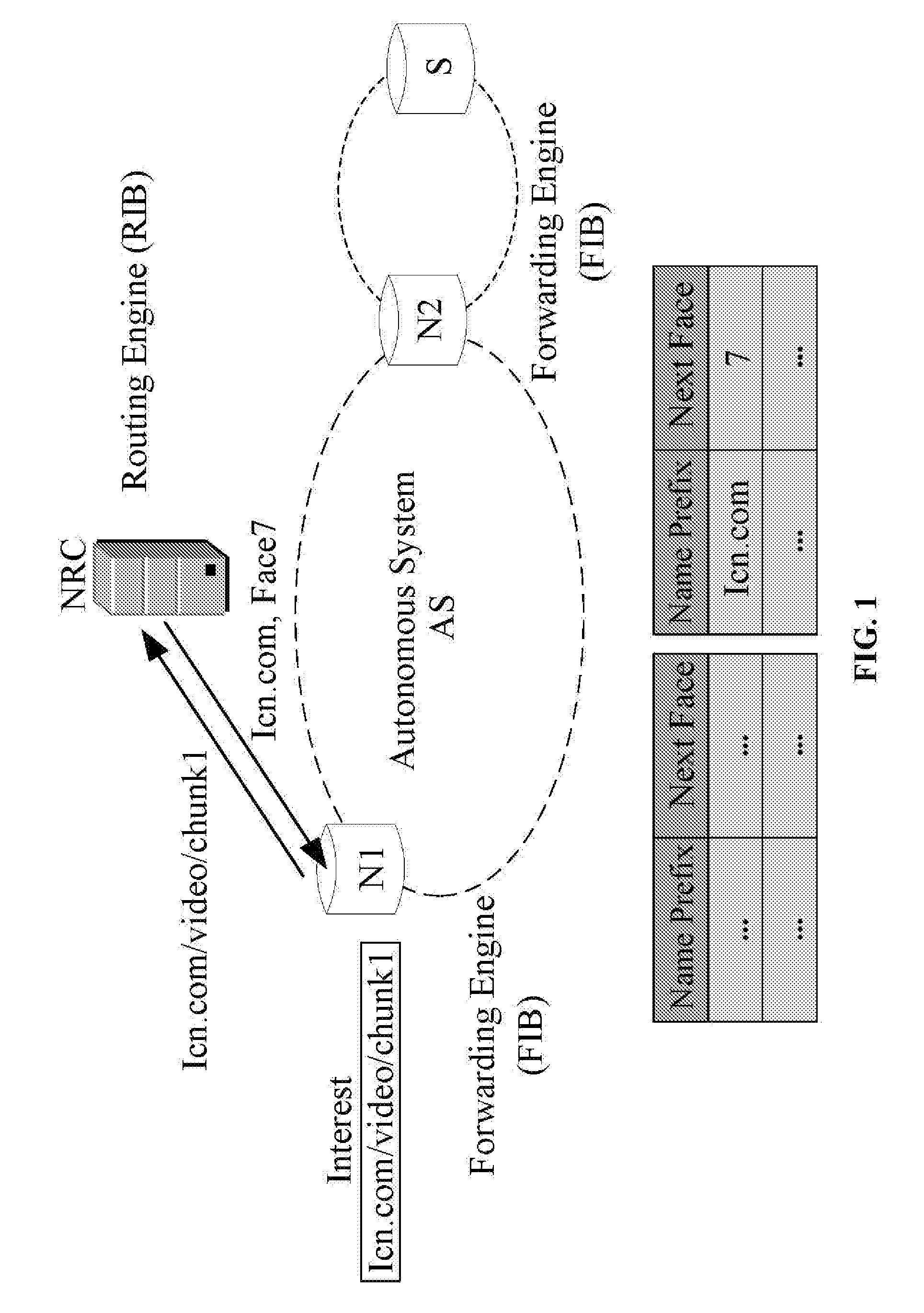

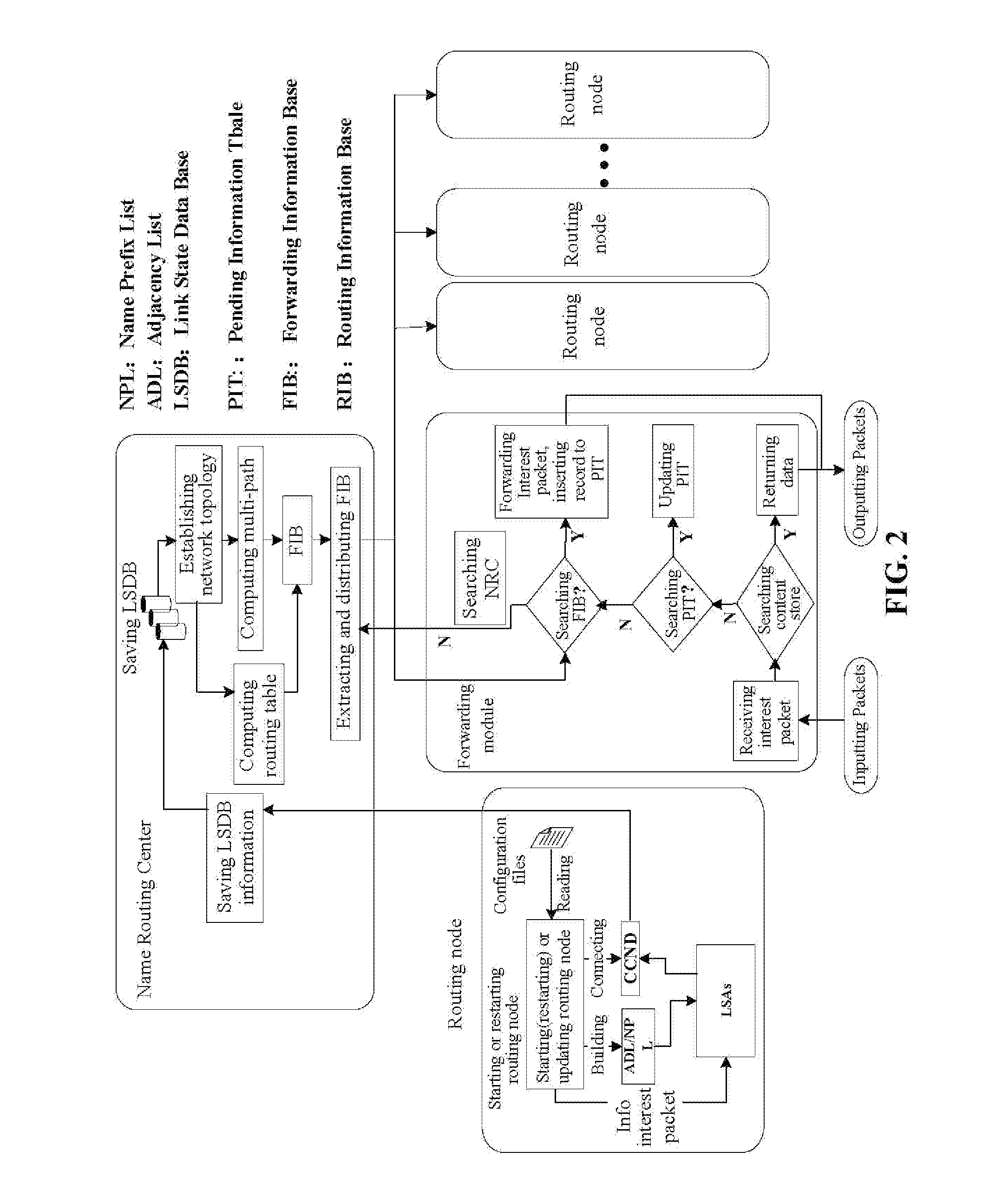

Content-based routing method and system

InactiveUS20160269272A1Reduce redundancyImprove efficiencyDigital data information retrievalData switching networksInformation repositoryInformation seeking

A content-based routing method, including: a) performing routing topology discovery and maintenance, centralized routing computation, and routing information inquiry by a name routing center of a controller; b) caching an active routing information by a forwarding information base; and c) acquiring inquired information of a routing node and updating the forwarding information base by the name routing center of the controller.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

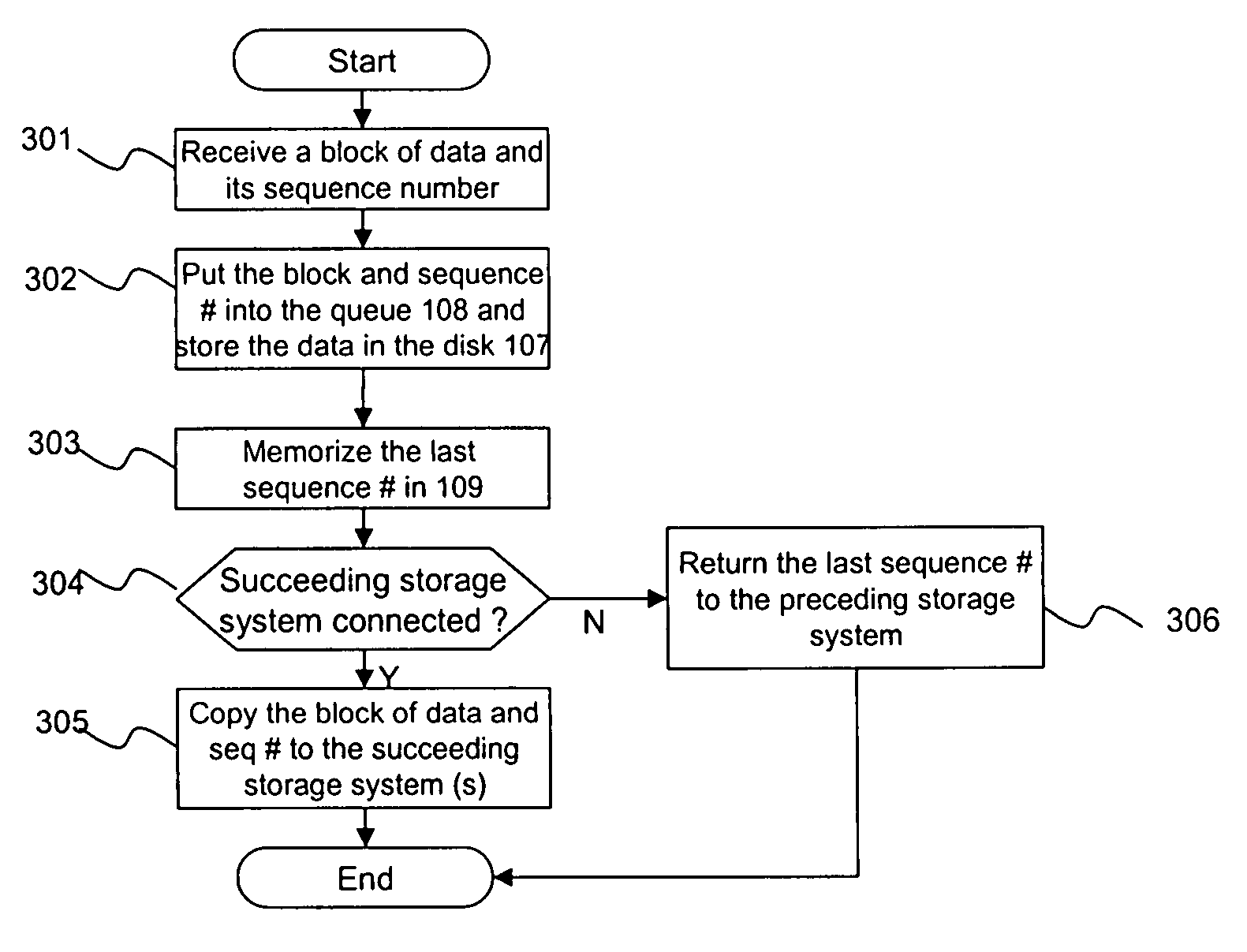

Data synchronization of multiple remote storage

InactiveUS7111139B2Cutting synchronizationMinimal amountData processing applicationsInput/output to record carriersData synchronizationSerial code

A storage system comprises a plurality of storage subsystems. One storage subsystem as a succeeding subsystem is configured to receive and store one or more blocks of data from another storage subsystem as a preceding subsystem. Each block of data has an associated sequence number in ascending order. The memory in each storage subsystem includes a queue to store the blocks of data and a sequence number associated with each block of data, a record to store a last sequence number associated with a last block of data received by the queue, and a table to store last sequence numbers stored in the last sequence number record gathered from each succeeding storage system. In some embodiments, a smallest last sequence number is determined from the last sequence numbers associated with the blocks of data in the storage subsystems. Blocks of data in the queue of each storage subsystem having associated sequence numbers less than or equal to the determined smallest last sequence number are deleted. In case of a failure of one or more storage subsystems, blocks of data are copied from the surviving storage subsystem having associated sequence numbers higher than the last sequence number of other surviving storage subsystems.

