Patents

Literature

51results about How to "Automatic placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

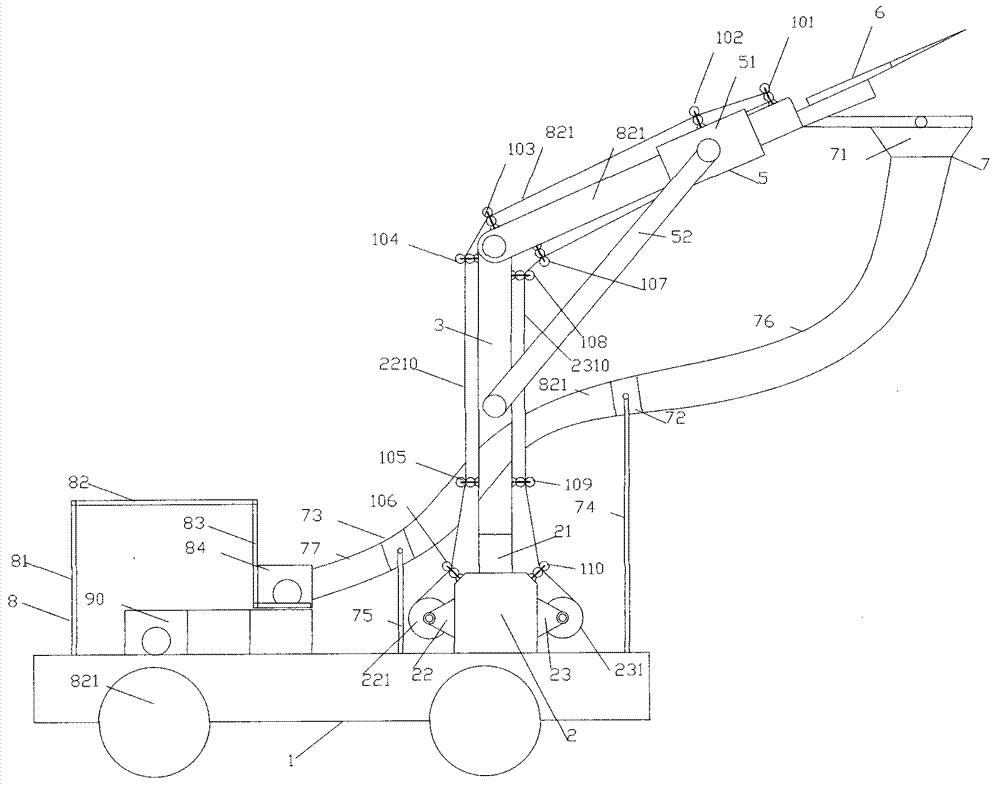

Apple picking machine and method for operating same

ActiveCN104255193AOptimization pathEasy to collectPicking devicesPulp and paper industryUltimate tensile strength

The invention discloses an apple picking machine and a method for operating the same. The apple picking machine comprises a framework, a shearing mechanism, an adjusting mechanism, a collecting channel, an accommodating mechanism and an apple box. The adjusting mechanism comprises a support column, a rotary column and a crank-slider mechanism; the bottom of the support column sleeves a base, and the top of the support column is hinged to an end of the rotary column; the crank-slider mechanism comprises a slider and a connecting rod, the slider sleeves the rotary column, one end of the connecting rod is hinged to the rotary column, and the other end of the connecting rod is hinged to the support column; the shearing mechanism is arranged on the top of the rotary column. The apple picking machine and the method have the advantages that the height of shears can be conveniently controlled via the crank-slider mechanism, and the apple picking machine can be controlled via motors and is simple in operation and low in labor intensity; an electromagnet is arranged at the tail of a handle of the shears, so that the apple picking machine can be conveniently manually operated, and the labor intensity can be reduced; the apple picking machine is provided with the collecting channel, so that apples can be conveniently collected while bruise due to an accommodating machine can be effectively prevented; the apples can be automatically placed by the accommodating mechanism which is matched with the apple box, and accordingly the labor time can be saved.

Owner:刘宝帅 +1

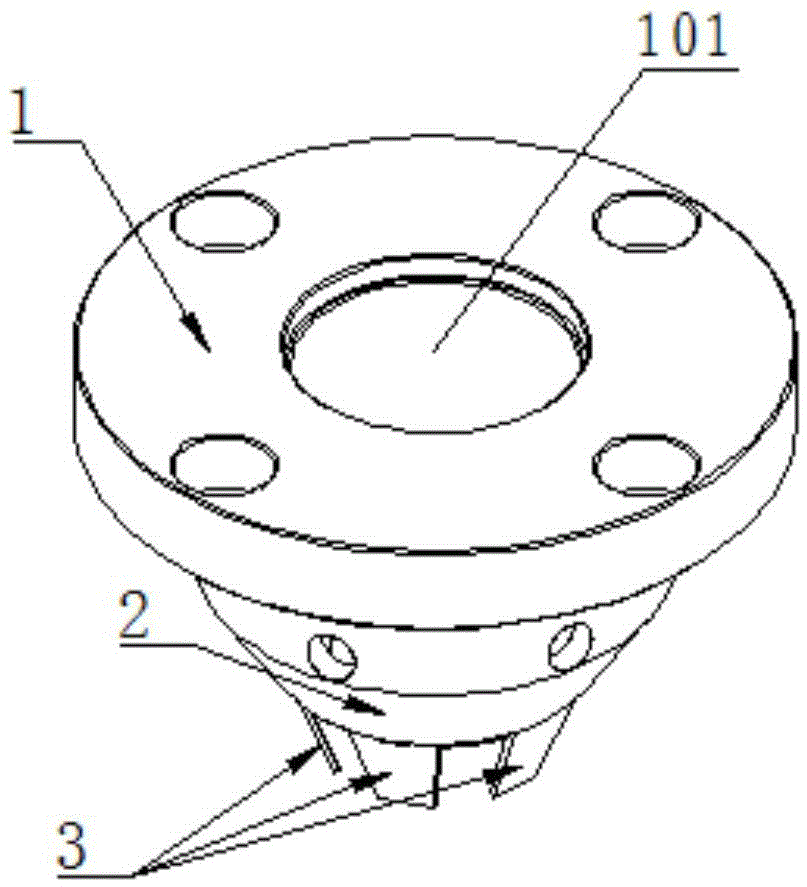

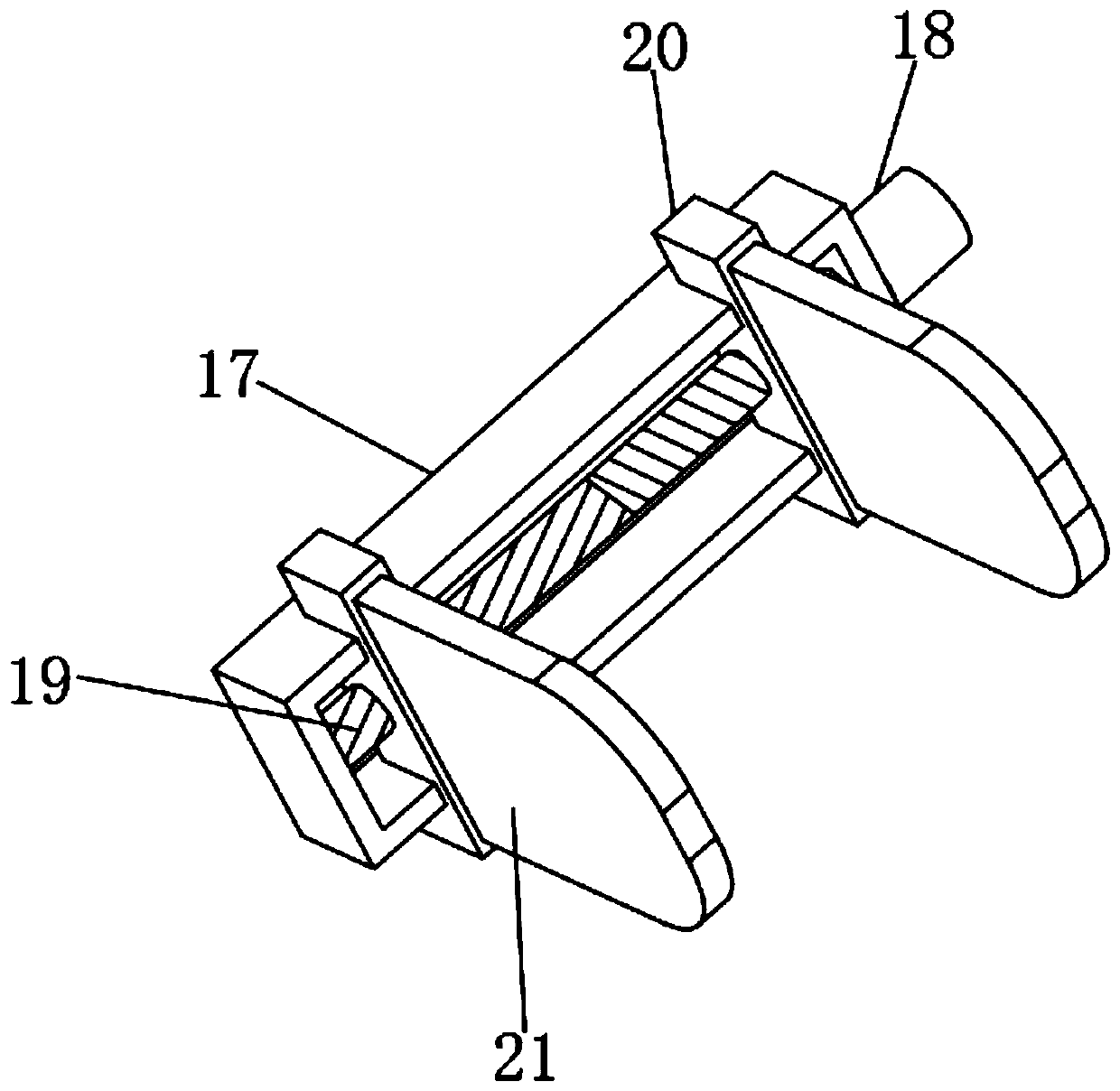

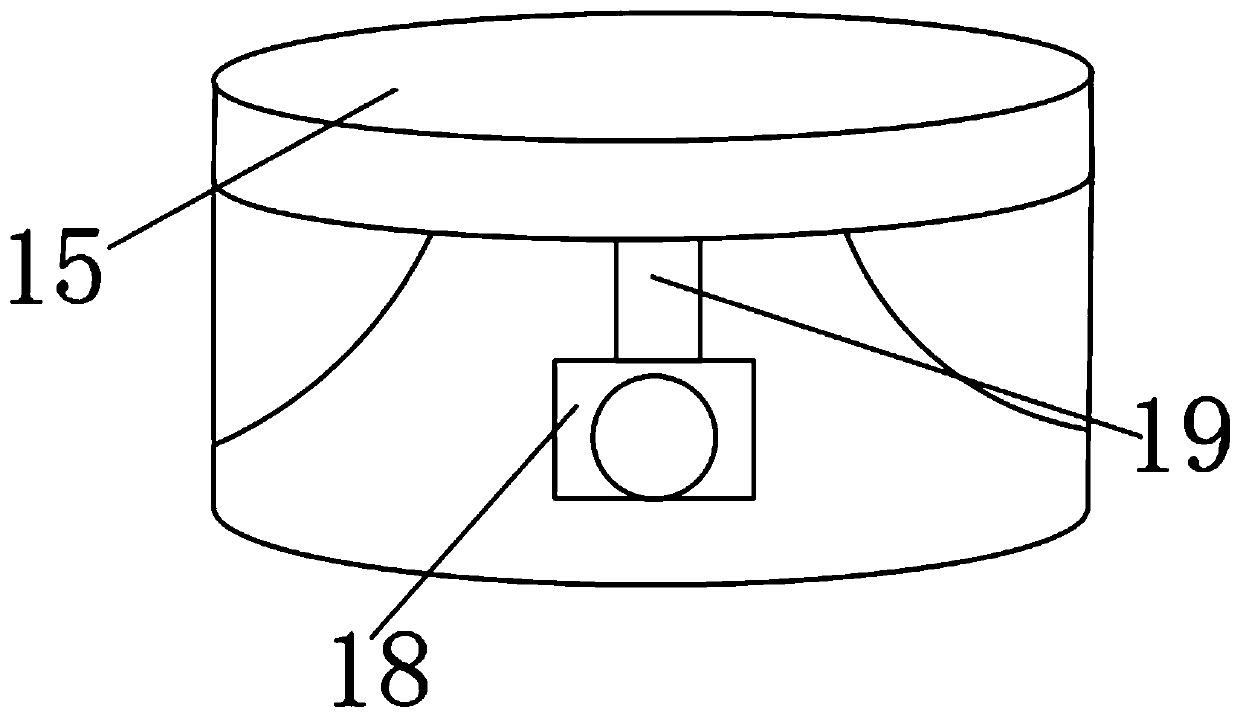

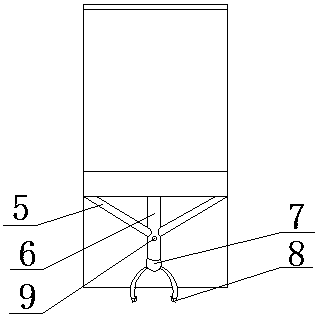

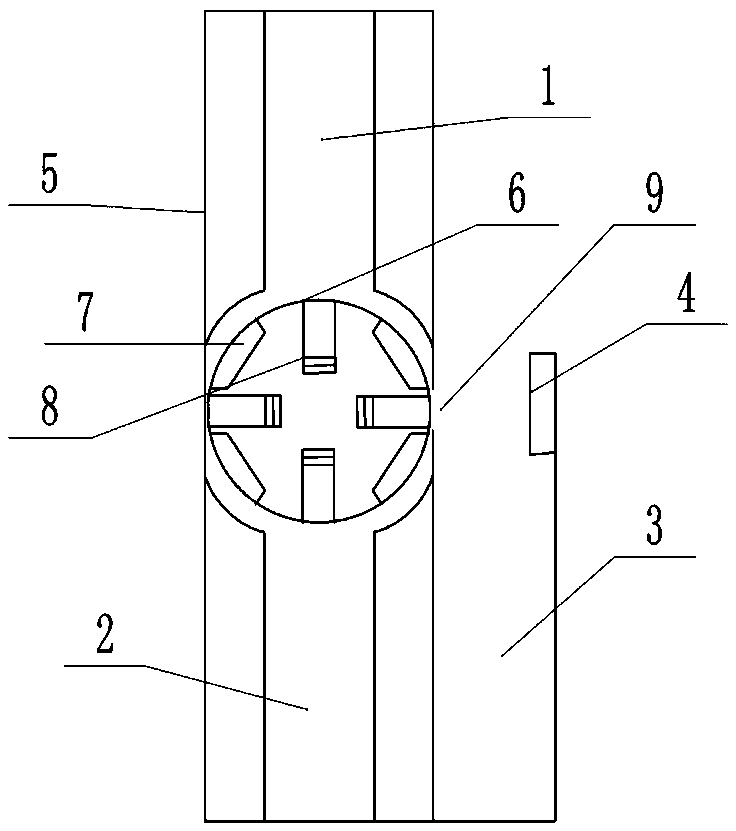

Automatic putting device for round paper scrip of fireworks

ActiveCN105571407AGuarantee processing qualityGuarantee the quality of fireworksFireworksInternal cavityLinear drive

The invention discloses an automatic putting device for round paper scrips of fireworks. The automatic putting device comprises a paper scrip compression rod which is connected with an up and down reciprocating linear drive mechanism; a paper scrip guide mechanism is arranged below the paper scrip compression rod and comprises a hole duct capable of passing through the paper scrip compression rod; a plurality of elastic claw bodies are arranged around the lower end of the hole duct; roots of the elastic claw bodies are arranged in the periphery of the hole duct; the plurality of elastic claw bodies are combined in a shape with big roots and small free ends. The device is capable of eliminating interference of factors, such as irregular paper tubes, the outer diameter of the round paper scrip being larger than the inner diameter of a paper tube, etc. on automatic machine putting work, and precisely and dynamically guiding a process that the round paper scrips are put into the inner cavity of the paper tube so that the round paper scrips are put automatically and smoothly; a tube body is not damaged, the round paper scrips are placed flatly, the processing quality is guaranteed; a center hole is not needed in a top sheet and thus the fireworks quality is guaranteed.

Owner:罗词芳

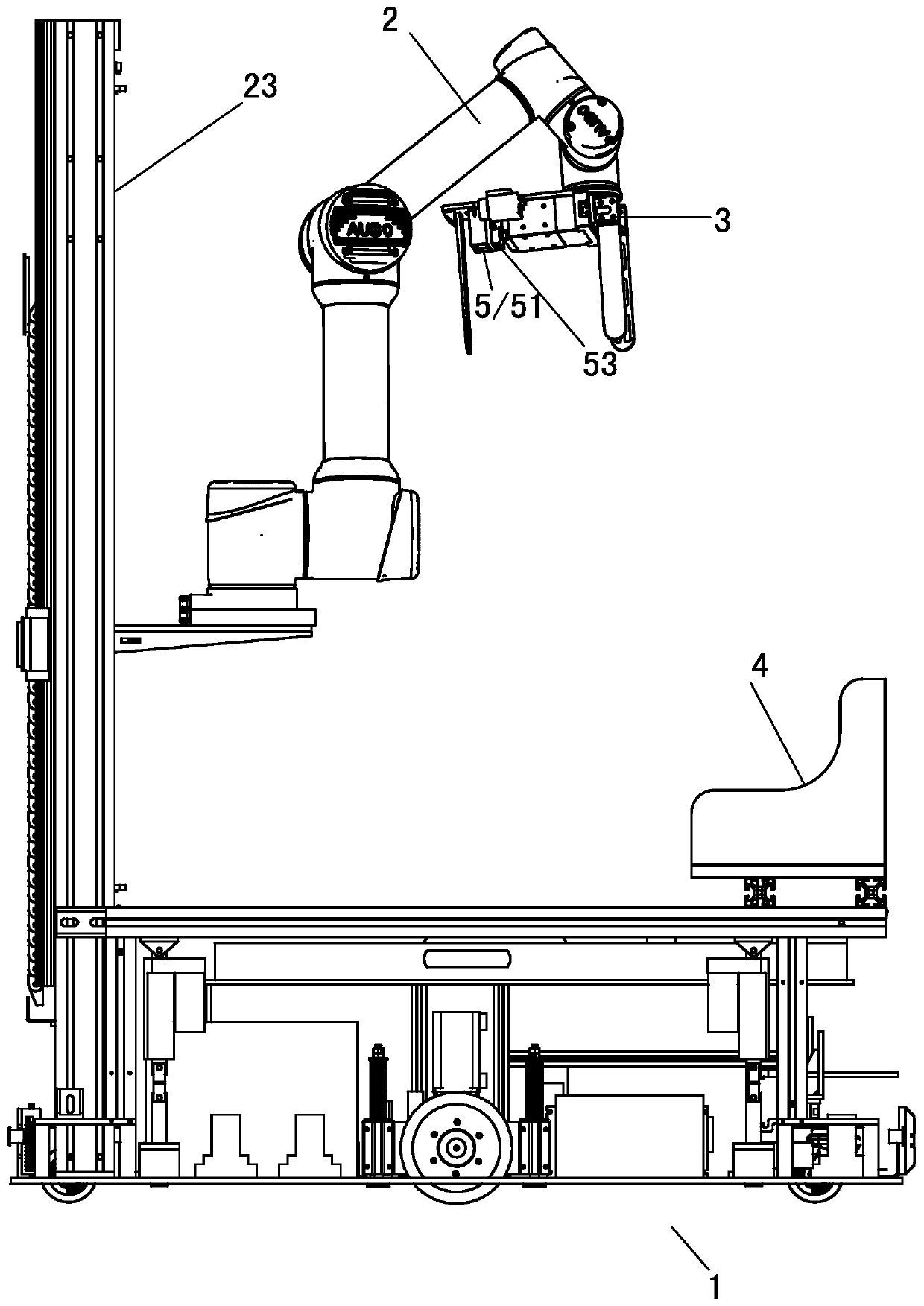

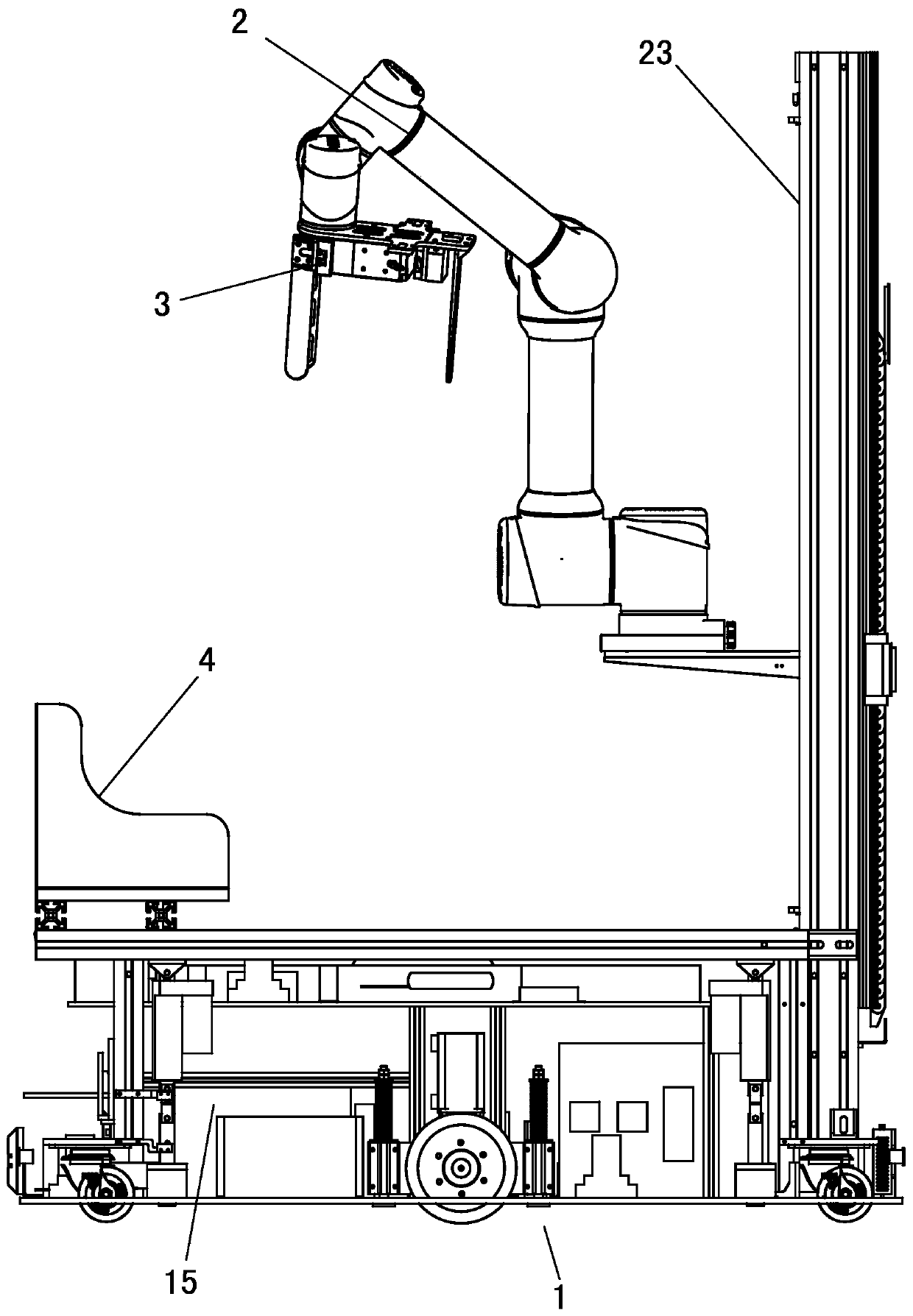

Archive management robot

PendingCN110355736AHigh degree of intelligence in mechanical automationImprove work efficiencyProgramme-controlled manipulatorIntelligent lightingMechanical equipment

The invention relates to the field of intelligent mechanical equipment for archive management, and particularly discloses an archive management robot. The archive management robot comprises an intelligent navigation and positioning transport vehicle, a manipulator, an electric clamping jaw, an archive transfer frame, an archive identification module and an archive management system server, whereinthe manipulator is mounted on the intelligent navigation and positioning transport vehicle; the electric clamping jaw is arranged on the free end of the manipulator; the archive transfer frame is installed on the intelligent navigation and positioning transport vehicle; the intelligent navigation and positioning transport vehicle includes a central control computer and a communication module; theactions of the intelligent navigation and positioning transport vehicle, the manipulator and the electric clamping jaw are controlled by the central control computer; the archive identification module is arranged on the electric clamping jaw; and the communication module can be used for the communication connection among the central control computer, the archive identification module and the archive management system server. The archive management robot has a higher degree of mechanical automation and intelligence, high working efficiency, stable work and low error rate, and can be used for checking, sorting, management, data traceability and other functions of archives.

