Patents

Literature

33results about How to "Synchronous delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

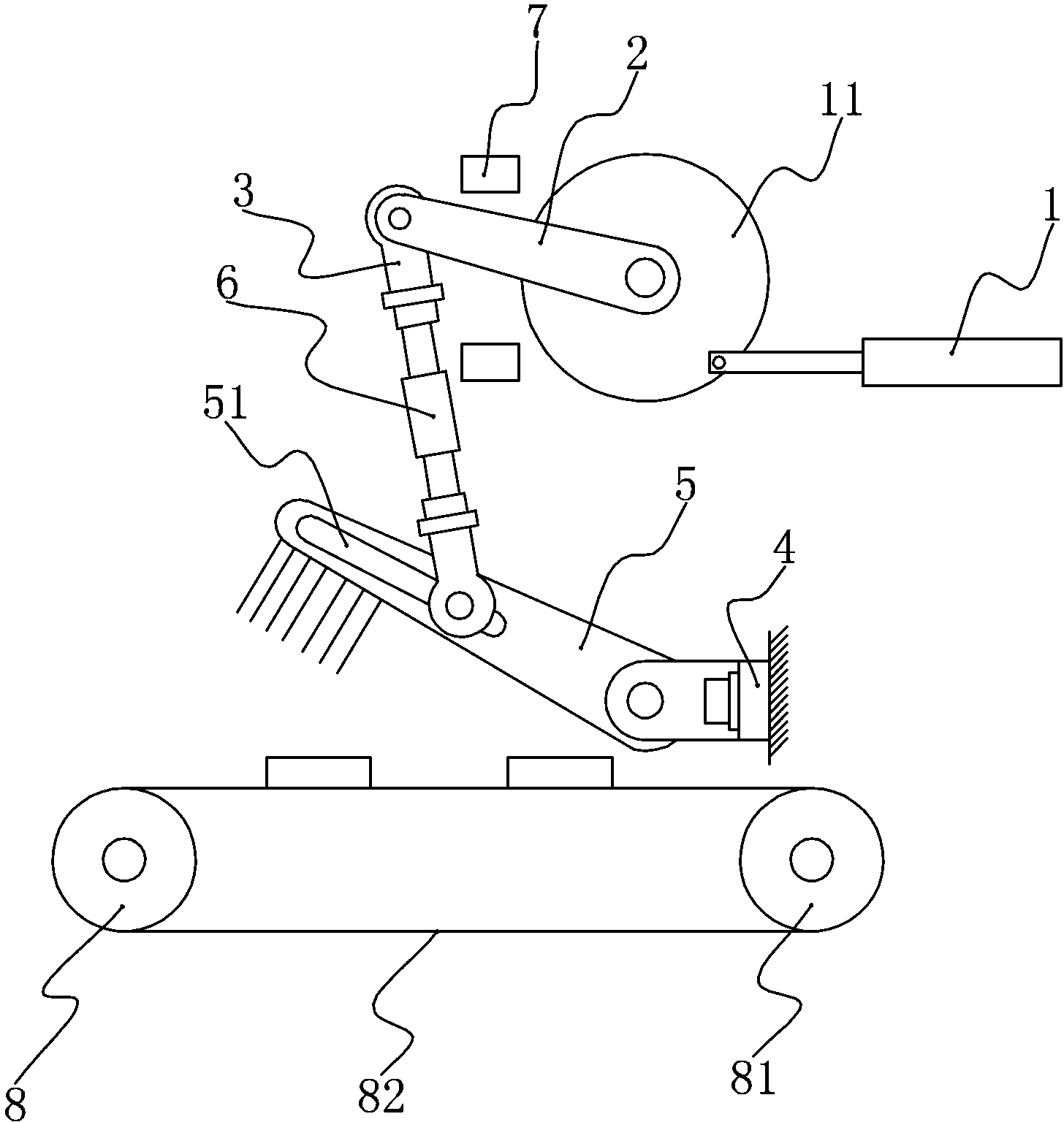

Rotary food feeding and slicing device

The invention discloses a rotary food feeding and slicing device. Under the driving of an air cylinder, a rotary disk swings back and forth, so that a rotary rod fixed to the rotary disk is driven to swing back and forth. Due to the fact that the rotary rod is hinged to a connecting rod and the sliding end of the connecting rod is fixed into a sliding groove of a cutter rod, the cutter rod also swings back and forth under the driving of the connecting rod, and the swing angle of the cutter rod is larger than the swing angle of the rotary rod. A traditional motor driving mode is abandoned and changed to the driving of the air cylinder due to the arrangement of the mechanism, and therefore the swing speed of the cutter rod is greatly increased, the swing amplitude can be freely adjusted according to the arrangement of the connecting rod and the sliding groove, and the using requirement for cutting materials is met. Besides, while the materials are conveyed by a conveying belt, the materials can be sliced when conveyed just by calculating the placing position of the materials, and high machining efficiency and machining precision are achieved.

