Processing method and technological equipment for cylindrical thin and long thin-walled workpiece

A technology of process equipment and processing methods, applied in the direction of metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of deformation of slender and thin-walled workpieces, helplessness of processing problems, increase of manufacturing costs, etc., to improve processing quality, The effect of shortening processing time and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

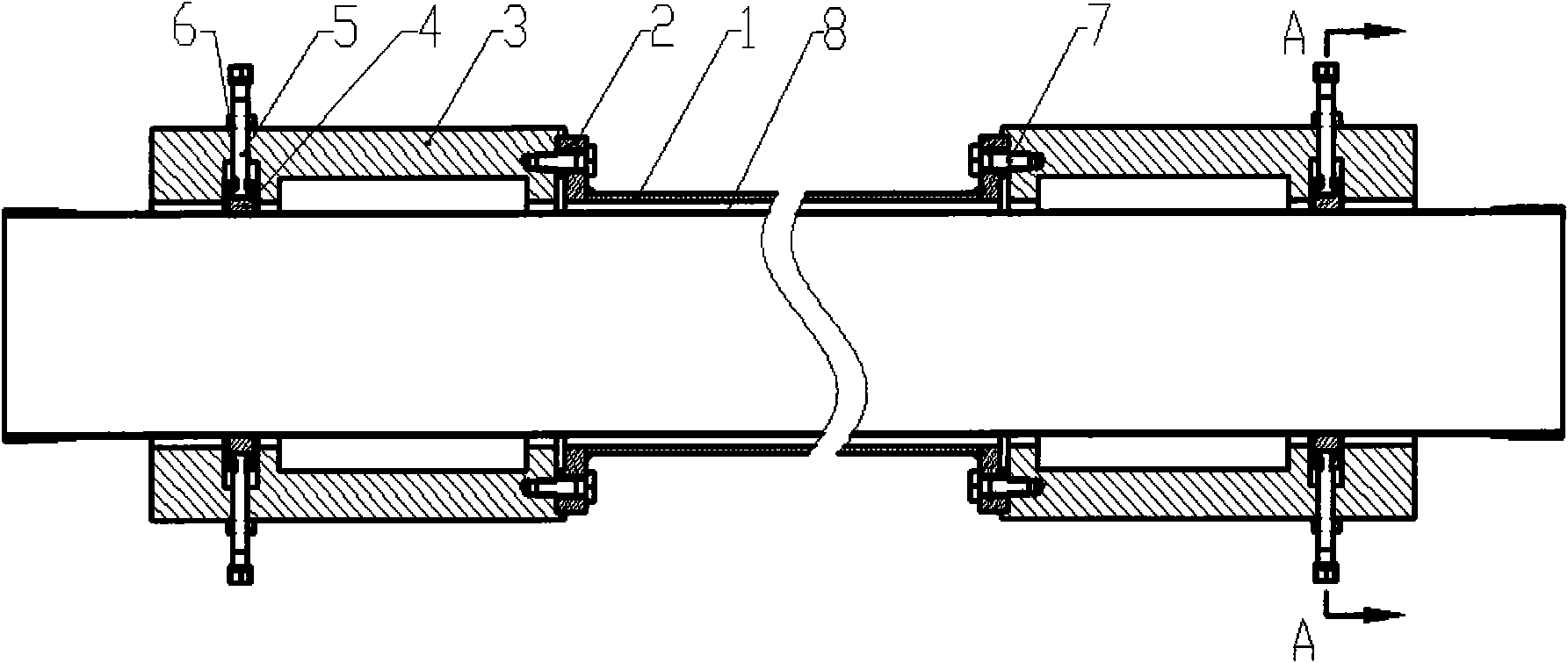

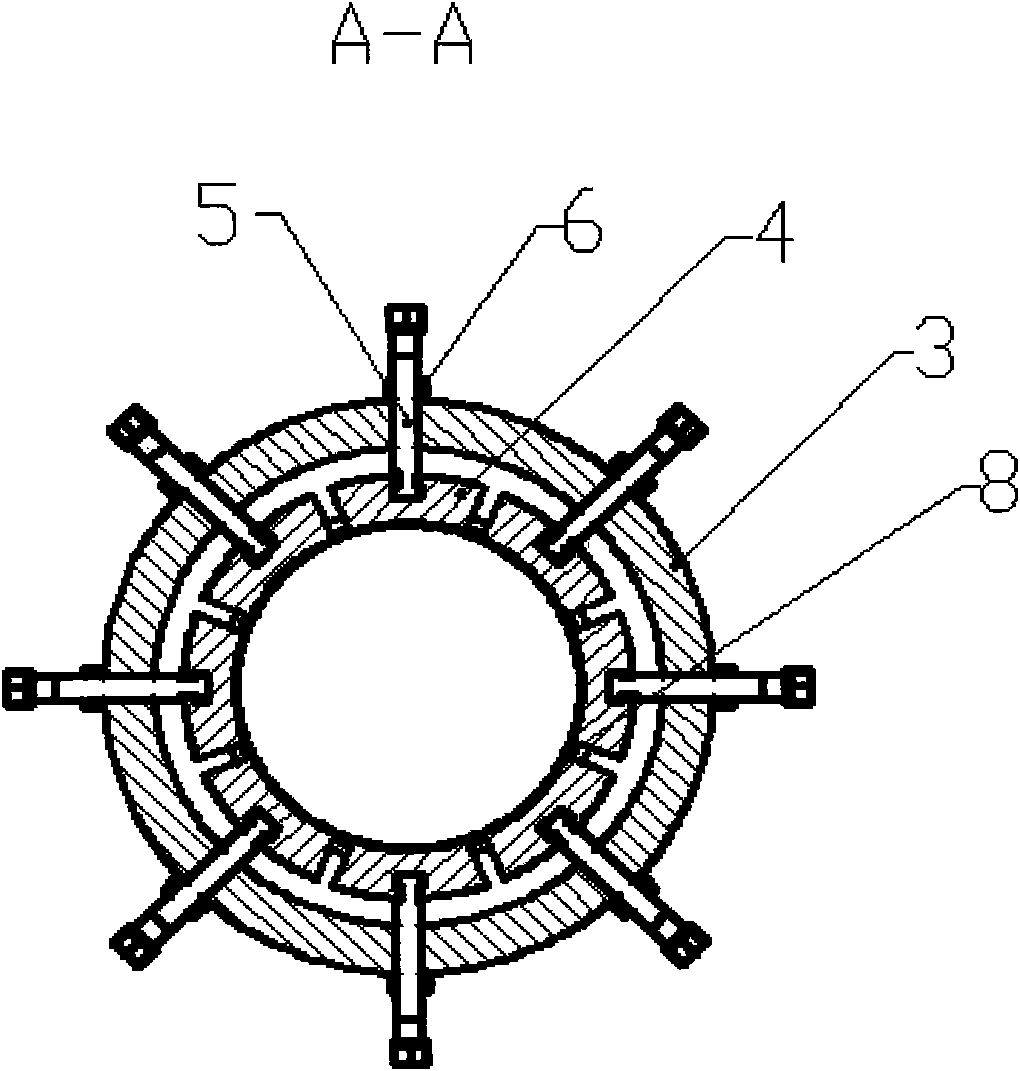

[0051] see figure 1 , 9 10: The present invention includes positioning tooling and alignment tooling; the positioning tooling is composed of a connecting cylinder 1, a connecting flange 2, a positioning cylinder 3, a compression block 4, a compression screw 5, a stop nut 6, a connection Composed of screws 7; the connecting cylinder 1 is fixedly connected with the positioning cylinder 3 through the connecting flange 2 and the connecting screw 7; the through holes are equidistantly distributed on the circumference of the connecting cylinder 1, and the compression screws 5 are respectively screwed into the stop nuts 6, The installation hole of the compression screw 6 on the positioning cylinder 3 and the compression block 4; the described aligning