Patents

Literature

207 results about "Fracture line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

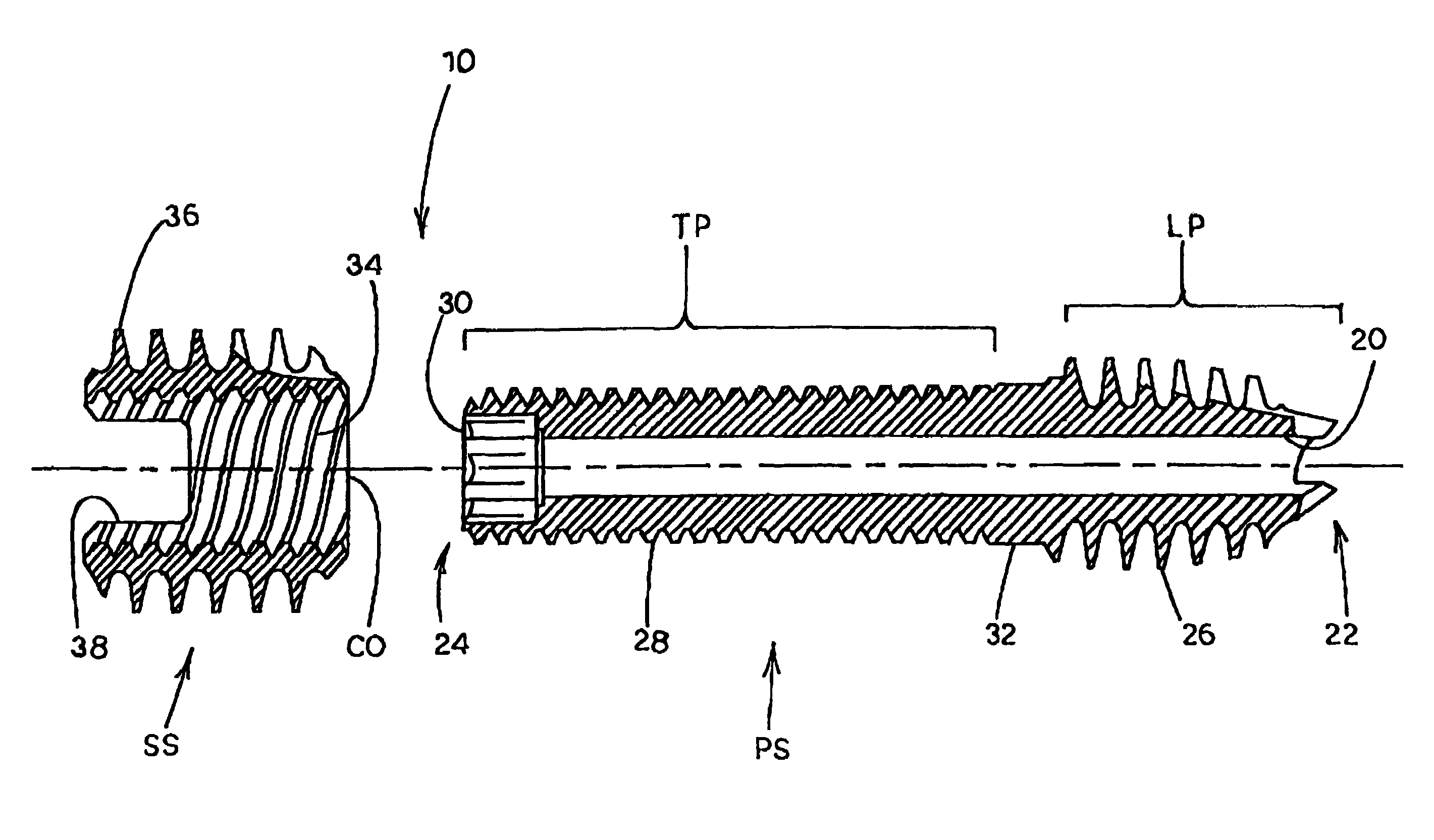

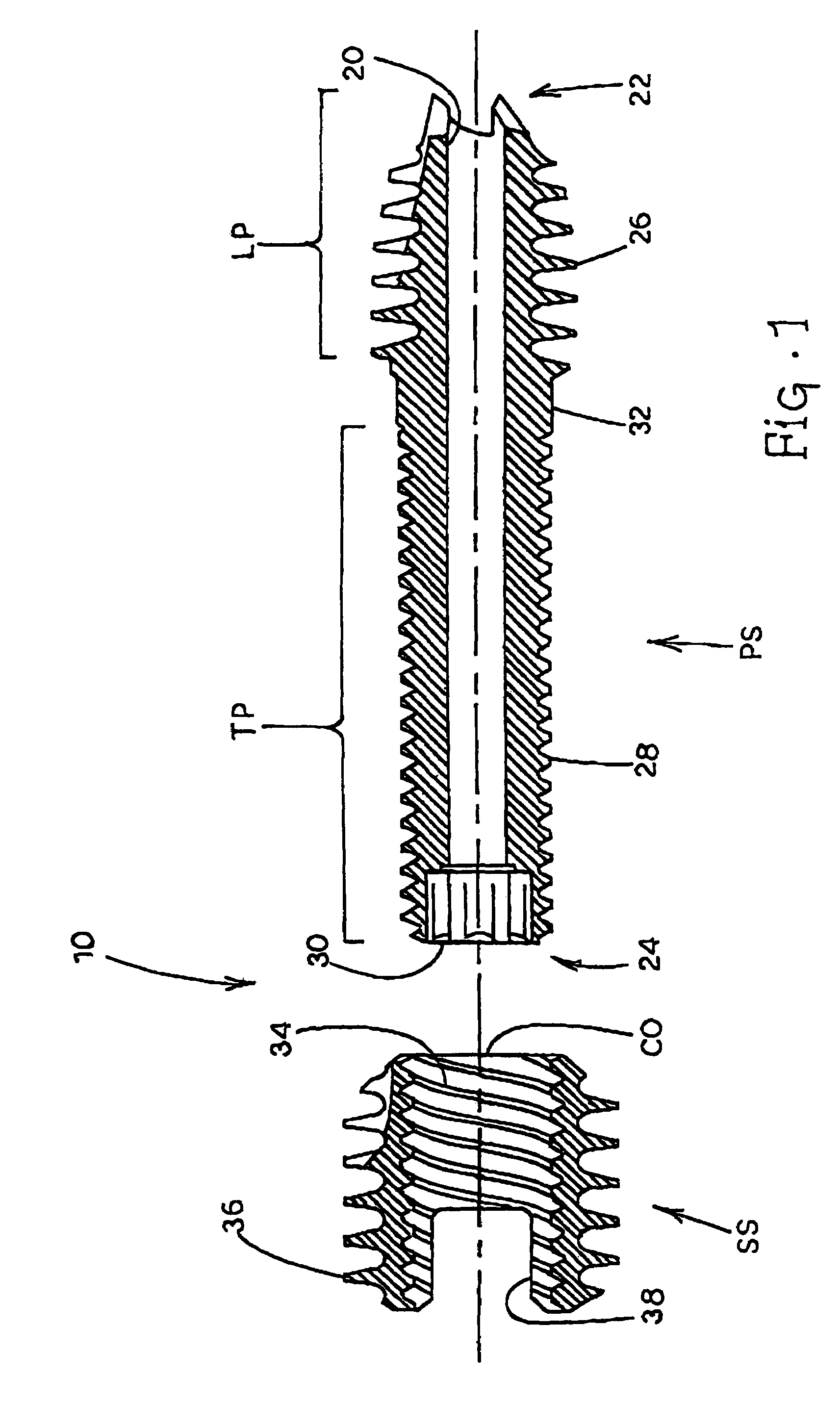

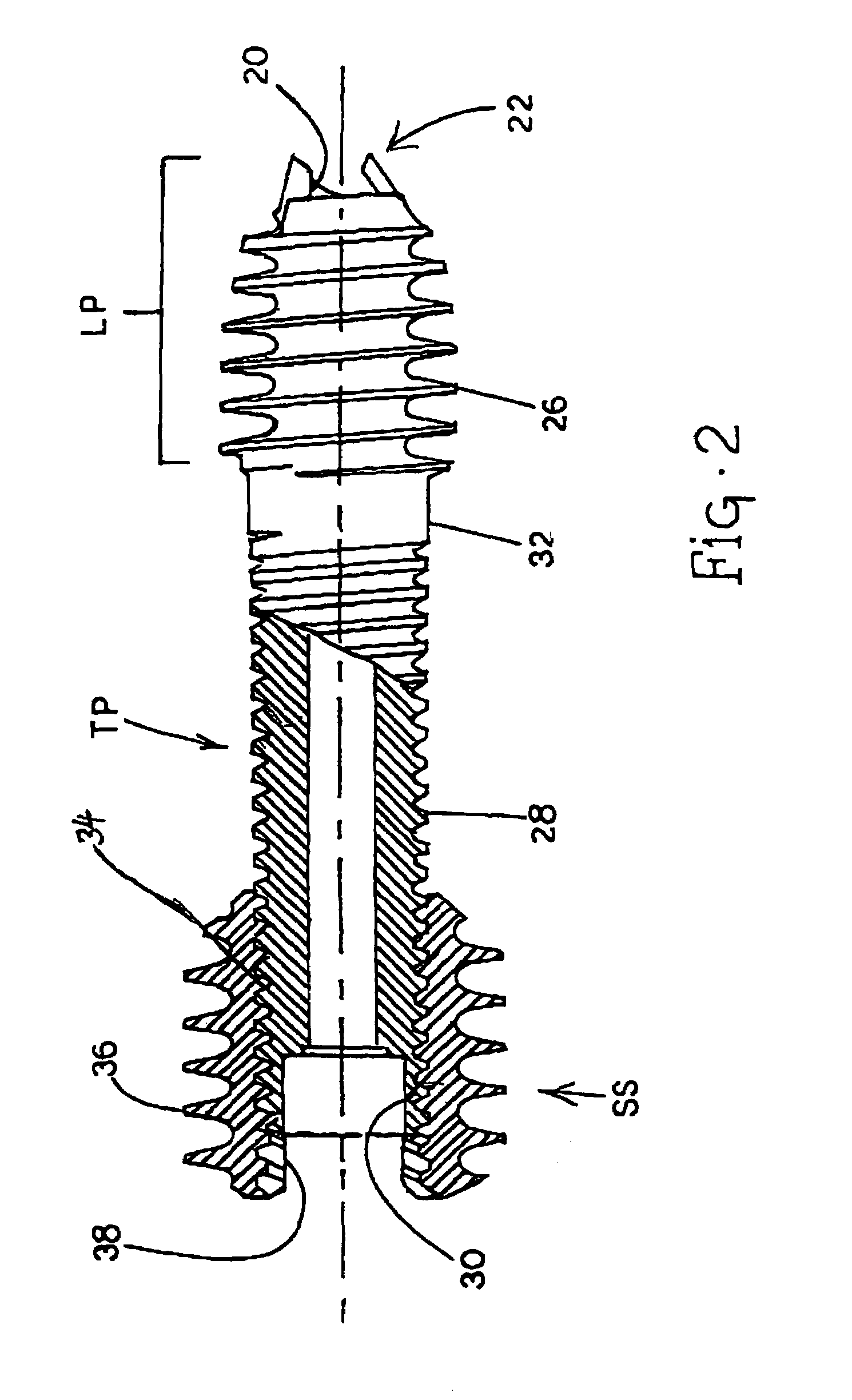

Compression screw apparatuses, systems and methods

InactiveUS7582107B2Easily and effectively be used to compress suitable materialsSuture equipmentsLigamentsEngineeringFracture line

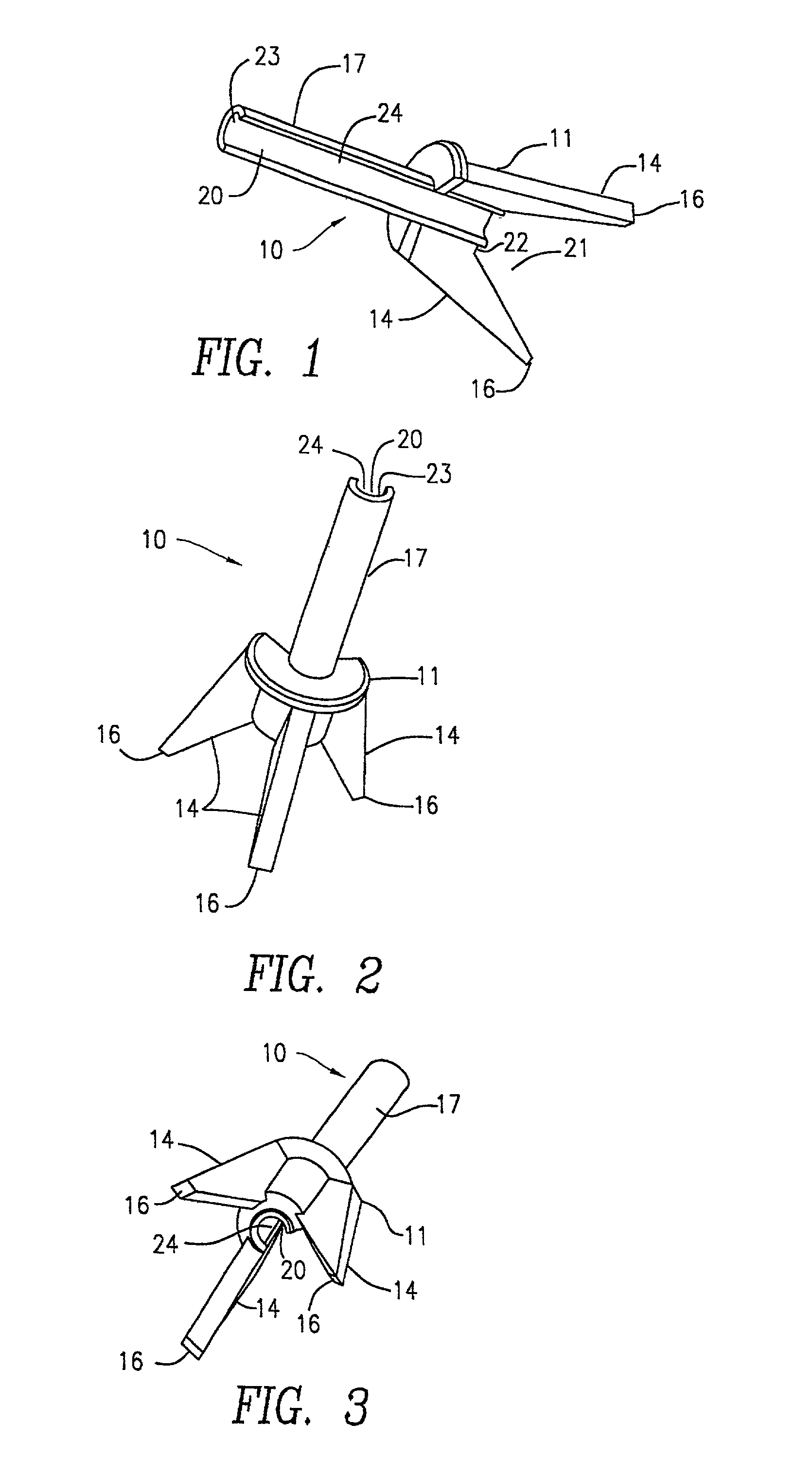

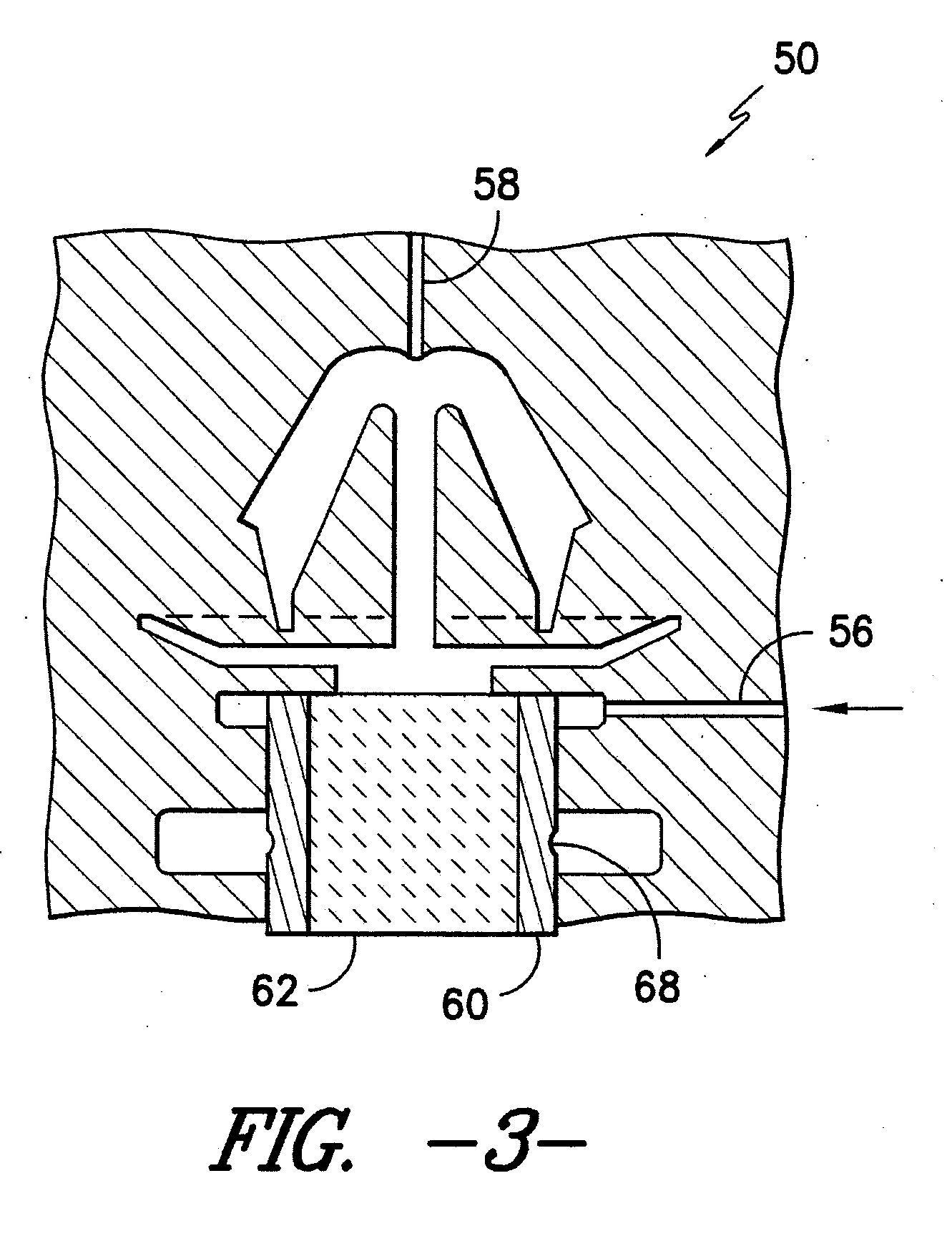

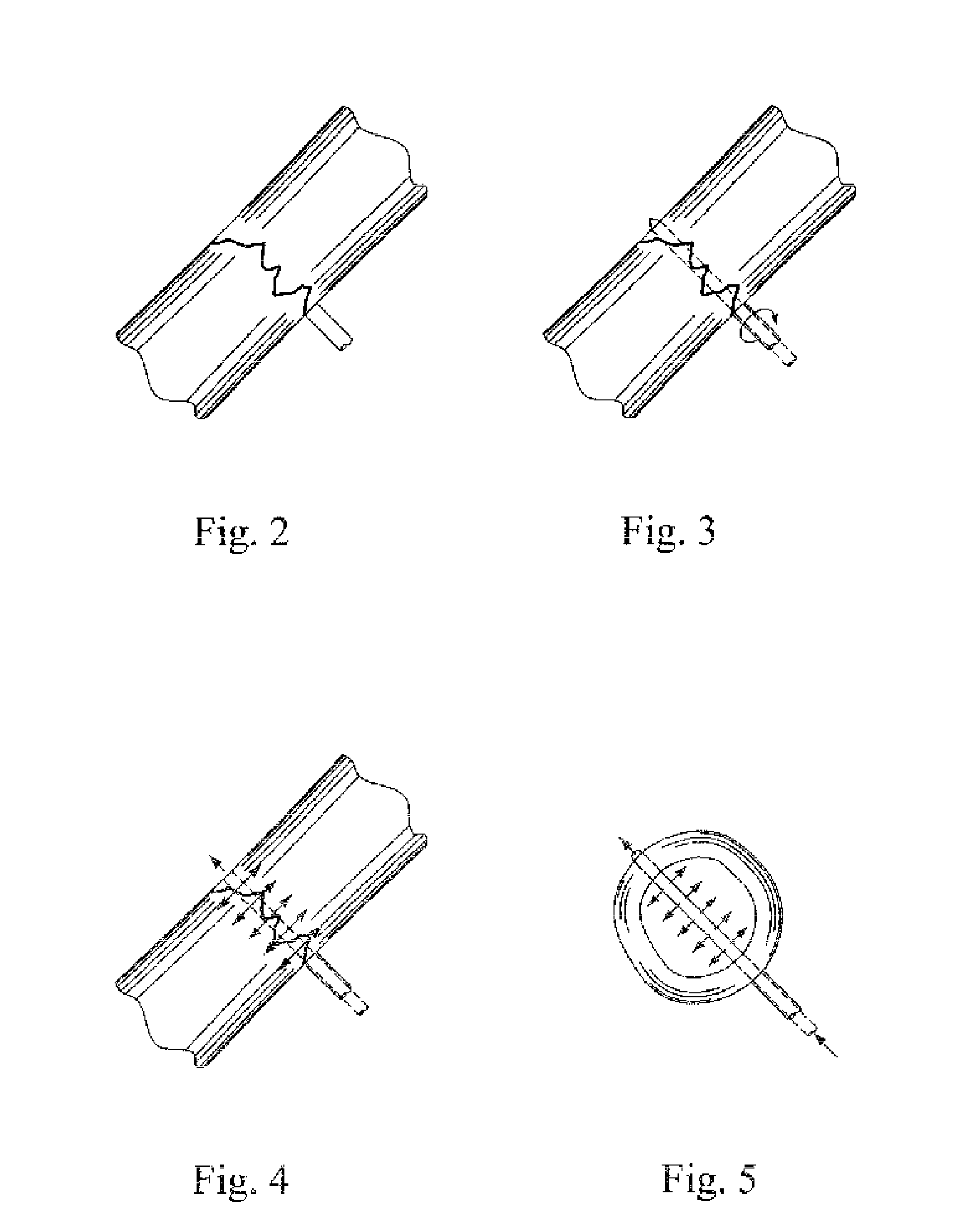

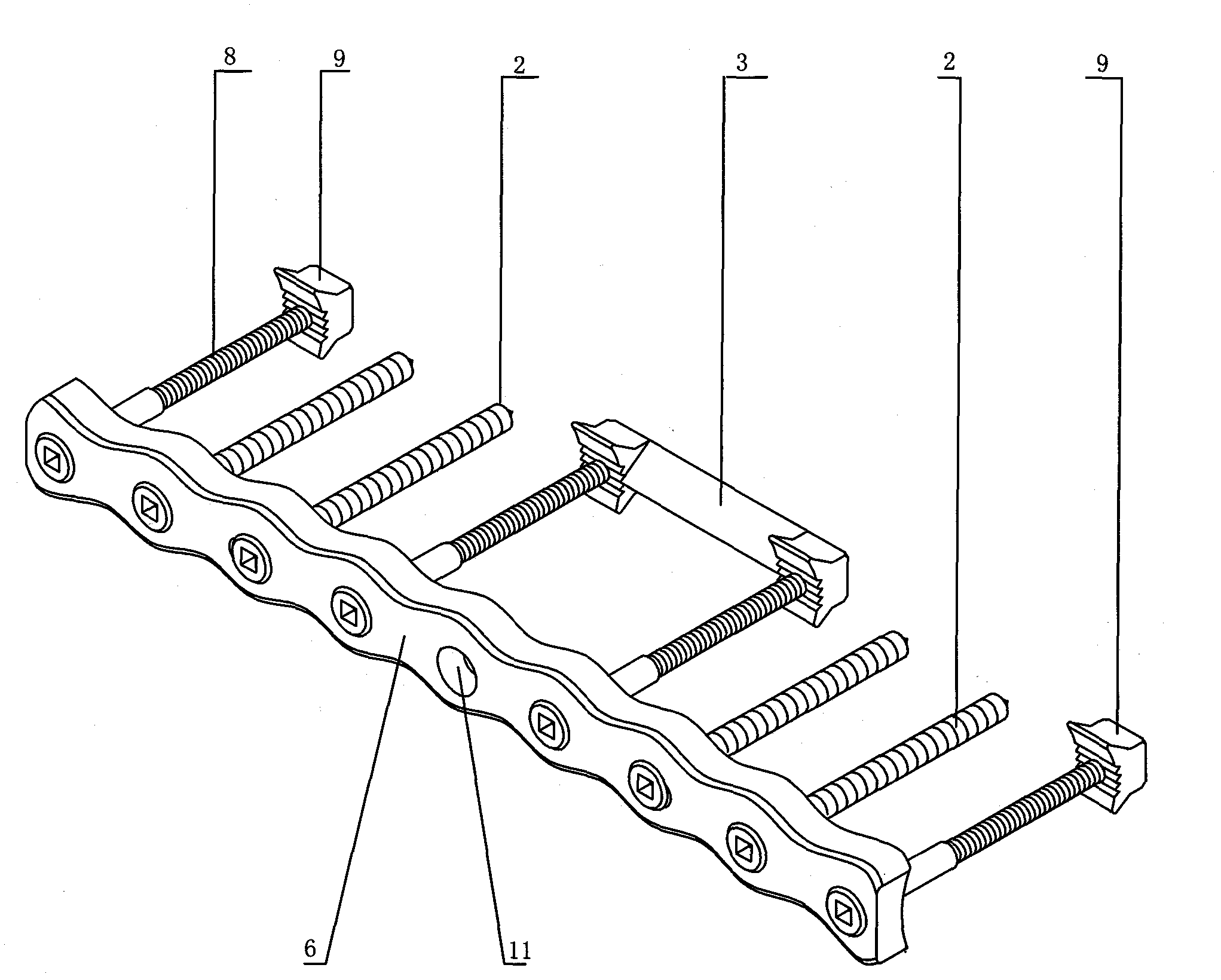

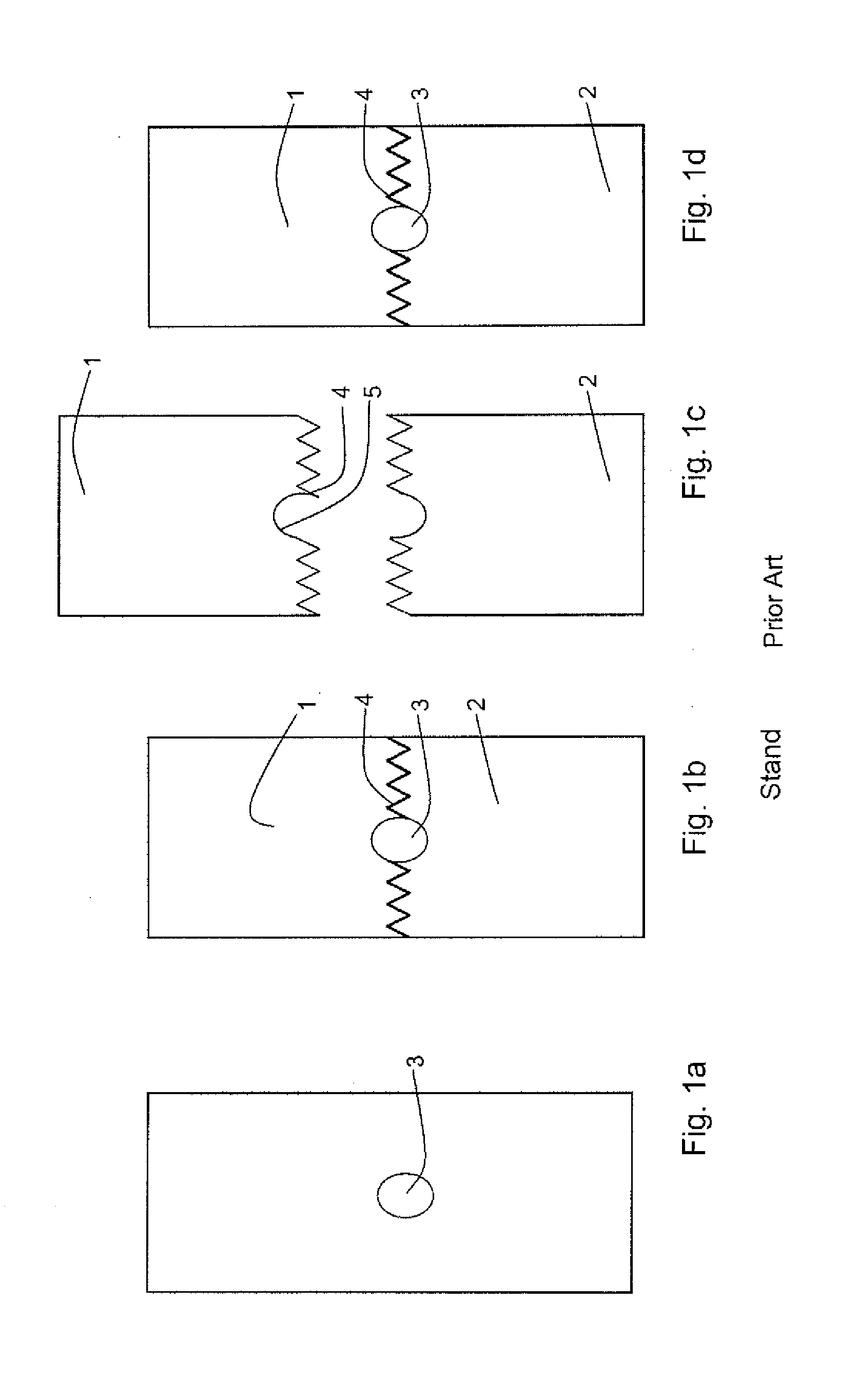

Compression screw apparatuses, systems and methods are disclosed. In one embodiment, the compression screw includes a primary screw and a secondary screw. The primary screw includes an at least partially threaded leading portion and an at least partially threaded trailing portion. The secondary screw includes outer threads and has a central opening which is also threaded and adapted for being screwed onto and matingly engaging the trailing portion of the primary screw. Drivers can be used to rotatably control the primary screw and the secondary screw to cause compression of spaced-apart material, particularly for compression of bone fragments across a fracture line.

