Patents

Literature

35 results about "Mucic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mucic acid, C₆H₁₀O₈ or HOOC-(CHOH)₄-COOH (also known as galactaric or meso-galactaric acid) is an aldaric acid obtained by nitric acid oxidation of galactose or galactose-containing compounds such as lactose, dulcite, quercite, and most varieties of gum.

Nicotine salts, co-crystals, and salt co-crystal complexes

The invention provides certain nicotine salts, co-crystals, and salt co-crystals and provides novel polymorphic forms of certain nicotine salts. In particular, nicotine salts with mucic acid, 3,5-dihydroxybenzoic acid, and 2,3-dihydroxybenzoic acid, and crystalline polymorphic forms of nicotine 4-acetamidobenzoate, nicotine gentisate, and nicotine 1-hydroxy-2-naphthoate are described. The invention further provides methods of preparation and characterization of such nicotine salts, co-crystals, and salt co-crystals and polymorphic forms thereof. In addition, tobacco products, including smoking articles, smokeless tobacco products, and electronic smoking articles comprising nicotine salts, co-crystals, and / or salt co-crystals are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Nicotine salts, co-crystals, and salt co-crystal complexes

Owner:R J REYNOLDS TOBACCO COMPANY

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

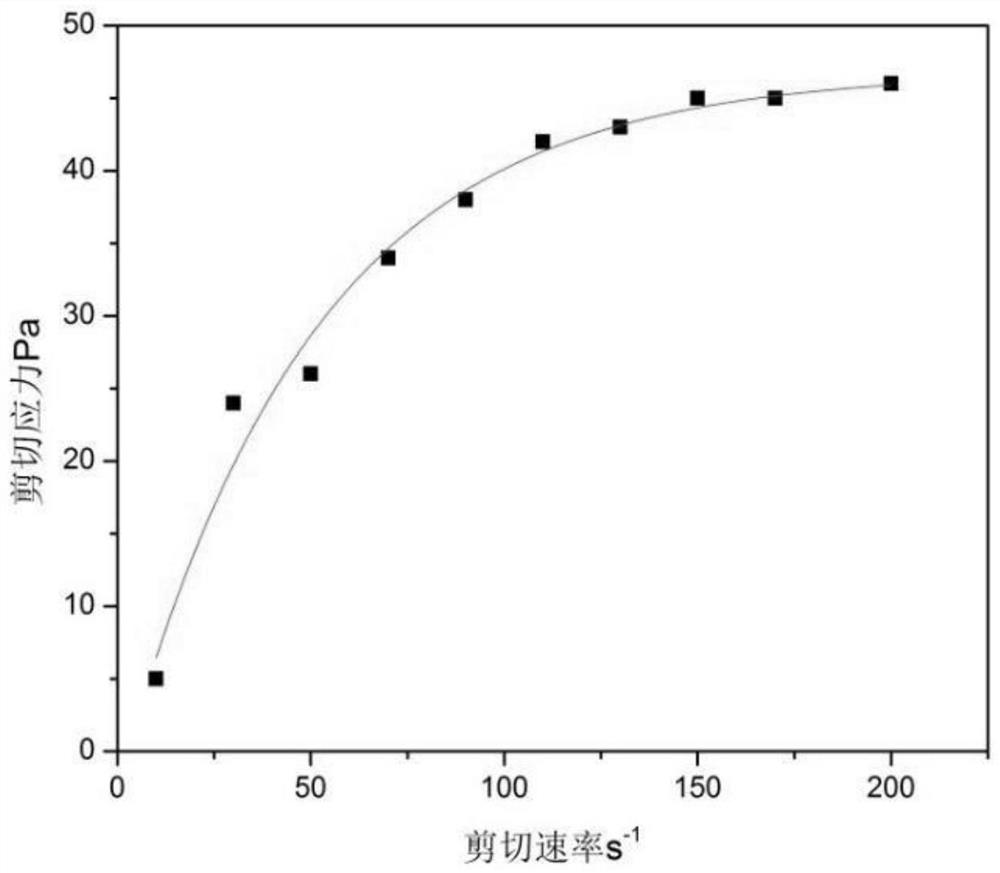

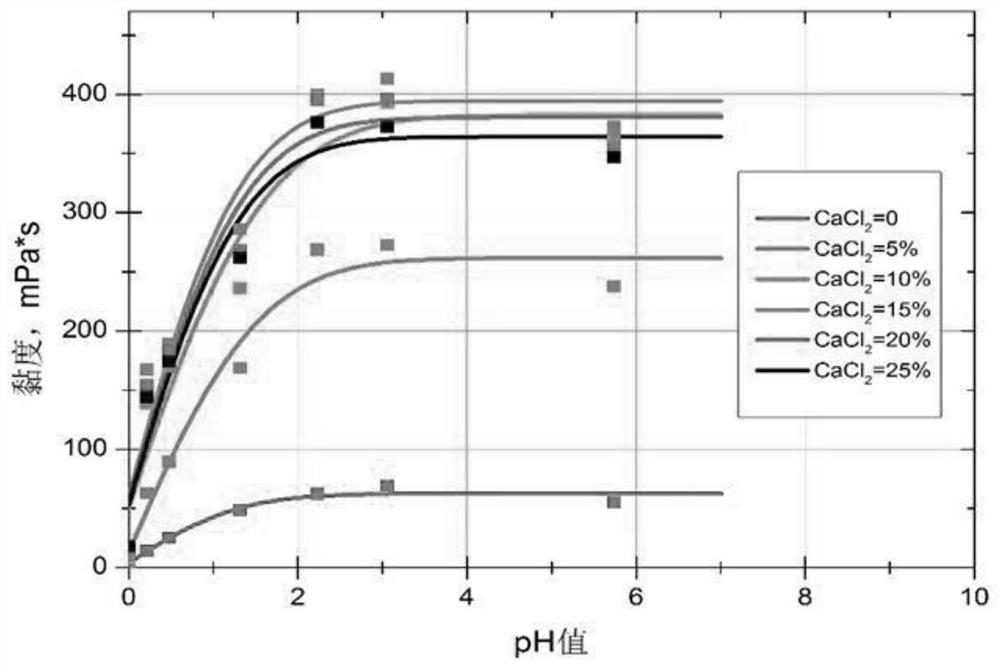

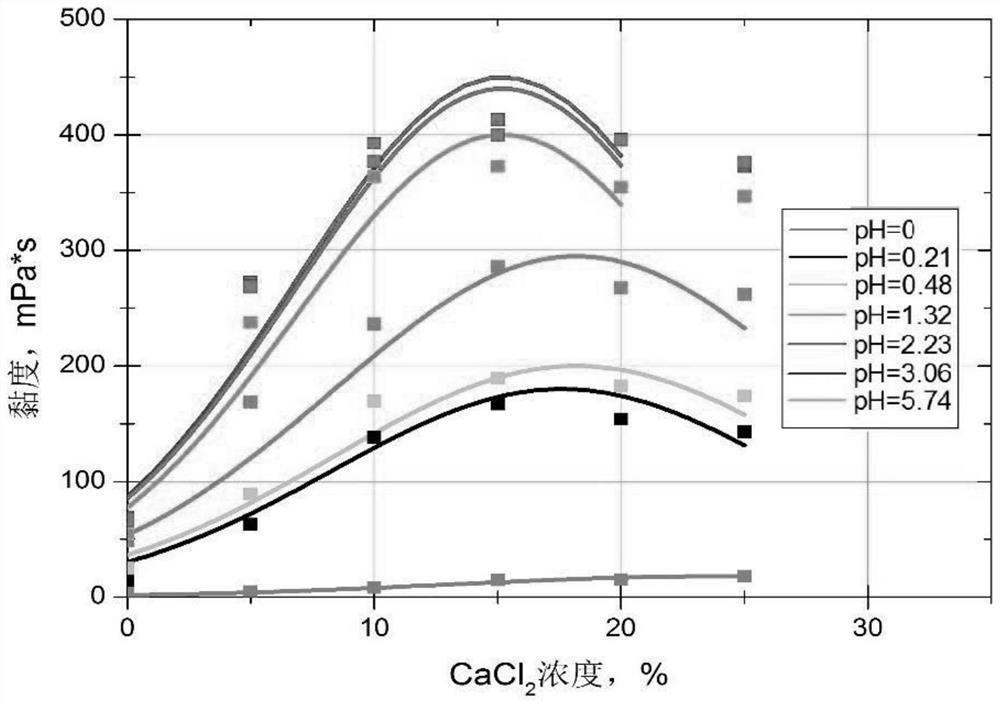

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

Acid-fracturing method for leading crack to extend downward

ActiveCN101864939ARealize the goal of directional deep acid fracturingFluid removalAcid fracturingTemperature control

The invention relates to an acid-fracturing method for leading a crack to extend downward. The acid-fracturing method comprises the following steps: injecting 5-20m3 of hydrochloric acid with the concentration of 10-20 percent into a formation at discharge capacity of 0.5-3.0m3 / minute; injecting 20-100m3 of gel into the crack of the formation at discharge capacity of 1.5-5.0m3 / minute, and then adding ammonium persulfate gel breaker with the concentration of 0.2 percent; pump-injecting 30-80m3 low-concentration carrying fluid with the volume content of hollow glass beads of 2-10 percent at discharge capacity of 1.0-4.0m3 / minute; pump-injecting 50-200m3 gel into the formation at discharge capacity of 3.0-7.5m3 / minute; pump-injecting 50-200m3 gel acid, temperature control various mucic acid into the formation at discharge capacity of 3.0-7.5m3 / minute; using quick water to jack the fracturing fluid in a shaft into the formation; and reaching a long-distance reservoir body which can not be communicated by the conventional acid-fracturing method and realizing the purpose of directional and deep acid-fracturing modification.

