Patents

Literature

4473 results about "Collagenan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Topical Nutraceutical Compositions with Selective Body Slimming and Tone Firming Antiaging Benefits

InactiveUS20040146539A1Cut skinReduction in signCosmetic preparationsToilet preparationsPimpleWrinkle skin

I have discovered cosmetic or topical pharmaceutical compositions for external body part or organ slimming, firming, cellulite reduction, fat-reduction, and obesity control benefits that are in synergistic combination with benefits for the treatment of skin aging, skin wrinkles reduction, skin exfoliating, treatment of acne, treatment of rosacea, age-spots reduction, skin surface whitening, skin surface brightening striae distensae (stretch marks) reduction, treatment of pimples, treatment of skin infections and lesions, spider veins reduction, blood microcirculation (venous insufficiency) improvement, UVA / UVB protection of skin, and skin redness reduction. These compositions thus provide multiple combinations of skin and external body part or organ enhancement benefits that can be selective and specific for external body parts and organs such as face, chin, cheeks, arms, "love handles" in abdomen area, eye lids and eye zone, neck, breasts, thighs, and hips. These compositions include a body beneficial composition selected from certain nutraceutical, cosmetic, and pharmaceutical ingredients, a composition to promote collagen and elastin synthesis in the skin, and a cosmetically or pharmaceutically acceptable delivery system.

