Patents

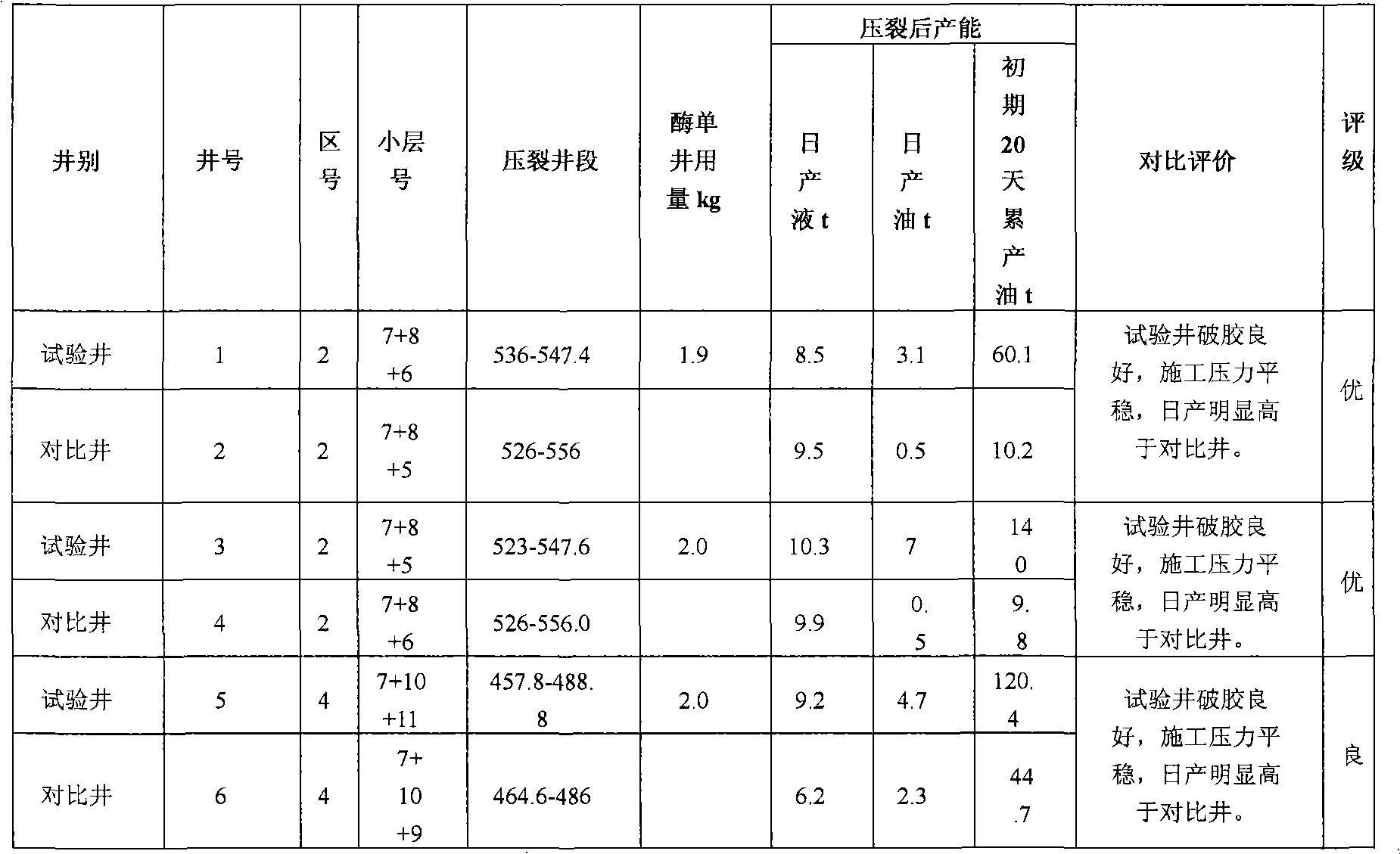

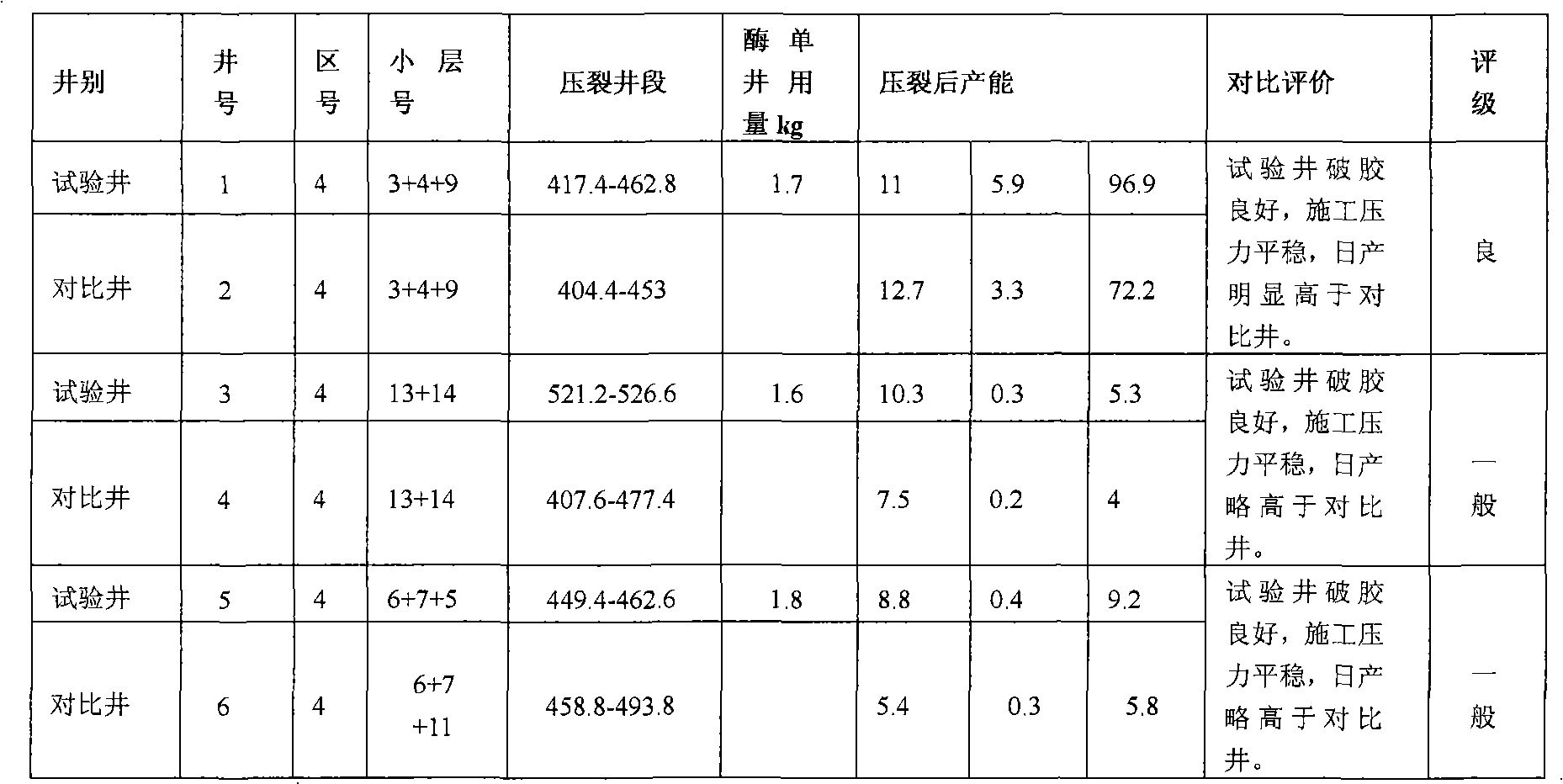

Literature

571results about How to "Improve diversion capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

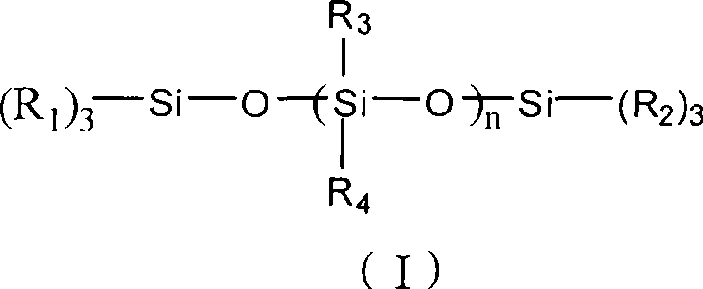

Functional resin tectorial membrane proppant and preparation method thereof

ActiveCN101531893AThrough highPrevent passageFluid removalDrilling compositionTectorial membraneSide chain

The invention relates to a functional resin tectorial membrane proppant and a preparation method thereof, and belongs to the technical field of oil-gas field development. The functional resin tectorial membrane proppant comprises aggregate and a resin film coated on the aggregate. Said resin film comprises organic silicon compounds of one or more active groups of amino, hydroxyl, carboxyl, alkoxyl and hydrosulphonyl. The side chain of the organic silicon compound is a hydrophobic group. The cured resin film has different wetting qualities for oil and water. The functional resin tectorial membrane proppant of the invention has a function of allowing the smooth permeation of oil gas and preventing water from penetrating through the proppant. Such a function improves the separation effect ofoil gas and water and reduces the oil production cost. The excellent hydrophobicity of the resin film facilitates the proppant to have excellent water resisting property and improves the crushing resistance of the proppant, so that the stream guidance effect is good for a long time.

