Patents

Literature

945 results about "Compression screw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible Screw

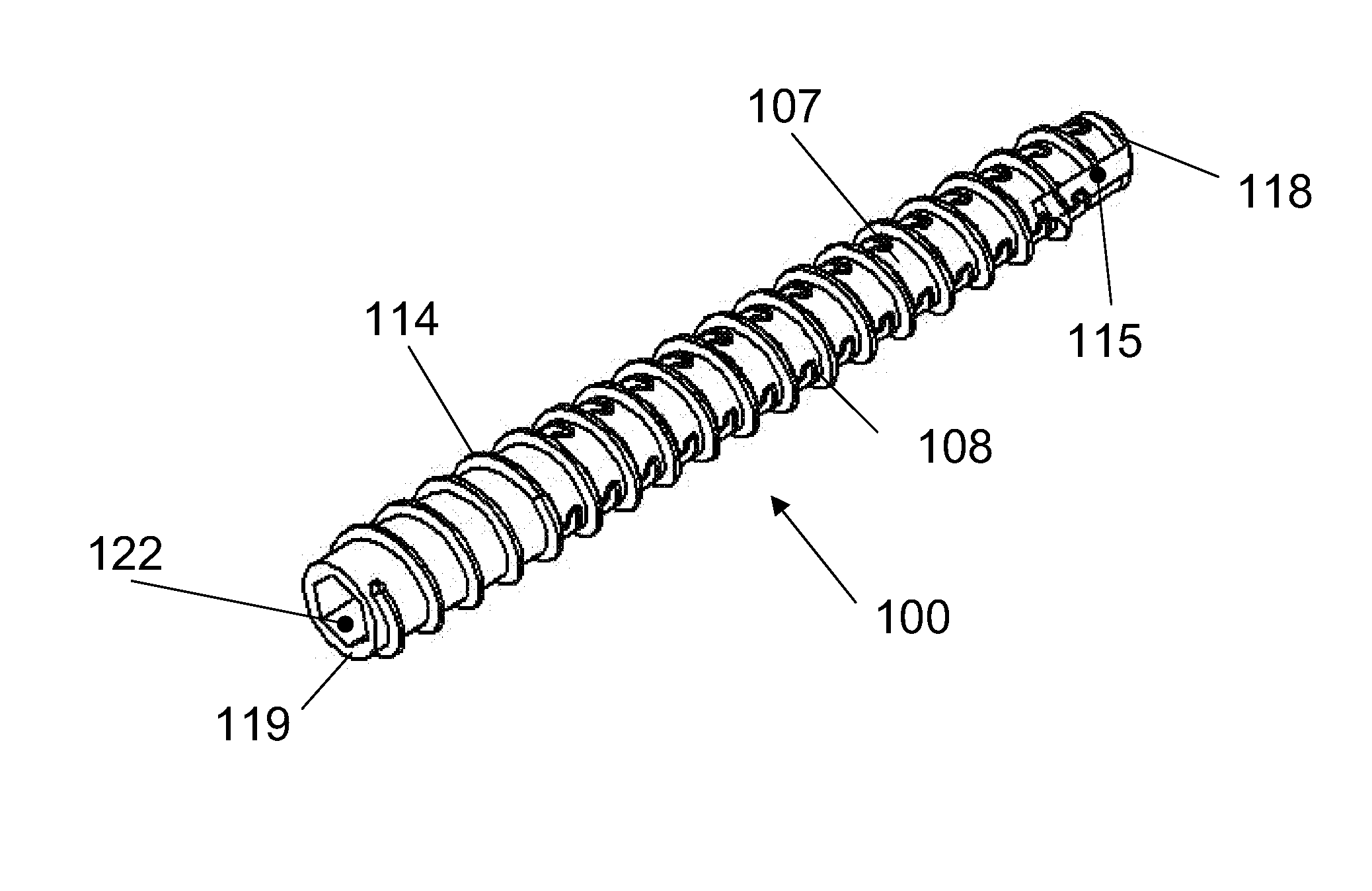

InactiveUS20110144703A1Increase flexibilityIncrease widthSuture equipmentsLigamentsLeading edgeEngineering

A flexible compression screw having multiple segments, one or more of which are flexible and one or more segments that also include threads. The flexibility is created through the use of at least one helical slot formed generally in the center segment of the element. Additional flexible segments also have at least one helical slot in either the same helical rotation and pattern or in an opposite rotation and / or different pattern. An elastomeric material can fill the hollow body, extend into the slots and / or encompass the exterior. The flexible screw can have a hollow body, including leading and trailing edge, or can have a partially hollow body.

Owner:FLEX TECH

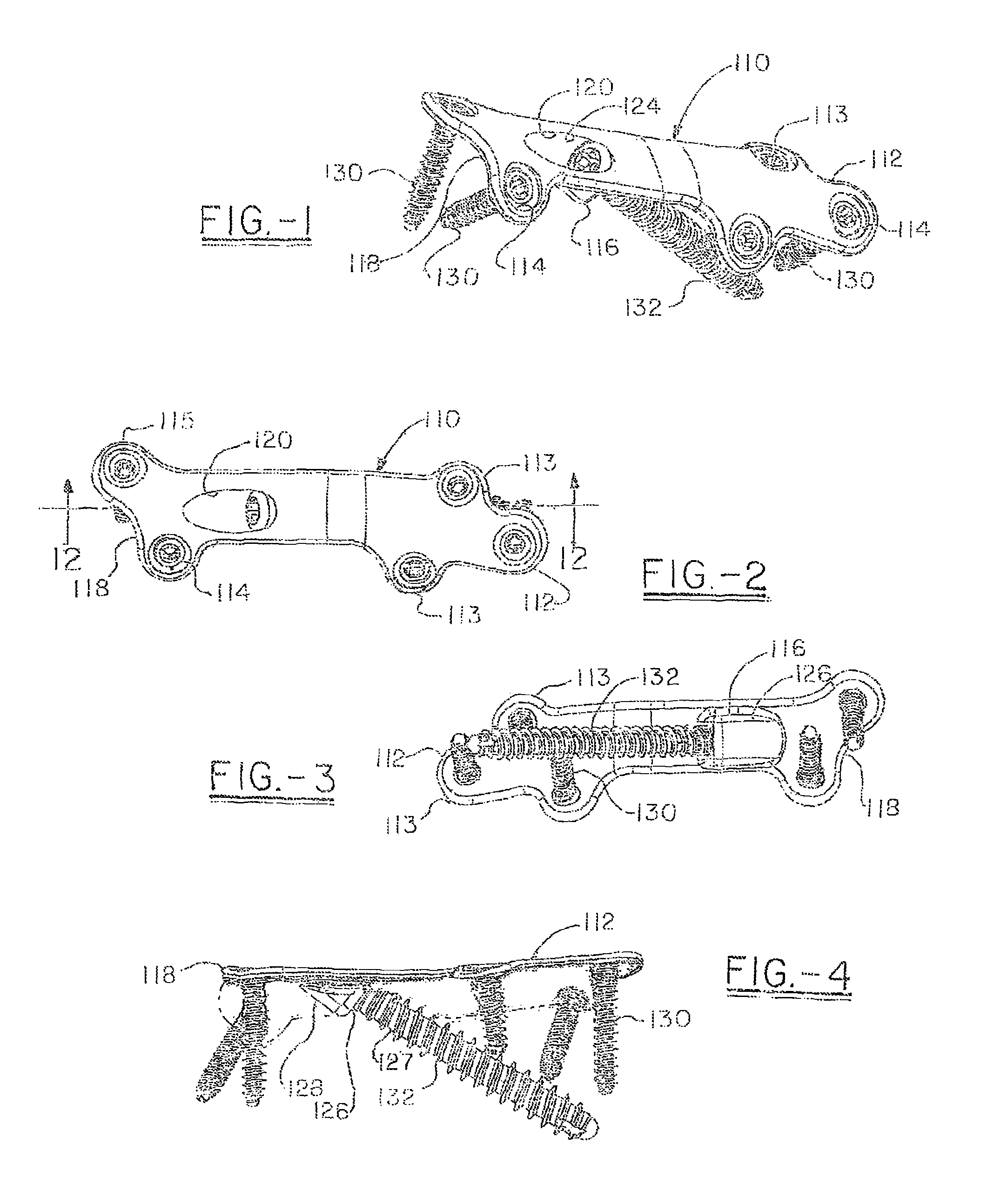

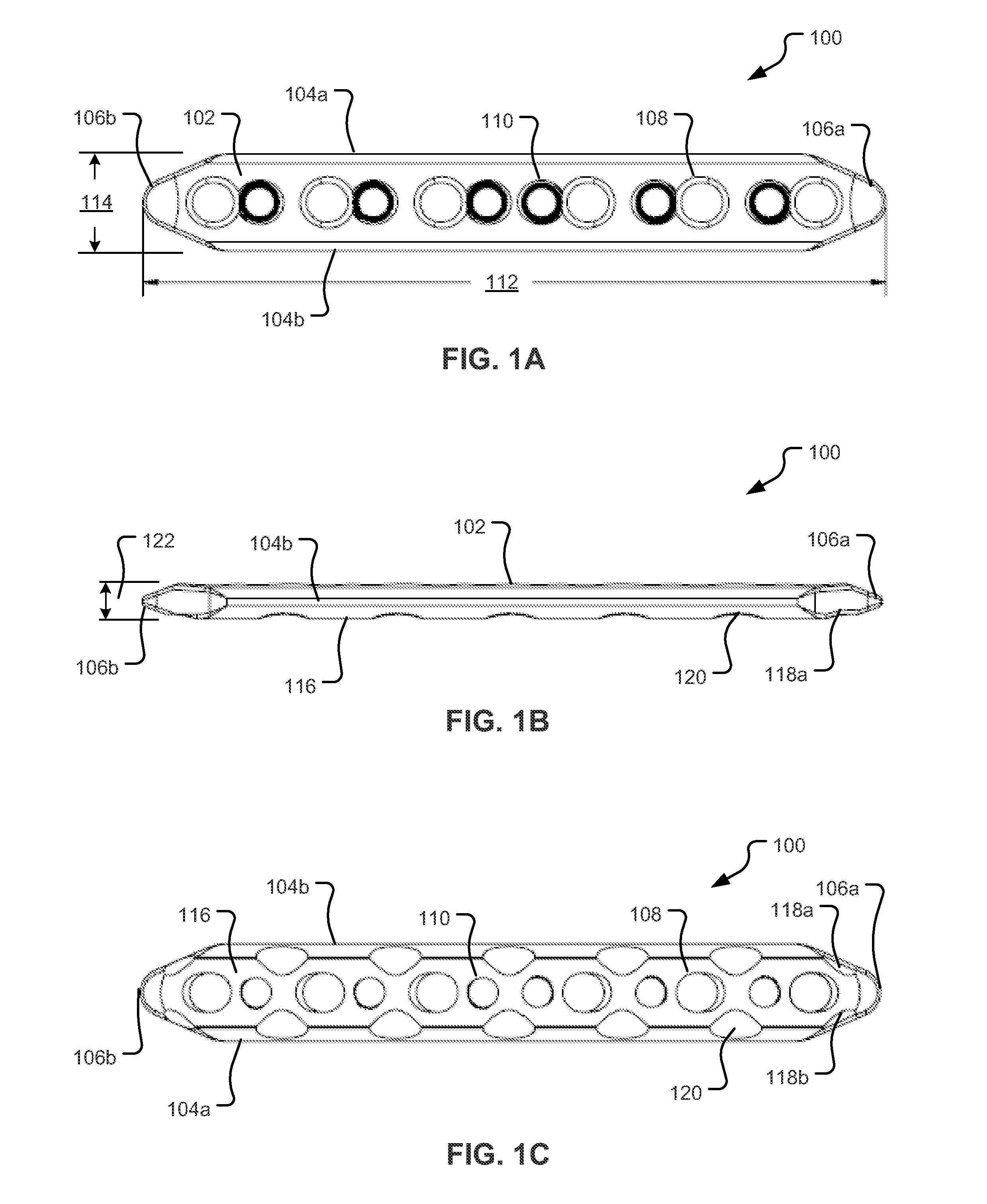

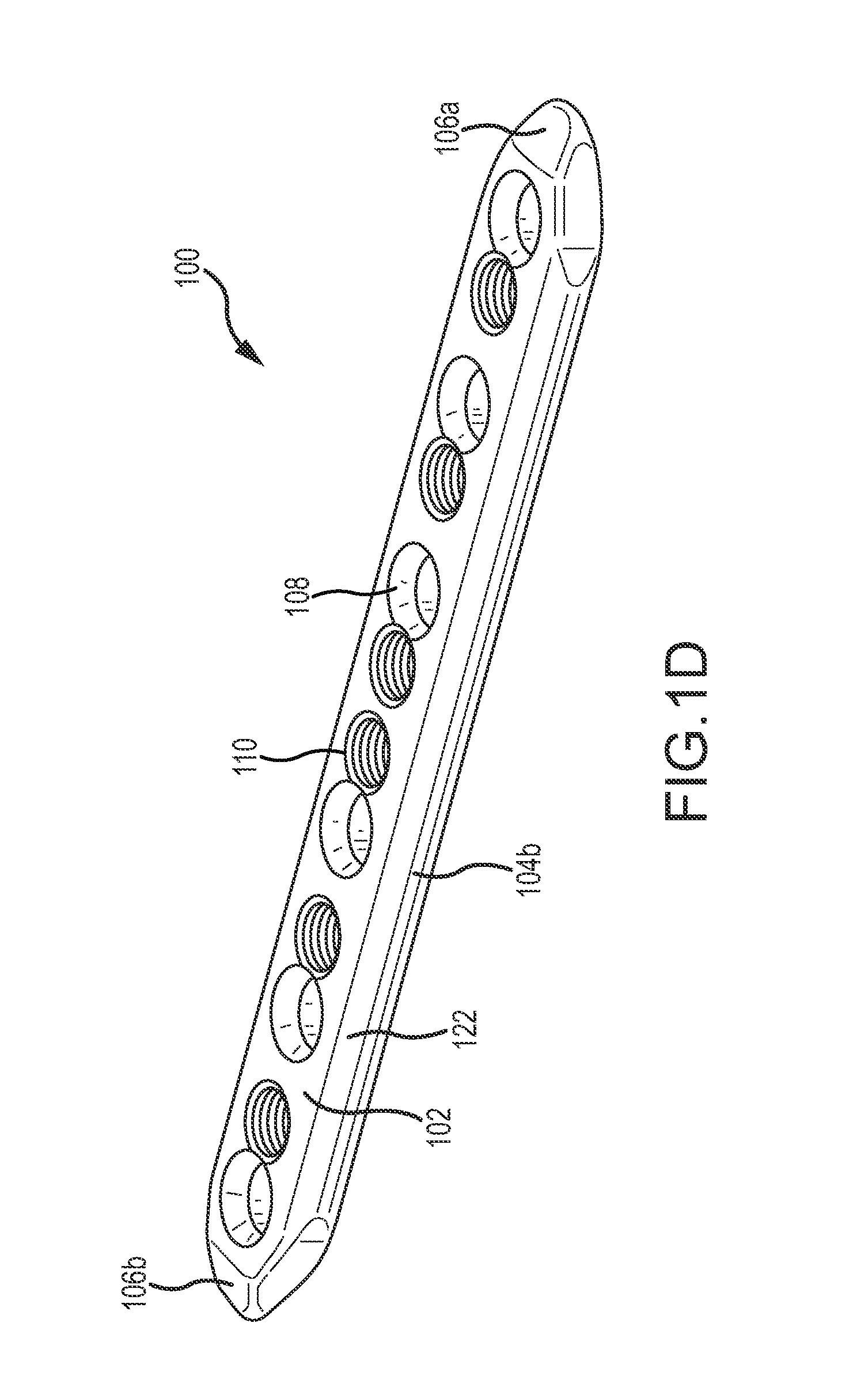

Bone plates and bone plate assemblies

Bone plates with an upper surface, a bone contacting surface, and at least one hole extending through the upper and bone contact surfaces are disclosed. A hole interchangeably accepts a compression screw for compression of a fracture and a locking screw that threads into the bone plate.