Owner:CHONGQING JIDING FOOD

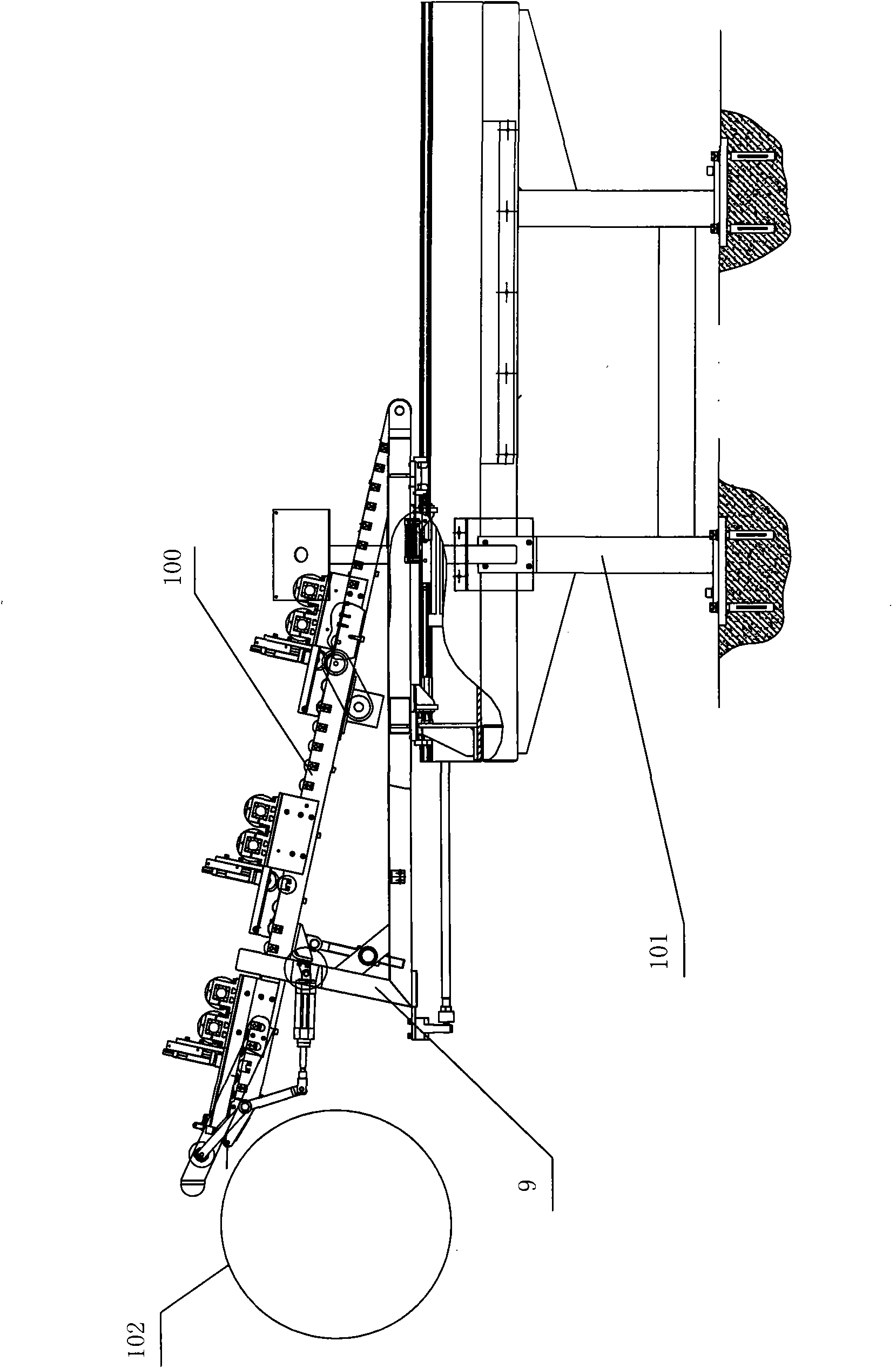

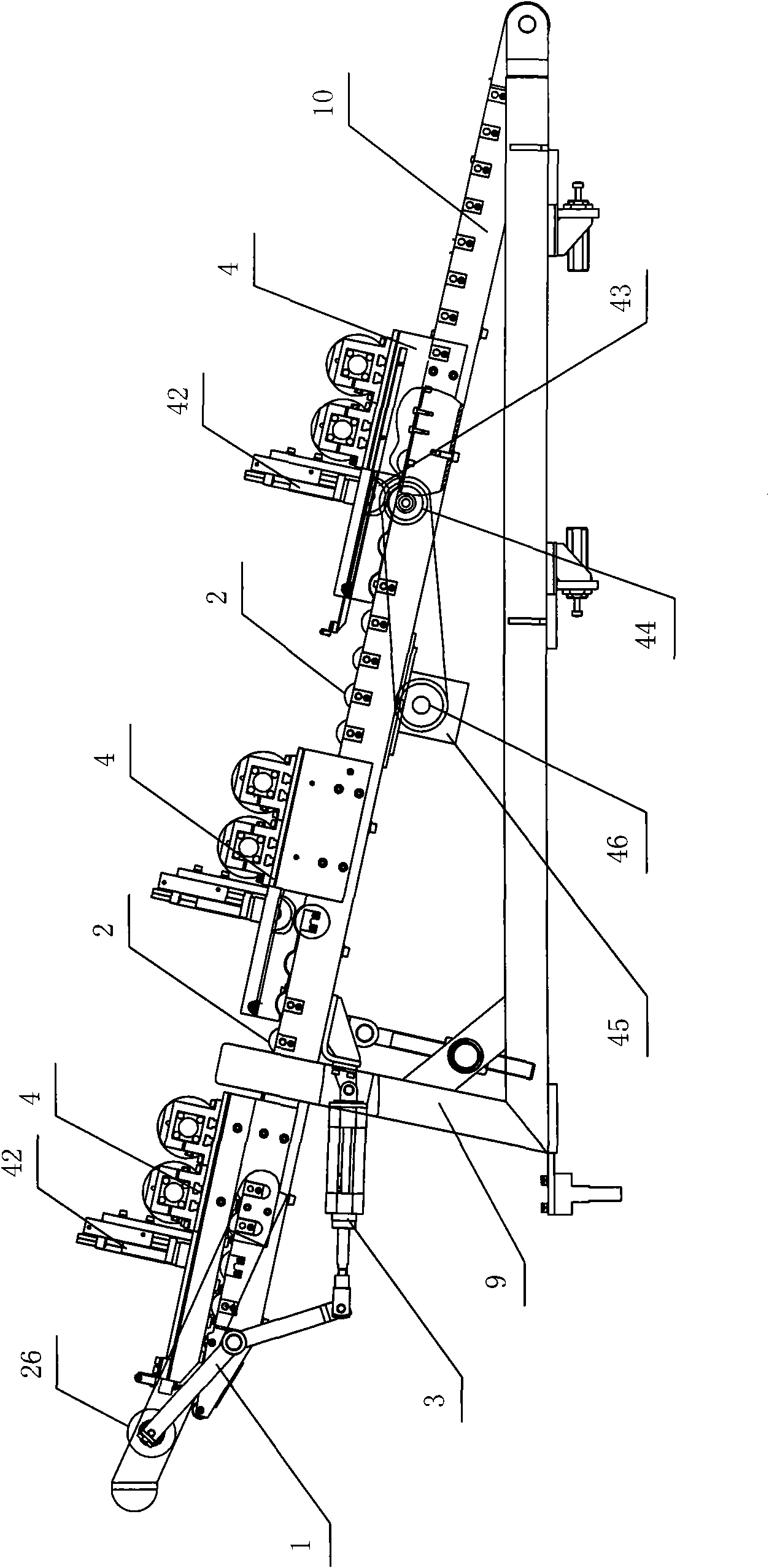

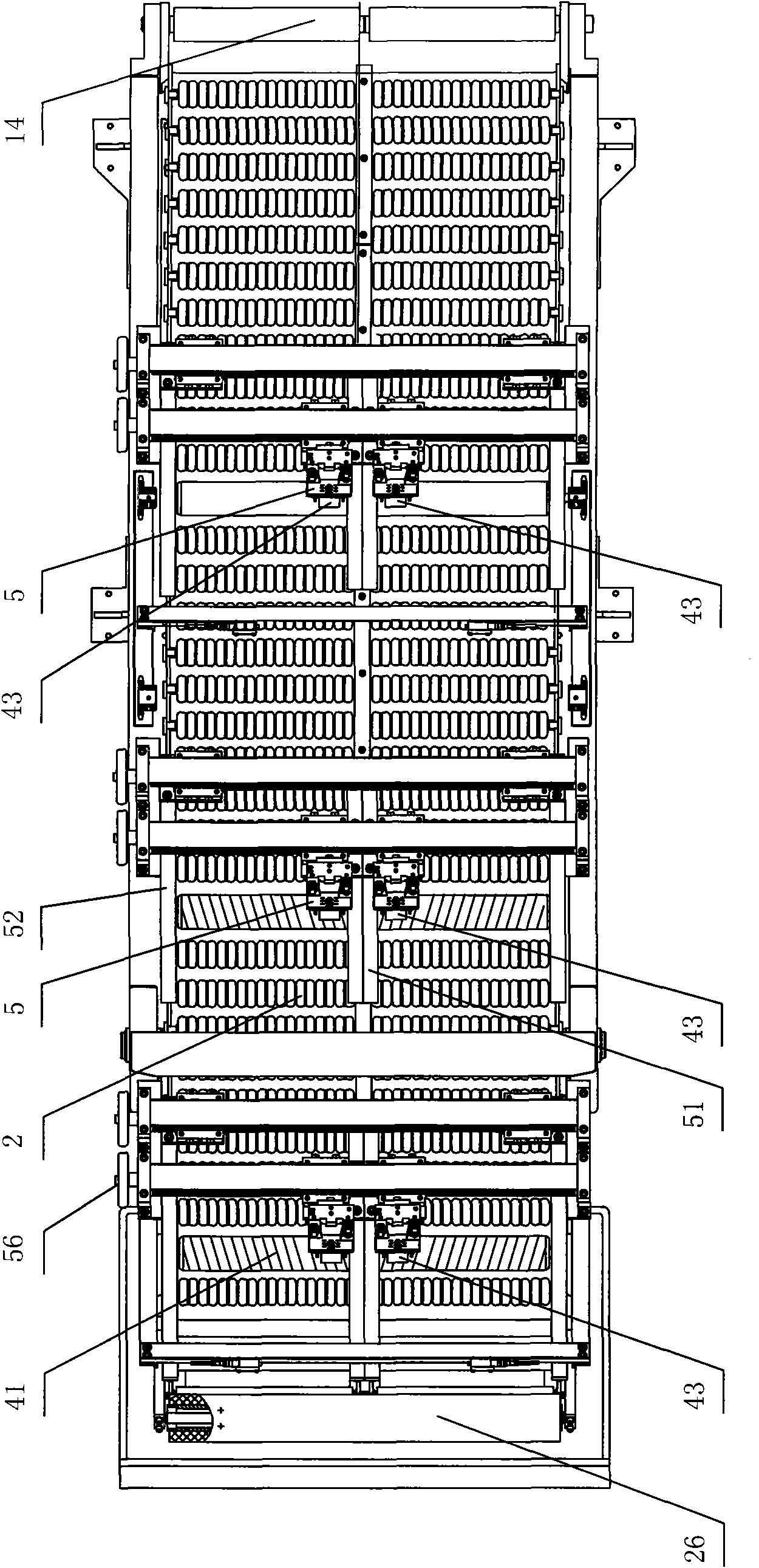

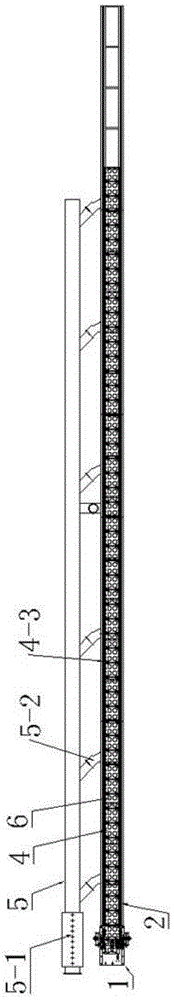

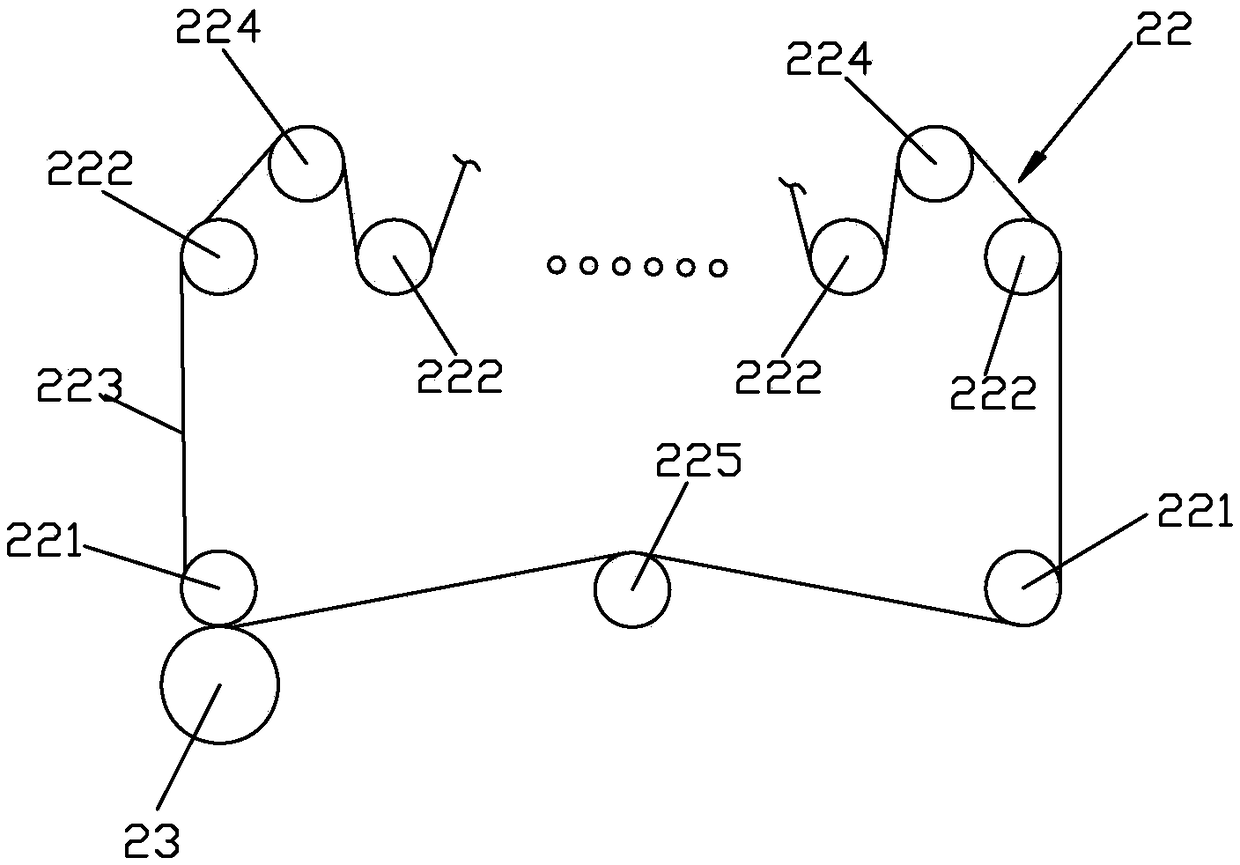

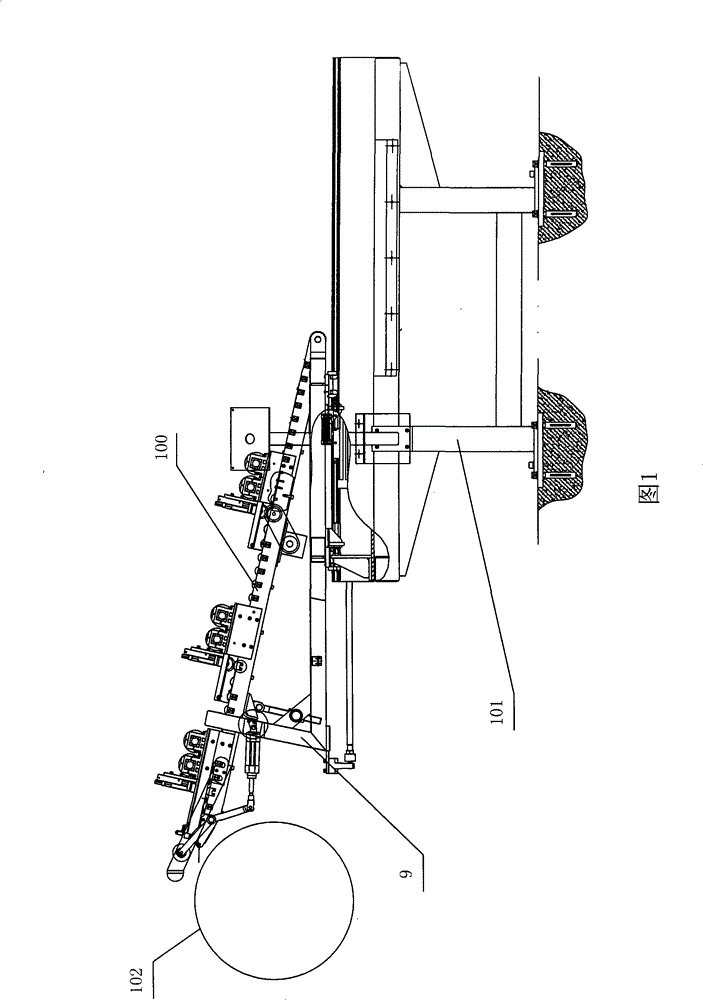

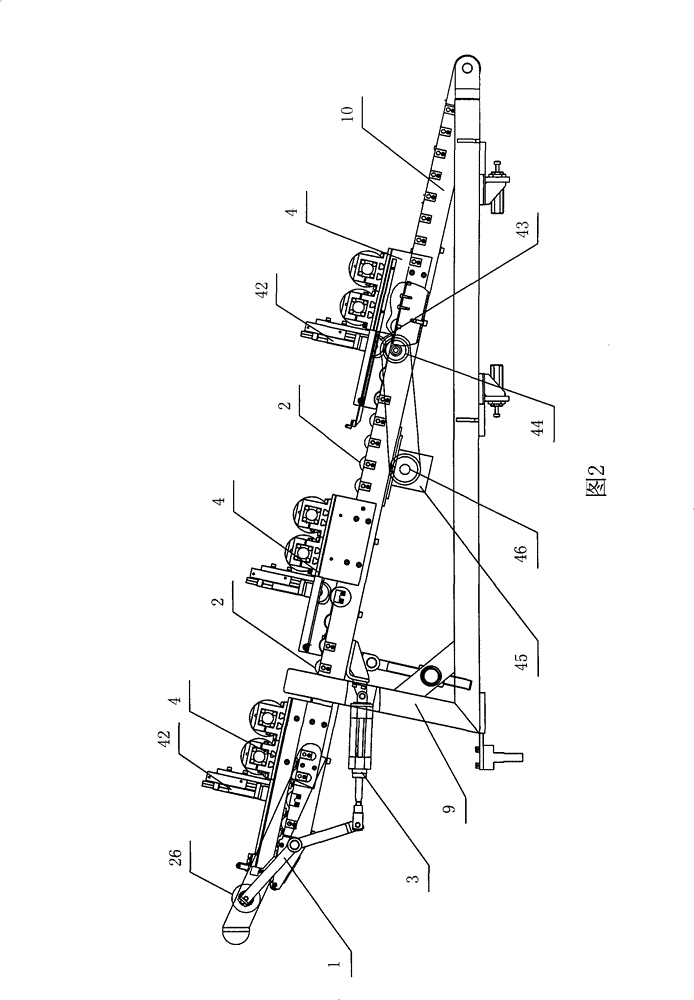

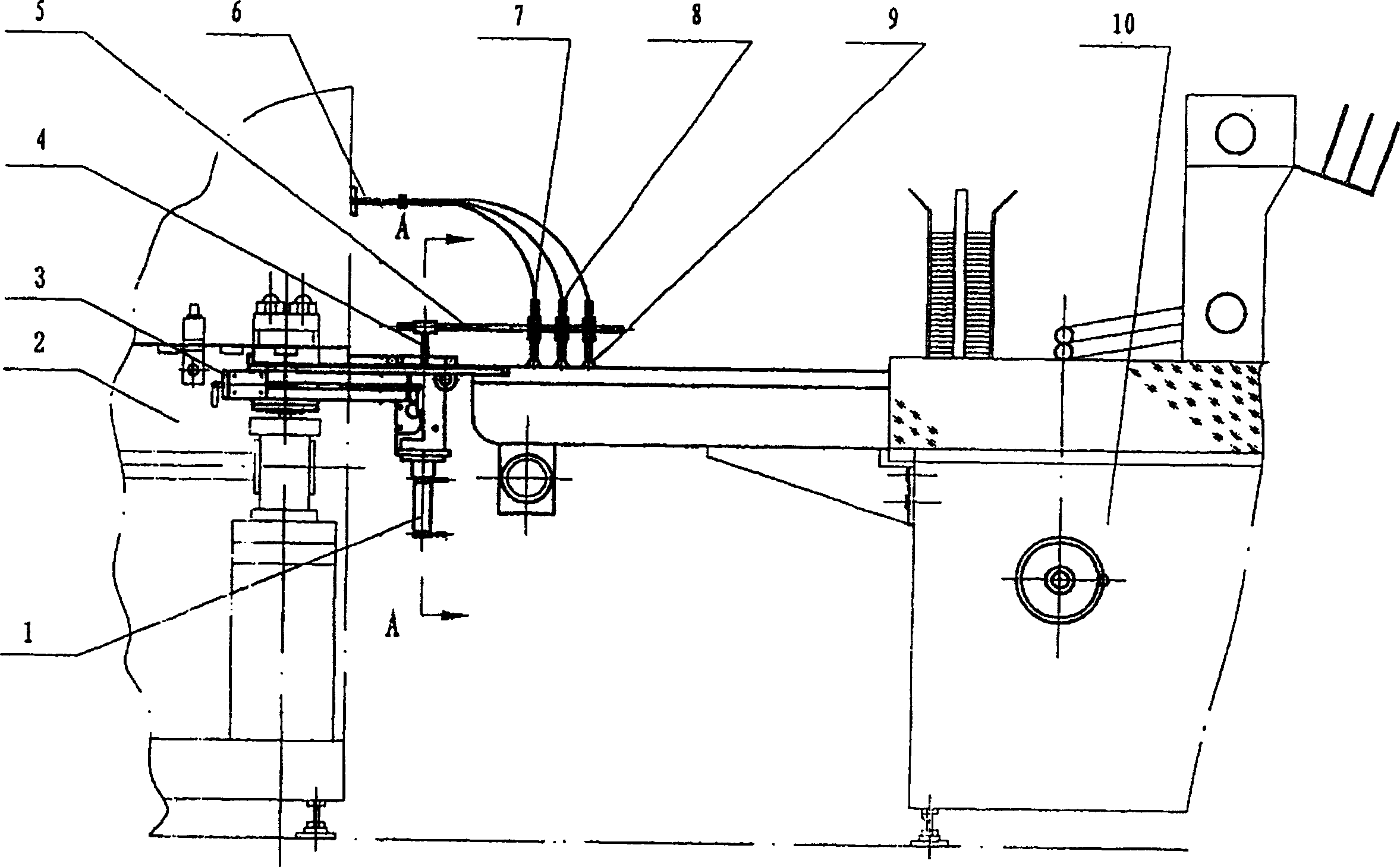

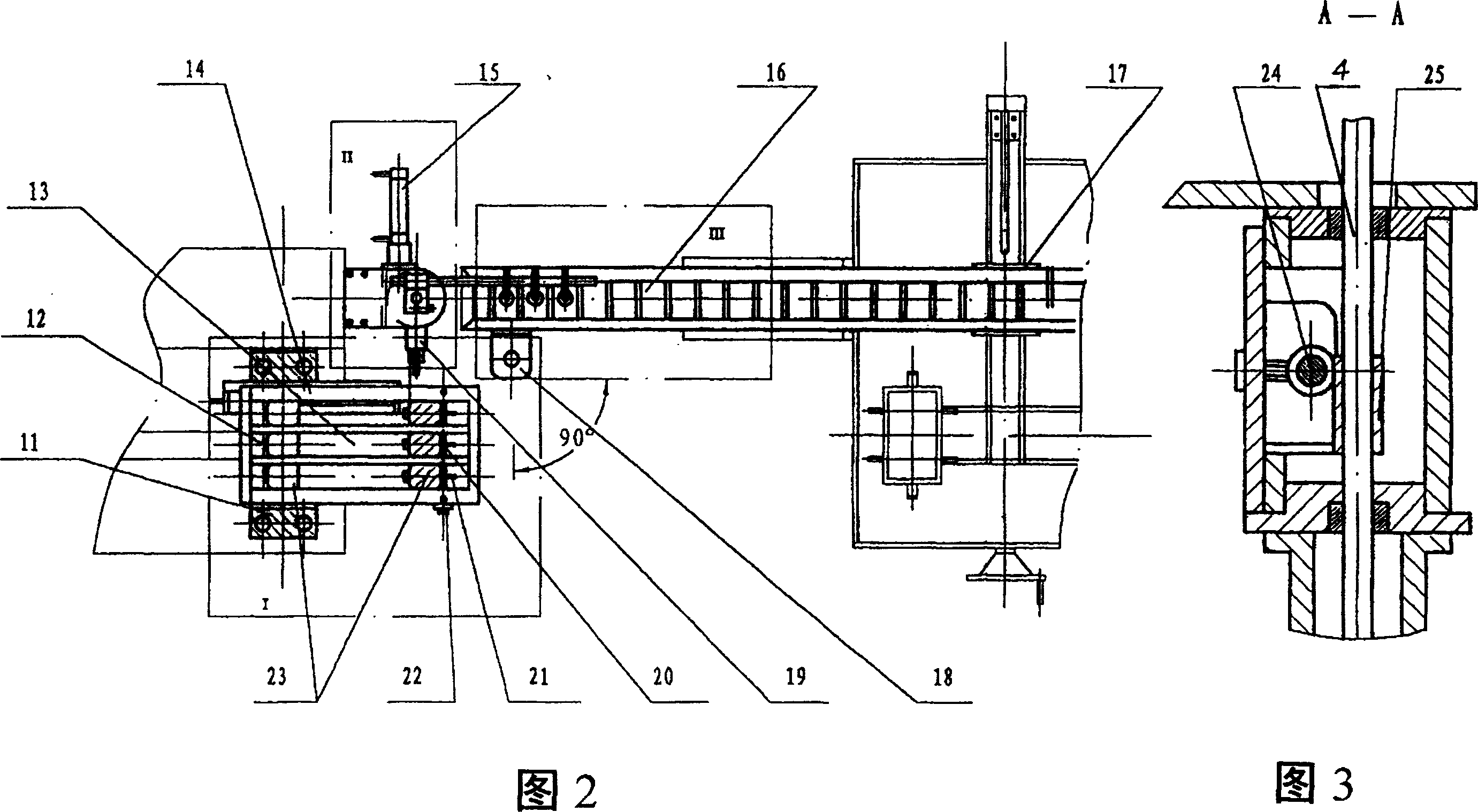

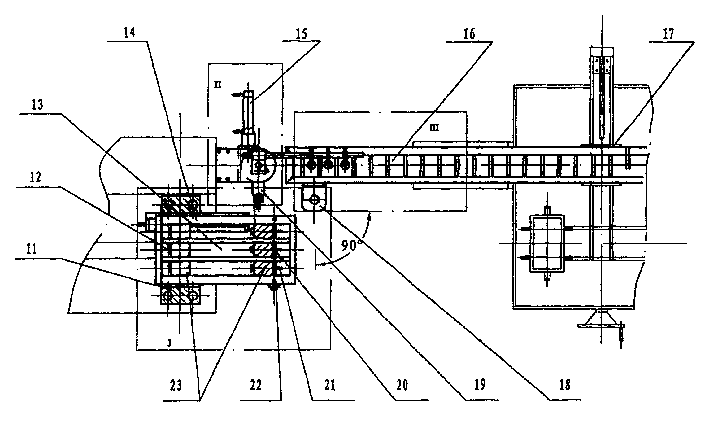

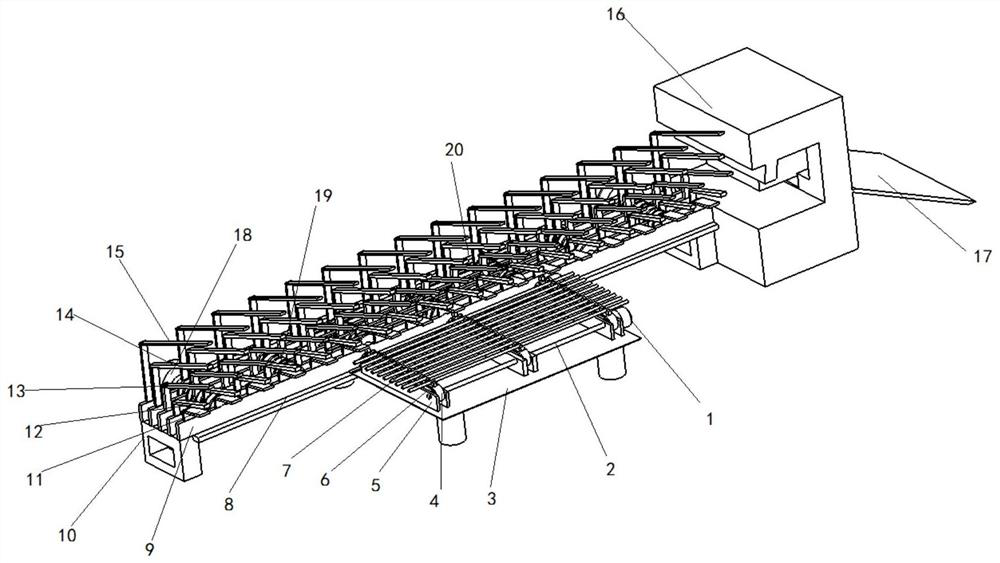

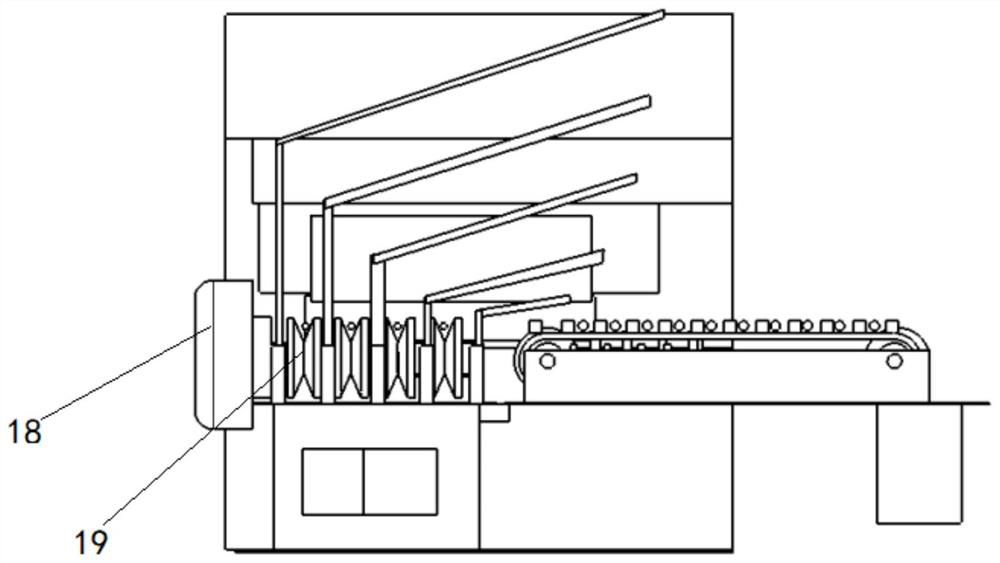

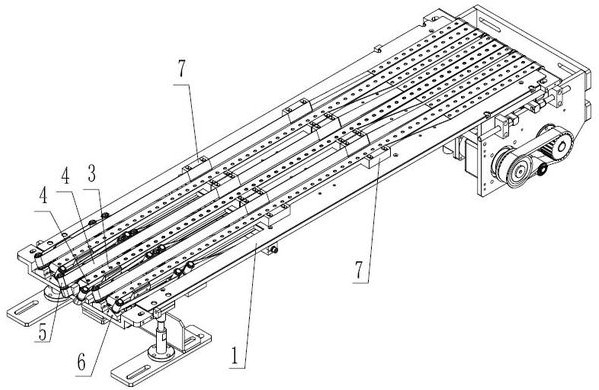

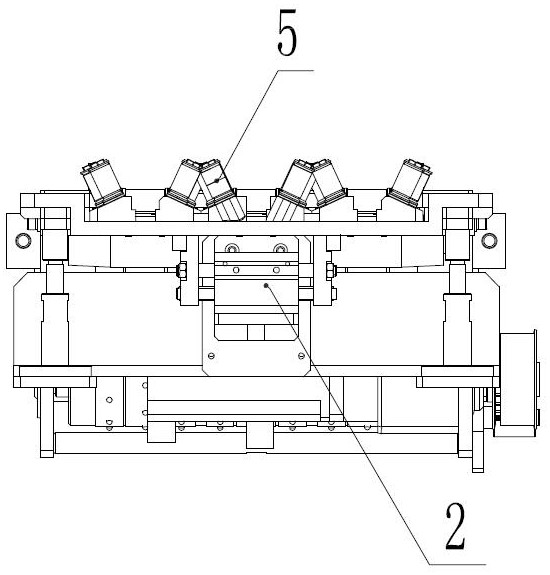

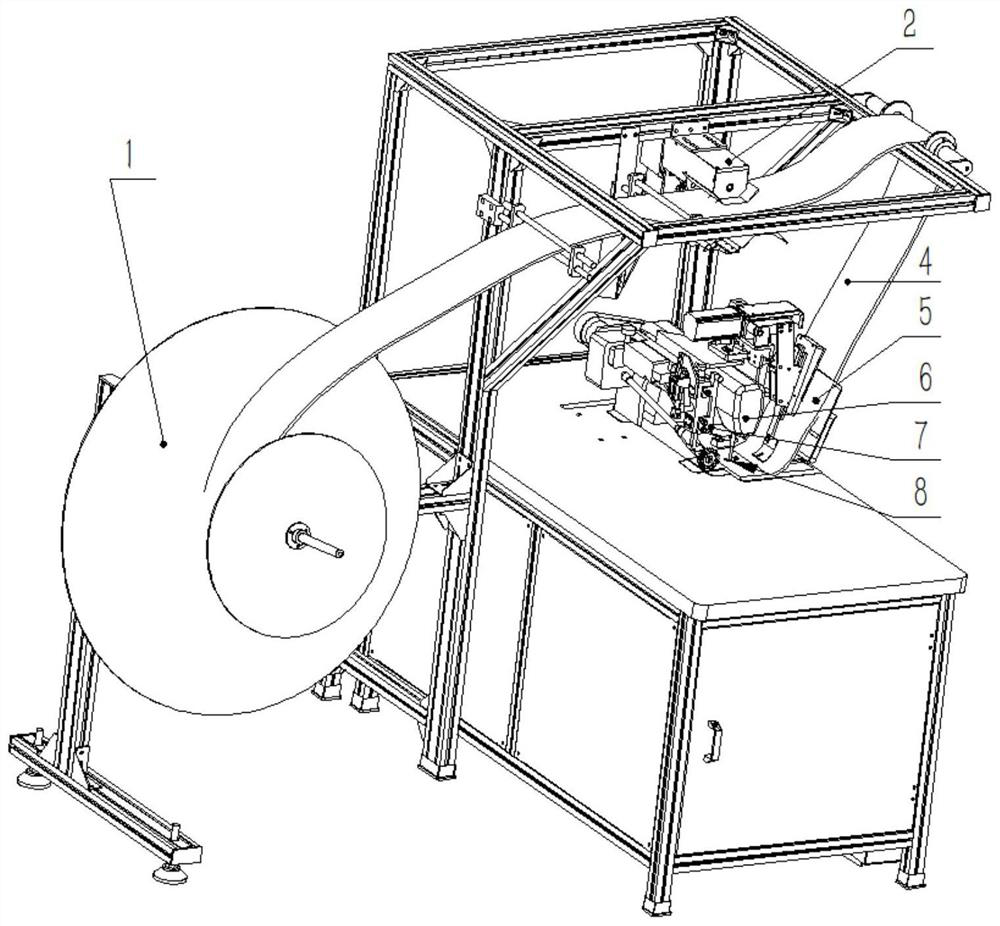

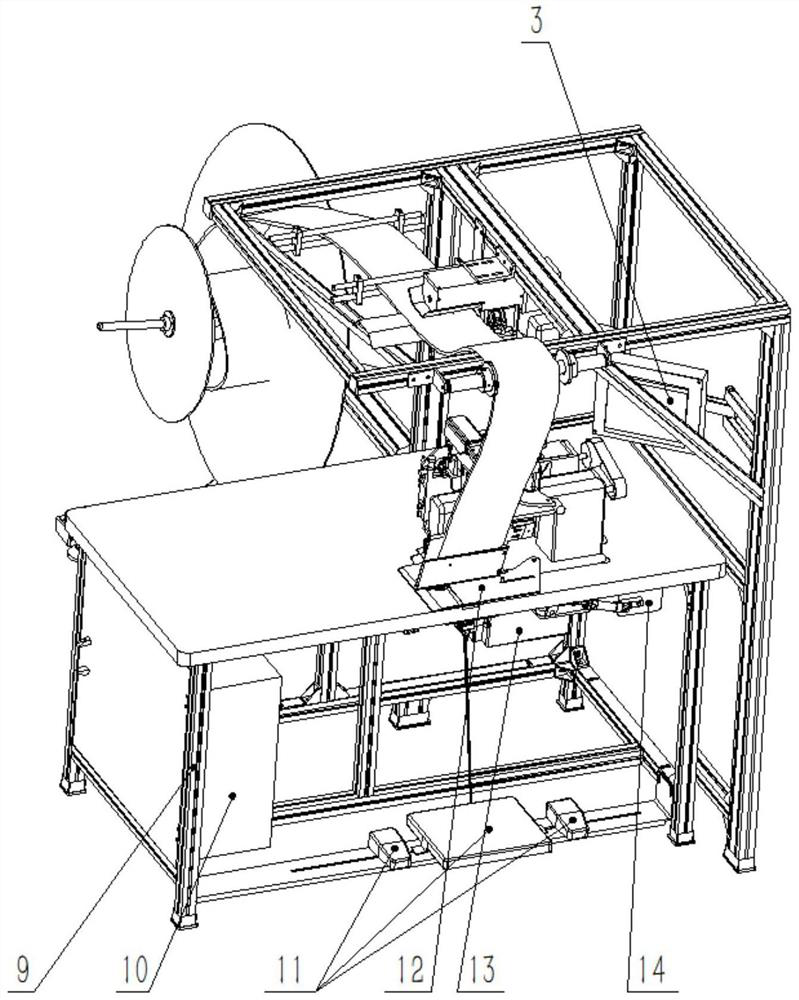

Shoulder wedge feeding frame and front guiding and positioning method thereof

ActiveCN101850628AOvercoming frictional resistancePrevent affecting the subsequent fit qualityTyresHelixSupport plane

The invention relates to a shoulder wedge feeding frame and a front guiding and positioning method thereof. A fixed edge guiding device and method capable of realizing the purpose of pressing downwards, rotating and pushing laterally simultaneously is used for realizing synchronous conveying of two shoulder wedges in limited conveying distance, thereby improving the conveying consistency of the two shoulder wedges to ensure that the two shoulder wedges can be accurately jointed on shoulder positions in parallel. The device is mainly provided with a conveying frame and a conveying template, wherein the conveying template is used for conveying shoulder wedges onto a forming drum and is installed on the conveying frame through a supporting frame. Different from the prior art, at least one group of fixed edge guiding mechanisms are arranged on brackets along the conveying direction of shoulder wedges. The fixed edge guiding mechanisms comprise at least one group of guiding rollers which are axially arranged between brackets at two sides and can axially rotate, and surface rollers of the guiding rollers are spirally arranged along the central line in the transverse direction and the brackets at two sides in the oblique direction. At least two groups of compression rollers which are driven by cylinders are arranged above the guiding rollers in the vertical direction, and the vertical central lines of the guiding rollers and the compression rollers are coincident.