Owner:GUPTA SHYAM K

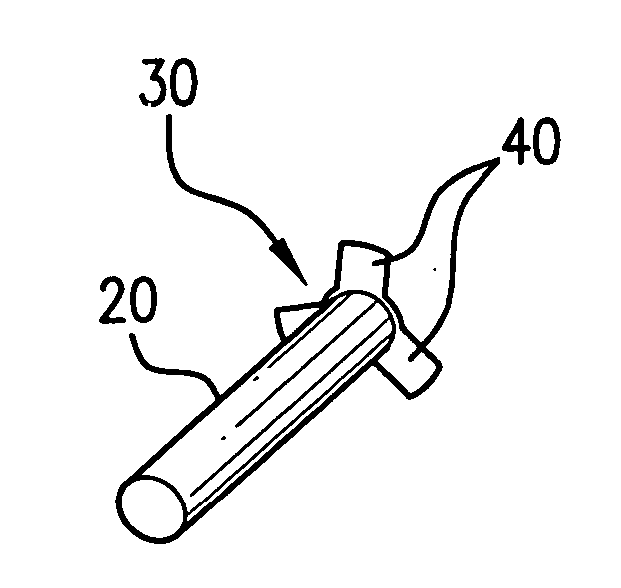

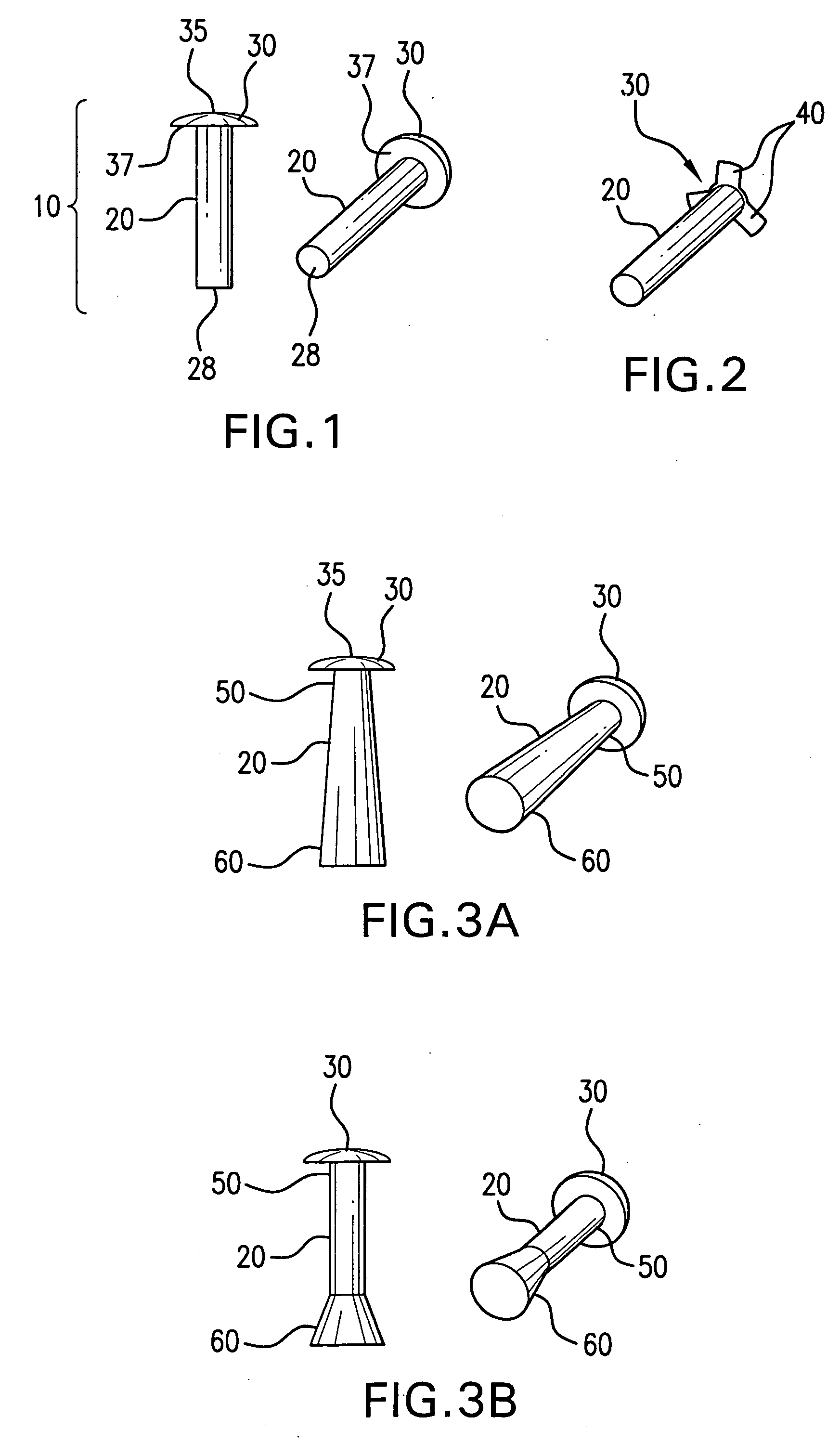

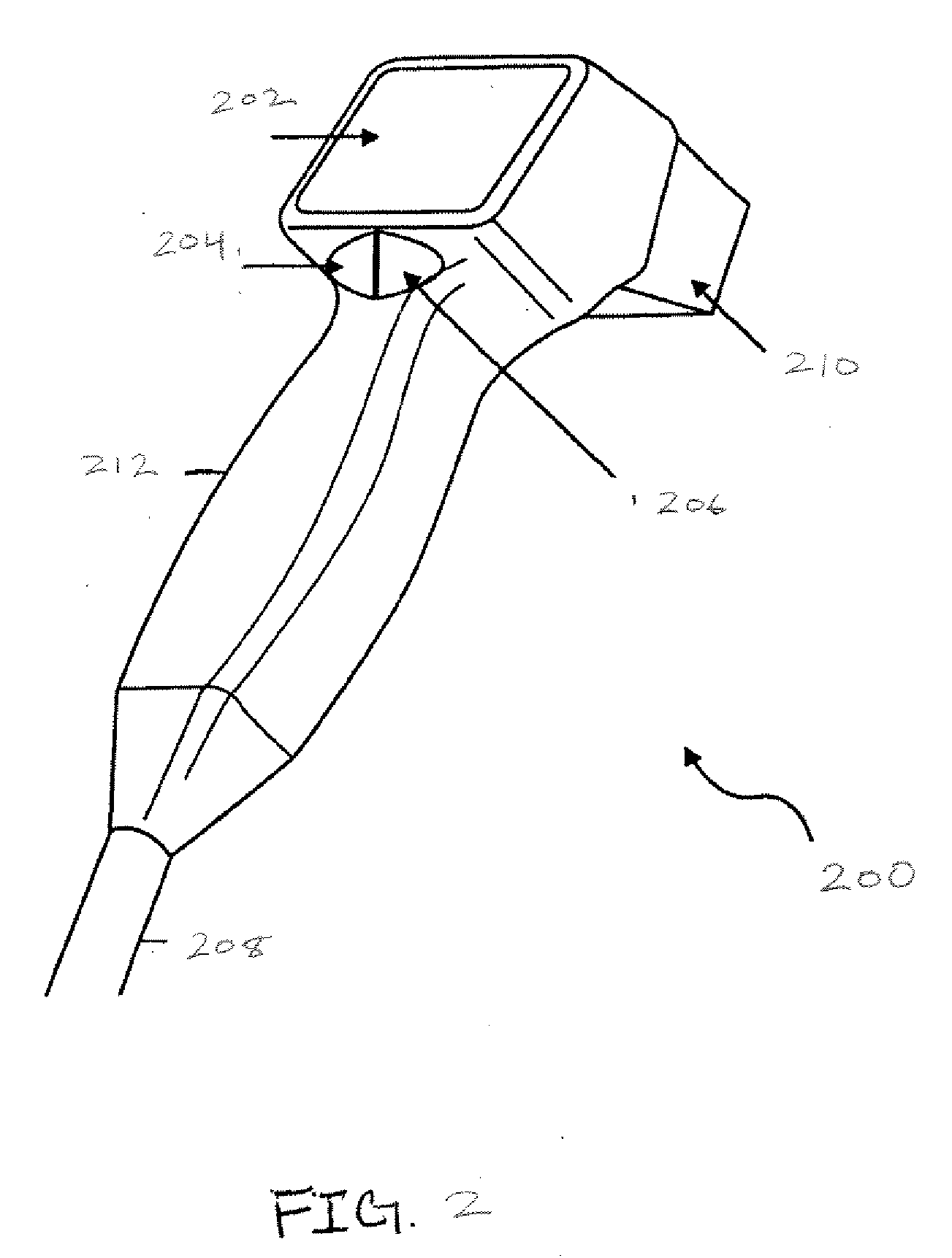

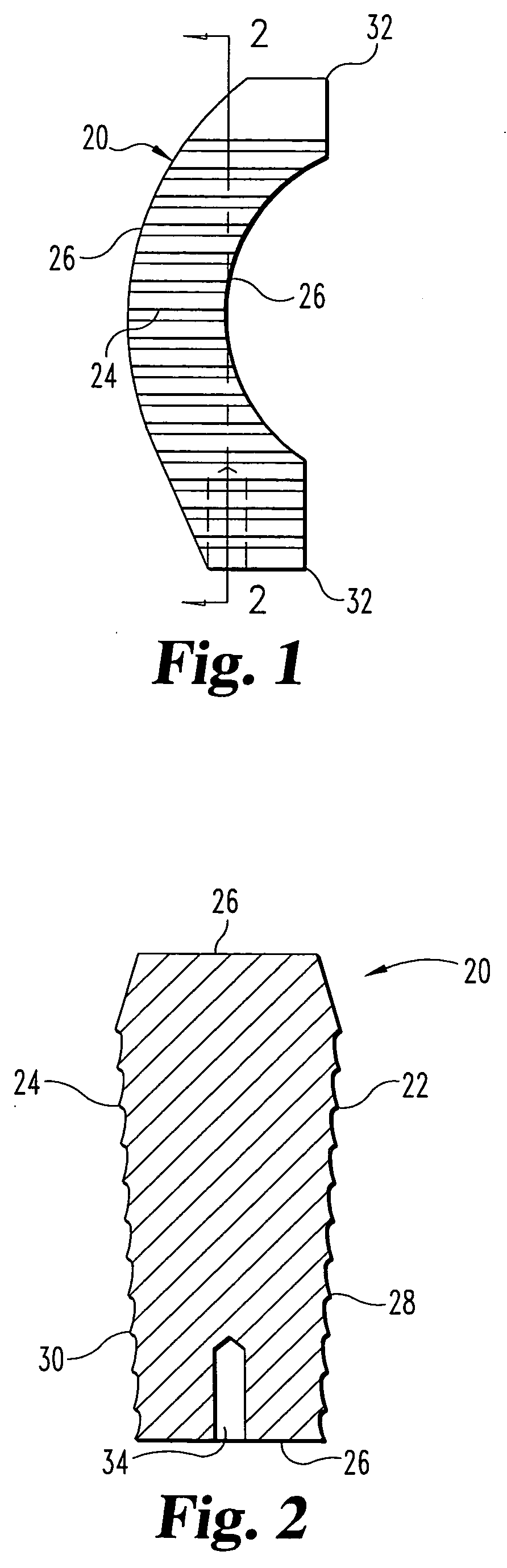

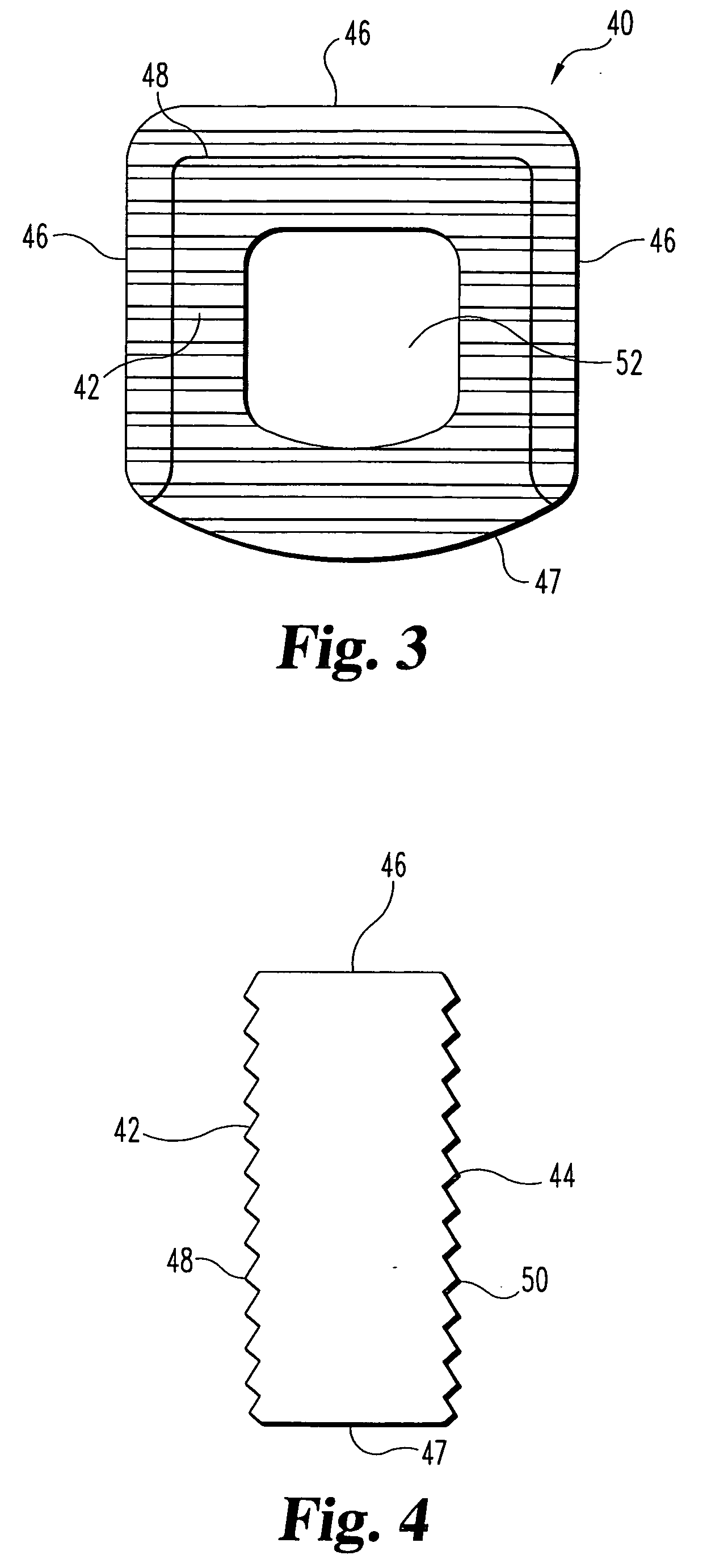

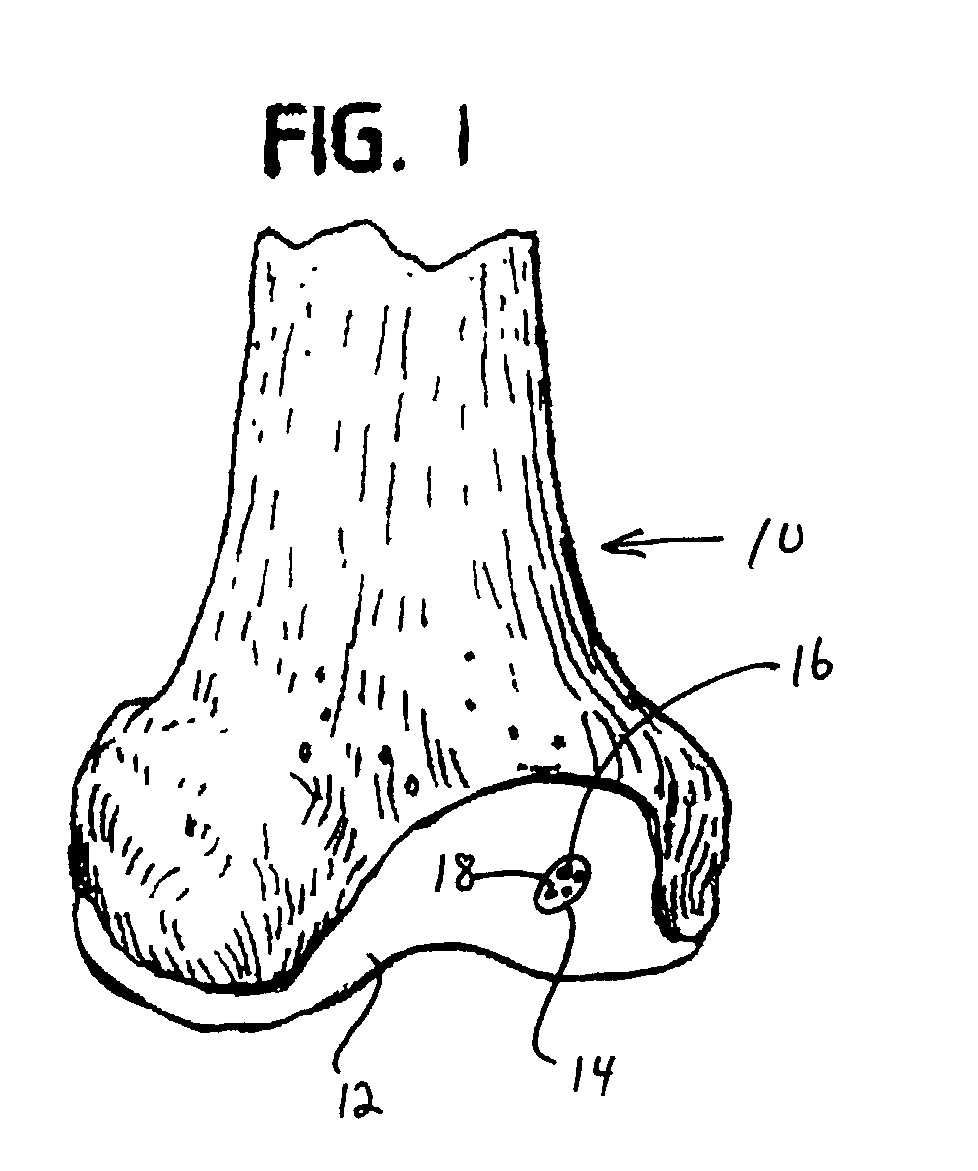

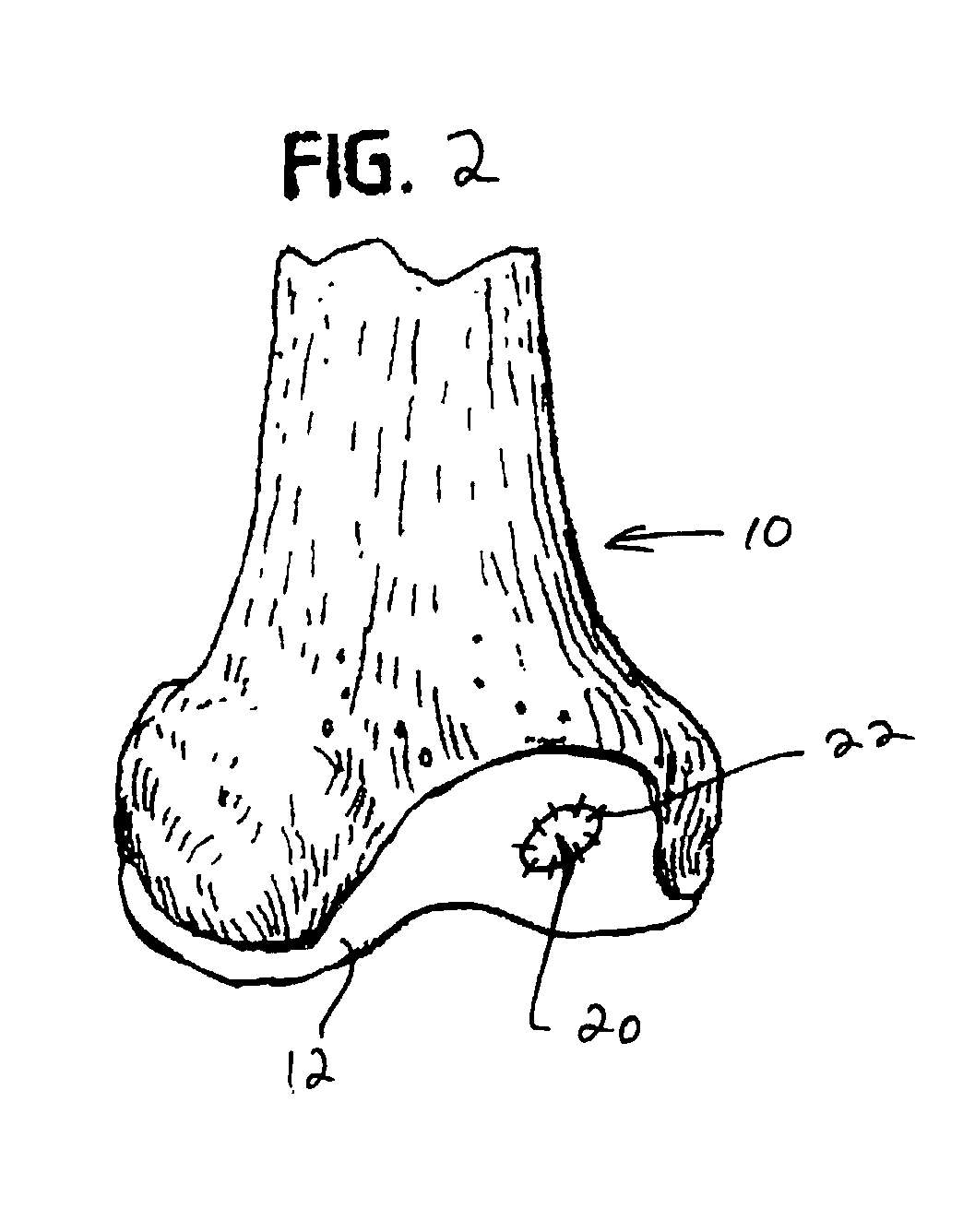

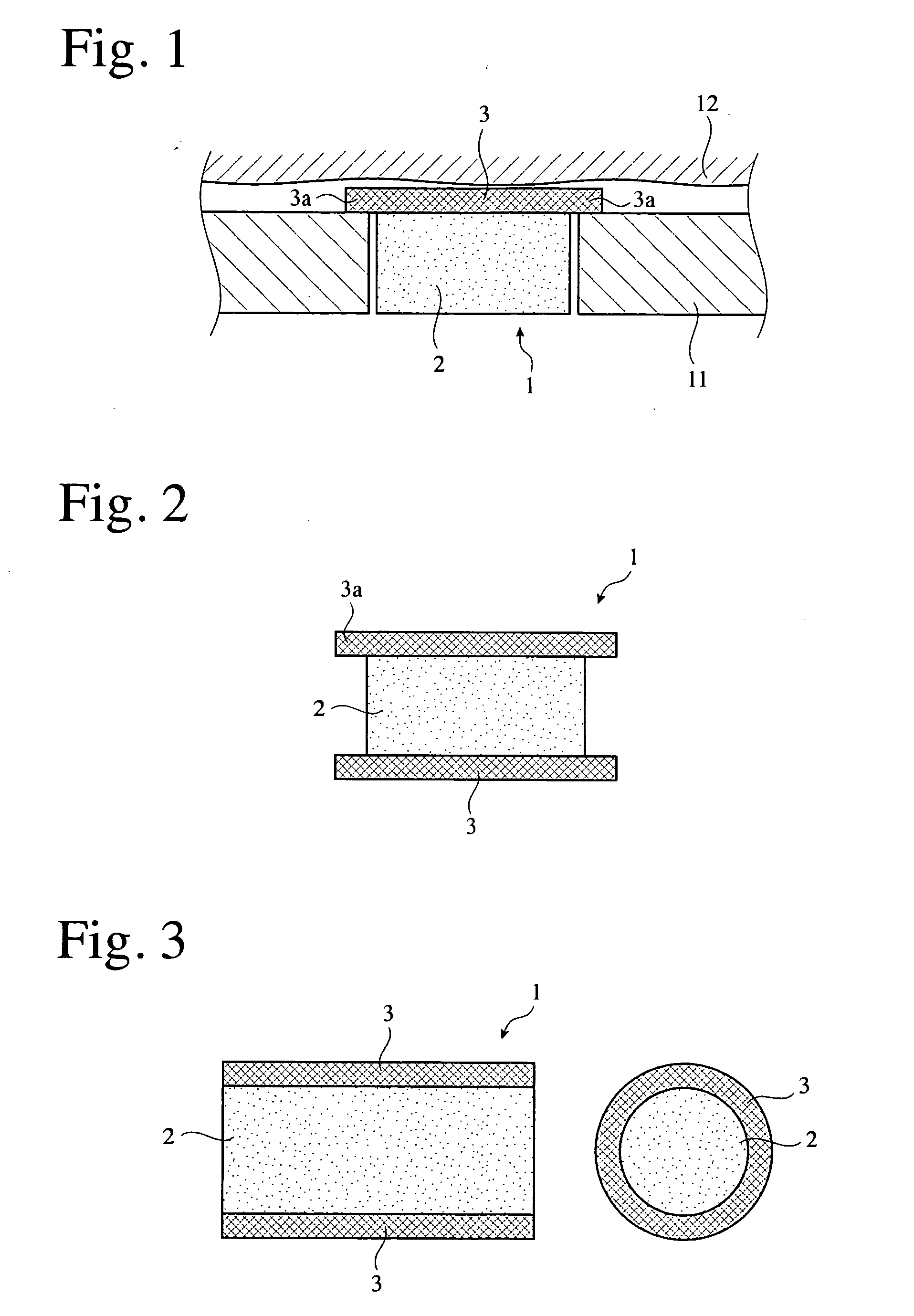

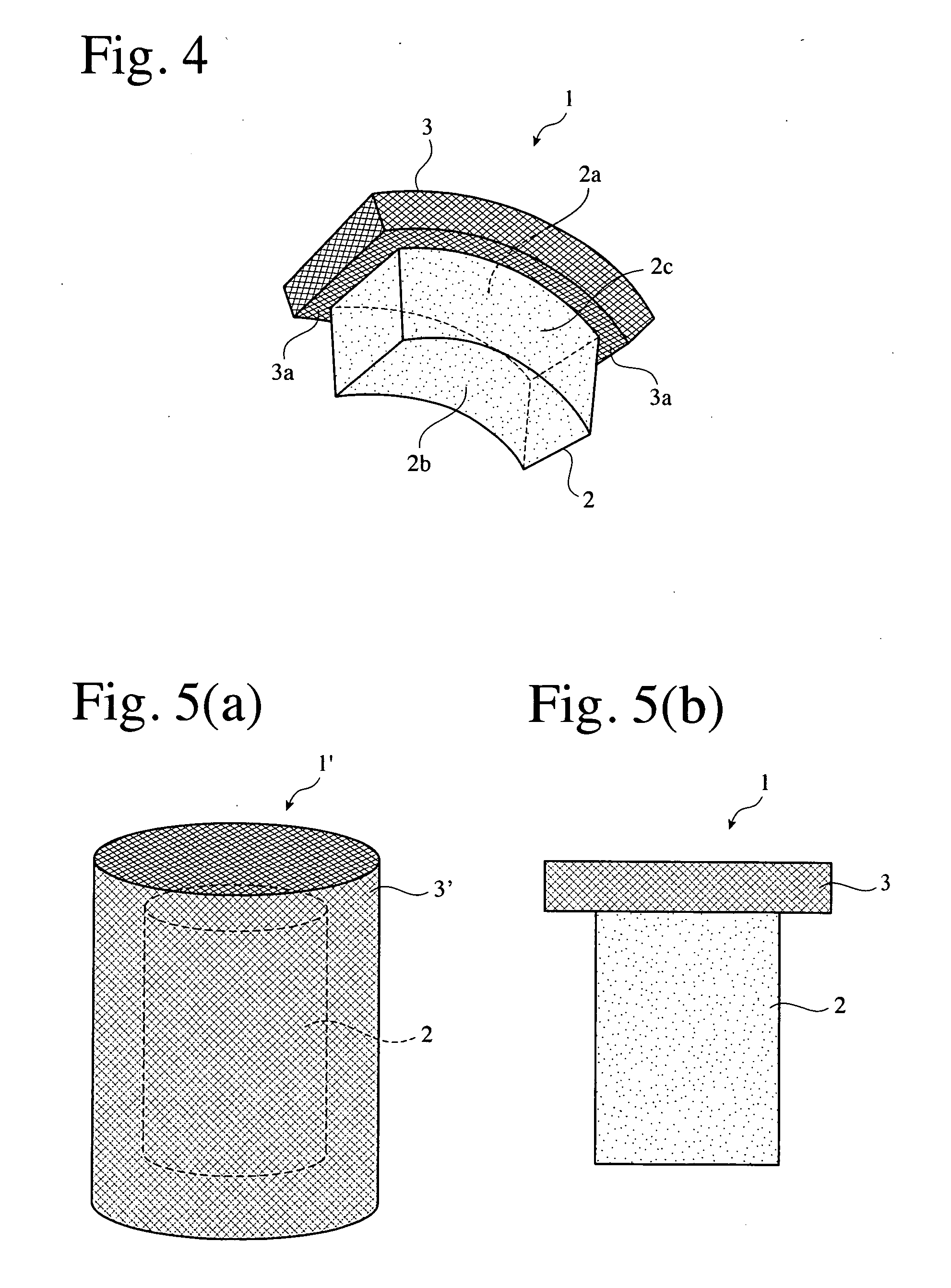

Ocular plug formed from placenta derived collagen biofabric

The present invention relates to ocular plugs formed from a biodegradable material. The plugs comprises a shaft and, optionally, a cap. The ocular plugs are intended to occlude, and to repair, discontinuities in the sclera, whether formed deliberately during injection or surgical foray into the eye, or accidentally. The method further provides methods of making the ocular plug. the invention also provides methods of using the ocular plugs to occlude and repair discontinuities in the sclera, or to deliver biologically active compounds to the sclera or the eye. Finally, the invention provides kits comprising one or more ocular plugs in a container.

Owner:LIU QING +1

Composition for promoting healthy bone structure

InactiveUS6447809B1Increase bone densityPrevents radial bone lossBiocideHeavy metal active ingredientsVitamin CRegimen

A dietary supplement for benefitting human bone health includes a calcium source, a source of vitamin D activity, and an osteoblast stimulant. A preferred calcium source is microcrystalline hydroxyapatite, which also contains protein (mostly collagen), phosphorus, fat, and other minerals. A preferred source of vitamin D activity is cholecalciferol, and a preferred osteoblast stimulant is ipriflavone. In addition to these basic ingredients, the composition can further include various other minerals known to occur in bone, vitamin C, and glucosamine sulfate, all of which exert beneficial effects on growth and maintenance of healthy bone. A method for benefitting human bone health involves administering a daily regimen of the dietary supplement.