Owner:FUJIAN QUANZHOU HIT RES INSTIUTE OF ENG & TECH

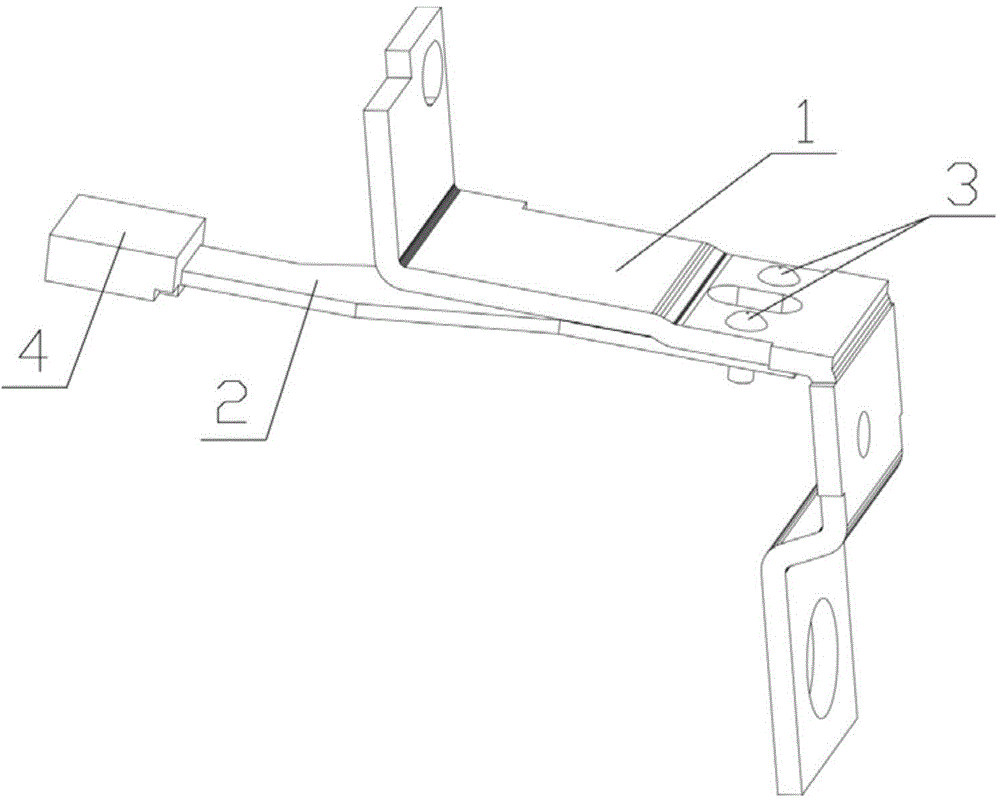

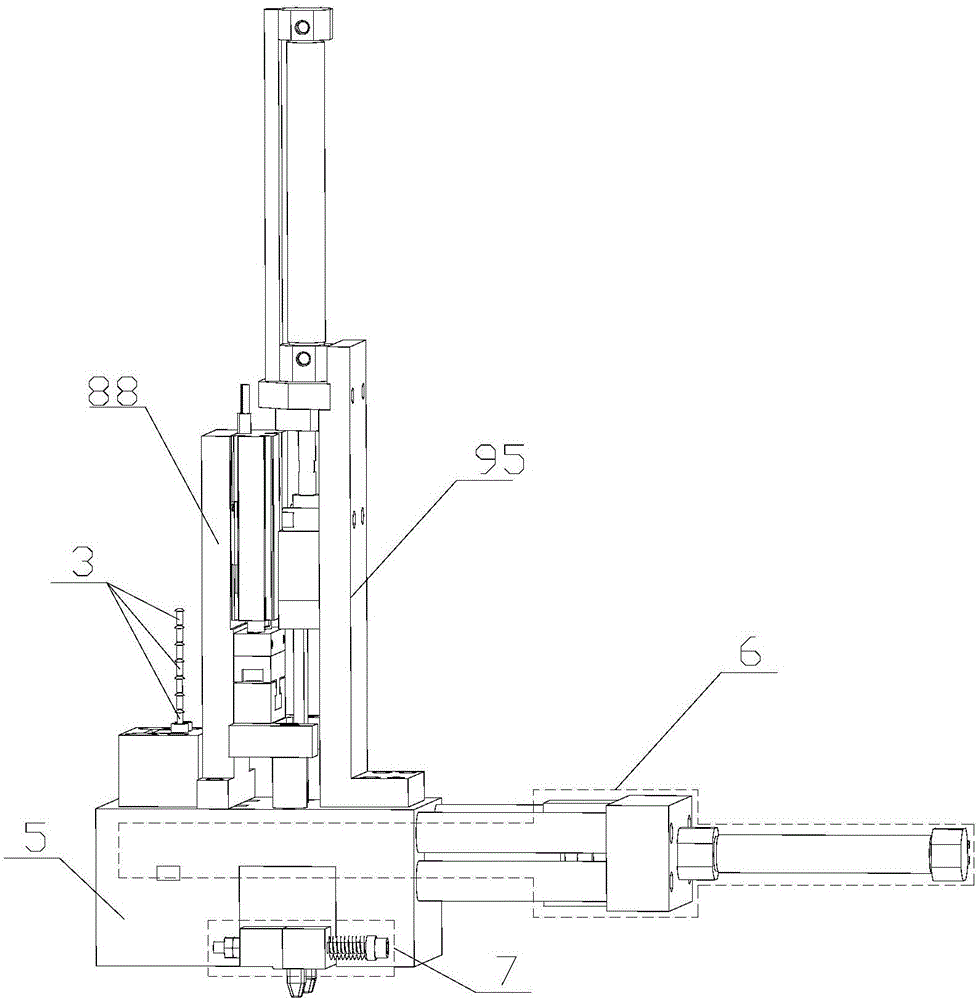

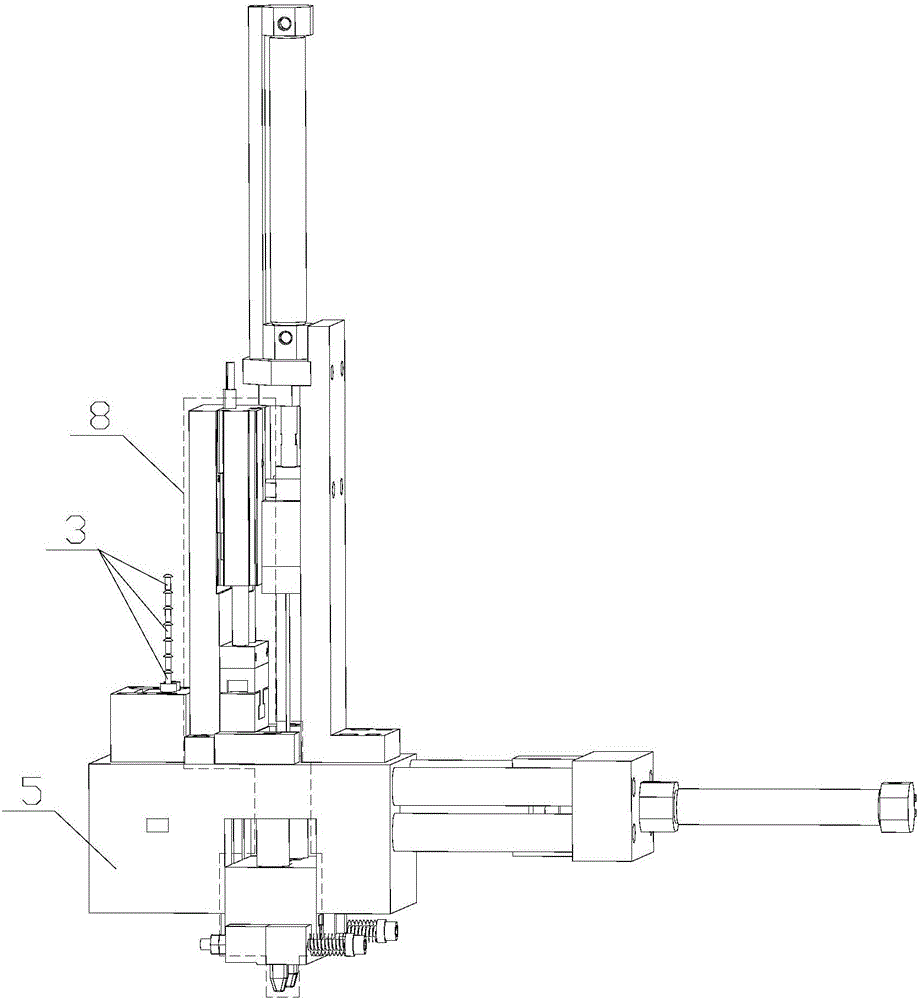

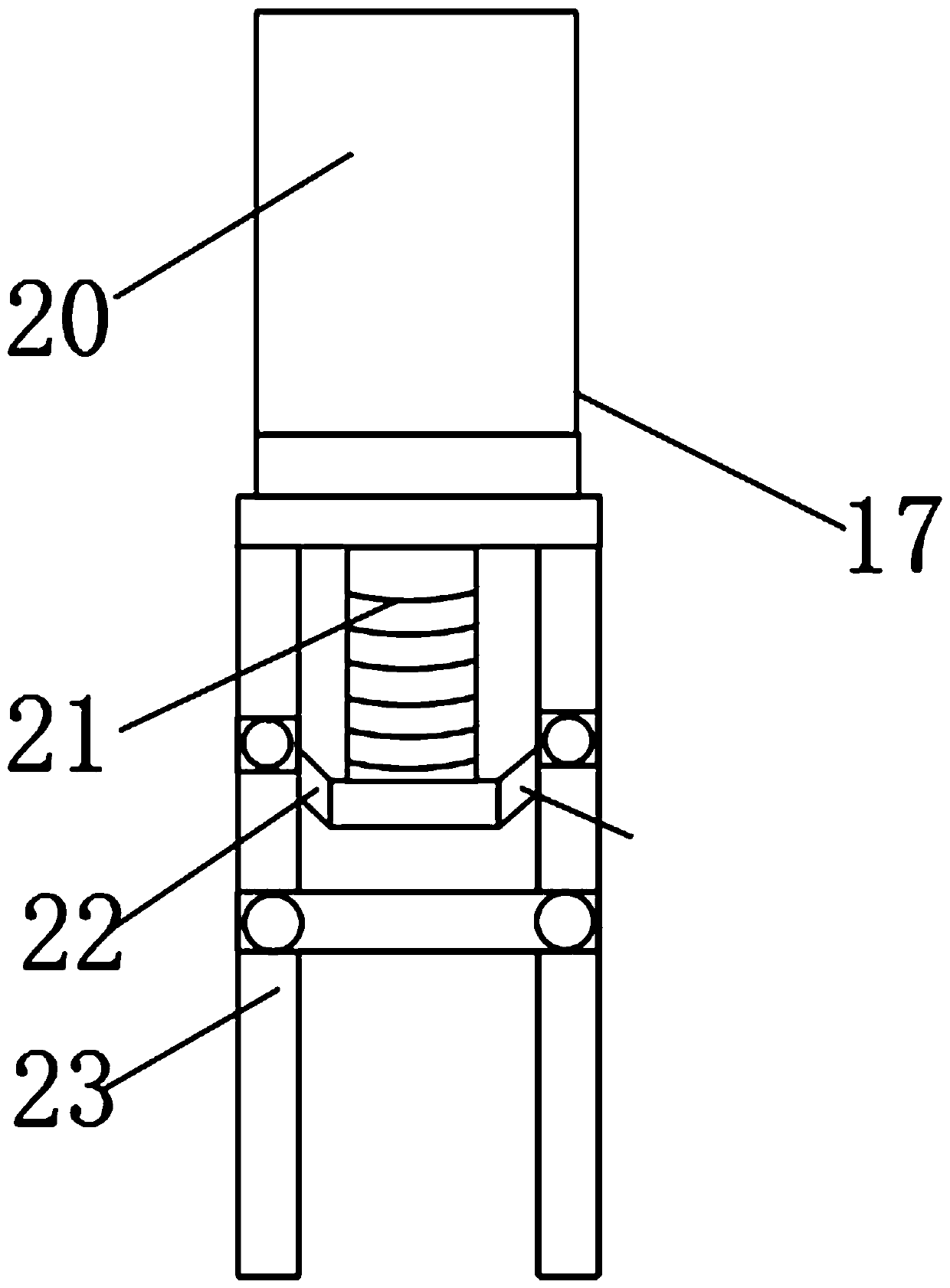

Automatic rivet installation device

The invention discloses an automatic rivet installation device. The automatic rivet installation device comprises an installation base, a conveying base, a rivet conveying part, a clamping part, a positioning part and a rivet pushing part. The rivet conveying part is used for separating rivets out from a rivet strip and conveying the separated-out single rivets to the position above a product on which the rivets need to be installed; the clamping part is installed in the installation base, located above the product and used for clamping the rivets falling under the effect of gravity; the positioning part is connected with the clamping part and used for pushing the clamping part onto the upper surface of the product; the rivet pushing part is used for pushing the rivets in the clamping parts into rivets holes of the product. Through the coordination action of the conveying base, the rivet conveying part, the clamping part, the positioning part and the rivet pushing part, the rivets can be automatically and accurately installed, labor cost is effectively lowered, and production efficiency is improved. The automatic rivet installation device is suitable for large-batch production.

Owner:苏州瑞玛精密工业股份有限公司

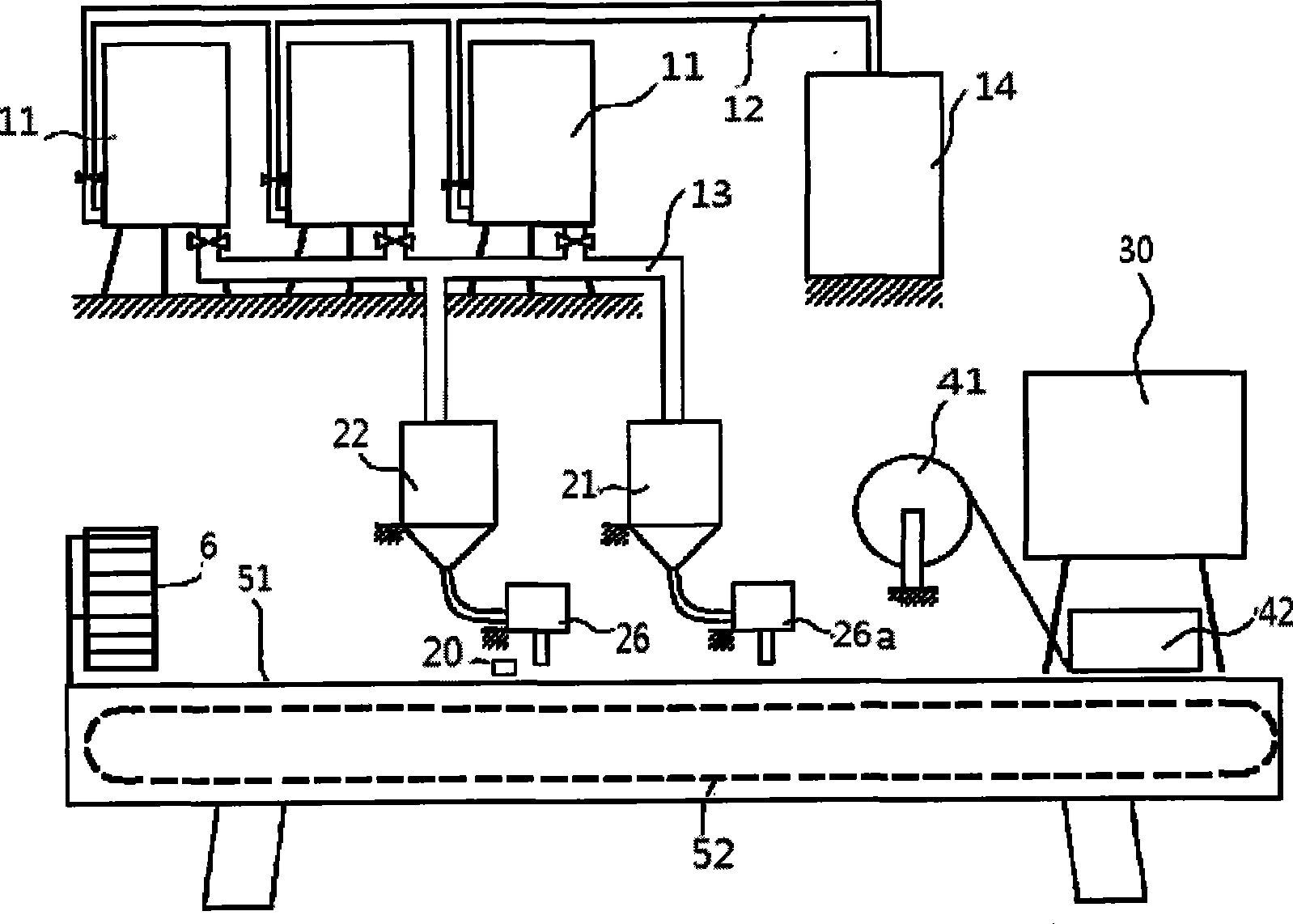

Equipment for automatically processing molding bean curd packed in box

InactiveCN101375708AAutomatic placementIncrease productivityCheese manufactureFood shapingProgrammable logic controllerData acquisition

The invention discloses fully-automatic processing equipment for packed bean curd formation. The equipment comprises a worktable, an aluminum mould conveyor chain, a plurality of size boiling kettles, a slurry hopper, a packing mechanism, a slurry filling mechanism, an additive filling mechanism, an automatic box falling mechanism, a printer and a control device, wherein, the control device consists of a programmable logic controller (PLC) and a frequency converter used for controlling the rotating speed of a motor M1 of the driving mechanism. Compared with the prior relay control, the programmable logic controller (PLC) adopted by the invention has the advantage that the programmable logic controller can ensure that the control device is compact and highly reliable, and has a long service life. Furthermore, the programmable logic controller can produce a network by expanding the communication function for remote operation, remote programming and data collection.

Owner:SHANGHAI WANGXIN BEAN PRODS EQUIP

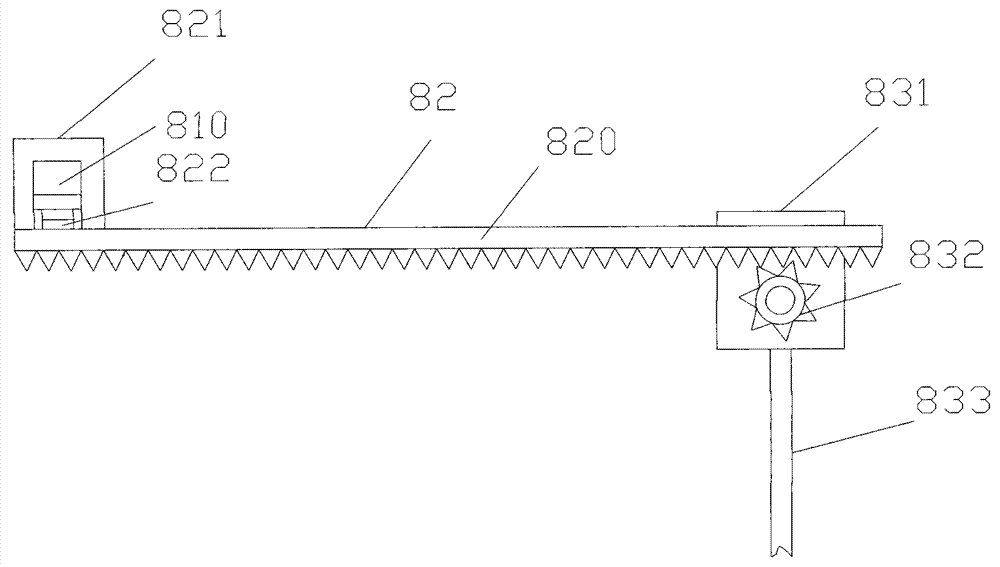

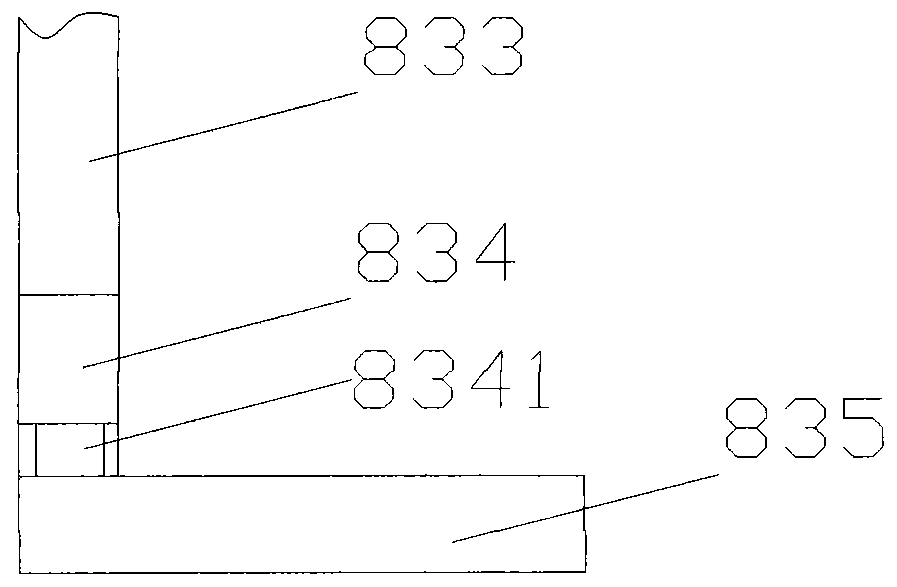

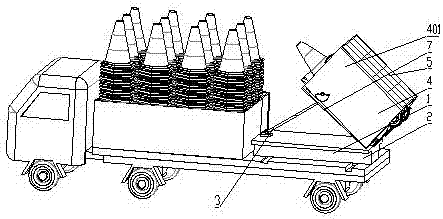

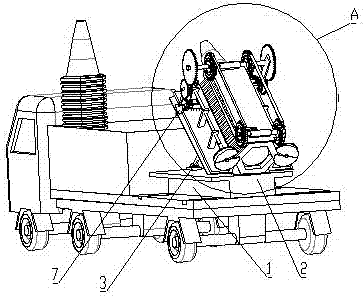

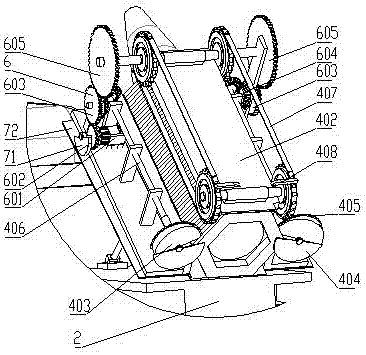

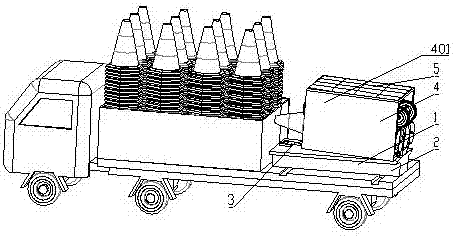

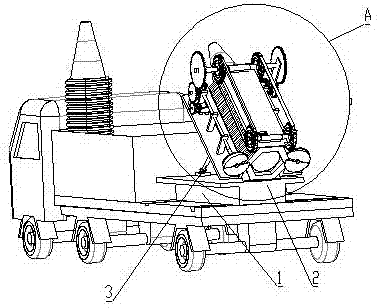

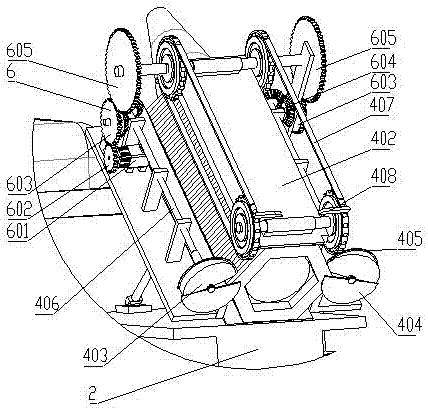

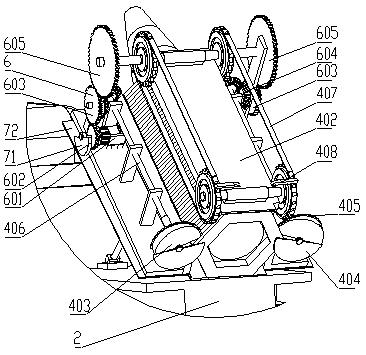

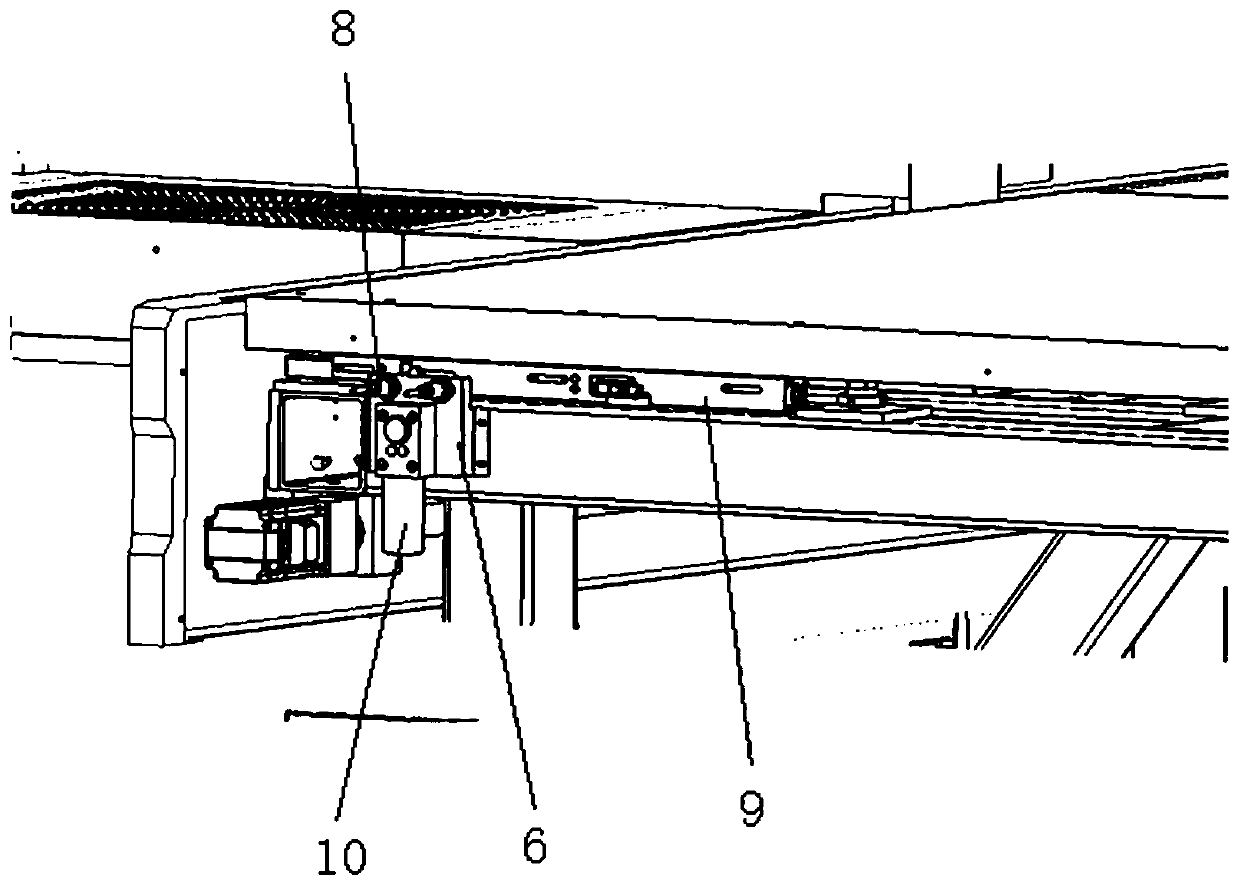

Traffic cone placing device

ActiveCN107476219ASimple structure and easy to manufactureAutomatic placementTraffic signalsRoad signsSimulationTruck

The invention discloses a traffic cone placing device and relates to the field of road traffic equipment. According to the technical scheme, the traffic cone placing device comprises a truck body and a truck bucket arranged on the rear portion of the truck body; a traffic cone placing unit is arranged on the rear side of the truck bucket and comprises a bottom platform and a traffic cone placing mechanism; the bottom platform is connected with the rear portion of the truck body through a rail; a telescopic pushing rod is arranged on the bottom platform; and one end of the telescopic pushing rod is fixedly connected with the bottom platform, and the other end of the telescopic pushing rod is fixedly connected with the lower surface of the traffic cone placing mechanism. A solar charging panel is arranged on the upper surface of a shell of the traffic cone placing mechanism, and the solar charging panel supplies power to the traffic cone placing mechanism through a storage battery. The traffic cone placing device has the beneficial effects that the traffic cone structure used in the traffic cone placing device is basically similar to the structure of an existing traffic cone, simple and easy to manufacture, the traffic cone placing unit and a truck are assembled together through a truck-mounted type structure, and in placing, traffic cones can be automatically placed in the advancing process of the truck only by additionally placing stacked traffic sets into the traffic cone placing device by people.