Owner:INTEGRA LIFESCI

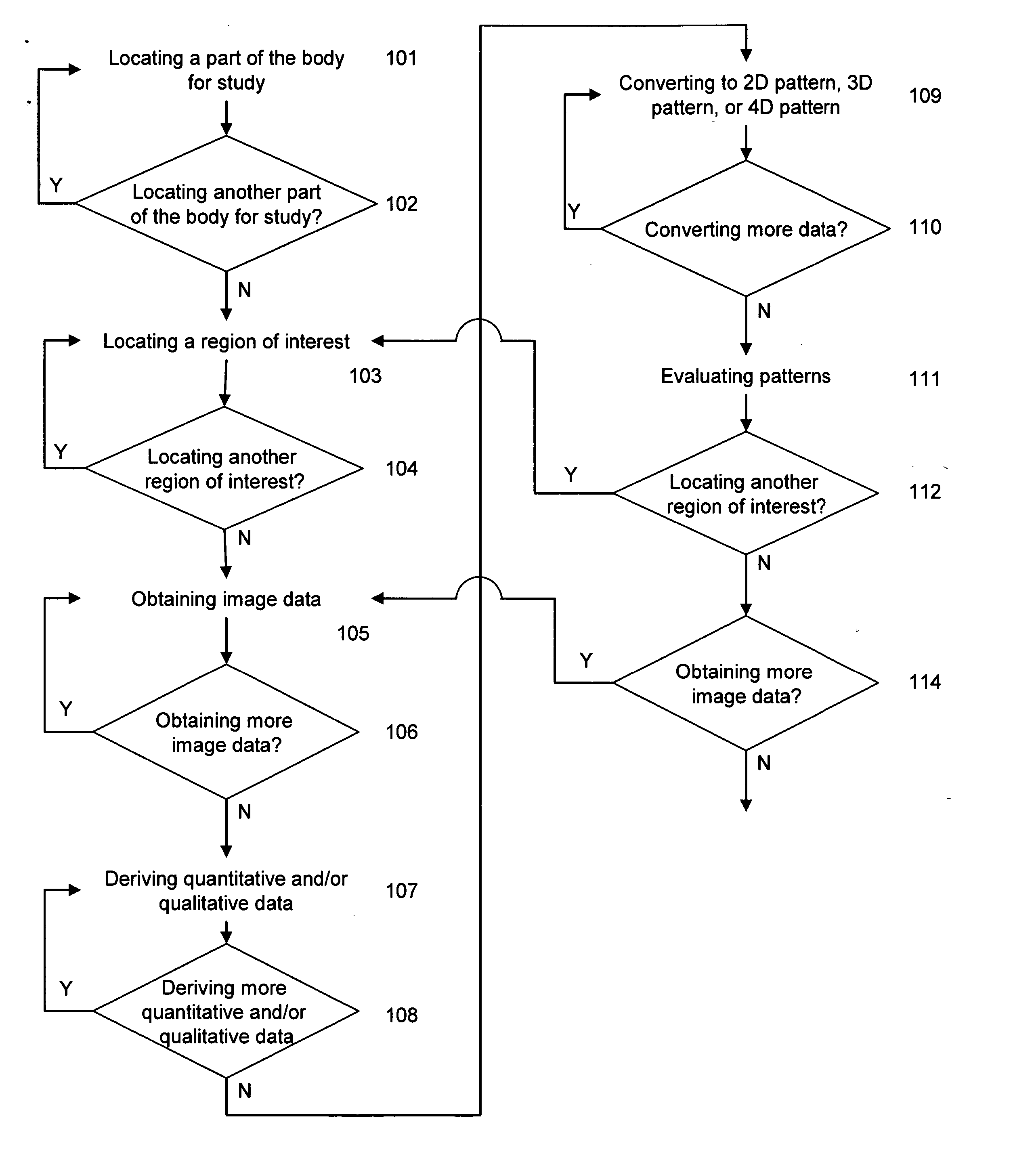

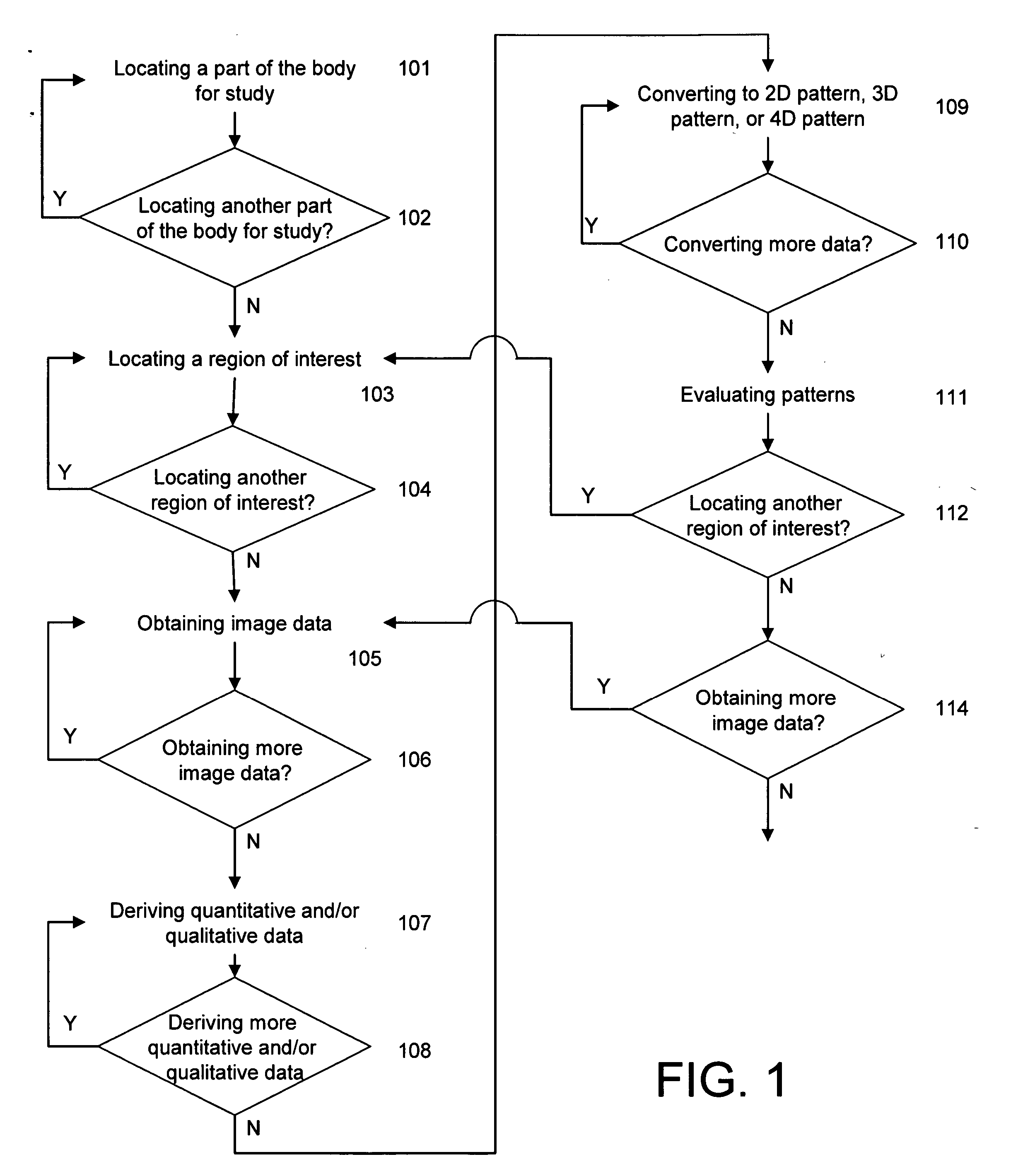

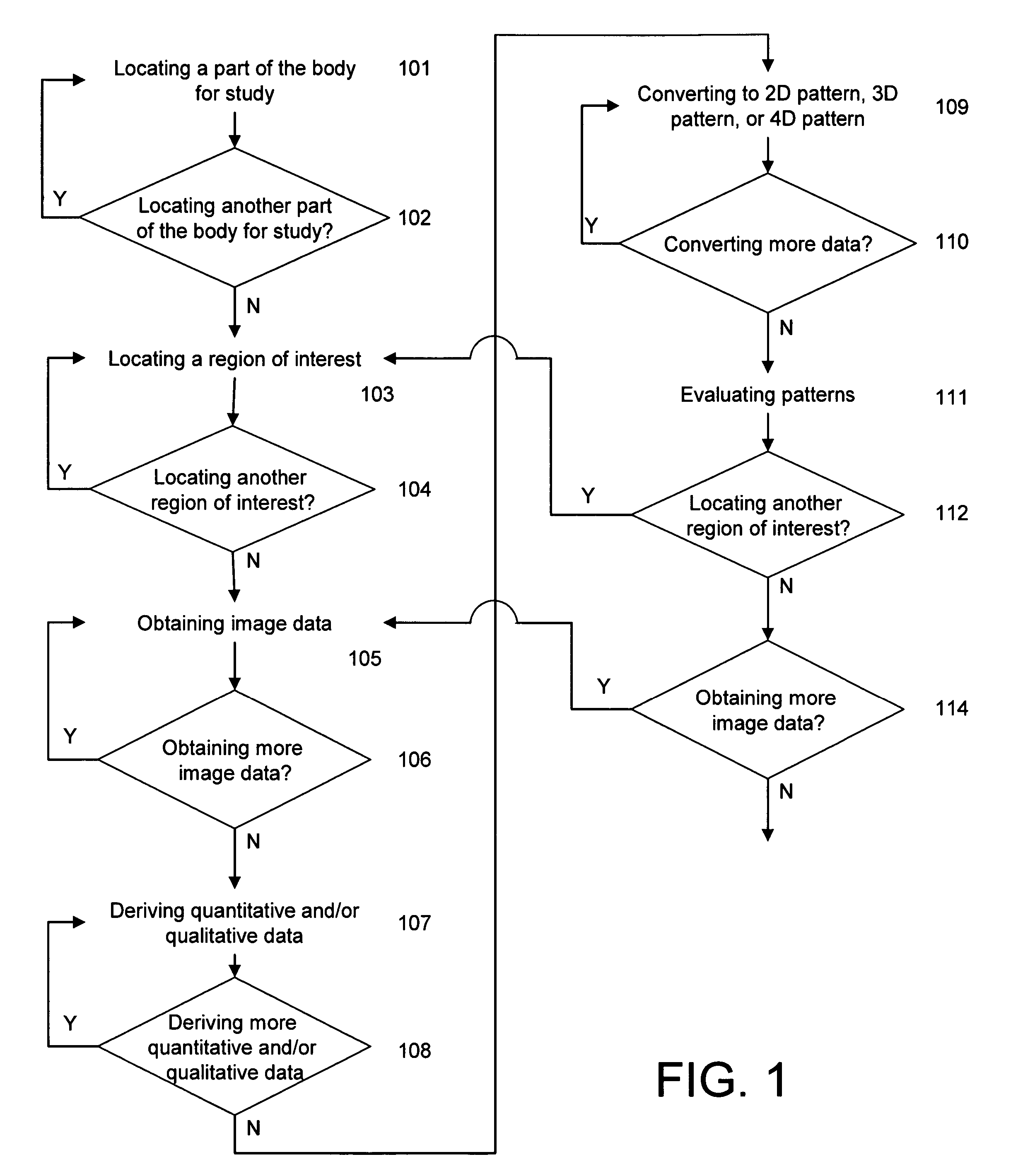

System and method of predicting future fractures

Methods of predicting fracture risk of a patient include: obtaining an image of a bone of the patient; determining one or more bone structure parameters; predicting a fracture line with the bone structure parameter; predicting a fracture load at which a fracture will happen; estimating body habitus of the patient; calculating a peak impact force on the bone when the patient falls; and predicting a fracture risk by calculating the ratio between the peak impact force and the fracture load. Inventive methods also includes determining the effect of a candidate agent on any subject's risk of fracture.

Owner:IMATX

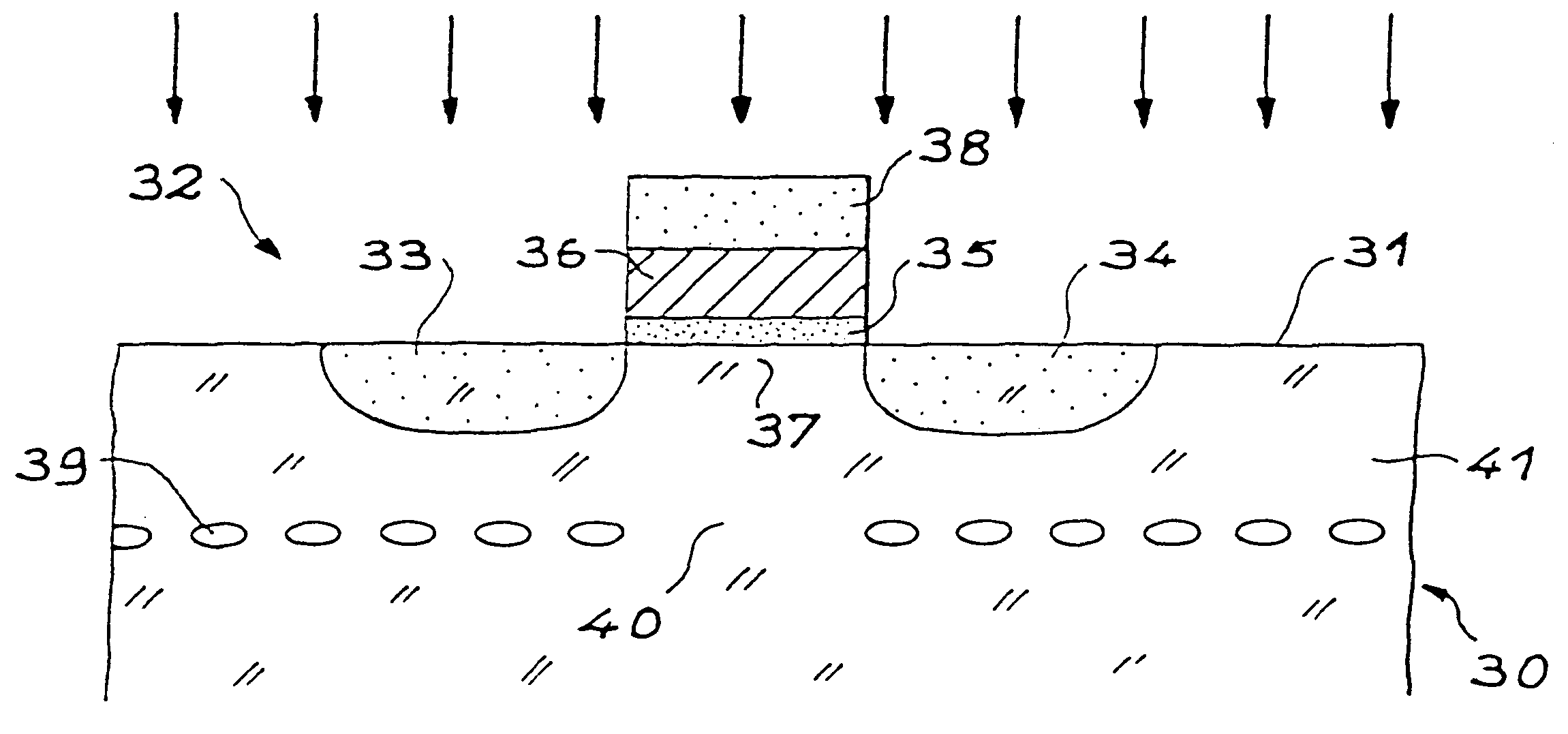

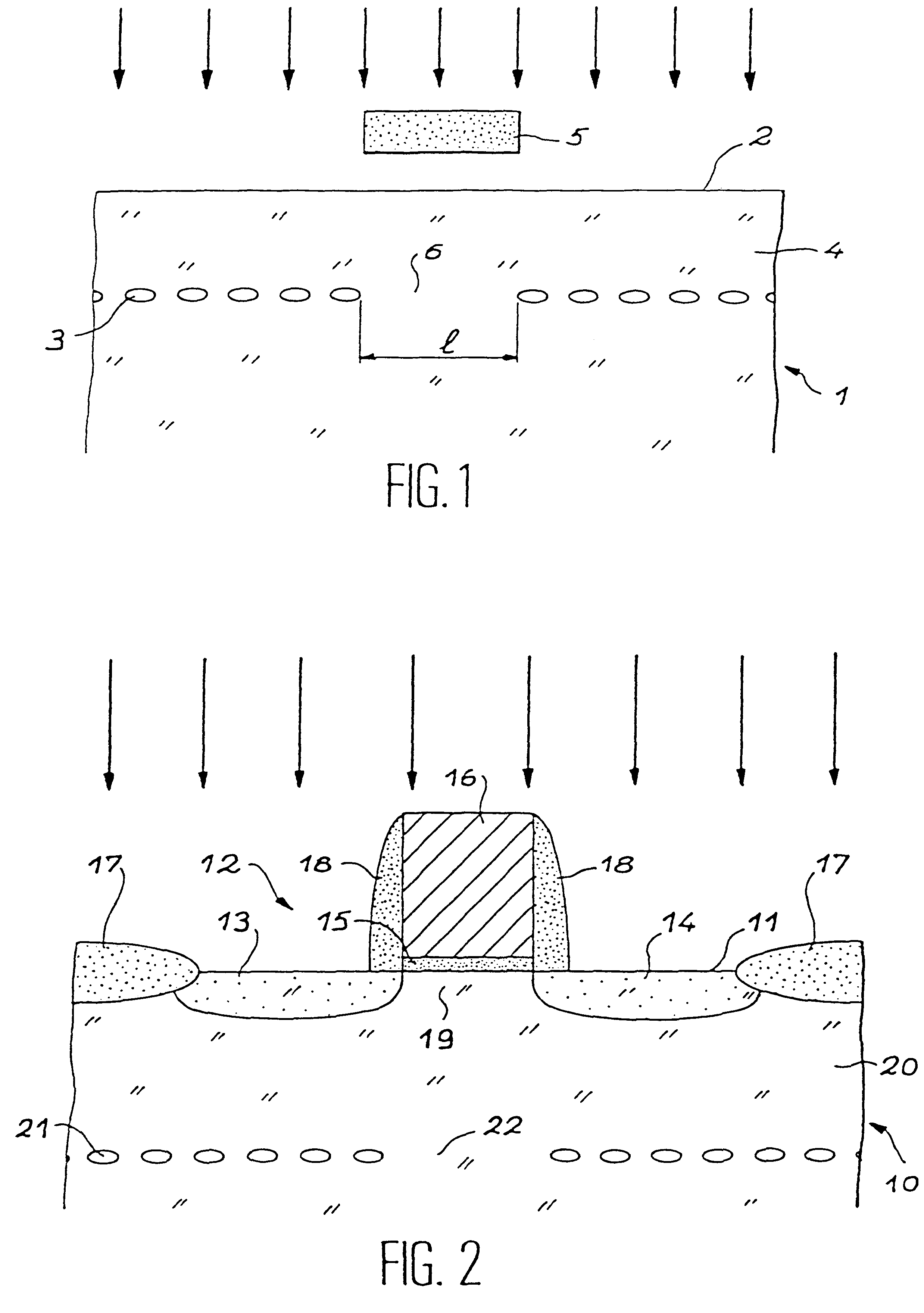

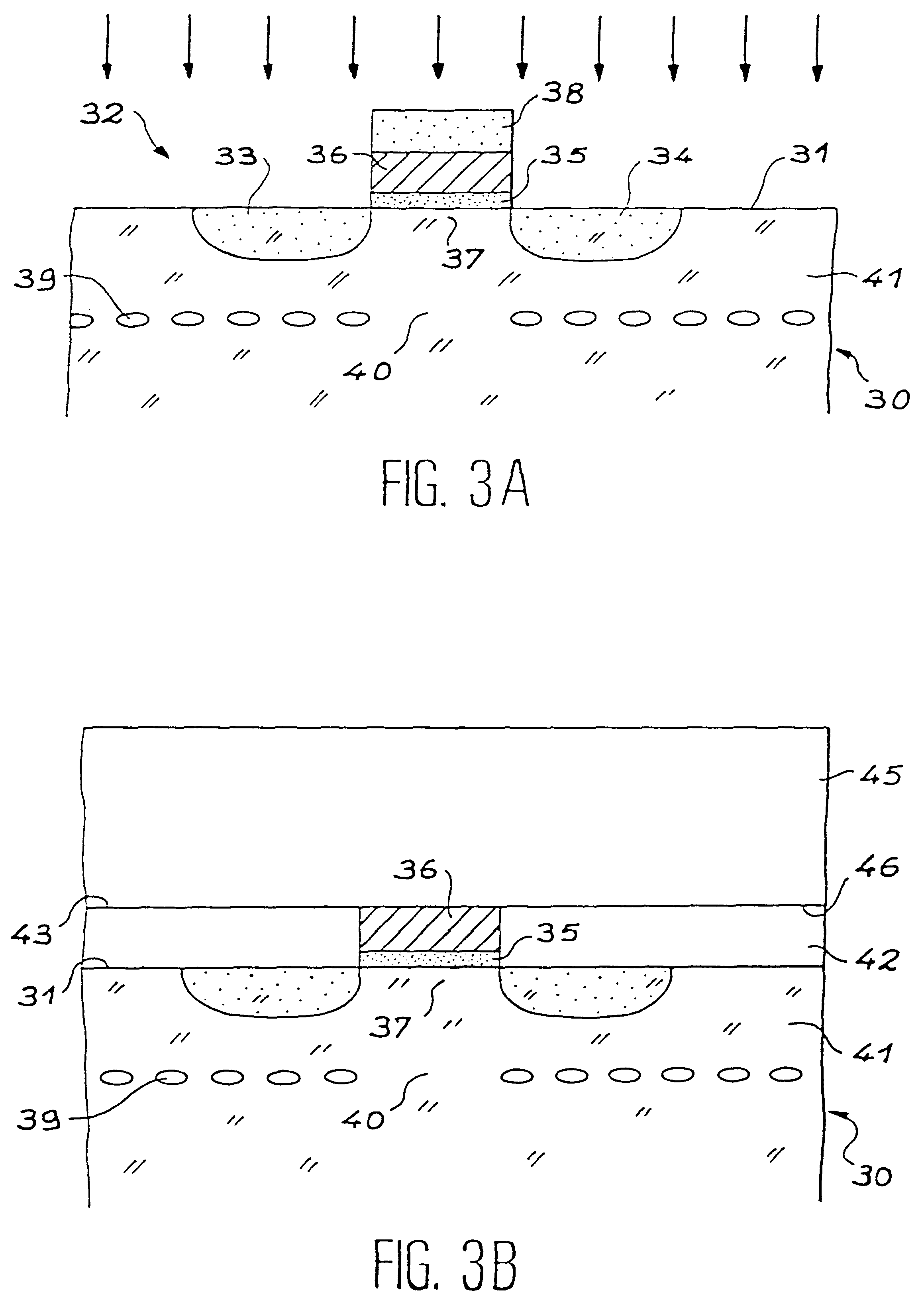

Method for obtaining a thin film in particular semiconductor, comprising a protected ion zone and involving an ion implantation

The invention relates to a process for obtaining a thin film from a substrate, the film being delimited in the substrate by ionic implantation and by heat treatment inducing a fracture line along which the film can be separated from the rest of the substrate. A particular area, for example composed of a gate oxide layer (15) and the channel area (19) of a MOS transistor (12) created in the substrate region (10) intended to form the tin film (20), this area may be protected by ionic implantation by masking using the transistor gate (16), which does not prevent the fracture from occurring provided that the width of the area does not exceed a limiting dimension determined for the material forming the substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

