Patents

Literature

144results about How to "Tempo sync" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

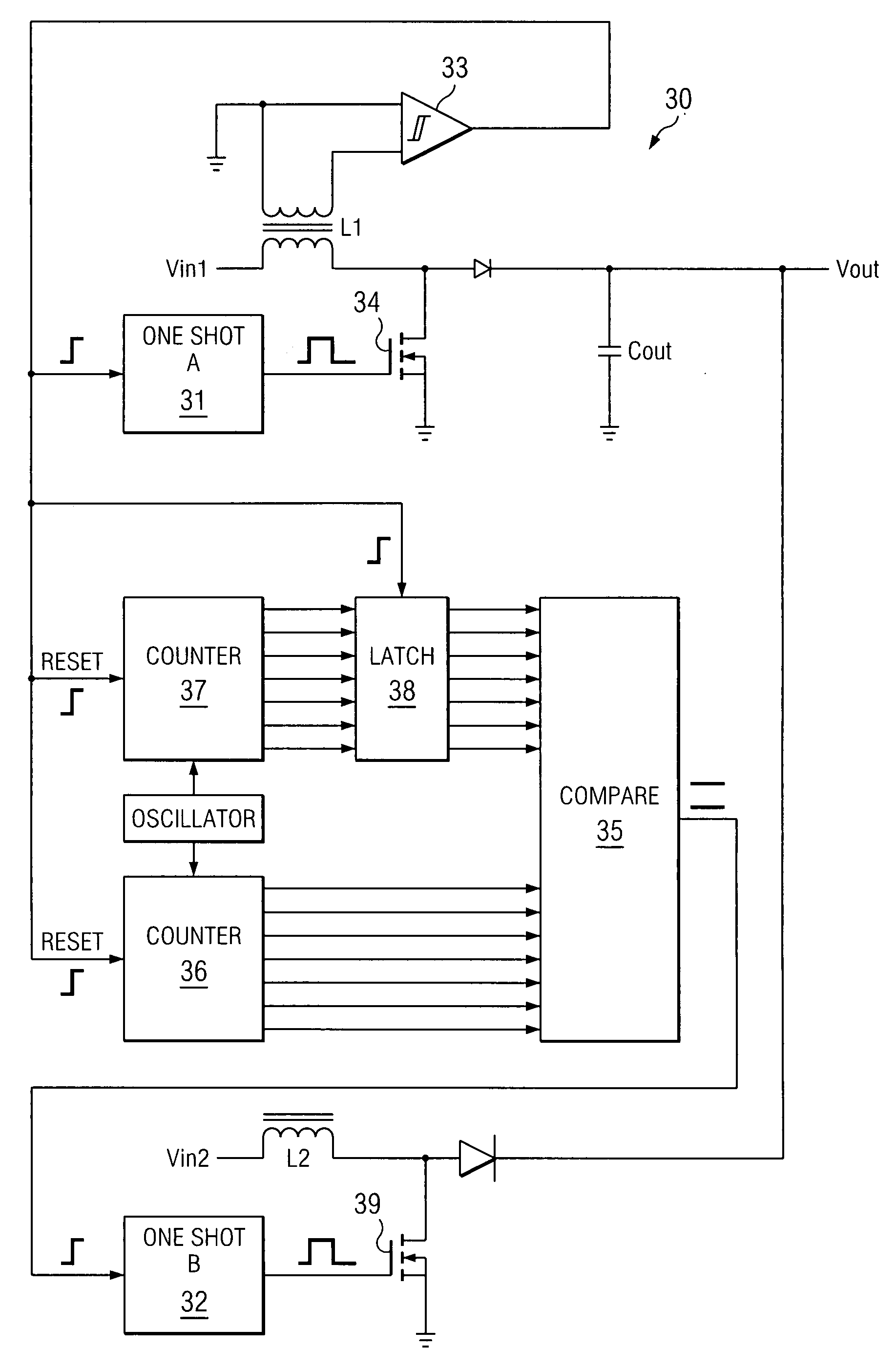

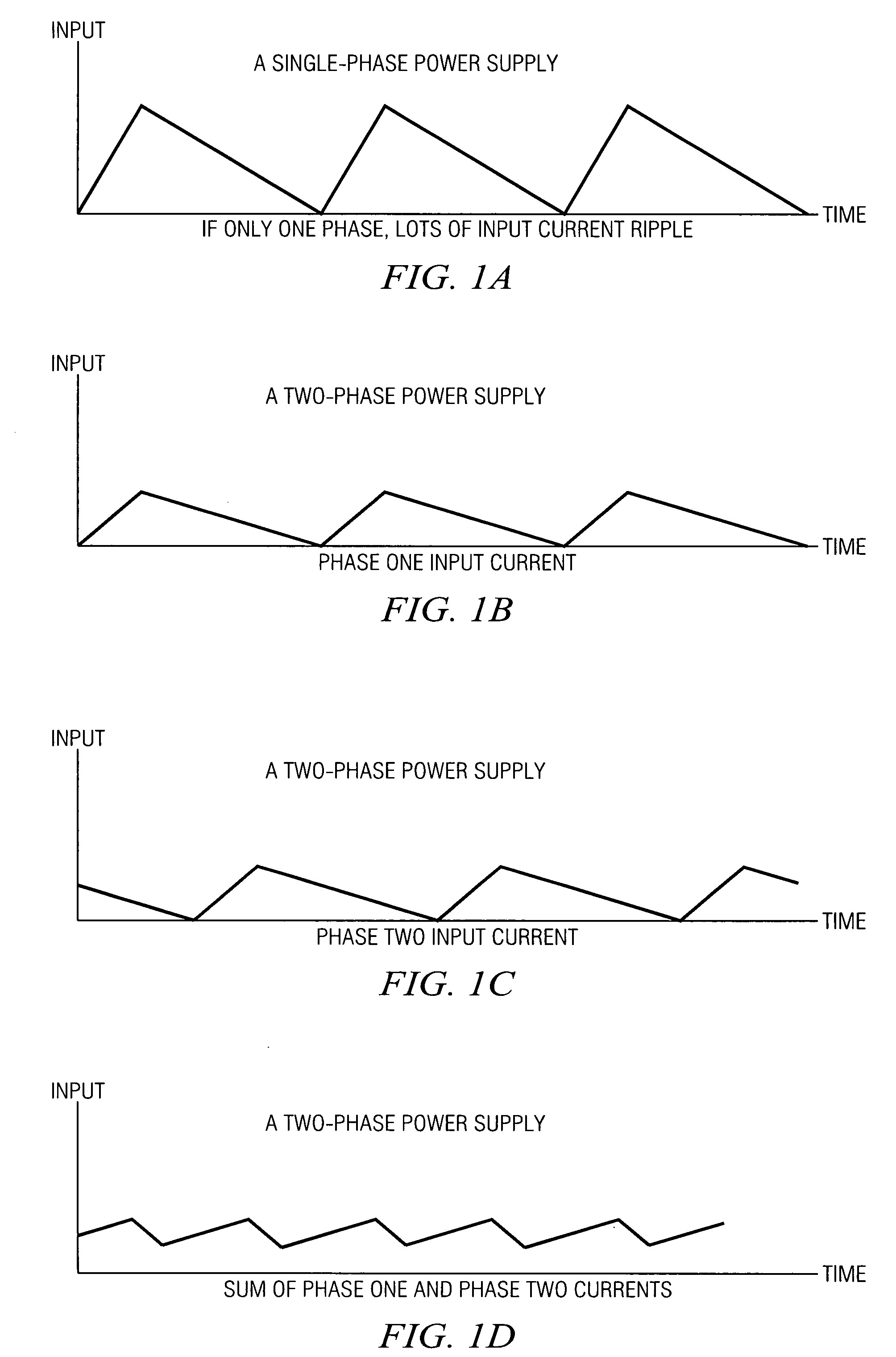

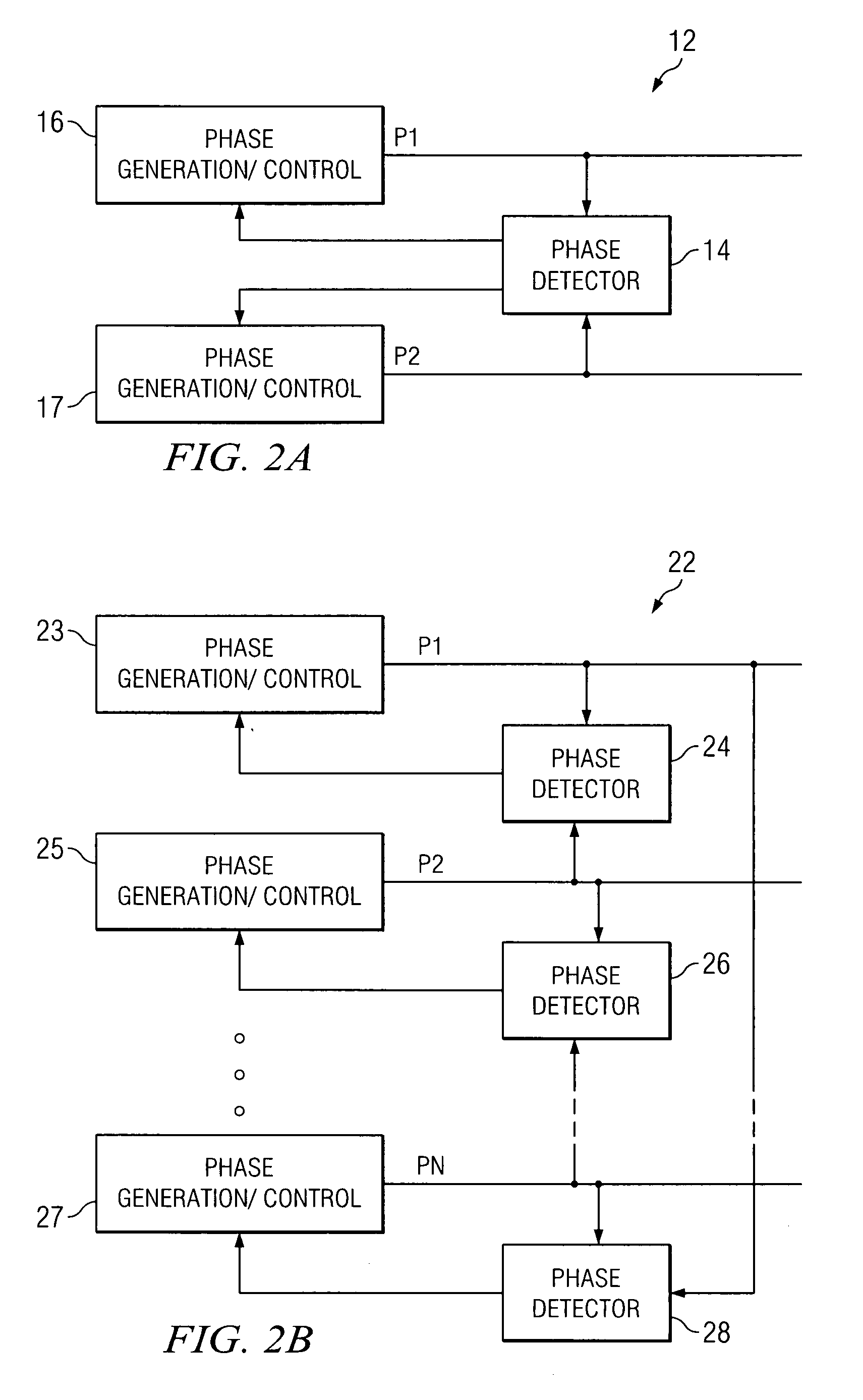

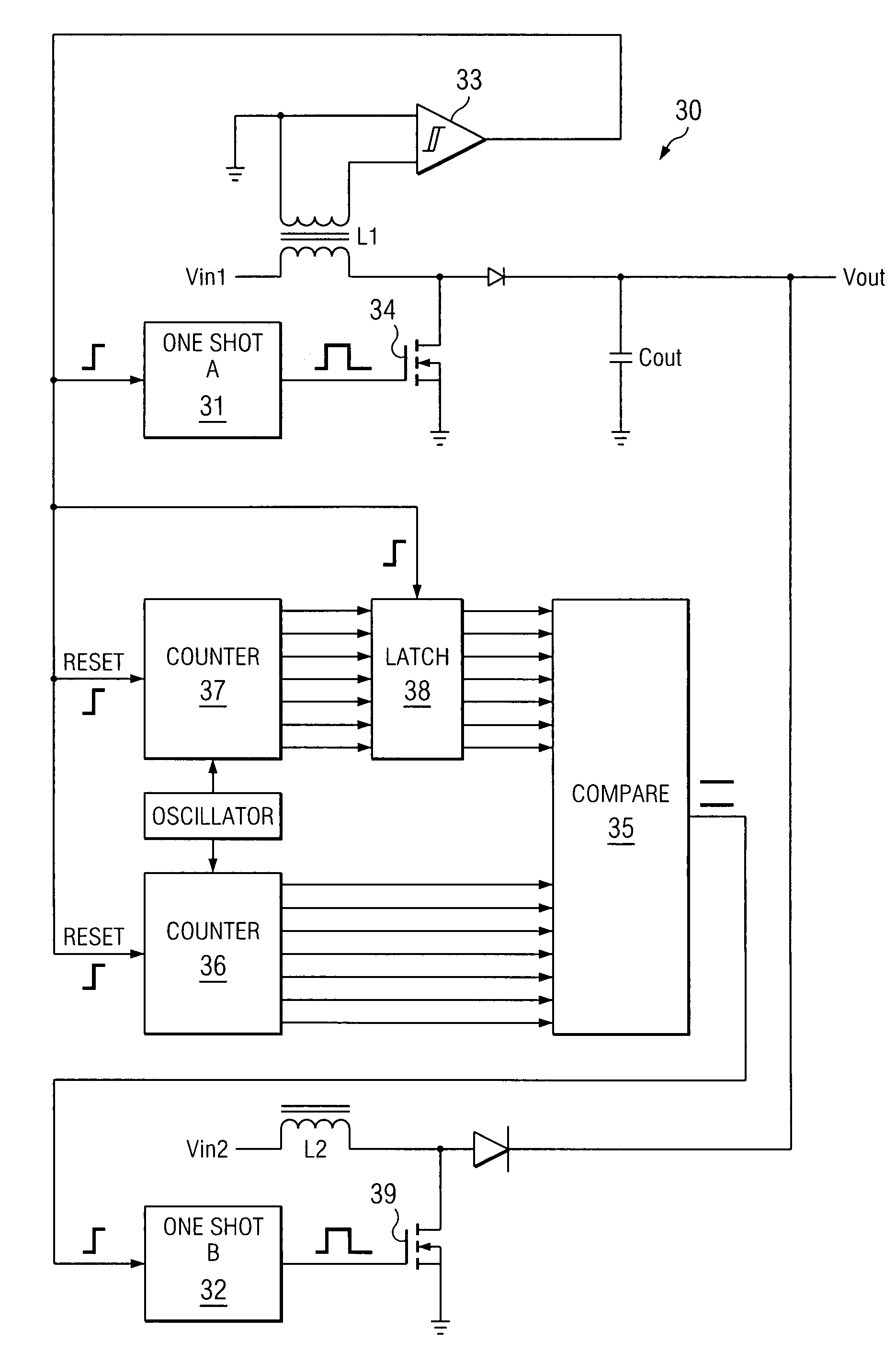

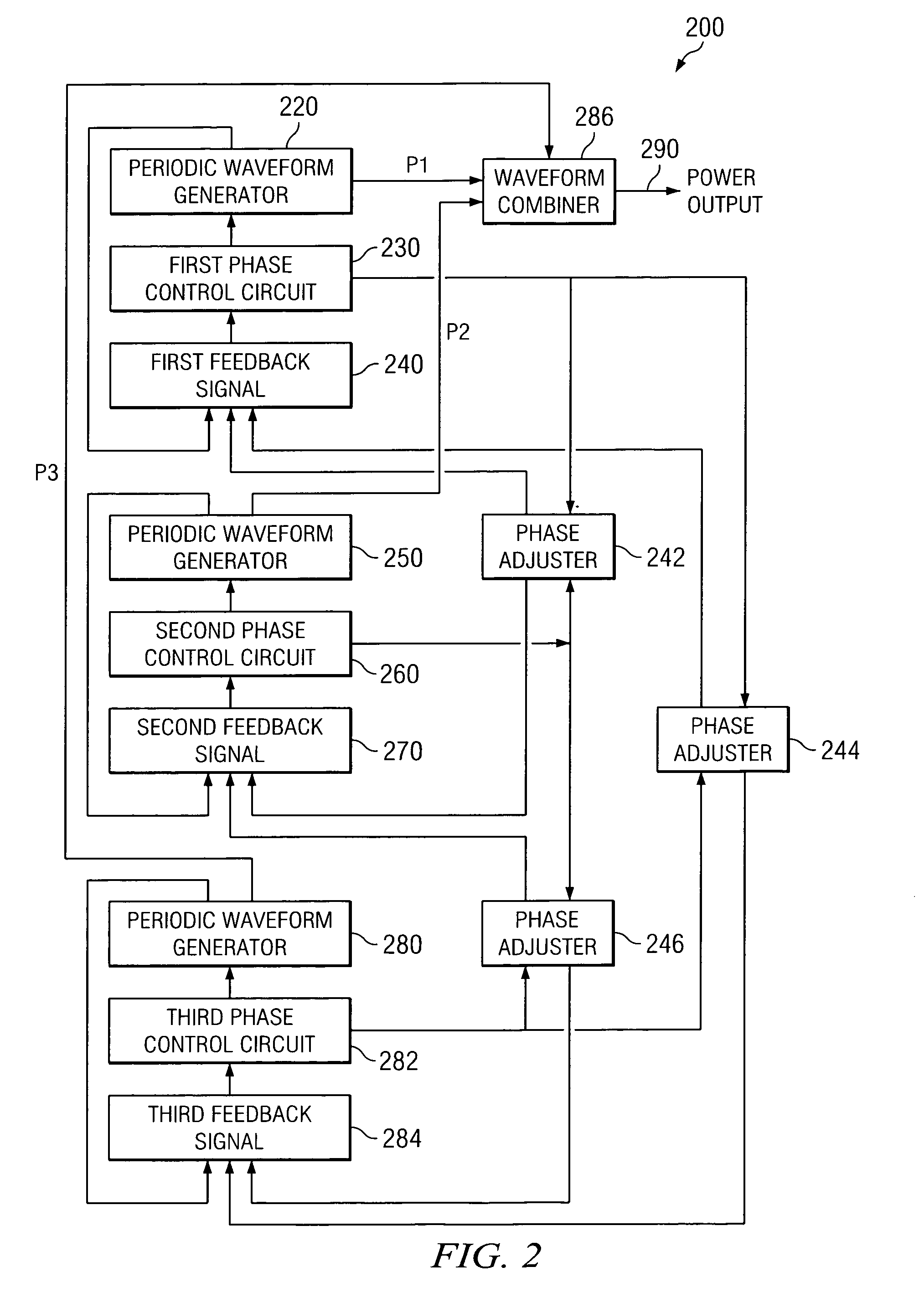

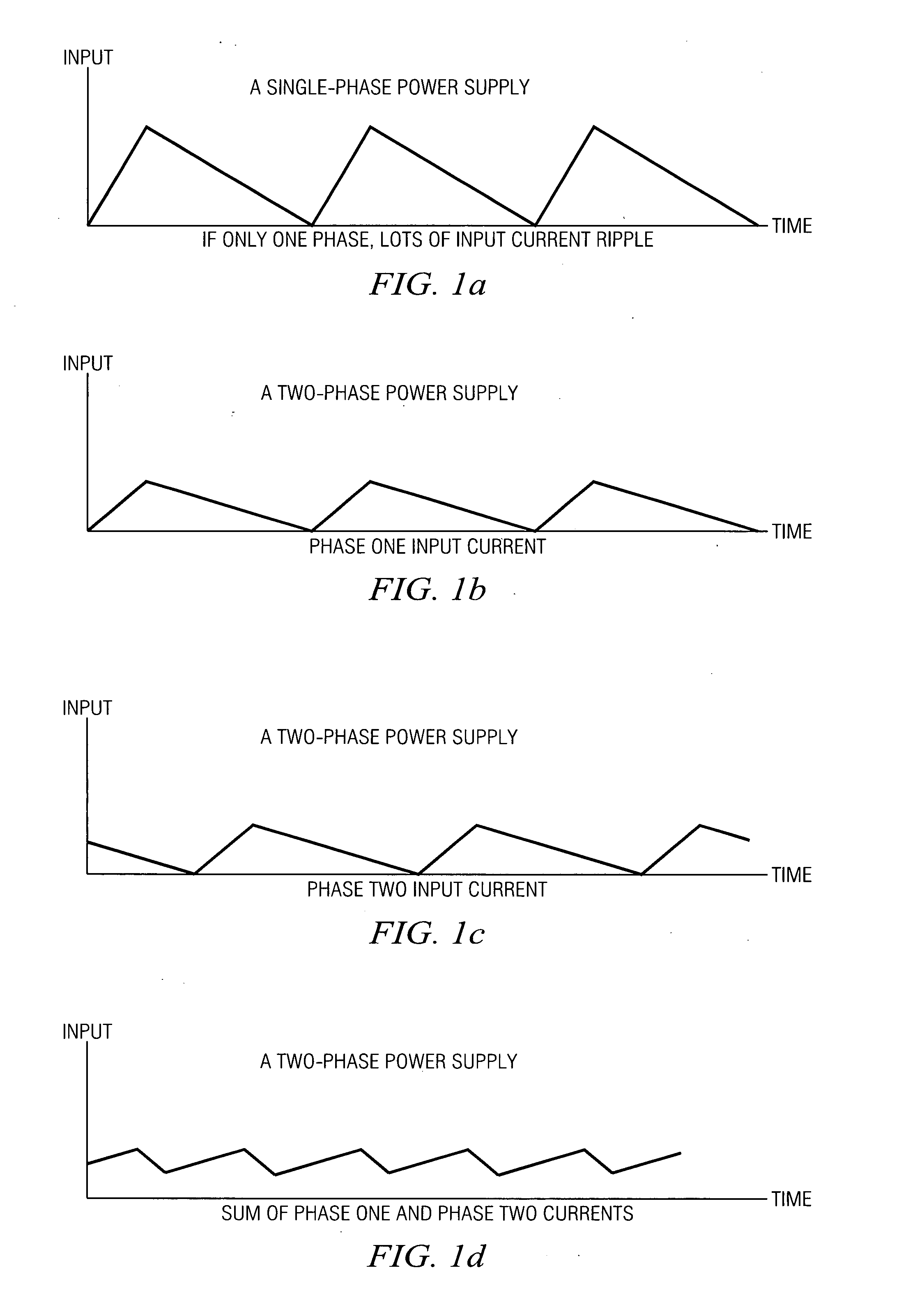

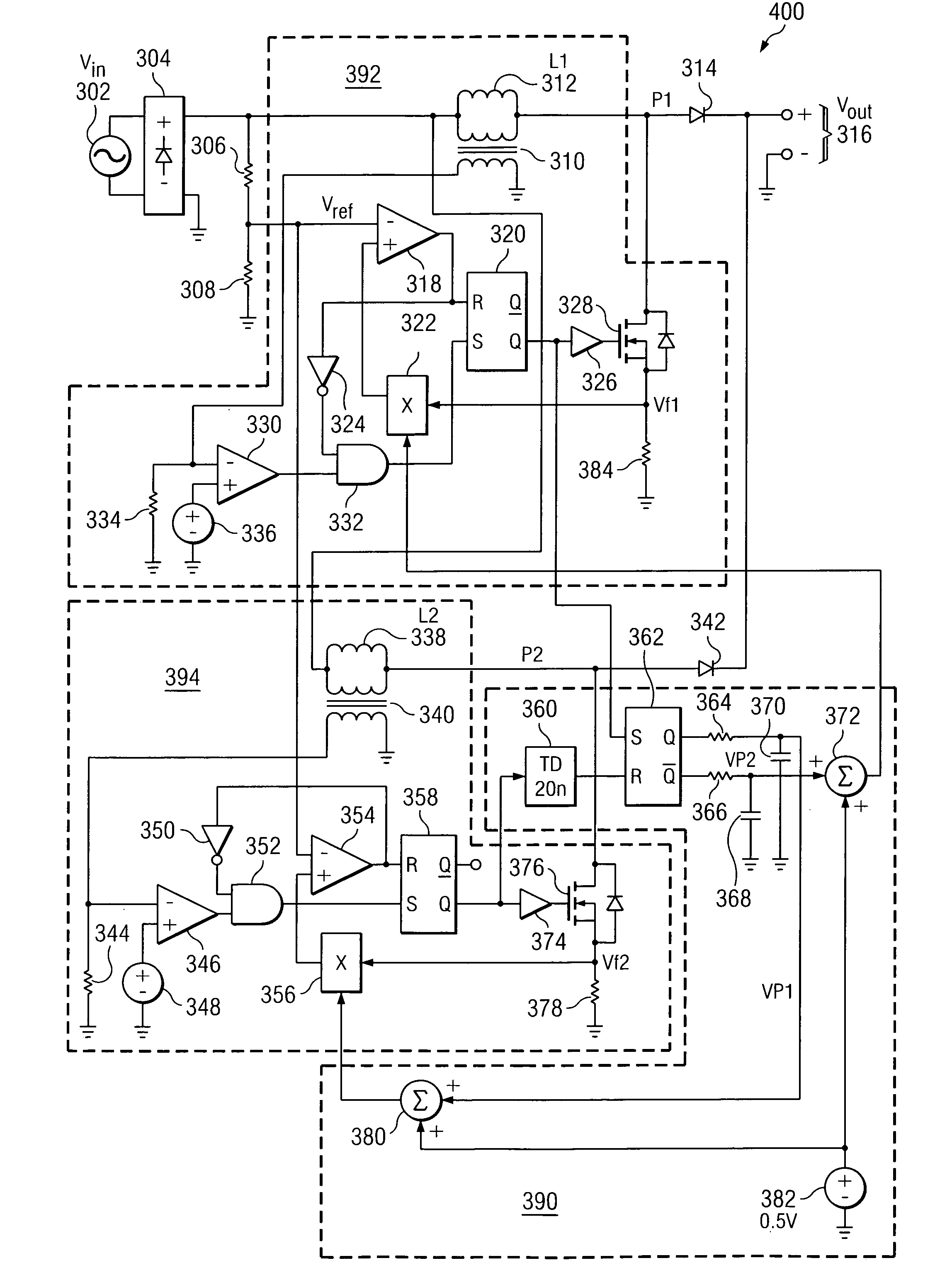

