Patents

Literature

514 results about "Acid fracturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Generating Acid Downhole in Acid Fracturing

An acid fracturing method is provided in which the acid is generated in the fracture by hydrolysis of a solid acid-precursor selected from one or more than one of lactide, glycolide, polylactic acid, polyglycolic acid, a copolymer of polylactic acid and polyglycolic acid, a copolymer of glycolic acid with other hydroxy-, carboxylic acid-, or hydroxycarboxylic acid-containing moieties, and a copolymer of lactic acid with other hydroxy-, carboxylic acid or hydroxycarboxylic acid-containing moieties. The solid acid-precursor may be mixed with a solid acid-reactive material to accelerate the hydrolysis and / or coated to slow the hydrolysis. Water-soluble liquid compounds are also given that accelerate the hydrolysis. The method ensures that the acid contacts fracture faces far from the wellbore.

Owner:SCHLUMBERGER TECH CORP

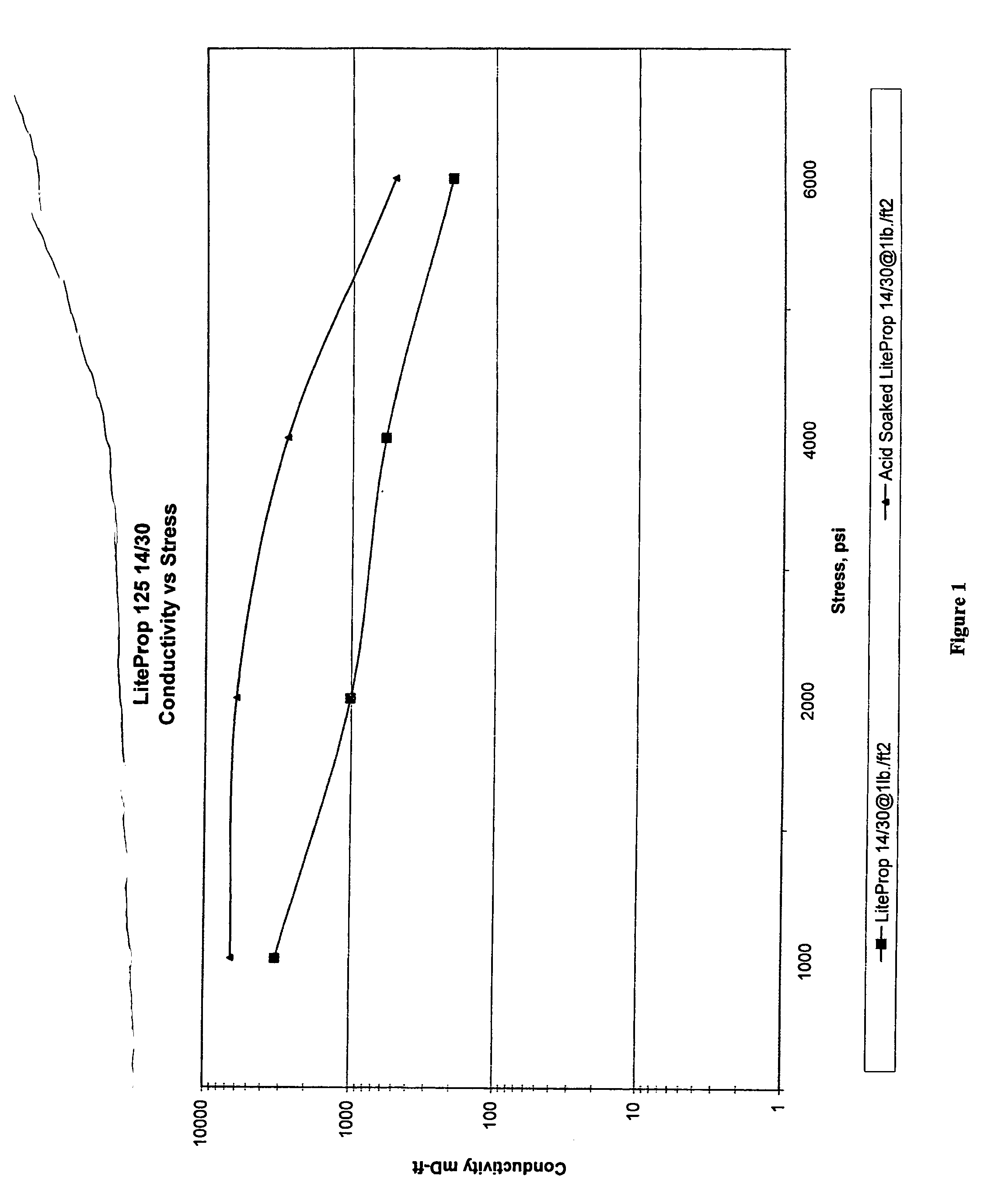

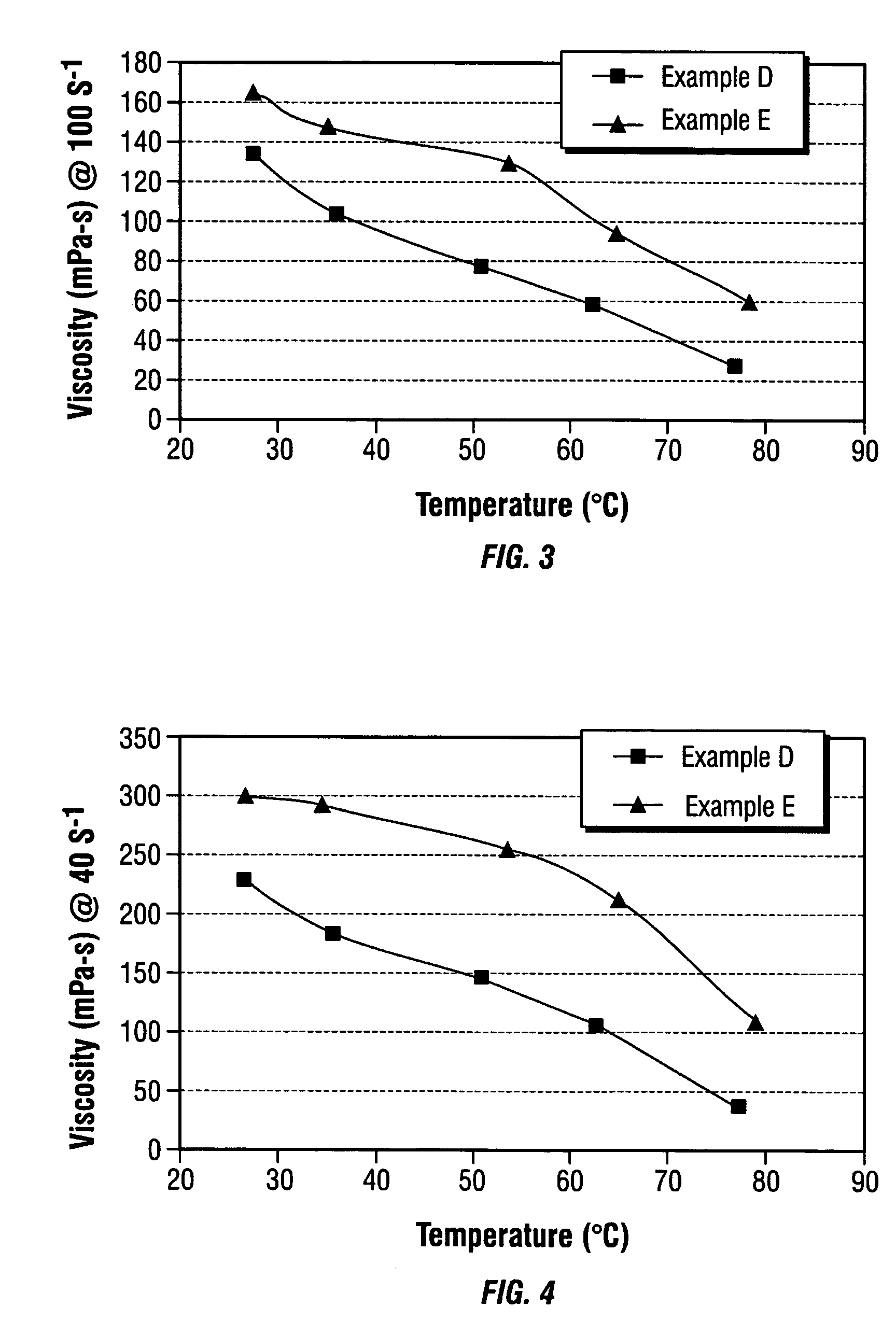

Well treating composition containing relatively lightweight proppant and acid

InactiveUS20060073980A1Satisfied with placementImprove productivityFluid removalFlushingParticulatesAcid fracturing

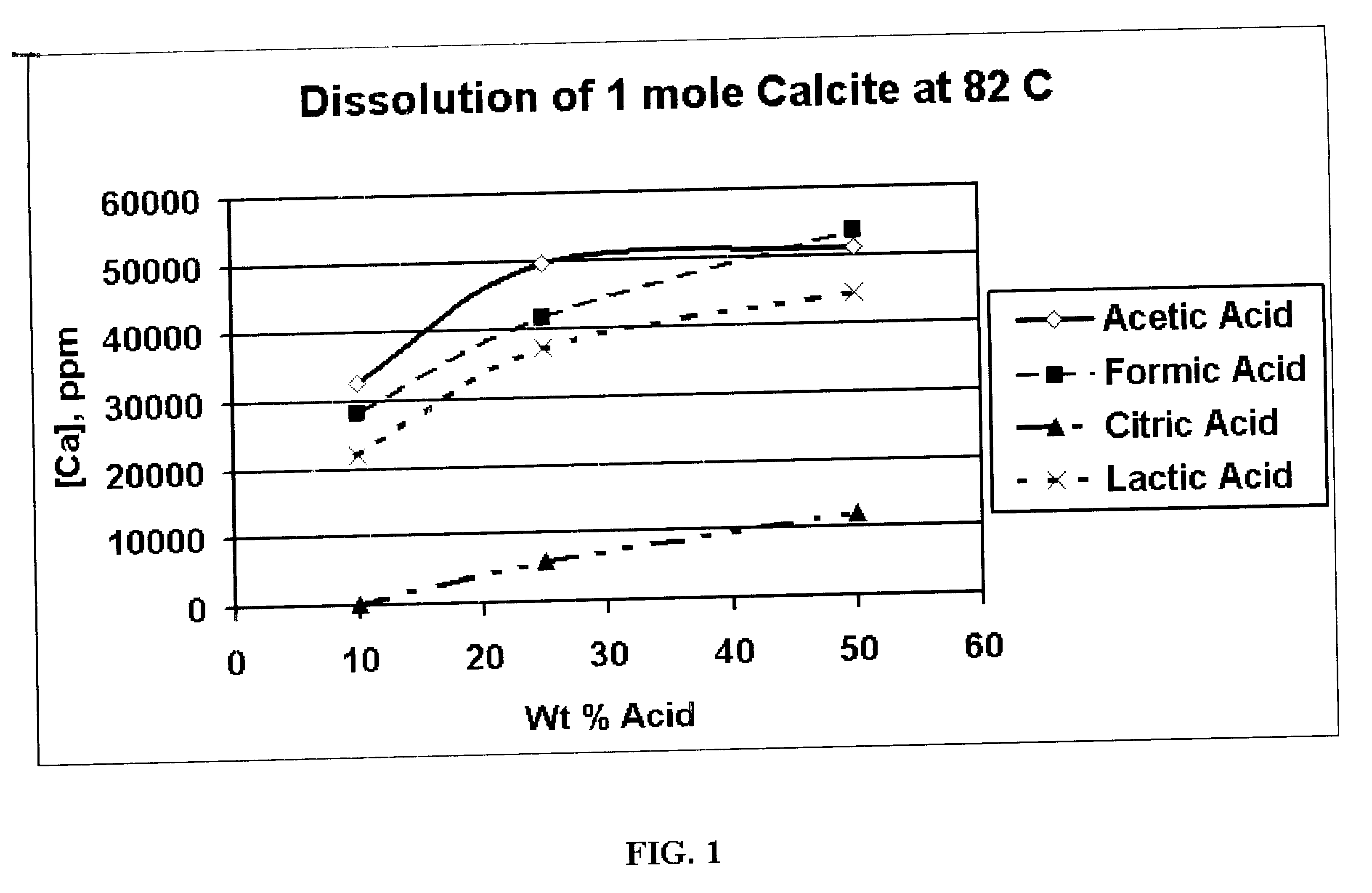

A well treating composition contains an aqueous acid and at least one relatively lightweight proppant, preferably having an apparent specific gravity (ASG) less than or equal to 2.45. The acid fracturing composition may used to acid fracture a hydrocarbon reservoir within a subterranean formation of an oil or gas well. The composition may further be used to stimulate the production of hydrocarbons. The proportion of relatively lightweight proppant to acid in the composition is such that the dimensional fracture conductivity (CfD) is in excess of 1.0. The aqueous acid typically has an ASG substantially equal to the ASG of the relatively lightweight particulate. As such, the relatively lightweight particulate is suspended in the aqueous acid.

Owner:BAKER HUGHES INC

Method of using controlled release tracers

Fluids produced from a fractured subterranean formation may be monitored by pumping into the well a fracturing fluid which contains a tracer. The method may be used to monitor produced hydrocarbons as well as produced water. The tracer may also be used in a sand control, frac pack or acid fracturing operation. The tracer is a component of a composite where it may be immobilized within a matrix (such as an emulsion) or porous particulate, onto a support or compressed with a binder into a solid particulate. The tracer may be slowly released from the composite.

Owner:BAKER HUGHES INC

Method for Treating a Subterranean Formation

ActiveUS20070235189A1Improve permeabilityReduce penetrationFluid removalFlushingAcid fracturingHydraulic fracturing

Disclosed are acid fracturing methods for subterranean siliceous formations employing a viscous dissolving fluid to create a permeable conduit that bypasses the near wellbore damage. The viscous dissolving fluids used according to the invention are acid-fracturing treatment fluids containing a dissolving agent viscosified with a material such as a viscoelastic surfactant, and the fluid is injected into a sandstone formation at a pressure sufficient to create a hydraulic fracture. Also, the viscous dissolving fluid leaks off into the faces of the fracture thus “stimulating” the formation. Hence when the hydraulic fracture has closed there is a part of the formation that has been effectively stimulated, creating a pathway for fluids to preferentially flow to the wellbore. The formation may then be flowed back to produce a substantial volume of the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

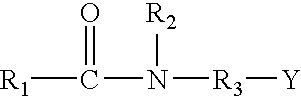

Compositions and methods for treating a subterranean formation

A method for diverting the majority of the fluid injected into a stratified subterranean formation, that has at least one problematic zone and at least one hydrocarbon zone, into the hydrocarbon zone includes injection of a viscous diverting fluid made with a gelling amount of a surfactant and an acid before the main treatment; after the treatment the acid decomposes the surfactant. The main treatment may be hydraulic fracturing, acid fracturing and matrix acidizing. The fluid used as the diverting fluid may also be used as the carrier fluid in hydraulic fracturing or gravel packing. Destruction of the surfactant alleviates the potential of diverters or carrier fluids to damage formations.