Owner:围场满族蒙古族自治县津通铸造材料有限公司

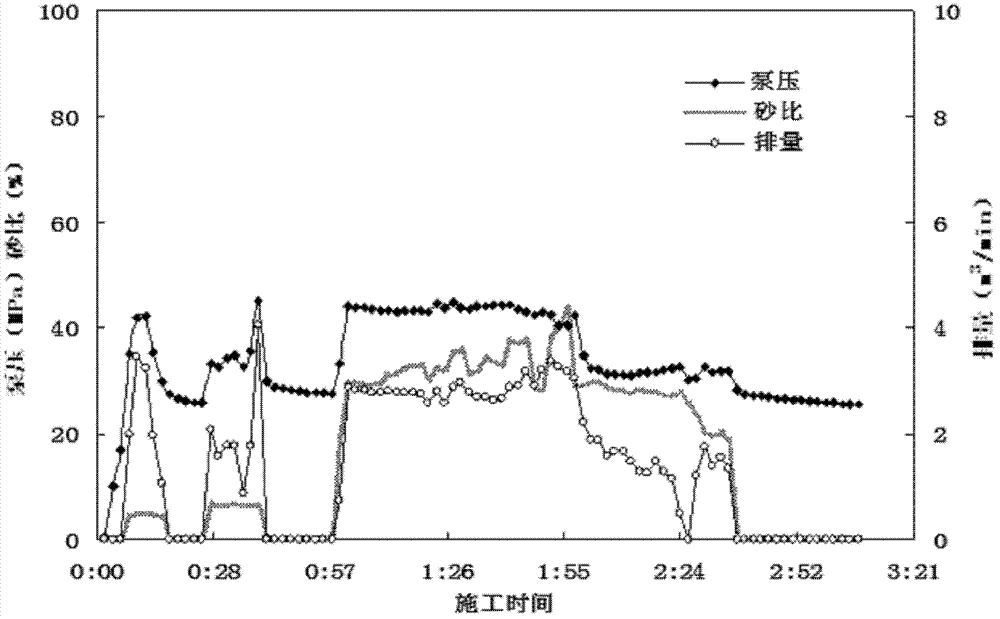

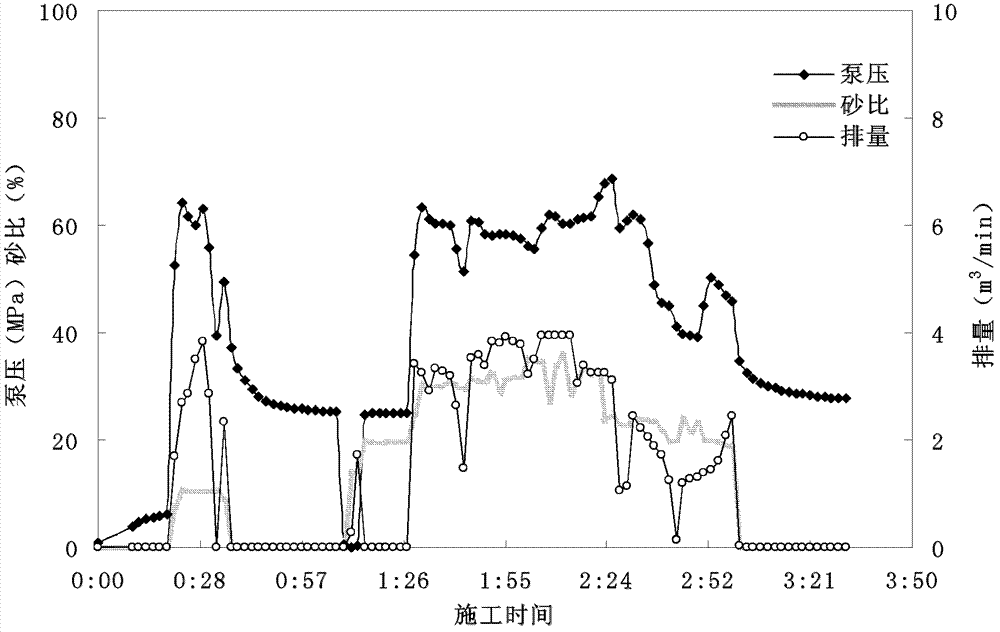

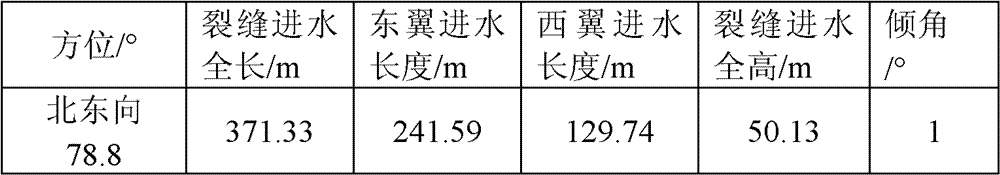

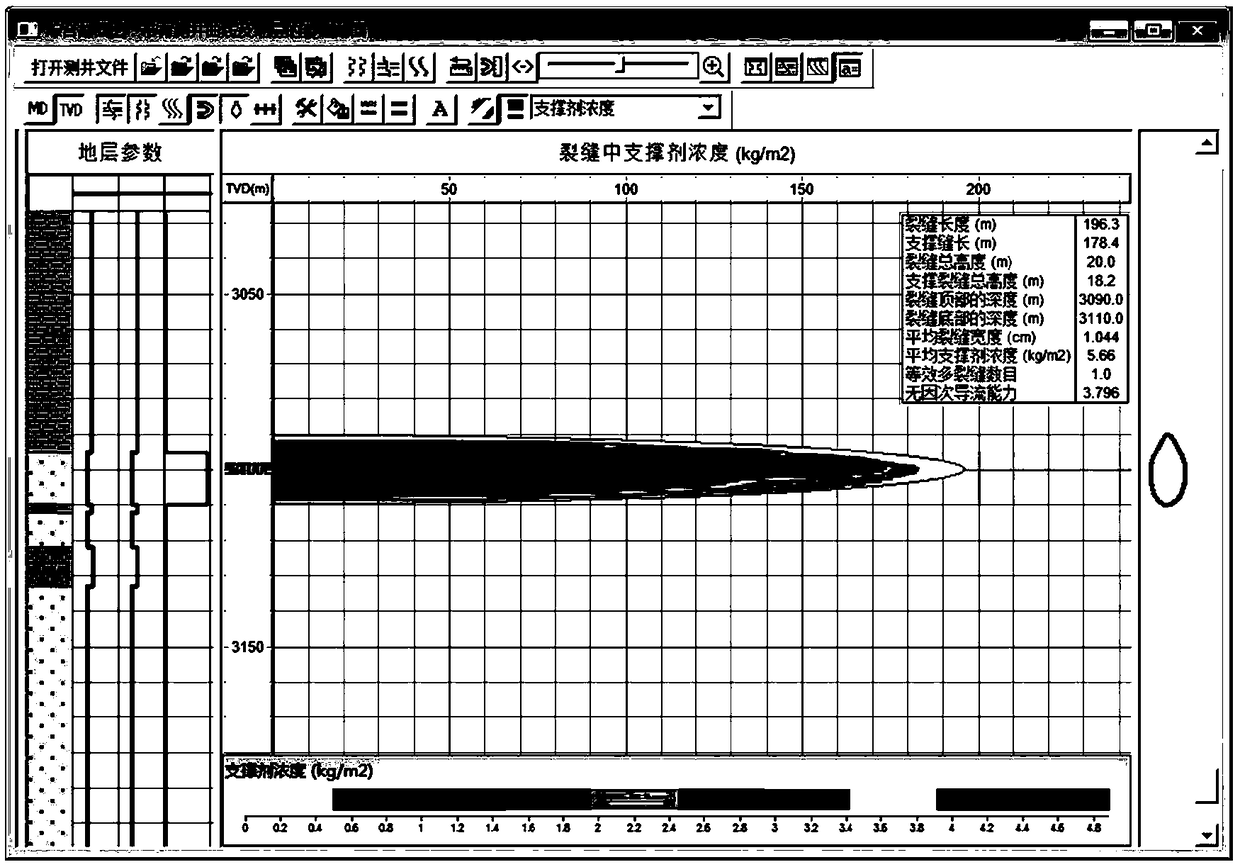

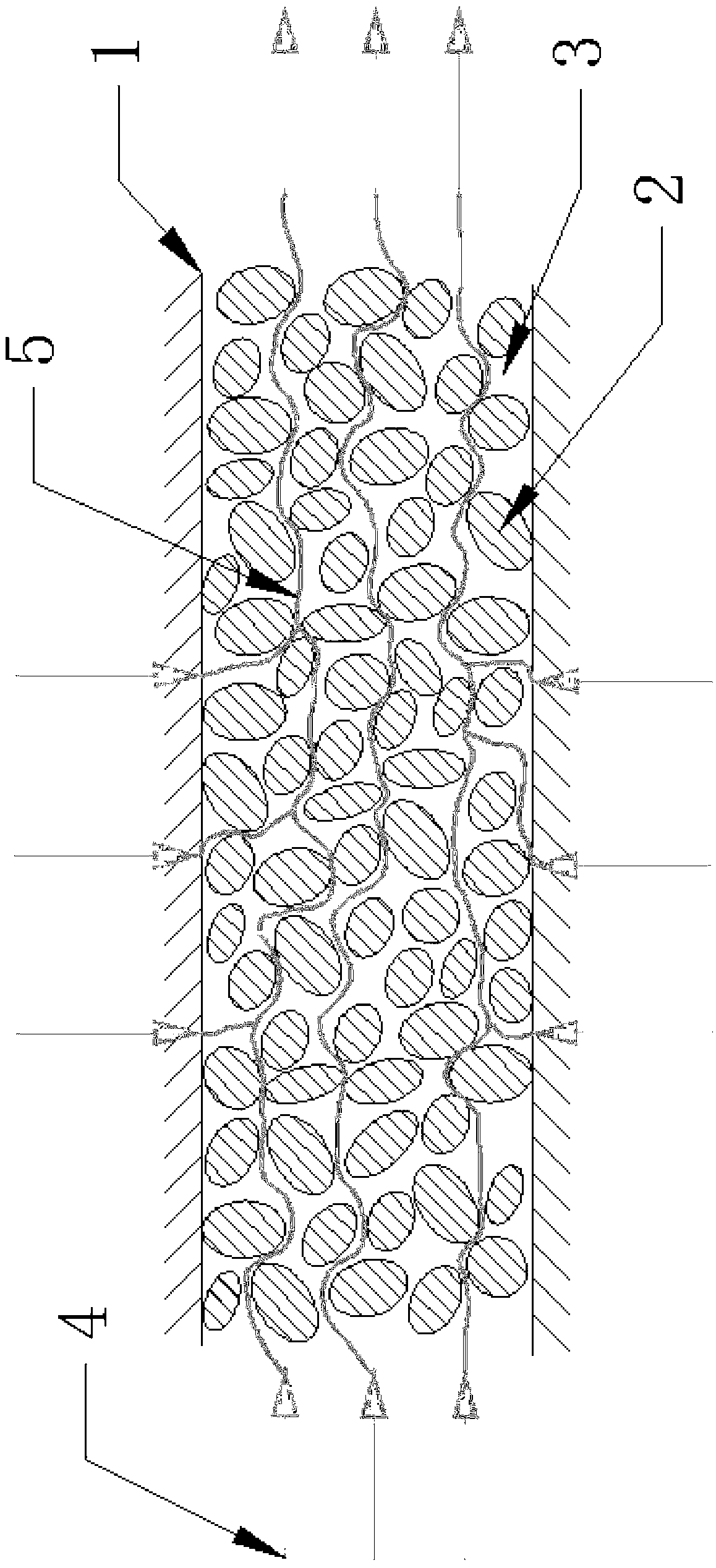

Old well re-transformation volume fracturing technology

ActiveCN105275442AImprove diversion capacityLarge reservoir stimulation volumeFluid removalSealing/packingFiberWater production

The invention relates to an old well re-transformation volume fracturing technology, which is characterized by mainly comprising the steps of carrying out primary fracturing analysis, pre-fracturing evaluation and well selection decision making on to-be-refractured wells with excavation potential, and determining a to-be-refractured well with excavation potential; screening fracturing fibers and particle temporary plugging agents; screening out the fracturing fibers and the temporary plugging agents storing re-transformation according to the temperature, the pressure, the water production rate, the mineralization degree and the fracturing fluid type of a reservoir stratum; carrying out dynamic and static performance evaluation on the screened fracturing fibers and the particle temporary plugging agents, and determining the fracturing fibers and the particle temporary plugging agents which are finally required; determining construction parameters; carrying out fracturing construction; completing transformation for reservoir stratum construction; and acquiring great reservoir stratum transformation volume, and enabling a near wellbore area major fracture to keep high flow conductivity. According to the invention, great reservoir stratum transformation volume can be acquired, and the near wellbore area major fracture is enabled to keep the high flow conductivity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

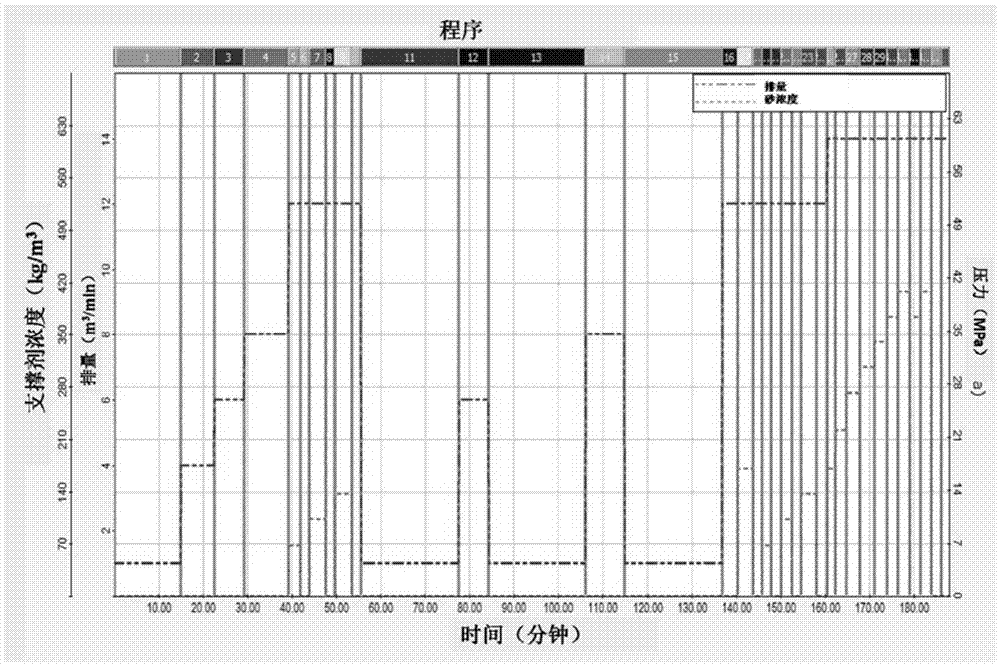

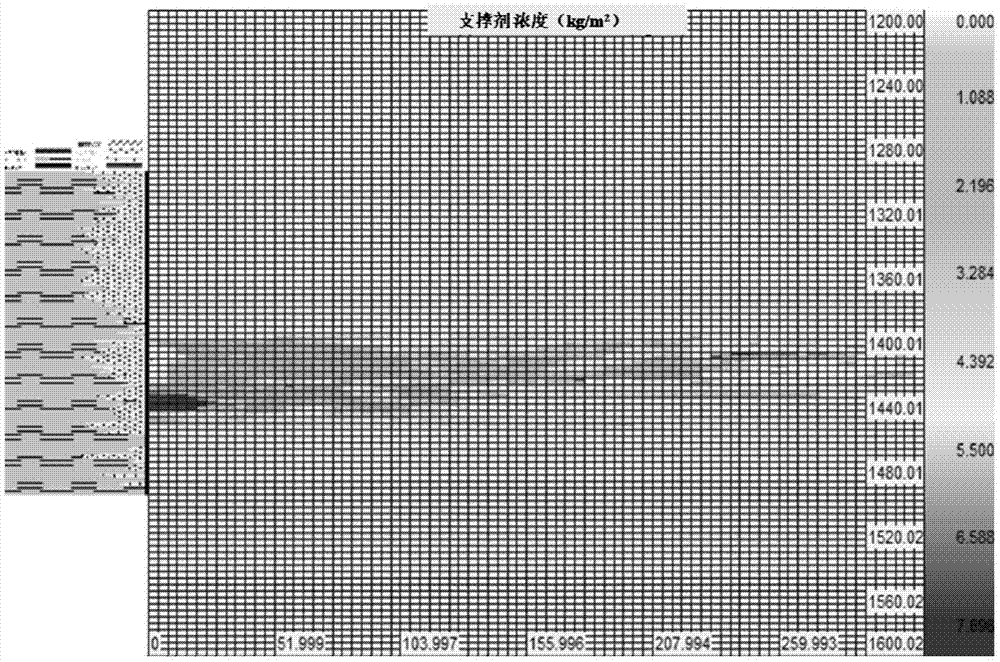

Volume transformation process of low permeability reservoir

ActiveCN102913221AImprove permeabilityAchieve transformationFluid removalMulti clusterCurrent limiting

The invention discloses a volume transformation process of a low permeability reservoir, and the volume transformation process sequentially comprises the following steps of (1) selecting a coal bed, shale, tight sand or other low-permeability reservoir; and (2) adopting a pitching current-limiting hydraulic fracturing way after perforating a plumb shaft; adopting a segmental multi-cluster perforation hydraulic fracturing way after perforating a horizontal well; and varying displacement, propping agent, fracturing fluid and sand ratio in the pumping process in both fracturing ways. Due to adopting the measures for varying the displacement, the sand ratio, the propping agent and the fracturing fluid in the hydraulic fracturing process, pitching current limitation can be adopted when the plumb shaft is fractured or the segmental multi-cluster perforation fracturing process is adopted for the horizontal well, and a netted crack system is formed in the reservoir. Due to adopting the volume transformation process, the volume transformation effect is realized, the weakness of the traditional hydraulic fracturing process that a single crank cannot conform to the commercial production capacity or the later yield is reduced too fast can be avoided, and technical support can be provided for the oil-gas resource development of the low-permeability reservoir.

Owner:HENAN POLYTECHNIC UNIV

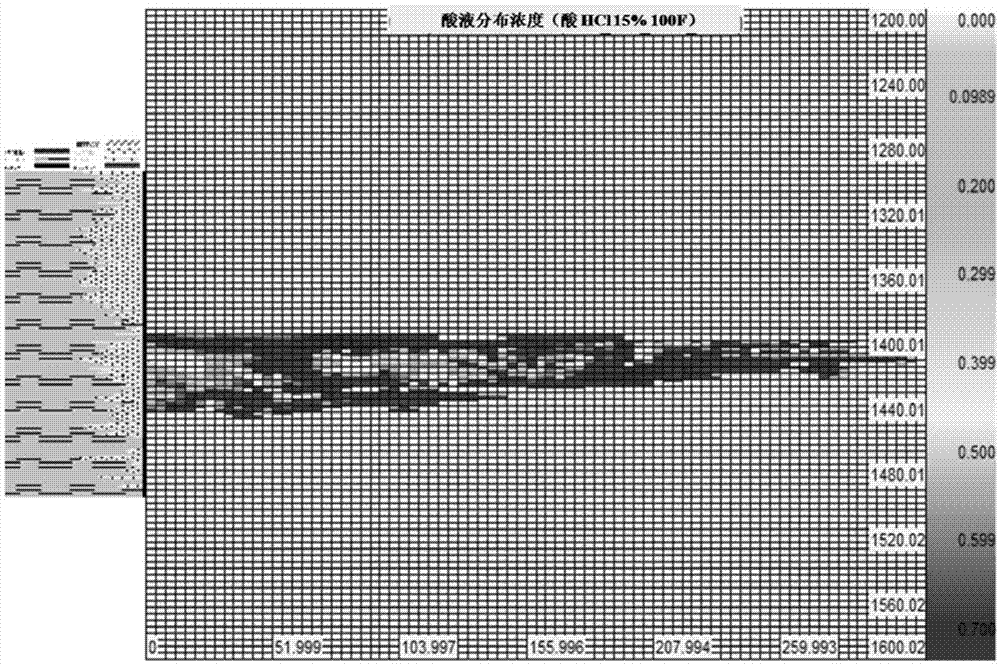

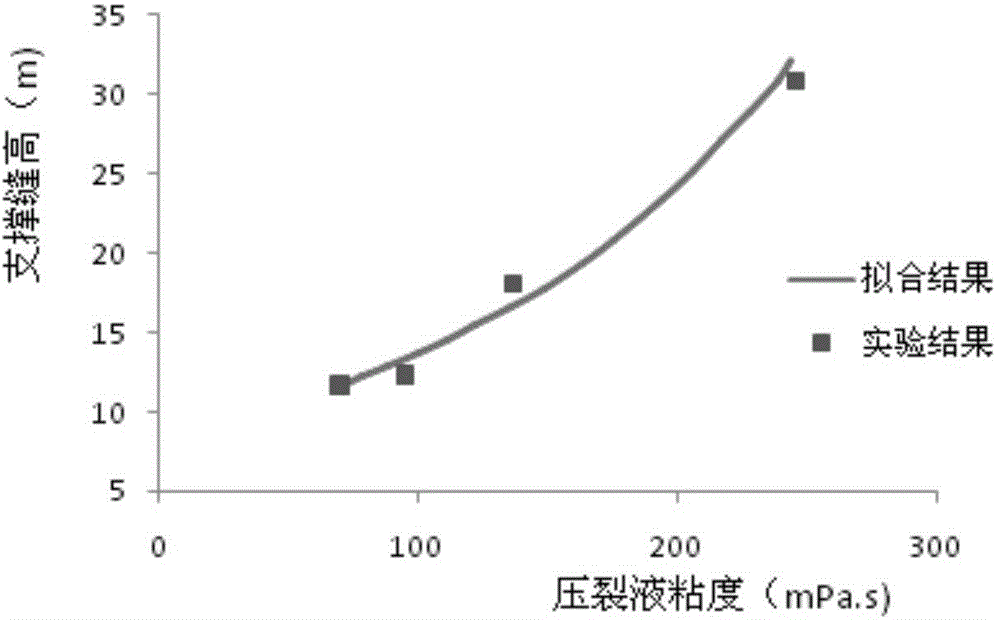

Method suitable for effective flow guide for fractures in fracturing of shale oil pool reservoir

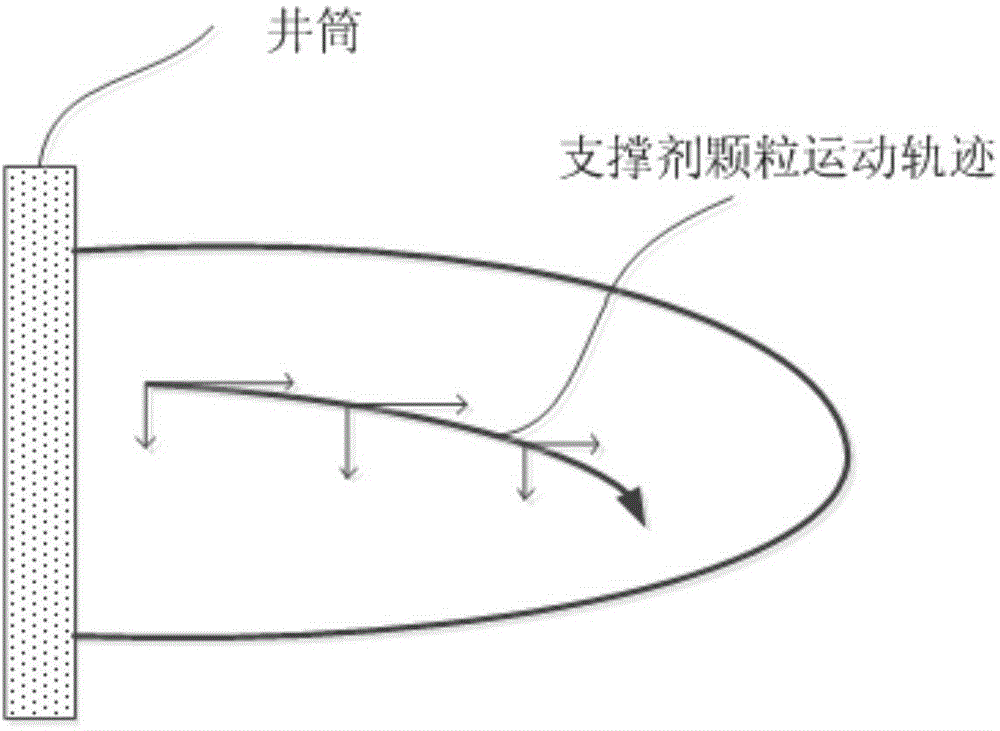

ActiveCN106907137AImprove diversion capacityIncrease "retrofit volumeFluid removalMicro fractureFracturing fluid

The invention relates to the technical field of hydraulic fracturing capacity increasing revamping of oil and gas reservoirs, in particular to a method suitable for effective flow guide for fractures in fracturing of a shale oil pool reservoir. The method includes the following steps that A, the reservoir is pretreated through acid liquor; B, the main fracture is constructed through low-viscosity fracturing fluid; C, the micro fractures and the branch fractures are opened by injecting low-viscosity slickwater; D, slugging is conducted by injecting low-viscosity acid liquor and low-viscosity slickwater alternately; E, low-viscosity slickwater carrying a proppant and low-viscosity fracturing fluid carrying a proppant are injected in sequence so as to support a micro fracture system and a branch fracture system, and the first proppant is different from the second proppant; F, intermediate-viscosity fracturing fluid carrying proppants is injected so as to support a main fracture system; and G, the fourth proppant in a shaft is completely displaced to the openings of the fractures by means of the low-viscosity slickwater.

