Patents

Literature

326results about How to "Reduce injection pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

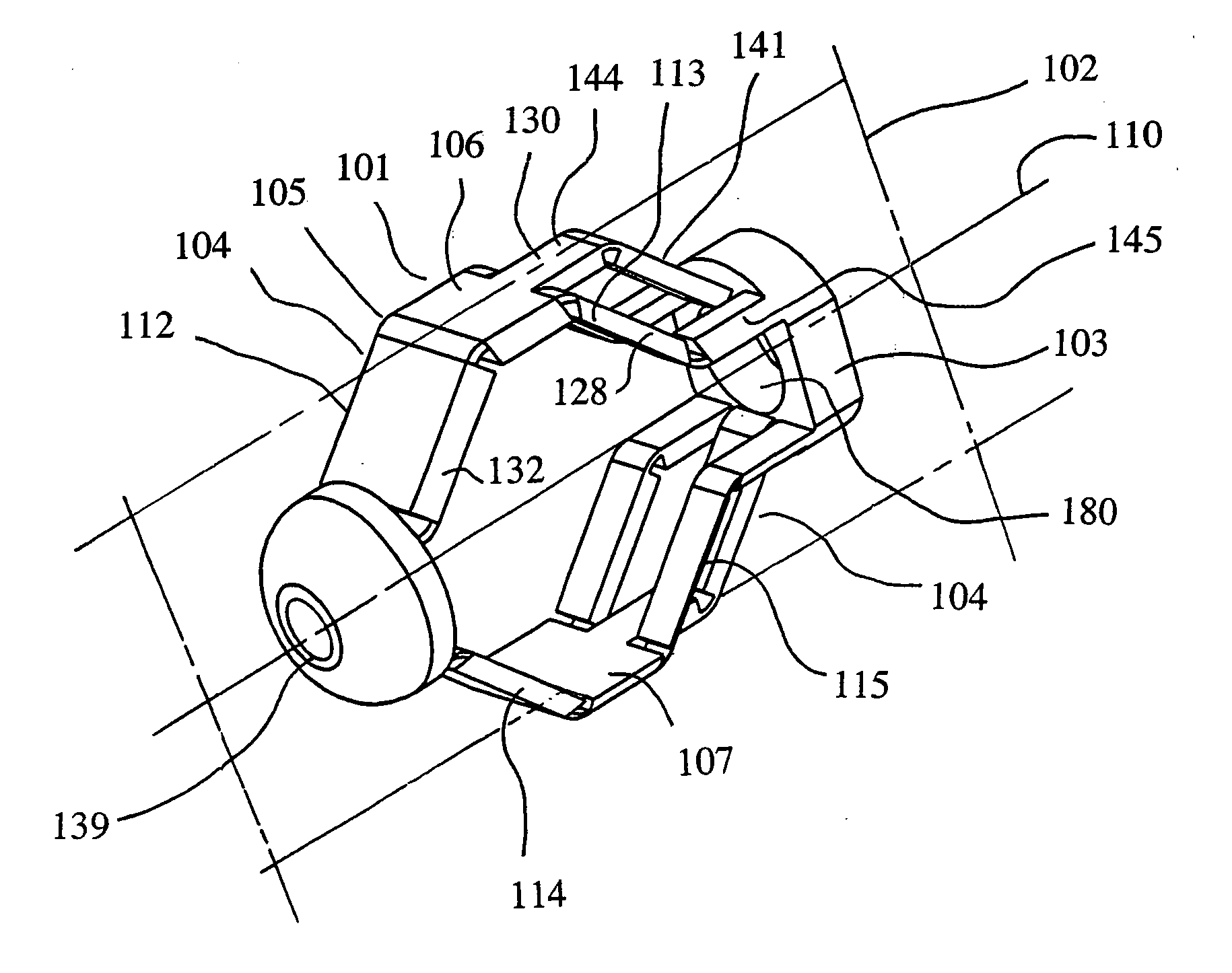

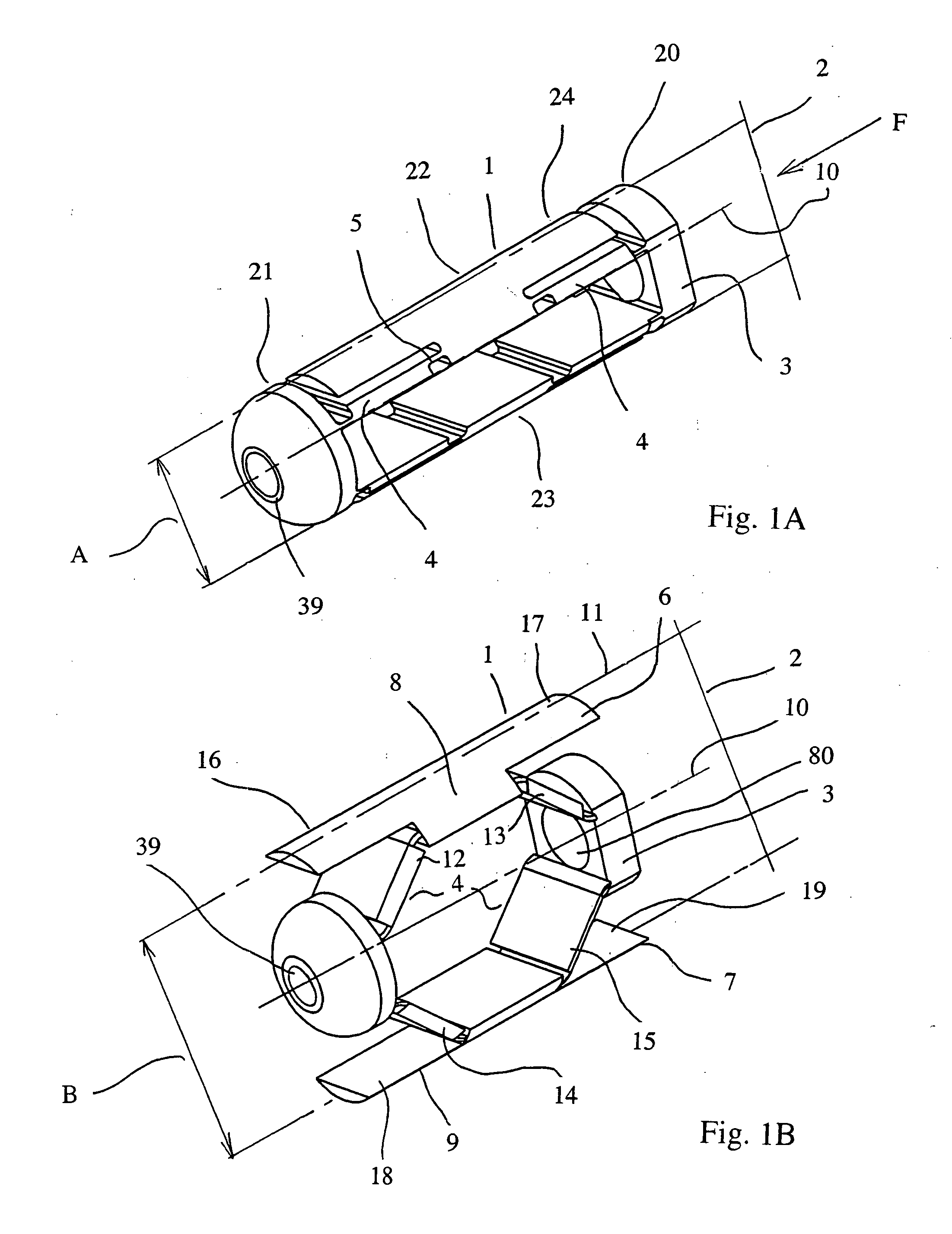

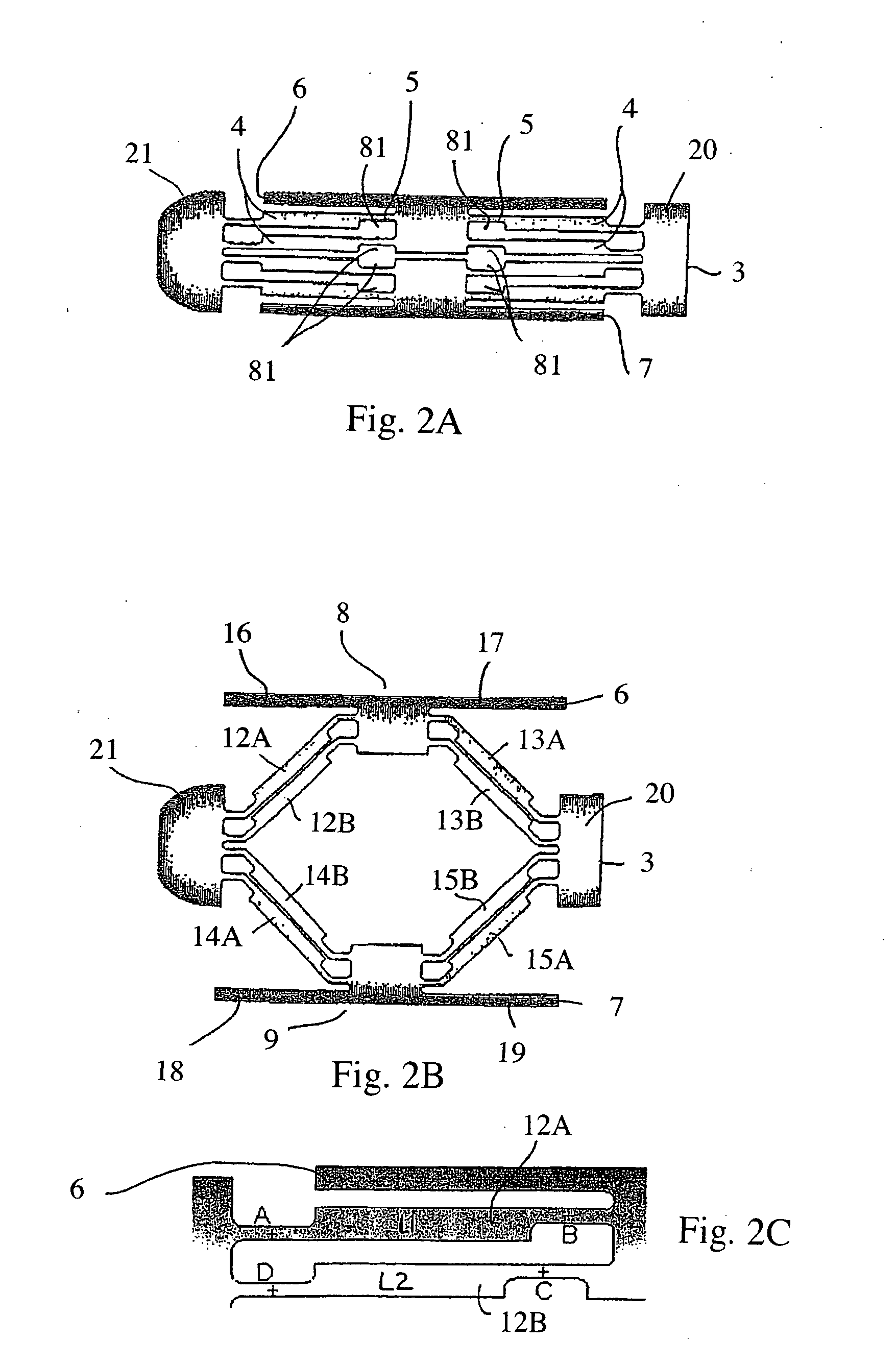

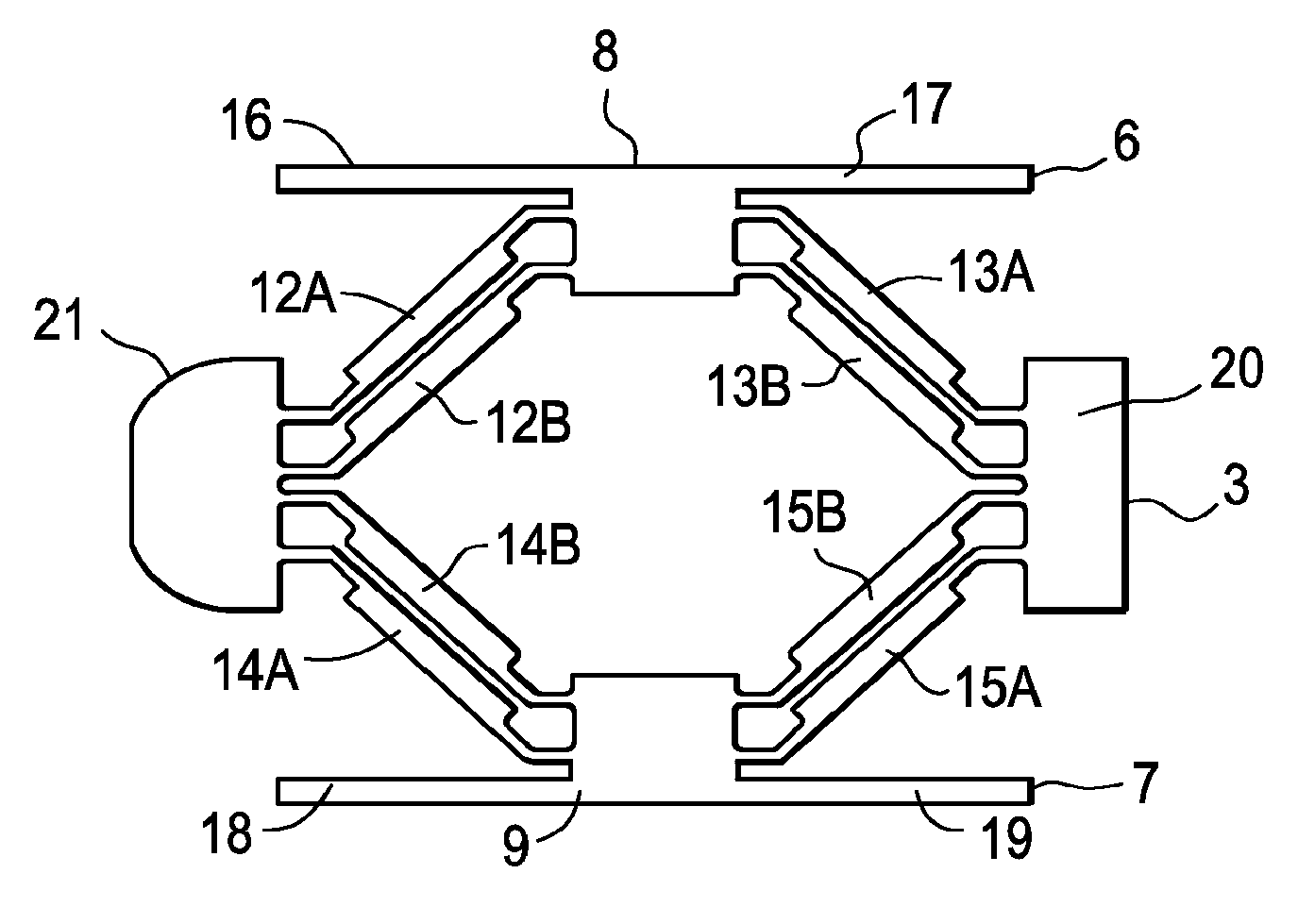

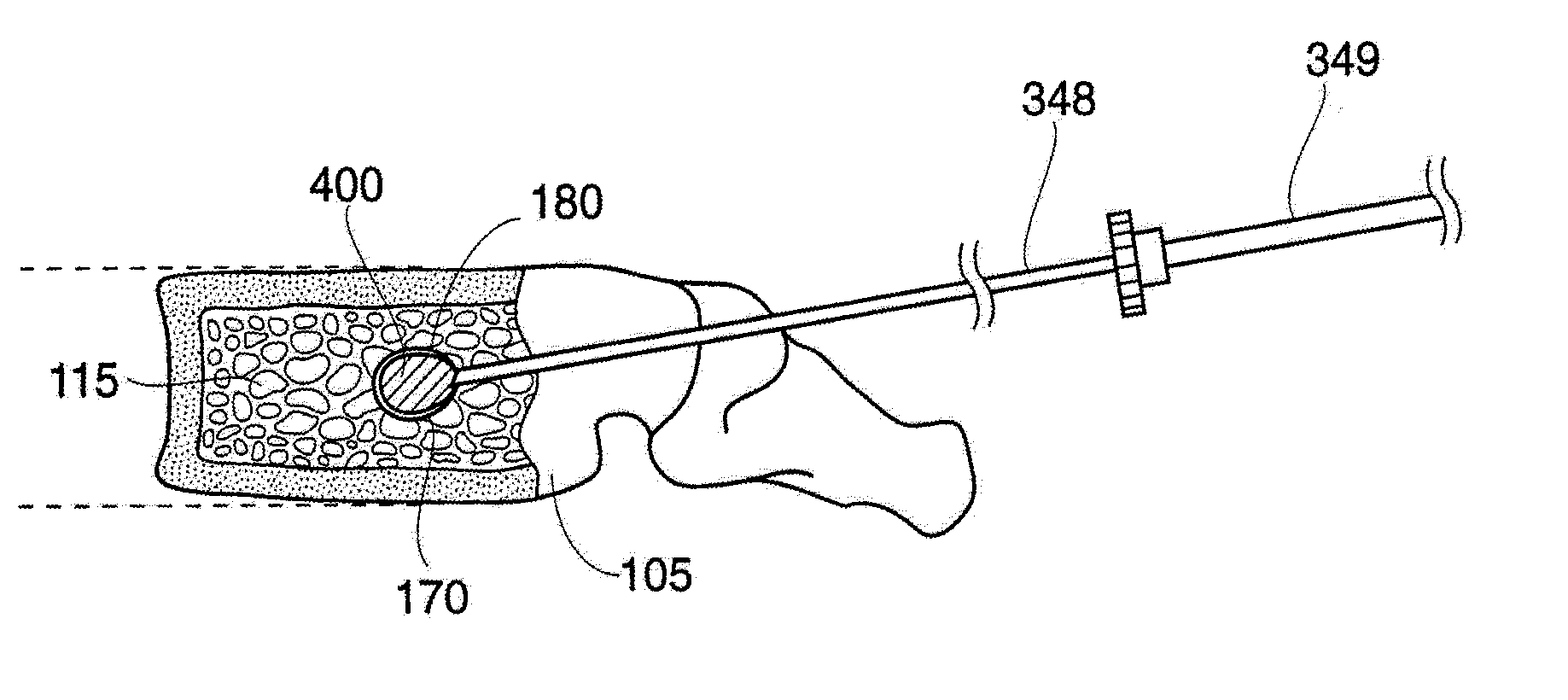

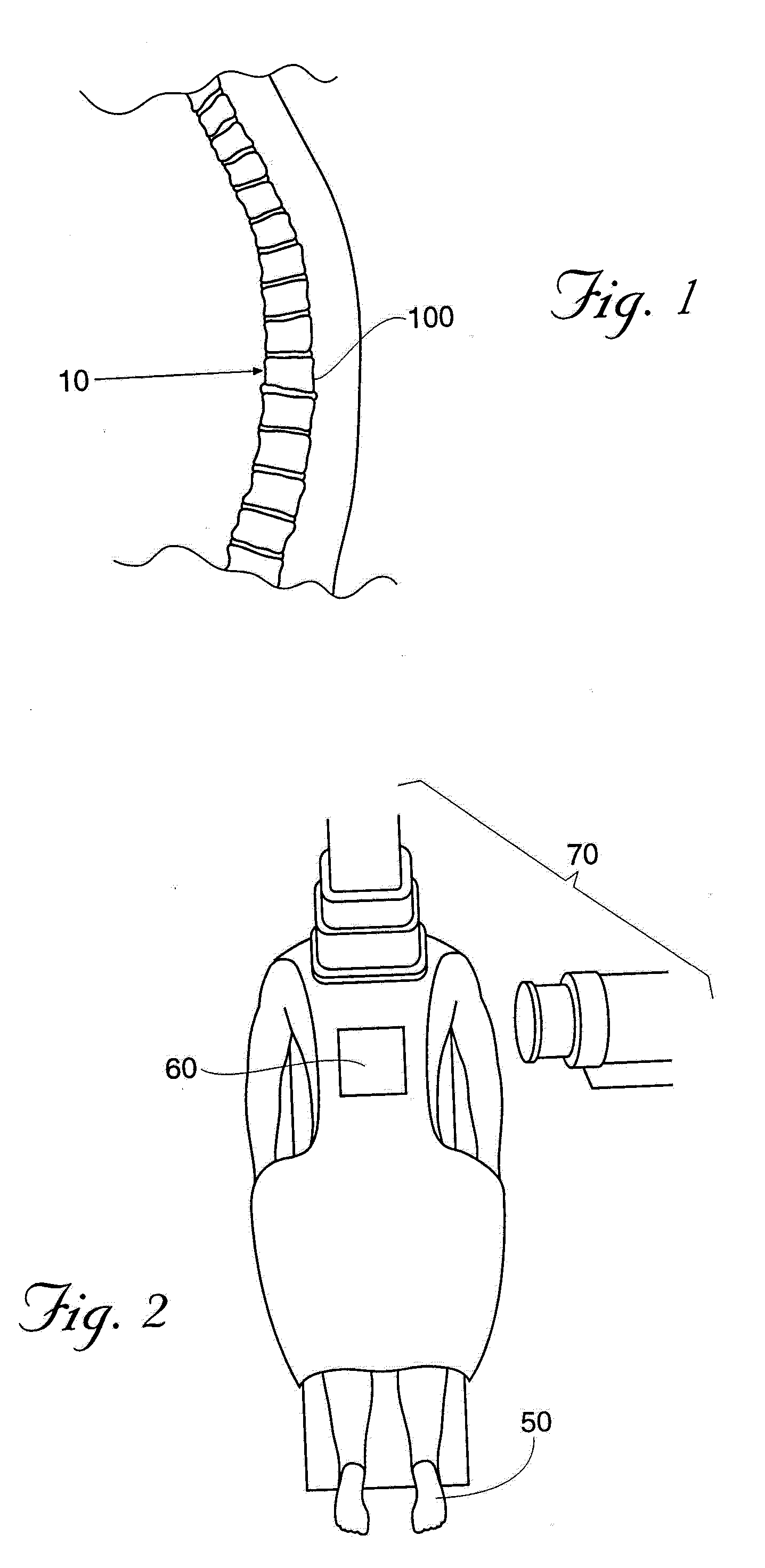

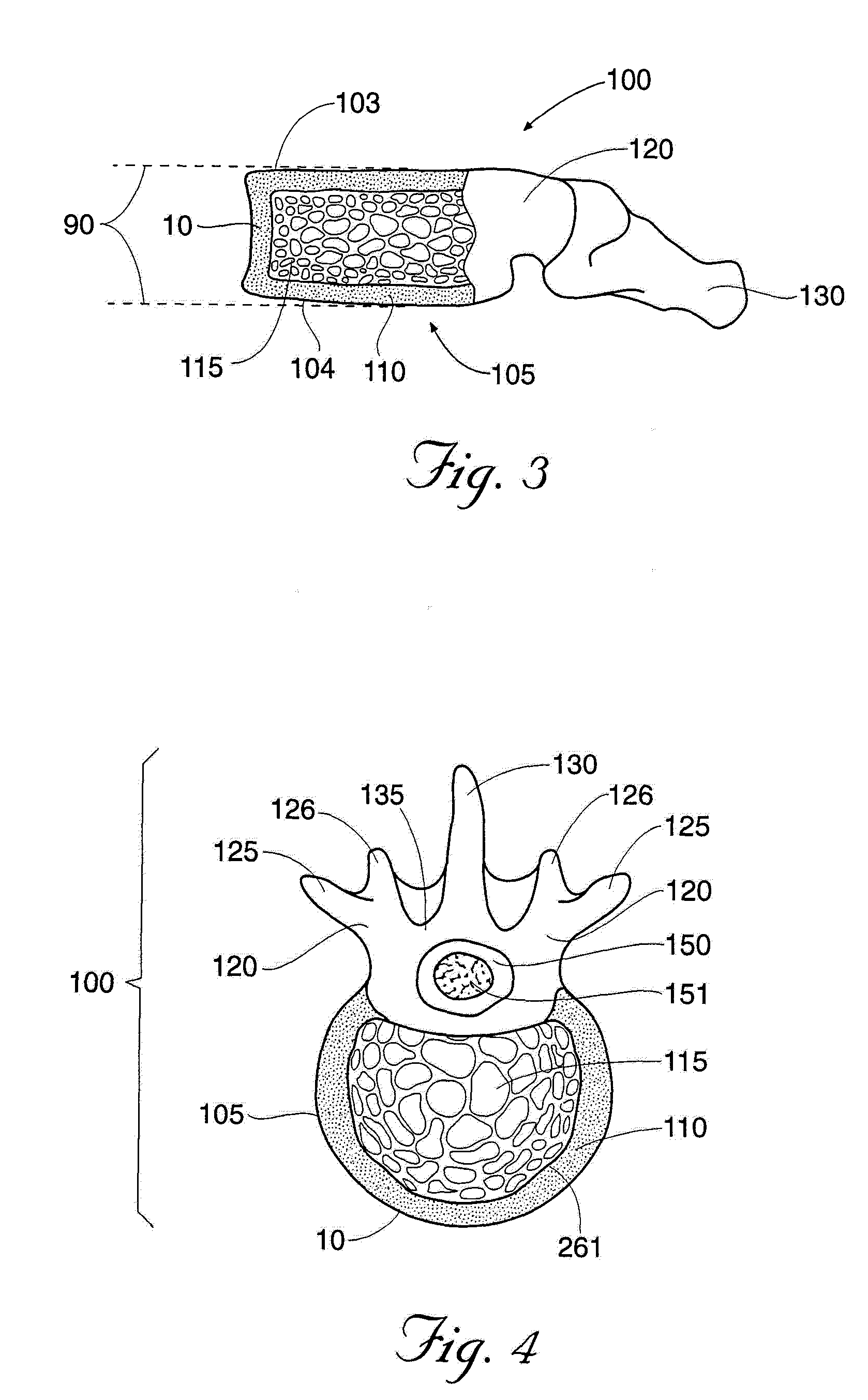

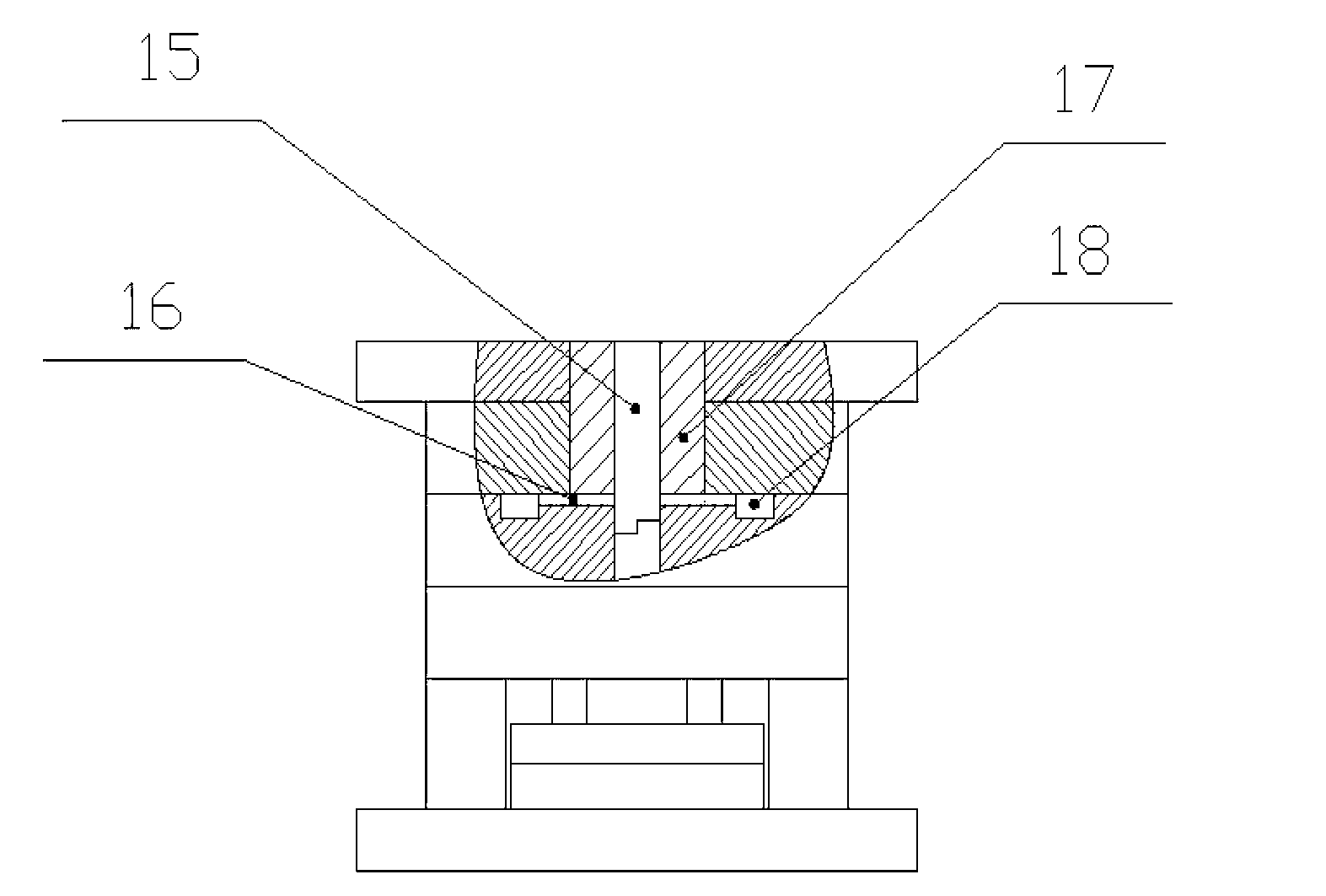

Methods and apparatuses for bone restoration

ActiveUS20060004455A1Reduce stressReduce injection pressureInternal osteosythesisBone implantRestoration methodBiomedical engineering

Methods and apparatuses for restoration of human or animal bone anatomy, which may include introduction, into a bone of an expansible implant capable of expansion in a single determined plane, positioning the expansible implant in the bone in order to correspond the single determined plane with a bone restoration plane and opening out the expansible implant in the bone restoration plane. A first support surface and a second support surface spread tissues within bone. The embodiments of the invention may also include injecting a filling material around the implant.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