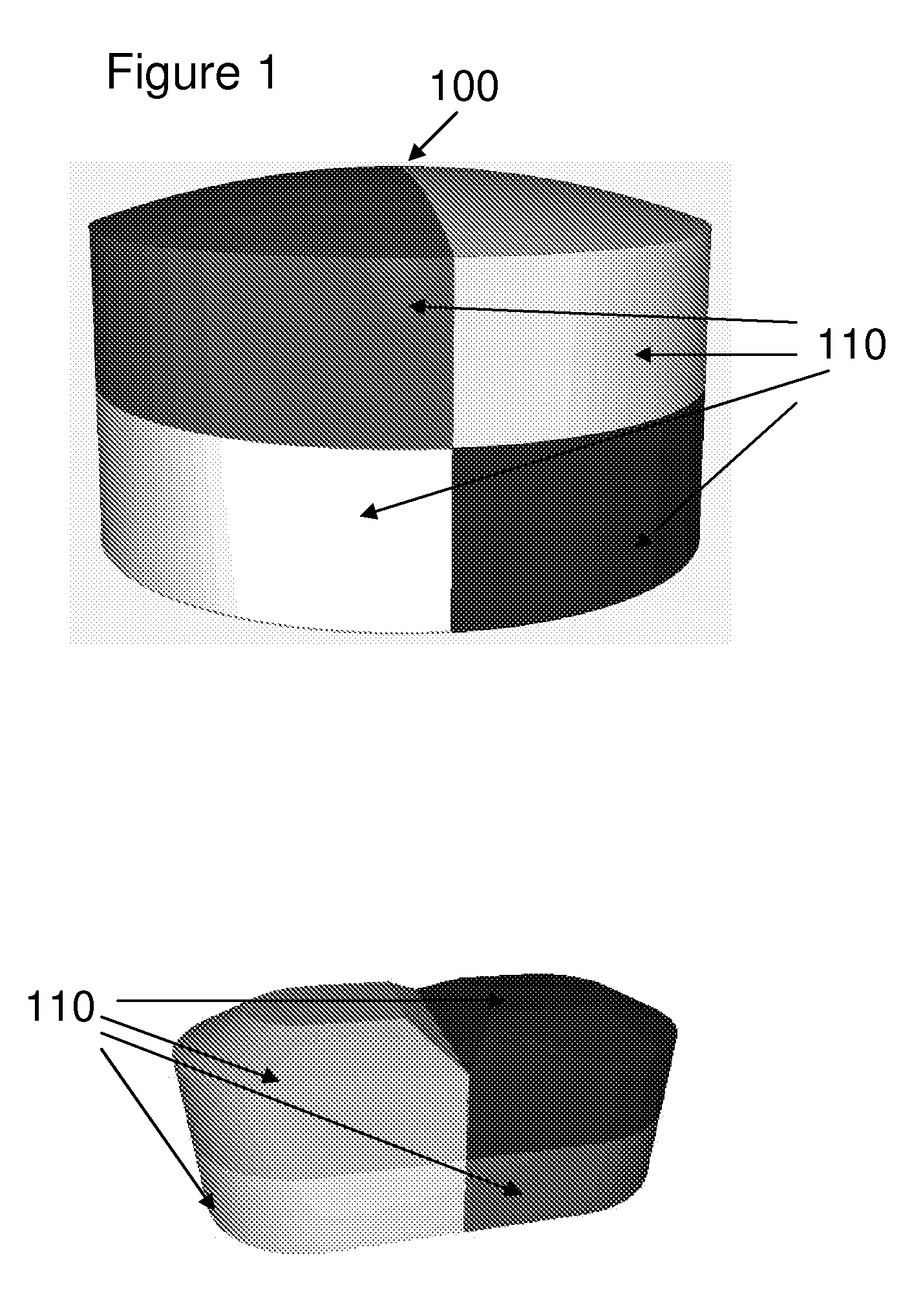

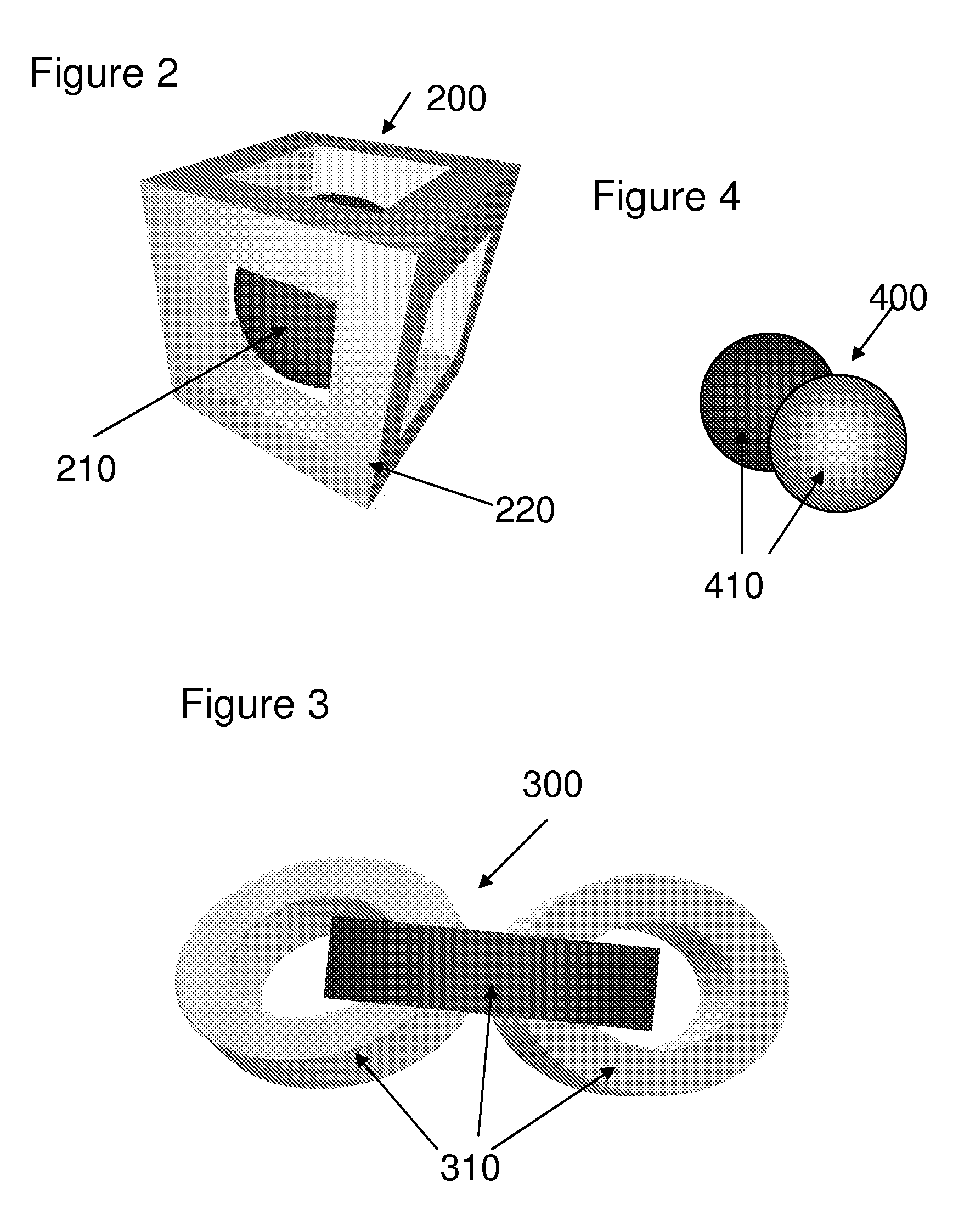

Dosage forms and methods of use thereof

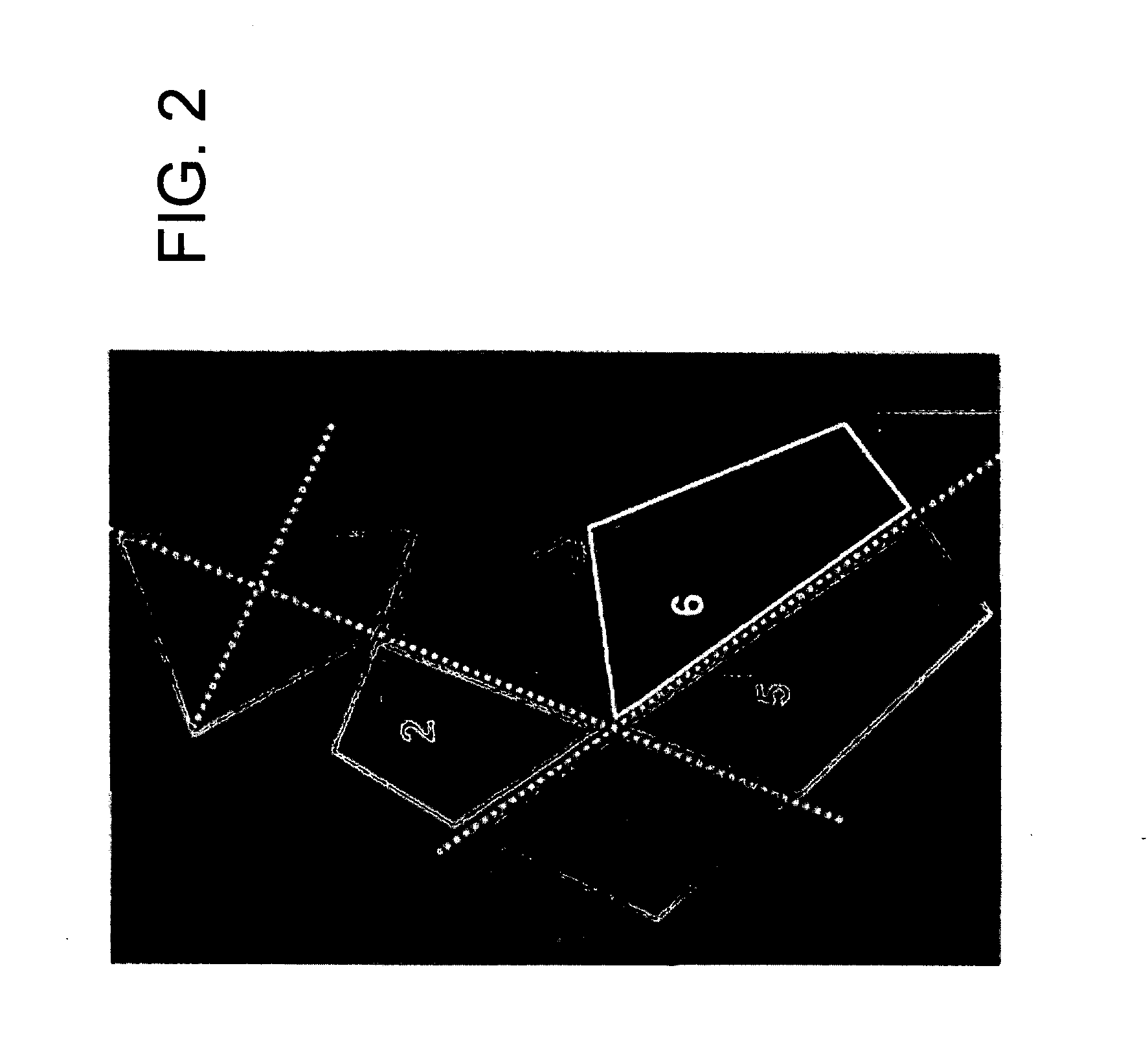

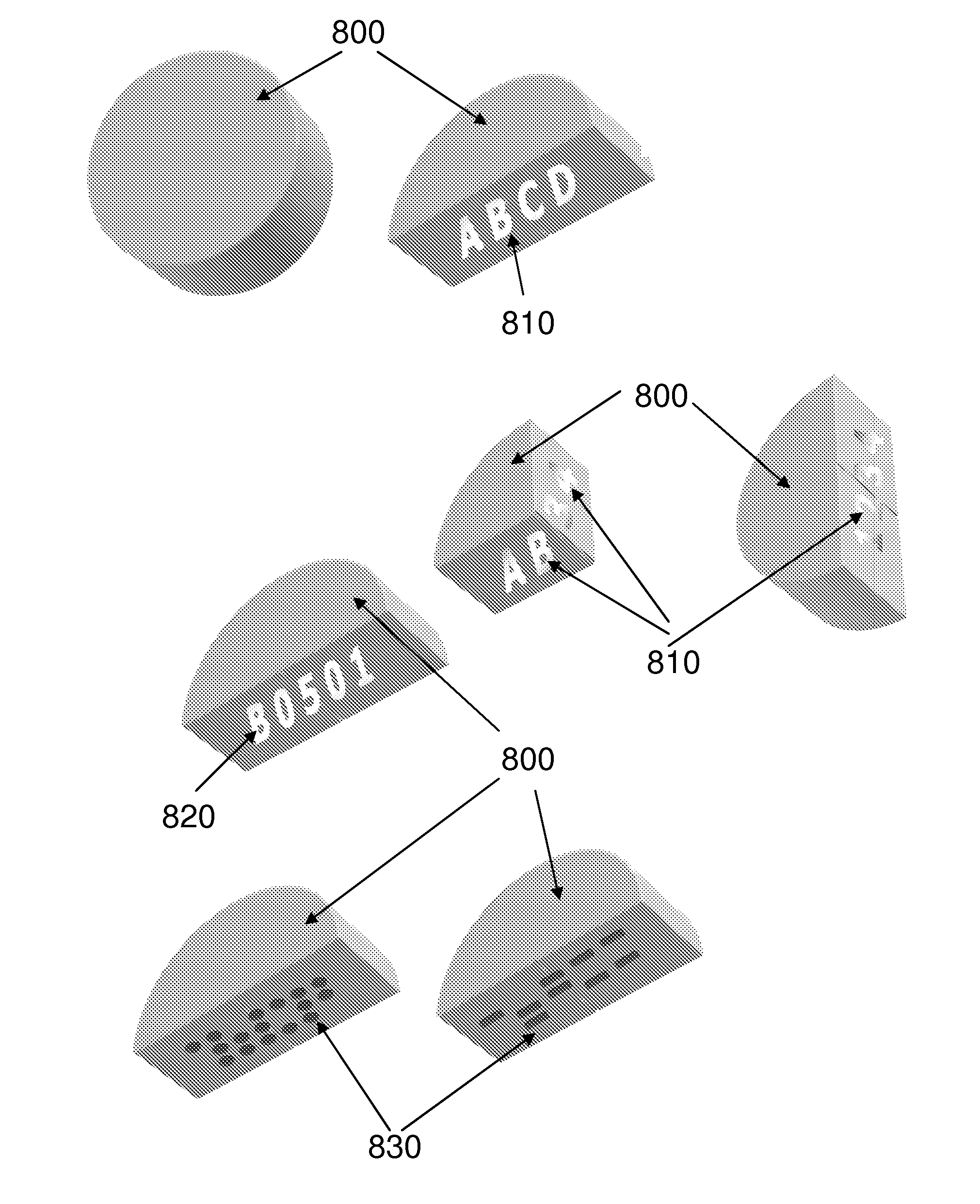

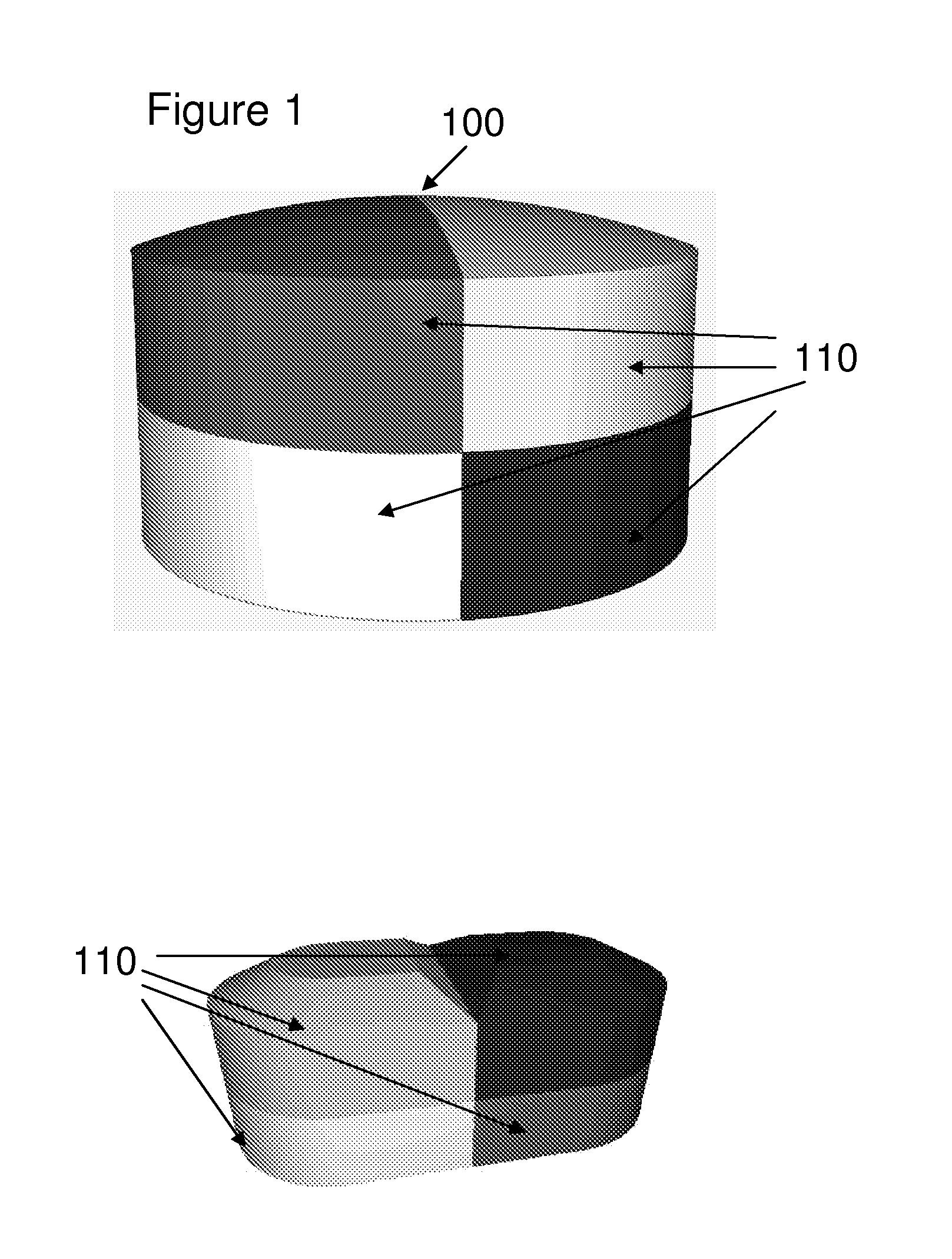

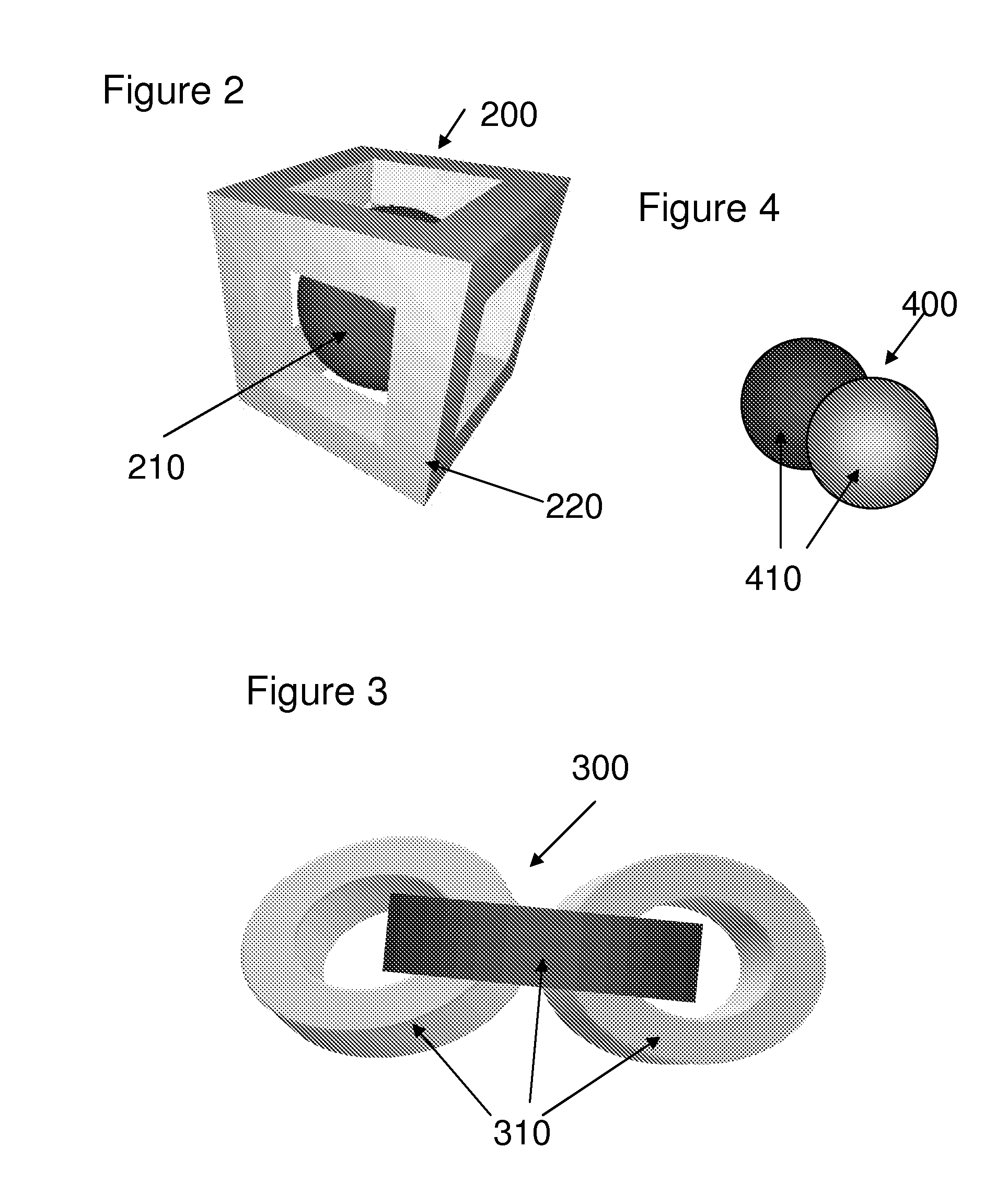

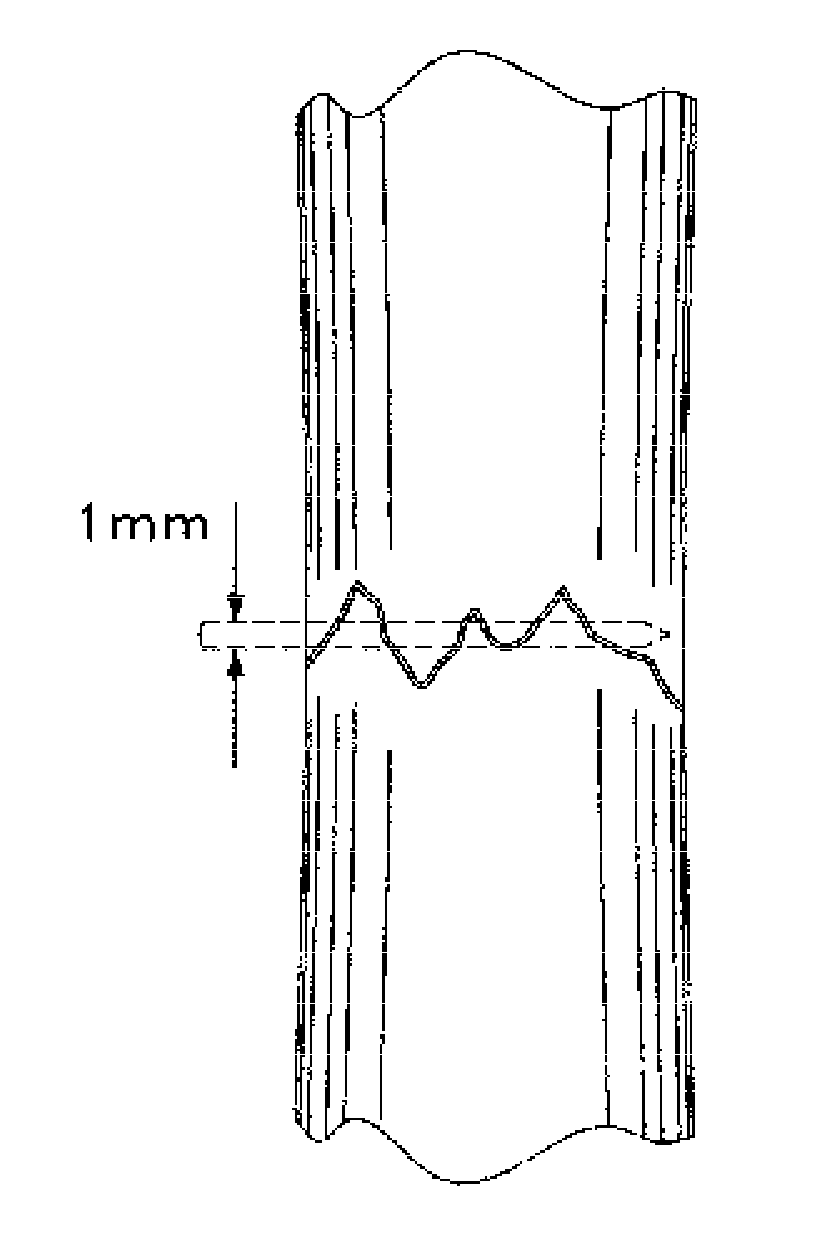

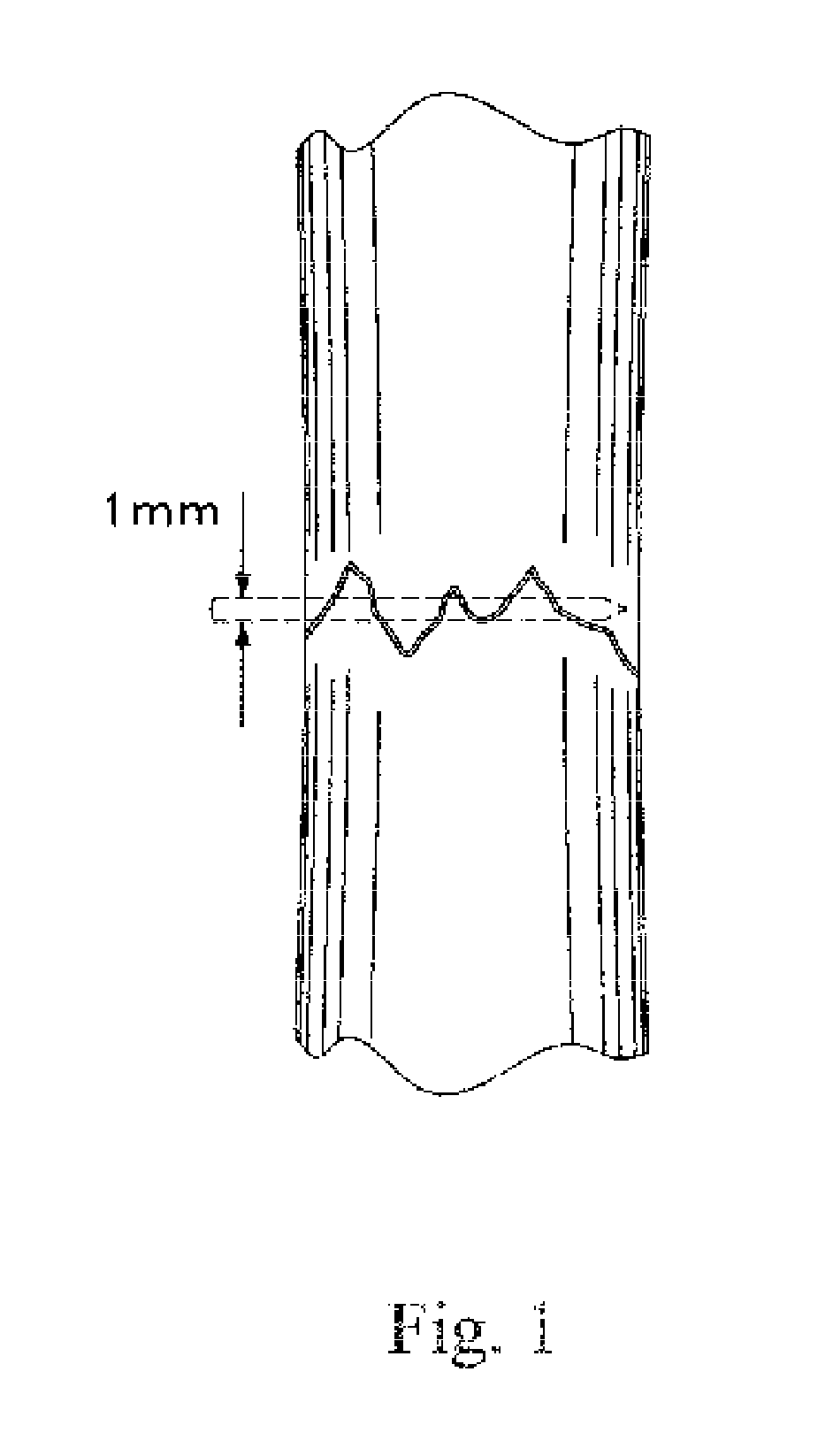

ActiveUS20070259010A1Not easy to copyEasy to observeAdditive manufacturing apparatusPill deliveryEngineeringFracture line

Pharmaceutical dosage forms with external or internal features to complicate counterfeiting and support authentication are described. External features include surface texture, surface markings defined by patterns of physical or chemical markers, or complex interlocking shapes. Internal features also include physical or chemical markers in two or three-dimensional patterns observable after sectioning, or after breaking along designed fracture lines. Methods of manufacture using solid freeform fabrication (SFF) techniques such as three-dimensional printing (3DP) are described. Method of authentication using dosage form patterns and batch codes are also described.

Owner:APRECIA PHARMA LLC

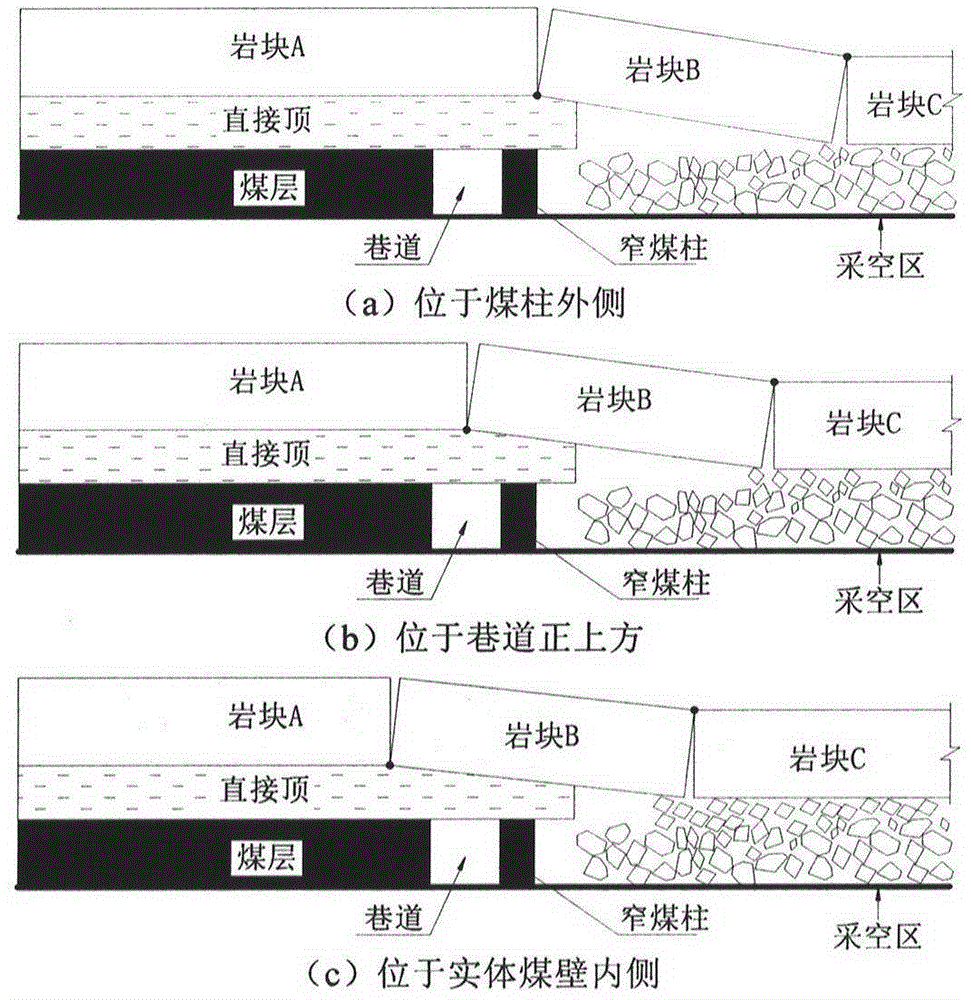

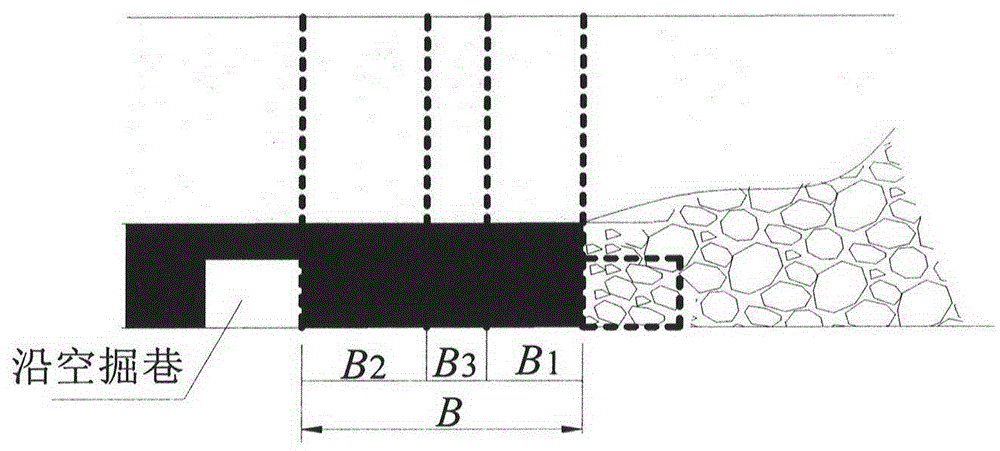

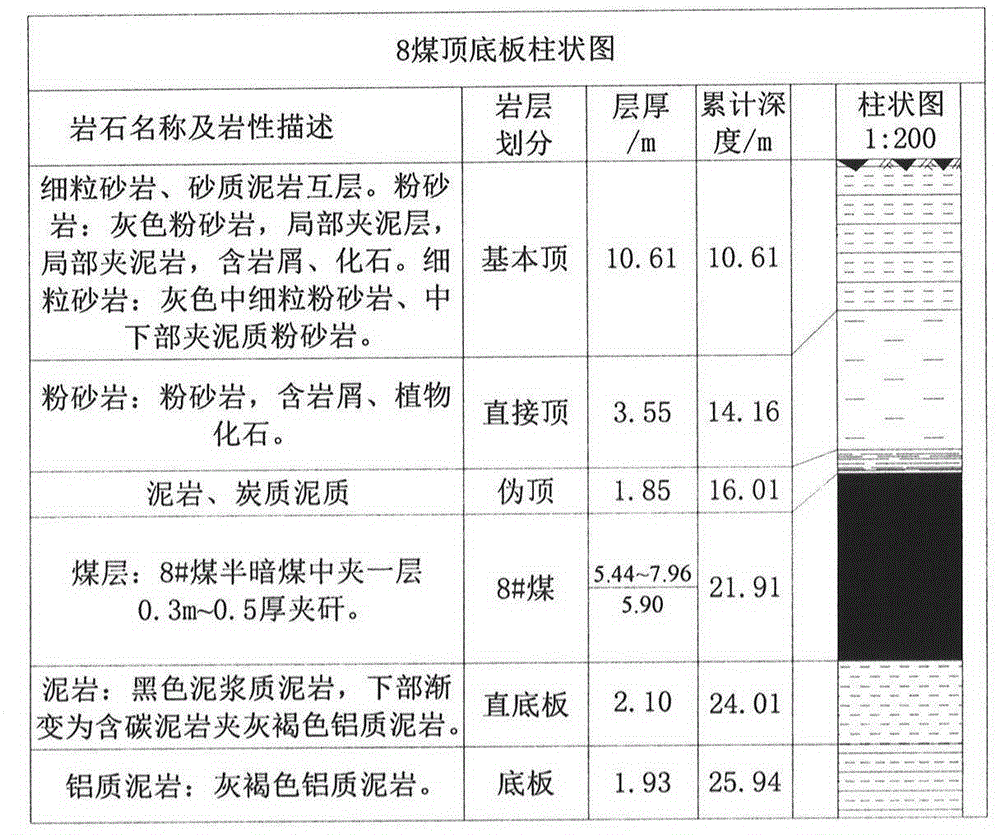

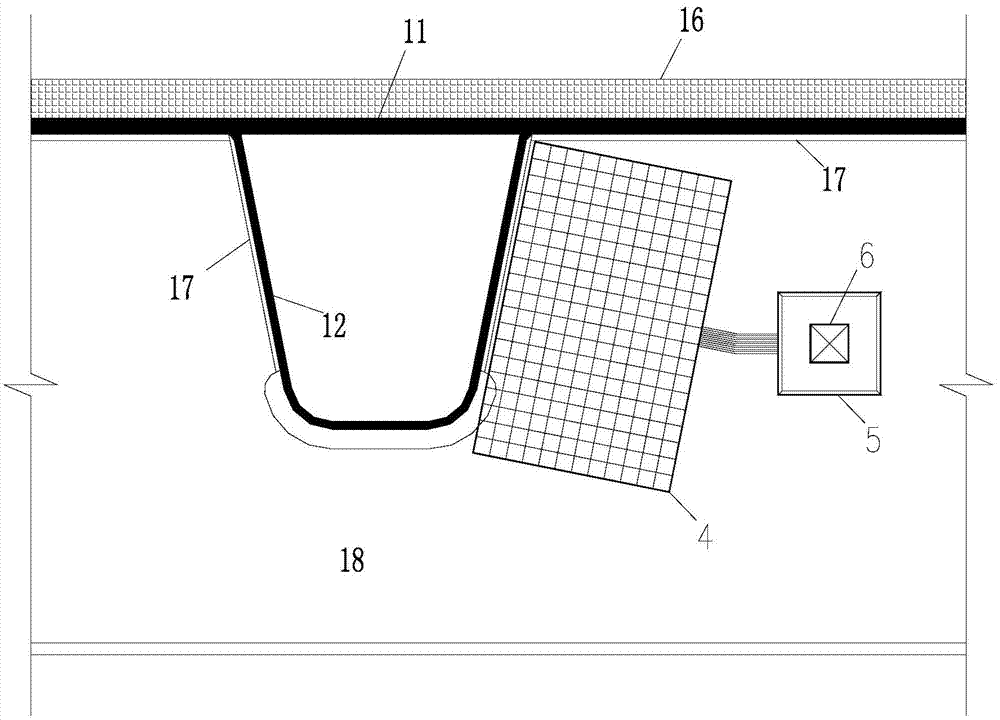

Method for determining reasonable width of gob-side entrydriving narrow coal pillar

InactiveCN104594899AGuaranteed long-term stabilitySafe and efficient miningUnderground miningSurface miningEngineeringFracture line

The invention discloses a method for determining a reasonable width of a gob-side entrydriving narrow coal pillar; theoretical calculation, numerical simulation, field actual measurement and other various means are adopted to determine the reasonable width of the coal pillar, a reasonable gob-side entrydriving position is determined, a fracture line of a main roof is guaranteed to be located at the side, close to a goaf, of the narrow coal pillar, long-term stability of the narrow coal pillar and a roadway is ensured, on one hand, the roadway latter maintenance work amount and maintenance costs are substantially reduced, on the other hand, safe and high-efficiency stoping of a working face is ensured. Therefore, the method for determining the reasonable width of the narrow coal pillar has relatively high theoretical significance and practical value.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

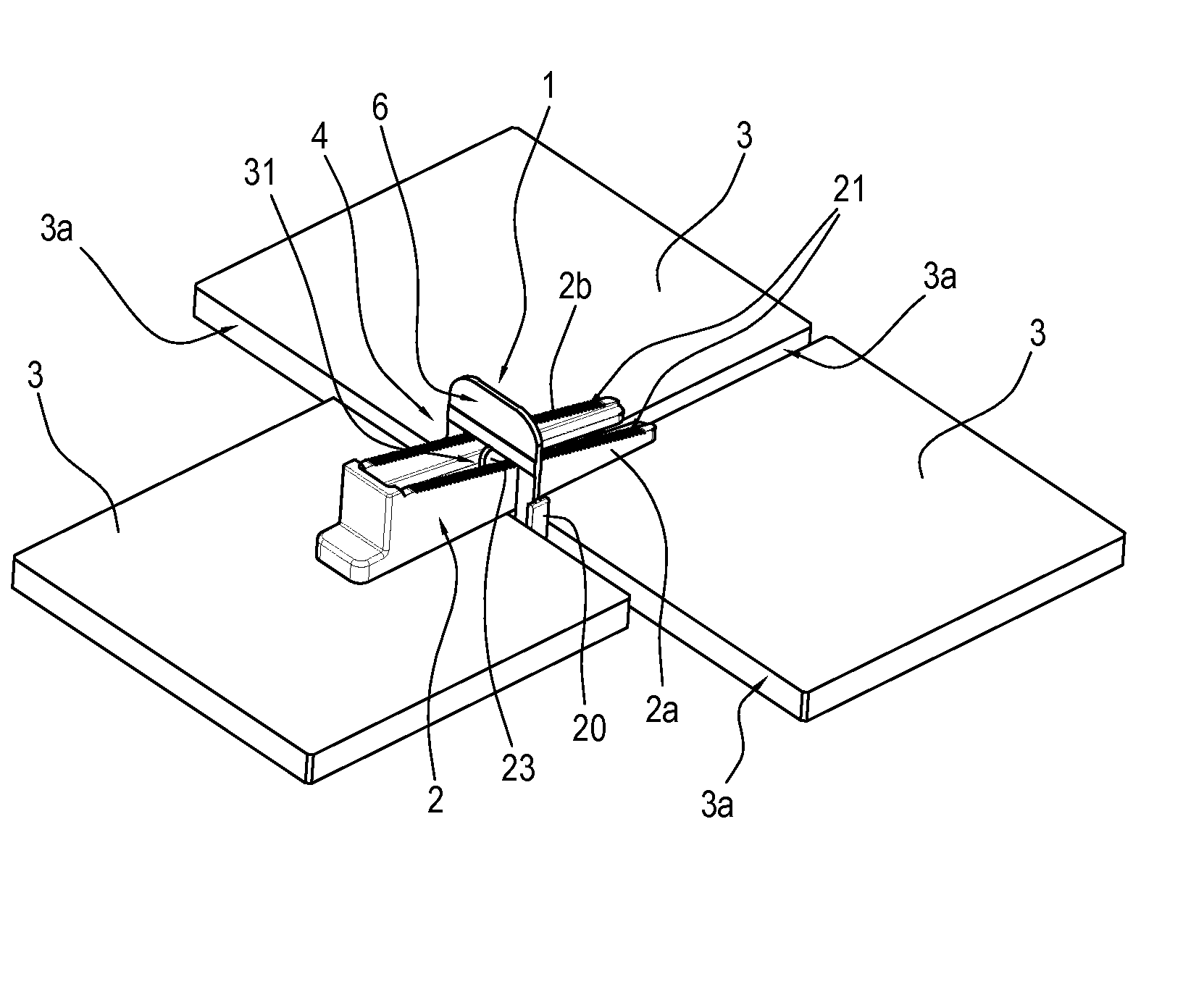

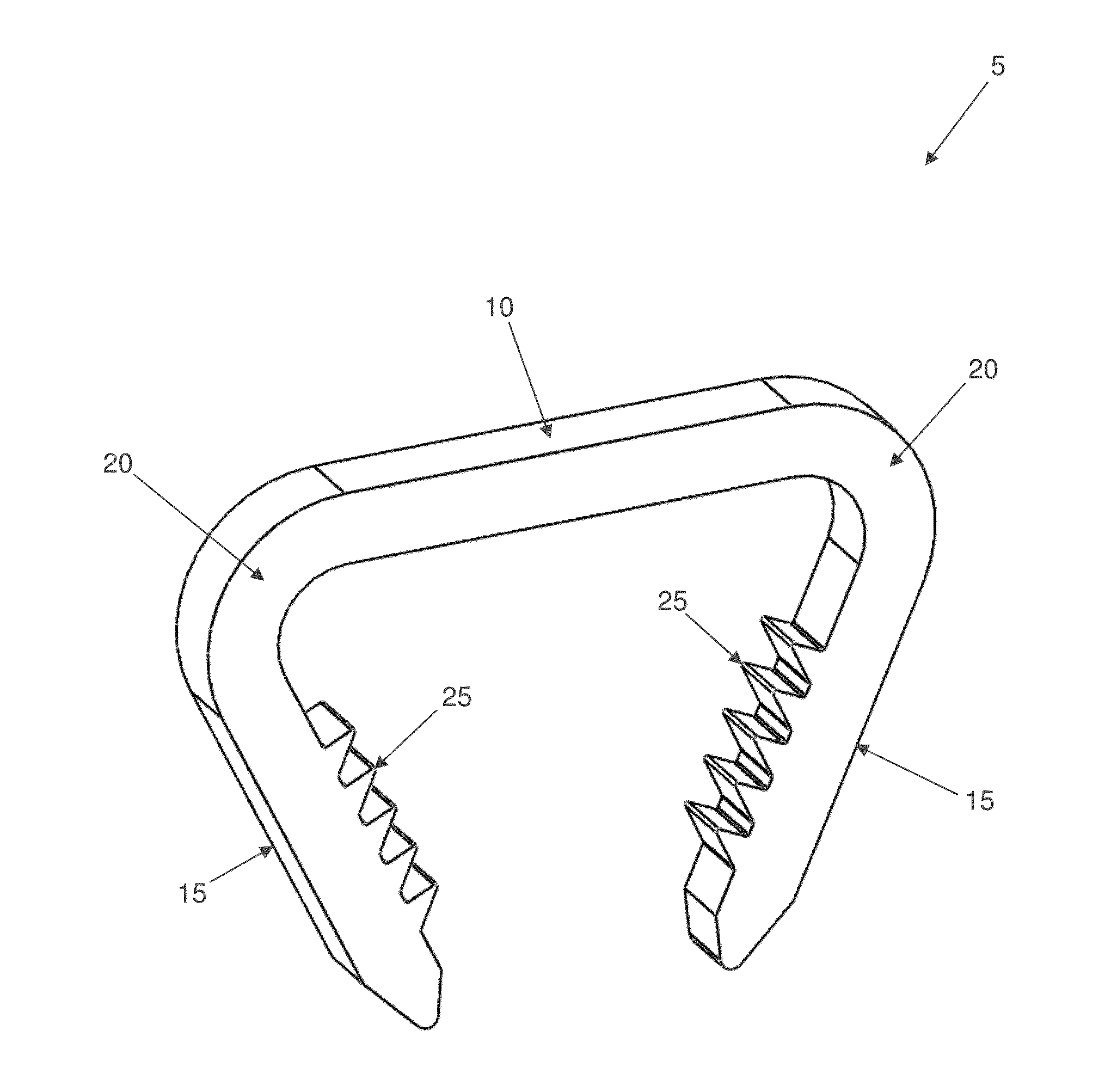

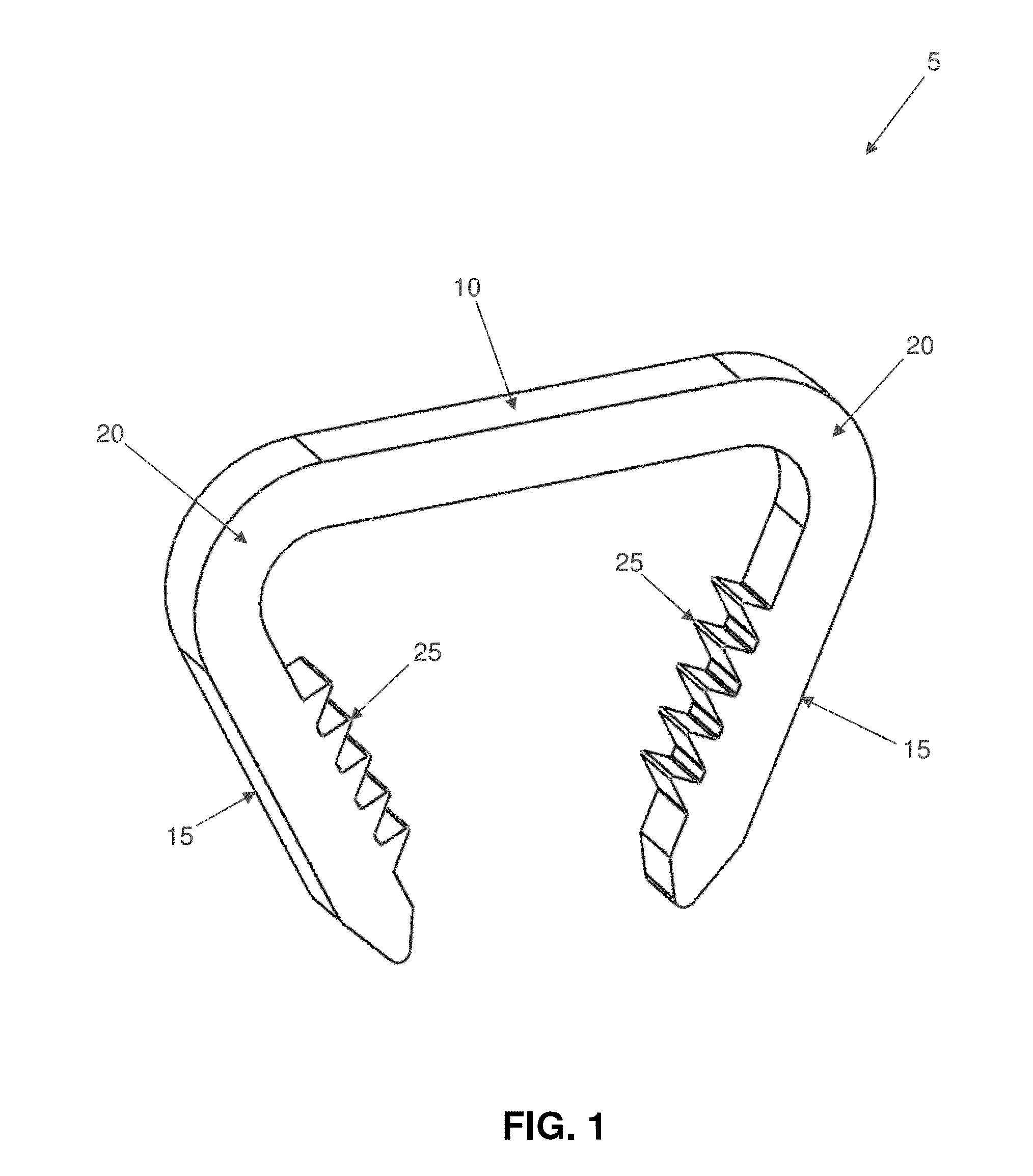

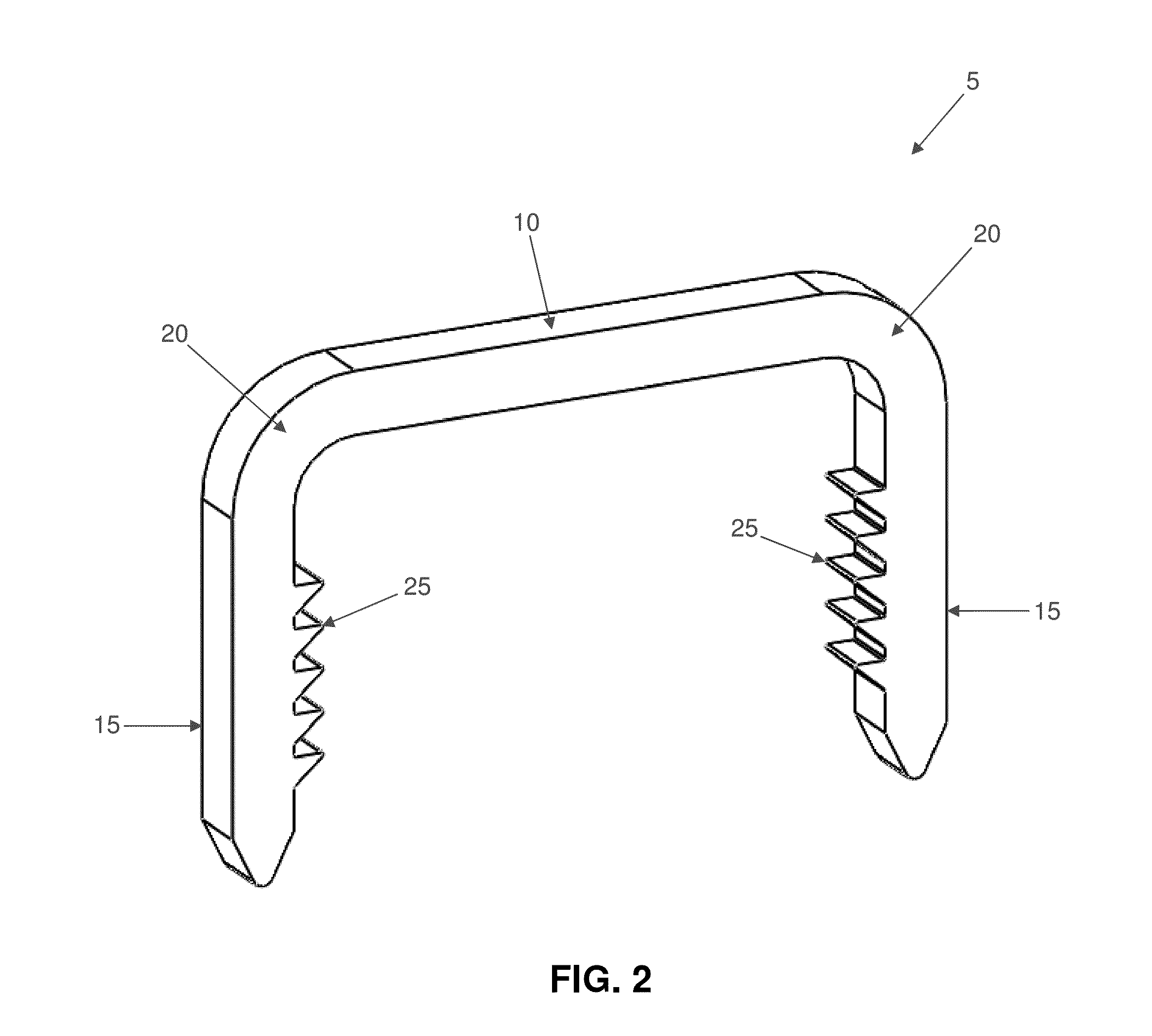

Staples for generating and applying compression within a body

ActiveUS20150133940A1Generate compressive loadReduce fracturesInternal osteosythesisJoint implantsEngineeringFracture line