Owner:CHINA PETROLEUM & CHEM CORP +1

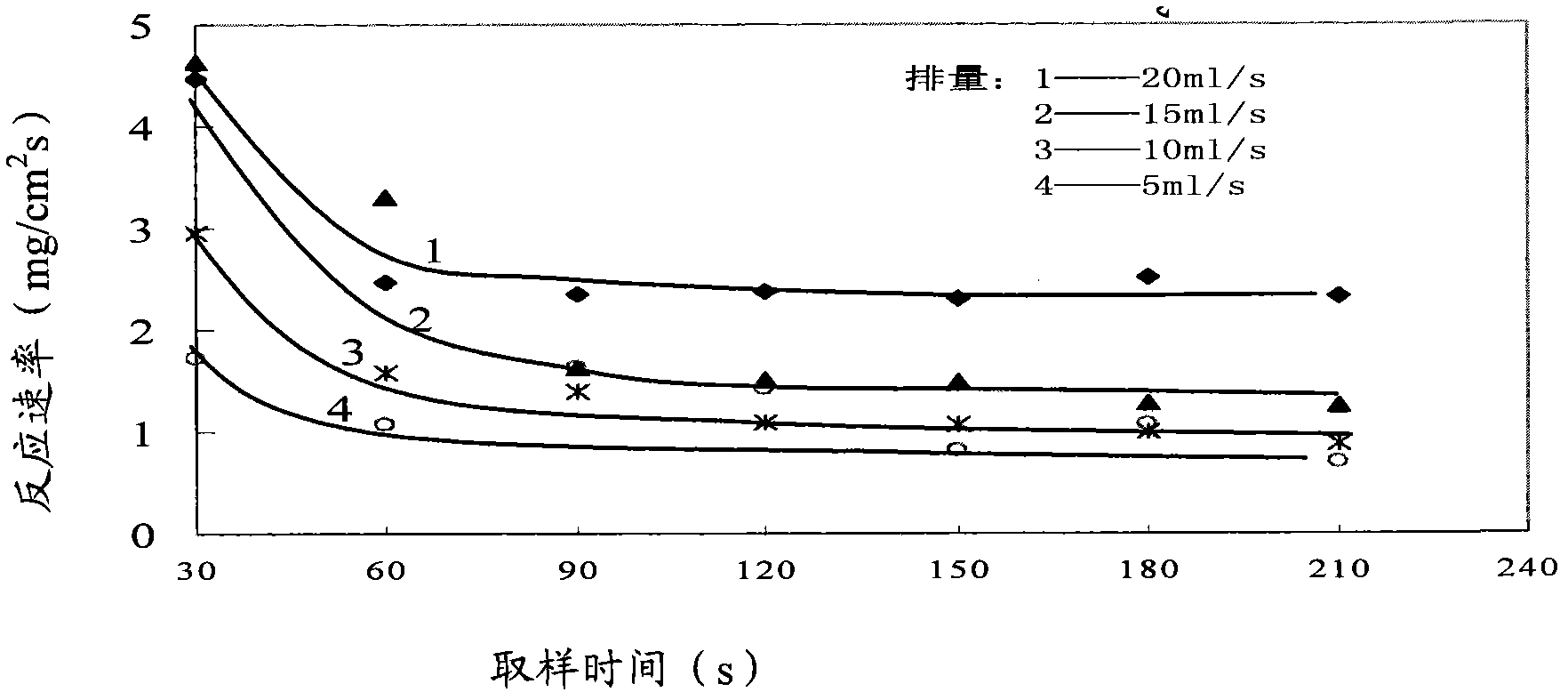

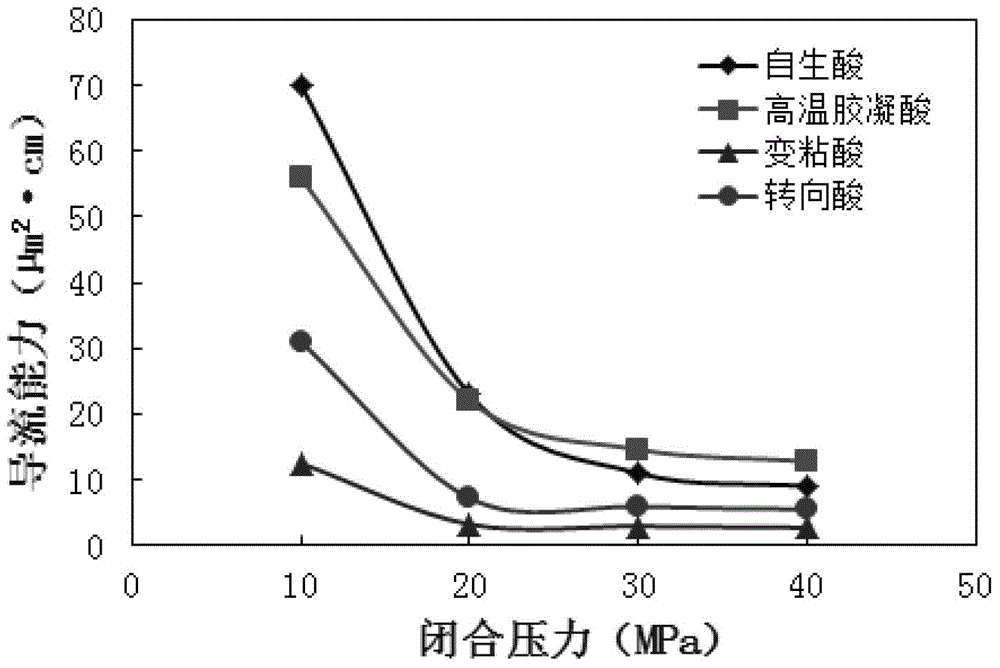

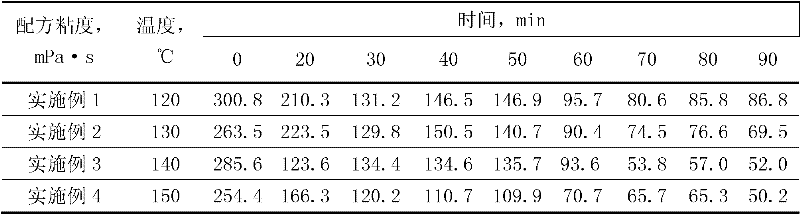

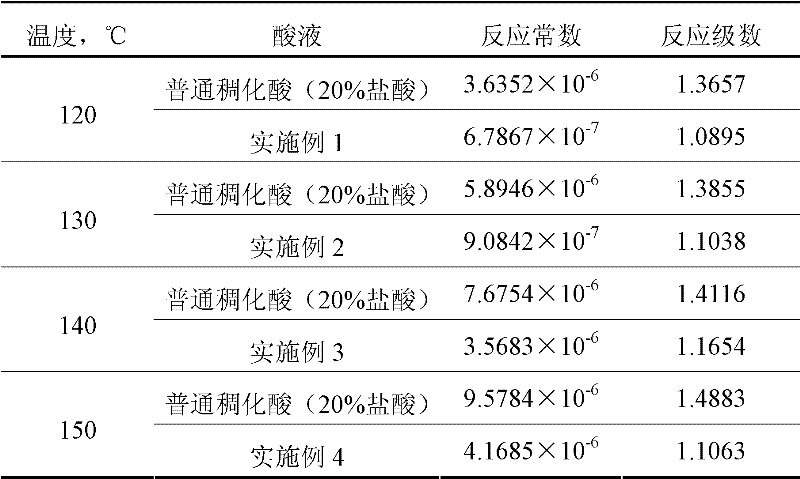

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

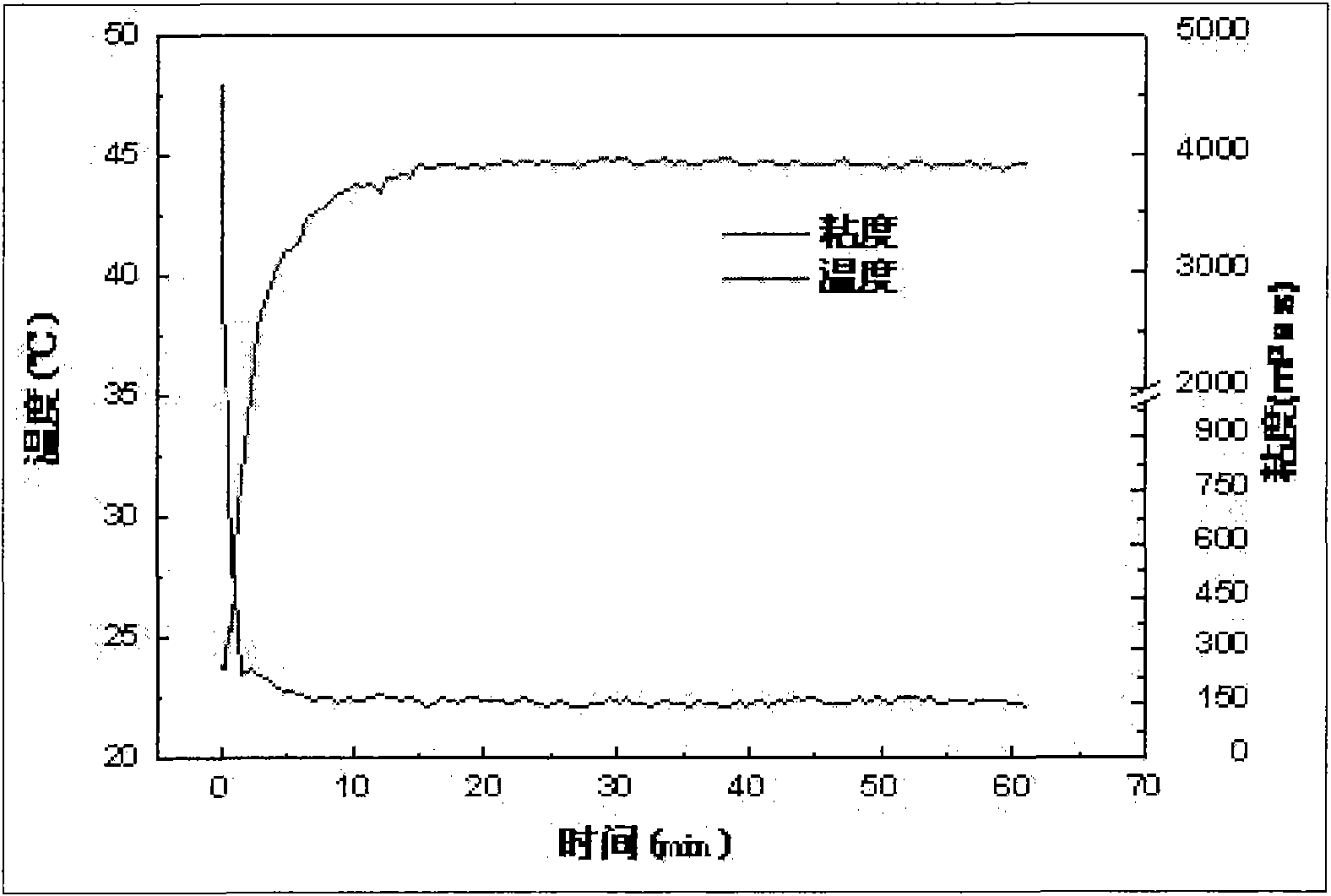

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

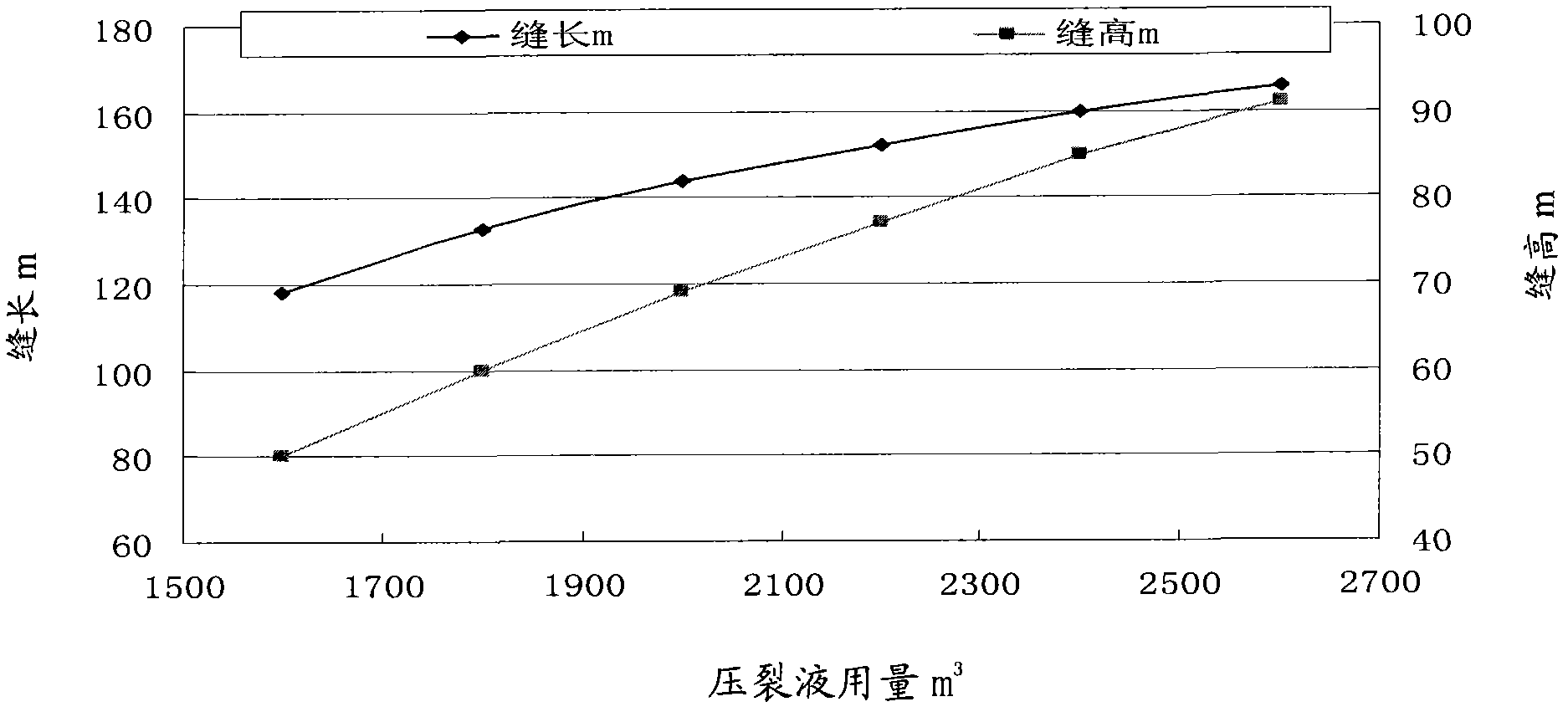

Large composite acid fracturing method of fracture cave type carbonate rock reservoir

The invention relates to a large composite acid fracturing method of a fracture cave type carbonate rock reservoir. The method is characterized by comprising the following steps of while communicating a plurality of fracture caves on the periphery of a shaft of the reservoir: (1) filling quick water into the stratum through the oil pipe of the mixed filling with the oil sleeve; (2) adding powdered ceramic to the stratum through the oil pipe; (3) filling acid liquid into the stratum through the oil pipe for the first time; (4) filling acid liquid into the stratum through the oil pipe for the second time; and (5) filling excess displacing liquid through the oil pipe or the mixed filling with the oil sleeve, wherein the large composite acid fracturing method indicates that the total construction liquid quantity is more than 2,000m<3>. The invention improves the length of an artificial acid fracturing fracture to reach longer than 140m and solves the problem that a conventional acid fracturing technology of a fracture cave type carbonate rock reservoir within the range of 200m of the shaft cannot communicate a far-shaft reservoir, and a new fracture cave reservoir is needed to be searched through side tracking.

