Patents

Literature

733 results about "Heavy oil reservoir" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

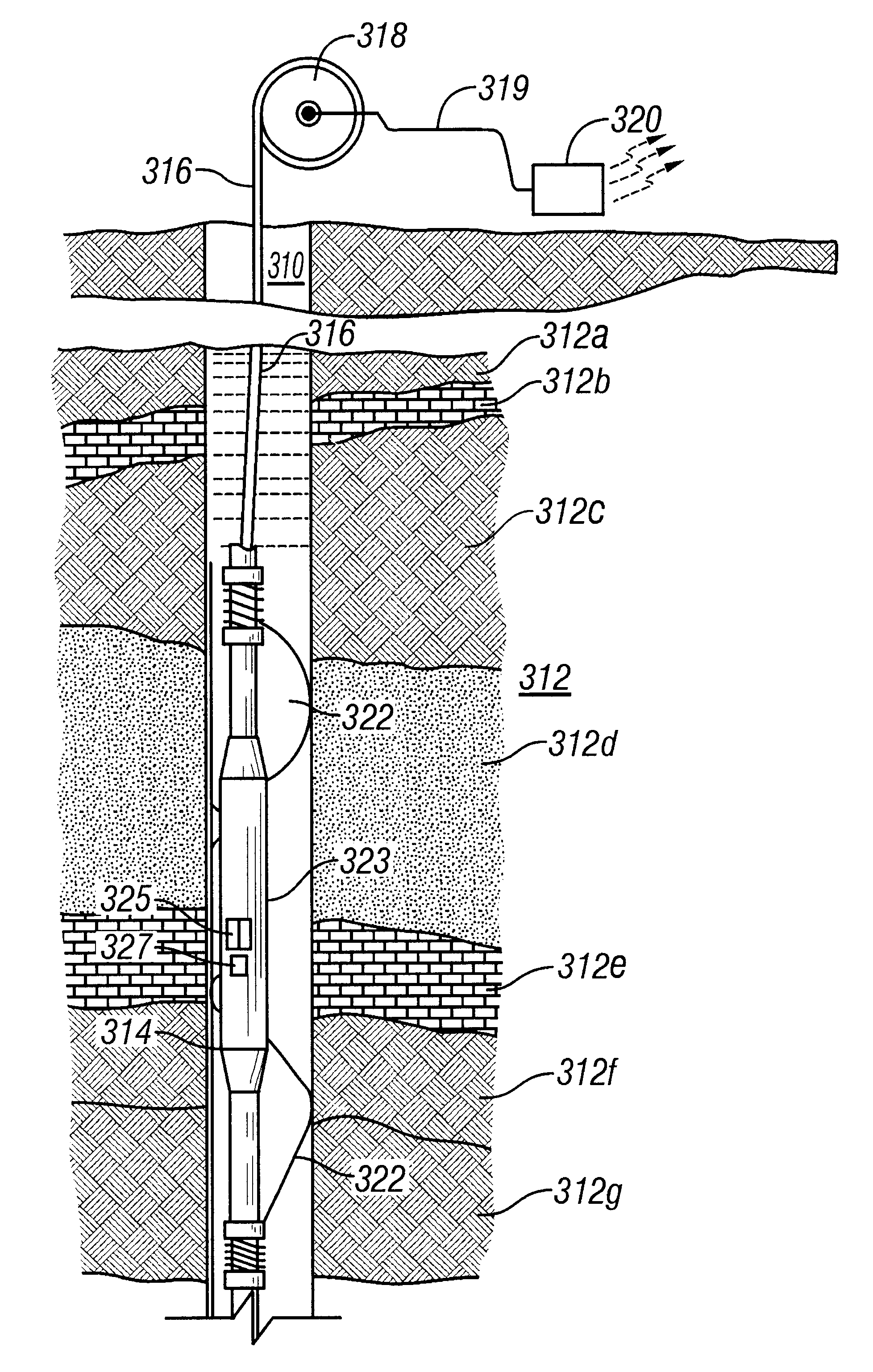

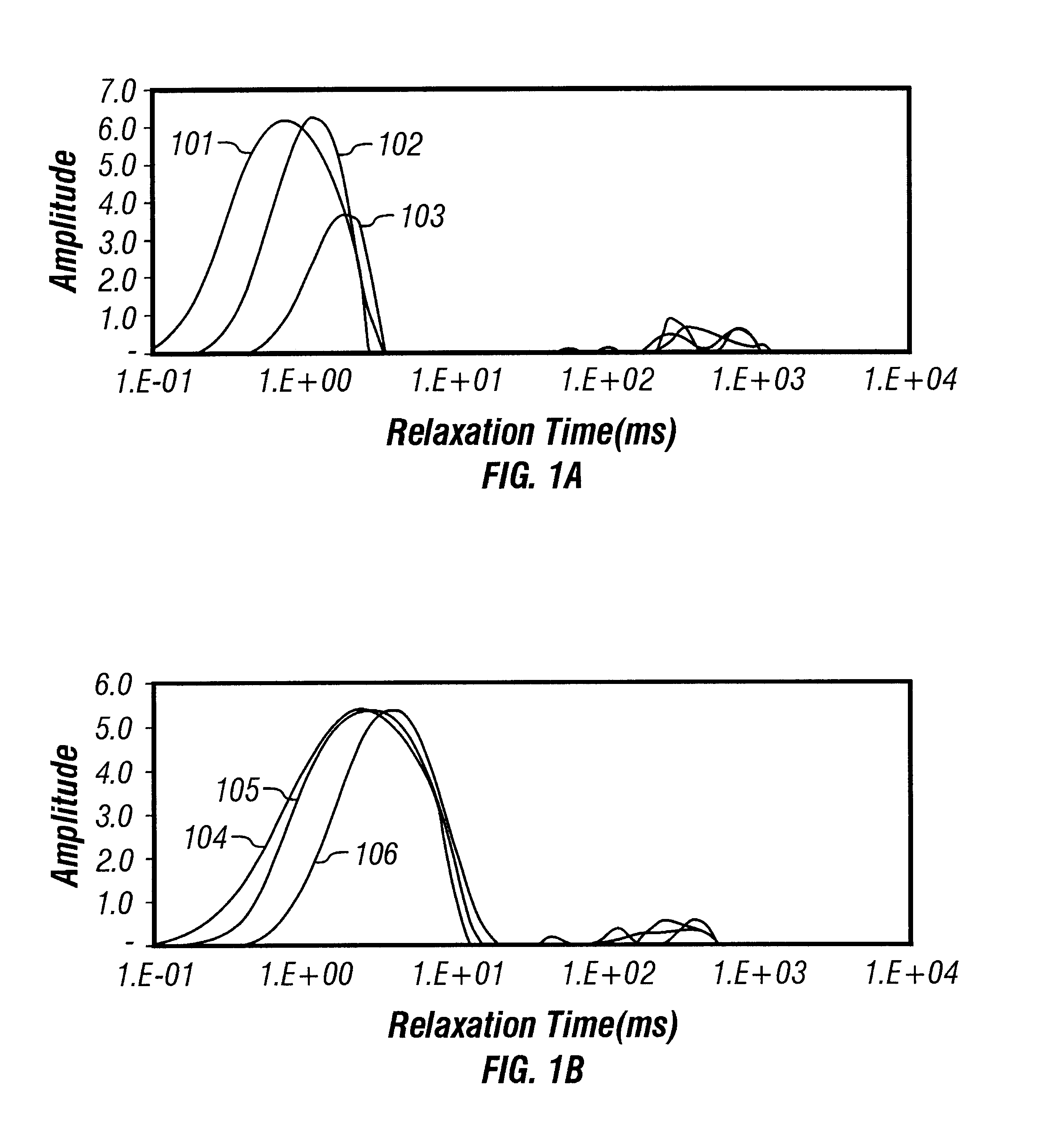

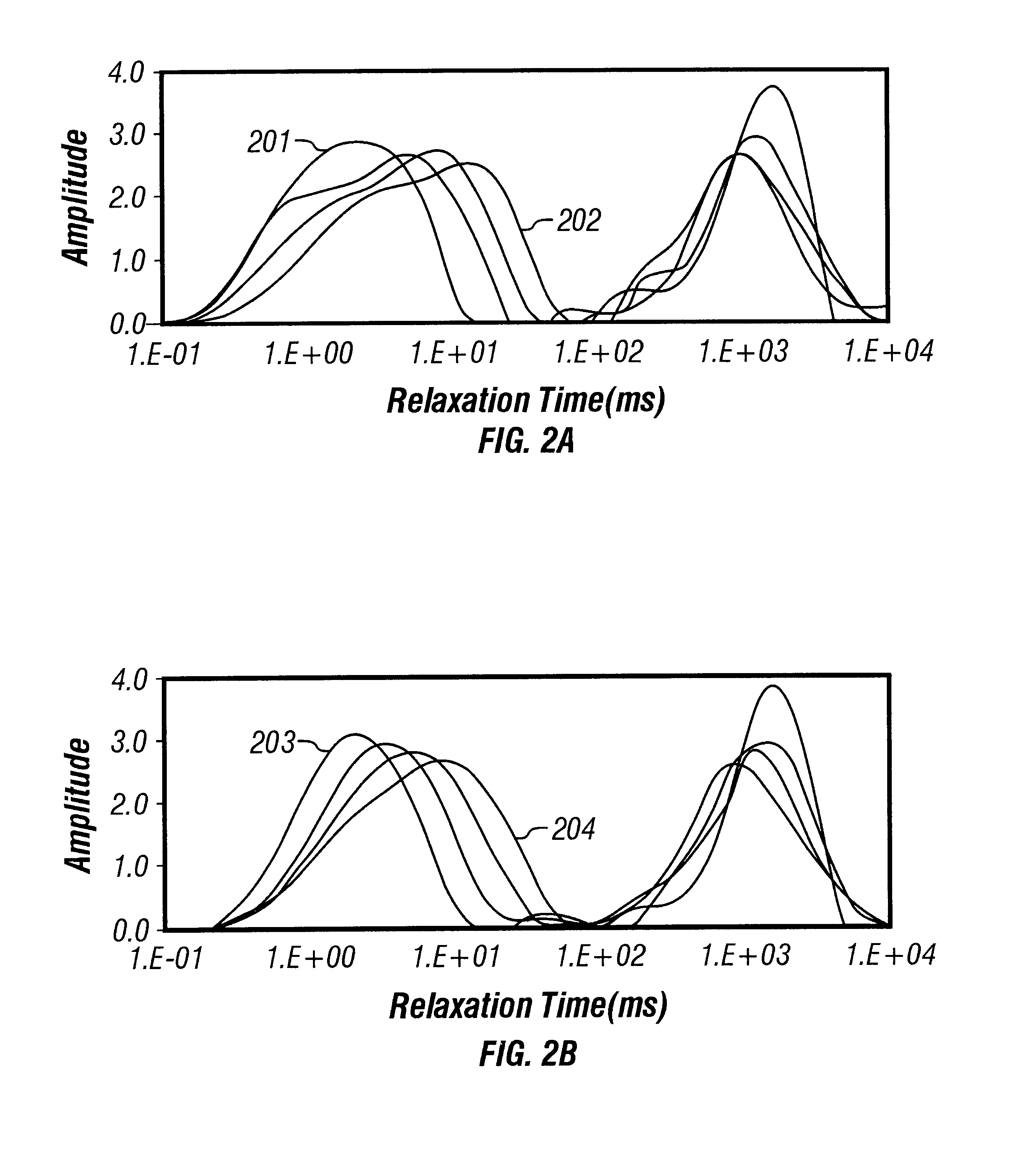

In-situ heavy-oil reservoir evaluation with artificial temperature elevation

Many reservoirs of interest include heavy oil. In such reservoirs, parti at normal temperatures, many instruments commonly used for formation evaluation may not be able to distinguish between heavy oil and bound water in the formation. Passive or active heating is used to elevate the temperature of the fluids in the formation. At elevated temperatures, distinguishing between heavy oil and bound water is easier. Of particular interest is the increase in the resolvability of the transverse relaxation time T2 of NMR spin echo measurements. Additionally, the dielectric constant and the loss tangents of water and heavy oil show different temperature and frequency dependence.

Owner:BAKER HUGHES HLDG LLC

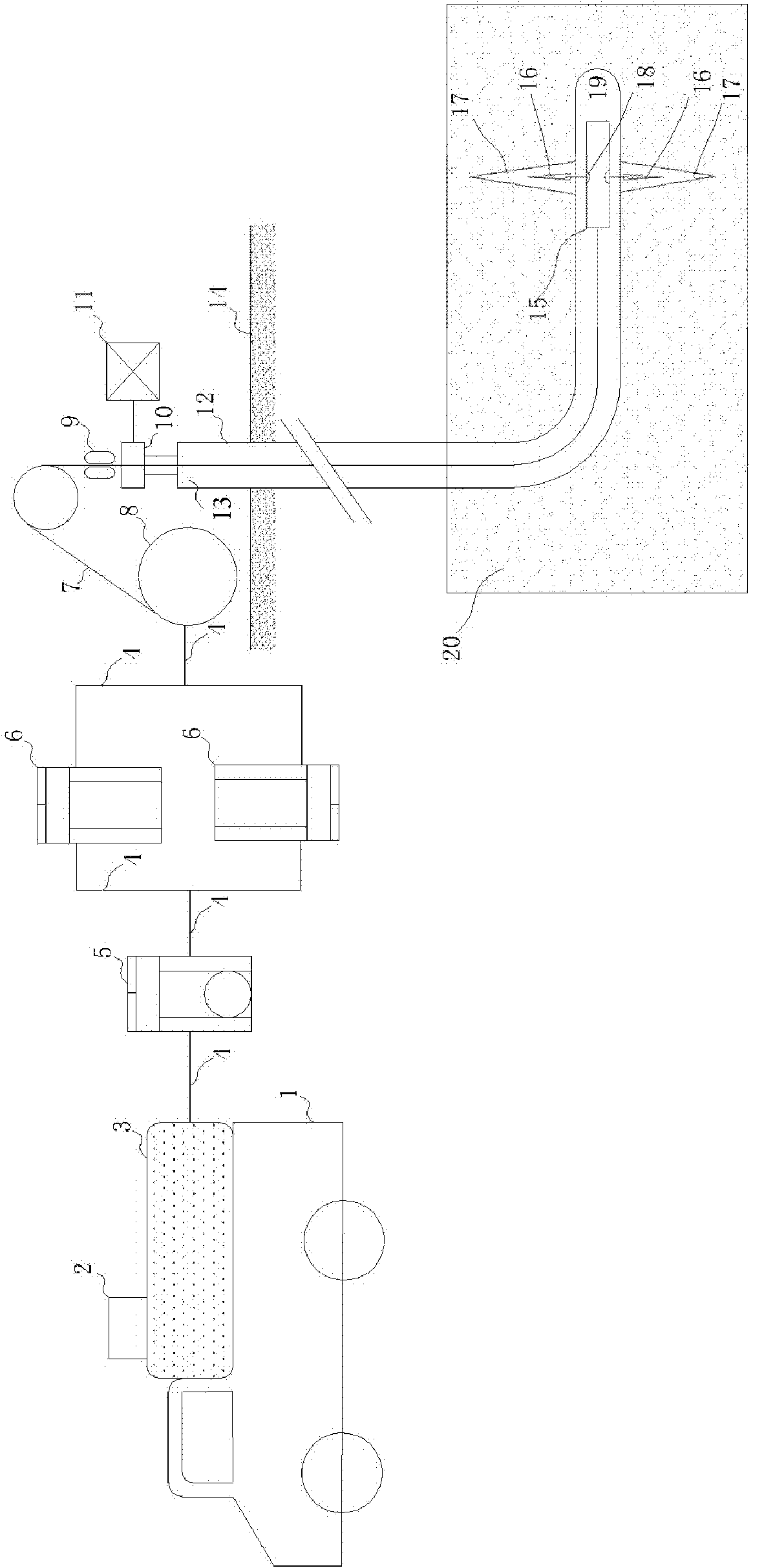

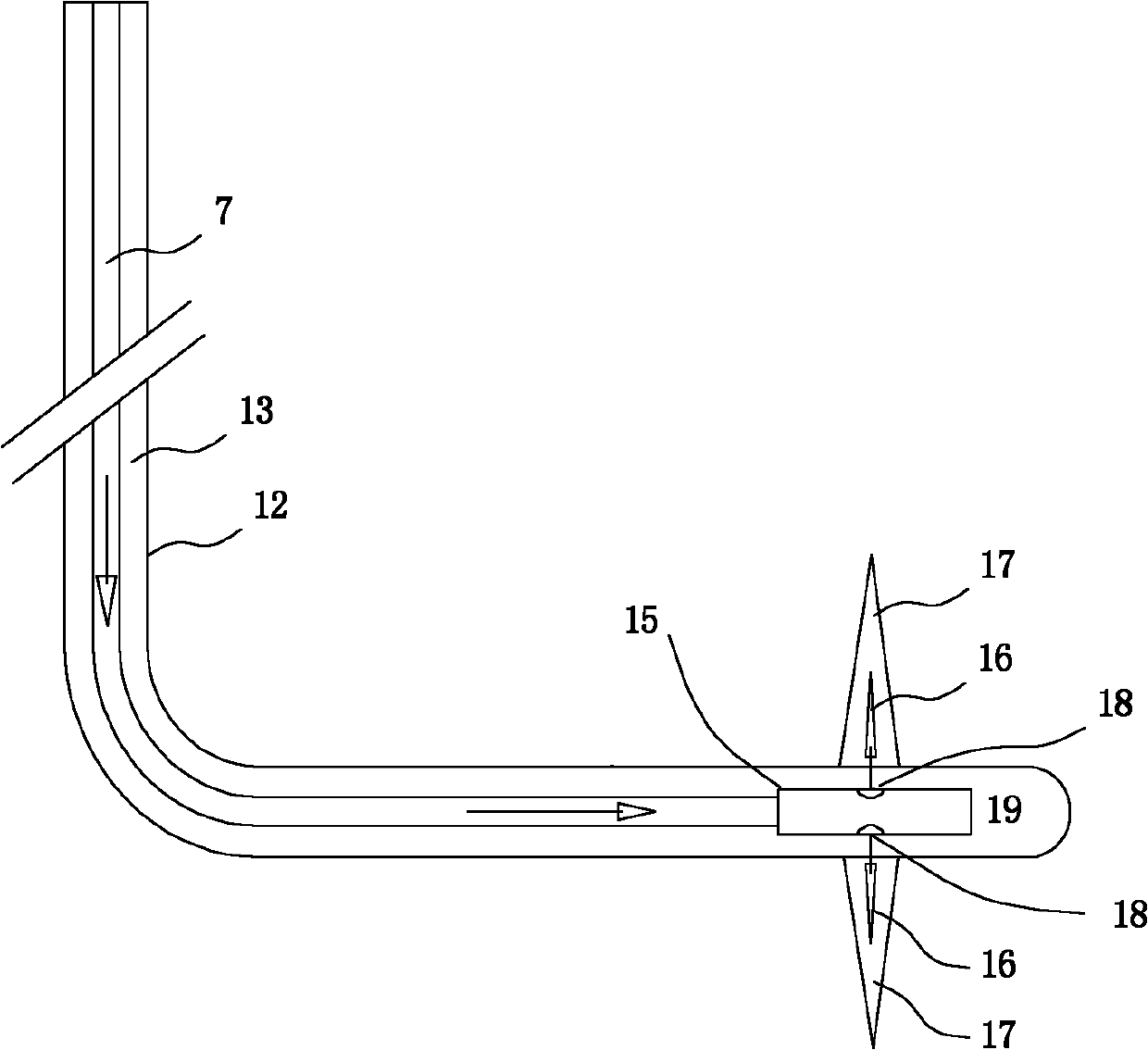

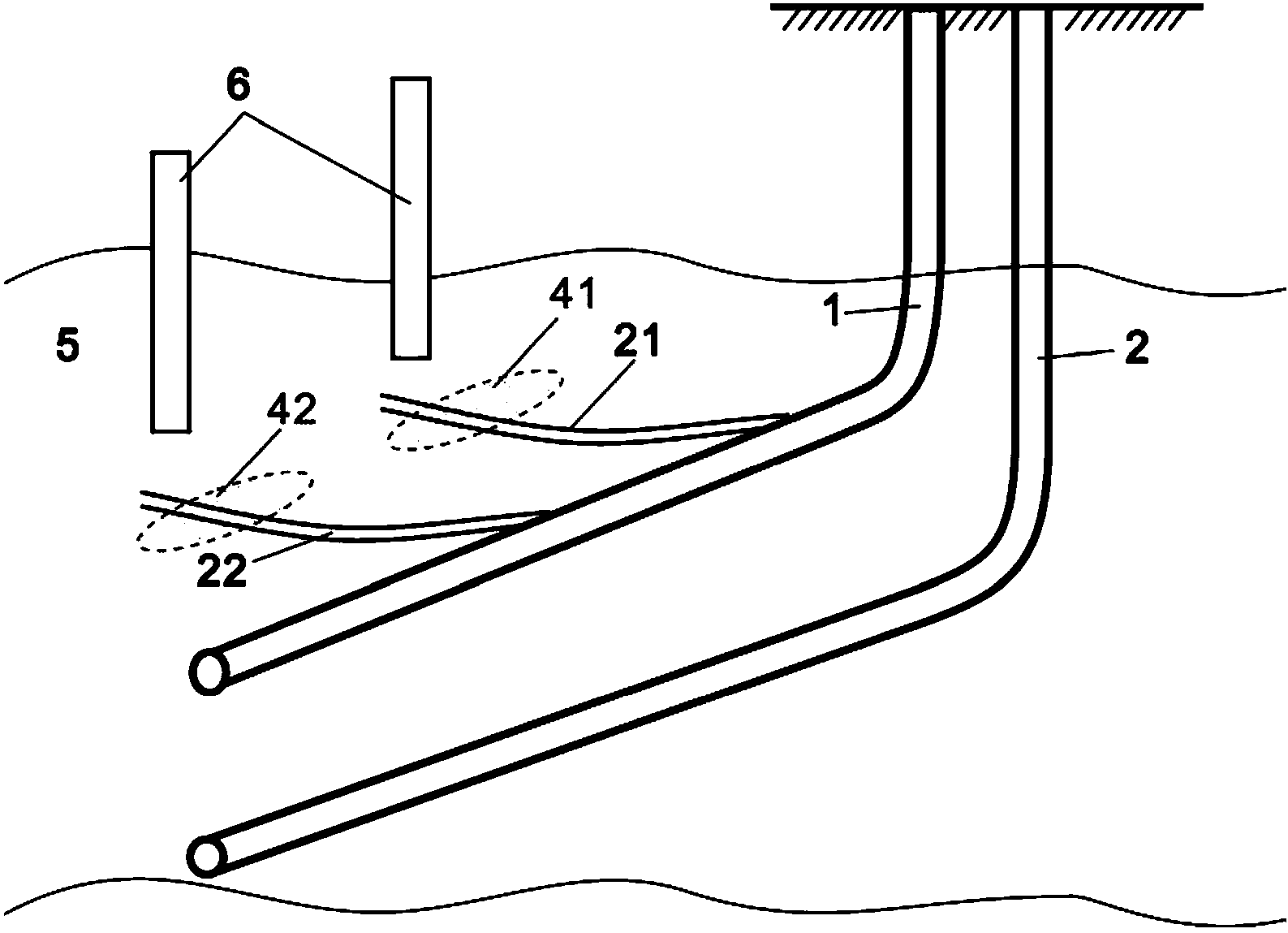

Coiled tubing supercritical CO2 jet fracturing method

ActiveCN102168545AJet rock breaking efficiency is highRock breaking threshold pressure is lowLiquid/gas jet drillingFluid removalWater basedFracturing fluid

The invention relates to a coiled tubing supercritical CO2 jet fracturing method. The method is used for performing jet fracturing on oil well reservoirs by taking supercritical CO2 as fracturing fluid. By the method, a supercritical CO2 fluid is used as the fracturing fluid to perform the jet fracturing; a supercritical CO2 sand jet perforating hole can reduce system pressure; the pressure needed by fissure extension can be further reduced by the characteristics of low viscosity and high dispersion performance of the supercritical CO2 fluid; most importantly, the supercritical CO2 jet fracturing does not pollute the reservoirs, but the supercritical CO2 can further improve the oil and gas recovery ratio after entering the reservoirs; the return discharge is not needed after the fracturing is completed; when the stage-by-stage jet fracturing is performed by using the coiled tubing, a tube pillar can be lifted or put down without mineshaft pressure relieving, the operation process is reduced and the operation cost is reduced, so that the method is extremely suitable for fracturing modification of unconventional oil-gas reservoirs such as thick oil reservoirs, low permeability and super-low permeability oil-gas reservoirs, shale gas reservoirs, coal bed methane reservoirs and the like of which the effects are low by using the conventional water-based fracturing fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