Owner:GOOGLE LLC

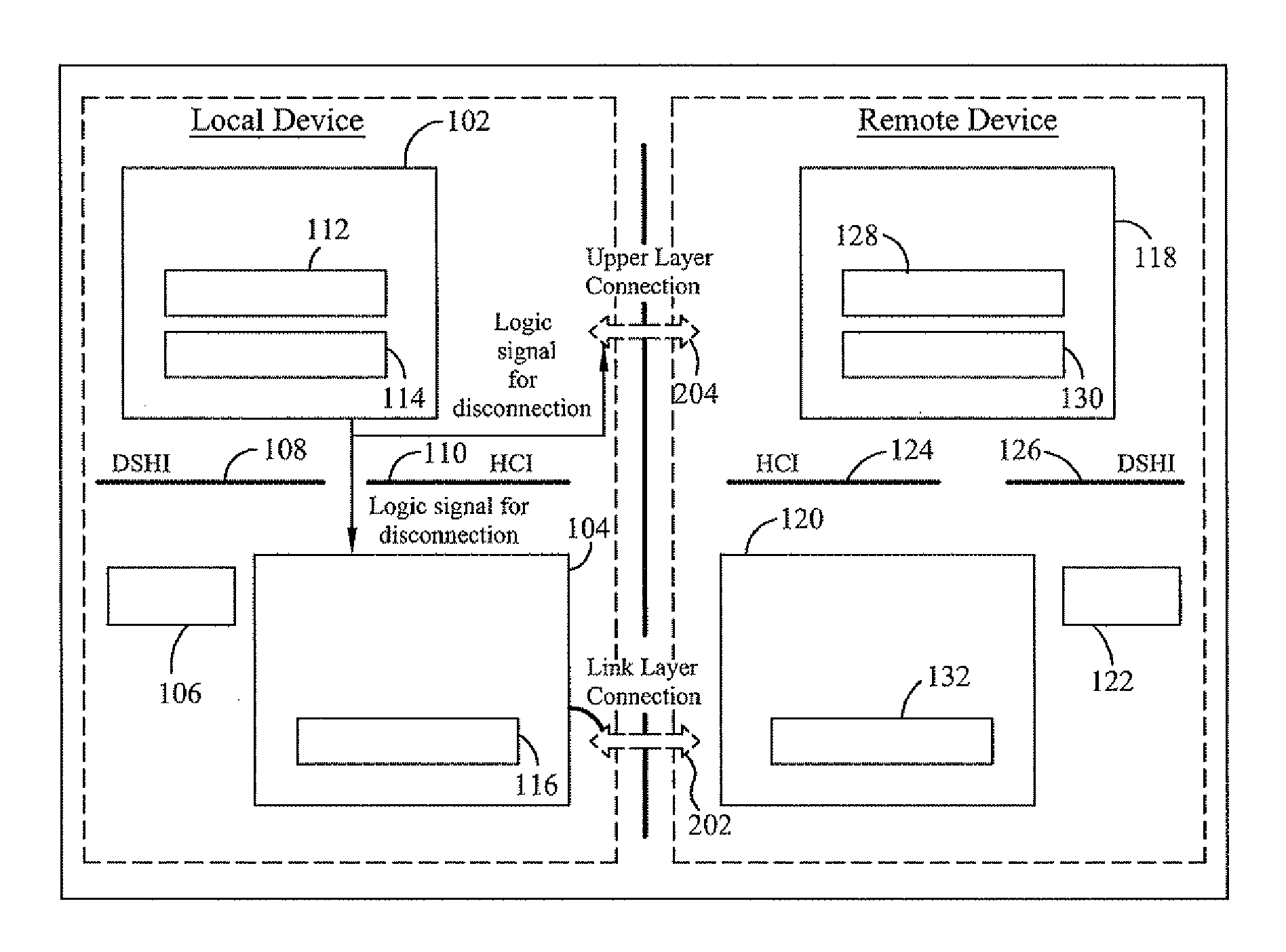

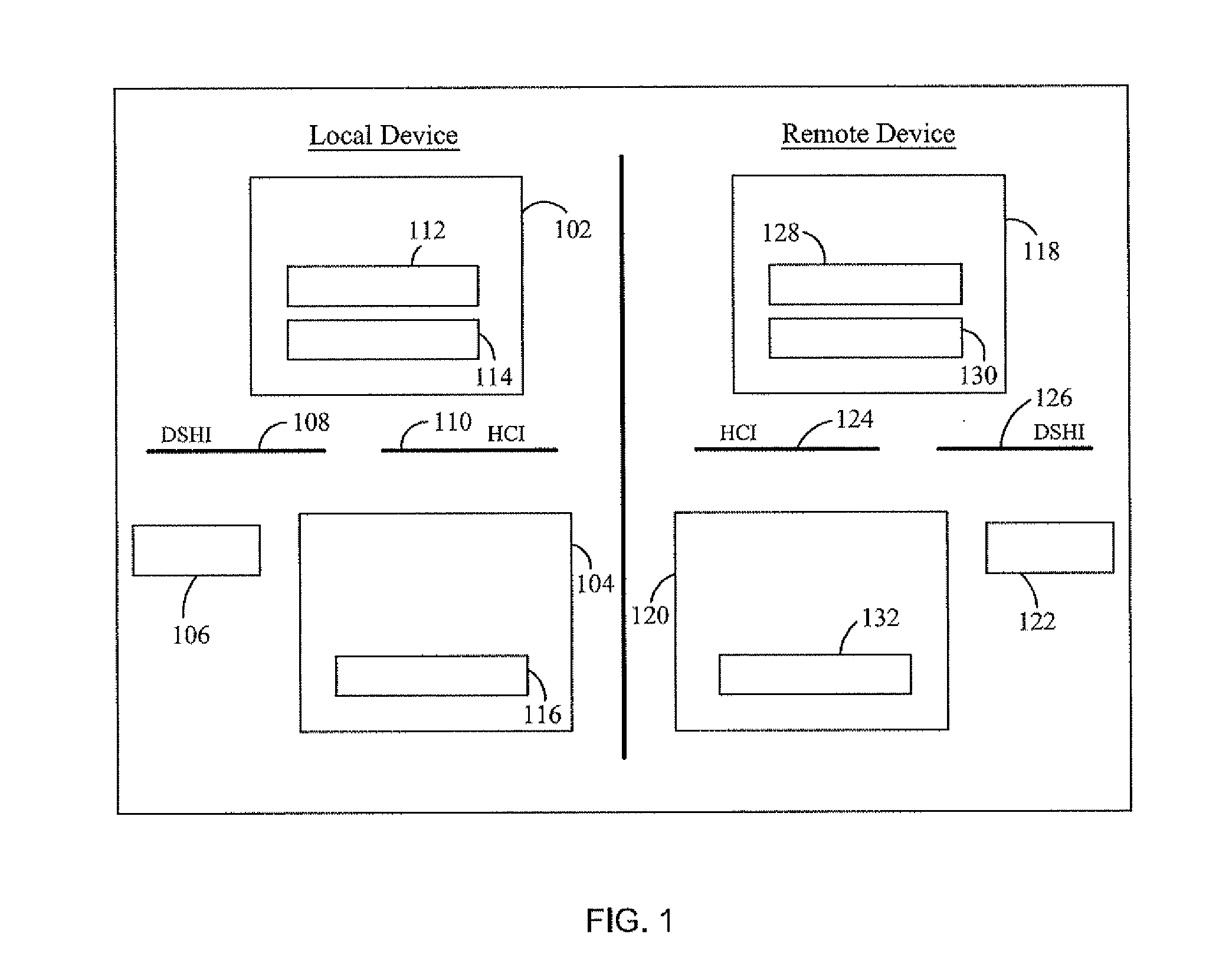

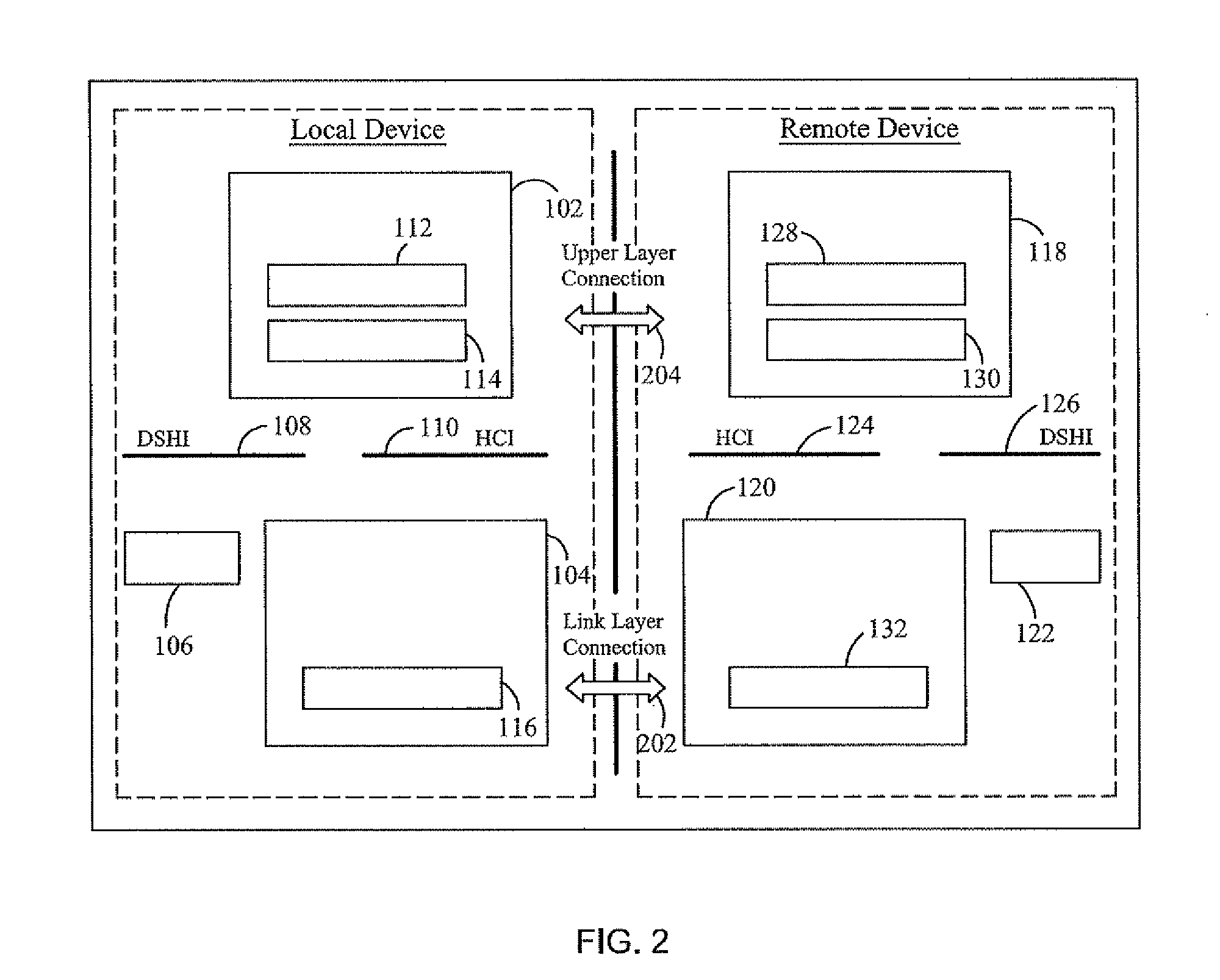

Method and system for optimizing power consumption and reducing mips requirements for wireless communication

InactiveUS20080270622A1Reduce system latencyReduce power consumptionEnergy efficient ICTPower managementWireless dataData traffic

The present invention discloses a system and a methodology for enhancing performance during wireless communications by reducing system latency, MIPS requirements and power consumption. The present invention discloses a system and method of wireless data communication in which part of upper layer stack processing is performed on a controller to relieve a host processor of some data intensive operations. After the initial connection establishment phase in which the controller retrieves certain information required for data transmission and stores the same locally, the data source provides data directly to the controller without routing the data through the host. The host is relieved of the data processing that needs to be done while the data is being transferred. Hence, the overall latency of the system is improved because of the optimal routing of data traffic. The host can even go to lower power modes while the controller is performing the data operations on behalf of the upper layer stack thereby saving power consumption of the overall system.

Owner:ST ERICSSON SA

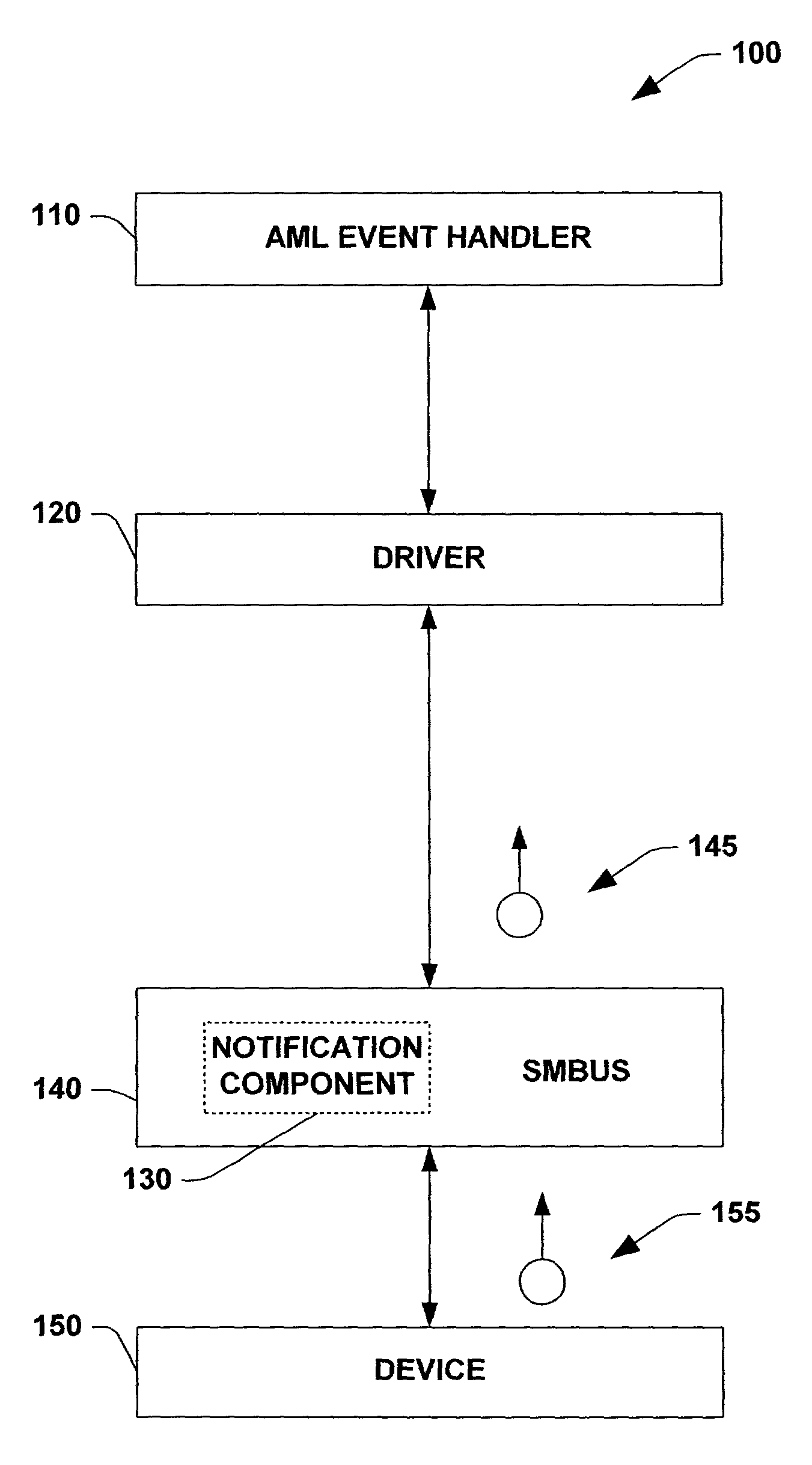

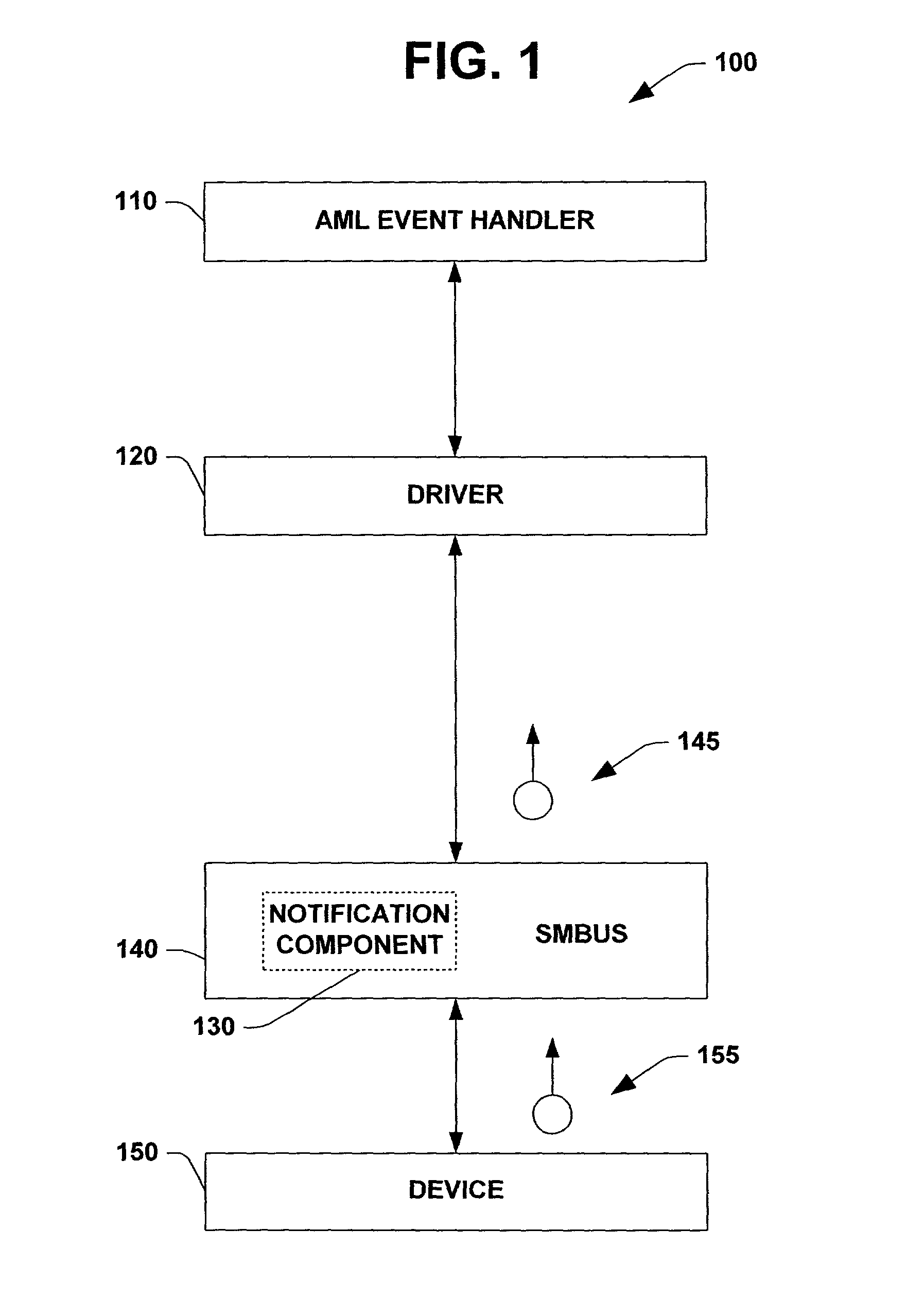

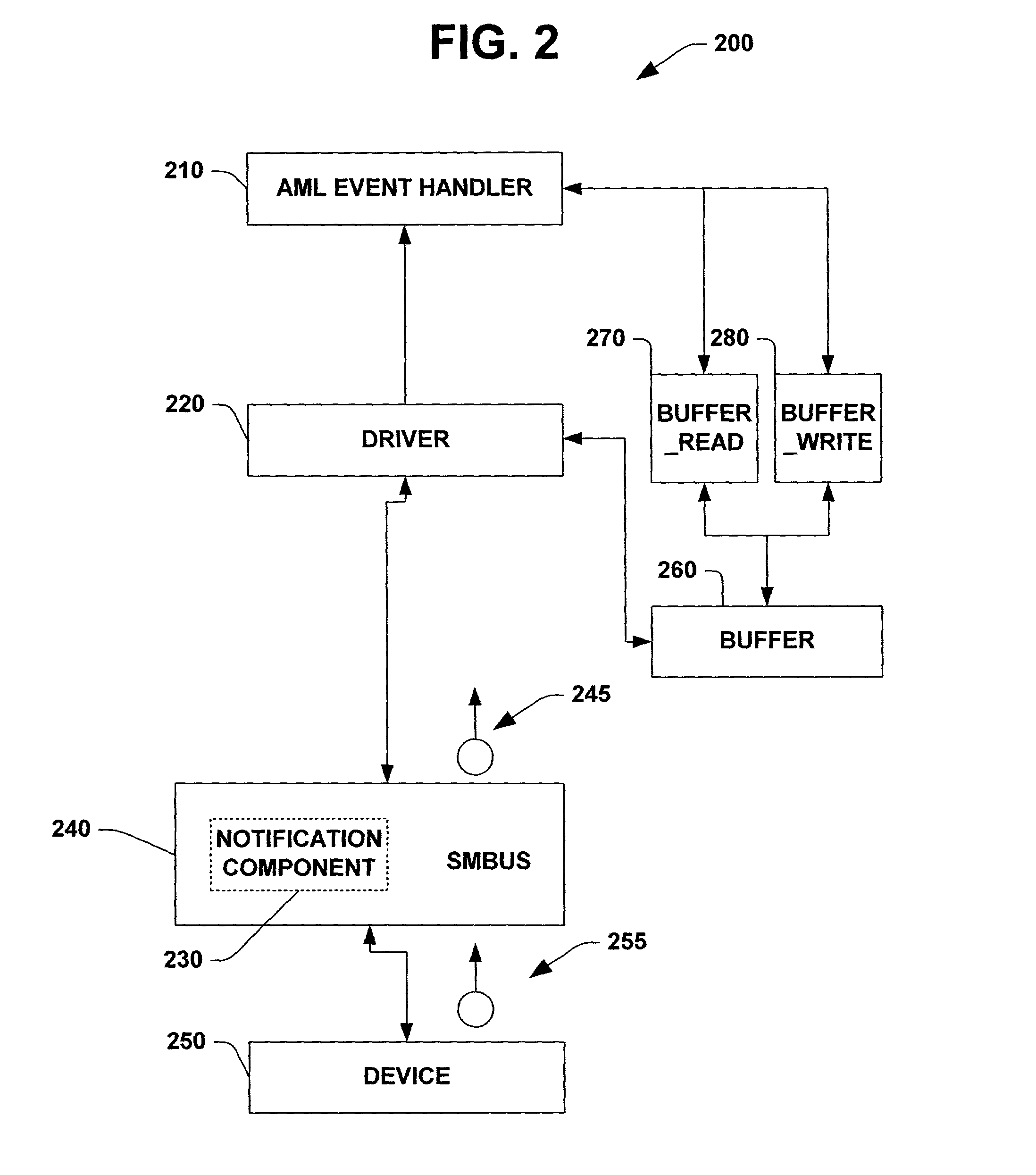

Employing three parameter buffer access in connection with SMBus notifications

InactiveUS7418714B2Easy to receiveEasy accessEnergy efficient ICTMultiprogramming arrangementsOpcode