Owner:SMITH & NEPHEW INC

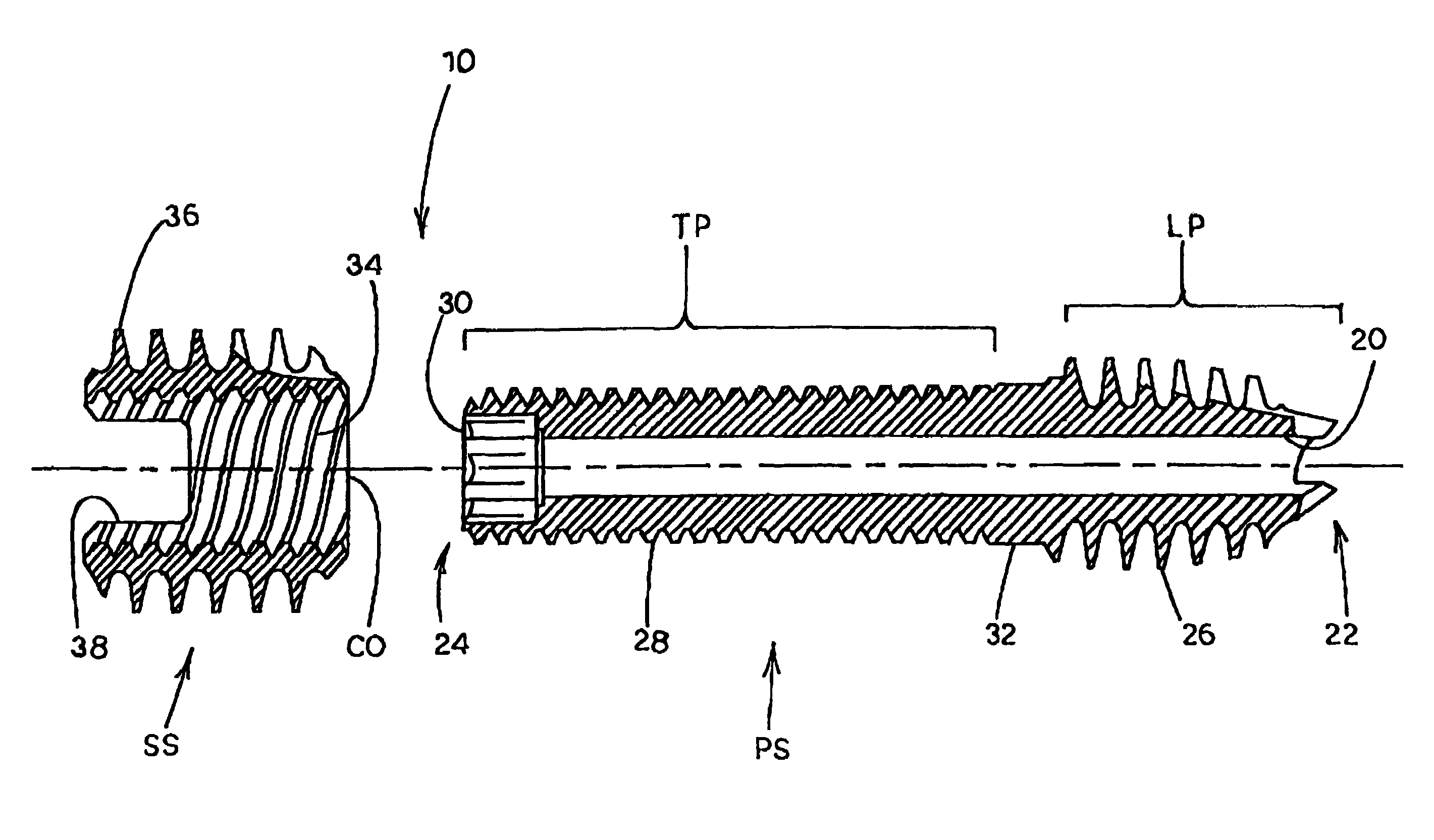

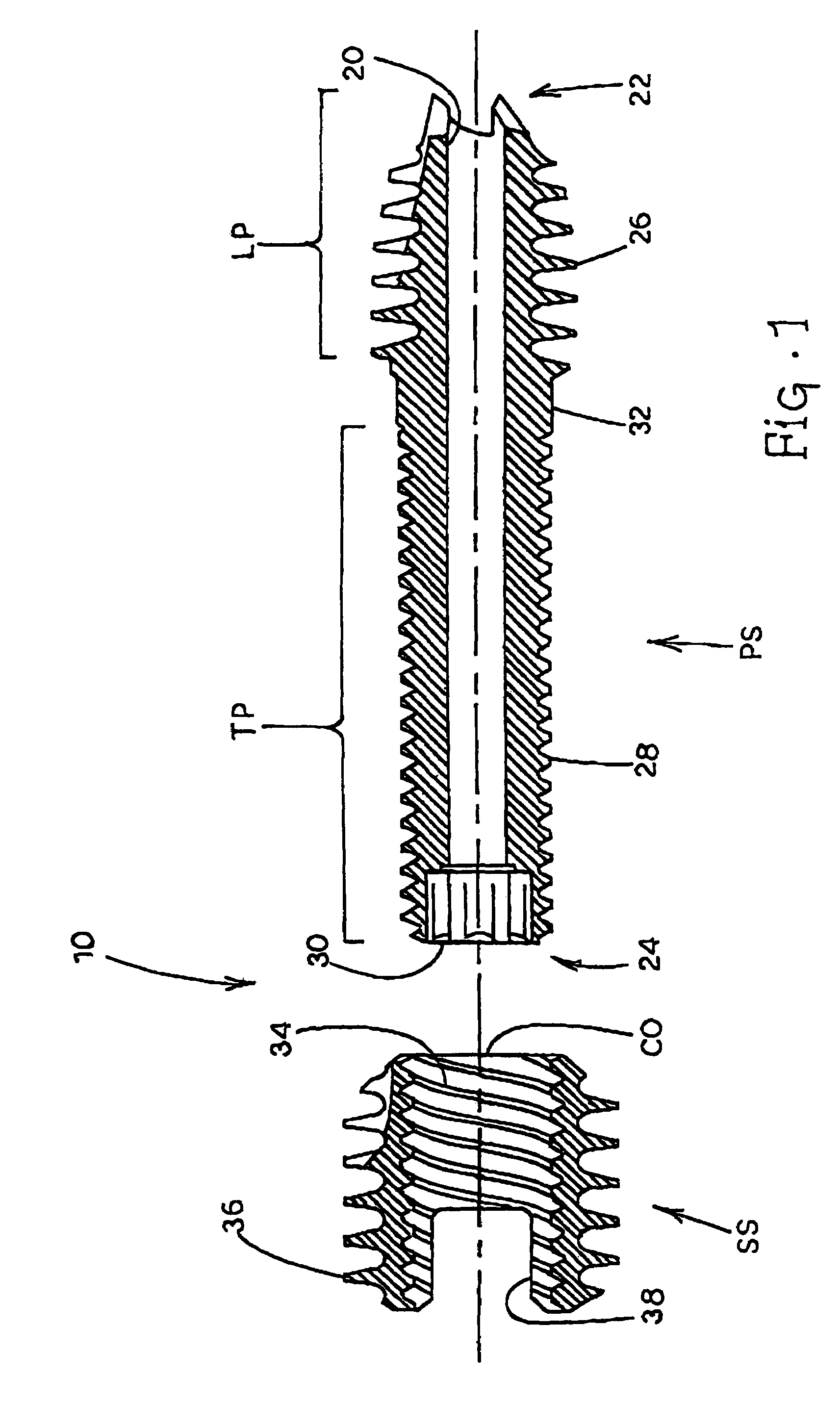

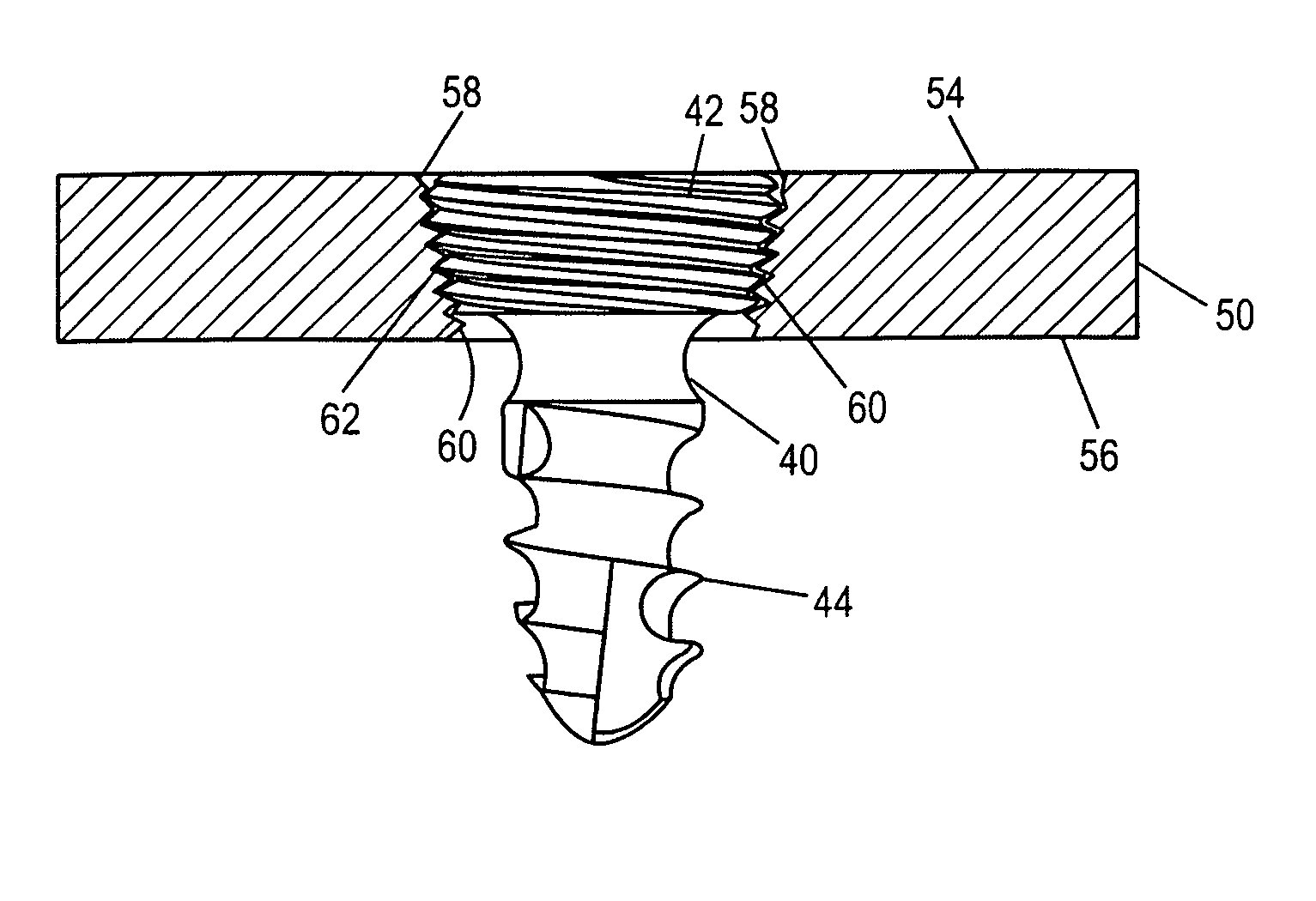

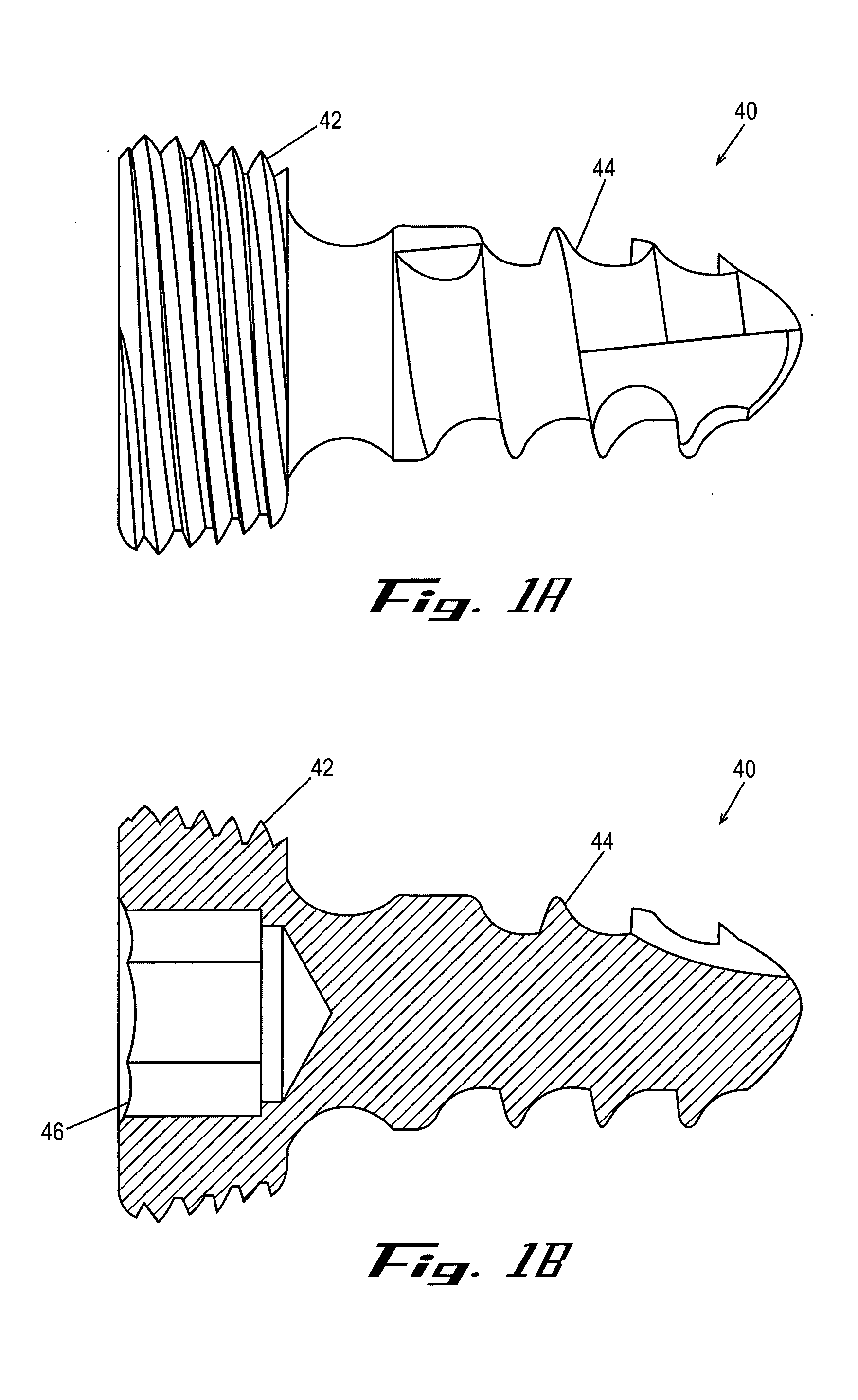

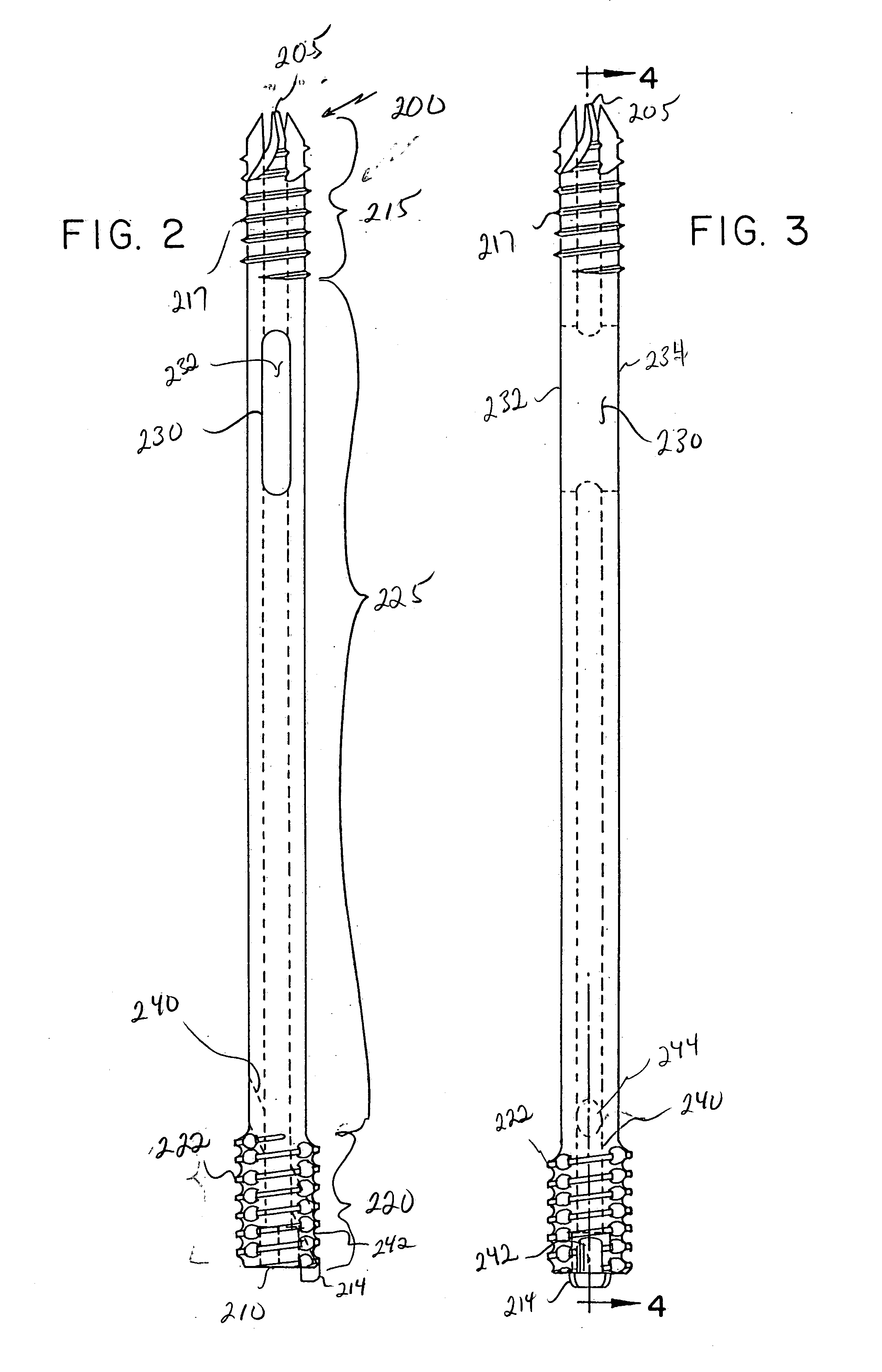

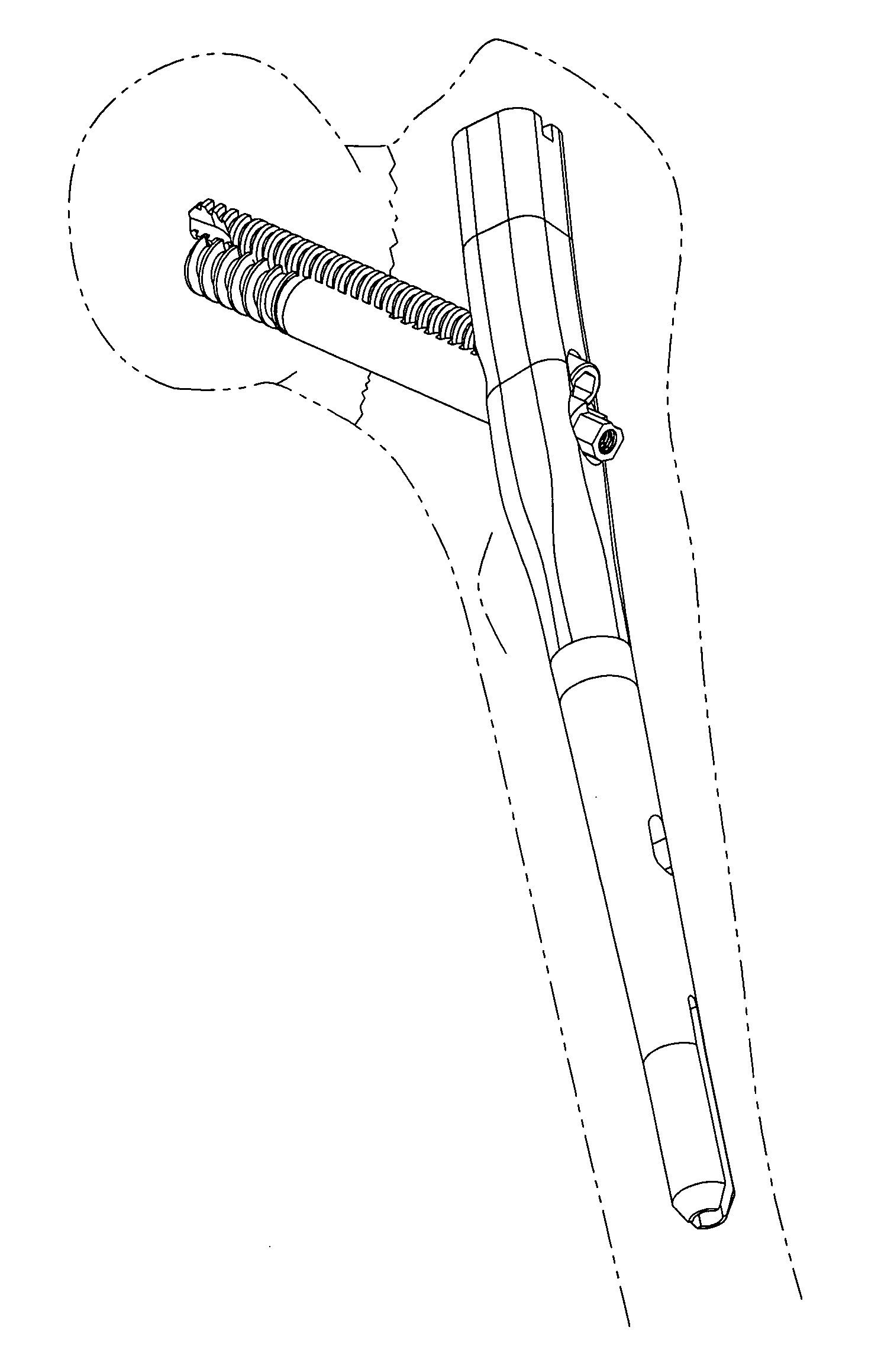

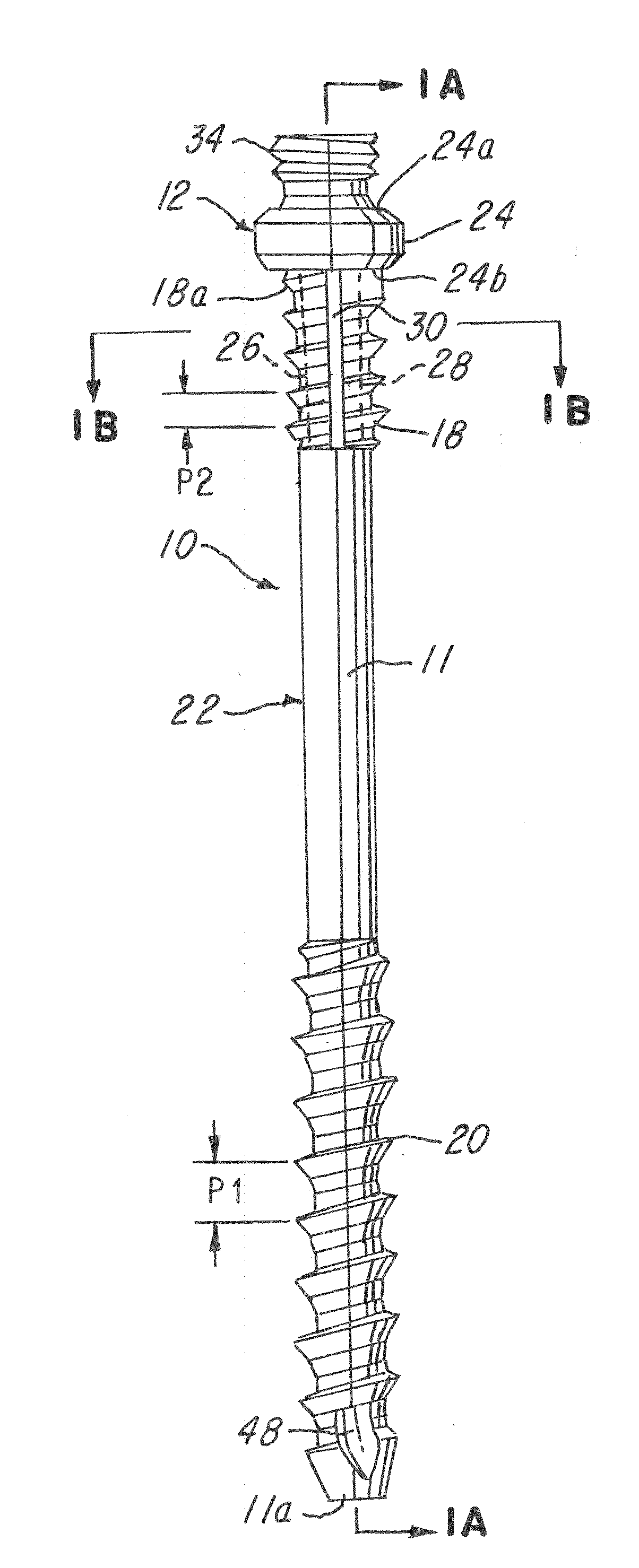

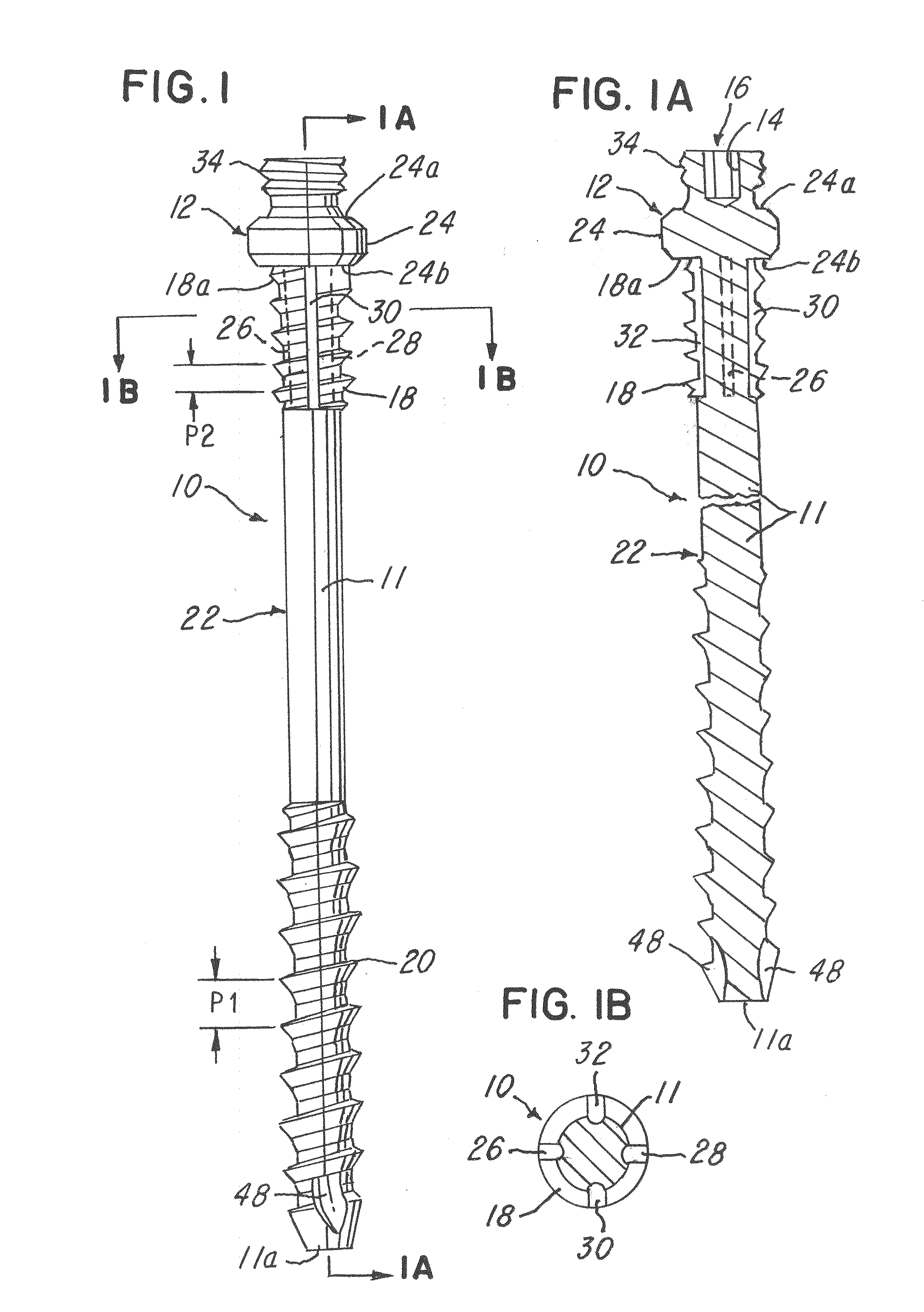

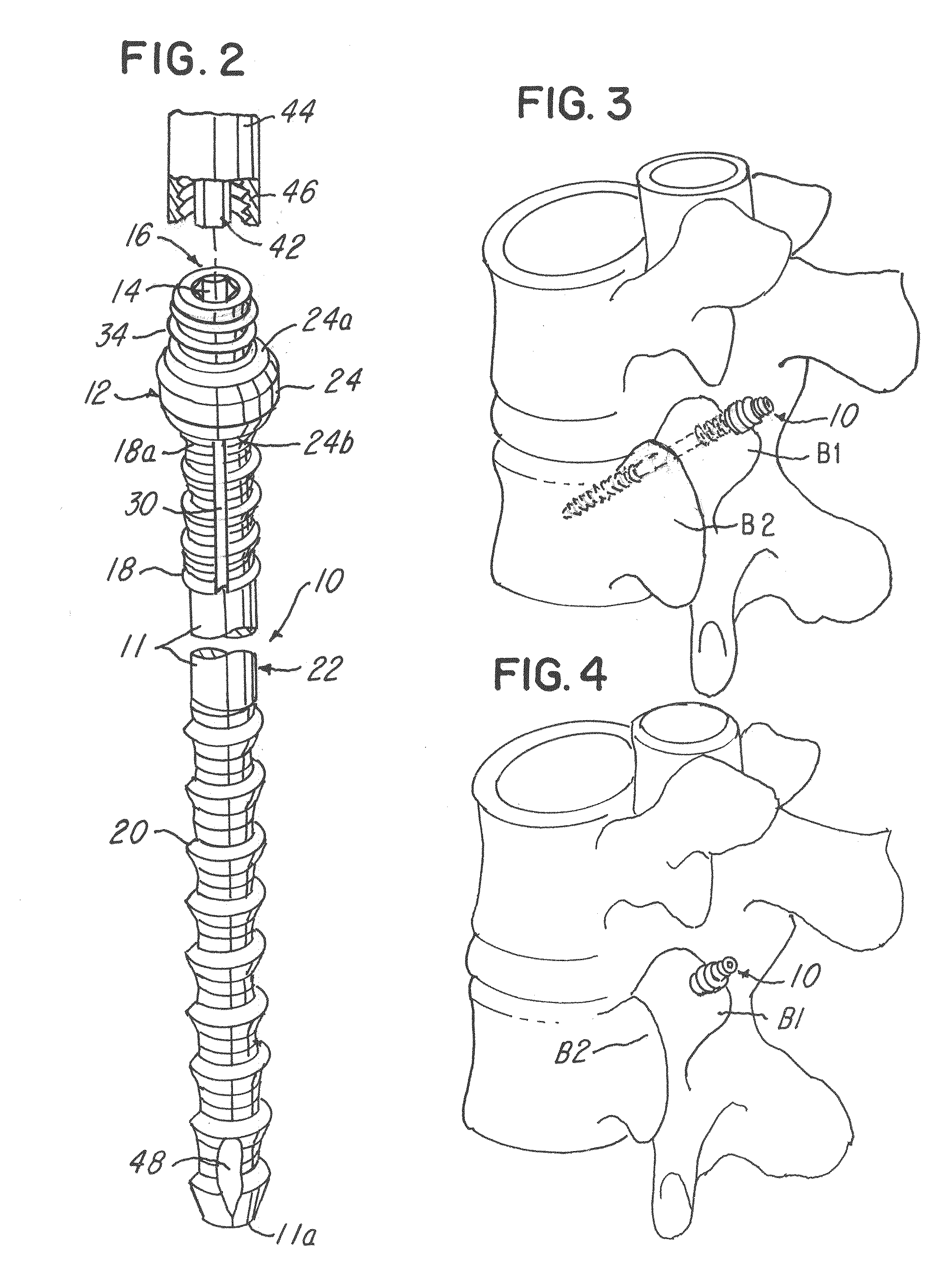

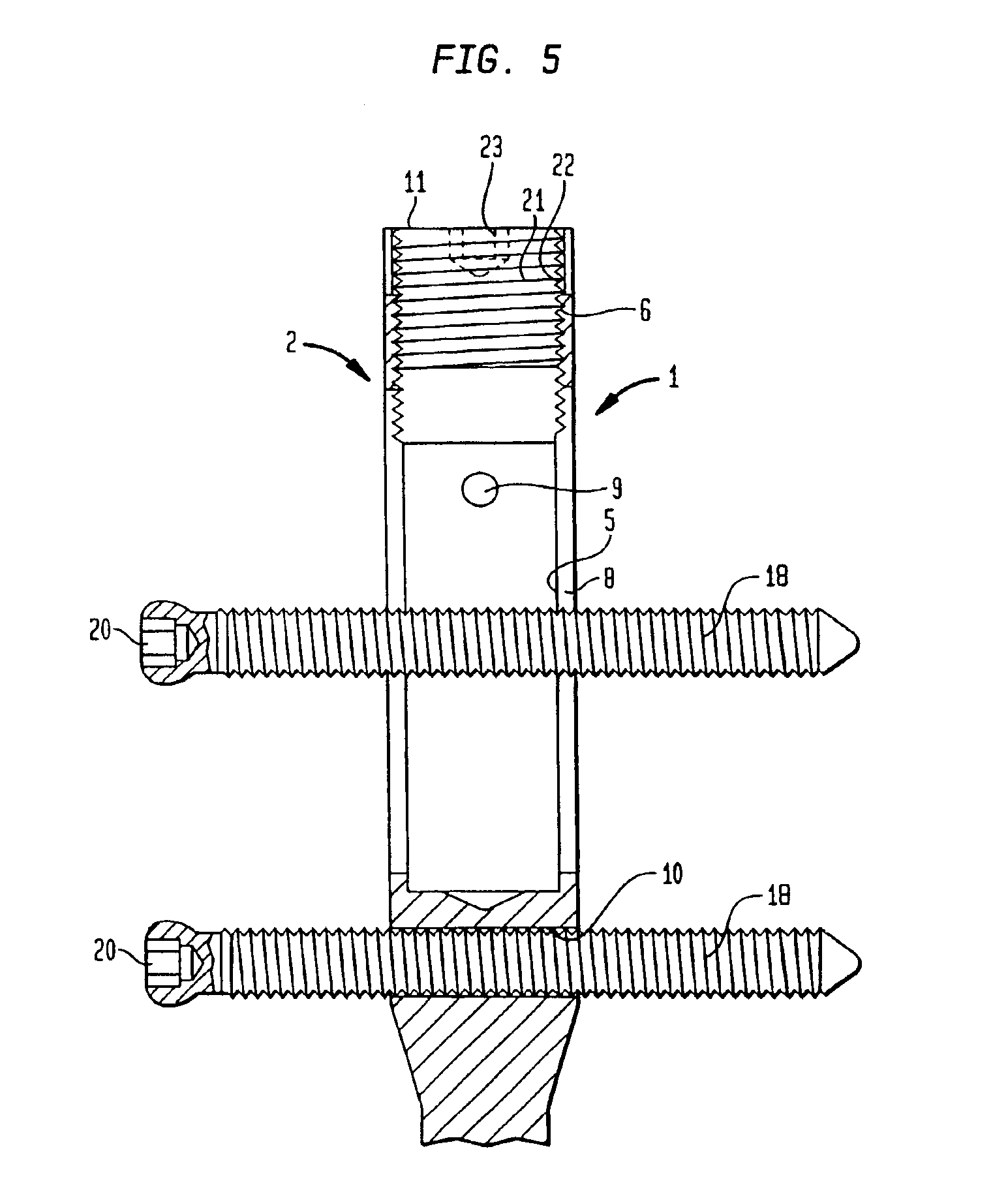

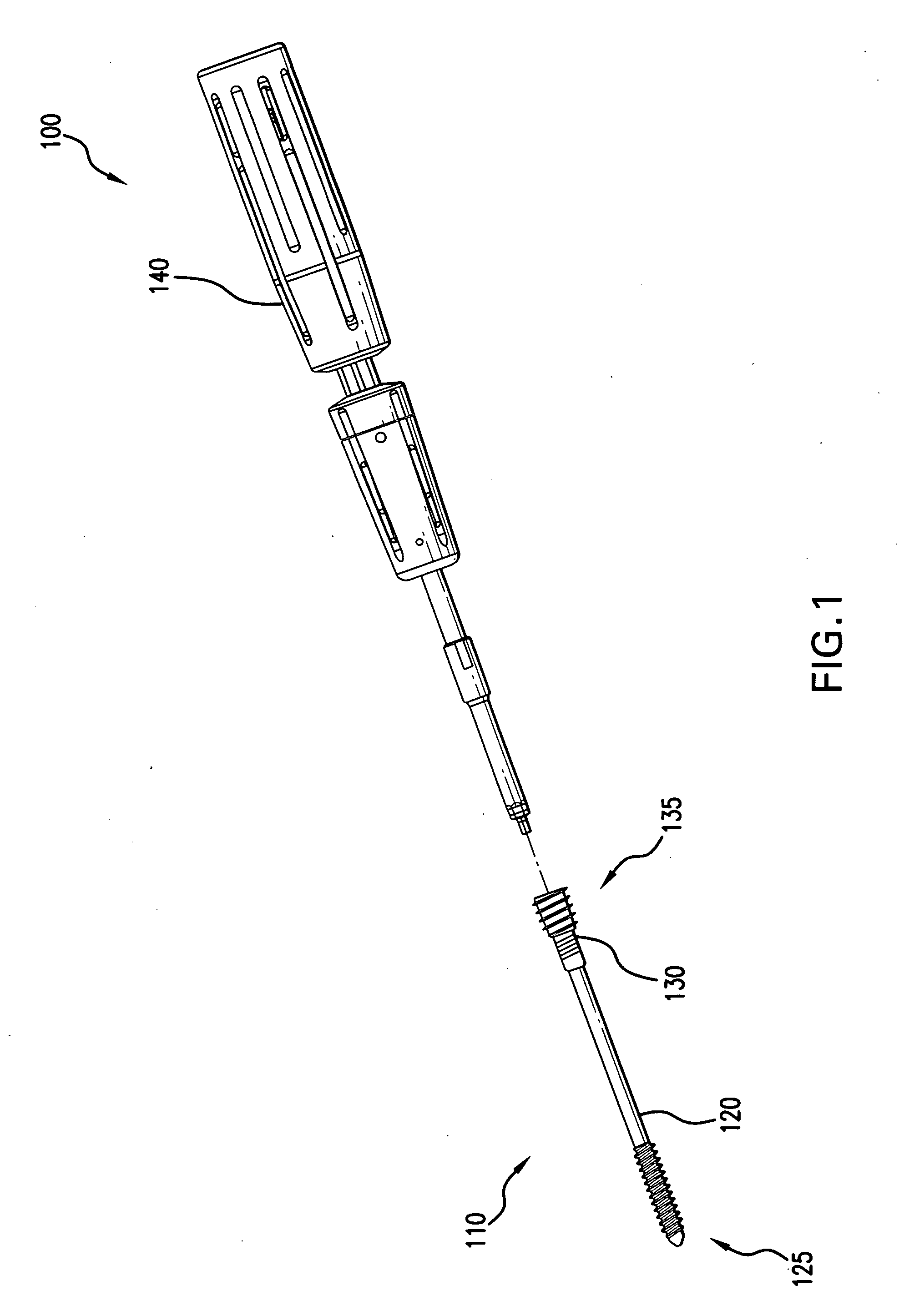

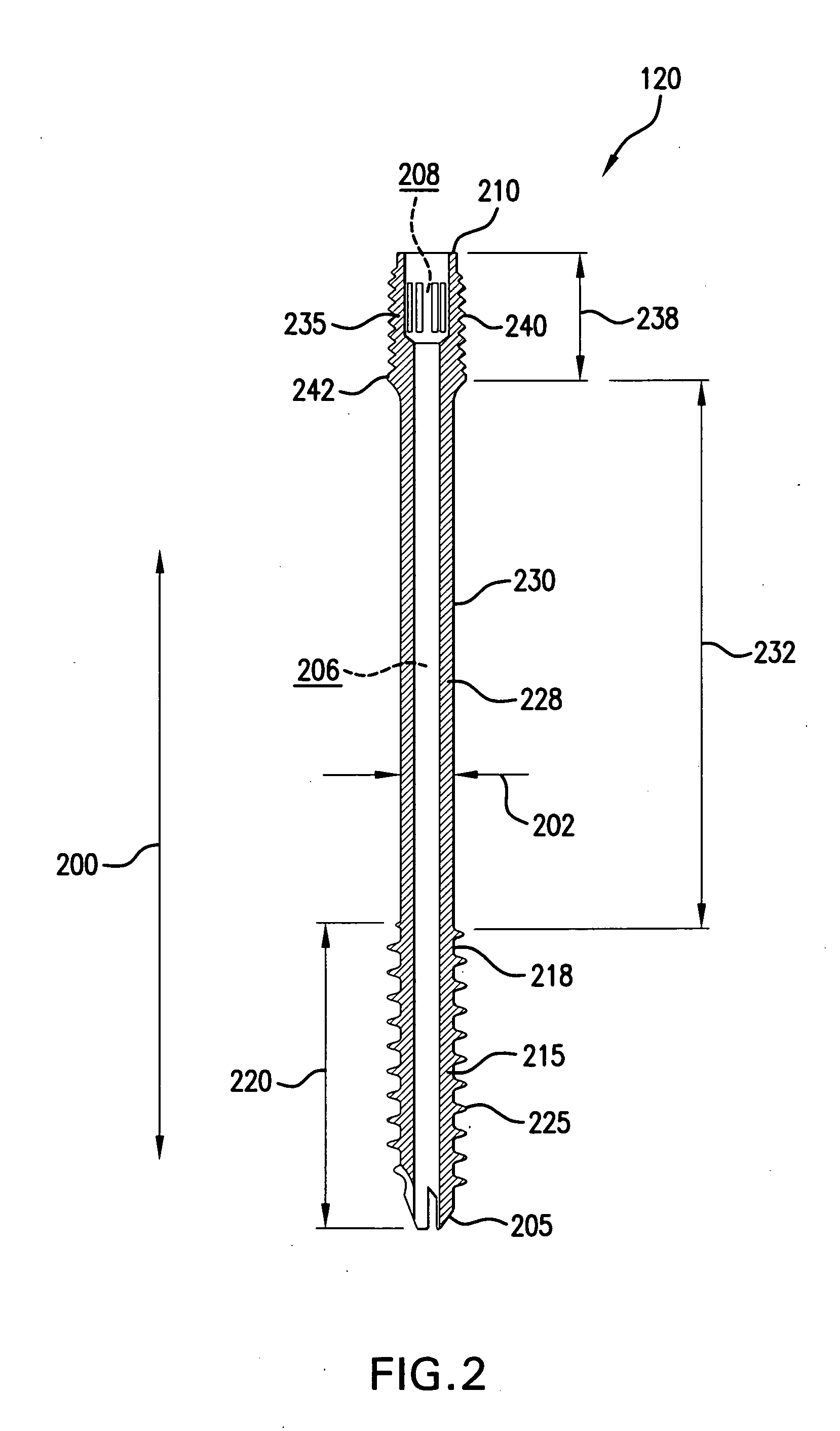

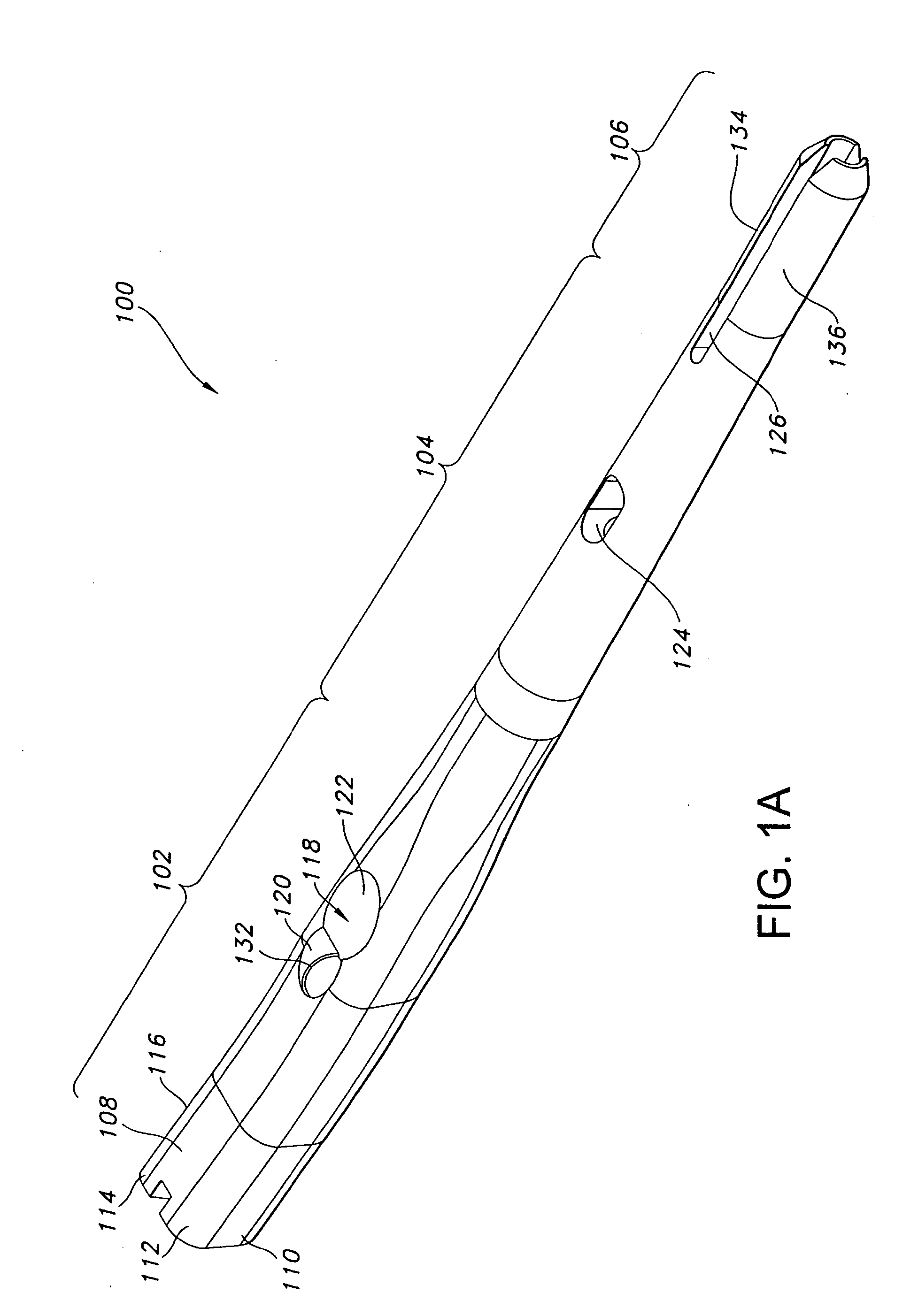

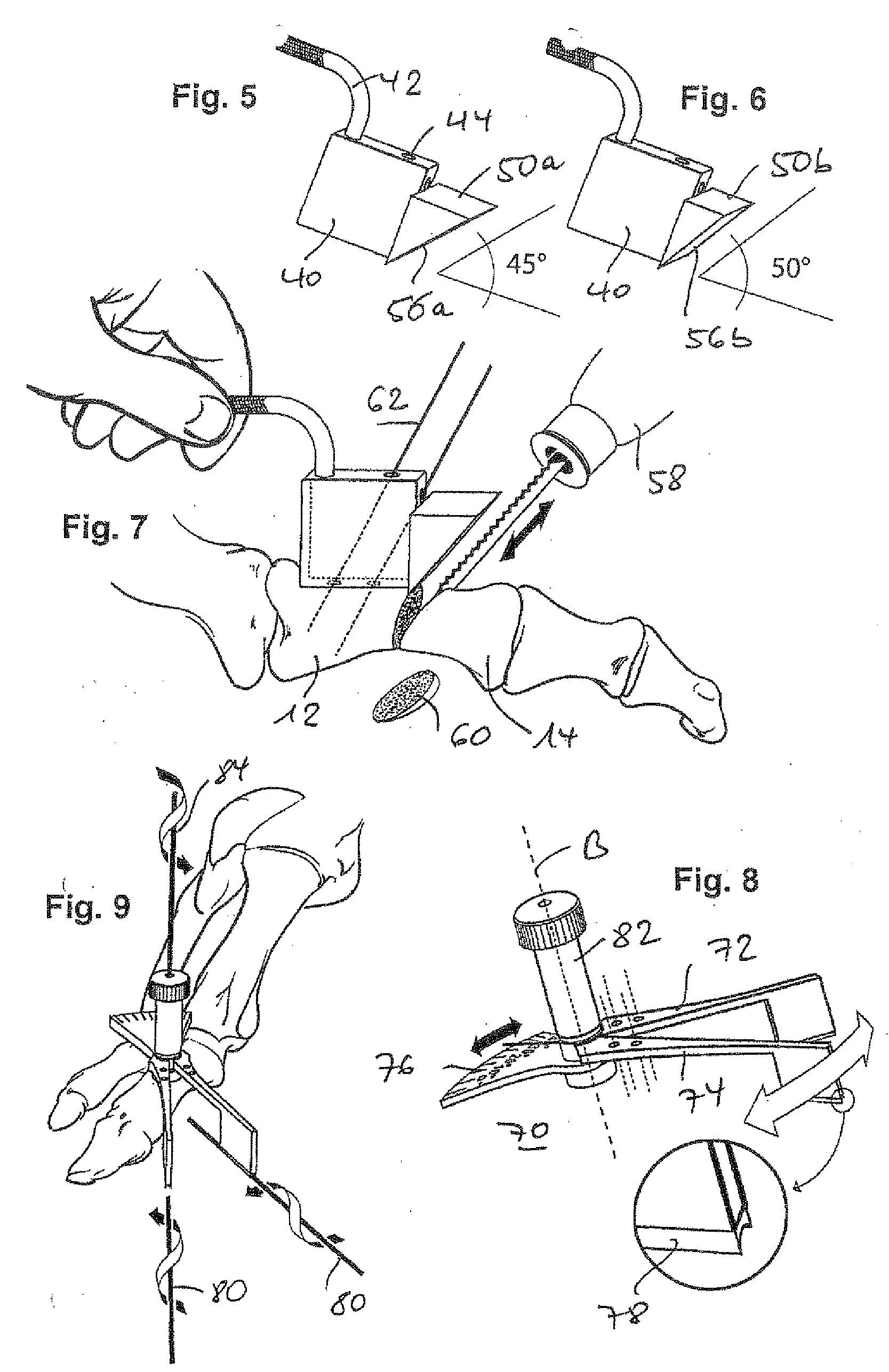

Compression screw apparatuses, systems and methods

InactiveUS7582107B2Easily and effectively be used to compress suitable materialsSuture equipmentsLigamentsEngineeringFracture line

Compression screw apparatuses, systems and methods are disclosed. In one embodiment, the compression screw includes a primary screw and a secondary screw. The primary screw includes an at least partially threaded leading portion and an at least partially threaded trailing portion. The secondary screw includes outer threads and has a central opening which is also threaded and adapted for being screwed onto and matingly engaging the trailing portion of the primary screw. Drivers can be used to rotatably control the primary screw and the secondary screw to cause compression of spaced-apart material, particularly for compression of bone fragments across a fracture line.

Owner:INTEGRA LIFESCI

Bone plates and methods for provisional fixation using same

Bone plates with an upper surface, a bone contacting surface, and a plurality of holes extending through the upper and bone contact surfaces for receiving bone screws are disclosed. Each hole interchangeably accepts a compression screw for compression of a fracture and a locking screw that threads into the bone plate. Provisional fixation of a bone plate to a bone may be accomplished using provisional fixation pins through the screw-receiving holes of the bone plate.

