Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Hair implant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

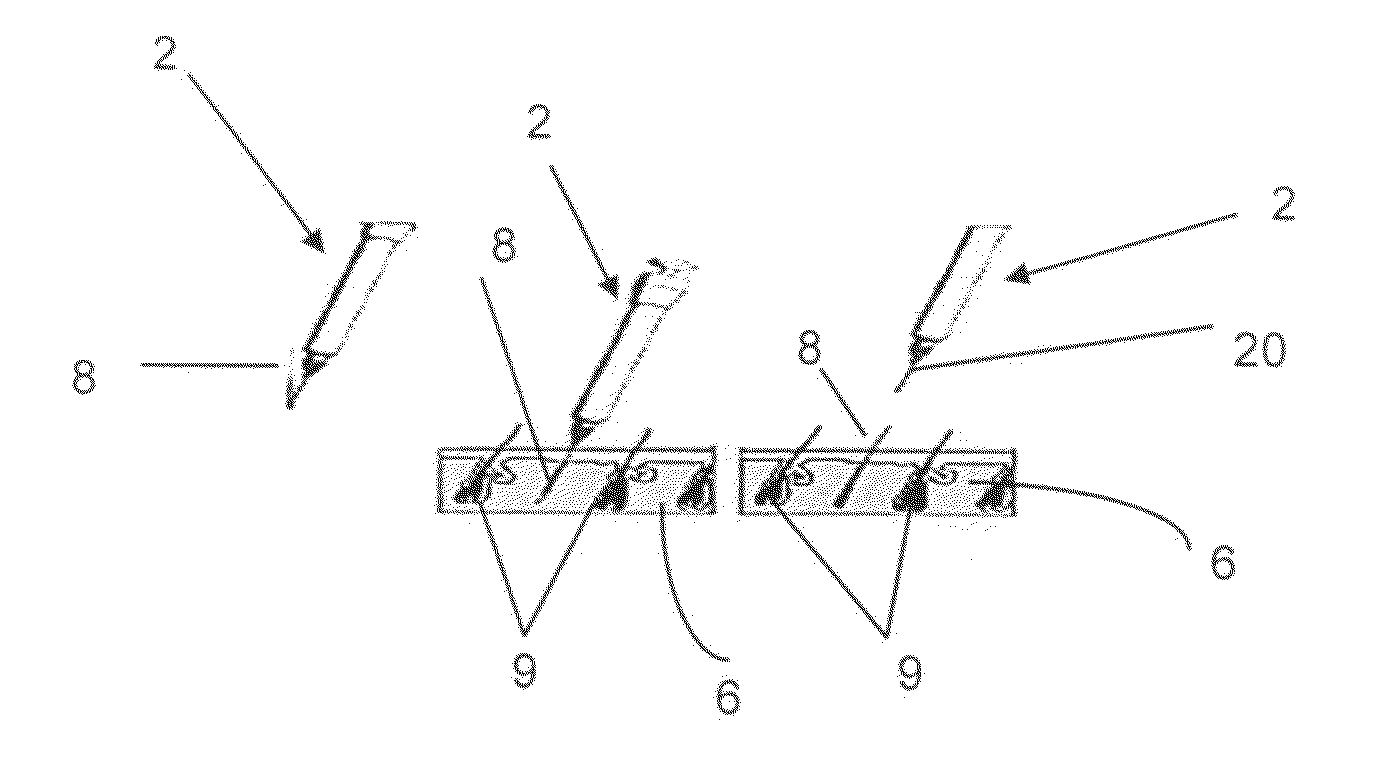

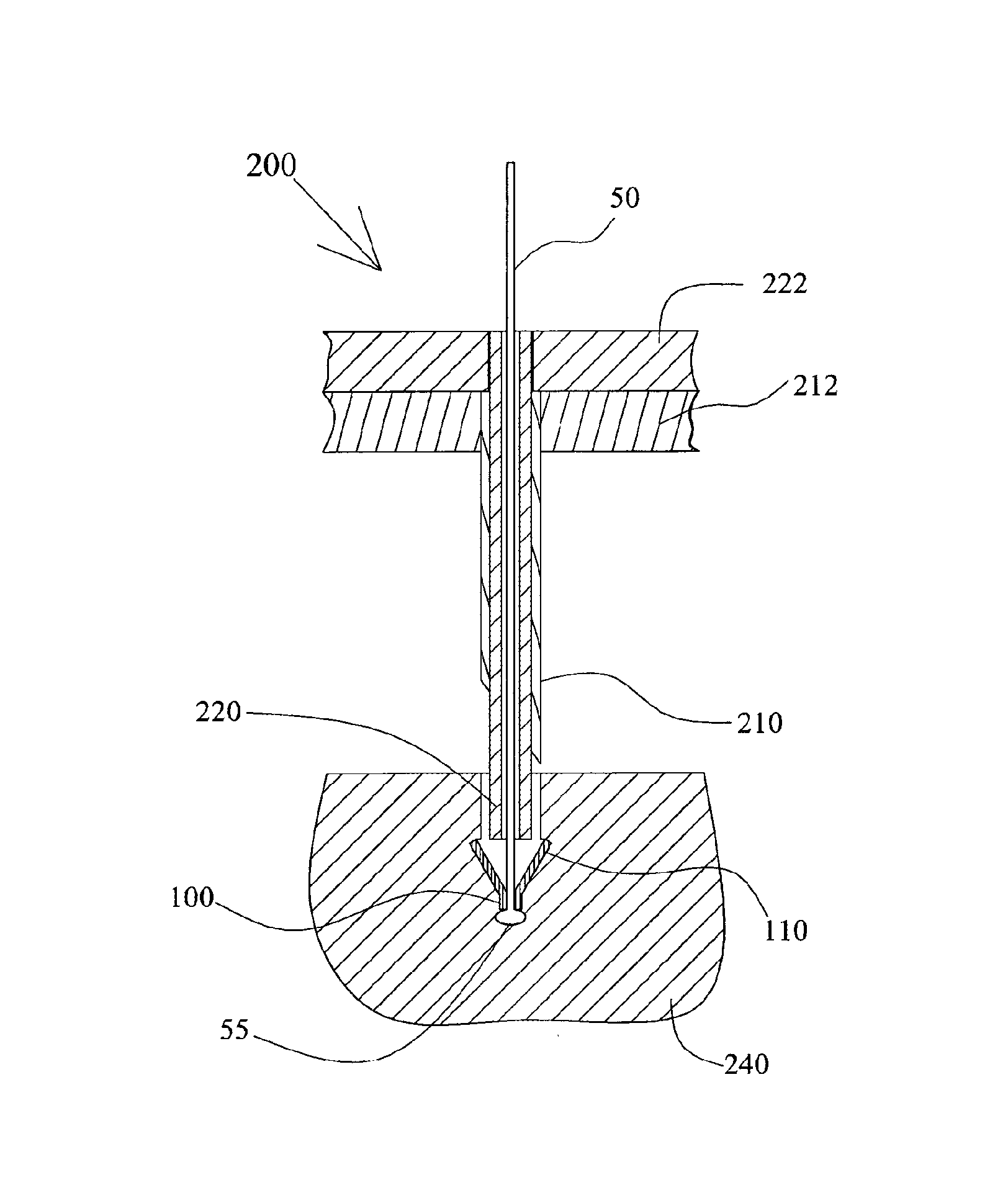

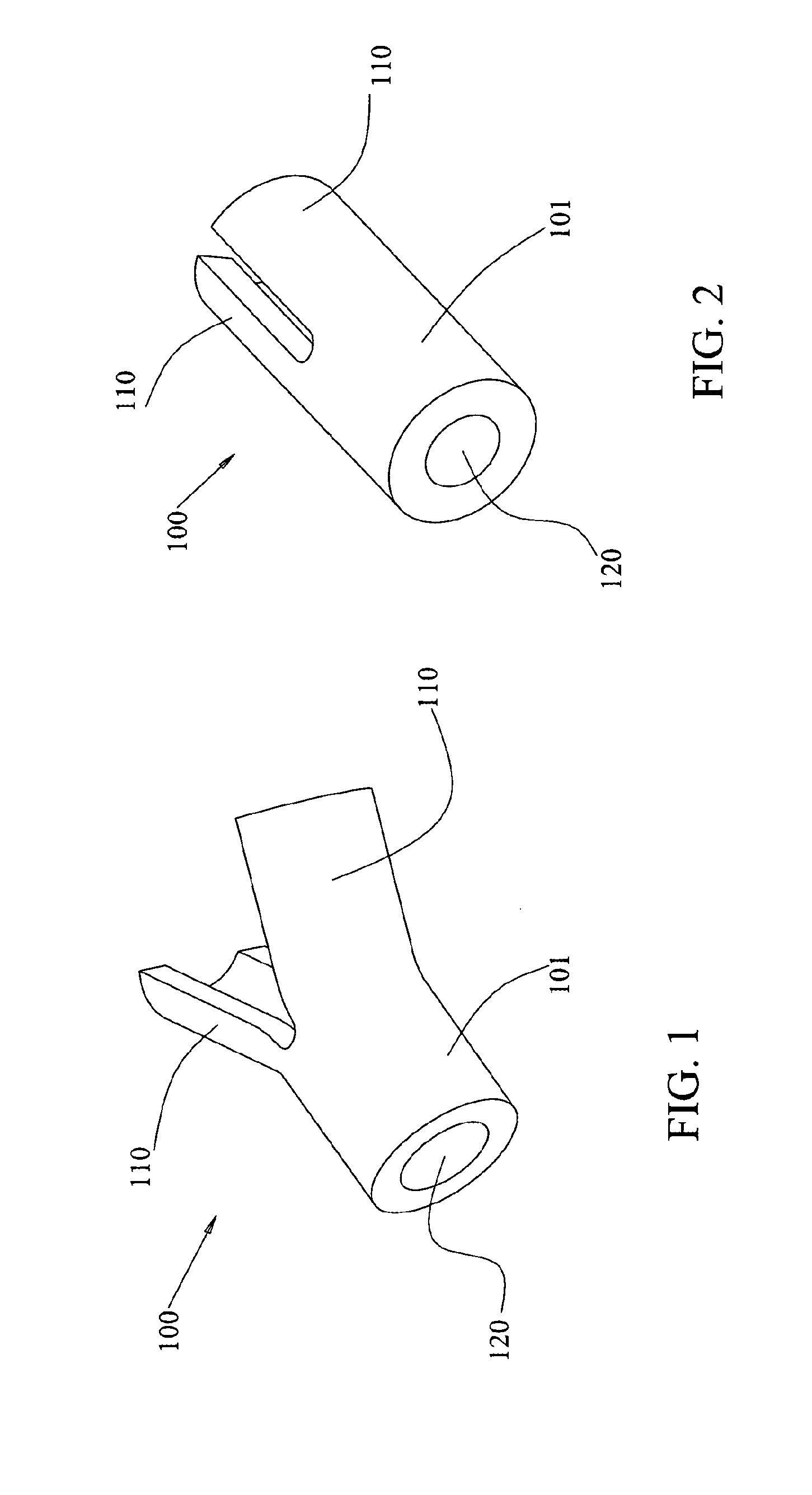

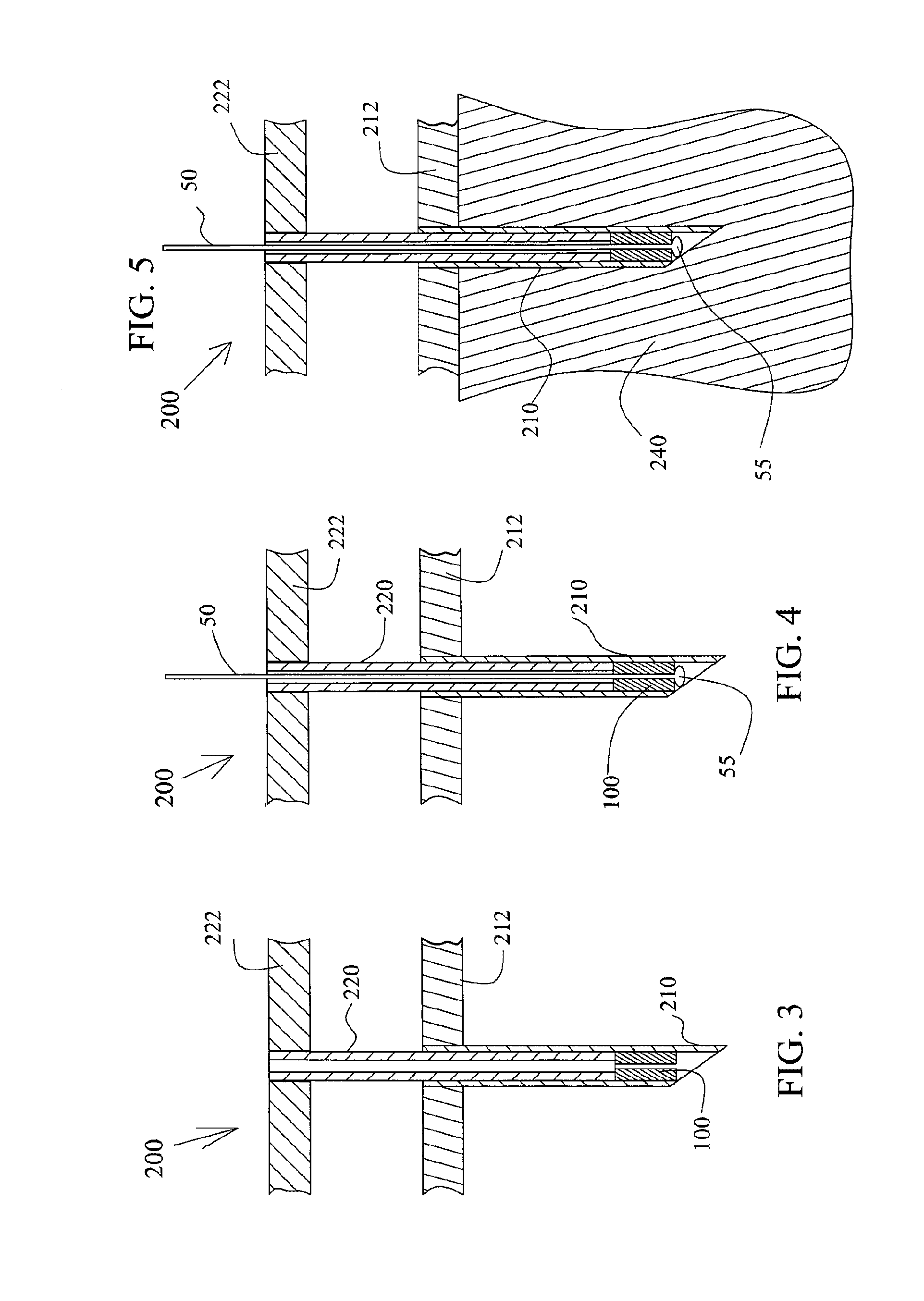

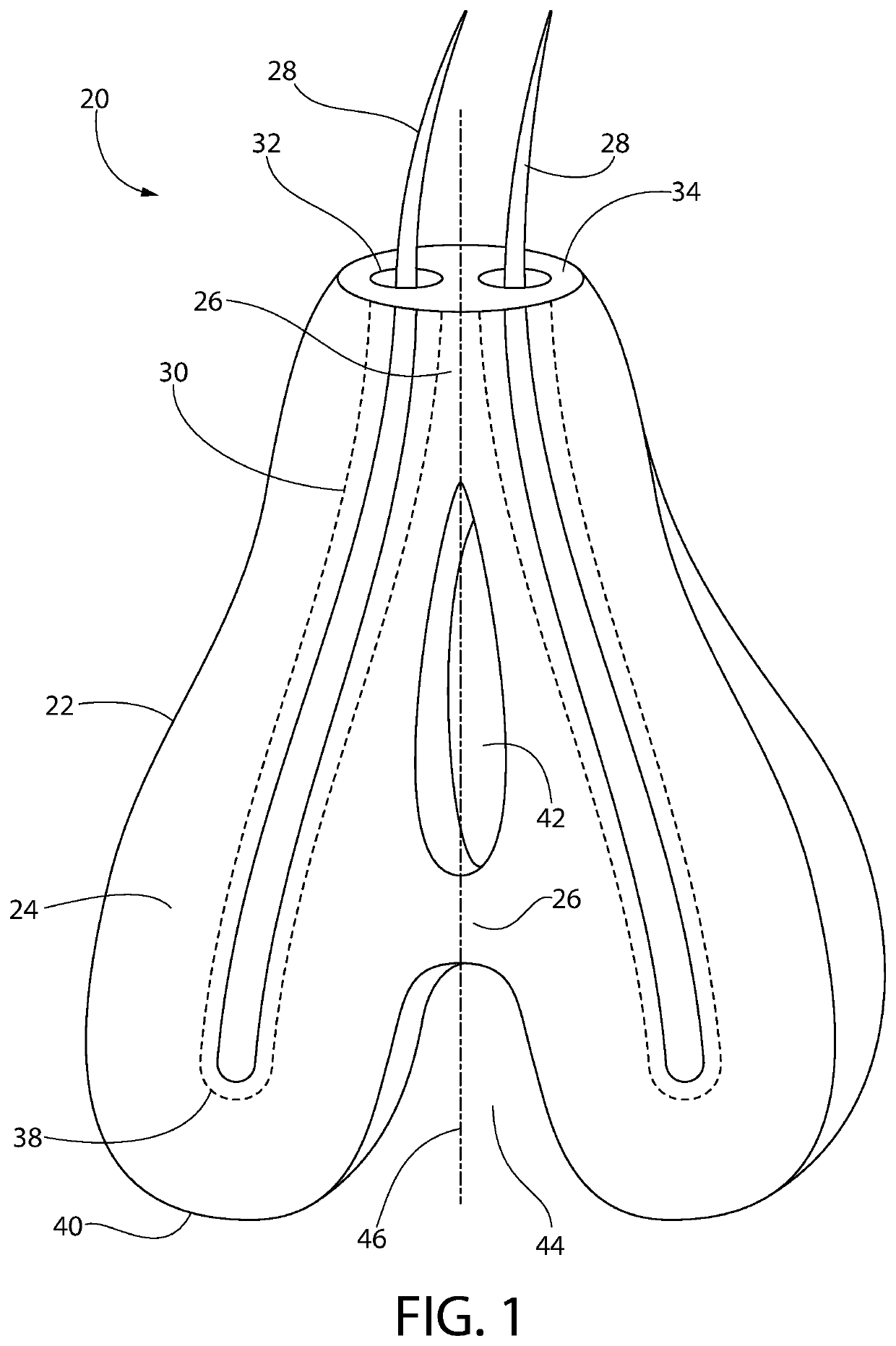

Hair implant anchors and systems and methods for use thereof

ActiveUS20120245612A1Easily implanted into target tissueEasy to useSuture equipmentsSkin implantsBiomedical engineeringHair implant