Owner:PETROCHINA CO LTD +1

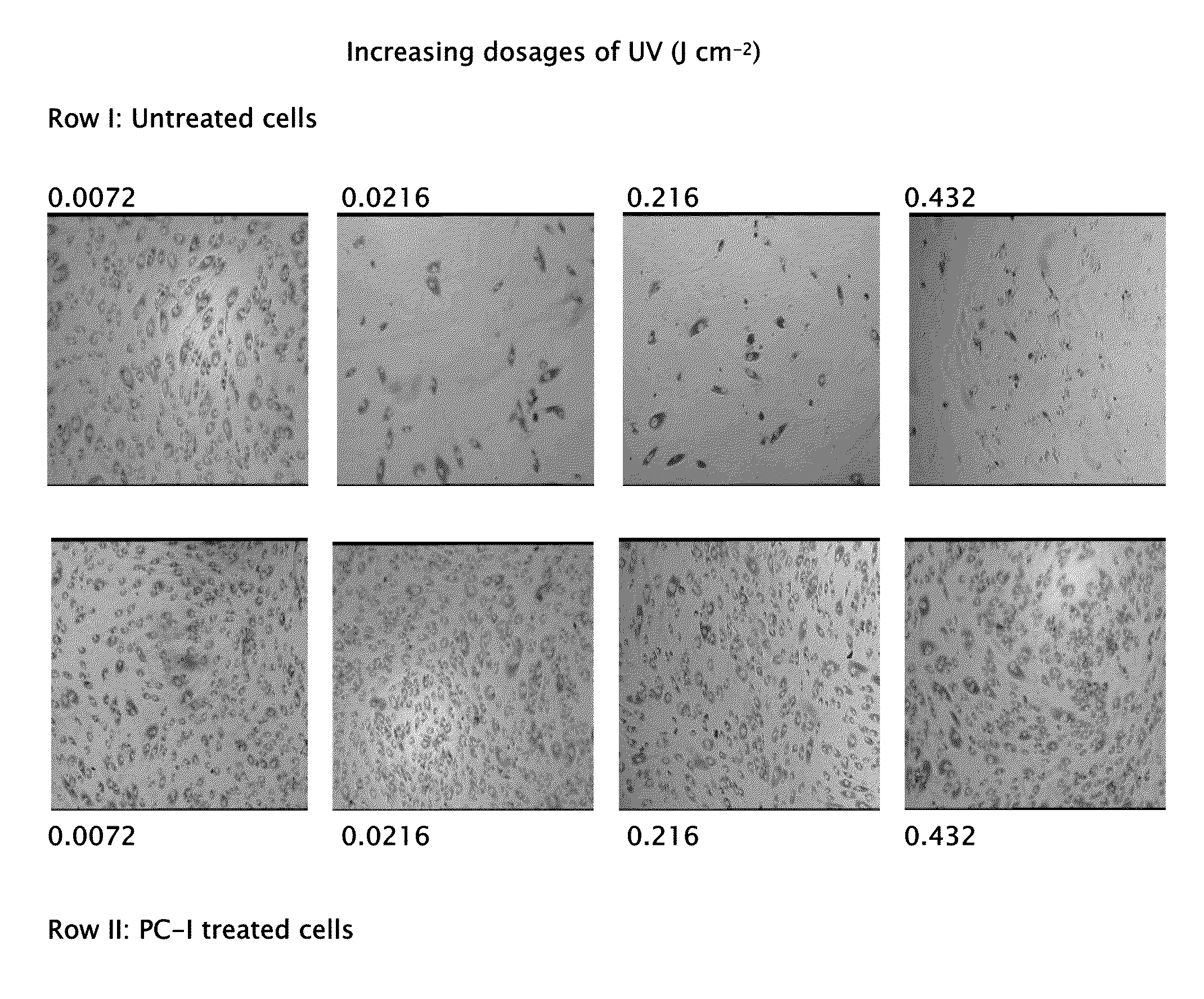

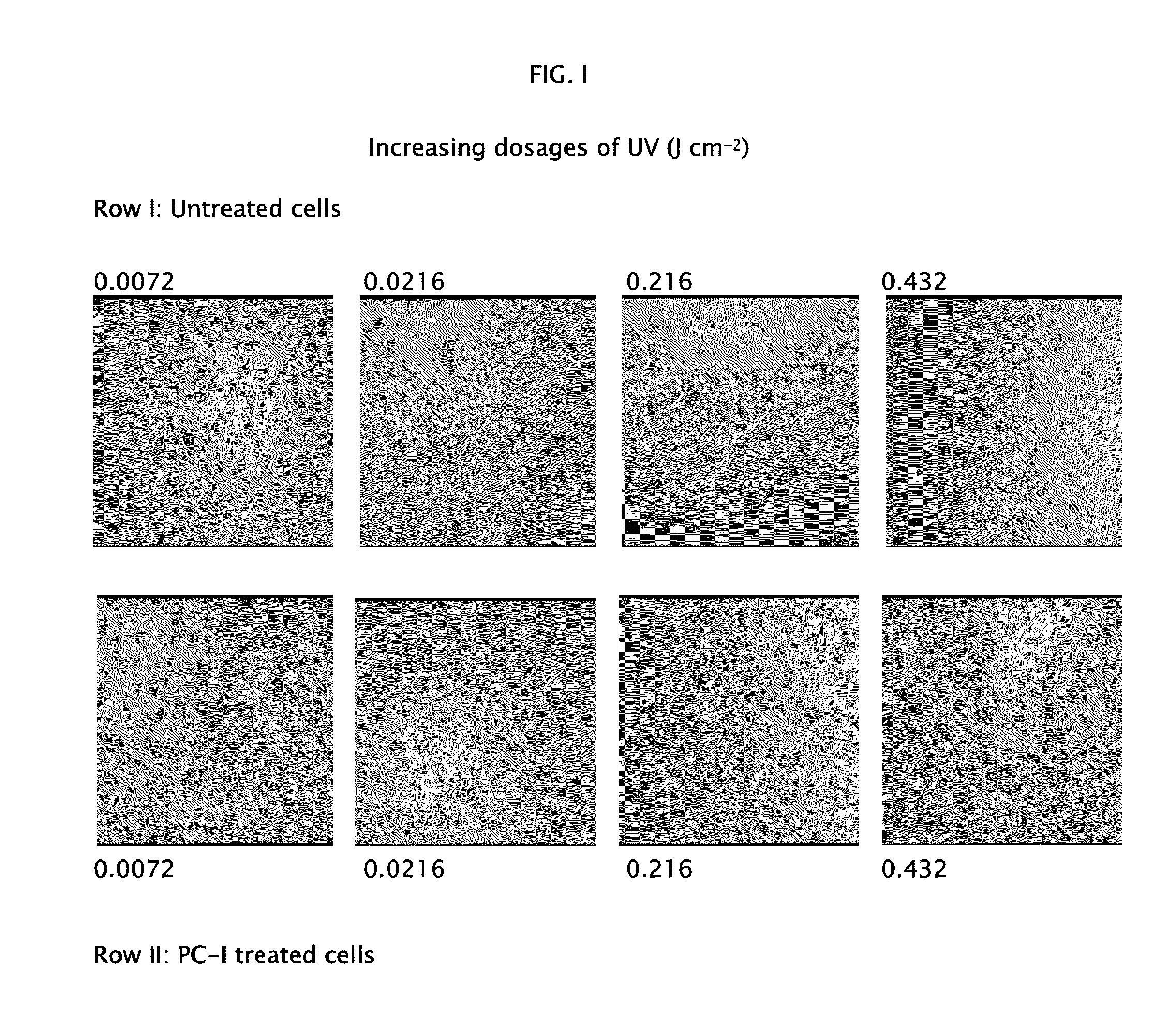

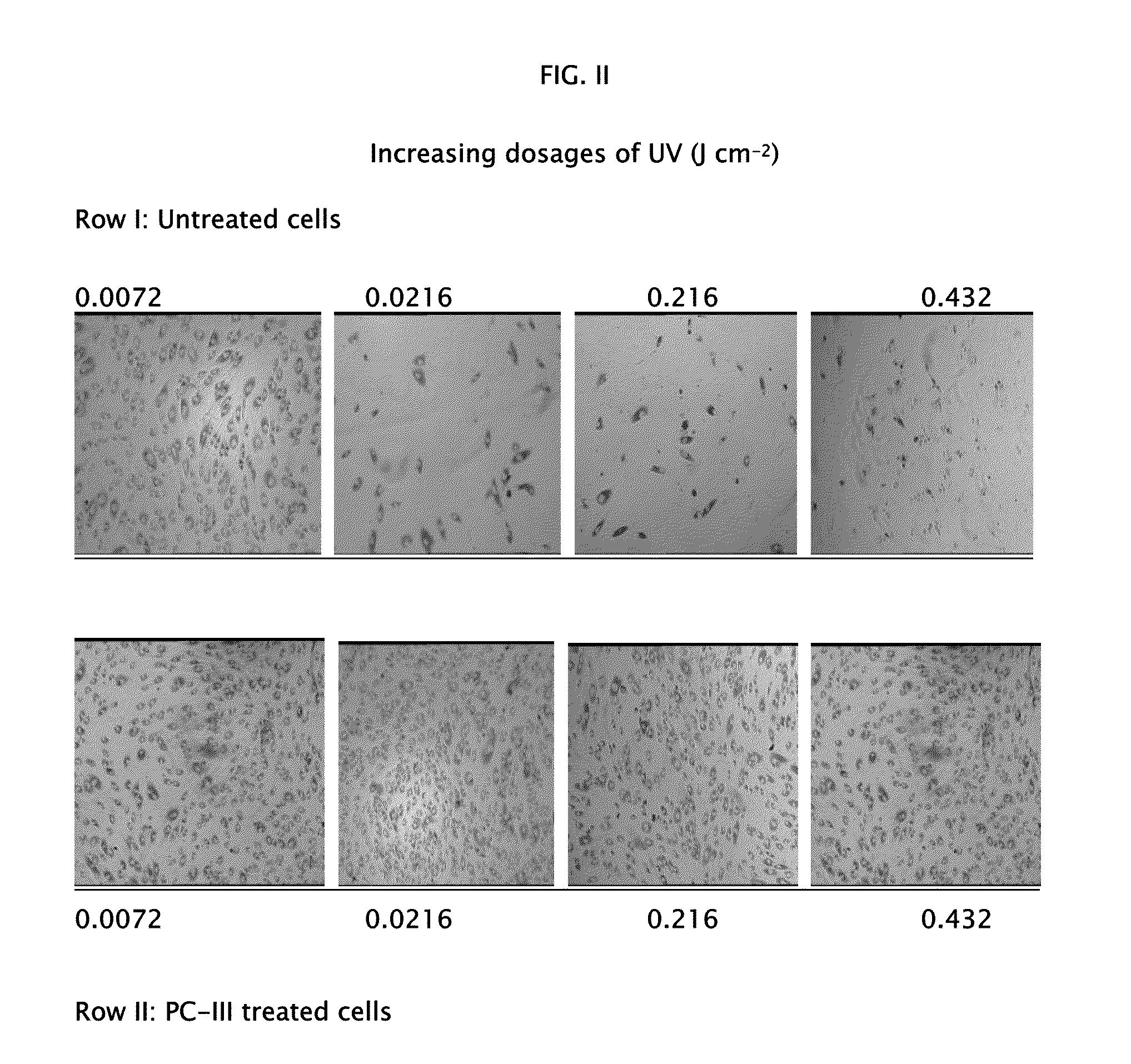

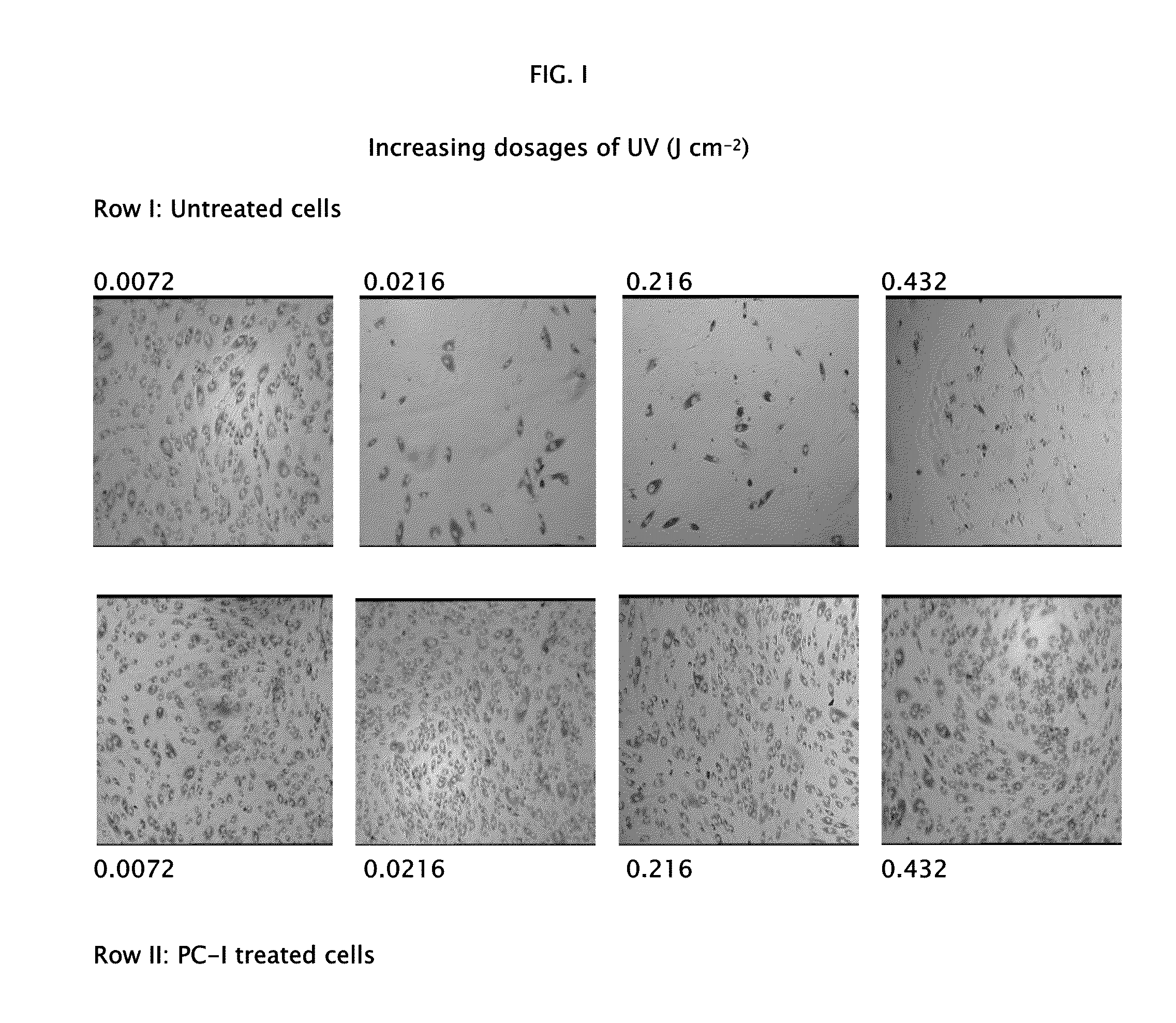

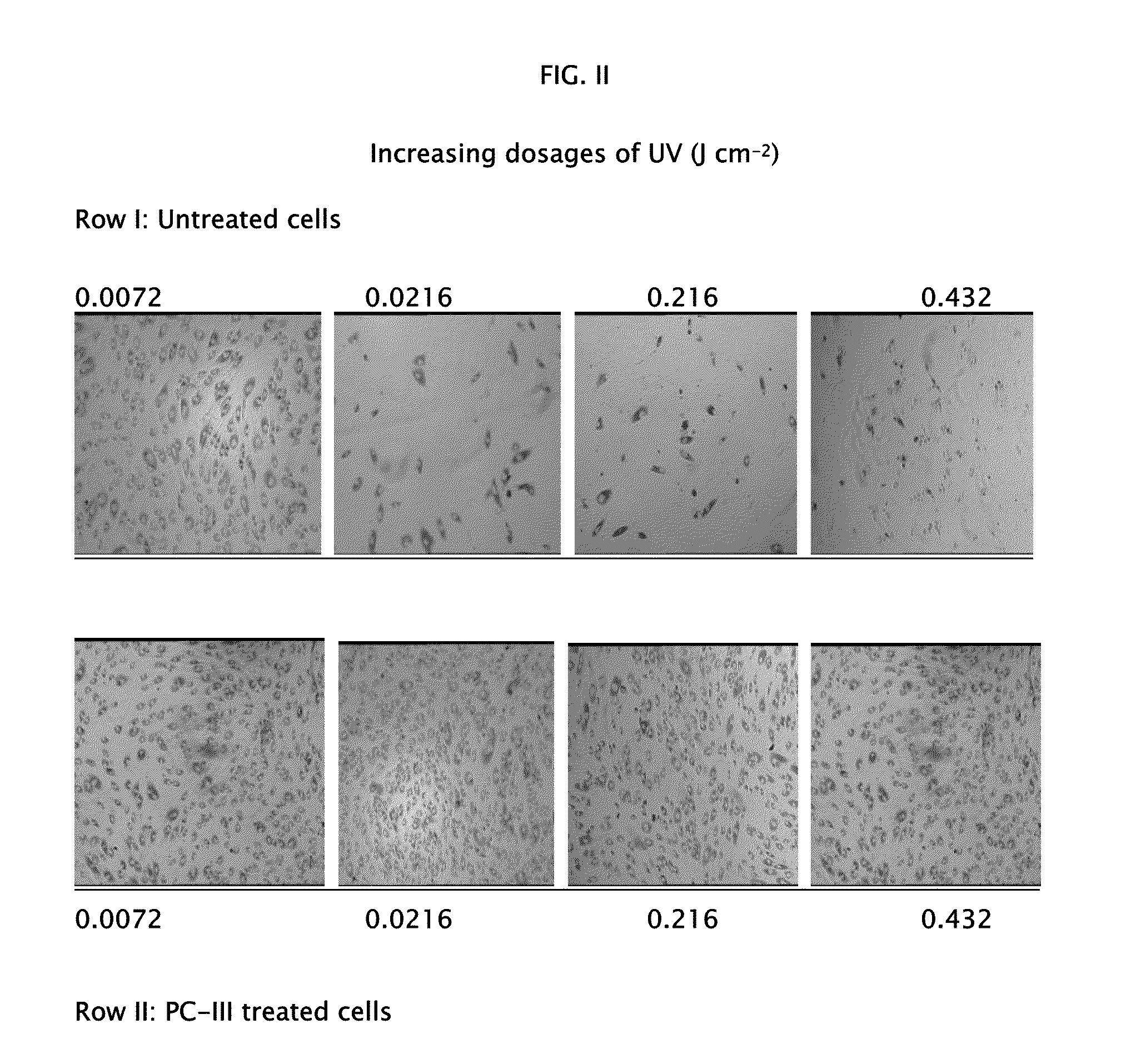

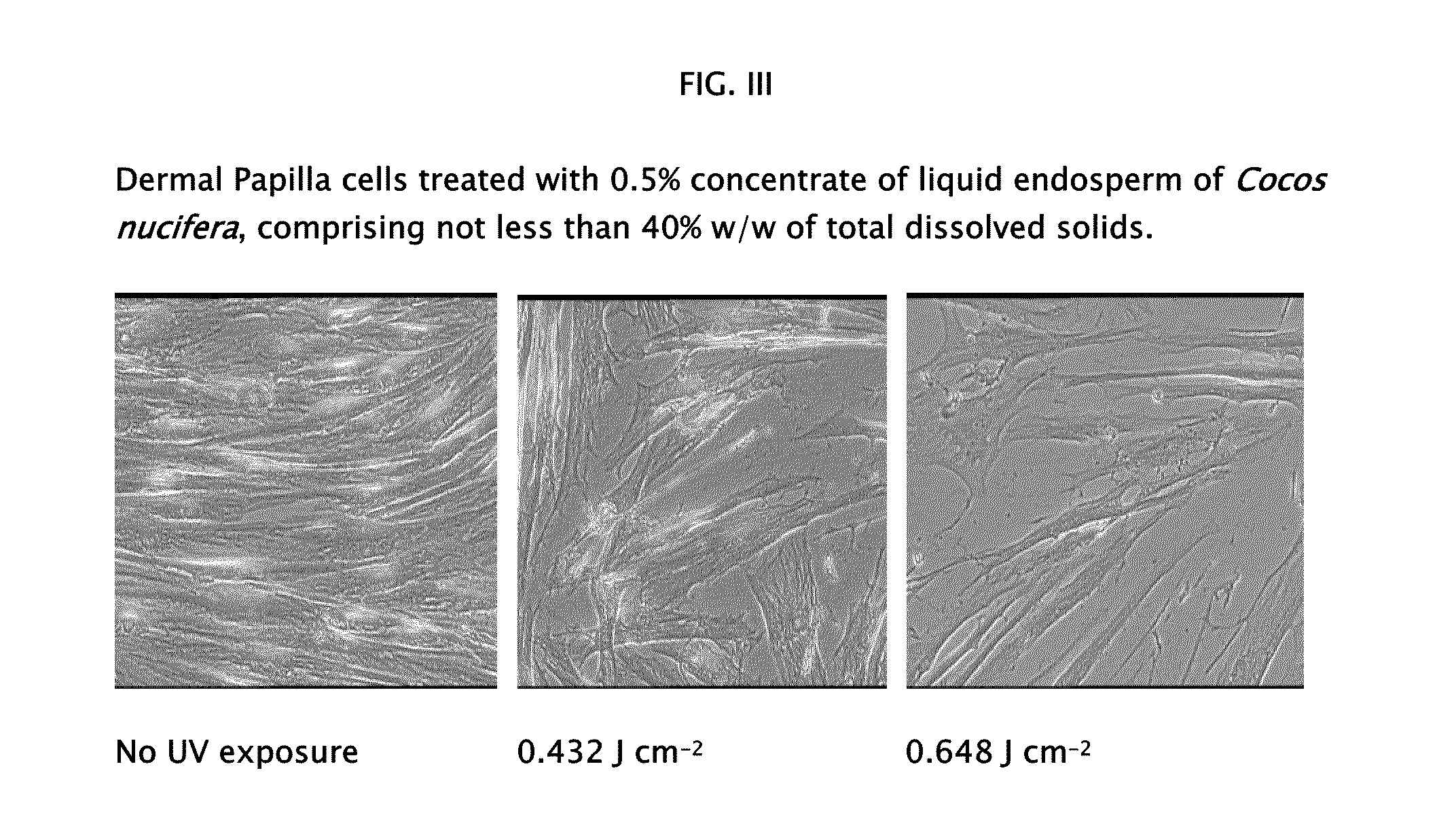

Protective Compositions for Dermal Papilla Cells

ActiveUS20110033565A1Avoid cell damagePromote hair growthCosmetic preparationsBiocideGlucose & ProteinHair growth

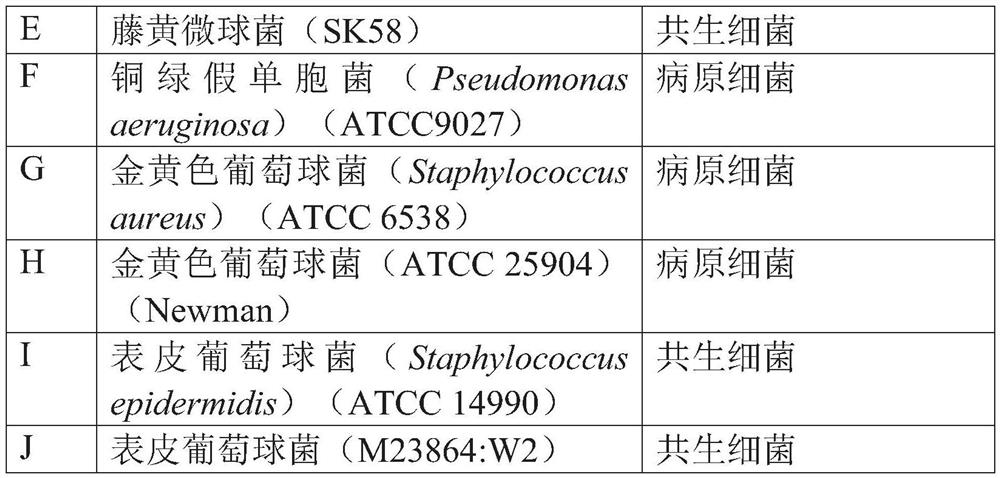

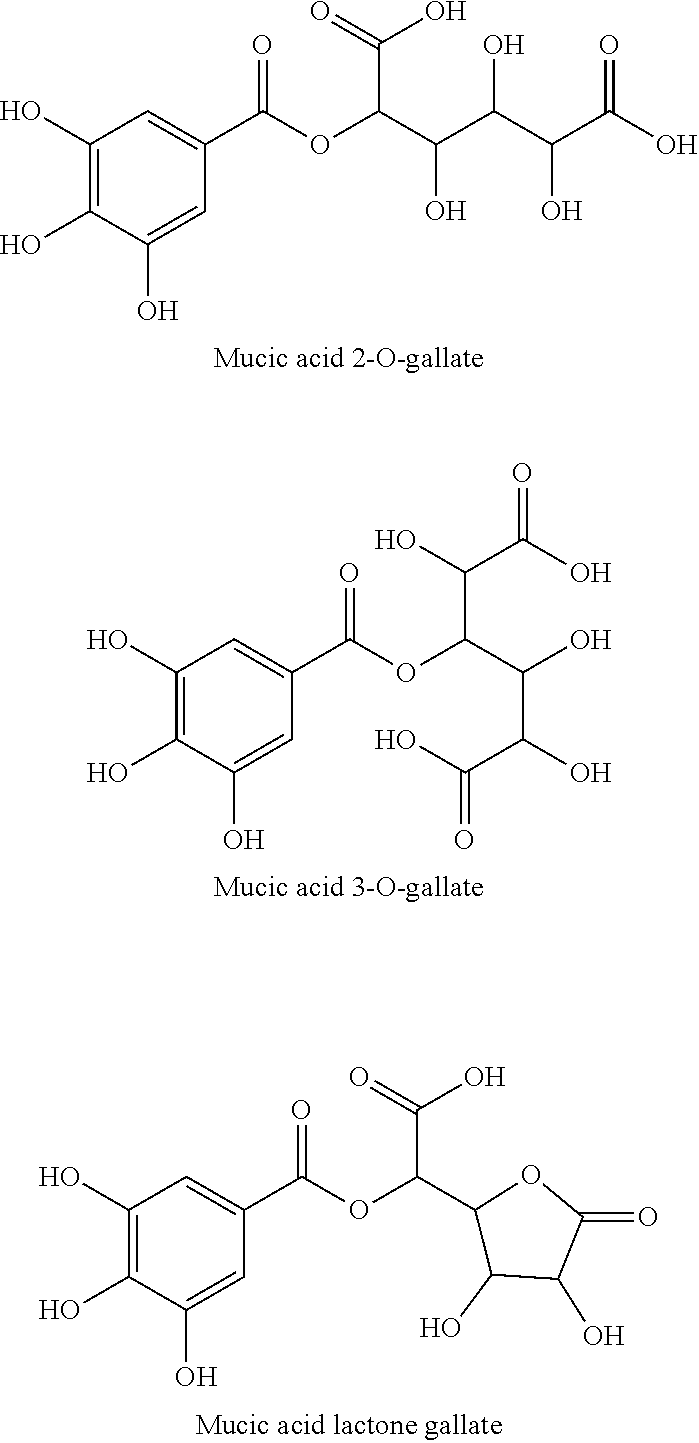

Disclosed are novel protective compositions for dermal papilla cells. In an embodiment the protective compositions of the present invention comprise 0.25% w / w or above of compositions comprising at least 10% w / w and above of 1-O-galloyl-β-D-glucose (β-glucogallin). In an embodiment, the said protective composition additionally comprises 50% to greater than 50% gallates including mucic acid 1,4-lactone 5-O-gallate, mucic acid 2-O-gallate, mucic acid 6-Methyl ester 2-O-gallate, mucic acid 1-Methyl ester 2-O-gallate and ellagic acid. In another embodiment the invention also encompasses synergistic protective compositions comprising the said protective compositions and 0.5% concentrate of liquid endosperm of Cocos nucifera, for dermal papilla directed towards helping the dermal papilla cells to form sufficient numbers and to retain a healthy morphology conducive for hair growth.

Owner:SAMI LABS LTD

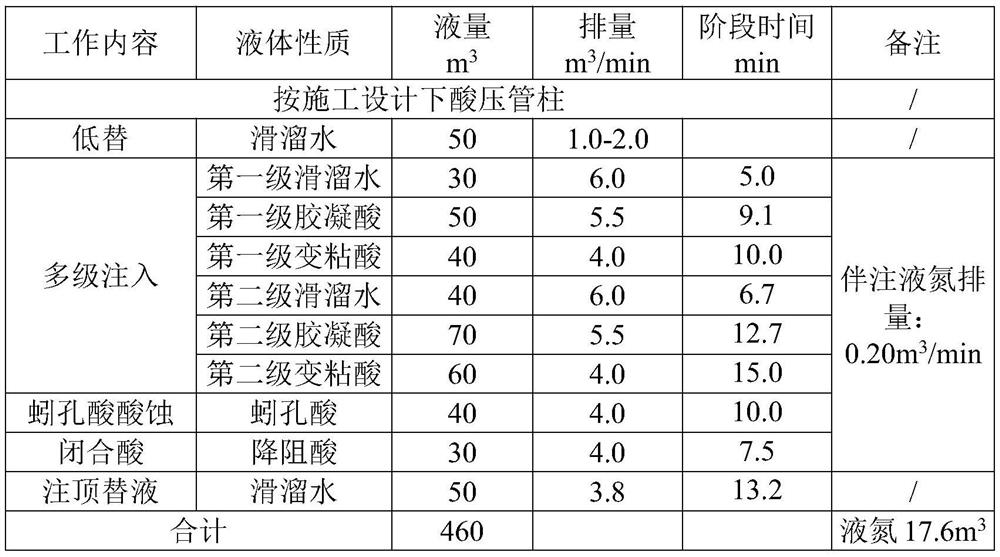

Production increase method for deep layer shale gas reservoir and application of production increase method

ActiveCN107366530ADisperse inflowIncrease seam resistanceFluid removalAcid fracturingStress evaluation

The invention relates to a production increase method for a deep layer shale gas reservoir. The production increase method comprises the following steps that (1) compressibility and ground stress evaluation is conducted on a stratum; (2) cluster perforation parameters are determined, and the perforation mode is circumferential perforation; (3) after crake parameters and construction parameters are determined, fracturing is conducted on target stratum shale; (4) pre-acid-fracturing treatment is conducted, and acid fracturing adopting high mucic acid and closed acidizing treatment adopting low mucic acid are included; (5) slickwater containing a propping agent is injected, and the sand-to-liquid ratio is gradually increased to be 20% from 1%; and (6) high viscosity glue liquid containing a propping agent is injected, and the sand-to-liquid ratio is gradually increased to be 23% from 5%. A deep layer shale gas well is transformed by using the production increase method, and the productive potential of the deep layer shale gas reservoir can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