Owner:SMITH & NEPHEW INC

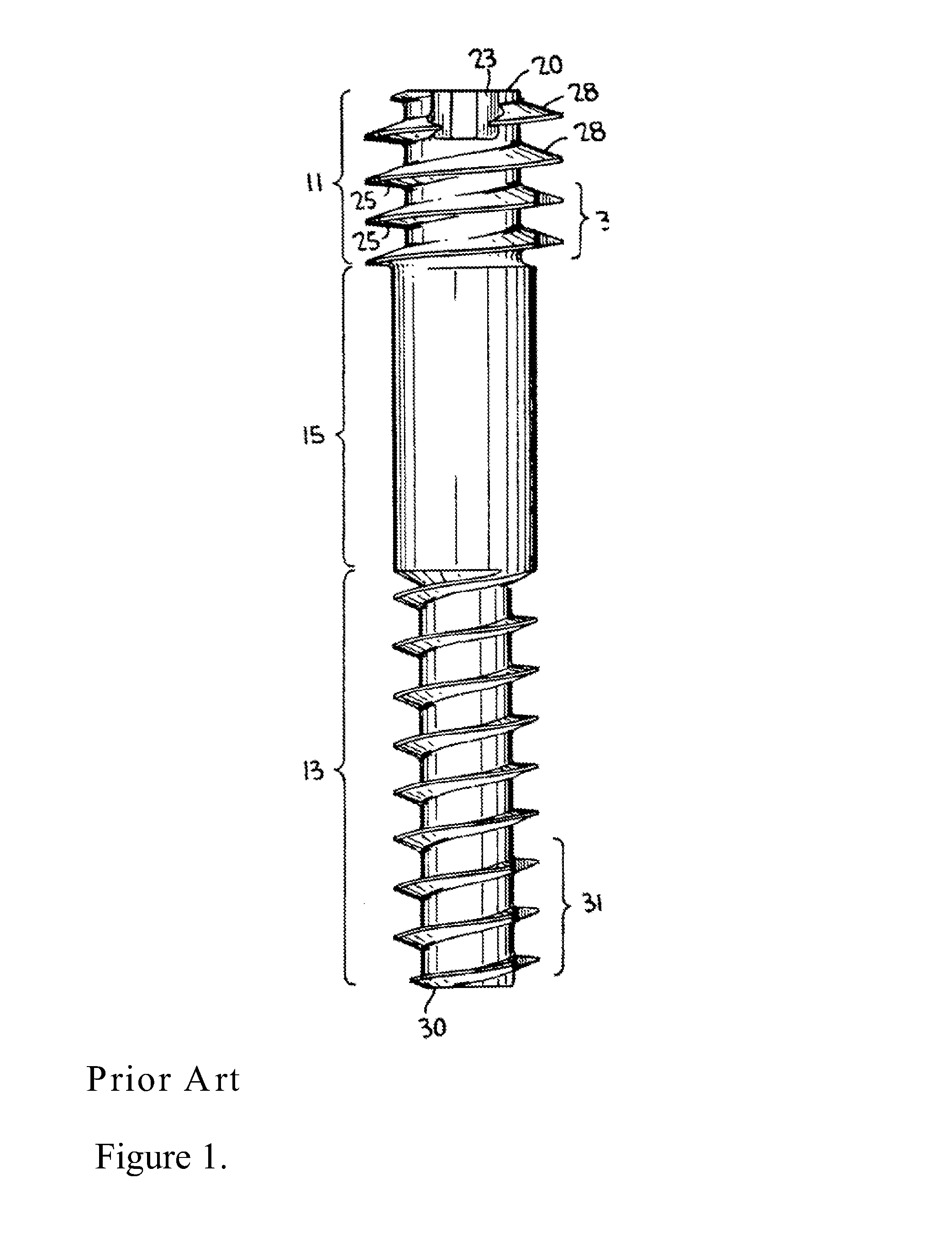

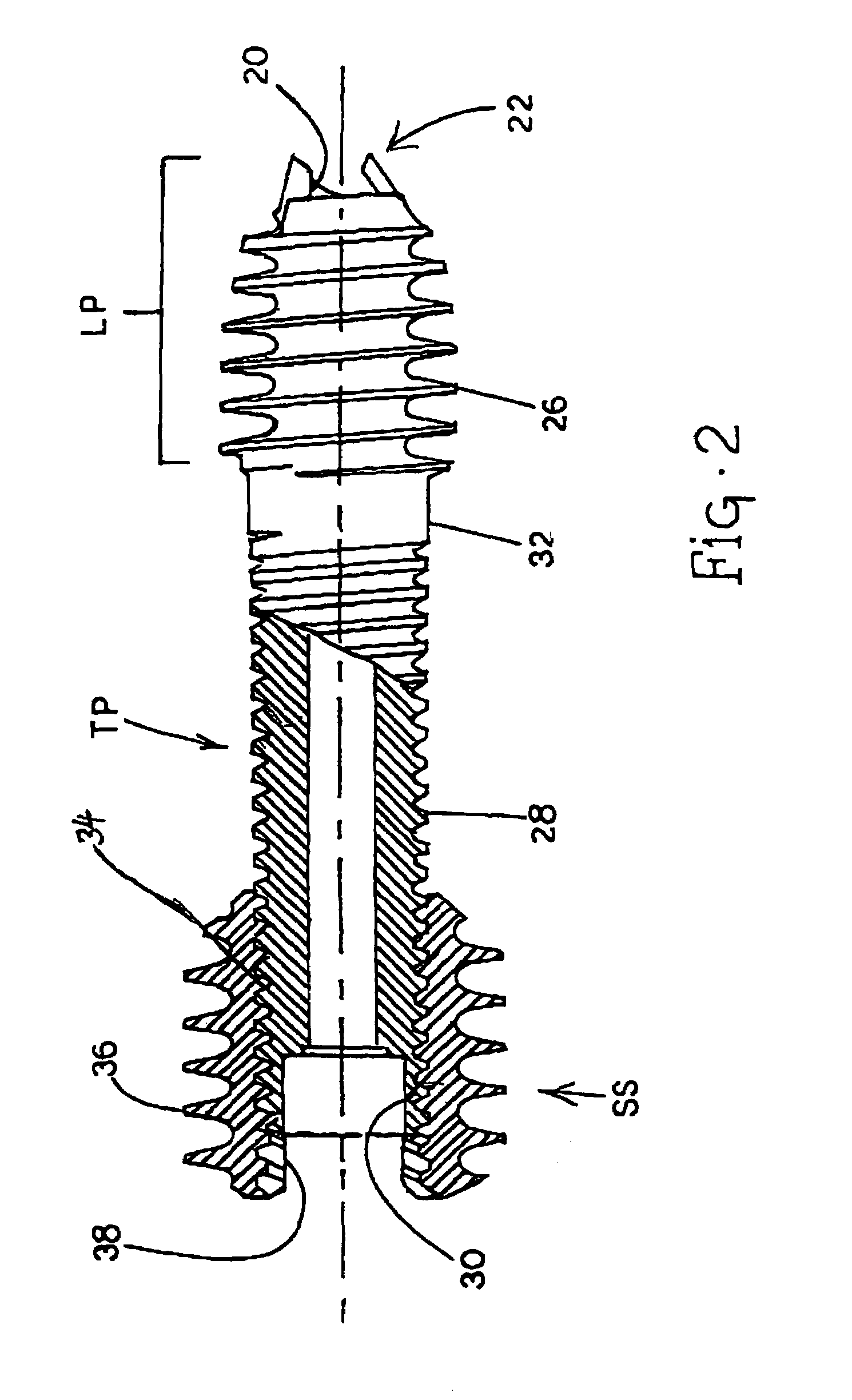

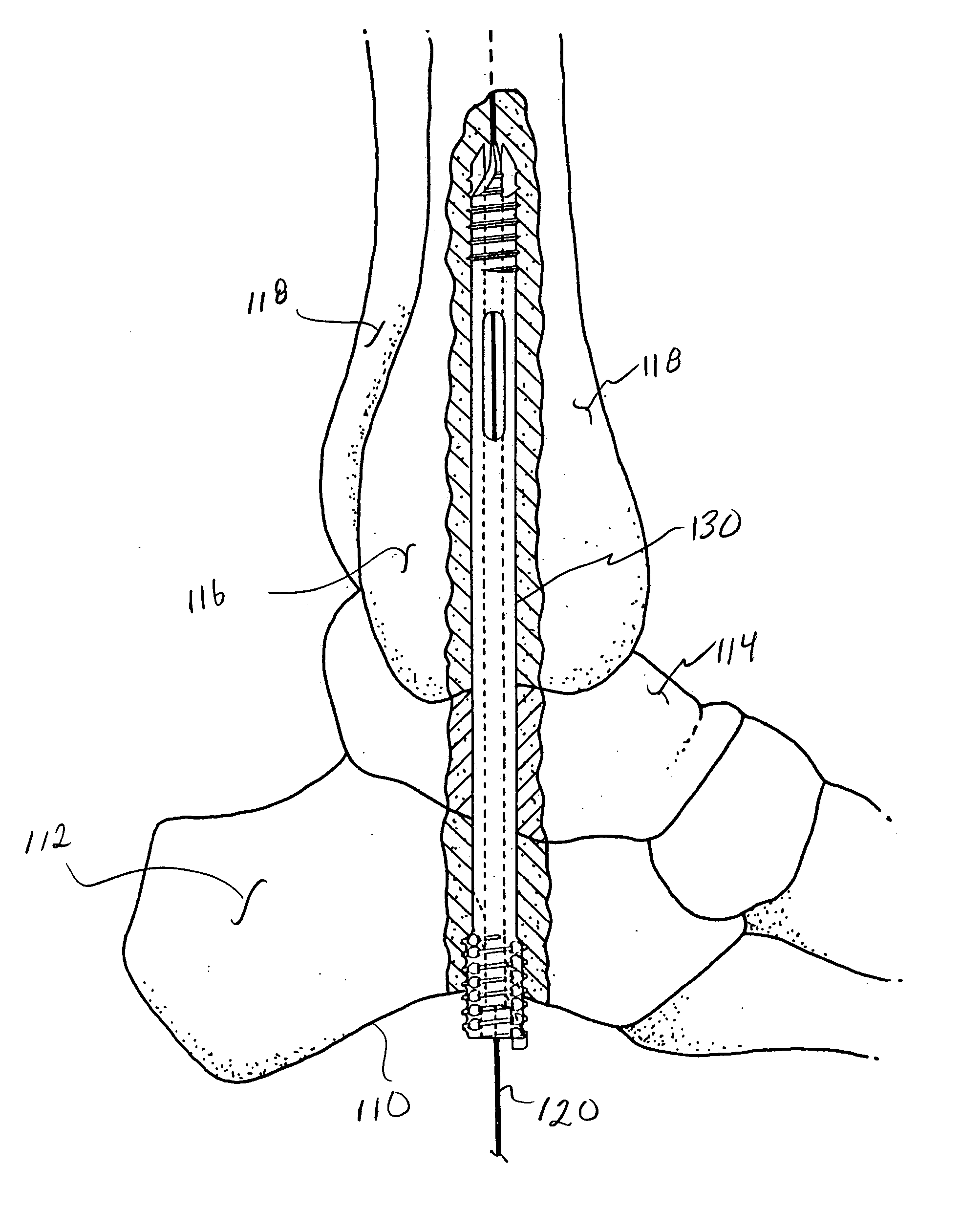

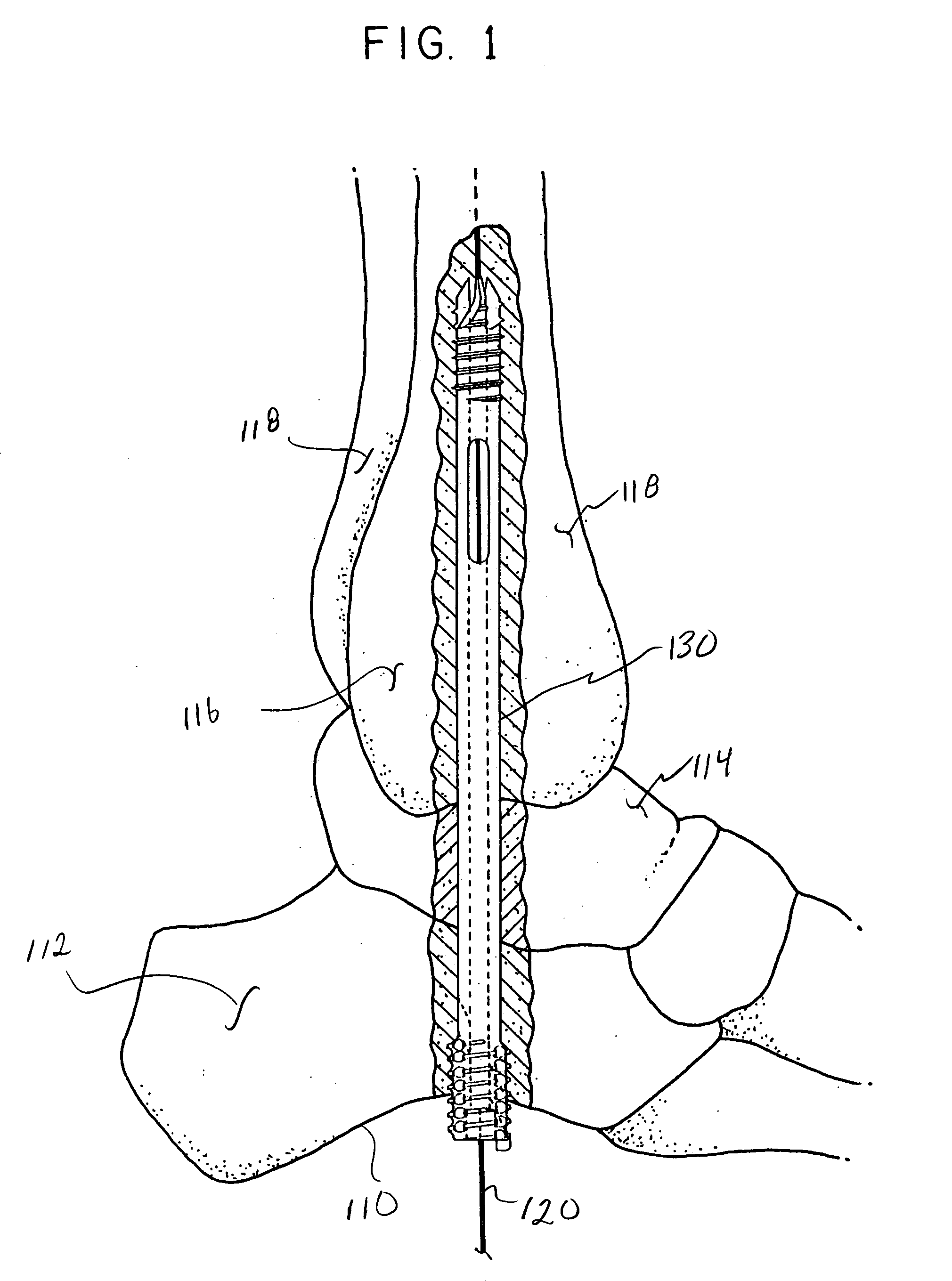

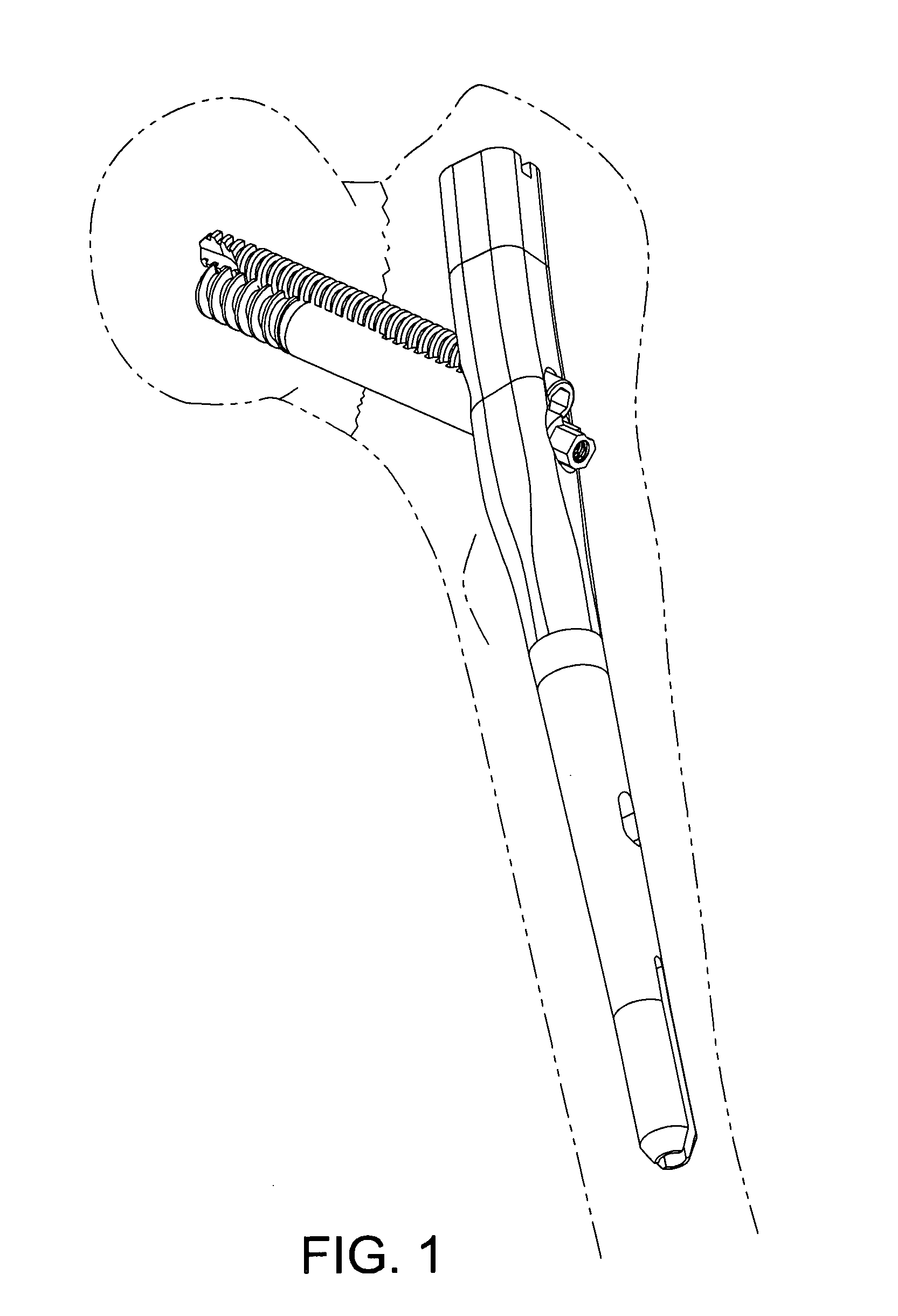

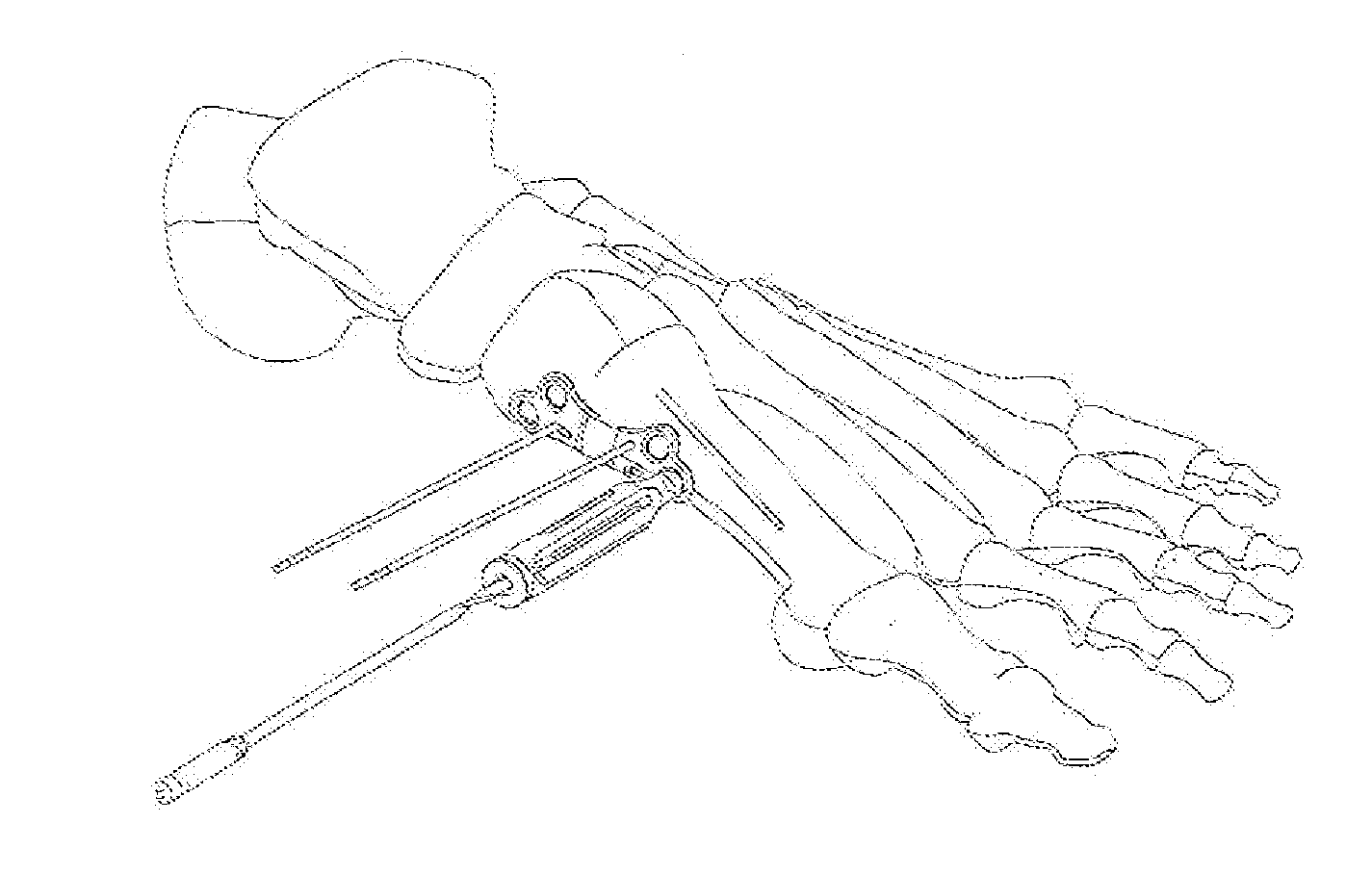

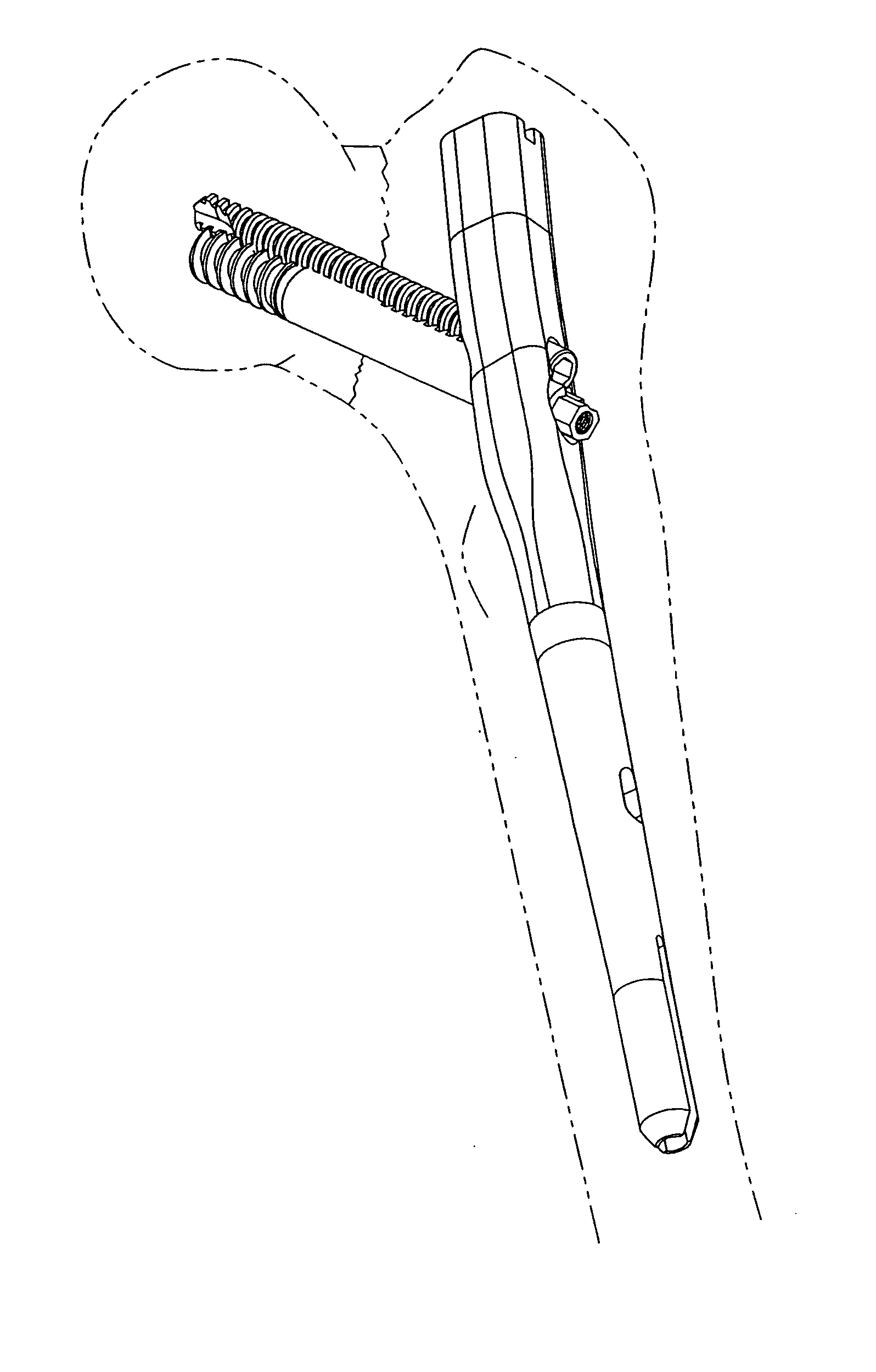

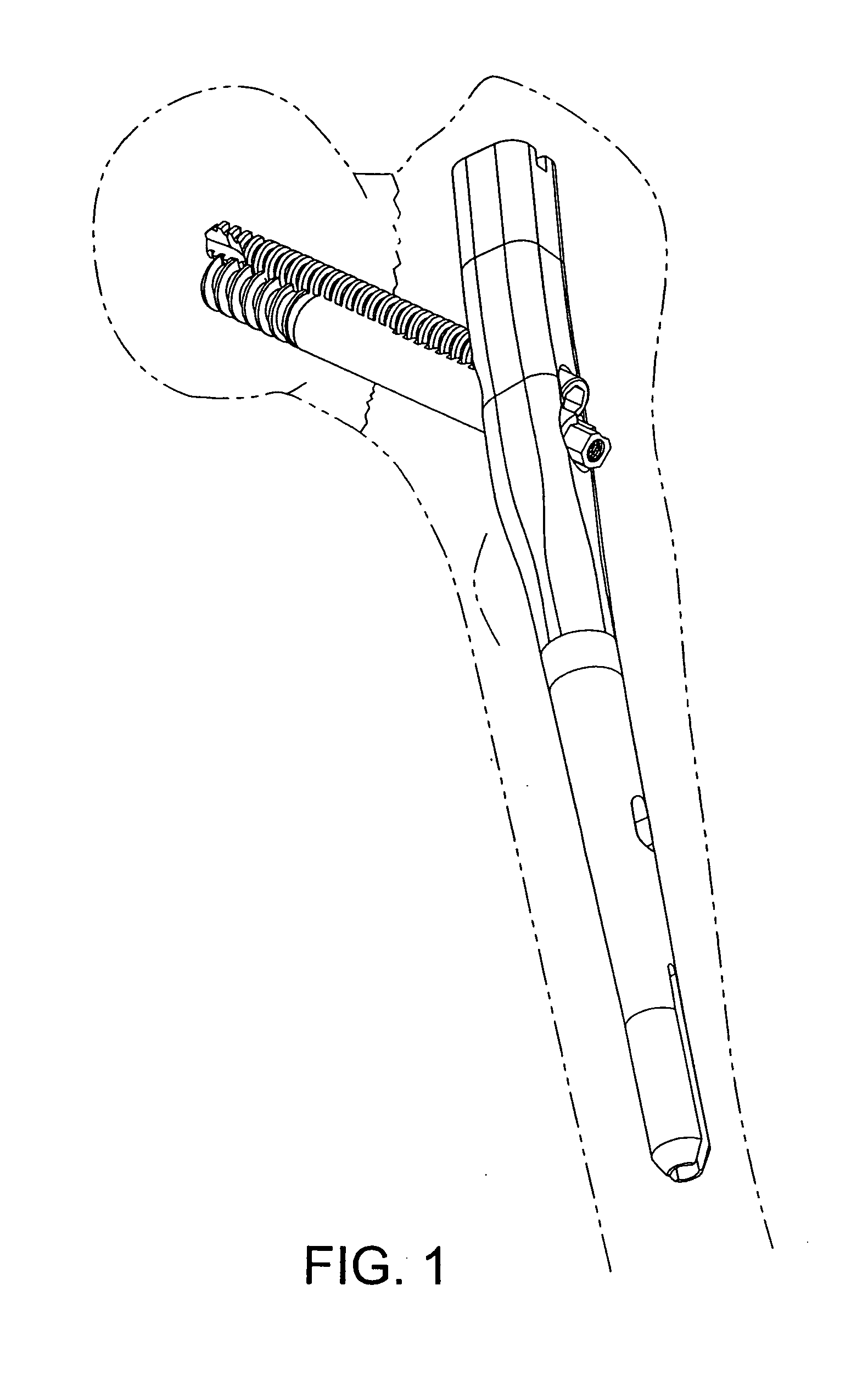

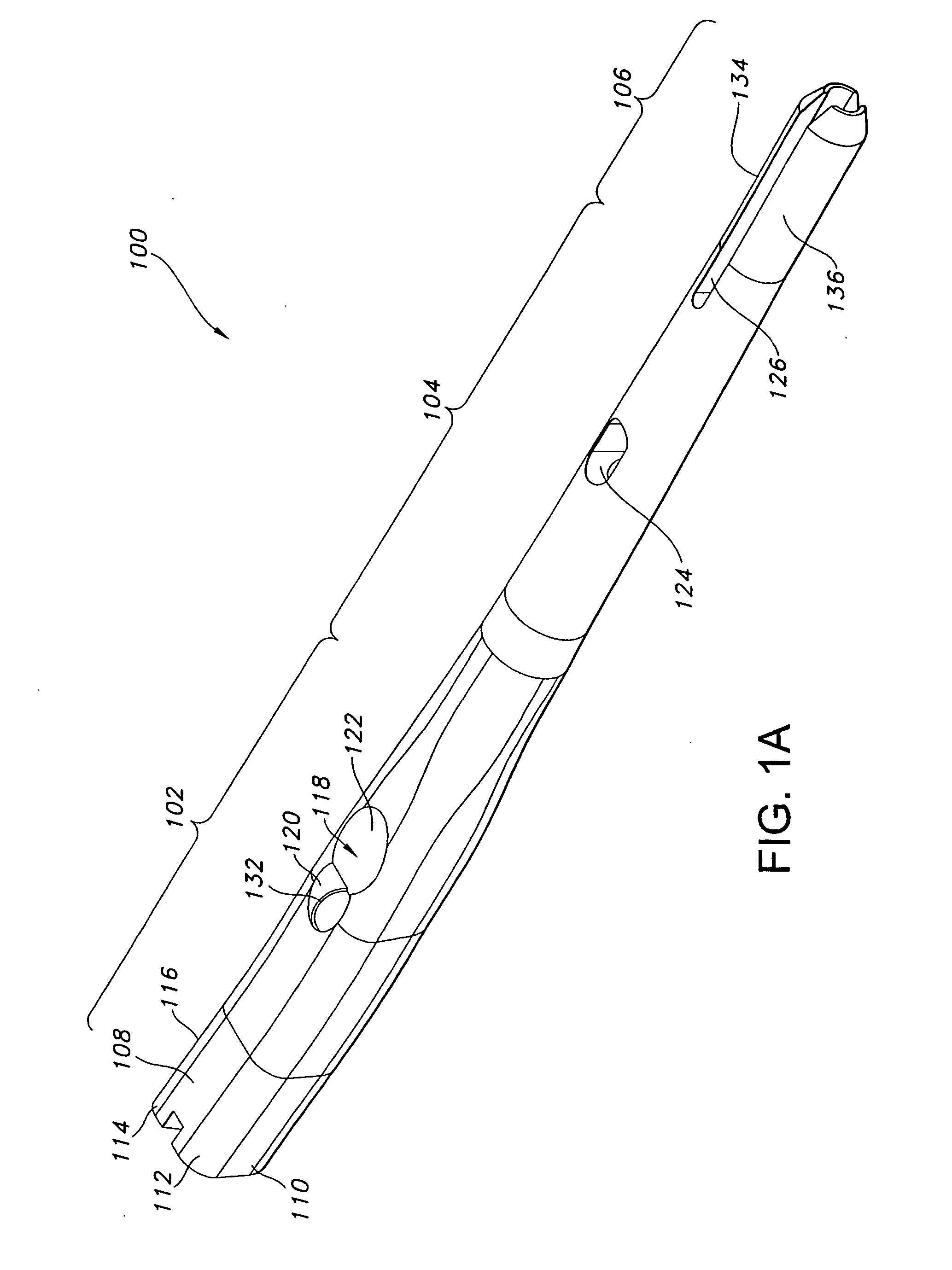

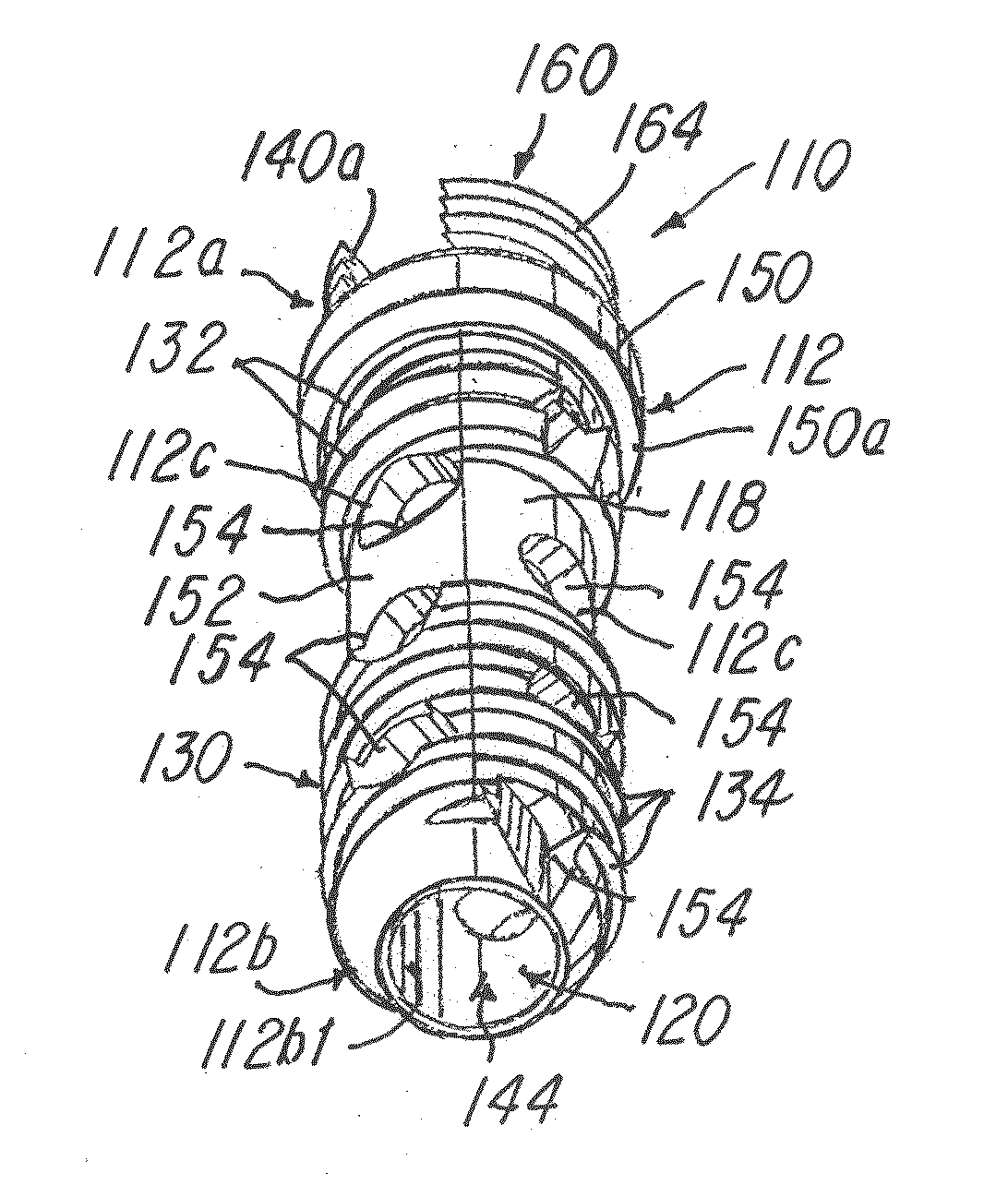

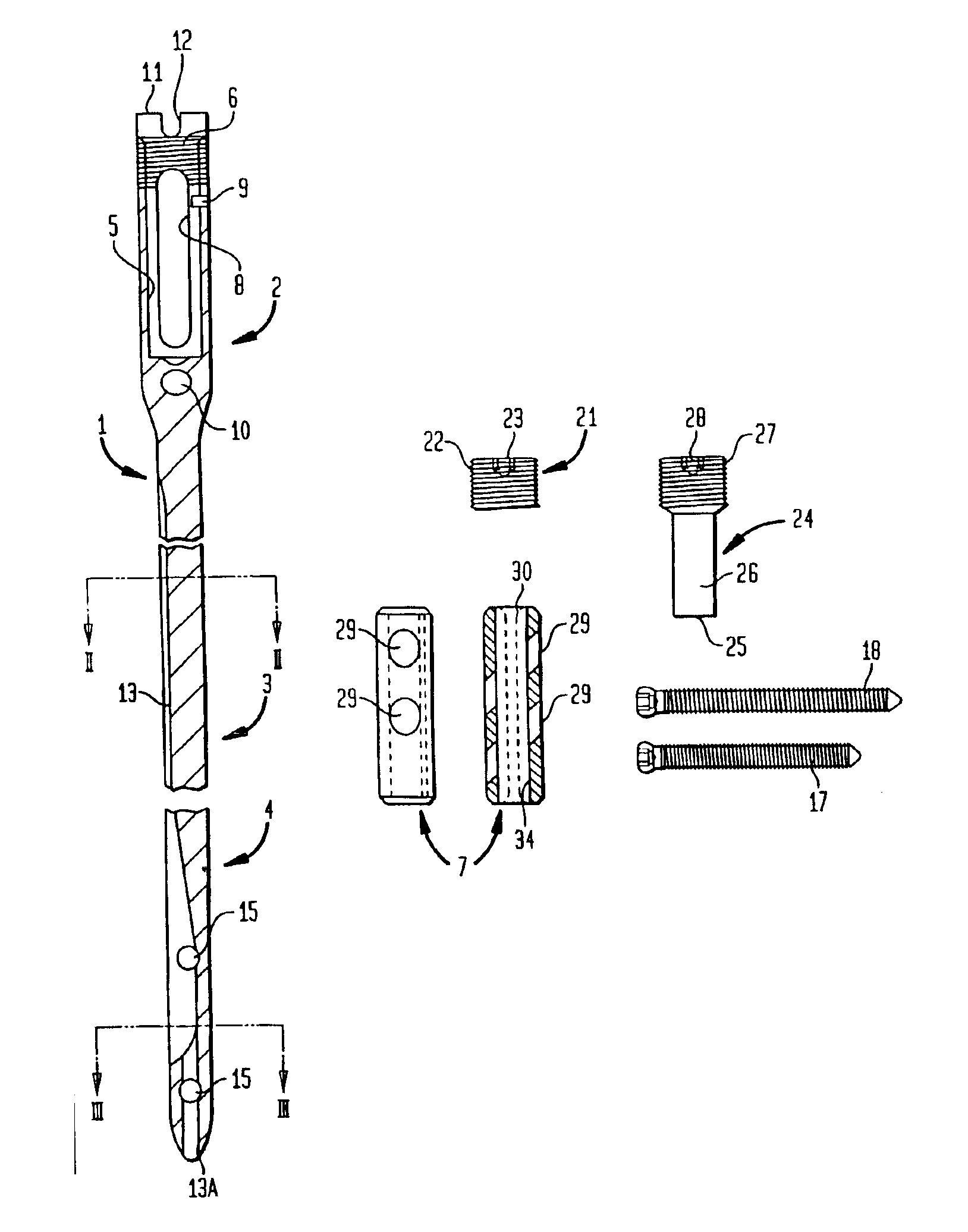

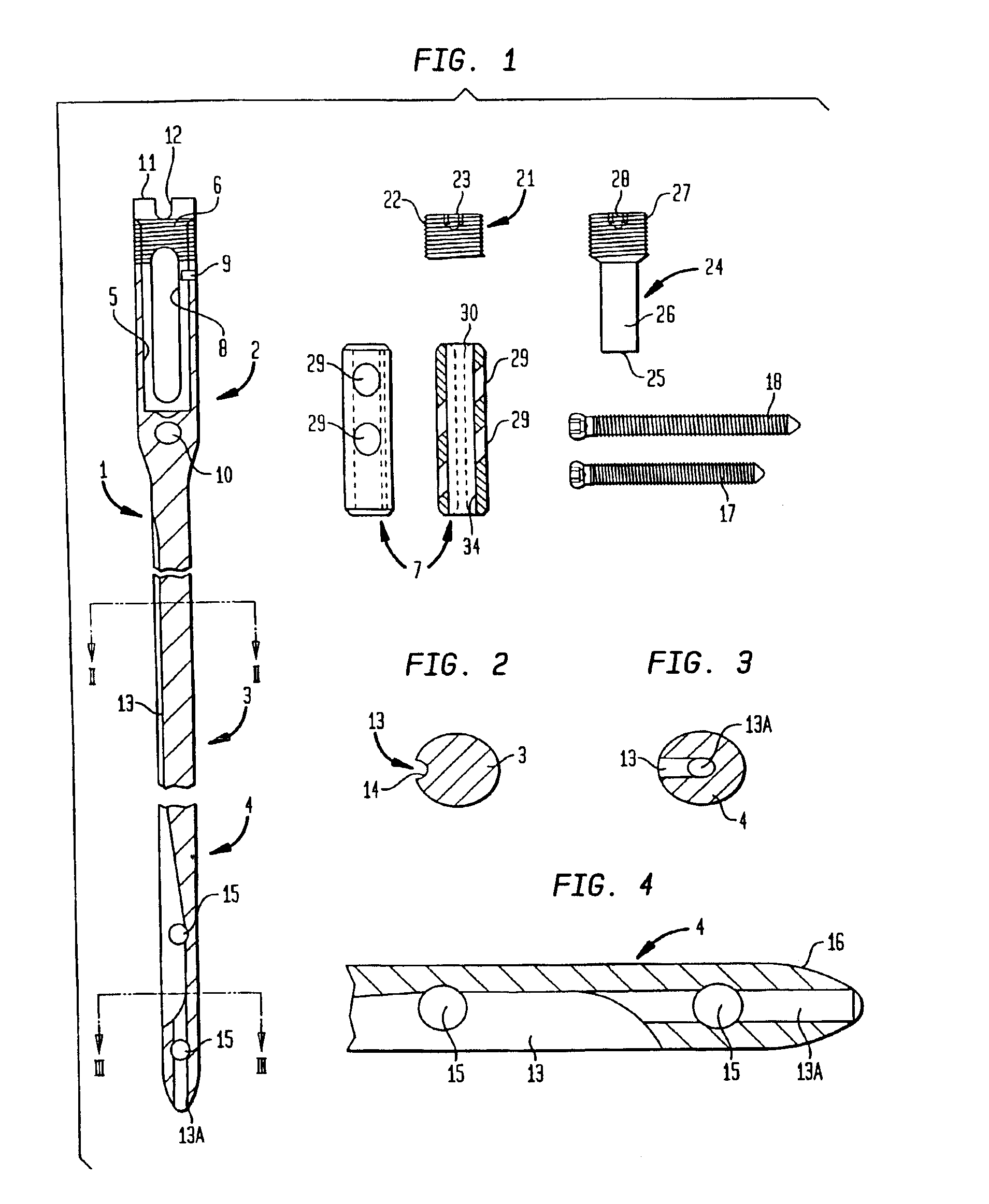

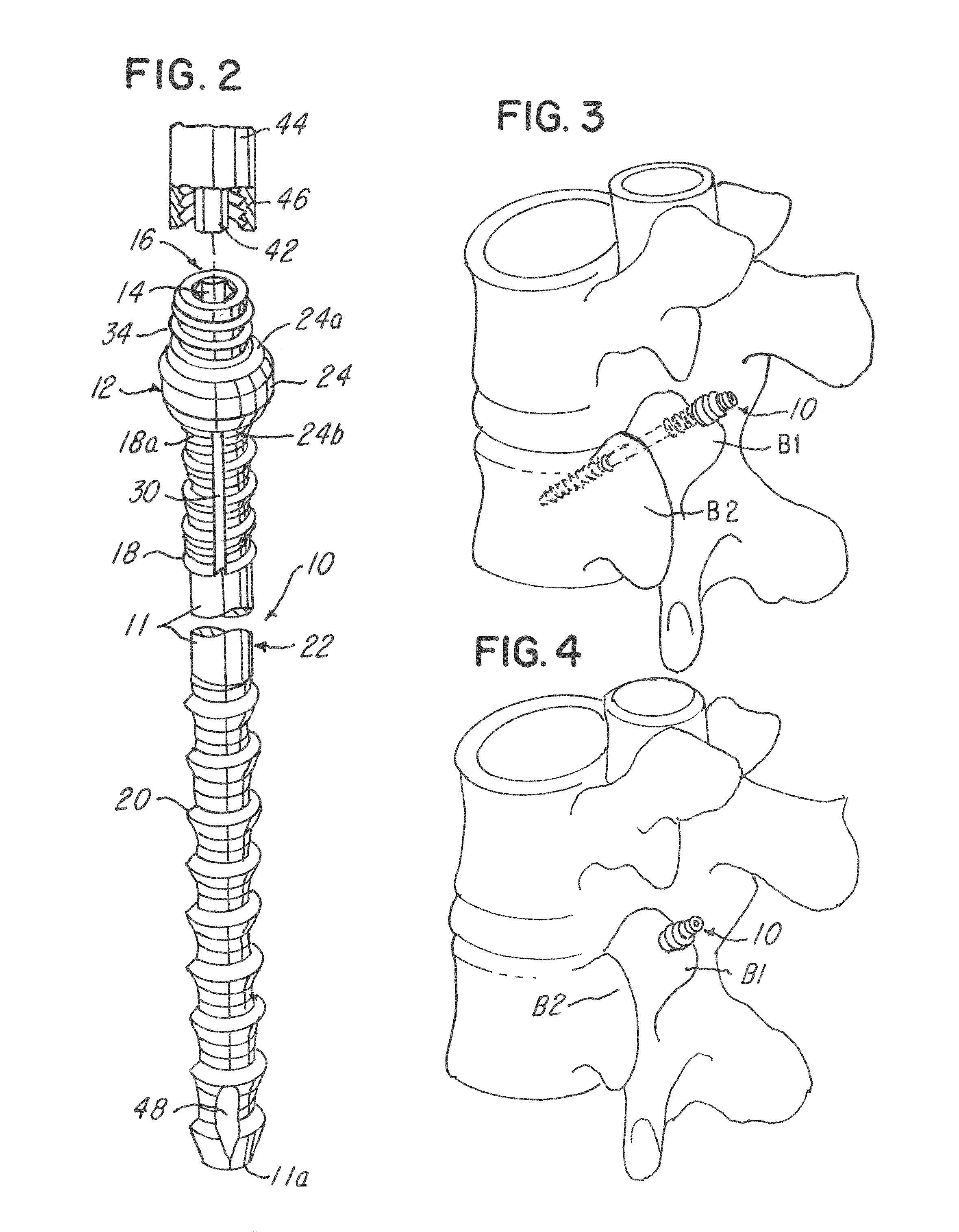

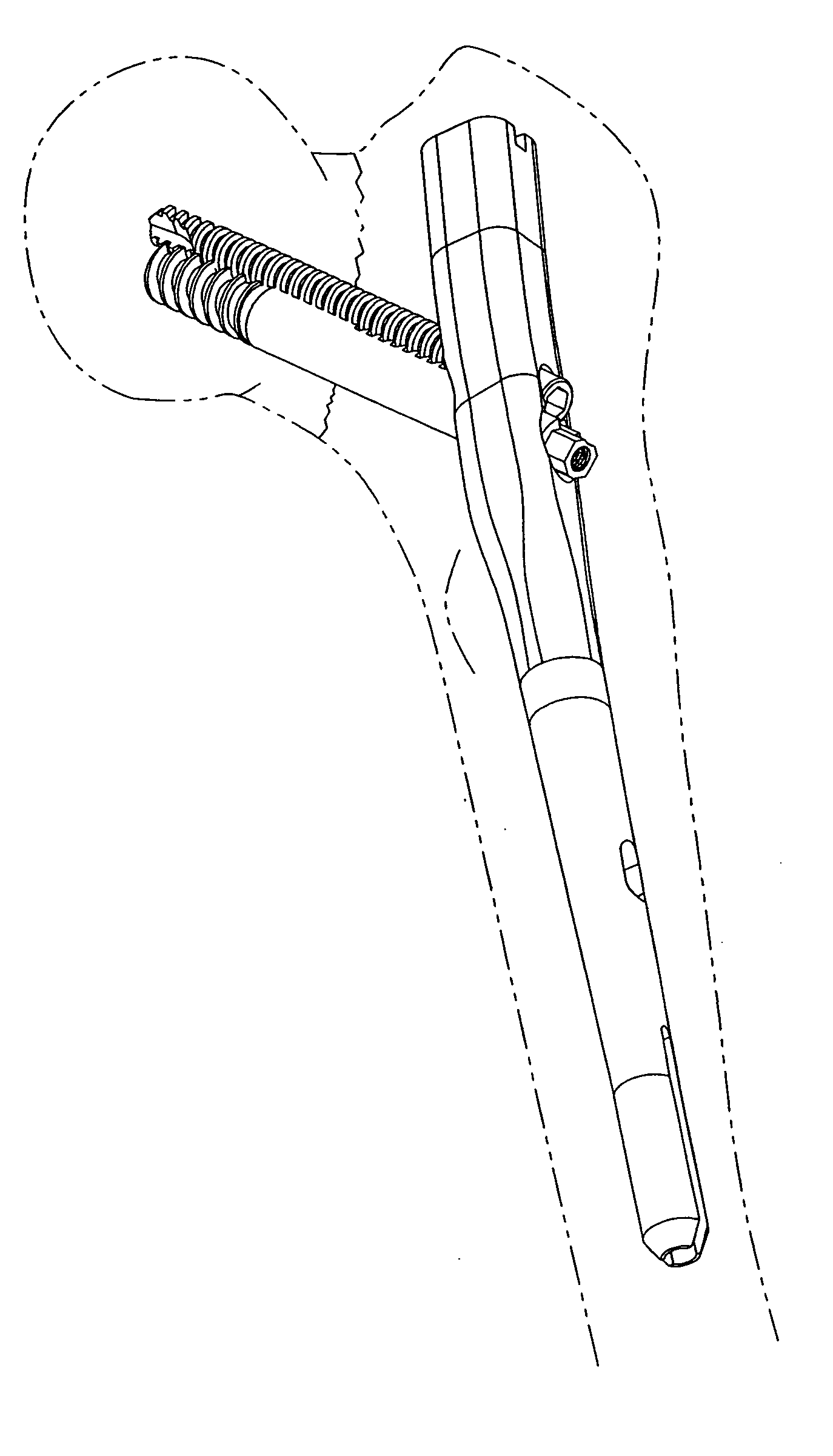

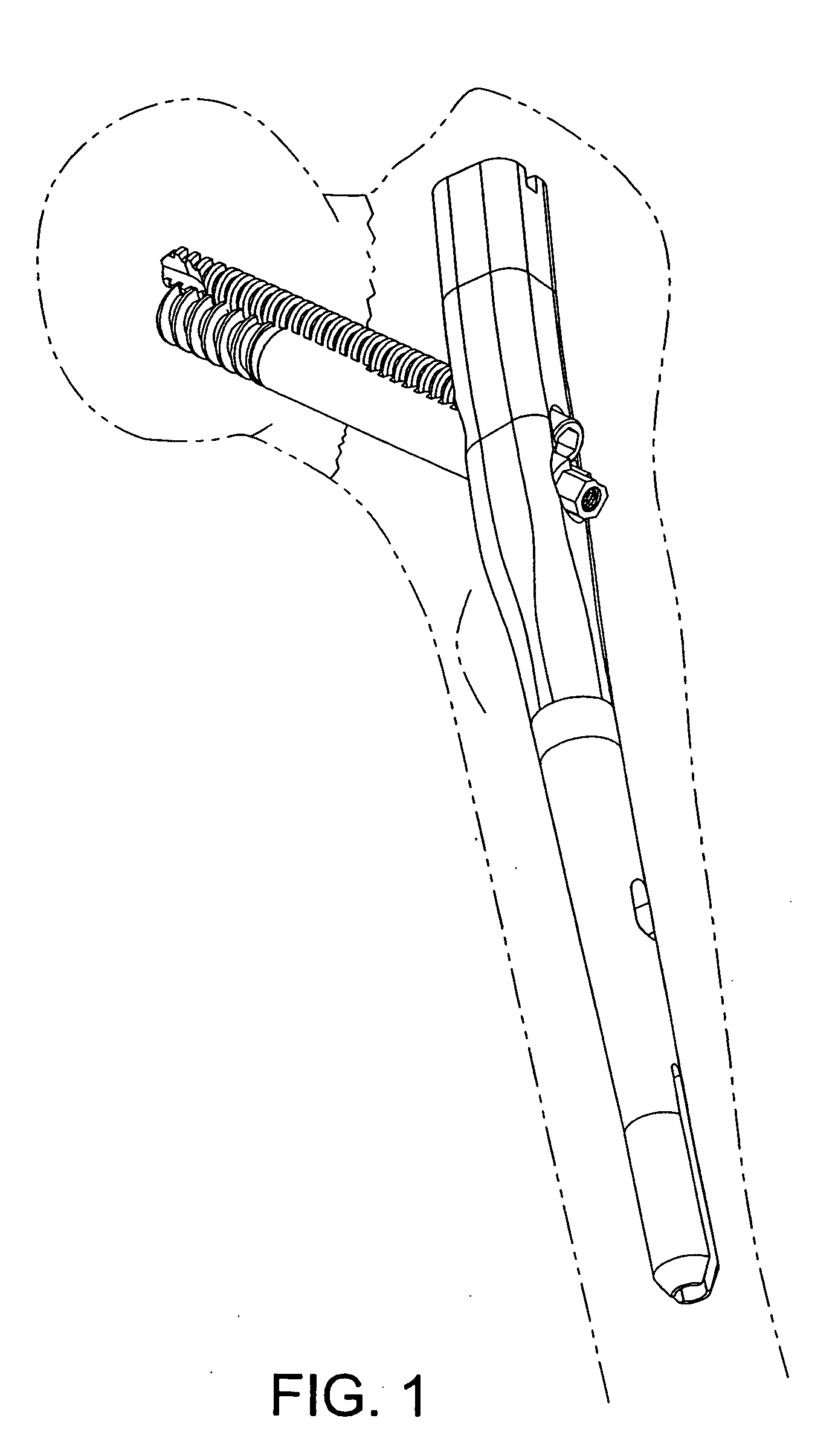

Intramedullary locked compression screw for stabiliziation and union of complex ankle and subtalar deformities

InactiveUS20050107791A1Easy to installReduce exposureInternal osteosythesisJoint implantsJOINT MALFORMATIONEngineering

An intramedullary lockable compression screw for stabilization and reconstruction of deformities of the ankle and subtalar joints, and which is particularly suitable for stabilization and fusion of the tibiotalar, talocalcaneal, tibiocalcaneal and / or tibiotalocalcaneal, is provided. The compression screw includes an elongated tubular member extending along a substantially straight first longitudinal axis between the leading end and the trailing end of the member. The tubular member includes a threaded leading end portion proximate the leading end, a threaded trailing end portion proximate to the trailing end, and an unthreaded shaft portion interconnecting the threaded leading end and the threaded trailing end portions. The diameter of the threaded leading end portion is smaller than the diameter of the threaded trailing end portion. A through-hole extends along a straight second longitudinal axis between a first opening, in a first area of an outer periphery of the tubular member proximate to the trailing end, and a second opening, in a second area of the outer periphery of the tubular member distal to the trailing end. The through hole is formed such that the second longitudinal axis intersects the first longitudinal axis at an angle of other than 90 degrees and so as to accommodate a locking screw.

Owner:MANDERSON EASTON L

Orthopaedic implant and screw assembly

InactiveUS20050055024A1High strengthIncrease resistanceInternal osteosythesisJoint implantsCompression deviceEngineering

Systems, devices and methods are disclosed for treating fractures. The systems, devices and methods may include one or both of an implant, such as an intramedullary nail, and a fastening assembly, such as a lag screw and compression screw assembly. The implant in some embodiments has a proximal section with a transverse aperture and a cross-section that may be shaped to more accurately conform to the anatomical shape of cortical bone and to provide additional strength and robustness in its lateral portions, preferably without requiring significant additional material. The fastening assembly may be received to slide, in a controlled way, in the transverse aperture of the implant. In some embodiments, the engaging member and the compression device are configured so that the compression device interacts with a portion of the implant and a portion of the engaging member to enable controlled movement between the first and second bone fragments. This configuration is useful for, among other things, compressing a fracture.