Owner:SCHLUMBERGER TECH CORP

Composition and Method for Treating a Subterranean Formation

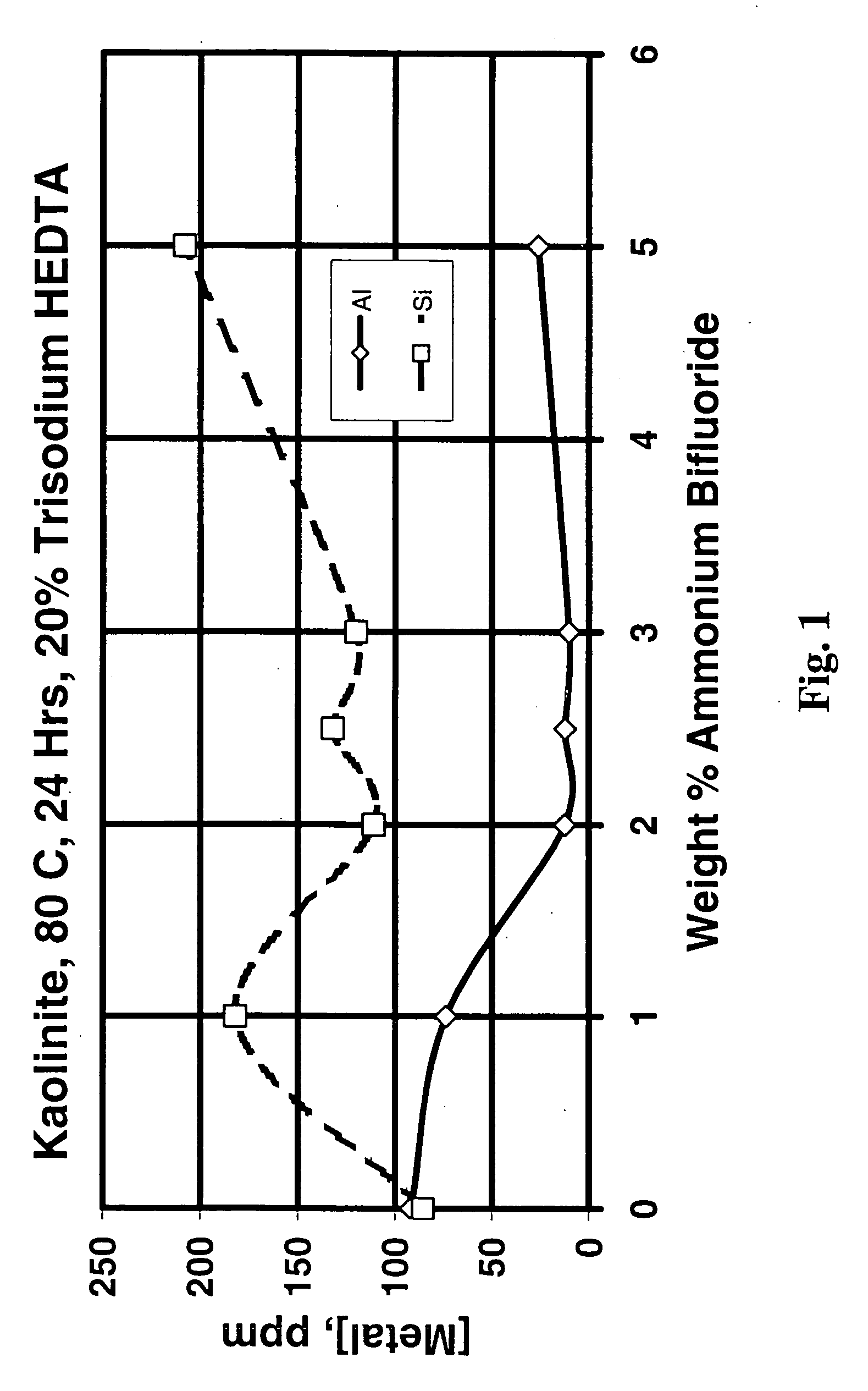

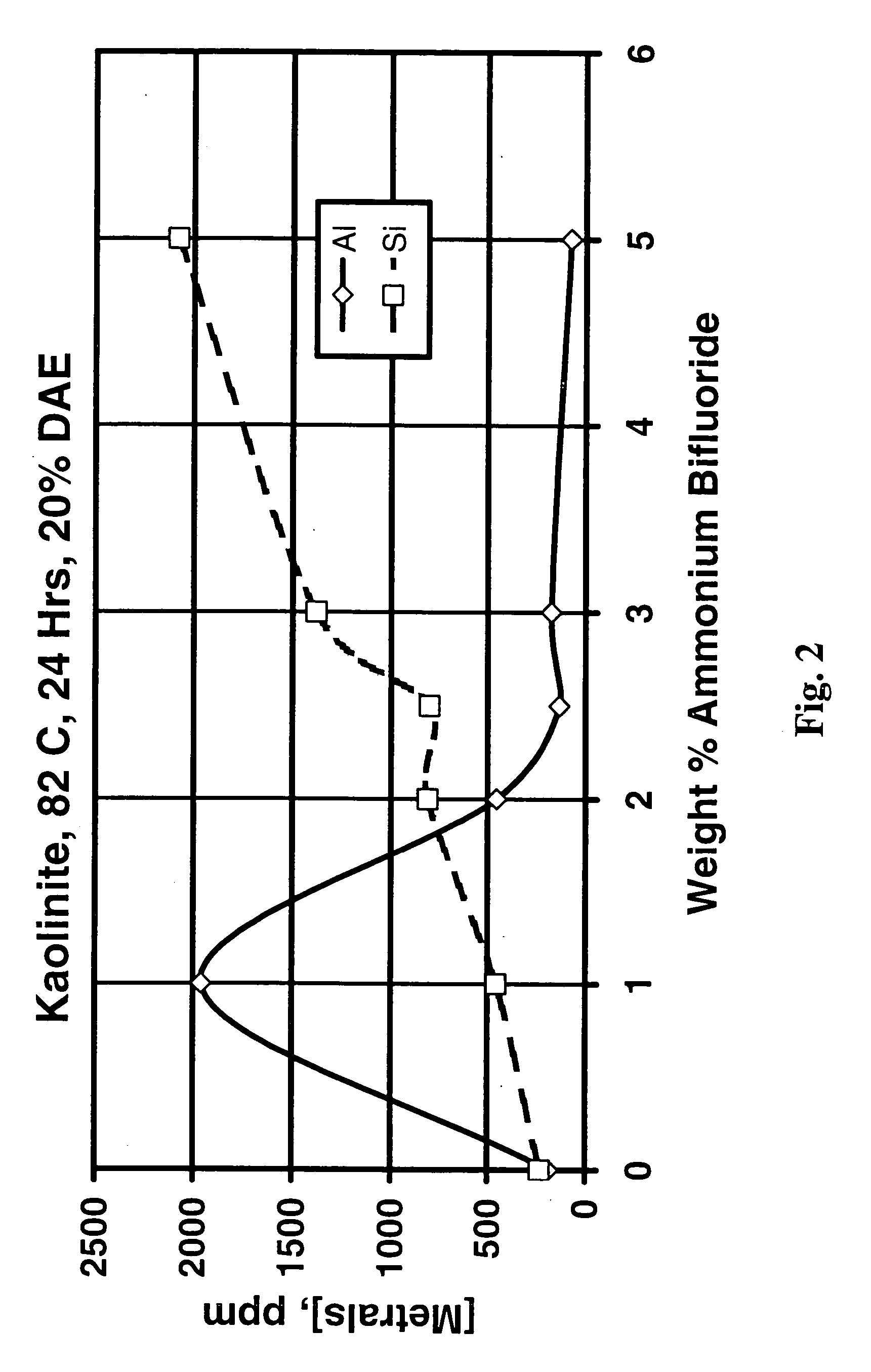

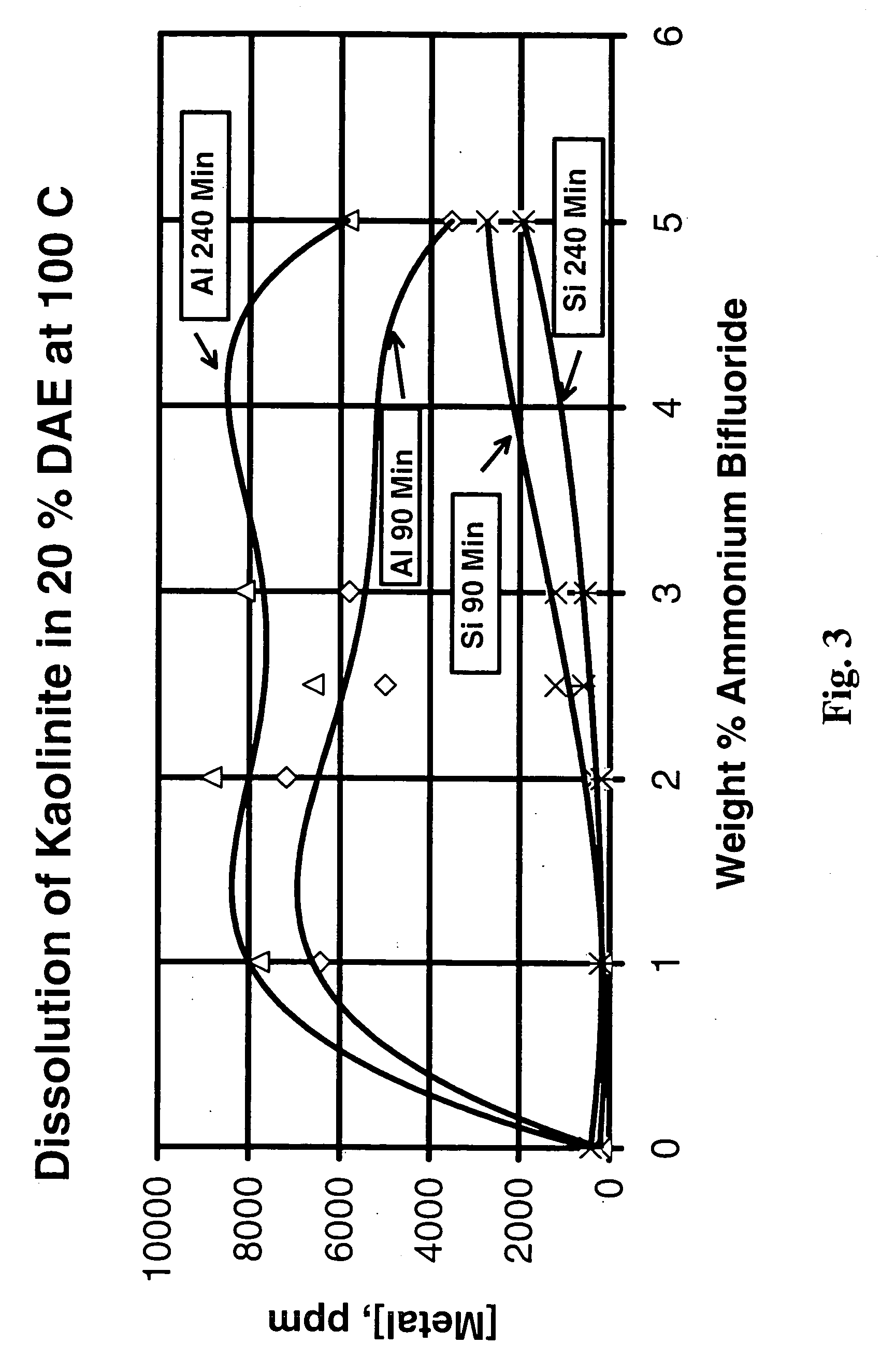

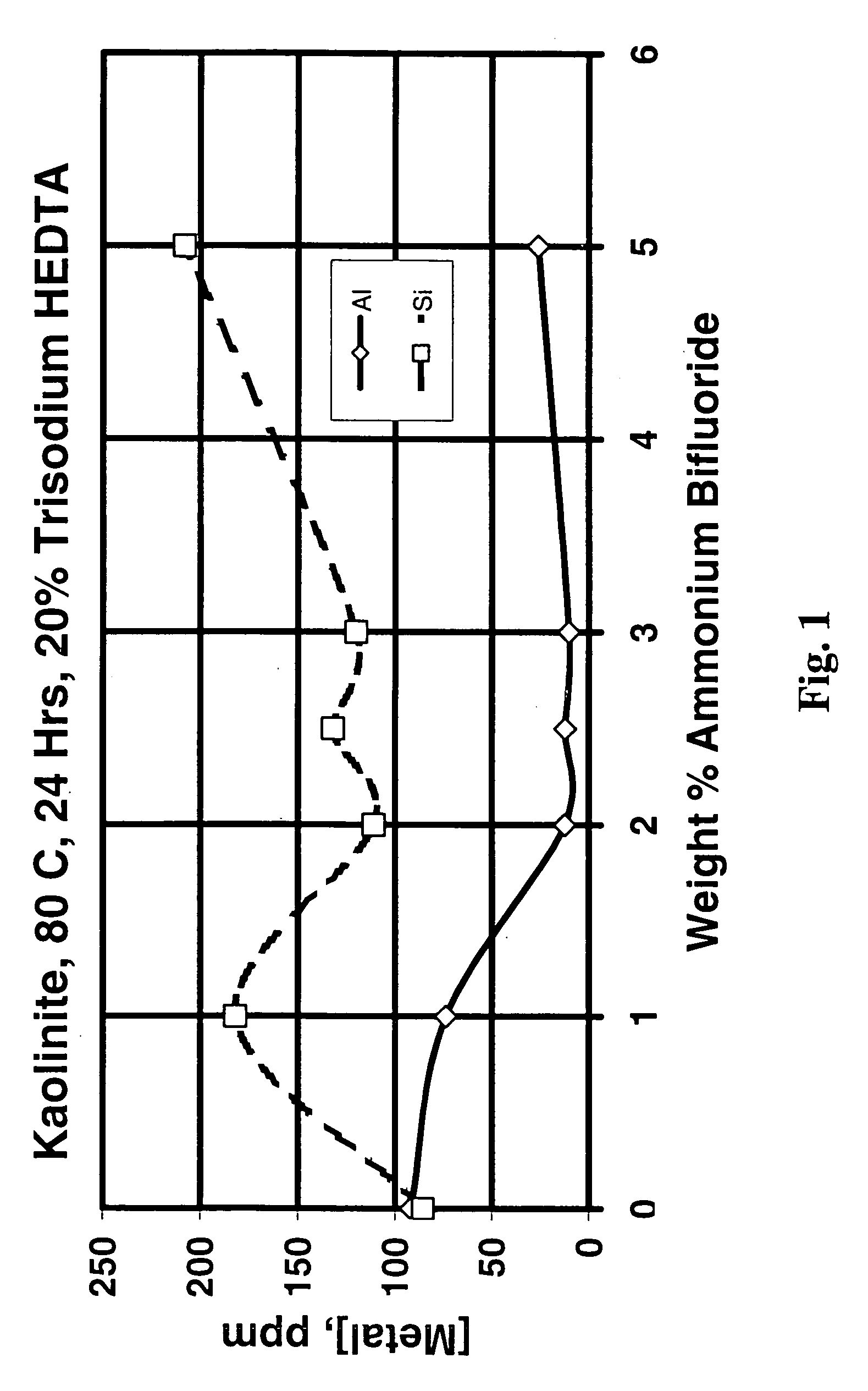

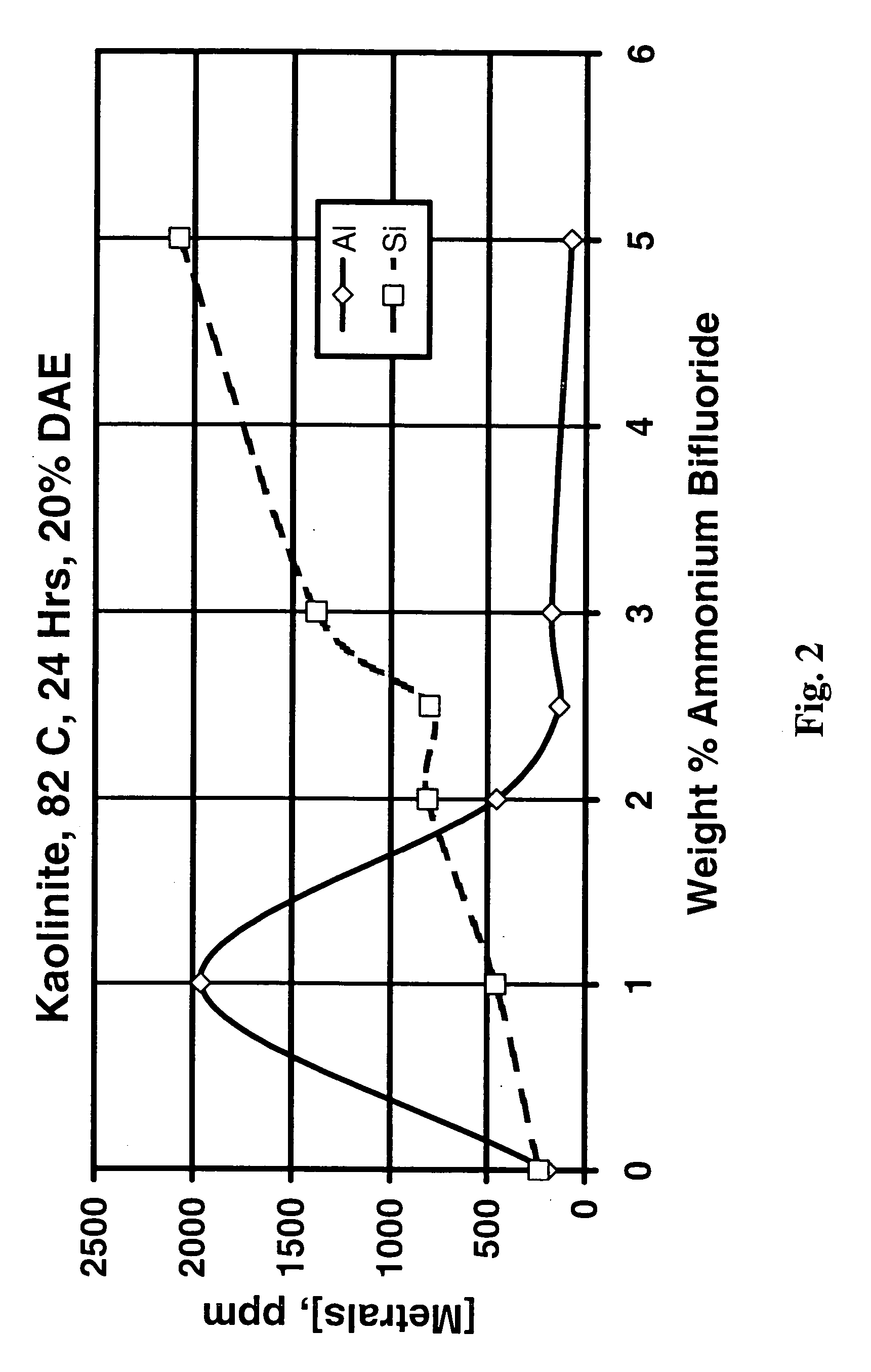

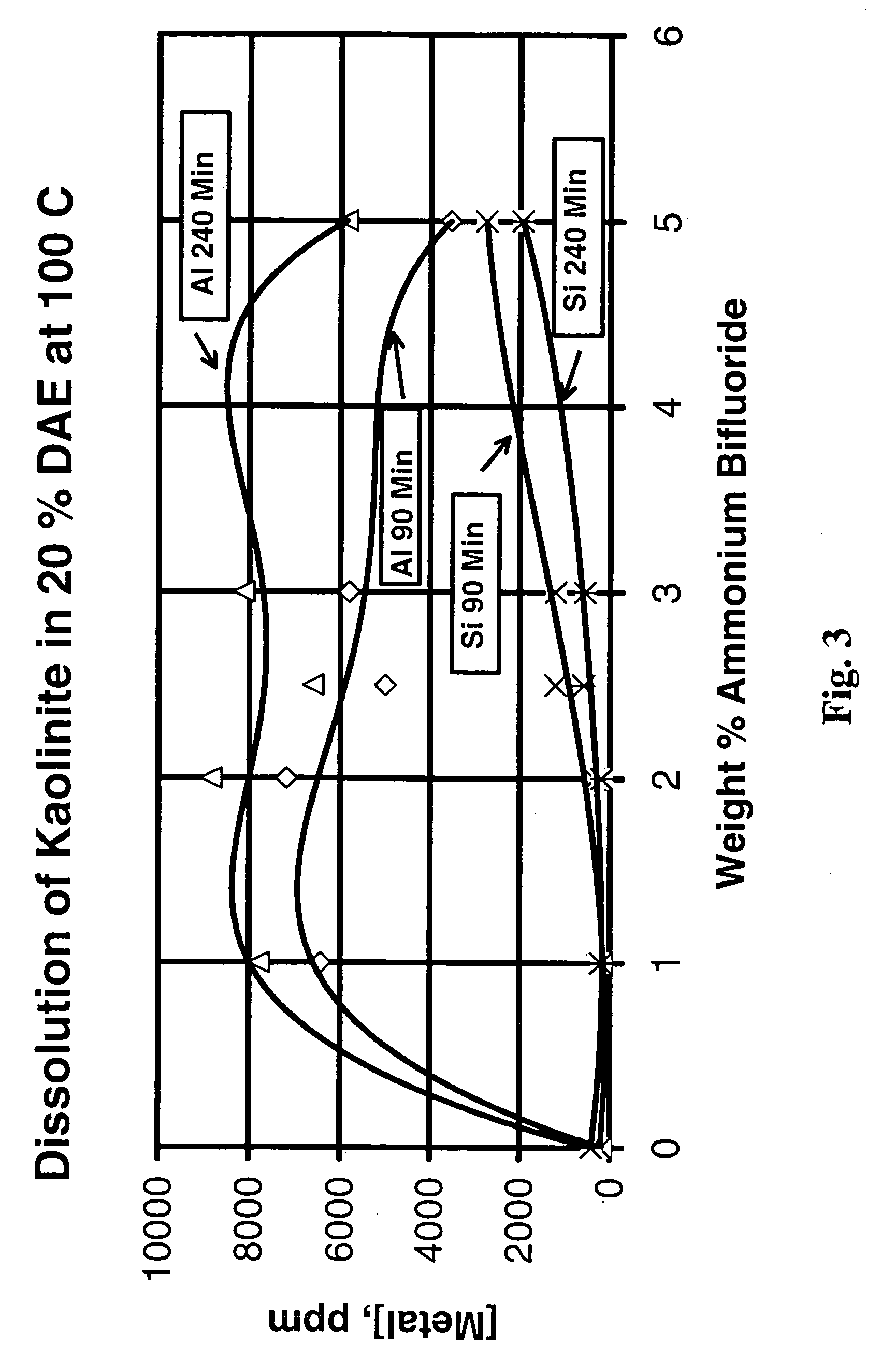

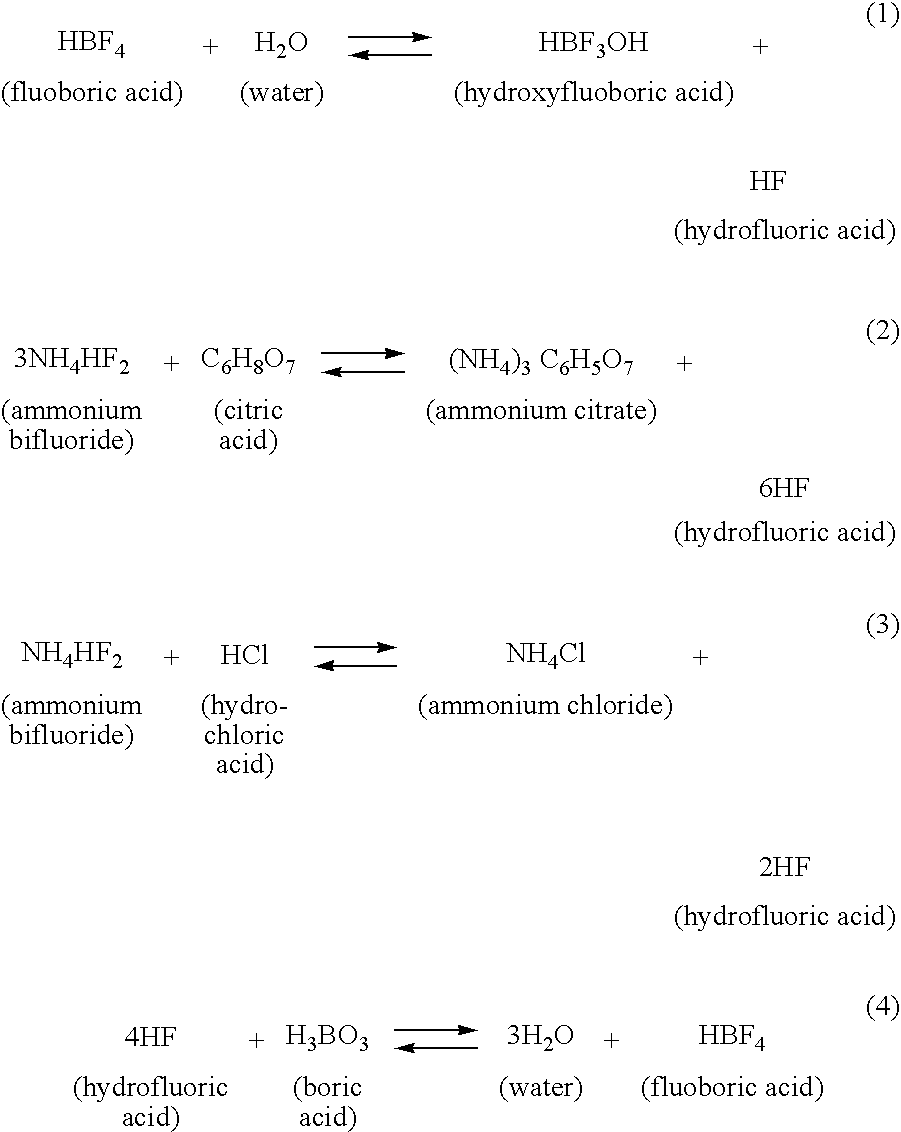

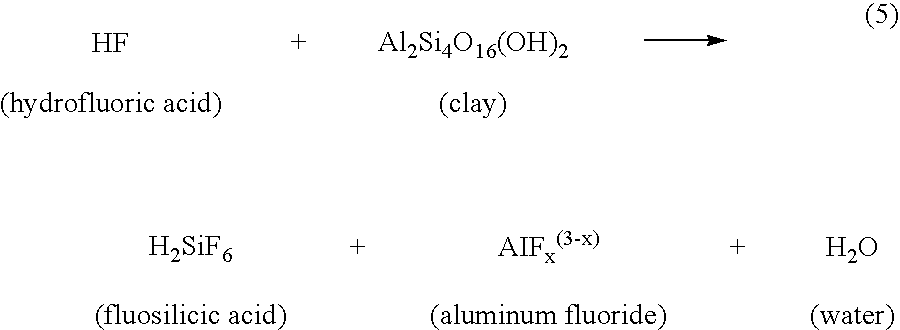

An aqueous oilfield treatment fluid containing a chelating agent and an HF source is described. This fluid is effective at dissolving siliceous materials such as clays and keeping the dissolved materials in solution. In particular it is effective at preventing re-precipitation of initially-dissolved silicon as silica and therefore reduces damage to sandstones with which it is contacted. Methods are given for using this fluid for sandstone matrix stimulation, removal of clay-containing drilling fluid components and filter cakes from wellbores, sandstone acid fracturing, and gravel pack and proppant pack cleaning.

Owner:SCHLUMBERGER TECH CORP

Viscoelastic fluids containing nanotubes for oilfield uses

InactiveUS20060046937A1Low fluid viscosityMaterial nanotechnologyFluid removalAcid fracturingInorganic salts

The present invention relates to viscoelastic fluids that contain nanotube structures that may be used advantageously as oilfield stimulation fluids in many different applications, most particularly as a fracturing fluid. Viscoelastic fluid compositions of the present invention include an aqueous medium, a viscoelastic surfactant, an organic or inorganic acids, or salt thereof, organic acid salts, inorganic salts, and a nanotube component. The invention is also called to a methods of treating a subterranean well bores in which the viscoelastic fluid is injected into the wellbore to perform operations such as fracturing, drilling, acid fracturing, gravel placement, removing scale, matrix acidizing, and removing mud cake. Further, a method of preparing a nanotube viscoelastic fluid comprising the steps of effectively mixing a carbon nanotube component into a viscoelastic fluid, and sonicating the mixture in order to incorporate the carbon nanotube component is claimed.

Owner:SCHLUMBERGER TECH CORP

Composition and method for treating a subterranean formation

An aqueous oilfield treatment fluid containing a chelating agent and an HF source is described. This fluid is effective at dissolving siliceous materials such as clays and keeping the dissolved materials in solution. In particular it is effective at preventing re-precipitation of initially-dissolved silicon as silica and therefore reduces damage to sandstones with which it is contacted. Methods are given for using this fluid for sandstone matrix stimulation, removal of clay-containing drilling fluid components and filter cakes from wellbores, sandstone acid fracturing, and gravel pack and proppant pack cleaning.