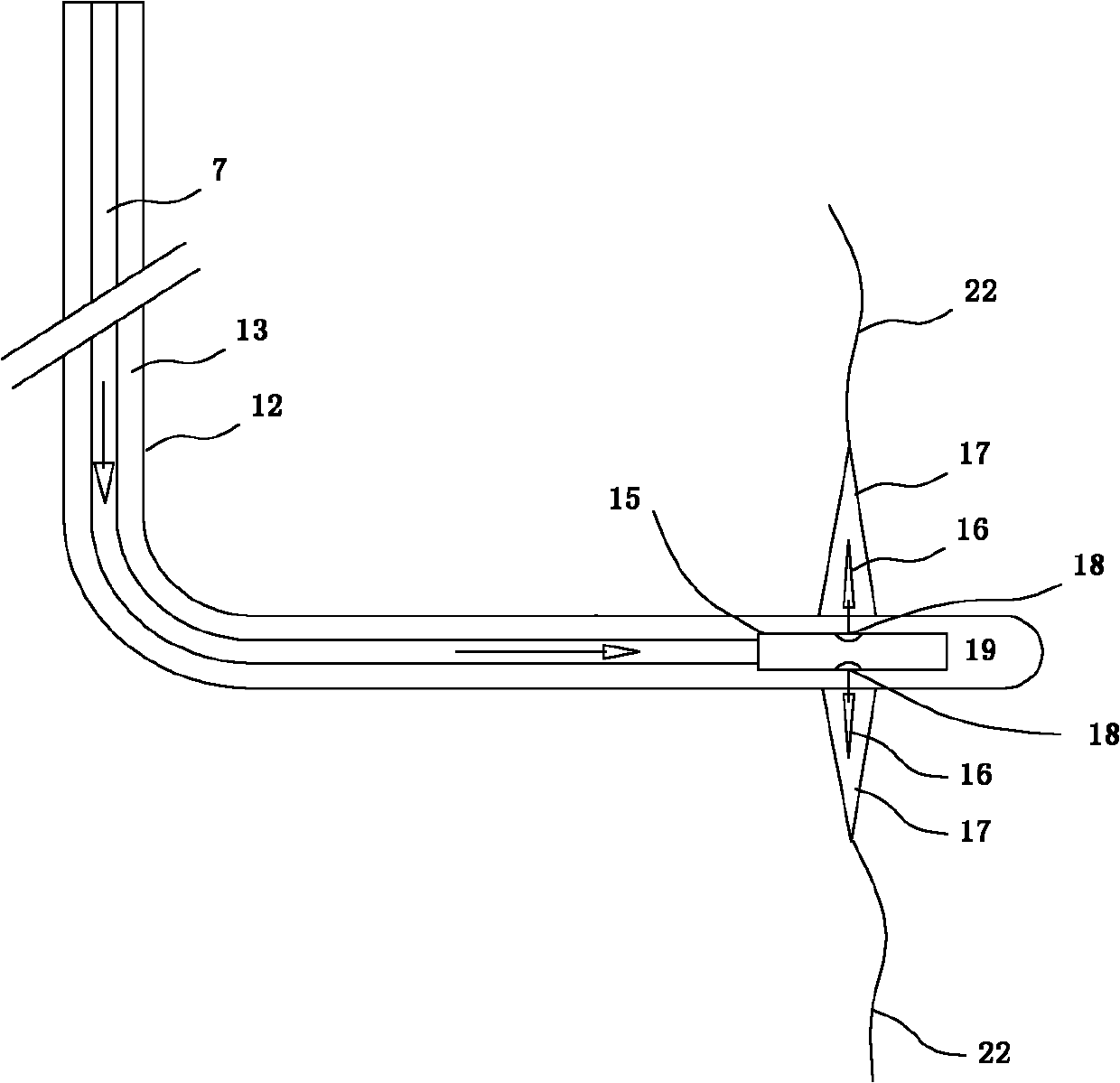

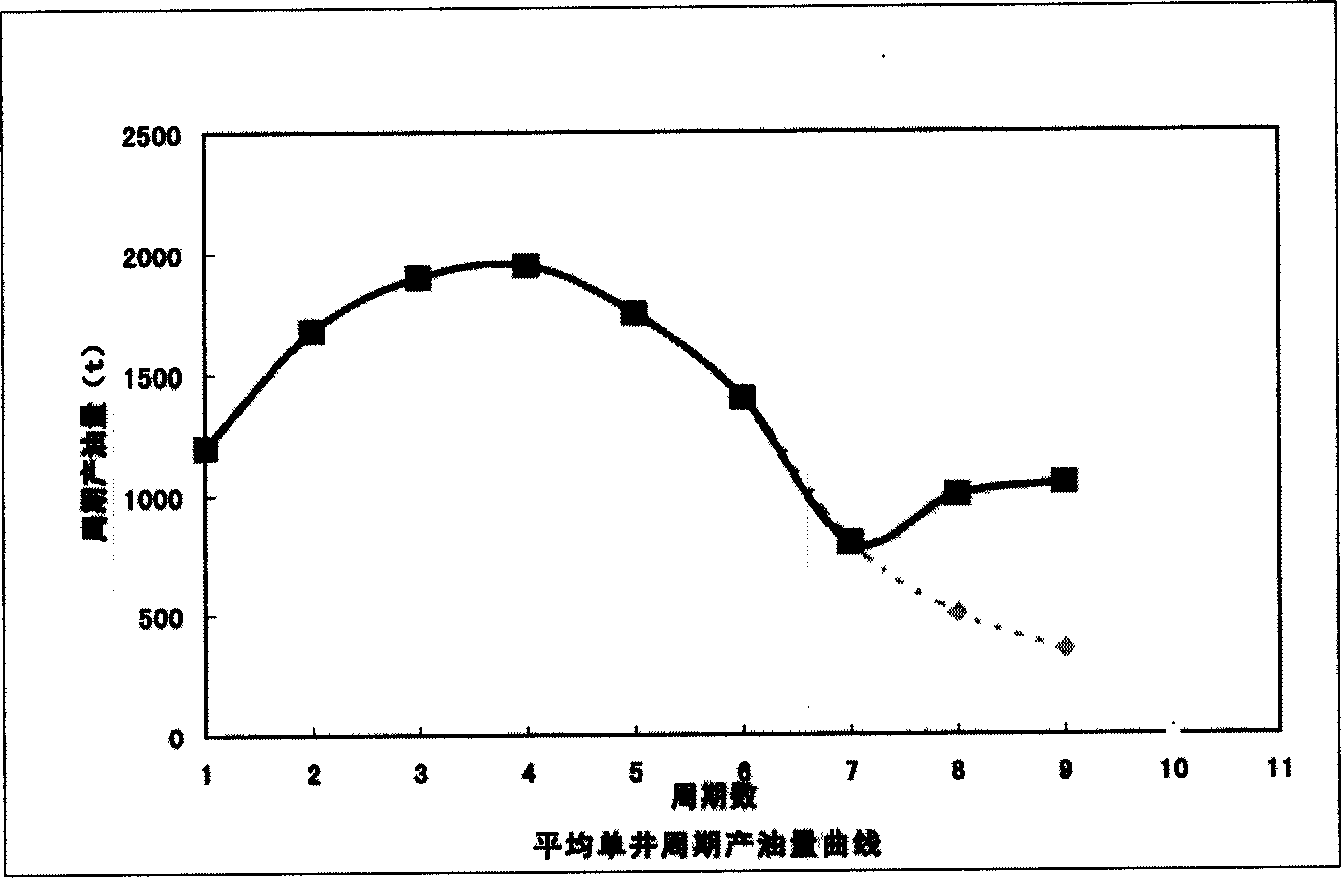

Thermochemistry auxiliary reinforced steam flooding method

The present invention relates to a thermochemistry assistant strengthening steam drive method for thermal recovery of horizontal well using oil-soluble compound viscosity reducer and carbon dioxide. The technique scheme is that: Drilling an horizontal well below the heavy oil reservoir layer, injecting periodically oil-soluble compound viscosity reducer, carbon dioxide liquid and steam in slug injection forms to horizontal well, after shutting in well and opening to blow, continuous oil extraction is operated by the inner lower pump in horizontal well. The present invention can reduce base oil viscosity of super heavy oil reservoir in lower or middle deep layers greatly, reduce steam injection pressure greatly, enhance steam hot wave and range, and enhance period exploitation effect. The scene experiment proves that the average period oil-steam ratio reaches to 0.75, average period oil production is 1800t, the room experiment proves that developing thermochemistry assistant strengthening steam drive in the late period of middle deep layer of super heavy oil reservoir, the final oil reservoir recovery can reach about 40%.

Owner:SHENGLI OILFIELD PETROLEUM DEV CENT

Method for high temperature steam

InactiveUS20060042794A1Reduces viscosity of oilImprove scanning efficiencyFluid removalGas phaseEngineering

A method for the recovery of upgraded oil from an oil-bearing formation is provided wherein a hot gas phase fluid comprising steam is brought into contact with a heavy oil reservoir, such as by injection, and the hot fluid heats at least a portion of the reservoir to a temperature high enough for steam cracking, and subsequently the steam is reacted with the heavy oil to produce steam cracked lighter oil.

Owner:PRECISION COMBUSTION

Exploitation technique for disgorging thick oil by pouring air to assistant steam

The present invention provides a method for production of heavy oil reservoir. It is technically characterized by that in the cyclic steam injection and steam-flooding process it utilizes air injection to raise recovery efficiency and engineering benefits. Said method includes the following steps: after the oil well is drilled, making casing sand control completion of heavy oil reservoir so as to inhibit sand inflow in after-production; constructing artificial bottom hole so as to resist high-pressure produced by injecting steam and high-pressure air; after well completion injecting hot steam (above 200 deg.C), and injecting air into same oil reservoir, reducing heavy oil viscosity, then closing well, making crude oil and oxygen gas produce oxidation reaction; after the wellhead pressure is stabilized, opening well and making production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