Owner:SMITH & NEPHEW INC

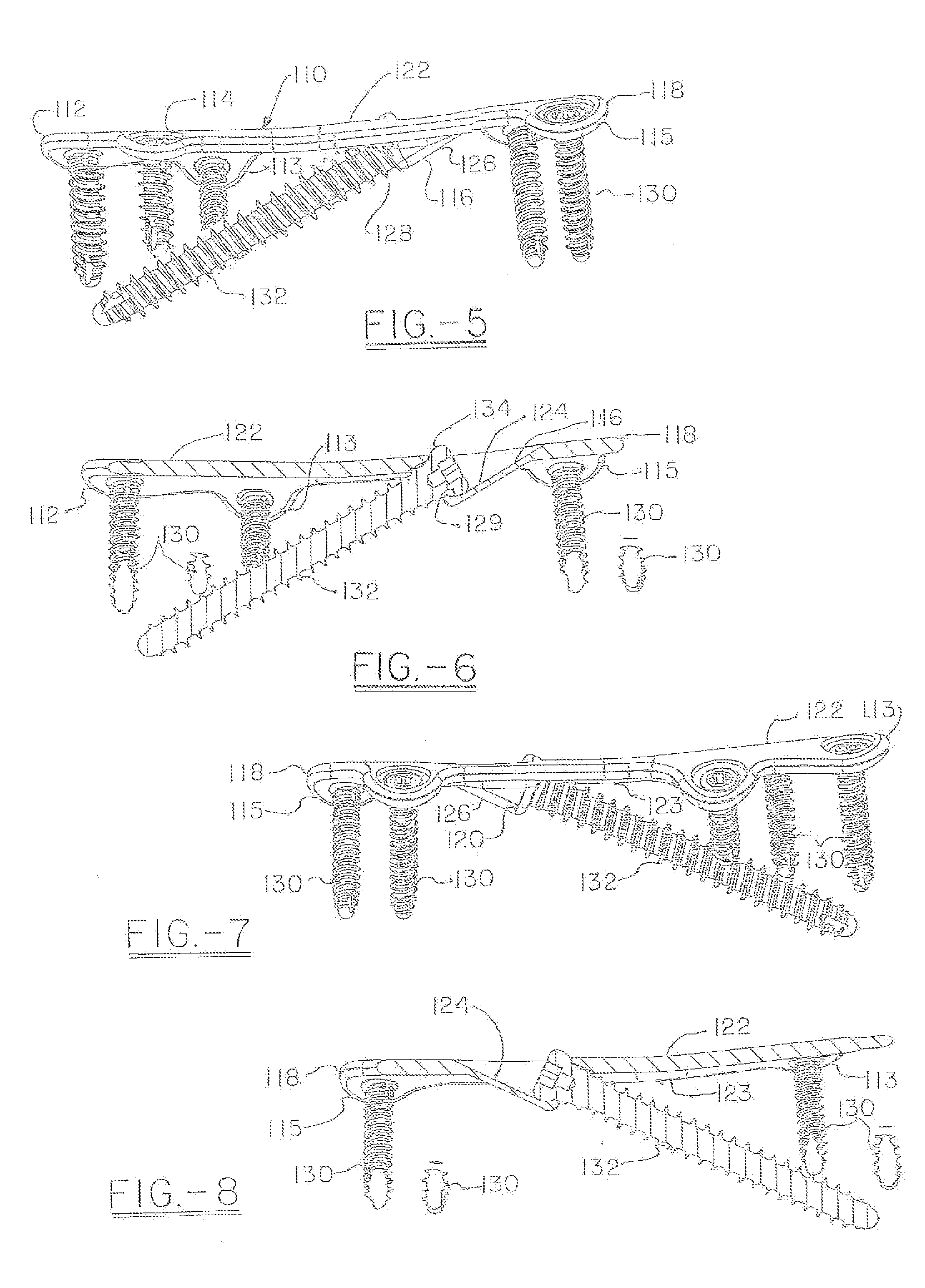

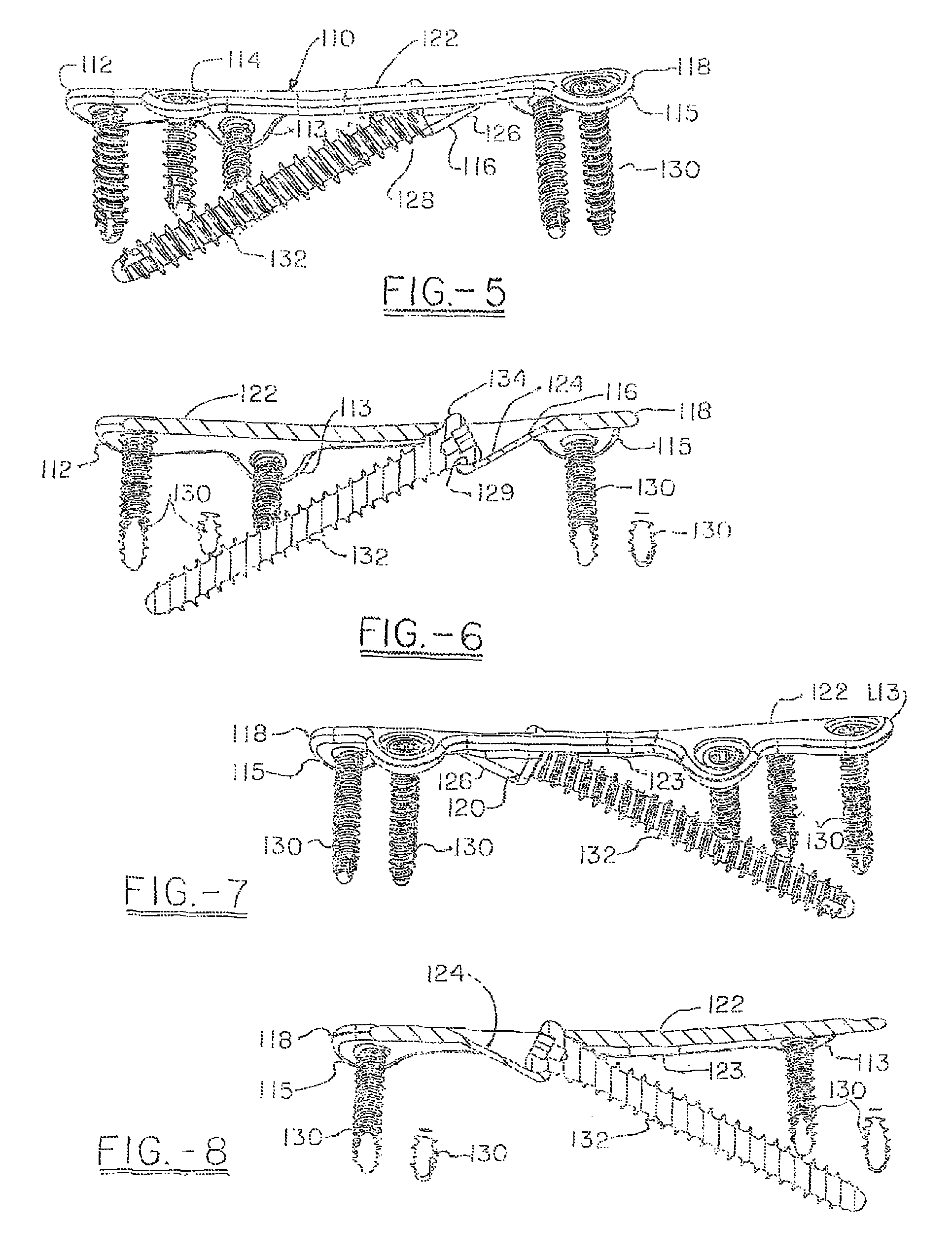

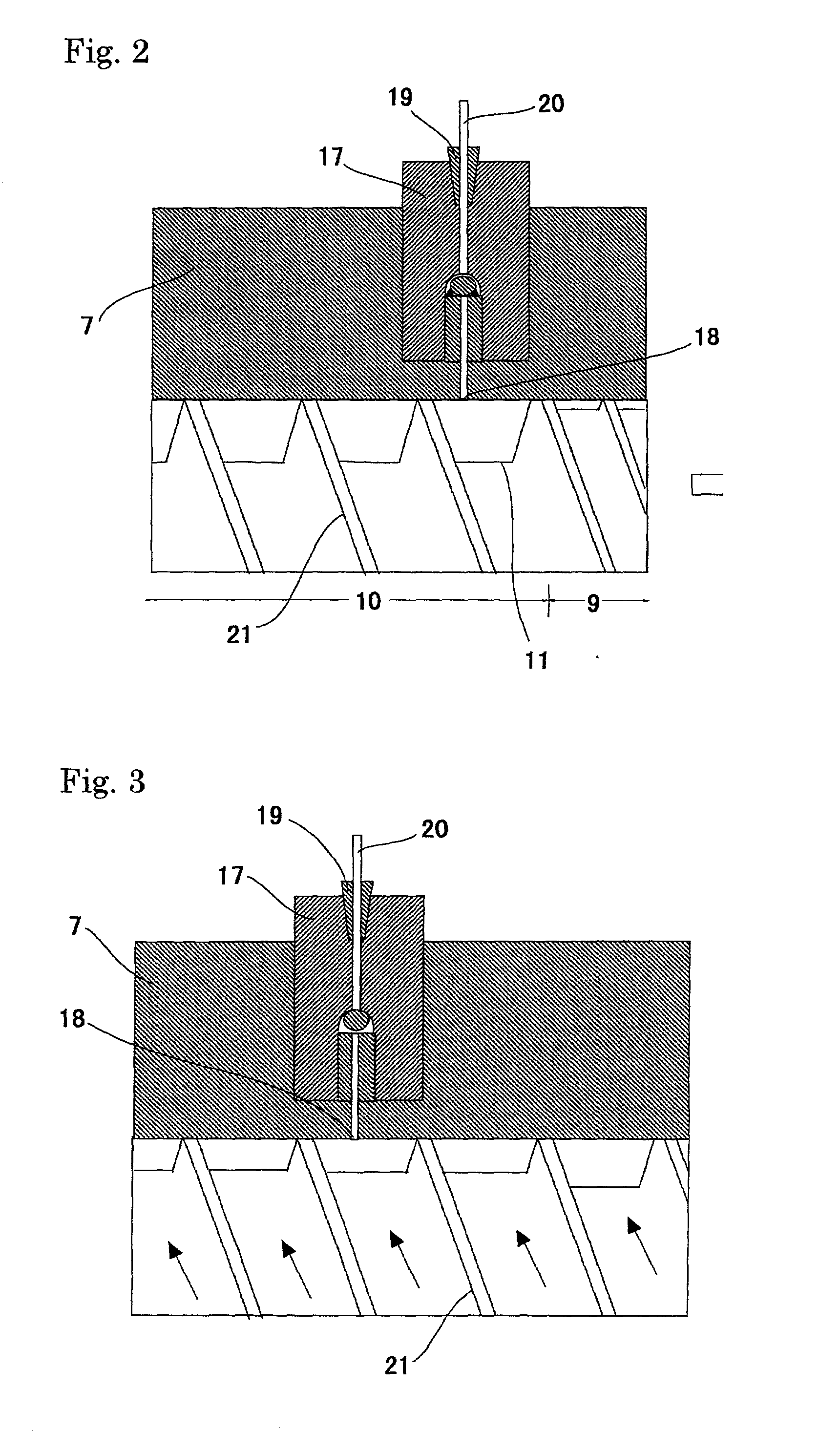

Orthopedic compression plate and method of surgery

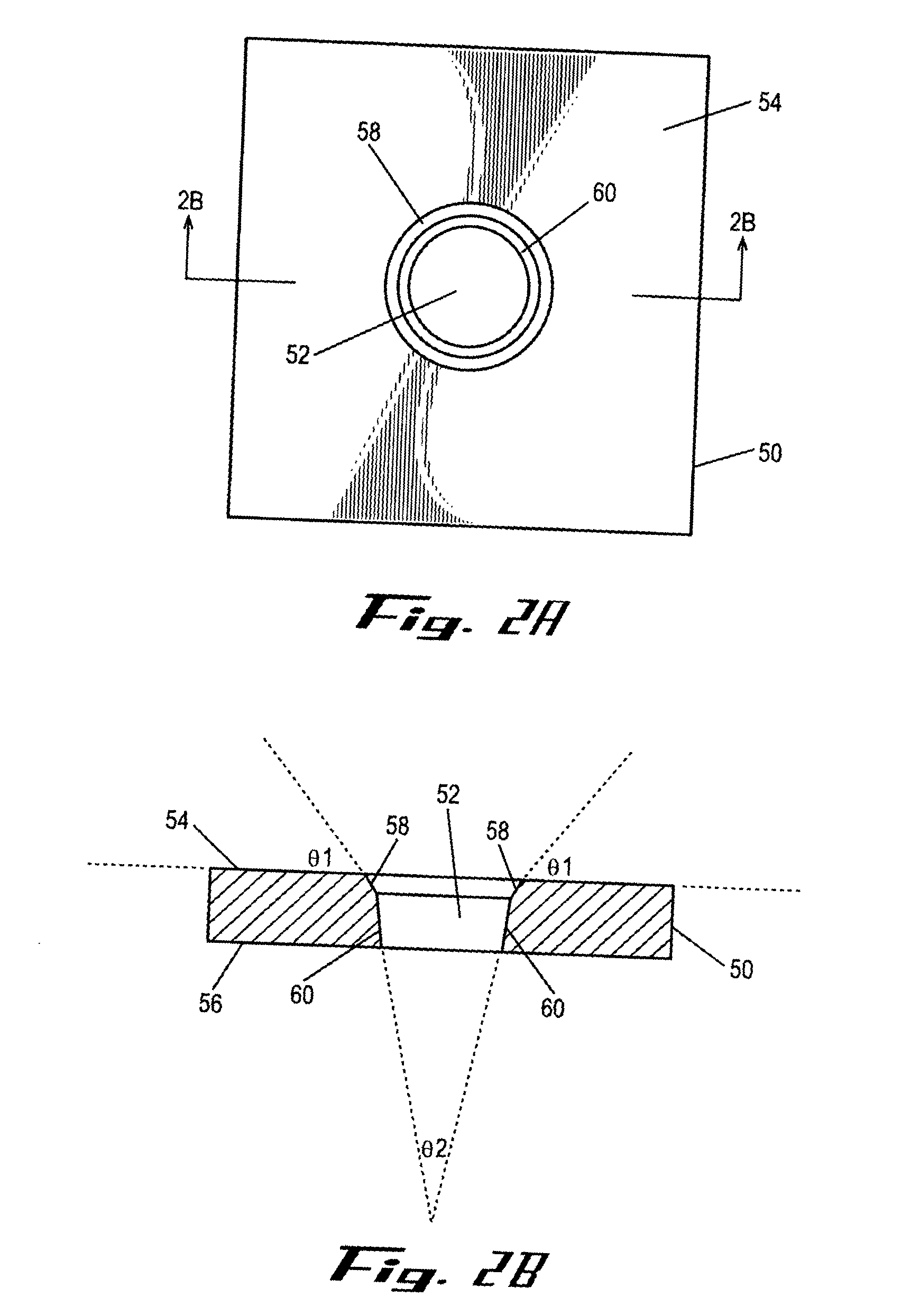

ActiveUS20130172942A1Address bad outcomesEasy alignmentFastenersBone platesEngineeringPlastic surgery

An orthopedic plate has a first end including a locking screw hole that receives a locking screw and spaced from that hole is a dosed compression housing that extends from the bone-facing side of the plate and which receives a compression screw that forms an angle of from about 10° to about 70° with a longitudinal axis of the plate. The compression housing is not located on the medial line of the plate, but is peripheral to the medial line, either in the longitudinal or the medial direction of the plate.

Owner:ORTHOHELIX SURGICAL DESIGNS

Device for fixing bone sections separated because of a fracture

InactiveUS6902567B2Readily and safely appliedSuture equipmentsInternal osteosythesisEngineeringIliac screw

Owner:VESE SILVANA

Orthopaedic implant and screw assembly

Systems, devices and methods are disclosed for treating fractures. The systems, devices and methods may include one or both of an implant, such as an intramedullary nail, and a fastening assembly, such as a lag screw and compression screw assembly. The implant in some embodiments has a proximal section with a transverse aperture and a cross-section that may be shaped to more accurately conform to the anatomical shape of cortical bone and to provide additional strength and robustness in its lateral portions, preferably without requiring significant additional material. The fastening assembly may be received to slide, in a controlled way, in the transverse aperture of the implant. In some embodiments, the engaging member and the compression device are configured so that the compression device interacts with a portion of the implant and a portion of the engaging member to enable controlled movement between the first and second bone fragments. This configuration is useful for, among other things, compressing a fracture.

Owner:SMITH & NEPHEW INC

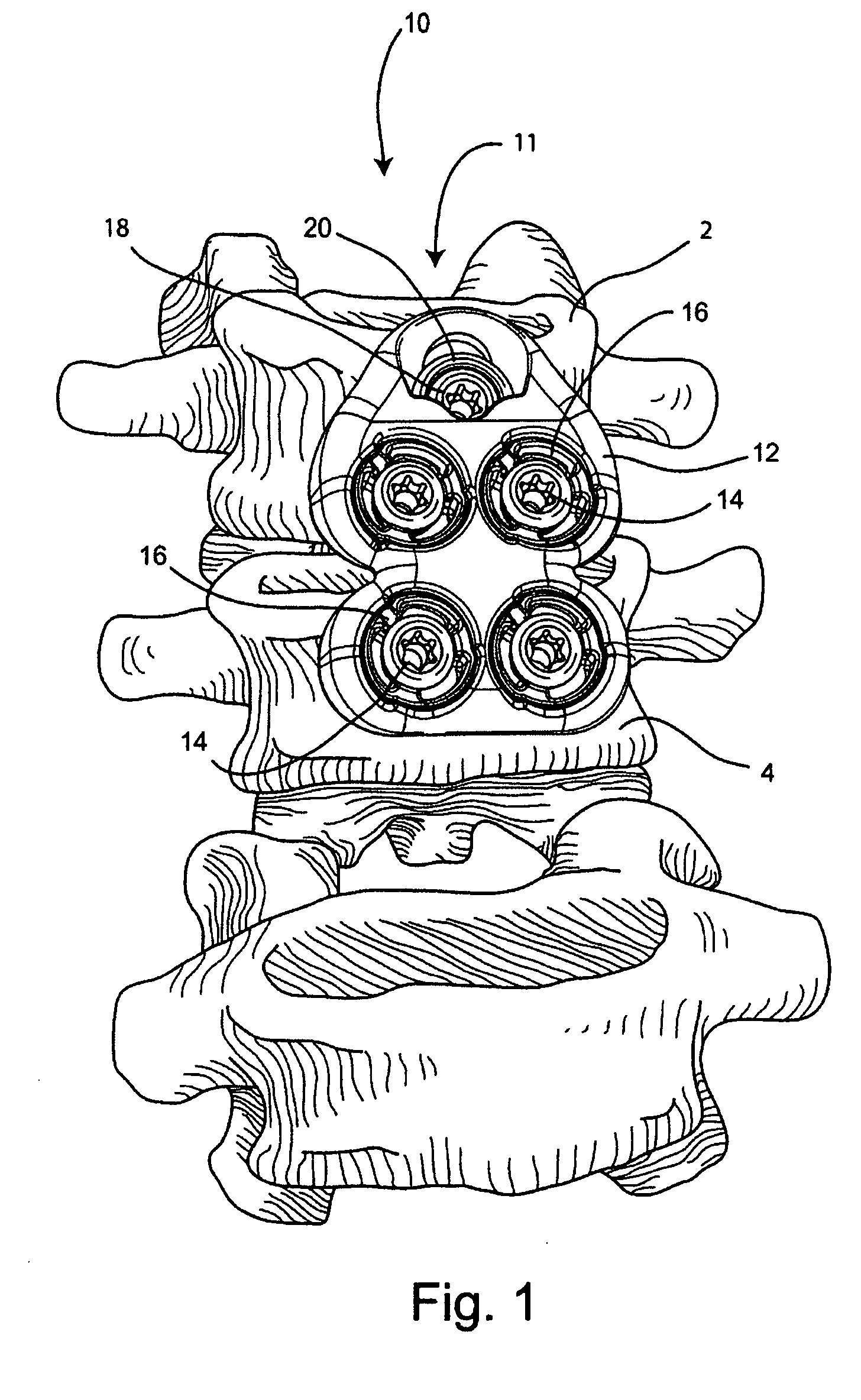

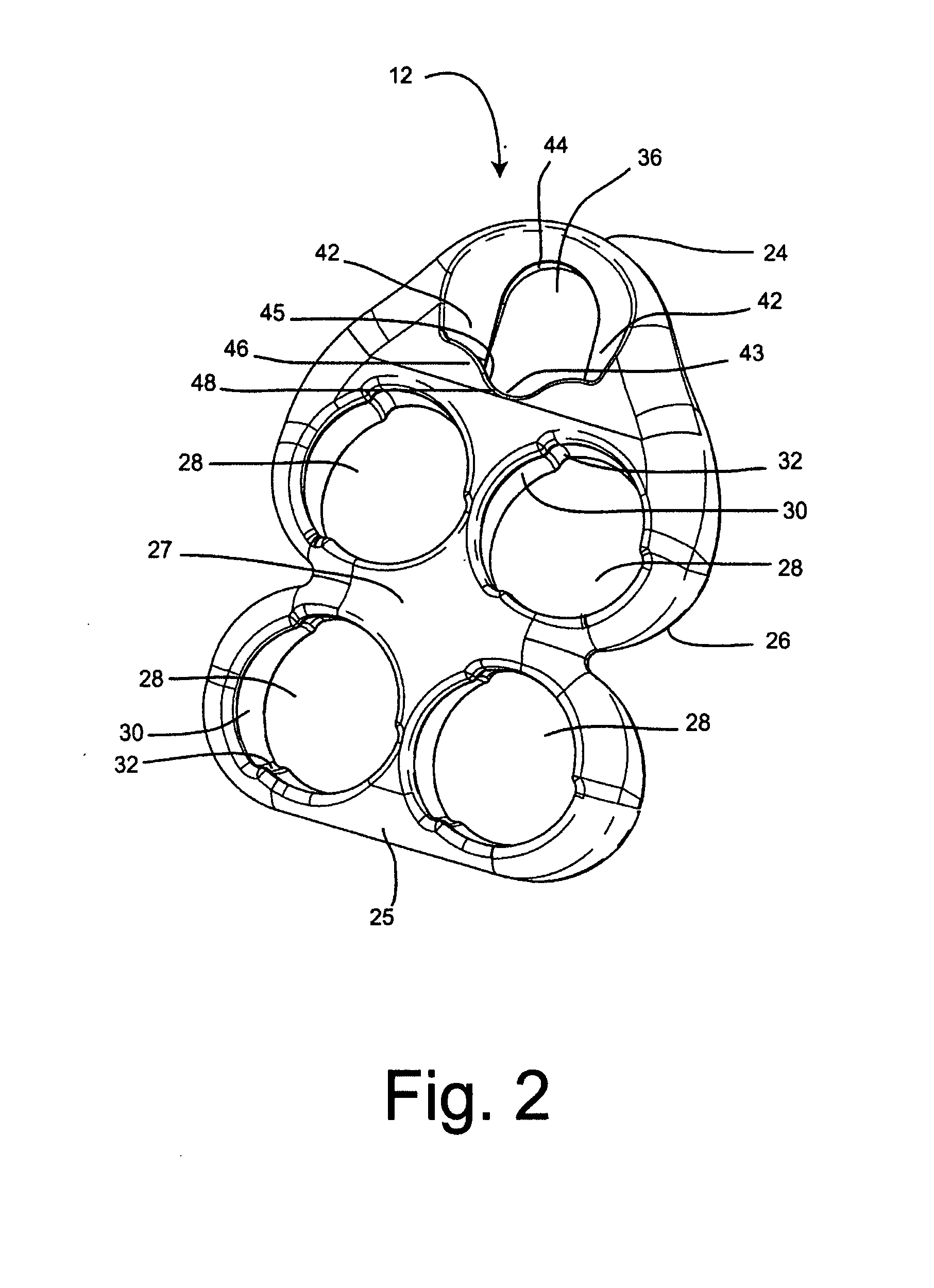

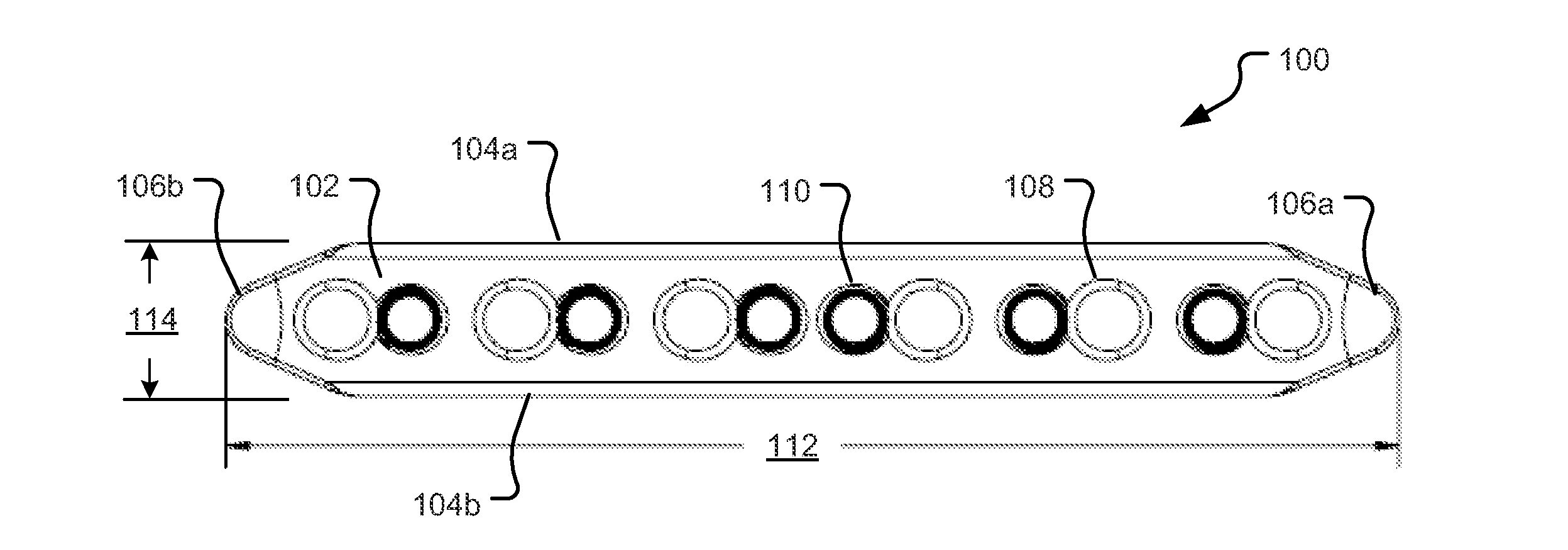

Minimally invasive spinal facet compression screw and system for bone joint fusion and fixation

ActiveUS20120197311A1Prevent the screw from looseningPrevent disengagementSuture equipmentsInternal osteosythesisSpinal columnBones joints

A system comprising a screw element having a generally cylindrical body having a bore or lumen therethrough and a plurality of fenestrations or windows through which biological material may be provided. The system comprises a tool for inserting the biological material into the screw element so that the biological material may extrude through the plurality of fenestrations or windows and through an aperture in the tip of the screw element thereby enabling providing a fusion mass across two adjacent facet bones or a facet joint wherein the screw itself provides both a fixation component and a screw component.

Owner:X SPINE SYST

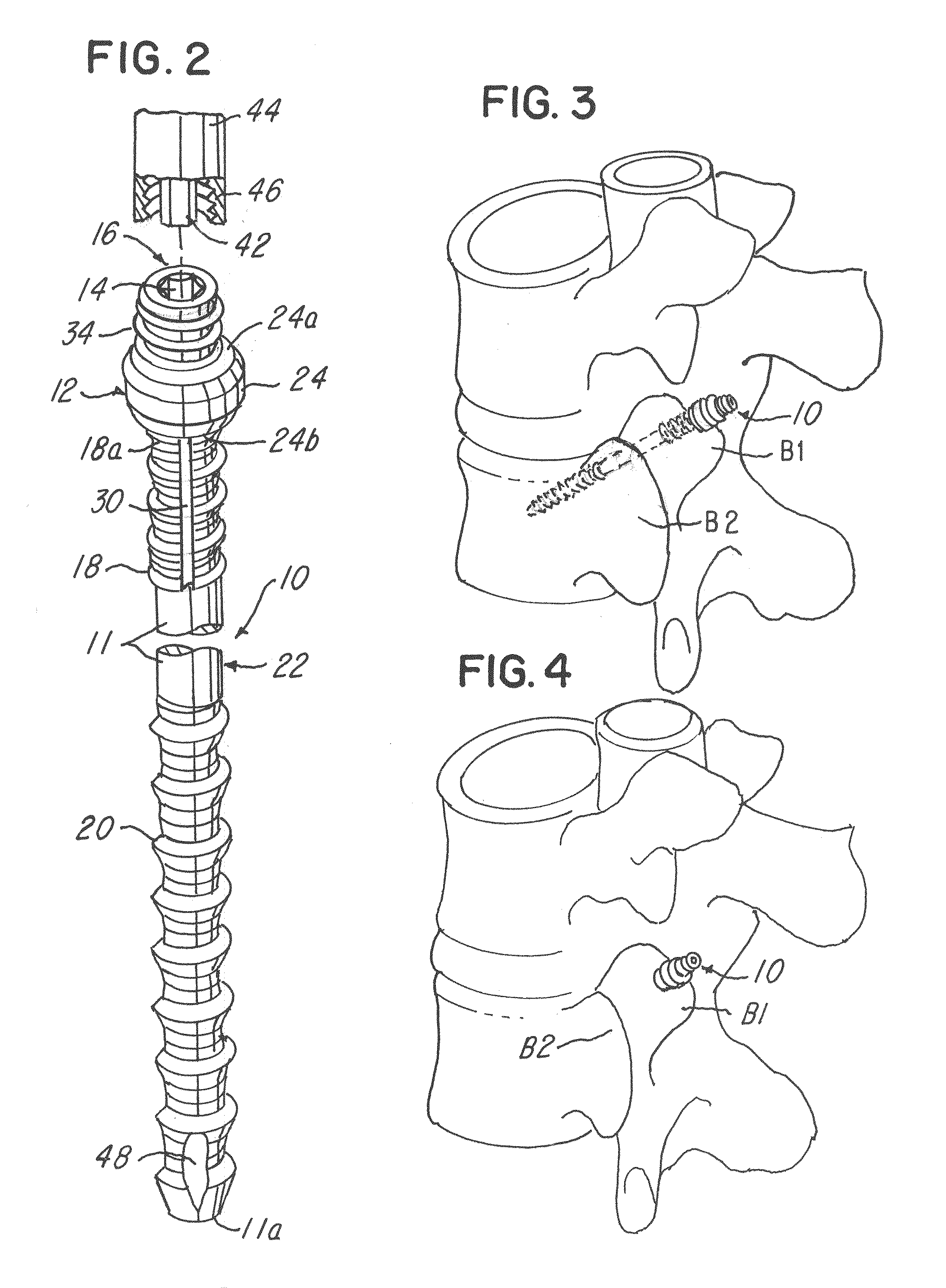

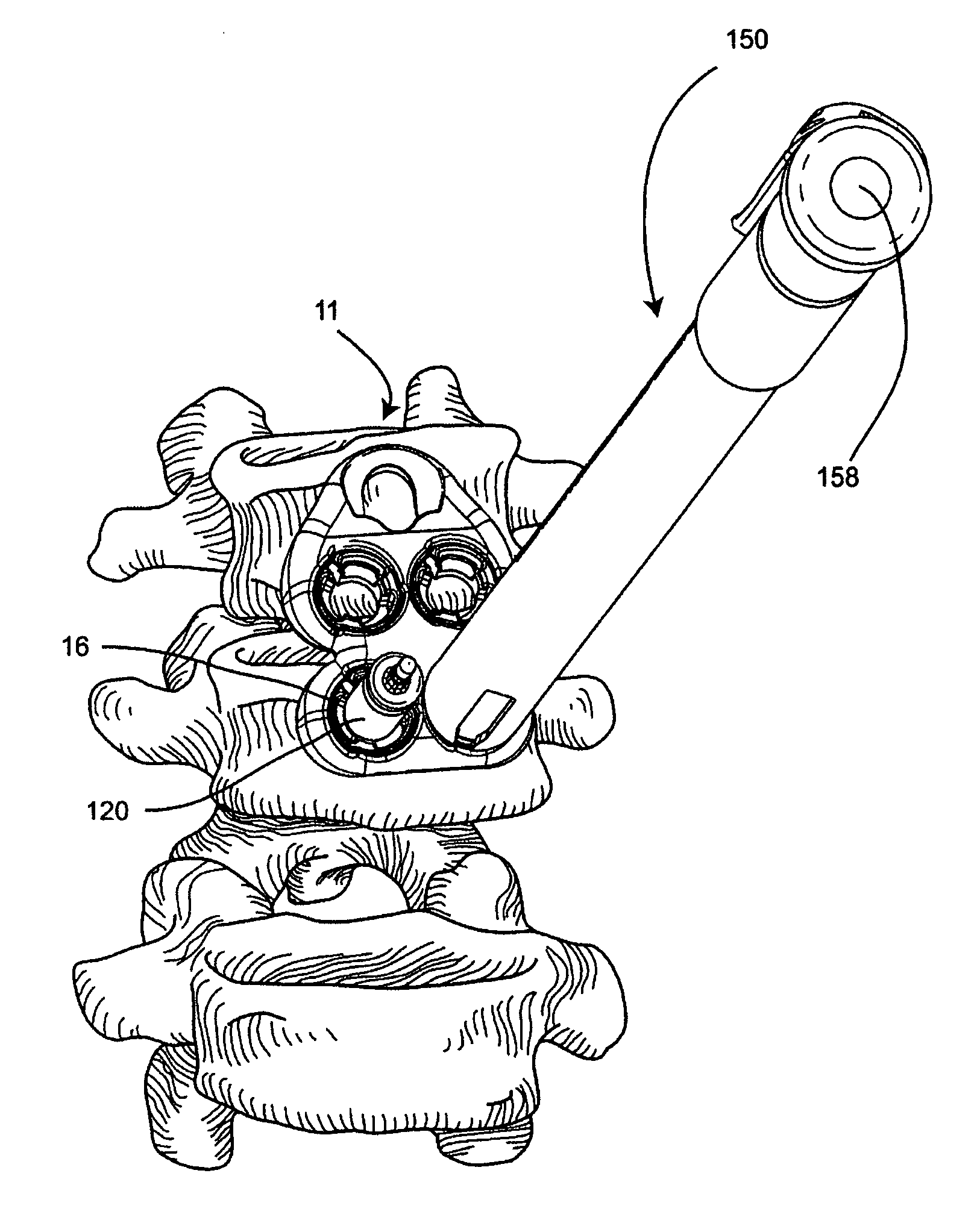

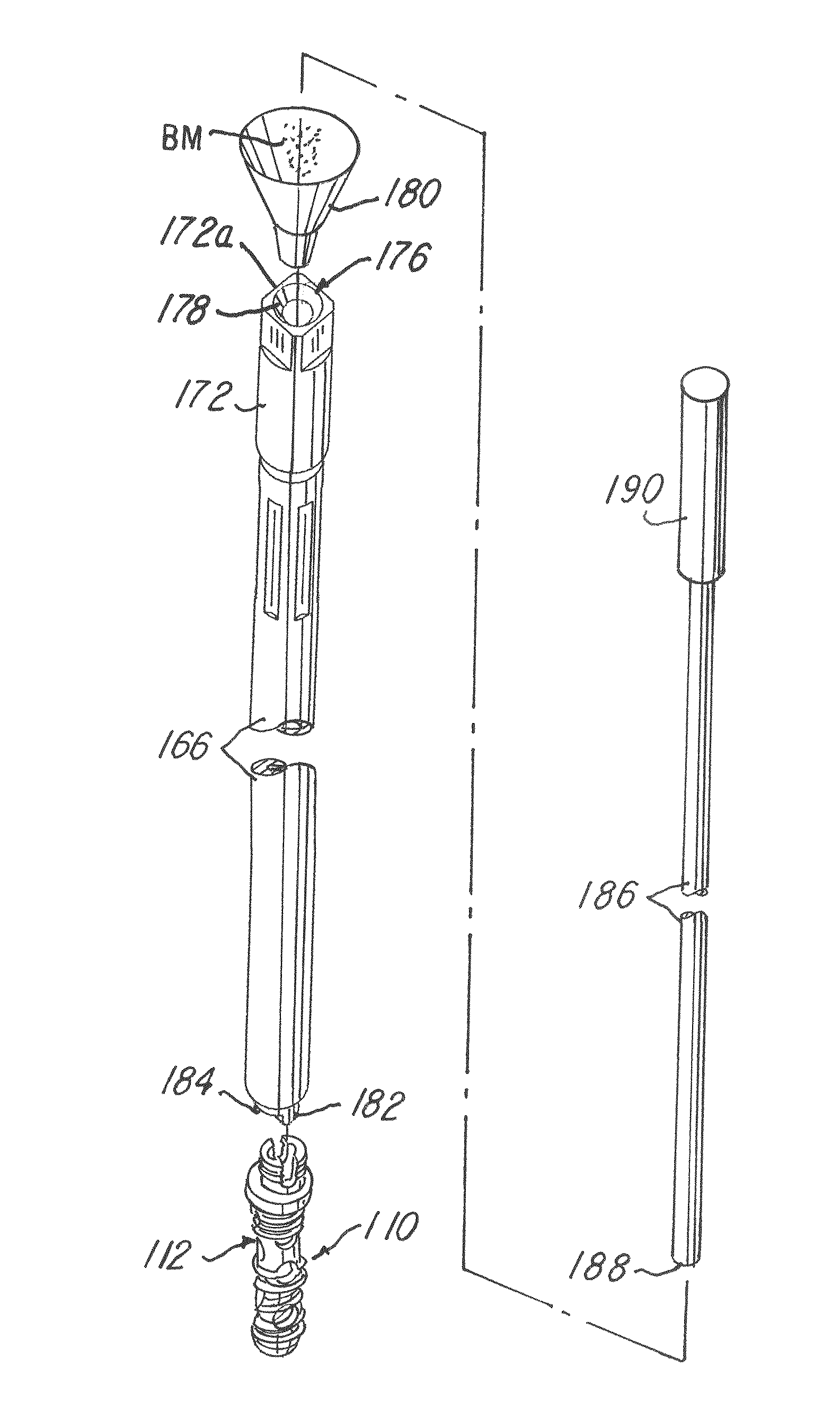

Pedicular percutaneous minimally invasive screw

InactiveUS20090299415A1Less recuperation timeLess postoperative painSuture equipmentsInternal osteosythesisMedicineLigament structure

A pedicular percutaneous minimally invasive screw for use in connection with progressive cannulae which allows screws to be installed in a patient without necessarily cutting or destroying ligaments and muscles, the progressive cannulae going from larger to smaller diameters until the point where a perforation is made, through which the pedicular percutaneous screw enters, guided by a fine filament which precisely positions the screw in the location desired. Adjacent screws are connected via a connection bar that unites the two screws and fixes the bones of a patient's column, wherein the connecting bar is attached to the screw by a compression screw, which is threaded on the body itself.