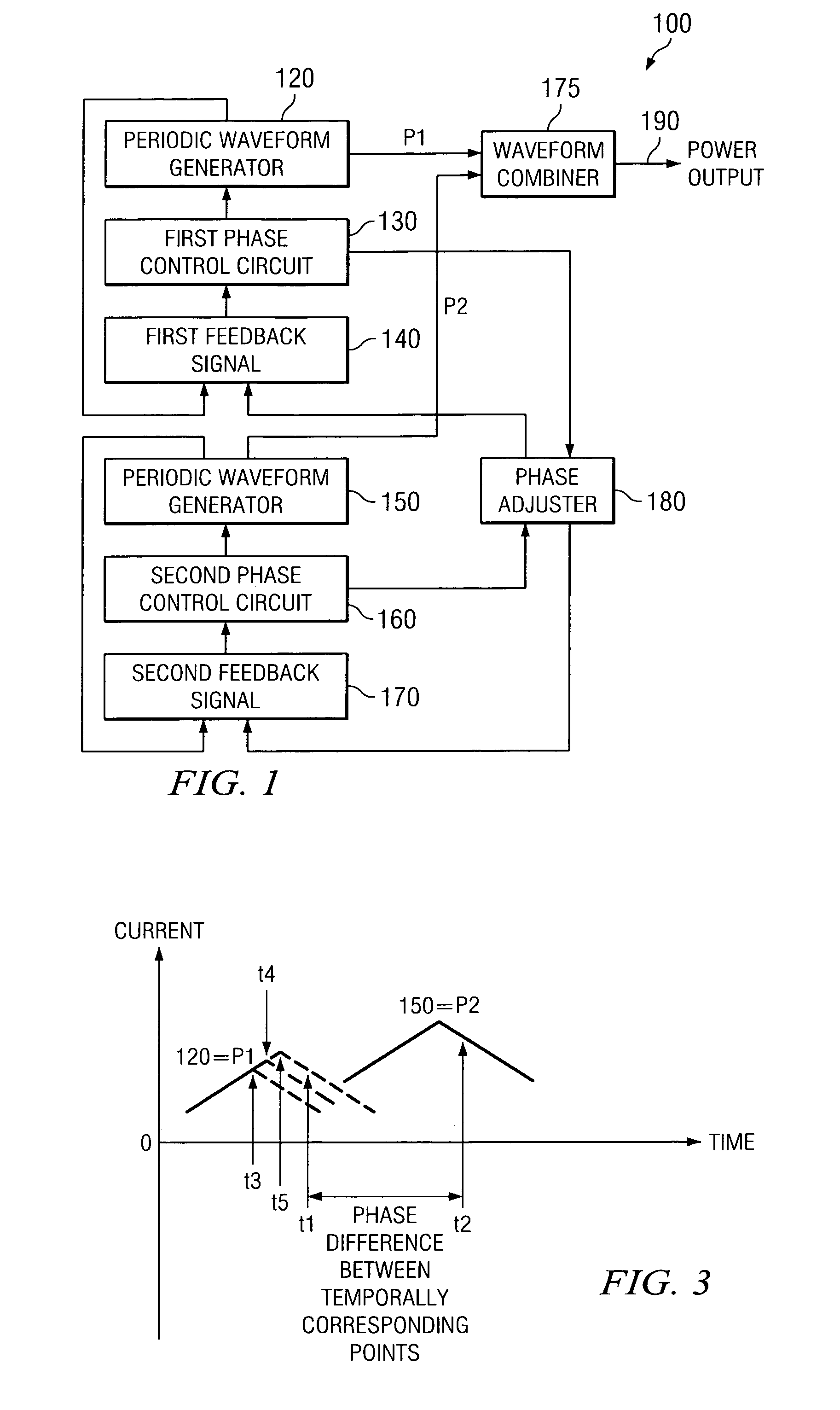

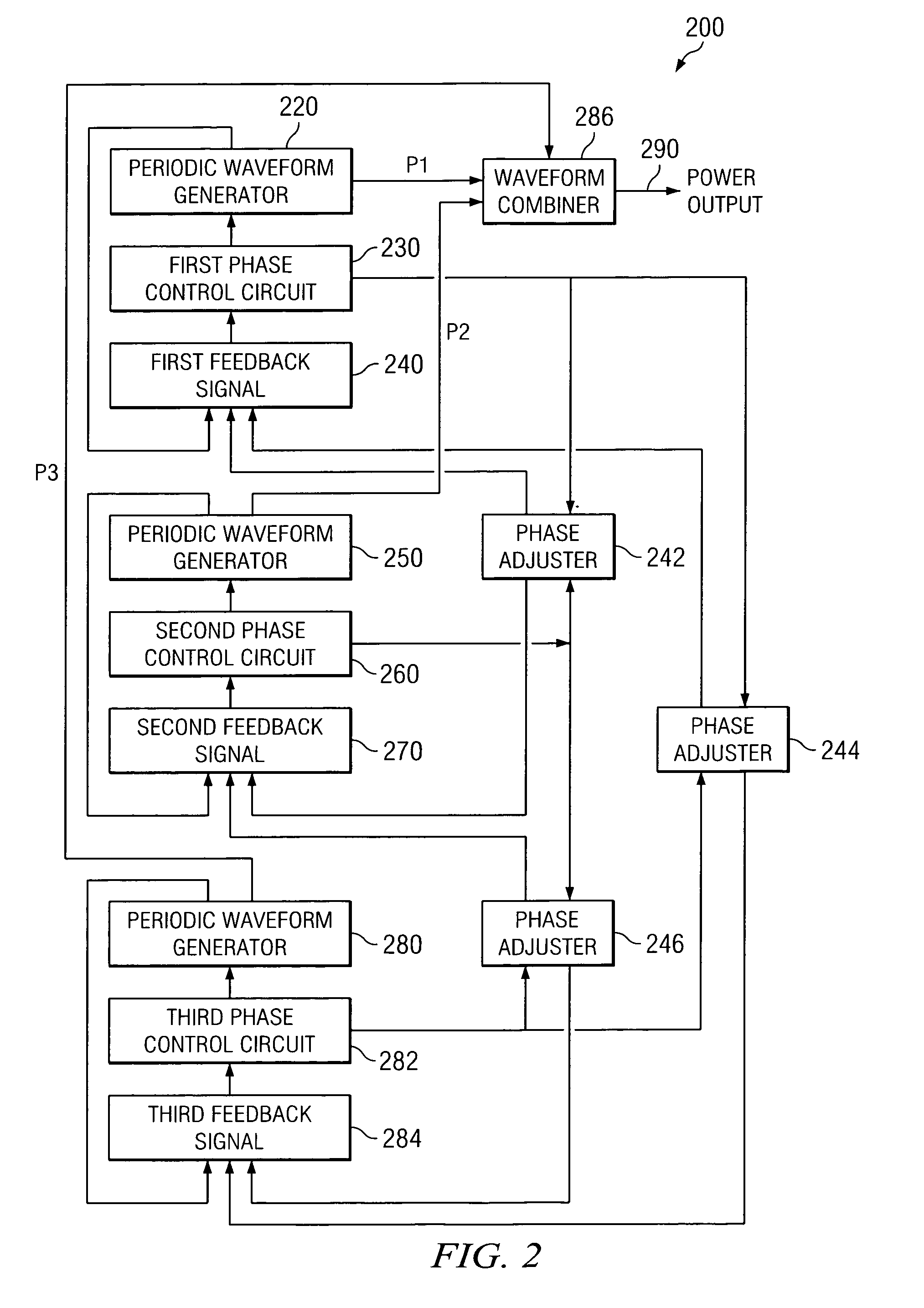

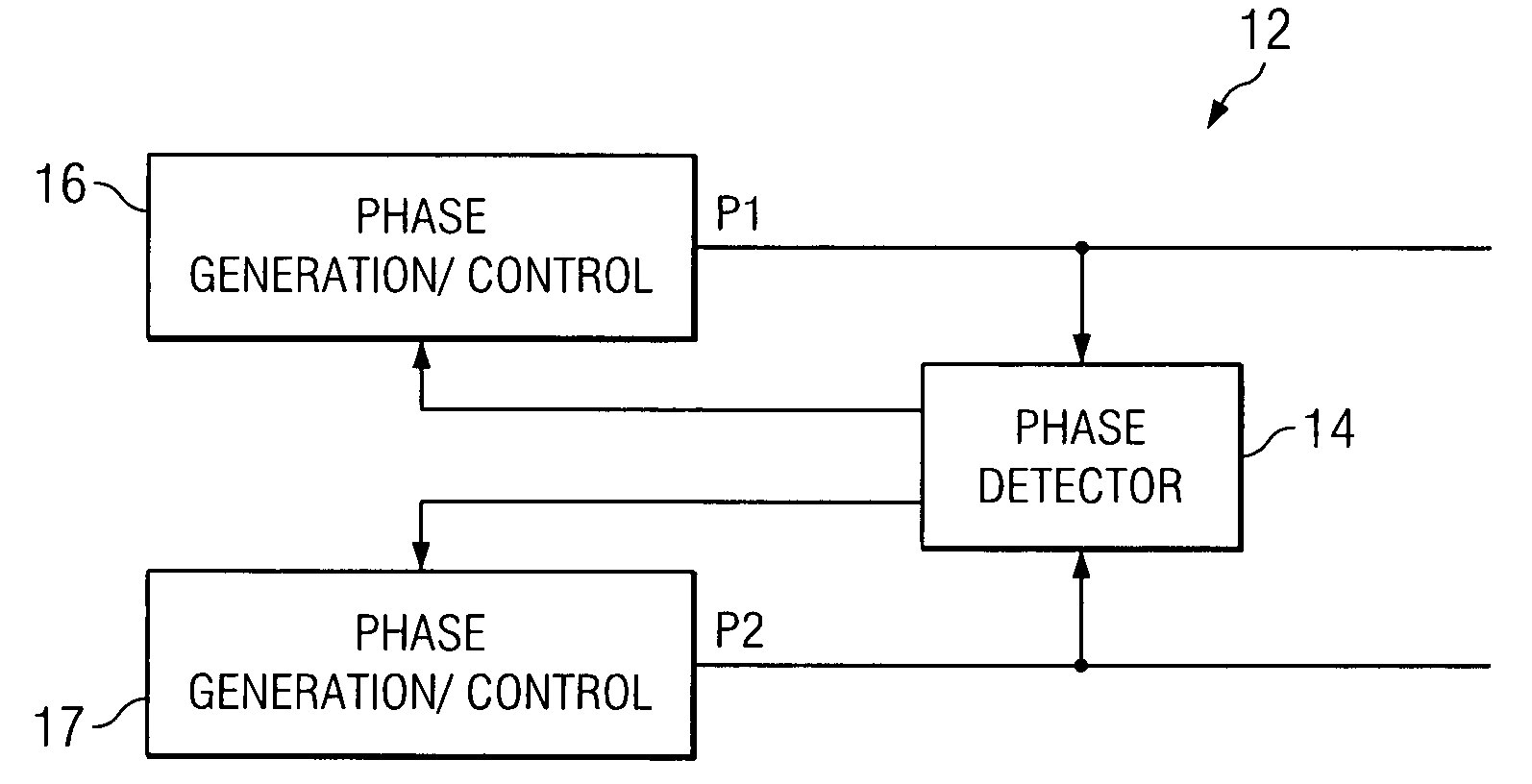

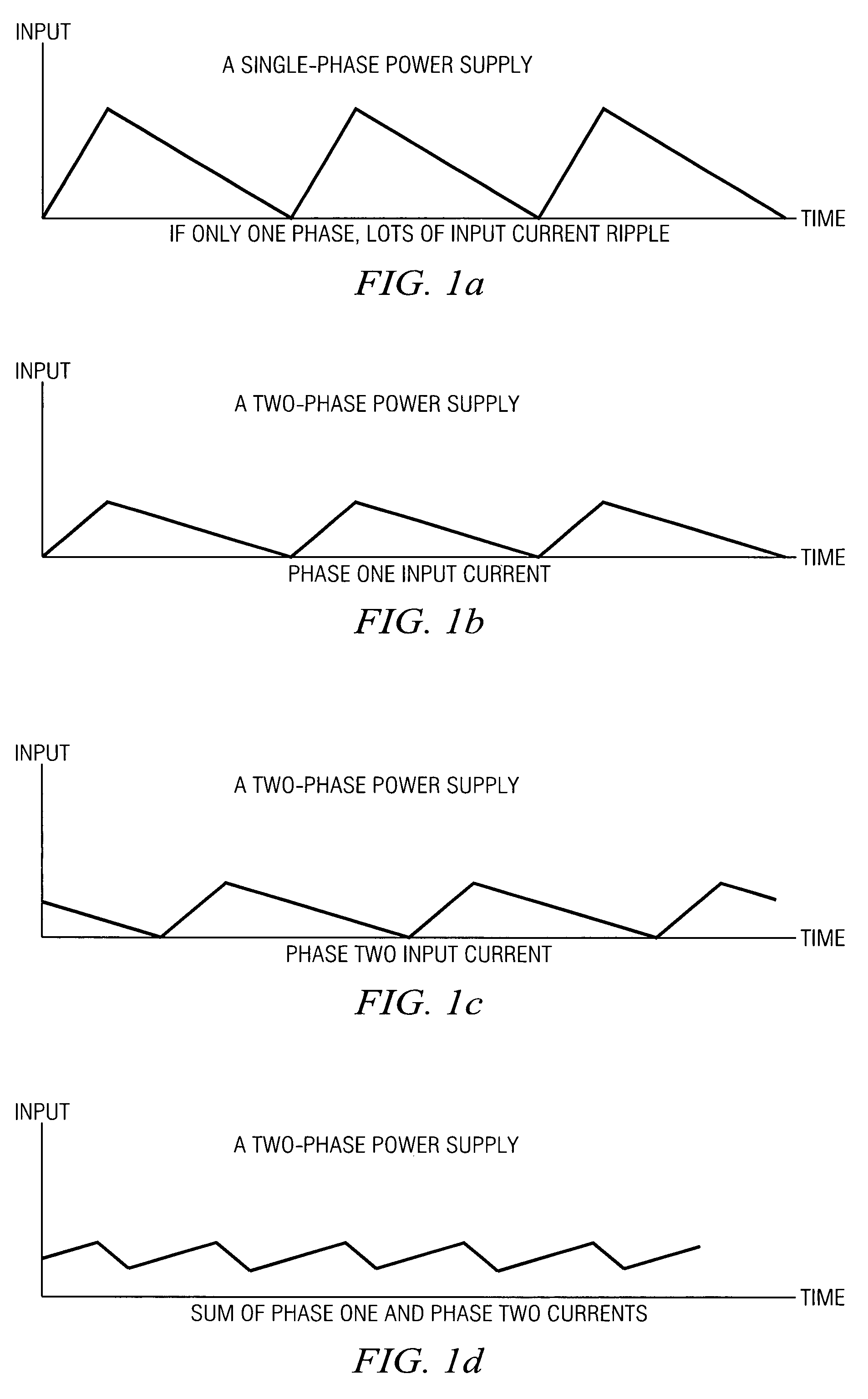

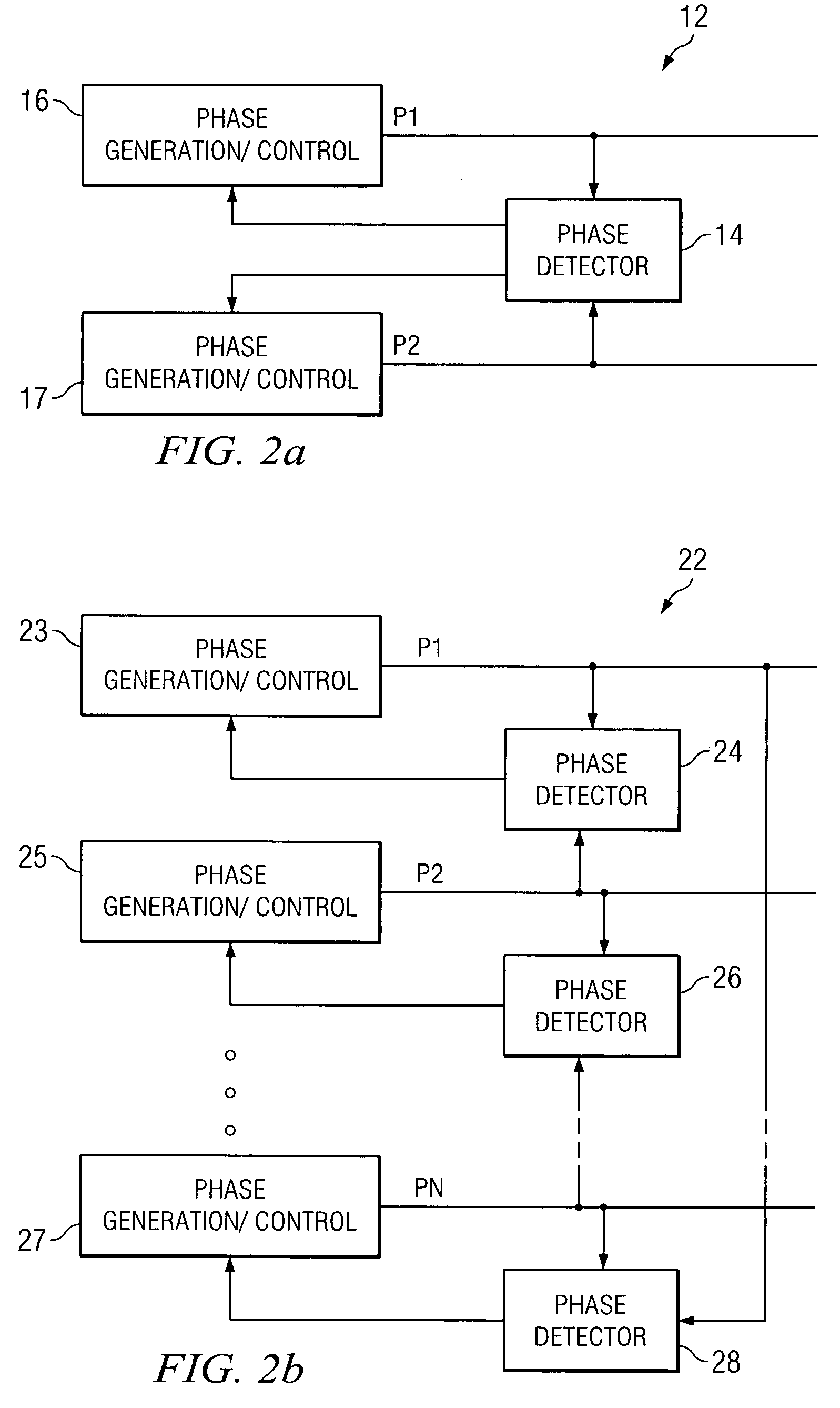

Method and apparatus for multi-phase power conversion

ActiveUS20070253223A1Improve circuit efficiencyReduce and eliminate impactEfficient power electronics conversionAc-dc conversionEngineeringSwitching frequency