Owner:CHINA PETROLEUM & CHEM CORP

Pulse sand fracturing method realizing high fracture conductivity of cracks

InactiveCN104727799AImprove fracture conductivityImprove single well productionFluid removalPetrologyChannel network

The invention discloses a pulse sand fracturing method realizing high fracture conductivity of cracks and belongs to the field of oilfield development. The pulse sand fracturing method includes steps of firstly, fracturing an ultralow-permeability reservoir horizontal well sectionally in multiple clusters, and judging whether high fracture conductivity of the cracks is formed or not by pulse sand fracturing by researching characteristics of the ultralow-permeability reservoir, if yes, executing a second step; secondly, solidifying sand by fiber fracturing fluid by pulse sand adding process in the fracturing process, and forming 'cylinder' support in an artificial crack, so that a channel network high in flow conductivity is formed in the artificial crack, and the artificial crack has high flow conductivity. By the pulse sand fracturing method realizing high fracture conductivity of the cracks, conductivity of the cracks can be improved, and single-well yield is greatly increased. The method has remarkable effect on the site, and by the method, via practical comparison, single-well yield is increased by 20% as compared with that of conventional fracturing optimized design of horizontal wells in the same area and is five to seven times of adjacent straight wells.

Owner:PETROCHINA CO LTD

Method and technique for preparing low-density propping agent

InactiveCN101200632AImprove deformation resistanceReduced resistance to deformationFluid removalDrilling compositionPlant fibreHydraulic fracturing

The present invention relates to propping agent which is widely applied to the oil and gas well hydraulic fracturing technology, and the present invention especially relates to a manufacturing method and a preparation technology of low-consistency propping agent and is characterized in that firstly, plant fibre material is used as the raw material and is crushed and grinded as plant fibre granules; secondly, modifying agent solution dips and solidifies the plant fibre granules; thirdly, macromolecular resin is used to covering the granules which are crushed and filtered again to form the propping agent. The propping agent prepared by the technology and method can conquers that the prior propping agent has large energy consumption and high expense of the whole construction, or the propping agent of the present invention does not easily cause the phenomena of propping agent disgorging or crack emptying.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

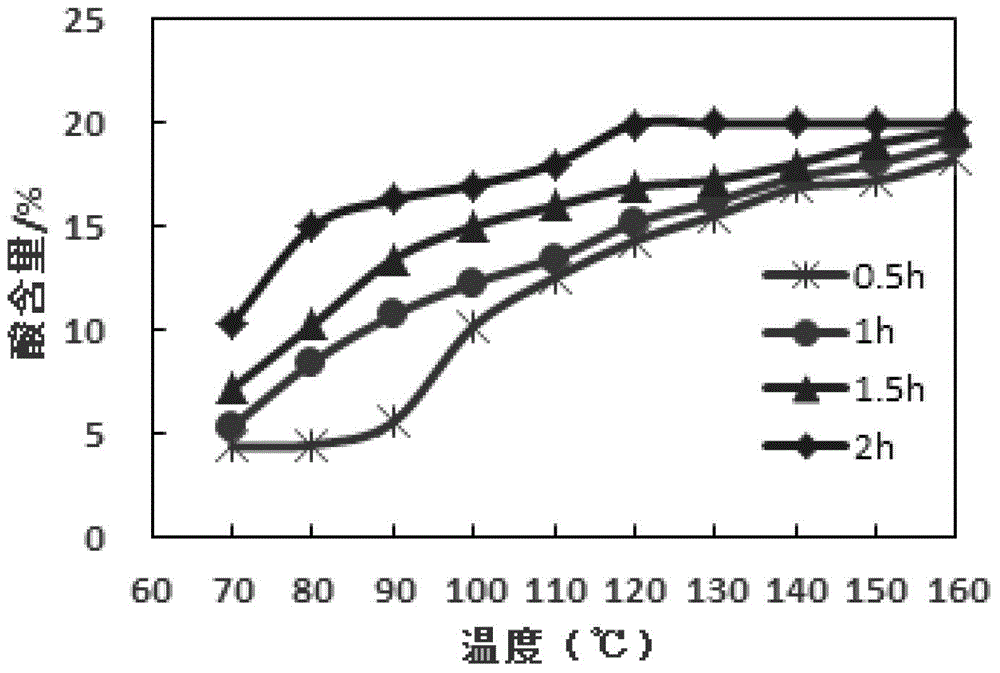

Self-born acid composite acid fracturing process for high-temperature deep well carbonate rock reservoir

ActiveCN104975840AImprove diversion capacityReduce corrosion rateFluid removalAcid fracturingHot Temperature

The invention relates to a self-born acid composite acid fracturing process for a high-temperature deep well carbonate rock reservoir. The process comprises the following work procedures of: (1) injecting slick water into a stratum through an oil pipe; (2) injecting non-crosslinked fracturing liquid into the stratum through the oil pipe; (3) injecting a self-born acid system into the stratum through the oil pipe; (4) injecting a gelled acid system into the stratum through the oil pipe in a low-displacement mode; and (5) injecting the slick water into the stratum through the oil pipe, wherein the volume proportions of liquid, accounting for the total liquid injected into the stratum, injected in the first to fifth work procedures are shown as follows: the slick water in the first work procedure accounts for 3 to 10 percent; the non-crosslinked fracturing liquid in the second work procedure accounts for 40 to 60 percent; the self-born acid system in the third work procedure accounts for 30 to 50 percent; the gelled acid system in the fourth procedure accounts for 3 to 10 percent; the volume proportion of the slick water in the fifth work procedure is 3 to 15 percent; and the volume unit is m<3>. Through the self-born acid composite acid fracturing process, the flow guide capability is improved by more than 140md.m, and the deep penetration effect of the high-temperature deep well carbonate rock reservoir is obvious.

Owner:CHINA PETROLEUM & CHEM CORP

Cross-linked acid and sand-carrying acid-fracturing method for ground with argillaceous dolomites

ActiveCN103089228AImprove diversion capacityImprove well productivityFluid removalAcid etchingCross-link

The invention discloses a cross-linked acid and sand-carrying acid-fracturing method for a ground with argillaceous dolomites. Cross-linked acid-fracturing for the ground is combined with cross-linked acid sand-carrying acid-fracturing for the ground in the method, and in other words, the cross-linked acid and sand-carrying acid-fracturing method includes performing the cross-linked acid-fracturing in a prepad fluid stage; and performing the cross-linked acid sand-carrying acid-fracturing for the ground in a main sand feeding stage. The cross-linked acid and sand-carrying acid-fracturing method has the advantages that the process is simple, operation is facilitated, and a construction effect is obvious; the method can be widely applied to transformation construction for complex lithologic oil and gas reservoirs with argillaceous dolomites and the like; a deep-penetration prop fracture with durable flow conductivity can be formed to the greatest extent under the combined effect of acid-fracturing and sand-feeding acid-fracturing technologies, acid etching and propping effects are played for the fracture, and the flow conductivity of the artificial fracture and the productivity of an oil well are greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

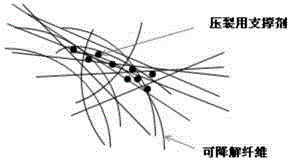

Fracturing method capable of improving sand-carrying performance of fracturing liquid

ActiveCN104405360AReduce sedimentation velocityImprove sand carrying capacityFluid removalFiberFracturing fluid

The invention provides a fracturing method capable of improving the sand-carrying performance of fracturing liquid. The method comprises the following steps: dispersing degradable fibers by virtue of a dispersion device, and uniformly dissolving the dispersed degradable fibers in a fracturing liquid base solution; pumping into a fracturing blender truck, and mixing with a propping agent for fracturing so as to form sand-carrying fluid; then pumping the sand-carrying fluid dissolved with the fibers into a strata so as to support a formed fracture geometry. When the degradable fibers added into the fracturing liquid are uniformly dispersed in the fracturing liquid, the fibers and a guanidine gum chain with a network structure form a tangled structure, so that the strength of the cross-linked network structure is enhanced, the sedimentation rate of the propping agent is reduced, the sand-carrying capacity of the fracturing liquid is improved, the propping agent is uniformly distributed in a whole crack, a supporting effect is fully realized, the crack is prevented from being closed and thus the fracturing period of validity is increased; furthermore, the added fibers are capable of effectively preventing the propping agent from flowing back and preventing formation sand flow; an oil gas flow passage is additionally increased, so that the fracturing yield-increasing effect is finally realized.

Owner:中石化胜利油田分公司采油工艺研究院 +1

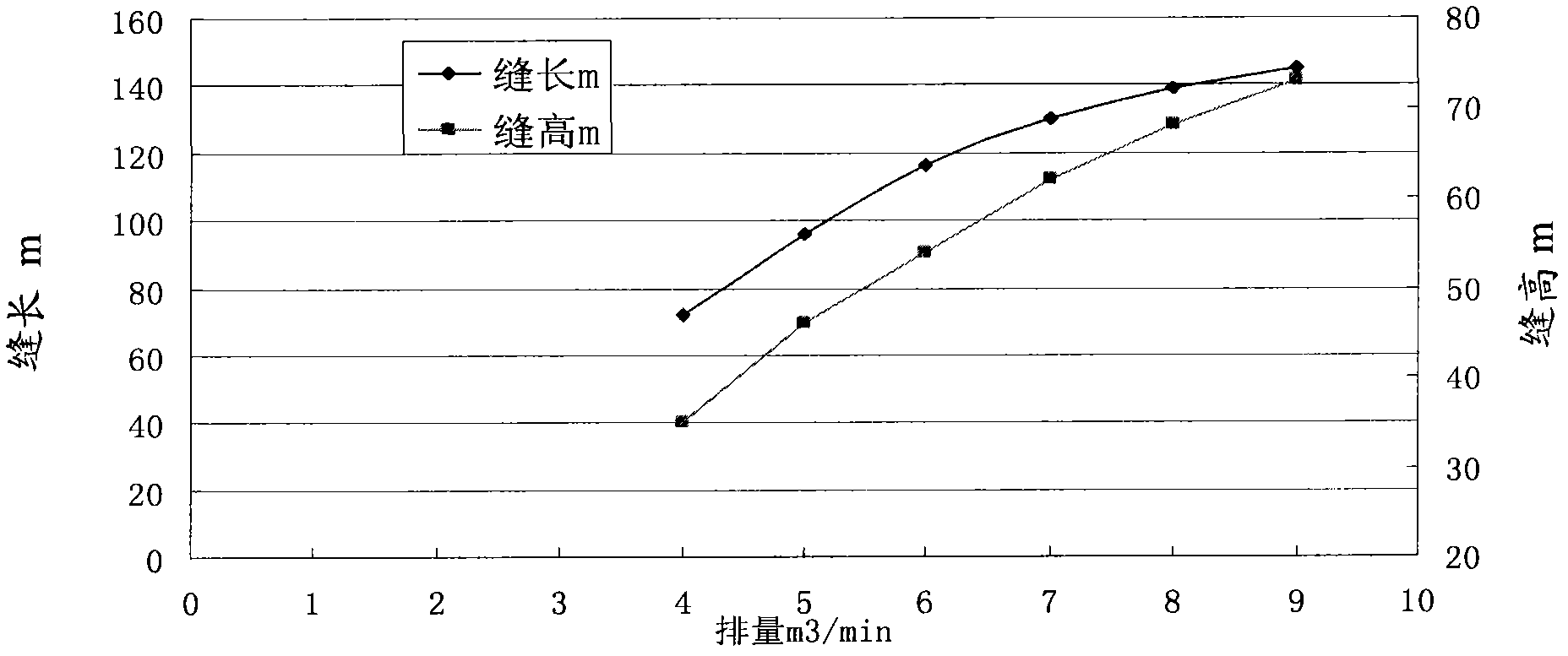

Active water fracturing technology of coal-bed gas well

ActiveCN102094612AImprove diversion capacityLarge flow areaFluid removalFracturing fluidHydraulic fracturing

The invention relates to the coal-bed gas exploitation technology, and in particular relates to an active water fracturing technology of a coal-bed gas well, which is used for solving the problem that the yield of coal-bed gas can not be effectively improved by the existing hydraulic fracturing technology owing to a poor fracturing effect. The fracturing technology comprises the following steps: (1) circulation; (2) pressure test; (3) extrusion test; (4) fracturing; (5) support; and (6) pressure release, wherein, in steps (1), (3), (4) and (5), a fracturing fluid is prepared from clear water, a surfactant and a bactericide based on the volume ratio of 2000:1:1; in steps (4) and (5), the pumping delivery of a fracturing pump is 5-9m<3> / min; and the fracturing fluid is infused into the well via a sleeve by utilizing the fracturing pump. By utilizing the fracturing technology, the problem that the yield of coal-bed gas can not be effectively improved by the existing hydraulic fracturing technology owing to a poor fracturing effect is effectively solved, thus the technology is applicable to coal-bed gas exploitation.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

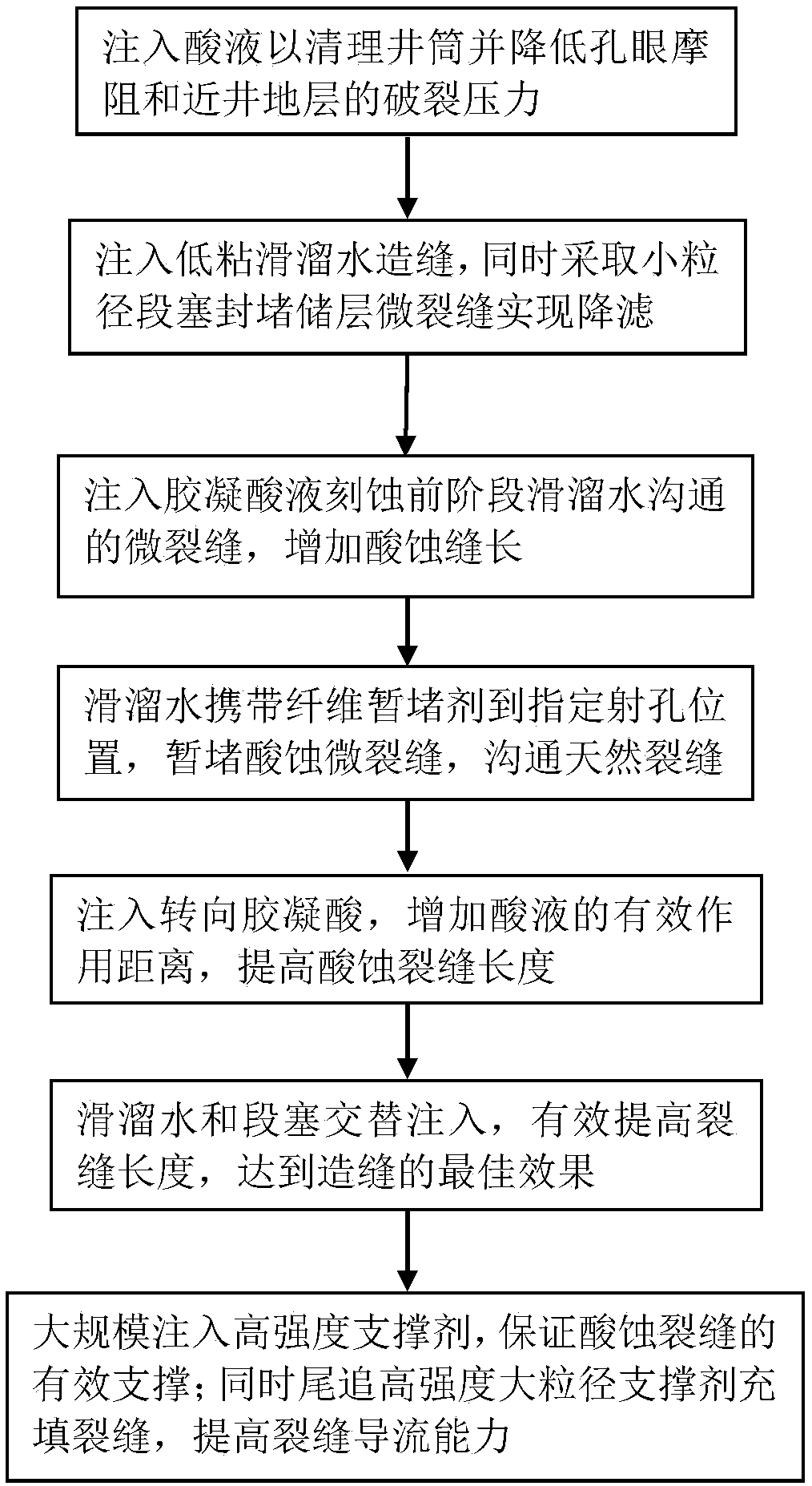

Volume fracturing method for crack net of carbonate reservoir

ActiveCN109296350AImprove diversion capacityReduce shut-in timeFluid removalAcid fracturingAcid etching

The invention relates to a volume fracturing method for a crack net of a carbonate reservoir. The volume fracturing method comprises the following steps that (1) initial crack initiation is conducted,specifically, slickwater is injected into a pretreated formation for crack making, then gel acid is injected for conducting acid etching transformation on cracks, and the crack length is increased; (2) temporary blocking in the cracks is conducted, specifically, microcracks formed by acid etching formation are temporarily blocked through temporary blocking agents carried by the slickwater; (3) turning for acid fracturing is conducted, specifically, gel acid is injected into the temporarily-blocked formation, and after the temporary blocking agents are displaced in place by the gel acid, the gel acid turns to other parts for acid etching transformation; (4) crack making through slickwater is conducted, specifically, slickwater is injected into the formation subjected to acid etching transformation in the step (3) for crack making; and (5) crack-expansion supporting is conducted, specifically, sand-carrying fluid is injected into the formation subjected to crack making in the step (4) for supporting. According to the volume fracturing method for the crack net of the carbonate reservoir, liquid leak-off can be effectively reduced, the effect of 'near-control and far-expansion' is achieved, the abundant secondary cracks can be formed, connectivity with main cracks and natural cracks is improved, and thus the transformation effect of volume fracturing is improved.