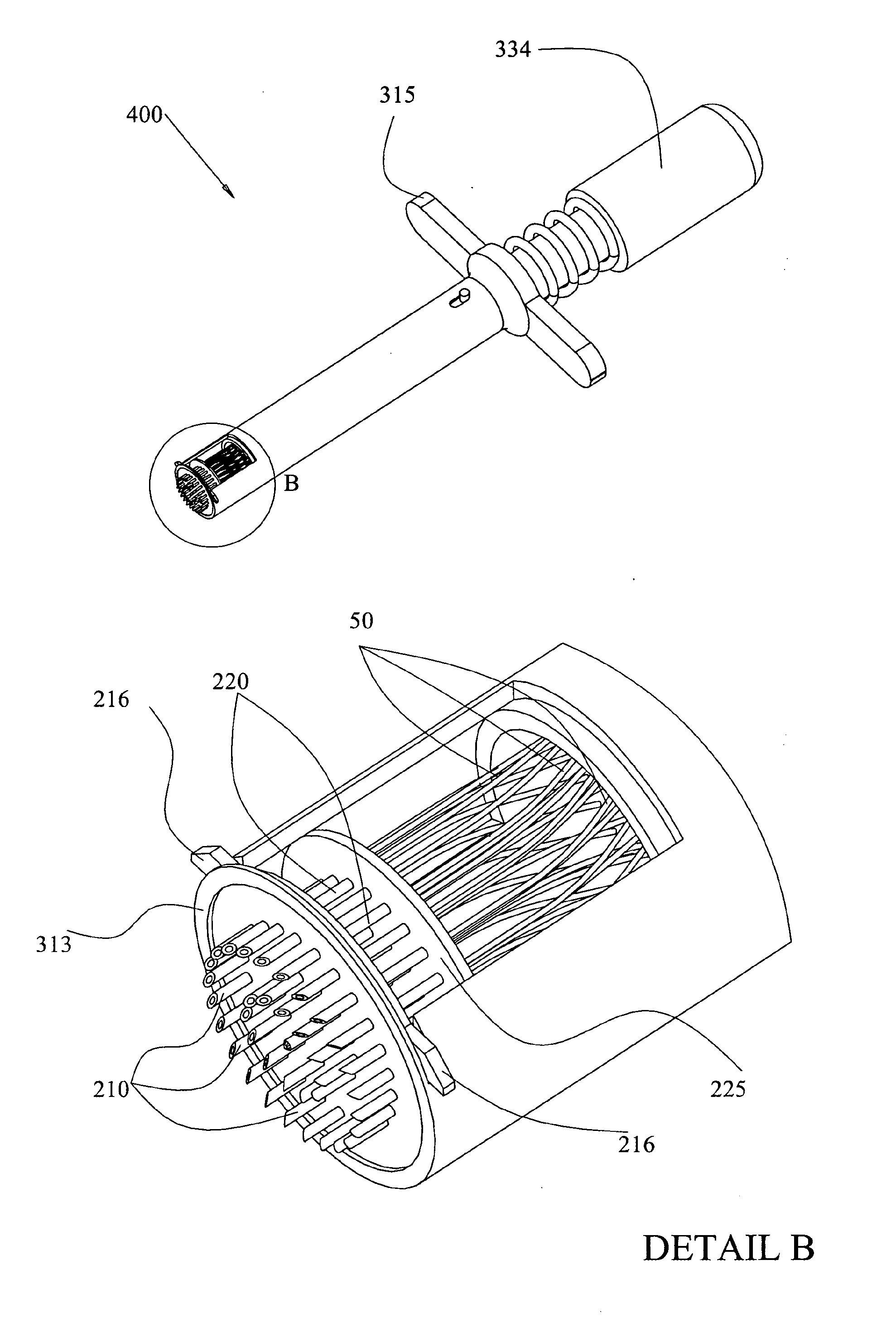

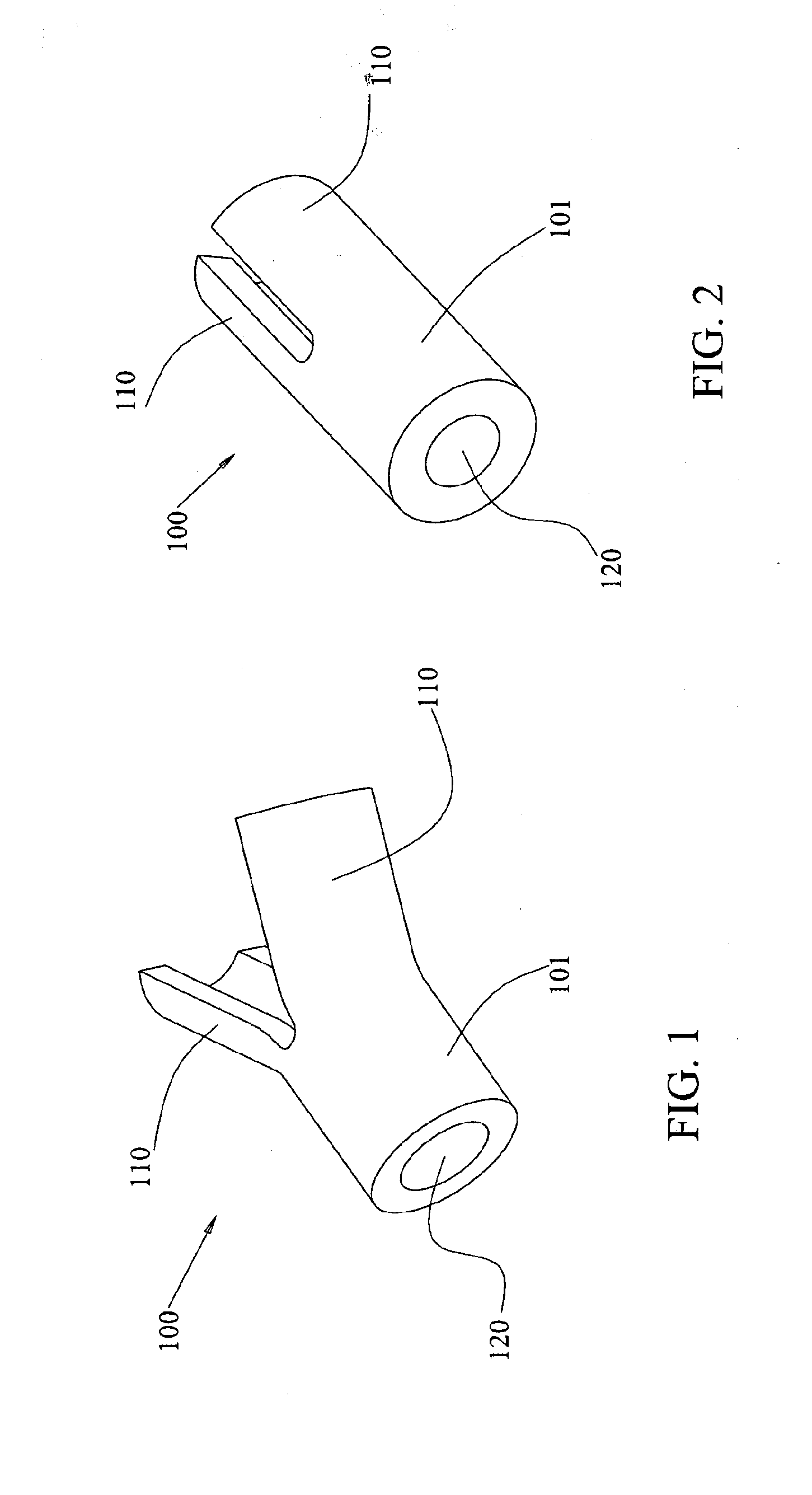

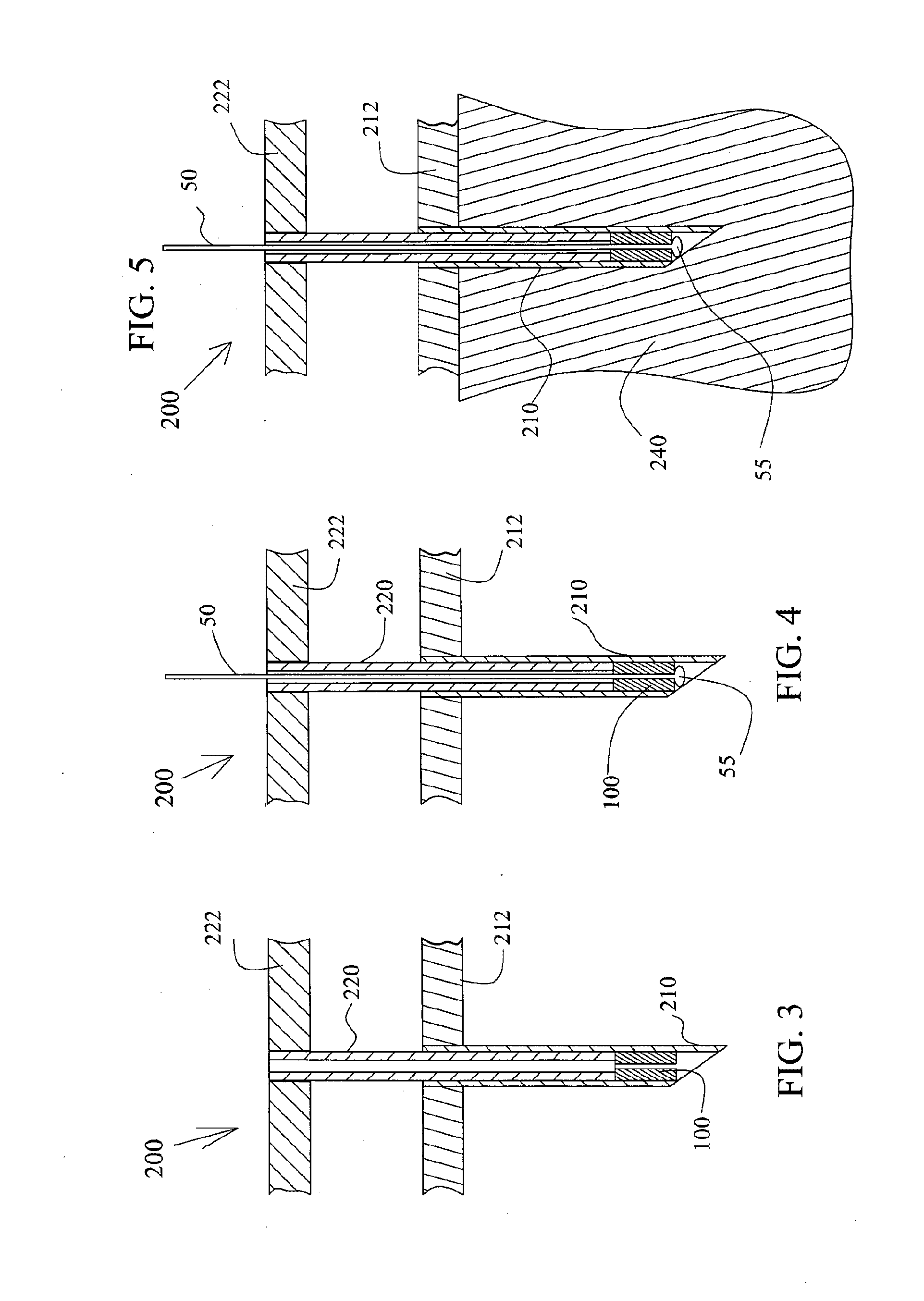

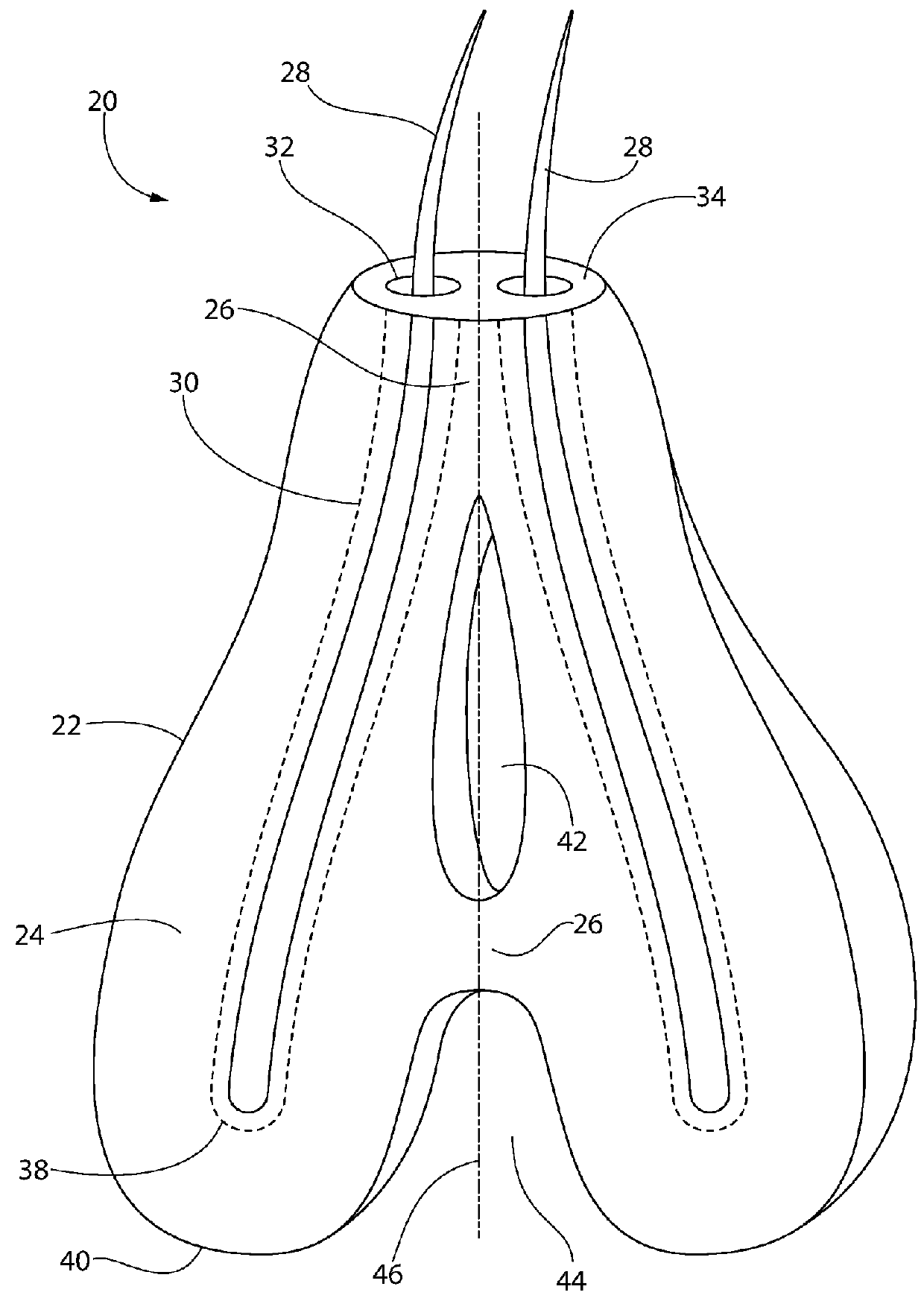

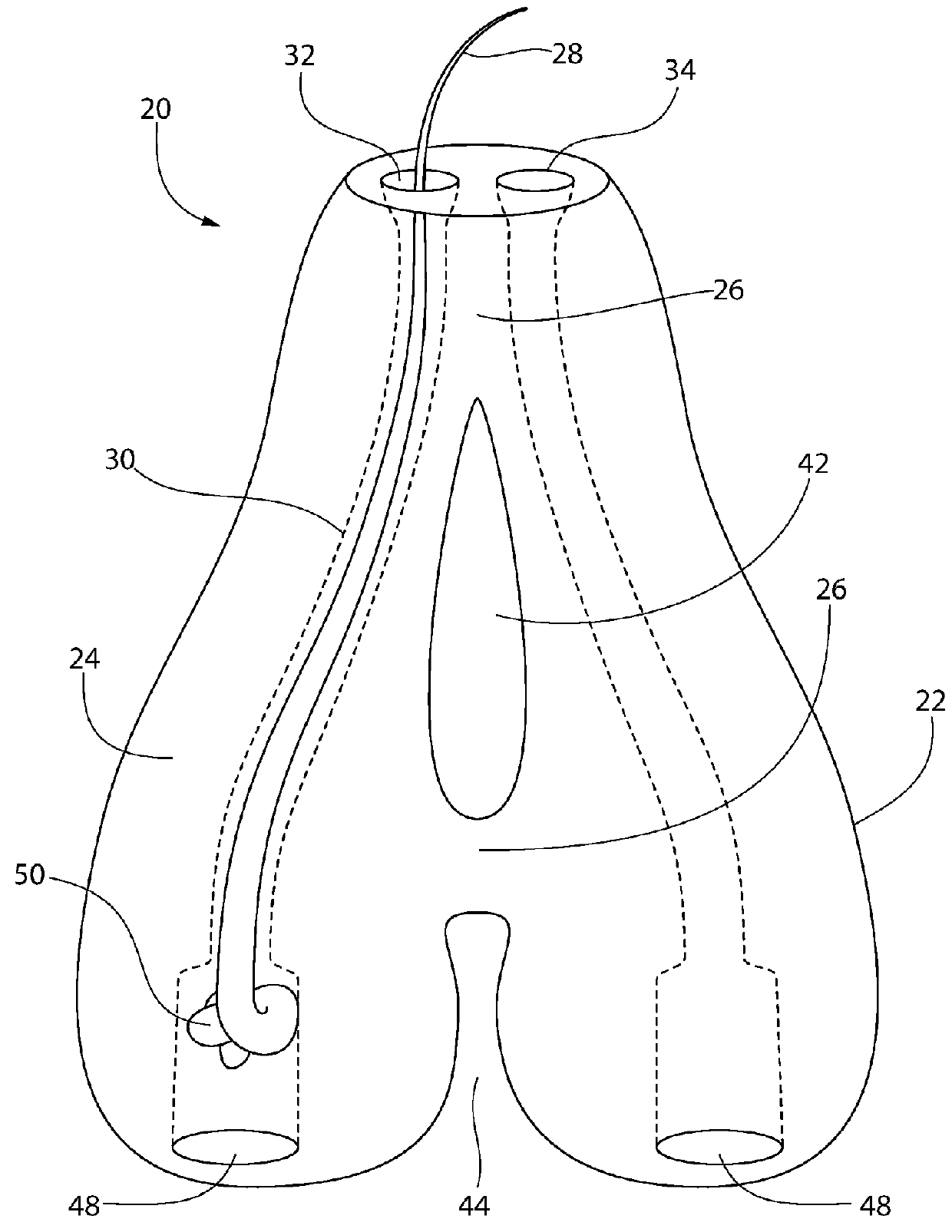

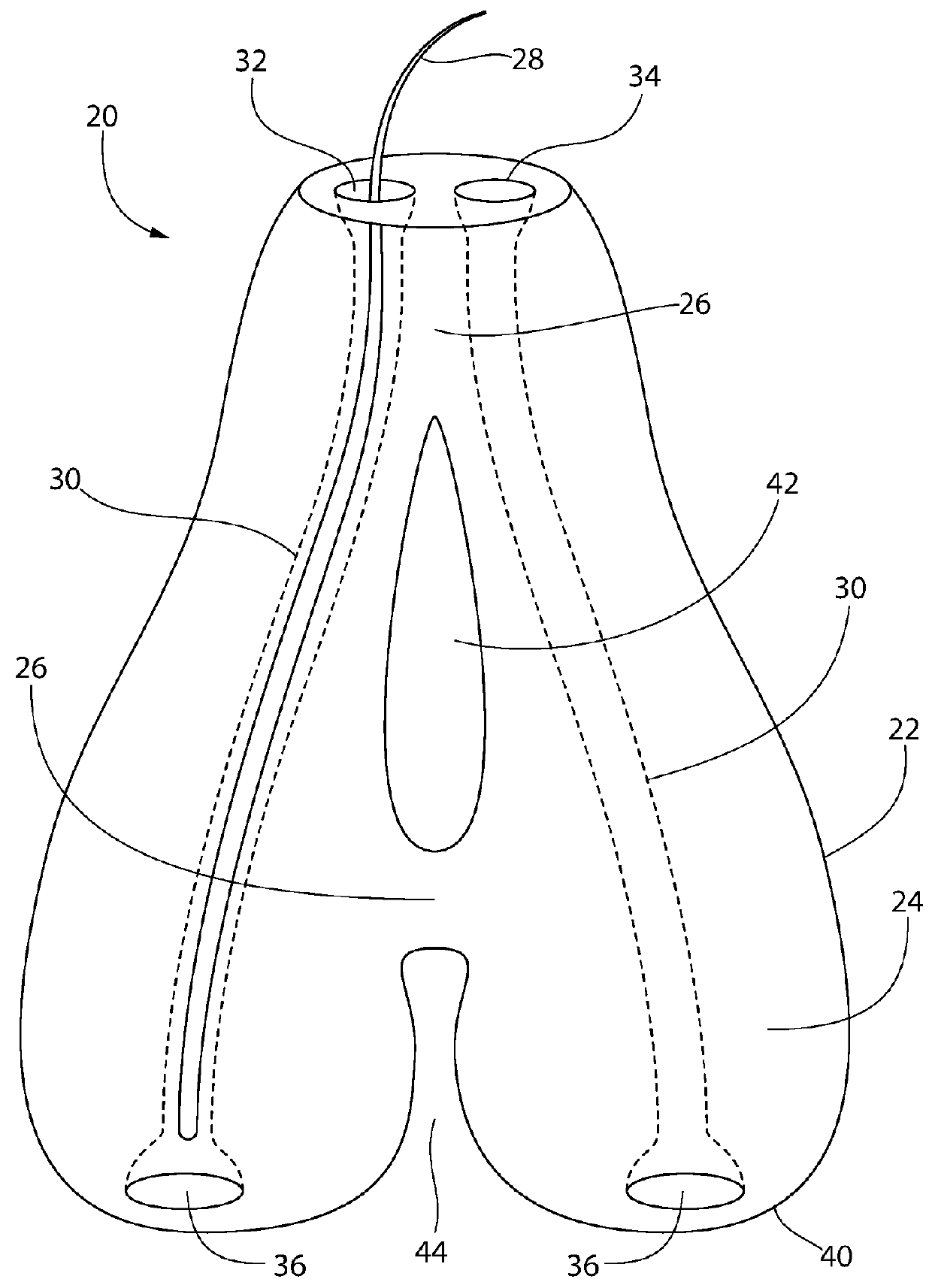

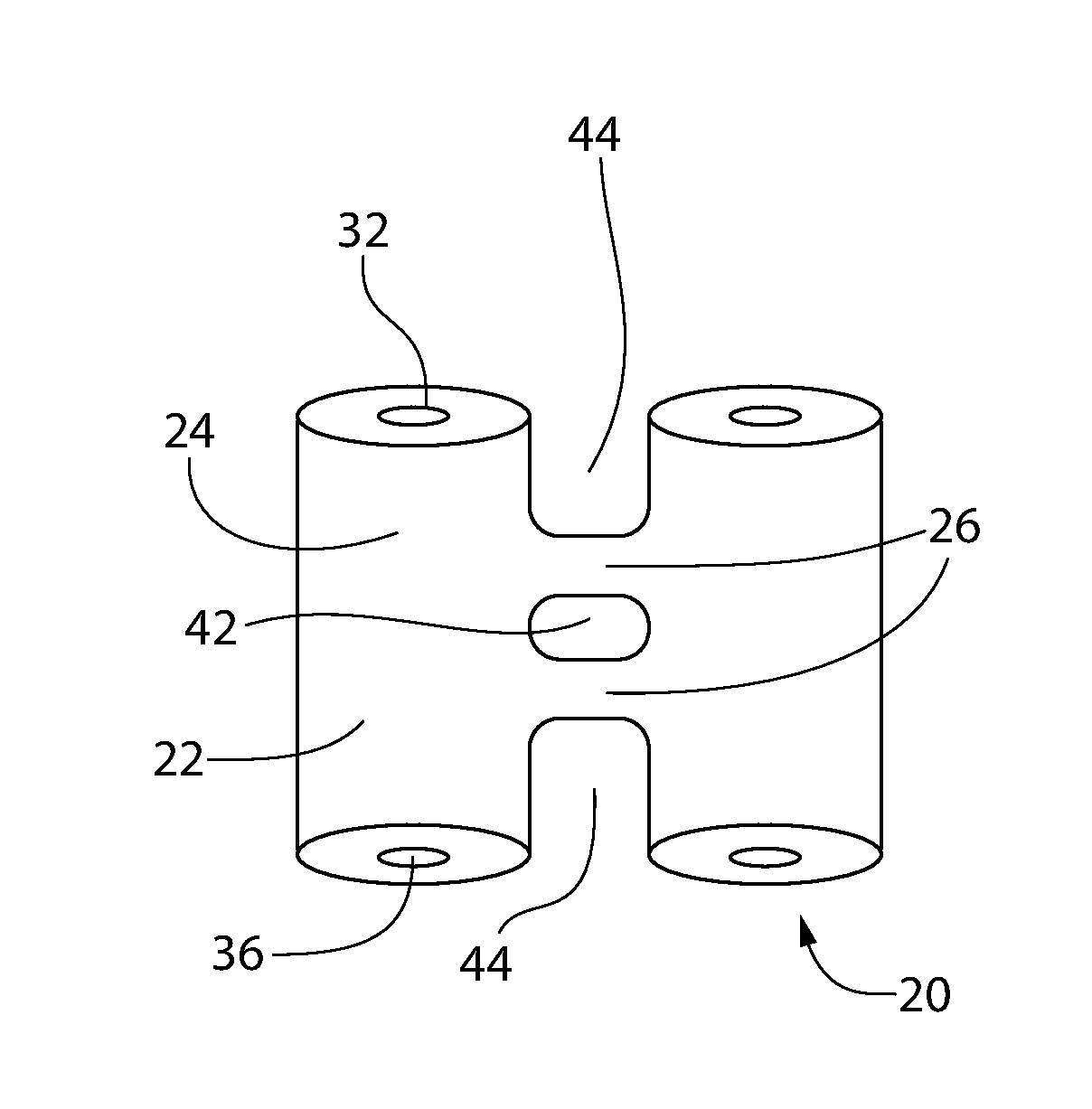

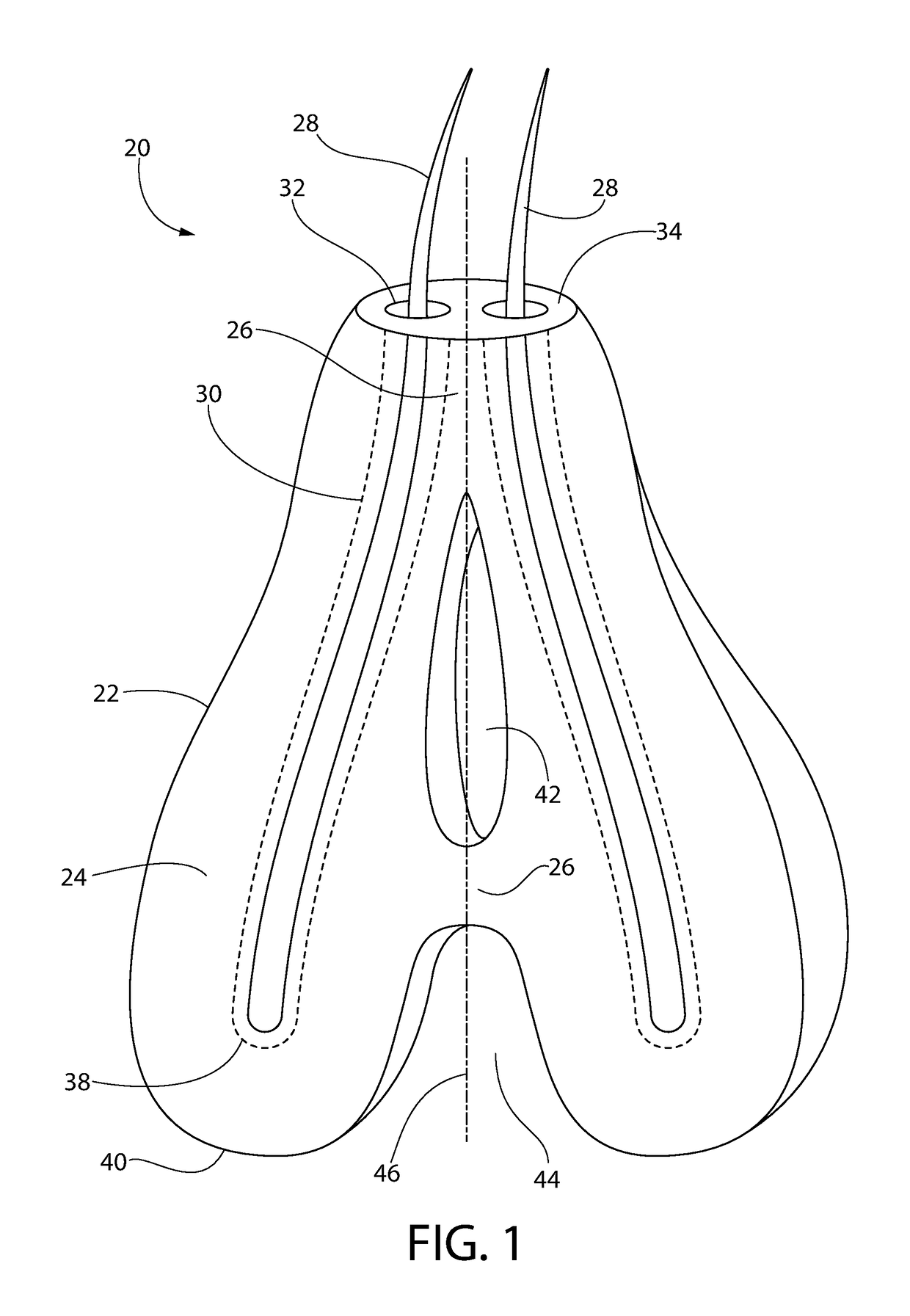

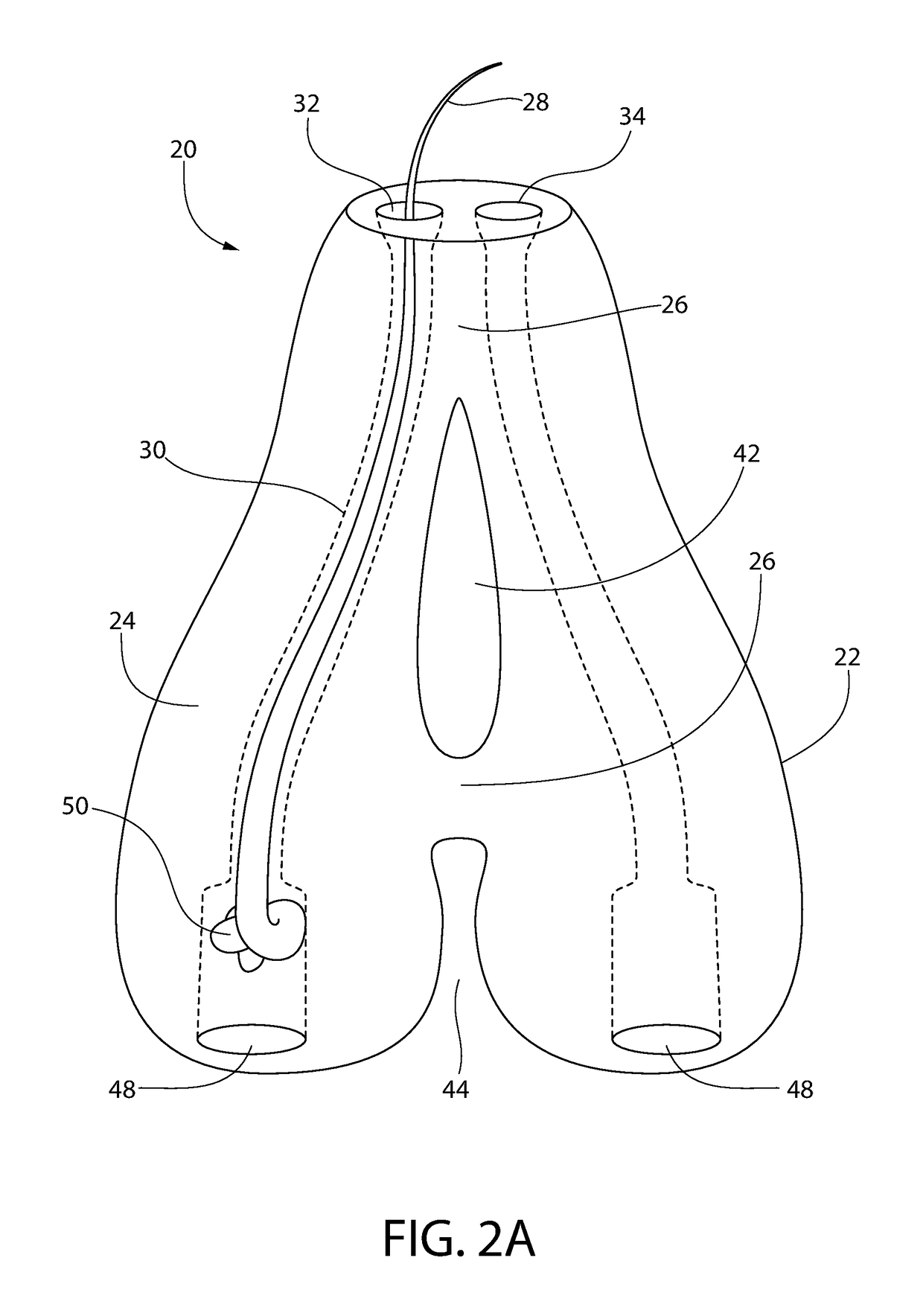

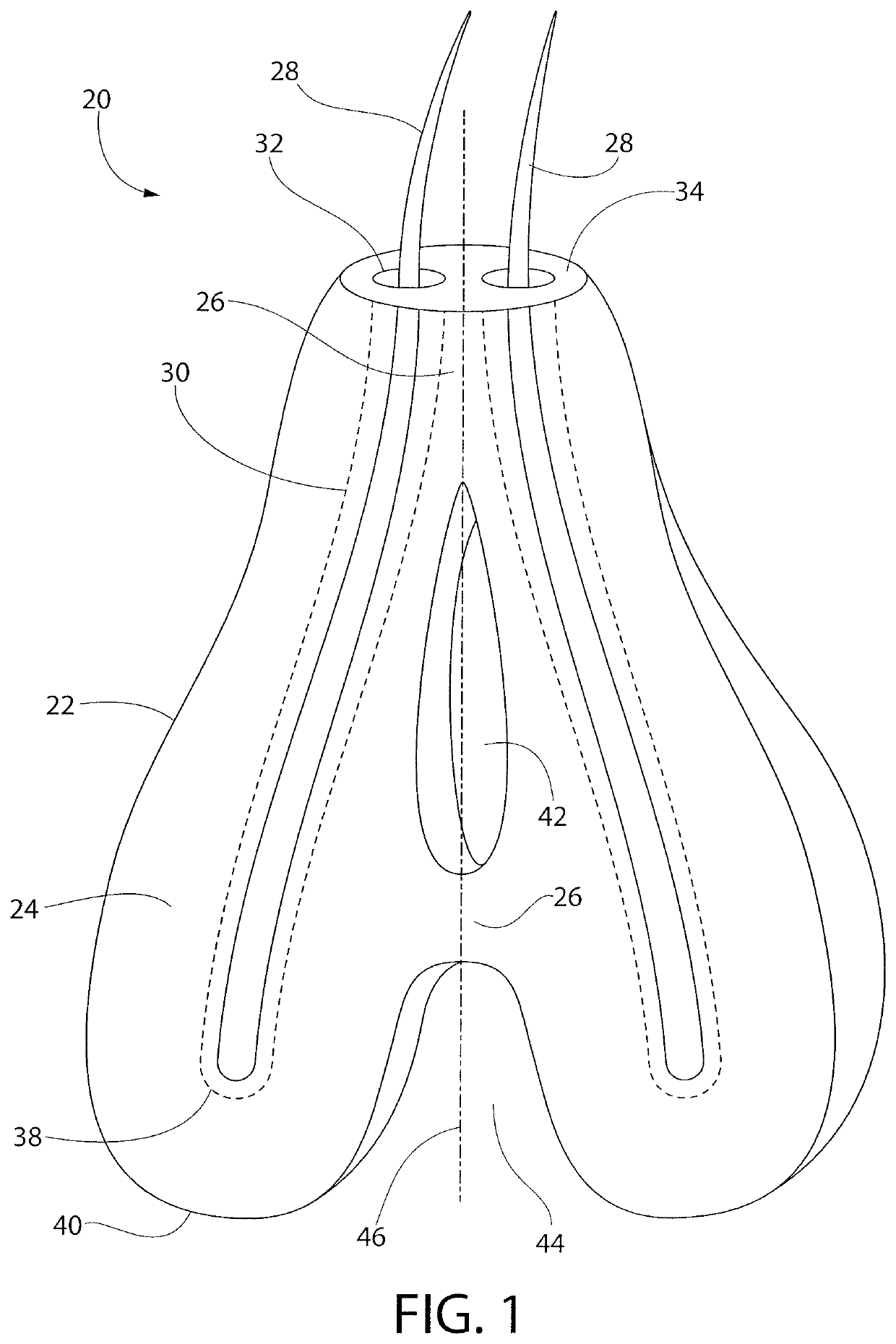

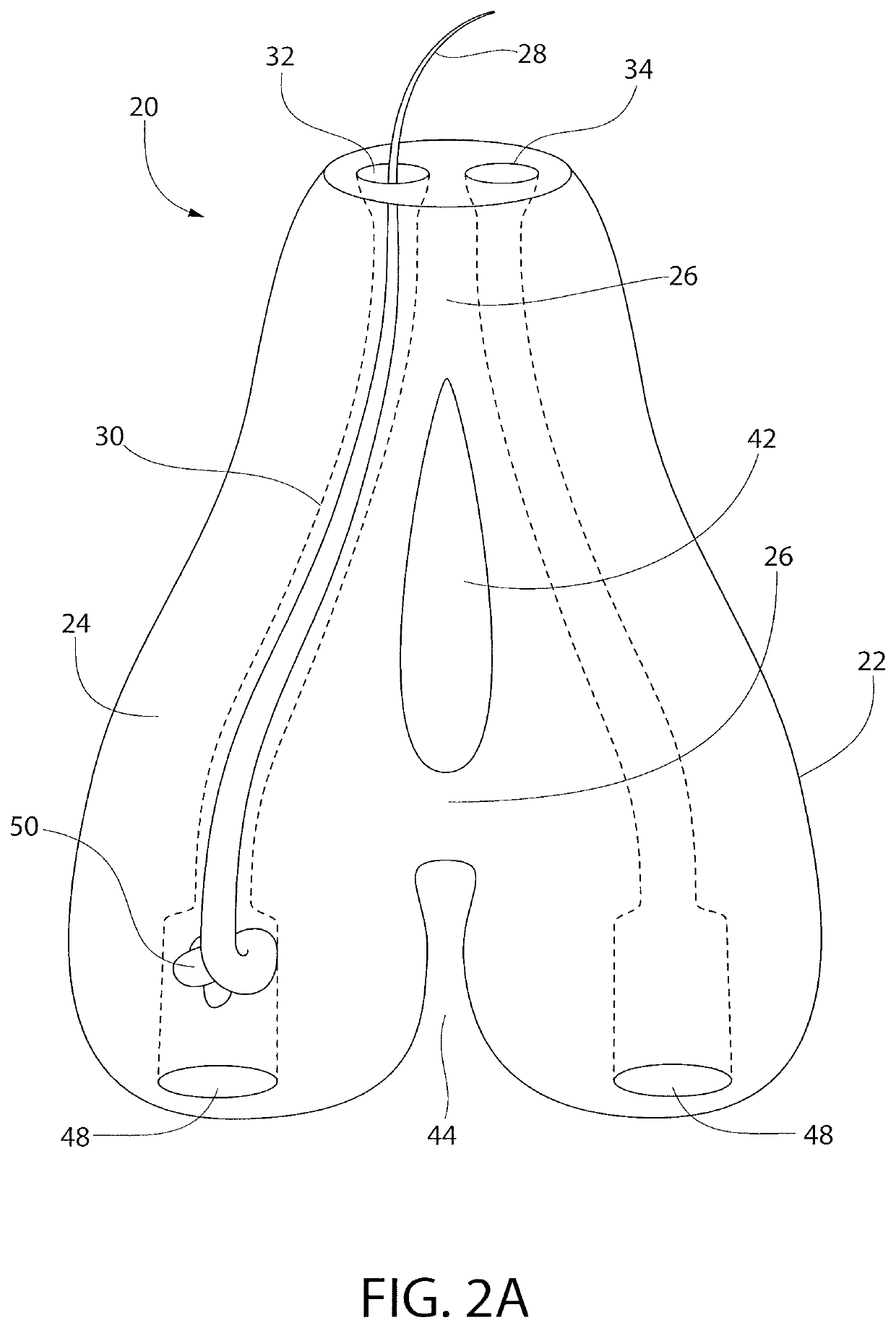

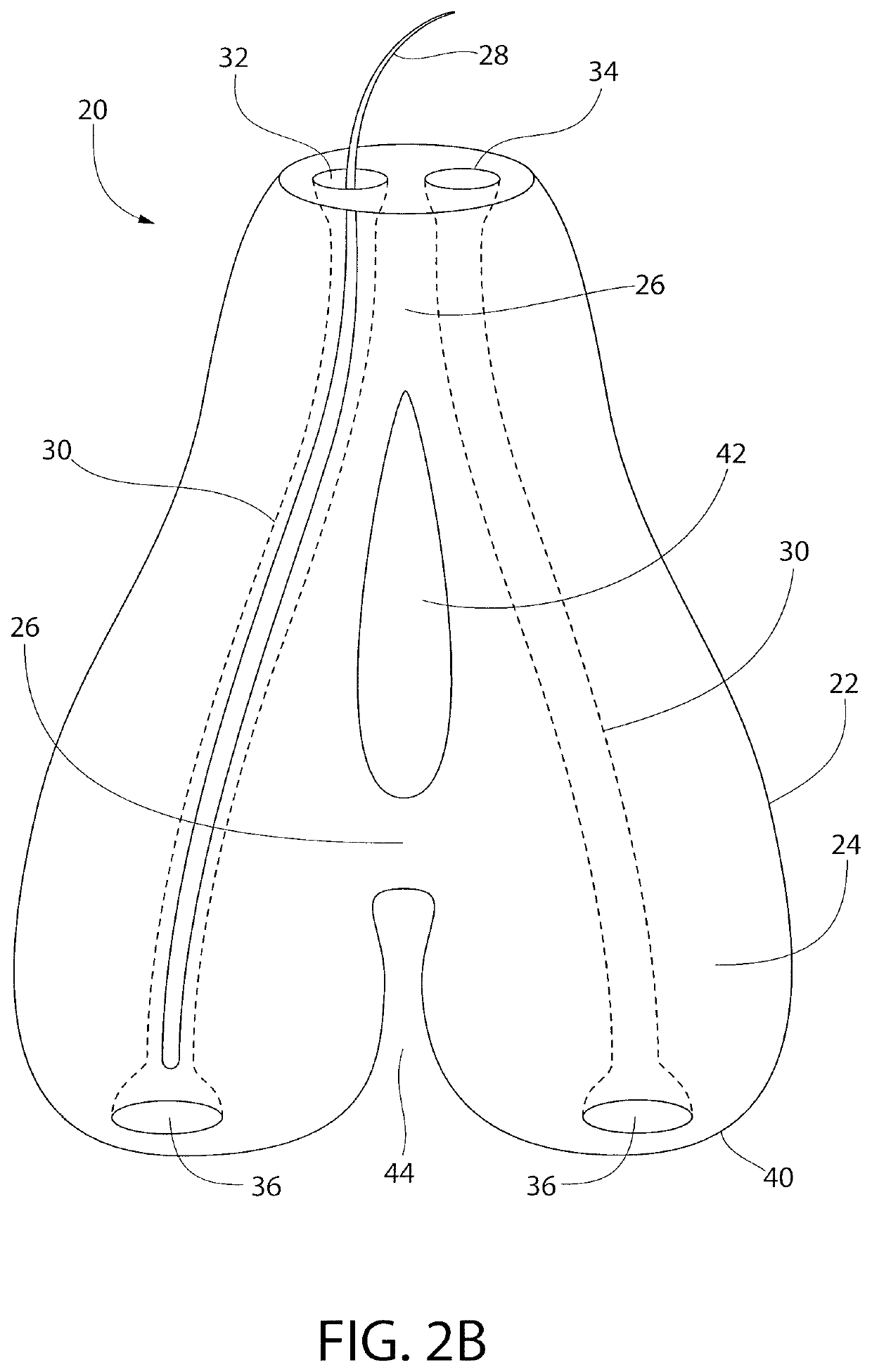

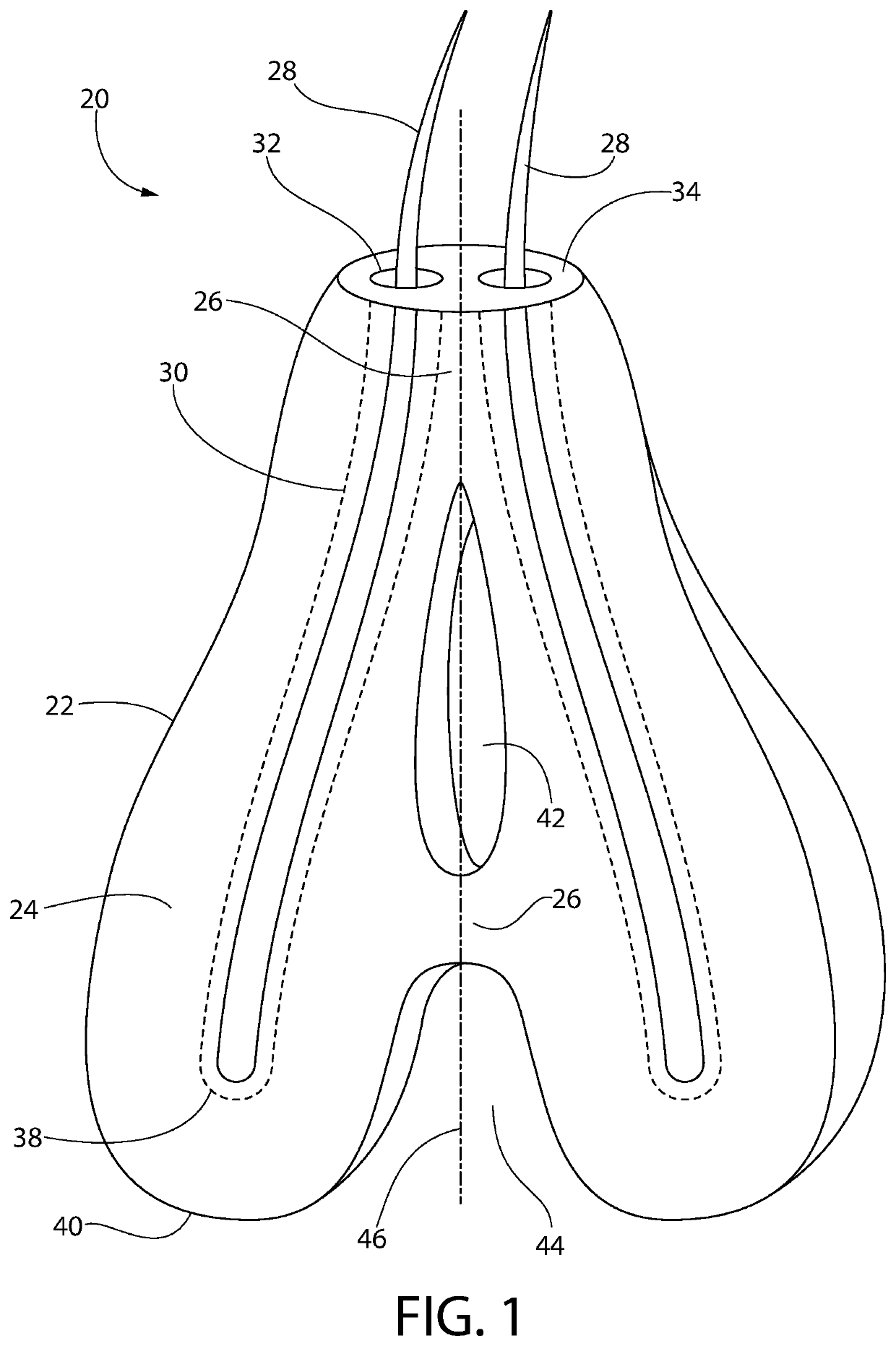

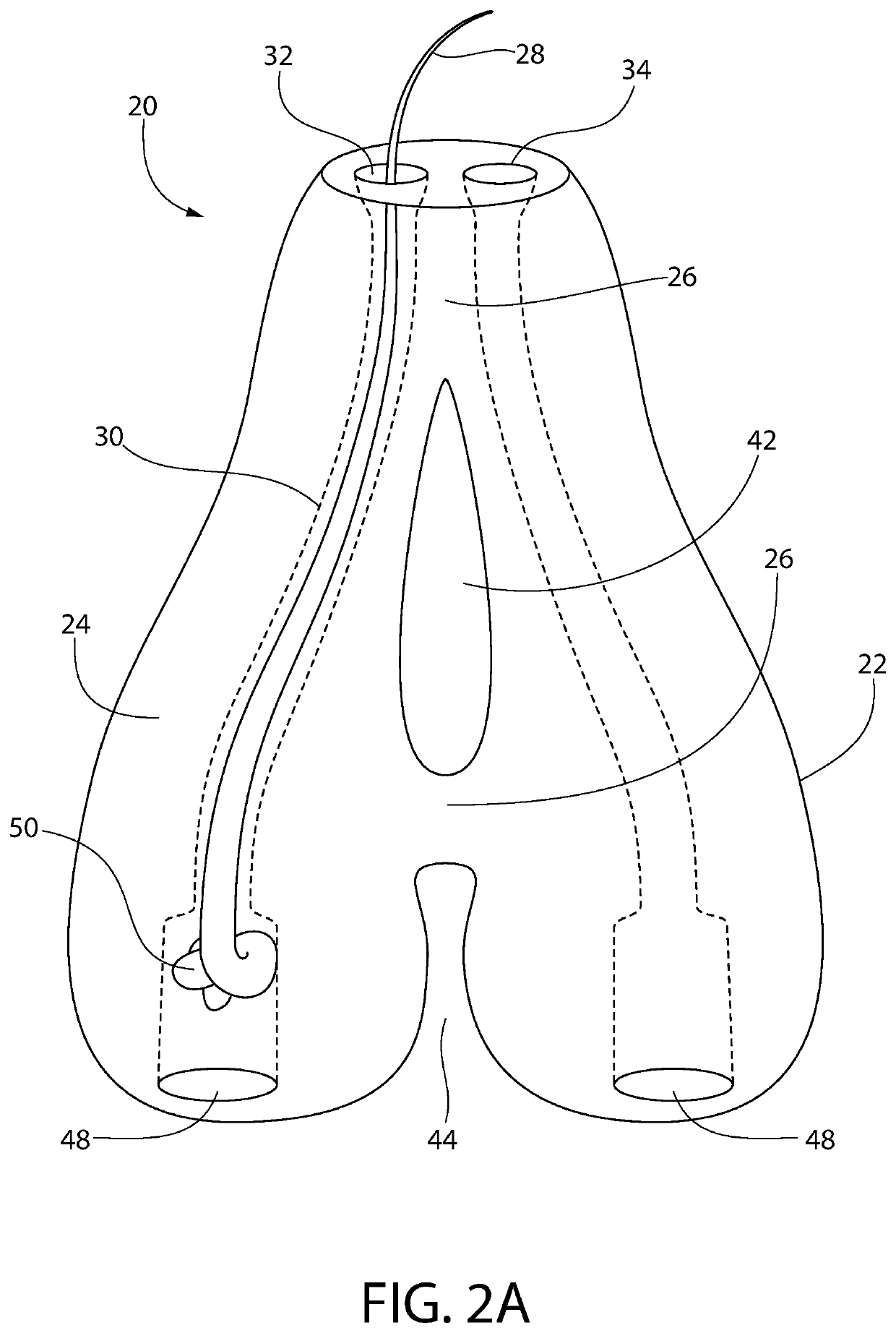

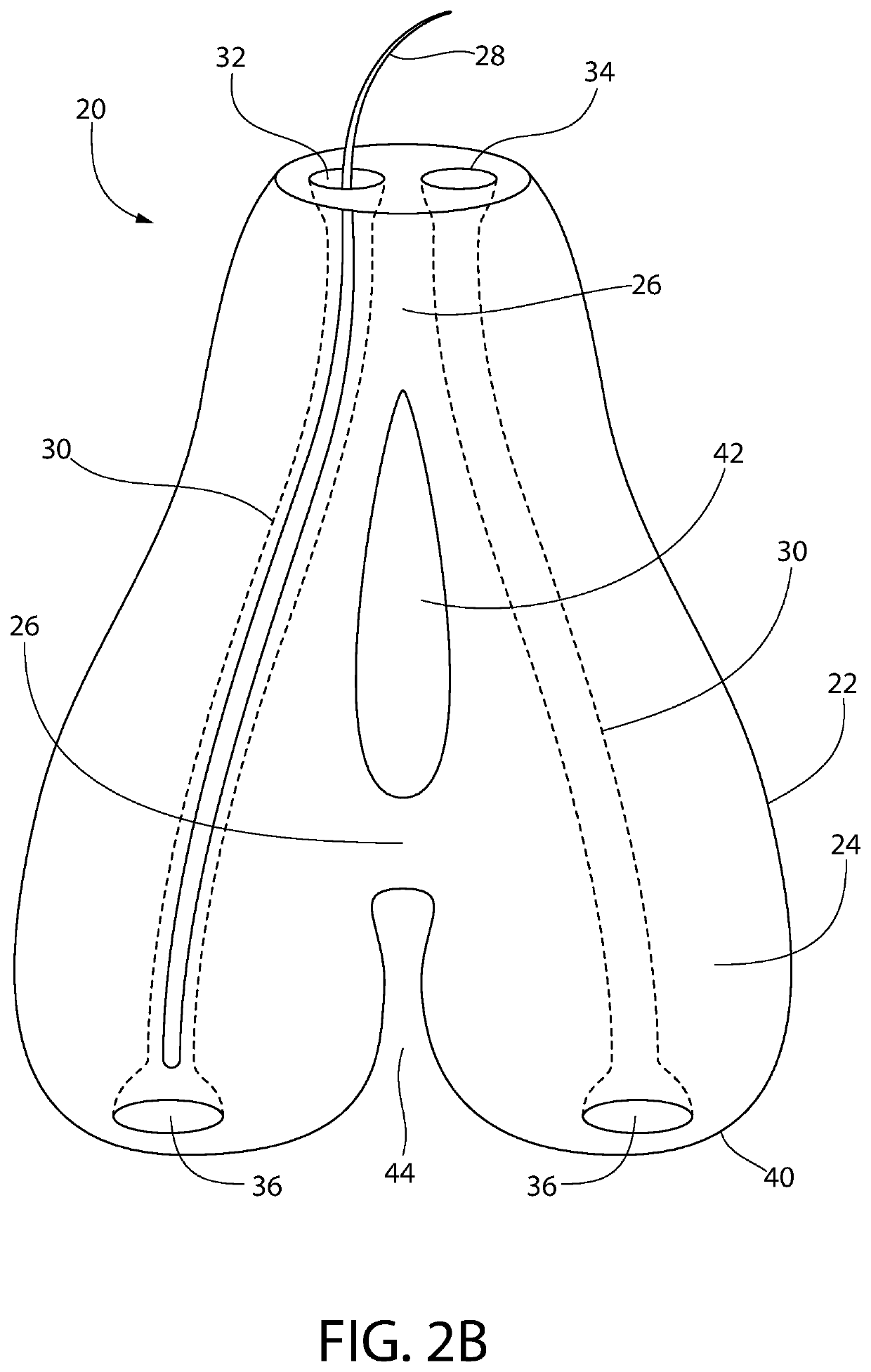

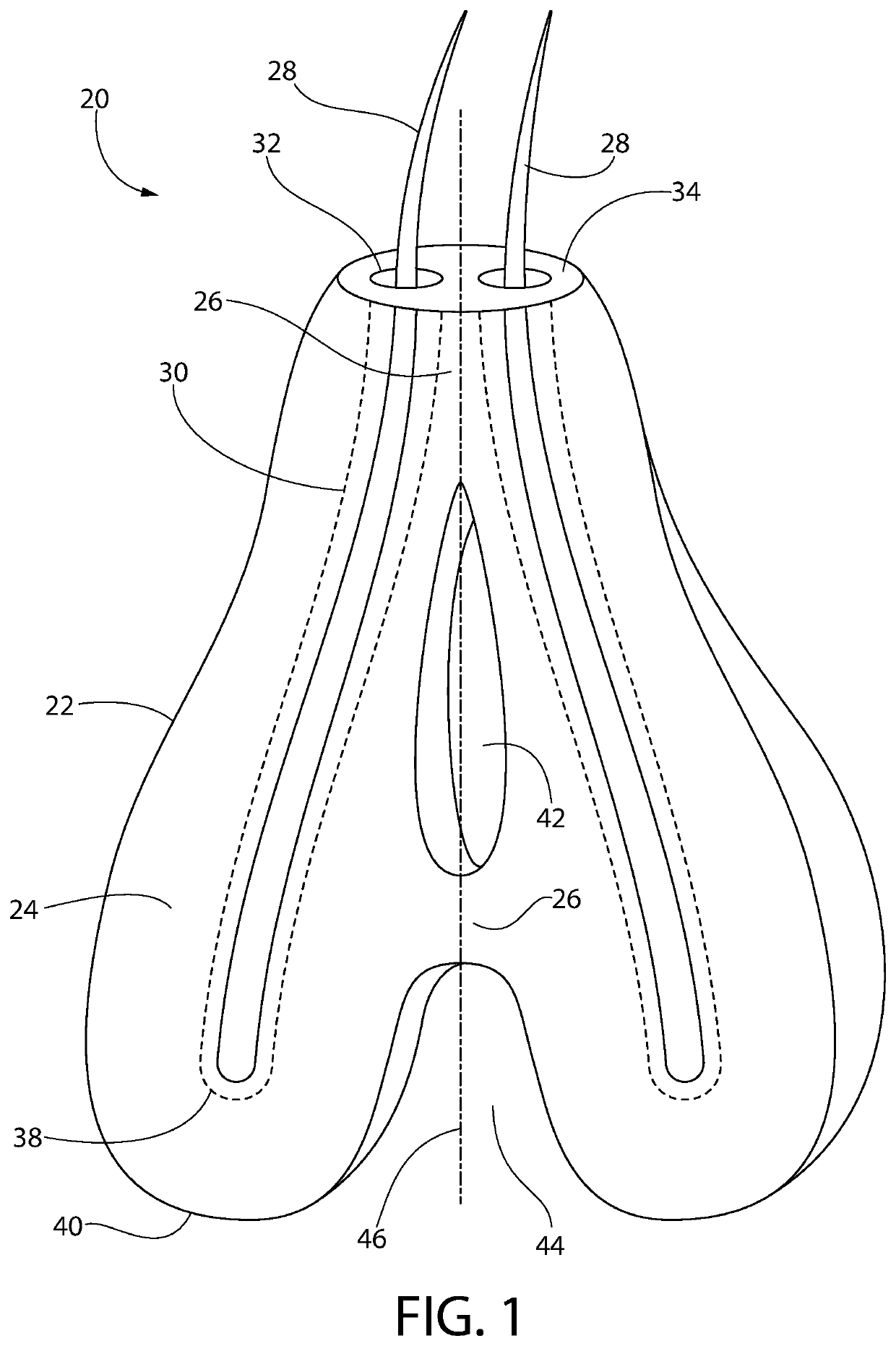

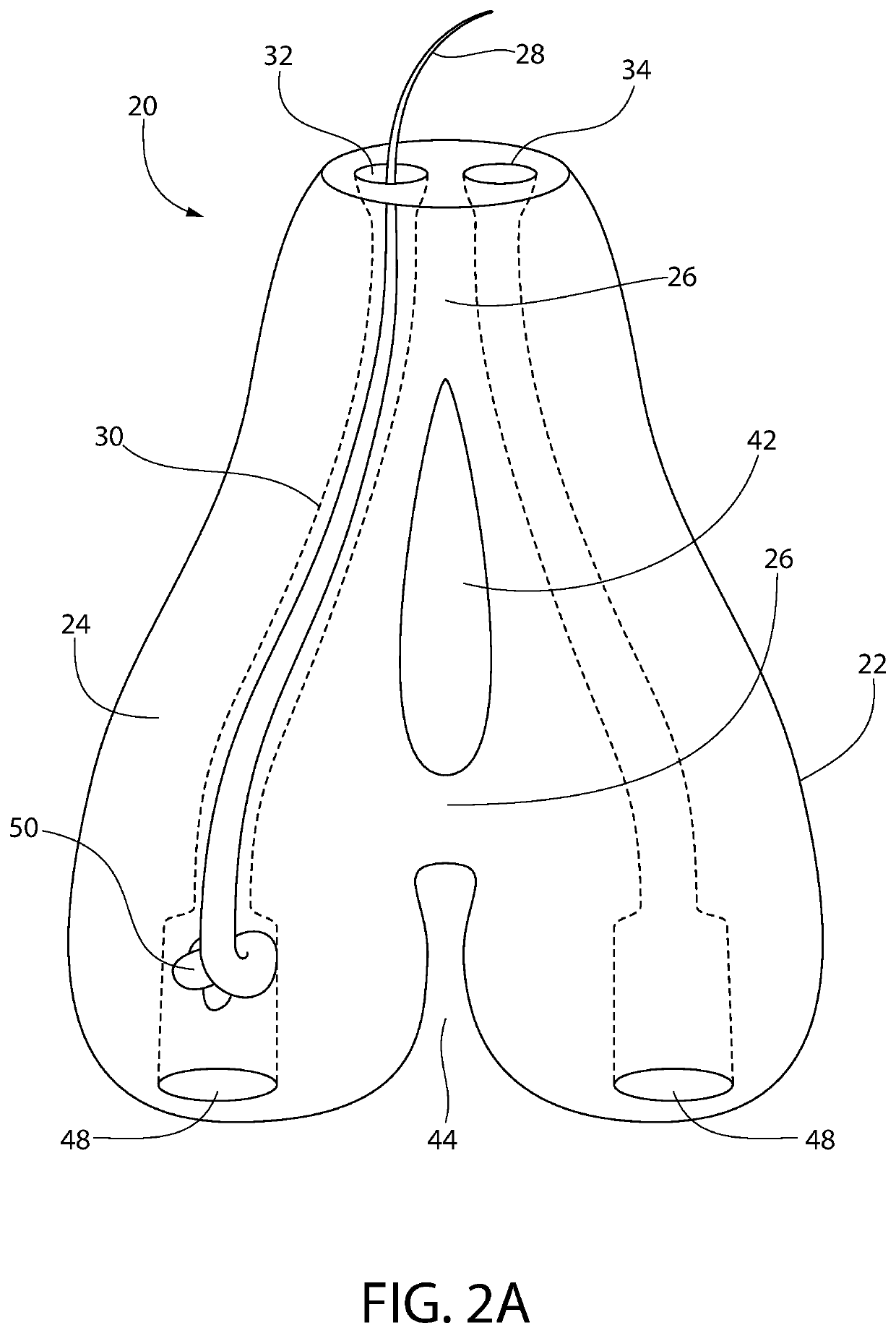

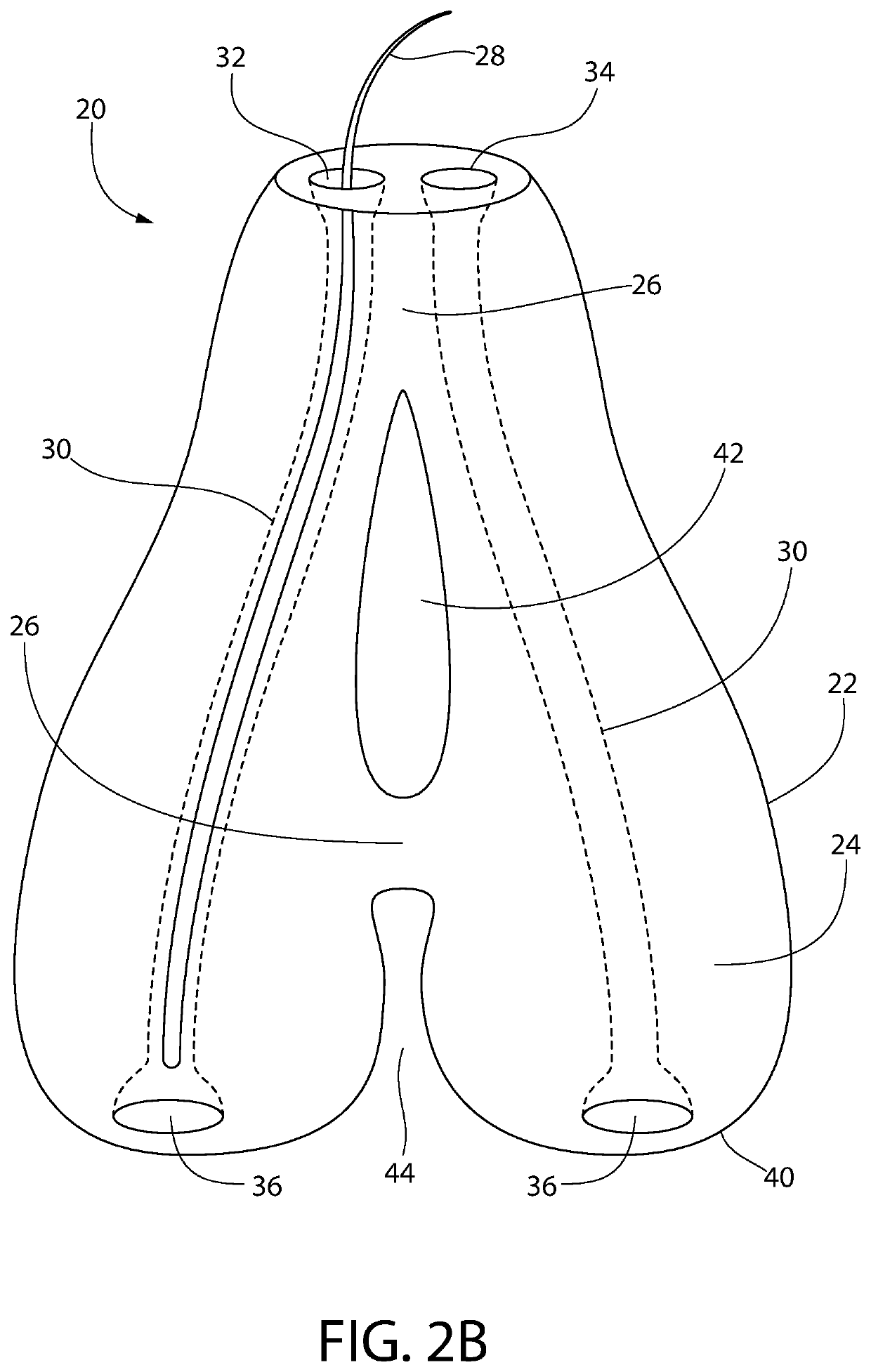

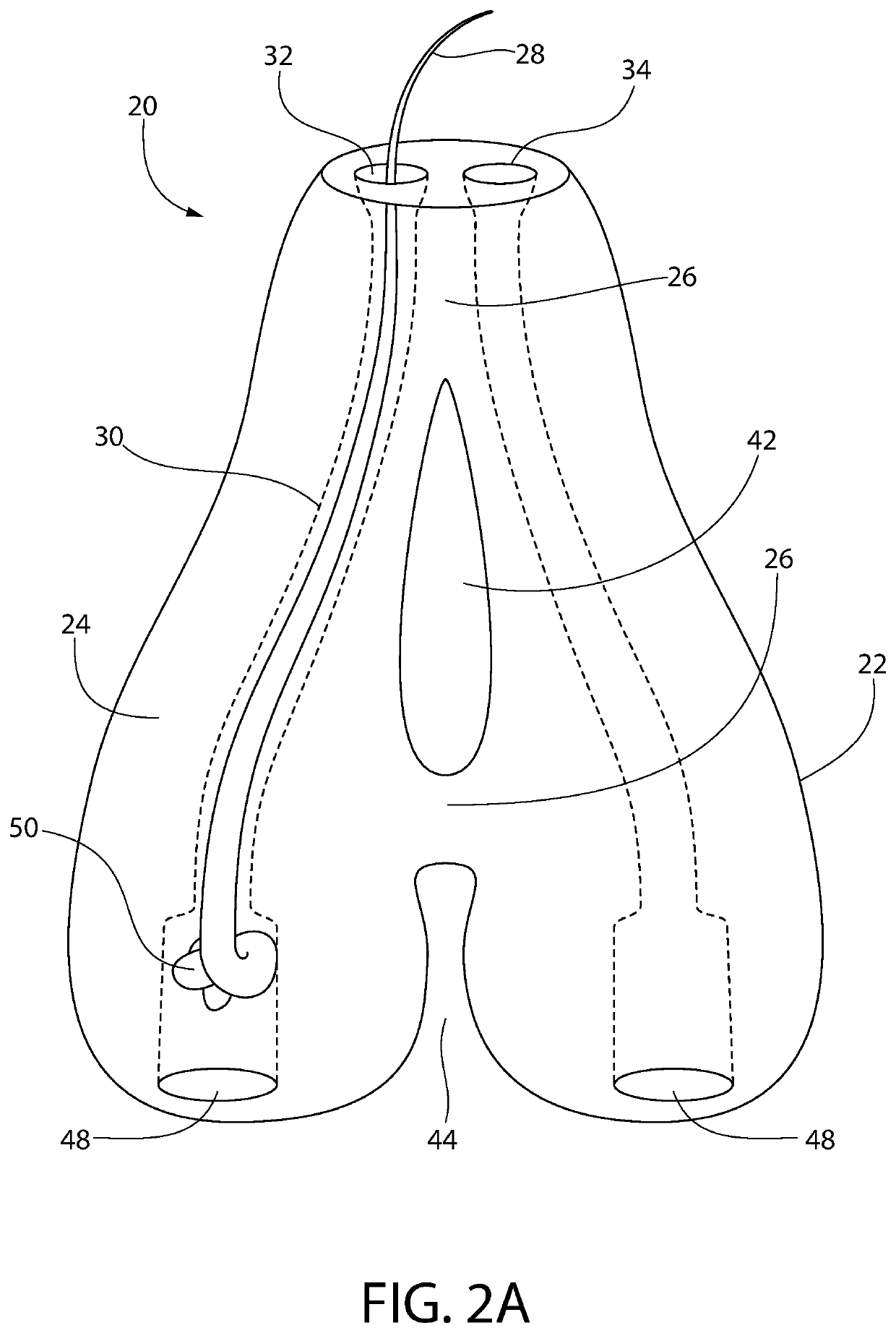

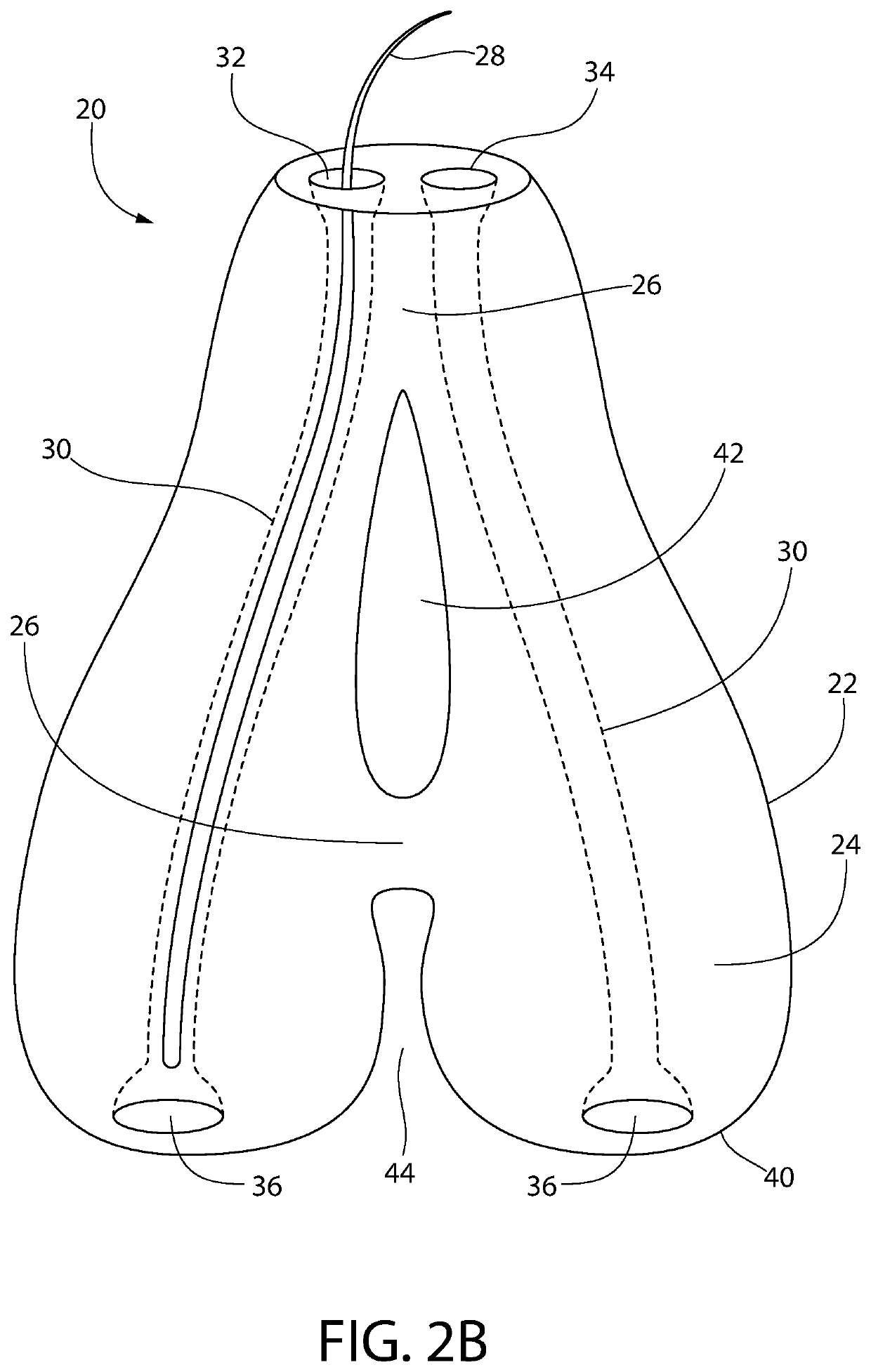

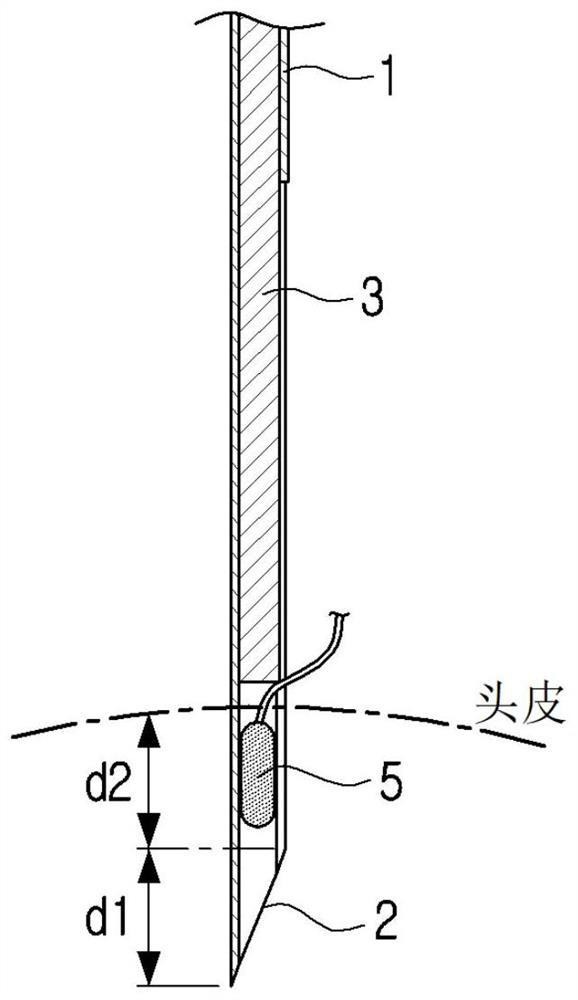

A hair implant anchor usable with a hair implant anchor deployment device for inserting one or more hairs into a tissue portion is provided. The hair implant anchor includes a holder configured to grip one or more hairs and one or more selectably deployable leaves formed with the holder. When the anchor is in its first configuration prior to implantation of the hairs, the leaves are constrained by the deployment device in a