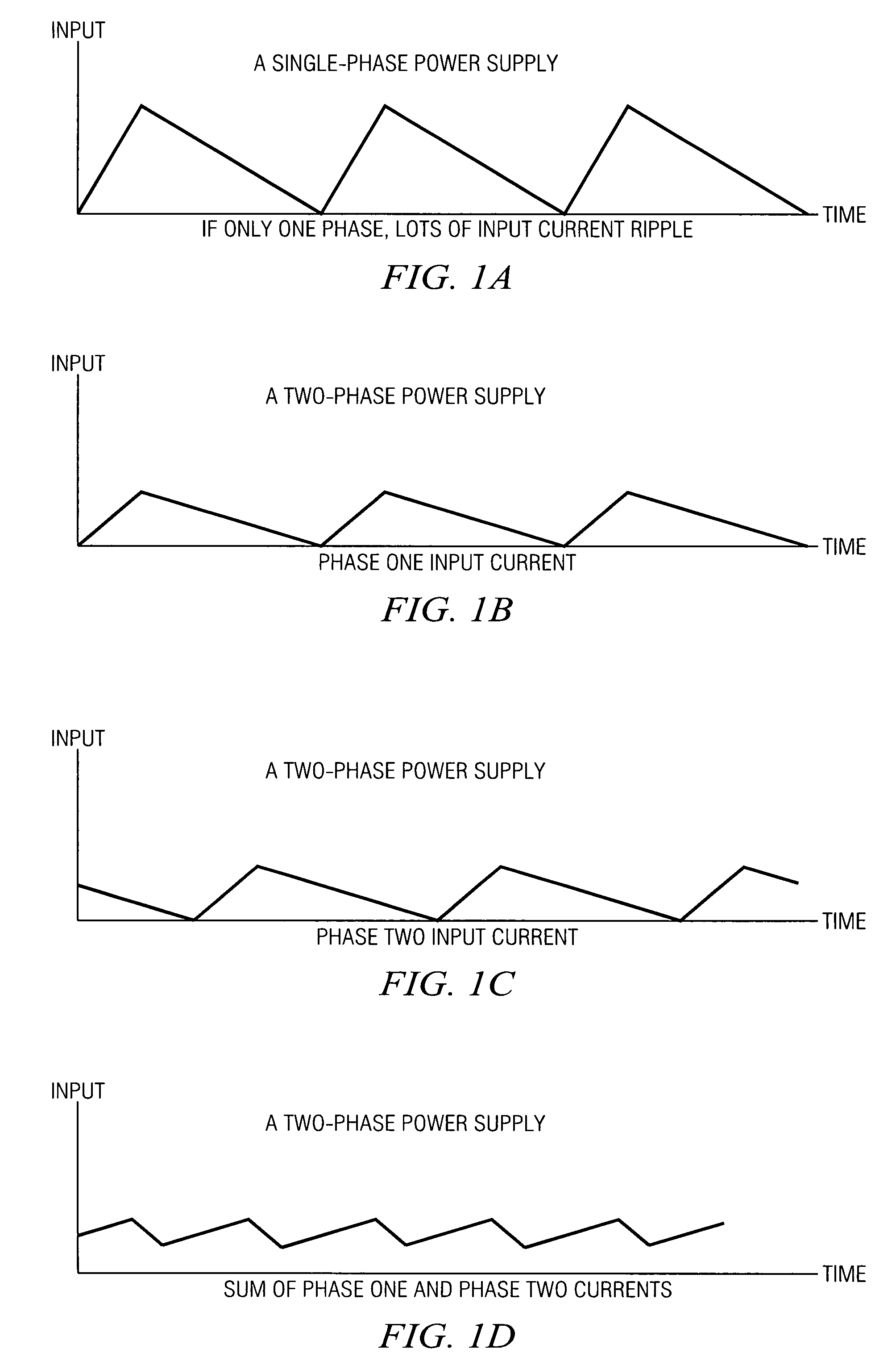

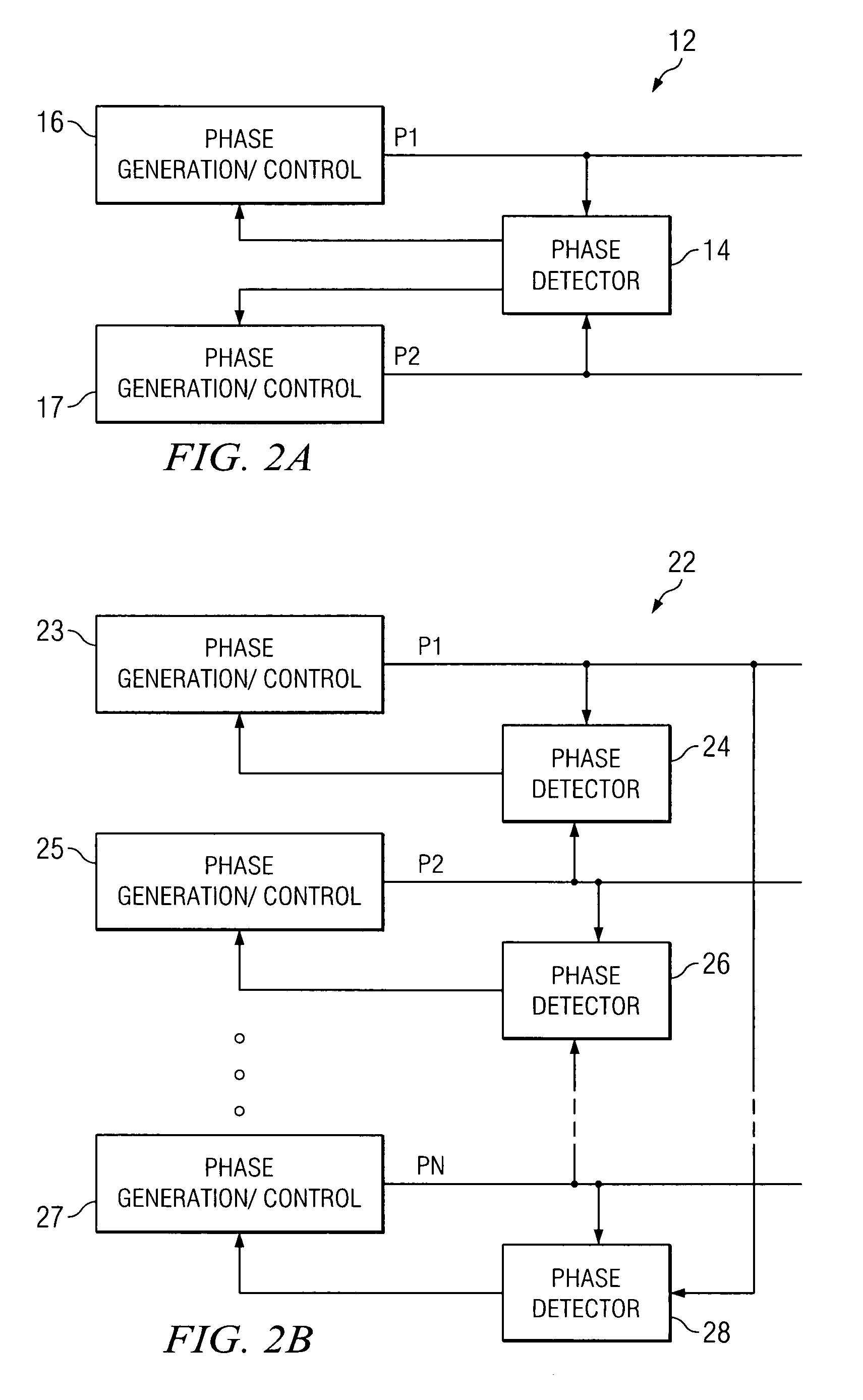

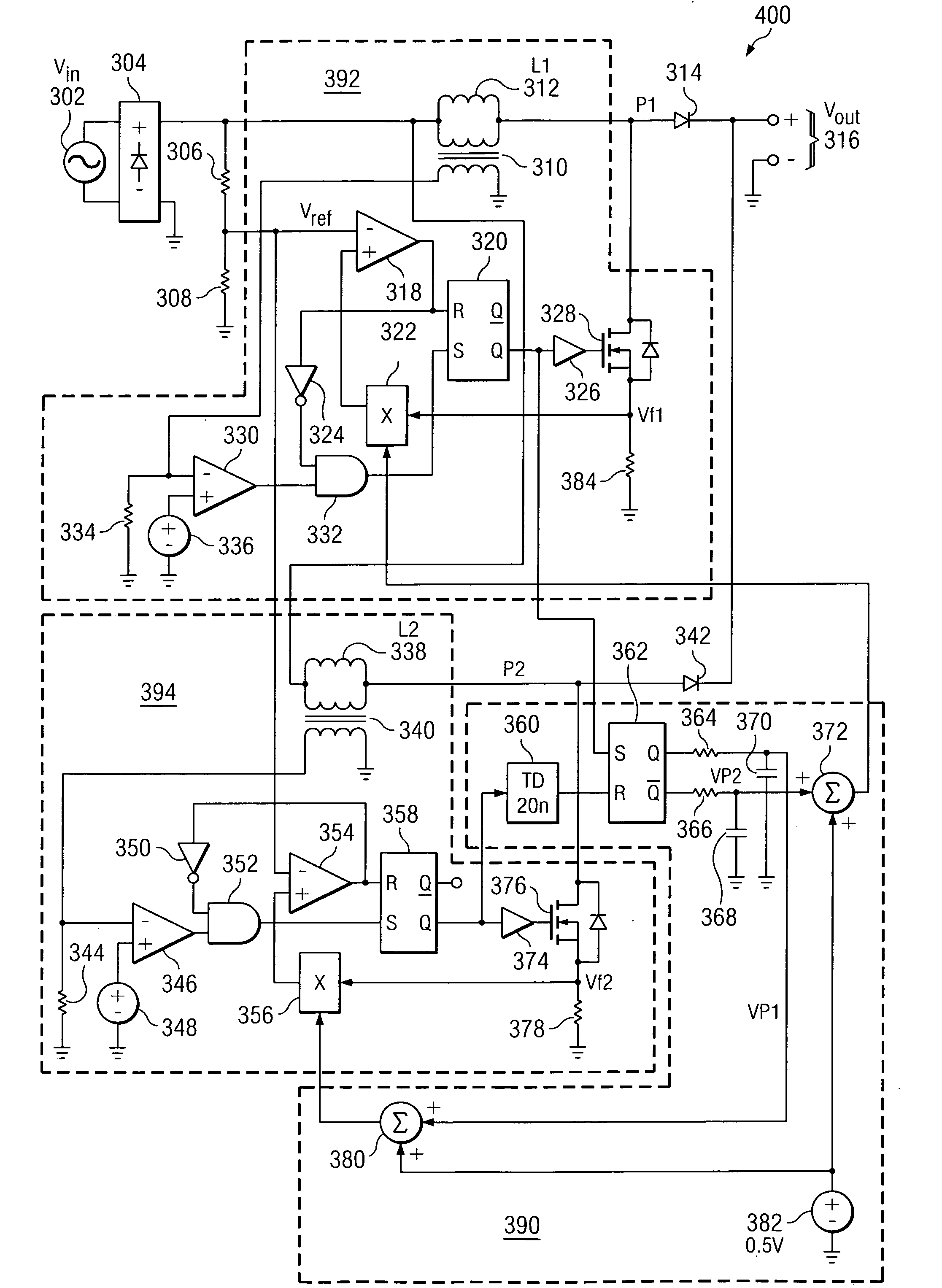

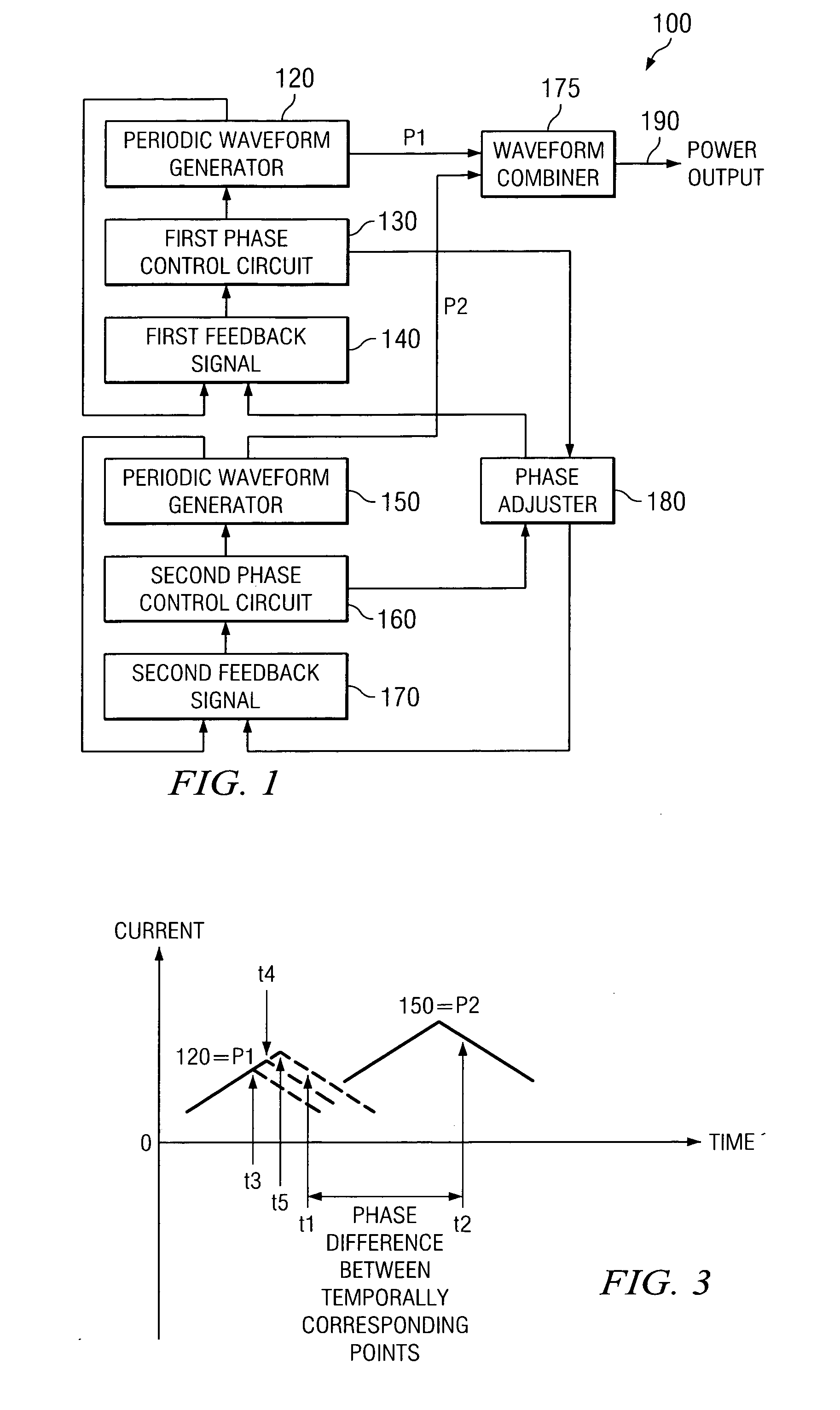

A system and method for power conversion synchronizes multiple phases at a desired phase angle difference. The power conversion involves variable frequency switching, fixed on-time and provides power factor correction. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The power conversion involves transition mode switching to help reduce switching losses. A phase angle difference detector may be provided for each phase. The various phases may have different inherent frequencies that vary with switching frequency, and are synchronized to an average frequency. Current measures can be taken with a single component, such as a resistor. A maximum frequency control limits period width to avoid high frequency switching. An added switch on time improves input voltage crossover distortion. One or more phases can be deactivated in light load conditions.

Owner:TEXAS INSTR INC

Method and apparatus for multi-phase power conversion

ActiveUS7706151B2Reduce switching lossesTempo syncEfficient power electronics conversionAc-dc conversionSwitching frequencyEngineering

A system and method for power conversion synchronizes multiple phases at a desired phase angle difference. The power conversion involves variable frequency switching, fixed on-time and provides power factor correction. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The power conversion involves transition mode switching to help reduce switching losses. A phase angle difference detector may be provided for each phase. The various phases may have different inherent frequencies that vary with switching frequency, and are synchronized to an average frequency. Current measures can be taken with a single component, such as a resistor. A maximum frequency control limits period width to avoid high frequency switching. An added switch on time improves input voltage crossover distortion. One or more phases can be deactivated in light load conditions.

Owner:TEXAS INSTR INC

Method and apparatus for power converters having phases spaced at desired phase angles

ActiveUS20070253224A1Reduce switching lossesTempo syncEfficient power electronics conversionAC/AC convertorsPhase angle differencePhase space

A system and method for power conversion synchronizes multiple phases at a desired phase angle difference. The power conversion involves variable frequency switching, fixed on-time and provides power factor correction. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The power conversion involves transition mode switching to help reduce switching losses. A phase angle difference detector may be provided for each phase. The various phases may have different inherent frequencies that vary with switching frequency, and are synchronized to an average frequency.

Owner:TEXAS INSTR INC

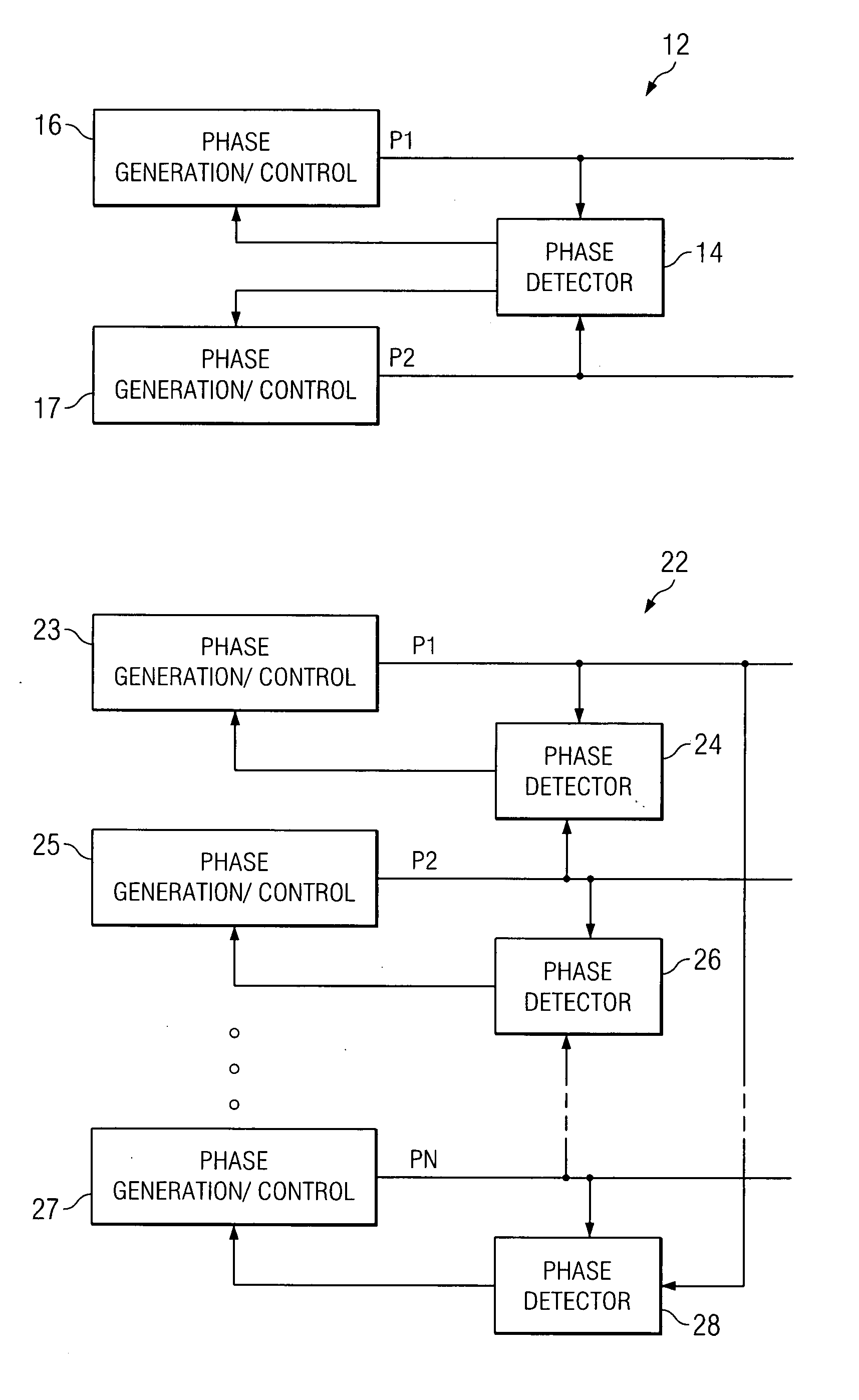

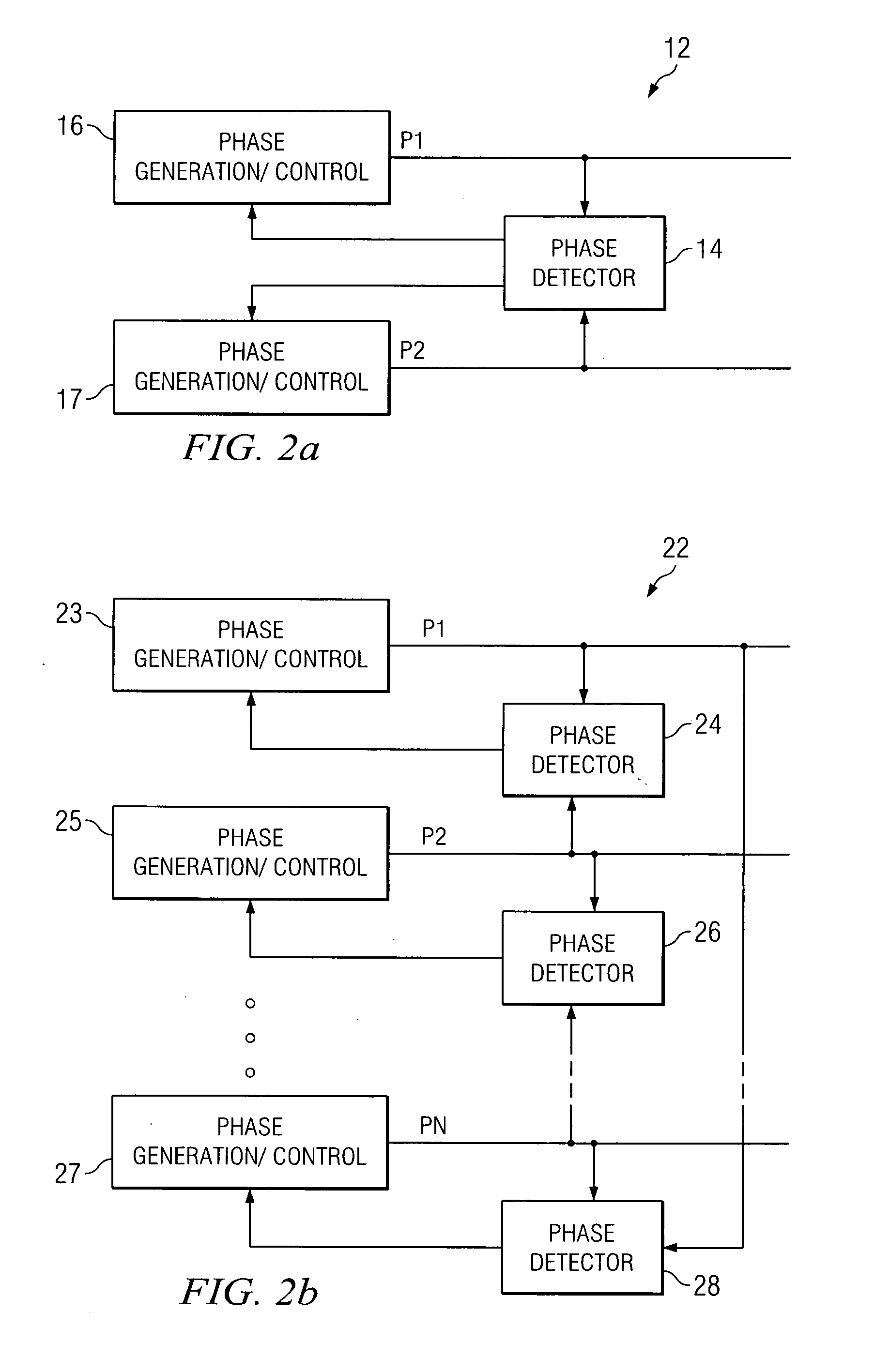

System and method for synchronizing multiple oscillators

ActiveUS20070262823A1Tempo syncReduce complexityPulse automatic controlPulse generation by logic circuitsPhase angle differencePhysics

A system and method for synchronizing an oscillator with multiple phases at a desired phase angle difference. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The various phases may have different inherent frequencies that are synchronized to a common frequency such as an average of the different frequencies.

Owner:TEXAS INSTR INC

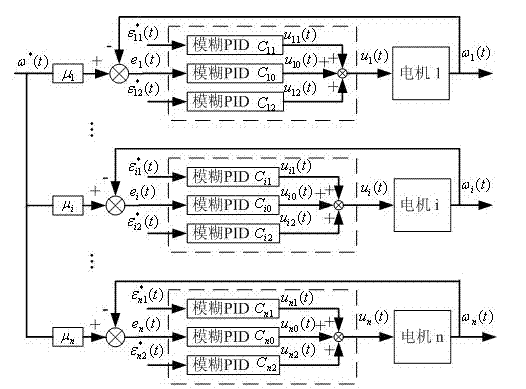

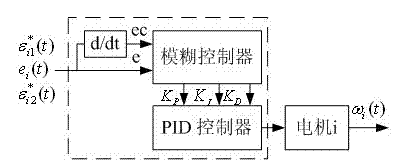

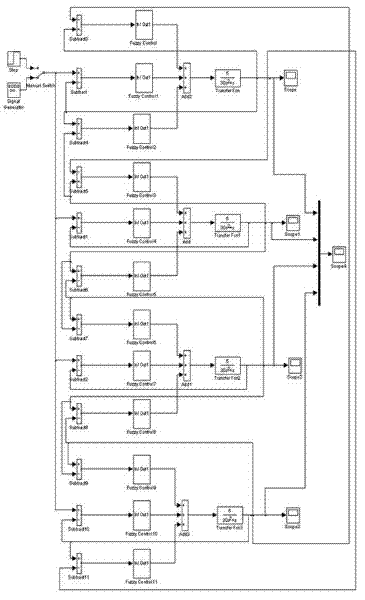

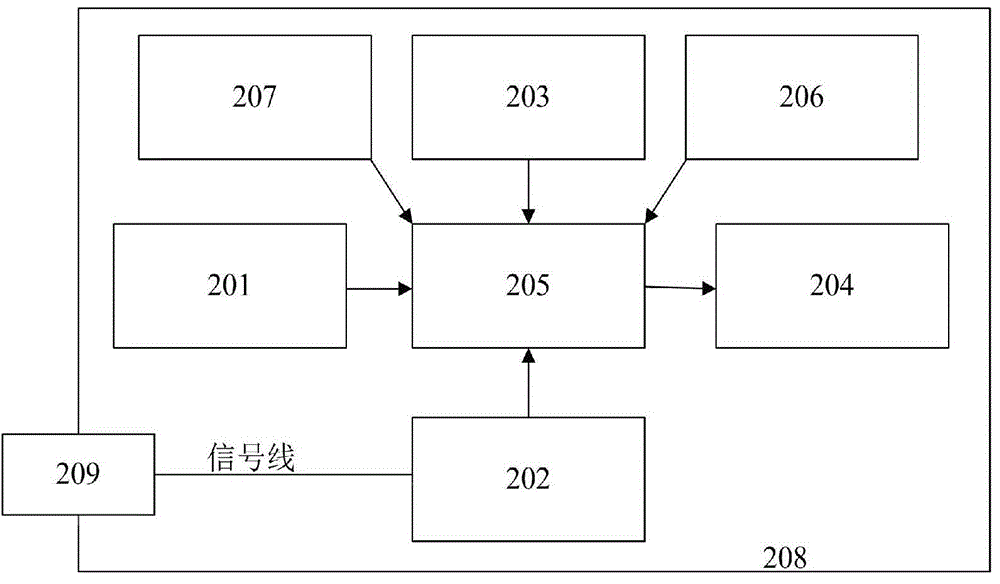

Multi-motor proportional synchronization control algorithm based on improved adjacent cross coupling

ActiveCN102420553ATempo syncOvercoming time-varying parametersMultiple dynamo-electric motors speed regulationComplex mathematical operationsElectric machineryProportion integration differentiation

The invention discloses a multi-motor proportional synchronization control algorithm based on improved adjacent cross coupling. By the algorithm, an adjacent cross-coupling control structure is improved, so that each motor in a multi-motor synchronization system can be synchronously run at proportional rotating speed. Simultaneously, for the characteristics of time varying, nonlinearity and the like of the motor, fuzzy proportion integration differentiation (PID) controllers are designed, and an improved adjacent cross-coupling multi-motor proportional synchronization fuzzy PID control algorithm is provided. Simulation comparison between the control algorithm and the conventional PID algorithm proves that the control algorithm has high convergence speed, high stability, high dynamic performance and practical value and capability of well realizing the proportional synchronous running of a plurality of motors.

Owner:NANJING UNIV OF SCI & TECH

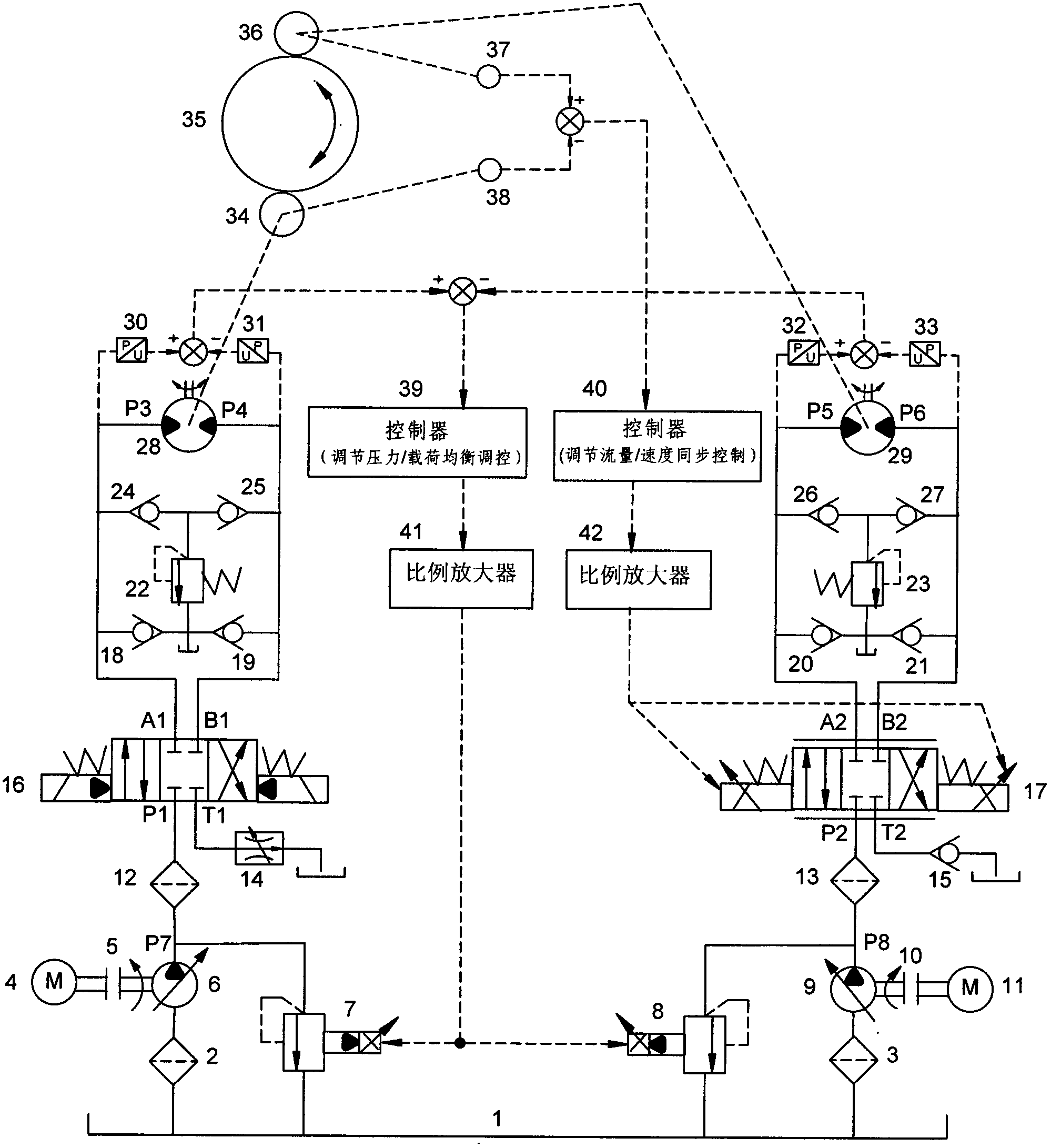

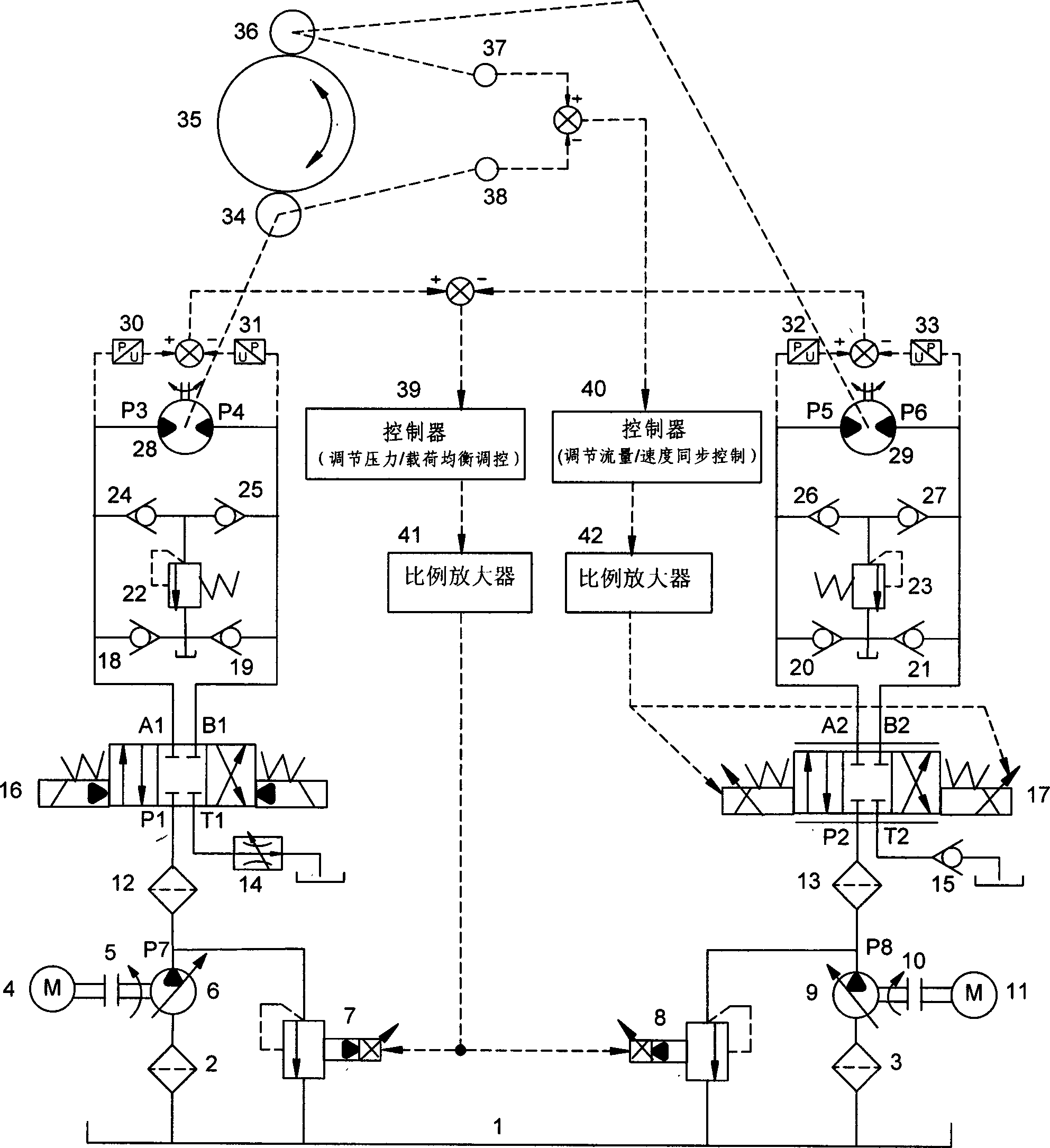

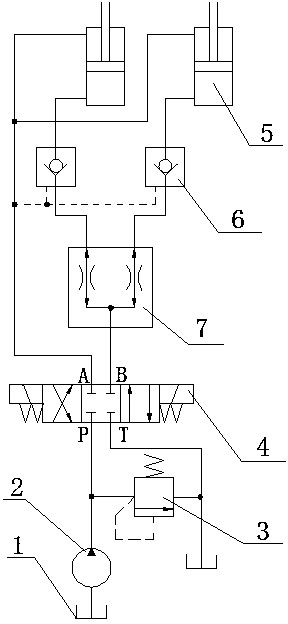

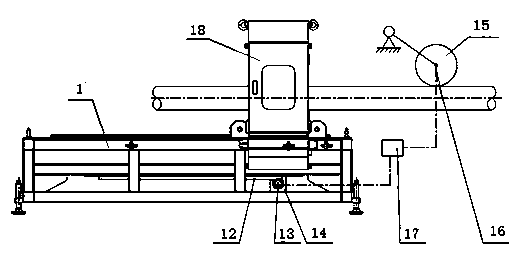

Hydraulic synchronous system for realizing load balance based on proportional relief valve

The invention discloses a hydraulic synchronous system for realizing load balance based on a proportional relief valve. The system comprises a hydraulic transmission loop and an electro-hydraulic control system and aims to realize high-precision synchronous motion on a condition of unbalance load; the hydraulic transmission loop comprises an oil case, a filter, a fine filter, a motor, a coupler, a variable capacity pump, a speed regulating valve, an electro-hydraulic reversing valve, a proportional relief valve, a proportional reversing valve, a one-way valve, a relief valve, dual-way hydraulic motors, a small gear and a large gear; and the electro-hydraulic control system comprises a speed synchronous control loop based on speed feedback and a load balance regulation and control loop based on pressure feedback. According to the invention, working pressure of hydraulic motors is directly regulated and controlled by the proportional relief valve specifically to a working condition of unbalance load, so that the load balance between different hydraulic motors is realized; the hydraulic synchronous system radically eliminates negative influence of the unbalance load on synchronous precision and realizes coordination between speed synchronization and load balance; and relatively high synchronous precision is acquired.