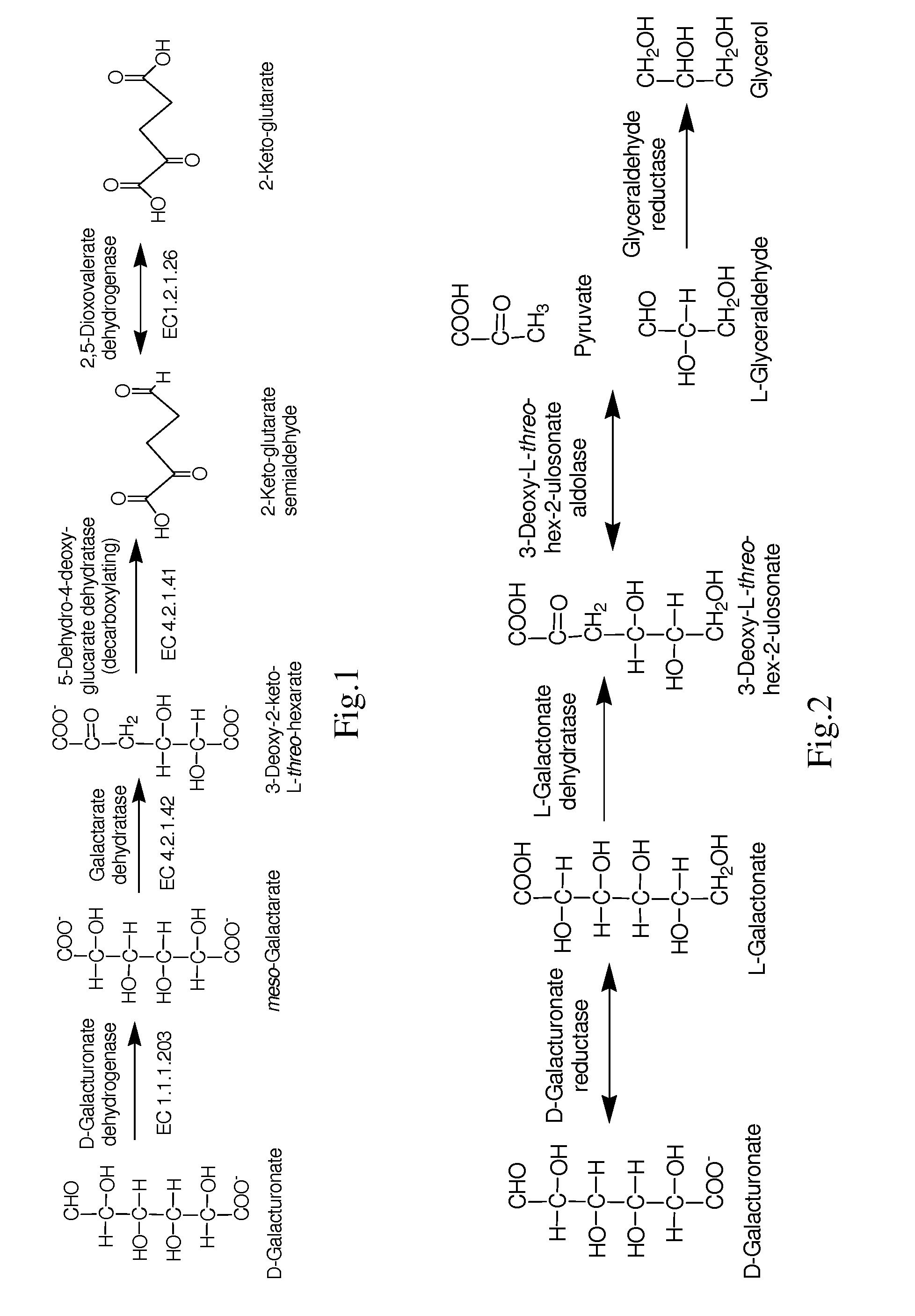

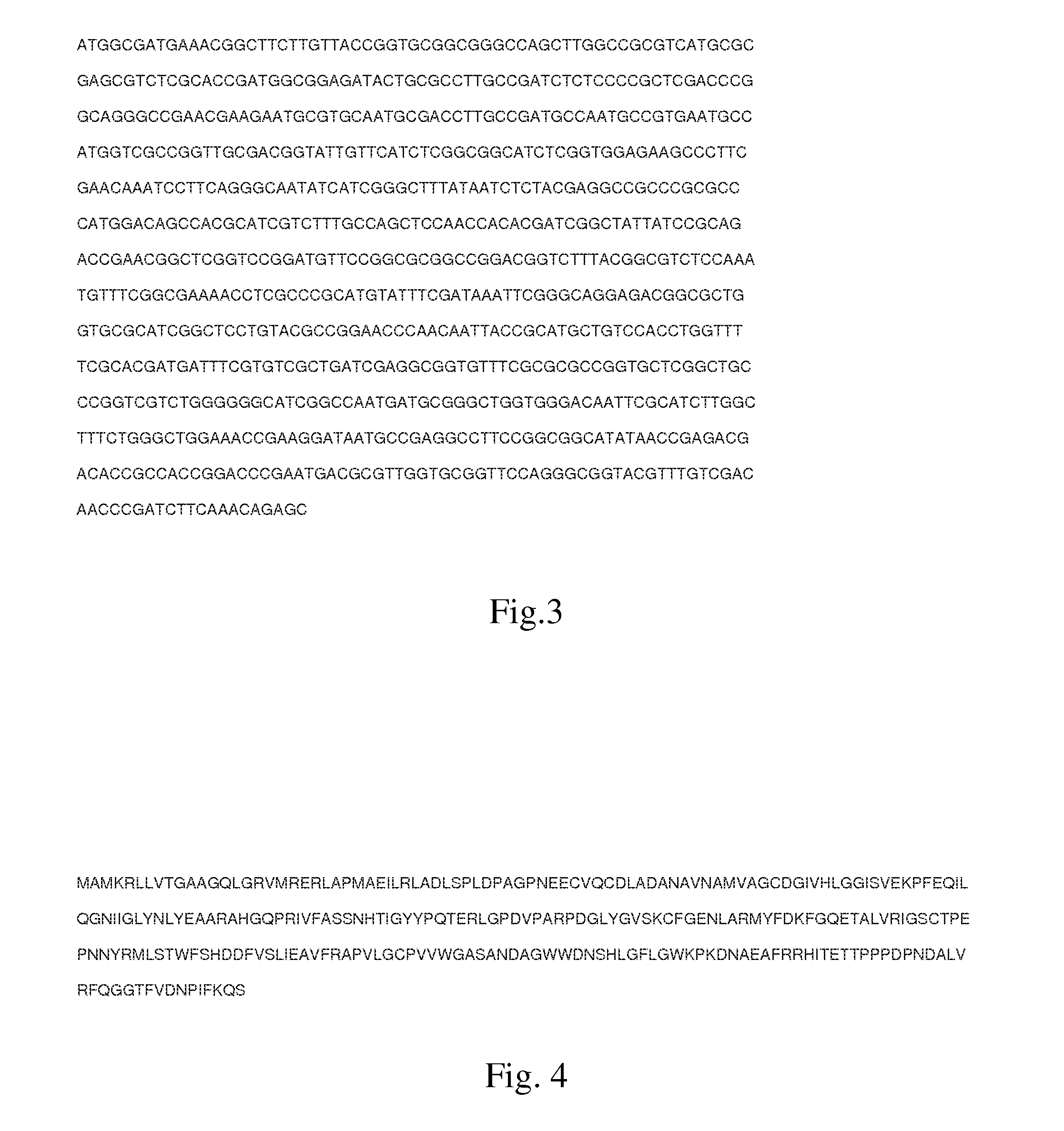

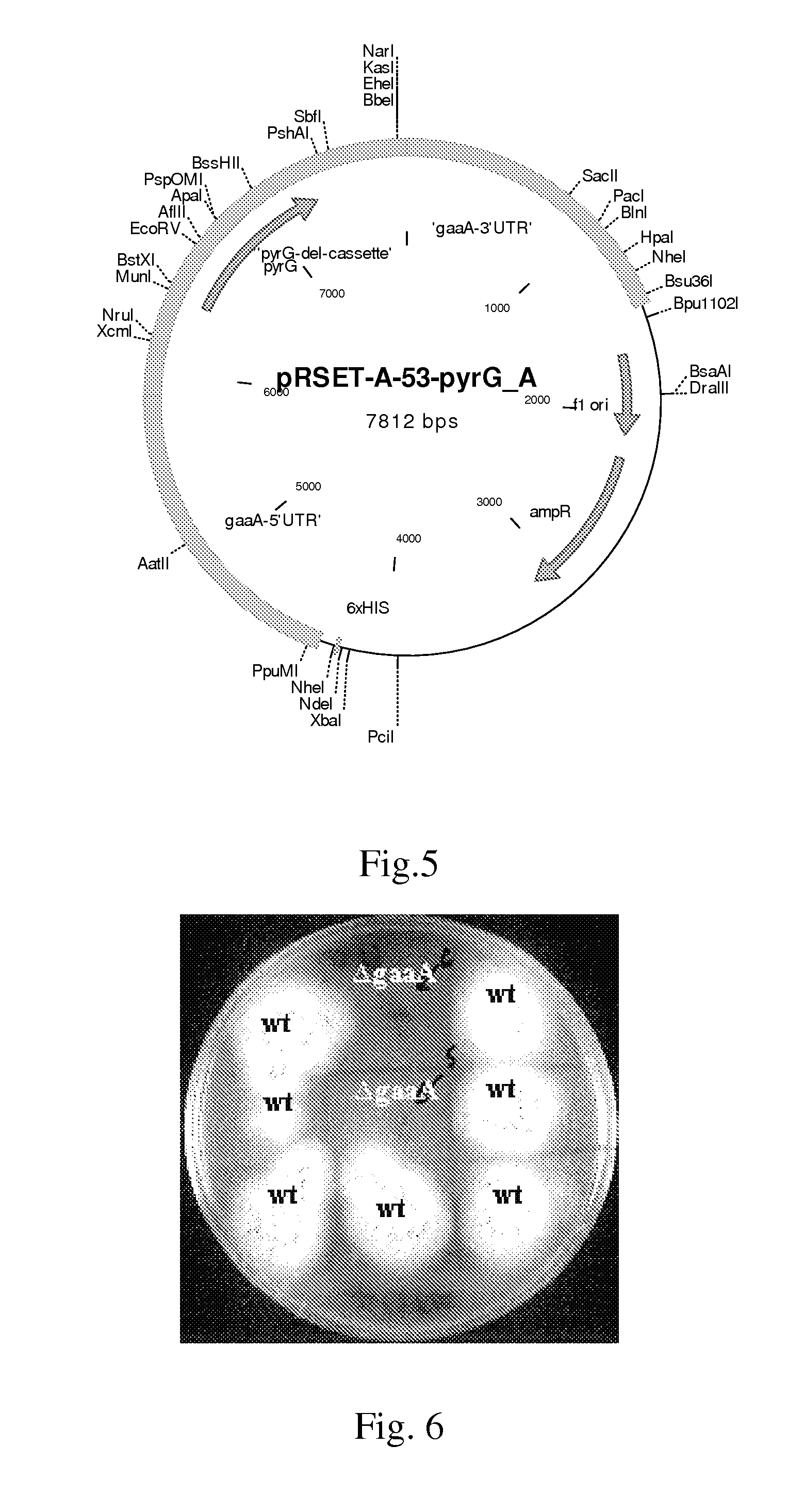

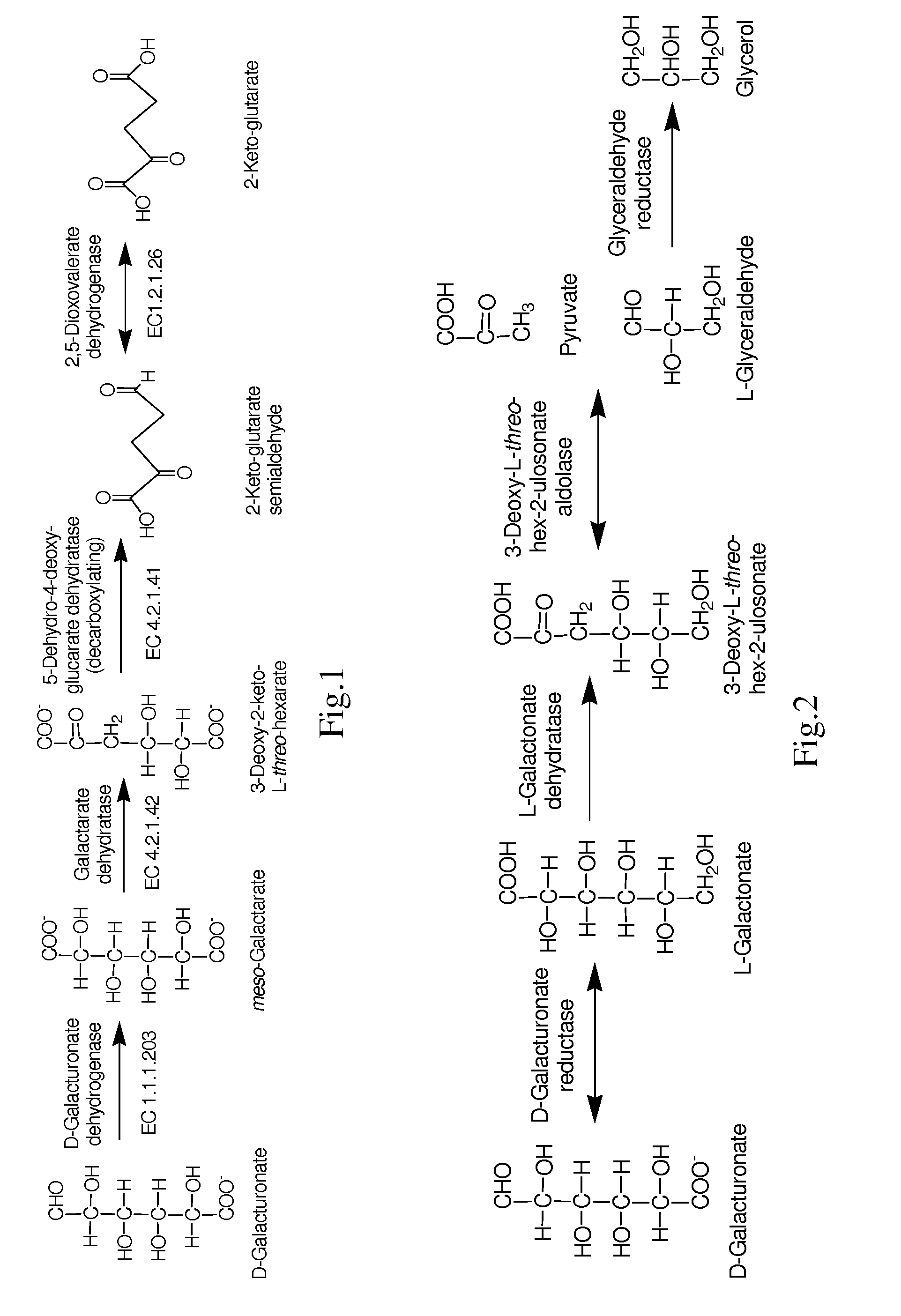

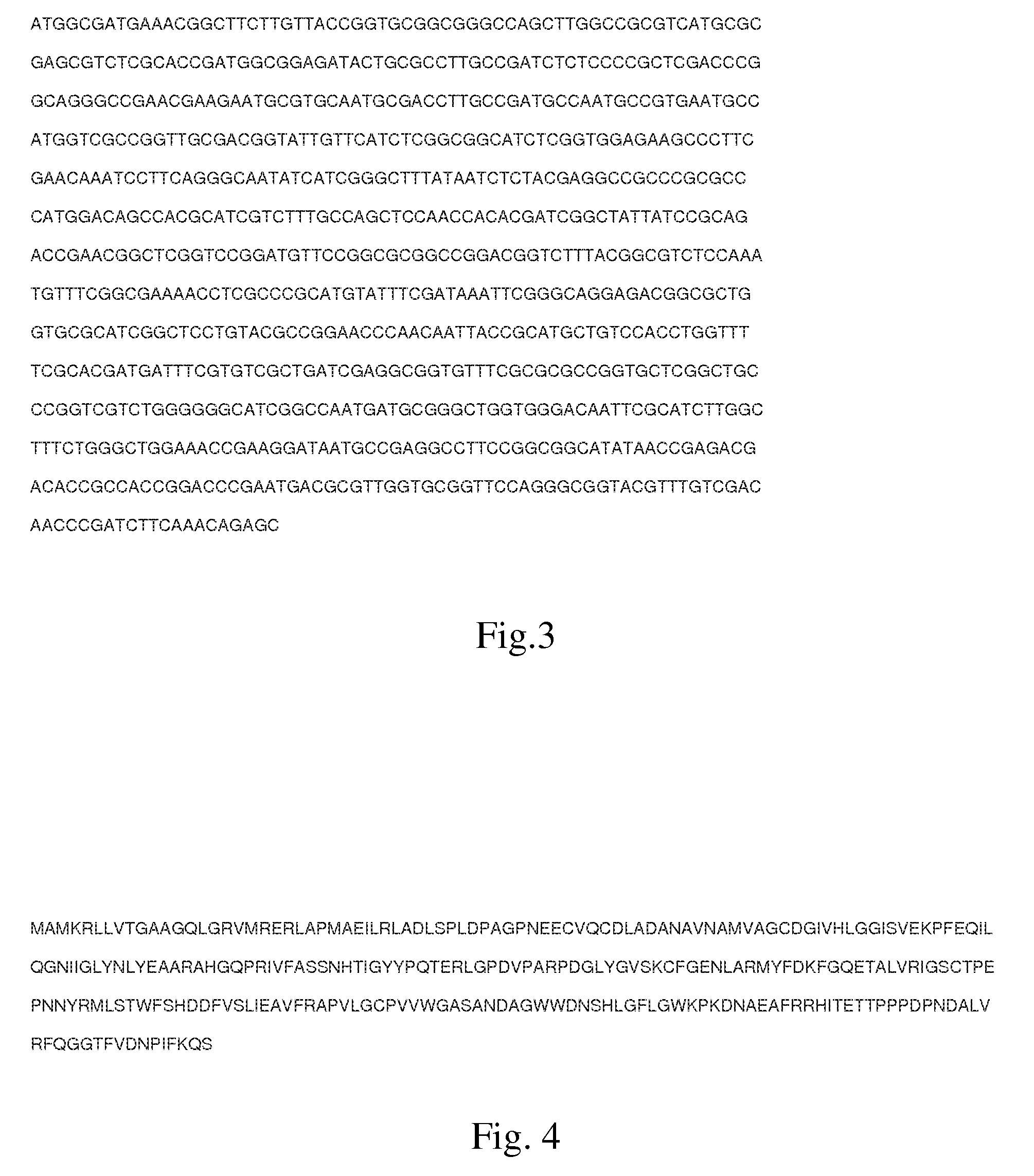

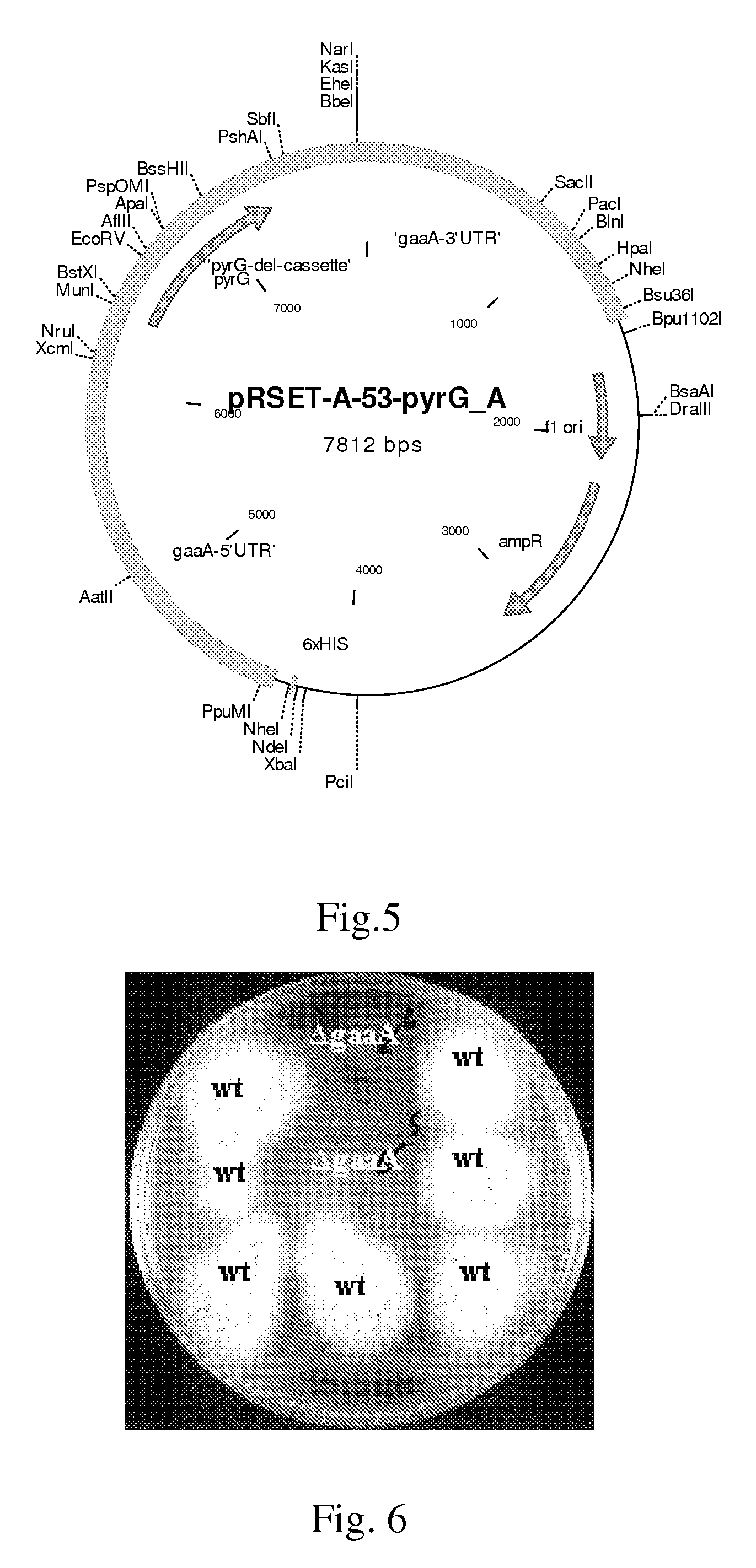

Conversion of hexuronic acid to hexaric acid

The present invention relates to a method and microbial host strain for converting a hexuronic acid to a hexaric acid. In particular, the invention relates to the con-version of D-galacturonic acid to meso-galactaric acid (mucic acid). The invention also concerns an isolated nucleotide sequence. According to the present method a microbial host strain genetically modified to express uronate dehydrogenase enzyme (EC 1.1.1.203) is contacted with a biomaterial comprising hexuronic acid and the con-version products are recovered. By using the recombinant microorganisms of the present invention it is possible to treat biomaterials comprising hexuronic acids and thereby decrease the amount of hexuronic acids released to the environment.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

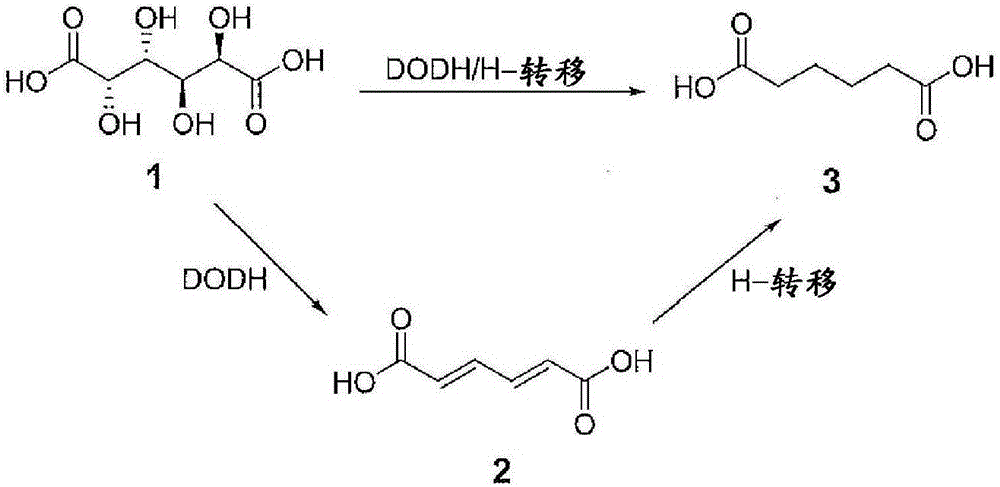

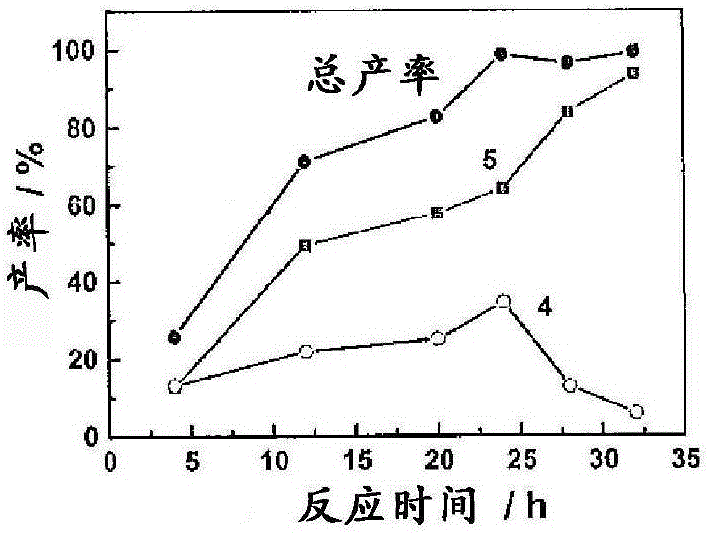

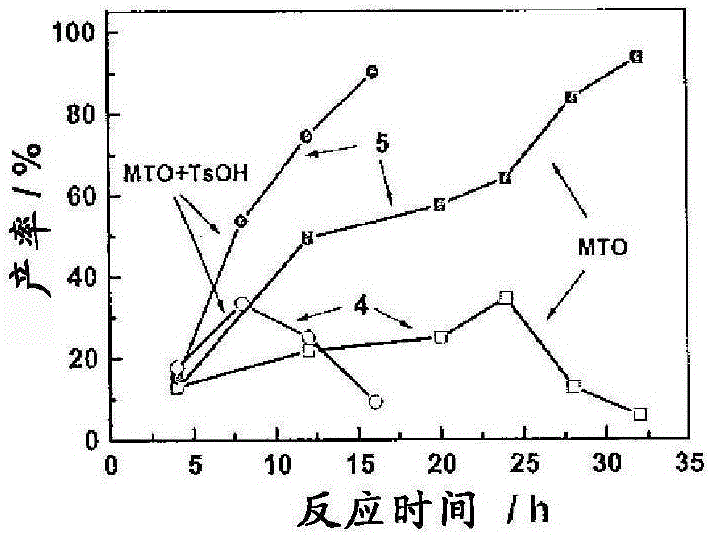

Chemical process to convert mucic acid to adipic acid

InactiveCN105899484AThe synthesis process is simpleMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationAdipic acidMucic acid

The present invention provides a method of synthesizing an ester of a saturated carboxylic acid from a saturated polyhydroxycarboxylic acid by performing a deoxydehydration reaction and a hydrogen transfer reaction.