Owner:SHANDONG JIANZHU UNIV

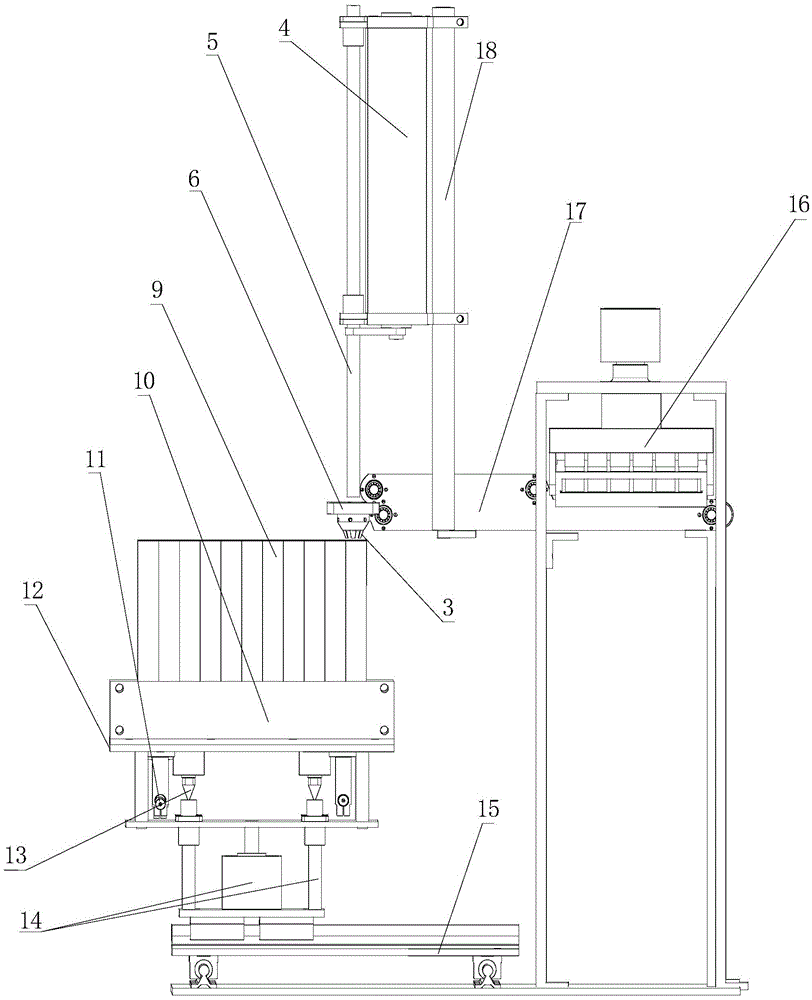

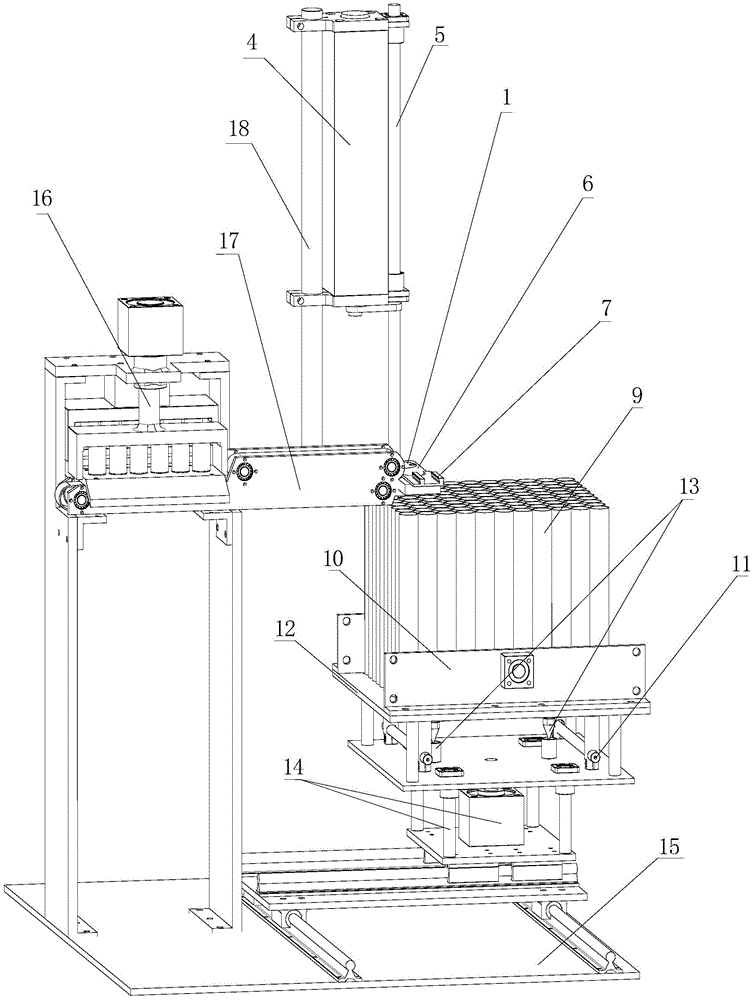

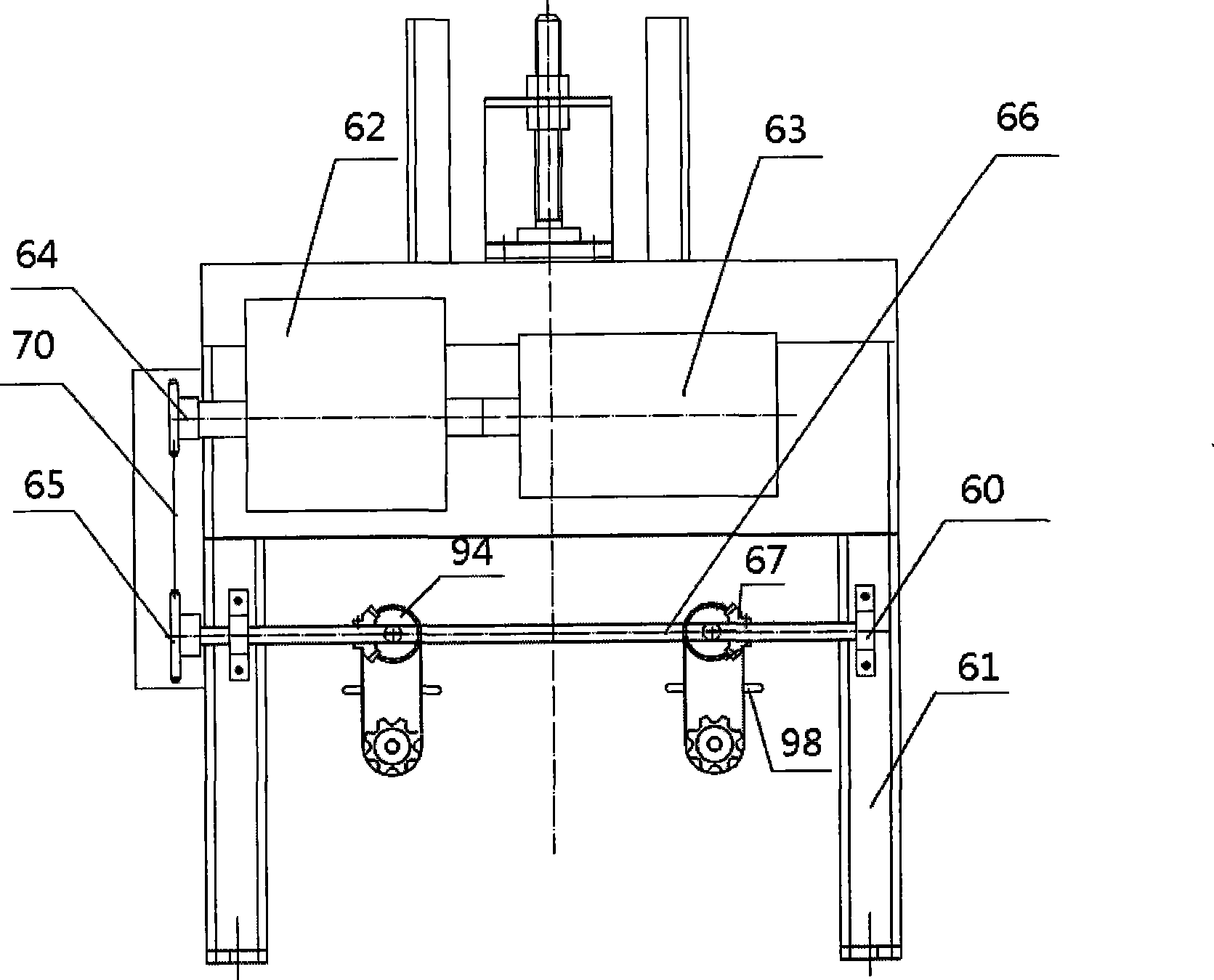

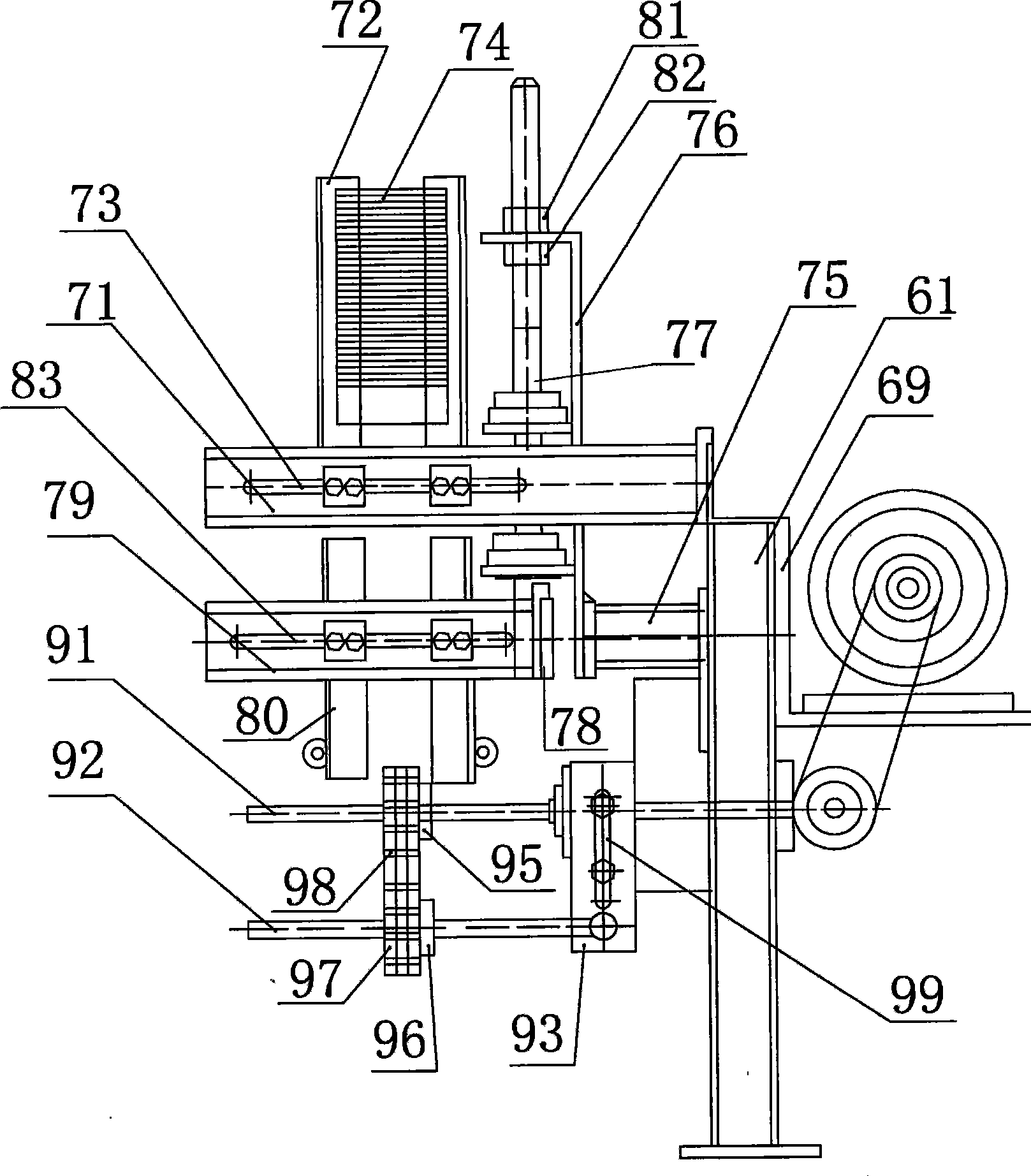

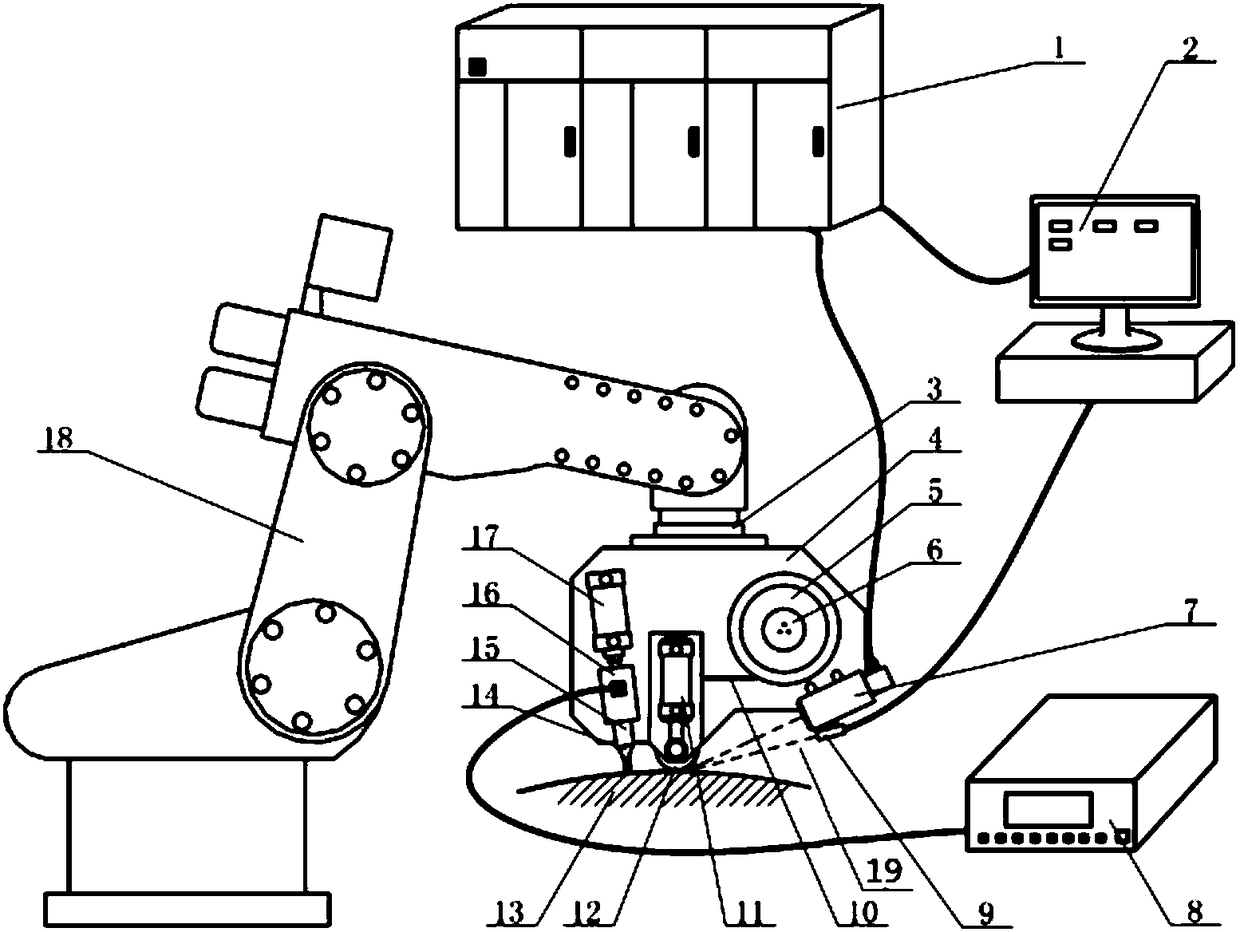

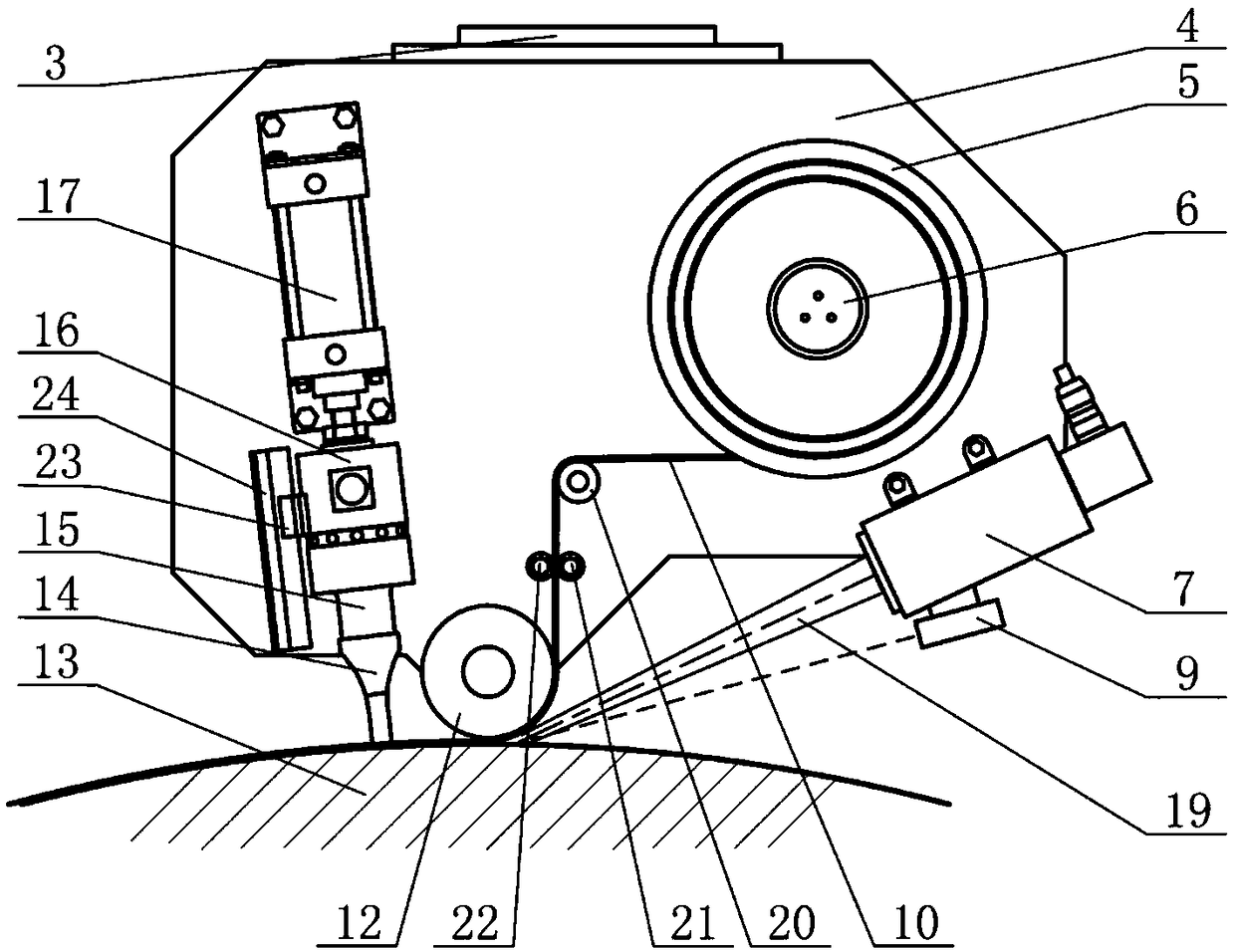

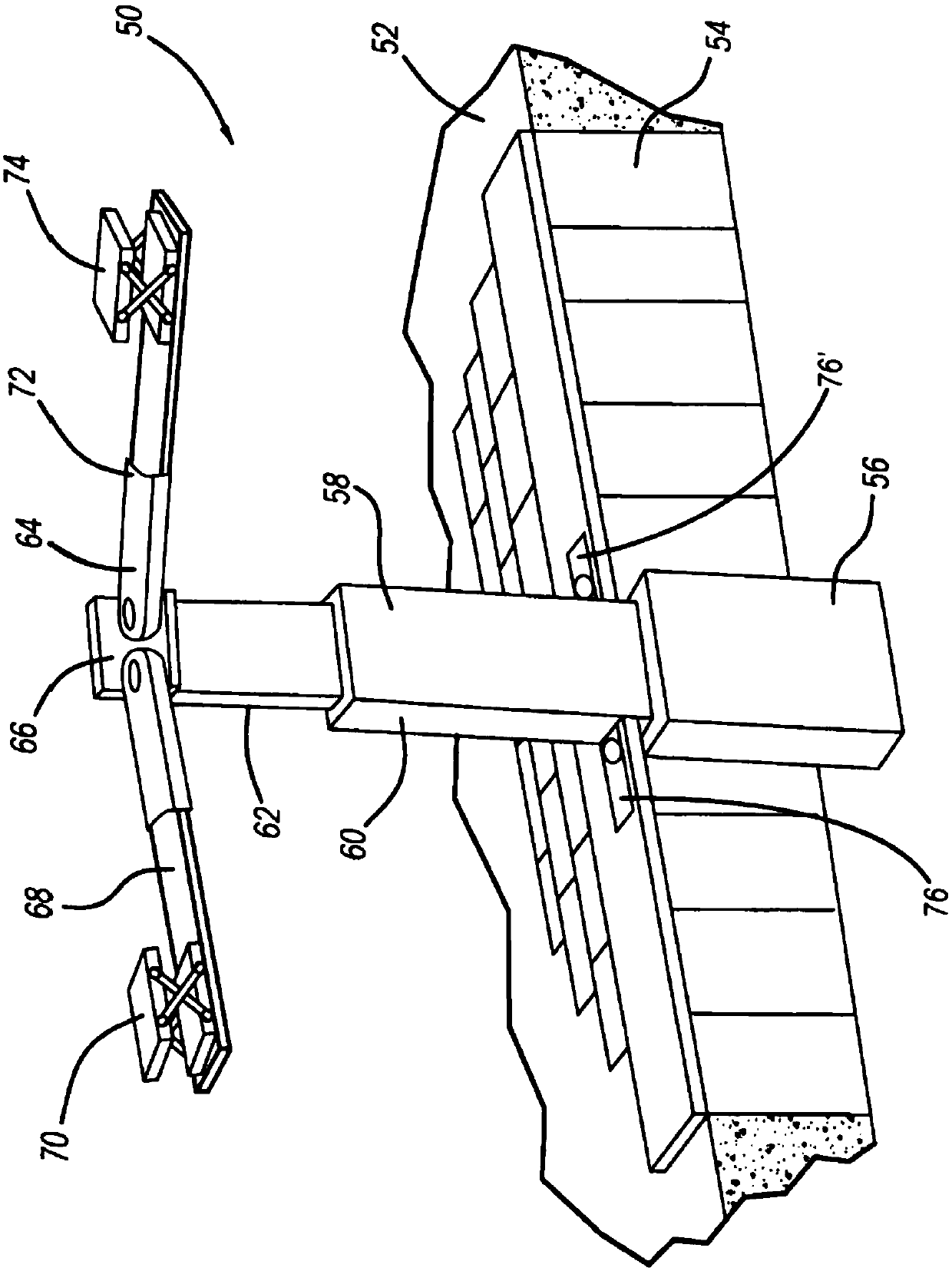

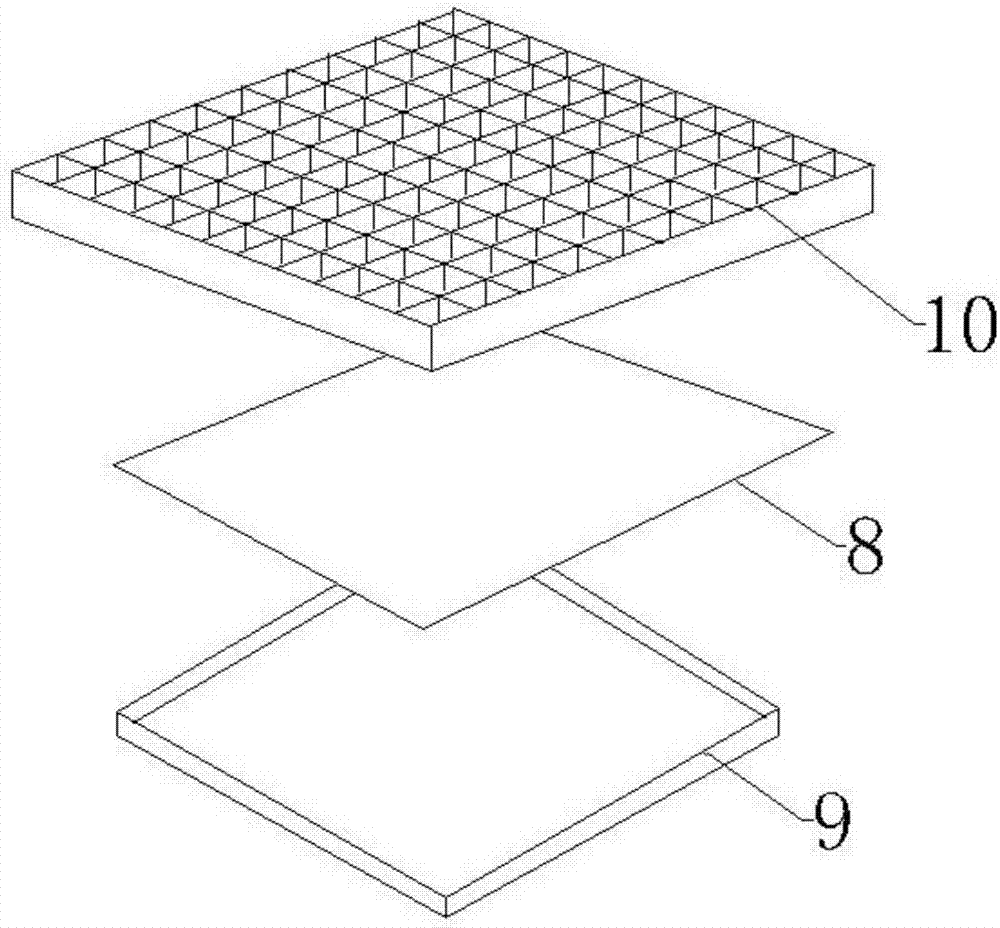

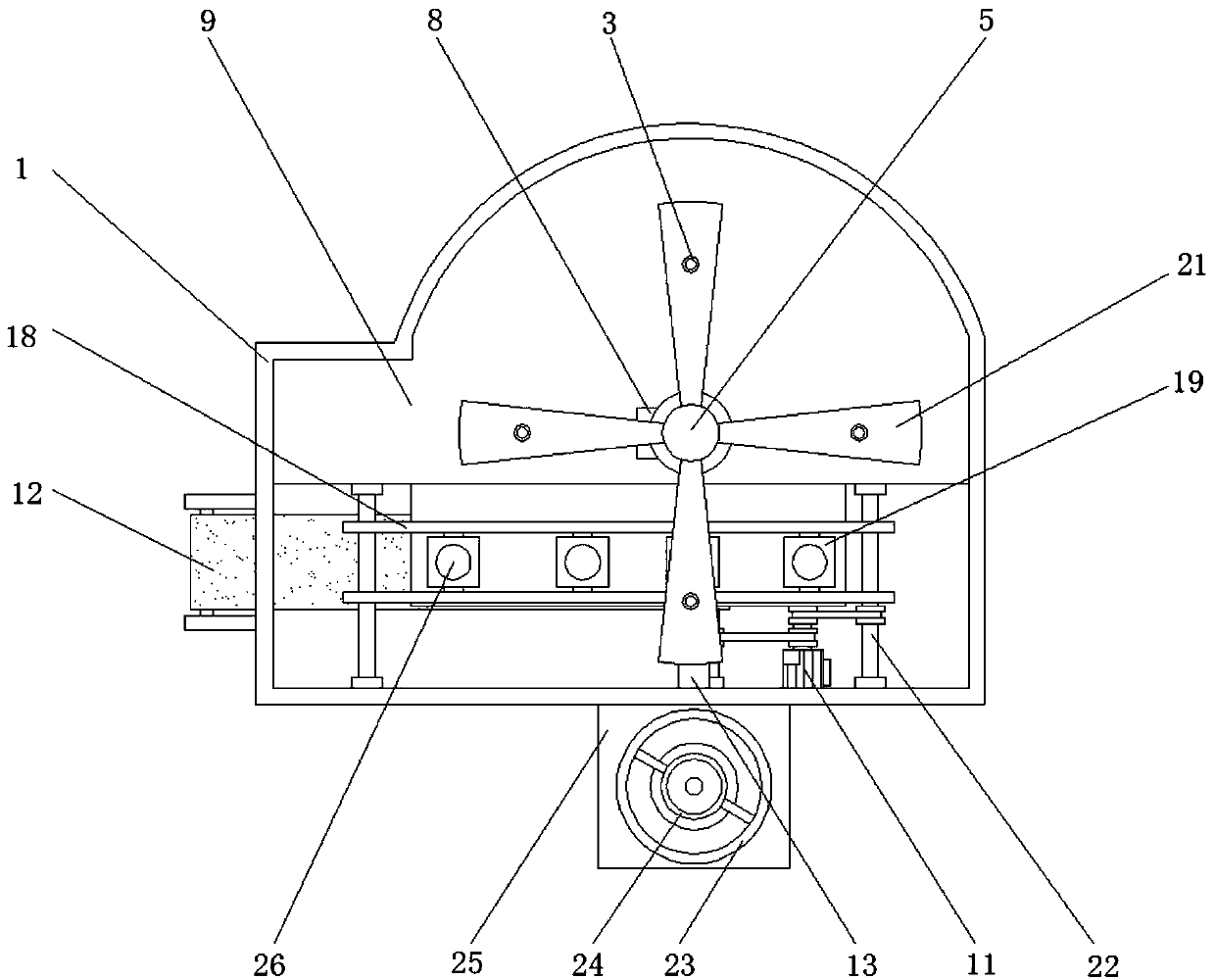

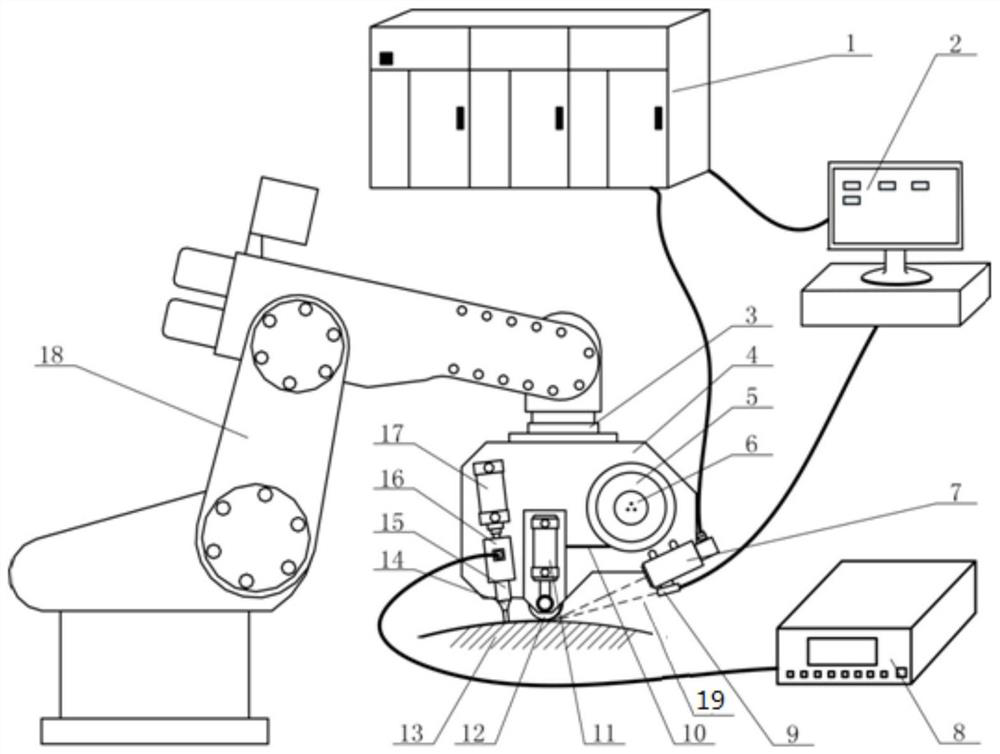

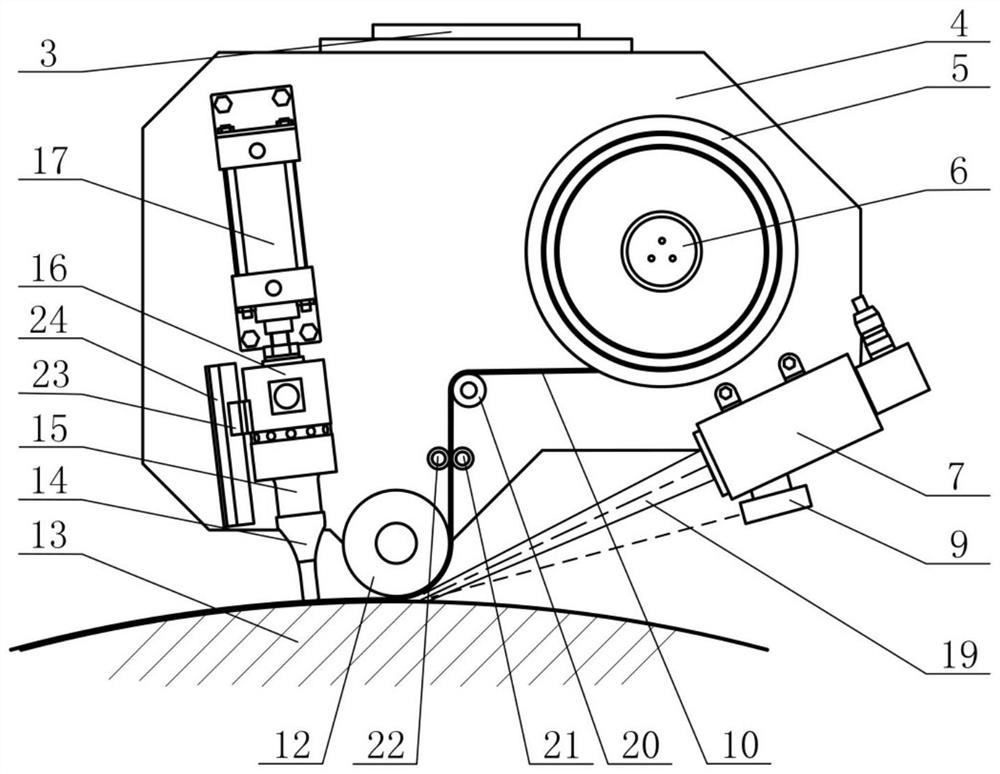

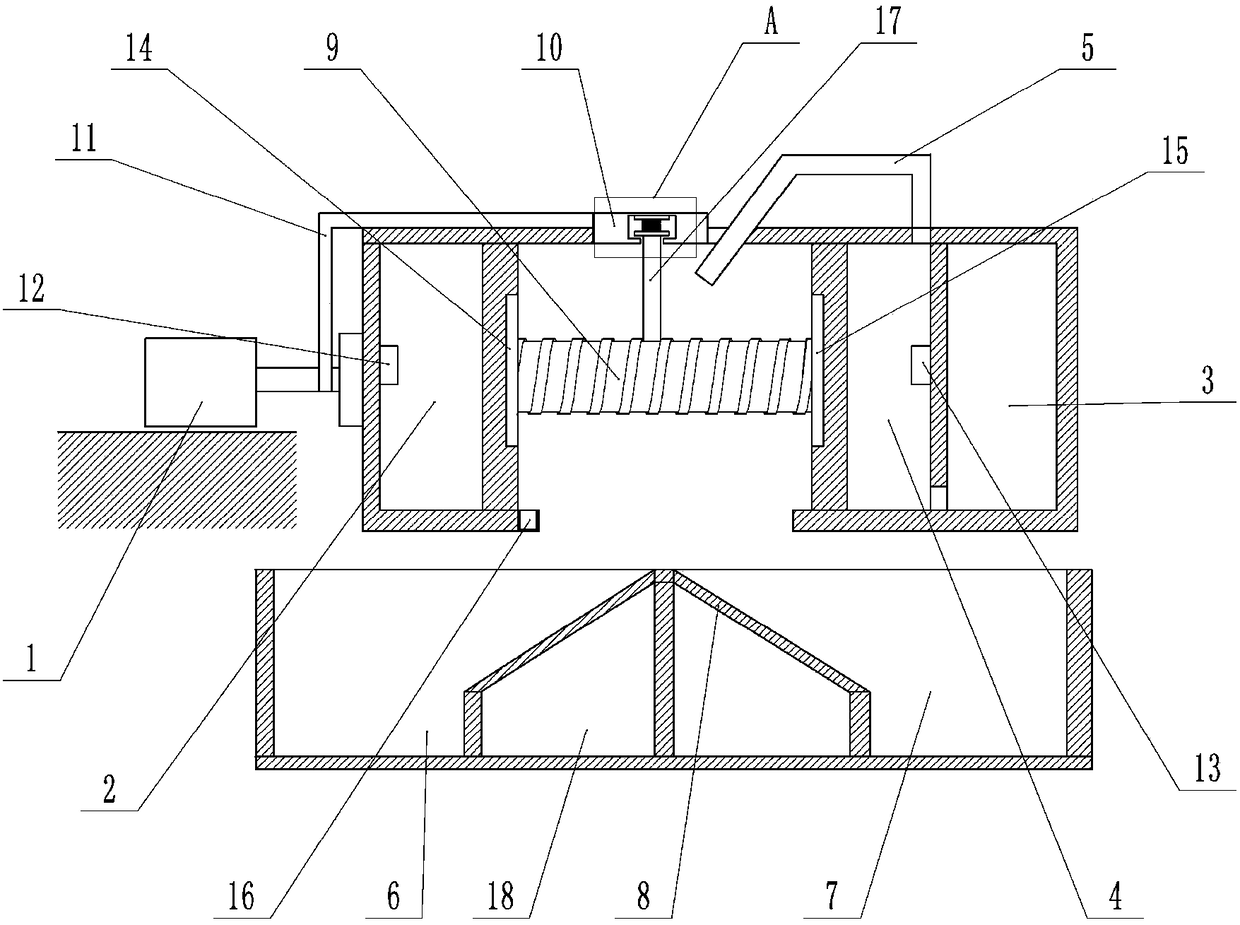

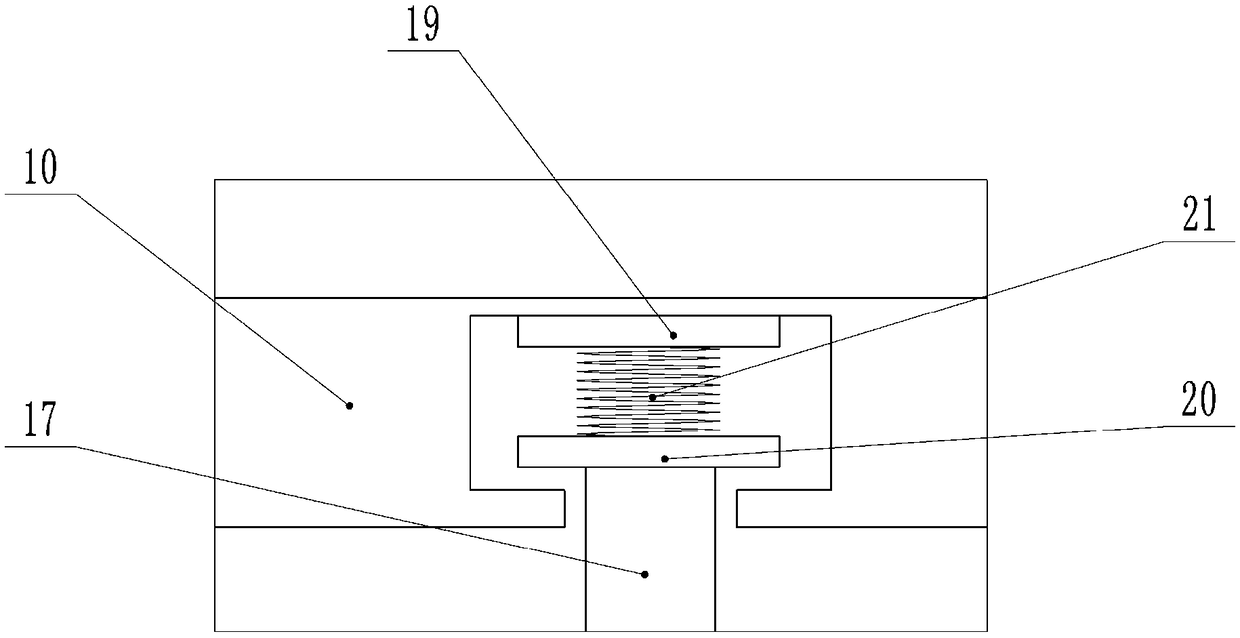

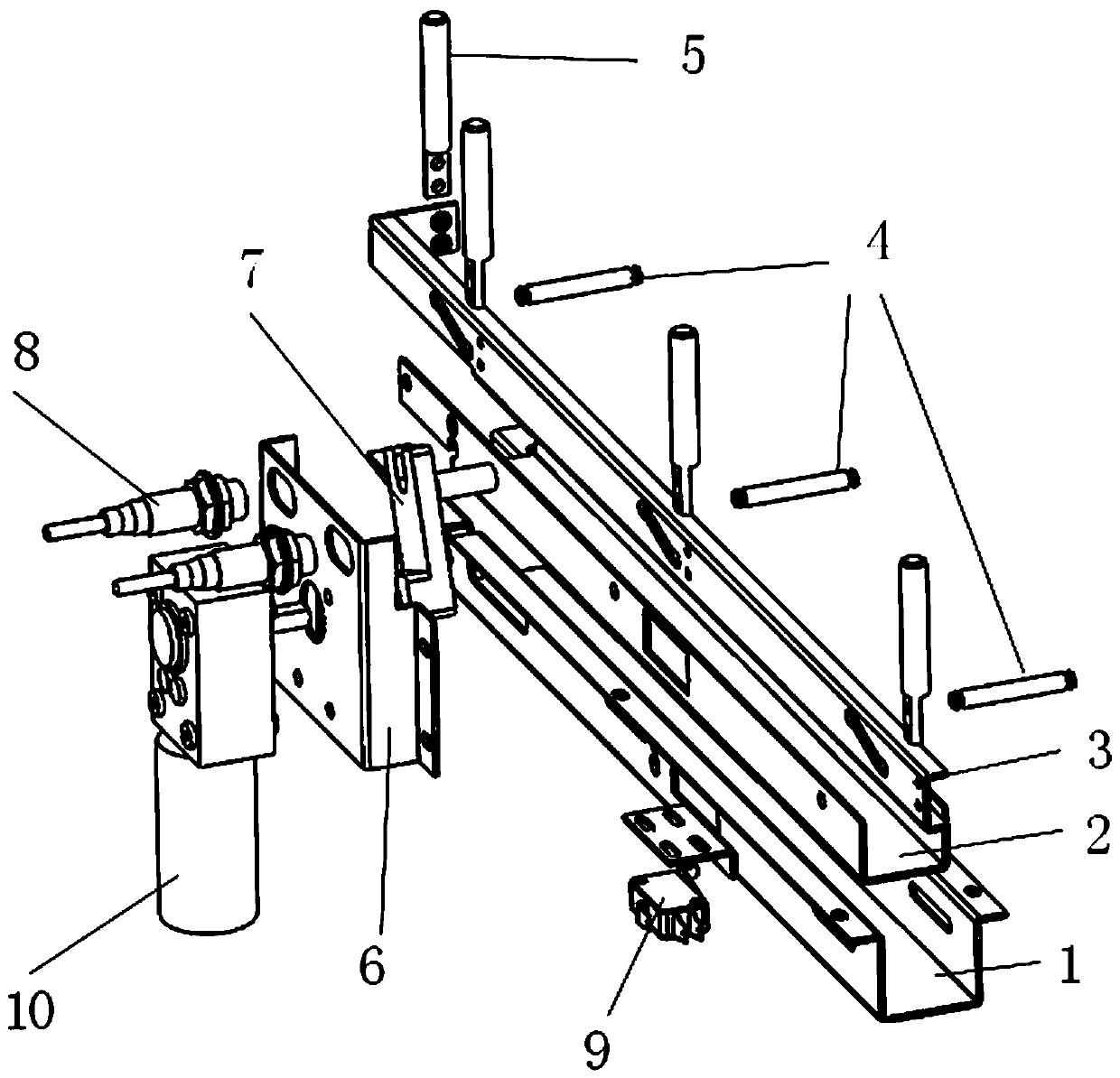

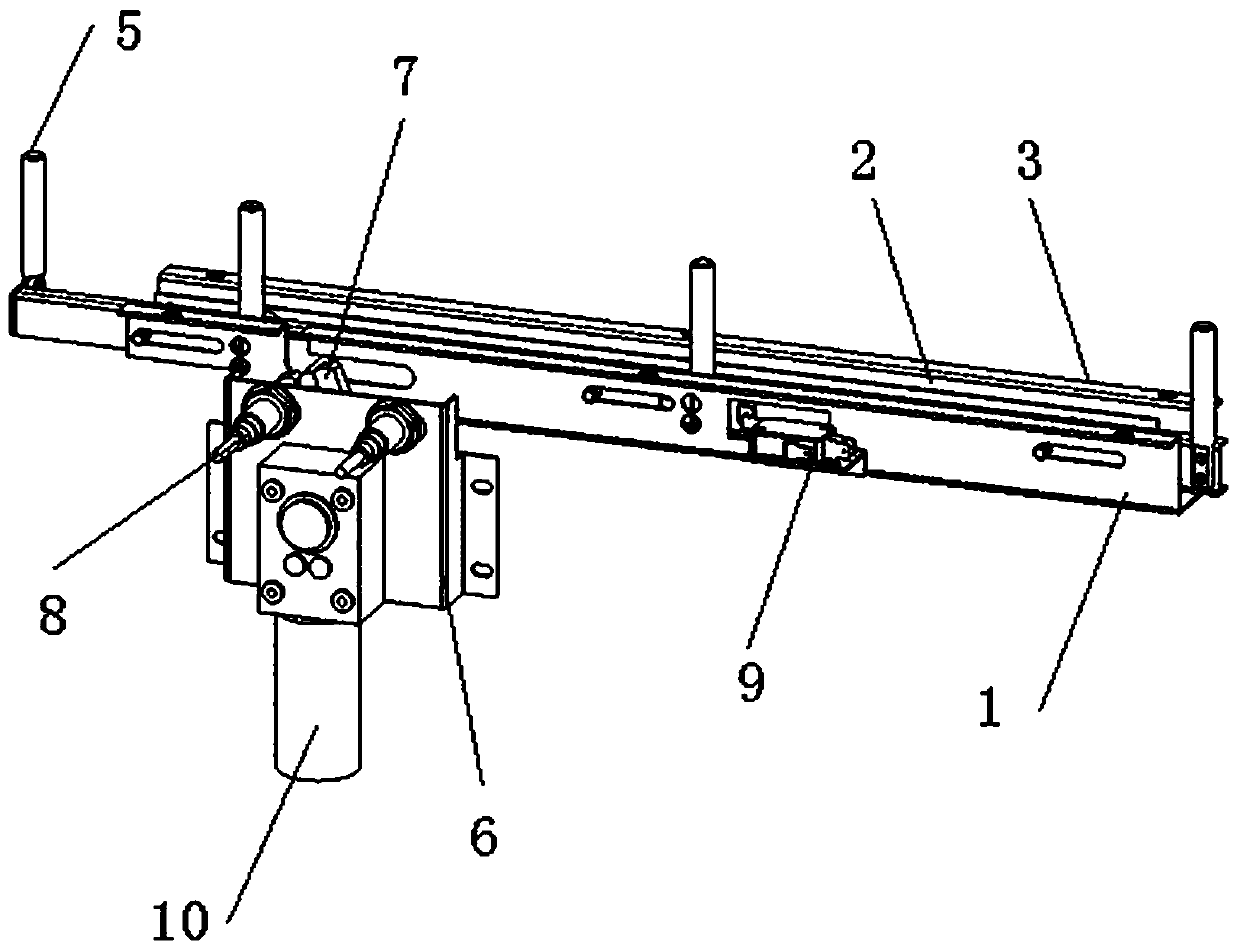

Thermoplastic composite material automatic placement device and method thereof

The invention discloses a thermoplastic composite material automatic placement device and a method thereof. The thermoplastic composite material automatic placement device comprises a placement device, and the placement device is mounted on a support plate, a laser welding head of a laser welding device is fixed on one side of the placement device, and an ultrasonic vibration device is fixed on the other side of the placement device; a thermoplastic prepreg tape wound on a reel by the placement device is conveyed to a pressure roller through a guiding wheel and main and auxiliary driving rollers, the pressure of the pressure roller is controlled, the thermoplastic prepreg tape is fully contacted with a substrate; the laser beam from the laser welding head obliquely irradiates at the junction of the thermoplastic prepreg tape and the substrate, and an infrared temperature probe detects the processing temperature and feeds back to a computer to control the processing temperature in realtime; an ultrasonic vibration device applies ultrasonic shock to the thermoplastic prepreg tape behind the pressure roller. The laser of the device is used as a heat source, and the heating area is precise, and the heating speed is fast; the ultrasonic energy is introduced to improve the interface connection strength; and the temperature closed-loop control is used to improve the quality of the processed part.