Owner:MESNAC

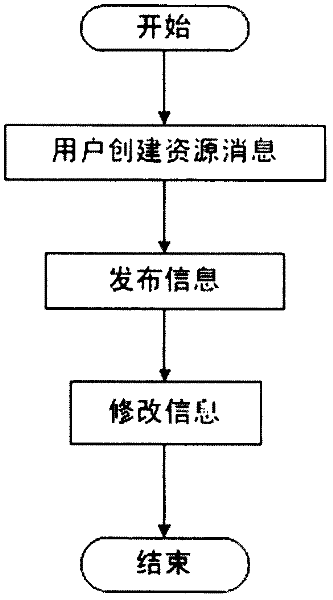

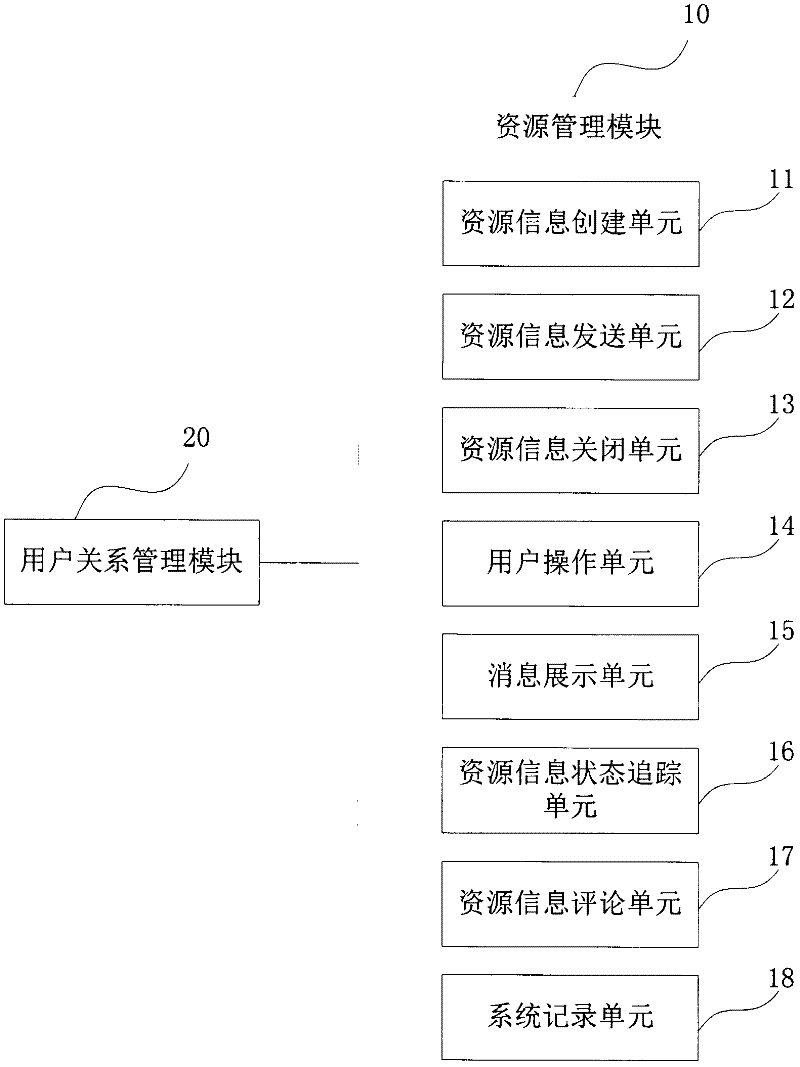

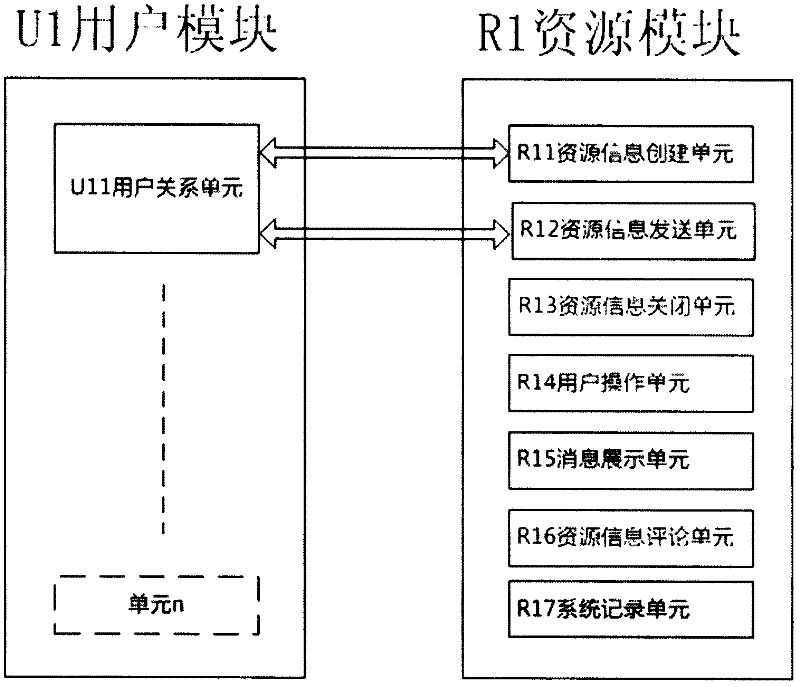

User resource information on-line supply system and method

InactiveCN102521259AEnhance resource sharing managementCloser relationshipsTransmissionSpecial data processing applicationsResource informationResource management

The invention discloses a user resource information on-line supply system and method. The user resource information on-line supply system comprises a resource management module and a user relationship management module, wherein the resource management module is used for managing resource allocation information; the user relationship management module is used for managing the user information; and the resource management module comprises a resource information establishment unit, a resource information transmission unit, a message presentation unit, a user operation unit and a resource information state tracking unit. The resource information state tracking unit is used for receiving the operation information of a resource information create user and an information receiving user for the resource, feeding back the resource information state into a database and showing the resource information to the related users. The user resource information on-line supply system and method can be used for enhancing the interpersonal resource sharing management, improving the information response efficiency and transfer effect, and lowering the communication cost.

Owner:陈晓亮

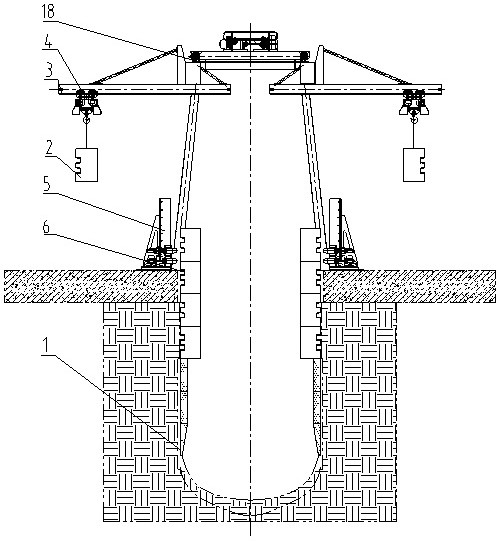

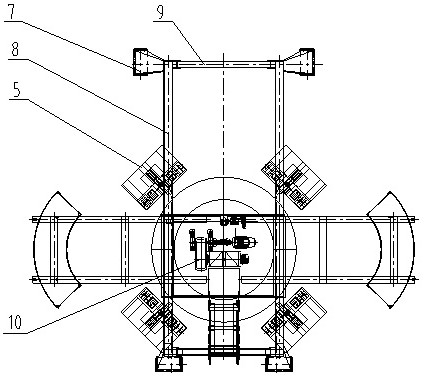

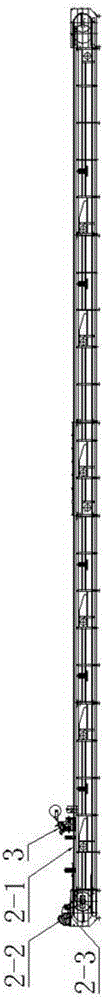

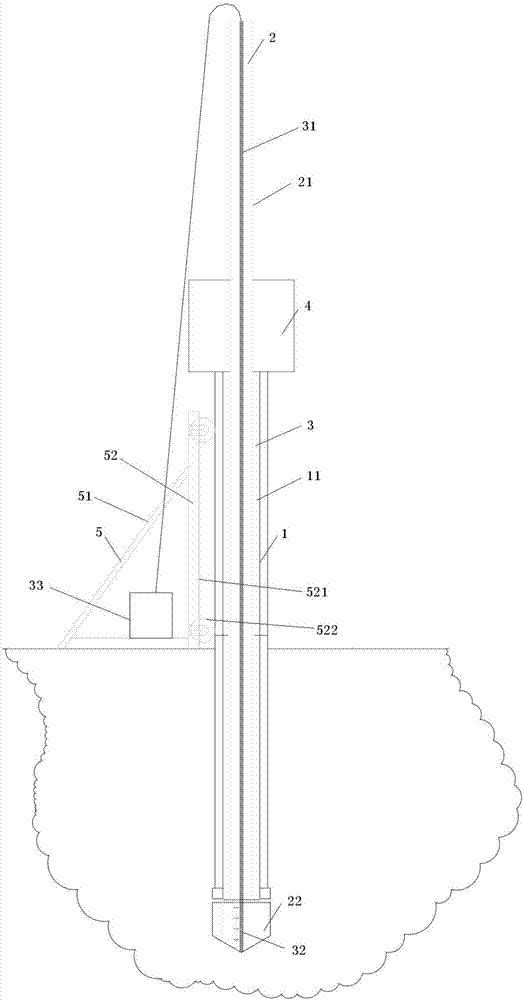

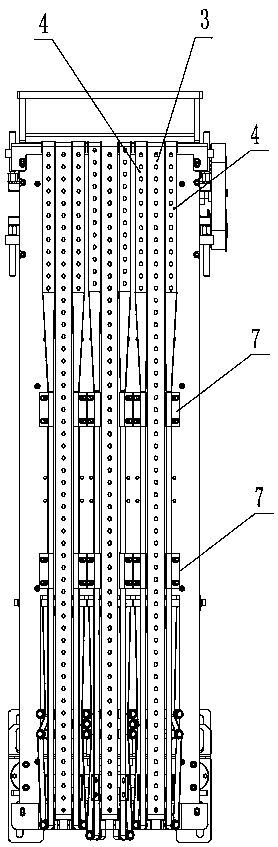

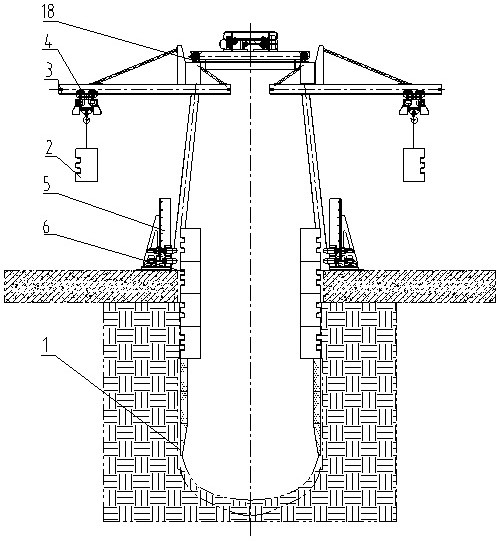

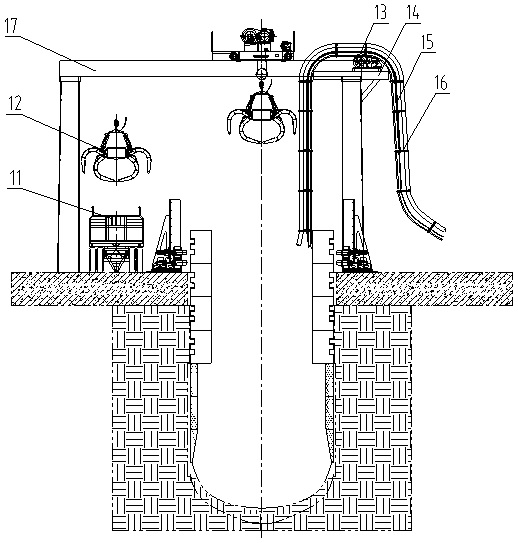

Segment assembling derrick and construction method thereof

ActiveCN111794754AQuick release and assemblyQuick assemblyShaft liningLine tubingArchitectural engineering

The invention discloses a segment assembling derrick and a construction method thereof. The segment assembling derrick comprises a frame; a running trolley is arranged on the frame in a sliding manner; a cable lowering mechanism is arranged at the end part of the frame; the running trolley is connected with a slag discharging mechanism; cantilever mechanisms are symmetrically arranged on the two sides of the frame; cranes are arranged on the cantilever mechanisms; a plurality of groups of segment lowering devices are symmetrically arranged under the frame; and the segment lowering devices arematched with the cranes. According to the segment assembling derrick, by erecting the running trolley and the cable lowering mechanism on the frame, the synchronous operation of lowering residue soiland pipelines in a vertical shaft is realized; by using the cantilever mechanisms symmetrically mounted on the two sides of the frame, segments are enabled to be rapidly hoisted conveniently; and meanwhile, under the cooperation of the segment lowering device, the whole ring of segments, which is hoisted in place and assembled, is rapidly lowered to a segment height so as to realize rapid segmentpreparing and assembling; and therefore, the assembling efficiency is high, and the reliability is good.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

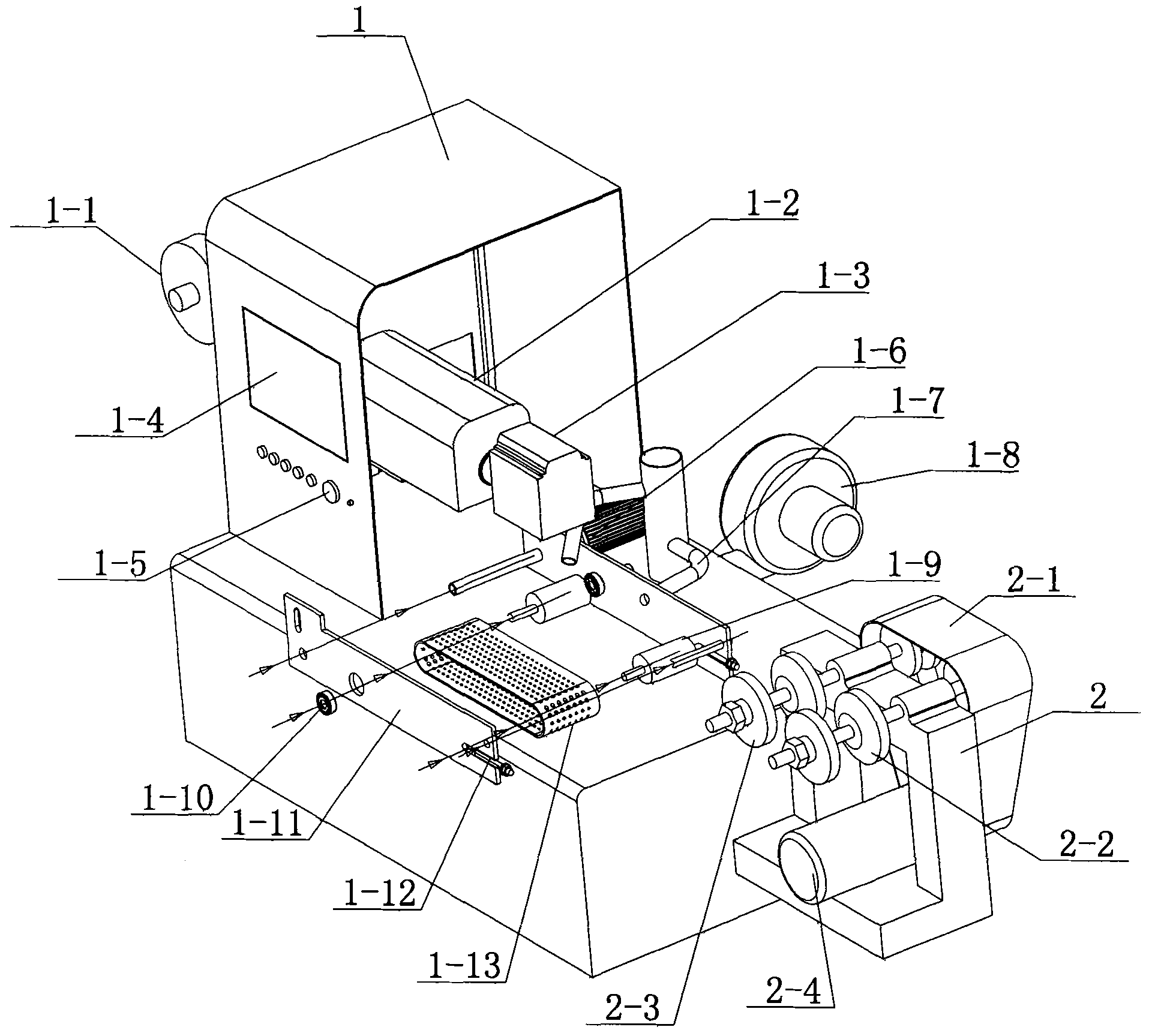

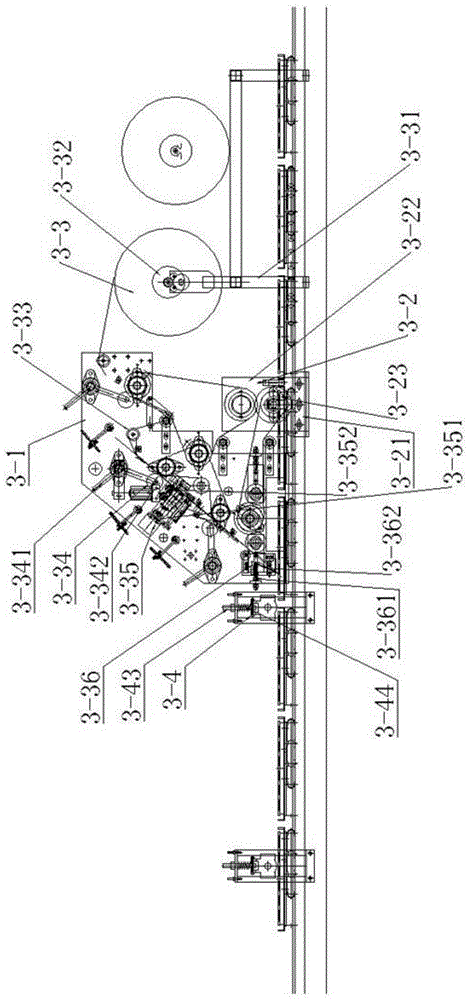

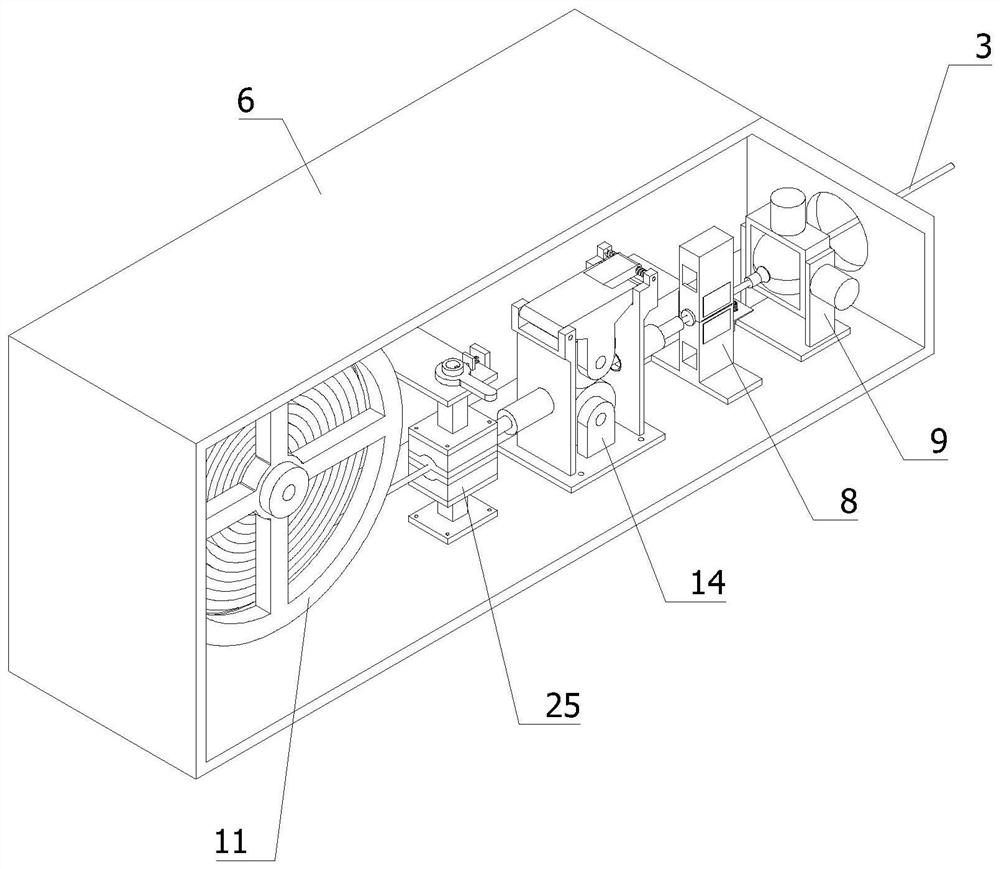

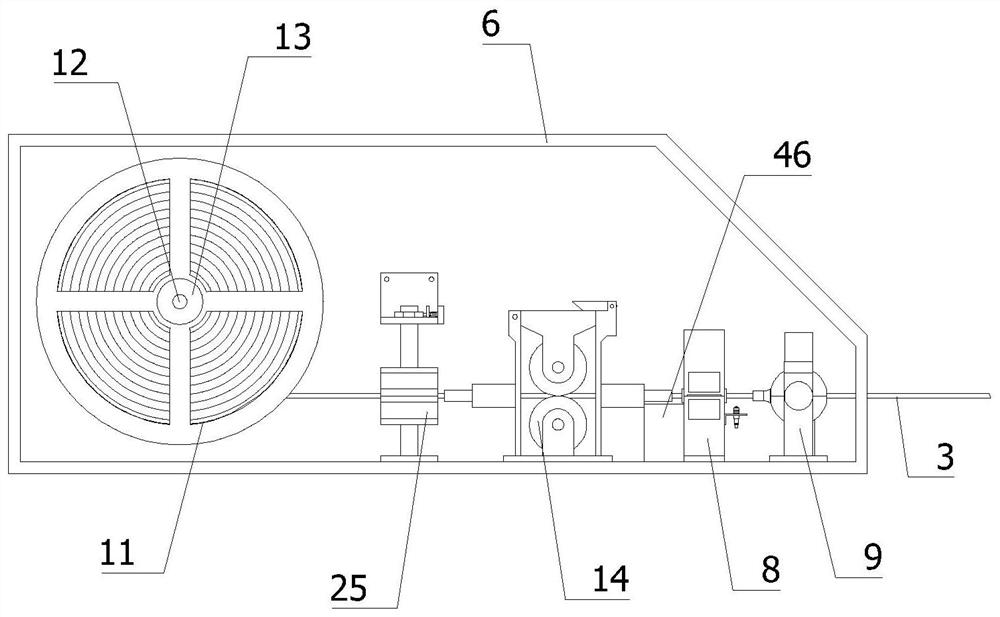

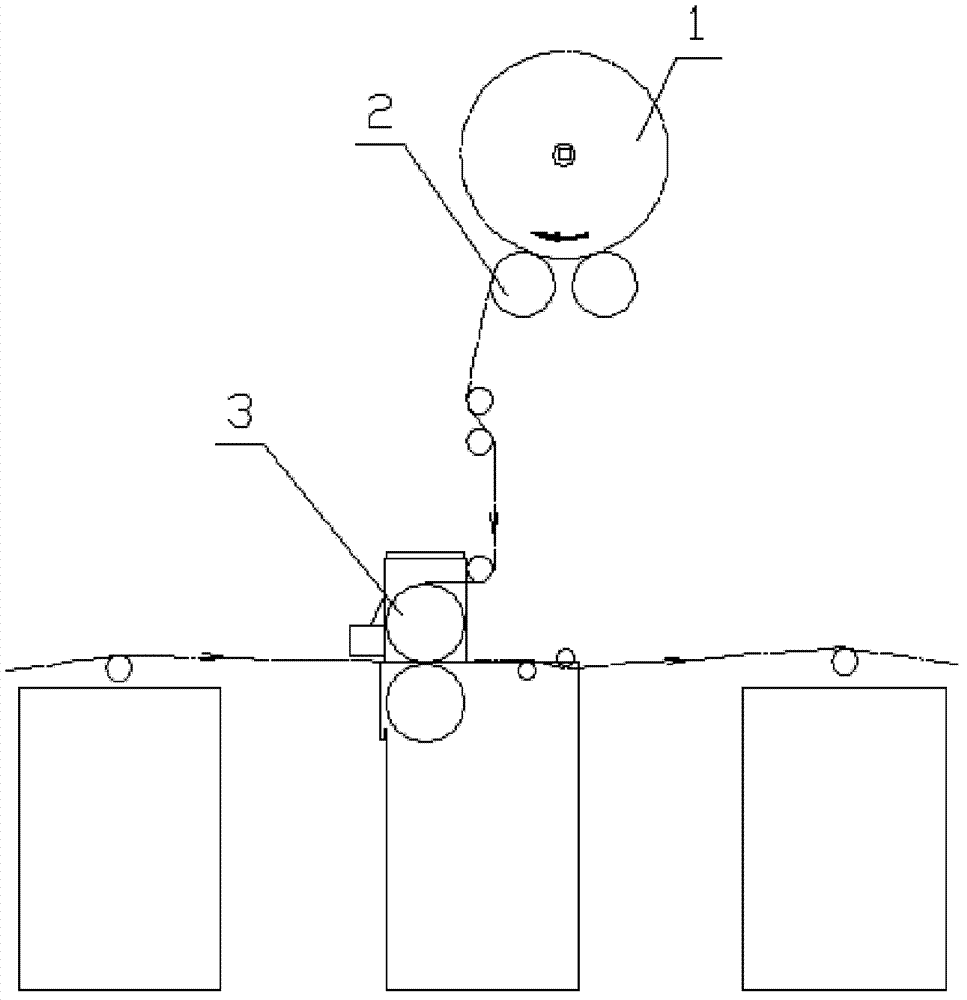

Laser cutting machine for reflective strip production

InactiveCN103658995AAvoid indentationSynchronous deliveryLaser beam welding apparatusNumerical controlLaser transmitter