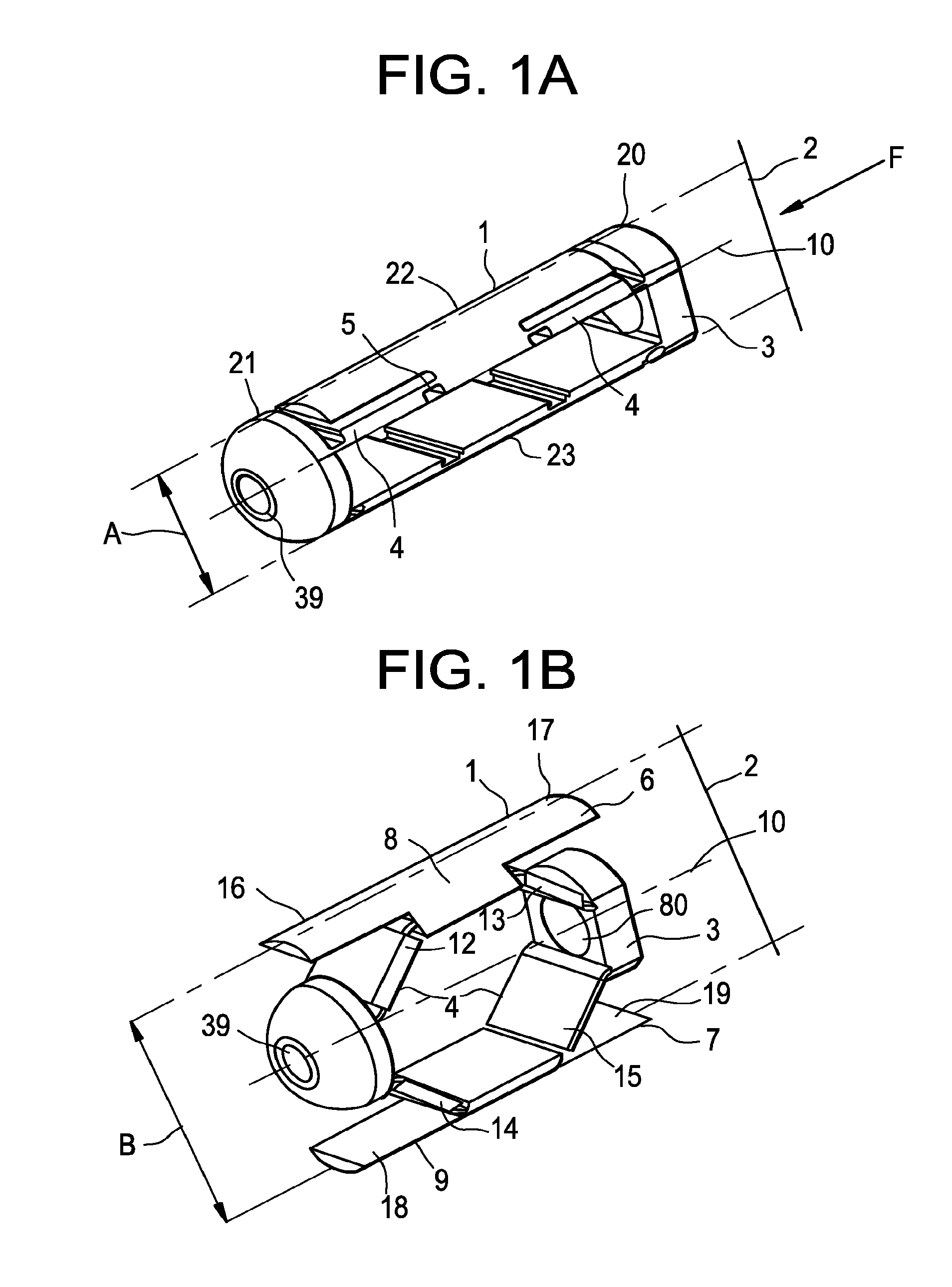

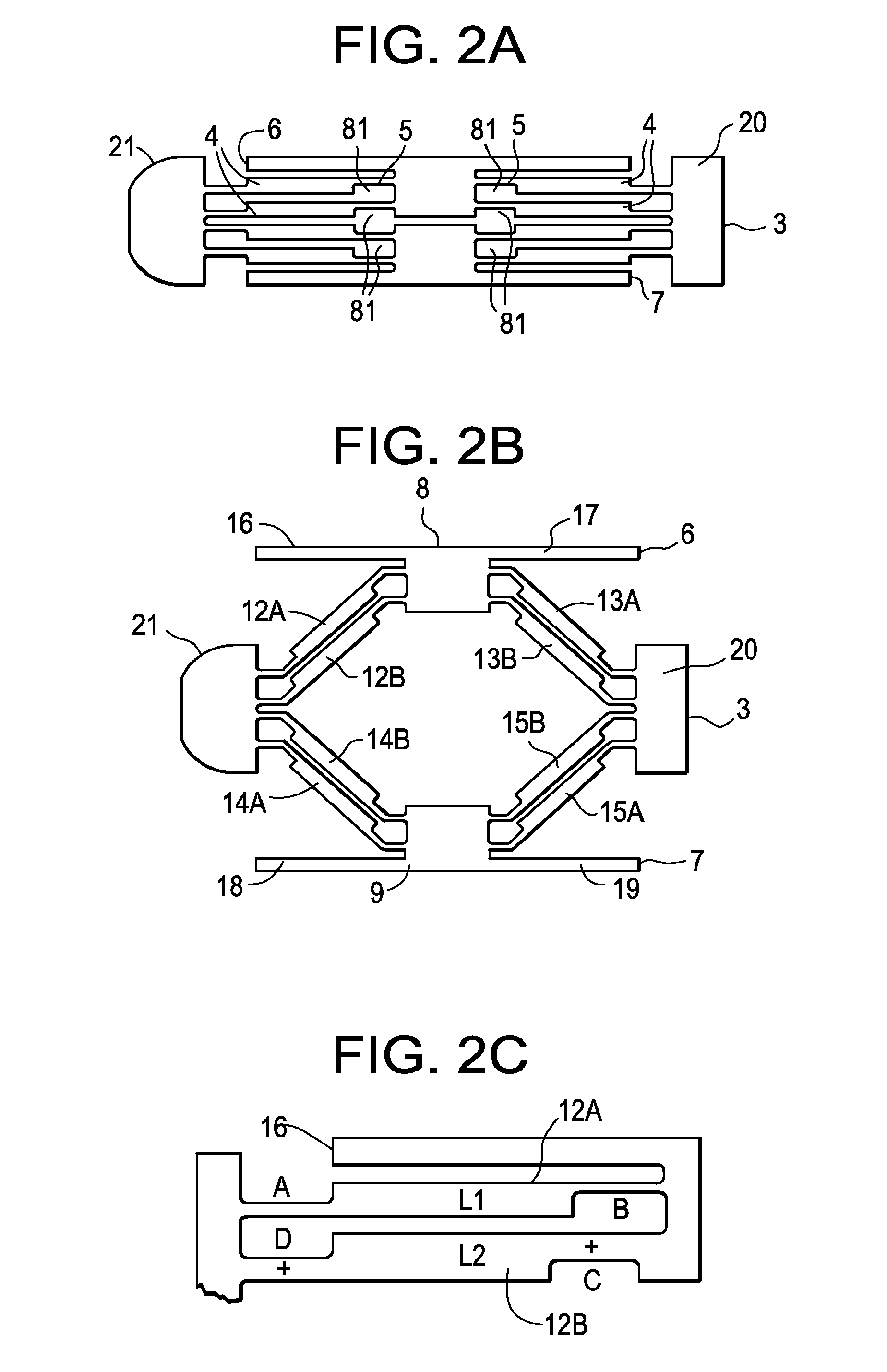

Methods and apparatuses for bone restoration

ActiveUS7846206B2Reduce stressReduce injection pressureInternal osteosythesisBone implantAnatomical structuresRestoration method

Methods and apparatuses for restoration of human or animal bone anatomy, which may include introduction, into a bone of an expansible implant capable of expansion in a single determined plane, positioning the expansible implant in the bone in order to correspond the single determined plane with a bone restoration plane and opening out the expansible implant in the bone restoration plane. A first support surface and a second support surface spread tissues within bone. The embodiments of the invention may also include injecting a filling material around the implant.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

Methods and devices for treating fractured and/or diseased bone

InactiveUS20020161373A1Opportunities decreaseOptimize allocationSurgical furnitureBone implantBiomedical engineering

Owner:ORTHOPHOENIX

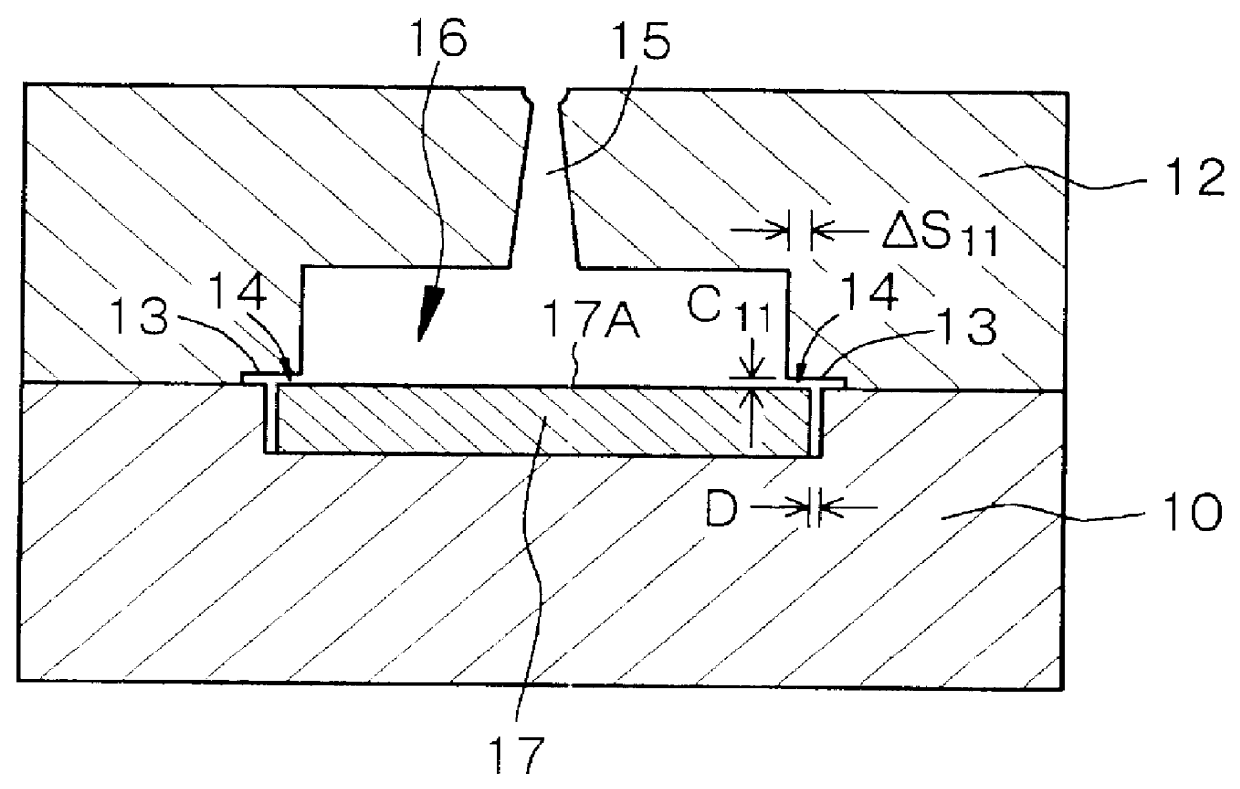

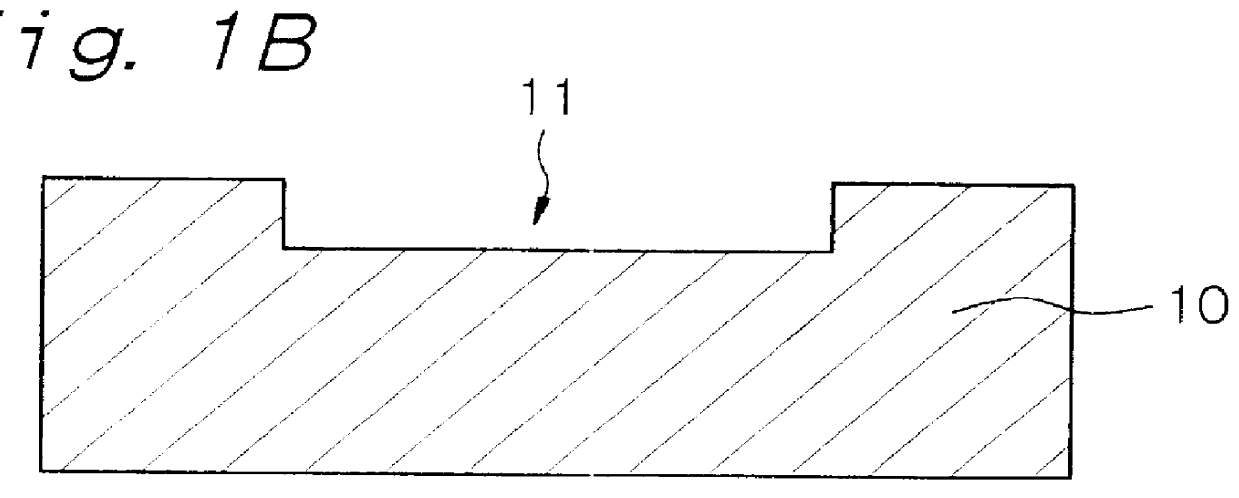

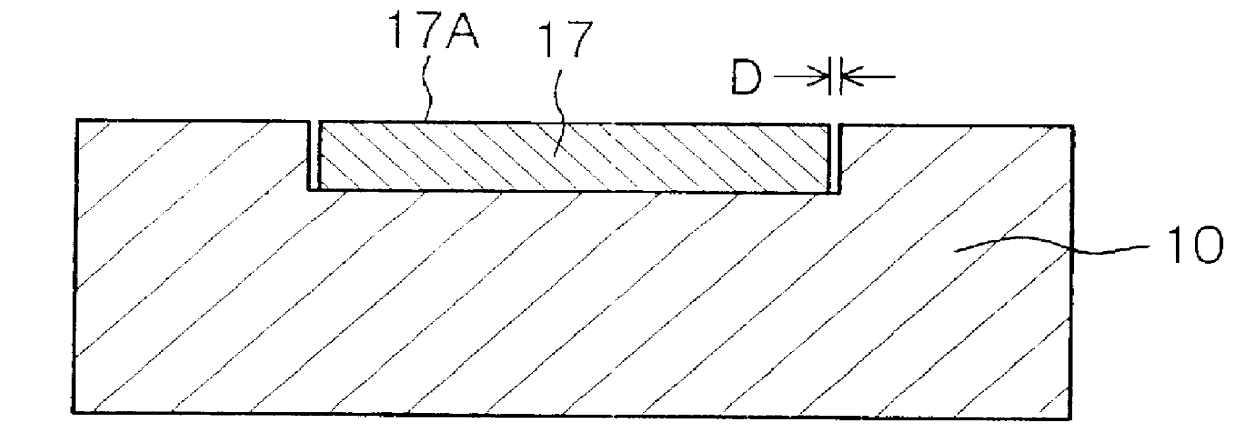

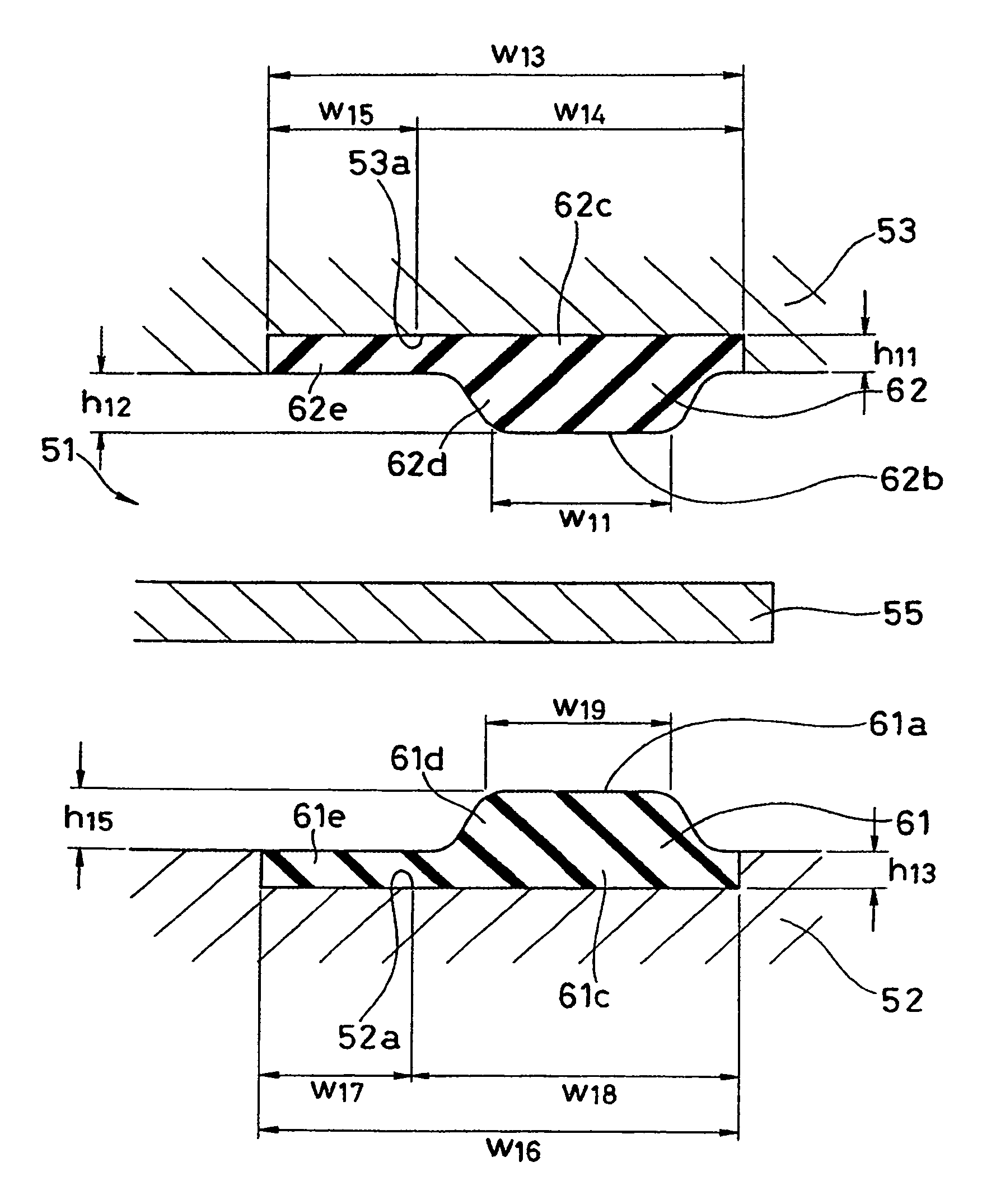

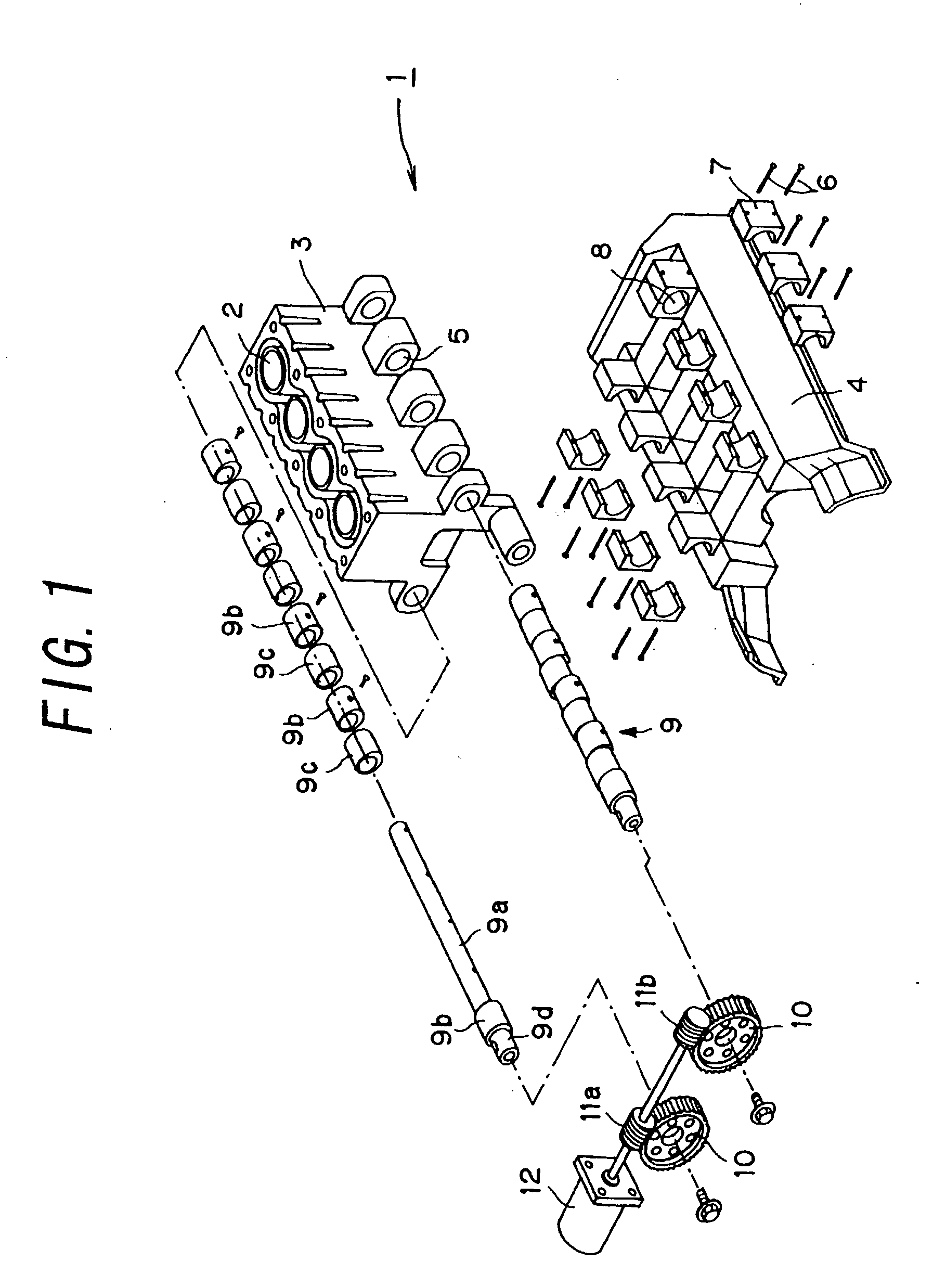

Mold assembly for molding thermoplastic resin and method of manufacturing molded article of thermoplastic resin

InactiveUS6165407AReduce residual stressReduce injection pressureConfectioneryOptical articlesMaterials scienceThermal conductivity

A mold assembly for molding a thermoplastic resin, which comprises; (a) a first mold member and a second mold member for manufacturing a molded article of a thermoplastic resin, (b) an insert block provided in the first mold member, said insert block constituting part of a cavity, having a thickness of 0.1 mm to 10 mm and being formed of a material having a thermal conductivity of 2x10-2 cal / cmxsecx DEG C. or less, and (c) a molten thermoplastic resin introduction portion provided in the second mold member, wherein an insert block covering portion is formed in the second mold member, and when the first mold member and the second mold member are clamped to each other, (A) a clearance between the insert block and the insert block covering portion is equal to, or less than, 0.03 mm, and (B) an amount of overlapping of the insert block and the insert block covering portion is equal to, or greater than, 0.5 mm.

Owner:MITSUBISHI ENG PLASTICS CORP

Gasket for fuel cell and method of forming it

In a gasket used for a fuel battery, in order to solve problems with respect to making a seal portion thin, improving an assembling property, preventing a position shift, making a surface pressure low, making the surface pressure uniform, and the like, a gasket lip made of a liquid rubber hardened material is integrally formed on a surface of a flat plate made of a carbon, a graphite, a conductive resin such as a conductive phenol resin or the like, an ion exchange resin, or a metal such as a stainless steel, a magnesium alloy or the like, or on a groove portion applied to the surface.

Owner:NOK CORP

Optimization of in-mold coating injection molded thermoplastic substrates

InactiveUS20020039656A1Reduce pressureIncrease coverageLiquid surface applicatorsMouldsPolyolefinShell molding

Owner:OMNOVA SERVICES

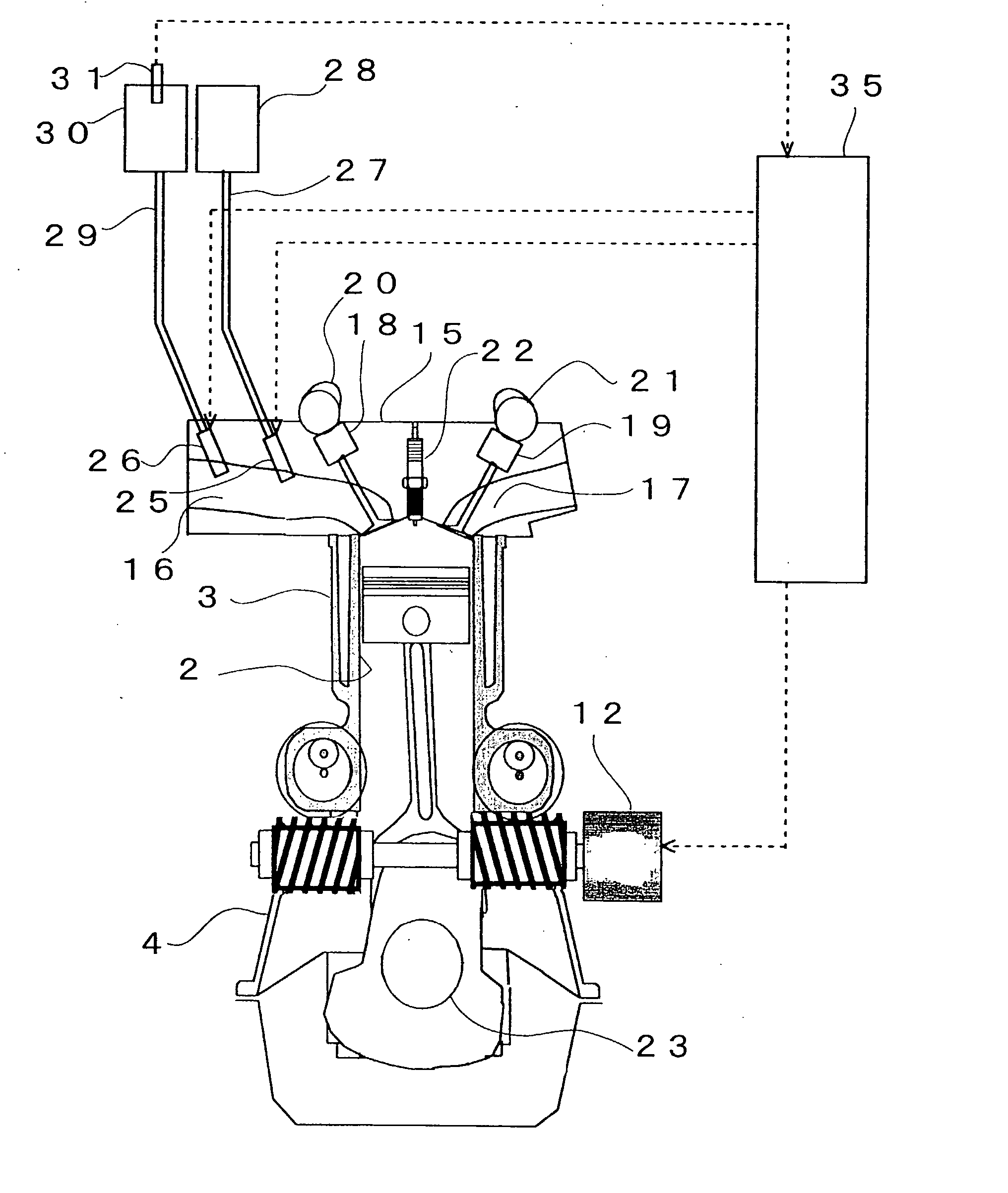

Variable Compression Ratio Internal Combustion Engine

InactiveUS20080022982A1Improve engine performanceImprove combustion efficiencyElectrical controlInternal combustion piston enginesCombustionFuel injection

The invention is directed to a variable compression ratio internal combustion engine in which the compression ratio of the engine can be varied and multiple types of fuels having different combustion velocities are used. The invention provides a technology for achieving excellent engine performance for respective types of fuels. In the variable compression ratio internal combustion engine in which the compression ratio can be varied and multiple types of fuels having different combustion velocities are injected through multiple fuel injection valves, maps from which a target compression ratio of the internal combustion engine is read out are switched in accordance with the fuel used, thereby suppressing knocking or other disadvantages.

Owner:TOYOTA JIDOSHA KK

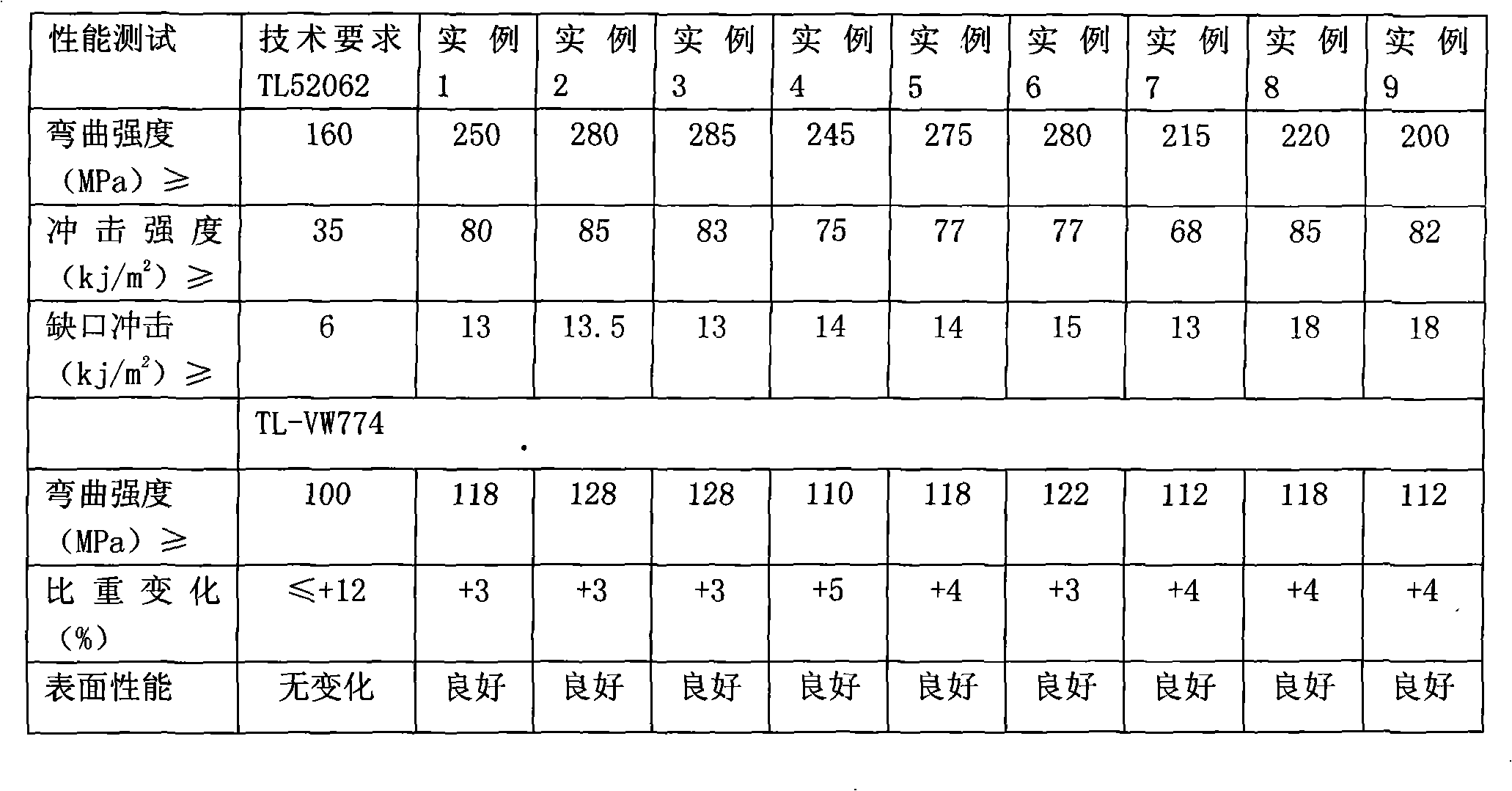

Alcoholysis resistance nylon composite material and preparation method thereof

The invention provides an alcoholysis resistance nylon composite material and a preparation method thereof; the composite material is applicable to the cooling water chamber of vehicles and comprises nylon, short glass fiber, glass fiber emergence resistance regulating additive, nucleating agent, colorant, heat stabilizer and alcoholysis resistance additive. The physical property of the nylon composite material provided by the invention can meet or exceed the TL52062 technical requirement and the alcoholysis resistance chemical property can meet the TL-VW774 technical requirement so that the surface of the product does not change and crack after being placing in 100% of glycol solution for 48h at 135 DEG C and the product has high shock resistance and dimension stability, thus ensuring that the stress cracking does not appear on joints.

