Automatic rivet installation device

A rivet and automatic technology, applied in the field of automatic rivet setting device, can solve the problems of low production efficiency, large labor input, and difficulty in ensuring placement, and achieve the effects of saving labor costs, accurate placement, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

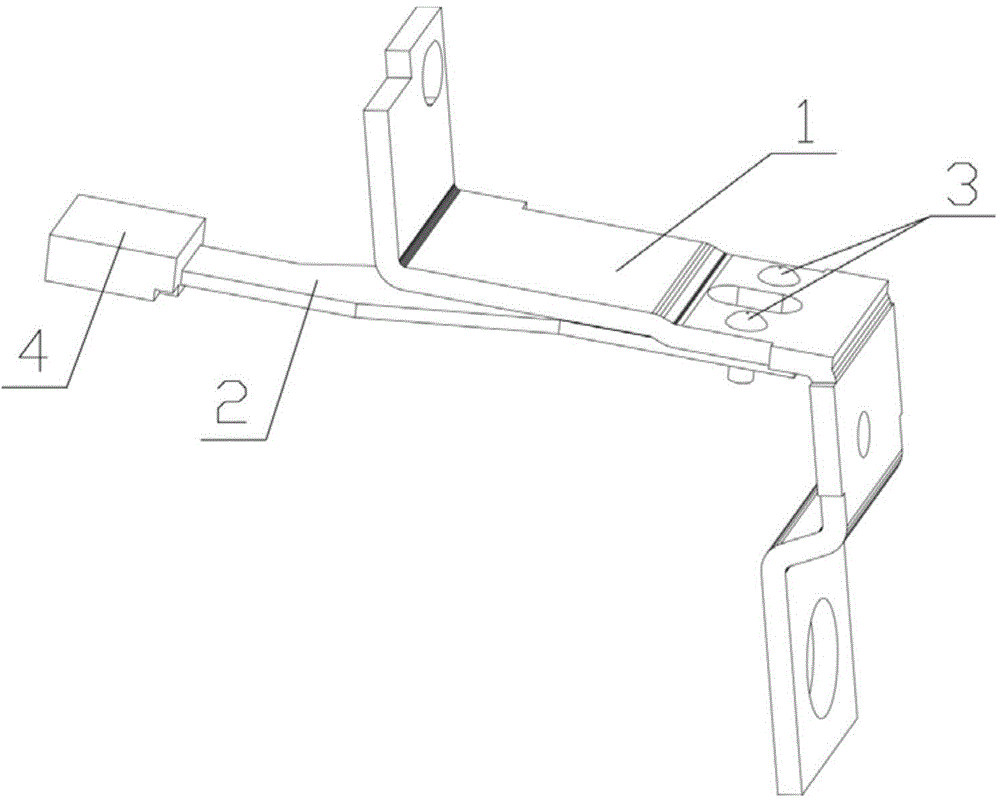

[0031] Such as figure 1 As shown, the entire assembled product includes a bent part 1 , a metal sheet 2 , a rivet 3 and a plastic cap 4 , and the rivet 3 runs through the bent part 1 and the metal sheet 2 . Before placing the rivet 3, both the bent part 1 and the metal sheet 2 have been accurately placed in place.