The invention relates to a cutting machine, in particular to a laser cutting machine for reflective strip production. A feeding device (1-1) is arranged on the upper portion the left side of a cutting device (1). A laser cooling device (1-2) is arranged on the right side of the feeding device (1-1). A metal tube laser emitter (1-3) is arranged on the right side of the laser cooling device (1-2). An air suction device (1-7) is arranged on the right side of a synchronous motor (1-6). A draught fan (1-8) is arranged on the rear side of the air suction device (1-7). A hole belt (1-13) is arranged below the metal tube laser emitter (1-3). The air suction device (1-7) is arranged on the lower portion of the hole belt (1-13). A belt tightness degree regulator (1-12) is arranged at the right end of a fixed support (1-11). According to the laser cutting machine for reflective strip production, a metal tube laser device is used for replacing a traditional glass tube laser device, a coder achieves synchronization of production numerical control, conveyance and cutting, and generation of material indentations is avoided due to the arrangement of the air suction device.

Owner:FOSHAN KACHUN GARMENT

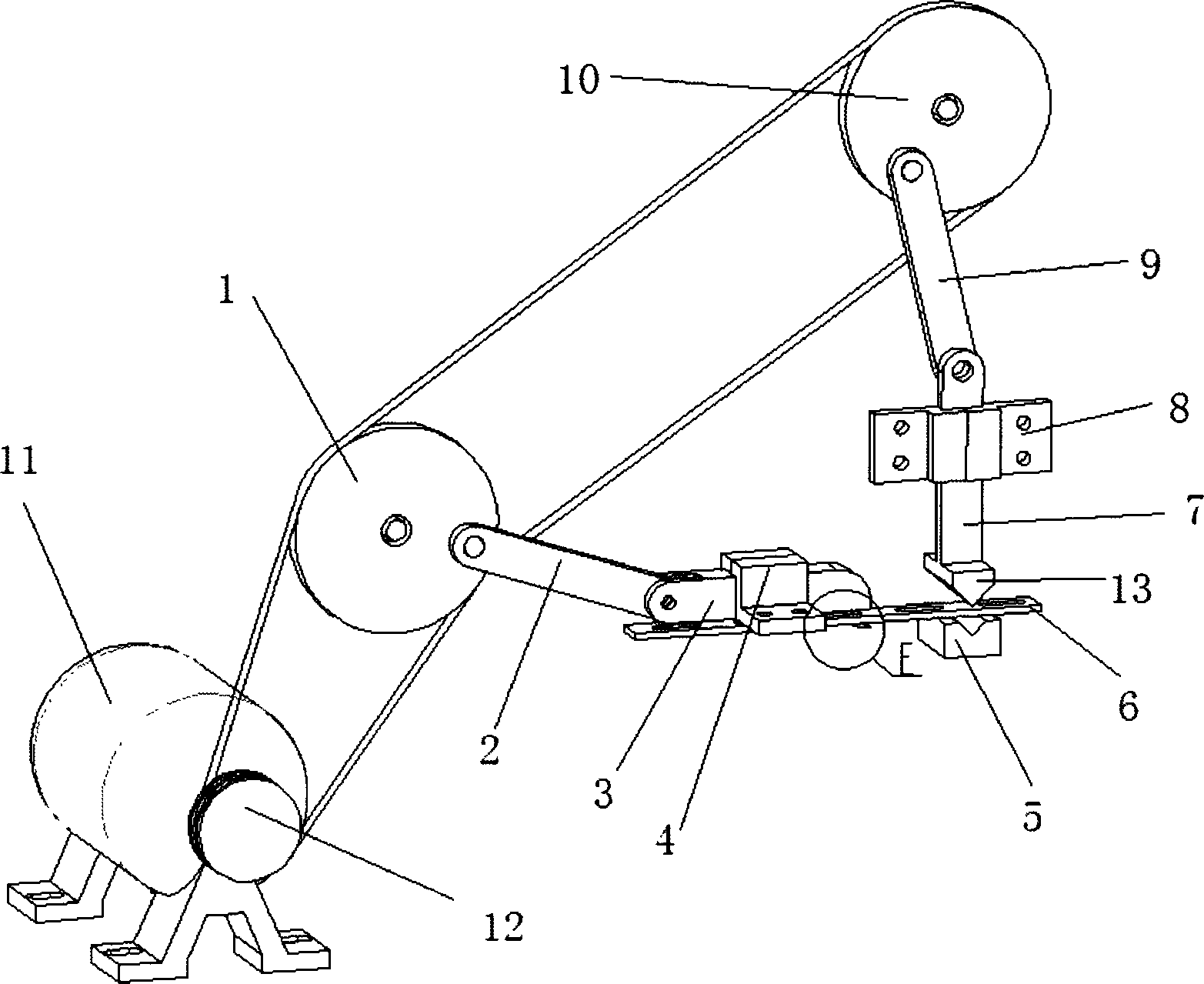

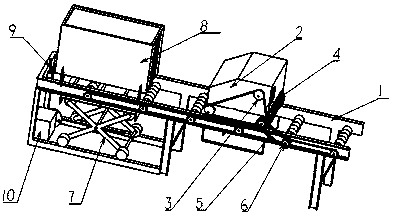

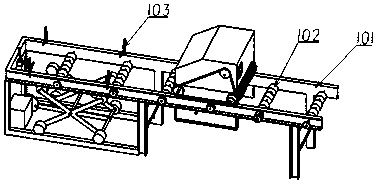

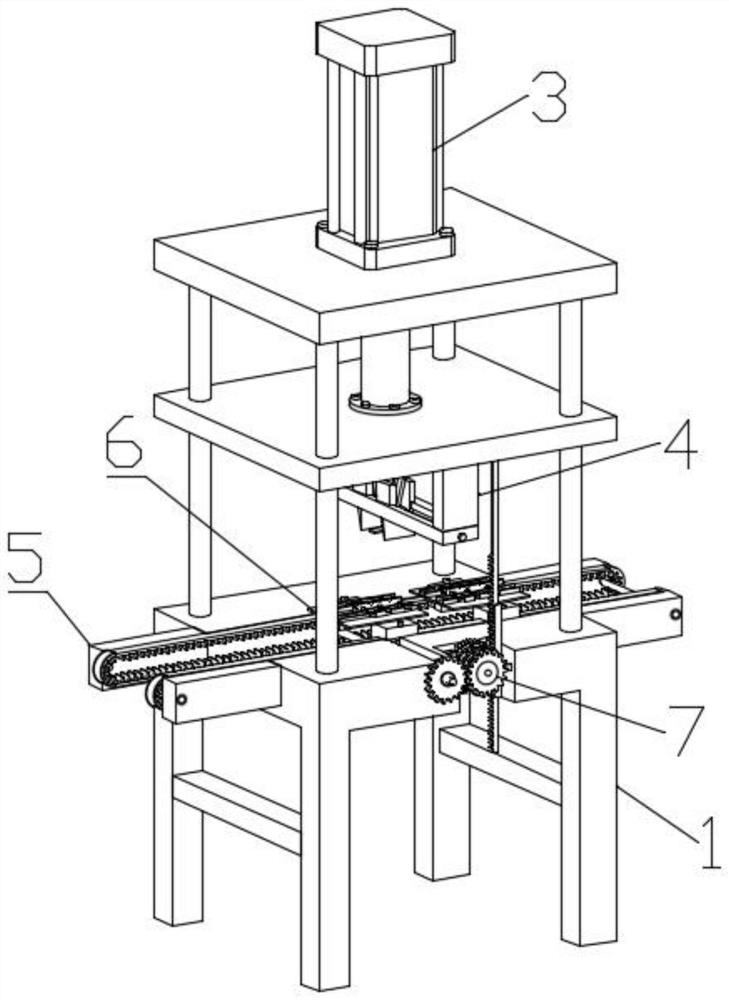

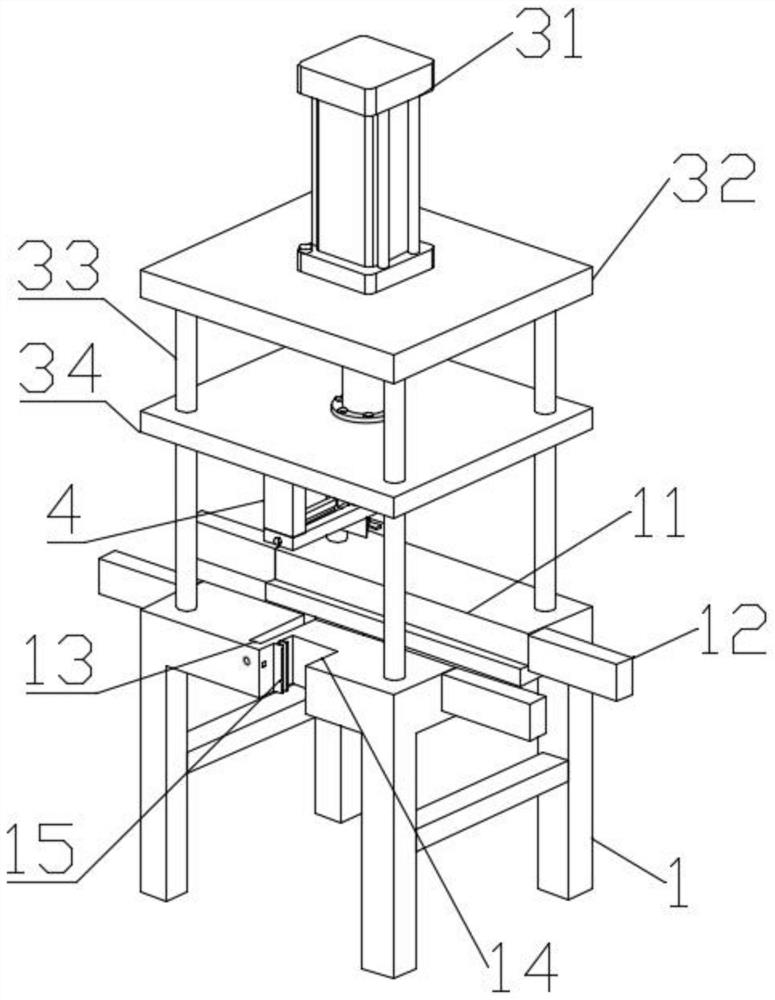

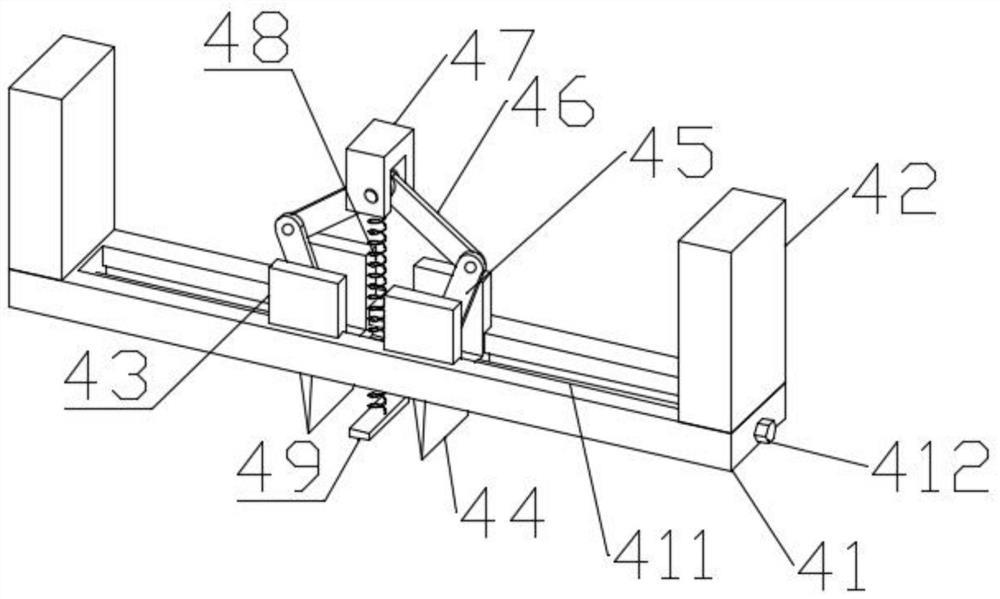

Blade belt cutting device

InactiveCN103317043ASynchronous deliveryMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to the field of blade producing and processing and discloses a blade belt cutting device which comprises a rack, a motor, a crank-slider transmission mechanism used for pushing a blade belt, and a crank-slider blanking mechanism used for cutting the blade belt. A belt wheel of the motor is in belt connection with a first crank wheel and a second crank wheel. By the blade belt cutting device, conveying and cutting of a blade can be performed synchronously.

Owner:苏州快吉刀片制造有限公司

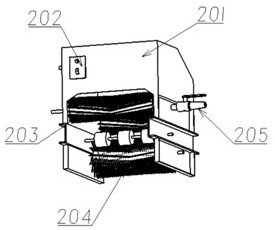

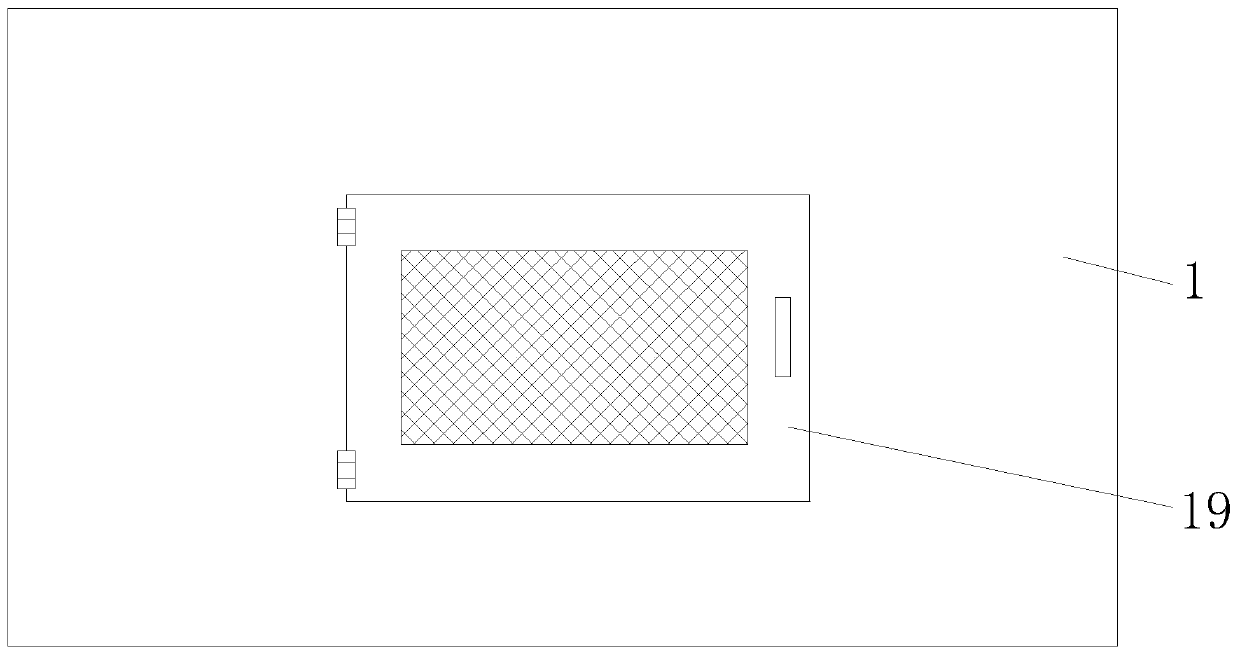

Automatic sticker production equipment for mosaic paving

ActiveCN104097448AReduce labor intensityIncrease productivityPaperhangingControl systemPulp and paper industry

The invention discloses automatic sticker production equipment for mosaic paving. The automatic sticker production equipment is characterized by further comprising a frame, and a conveying device, an automatic paper sticking mechanism, a screen plate positioning mounting mechanism and a control system for controlling the actions of all the mechanisms, wherein the conveying device, the automatic paper sticking mechanism, the screen plate positioning mounting mechanism and the control system are arranged on the frame. The automatic sticker production equipment not only can improve the production efficiency and reduce the labor intensity, but also can realize the accurate and automatic paper sticking; and the paper sticking precision is high.