Owner:PHOENIX DICHTUNGSTECHN +1

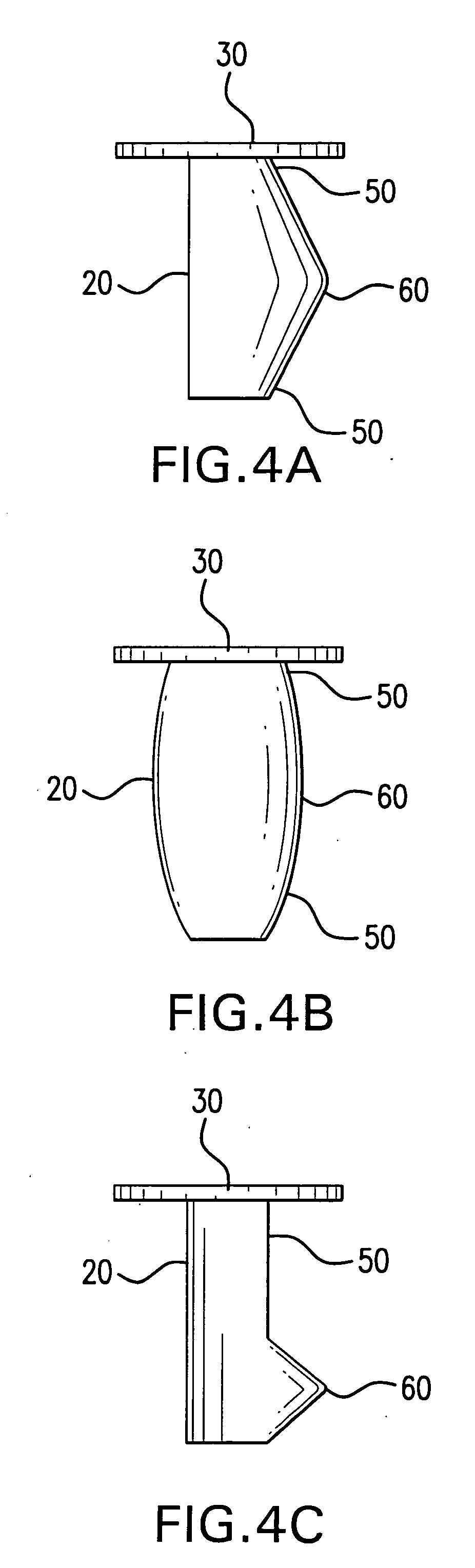

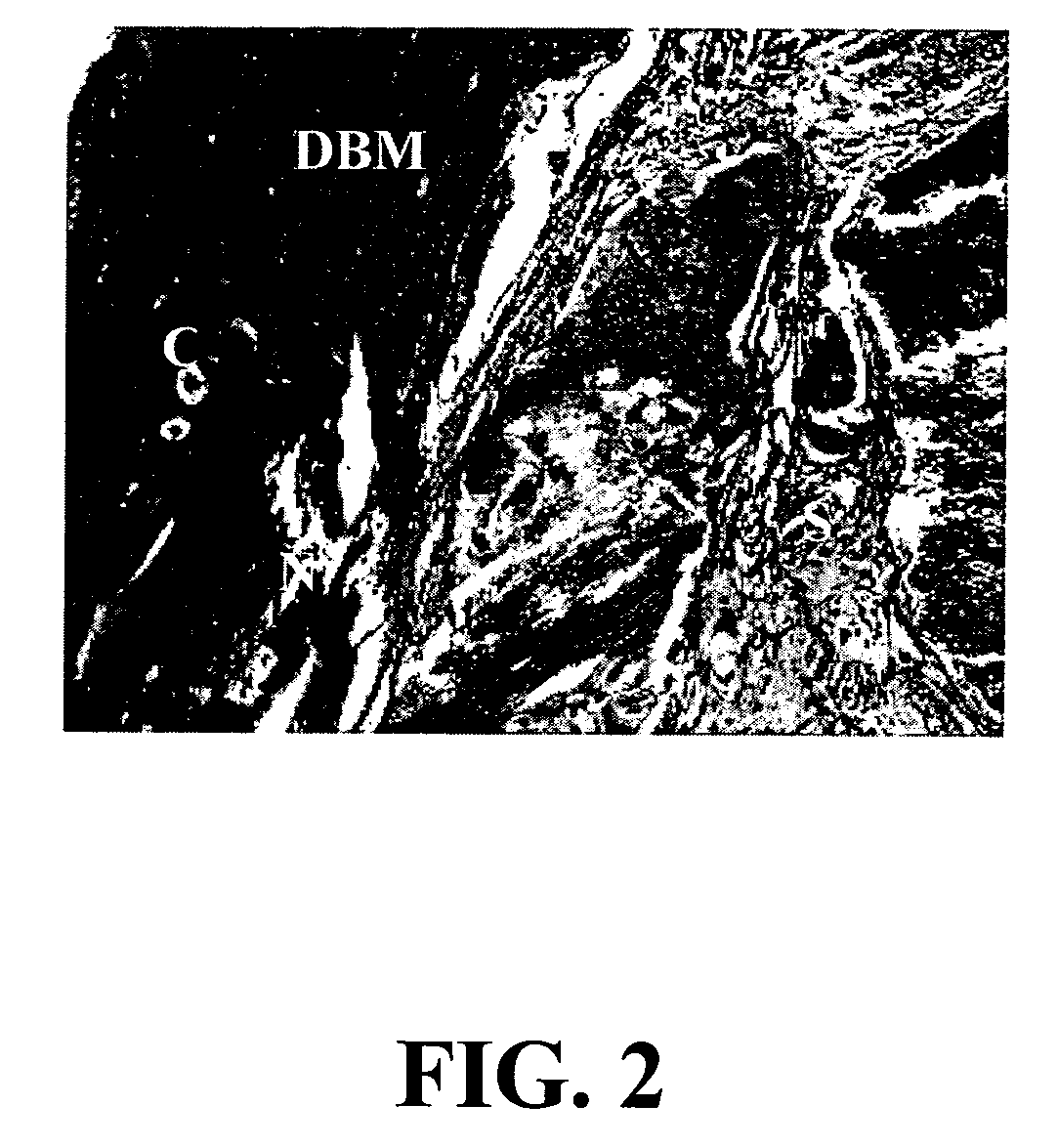

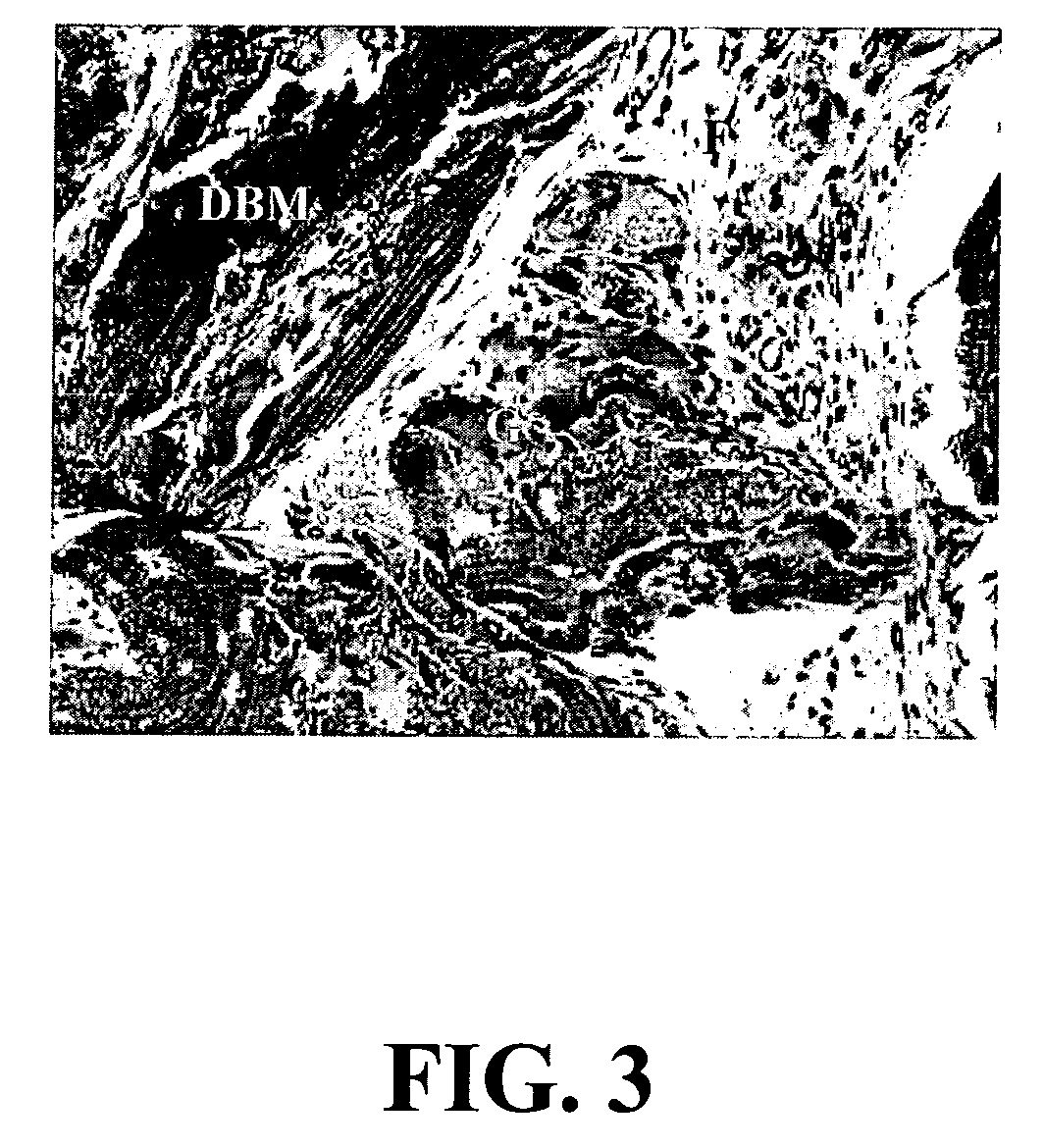

Crosslinked compositions comprising collagen and demineralized bone matrix, methods of making and methods of use

A composition comprising a collagen protein and demineralized bone matrix is described wherein the composition is chemically cross-linked with a carbodiimide such as N-(3-dimethylaminopropyl)-N-ethylcarbodiimide hydrochloride (EDC). The crosslinking reaction can be conducted in the presence of N-hydroxysuccinimide (NHS). The collagen can be in a porous matrix or scaffolding. The DBM can be in the form of particles dispersed in the collagen. A method of making the composition is also described wherein a collagen slurry is cast into the desired shape, freeze dried to form a porous scaffolding and infitrated with a solution comprising the cross-linking agent. The composition can be used as an implant for tissue (e.g., soft tissue or bone) engineering.