position generally parallel to an insertion axis, and in a second configuration, subsequent to implantation of the hair, the leaves adopt a position extended away from the insertion axis, thereby securing the holder and hair gripped thereby within the tissue portion. The invention also provides a method for use of the anchor, a hair implantation system, a multi-hair implantation system and a hair implantation assembly.

Owner:HAIRSTETICS

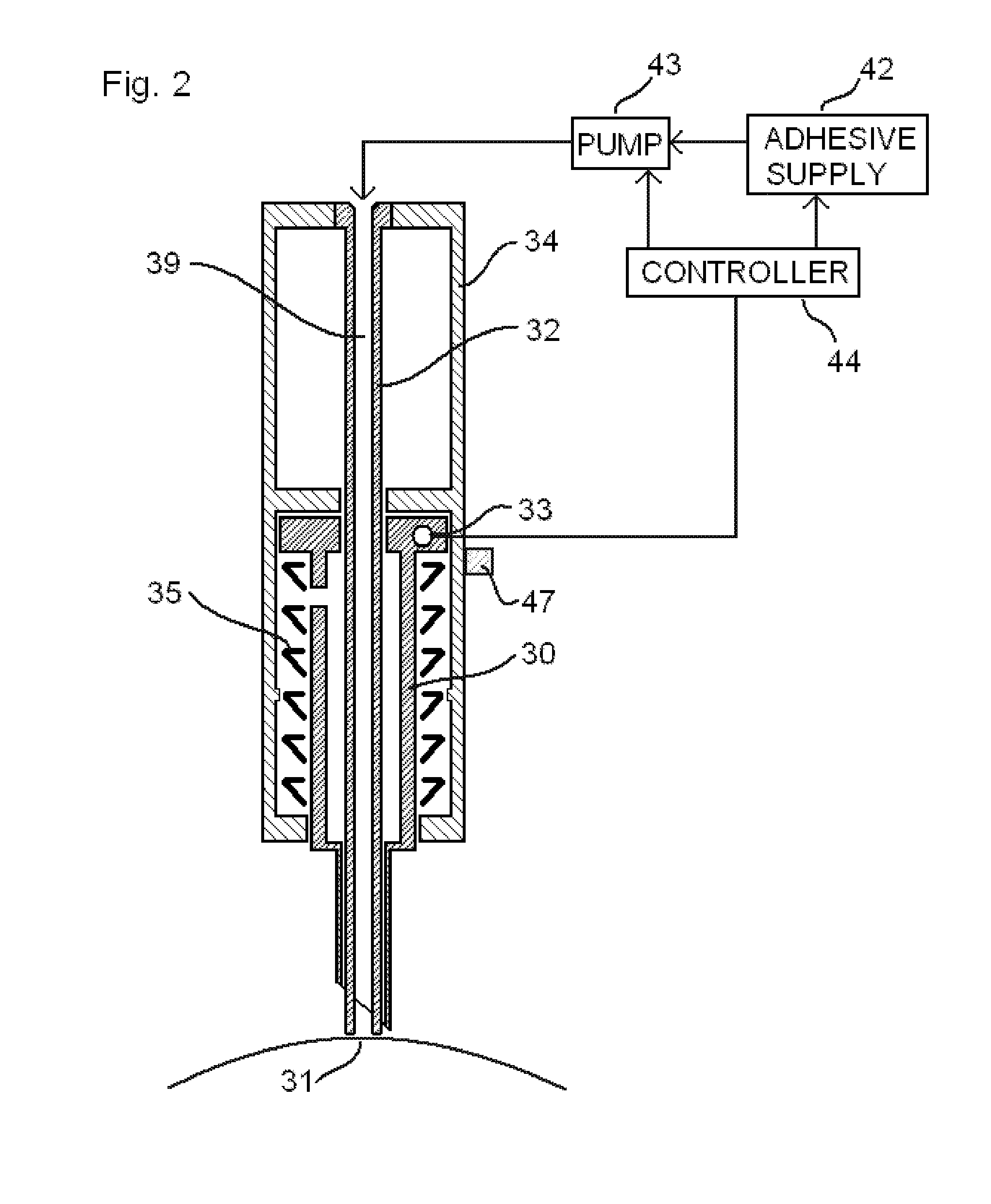

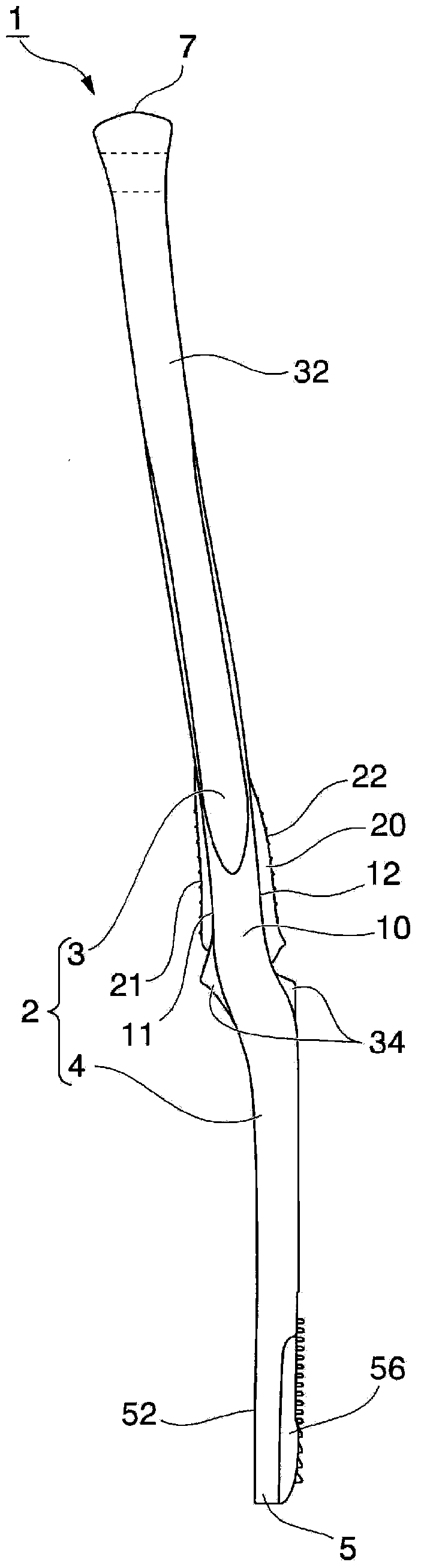

Hair implant apparatus and method for its use

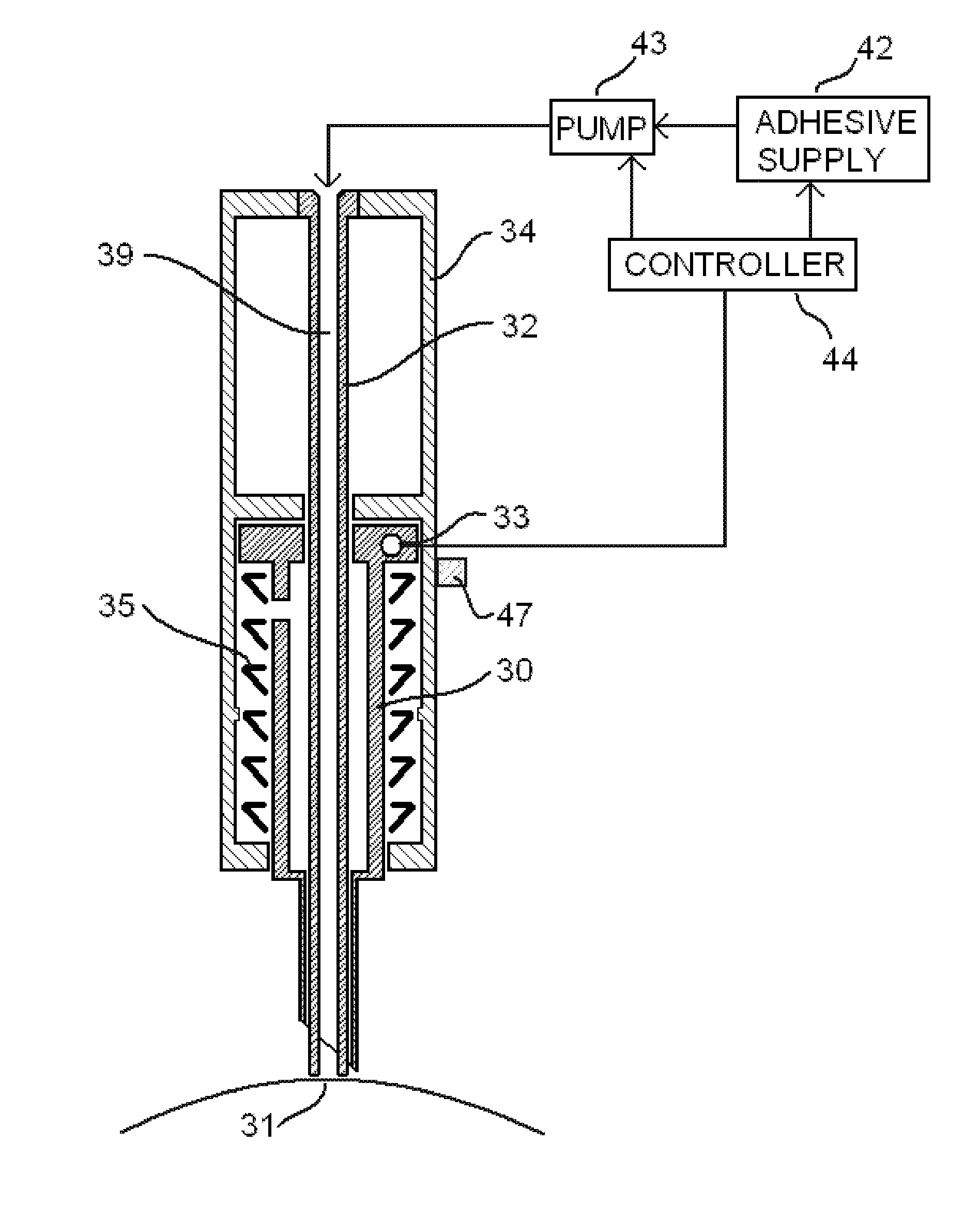

InactiveUS20080051816A1Highly controllableGood choiceSkin implantsSurgical needlesAdhesiveSkin surface

Apparatus for implanting single hair grafts in implant sites in a skin is adapted to apply a tiny adhesive dot in a manner to secure the implanted graft to the skin surface. The quick hardening of the adhesive allows the placement of implants in closely spaced, neighboring sites without causing dislodgment of previously implanted grafts. Illustrative apparatus for providing such implants comprises a hollow needle with a coaxial solid rod in a fixed position. The needle is moved along its axis for implanting a graft and a channel in the rod is positioned to deliver the adhesive dot.