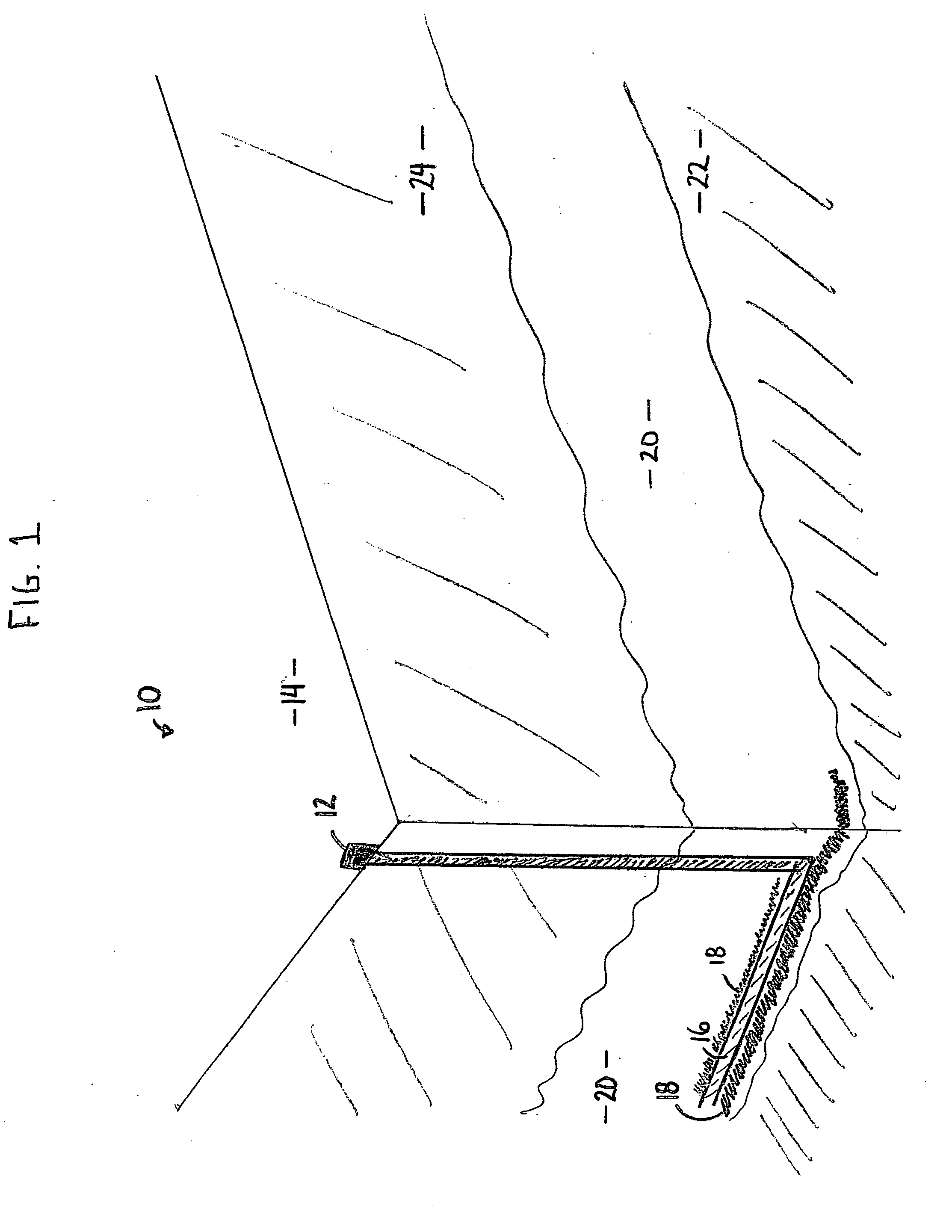

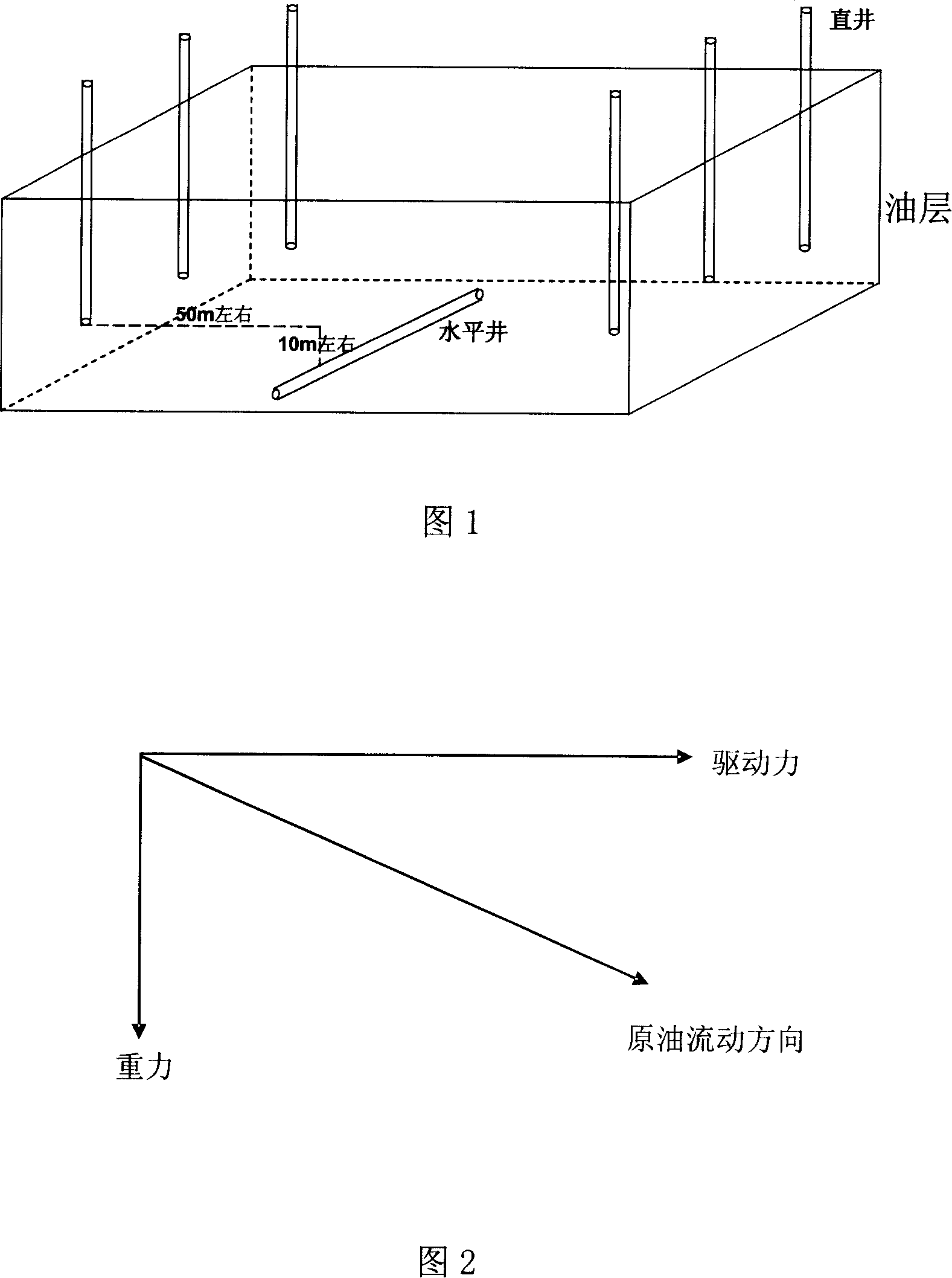

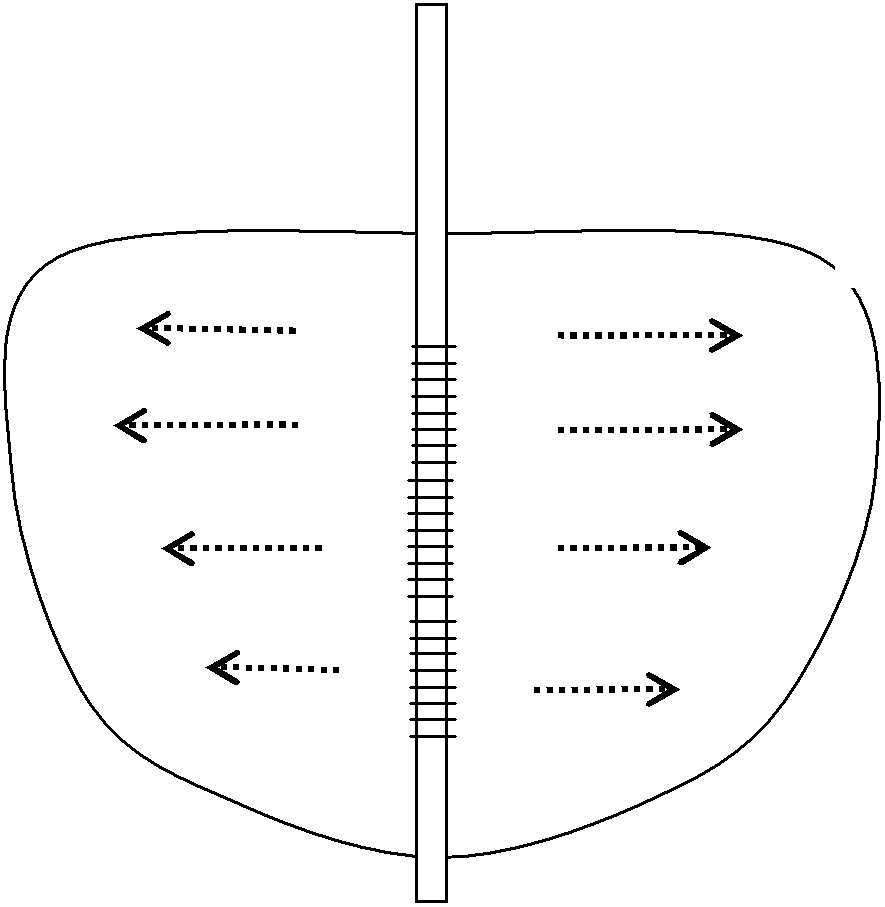

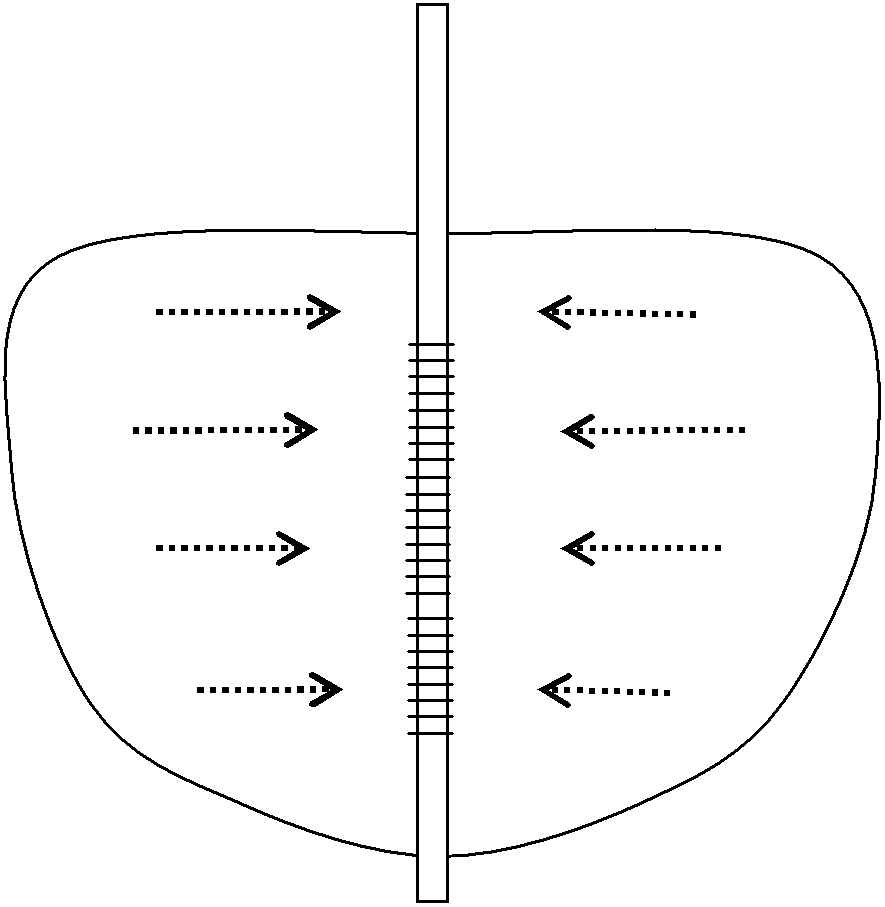

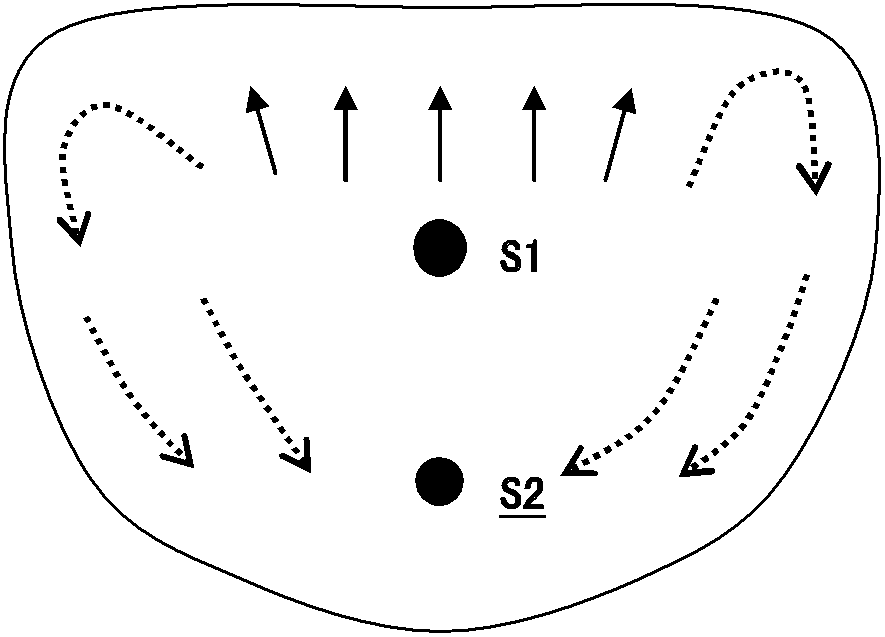

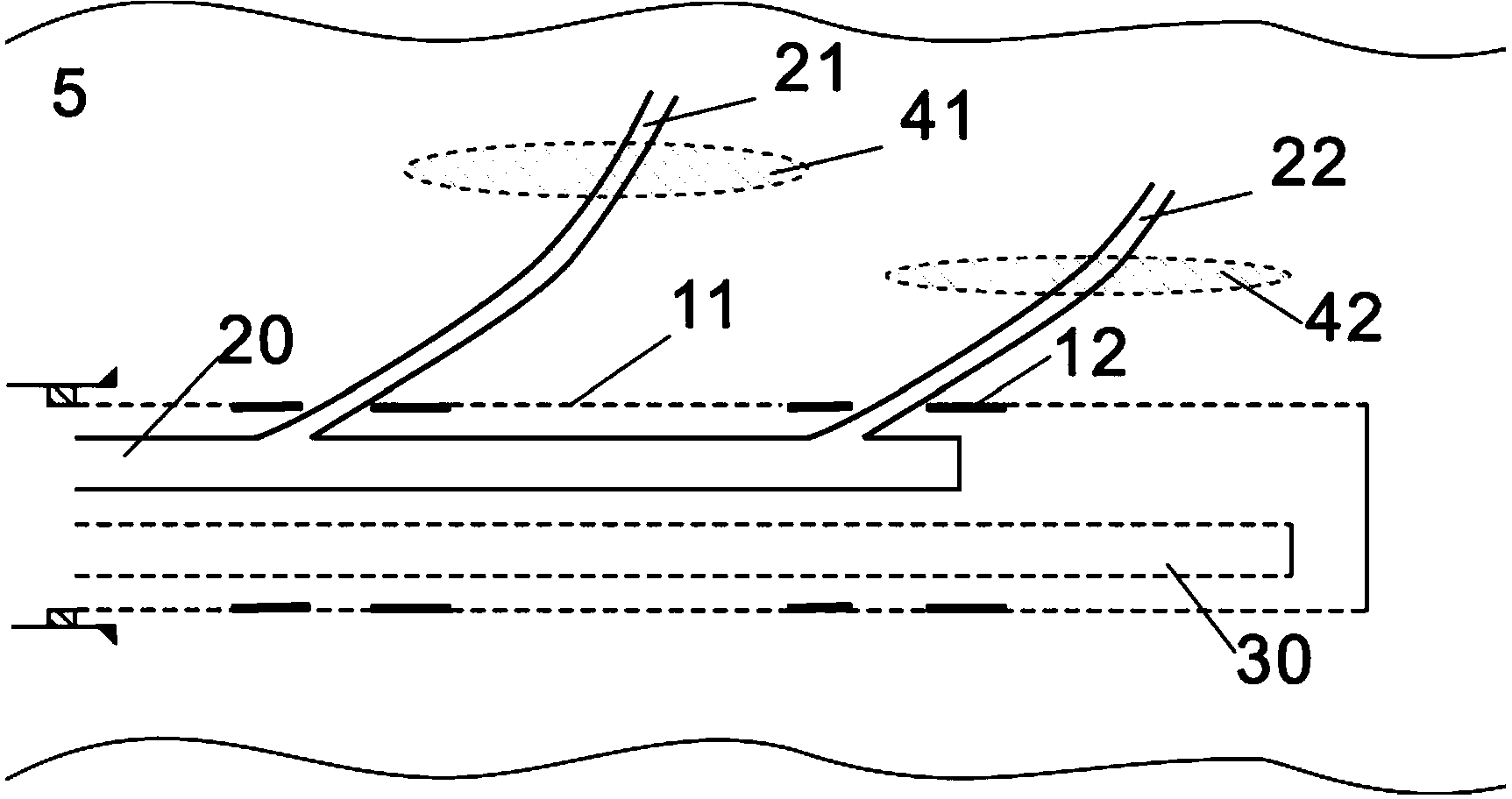

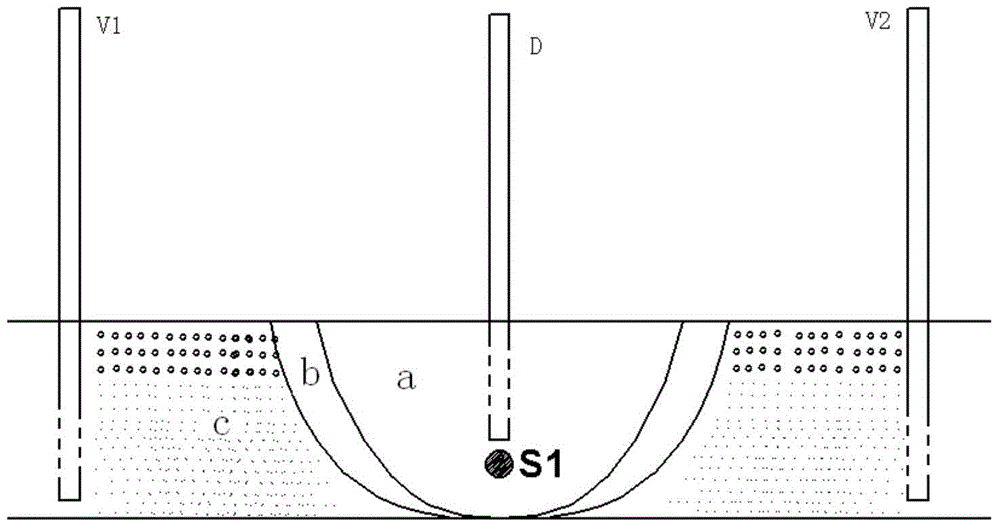

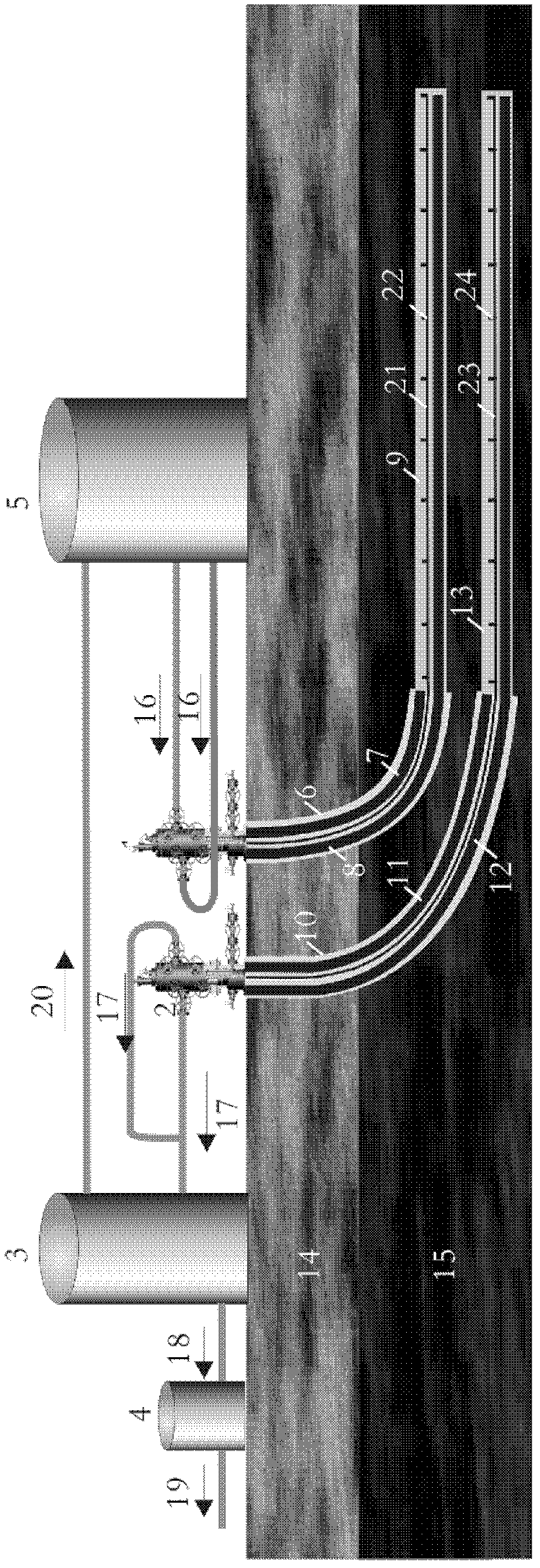

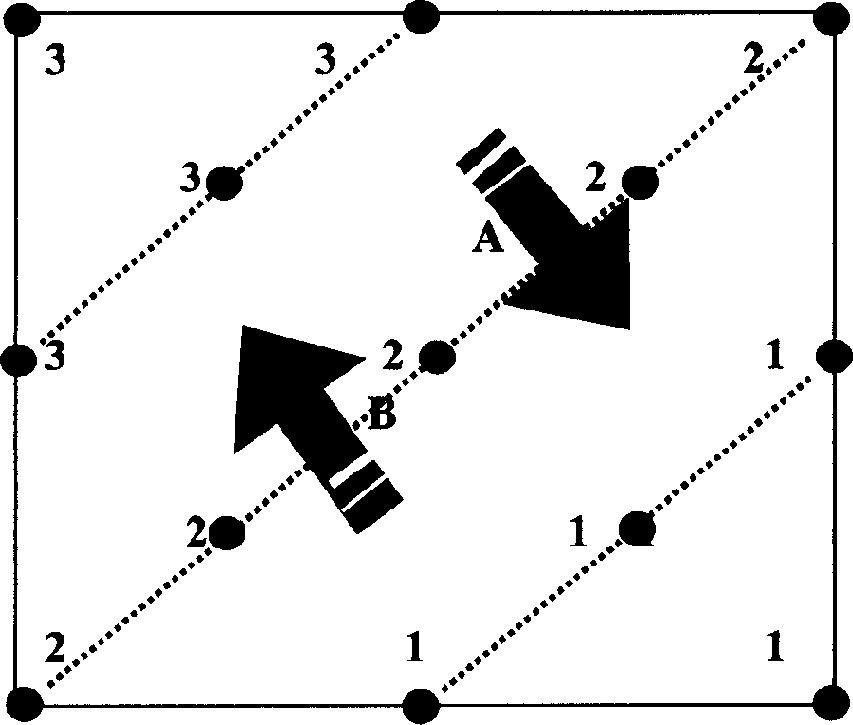

Gravity-assisted steam flooding exploitation method for heavy laver common heavy oil reservoir

The invention relates to a gravity-assisted steam flooding mining method for exploiting thick-bed ordinary heavy oil reservoirs. In the thick-bed ordinary heavy oil reservoirs, the methods of steam injection in vertical wells and production in horizontal wells or steam injection in horizontal wells and production in horizontal wells are adopted . For the oil reservoir blocks that have been developed by vertical wells, the combination of vertical wells and horizontal wells can be used to drill horizontal production wells along the lower part of the oil layer in the known oil reservoir blocks, so that the vertical steam injection wells are obliquely above the horizontal wells, and the production wells and injection wells Simultaneous huff and puff of steam wells for 2-4 cycles or thermal communication between steam injection wells and production wells or formation of reservoir pressure down to 3-4MPa, transfer to steam injection wells and steam injection production wells for production and production; or steam injection wells and production wells have formed thermal communication , After the newly drilled horizontal production well huffs and puffs for one cycle and removes the pollution near the wellbore, the steam injection production well is transferred to the steam injection well for production and production. The invention can exert the sweeping effect of the displacement fluid in both vertical and horizontal directions, increase the sweeping range of the driving fluid, and increase the crude oil recovery rate of the thick common heavy oil reservoir.

Owner:PETROCHINA CO LTD

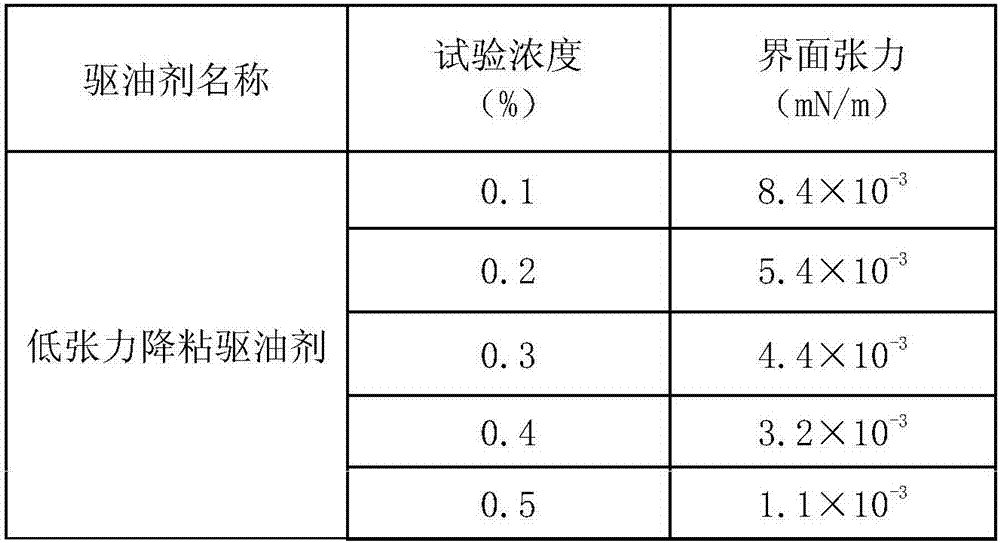

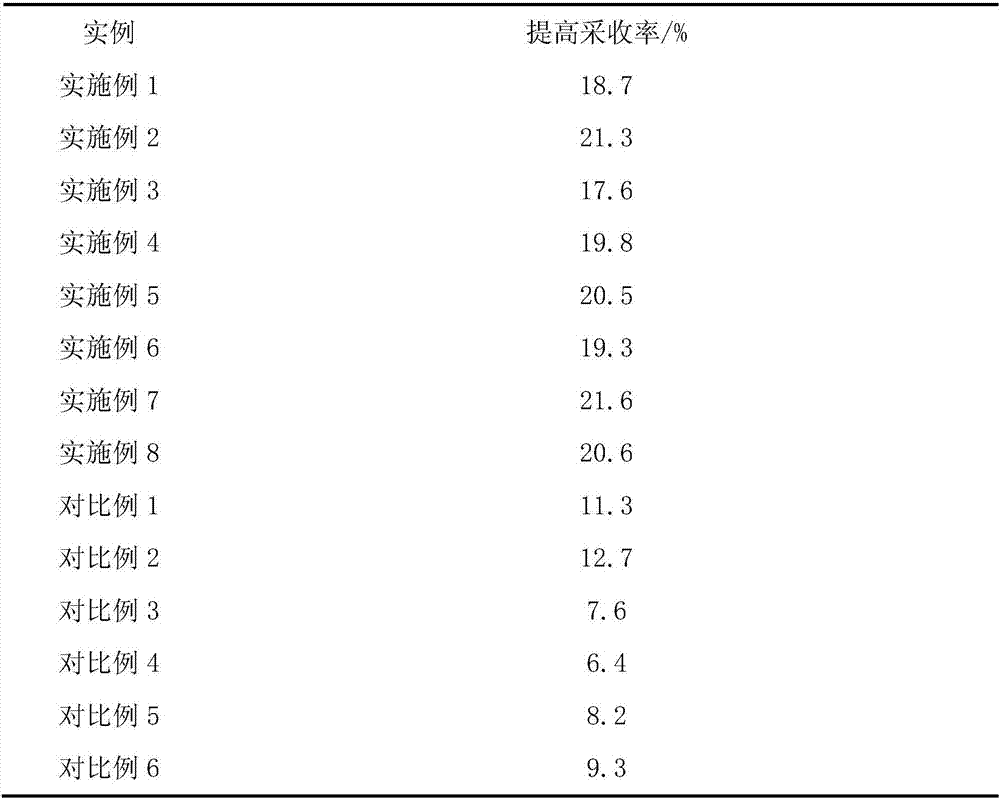

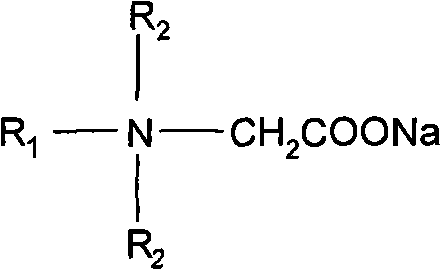

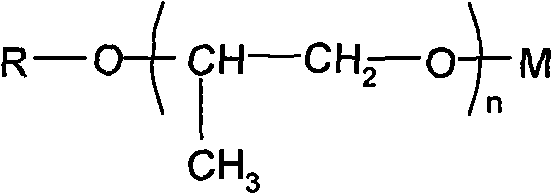

Viscosity-reducing oil displacement agent for common heavy oil reservoirs, and preparation method thereof

ActiveCN107365574ALower mobility ratioReduce interfacial tensionDrilling compositionPolyacrylamidePOLYOXYETHYLENE ETHER

The invention discloses a low-tension viscosity-reducing oil displacement agent, which is used for common heavy oil reservoirs, has a good viscosity-reducing effect, has good compatibility with formation water, can form ultra-low interfacial tension with crude oil, and is prepared from the following components by weight: 30-50% of an alkyl alcohol polyoxyethylene ether sulfate salt, 15-25% of a nonionic surfactant, 15-25% of an anionic surfactant, 2-5% of an organic solvent, 0.1-3% of sodium chloride, and 5-25% of water. According to the present invention, during the use, the low-tension viscosity-reducing oil displacement agent and the polyacrylamide polymer form the composite oil displacement system, wherein the polyacrylamide polymer can provide effects of water phase viscosity increasing, water-oil mobility ratio reducing, conformance expanding and profile control expanding, and the low-tension viscosity-reducing oil displacement agent can provide effects of oil-water interface tension reducing, oil displacement efficiency improving and crude oil viscosity reducing so as to further improve the water-oil mobility ratio, such that the extraction rate of the common heavy oil reservoir can be substantially improved through the synergetic effect of the polyacrylamide polymer and the low-tension viscosity-reducing oil displacement agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

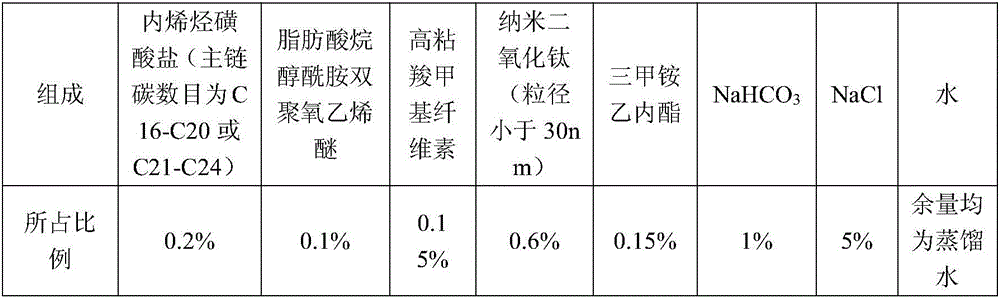

Temperature-resistant and salt-tolerant foaming agent system for thermal recovery of heavy oil reservoir and preparation method

InactiveCN106753307AImprove solubilityImprove performanceDrilling compositionInorganic saltsSolubility

The invention relates to the technical field of heavy oil recovery, in particular to a foam agent system used for switching water drive into steam drive of a heavy oil reservoir or steam huff and puff to improve the oil recovery efficiency. According to the technical scheme, the temperature-resistant and salt-tolerant foaming agent system for thermal recovery of the heavy oil reservoir is characterized by comprising a foaming agent base, a foam stabilizer, a foam fixing agent, a foam promoter, an alkali substance, inorganic salt and a solvent. The foaming agent system can resist the temperature of 350 DEG C and has good thermal stability and better foamability; the foaming agent base in the system is lower than the critical micelle concentration and can produce more foam, the apparent viscosity is substantially increased, and the cost is saved; the foaming agent system has better solubility, causes little damage to formation and is environment-friendly.

Owner:NORTHEAST GASOLINEEUM UNIV

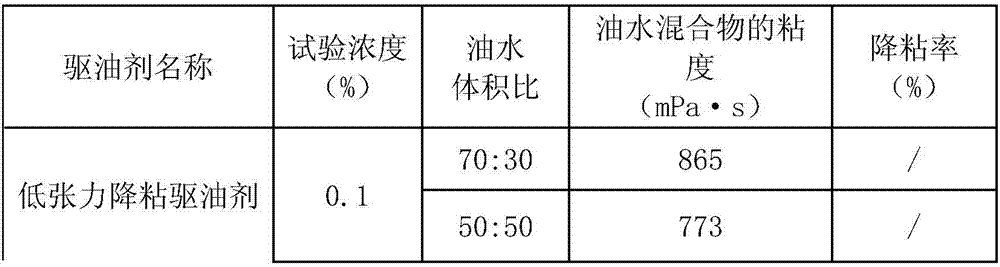

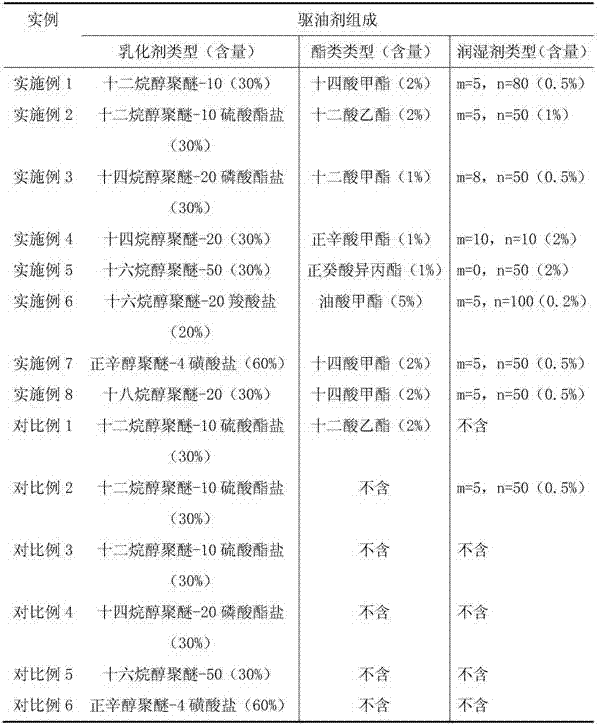

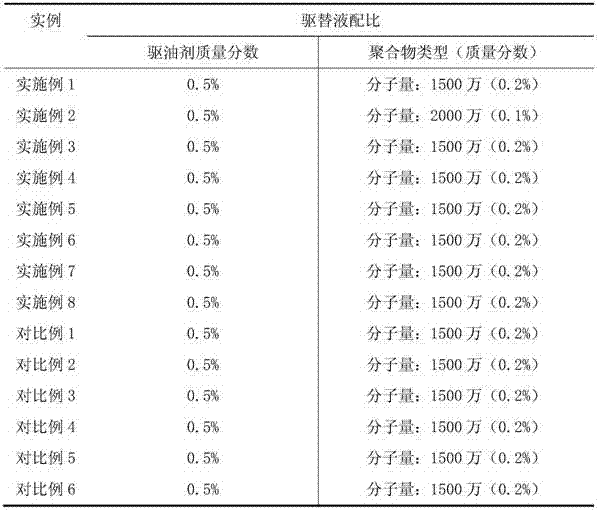

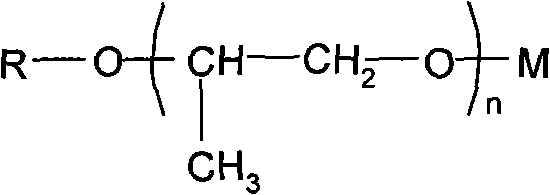

Viscosity-reducing oil displacement agent and oil displacement system for heavy oil reservoirs

ActiveCN107365575AHigh viscosityIncrease viscosityFluid removalDrilling compositionViscosityHeavy oil reservoir

The invention discloses a viscosity-reducing oil displacement agent for heavy oil reservoirs, wherein the components comprise, by weight, 20-60% of an emulsifier, 1-5% of an ester-based compound, 0.2-2% of a wetting agent, and the balance of water. The invention further discloses a viscosity-reducing oil displacement agent-polymer system for heavy oil reservoirs, wherein the viscosity-reducing oil displacement agent-polymer system comprises 0.1-1% of the oil displacement agent, 0.05-0.3% of a polymer and the balance of water, and the polymer is polyacrylamide with a molecular weight of 8000000-20000000. According to the present invention, the viscosity-reducing oil displacement agent and the viscosity-reducing oil displacement agent-polymer system can provide good effects of viscosity reducing and emulsifying for heavy oil, can substantially reduce the viscous force of heavy oil in rock pores, can provide good profile control and water blocking effect, can effectively improve oil displacement efficiency, can improve heavy oil recovery, and are suitable for heavy oil reservoirs with a stratum viscosity of more than 200 mPa.s.