Owner:SCHLUMBERGER TECH CORP

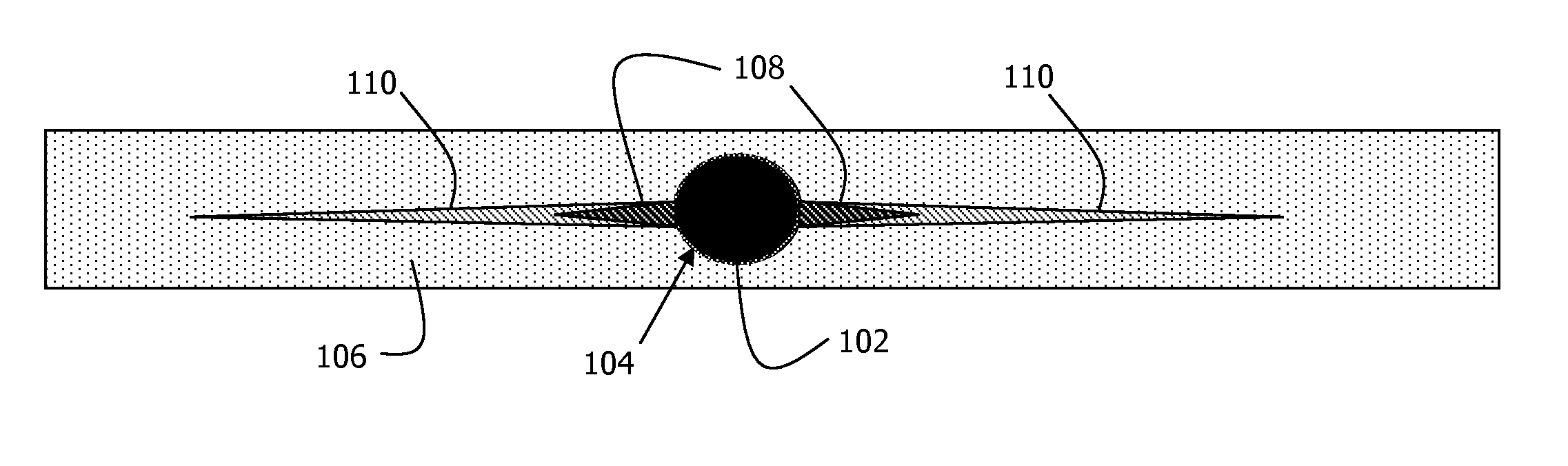

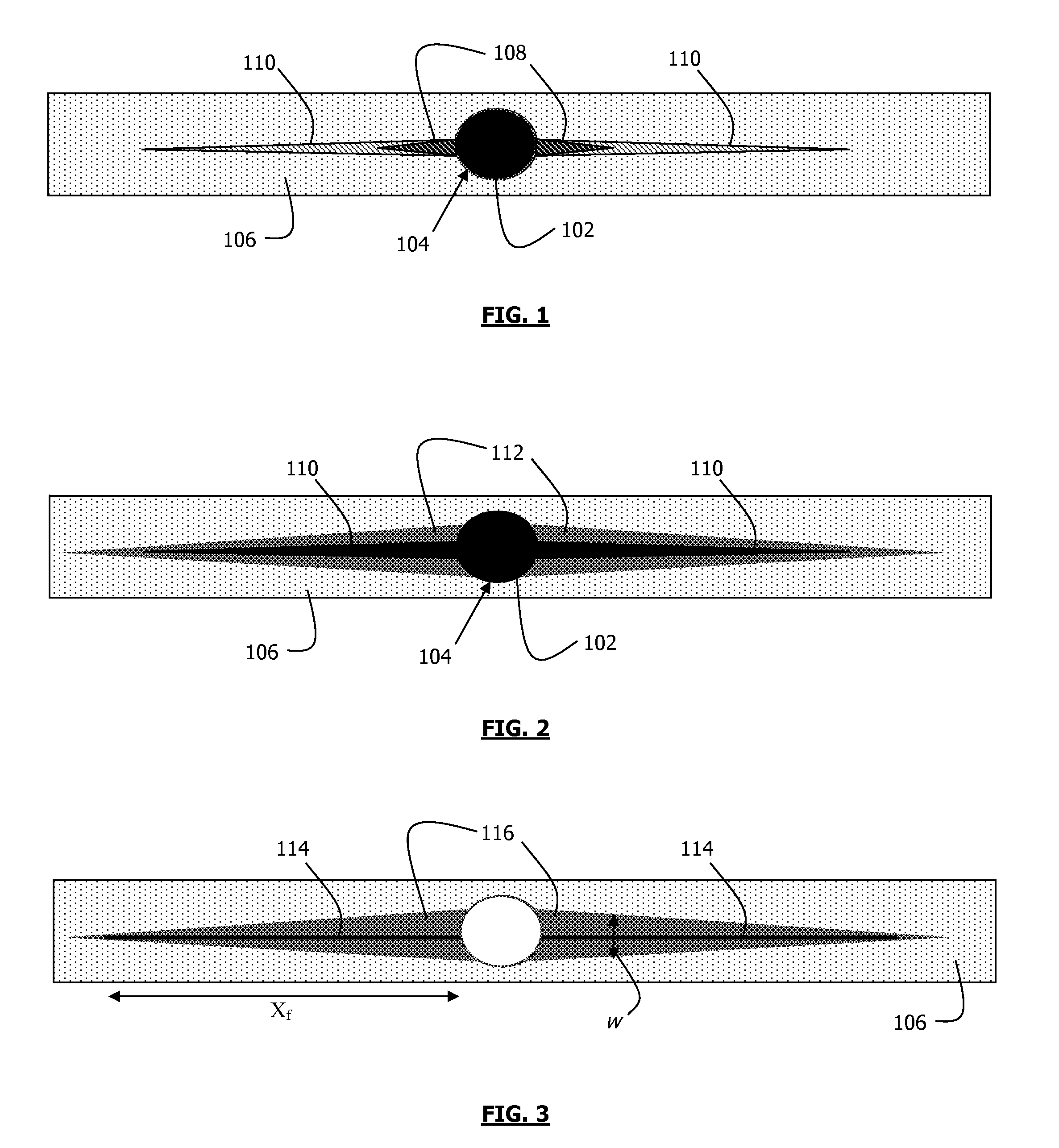

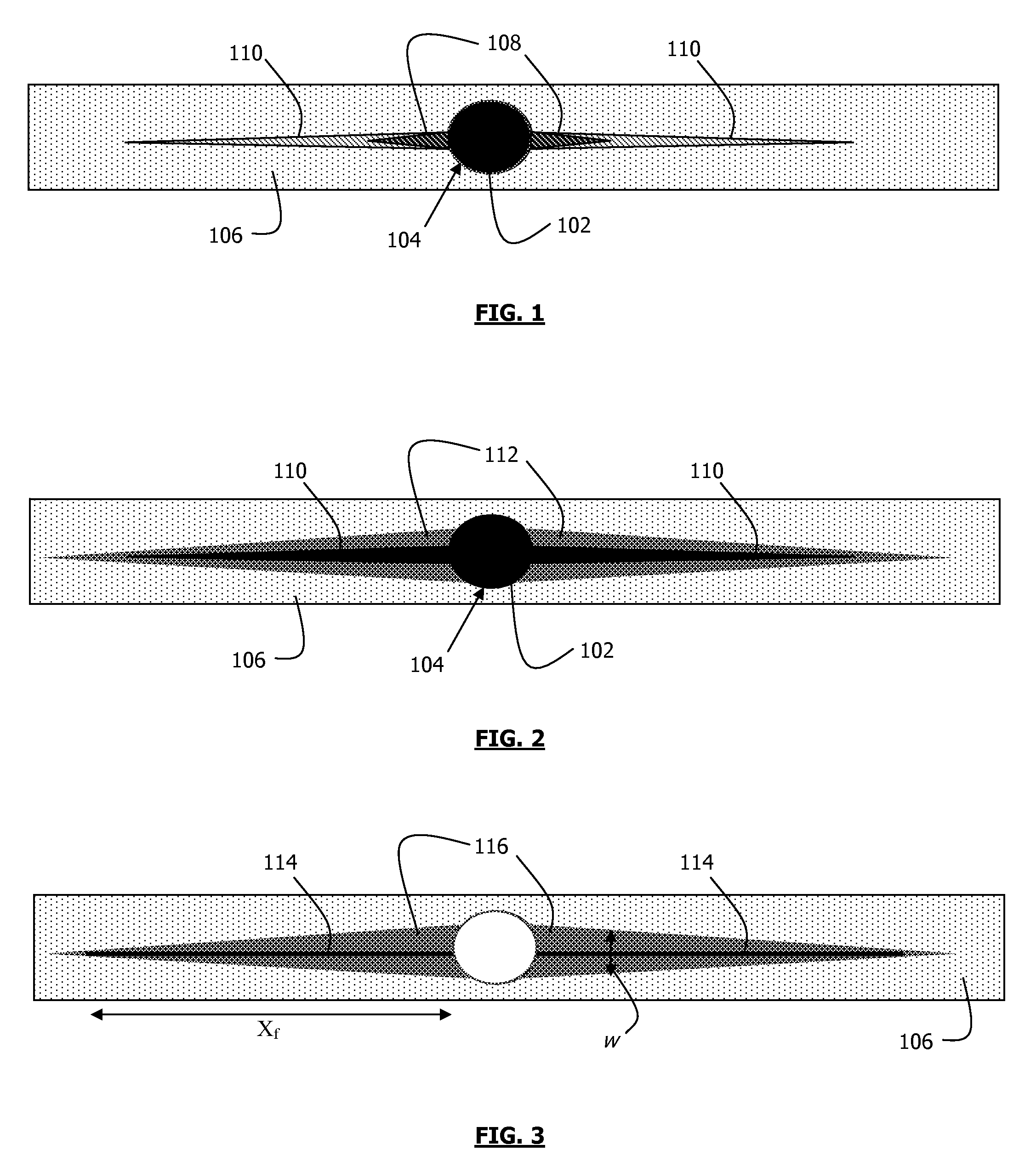

Selective fracture face dissolution

A method is given for acid fracturing a subterranean formation for improving the flow of fluids. The principal source, optionally the sole source, of the acid is a solid acid-precursor, optionally injected with an additional solid that is inert and that masks a portion of the newly created fracture faces so that the fracture face etching by the acid is not uniform. The method ensures a good flow path for fluids between the fracture tip and the wellbore.

Owner:SCHLUMBERGER TECH CORP

Shale gas acid fracturing drag reducer and reparation method thereof

InactiveCN103694984AImprove acid resistanceImprove stabilityDrilling compositionEthylenediamineOil phase

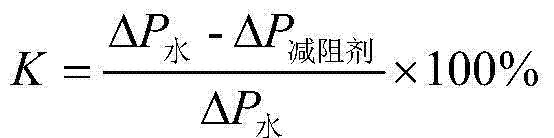

The invention discloses a shale gas acid fracturing drag reducer and a reparation method of the shale gas acid fracturing drag reducer. The preparation method comprises the following steps: mixing monomer acrylic acid and 2-acrylamide-2 methyl propane sulfonic acid, dissolving in water, subsequently adding acrylamide, and finally adding ethylenediamine tetraacetic acid disodium to prepare into a water phase; mixing and dissolving a compounded surfactant with base oil to form an oil phase; performing inverse emulsion polymerization on the oil phase and the water phase to prepare the shale gas acid fracturing drag reducer. As a great amount of acid resistance monomers are introduced into the drag reducer, the acid resistance of the dreg reducer is greatly improved; the dreg reducer is milk white emulsion in appearance, is high in stability, non-ignitable, non-explosive, safe to transport and store, rapid to dissolve in water and free of fisheye; the requirements of continuous blending in shale gas acid fracturing can be met; the resistance reduction rate of a dreg reducer solution with the mass percentage of 0.2% can be greater than 70%.

Owner:SOUTHWEST PETROLEUM UNIV

Method for treating a subterranean formation

ActiveUS7306041B2Improve permeabilityHigher the percentage of acidFluid removalFlushingAcid fracturingHydraulic fracturing

Disclosed are acid fracturing methods for subterranean siliceous formations employing a viscous dissolving fluid to create a permeable conduit that bypasses the near wellbore damage. The viscous dissolving fluids used according to the invention are acid-fracturing treatment fluids containing a dissolving agent viscosified with a material such as a viscoelastic surfactant, and the fluid is injected into a sandstone formation at a pressure sufficient to create a hydraulic fracture. Also, the viscous dissolving fluid leaks off into the faces of the fracture thus “stimulating” the formation. Hence when the hydraulic fracture has closed there is a part of the formation that has been effectively stimulated, creating a pathway for fluids to preferentially flow to the wellbore. The formation may then be flowed back to produce a substantial volume of the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

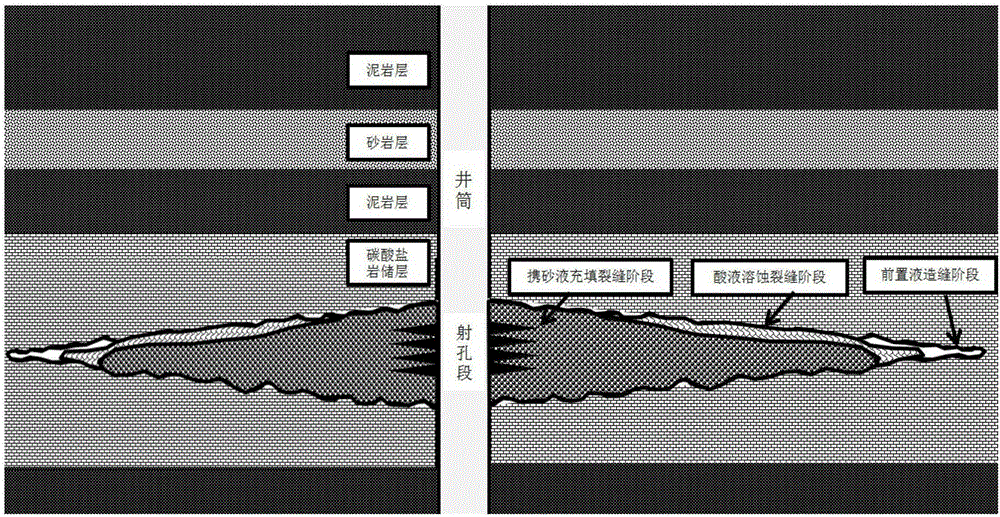

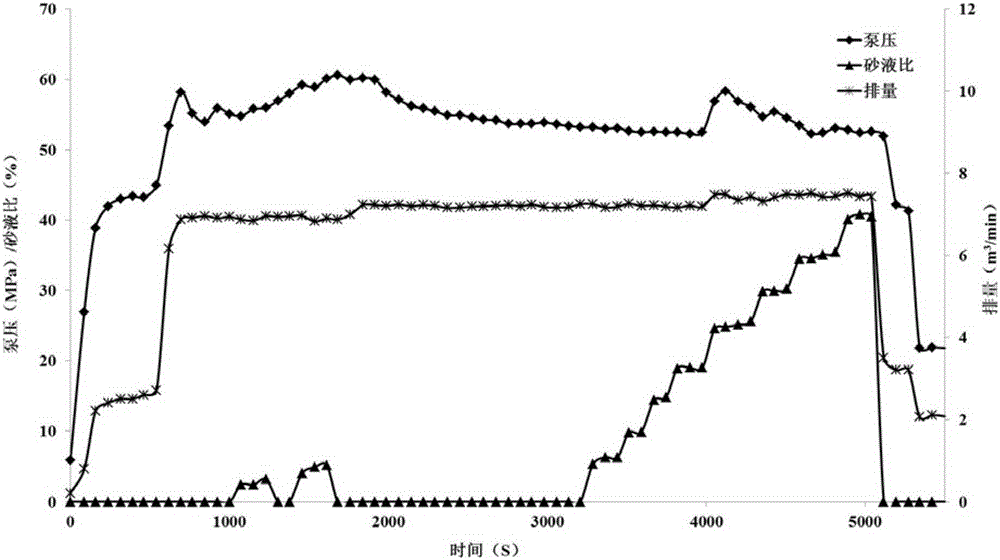

High-flow-conductivity acid fracturing method for carbonate rock reservoirs

The invention discloses a high-flow-conductivity acid fracturing method for carbonate rock reservoirs, and belongs to the field of reservoir reconstruction technologies. The high-flow-conductivity acid fracturing method includes applying acid fracturing processes for corroding crack by acid fluid and hydraulic fracturing processes for filling the crack with added sand in a combined manner, to be more specific, forming the crack in the carbonate rock reservoirs by the aid of non-reactive ahead fluid and reducing the surrounding temperatures of wall surfaces of the crack; injecting high-concentration acid fluid systems to corrode the wall surfaces of the artificial crack and forming uneven grooves in the wall surfaces of the crack by means of corroding to allow the crack to have certain flow-conductivity after the crack is closed; enabling high-viscosity sand-carrying fluid to carry proppants and flow into crack systems and filling the crack with the high-viscosity sand-carrying fluid to further improve the flow-conductivity of the crack. The high-flow-conductivity acid fracturing method has the advantages that the high-flow-conductivity acid fracturing method is reasonable in design, simple in process and convenient to implement in fields, the high-flow-conductivity crack systems with the acid-corroded crack and crack closing supporting functions can be formed, oil and gas flow resistance can be reduced, the acid fracturing reconstruction effects can be improved for the carbonate rock reservoirs, and the high-flow-conductivity acid fracturing method can be widely used for acid fracturing reconstruction construction for limestone, dolomite and carbonate rock oil and gas reservoirs with mud.

Owner:CHINA PETROLEUM & CHEM CORP +1

Viscoelastic fluids containing nanotubes for oilfield uses

InactiveUS7244694B2Low fluid viscosityMaterial nanotechnologyFluid removalInorganic saltsOrganic acid

The present invention relates to viscoelastic fluids that contain nanotube structures that may be used advantageously as oilfield stimulation fluids in many different applications, most particularly as a fracturing fluid. Viscoelastic fluid compositions of the present invention include an aqueous medium, a viscoelastic surfactant, an organic or inorganic acids, or salt thereof, organic acid salts, inorganic salts, and a nanotube component. The invention is also called to a methods of treating a subterranean well bores in which the viscoelastic fluid is injected into the wellbore to perform operations such as fracturing, drilling, acid fracturing, gravel placement, removing scale, matrix acidizing, and removing mud cake. Further, a method of preparing a nanotube viscoelastic fluid comprising the steps of effectively mixing a carbon nanotube component into a viscoelastic fluid, and sonicating the mixture in order to incorporate the carbon nanotube component is claimed.

Owner:SCHLUMBERGER TECH CORP

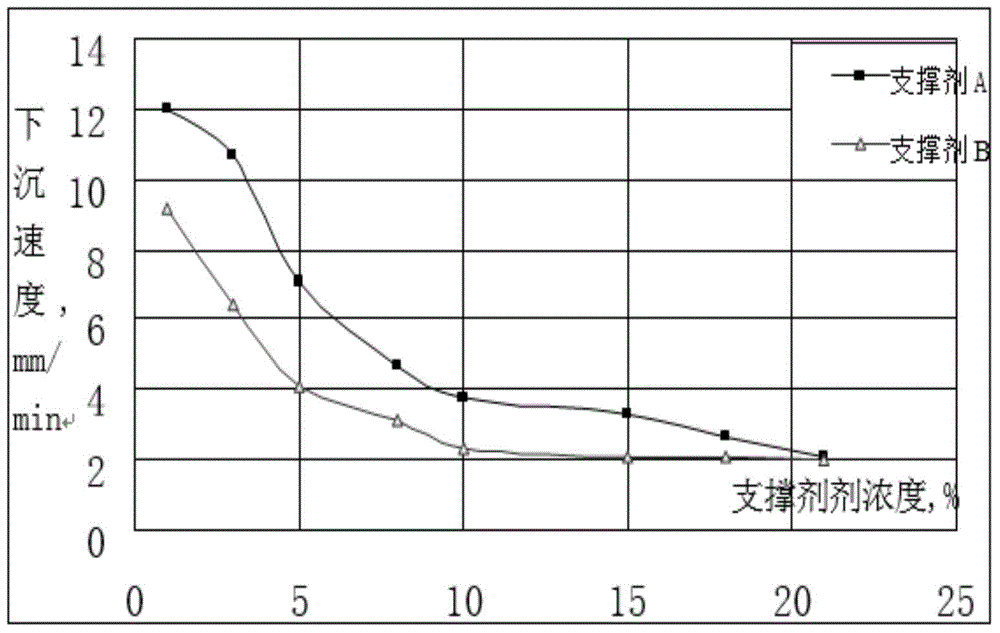

Pumping stop sand setting fracture-height-controlling acid fracturing process method applicable to carbonate reservoir

InactiveCN104564002AReduce fluid lossIncrease the lengthFluid removalAcid fracturingFracturing fluid

The invention relates to a pumping stop sand setting fracture-height-controlling acid fracturing process method applicable to a carbonate reservoir. The method comprises the following work procedures that before the normal fracturing, low-viscosity slickwater is adopted for fracture making, and the initial fracture height is controlled; then, after the slickwater enters the stratum in a way of carrying support agent sand, the pumping stop is adopted for prompting the support agent sand to be settled near a fracture opening, so that each stage of support agent sand shields the back section in advance, a high-intensity artificial separation layer is formed, the stress state is changed, and the goal of effectively controlling the lower fracture height extending to prevent the communication with the lower part water body is achieved; low-viscosity fracturing fluid is injected for fracture making at a stable discharge capacity; after the fracturing fluid enters the stratum, acid liquid is injected for etching the stratum, and high-flow-guide capability artificial fractures are formed; after the acid liquid is extruded into the stratum, the pumping is stopped for measuring the pressure drop, and the construction is completed. The process has the advantages that the artificial separation layer can be formed, the fracture height vertical direction extending can be controlled, the stress state is changed, and the goals of effectively controlling the lower fracture height extending and preventing the communication with the lower part water body are achieved.