Owner:辰东意普万新材料(广东)有限公司

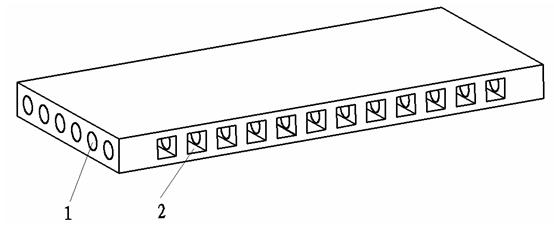

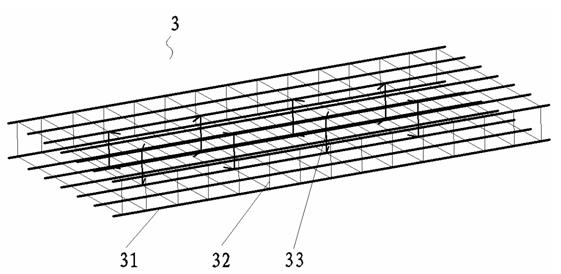

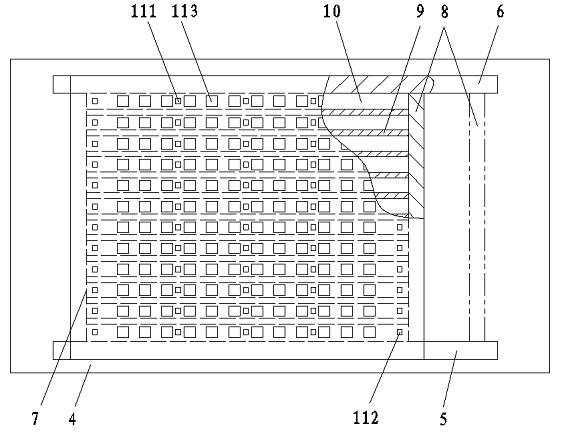

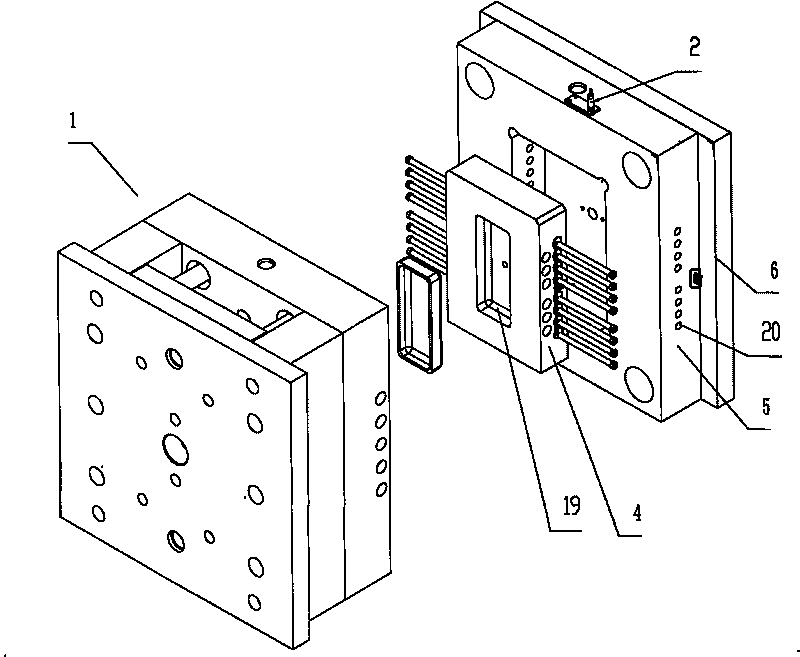

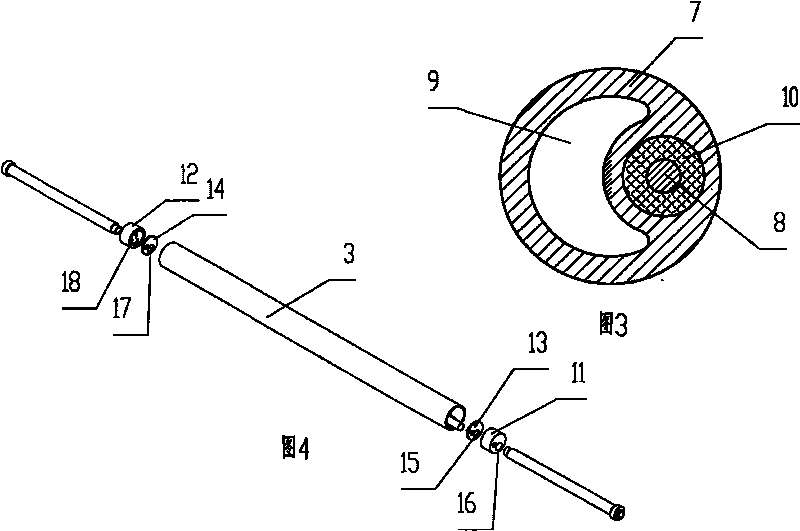

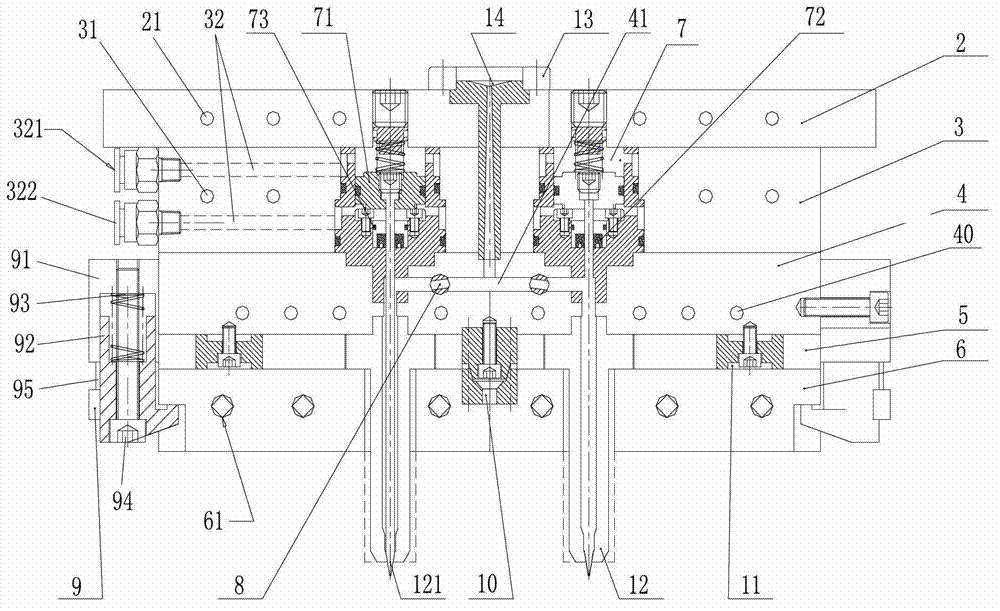

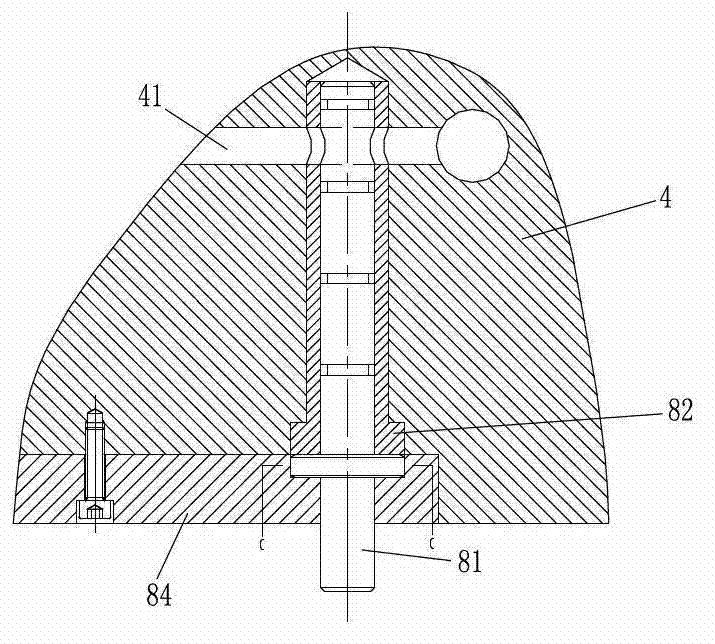

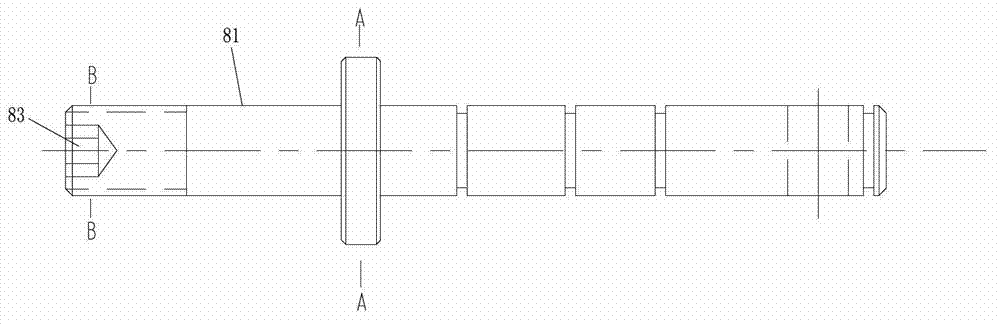

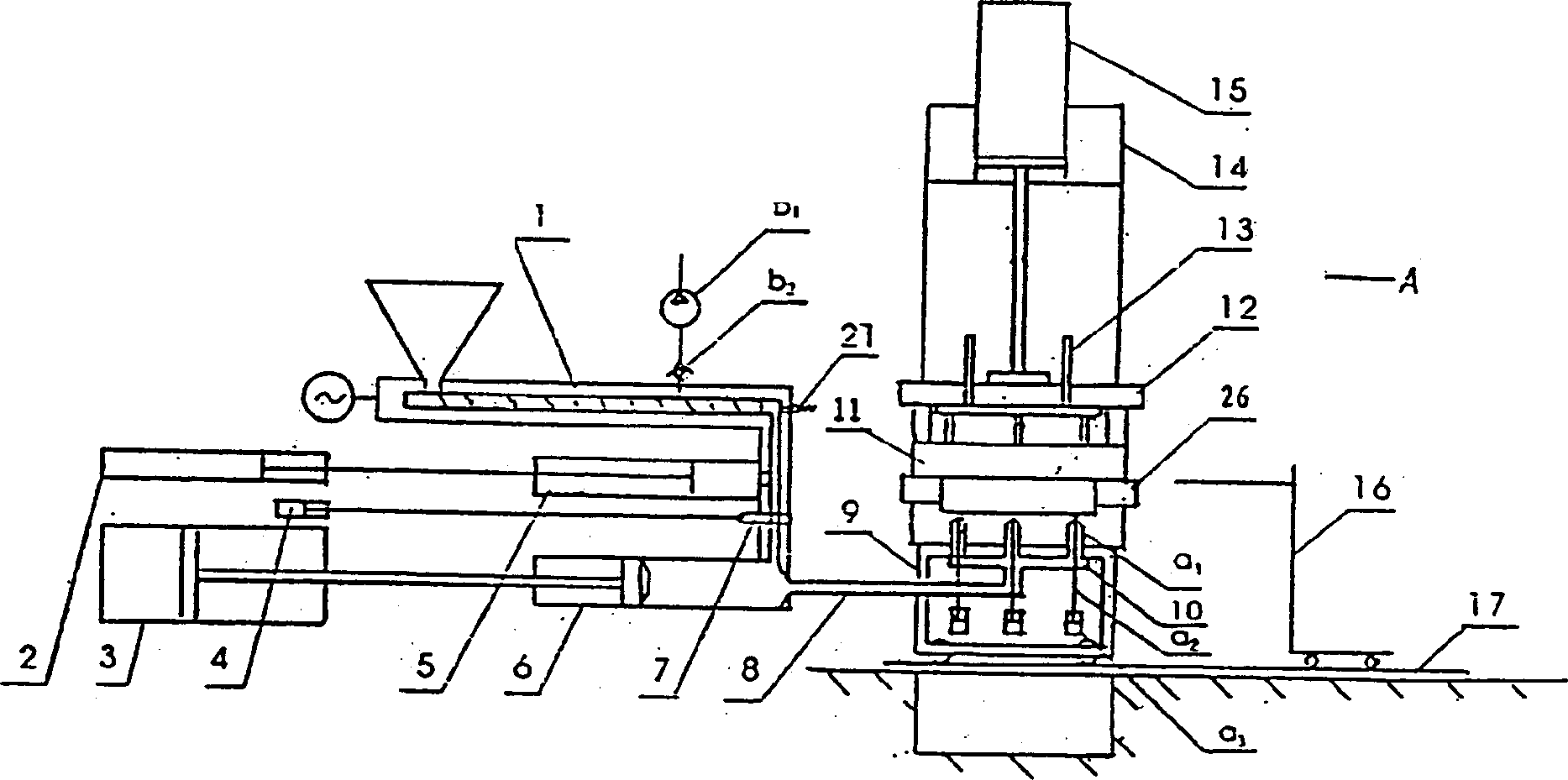

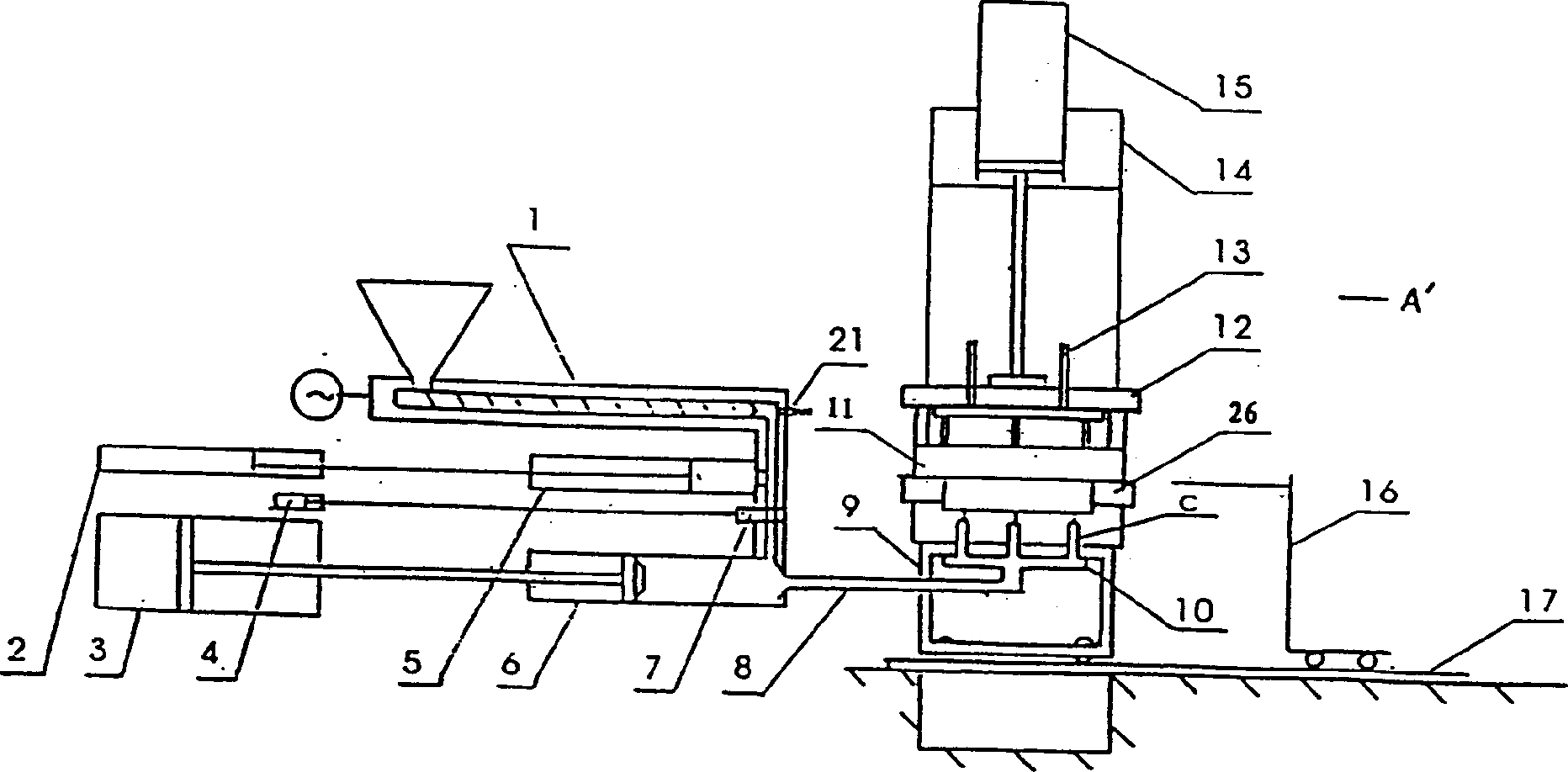

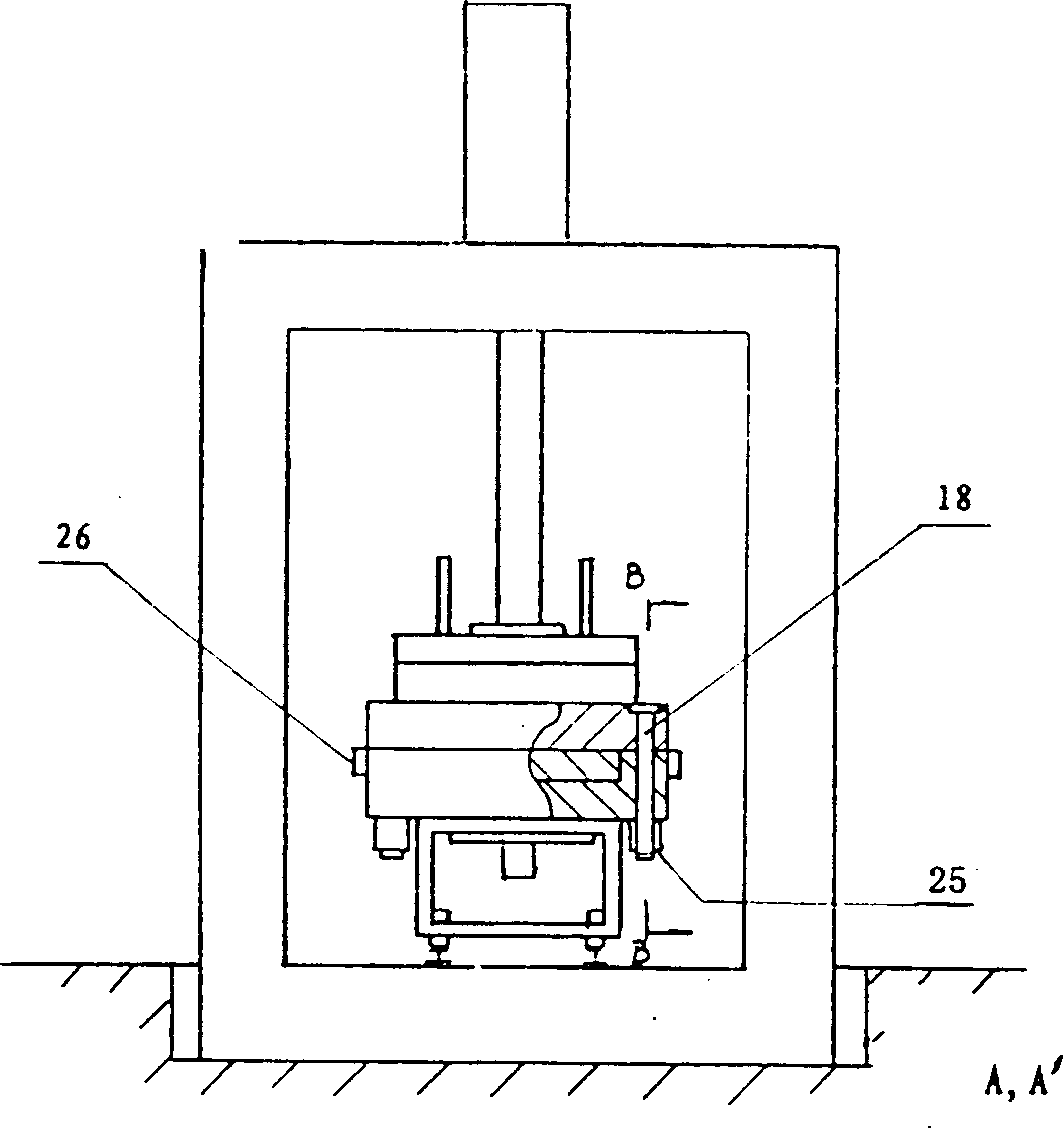

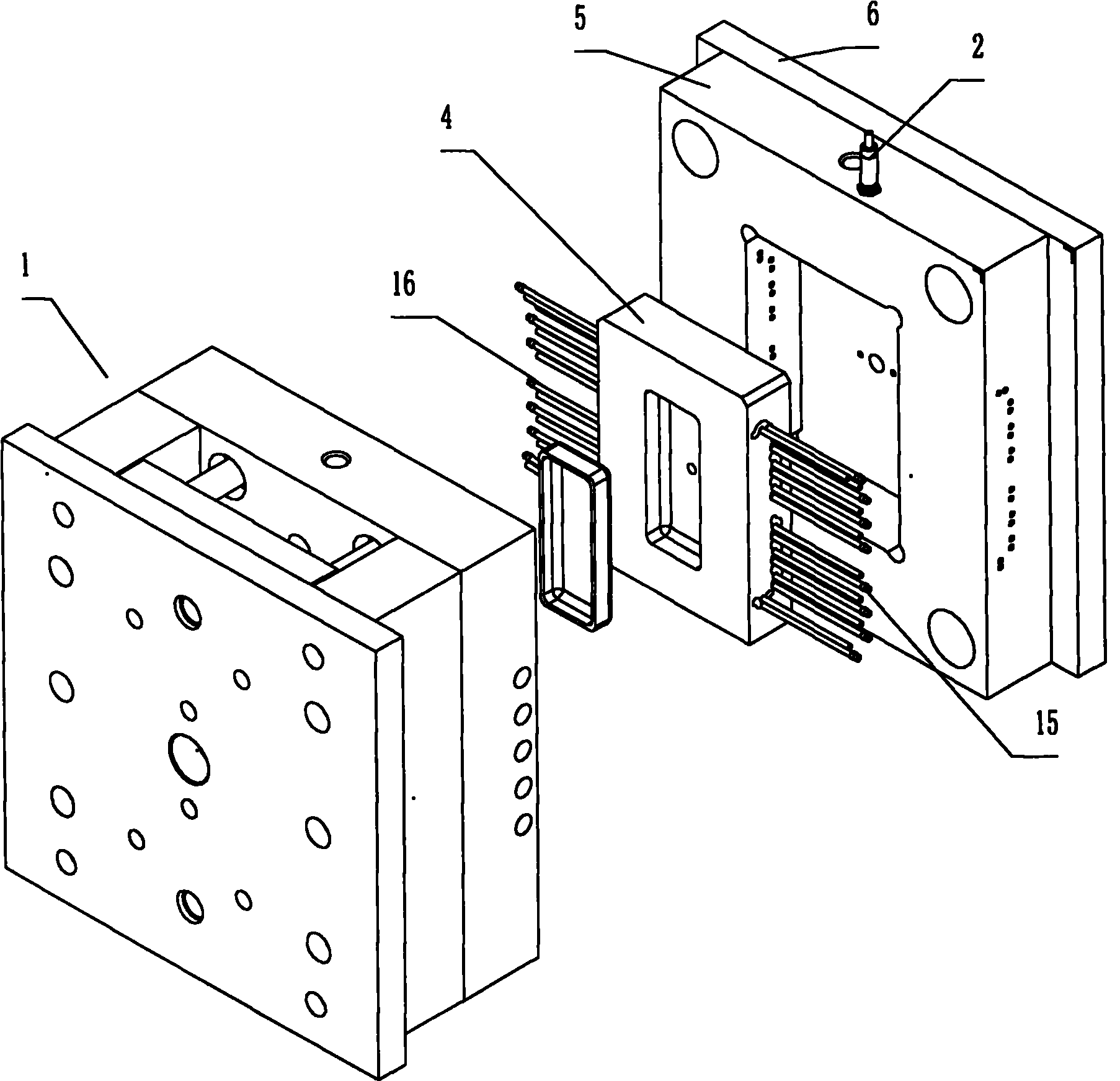

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

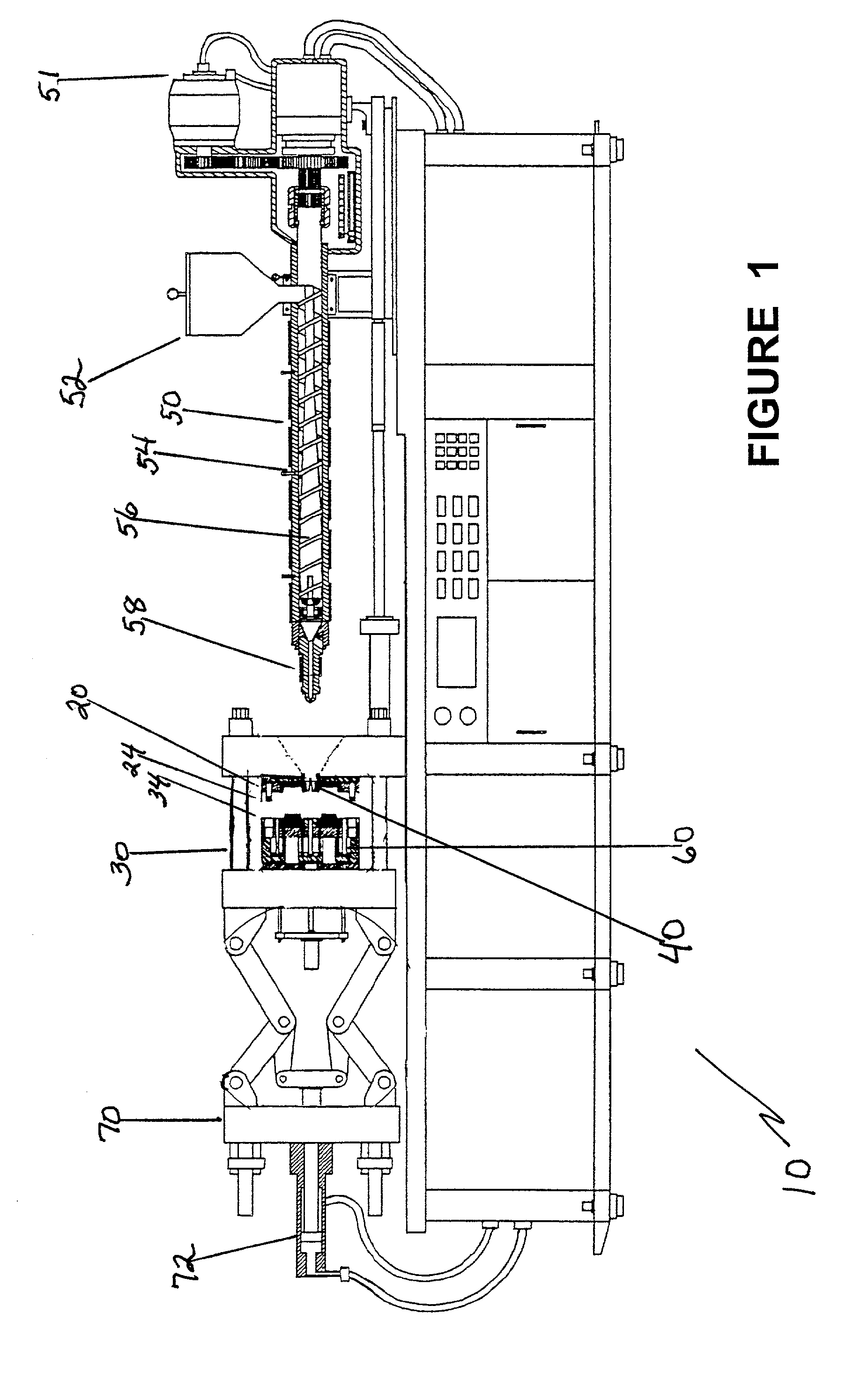

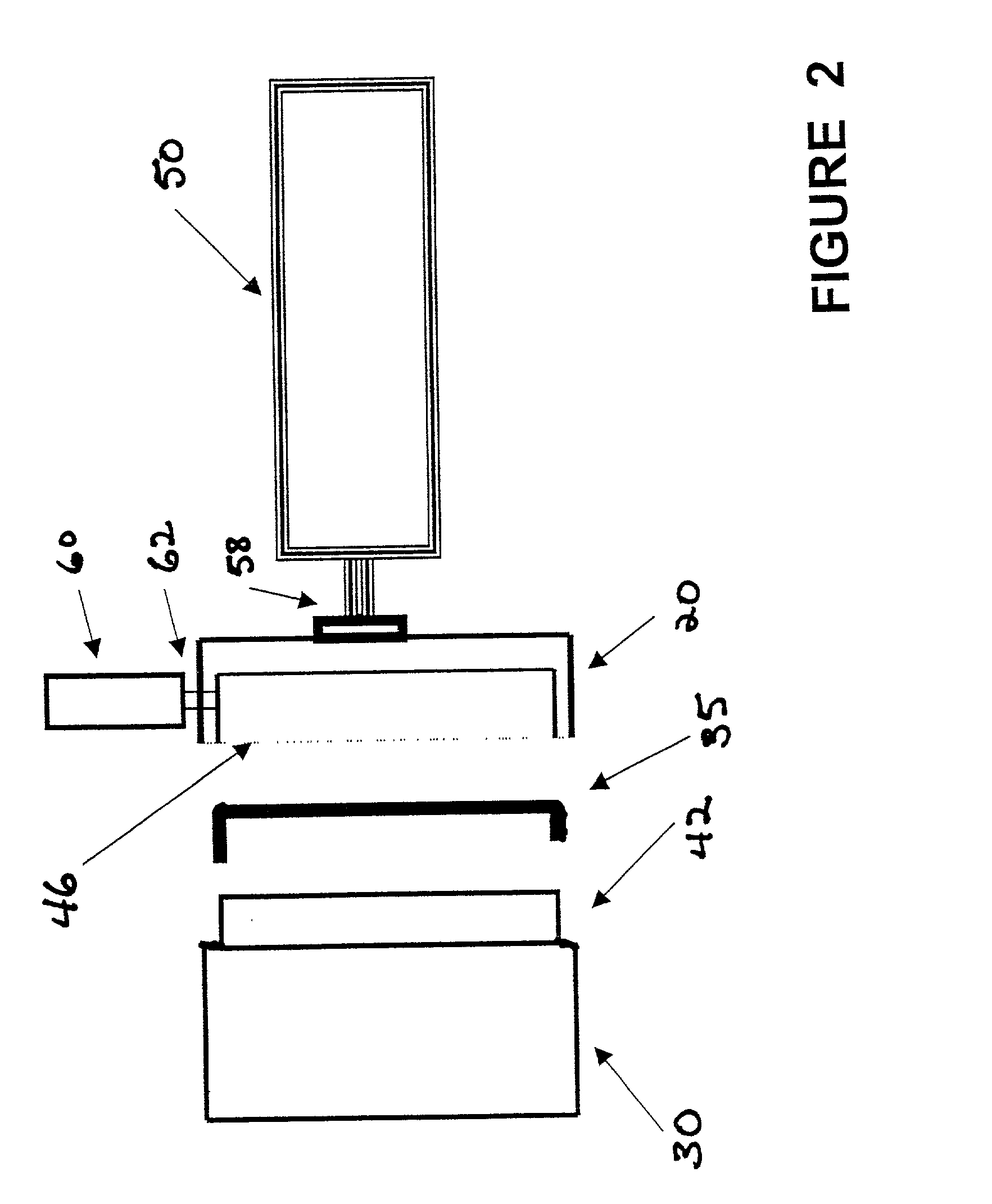

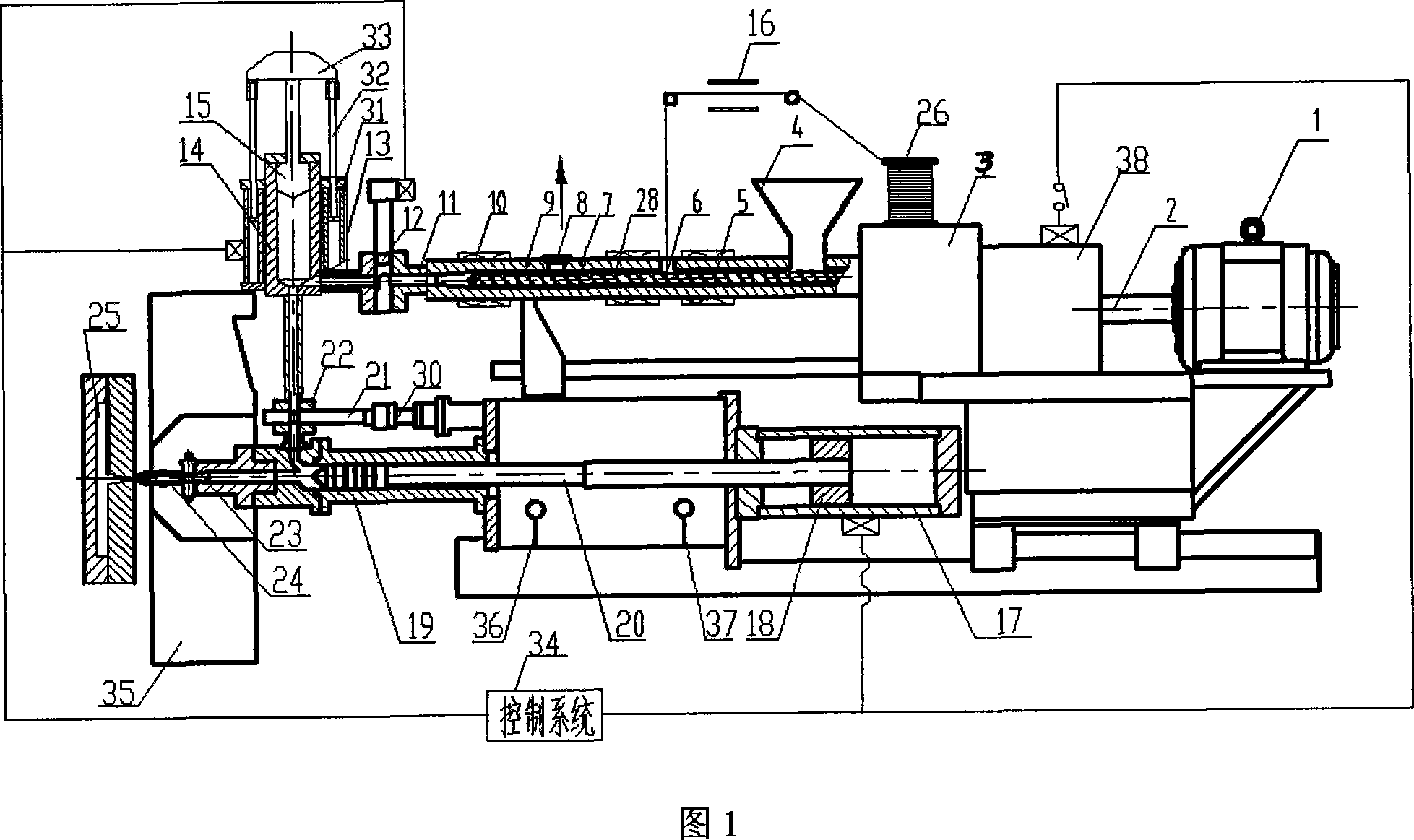