Owner:CHINA PETROLEUM & CHEM CORP +2

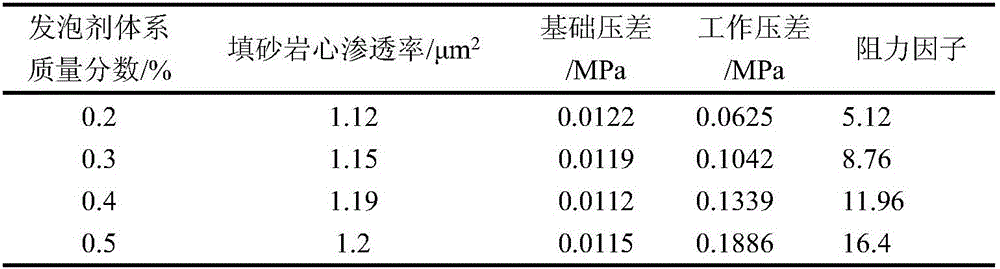

Foaming agent with low gas liquid ratio foam for common heavy oil reservoir and injection method thereof

InactiveCN101580705AReduce interfacial tensionHigh interface activityFluid removalDrilling compositionFoaming agentLiquid ratio

The invention provides a foaming agent for low gas liquid ratio foam flooding for improving recovery ratio of common heavy oil reservoir and an injection method thereof. The foaming agent is prepared from a nonionic-anionic surfactant, a betaine type amphoteric surfactant and water, wherein the nonionic-anionic surfactant accounts for 0.01 to 0.03 weight percent of the total weight; the betaine type amphoteric surfactant accounts for 0.05 to 0.3 weight percent of the total weight; and the balance is oil field injection water. The foaming agent has good foaming tendency, can reduce the interfacial tension of oil and water to the lowest under the condition of not adding alkali, and can give full play to the foam flooding and the improvement of conformance factor and displacement efficiency. On the basis of the foaming agent, when the gas liquid ratio is between 0.1:1 and 0.3:1 (volume ratio), the generated foam can improve the recovery ratio by over 10 percent, and the technology with low cost and good effect for improving the recovery ratio of the heavy oil reservoir is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

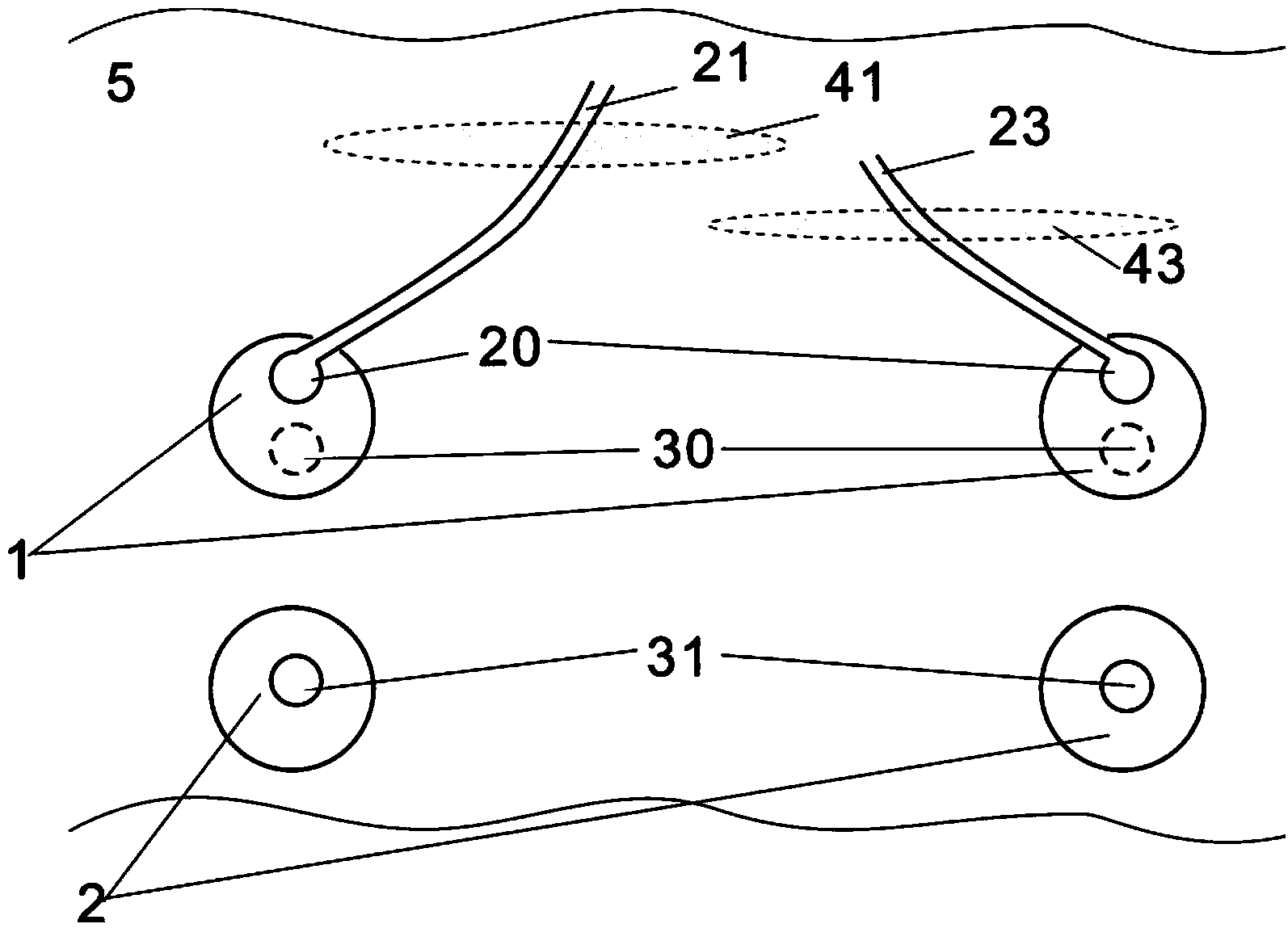

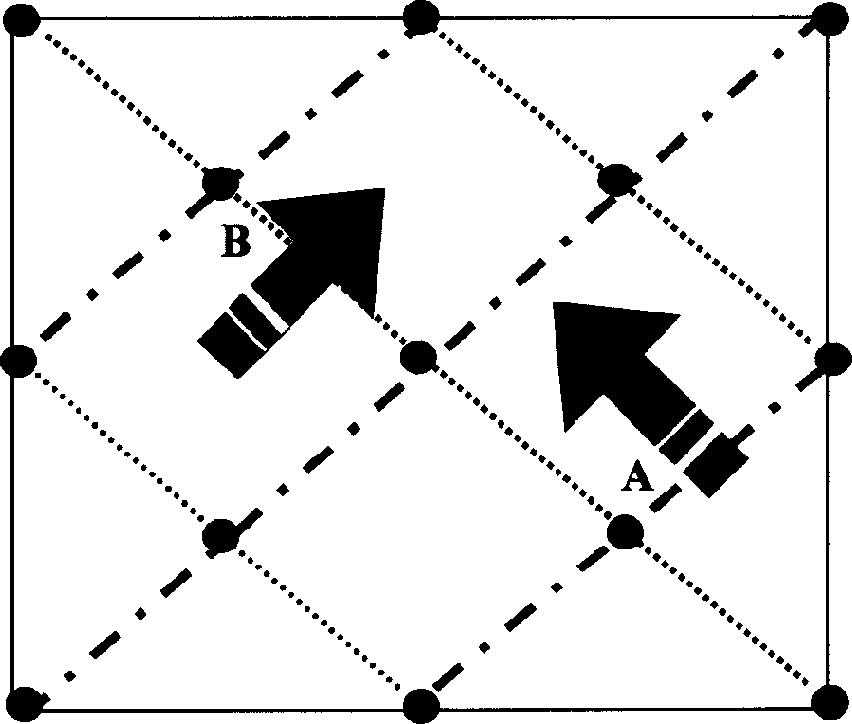

A method of gravity drainage assisted steam flooding to enhance the recovery of deep ultra-heavy oil reservoirs

The invention relates to a method for improving the oil deposit recovery ratio of deep massive extremely-viscous oil in an extraction mode of gravity drainage assisted steam flooding. In the method, superposition horizontal wells are arranged among wells by combining results of researches on the fine contrast of small geological strata of massive oil deposit, the distribution rule of interlayer, the distribution rule of remaining oil and the like and a fine research on numerical simulation; an upper superposition horizontal well is used for injecting steam, a peripheral vertical shaft is used for production, and a lower superposition horizontal well is used for discharging liquid (crude oil between condensate water and the horizontal wells); and thus, a production-injection ratio of high-speed steam injection of deep oil deposit is improved, the dryness of steam on the well bottom is improved, the pressure of an oil layer is reduced, a steam cavity is easy to expand, the swept volume is improved, a development effect is improved, and the aim of improving the recovery ratio finally is fulfilled.

Owner:PETROCHINA CO LTD

Displacement developing method for artificial foamed oil of heavy oil reservoir

ActiveCN104265252AViscosity reduction by a large marginNot easy to degasFluid removalDrilling compositionFoaming agentHorizontal wells

The invention provides a displacement developing method for artificial foamed oil of a heavy oil reservoir. The method comprises the following steps: adopting a vertical well or a horizontal well to displace a well pattern; injecting an oil soluble viscosity reducer and a solvent based foaming agent in an injection well repeatedly and alternatively, or injecting an oil-in-water emulsified viscosity reducer solution and a high oil-resisting foaming agent in an injection well repeatedly and alternatively, wherein during the injection process, a producing well produces continuously. With the adoption of the method, the purposes that the heavy oil reservoir mined through steam injection and the heavy oil reservoir difficulty produced by a conditional mining method can be effectively produced and developed, heavy oil is economically and efficiently developed and the recovery efficiency is improved greatly are achieved.

Owner:PETROCHINA CO LTD

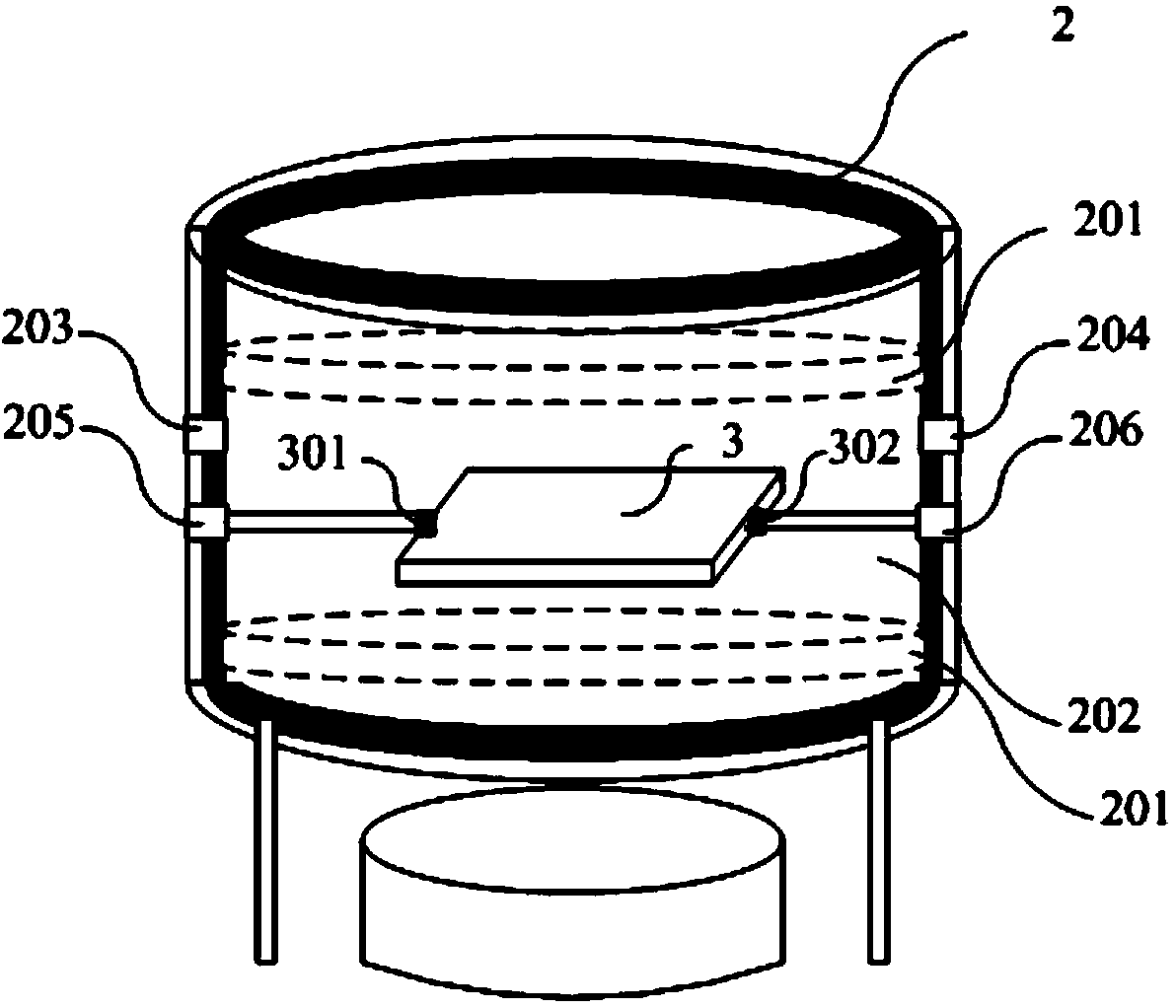

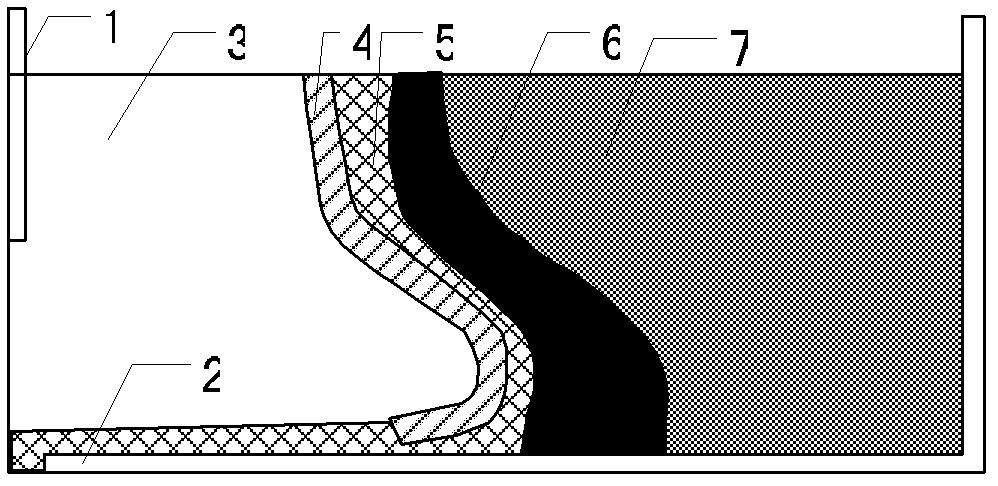

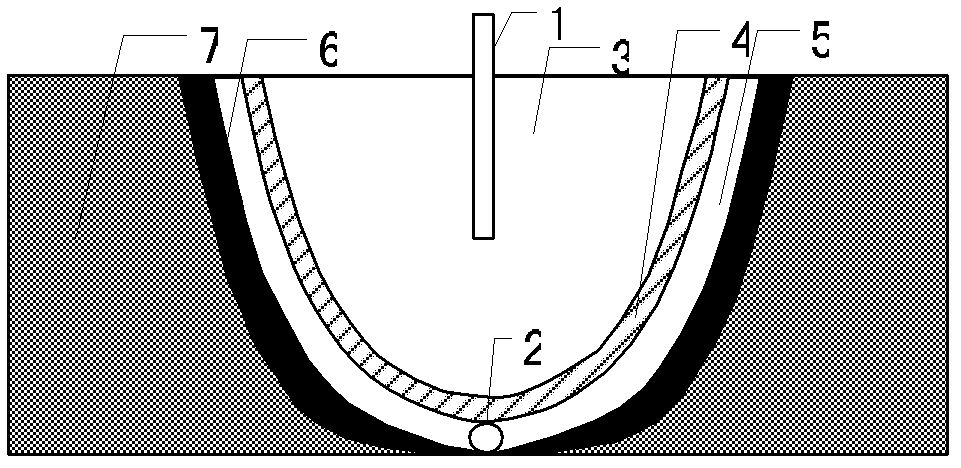

Two-dimensional microcosmic visual thickened oil replacement simulation experiment system and use method thereof

ActiveCN104265255AMeet the needs of development researchReduce experiment costFluid removalFlat glassLine tubing

The invention provides a two-dimensional microcosmic visual thickened oil replacement simulation experiment system and a use method thereof. The two-dimensional microcosmic visual thickened oil replacement simulation experiment system comprises a microcosmic simulation experiment device, a visual data acquisition device, a support device, a multivariate thermal fluid injection device, a confining pressure tracking device and a metering device, wherein the microcosmic simulation experiment device comprises a heating jacket, a clamper and a plate glass microcosmic model; the visual data acquisition device comprises a microscopic shooting device and a computer; the multivariate thermal fluid injection device comprises an ISCO injection pump, an oven and a replacement medium intermediate container, a water intermediate container, a thickened oil intermediate container, a first heat traced pipeline and a bypass pipeline; the confining pressure tracking device comprises an annular pressure tracking pump, an annular pressure tracking pump pressure meter, a vacuum pump and a first vacuum valve. The two-dimensional microcosmic visual thickened oil replacement simulation experiment system give full consideration to characteristics of the thickened oil reservoirs, provides convenience for research on a thickened oil replacement mechanism through microcosmic experiments, has the advantages of low experiment cost, high work efficiency and the like, and can meet with demands on development and research of the thickened oil reservoirs.

Owner:PETROCHINA CO LTD

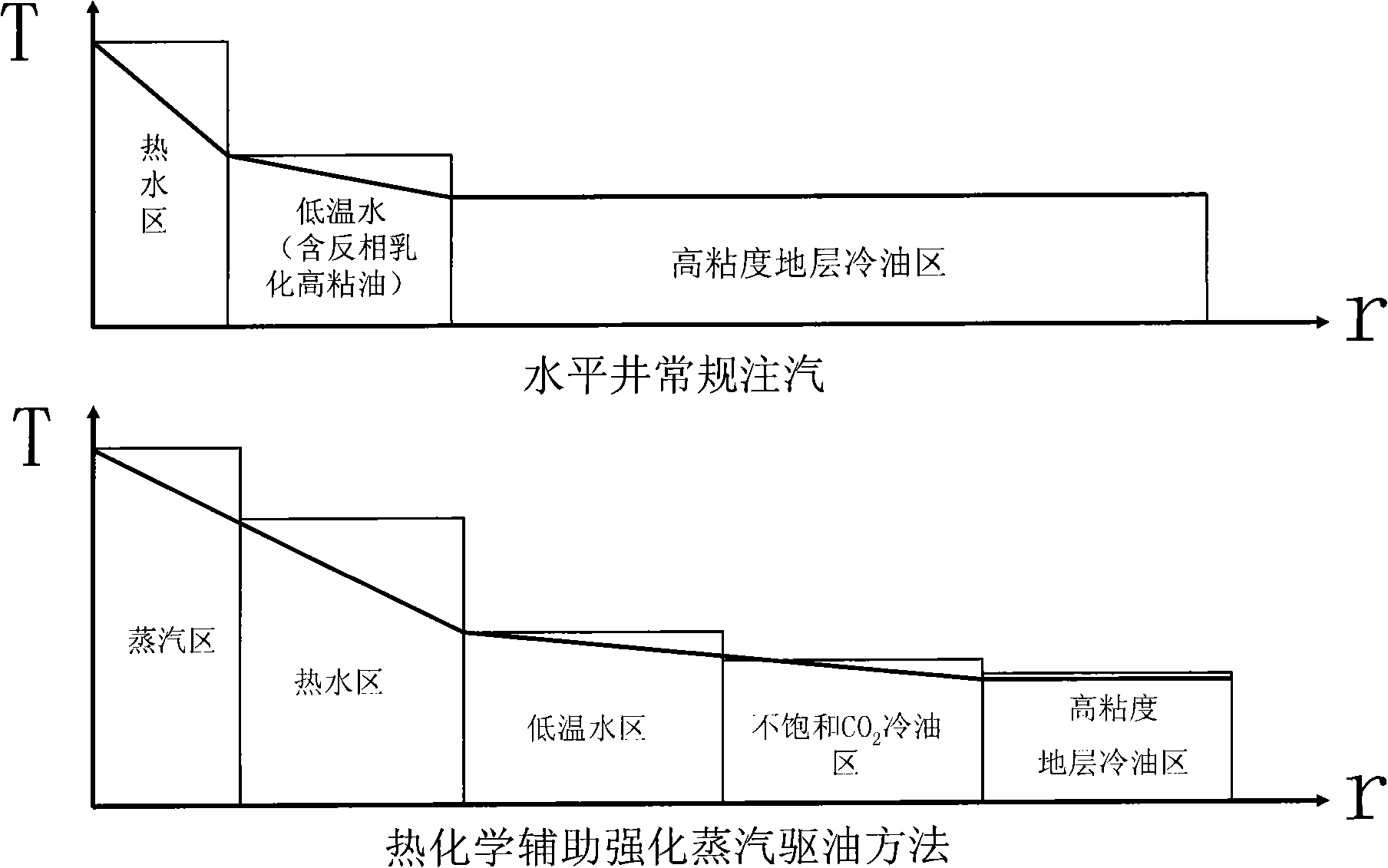

Method and well network structure for improving steam assisted gravity drainage for extracting heavy oil reservoirs by aid of solvents

The invention discloses a method and a well network for improving steam assisted gravity drainage for extracting heavy oil reservoirs by the aid of solvents. The well network comprises SAGD (steam assisted gravity drainage) horizontal well pairs; horizontal sections of steam injection wells are subjected to well completion by the aid of slotted screen pipes; branched well sections are drilled in the horizontal sections of the steam injection wells and penetrate the middles of inner sandwich layers in oil layers; the various branched well sections are subjected to well completion by the aid of tail pipes; first long oil pipes which extend to toes of the steam injection wells descend into screen pipes of the steam injection wells; solvent injection main pipes which are parallel to the first long oil pipes descend into the screen pipes of the steam injection wells and are hermetically connected with the tail pipes in the various branched well sections by tail pipe hangers; second long oil pipes descend into production wells and reach the tail ends of horizontal sections of the production wells; vertical monitoring wells are further deployed in the well network. The method and the well network have the advantages that steam flows into the oil layers to upwardly develop steam cavities, and the hot solvents and steam mixed systems flow into the oil layers on the upper portions of the sandwich layers from the main pipes via the tail pipes, so that heat communication and fluid communication among the oil layers and the steam cavities can be accelerated, the sandwich layers can be forcedly broken through, development of the steam cavities on the upper portions of the sandwich layers can be promoted, and the recovery efficiency can be greatly improved.