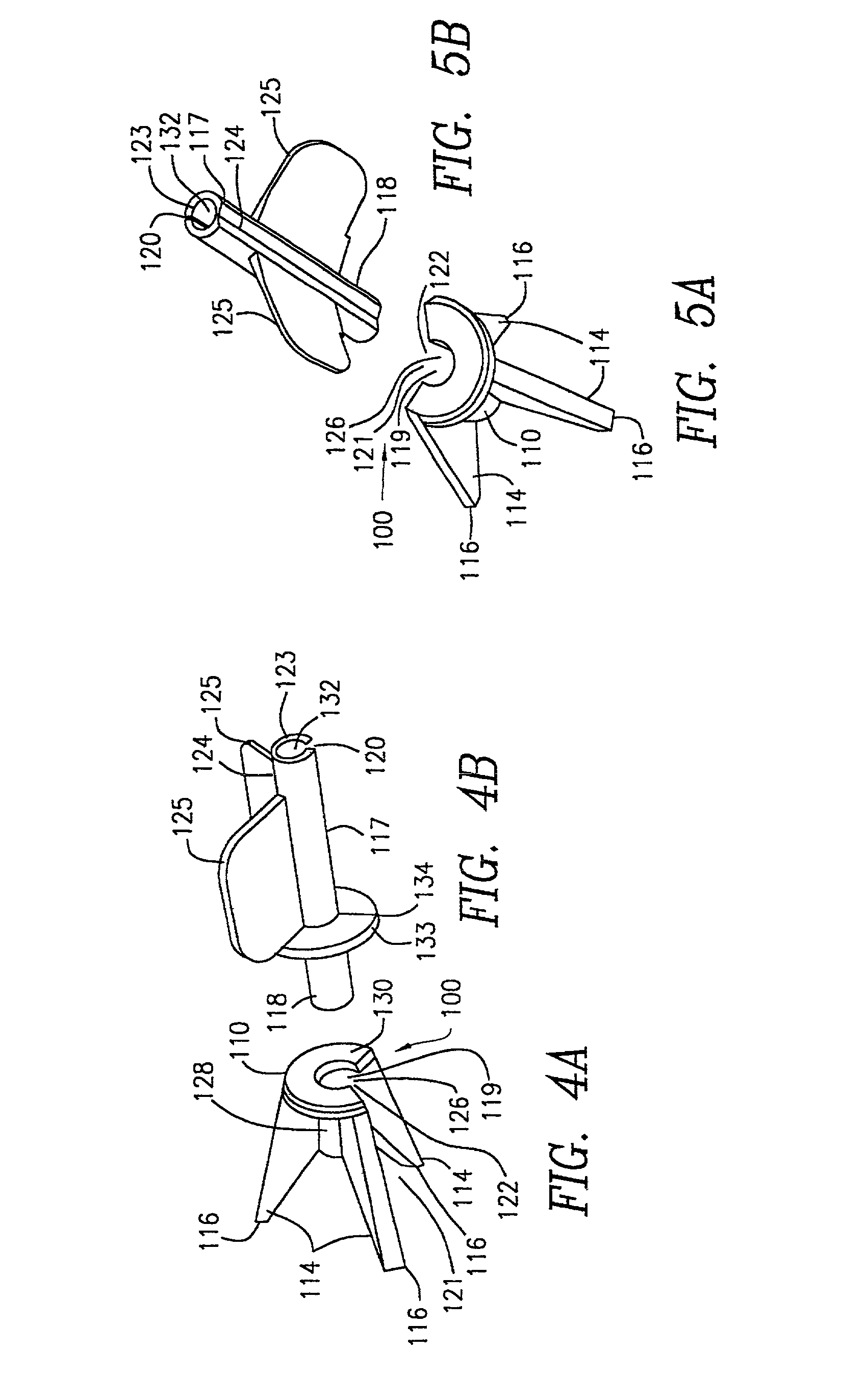

A staple comprising: a bridge configured to be elastically stretchable; a first leg connected to said bridge and configured to be elastically bendable; and a second leg connected to said bridge and configured to be elastically bendable; said first and second legs being connected to said bridge so that they are angled toward one another when they are in an unstrained state; such that when said bridge is elastically strained into an elongated condition, and said first and second legs are elastically strained so that they extend substantially parallel to one another, and said first and second legs are disposed in appropriate holes on opposing sides of a fracture line, and when the strain on said staple is thereafter released, compression will be provided across the fracture line by both said bridge and said first and second legs.

Owner:ARTHREX

Dosage forms and methods of use thereof

Pharmaceutical dosage forms with external or internal features to complicate counterfeiting and support authentication are described. External features include surface texture, surface markings defined by patterns of physical or chemical markers, or complex interlocking shapes. Internal features also include physical or chemical markers in two or three-dimensional patterns observable after sectioning, or after breaking along designed fracture lines. Methods of manufacture using solid freeform fabrication (SFF) techniques such as three-dimensional printing (3DP) are described. Method of authentication using dosage form patterns and batch codes are also described.

Owner:APRECIA PHARMA LLC

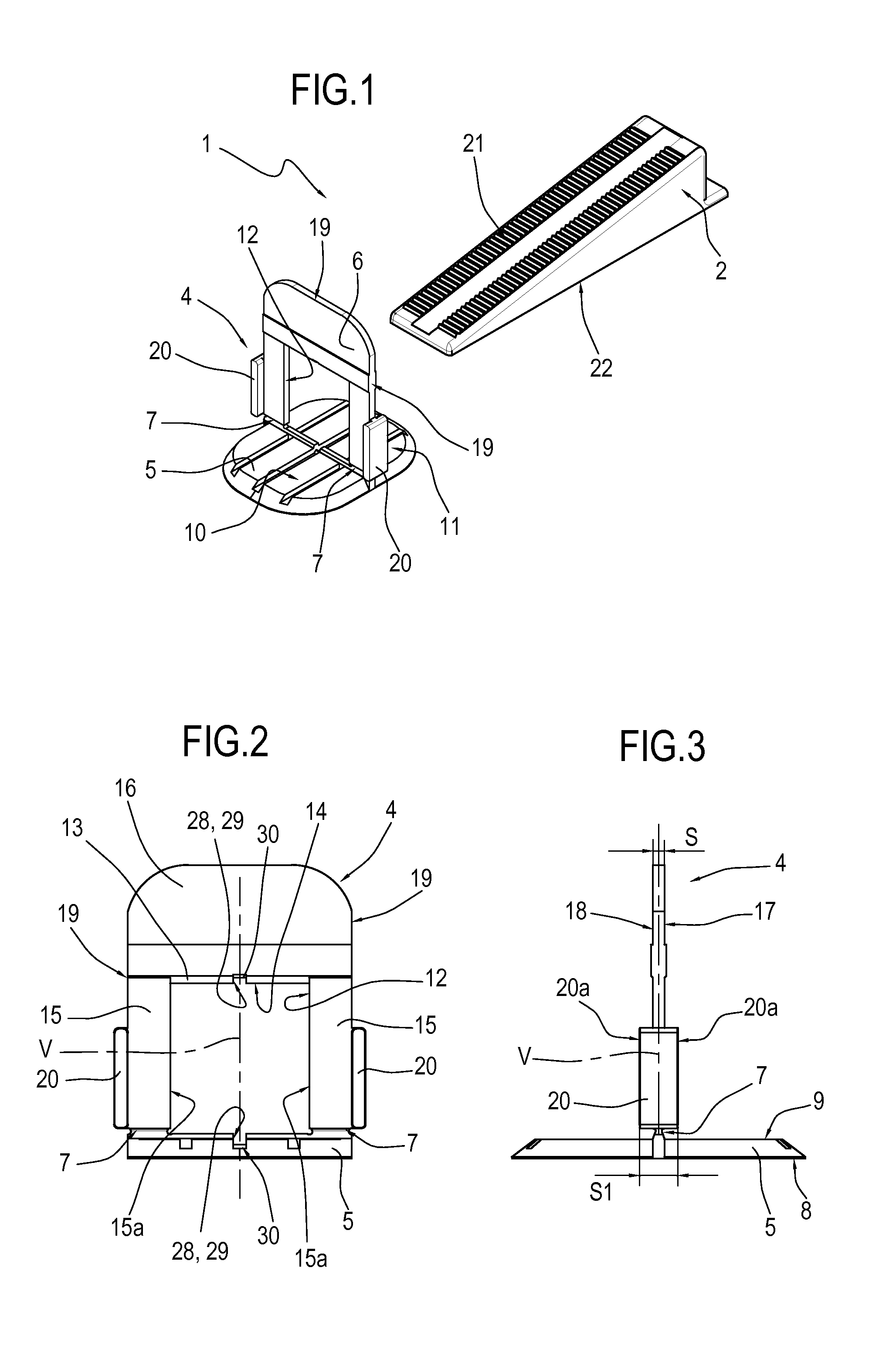

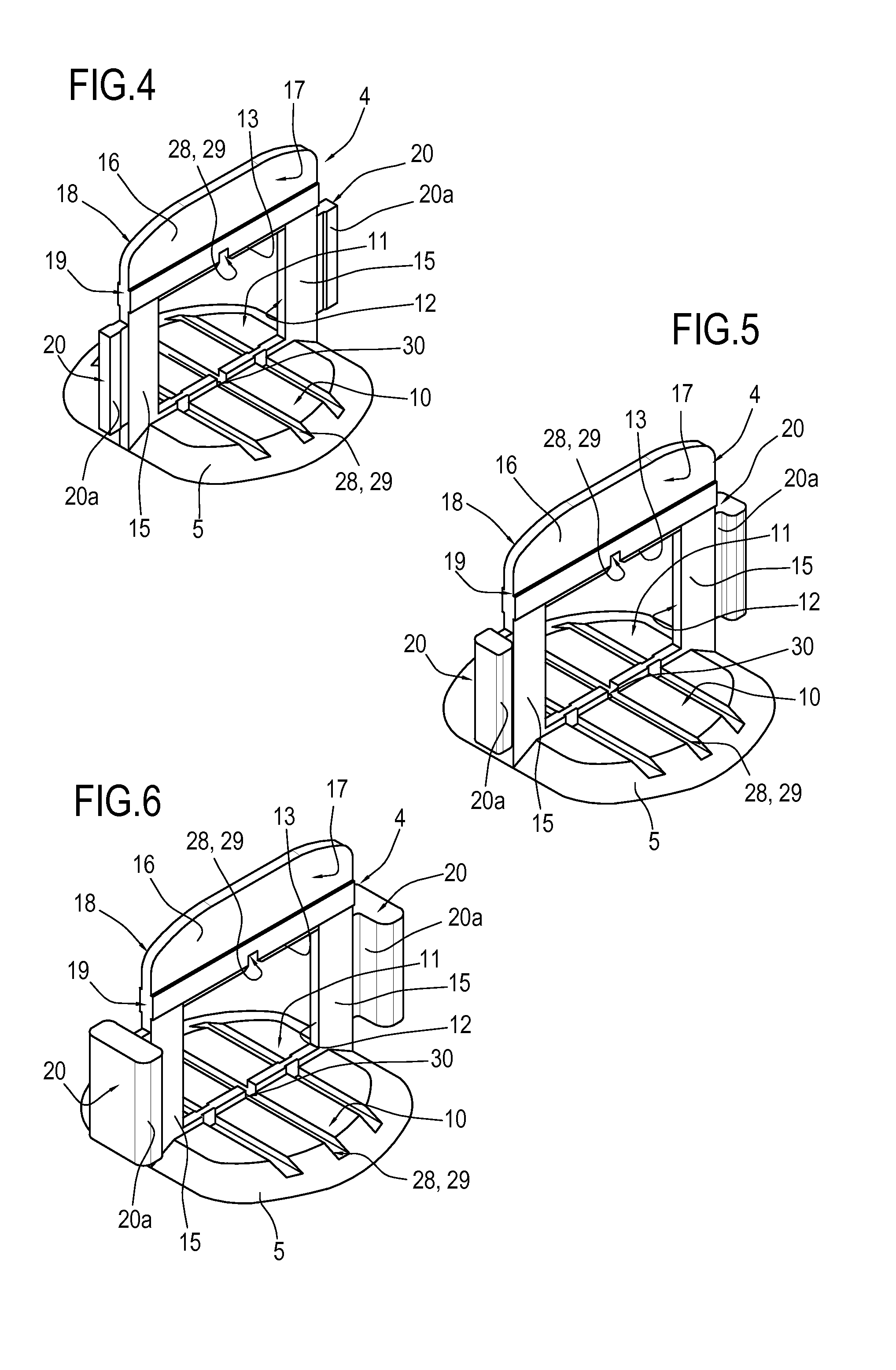

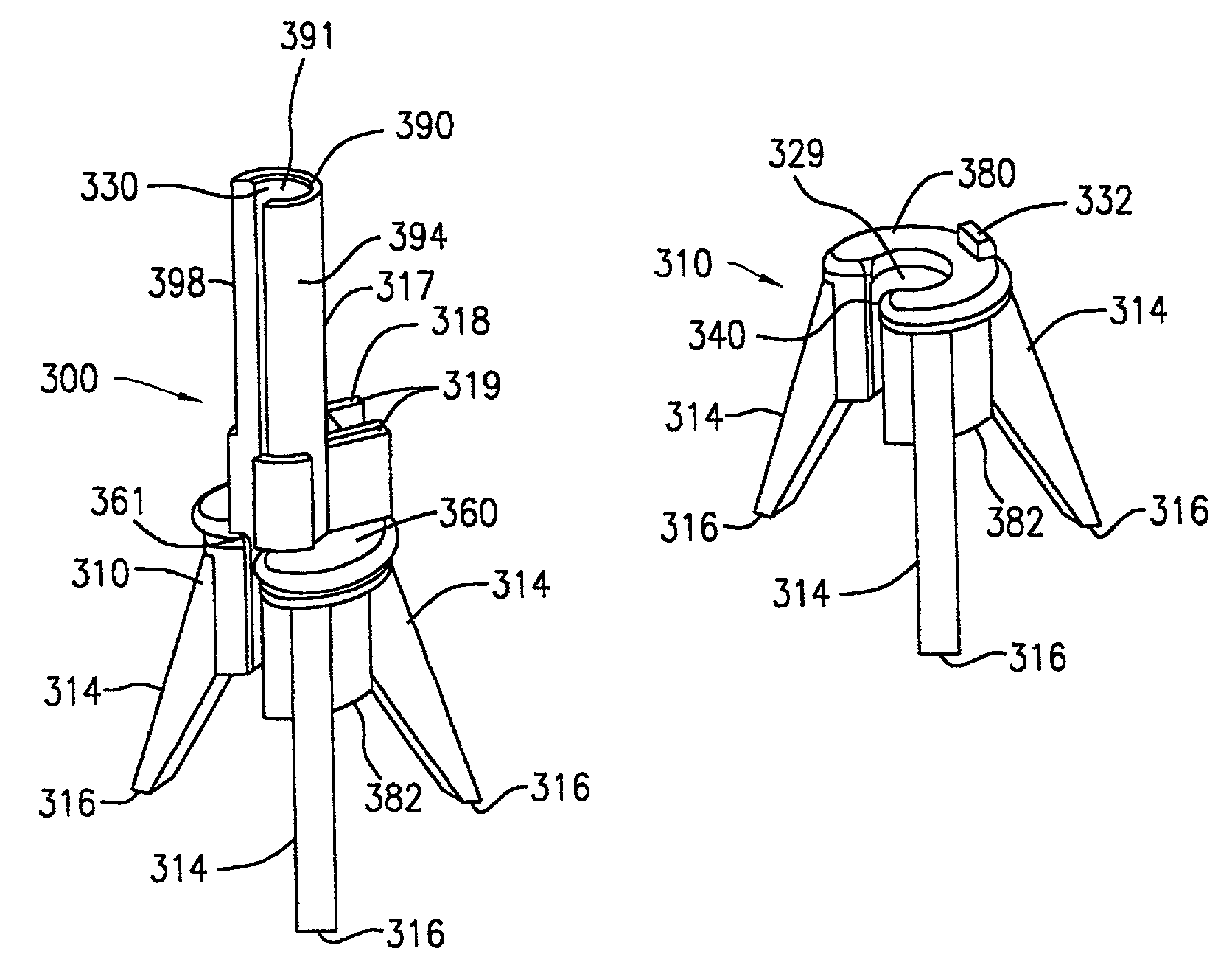

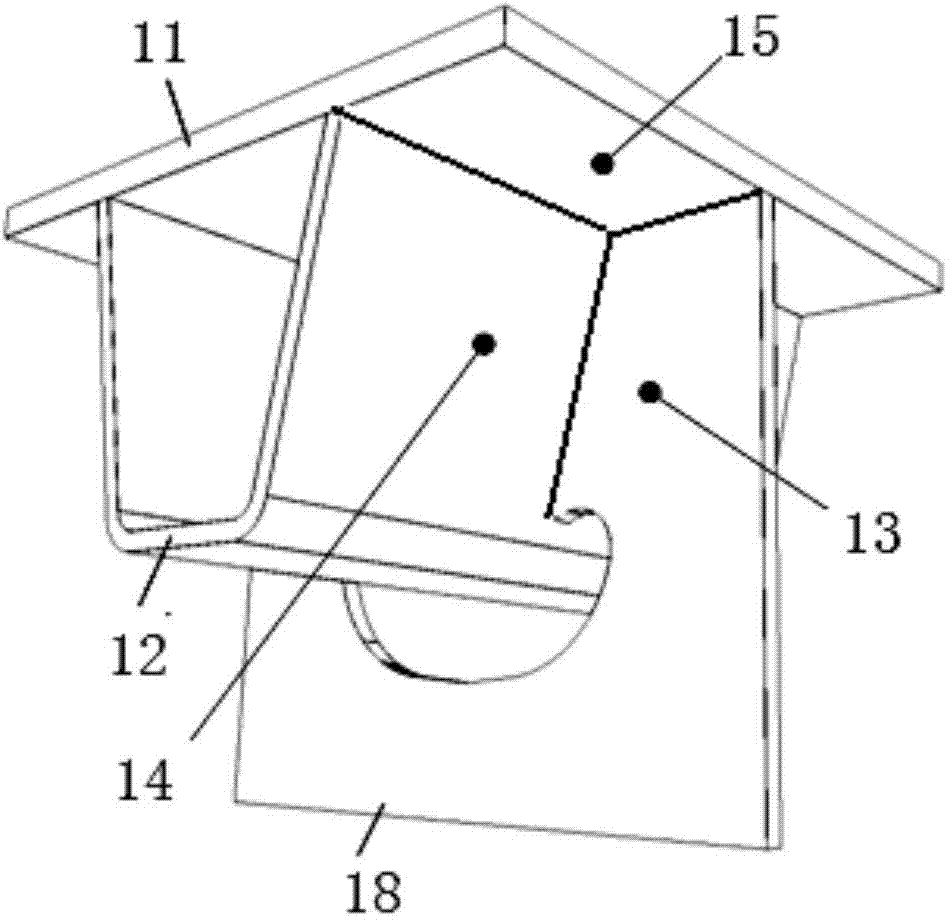

Slotted catheter guide for perpendicular insertion into a cranium orifice

A catheter guide for controlling an angle of entry of a catheter into a human cranium at an angle of 90 degrees to the surface and allowing for easy removable of the catheter guide from the catheter after use. A tubular member defines a catheter guide lumen to permit the passage therethrough of a catheter. A base supports the tubular member. In a two piece assembly, the tubular member may have a fracture line allowing the catheter guide to be separated from the catheter. In an integrated, break-away assembly, the catheter guide may be broken apart to allow for the removal of the catheter guide from the catheter. Alternatively, in an integrated assembly or in a two piece assembly, the catheter guide may be removed from a catheter through a slot in the catheter guide.

Owner:NEURODYNAMICS

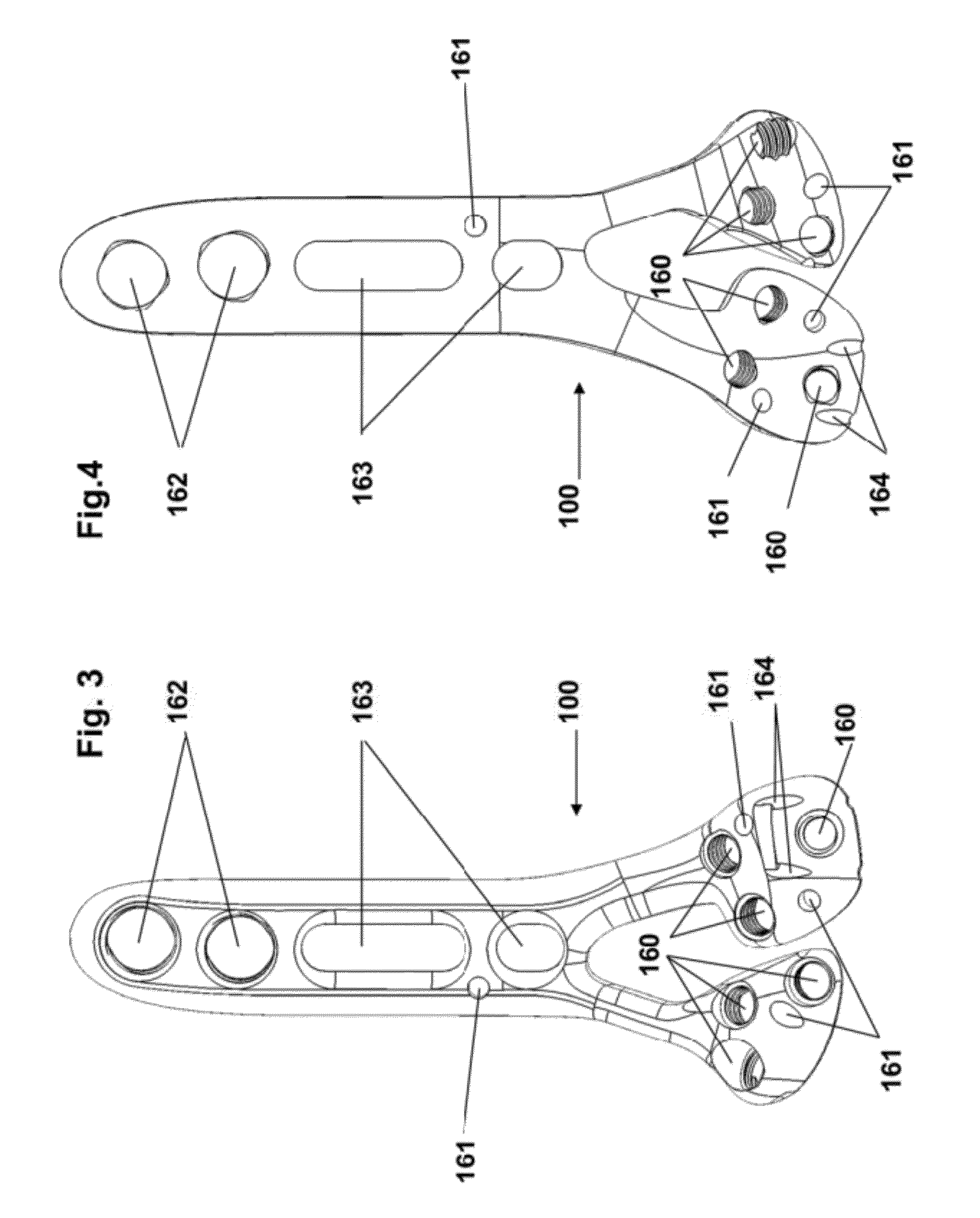

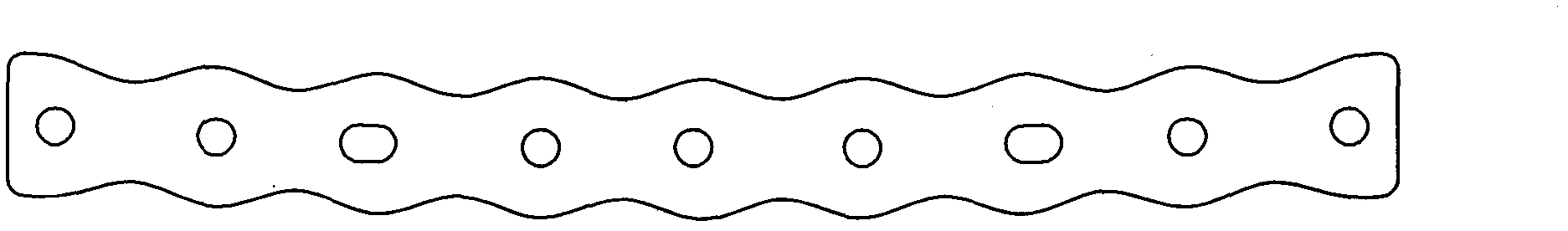

Fracture fixation plate

Owner:SKELETAL HLDG LLC

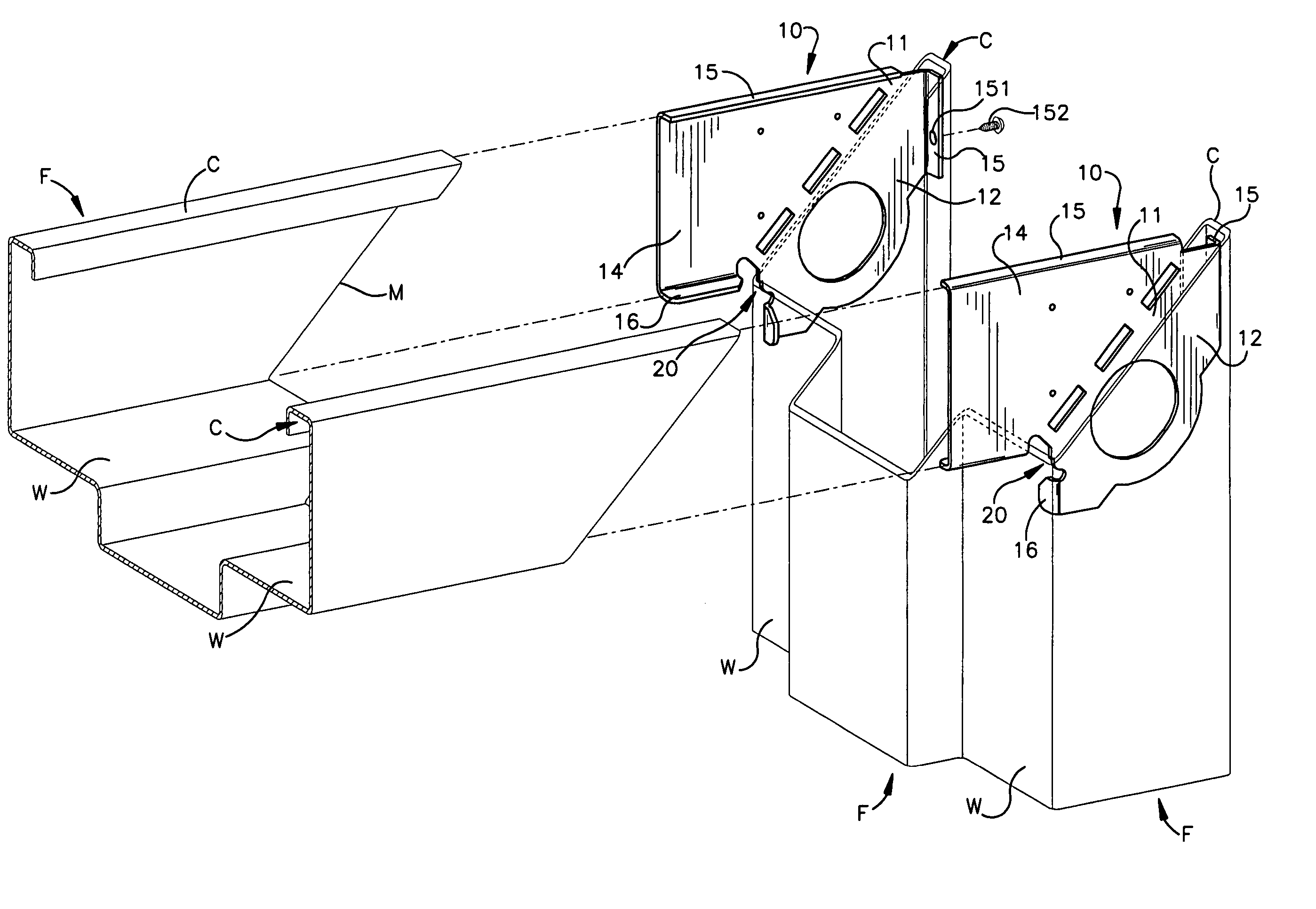

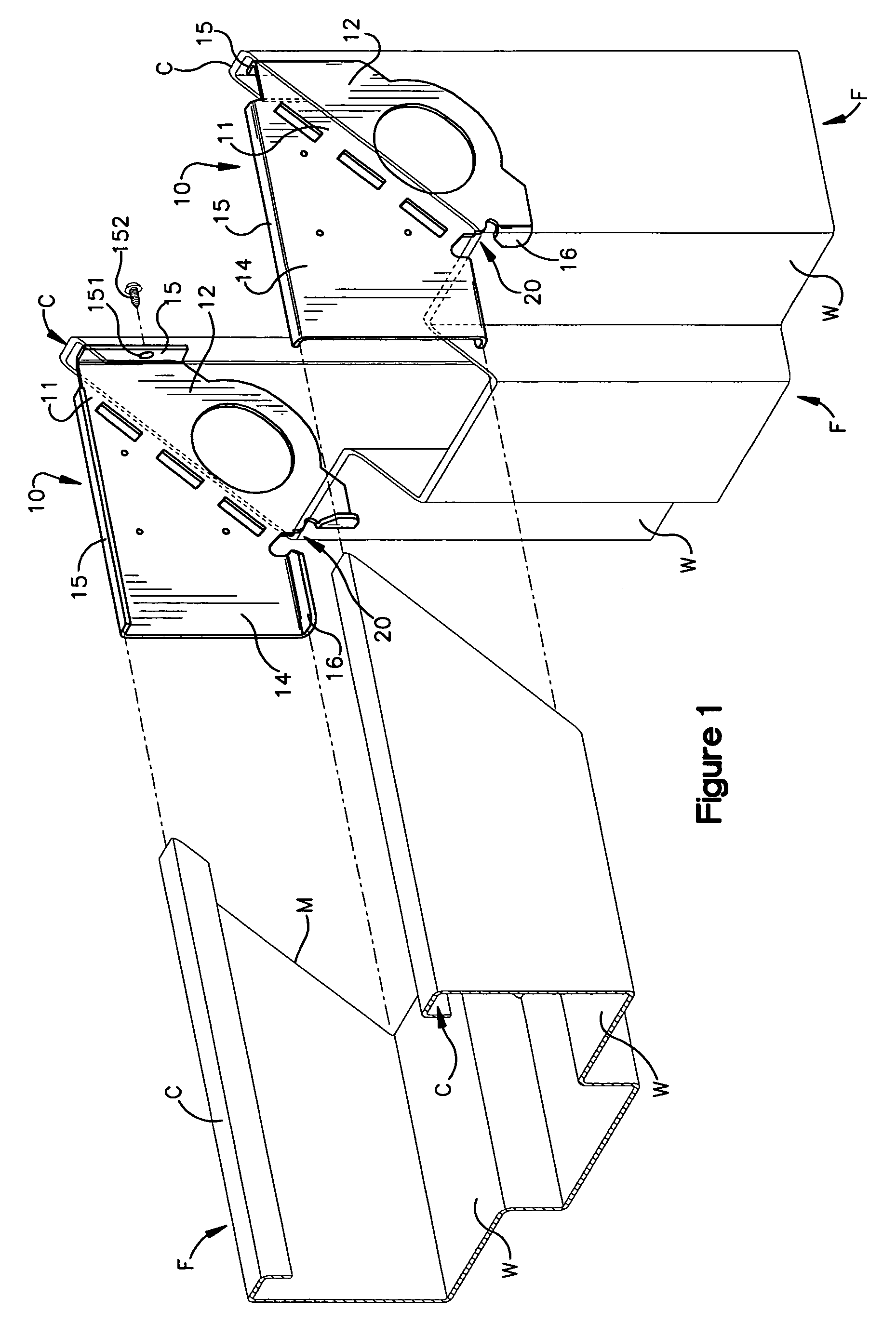

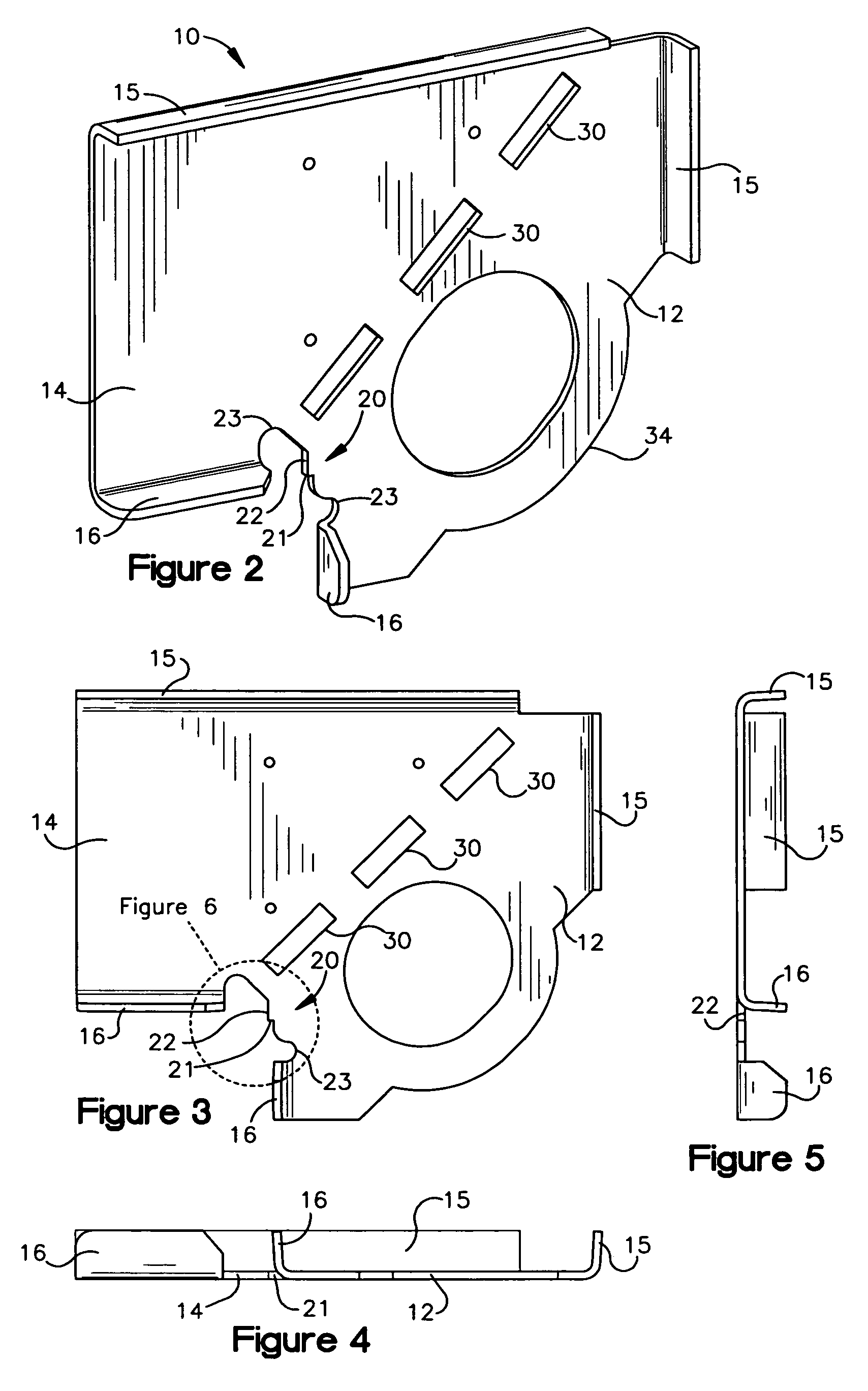

Door frame miter brace

A frame member miter guide or brace has first and second legs configured for insertion and engagement with adjoining frame members at a mitered joint, the miter guide having a stop with stop edges which accurately position intersecting walls of the frame members for precise alignment of the mitered joint. Stop edges of the stop correspond with the correct positions of the frame members, so that the members are held in place for final attachment and installation. Positive engagement of edges of the frame member walls with the stop edges insures highly accurate orientation of the mitered joint. A fracture line for welded installation of the frame members, and a leg profile which minimizes damage in handling and installation is also described.