Owner:PAK JAE P +1

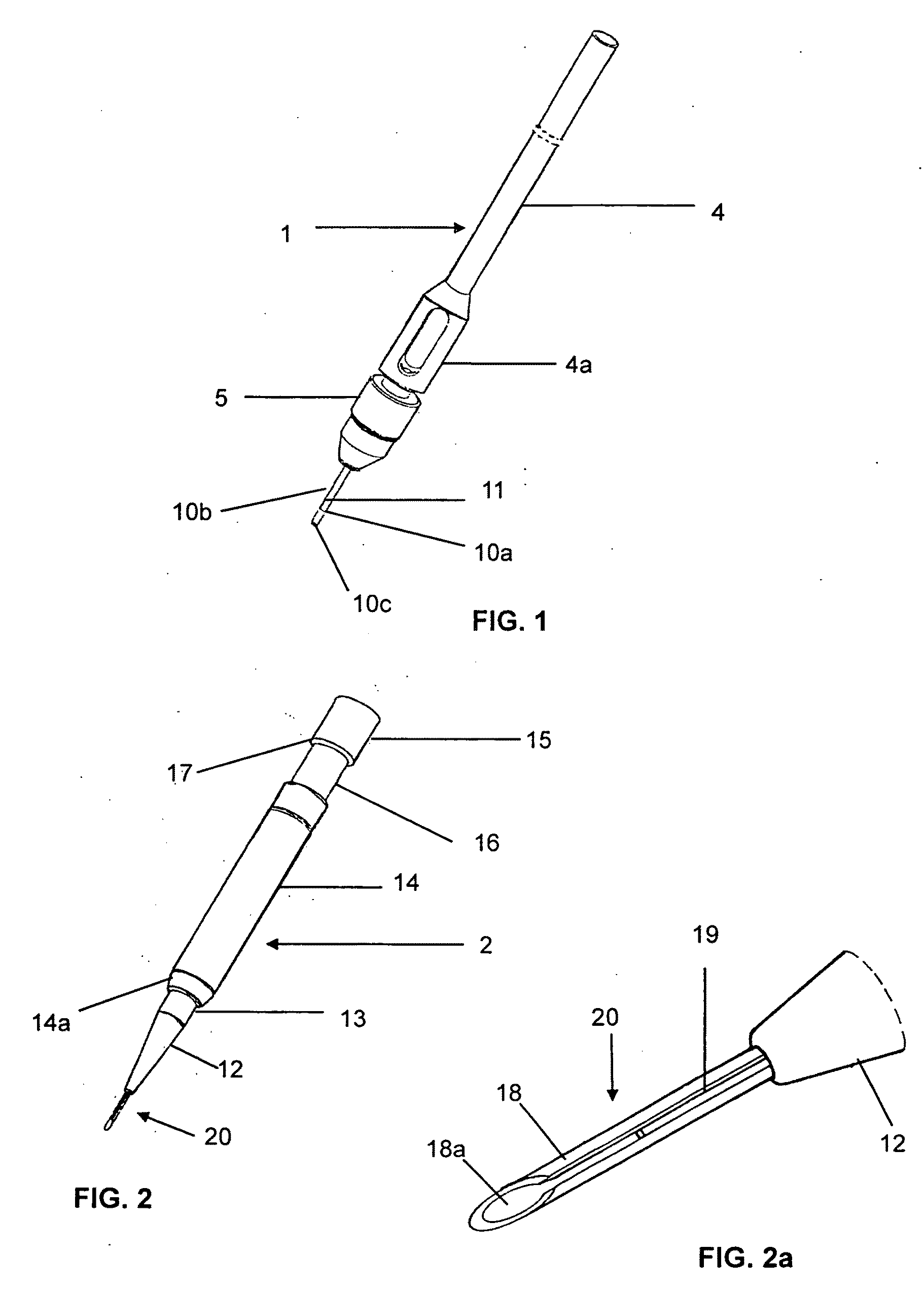

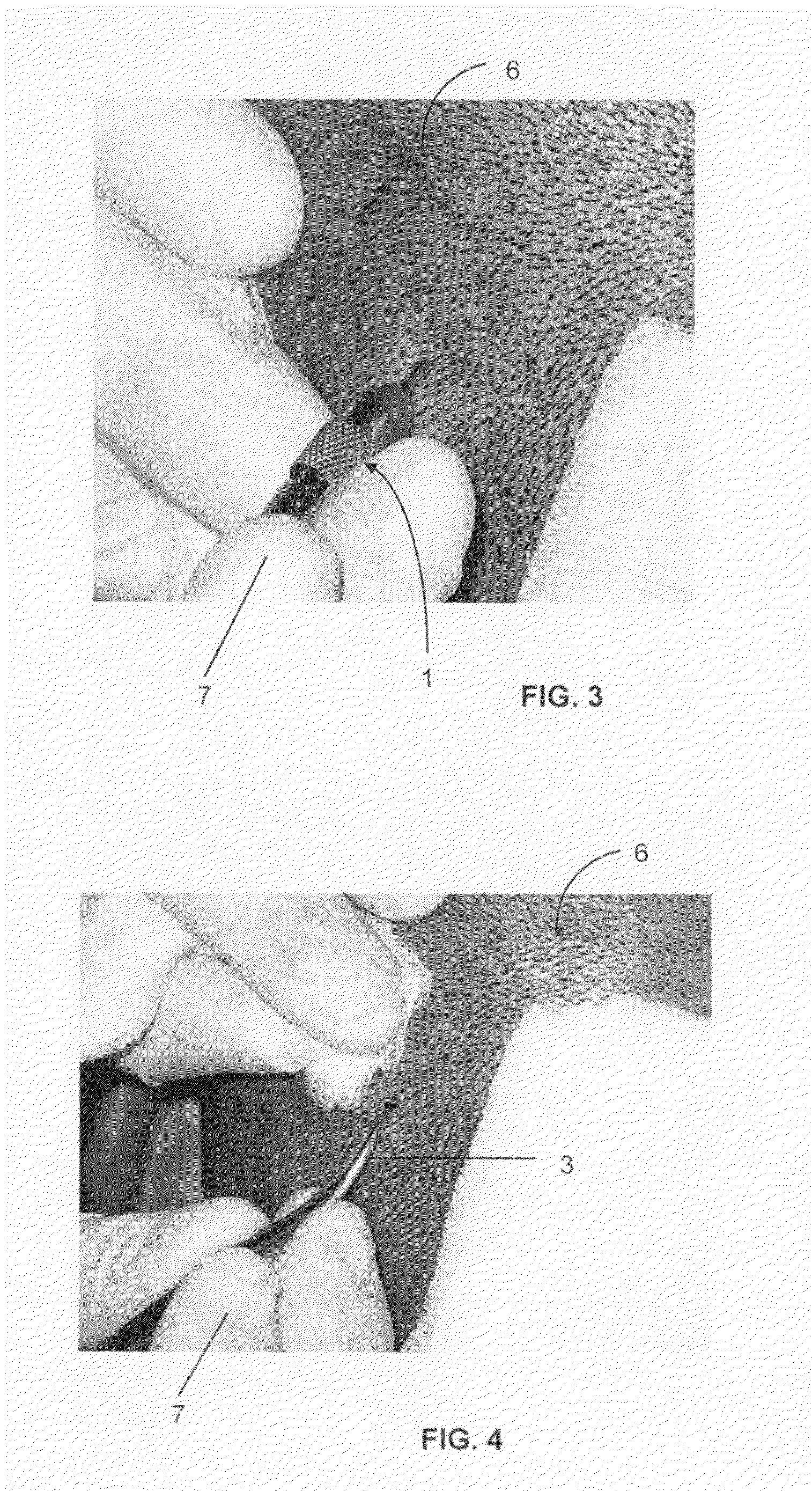

Method of direct hair implantation

InactiveUS20110046639A1Minimizing fatigue factorReduced anesthesiaSurgical needlesExcision instrumentsMedicineHair follicle

Method of direct hair implantation consisting in sequentially harvesting single hair follicles from a donor region and directly implanting the same at a recipient region of the scalp, wherein the method employs a hair harvesting instrument with a sterile disposable punch of appropriately small diameter adapted to successively perform cutting of a single hair follicle when it is brought in contact with the root of the hair follicle and is manually rotated around the perimeter of the same. A micro gripper means is thereafter used for the extraction of the cut hair follicle and for loading a forwardly projecting tubular needle of a hair implanting instrument with the extracted hair follicle. A hair implanting instrument is then employed for a selective placement of said hair follicle in the appropriate direction and at an appropriate position on a demarcated recipient region of the scalp. The process of single hair follicle harvesting, extraction and direct implantation is repeated until completion of the planned direct hair implantation procedure.

Owner:GIOTIS KONSTANTINOS

Hair implant anchors and systems and methods for use thereof

ActiveUS9492196B2Easily implanted into target tissueEasy to useSuture equipmentsSkin implantsBiomedical engineeringHair implant

Owner:HAIRSTETICS

Hair implants comprising enhanced anchoring and medical safety features

ActiveUS9993334B1Avoid bacterial infectionInhibition is effectiveSuture equipmentsSkin implantsSubcutaneous implantCollagenan

A hair implant includes at least two strands including at least one of mammalian hair and synthetic hair; and an anchor, which: (a) includes silicone, (b) is configured for subcutaneous implantation, (c) includes a fracture line configured to facilitate fracturing of the anchor along the fracture line for ease of removal of the implant after subcutaneous implantation, and (d) is configured to provide a scaffold for collagen growth after subcutaneous implantation, wherein at least one of the at least two strands is joined to the anchor on one side of the fracture line and at least one of the at least two strands is joined to the anchor on an opposite side of the fracture line such that each fragment formed by fracturing the implant includes at least one of the at least two strands. Looped implants, a hair restoration method and an implant manufacturing method are also disclosed.

Owner:LORIA HAIR IMPLANT CO LLC

Hair implants comprising enhanced anchoring and medical safety features

ActiveUS10105212B1Avoid bacterial infectionInhibition is effectiveSuture equipmentsSkin implantsAnatomySubcutaneous implant

Owner:LORIA HAIR IMPLANT CO LLC

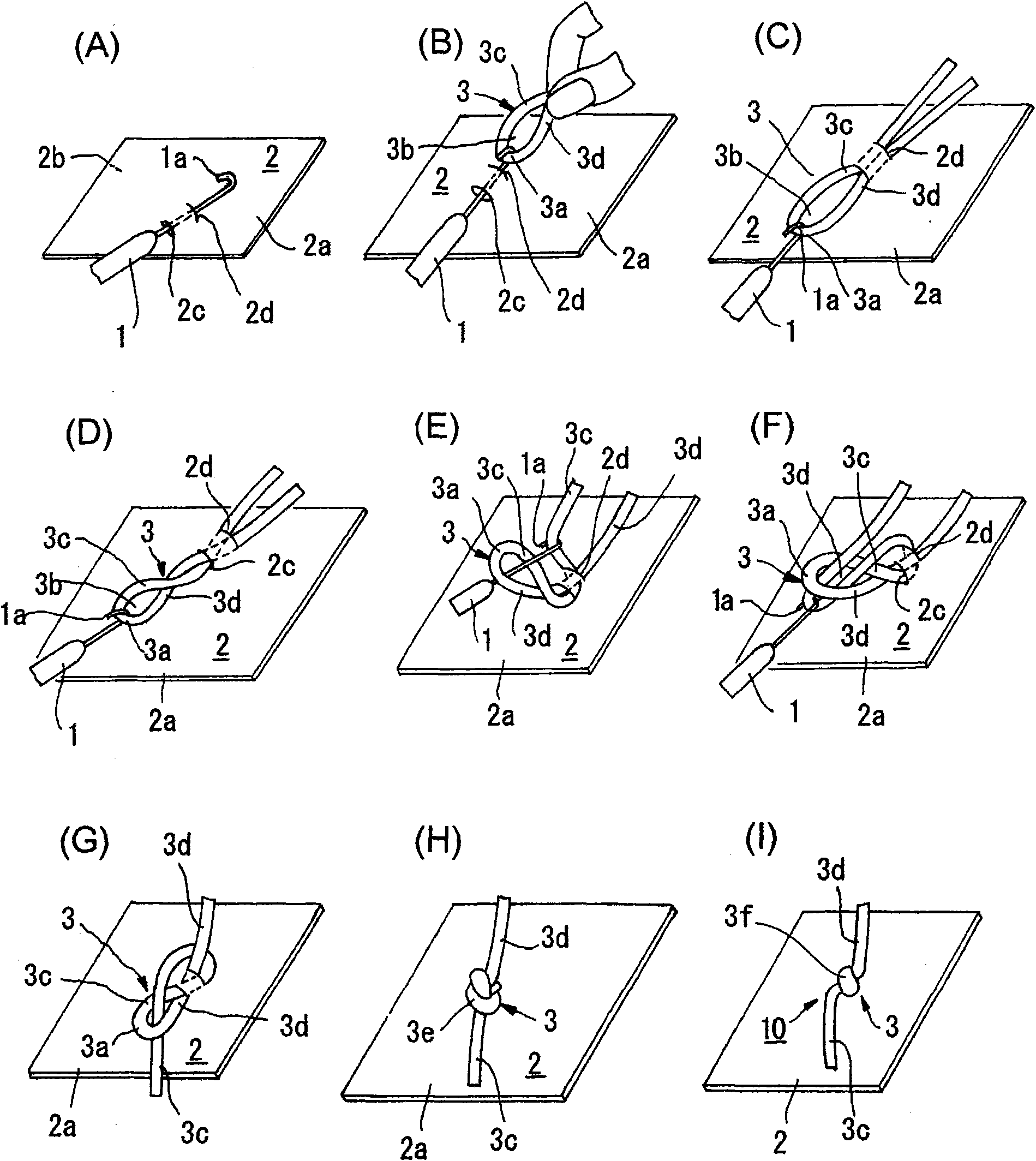

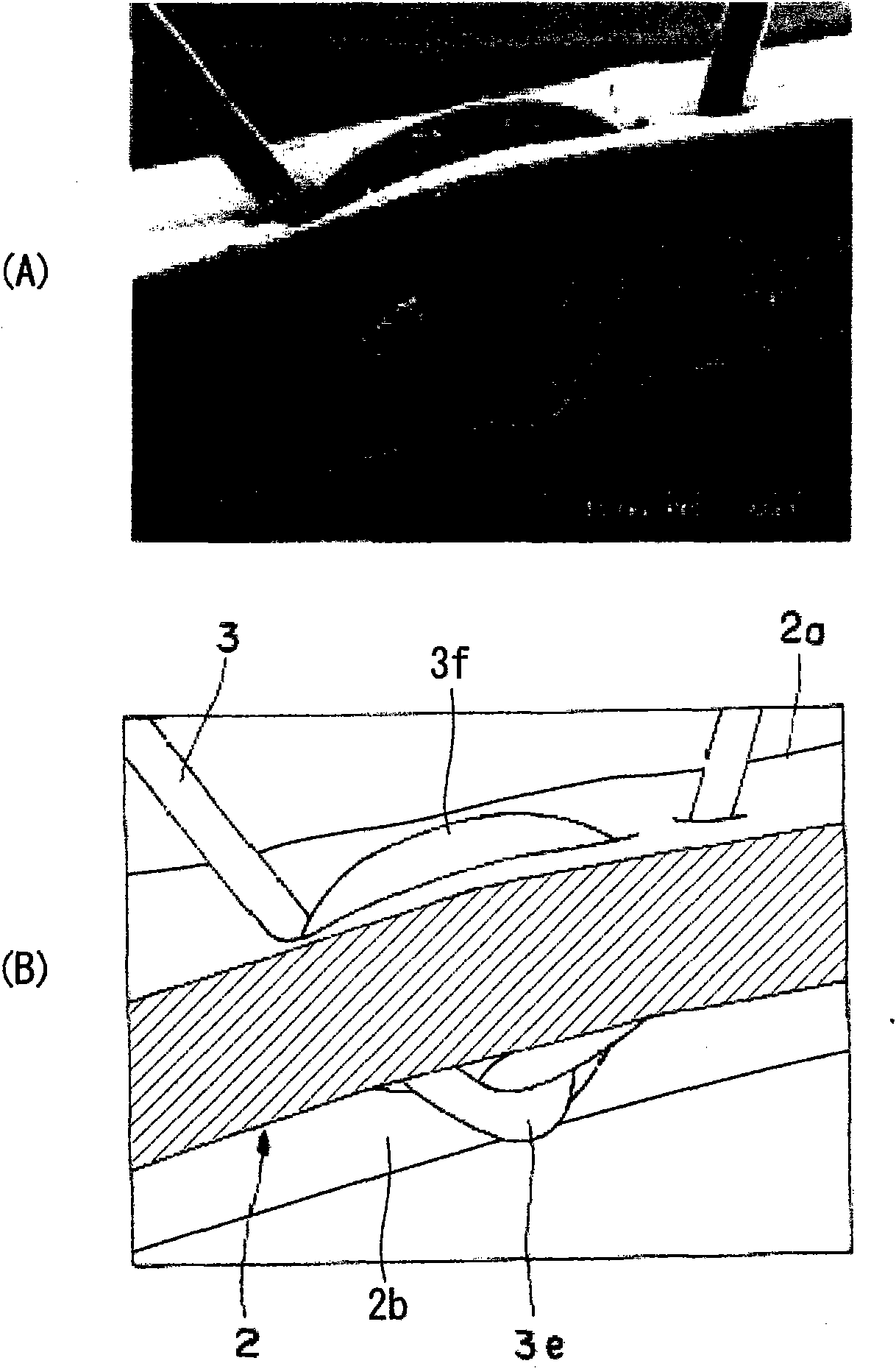

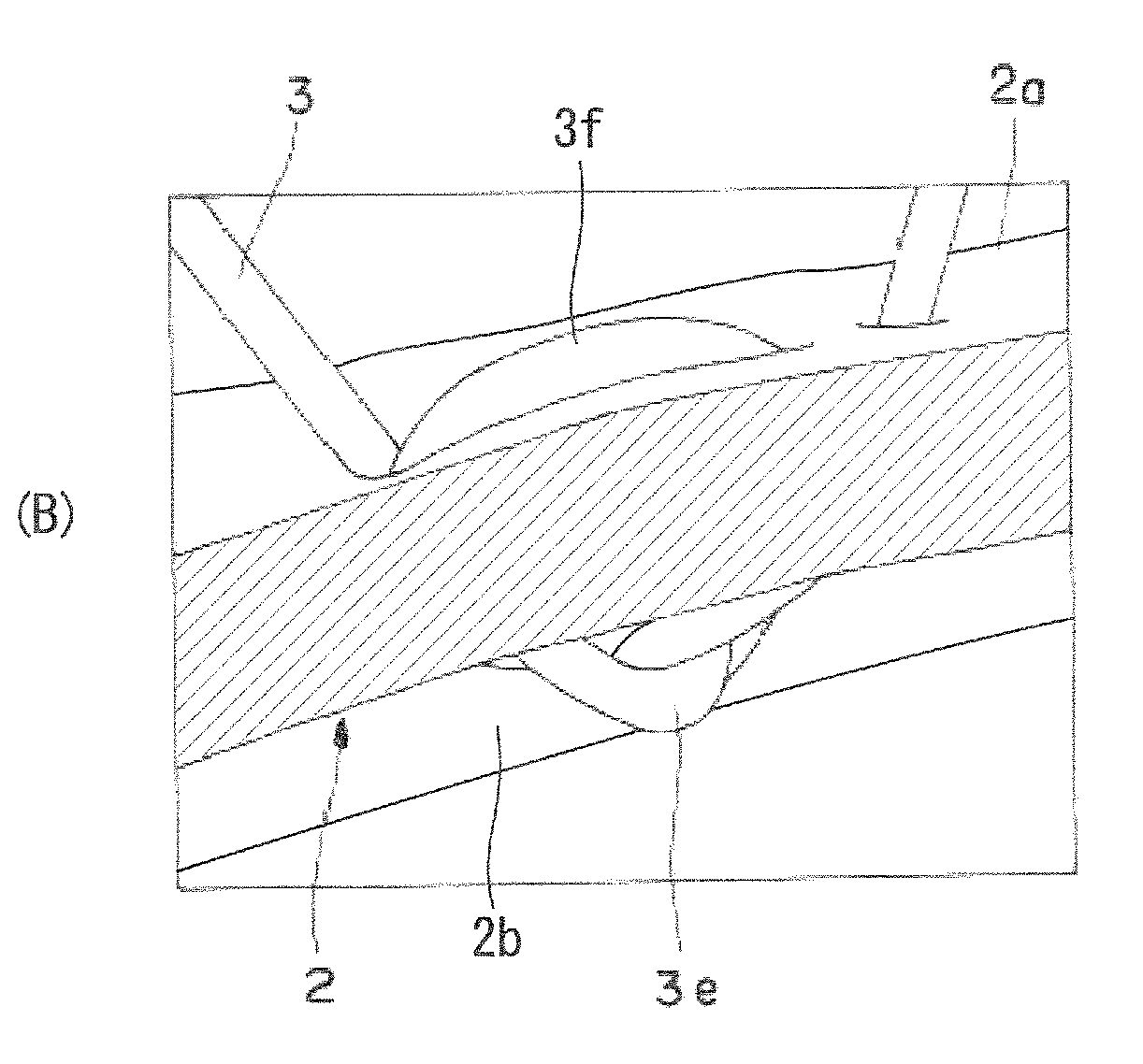

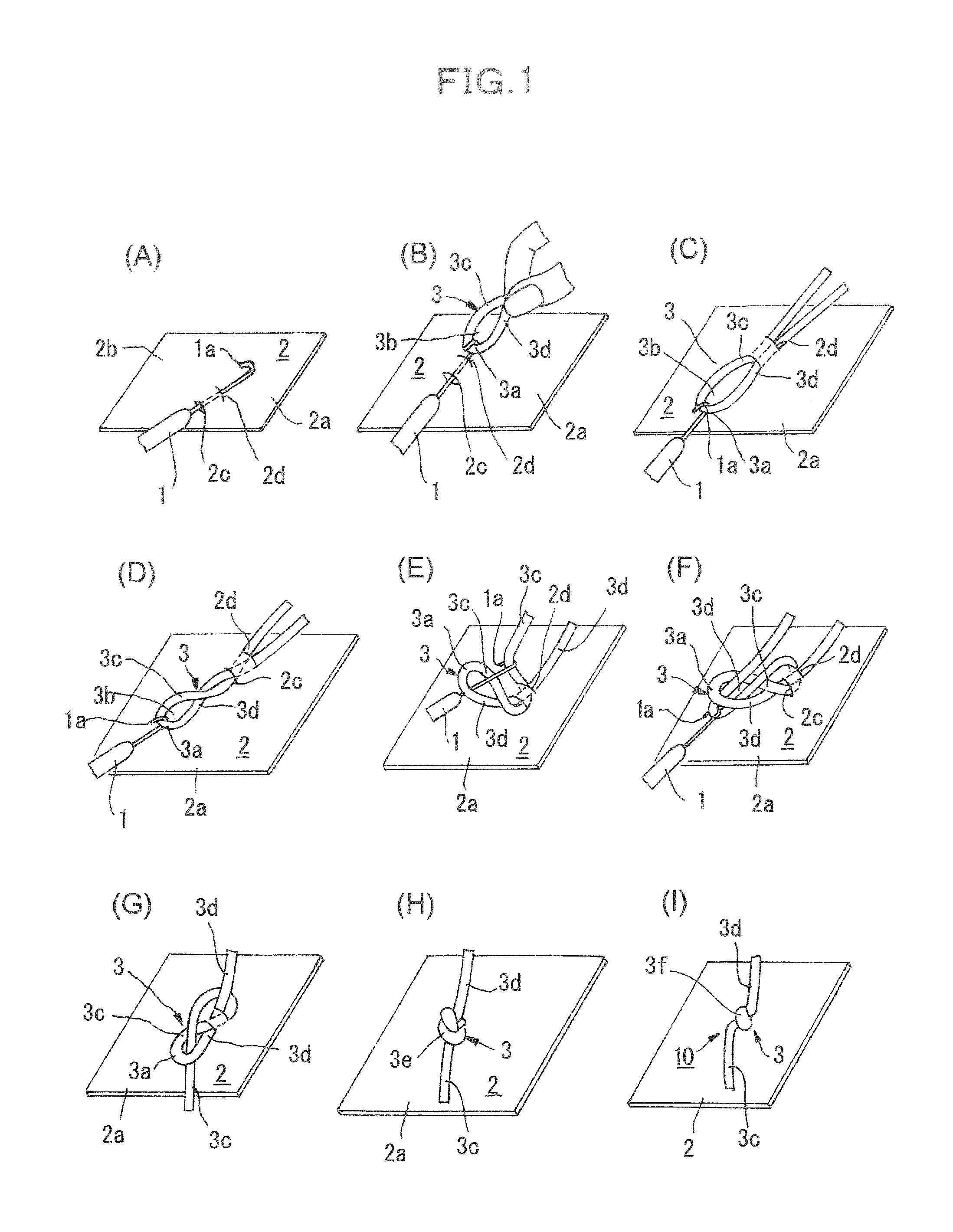

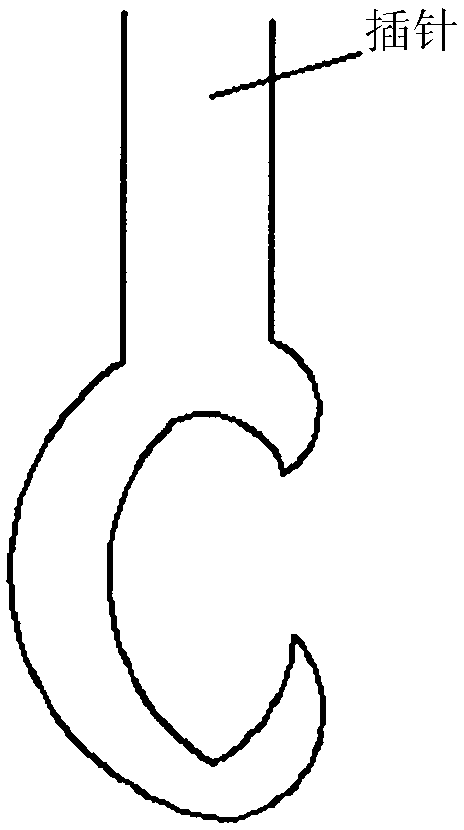

Wig, and its manufacturing method

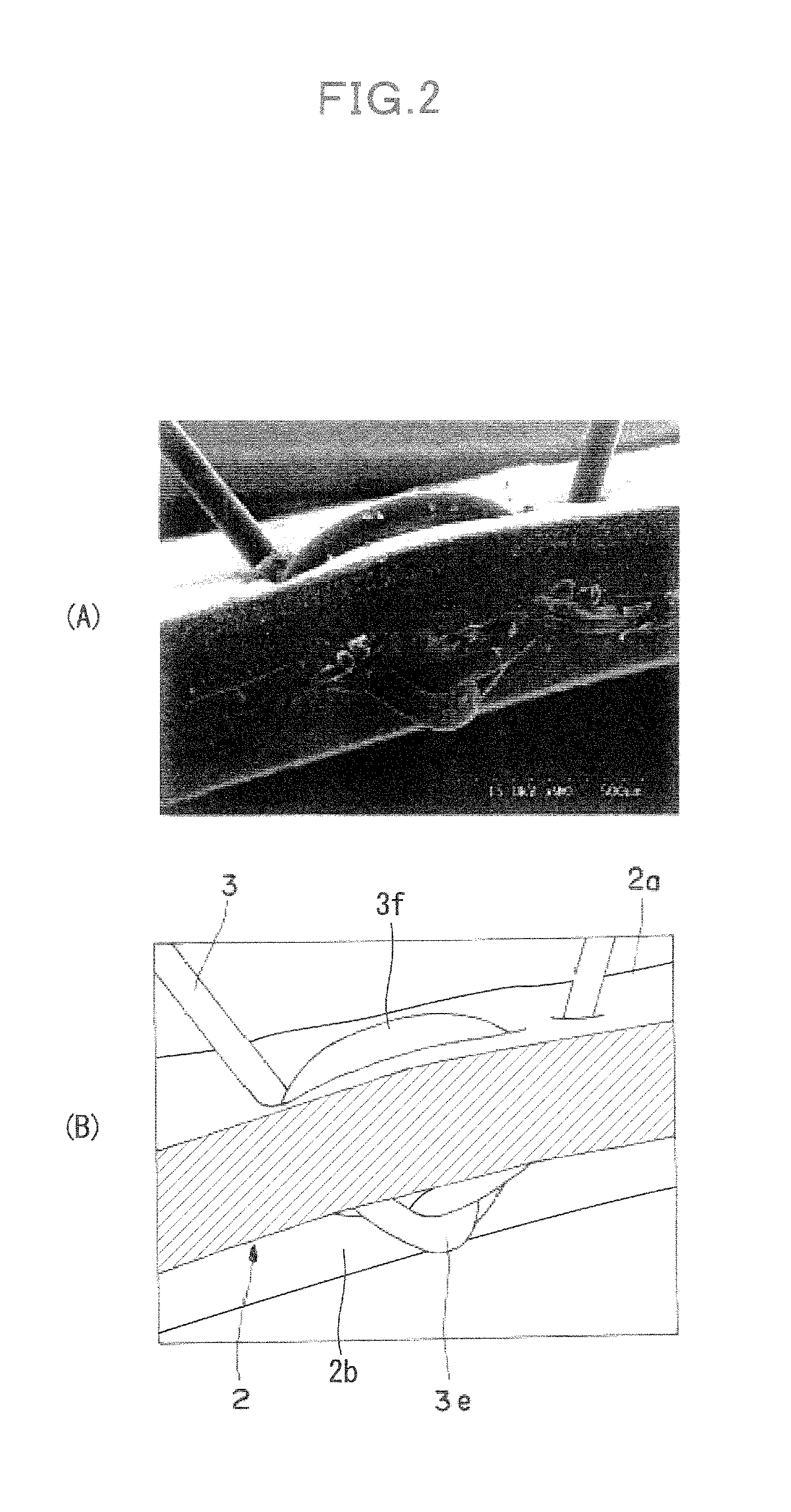

This aims to provide a wig manufacturing method comprising a first step for inserting the hook portion (1a) of a hair-implanting needle (1) from the surface (2a) to the back (2b) of a wig base (2), bringing the hook portion from another portion to the surface of the wig base, a second step for hooking a loop (3b) formed at the folded-back portion of a double-folded hair element (3), on the hook portion (1a), a third step for extracting the loop (3b) from the wig base (2) with the hair element being hooked by the hair-implanting needle (1), a fourth step for hooking the hook portion (1a) on the one-end side (3c) of the hair element, a fifth step for extracting the hair-implanting needle in this state from the loop (3b), a sixth step for holding the other-end side (3d) of the hair element and pulling the one-end side (3c) thereby to form a knot (3e), and a seventh step for pulling the other-end side (3d) while holding the one-end side (3c), to move the knot (3e) to the back (2b) of the wig base. Thus, the wig is constituted such that the knot (3e) of the hair element (3) is positioned on the back (2b) of the wig base.