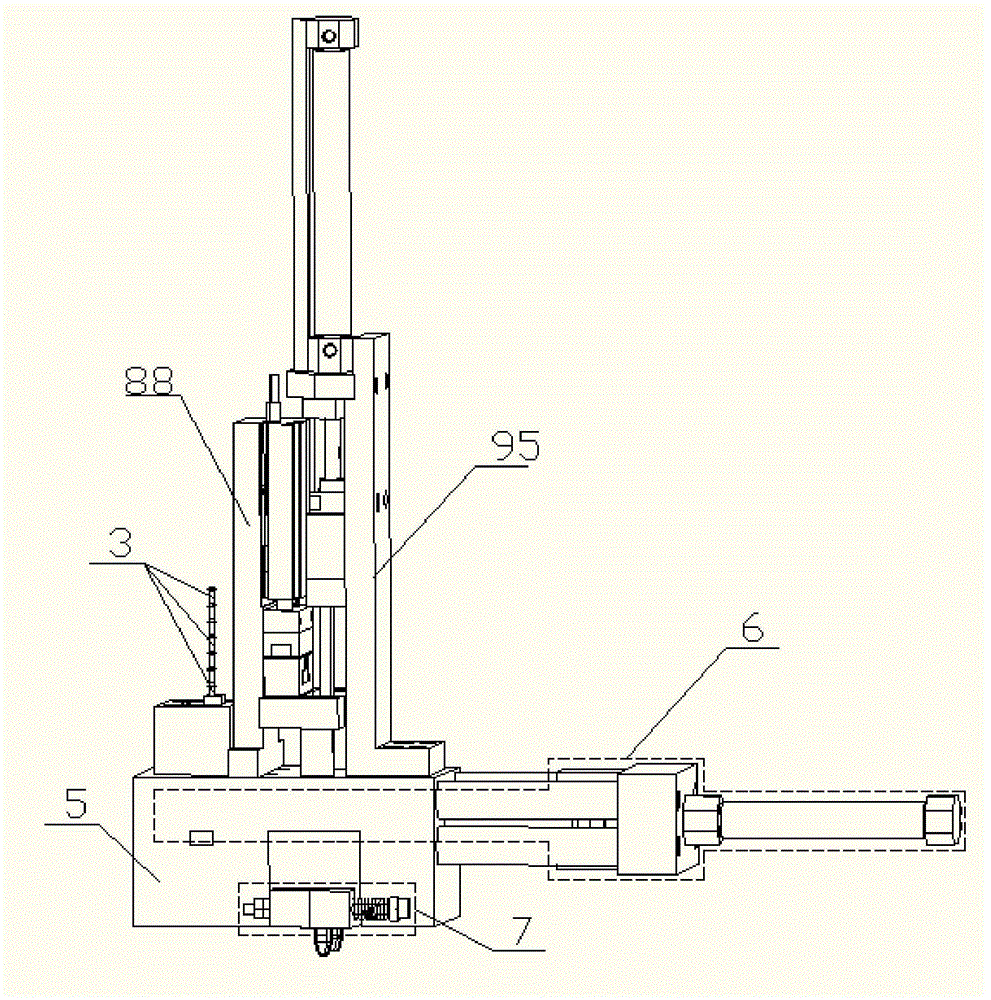

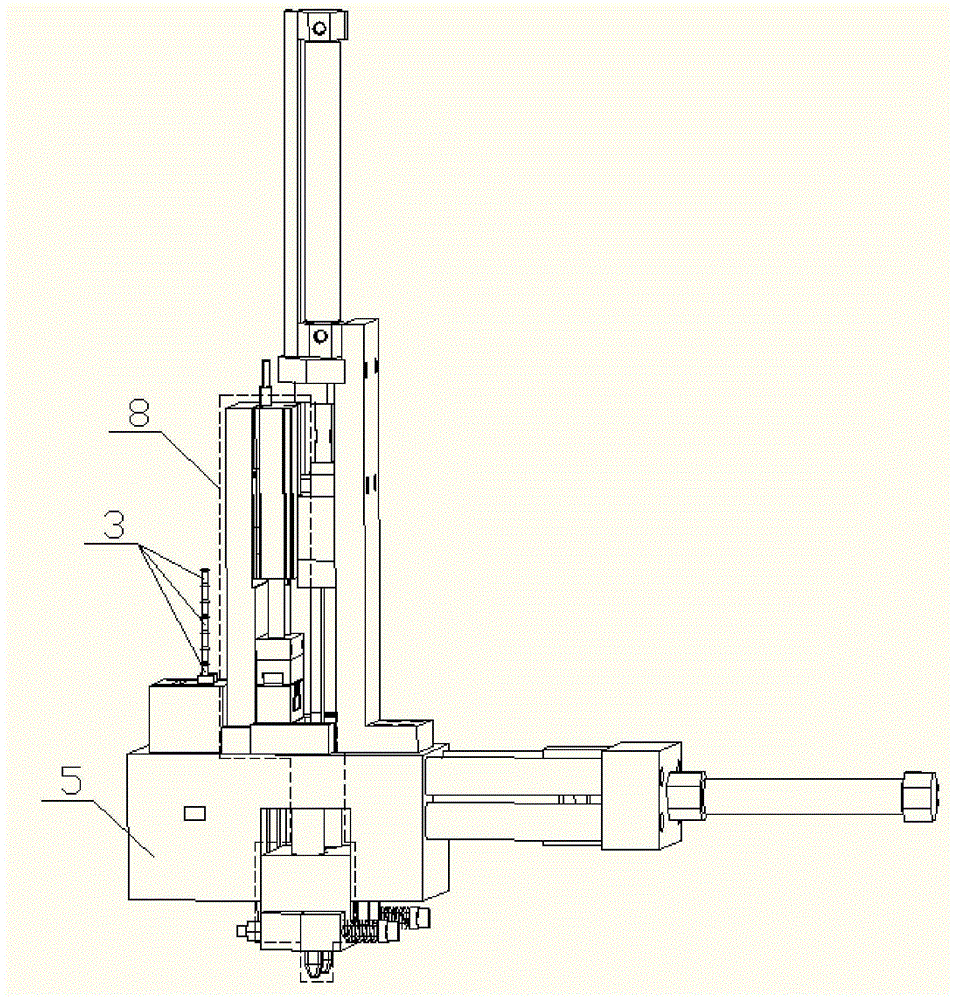

[0032] Such as figure 2 As shown, the automatic rivet setting device includes an installation base 5, a delivery seat 11 installed on the installation base 5 for placing the rivets 3 connected in strips, and for separating the rivets 3 from the strips of rivets 3 Come out and send the separated single rivet 3 to the riveting part 6 above the product to be riveted, installed in the installation base 5 and located above the product to be riveted and used for clamping and falling under the action of gravity The clamping part 7 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com