Patents

Literature

2193 results about "Transverse groove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

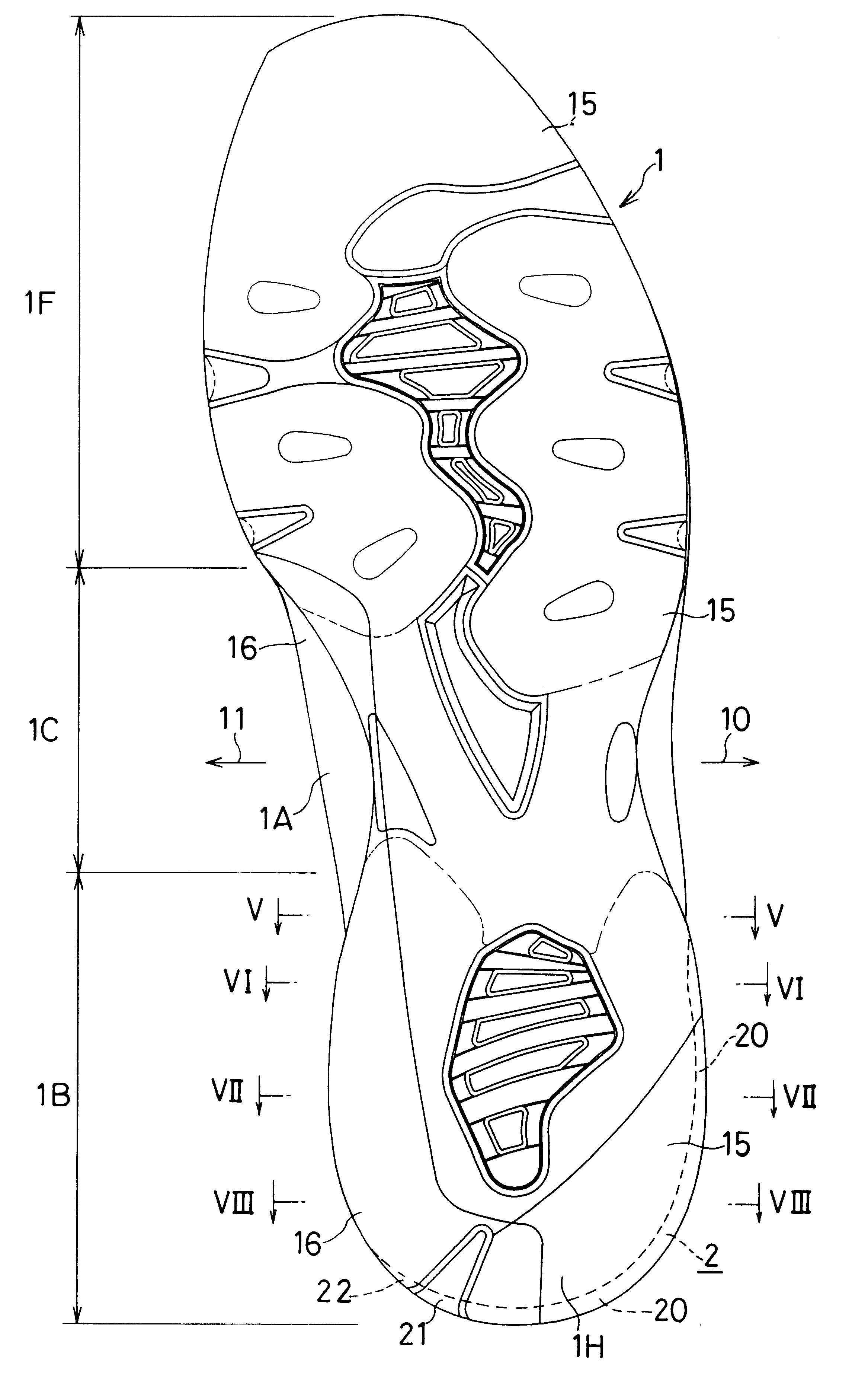

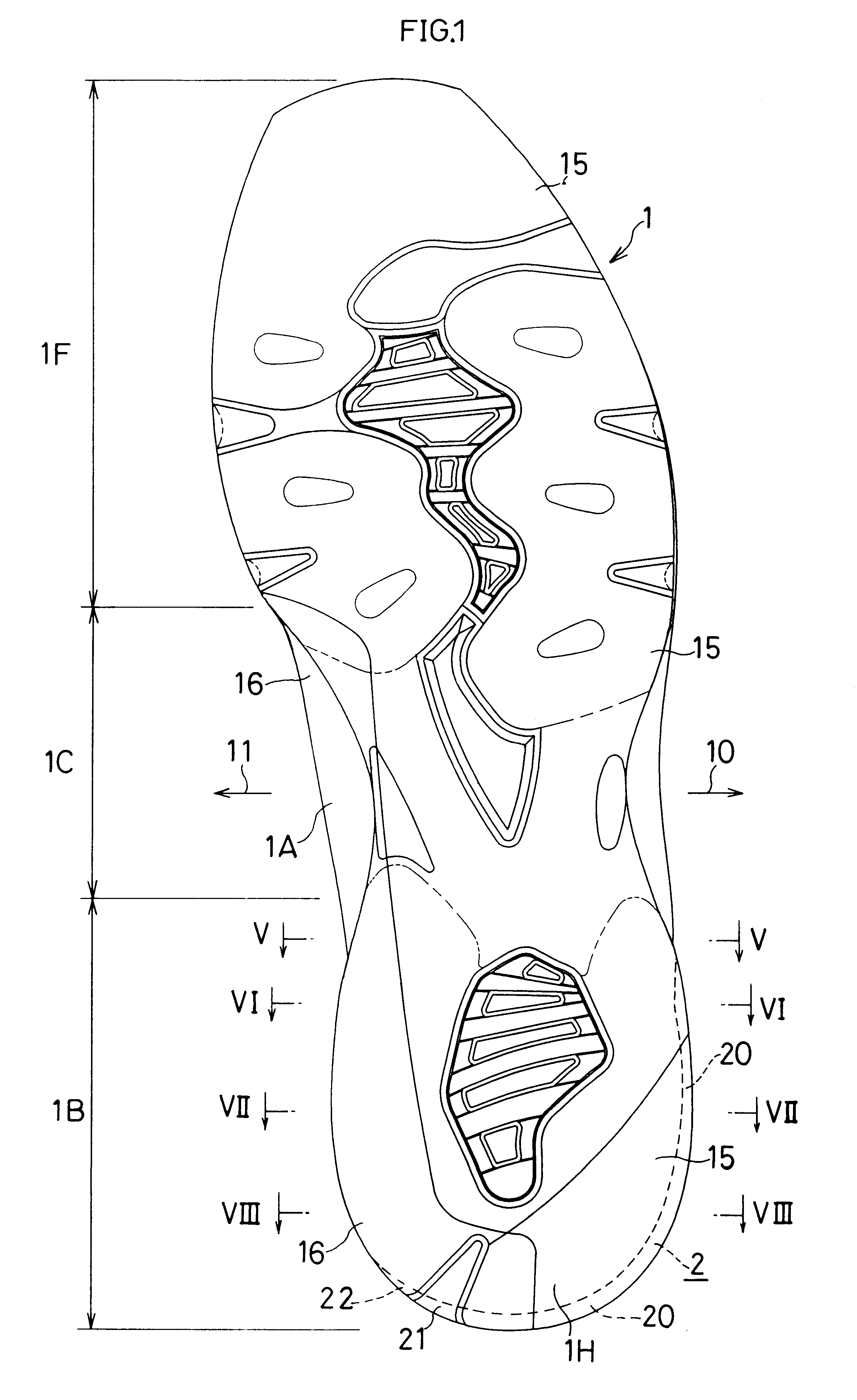

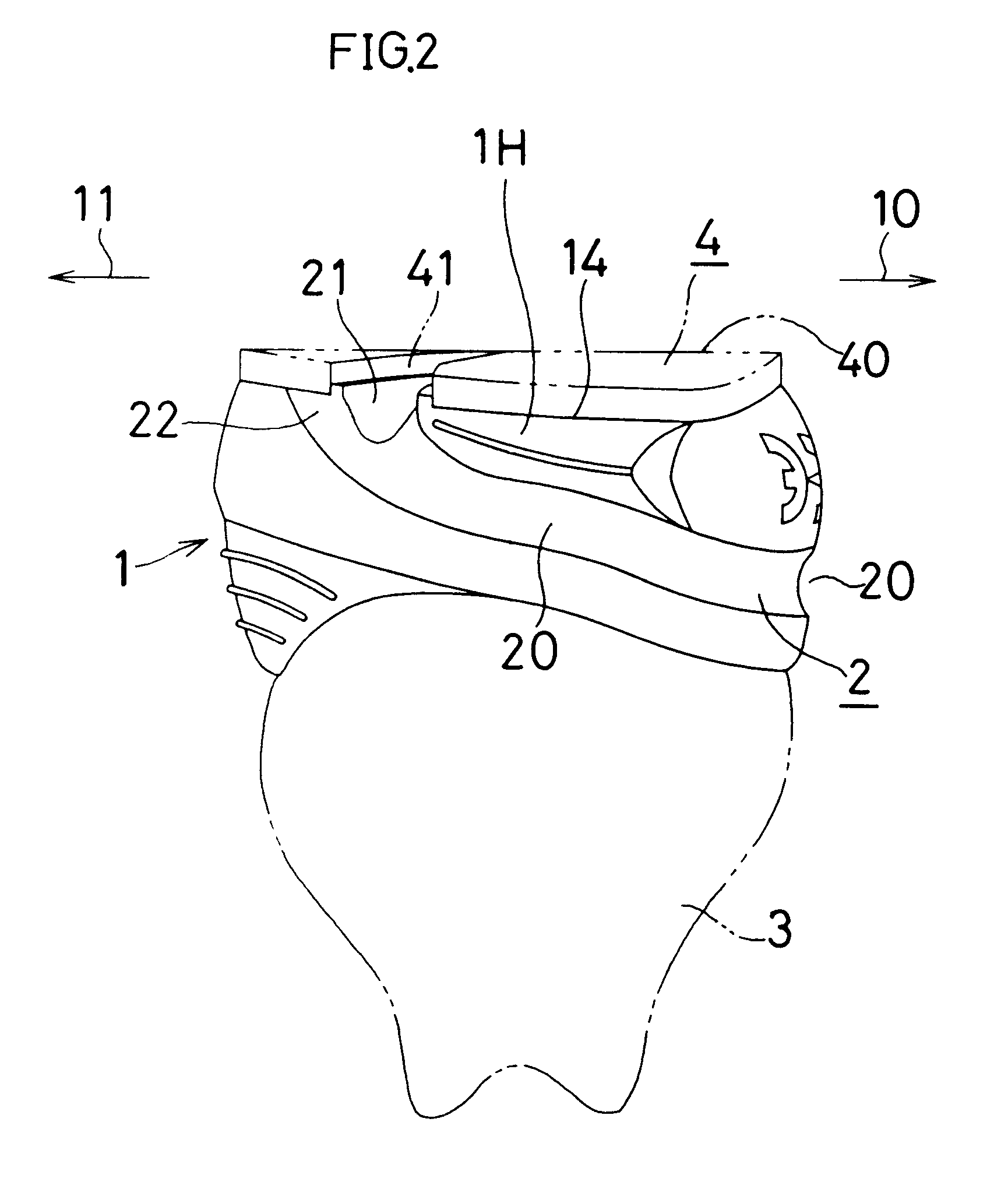

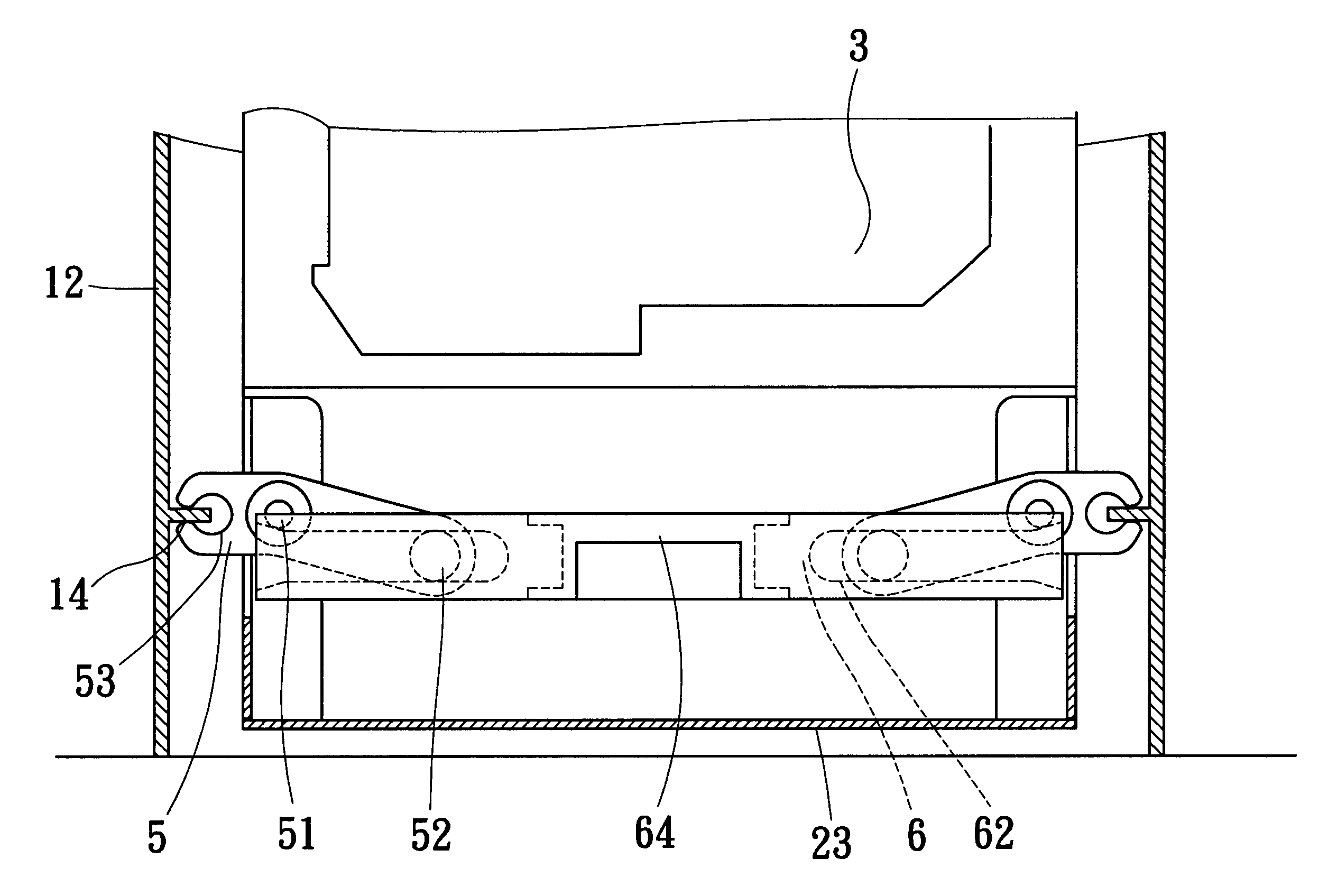

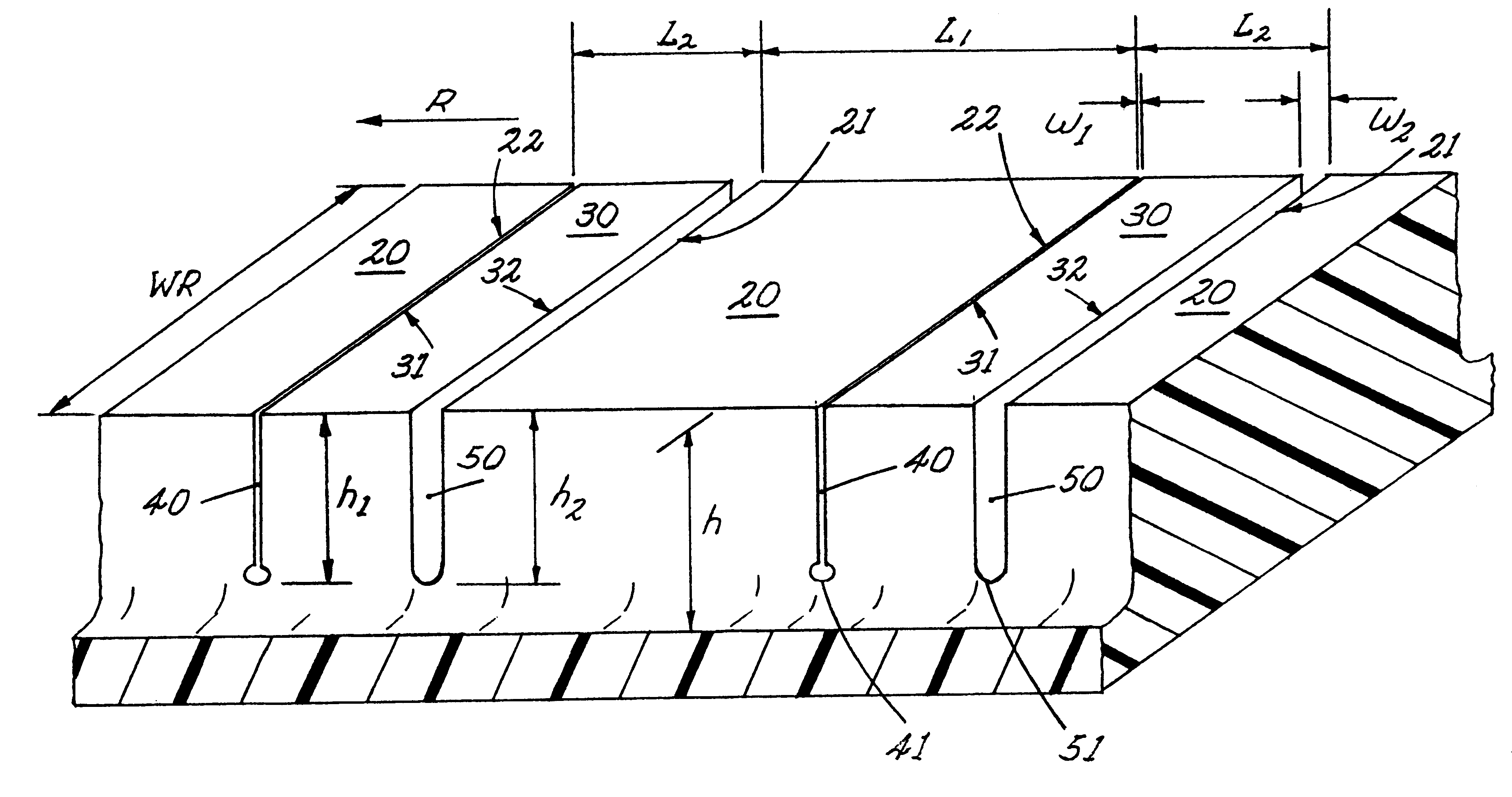

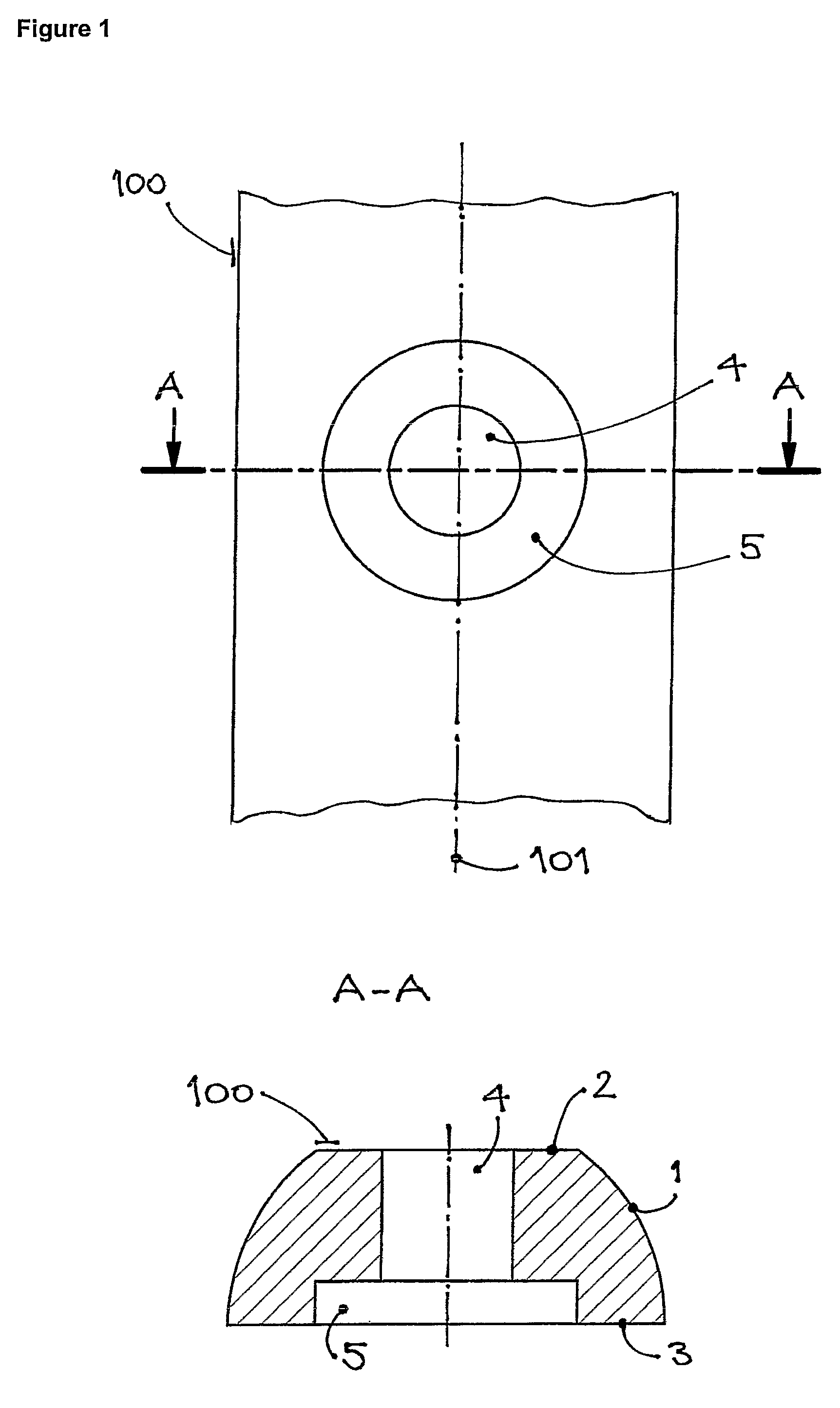

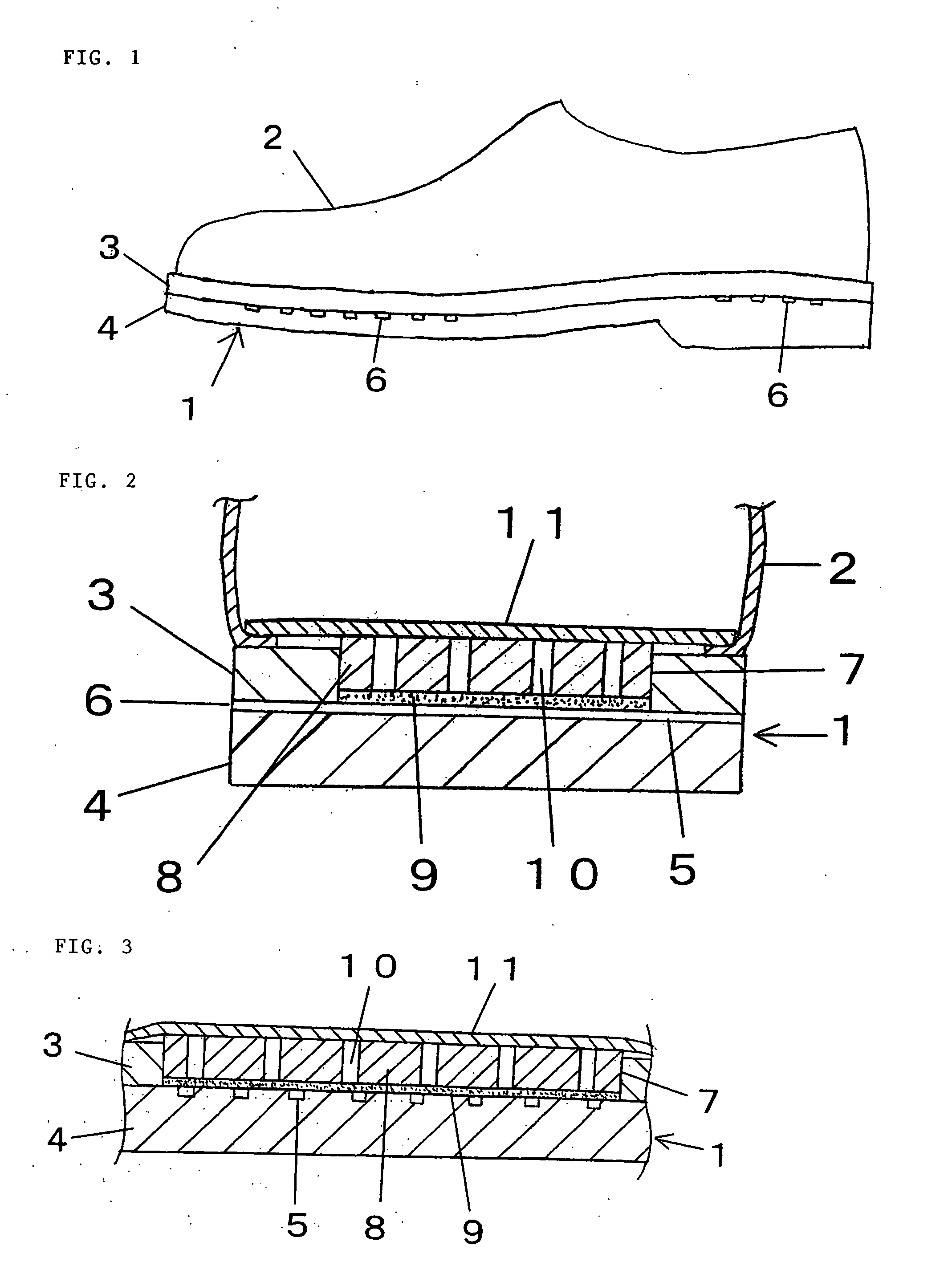

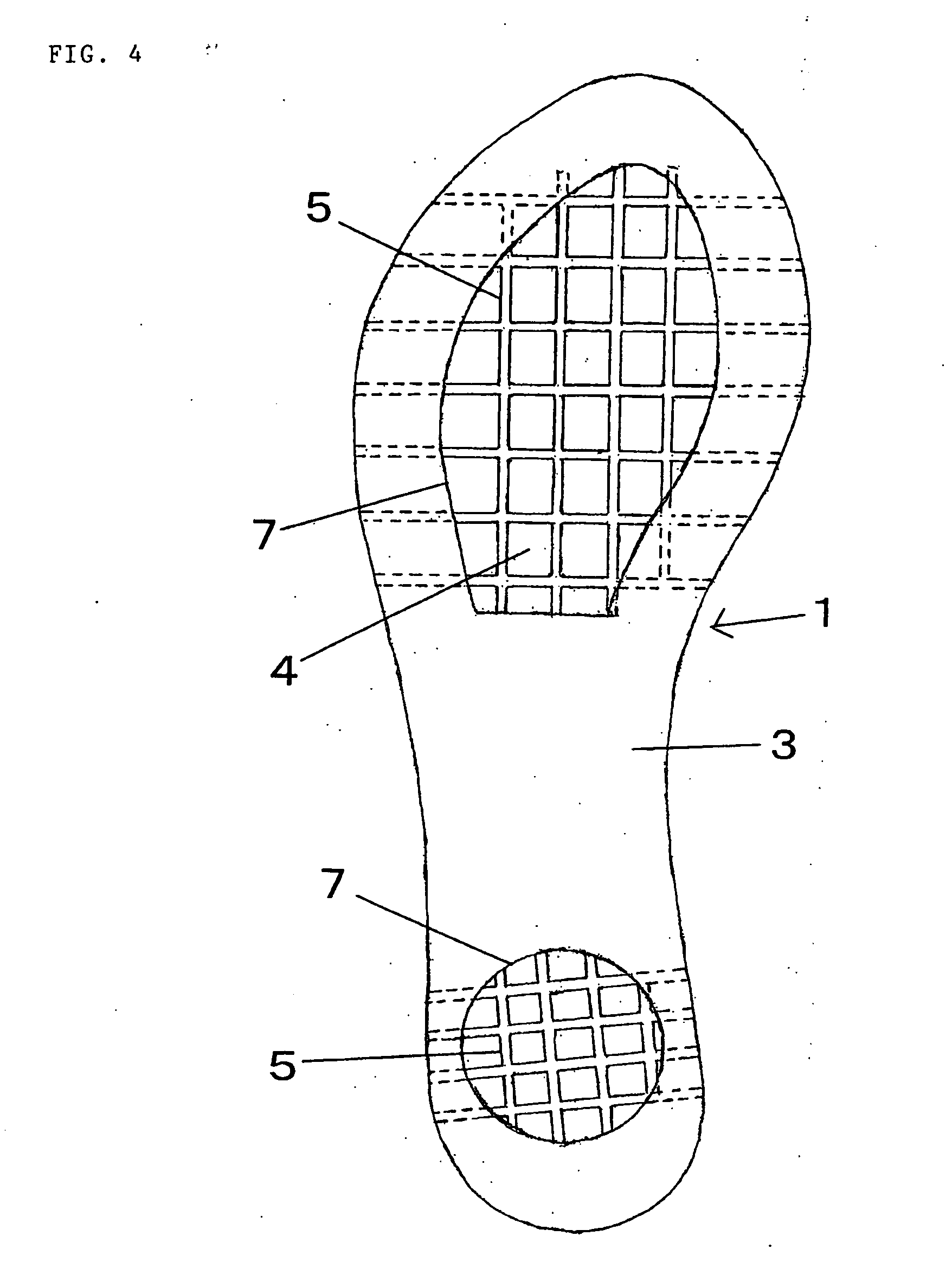

Athletic shoe

An athletic shoe comprises an upper (3) for accommodating an instep of a foot, and outer sole (4) having a tread on bottom surface, and a midsole (1) interposed between the upper (3) and the outer sole (4). A shock absorbing groove (2) is formed in the midsole (1). The shock absorbing groove (2) is formed of a long transverse groove (20) and a short longitudinal groove (21) in a continuous manner. The transverse groove (20) is formed on the midsole (1) extending from a side face of a rear foot part (1B) of the midsole (1) on lateral side (10) of the foot to a back face of a heel part (1H) of the midsole (1) and has an end (22) on the heel part (1H). The longitudinal groove (21) is formed in such a manner as to cut out the heel part (1H) of the midsole (1) from a lower end face of the midsole (1) toward the end of the transverse groove (20).

Owner:ASICS CORP

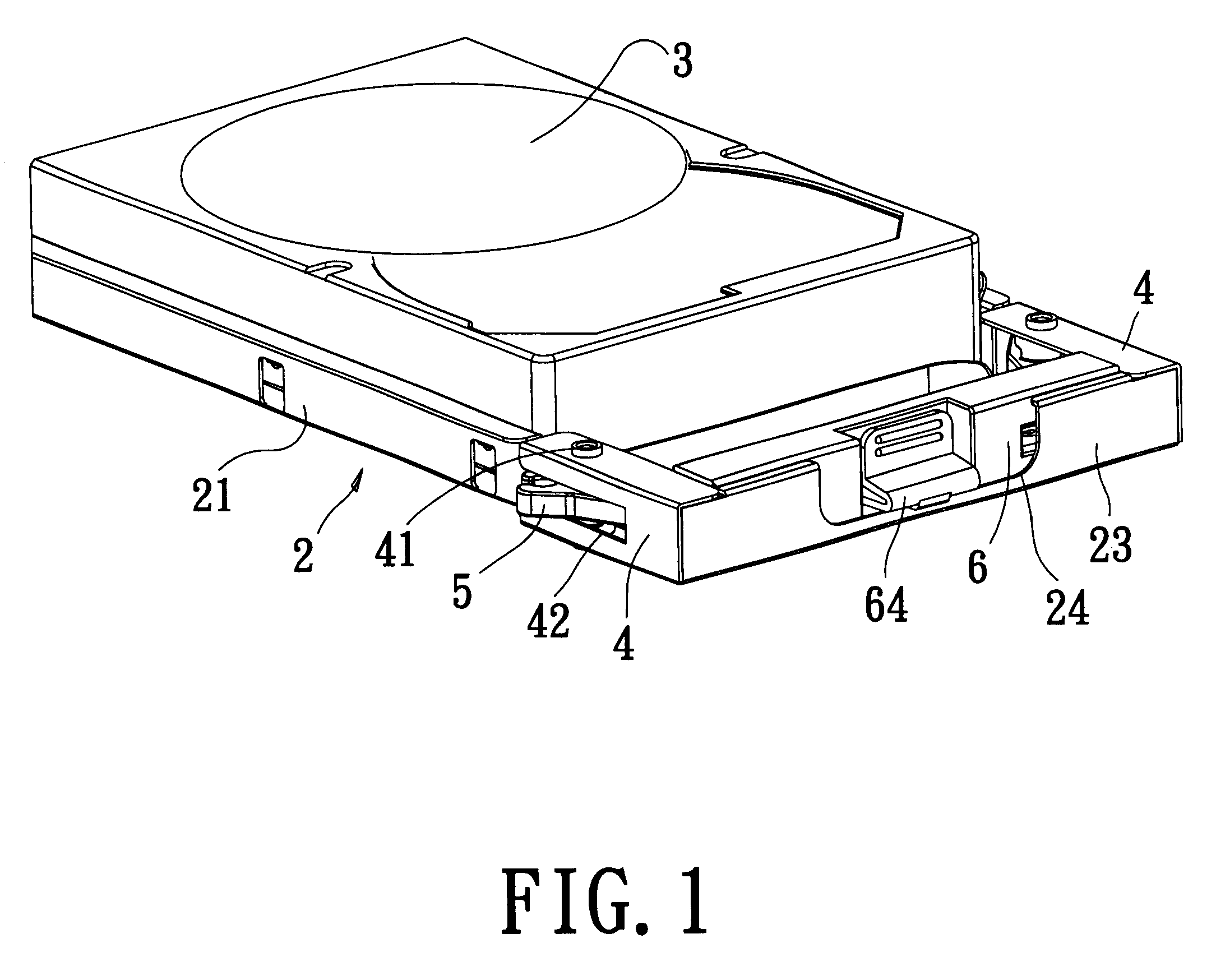

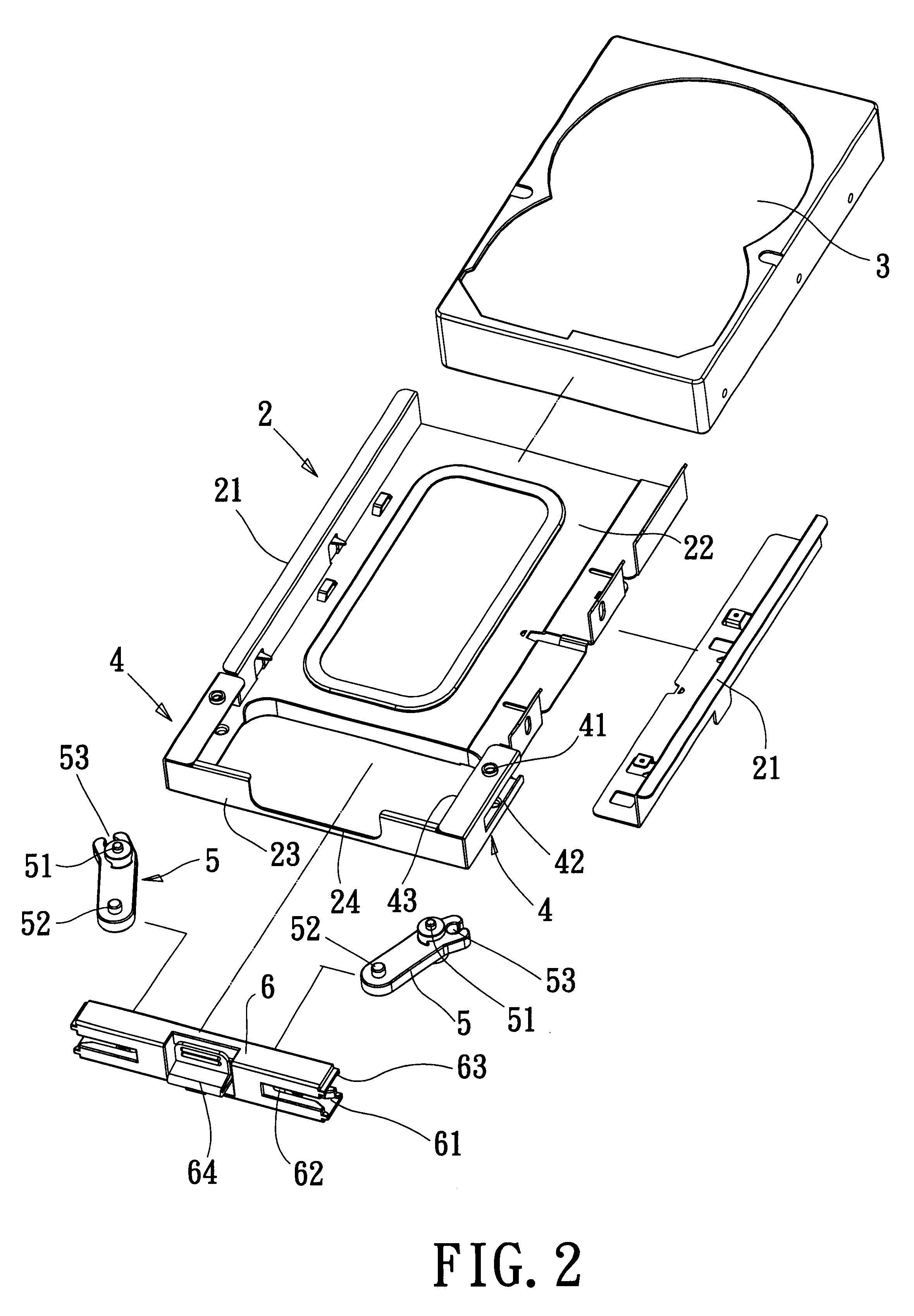

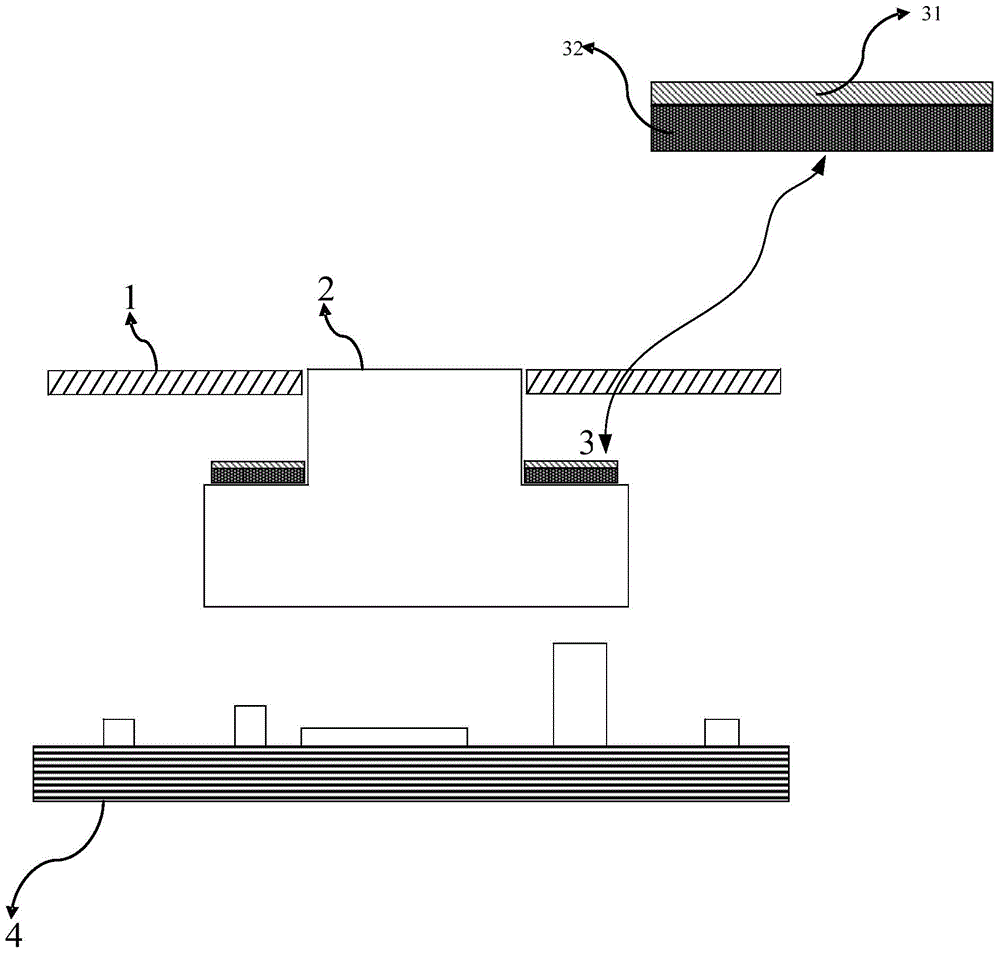

Extracting and positioning structure for hard disk drive

InactiveUS6351379B1Simple structureCarrier constructional parts dispositionDigital data processing detailsHard disc driveTransverse groove