Owner:ADERANS CO LTD

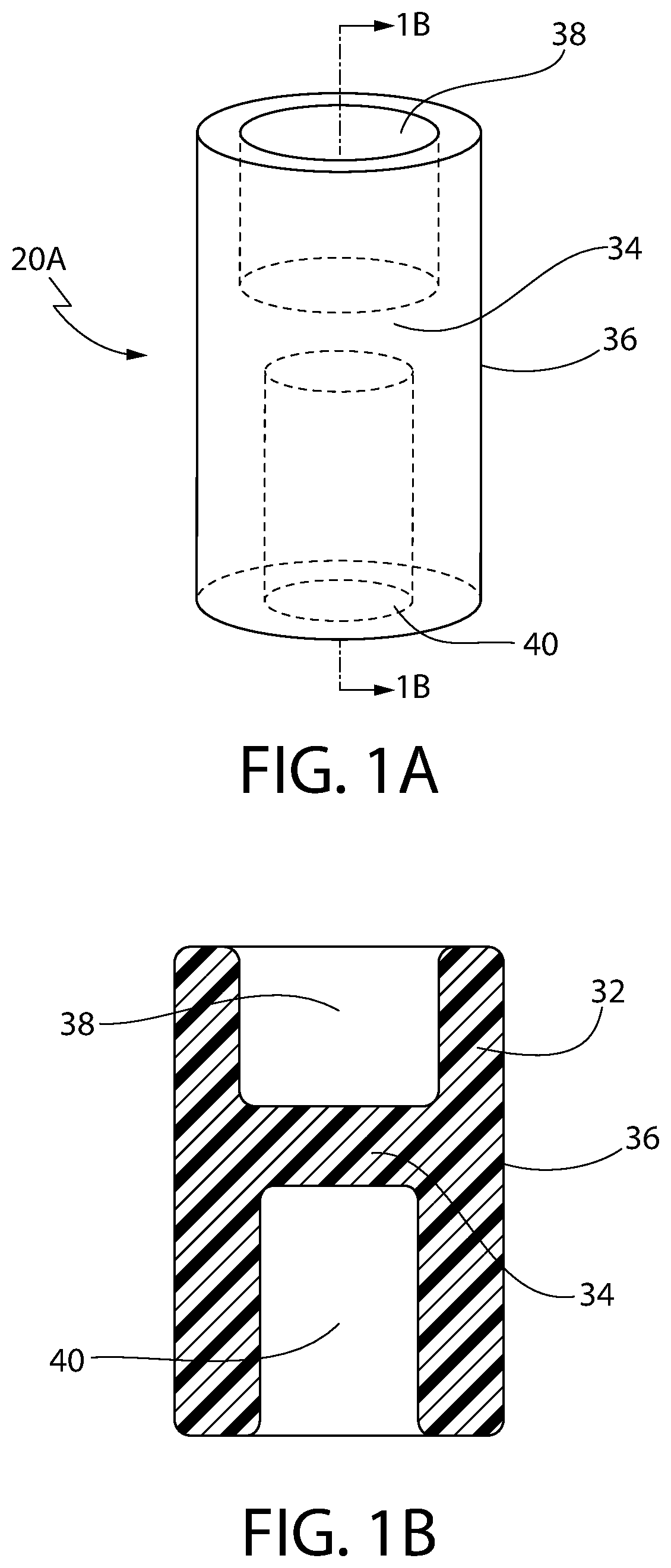

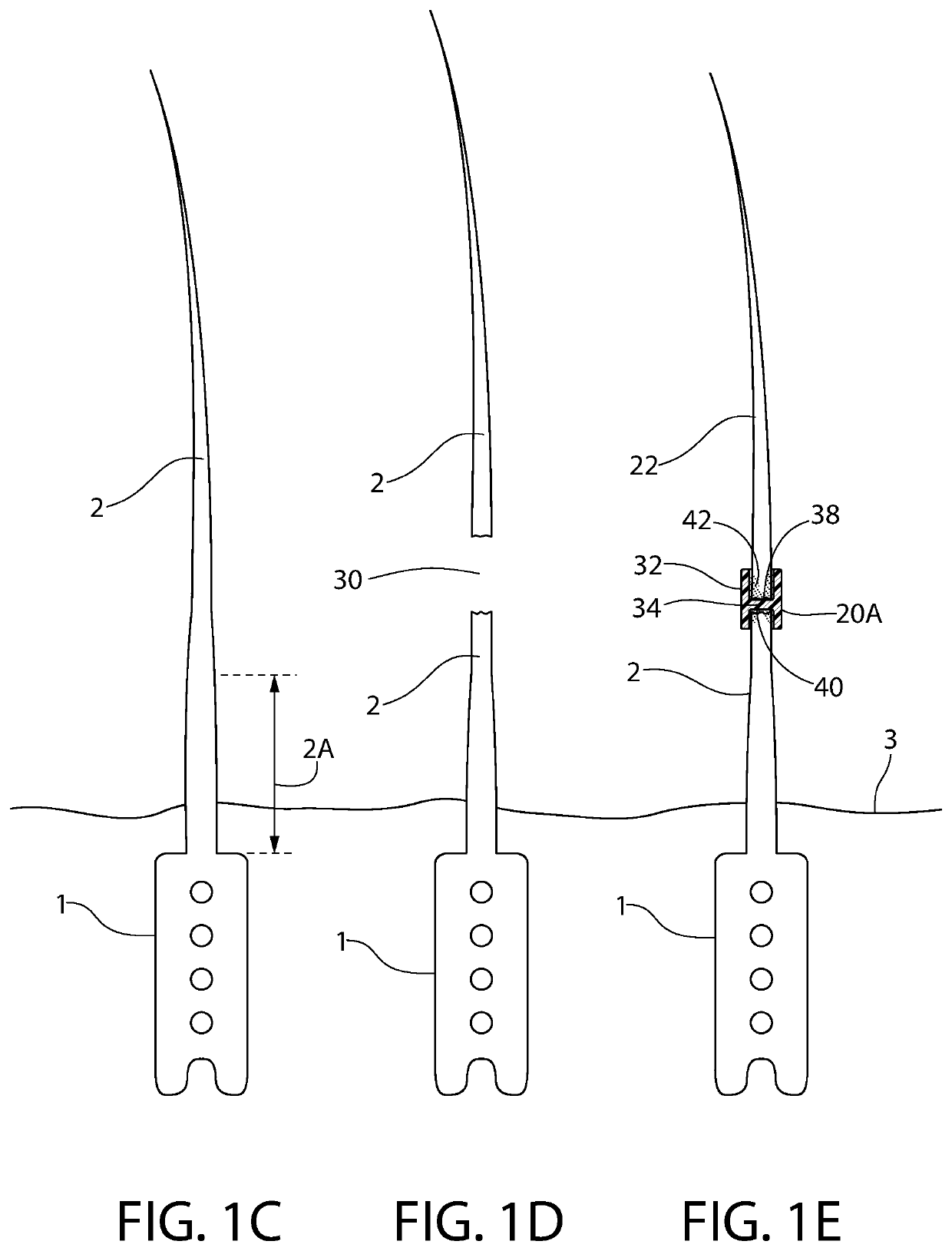

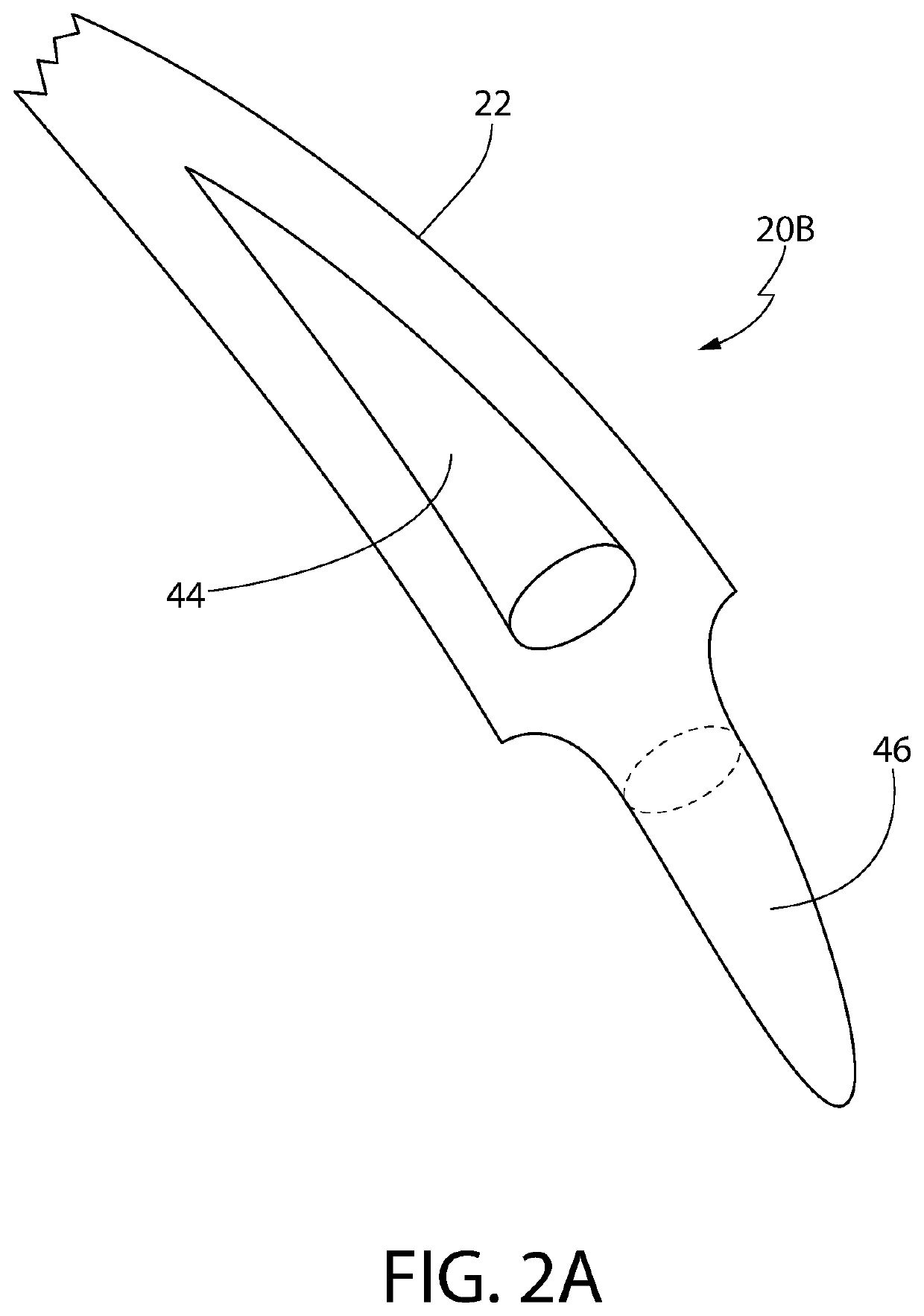

Extension apparatus for artificial hair implants

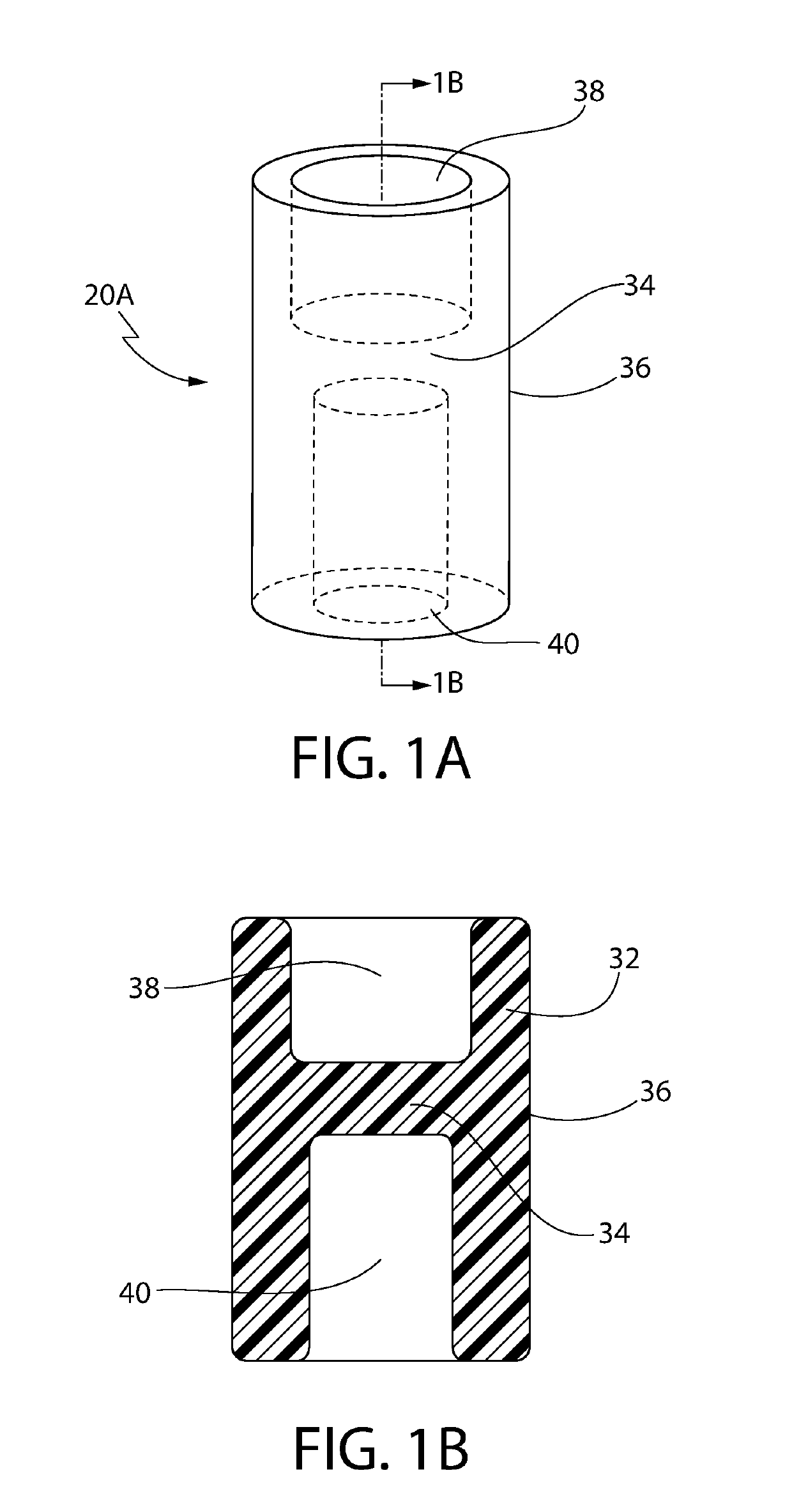

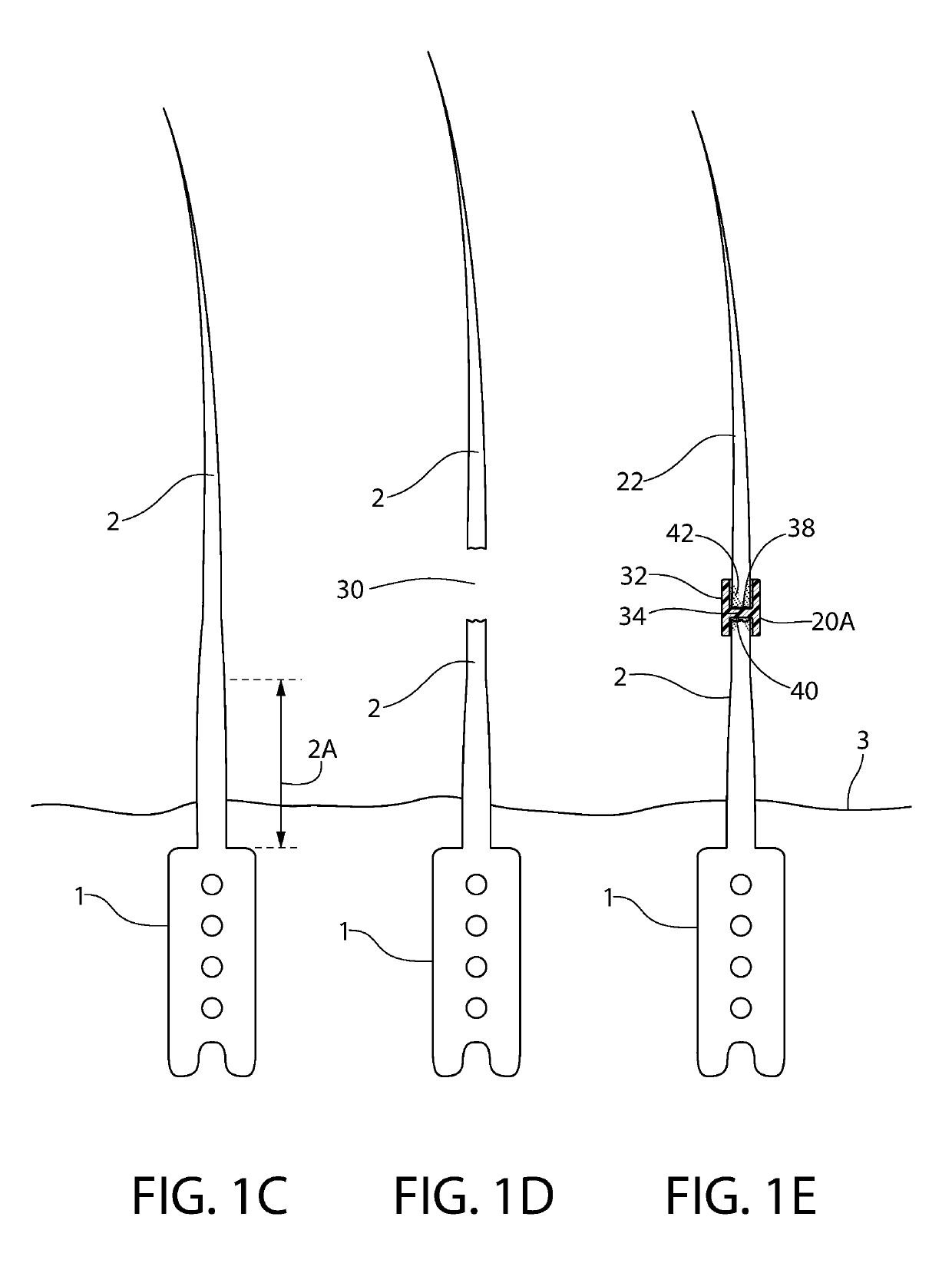

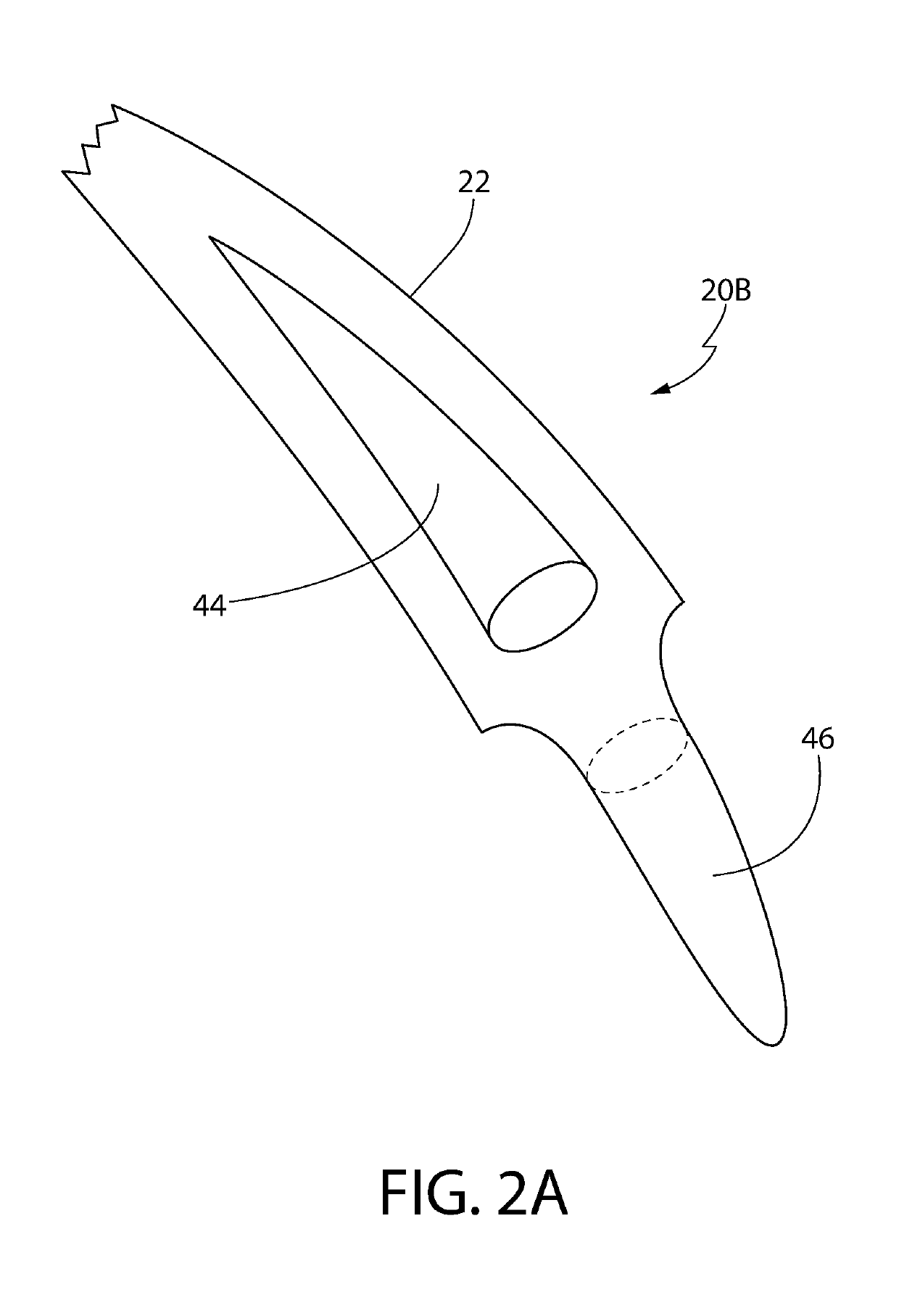

ActiveUS20190117378A1Minimal and no side effectHair accessoriesSkin implantsBudBiomedical engineering

Extension devices for attaching hair extension elements to artificial hair elements that protrude from a subcutaneously implanted hair implant anchor body. One extension device involves a cylindrical structure having respective cavities on opposing ends. One cavity receives the distal end of the artificial hair element while the other cavity receives the hair extension therein. Another extension device involves a hair extension element forming a first portion of the device while a second opposite portion includes a projection that is received inside a hollow interior of the artificial hair element. A third extension device involves a core having a hair extension element projecting from one side of the core while a single cavity is located on a second side, opposite the one side, and which receives the distal end of the artificial implanted hair element therein. The hair extension may comprise ancillary hair elements and bud structures. Ornamental structures may be included on the distal ends of the hair extension element.