Owner:CHINA PETROLEUM & CHEM CORP

Acid clean fracturing fluid and preparation method thereof

InactiveCN101812290AImprove fracturing efficiencyImprove fracturing effectDrilling compositionInorganic saltsAcid fracturing

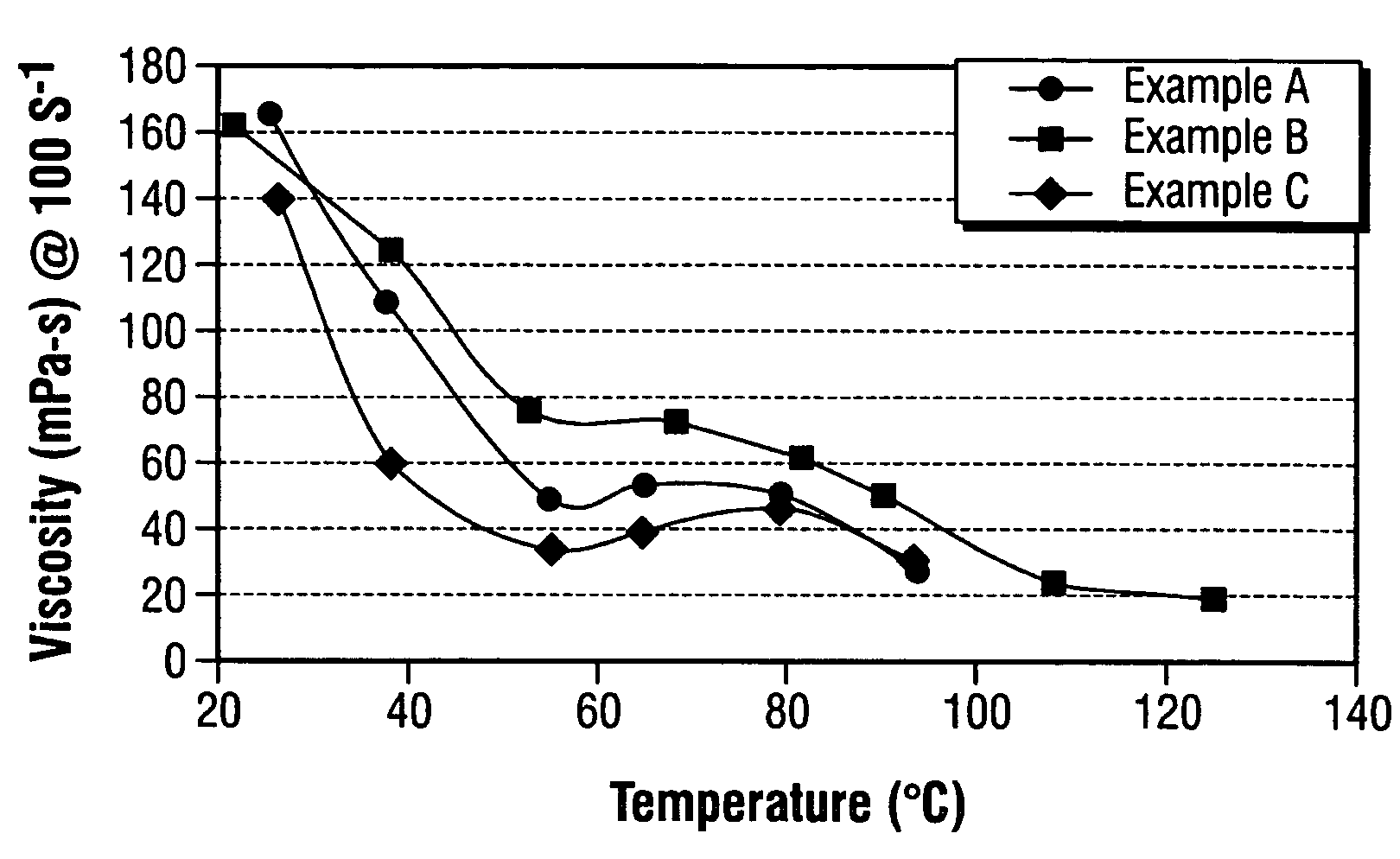

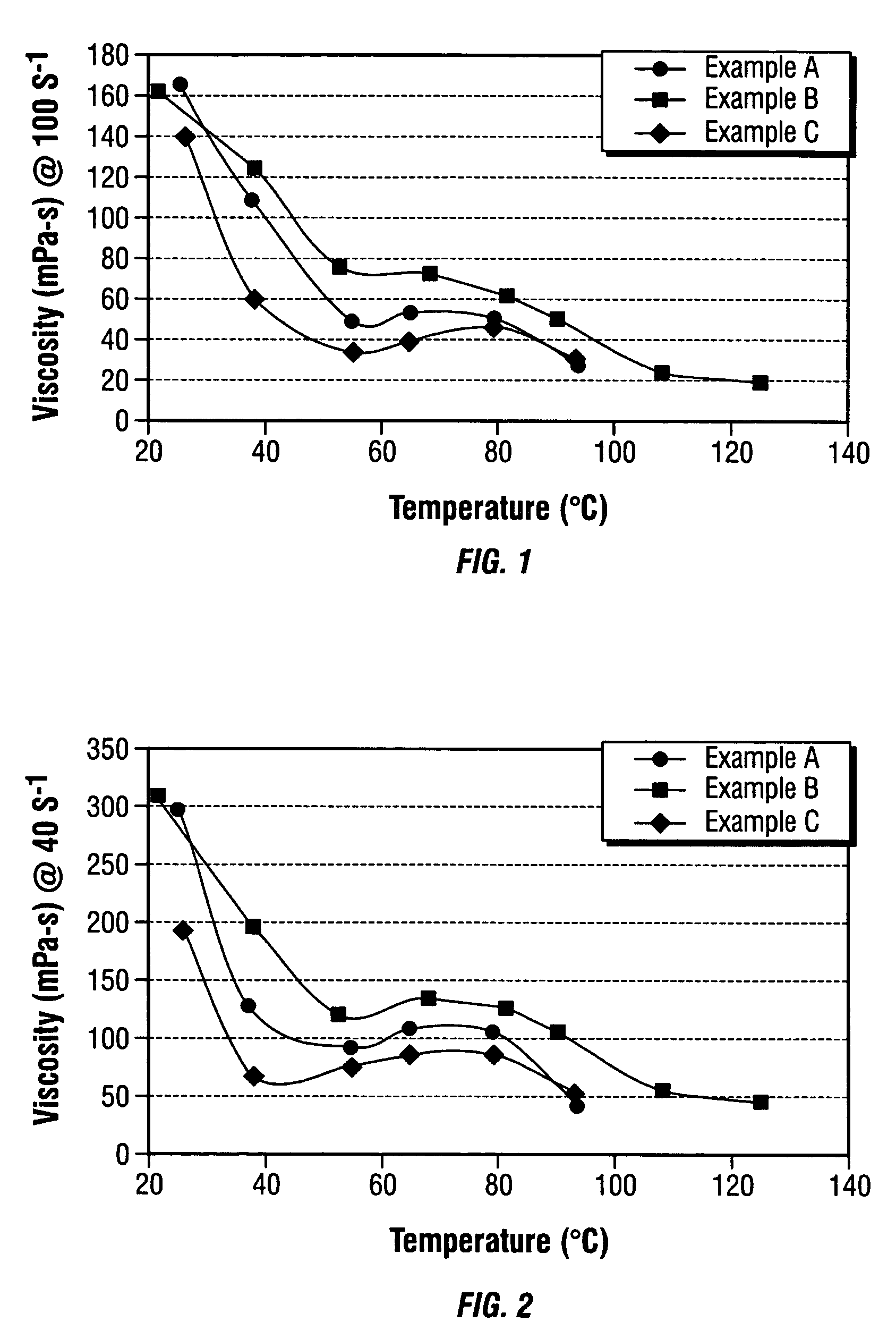

The invention relates to acid clean fracturing fluid and a preparation method thereof. The acid clean fracturing fluid consists of the following components in percentage by mass: 2 to 6 percent of surfactant, 1 to 4 percent of inorganic salt, 0.05 to 0.15 percent of counter-ion salt, 0.1 to 0.3 percent of cosolvent, 2 to 10 percent of acid and the balance of water. The method comprises the following steps of: dissolving the surfactant in the acid to prepare uniform liquid; adding the liquid into aqueous solution containing the inorganic salt, the counter-ion salt and the cosolvent; and stirring the mixture for 1 to 2 minutes to obtain the fluid having good viscoelasticity. The acid clean fracturing fluid is used for the fracturing of oil-gas fields at the temperature of between 60 and 120 DEG C, has the advantages of low viscosity, high elasticity, low friction resistance, high sand carrying, high effective control joints, increment on joint length and the like, can realize sand acid fracturing and finish all processes of acid fracturing and acidification, and has no residues after gel breaking and no damage to stratums.

Owner:SHAANXI UNIV OF SCI & TECH

Differential etching in acid fracturing

A method for fracturing a subterranean formation is provided in which inert masking material particles are injected into the formation with a dissolution agent so that the masking material inhibits dissolution where it contacts a portion of one or both fracture faces. The undissolved regions provide support to keep the fracture open after the treatment and the dissolved regions provide a conductive pathway for flow of fluid to or from the wellbore.

Owner:SCHLUMBERGER TECH CORP

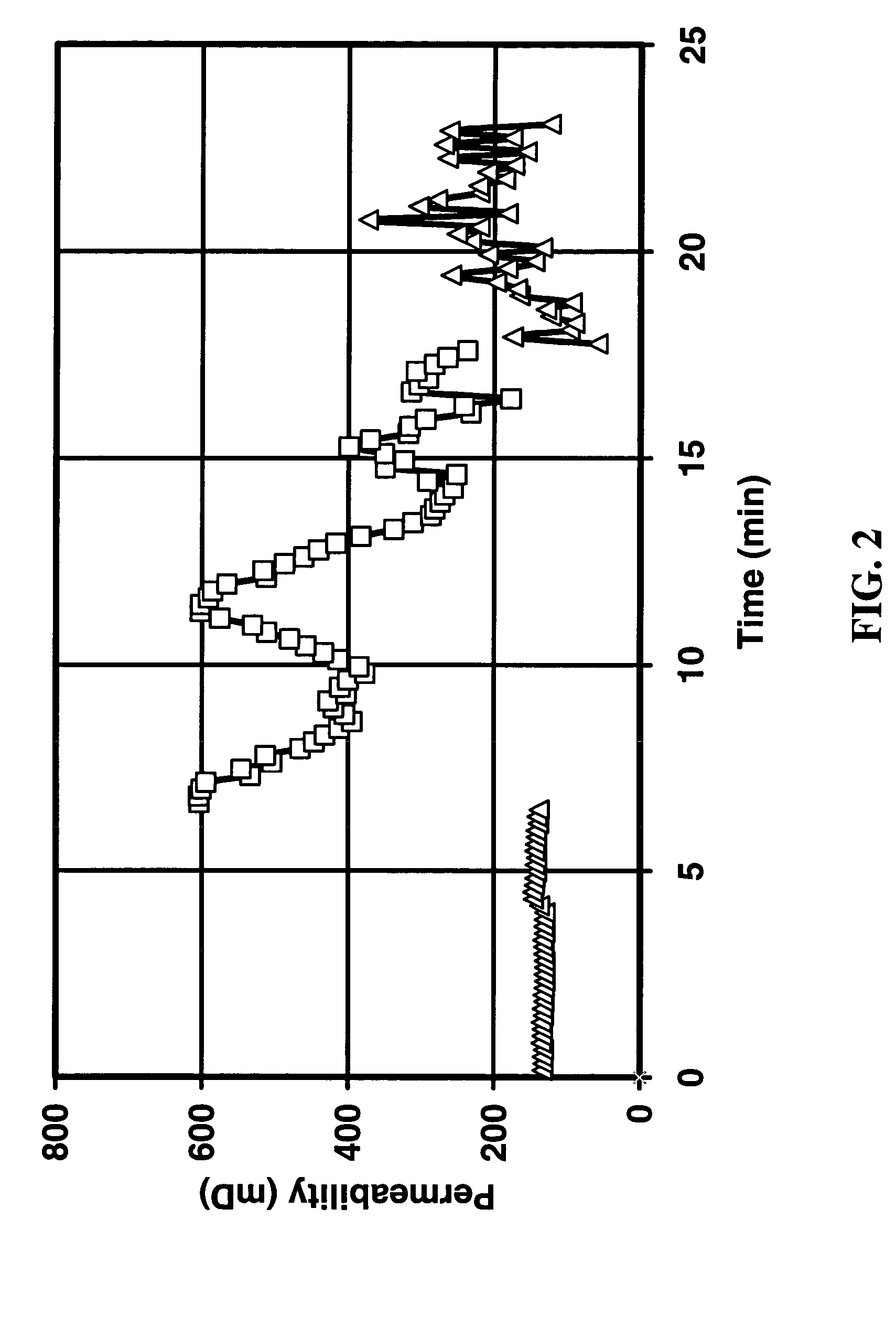

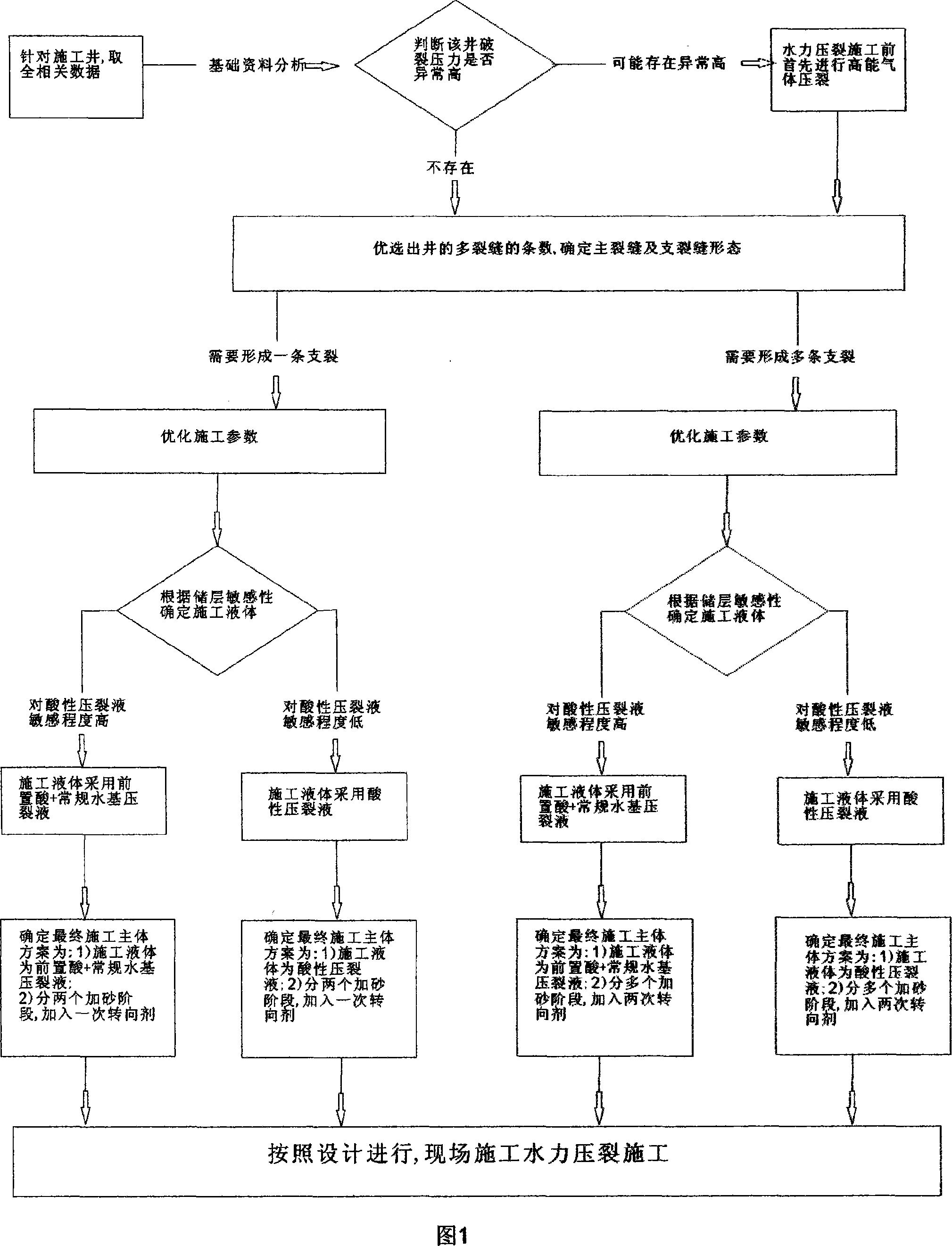

Fracturing process for enhancing low permeability reservoir deliverability

ActiveCN101113669AGuaranteed permeabilityIncreased productivity after pressingFluid removalAcid fracturingClay minerals

The invention relates to an oil field production technique, in particular to a fracturing method applied under the oil well to improve new well production capacity of low permeability reservoir before being brought into production. The fracturing reformation course at least comprises common fracturing technique and is characterized in that the method uses a compound application of more than two techniques of the use of acid fracturing liquid, or diversion agent or acid liquid and diversion agent by adopting high-energy gas fracturing technique; the upper sealed fracturing pipe is adopted during the working of hydraulic fracturing; the acid liquid is adopted during a pad fluid stage as the working liquid; the diversion agent is added for one or more times to seal fractured cracks; an increasing working flow rate is adopted before and after the adding of the diversion agent. The method of the invention can increase oil discharging area after fracturing, reduce expansion rate of clay minerals in fractured reservoir and improve completion of oil well reformation, fracturing effect and production capacity of low permeability reservoir after fracturing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