Owner:CHANGCHUN UNIV OF SCI & TECH

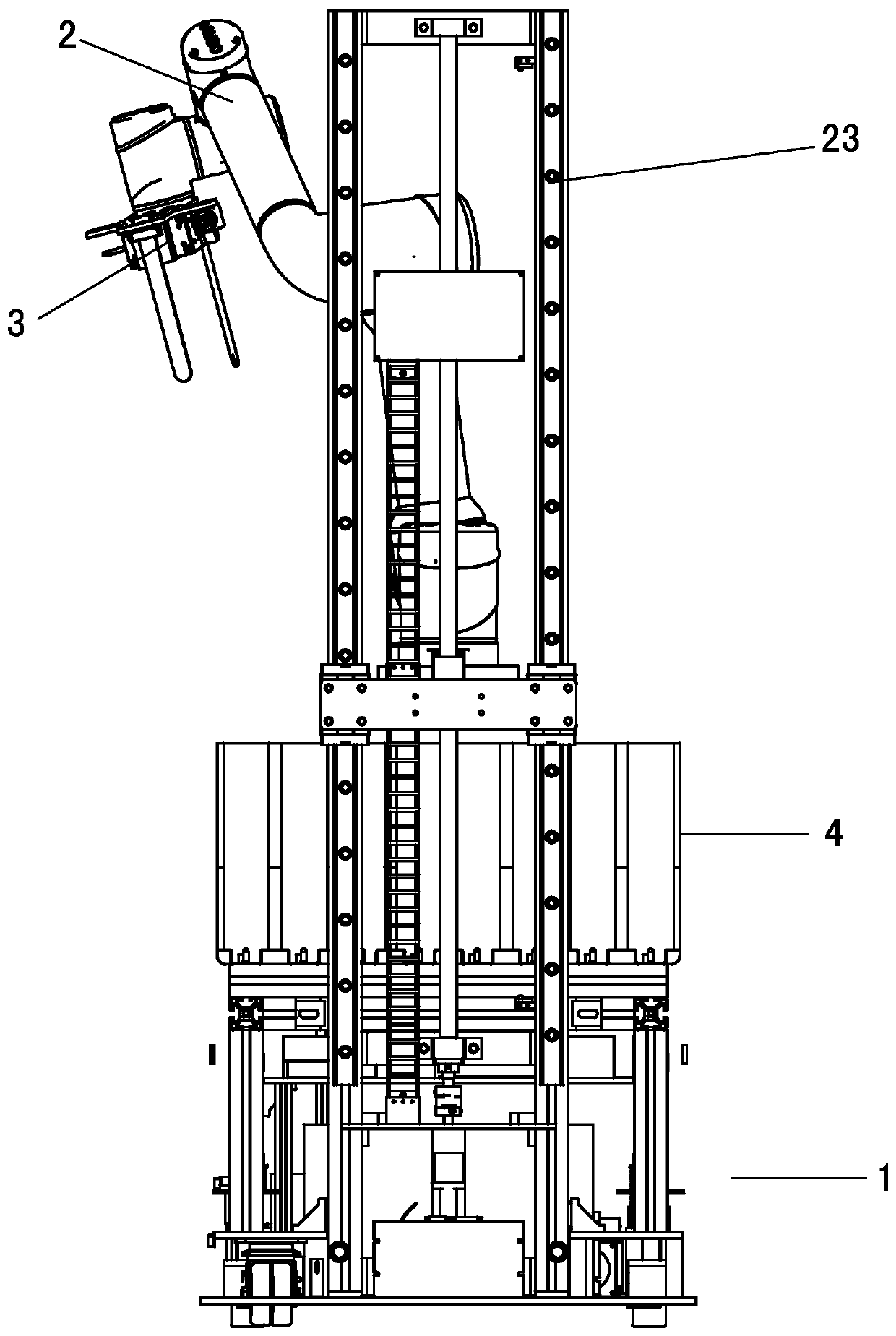

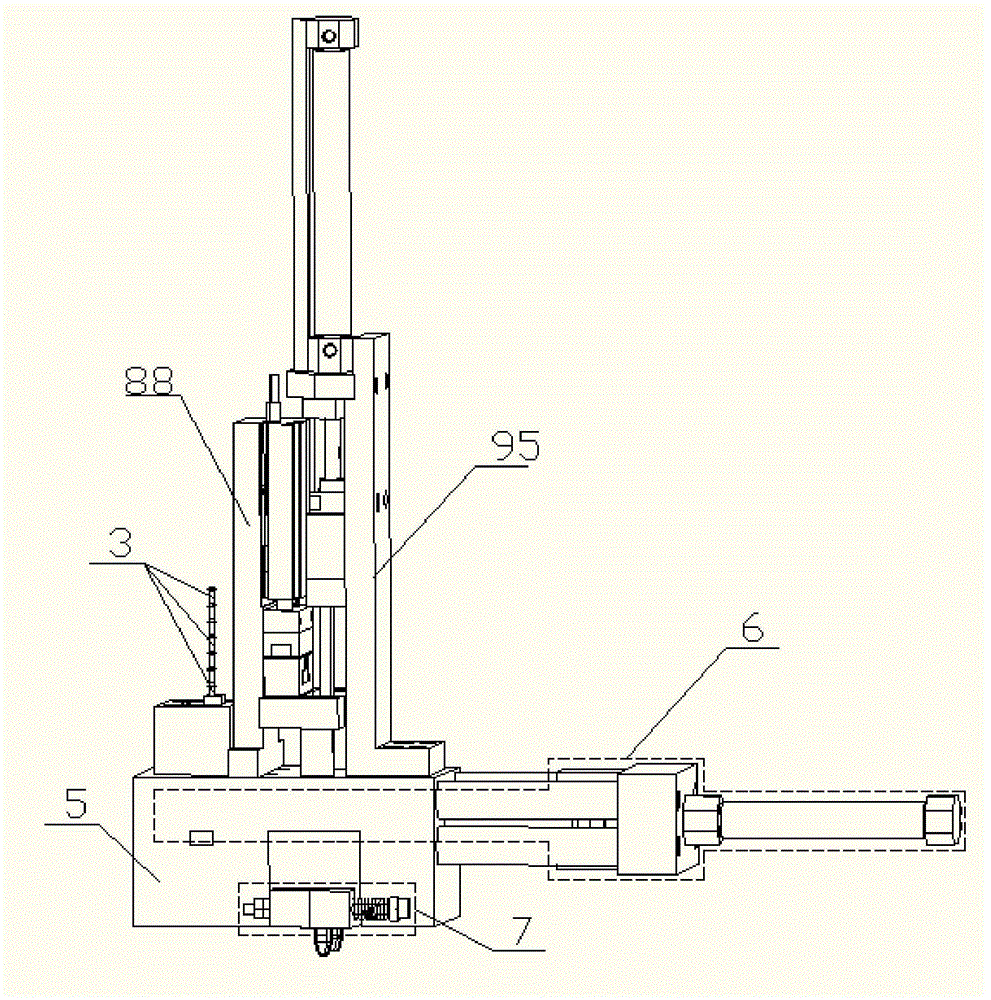

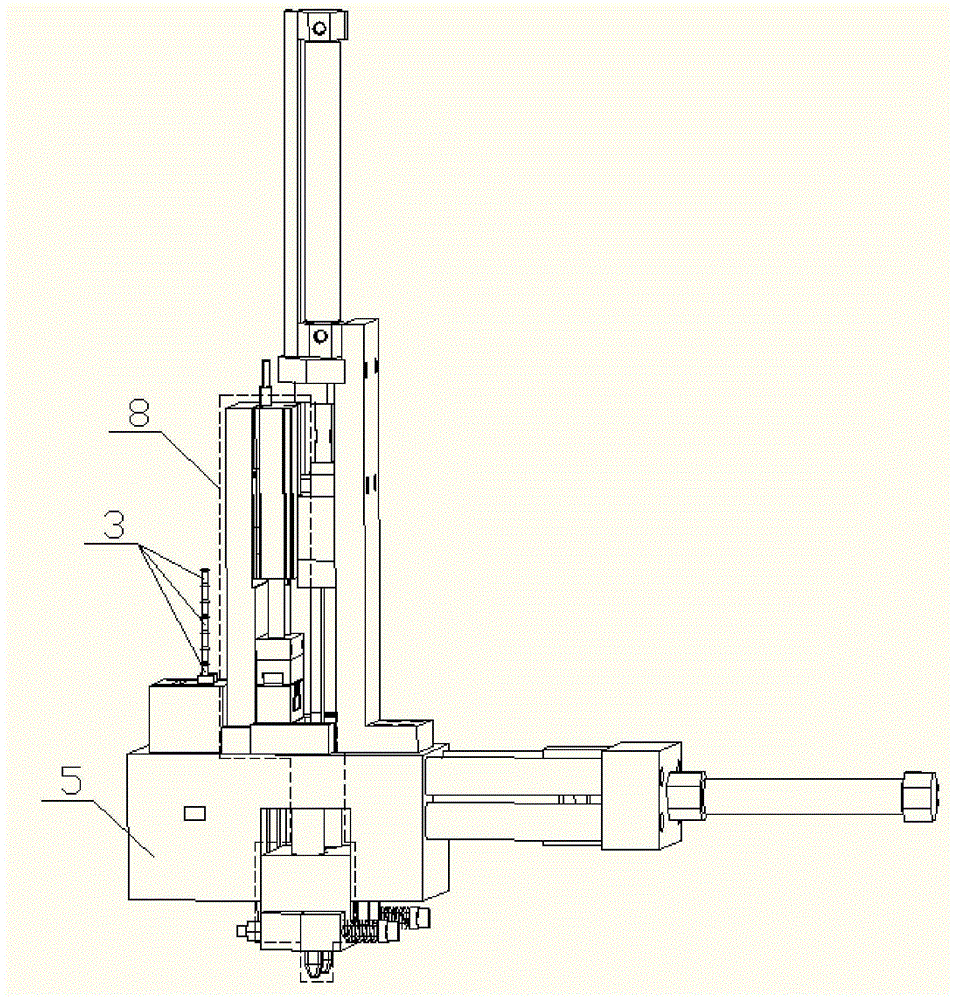

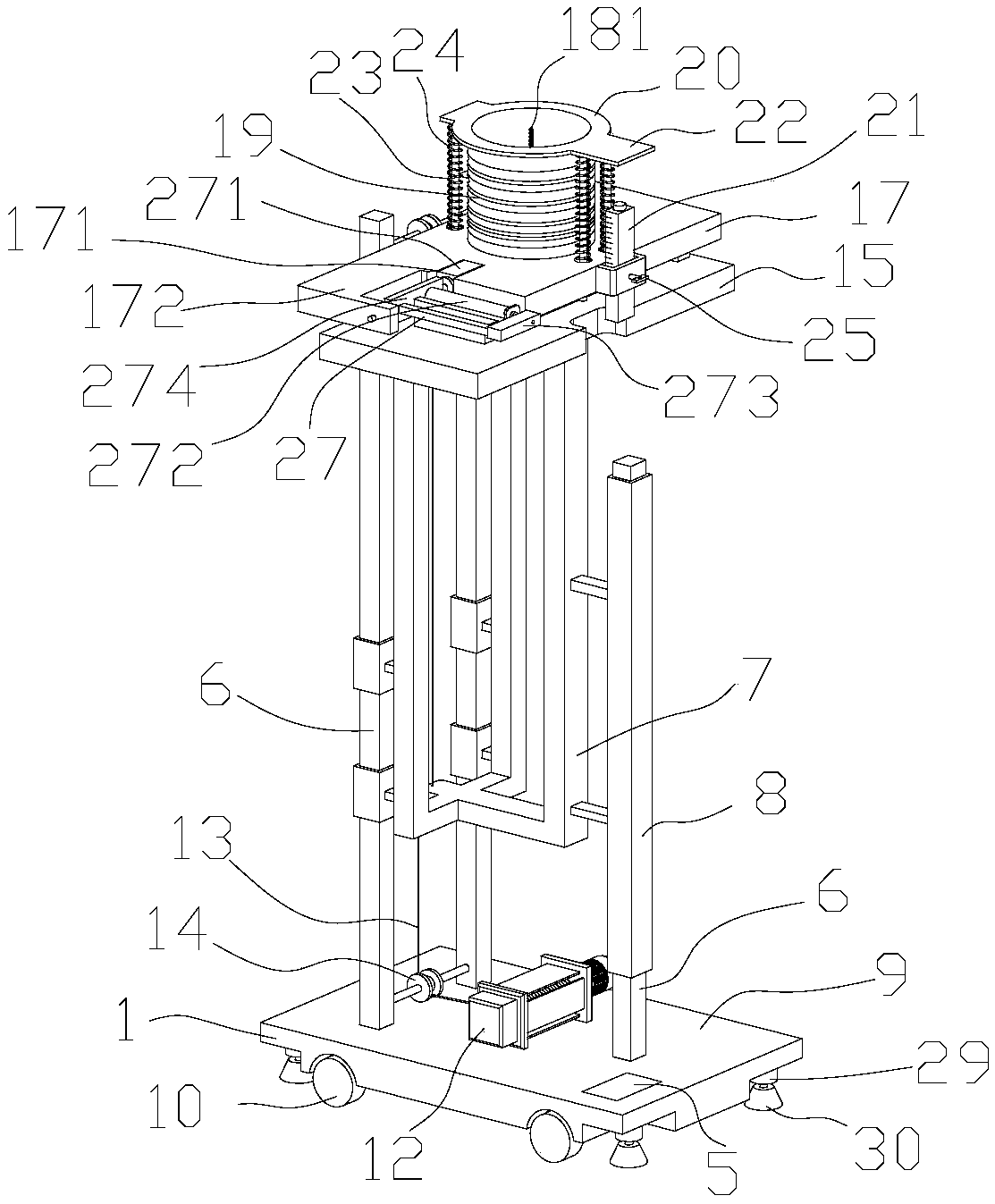

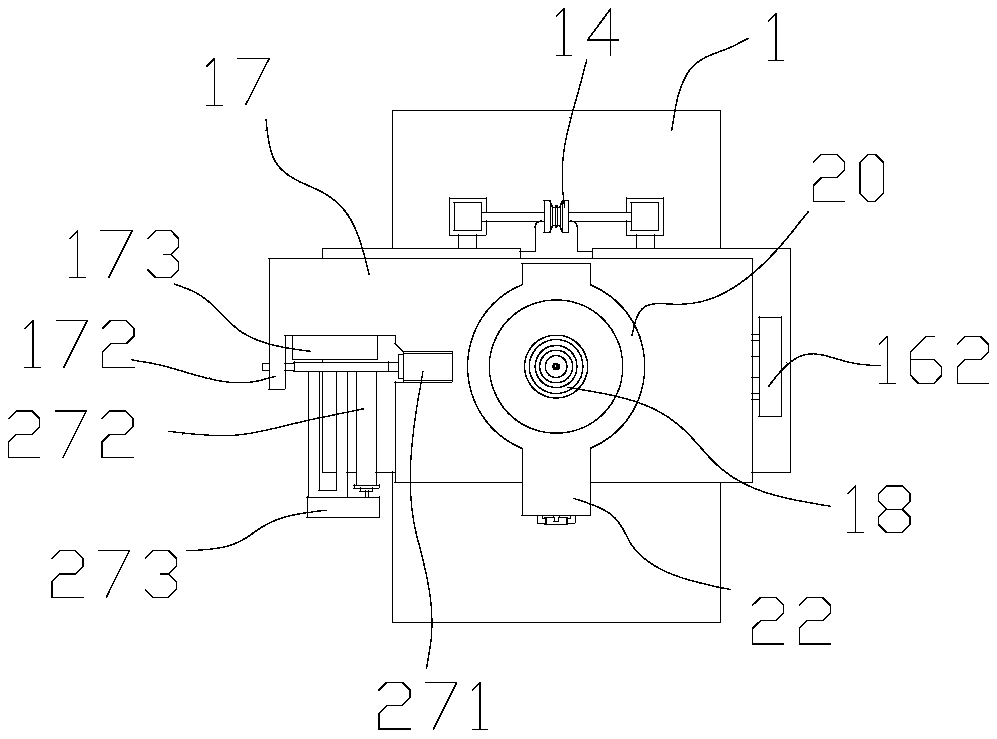

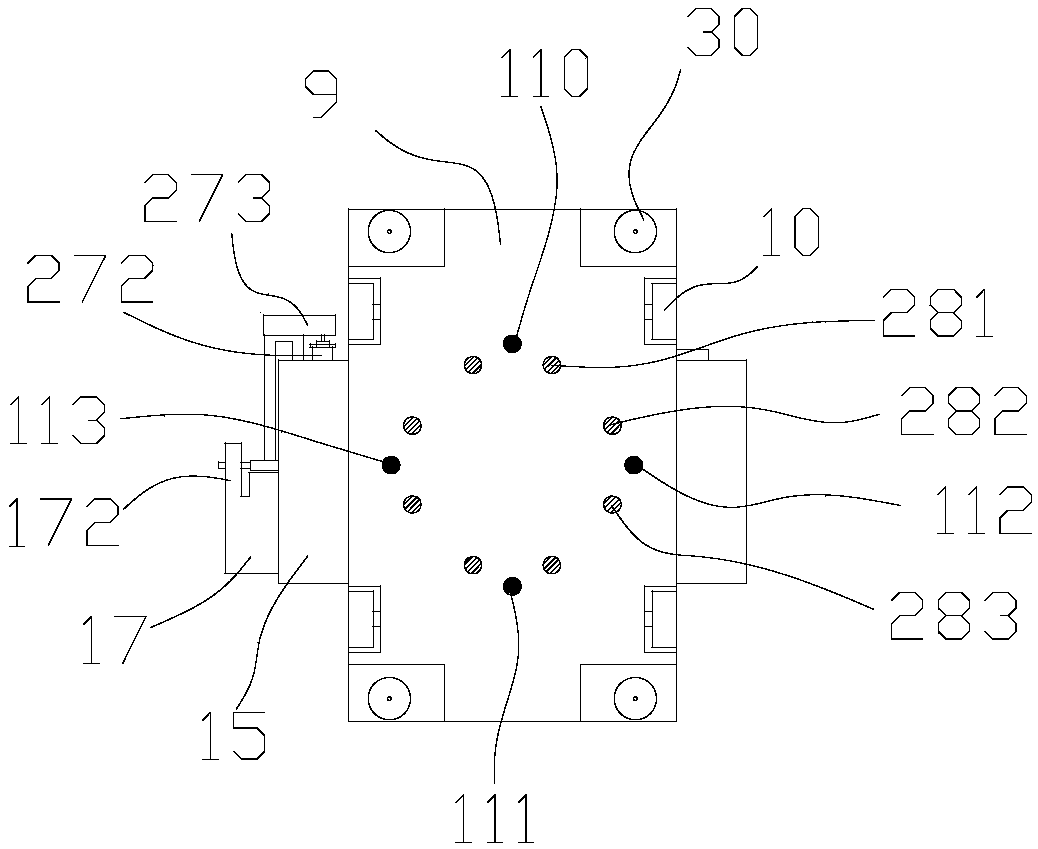

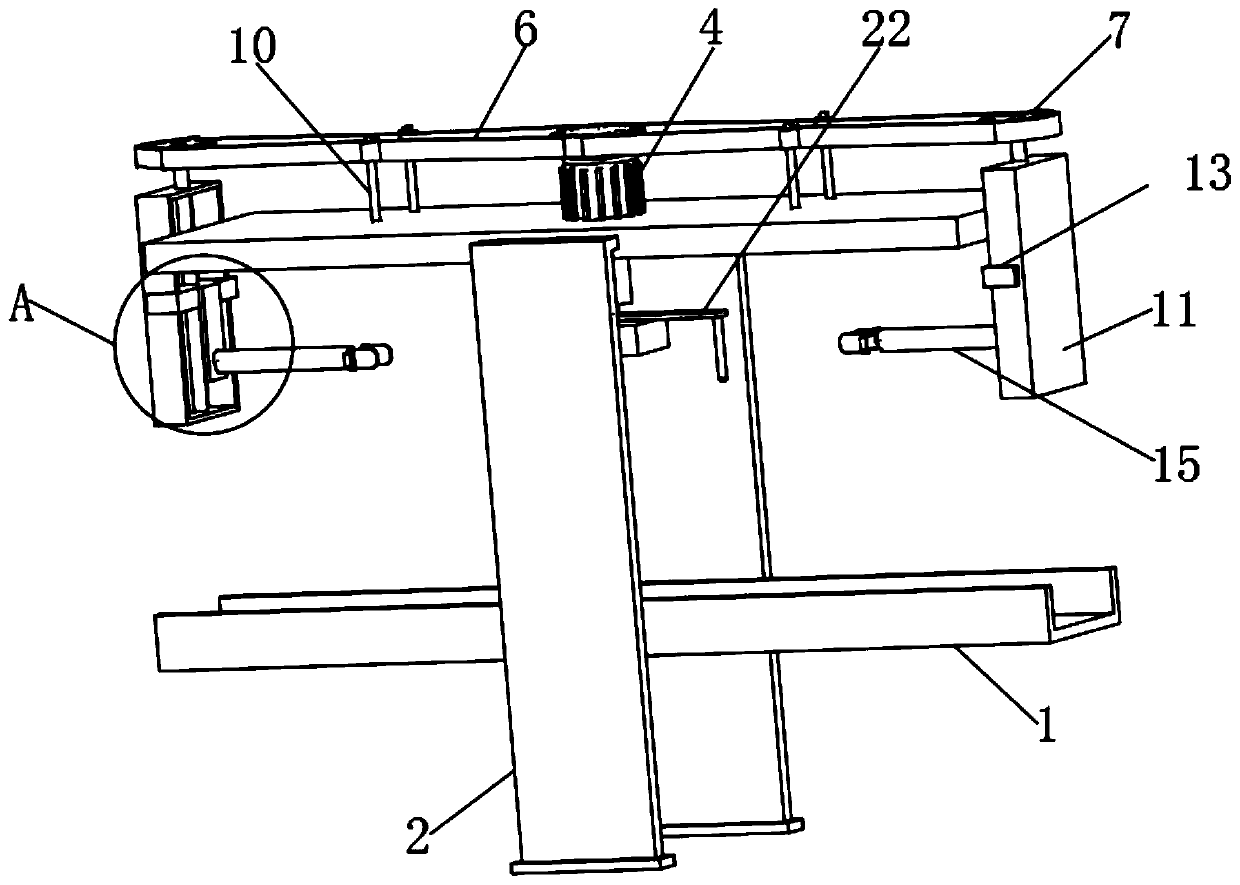

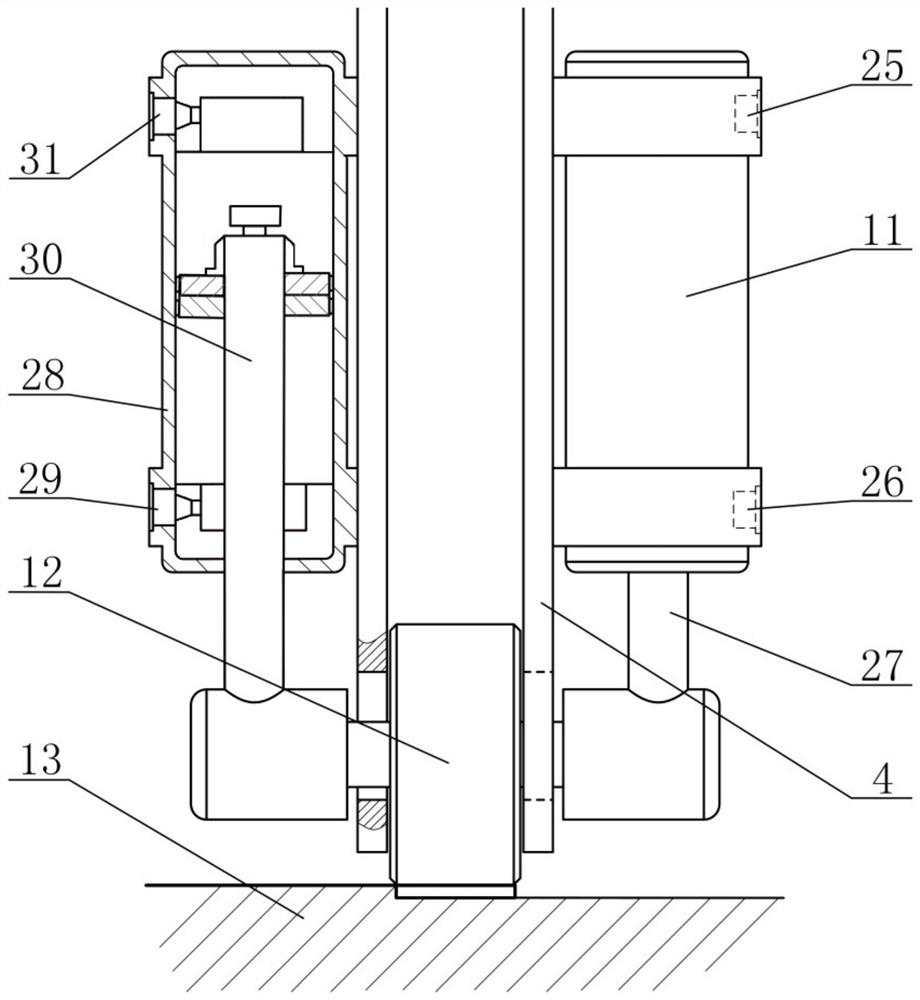

Hole punching robot with point self-finding function

PendingCN109555477ARealize automatic point findingAutomatic placementDerricks/mastsMetal working apparatusHammer drillIndustrial engineering

The invention discloses a hole punching robot with a point self-finding function. The hole punching robot with the point self-finding function comprises a track finding vehicle, a lifting supporting frame, a supporting panel, a hole punching mechanism and a controller. The lifting supporting frame mainly comprises a fixed rack and a lifting rack, the fixed rack is arranged on the track finding vehicle, the supporting panel is arranged at the upper end of the lifting rack, the hole punching mechanism is arranged on the supporting panel, and the controller is arranged on the track finding vehicle. The track finding vehicle mainly comprises a vehicle body, vehicle wheels, a track finding sensor and a power module, the supporting panel mainly comprises a bottom panel, a sliding platform air cylinder and a top panel, the hole punching mechanism mainly comprises an electric hammer drill, a dust collecting cover, a supporting ring and a travel switch, a bolt ejecting mechanism is arranged atthe left end of the top panel, and the bolt ejecting mechanism mainly comprises a rotating air cylinder, an ejecting air cylinder and a bolt clamp. According to the hole punching robot with the pointself-finding function, manual operating on a scaffold is avoided, point self-finding is realized, automatic hole punching is realized, an expansion bolt can be automatically placed, and dust generatedby construction can be reduced.

Owner:潍坊鑫起机械科技有限公司

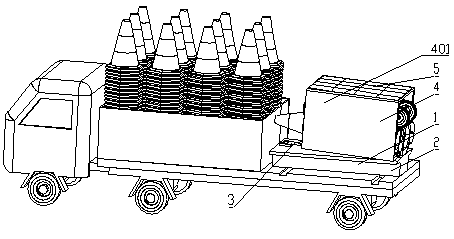

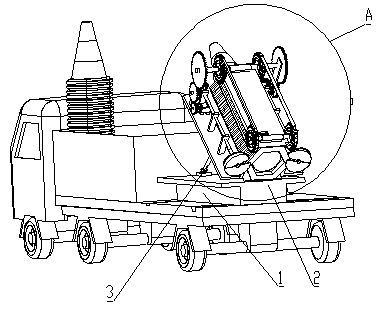

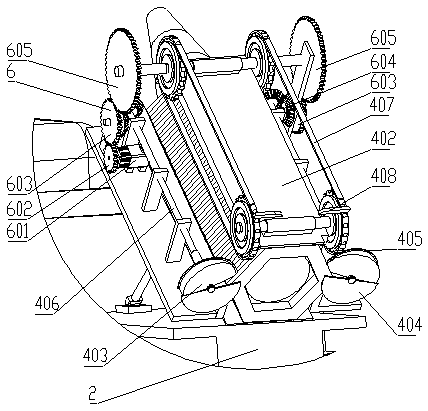

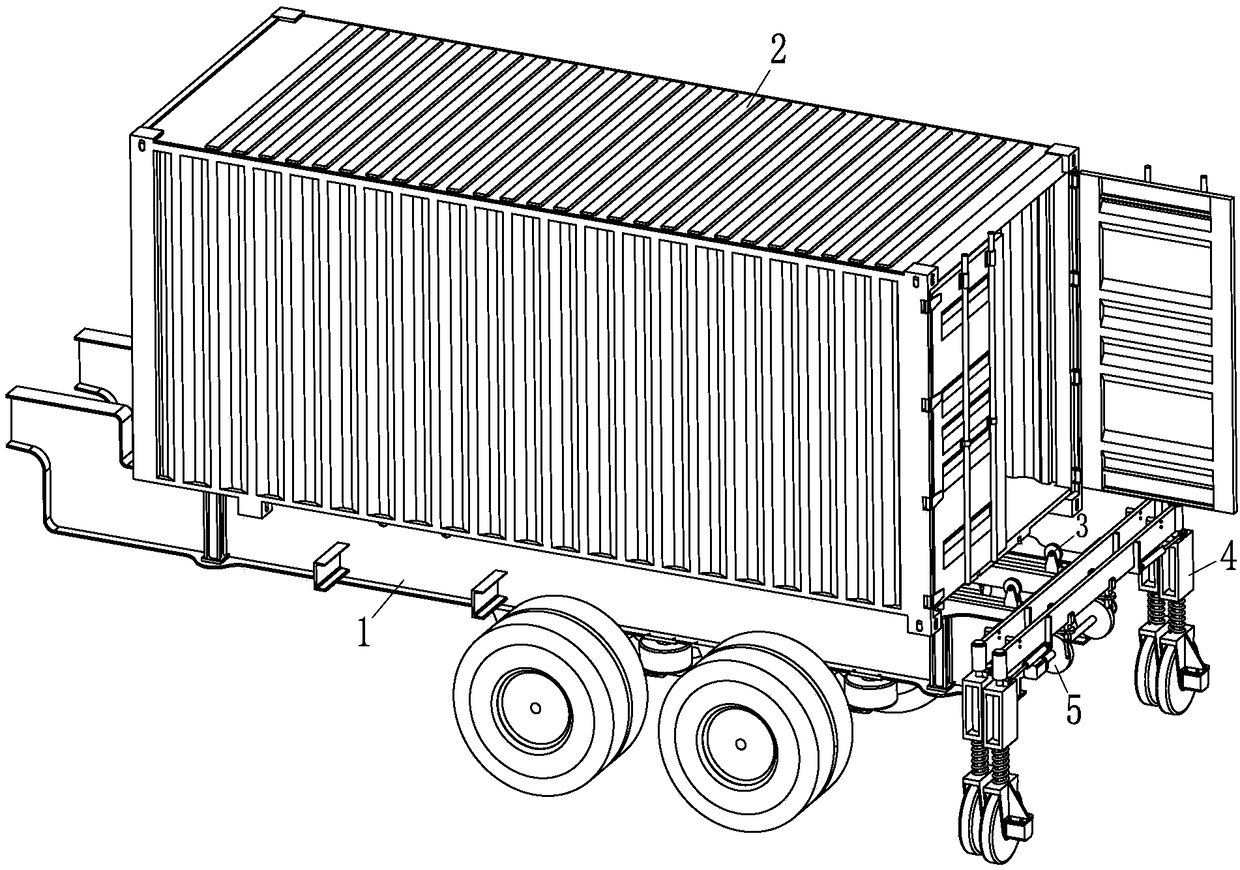

Traffic cone placement vehicle

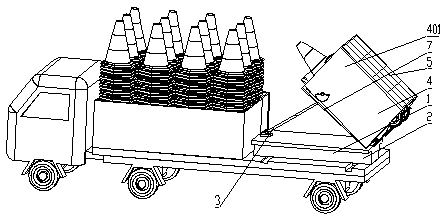

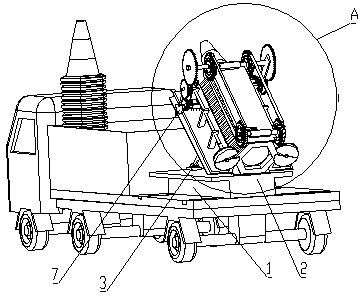

ActiveCN107503302ASimple structure and easy to manufactureAutomatic placementTraffic signalsRoad signsTruckEngineering

The invention discloses a traffic cone placement vehicle, and relates to the field of road traffic equipment. According to the technical scheme, the traffic cone placement vehicle comprises a truck body and a vehicle hopper arranged on the rear portion of the truck body, and a traffic cone placement unit is arranged on the rear side of the vehicle hopper; the traffic cone placement unit comprises a bottom table and a traffic cone placement mechanism, the bottom table is connected with the rear portion of the truck body through a rail, and a telescopic push rod is arranged on the bottom table; one end of the telescopic push rod is fixedly connected with the bottom table, and the other end of the telescopic push rod is fixedly connected with the lower surface of the traffic cone placement mechanism; a solar charging panel is arranged on the upper surface of a shell of the traffic cone placement mechanism, and the solar charging panel supplies power to the traffic cone placement mechanism through a storage battery. The traffic cone placement vehicle has the advantages that a traffic cone structure used by the device is basically similar to an existing traffic cone and is simple and easy to manufacture; the traffic cone placement unit and a truck are assembled together through a vehicle-mounted structure, and people only need to add traffic cones into the traffic cone placement unit during placement to automatically place the traffic cones in the advancing process of the vehicle.

Owner:山东正晨科技股份有限公司

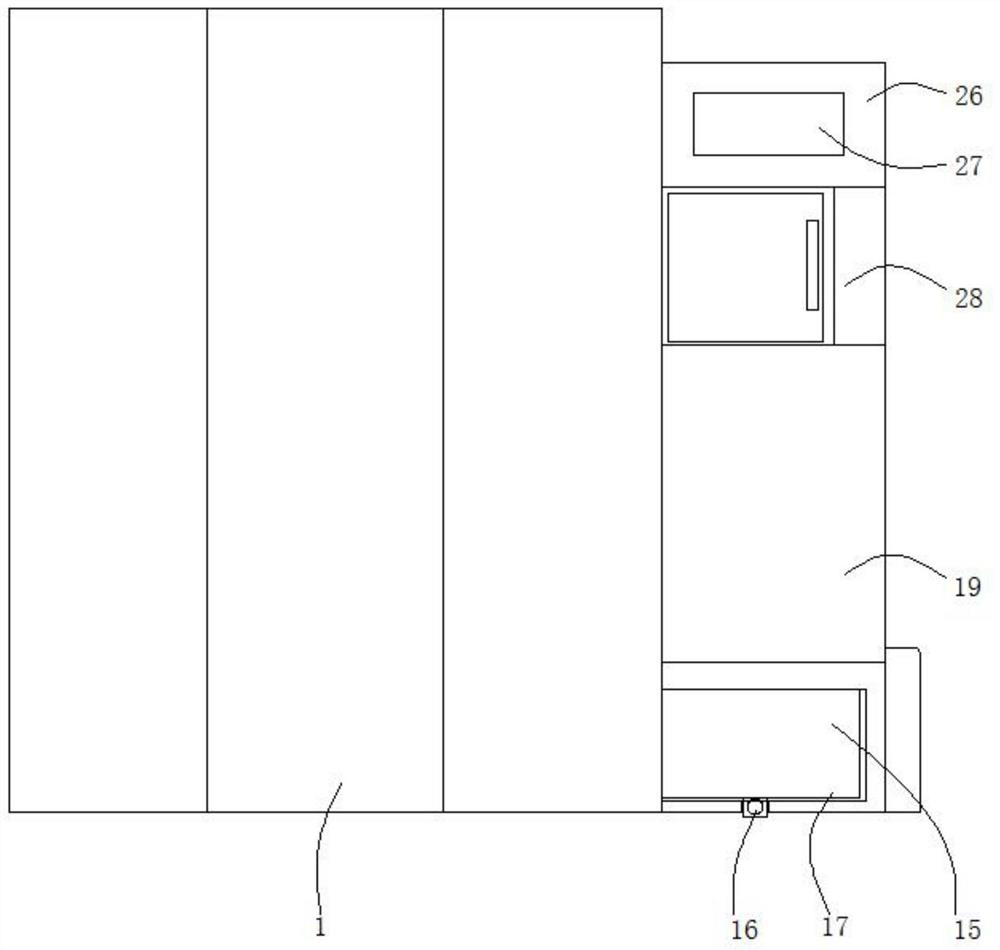

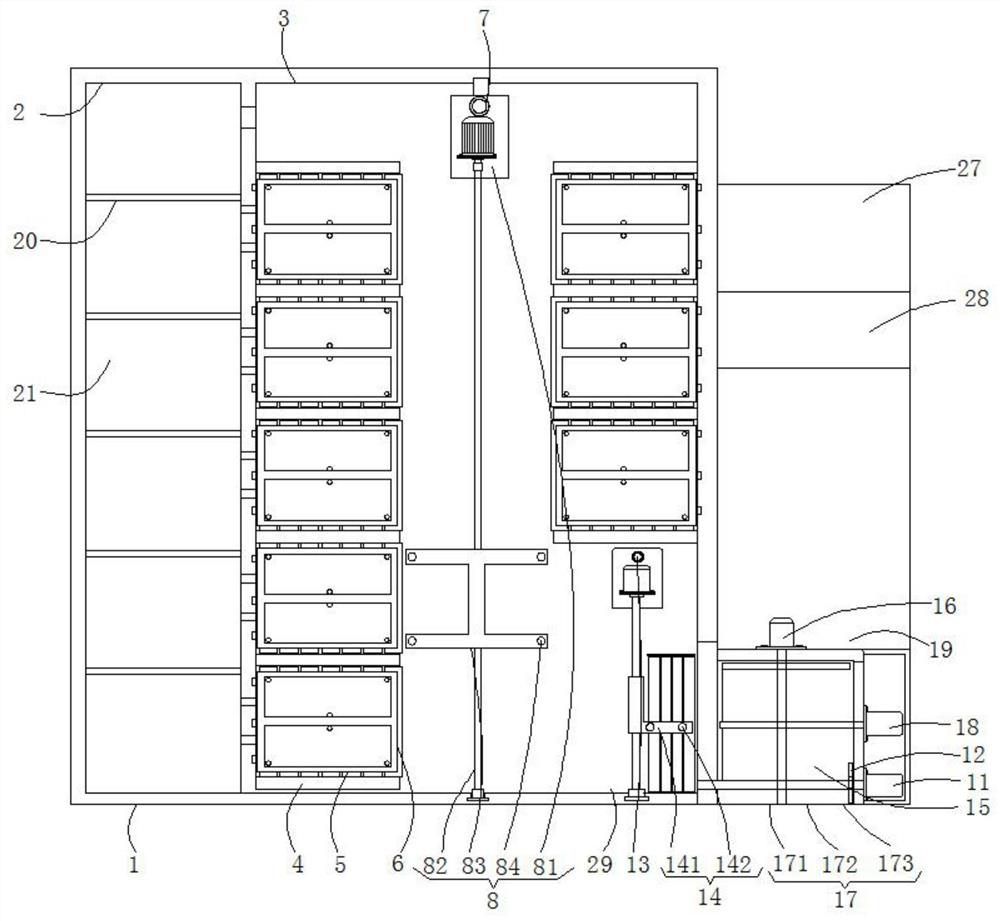

Multifunctional intelligent shoe cabinet and control method thereof

ActiveCN111772354AKeep warmComfortable to wearWardrobesLavatory sanitoryStructural engineeringMechanical engineering

The invention discloses a multifunctional intelligent shoe cabinet comprising a cabinet body; the interior of the cabinet body is divided into a season changing storage area and a common storage areathrough a baffle. A plurality of first partition plates are arranged on one side of the baffle and located in the common storage area. A containing cavity is formed between every two adjacent first partition plates, a plurality of supporting plate rolling wheels are arranged between the two sides of the inner wall of each containing cavity, shoe storage trays are arranged at the tops of the supporting plate rolling wheels, a lifting assembly is arranged on one side of the interior of the common storage area, and a lifting sliding table is connected to the lifting assembly in a transmission mode. The invention relates to the technical field of shoe cabinet. According to the multifunctional intelligent shoe cabinet and a control method thereof, a conveying assembly is arranged to be matchedwith supporting assemblies, bearing assemblies and pushing assemblies so that shoes can be automatically placed and taken out; and different placing cavities and the plurality of supporting assembliesare arranged, so that shoes of different users can be placed in a classified manner, the shoes can be correspondingly placed on the supporting assemblies, and the shoes can be placed more neatly andorderly.

Owner:张盘

Automatic rivet setting device

The invention discloses an automatic rivet installation device. The automatic rivet installation device comprises an installation base, a conveying base, a rivet conveying part, a clamping part, a positioning part and a rivet pushing part. The rivet conveying part is used for separating rivets out from a rivet strip and conveying the separated-out single rivets to the position above a product on which the rivets need to be installed; the clamping part is installed in the installation base, located above the product and used for clamping the rivets falling under the effect of gravity; the positioning part is connected with the clamping part and used for pushing the clamping part onto the upper surface of the product; the rivet pushing part is used for pushing the rivets in the clamping parts into rivets holes of the product. Through the coordination action of the conveying base, the rivet conveying part, the clamping part, the positioning part and the rivet pushing part, the rivets can be automatically and accurately installed, labor cost is effectively lowered, and production efficiency is improved. The automatic rivet installation device is suitable for large-batch production.