Owner:PIMENTA LUIS HENRIQUE MATTOS +1

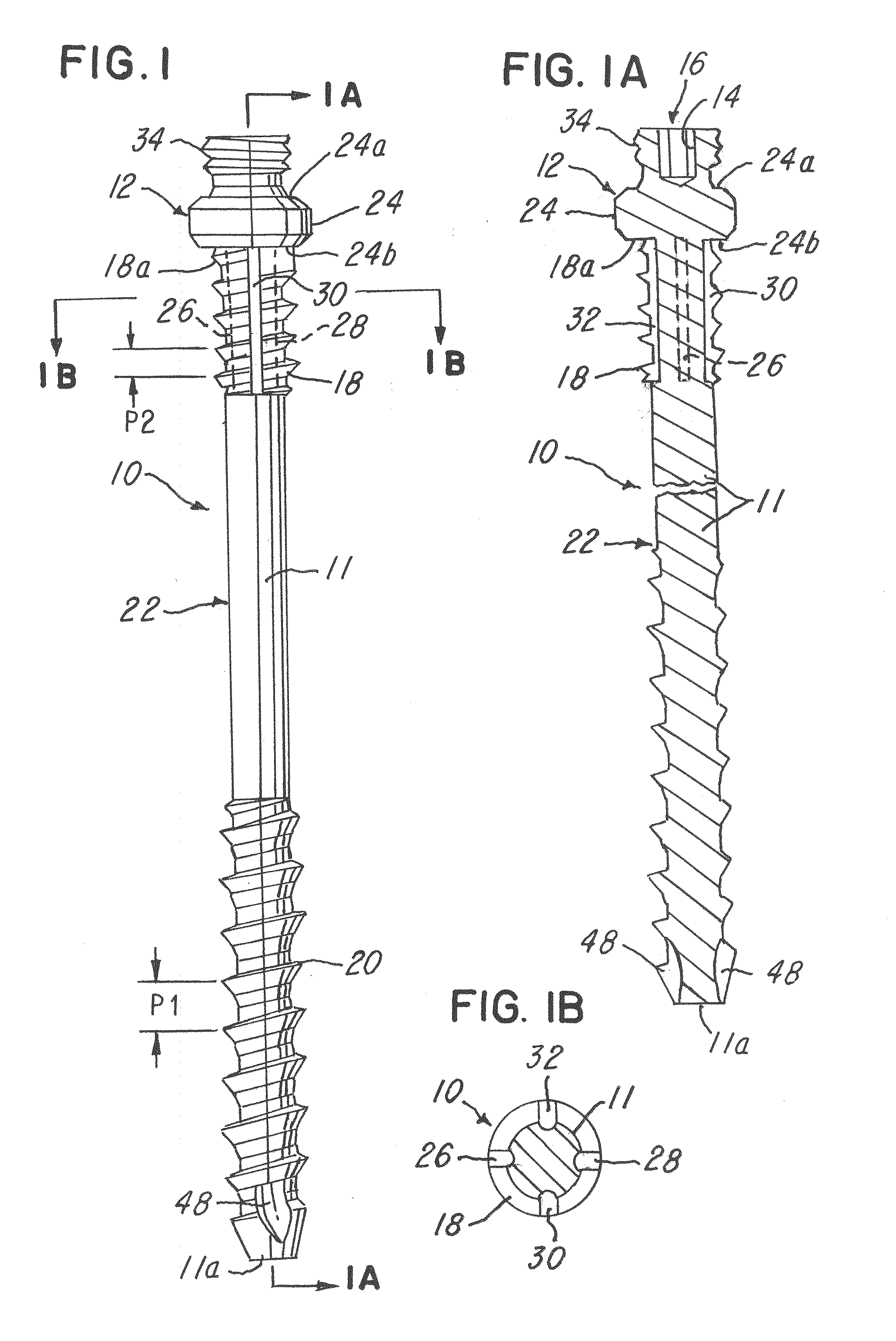

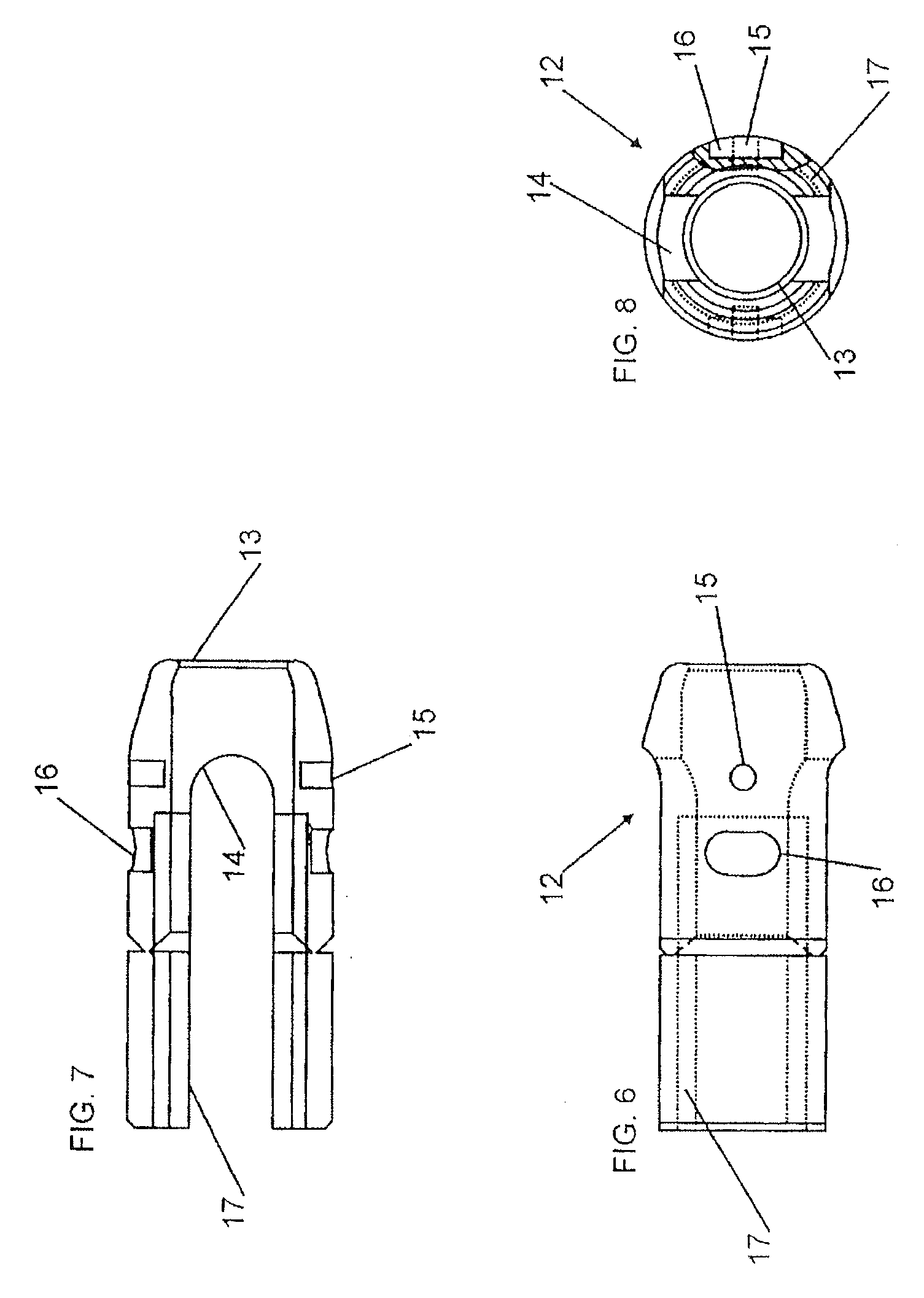

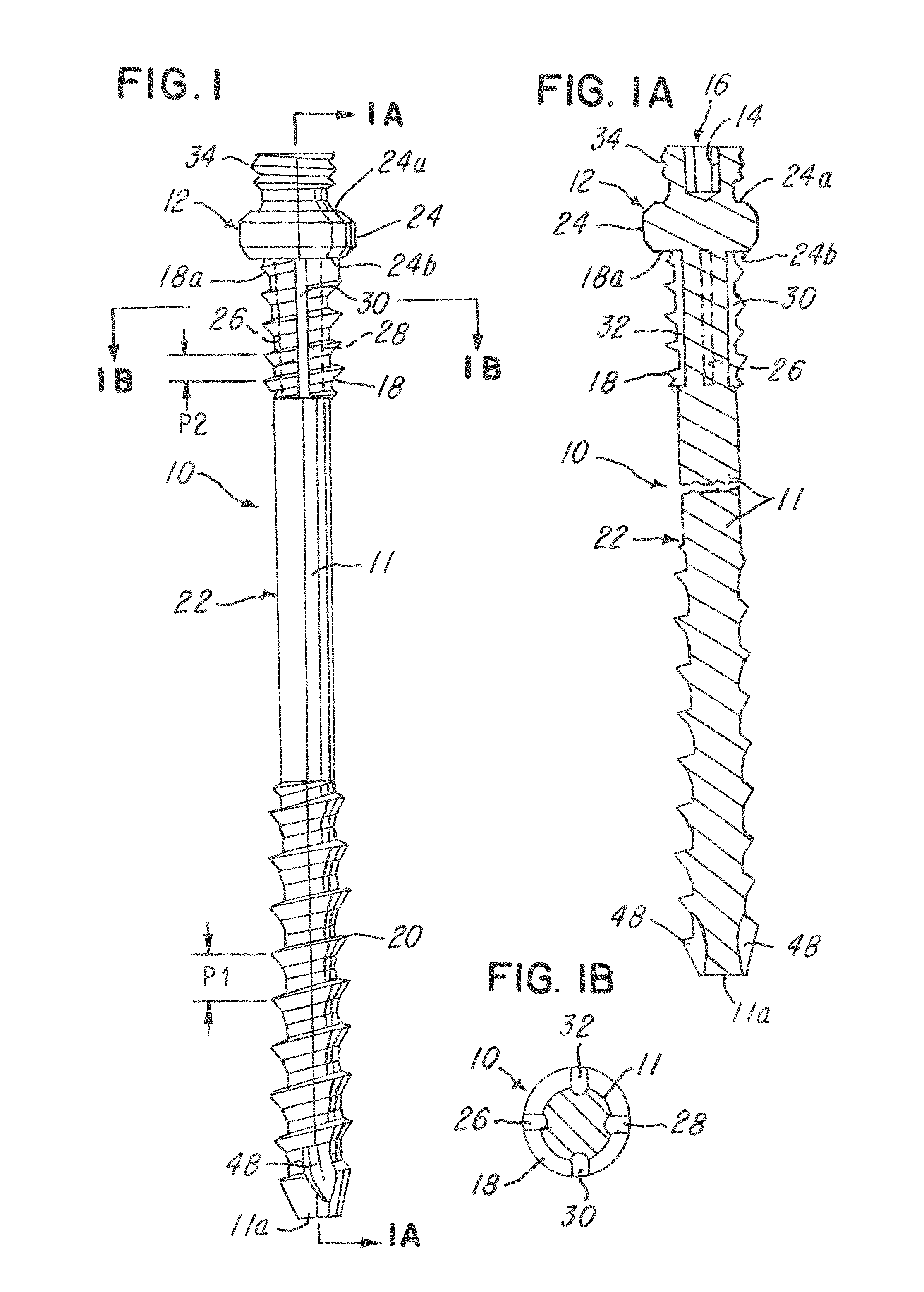

Spinal facet compression screw with variable pitch thread zones and buttress head

ActiveUS20120022603A1Prevent the screw from looseningPrevent disengagementSuture equipmentsInternal osteosythesisIliac screwScrew thread

A surgical implant comprising a screw element having a screw head, a first thread having a first thread pitch, a second thread having a second thread pitch and an intermediate portion coupling the first and second thread pitches with the first and second thread pitches being different. The implant has a buttressing head associated with the first thread, and it is dimensioned to be larger than a diameter of the first threads to provide external buttressing as the first and second threads compress a first bone and a second bone together.

Owner:X SPINE SYST

Modular intramedullary nail

InactiveUS6932819B2Improve biomechanical stabilityPromote vascularizationInternal osteosythesisJoint implantsDistal portionIliac screw

An intramedullary nail, comprises a proximal portion, a middle portion and a distal portion. The proximal portion has a longitudinal slot and the distal portion has at least one transversal bore. The proximal portion has a longitudinal axis and a longitudinal bore extending over the longitudinal extension of the slot in the distal direction. The longitudinal bore has an internal thread. An insert which is intended to be inserted in the longitudinal bore. The insert comprises a guiding bore in the form of a slot which is intended to receive fixing elements. The alignment of the guiding bore of said insert is transverse with respect to the longitudinal axis of the proximal portion. The insert has a compression screw adapted to be screwed into said internal thread of the longitudinal bore of the proximal portion to move a fixing element in the direction of the longitudinal axis of the intramedullary nail.

Owner:STRYKER EURO OPERATIONS HLDG LLC

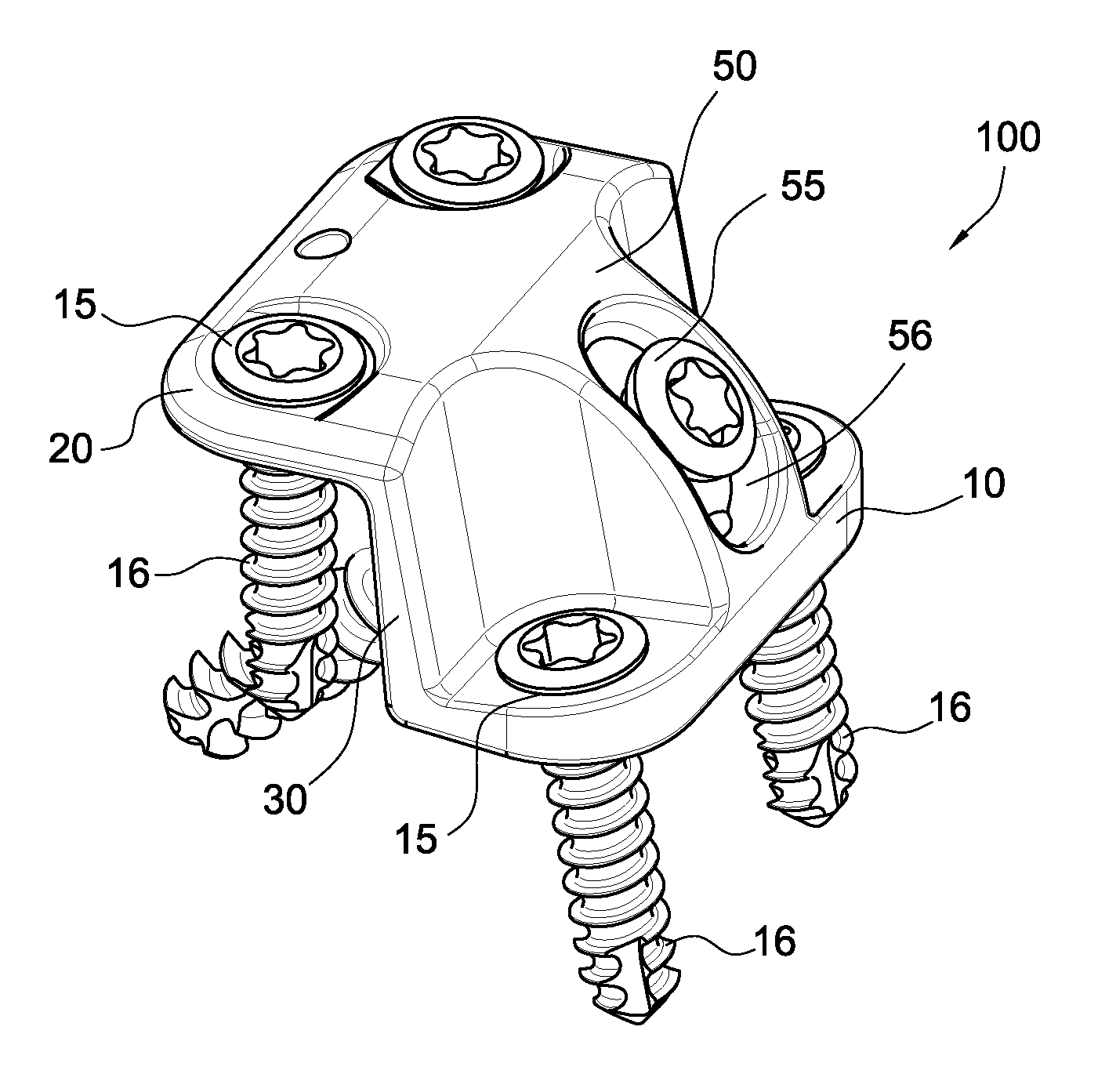

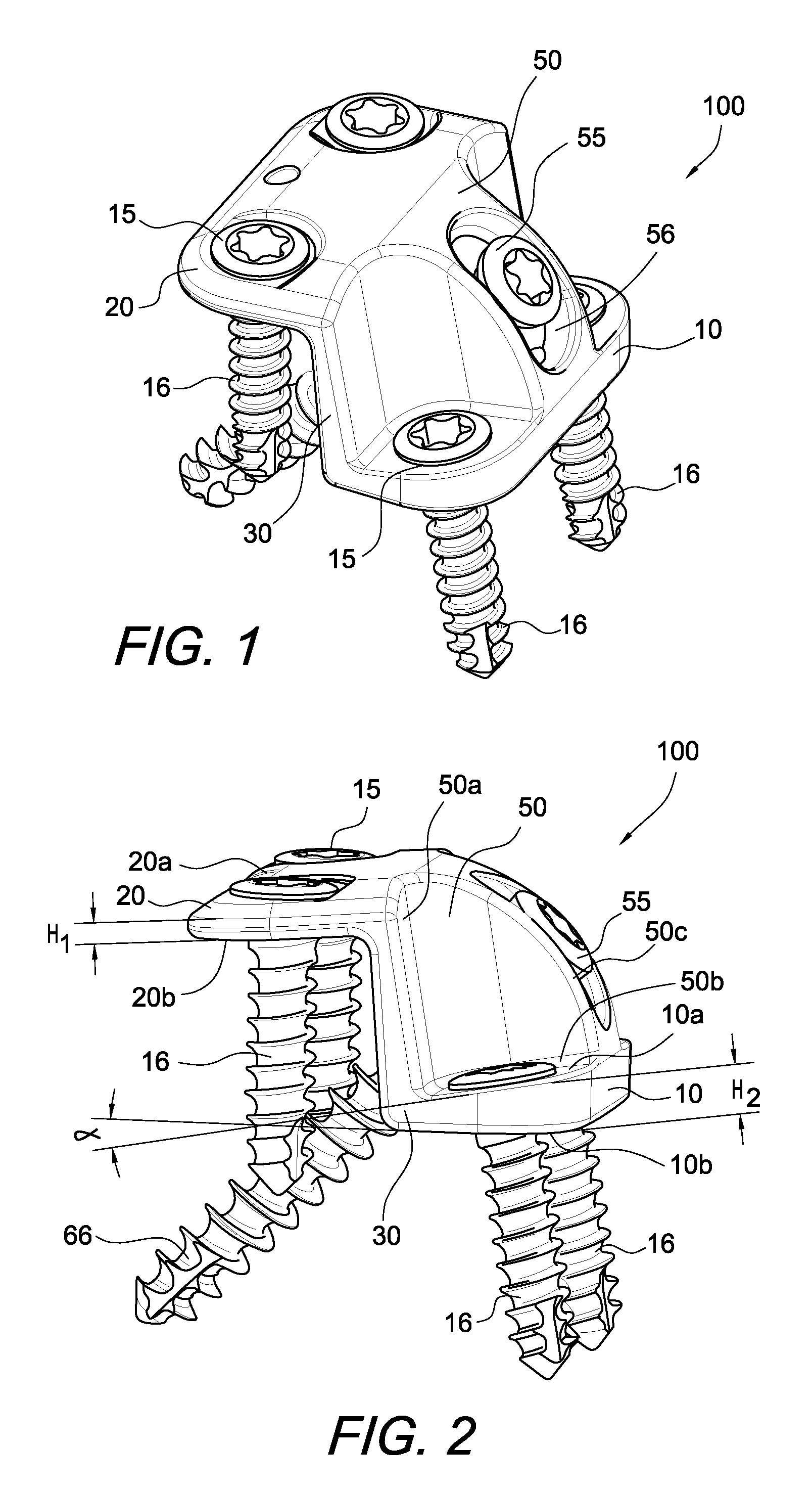

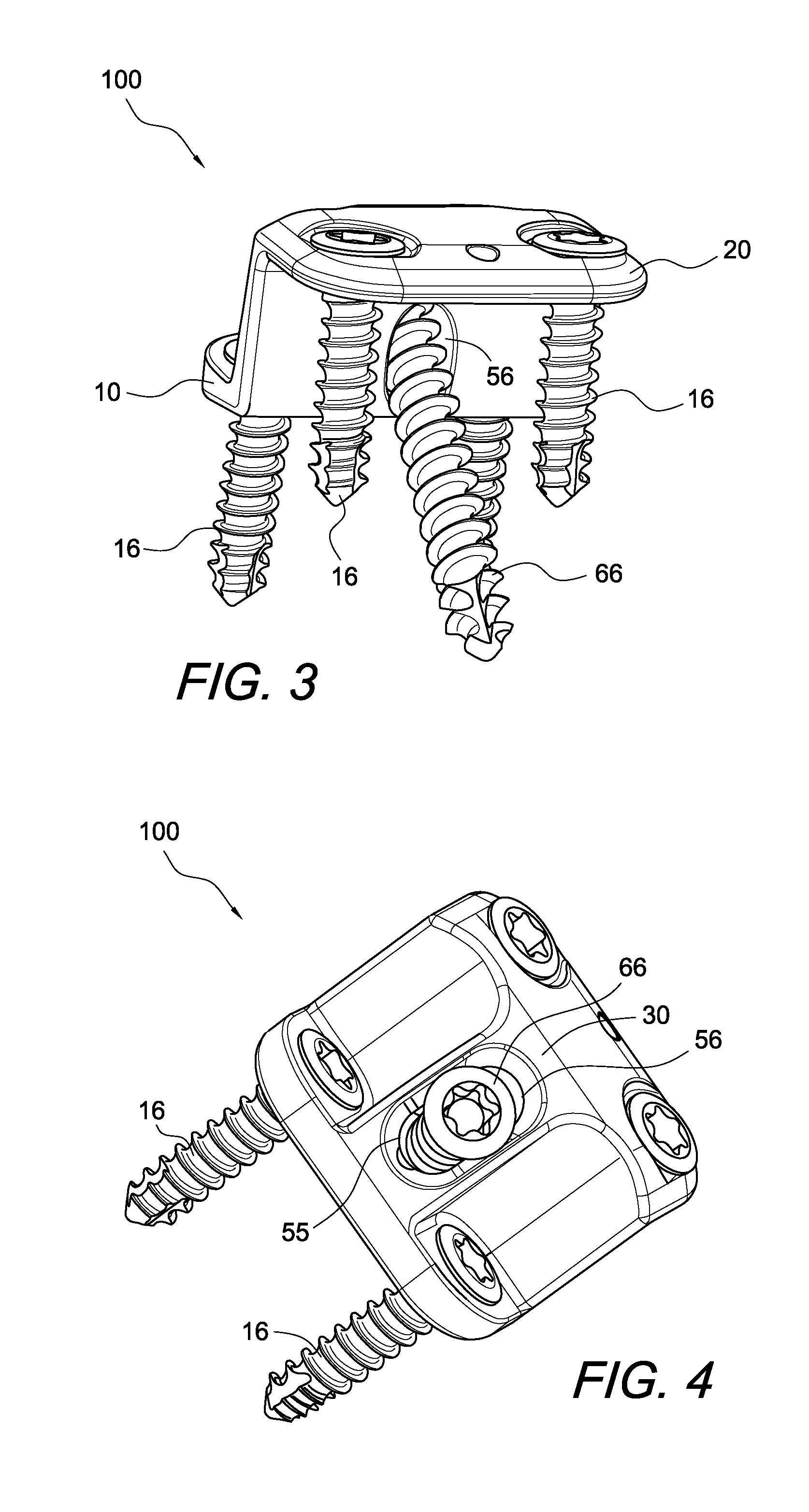

System and method for vertebral body plating

A spinal plating system for vertebral fixation includes a plate, a compression screw, multiple fixation members and polyaxially adjustable locking rings. The plate is shaped to conform to the curvature of the spine and the surfaces of the vertebral bodies. The compression screw fits through an insert, and together they are guided by the plate as the screw is driven into one of the vertebrae, producing compression between the adjacent vertebrae. A retaining lip on the plate prevents backout of the compression screw. The polyaxial locking rings can be polyaxially pivoted to attain a desired orientation, and are lockable to the plate to maintain the orientation. The fixation members fit through openings in the polyaxial locking rings and the plate to fix the plate to the vertebrae. Locking the polyaxial locking rings fixes the position of the fixation members relative to the plate, and prevents backout of the fixation members.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Minimally invasive spinal facet compression screw and system for bone joint fusion and fixation

ActiveUS8945193B2Prevent the screw from looseningPrevent disengagementSuture equipmentsInternal osteosythesisSpinal columnBones joints

A system comprising a screw element having a generally cylindrical body having a bore or lumen therethrough and a plurality of fenestrations or windows through which biological material may be provided. The system comprises a tool for inserting the biological material into the screw element so that the biological material may extrude through the plurality of fenestrations or windows and through an aperture in the tip of the screw element thereby enabling providing a fusion mass across two adjacent facet bones or a facet joint wherein the screw itself provides both a fixation component and a screw component.

Owner:X SPINE SYST

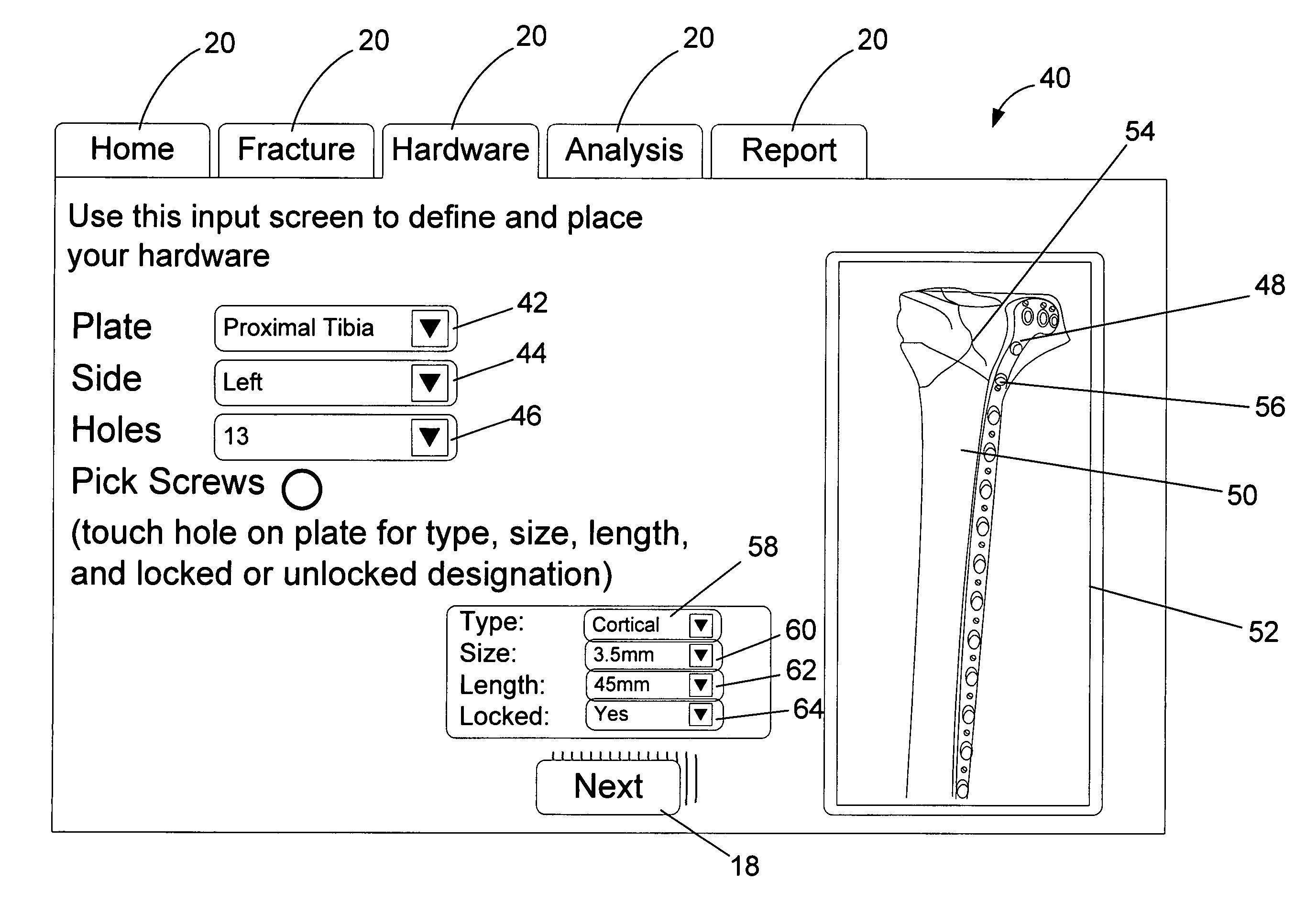

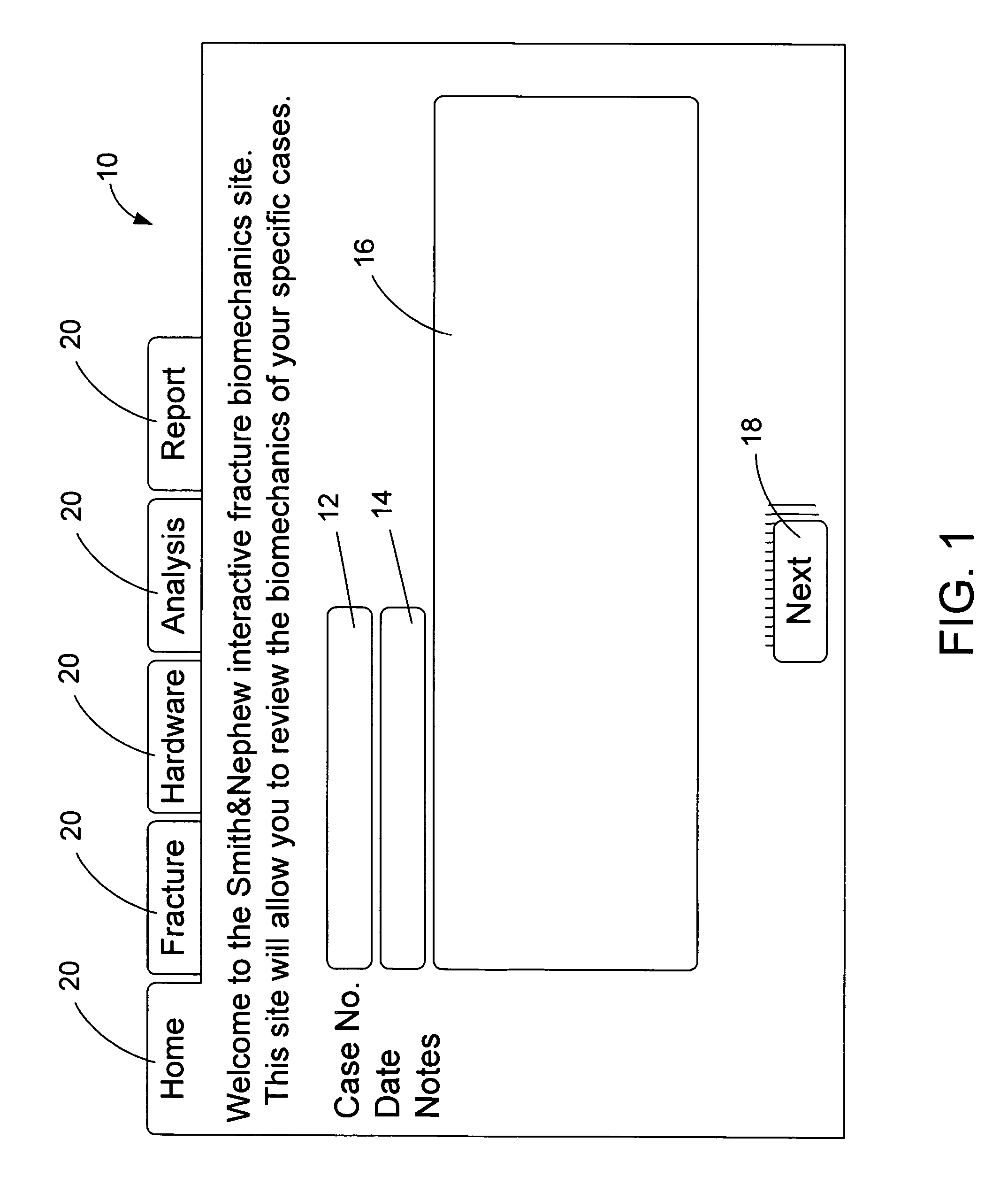

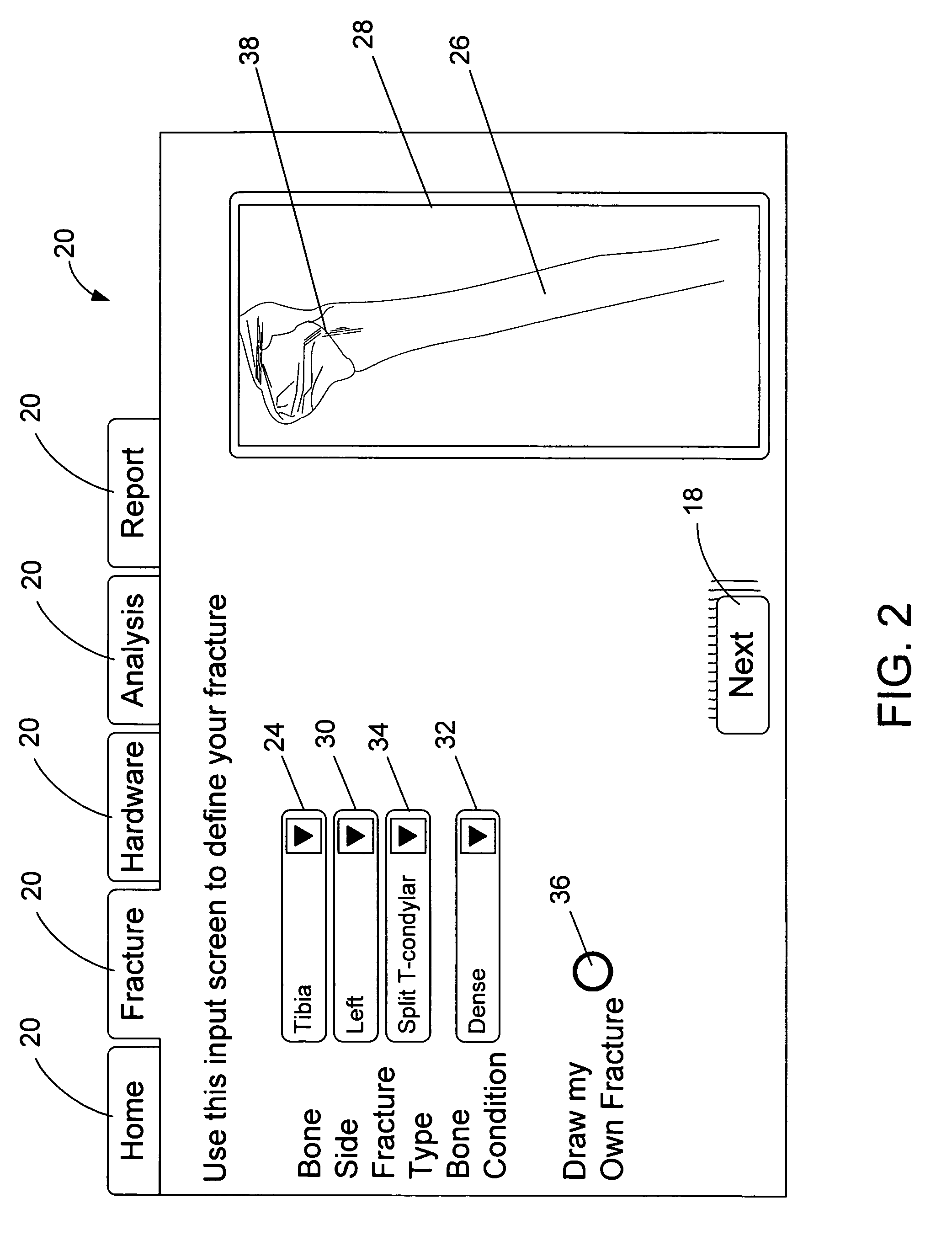

Interactive orthopaedic biomechanics system

Methods of selecting a configuration of fixation and compression screws for a bone plate to be installed on a bone of a patient. A computer or website allows a user to load images of a fractured bone and specify a particular configuration of fixation and compression screws with a plate on the loaded bone. The computer replicates stresses imposed on the bone by regular activities using finite element analysis and provide information about the suitability of the selected configuration.

Owner:SMITH & NEPHEW INC

Orthopedic compression plate and method of surgery

ActiveUS9060822B2Address bad outcomesEasy alignmentFastenersExternal osteosynthesisEngineeringPlastic surgery