Owner:LITE ON ENCLOSURE

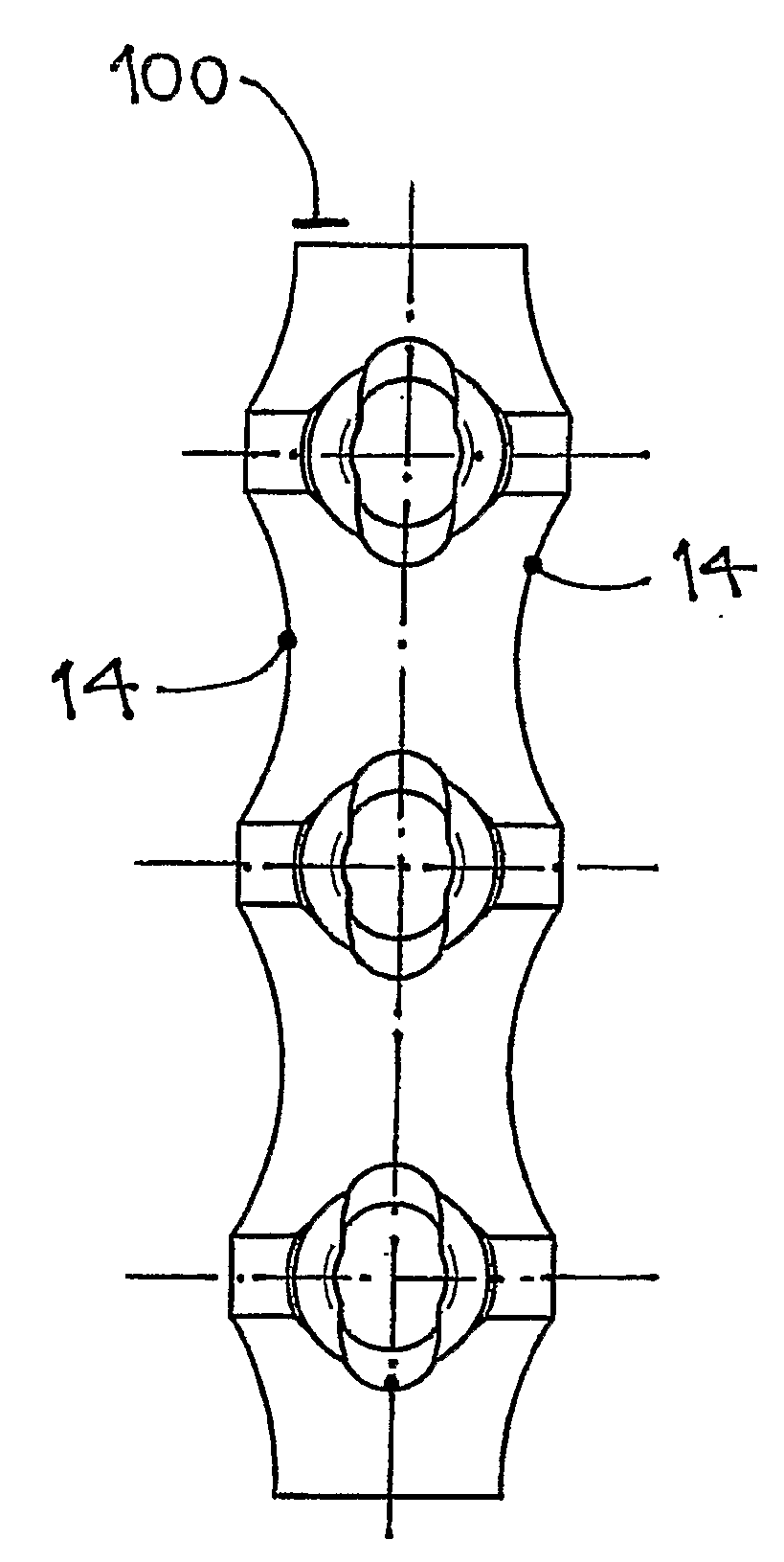

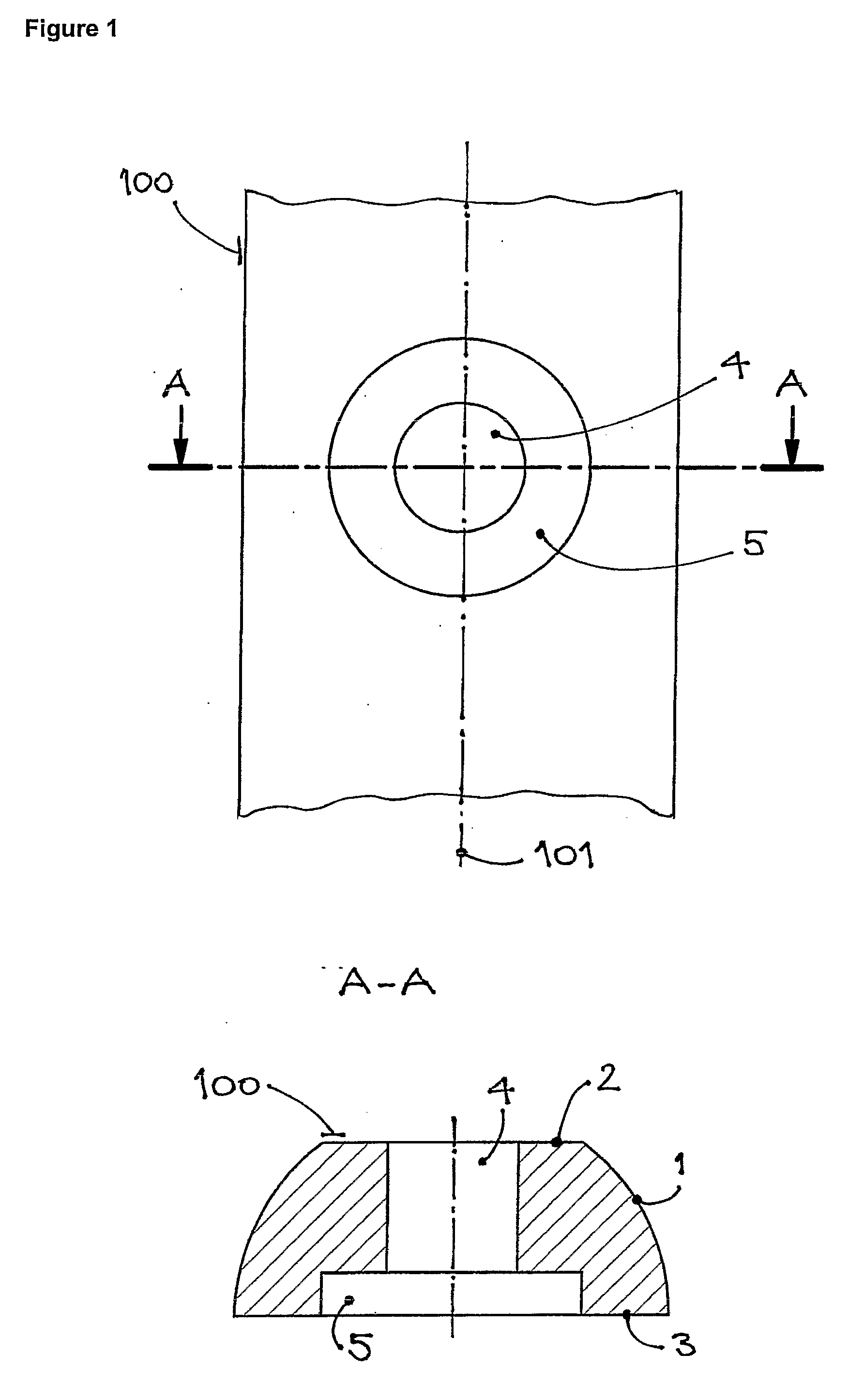

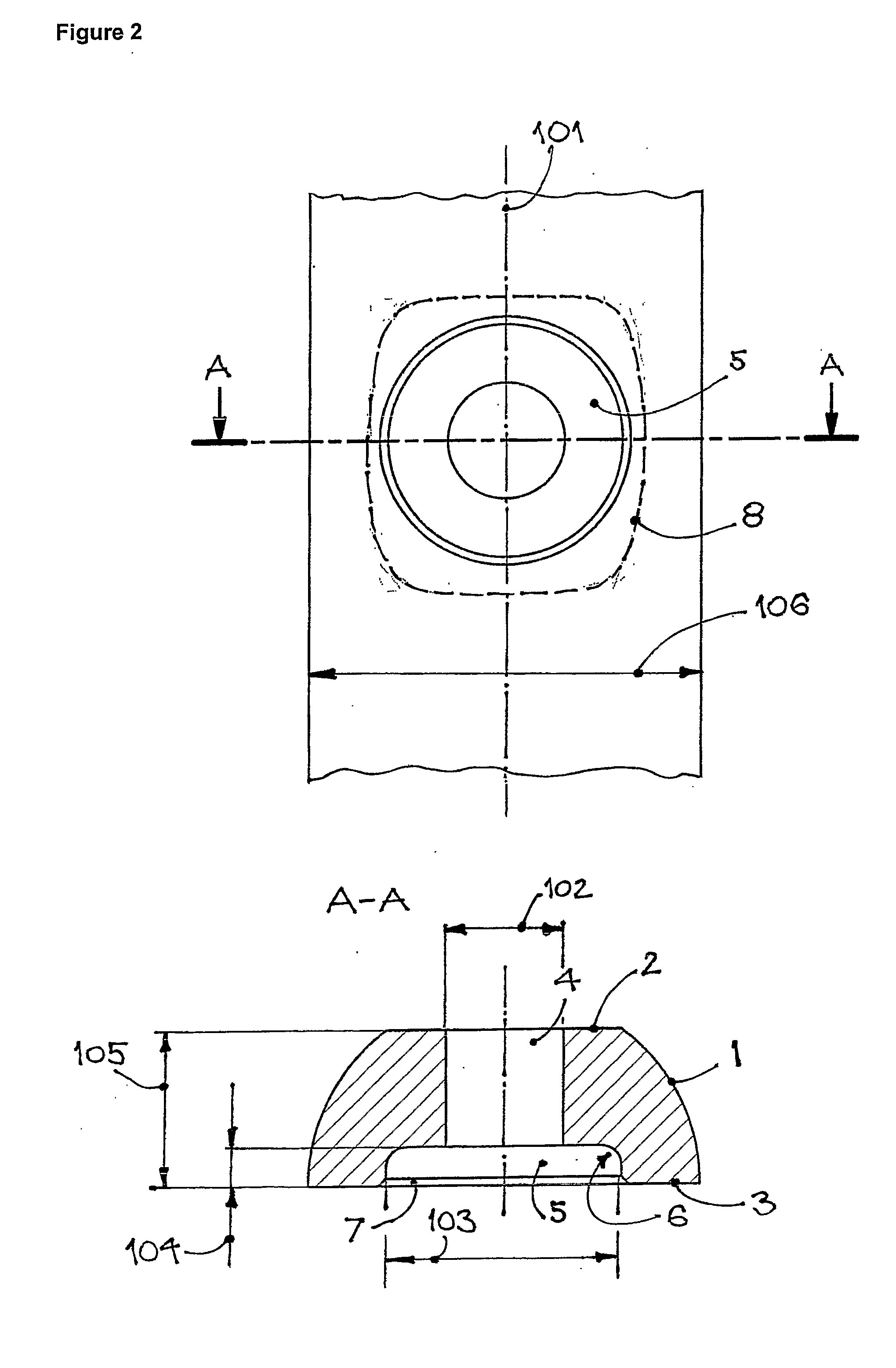

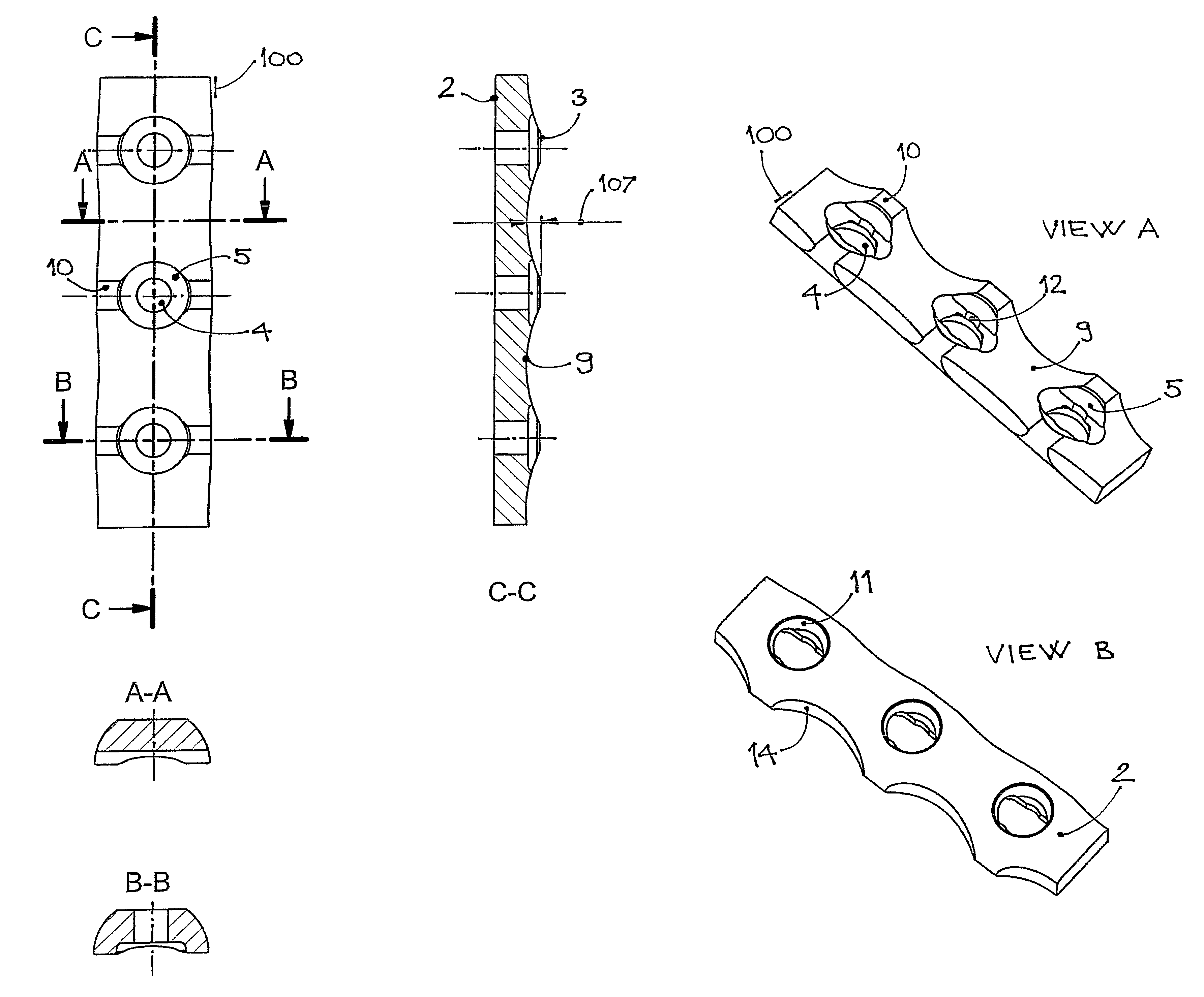

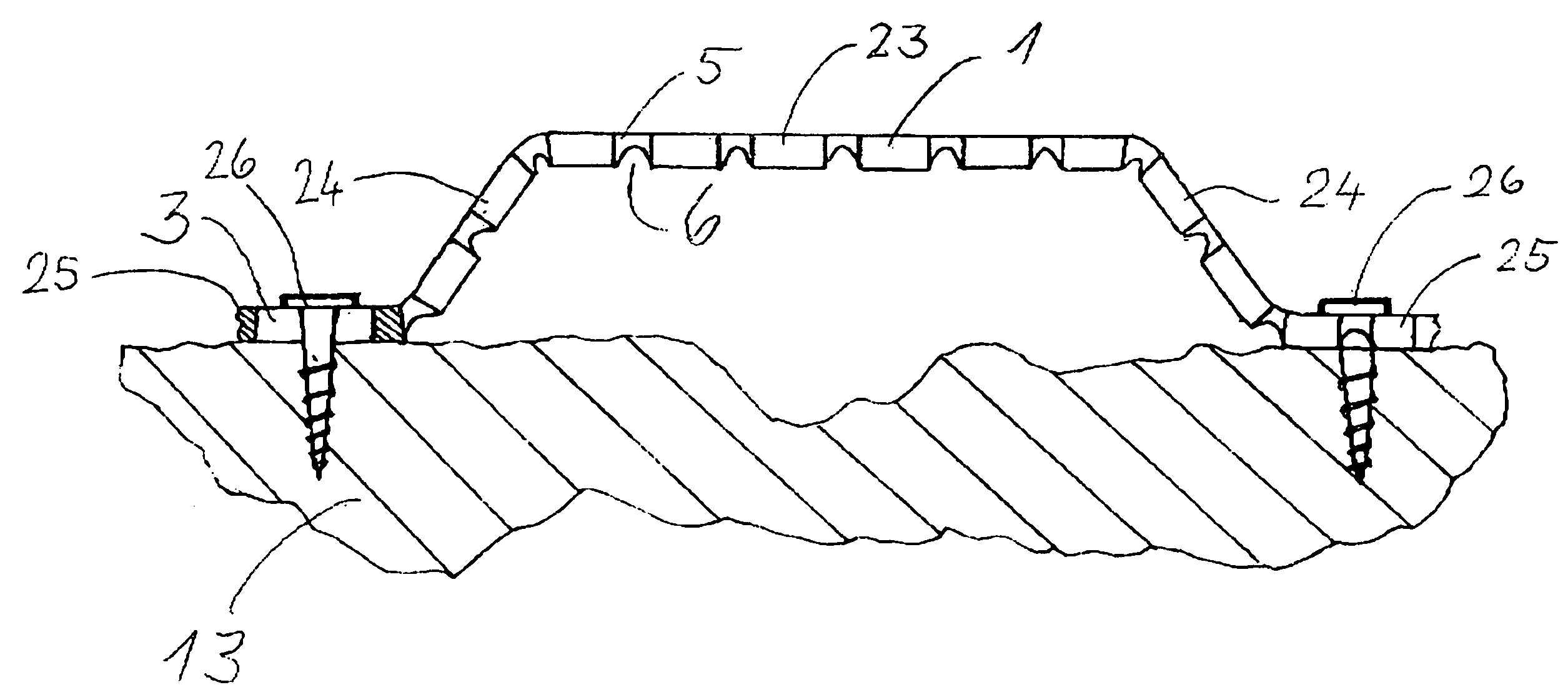

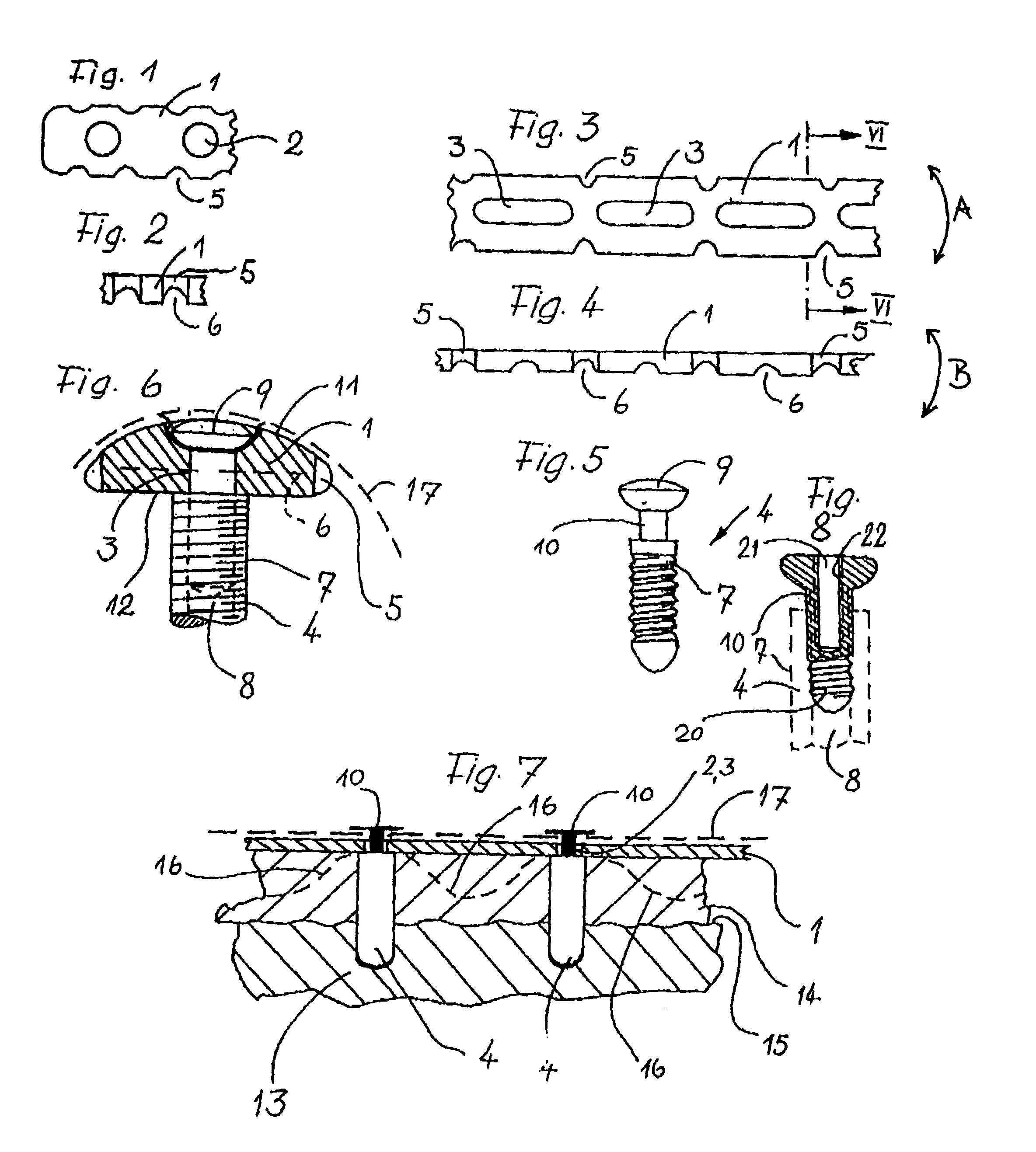

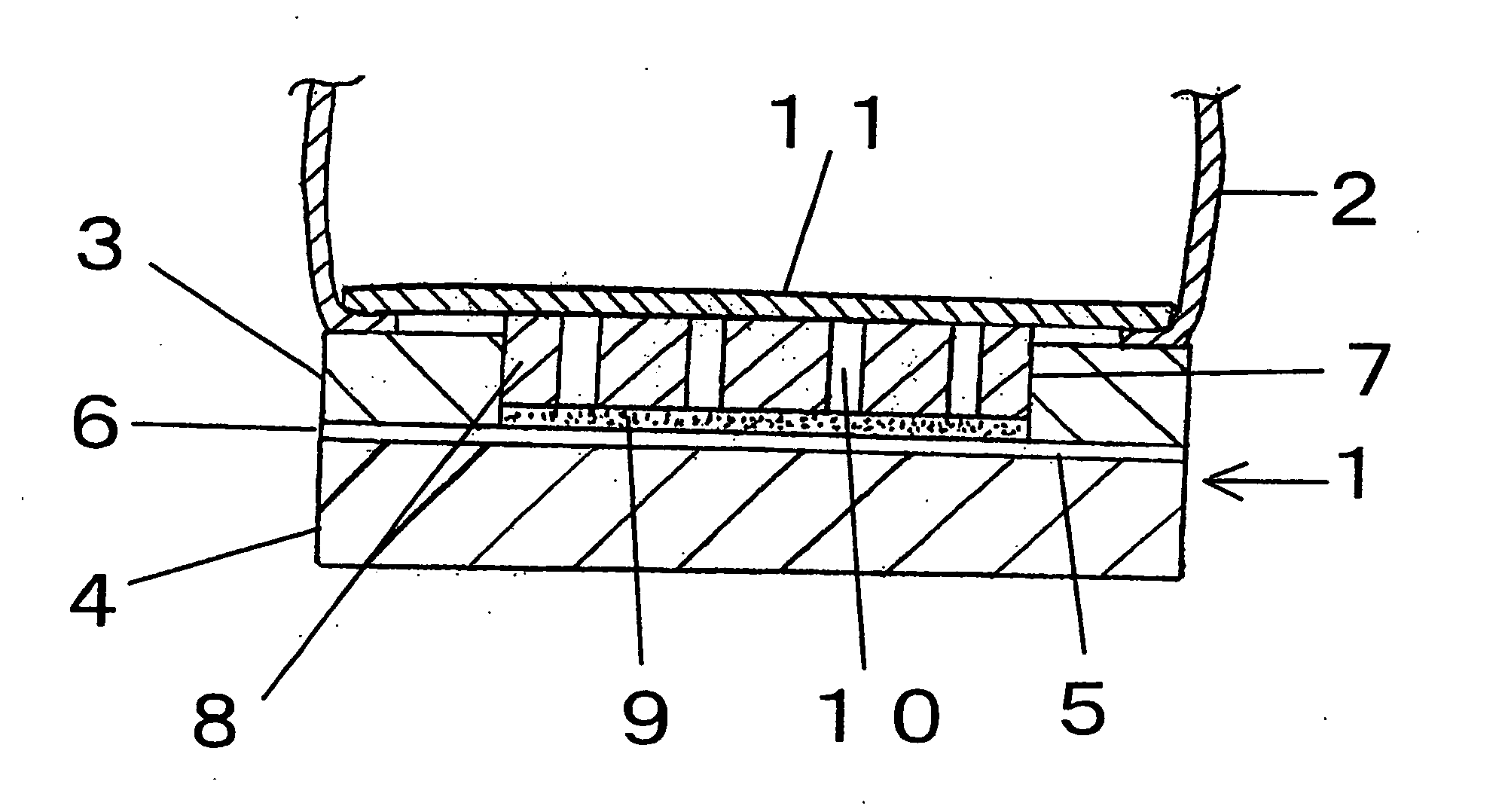

Plate and Screws for Treatment of Bone Fractures

ActiveUS20080200955A1Eliminate potential contactRelieve pressureSuture equipmentsLigamentsTransverse grooveEngineering

A plate for treatment of bone fractures with reduced potential contact to bone through a combination of annular recesses surrounding the screw holes at the lower, bone facing surface of the plate and transverse grooves between the holes, allows for use of locking as well as conventional bone screws. With the transverse grooves cut into the plate from the lower side, as well as from the sides, the strength of the plate at the span between the holes is lower than at the screw holes. The plate can be bent in both planes without undue deformation of the screw holes. Protection of the holes during bending is afforded by hole plugs, which may be provided pre-installed in order to reduce surgery time. Screw hole plugs may then be left in place in the holes not used for bone screws.

