Attachment assembly for firearm handguard and method of attaching handguard to a firearm

a technology of handguards and attachment assemblies, which is applied in the direction of traveller's bags, butts, travelling articles, etc., can solve the problems of handguards being prone to loosening or separating from the firearm, handguards being loose or detached, and posing a risk of injury to users, so as to reduce the movement of handguards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

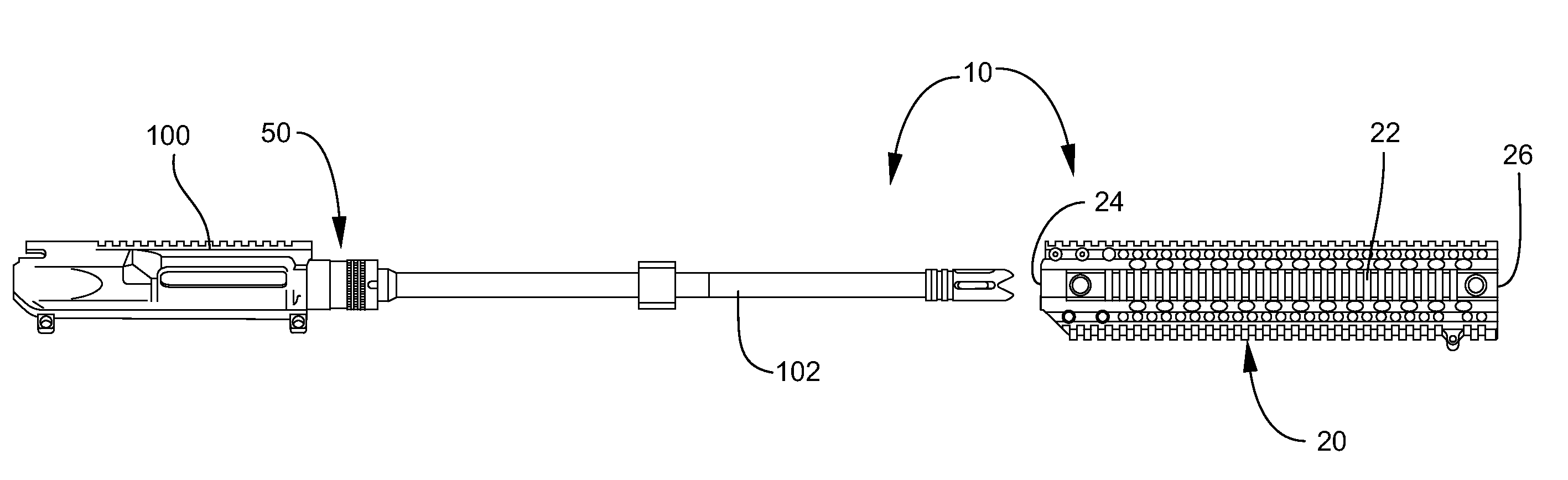