Owner:FOSHAN RONGGUAN GLASS MATERIAL FOR BUILDING

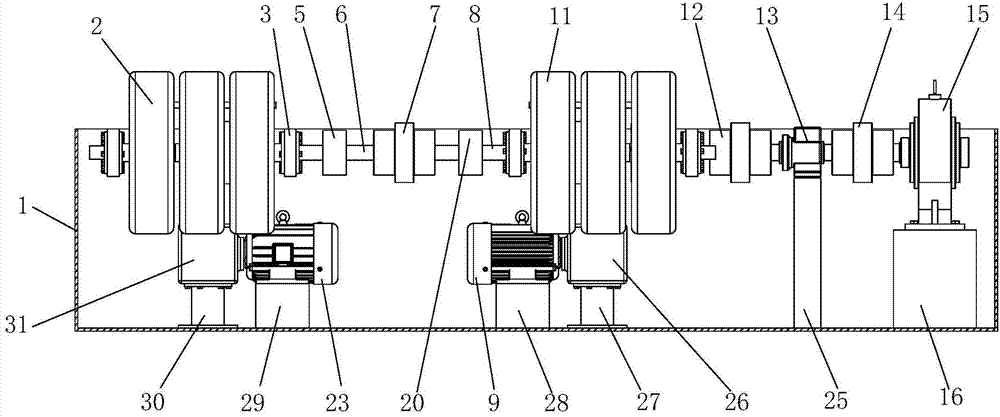

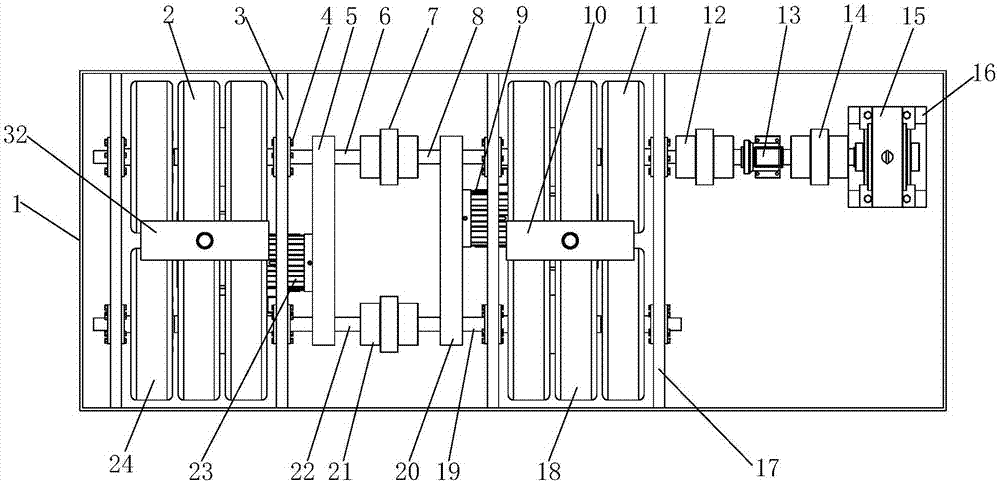

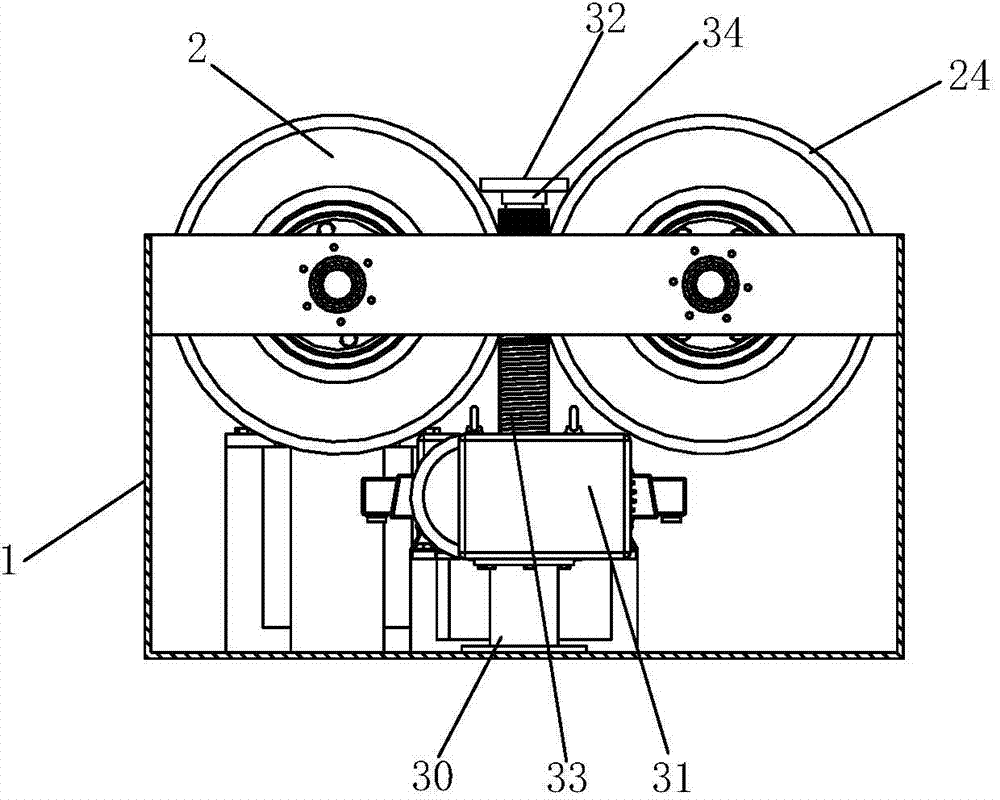

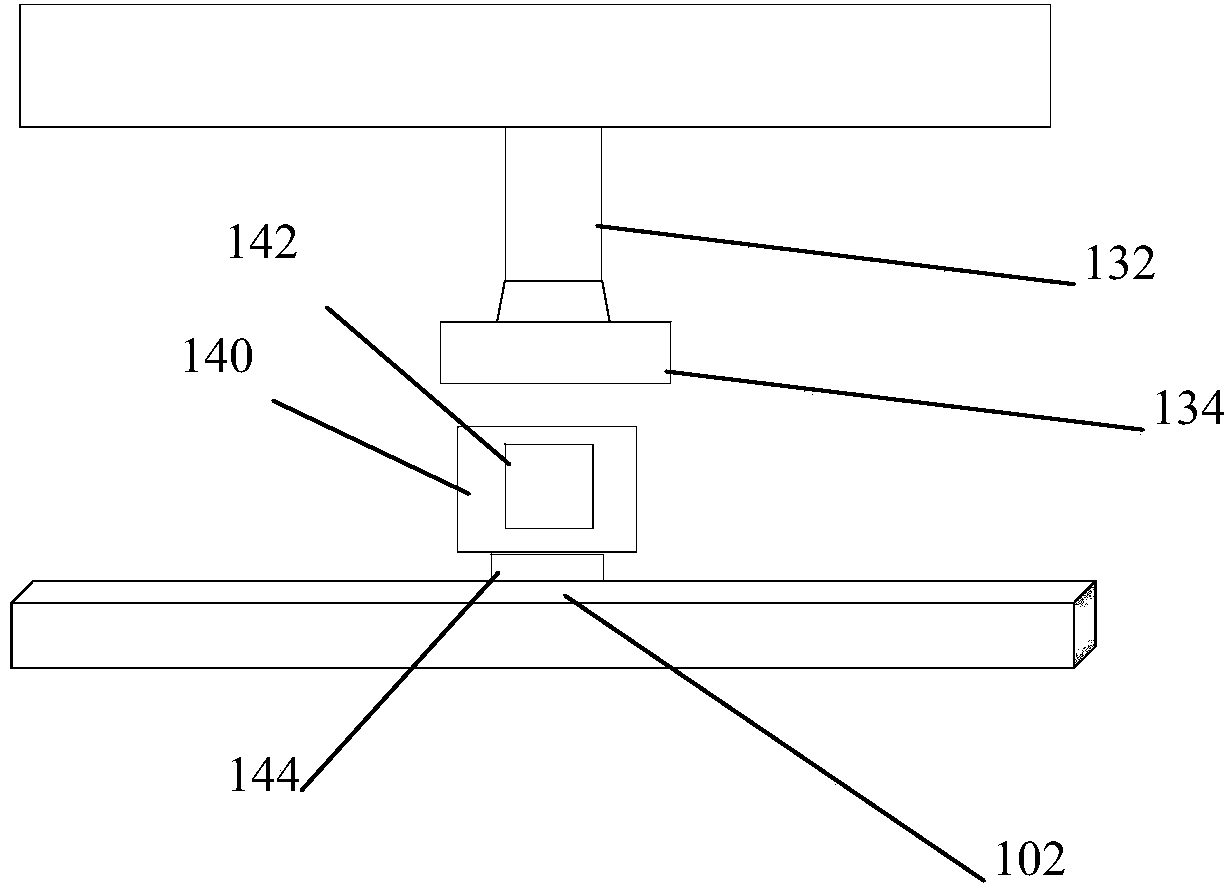

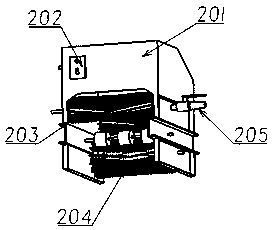

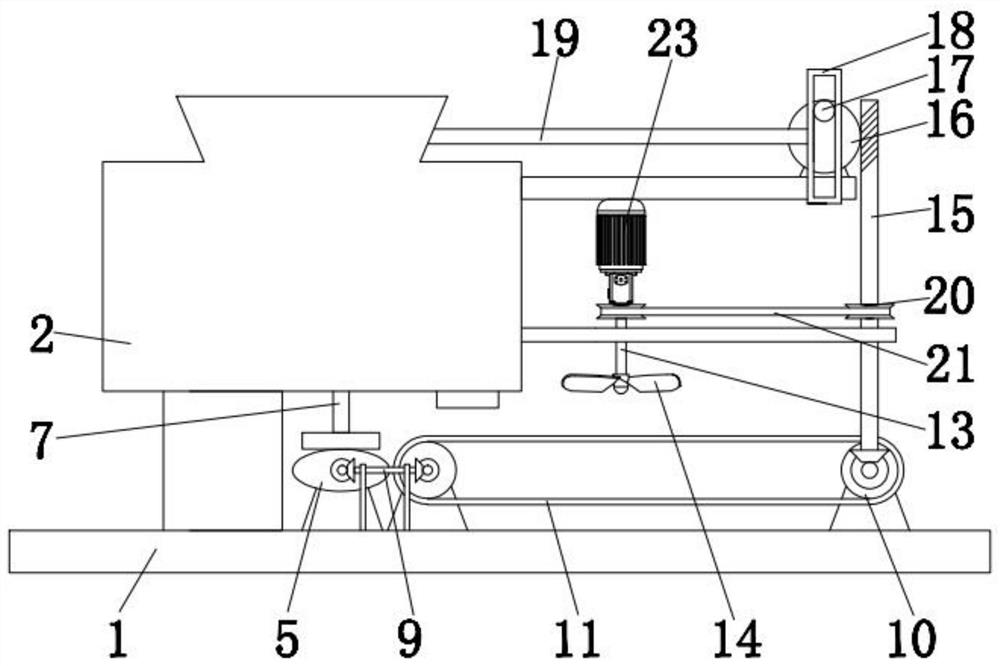

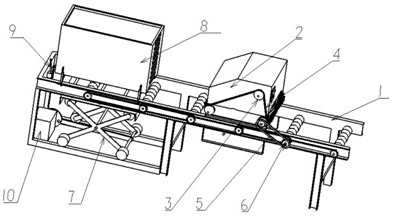

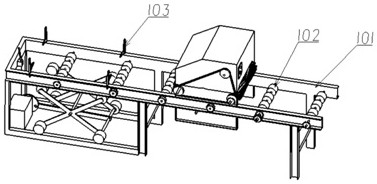

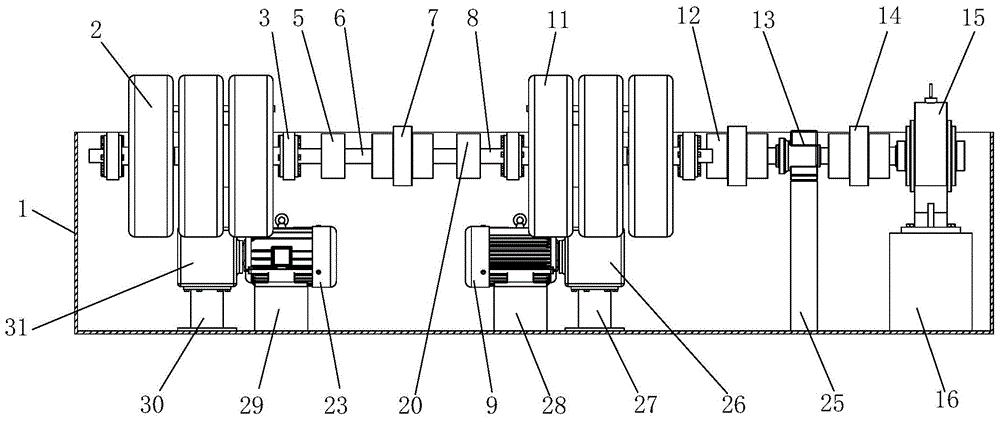

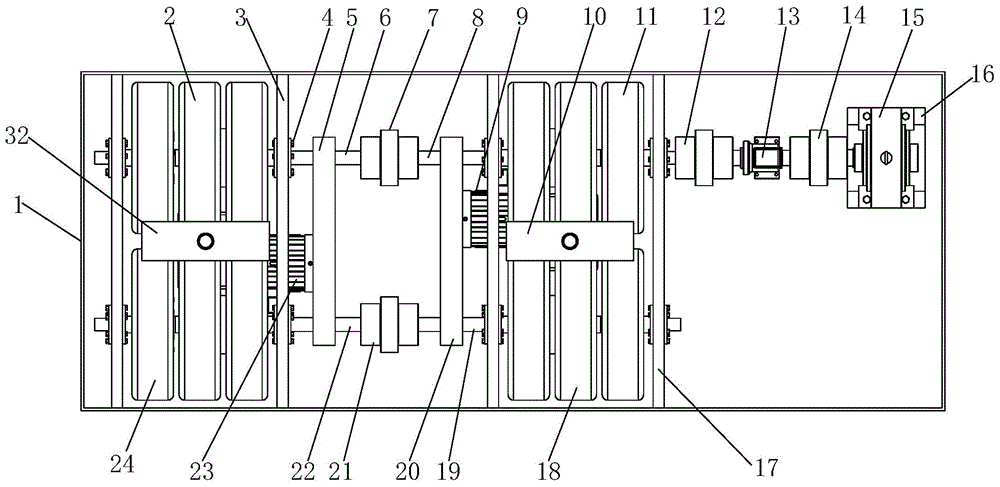

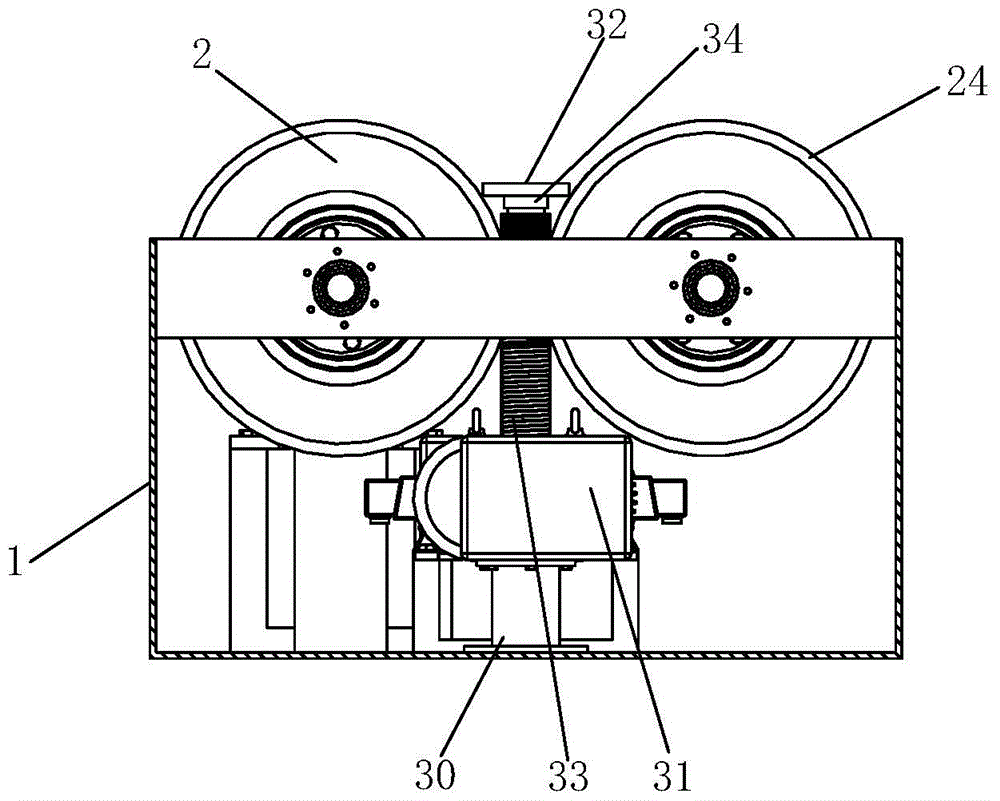

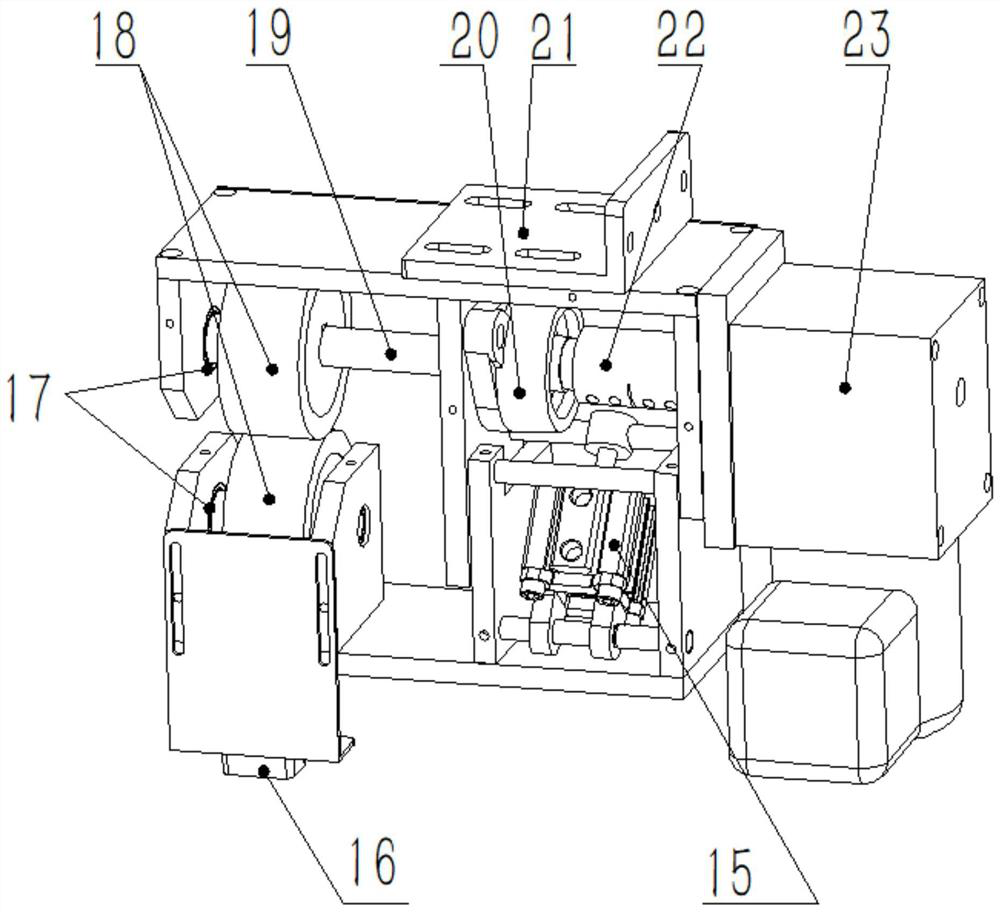

Wheel type cold milling machine pre-delivery detection device

ActiveCN103940631ASimple structureNovel and reasonable designWork measurementStructural/machines measurementDynamometerEddy current

The invention discloses a wheel type cold milling machine pre-delivery detection device, comprising a running system dynamometer and a milling drum dynamometer; the running system dynamometer comprises a rack, a torque and seed sensor, a magnetic powder brake, a first roller, a second roller, a third roller and a fourth roller, wherein one end of a second central shaft on the second roller is connected with one end of a fourth central shaft on the fourth roller, one end of a first central shaft on the first roller is connected with one end of a third central shaft on the third roller, the other end of the third central shaft is connected with one end of a rotation shaft of the torque and speed sensor, and the other end of the rotation shaft of the torque and speed sensor is connected with an output shaft of the magnetic powder brake; the milling drum dynamometer comprises an electric eddy current dynamometer and a connection disc, wherein one end of the connection disc is connected with a rotation shaft of the electric eddy current dynamometer while the other end of the connection disc is connected with a rotation shaft of a milling drum. The detection device can rapidly obtain the speed parameter and torque parameter of the running system and the rotation speed and torque parameter of the milling drum, and can be applied to performing pre-delivery detection to the wheel type cold milling machine.