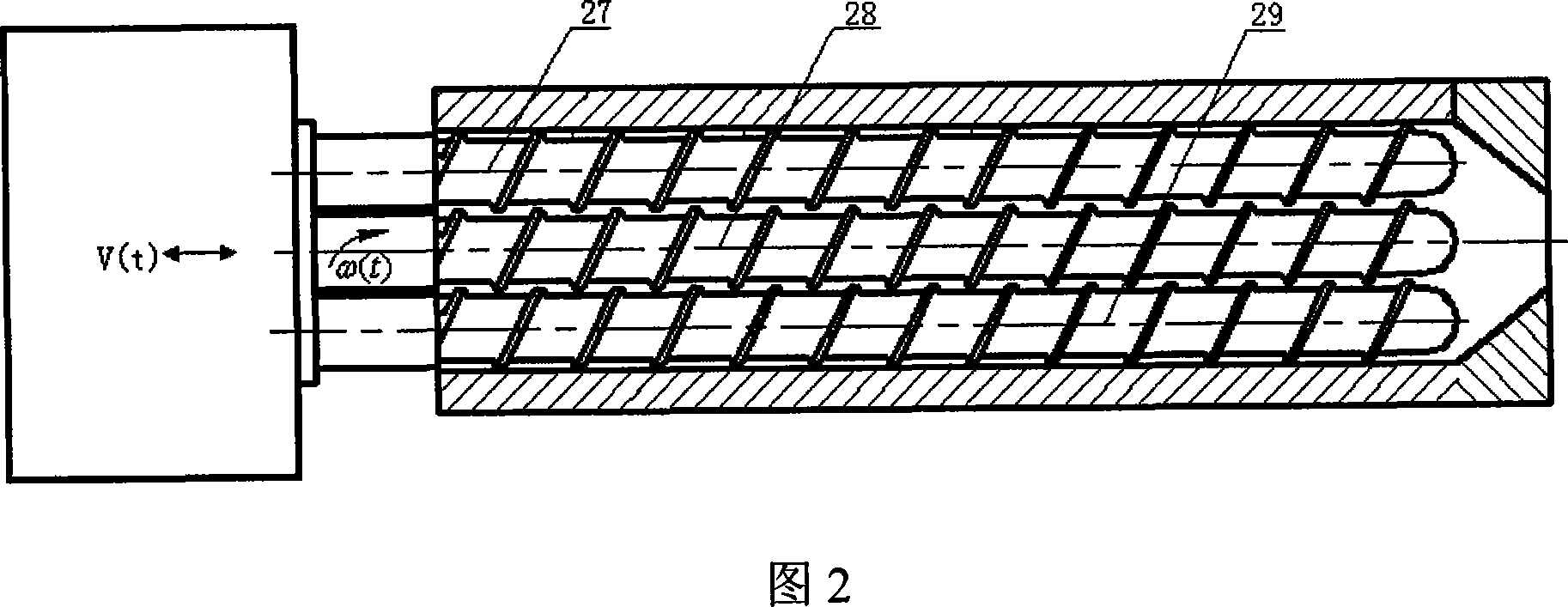

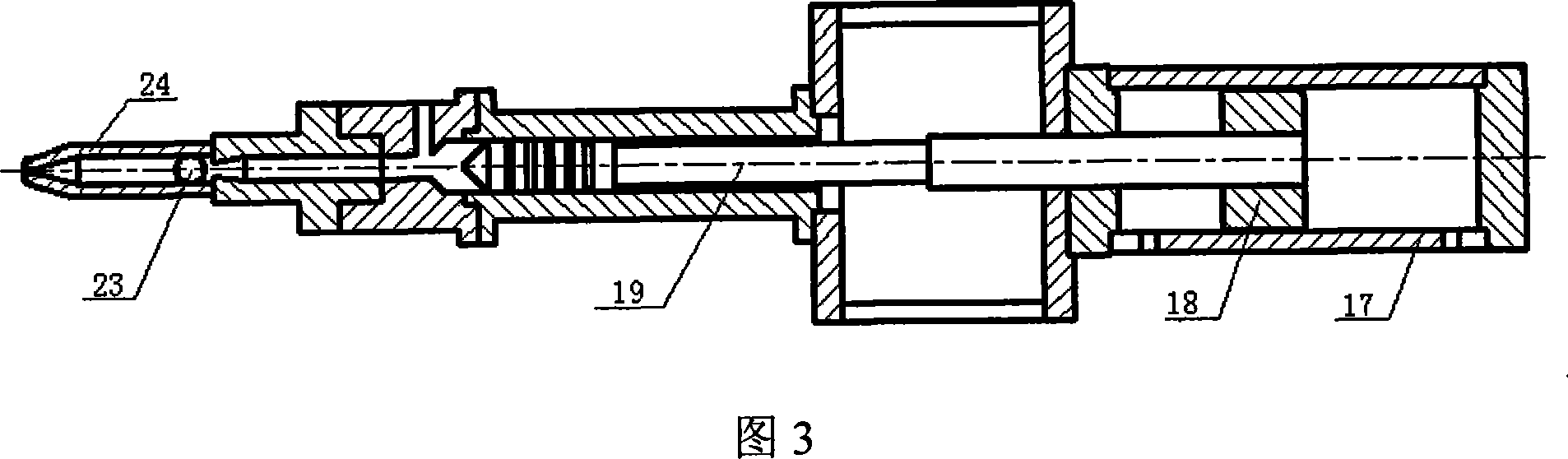

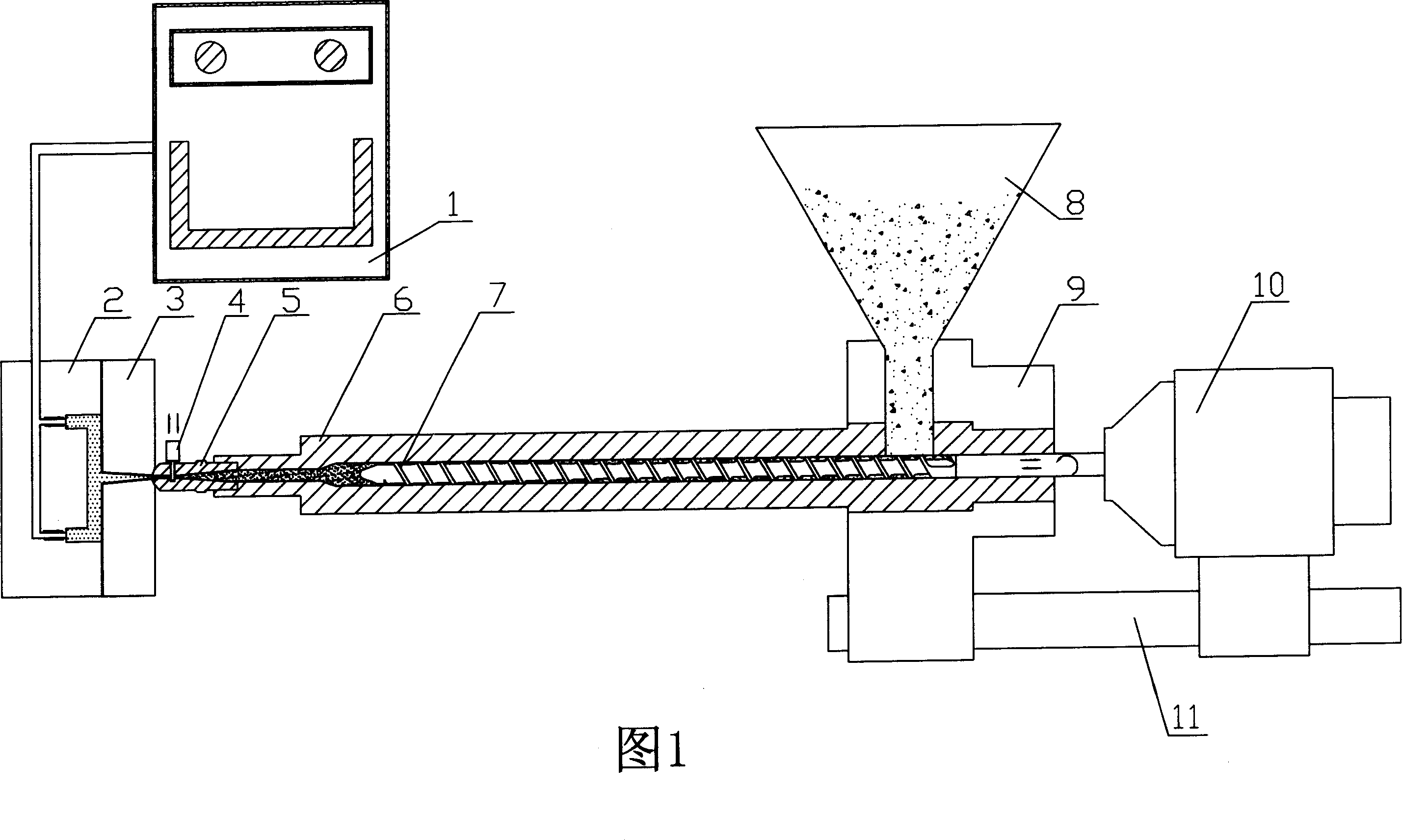

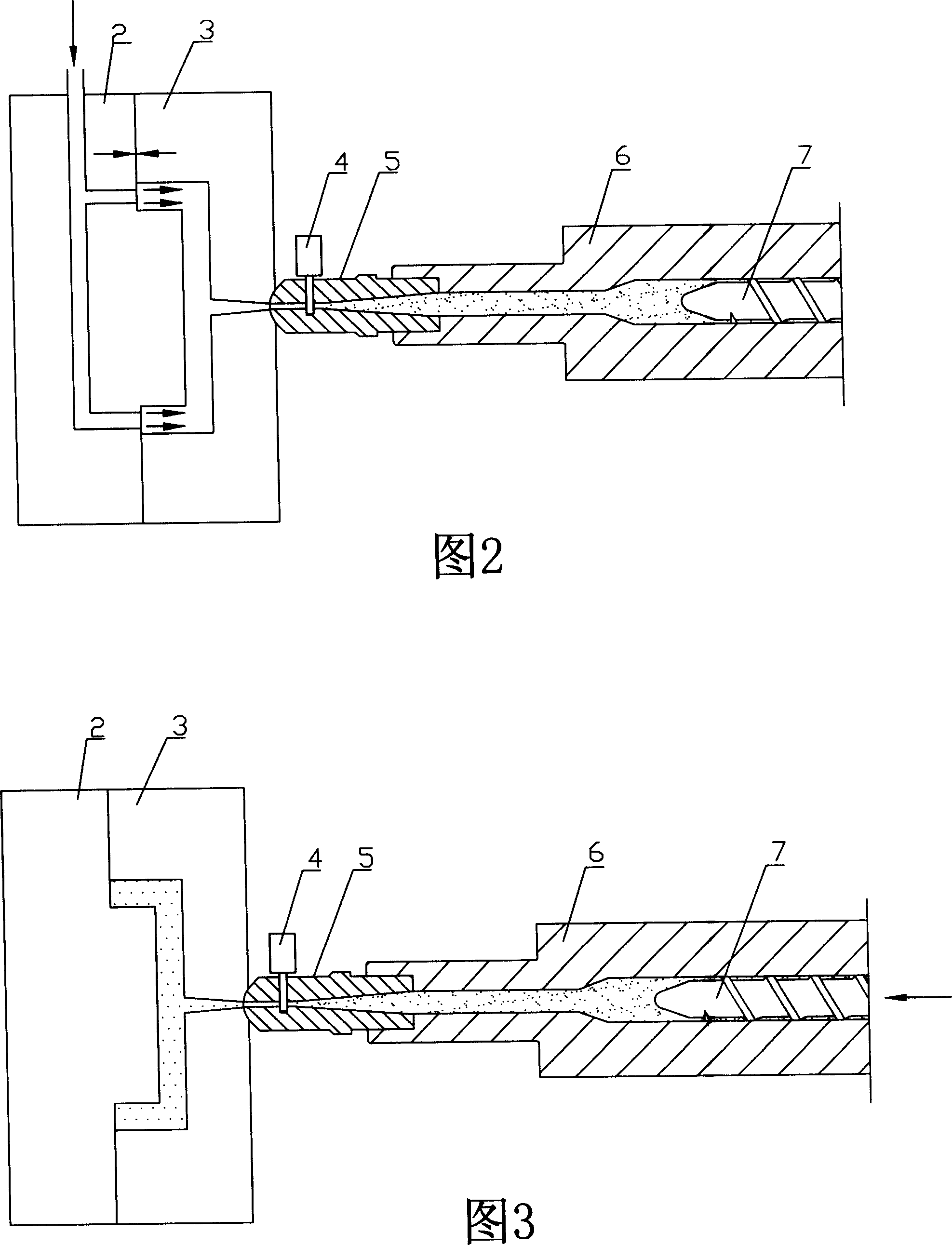

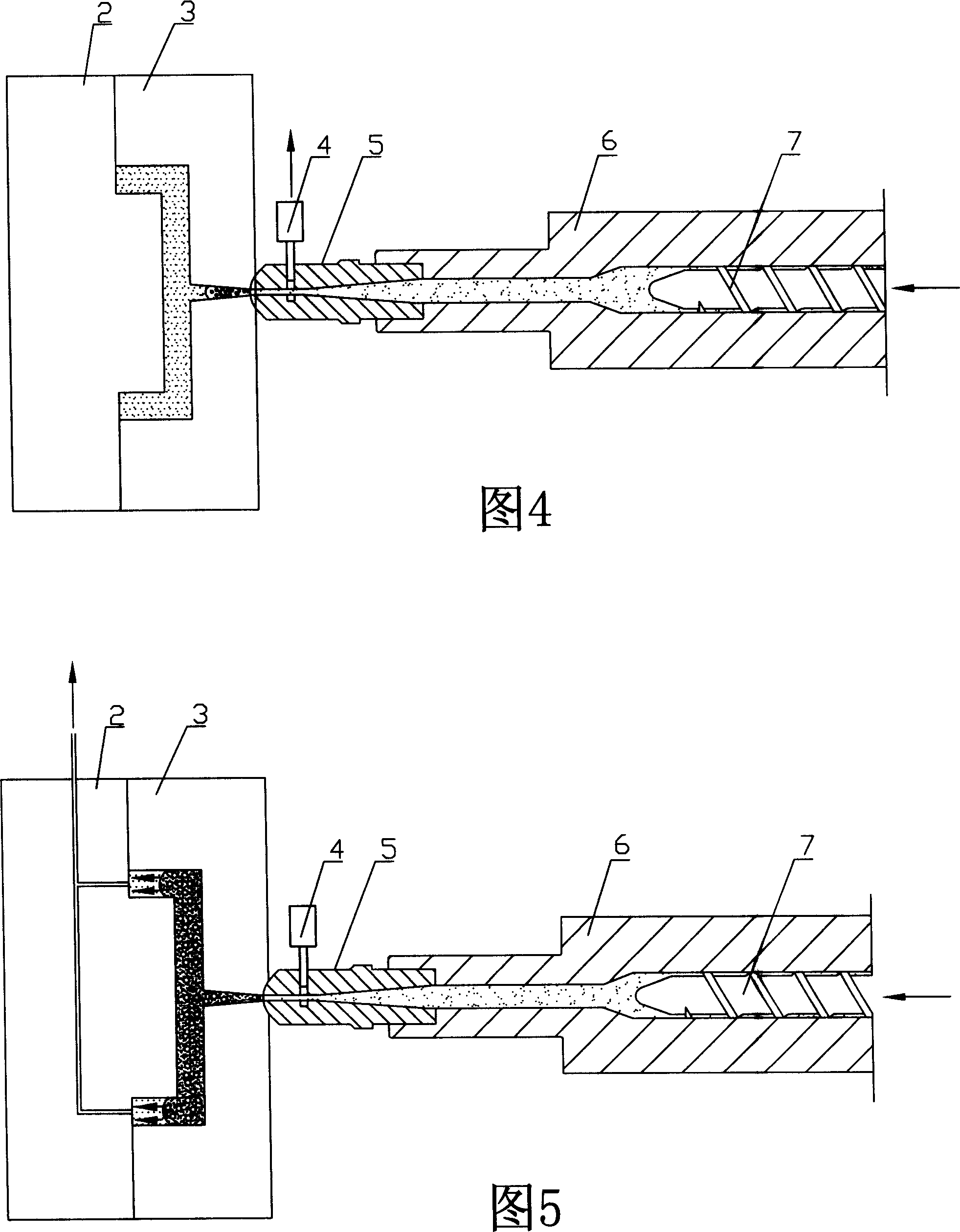

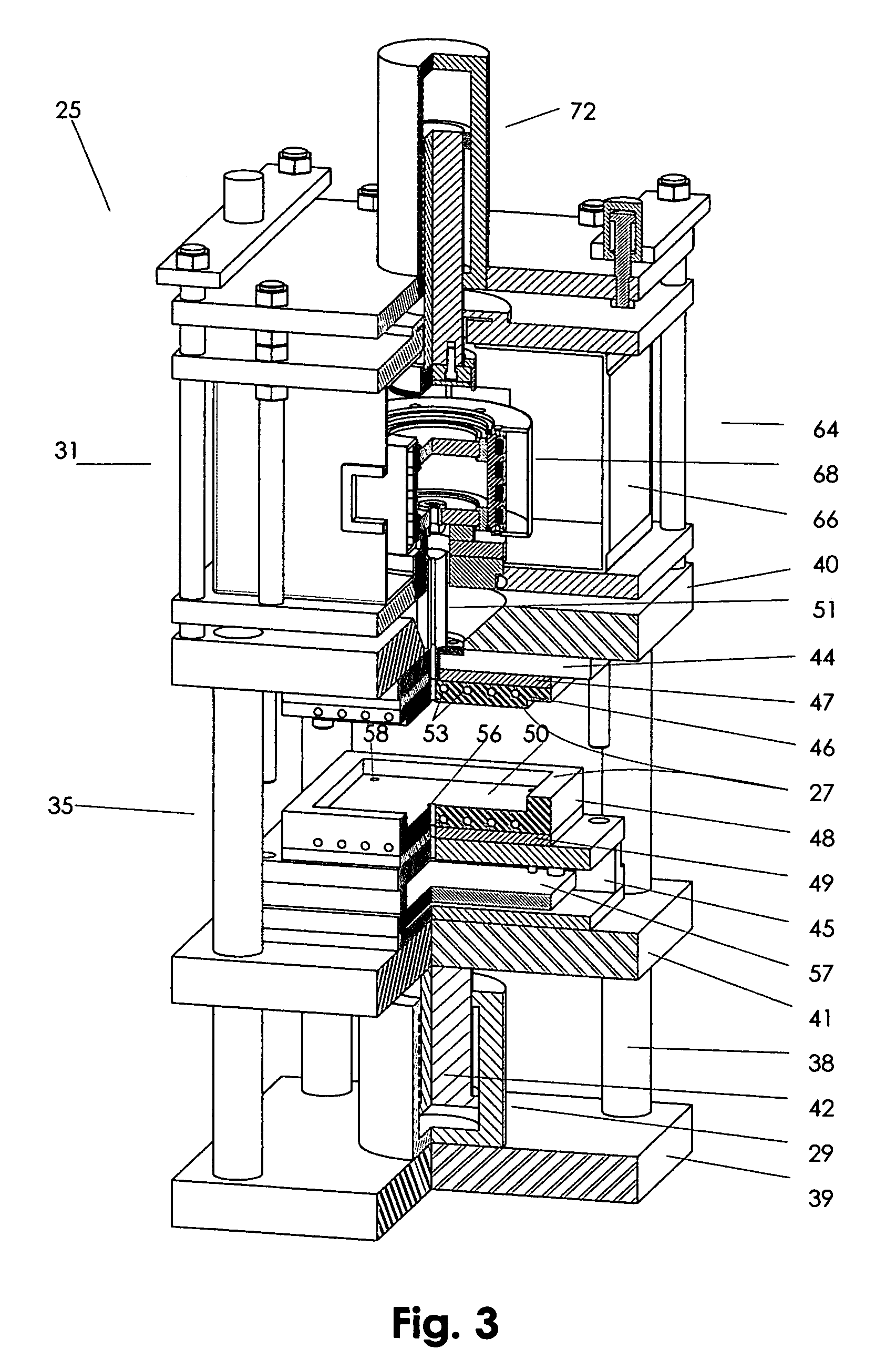

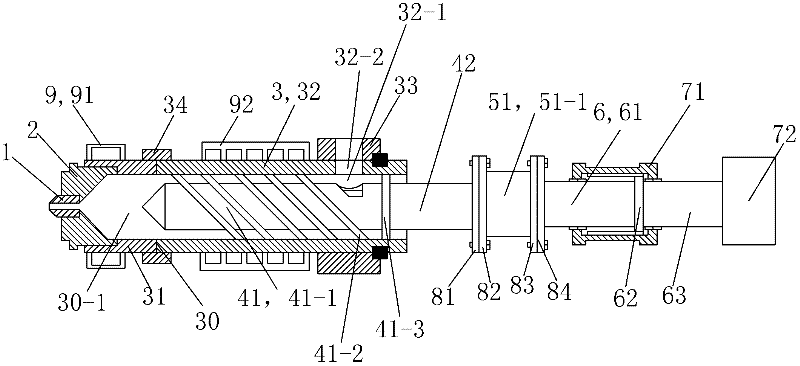

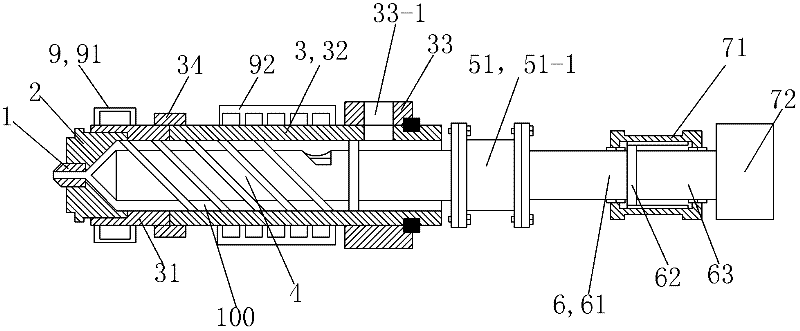

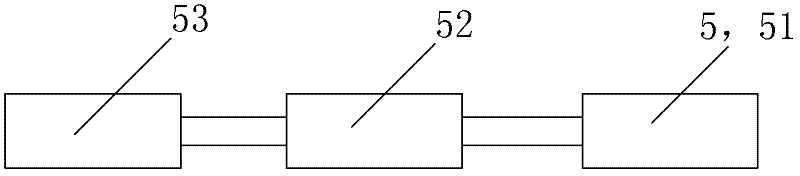

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

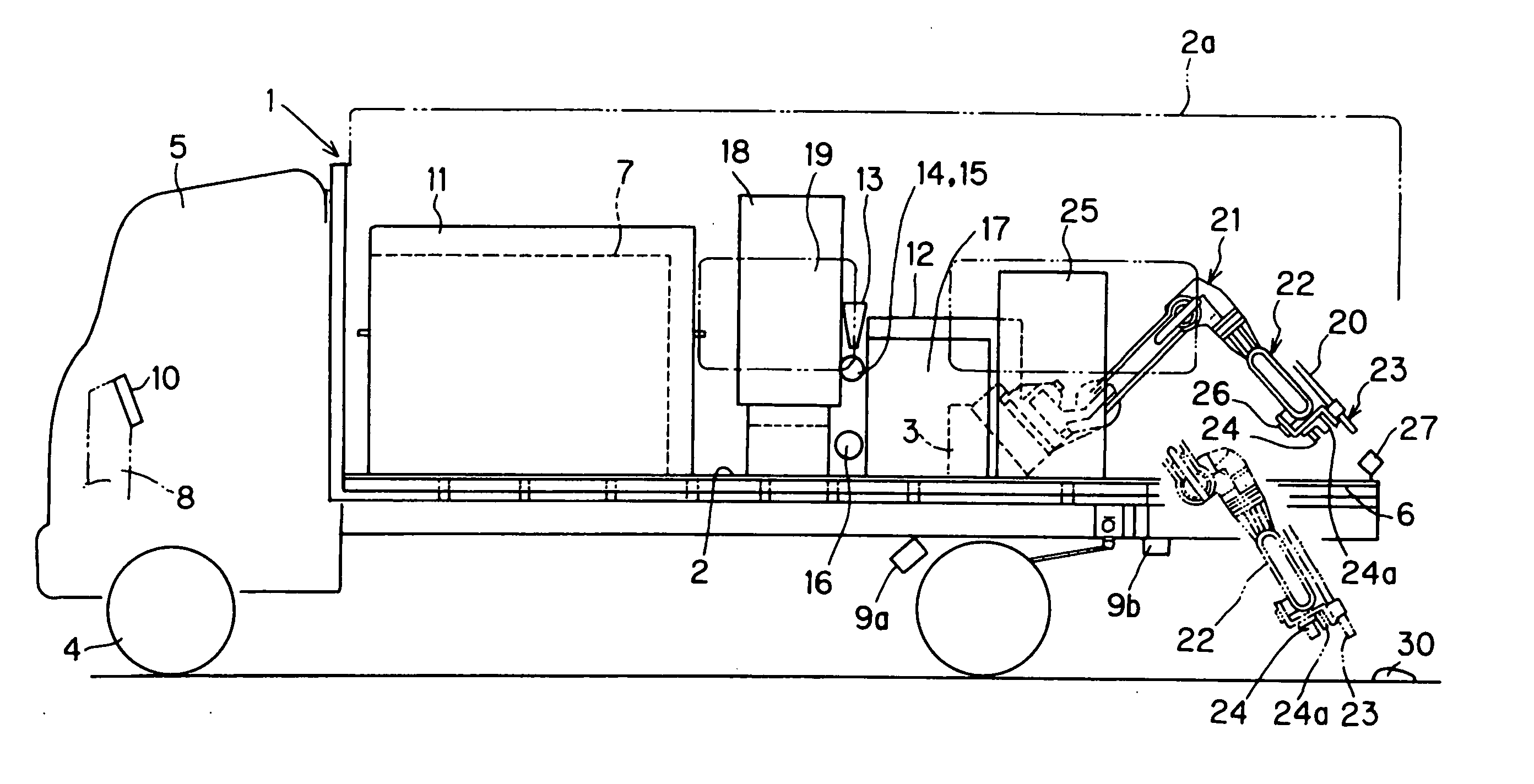

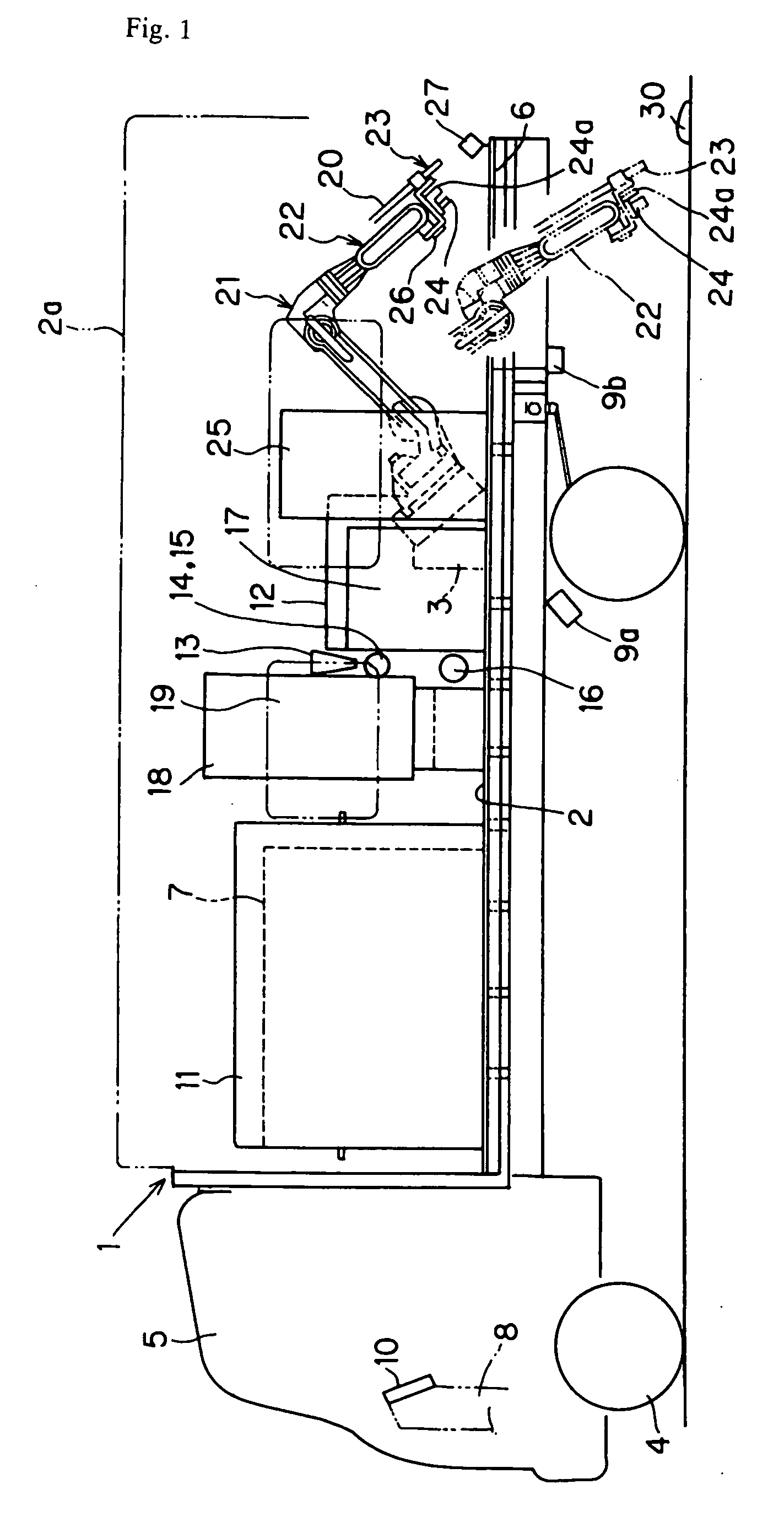

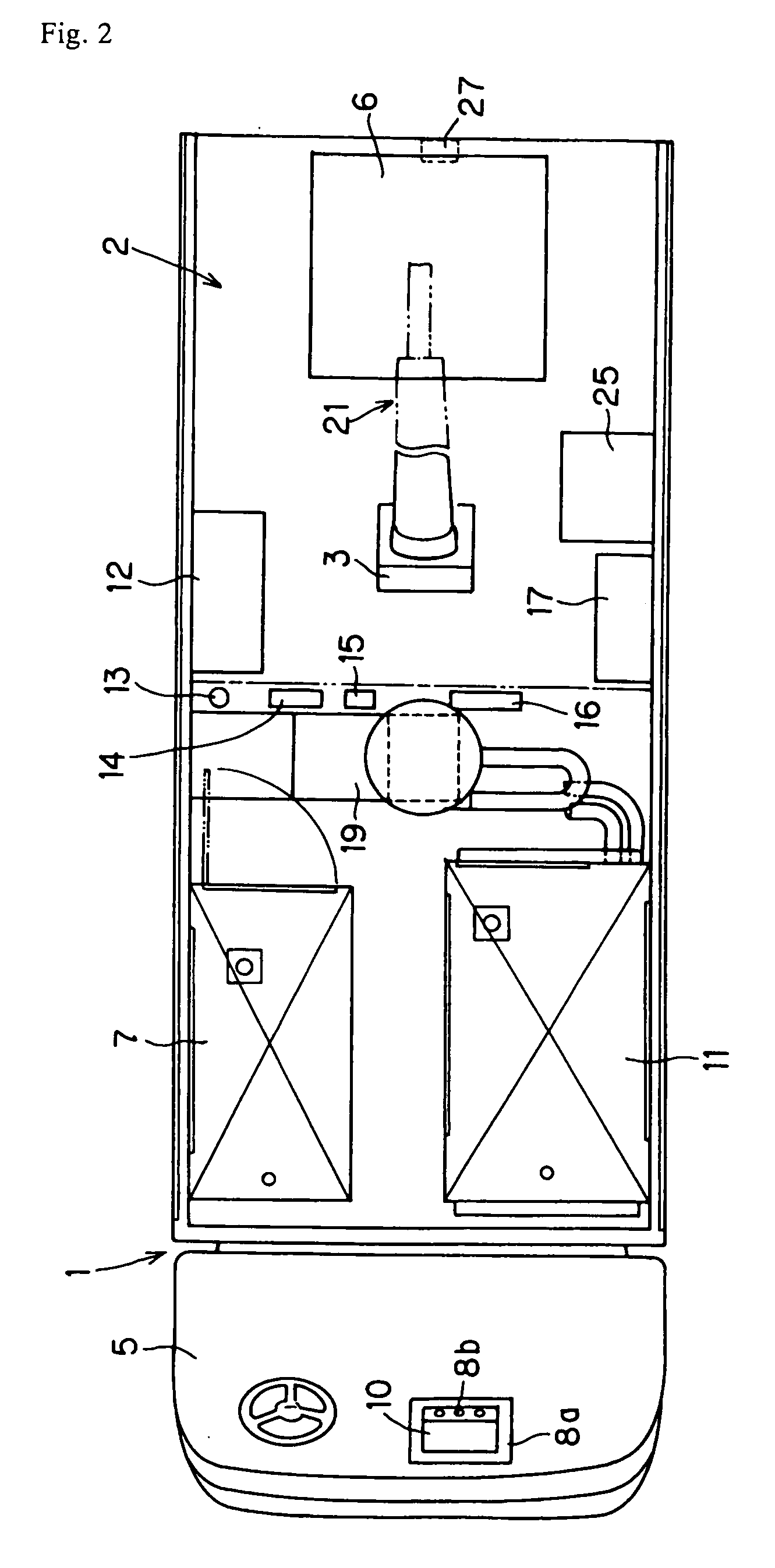

Method and system for cleaning

ActiveUS20070037484A1Environmental loading can be suppressedImprove propertiesGrinding feed controlTraffic signalsRoad surfaceEngineering