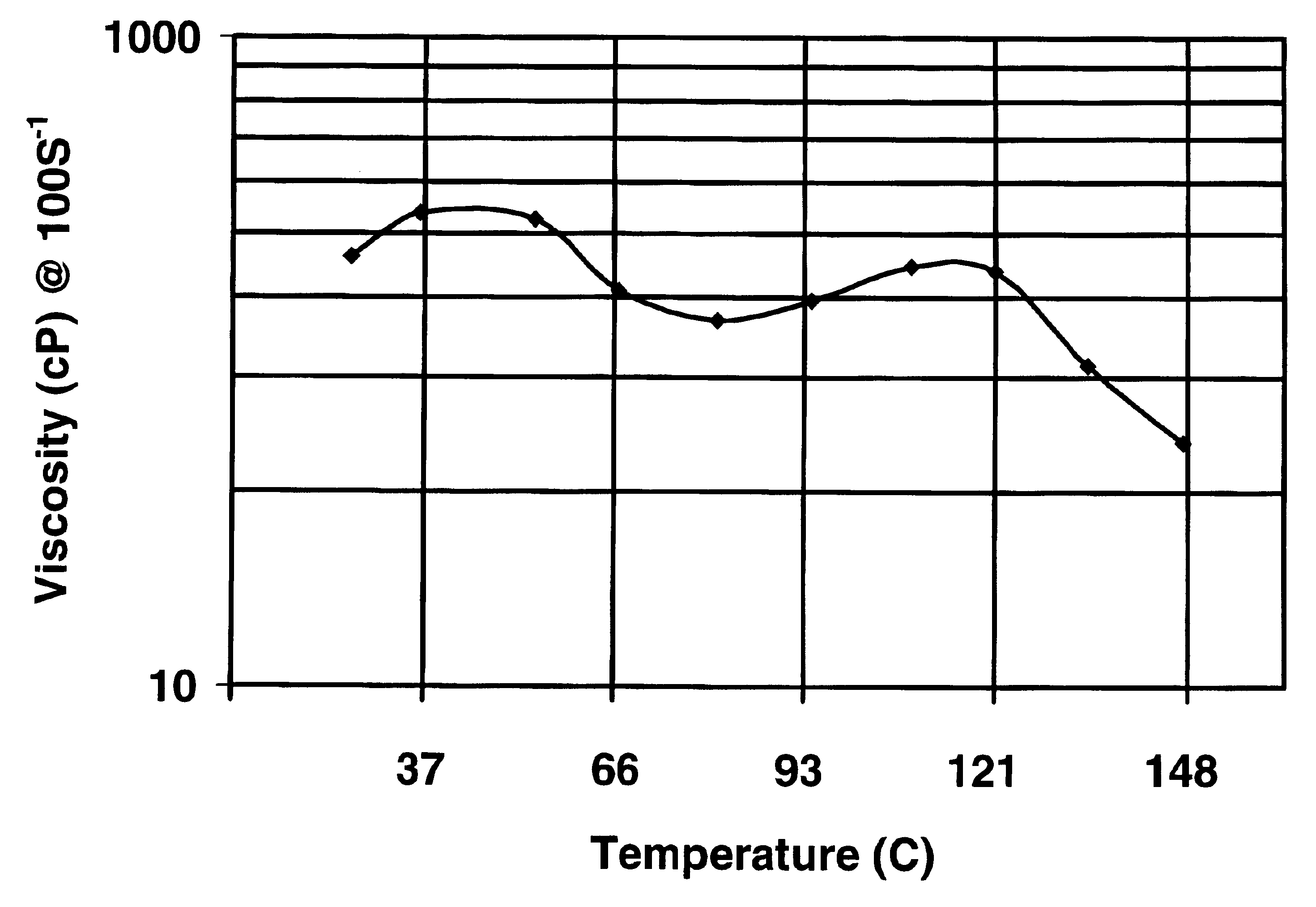

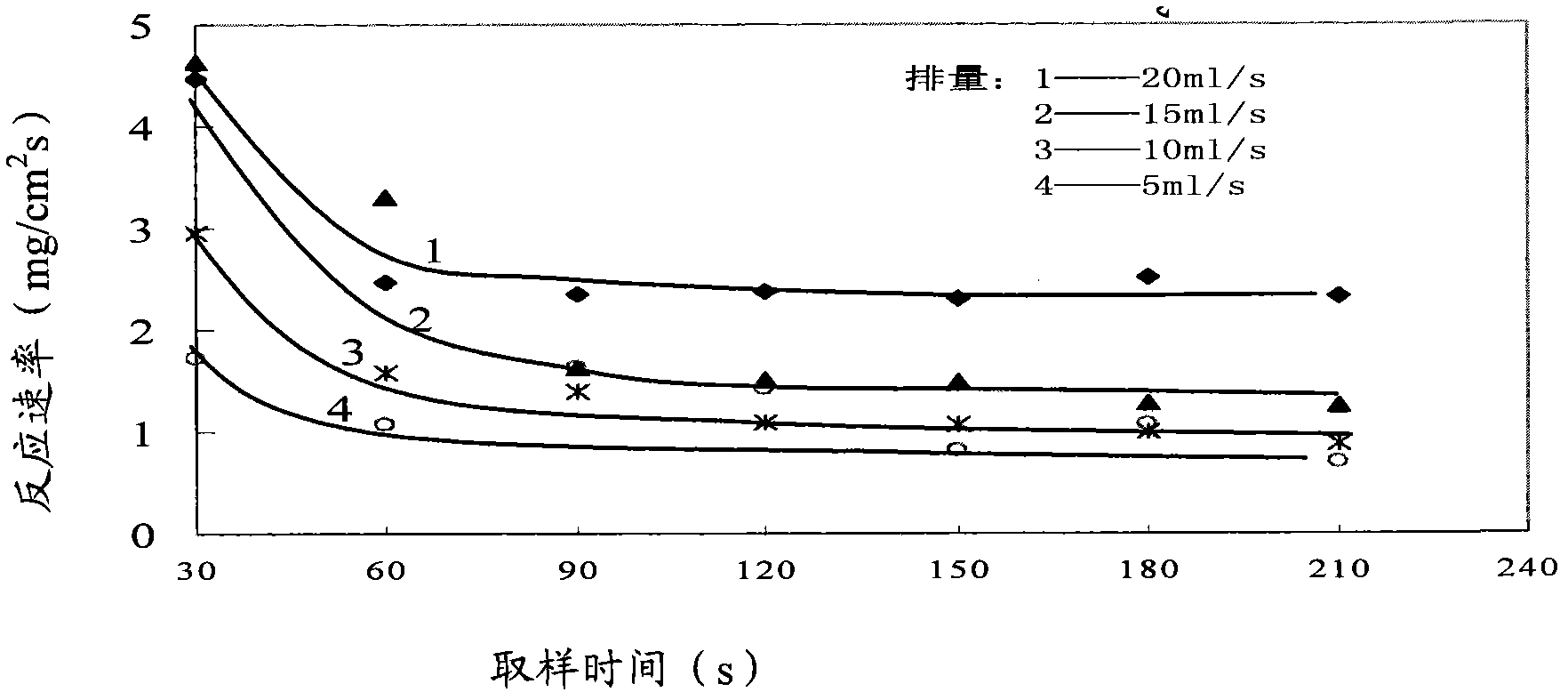

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

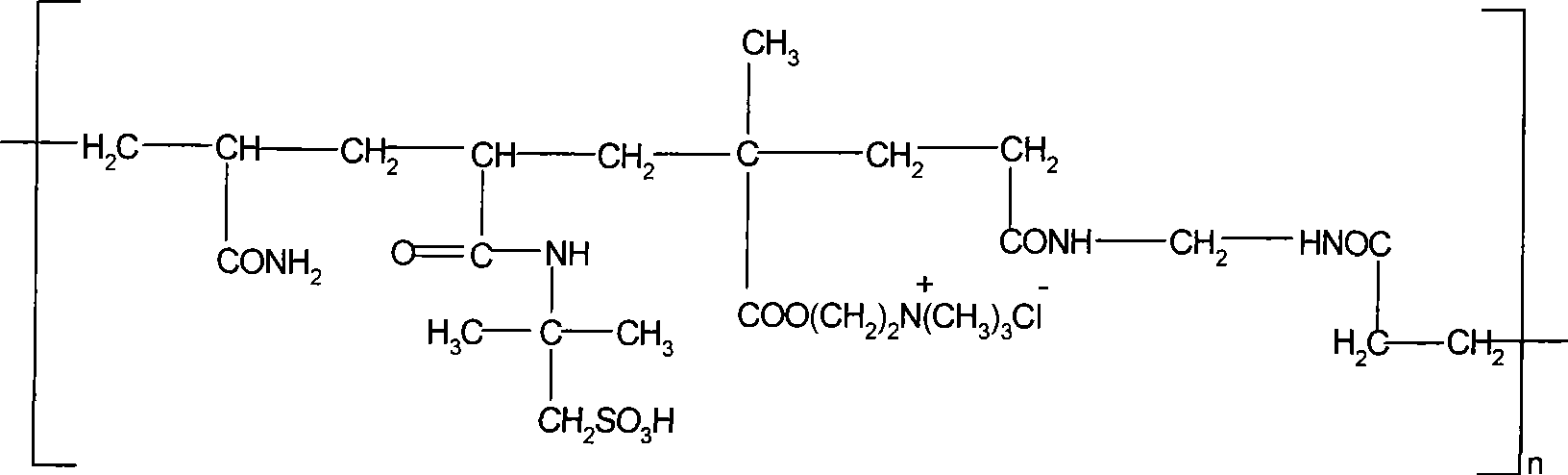

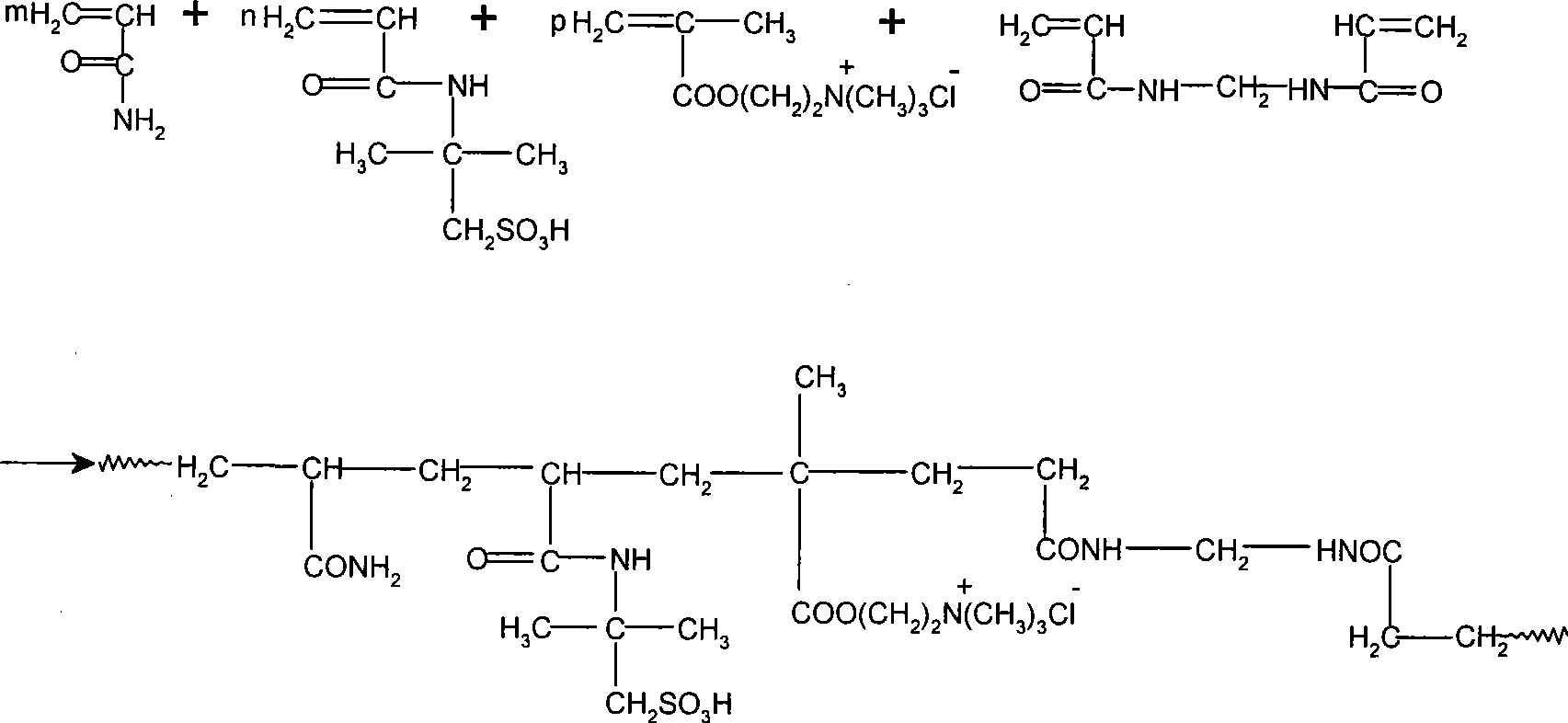

Acid fracturing thickening agent and preparation thereof

InactiveCN101412906AHigh viscosityImprove high temperature resistanceDrilling compositionTemperature resistancePetroleum

The invention discloses a novel acidified fractured thickening agent and a preparation method thereof, and belongs to the field of macromolecular synthesis. The thickening agent is prepared by the method comprising the following steps: adopting a water solution polymerizing method, oxidizing and reducing an evocating agent, adding proper amount of chain extender into a sealed system, and copolymerizing the mixture by the reaction of methacryloyloxy trimethyl-ammonium chloride (DMC), acrylamide (AM) and 2-acrylamido-2-methyl propane sulfonic acid (AMPS). The thickening agent has the advantages of acid resistance and high temperature resistance, has favorable thickening effect, and is applied to the fields of acidified fracturing construction, strengthening oil extraction work and the like in petroleum extraction.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