A system that facilitates access to an SMBus is provided. The system includes a notification component that identifies an SMBus event and a driver that dispatches the SMBus event to an AML event handler. A method for SMBus event handling is also provided. The method includes receiving an SMBus event notification, identifying the SMBus event notification, dispatching the SMBus event notification to an AML event handler, and handling the SMBus event notification in AML code. Two new ACPI opcodes, which are a three parameter operation region read and a three parameter operation region write can be utilized in accordance with the present invention.

Owner:MICROSOFT TECH LICENSING LLC

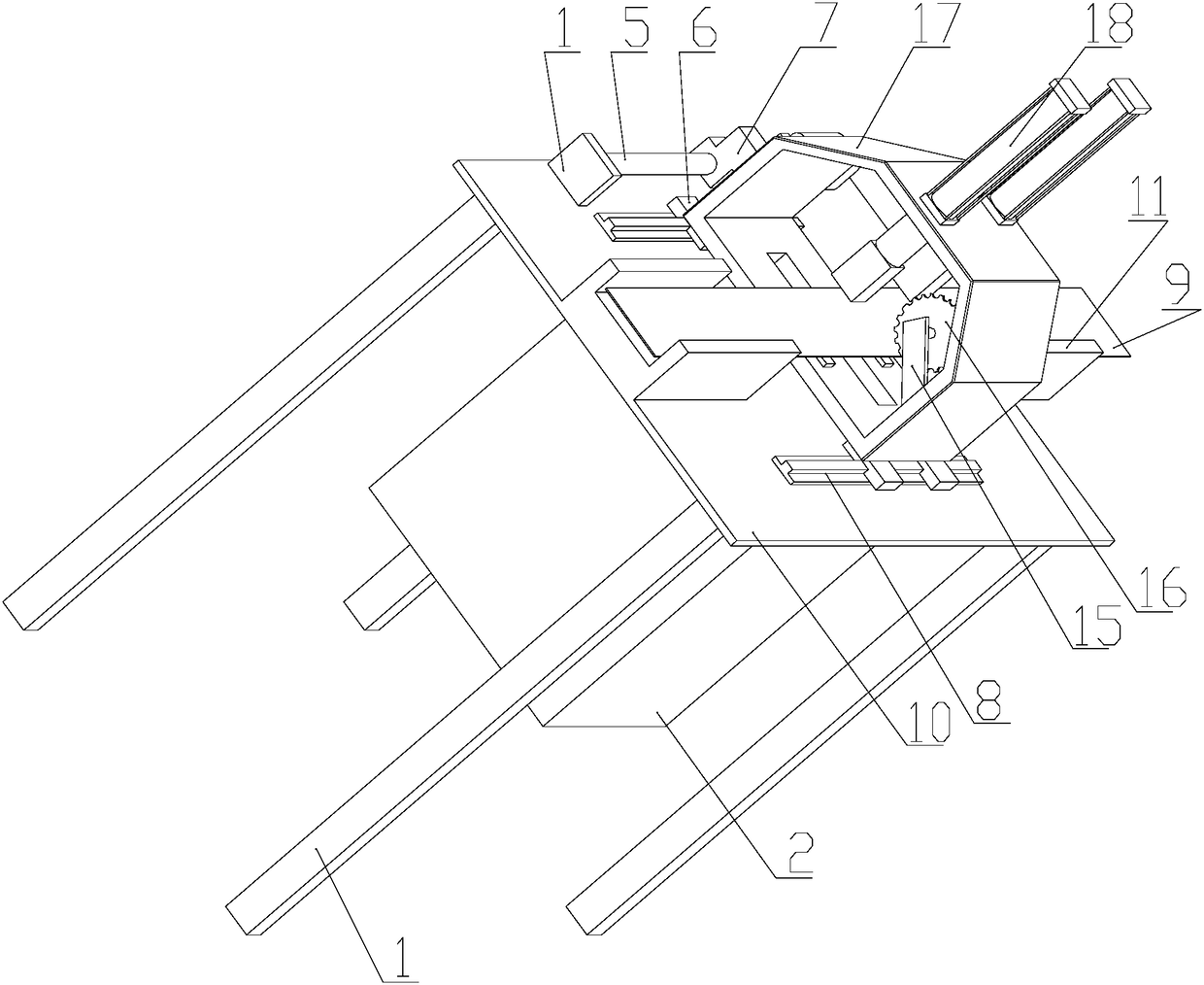

Synchronous cutting device for door frame panel

InactiveCN108115200ACutting synchronizationAvoid downtime pitfallsMetal sawing devicesProduction lineEngineering

The invention discloses a synchronous cutting device for a door frame panel. The synchronous cutting device for the door frame panel comprises a rack, wherein a working table is arranged on the top part of the rack; two guide rails are arranged on the working table in parallel; a plurality of sliding blocks are slidably arranged on the guide rails in a matching way; a sliding platform is fixedly arranged on the top parts of the sliding blocks; a saw blade cutting device is arranged on the sliding platform; a synchronous drive device for diving the sliding platform to translate and slide is arranged on a side face of the sliding platform; a support box body is arranged on the top part of the sliding platform; a clamping air cylinder is arranged on the top part of the support box body; and aclamping head is arranged at the tail end of a piston rod of the clamping air cylinder, and is matched with a cushion block on the sliding platform so as to clamp and position the panel. The cuttingdevice can be used for carrying out synchronous operation with a door frame wire rod production line, and effectively cutting wire rods while ensuring the production at the same time, so that the production efficiency is further improved, and an automation process is improved.

Owner:YICHANG PANBAOBAO NEW MATERIAL TECH CO LTD

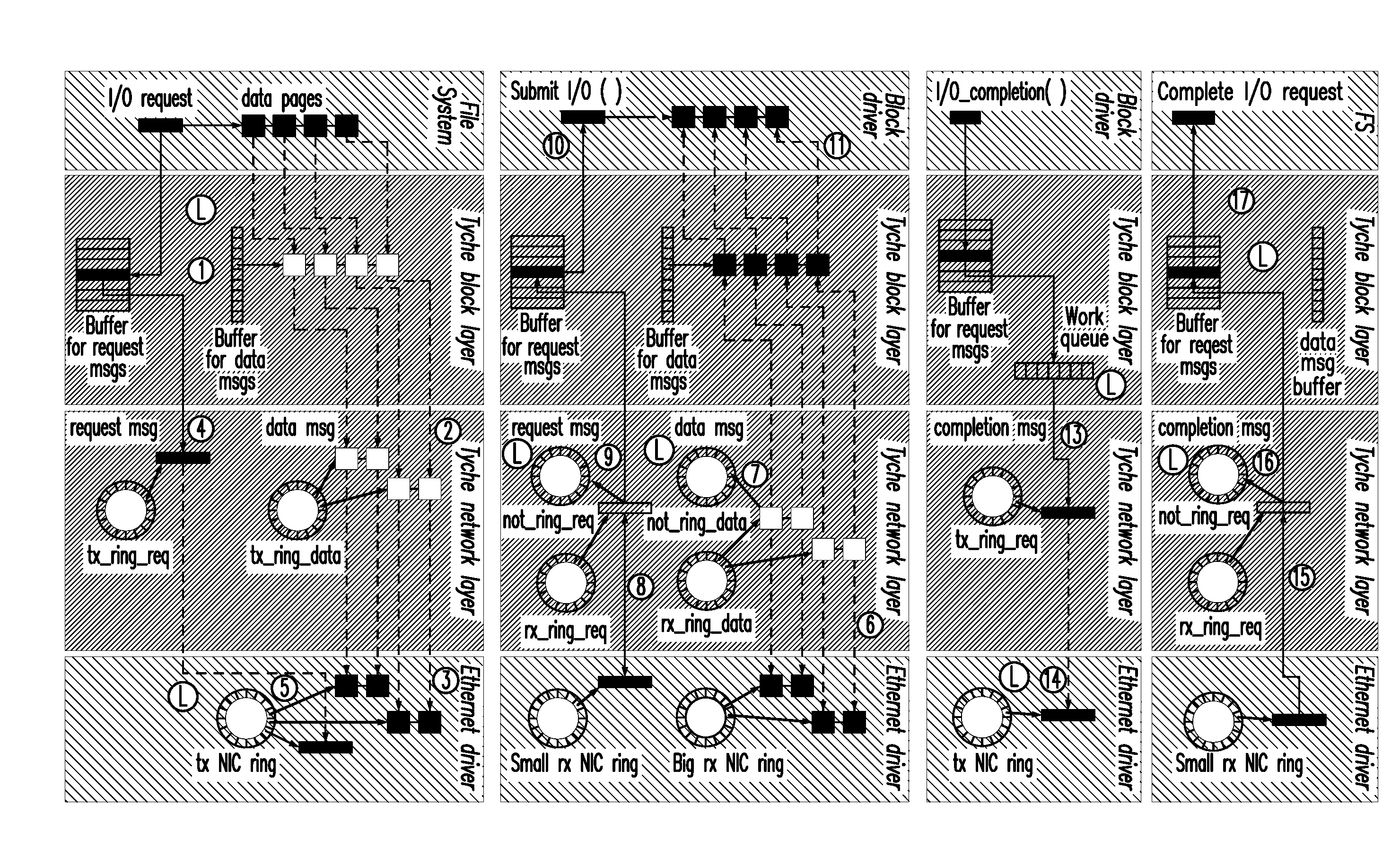

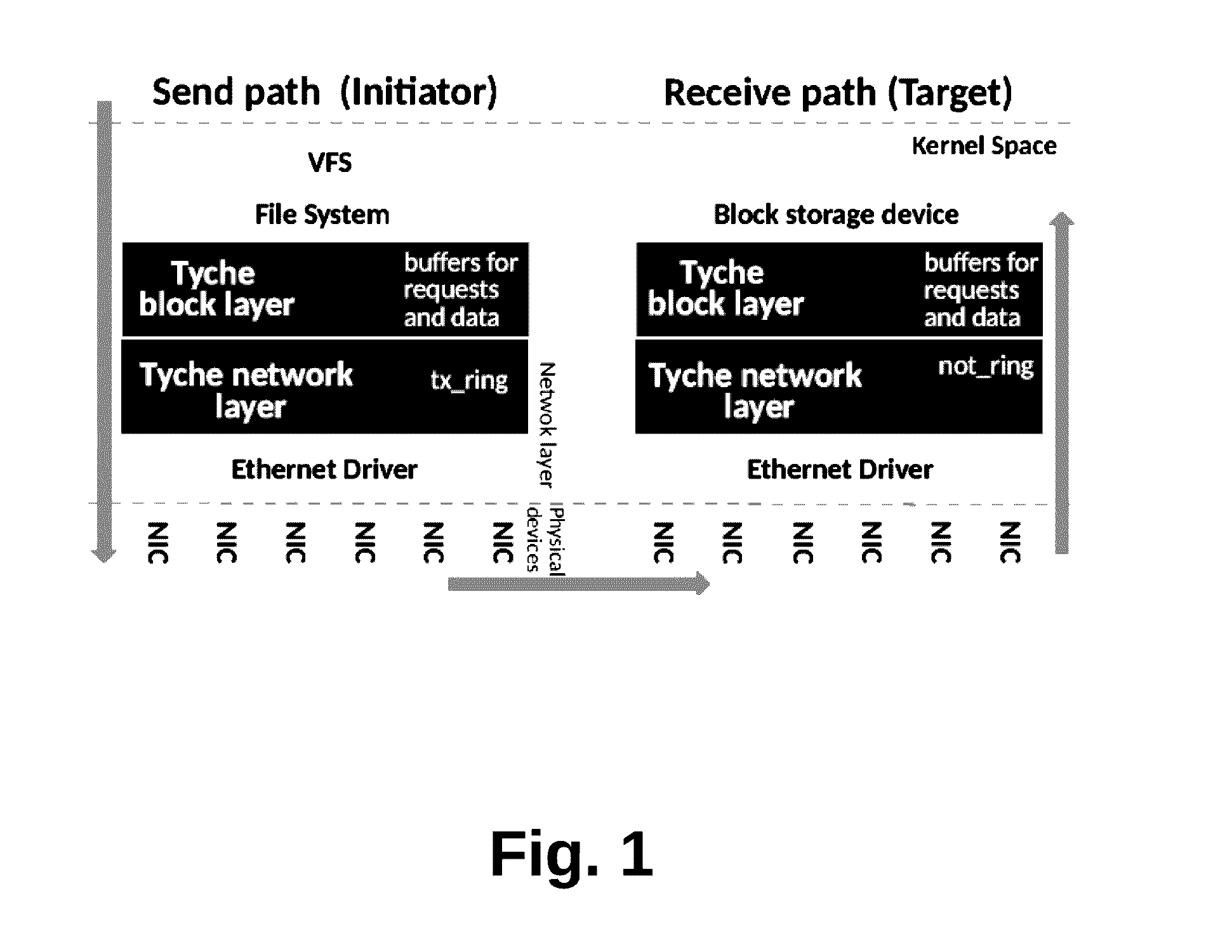

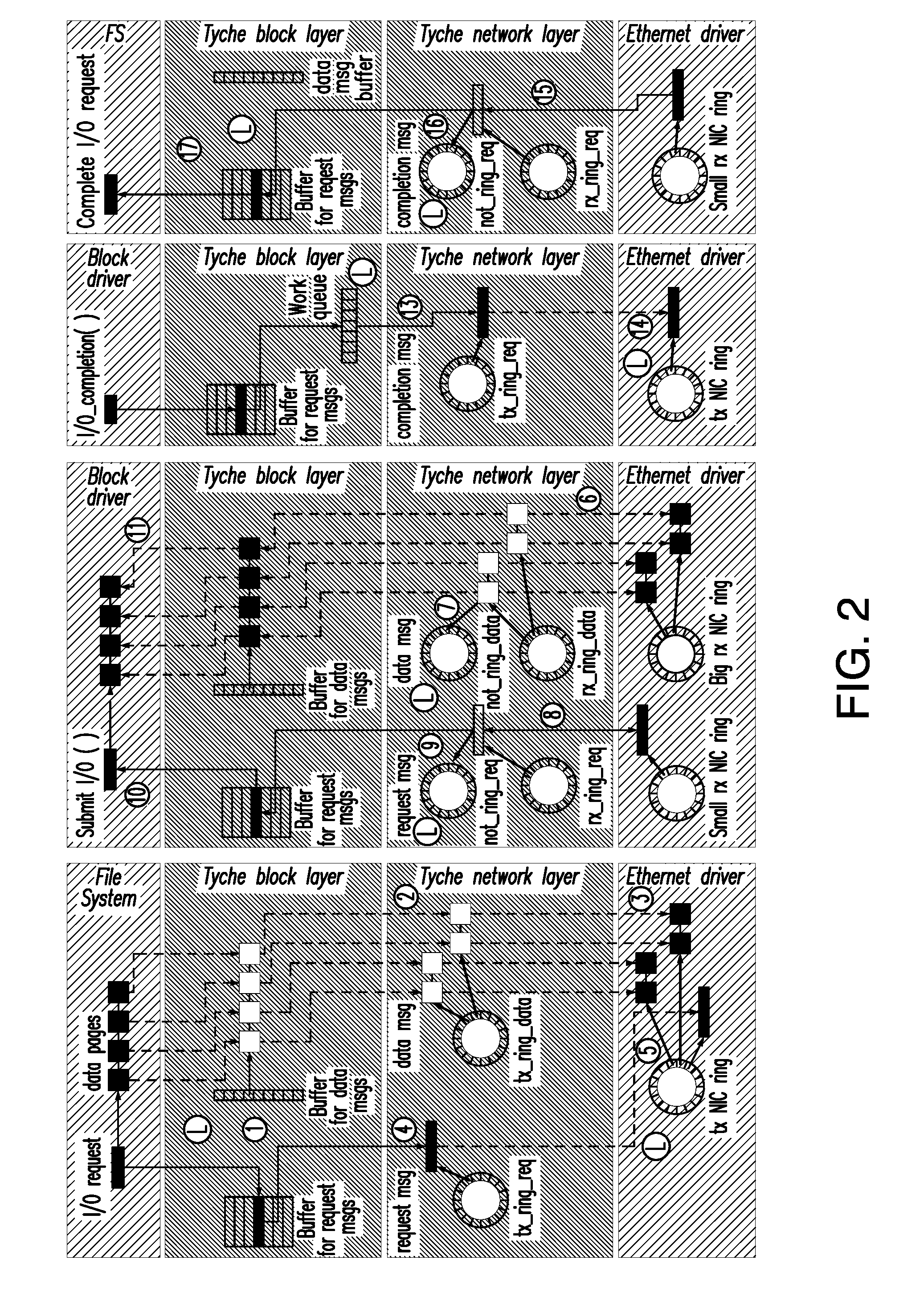

Network Storage Protocol and Adaptive Batching Apparatuses, Methods, and Systems

ActiveUS20160285971A1Reduce overheadReduce synchronizationData switching networksData bufferSelf adaptive