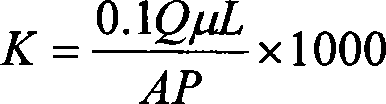

A method and a system for cleaning the glass surface of an object, such as a surface light, a run way guide light, or a reflector, installed on various pavements or roads, by propelling a cleaning agent from a blast nozzle to the glass surface. The blast nozzle is installed on the front end of an arm of a working robot mounted on a truck. A truck mounted with a cleaning agent blaster and a working robot (21) provided with a blast nozzle (23) and a CCD camera (24) at the forward end of a manipulator is stopped at a specified position in the vicinity of an object to be cleaned, i.e. surface light or a reflection mirror (30). Based on an image of the object taken by the CCD camera (24), dimensions are recognized from distance information through processing by a vehicle-mounted computer, the image shape of the object is collated with a stored shape and recognized, and then positional information of the recognized object is searched. Cleaning agent is propelled from the blast nozzle (23) at the forward end of the manipulator (22) toward the object while measuring the extent of cleaning, brightness or light intensity of the cleaned object is determined by the CCD camera, and automatic cleaning is performed.

Owner:SANKI ENG CO LTD

Three-segment type block releasing technique for oil layer

InactiveCN101196109ARestore or increase permeabilityReduce energy consumptionFluid removalDrilling compositionChemistryMaterial Perforation

The invention relates to an oil layer three-section block removing technology with excellent block removing effect. A block removing agent will be injected at three sections; then, clear water will be injected after the reaction of 4 to 24 hours at each section; the quantity of clear water will be 1 to 2 times of the sum between the volume of an oil pipe and the volume of the circular space from the bottom of the oil pipe to the top of a perforation interval. Because the composition and function of the block removing agents different from each other, the invention can be applied in a broad scope to adopt to the needs in various stratum, realize excellent block removing effect with the removing rate of over 75 percent, thus satisfying the industrial needs.

Owner:DAQING GASOLINEEUM INST +1

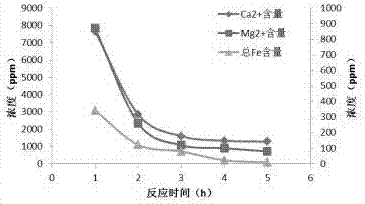

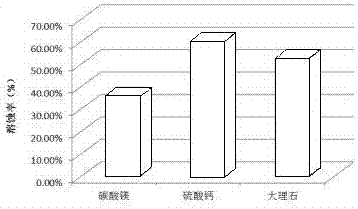

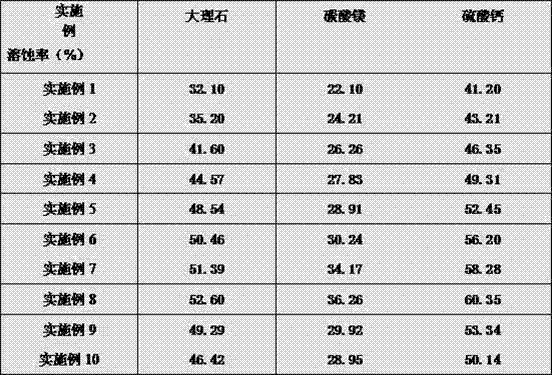

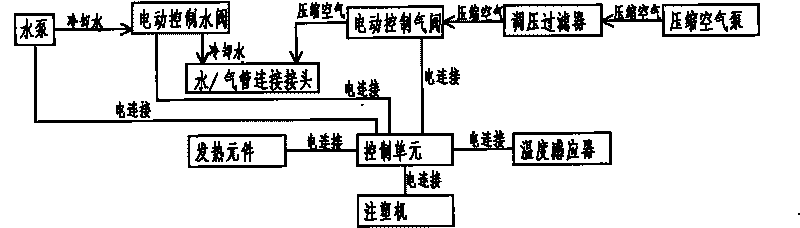

Chelate blocking remover suitable for complicated scaling reservoir layers, and preparation method of chelate blocking remover

ActiveCN106867490ASatisfy the blocking conditionLow flow resistanceDrilling compositionInjection pressureSulfate

The invention provides a chelate blocking remover suitable for complicated scaling reservoir layers, and a preparation method of the chelate blocking remover. The chelate blocking remover is prepared from the following components by mass percent: 5-20% of a chelating agent, 0.5-1% of a scale inhibitor, 1-5% of an activator, 0.5-2% of a penetrant and the balance of distilled water. The chelate blocking remover can remove most of complex blockages, formed by complex inorganic scale such as carbonate scale and sulphate scale, and organic scale at immediate vicinity of wellbore zones with scaled oil reservoir, can inhibit the growth of the scale, and prolongs the action time. The chelate blocking remover is mainly used for removing complex scale blockages such as calcium carbonate, calcium sulfate, barium strontium sulfate scale and iron sulfide; the scale blockages are removed by means of saturated dispersion, chelating solubilization and crystal nucleus distortion; the chelate blocking remover can be used for dredging seepage channels of shafts and stratum, reducing oil gas water flow resistance, increasing the yield of an oil-gas well and reducing the injection pressure of a water injection well; furthermore, the chelate blocking remover has certain corrosion inhibition property and dissolution property, thus meeting the blockage removing conditions of the complicated scaling reservoir layers.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

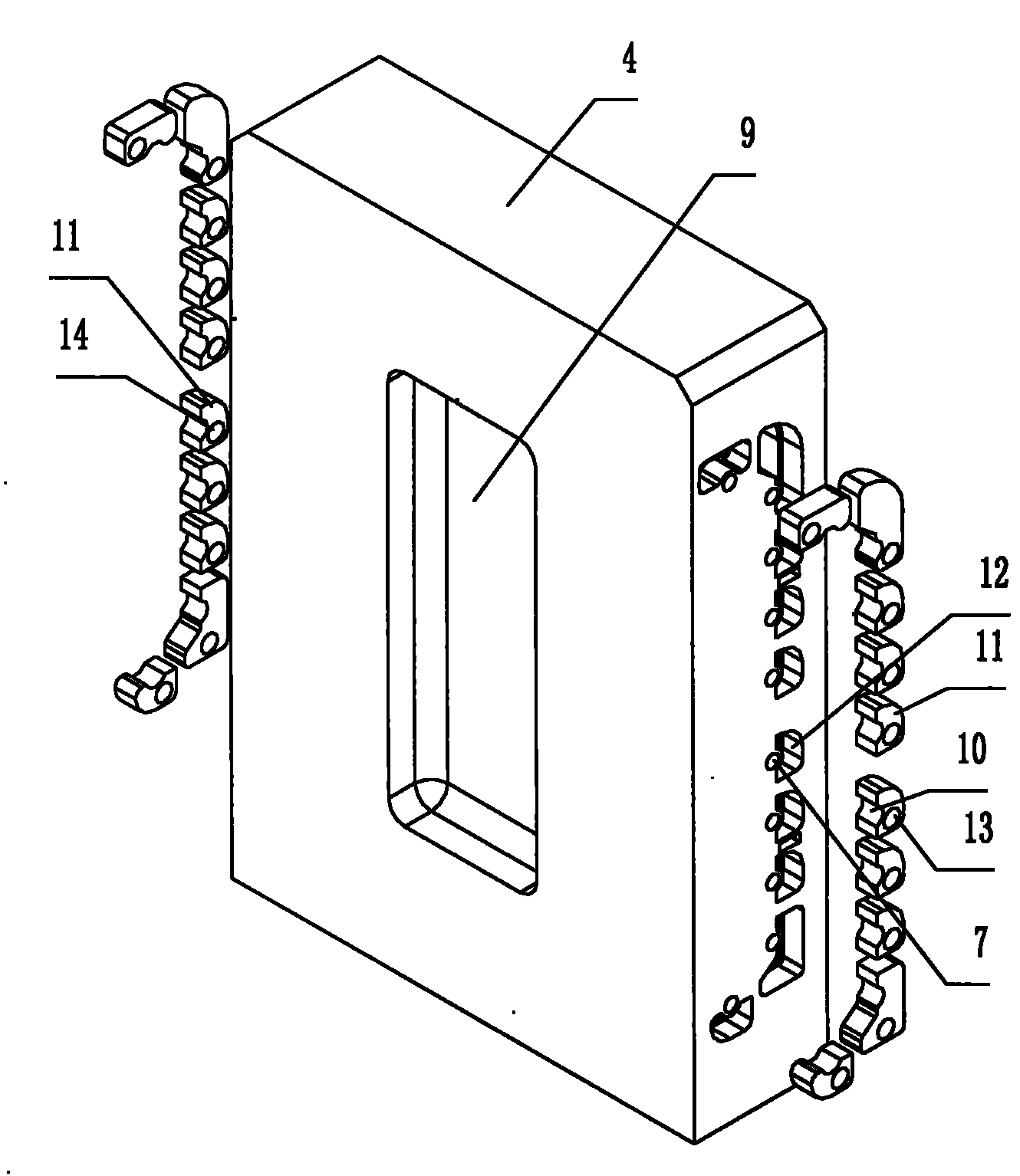

Mold heating and cooling rod and mold capable of realizing rapid cooling and rapid heating

The invention relates to a mold heating and cooling rod which comprises a heating and cooling rod body and a heating element, a cooling thermal insulation hole for introducing a cooling medium when a mold needs to be cooled and discharging the cooling medium when the mold needs to be heated and a heating element accommodating hole are arranged in the heating and cooling rod body along the axial direction, and the heating element is mounted in the heating element accommodating hole; the mold capable of realizing rapid cooling and rapid heating comprises a mold core and the heating and cooling rod, and the heating and cooling rod is in contact with the mold core; and one side of the heating and cooling rod which is provided with the heating element is near to a molding surface of the mold core. The advantages are that, as the molding surface can be rapidly and evenly heated and cooled and rapidly heated to the temperature which is near to or equal to that of melting materials, a molded product has the advantages of good quality, difficult production of weld marks, flow marks, surface bubbles and the like, even color and luster, even density of the product, small shrinkage and ability of reducing the injection pressure and the product deformation caused by residual stress after consolidating and molding the molten materials.

Owner:杨东佐

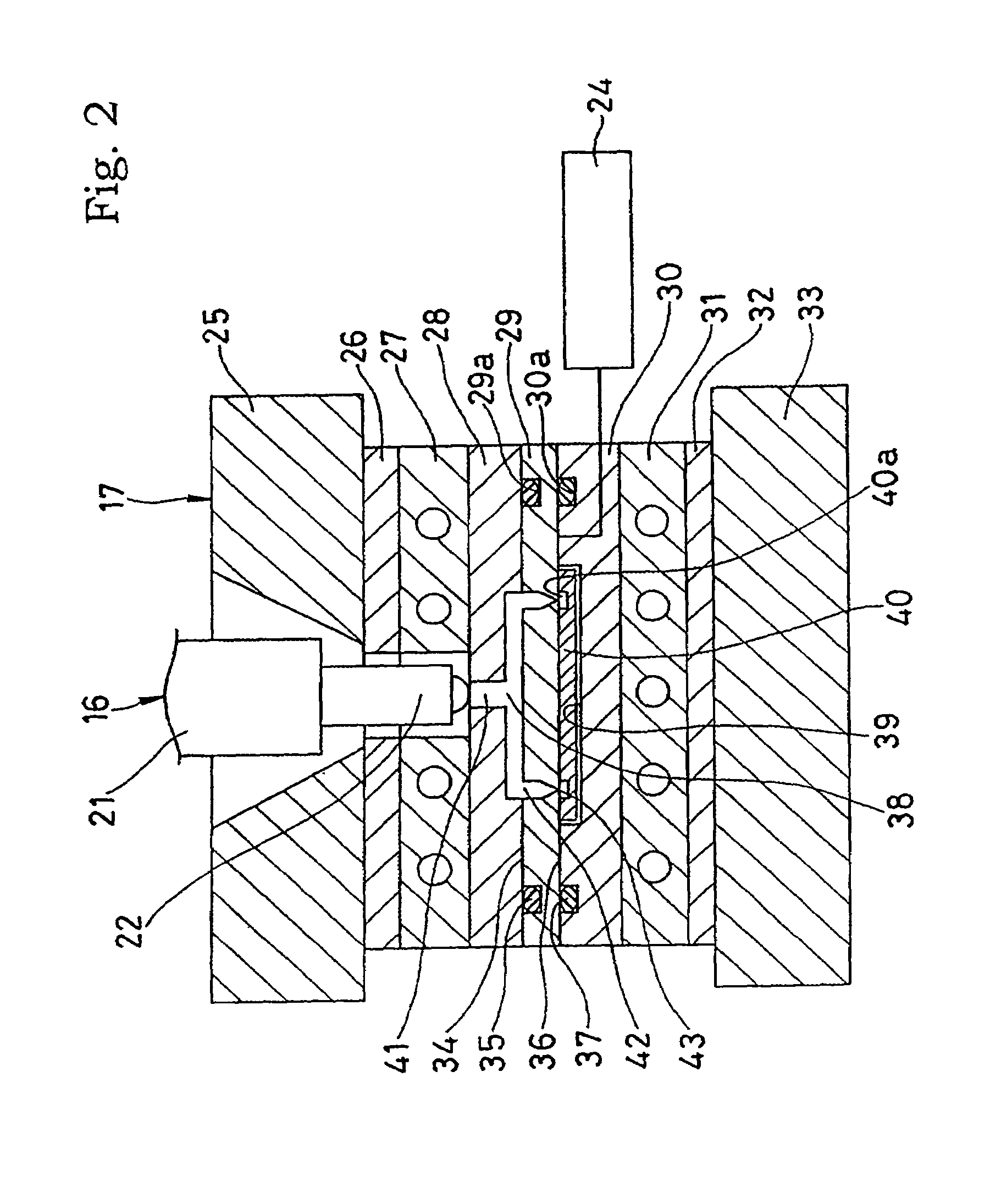

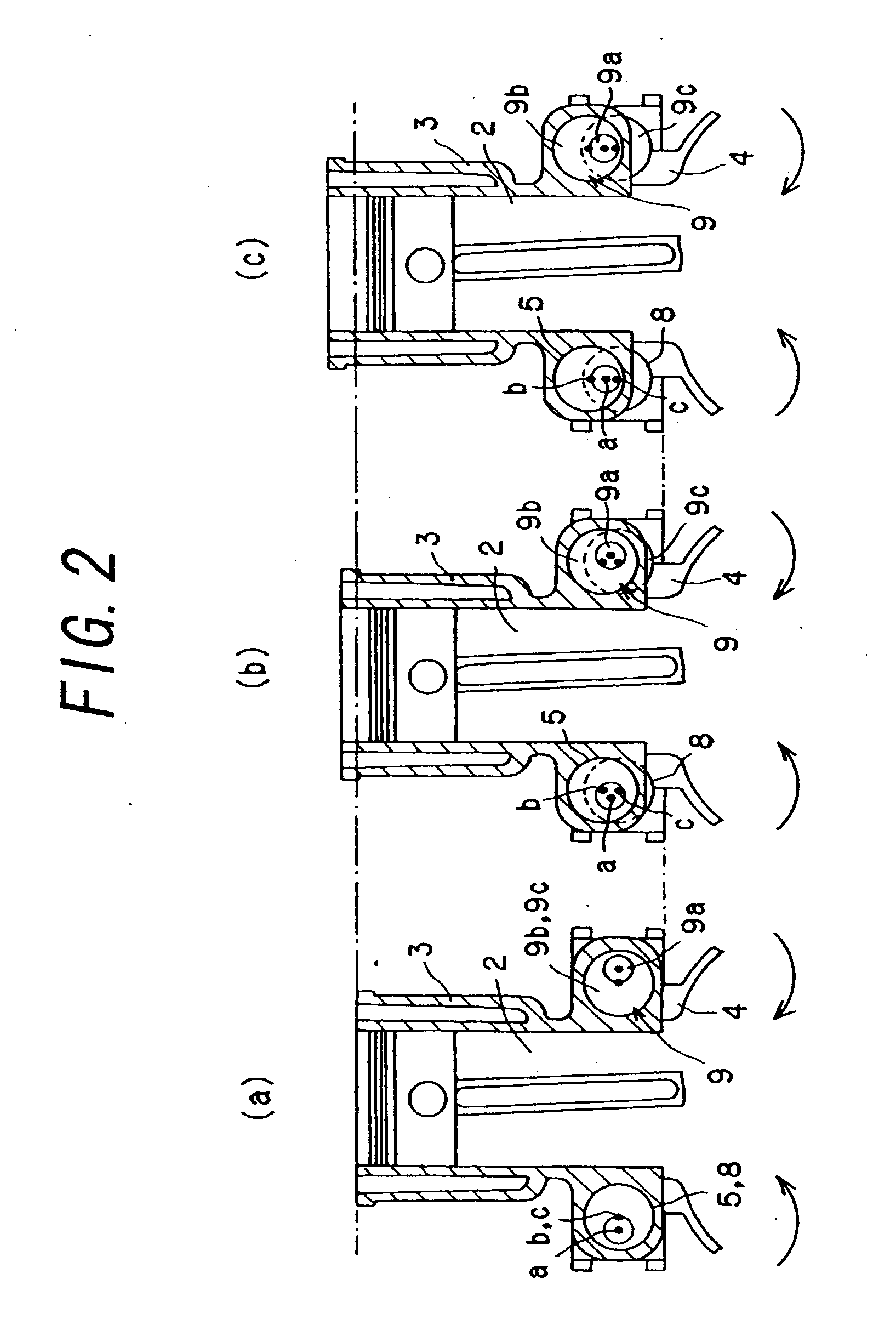

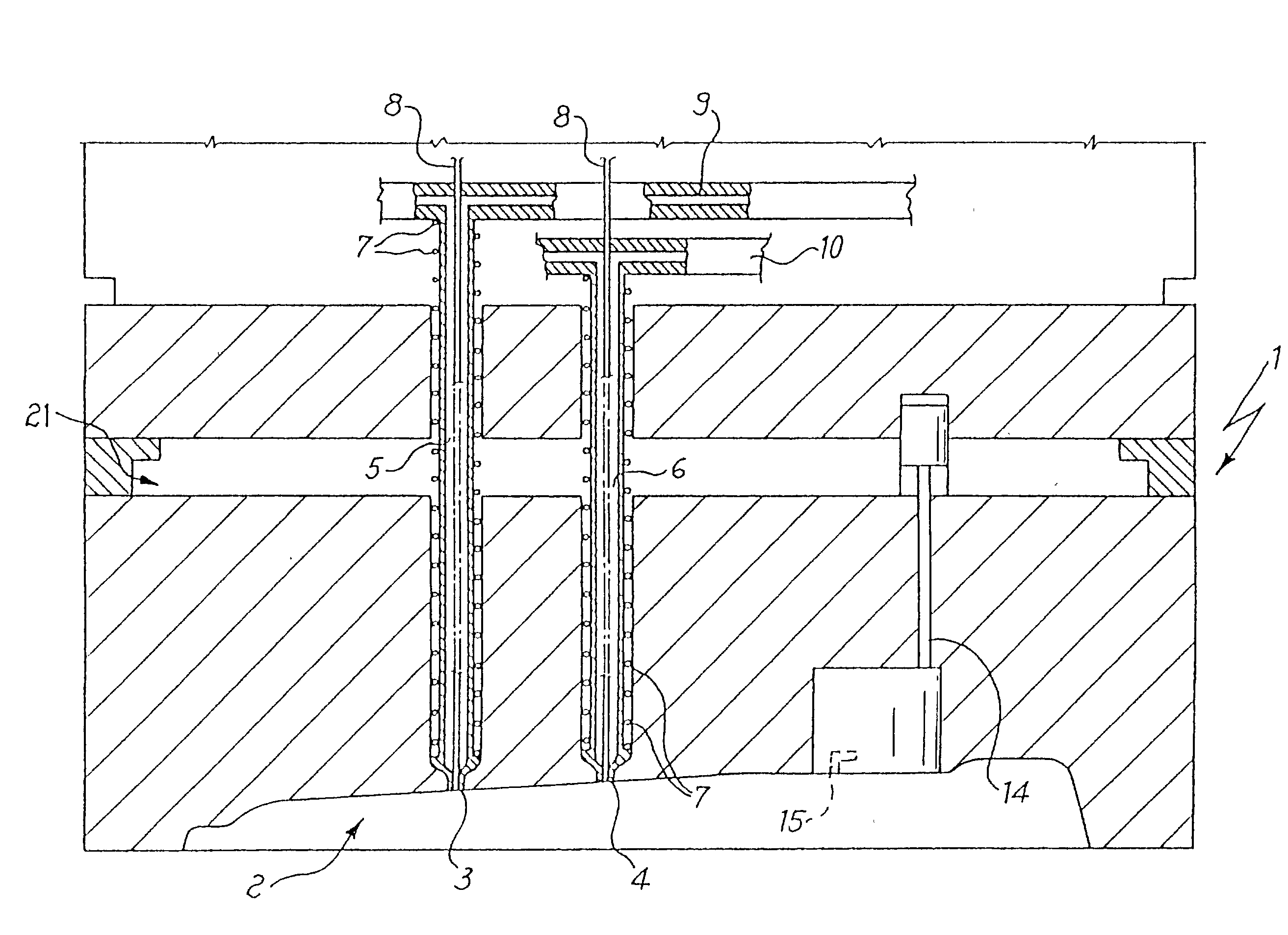

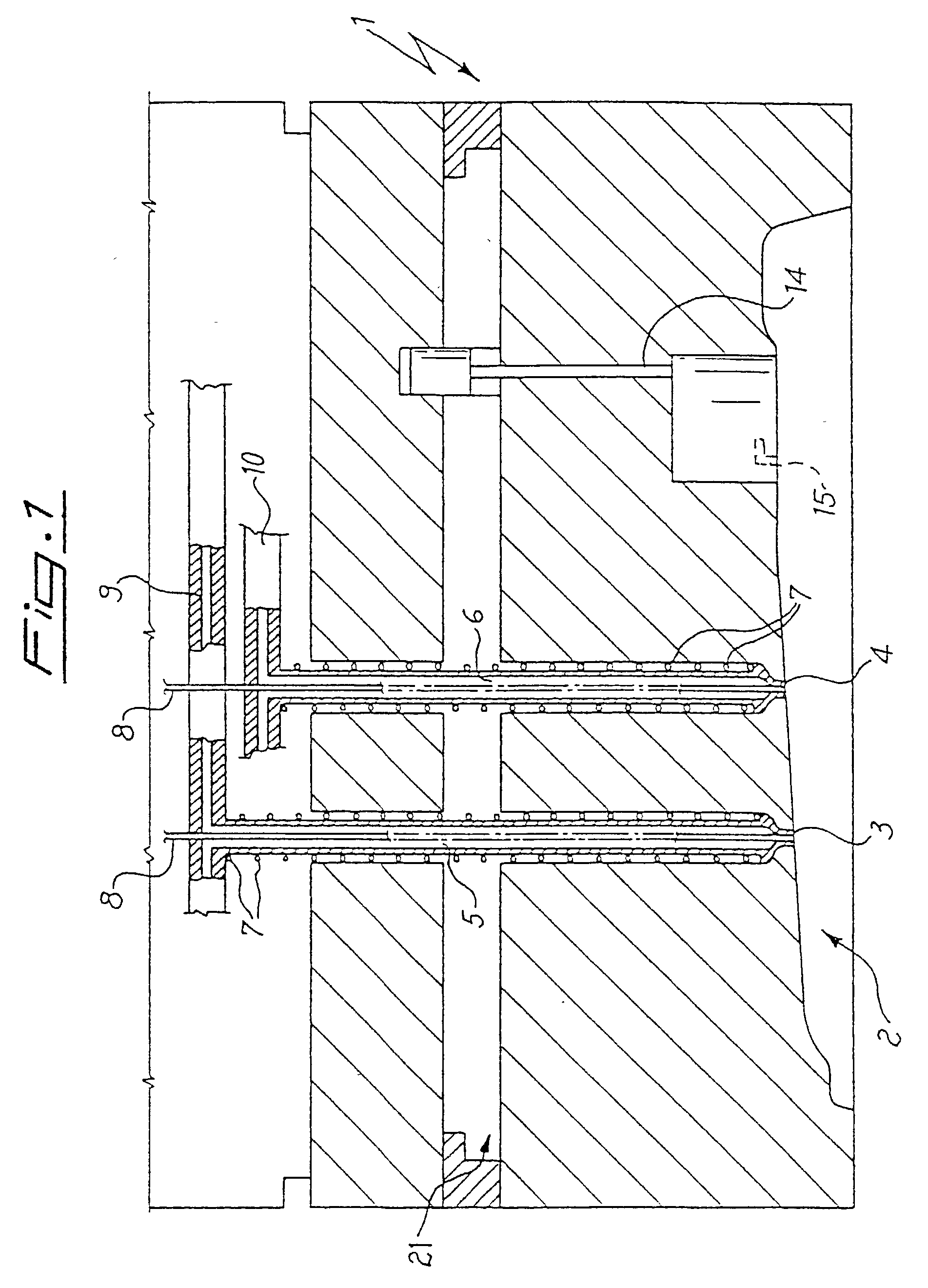

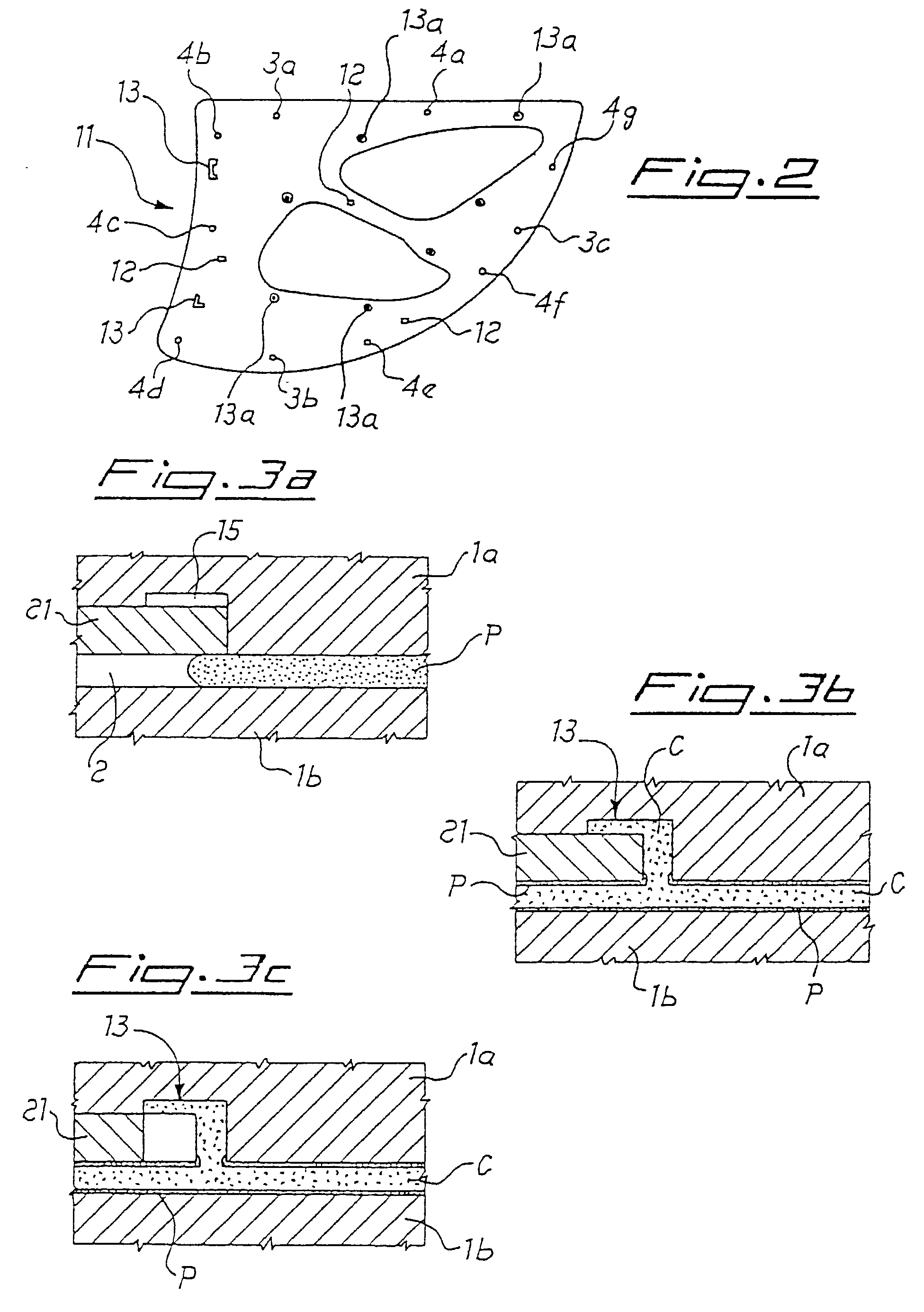

Process and device for coinjection molding multilayer products

InactiveUS20030012837A1Economical and simpleConstant thicknessConfectioneryCeramic shaping apparatusBiomedical engineeringNozzle

Multilayer products, such as vehicle trim panels, provided with an external skin layer and an internal core layer are co-injection molded by injecting external material (P) through a first plurality of points of injection (3a-3c) and injecting the core material (C) through a second plurality of points of injection (4a-4g), the points and nozzles of injection of one material being physically distinct from those of the other material.