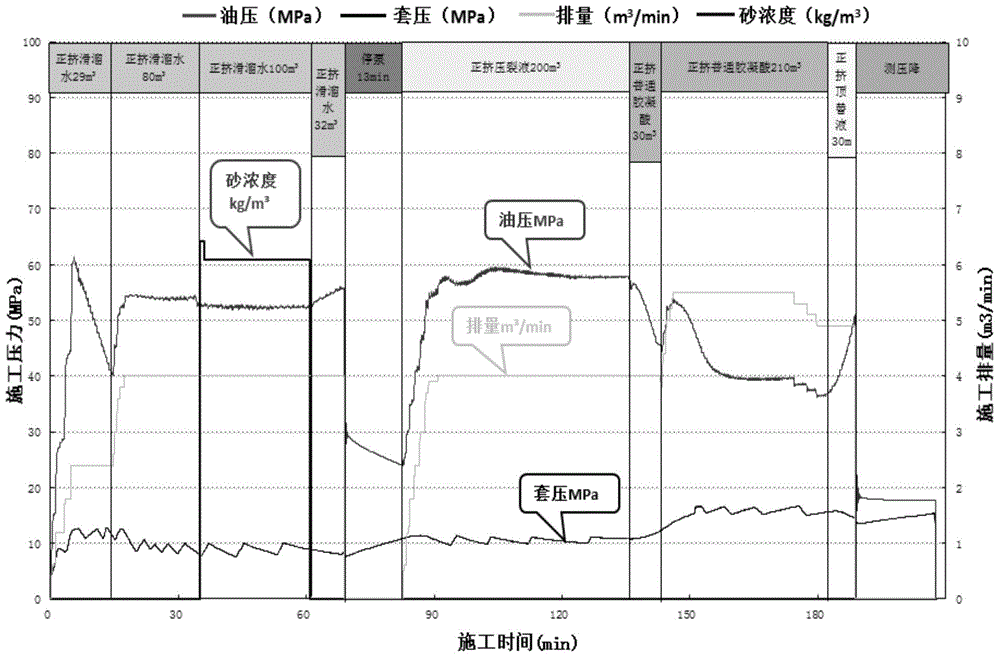

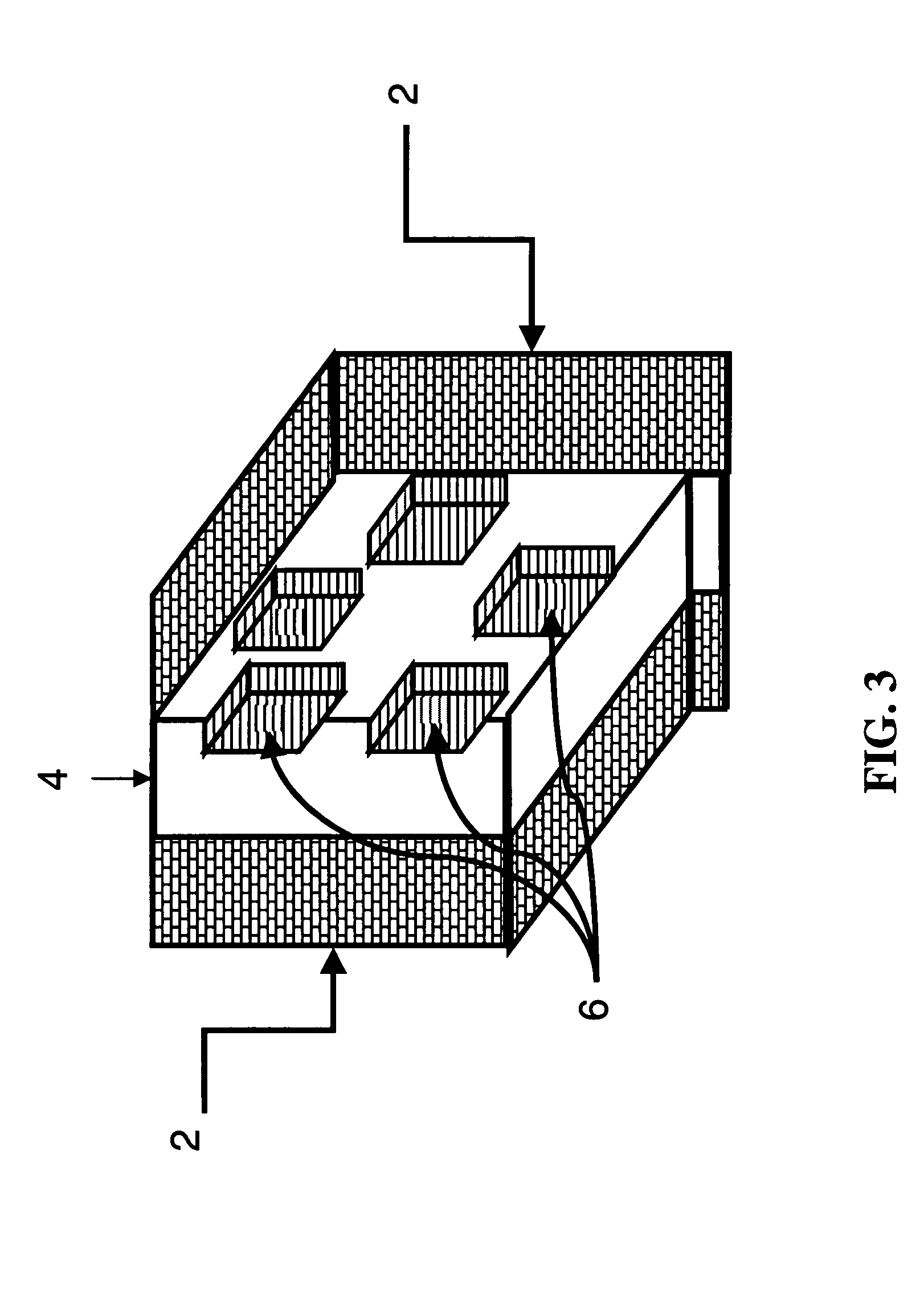

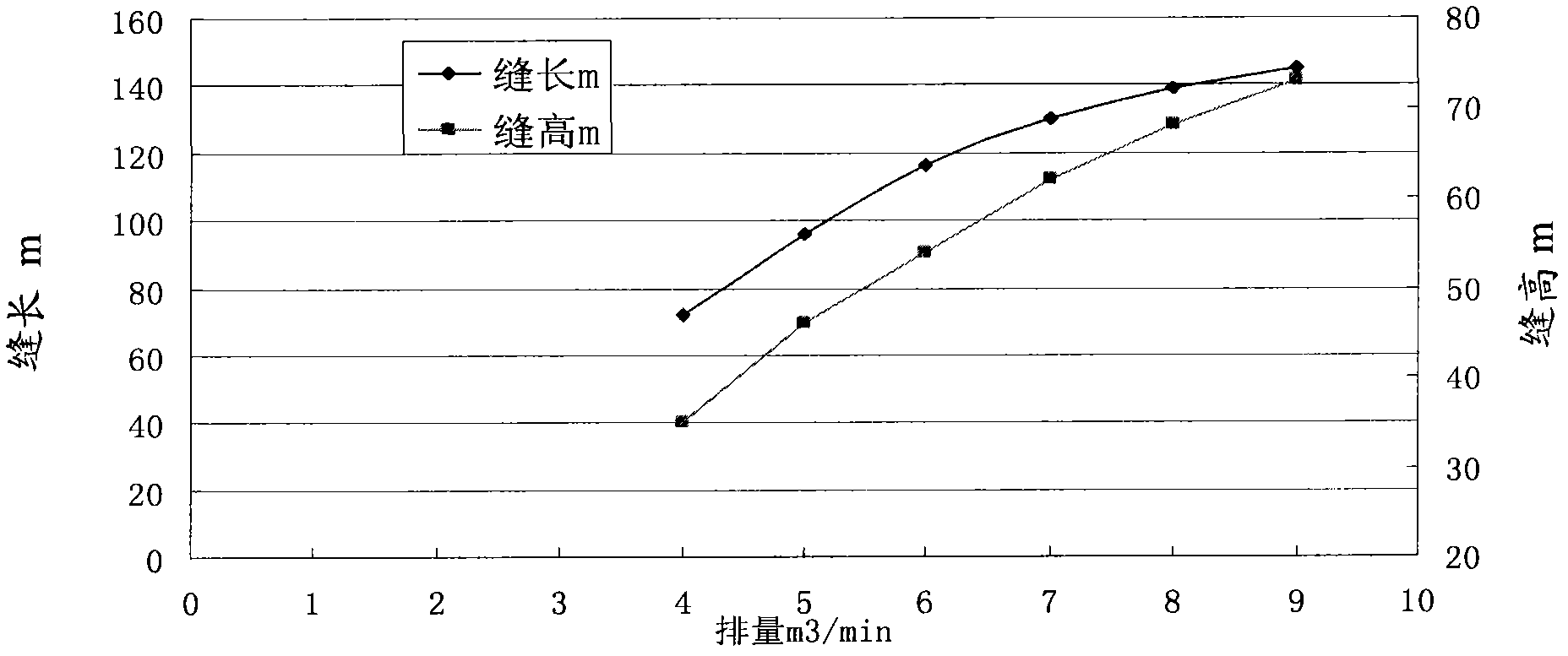

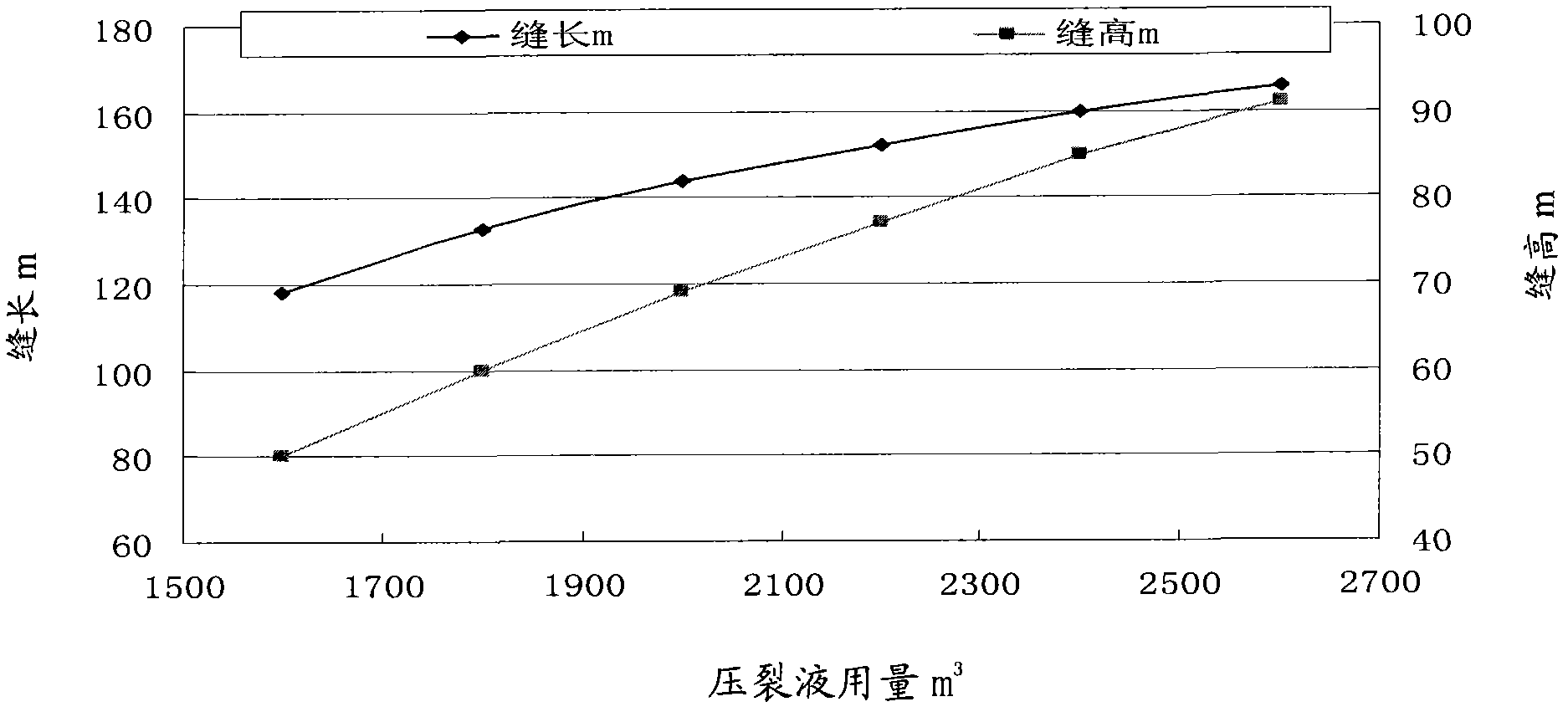

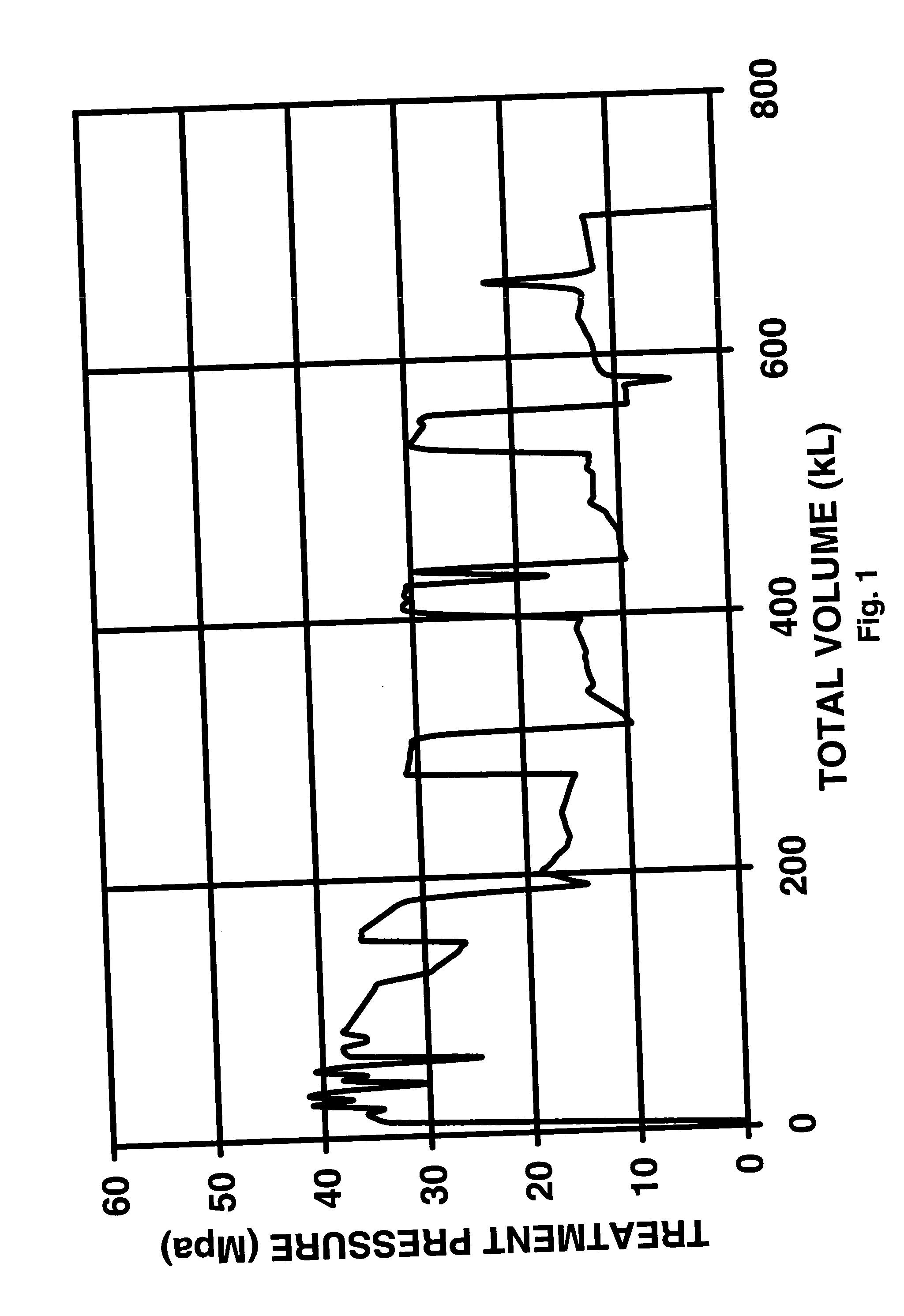

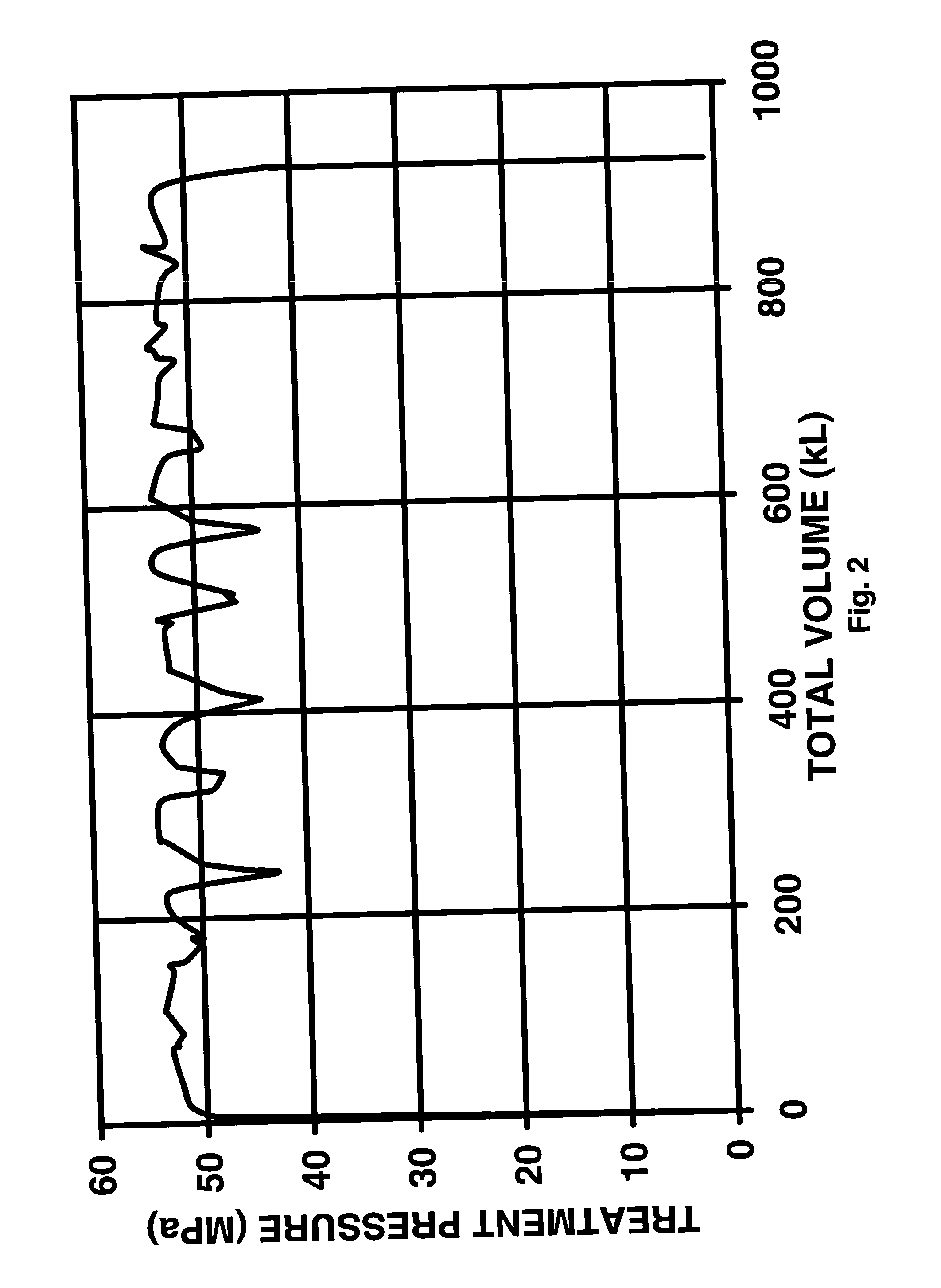

Large composite acid fracturing method of fracture cave type carbonate rock reservoir

The invention relates to a large composite acid fracturing method of a fracture cave type carbonate rock reservoir. The method is characterized by comprising the following steps of while communicating a plurality of fracture caves on the periphery of a shaft of the reservoir: (1) filling quick water into the stratum through the oil pipe of the mixed filling with the oil sleeve; (2) adding powdered ceramic to the stratum through the oil pipe; (3) filling acid liquid into the stratum through the oil pipe for the first time; (4) filling acid liquid into the stratum through the oil pipe for the second time; and (5) filling excess displacing liquid through the oil pipe or the mixed filling with the oil sleeve, wherein the large composite acid fracturing method indicates that the total construction liquid quantity is more than 2,000m<3>. The invention improves the length of an artificial acid fracturing fracture to reach longer than 140m and solves the problem that a conventional acid fracturing technology of a fracture cave type carbonate rock reservoir within the range of 200m of the shaft cannot communicate a far-shaft reservoir, and a new fracture cave reservoir is needed to be searched through side tracking.

Owner:CHINA PETROLEUM & CHEM CORP

Self-diverting foamed system

ActiveUS7148184B2Improve foam stabilityIncrease changeFluid removalFlushingAcid fracturingSURFACTANT BLEND