Owner:ORTHOHELIX SURGICAL DESIGNS

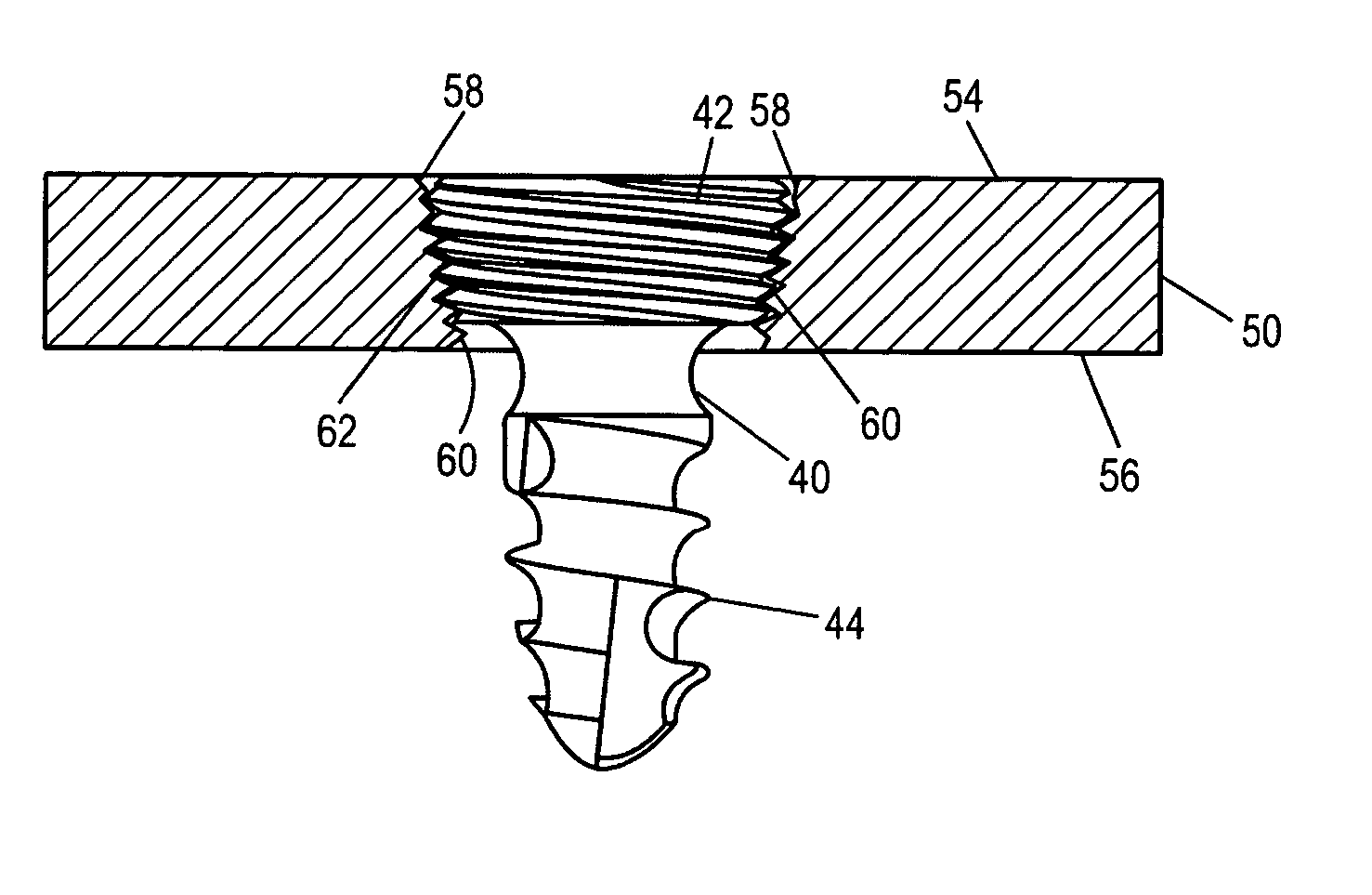

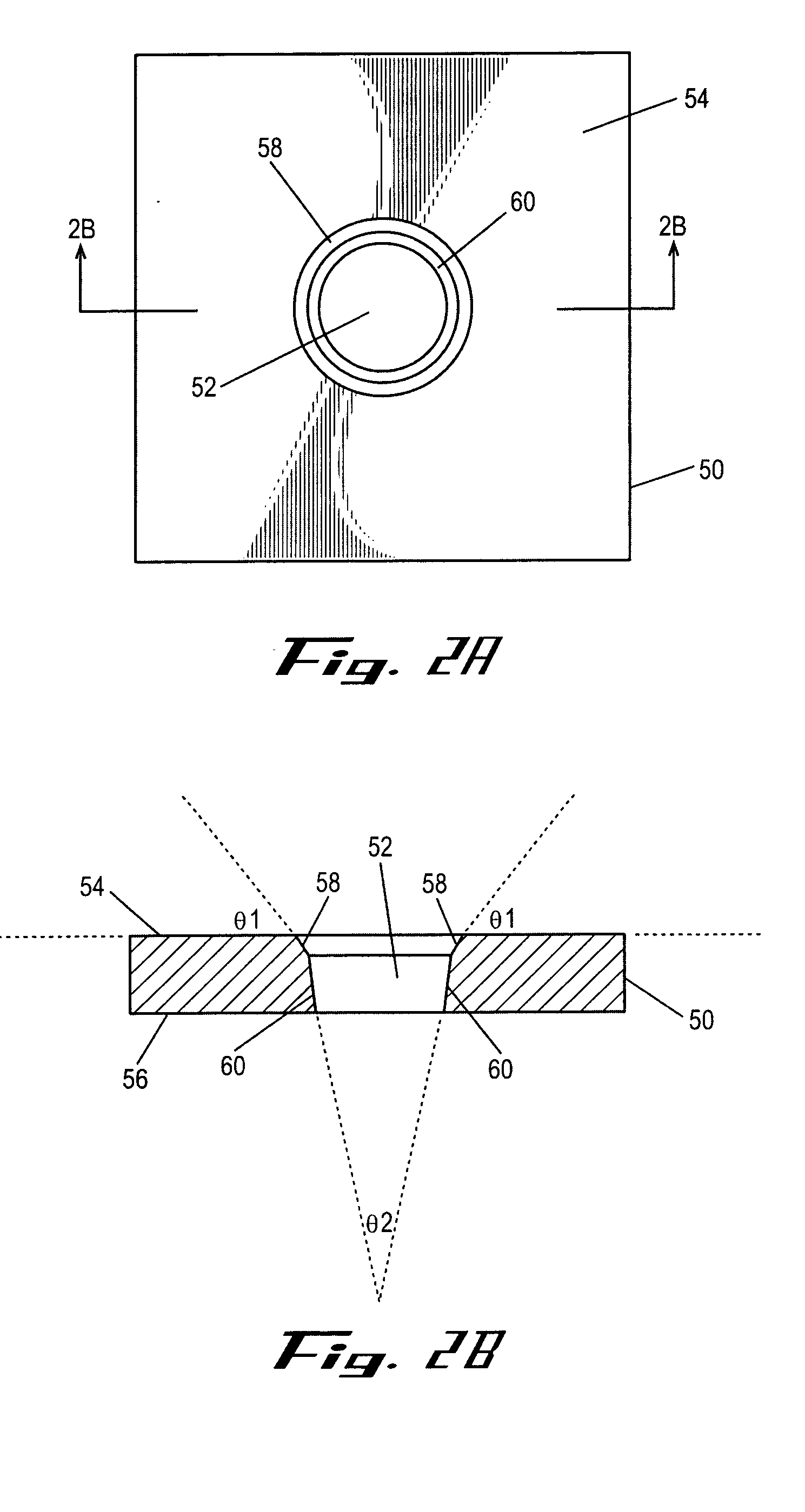

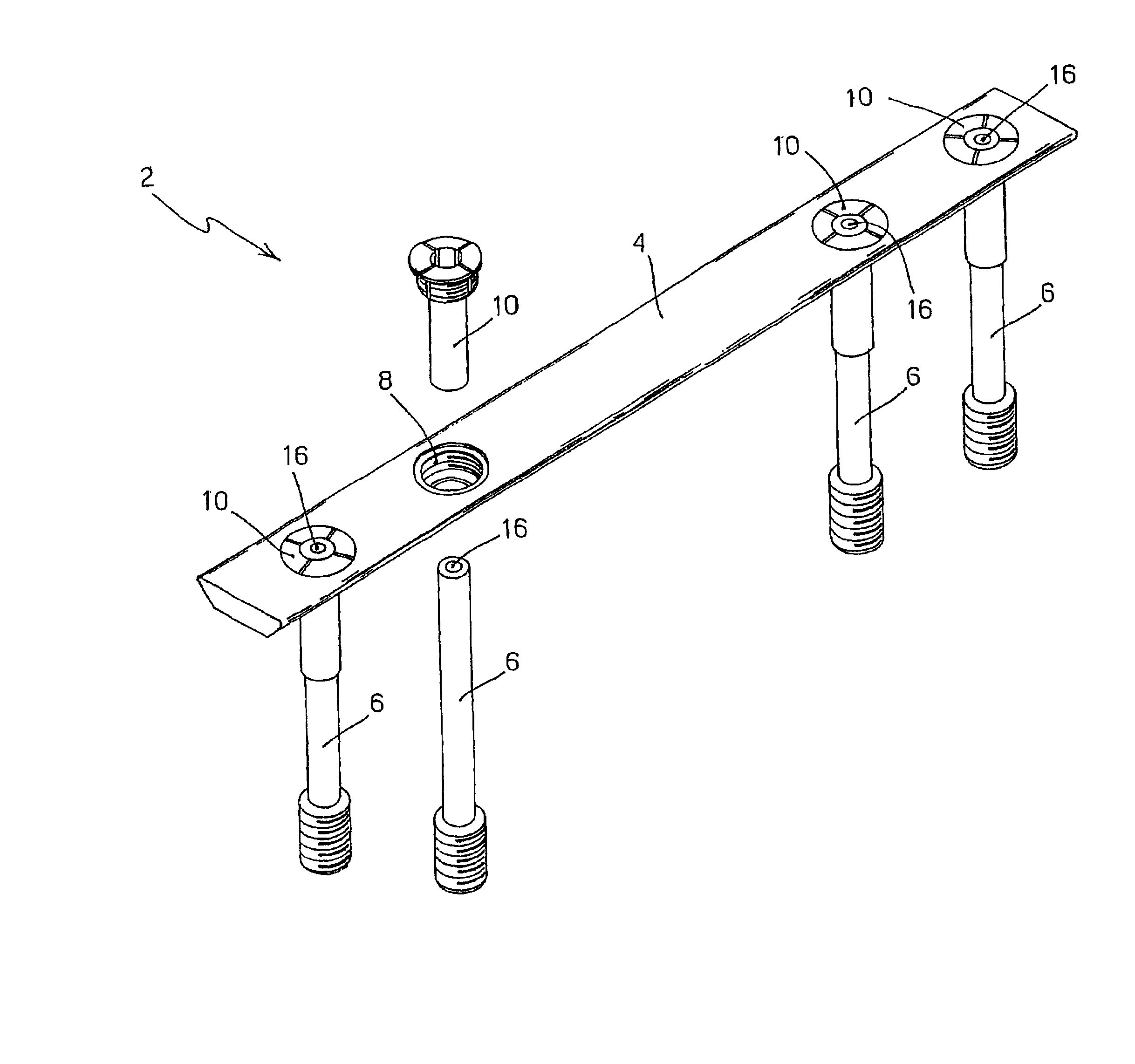

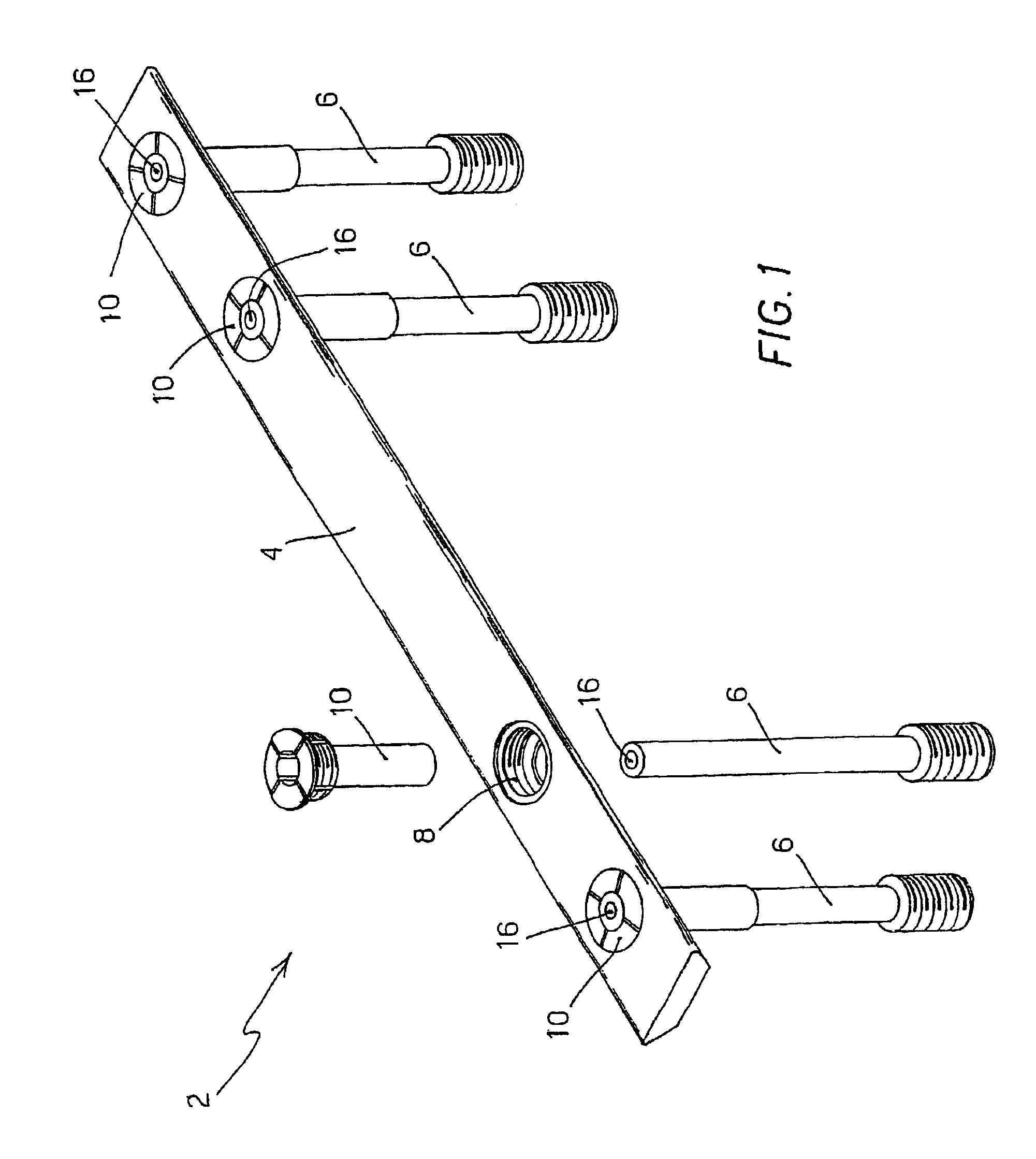

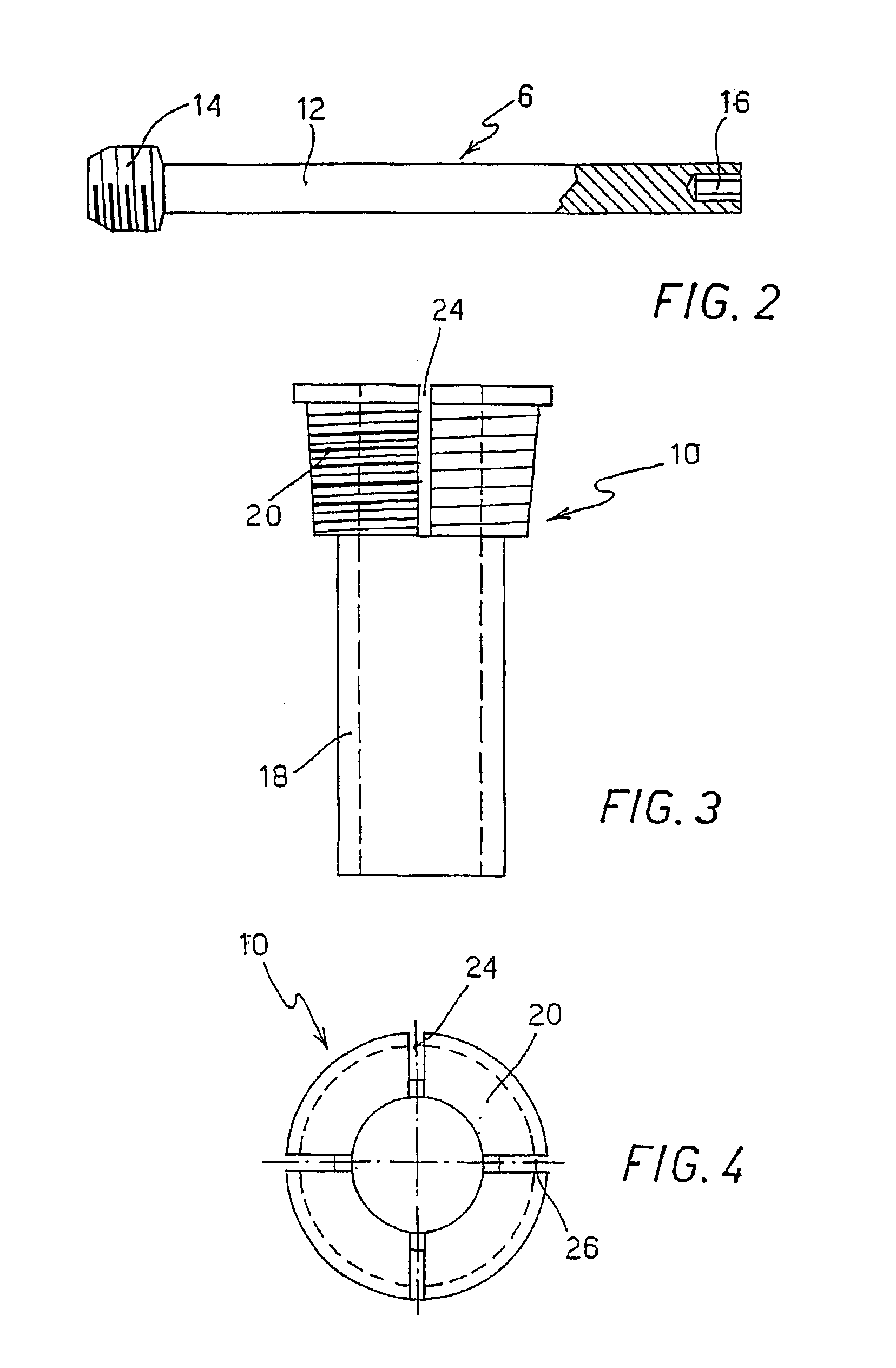

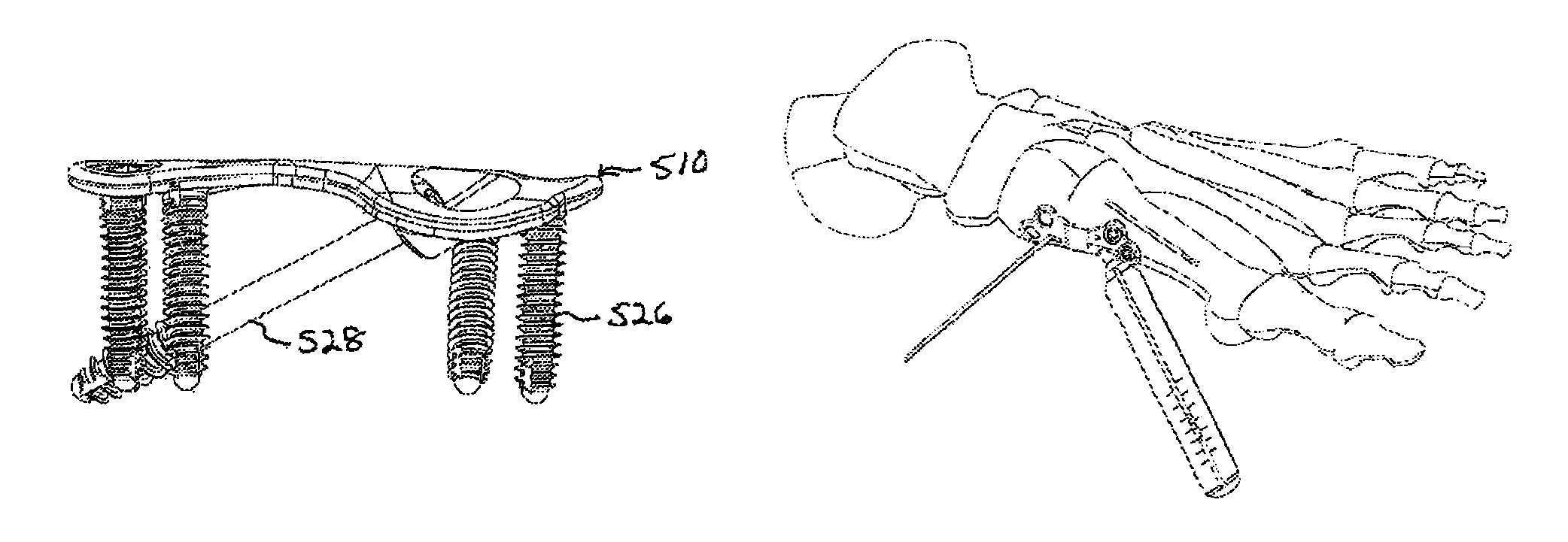

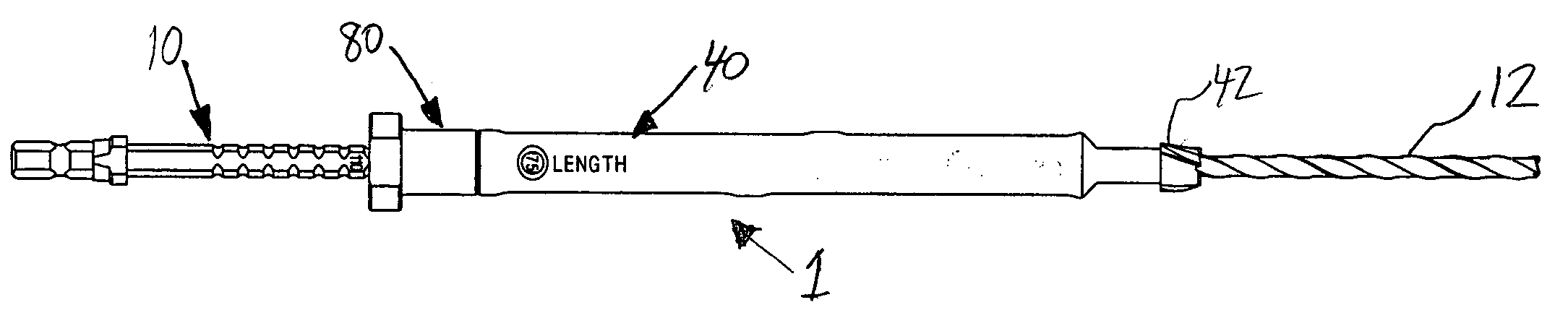

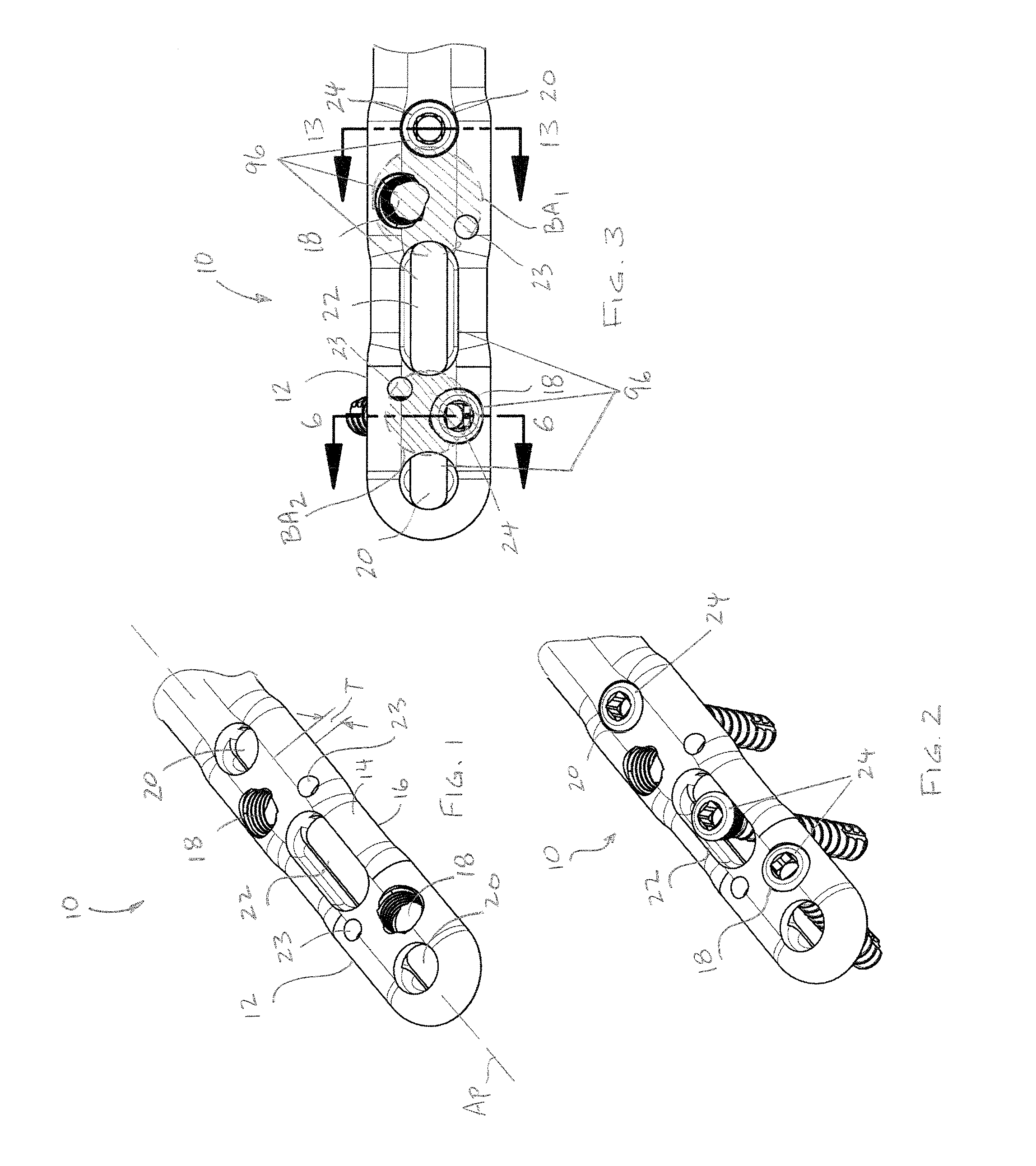

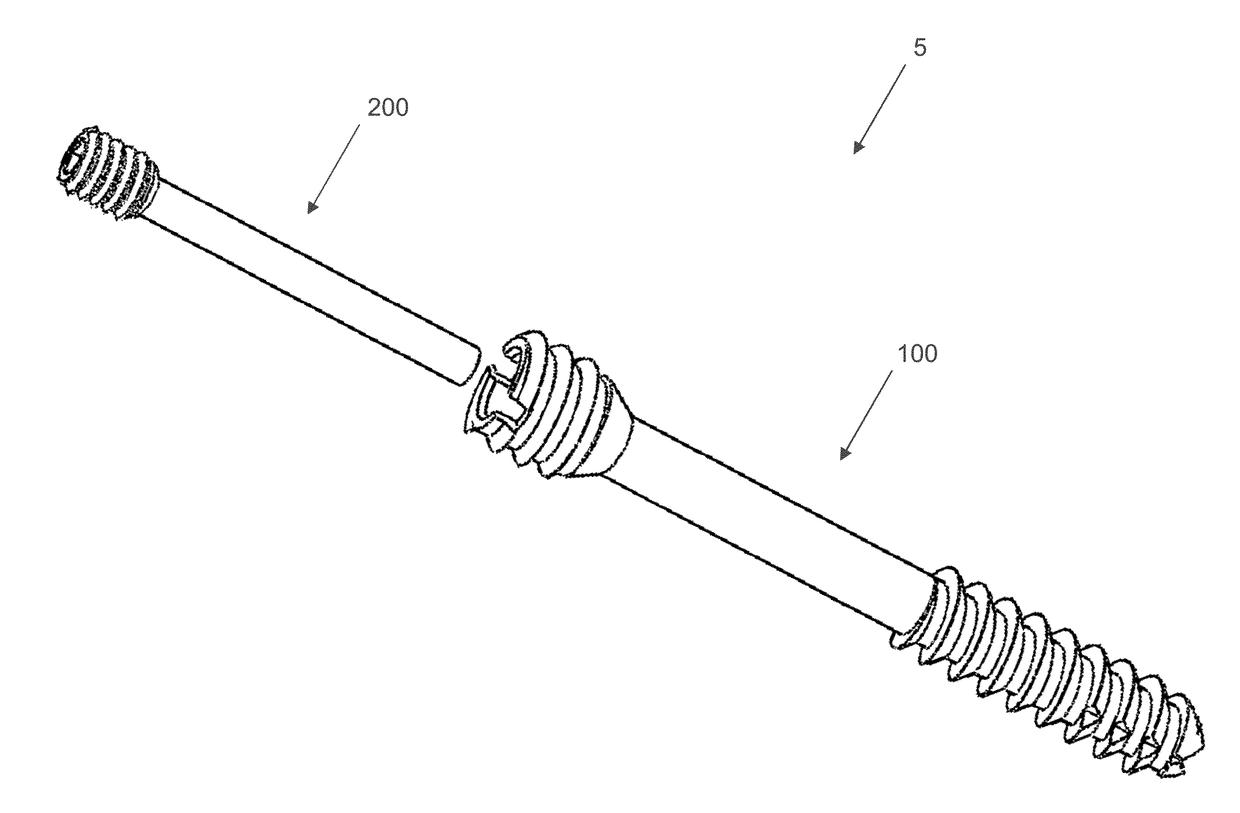

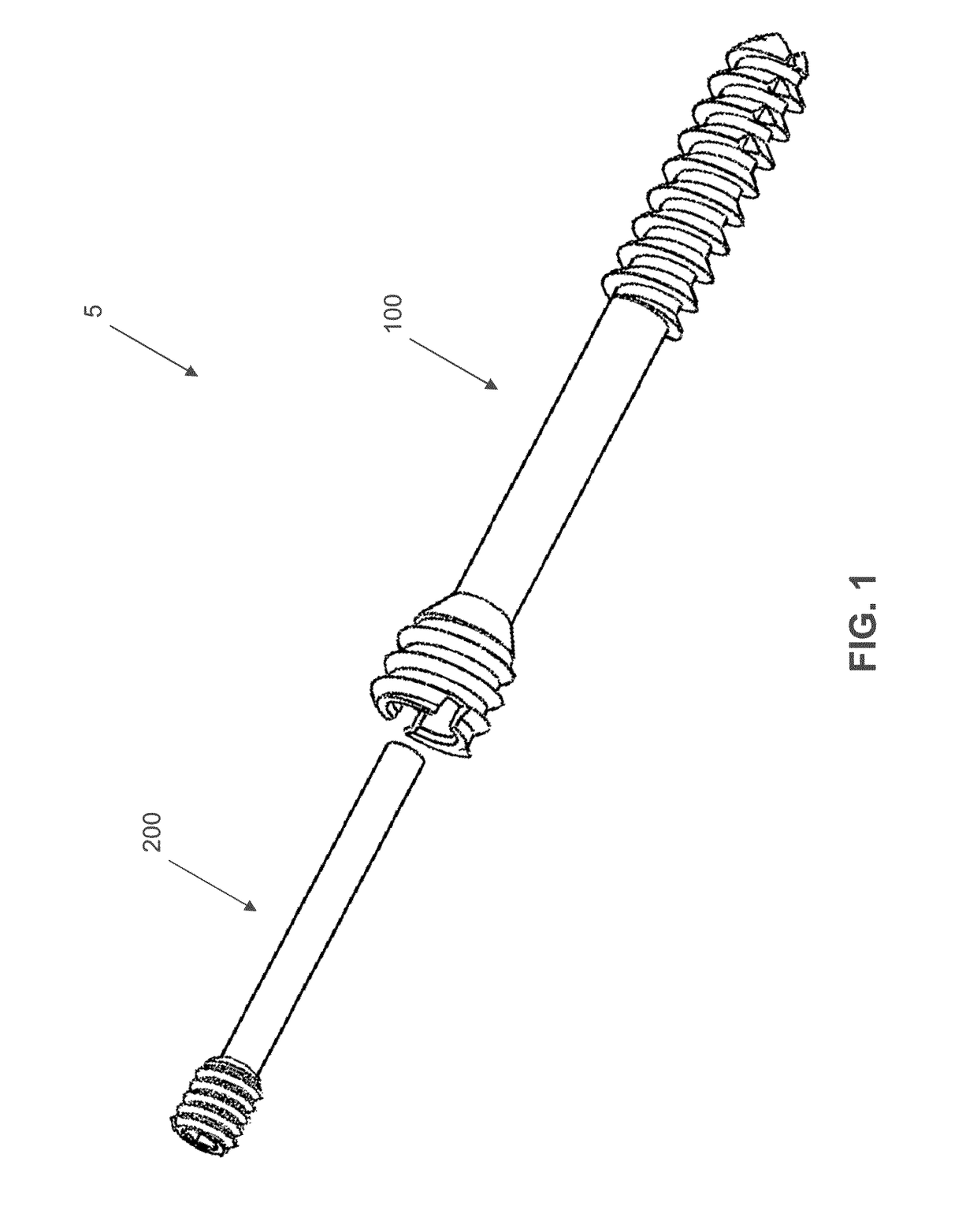

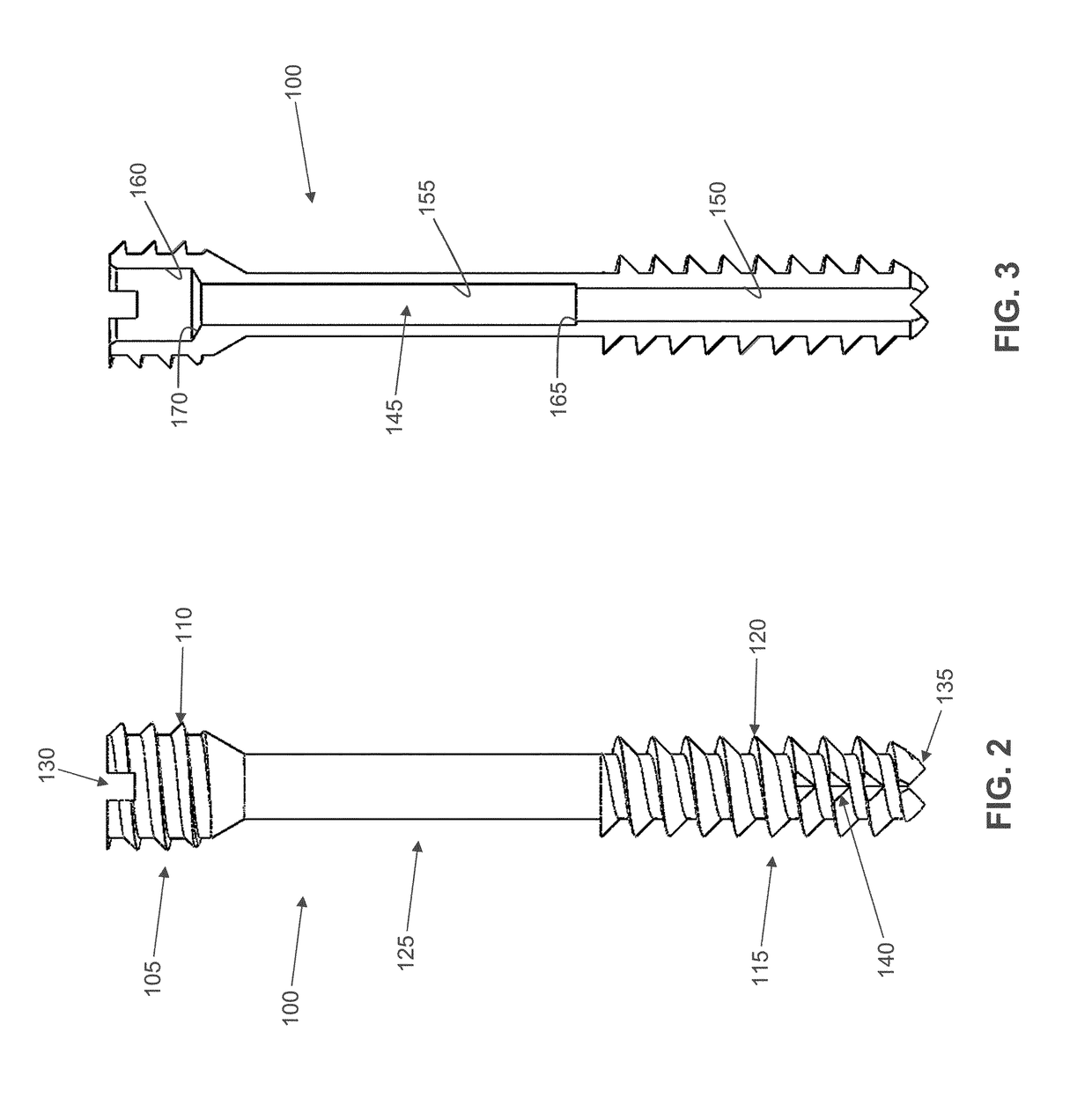

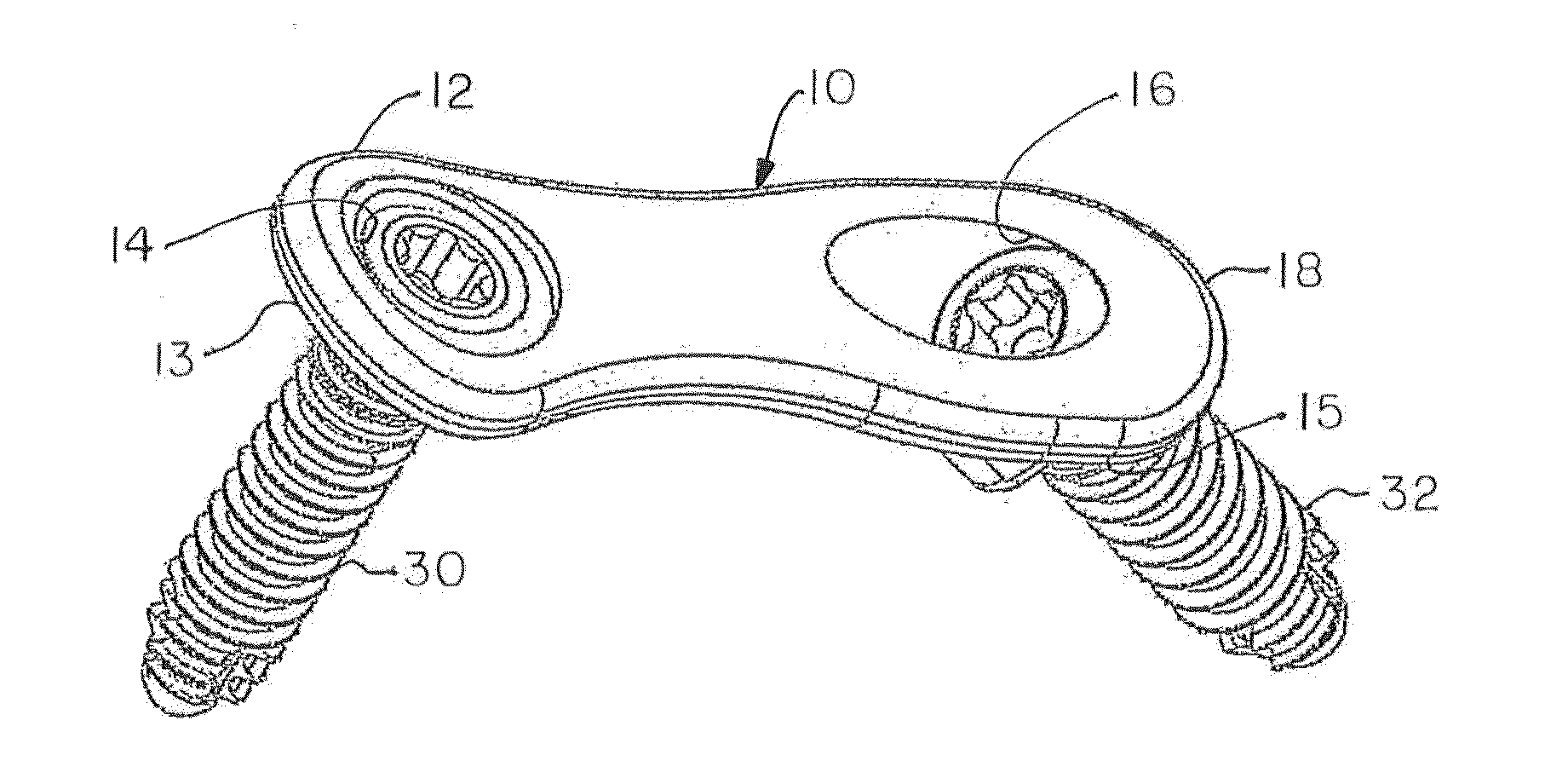

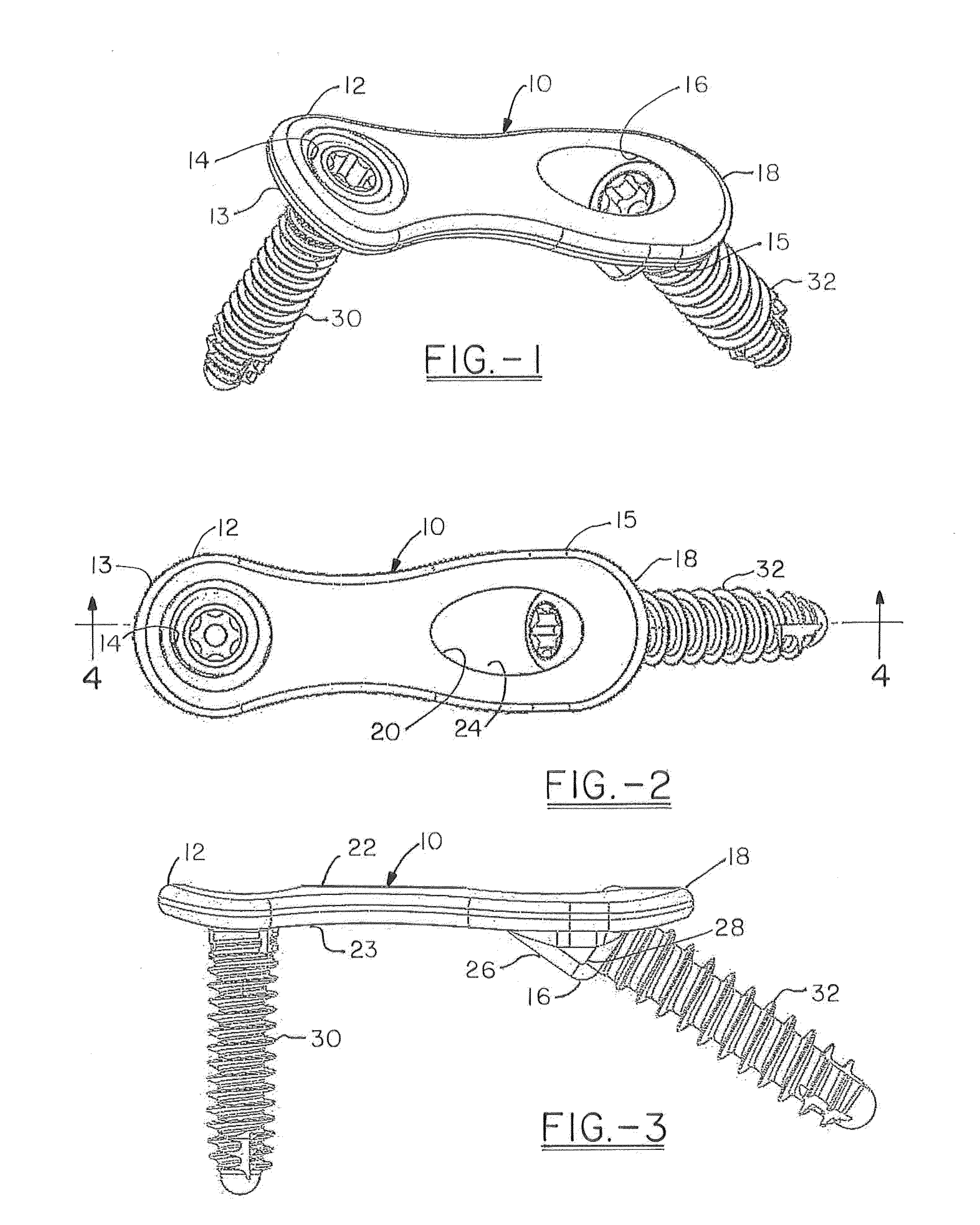

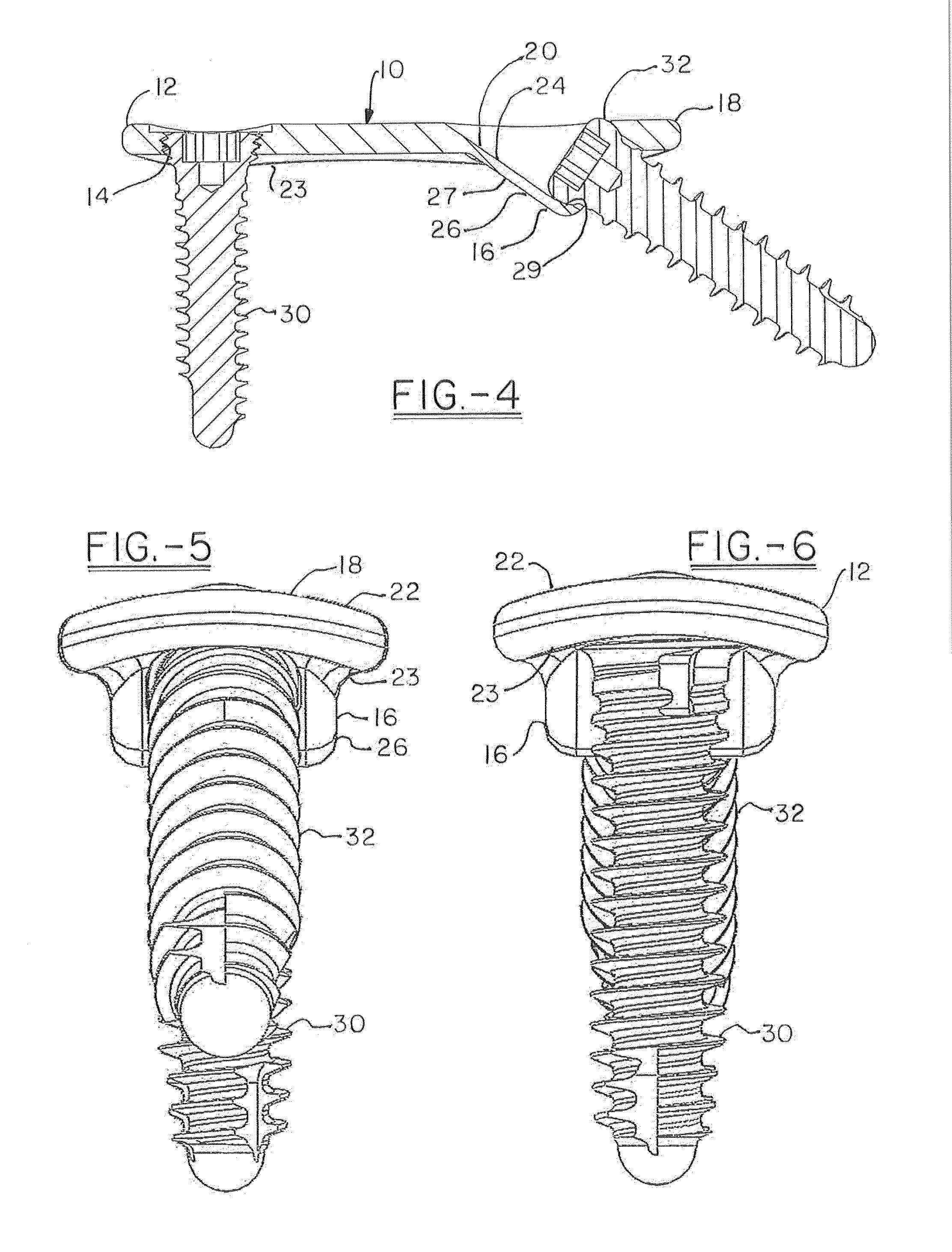

Compression screw assembly, an orthopedic fixation system including a compression screw assembly and method of use

A compression screw assembly includes a first primary member having a threaded leading portion of a first pitch, a smooth middle portion and a threaded trailing portion of a second pitch with the trailing portion residing directly opposite leading portion. The compression screw assembly includes a second threaded screw head member positioned at a distal end having external threads, which are of the same pitch as the plurality of threads of the leading portion, and internal threads of a fourth pitch and dissimilar screw leads from the external threads. The difference in screw leads causes the compression screw member to apply a compressive force on bone fragments when compression screw assembly is inserted into bone fragments.