Owner:JOHNSON CONTROL

High speed injecting molding method by counter pressure method and chemical foaming method

The invention involves a counter-pressure chemical foaming high speed injection moulding shaping method. The invention provides a method which utilizes injection moulding shaping machine equipment, and dies, general gas energy, plastic raw materials and other system resources comprehensively, produces thick-wall plastic-foam product high speed and high effectively. The invention first closes the die and injects gas into die cavity, then injects molten material into die cavity, the welding fluid is full of die cavity after inner foaming, the molten material surface is closed to the metal wall-surface of die cavity, the molten material in die cavity is solidified and shaped after cooled, then opens the moving mold and static mold, the plastic products are prepared which surface is smooth and dense and inner is distributed with uniform foam. The invention can eliminate or reduce the converging cave and warping deformation of product surface, reduces injection moulding pressure, thereby reduces the lock-mode pressure of injection machine; reduces equipment operating costs, thereby improves the size accuracy and strength of products, can reduces 15% ~ 35% raw material consumption effectively, products have higher mechanical property and weight proportion.

Owner:DONGHUA MACHINERY

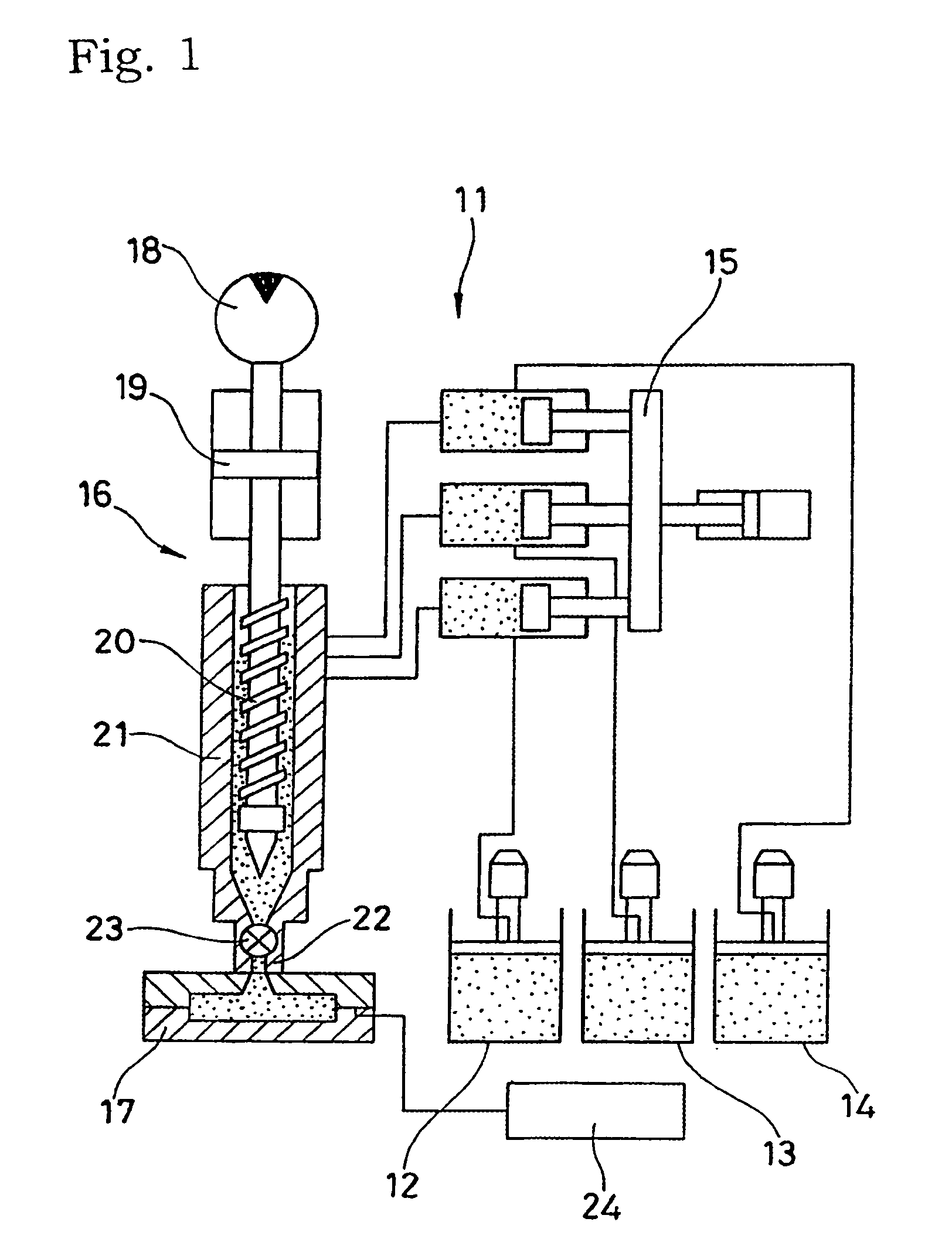

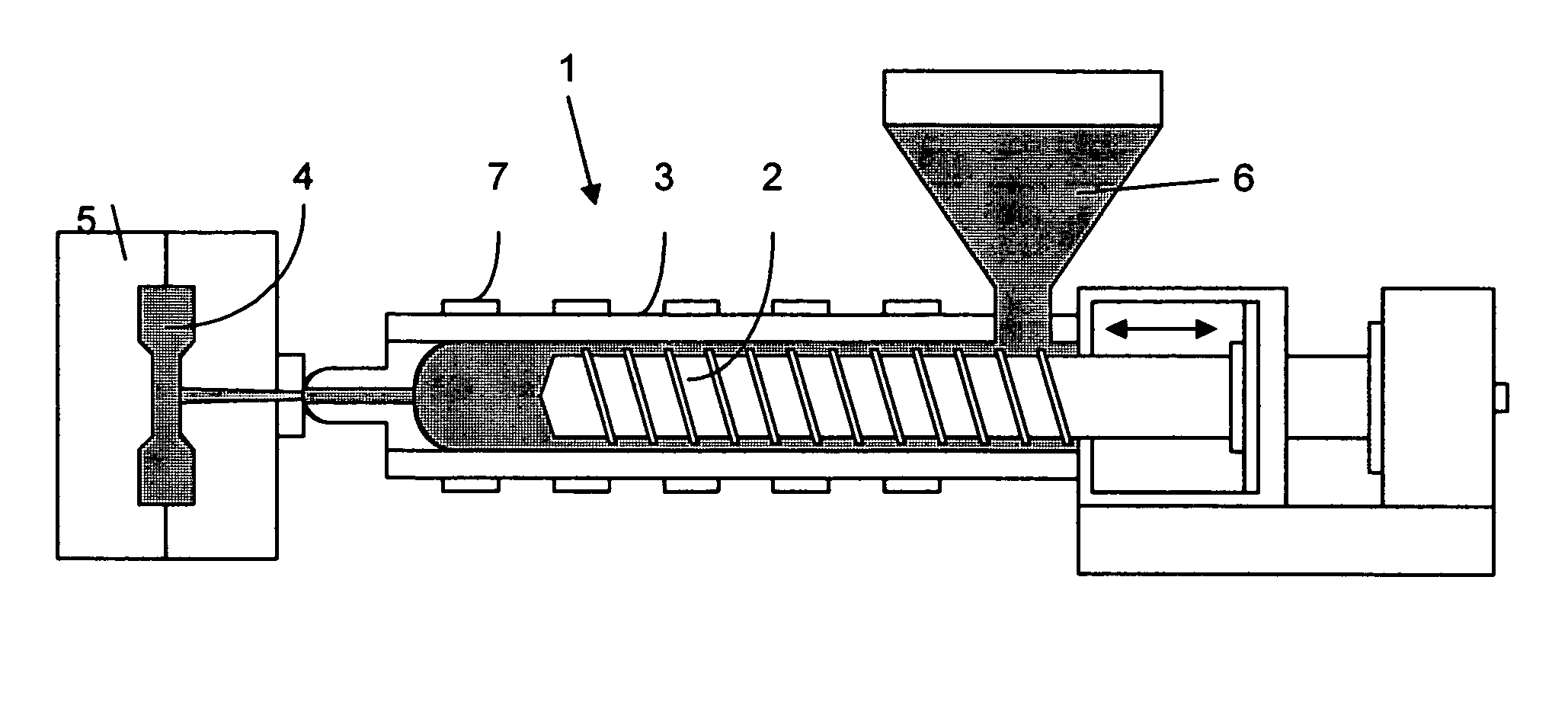

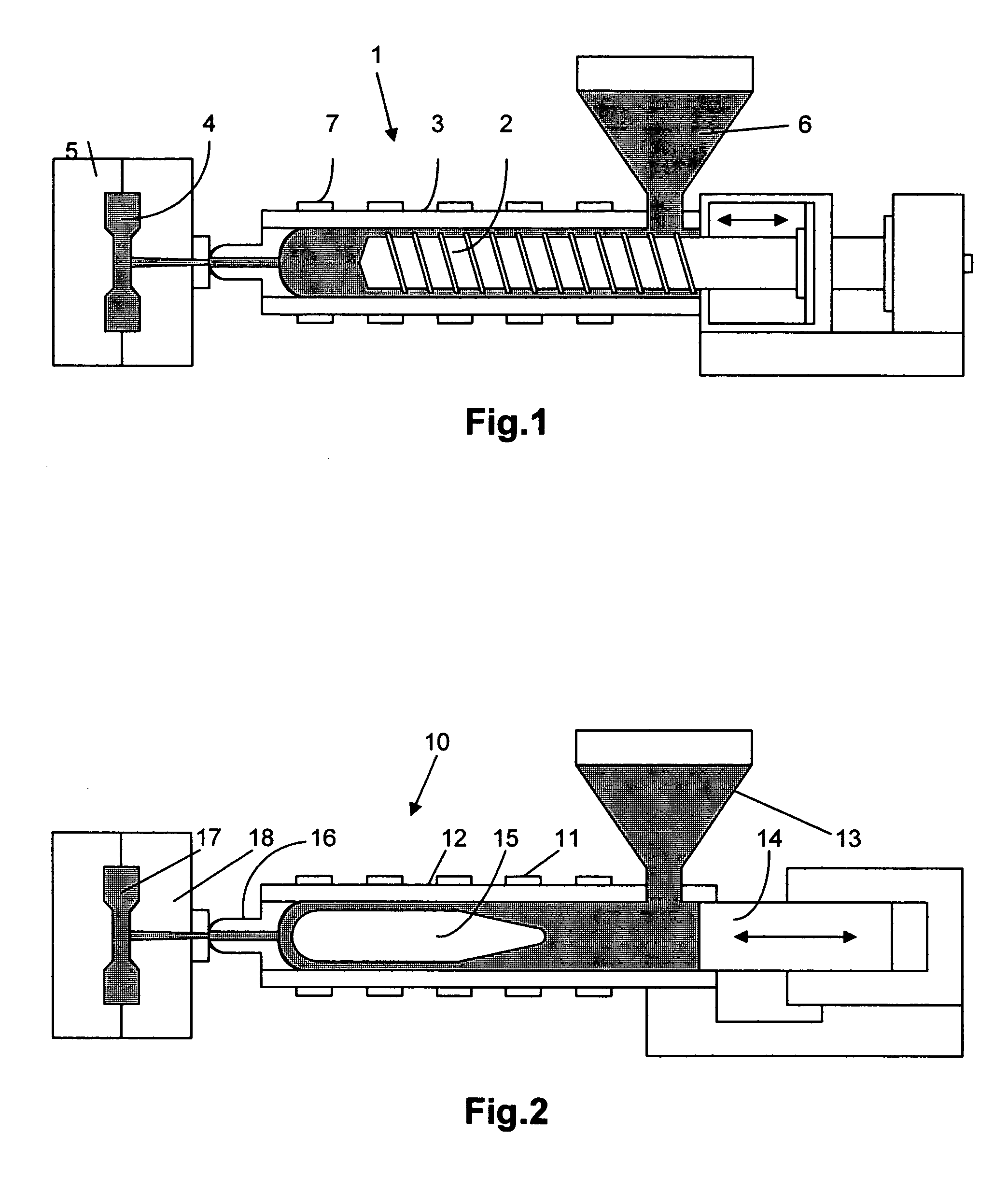

Injection molding of polymers by microwave heating

InactiveUS20050184434A1Little orientationReduce injection pressureDielectric heatingFood shapingMicrowave ovenActuator

Injection molding machine utilizes microwave heating. A microwave oven adapted to receive a microwave absorbent plasticizing vessel is utilized with or incorporated into an injection molding system to form a plasticizing unit for heating polymer granules to an injection temperature and injection of the melt into the cavity of the injection mold. The polymer granules may be preheated by conventional heating systems to a temperature at which the granules become microwave absorbent before heating to the injection temperature in the microwave oven. The injection molding machine also contains a hydraulic actuator for injection of the melt. The ceramic materials forming the plasticizing vessel are selected to provide equal heating rates of mold members and relatively uniform heating of polymer to desired injection temperature.

Owner:AKOPYAN RAZMIK L

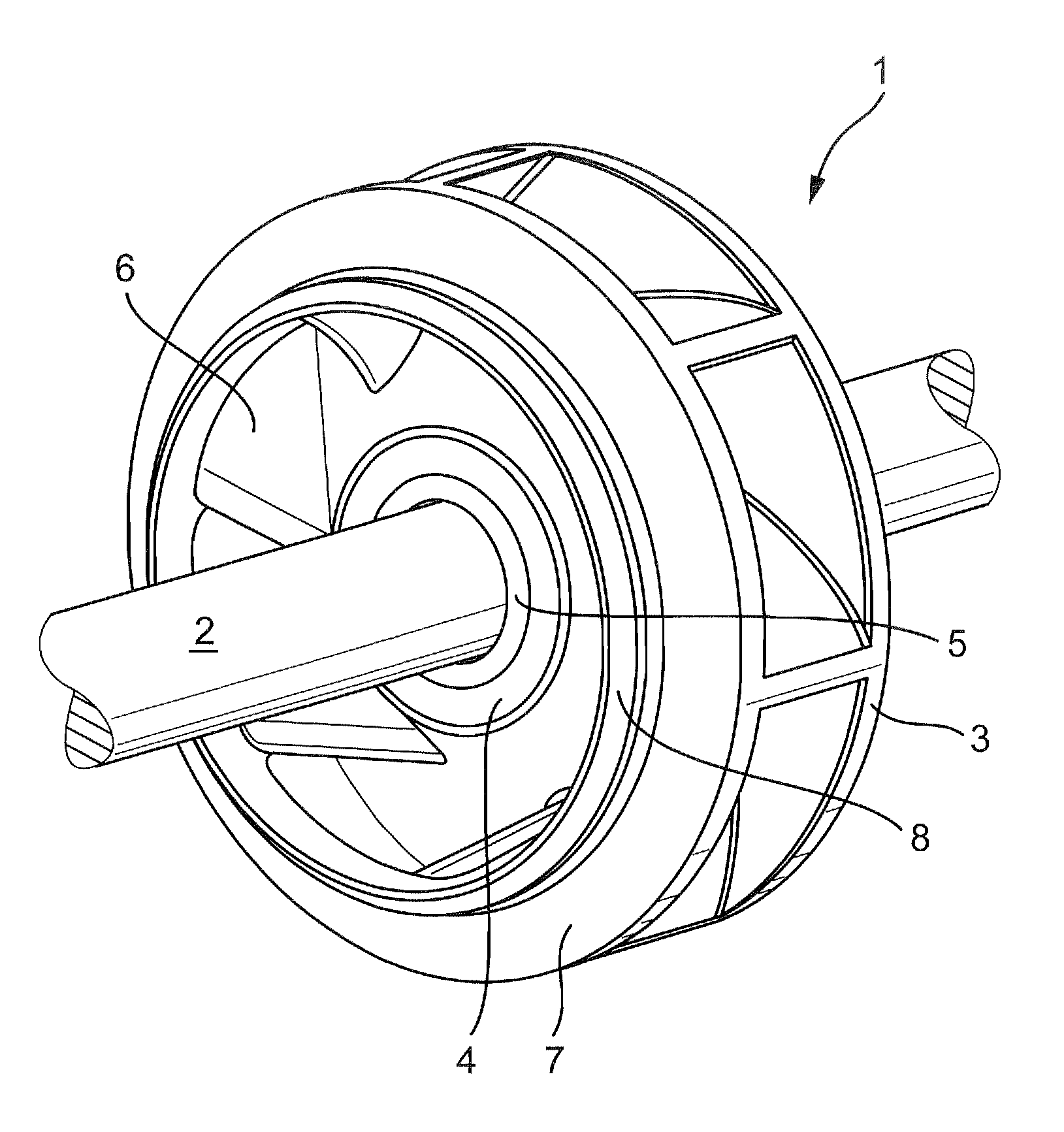

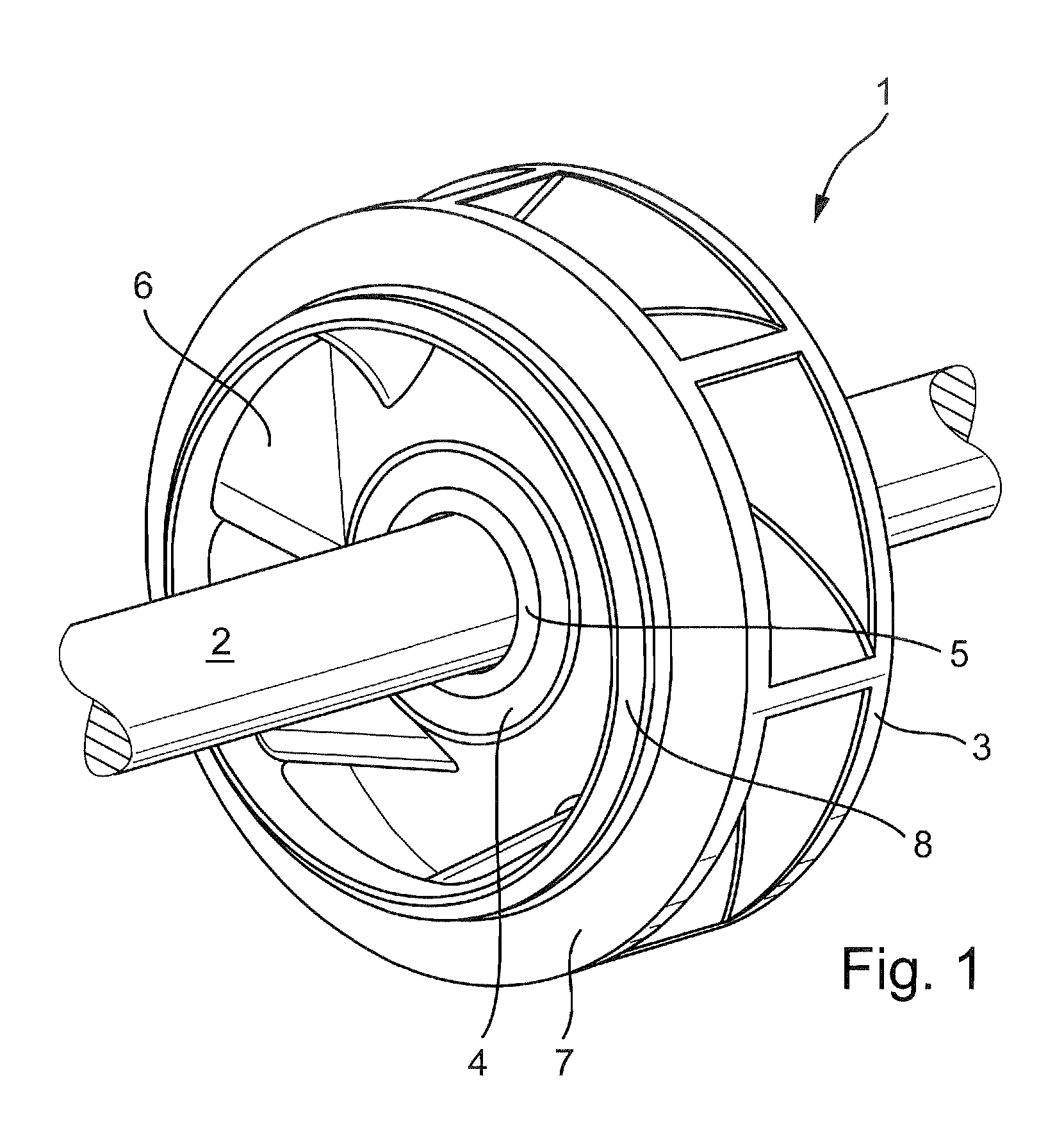

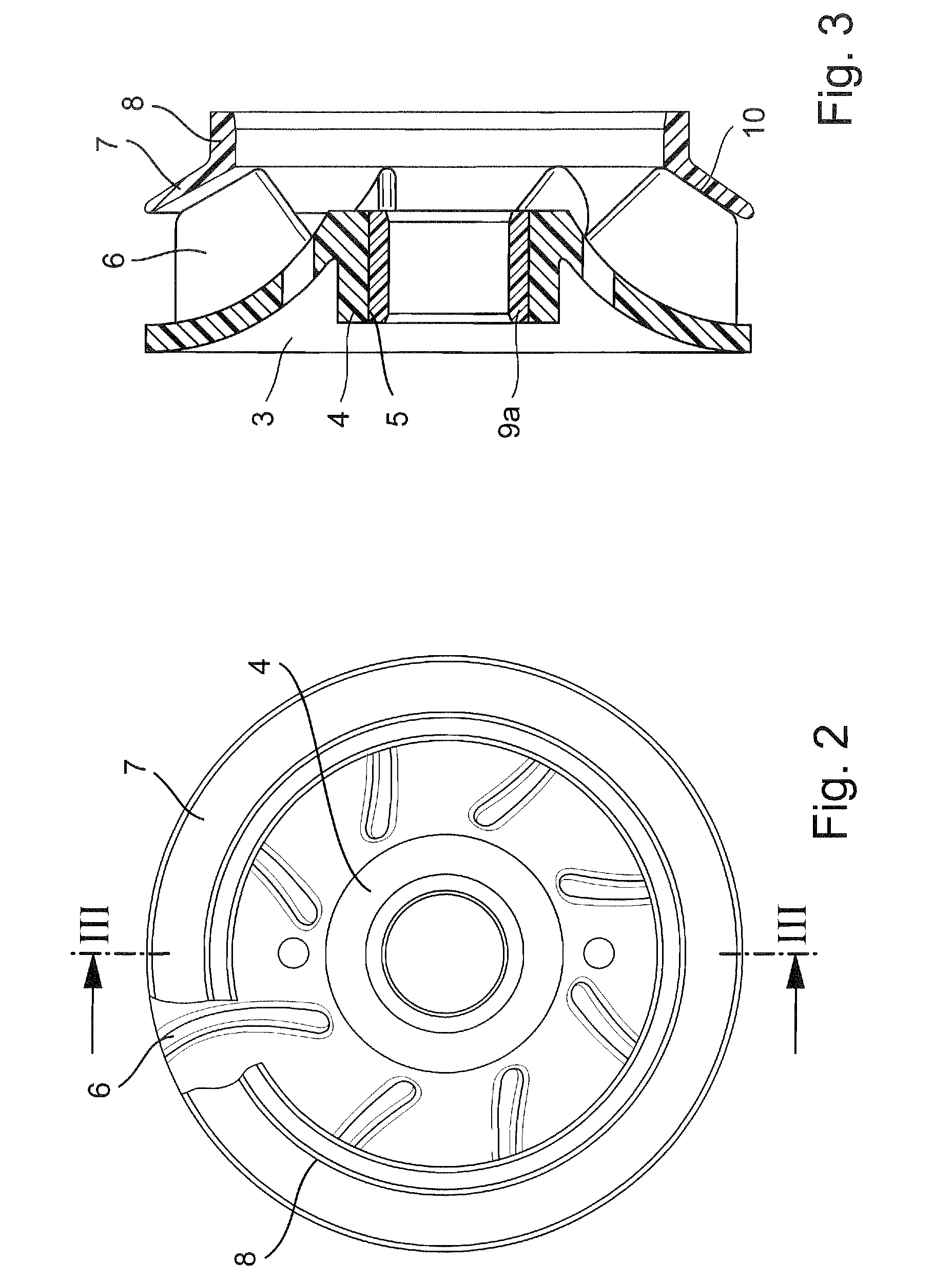

Water Pump Impeller

InactiveUS20080199319A1Enhance resistanceLow crack susceptibilityPropellersRotary propellersImpellerEngineering

Owner:SCHAEFFLER KG

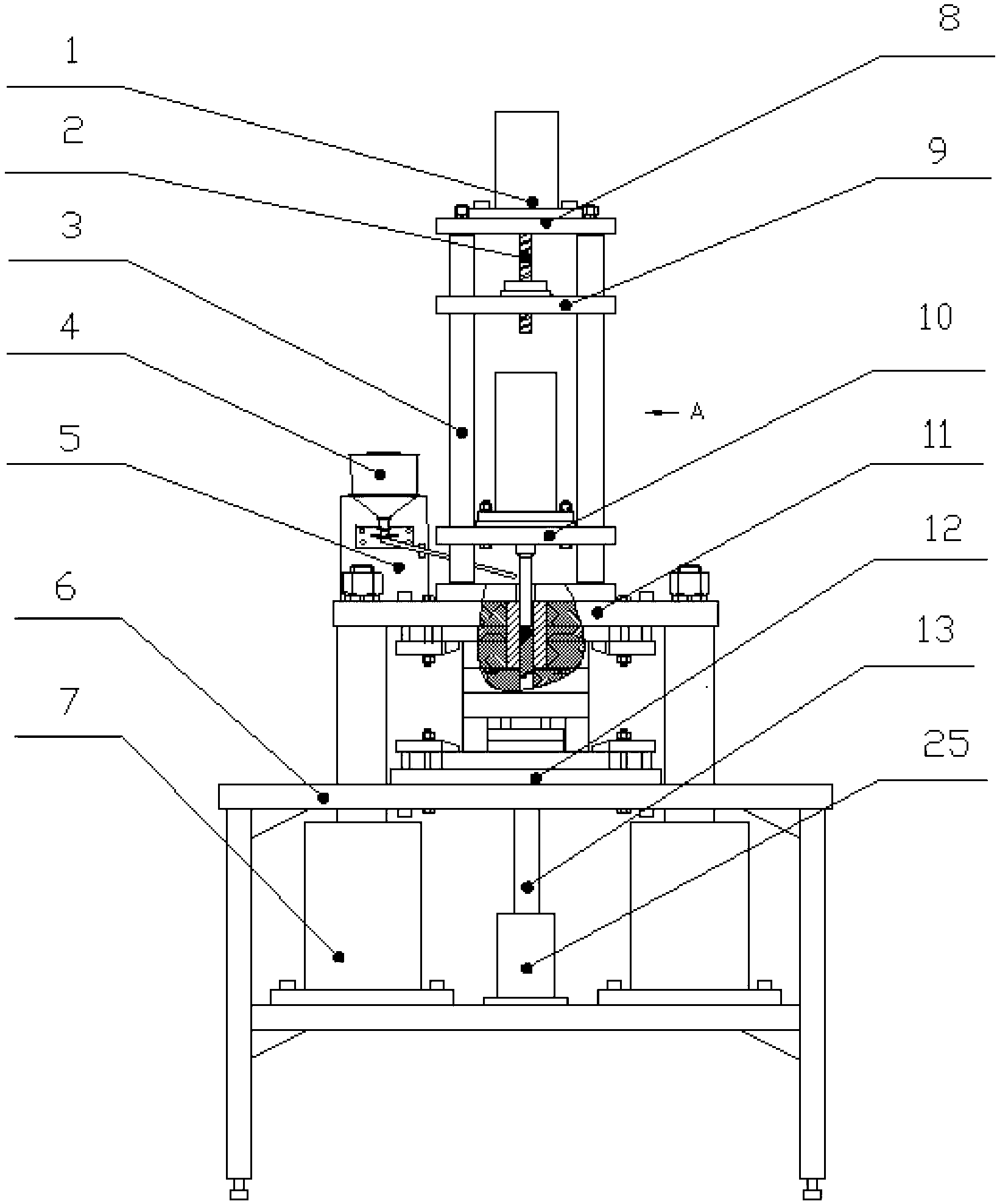

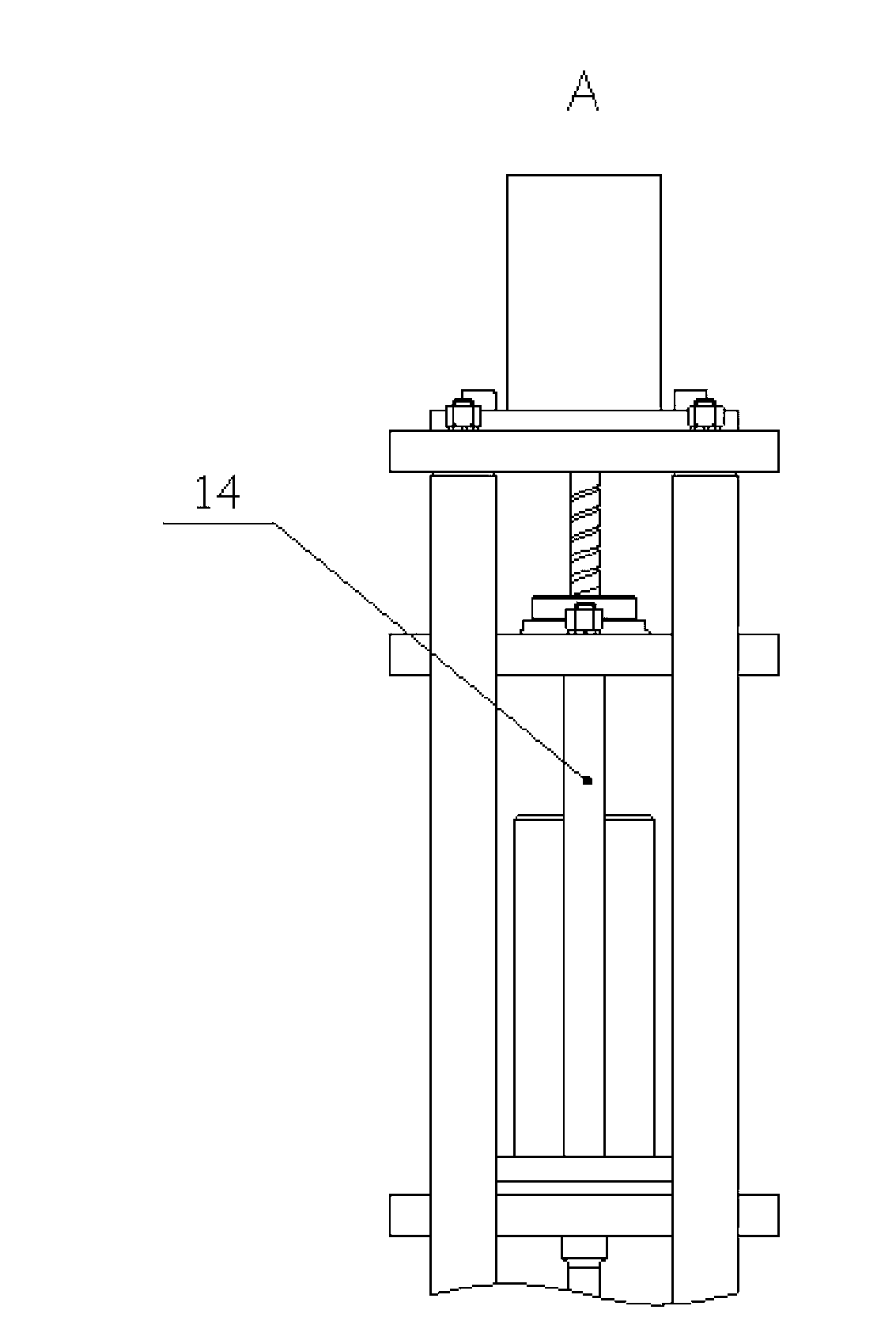

Screw-free ultrasonic microinjection molding device for molten and plasticized polymer and molding method

The invention discloses a screw-free ultrasonic microinjection molding device for a molten and plasticized polymer and a molding method. An injection part comprises an injection motor, a lead screw, an injection push plate and a connecting rod; an ultrasonic vibration system comprises an ultrasonic generator, an energy converter, an amplitude-change pole and a tool head; an injection module is provided with a plasticizing hole, a sub-runner and a mould cavity; a feeding system comprises a hopper and a support; and a mould closing and ejecting system comprises a mould closing hydraulic cylinder, an ejecting hydraulic cylinder, an upper mould fixing plate, a lower mould fixing plate and an ejector rod. A solid polymer is molten into a liquid under the action of frication thermogenesis and viscoelasticity thermogenesis applied into the polymer particle process through ultrasonic vibration, and meanwhile, ultrasonic waves play a cavitation role in the polymer liquid, so that the apparent viscosity is reduced, the phenomenon of short shot or insufficient filling in the machining process is overcome, the injection molding of a small plastic device can be well realized, the energy consumption is reduced, the difficulty in controlling the process is lowered, the economic efficiency of the device is increased, and the production cost is reduced.