Owner:CHANGAN UNIV

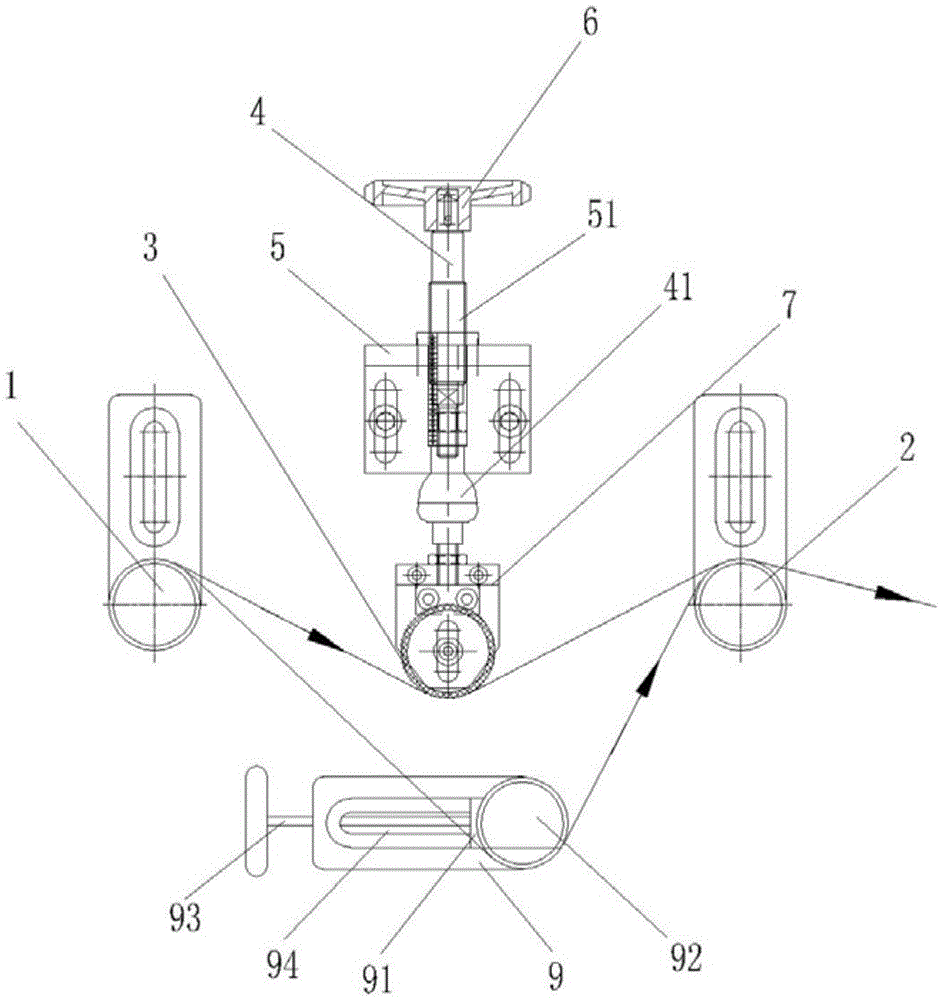

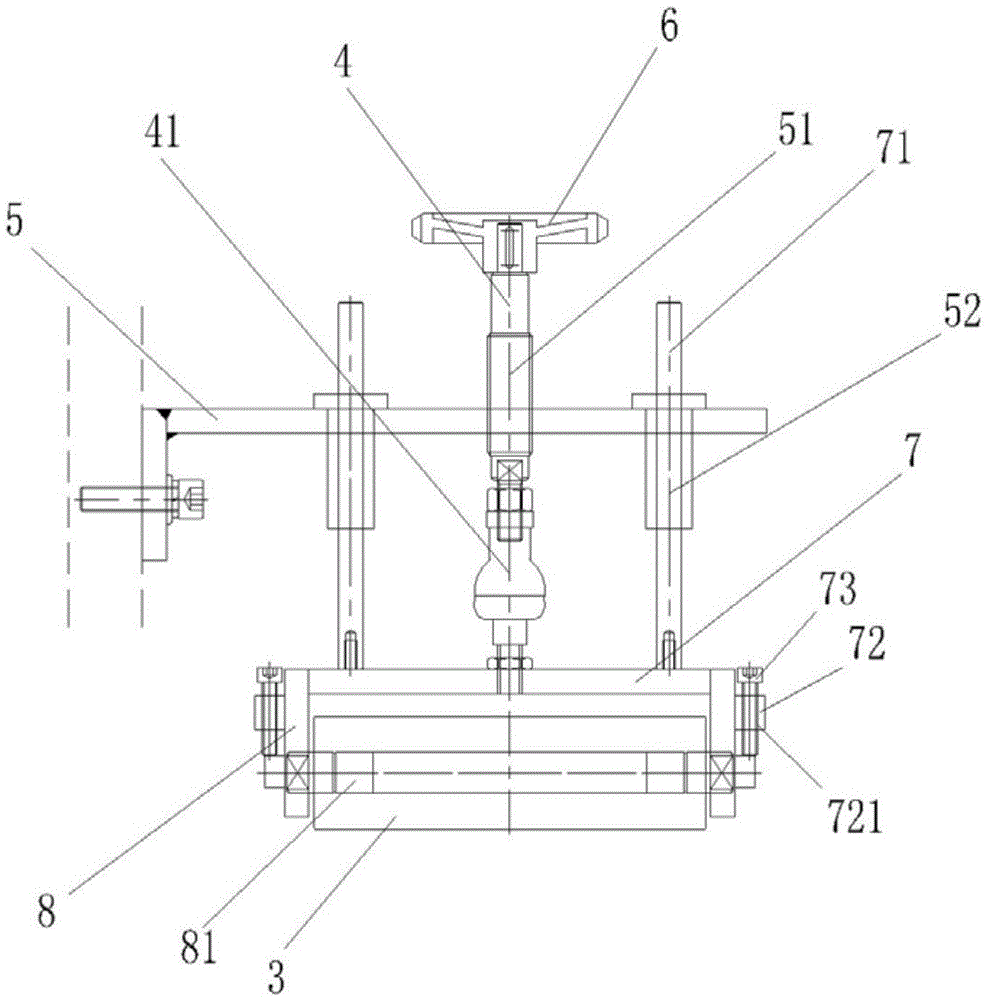

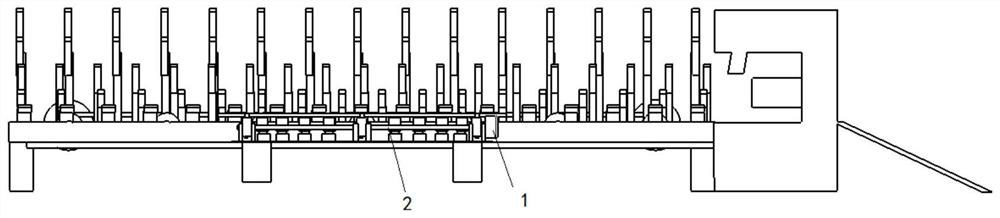

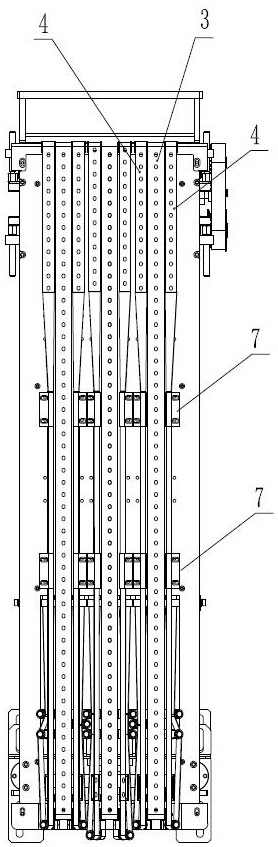

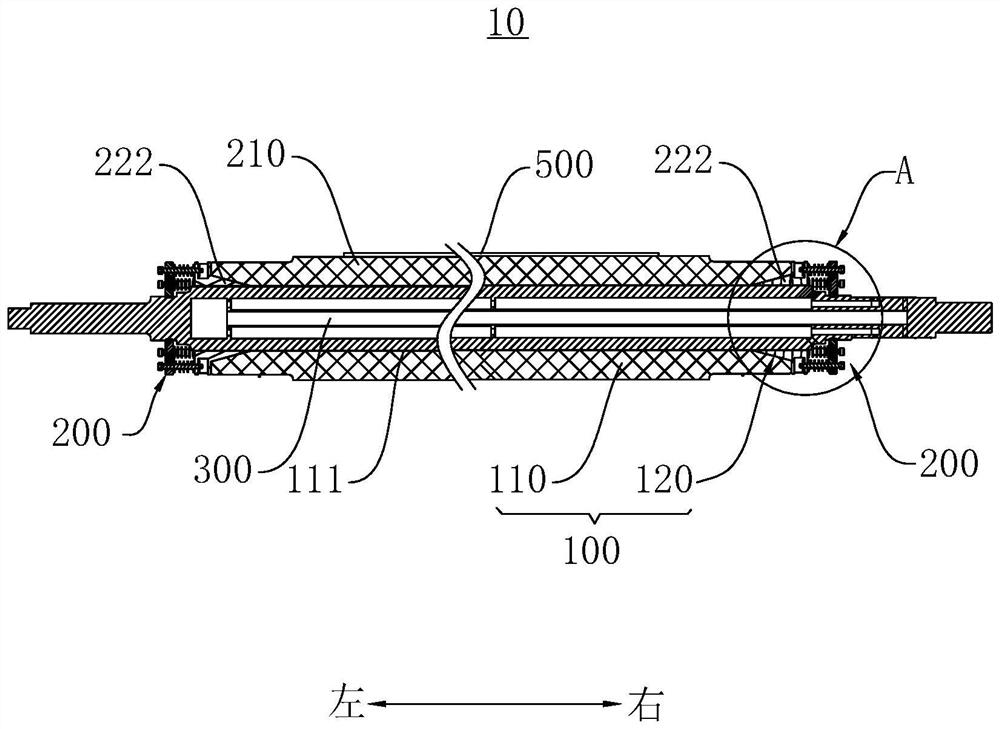

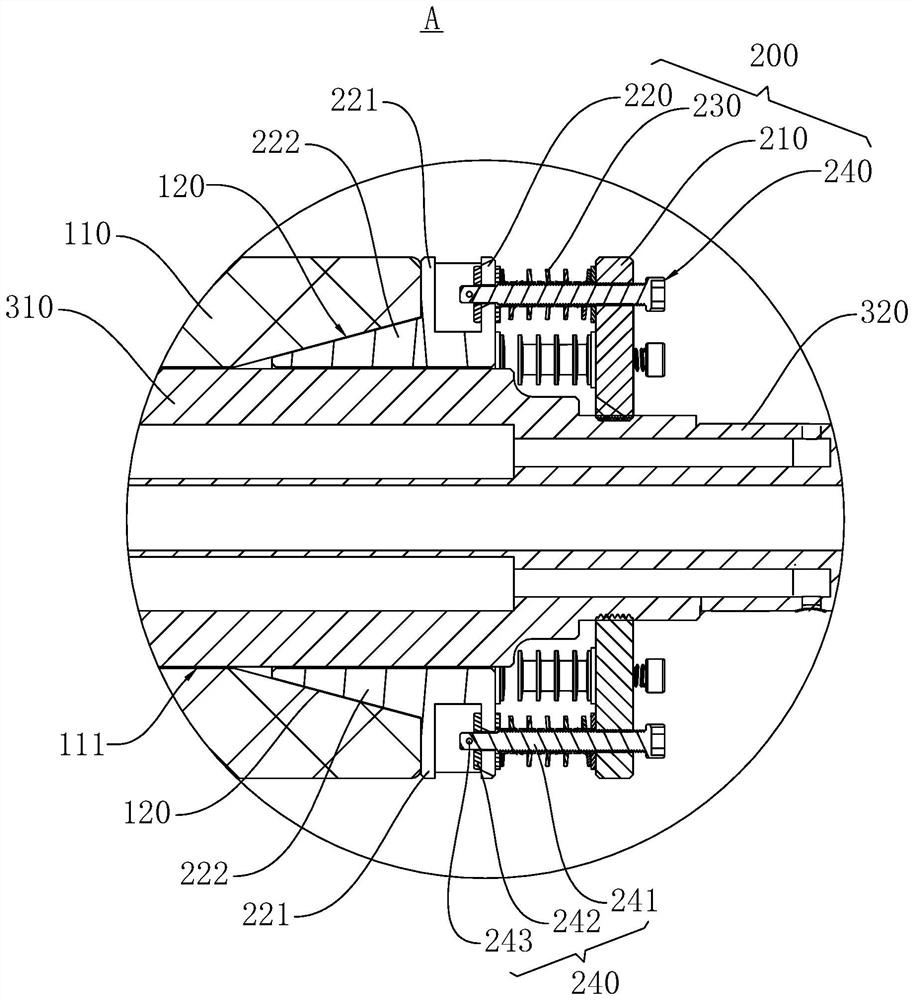

Adjusting device for multiple sets of strip-shaped materials

The invention relates to disposable sanitary product production line equipment, in particular to an adjusting device for multiple sets of strips-shaped materials. A main material adjusting mechanism comprises a material guide roller, an adjusting rod, a fixed base and an adjusting hand wheel; a guide sleeve with an internal thread is arranged on the fixed base, an external thread is arranged on the adjusting rod which is sleeved with the guide sleeve, and a rotary movement structure is formed. One end of the adjusting rod is fixedly connected with the adjusting hand wheel, and the other end of the adjusting rod is connected with a knuckle bearing. The knuckle bearing is connected with the material guide roller. Due to the fact that the main material adjusting mechanism and an auxiliary material adjusting mechanism are arranged between a feeding roller shaft and a receiving roller shaft according to the structure, when different kinds of materials are adjusted, the adjustment motion can be completed only by adjusting the adjusting hand wheel to enable the material guide roller to move up and down, the two kinds of materials can be synchronously conveyed, and adjustment is convenient without a halt.

Owner:JIANGSU JWC MACHINERY

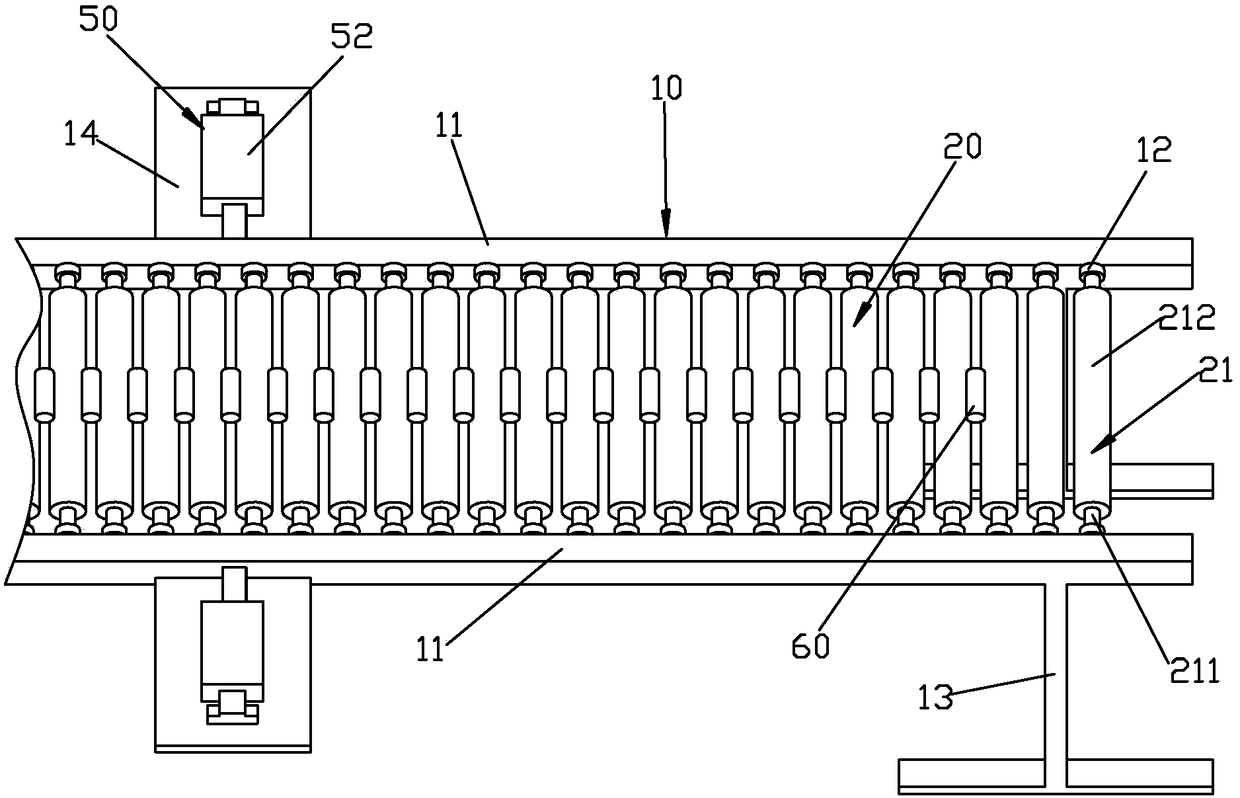

Case appearance automatic detection device

PendingCN108088852AImprove efficiencyHigh culling accuracyMaterial analysis by optical meansEngineeringOutput device

The invention discloses a case appearance automatic detection device, which comprises a machine frame, wherein a conveying device, an image collecting device, a processing device and a eliminating device are arranged on the machine frame; the conveying device drives a battery case to roll and move ahead along the conveying direction of the conveying device so as to realize the moving and the autoroatation of the case; the image collecting device is relatively fixed on the machine frame, and comprises an image collector and a light source arranged at the object side of the image collector; thelight source irradiates the case; the image collector is used for collecting a case image; the processing device is connected with the image collector; the processing device is used for obtaining thecase image and judges the appearance defect and position of the case according to the case image; the eliminating device is connected with the processing device and is used for pushing a case defective product out of an output device when the case defective product occurs. The case appearance automatic detection device has the following advantages that the case conveying, detection and eliminationare synchronously performed; the detection period is shortened.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

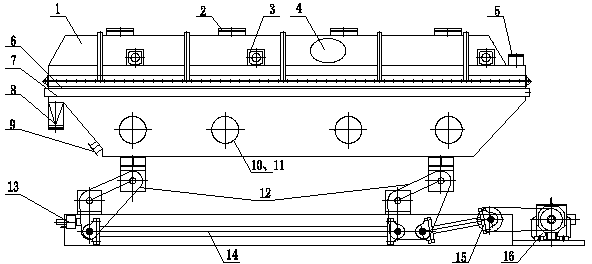

Novel crank pull rod type vibration fluid bed drying machine

InactiveCN103344094AEven by forceConsistent heating timeDrying solid materials with heatHearth type furnacesPhysicsElectric machinery

The invention relates to a novel crank pull rod type vibration fluid bed drying machine which comprises a machine body. A sieve plate is arranged inside the machine body, a vibration cross beam which supports the machine body is arranged on the lower portion of the machine body, and the vibration cross beam is connected with a driving motor through a linkage mechanism. The vibration cross beam rotates under the driving of linking rods, so that the machine body moves up and down and front and back. The novel crank pull rod type vibration fluid bed drying machine is wide in application range, good in drying quality and high in efficiency.

Owner:PENGFEI CHEM EQUIPS FACTORY JIANGDU CITY +2

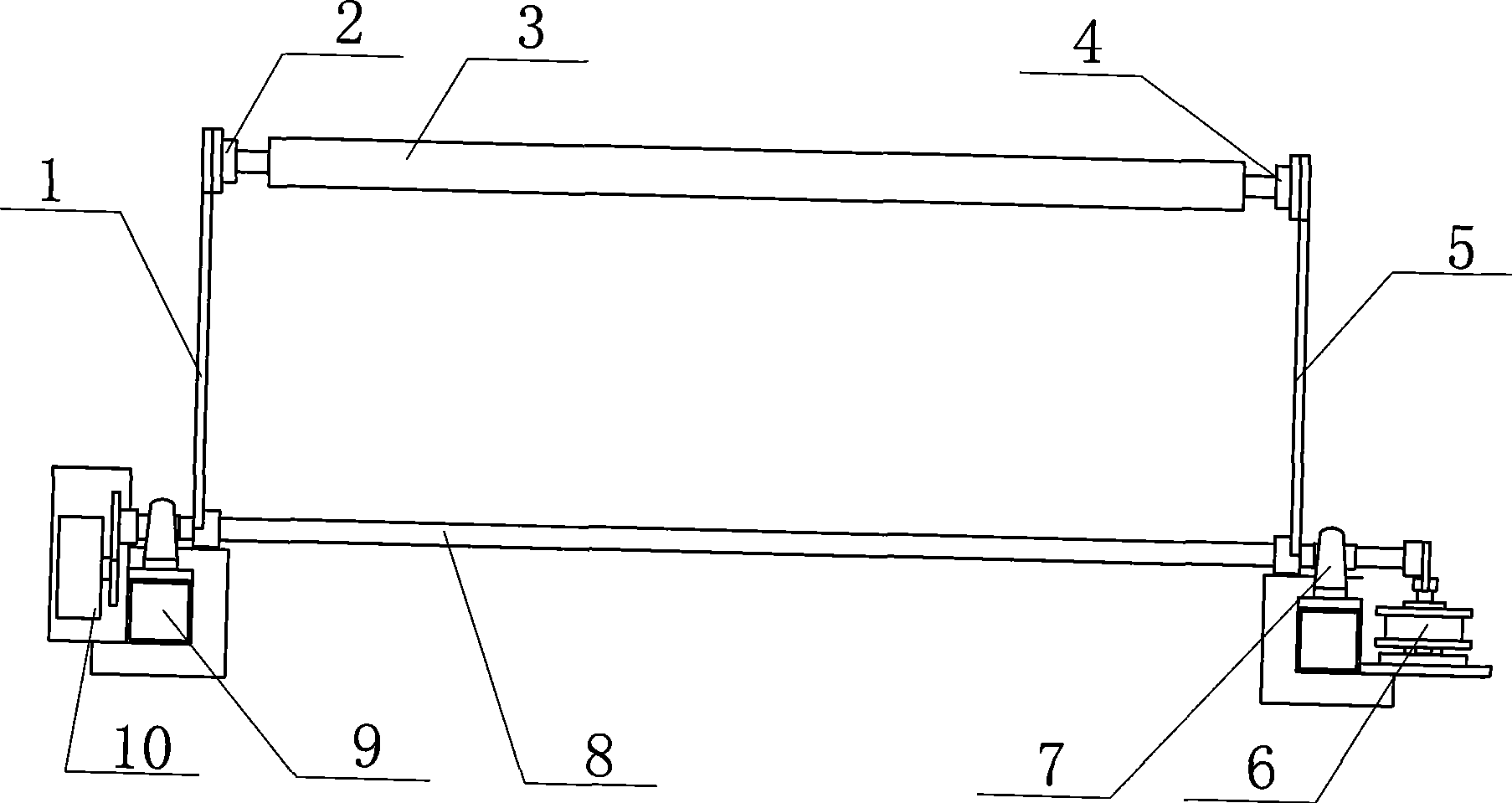

Tension self control structure for continuous crabbing machine

InactiveCN101424017ASynchronous deliveryStable deliveryTextile treatment machine partsWebs handlingSmall amplitudeDrive shaft

The invention relates to a tension autocontrol structure for a continuous crabbing machine. The tension autocontrol structure has high precision in controlling the rotation of a swinging rod; fabric has small amplitude of tension change in the whole transportation mechanism, can realize synchronization and has smooth transportation. The tension autocontrol structure is characterized in that the structure comprises a rotating shaft which is arranged on a bearing seat; one end of the rotating shaft is connected with a piston rod of a cylinder; the other end of the rotating shaft is provided with a sensor; the sensor is in electric control connection with an electromagnetic valve for controlling the cylinder; two ends of the rotating shaft are sleeved and connected with a connecting rod respectively; two ends of the rotating shaft and the connecting rods are in rotary connection; and the connecting rods are connected with a guide roller through the bearing seat respectively.