Owner:PETROCHINA CO LTD

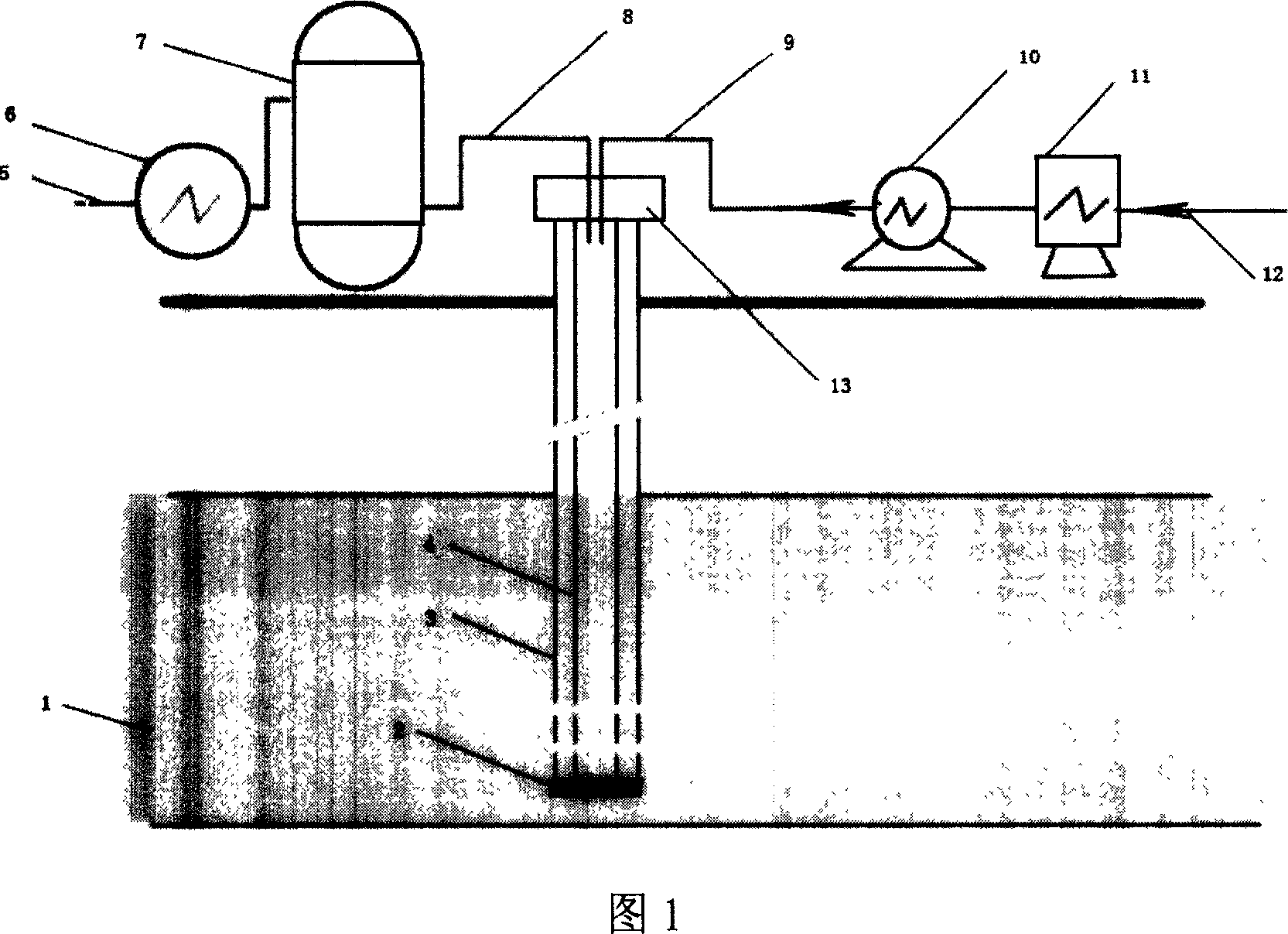

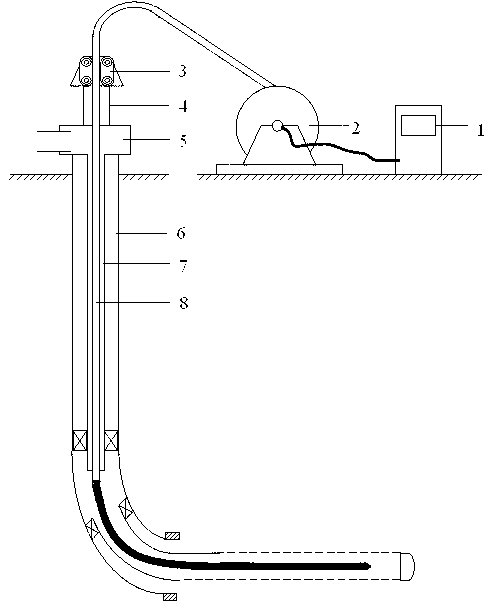

Method for compensating thermal energy of horizontal well mining heavy oil reservoirs in large power and subsection mode in pit

The invention relates to a method of heavy oil thermal production in an oil field and underground coal bed thermal cracking gas production, in particular to a method for compensating thermal energy of horizontal well mining heavy oil reservoirs in a large power and subsection mode in a pit. According to the method, an oil well tubular column and an electric heater system are included. The oil well tubular column is composed of a well mouth device, a casing pipe, an oil pipe, a horizontal section sieve pipe and a packer. The electric heater system is composed of a ground part and an underground part. The ground part is composed of a power source control cabinet, a cable roller, a cable injection head, a cable conductor and a cable sealer. The underground part is a cable system composed of a mineral heating cable at the hot end and a mineral conductor cable at the cold end from bottom to top, so that injected steam of a straight well, an inclined well and a horizontal well of middle and deep heavy oil reservoirs are compensated, and the method can be used for crude oil production tracing heating of a horizontal section of the horizontal well and a fireflood oil production igniter.

Owner:SHENYANG MOGEN ENERGY EQUIP CO LTD

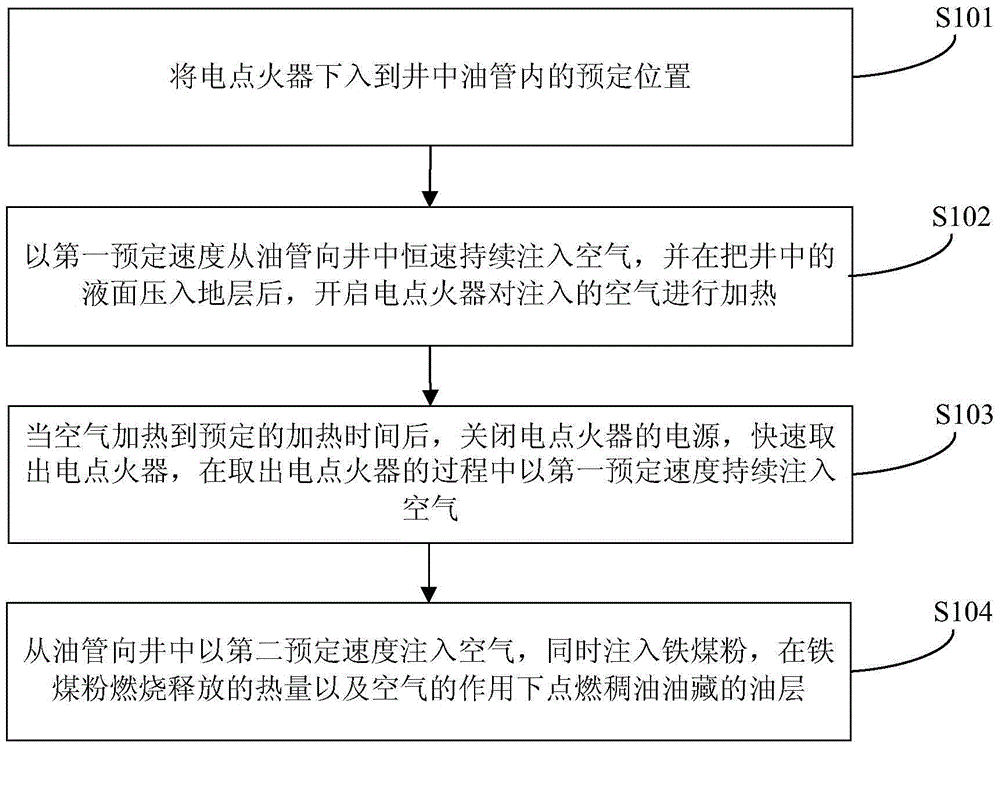

In-situ combustion combustion-supporting ignition method

ActiveCN104453817AReduce moisturePlay the role of profile control and channel sealingFluid removalElectricityHeating time

The invention discloses an in-situ combustion combustion-supporting ignition method. The method comprises the steps that an electric igniter is tripped in the preset position in an oil tube in a well; air is continuously injected into the well from the oil tube at a first preset speed, and after a liquid level in the well is pressed into a stratum, the electric igniter is started to heat the injected air; after the air is heated by the preset heating time, a power source of the electric igniter is turned off, the electric igniter is taken out, and the air is continuously injected at the first preset speed in the process of taking out the electric igniter; air is injected into the well from the oil tube at a second preset speed, meanwhile, iron pulverized coal is injected, and an oil layer of a heavy oil reservoir is ignited under the action of heat released by combustion of the iron pulverized coal and the air. Through the electric igniter, the oil layer is preheated, and water of near bore zones is reduced. The iron pulverized coal has the functions of profile correction and channeling blocking, combustion products are stored in holes, a gas entry profile continues to be adjusted, ignition is facilitated better, gas channeling is reduced, and meanwhile fast ignition is achieved.

Owner:PETROCHINA CO LTD

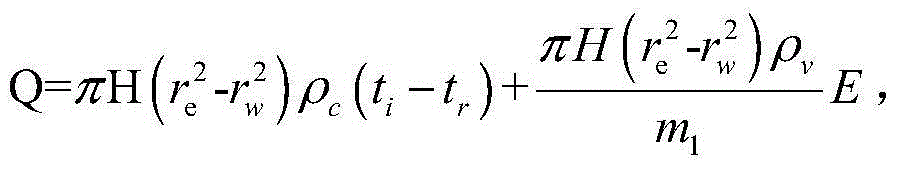

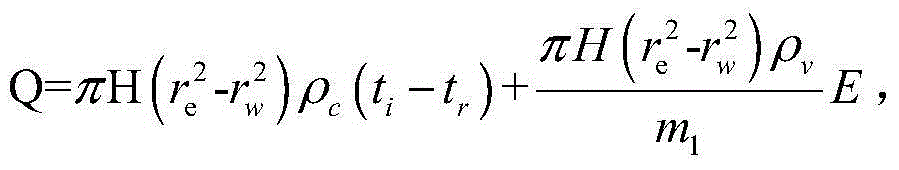

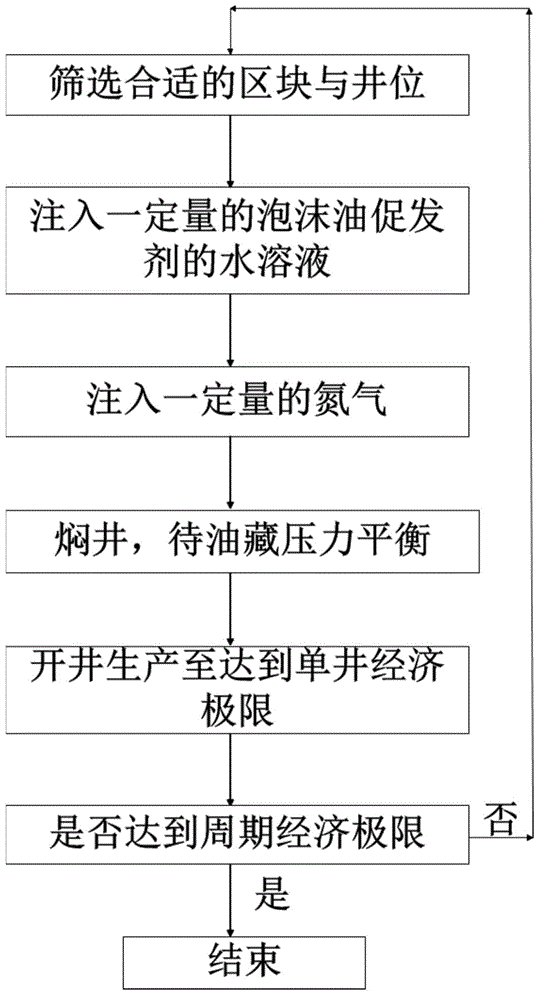

Artificial foaming-oil huff and puff oil production method for heavy oil reservoir

ActiveCN104314539AReduce interfacial tensionImprove liquidityFluid removalMass ratioDifferential pressure

The invention provides an artificial foaming-oil huff and puff oil production method for a heavy oil reservoir. The method comprises the following steps: filling aqueous solution of foaming oil accelerant and nitrogen into the heavy oil reservoir, wherein the foaming oil accelerant comprises a foaming oil accelerant A, a foaming oil accelerant B and a foaming oil accelerant C of which the mass ratio is 1:1:1; soaking for 1 to 5 days; opening a well to produce oil in a certain production differential pressure range and stopping producing oil when the single-well daily oil production reaches single-well economic limit; repeating the step 1 to the step 3 and stopping production until the single-well cyclic oil production reaches cyclic economic limit, wherein the heavy oil reservoir has a reservoir thickness of over 2m, reservoir permeability of over 10*10<-3> mu<m2>, a reservoir temperature of lower than 120 DEG C, viscosity of crude oil of over 50mPas, oil saturation of over 30 percent and water saturation of over 50 percent. According to the artificial foaming-oil huff and puff oil production method for the heavy oil reservoir, which is provided by the invention, the viscosity of crude oil can be reduced and elastic energy of fluid can be increased so as to increase single-well productivity and a recovery ratio of an oil field.

Owner:PETROCHINA CO LTD

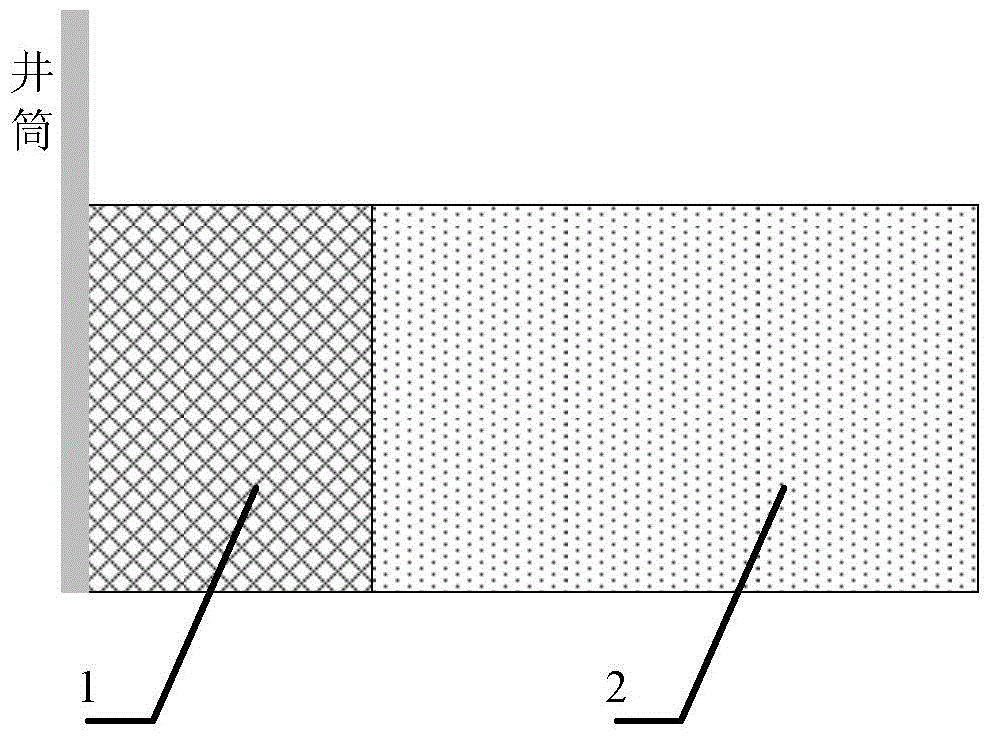

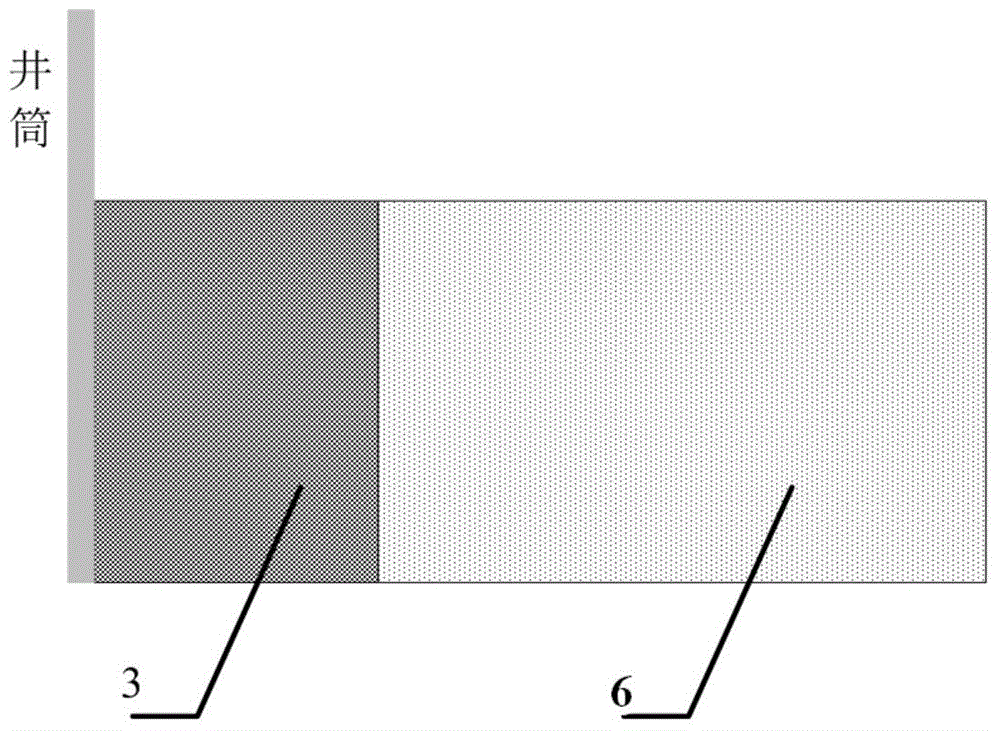

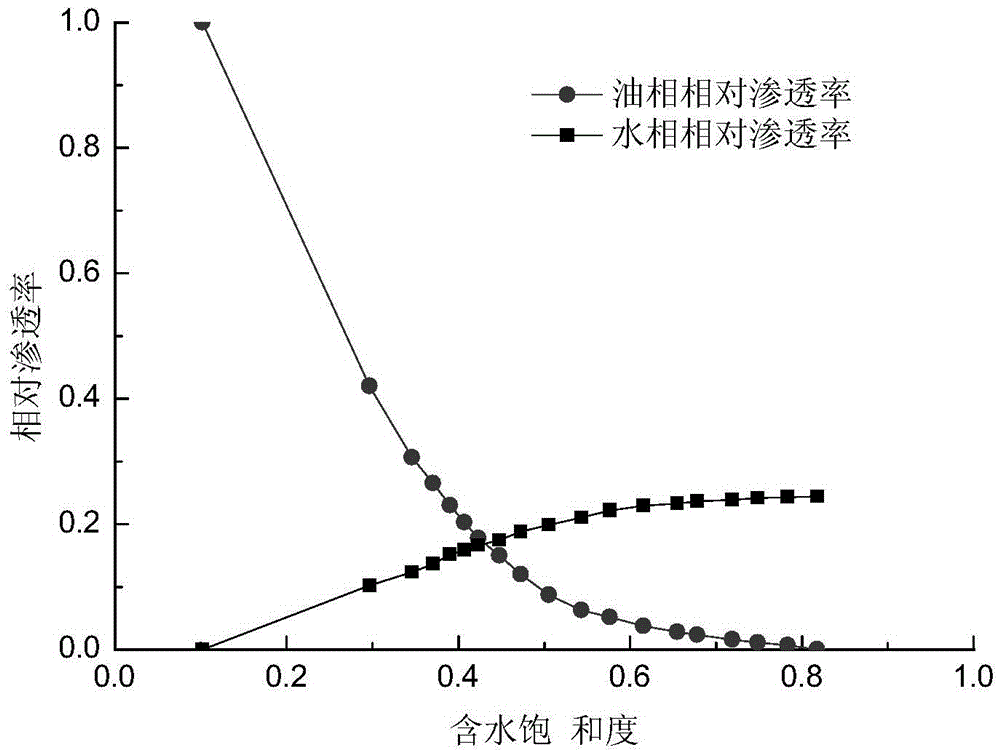

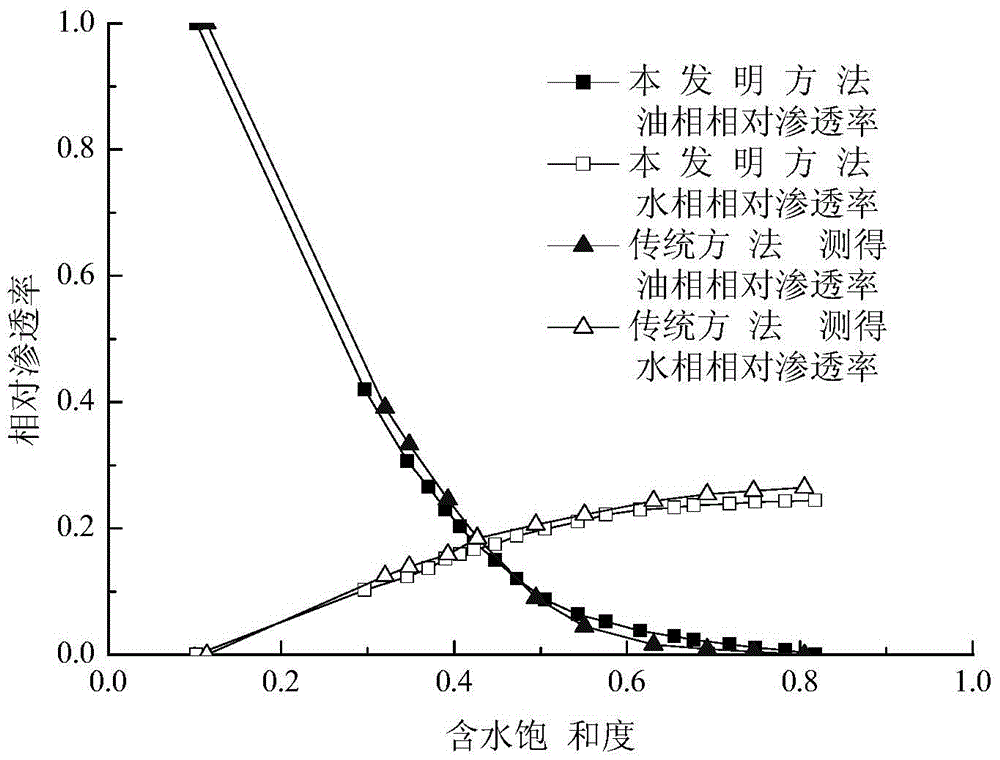

Measuring method of high-temperature oil-water relative permeability of heavy oil reservoir

InactiveCN105606509AReduce the difficulty of measurementGuaranteed viscosity ratioPermeability/surface area analysisOil waterHigh pressure

The invention discloses a measuring method of high-temperature oil-water relative permeability of a heavy oil reservoir. A method for replacing high-temperature oil-water relative permeability of the heavy oil reservoir with oil-water relative permeability under the low-temperature oil-water system condition is put forward for the first time, reduces the measuring difficulty of the high-temperature oil-water permeability of the heavy oil reservoir, avoids potential safety hazards caused by high-temperature and high-pressure experiment conditions and simplifies experiment processes and operation requirements, and the oil-water relative permeability obtained with the two measuring methods is basically identical on the premise that the oil-water viscosity ratio is equal, thus, simple, time-saving, safe and accurate measurement of the high-temperature heavy oil relative permeability is realized with the method.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Thickened oil steam production synergist and its preparing method

InactiveCN1554725ARapid expansion of heating radiusImprove the mining effectFluid removalProduct gasSURFACTANT BLEND

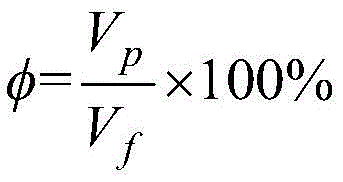

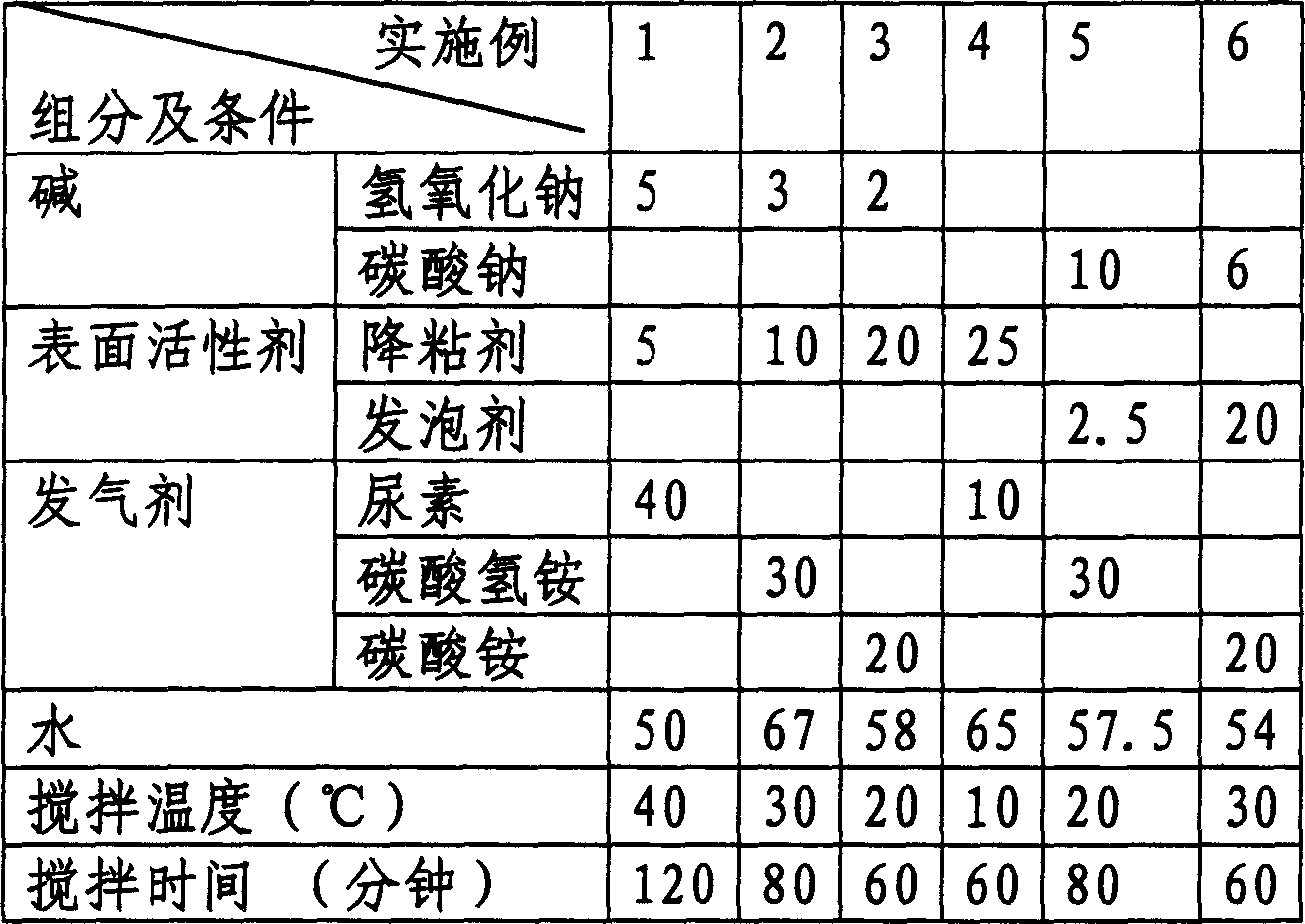

The synergist for steam exploitin thickened oil consists of gas creating agent 10-40 wt%, surfactant 5-25 wt% and alkali 0-5 wt% except water. The preparation process includes the steps of: dissolving sodium hydroxide and / or sodium carbonate; adding surfactant via stirring for mixing and adding the gas creating agent via stirring. Under steam temperature urea as the gas creating agent is decomposed to generate CO2 and CO2 and the surfactant form foam to expand the steam wave and volume to raise the oil displacing efficiency and reach the synergistic effects of modifying profile and lower viscosity obviously. The present invention is suitable for exploiting shallow, thin, dense and dispersed thickened oil reservoir. The present invention can raise oil yield and steam heat efficiency.