A computer network-storage protocol system, including at least one initiator device having an initiator block layer and an initiator network layer interfacing with a first network driver; at least one target device having a target block layer and a target network layer interfacing with a second network driver; a plurality of network interface controllers (NICs) interfacing with the first network driver and the second network driver; a plurality of distinct channels, each channel establishing a connection between the initiator device and the target device and being configured to transmit packets between the initiator device and the target device, wherein each channel is mapped to only one NIC; and wherein the initiator block layer includes at least one request message buffer and at least one data message buffer.

Owner:FOUND FOR RES & TECH HELLAS

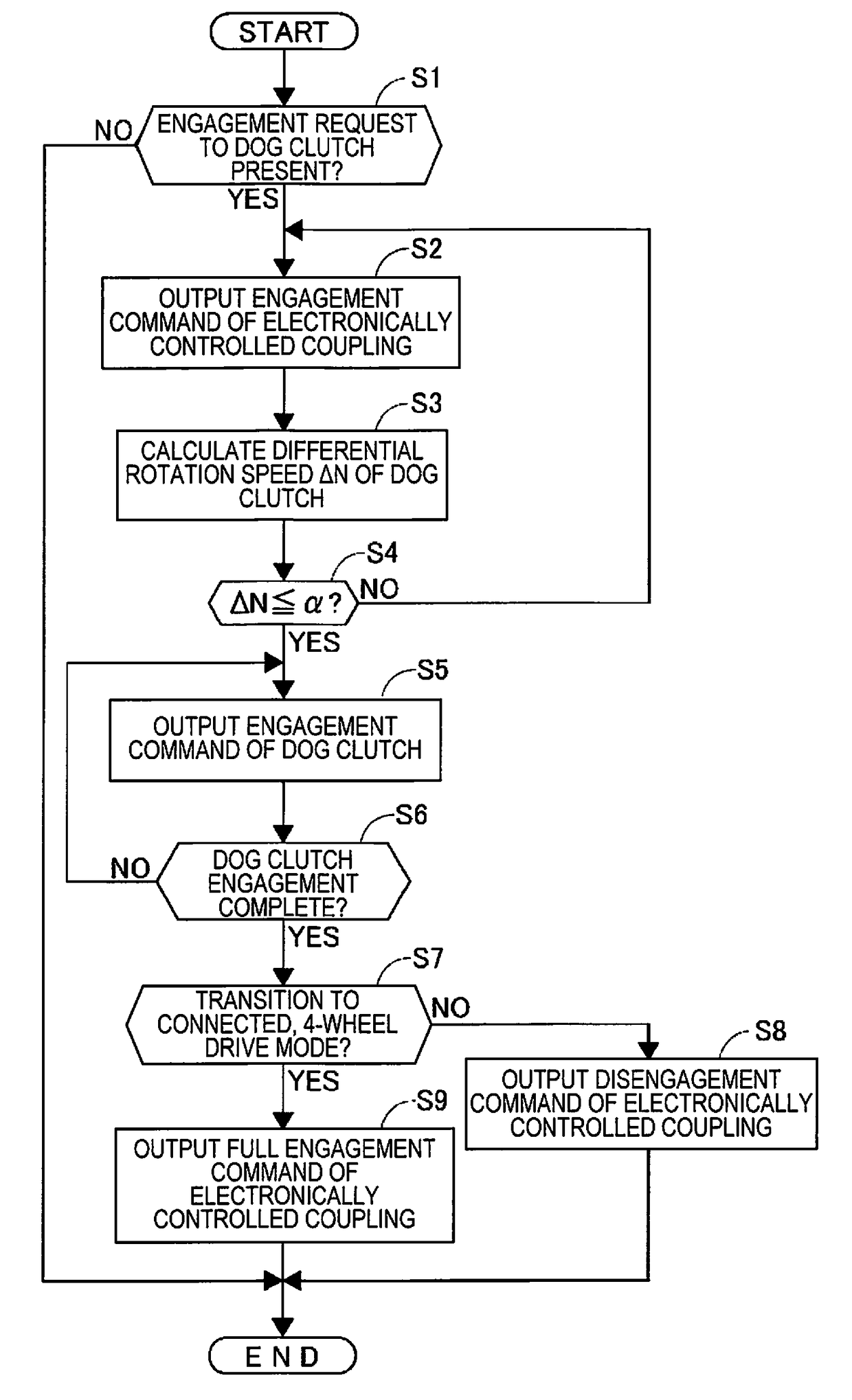

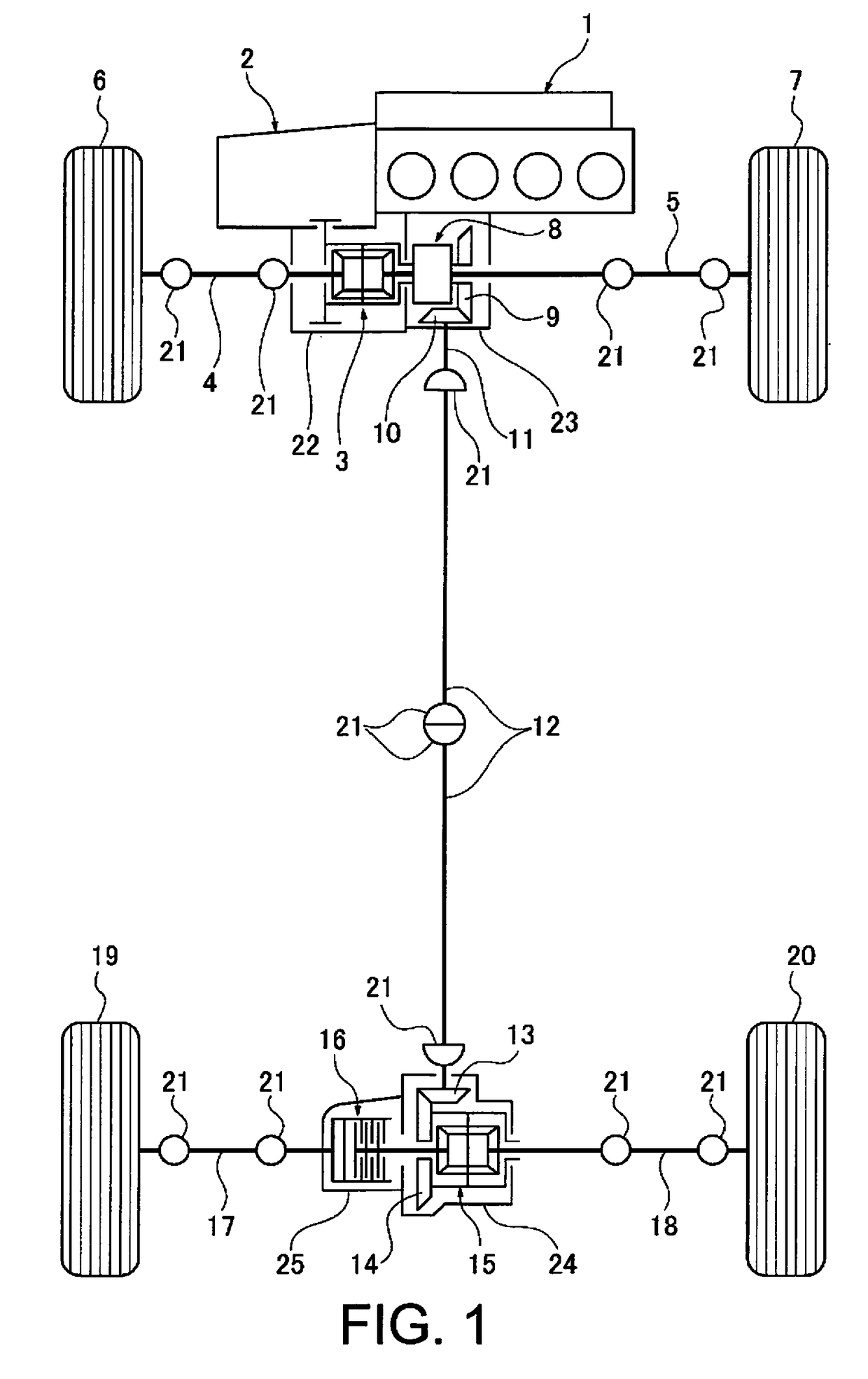

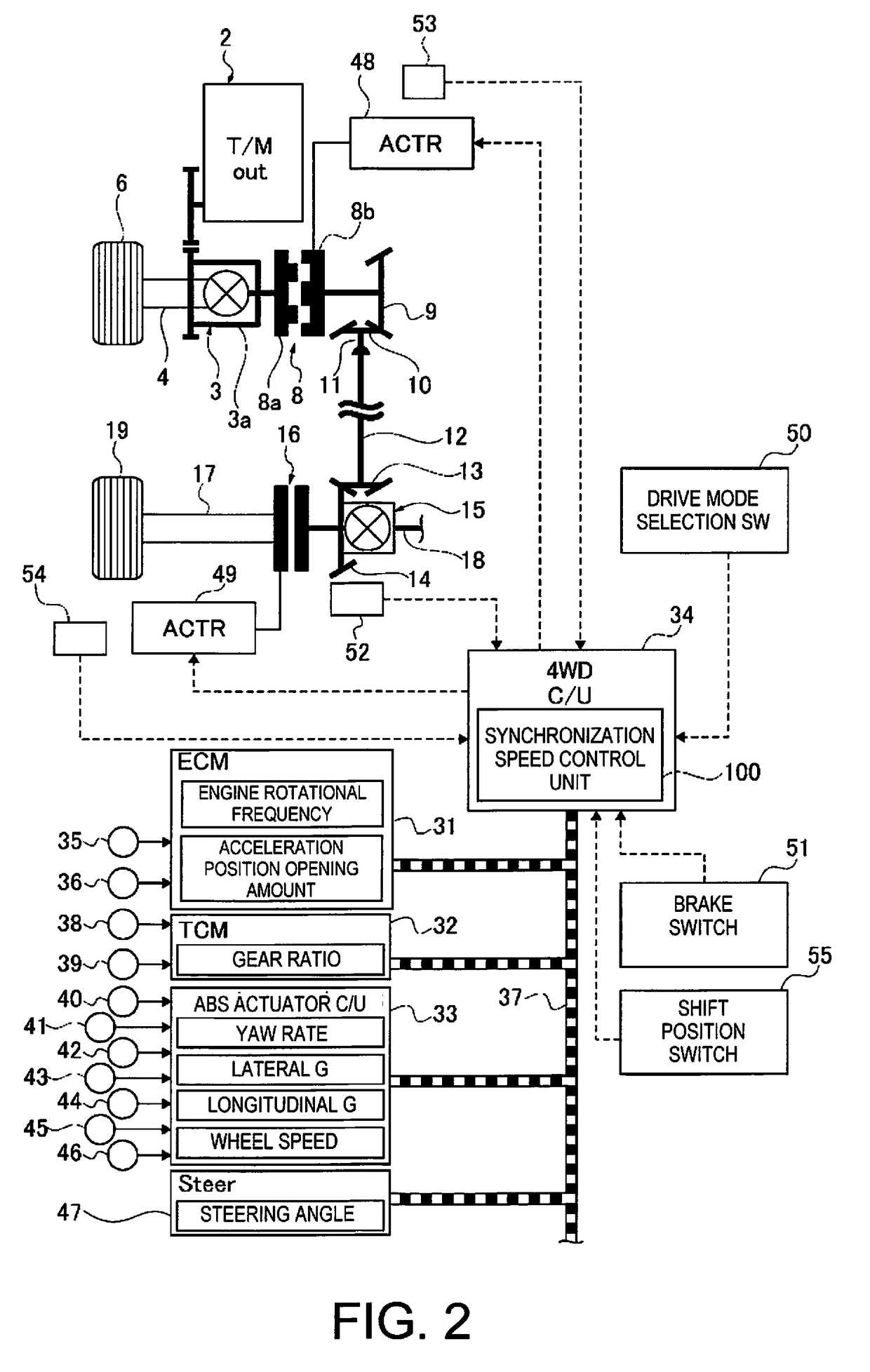

Clutch control device for 4-wheel drive vehicle

ActiveUS20170166052A1Improvement in sound and vibration levelControl response be increaseVehicle sub-unit featuresFriction clutchesWheel driveTwo-wheel drive

A clutch control device is provided for a 4-wheel drive vehicle. The clutch control device includes a 4WD control unit that controls the engagement and release of a friction clutch and a dog clutch which are arranged separately in the two paths. The 4WD control unit has a synchronization speed control unit, and at a time of transition from a disconnected, two-wheel drive mode, in which the friction clutch and the dog clutch are released, to a connected, four-wheel drive mode, in which the friction clutch and the dog clutch are engaged, the synchronization speed control unit reduces a synchronization speed of the dog clutch more during vehicle deceleration than when the vehicle is not decelerating.