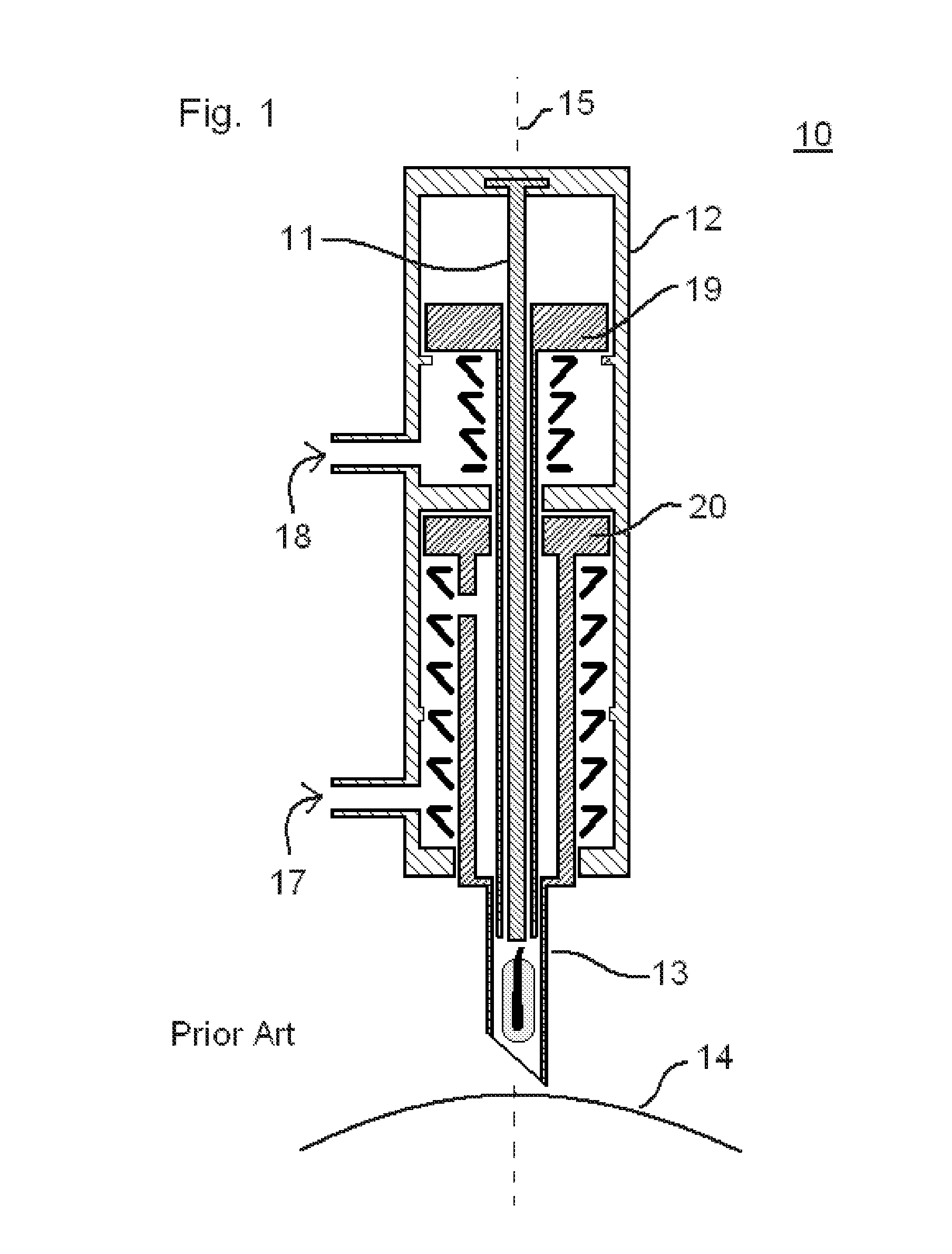

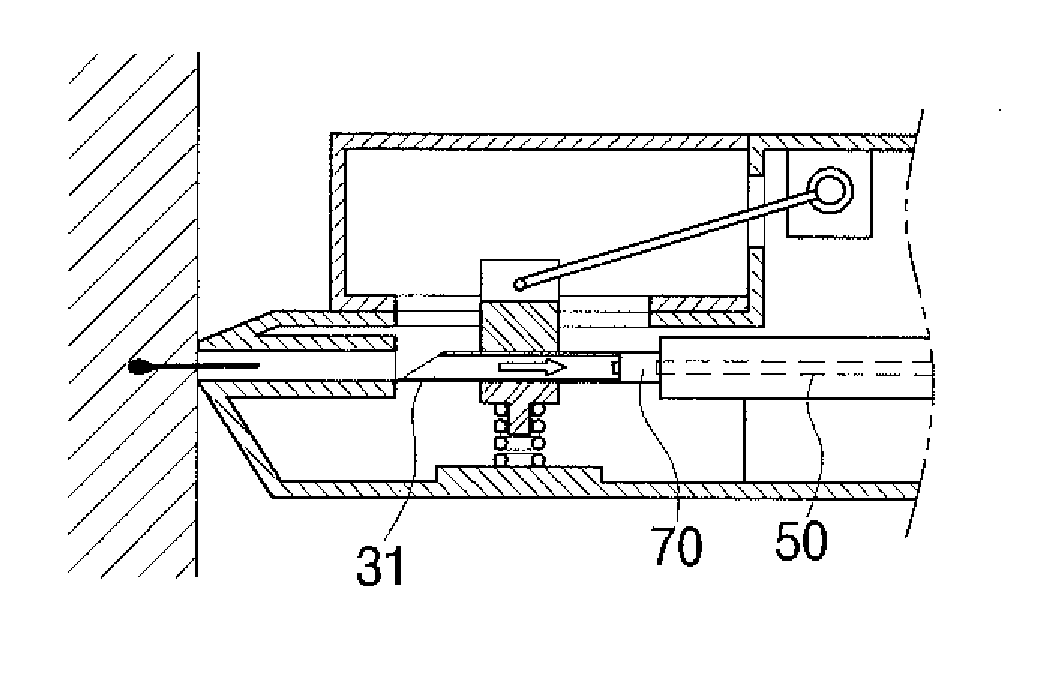

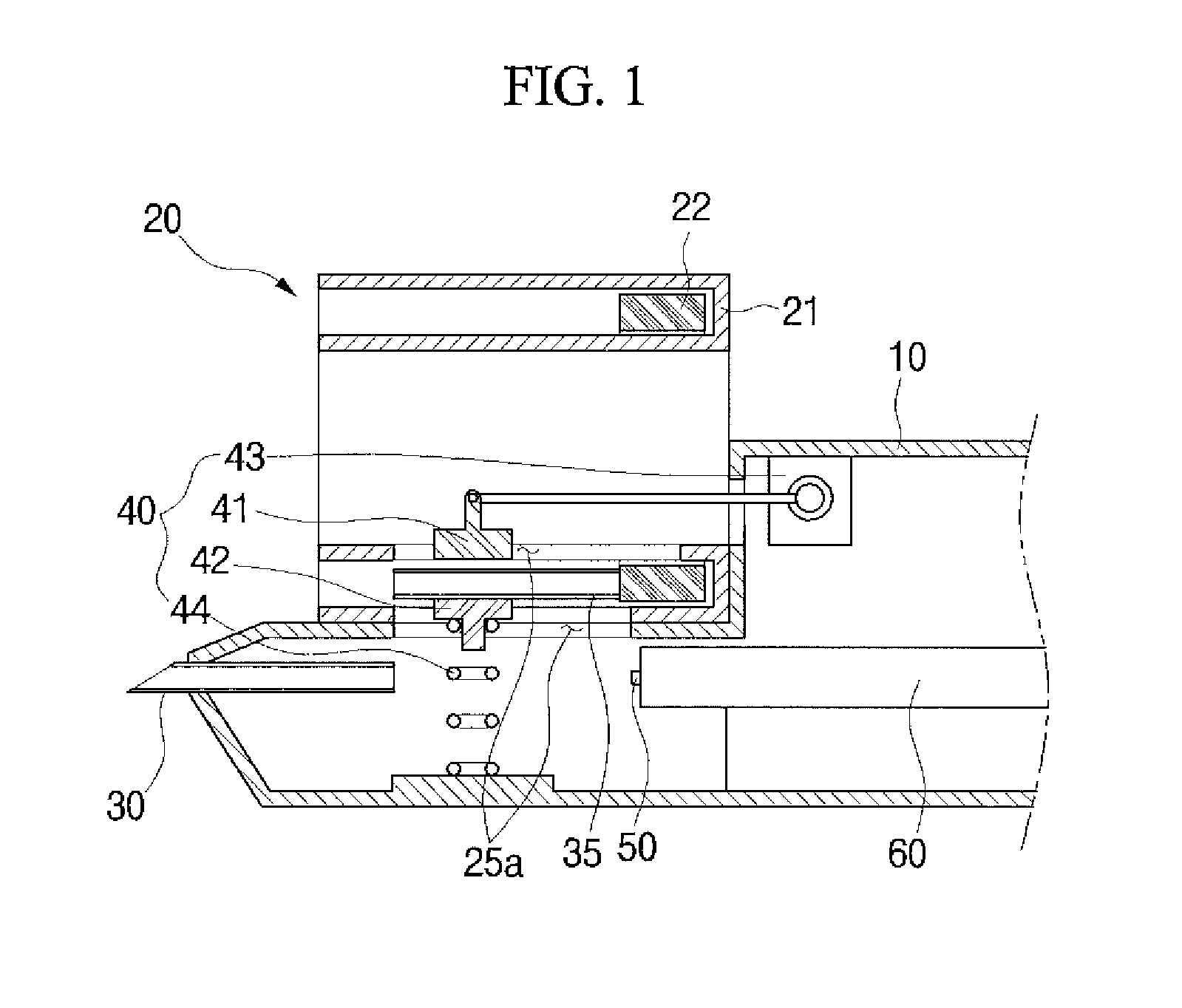

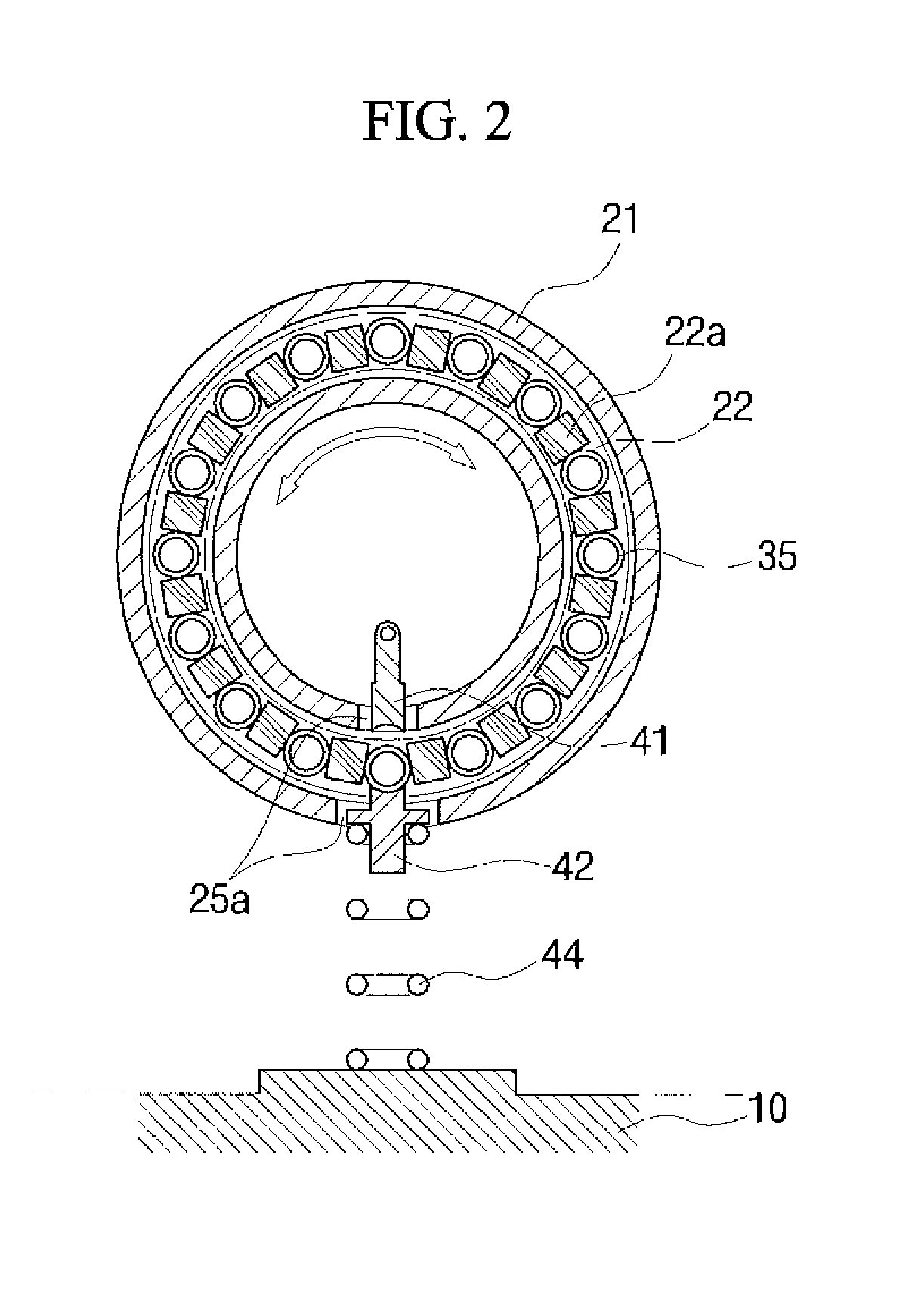

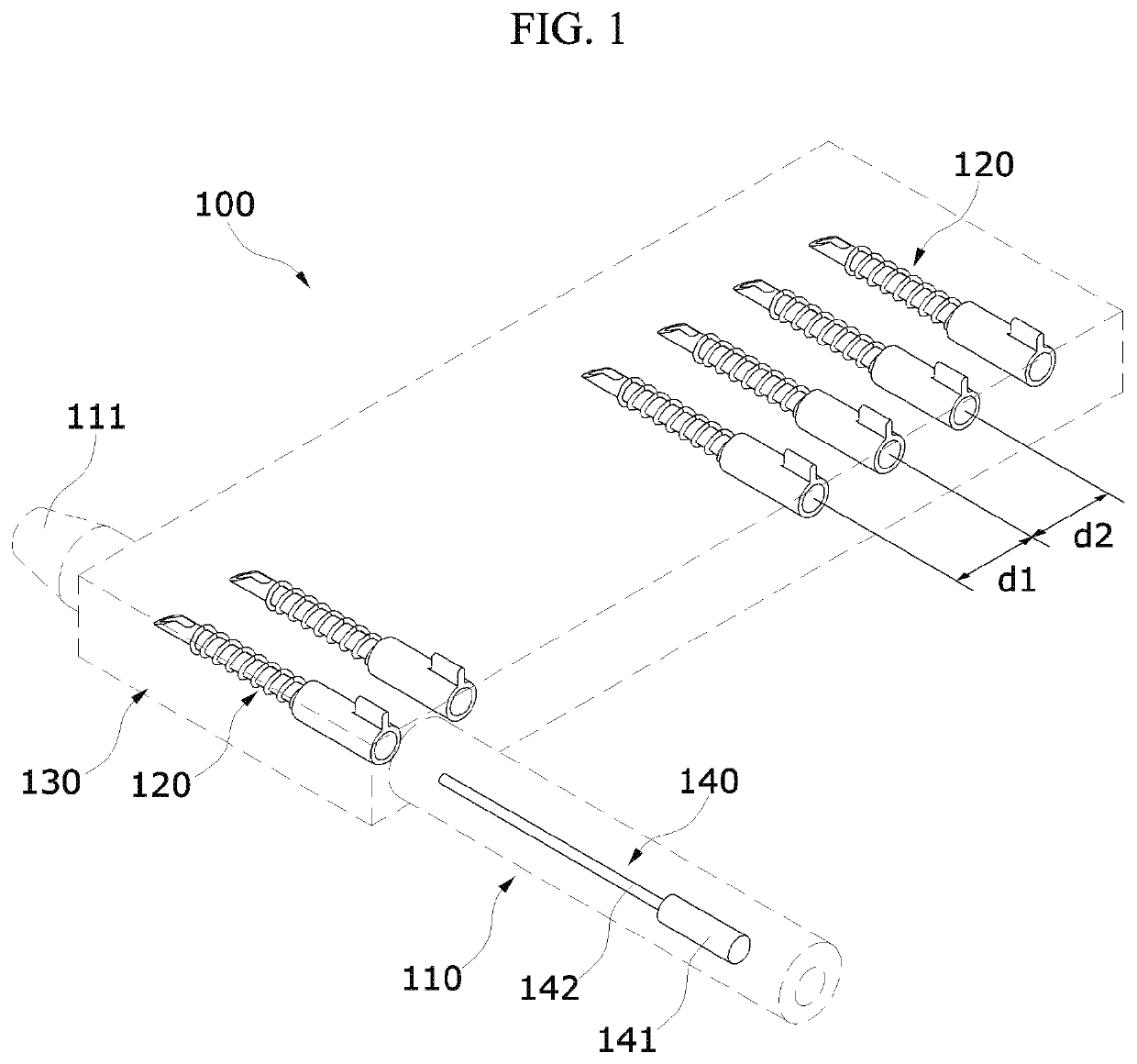

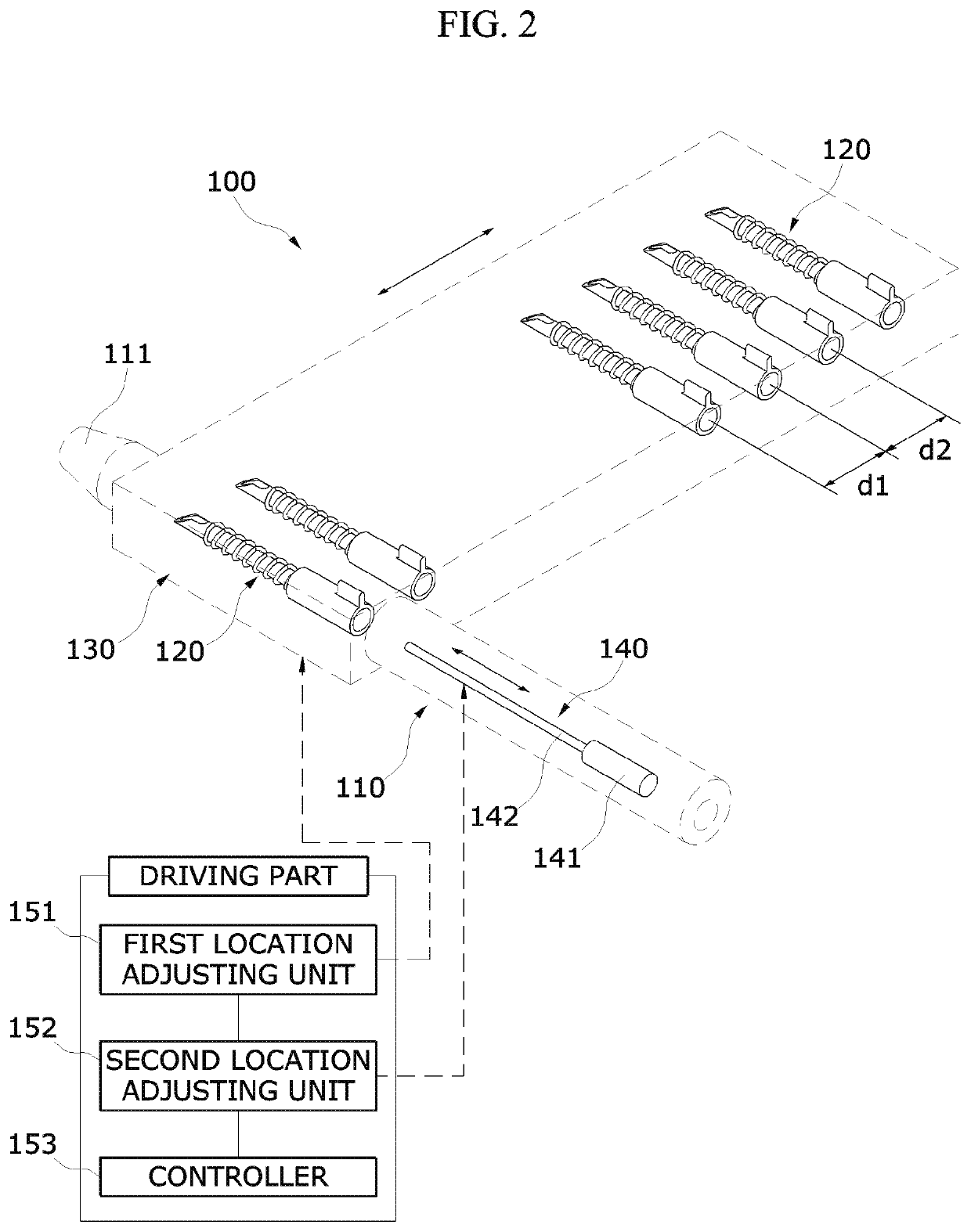

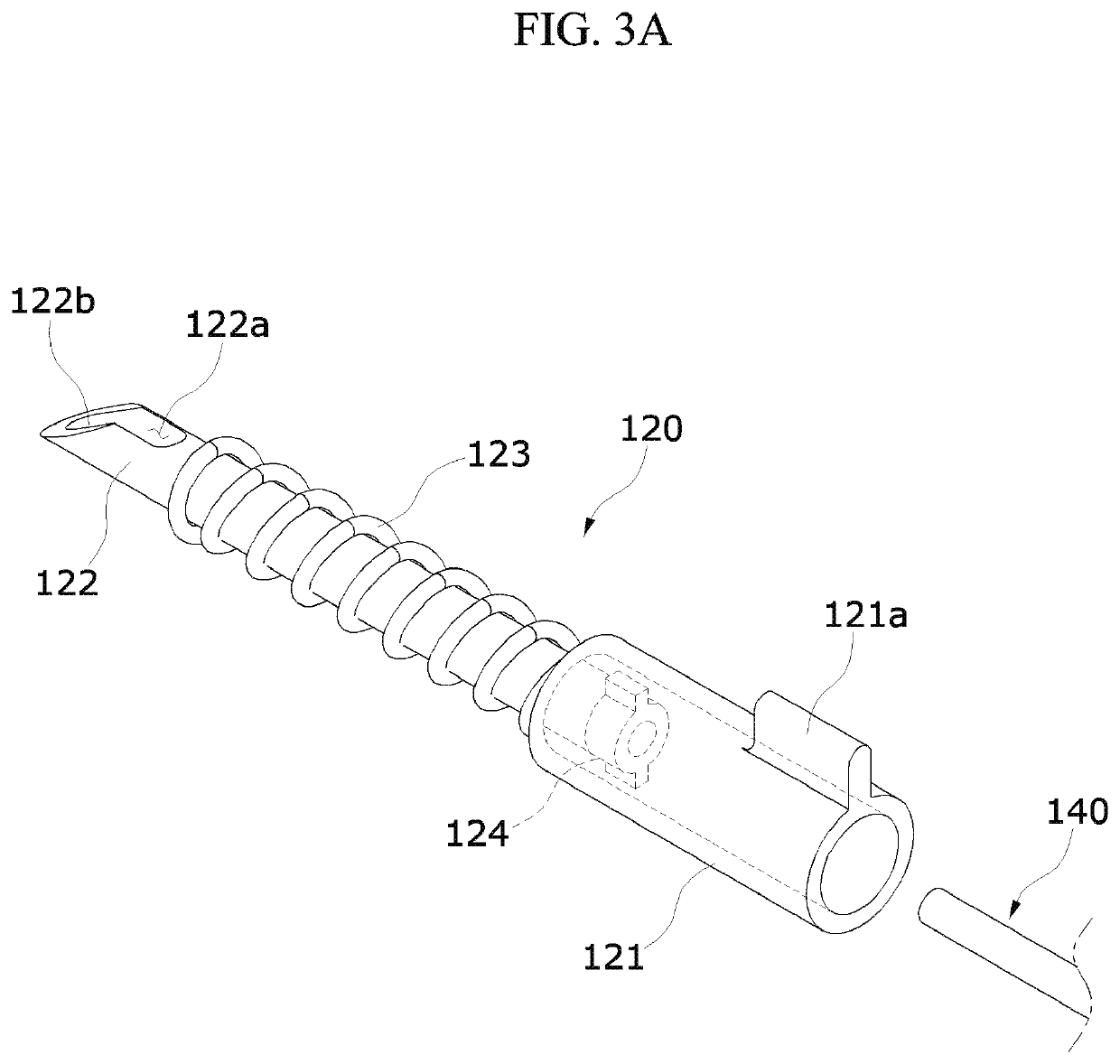

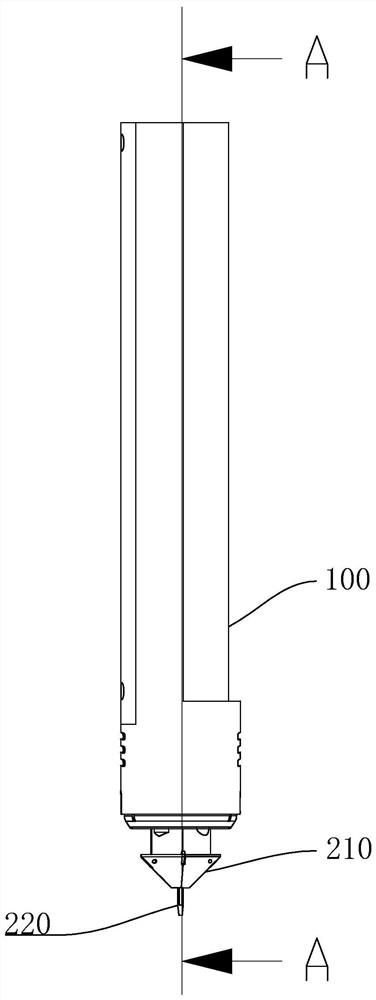

Injector for hair implant with automatic follicle supply function

InactiveUS20160045223A1Rapidly and easily implanted into scalpSkin implantsSurgical needlesHair follicleHair streams

Disclosed is an injector for hair implant, and more particularly, to an injector for hair implant with an automatic follicle supply function which is capable of continuously and automatically supplying follicles so that the follicles are rapidly and easily implanted into a scalp.

Owner:ELECTRONICS & TELECOMM RES INST

Hair implants comprising enhanced anchoring and medical safety features

ActiveUS10682223B2Avoid bacterial infectionInhibition is effectiveSuture equipmentsSkin implantsAnatomyEngineering

A hair implant suitable for subcutaneous implantation is provided having an anchor comprising an anchor body, and at least one collagen receiving structure selected from the group consisting of at least one tunnel disposed through the anchor body and an external surface feature of the anchor body. The anchor further comprises at least one hair strand projecting from a distal end of the anchor body, wherein the at least one collagen receiving structure is configured to support collagen ligature growth after subcutaneous implantation of the hair implant so as to anchor the anchor to a hair implant recipient, and the collagen receiving structure is free of hair.

Owner:LORIA HAIR IMPLANT CO LLC

Hair implants comprising enhanced anchoring and medical safety features

ActiveUS10561490B2Avoid bacterial infectionInhibition is effectiveSkin implantsSubcutaneous implantCollagenan

A hair implant suitable for subcutaneous implantation is provided having an anchor comprising an anchor body, and at least one collagen receiving structure selected from the group consisting of at least one tunnel disposed through the anchor body and an external surface feature of the anchor body. The anchor further comprises at least one hair strand projecting from a distal end of the anchor body, wherein the at least one collagen receiving structure is configured to support collagen ligature growth after subcutaneous implantation of the hair implant so as to anchor the anchor to a hair implant recipient, and the collagen receiving structure is free of hair. A fracture line in the anchor body allows the body to fragment, thereby releasing collagen ligatures and allowing the implant fragments to “release” and fall out of the skin. The at least one hair strand may comprise a primary hair element with emerging hair elements.

Owner:LORIA HAIR IMPLANT CO LLC

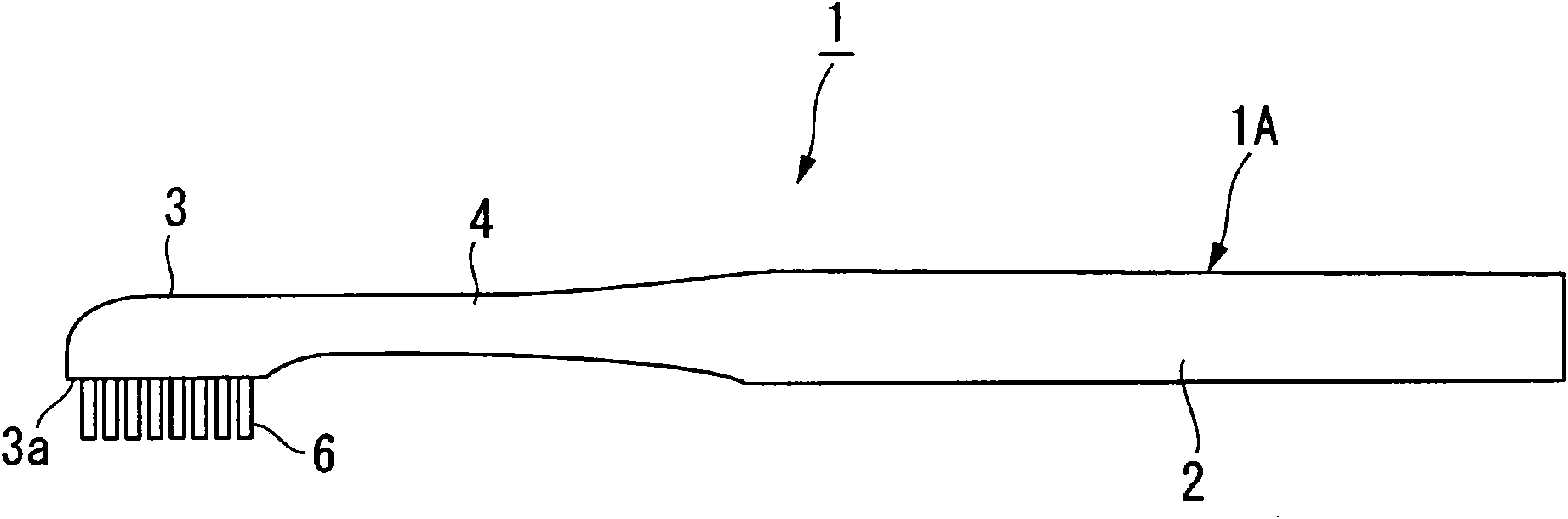

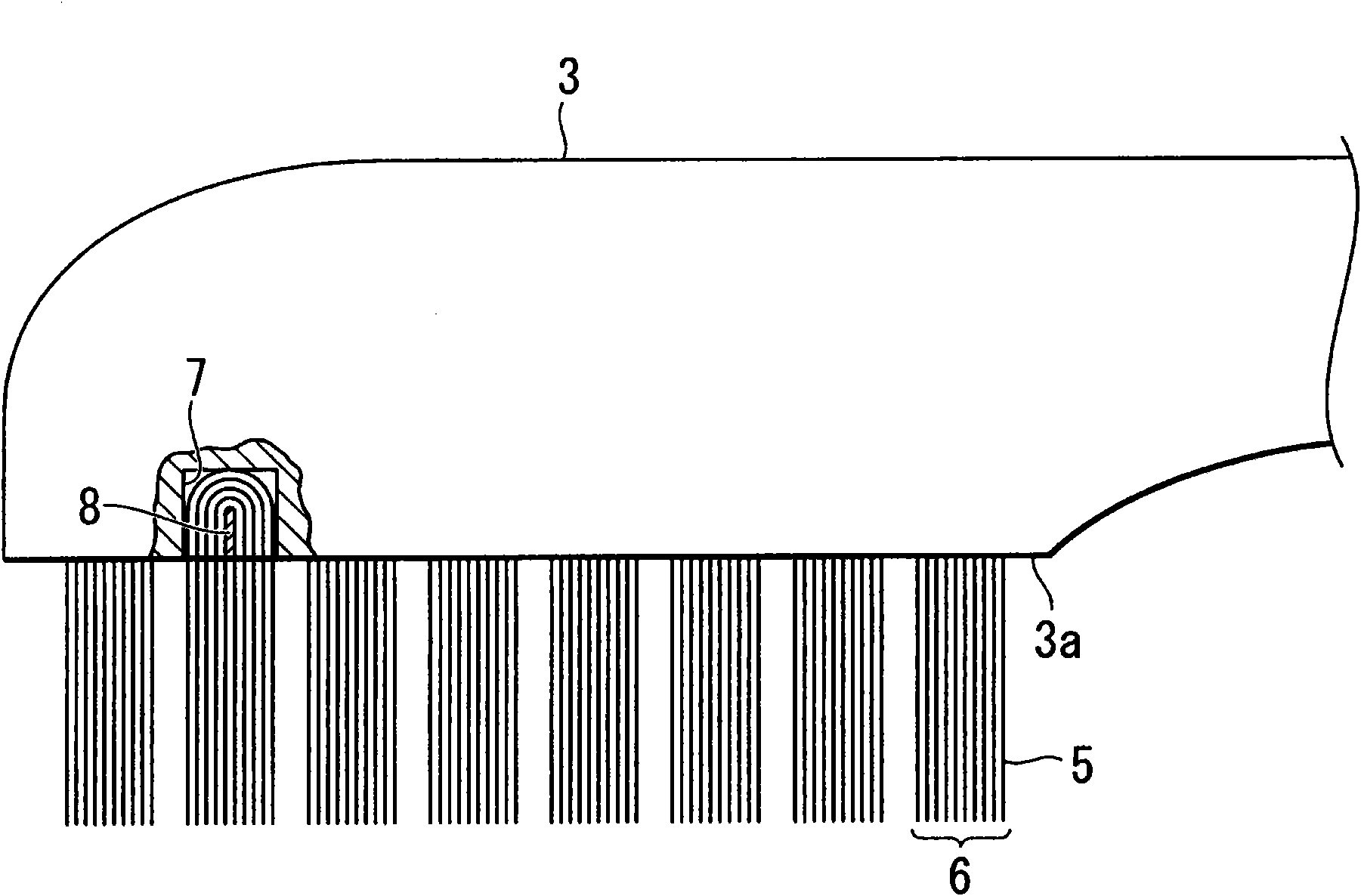

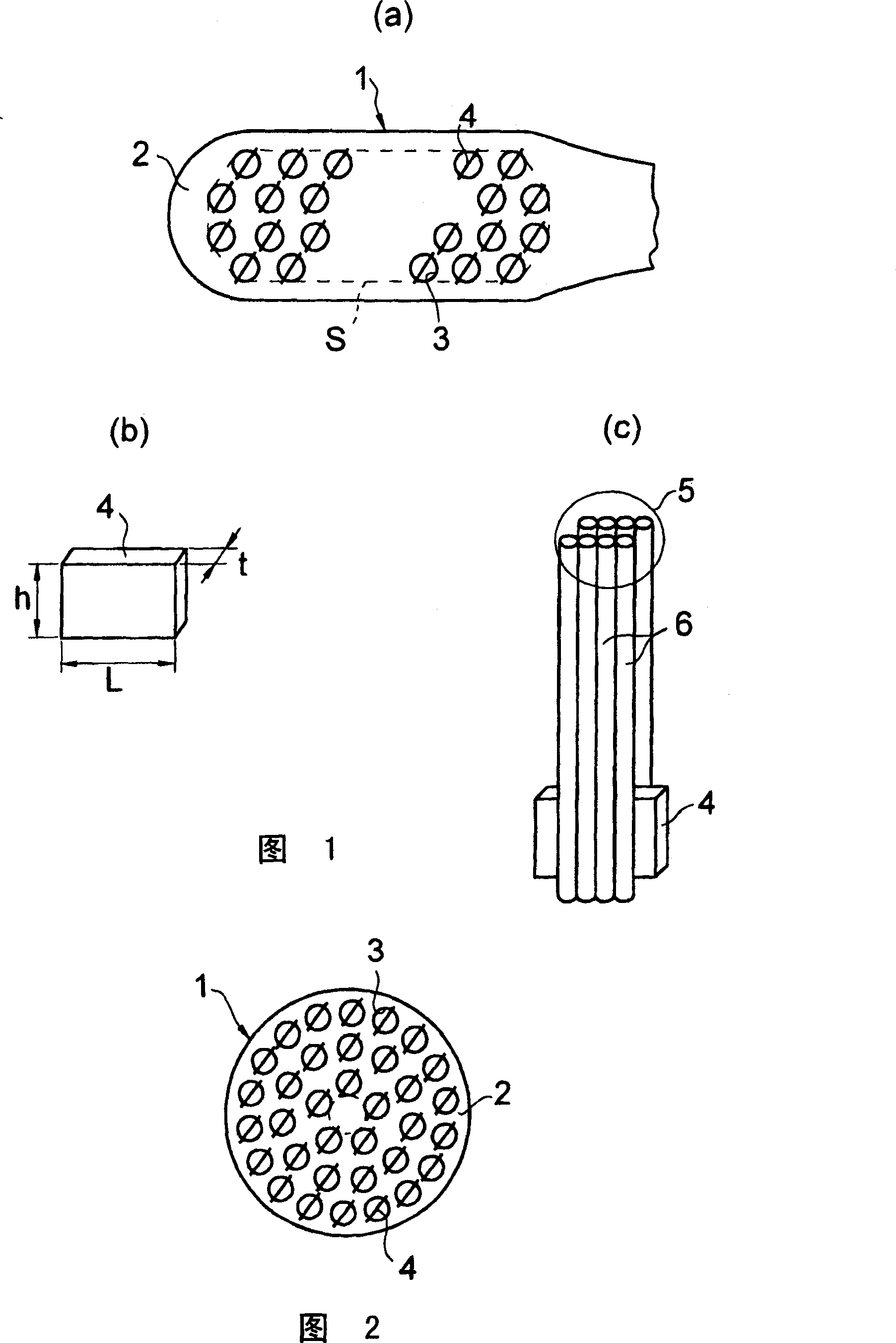

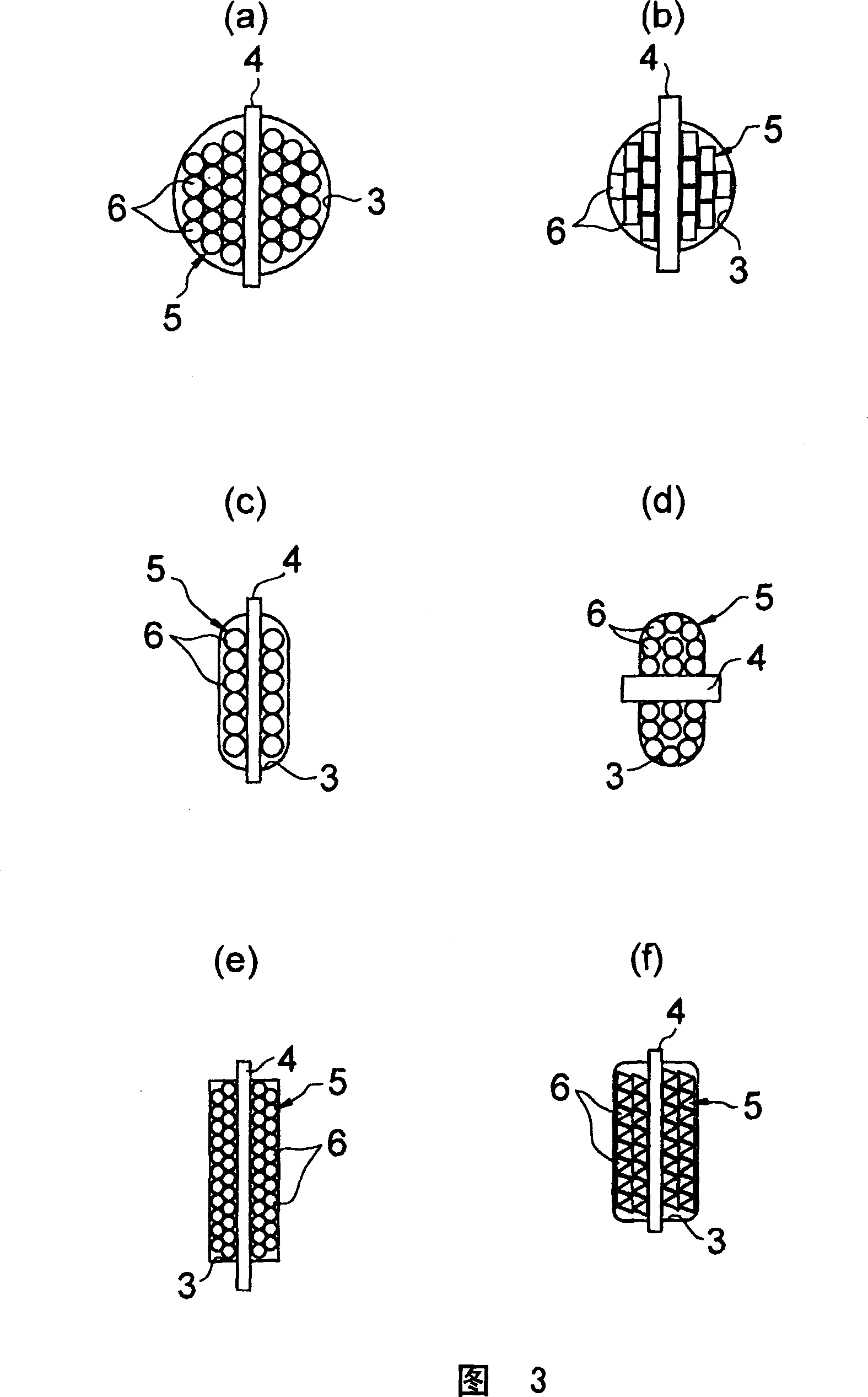

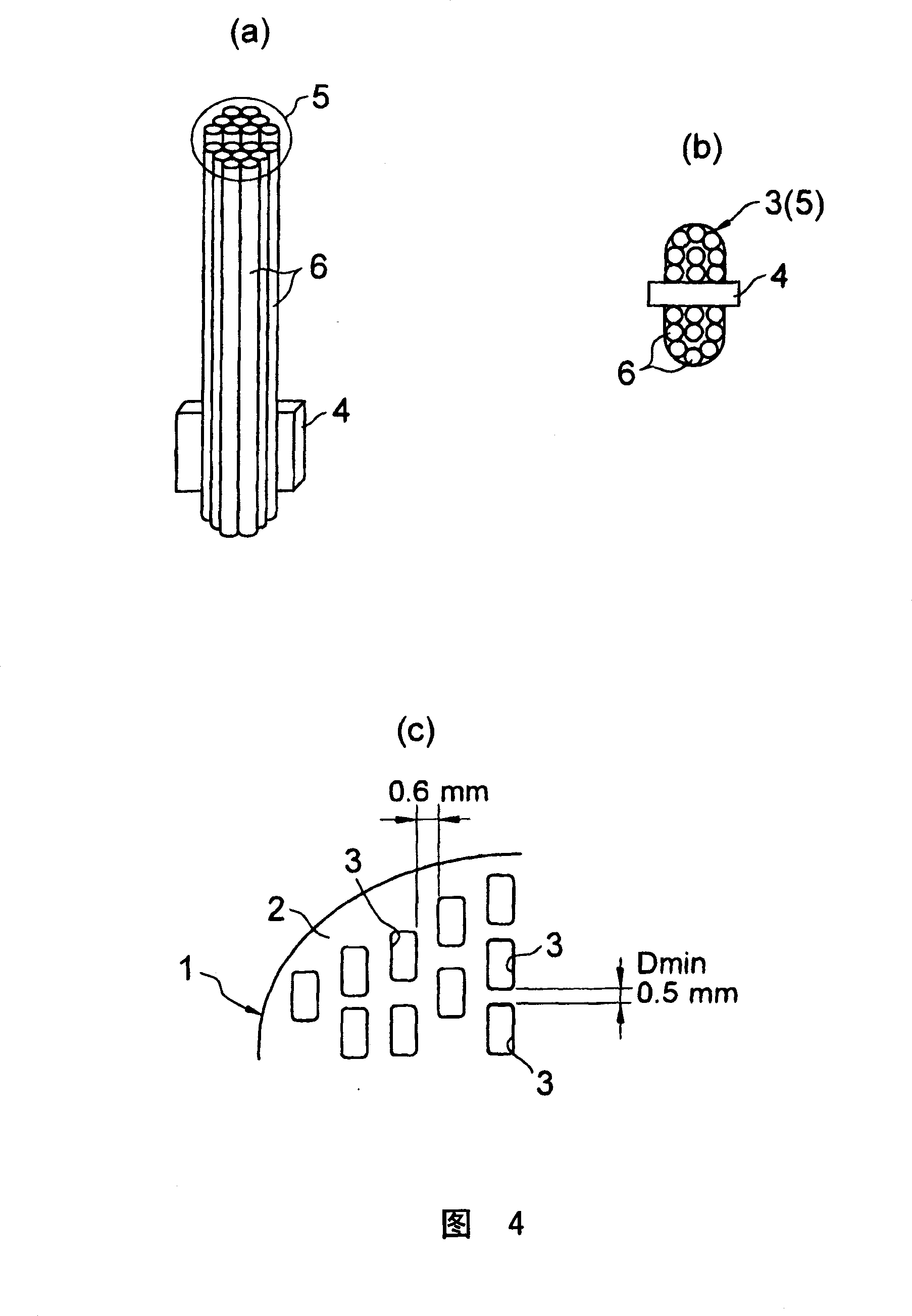

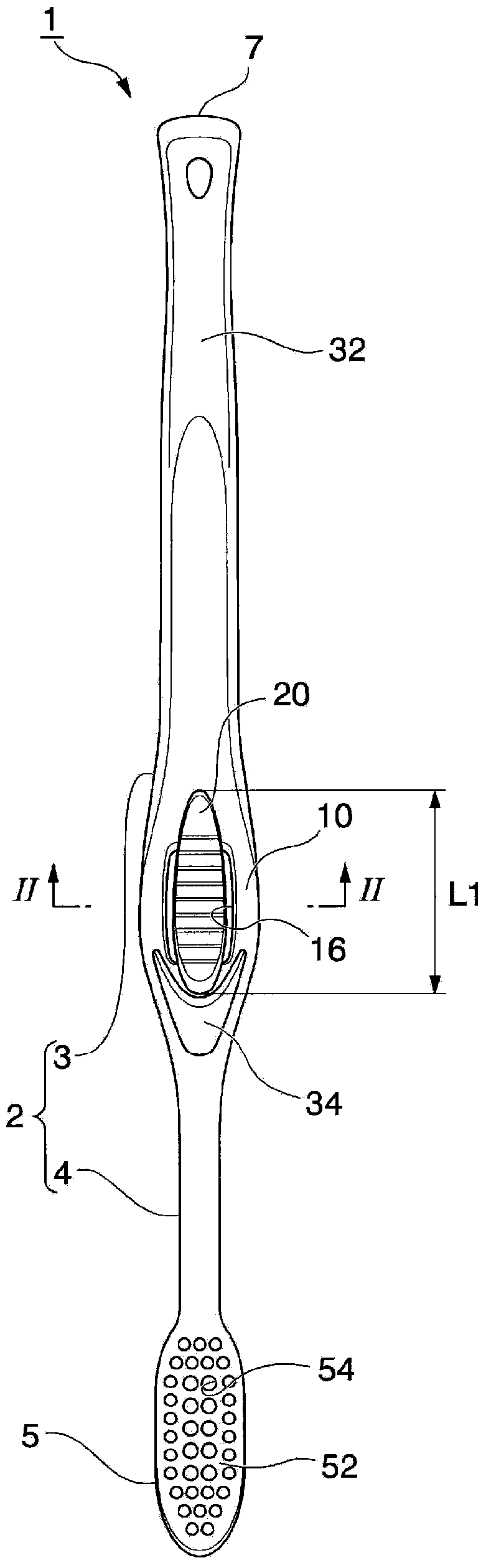

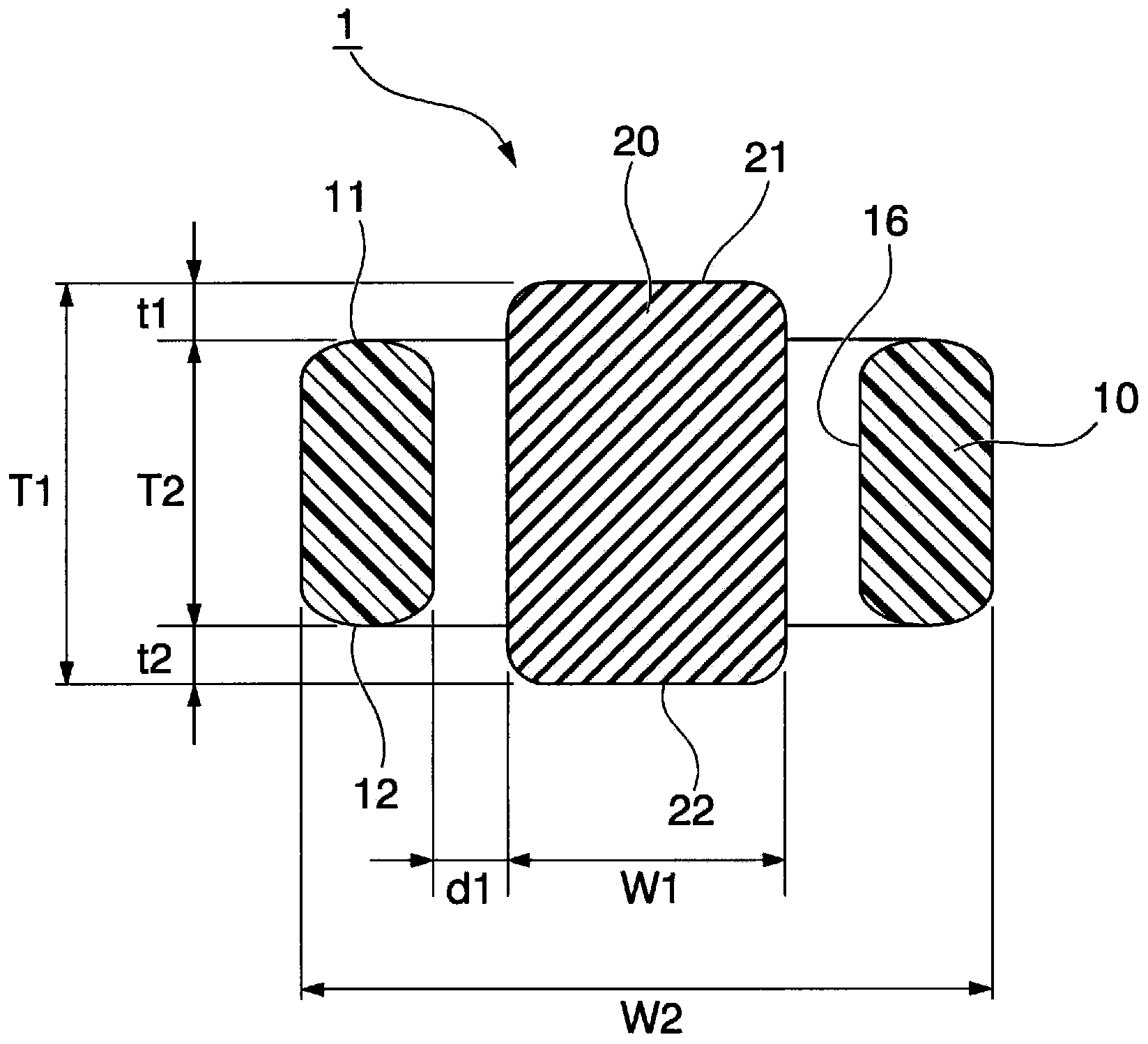

Toothbrush

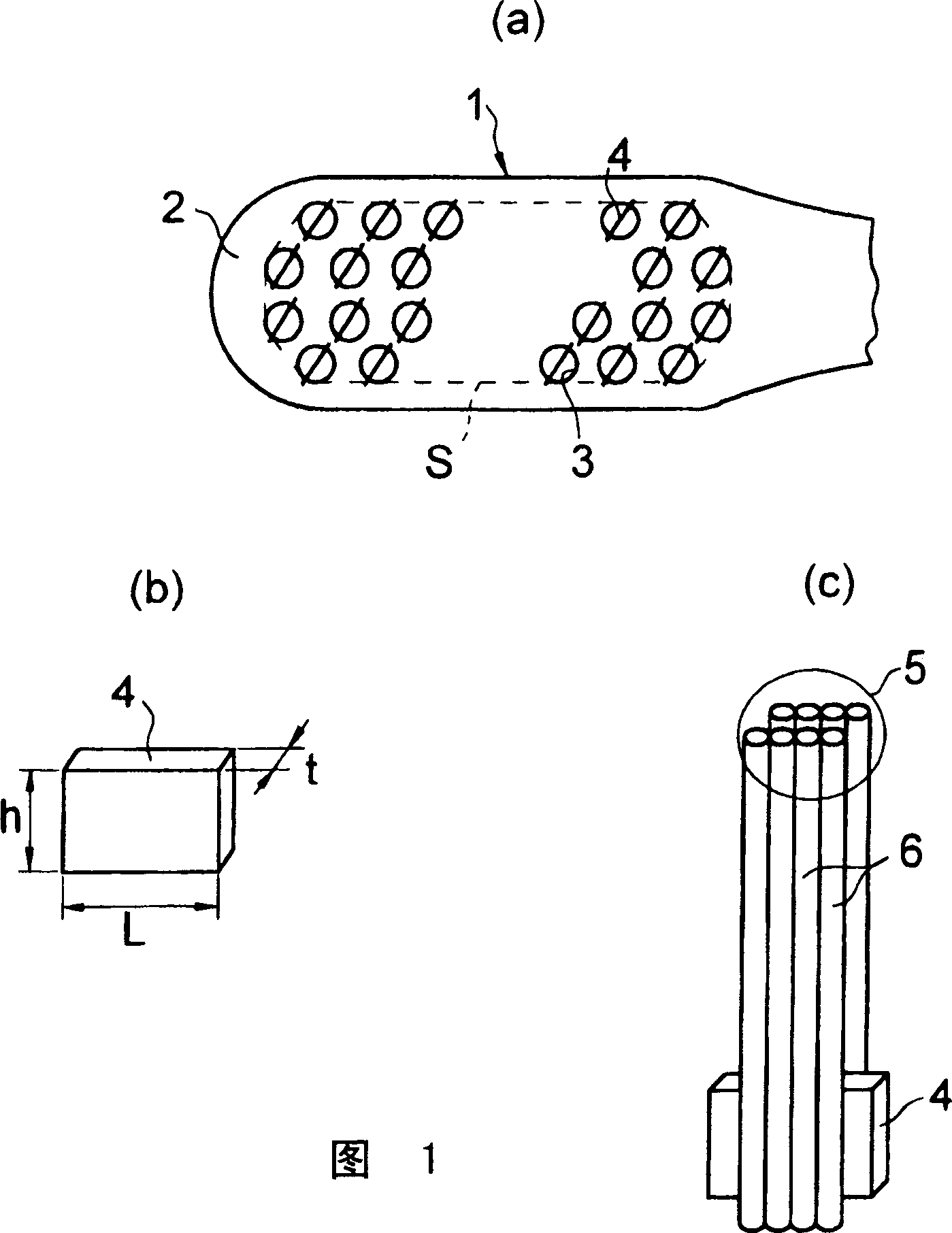

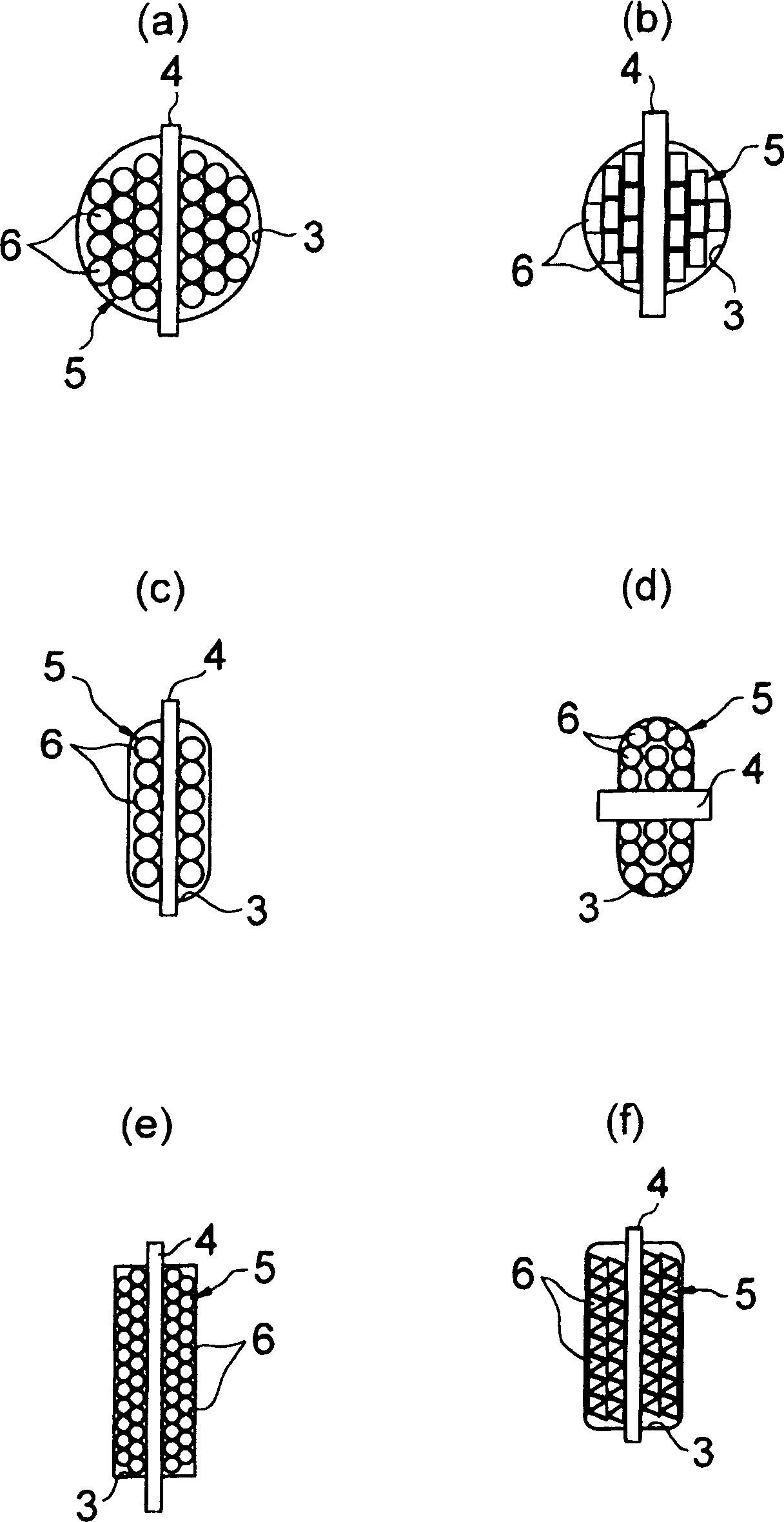

Provide a flat-wire hair-planting toothbrush with high-density hair-planting of hair bundles, and provide a hair-planting defect that does not cause cracks or whitening, bending, and flat wires that do not fall off when the hair is planted, and is soft and tactile. Good, high-quality toothbrush with good penetration into small gaps. The bundle of hairs (5) bundled with a plurality of bristles (6) is folded in half with a flat wire (4) and planted in the hair-planting hole (3) of the hair-planting surface (2) of the head (1). (4) The thickness (t) is not less than 0.10 mm and not more than 0.22 mm, and the width (h) is not less than 0.9 mm and not more than 2.5 mm. The number of hair-planted hair bundles (5) per unit hair-planting area is more than 25 bundles / cm2 and less than 80 bundles / cm2, and the cross-sectional area of the bristles (6) in the folded state for each hole of the hair-planting hole The sum of them is 1.0mm2 or less.