Owner:CENT SOUTH UNIV

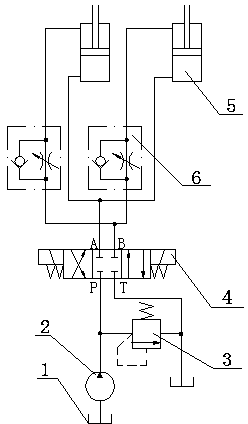

Unilateral throttling synchronism loop of dual-column gantry lifting machine

InactiveCN104235092ALow costSimple structureServomotor componentsServomotorsChoke valveHydraulic pump

The invention discloses a unilateral throttling synchronism loop of a dual-column gantry lifting machine and belongs to the filed of hydraulic transmission. The unilateral throttling synchronism loop comprises an oil tank, a hydraulic pump, an overflow valve, a reversal valve, a hydraulic cylinder and a one-way throttle valve, wherein an inlet oil tube of the hydraulic pump is connected with the oil tank, and an outlet oil tube of the hydraulic pump is respectively connected with the overflow valve and the reversal valve; oil return tubes of the overflow valve and the reversal valve are connected with the oil tank; the one-way throttle valve is connected with a connecting oil way of the hydraulic cylinder and the reversal valve in series. The unilateral throttling synchronism loop can be used for solving the problem that the lifting speed and displacement of an existing dual-column gantry lifting machine in a lifting process are difficult to synchronize, and has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:芜湖高昌液压机电技术有限公司

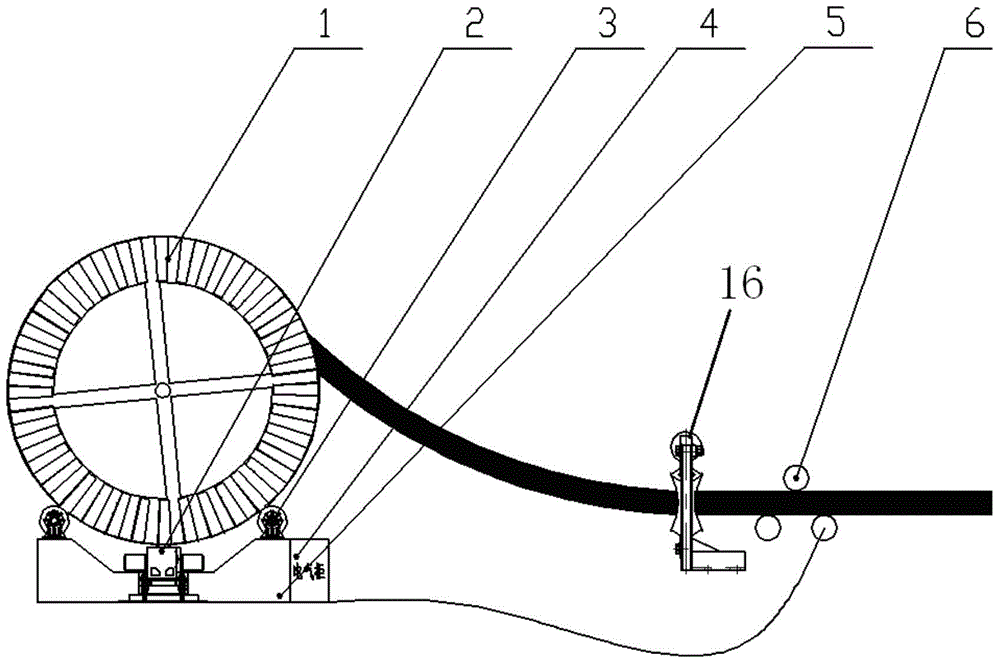

Automatic control type cable uncoiling device

Owner:CHANGLAN CABLE ACCESSORIES

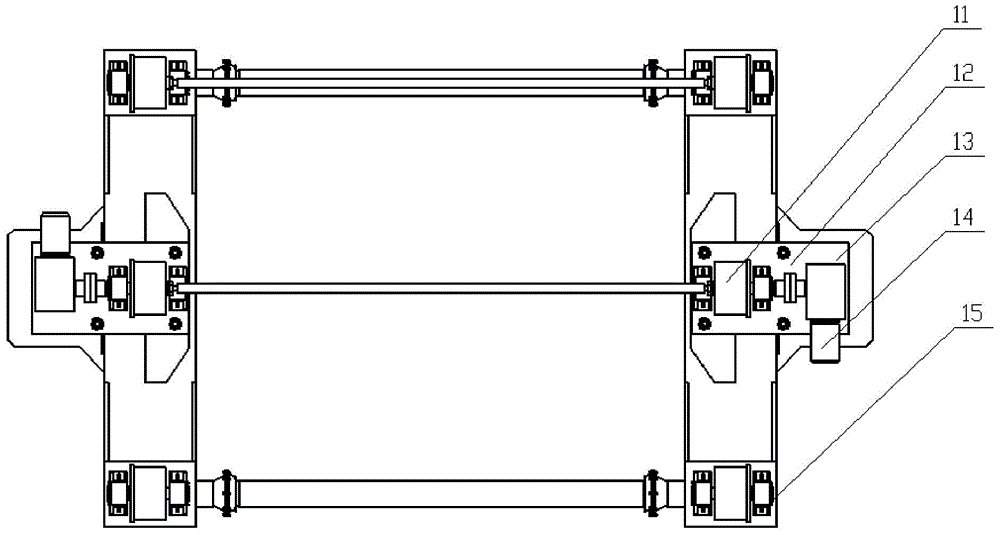

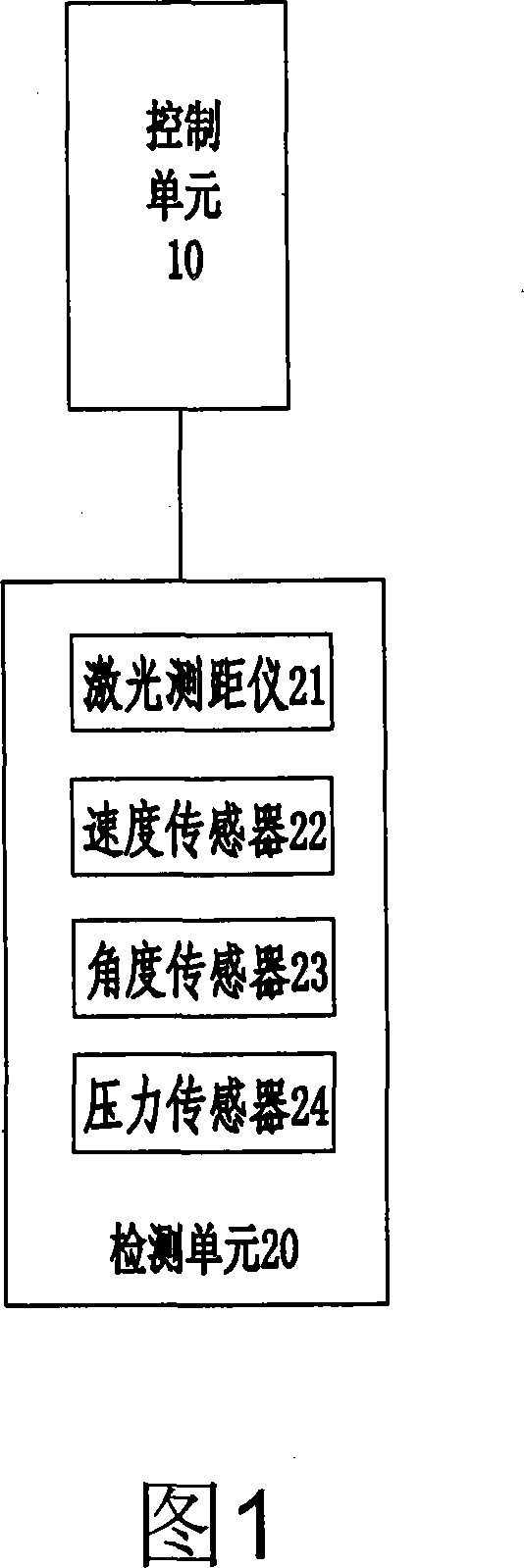

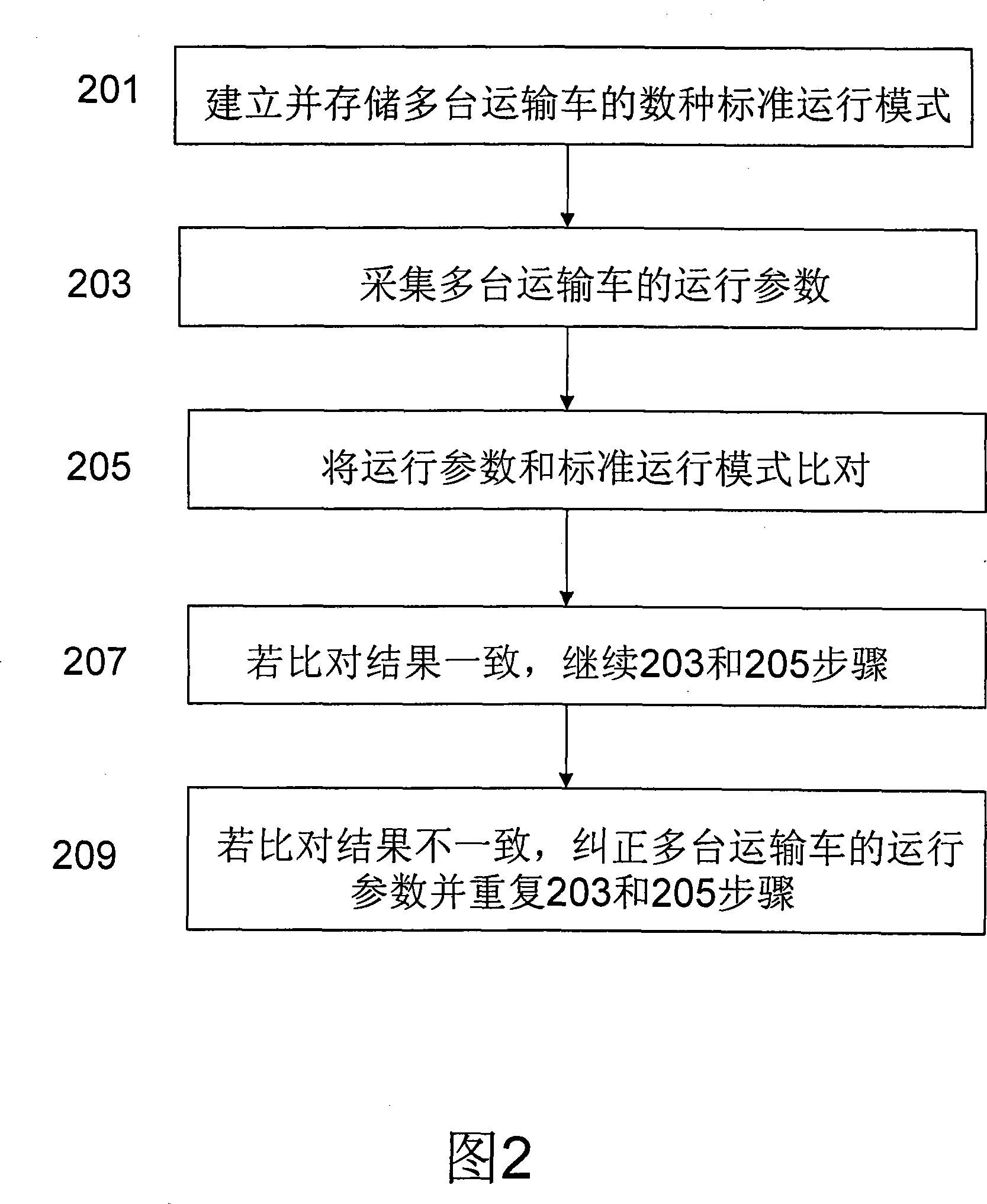

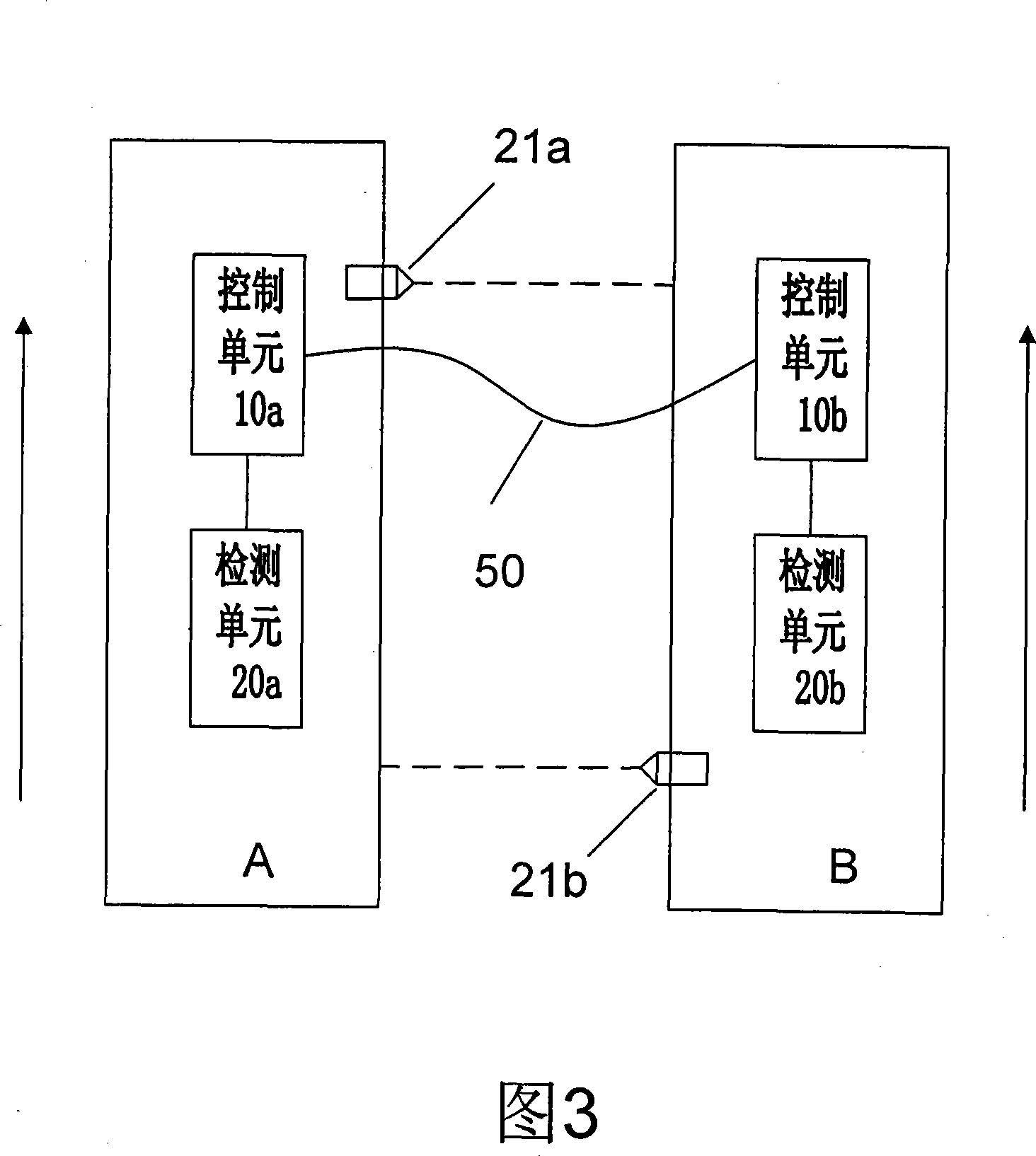

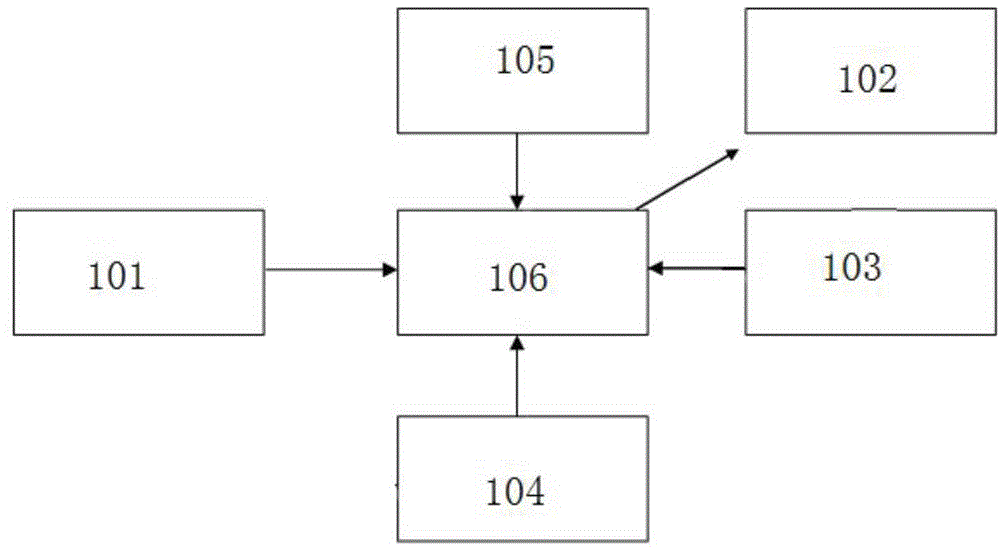

Lifting and transporting controlled system used for a plurality of hydraulic trucks and its method

InactiveCN101077739AWith automatic error correction functionTempo syncRoad vehicles traffic controlVehicle to carry long loadsTruckHuman power

The present invention relates to control system and method for several raising and conveying hydraulic transporters. The control system includes control units mounted separately in the hydraulic transporters and connected mutually for receiving and outputting control signal; and detection units comprising range finder and sensor and connected to the control unit for detecting the running state of the hydraulic transporter and outputting the detected data to the control unit. The present invention can ensure the sync operation of the hydraulic transporters for stable transportation. In addition, each of the hydraulic transporters is equipped with control unit, so that only one driver is needed to control all the hydraulic transporters in saved manpower.

Owner:SHANGHAI PORT MACHINERY HEAVY IND

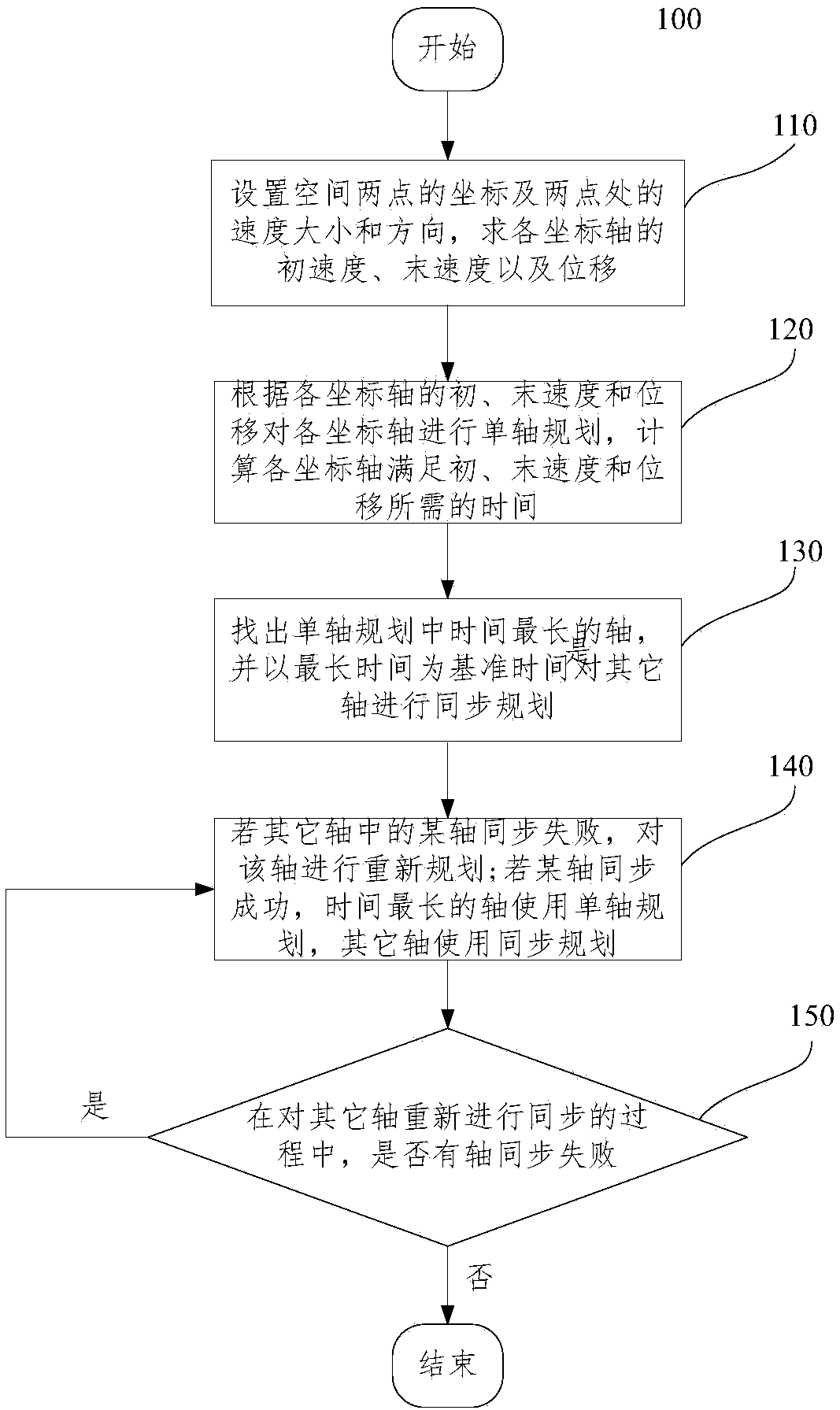

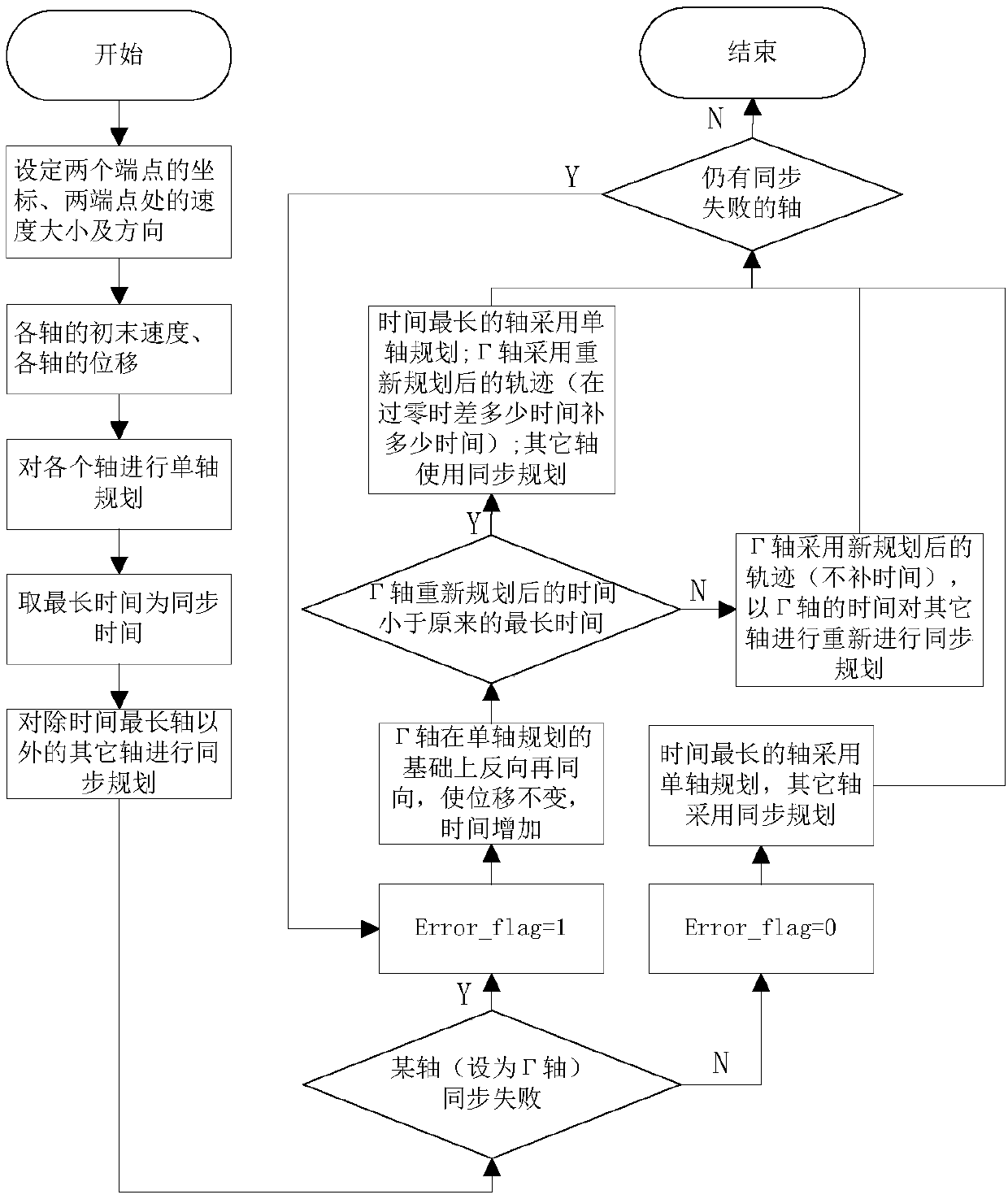

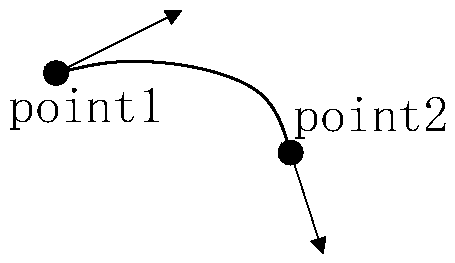

Multi-axis synchronous track planning method and system and computer readable storage medium

ActiveCN108890644AShift synchronizationTempo syncProgramme-controlled manipulatorSimulationFast mode

The invention discloses a multi-axis synchronous track planning method and system and a computer readable storage medium. The method comprises the steps that according to the initial and final speedsand displacements of all coordinate axes, the single axis planning is conducted on all the coordinate axes, the required time of meeting the initial and final speeds and the displacements is calculated, and the longest time is taken as the reference time to conduct synchronous planning on other axes; if the synchronization conducted on some axis fails, replanning is conducted on the axis; if the synchronization conducted on some axis succeeds, the axis which requires the longest time is subjected to the single axis planning, and synchronous planning is conducted on other axes. In the process of resynchronizing other axes, if the synchronization conducted on some axis still fails, the last step is repeated until the synchronization is conducted on all the axes successfully. By the means ofthe method, it is achieved that the displacement and the speed are synchronous, and the constant accelerated speed is utilized for accelerating or reducing the final speed in a fastest mode to make the speed meet the requirements, it is ensured that the motion time is short as far as possible, and the stability in the motion process is improved.