Owner:SCHLUMBERGER TECH CORP

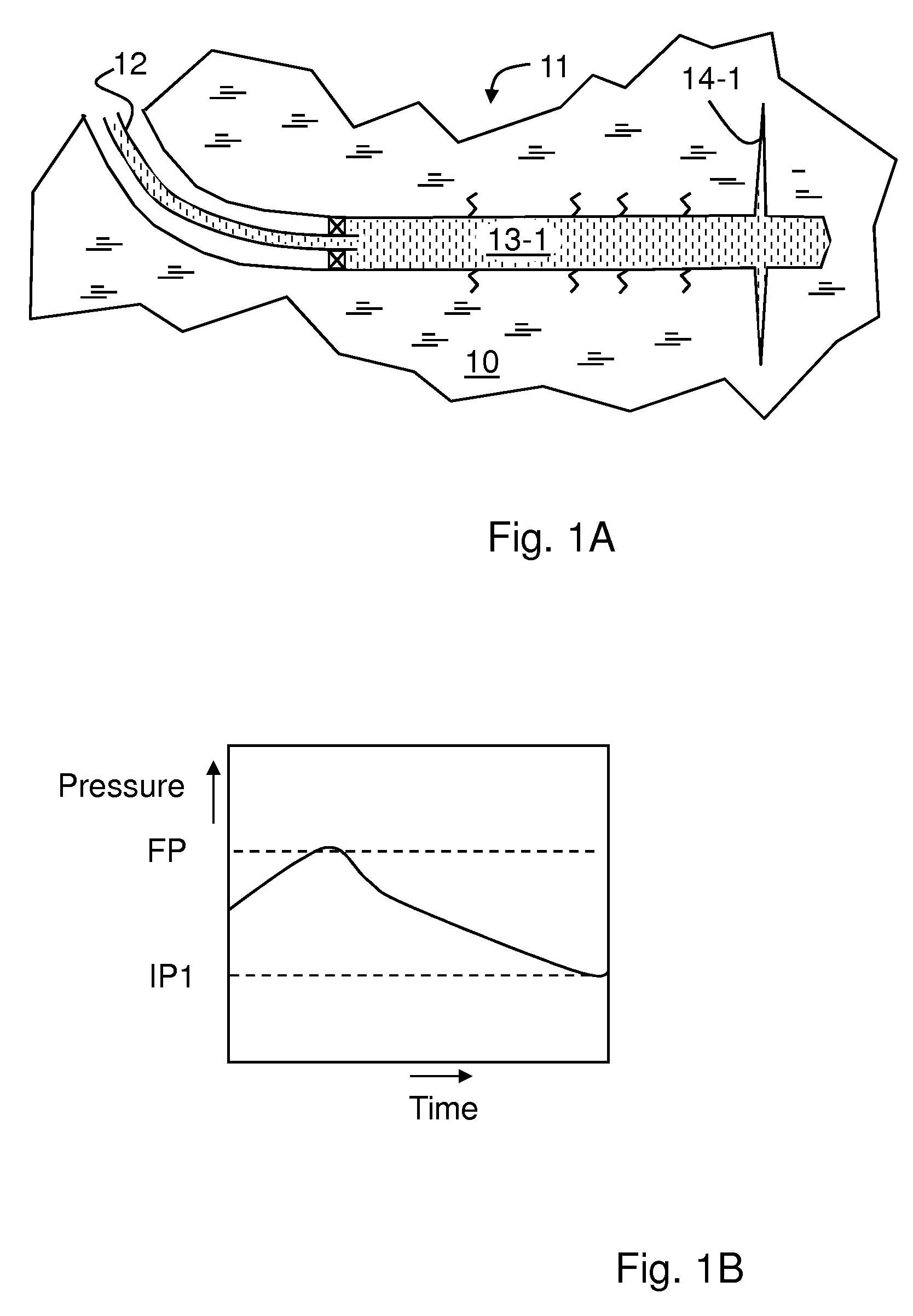

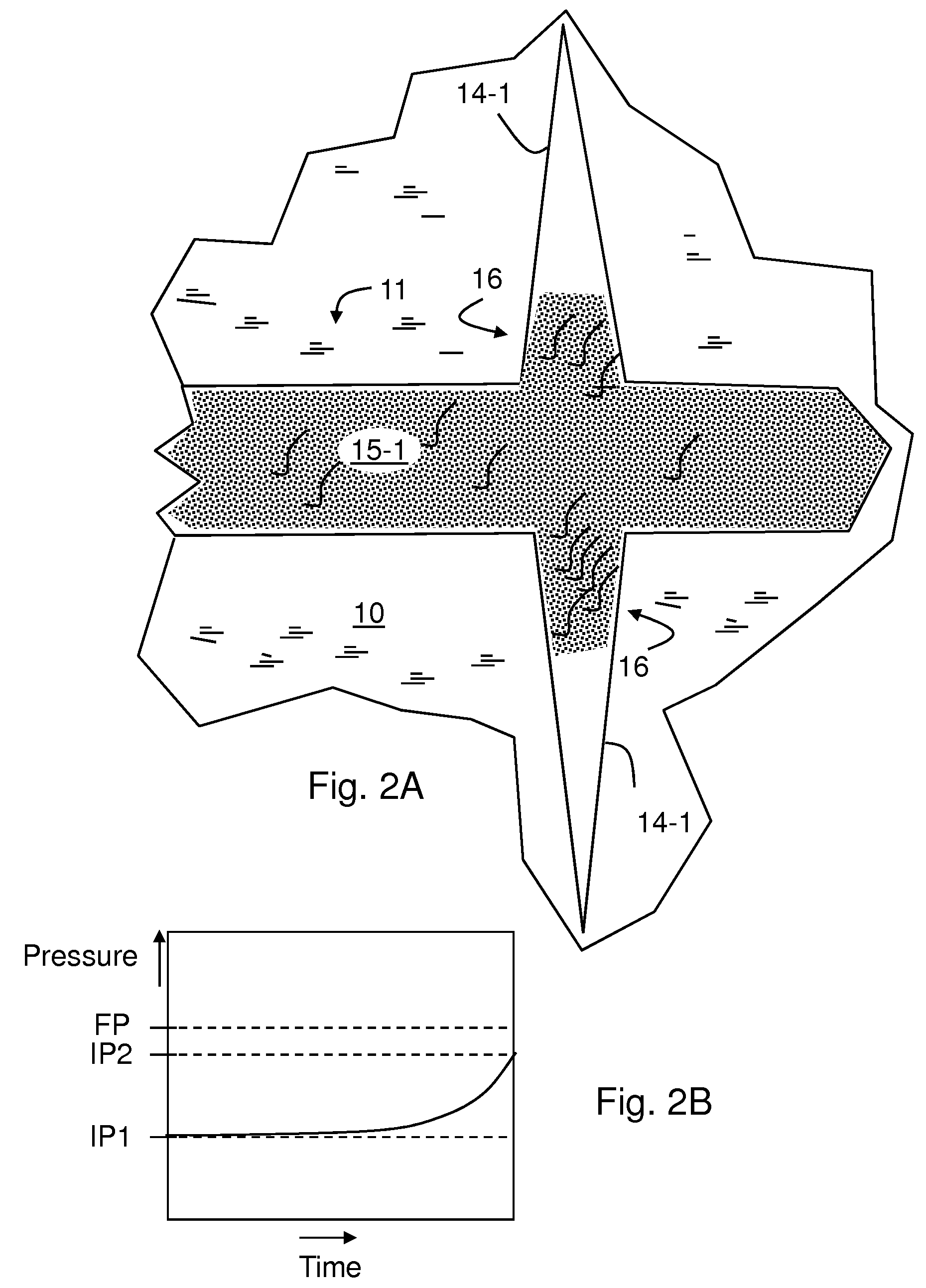

Fracturing method for subterranean reservoirs

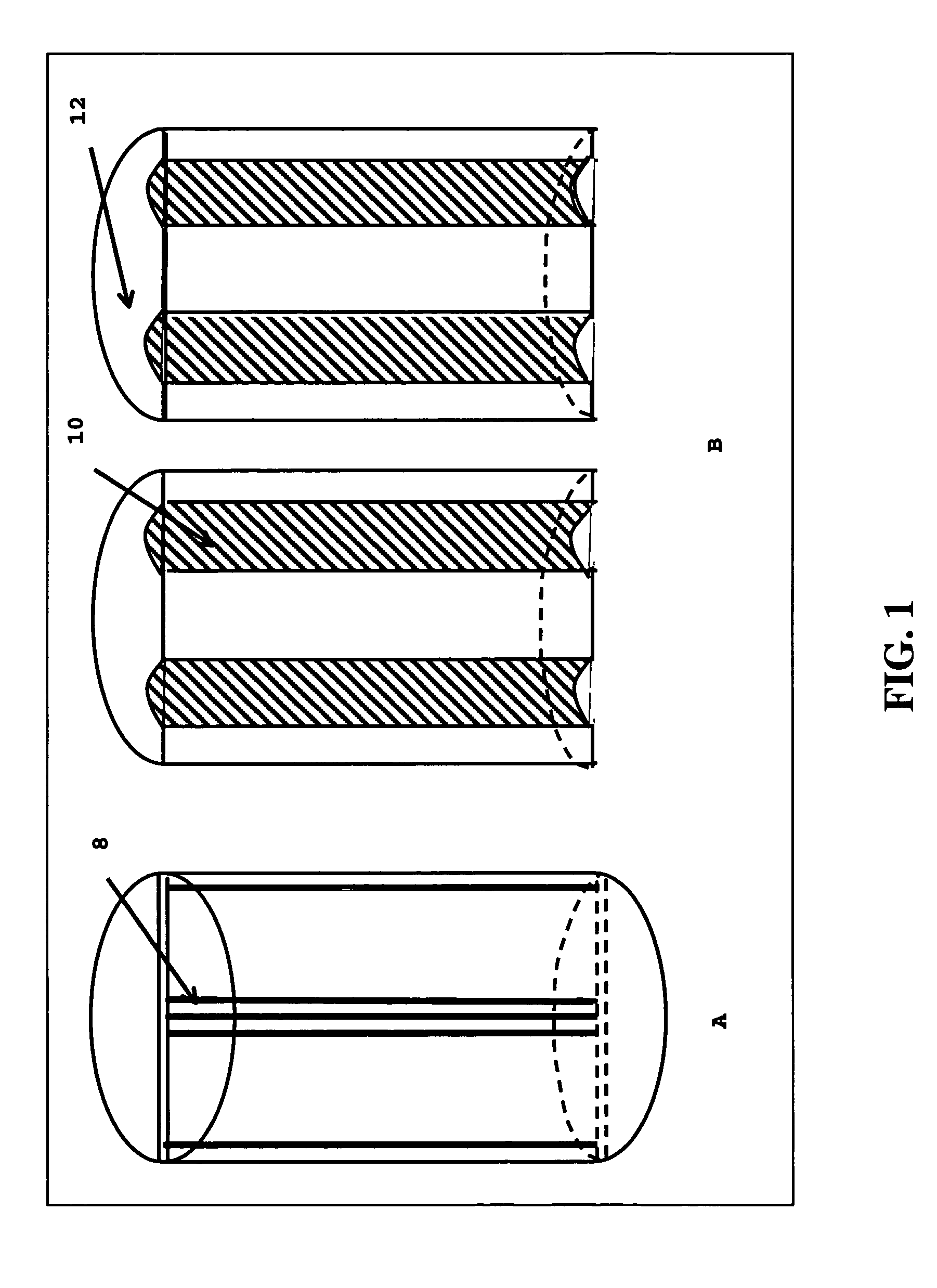

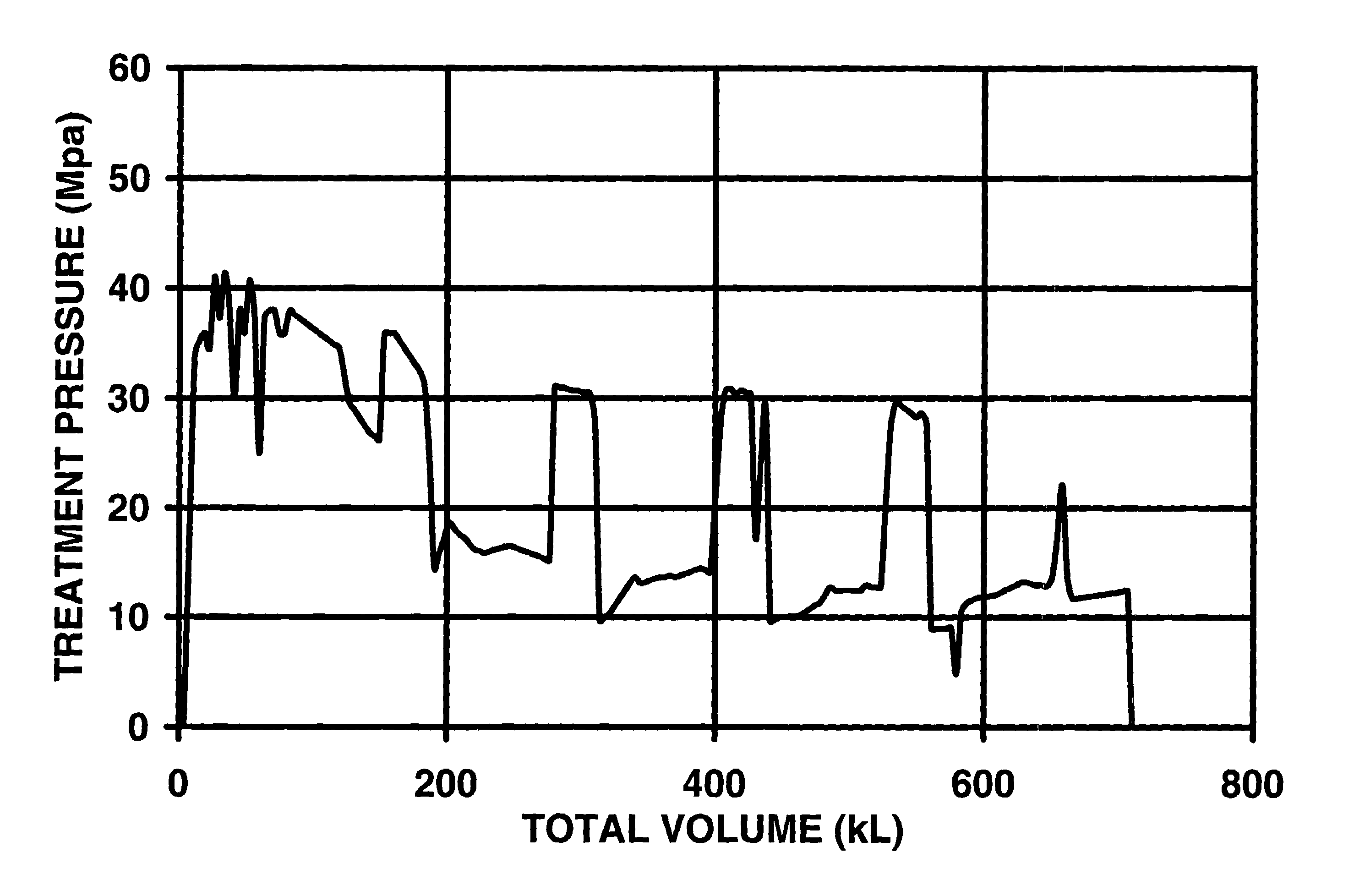

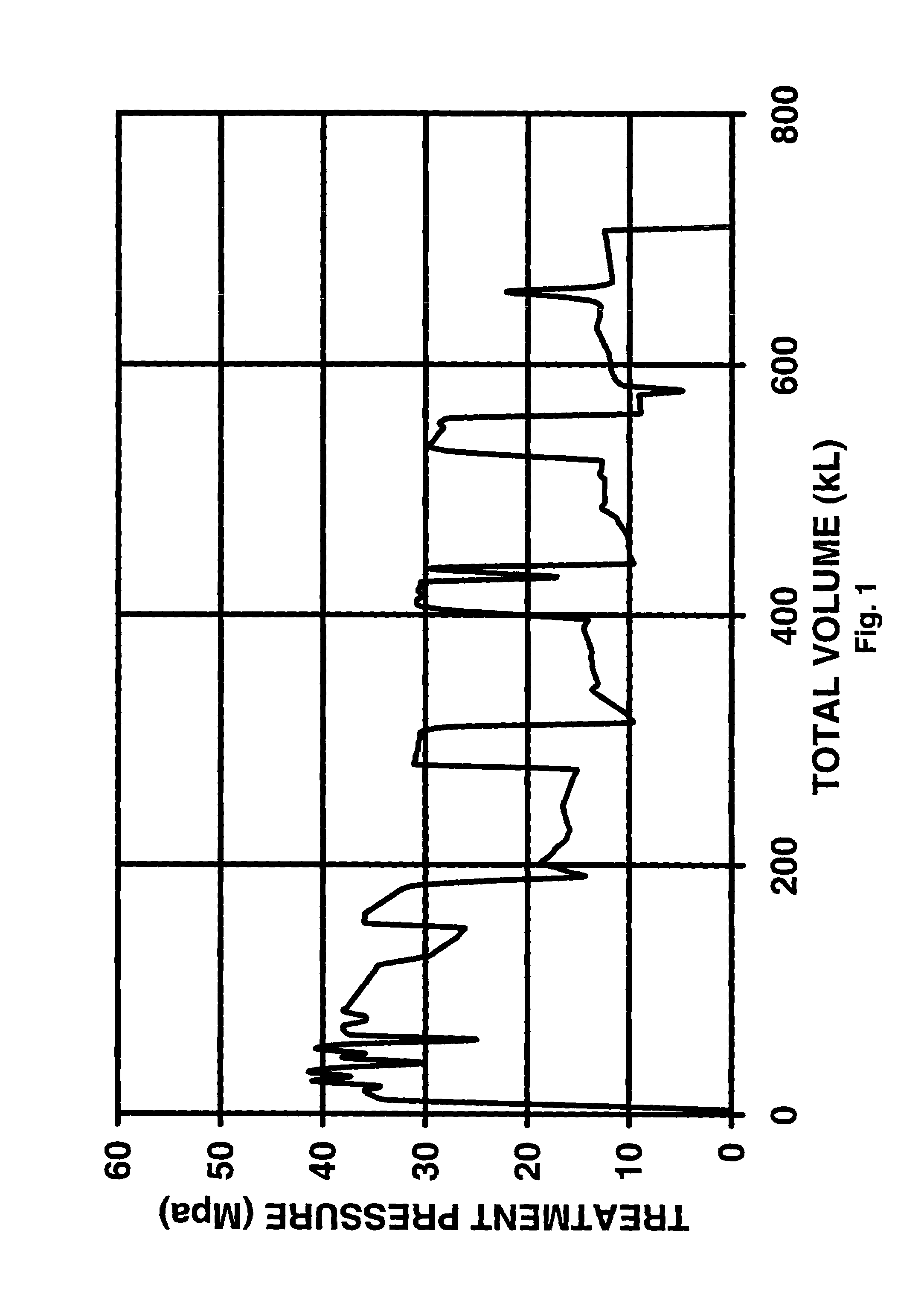

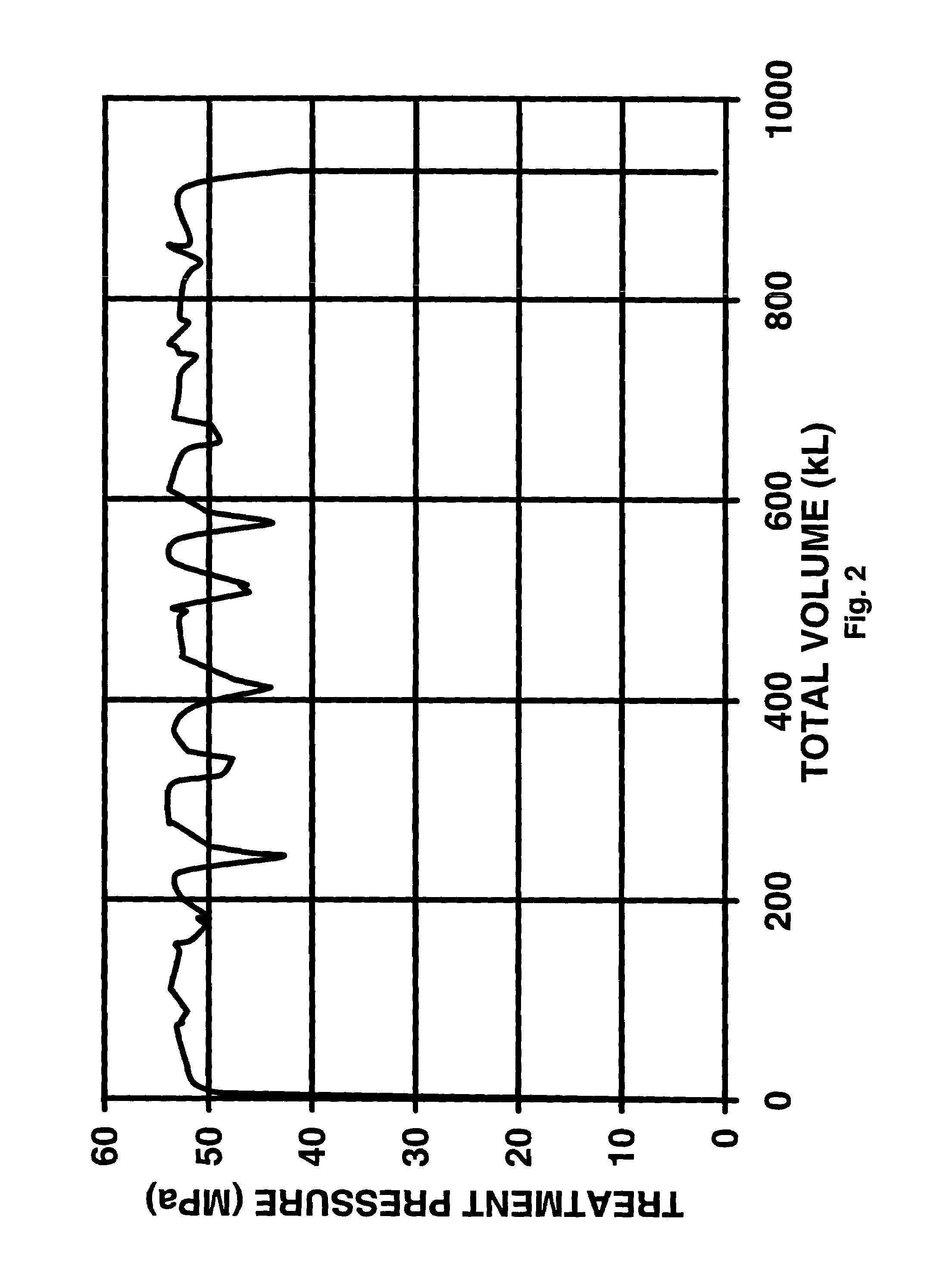

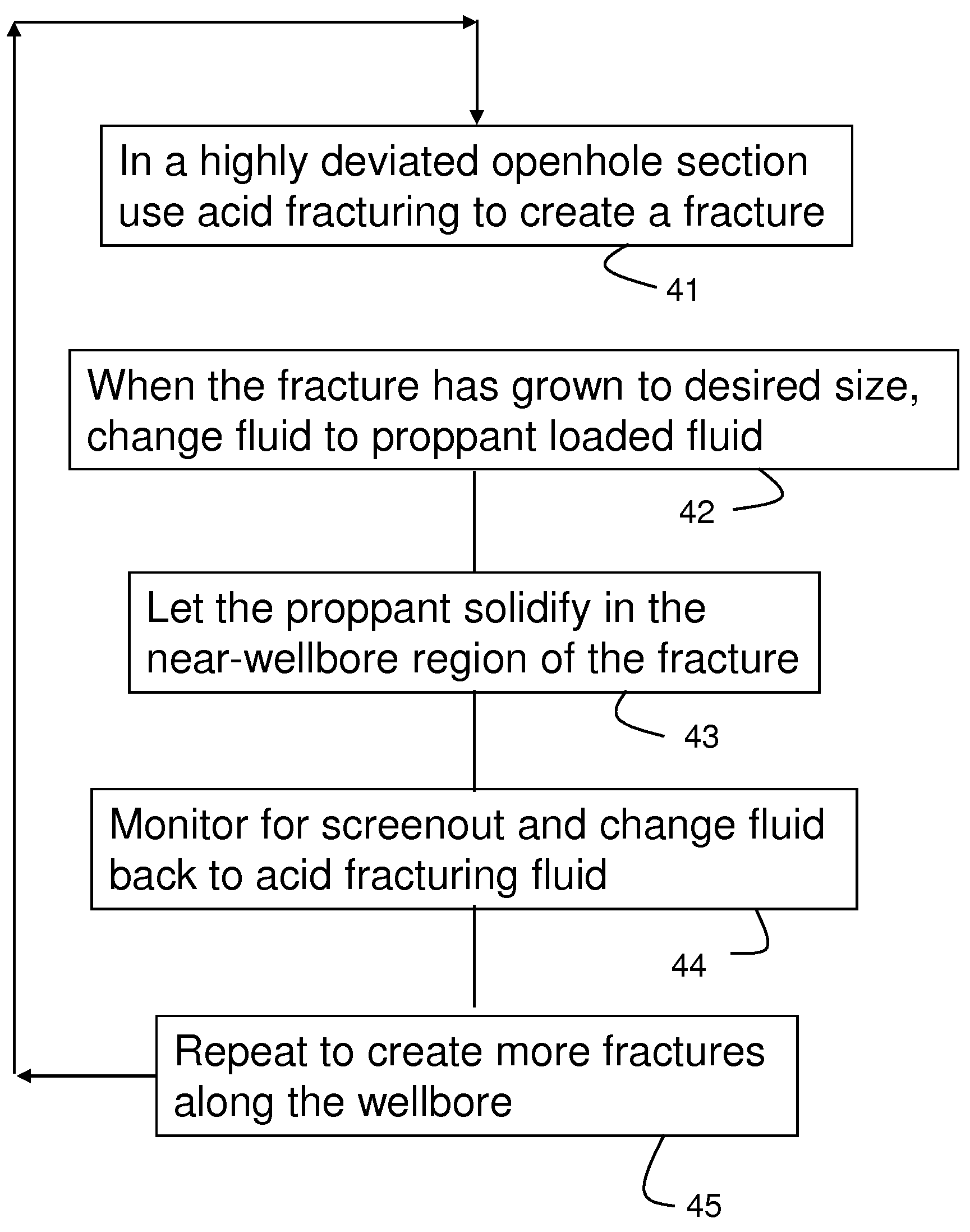

A method of creating multiple fractures in a well traversing a formation is described using pressurized fluids in a highly deviated or horizontal section of the well at a pressure above the fracturing pressure of the formation, wherein for creating a fracture the pressurized fluid is alternated between an acid fracturing fluid and a proppant loaded fluid, such that the proppant blocks the flow of pressurized fluid into a fracture created during a previous step of the method and the subsequently pressurized acid fracturing fluid creates a new fracture at a location along the highly deviated or horizontal section different from the location of the previously created fracture.

Owner:SCHLUMBERGER TECH CORP

Composition and method for treating a subterranean formation

InactiveUS7380602B2Reduce friction pressureEasy to controlFluid removalDrilling compositionAcid fracturingSURFACTANT BLEND

A method of treating a subterranean formation with a retarded self-diverting fluid system. The method includes contacting the formation with a mixture of acid, chelating agent, and betaine surfactant in which the betaine surfactant is mixed with an aqueous solution of the chelating agent in which the pH has been adjusted to a pH of below about 3.0, but above the pH at which the free acid of the chelating agent precipitates, and the resulting fluid system is utilized for both acid fracturing and matrix stimulation, as well as workover procedures such as scale and filter cake removal, especially in high temperature formations.

Owner:SCHLUMBERGER TECH CORP

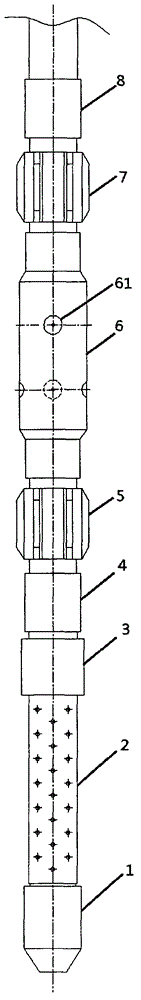

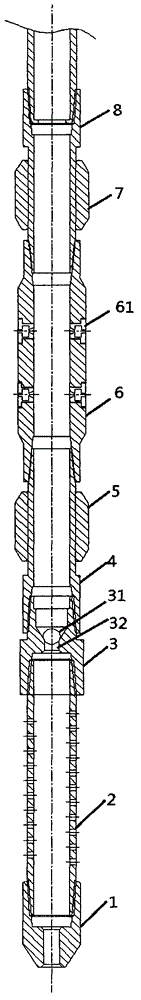

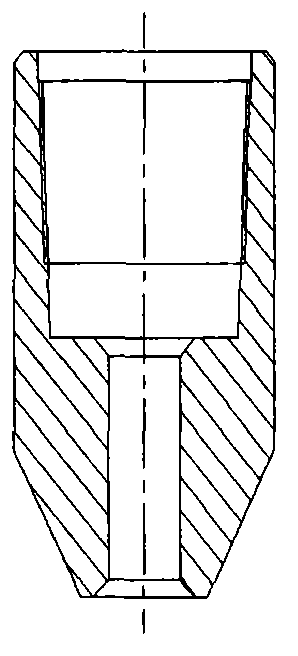

Device and method for immovable-string type packer-free sliding-sleeve hydraulic-jet pulsed acid fracturing

InactiveCN102979497AAvoid the problem of repeated sealing and unsealing, which is easy to failIncrease the lengthDrilling rodsFluid removalAcid fracturingSelf excited oscillation

The invention relates to a device and a method for immovable-string type packer-free sliding-sleeve hydraulic-jet pulsed acid fracturing, belonging to the field of oilfield exploitation and relating to the device and the method for carrying out acid fracturing in a reservoir of an oil / gas well. The device comprises a guide head, a porous tubing nipple, a one-way valve, a first lower nipple, a first centralizer, a first spray gun, a second centralizer and a first upper nipple in sequence from bottom to top, wherein the one-way valve is used for realizing the closing and opening of the device, and the first spray gun is provided with a self excited oscillation nozzle for realizing hydraulic-jet pulsed perforating and acid fracturing. According to the invention, by utilization of a hydraulic entrainment packing effect produced by high-speed pulsed jet to carry out acid fracturing packing, the advantages of simple structure, safety and reliability are achieved; more layers can be subjected to acid fracturing by descending the device for acid fracturing in one step, balls are thrown stepwise to open a sliding sleeve so as to realize the stepwise acid fracturing of multilayer sections of the reservoir by an immovable string, and meanwhile, hydraulic perforating, hydraulic self-packing and pulsed acid fracturing can be realized at the same time; and by means of producing higher fluctuant stagnation pressure on a casing pipe and a well wall, a directional perforated hole can be formed rapidly, and compact belts generated due to explosion of a perforating bullet are prevented for the perforated hole.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

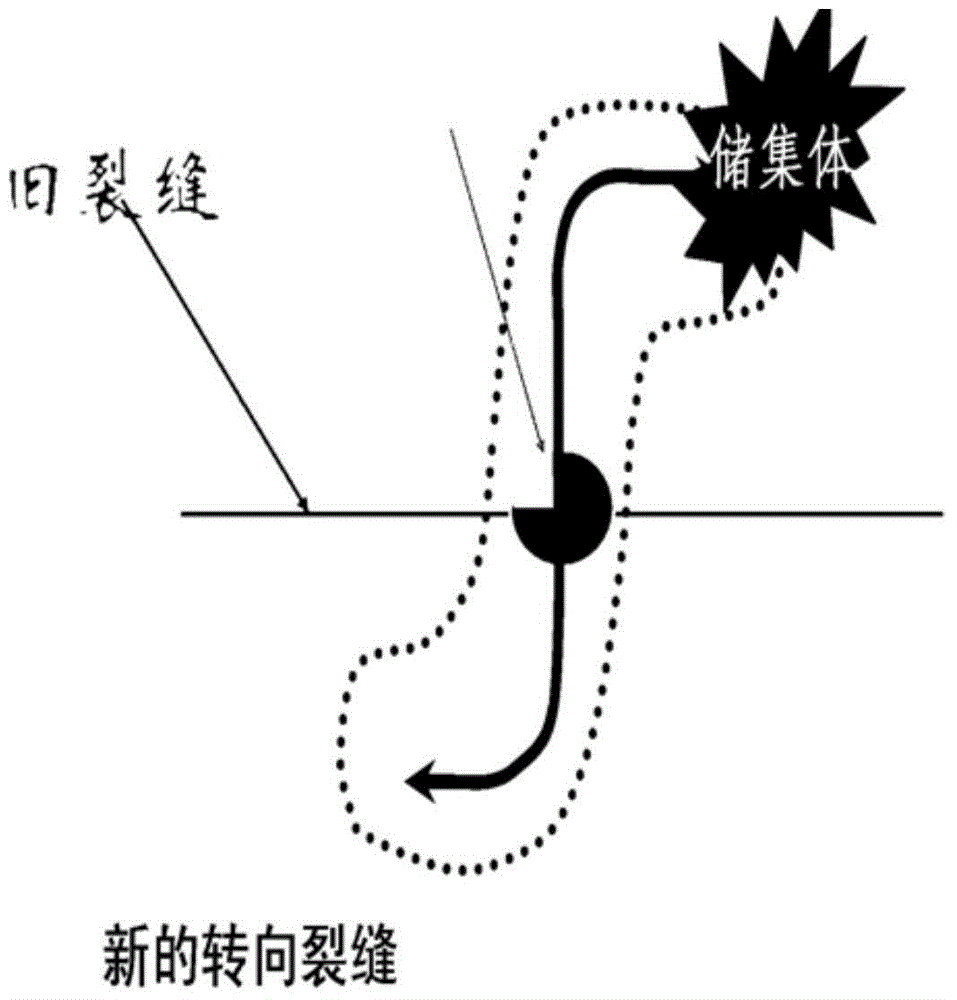

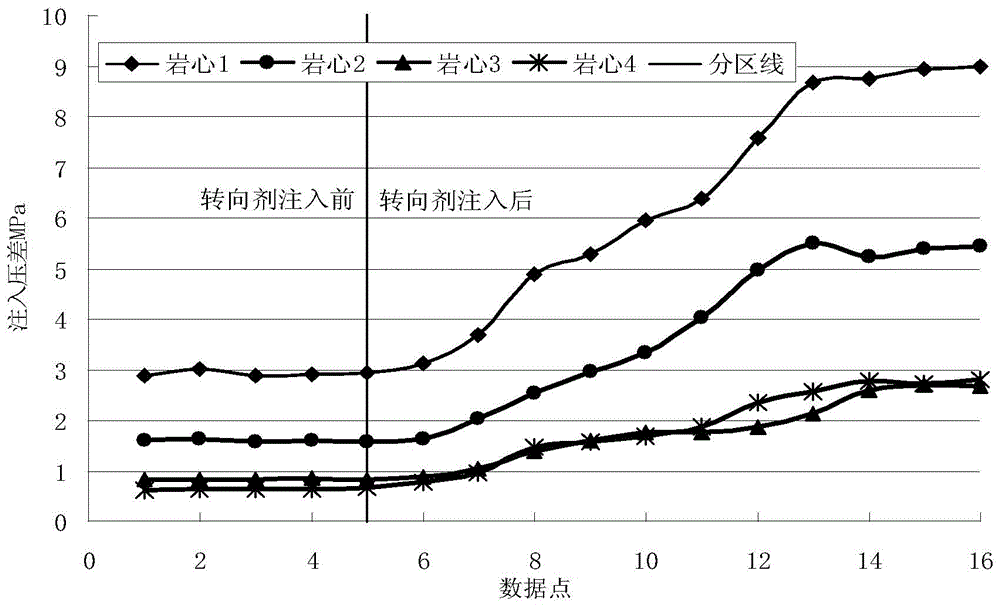

Fractural diverting acid-fracturing method for carbonate oil-gas reservoirs

InactiveCN105041288AImprove acid fracturing efficiencyFluid removalSealing/packingAcid fracturingAcid etching

The invention provides a fractural diverting acid-fracturing method for carbonate oil-gas reservoirs. The method includes the steps of 1, injecting 50-5000 cubic meters of fracturing fluid into a stratum at a displacement speed of 2.0-15.0 m<3> / min; 2, injecting 5-100 cubic meters of material fluid into the stratum at a displacement speed of 1.0-15.0 m<3> / min, and allowing pumping at a displacement speed of 0.5-4.0 m<3> / min after the material fluid enters a preset intra-fracture bridge plug; 3, injecting 50-500 cubic meters of fracturing fluid into the stratum at a displacement speed of 3.0-15.0 m<3> / min to allow forced fractural diverting; 4, injecting 20-300 cubic meters of acid fluid at a speed of 2.0-15.0 m<3> / min to allow modification by acid etching; performing at least one operation of steps from 2 to 4. The method has the advantages that multiple diverted acid-fracturing fractures can be formed after repeated multiple of temporary plugging and fracture forming, temporary plugging material degrades after acid-fracturing construction is complete, low pollution is caused to reservoirs, and the method helps improve acid-fracturing efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +3