Owner:NISSAN MOTOR CO LTD

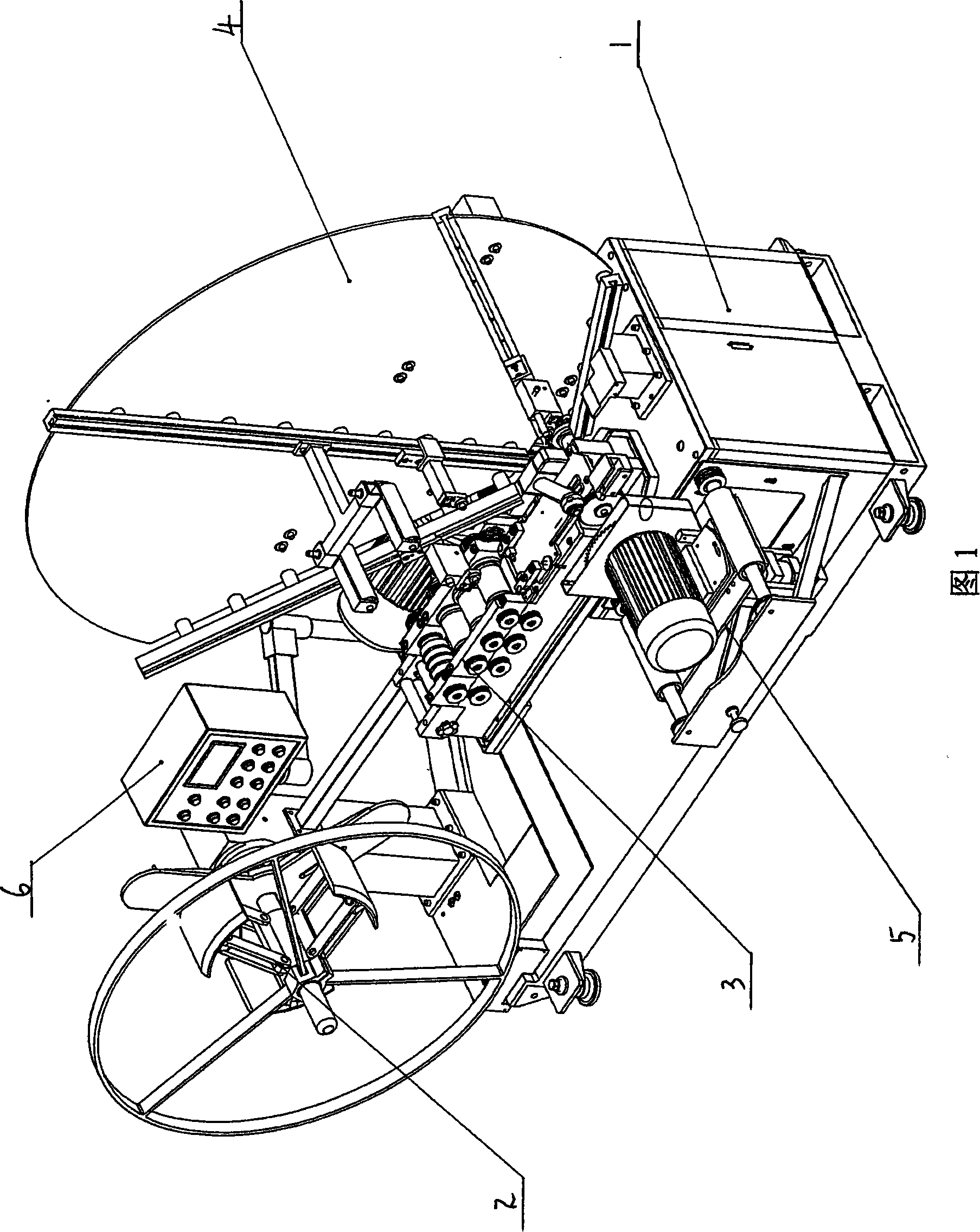

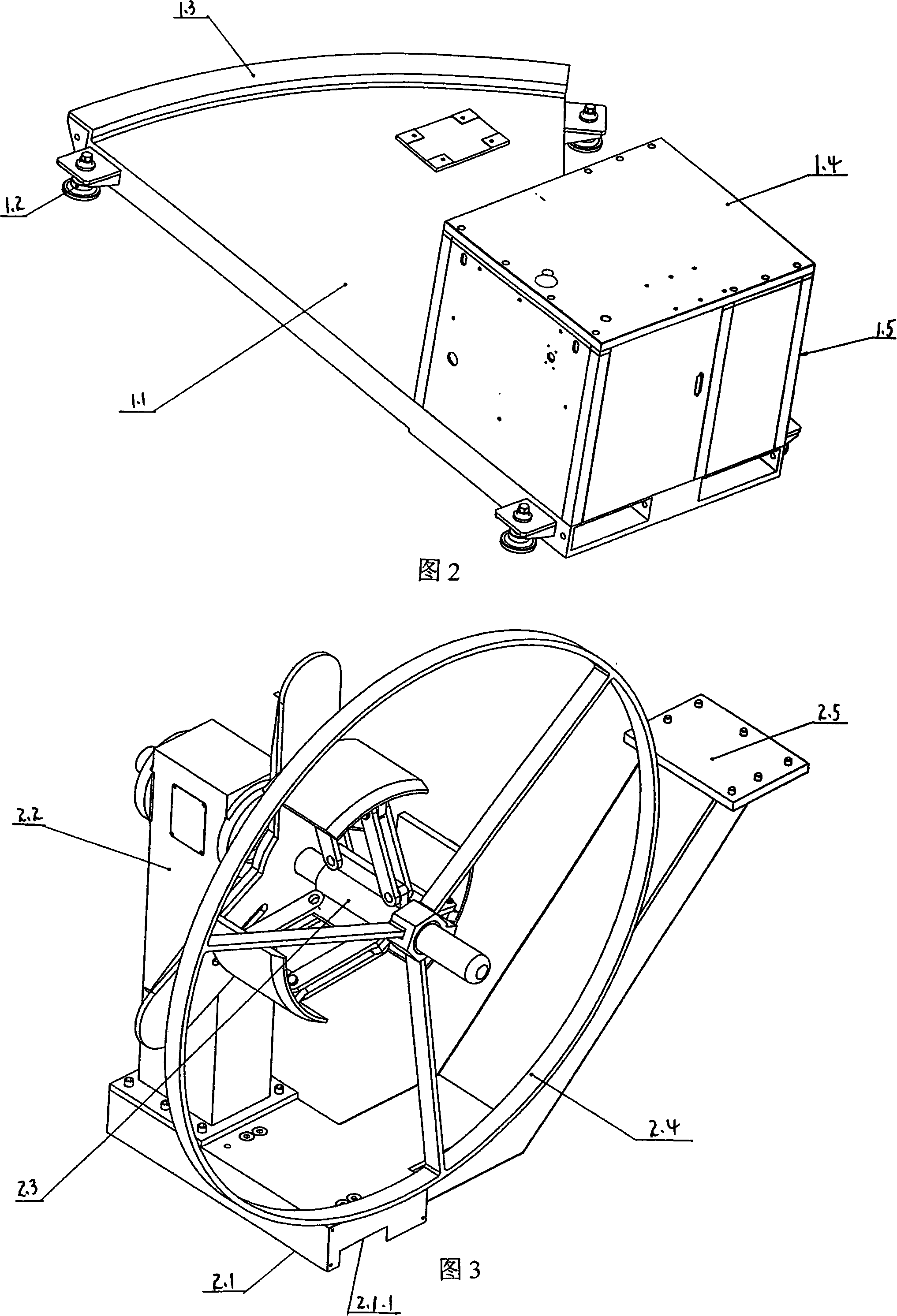

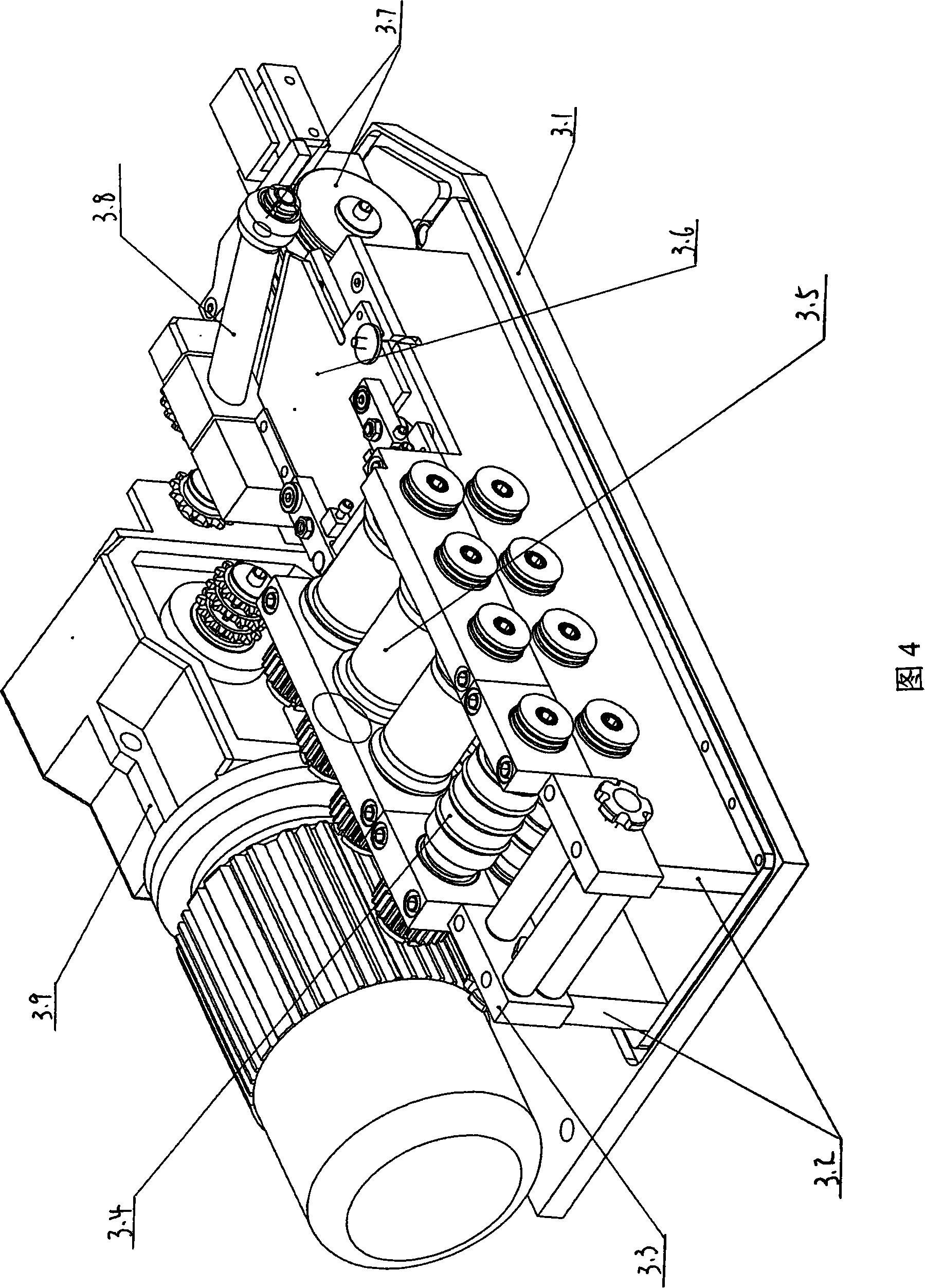

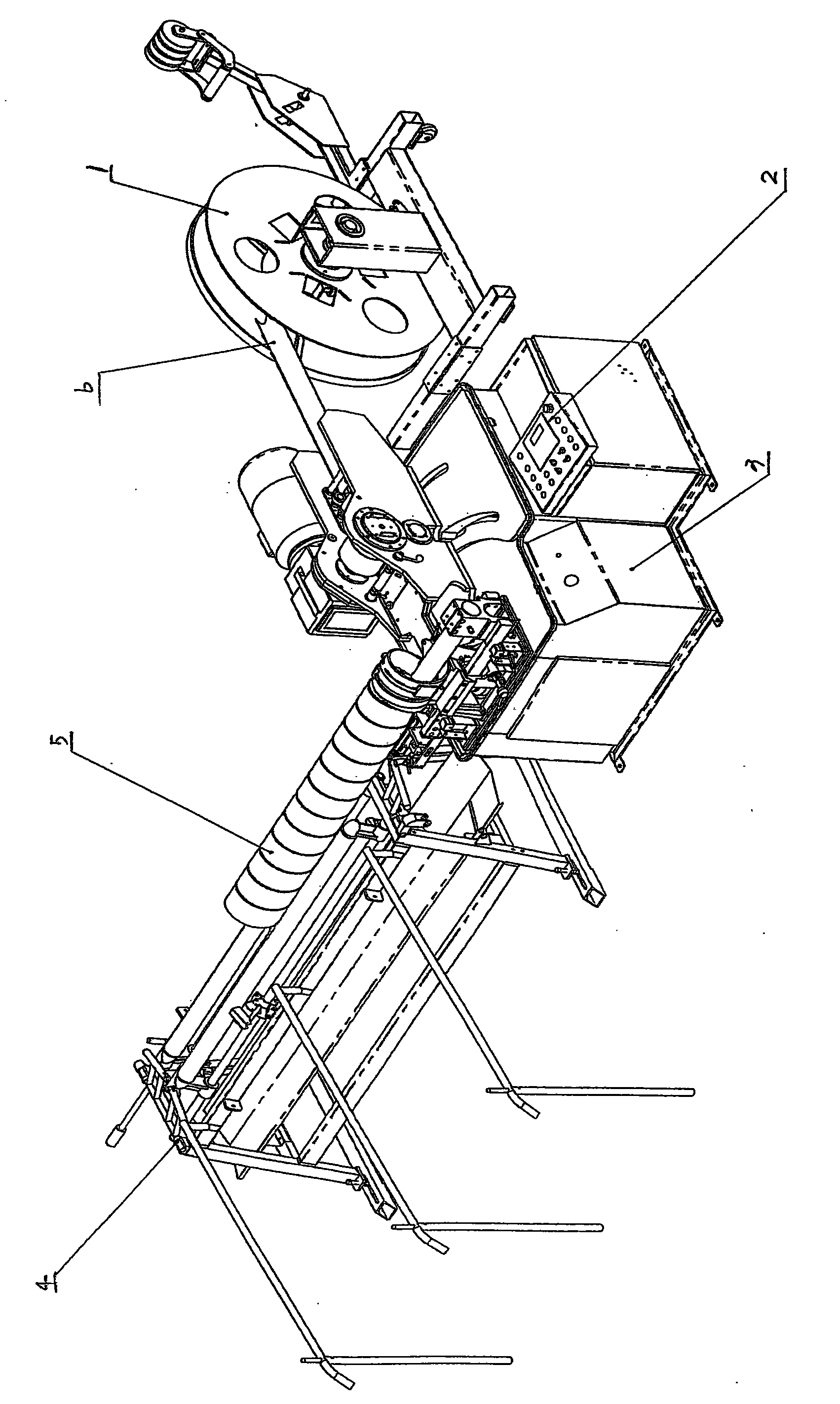

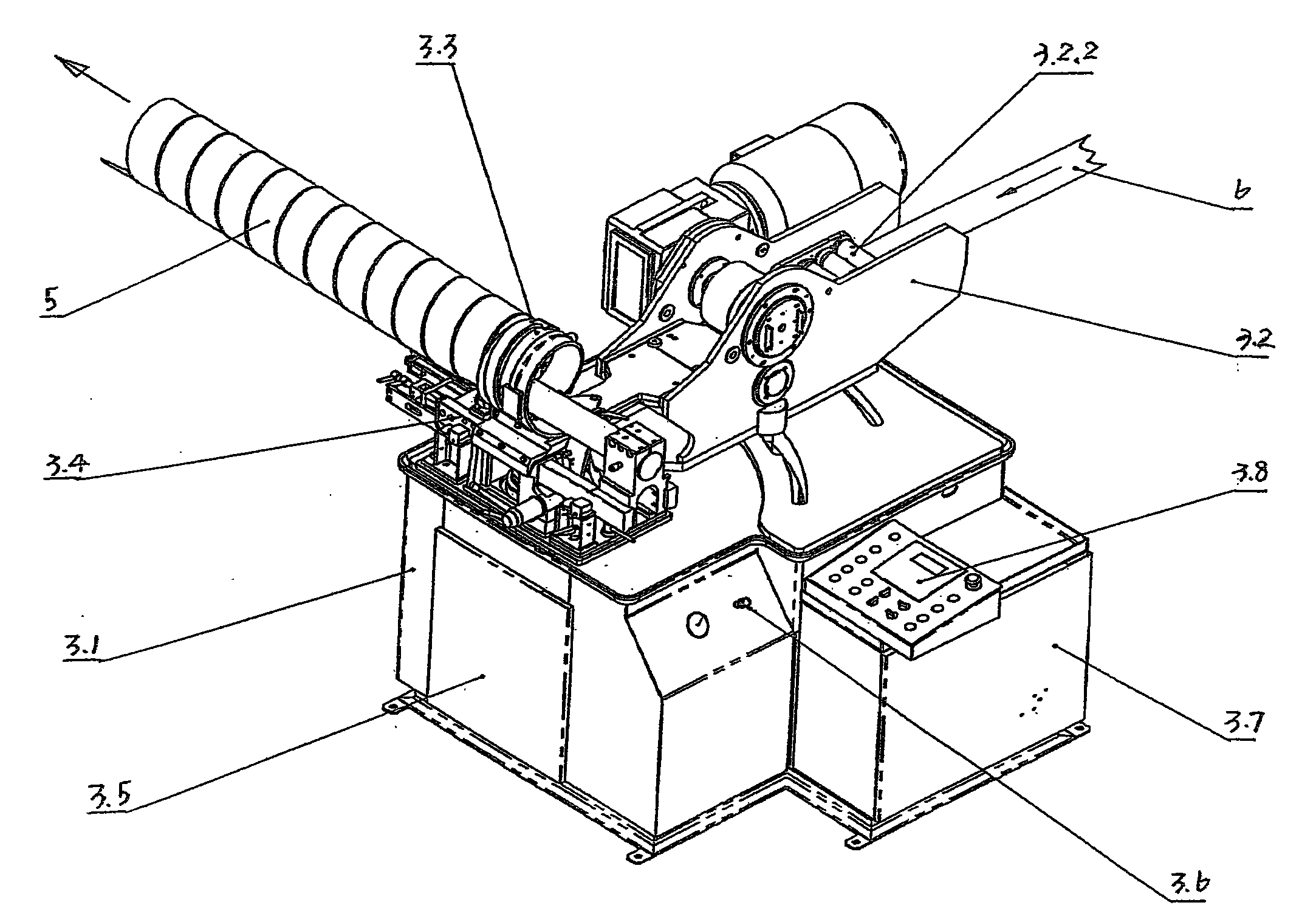

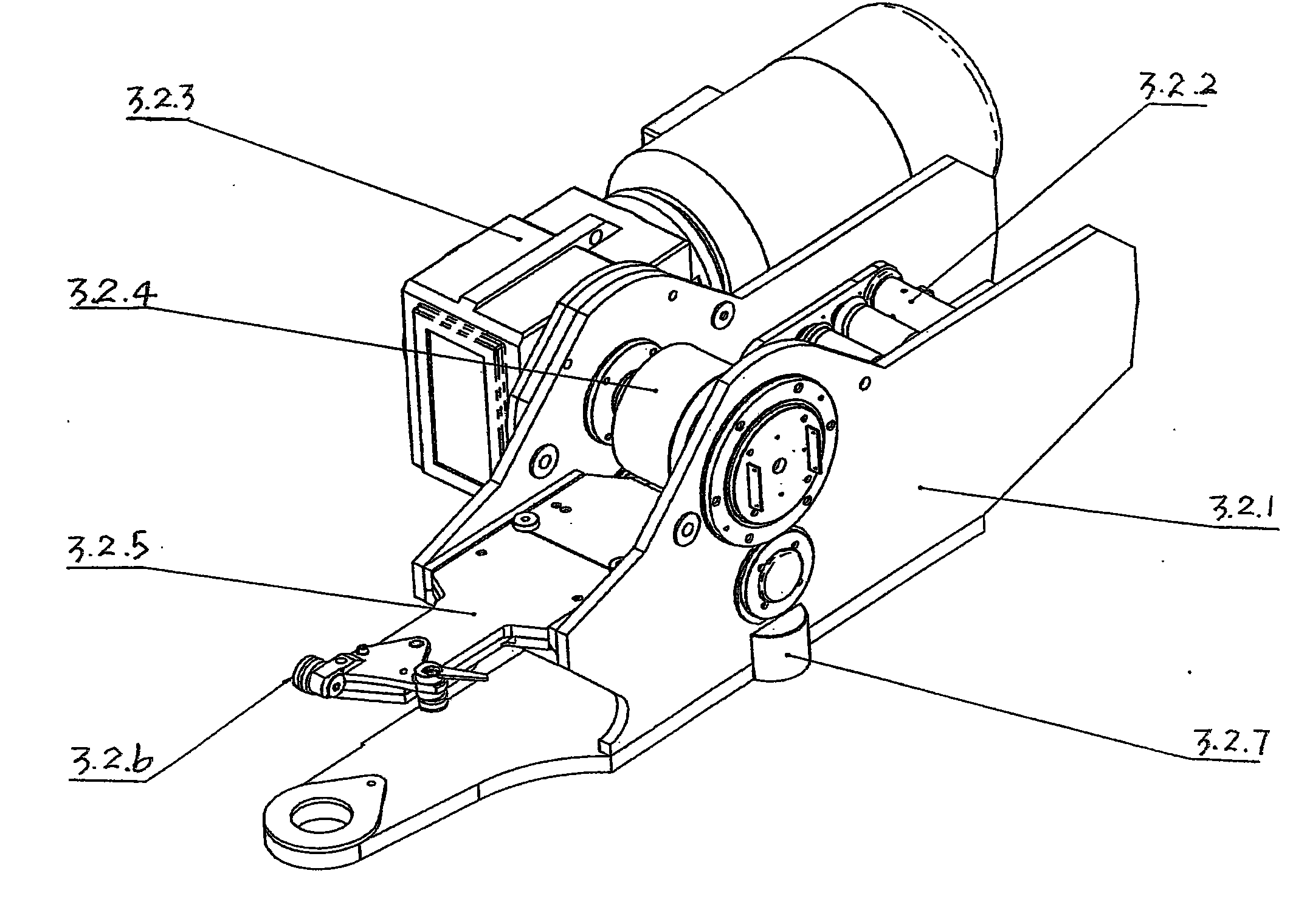

Helical gas pipe forming machines

The invention relates to a novel spiral gas tube forming machine, which is applicable for spiral ducts formed by rolling strip steel roll material along a spiral involute track. The spiral gas tube forming machine comprises a frame (1); a material shelf (2), a lock forming set (3), a mold frame (4) and a cutting machine (5) arranged on the frame (1); and a discharge shelf (7) arranged on the front side of the cutting machine (5); wherein the frame (1) comprises a bottom plate (1.1), level adjusting bases (1.2), material shelf guide rails (1.3) and a platform (1.4); the material shelf (2) comprises a slider (2.1), a pillar (2.2), a main body (2.3) and a connection crank arm (2.5); the lock forming set (4) comprises a bottom plate (3.1), wall plates (3.2), a feed leveling device (3.3), an upper and a lower rib-pressing rollers (3.4), an upper and a lower roller groups (3.5), a discharge guide plate (3.6), an upper and a lower engagement wheels (3.7), and a pressing crank arm (3.8); and the mold frame comprises a support frame (4.1), guide rails (4.2), a template (4.3) and wind pipe baffles (4.5). The spiral gas tube