Owner:LION CORP

Extension apparatus for artificial hair implants

Owner:LORIA HAIR IMPLANT CO LLC

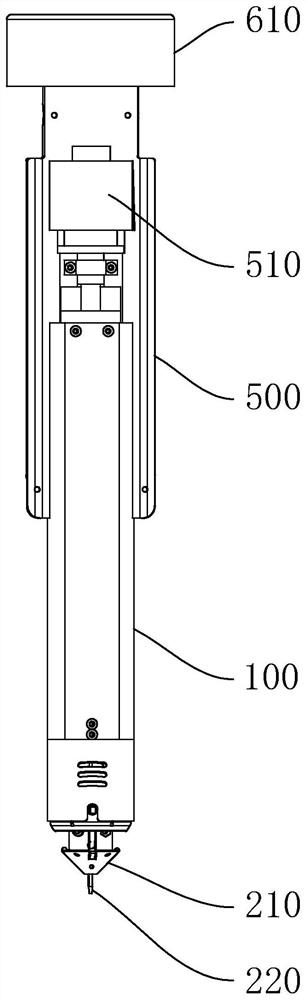

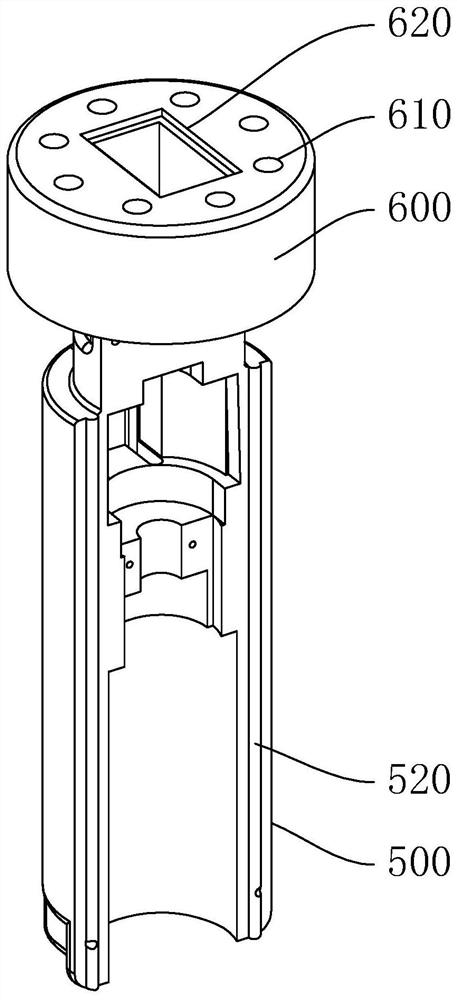

Automatic hair implant apparatus

An automatic hair implant apparatus according to the present disclosure includes a cylinder including a nozzle at an exit side and having a supporting part partially opened on a path, an implant unit configured to pass through the nozzle to implant an embedded follicle into target skin, a cartridge disposed on the supporting part of the cylinder and configured to sequentially replace the implant unit, and a push rod configured to guide the implant unit to the nozzle and return to its original position when the follicle is implanted into the target skin.

Owner:ELECTRONICS & TELECOMM RES INST

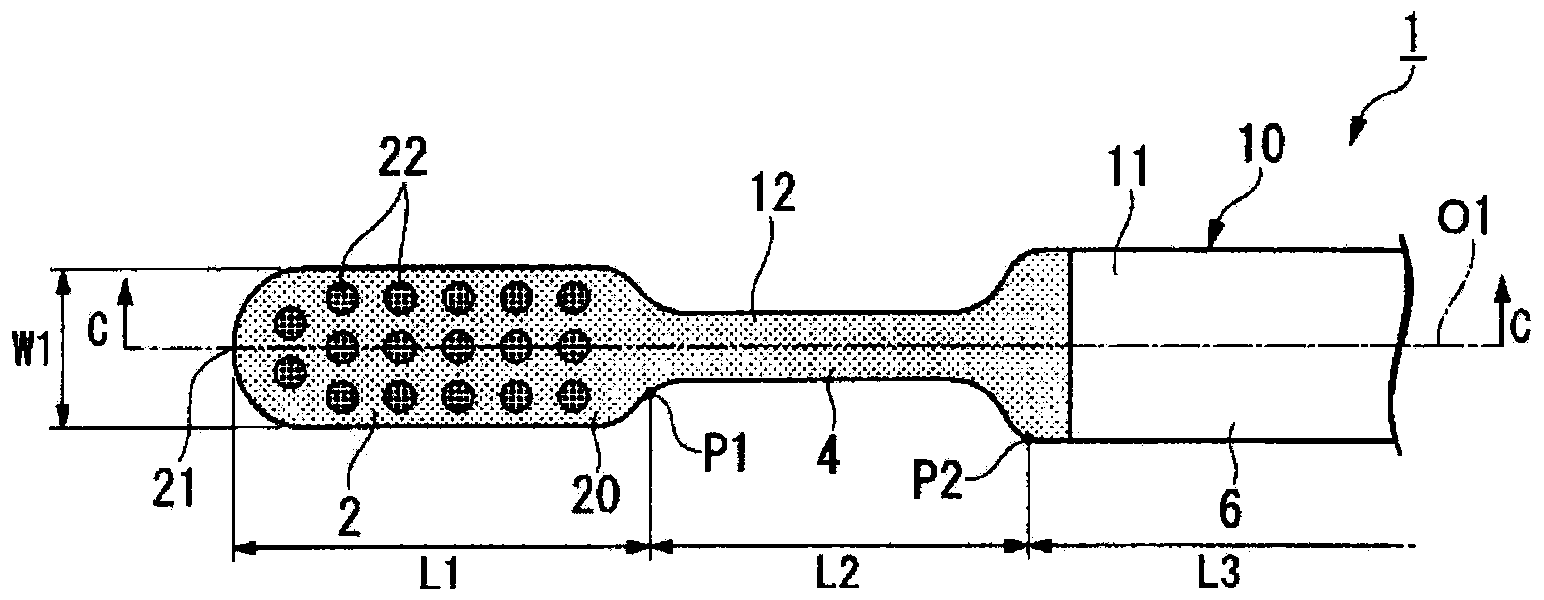

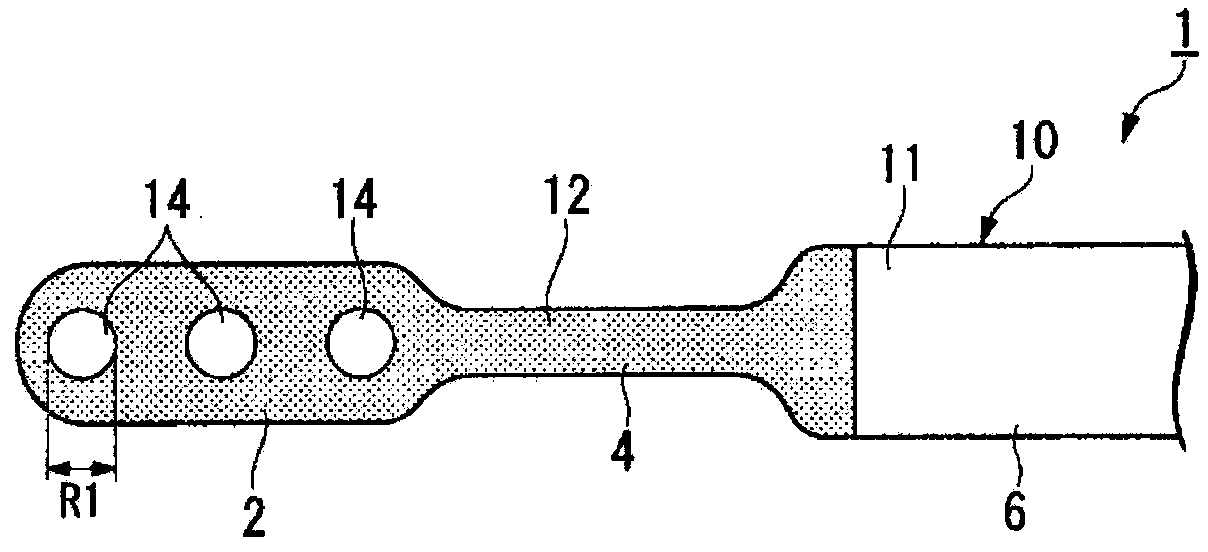

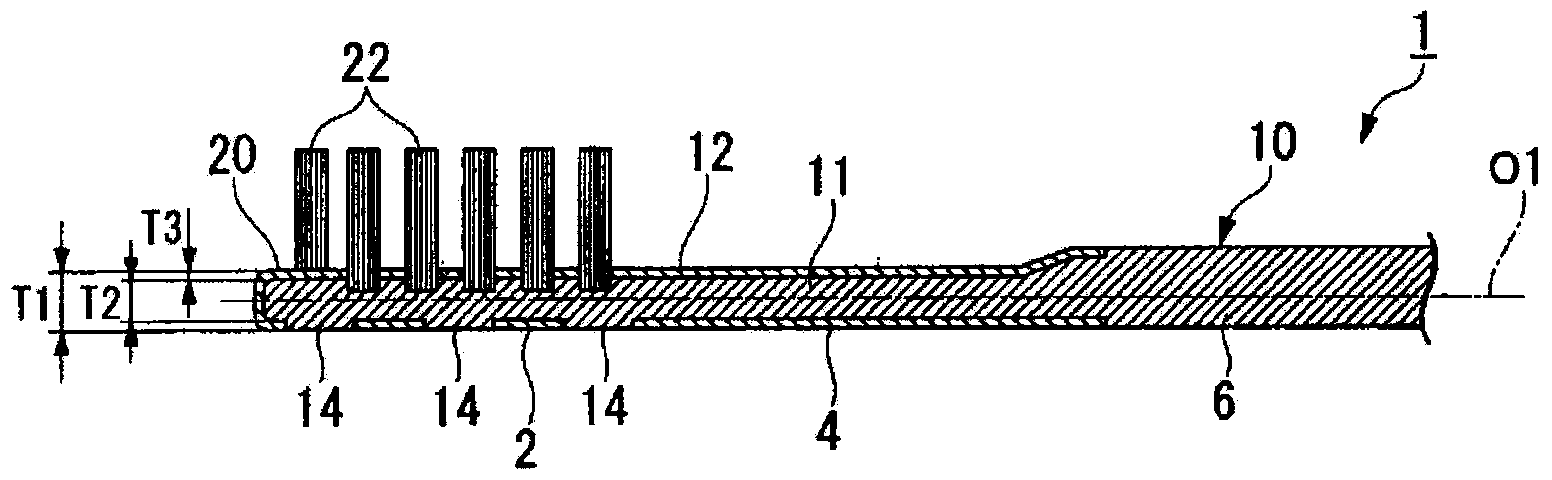

Toothbrush

The present invention relates to a toothbrush (1) provided with a handle body (10) comprising a head portion (2) where at least two bundles of hair (22) have been transplanted to a hair implant surface (20), a neck portion (4) disposed in the head portion (2), and a handle portion (6) disposed in the neck portion (4). In the handle body (10), a cover layer (12) is formed of a soft resin covering at least 70% of the total of the surface area of the head portion (2) and the surface area of the neck portion (4), and is disposed on the surface of a base (11) formed of a rigid resin. At least one exposed portion (14) where the base (11) is exposed is disposed on the cover layer (12) of the toothbrush (1), and the exposed part (14) is not disposed in a two-fold symmetrical area with a shaft line (O1) of the neck portion (4) being an axis of symmetry. According to the present invention, damage and breakage of the head portion and the neck portion may be prevented, and the toothbrush may be manufactured with ease.

Owner:LION CORP

Hair implants comprising enhanced anchoring and medical safety features

ActiveUS20190380827A1Avoid bacterial infectionInhibition is effectiveSkin implantsSubcutaneous implantationOrthodontic ligature

A hair implant suitable for subcutaneous implantation is provided having an anchor comprising an anchor body, and at least one collagen receiving structure selected from the group consisting of at least one tunnel disposed through the anchor body and an external surface feature of the anchor body. The anchor further comprises at least one hair strand projecting from a distal end of the anchor body, wherein the at least one collagen receiving structure is configured to support collagen ligature growth after subcutaneous implantation of the hair implant so as to anchor the anchor to a hair implant recipient, and the collagen receiving structure is free of hair. A fracture line in the anchor body allows the body to fragment, thereby releasing collagen ligatures and allowing the implant fragments to “release” and fall out of the skin. The at least one hair strand may comprise a primary hair element with emerging hair elements.

Owner:LORIA HAIR IMPLANT CO LLC

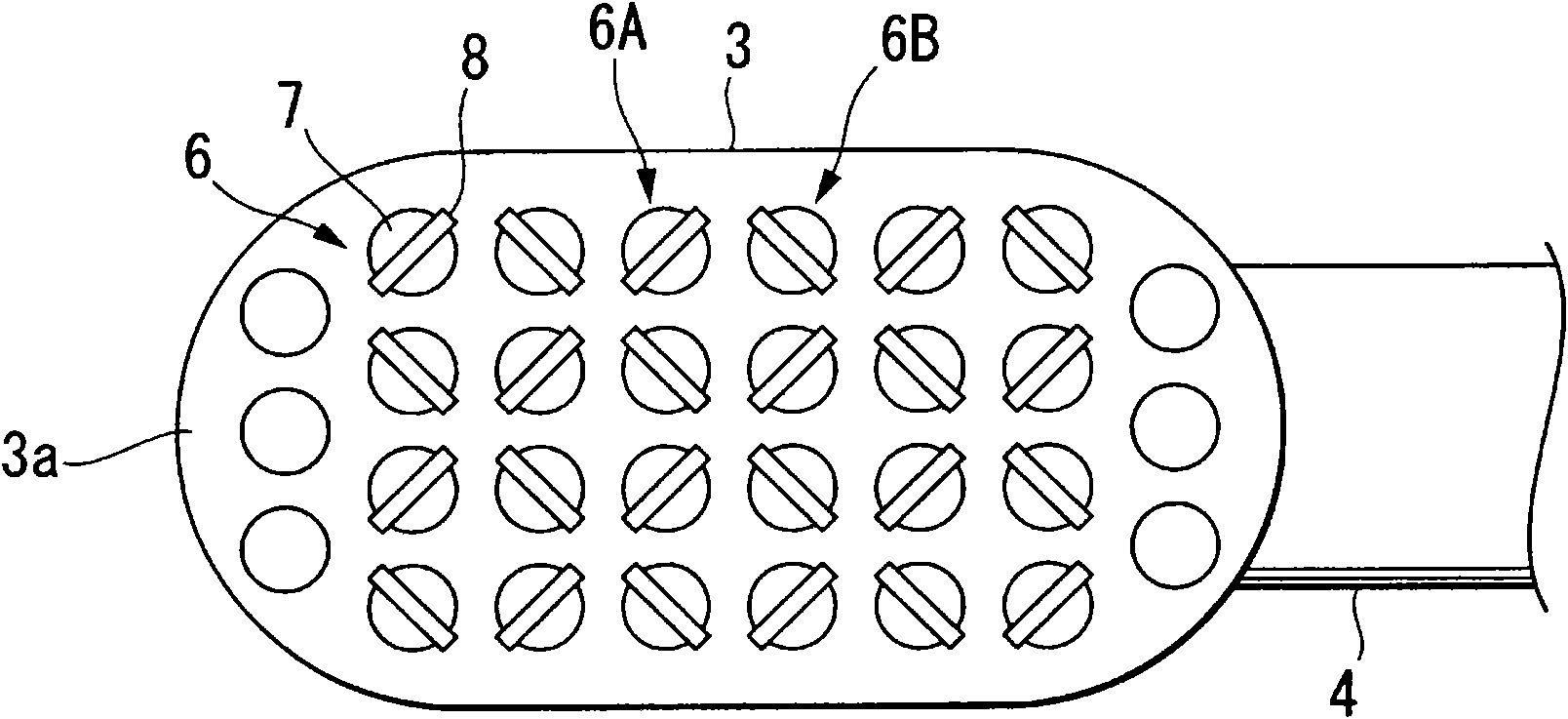

Toothbrush

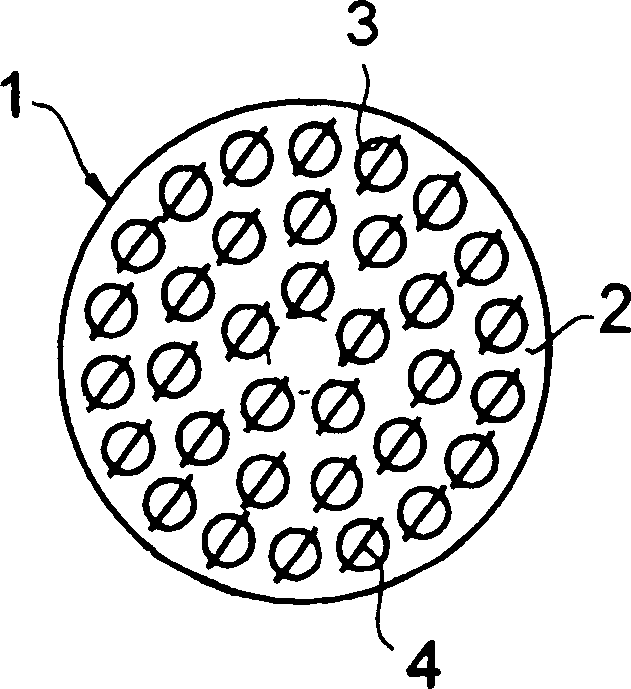

InactiveCN101932264AAnisotropicGuaranteed cleanlinessBristleTooth cleaningBiomedical engineeringHair implant

A toothbrush in which a plurality of hair implant holes (7) are arranged on the hair implant surface (3a) of a head portion (3) at a predetermined interval in the length direction and the width direction of the head portion, and a bundle of brush flexible in one direction is implanted in each hair implant hole (7). Out of hair bundles (6A, 6B) adjoining in the length direction and the width direction of the head portion (3), the flat line (8) of one hair bundle (6A) and the flat line (8) of the other hair bundle (6B) are arranged obliquely with respect to the arrangement direction of the hair bundle (6) and the inclining direction of the flat lines (8) is set reverse so that one hair bundle (6A) and the other hair bundle (6B) are arranged alternately in the length direction and the width direction of the head portion (3).

Owner:LION CORP

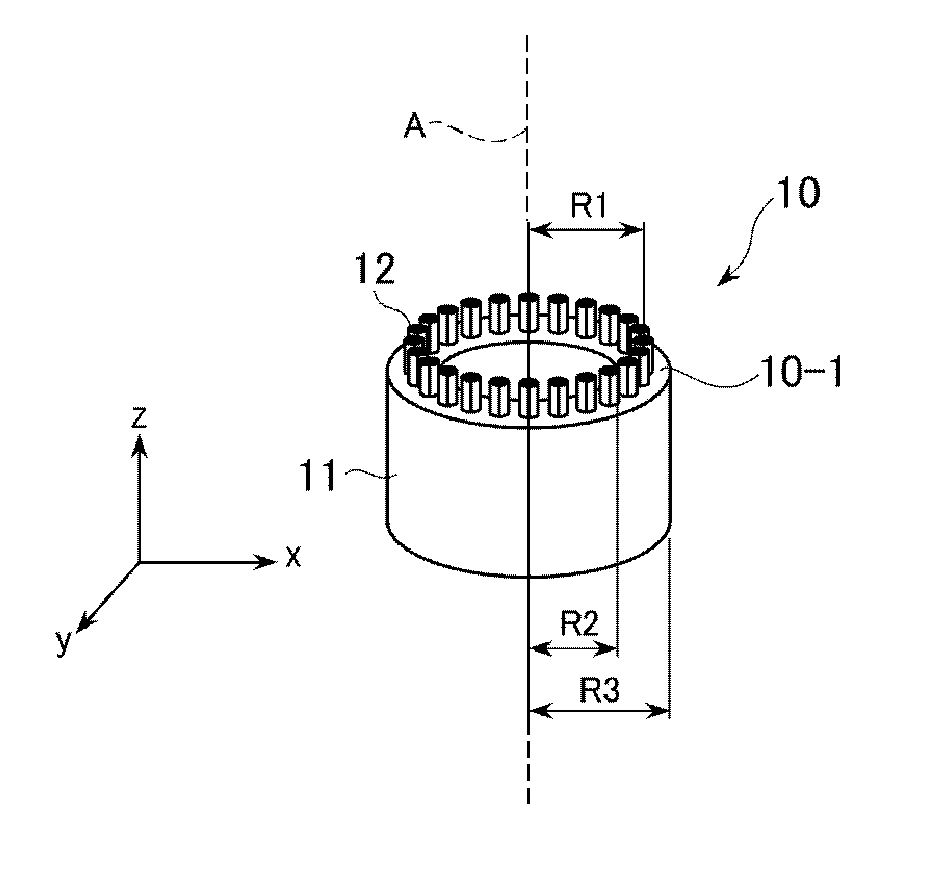

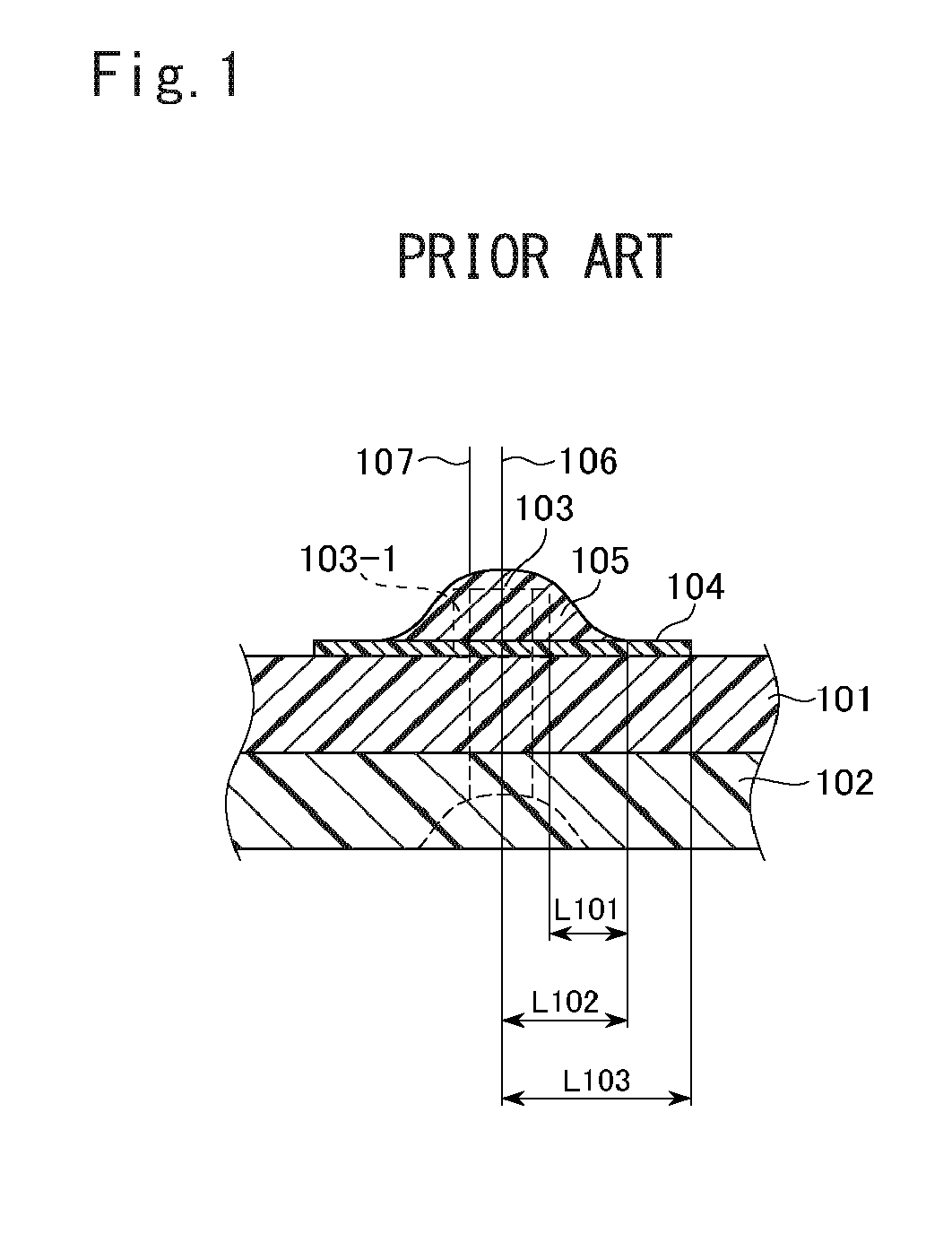

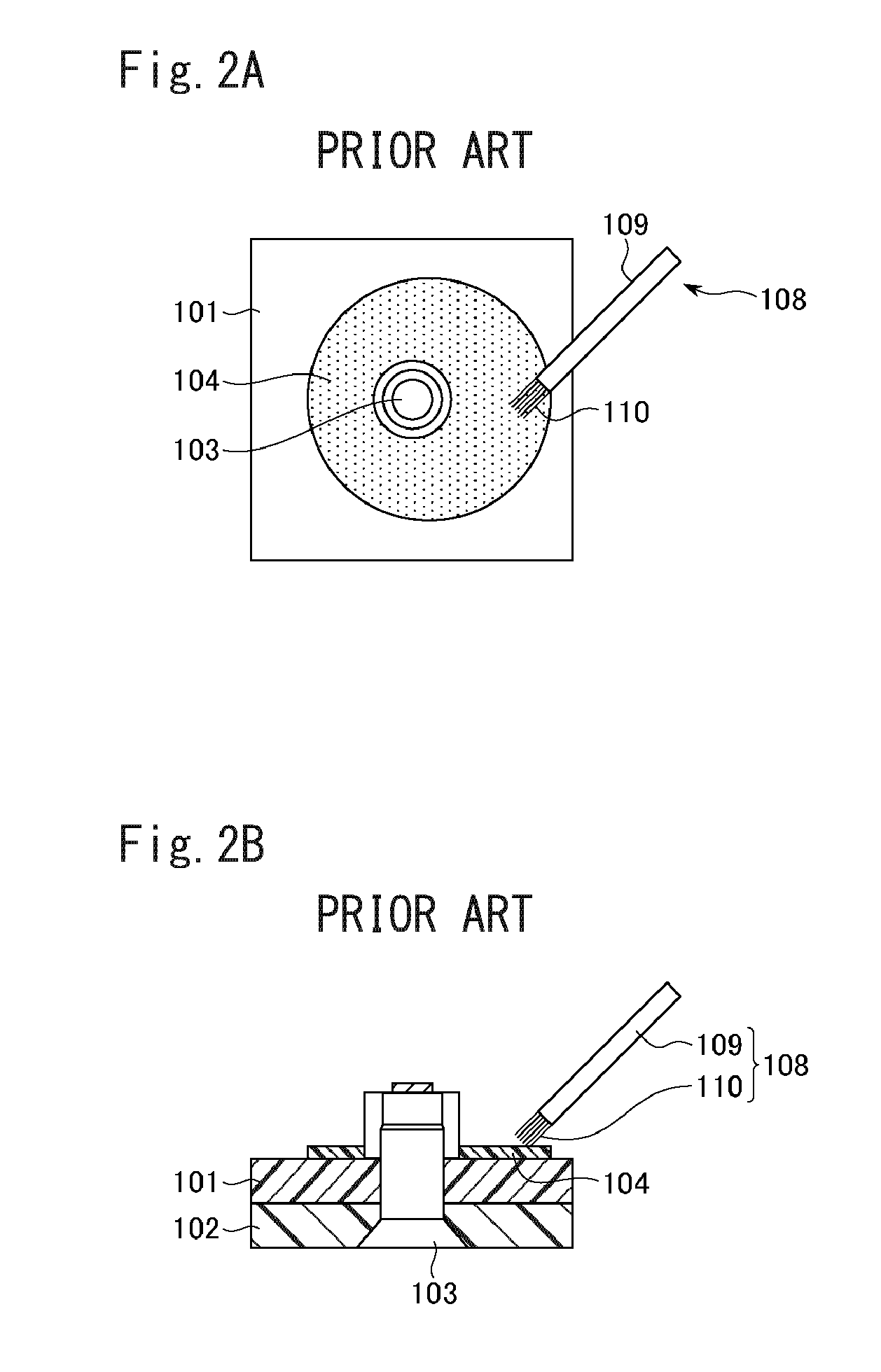

Sealant applying brush and sealant applying method

To facilitate to apply a base sealant around a prominence uniformly in a high quality is required for a composite material. A sealant applying brush includes a supporting section having a hole opened in a longitudinal direction and a ring shape on a plane orthogonal to the longitudinal direction; and a brush section having hairs implanted in a surface of the ring shape. By supplying such a brush with sealant, and eccentrically rotating the brush such that an inner circumference surface of the hole contacts the prominence of the surface of the workpiece, the sealant can be applied in a circular area around the prominence.