tool is made of the aligning tool base plate 9, bearing seat 10, mandrel 11, and ball bearing 12; the ball bearing 12 is covered in On the mandrel 11, the mandrel 11 is installed in the bearing hole of the bearing housing 10, and the f...

Embodiment 2

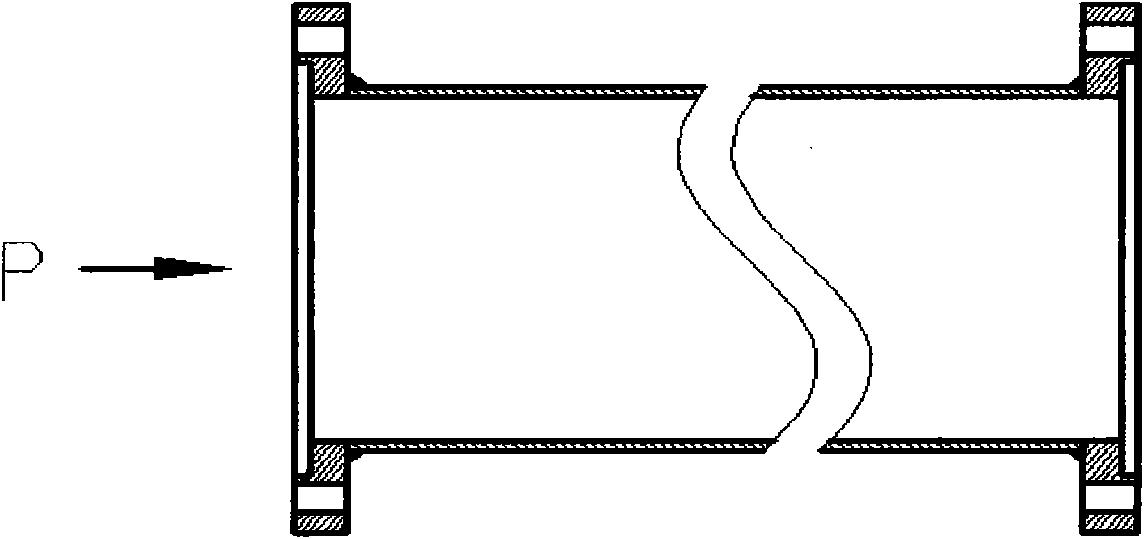

[0054] To process material 30Si2MnCrMoVE, outer diameter the inside diameter of (+0.05 / 0), the total length of the workpiece is 1700, the ratio of length to diameter is 1700 / 137=12.4, the ratio of outer diameter to wall thickness is 137 / 1.0=137, the length of the two ports is about 80, and the inner holes of the machined parts at both ends are connected Taking a cylindrical elongated thin-walled part with a coaxiality of 0.1 as the axis as an example, how to process and use the special processing device for processing cylindrical elongated thin-walled parts according to the present invention is described.

[0055] It is suitable for manual operation of ordinary lathes, and is characterized in that: the deformation problem in the process of processing cylindrical slender thin-walled parts is solved by the following method steps:

[0056] Step 1: The cylindrical slender and thin-walled part passes through the inner hole of the tooling, leaving a processing position at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com