forming machine has the advantages of simple structure, integration of the material shelf and the machine, good lock formability, multi-purpose of the mold frame, synchronous cutting without stopping, high production efficiency and good product quality.

Owner:陶国荣

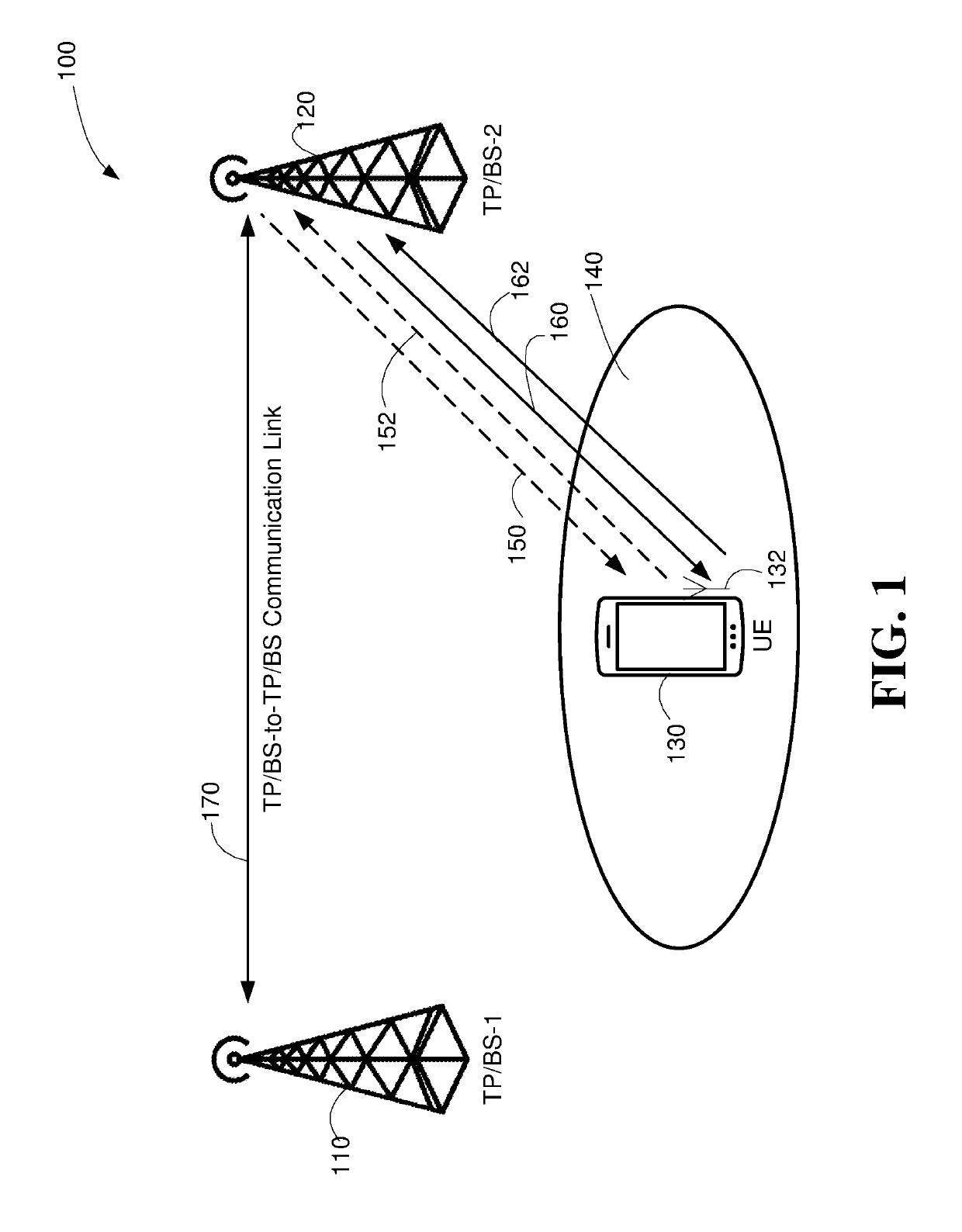

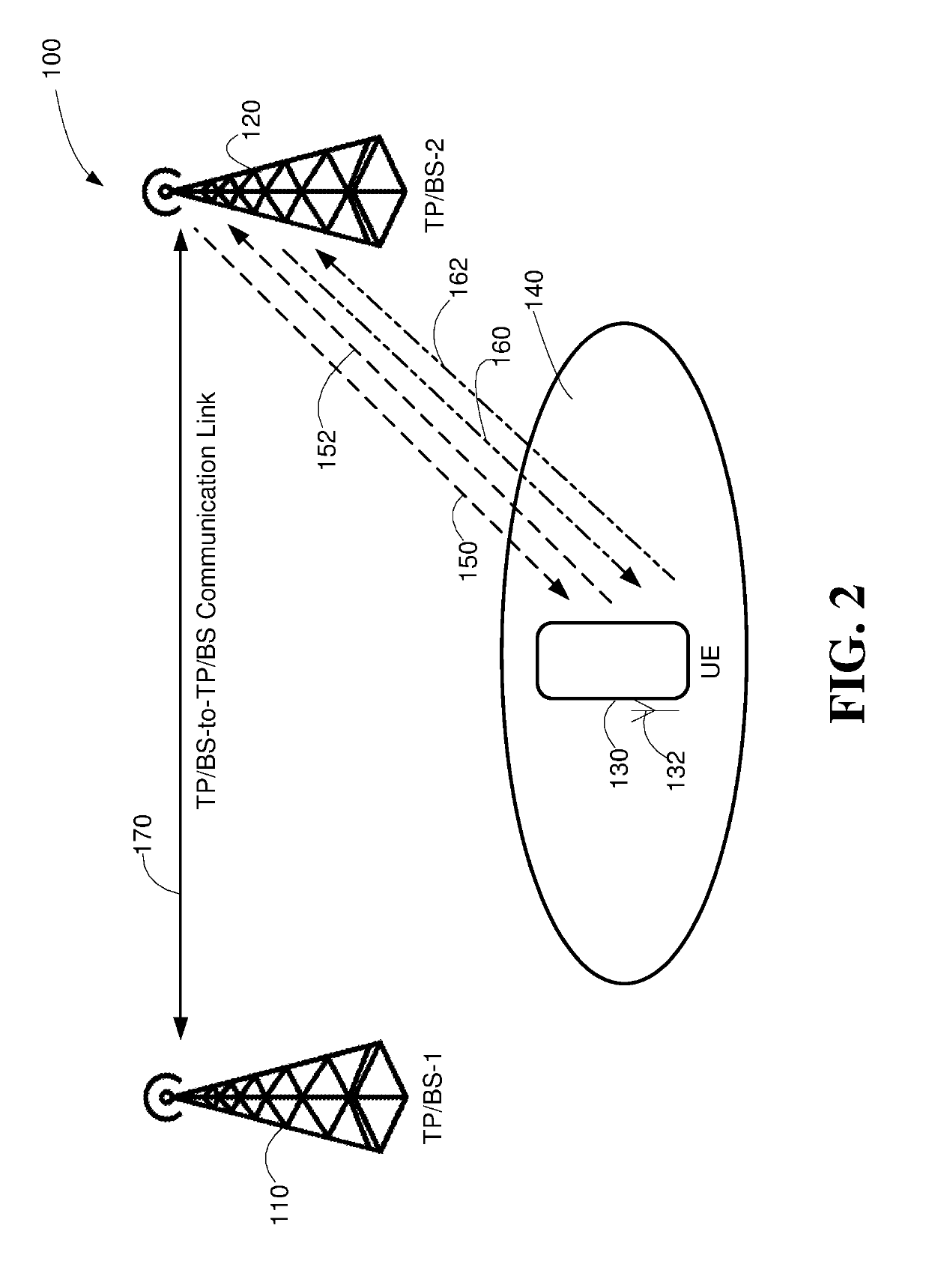

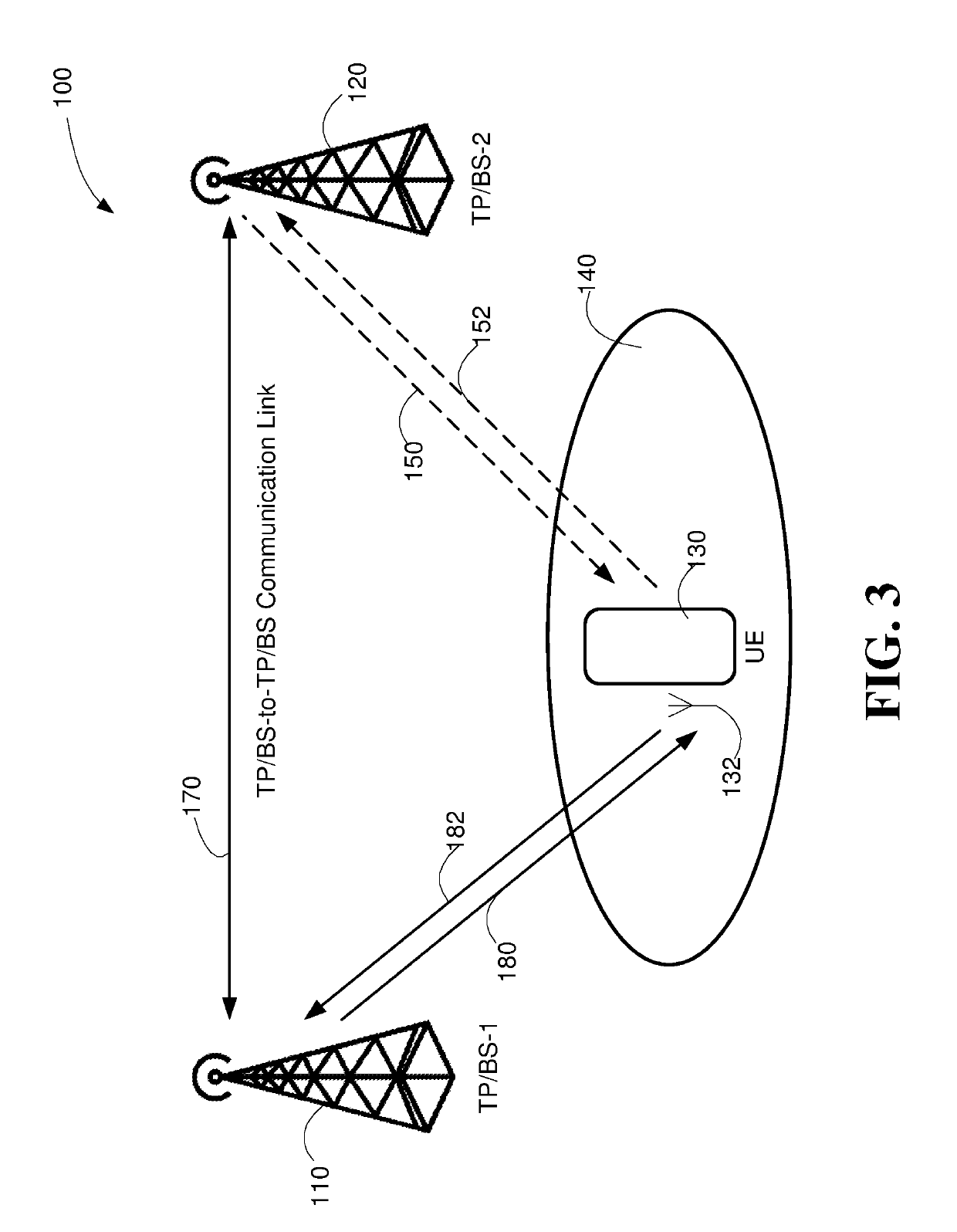

Radar-assisted tracking of mobile devices to improve the communication link in high frequency communciation

ActiveUS20190265348A1Save power consumptionCutting synchronizationLocation information based serviceNetwork planningTelecommunications linkRadar

Pulse signal transmission, such as radar pulses or the like are used in a high frequency mobile communication network as a means for determining or assisting in determining the likely presence of User Equipment (UE) and / or tracking UE in a predetermined area. As a result of determining the likely presence of UE and / or tracking UE, such information may be used to expedite either a handover or establish re-connection within the communication network. In this regard, more targeted beam sweeps or more frequent sweeps can be made in the direction where the UE has been determined to likely be present in order to hasten the establishment of the communication link between the targeted transmission point, such as a Base Station (BS) or the like, or reconnection to the existing transmission point.