Owner:中石化石油工程技术服务有限公司 +1

Composite blocking-removal method for improving flow conductivity of triple-low sandstone reservoir

ActiveCN102635344AImprove diversion capacityGood compatibilityFluid removalDrilling compositionOil productionSodium nitrite

The invention discloses a composite blocking-removal method for improving the flow conductivity of a triple-low sandstone reservoir, which is applied to the improvement on the flow conductivity of a low-pressure, low-permeability and low-fluidity reservoir in an oilfield so as to improve the outputs of oil wells. The method comprises the following steps of: carrying out preparations for construction, namely respectively filling four kinds of prepared blocking-removal liquid including ammonium-chloride chemical heat-generating liquid, sodium-nitrite chemical heat-generating liquid, surfactant liquid and sandstone deep-penetrating retarded acid liquid into storage and transportation tanks, and transporting the storage and transportation tanks to an oil-well operation site; respectively filling the four kinds of liquid into an oil well by oil tubes or an annular space between an oil tube and a casing pipe; then filling displacement fluid into the oil well; finally closing the oil well, and reacting for four hours so as to complete the composite blocking-removal construction; and opening the oil well, and putting the oil well in oil production. The method disclosed by the invention has the effects that: the reservoir blocking caused by inorganic scales, organic scales and microbial germ contamination can be simultaneously and effectively removed, thereby achieving the purposes of restoring or improving the in-place permeability and improving the outputs of oil wells.

Owner:PETROCHINA CO LTD

Environment-friendly and bio-available green fracturing fluid system

InactiveCN101838528AReduce friction coefficientReduce construction costsDrilling compositionCross-linkWorking fluid

The invention relates to a fracturing fluid system, in particular to an environment-friendly and bio-available green fracturing fluid system, which contains the following components in parts by weight: 0.30-0.55% of vegetable gum polymer, 10-20ppm of biofungicide, a cross-linking agent (1-1.5% of borax water solution, and cross-linking ratio: 100:5 to 100:10), a pH value adjusting agent, 0.018-0.025% of biological discharge aiding agent, 5-30ppm of enzyme breaker, 1-3% of clay stabilizer, 0.25-0.3% of fracturing optimizer, and the balance of water. The fracturing fluid system furthest uses non-toxic and innoxious natural products to replace toxic and noxious chemical additive, thus achieving environment friendliness; and working fluid which is injected into the formation and returned to the ground is biodegradable and bio-repairable, and flowback liquid can be recycled, thus saving energy and reducing emission. The fracturing fluid system is a more ideal fracturing fluid system.

Owner:DALIAN BITEOMICS INC

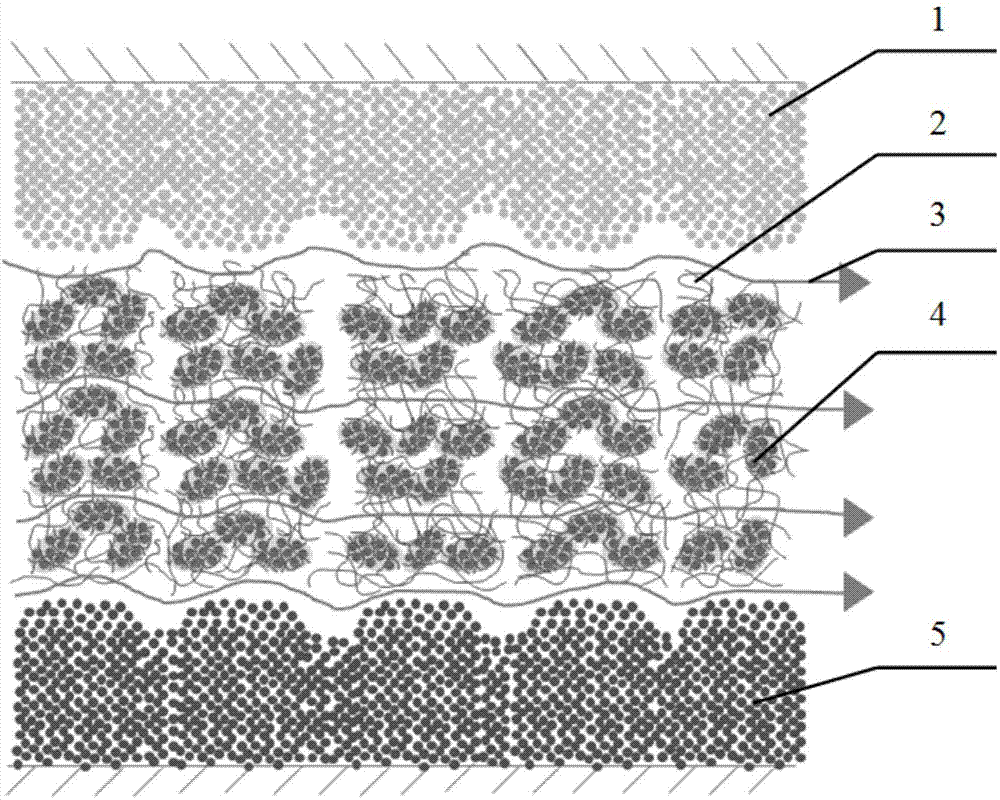

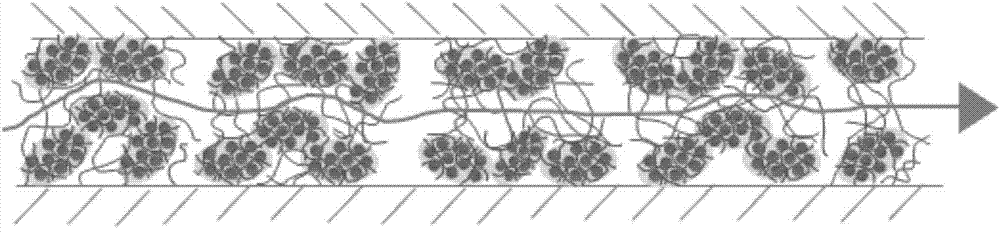

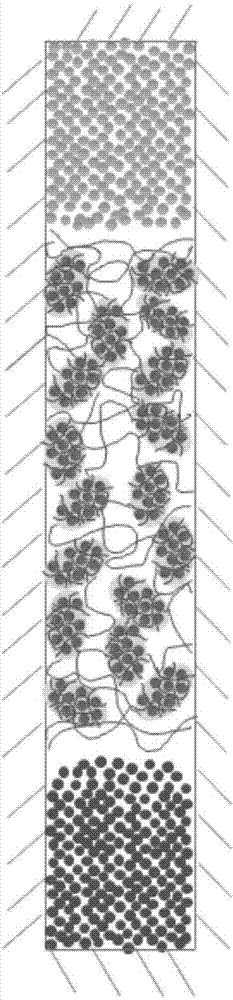

Fracturing technology using propping agent density variation for obtaining large channels

ActiveCN104727801AEasy to closeImprove diversion capacityFluid removalDrilling compositionFiberHigh density

The invention relates to a fracturing technology using propping agent density variation for obtaining large channels. The fracturing technology includes the following steps that propping agent fracturing fluid low in density, intermediate in density and high in density is prepared, and fibers are added into the propping agent fracturing fluid intermediate in density to form propping agent clusters serving as the premise of channel fracturing; at the beginning of fracturing, prepad fluid is pumped into the stratum so that the stratum can form a crack of a certain width and a certain length, and the propping agent fracturing fluid of the three densities is together pumped into the stratum; because no fibers are added into low-density propping agent particles and high-density propping agent particles, the low-density propping agent particles and the high-density propping agent particles can freely float and precipitate at the top and the upper portion of the crack; the propping agent fracturing fluid intermediate in density is injected in a pulse mode, and the channels of a certain size can be formed between the propping agent clusters. The large channels of larger sizes are formed between an intermediate-density propping agent zone and a low-density propping agent zone as well as between the intermediate-density propping agent zone and a high-density propping agent zone.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC +1

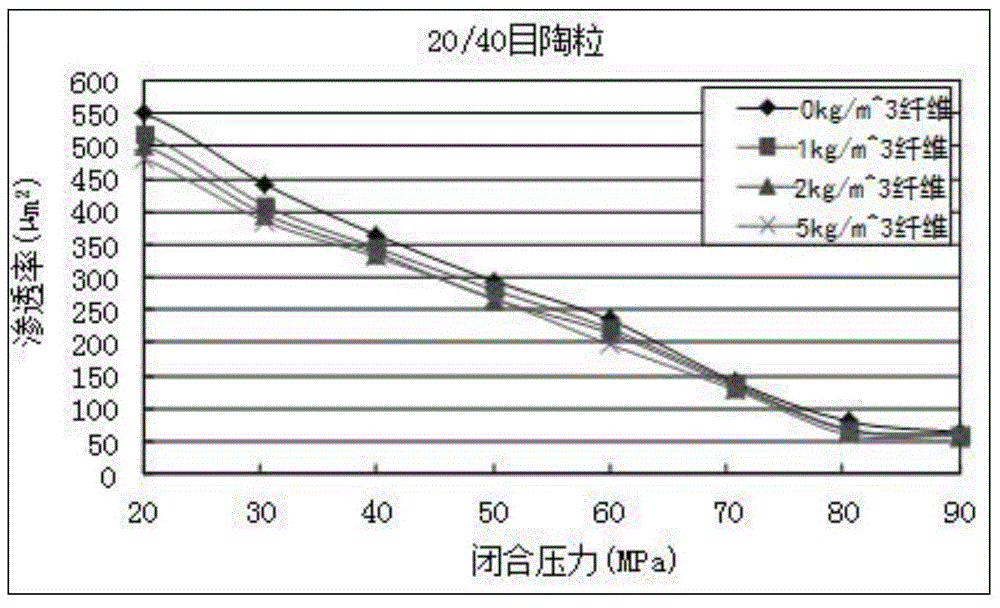

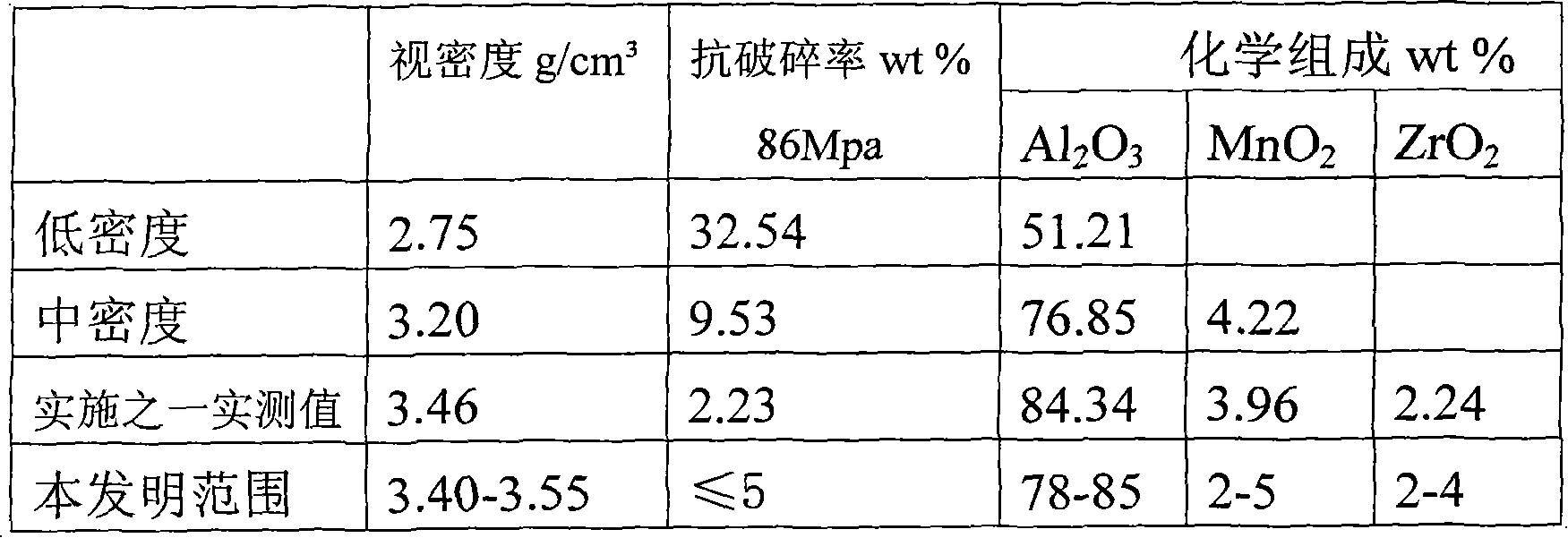

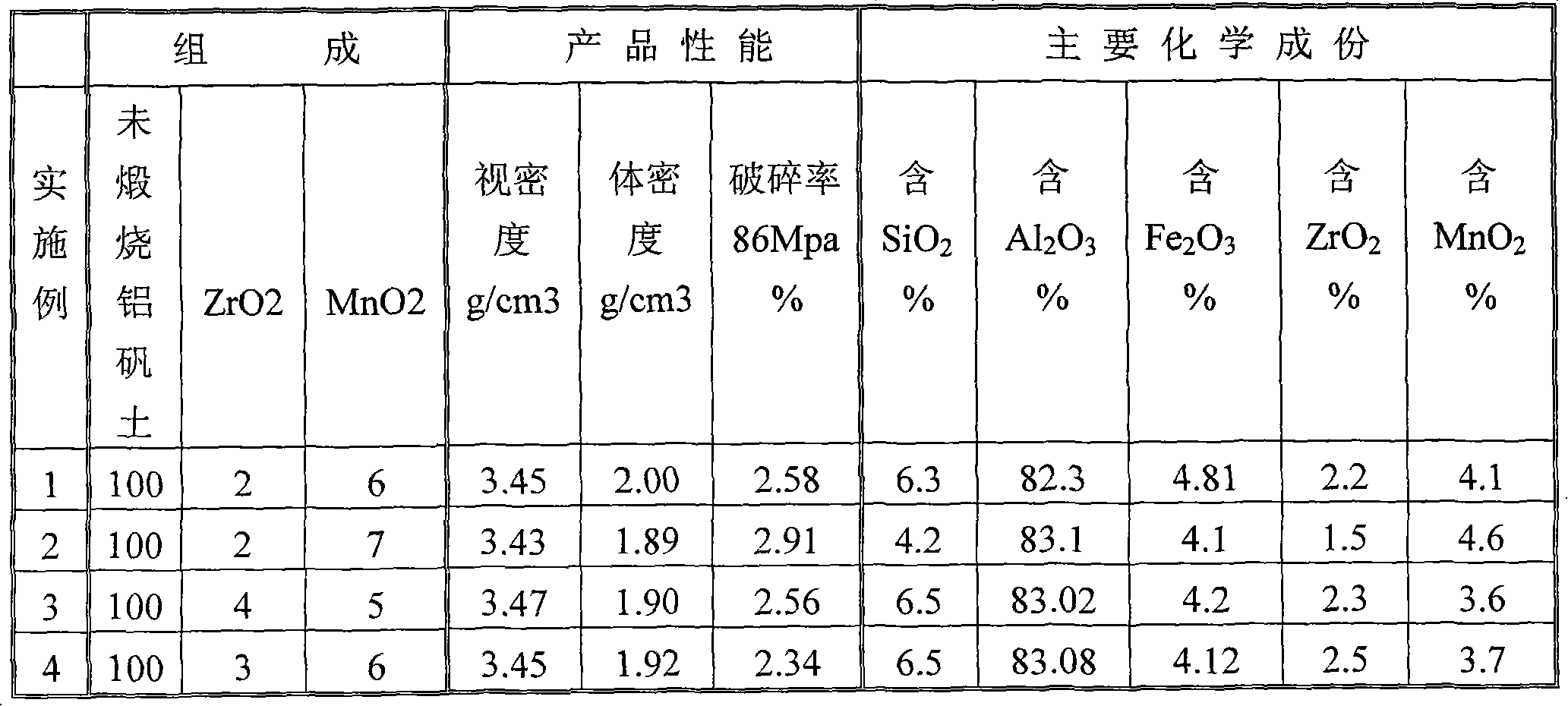

High-density high-strength pressure crack proppant

InactiveCN101168660ASatisfied with fracturing floodingHigh densityFluid removalApparent densityChemical composition

The invention relates to a high closing pressure extra-deep oil well and an extra-deep gas well, and pressing crack driving adopts high density and high strength pressing crack propping agent. The invention is characterized in that the composition is as follows: 100 parts of non-annealing bauxite with more than or equal to 75 percent of Al2O3, and 3 to 8 parts of MnO2, and 1 to 5 parts of ZrO2, the apparent density after balling is fired is 3.40-3.55 kg / cm <3>, the anti- fragmentation capacity under 86 MP pressure is more than or less than 5 percent (20 / 40 meshes), the main chemical composition is 78 to 85 wt percent of Al2O3, 2 to 5 wt percent of MnO2, 78 to 85 wt percent of Al2O3, 2 to 5 wt percent of MnO2, and 2 to 4 wt percent of ZrO2. The propping agent of the invention has small composition material, simple preparation, low cost and good economical efficiency, the apparent density reaches the density limiting of 3.40 to 3.55 g / cm <3>, the compressive strength is high, the propping agent has 20 / 40 meshes of grain size, the anti-fragmentation capacity is (SY / T5108-2007) 86 MPa which is more than or less that 5 percent, the maximum can reach 100 MPa which is more than and less than 8 percent, the invention can satisfy the pressing crack driving of the high pressure extra-deep oil well and the extra-deep gas well under the formation closing pressure more than and equal to 86 MPa, the formation crack is supported under the high pressure, and the flow conductivity can be greatly improved.