Owner:AGENCY FOR SCI TECH & RES

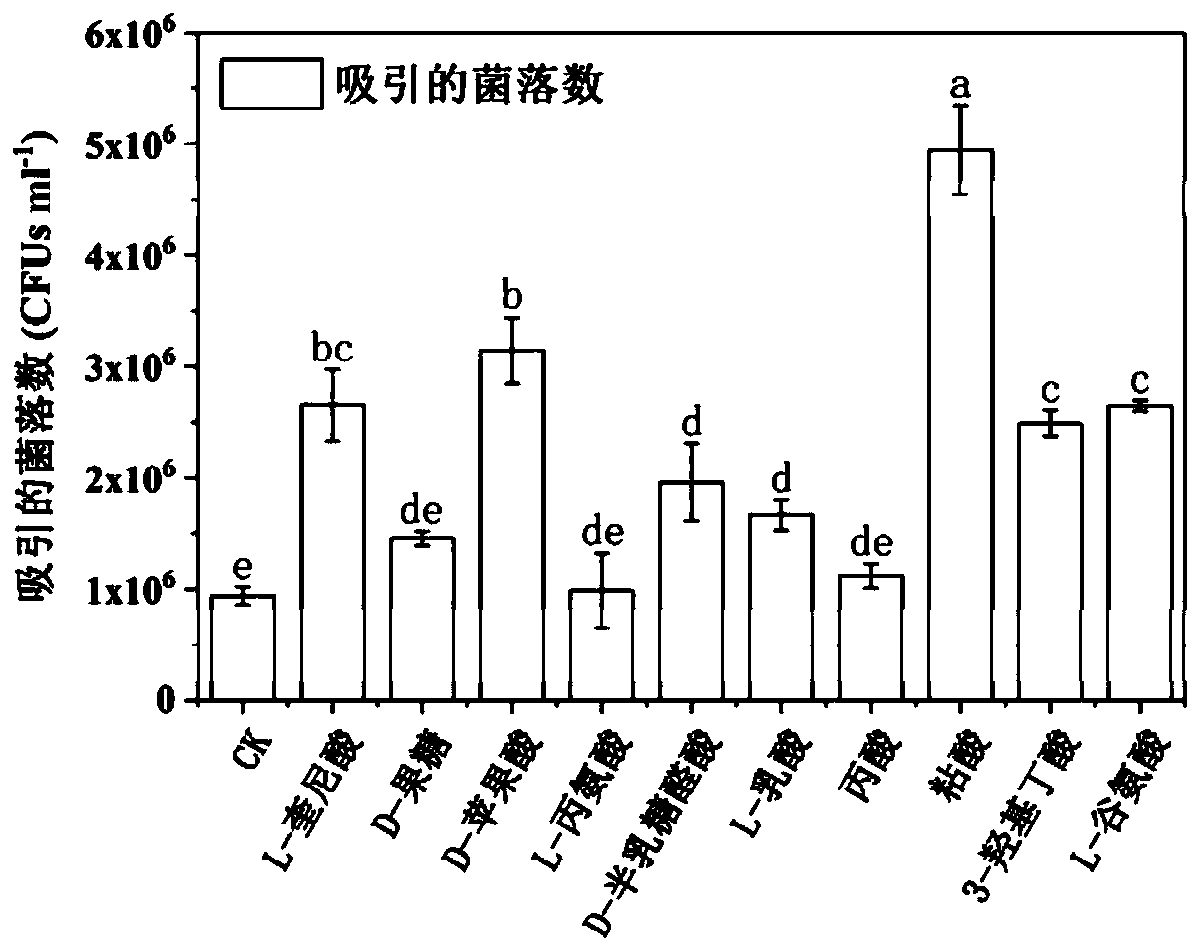

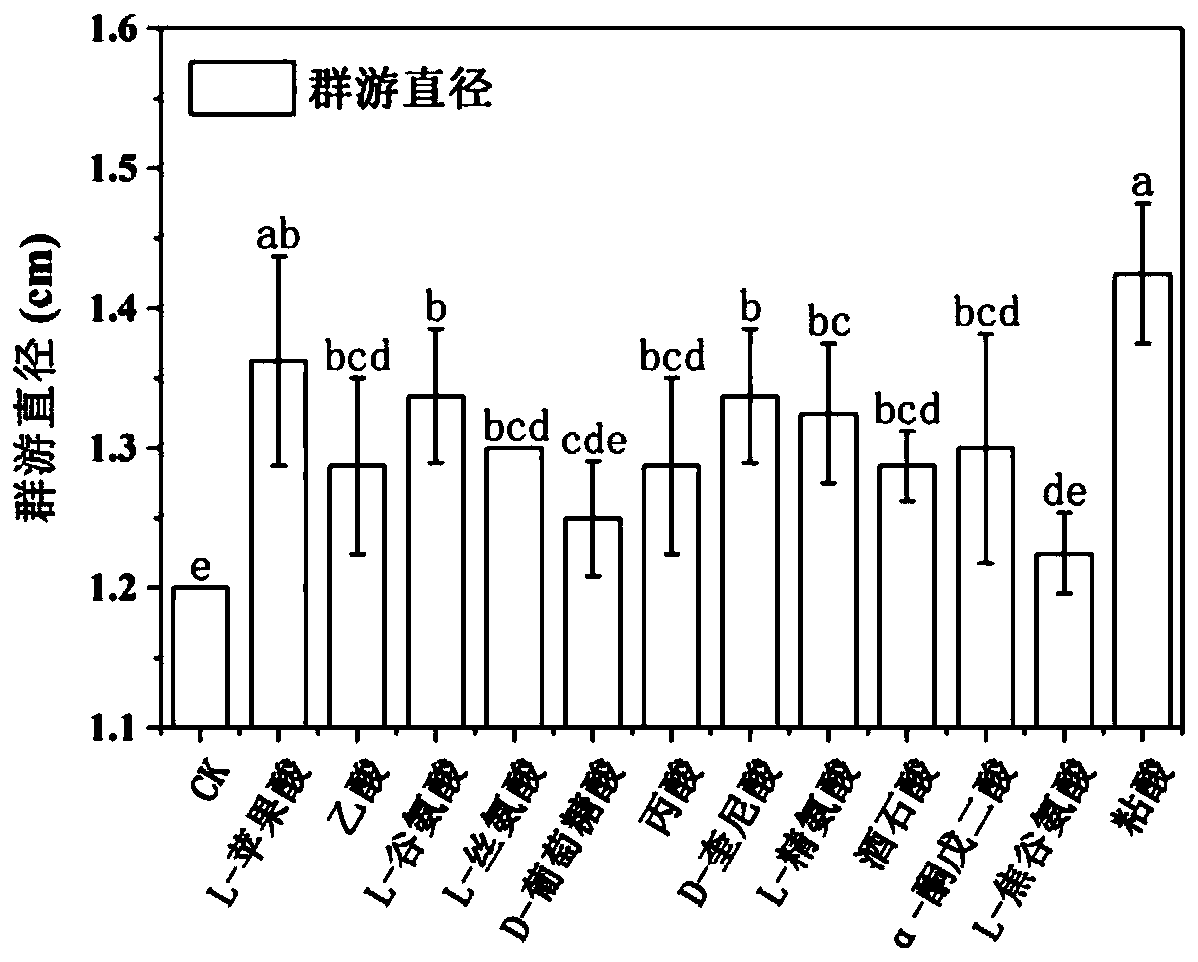

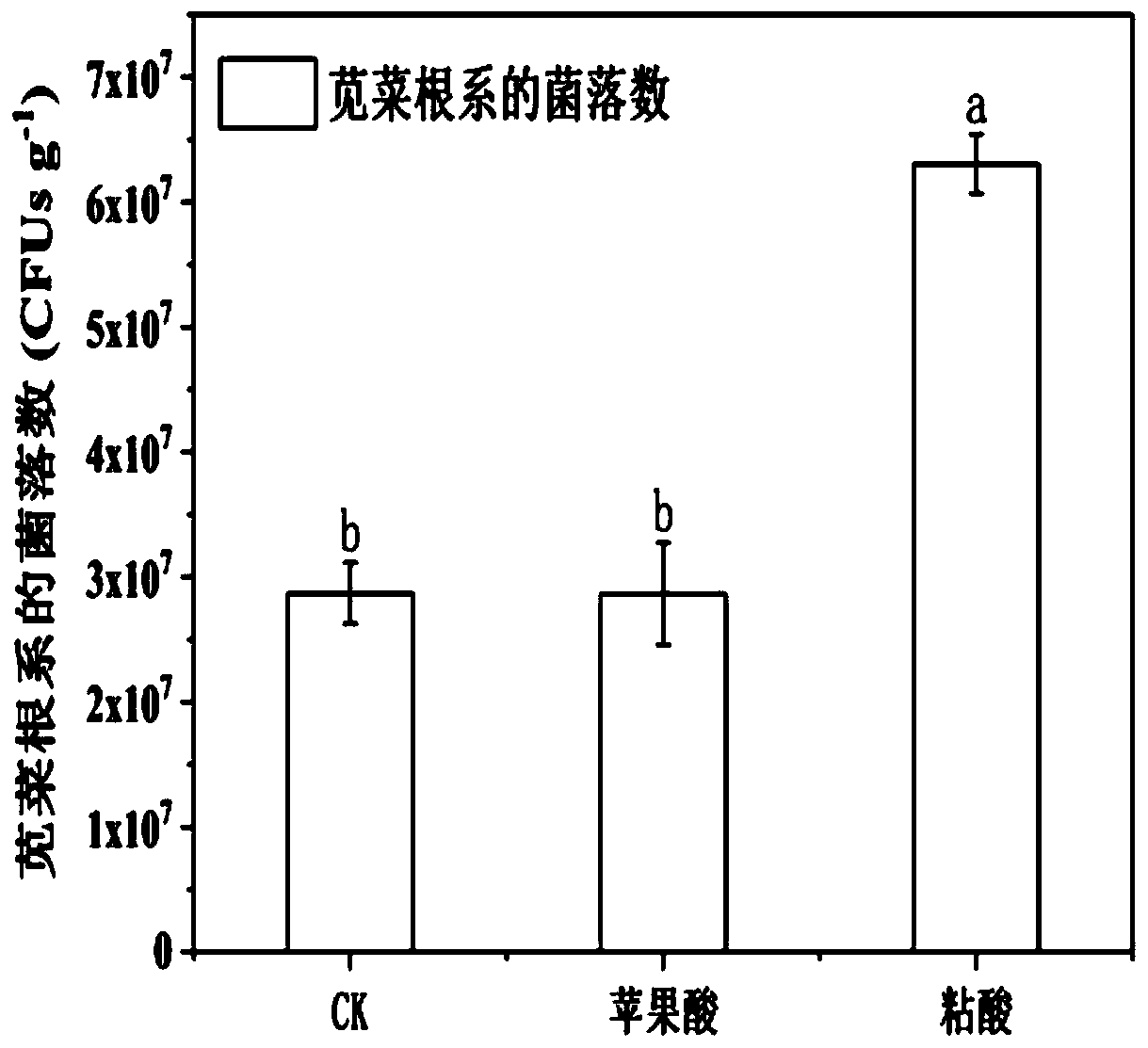

Method of promoting colonization of delftia tsuruhatensis at plant rhizospheres

ActiveCN110484473APromote colonizationPromote reproductionBacteriaMicroorganism based processesPlant rootsRoot weight

The invention discloses a method of promoting colonization of delftia tsuruhatensis at plant rhizospheres, and provides application of mucic acid in the aspects of promoting colonization of delftia tsuruhatensis at the plant rhizospheres and preparing preparations for promoting colonization of delftia tsuruhatensis at the plant rhizospheres. By adopting the method, a signal molecule, namely mucicacid capable of promoting colonization of delftia tsuruhatensis at the plant rhizospheres is screened out from secretions of plant root systems, research shows that mucic acid has significant chemotactic and swarming effects on delftia tsuruhatensis and can significantly promote colonization of delftia tsuruhatensis at the plant rhizospheres; besides, when mucic acid and delftia tsuruhatensis comeinto play together, reproduction of delftia tsuruhatensis at the plant rhizospheres can be significantly promoted; the total fresh weight, the total root weight, the plant height, the chlorophyll content and the root system nifH gene abundance of plants are significantly increased; a growth-promoting effect on the plants is further improved significantly, and thus the method has excellent application value and broad development space.

Owner:JINAN UNIVERSITY

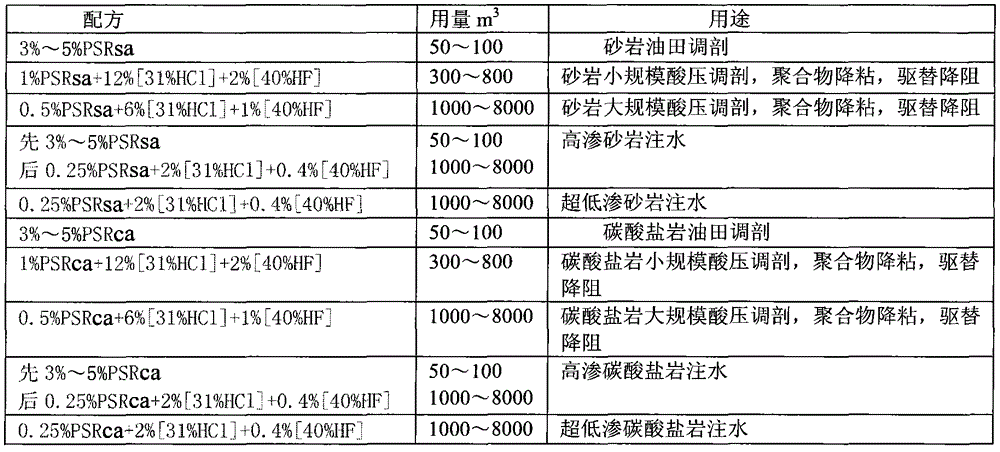

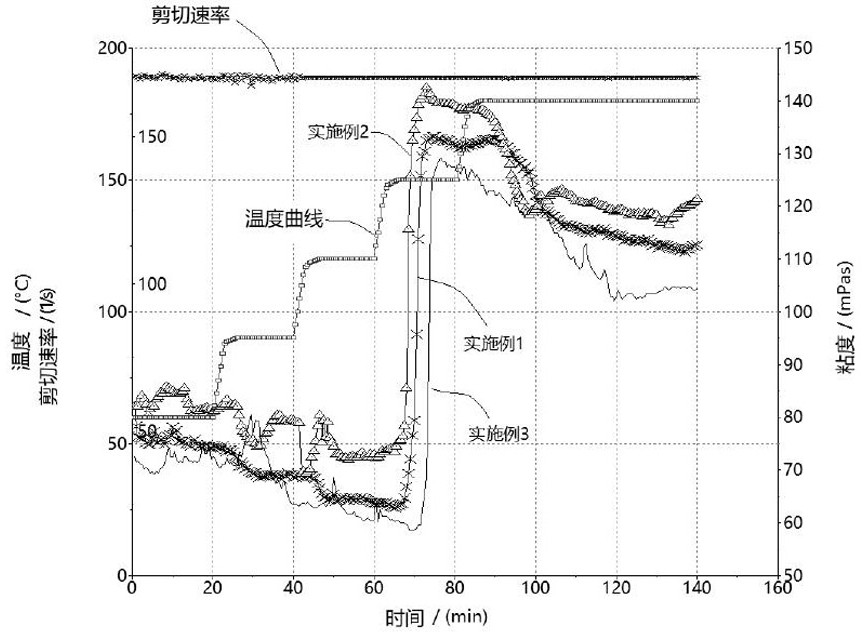

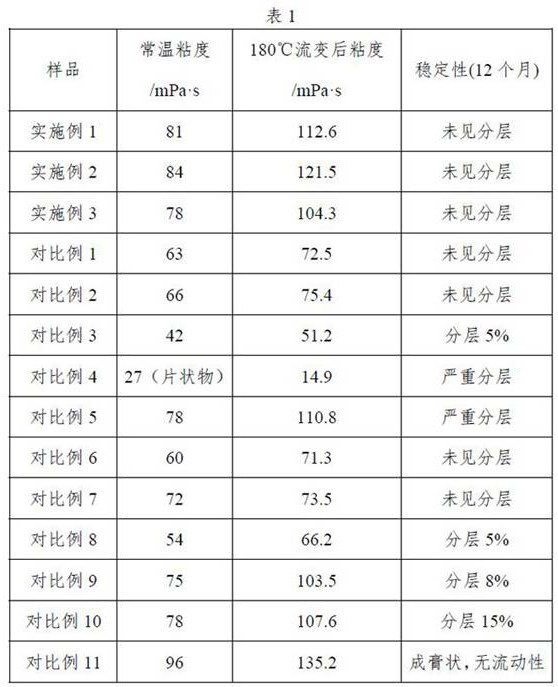

Preparation method of polymer viscosity-reducing profile-control resistance-reducing physical dissolution agent PSR

InactiveCN105860948AImprove the spread factorImprove displacement and resistance reduction rateDrilling compositionPolymer scienceDepolymerization

The invention belongs to the technology of oil field acid fracturing and water injection for recovery rate enhancement. A physical solute of reducing viscosity and resistance PSR has the general principles: the PSR is prepared through optimization of a profile control agent PCA, a polymer physical solute PPS and a rock physical solute RPS, and profile control, the polymer viscosity reduction rate and the displacement resistance-reducing rate are the maximum. The PSR has the characteristics of no oxidizing agent, safety, environmental friendliness, no toxicity, neutral property, no corrosion, no flammable or explosive materials, low molecules, no harm, no impurities, low friction resistance, and no deterioration; the corrosion inhibition rate and the retardance rate of organic acids and inorganic acids are greatly improved, and the acidification is fully effective; the dissolved polymer chain-breaking viscosity-reducing rate is high; fillings and cements in rock pore seams are dissolved, nano pore seams are opened and expanded, and the resistance reduction rate is high; the profile control is good, and the injection pressure is not increased but falls. The PSR is used for high permeability, ultra-low permeability oilfield profile control, polymer viscosity reduction, acid fracturing, water injection and oil driving, improves the polymer depolymerization viscosity reduction rate, improves the displacement resistance-reducing rate, improves the ultralow-permeability rock permeability rate, and increases reservoir, injection and yield.

Owner:CHENGDU NENGSHENGCAI SCI & TECH DEV CO LTD

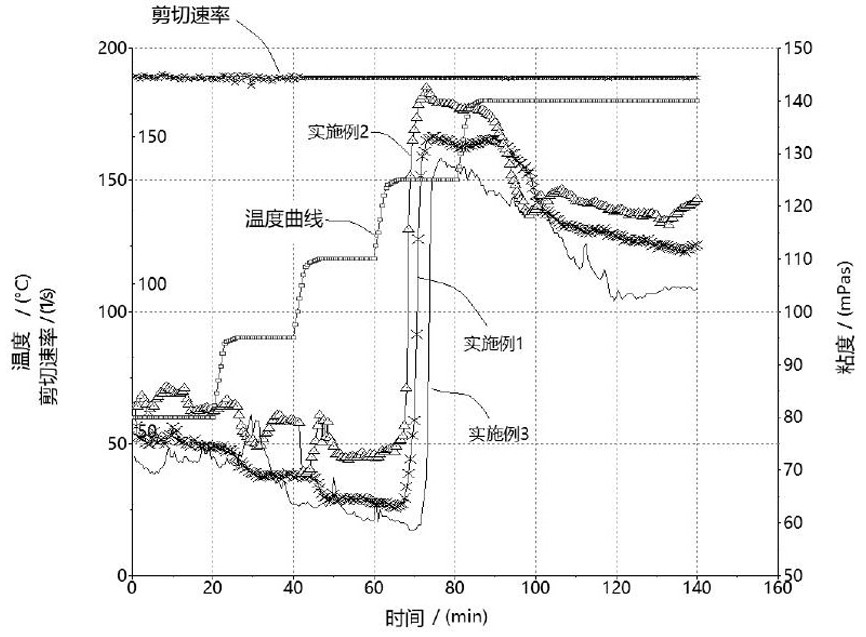

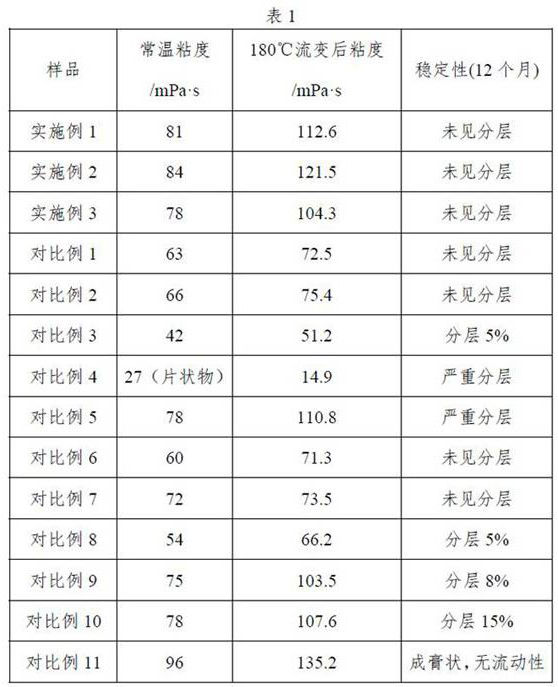

Water-in-oil type nano-emulsion, nano-emulsion composite response type variable-viscosity acid thickening agent and preparation methods of water-in-oil type nano-emulsion and nano-emulsion composite response type variable-viscosity acid thickening agent

ActiveCN113372485AHigh viscosityInhibition of reduction reactionDrilling compositionPolymer scienceMorpholine

The invention relates to the technical field of oil and gas field development, and provides a water-in-oil nano-emulsion, a nano-emulsion composite response type variable-viscosity acid thickening agent and preparation methods of the water-in-oil type nano-emulsion and the nano-emulsion composite response type variable-viscosity acid thickening agent. The nano-emulsion composite response type variable-viscosity acid thickening agent is composed of the following components in parts by weight: 200-350 parts of thickening agent ultrafine powder, 15-20 parts of a coating agent, 5-10 parts of an activating agent, 135-235 parts of white oil, and 390-650 parts of the water-in-oil type nano-emulsion. According to the thickening agent, ultrafine powder is used as a core, a suspension system is used as a middle layer, and the nano-emulsion is used as an outer layer; the nano-emulsion comprises a water phase, an oil phase and a phase inversion agent, and is a copolymer of acrylamide, acryloylmorpholine, a tackifying monomer, dimethyl diallyl ammonium chloride and a hydrophobic monomer; the ultrafine powder is a copolymer of acrylamide, acryloyl morpholine, a cationic monomer and a response monomer; the suspension system is a coating system composed of a coating agent, an activating agent and white oil, and is suitable for acidification construction operation of oil and gas fields of deep wells and ultra-deep wells.