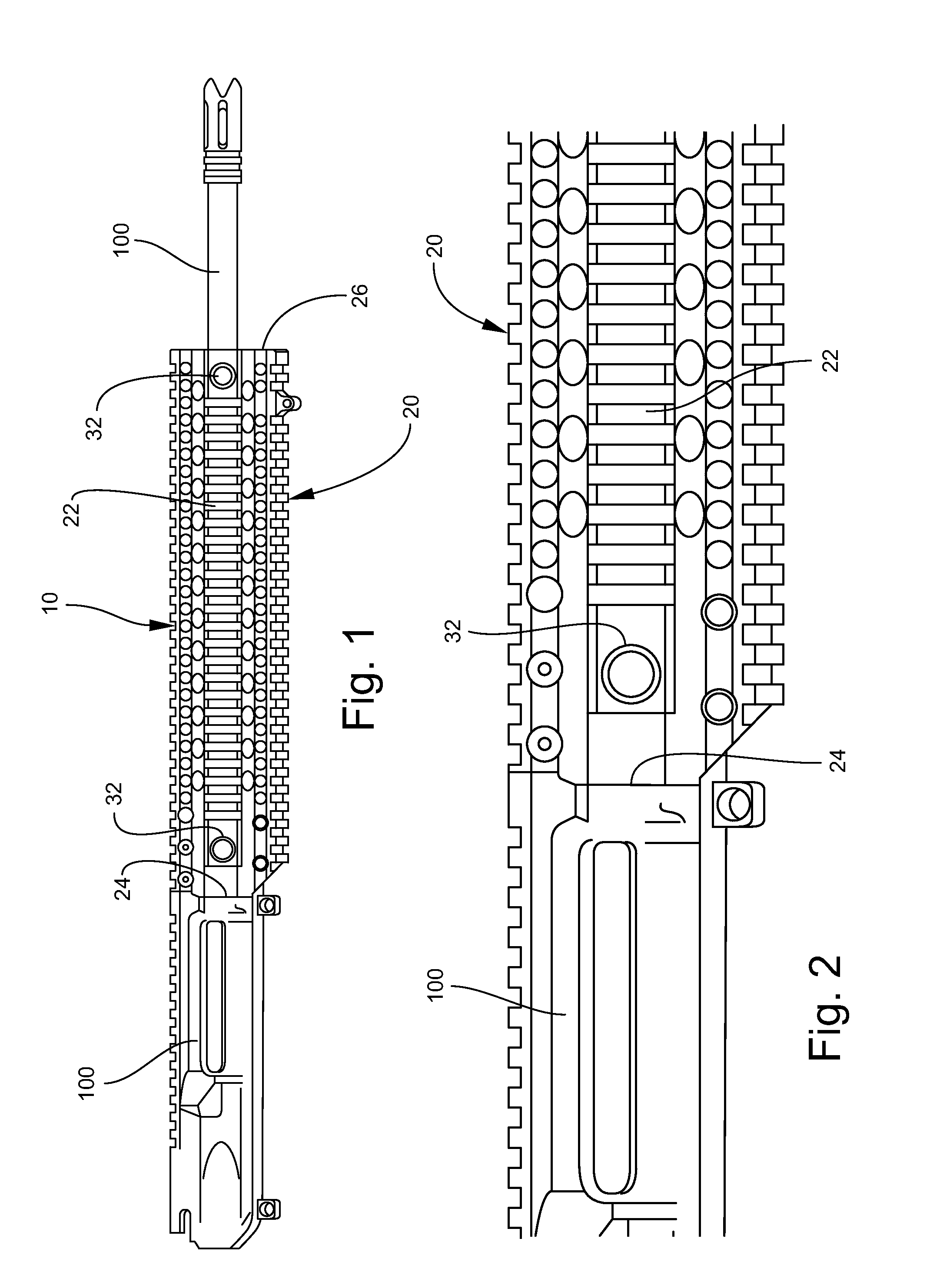

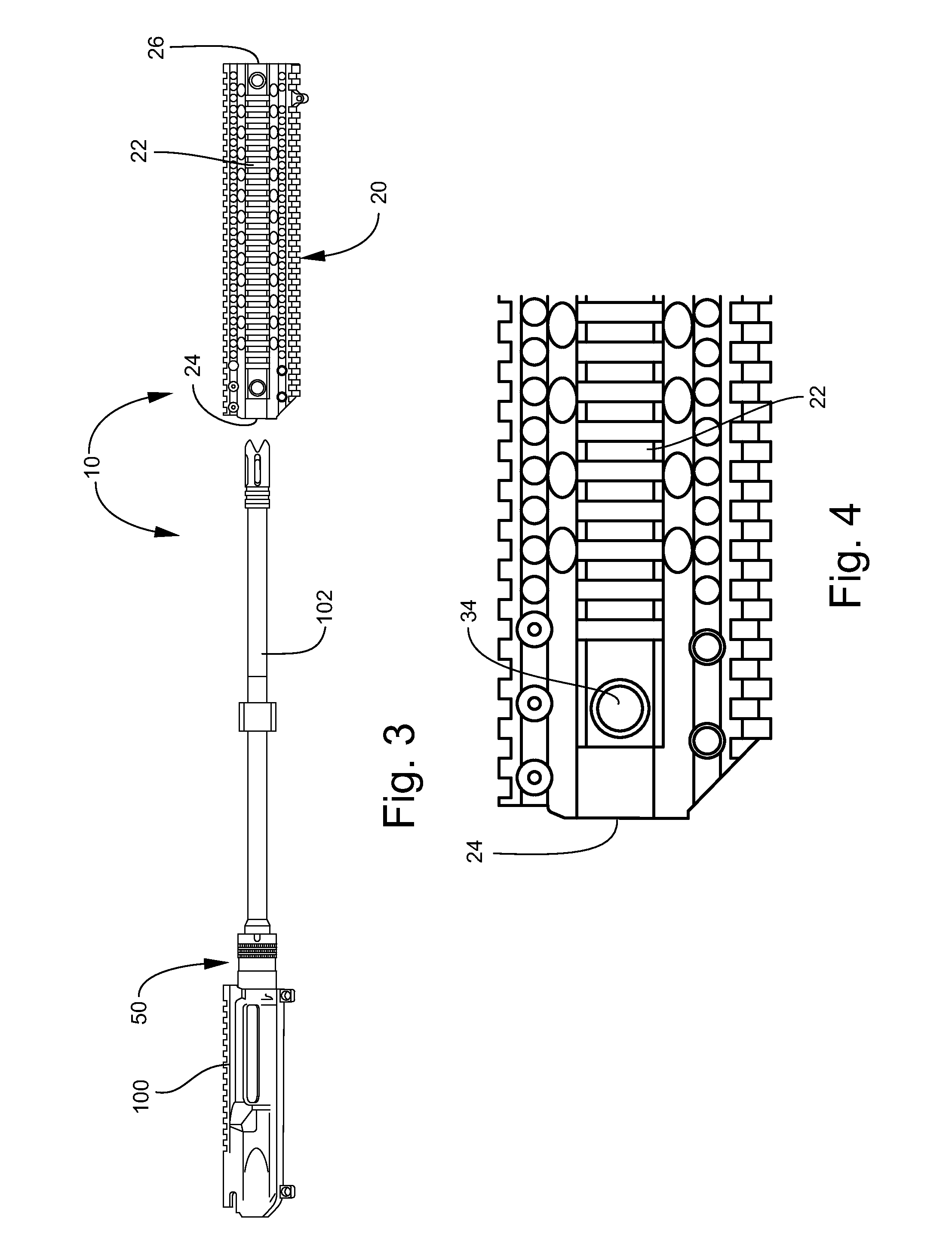

[0040]An attachment assembly for a firearm handguard according to a preferred embodiment of the invention is illustrated in FIGS. 1-3, and shown generally at reference numeral 10. As shown in FIG. 3, the handguard attachment assembly 10 comprises a barrel nut 50 for attaching a handguard 20 to a firearm's upper receiver 100. The handguard 20 includes an elongate rail section 22 with an open receiving end 24 and an open exit end 26, located at opposite longitudinal ends of the rail section 22.

[0041]As shown in FIGS. 5 and 6, the barrel nut 50 is mounted on the barrel 102 of the firearm upper receiver 100. Preferably, the barrel nut 50 is made of steel and can be about 0.875 inch to 8.000 inches in length. Most preferably, the barrel nut 50 is two inches long. As shown in FIGS. 6 and 7, the barrel nut 50 comprises a first section 52 having interior female threads for mating with male threads of the firearm's upper receiver 100. A second section 56 of the barrel nut 50 receives the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com