Owner:CENT SOUTH UNIV

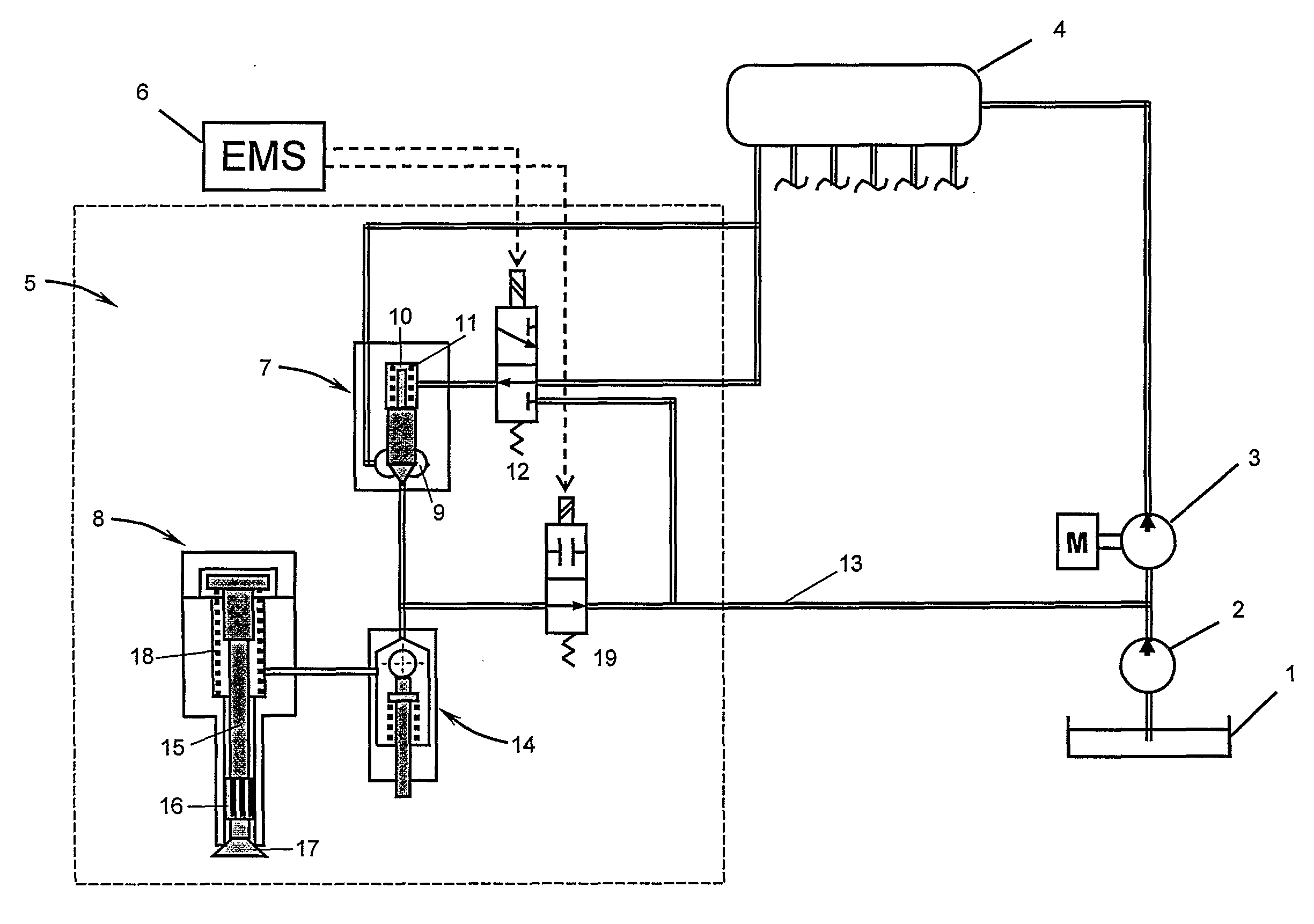

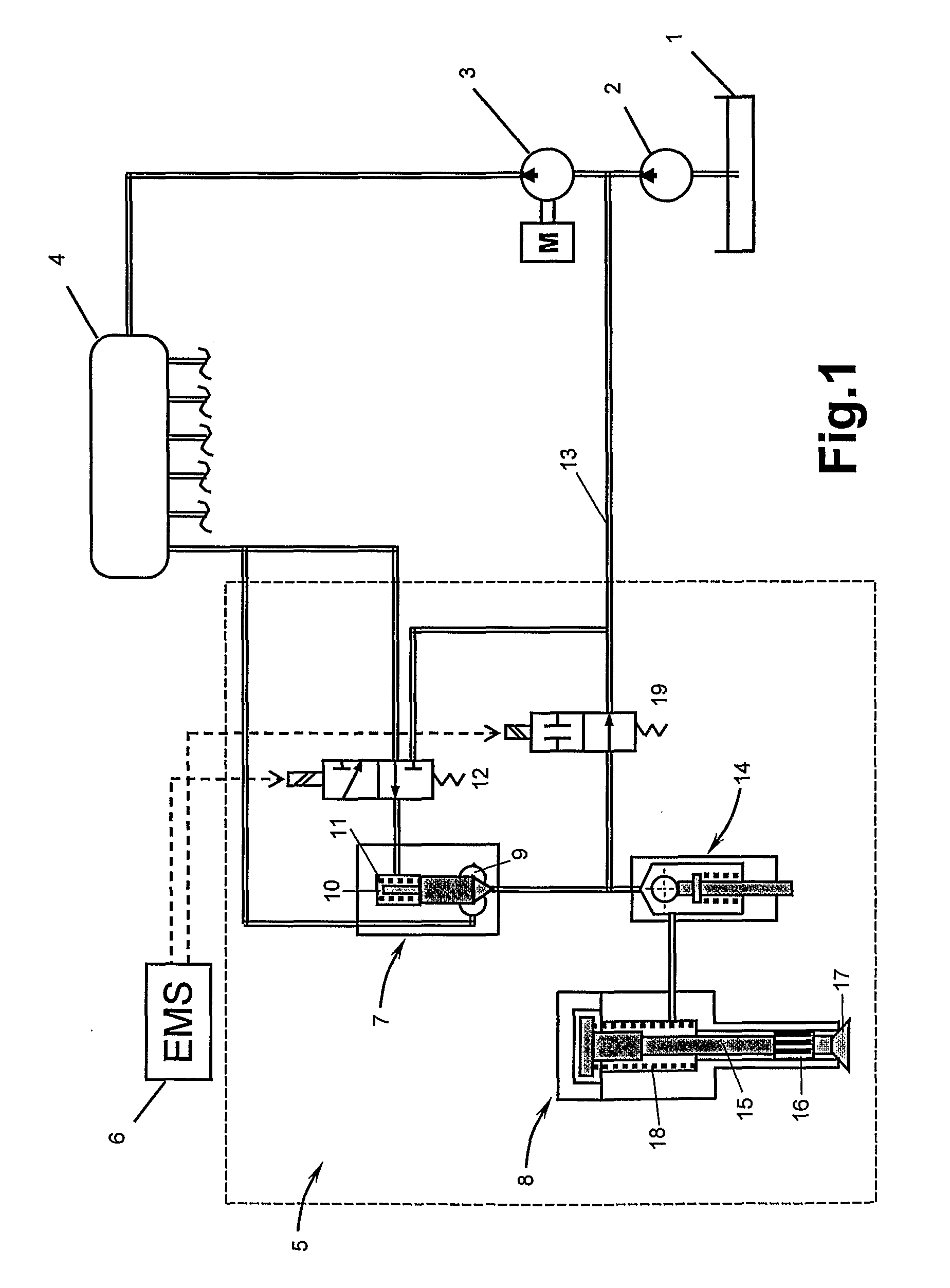

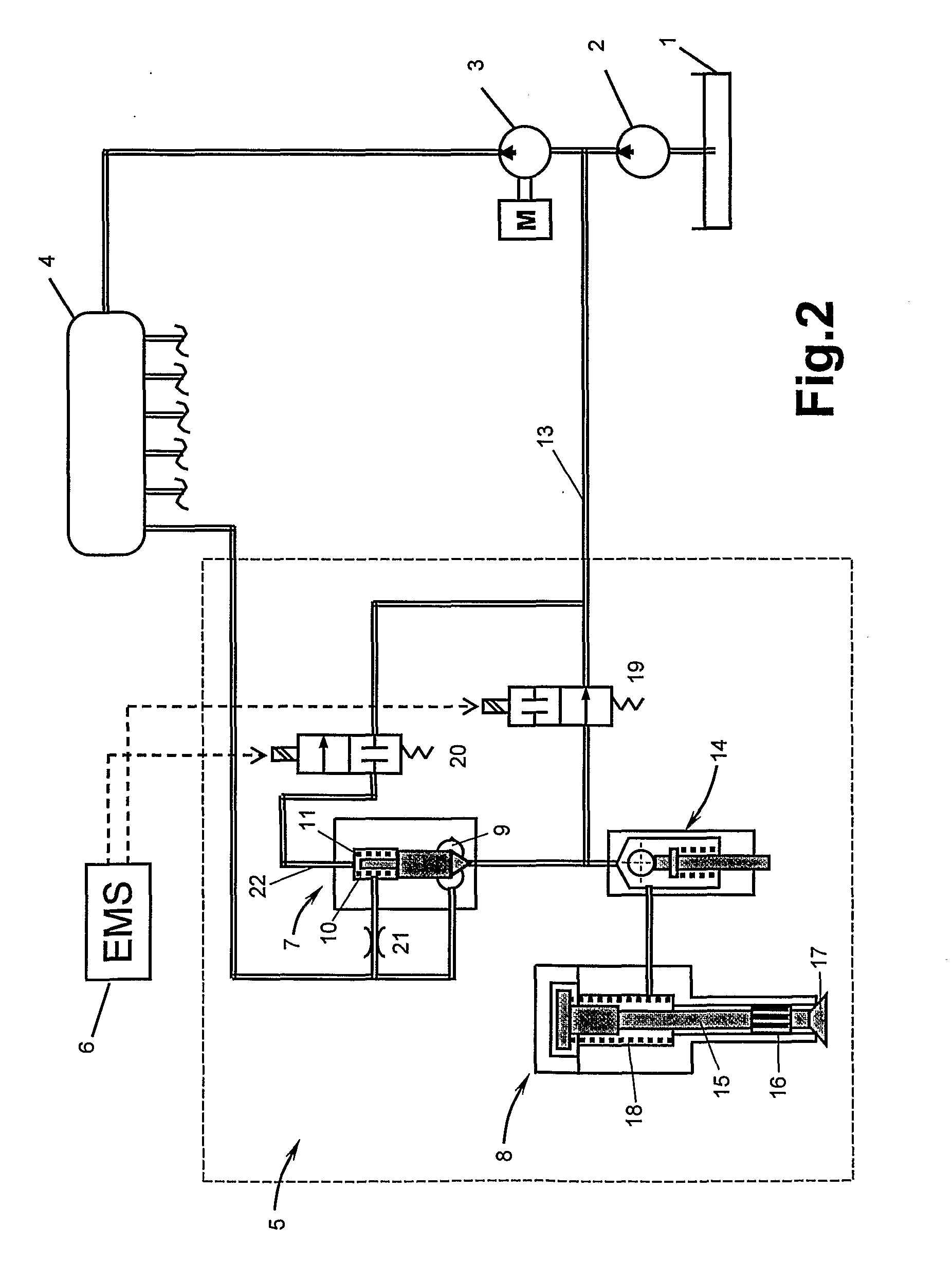

Fuel Injection System Suitable for Low-Viscosity Fuels

InactiveUS20080202471A1Reduce injection pressureImprove efficiencyInternal combustion piston enginesFuel supply apparatusCommon railViscosity

A fuel injection system for an internal combustion system includes an Engine Management System (EMS), a fuel feed pump, a return line, a high-pressure pump, supplying fuel under pressure to a common rail, a hydraulically operated valve forming an outlet chamber connected to the common rail and a control chamber, the valve being designed such that, in its closed position, the valve prevents the flow out of the outlet chamber, and an electrically operated pilot valve. A nozzle with a resilient member that biases the nozzle towards closing is connected to the outlet of the hydraulically operated valve in such a way that pressure at the outlet of the hydraulically operated valve tends to overcome the force of the resilient member and open the nozzle. An electrically operated spill valve is connected between the outlet of the hydraulically operated valve and the return line.

Owner:VOLVO LASTVAGNAR AB

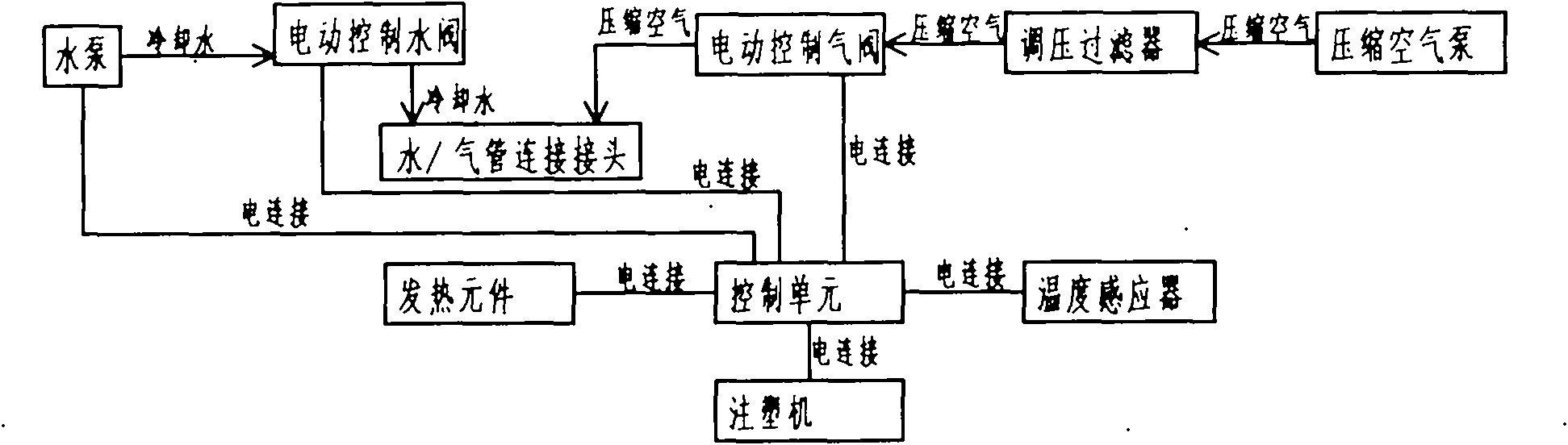

Modularized cold runner system

ActiveCN102825730AShorten the production cycleShorter injection molding cycle timesEngineeringHeat balance

A modularized cold runner system relates to an injection molding die of a colder runner. The system can effectively isolate heat exchange between a high-temperature mold cavity and a low-temperature cold runner system, maintain heat balance of the whole modularized cold runner system, always keep low-temperature flow, prevent materials from being heated and vulcanized in the flow channel, and achieve molding for products without the runner. The system is good in controllability and versatility. The system is provided with, from top to bottom, a stationary mold base plate, a sprue bush, a cylinder installing plate, a cylinder, a cold runner plate, a heat isolation plate, a heating plate, a fluid modulation apparatus, a conicity locating piece, pressure blocks, a water-cooled needle-valve nozzle and a quickly-changed clamp, wherein the stationary mold base plate, the cylinder installing plate, the cold runner plate, the heat isolation plate and the heating plate are sequentially arranged from top to down and fixedly connected through fasteners.

Owner:XIAMEN UNIV OF TECH +1

Submucosal cushioning agent

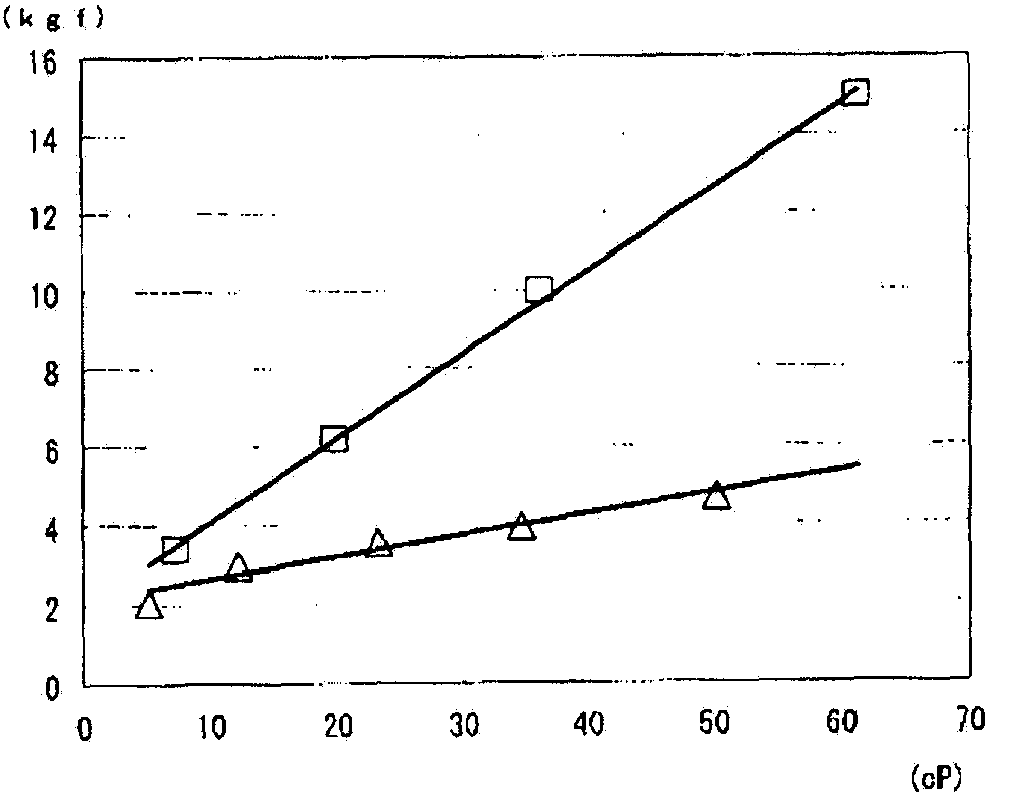

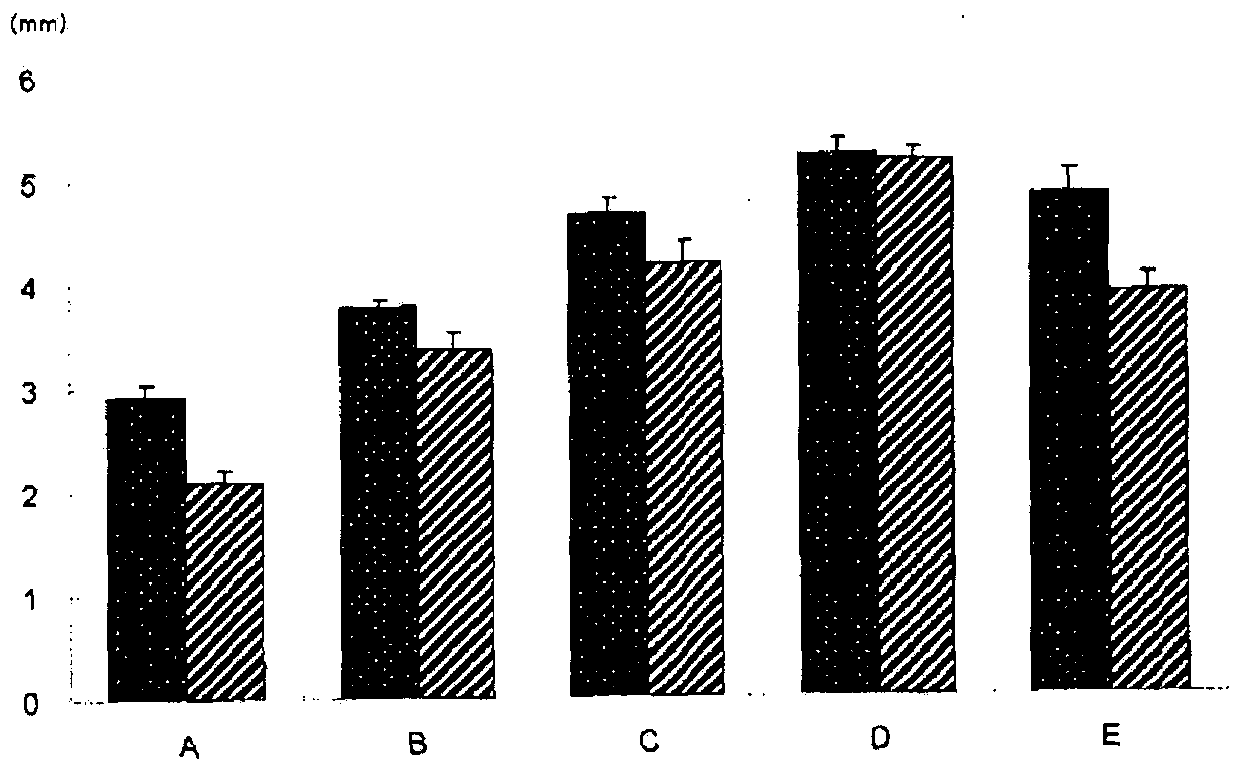

InactiveCN103957954AReduce injection pressureEasy to injectSurgeryPharmaceutical delivery mechanismGellan gumMucosal resection

In order to improve the resection efficiency, operability, and safety of endoscopic mucosal resection operations, a method has conventionally been employed wherein a cushioning agent such as physiological saline is injected into the layer below the area designated for resection, causing the lesion to lift and protrude (hereafter simply referred to as "protrusion"), after which the lesion is removed. It is difficult to accurately remove the intended area using conventional cushioning agents because applying pressure to the protrusion tends to cause deformation thereof, the degree of protrusion is low, and the cushioning agent diffuses immediately after injection into the peripheral tissue, thereby causing the protrusion to disappear. The present invention solves these problems by employing a polysaccharide having a pseudoplastic viscosity such as xantham gum, carrageenan, gellan gum, guar gum, locust bean gum, sacran, or the like as a cushioning agent.

Owner:CHUGAI PHARMA CO LTD

Blended polymer compositions with improved mold release properties

InactiveUS20140275368A1Increase mold release propertyMinimize production waste and costPolycarbonateChemistry

Disclosed herein are methods and compositions of blended polycarbonate compositions with improved mold release characteristics. The resulting compositions, comprising one or more polycarbonate polymers, an impact modifier, a polycarbonate-siloxane copolymer, and an alkyl sulfonate salt, can be used in the manufacture of articles requiring improved mold release characteristics while still retaining the advantageous physical properties of blended polycarbonate compositions. This abstract is intended as a scanning tool for purposes of searching in the particular art and is not intended to be limiting of the present invention.

Owner:SABIC GLOBAL TECH BV

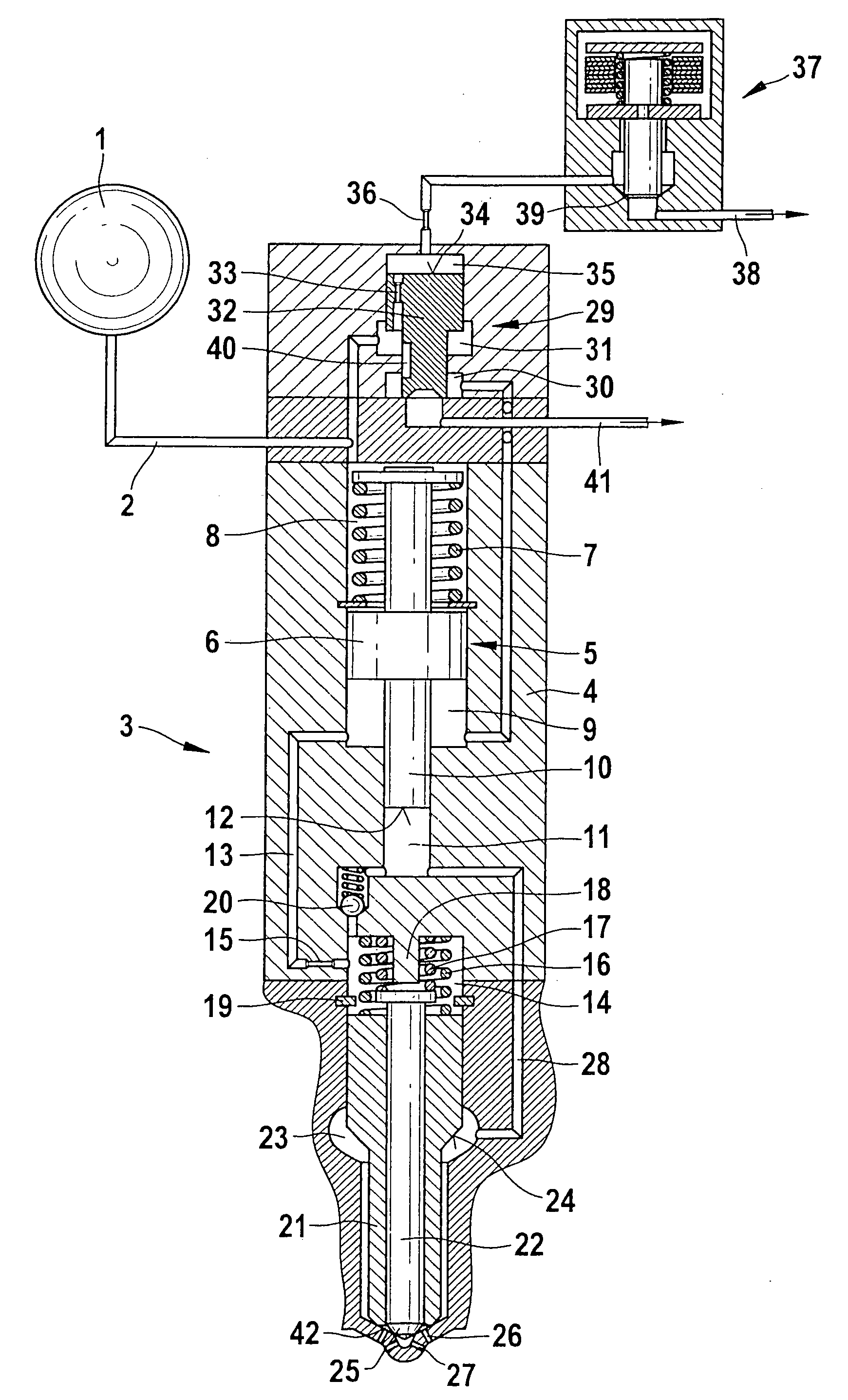

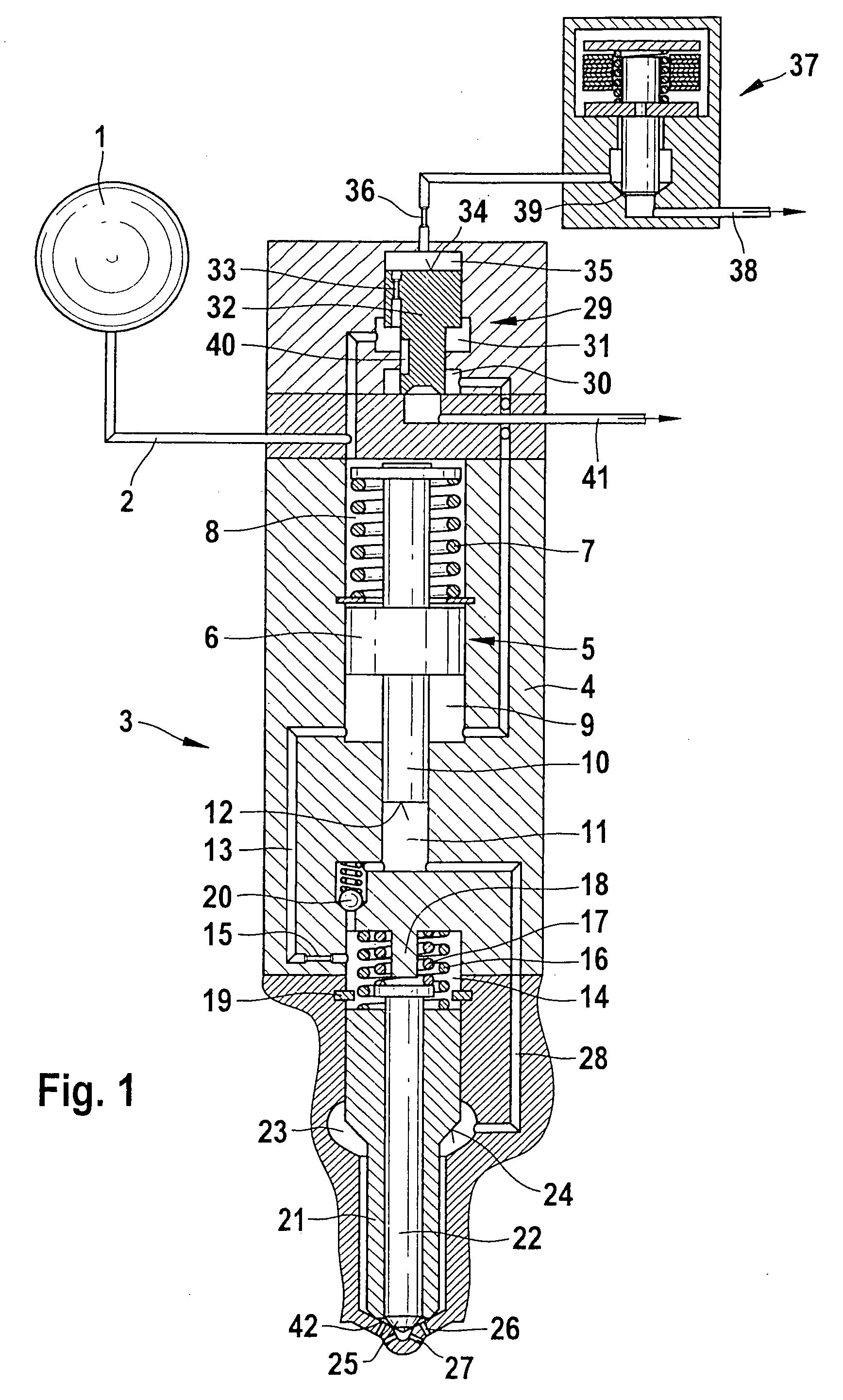

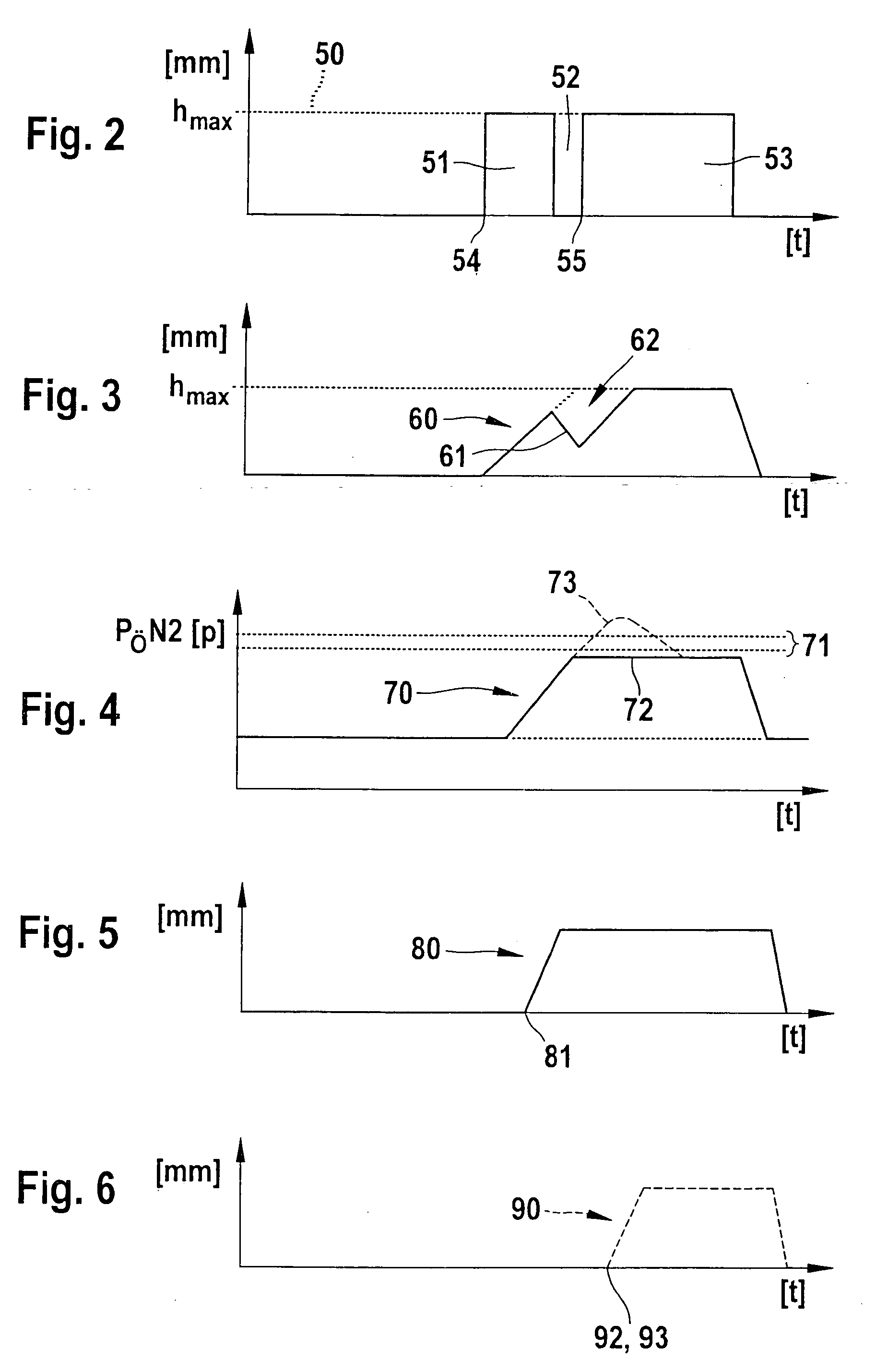

Method and device for shaping the injection pressure in a fuel injector

InactiveUS20050252490A1High pressureGood influenceMachines/enginesFuel injecting pumpsCombustion chamberDifferential pressure

A method for triggering a fuel injector via an on / off valve and a control valve that actuates it. The fuel injector has a pressure booster whose piston parts separate a working chamber from a differential pressure chamber. Via a compression chamber of the pressure booster, a nozzle chamber of the fuel injector can be acted on with highly pressurized fuel. The working chamber of the pressure booster communicates continuously with a common rail. During the main phase in which fuel is injected into the combustion chamber of an internal combustion engine, the control valve that actuates the on / off valve is triggered once or multiple times so that the maximum pressure level occurring at the combustion chamber end of a one-part or multipart injection valve member falls below the maximum achievable pressure level.