Owner:KYON

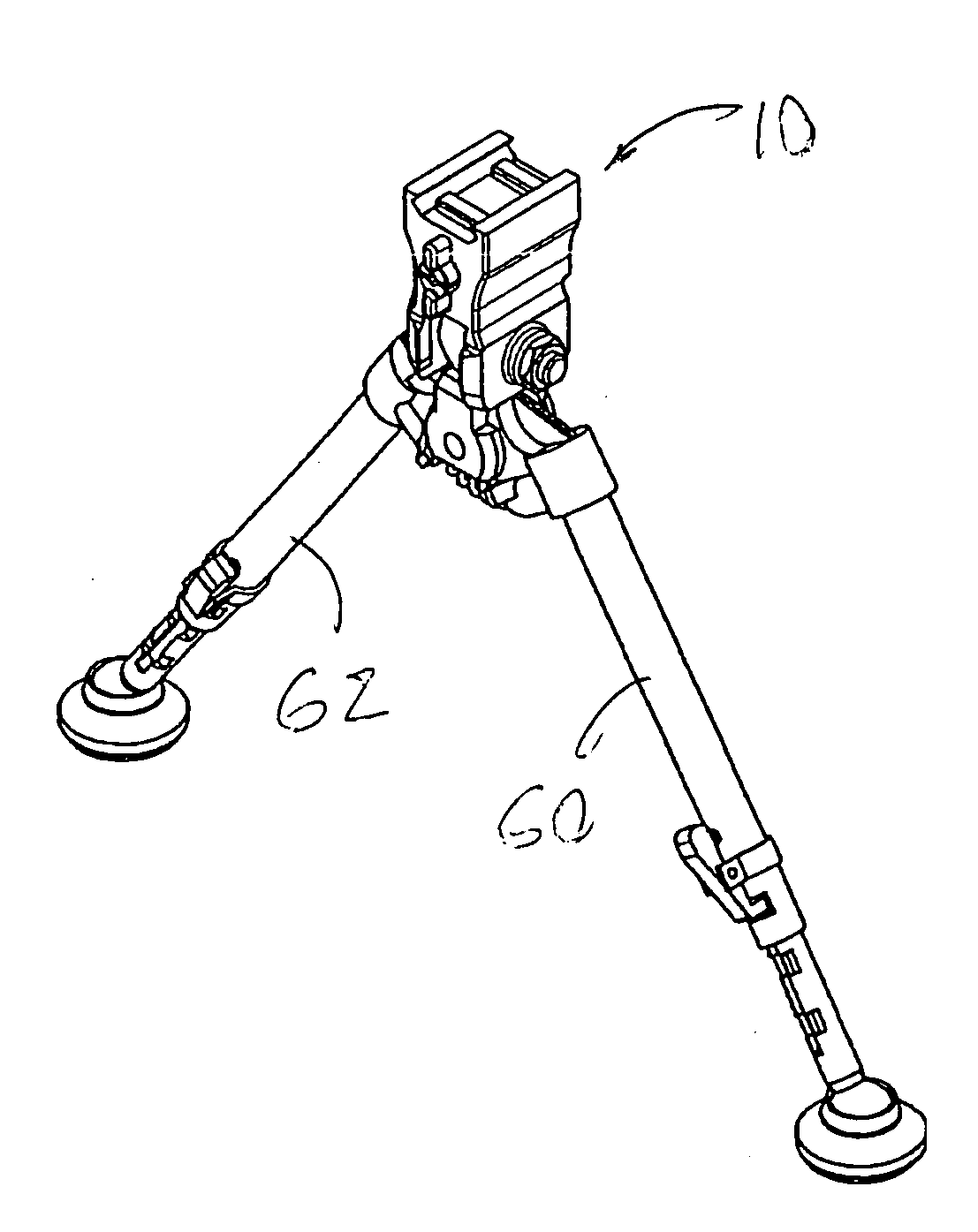

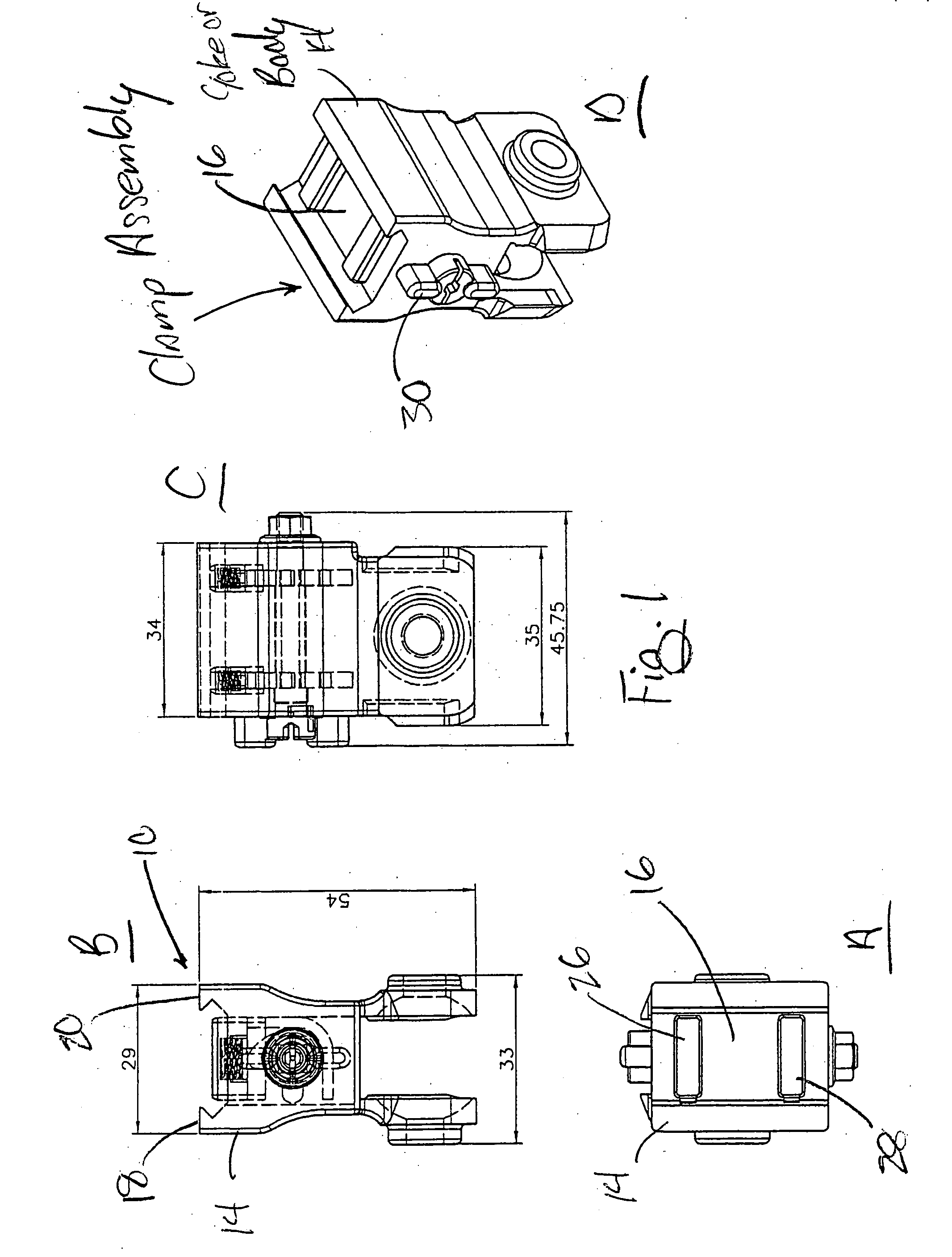

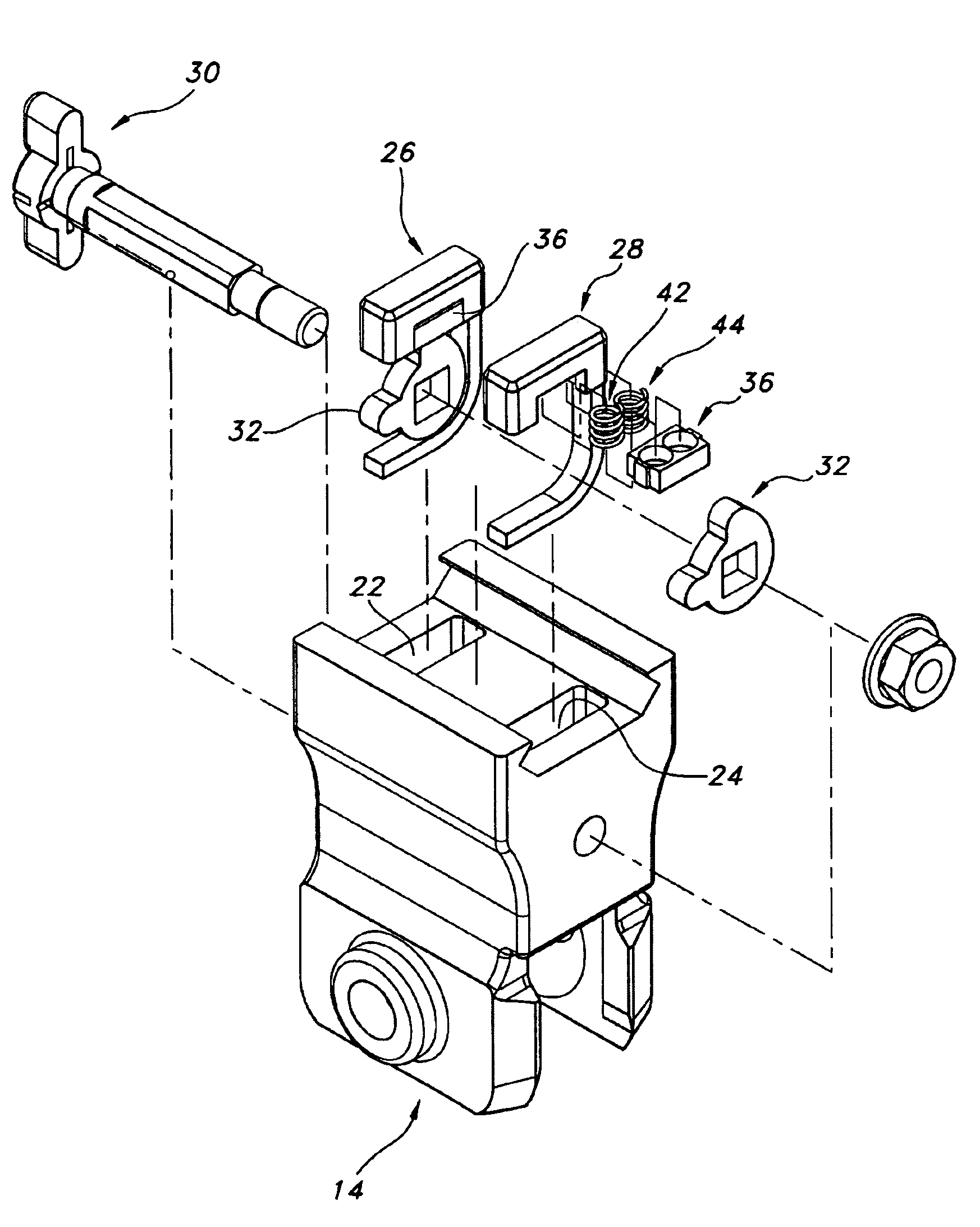

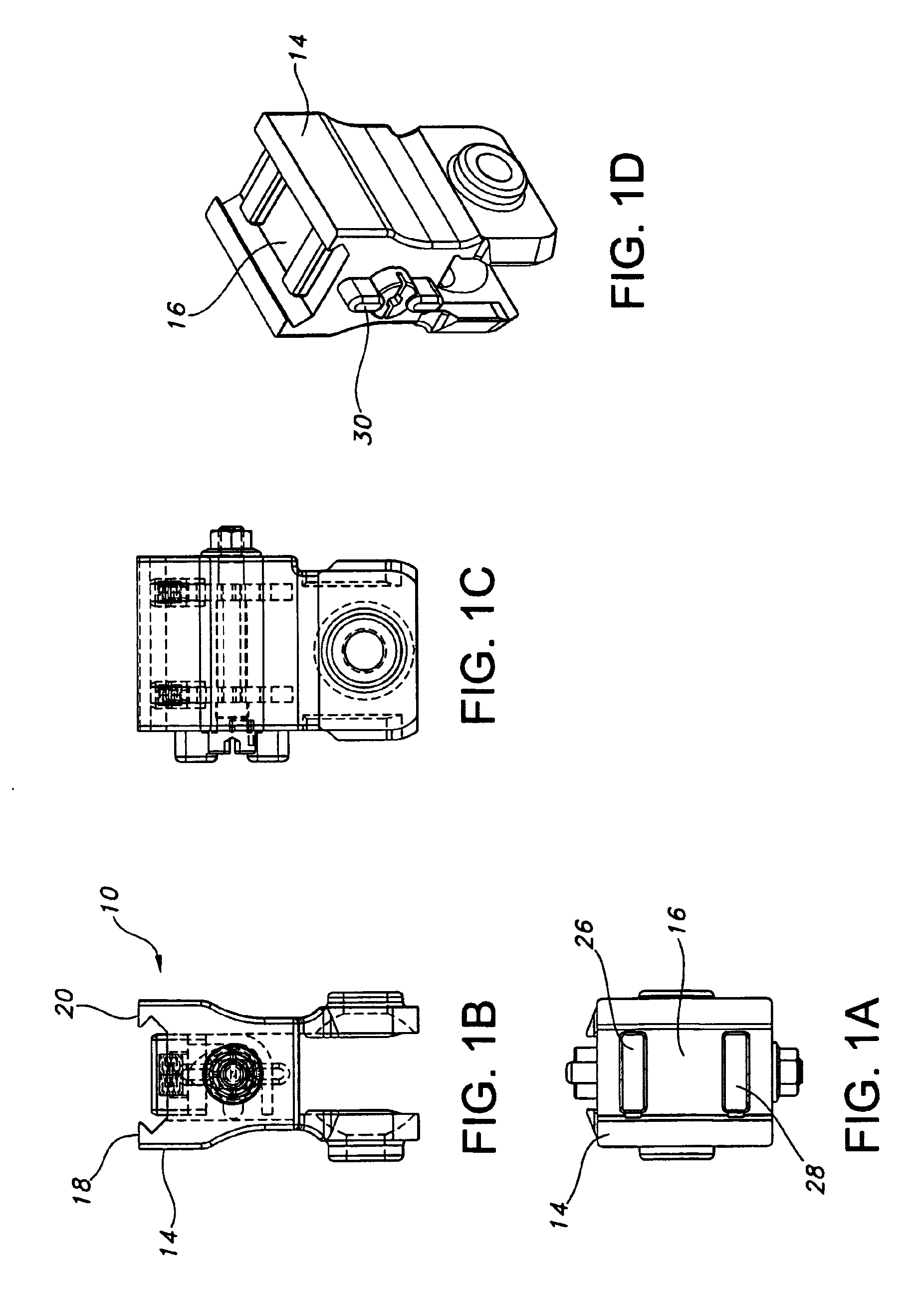

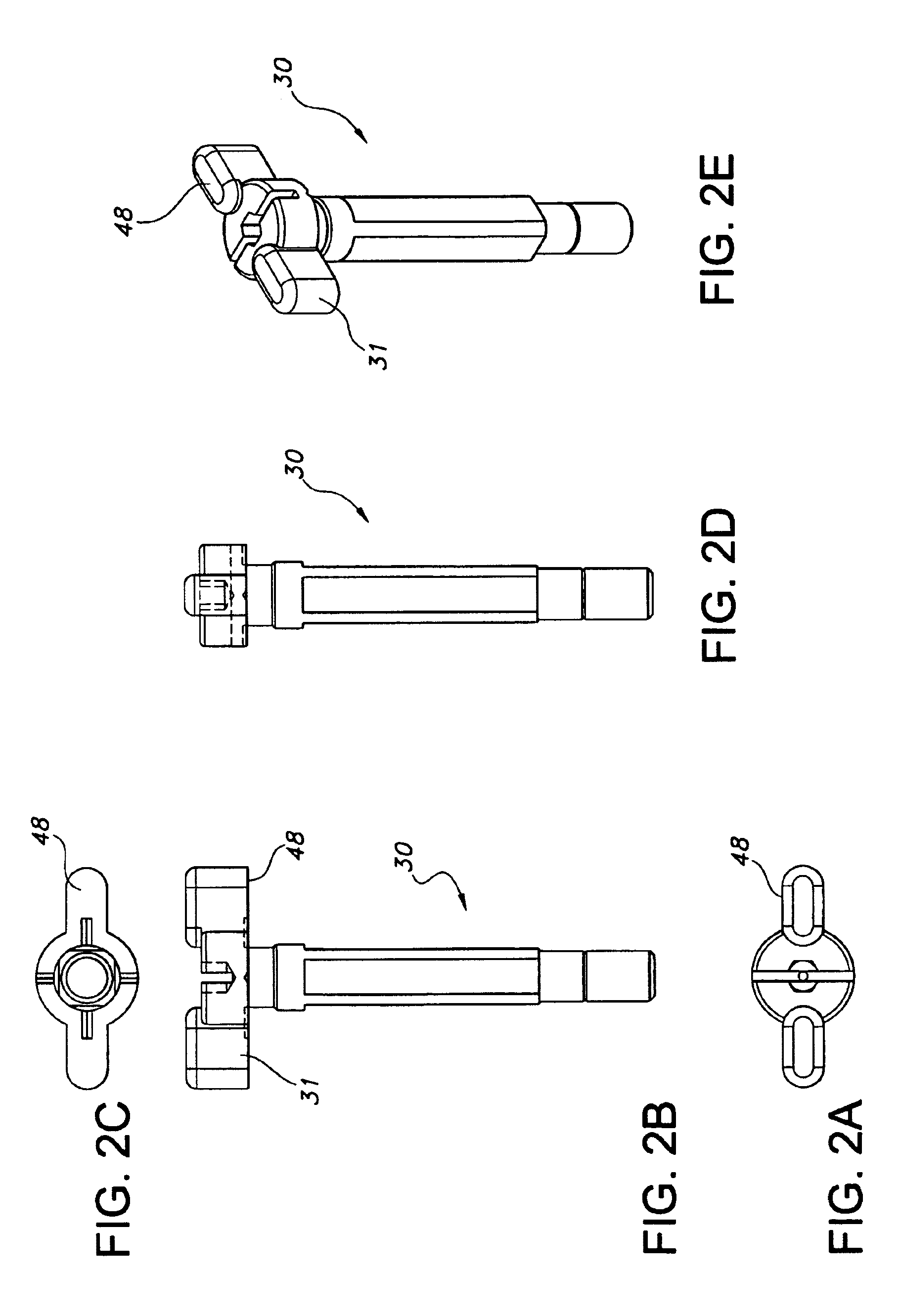

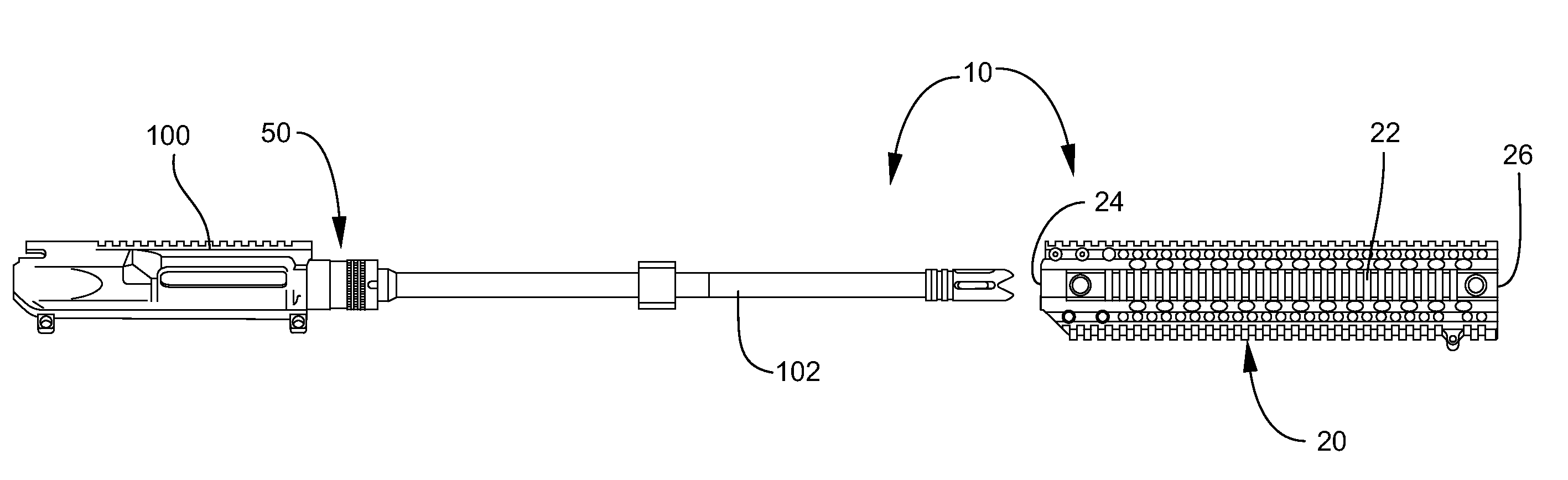

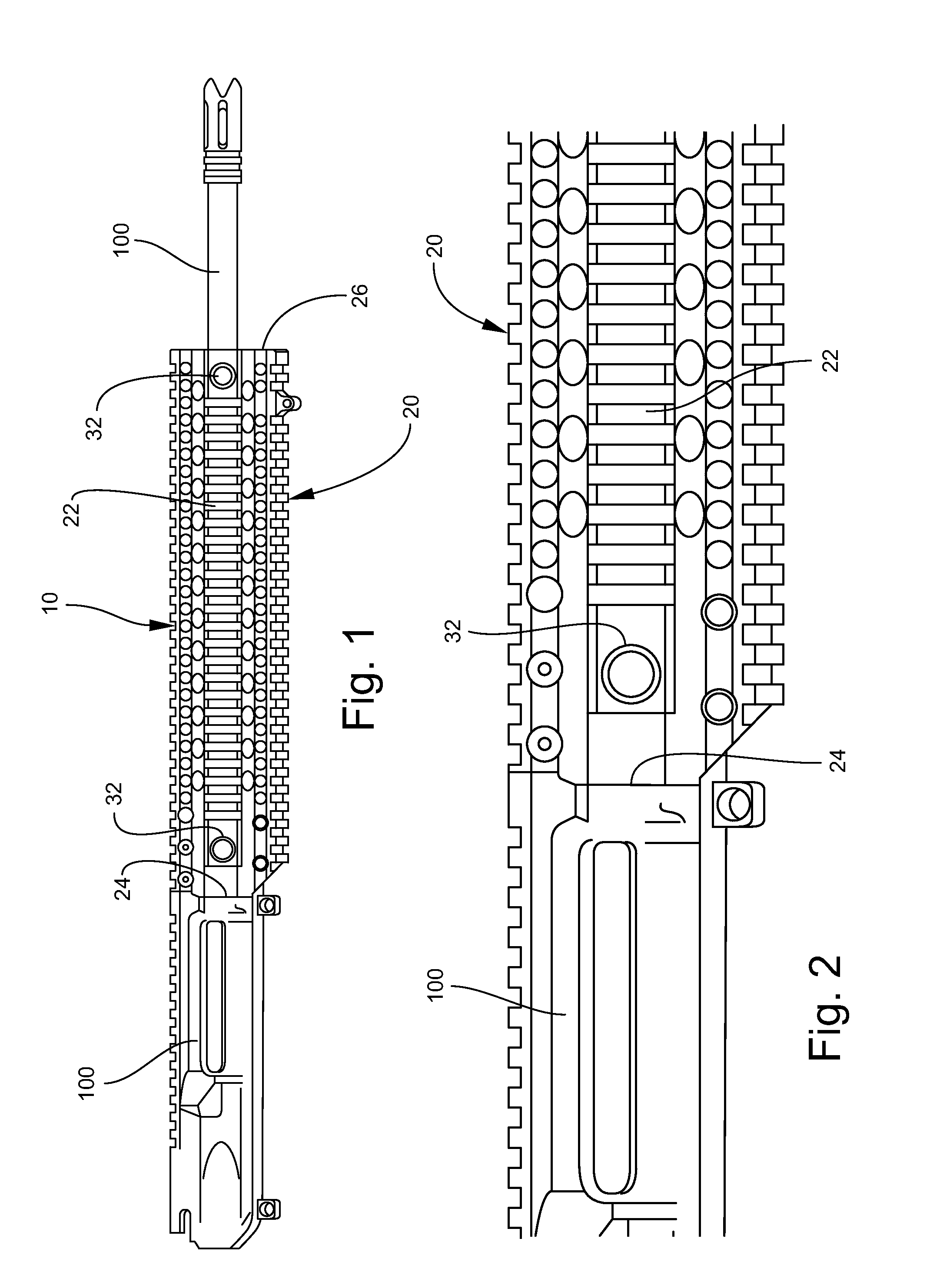

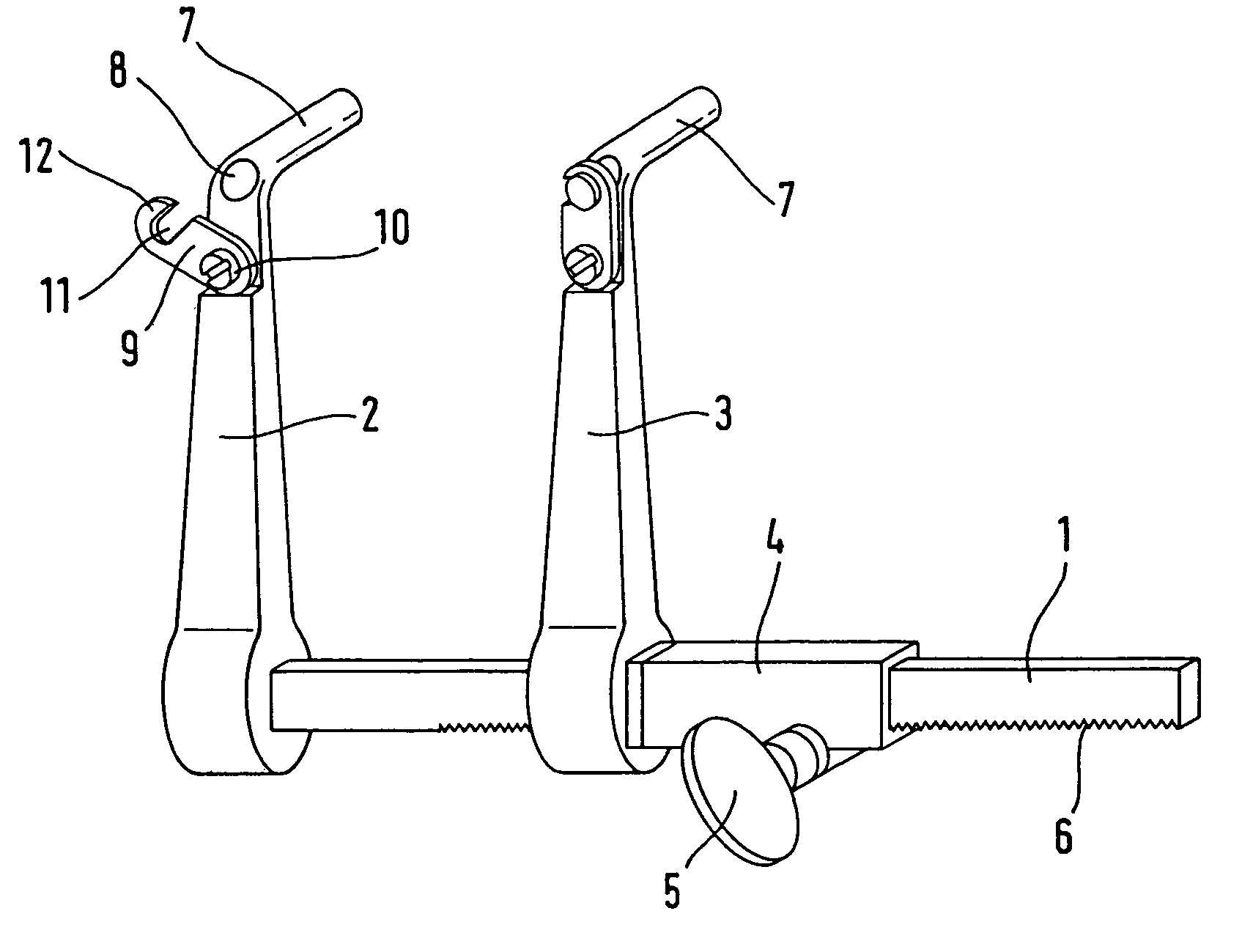

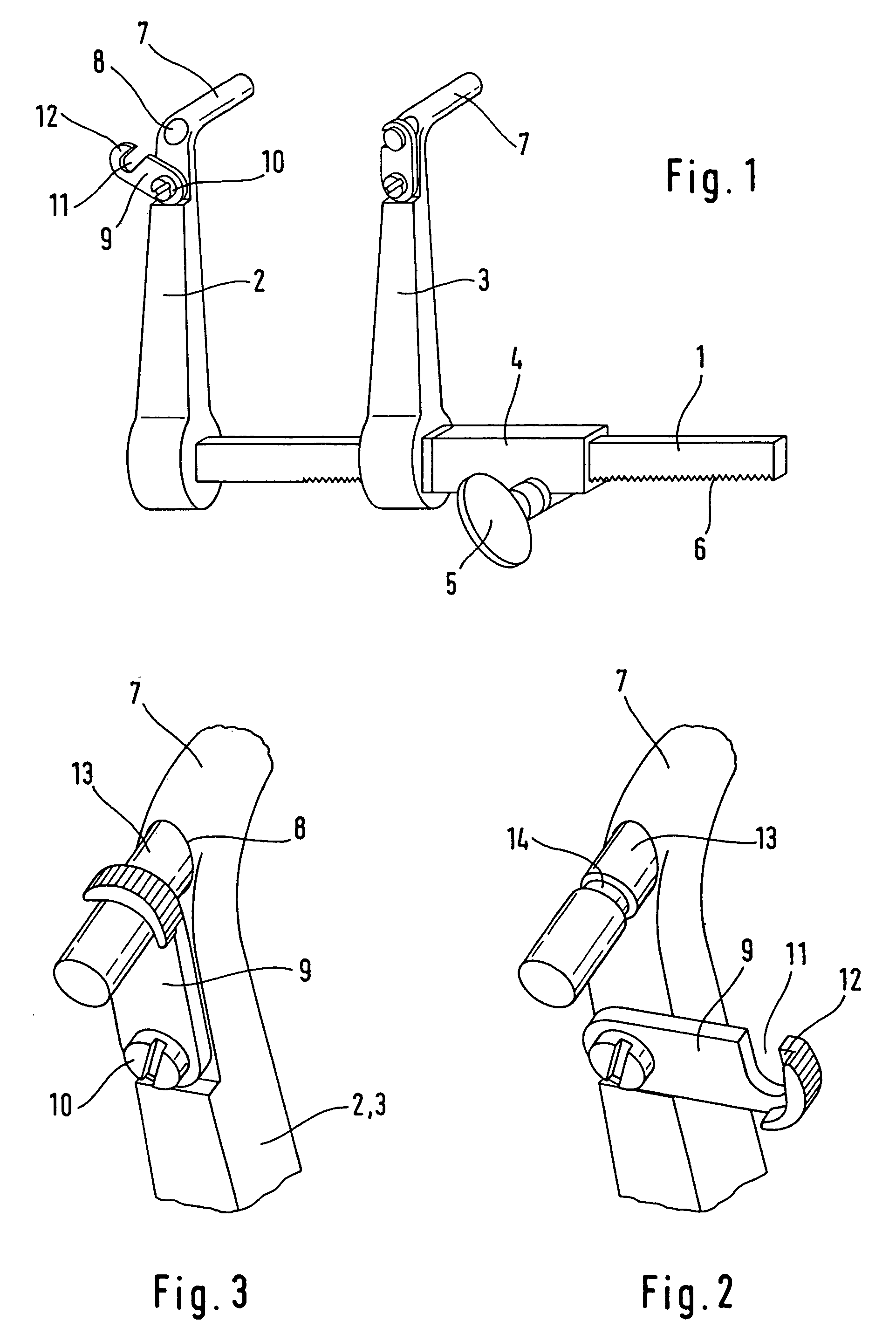

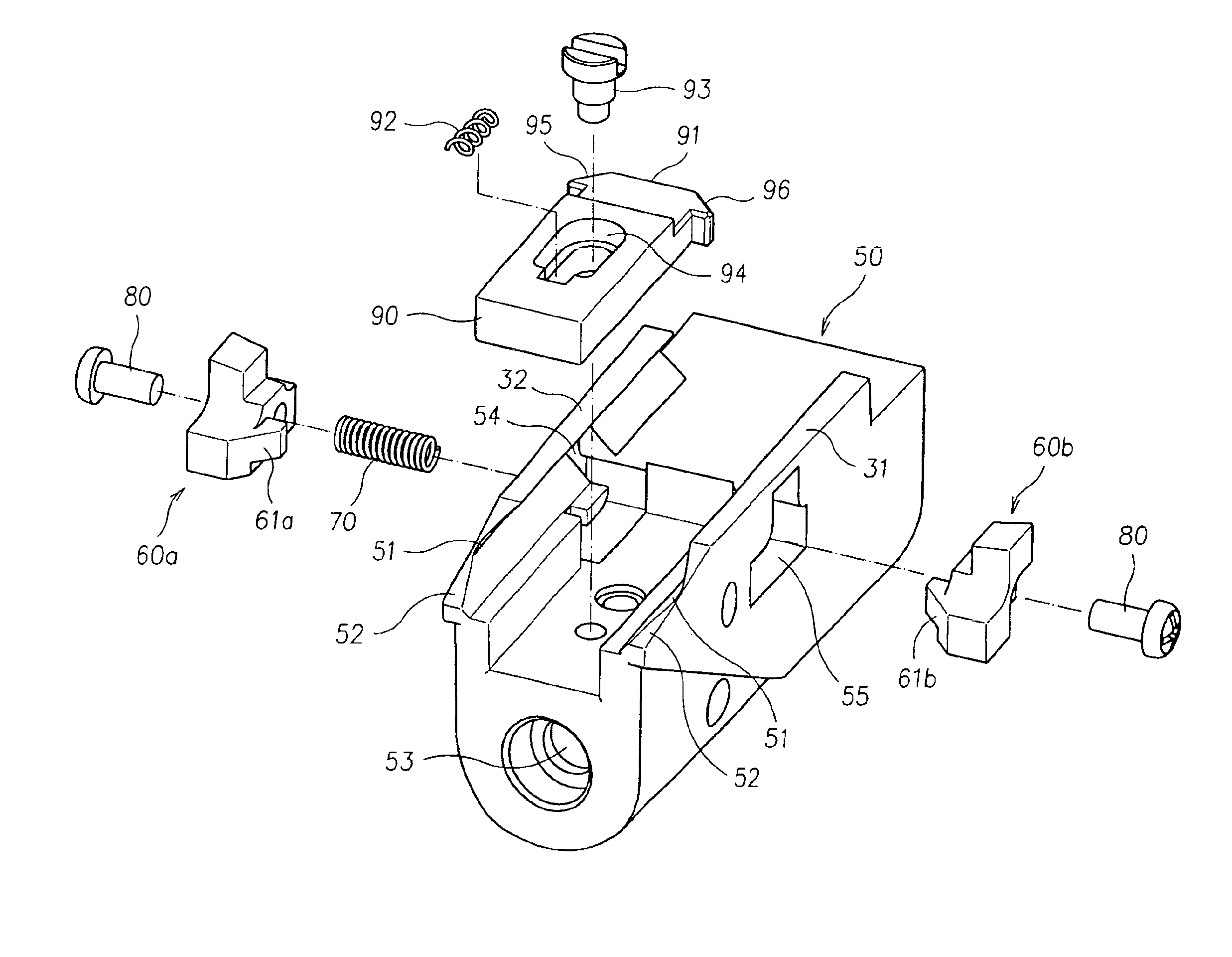

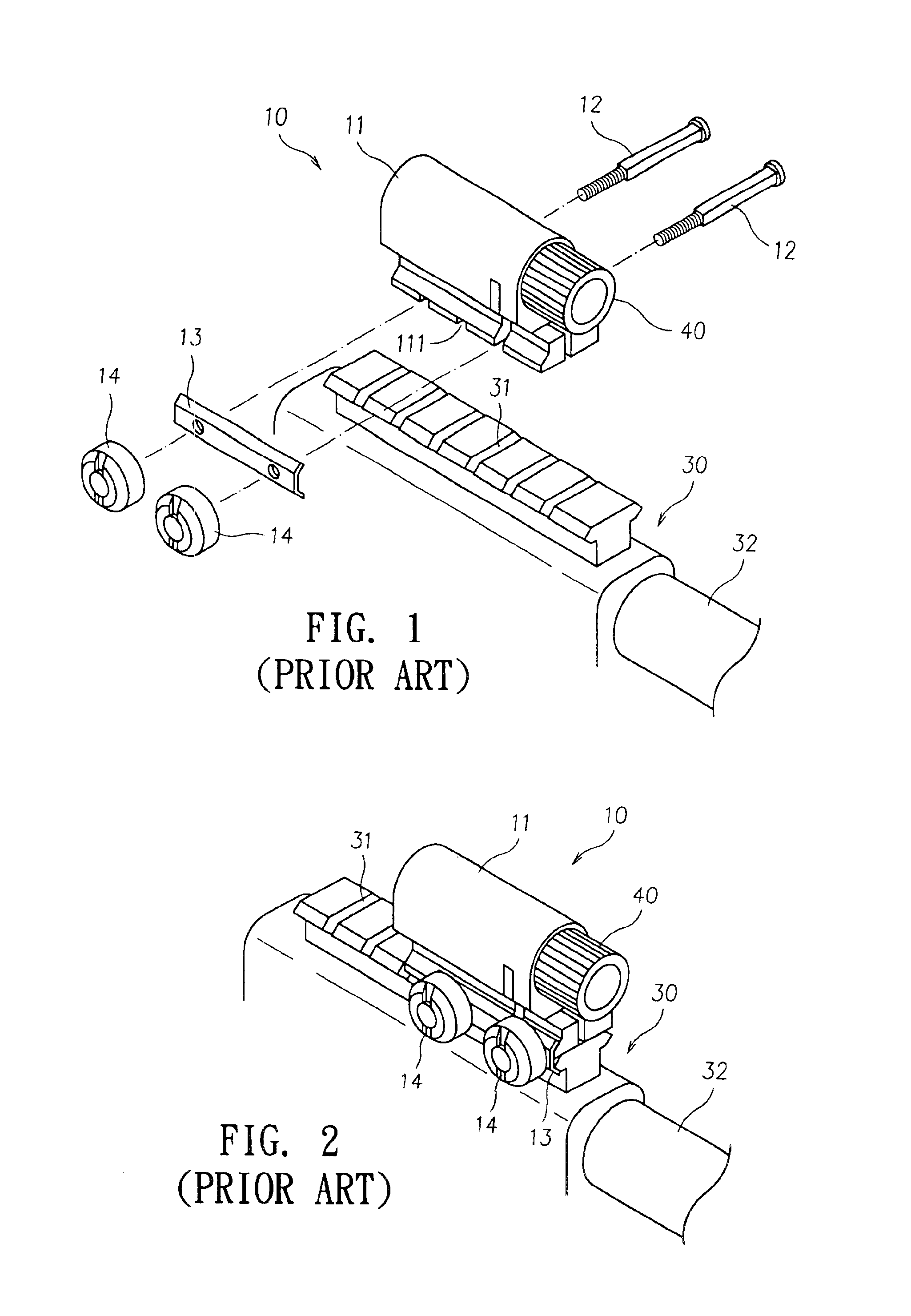

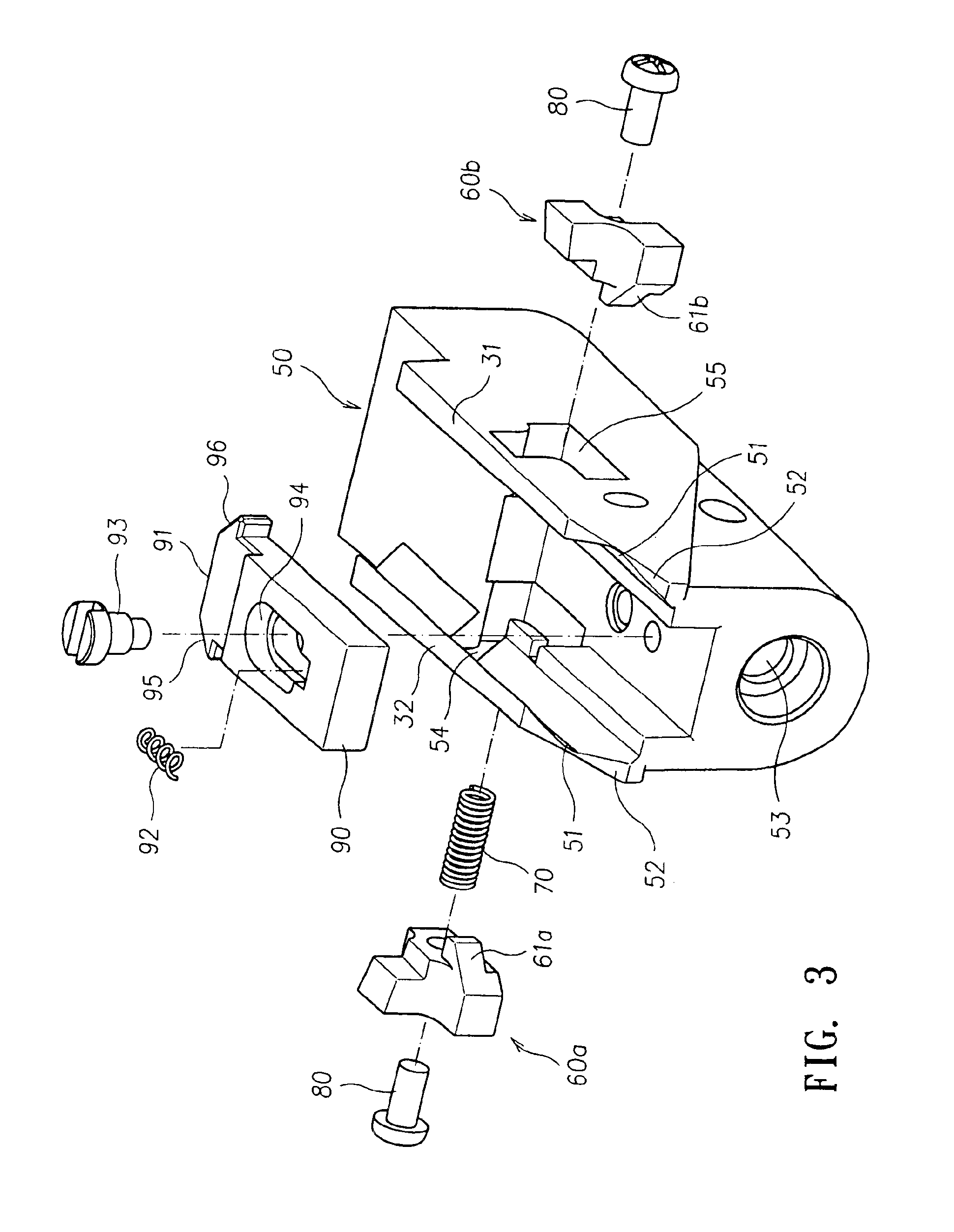

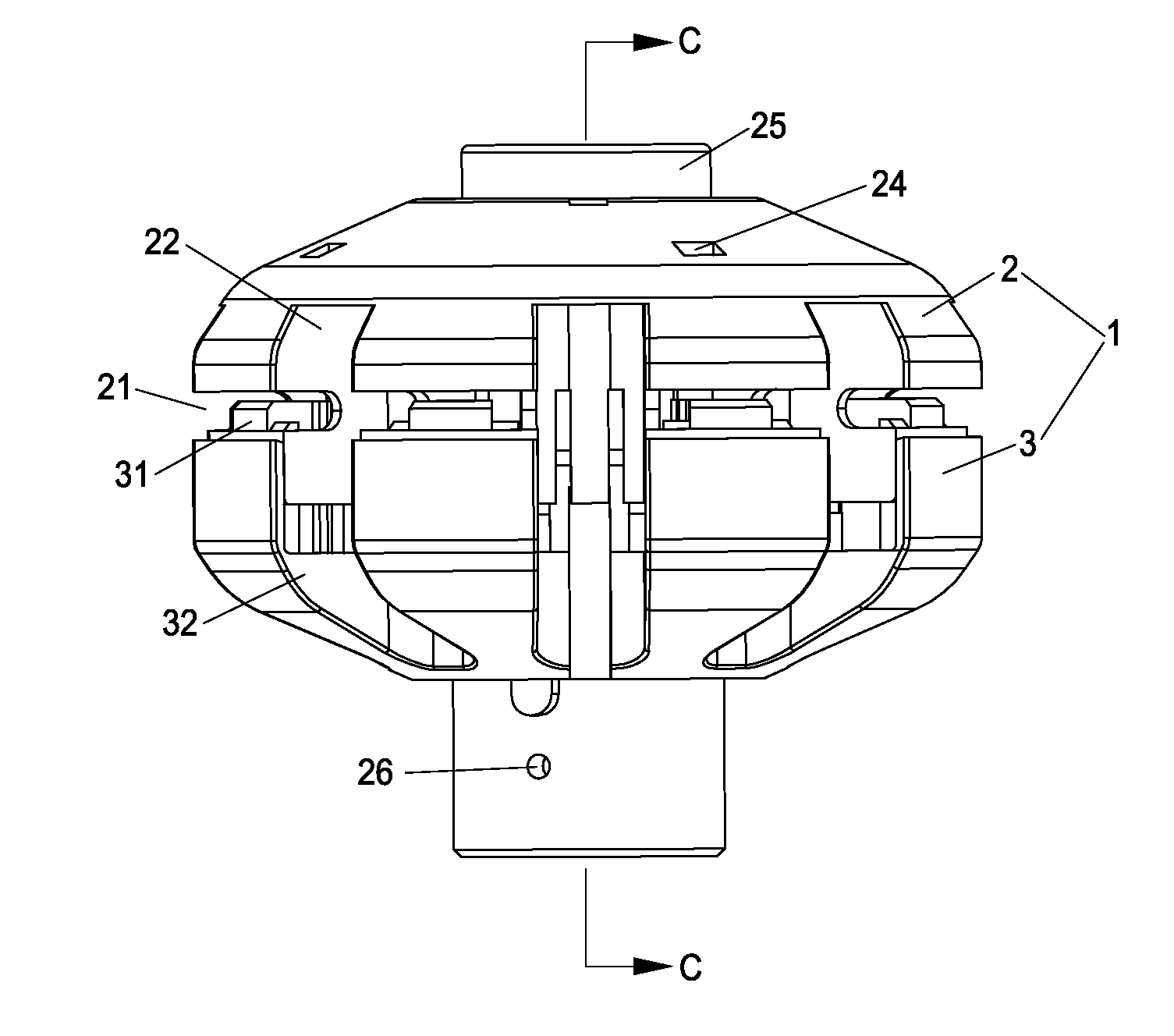

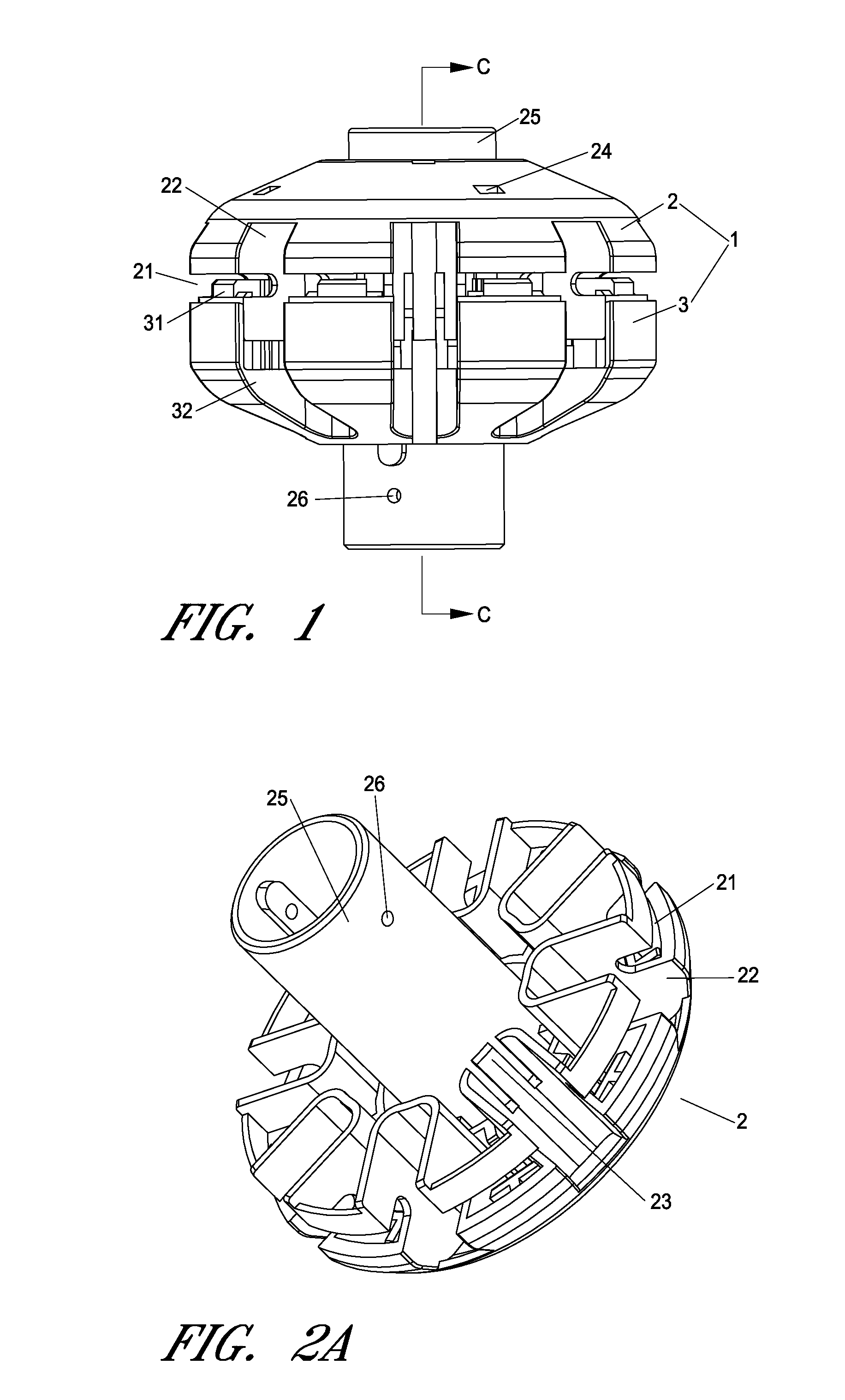

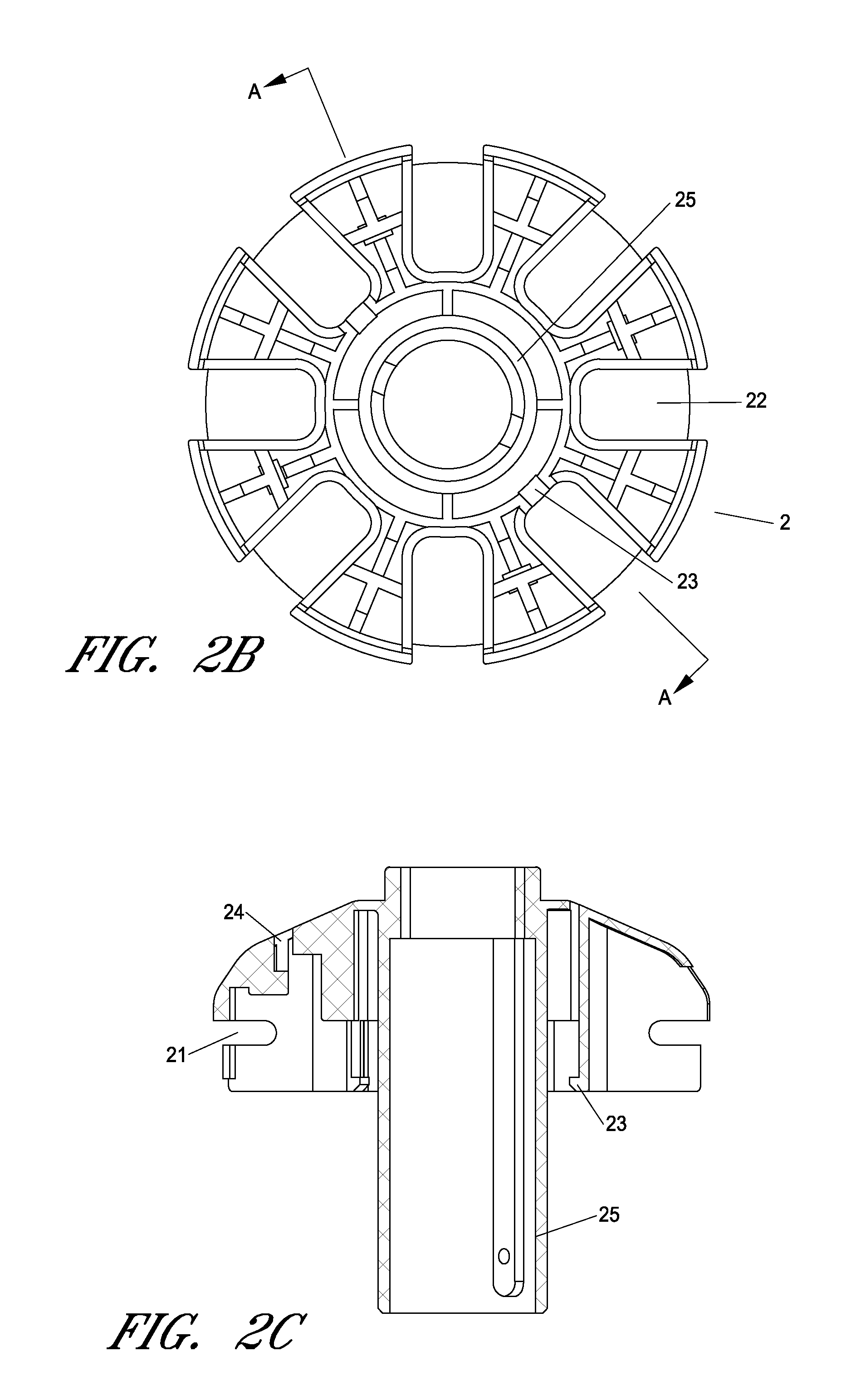

Quick disconnect bipod mount and clamp assembly

A quick disconnect clamping assembly for releaseably attaching an accessory such as a bipod to an elongate support such as a picatinny-style mounting rail comprises a clamp body with a mounting yoke that is adapted to slide over and receive the picatinny rail. The yoke includes a substantially rectangular base plate defining the central upper surface of a clamp body and includes a pair of parallel sidewalls extending upwardly therefrom. The base plate has, in one embodiment, first and second transverse bores for first and second substantially rectangular upwardly movable bolts actuable to project upwardly from the yoke base plate. The clamp body's first and second transverse bolts, when raised and aligned with the transverse grooves of the picatinny rail, are received in the spaced transverse grooves of the rail to attach the yoke to the rail.