Owner:TSINGHUA UNIV

Method and apparatus for power converters having phases spaced at desired phase angles

ActiveUS7701730B2Reduce switching lossesTempo syncEfficient power electronics conversionAC/AC convertorsPhase spacePhase angle difference

A system and method for power conversion synchronizes multiple phases at a desired phase angle difference. The power conversion involves variable frequency switching, fixed on-time and provides power factor correction. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The power conversion involves transition mode switching to help reduce switching losses. A phase angle difference detector may be provided for each phase. The various phases may have different inherent frequencies that vary with switching frequency, and are synchronized to an average frequency.

Owner:TEXAS INSTR INC

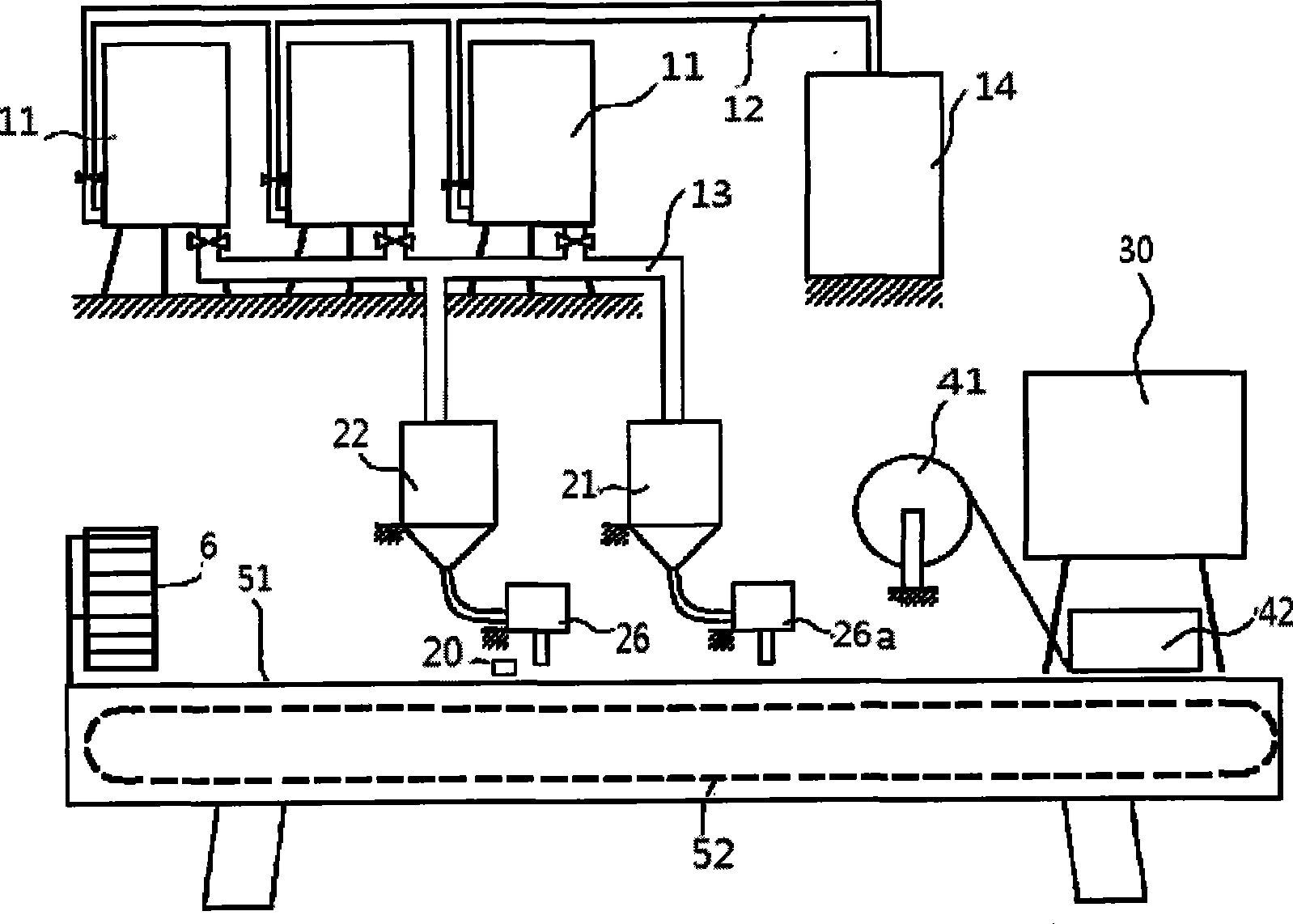

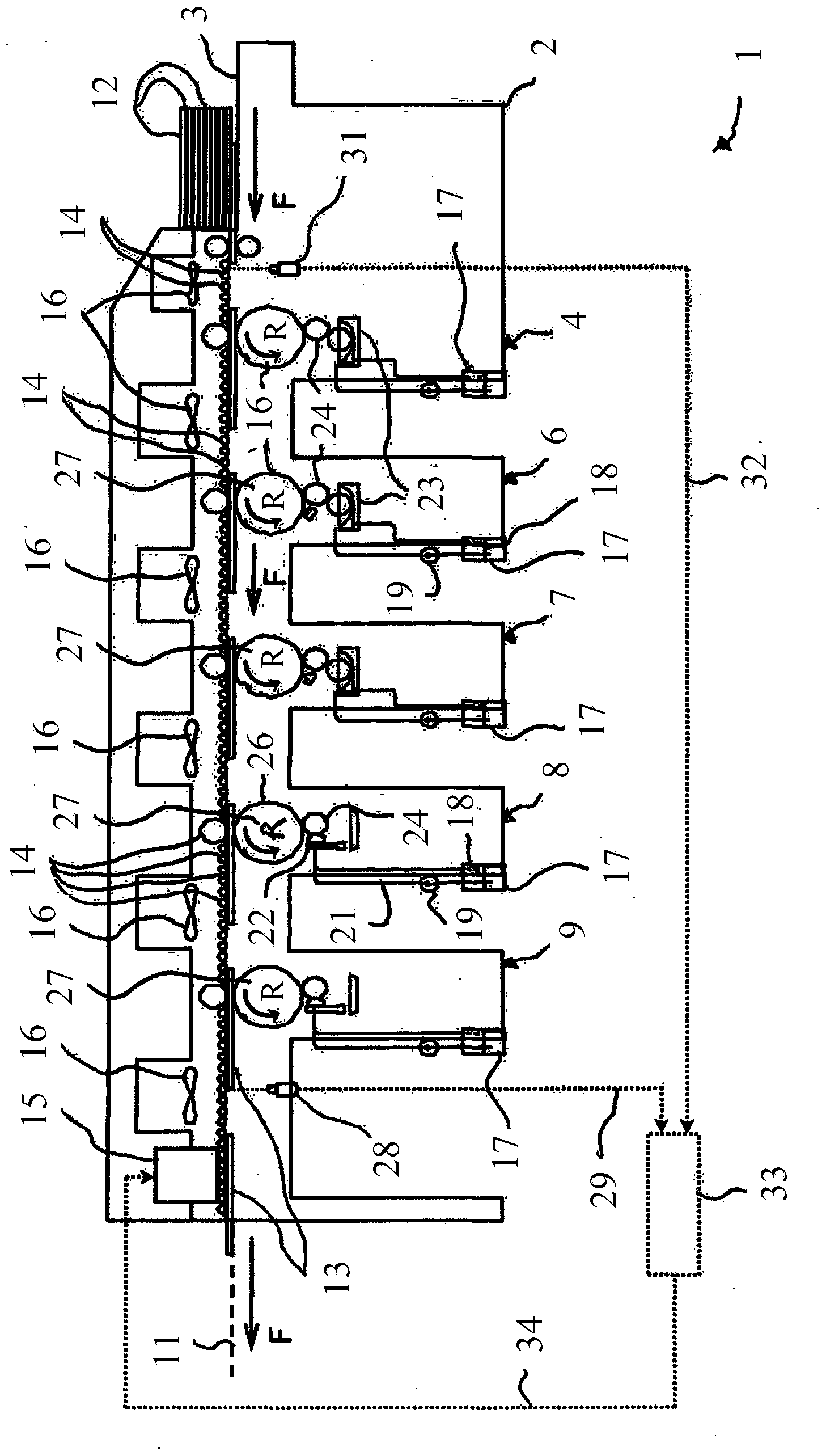

Equipment for automatically processing molding bean curd packed in box

InactiveCN101375708AAutomatic placementIncrease productivityCheese manufactureFood shapingProgrammable logic controllerData acquisition

The invention discloses fully-automatic processing equipment for packed bean curd formation. The equipment comprises a worktable, an aluminum mould conveyor chain, a plurality of size boiling kettles, a slurry hopper, a packing mechanism, a slurry filling mechanism, an additive filling mechanism, an automatic box falling mechanism, a printer and a control device, wherein, the control device consists of a programmable logic controller (PLC) and a frequency converter used for controlling the rotating speed of a motor M1 of the driving mechanism. Compared with the prior relay control, the programmable logic controller (PLC) adopted by the invention has the advantage that the programmable logic controller can ensure that the control device is compact and highly reliable, and has a long service life. Furthermore, the programmable logic controller can produce a network by expanding the communication function for remote operation, remote programming and data collection.

Owner:SHANGHAI WANGXIN BEAN PRODS EQUIP

Synchronizing circuit of flow distributing and collecting valve for two-column gantry lifter

InactiveCN104196806AAchieving Tempo SynchronizationStrong correction abilityServomotor componentsServomotorsHydraulic pumpHydraulic control

The invention discloses a synchronizing circuit of a flow distributing and collecting valve for a two-column gantry lifter and belongs to the field of hydraulic transmission. The two-column gantry lifter comprises an oil tank, a hydraulic pump, an overflow valve, a reversing valve, hydraulic cylinders, hydraulic control one-way valves and the flow distributing and collecting valve. An inlet oil pipe of the hydraulic pump is connected with the oil tank, an outlet oil pipe is respectively connected with the overflow valve and a reversing valve, an oil return pipe of the overflow valve and the reversing valve is connected with the oil tank, the flow distributing and collecting valve is connected with an oil port B of the reversing valve, the hydraulic control one-way valves are serially connected on connecting oilways of the hydraulic cylinders and the flow distributing and collecting valve, and control oilways of the hydraulic control one-way valves are connected on an oil port A of the reversing valve. The synchronizing circuit solves the problem that during operating of the two-column gantry lifter, ascending and descending speed and displacement are less synchronous of the hydraulic cylinders, and has the advantages of simple structure, reasonableness in design and manufacturability.

Owner:芜湖高昌液压机电技术有限公司

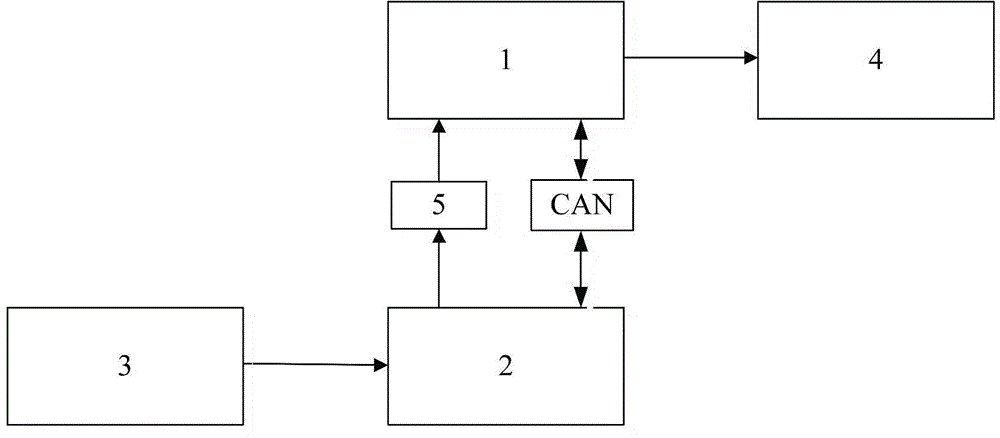

Dual-motor coordination control electric wheelchair control device

ActiveCN104881055AFast reversing speedReduce lossField or armature current controlSpeed/accelaration control using electric meansMotor driveWheelchair

The invention relates to a dual-motor coordination control electric wheelchair control device, and relates to a motor driving wheelchair; the electric wheelchair control device comprises a controller, a manual operator, a storage battery and motors; a connecting mode of the parts are that one end of the manual operator is connected with the controller through a relay, and the other end of the manual operator is connected with the storage battery; the controller and the manual operator communicate through CAN; an output end of the controller is connected with the motors; the storage battery provides power for the controller, the manual operator and the motors; the brushless DC motors are employed, a double-wheel coordination differential velocity control method is used, and a feedback compensation mode enables the wheelchair to keep left and right wheels in synchronization in operation, so the wheelchair is stable in motion, thus solving the problems in the prior art that a brush DC motor is slow in commutation speed, large in noise, and the motor is easy to be damaged in long term wearing state of the motor, and solving the disadvantages in the prior art that a conventional electric wheelchair is unstable in motion process and left and right wheel driving are not in synchronization.

Owner:HEBEI UNIV OF TECH

System and method for synchronizing multiple oscillators

ActiveUS7567134B2Tempo syncReduce complexityPulse automatic controlPulse generation by logic circuitsPhase angle differenceMulti phase

A system and method for synchronizing an oscillator with multiple phases at a desired phase angle difference. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The various phases may have different inherent frequencies that are synchronized to a common frequency such as an average of the different frequencies.

Owner:TEXAS INSTR INC

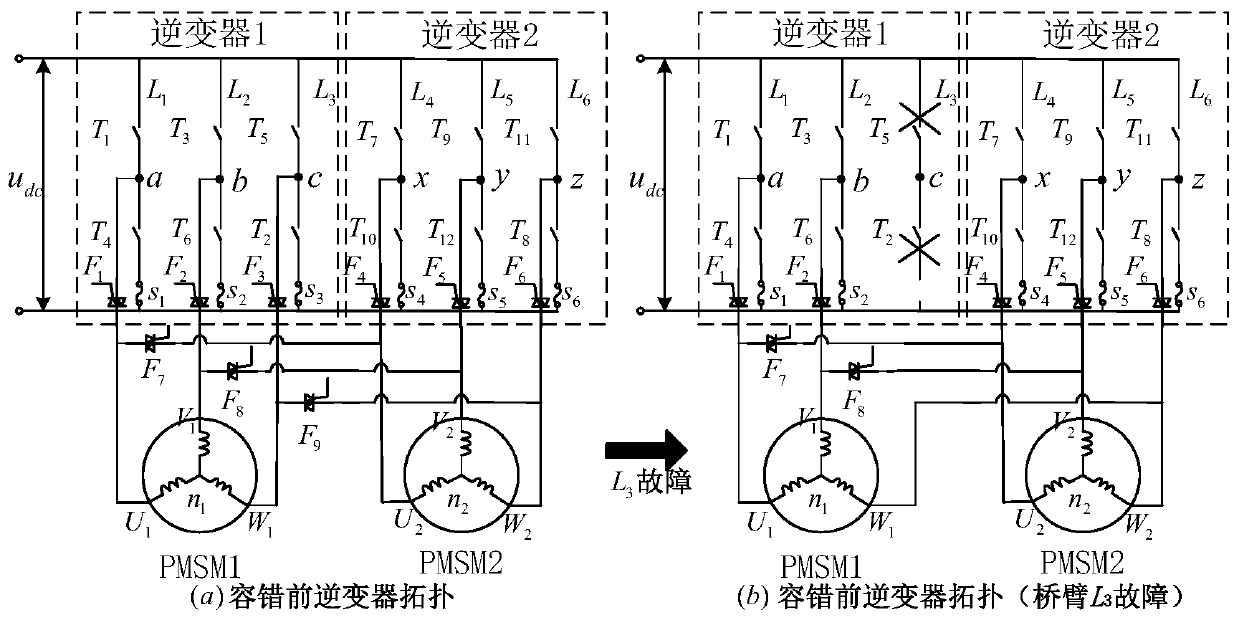

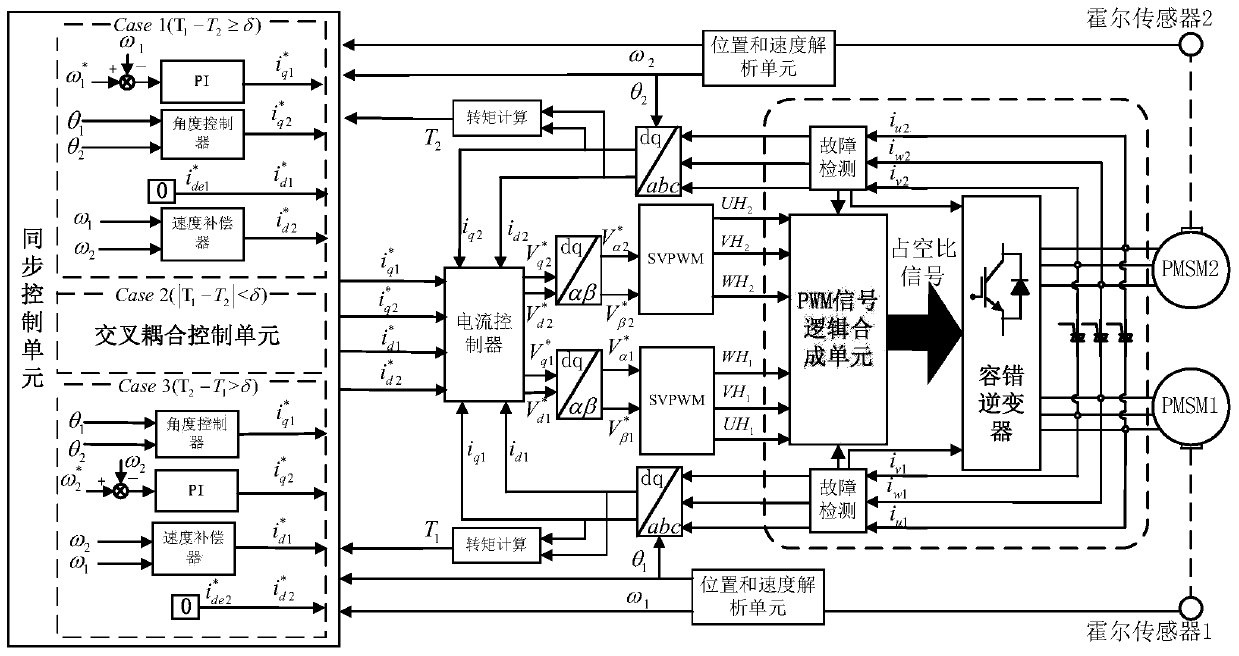

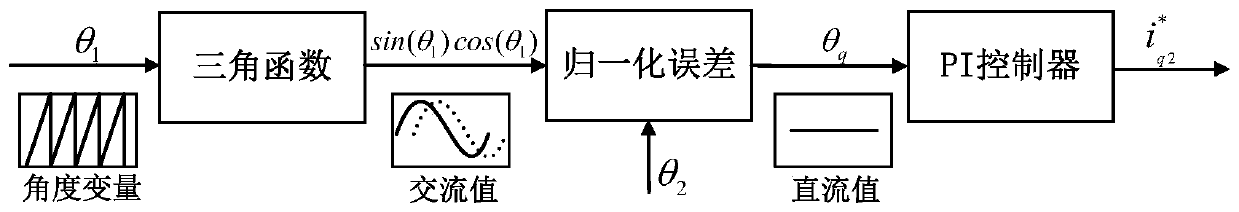

Fault-tolerant control method of dual-motor synchronous control system

ActiveCN111211711AImplement fault toleranceImprove reliabilityElectric motor controlVector control systemsPhase currentsReference current

The invention discloses a fault-tolerant control method of a dual-motor synchronous control system. A feedback rotating speed and a rotor position are input into a synchronous control unit, three-phase currents of double motors are converted through Park and Clark to obtain respective feedback quadrature-direct axis currents, corresponding torques are input into the synchronous control unit to becompared, and a corresponding angle and speed compensation strategies are determined; a quadrature-axis reference current and a direct-axis reference current are compared with the feedback quadrature-direct axis current of the double motors, and respective quadrature-direct axis reference voltages are calculated; Park inverse transformation is performed on the quadrature-direct axis reference voltage of the double motors to obtain two voltage components under a static coordinate system, and three duty ratio signals are obtained; and a fault bridge arm of the inverter is judged by detecting a three-phase current of the double motors, fault signals are sent to a fault-tolerant inverter and a PWM signal logic synthesis unit to complete reconstruction of a fault-tolerant topology and implementation of a fault-tolerant algorithm, and finally fault-tolerant control of the double permanent magnet synchronous motors is achieved. System reliability is high.

Owner:CHECC DATA CO LTD +1

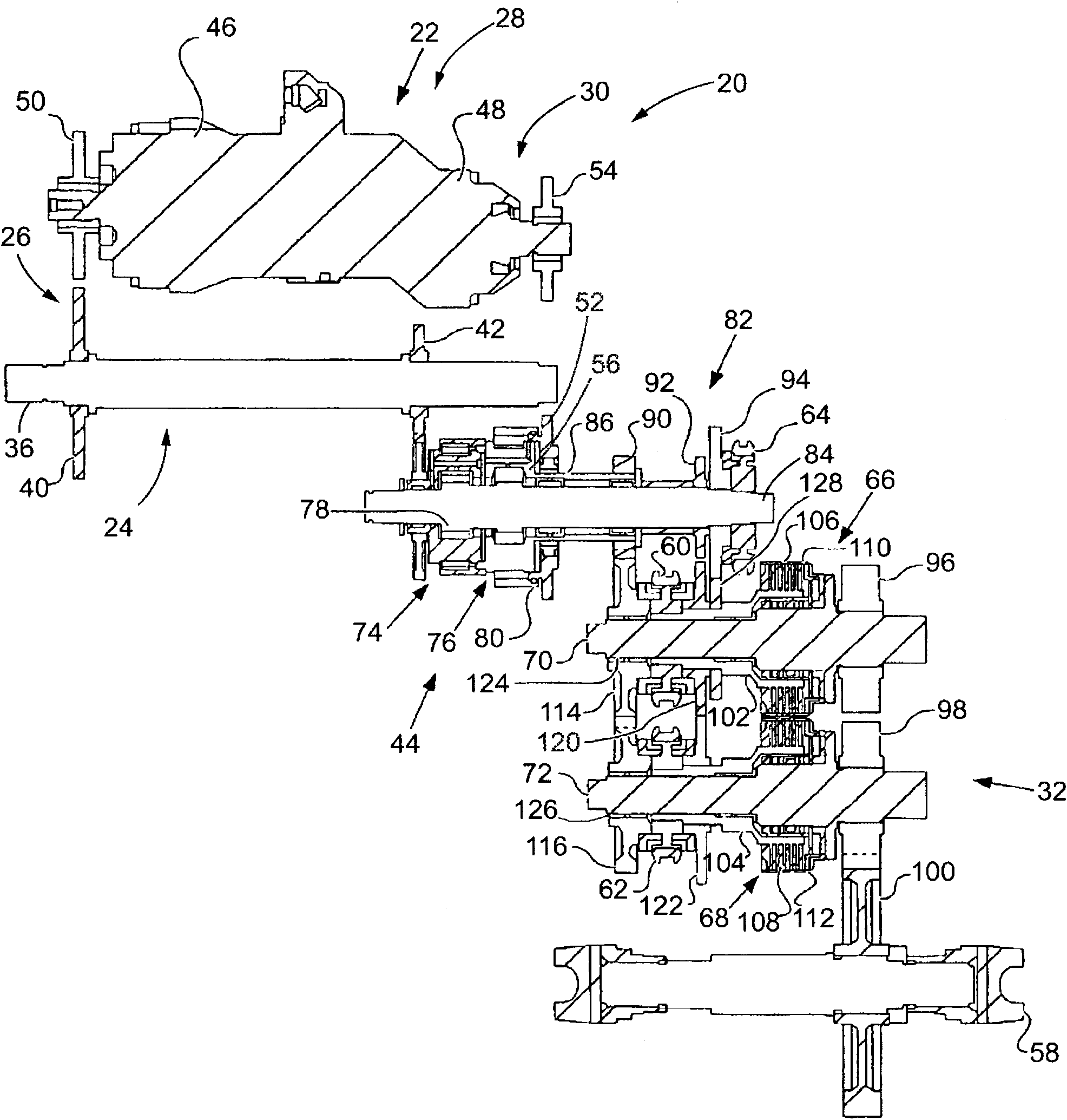

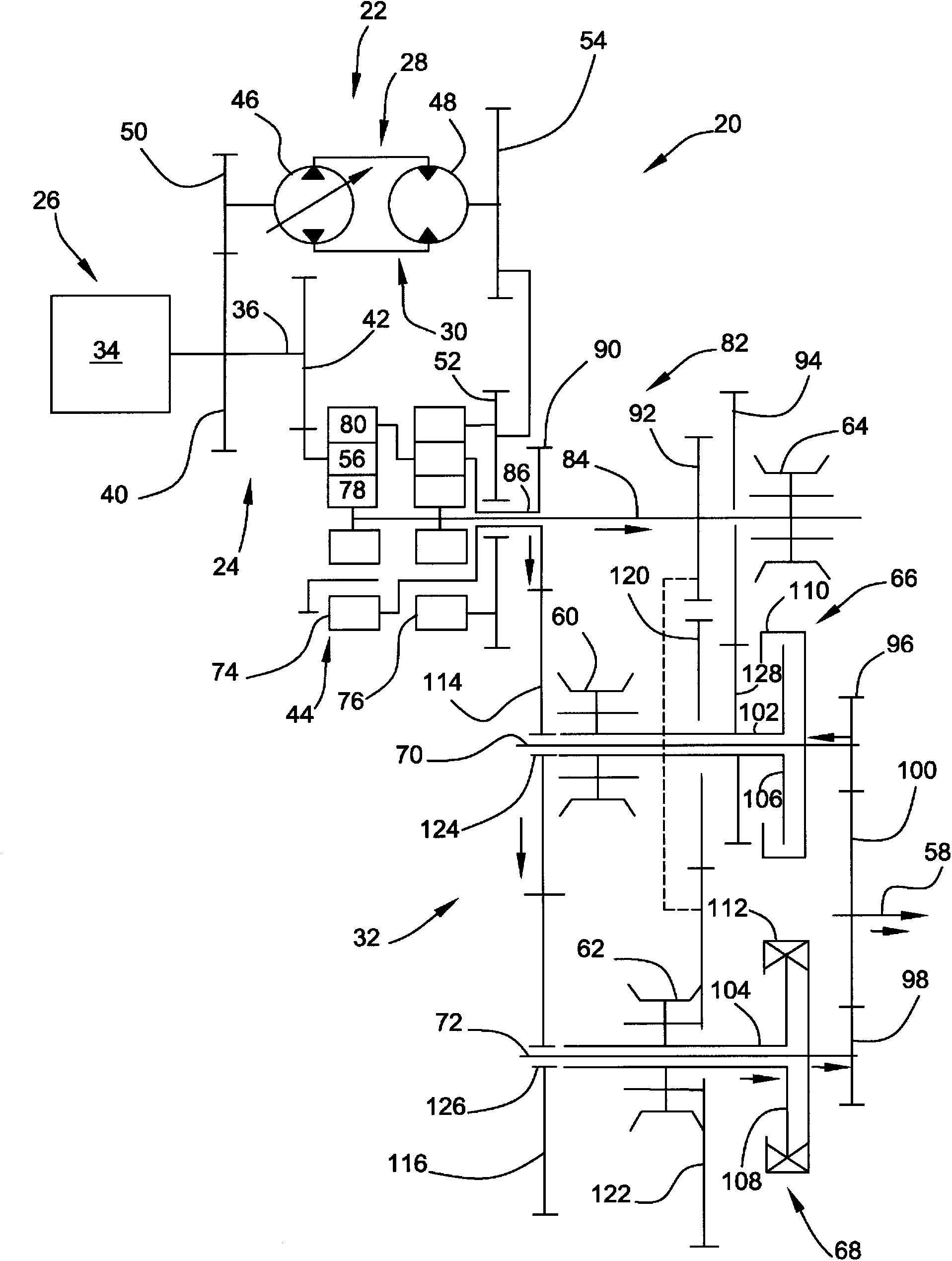

Method of synchronizing in split torque continuously variable dual clutch transmission

A method including activating a first clutch assembly (66) to connect a first rotatable member (106) to a rotating final output member (58) until a shift trigger point is reached to provide a rotational speed to the first rotatable member (106) from the final output member (58). The first clutch assembly (66) is then deactivated. The second clutch assembly (68) that connected a synchronized second rotatable member (108) with the final output member (58) is then deactivated. A third synchronizer (64) engaged with the first rotatable member (106), and the first clutch assembly (66) is activated to connect the first rotatable member (106) to the final output member (58).