Owner:ANCHOR TOOL & DIE

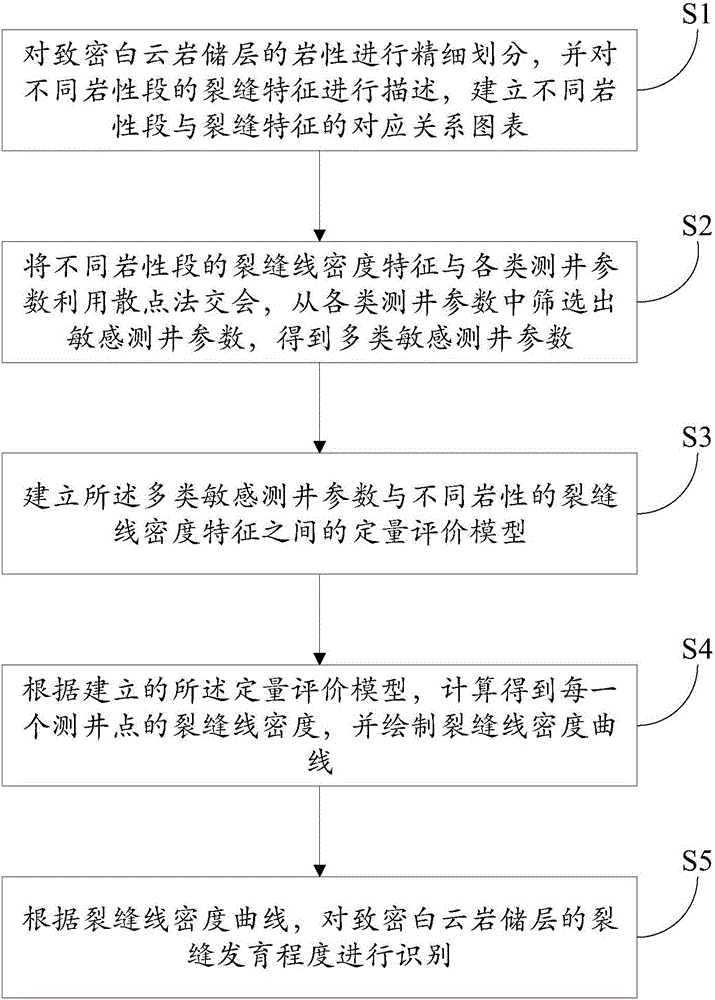

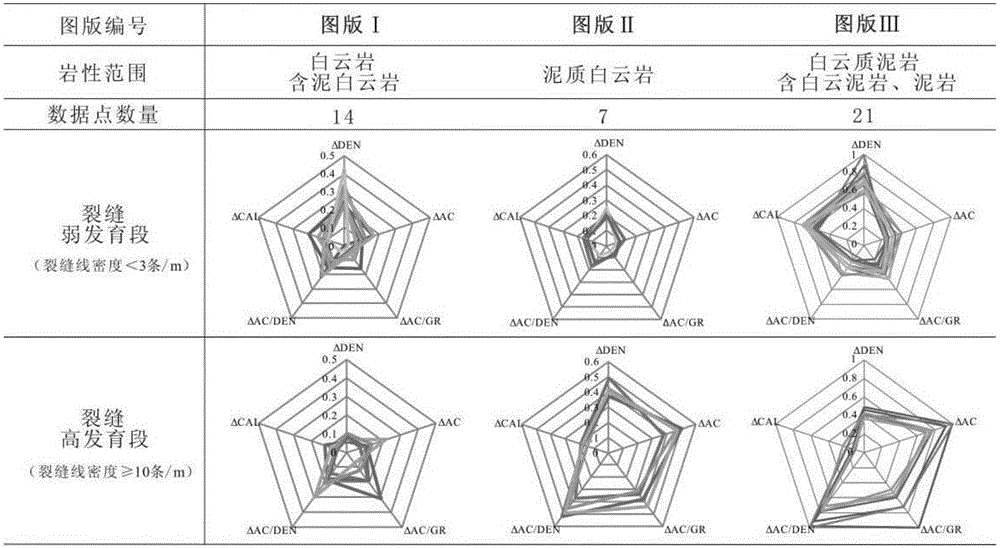

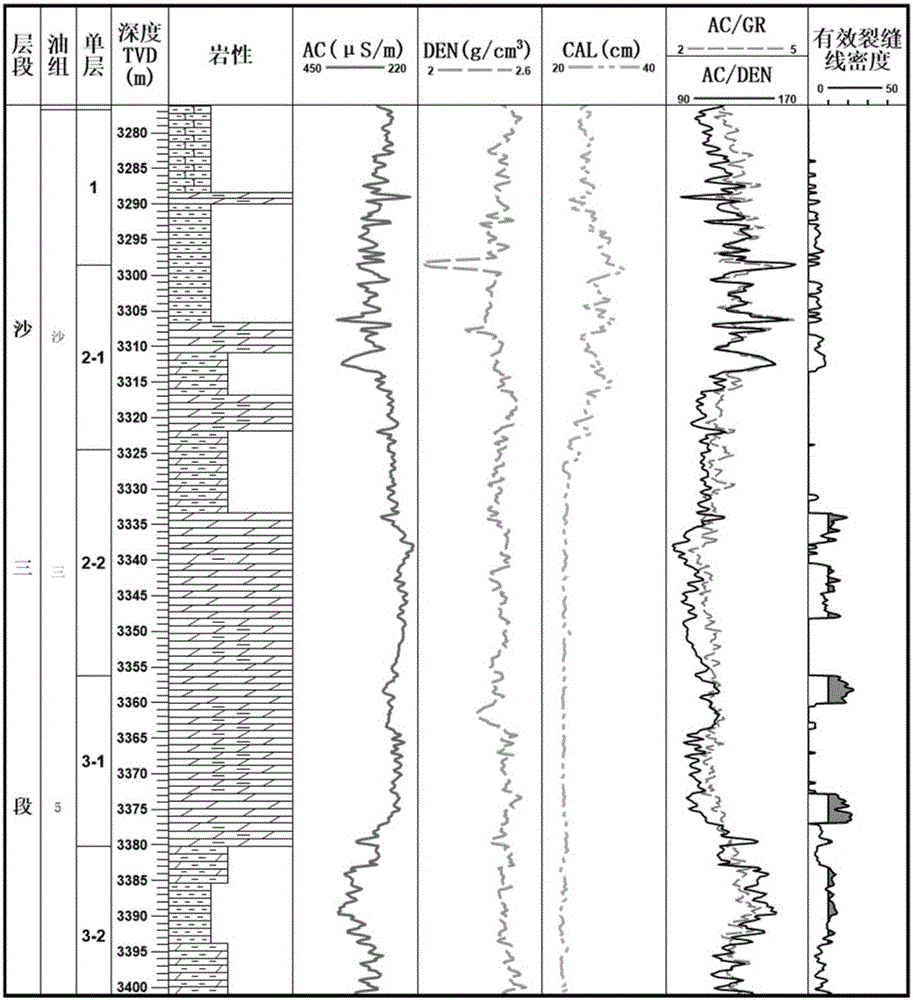

Fracture development degree identifying method of dense dolomite reservoir

The invention discloses a fracture development degree identifying method of a dense dolomite reservoir. The fracture development degree identifying method comprises the steps that the lithological refined division of the dense dolomite reservoir is carried out, and fracture characteristics of different lithological segments are described, and a chart of a corresponding relation between the different lithological segments and the fracture characteristics is established; the fracture line density characteristic values of the different lithological segments are intersected with various well logging parameters by using a scattering method; various sensitive well logging parameters are selected from the various well logging parameters, and a quantitative evaluation model between the various sensitive well logging parameters and the fracture line density characteristic values of the different lithological segments is established; according to the established quantitative evaluation model, the fracture line density value of every well logging point is calculated, and a fracture line density curve is drawn, and the fracture development degree of the dense dolomite reservoir is identified. By adopting the method provided by the invention, a fracture development degree of a dense dolomite type oil reservoir is effectively evaluated, and then a scientific basis is provided for the reasonable development of the dense dolomite oil reservoir.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

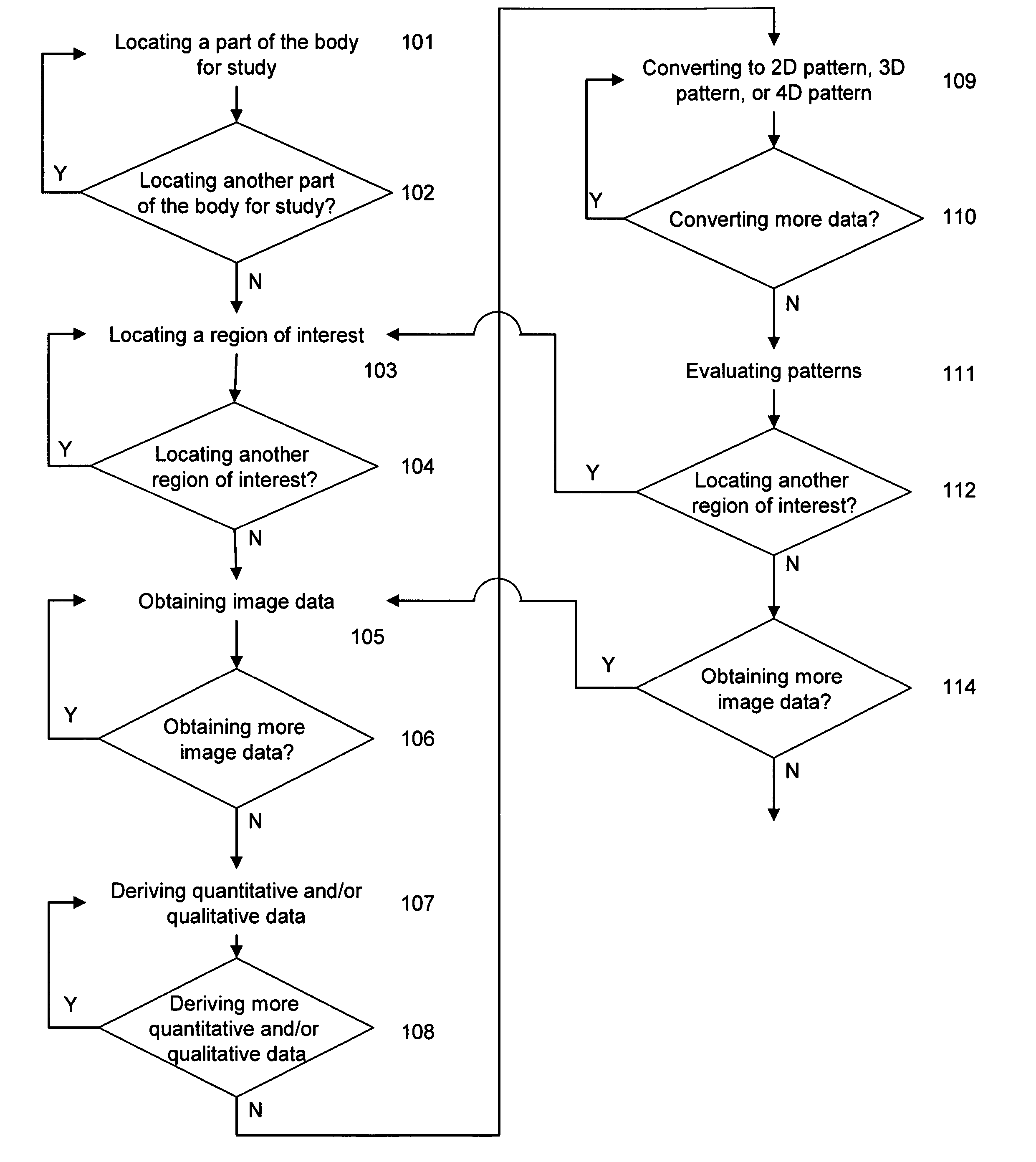

System and method of predicting future fractures

Methods of predicting fracture risk of a patient include: obtaining an image of a bone of the patient; determining one or more bone structure parameters; predicting a fracture line with the bone structure parameter; predicting a fracture load at which a fracture will happen; estimating body habitus of the patient; calculating a peak impact force on the bone when the patient falls; and predicting a fracture risk by calculating the ratio between the peak impact force and the fracture load. Inventive methods also includes determining the effect of a candidate agent on any subject's risk of fracture.