Owner:KENGS FIREARMS SPECIALTY

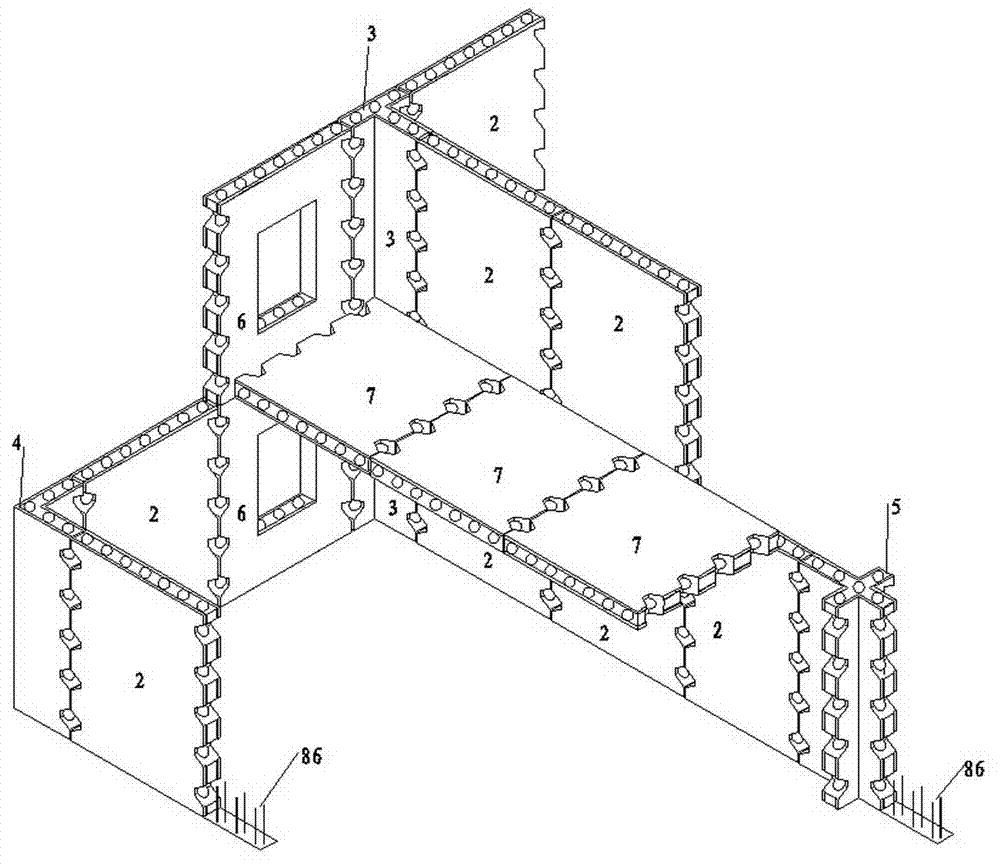

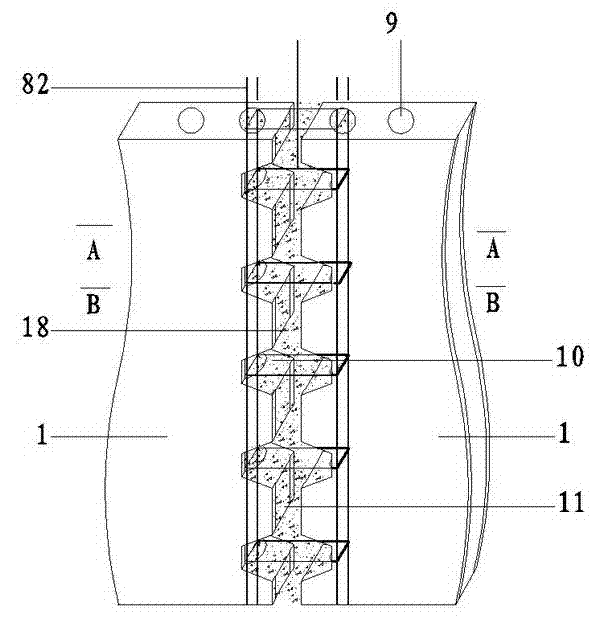

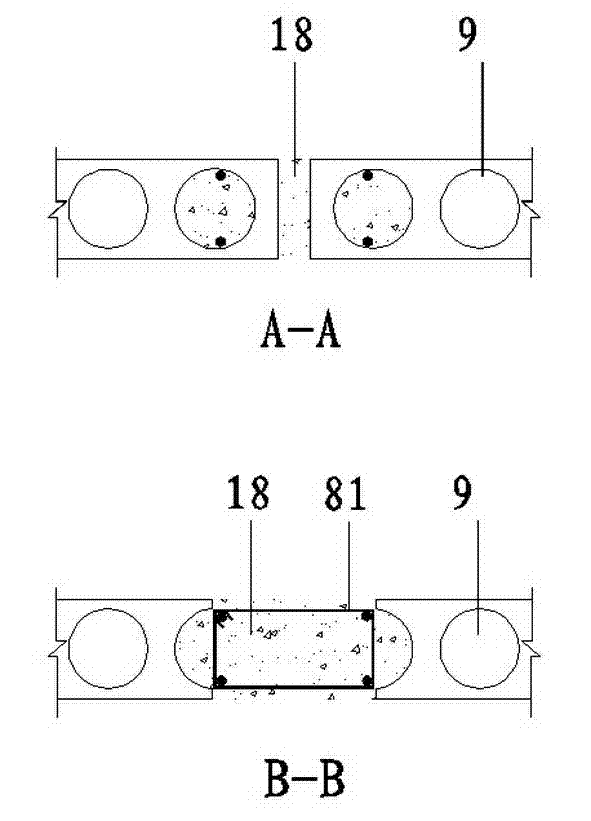

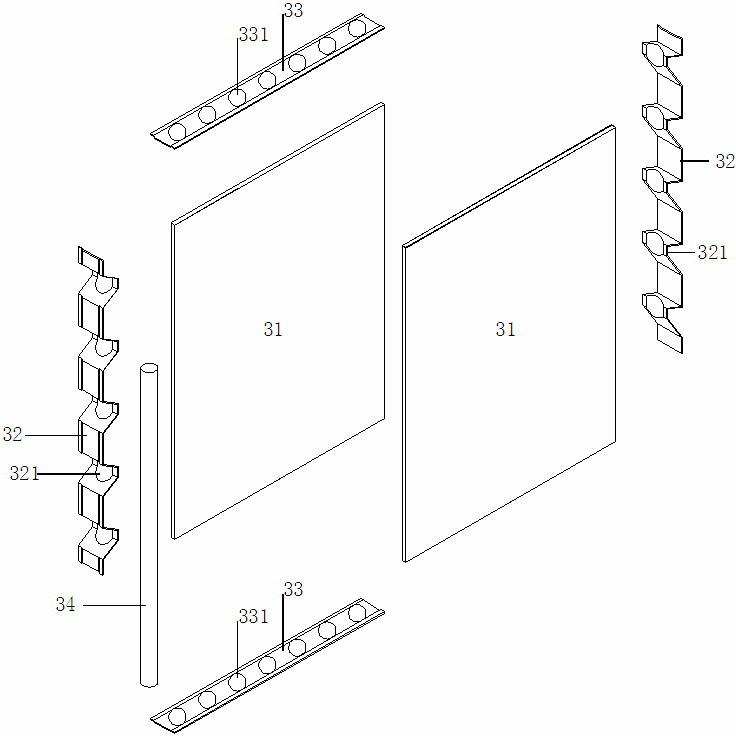

Assembled monolithic shear wall building structure and construction method thereof

InactiveCN102808450AImprove the level of industrializationIncrease productivityConstruction materialWallsTransverse grooveCross wall

The invention relates to an assembled monolithic shear wall building structure and a construction method thereof, and belongs to the technical field of buildings and construction thereof. The assembled monolithic shear wall building structure is formed by connecting prefabricated concrete members which comprise a prefabricated wall plate member, a floor member, a T-shaped wall column member, an L-shaped wall column member, a cross wall column member and a wall member with an opening. The structure is characterized in that a plurality of longitudinal through holes which are parallel to the surface are formed in each prefabricated concrete member; transverse grooves crossed with at least one longitudinal hole are formed on the longitudinal edge at intervals; transverse anchoring steel bars are arranged at the transverse grooves among different prefabricated members; longitudinal anchoring steel bars are arranged in the longitudinal holes; a layer of structural unit or a single-layer building structure is formed by filling concrete in the longitudinal holes and the transverse grooves; and a plurality of structural units are connected to form a multi-layer or high-rise assembled monolithic shear wall structure. The structure can be used in a multi-layer or high-rise shear wall building structure and a frame-shear wall building structure, the industrial level of the building structure can be improved, stress performance is improved, and resources are saved.

Owner:初明进

Quick disconnect bipod mount and clamp assembly

A quick disconnect clamping assembly for releaseably attaching an accessory such as a bipod to an elongate support such as a picatinny-style mounting rail comprises a clamp body with a mounting yoke that is adapted to slide over and receive the picatinny rail. The yoke includes a substantially rectangular base plate defining the central upper surface of a clamp body and includes a pair of parallel sidewalls extending upwardly therefrom. The base plate has, in one embodiment, first and second transverse bores for first and second substantially rectangular upwardly movable bolts actuable to project upwardly from the yoke base plate. The clamp body's first and second transverse bolts, when raised and aligned with the transverse grooves of the picatinny rail, are received in the spaced transverse grooves of the rail to attach the yoke to the rail.

Owner:KENGS FIREARMS SPECIALTY

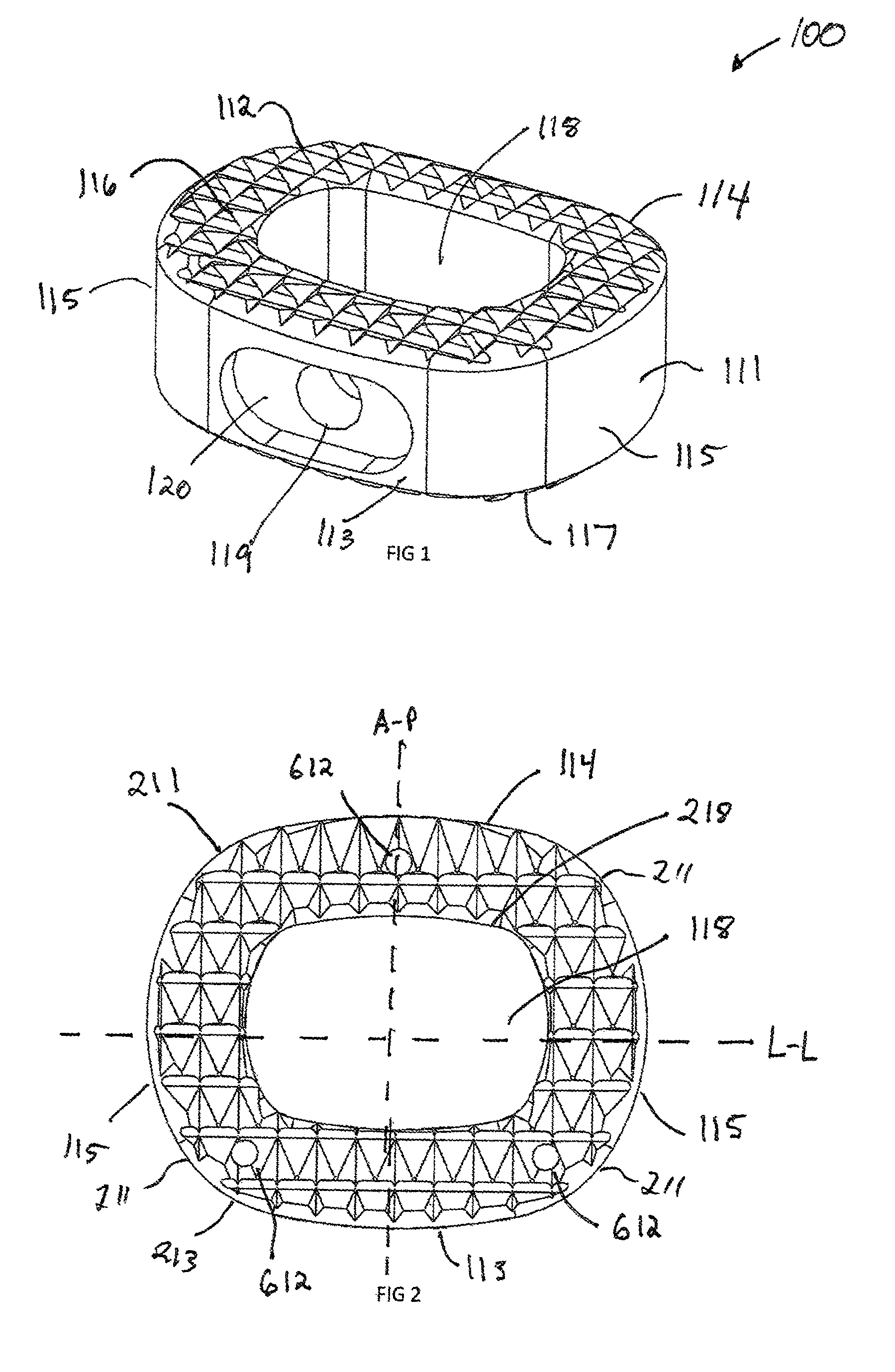

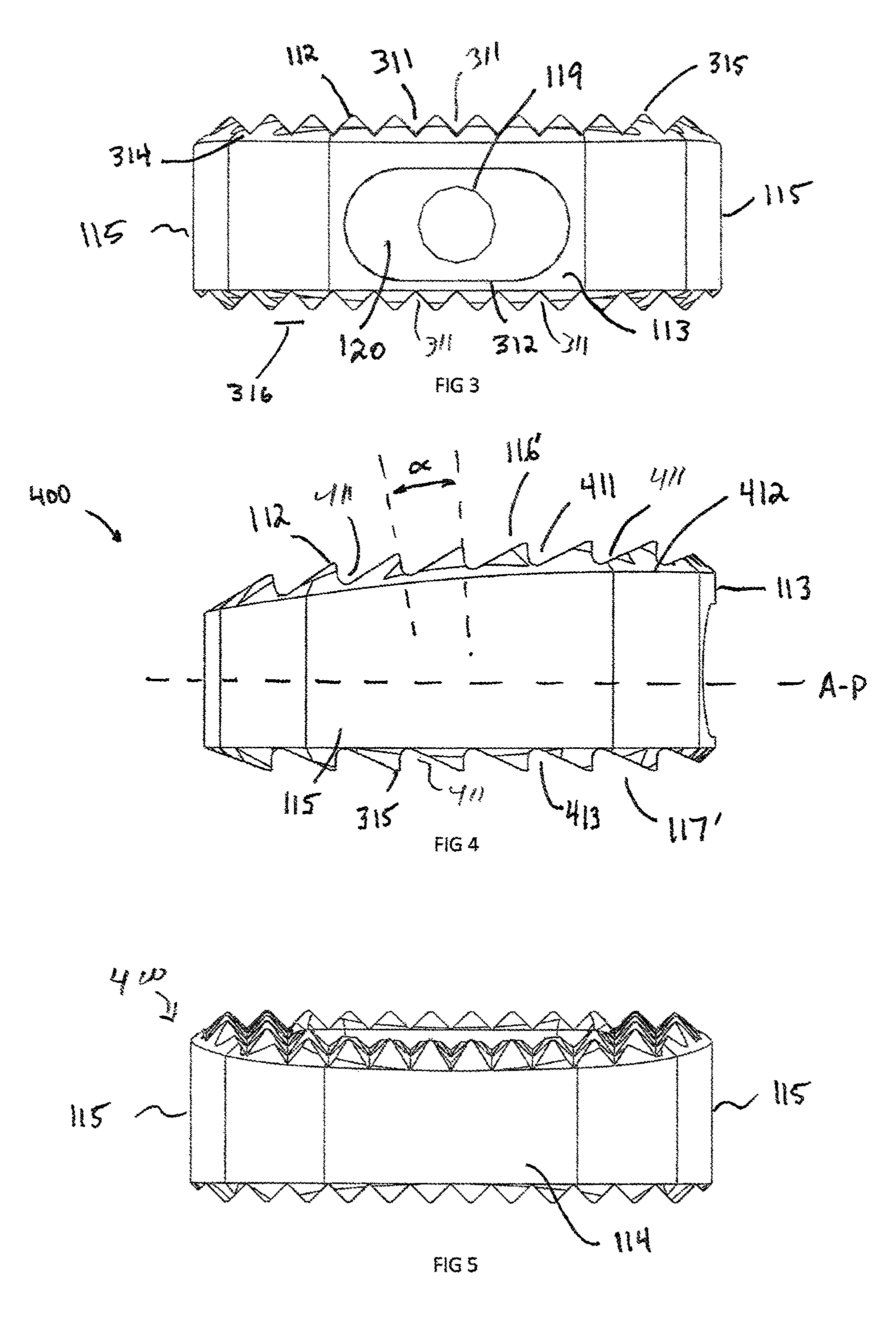

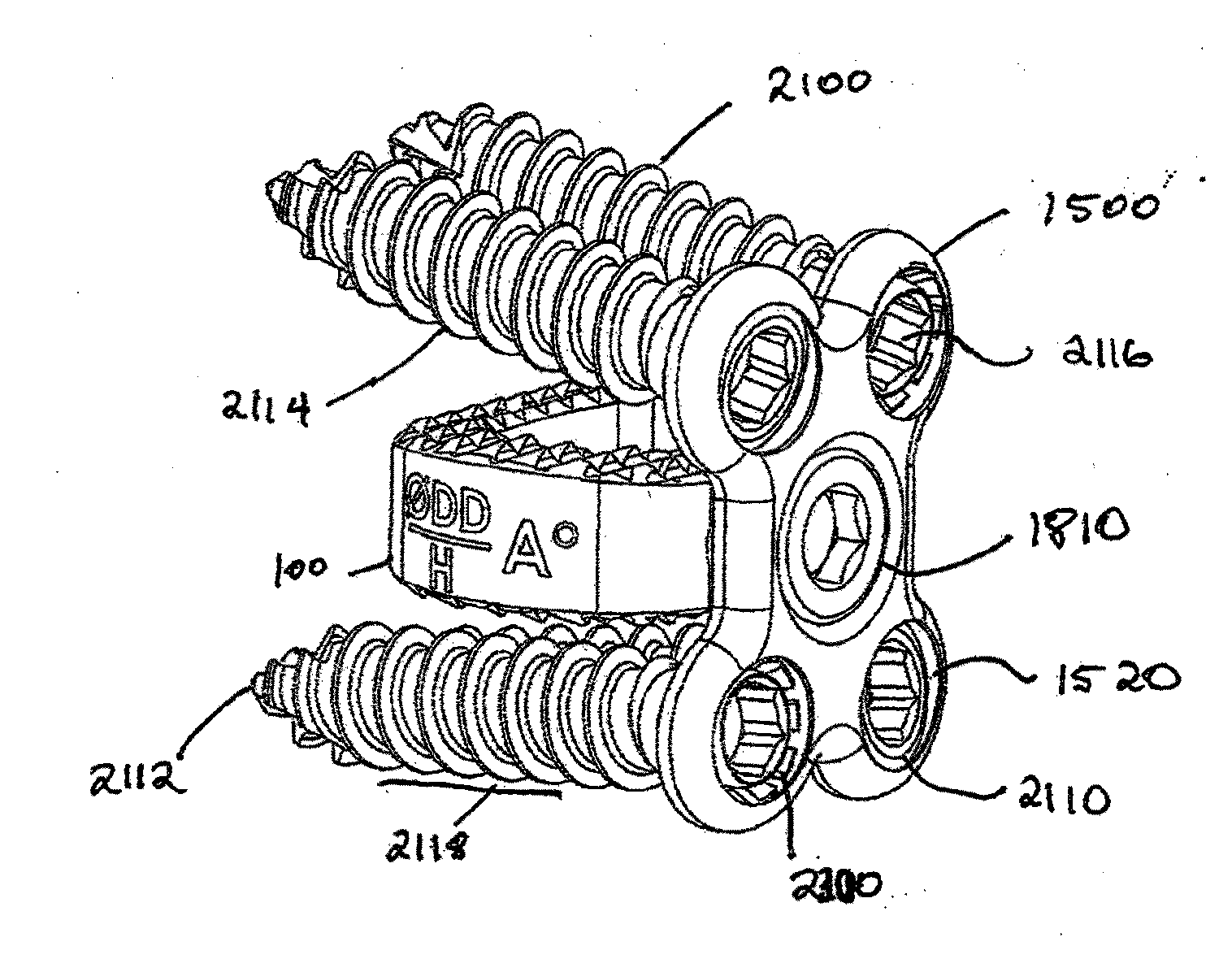

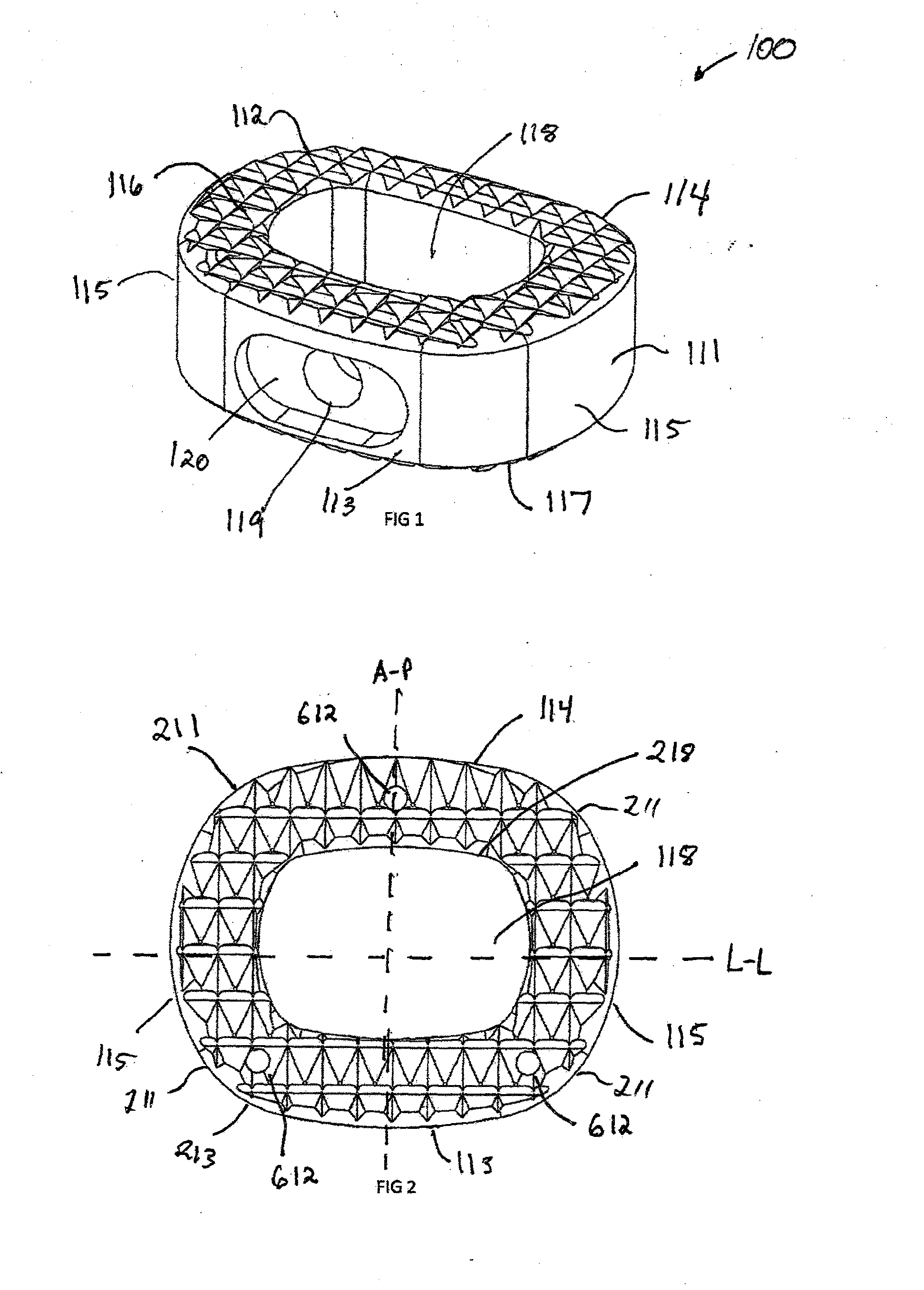

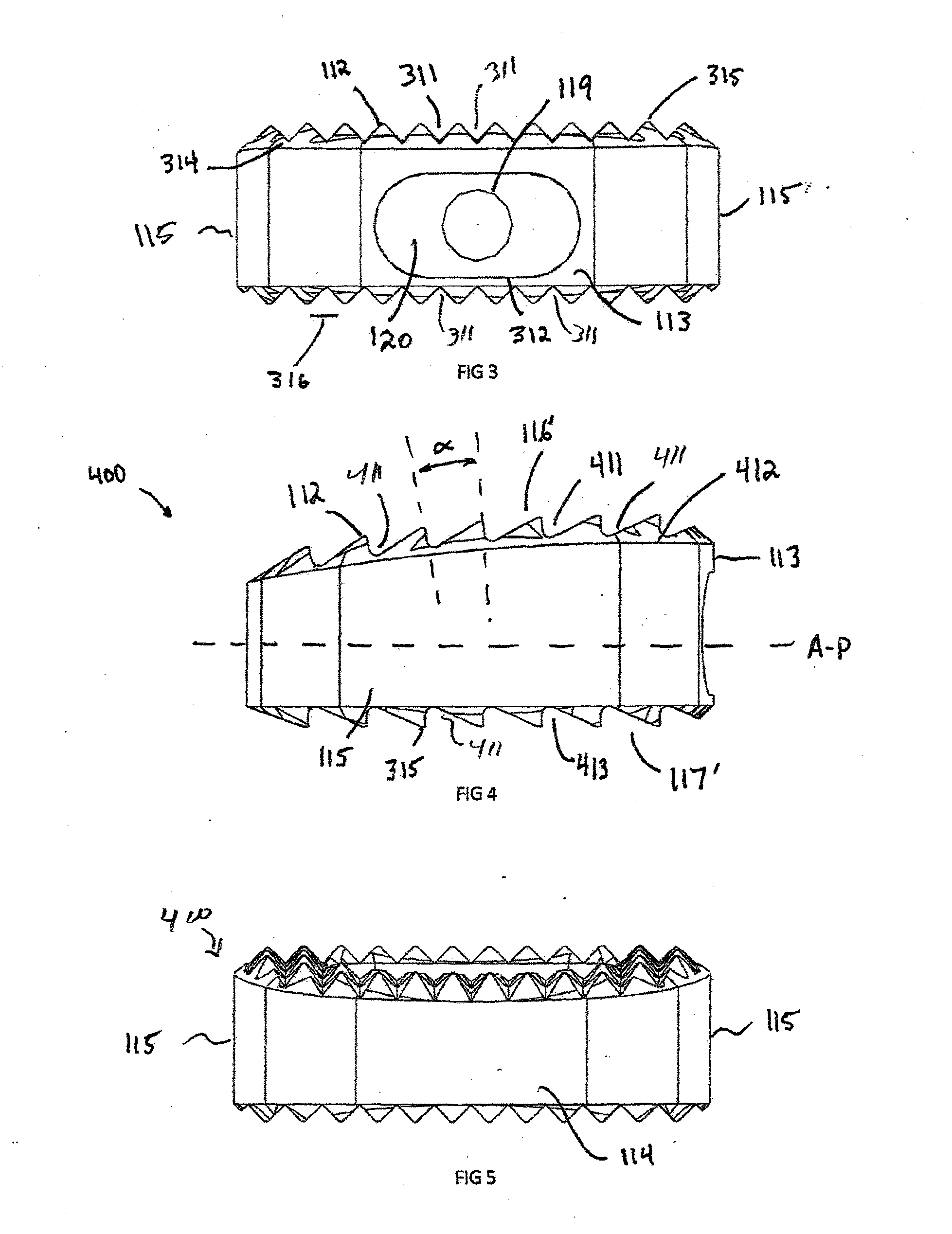

Orthopedic systems for spine and tracking control

An orthopedic implant system includes an intervertebral implant. The implant includes a body having an upper surface extending generally in a first plane. The upper surface has a first plurality of longitudinal grooves and a second plurality of transverse grooves extending therealong. Portions of the upper surface extend between adjacent longitudinal grooves and transverse grooves form individual peaks. A lower surface extends generally in a second plane, parallel to the first plane. The lower surface has a third plurality of longitudinal grooves and a fourth plurality of transverse grooves extending therealong. Portions of the lower surface extend between adjacent longitudinal grooves and transverse grooves form individual peaks.

Owner:TYBER MEDICAL

Attachment assembly for firearm handguard and method of attaching handguard to a firearm

InactiveUS20110247254A1Minimize movementIncreased frictional contactTravelling carriersHoldersTransverse grooveEngineering

An attachment assembly for a firearm handguard includes a barrel nut for mounting on a firearm barrel and engaging the firearm handguard thereon. The barrel nut includes a first end for engaging an upper receiver of a firearm, a second end opposite the first end for receiving the firearm handguard, and a transverse groove formed on an exterior surface of the barrel nut between the first end and the second end, which mechanically locks the firearm handguard on the barrel nut. The barrel nut can include an interior surface with threads formed thereon proximate the first end for engaging complementary threads of the upper receiver. A knurled section can be formed on the exterior surface between the transverse groove and the second end, which provides frictional engagement at the interface of the barrel nut and the handguard.

Owner:BARNES ANDREW S

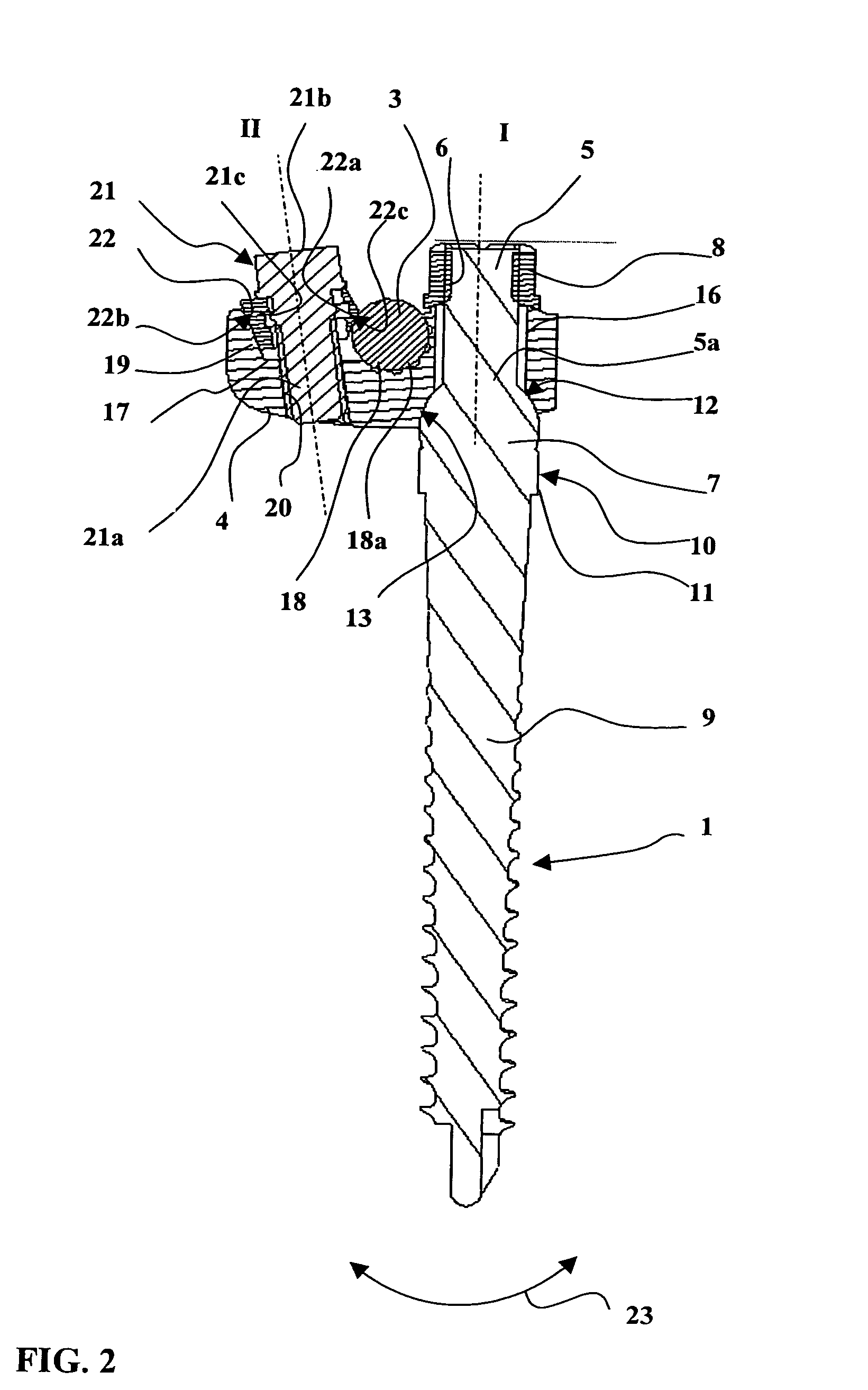

Bone separator

ActiveUS7927337B2Arrangement is especially simple and clearInternal osteosythesisProsthesisTransverse grooveEngineering

A bone spreader includes two tubular pin holders which are connected to one another by a parallel guide system, and two pins that are configured to be connected to the bone parts that are to be spread apart. In order to give the bone parts that are to be spread apart a more secure position in relation to one another, at least one of the pin holders is provided with a locking device for a pin located in the pin holder. This locking device includes a locking finger which is movable tangentially with respect to the pin holder and which, in the locking position, engages in a transverse groove of the associated pin and can be formed by a pivotably mounted hook.

Owner:CERVITECH INC

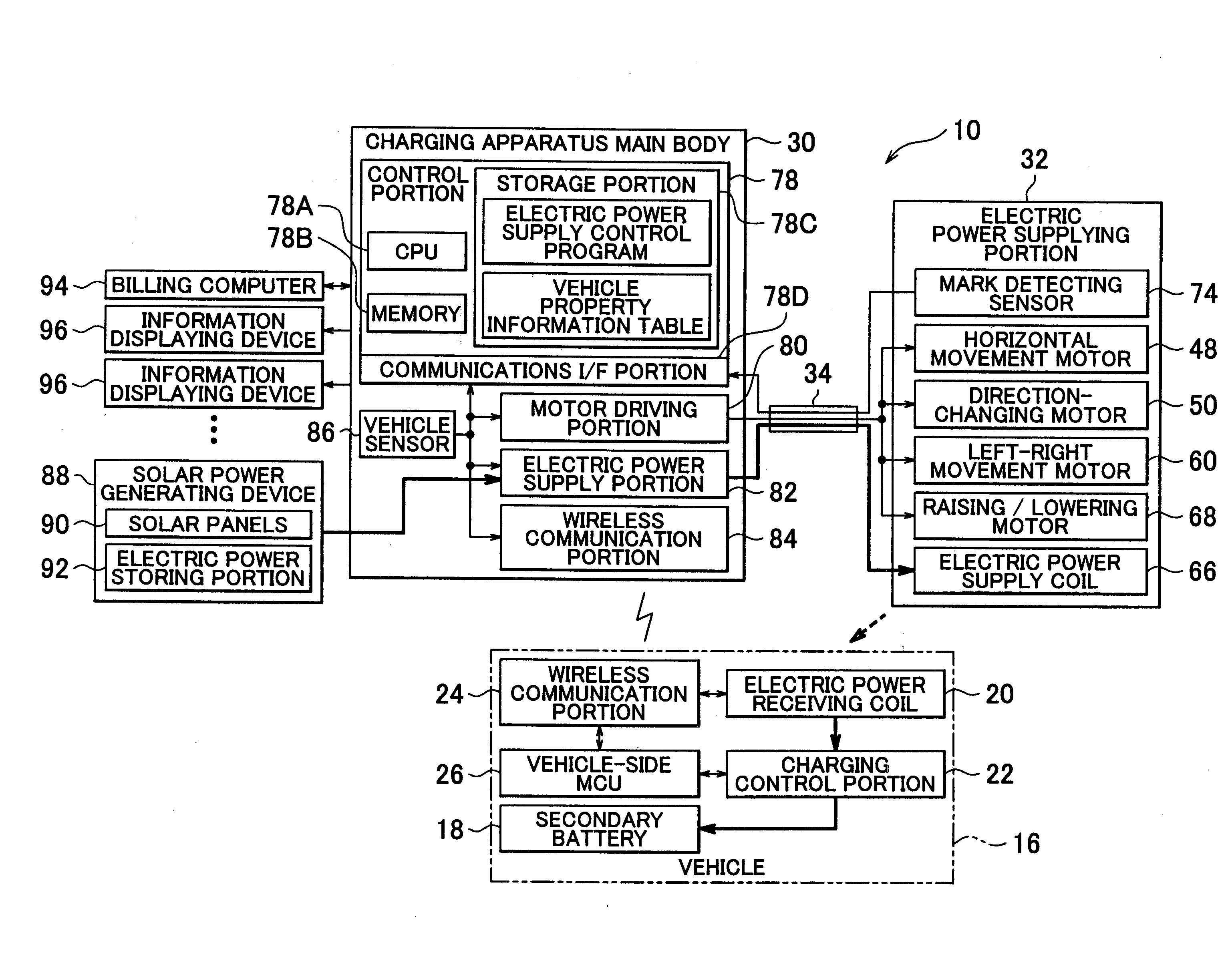

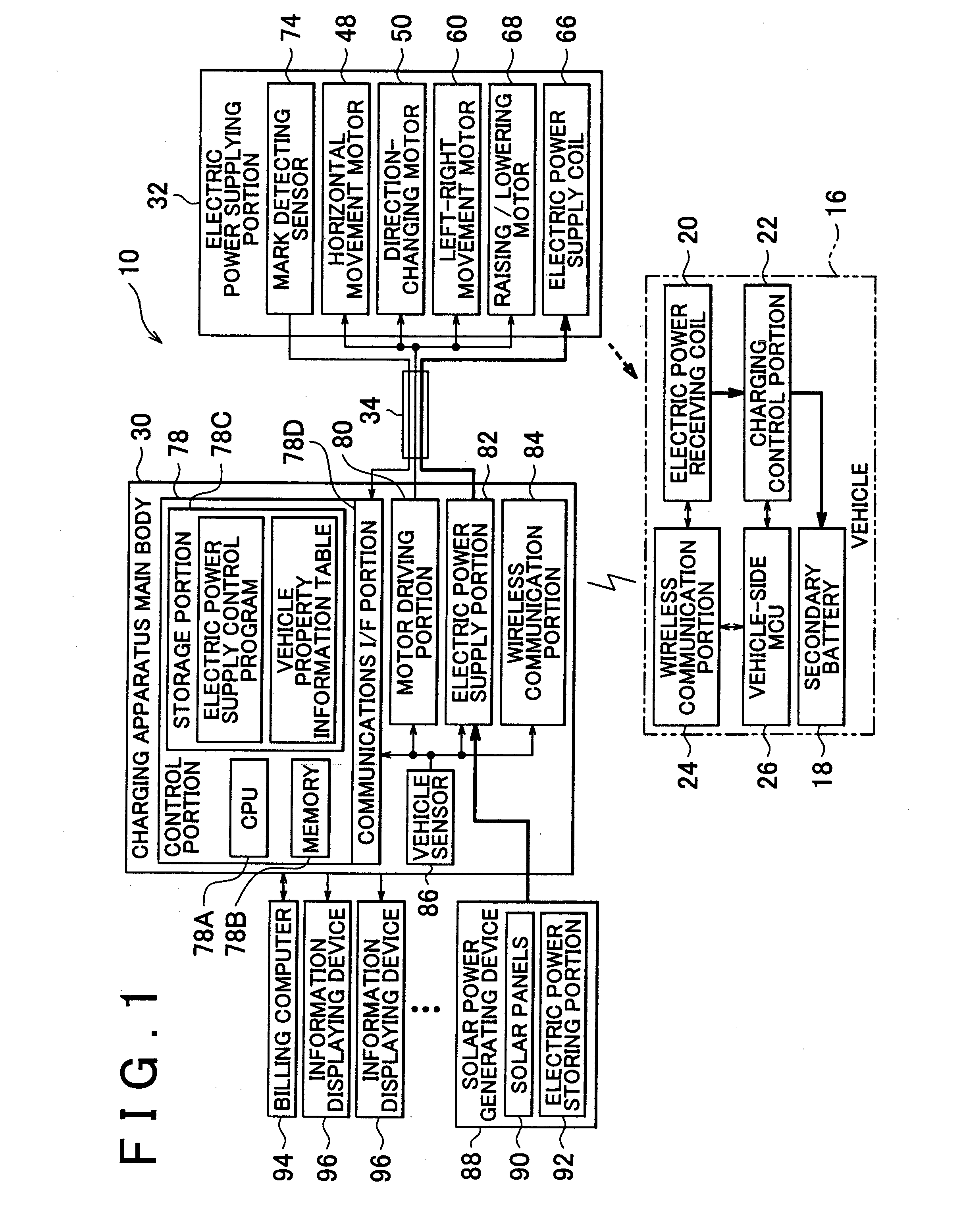

Charging apparatus

InactiveUS20130076296A1Complete chargingReduce the amount requiredCharging stationsElectric devicesElectric power systemTransverse groove

A charging apparatus charges a secondary battery of a vehicle by moving an electric power supplying portion along a transverse groove and a longitudinal groove to a position that enables electric power to be supplied to a parked vehicle, and then supplying electric power to the vehicle from the electric power supplying portion, each time a vehicle is parked in a parking space of a parking lot, when the parked vehicle is an authorized vehicle and a state of charge of the secondary battery is equal to or less than a predetermined value.