Owner:SHANDONG NUOER BIOLOGICAL TECH

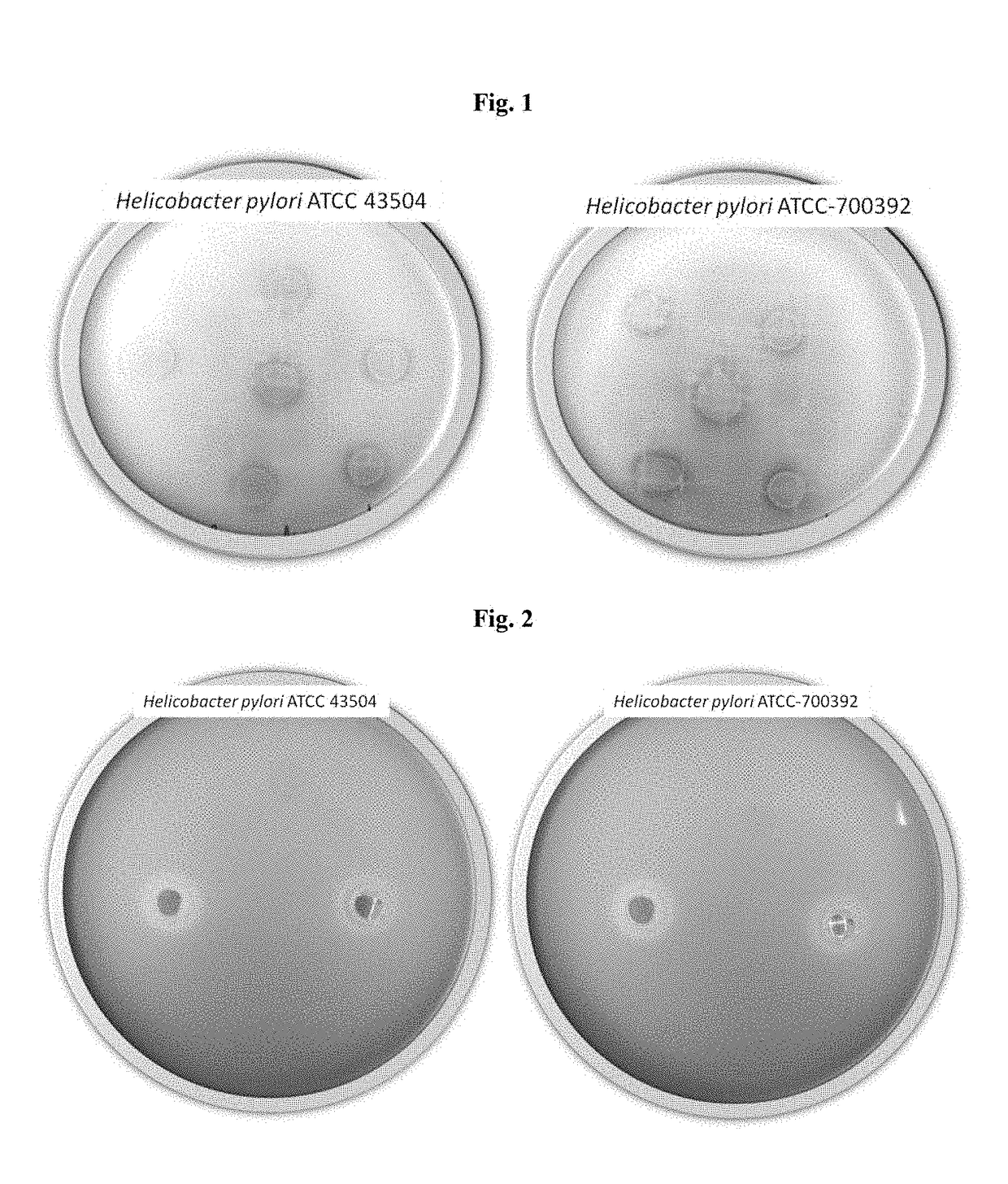

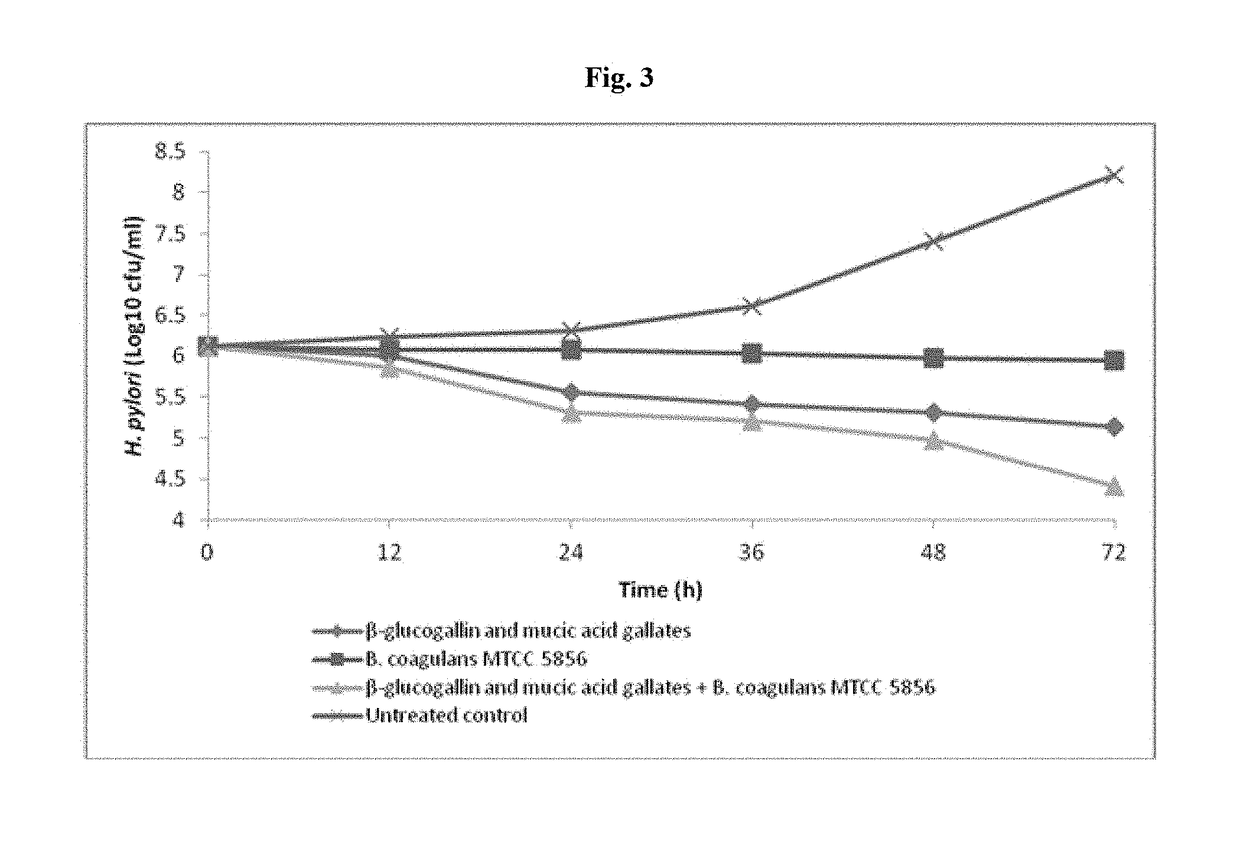

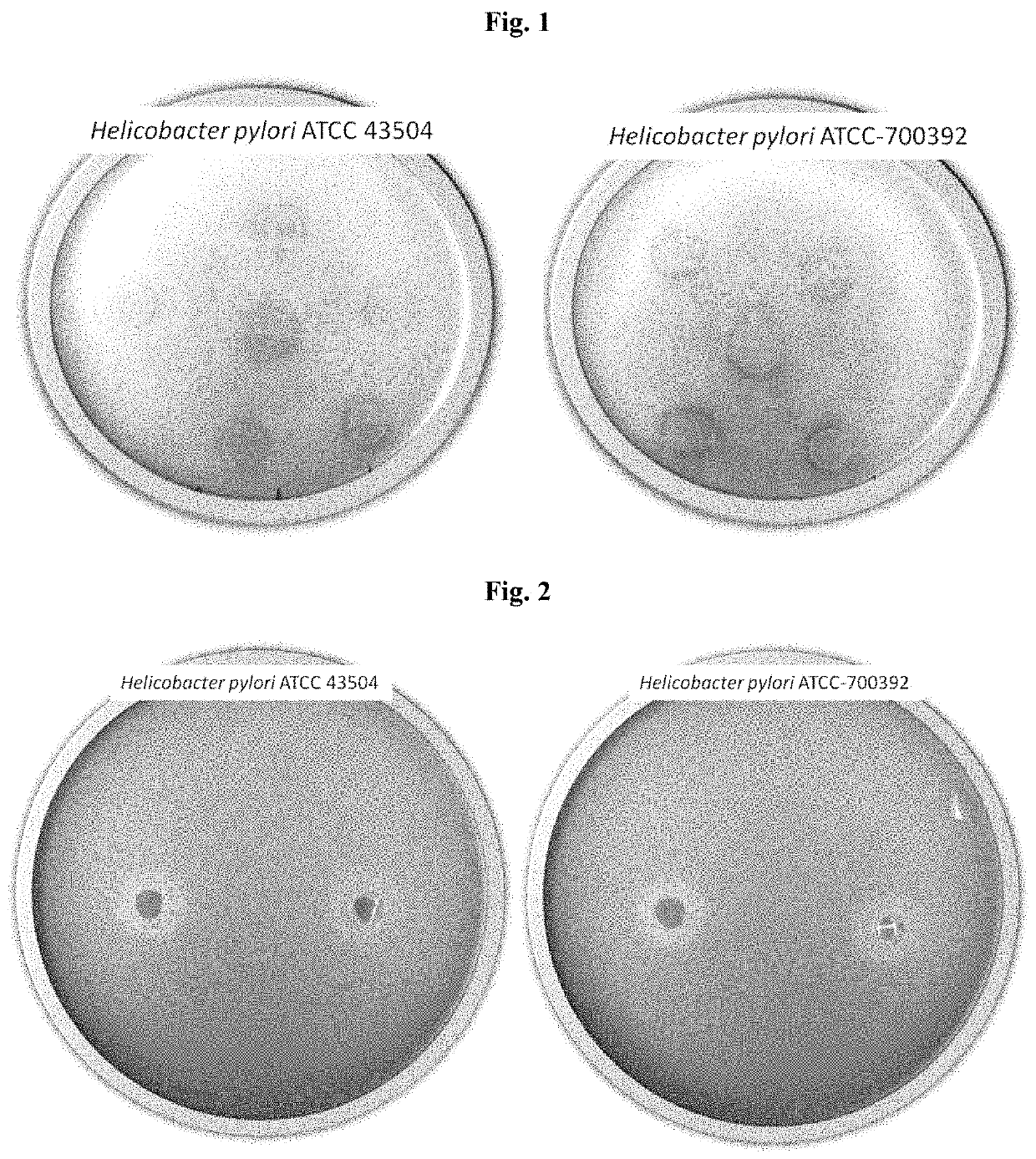

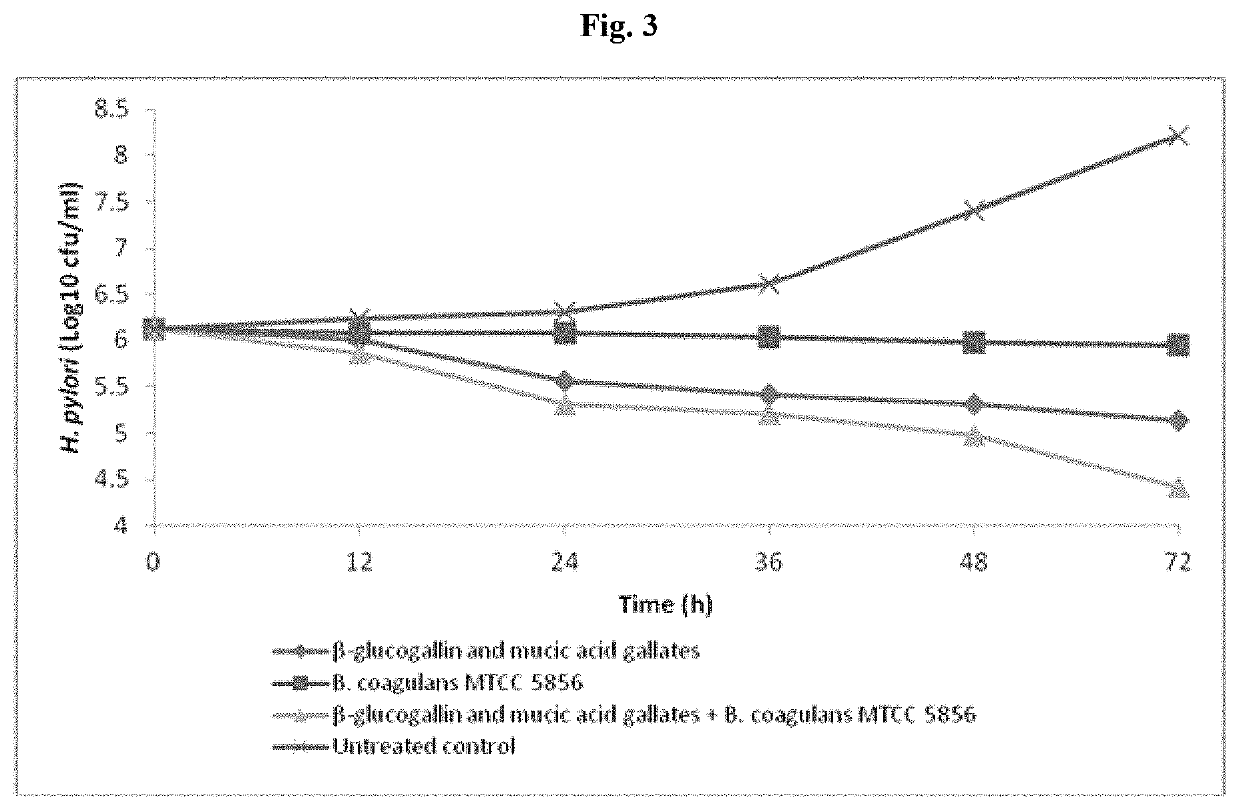

Compositions for management of helicobacter pylori infections

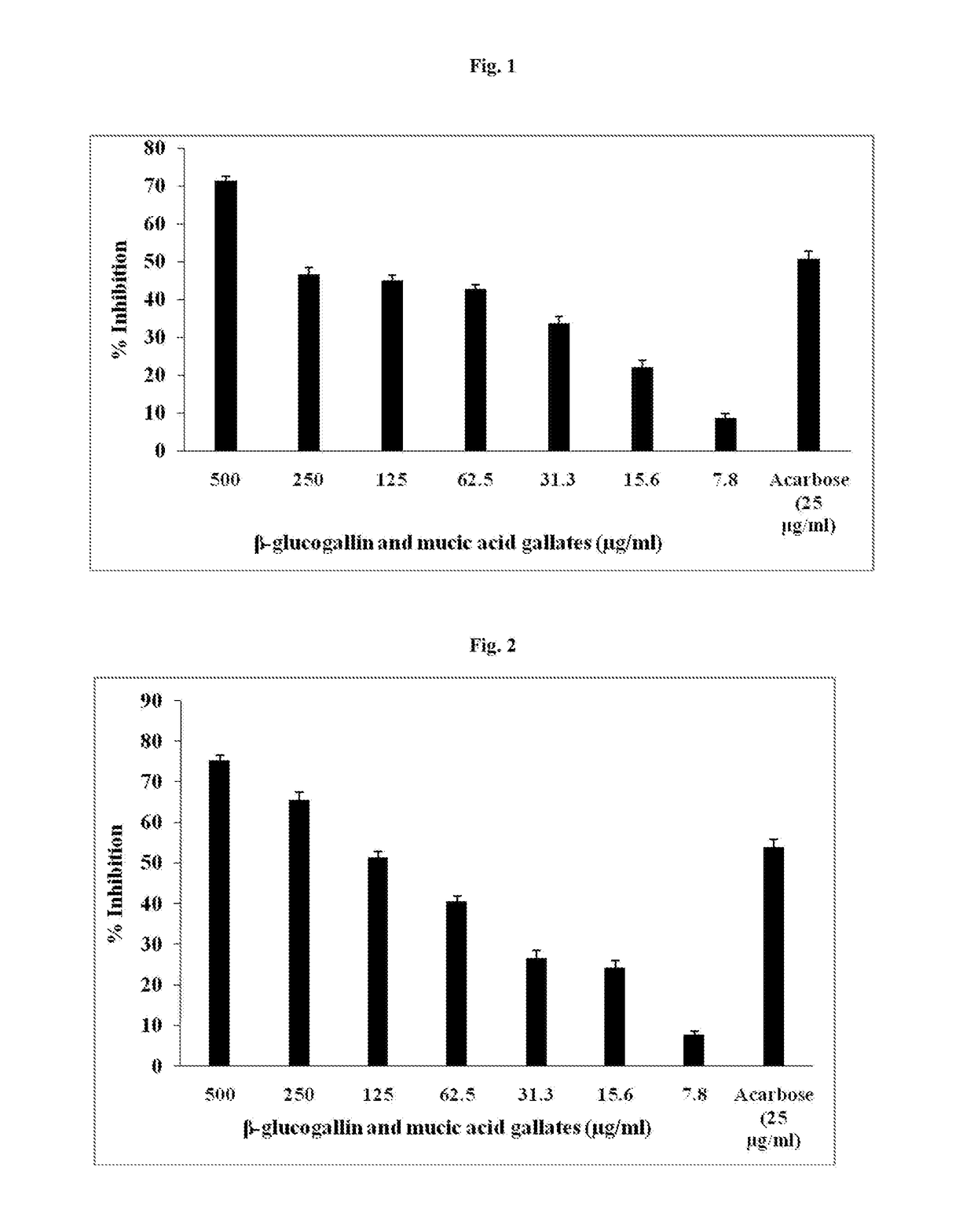

ActiveUS20180344754A1Growth inhibitionAntibacterial agentsOrganic active ingredientsBiotechnologyGallic acid ester

Disclosed are compositions containing at least 10% w / w or above of 1-O-galloyl-β-D-glucose (β-glucogallin) which additionally comprising of about 10% w / w to greater than 60% w / w total mucic acid gallates including mucic acid 1,4-lactone 5-O-gallate, mucic acid 2-O-gallate, mucic acid 6-Methyl ester 2-O-gallate, mucic acid 1-Methyl ester 2-O-gallate and ellagic acid, and a probiotic bacteria Bacillus coagulans MTCC 5856, individually or in combination for inhibiting the growth and managing infections of Helicobacter pylori.

Owner:SAMI LABS LTD

Compositions for management of Helicobacter pylori infections

Disclosed are compositions containing at least 10% w / w or above of 1-O-galloyl-β-D-glucose (β-glucogallin) which additionally comprising of about 10% w / w to greater than 60% w / w total mucic acid gallates including mucic acid 1,4-lactone 5-O-gallate, mucic acid 2-O-gallate, mucic acid 6-Methyl ester 2-O-gallate, mucic acid 1-Methyl ester 2-O-gallate and ellagic acid, and a probiotic bacteria Bacillus coagulans MTCC 5856, individually or in combination for inhibiting the growth and managing infections of Helicobacter pylori.

Owner:SAMI LABS LTD

Protective compositions for dermal papilla cells

ActiveUS8247003B2Avoid cell damagePromote hair growthBiocideCosmetic preparationsDermal papillaeGallate

Disclosed are novel protective compositions for dermal papilla cells. In an embodiment the protective compositions of the present invention comprise 0.25% w / w or above of compositions comprising at least 10% w / w and above of 1-O-galloyl-β-D-glucose (β-glucogallin). In an embodiment, the said protective composition additionally comprises 50% to greater than 50% gallates including mucic acid 1,4-lactone 5-O-gallate, mucic acid 2-O-gallate, mucic acid 6-Methyl ester 2-O-gallate, mucic acid 1-Methyl ester 2-O-gallate and ellagic acid. In another embodiment the invention also encompasses synergistic protective compositions comprising the said protective compositions and 0.5% concentrate of liquid endosperm of Cocos nucifera, for dermal papilla directed towards helping the dermal papilla cells to form sufficient numbers and to retain a healthy morphology conducive for hair growth.

Owner:SAMI LABS LTD

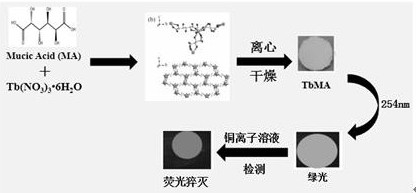

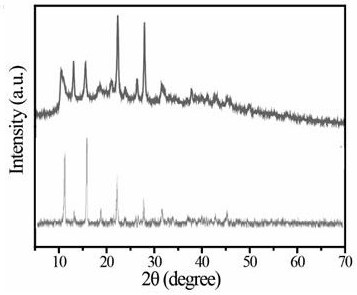

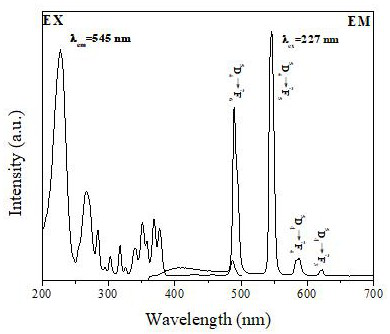

Preparation and application of rare earth fluorescent material for detecting heavy metal Cu<2+>

ActiveCN113443980AAccurate detectionTypical Fluorescent PropertiesOrganic compound preparationCarboxylic acid salt preparationNitrateCentrifugation

The invention relates to preparation and application of a rare earth fluorescent material capable of being used for Cu<2+> ion detection. The preparation method comprises the following steps: S1, selecting raw materials including terbium nitrate hexahydrate and mucic acid; S2, dissolving the mucic acid in distilled water, and conducting stirring; S3, adding a potassium hydroxide solution into the solution obtained in the S2, and conducting stirring; S4, adding a terbium nitrate hexahydrate solution into the solution obtained in S3, and conducting stirring; S5, stopping stirring, carrying out standing and aging, conducting centrifugation to collect a white precipitate, washing the white precipitate and drying the white precipitate to obtain a white sample of a rare earth metal organic framework fluorescent material (a rare earth fluorescent material for short); and S6, applying the obtained rare earth fluorescent material to detection of heavy metal Cu<2+> ions. The rare earth fluorescent material is a rare earth metal organic framework fluorescent material prepared by a simple method, and the material can be used for quantitatively detecting the existence of heavy metal Cu<2+> ions in a water body.