Owner:CATERPILLAR INC

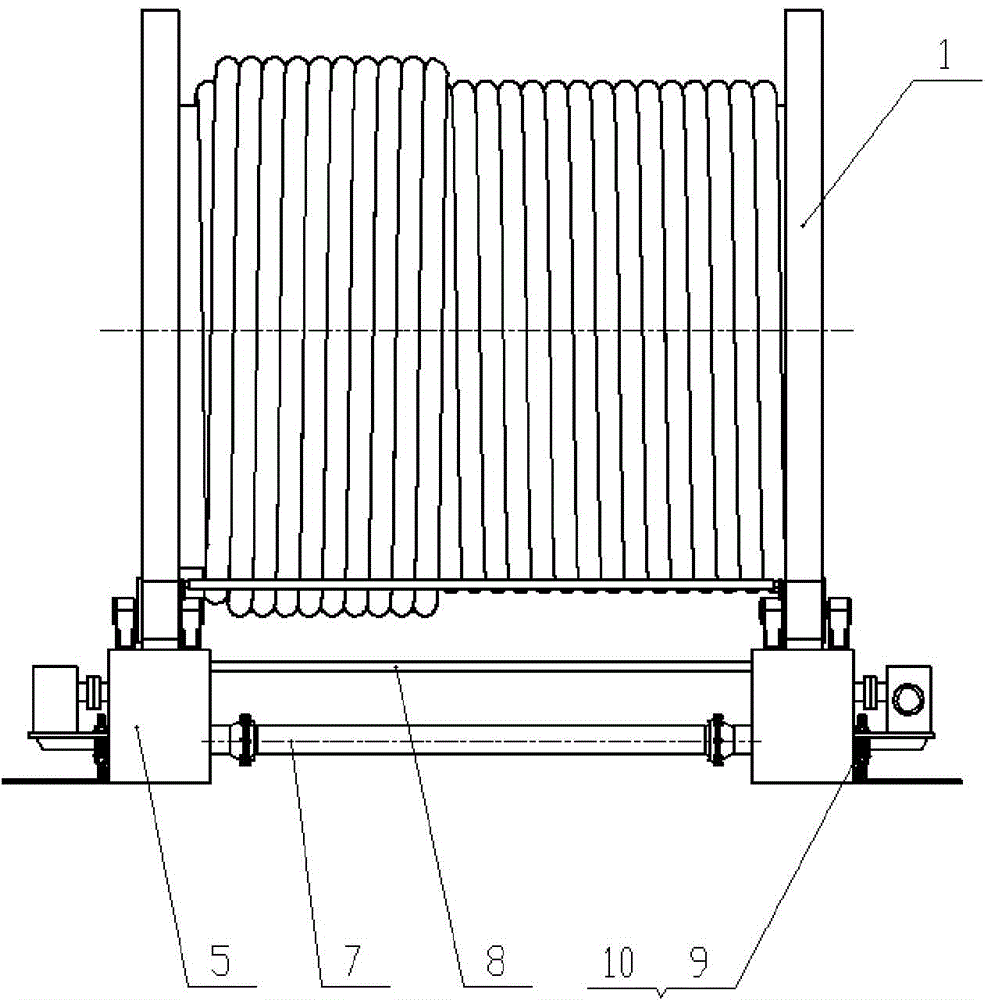

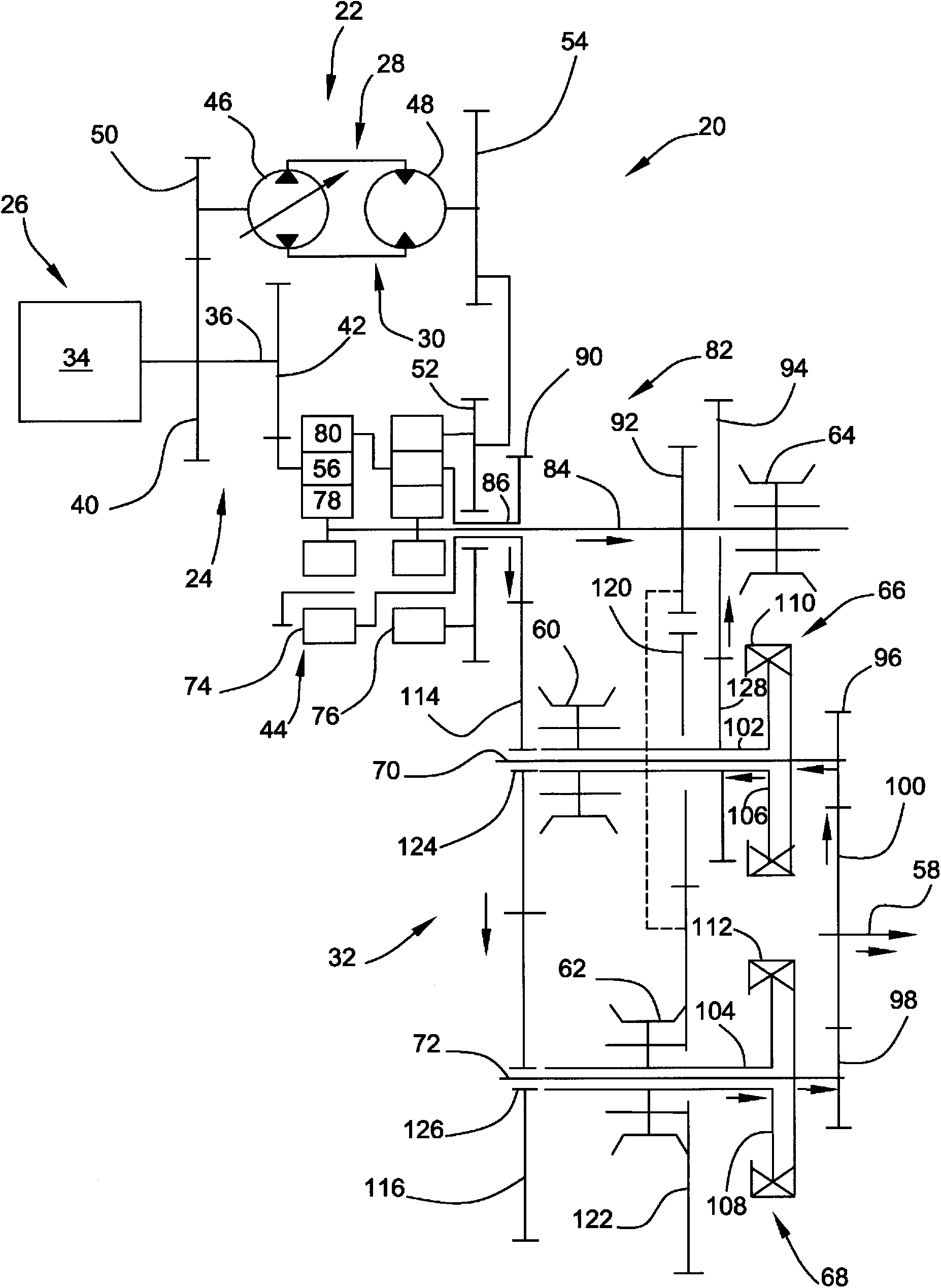

Master-slave control system for automatically tensioning winch mooring rope of anchor moored positioning system

InactiveCN104443275ATempo syncSimple control systemAnchoring arrangementsFrequency changerHuman–machine interface

The invention provides a master-slave control system for automatically tensioning a winch mooring rope of an anchor moored positioning system. The master-slave control system comprises a man-machine interface, a control unit, a transmission unit and an execution unit. The transmission unit comprises an ABB master frequency converter and an ABB slave frequency converter. The execution unit comprises a tension winch motor, a rope storage winch motor, a tension winch and a rope storage winch. The control unit is in communication connection with the ABB master frequency converter and the ABB slave frequency converter. The ABB master frequency converter is connected with the tension winch motor, the ABB slave frequency converter is connected with the rope storage winch motor, and the ABB master frequency converter is in communication connection with the ABB slave frequency converter. Software mathematic models of alternating current asynchronous motors are arranged in the ABB master frequency converter and the ABB slave frequency converter and capable of controlling the rotating speeds of the tension winch motor and the rope storage winch motor respectively, speed synchronization between the tension winch and the rope storage winch is kept, and the automatic tensioning function of the tension winch and the rope storage winch is achieved.

Owner:WUHAN MARINE MACHINERY PLANT

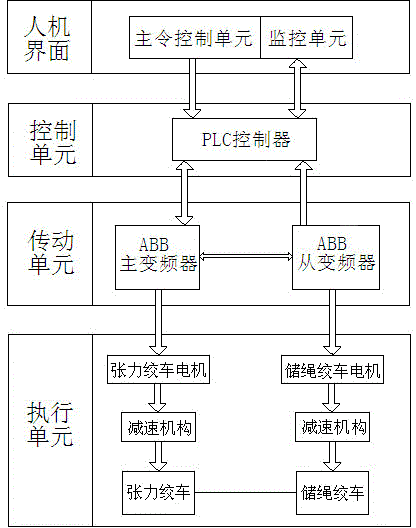

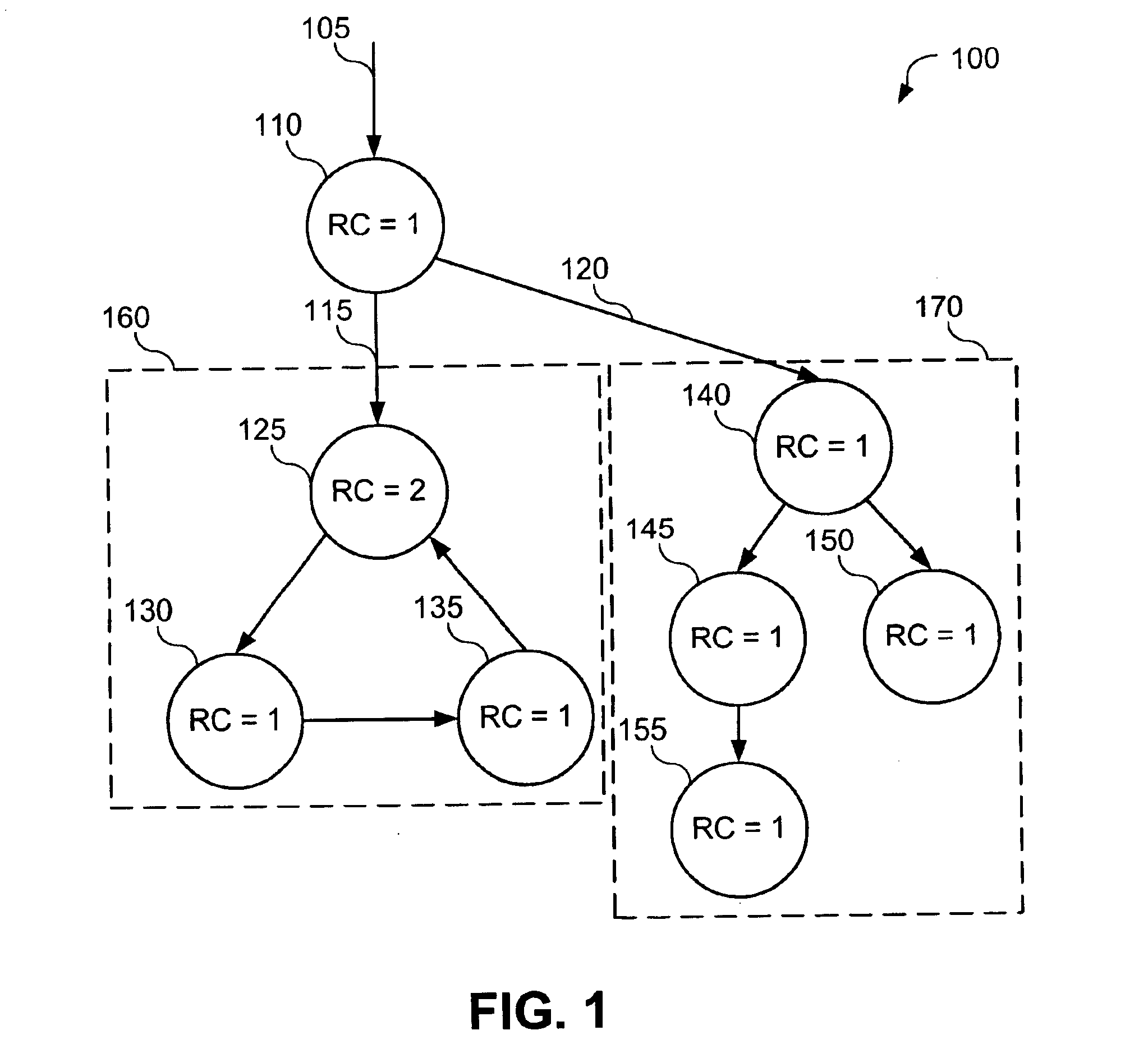

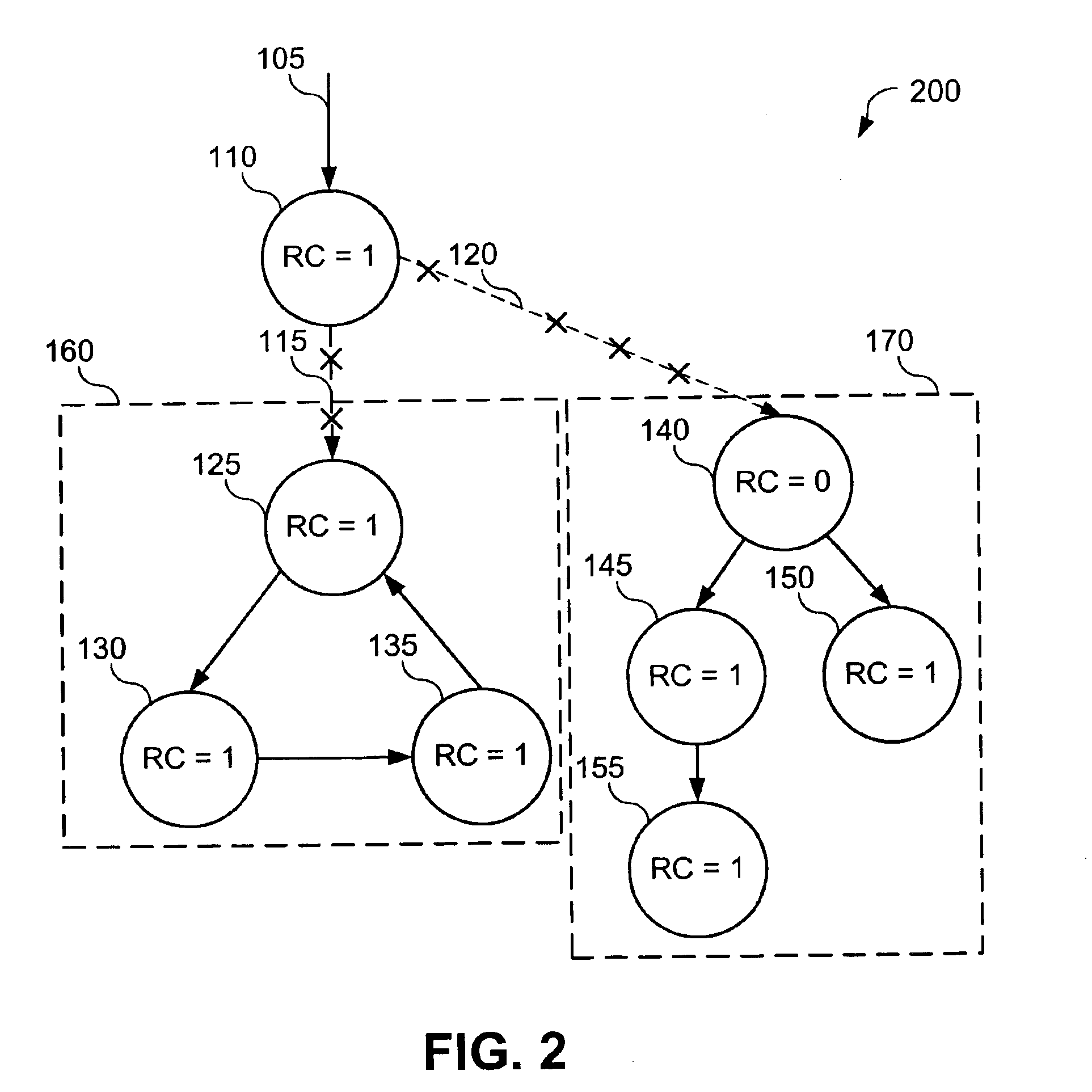

Synchronous collection of cyclic garbage in reference counting systems

InactiveUS6879991B2Speed synchronous garbage collectionTempo syncData processing applicationsDigital data processing detailsReference countingTheoretical computer science

Techniques are provided that speed synchronous garbage collection in systems that use reference counting. The present invention performs each of the steps of marking, scanning, and collecting on all nodes that are possibly nodes in a cycle of garbage. These nodes are referred to as “root” nodes herein. In other words, an aspect of the present invention performs the step of marking on each root node, the step of scanning on each root node, and the step of collecting on each root node. Performing one or more of these steps on all of the root nodes results in a lower number of operations than selecting single root nodes, performing these steps on each root node, and iterating until all root nodes are selected. Additionally, before root nodes are added to a buffer, they are examined to determine if they are already in the buffer. If they are, they are not added to the buffer. This prevents the same root node from being examined multiple times. Finally, nodes are examined to determine whether they are acyclic. Acyclic nodes are ignored when finding cyclic garbage.

Owner:IBM CORP

Method for machining self-adhesive label

The invention discloses a method for machining a self-adhesive label and relates to the label manufacturing field. The method comprises the seven steps of unreeling, coating, stoving, sand blasting, printing, laminating and calendaring. Continuous unreeling is adopted, backing paper is placed on a rotary label machine, tension applied to the backing paper is manually adjusted and correction and rectifying are conducted at the same time, and then Synchronization of the reeling speed and the unreeling speed is guaranteed, stress is even, the backing paper can be flattened, and coating operation is facilitated; the backing paper is placed on a metal surface heated by an electric heating wire and polished to be pressed and cooled gradually till a glossy film surface is formed on a label, clear dopes used for polishing and coating are made denser and smoother, an ideal high-gloss and high-brightness mirror surface film effect is achieved, and the grade and market competitiveness of a printed product are improved.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

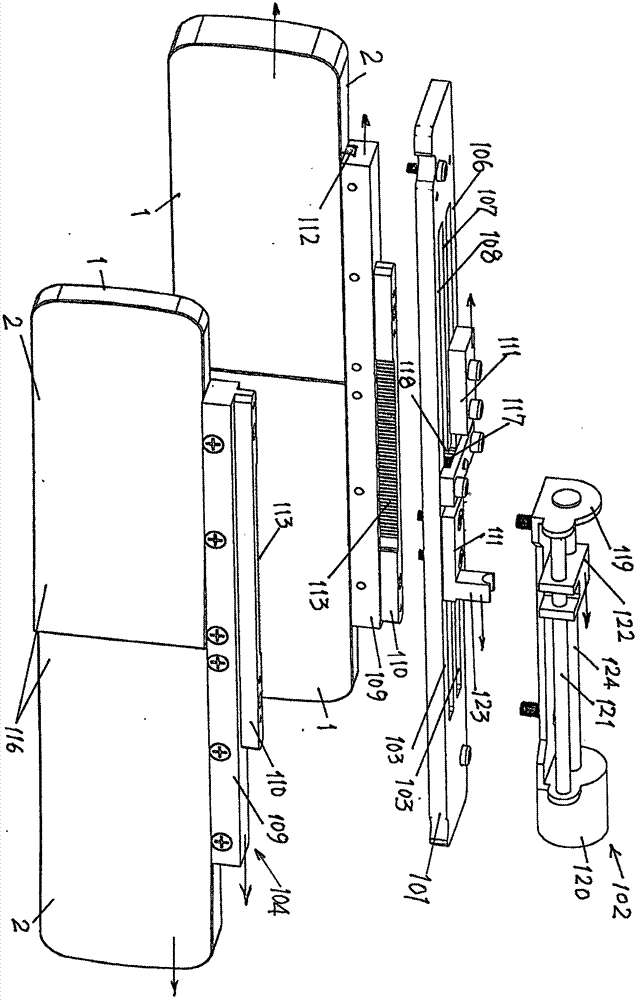

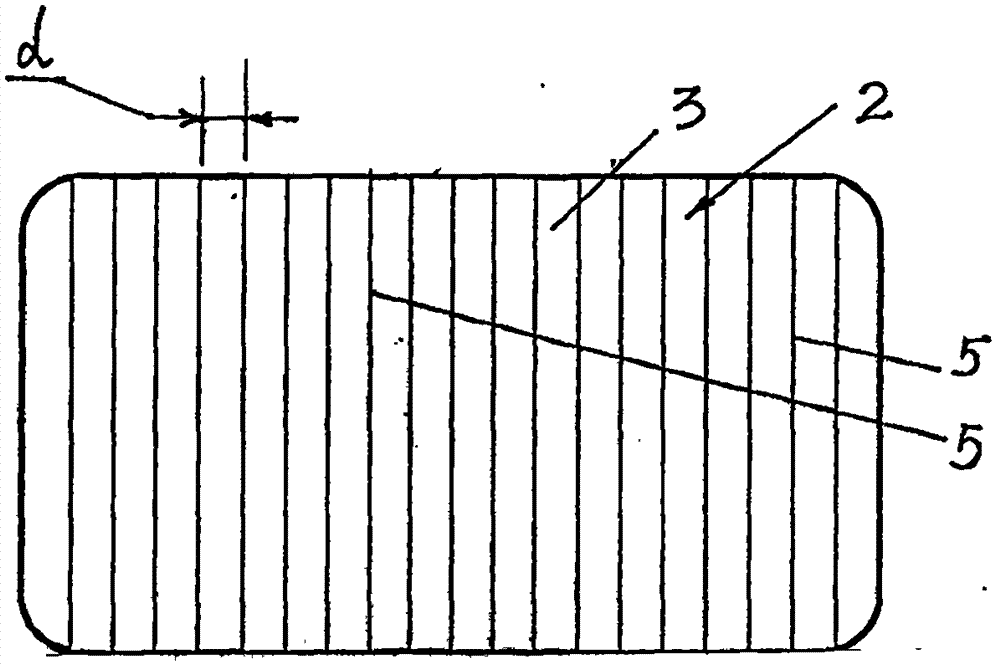

Horizontal single-motor driving device for eyesight rectification overlapped lens group sliding

The invention provides a horizontal single-motor driving device for eyesight rectification overlapped lens group sliding, belonging to a device electrically driving the two groups of parallel optical lenses to perform slidable focal length variation eyesight rectification. The horizontal single-motor driving device includes a deceleration motor assembly fixed on an L-shaped support plate at one end on a double-hole strip-shaped plate, two slidable lens assemblies are respectively arranged in the two strip-shaped holes of the double-hole strip-shaped plate, each lens assembly includes lenses with multiple vertical equidistant focal length variation striped surfaces, a grooved strip connecting the lenses, a slide substrate, a top clamp plate that are connected successively and mutually from the bottom to the top, the two lenses with multiple vertical equidistant focal length variation striped surfaces connected in the grooved strip form a double-lens group, the deceleration motor enable the two lens assemblies to slide in the opposite directions through the engaging gears at the two sides, and the overlapped two lenses generate a lot of combined diopter. A motor is additionally provided with a gear, so that the two double-lens groups can be driven to perform the constant speed movement in the opposite directions at the constant speed. The focal length variation training device is helpful in storing myopia vision.