Owner:WARSAW ORTHOPEDIC INC

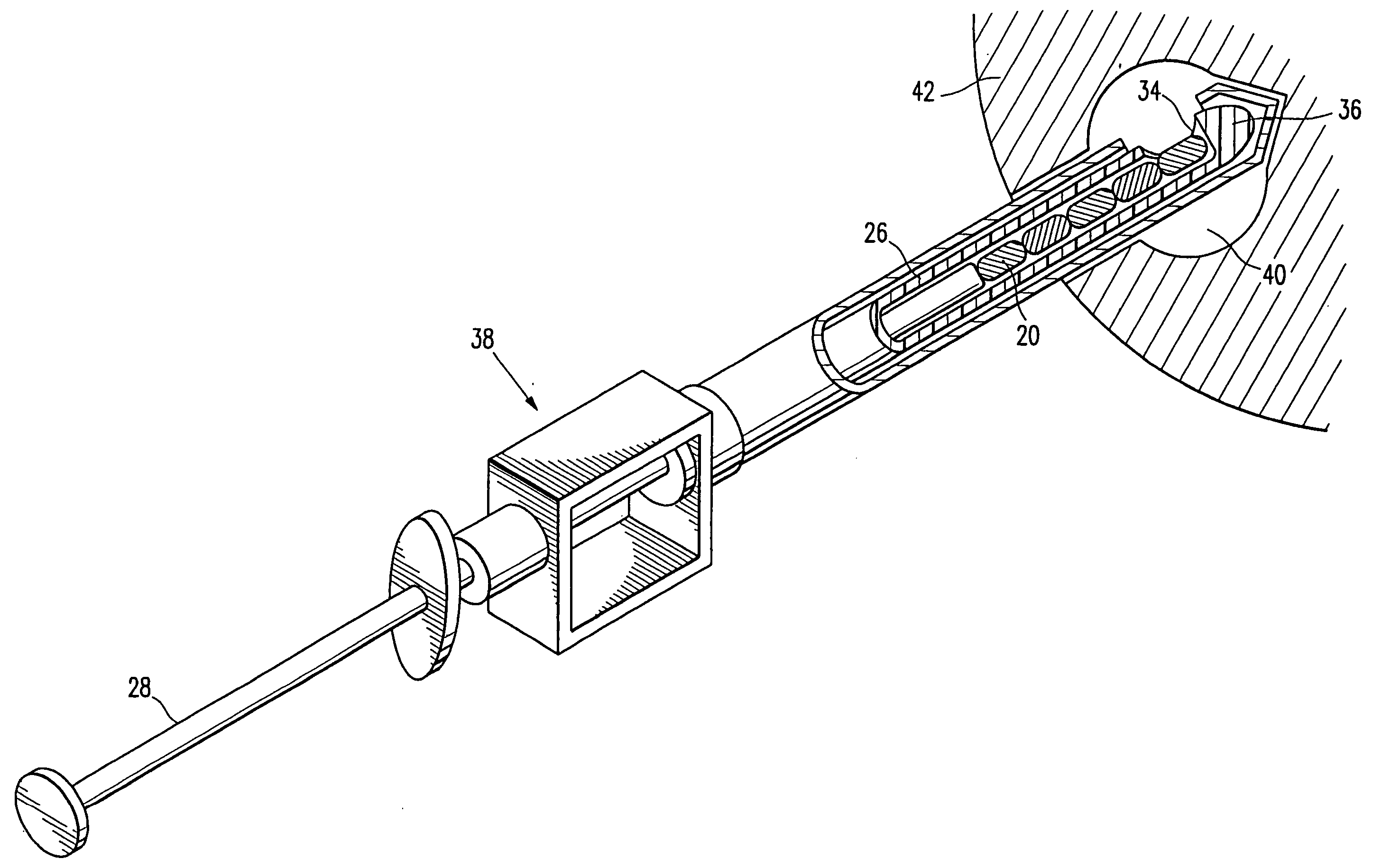

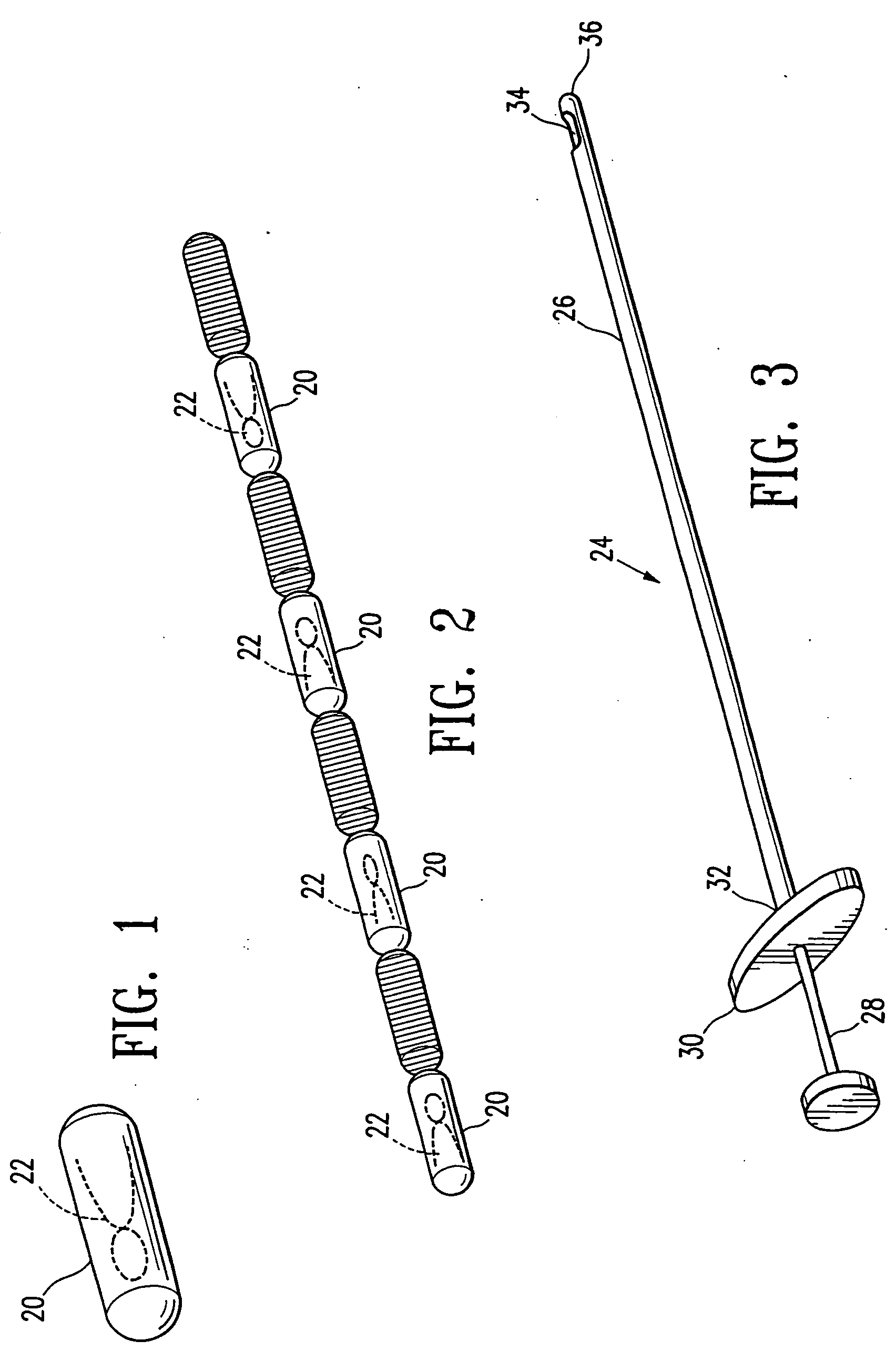

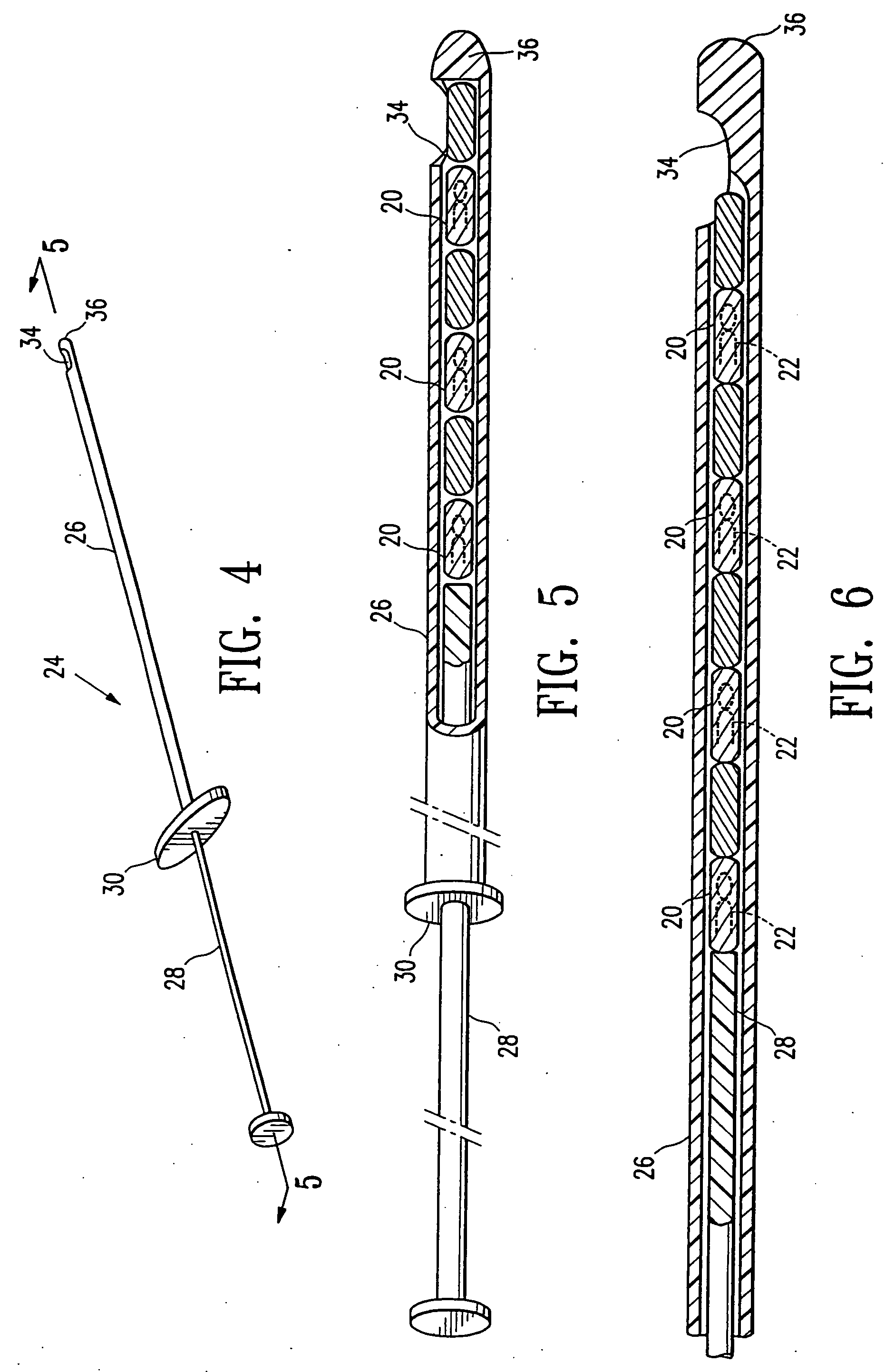

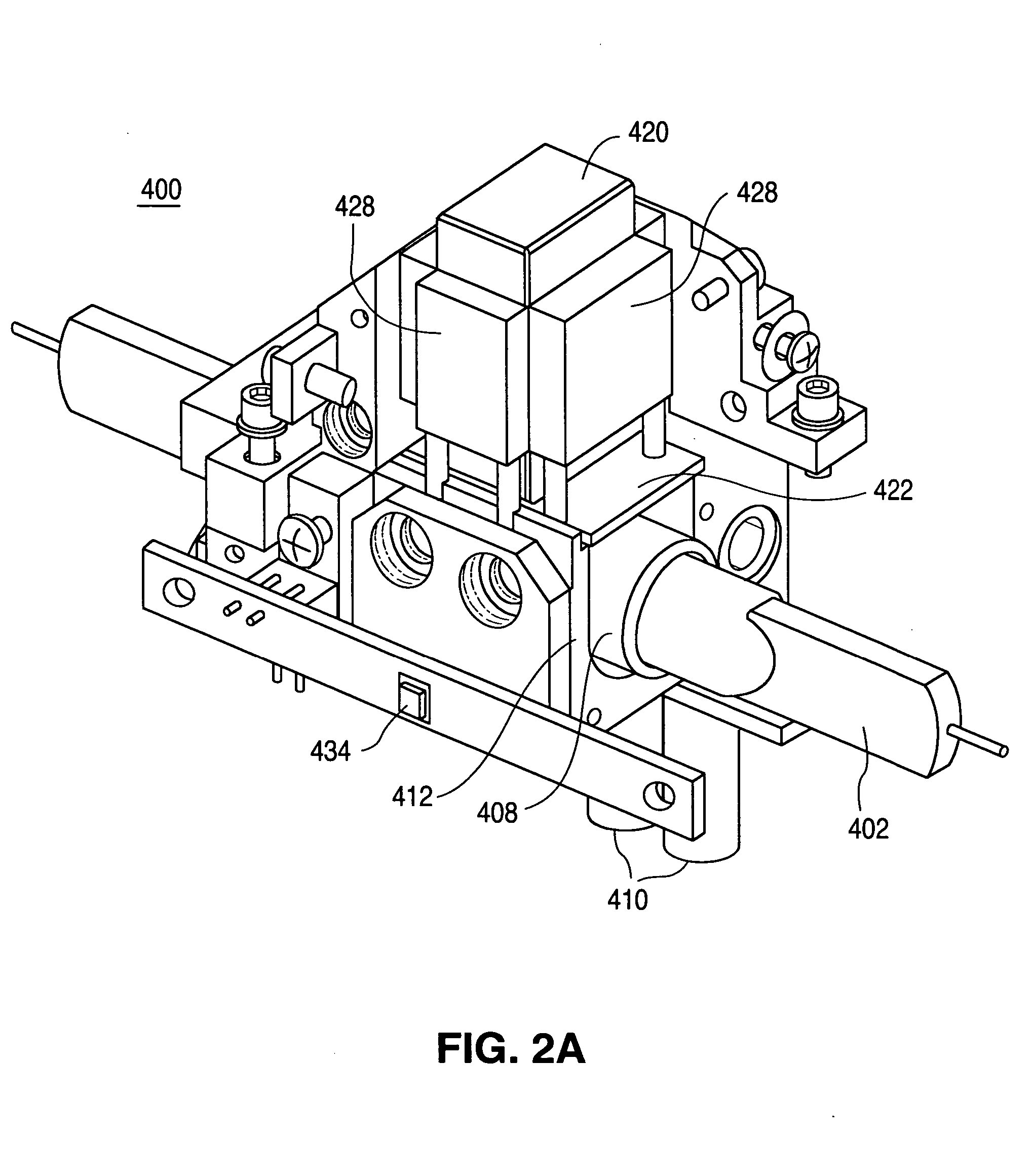

Imageable biopsy site marker

InactiveUS20060122503A1Accurately excise and remove a quantityMark accuratelyLuminescence/biological staining preparationOrgan movement/changes detectionRadiologyPiston

A biopsy site marker having at least one small marker body or pellet of bioresorbable material such as gelatin, collagen, polylactic acid, polyglycolic acid which has a radiopaque object, preferably with a non-biological configuration. The at least one bioresorbable body or pellet with a radiopaque object is deposited into the biopsy site, by an delivery device that includes an elongated tubular body with a piston slidable within the tubular body. One end of the tube is placed into the biopsy site. At least one but preferably several marker bodies or pellets are deposited sequentially into the biopsy site through the tube. At least the bioresorbable materials of the detectable markers remain present in sufficient quantity to permit detection and location of the biopsy site at a first time point (e.g., 2 weeks) after introduction but clear from the biopsy site or otherwise do not interfere with imaging of tissues adjacent the biopsy site at a second time point (e.g., 5-7 months) after introduction.