Owner:苏州瑞玛精密工业股份有限公司

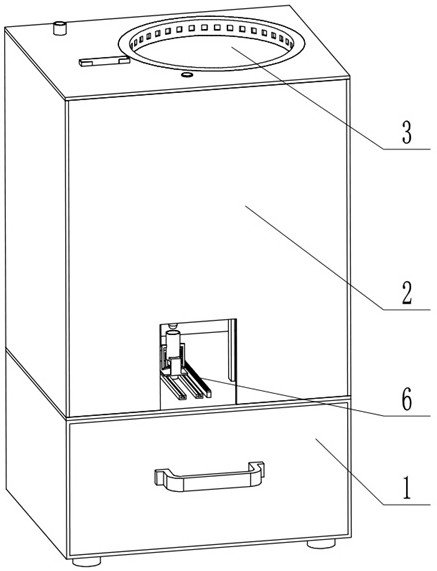

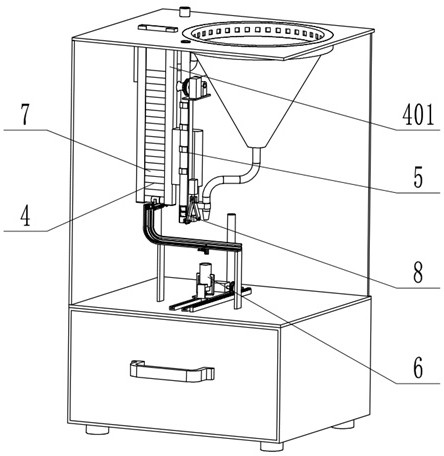

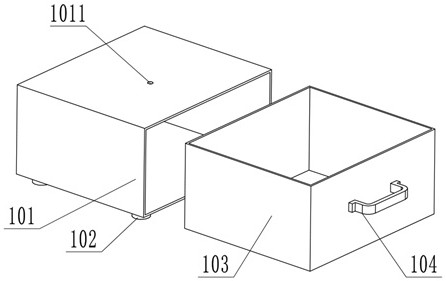

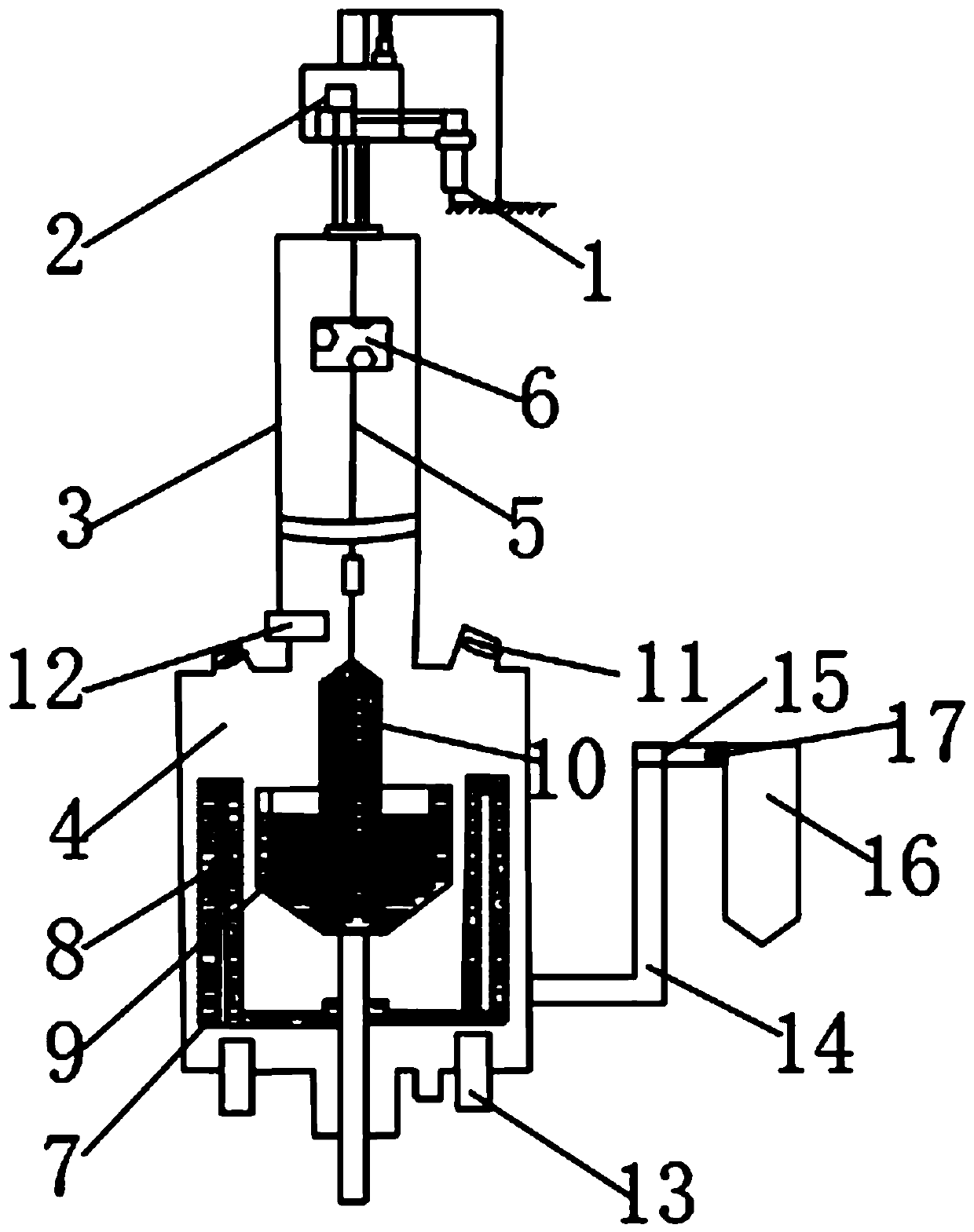

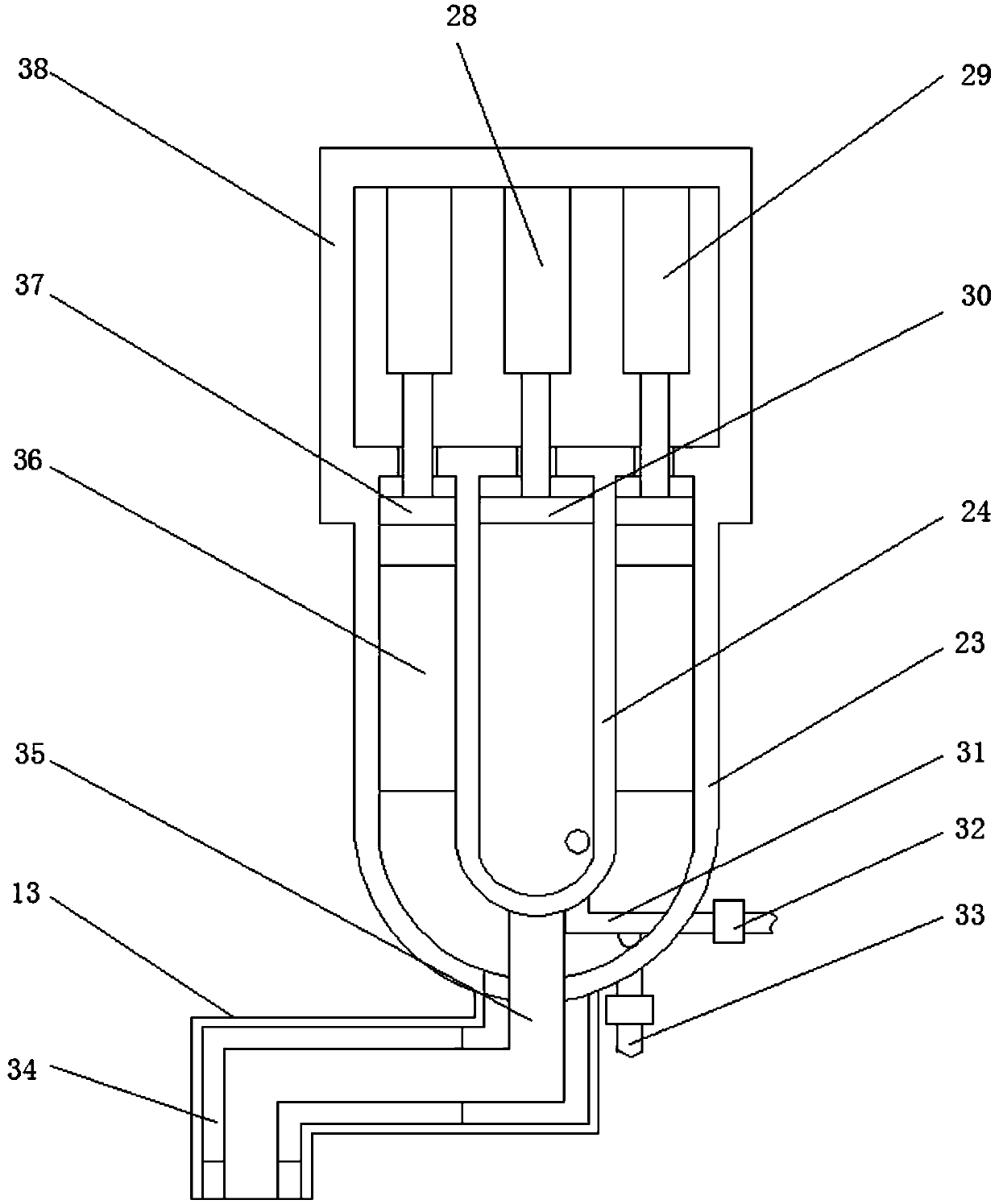

Urine collection device for urology department

PendingCN113749691AAutomated cleaningAutomatic placementSurgeryVaccination/ovulation diagnosticsUrine collectionUrine collection device

The invention discloses a urine collection device for urology department. The urine collection device for urology department comprises a base sewage tank, an upper tank cover, a urine collecting hopper, a test tube placing device, a tube cover mounting device and a test tube pushing and clamping device. The base sewage tank is a mounting base and also a sewage storage tank; the upper tank cover is arranged above the base sewage tank and the base sewage tank is a mounting rack for the urine collecting hopper, the test tube placing device, the tube cover mounting device and the test tube pushing and clamping device; human urine is directly put into the urine collecting hopper; the test tube placing device is used for storing and placing test tubes; the tube cover mounting device places tube covers on the test tubes; and the test tube pushing and clamping device is used for conveying the test tubes with collected urine out of an to-be-taken opening. The urine of a human body can be directly sprinkled into the urine collecting hopper. The urine collection device is automatically cleaned. The urine is automatically stored in the test tubes.

Owner:邹菊仙

Automatic packaging device for fertilizer production and processing

InactiveCN110466848AImprove seal qualityImprove packaging efficiencyPackagingEngineeringMechanical engineering

The invention discloses an automatic packaging device for fertilizer production and processing. The device comprises a conveying table, wherein a supporting frame is arranged on the outer side of thetop end of the conveying table, a driving device is fixedly connected to the top end of the supporting frame, the output end of the driving device is provided with a leveling device, and an adjustingpaper placing device is arranged at the top end of the interior of the supporting frame. According to the automatic packaging device for fertilizer production and processing, the supporting frame is additionally arranged on the outer side of the conveying table and the leveling device is driven by the driving device arranged on the supporting frame so that an opening of a packaging bag can be leveled by applying force, and the sealing quality of the packaging bag is effectively improved; and label paper can be automatically placed inside the packaging bag through the arranged adjusting paper placing device while the opening of the packaging bag is leveled by the leveling device, so that the packaging efficiency of fertilizer is improved, and the manpower is saved.

Owner:嘉兴金芯研电子科技有限公司

Monocrystalline silicon growth furnace with high safety performance

InactiveCN110528065AAutomatic placementReduce riskPolycrystalline material growthBy pulling from meltThermal insulationEngineering

The invention discloses a monocrystalline silicon growth furnace with high safety performance. The monocrystalline silicon growth furnace comprises a growth furnace body, wherein the growth furnace body comprises a lifting rotating system, an upper furnace cover and a lower furnace body, the lifting rotating system is located at the upper end of the upper furnace cover, a lifting rope is arrangedin the upper furnace cover, the upper end of the lifting rope is connected with the lower end of the lifting rotating system, the lower end of the lifting rope is connected with a monocrystalline rod,the lower furnace body comprises a graphite heater and a quartz crucible, the monocrystalline rod is located in the quartz crucible, the graphite heater is arranged on the outer surface of the quartzcrucible, a thermal insulation cover is arranged on the graphite heater, and a gas inlet is formed in the lower end of the lower furnace body. Through a rotating table and a manipulator, the monocrystalline rod can be automatically mounted when discharged out of the furnace, and danger caused by high temperature of the monocrystalline rod is reduced; and through the lifting structure, labor can be saved, the working efficiency can be improved, and motor consumption can be reduced.

Owner:萧县威辰机电工程设备有限公司

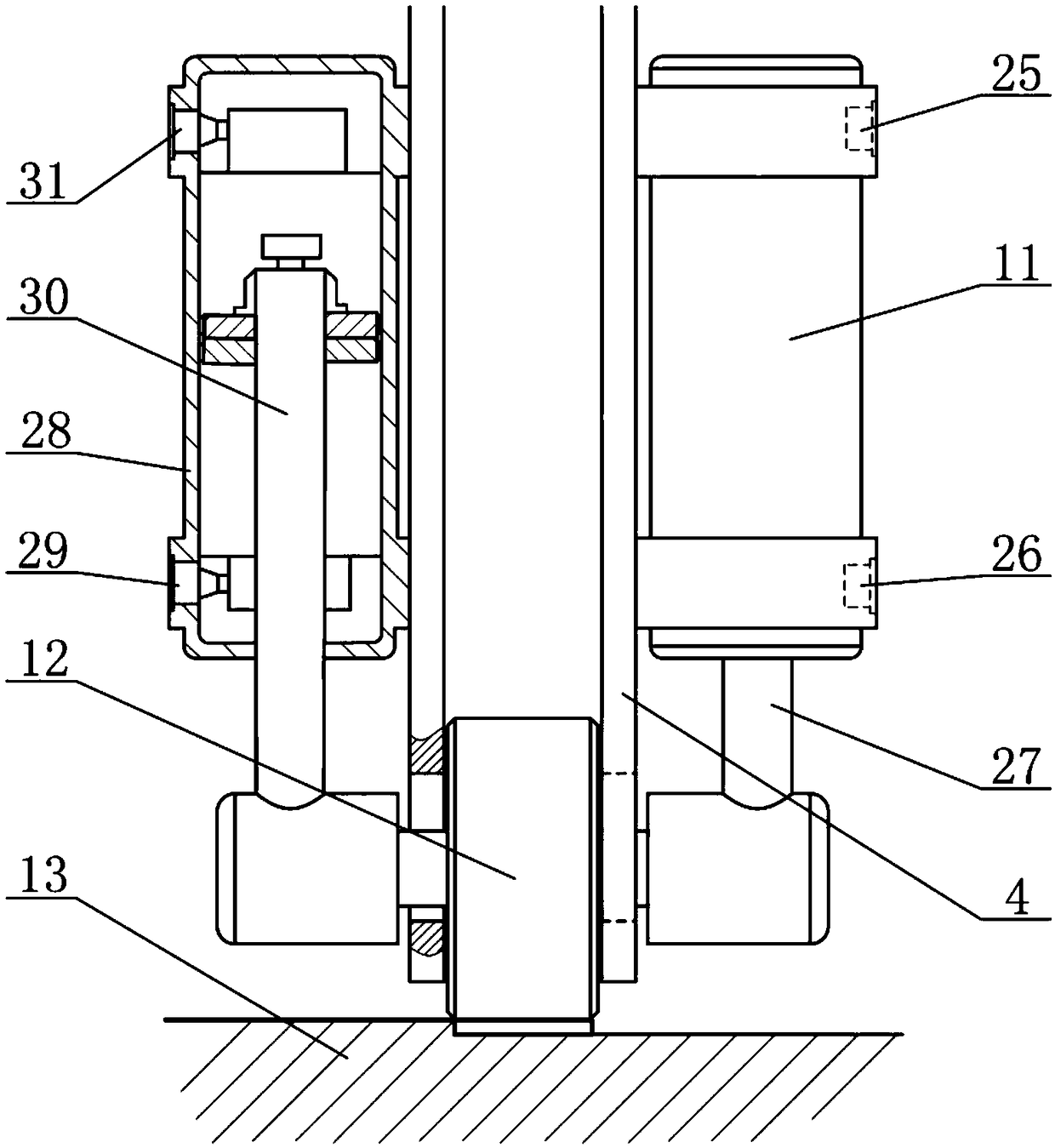

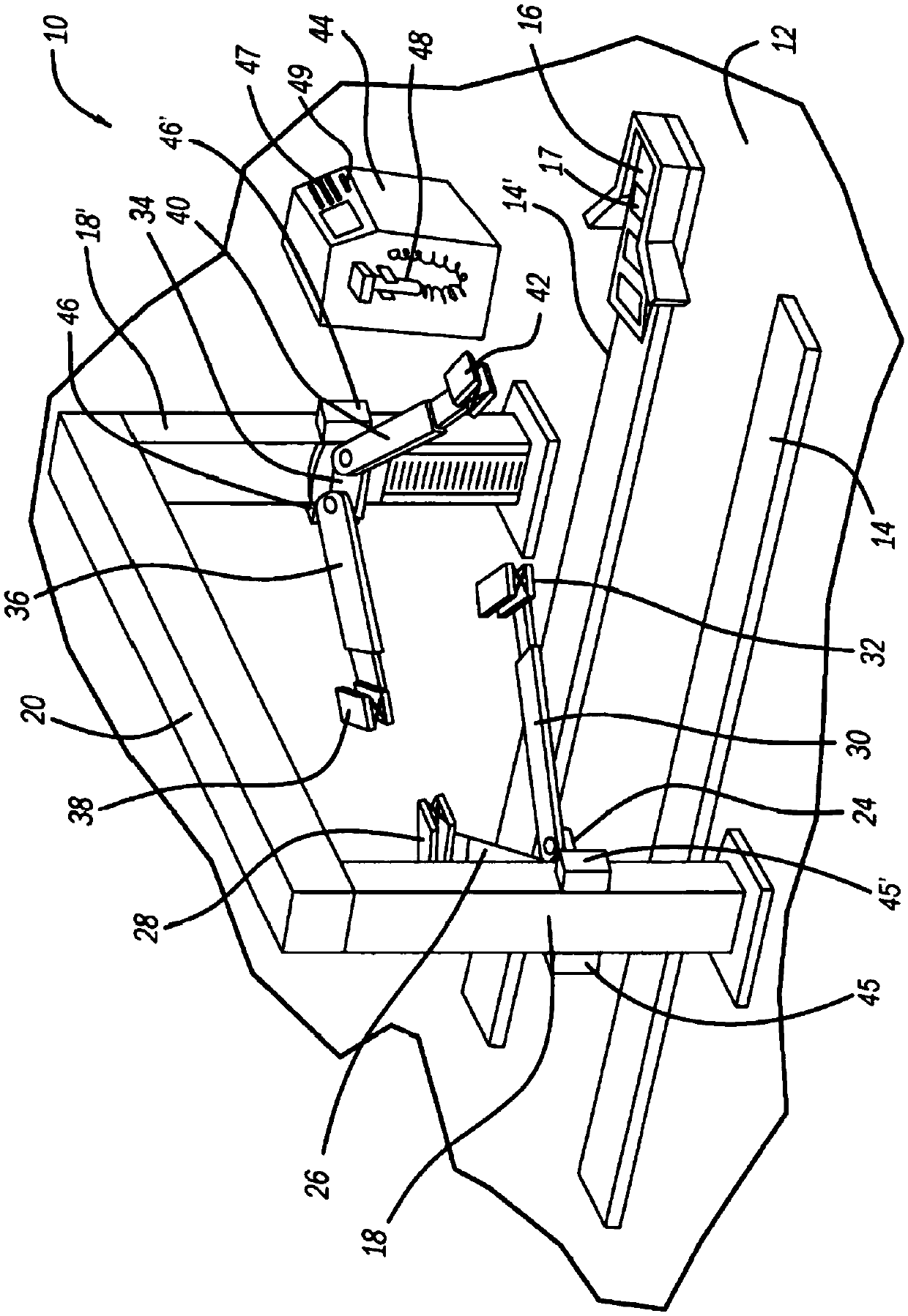

Fully autonomous vehicle lift

InactiveCN109775613AAutomatic placementLifting framesVehicle servicing/repairingLift systemAerospace engineering

The disclosed inventive concept provides an autonomous vehicle lift system in which the lift arms are automatically placed into their correct positions prior to the vehicle being lifted for servicing.The system includes a pair of spaced apart vertical posts and a wheel locator. Each post is fitted with a vertically movable lift arm assembly. Each lift arm assembly includes a pair of independentlyoperating lift arms and drive systems for both rotating the arm into position and for extending the arm. At the end of each lift arm is a lift pad. Each lift pad may include a scissors system for lifting and lowering the pad relative to the associated arm. An operator's station is provided for inputting vehicle information. Once the information is entered, the autonomous lift system is initiated.The lift arms automatically move into their correct predetermined positions and the vehicle is ready to be lifted.

Owner:FORD GLOBAL TECH LLC

A traffic cone display vehicle

ActiveCN107503302BSimple structure and easy to manufactureAutomatic placementTraffic signalsRoad signsElectricityEngineering

A traffic cone placing vehicle, related to the field of road transport equipment, comprising a truck body and a hopper provided at the rear part of the truck. A traffic cone placing unit (1) is provided at the rear side of the hopper. The traffic cone placing unit (1) comprises a base mesa (2) and a traffic cone placing mechanism (4). The base mesa (2) is connected to the rear part of the truck body via a track. A telescoping pushrod (3) is provided on the base mesa (2). The telescoping pushrod (3) is fixedly connected at one extremity to the base mesa (2) and fixedly connected at the other extremity to the lower surface of the traffic cone placing mechanism (4). A solar panel (5) is provided on the upper surface of a housing (401) of the traffic cone placing mechanism (4). The solar panel (5) supplies electricity to the traffic cone placing mechanism (4) via a rechargeable battery.