Owner:陈奎

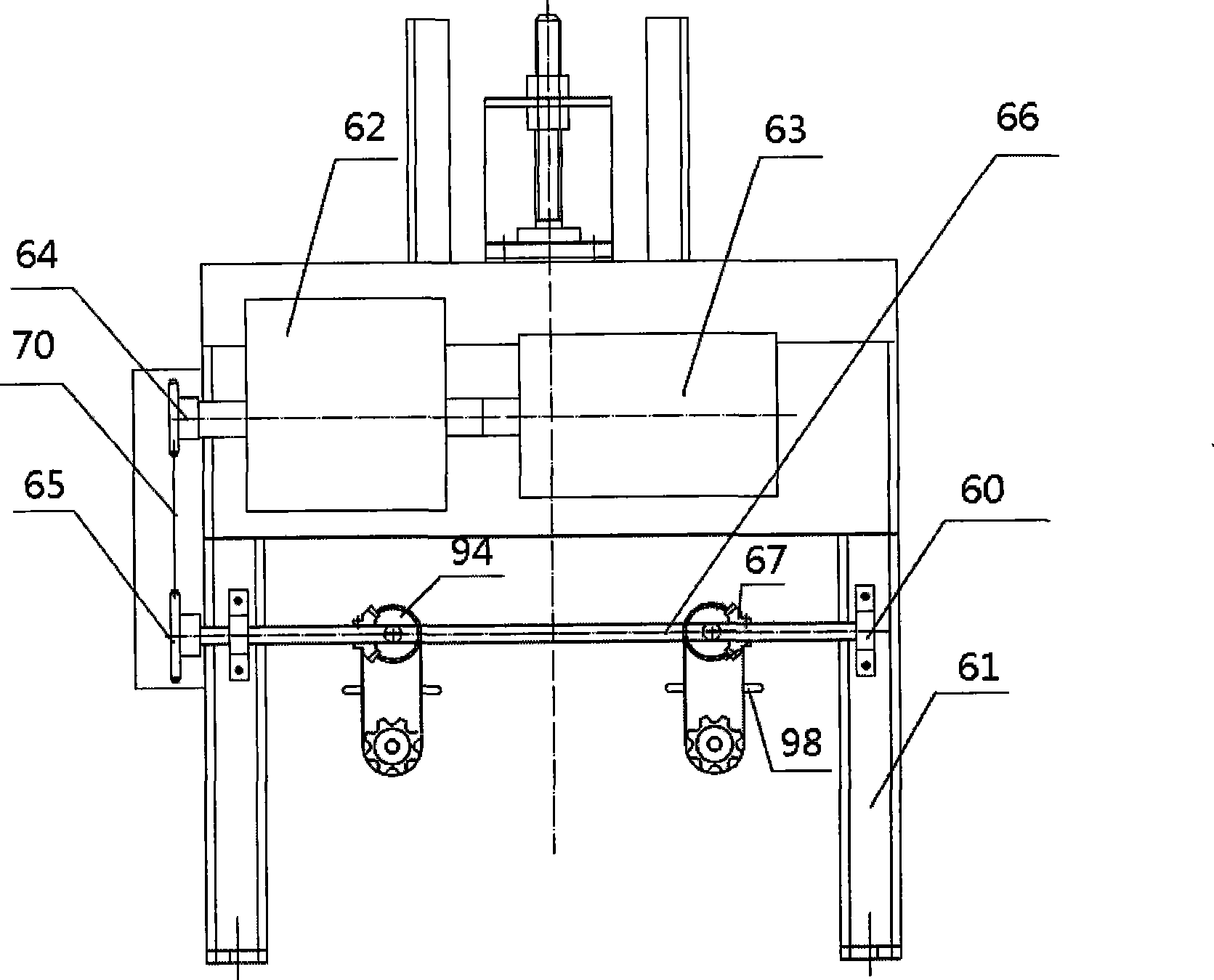

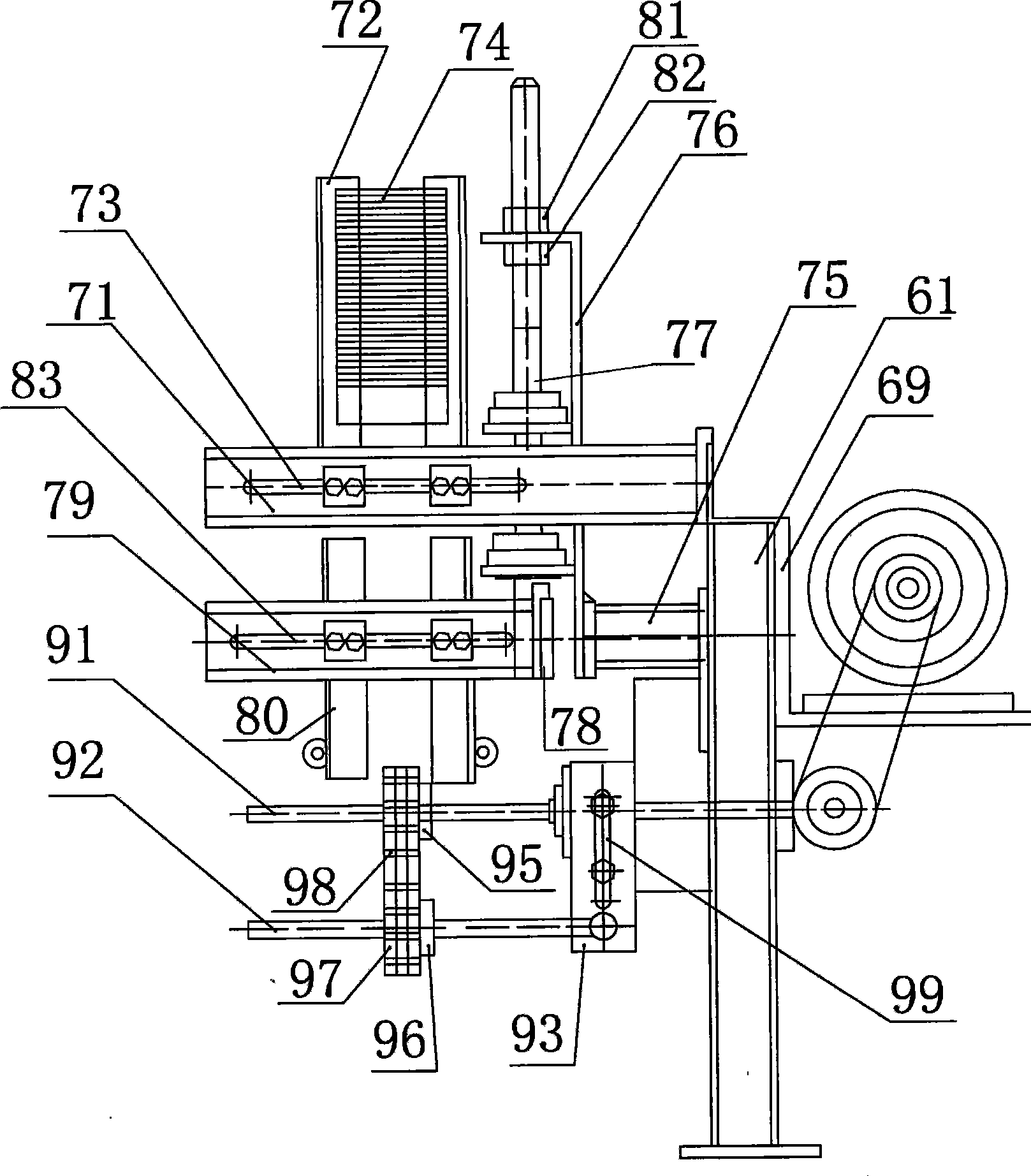

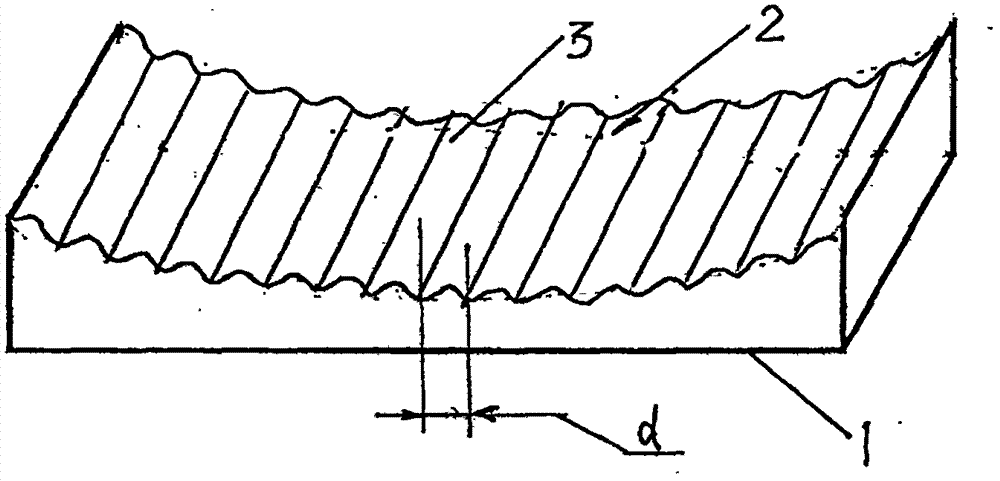

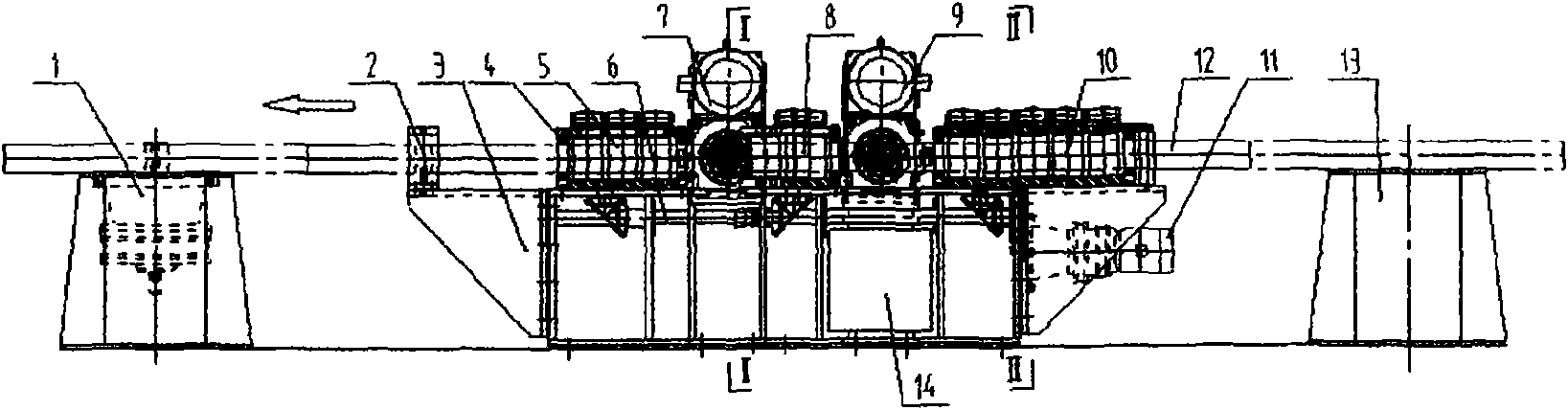

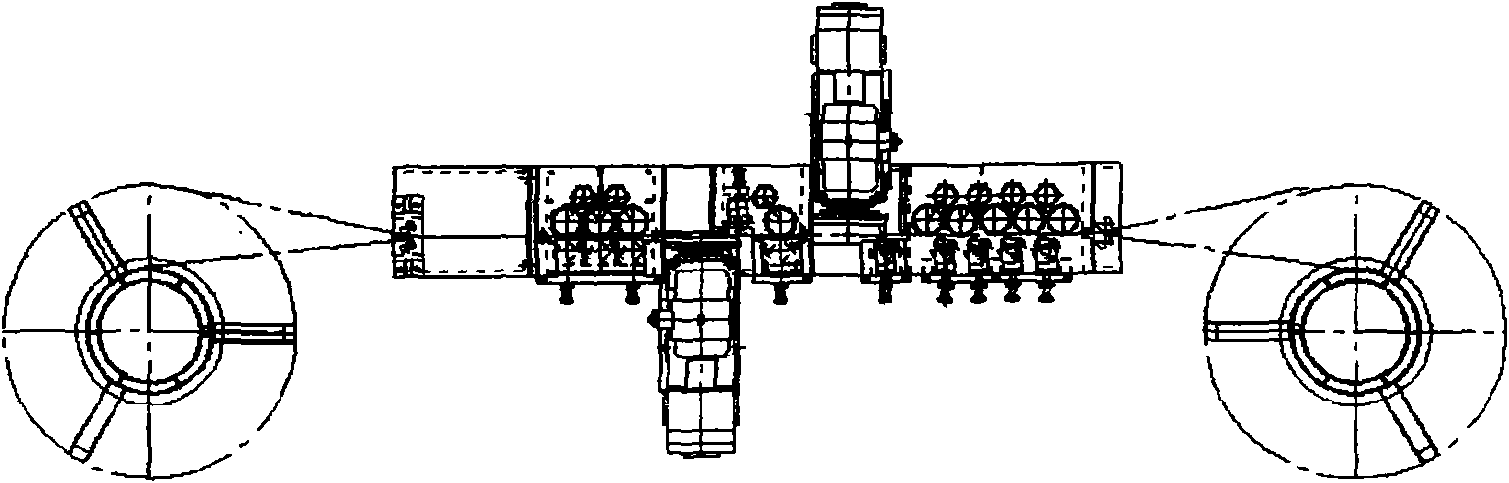

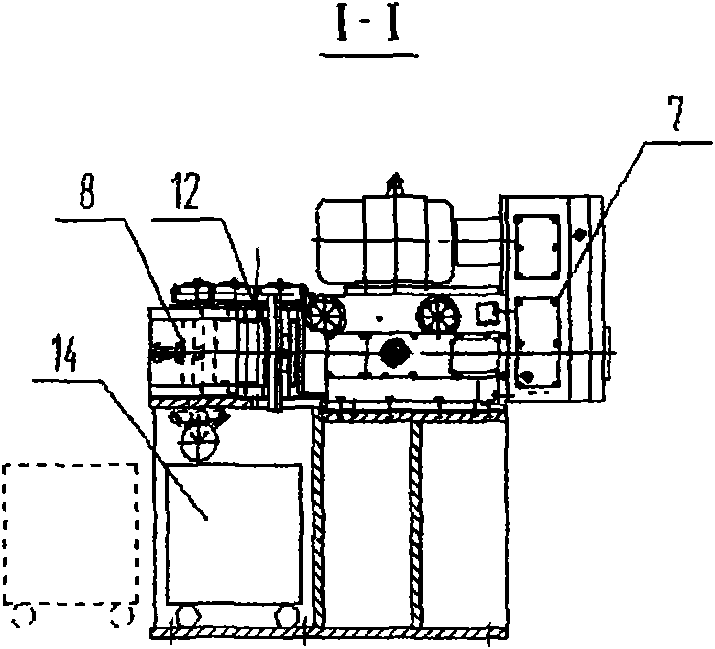

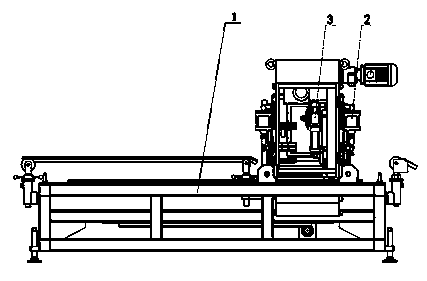

Continuous double-face milling device for narrow-band blank

InactiveCN102049558AEasy to adjustEasy to cutMilling equipment detailsMilling cutterElectrical control

The invention discloses a continuous double-face milling device for a copper alloy narrow-band blank with the width of less than 200mm. In special industries such as the special-shaped copper strip processing industry and the like, the copper alloy narrow-band blank with the width of less than 200mm is generally taken as a raw material to be processed due to the cost, and small enterprises cannotafford investment in the conventional continuous double-face milling device; therefore, the invention provides the continuous double-face milling device which has a simple and practical structure andsmall investment. The technical scheme is that: a standard combined power head is matched with an indexable face milling cutter in the device; different from that of the conventional continuous double-face milling device, the strip blank is vertically arranged instead of horizontally arranged, so that gang milling is convenient to perform; in addition, a vertical pinch roller and a straightening device are concentratedly driven by a driving device through a long axis transmission device, so that speed synchronization is ensured, and electrical control is simple.

Owner:上海格林赛高新材料有限公司

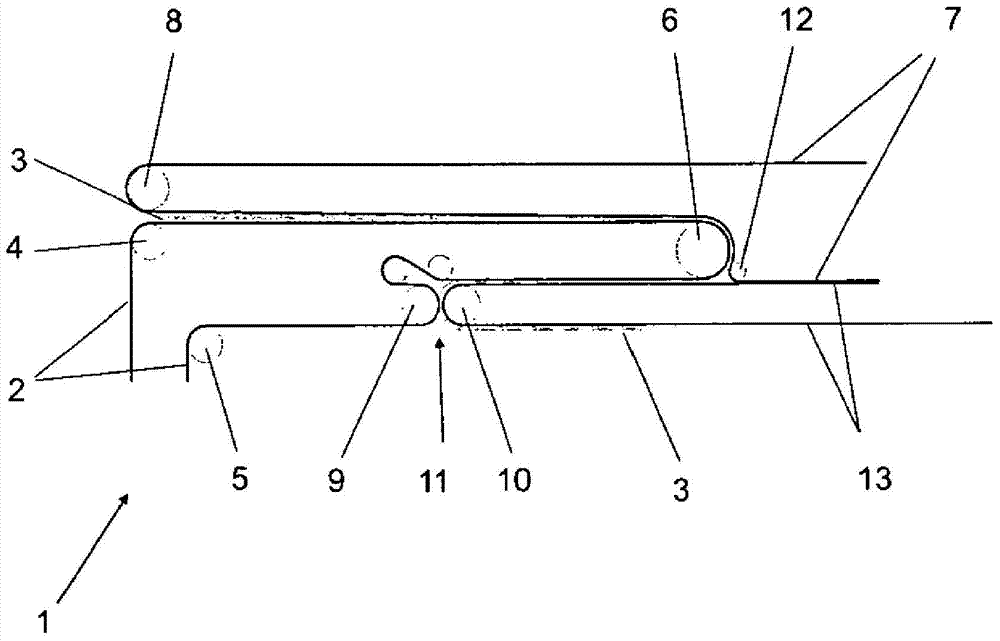

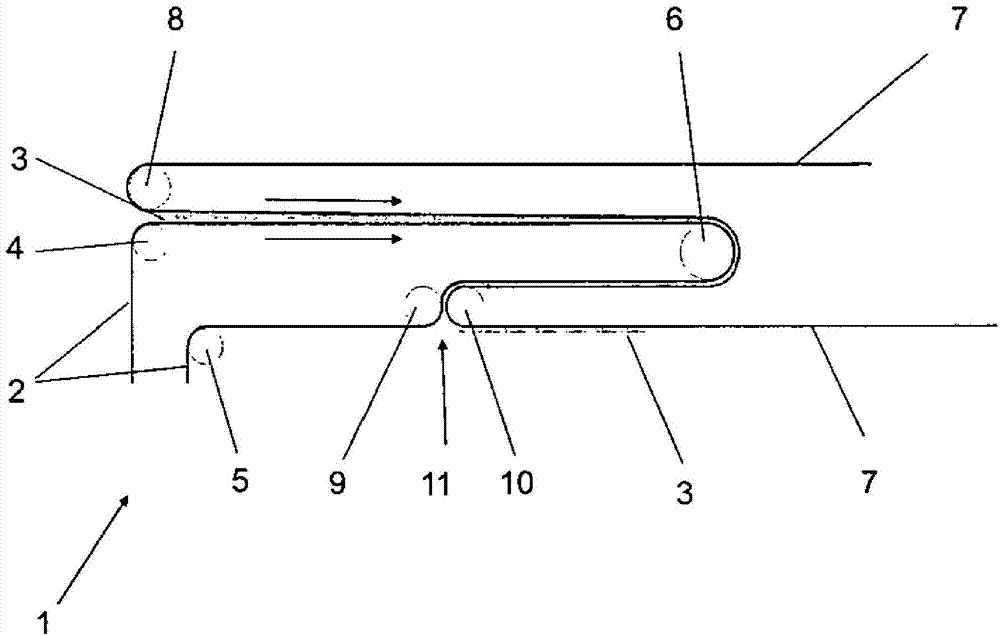

Crosslapper and method for operating crosslapper

The invention relates to a crosslapper used for formation of a fleece made of many layers of fibrous web. The crosslapper comprises at least one continuously revolving input belt (2) which supplies the fibrous web (3) from the inlet region of the crosslapper up to a laying gap (11) of the laying carriage, and a continuously circulating cover belt (7) which fixes the fibrous web (3) on the input belt (2). The crosslapper is characterized in that the cover belt (7) fixes the fibrous web (3) from the inlet region of the crosslapper (1) up to the laying gap on the input belt(2).

Owner:TRUETZSCHLER GRP SE

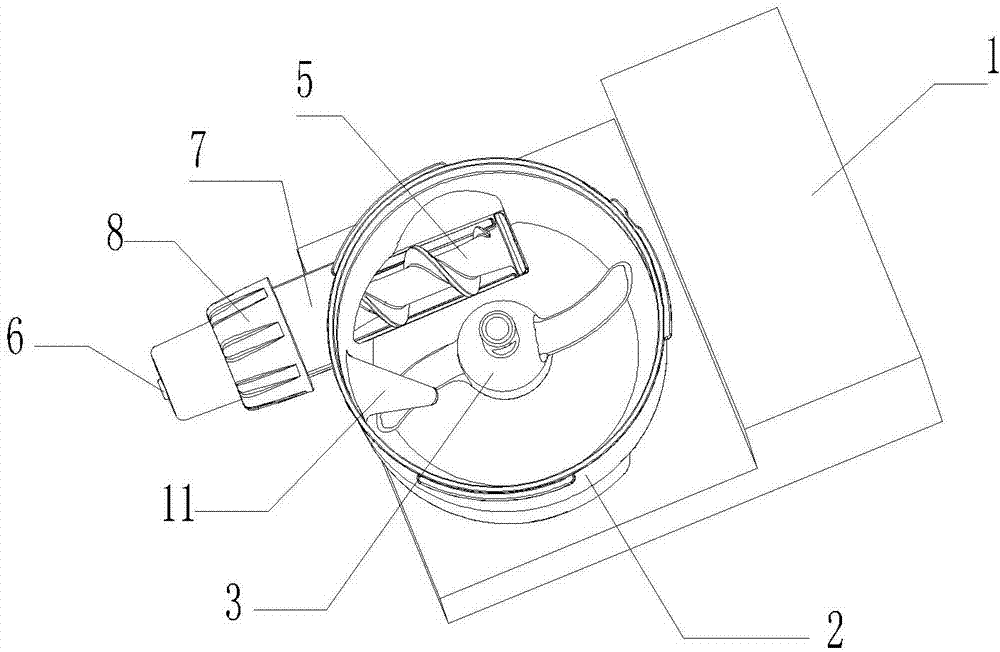

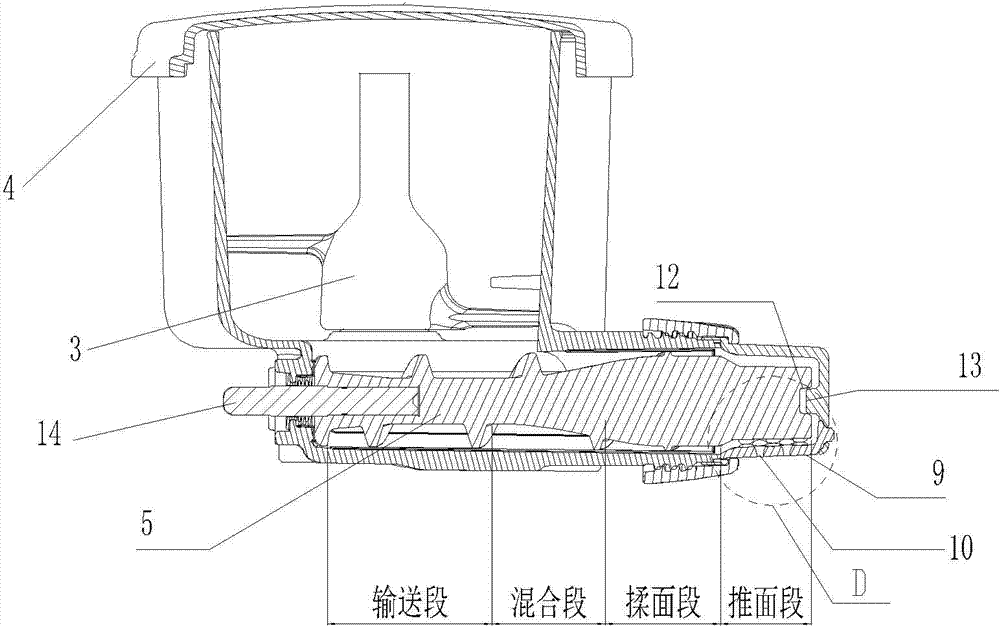

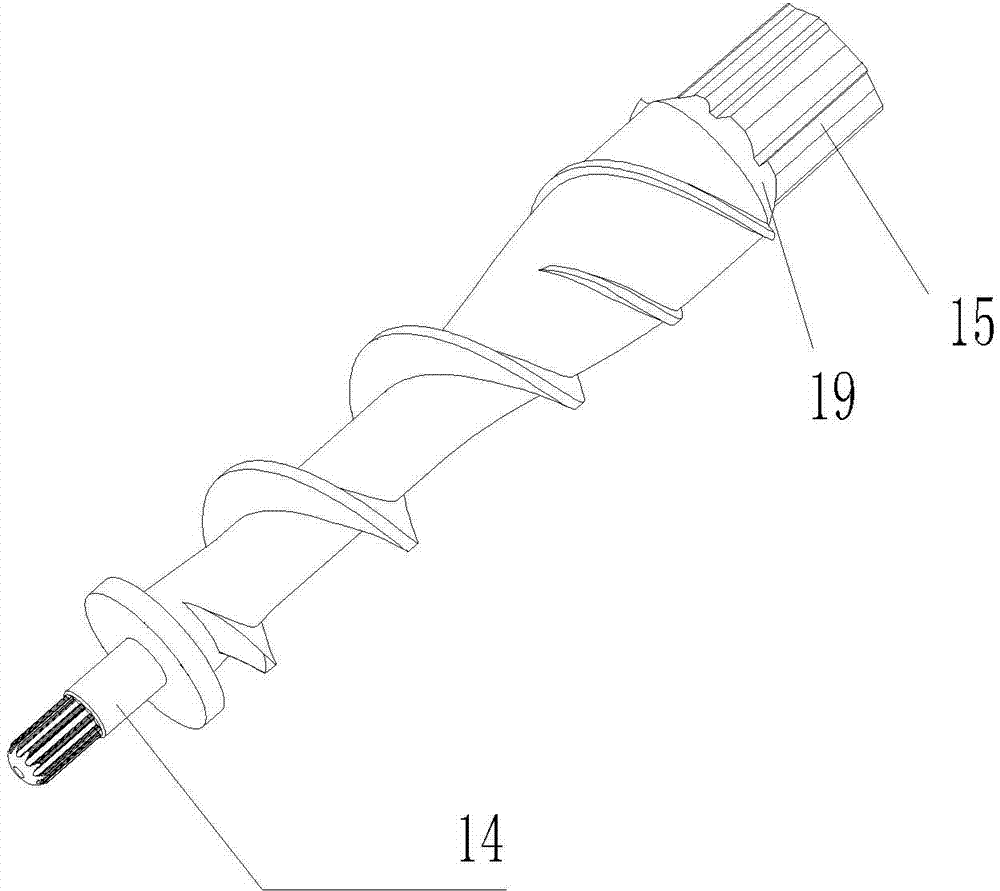

Noodle maker capable of rapidly making noodles

ActiveCN105432704AEasy extrusionAvoid excessive temperatureMixing/kneading with vertically-mounted toolsDough extruding machinesMechanical engineering

The invention discloses a noodle maker capable of rapidly making noodles. The noodle maker is used for stirring flour and water to obtain dough, and then pressing the dough into noodles. The noodle maker comprises a main machine with a motor, a stirring assembly and an extruding assembly, wherein the extruding assembly comprises a screw rod, a die head and a dough extruding cylinder; a thread is formed in the screw rod; the extruding assembly is horizontally arranged on one side of the main machine, and the die head is mounted at the end part of the dough extruding cylinder; the die head comprises a forming region, wherein a forming hole is formed in the forming region; the screw rod sequentially comprises a conveying segment and a dough pushing segment in the noddle extruding direction, wherein the dough pushing segment comprises a dough pushing segment body, and dough pushing teeth are formed in the outer circumferential surface of the dough pushing segment body; the areas of the dough pushing teeth, acted on the dough are large, so that the noodles are rapidly formed from the forming hole in the corresponding segment of the dough pushing teeth, and the thickness of the noodles is uniform; useless work rotation of the dough driven by the screw rod in the working process is avoided, so that too high temperature generated by the friction of the rotation of the dough is also avoided, and the noodles are chewy.

Owner:JOYOUNG CO LTD

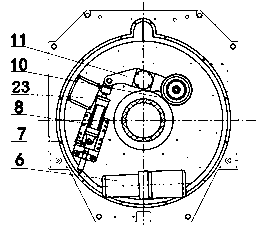

Hybrid control synchronous valve

ActiveCN109667802AReduce outflowConsistent motion displacementOperating means/releasing devices for valvesServomotor componentsPistonPetroleum engineering

A hybrid control synchronous valve comprises a valve body of which the lower part is provided with an oil inlet cavity, and the oil inlet cavity is internally provided with a main valve core; an oil inlet is formed in the position, below the oil inlet cavity, of the valve body, and the both side faces of the upper part of the valve body are provided with a left oil outlet and a right oil outlet separately; the left oil outlet communicates with the oil inlet cavity through a left channel, and the right oil outlet communicates with the oil inlet cavity through a right channel; a left oil cavityis arranged at the position, above the left channel, of the valve body, and a right oil cavity is arranged at the position, above the right channel, of the valve body; the left oil cavity and the right oil cavity are provided with oil outlet valve cores; the right and left ends of the main valve core are provided with a right piston and a left piston, and the right side of the valve body is provided with a driving unit; the right end of the right piston is provided with a control part; the left end of the oil inlet cavity is provided with a through hole which is provided with an oil inlet sealing bolt, and a spring is arranged between the oil inlet sealing bolt and the left piston; and the upper ends of the left oil cavity and the right oil cavity are provided with through holes which areprovided with oil outlet sealing bolts, and springs are arranged between the oil outlet sealing bolts and the oil outlet valve cores. According to the hybrid control synchronous valve, the control accuracy is improved, and the cost is saved greatly; and the wording efficiency is improved.