Owner:SICHUAN NORMAL UNIVERSITY

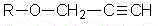

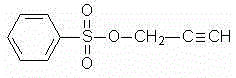

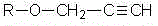

Non-aldehyde acidification corrosion inhibitor and preparation method thereof

InactiveCN102226281BAvoid the disadvantage of larger formation damageThe synthesis method is simpleBorehole/well accessoriesActive agentAcetylenic alcohol

The invention relates to an aldehyde-free acidification corrosion inhibitor suitable for good solubility in acid liquid, high temperature resistance and high cost performance and a preparation method. The mass percent of each component of the corrosion inhibitor is: 20-50% of acetylenic alcohol ether containing benzene ring; 3-5% of non-ionic surfactant; 40-70% of low-molecular alcohol solvent; 0.5-1.0% of potassium iodide; Wherein, the acetylenic alcohol ether containing a benzene ring has the following general structural formula: wherein R is a group containing a benzene ring. The specific steps are: first react propynyl alcohol with an inorganic base to form a salt, then react with a benzene ring-containing chloride to form an ether, and then compound and dilute with a nonionic surfactant, potassium iodide, and a low-molecular alcohol solvent to obtain an acidifying corrosion inhibitor . The acidification corrosion inhibitor provided by the invention has a simple synthesis method, good high-temperature corrosion inhibition performance, mild reaction conditions, does not contain formaldehyde, can be applied to acid liquid systems such as gelling acid and viscous acid, has good compatibility, and has wider Suitability for acid systems.

Owner:UNIV OF SCI & TECH BEIJING

Conversion of hexuronic acid to hexaric acid

InactiveUS8895273B2Reduce the amount requiredSugar derivativesMicroorganismsPresent methodNucleotide

The present invention relates to a method and microbial host strain for converting a hexuronic acid to a hexaric acid. In particular, the invention relates to the conversion of D-galacturonic acid to meso-galactaric acid (mucic acid). The invention also concerns an isolated nucleotide sequence. According to the present method a microbial host strain genetically modified to express uronate dehydrogenase enzyme (EC 1.1.1.203) is contacted with a biomaterial comprising hexuronic acid and the conversion products are recovered. By using the recombinant microorganisms of the present invention it is possible to treat biomaterials comprising hexuronic acids and thereby decrease the amount of hexuronic acids released to the environment.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958BReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid fracturingDemulsifier

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control andvariable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

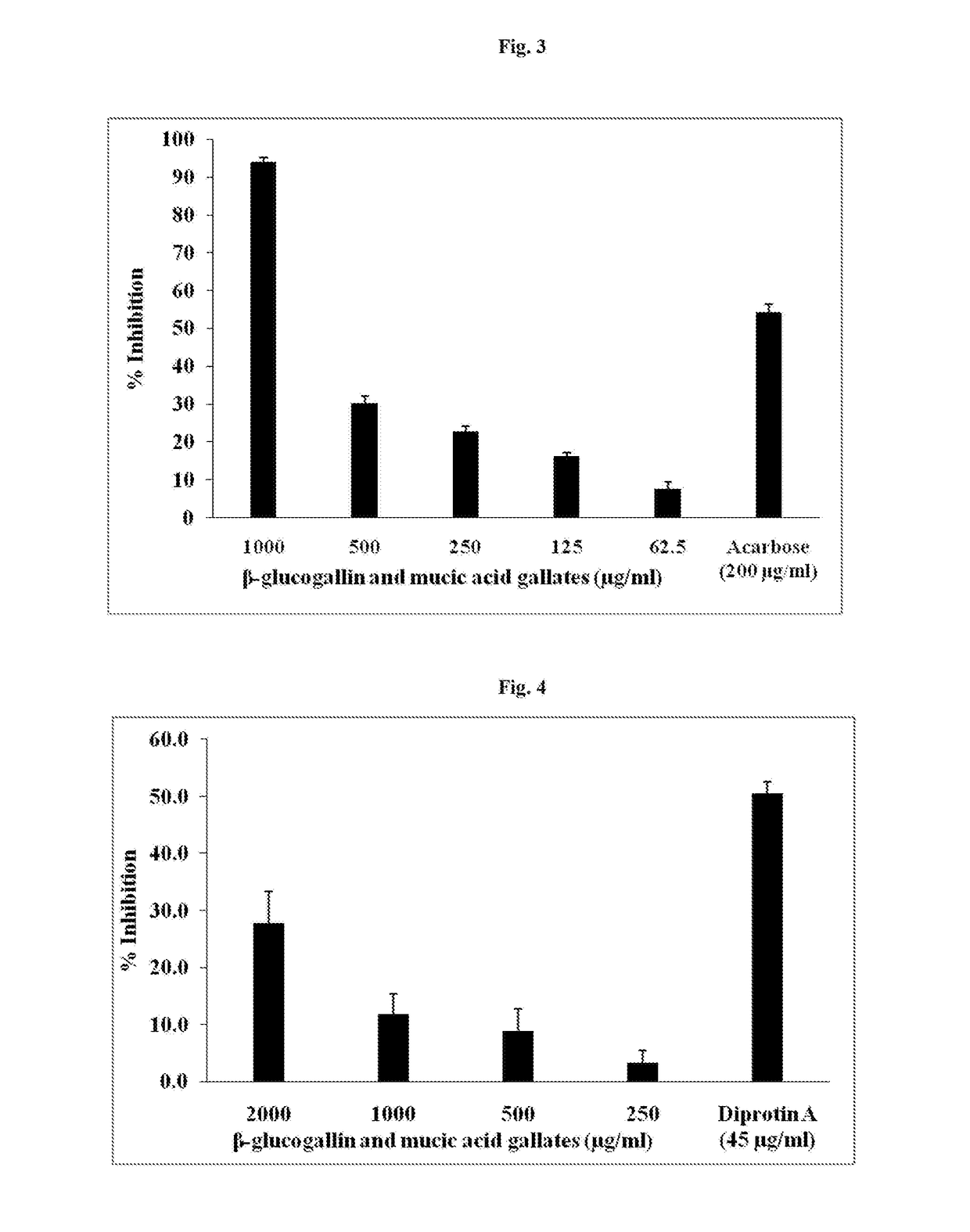

Compositions comprising beta-glucogallin and therapeutic applications thereof in controlled kinetics of carbohydrate breakdown and monosaccharide absorption

InactiveUS20190060337A1Organic active ingredientsMetabolism disorderDipeptidyl peptidaseGlucose & Protein

Disclosed are the compositions for the effective regulation of carbohydrate breakdown and absorption. More specifically, the invention discloses compositions containing at least 10% w / w or above of 1-O-galloyl-β-D-glucose (β-glucogallin) and additionally comprising of about 10% w / w to greater than 60% w / w total mucic acid gallates for the effective regulation of carbohydrate breakdown and absorption by the inhibition of enzymes amylase, glucosidase and dipeptidyl peptidase.

Owner:SAMI LABS LTD

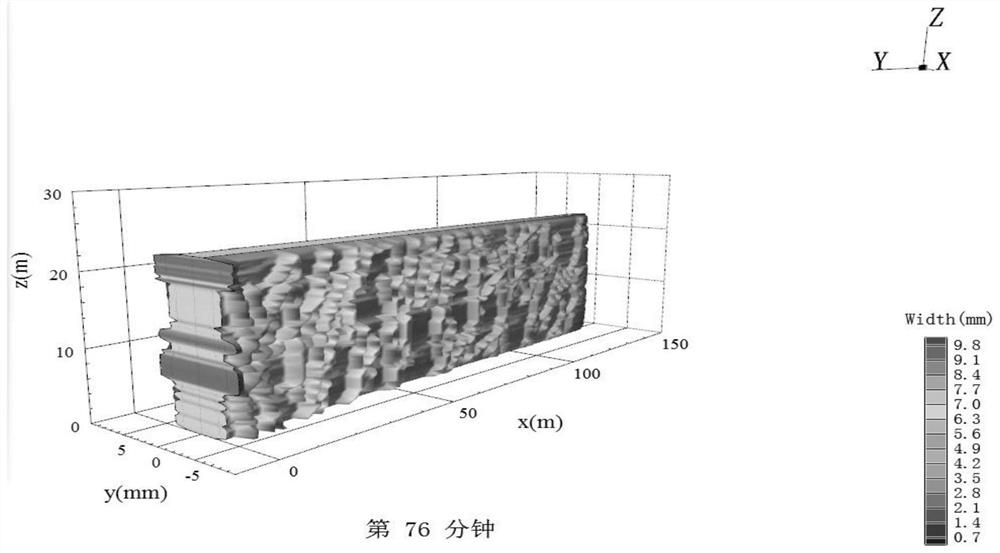

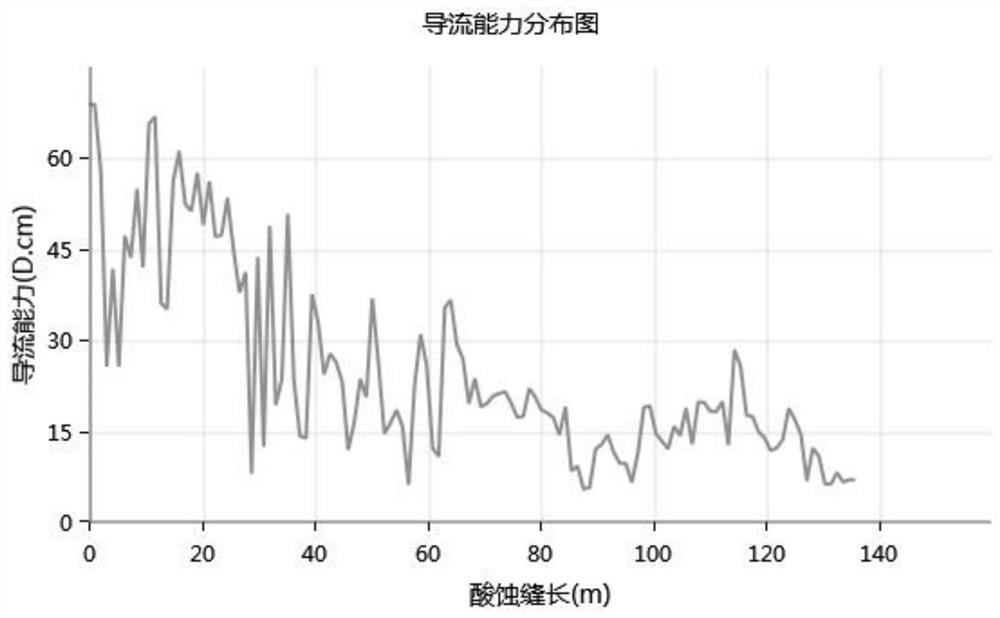

A large-displacement composite acid fracturing method for carbonate reservoirs

ActiveCN110388199BSlow reaction rateIncrease the lengthFluid removalDrilling compositionAcid fracturingSoil science

The invention relates to the technical field of fracturing in oil and gas fields, in particular to a large-displacement composite acid fracturing method for carbonate rock reservoirs, which reduces the acid reaction rate by using slick water, gelling acid, and viscous acid for multi-stage alternate injection , increase the length of acid-etched fractures, which is conducive to the communication of natural fractures and increase the volume of reservoir acid fracturing; the use of wormhole acid-acid system can realize the deep penetration of acid in fractures, forming a longer effective distance and improving Conductivity; the use of resistance-reducing acid in the later stage can expand the acid erosion degree of the reservoir around the wellbore and further improve the reservoir conductivity in the near-wellbore zone; volumetric acid fracturing of carbonate reservoirs with well-developed fractures can make full use of The natural fractures of the reservoir, with the help of acid solution on the dissolution of carbonate minerals, expand and extend the fractures and caves, at the same time, communicate with natural fractures, increase the diversion capacity of seepage channels, and achieve the purpose of maximizing production increase.

Owner:PETROCHINA CO LTD

Photovoltaic inverter box

InactiveCN106046949ANormal work impactImprove cooling effectPolyurea/polyurethane coatingsCellulosePropionate

The invention discloses a photovoltaic inverter box. Heat dissipation coating layers are brushed on inner and outer walls of the photovoltaic inverter box; each heat dissipation coating layer is prepared from the following components: beta-(3,5-ditert-butyl-4-hydroxyphenyl)cellulose propionate, tetracosane, mucic acid dimethyl ester, tetraethylenepentamine, methyl gallate, hyperoside and polyisocyanurate; the contents of all the components are as follows in parts by weight: 45 to 55 parts of the beta-(3,5-ditert-butyl-4-hydroxyphenyl)cellulose propionate, 5 to 15 parts of the tetracosane, 30 to 40 parts of the mucic acid dimethyl ester, 2 to 10 parts of the tetraethylenepentamine, 25 to 40 parts of the methyl gallate, 3 to 15 parts of the hyperoside and 25 to 40 parts of the polyisocyanurate. The photovoltaic inverter box has a good heat dissipation property and has no influences on normal work of a photovoltaic inverter.

Owner:无锡昌悦重工科技有限公司

Novel bonder for lithium ion batteries

InactiveCN101924216ALarge specific surface areaImprove adsorption capacityNon-macromolecular adhesive additivesCell electrodesHigh absorptionElectrical battery