Owner:宜兴东方石油支撑剂有限公司

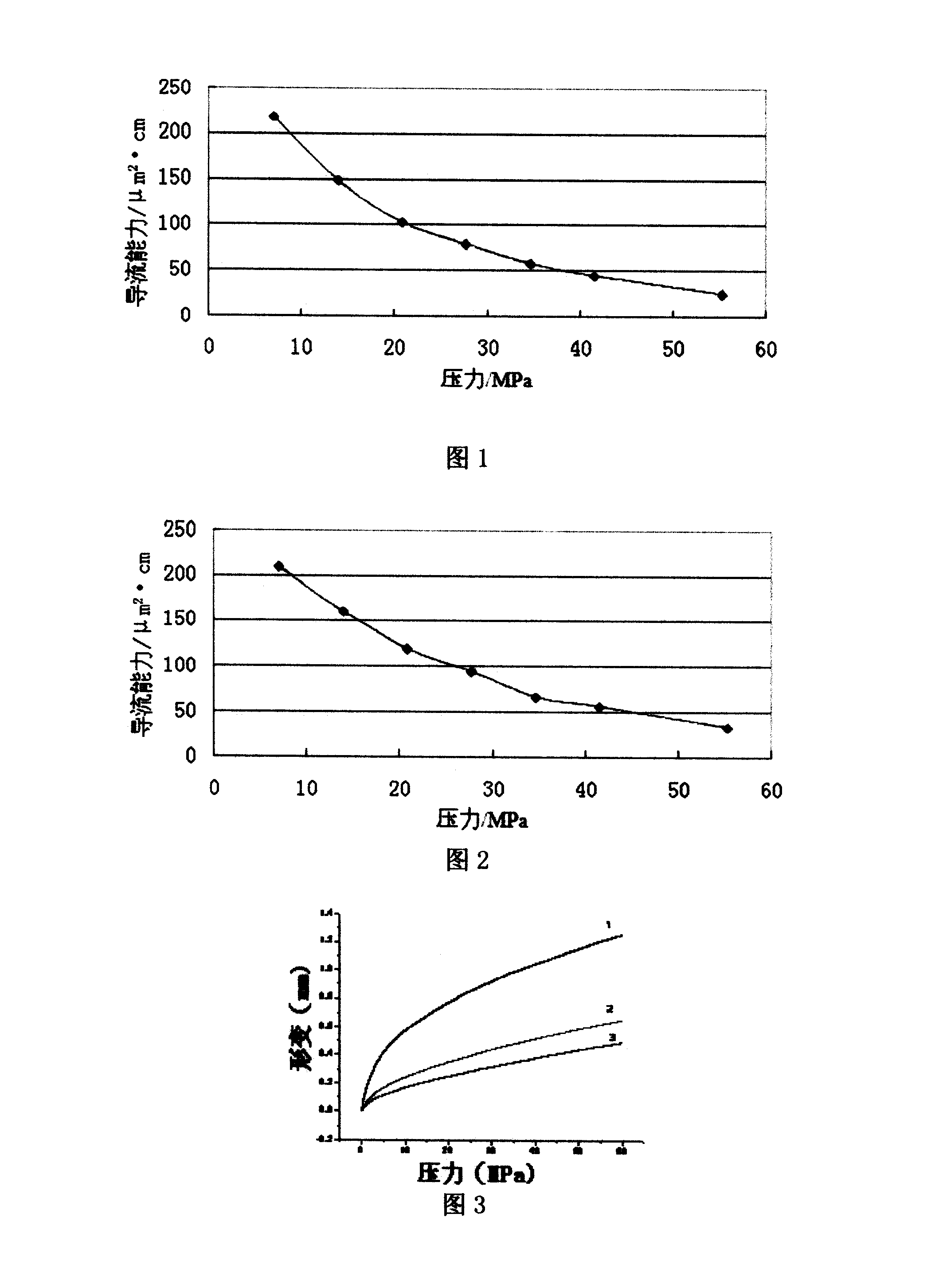

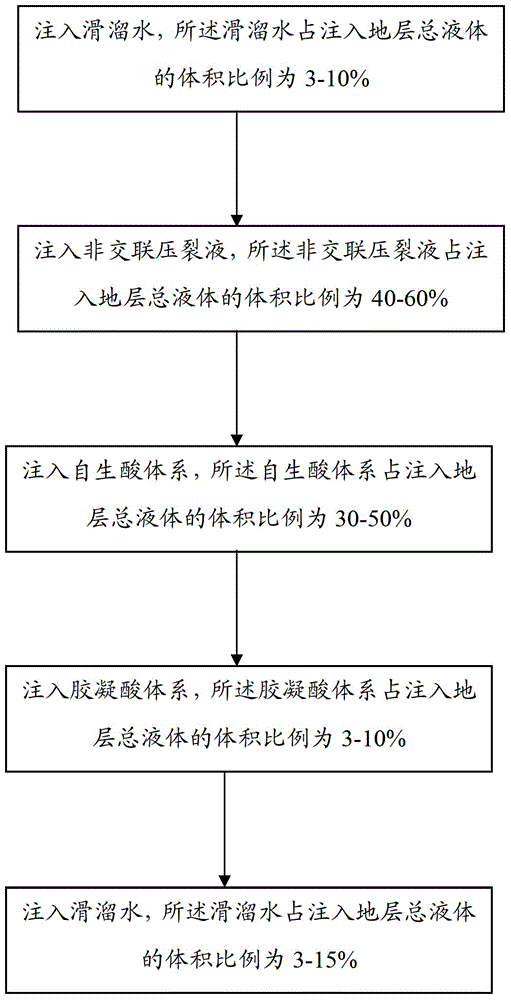

Fracturing technology for implementing ultrahigh flow conductivity

ActiveCN103306659ALow effective concentrationReduce the overall heightFluid removalMaterial PerforationOrder of magnitude

The invention relates to a fracturing technology for implementing the ultrahigh flow conductivity, which comprises the following steps: 1, judging whether geomechanics parameters of a target reservoir is suitable for the fracturing technology disclosed by the invention or not; 2, judging whether completion perforation of a target well is suitable for the fracturing technology disclosed by the invention or not, and if no, changing a perforating scheme of a well bottom; 3, before fracturing, selecting related fracturing materials; 4, carrying out fracturing on the target well by using a unique pumping program of the fracturing technology disclosed by the invention. According to the fracturing technology, proppant struts are formed in a stratum; flow conductivity of a stratum fracture is not improved by a filling layer of a proppant, but oil gas passes through by passages between the proppant struts; the flow conductivity is obviously improved by the open flowing passages; the flow conductivity of an existing conventional fracturing technology is not more than 200mum<2>*cm generally, but the flow conductivity of the fracturing technology for implementing the ultrahigh flow conductivity, which is disclosed by the invention, is higher than that of the conventional fracturing technology by 1 to 3 orders of magnitude; the fracturing technology reduces a pressure drop in the fracture, is helpful for improving drainage capacity and increases the effective fracture half-length and the production increase volume of the reservoir so as to improve yield.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

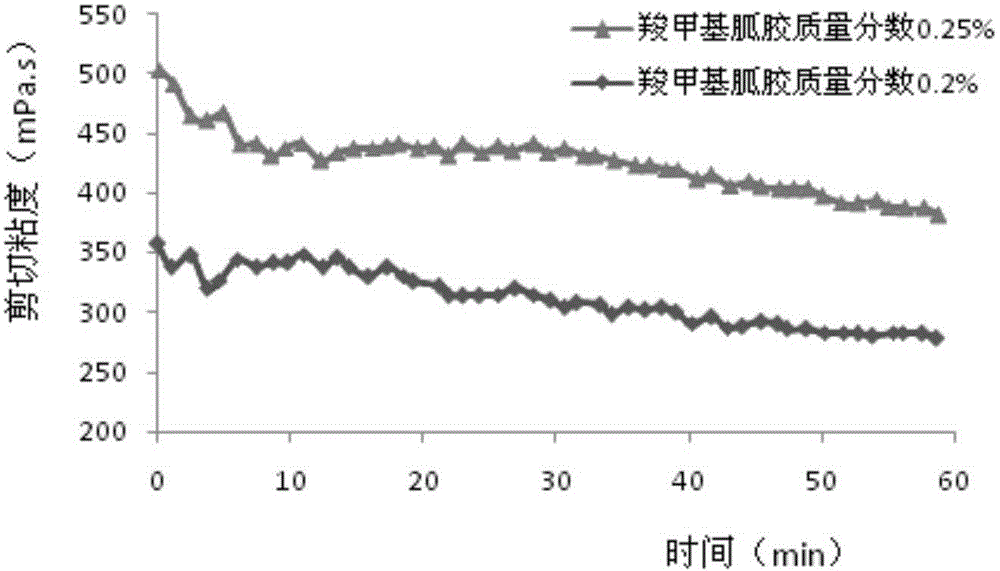

Coal bed methane hydrofracture method

ActiveCN104088616ALow viscosityLow priceFluid removalDrilling compositionFracturing fluidMethane production

The invention relates to a coal bed methane hydrofracture method. Active water fracturing fluid is used as prepad fluid and displacing fluid, carboxymethyl guanidine gum fracturing fluid is used as sand-carrying fluid, four kinds of quartz sand different in particle size range are used as propping agents, the 100-mesh-to-70-mesh mealy sand and the 70-mesh-to-40-mesh fine sand serve as the propping agents in the prepad fluid, the 40-mesh-to-20-mesh medium sand and the 20-mesh-to-14-mesh coarse sand serve as the propping agents in the sand-carrying fluid, and the proportions of the added sand which is different in particle size and serves as the propping agents are different. The concentrations of clay stabilizers KCL in the active water fracturing fluid and the carboxymethyl guanidine gum fracturing fluid are determined according to the GR average value, represented with the API unit, of fractured objective layer section logging data. By means of the coal bed methane hydrofracture method, the coal bed methane production increasing effect is improved to a great extent, and the preparing cost of the fracturing fluid is reduced to the maximum degree while swelling is effectively prevented.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

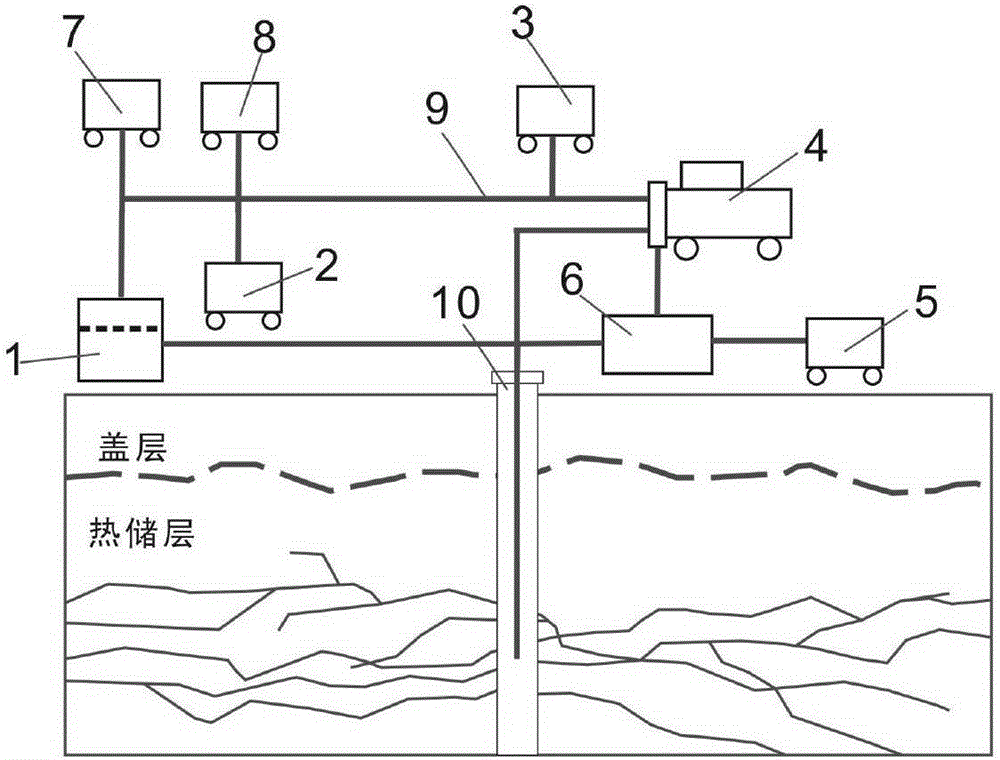

Thermal stimulation and chemical stimulation combined process of hot-dry-rock thermal reservoir

InactiveCN105332681AImprove diversion capacityEfficient removalCleaning apparatusFluid removalChemistryMicroseism

The invention relates to a novel modification system and process of a hot-dry-rock thermal reservoir, characterized by the combination of two stimulation measure processes, thermal stimulation and chemical stimulation. The process is characterized in that a naturally present fracture network is destructed by thermal stimulation to enhance permeability, partial minerals, scale and obstruction in shafts and fractures are dissolved by the chemical stimulation, and flow guiding capacity of the fractures is further improved. The repeating of the process enables a larger range of thermal reservoirs to be modified. By using the process, the problem of the prior art that after thermal stimulation, part of the fractures are closed along with the rise of the temperature of a cooling area and the problem that that a chemical stimulant disappears nearby an injection location during its excess speed of reacting with rock minerals at high temperature are solved, and the process enables greatly reduction in the risk of frequent microseism in a reservoir modification process when compared to traditional hydrofracturing. The process is widely applicable to the modification of hot-dry-rock thermal reservoirs.