Owner:IMATX INC

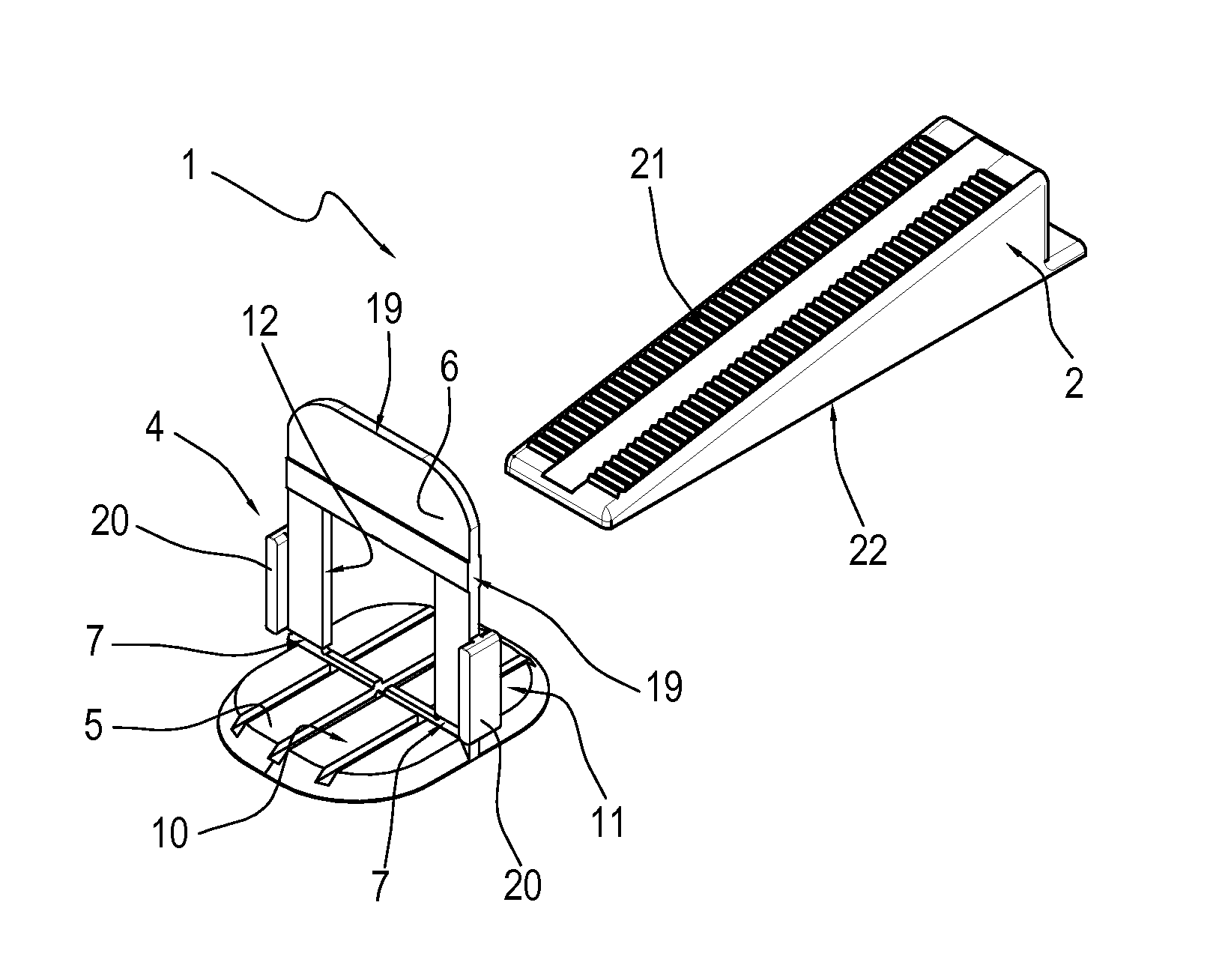

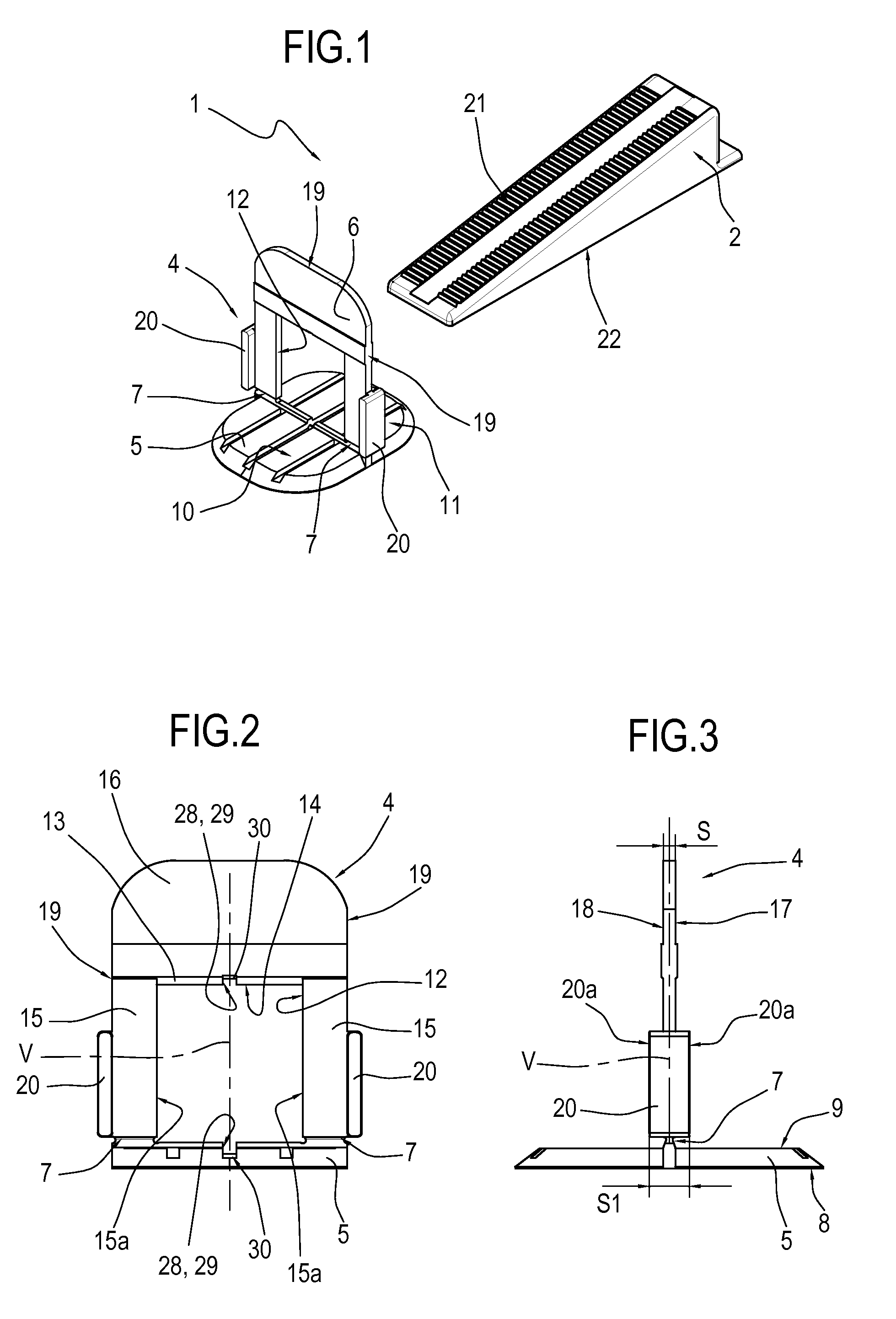

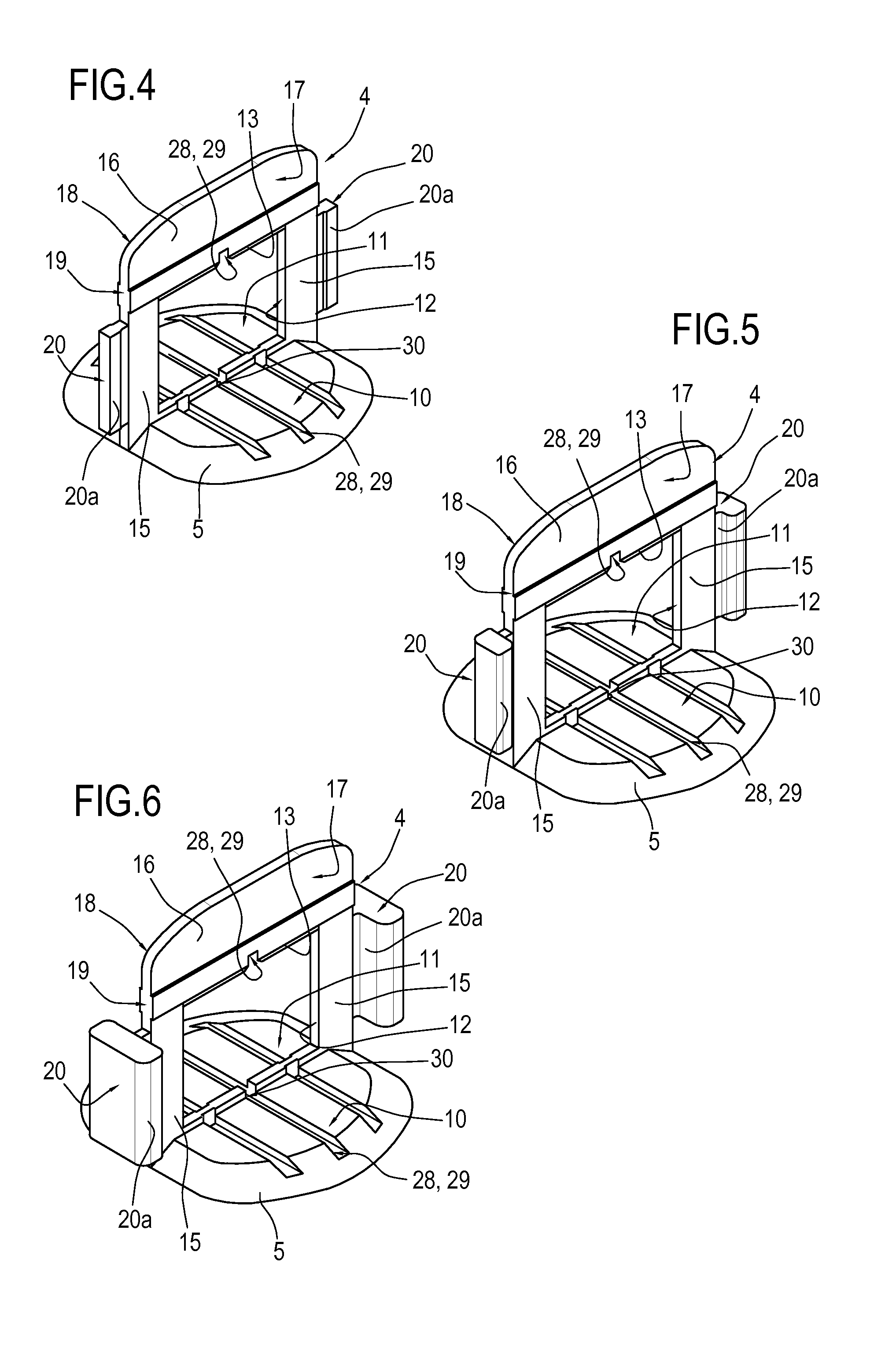

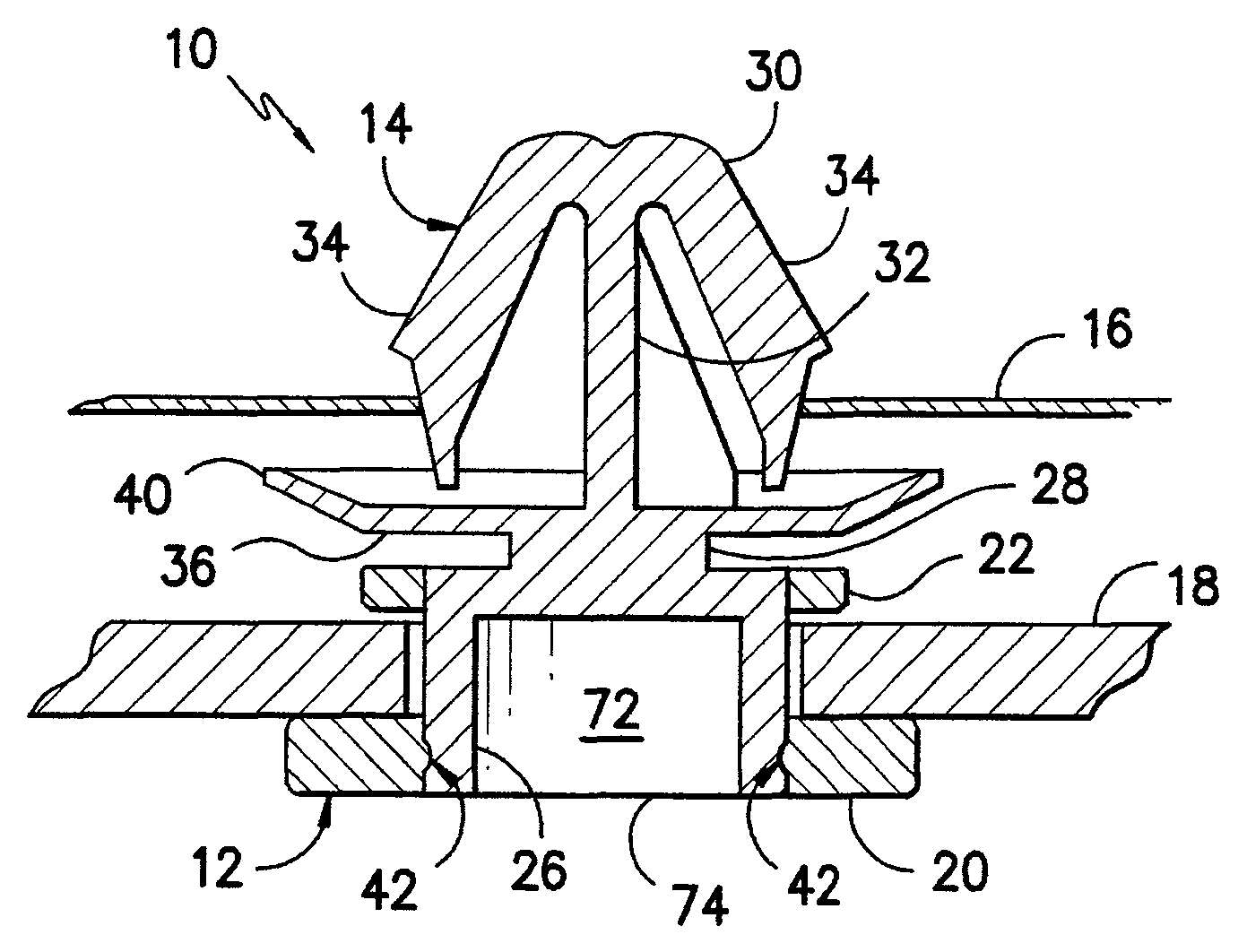

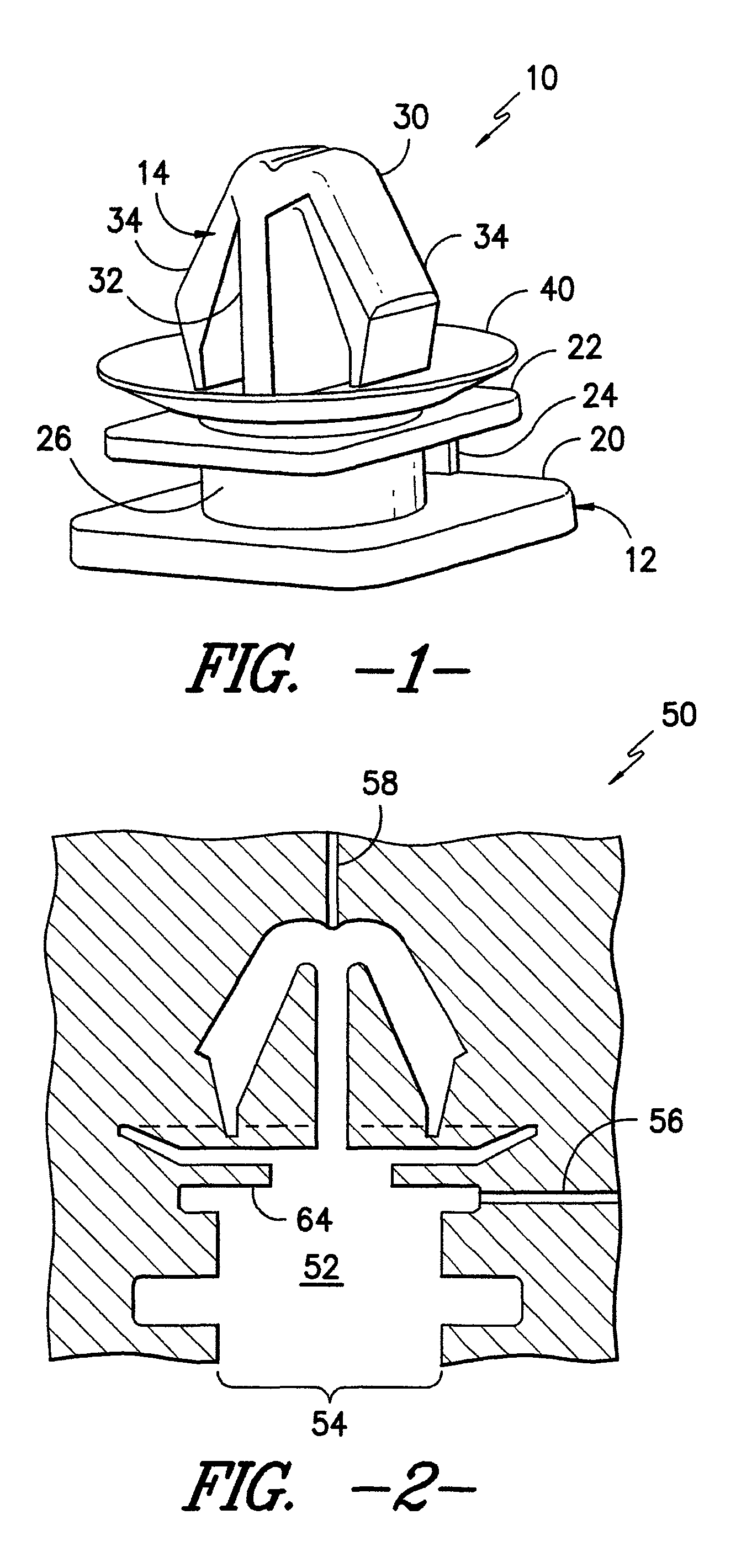

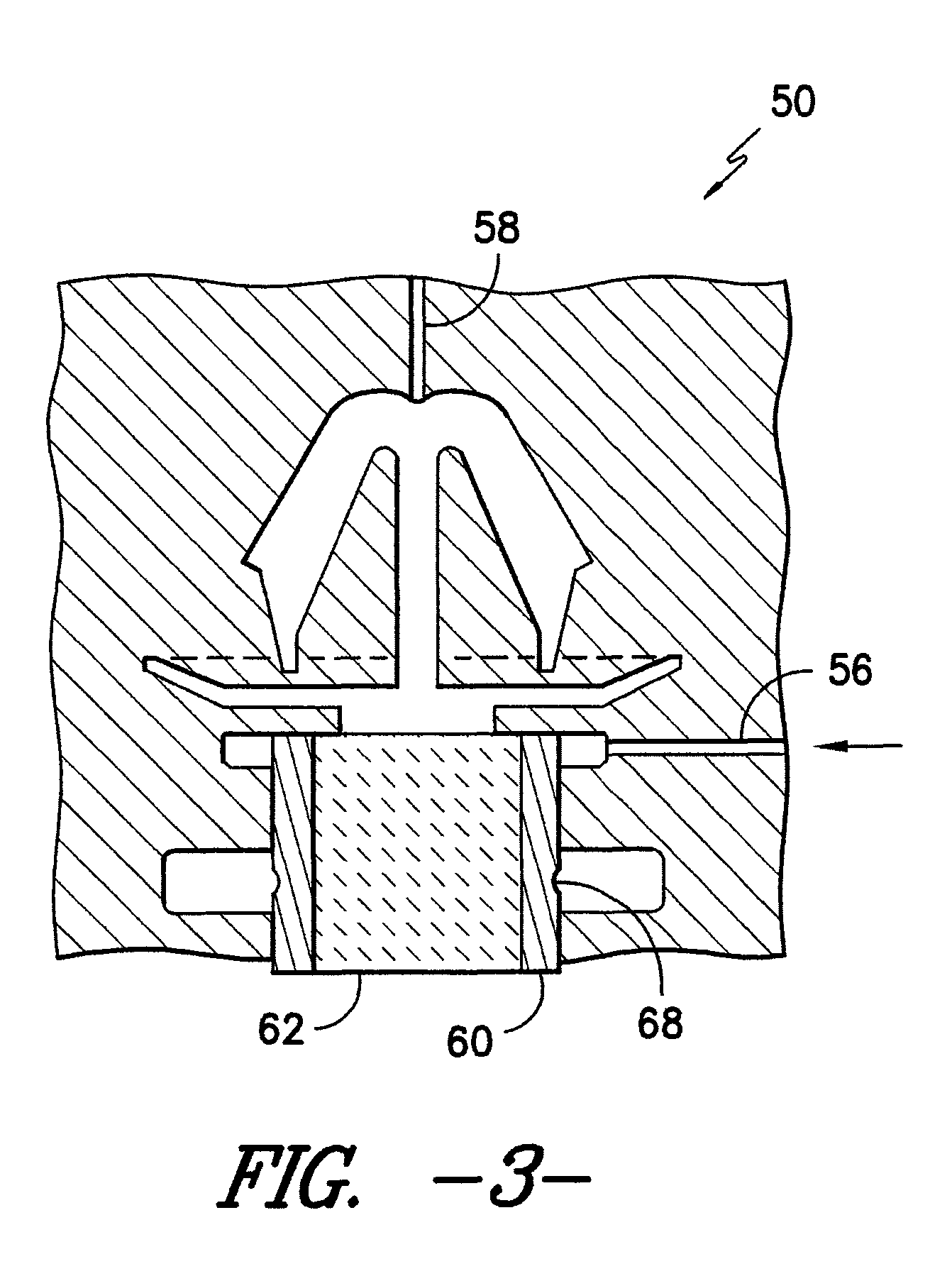

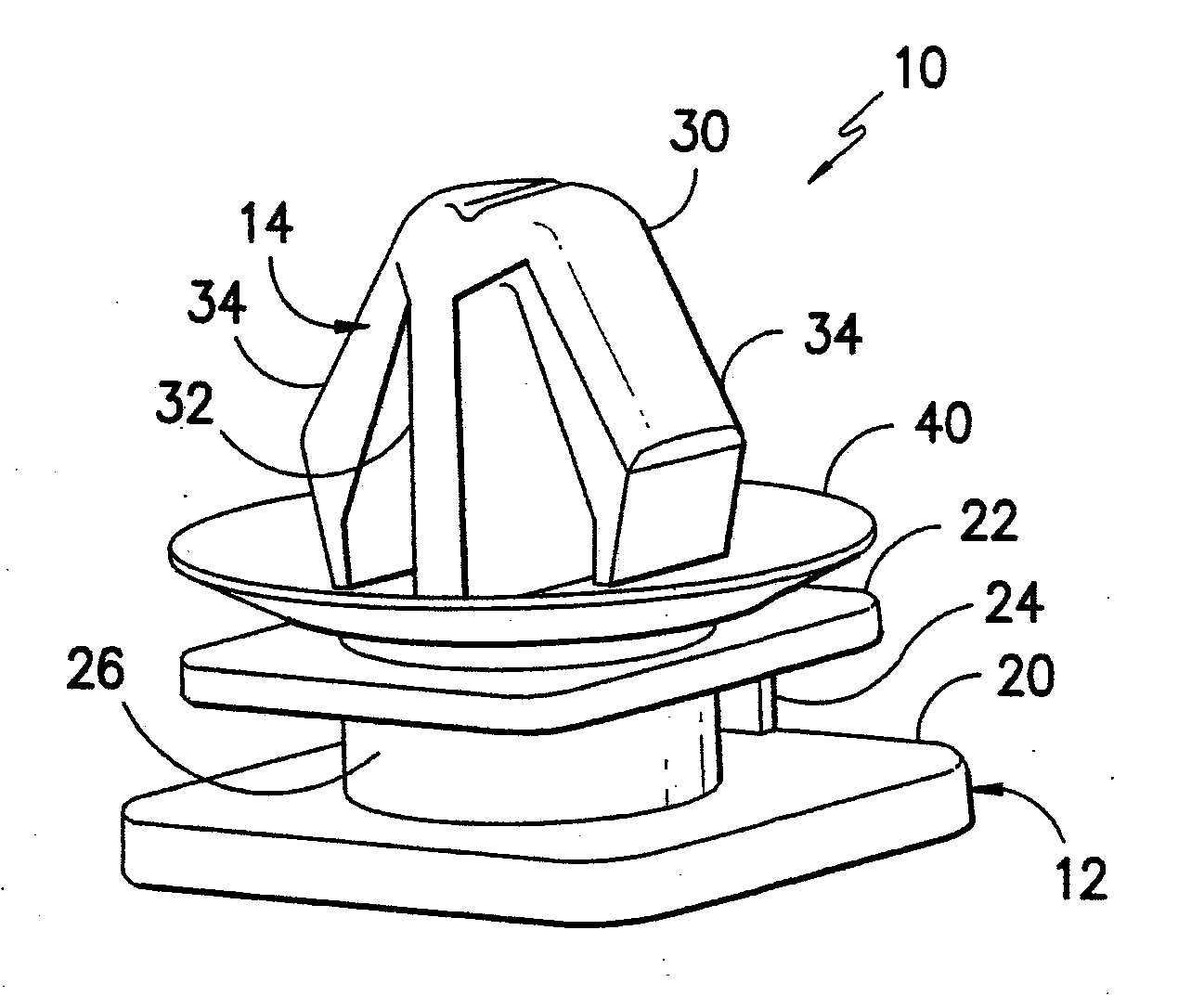

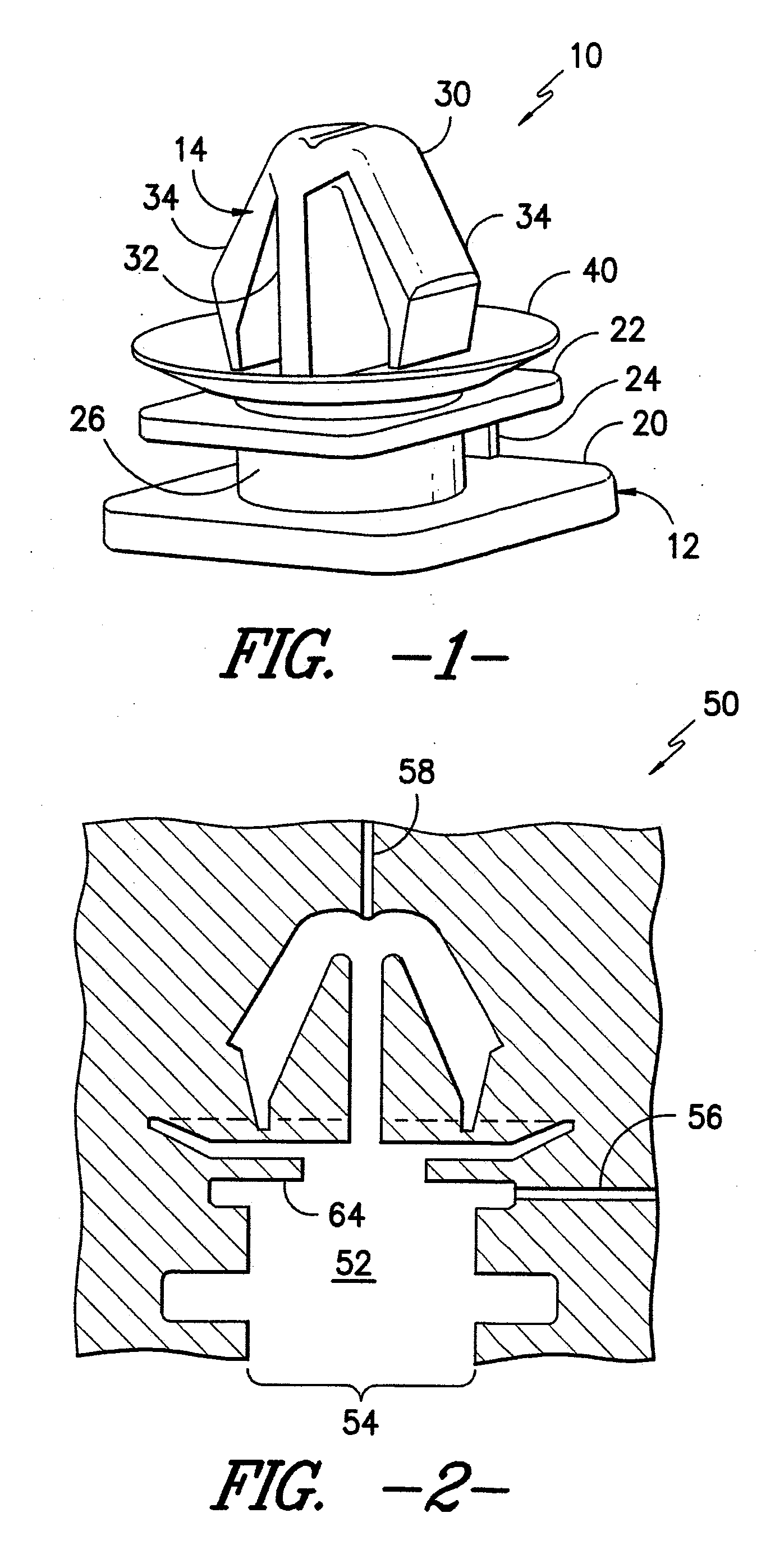

Serviceable snap-in fastener

A one piece snap-in retainer of multi-shot molded construction adapted to separate along a molded-in fracture line upon application of axial tensioning force. The retainer includes a base clip portion of molded polymer with a proximal barrel segment and a distal snap-in element projecting outwardly away from the barrel segment. The retainer also includes a head portion of molded polymer at least partially surrounding the proximal barrel segment. The molded-in fracture line includes a protuberance molded into the proximal barrel segment or the head portion at the interface in combination with an opposing complimentary mating depression molded into the other of the proximal barrel segment or the head portion.

Owner:ILLINOIS TOOL WORKS INC

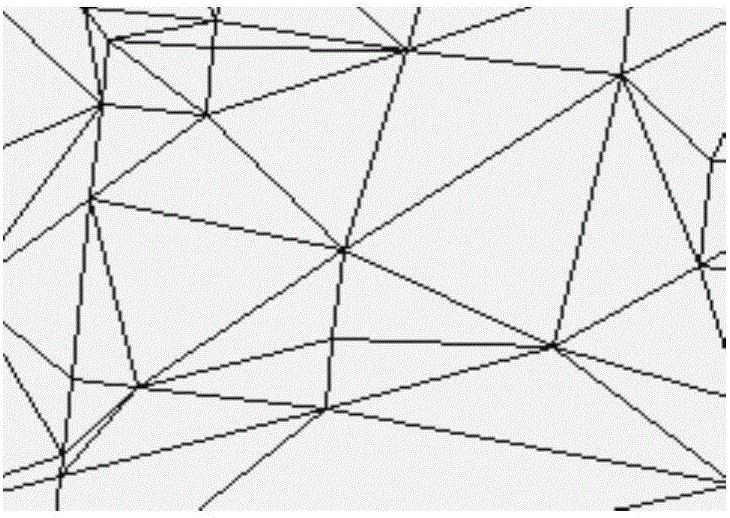

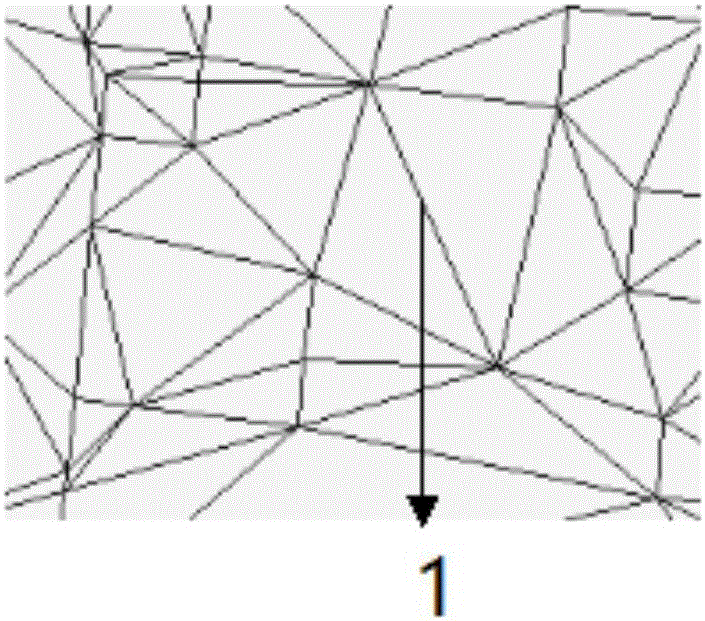

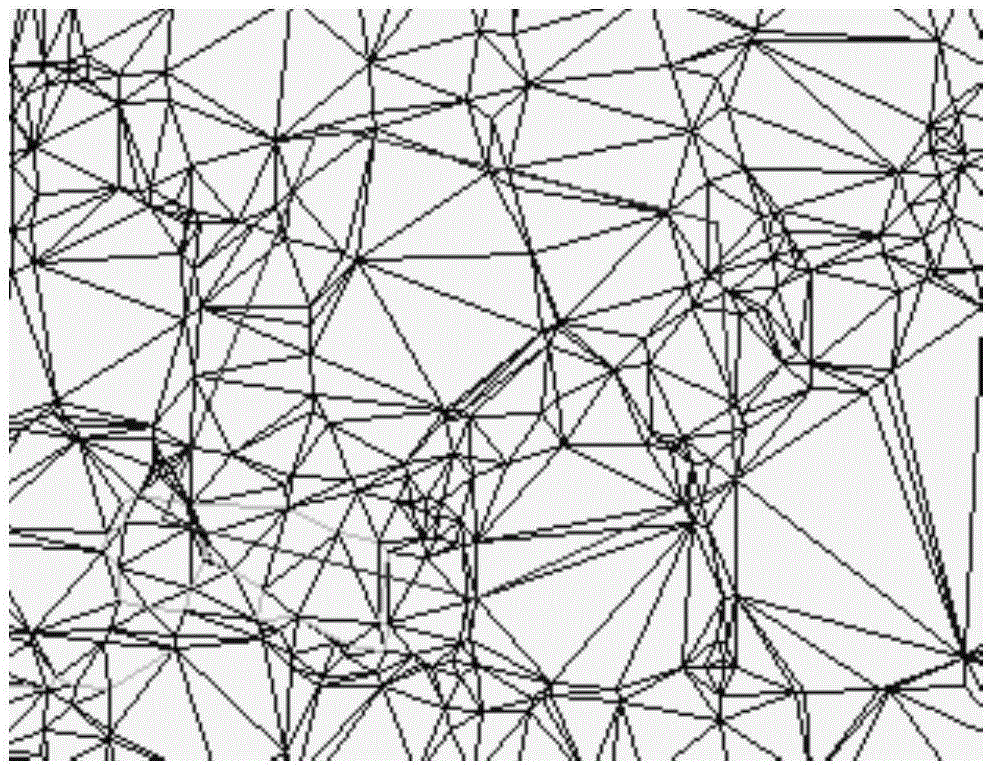

Contour line generation method and device

ActiveCN106097450AImprove production efficiencyTroubleshoot disconnect handlingImage generation3D modellingTerrainComputer graphics (images)

The invention relates to a contour line generation method and device, and belongs to the field of the geographic information system. Firstly a digital elevation model based on a Delaunay triangulation network is established, and the form of the network shape is improved; then the network shape is corrected according to various terrain lines, fracture lines and surface feature symbols so that a DTM is ensured to restore the original terrain according to the actually measured data to the greatest extent; then the contour line is tracked according to the accurate DTM so that the accuracy of the contour line is guaranteed; and finally the curve polygon boundary of the contour line for the surface feature symbols is disconnected so that the problem of disconnection processing of meeting of the contour line and the surface features, especially overlapping features and large area features, can be greatly solved. The established DTM can be used for tracking the contour line and can also be used for the field of earthwork and stonework computation and section processing and engineering design. Therefore, the elevation model is also established in slopes and roads and other areas with no requirement for drawing the contour line.

Owner:武汉瑞得信息科技有限责任公司

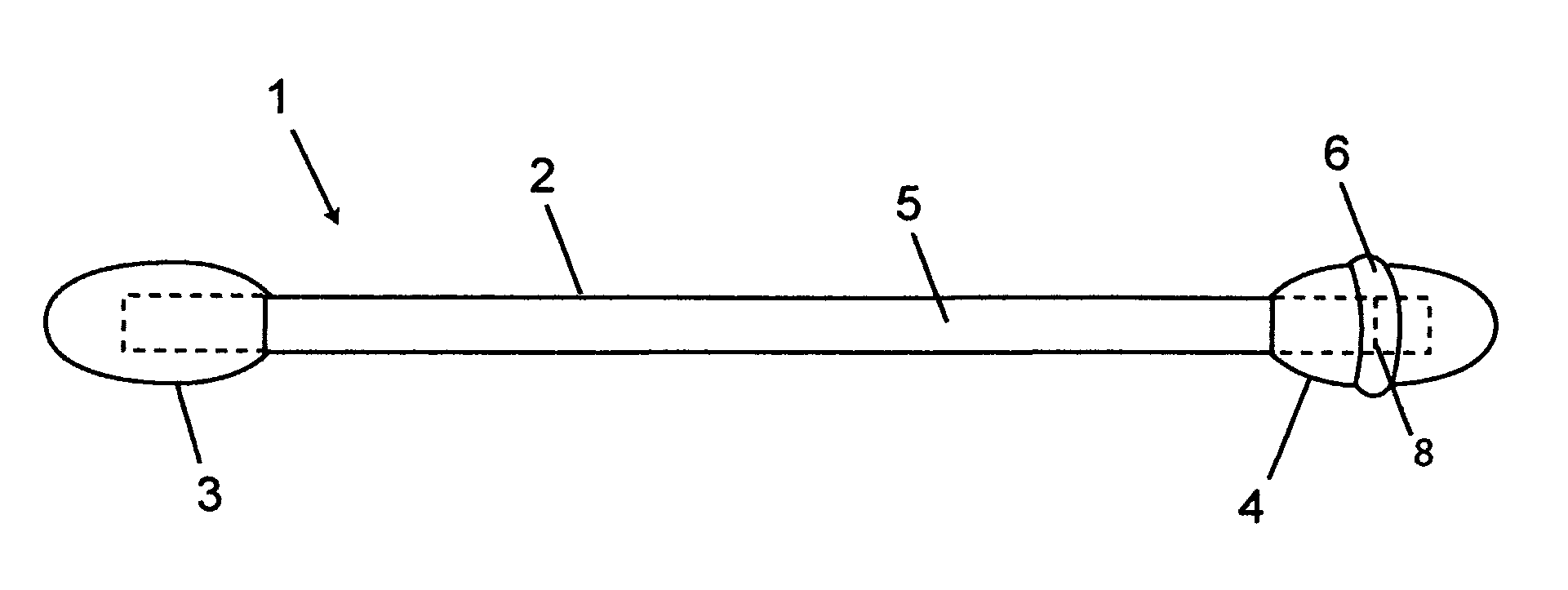

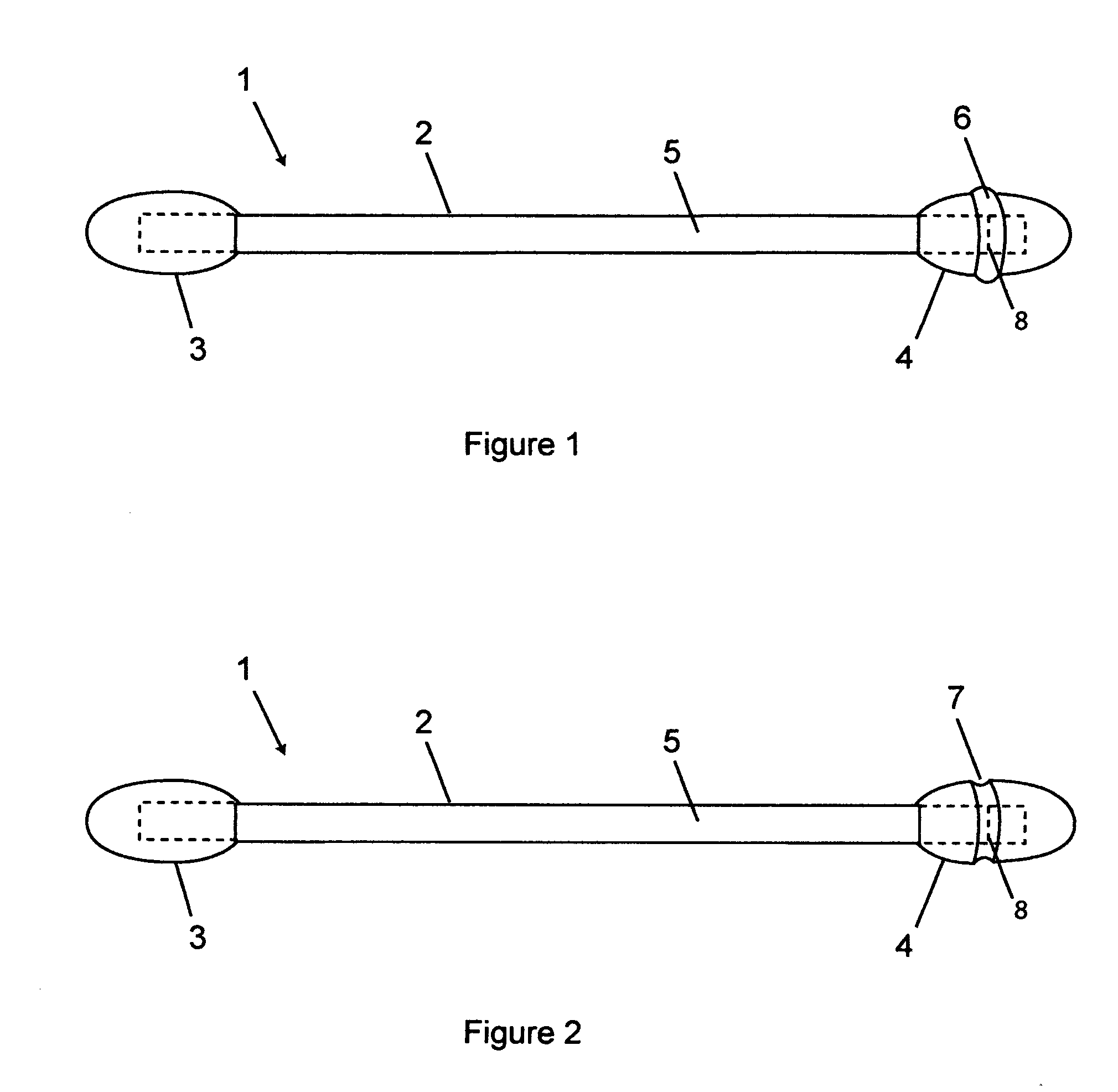

Identification means for swab applicator

An identification means for swab applicator that enables a person to distinguish one end of the swab applicator from the other end even with impaired vision or in low light conditions. In addition, the identification means enables one to accurately determine the position of a fracture line on the swab applicator for release of the fluid enclosed within the swab applicator. The identification means for swab applicator comprises of a raised ring or a ring of channel on the applicator tip positioned near the fracture line on the swab applicator that can be seen and felt.

Owner:TSAUR GARRY

Serviceable snap-in fastener

A one piece snap-in retainer of multi-shot molded construction adapted to separate along a molded-in fracture line upon application of axial tensioning force. The retainer includes a base clip portion of molded polymer with a proximal barrel segment and a distal snap-in element projecting outwardly away from the barrel segment. The retainer also includes a head portion of molded polymer at least partially surrounding the proximal barrel segment. The molded-in fracture line includes a protuberance molded into the proximal barrel segment or the head portion at the interface in combination with an opposing complimentary mating depression molded into the other of the proximal barrel segment or the head portion.

Owner:ILLINOIS TOOL WORKS INC

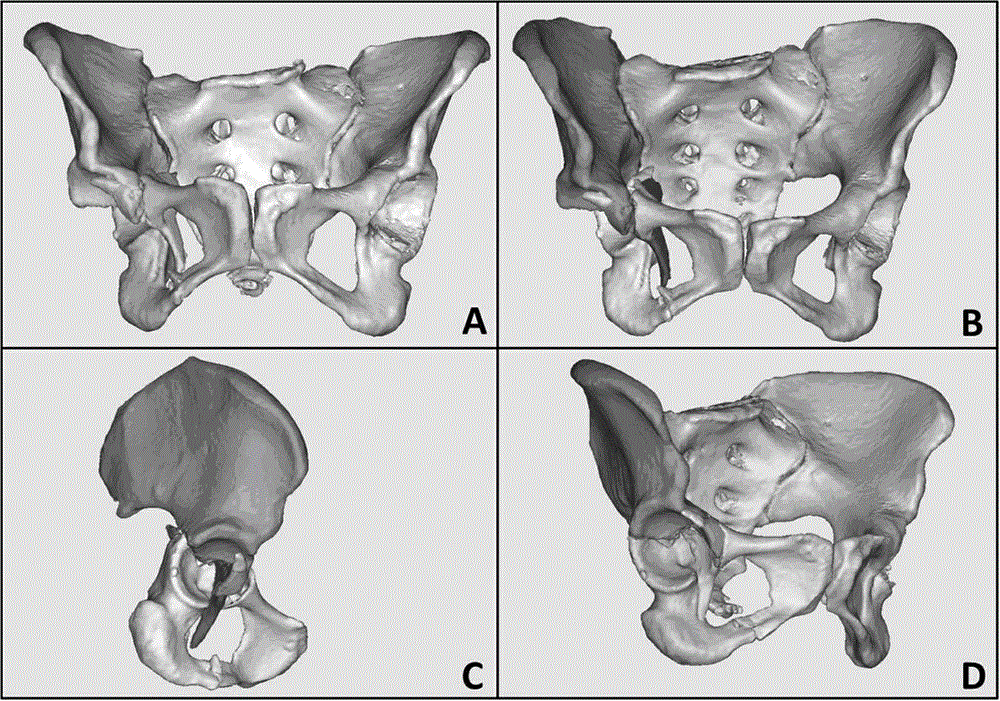

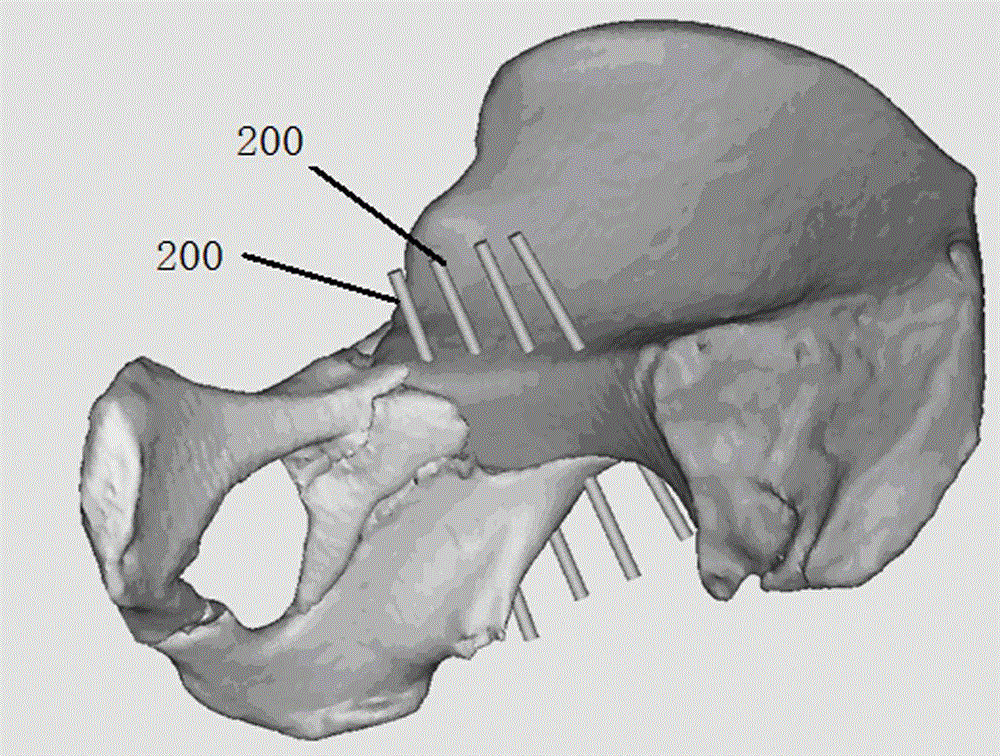

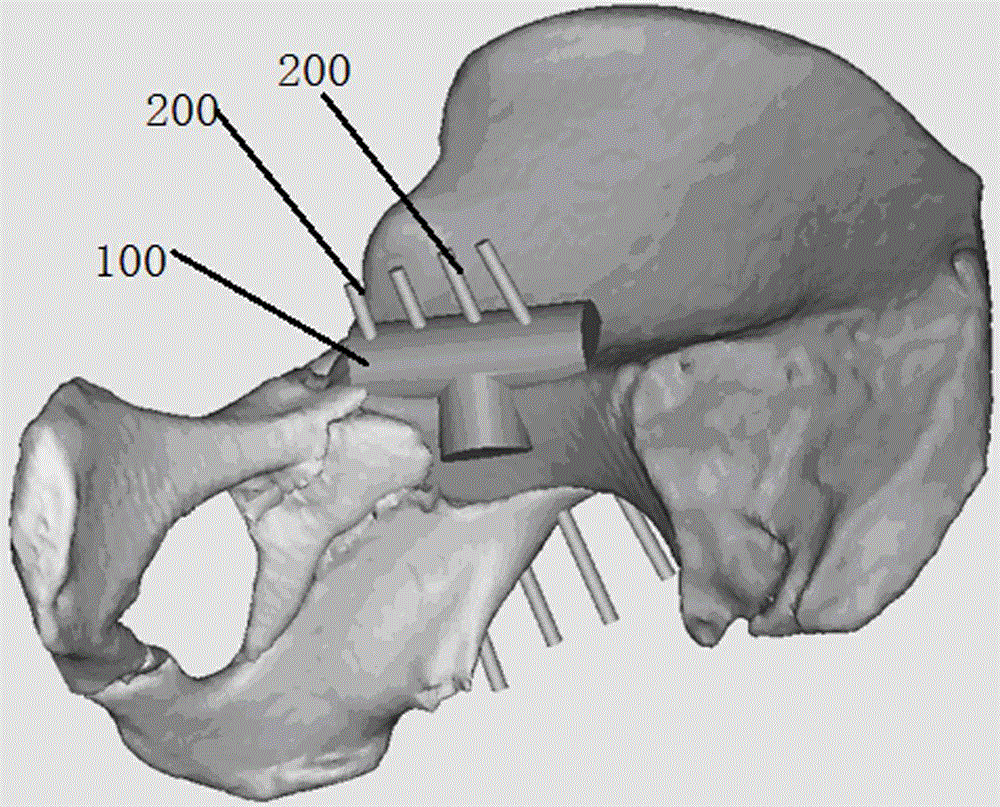

Manufacturing method for posterior column lag screw 3D navigation module used for acetabulum fracture

InactiveCN104983458AHigh precisionImprove securityFastenersFracture reductionManufacturing technology

A manufacturing method for a posterior column lag screw 3D navigation module used for acetabulum fracture comprises the following steps that A, according to simulation reestablishing, 3D reestablishing is performed according to pelvis thin layer CT scanning data of an object with the acetabulum fracture so as to obtain an original 3D reestablished model, on the basis of the original 3D reestablished model, fracture block division is performed along the fracture line, and the femur head is removed so as to obtain a fracture block separation model, and on the basis of the fracture model, a single fracture block 3D space position is adjusted to recover the normal anatomic form of the acetabulum, so that a fracture reduction model is obtained; B, according to virtual posterior column slag screw implanting simulation, on the basis of the fracture reduction model, a posterior column slag screw implanting fracture reduction model is simulated with a cylinder on the fracture reduction model; C, according to obtaining of a navigation module simulation body, the navigation module simulation body is established according to the cylinder, so that the navigation module simulation body with screw channels is obtained; D, the navigation module is obtained through 3D printing. The manufactured navigation module has the advantages that the manufacturing technology is simple, precision is high, and safety is good.