Owner:叶建清

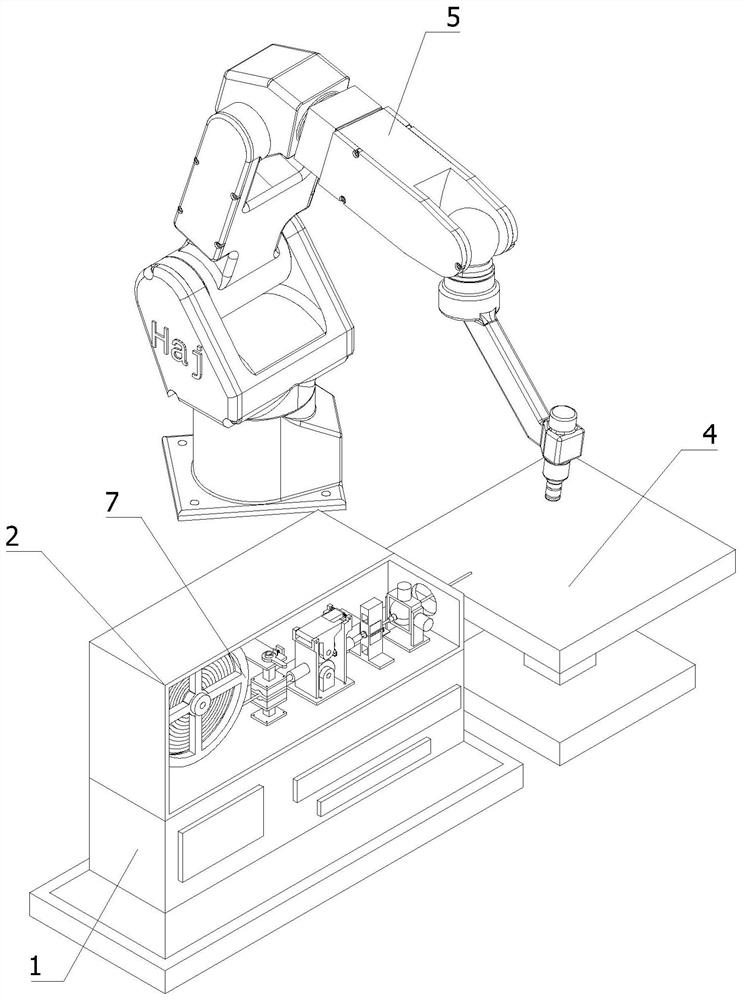

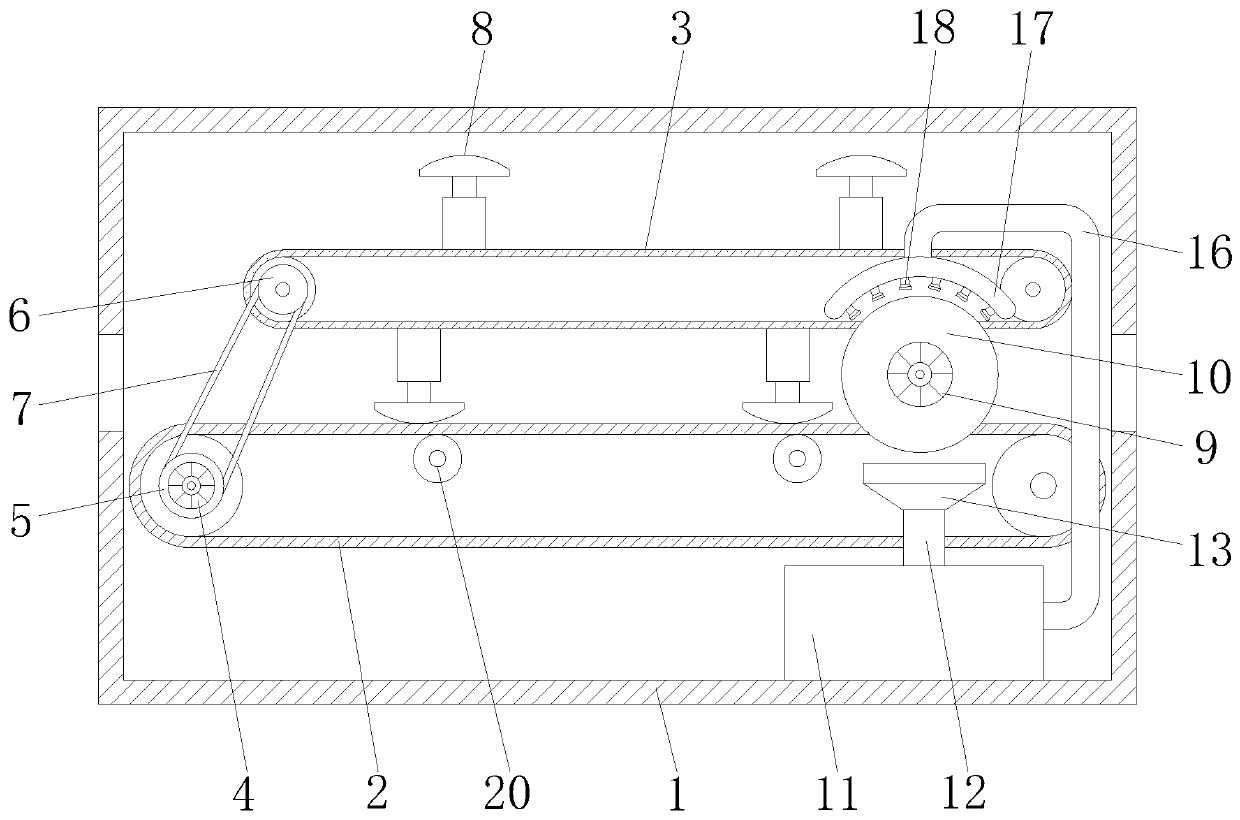

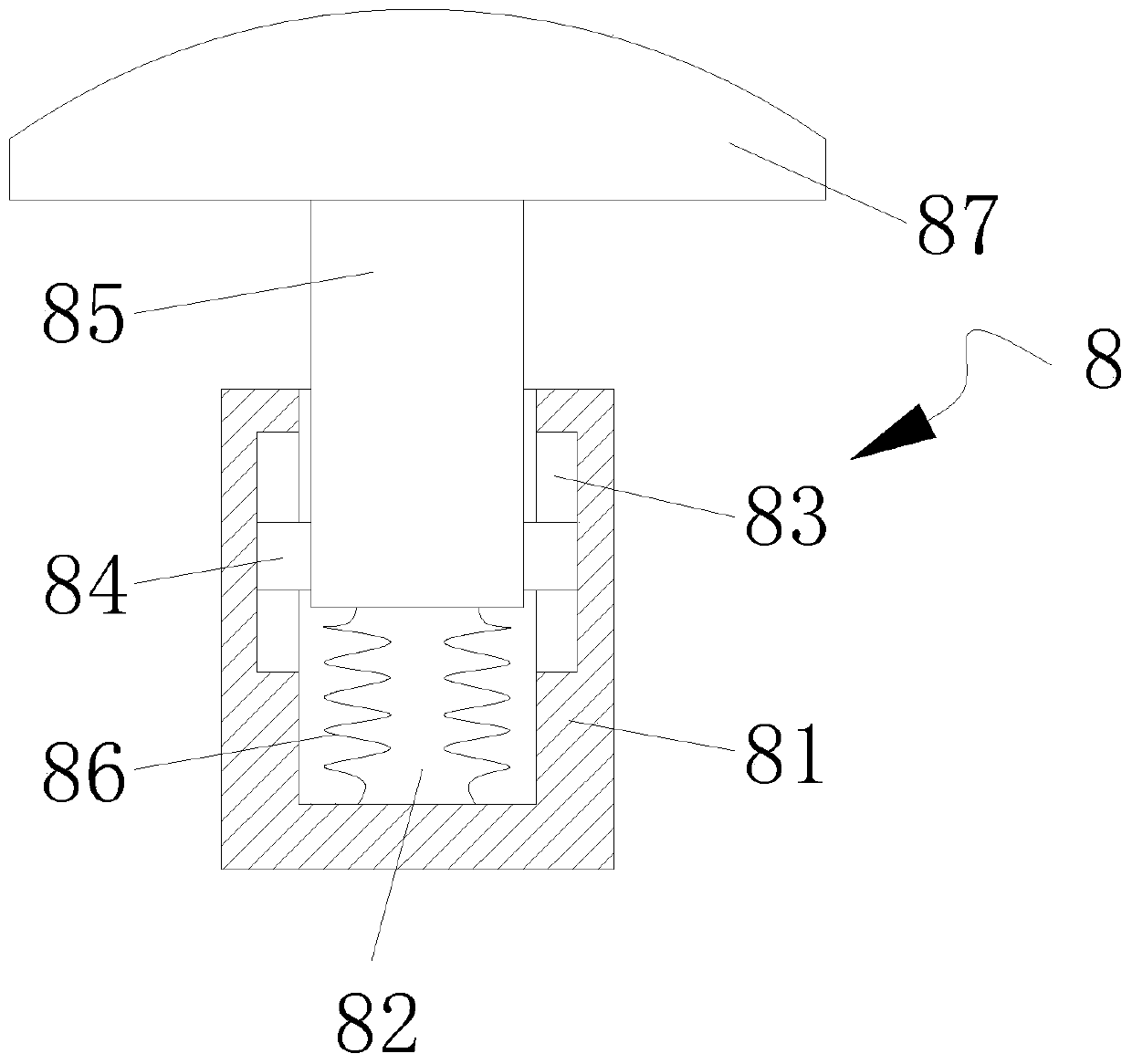

Intelligent welding machine using rod-shaped welding wires

ActiveCN113399786AImprove welding efficiencyWire delivery remains stableWelding accessoriesEngineeringWelding

The invention relates to the technical field of welding, in particular to an intelligent welding machine using rod-shaped welding wires. The machine comprises an industrial robot, a wire feeding device, a welding table and a welding robot; the welding table is used for placing workpieces and is arranged beside the wire feeding device; the wire feeding device comprises an adjustable wire feeding assembly and an angle adjusting assembly; the adjustable wire feeding assembly is used for adjusting the wire feeding speed of the welding wires according to the welding efficiency of the workpieces and comprises a shell, a wire rolling mechanism and a wire feeding speed sensing mechanism; a displacement sensor used for sensing the conveying amount of the welding wires is arranged on the wire feeding speed sensing mechanism; and the wire rolling mechanism, the wire feeding speed sensing mechanism and the angle adjusting assembly are all located on the unified horizontal line. through cooperation of the wire rolling mechanism and the wire feeding speed sensing mechanism, the welding wire conveying speed can be conveniently adjusted according to the welding condition, and the angles of the welding wires can be freely adjusted through the angle adjusting assembly during welding, so that the welding efficiency and the welding precision are improved.

Owner:广州市顺卓建设工程有限公司

Intelligent cleaning device

ActiveCN111559628AGuaranteed cleanlinessSynchronous deliveryConveyorsHollow article cleaningControl engineeringElectric machinery

An intelligent cleaning device includes a conveying table, a cleaning bin, a wheel set A, a belt A, a belt B, a belt pulley set, a tray jacking machine, a tray collecting bin, a starting switch and adriving motor; the conveying table, the cleaning bin, the tray jacking machine, the tray collecting bin and other mechanisms are mutually matched to realize automatic washing and automatic storage; adriving shaft in the cleaning bin drives a V-shaped brush and a rolling brush to simultaneously drive the belt pulley set, a seedling tray enters the cleaning bin under the driving of a roller set, the starting switch is triggered after the seedling tray exits the cleaning bin, the driving motor is started to drive the tray jacking machine, and the tray jacking machine lifts the seedling tray to the tray collecting bin, so that automatic washing and automatic storage are synchronously carried out.

Owner:山东同其智能科技有限公司

Shoulder wedge feeding frame and front guiding and positioning method thereof

The invention relates to a shoulder wedge feeding frame and a front guiding and positioning method thereof. A fixed edge guiding device and method capable of realizing the purpose of pressing downwards, rotating and pushing laterally simultaneously is used for realizing synchronous conveying of two shoulder wedges in limited conveying distance, thereby improving the conveying consistency of the two shoulder wedges to ensure that the two shoulder wedges can be accurately jointed on shoulder positions in parallel. The device is mainly provided with a conveying frame and a conveying template, wherein the conveying template is used for conveying shoulder wedges onto a forming drum and is installed on the conveying frame through a supporting frame. Different from the prior art, at least one group of fixed edge guiding mechanisms are arranged on brackets along the conveying direction of shoulder wedges. The fixed edge guiding mechanisms comprise at least one group of guiding rollers which are axially arranged between brackets at two sides and can axially rotate, and surface rollers of the guiding rollers are spirally arranged along the central line in the transverse direction and the brackets at two sides in the oblique direction. At least two groups of compression rollers which are driven by cylinders are arranged above the guiding rollers in the vertical direction, and the vertical central lines of the guiding rollers and the compression rollers are coincident.

Owner:MESNAC

Pneumatic telescopic-pendulum-adsorption medicine-plate conveying mechanism

InactiveCN1180954CThe interface is stable and reliableStable deliveryPackagingEngineeringManufacturing line

The pneumatic pendulum-extending adsorption medicine plate conveying mechanism relates to improvement of safety interface of whole flow automatic production line formed from aluminium-plastics bubbling cap packaging machine and automatic medicine plate boxing machine, which comprises three portions of die-cutting medicine plate receiving, delivery and positioning device, pendulum-extending adsorption medicine plate graduation device and medicine plate conveying device. The described die-cutting medicine plate receiving delivery and positioning device includes receiving guide plate, plate-pushing cylinder and medicine plate positioning card which are mounted on the die-cutting frame, and the pendulum-extending adsorption medicine plate graduation device includes pendulum shaft, lifting cylinder, pendulum bar and sucking disk, and the medicine plate, conveying device is formed from conveyer belt.

Owner:浙江圣雷机械有限公司

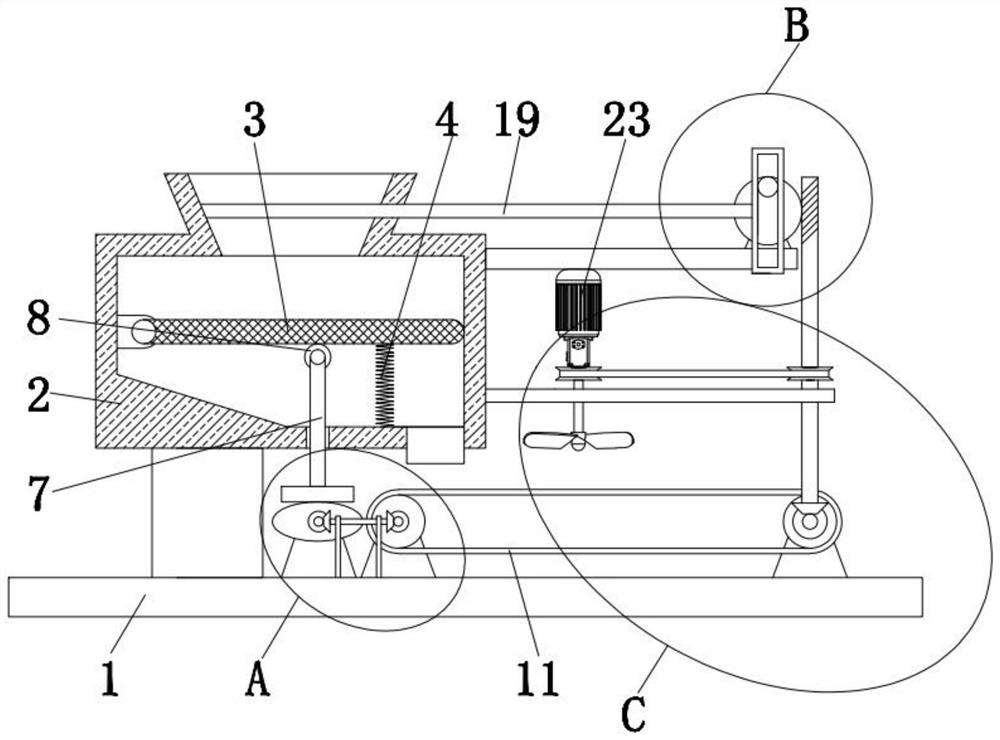

Wheat screening equipment for flour processing and using method thereof

InactiveCN112452757AImprove screening efficiencyAvoid problems with low screening efficiencySievingGas current separationAgricultural engineeringDust control

The invention relates to the technical field of screening equipment, and discloses wheat screening equipment for flour processing and a using method thereof, wherein the wheat screening equipment comprises a base, a shell is fixedly installed at the top of the base, a screen is rotatably installed in the shell, and the top end of a spring is fixedly installed at one side of the bottom of the screen; the bottom end of the spring is fixedly installed on the inner wall of the bottom of the shell, a rotating wheel is rotatably installed at one side of the top of the base, a moving plate movably abuts against the top of the outer side of the rotating wheel, the bottom end of a moving rod is fixedly installed at the top of the moving plate, and the top end of the moving rod extends into the shell and is rotatably provided with a roller; and the outer side of the roller is mounted at the bottom of the screen in a rolling manner. The wheat screening equipment is reasonable in design; wheat screening and conveying and wheat quantitative input can be synchronously carried out, so that the working efficiency is improved, the use number of motors is reduced, and time is saved; and by arrangingfan blades, qualified materials can be subjected to dust removal work.