Owner:JILIN UNIV +1

Preparation method of multi-component organic cross-linked acid liquid

The invention relates to a preparation method of multi-component organic cross-linked acid liquid, which comprises base liquid and a cross-linking agent, wherein the weight ratio of the base liquid and the cross-linking agent is 100:0.6-0.8; the base liquid comprises the following components in percentage by weight: 3.6-9 percent of formic acid, 4.8-12 percent of acetic acid, 5.5-13.75 percent ofhydrochloric acid, 0.6-0.8 percent of thickening agent, 4.0-5.0 percent of high-temperature corrosion inhibitors, 0.5-1.0 percent of long-term clay stabilizer, 1.0-1.5 percent of ferric ion stabilizers, 0.5-1.0 percent of broken emulsion discharge aiding agent and the balance is water; and the sum of the mass percentages of all the components is 100%. The method has the beneficial effects that the acid liquid system can be cross-linked under the conditions of high temperature and strong acid and is good in temperature resistance and shear resistance, less in filtration and complete in gelout;after the acid liquid is cross-linked, an acid rock is remarkably lower than ordinary gelled acid in reaction speed and is good in speed retarding performance; and the multi-component organic cross-linked acid liquid can be used for realizing the modification of depth acid pressure in a high-temperature deep well of a carbonate rock.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

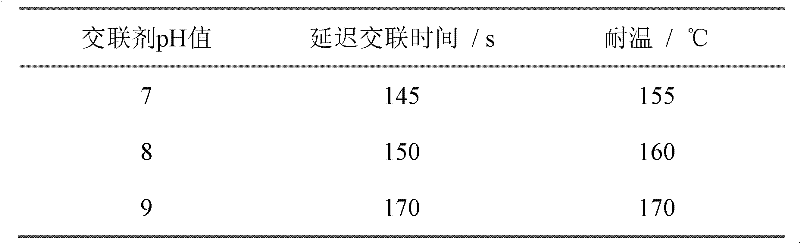

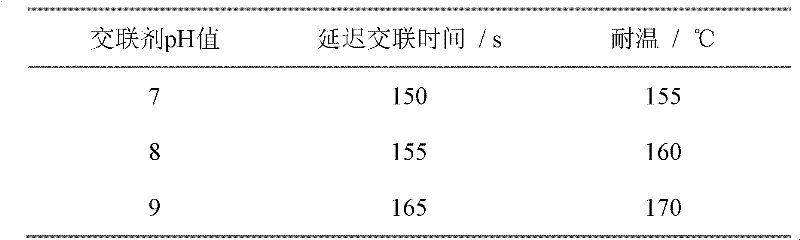

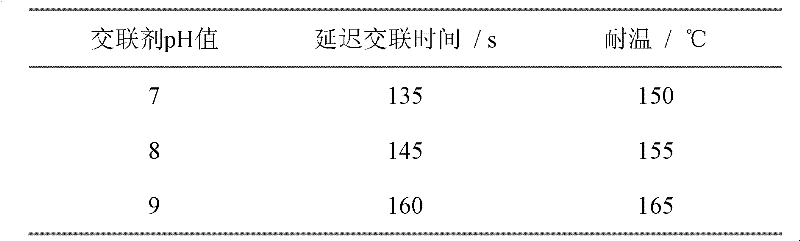

Method for preparing high temperature retarding-type organic boron zirconium cross linking agent

InactiveCN102337113AImprove diversion capacityIncrease production capacityDrilling compositionCross-linkGlycerol

The invention relates to a method for preparing a high temperature retarding-type organic boron zirconium cross linking agent, which comprises the following steps of: adding organic zirconium salt into a three-neck flask filled with a mixed solvent of water and glycerol; stirring to ensure the organic zirconium salt to be totally dissolved; then adding a boron compound; performing a reaction for 30 to 60 minutes at a temperature of 60 DEG C; adding polyatomic alcohol, triethanolamine and EDTA-2Na (Ethylene Diamine Tetraacetic Acid-2Na); heating to a temperature of 80 DEG C and performing a reaction for 4 to 5 hours; and regulating the pH to the range of 7 to 9 by aqueous solution of NaOH with the concentration of 20 percent to obtain the boron zirconium cross linking agent. The cross linking agent prepared by the method disclosed by the invention has the characteristics of small using amount, controllable retarding cross-linking time, high temperature resistance, easiness for gel breaking, low damage and low fraction resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Fracturing fluid stock solution, full-filling preposition-free sand adding fracturing method and fracturing fluid cross-linking solution thereof

ActiveCN101747886AReduce the amount of fluid entering the wellImprove efficiencyFluid removalDrilling compositionHigh fractureFracturing fluid

The invention relates to the technical field of petroleum extraction, in particular to a fracturing fluid stock solution, a full-filling preposition-free sand adding fracturing method and a fracturing fluid cross-linking solution thereof. The fracturing fluid stock solution is prepared from guargum, clay stabilizer, potassium chloride, cleanup additive, bactericide, pH regulator, fluid loss additive, low-temperature activator and water. The invention reduces the well entrance solution amount of the fracturing fluid, reduces the secondary pollution and damage to sensitive ground layers by the fracturing fluid, shortens the occupation and production period, reduces the operation cost and has high fracturing fluid efficiency. The supporting crack is fully filled, wide seams are formed in zones near a well, the diversion capability of cracks near the well is effectively improved, and the after pressure yield of the single well is improved. The process is simple and can be completed without the assistance by special equipment, so the in-site operation is convenient. The invention can be widely used for the oil layer transformation of low-seepage and water-sensitive storage layer oil gas zone blocks.

Owner:新疆石油管理局采油工艺研究院

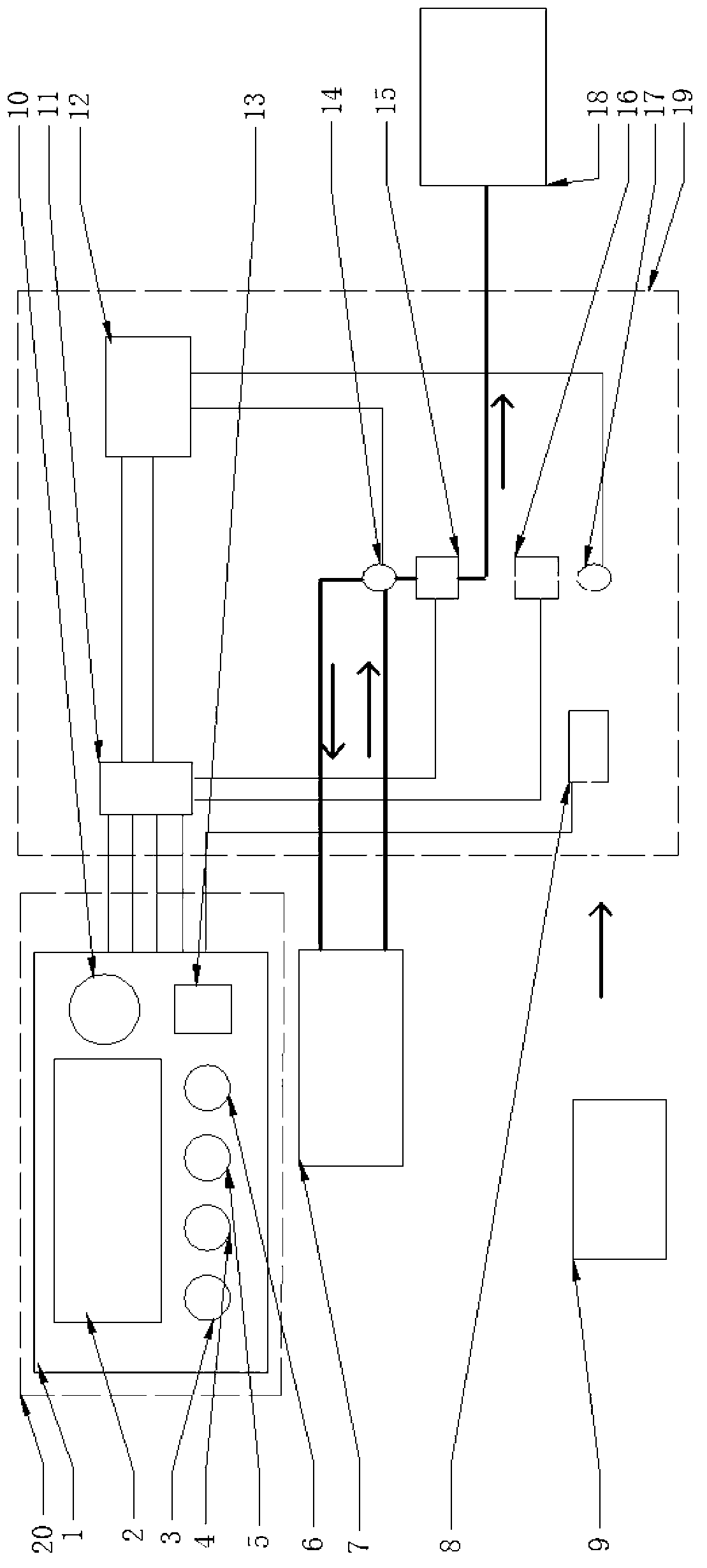

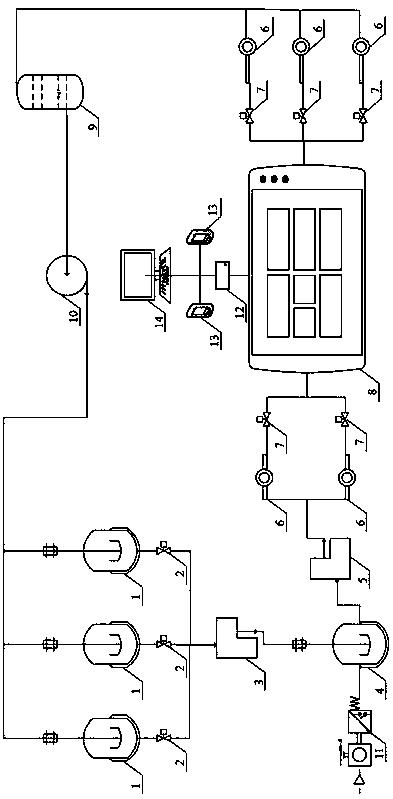

Fracturing pulse sand filling system with ultrahigh flow conductivity and method for operating fracturing pulse sand filling system

The invention relates to a fracturing pulse sand filling system with ultrahigh flow conductivity. The fracturing pulse sand filling system comprises an external control unit, an internal controlled unit, an external fracturing pump truck unit, a sand mixing truck and a fluid storage tank. Fracturing sand-mixed fluid is accommodated in the sand mixing truck, fracturing base fluid is accommodated in the fluid storage tank, the external control unit controls the internal controlled unit, so that the sand-mixed fluid in the sand mixing truck and the base fluid in the fluid storage are alternately pumped into the external fracturing pump truck unit at intervals, and the sand-mixed fluid and the base fluid are finally alternately pumped into underground exploitation cracks at intervals by the external fracturing pump truck unit. The fracturing pulse sand filling system has the advantages that propping agent slugs added with fibers can be injected in a pulse manner under the control of the system, the flow conductivity of the prop cracks is greatly improved, a lag effect due to continuous opening and closing of an existing sand mixing truck is prevented, damage to the sand mixing truck is reduced, and pressure building during propping agent injection can be effectively prevented by the system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Film-coated modified propping agent, and preparation method and application thereof

The invention discloses a film-coated modified propping agent, and a preparation method and an application thereof. The film-coated modified propping agent is composed of a matrix and a resin layer uniformly coated out of the matrix, wherein the matrix is Hobq quartz sand; the resin layer is 1-10 wt% based on that of the matrix; and the resin layer comprises a resin binder and a curing agent, wherein the resin binder is bisphenol A epoxy resin, polyurethane resin or a combination thereof, the curing agent is an aliphatic polyamine curing agent an oralicyclic amine curing agent, and the usage amount of the curing agent is 10-50 wt% based on that of the resin layer. The preparation method of the film-coated modified propping agent is that the resin layer is coated on the outer surface of the matrix. The film-coated modified propping agent can be applied in fields of fracturing exploitation of oil and gas wells, is helpful to increase sand ratio and reduce usage amount of fracturing liquid, can effectively prevent backflow phenomenon, alleviates insertion of the propping agent, increases crack diversion capability, prolongs fracturing validity period, is helpful to increase oil output, reduces water yield and has significant meaning for solving the exploitation of low permeability oil field.

Owner:亿利沙材料科技有限责任公司

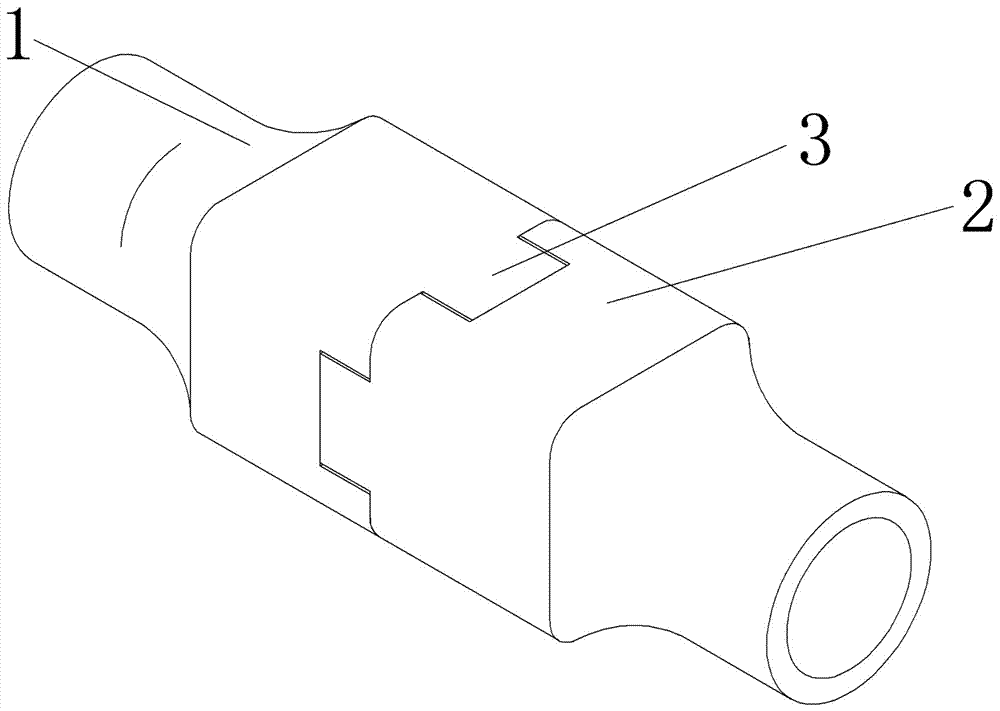

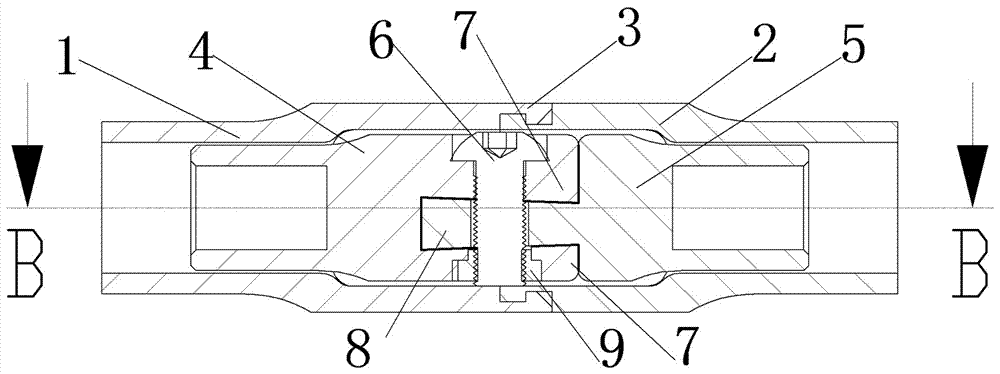

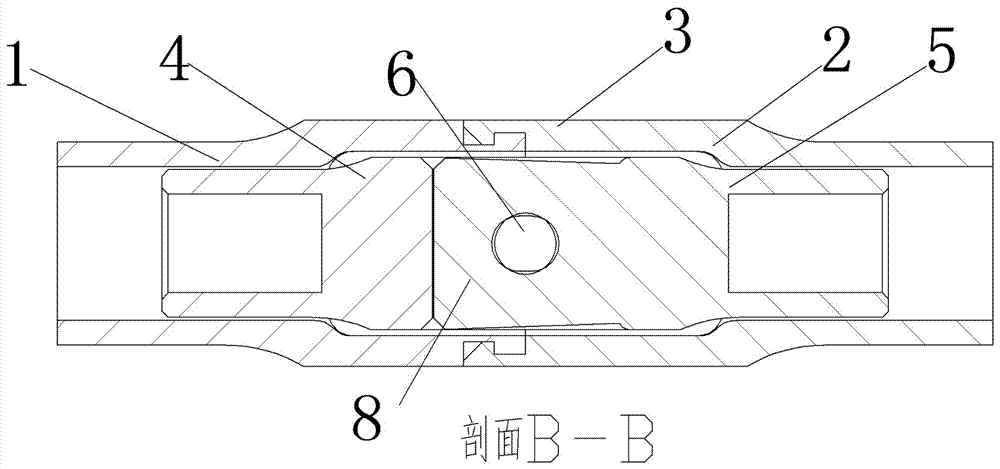

Safety-type large-power, large-current and high-voltage-resistant composite electrical connector

ActiveCN106953181AFully contactedReduce contact resistanceCoupling device detailsTwo-part coupling devicesContact impedanceElectrical connection

The invention discloses a safety-type large-power, large-current and high-voltage-resistant composite electrical connector, and the connector comprises a conductive connection module and insulating protection bushings, wherein the conductive connection module comprises a conductive connection male head, a conductive connection female head, and a locking bolt. The conductive connection male head and the conductive connection female head are in holding-on connection, and are fastened through the locking bolt. The two insulating protection bushings are arranged symmetrically, and respectively sleeve the tail parts of the male head and the female head. When the bolt of the connector is screwed up, the inclined surfaces of two sides of a clamping head are pressed to slide oppositely, and plastic deformation is aroused. Not only are the upper and lower surfaces pressed, but also the inner end face and the outer end face are pressed. A rough line in a specific reference map represents a conductive junction surface, and the conductive junction surface enables the surface contact to be more complete, thereby reducing the contact impedance, and improving the current conducting capability.