Owner:山东正晨科技股份有限公司

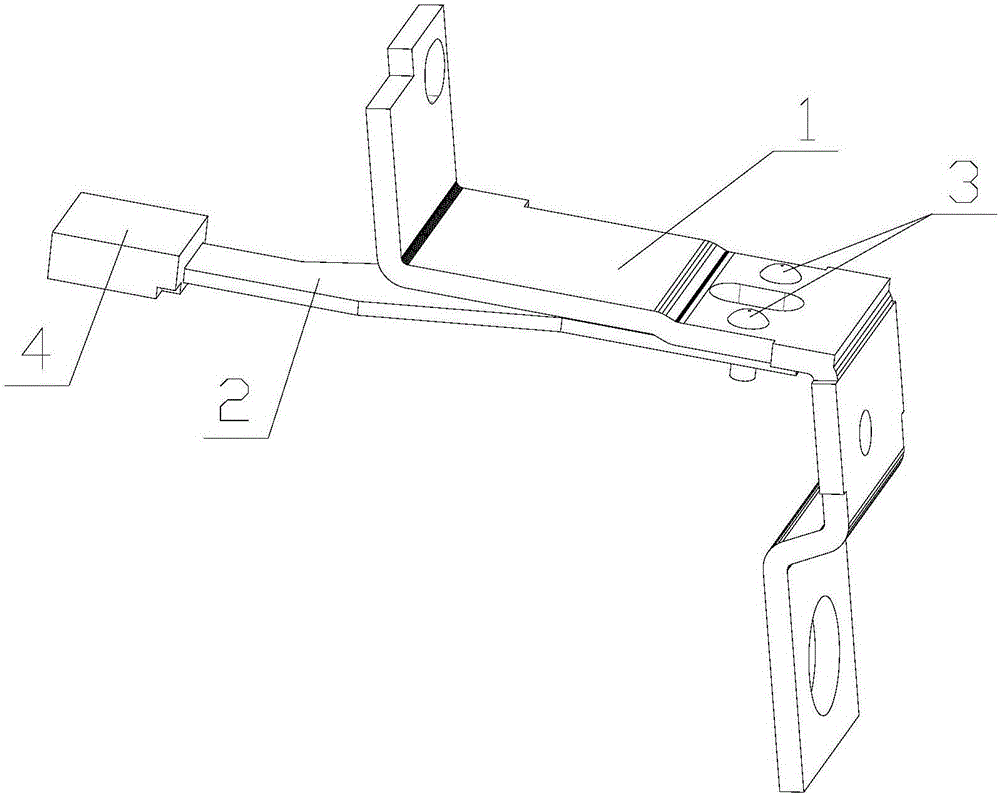

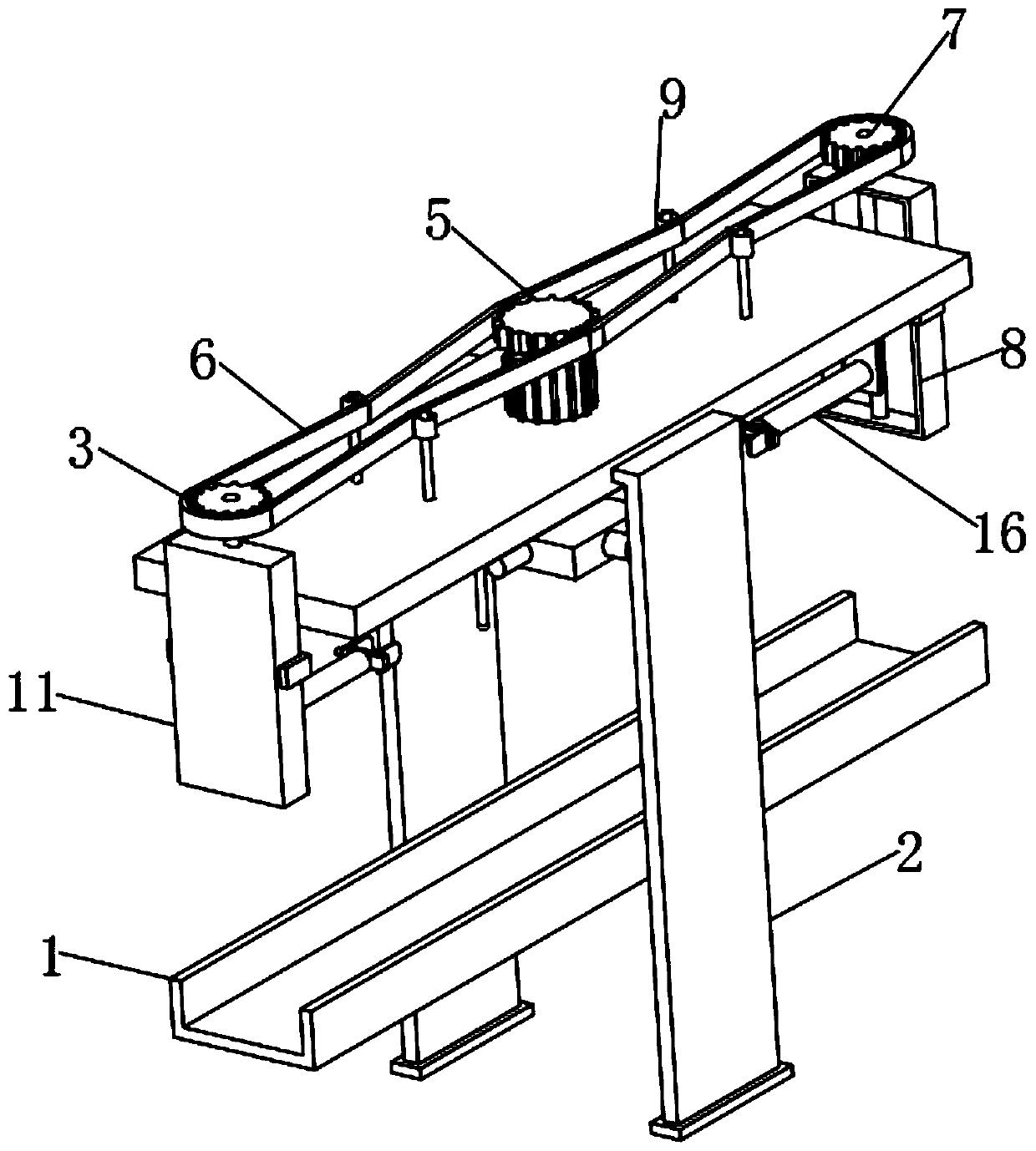

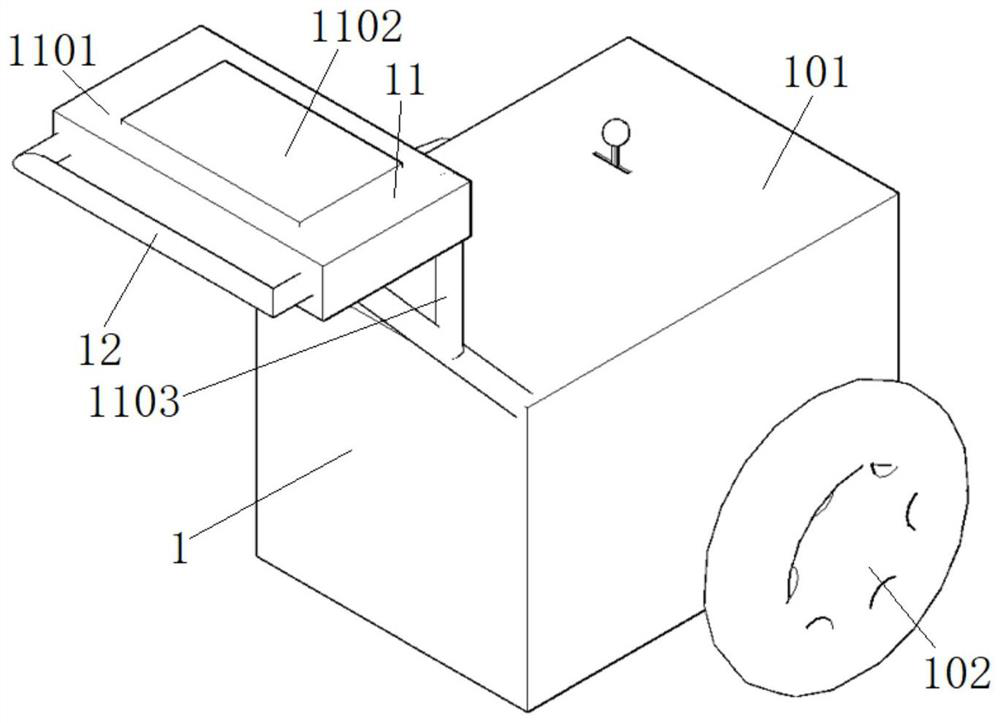

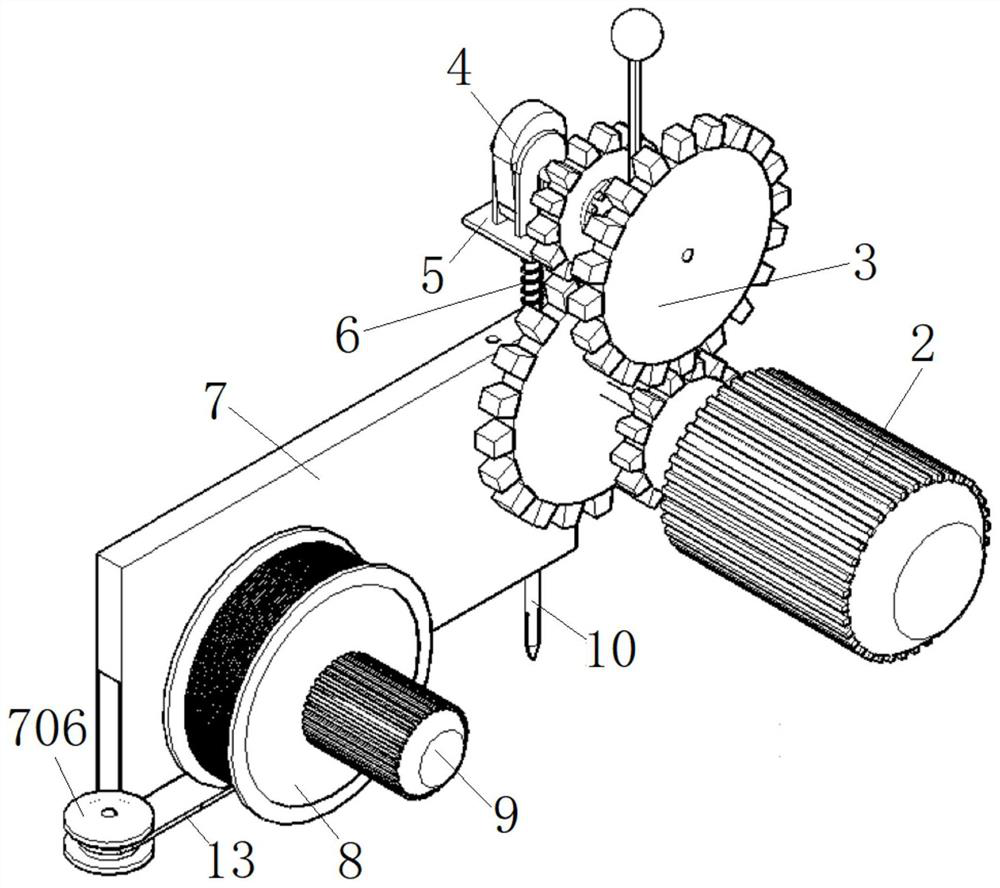

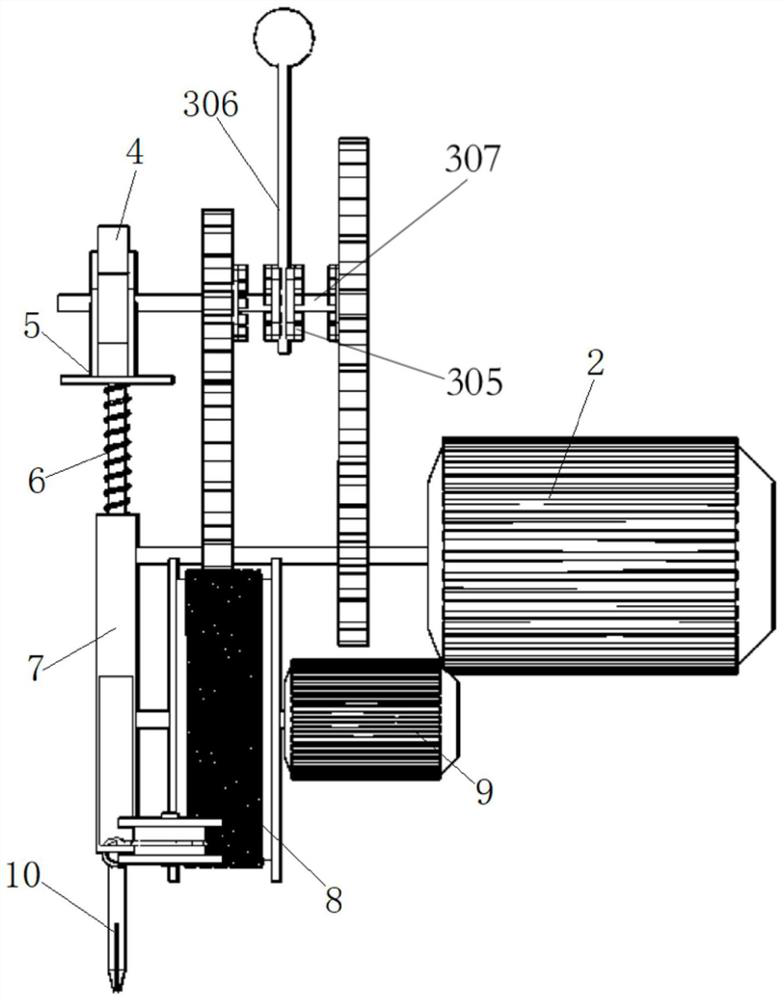

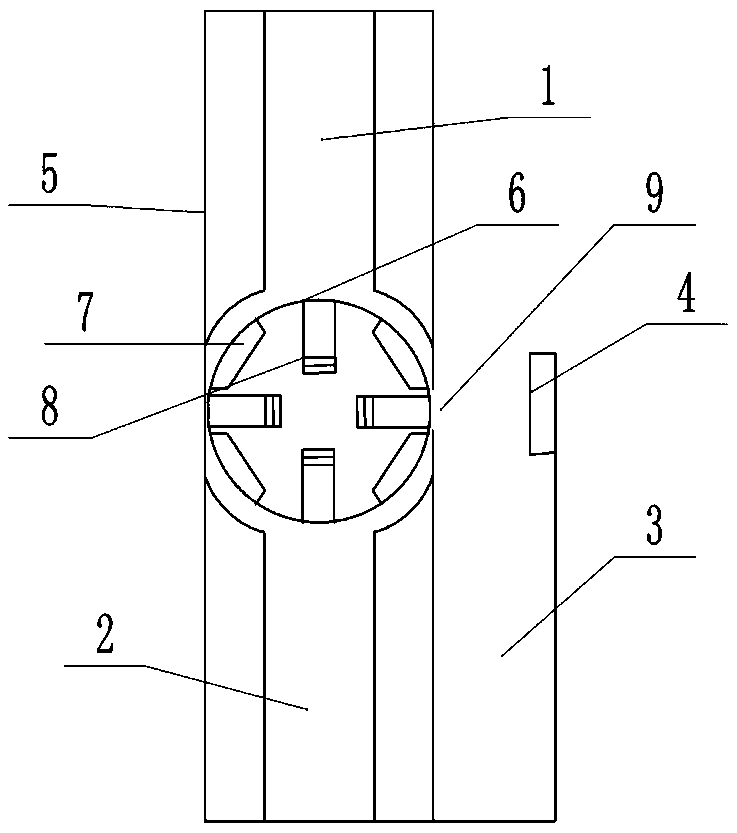

Variable electrode distance winding displacement device for high-density resistivity method

ActiveCN112234517APrecise positioningEmbedded accuratelyMechanical energy handlingElectric/magnetic detectionElectric machineryEngineering

The invention discloses a variable-electrode-distance wire arrangement device for a high-density resistivity method. The device comprises a vehicle body which is provided with a wire clamping box, wherein the wire clamping box is internally provided with a horizontal wire groove and a staple bolt groove, a wire is disposed in the horizontal wire groove in a penetrating manner, and the staple boltgroove is provided with a plurality of staple bolts; an upper end of the staple bolt is in contact with the lower end of the telescopic rod; the telescopic rod is vertically arranged below the cam mechanism, the input end of the cam mechanism is connected with the output end of the speed change mechanism, and the input end of the speed change mechanism is connected with the output end of the driving motor; vertical lifting of the telescopic rod is driven through the cam mechanism, the cam mechanism inputs power through the driving motor and the speed change mechanism, variable-speed motion ofthe cam mechanism is achieved, and variable-speed lifting of the telescopic rod is driven; through variable-speed lifting of the telescopic rod, a distance between the clamping nails buried underground is adjusted in the moving process of the vehicle body, and the structure is simple; wire arrangement of the variable electrode distance can be achieved only by controlling variable speed control ofinput power, and wire arrangement precision and working efficiency are high.

Owner:GUIZHOU UNIV

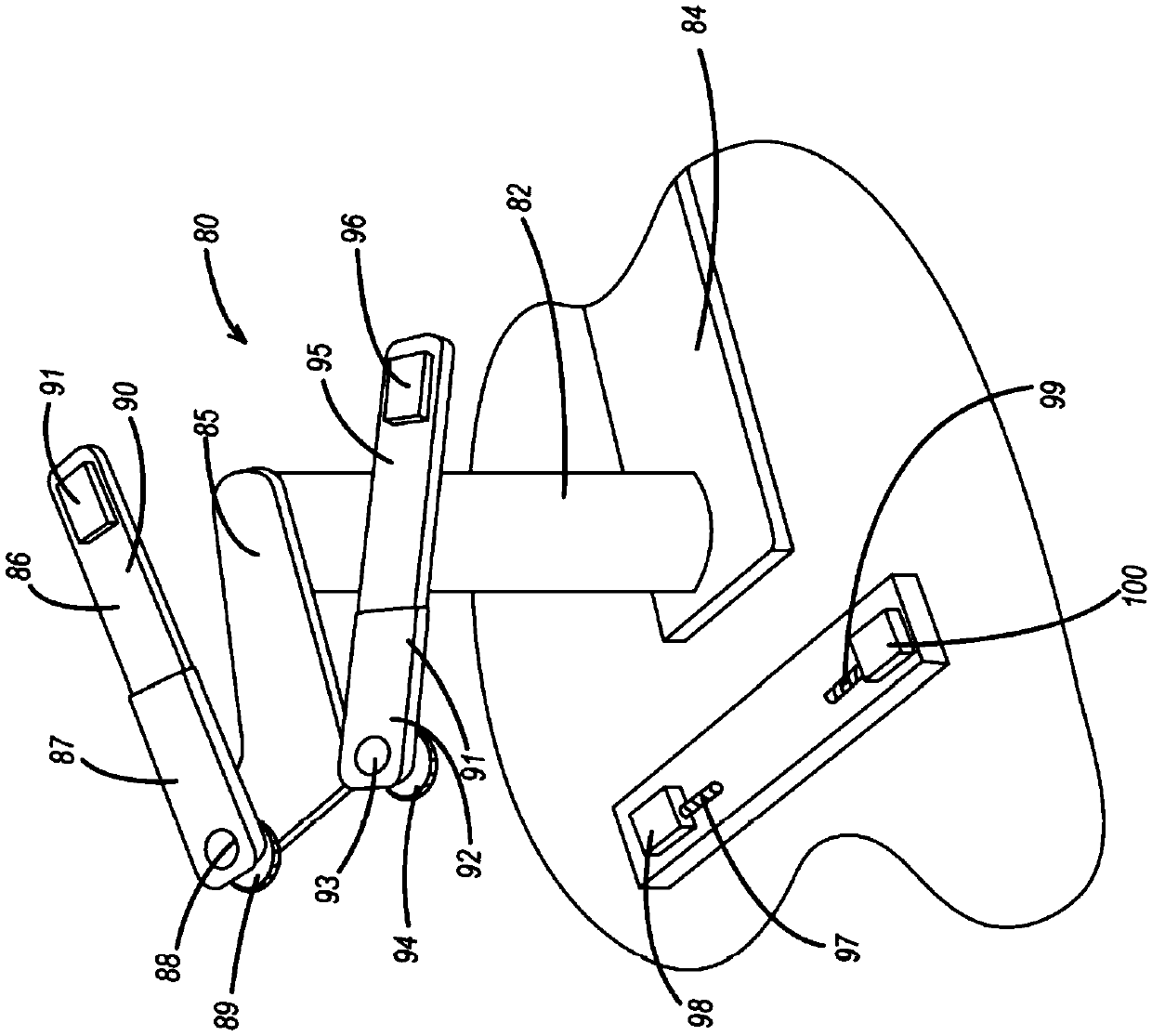

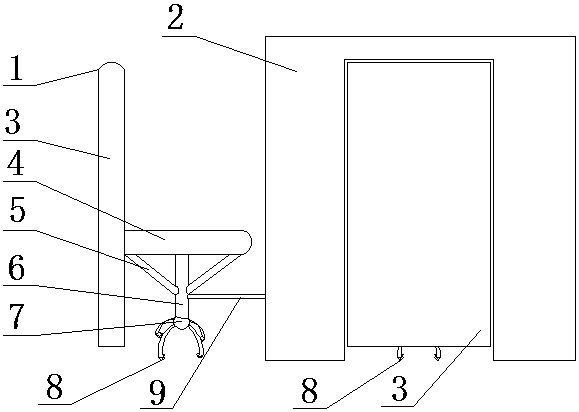

Hidden chair

InactiveCN107550083ASimple structureAutomatic placementStoolsCombination furnitureElectric machineryCushion

The invention discloses a hidden chair and belongs to the technical field of household supplies. The hidden chair comprises four seats and a desk. The four seats have the same structure and function,and the four seats are distributed around the desk in two-to-two symmetry. The desk comprises a backboard, a seat cushion, a secondary support, a primary support, a telescopic tube, a wheel disc and wheels. A motor, a CPU and a power supply are arranged inside the desk. The motor is connected with the CPU, and the power supply can supply power to the motor and the CPU. Four spaces for accommodating the seats are formed around the interior of the desk. When the telescopic tube is telescoped, the seats move into the desk, and the seats and the desk are combined into a whole, so as to achieve theaim of hiding. When the chair is used, the power supply of the chair is turned on, an ON button is pressed down, the motor rotates, the telescopic tube extends, the seats move out, and the desk is put in place. When a person does not use the chair, an OFF button is pressed down, the telescopic tube shrinks, and the seats automatically return into the desk. The hidden chair is simple in structure,can be automatically placed, does not occupy space, and is practical.

Owner:FOSHAN JIA YUN HANG TECH CO LTD

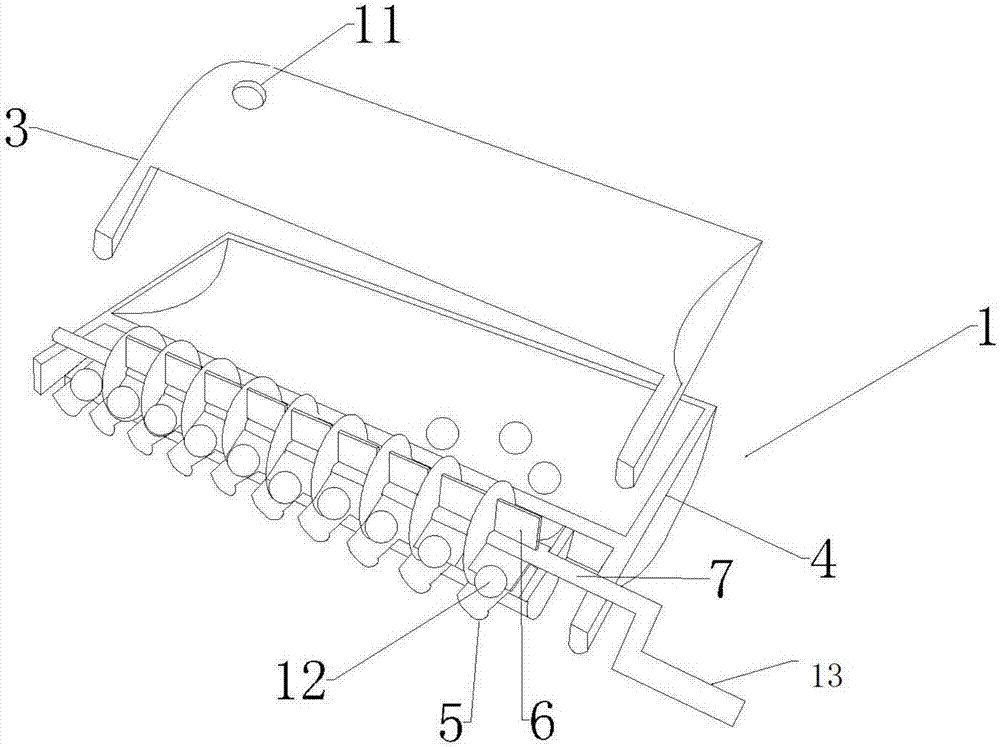

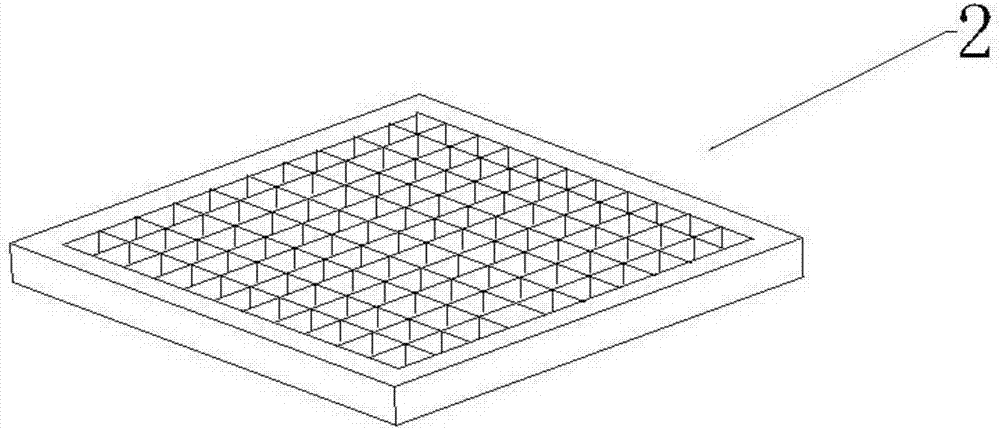

Seed germinating and seed placing device

The invention relates to a seed germinating and seed placing device. The seed germinating and seed placing device comprises a seed outlet system and a germinating bed; the seed outlet system comprises a seed storage box and a blade rotating shaft system; a pieces of outlet channels are formed in one side of the seed storage box; the blade rotating shaft system comprises a rotating shaft and a pieces of blade units arranged on the rotating shaft in parallel; the blade units are arranged at the outlet channels correspondingly; the seeds in the seed storage box are discharging on the germinating bed by rotating the rotating shaft. The seed placing device can place the seeds automatically, rapidly and tidily, does not need to place the seeds one by one, and is time-saving, labor-saving, rapid and convenient.

Owner:SOUTHWEST UNIVERSITY

Donkey-hide gelatin natto cake and preparation method thereof

PendingCN109601868AIncrease contentBright colorFood preservationFood coatingVillosa choctawensisSugar

The invention discloses a donkey-hide gelatin natto cake and a preparation method thereof, and belongs to the field of food manufacturing. The donkey-hide gelatin natto cake comprises the following raw materials in parts by weight: 10-20 parts of donkey-hide gelatin, 100-120 parts of soybeans, 2-5 parts of yellow rice wine, 5-10 parts of fine sugar, 2-6 parts of maltose, and 3-8 parts of sesame oil. The preparation method comprises the following steps: taking, boiling and filtering the soybeans to obtain soybeans and a soybean liquid, mixing the soybeans into a soybean paste, preparing donkey-hide gelatin pulp, adding the fine sugar and the maltose, stir-frying the soybean paste into mashed soybeans, fermenting the mashed soybeans, fermenting the soybean liquid and the donkey-hide gelatinpulp, and wrapping the outer surface of a donkey-hide gelatin natto mixture with the unfermented mashed soybeans, and performing extrusion forming to obtain the donkey-hide gelatin natto cake. According to the invention, tplacing plates are evenly arranged on a turntable, and electromagnets are arranged at both ends of the bottom of an extrusion plate, which facilitates the placement and collection of magnetic separation cylinders in the process of processing and forming the donkey-hide gelatin natto cake, and facilitates the separation of the internal stuffing of the donkey-hide gelatin nattocake and the unfermented mashed soybeans. The automatic production improves the production efficiency.

Owner:黄绪明

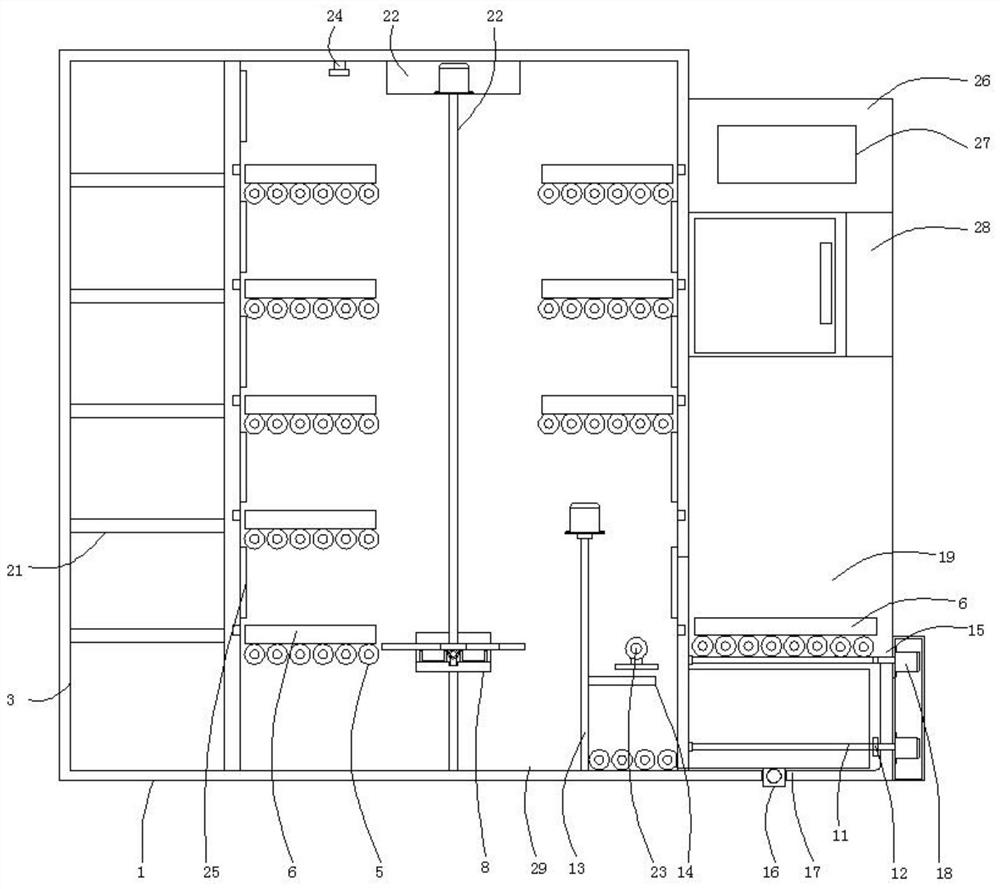

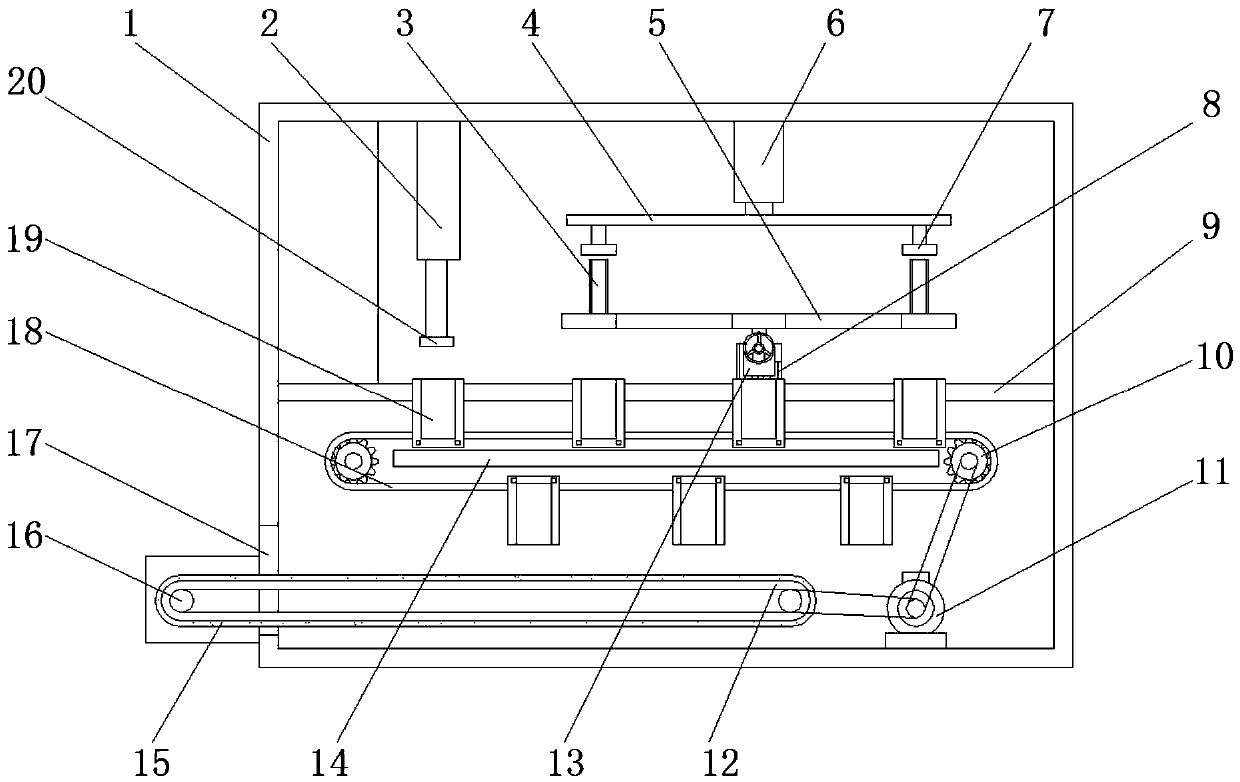

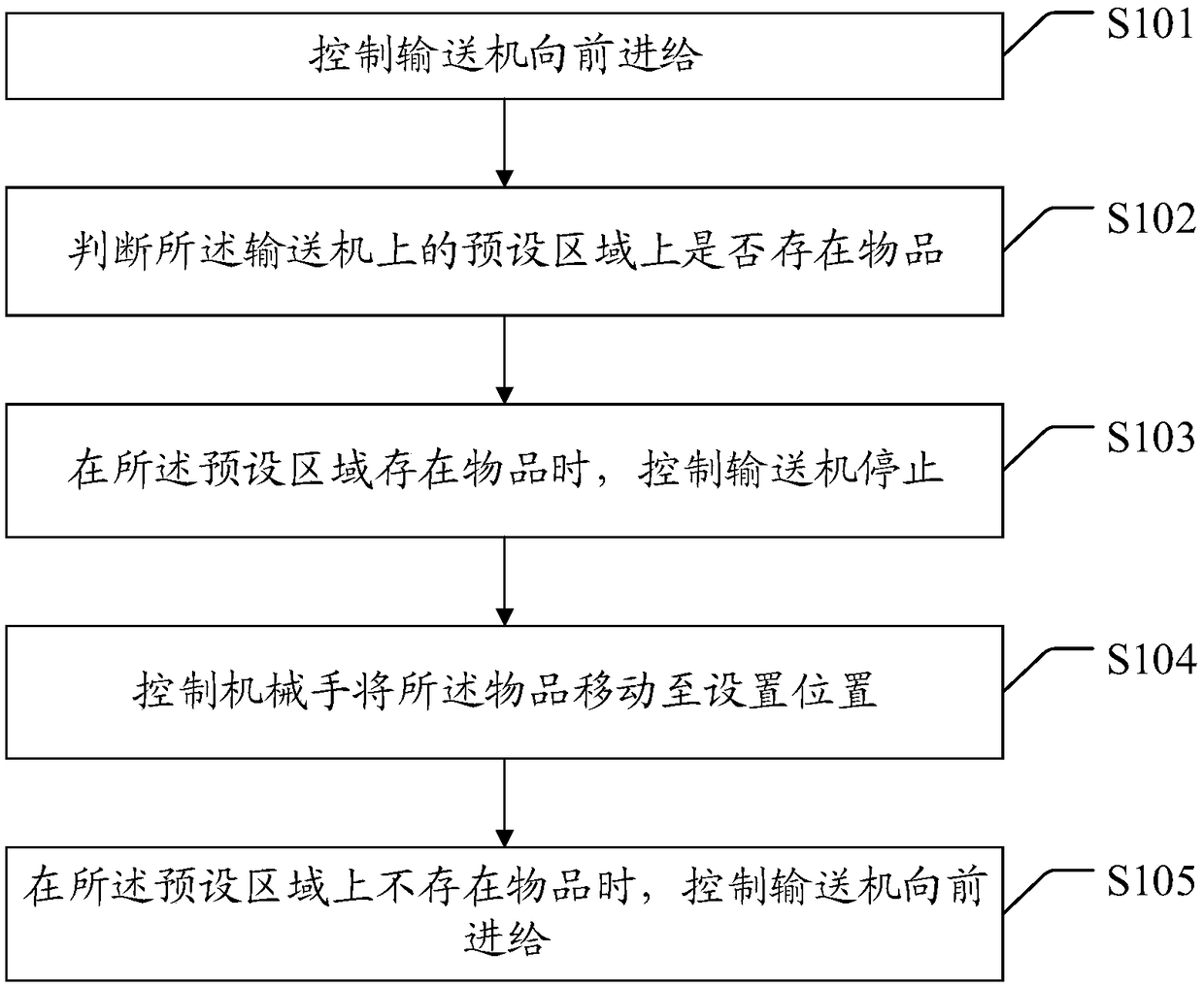

Temporary storage and feeding method and device and computer readable storage medium

InactiveCN109353778AAutomatic placementImprove work efficiencyImage analysisConveyorsManipulatorTemporary storage

The invention discloses a temporary storage and feeding method and device and a computer readable storage medium. The temporary storage and feeding method is used for distributing and guiding parcel flows and comprises the steps that a conveyer is controlled to advance forwards; whether objects exist on a preset area on the conveyer or not is judged; if objects exist on the preset area, the conveyer is controlled to stop, and a mechanical arm is controlled to move the objects to a set position; and if no object exists on the preset area, the conveyer is controlled to advance frontward. The temporary storage and feeding method and device have the beneficial effects of achieving automatic goods placing and improving the work efficiency.