Owner:中国石油化工股份有限公司河南油田分公司石油工程技术研究院 +1

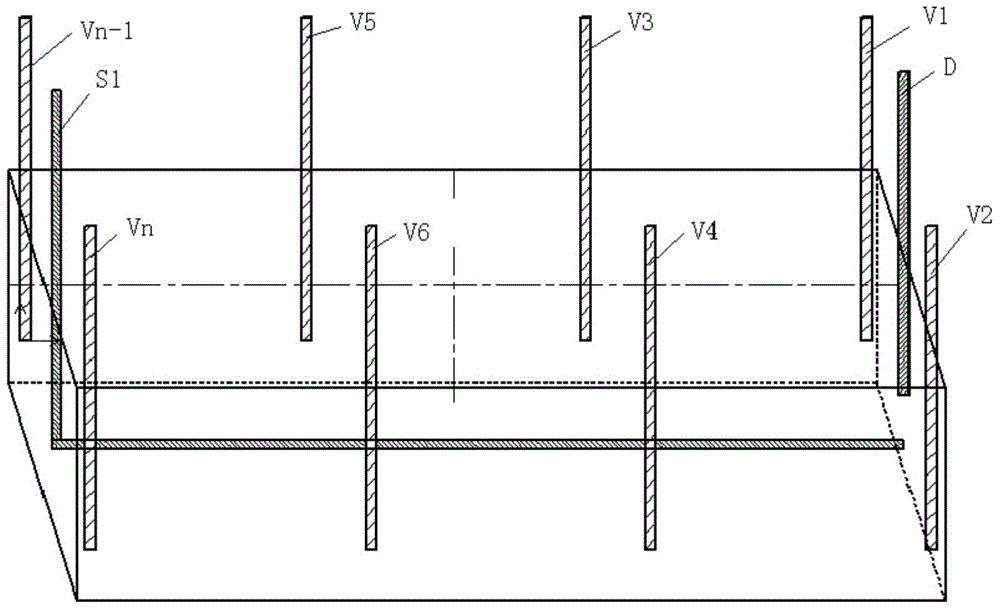

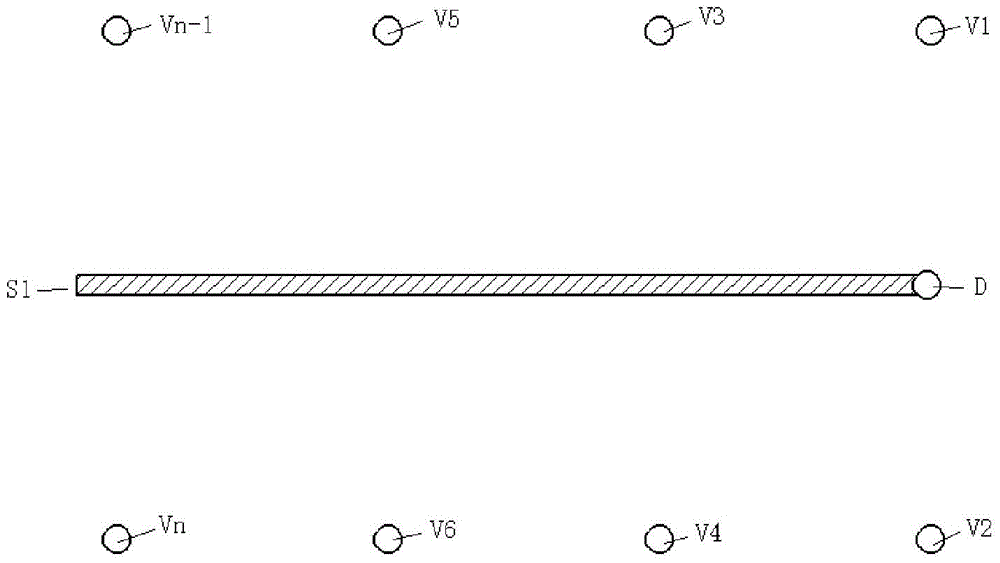

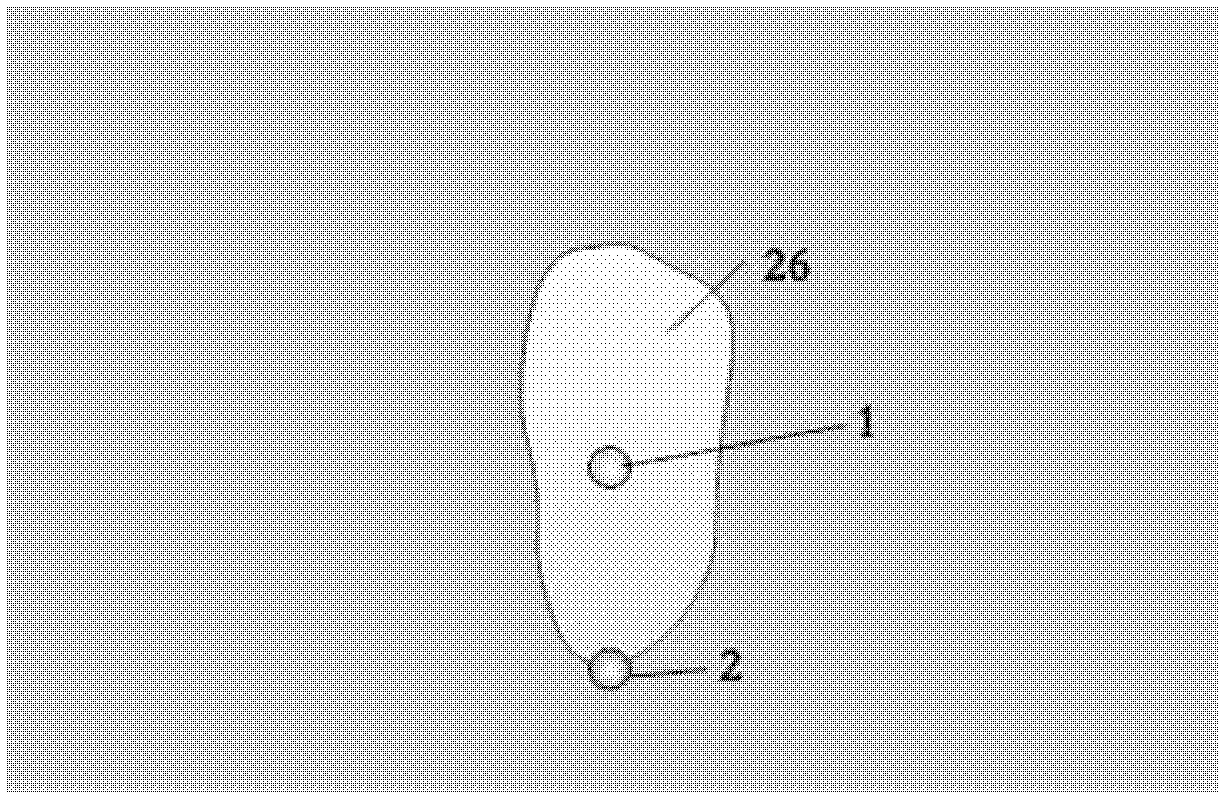

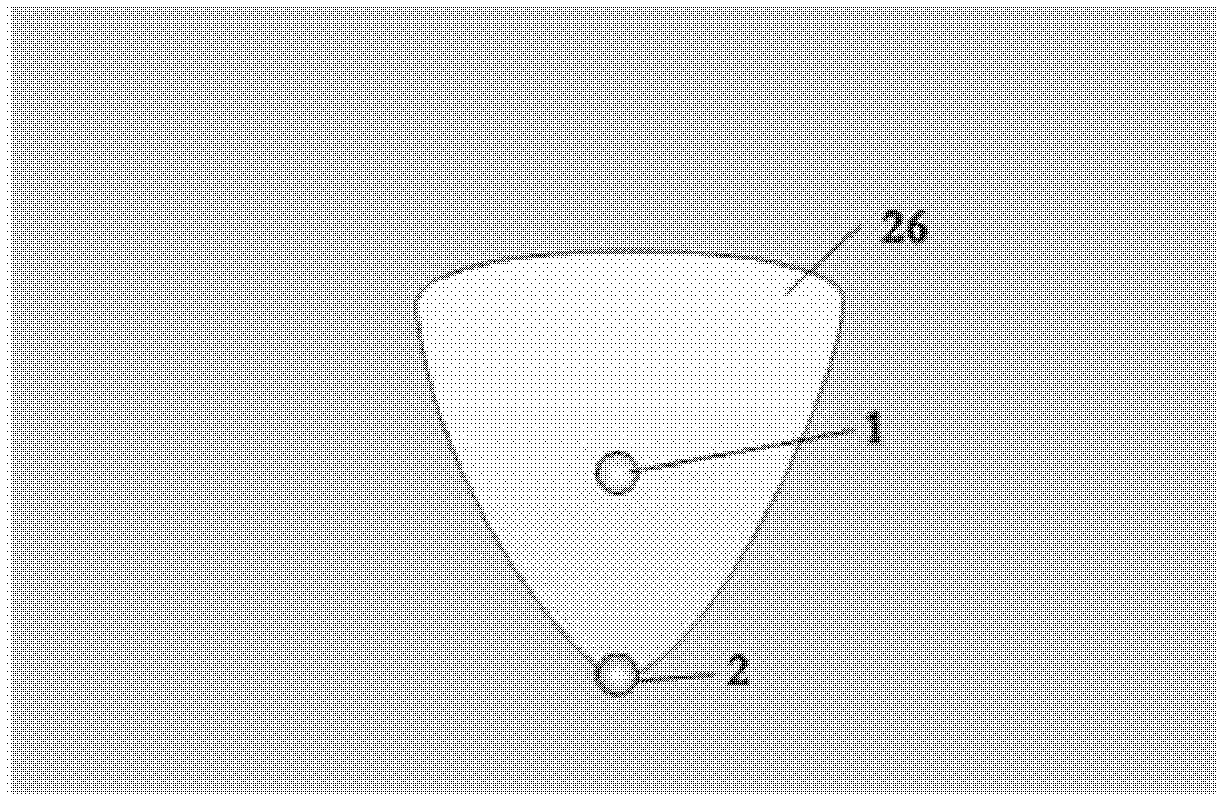

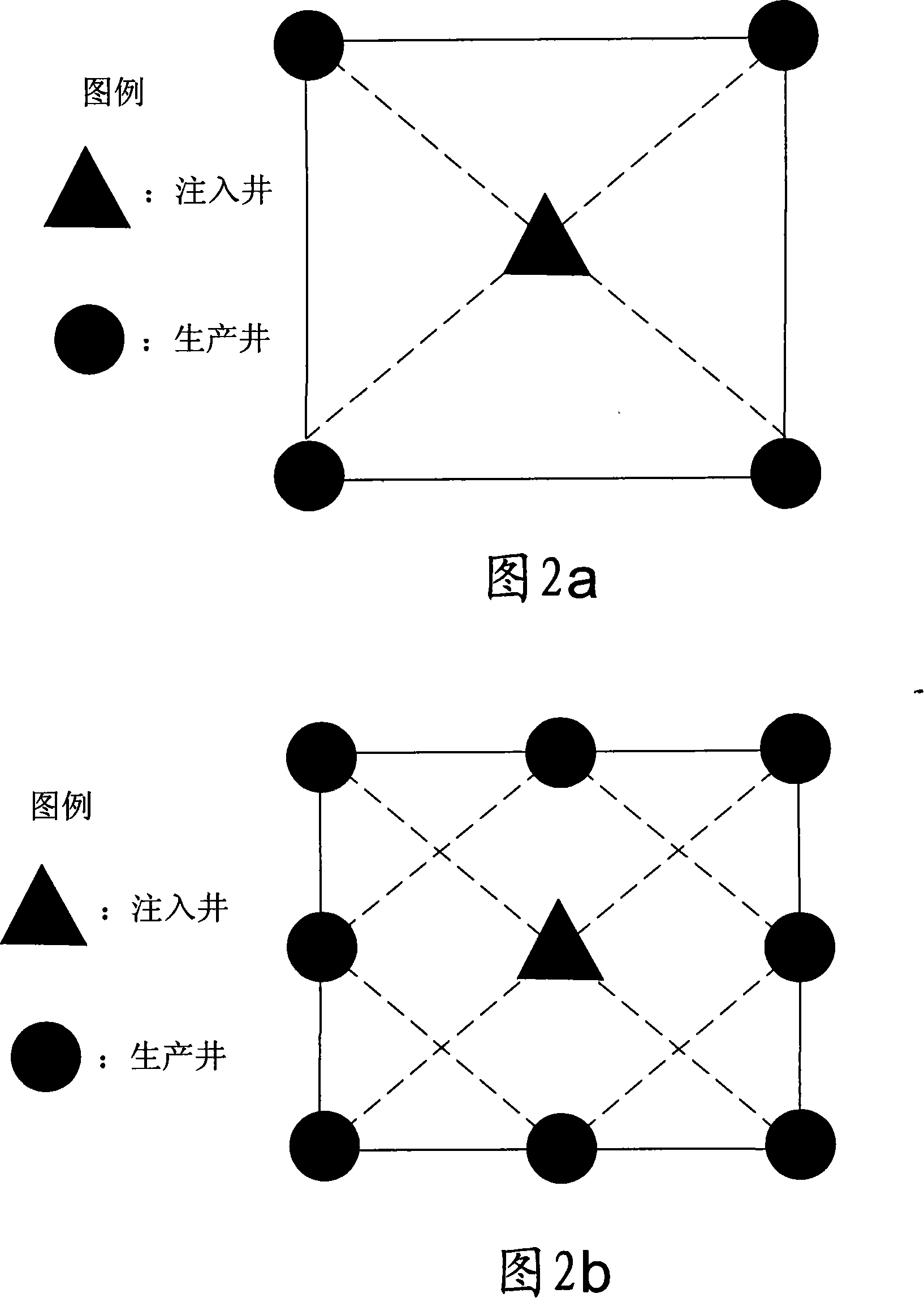

Mining method for heavy oil reservoir and well network thereof

The invention relates to a mining method for a heavy oil reservoir and a well network used in the same. The mining method comprises a well network arrangement stage, a preheating stage, a gravity fire flooding stage and a steam flooding stage; the gravity fire flooding stage comprises an ignition stage and a fire wire propulsion stage. The well network comprises a plurality of mining well groups. Each mining well group comprises a horizontal well, a middle vertical well and a plurality of side vertical wells, wherein the plurality of side vertical wells are arranged in two lines; the first line of the side vertical wells and the second line of the side vertical wells are symmetrical about the horizontal well; each line of side vertical wells are arranged at intervals in the direction from the tiptoe to the heel of the horizontal well and are in parallel to the horizontal well. According to the invention, combination of gravity fire flooding and steam flooding is adopted, so that utilization of heat after fire flooding is improved; thermal communication of injection and production wells is established by steam huff and puff auxiliary gravity fire flooding, so that a steam flooring mining effect is improved; well completion cost and drilling cost are reduced.

Owner:PETROCHINA CO LTD

Highly effective pour depressant for thermodynamic oil extraction process

ActiveCN101210173AImprove applicabilityStrong pouring capacityDrilling compositionWater basedDepressant

A high-efficiency pour point depressant for thermal recovery process comprises (1) biphenyl, polycyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbon derivatives free of chlorine and sulfur elements; (2) liquid petroleum products containing arene larger than 5%, petroleum resin in liquid state at normal temperature or natural hydrocarbon aggregates in particle state at normal temperature; (3) surfactant; (4) fusel oil; (5) alcohol ethers having a closed cup flash point larger than 20 DEG C; and (6) oil-soluble or water-soluble polymers respectively having a nonpolar section eutectic with paraffin molecule and a polar section for twisting crystal form of wax crystal on a main chain and / or a branch chain. The high-efficiency pour point depressant of the invention performs all functions of both water-base pour point depressant and oil-base pour point depressant, and can efficiently assist the prior various thermal recovery processes in exploring high pour-point oil and heavy oil reservoirs, with the advantages of greatly reduced exploitation cost, prolonged production cycle of the oil well, increased output of the oil well, increased ultimate recovery of the oil reservoir,as well as significant economic benefit.