Owner:宿州市超王面业有限责任公司

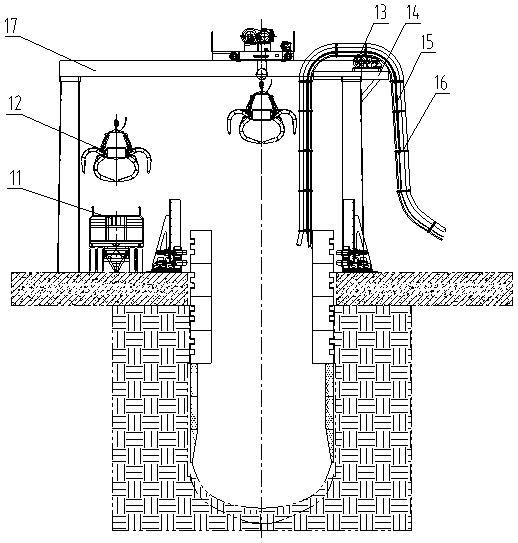

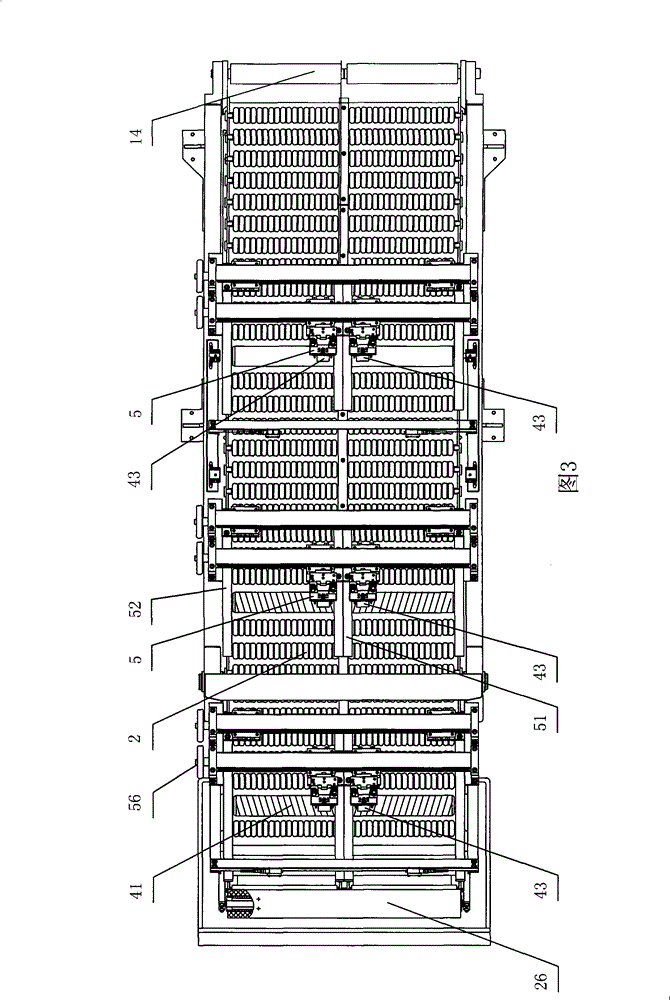

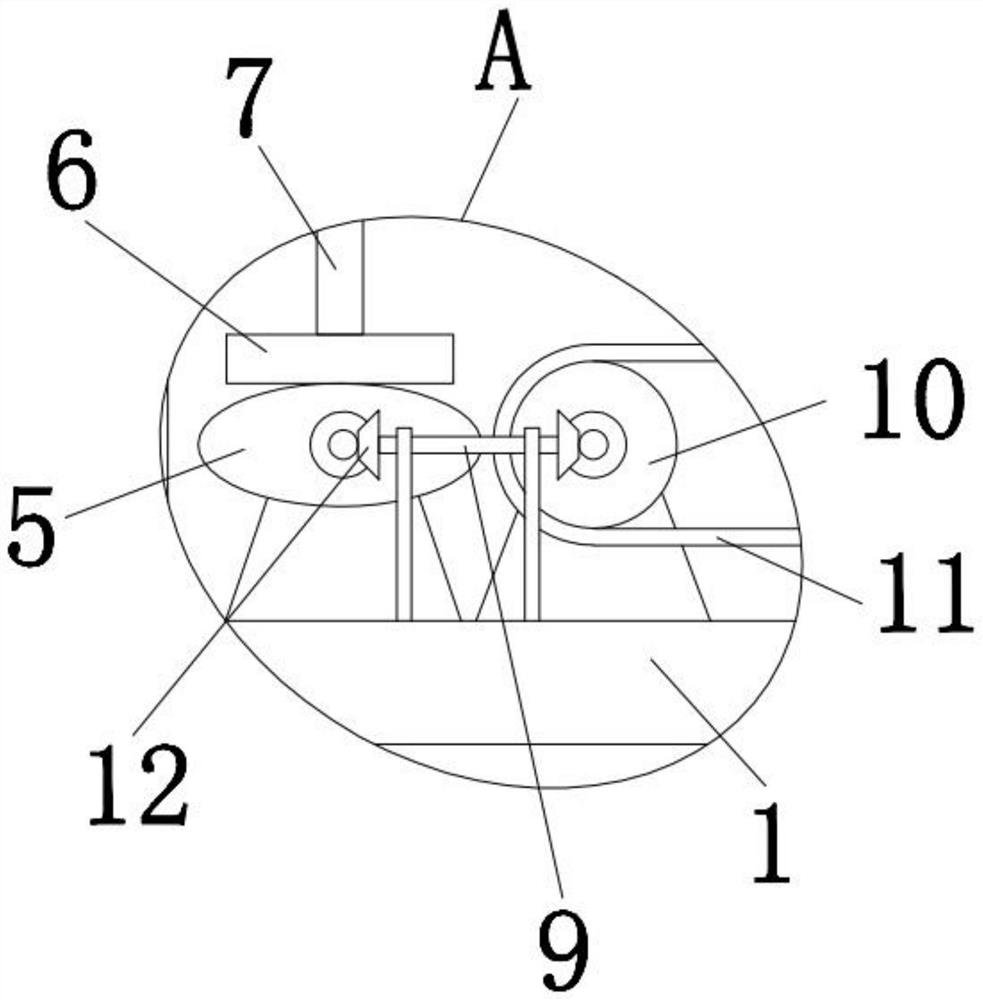

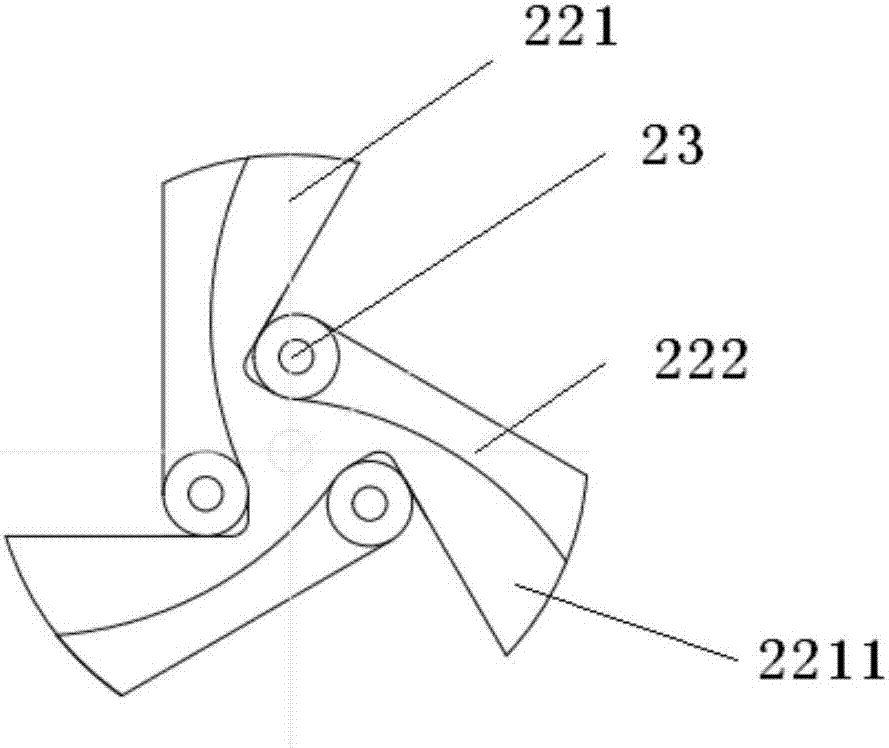

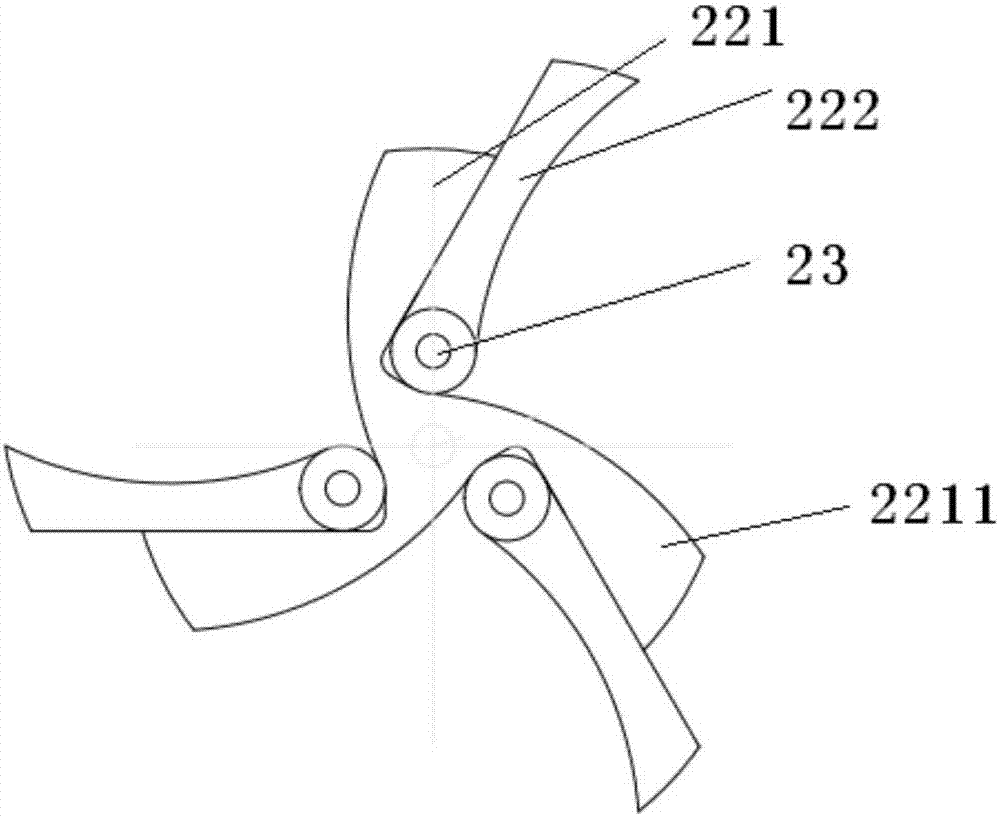

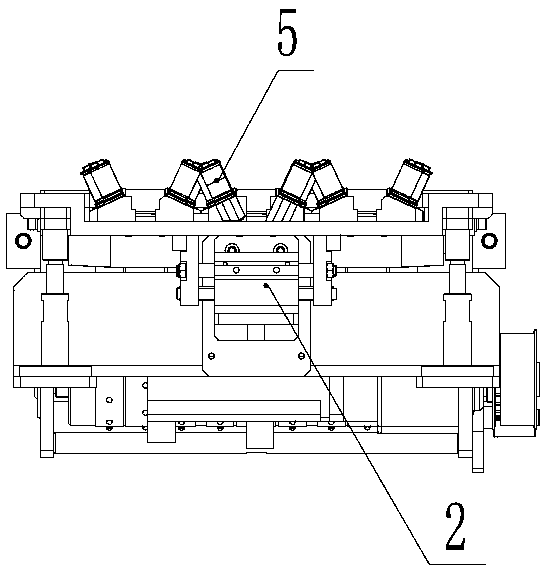

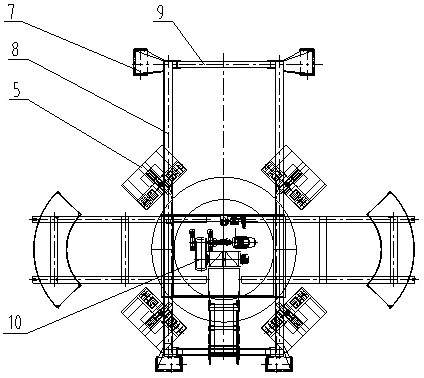

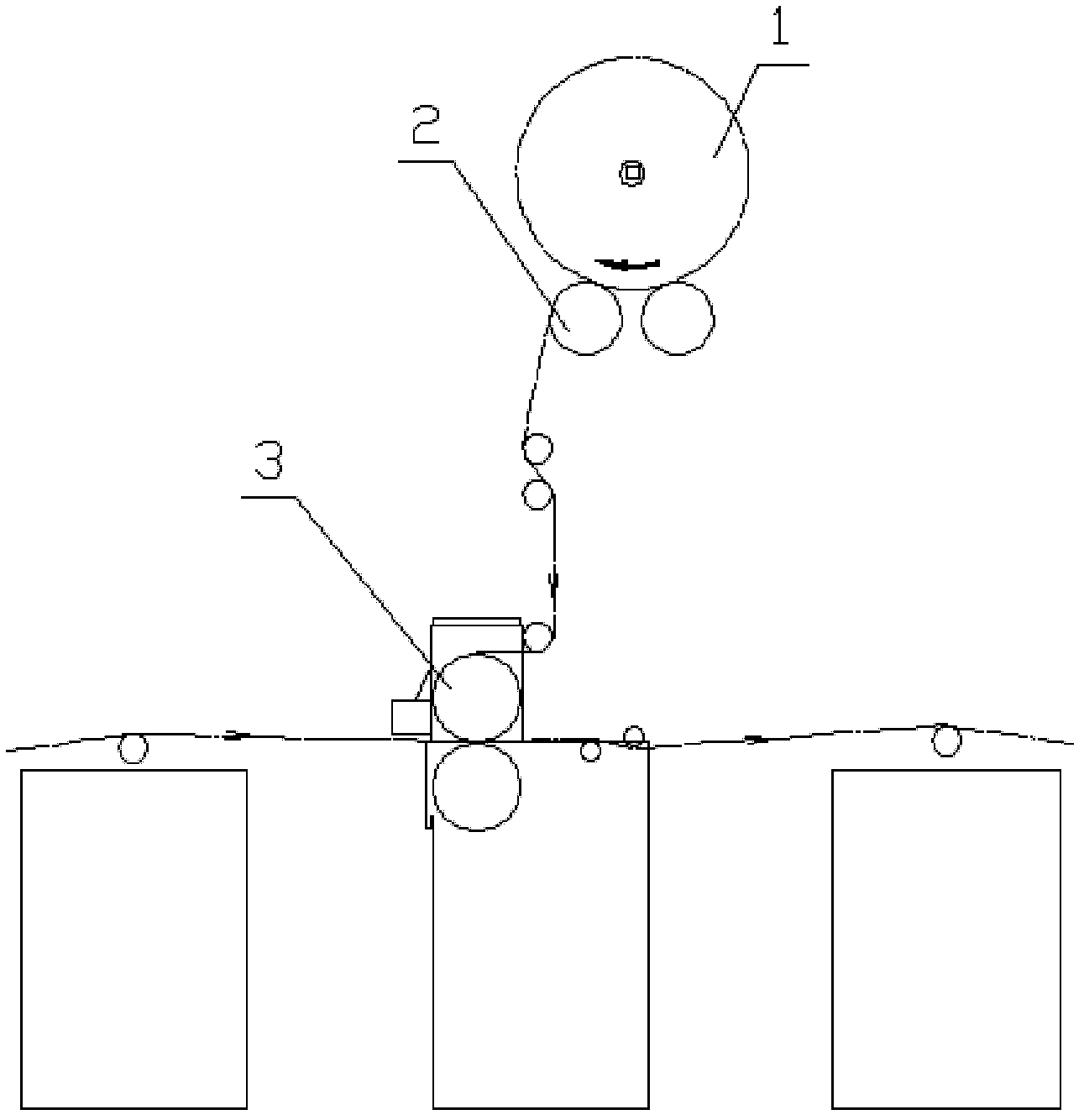

Sinking construction device of underground building

PendingCN107386295AGuaranteed cutting and crushing strengthSinking smoothlyDrill bitsDrilling with mechanical conveyingEngineeringBuilding construction

The invention relates to the technical field of underground construction, in particular to a sinking construction device of an underground building. The sinking construction device of the underground building comprises an excavation mechanism (2), a conveying mechanism (3) and a drive mechanism (4). The excavation mechanism (2) is detachably connected with a prefabricated outer wall board (1) buried in advance and excavates earth and stone under the buried prefabricated outer wall board (1). The conveying mechanism (3) conveys the earth and stone excavated by the excavation mechanism (2) to the ground. The drive mechanism (4) is used for driving the excavation mechanism (2) and the conveying mechanism (3). The excavation mechanism (2) is a blade assembly used for cutting earth and stone. In the excavation process, the sinking construction device of the underground building has a great cutting and breaking function on the earth and stone and can guarantee that a wall smoothly goes down.

Owner:NENGCHENG GRP

An intelligent cleaning device

ActiveCN111559628BGuaranteed cleanlinessSynchronous deliveryConveyorsHollow article cleaningDrive shaftControl engineering

An intelligent cleaning device, comprising: a conveying table, a cleaning bin, a wheel set A, a belt A, a belt B, a pulley set, a top plate machine, a closing bin, a start switch, and a driving motor; The machine, the closing bin and other mechanisms cooperate with each other to realize automatic flushing and automatic storage; the drive shaft in the cleaning bin drives the V-shaped brush and the roller brush at the same time drives the pulley set, the seedling tray enters the cleaning bin under the drive of the roller set, and the seedling tray goes out of the cleaning bin Then touch the start switch, drive the motor to start, drive the jacking machine, and the jacking machine lifts the seedling tray to the closing bin, so as to realize automatic washing and automatic storage simultaneously.

Owner:山东同其智能科技有限公司

Material head cutting mechanism for synthetic plastic part production

InactiveCN114012982ASynchronous deliveryHigh cutting precisionMetal working apparatusRatchetReciprocating motion

The invention discloses a synthetic plastic part production material head cutting mechanism, and belongs to the technical field of material head cutting mechanisms, the synthetic plastic part production material head cutting mechanism comprises a bottom frame, a rectangular through groove is formed in the upper surface of the bottom frame, rectangular blocks are fixedly arranged on the two sides of the bottom frame, and a conveying mechanism is rotatably mounted between the rectangular blocks; The upper surface of the bottom frame is provided with a turning groove and an installation groove. A material head assembly is clamped and fixed through a clamping groove of a concave strip and fixedly installed on a toothed belt, a guide plate is pushed by an air cylinder to slide up and down in a reciprocating mode along a sliding rod, the material head is cut off through a cutter, a spring can be extruded when a fixing base moves, the material head assembly is pressed through a pressing block, and the cutting-off precision is improved; a pressing block is pushed through bounce of the spring to enable the material head assembly to be separated from the cutter, the rack reciprocates and drives the outer gear ring to rotate, the first gear can rotate intermittently by being connected with the double ratchet wheels, and therefore, the synchronization of template conveying and cutting is achieved.

Owner:徐州甲子丙复合材料有限公司

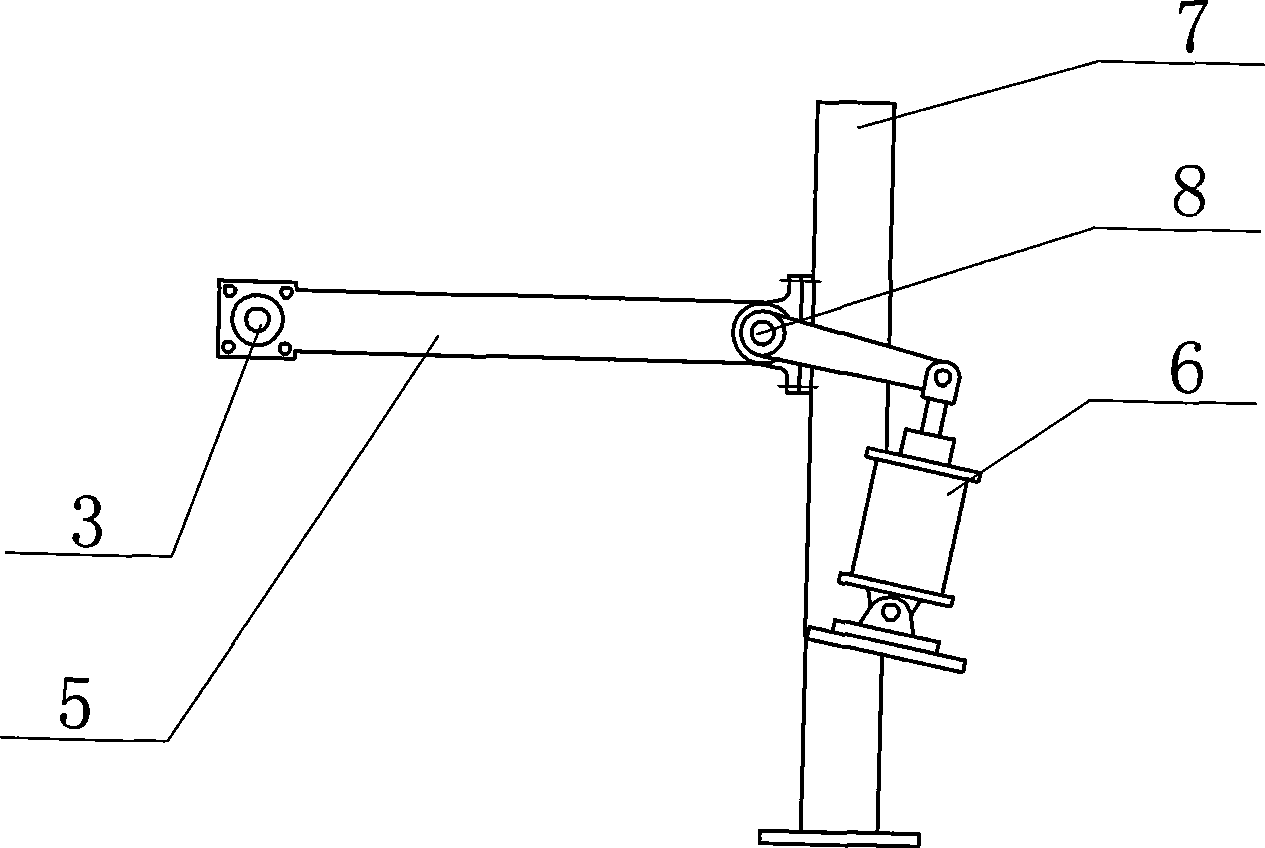

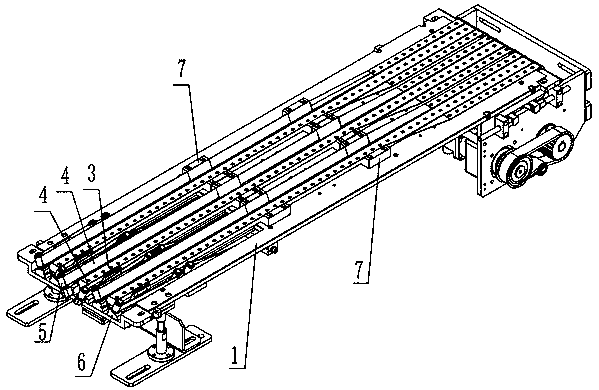

Anchor rod inclined head shearing device

ActiveCN113523413AStable and reliable feedingSynchronous deliveryShearing machine accessoriesTransmission beltElectric machinery

The invention discloses an anchor rod inclined head shearing device which comprises a base, first supporting plates, a belt wheel, a transmission belt, a rotating shaft, a telescopic rod, a support, second supporting plates, a roll shaft, rollers, a chain, guide plates, and a shearing machine. The belt wheel is arranged between the first supporting plates; the transmission belt is arranged on the belt wheel in a sleeving mode and provided with a check block; the rotating shaft is connected with the belt wheel; one end of the rotating shaft is connected with a first motor; the telescopic rod is arranged on the base; a bracket is arranged at the upper end of the telescopic rod; a pneumatic rod is arranged on the bracket; the side face of the support is provided with a guide rail matched with the base; the second supporting plates are arranged on the support; the roll shaft is arranged between the second supporting plates; one end of the roll shaft is connected with a chain wheel connected with a second motor; the rollers are arranged on the roller shaft in a sleeving manner, are located between the second supporting plates and form a conveying line; the chain is annularly arranged on the chain wheel; the guide plates are arranged on the support and are sequentially provided with a first guide plate, a second guide plate, a third guide plate, a fourth guide plate and a fifth guide plate from one side close to the base to one side far away from the base; and the shearing machine is arranged at the end part of the support. The anchor rod inclined head shearing device has the advantages of reliable feeding, synchronous conveying of multiple materials and synchronous shearing.

Owner:济宁落陵矿山支护材料厂

Bonding and sending device for base cloth

Owner:KUSN ACHILLES ARTIFICIAL LEATHER

Corner enclosing method for food

The invention belongs to the technical field of food processing and particularly relates to a corner enclosing method for enclosing coroners of filled food. The method comprises the steps as follows:a clamping device clamps food from the last station and downwards places the food between two corner enclosing surfaces of an enclosing mechanism to enclose corners of two ends of the food, the corned-enclosed food is conveyed to the tail end of a conveying frame plate under the joint action of side belts and a bottom belt. The corner-enclosed food is conveyed by the bottom belt and the side beltsand cannot adhere to the corner enclosing mechanism, as the side belts are arranged on two sides, the two ends of the food can be conveyed synchronously, deflection of the food can be avoided, and the following arrangement procedure can be performed smoothly.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Segment-assembled derrick and its construction method

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Trimming device for aluminum curtain wall material board processing

InactiveCN109702263ASynchronous deliveryImprove cutting accuracyShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to the technical field of aluminum curtain wall material board trimming, and discloses a trimming device for aluminum curtain wall material board processing. The trimming devicecomprises a tank; a feeding inlet and a discharging outlet are formed in the middles of the left side face and the right side face of the tank separately; a first conveying belt and a second conveyingbelt are installed on the inner wall of the tank; a first motor is fixedly installed on the inner wall of the front face of the tank; an output shaft of the first motor is fixedly connected with a rotary shaft on the first conveying belt; the rotary shaft on the first conveying belt is sleeved with a large belt wheel; a rotary shaft on the second conveying belt is sleeved with a small belt wheel;the small belt wheel and the large belt wheel are in transmission connection through a belt; and compressing mechanisms arrayed at equal distance are fixedly installed on the outer surface of the second conveying belt. The trimming device solves the problems that an existing aluminum veneer cutting device is poor in fixing of boards, the boards shift easily during cutting, the cutting precision is low, cutting chippings cannot be effectively controlled, and staff are injured easily.

Owner:安徽唯楚新材料有限公司

A wheel-type cold milling machine factory inspection device

ActiveCN103940631BSimple structureNovel and reasonable designWork measurementStructural/machines measurementEddy currentDynamometer

The invention discloses a factory inspection device for a wheeled cold milling planer, which includes a walking system dynamometer and a milling drum dynamometer, and the walking system dynamometer includes a frame, a torque speed sensor, a magnetic powder brake and a first roller , the second drum, the third drum and the fourth drum, one end of the second central shaft on the second drum is connected to one end of the fourth central shaft on the fourth drum, and one end of the first central shaft on the first drum is connected to the third drum. One end of the third central shaft is connected, the other end of the third central shaft is connected to one end of the rotating shaft of the torque speed sensor, and the other end of the rotating shaft of the torque speed sensor is connected to the output shaft of the magnetic powder brake; the milling drum dynamometer includes an eddy current dynamometer One end of the connecting plate is connected with the rotating shaft of the eddy current dynamometer, and the other end of the connecting plate is connected with the rotating shaft of the milling drum. The detection device can quickly obtain the speed parameters and torque parameters of the traveling system, the milling drum speed and torque parameters, and carry out the factory inspection of the wheel cold milling machine.

Owner:CHANGAN UNIV

A method for closing corners of food

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Bonding and sending device for base cloth

ActiveCN102806743AOvercoming the effects of stretchingTempo syncLaminationLamination apparatusDrive motorWheel drive

Owner:KUSN ACHILLES ARTIFICIAL LEATHER

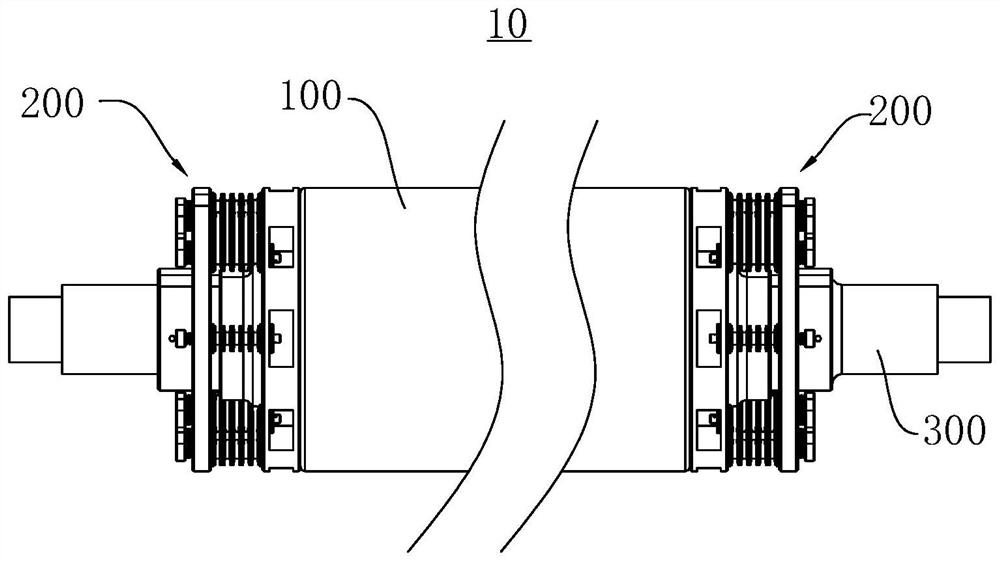

Ceramic roller and roller table

PendingCN113816066AEnsure safe deliverySmooth rotationRollersRoller-waysMaterials scienceFriction force

The invention discloses a ceramic roller and a roller table. The ceramic roller comprises a ceramic piece and two end mechanisms, wherein the ceramic piece is provided with a main body part and first assembling parts arranged at the two ends of the main body part; the circumferential surface of the main body part is used for bearing a product; the ceramic piece is assembled and connected between the two end mechanisms; each end mechanism is provided with a second assembling part; and the second assembling parts are matched with the first assembling parts in an embedded mode and abut against the first assembling parts in the radial direction of the ceramic piece. According to the scheme provided by the invention, the second assembling parts of the end mechanisms are matched with the first assembling parts of the ceramic piece in the embedded mode, and enough friction force exists between the second assembling parts and the first assembling parts, so that the end mechanisms and the ceramic piece are fixed in the circumferential direction. Compared with the prior art that the ceramic piece and the end mechanisms are bonded and fixed, the problem that the ceramic piece and the end mechanisms are not stably connected in a high-temperature environment is solved, so that the ceramic piece and the end mechanisms are ensured to normally rotate synchronously, and then glass is ensured to be normally conveyed.

Owner:深圳南玻科技有限公司 +2

Automatic wrinkling machine for double-layer mattress foxing

PendingCN114232230ASynchronous deliveryGood effectWork-feeding meansSewing-machine control devicesEngineeringNonwoven fabric

The invention discloses a double-layer mattress foxing automatic wrinkling machine which comprises a discharging device, the discharging device is composed of a main frame and a discharging frame, the discharging frame is installed on one side of the main frame, a cloth feeding device is installed at the top of the main frame, a sewing machine head is installed in the middle of the main frame, and a wrinkling device, a traction device and a machine head presser foot are arranged on the sewing machine head. The wrinkling device is installed on one side of the sewing machine head, and a main shaft of the wrinkling device is connected with a rotating shaft of the sewing machine head through a belt. Limiting rods are symmetrically installed on the side, close to the discharging frame, of the top of the main frame, and a material supporting roller is installed on the side, away from the discharging frame, of the top of the main frame. The whole large non-woven fabric and the fabric are sewn through the sewing machine, when the non-woven fabric and the fabric reach the corner position, the machine can conduct automatic corner sewing till four corners are completed, one-time forming is achieved, the process can be completed only by one person, and the advantages of being high in speed, high in production efficiency, uniform in wrinkling, good in effect, capable of achieving data control, accurate and efficient are achieved.

Owner:广州喜登堡床垫机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com