Owner:TOYOTA JIDOSHA KK

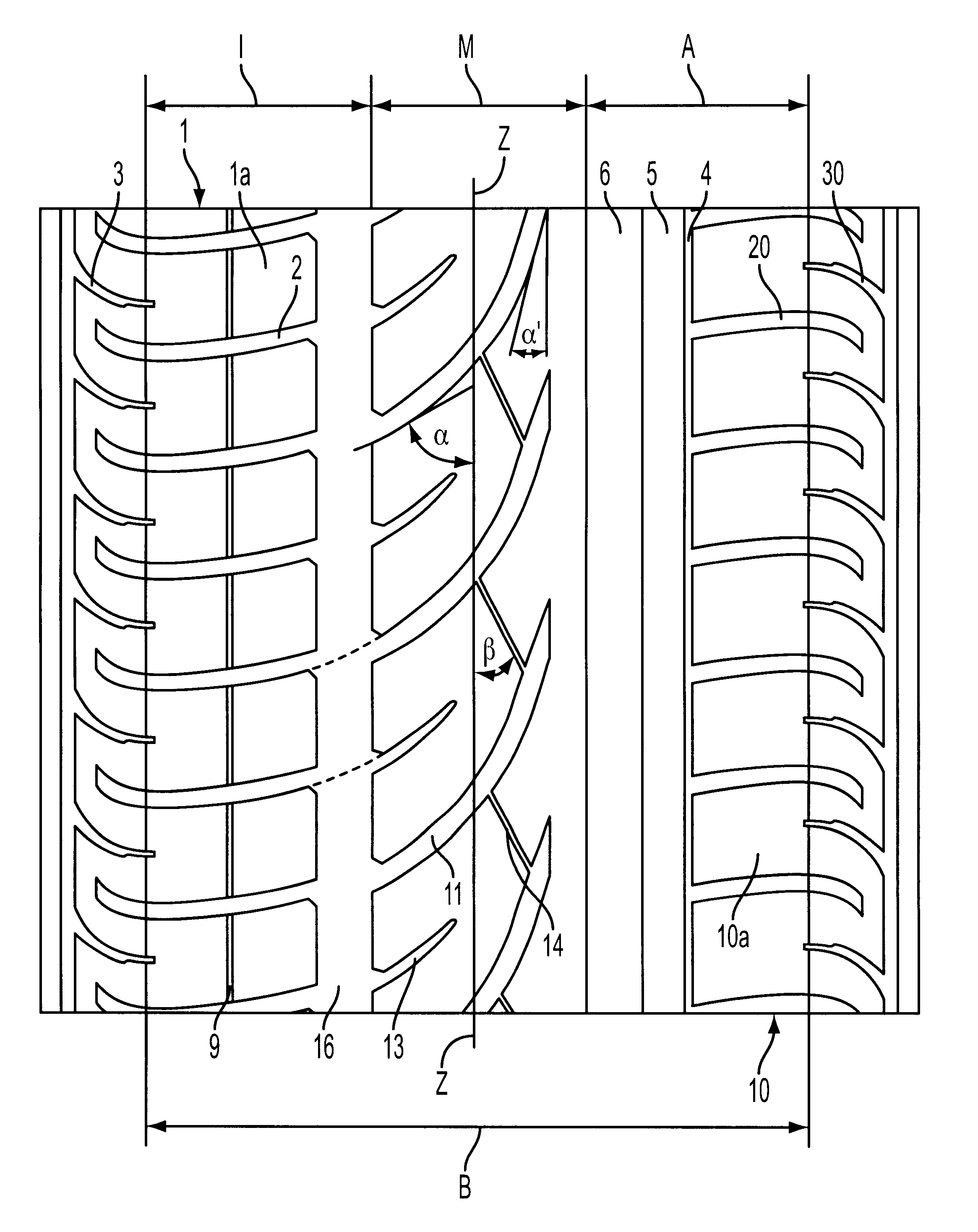

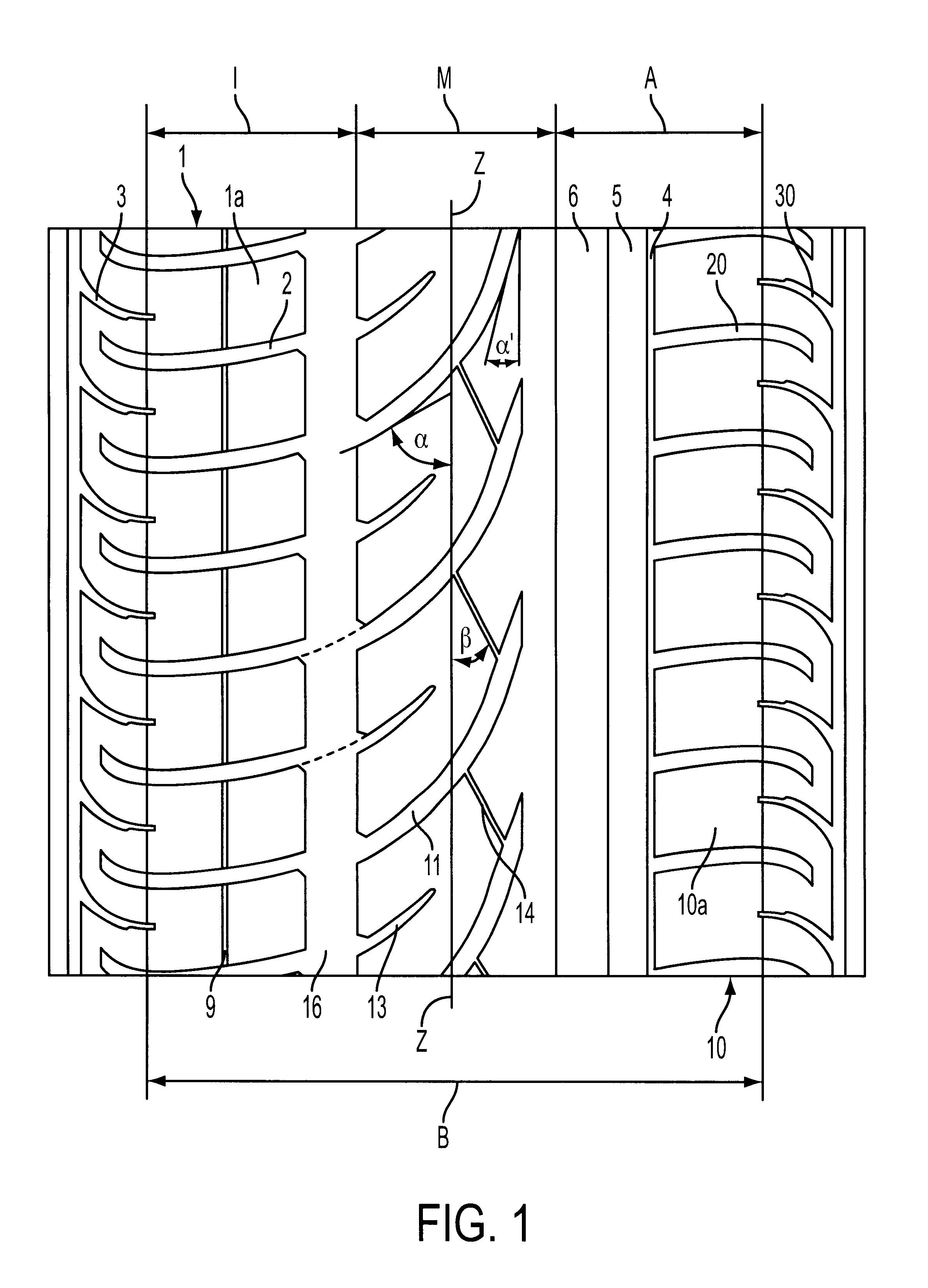

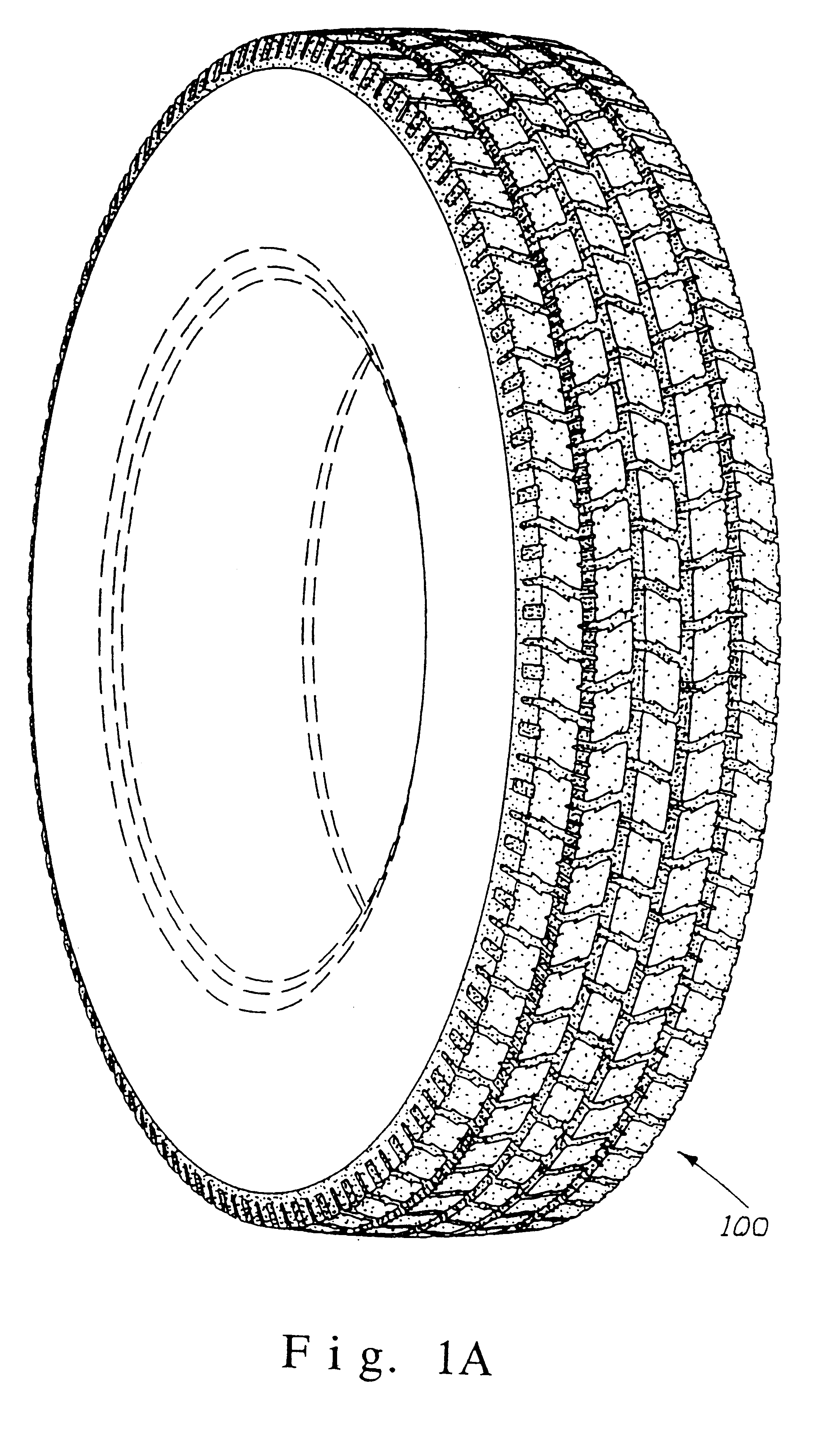

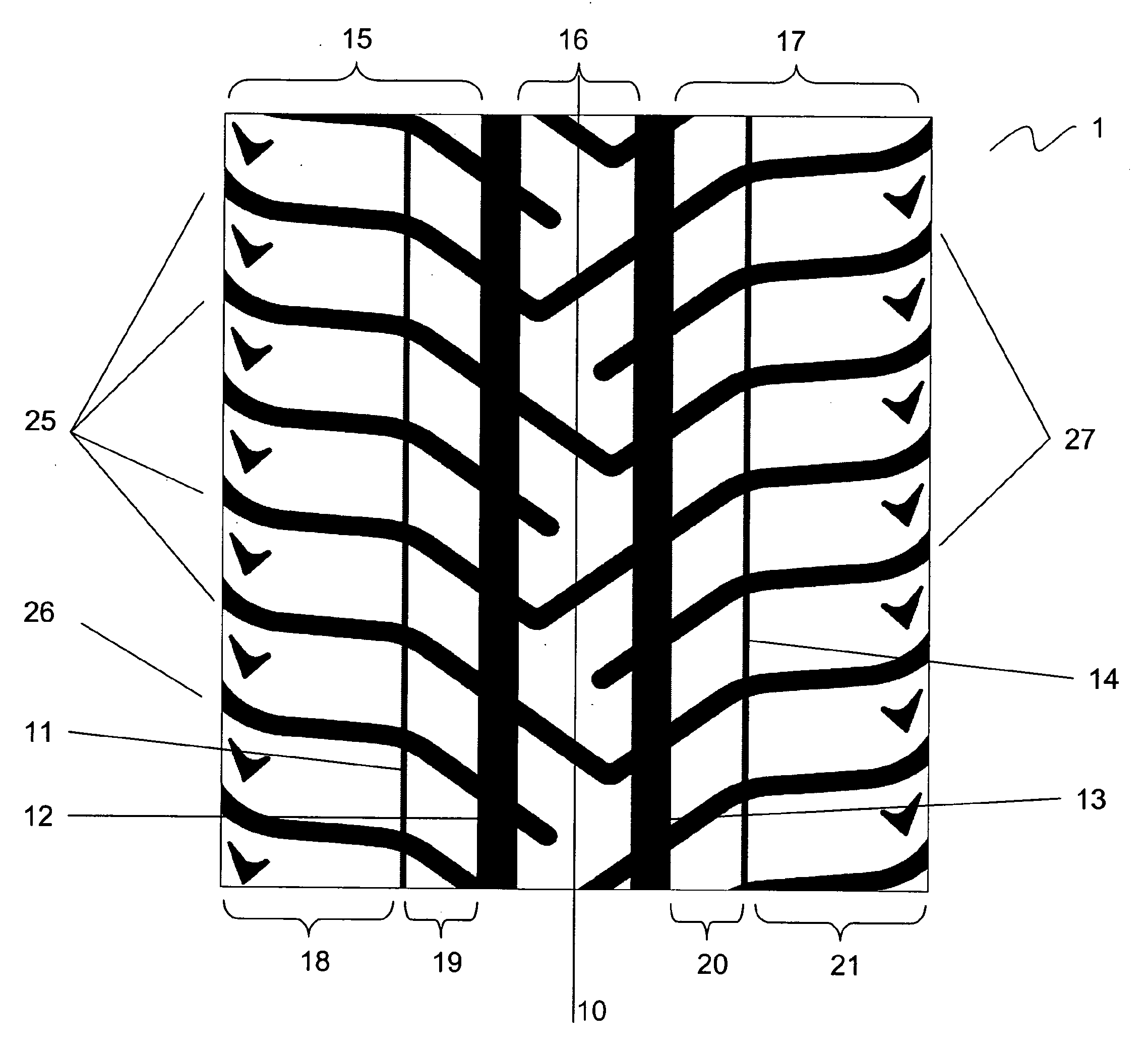

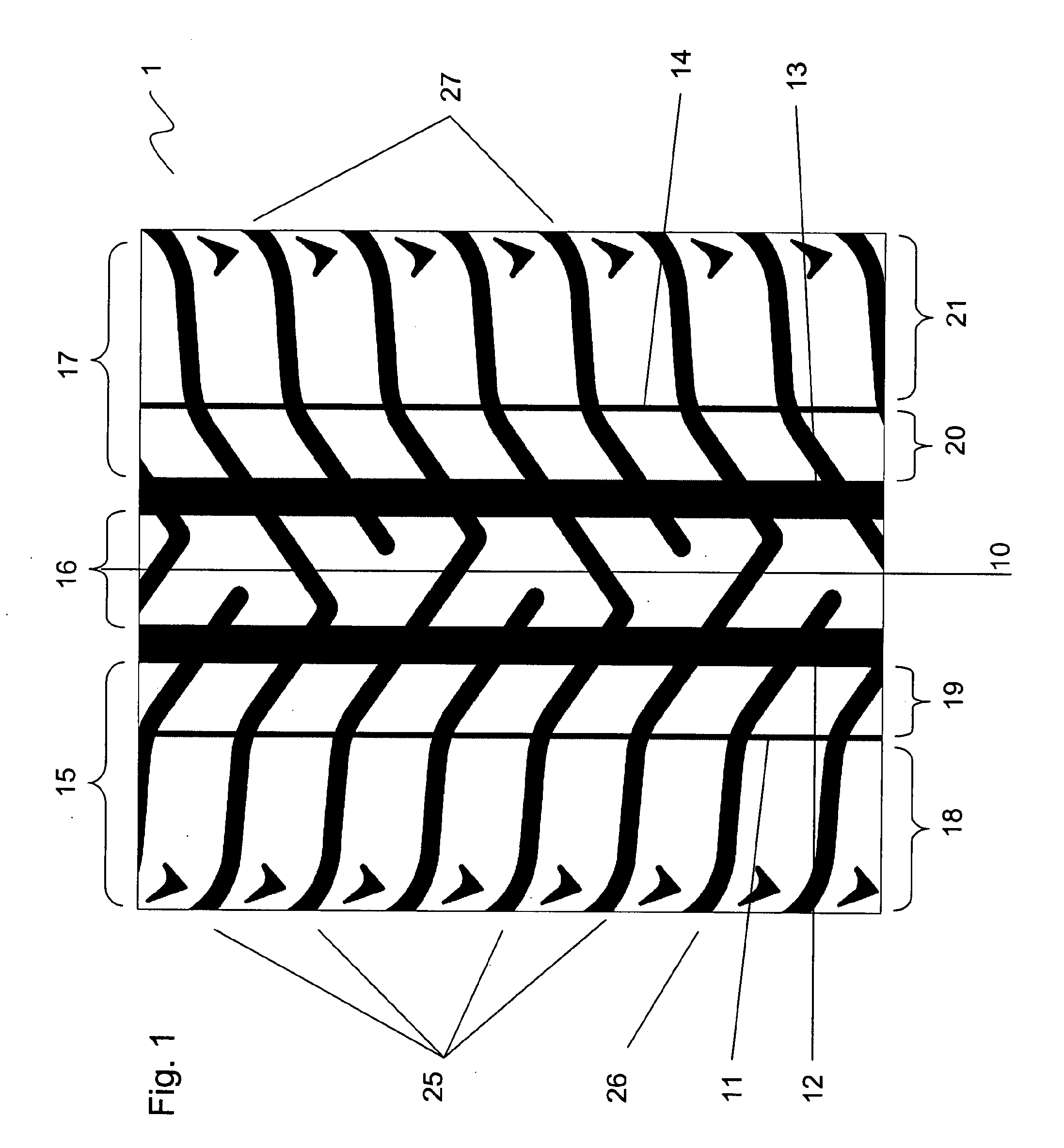

Vehicular pneumatic tire and process of making vehicular pneumatic tire

InactiveUS6439286B1Narrow profileAvoid impactTyresTyre tread bands/patternsTransverse grooveEngineering

Vehicular pneumatic tire having an asymmetric tread formed in relation to a circumference of a running surface and process of making vehicular pneumatic tire. The vehicular pneumatic tire includes an outside region that includes an outside shoulder block row and an outside circumferential groove, an inside region that includes an inside shoulder block row and an inside circumferential groove, and a center region that is laterally delimited by the outside circumferential groove and the inside circumferential groove. A plurality of transverse grooves are arranged within the inside shoulder block row, and the plurality of transverse grooves further are arranged to extend into the center region. No more than about one-half of the plurality of transverse grooves are arranged to at least nearly entirely traverse the center region and are oriented to form an angle to a circumferential equator line of no more than approximately 30° over at least one-third of their longitudinal extensions. The process includes forming an outside region to include an outside shoulder block row and an outside circumferential groove, forming an inside region to include an inside shoulder block row and an inside circumferential groove, and laterally delimiting a center region with the outside circumferential groove and the inside circumferential groove. The process further includes arranging a plurality of transverse grooves within the inside shoulder block row and to extend into the center region. No more than one half of the plurality of transverse grooves are arranged to at least nearly entirely traverse the center region and are oriented to form an angle to a circumferential equator line of no more than approximately 30° over at least one-third of their longitudinal extensions.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Connecting device for weapon accessory

InactiveUS6874269B2Reliably securedQuickly and conveniently removedSighting devicesButtsTransverse grooveEngineering

A connecting device for a weapon accessory has a seat having a sliding rack that removably connects the longitudinal groove of a weapon, and one or more gripping blocks disposed adjacent corresponding side walls of the seat. The gripping block assumes a first position where the gripping block extends inwardly towards the sliding rack to engage a selected transverse groove of the weapon, and a second position where the gripping block extends outwardly away from the respective side wall of the seat to release the longitudinal groove of the weapon. The connecting device also includes a control mechanism operatively coupled to the gripping block. The control mechanism assumes a normal position with the control mechanism controlling the gripping block to maintain the gripping block in the first position, and actuation of the control mechanism causes the gripping block to assume the second position.

Owner:QUARTON

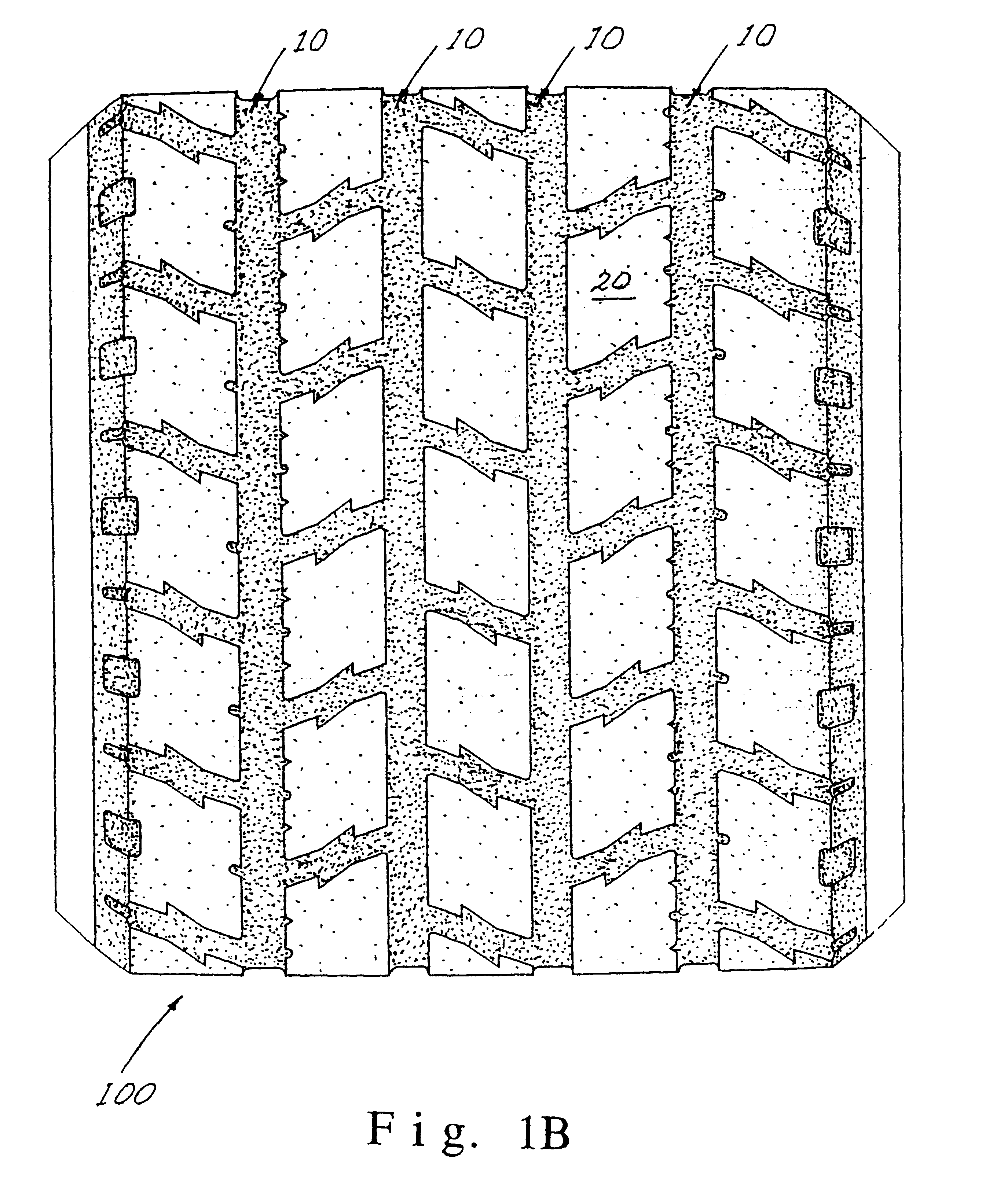

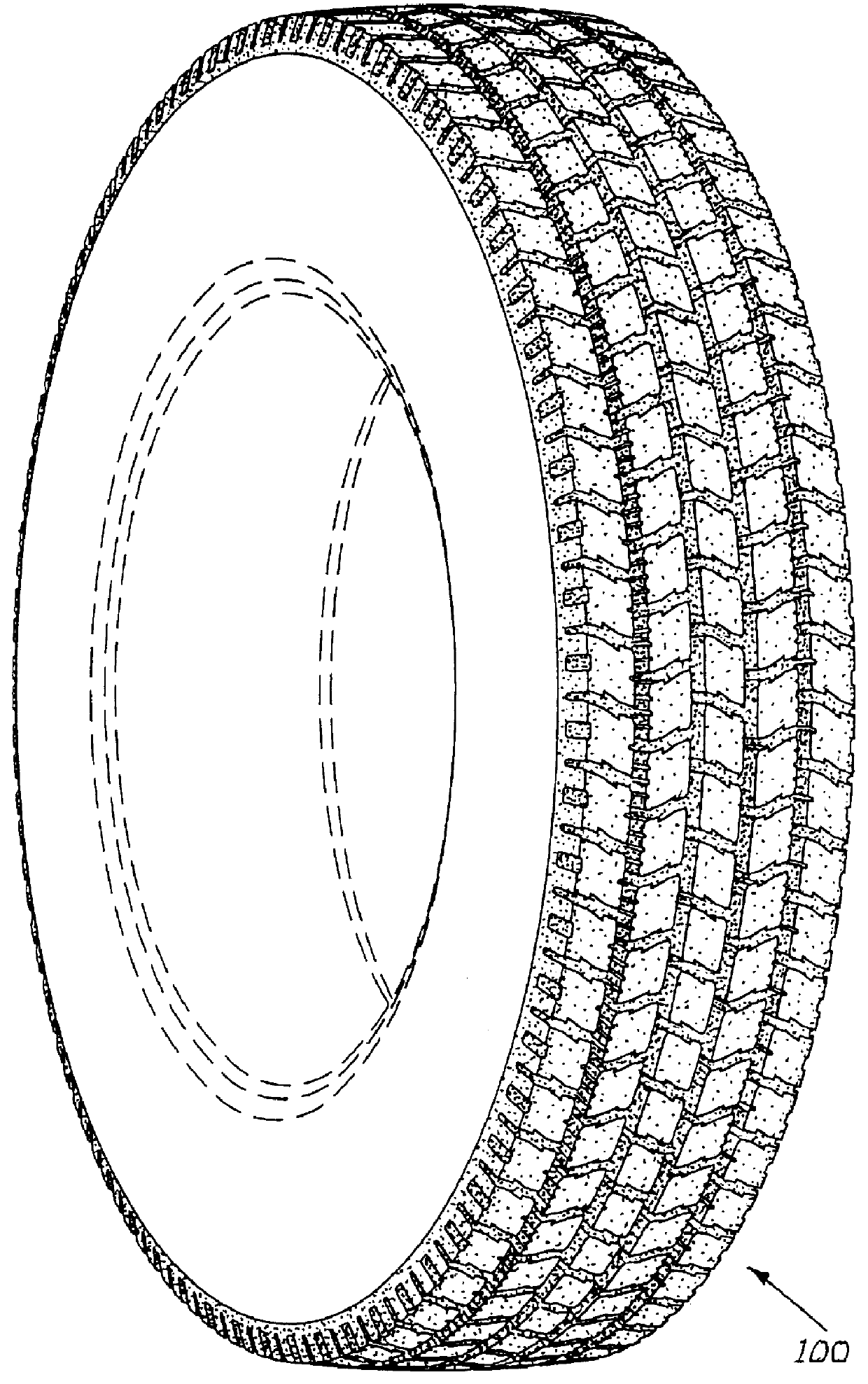

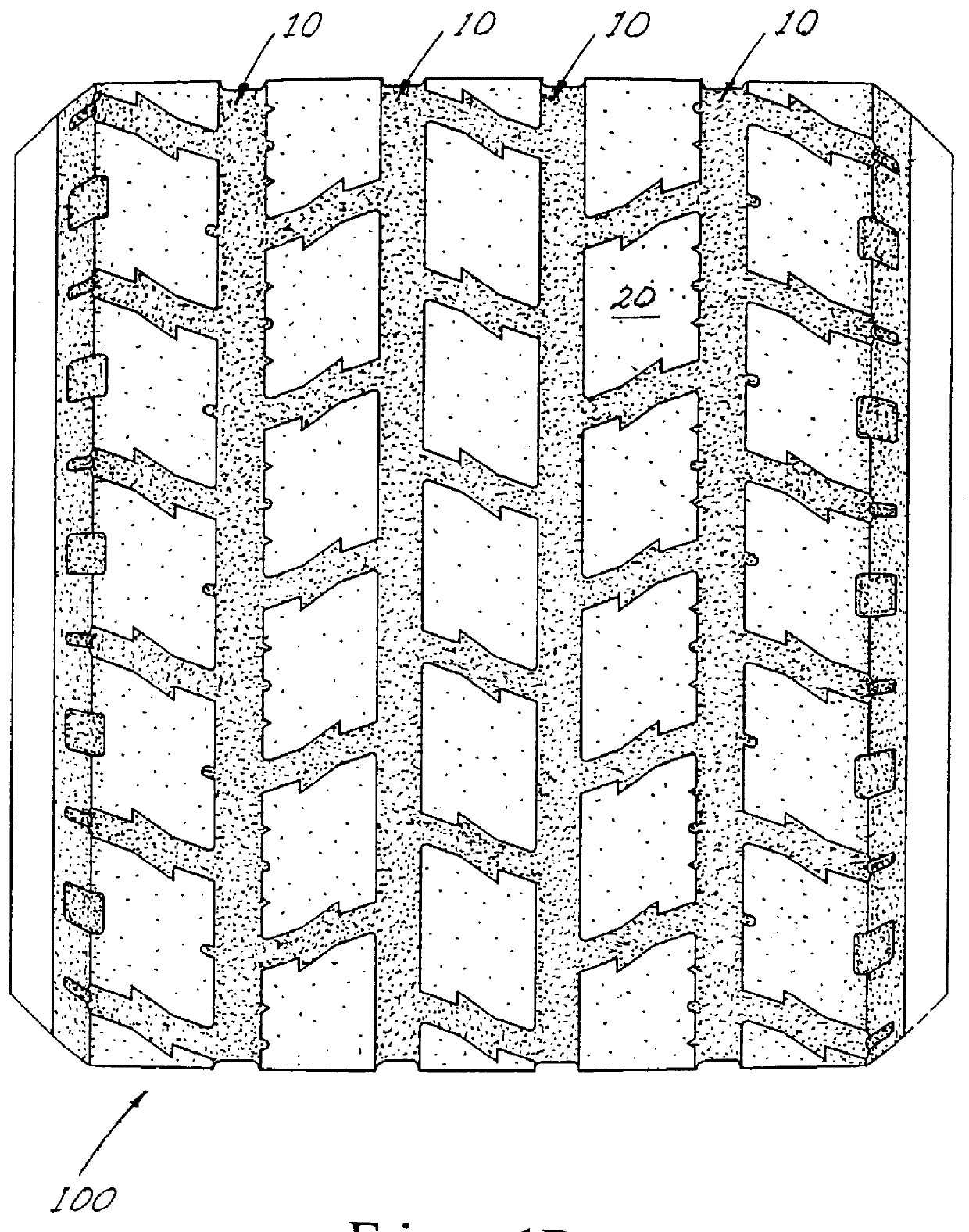

Tire having sacrificial bridging

The present invention provides a pneumatic tire having a tread portion comprising a plurality of axially spaced apart essentially longitudinal grooves separating essentially longitudinal ribs. On at least one of said ribs, transverse grooves or cuts repeat in the circumferential direction to form first and second land portions wherein the first land portions comprise blocks having a circumferential length greater than that of the second land portions. Said second land portion acts as a sacrificial bridge which provides traction improvement and minimizes undesirable surface anomalies during the service life of the tire.

Owner:MICHELIN RECH & TECH SA

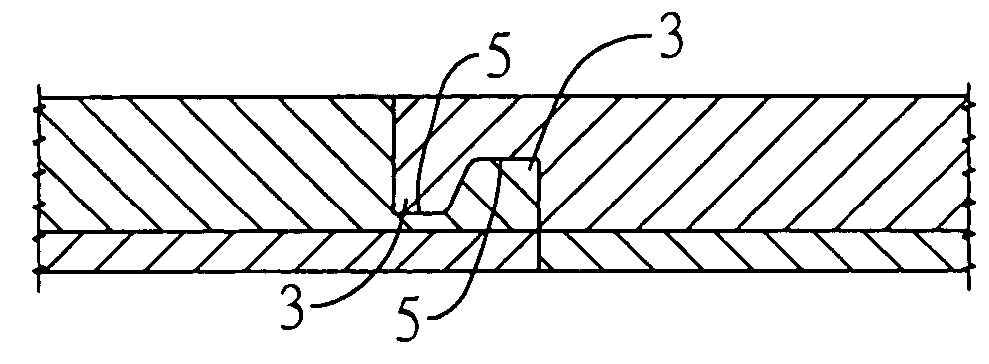

Parquet block with woodwork joints

A parquet block with a woodwork joint has two parallel abutting sides, a longitudinal notch, a longitudinal tongue, two transverse grooves and two transverse tongues. The longitudinal notch, the longitudinal tongue, the transverse grooves and the transverse tongues on adjacent parquet blocks interlock to hold the parquet blocks securely in the longitudinal and transverse directions.

Owner:LIU MEI LING

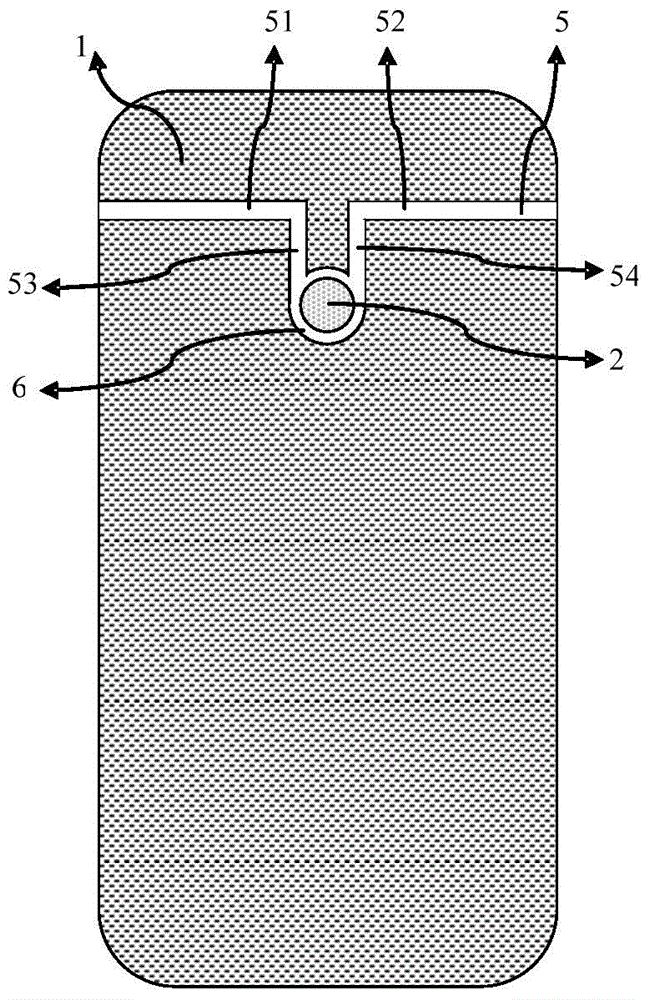

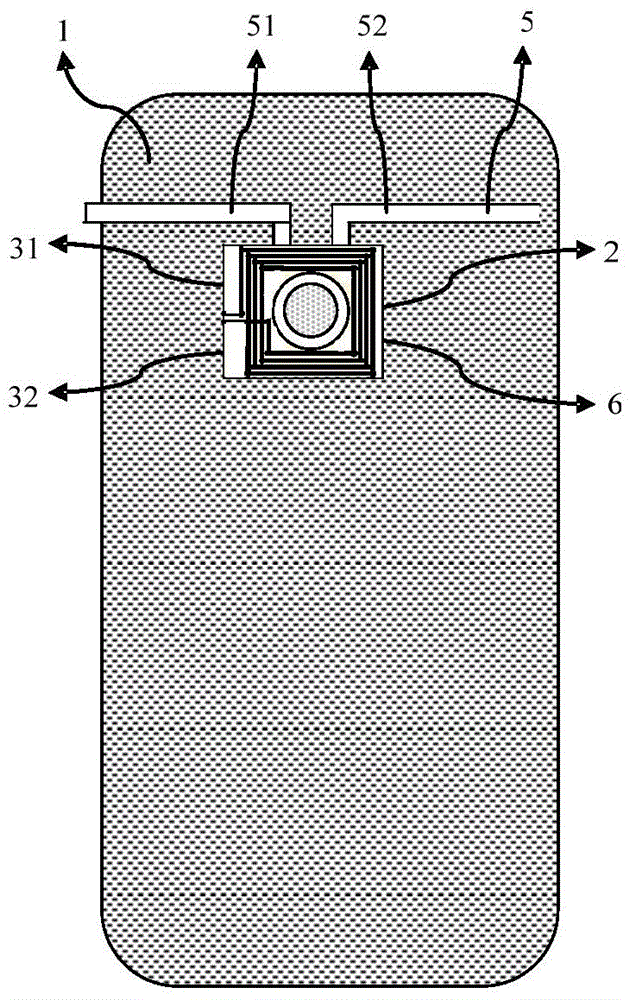

NFC antenna structure for metal back cover mobile phone

InactiveCN104993216AReduce distractionsGuaranteed to workLoop antennas with ferromagnetic coreAntenna supports/mountingsMagnetic field couplingTransverse groove

The invention relates to an NFC antenna structure for a metal back cover mobile phone. An NFC antenna with a coil form is arranged in a metal back cover of a mobile phone. The metal back cover of the mobile phone is provided with a concave groove used for blocking a vertex of the metal back cover of the mobile phone and a hole used for arranging a camera. The NFC antenna communicates with an external reader-writer antenna via the concave groove and the hole based on magnetic field coupling. The NFC antenna comprises an NFC coil and a ferrite magnetic sheet. The concave groove starts at one side of the metal back cover of the mobile phone and ends at the opposite side of the metal back cover of the mobile phone. The concave groove comprises two transverse grooves and two vertical grooves. The NFC antenna employs the opening for arranging the camera in the metal back cover of the mobile phone for radiation and the metal back cover of the mobile phone is provided with the concave groove, so that the vortex of the metal back cover is prevented from causing magnetic field interference to the NFC antenna and the excellent electrical performance of the NFC antenna and the reader-writer can be guaranteed during work.