Owner:盘锦河升大地石油科技有限公司

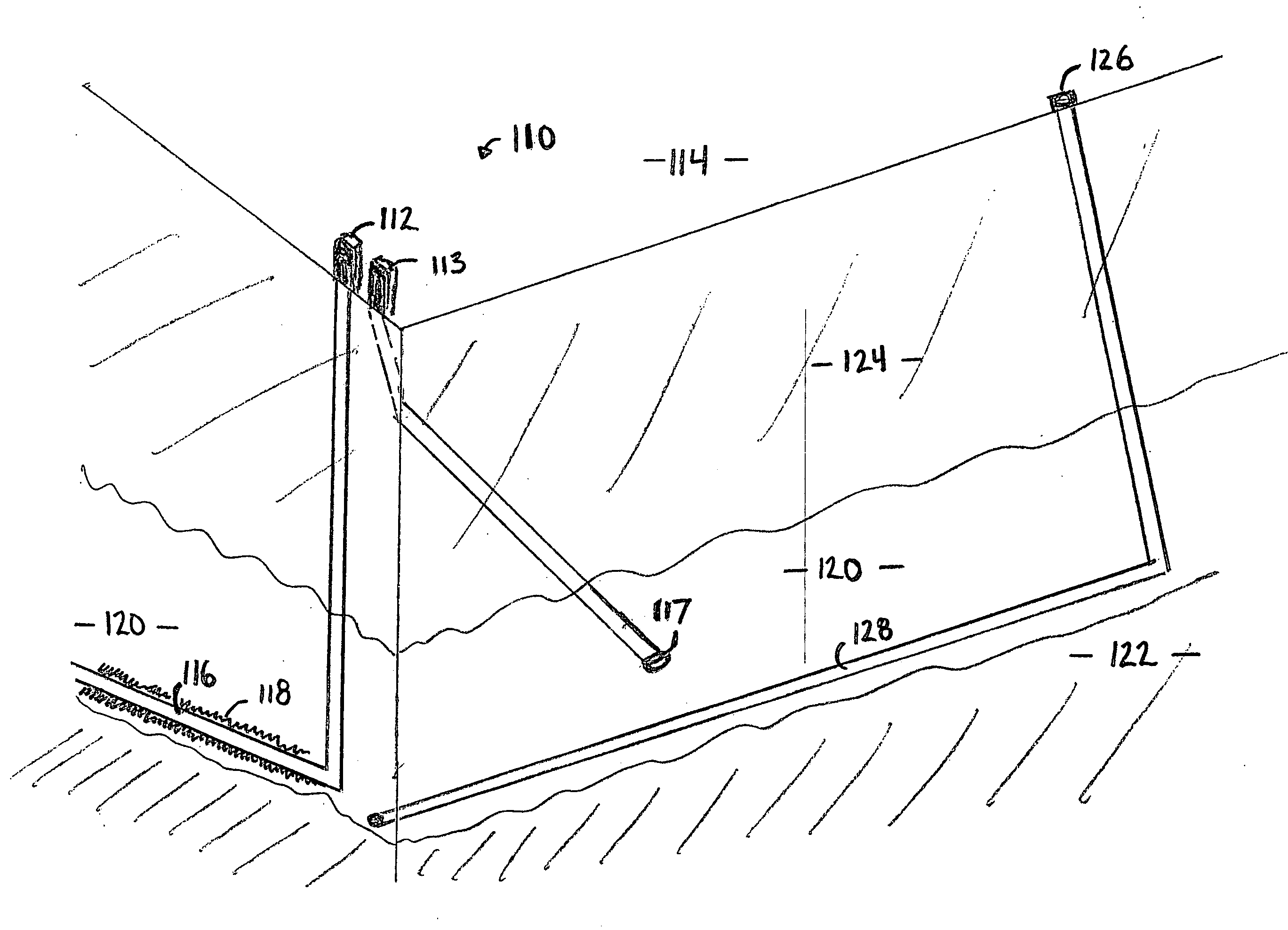

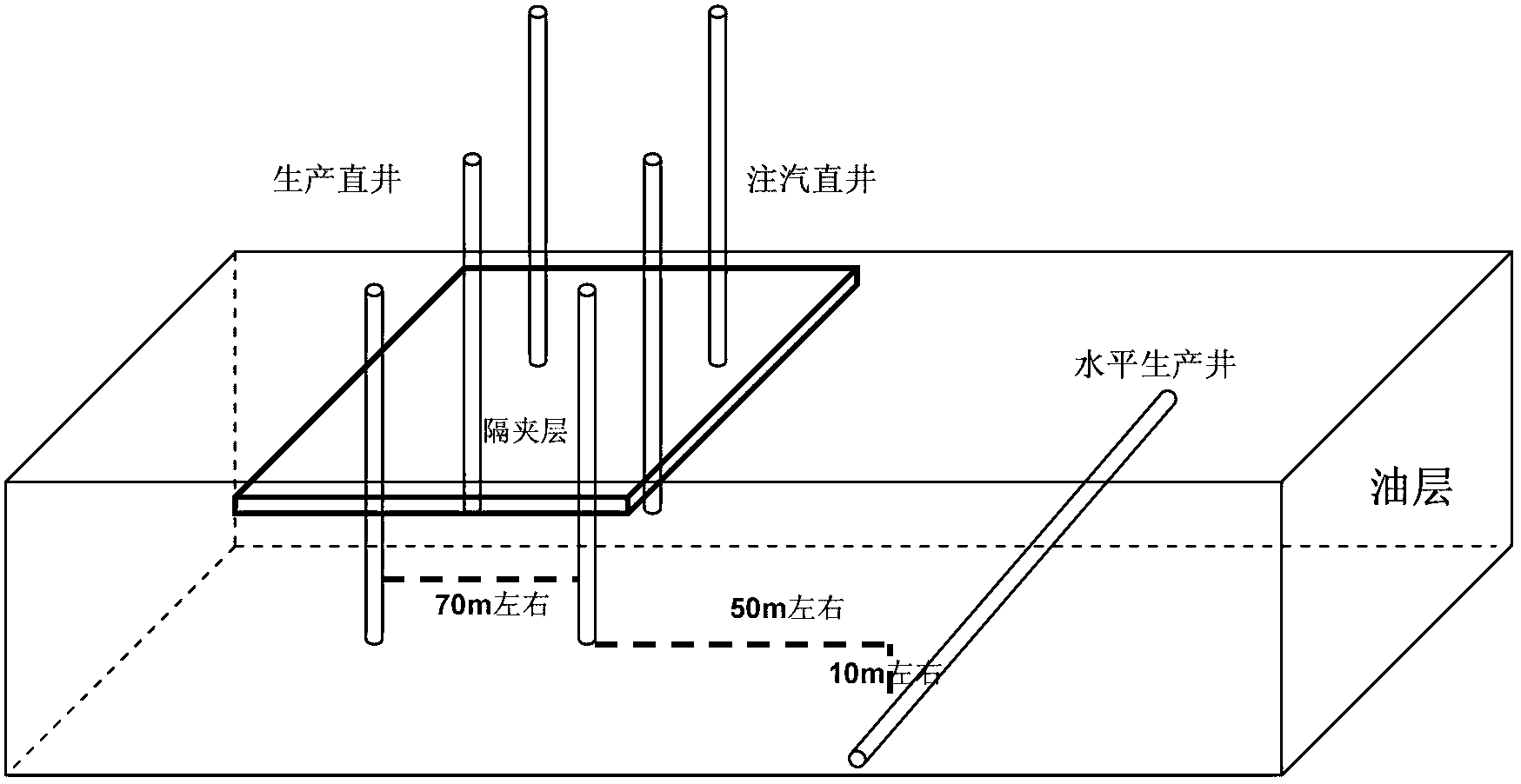

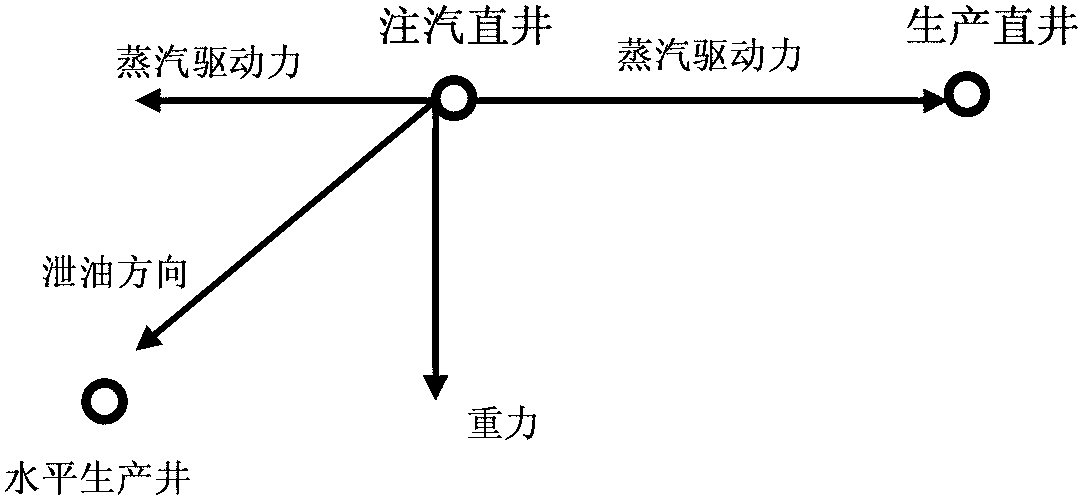

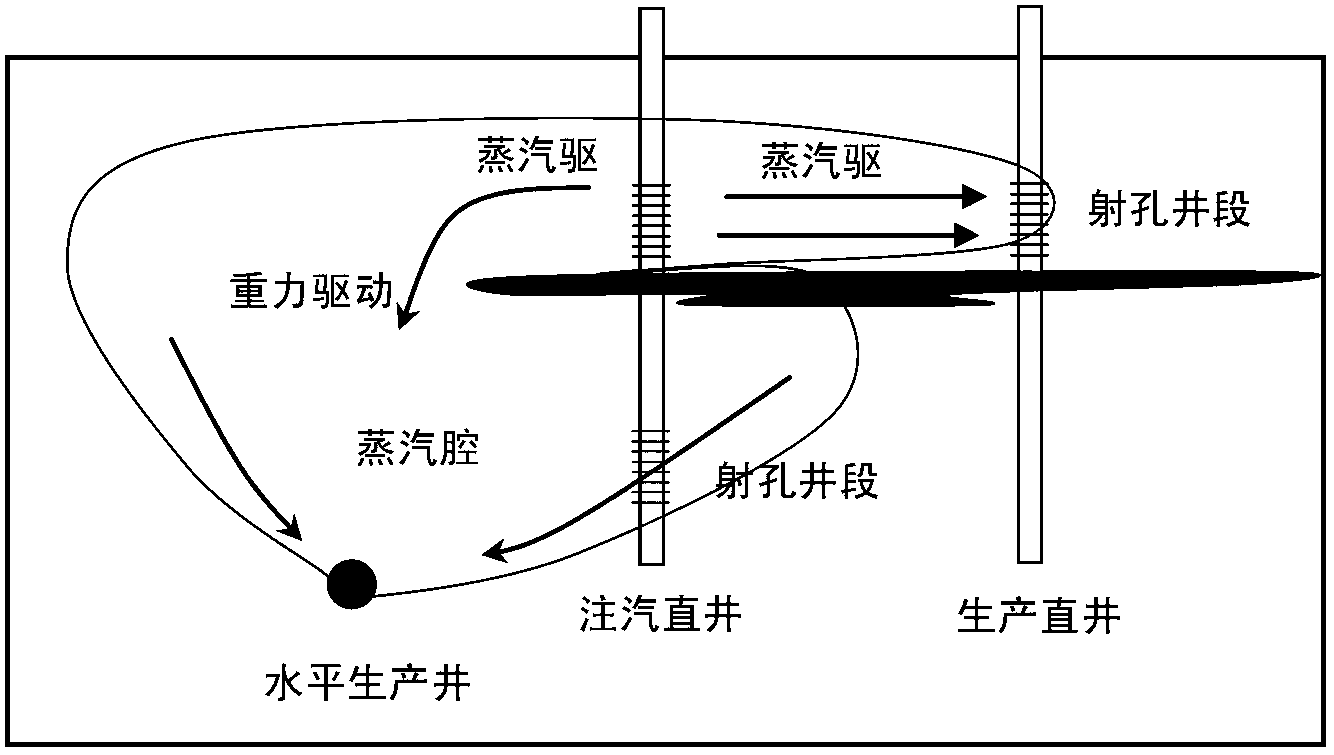

Gravity and steam flooding combined mining method of thick layer containing interlayer common heavy oil reservoir

ActiveCN103174403AEfficient use ofEnhanced overall recoveryFluid removalMaterial PerforationReservoir pressure

The invention provides a gravity and steam flooding combined mining method of a thick layer containing an interlayer common heavy oil reservoir. The method comprises the following steps: 1) whether geological parameters and fluid characteristics in an oil deposit block can satisfy mining conditions or not is ensured; 2) in an interlayer oil deposit block, a straight well and horizontal well combined well spacing mode is adopted, a horizontal producing well is drilled on the lower portion close to an oil layer, a steam injection straight well is arranged diagonally above the horizontal producing well, and a producing straight well is arranged in an area on the same layer with the steam injection straight well according to growing circumstances of the interlayer; 3) huff and puff are conducted simultaneously by the horizontal producing well and the steam injection straight well so that hot communication is formed by the steam injection straight well and the horizontal producing well, the reservoir pressure drops to 3-4MPa, and then steam is injected by the steam injection straight well, and production and mining are conducted by the horizontal producing well; and 4) after the oil layer on the lower portion of the interlayer is put into use basically, perforation is conducted on the parts, arranged on the upper portion of the interlayer, of the steam injection straight well and the producing straight well, steam injection well points are increased and steam quantity is improved at intervals, and production and mining are conducted simultaneously by the horizontal producing well and the producing straight well.

Owner:PETROCHINA CO LTD

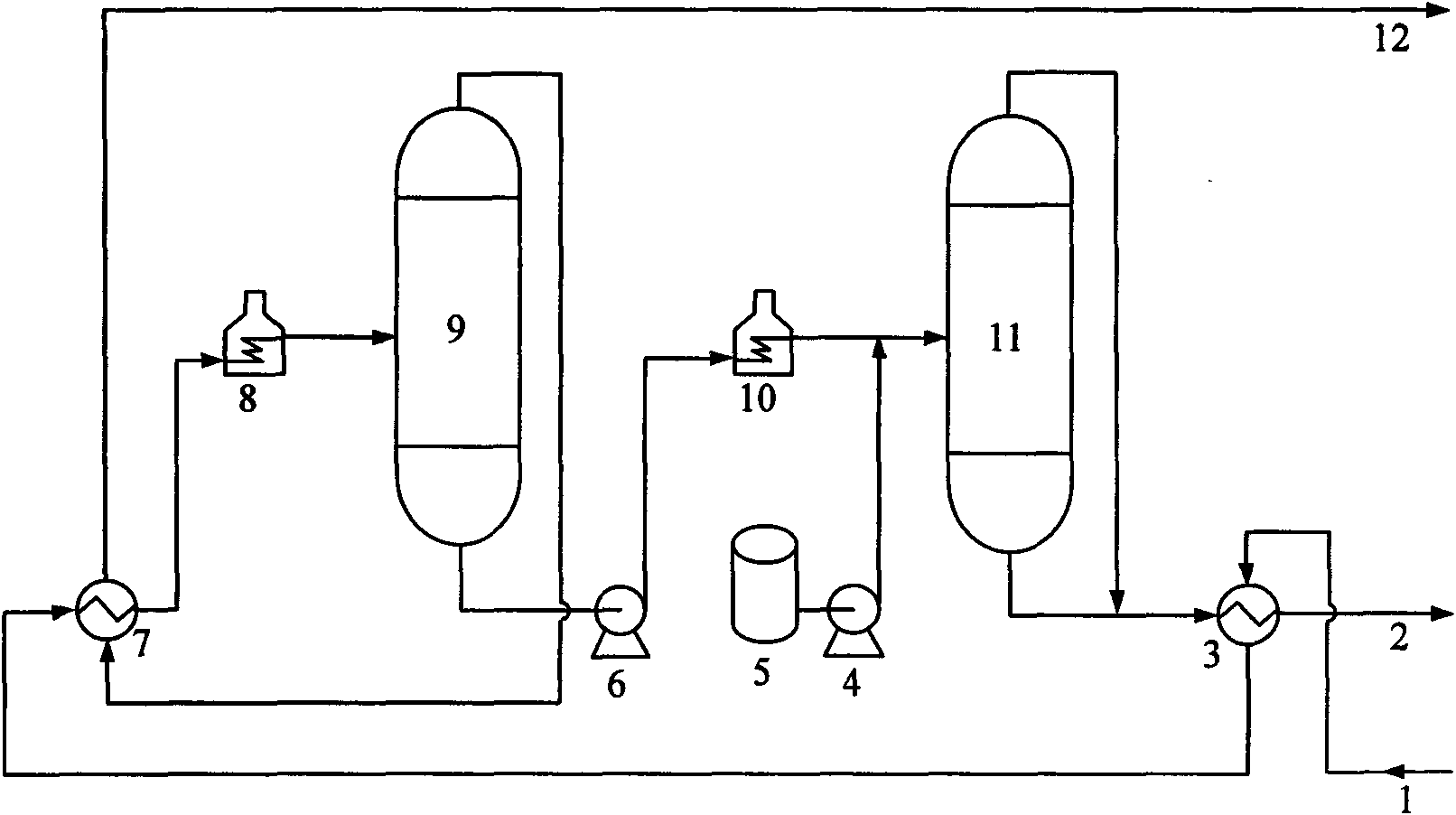

Method for integrally catalyzing, reforming, reducing viscosity, extracting and transporting thick oil

The invention relates to a method for integrally catalyzing, reforming, reducing the viscosity, extracting and conveying thick oil in thick oil deposit extraction, which can reduce the mixing amount of thin oil and lead the separated thick oil to be transported outside after catalyzing, quality improving and viscosity reducing. The method comprises the following steps: mixing thin oil with thick oil in a pitshaft according to the mass ratio of 0.4-1.0 of the thin oil to the thick oil so as to reduce the viscosity of the thick oil; extracting the thick oil mixed with the thin oil from the pitshaft, warming up by a heat exchanger, heating by a heating furnace to 350 DGE C, leading the oil to enter a distilling tower, collecting distillate oil with the temperature being lower than 350 DGE C,cooling the oil by the heat exchanger and filling the thick oil mixed with thin oil into the pitshaft for cycling; conveying heavy distillate oil with the temperature being up to 350 DGE C to the heating furnace by a pump for warming up, adding a reforming catalyst by a pump, and conveying the mixture to a reaction tower; catalyzing and reforming the heavy distillate oil into thick oil with low viscosity under the action of the reforming catalyst, and directly transporting the reformed thick oil outside after heat exchange. The thin oil mixed by the method can be cycled, and separating the thick oil from the thin oil does not damage the characteristics of oil. The method which has wide application range and favorable viscosity reduction effect and enables the quality of thick oil to be improved is used for thick oil extraction.

Owner:SOUTHWEST PETROLEUM UNIV

Oil extraction method

ActiveCN102587880AIncrease Controlled ReservesExpand well spacingFluid removalLayer thicknessFront edge

The invention discloses an oil extraction method for extracting raw oil in a horizontal well. The oil extraction method comprises the steps of: A, fracturing the horizontal well; and B, performing horizontal well fireflood assisted gravity drainage on the fractured horizontal well. According to the oil extraction method, the fracturing technology is combined with the single horizontal well fireflood assisted gravity drainage extraction technology, the double advantages of horizontal crack leading fireflood front edge expansion and gravity assisted drainage are made full use of, and a thick oil deposit with an oil layer thickness of more than 4m can be economically and effectively developed.

Owner:PETROCHINA CO LTD

Thick oil reservoir fire flooding oil extraction combustion-supporting ignition method

InactiveCN102071918AConducive to production operationEasy to implementFluid removalCombustionEquivalent weight

The invention belongs to the technical field of fire flooding oil extraction and in particular relates to a thick oil reservoir fire flooding oil extraction combustion-supporting ignition method. The method is implemented by the following steps of: (1) building an injection well on the conventional well network and a plurality of production wells at the periphery of the conventional well network according to oil layer geological information to form an area well network or a row-line type well network, wherein in the row-line type well network, one well row is the injection well and the adjacent well rows are the production wells; (2) injecting high-temperature steam with equivalent weight of 250 to 300 cubic meters of water into the injection well in the step (1) and preheating a ground layer to 210 to 250 DEG C; and (3) at the later stage of injecting the steam, mixing a combustion improver and crude oil according to the weight ratio of the combustion improver to the crude oil of 8.5 to 11.6 percent, injecting the mixture into the ground layer together with the high-temperature steam, and then continuously injecting sufficient air. By the method, the threshold temperature of high-temperature oxidation of the crude oil is greatly reduced and oil is easy to ignite; ignition is easy to implement; the ignition time is shortened; the ignition success rate is high; and construction is performed conveniently.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

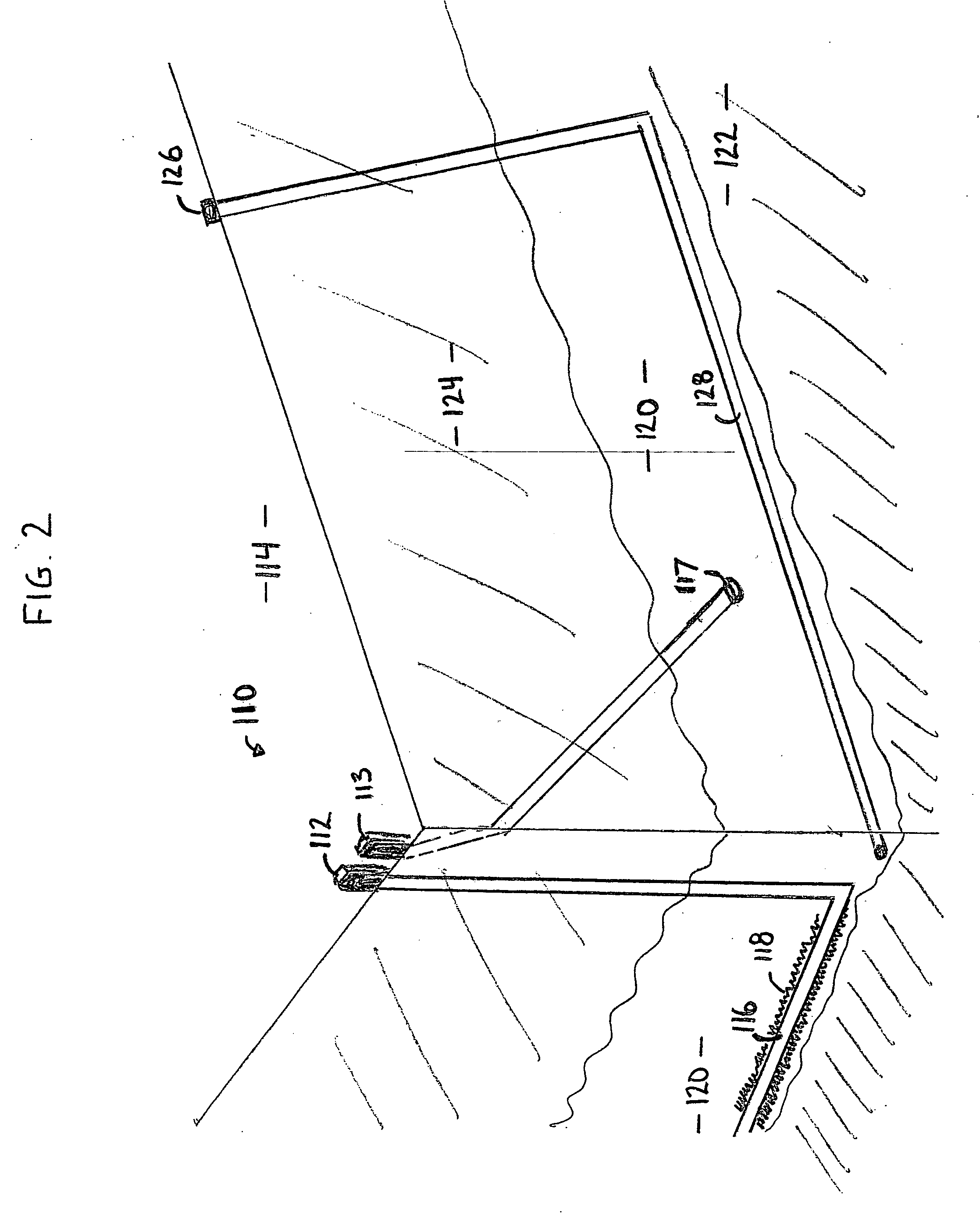

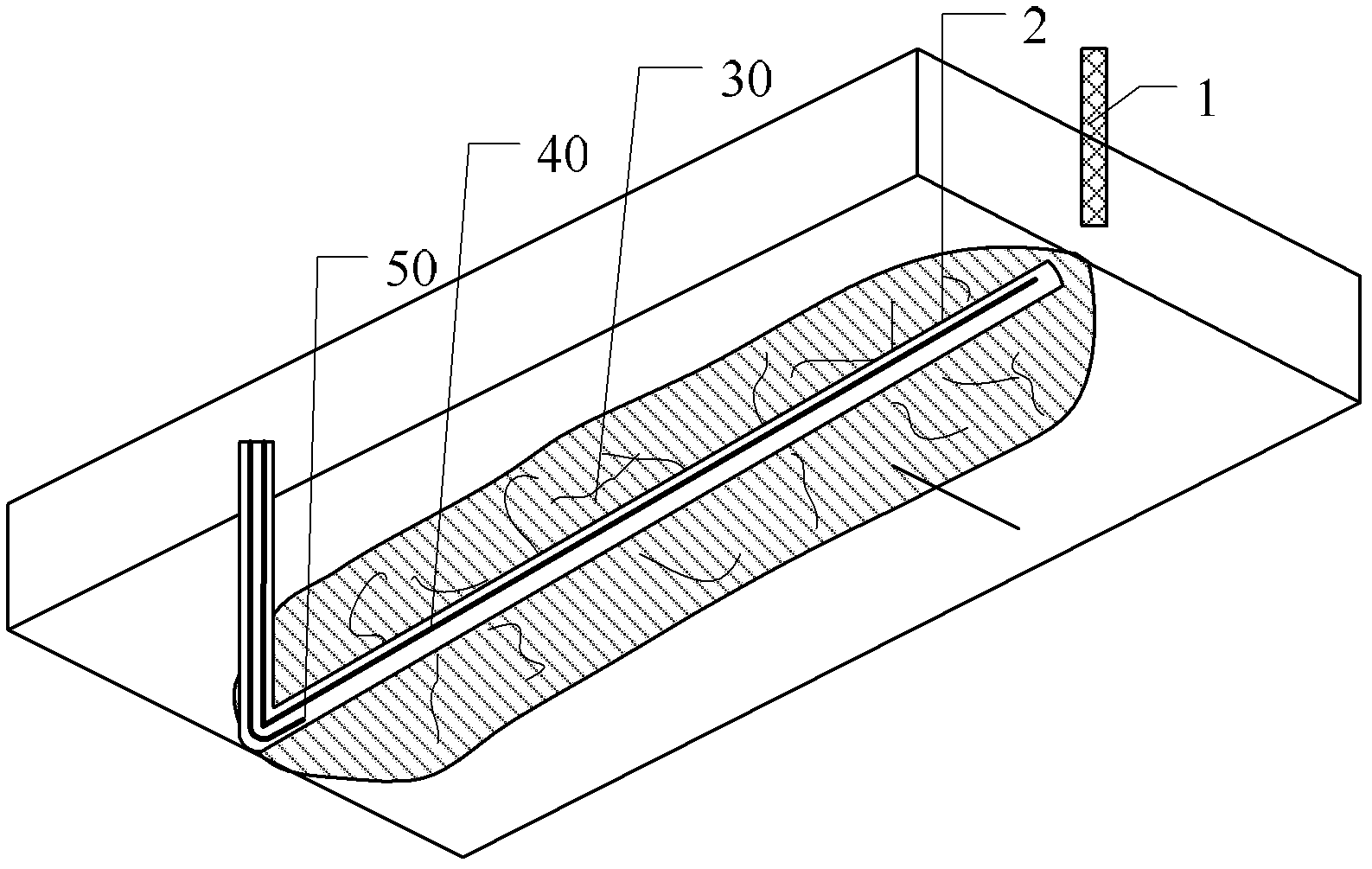

Propane-injecting shallow heavy oil reservoir exploitation method

The invention relates to a propane-injecting shallow heavy oil reservoir exploitation method. The propane-injecting shallow heavy oil reservoir exploitation method includes the following steps: a horizontal injection and production well network is arranged in a shallow heavy oil reservoir exploitation area, an injection well and a production well are arranged in the oil layers at the same vertical plane position to form an injection and production well pair, the injection well is a horizontal injection well, the production well is a horizontal production well, and the horizontal injection and production well network comprises at least one injection and production well pair; injected steam circulation preheating is carried out simultaneously via the injection well and the production well; after the temperature of the oil layer between the horizontal section of the injection well and the horizontal section of the production well is increased to a predetermined temperature, the injection well and the production well simultaneously stop circulation preheating, propane starts to be continuously injected into the injection well, and the amount of the injected propane is 5000m3 / d to 25000m3 / d; and the production well starts continuous oil production. The propane-injecting shallow heavy oil reservoir exploitation method has the characteristics of high recovery rate, propane recycling, low exploitation cost, high economic benefit, low energy consumption, low emission, environment-friendliness and the like, and is easy and safe to operate.

Owner:PETROCHINA CO LTD

Method of integral throughput in multiple wells for extracting thick oil

InactiveCN1601052APrevent steam channelingSupplementary pressure energyFluid removalPorosityLayer thickness

The invention is a method for multi-well cyclic steam stimulation thickened oil recovery by thermal recovery-steam injection technique, selecting: oil-layer depth in oil reservoir<1800m, residual oil saturation > 0.40, total oil-layer thickness > 5.0m, net-total thickness ratio >0.4, oil-layer porosity >0.15, and permeation rate variation coefficient <0.8; placing adjacent steam channeling wells and steam channeled wells (above two) together in the same group, simultaneously making steam injection in the well drainage sequence or block cluster well sequence, where steam injection strength of single well is 50-200 cu m / m and the well-bottom dryness fraction is greater than 50%, then stewing them, and finally opening them for production in the same sequence as above-mentioned. It can prevent steam channeling and interference between wells, effectively supplements pressure energy to oil layers and helps enlarge the steam spread range, and can increase the oil-layer pressure by about 2MPa as compared with single well steam stimulation method. It can both increase single-well output and prolong the life of steam stimulation.