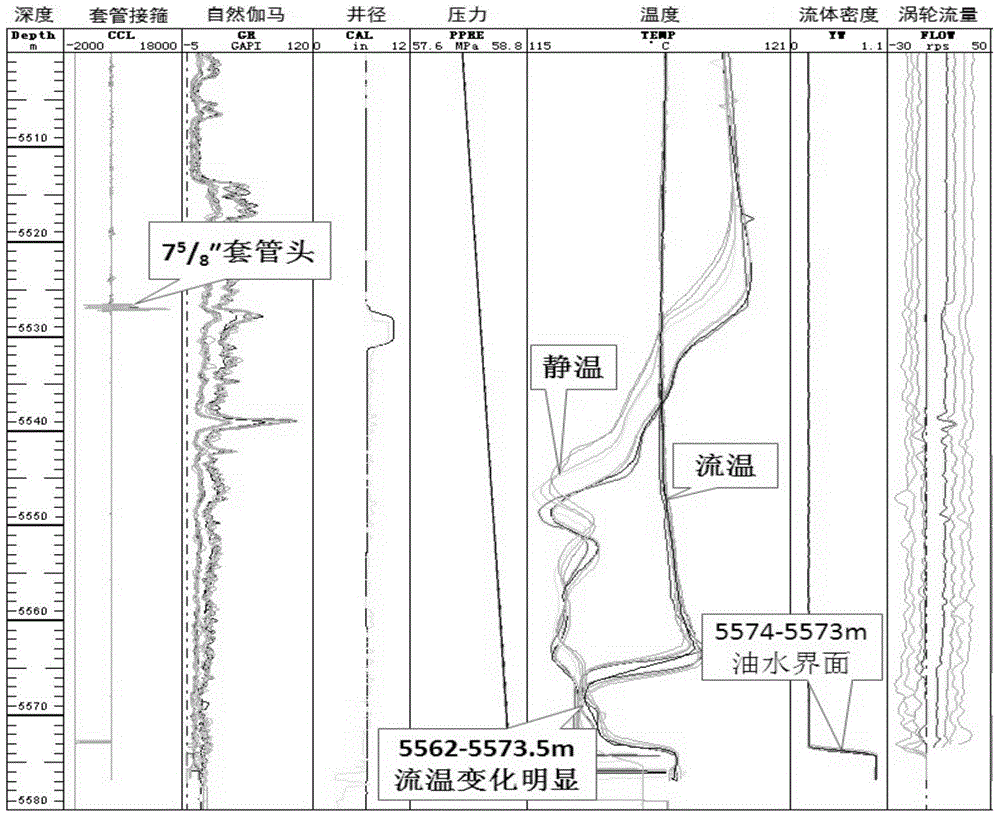

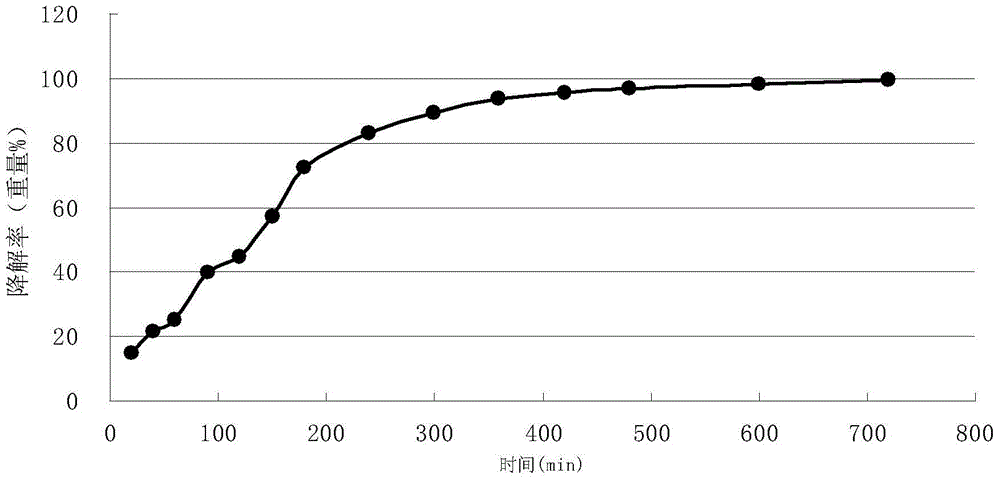

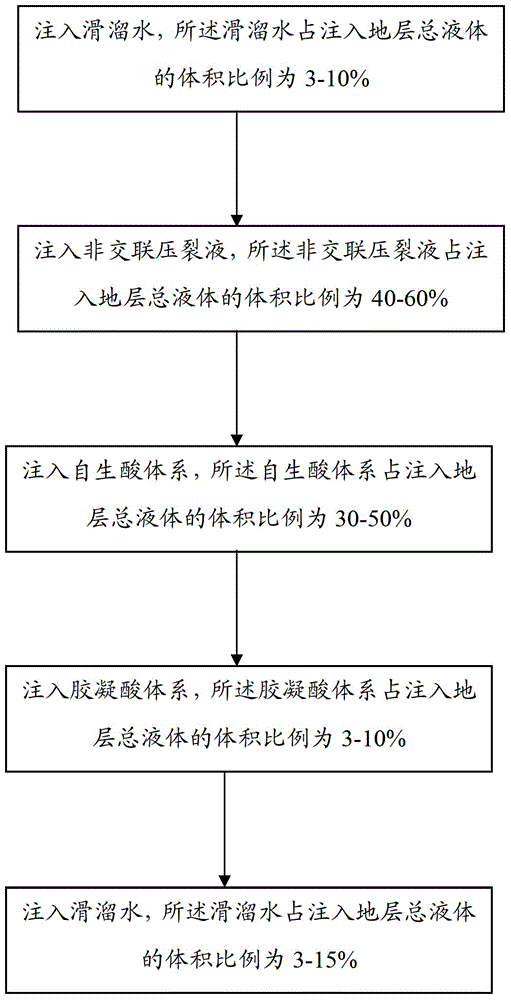

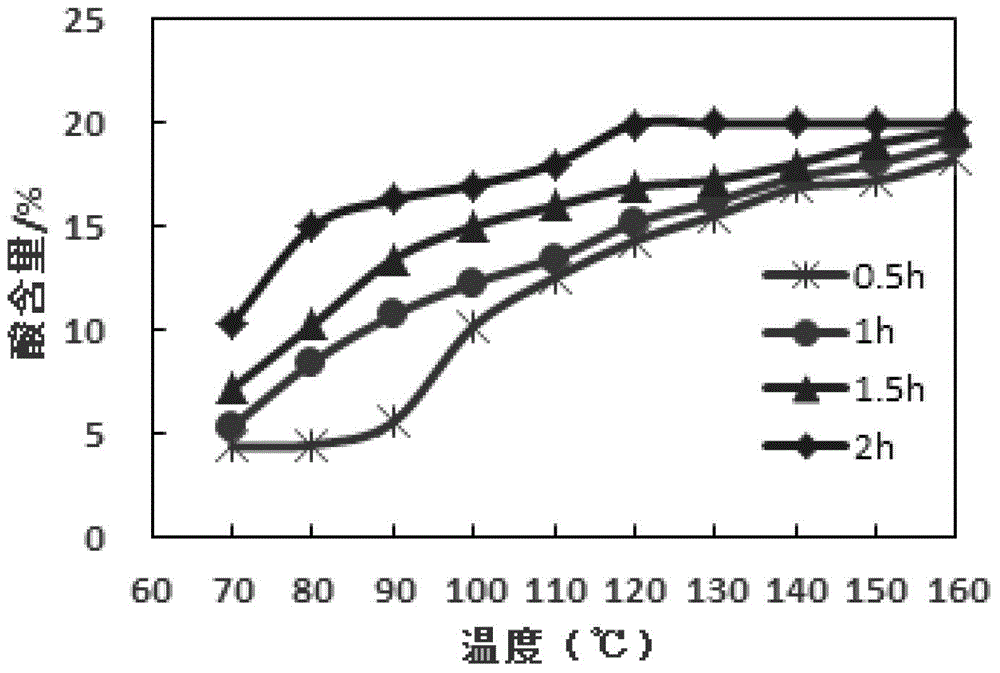

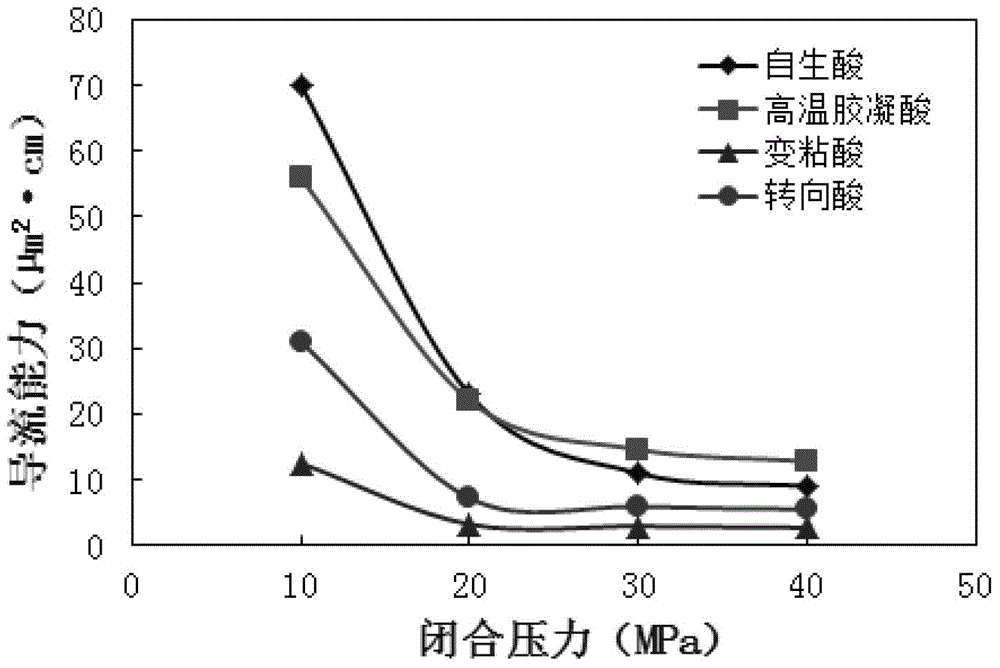

Self-born acid composite acid fracturing process for high-temperature deep well carbonate rock reservoir

ActiveCN104975840AImprove diversion capacityReduce corrosion rateFluid removalAcid fracturingHot Temperature

The invention relates to a self-born acid composite acid fracturing process for a high-temperature deep well carbonate rock reservoir. The process comprises the following work procedures of: (1) injecting slick water into a stratum through an oil pipe; (2) injecting non-crosslinked fracturing liquid into the stratum through the oil pipe; (3) injecting a self-born acid system into the stratum through the oil pipe; (4) injecting a gelled acid system into the stratum through the oil pipe in a low-displacement mode; and (5) injecting the slick water into the stratum through the oil pipe, wherein the volume proportions of liquid, accounting for the total liquid injected into the stratum, injected in the first to fifth work procedures are shown as follows: the slick water in the first work procedure accounts for 3 to 10 percent; the non-crosslinked fracturing liquid in the second work procedure accounts for 40 to 60 percent; the self-born acid system in the third work procedure accounts for 30 to 50 percent; the gelled acid system in the fourth procedure accounts for 3 to 10 percent; the volume proportion of the slick water in the fifth work procedure is 3 to 15 percent; and the volume unit is m<3>. Through the self-born acid composite acid fracturing process, the flow guide capability is improved by more than 140md.m, and the deep penetration effect of the high-temperature deep well carbonate rock reservoir is obvious.

Owner:CHINA PETROLEUM & CHEM CORP

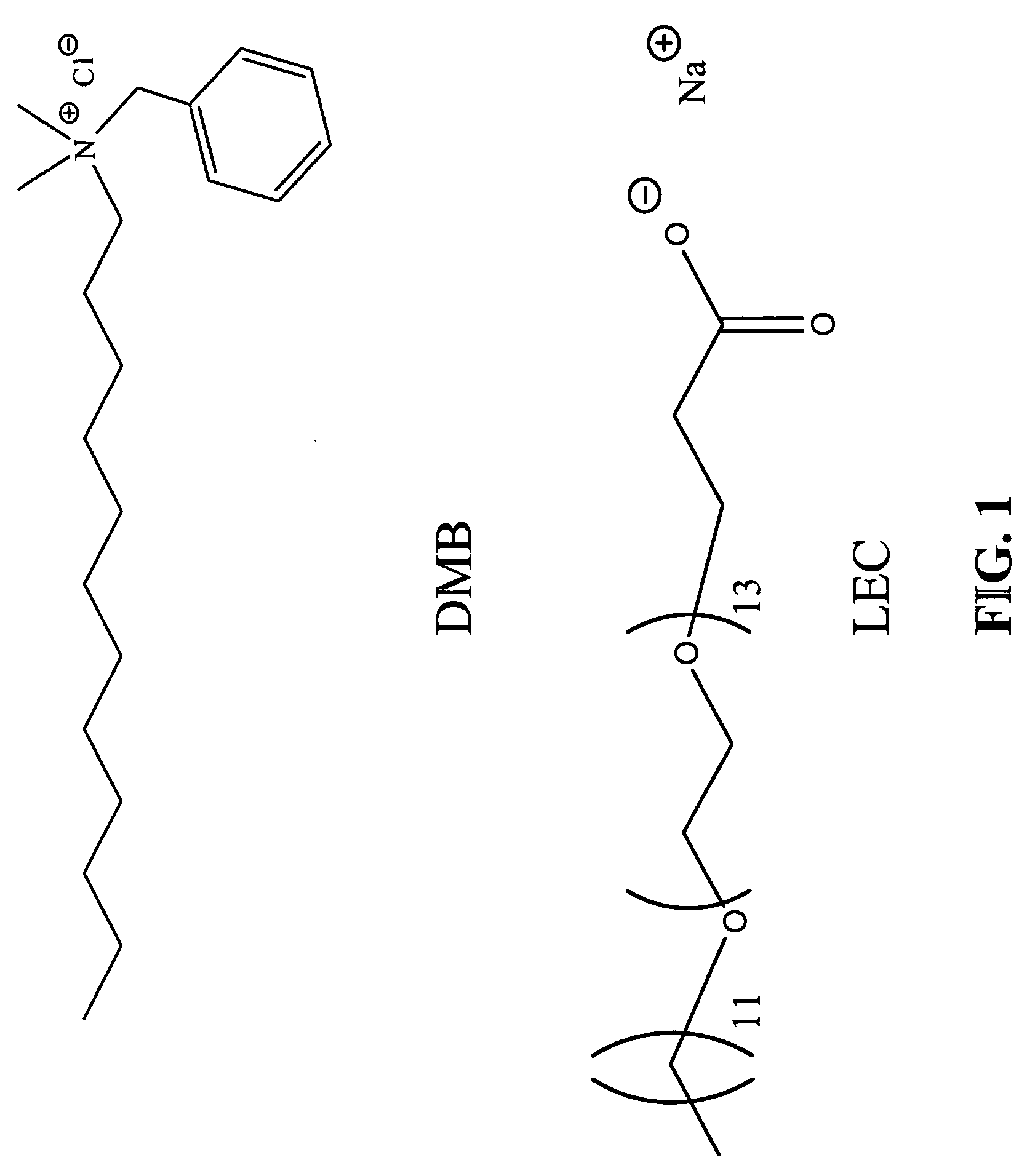

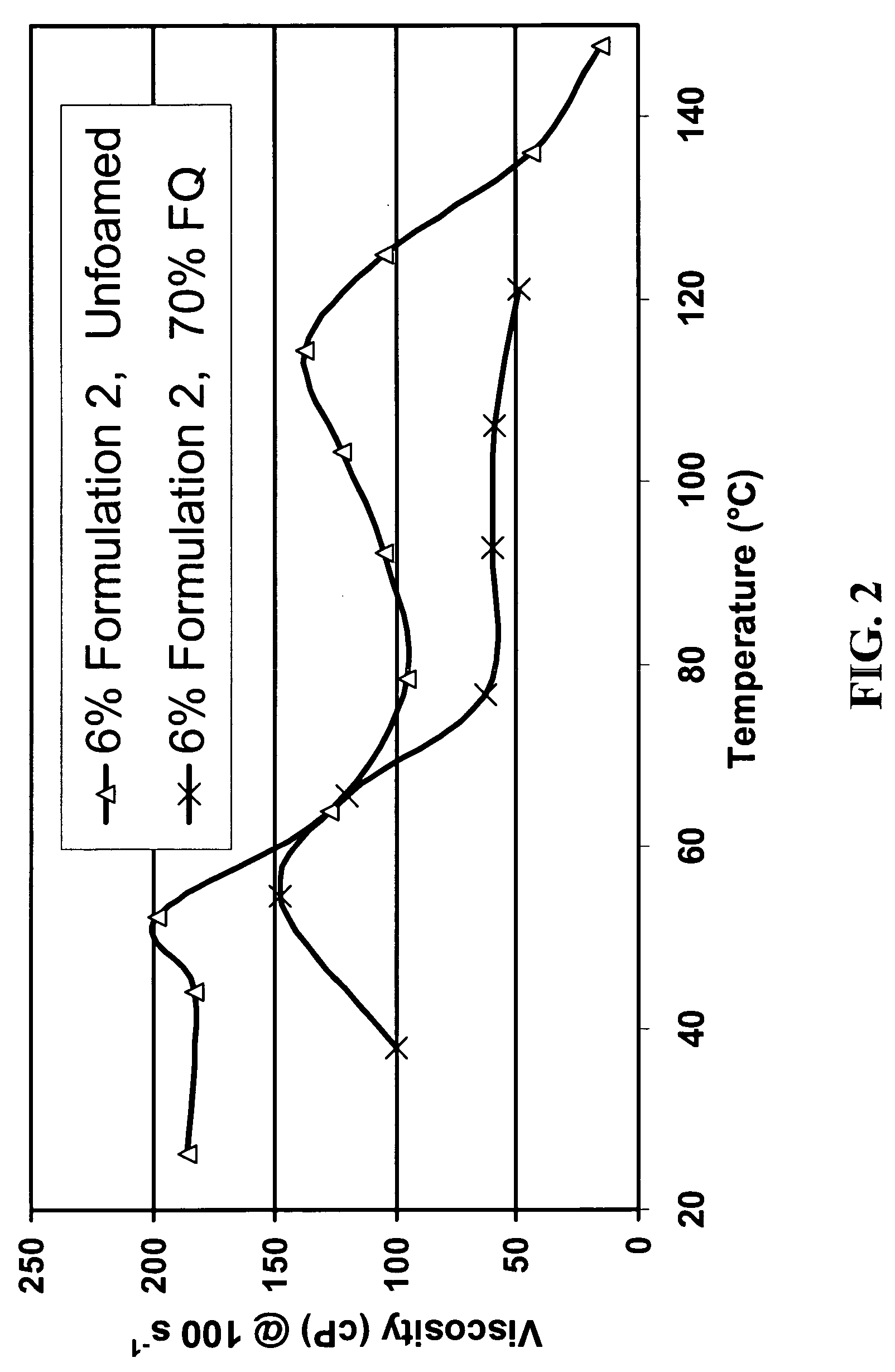

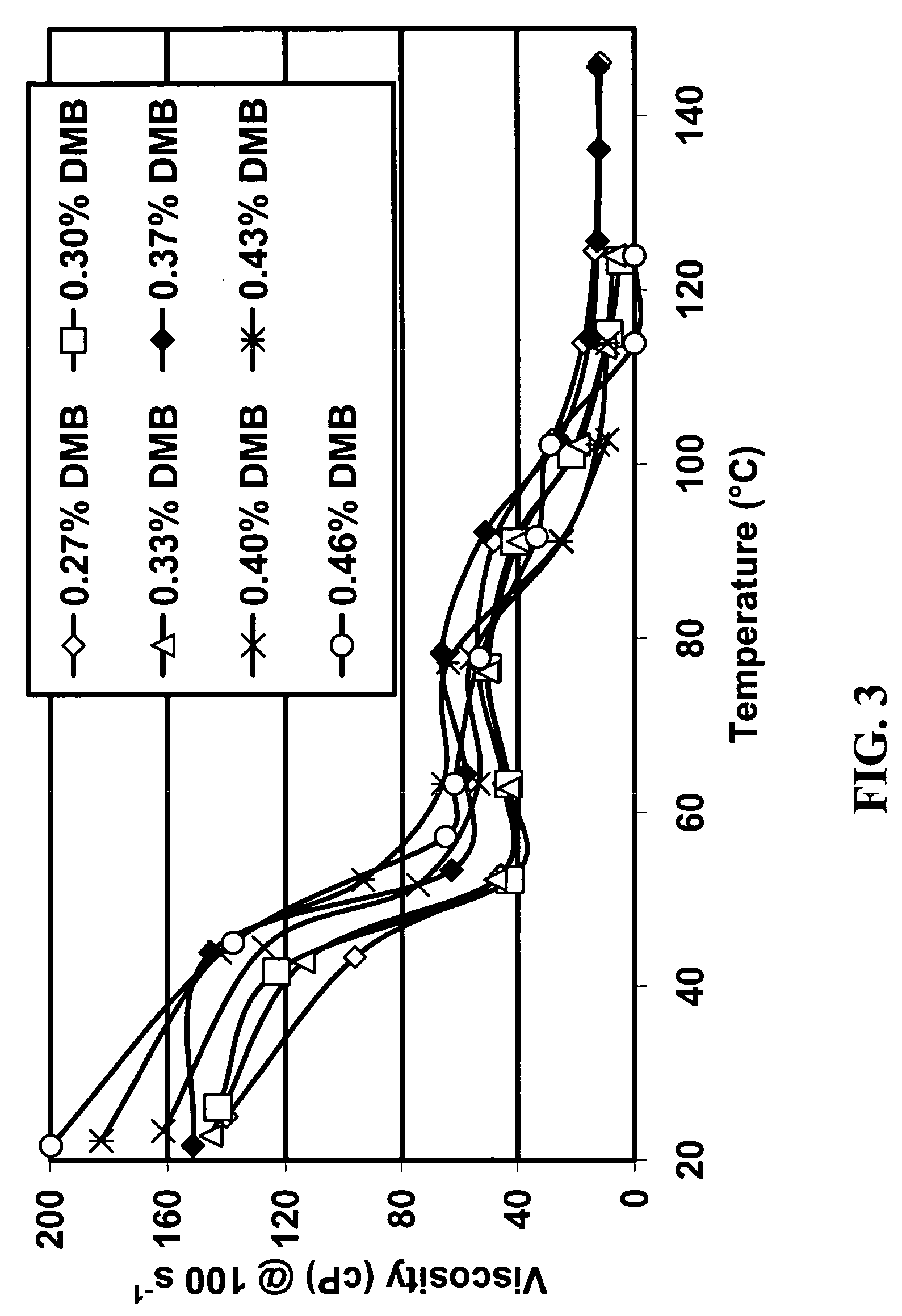

Self-diverting foamed system

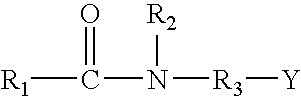

ActiveUS20050020454A1Improving self-diversion performanceHigh viscosityFluid removalFlushingAcid fracturingViscosity

A method is given for diverting acids in matrix acidizing and acid fracturing. The acids are diverted with a diverting agent that is an energized or foamed acidic viscoelastic surfactant system that contains a viscoelastic surfactant that gels and increases in viscosity when the acid in the foamed acidic viscoelastic surfactant system is spent. The method provides a synergistic combination of the diverting capabilities of foams and the diverting capabilities of viscoelastic gel systems. The resistance to flow of the gelled foamed viscoelastic surfactant system is greater than expected from a foam or a viscoelastic gel system alone.

Owner:SCHLUMBERGER TECH CORP

Composition and method for treating a subterranean formation

InactiveUS20060102349A1Reduce friction pressureFacilitate leak off controlFluid removalFlushingAcid fracturingSURFACTANT BLEND

A method of treating a subterranean formation with a retarded self-diverting fluid system. The method includes contacting the formation with a mixture of acid, chelating agent, and betaine surfactant in which the betaine surfactant is mixed with an aqueous solution of the chelating agent in which the pH has been adjusted to a pH of below about 3.0, but above the pH at which the free acid of the chelating agent precipitates, and the resulting fluid system is utilized for both acid fracturing and matrix stimulation, as well as workover procedures such as scale and filter cake removal, especially in high temperature formations.

Owner:SCHLUMBERGER TECH CORP

Self diverting matrix acid

A method is described for treating a subterranean formation with a low viscosity fluid system that contains a viscoelastic surfactant at a concentration too low to viscosify the fluid, but that is concentrated in the formation so that the fluid system gels. The fluid optionally contains a formation-dissolving agent. The fluid is used in matrix acidizing, acid fracturing, and diversion.

Owner:SCHLUMBERGER TECH CORP

Carbon dioxide foamed fluids

ActiveUS20050124500A1Improve compatibilityOther chemical processesTransportation and packagingAcid fracturingPolymer science

An aqueous viscoelastic surfactant (VES) fluid foamed or energized with carbon dioxide, in which the VES is more compatible with the carbon dioxide, is made by the addition of one or more than one synergistic co-surfactant. The synergist co-surfactant includes quaternary amines and ethoxylated carboxylates having a hydrophobic chain shorter than the hydrophobic chain of the VES. Improved compatibility is evidenced for a given surfactant concentration either by formation and maintenance of a foam under conditions at which the foam could not otherwise have been formed or maintained, or by either higher viscosity of the foamed fluid at a given temperature or longer foam life at a given temperature or a higher temperature at which useful fluid viscosity can be generated or maintained for a useful time. The aqueous carbon dioxide foamed fluids may be used in acidizing, acid fracturing, gravel packing, diversion, and well cleanout.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com