Owner:SOUTHERN MEDICAL UNIVERSITY

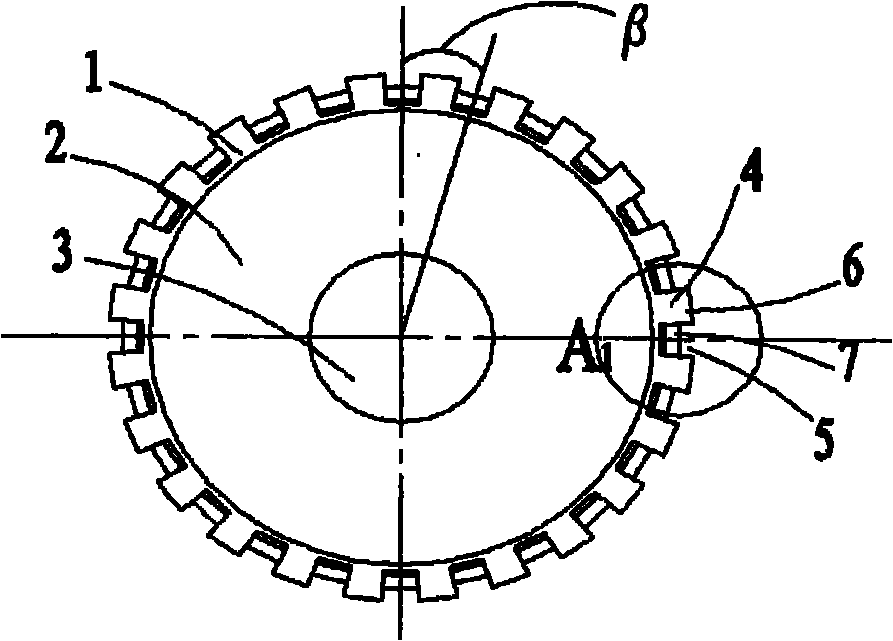

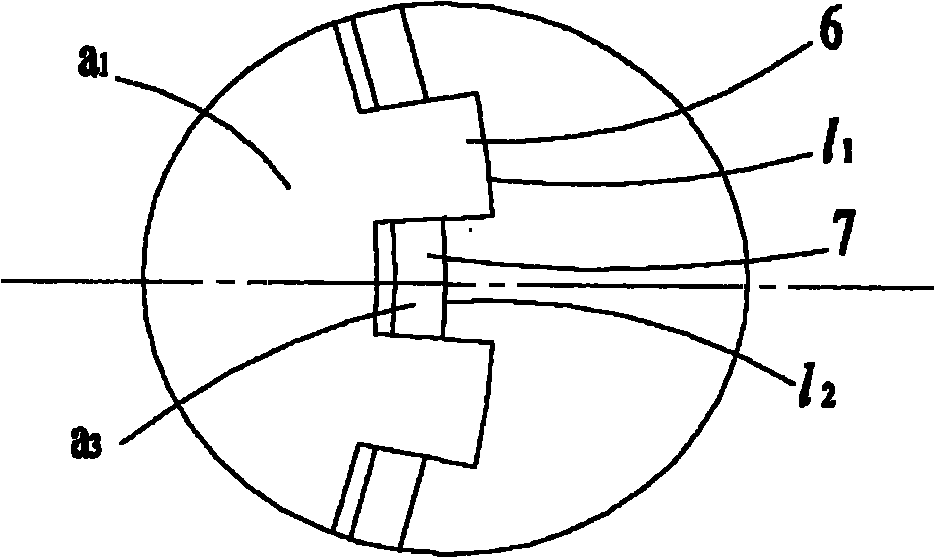

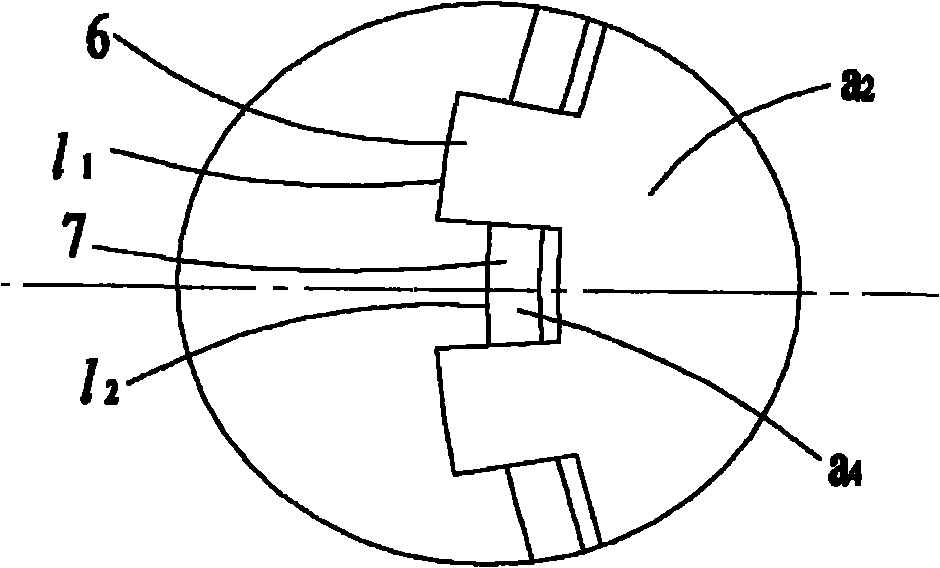

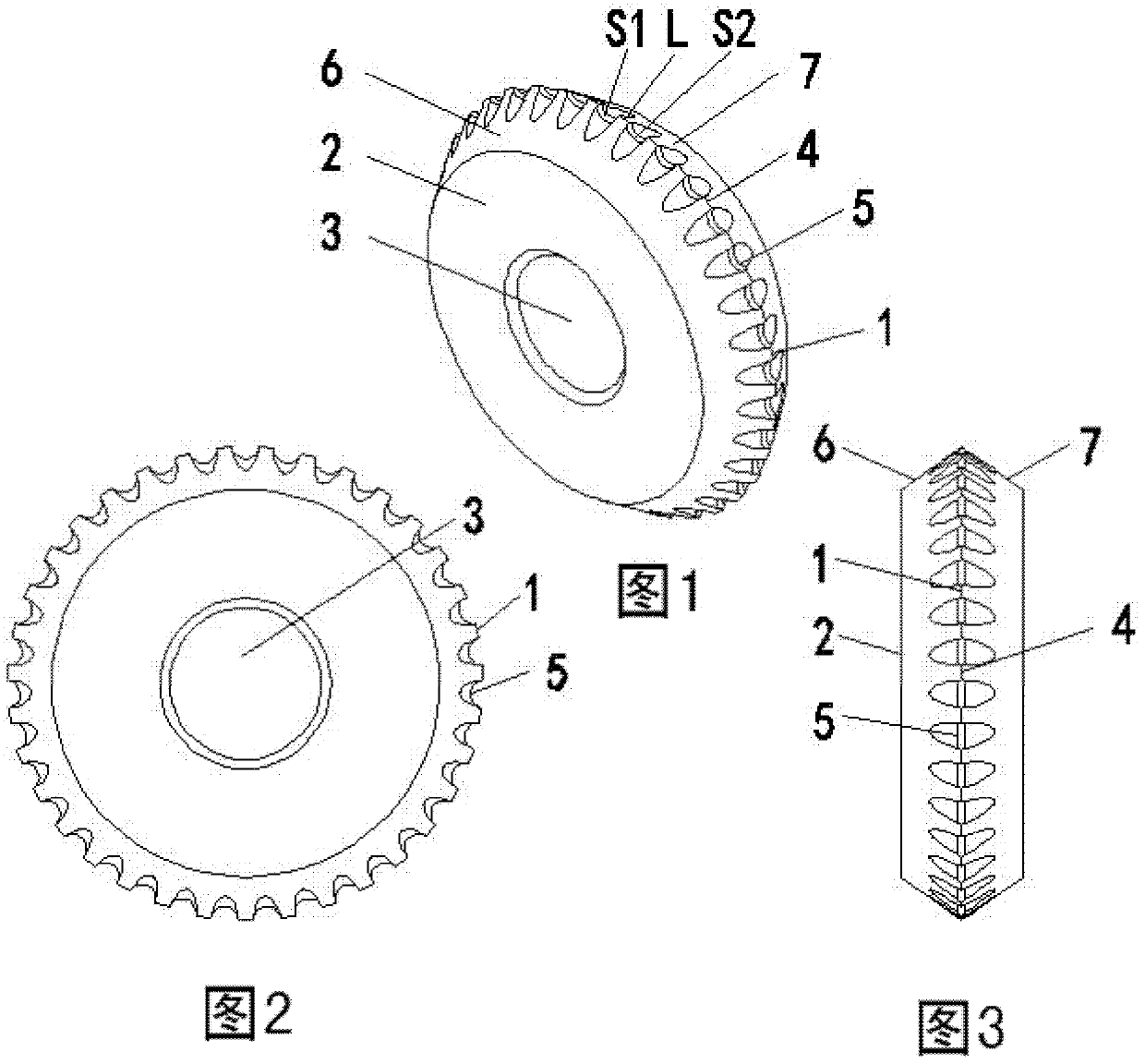

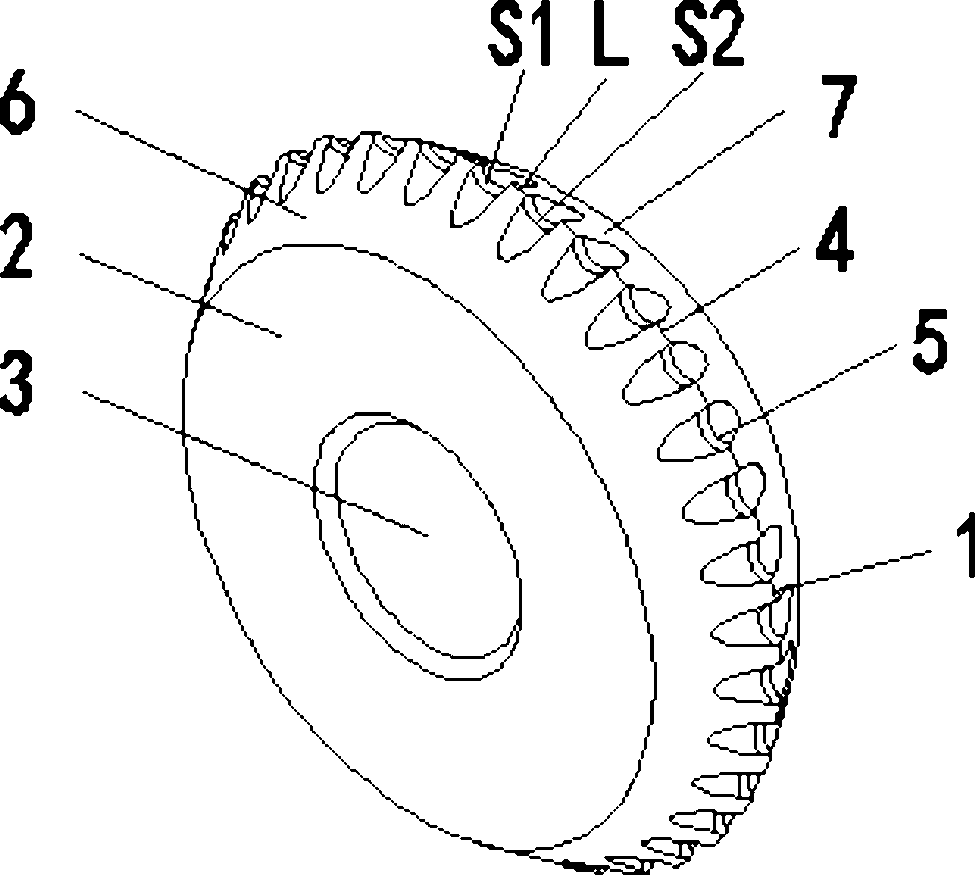

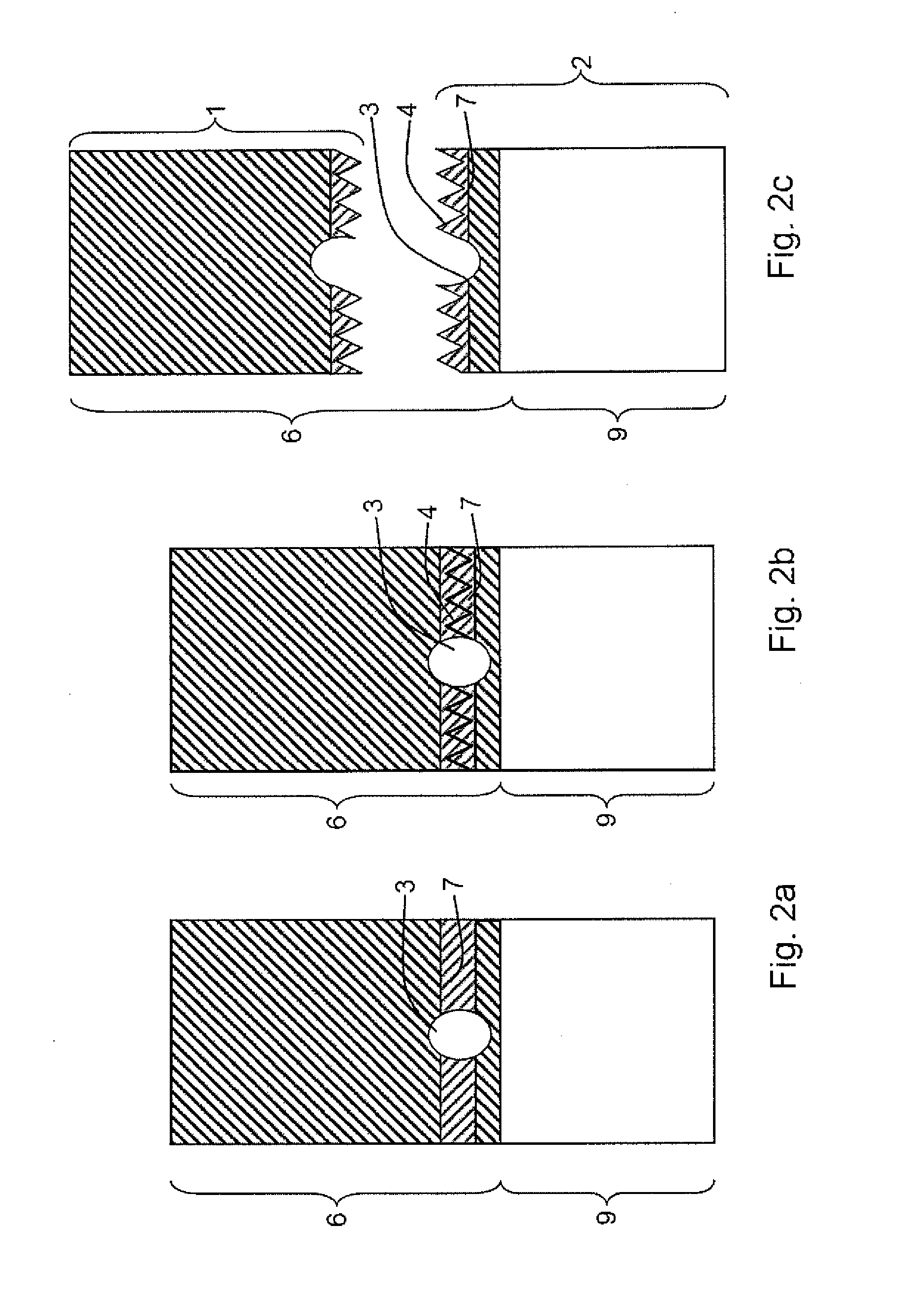

Cutter wheel for cutting glass materials and processing method thereof

The invention discloses a cutter wheel for cutting glass materials. The cutter wheel for cutting glass materials comprises a V-shaped cutting blade part (1) which is formed by a curved surface a1, a curved surface a2 and an outer edge ridge 1 and has an angle psi 1, wherein the periphery of the outer edge ridge 1 of the V-shaped cutting blade part (1) is provided with cutting blades (4) and concave structures (5) which are arranged alternately. The cutter wheel is characterized in that the cutting blade part (1) has two layers of V-shaped cutting edges, wherein the alternately distributed cutting blades (4) are used to form the first layer of V-shaped cutting edge (6) with the angle psi 1; and the bottoms of the alternately distributed concave structures (5) are used to form the second layer of V-shaped cutting edge (7). The curved surfaces a1 and a2 on the two sides of the V-shaped cutting blade part (1) of the cutter wheel are machined with two corresponding curved surfaces a5 and a6 positioned close to the disc of the cutter wheel. The included angle of the curved surfaces a5 and a6 is phi 3. The angle phi 3 is smaller than the angle of the first layer of V-shaped cutting edge (6) and ranges from 60 to 160 degrees. By adopting the cutter wheel provided by the invention, the blockage of the cutter wheel can be avoided, the glass and fracture lines can be prevented from being damaged, and the cutting quality of glass can be high.

Owner:天津北斗智能科技有限公司

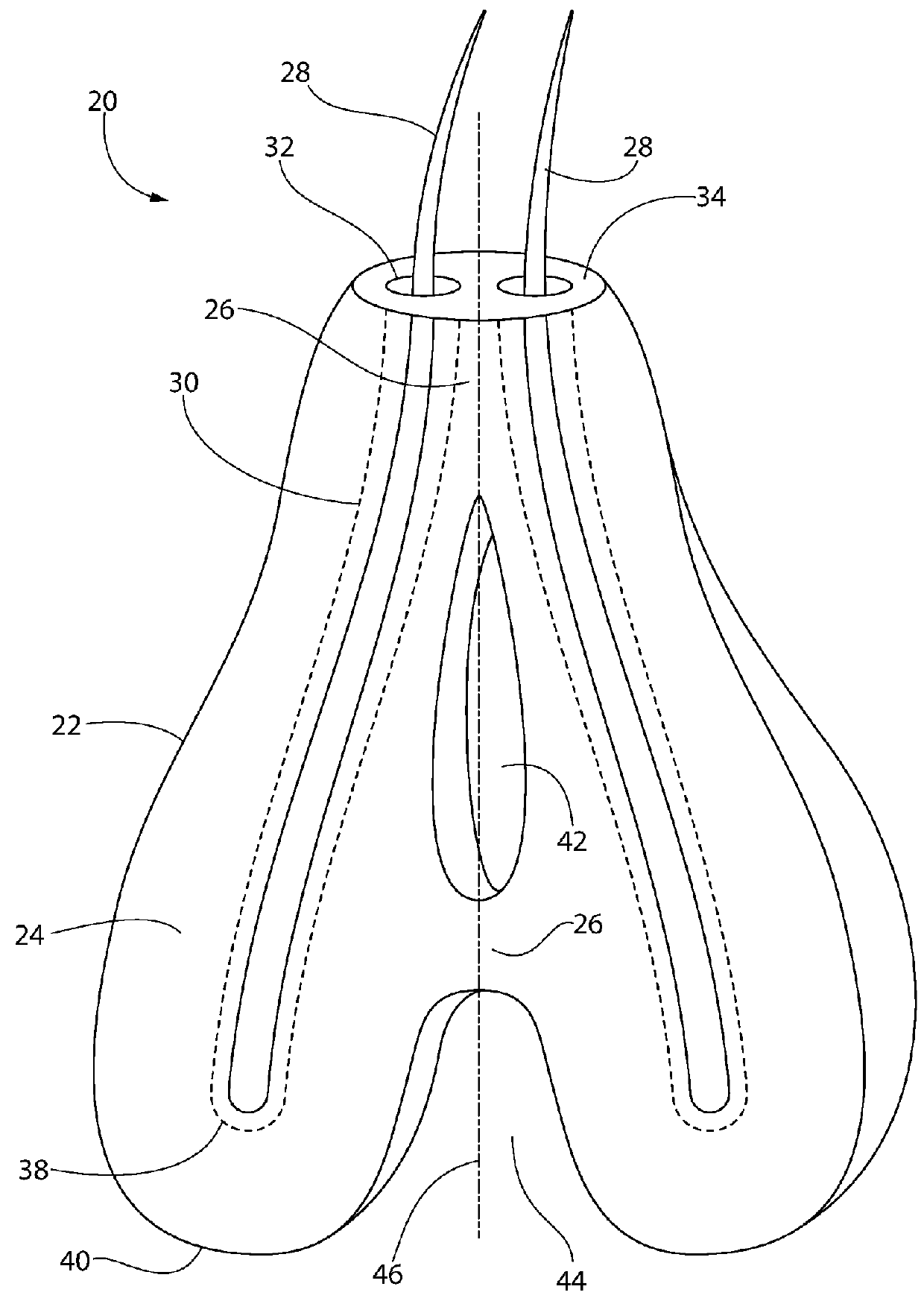

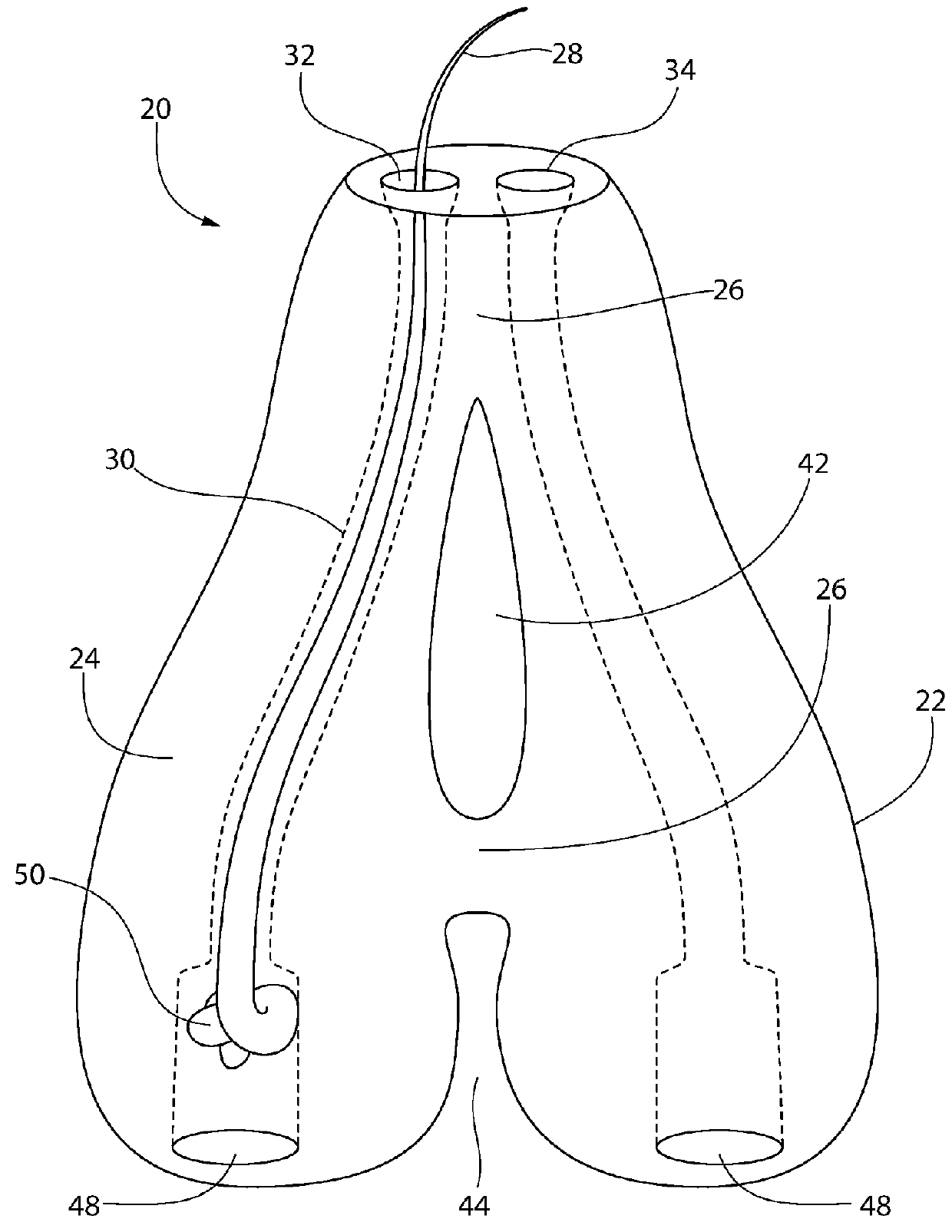

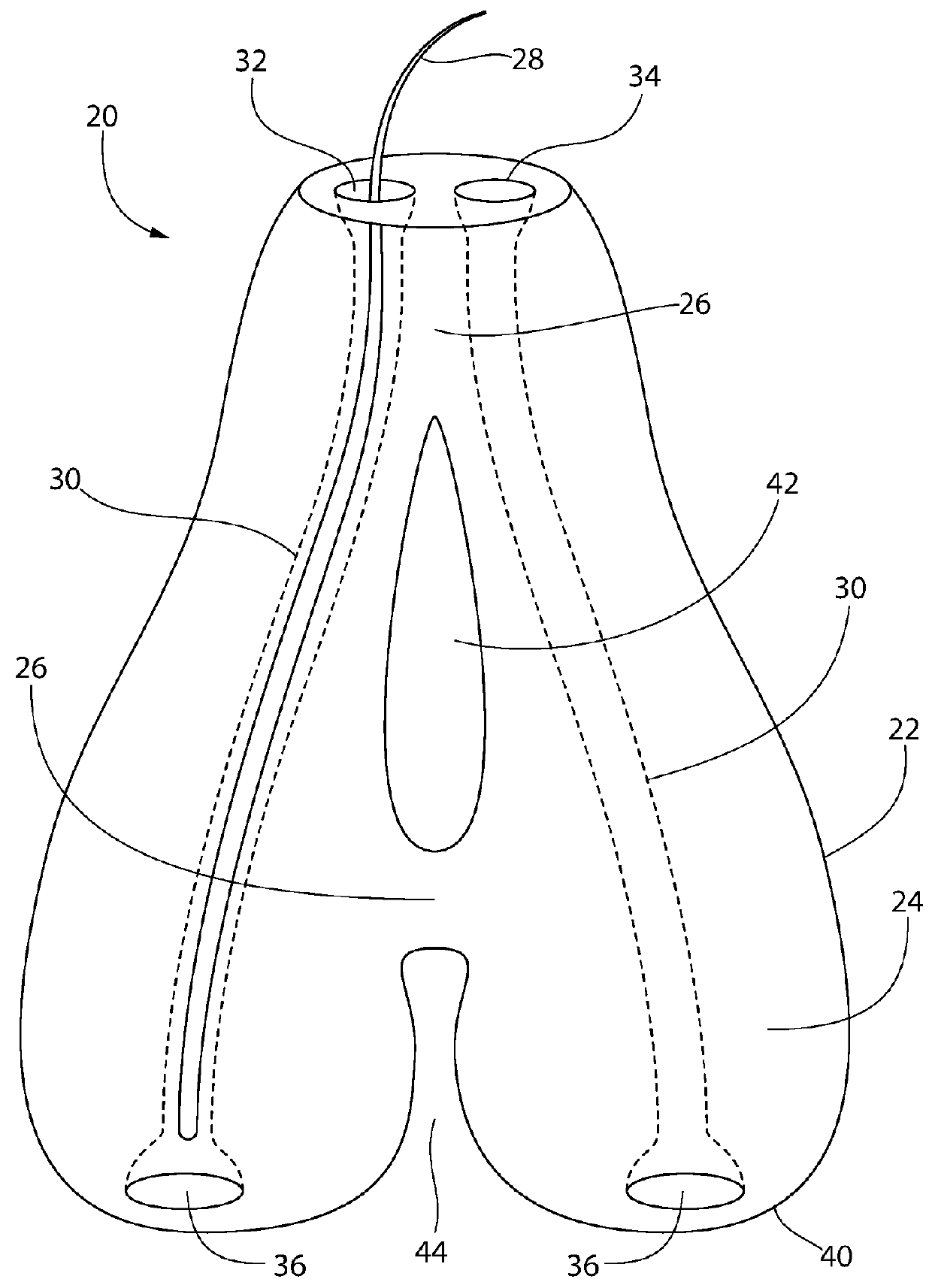

Hair implants comprising enhanced anchoring and medical safety features

ActiveUS9993334B1Avoid bacterial infectionInhibition is effectiveSuture equipmentsSkin implantsSubcutaneous implantCollagenan

A hair implant includes at least two strands including at least one of mammalian hair and synthetic hair; and an anchor, which: (a) includes silicone, (b) is configured for subcutaneous implantation, (c) includes a fracture line configured to facilitate fracturing of the anchor along the fracture line for ease of removal of the implant after subcutaneous implantation, and (d) is configured to provide a scaffold for collagen growth after subcutaneous implantation, wherein at least one of the at least two strands is joined to the anchor on one side of the fracture line and at least one of the at least two strands is joined to the anchor on an opposite side of the fracture line such that each fragment formed by fracturing the implant includes at least one of the at least two strands. Looped implants, a hair restoration method and an implant manufacturing method are also disclosed.

Owner:LORIA HAIR IMPLANT CO LLC

Making method for fracture model of artificial bone

InactiveCN102522039ASimple and fast operationImprove performanceEducational modelsDICOMBone specimen

The invention discloses a making method for a fracture model of artificial bone, which comprises the following steps: carrying out continuous spiral CT (computed tomography) scanning on affected bone along the cross section to obtain a multi-layer image, storing according to a Dicom 3.0 standard and making out a three-dimensional reconstruction model of the bone and a fractured section by utilizing Mimics software; fractioning the model to be processed by UG (Unigraphics) software and making an appearance mold of the bone and a mark groove for the position of a fracture line of the archetypalbone by numerically-controlled mill processing; and carrying out three-dimensional printing to obtain a fractured section model, also placing at the position of the mark groove of the corresponding bone appearance mold, jointing an upper mold and a lower mold, filling polymethyl methacrylate, standing at room temperature, solidifying and taking out the fractured section model so as to obtain a specimen of the fracture model of the artificial bone. In this way, the prepared fracture model is made in one step, and the complicated processes of obtaining a bone specimen and afterwards making fracture artificially, the consumption of equipment and the worry of enhancing the cost are omitted. The condition of stress between fractured sections is comprehensively and truly reflected by an obtained fracture interface, and the assistance is provided to the treatment of clinical fracture.

Owner:TIANJIN HOSPITAL

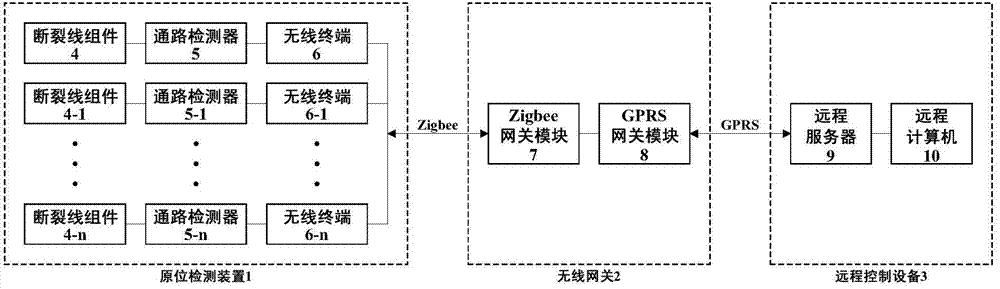

Remote monitoring system and method for fatigue cracks of orthotropic steel bridge deck slab

ActiveCN103944970AMake sure there are no dead endsLabor savingMaterial analysis by optical meansTransmissionShortest distanceAgricultural engineering

The invention provides a remote monitoring system and method for fatigue cracks of an orthotropic steel bridge deck slab. The remote monitoring system for the fatigue cracks of the orthotropic steel bridge deck slab comprises an in-situ detection device, a wireless gateway and a remote control device, wherein the in-situ detection device is composed of a fracture line assembly, a path detector and a wireless terminal, the wireless gateway is composed of a Zigbee gateway module and a GPRS gateway module, the remote control device is composed of a remote server and a remote computer, the fracture line assembly is composed of optical fibers or resistance fracture lines which are arranged in a bidirectional and orthorhombic mode, the path detector is connected with the facture line assembly and used for detecting the connection and disconnection of each fracture line in the fracture line assembly according to a command of the wireless terminal, a Zigbee short-distance wireless transmission network is formed between the Zigbee gateway module and the wireless terminal, and the GPRS gateway module is in remote communication with the remote server through an GPRS. By the adoption of the remote monitoring system and method for the fatigue cracks of the orthotropic steel bridge deck slab, long-term remote monitoring of the fatigue cracks of the orthotropic steel bridge deck slab is achieved, and the system and method can be applied to practical engineering.

Owner:SHANGHAI JIAO TONG UNIV

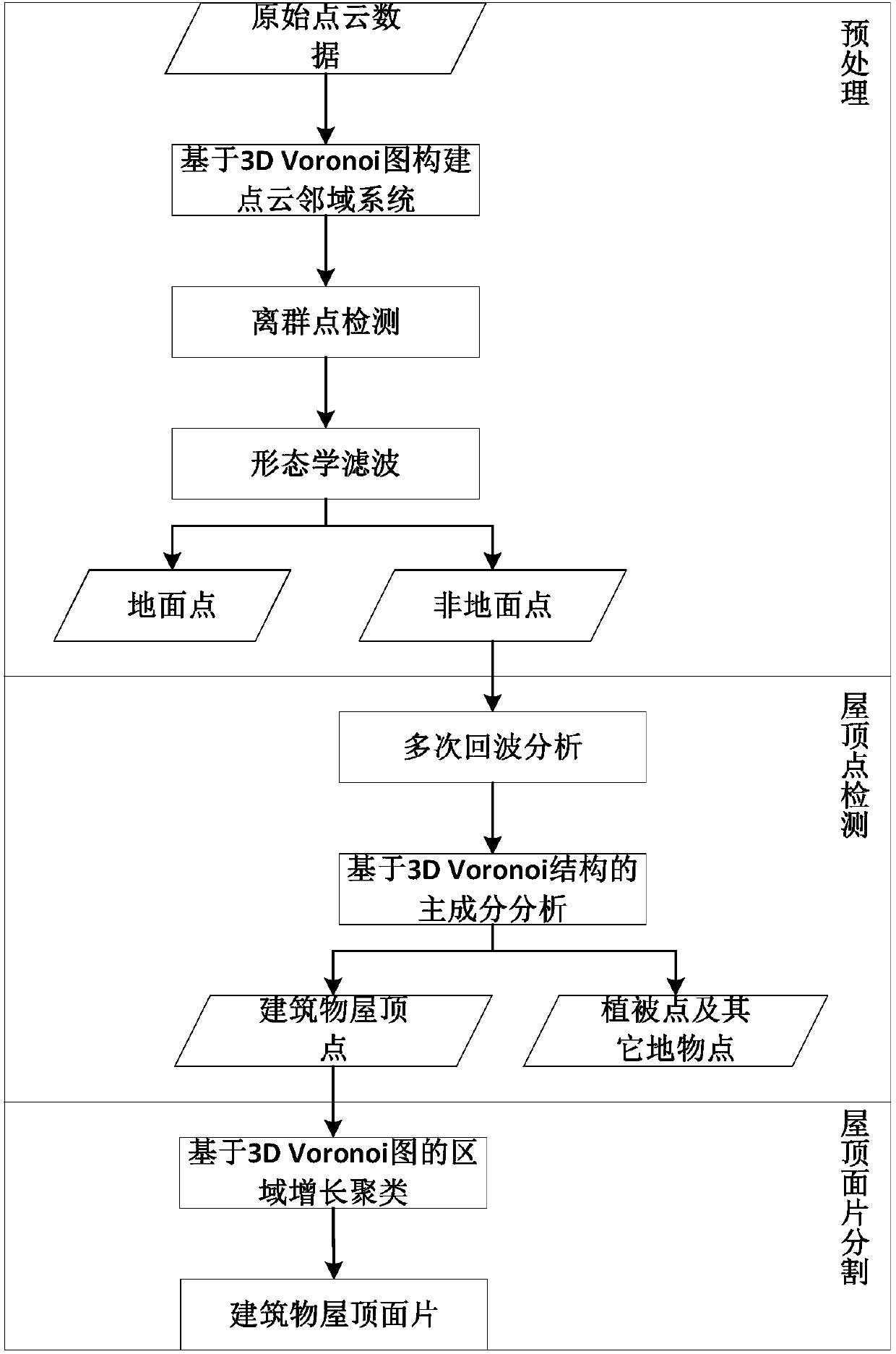

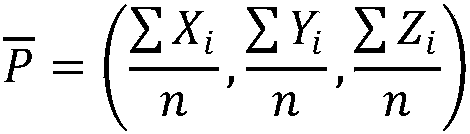

Airborne LiDAR point cloud roof patch segmentation method and system

InactiveCN107644452ADisplay spaceShow Proximity AnalysisElectromagnetic wave reradiation3D-image renderingVegetationPoint cloud

The invention provides an airborne LiDAR point cloud roof patch segmentation method and system. Based on a 3D Voronoi diagram, airborne LiDAR point cloud roof patch segmentation is carried out. The method comprises the steps that a point cloud neighborhood system is built based on the 3D Voronoi diagram for airborne LiDAR point cloud data; outlier detection is carried out, and outliers are deleted; morphological filtering is used to separate ground points and non-ground points in the point cloud data; the difference between a building and vegetation in multiple echo information of the point cloud data is used to initially distinguish building points and vegetation points to acquire initial building point cloud; based on a 3D Voronoi neighborhood, vegetation points and fracture line pointson the ridge of the building are removed from the initial building point cloud; the characteristic that a building wall normal vector is perpendicular to the direction of a plumb line is used to remove the wall points of the building to acquire the roof points of the building; and based on the 3D Voronoi neighborhood connectivity, the final building roof patch is acquired through area growth.