Owner:SHENZHEN DORABOT ROBOTICS CO LTD

A traffic cone placement device

ActiveCN107476219BSimple structure and easy to manufactureAutomatic placementTraffic signalsRoad signsSimulationTruck

Owner:SHANDONG JIANZHU UNIV

Thermoplastic composite material automatic laying device and method

ActiveCN108819292BAutomatic placementPrecise heating areaUltrasonic vibrationThermoplastic composites

Owner:CHANGCHUN UNIV OF SCI & TECH

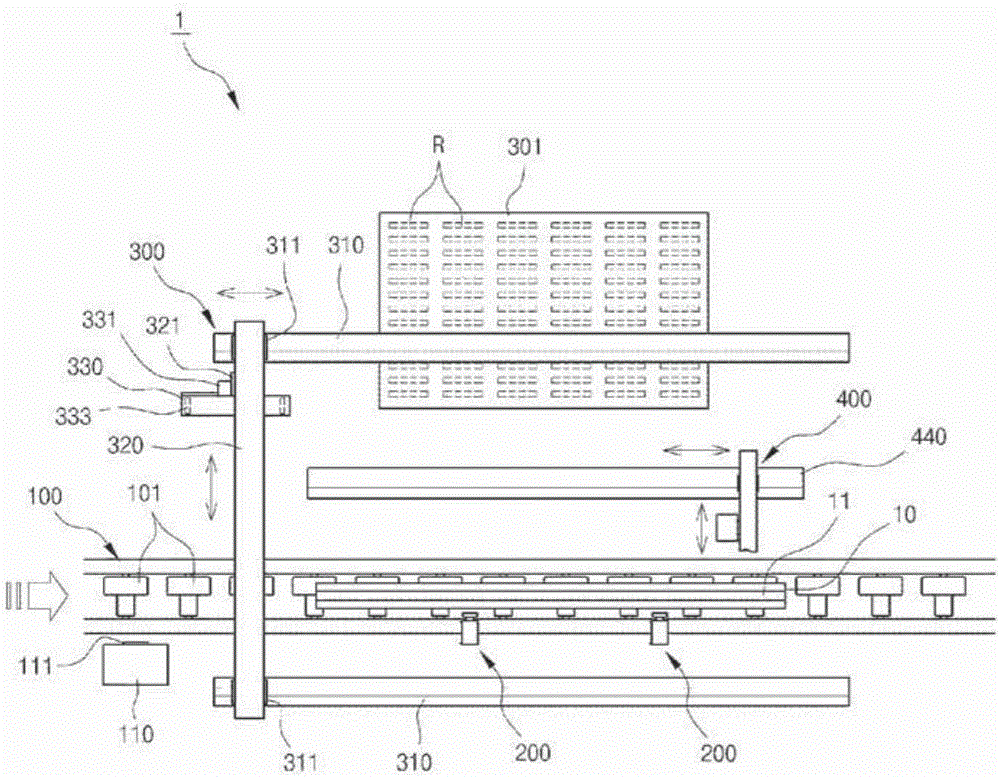

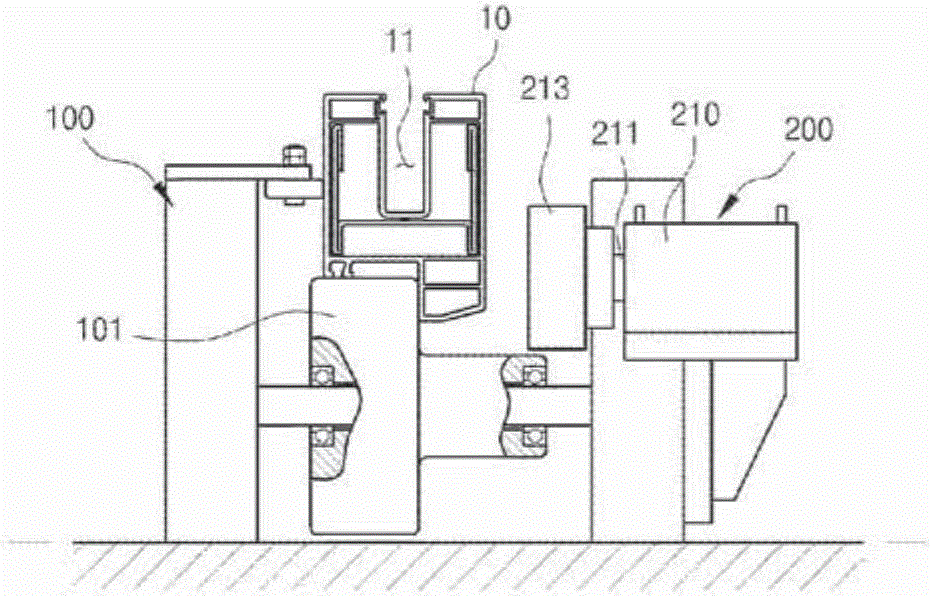

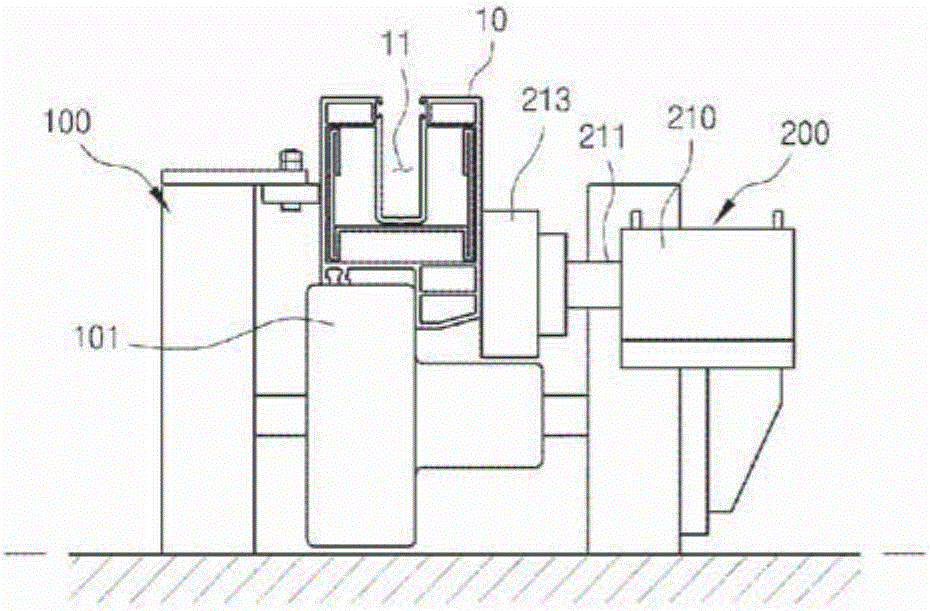

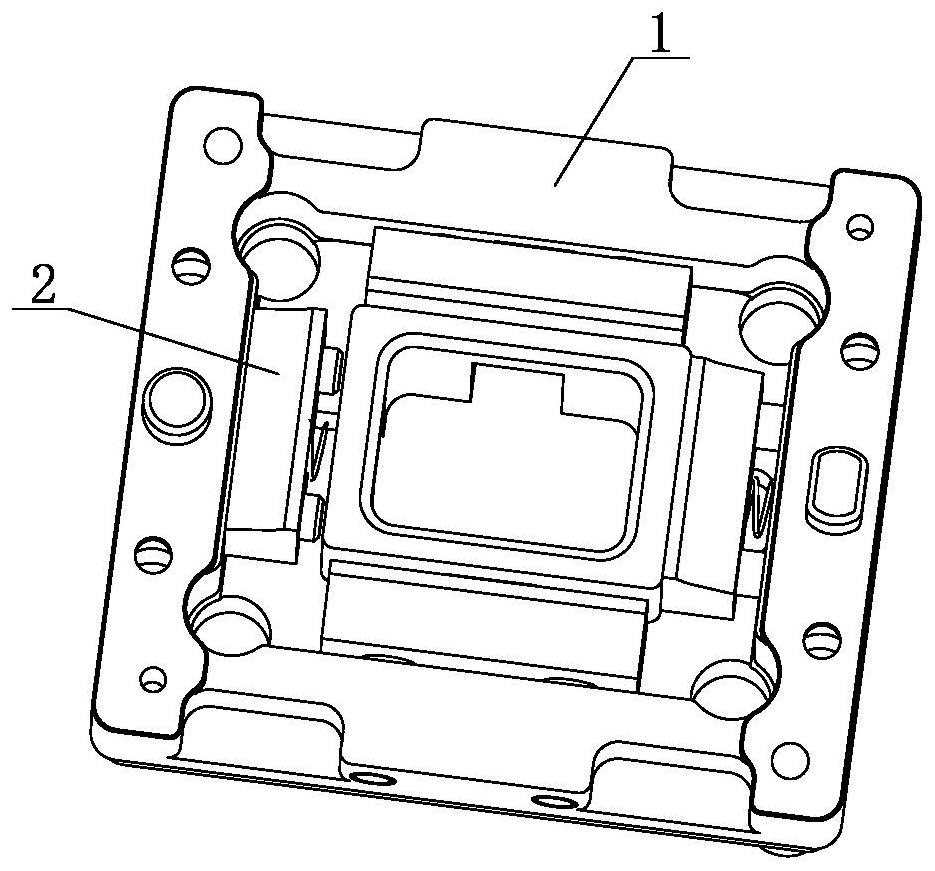

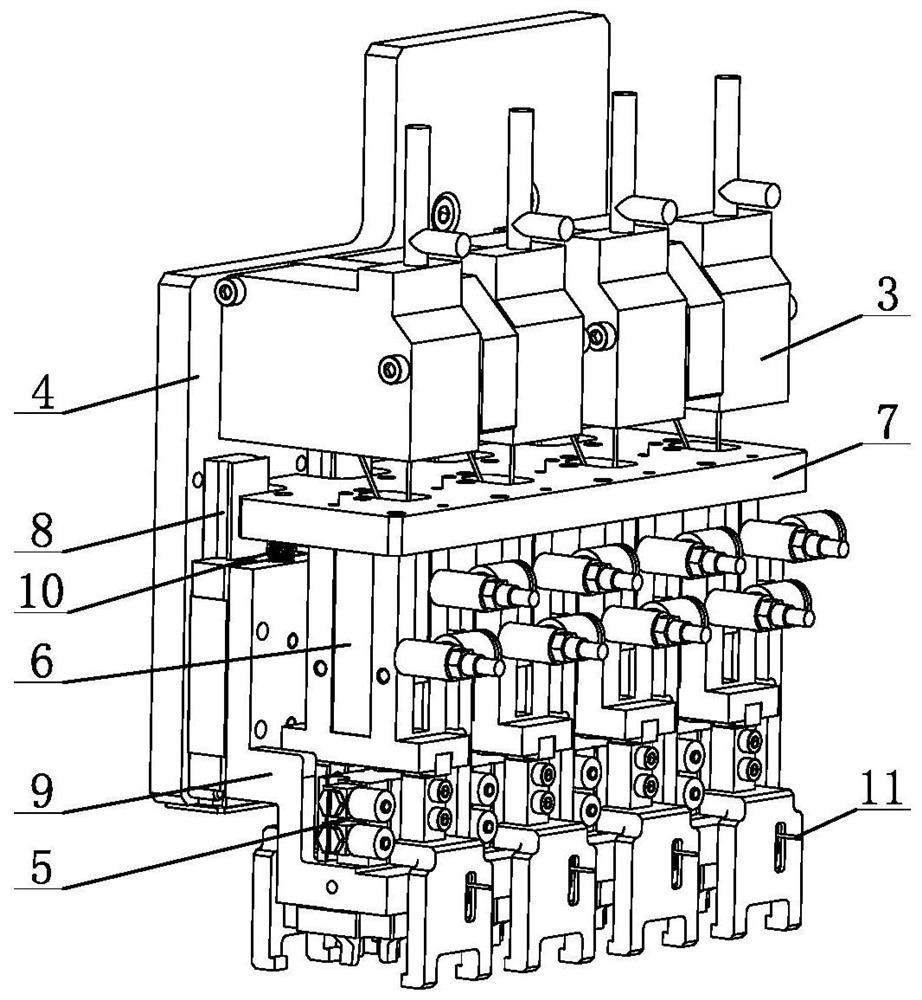

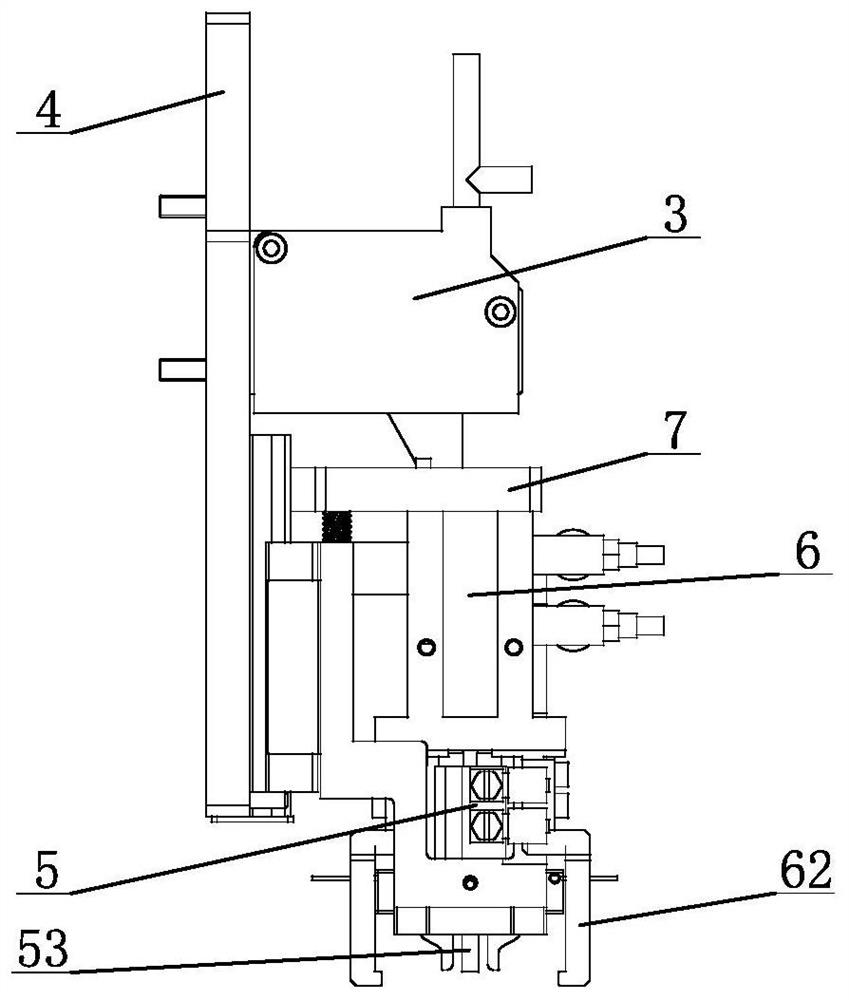

Roller assembly machine for window

ActiveCN105008644AAutomatic placementShorten the timeWing arrangementsWing suspension devicesEngineeringAssembly machine

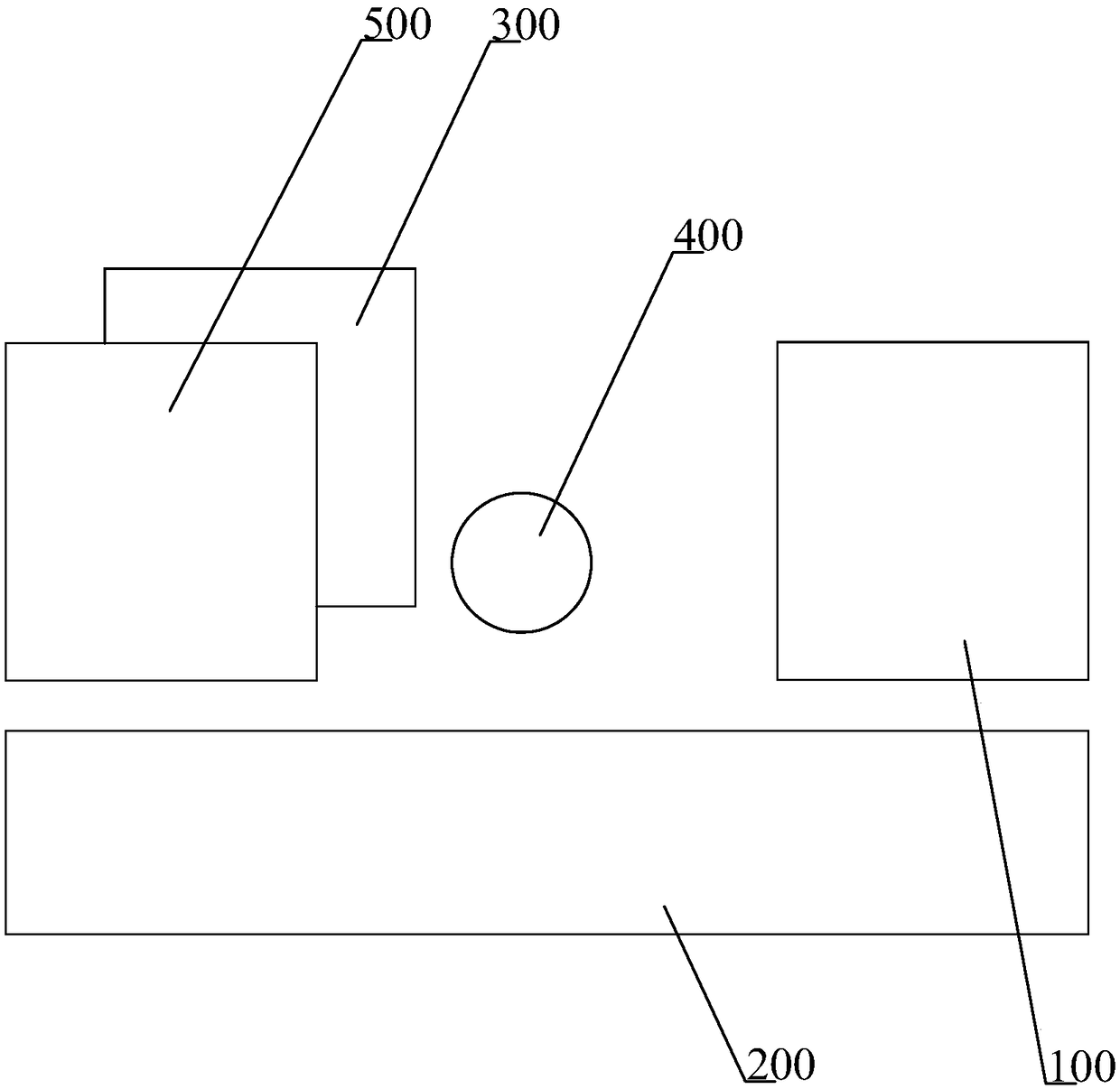

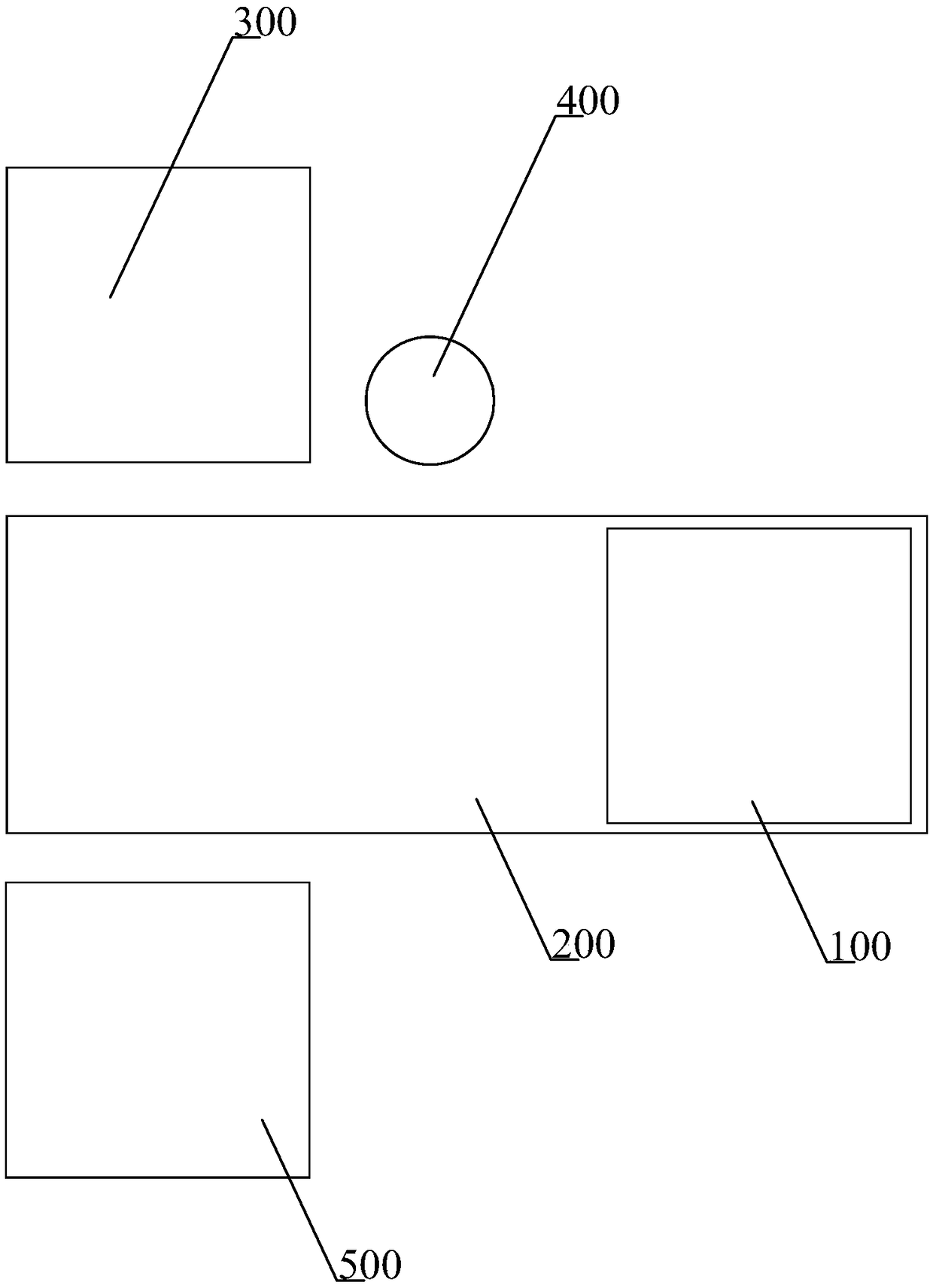

Disclosed therein is a roller assembly machine for window, which can automatically locate a roller into a seating recess of a window profile and fix the located roller by means of a joining member. The roller assembly machine for window includes: a conveying part(100) for conveying a profile(10) for manufacturing a window to one side; a clamping part(200) for fixing the conveyed profile(10) at a predetermined position; a roller supply part(300) for positioning at least one roller assembly(R) on a seating recess(11) of the fixed profile(10); and a joining member assembly part(400) for fixing the roller assembly(R) located in the seating recess(11) by means of a joining member. Because the roller supply part includes a plurality of the fingers, the plural roller assemblies are grasped from the feeder at once and sequentially located inside the seating recess of the conveyed profile. Therefore, the roller assembly machine for window according to the preferred embodiment of the present invention can reduce time and the number of work processes required for reciprocating the roller supply part, thus enhancing work efficiency.

Owner:LG HAUSYS LTD

Environment-friendly dust removal method

The invention relates to the technical field of cleaning of threaded workpieces, in particular to an environment-friendly dust removal method. The environment-friendly dust removal method comprises the following steps that S1, a controller controls a first electromagnet on a piston of an air cylinder and a second electromagnet on a piston of a hydraulic cylinder to be powered on to clamp the two ends of a threaded workpiece, then a cleaning rod is placed in a threaded gap of the end, close to the hydraulic cylinder, of the threaded workpiece, and the cleaning rod is made to abut against the gap of the threaded workpiece; and S2, a microcontroller controls a motor to rotate forwardly, a rocking bar fixedly connected with an output shaft of the motor rotates around the air cylinder, a sliding block connected with the rocking bar slides between the air cylinder and the hydraulic cylinder, and the cleaning rod on the sliding block slides in the thread direction of the threaded workpiece; and the threaded workpiece moves to one side of the hydraulic cylinder, the piston of the air cylinder slides to one side of the hydraulic cylinder, and the piston on the hydraulic cylinder slides to the interior of the hydraulic cylinder.

Owner:宁波隆锐机械制造有限公司

Shaft conveying device

The invention belongs to conveying devices and particularly relates to a shaft conveying device. The shaft conveying device comprises a first conveyer belt. A rotation disk is arranged between the first conveyer belt and the second conveyer belt. Vertical grooves are evenly distributed on the circumference of the rotation disk. A transverse groove is arranged in the interval between every two adjacent vertical grooves. The depth of each vertical groove and the length of each transverse groove are equal and both equal to the length of a shaft needing to be conveyed. Metal plates are connected into the vertical grooves in a sliding manner. A third conveyer belt is arranged on one side of the second conveyer belt. Baffles are arranged on the first conveyer belt and the second conveyer belt. The input end of the third conveyer belt is provided with a support plate. The support plate is provided with a permanent magnet. A connection plate used for limiting is arranged between the first conveyer belt and the second conveyer belt. The side, close to the second conveyer belt, of the connection plate is provided with an opening. The length of the opening is larger than the diameter of the shaft to be conveyed. By the adoption of the shaft conveying device, the shafts can be automatically arranged on the conveying device in order and conveyed to a storage site, the work time is saved, and the efficiency is improved.

Owner:宁波信基机械科技有限公司

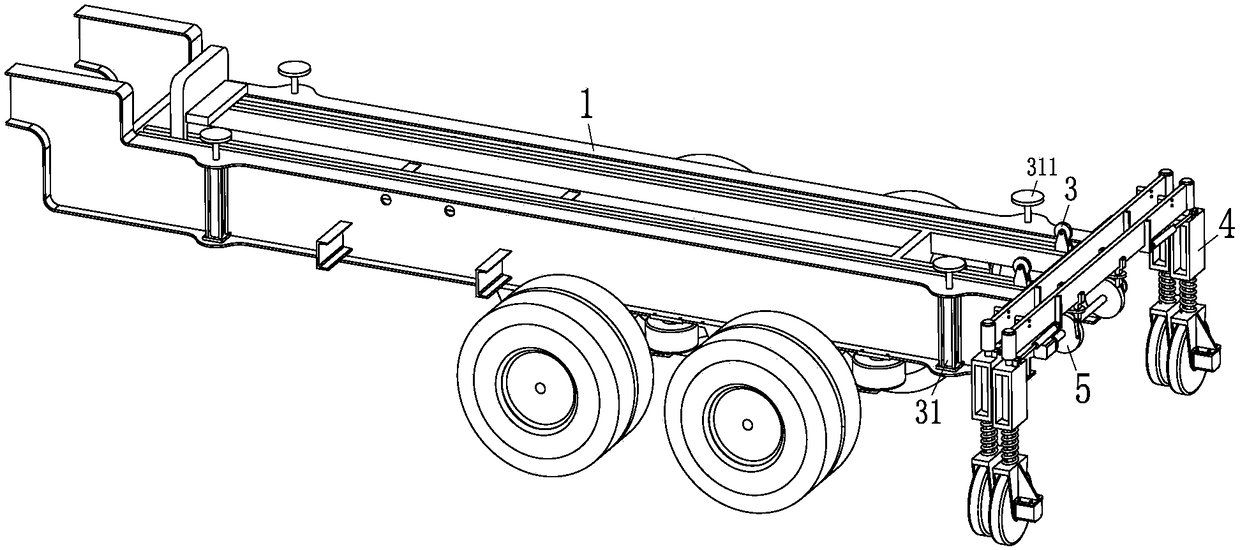

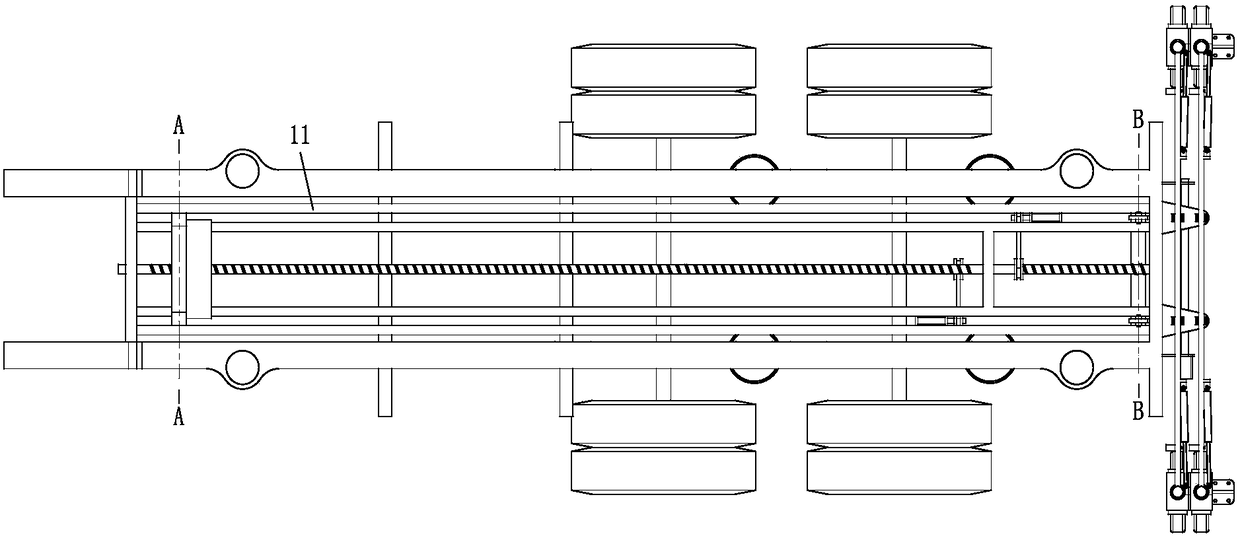

An easy unloading container semi-trailer

ActiveCN106274612BNo tiltWon't cause tremblingVehicle with removable loadingTractor-trailer combinationsEngineeringSemi-trailer

Owner:蒙城县东正汽车有限公司

Shaft transport equipment

Owner:宁波信基机械科技有限公司

Positioning device and method for automatically and quickly positioning intelligent flatbed printer and installation method

ActiveCN110435312AAutomatic placementAutomatic quick placementOther printing apparatusDrive motorEngineering

The invention discloses a positioning device and method for automatically and quickly positioning an intelligent flatbed printer and an installation method. The positioning device comprises a platformlimiting installation plate, platform limiting moving plates, a platform positioning lifting plate, a platform limiting sliding pin group, a platform positioning pin group, a platform limiting motorfixing plate, a platform limiting motor swing arm, a proximity switch, a travel switch and a driving motor, wherein the platform limiting moving plates are installed on both sides of the platform limiting installation plate, the platform positioning pin group is installed on the platform positioning lifting plate and is fixedly put in the platform limiting installation plate by virtue of a screw,the platform limiting sliding pin group is connected with the platform limiting installation plate, the platform limiting moving plates and the platform positioning lifting plate, the driving motor isinstalled on the platform limiting motor fixing plate, the platform limiting motor swing arm is connected with a shaft of the driving motor, and the proximity switch is installed on the platform limiting motor fixing plate. According to the embodiment of the positioning device, the flatbed printer can be automatically and quickly positioned to print patterns, and the automatic and quick positioning function of UV flatbed printing is realized.

Owner:广州来丽智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com