Owner:SONY CORP

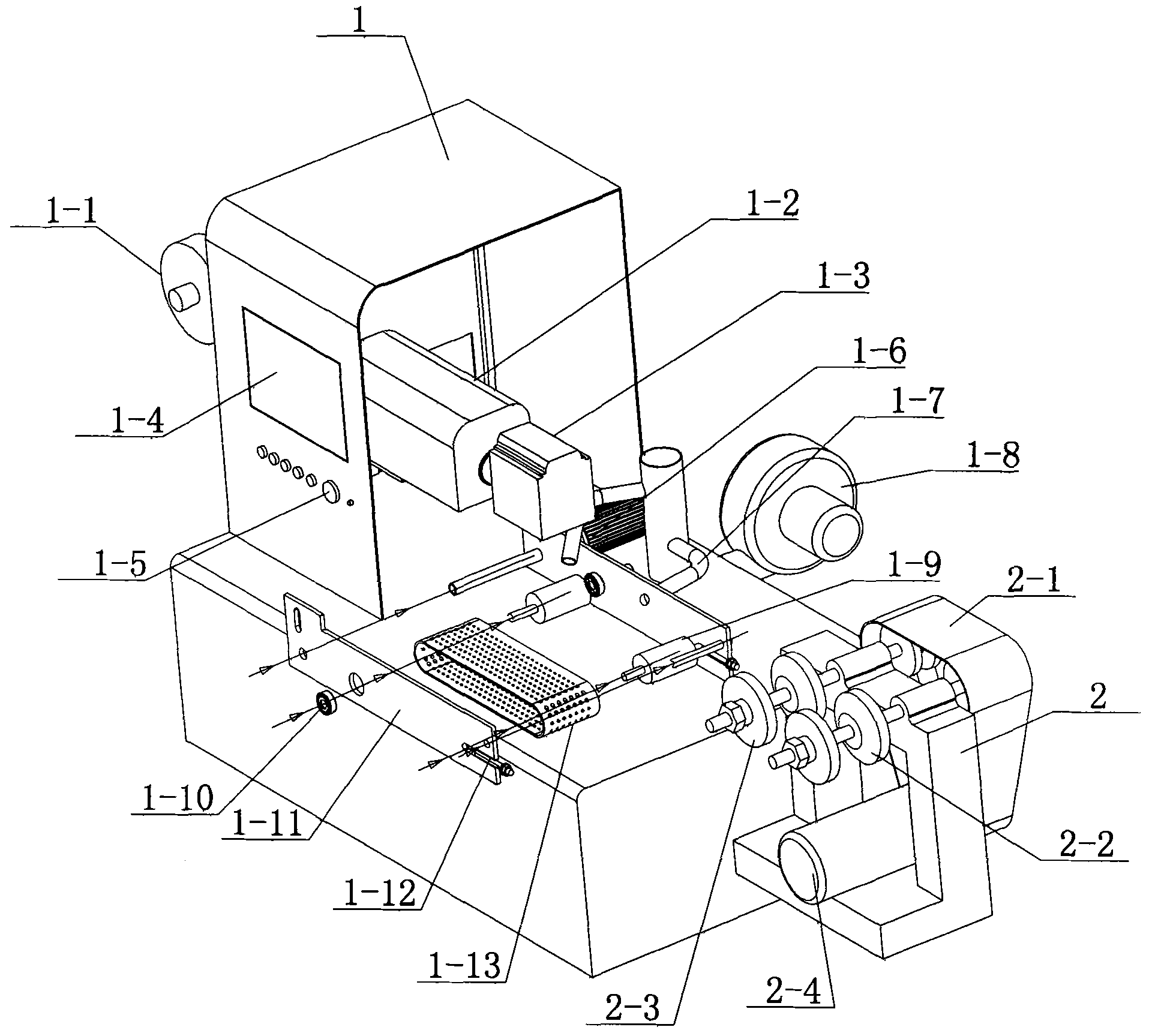

Laser cutting machine for reflective strip production

InactiveCN103658995AAvoid indentationSynchronous deliveryLaser beam welding apparatusNumerical controlLaser transmitter

The invention relates to a cutting machine, in particular to a laser cutting machine for reflective strip production. A feeding device (1-1) is arranged on the upper portion the left side of a cutting device (1). A laser cooling device (1-2) is arranged on the right side of the feeding device (1-1). A metal tube laser emitter (1-3) is arranged on the right side of the laser cooling device (1-2). An air suction device (1-7) is arranged on the right side of a synchronous motor (1-6). A draught fan (1-8) is arranged on the rear side of the air suction device (1-7). A hole belt (1-13) is arranged below the metal tube laser emitter (1-3). The air suction device (1-7) is arranged on the lower portion of the hole belt (1-13). A belt tightness degree regulator (1-12) is arranged at the right end of a fixed support (1-11). According to the laser cutting machine for reflective strip production, a metal tube laser device is used for replacing a traditional glass tube laser device, a coder achieves synchronization of production numerical control, conveyance and cutting, and generation of material indentations is avoided due to the arrangement of the air suction device.

Owner:FOSHAN KACHUN GARMENT

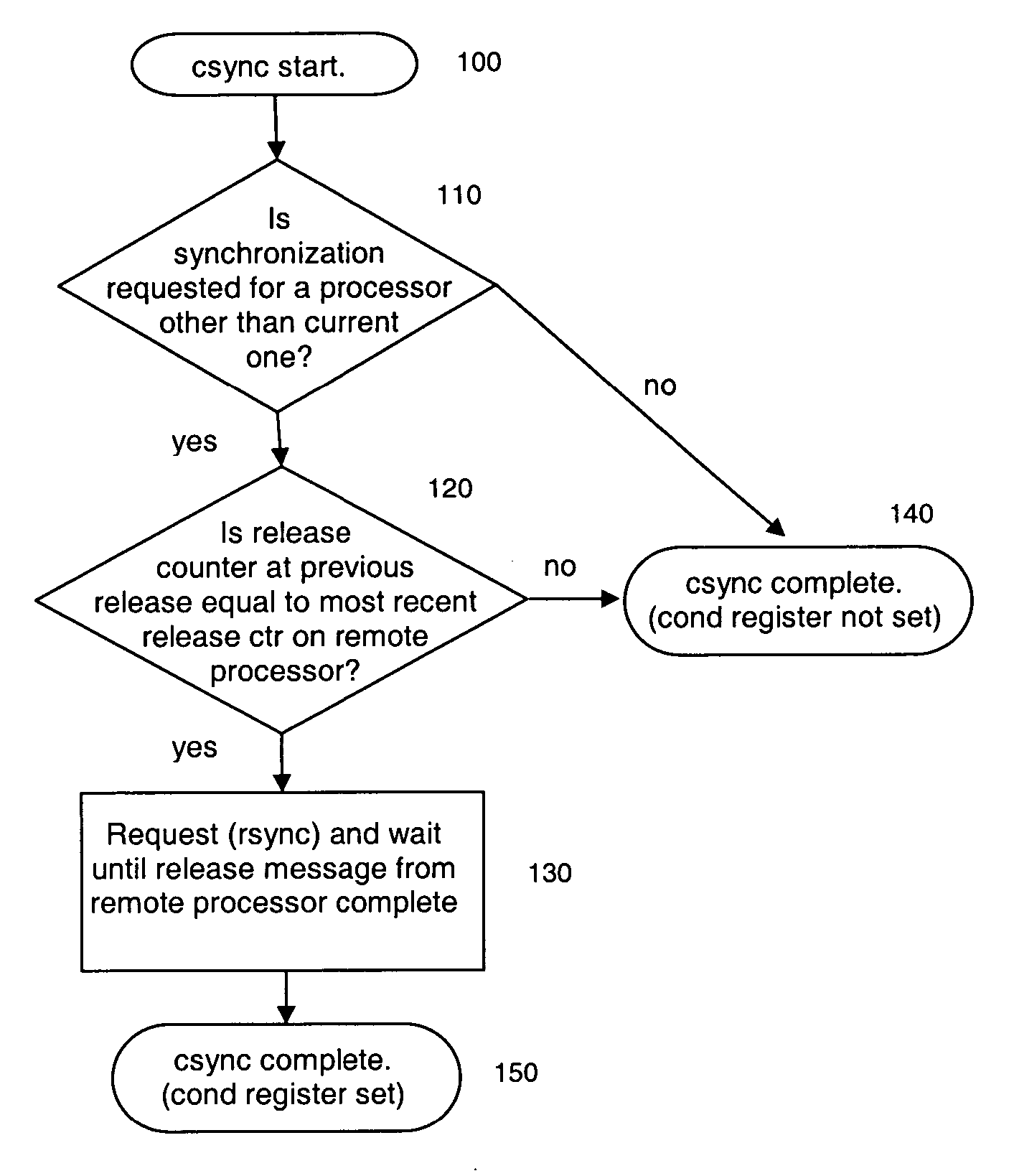

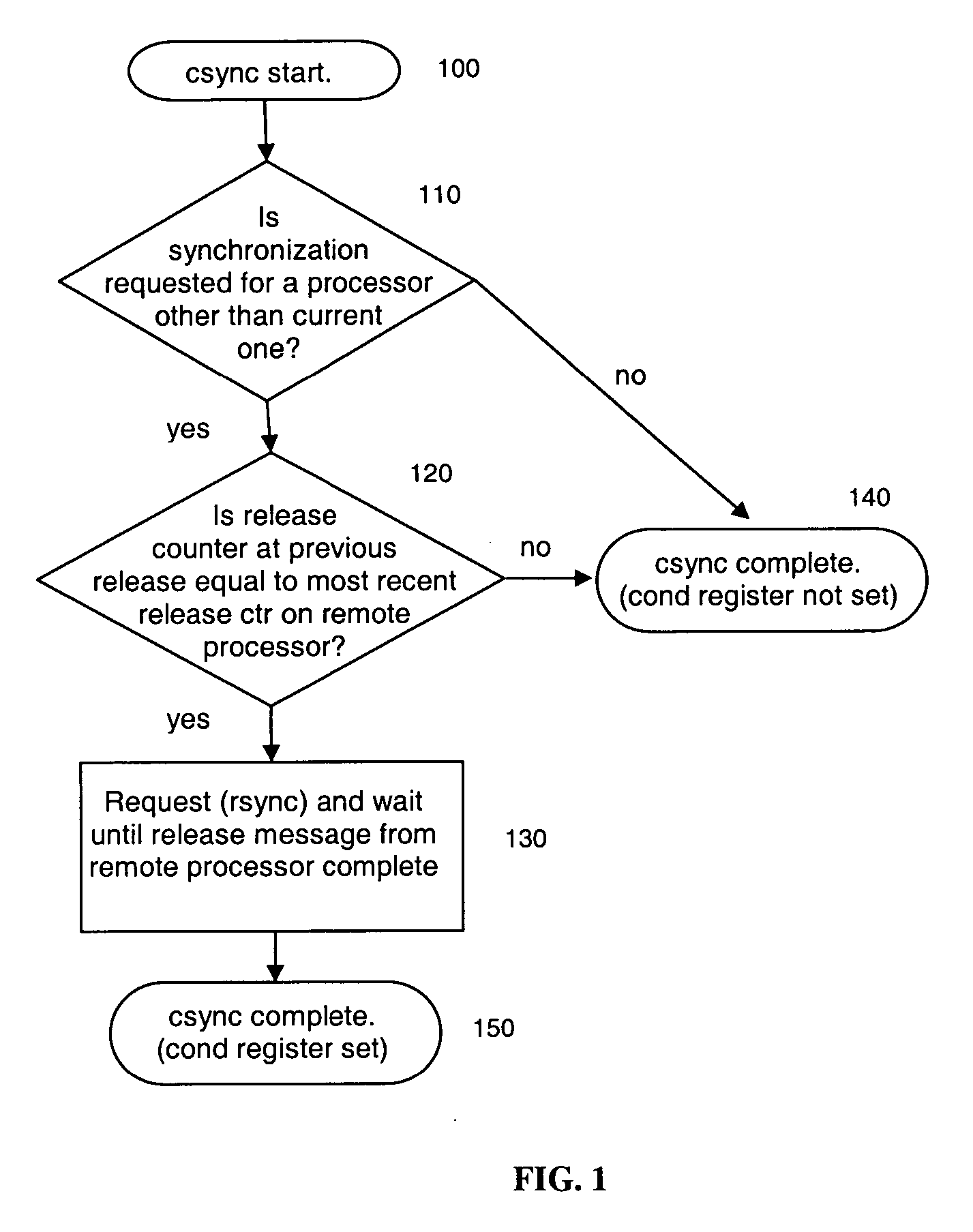

Method and apparatus for conditional memory ordering

InactiveUS20060277385A1Avoid overheadReduce frequencyProgram synchronisationDigital computer detailsMulti processorMemory ordering

A method and apparatus for conditional memory ordering are disclosed. The cost of memory ordering is reduced by determining circumstances in which a memory ordering operation is unnecessary and avoiding the overheads of these operations by reducing the frequency of invoking hardware memory ordering mechanisms. Hardware instructions for implementing a conditional memory ordering method and apparatus is described which may be implemented in a multiprocessor environment. The conditional memory ordering instruction executes locally using a release vector containing release numbers for each processor in the system. The instruction first determine whether a processor identifier of the release number is associated with the current processor. Where it is not, a conditional registered is examined and appropriate remote synchronization operations are commanded where necessary.

Owner:IBM CORP

Helical air duct forming machine with main machine capable of synchronously cutting without halt

The invention relates to a helical air duct forming machine with a main machine capable of synchronously cutting without halt, which is used for rolling a band steel roll material used as a base material into a helical air duct along the helical involute trajectory. The forming machine comprises a decoiler (1), a main machine (3) and a discharge table (4). The main machine (3) comprises a main machine chassis (3.1), a machine head box assembly (3.2), a die (3.3) and a flying shear assembly (3.4). The discharge table (4) comprises a chassis (4.1), a roll-over stand (4.2), a load bearing roller (4.3), a photoelectric length measurement device (4.4), a lubricating material roller (4.5), a water collection tray (4.6) and a material agitating cylinder (4.7). The main machine of the forming machine can synchronously cut without halt.