Owner:SUZHOU NANOANT COMM TECH CO LTD

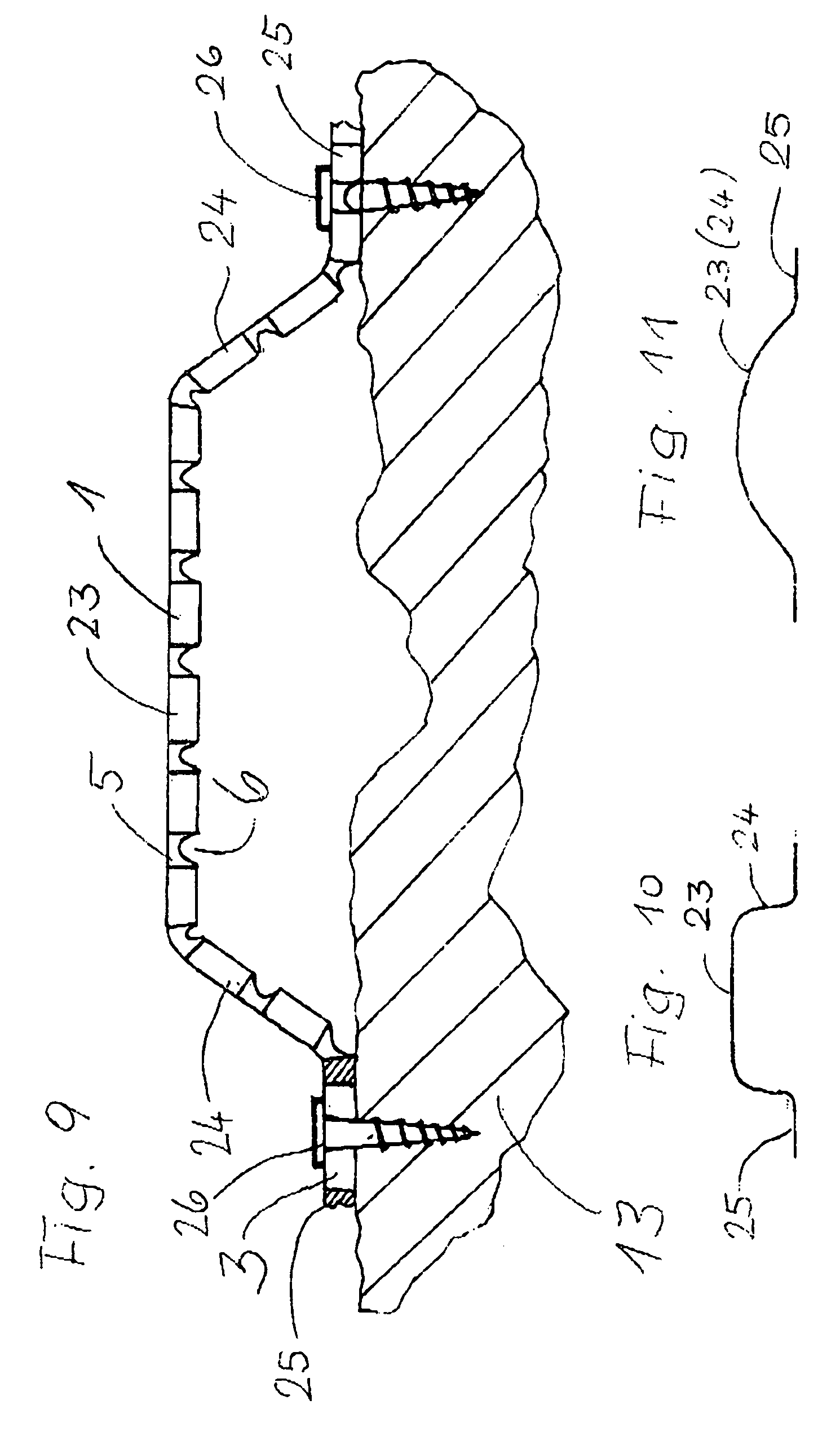

Device for regenerating, repairing, and modeling human and animal bone, especially the jaw area for dental applications

InactiveUS7172422B1Reduce stress loadStabilization and protectionDental implantsInternal osteosythesisTransverse grooveBone replacement

A device for reshaping human or animal bone with bone replacement material includes at least two spaced apart implants and a bar connected to the at least two spaced apart implants and bridging at least one reshaping location. The bar has notches at the longitudinal sides and transverse grooves at the underside. The bar has slotted holes extending in the longitudinal direction of the bar for receiving the implants, respectively, fasteners of the implants.

Owner:ESSIGER HOLGER K

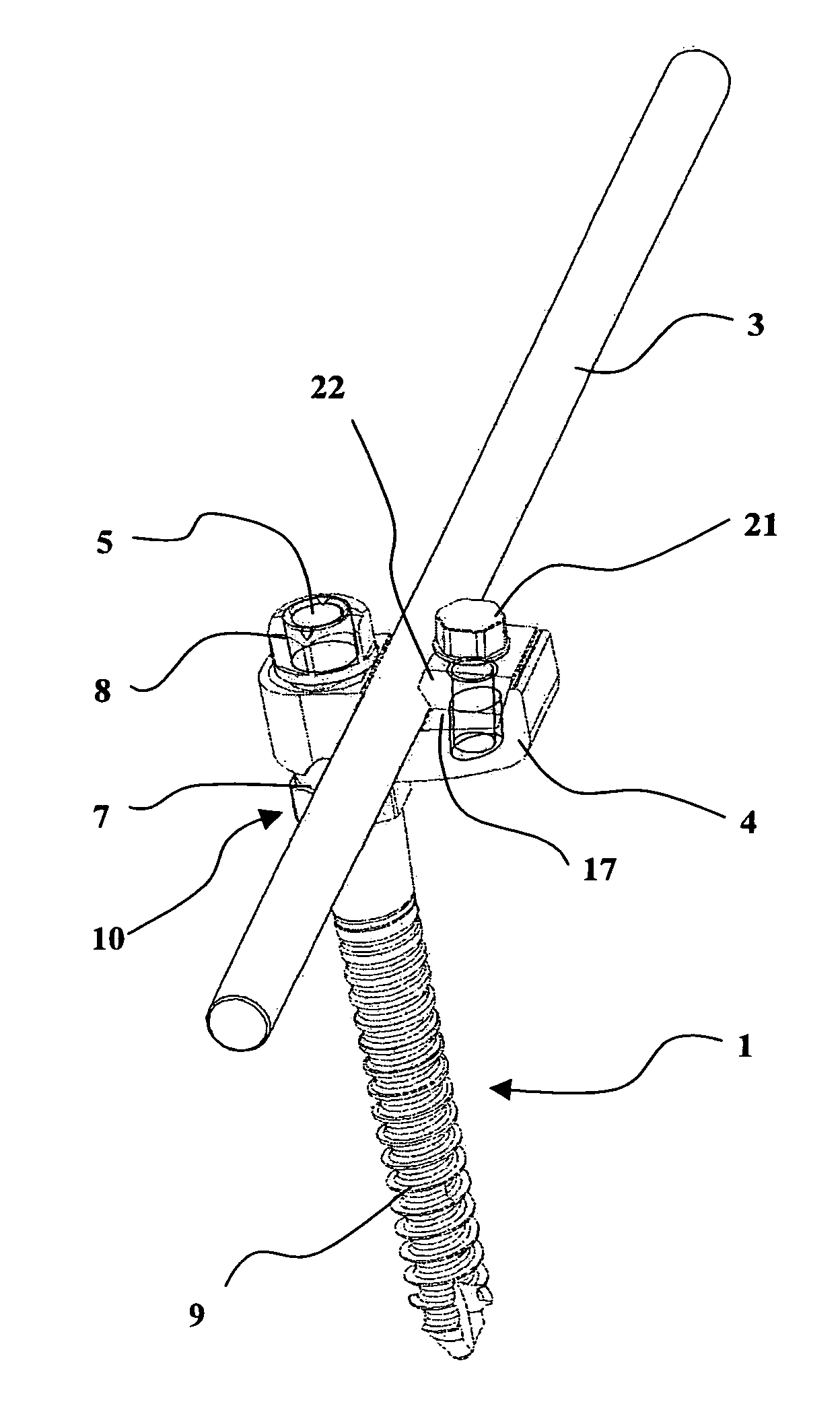

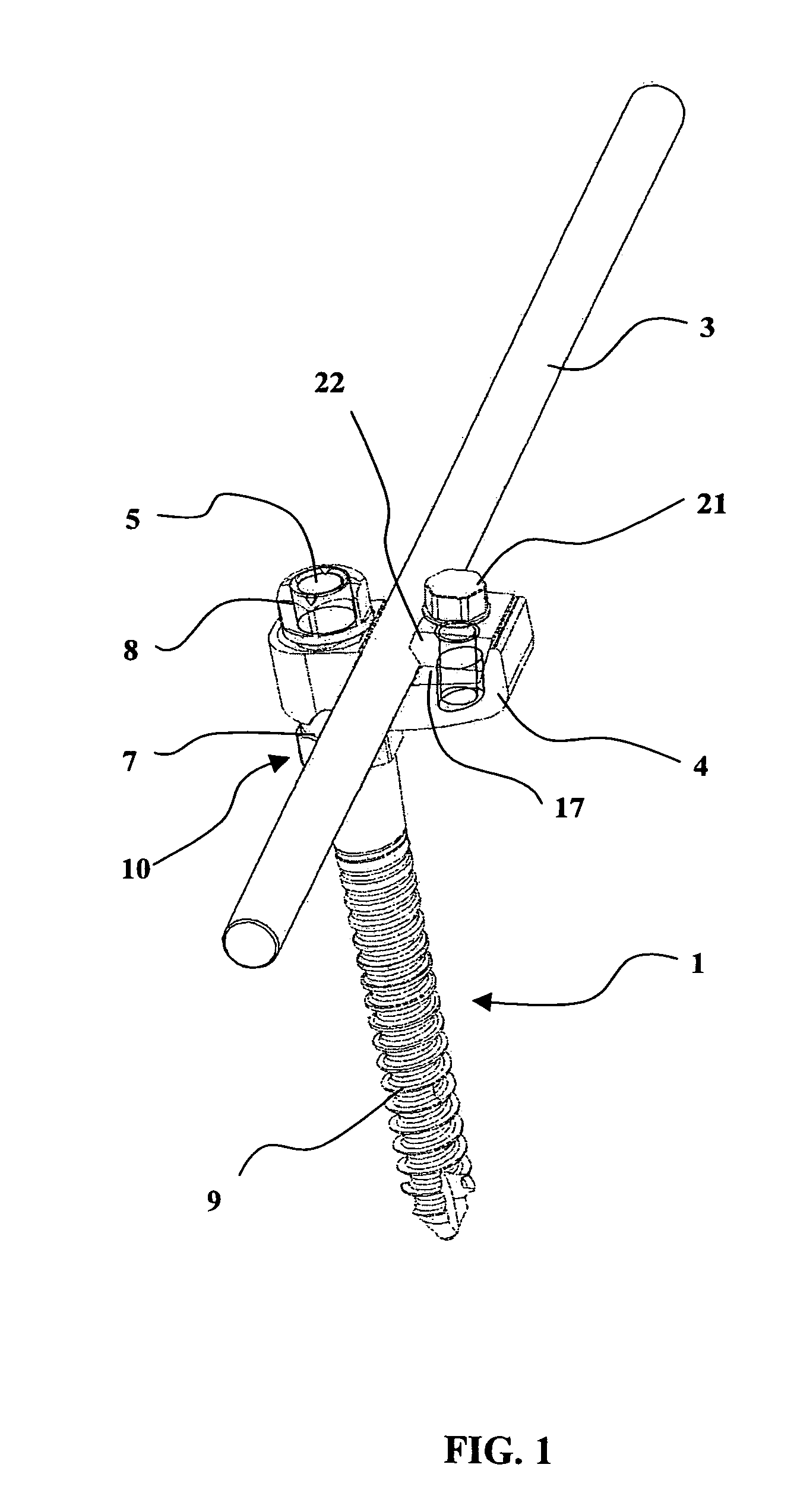

Vertebral column support device which is assembled by means of clamping

InactiveUS7094237B2Good for healthSecures the vertebrae much more effectivelyInternal osteosythesisJoint implantsTransverse grooveEngineering

Owner:LAPE MEDICAL

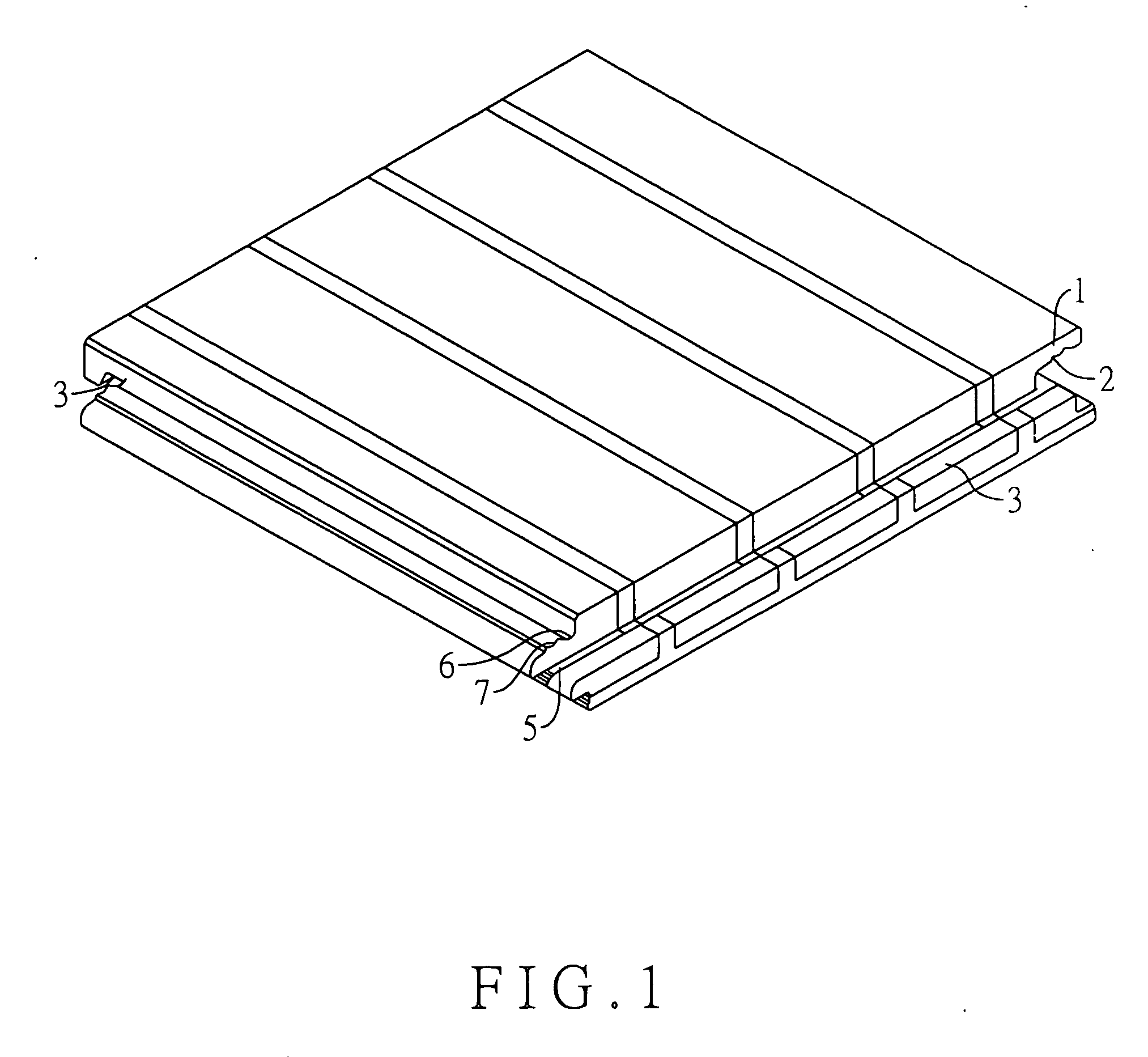

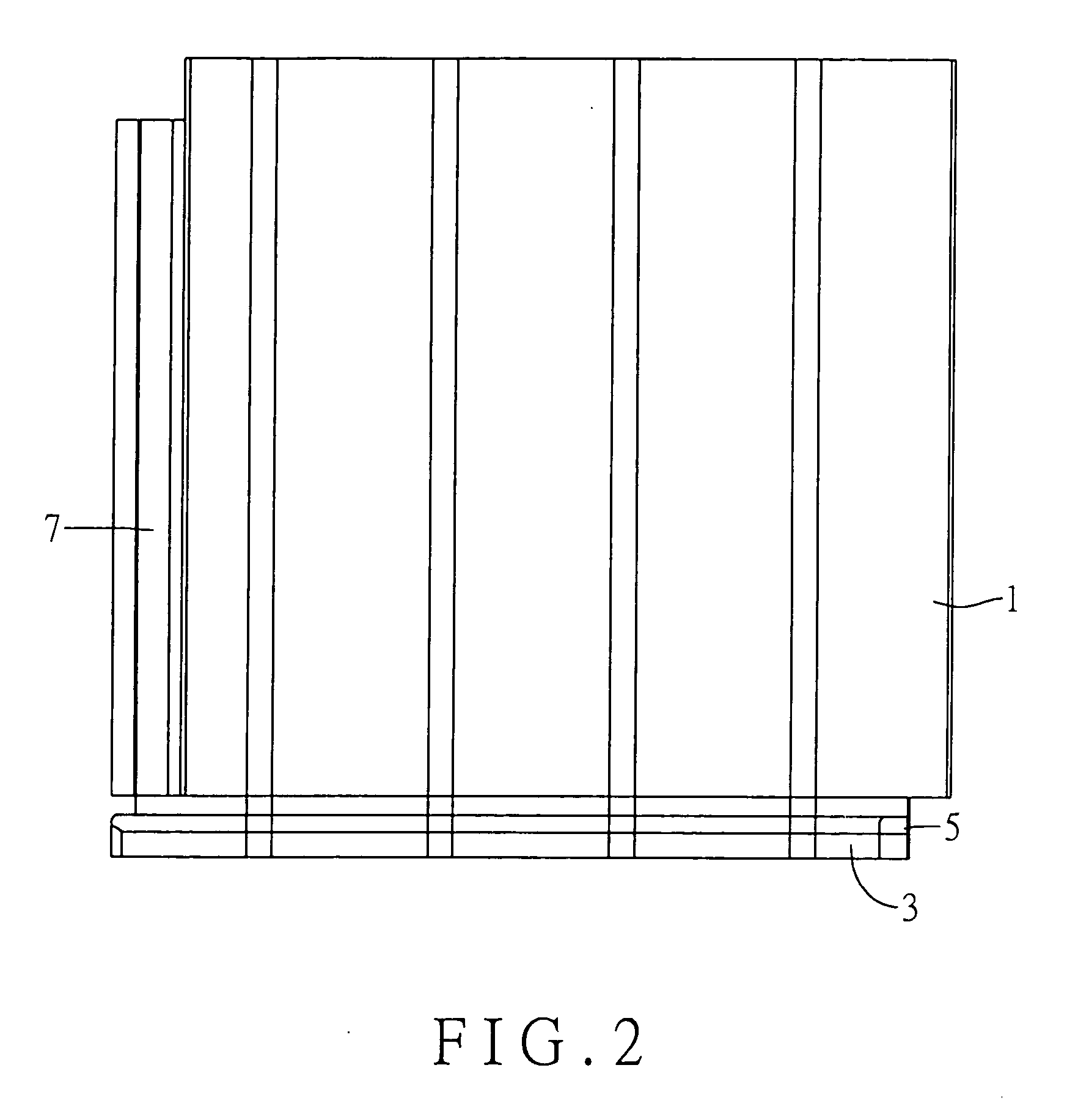

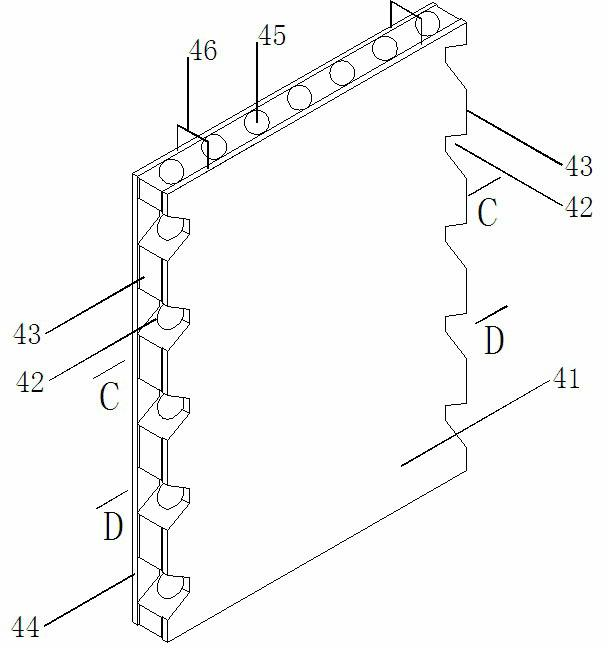

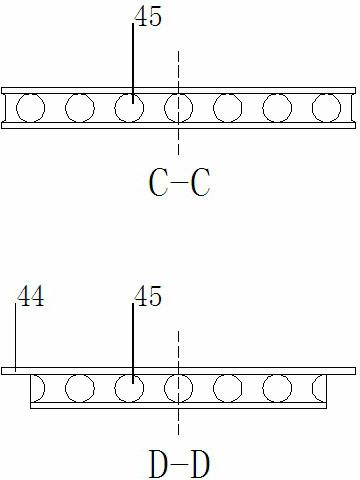

Prefabricated reinforced concrete component with grooves and manufacturing method thereof

ActiveCN102635197AIncrease productivityQuality improvementConstruction materialWallsReinforced concreteVertical edge

The invention relates to a prefabricated reinforced concrete component with grooves and a manufacturing method thereof and belongs to the technical field of components in a prefabricated reinforced concrete structure. The component uses a cored slab prefabricated by reinforced concrete; and transverse grooves are arranged at the vertical edge of the reinforced concrete prefabricated slab at intervals, and are interacted with vertical holes parallel to the surface in the prefabricated slab. The manufacturing method provided by the invention comprises the following steps of: combining templates, such as a bottom die, a top die, a side die, a steel pipe inner die and the like on a production field of prefabricated slabs; arranging reinforcing meshes; then pouring concrete; drawing a steel pipe before hardening the concrete; and dismounting the templates after the concrete reaches to the expected strength. According to the prefabricated reinforced concrete component and the manufacturing method thereof provided by the invention, the industrial level of a building structure is improved, the load-carrying capability is improved, and resources can be saved. The prefabricated reinforced concrete component can be applied to various wall body bearing structures.

Owner:初明进

Tire having sacrificial bridging

The present invention provides a pneumatic tire having a tread portion comprising a plurality of axially spaced apart essentially longitudinal grooves separating essentially longitudinal ribs. On at least one of said ribs, transverse grooves or cuts repeat in the circumferential direction to form first and second land portions wherein the first land portions comprise blocks having a circumferential length greater than that of the second land portions. Said second land portion acts as a sacrificial bridge which provides traction improvement and minimizes undesirable surface anomalies during the service life of the tire.

Owner:MICHELIN RECH & TECH SA

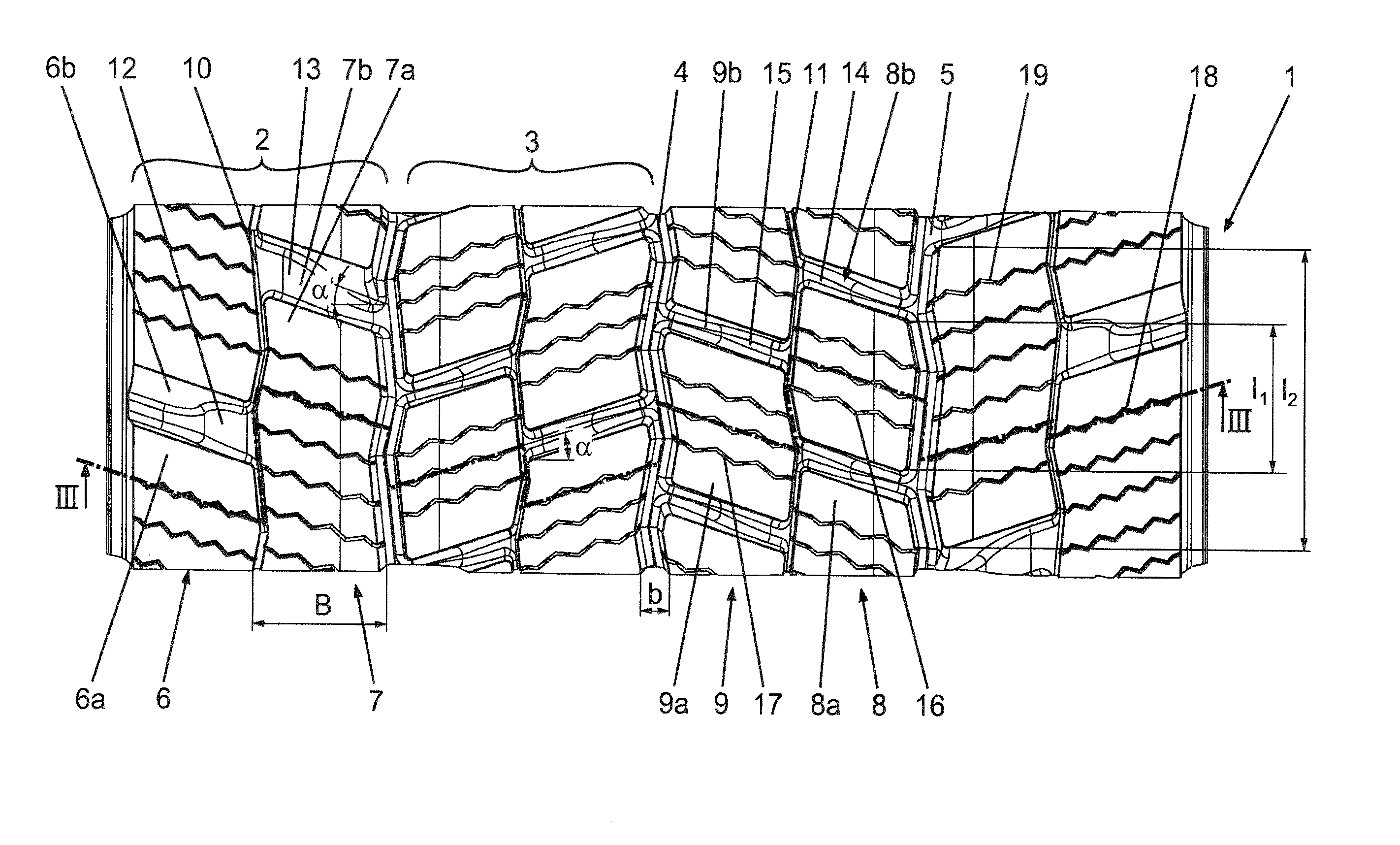

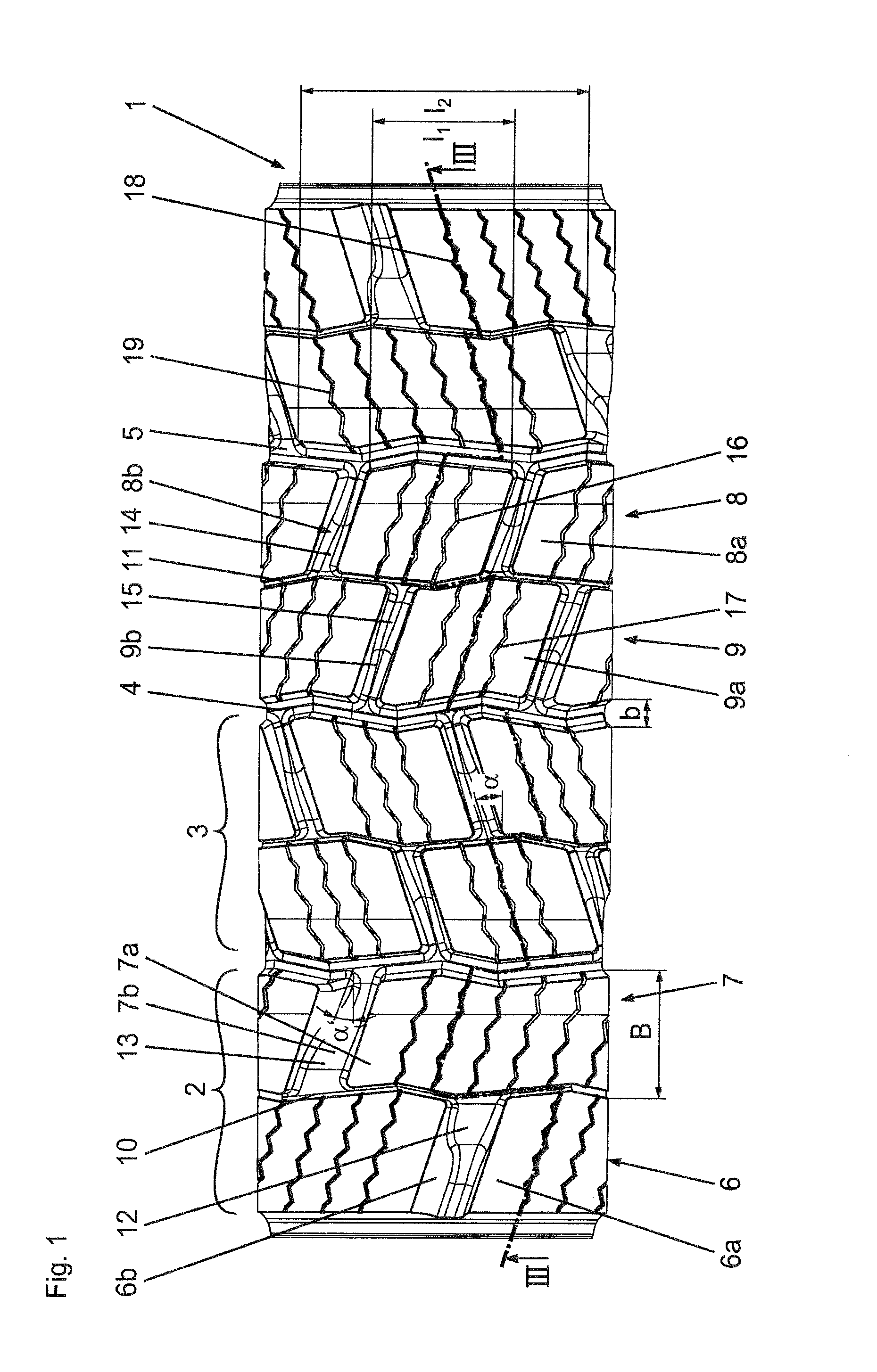

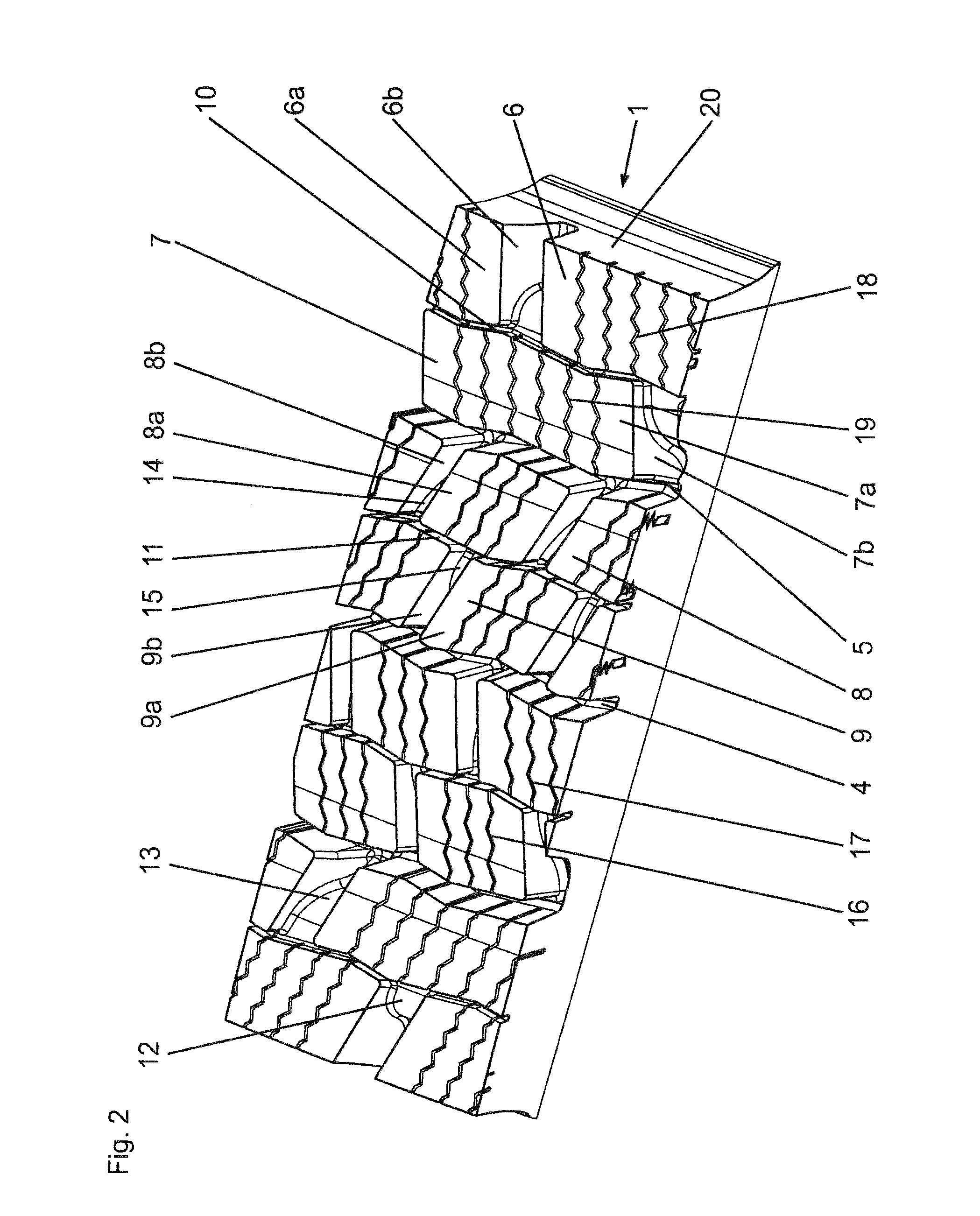

Pneumatic vehicle tire

ActiveUS20150251500A1Improve featuresGreat tractionHeavy duty tyresHeavy duty vehicleTransverse grooveEngineering

A vehicle tire has outer shoulders and two tread halves. The vehicle tire includes a tire tread having six block rows and a plurality of circumferential grooves. Mutually adjacent ones of the block rows are separated from each other by a corresponding one of the plurality of circumferential grooves. Each of the block rows has a plurality of individual blocks and the individual blocks of each of the block rows are separated from each other by mutually parallel essentially straight transverse grooves running at an angle to the axial direction of the tire. The circumferential grooves includes first circumferential grooves having a maximum profile depth and second circumferential grooves. The block rows are arranged such that each tread profile half has two pairs of block rows. The pairs of block rows of each tread profile half are separated from each other by a corresponding one of the first circumferential grooves. The block rows of each of the pairs of block rows are separated from each other by a corresponding one of the second circumferential grooves. The second circumferential grooves have a second profile depth less than the maximum profile depth. A first portion of the transverse grooves defines first outlet locations to the first circumferential grooves and a second portion of the transverse grooves has first outlet locations to the outer shoulders. The transverse grooves have a depth approximately corresponding to the maximum profile depth at the first outlet locations. The transverse grooves define second outlet locations to a corresponding one of the second circumferential grooves. The transverse grooves have a depth corresponding to the second profile depth at the second outlet locations.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

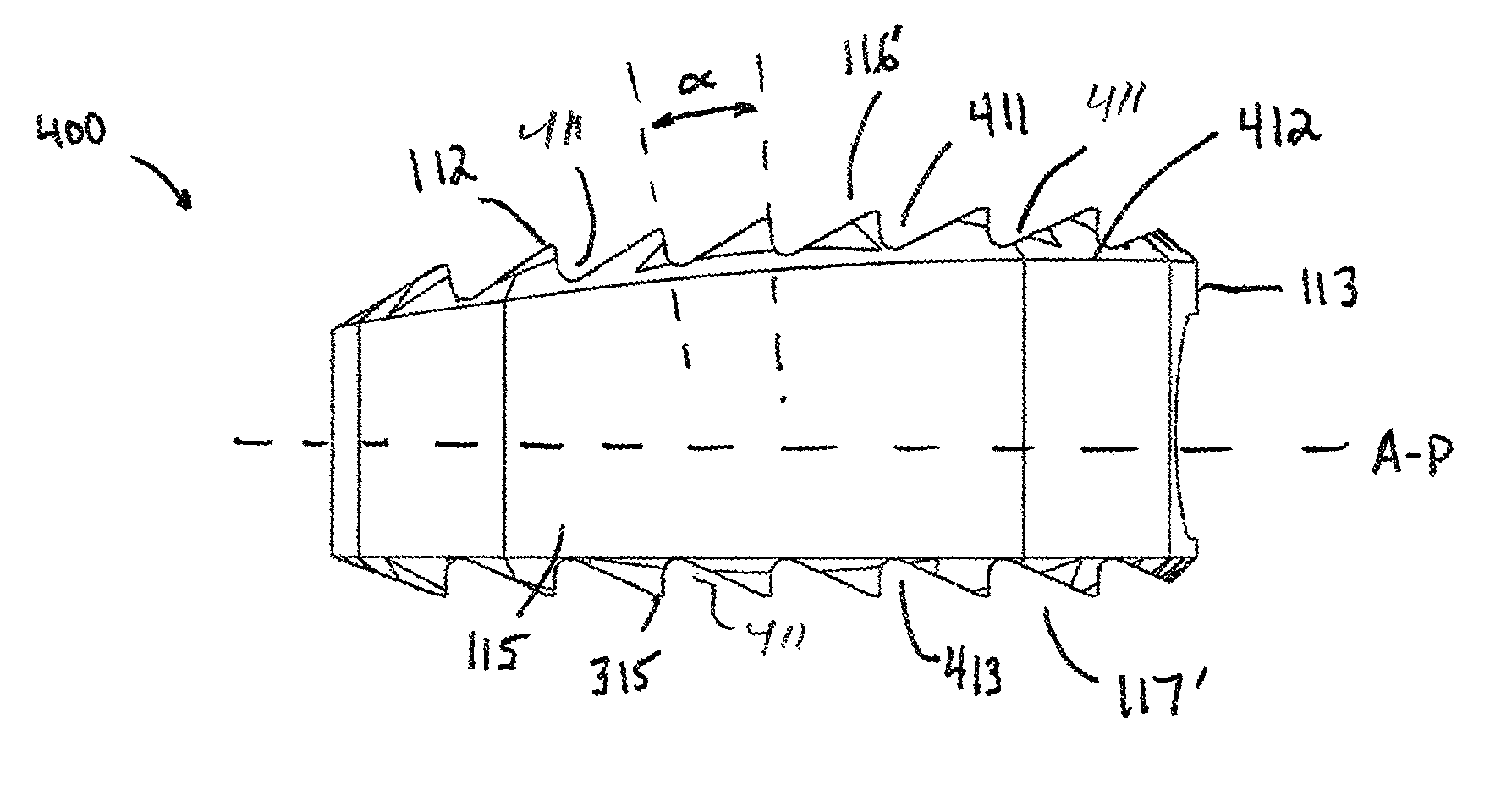

Wedge Osteotomy Device and Method Of Use

An orthopedic implant system includes a wedge implant. The implant includes a body having an upper surface extending generally in a first plane. The upper surface has a first plurality of longitudinal grooves and a second plurality of transverse grooves extending therealong. Portions of the upper surface extend between adjacent longitudinal grooves and transverse grooves form individual peaks. A lower surface extends generally in a second plane, parallel to the first plane. The lower surface has a third plurality of longitudinal grooves and a fourth plurality of transverse grooves extending therealong. Portions of the lower surface extend between adjacent longitudinal grooves and transverse grooves form individual peaks.