Owner:EXTREMITY MEDICAL

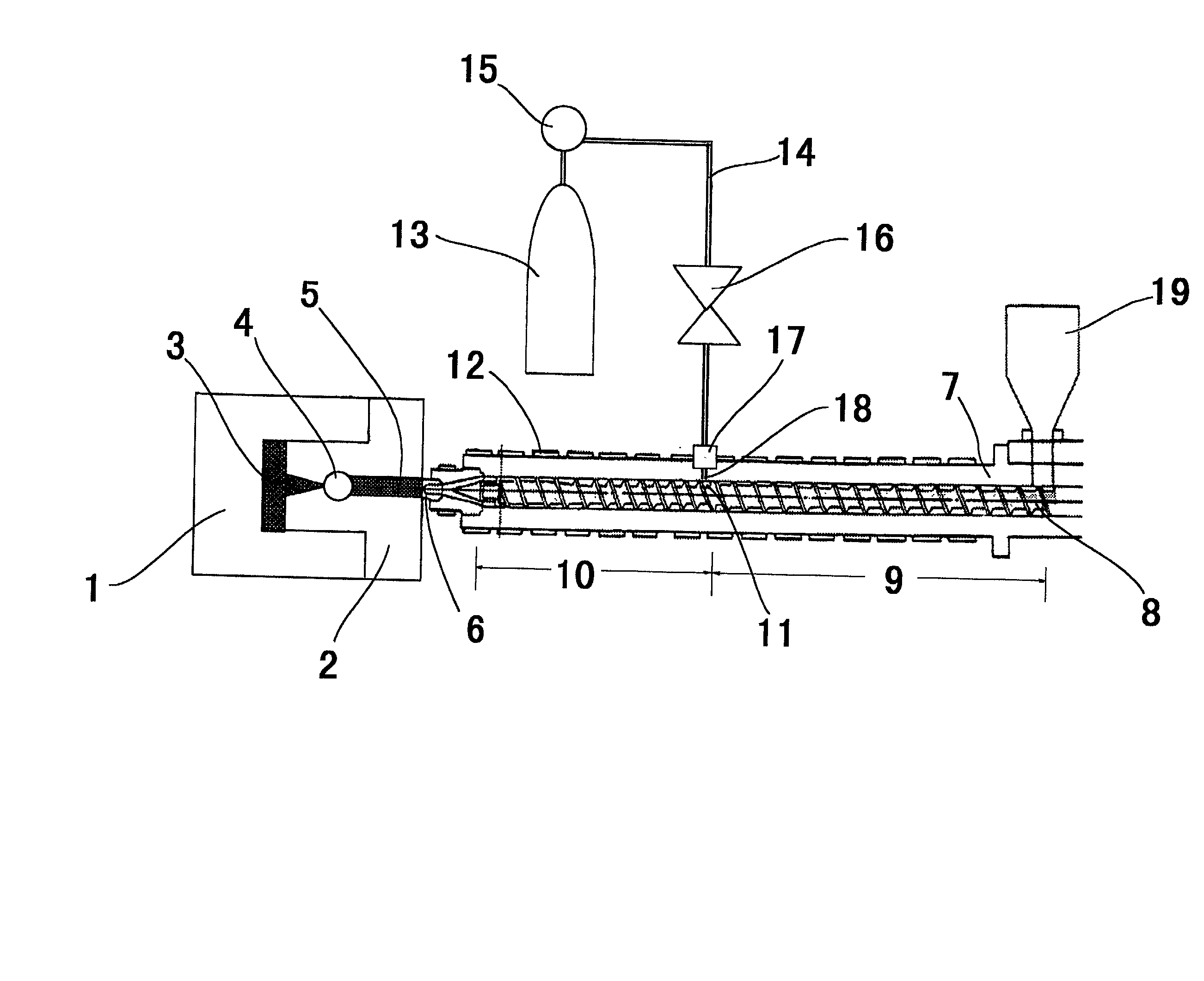

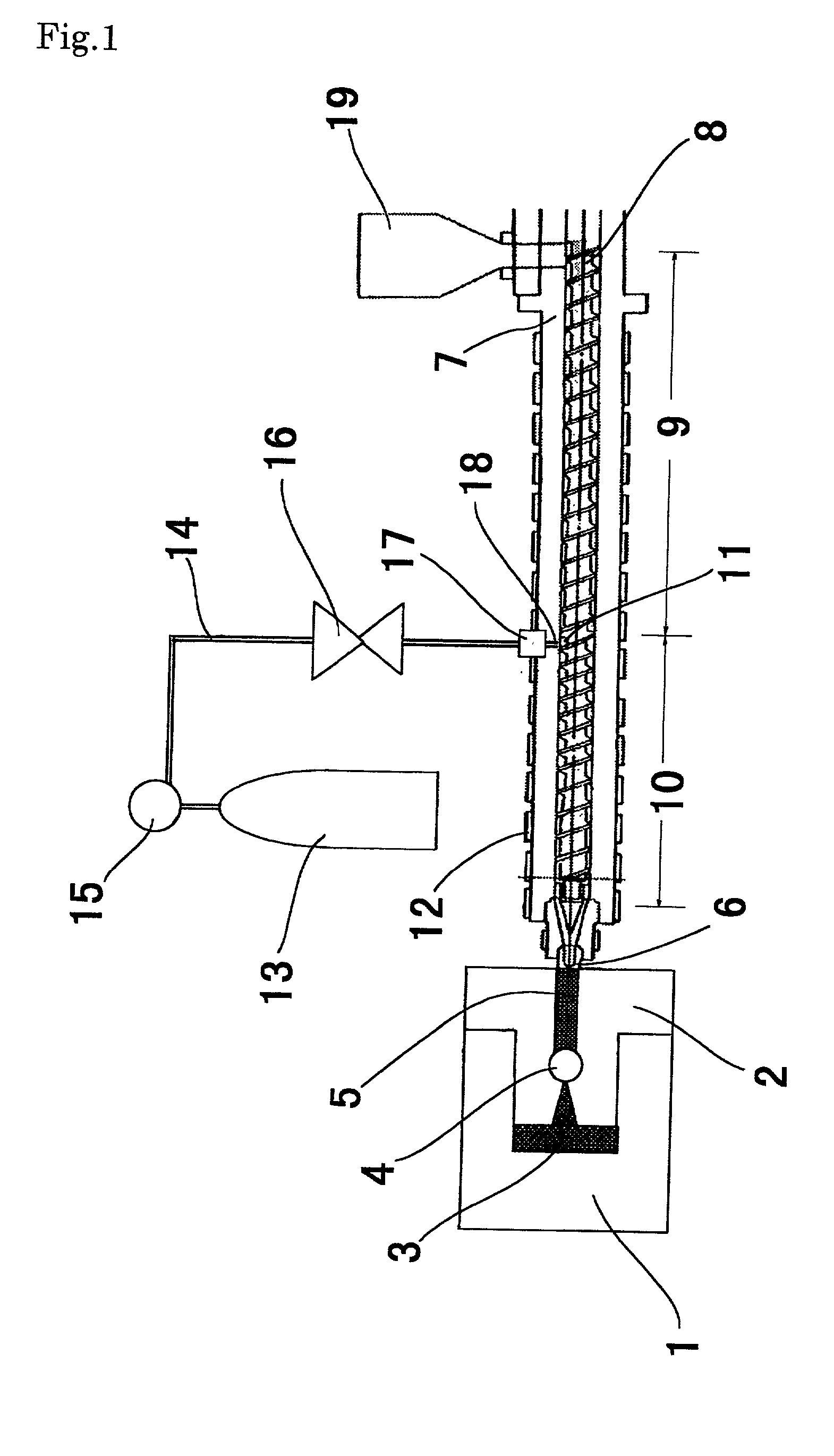

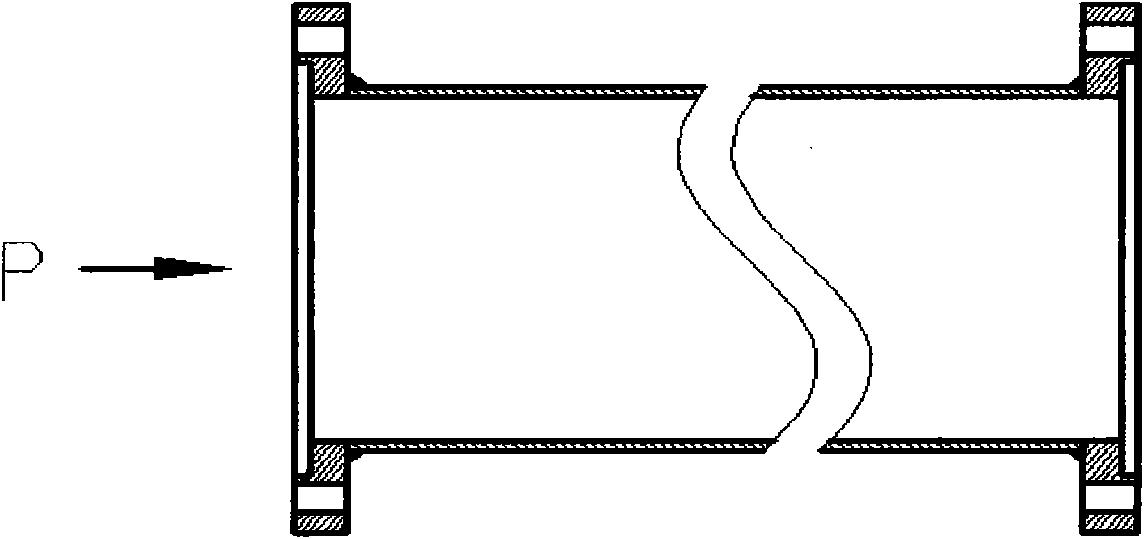

Process for injection foaming, and machine and composition therefore

A process for injection-foaming a thermoplastic resin by using an injection molding machine with a two-stage-compression screw, injecting a physical foaming agent into the cylinder of the machine at a pressure lower than the storage pressure of the physical foaming agent, mixing it with a melted resin and expanding the volume of the cavity of the mold at the time of injection, and an injection molding machine and resin composition suitable therefore.

Owner:MITSUI CHEM INC

Orthopaedic plate and screw assembly

Systems, devices and methods are disclosed for treating fractures. The systems, devices and methods may include one or both of an implant, such as an intramedullary nail, and a fastening assembly, such as a lag screw and compression screw assembly. The implant in some embodiments has a proximal section with a transverse aperture and a cross-section that may be shaped to more accurately conform to the anatomical shape of cortical bone and to provide additional strength and robustness in its lateral portions, preferably without requiring significant additional material. The fastening assembly may be received to slide, in a controlled way, in the transverse aperture of the implant. In some embodiments, the engaging member and the compression device are configured so that the compression device interacts with a portion of the implant and a portion of the engaging member to enable controlled movement between the first and second bone fragments. This configuration is useful for, among other things, compressing a fracture.

Owner:SMITH & NEPHEW INC

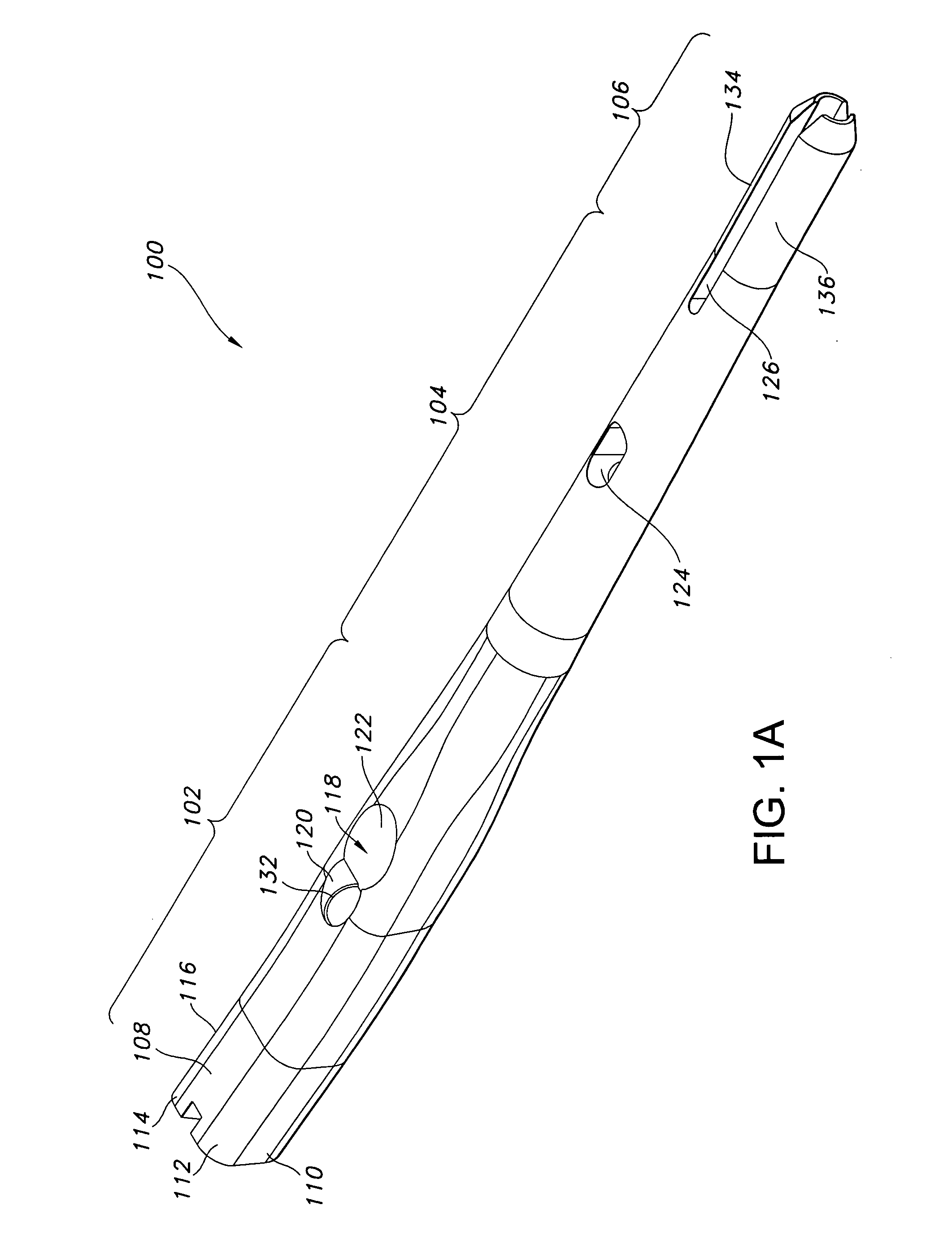

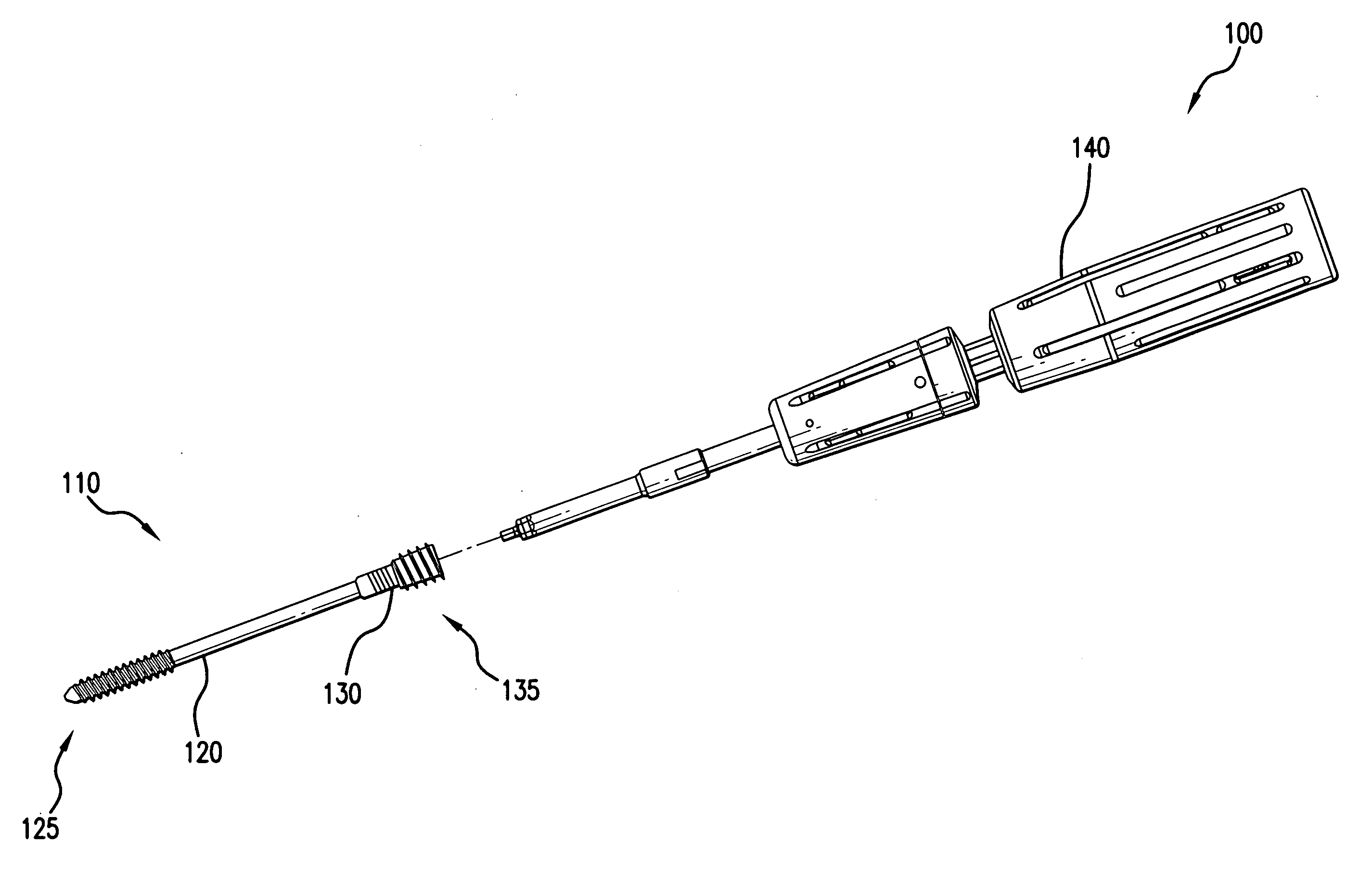

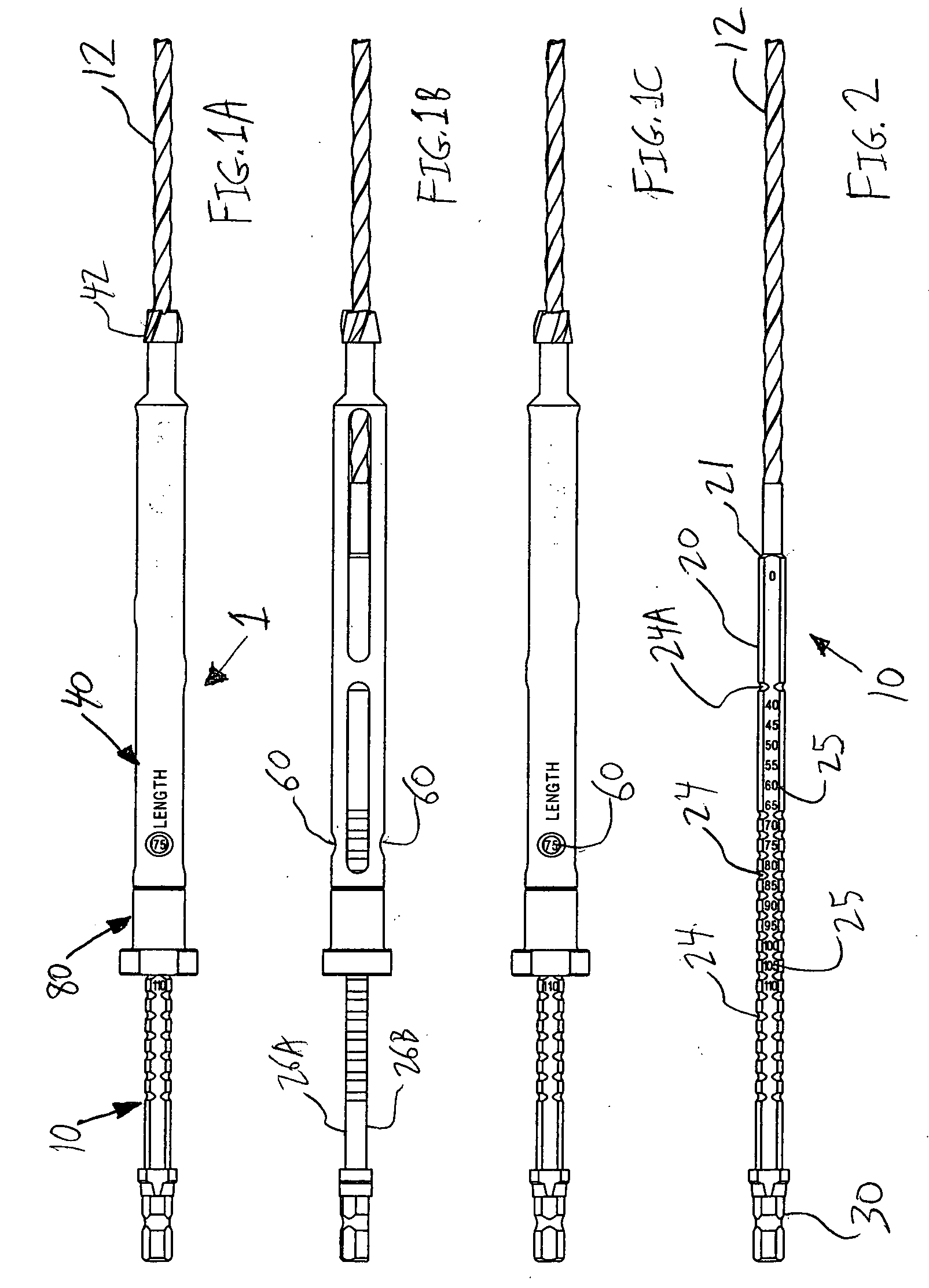

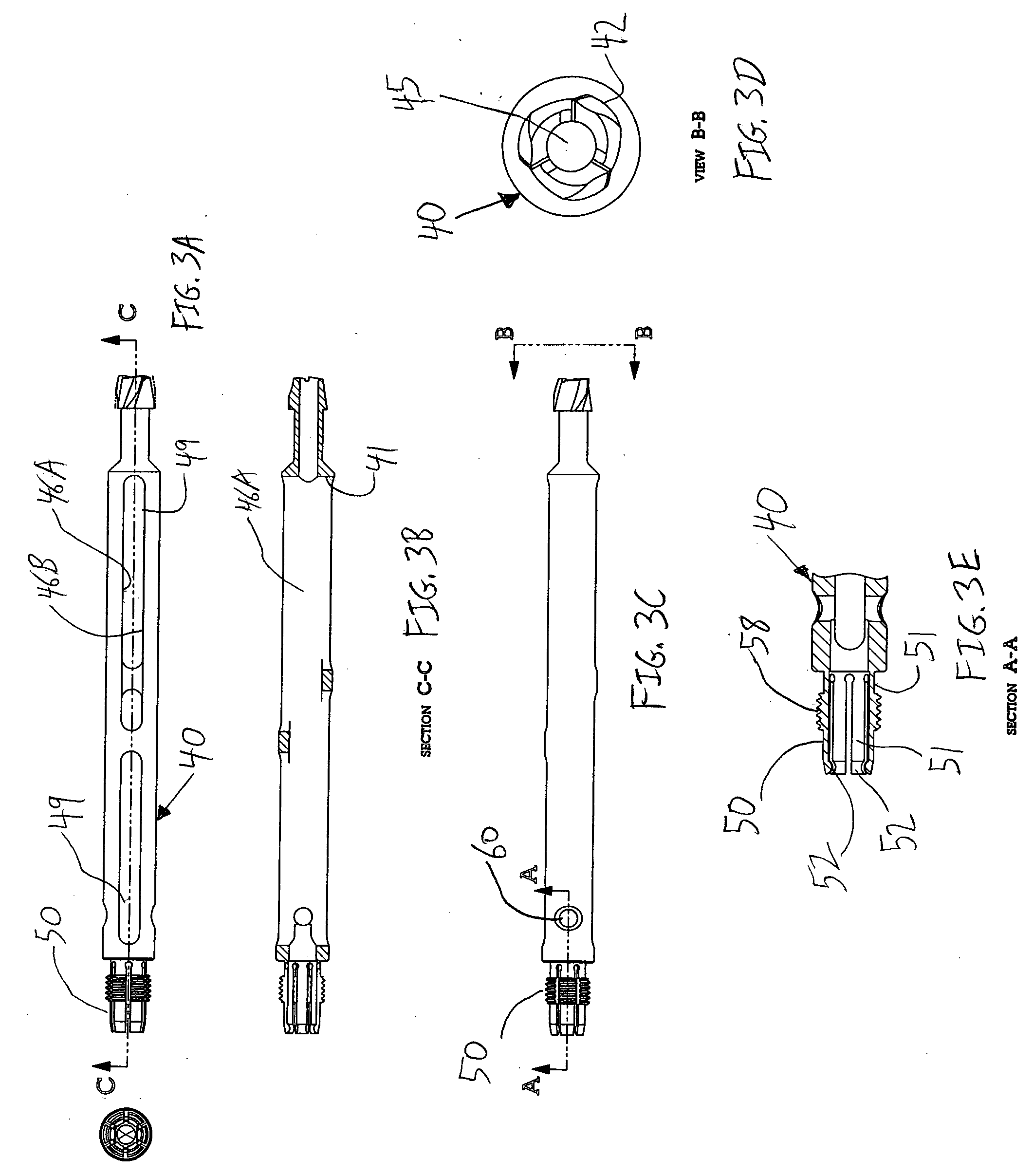

Instruments for bone screws

An adjustable drill for use in implanting orthopedic screws, such as adjustable compression screws having a separate adjustable head. The adjustable drill comprises a primary drill bit and a countersink drill bit encircling the primary drill bit. The countersink drill bit is configured to selectively slide along the primary drill bit for use in selecting a drill depth. The countersink drill bit is associated with a stop member that is configured to selectively lock the countersink drill bit at one of a plurality of selected positions along the primary drill bit to thereby establish a drill depth. The drill depth corresponds to the size of a selected screw implant, allowing the drill to be used as a trial. The adjustable drill forms a bore having a primary bore and a countersunk entry.

Owner:WRIGHT MEDICAL TECH

Reduced component bone plating system

ActiveUS8632574B2Increased compressive loadEasy to adaptSuture equipmentsLigamentsScrew systemEngineering

An orthopedic screw system includes a screw with a locking head that can both lockingly engage in a fixed angle threaded screw hole to secure a plate to a bone without compression, and non-lockingly engage at a compression screw hole to provide compression between the plate and the bone. The structure of the system is particularly well adapted to plates and screw of small dimensions, such as screws smaller than 3.5 mm and is capable of providing high compressive force, on the order of 120 lbs of axial load, without significant plastic deformation between the screw and plate.

Owner:BIOMET CV

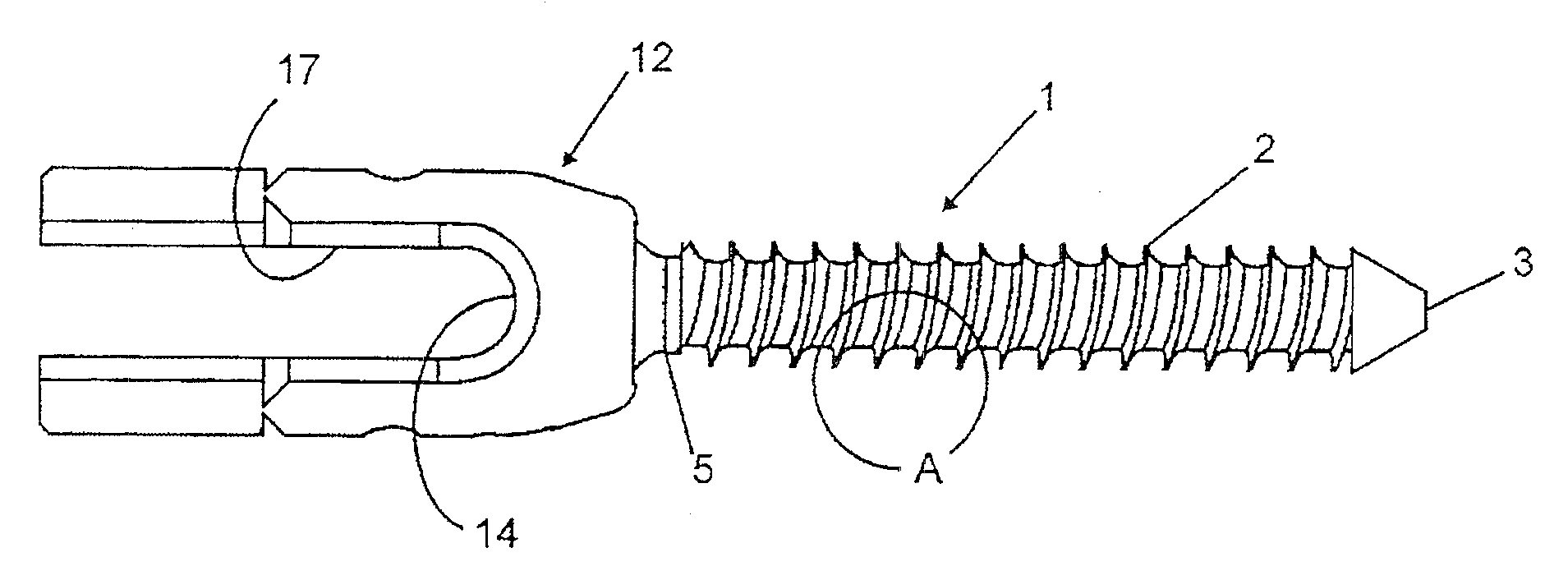

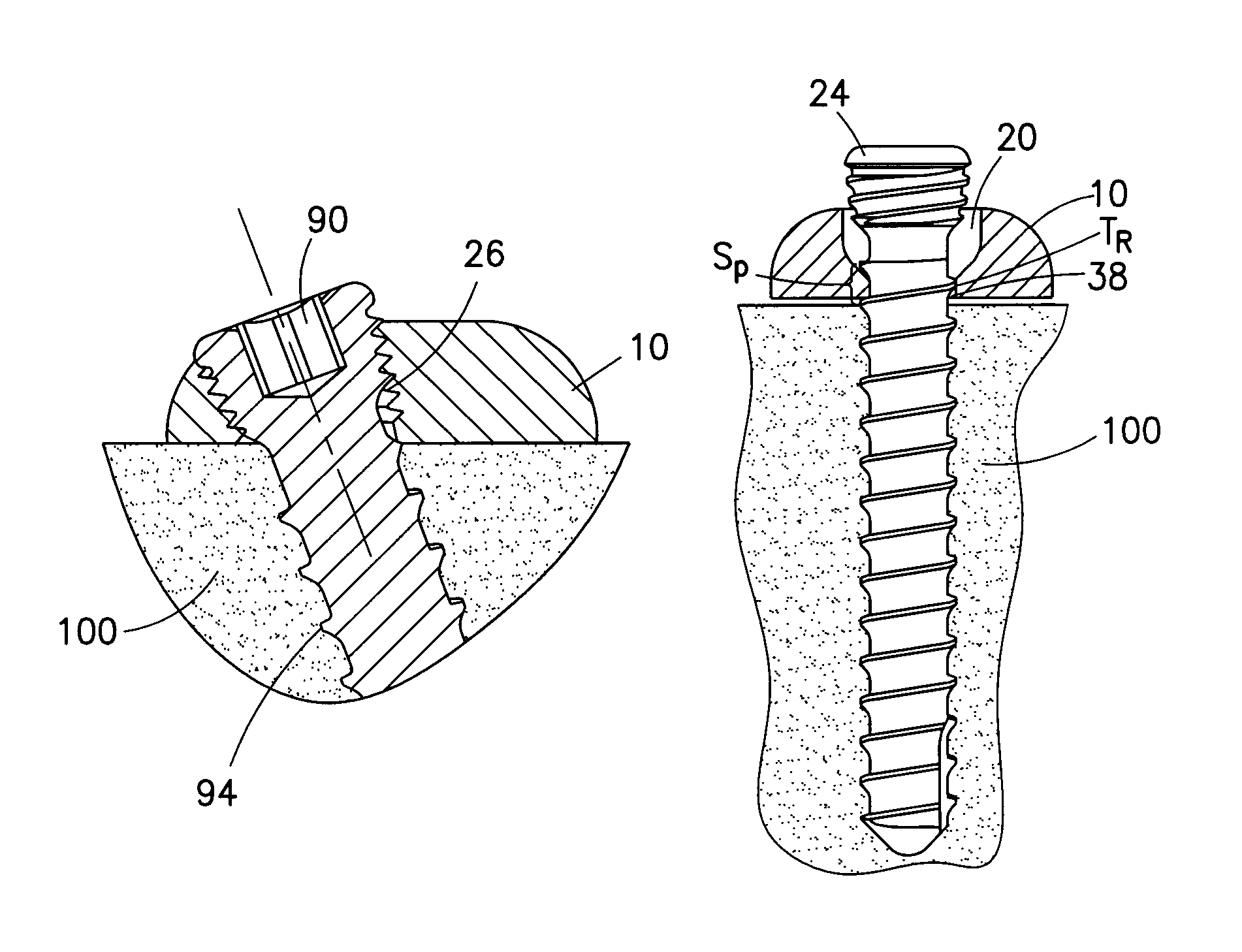

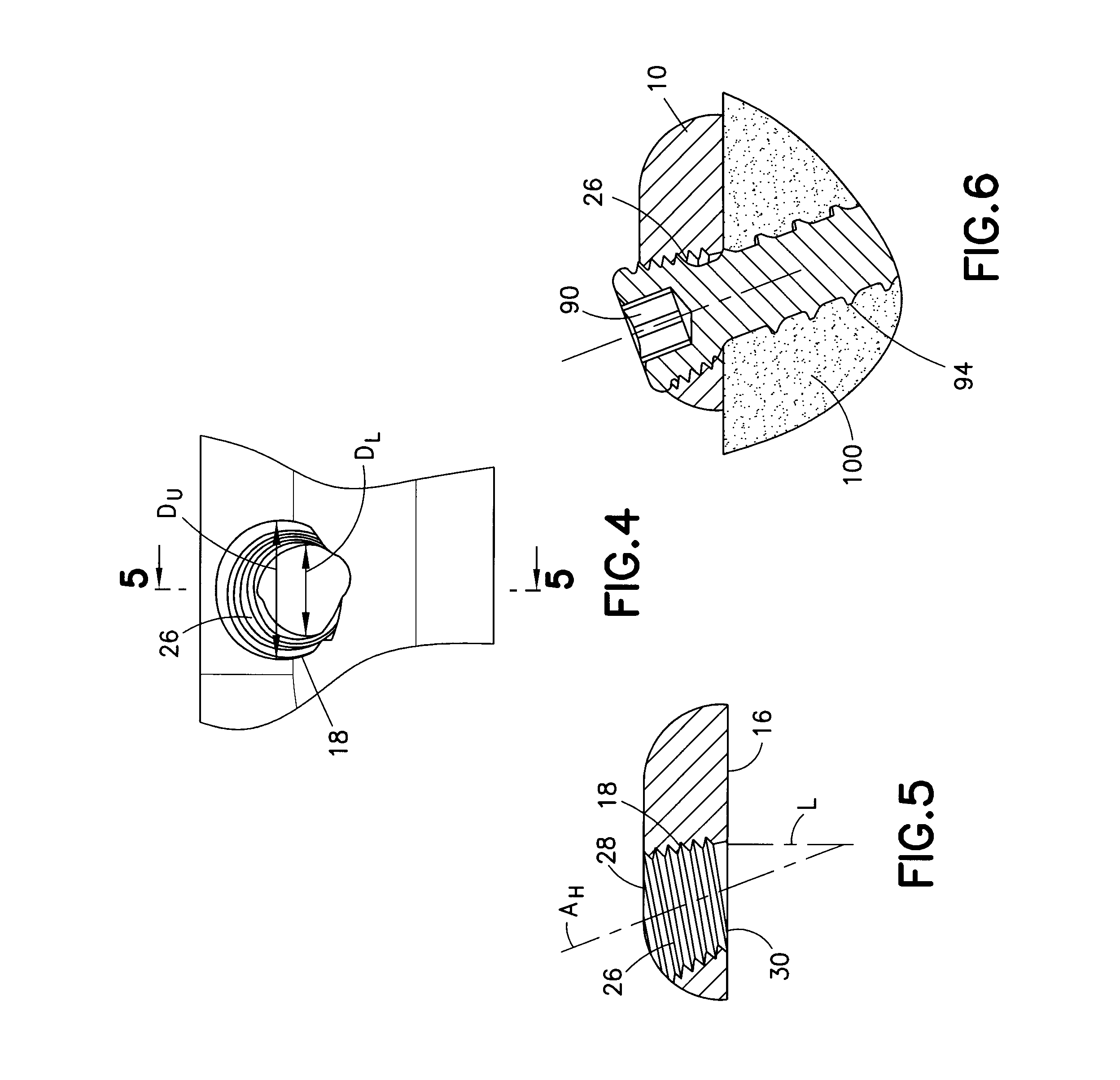

Orthopedic compression screw

InactiveUS20080132958A1Simple and elegant mannerEffectively introduced into and onto boneSuture equipmentsDiagnosticsEngineeringPlastic surgery

The invention relates to an orthopedic compression screw, in particular a compression screw for osteosynthesis and / or fixation of bone segments (12, 14), with a threaded portion (20) and a screw head (18), the screw head (18) widening conically toward its distal end and the screw being provided along its longitudinal axis (A) with a bore (26) for interaction with an orthopedic guide element, in particular a guide wire, and the periphery of the screw head (18) having at least one flat that forms a plane outer surface (30) preferably extending parallel to the longitudinal axis.

Owner:NORMED MEDIZIN TECHN VERTRIEBS

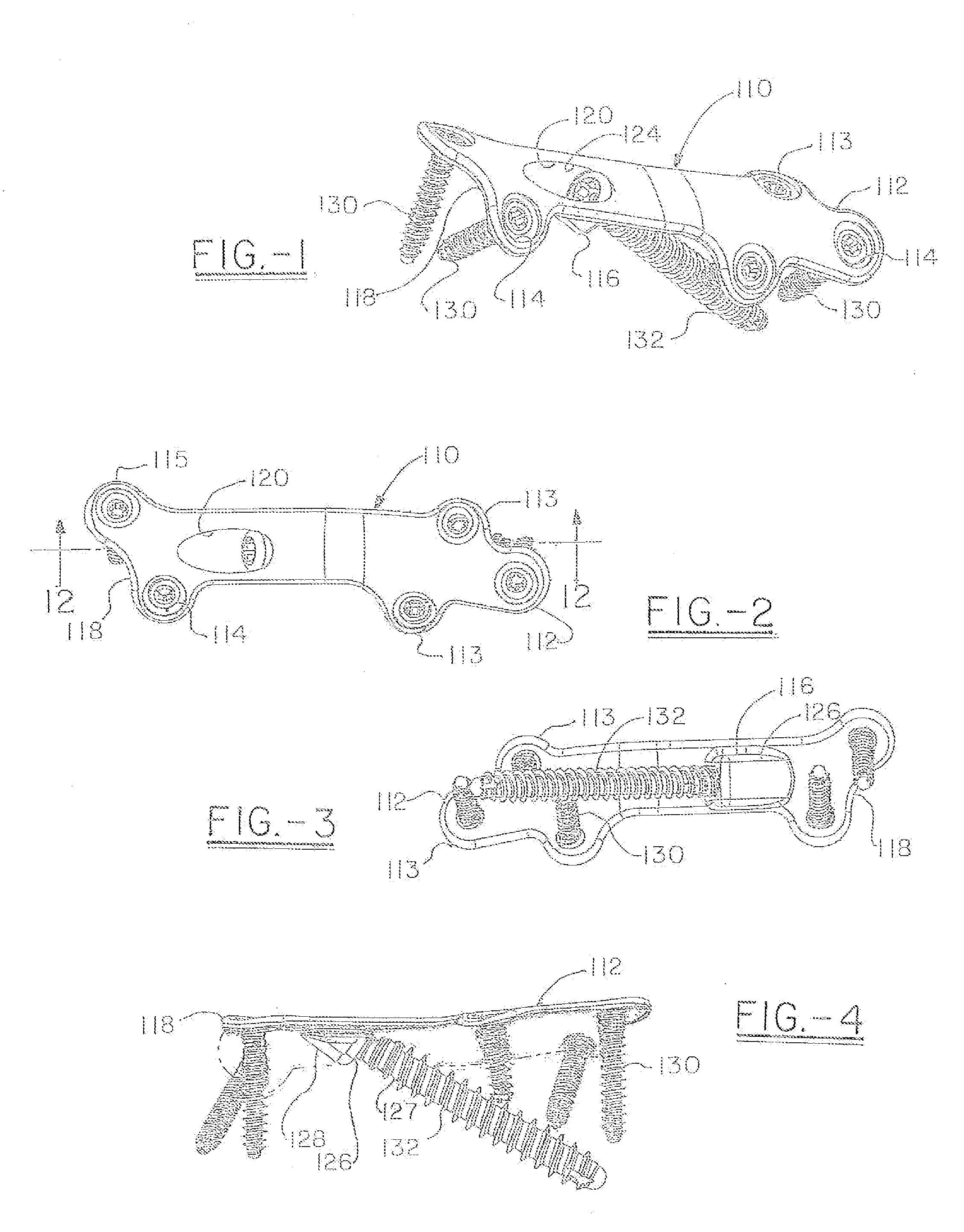

Calcaneus step plate

A calcaneus plate provided with two vertically-spaced plate sections, with corner-located screw holes. An intermediate wall connects the plate sections. An arcuate protrusion extends from the intermediate wall and contains an internal sliding mechanism for a compression screw. The sliding mechanism includes an arc-shaped compression hole with an elongated opening that includes a ridge upon with the compression screw head can slide.

Owner:ARTHREX

Screws for generating and applying compression within a body

A compression screw system, said compression screw system comprising:a compression screw comprising a shaft, a screw thread formed on said shaft at a distal location, and a bone-engaging feature formed on said shaft at a proximal location, wherein at least a portion of said shaft disposed between said screw thread and said bone-engaging feature is capable of being stretched; anda holding element connectable to said compression screw for releasably holding said at least a portion of said shaft in a stretched condition.

Owner:ARTHREX

Bone plate

ActiveUS20150073486A1Reduce fracturesPrevent movementFastenersExternal osteosynthesisFracture reductionIliac screw

Bones fracture in any number of various ways and, in order to properly reduce a fracture, it may be necessary to place compression screws in any number of combinations along a bone plate to bring the various bone fragments together. A bone plate is provided with an optimal number and combination of threaded holes and non-threaded holes. In embodiments, the bone plate comprises one or more “hole pairs” in which a non-threaded hole and a threaded hole are placed adjacent to one another. The use of hole pairs enables a surgeon to place a compression screw and a locking screw in close proximity, facilitating both bone reduction and bone plate stabilization in a proximate location on the bone plate. In embodiments, the bone plate has an optimal thickness that promotes structural integrity while maximizing the number and combination of holes and reducing the profile of seated screws.