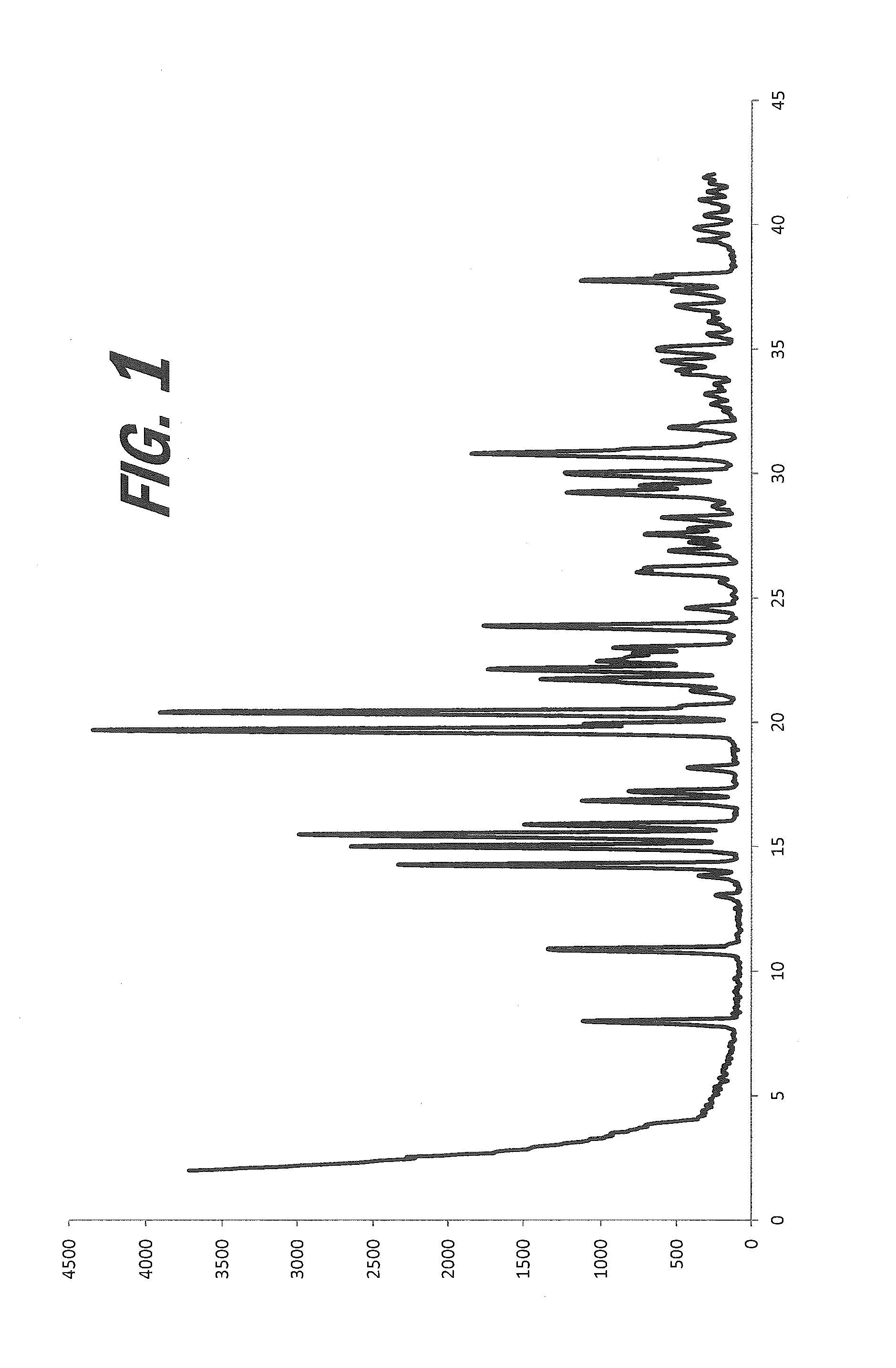

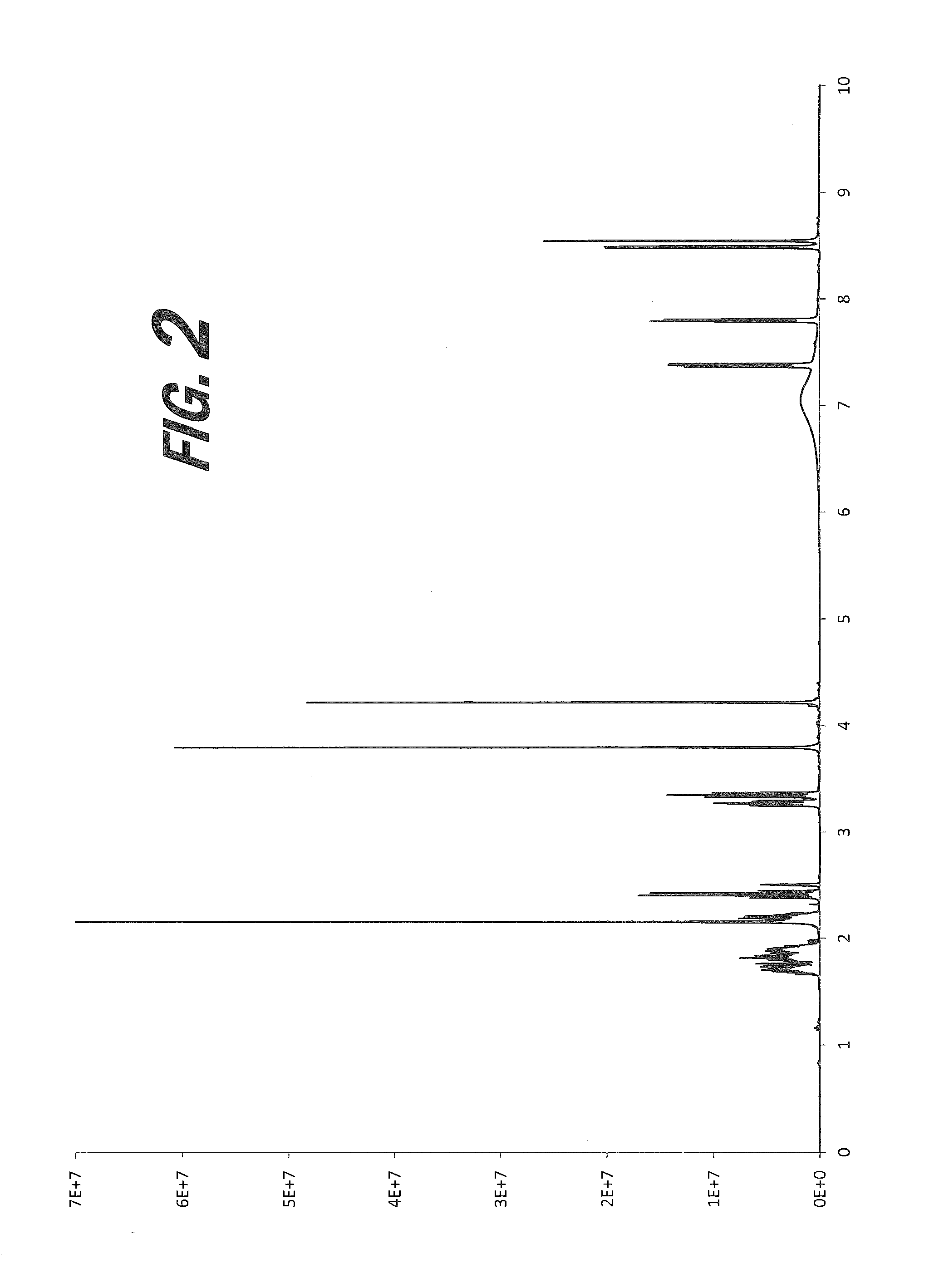

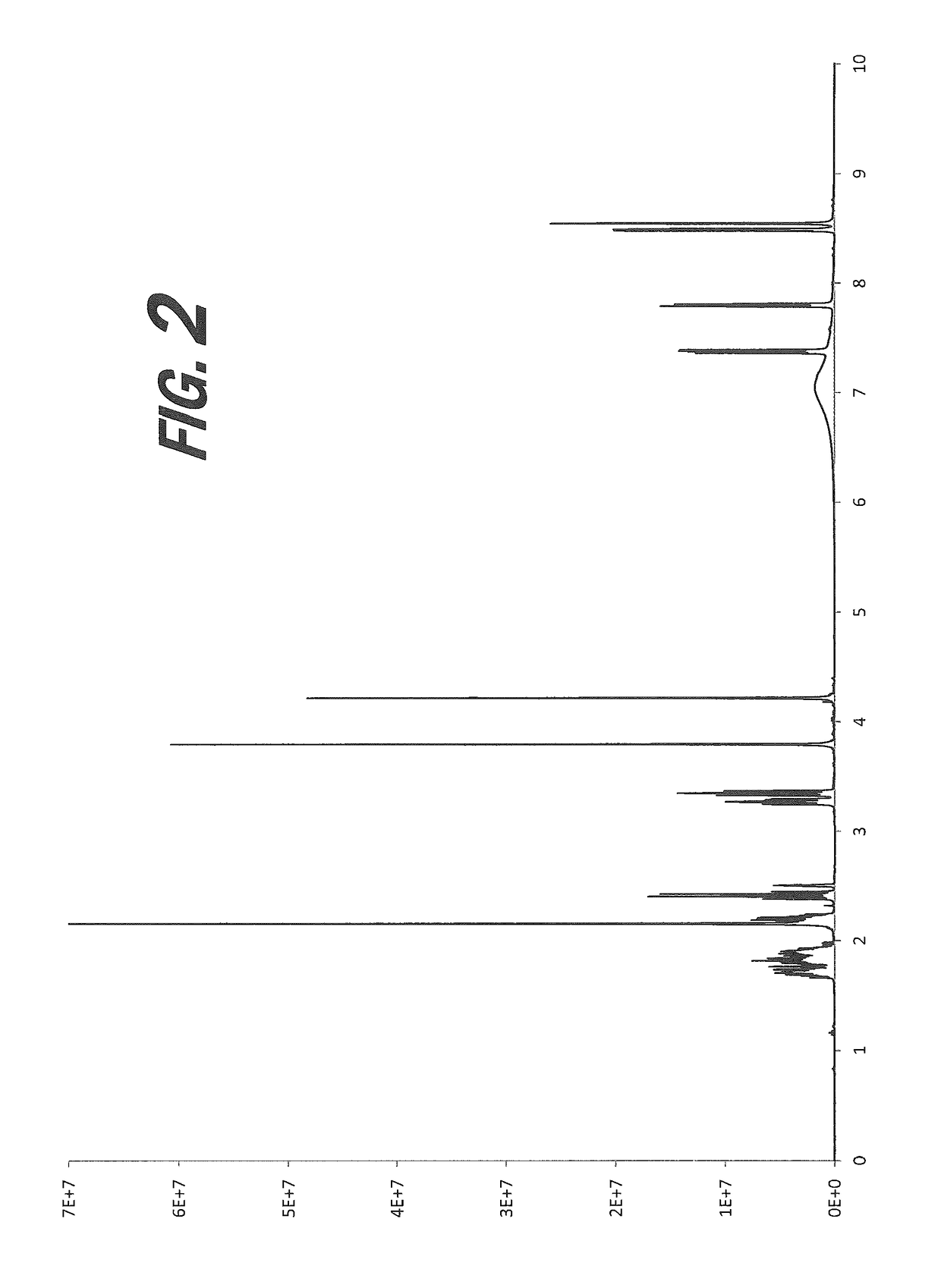

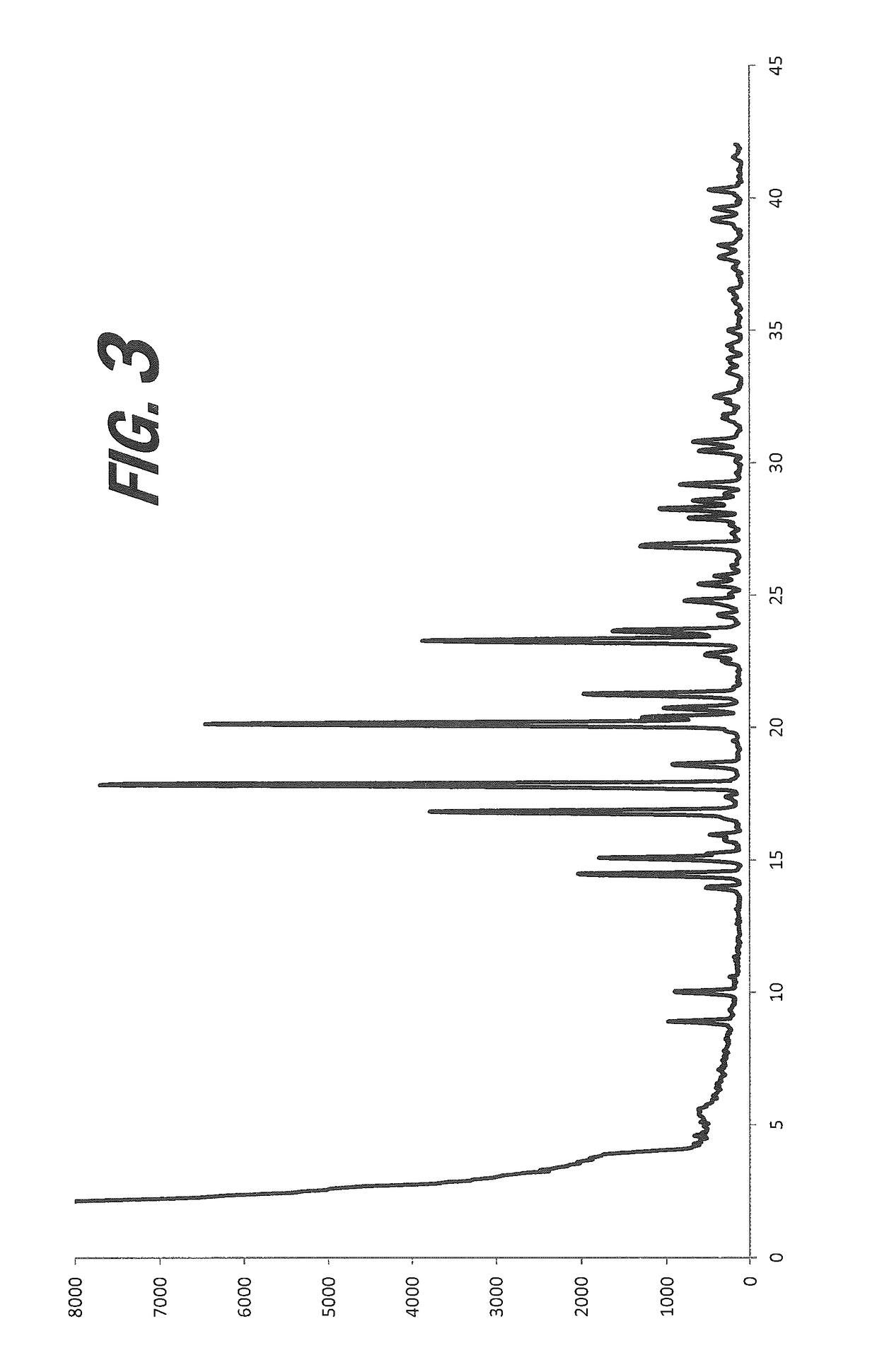

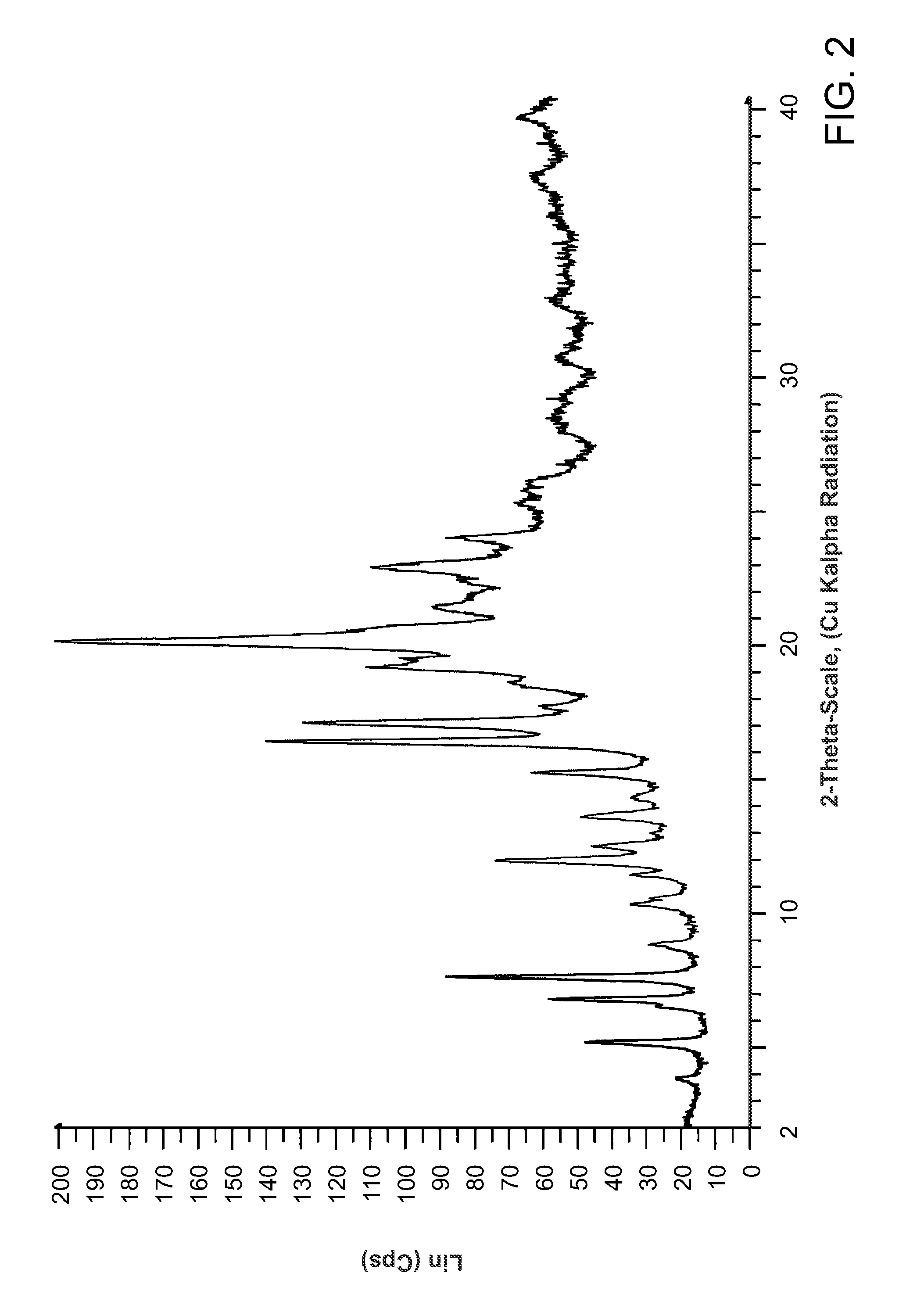

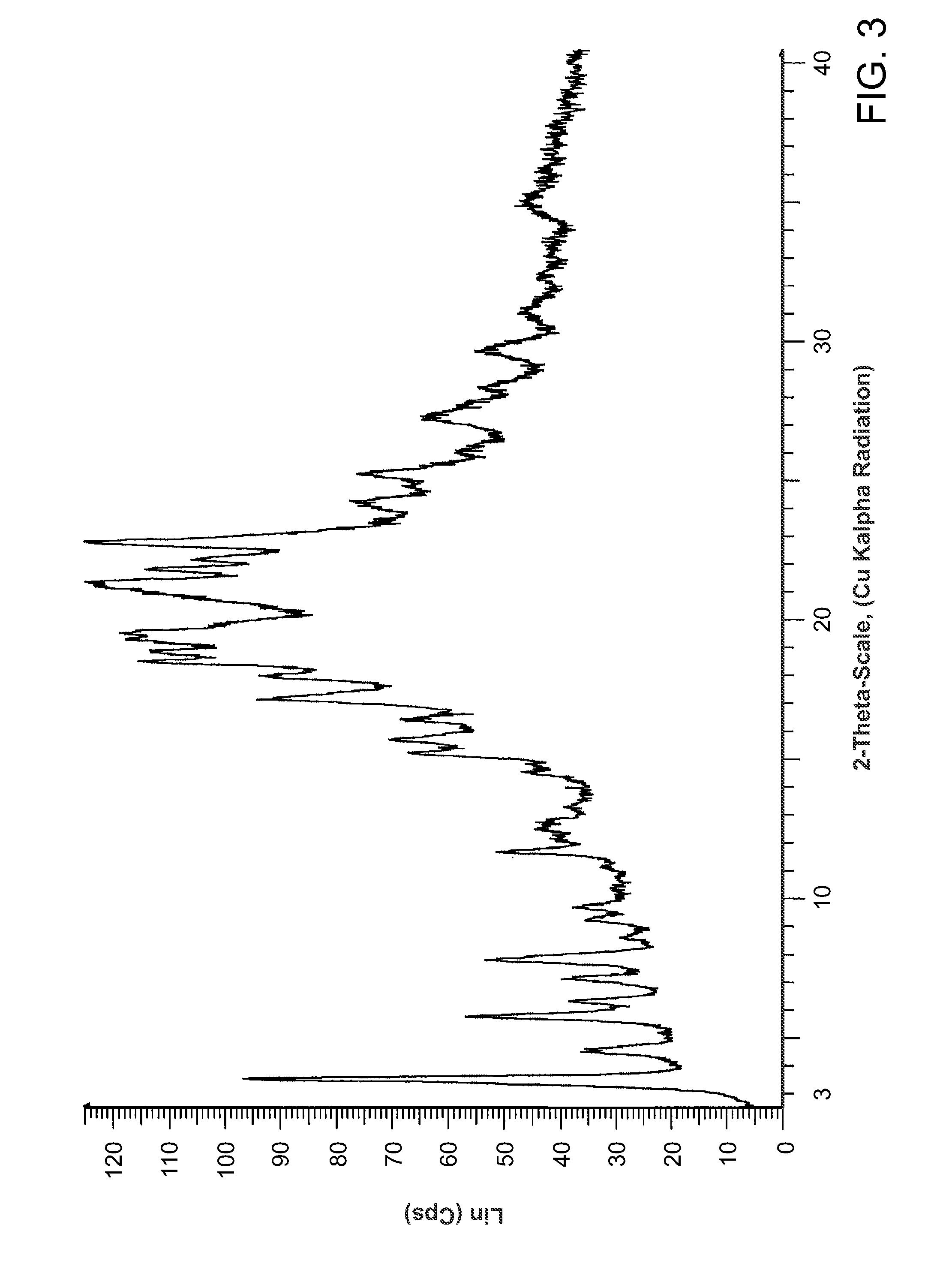

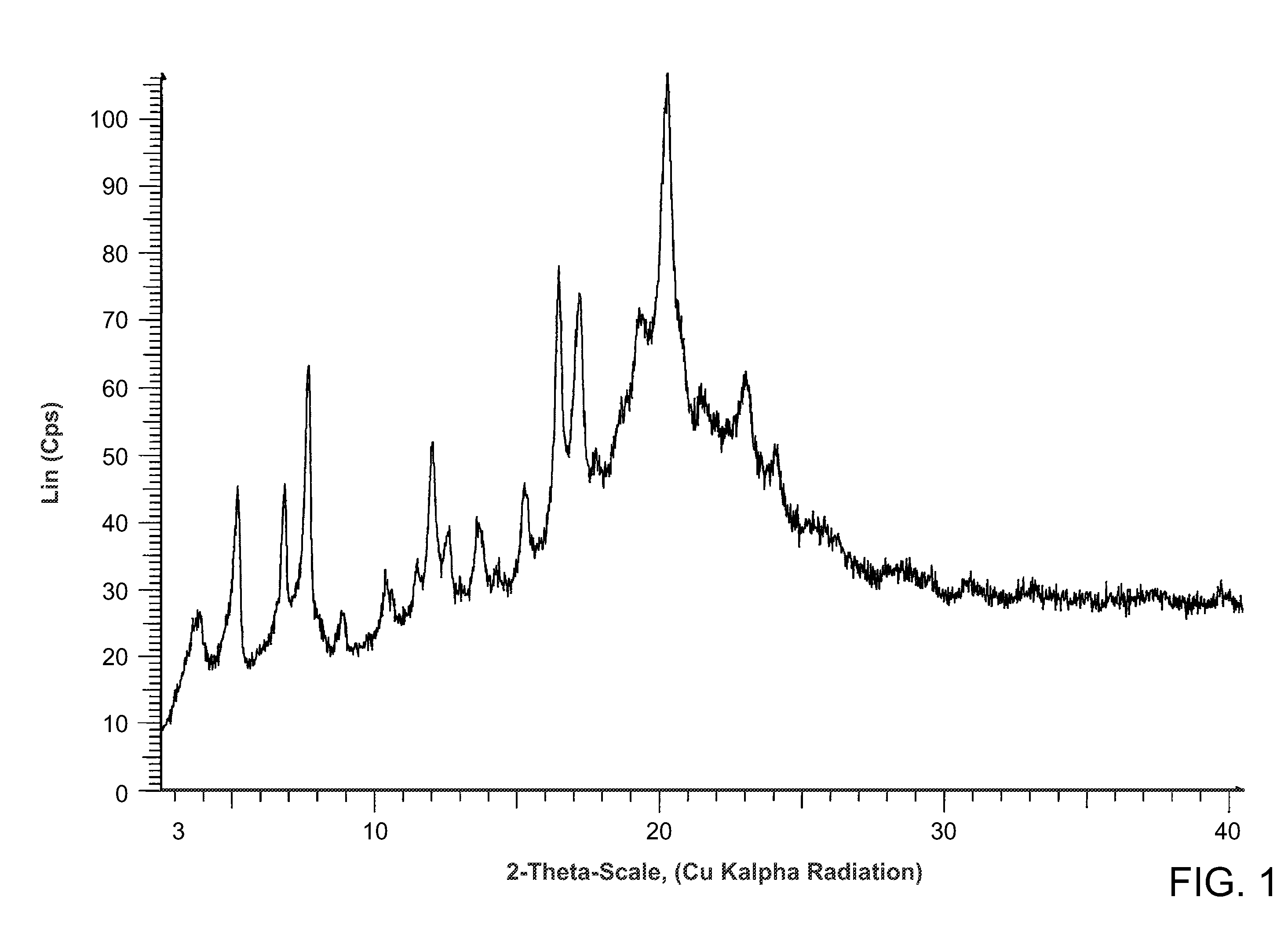

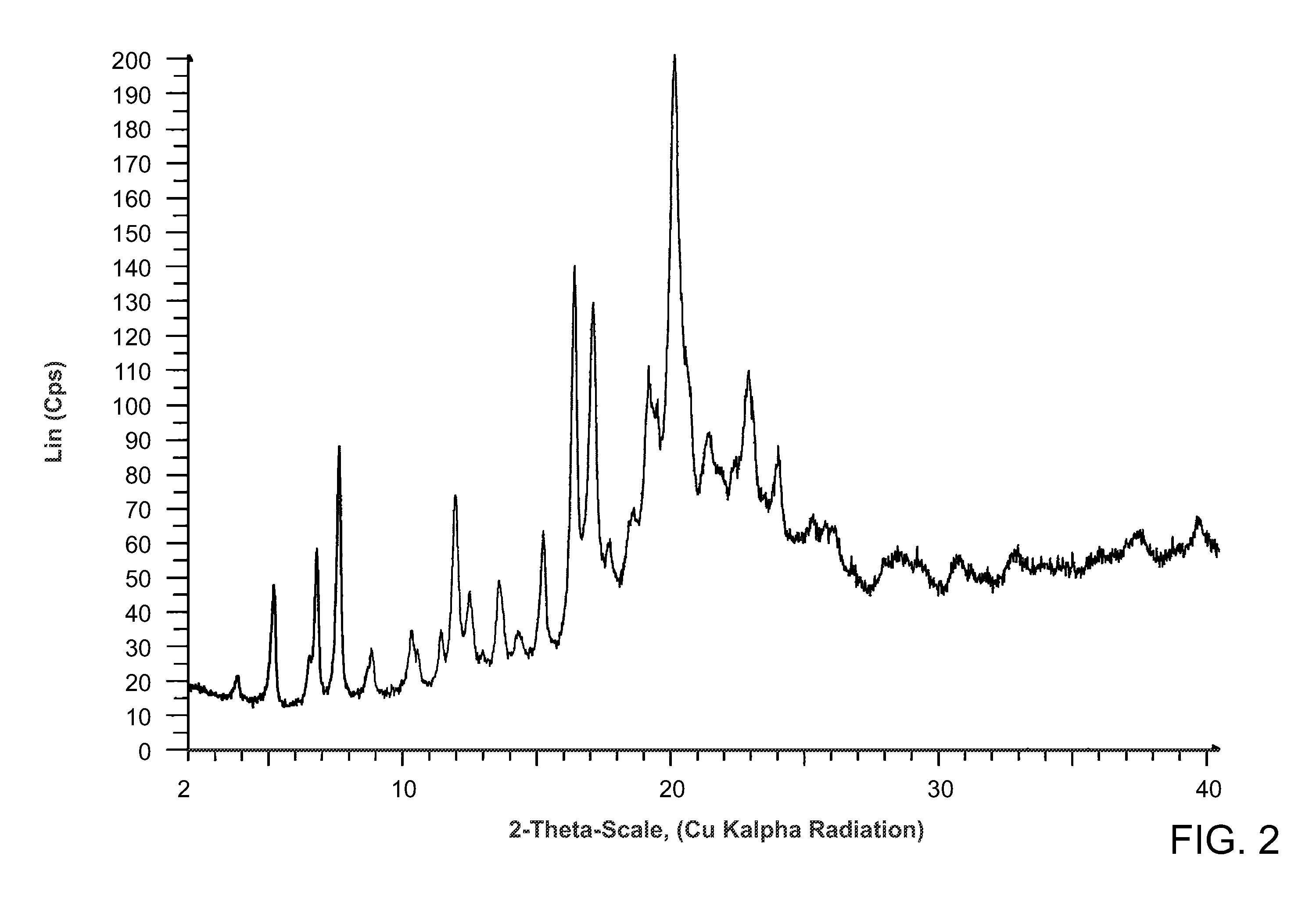

The invention relates to a novel battery bonder, in particular to the bonder applied to a lithium ion battery system. The bonder is characterized in that: the bonder is prepared by uniformly mixing and copolymerizing polymers, such as sized or nano manganese mucic acid complex powder of which micro-topography is shown as pictures 1 and 2, vinylidene fluoride and the like, wherein mass percentage manganese mucic acid concentration of the bonder ranges from 1 to 30 percent. The novel bonder for lithium ion batteries has the characteristics of large specific surface area, high absorption capacity and high film formability. The charge and discharge capacity of the lithium ion batteries prepared by the bonder of the invention can be improved, while cycle characteristics are improved.

Owner:ZHEJIANG NORMAL UNIVERSITY

Salts of methyl 2-((R)-(3-chlorophenyl)((R)-1-((S)-2-(methylamino)-3-((R)-tetrahydro-2H-pyran-3-yl)propylcarbamoyl)piperidin-3-yl)methoxy)ethylcarbamate

InactiveUS8372978B2Good water solubilityImprove oral bioavailabilityBiocideSenses disorderStructural formulaPyran

Owner:VITAE PHARMA INC

An Acid Stress Simulation Method Considering the Dynamic Process of Mucosal Acid

ActiveCN110797092BOvercome the defect of low compliance rateFluid removalChemical processes analysis/designAcid fracturingMechanical engineering

Owner:CHENGDU NORTH OIL EXPLORATION DEV TECH

Acid-fracturing method for leading crack to extend downward

ActiveCN101864939BRealize the goal of directional deep acid fracturingFluid removalTemperature controlAcid fracturing

The invention relates to an acid-fracturing method for leading a crack to extend downward. The acid-fracturing method comprises the following steps: injecting 5-20m3 of hydrochloric acid with the concentration of 10-20 percent into a formation at discharge capacity of 0.5-3.0m3 / minute; injecting 20-100m3 of gel into the crack of the formation at discharge capacity of 1.5-5.0m3 / minute, and then adding ammonium persulfate gel breaker with the concentration of 0.2 percent; pump-injecting 30-80m3 low-concentration carrying fluid with the volume content of hollow glass beads of 2-10 percent at discharge capacity of 1.0-4.0m3 / minute; pump-injecting 50-200m3 gel into the formation at discharge capacity of 3.0-7.5m3 / minute; pump-injecting 50-200m3 gel acid, temperature control various mucic acid into the formation at discharge capacity of 3.0-7.5m3 / minute; using quick water to jack the fracturing fluid in a shaft into the formation; and reaching a long-distance reservoir body which can not becommunicated by the conventional acid-fracturing method and realizing the purpose of directional and deep acid-fracturing modification.