Owner:TYBER MEDICAL

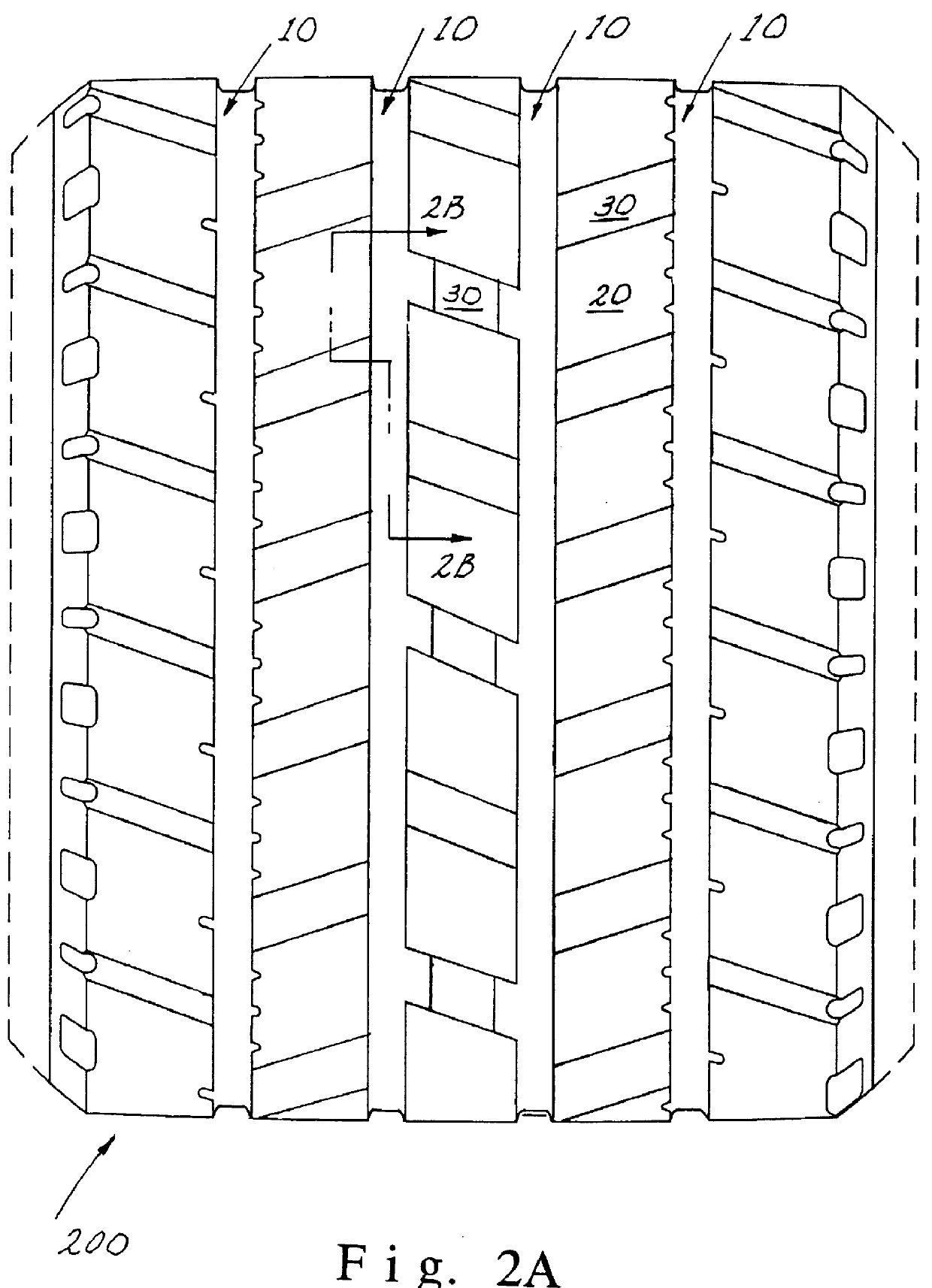

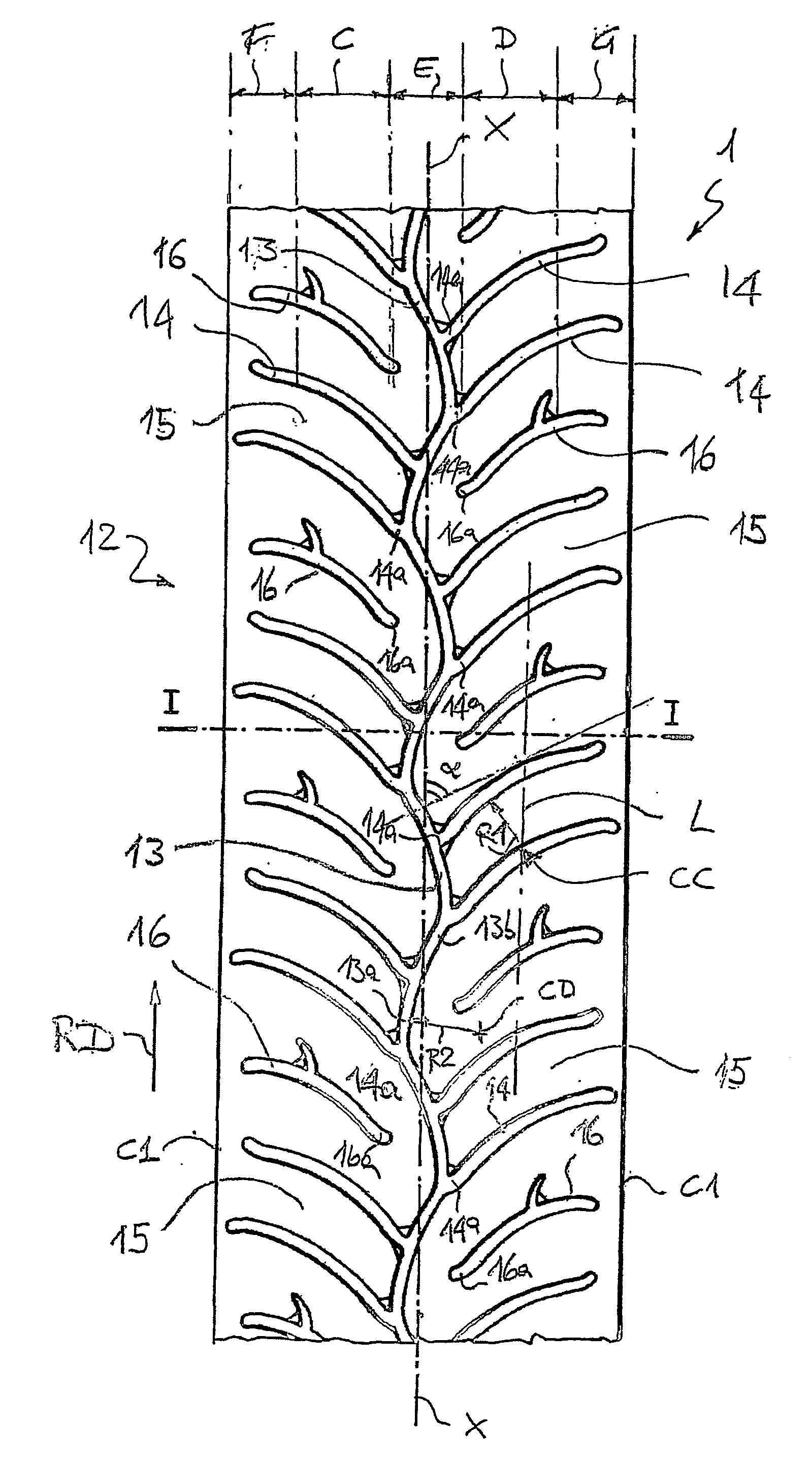

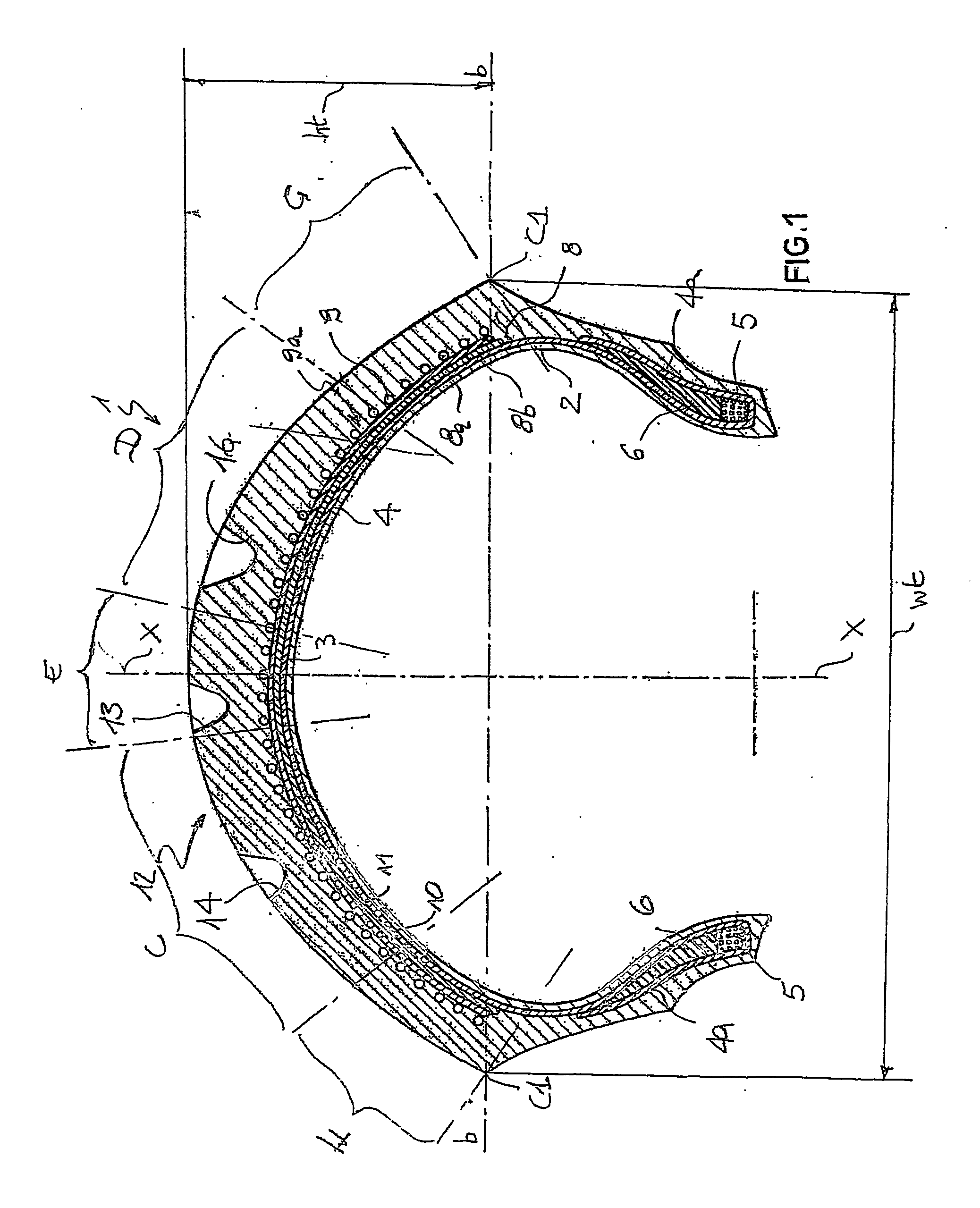

Tyre for vehicle wheels having improved tread pattern

InactiveUS20100132864A1Reduced flexibilityReduce noiseTyre tread bands/patternsNon-skid devicesTransverse grooveShoulder region

A tyre for vehicle wheels having a tread pattern includes: a) two circumferential grooves, which define a first and a second shoulder region, and one central region; b) a plurality of asymmetric transverse grooves having a substantially “V” shape, which extend for the whole width of the tread, including an alternate sequence of a first and a second asymmetric transverse groove defining an alternate sequence of a first and a second asymmetric module; and c) a plurality of lateral transverse grooves, which includes one first lateral transverse groove extending for the whole width of the first shoulder region and for a portion of the central region of the first asymmetric modules, and one second lateral transverse groove extending for the whole width of the second shoulder region and for a portion of the central region of the second asymmetric modules.

Owner:PIRELLI TYRE SPA

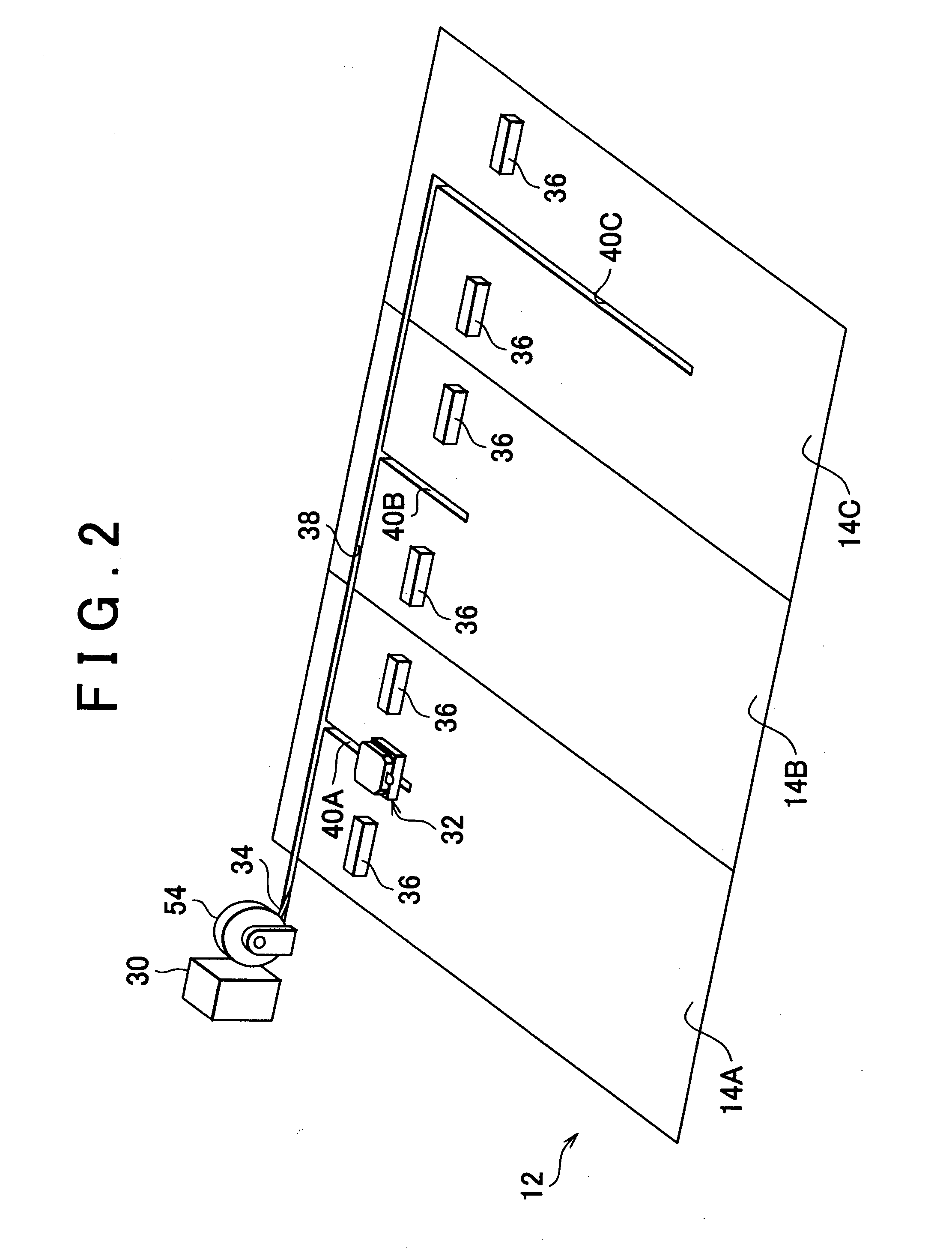

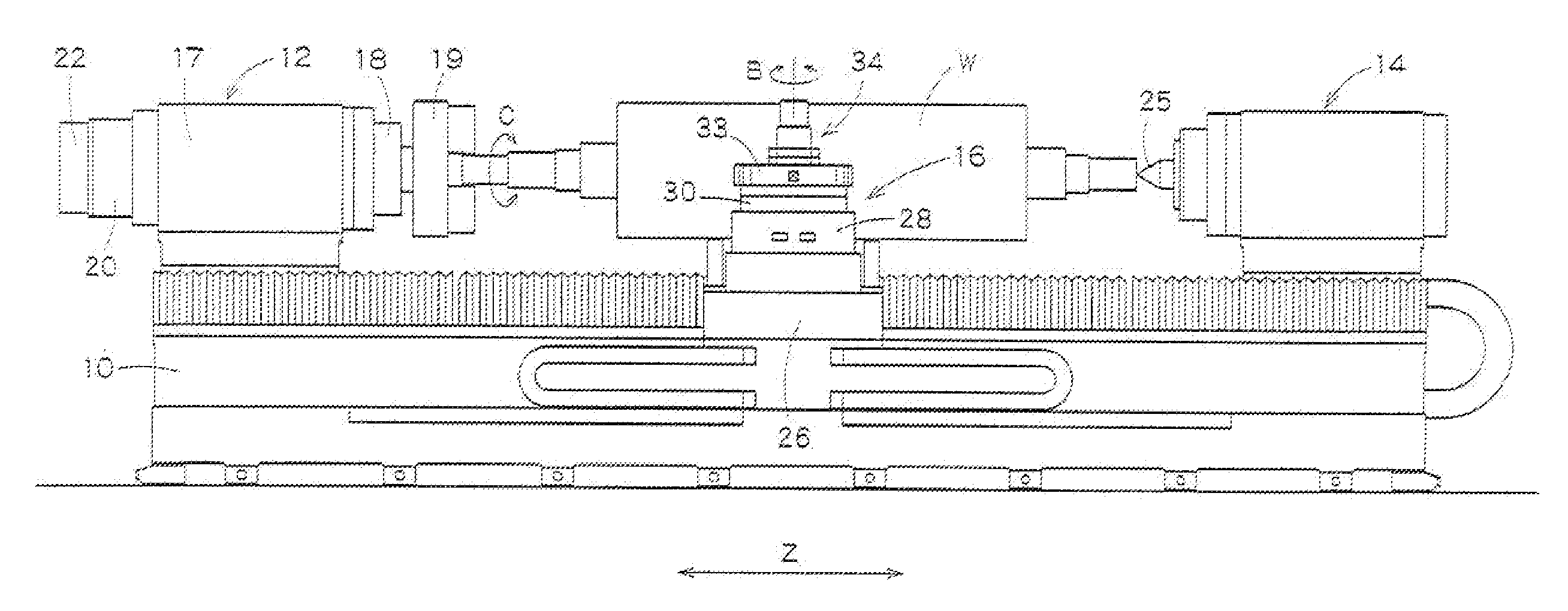

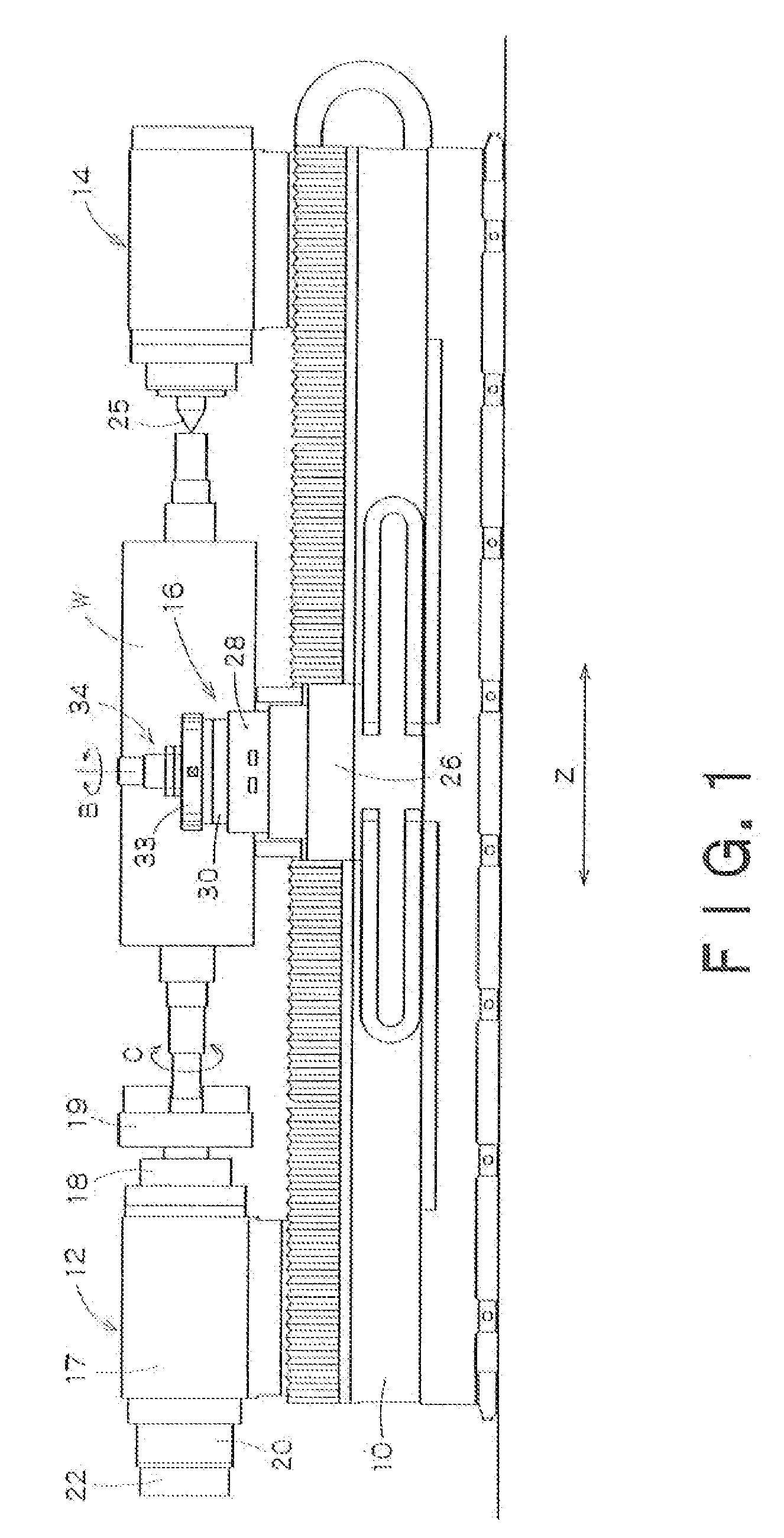

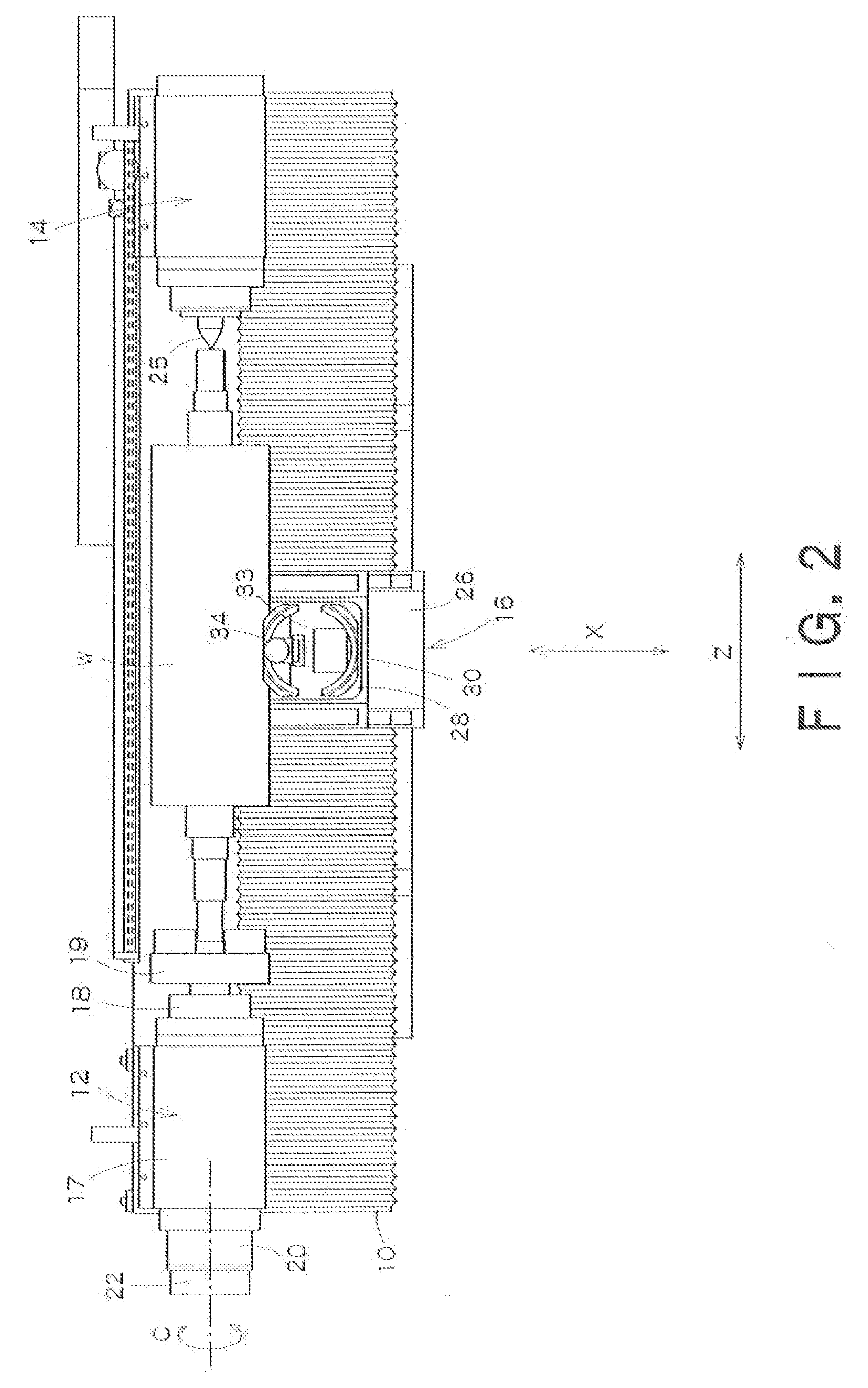

Precision roll turning lathe

ActiveUS20070251360A1High precision machiningAvoid low machining accuracyAutomatic/semiautomatic turning machinesPropelling pencilsTransverse grooveHeadstock

There is provided a precision roll turning lathe which can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface. The precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 34 and having a cutter spindle for rotating a fly cutter 39.

Owner:TOSHIBA MASCH CO LTD

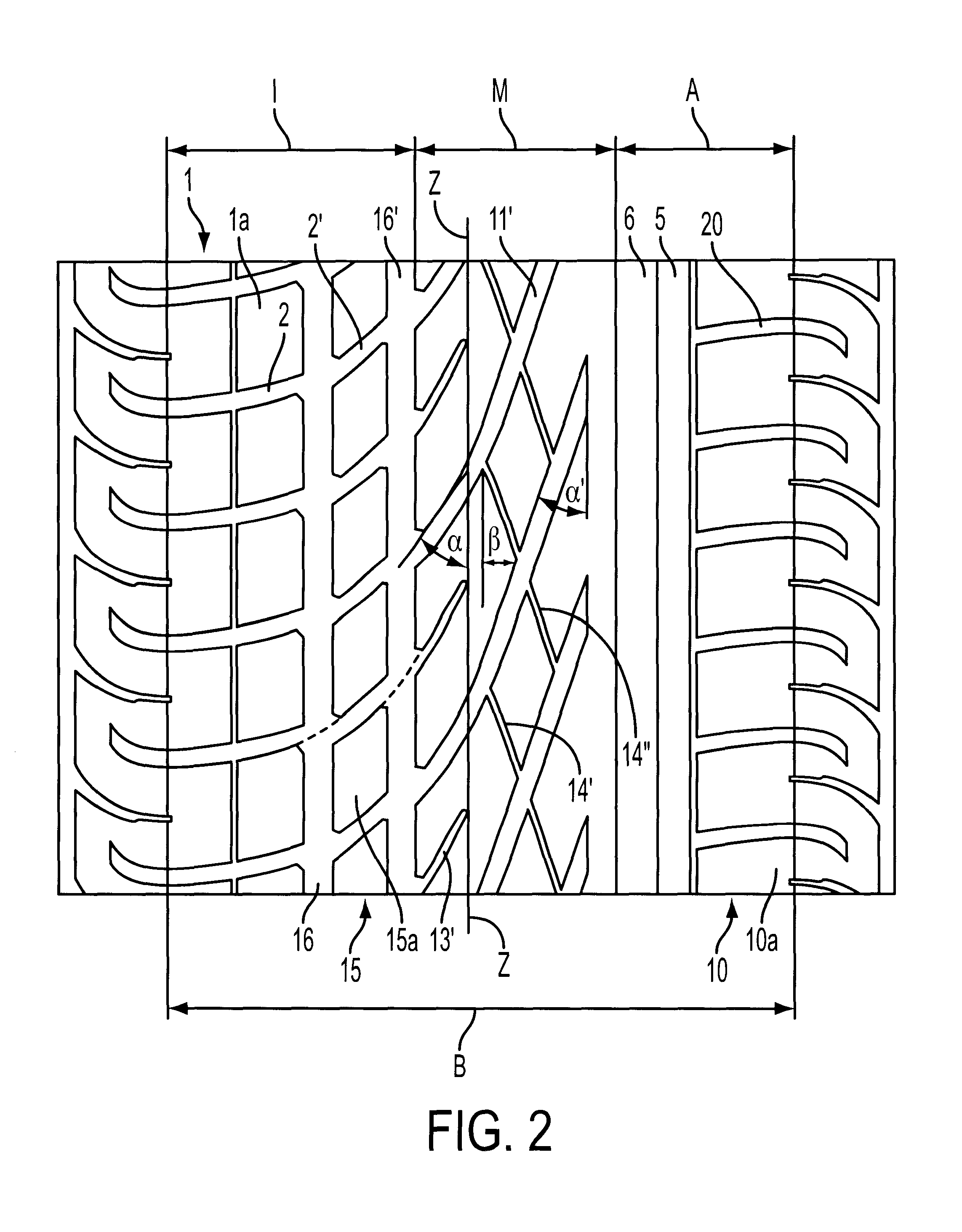

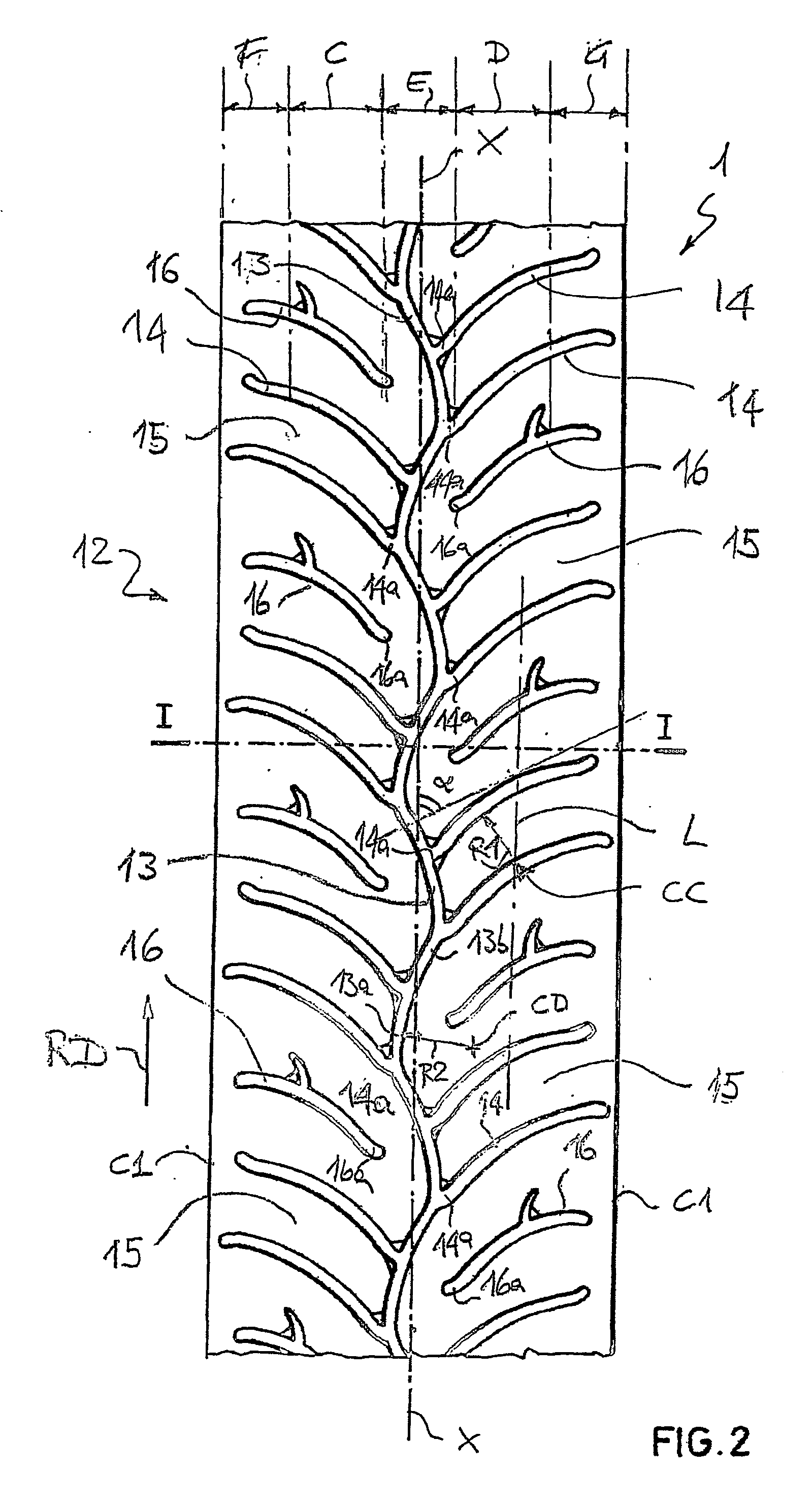

Pair of front and rear pneumatic tires for motorcycles and method of improving the performance on both wet and dry ground of a motorcycle equipped with said pair

InactiveUS20060219342A1Improve performanceMotorcycle tyresTyre tread bands/patternsMotorcycle tyreTransverse groove

A pair of motorcycle tires includes front and rear tires. The front tire's tread band includes at least one circumferential groove and a plurality of transverse grooves. The at least one circumferential groove extends at an equatorial plane of the front tire within a central zone of the tread band. The transverse grooves include axially inner ends lying within the central zone that alternately extend from the central zone toward axially opposite shoulder zones. At least some of the transverse grooves are connected to the at least one circumferential groove. The rear tire's tread band includes an area defining a substantially null sea / land ratio within a central zone of the tread band. The central zone of the rear tire's tread band has a width greater than or equal to about 5% and less than or equal to about 30% of an axial development of the rear tire's tread band.