Owner:JIANGYIN SANBEN TECH CO LTD

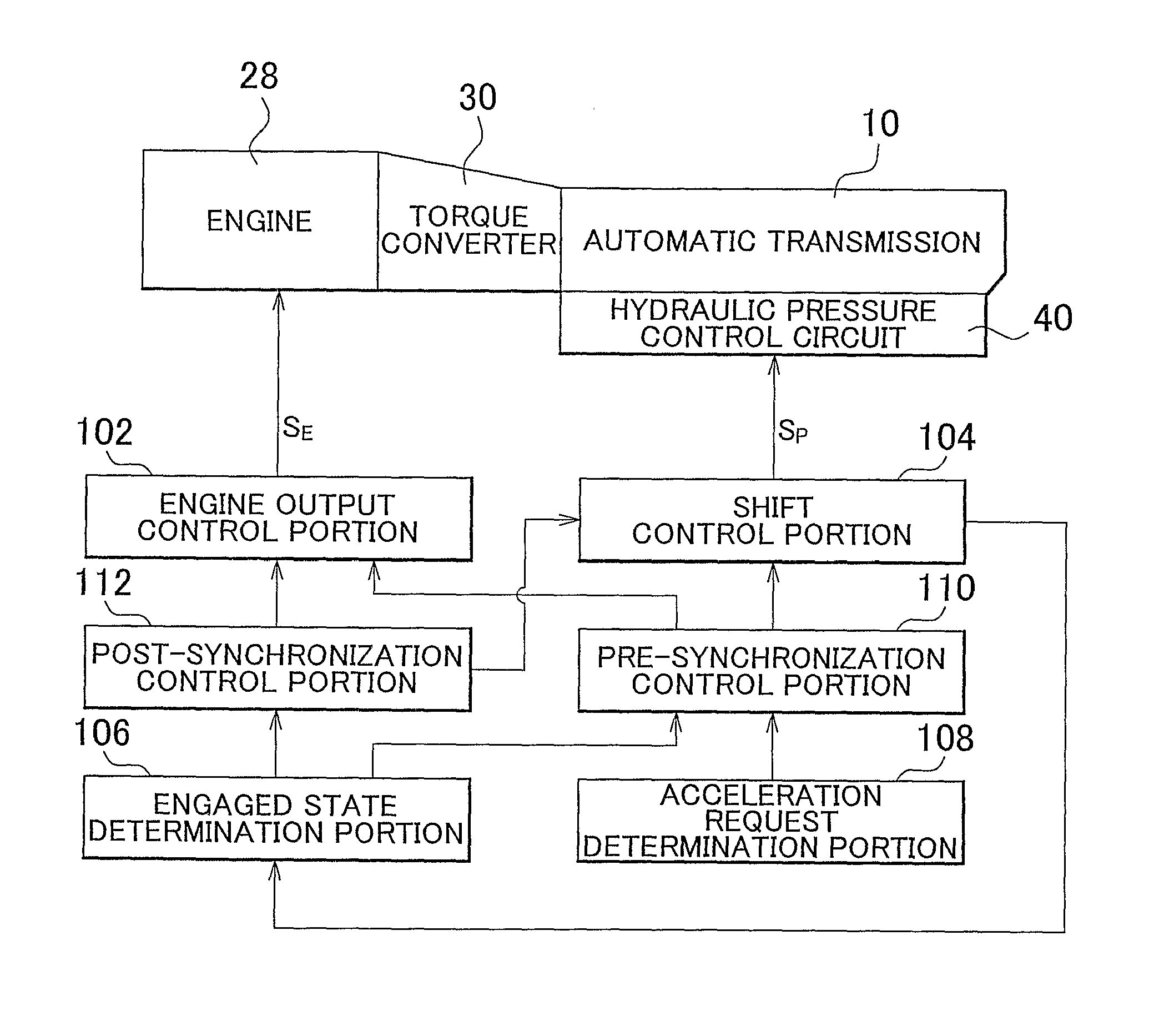

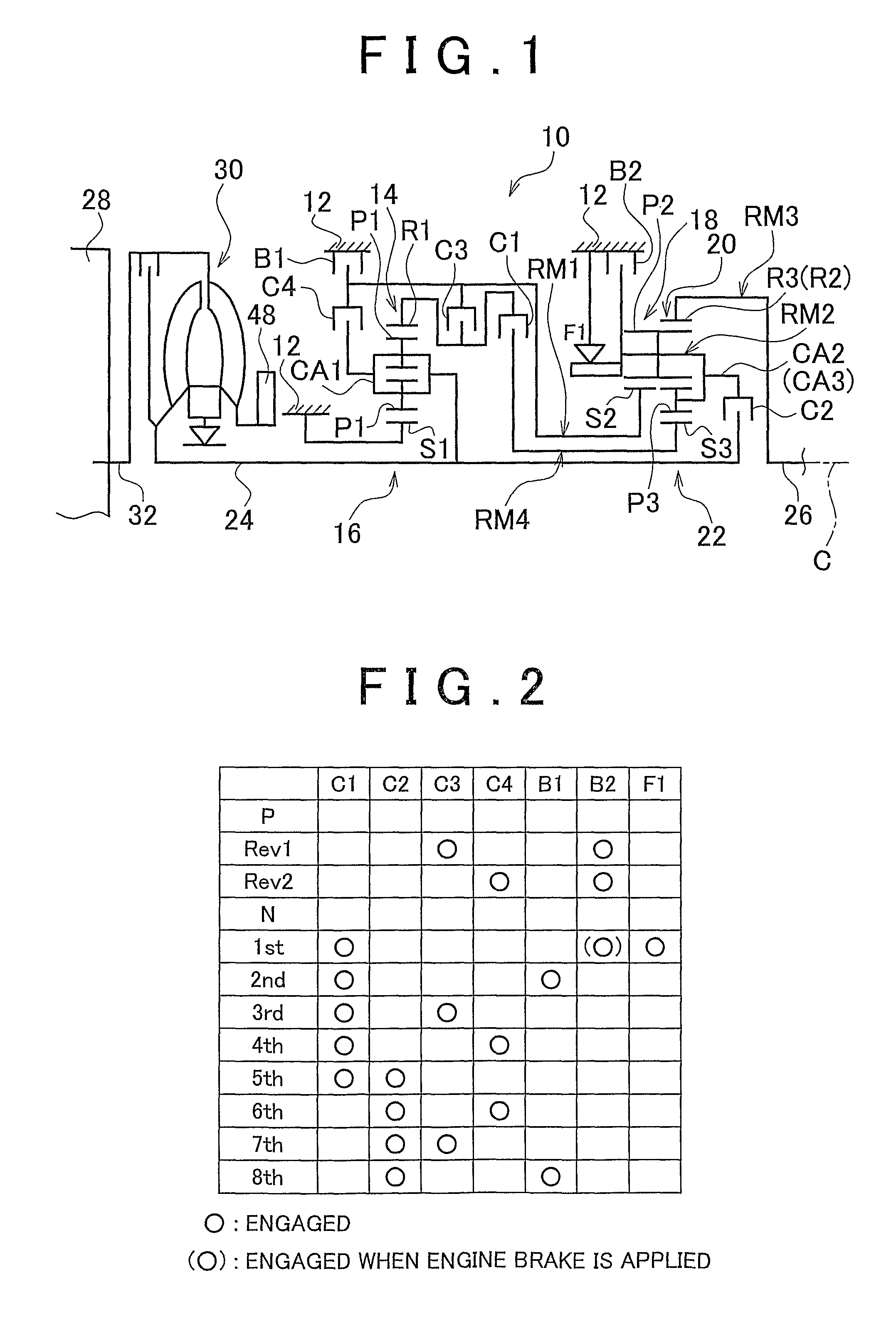

Control apparatus and control method for vehicle automatic transmission

ActiveUS20110125375A1Suppress synchronization shockPower response is improvedDigital data processing detailsGearing controlAutomatic transmissionSynchronous control

In a control apparatus and a control method for a vehicle automatic transmission in which a plurality of gears with different speed ratios are achieved by selectively engaging a plurality of friction engagement devices and a one-way clutch, if an acceleration request is made in the case where the one-way clutch is in an idling state when a first predetermined gear is to be achieved by engaging the one-way clutch, a pre-synchronization control is executed to transmit torque through a predetermined friction engagement device used to achieve a second predetermined gear at which the one-way clutch is maintained in an idling state, and to continue to change a rotational direction of the one-way clutch toward a rotational direction in which the one-way clutch is brought to a synchronized state, according to the acceleration request.

Owner:TOYOTA JIDOSHA KK

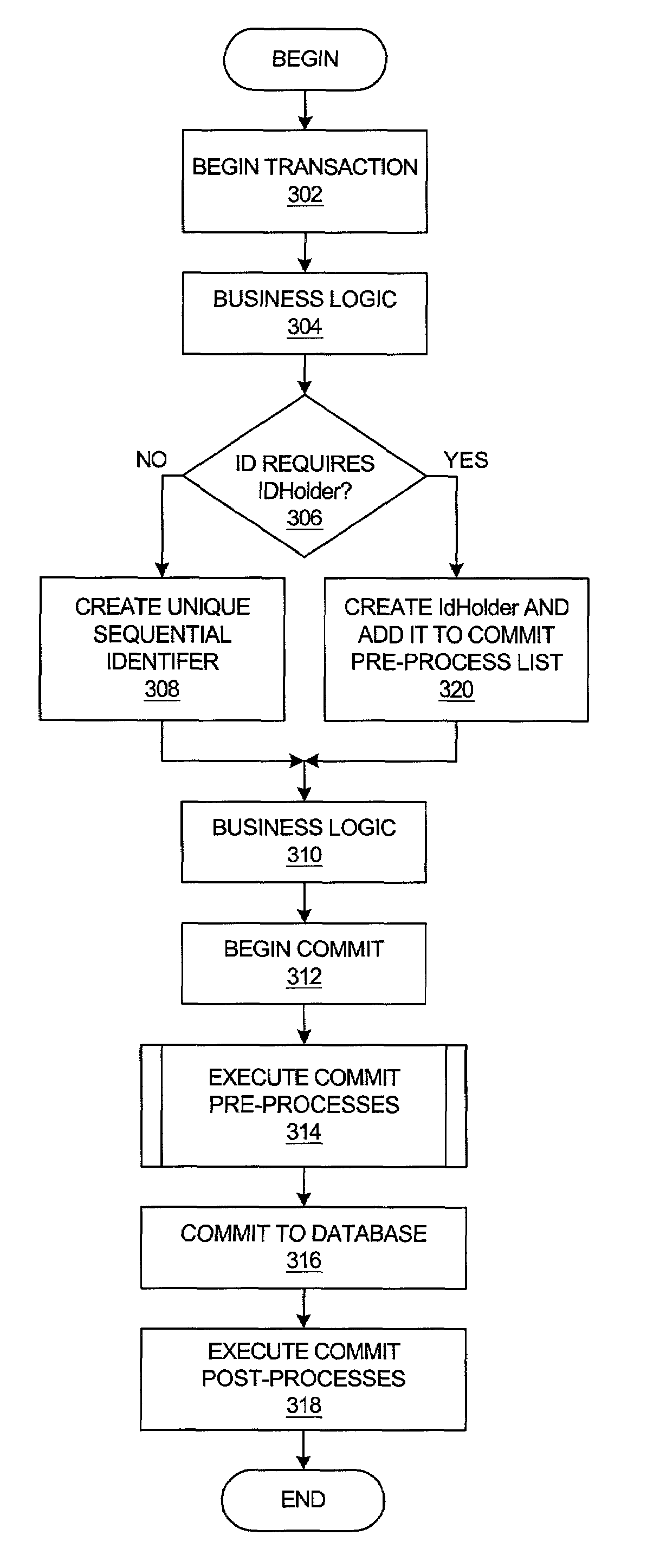

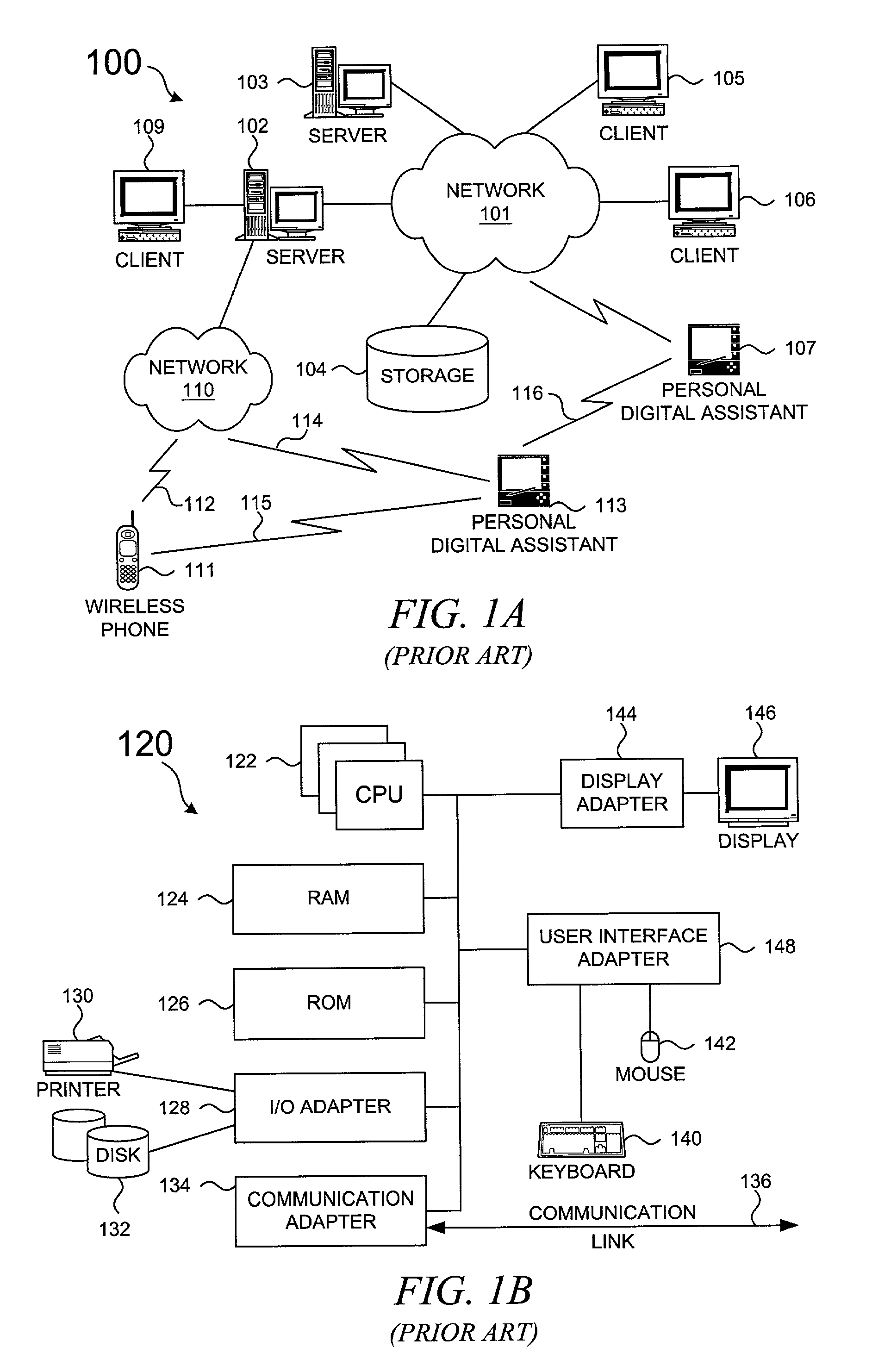

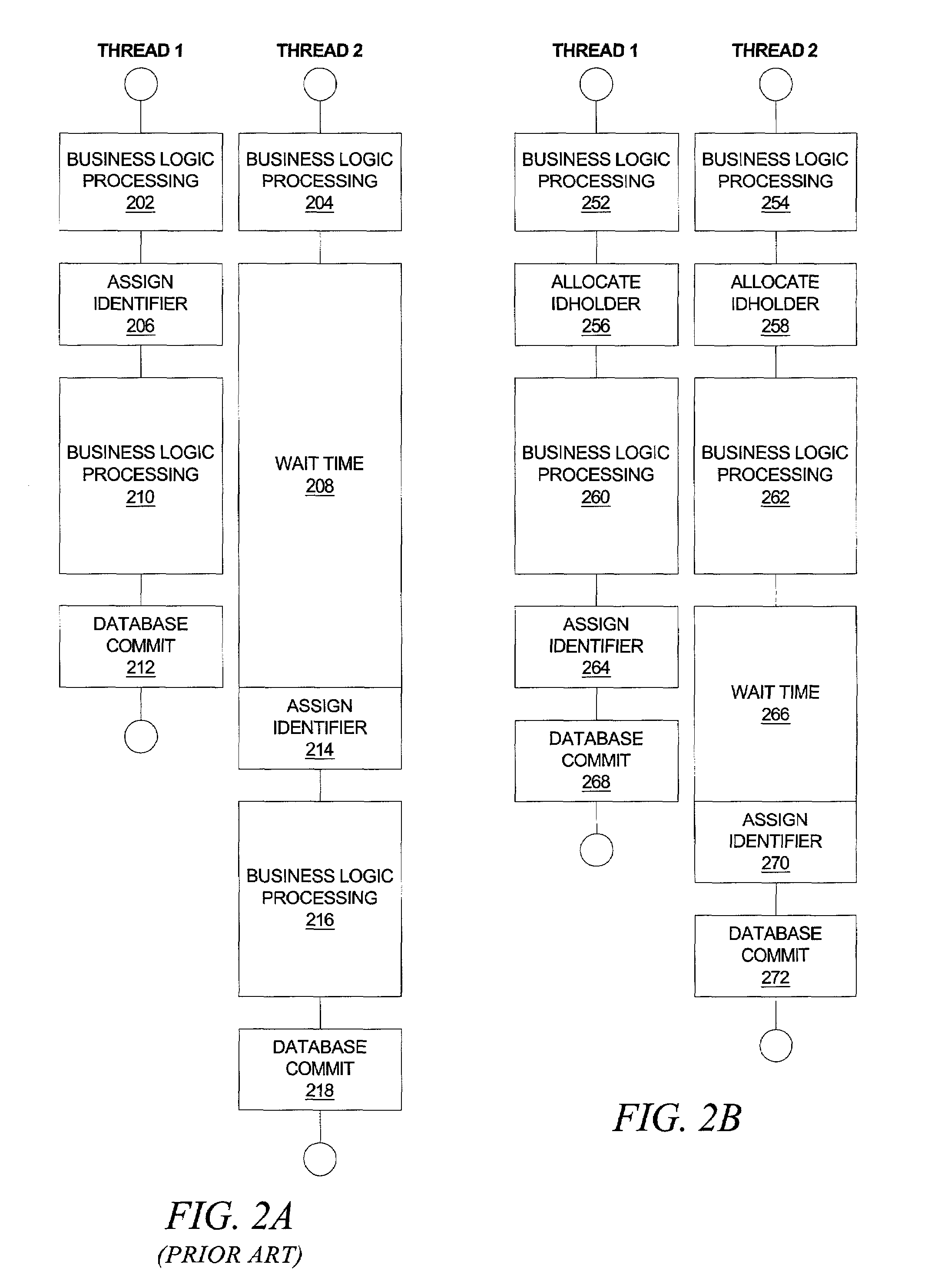

Method and system for reducing synchronization waits when allocating sequenced identifiers in a multi-threaded server

InactiveUS7305678B2Reducing synchronization waitCutting synchronizationData processing applicationsDigital data processing detailsComputer scienceComputer program

A method, a system, an apparatus, and a computer program product are presented for reducing synchronization waits when unique sequential identifiers are being allocated for transactions committed to a database that are occurring in a multi-threaded server environment. A transactional object containing an identifier data item is created for a transaction in an object-oriented environment. A pre-process object is then generated that contains the transactional object; when subsequently processed, the pre-process object allocates a sequential identifier value for the identifier data item. The pre-process object is added to a list of pre-process objects that are to be processed prior to completing the transaction, such as committing the transaction to a database. After some initial business logic processing, a commit operation for the transaction is commenced during which the pre-process object is processed, thereby allocating a sequential identifier value for the identifier data item just prior to committing the transaction.

Owner:GOOGLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com