Owner:MITSUBISHI HEAVY IND LTD

Wig and its manufacturing method

InactiveUS20100307524A1Load minimizationPromote erectionHair accessoriesToupeesBiomedical engineeringHair implant

Owner:UNIHAIR COMPANY LIMITED

Brush for scalp

InactiveCN101518391AImprove cleanlinessImprove massage effectBristleHair cleaningBiomedical engineeringHair implant

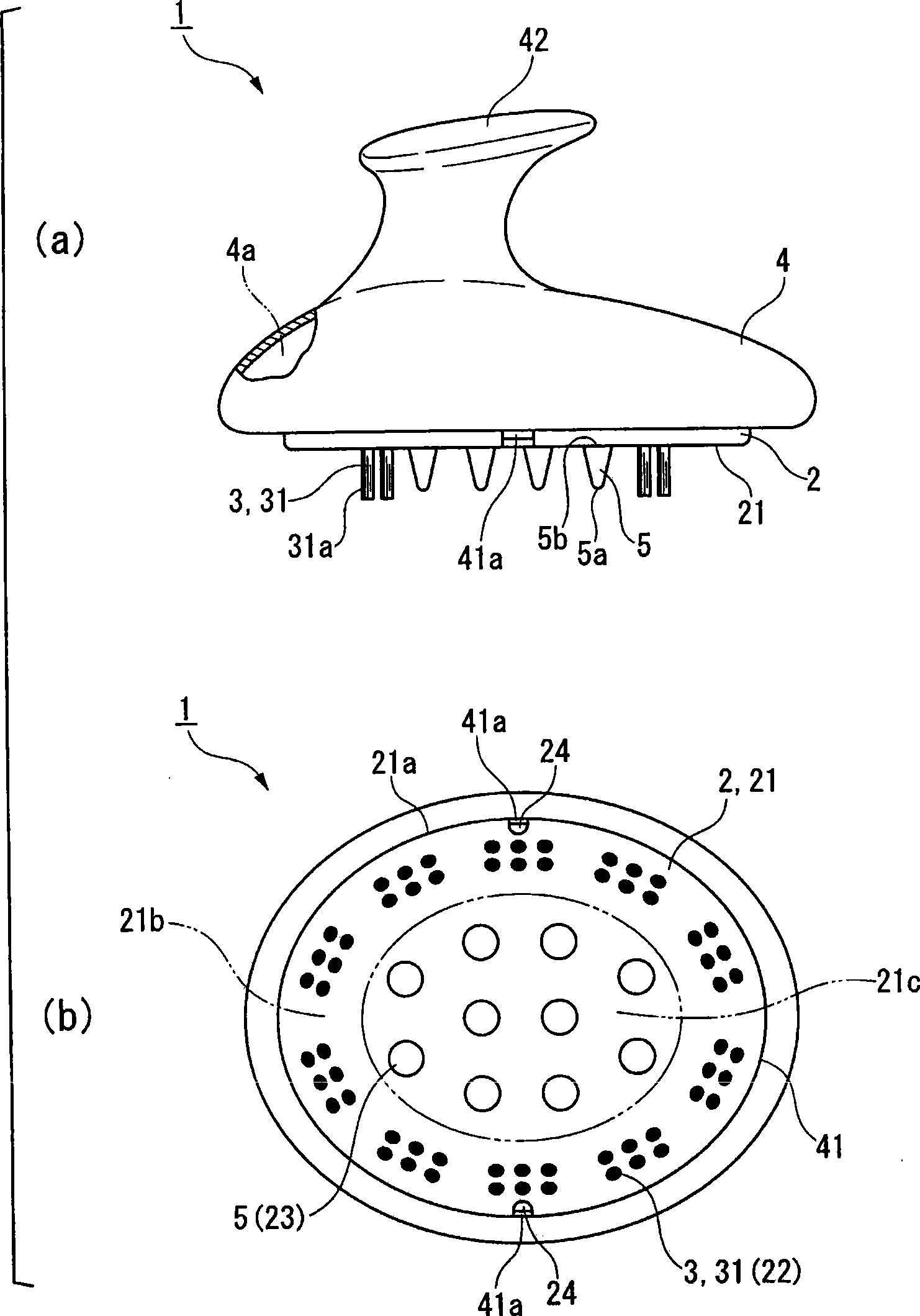

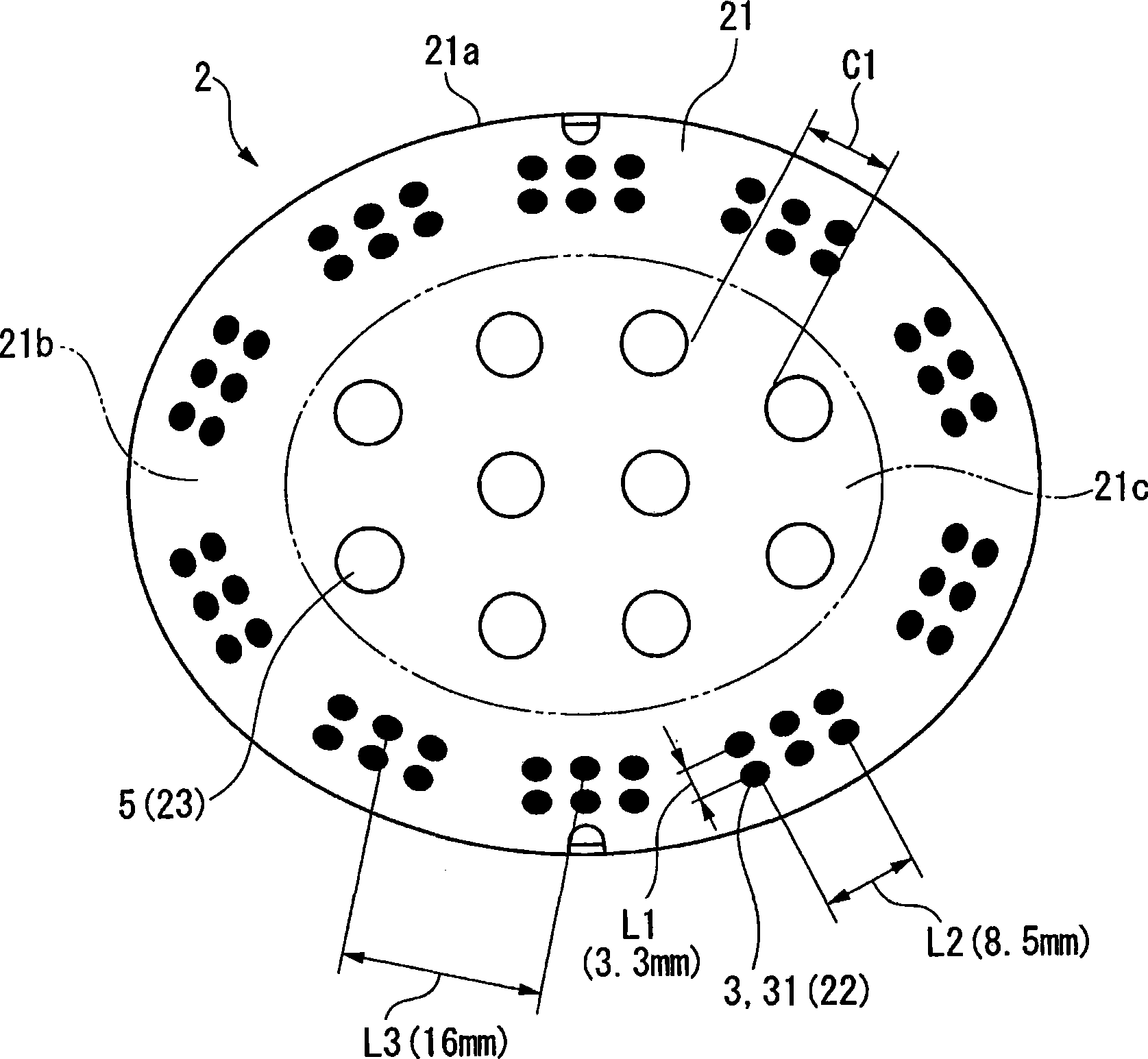

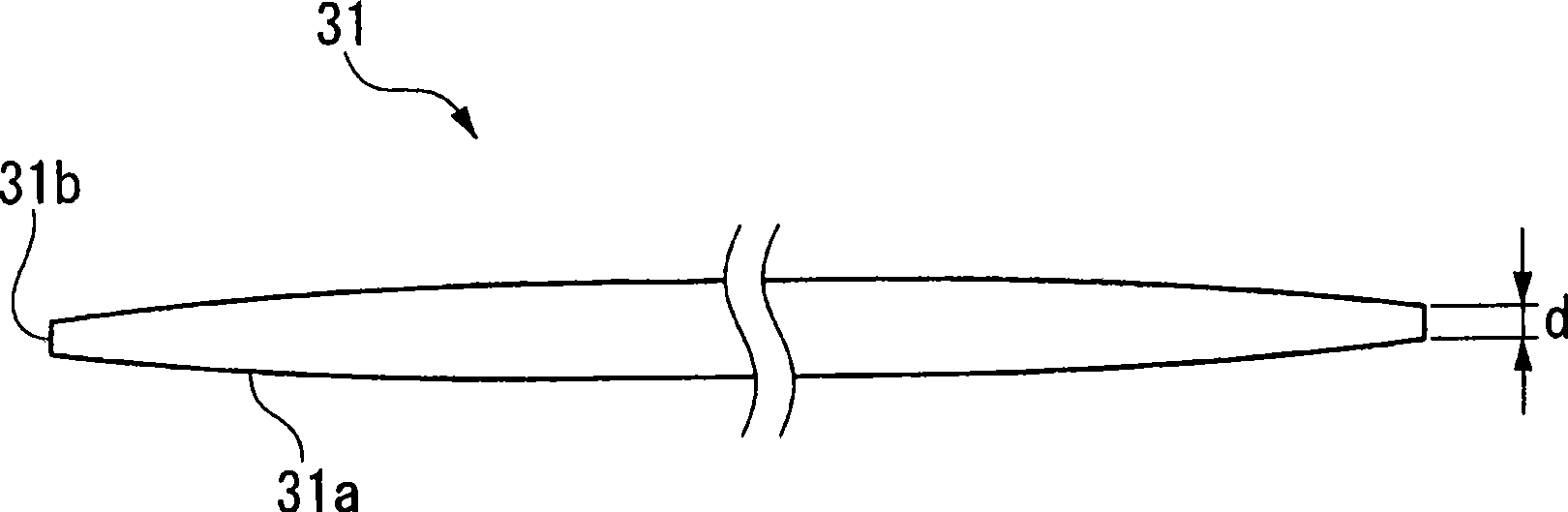

A brush for scalp compries: hair bundles(3) which is bound by brush hair(31) with at least an end in a taper shape and a top having a diameter smaller than that of the scalp pore; cone-shaped salients(5) made of elastic materials with chamfered top ends(5a); and a base seat(2) having a brush face(21) equipped with a plurality of hair implanting pores(22) and a plurality of salients installation pores(23). Hair bundles(3) are implanted in the hair implanting pores(22) in a density state in which the hair implanting pores(22) can be observed from outside; cone-shaped salients(5) are installed in the salients installation pores(23); on the brush face(21), hair bundles(3) are arranged on the periphery(21b) along the circumference of the brush face(21); the cone-shaped salients(5) are arranged on the inner circumference(21c) inside the periphery(21b) implanted with hair bundles(3). The invention can massage scalp while cleanning pores.

Owner:LION CORP

Toothbrush

Owner:LION CORP

Hair implants comprising enhanced anchoring and medical safety features

ActiveUS20220061981A1Easy to disassembleAvoid bacterial infectionSkin implantsTissue regenerationAnatomySubcutaneous implant

A hair implant includes: (a) a hair strand anchor including: an anchor body; at least one hair chamber disposed within the anchor body; and at least one tunnel through the anchor body, where the tunnel is free of a hair; and (b) at least one hair strand having a portion thereof retained in the at least one of the hair chamber; wherein the tunnel is configured to support collagen ligature growth after subcutaneous implantation by receiving and retaining collagen ligatures that anchor the hair implant to a hair implant recipient. Also disclosed is a hair implant including an anchor with first and second anchor bodies and at least one bridge connecting the anchor bodies and bridging at least one void between the anchor bodies, wherein the bridge supports and retains collagen ligature growth. One-piece implants are also disclosed, as are anchors, hair restoration and manufacturing methods.

Owner:LORIA PROD LLC

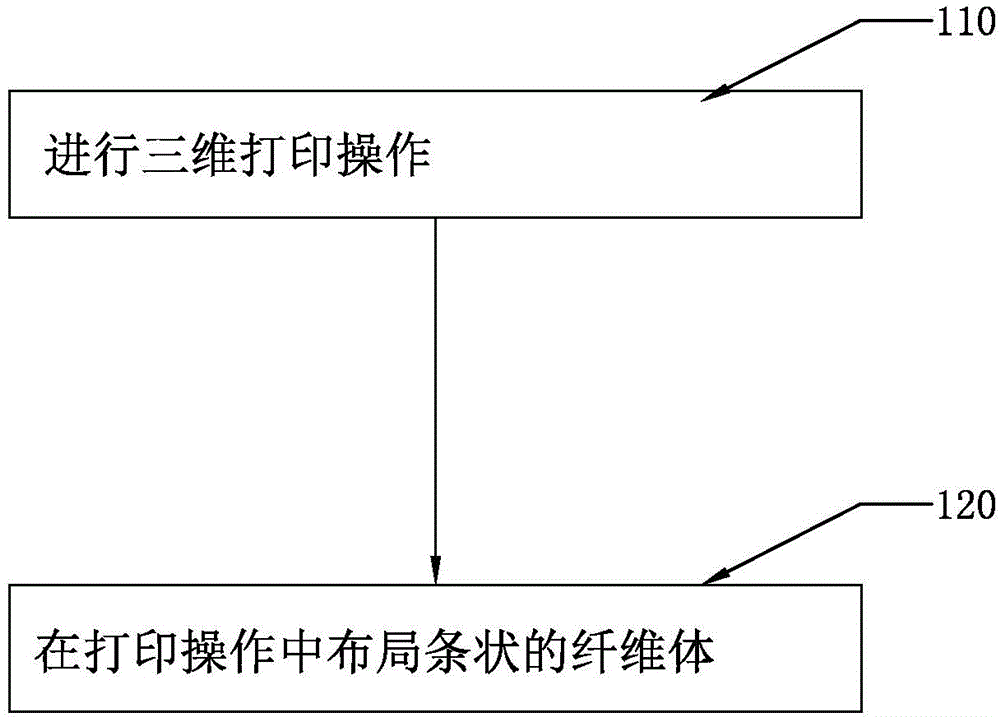

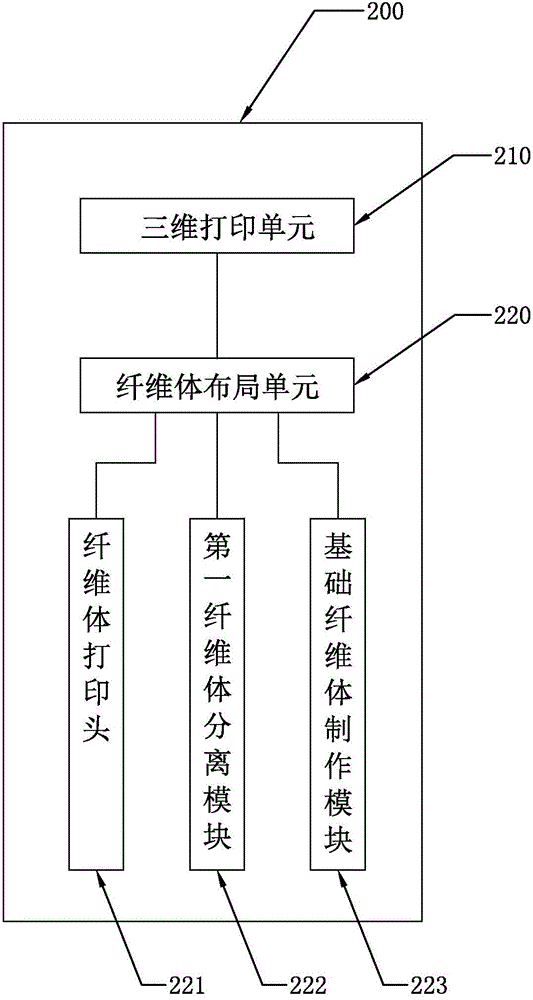

Three-dimensional (3D) printing sculpture method, 3D printing sculpture terminal and products of 3D printing sculpture

The invention provides a three-dimensional (3D) printing sculpture method, a 3D printing sculpture terminal and products of 3D printing sculpture, belonging to the technical field of a 3D printing technology. The method comprises the steps of carrying out a 3D printing operation; arranging strip-shaped fiber bodies in the layered tangent plane of printing, wherein the fiber bodies comprise hair, elastic support bodies or hair-elastic mixtures. According to the method, a hair implanting operation is carried out on the 3D sculpture by a 3D printing way, so that the original appearance of a 3D statue is embodied more truly; or the elasticity of the 3D statue is improved. After the technical scheme is adopted, 3D printing sculpture with better use advantages can be obtained.

Owner:上海研兴电子科技事务所

Hair transplanting device with needle shaft conveying part

PendingCN114431930AReduce penetration depthAvoid damageSkin implantsCannulasHair transplantingAnatomy

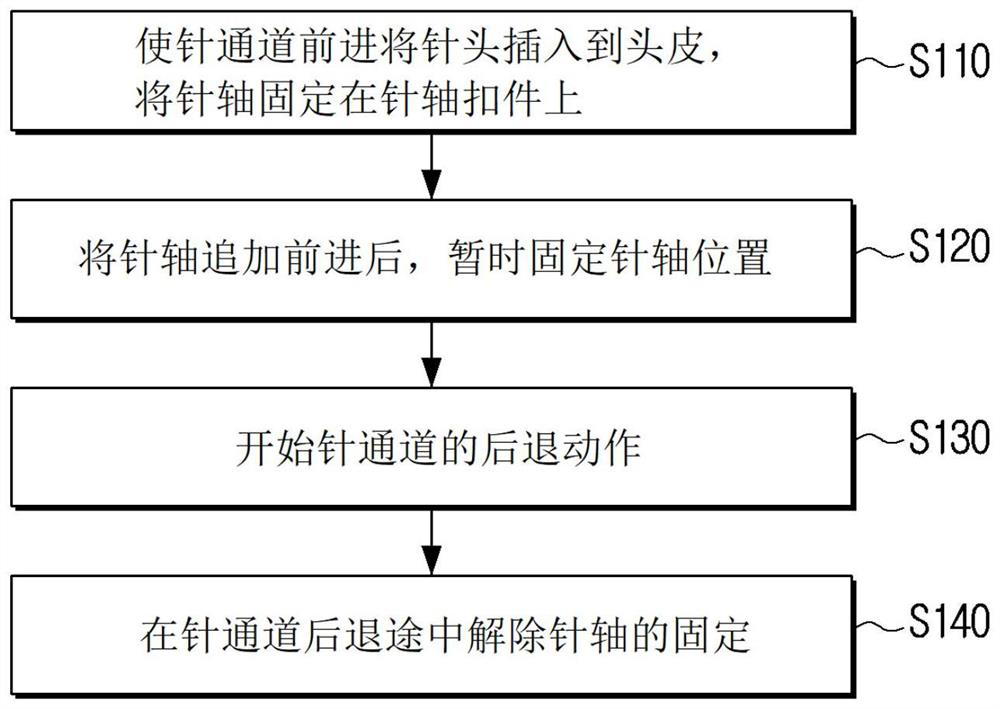

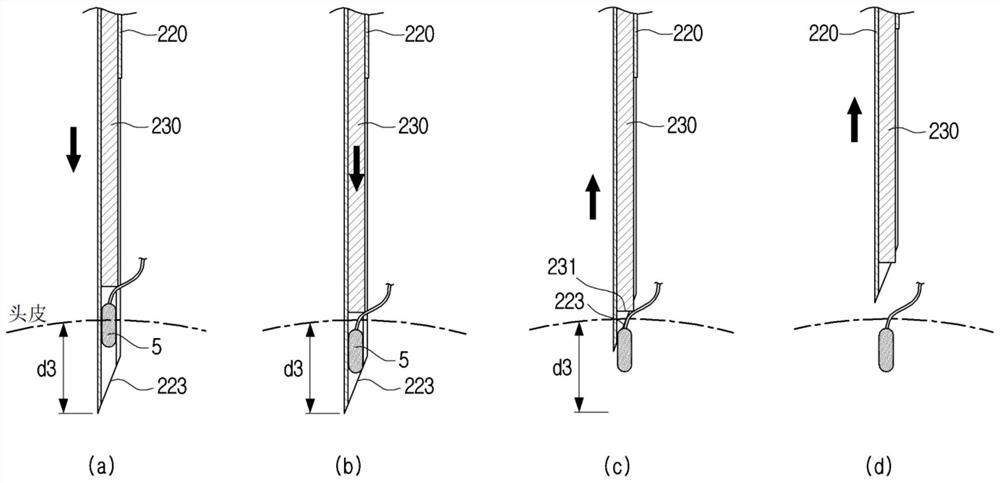

According to one embodiment, the present invention relates to a hair implant comprising: a needle channel bundle provided with a central shaft and a plurality of needle channels coupled to the outer peripheral surface of the central shaft so as to be slidable in the vertical direction; a first spring for pushing downward forward one of the plurality of needle passages; and a second spring for retracting the needle passages advancing downward to the upper side, each of the needle passages including a main body portion having a tubular inner space, a needle head coupled to the lower portion of the main body portion, and a needle shaft slidably provided in the tubular inner space.

Owner:GODAI

Hair implanting pen

PendingCN112998825AImplement extractionAchieve transferSurgical needlesTrocarEngineeringMechanical engineering

Owner:SHANTOU UNIV

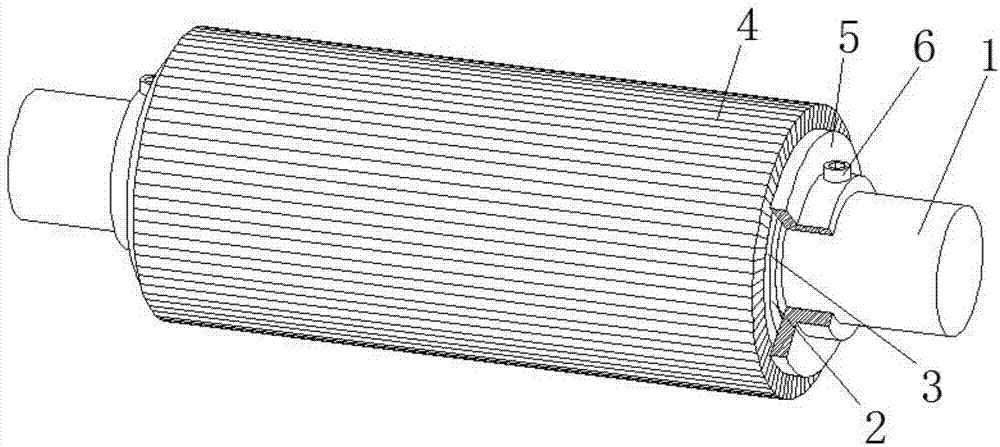

Roller brush and production technology thereof

InactiveCN106985088AEasy to makeSurface continuous enrichmentFlexible-parts wheelsGrinding devicesBristlePulp and paper industry

The invention discloses a roller brush and its production process. The roller brush includes a roller and bristles. The roller is a hollow cylindrical structure with two ends fixedly connected with connecting shafts. The outside of the roller is sleeved with The flocking layer, the outside of the flocking layer is connected with bristles, the bristles are in strip-shaped sheet structure, evenly and tightly distributed along the circumference of the flocking layer, the two ends of the bristles are respectively connected with compression covers, and the compression The cover is fixedly connected to the connecting shaft by locking screws. The production process of the roller brush includes the following steps: preparing polished cloth strips, pressing and shaping the polished cloth strips, applying glue to the polished cloth strips, assembling and positioning the rollers, and planting bristles. , Assemble the compression cover, and the bristles are smooth. In the present invention, the bristles of an integral polishing strip are covered and fixed on the roller by means of adhesive splicing, which improves the production efficiency, the bristles are more compact, the surface is continuous and full, and the polishing effect is good. The cover structure prolongs the service life of the roller brush.

Owner:ANHUI ZHEN DA BRUSH IND

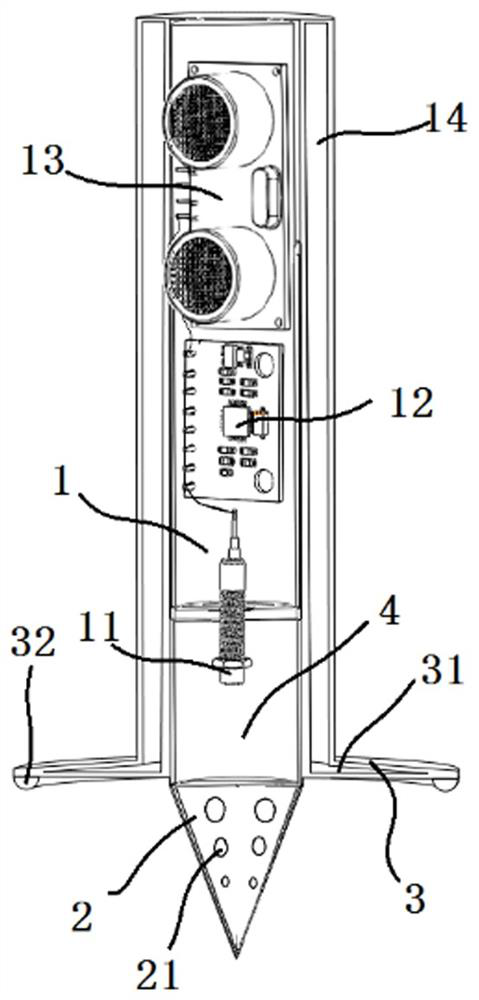

Wearable monitoring system convenient to disassemble and assemble and using method of wearable monitoring system

The invention discloses a wearable monitoring system convenient to disassemble and assemble and a using method of the wearable monitoring system. The wearable monitoring system comprises a wig hair shaft and hair roots connected to the hair shaft, wherein the hair shaft is of a hollow cylinder structure, a measuring cavity is formed in a cavity of the hair shaft, a microprocessor is arranged in the measuring cavity, a sample cavity is further formed in the cavity of the hair shaft and is located on the side, close to the hair roots, of the measuring cavity, and the sample cavity is tightly attached to the hair roots and communicates with the hair roots through a filter screen; a fixing mechanism is arranged at the connecting position of the sample cavity and the hair roots and is a fixingring arranged on the outer wall of the sample cavity, the fixing ring is made of a flexible material, and an inner ring of the fixing ring is tightly attached to the outer wall of the sample cavity; and flame retardant liquid is arranged in the interlayer of the side wall of the hair shaft, a cavity is formed in the fixing ring and communicates with the interlayer of the side wall of the hair shaft, and a sealing ring is arranged on the side, facing the hair roots, of the outer ring of the fixing ring. According to the wearable monitoring system, the flame retardant liquid is arranged outsidethe implantable wig, and meanwhile, the convenience of implanting and pulling out the wig is improved through the mobility of the flame retardant liquid.

Owner:石家庄一稻一科技有限公司

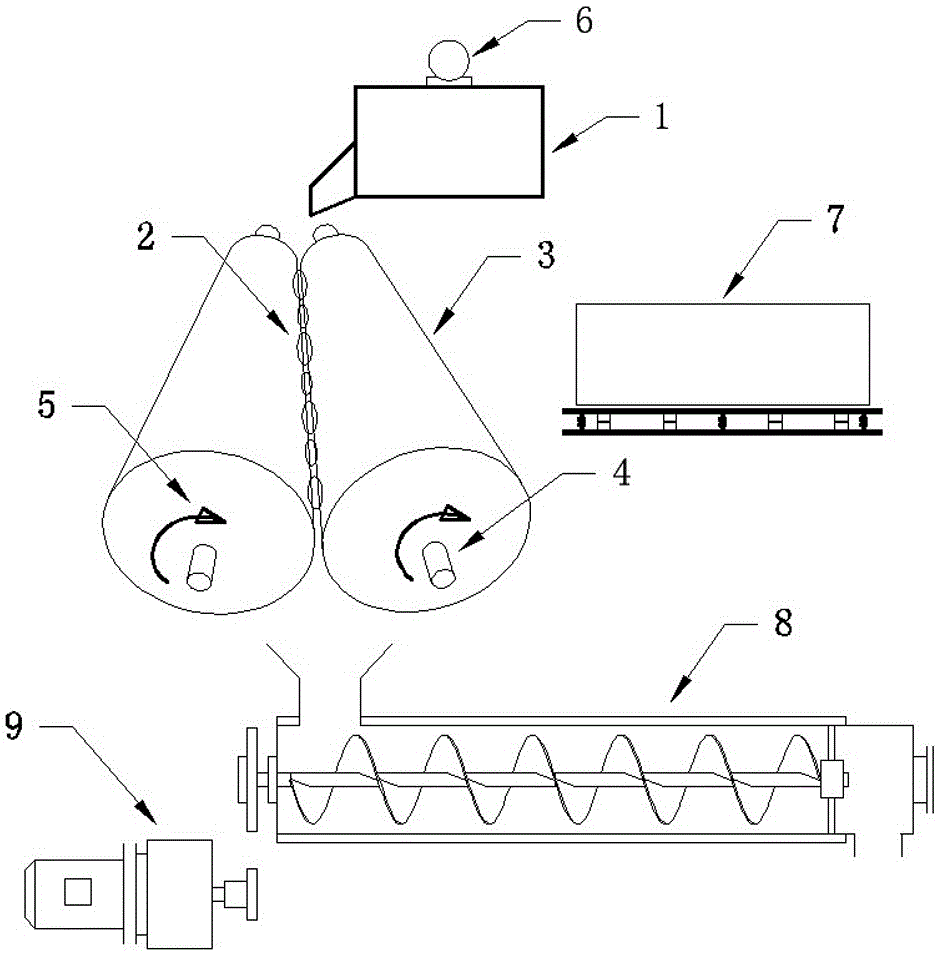

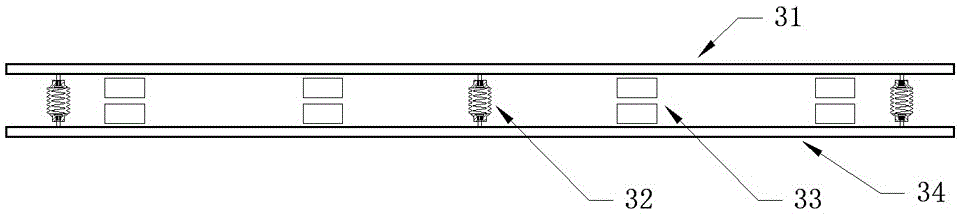

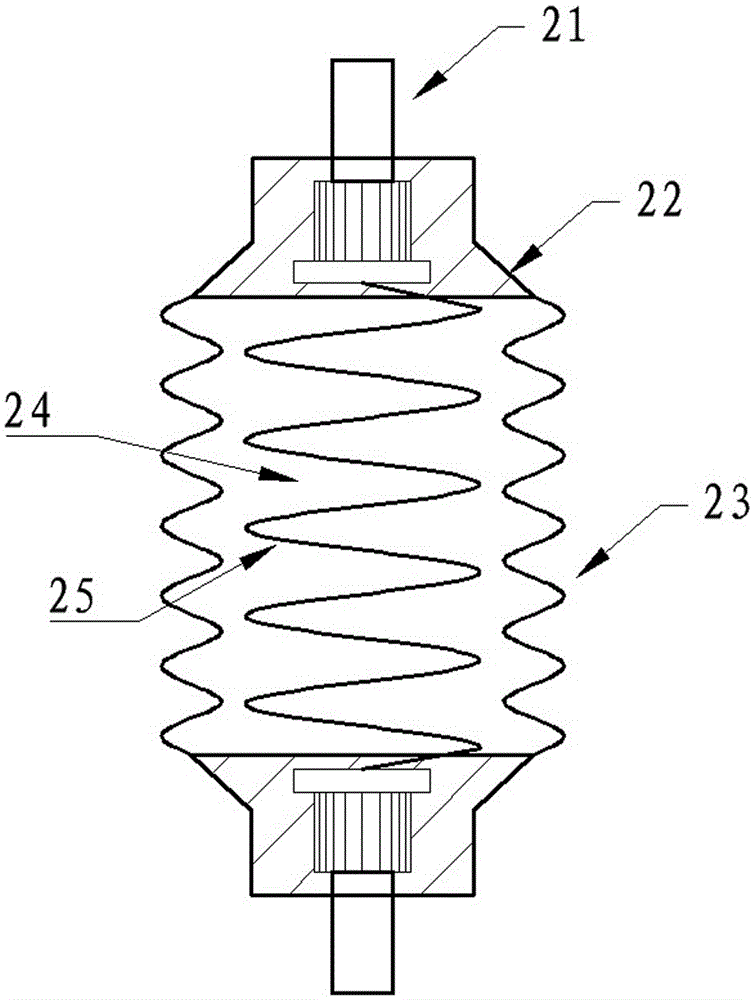

Spiral delivery taper drum type electric cabinet damping kiwi fruit hair removing device

The invention discloses a spiral delivery taper drum type electric cabinet damping kiwi fruit hair removing device. A V-shaped hair removing chamber is formed by the interval between two taper drums which are arranged side by side and rotate in the same direction; a vibration feeding cabinet is arranged above the V-shaped hair removing chamber, and consists of a vibration motor and a feeding cabinet; the circuit system of the device is controlled by the electric cabinet; when falling into the V-shaped cavity between the two taper drums, a kiwi fruit is linearly speeded up step by step to rotate under the action of gravity and friction of the two taper drums, and moves to big ends of the taper drums; and the kiwi fruit can be completely centrifugally rotated under a condition of no extrusion or friction damage along with higher and higher linear speed, so that the kiwi fruit hair can be removed by means of centrifugal force and soft hair brushing. By adopting the creative thought, the fiber hair implanted taper drums are used for centrifugally brushing the kiwi fruits to remove hair, the hair can be completely removed, and the kiwi fruit cannot be damaged at all; a sine-wave damping shock absorber is beneficial to damping, buffering and eliminating vibration energy, and is beneficial to prolonging the device service life.

Owner:JISHOU UNIVERSITY

Toothbrush

ActiveCN103763981AEasy to cleanProperly cleanedBrush bodiesBristleFixed positionBiomedical engineering

The present invention comprises a head portion, and a handle portion which is extended from the head portion, a hair bundle being disposed at a hair implant surface of the head portion. At the handle portion of the toothbrush, a projecting section which protrudes to a back side of the hair implant surface of the toothbrush is disposed, and a tubular enclosing section is disposed to surround the projecting section. A tip of the projecting section protrudes from the tubular enclosing section. The tubular enclosing section may be displaced relatively in a direction of the tip when the tip and a tip side of the handle portion are at a fixed position, and the head portion is weighted from the hair implant surface. By adoption of the toothbrush, a brushing pressure may be detected with ease by a user, and the oral cavity of the user may be cleaned at an appropriate brushing pressure.

Owner:LION CORP

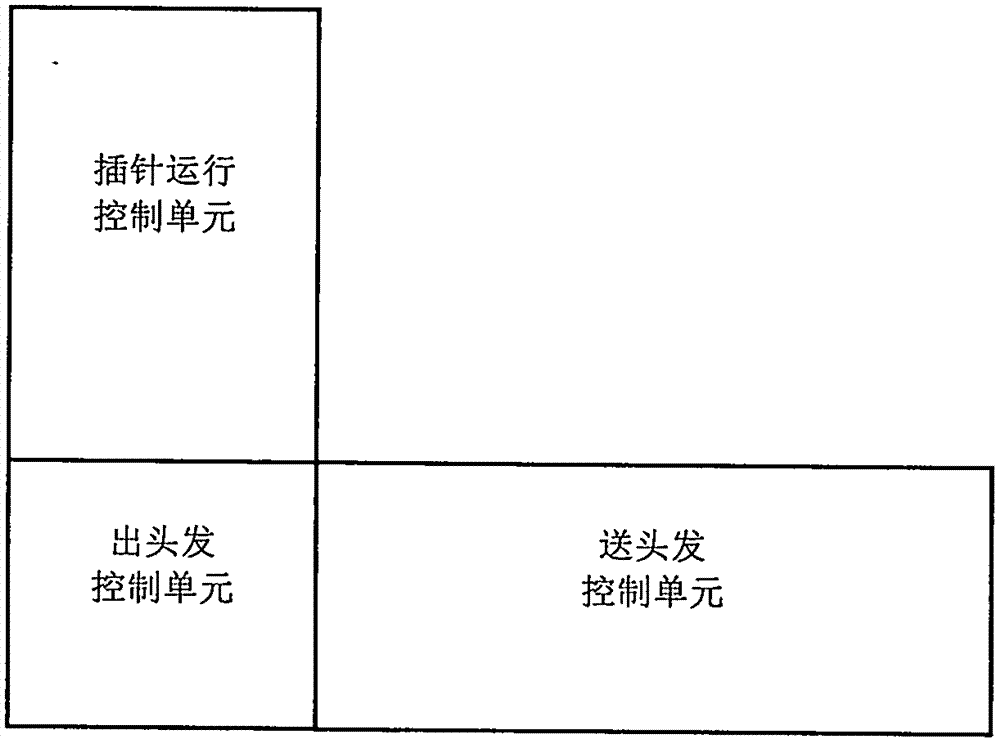

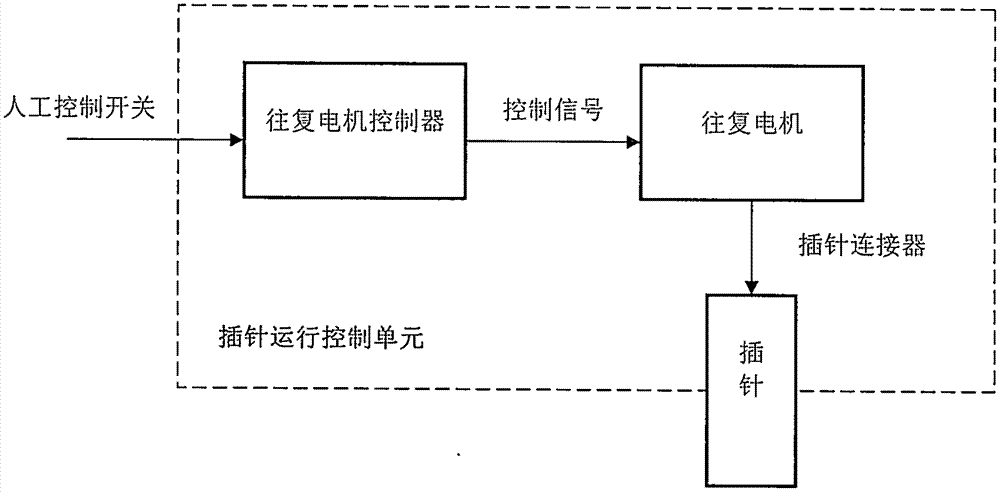

Training head automatic processing device

The invention discloses an automatic processing device for a teaching head, which comprises a needle insertion operation control unit, a hair output control unit, and a hair delivery control unit. The control unit is composed of a propeller and a hair container; the hair control unit is composed of a track, a baffle plate, a sliding plate and a departure port. The teaching head automatic processing device manufactured by the present invention can automatically install, send and implant hair, and greatly improve the production efficiency of the teaching head.

Owner:何宇东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com