Owner:PIRELLI TYRE SPA

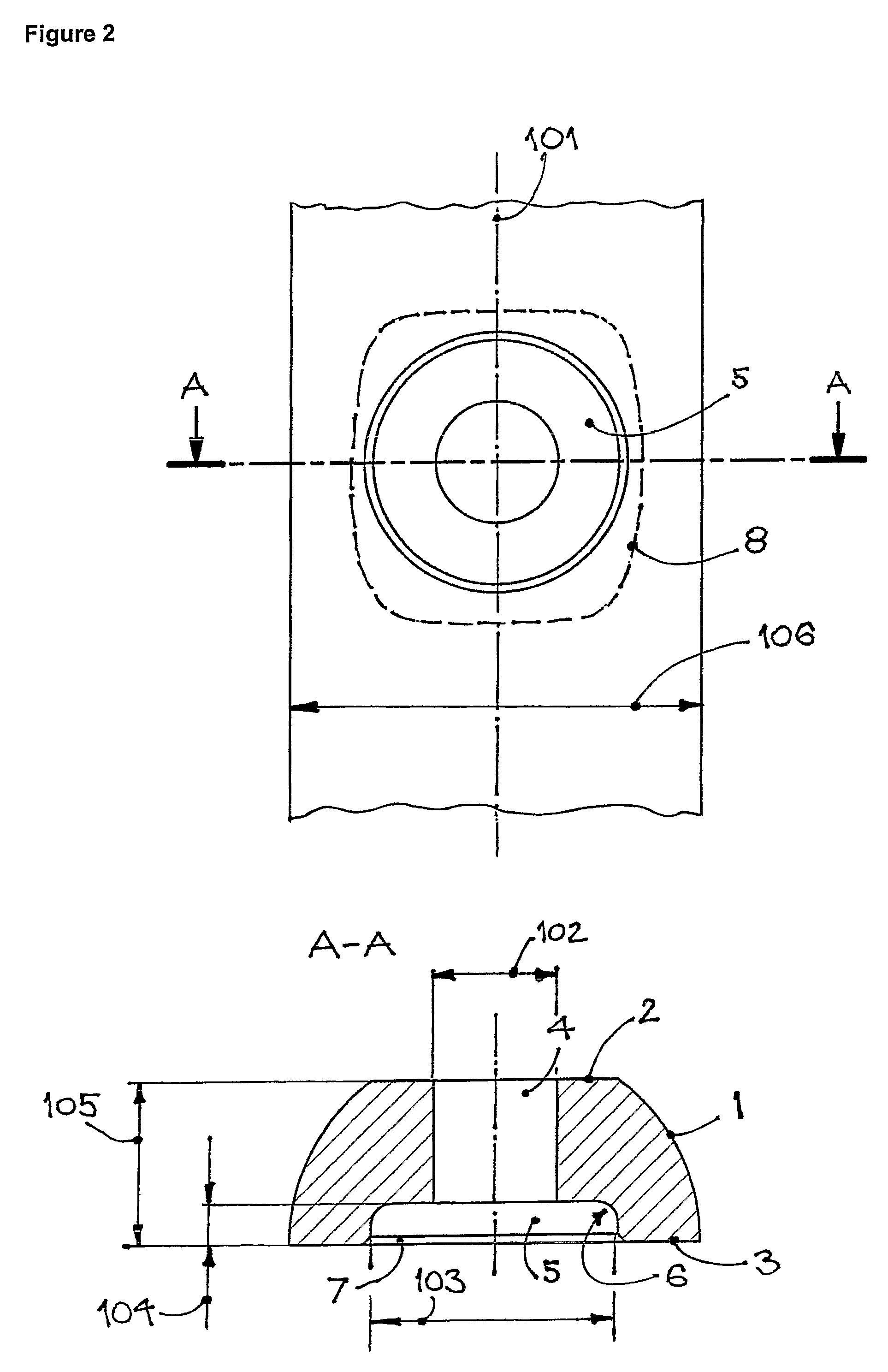

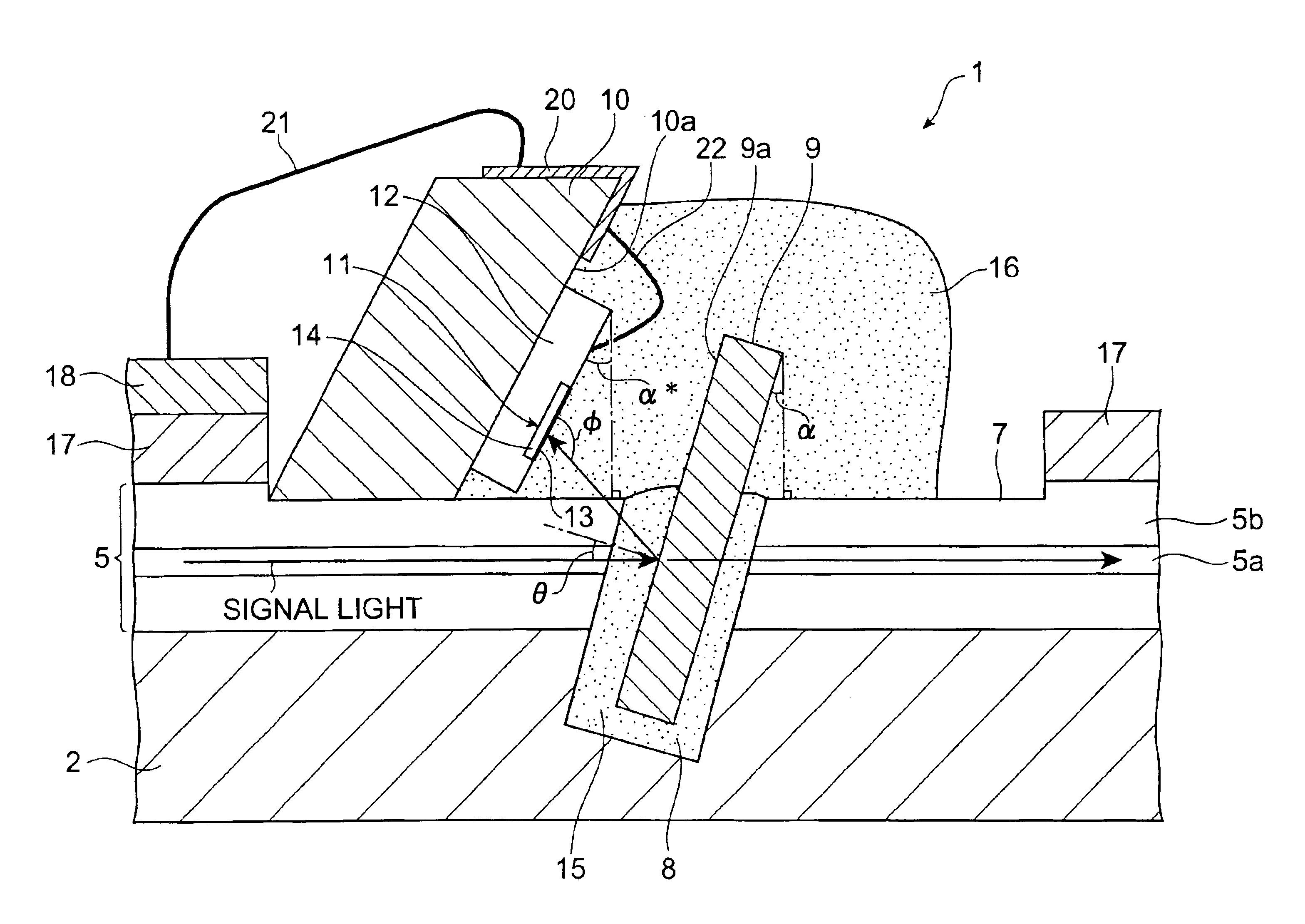

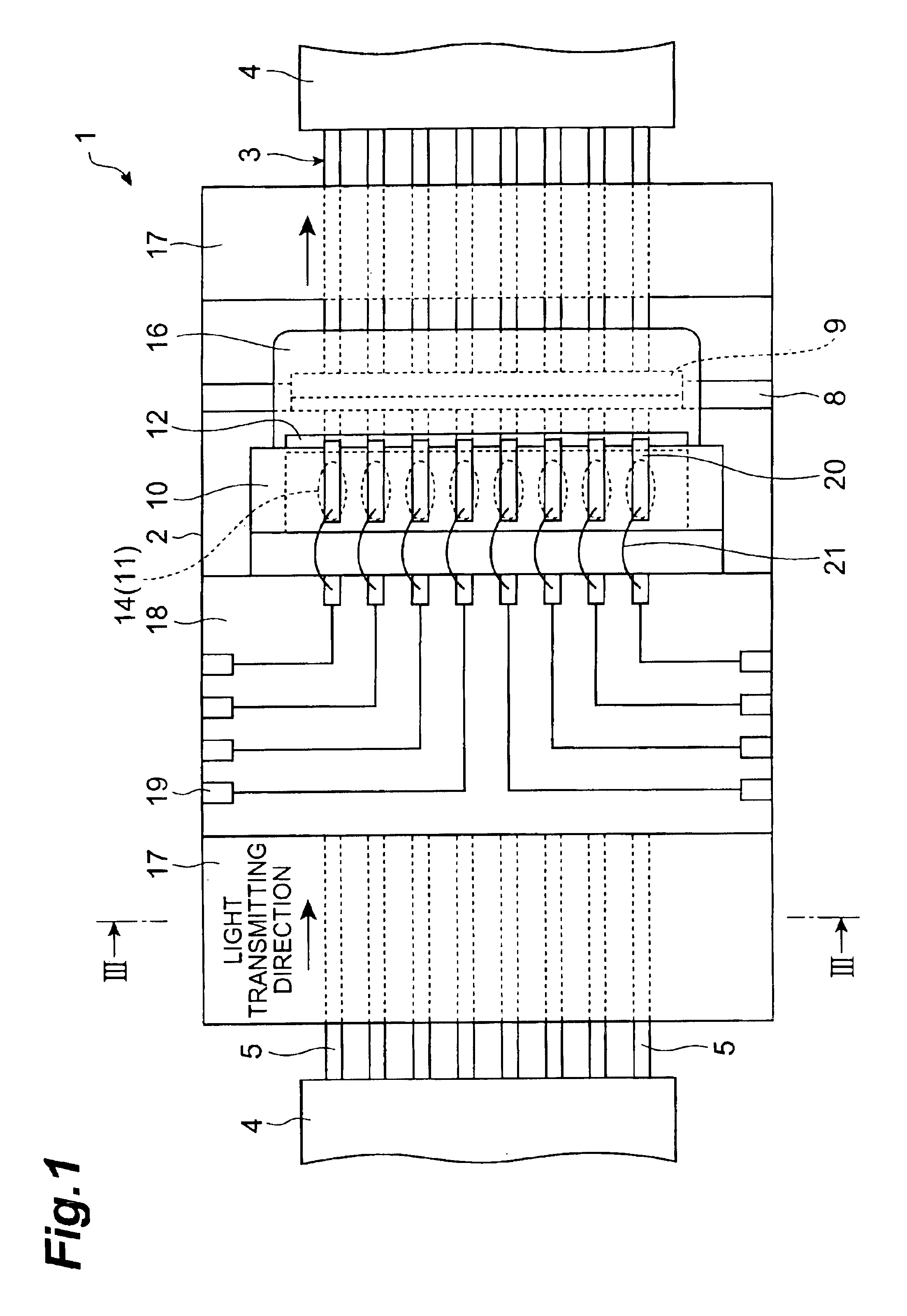

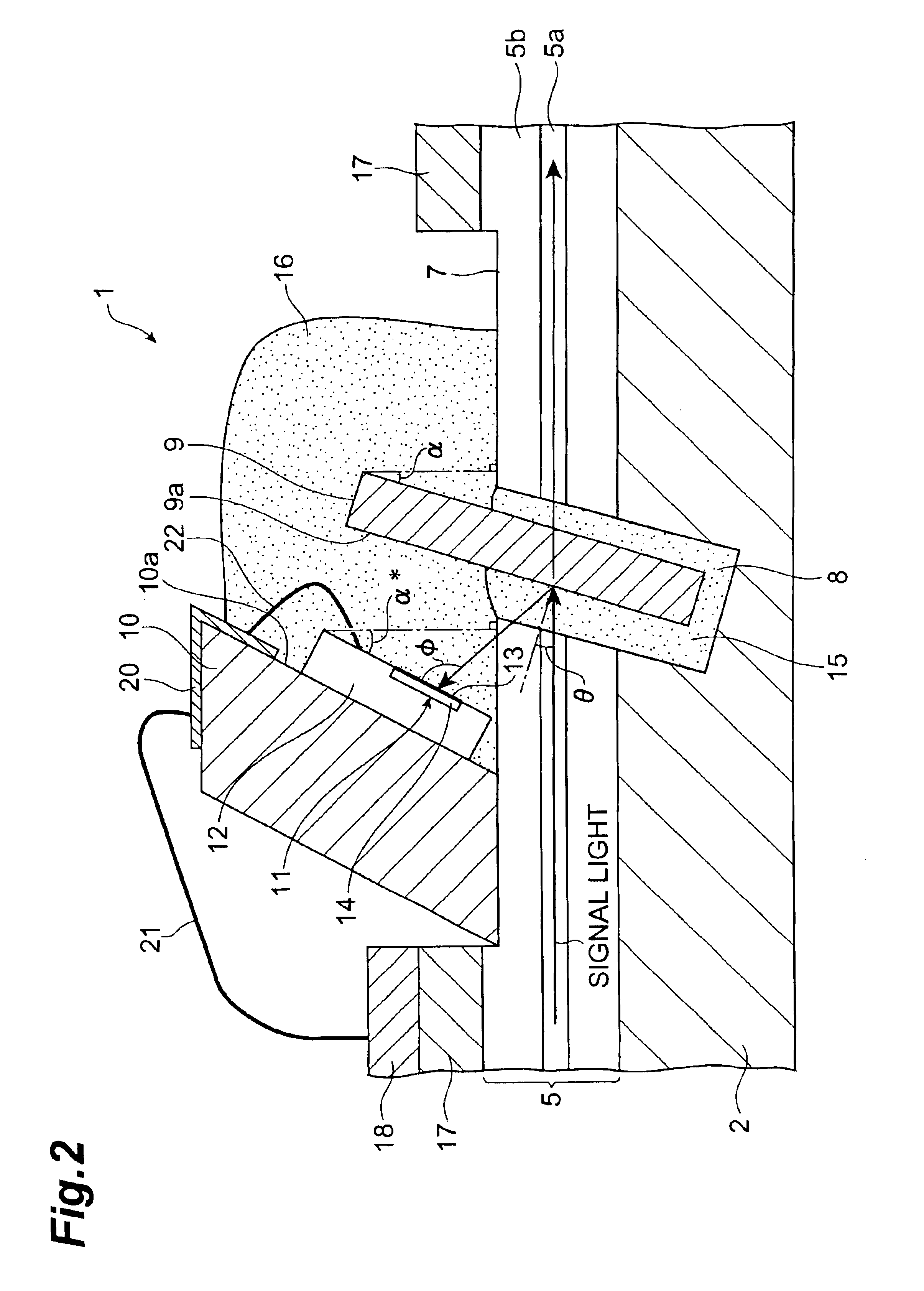

Optical device

InactiveUS6850674B2Deterioration of characteristicCheap to achieveLaser detailsCoupling light guidesPhotovoltaic detectorsPhotodetector

An optical device 1 has a substrate 2, whereas bare fibers 5 exposed from a coated optical fiber tape 3 by removing a coating 4 from its middle part are secured to the upper face part of the substrate 2. In the substrate 2, a transverse groove 8 is formed obliquely with respect to an axis of the bare fibers 5 so as to traverse core parts 5a of the bare fibers. An optical member 9 for reflecting a part of signal light transmitted through the bare fibers 5 is inserted in the transverse groove 8. A support member 10 is provided on the upper side of the bare fibers 5, whereas a support surface 10a of the support member 10 is provided with photodetectors 11 for detecting light reflected by the optical member 9. The support surface 10a of the support member 10 is inclined with respect to the upper face of the substrate 2, whereby the light entrance surface 13 of each photodetector 11 is inclined by a predetermined angle with respect to the upper face of the substrate 2. Such a configuration realizes an optical device which can lower the polarization dependence of received light in the photodetectors.

Owner:SUMITOMO ELECTRIC IND LTD

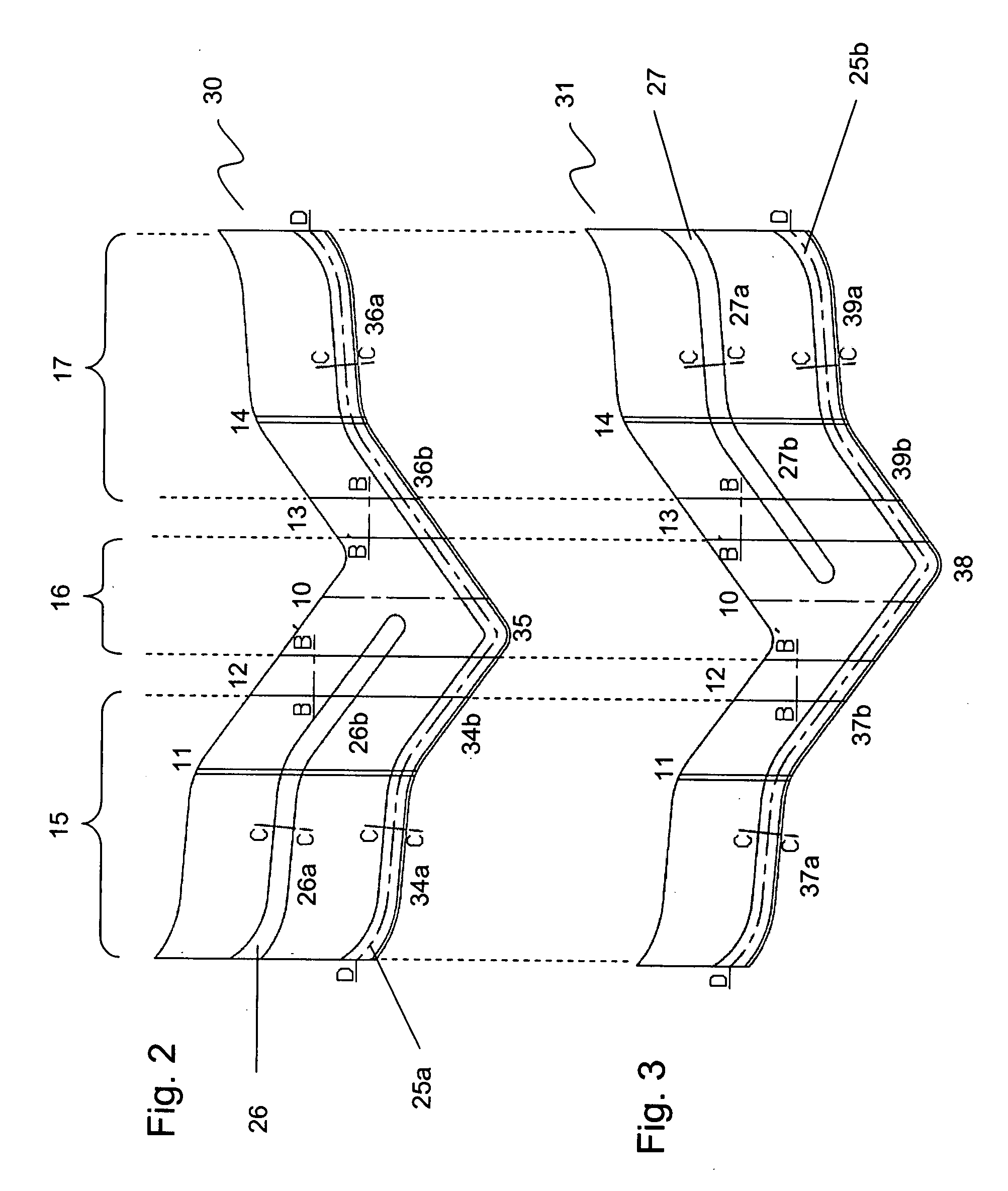

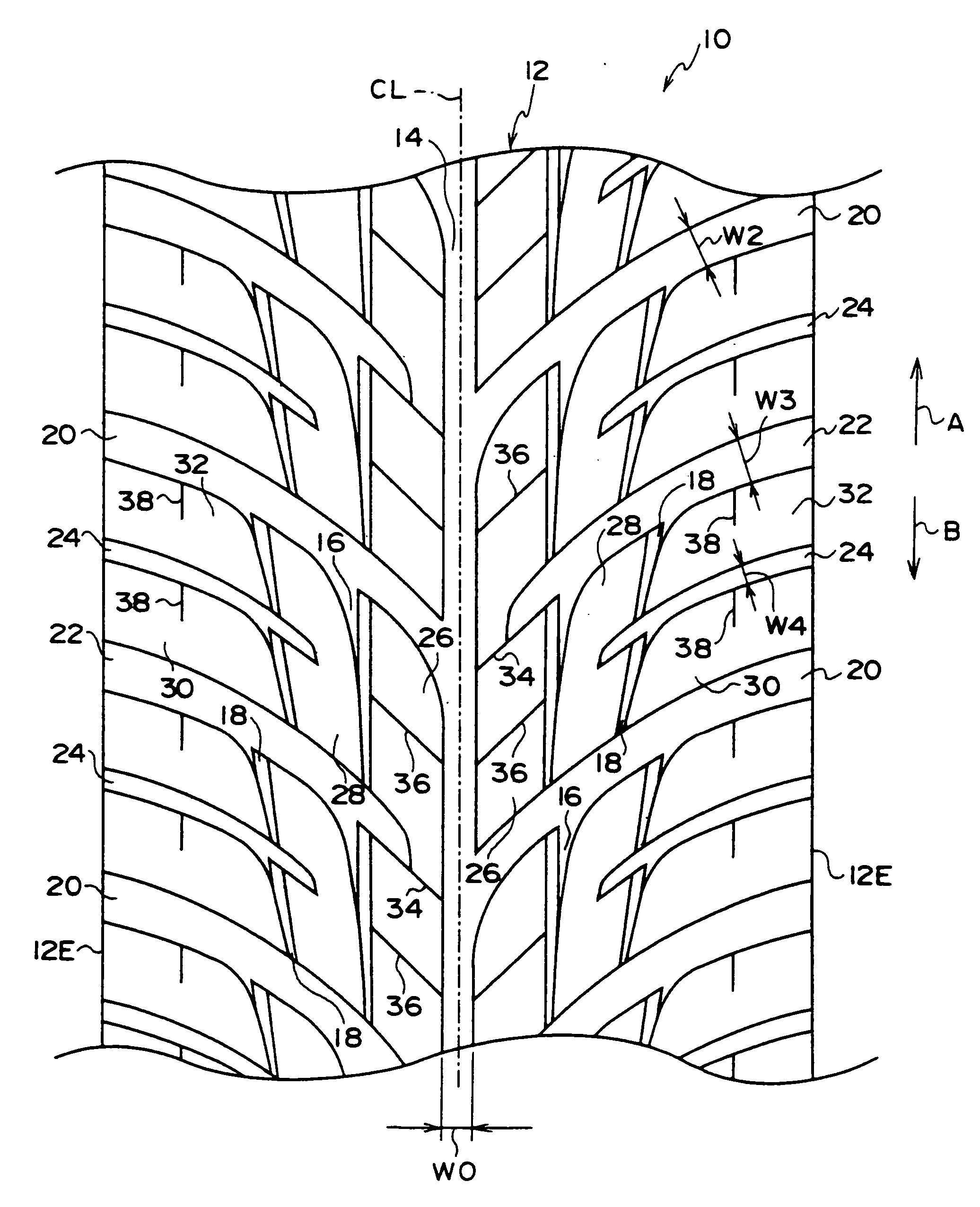

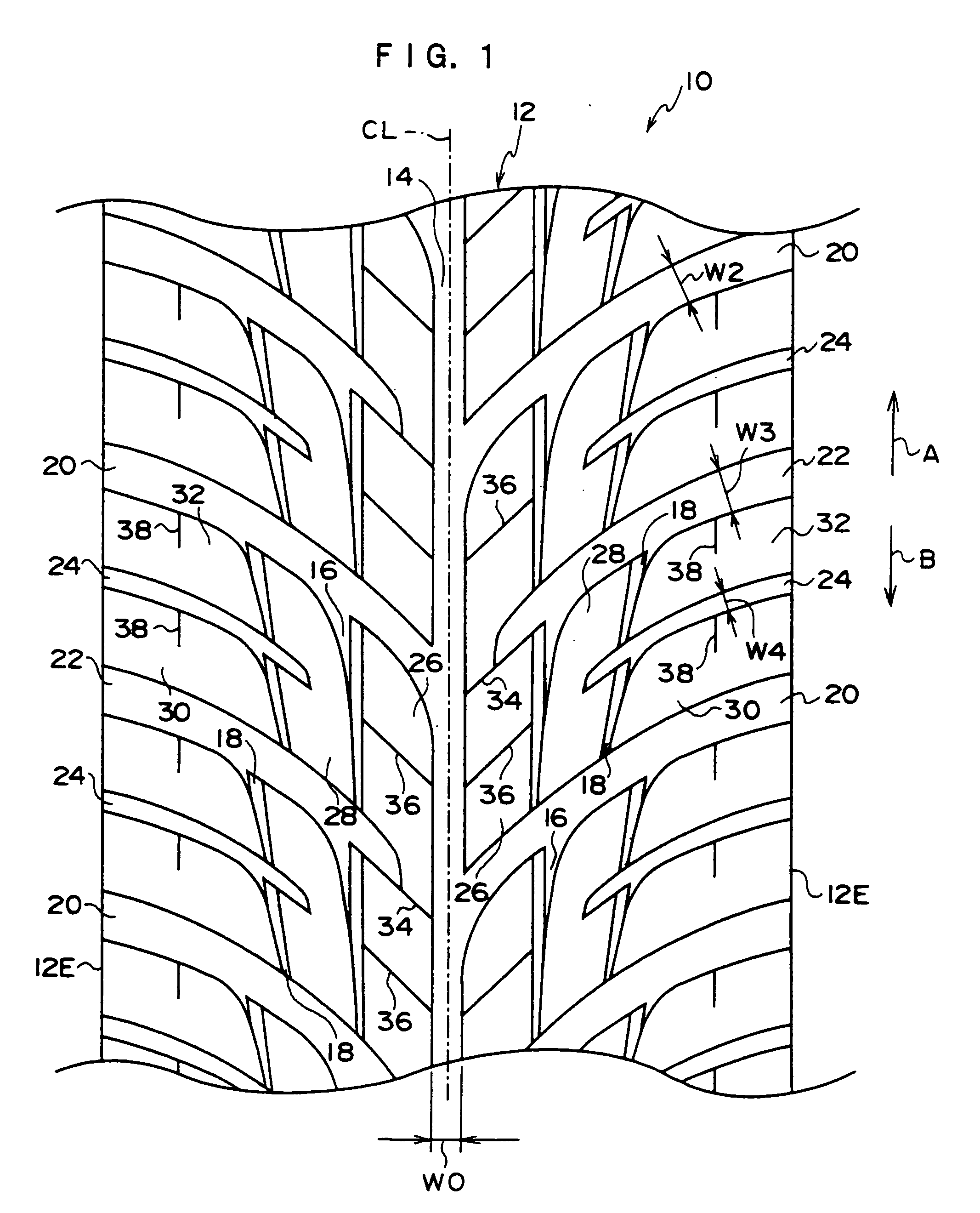

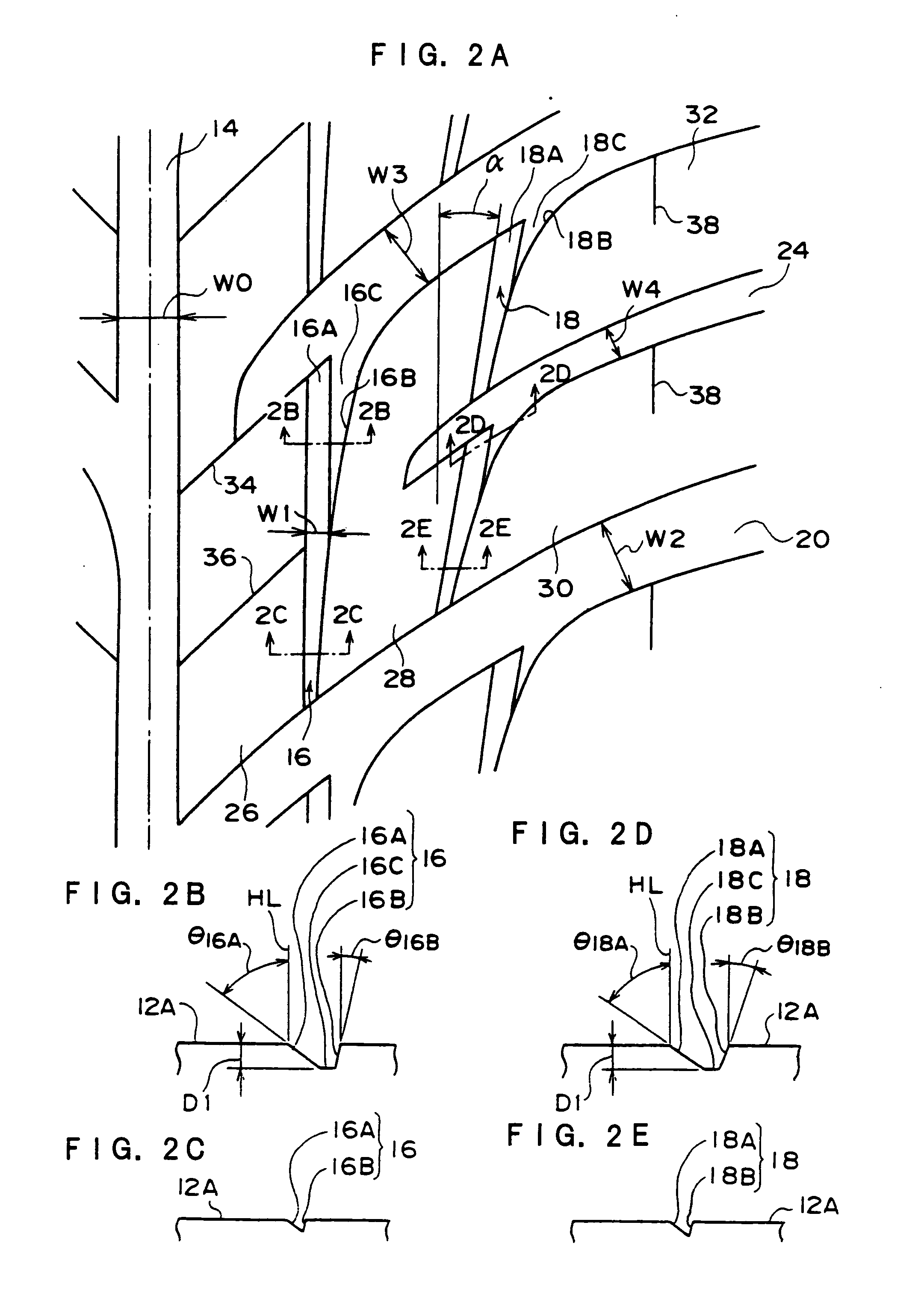

Pneumatic Tire

InactiveUS20070215258A1Good effectHigh wet drainage performanceTyre tread bands/patternsNon-skid devicesTransverse grooveWear resistant

The present invention provides a pneumatic tire which can obtain a high wet drainage performance, roadholding ability, and wear-resistant property without sacrificing other capabilities A directional pattern is formed by a circumferential wide major groove 14, a first narrow circumferential minor groove 16, a second narrow circumferential minor groove 18, a first transverse groove 20, a second transverse groove 22, and a third transverse groove 24. The circumferential wide major groove 14 is provided in a center region in a tire width direction of a tread 12. The first narrow circumferential minor groove 16 is arranged on the outside in a tire axis direction of the circumferential wide major groove 14. The second narrow circumferential minor groove 18 is arranged on the outside in the tire axis direction of the first narrow circumferential minor groove 16. The first transverse groove 20 is extended from a tread end 12E and coupled to the circumferential wide major groove 14. The second transverse groove 22 is arranged between the first transverse grooves 20, and the second transverse groove 22 is extended from the tread end 12E and terminated while not coupled to the circumferential wide major groove 14. The third transverse groove 24 is arranged between the first transverse groove 20 and the second transverse groove 22, and the third transverse groove 24 is extended from the tread end 12E and terminated between the first narrow circumferential minor groove 16 and the second narrow circumferential minor groove 18. Therefore, in wet road surface driving, the water between the pneumatic tire and a road surface flows efficiently into each groove to obtain high wet performance. Because the high wet performance is obtained while an increase in negative ratio is suppressed, a wheel tread area of a block is secured to improve a wear-resistant property. A circumferential length of a second block 28 becomes a substantial half of a first block 26, and circumferential lengths of a stepping-on side third block 30 and a kickout side third block 32 become a substantial half of the second block 28. Therefore, a wet drainage property can be improved on both sides of the tread while block rigidity is increased on a tread central region to improve traction performance, brake performance, and cornering performance. Furthermore, when the pneumatic tire of the invention is used in a front wheel, handling performance is improved by increasing the block rigidity in a central region in the tire axis direction. Widths and depths of the first narrow circumferential minor groove 16 and second narrow circumferential minor groove 18 are decreased from a kickout side toward a stepping-on side of the block in a range where the block is zoned by the first and second narrow circumferential minor grooves 16 and 18. Therefore, the block rigidity is increased on the stepping-on side of the blocks located on both sides of the first and second narrow circumferential minor grooves 16 and 18, and thereby the traction performance, brake performance, and cornering performance are improved.

Owner:BRIDGESTONE CORP

Umbrella quick frame assembly systems and methods

ActiveUS20130276843A1Quick assemblySimple and flexible assemblyWalking sticksUmbrellasTransverse grooveEngineering

An umbrella hub is provided that comprises an inner portion, an outer periphery, a lower portion and an upper portion. A plurality of vertical grooves is disposed in the outer periphery and is configured to receive umbrella ribs or struts. A plurality of grooves extends transverse to the vertical grooves. A retention member is disposed in each of the transverse grooves. A first configuration of the hub permits deflection of the retention member such that a transverse pin coupled with the umbrella ribs or struts can be inserted into the transverse groove in which the retention member is disposed. A second configuration of the hub prevents deflection of the retention member such that inadvertent withdrawal of the pin from the transverse groove in which the retention member is disposed is prevented.

Owner:OLIVER JOEN AN MA

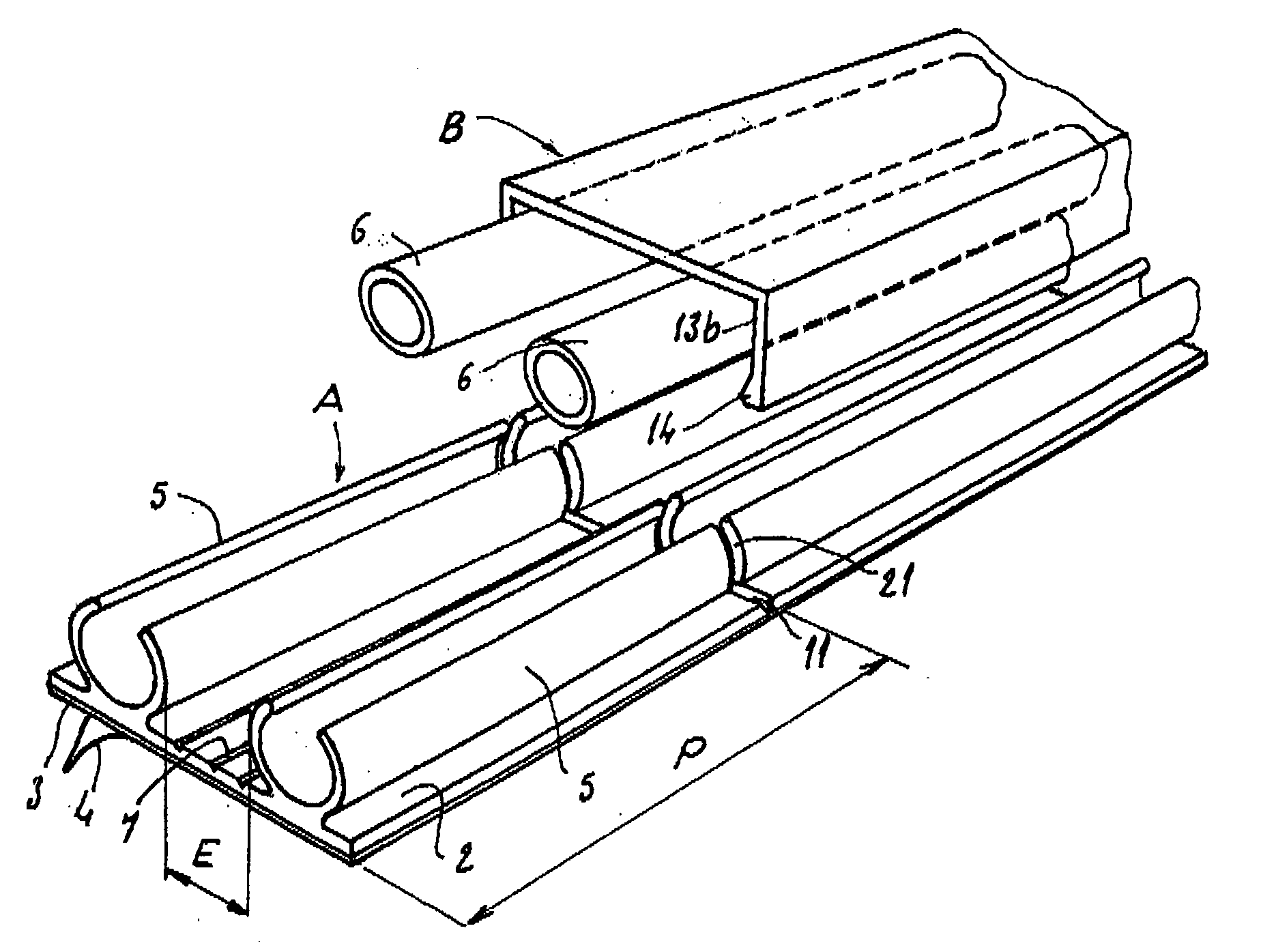

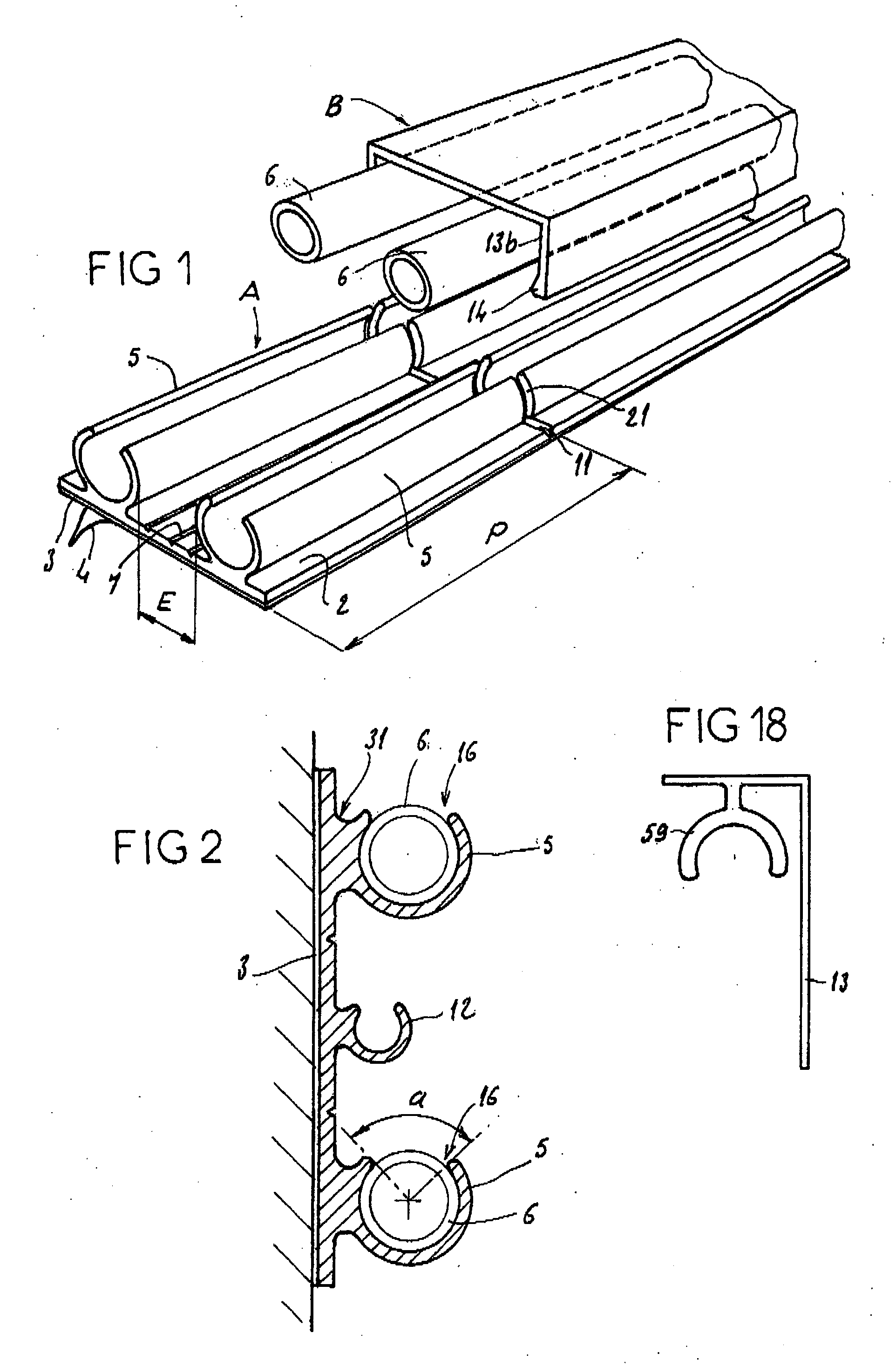

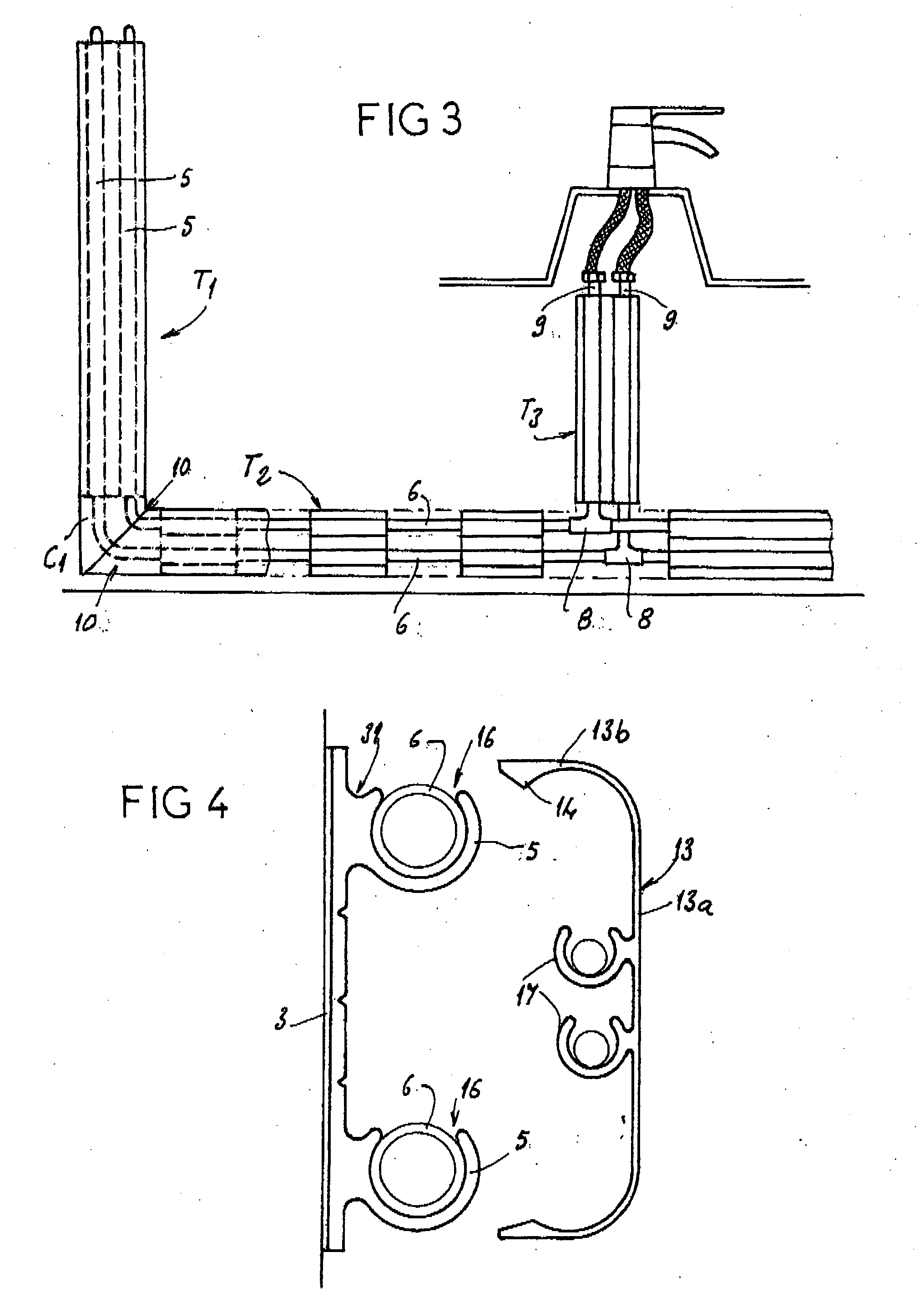

Device for laying and fixing pipes for various circuits, domestic or industrial

InactiveUS20050120652A1Simplify the installation processLow costPipe supportsElectrical apparatusTransverse grooveEngineering

The invention concerns a device comprising a profiled section A made of plastic material with a base plate (2) whereof the reverse side is equipped with means for adhesive fixing (3) against a wall and the face is provided with elastically deformable wings defining in pairs longitudinal troughs (5) with C-shaped cross-section, arranged projecting and transversely spaced apart from one another, at least one of the wings of each trough being integral with the base plate and made of the same semirigid material. The base plate (2) is divided into sections by cleavable or precut transverse lines, coincident with transverse grooves (21) provided in the trough (5), to form in the profiled section independent laying supports. A finish profiled section made of plastic material B provided with snap-on fixing means on the trough (5), is longitudinally cleavable to cover one or several laying supports and the associated pipes (6).

Owner:CACCIANI FABIEN +1

Air-permeable shoe

InactiveUS20070028483A1Effective ventilationImprove breathabilityFootwearTransverse grooveEngineering

Owner:MORITA MIYATA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com