Owner:PETROCHINA CO LTD

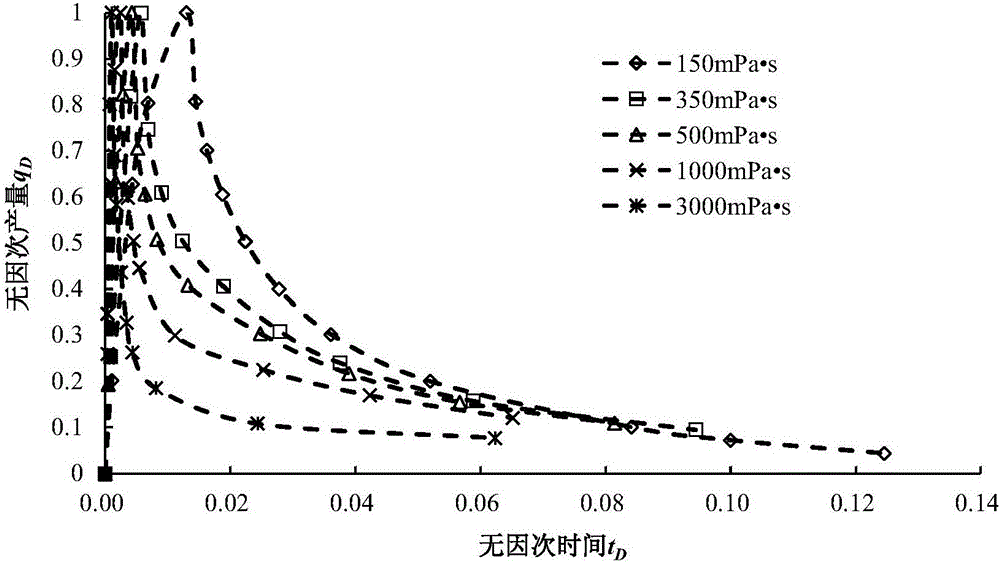

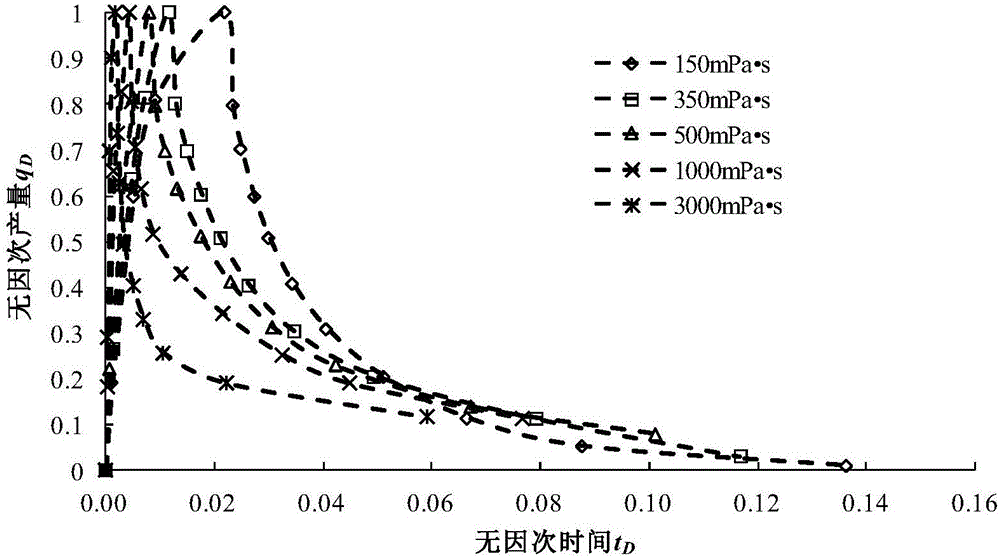

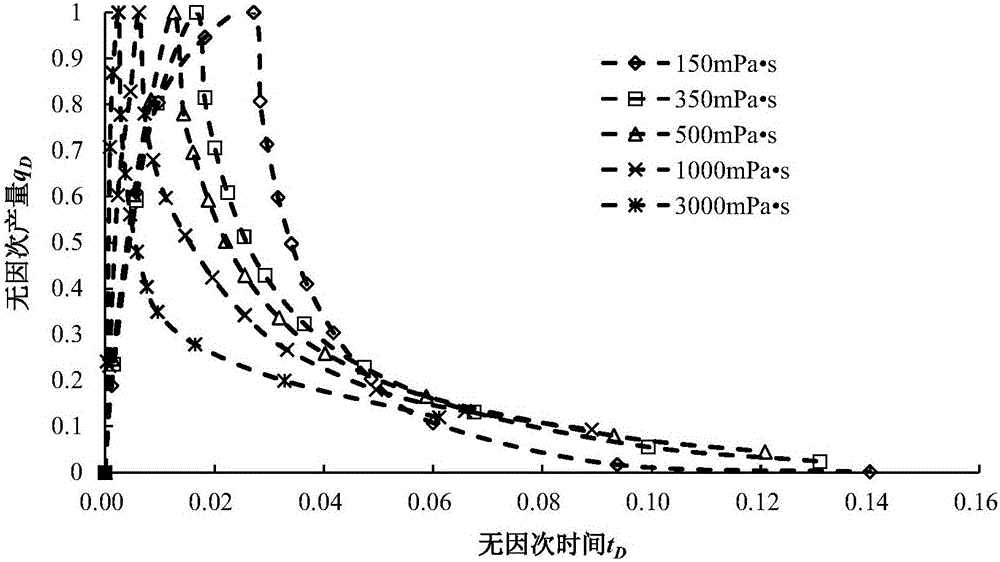

Method of predicting steam huff-puff early productivity of heavy oil reservoir horizontal well

The invention relates to a method of predicting steam huff-puff early productivity of a heavy oil reservoir horizontal well and belongs to the field of oil-gas field development. The method comprises the steps of 1) establishing a heavy oil reservoir thermal recovery mathematical model based on percolation theory; 2) establishing a nondimensional productivity curve for the horizontal well; 3) recognizing major factors influential to the nondimensional productivity curve of step 2); 4) drawing a nondimensional productivity chart of the horizontal well; 5) predicting steam huff-puff early oil production of the horizontal well under test based on the nondimensional productivity chart of the horizontal well in step 4). The method of the invention has the advantages that initial multiple regression is performed according to the factors influential to the steam huff-puff productivity of a horizontal well to obtain a formula of calculating maximum daily oil production peak of the horizontal well; the steam huff-puff early productivity of a horizontal well can be predicted conveniently and accurately according to the nondimensional productivity chart provided herein.

Owner:CHINA NAT OFFSHORE OIL CORP +1

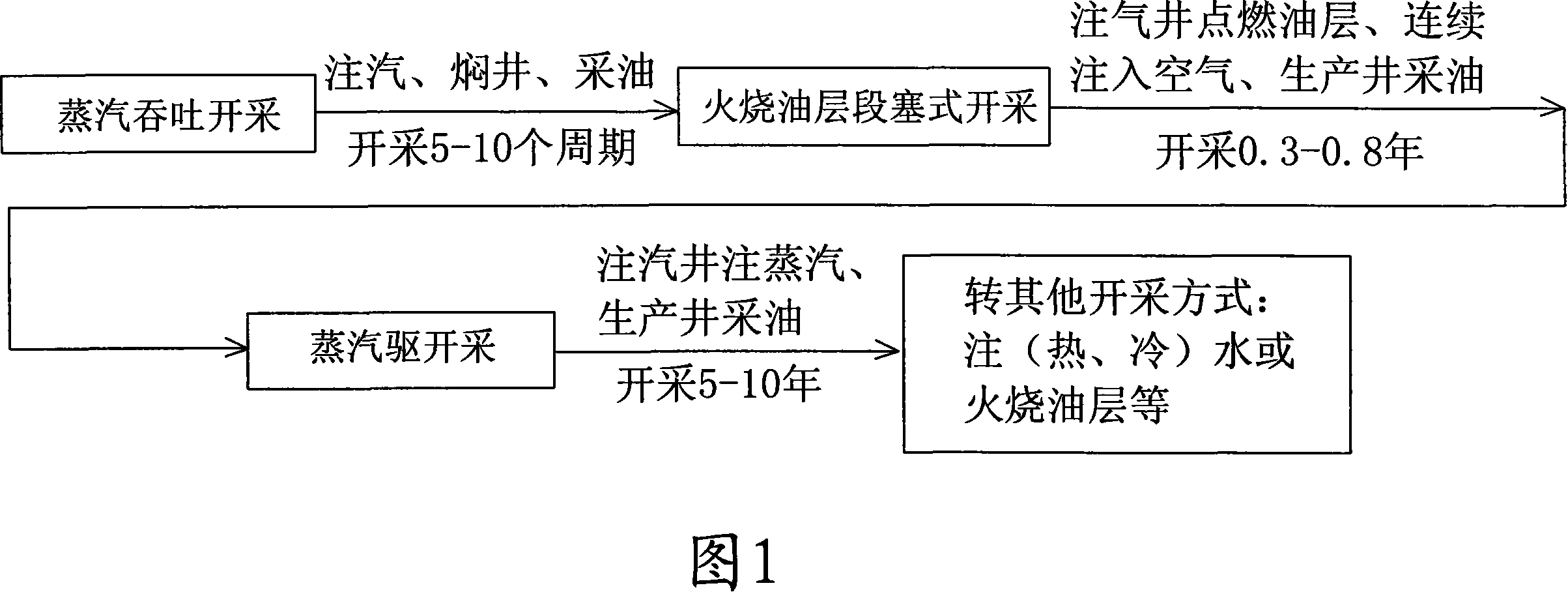

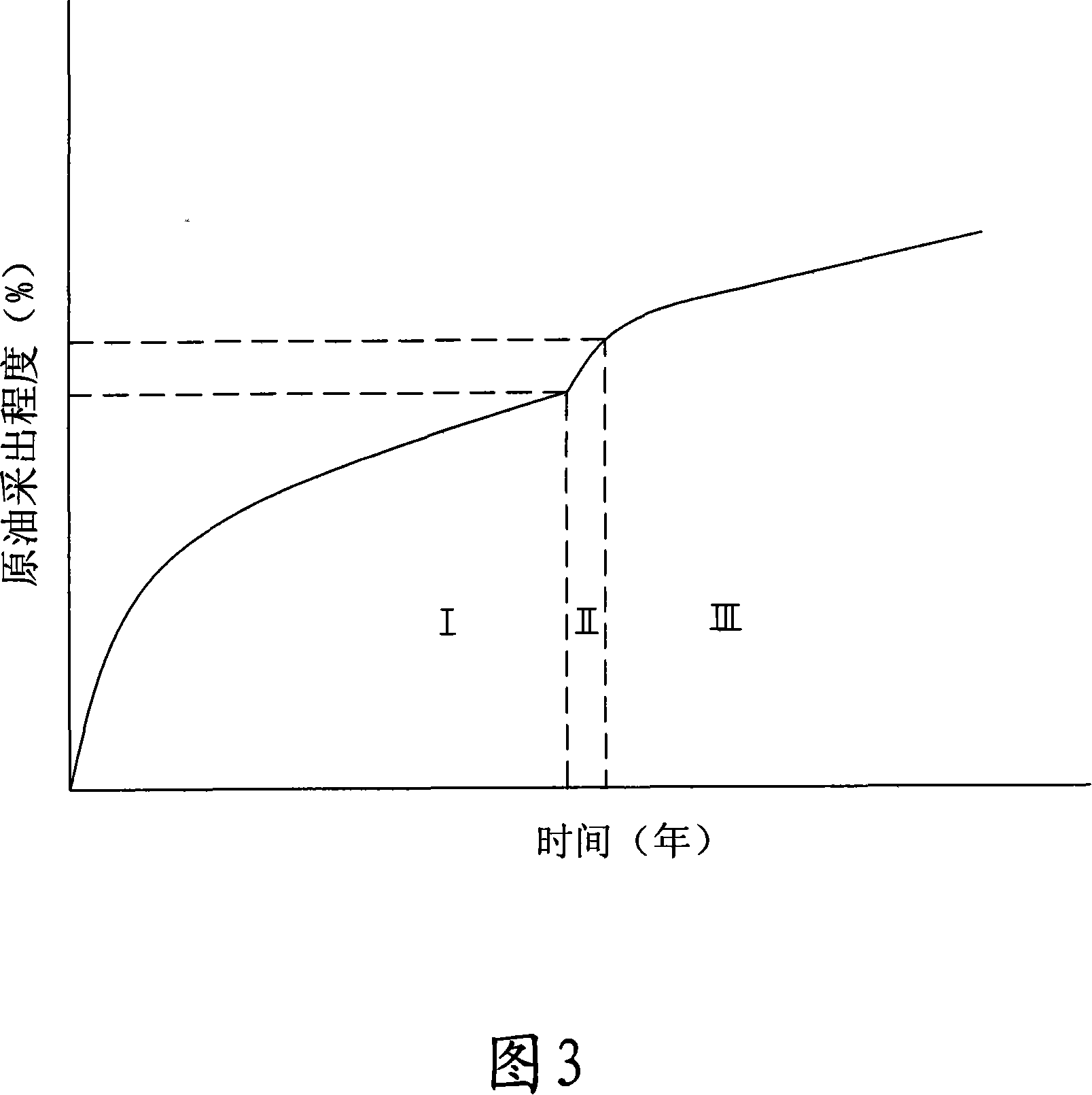

In situ combustion slug and steam driving combined type crude oil producing method

The invention discloses a method of oil pumping which adopts the combination of fire oil layer slug and steam drive and is applicable for the pumping of thick oil reservoir. After the steam soaking of the thick oil reservoir and before the pumping of the steam drive, the fire oil layer slug type pumping is performed; an ignition technology is adopted to ignite the oil layer to burn; an air compressor is used to inject air into the oil layer continuously from a center injection well; after 0.3 to 0.8 years of pumping, steam is injected into the oil layer through an injection well, and the steam drive type pumping is performed. The invention can generate the high temperature of 400 to 800 DEG C in the burning zone of the fire oil layer slug, which is in favor of the water stored in an individual well after the steam soaking to be vaporized as high-dryness steam; the temperature of the bottom of the injection well, and the dryness of the steam injected by the following steam drive are improved; the strata pressure is improved; larger producing pressure differential is achieved, which is in favor of improving the lifting rate of the oil well; moreover, the invention is in favor of shortening the low-production period at the beginning period of the steam drive and improving the developing effects of the steam drive and the recovery ratio of crude oil.

Owner:富象油气技术服务有限公司

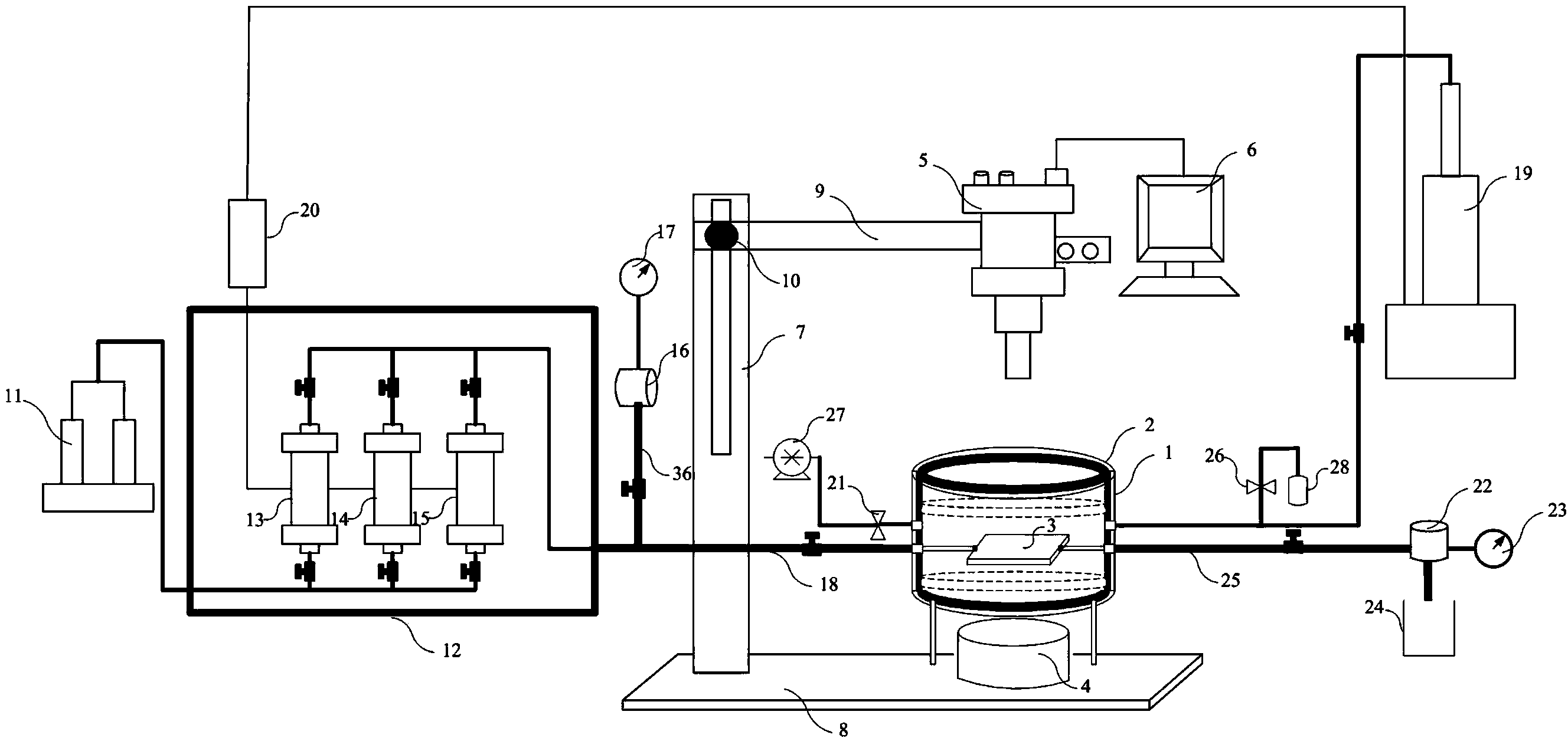

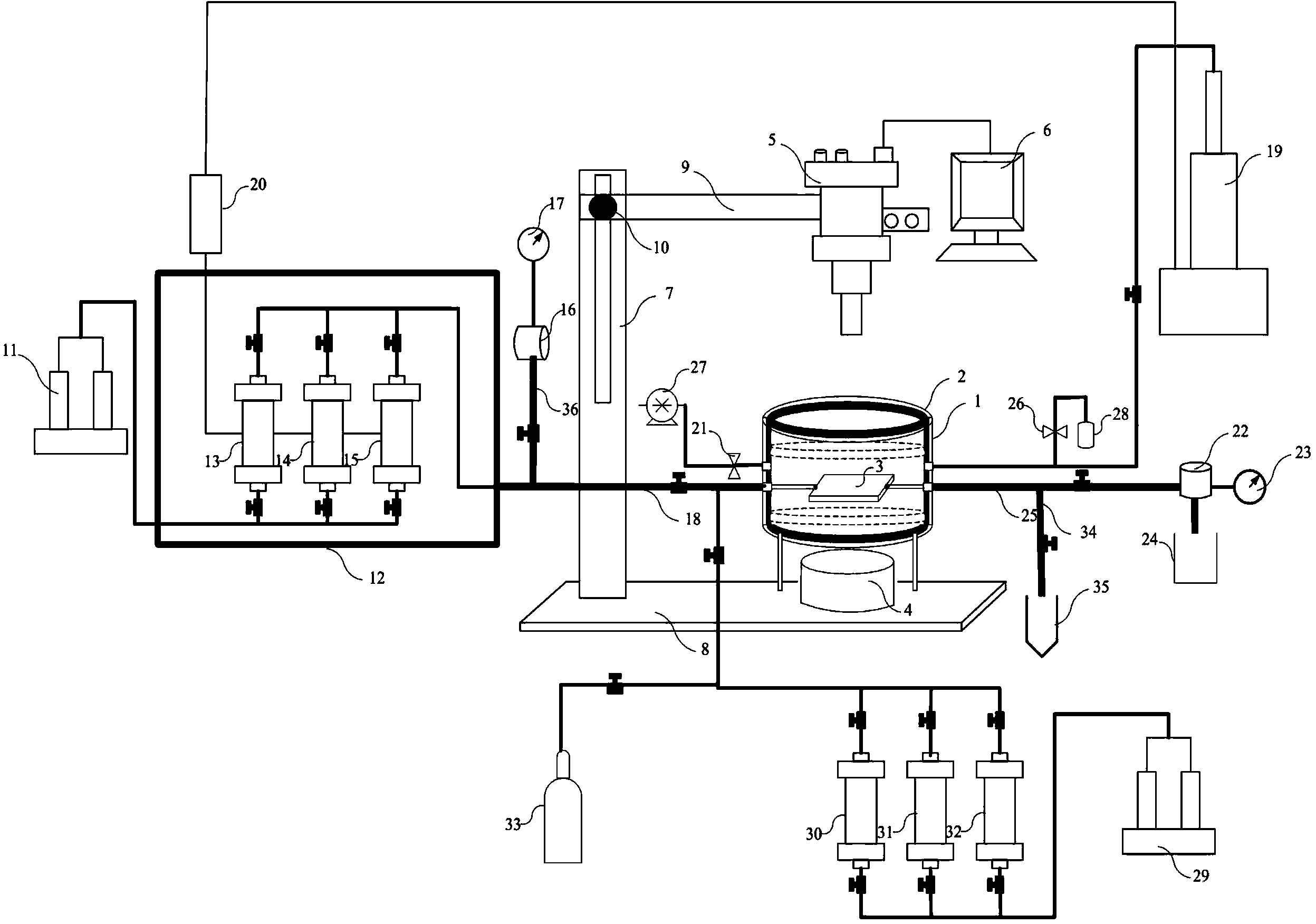

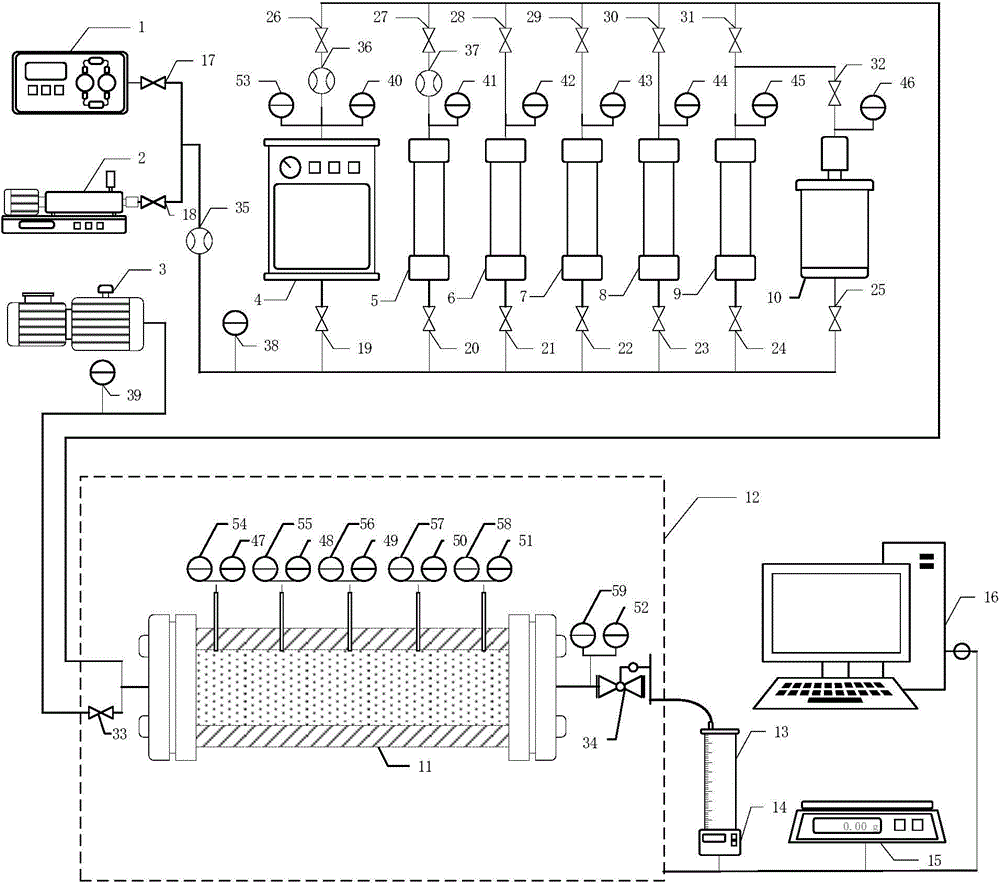

Experimental device and method of super heavy oil reservoir steam-nitrogen-viscosity reducer composite steam stimulation

The invention discloses an experimental device and method of super heavy oil reservoir steam-nitrogen-viscosity reducer composite steam stimulation. The device comprises an injection system, a model system, a constant-temperature control system, an output metering system and a data collection system. The injection system comprises a steam injection device, a gas buffer device, a viscosity reducer injection device and an oil and water saturation device which are connected in parallel, and the outlet ends of all the devices are connected with the model system. The model system is arranged in the constant-temperature control system, the inlet end of the model system is connected with the injection system, and the outlet end of the model system is connected with the output metering system. The output metering system comprises a return pressure control device and an ultrasonic oil and water separating and metering device, one end of the return pressure control device is connected with an outlet of the model system, and the other end of the return pressure control device is connected with the ultrasonic oil and water separating and metering device. The data collection system comprises a pressure sensor, a temperature sensor, a flowmeter, an electronic scale, a computer data collection system and a data analysis system, and the computer data collection system and the data analysis system achieve data collection and calculation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com