Owner:ROBERT BOSCH GMBH

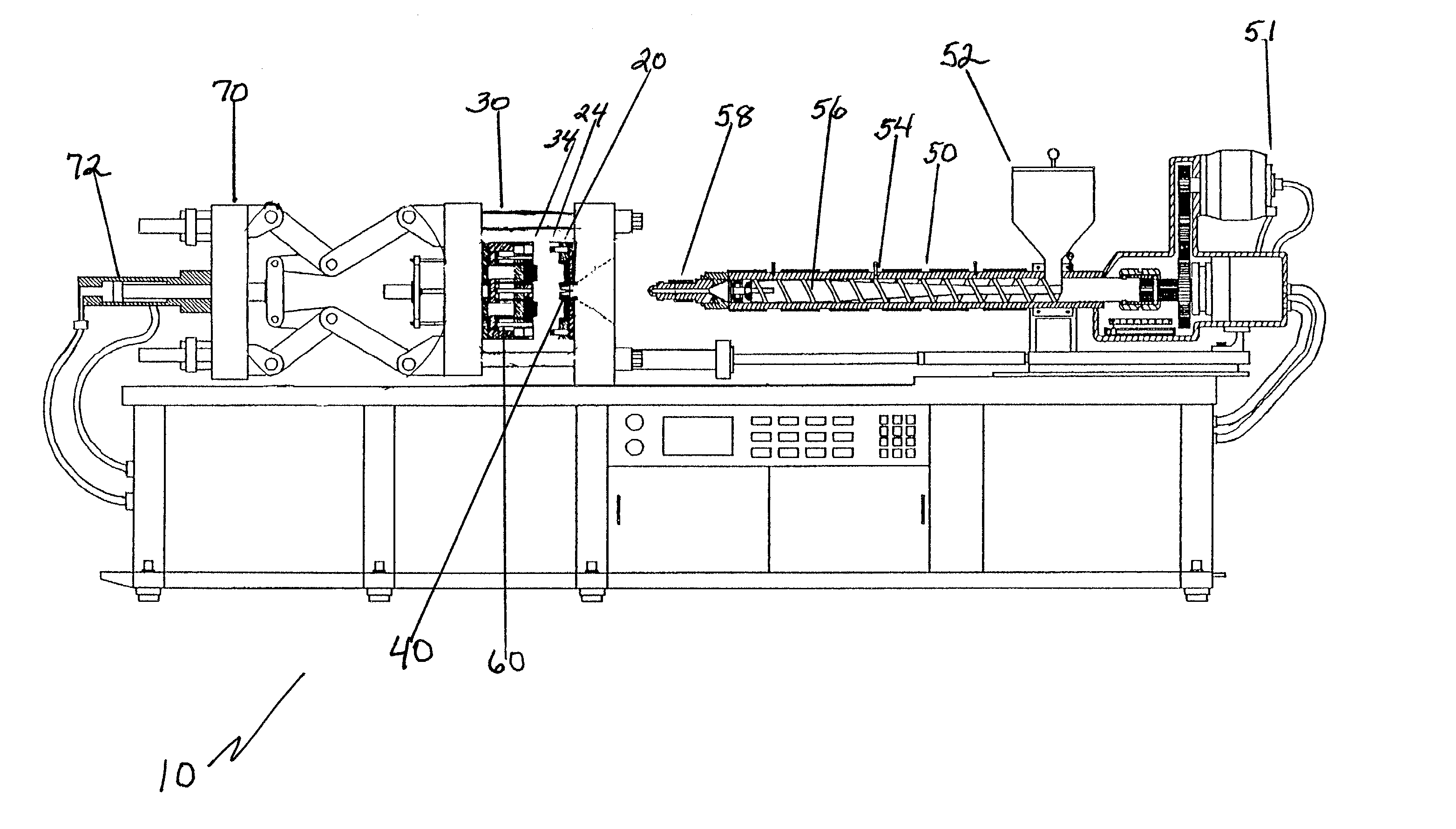

Super-large size plastic injection moulding process and its equipment

The super-large-type plastic injection moulding process includes the following steps: storage injection, premoulding mechanism is controlled by frequency converter and continuously rotated, general nitrogen gas is passed through pressure pump and one-way valve and pressed into rear portion of screw homogenizing stage and fed into the injection cylinder and storage cylinder together with molten material fully mixed with high-pressure nitrogen gas, if the process is incorrect, the molten material can be discharged out from safe discharge valve of said system. Said technological equipment is characterized by that the storage oil cylinder is connected with storage injection and premoulding mechanism, storage cylinder, injection cylinder and distributer, its one-way valve is connected with storage injection premoulding mechanism.

Owner:天津市康库得机电技术有限公司

Piezoelectric dynamic plasticizing forming device and injection molding method thereof

The invention discloses a piezoelectric dynamic plasticizing forming device and an injection molding method thereof. The forming device is characterized in that: the forming device comprises, sequentially connected from front to back, a nozzle, a nozzle seat, a material tube, a compression screw, a piezoelectric ceramic driving system, a hydraulic cylinder, and a hydraulic motor; the material tube is provided with a heating jacket, and the hydraulic cylinder and the hydraulic motor are connected with a hydraulic pump; the nozzle seat is connected to the front end of the material tube, and the nozzle is connected to the nozzle seat; the compression screw is positioned in the space of the material tube, and the back end of the piston rod, which extrudes the material tube, is connected with the front end of a piezoelectric ceramic; the back end of the piezoelectric ceramic is connected with a piston rod, two ends of the piston rod extrude the hydraulic cylinder, and the back end of the piston rod is fixedly connected with the hydraulic motor. The injection molding method comprises the following steps: a reverse piezoelectric effect of the piezoelectric ceramic is utilized, and a computer controls the piezoelectric ceramic to generate a driving signal, so the piezoelectric ceramic vibrates in an axial direction and the frequency and the amplitude of the vibration are controllable; the compression screw reciprocatingly vibrates in a small amplitude, high frequency, and high acceleration mode; and products with higher intensity than common products are finally obtained by mixing and injection molding.

Owner:重庆市仁盛机械有限公司

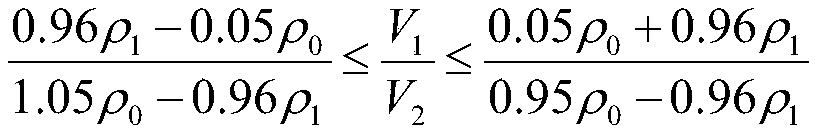

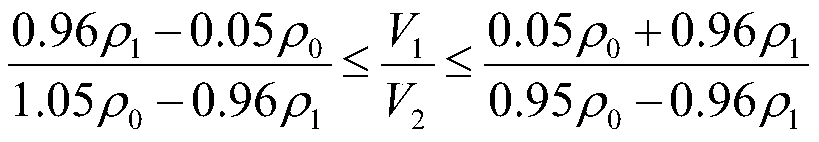

Method of preparing functional ceramic part of complex structure by powder injection molding

ActiveCN110480016AImprove product performanceShort degreasing cycleTransportation and packagingMetal-working apparatusAir atmosphereAdhesive

The invention relates to a method of preparing a functional ceramic part of complex structure by powder injection molding. The method is characterized by comprising the following steps: S1, feed preparation: uniformly mixing functional ceramic powder with an adhesive to form a feed; S2, injection moulding: putting the feed prepared in the S1 in a powder injection moulding machine, and injecting the feed into a mold cavity under conditions of an injection pressure of 80-200 MPa and an injection temperature of 160-200 DEG C to form an injection blank; S3, degreasing: catalytically degreasing theinjection blank prepared in the S2 to form a catalytically degreased blank; S4, thermal degreasing: thermally degreasing the catalytically degreased blank prepared in the S3 to obtain a thermally degreased blank; and S5, sintering: putting the thermally degreased blank prepared in the S4 in a sintering furnace, and sintering the thermally degreased blank in an air atmosphere to obtain a sinteredblank. By setting a volume ratio range of the functional ceramic powder and the adhesive, the functional ceramic powder can be totally coated by the adhesive, so that the flawless injection blank is more easily obtained.

Owner:CHANGZHOU GIAN TECH

Mould capable of realizing rapid heat cycle

The invention discloses a mould capable of realizing a rapid heat cycle, which comprises a mould core provided with a moulding surface and heating rods with set number. Heating rod accommodating holes are formed at positions close to the moulding surface in the mould core and accommodate the heating rods; cooling insulation holes corresponding to the heating rods are formed at positions close to the heating rods in the mould core provided with the moulding surface, and are positioned on one side of the heating rods far from the moulding surface; the overall outline of the cross section of each cooling insulation hole is a closed curve; and one or more cooling insulation holes enclose corresponding heating rods in three directions. The mould has the advantages that: the moulding surface can be rapidly and uniformly heated and cooled, and can be rapidly heated to the temperature approaching to or equal to the temperature of a fused material, so the moulded products have good quality, weld marks, flow marks, surface bubbles and the like are not generated easily, the products have uniform luster and density and low shrinkage, and injection pressure and product deformation caused by residual stress after the fused material is solidified and moulded are reduced.

Owner:杨东佐

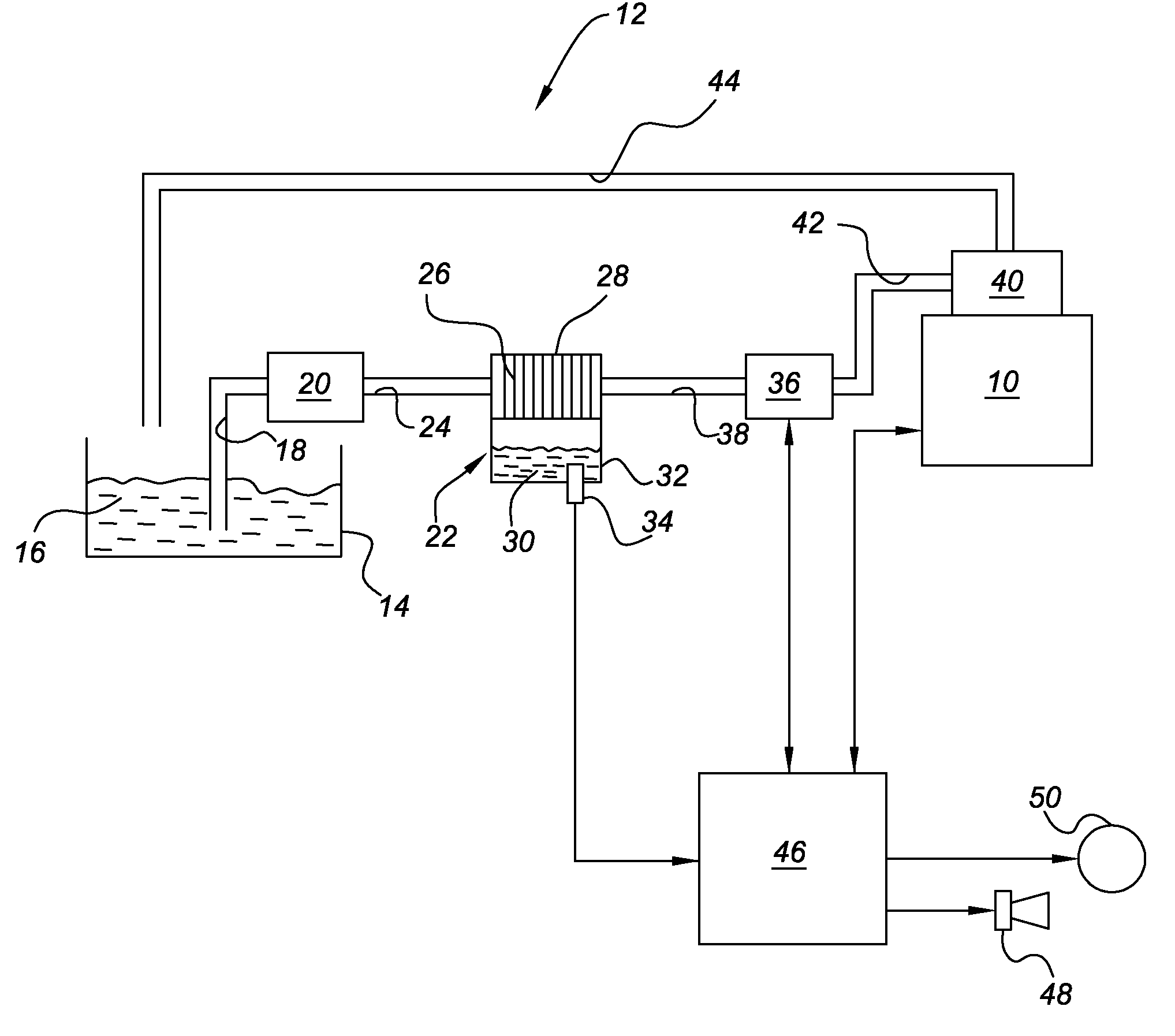

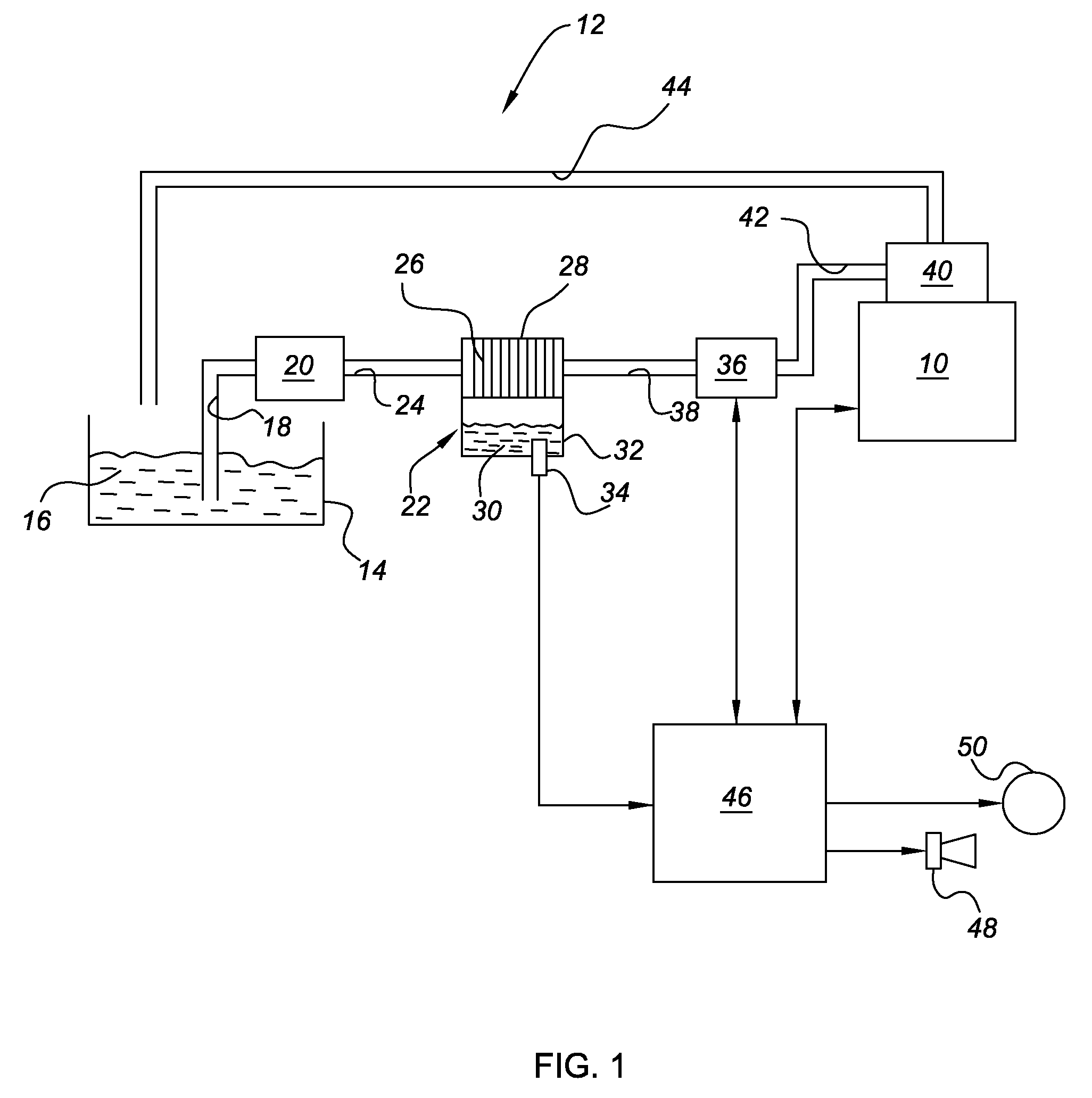

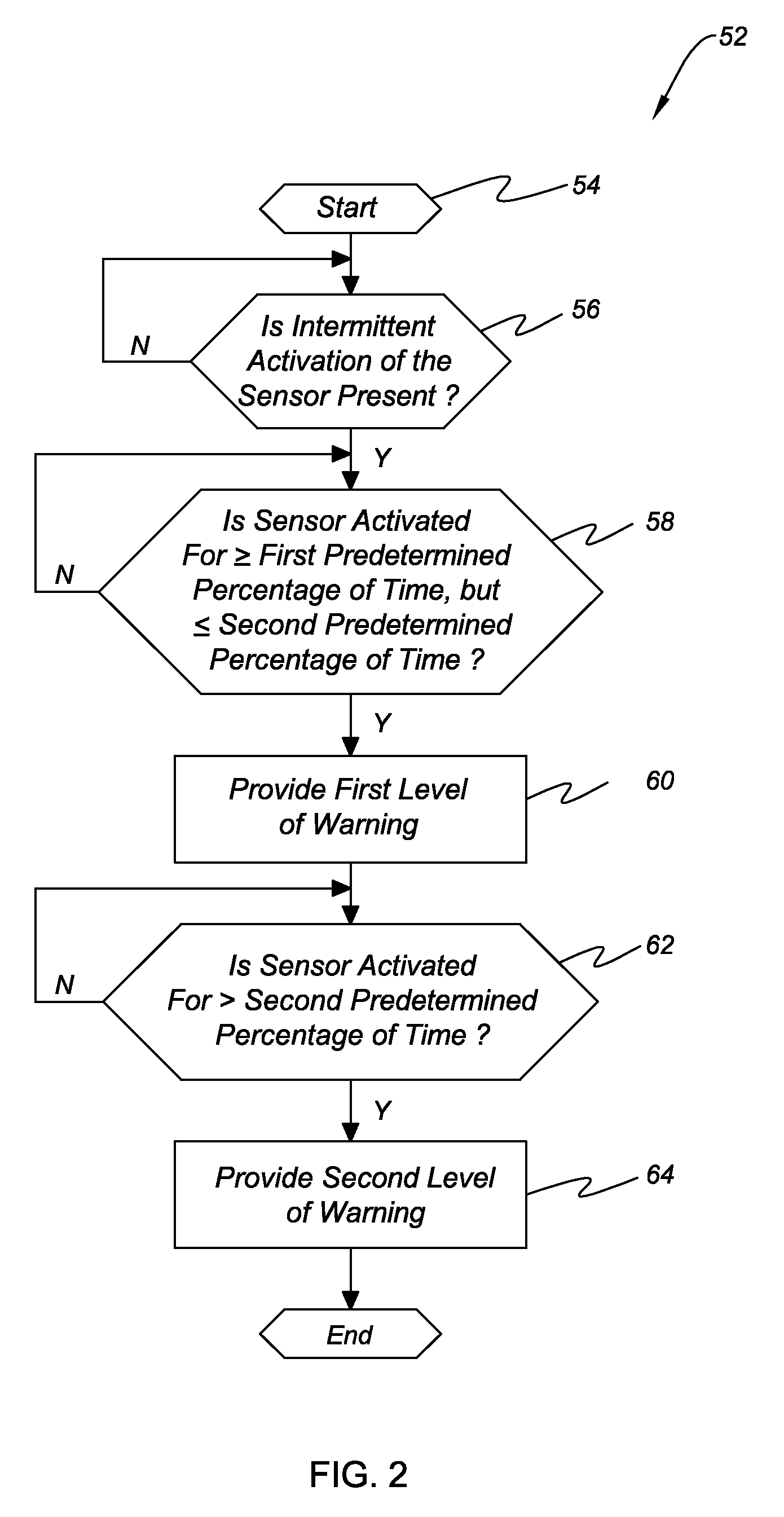

Apparatus and method for sensing water within a fuel-water separator assembly

InactiveUS20080150552A1Reduce injection pressureSolve the power is smallResistance/reactance/impedenceElectric ignition installationEngineeringInternal combustion engine

A method of sensing water within a fuel-water separator assembly disposed within a fuel system of an internal combustion engine is provided. The method includes the steps of: A) monitoring a single selectively activatable sensor within the fuel-water separator assembly to detect the presence of water; B) determining if the sensor is activated for greater than or equal to a first predetermined percentage of time, but less than or equal to a second predetermined percentage of time and providing a first level of warning if true; and C) determining if the sensor is activated for greater than the second predetermined percentage of time and providing a second level of warning if true. An apparatus configured to perform the claimed method is also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

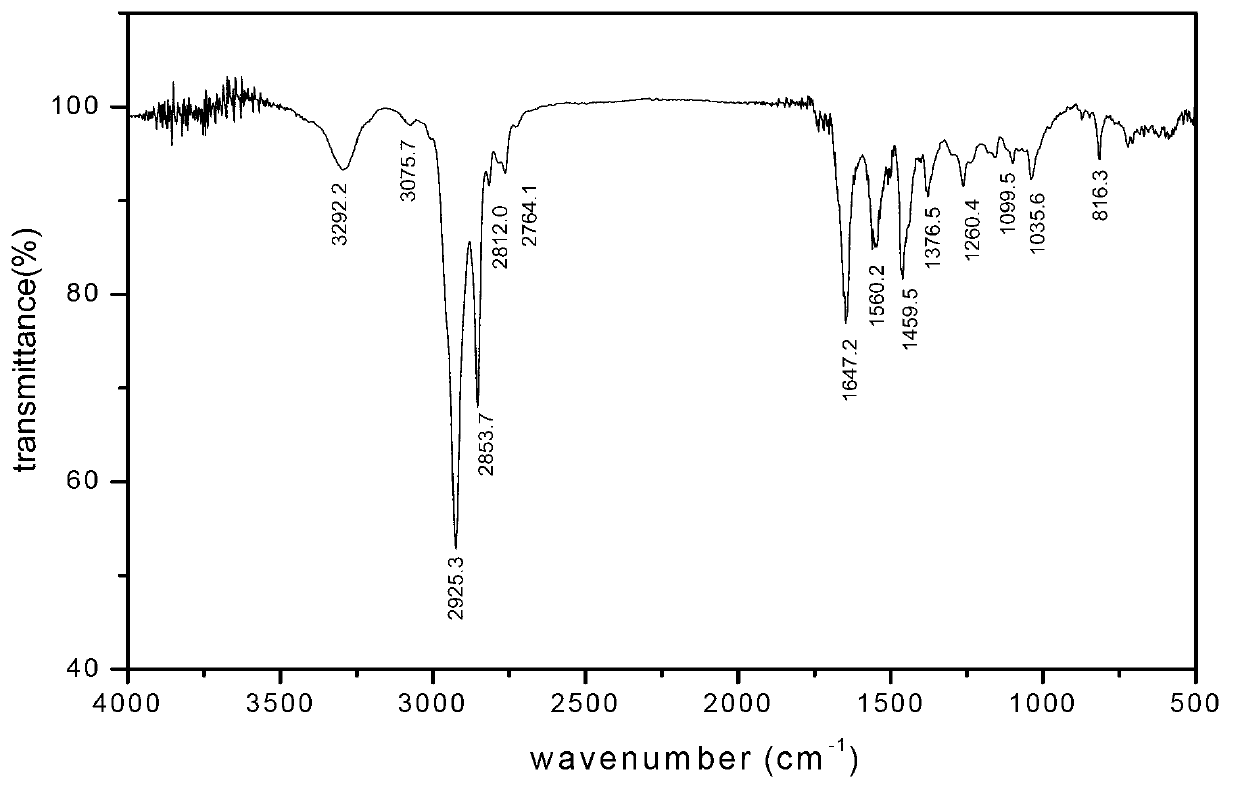

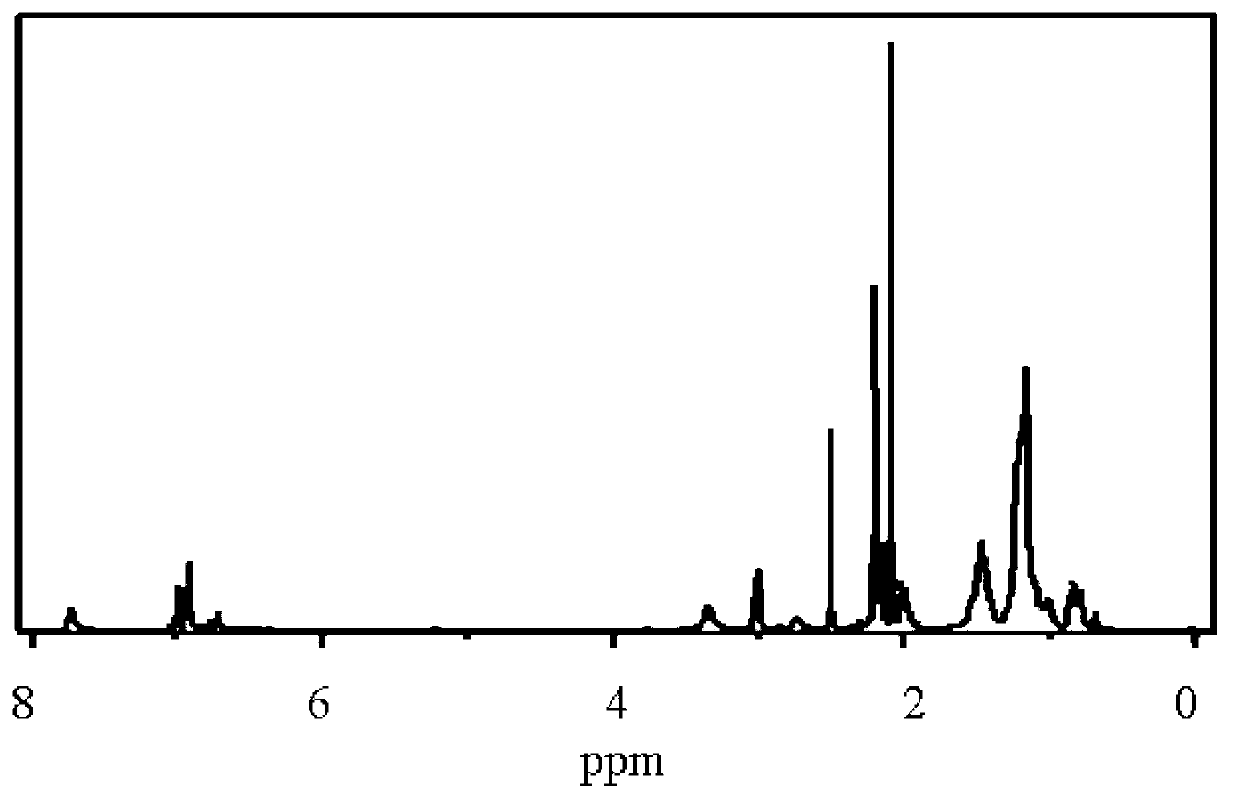

Aromatic group-containing amine oxide type ampholytic surfactant, and preparation method and application thereof

ActiveCN103272522AReduce interfacial tensionWeaken the separation effectTransportation and packagingMixingArylStructural formula

The invention provides an aromatic group-containing amine oxide type ampholytic surfactant, and a preparation method and application thereof. The structural formula of the aromatic group-containing amine oxide type ampholytic surfactant is shown as a formula 1, wherein m is 0 or 1, and n is 0 or 1. The invention further provides a surfactant composition which contains more than two types of the aromatic group-containing amine oxide type ampholytic surfactants shown as the formula 1. The preparation method of the aromatic group-containing amine oxide type ampholytic surfactant comprises the following step of: enabling aryl alkyl tertiary amine and hydrogen peroxide to react for 4-5 hours at 70-80 DEG C to obtain the aromatic group-containing amine oxide type ampholytic surfactant. The invention further provides the application of the aromatic group-containing amine oxide type ampholytic surfactant or the surfactant composition in tertiary oil recovery. The surfactant provided by the invention has better interfacial activity and tackifying performance, and can be used for increasing the petroleum recovery rate when being used in the tertiary oil recovery.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com