Owner:PETROCHINA CO LTD +1

Paratyphoid c and salmonella cholerae identification kit and preparation and use methods thereof

The invention relates to a paratyphoid c and salmonella cholerae identification kit and preparation and use methods thereof, and mainly solves the technical difficulty in quick screening and identification of paratyphoid c and salmonella cholerae in clinical infective cases and specimens such as an environment source, a food source and a livestock animal source. The paratyphoid c and salmonella cholerae identification kit comprises 1, salmonella C-group immune rabbit antiserum; 2, salmonella H-phase immune rabbit antiserum; 3, salmonella H-phase Vi immune rabbit antiserum; 4-6, dulcite, arabinose and tan sugar fermentation pipe; 7, mucic acid biochemical identification pipe; 8, potassium tartrate biochemical identification pipe; 9, sterilization mineral oil; 10, H-phase special induction soft agar; 11, induction serum H: c and H: 5 factor. The paratyphoid c and salmonella cholerae identification kit is mainly used for screening and identifying paratyphoid c and salmonella cholerae in conventional work.

Owner:上海市普陀区疾病预防控制中心 +1

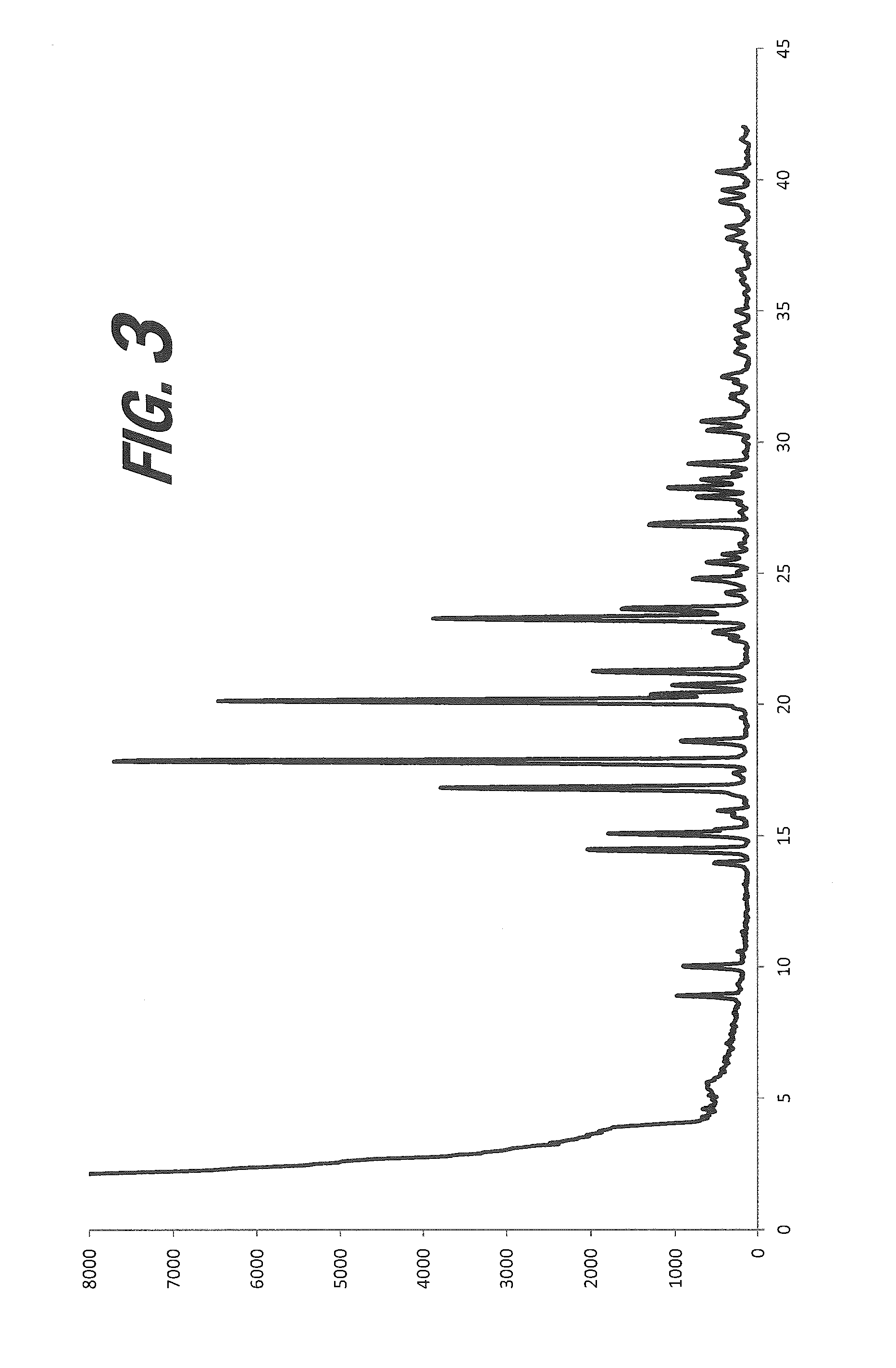

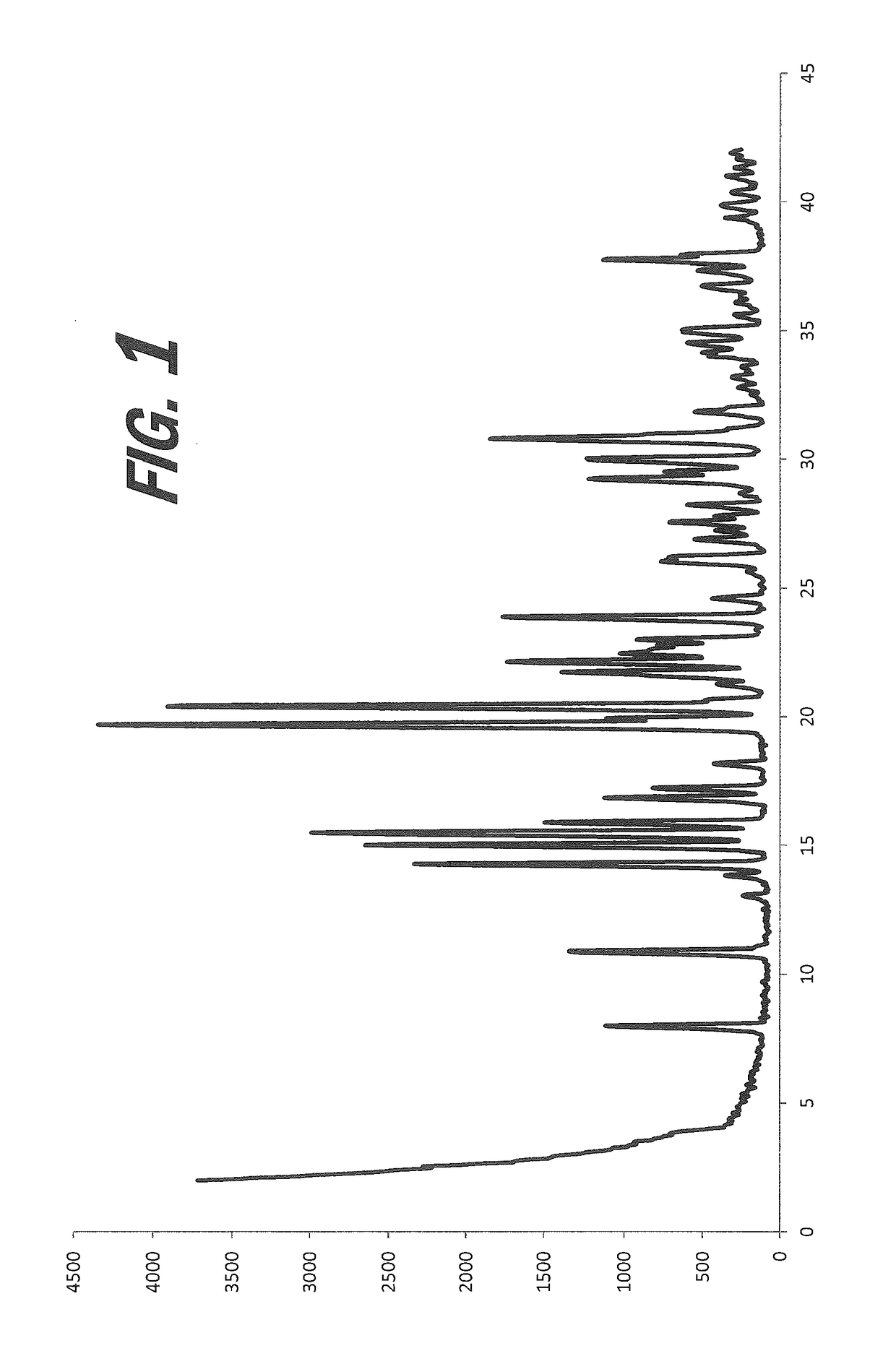

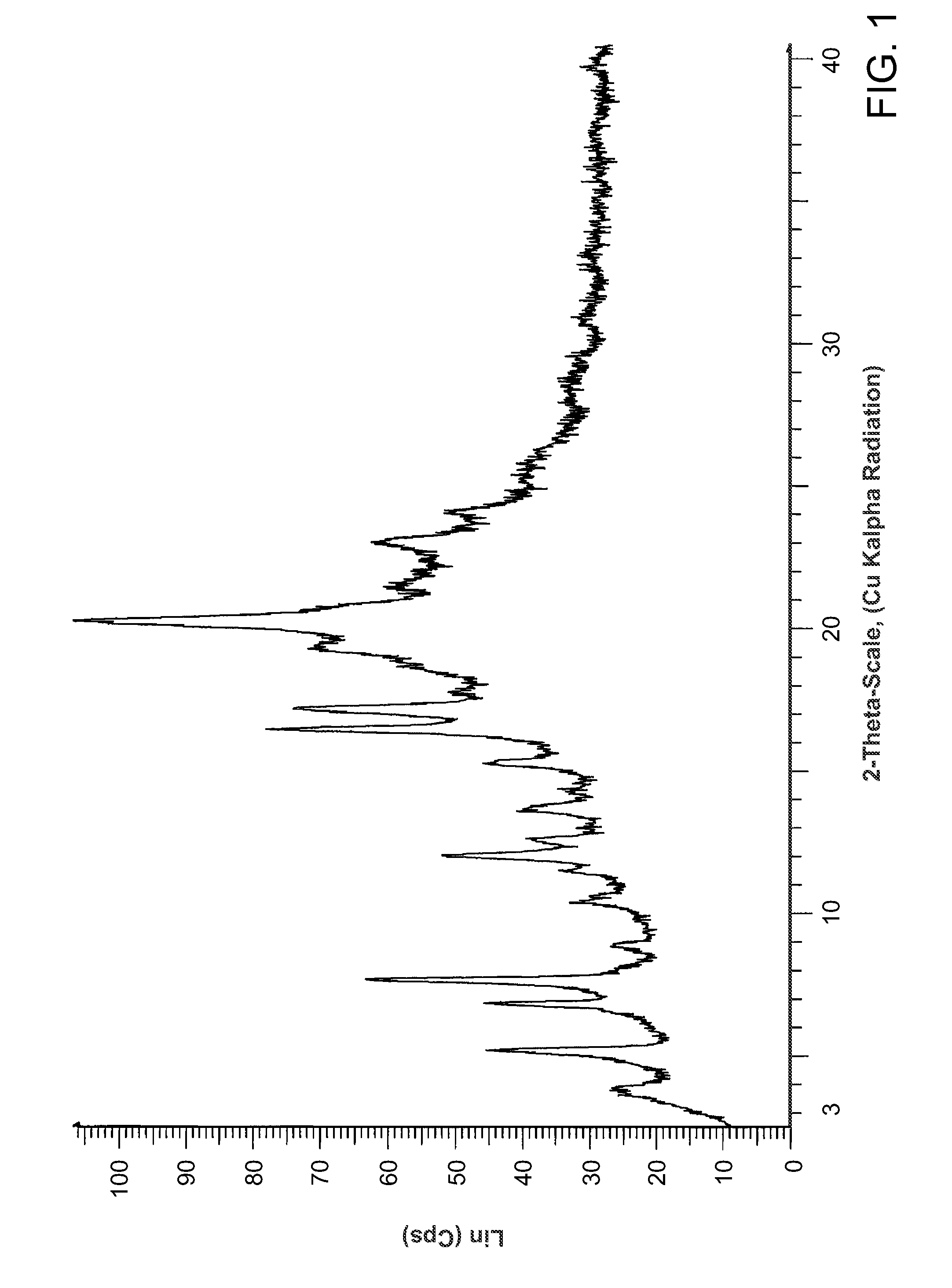

Salts of methyl 2-((r)-(3-chlorophenyl)((r)-1-((s)-2-(methylamino)-3-((r)-tetrahydro-2h-pyran-3-yl)propylcarbamoyl)piperidin-3-yl)methoxy)ethylcarbamate

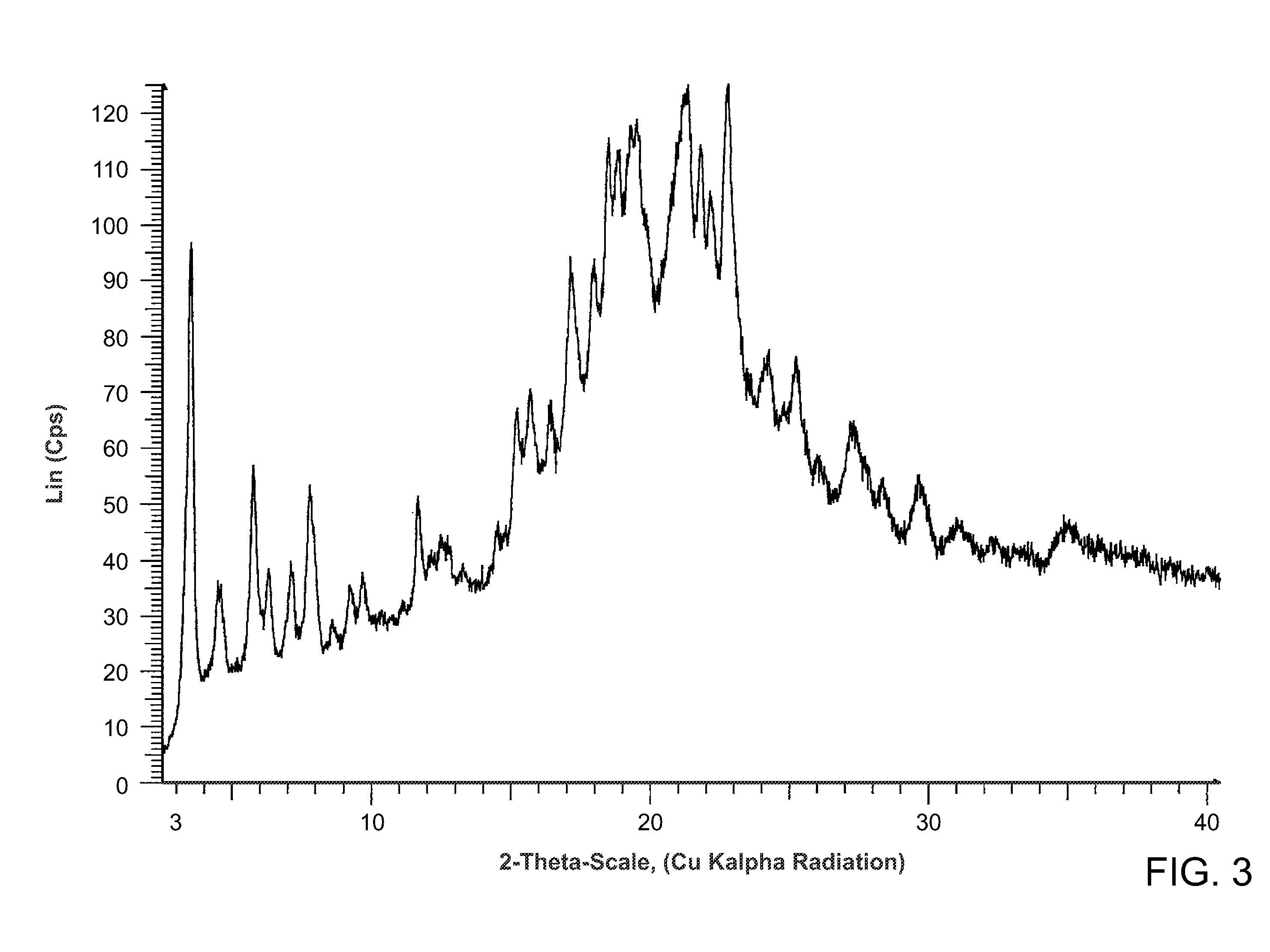

InactiveUS20110098321A1Good water solubilityImprove oral bioavailabilityBiocideSenses disorderStructural formulaMucic acid

Mucic acid salts of a compound represented by the following structural formula:are disclosed. In particular, single crystalline mucic acid salts of the compound represented by structural formula (I) are characterized by a variety of properties and physical measurements. Methods of producing the mucic acid salts, using the salts to antagonize one or more aspartic proteases, and methods of treating a number of aspartic protease mediated disorders using the salts are described herein.

Owner:VITAE PHARMA INC

A kind of water-in-oil type nanoemulsion, nanoemulsion composite response type viscous acid thickener and preparation method thereof

ActiveCN113372485BHigh viscosityInhibition of reduction reactionDrilling compositionPolymer scienceMorpholine

The invention relates to the technical field of oil and gas field development, and provides a water-in-oil nanoemulsion, a nanoemulsion composite response type viscosity-changing acid thickener and a preparation method thereof, and the nanoemulsion composite response type viscosity-changing acid thickener It contains the following components: thickener superfine powder 200~350 parts, coating agent 15~20 parts, activator 5~10 parts, white oil 135~235 parts, and water-in-oil nanoemulsion 390~650 parts The thickening agent of the present invention takes superfine powder as the core, the suspension system is the middle layer, and the nanoemulsion is the outer layer; the nanoemulsion includes an aqueous phase, an oil phase and a phase inversion agent, which is acrylamide, acryloyl morpholine, and a viscosifying unit body, dimethyl diallyl ammonium chloride, copolymer of hydrophobic monomer; superfine powder is a copolymer of acrylamide, acryloyl morpholine, cationic monomer and responsive monomer; suspension system is coating agent, The package system composed of activator and white oil is suitable for deep well and ultra-deep well oil and gas field acidizing construction operations.

Owner:SHANDONG NUOER BIOLOGICAL TECH

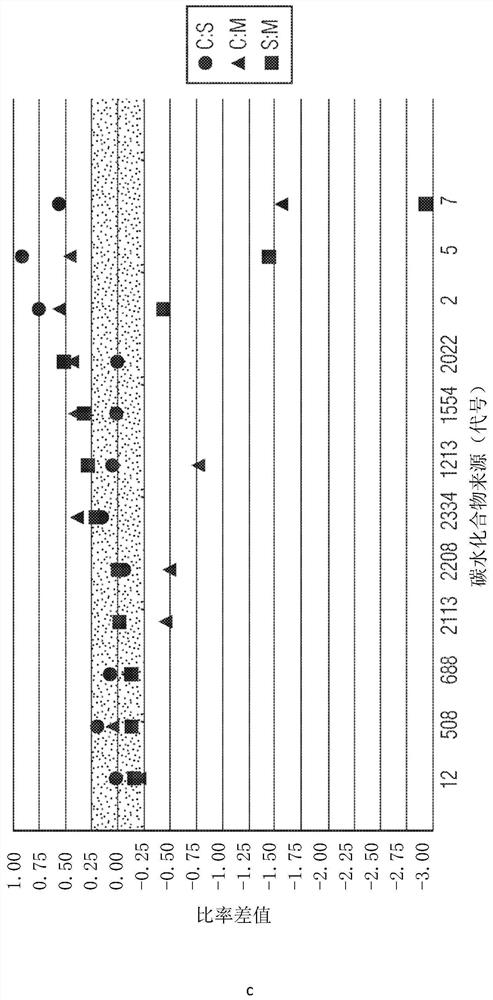

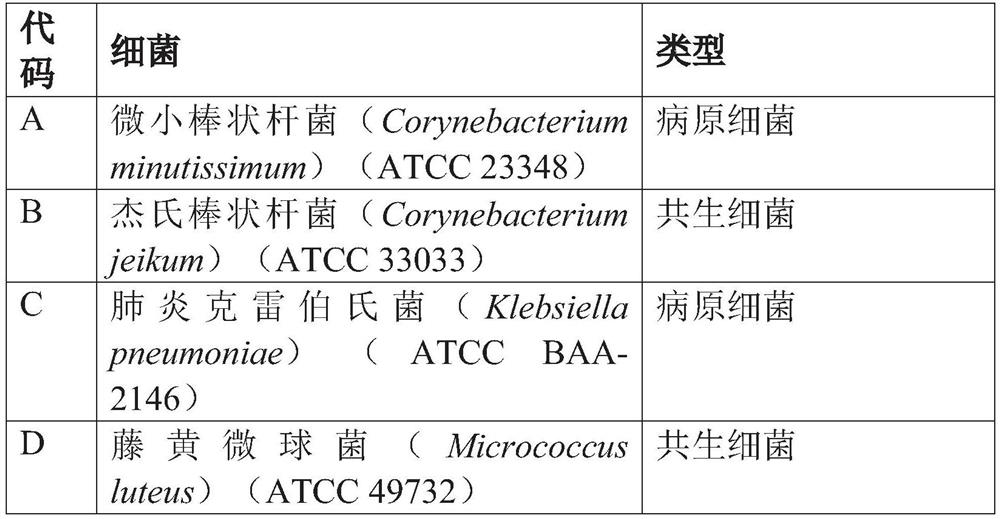

Prebiotic compositions and methods for maintaining a healthy skin microbiota

A composition for providing or maintaining a healthy skin microbiota and methods of providing or maintaining a healthy skin microbiota are disclosed. The composition can be a prebiotic composition that can include a carrier and a skin microbiota balancing agent. In some aspects, the skin microbiota balancing agent can include at least one combination of carbohydrate sources including a first carbohydrate source and a second carbohydrate source. The skin microbiota balancing agent can be configured to provide at least two of the following desired ratios: a first desired ratio of Corynebaderiumto Staphylococcus of 1.3, a second desired ratio of Corynebaderium to Micrococcus of 1.4, and a third desired ratio of Staphylococcus to Micrococcus of 1.1. The carbohydrate sources may be D-alanine,D-threonine, L-alanyl-glycine, succinic acid, alpha-keto-glutaric acid, m-tantaric acid, bromo succinic acid, mucic acid, phenylethyl-amine, inulin, oxalic acid, pectin, Tween 40 etc.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com