Owner:CARDINAL HEALTH 247 INC

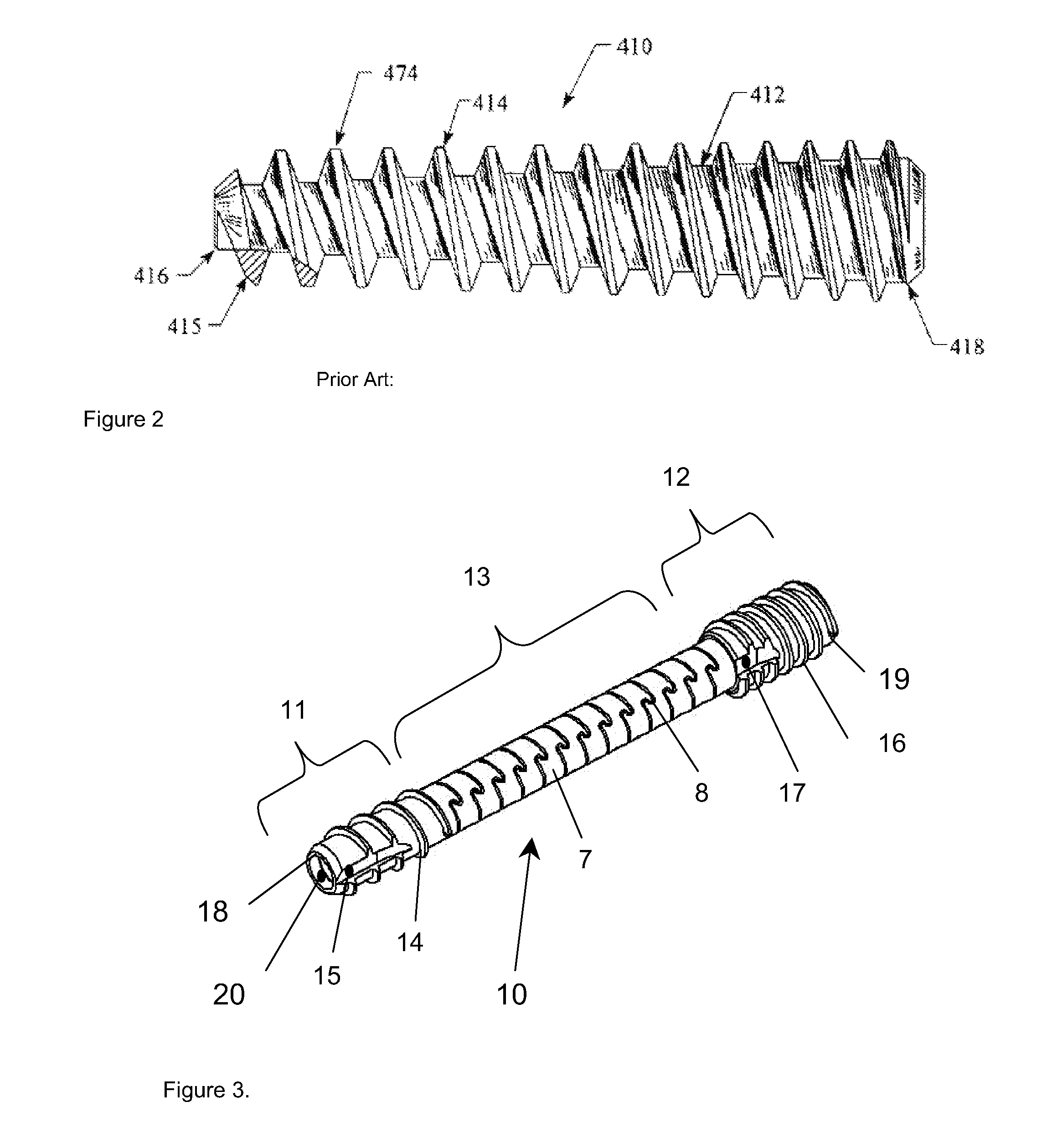

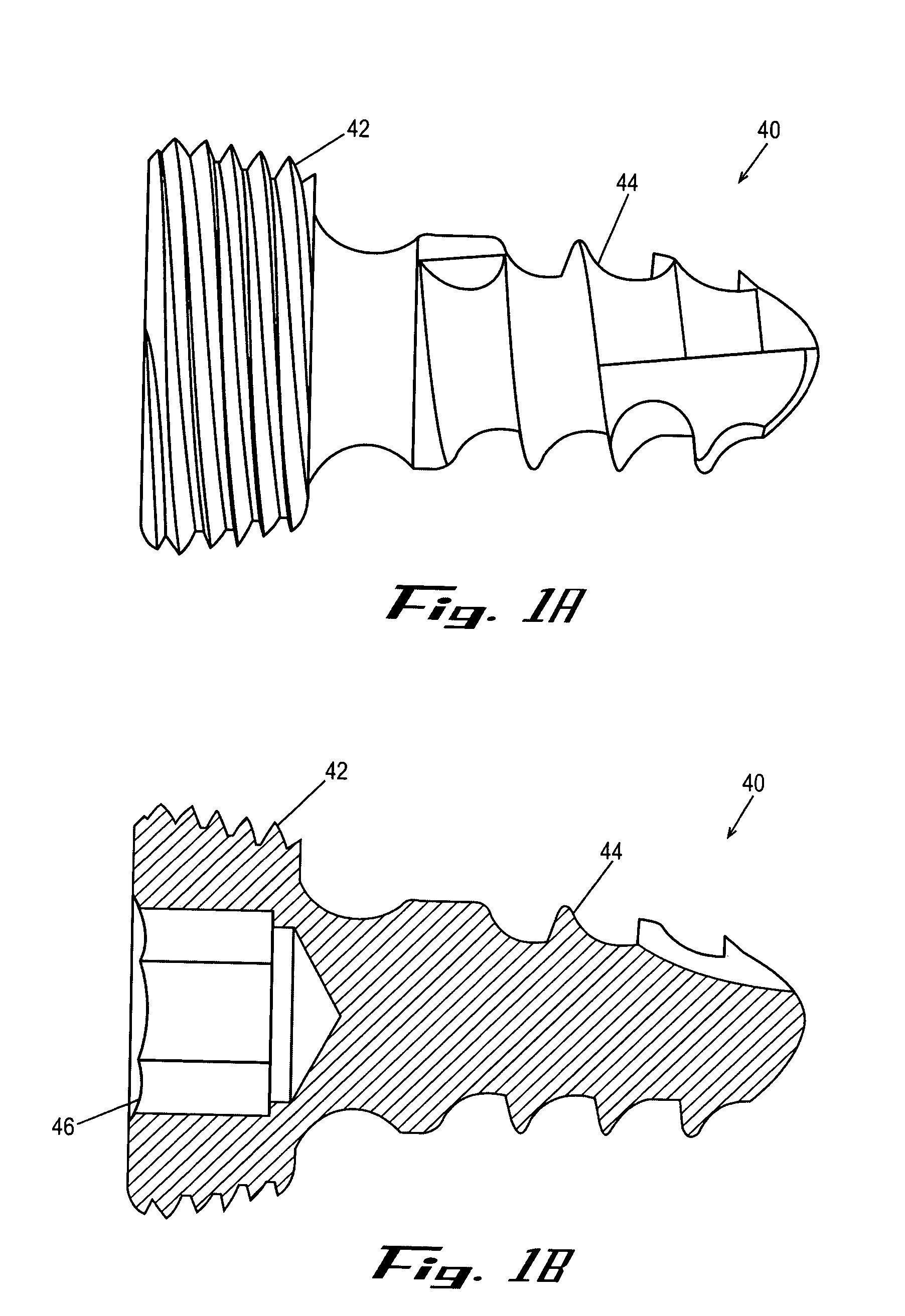

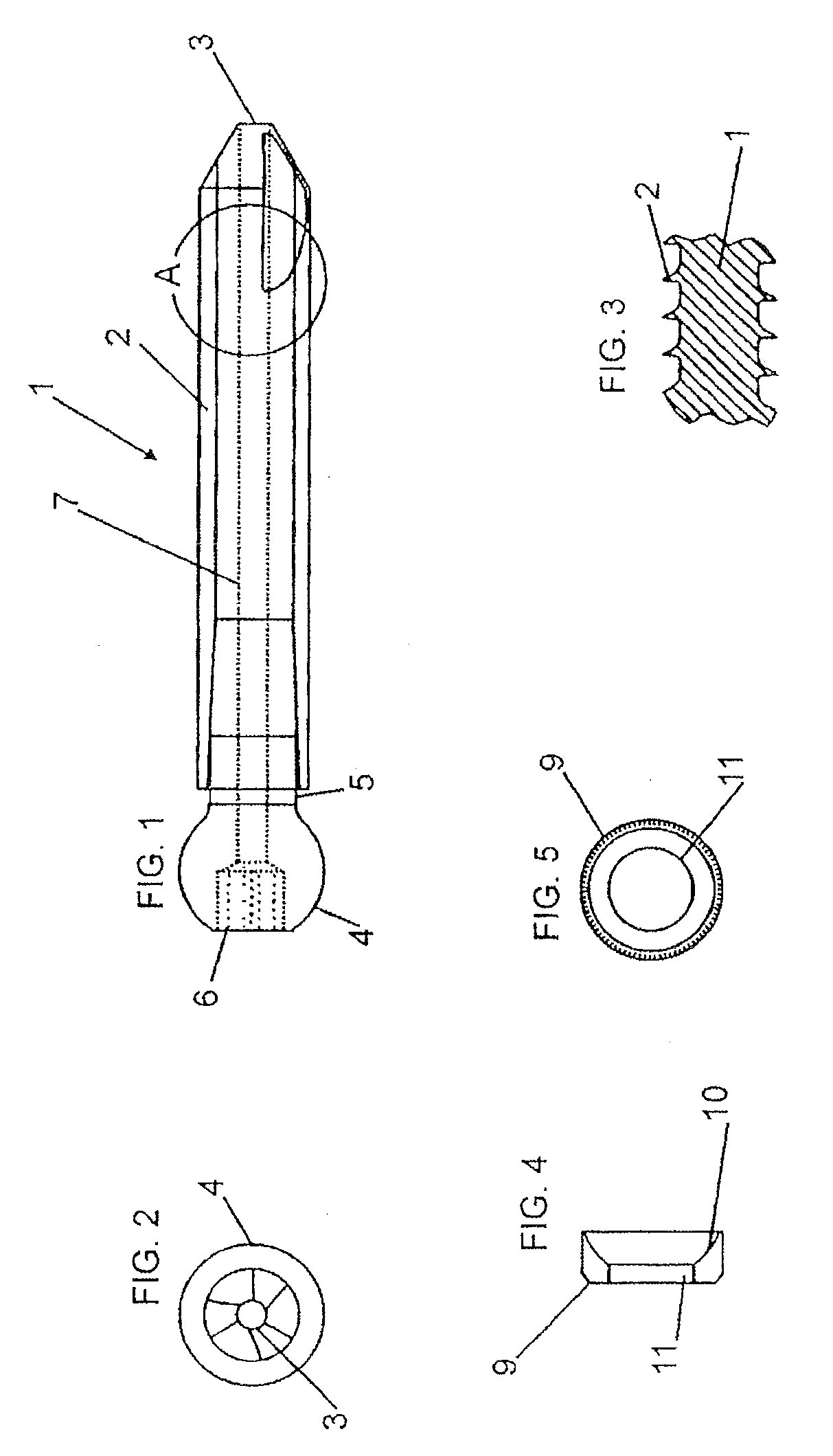

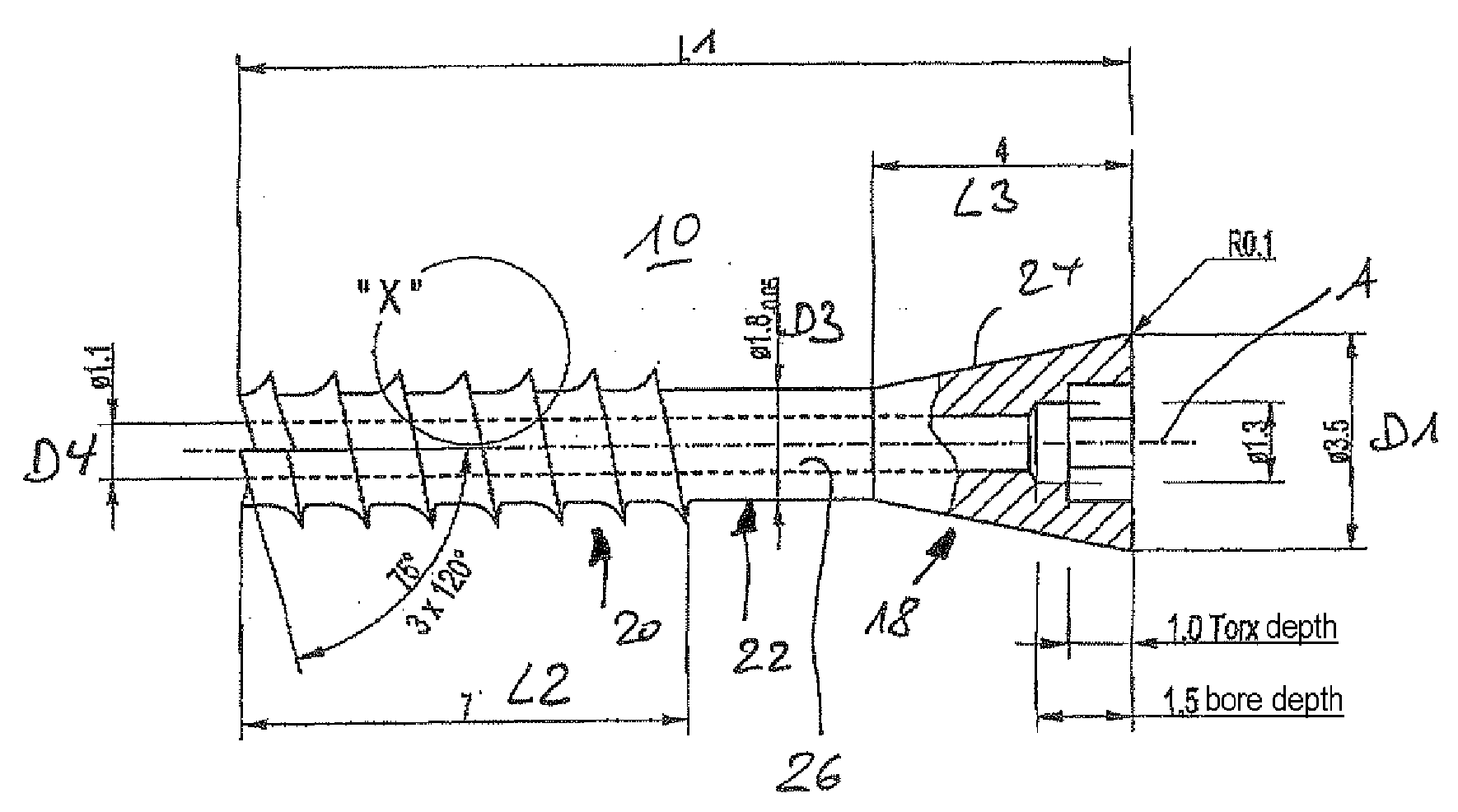

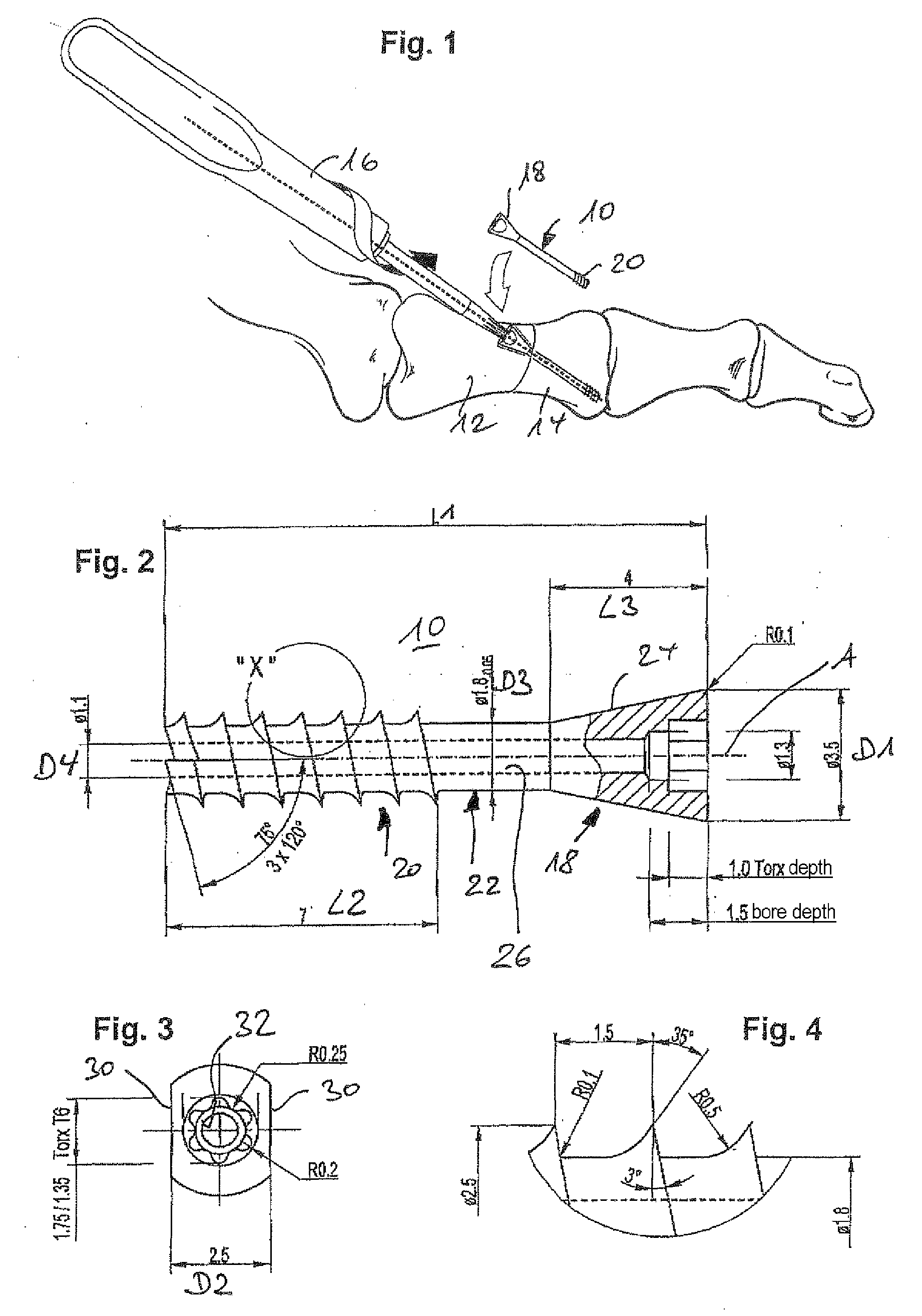

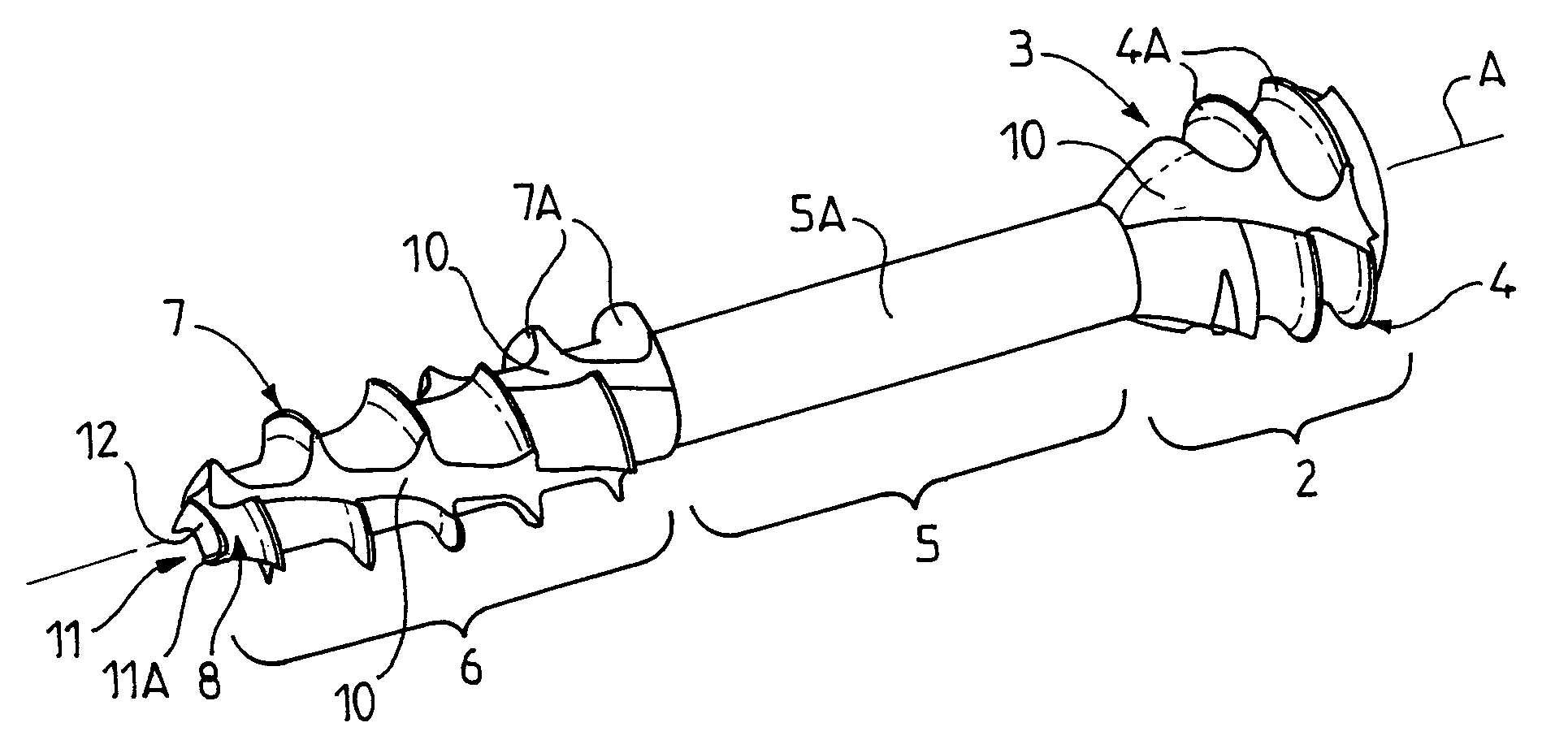

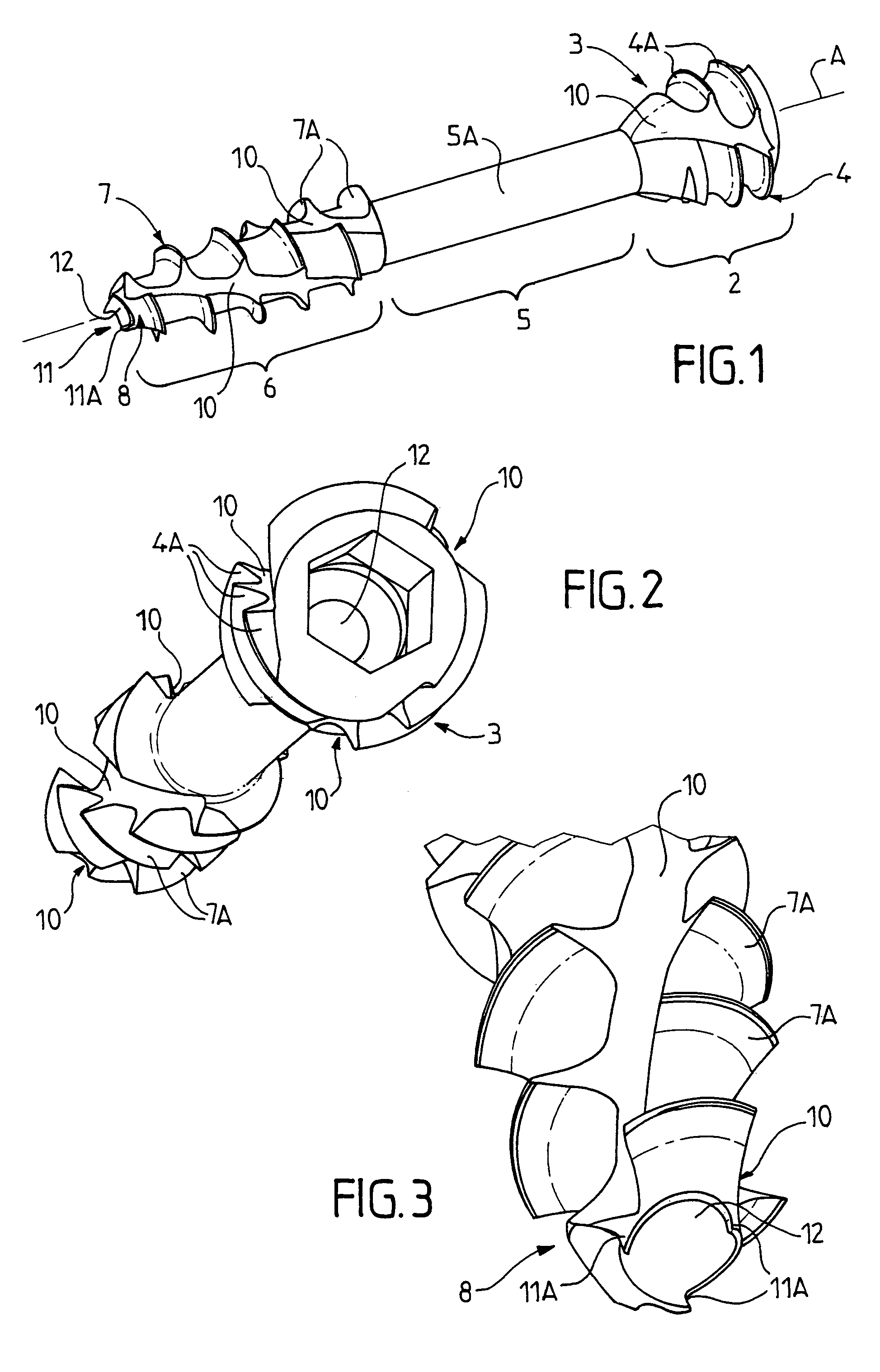

Self-boring and self-tapping screw for osteosynthesis and compression

ActiveUS7708738B2Easy to installGood strength performanceSuture equipmentsLigamentsDistal portionIliac screw

The invention provides an osteosynthesis and compression screw that is self-boring and self-tapping for the purpose of coaptation of small bone fragments. The screw comprises:a proximal portion formed by a screw head provided with an outside thread;an intermediate portion having no thread; anda distal portion provided with an outside thread.Wherein:each of the screw head and the distal portion includes at least one groove, firstly extending over the entire axial length of its thread, and secondly being formed through each thread in such a manner to form tapping means; andthe terminal zone of the distal portion is provided with preparation means for preparing a housing in the bone fragments for receiving the intermediate and distal portions of the screw.

Owner:SMITH & NEPHEW INC

Orthopedic compression plate

An orthopedic plate has a first end including a locking screw hole that receives a locking screw and spaced from that hole is a compression housing that extends from the bone-facing side of the plate and which receives a compression screw that forms an angle of from about 10° to about 70° with a longitudinal axis of the plate. In a further embodiment, the plate also includes a second end with a chamfer for insertion of the plate into bone, and in a still further embodiment, the plate is an MTP plate.

Owner:ORTHOHELIX SURGICAL DESIGNS

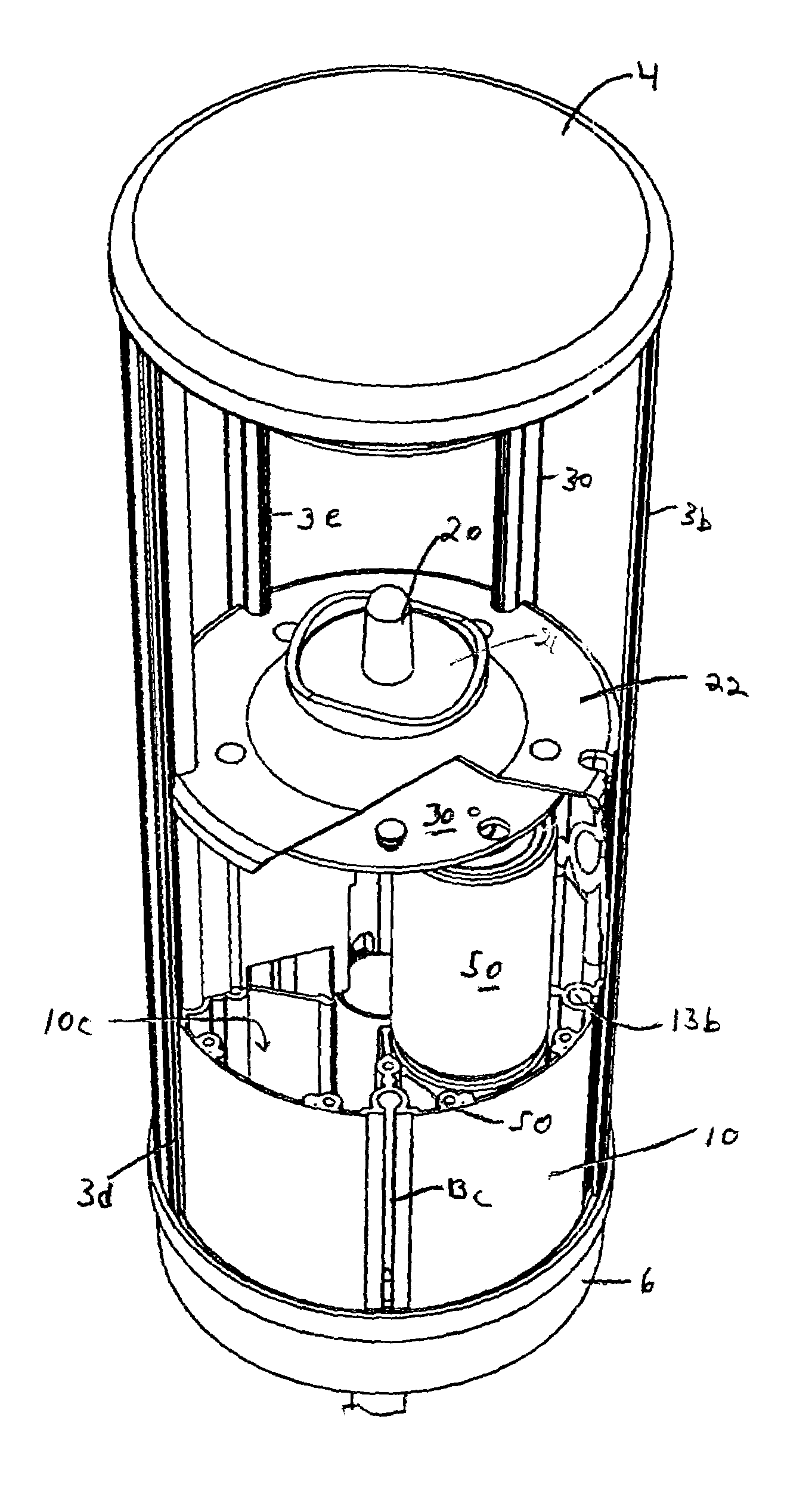

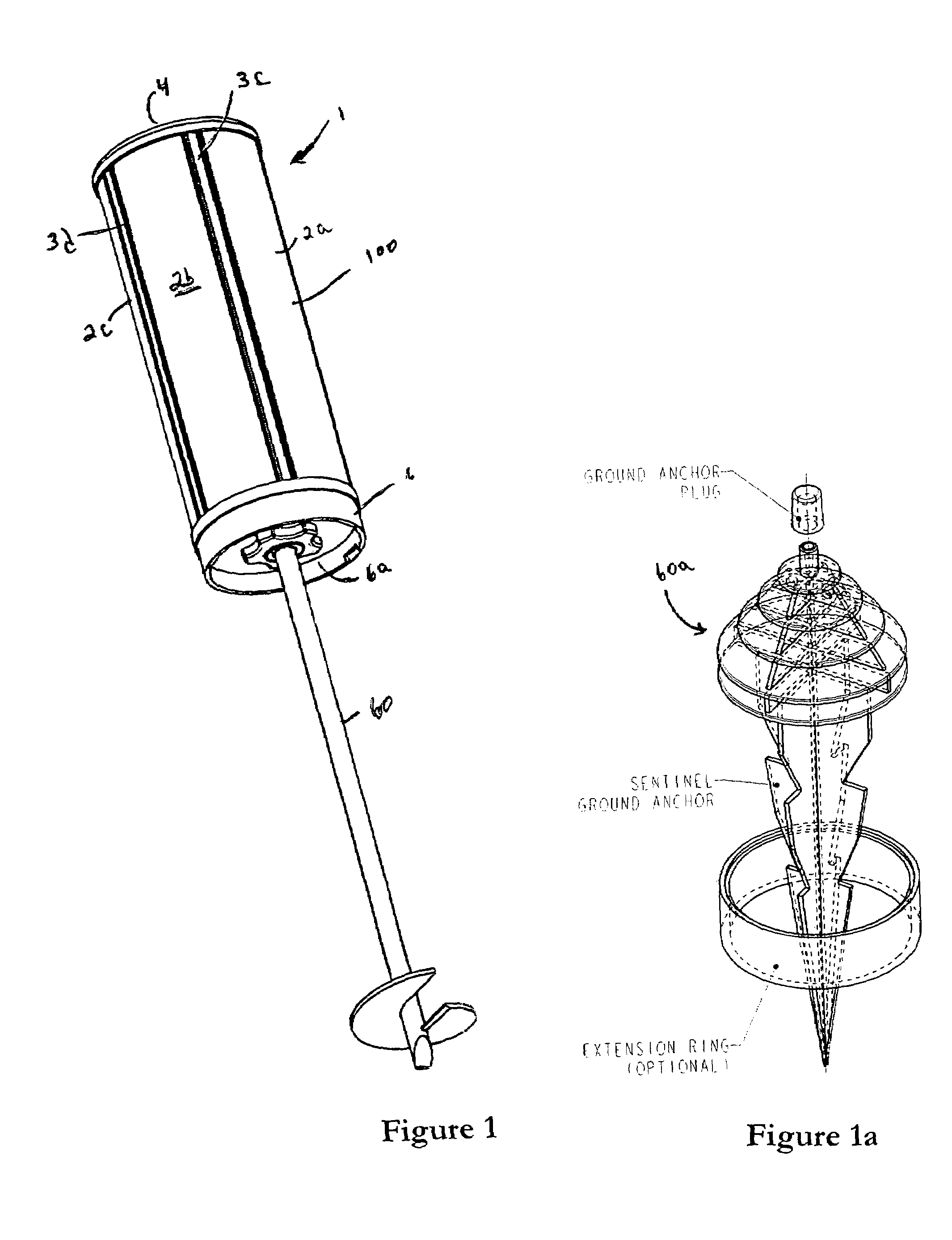

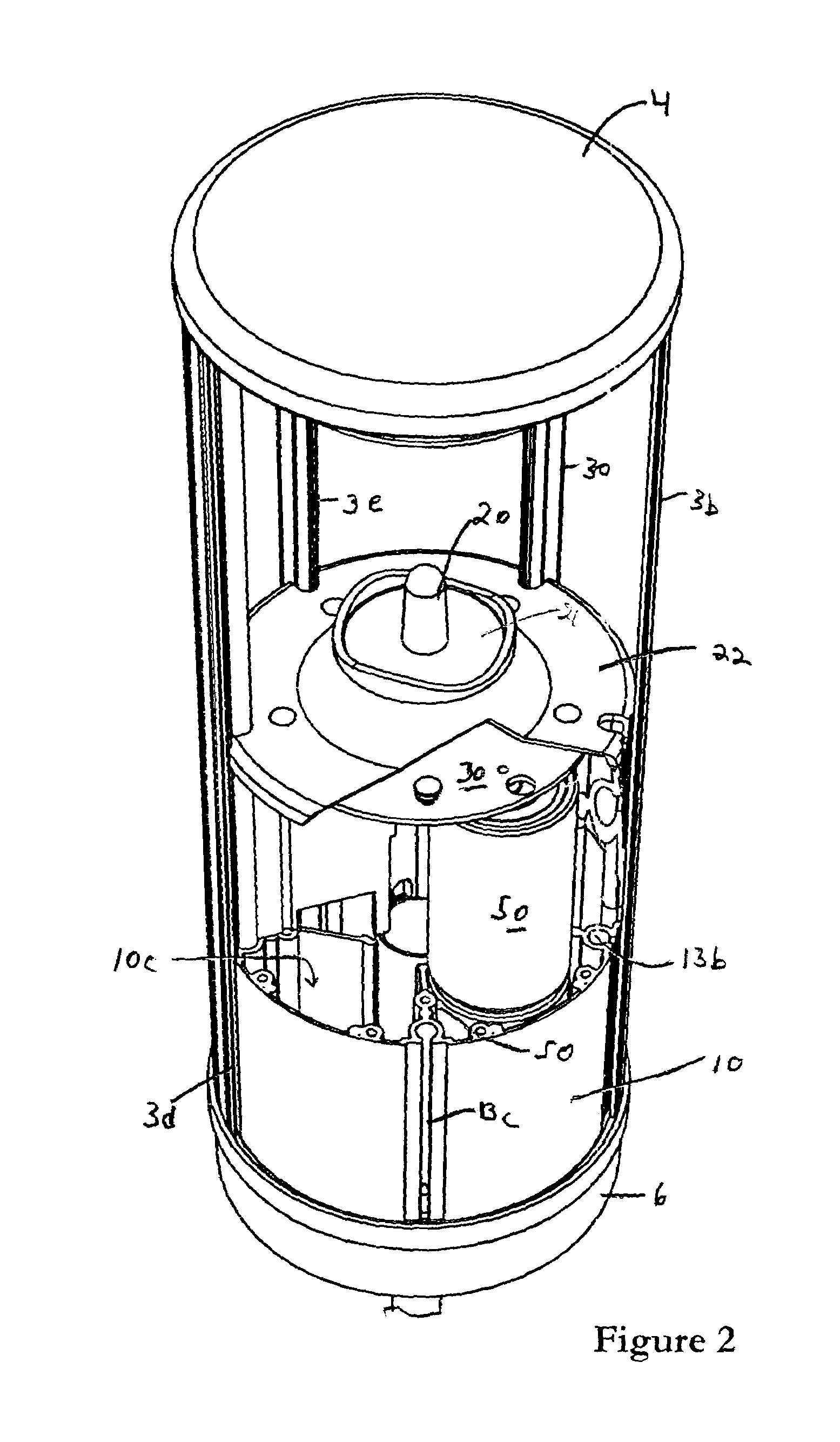

Modular electronic candle

InactiveUS7011426B2Simulate the realEasy to deployCandle holdersPoint-like light sourceElectricityEffect light

A self standing or base supportable modular cylindrical electric candle with multiple battery compartments of parallel pairs and dual end plate terminal contacts, which are compressed with a screwed compression to complete a lighting circuit with a bulb, LED or other lighting source. The plates are adapted to prevent incorrect battery placement. A candle emulating lighting source is contained within a transparent cylinder of the candle with the contact plates electrically connected to terminals of a flicker circuit emulating board. The board is adaptable to LEDs of different colors (e.g., red, green, blue or yellow). One end of the cylinder is closed with a cavity member having peripheral space for placement of visible indicia. A compression screwing handle is provided with a turn locking member to prevent unauthorized battery removal. The base is configured to be engaged by a supporting member or ground anchor.

Owner:GABOR LEDERER

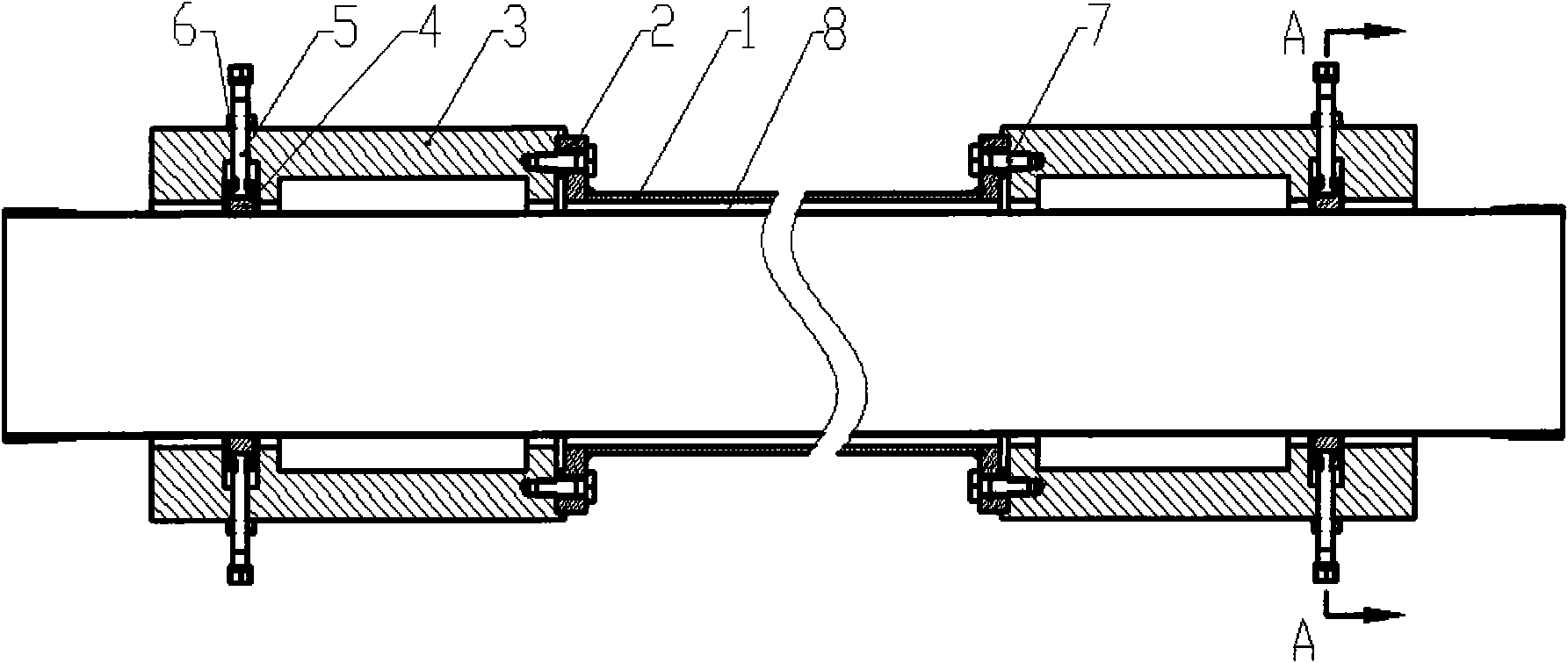

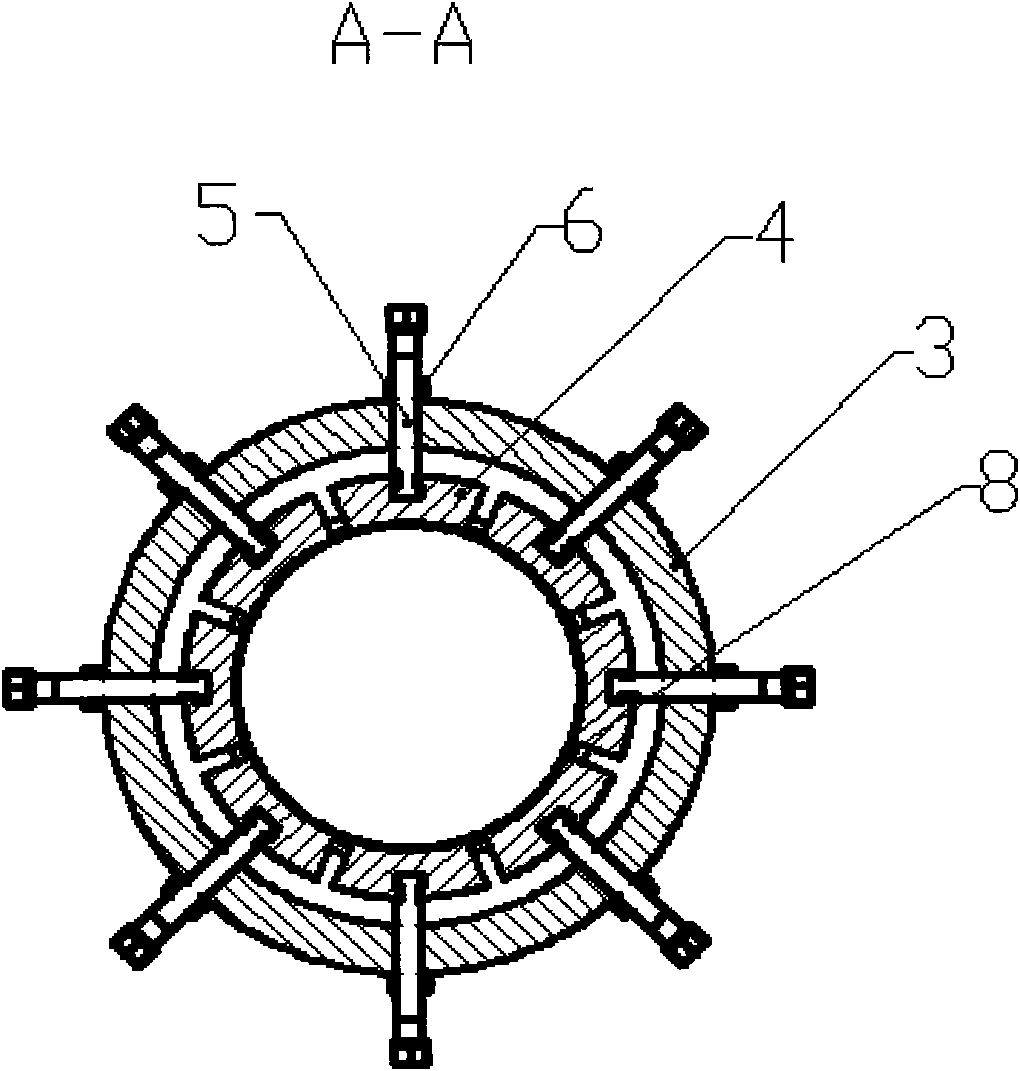

Processing method and technological equipment for cylindrical thin and long thin-walled workpiece

InactiveCN102049695AReduce distortionReduce the impact of machining accuracyAuxillary equipmentPositioning apparatusBall bearingEngineering

The invention relates to a processing method and technological equipment for a cylindrical thin and long thin-walled workpiece, which comprises positioning technological equipment and aligning technological equipment, wherein the positioning technological equipment consists of a connecting cylinder, a connecting flange, a positioning cylinder, a compression block, a compression screw, a stop nut and a connection screw; and the aligning technological equipment consists of an aligning technological equipment bottom plate, a bearing pedestal, a core shaft and a ball bearing. The processing method of the invention comprises a processing method suitable for manual operation of ordinary lathe and a processing method for operation of a hydraulic clamping center rest. The invention has the advantages that the deformation of the cylindrical thin and long thin-walled workpiece brought by clamping can be effectively reduced, the influence of workpiece clamping force on the workpiece processing precision is reduced, the processing quality is improved, the processing procedure is simplified, the processing time is shortened, the processing efficiency is improved, the high-quality product rate reaches 100%, the cost is saved at the same time, and the effect in batch production is more obvious.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com