Owner:GUANGDONG IND TECHN COLLEGE

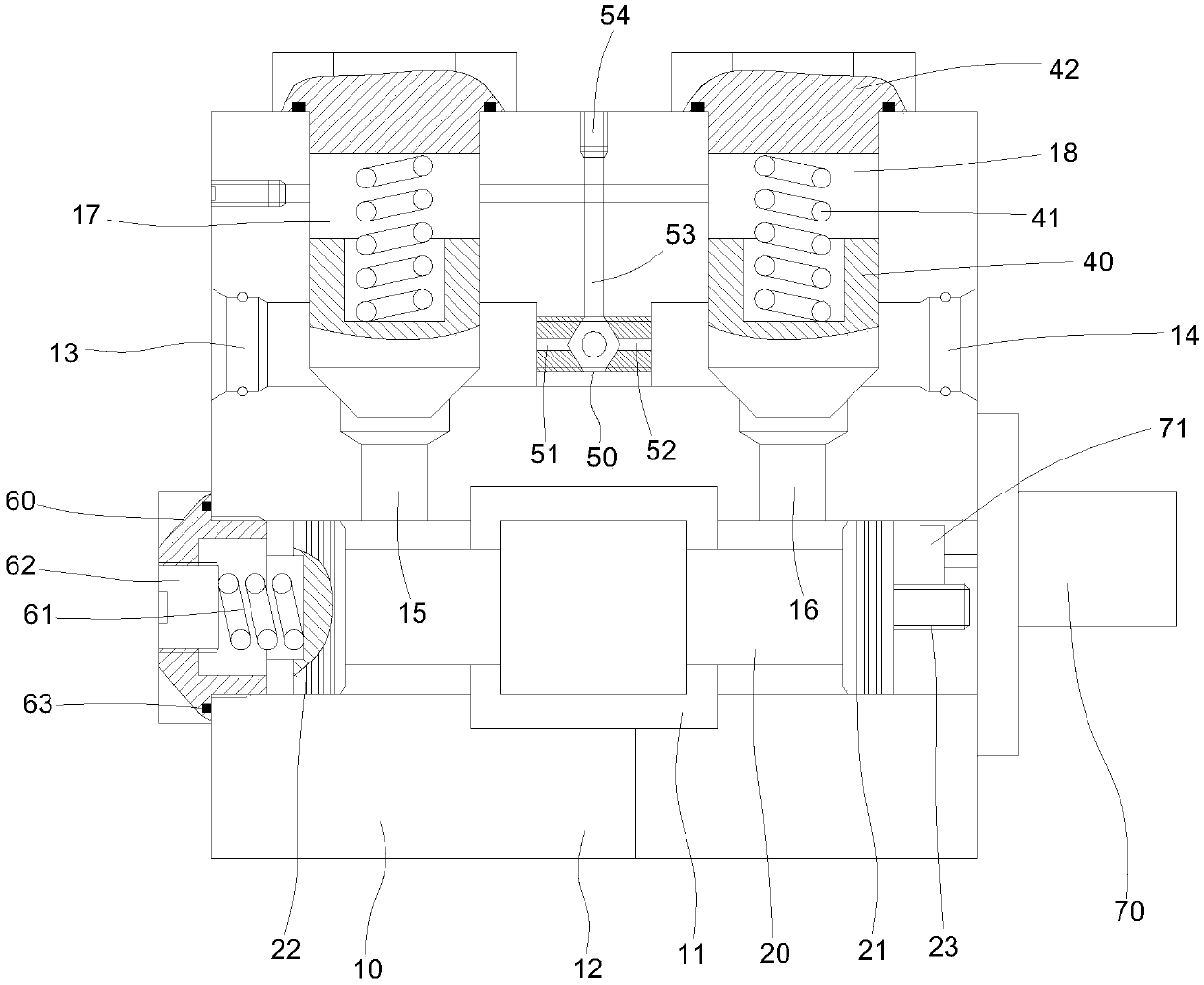

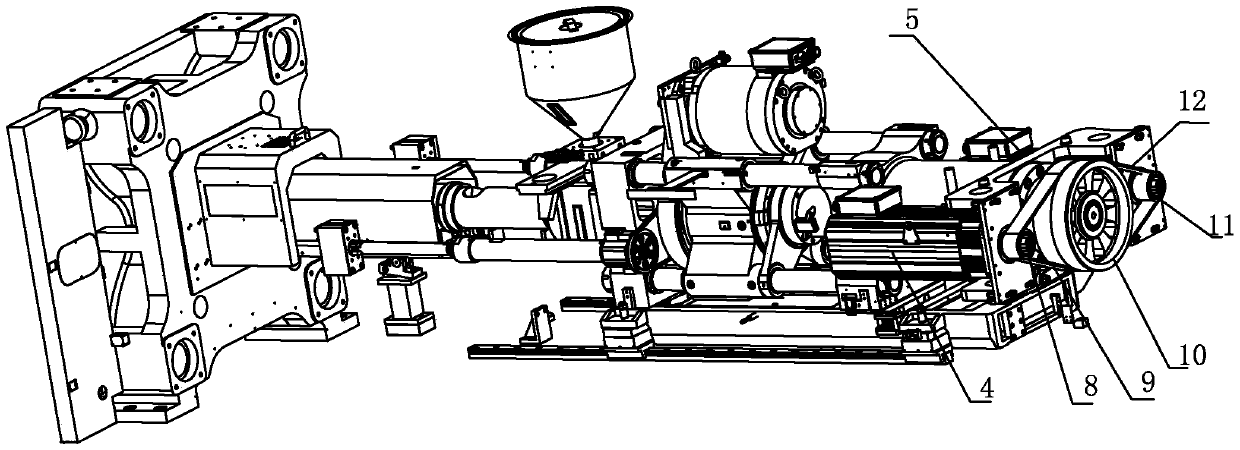

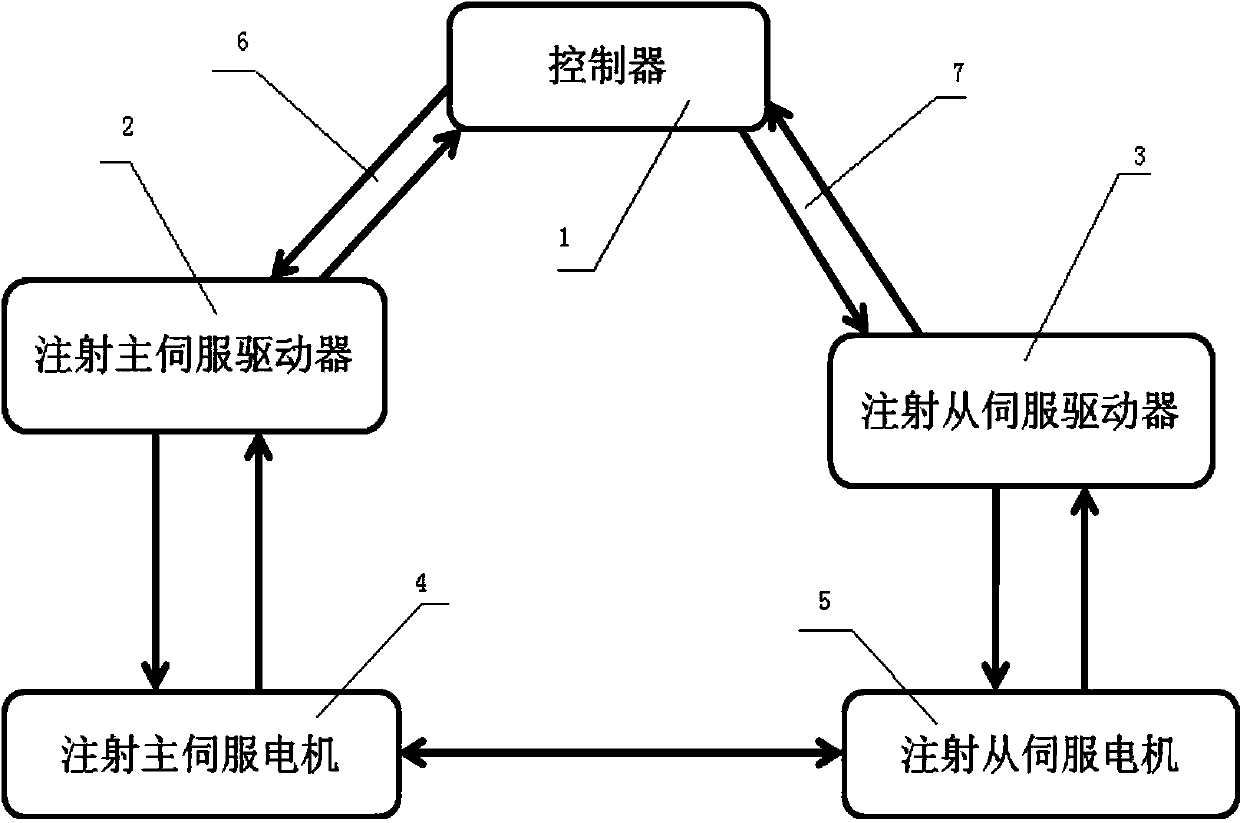

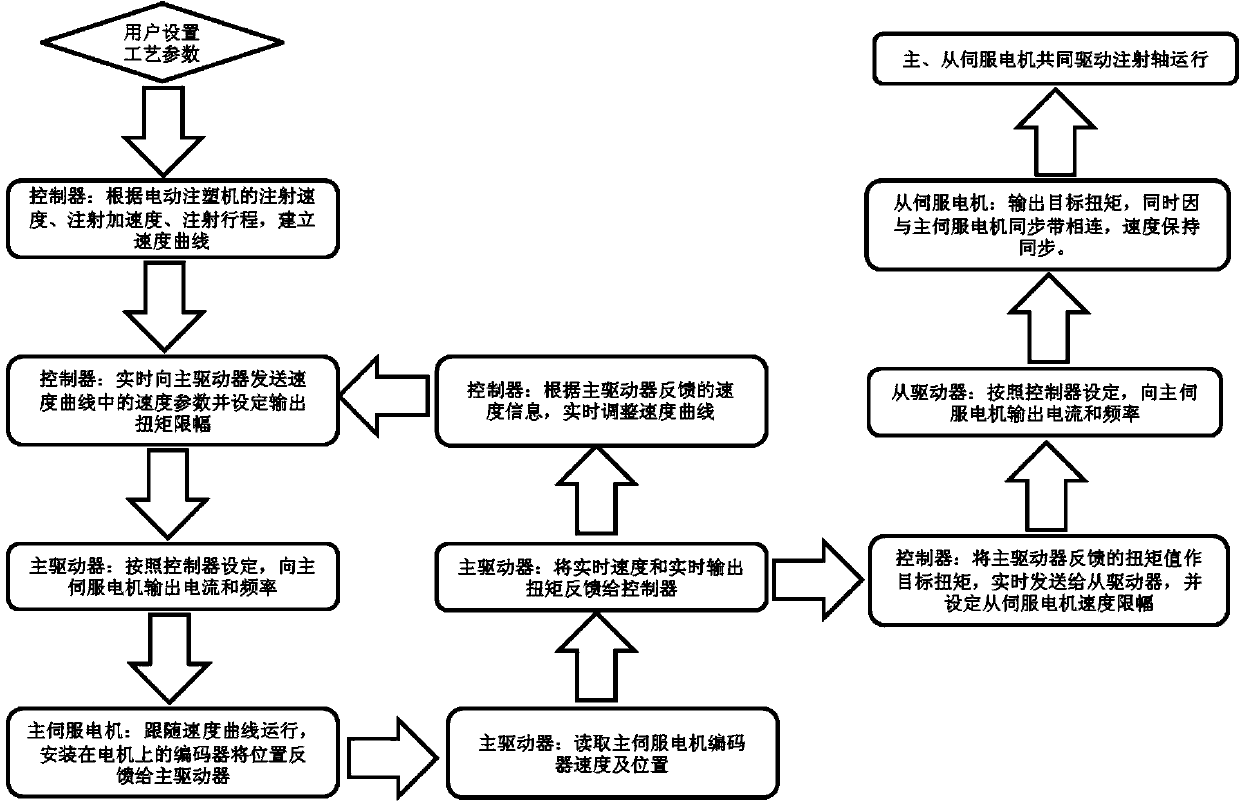

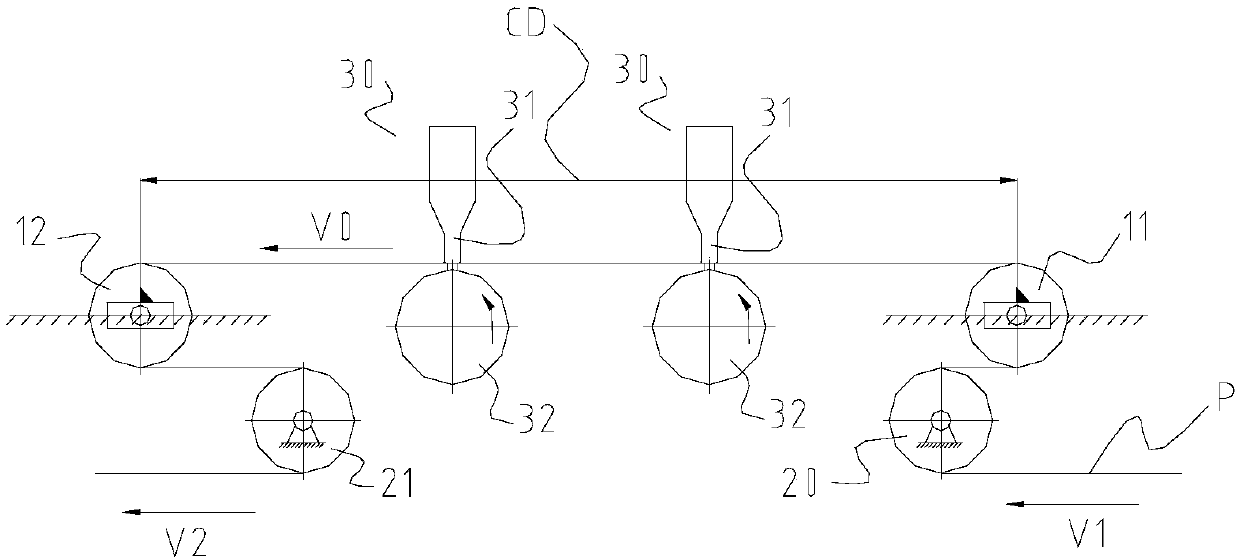

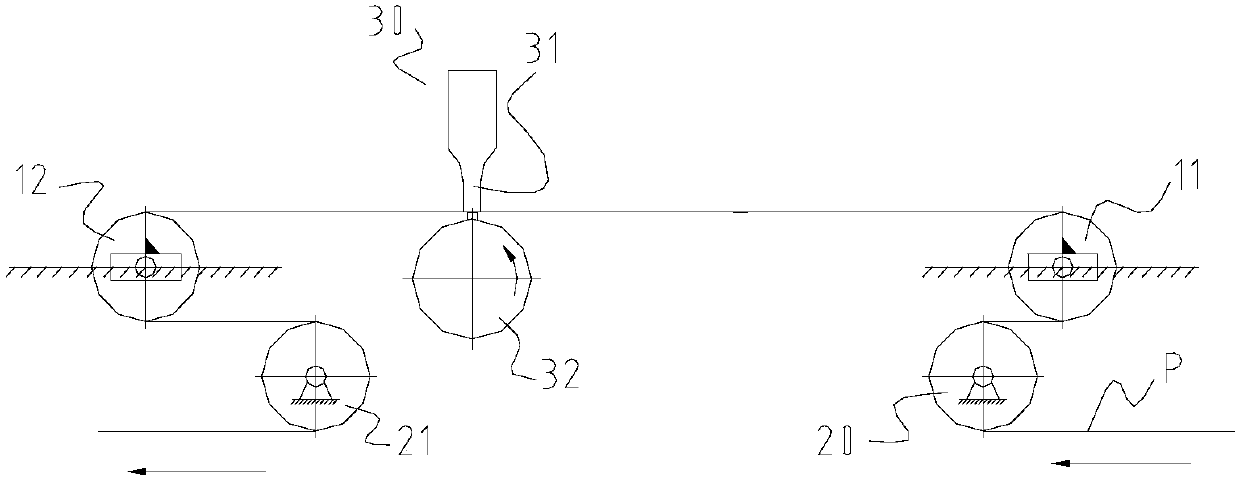

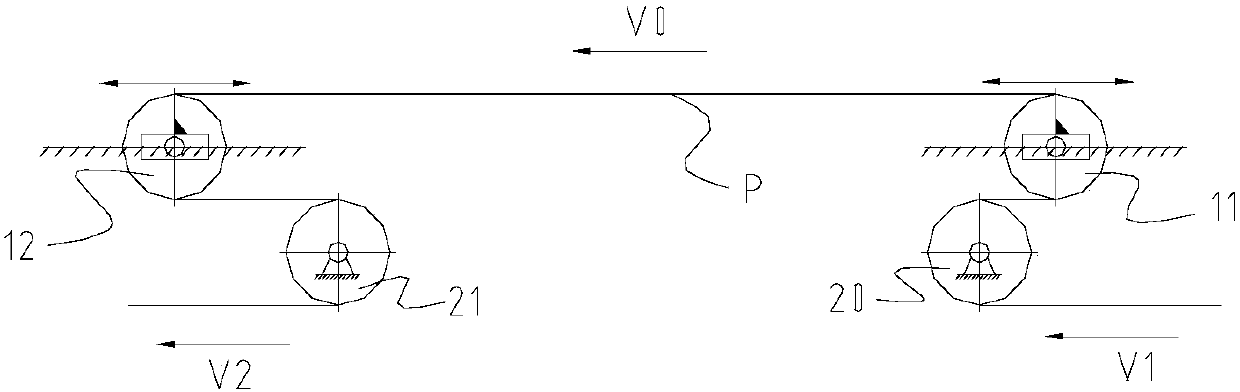

Dual-motor parallel injection control method of electric injection molding machine

The invention discloses a dual-motor parallel injection control method of an electric injection molding machine. The dual-motor parallel injection control method comprises the steps that the controller establishes a motion model through reading a set process parameter, and sends speed and torque parameter instructions to a master driver and a slave driver respectively; the two drivers respectively output frequency and current according to the instructions of the controller to drive servo motors to execute actions. The controller balances output torque of the two servo motors by controlling the two drivers to ensure that the torque of the two servo motors is overlapped. Meanwhile, the controller ensures that a system achieves speed synchronization through speed control on the master driver and driving of a synchronization belt between the two servo motors. The dual-motor parallel injection control method has the advantages of reducing the cost and lowering the inertia of the servo motors.

Owner:NINGBO ZHAFIR PLASTICS MACHINERY

Welding system for tablets

PendingCN107662344AExtension of timeImprove reliabilityDomestic articlesUltrasonic weldingEngineering

The invention discloses a welding system for tablets. The welding system comprises ultrasonic welding devices and a speed changing device; the speed changing device comprises a first floating roller for receiving the tablets sent from the upstream position, a second floating roller for sending the processed tablets downwards, a first driving mechanism for enabling the first floating roller and thesecond floating roller to reciprocate transversely in the same direction as well as a second driving mechanism for enabling the first floating roller and the second floating roller to rotate at the variable speed; and one or more groups of the ultrasonic welding devices are arranged between the first floating roller and the second floating roller and perform welding operations on the tablets at the time intervals when the linear speed between the two floating rollers is decreased. The welding system has the advantages of being compact in structure, high in rigidity, low in cost, convenient tomount, prone to minimization and the like, the welding time for materials can be fully guaranteed and can be adjusted flexibly according to the welding effect, and the high-speed production requirement of products can be met while the welding effect is guaranteed.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Scrap-free planetary cutting machine for PE (polyethylene) tubes

ActiveCN103692471AReduce energy consumptionCutting stabilityMetal working apparatusManufacturing lineScrap

The invention discloses a scrap-free planetary cutting machine for PE (polyethylene) tubes. The planetary cutting machine comprises a frame. A servo follower and a cutting device are sequentially arranged on the frame. The cutting device comprises a mounting plate, a turnplate, a clamping mechanism, a cutting mechanism and a power source guide device. The turnplate is arranged coaxially with the mounting plate, the clamping mechanism is arranged on the mounting plate, and the cutting mechanism is arranged on the turnplate. The scrap-free planetary cutting machine is reliable in cutting, cuts are free of protruding edges, quality of the tubes can be improved on the premise of speed synchronization of a cutting trolley and a tube production line, and mechanical failure rate is reduced.

Owner:GUANGDONG LIANSU MACHINERY MFG

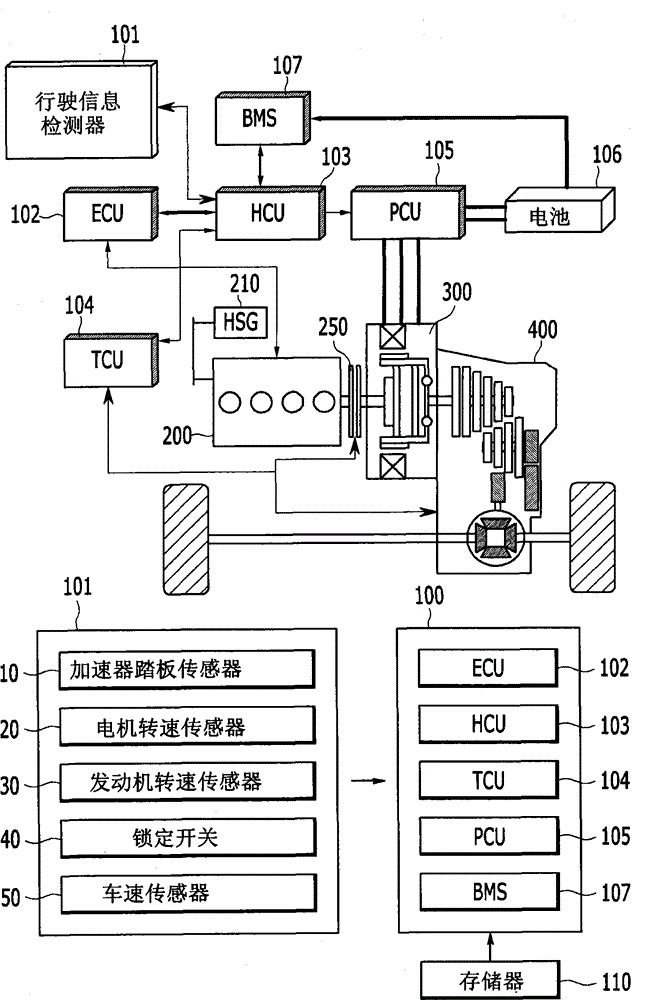

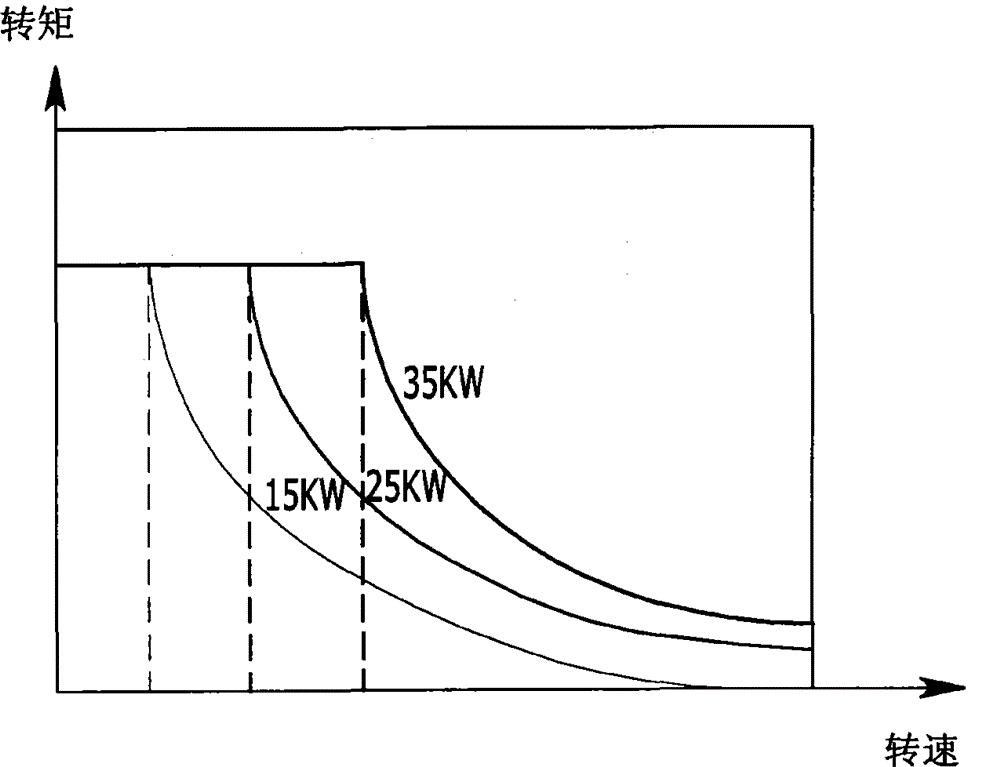

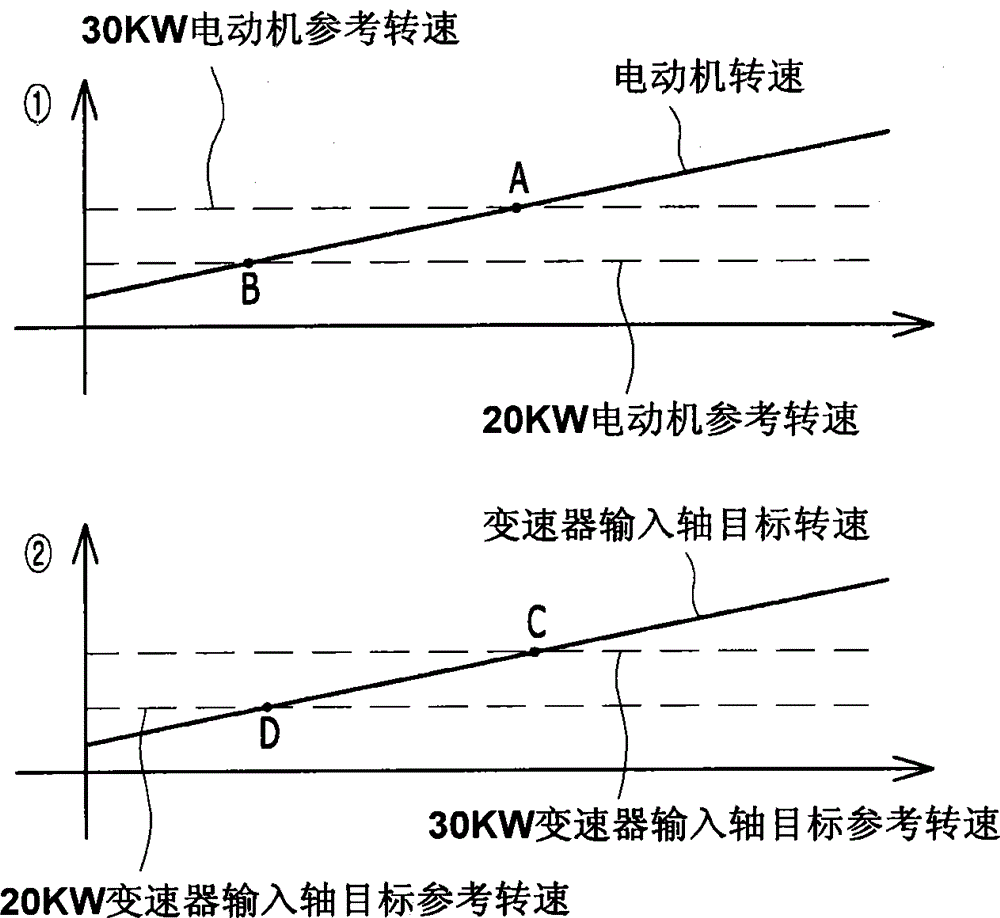

Hybrid vehicle and control method for the same

InactiveCN104627172ATempo syncHybrid vehiclesPlural diverse prime-mover propulsion mountingMotor speedAutomatic transmission

A control method of a hybrid vehicle is provided and includes determining whether a current vehicle driving mode is an EV mode, whether a current vehicle driving state satisfies a kick-down shift condition, and whether the current vehicle driving state satisfies a driving mode conversion condition for conversion into an HEV mode. The engine is started when the kick-down shift and the driving mode conversion conditions are satisfied. A current motor speed and discharging power of the battery are measured. The measured motor speed and predetermined motor reference speed are compared based on discharging power of the battery. A transmission input shaft target speed for the kick-down shift is calculated and compared to a predetermined transmission input shaft target reference speed based on discharging power of the battery. A control order is determined based on the comparisons and the kick-down shift and the engagement of the engine clutch are performed.

Owner:HYUNDAI MOTOR CO LTD +1

Setup method and arrangement for printing machine

ActiveCN103987524ATangential Speed SynchronizationImprove printing qualityCylinder pressesOther printing apparatusPrinting pressControl theory

Owner:BOBST MEX SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com