Preparation method of polymer viscosity-reducing profile-control resistance-reducing physical dissolution agent PSR

A physical dissolution and polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as oil cannot be recovered, achieve large demand, break through international blockade, and achieve large market effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

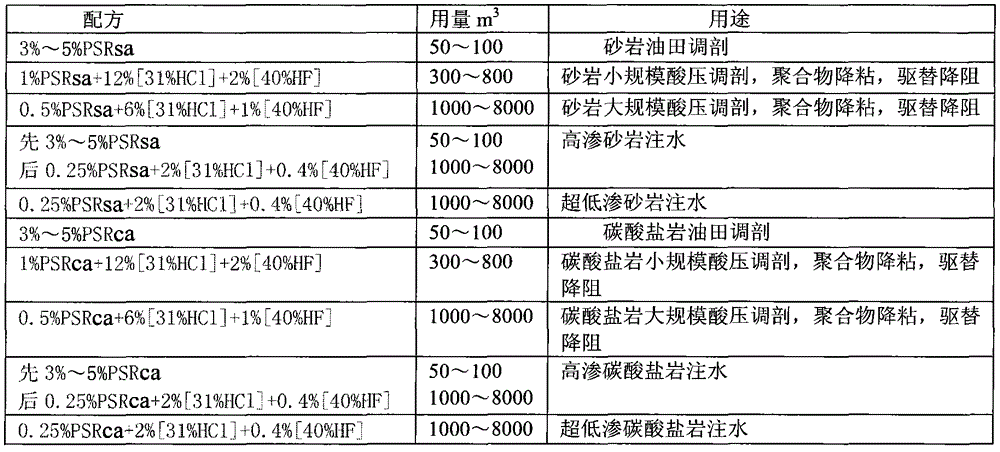

[0024] High-permeability sandstone oilfield water injection well or oil well small-scale reduction of viscosity and resistance physical solvent PSRsa acid fracturing

[0025] Construction Program:

[0026] The first step, 1% PSRsa, dosage 20 ~ 30m 3 , wash the well with reverse circulation, remove the organic and inorganic scale in the wellbore;

[0027] The second step, 3% ~ 5% PSRsa, dosage 50 ~ 100m 3 , Profile adjustment;

[0028] The third step, 1%PSRsa+12%[31%HCl]+2%[40%HF], dosage 300~800m 3 , profile control, polymer viscosity reduction, displacement and resistance reduction;

[0029] The fourth step is to discharge the residual liquid immediately;

[0030] In the fifth step, the water injection well injects water normally, and the oil well produces normally.

[0031] Features: Small-scale profile control improves sweep coefficient, dissolves polymers to remove plugging and reduce viscosity, dissolves fillings, cements and nanopore walls in ultra-low permeability...

example 2

[0033] High-permeability sandstone oilfield water injection well large-scale reduction of viscosity and resistance of physical solvent PSRsa acid fracturing

[0034] Construction Program:

[0035] The first step, 1% PSRsa, dosage 20 ~ 30m 3 , wash the well with reverse circulation, remove the organic and inorganic scale in the wellbore;

[0036] The second step, 3% ~ 5% PSRsa, dosage 50 ~ 100m 3 , Profile adjustment;

[0037] The third step, 0.5%PSRsa+6%[31%HCl]+1%[40%HF], dosage 1000~8000m 3 , profile control, polymer viscosity reduction, displacement and resistance reduction;

[0038] In the fourth step, the water injection well is injected normally.

[0039] Features: Large-scale profile control improves sweep coefficient, dissolves polymers to remove plugging and reduce viscosity, dissolves fillings, cements and nanopore walls in ultra-low-permeability sandstone bedrock nanopores, expands nanopores, improves displacement and drop Resistivity, increase desorption spee...

example 3

[0041] Ultra-low permeability sandstone oilfield water injection well or oil well small-scale reduction of viscosity and resistance physical solvent PSRsa acid fracturing

[0042] Construction Program:

[0043] The first step, 1% PSRsa, dosage 20 ~ 30m 3 , wash the well with reverse circulation, remove the organic and inorganic scale in the wellbore;

[0044]The second step, 1% ~ 3% PSRsa, dosage 50 ~ 100m 3 , fine-tune profile;

[0045] The third step, 0.8% ~ 1% PSRsa + 8% ~ 12% [31% HCl] + 1% ~ 2% [40% HF], the dosage is 300 ~ 800m 3 , profile control, displacement and resistance reduction;

[0046] The fourth step is to discharge the residual liquid immediately;

[0047] In the fifth step, the water injection well injects water normally, and the oil well produces normally.

[0048] Features: Small-scale profile control improves sweep coefficient, dissolves fillings, cements and nano-pore walls in nano-pores and cracks of ultra-low-permeability sandstone rocks, expands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com