Cassette for dispensing flexible tubing therefrom

a cassette and flexible tubing technology, applied in the field of cassettes, can solve the problems of cassettes being installed upside down, sanitary and odor problems, and affecting the quality of the product, and achieve the effect of minimizing the likelihood of improper installation of cassettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

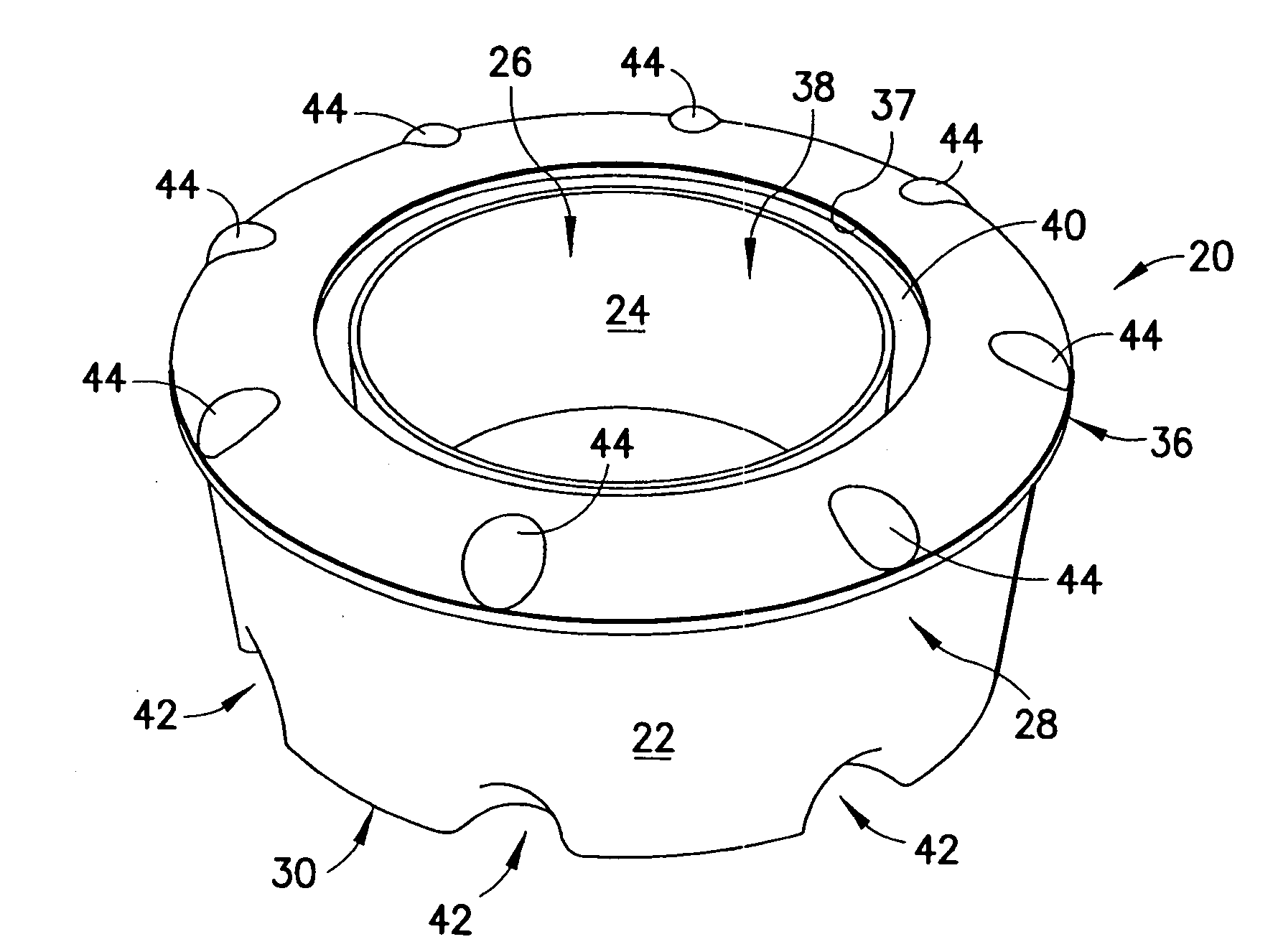

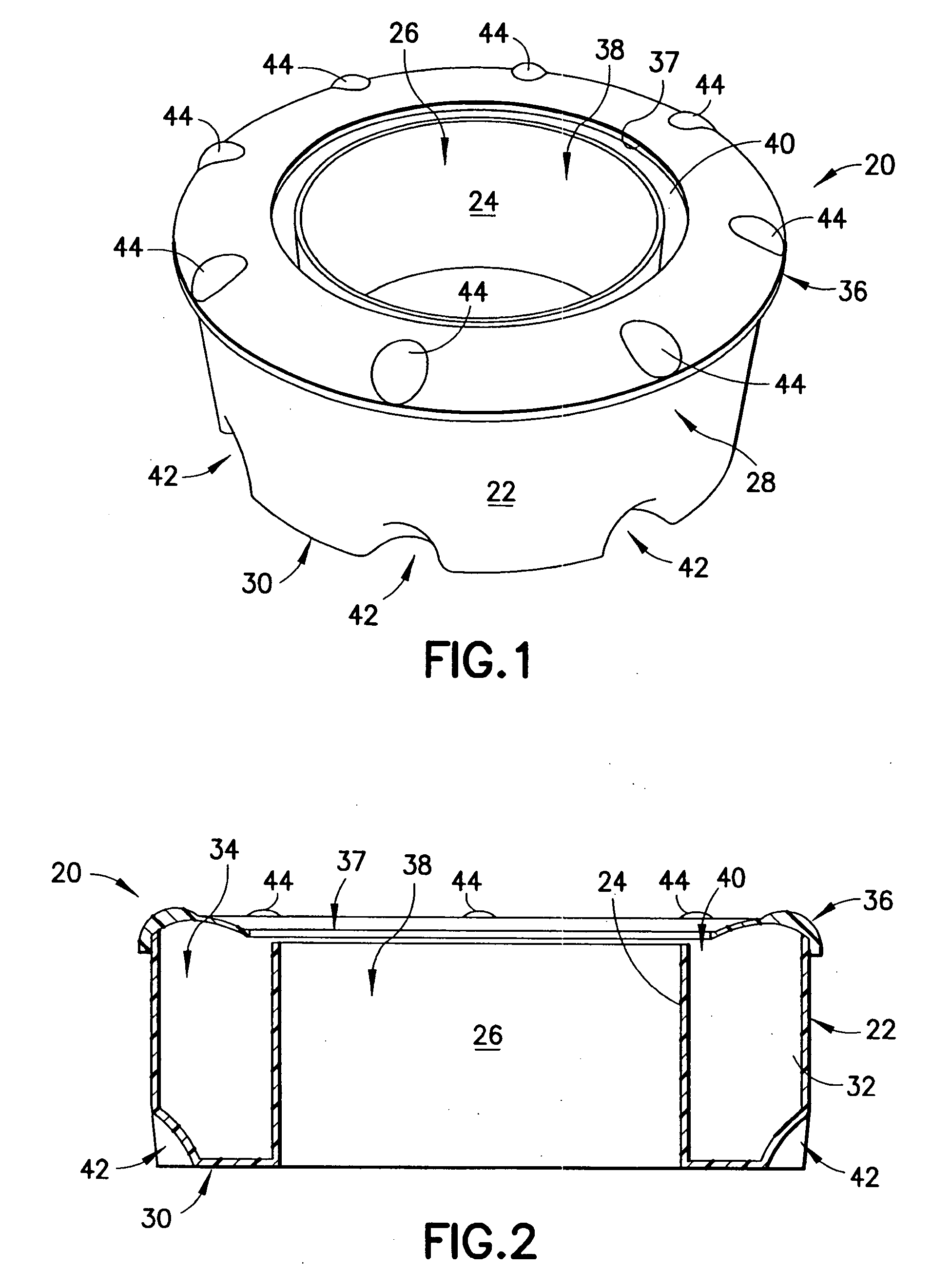

[0027]As shown in FIGS. 1 and 2, a cassette for dispensing plastic tubing is generally designated by the reference number 20. The cassette includes a cassette body generally designated by the reference number 22. The cassette body is defined by a tubular central portion 24 having an aperture 26 extending therethrough. An outer wall 28 surrounds the tubular central portion 24 and is connected thereto by a cassette bottom 30. The tubular central portion 24, the outer wall 28 and the cassette bottom 30 cooperate together to define an interior area 32 into which a length of flexible tubing 34 is operably positioned. A cover generally designated by the reference number 36 is attached to the body 22. The cover 36 has an interior peripheral edge 37 that defines an opening 38 extending through the cover. The opening 38 is sized to form a gap 40 between the tubular central portion 24 and the interior peripheral edge 37 of the cover 24. While the cassette 20 has been shown in the illustrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com