Owner:新乡北方车辆仪表有限公司

Enzyme-microbe coupled fracturing fluid system and preparation method and applications thereof

ActiveCN101880523APromote degradationImprove diversion capacityFluid removalDrilling compositionWorking fluidNatural product

The invention relates to a fracturing fluid system, in particular to a new aqueous fracturing enzyme-microbe coupled fracturing fluid system used in the petroleum and natural gas exploitation, wherein the chemical additives in the original aqueous fracturing fluid are replaced by the biological additives with the same function, and inoculating microbe degrading residue and gel are added to react so as to greatly increase the gel-breaking efficiency and reduce formation damage. The fracturing fluid system comprises the following components: 0.30-0.55wt% of vegetable gum polymer, 0.002-0.2wt% of biological bactericide, 0.025-0.05wt% of biological cleanup additive, 0.05-0.1wt% of ahead fluid biological optimizer, 0.05-0.1wt% of microbial enhanced production-increasing agent, 1-3wt% of clay stabilizer, pH regulator, 10-30mg / L of enzyme breaker and the balance water. The fracturing fluid system of the invention uses non-toxic and harmless natural products to the maximum to replace toxic and harmful chemical additives, achieves the aims of degradable working fluid creatures which are injected in the formation, energy conservation and emission reduction and environmental protection and is an ideal fracturing fluid system.

Owner:DALIAN BITEOMICS INC

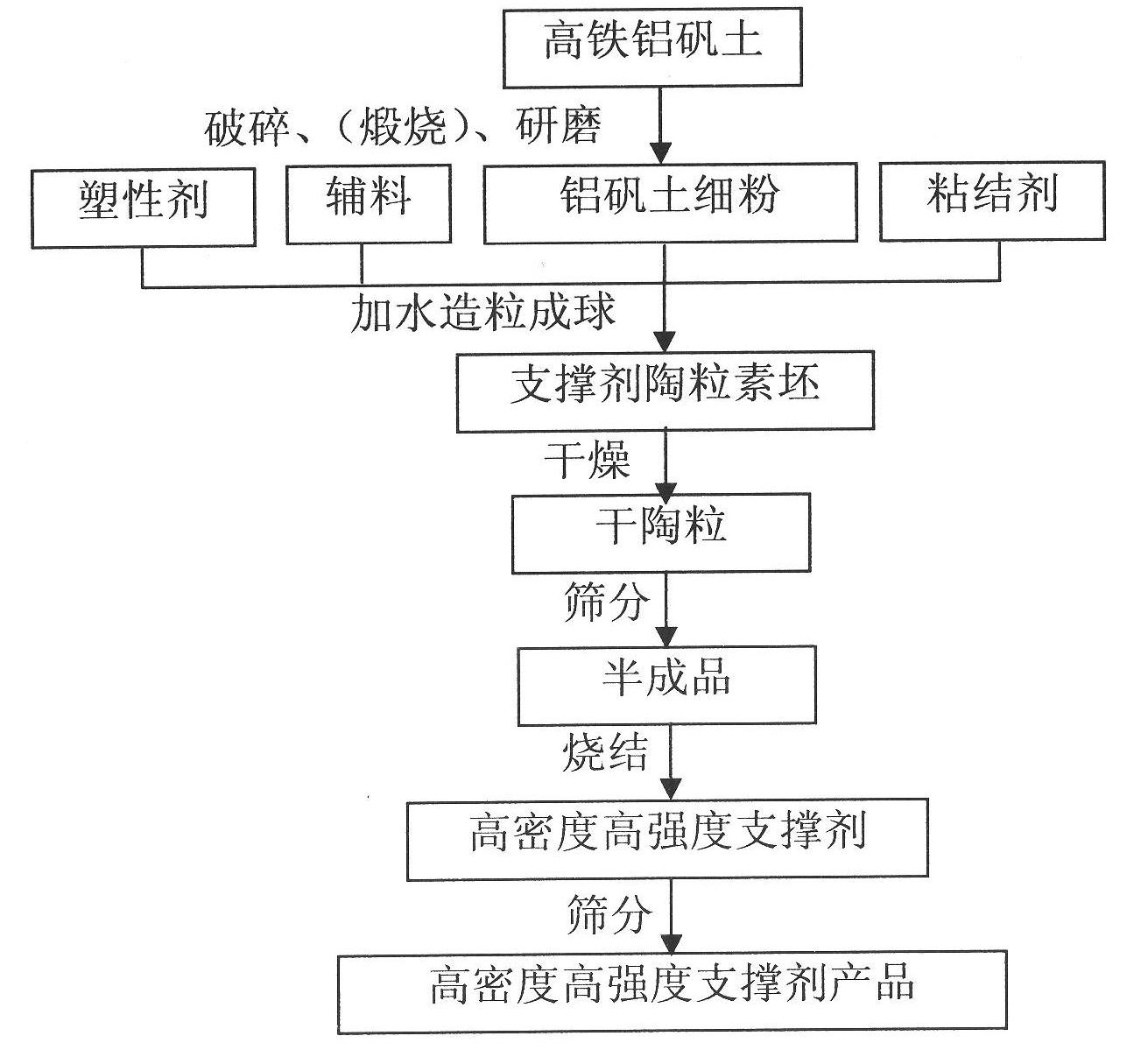

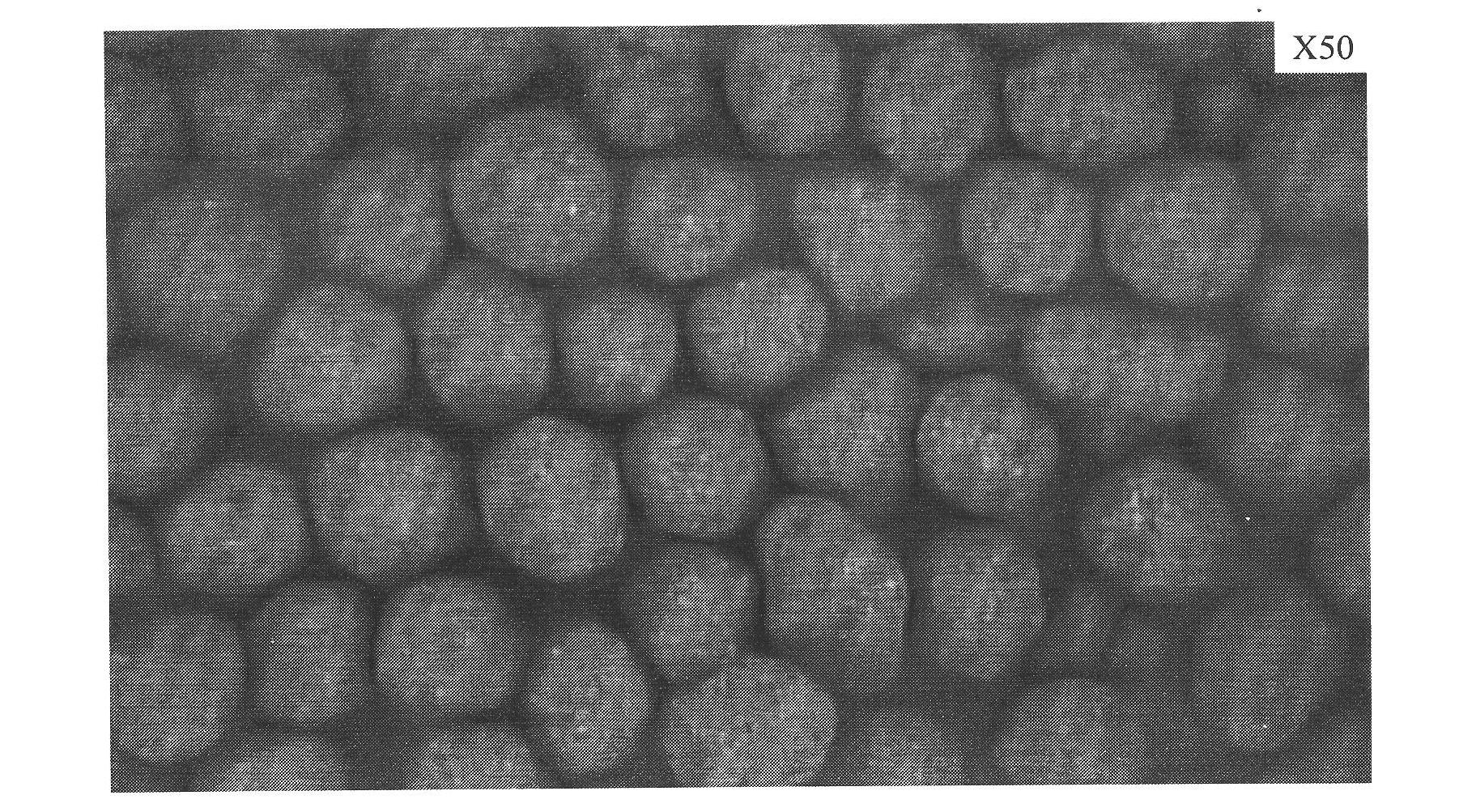

High-density high-strength fracturing propping agent for oil and gas wells and preparation method thereof

The invention relates to a high-density high-strength fracturing propping agent for oil and gas wells and a preparation method thereof, belonging to the field of fracturing propping agents for oil. The high-density high-strength fracturing propping agent comprises alumina with content of not more than 75 percent by weight and iron oxide with the content of not less than 10 percent by weight; and the broken rate of a product with apparent density of not less than 3.35 g / cm<3> and a grain diameter of 20 / 40 meshes or a smaller grain diameter is less than 5 percent under the pressure of 69 MPa. The preparation method of the fracturing propping agent comprises the following steps of: selectively adding one or a composite of more of the iron oxide and manganese oxide as an auxiliary material bytaking high iron bauxite containing Al2O3 with the content of not less than 40 percent by weight and not more than 75 percent by weight, Fe2O3 with the content of not less than 10 percent by weight and not more than 50 percent by weight and SiO2 with the content of not less than 2 percent by weight and not more than 20 percent by weight (content corresponding to dewatered clinker aggregates) as main raw materials; crushing, calcining or grinding without calcining, and then adding a right amount of plastic agents and cementing agents; adding water to a granulated ball forming mill to rotate into balls so as to form a propping agent haydite biscuit; and then drying and sintering so as to prepare the high-density high-strength fracturing propping agent.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

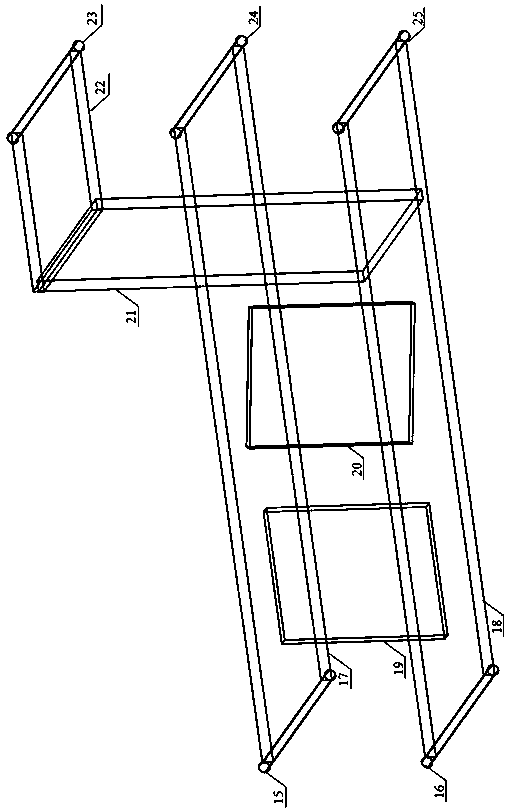

Shale bedding inner supporting agent transportation simulating device and evaluation method

PendingCN107701164AImprove diversion capacityRealize quantitative evaluationFluid removalDesign optimisation/simulationData processing systemEngineering

The invention discloses a shale bedding inner supporting agent transportation simulating device and an evaluation method. The shale bedding inner supporting agent transportation simulating device comprises a continuous liquid mixing system, an automatic sand mulling system, a control and data processing system and a bedding seam internal flow simulating system. The continuous liquid mixing systemis connected with the automatic sand mulling system, the automatic sand mulling system is connected with the bedding seam internal flow simulating system, and the bedding seam internal flow simulatingsystem is connected with the control and data processing system. According to the shale bedding inner supporting agent transportation simulating device and the evaluation method, slugging type sand adding, continuous sand adding and various liquid system mixed fracturing pump injection procedure simulation on a fracturing site can be achieved, quantitative evaluation of the supporting effects ofdifferent cracks is achieved, and the theoretical basis and experimental support are provided for on-site pump injection procedure simulation optimization and fracturing parameter quantitative evaluation.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

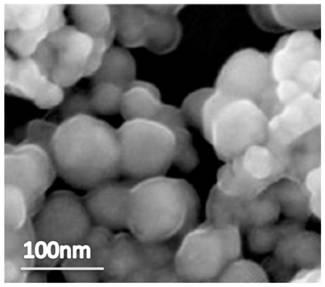

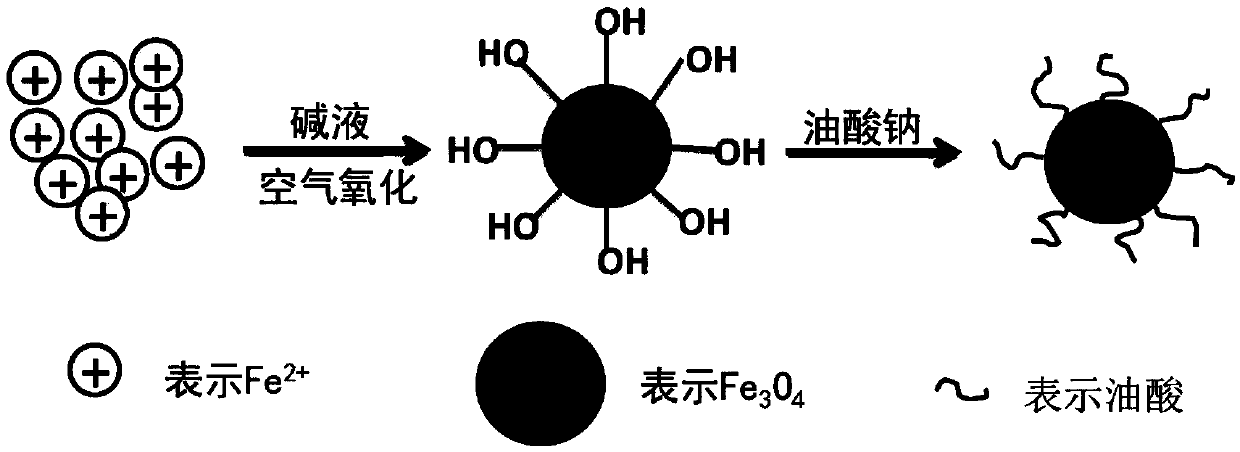

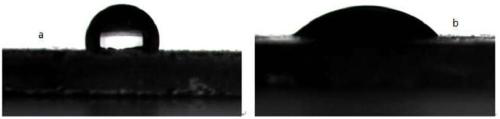

Nano magnetofluid fracturing fluid imbibition oil-increasing method for tight reservoir and modified nano magnetic particles

ActiveCN110454132AStrong lipophilic and hydrophobic propertiesSimple preparation processFluid removalDrilling compositionWater productionMagnetite Nanoparticles

The invention relates to a nano magnetofluid fracturing fluid imbibition oil-increasing method for a tight reservoir and modified nano magnetic particles. The nano magnetofluid fracturing fluid imbibition oil-increasing method comprises the steps that magnetic fracturing prepad fluid is pumped into a formation, a crack is formed in the formation, a magnetic field is applied to the well bottom, andthe modified nano magnetic particles in the magnetic fracturing prepad fluid are delivered to a target oil reservoir; a fracturing fluid base fluid and a propping agent for fracturing are mixed to form sand-carrying fluid to be pumped into the crack formed in the formation, so as to support the geometrical shape of the crack; and after fracturing construction, the magnetic field is applied to thewell bottom, thus the nano magnetic particles adsorbing crude oil flow back into a wellbore and then recovered out of the ground, and the magnetic particles are recovered through the magnetic force effect. The nano magnetofluid fracturing fluid imbibition oil-increasing method for the tight reservoir and the modified nano magnetic particles are suitable for an oilfield with the high water content, the modified nano magnetic particles have high lipophilicity and hydrophobicity, thus the magnetic particles adsorb the crude oil in the target oil reservoir and flow back to the wellbore through the pressure difference at the well bottom and the effect of the externally applied magnetic field, the crude oil output can be well increased, water production is reduced, the magnetic nanoparticles are recovered out of the ground in the oil recovery process, and the magnetic particles can be recovered through magnetic force to be reused, so that the production cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com