Owner:WUHAN UNIV

High-permeability glass cutter wheel with chamfer on side edge of concave part of cutting edge

ActiveCN102557424AGuaranteed impact strengthReduce areaGlass severing apparatusGlass chipEngineering

The invention relates to a high-permeability glass cutter wheel with a chamfer on the side edge of a concave part of a cutting edge. The cutter wheel is provided with a V-shaped cutting edge part, a disc surface and a shaft hole, wherein the V-shaped cutting edge part comprises a first curved surface S1, a second curved surface S2 and an outer edge ridge L. The cutting edge and the concave part are formed on the periphery of the outer edge ridge L of the V-shaped cutting edge part; and a first chambering oblique surface and a second chambering oblique surface which are symmetrical with each other are formed on the side edge of the concave part. Due to the adoption of the structure, the blockage of glass chips in the concave part of the cutter wheel can be avoided or reduced, the cutting pressure is reduced, and a destructive fracture line at the cutting edge of glass is reduced, so that the glass cutting quality is improved, and the service life of the cutter wheel for cutting the glass is improved.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

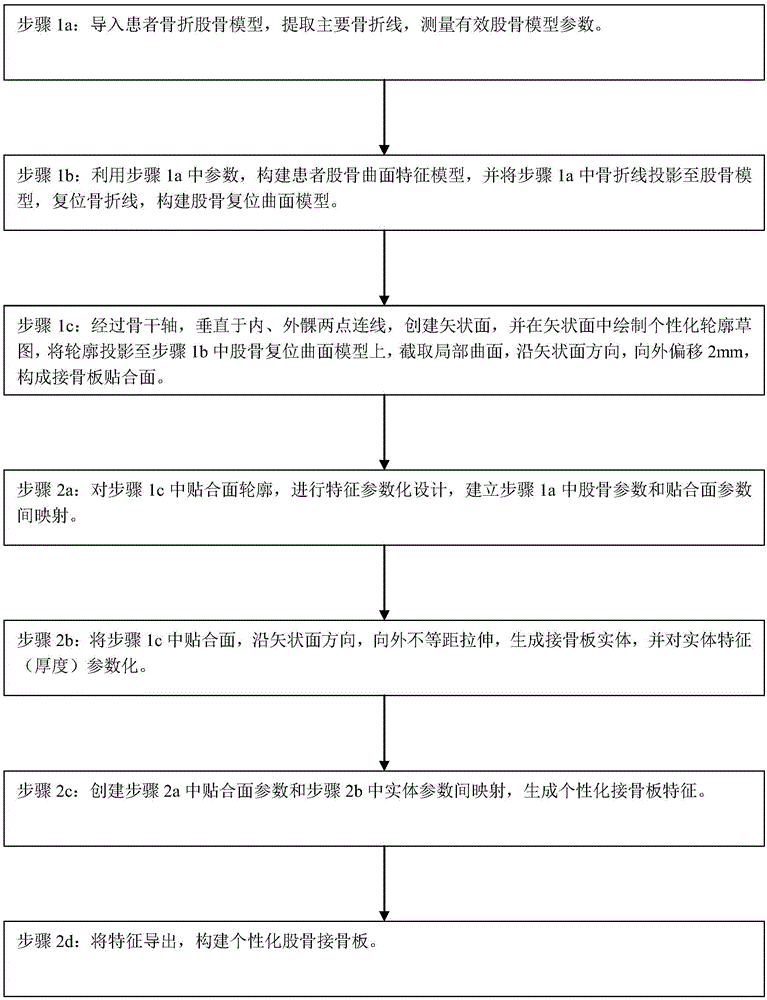

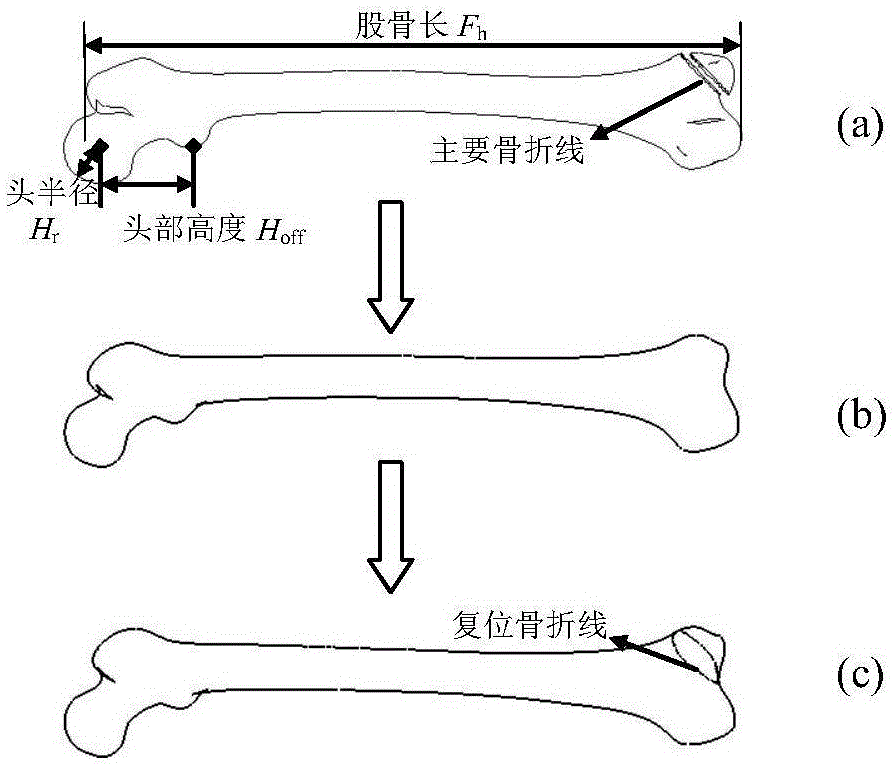

Customized far-end dissect type bone plate design method based on patient femur parameter

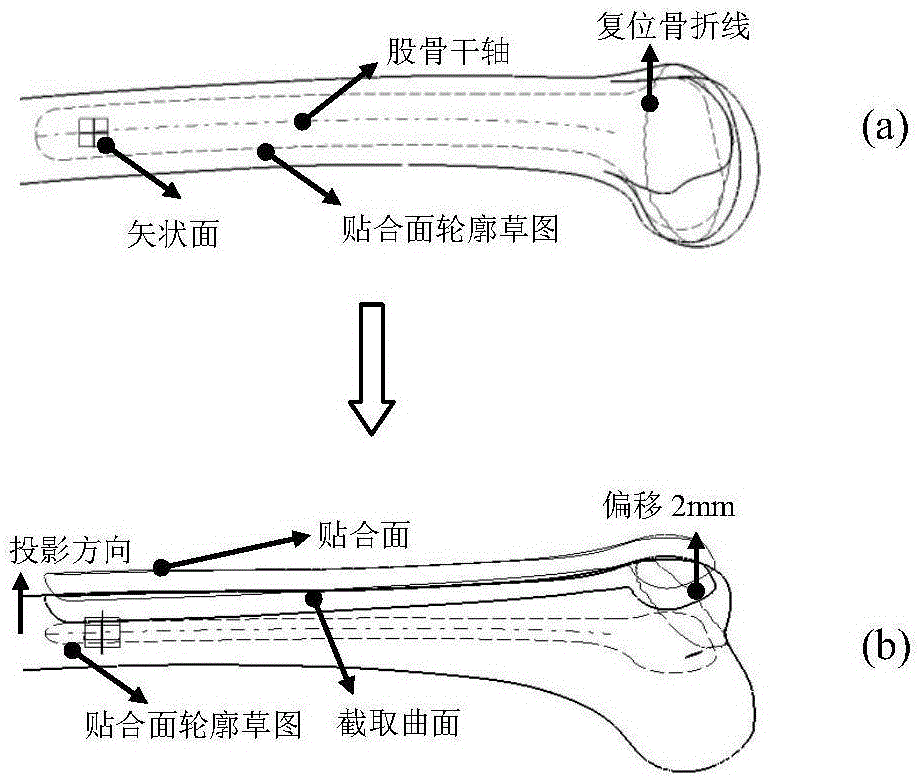

InactiveCN105069181AImprove operational efficiencyImprove the effect of surgerySpecial data processing applicationsBone platesSagittal planeModel parameters

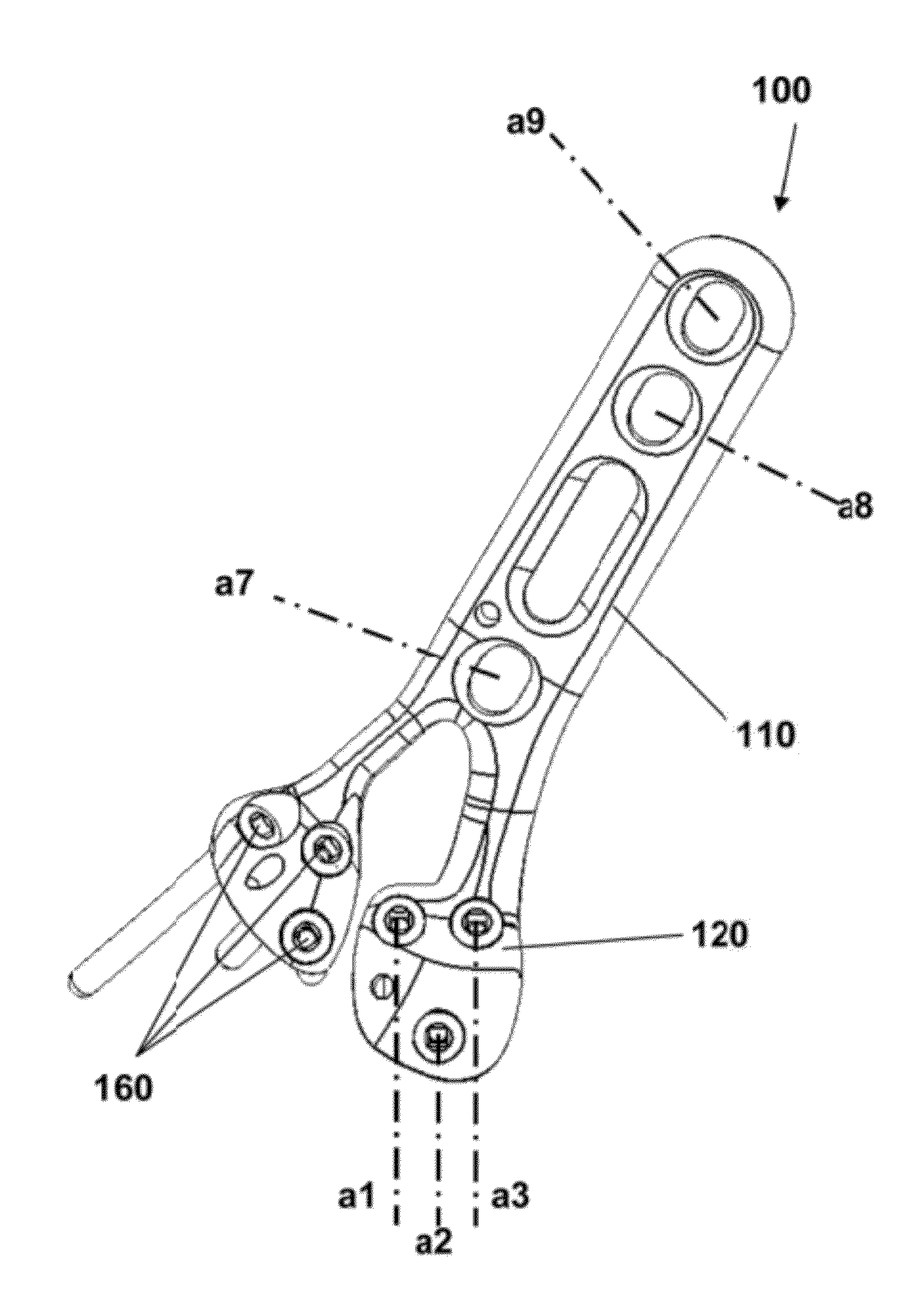

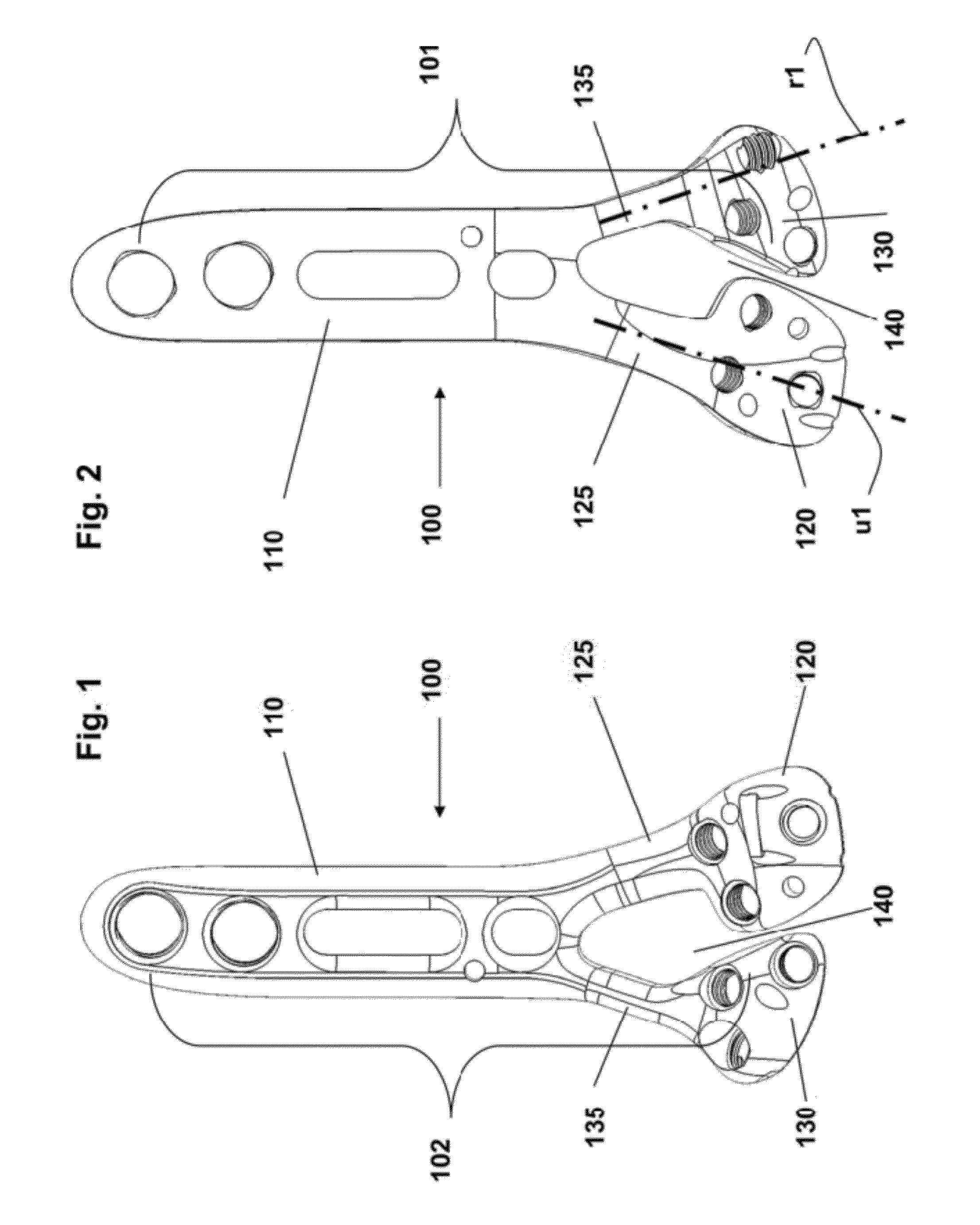

The invention discloses a customized far-end dissect type bone plate design method based on patient femur parameters; the method comprises the following steps: leading in a patient fracture model, and measuring effective femur model parameters; using the effective femur parameters to build up a patient femur curved surface characteristic model, projecting a main fracture line to the femur model, restoring main fracture traces, and building up a femur fracture reset curved surface model; drafting a customized contour sketch on a femur sagittal surface, projecting the contour to the femur reset model, obtaining a local curved surface to form a femur binding surface, parameterizing the binding surface contour, and building up mapping between the femur parameters and the binding surface parameters; extending the binding surface outwards at unequal pitchs in a sagittal surface direction so as to build up a bone plate entity, defining entity characteristics, building up mapping between the binding surface and entity characteristic parameters, and forming bone plate characteristics; leading out the characteristics so as to generate a customized bone plate. The customized far-end dissect type bone plate design method uses patient femur parameters to directly and accurately build up the customized dissect type bone plate, can fast generate a same kind bone plate according to parametric modification, thus providing important meanings for customized design of the patient bone plate in a bone surgery.

Owner:HOHAI UNIV CHANGZHOU

Methods and kits for treating fractures with a biological agent

A method and kit for treating fractures in a subject entailing placing a temporary fixation device containing a wire in a percutaneous manner across a fracture line, drilling across the fracture line and delivering a biological agent. The biological device is delivered through an injection device which may be the same as the drilling device or different therefrom. The biological agent is delivered uniformly across the complete fractured bone and to the contralateral surface of the fractured bone through an injection device. The method may comprise additional steps of sliding a cannula over the fixation device and affixing the cannula to an outer surface of the fracture. In this embodiment, the drilling device, and later the injection device are placed within the cannula.

Owner:WARSAW ORTHOPEDIC INC

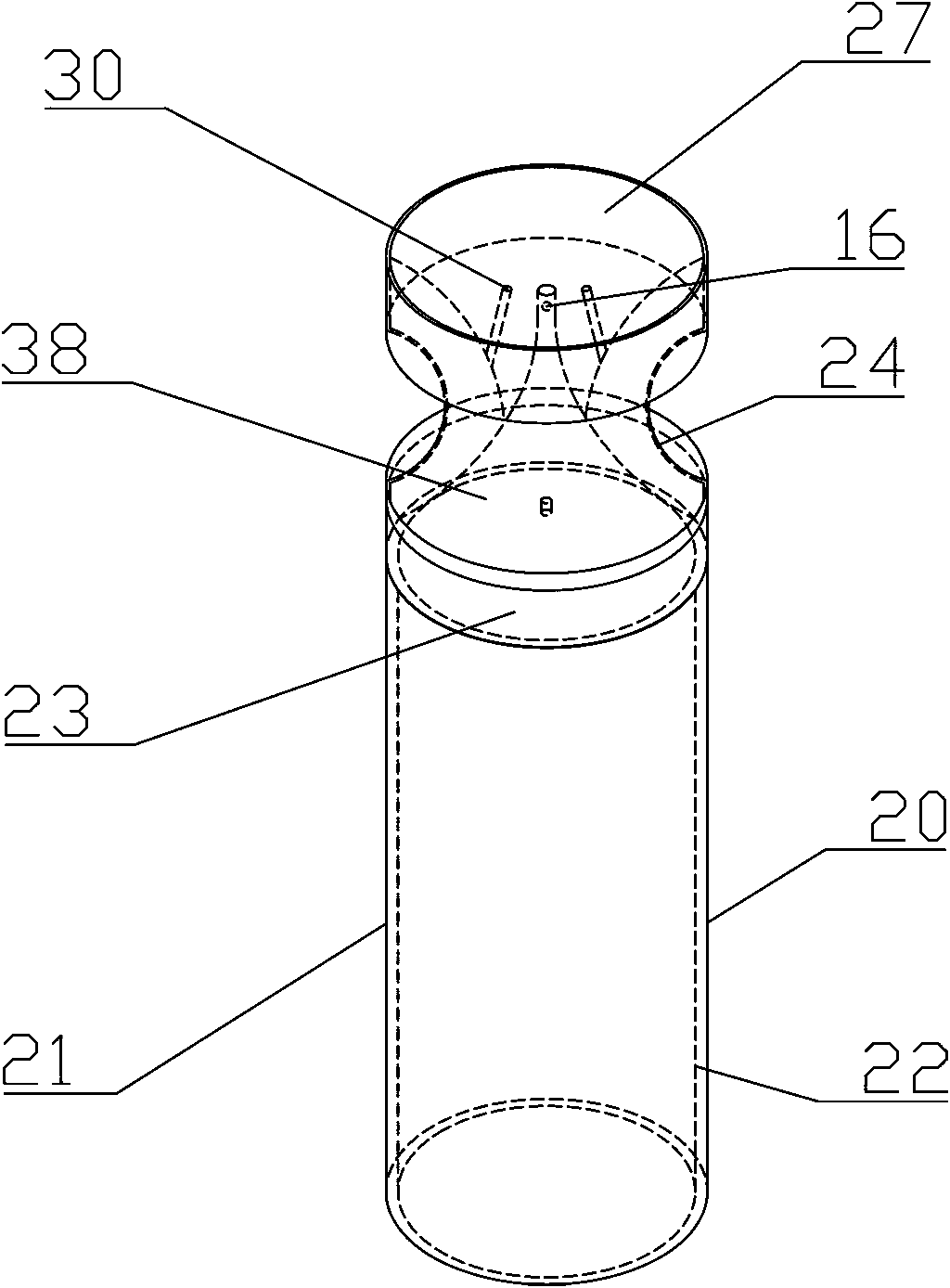

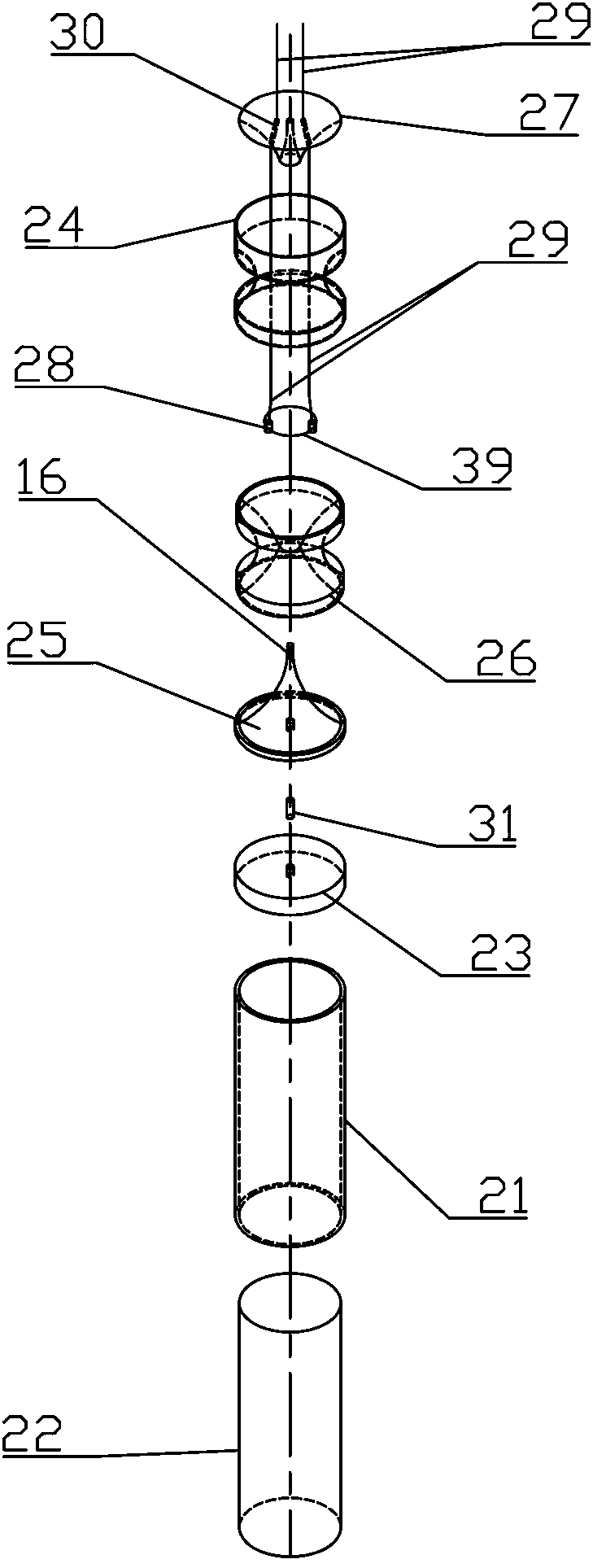

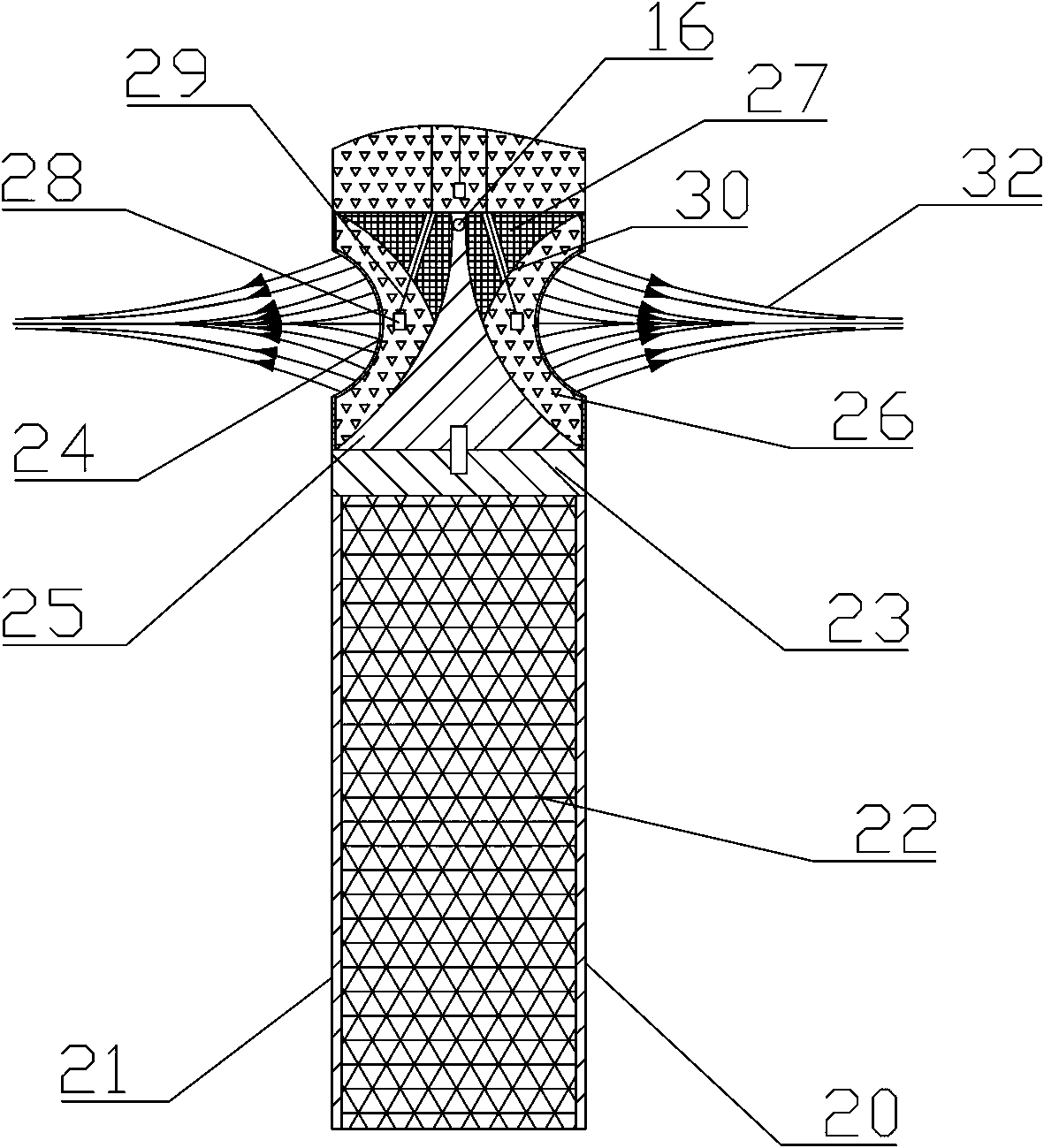

Composite reflection energy concentration and buffering energy dissipation device and blast construction method based on device

PendingCN108645300AImprove securityEasy to processBlastingClimate change adaptationEngineeringDual energy

The invention relates to the technical field of engineering blasting and provides a composite reflection energy concentration and buffering energy dissipation device. The composite reflection energy concentration and buffering energy dissipation device comprises a buffering energy dissipation cushion layer, a rigid cushion layer, a reflection energy concentration buffering cushion layer and an energy conservation jet device. During explosive initiation, energy concentration jet flow and reflection energy concentration jet flow produced by buses of the energy conservation jet device and the reflection energy concentration buffering cushion layer have the dual energy conservation effect, a horizontal fracture line of a rock at the bottoms of blast holes can be increased, and the blasting effect can be enhanced. A composite cushion layer composed of the reflection energy concentration buffering cushion layer, the rigid cushion layer and the buffering energy dissipation cushion layer has the three-time energy dissipation buffering effect and can reduce explosion energy and blasting damage to the bottoms of the blast holes and guarantee the quality of the rock of the bottoms of the holes. A blast construction method comprises the steps of firstly, drilling rows of blast holes in a rock body; secondly, leveling the bottoms of the blast holes; thirdly, stacking the composite reflection energy concentration and buffering energy dissipation devices, main charge explosives, detonating materials and blocking sections in the blast holes; and finally, conducting initiation. Through themethod, the blasting damage to the bottoms of the blast holes can be reduced, the blasting flatness of a foundation base surface can be improved, and the blasting effect can be improved.

Owner:河南省水利第二工程局集团有限公司 +2

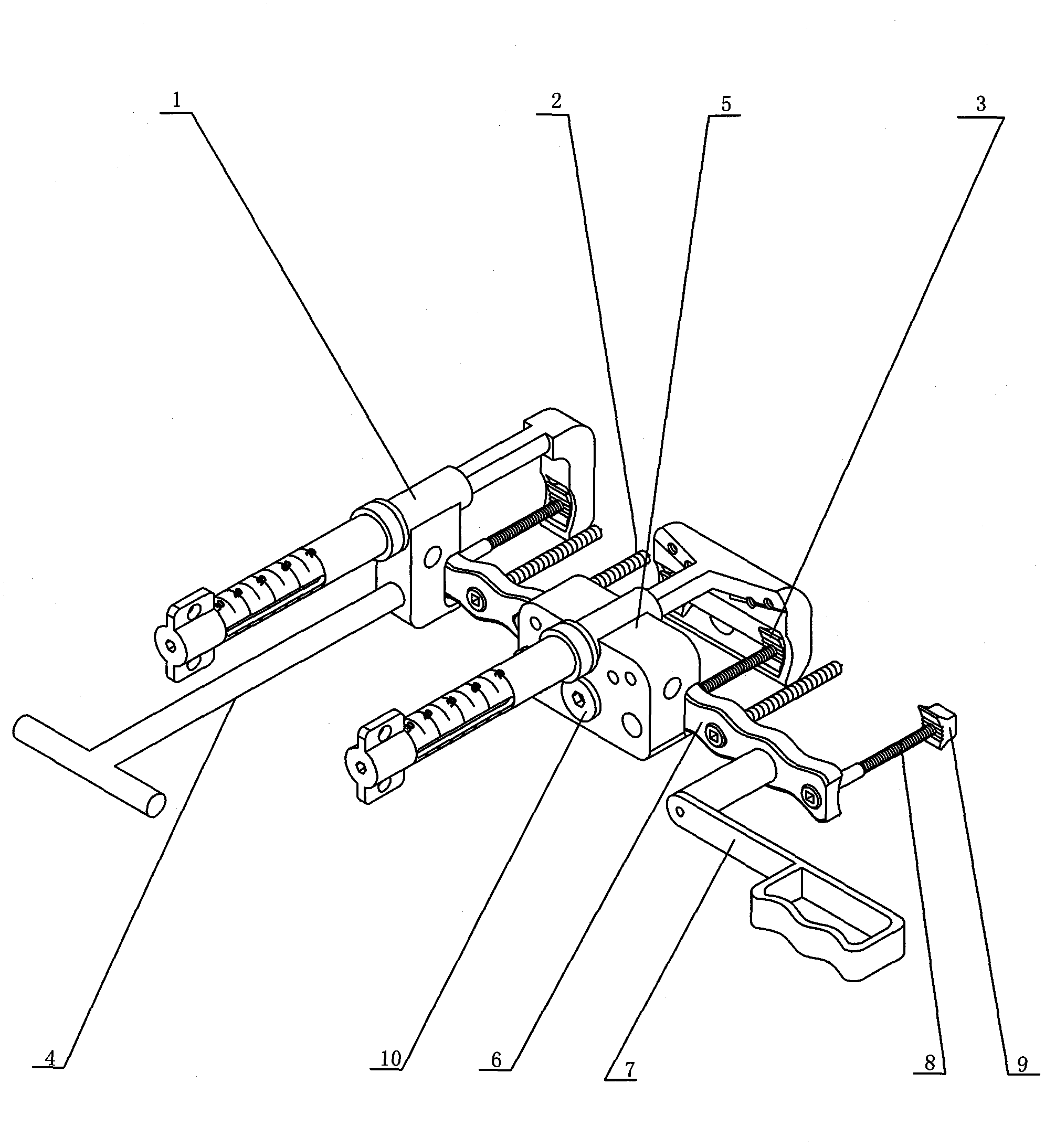

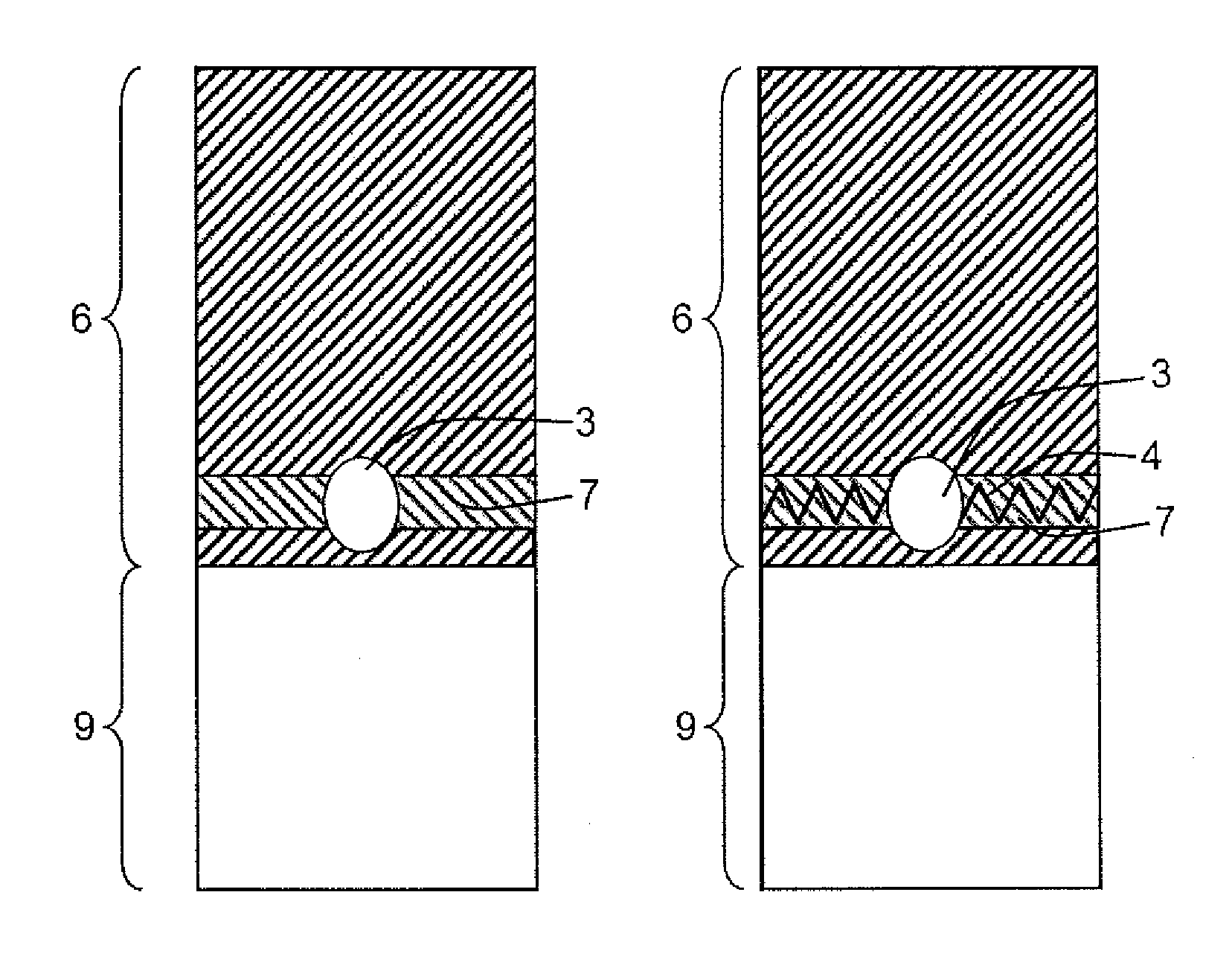

Femoral shaft fracture internally fixing instrument

InactiveCN102415913AEven by forceFacilitate fracture reductionInternal osteosythesisFastenersFunctional exercisesFunctional exercise

The invention belongs to the field of medical apparatus and instruments, and relates to a femoral shaft fracture internally fixing instrument, which comprises a lockable steel plate and an aiming assembly of the lockable steel plate, wherein the lockable steel plate comprises a steel plate, a single lock, a linkage lock and a lock nail; the aiming assembly comprises a single lock aiming fixator and a linkage lock aiming fixator; an auxiliary assembly bone nail, a bone nail hole positioning hook and a combined screwdriver. In the femoral shaft fracture internally fixing instrument, an arc which corresponds to the forward physiological curve of a femoral shaft is designed on the steel plate longitudinally; an arc which corresponds to the transverse diameter of the femoral shaft is designed transversely near a bone surface, so that the arc is put in the middle of the fracture position along an arc line of the femoral shaft to contact bones in a limited mode; and the lateral surface is circular arc curved surfaces which are distributed symmetrically and uniformly. The linkage lock strides over a fracture line on the inner side of the femoral shaft, and the single lock is away from the fracture line; and the aiming assembly is used for aiming, fixing, drilling and assembling, and is easy to operate. The femoral shaft has the advantages that the fixation is stable, postoperative additional fixation is avoided, functional exercise can be performed in early stage, and the union of fracture is facilitated, and internal fixtures are convenient to dismantle after union.

Owner:马丽昕 +1

Process for Producing Metallic Components

ActiveUS20120295124A1Improve design flexibilityIncreased processing flexibilityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringFracture line

A process for producing a metallic component with an opening or a hollow space by selective laser sintering or laser melting includes melting a metallic powder in layers at appropriate cross-sectional regions by using laser radiation. After the laser sintering or laser melting process, the component is subjected to a fracture splitting process, in which the component is fractured into at least two fractional parts along a fracture line and then the at least two fractional parts are connected to one another at the sites of fracture to form the component. The fracture line contacts or passes through the opening or the hollow space.

Owner:MAN NUTZFAHRZEUGE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com