Owner:SENORX

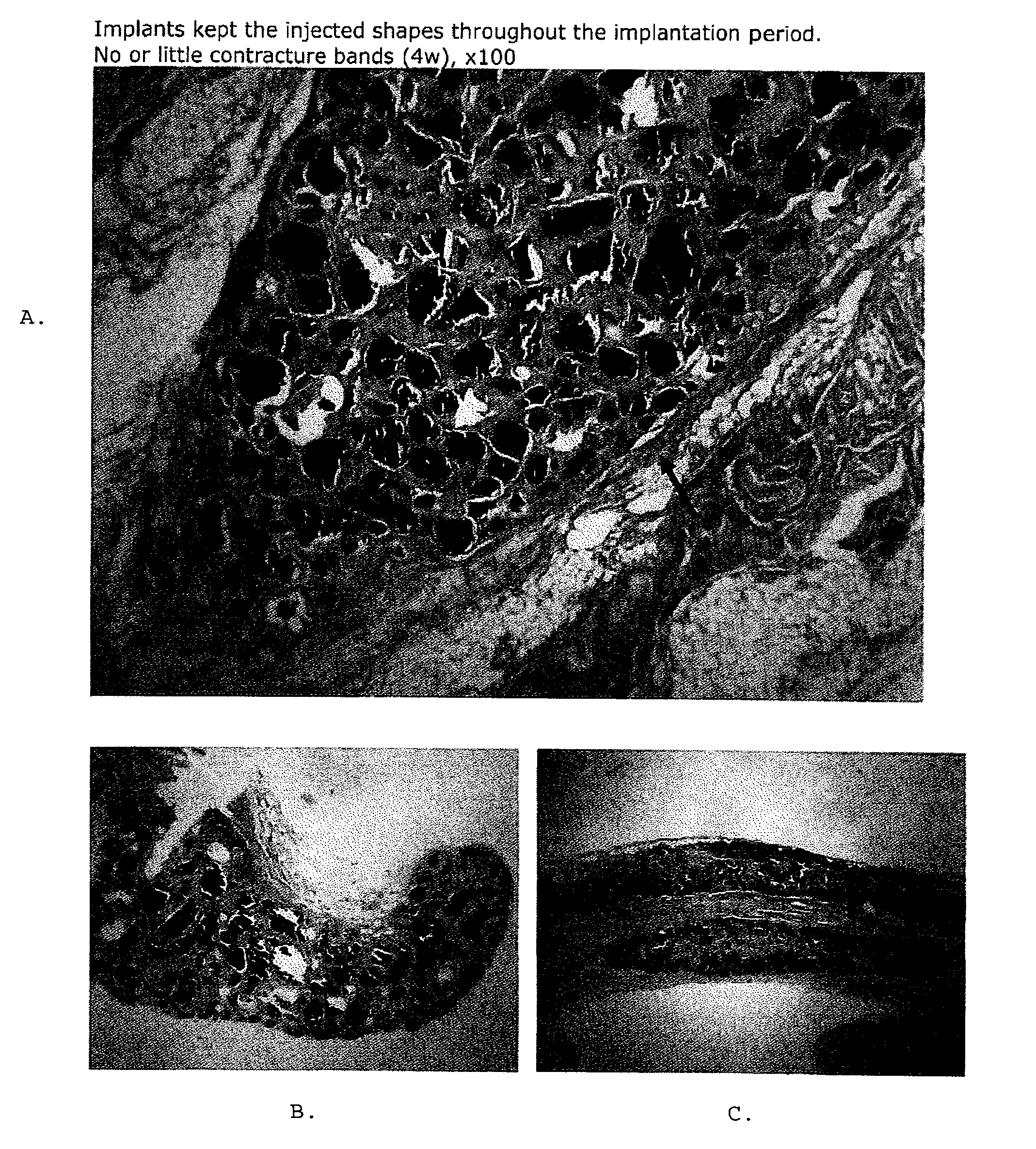

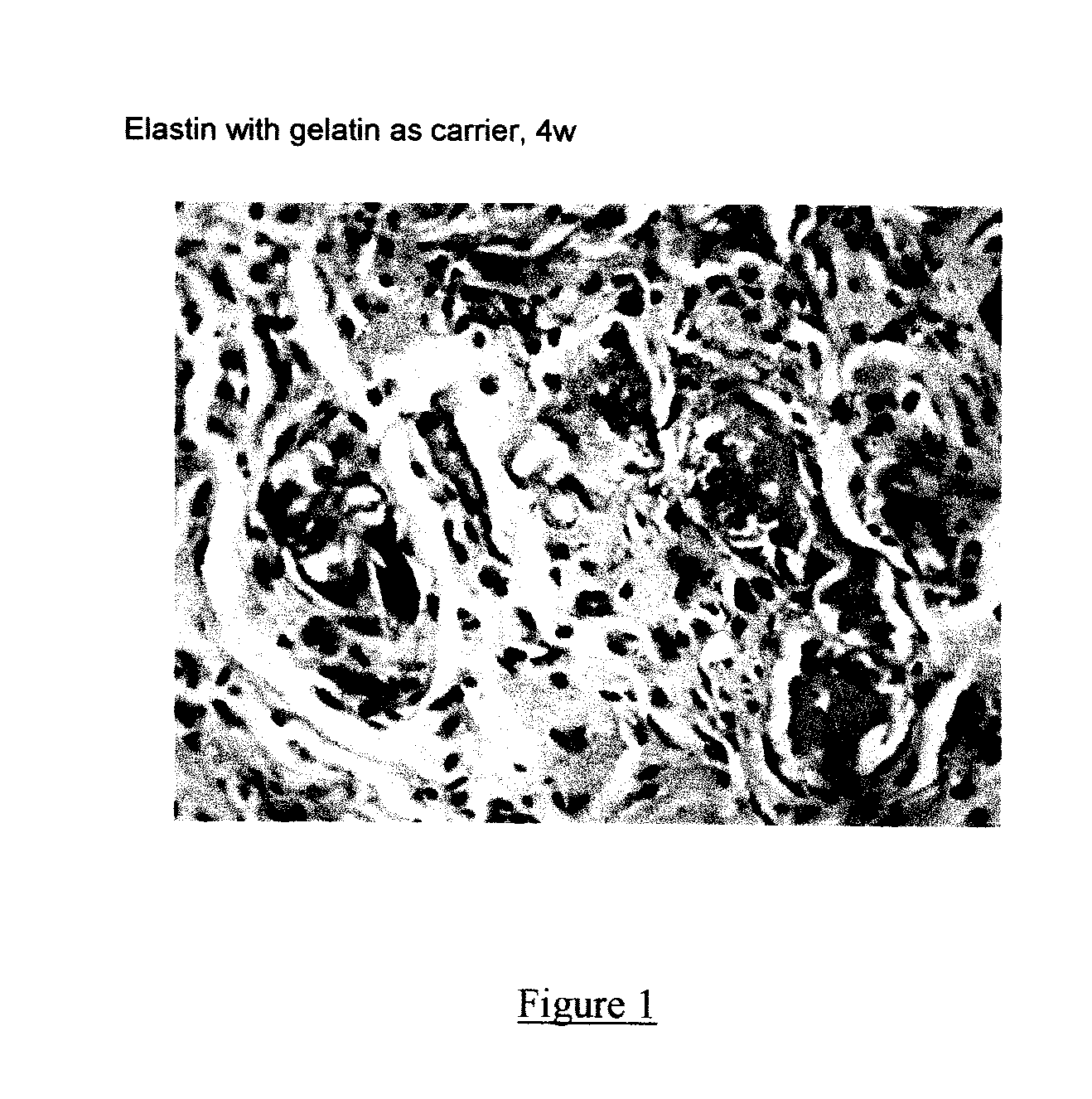

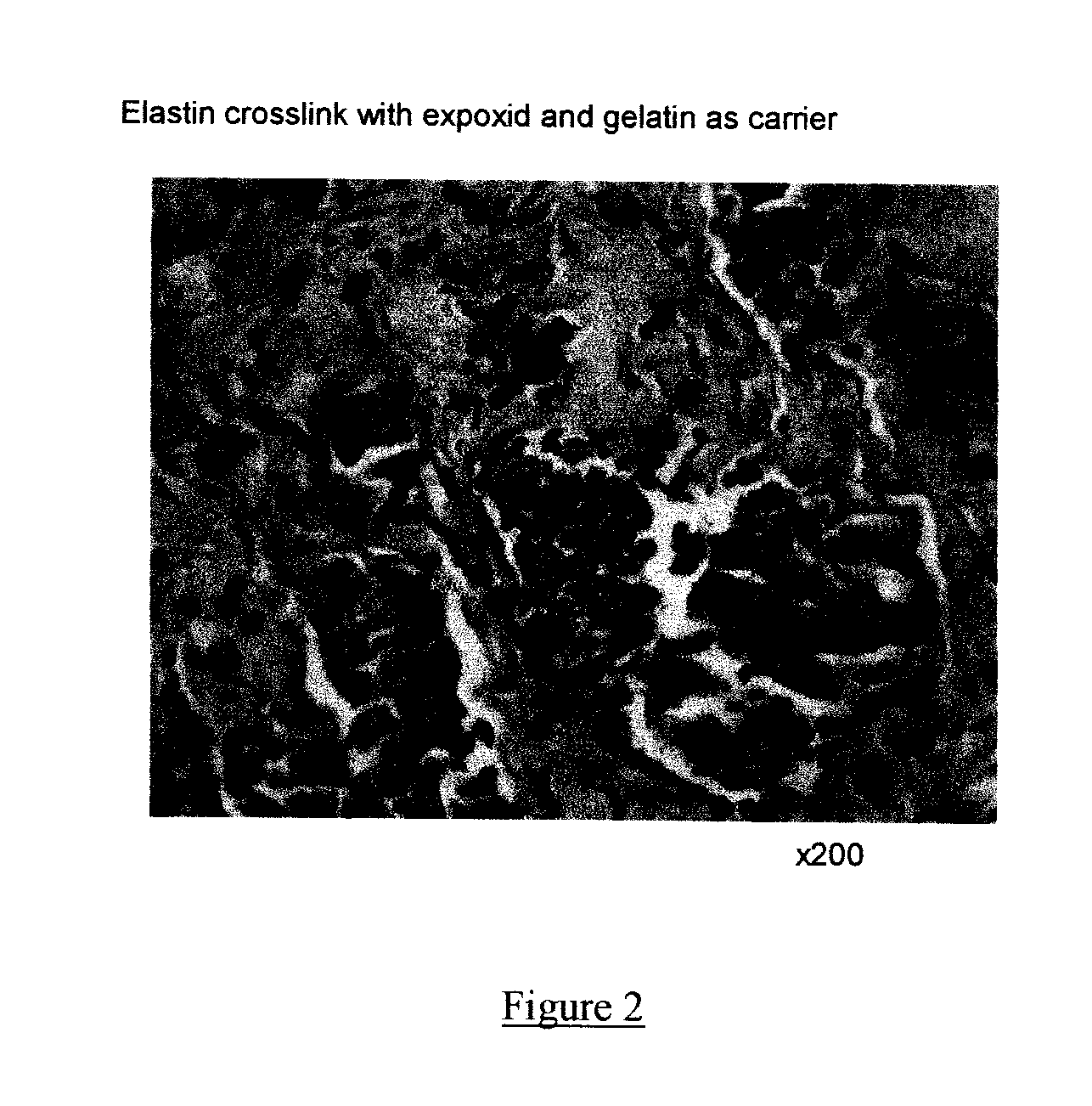

Composite containing collagen and elastin as a dermal expander and tissue filler

ActiveUS20120010146A1Easy injectionLesser tendency can be reactiveCosmetic preparationsPeptide/protein ingredientsTissue expansionCollagen VI

An injectable composition having dermal filling and tissue expanding activity comprises (1) a quantity of elastin sufficient to bring about dermal filling and tissue expansion when injected into a subject in need of dermal filling and tissue expansion, and (2) a pharmaceutically acceptable carrier. The composition can further comprise collagen, in other alternatives, the composition can further comprise hyaluronic acid, and one or more of the elastin, the collagen, and the hyaluronic acid, if present can be cross-linked, either intramolecularly or intermolecularly. The elastin, however, is the primary filler, even if collagen or hyaluronic acid are included in the composition

Owner:TRUELASTIN LAB INC

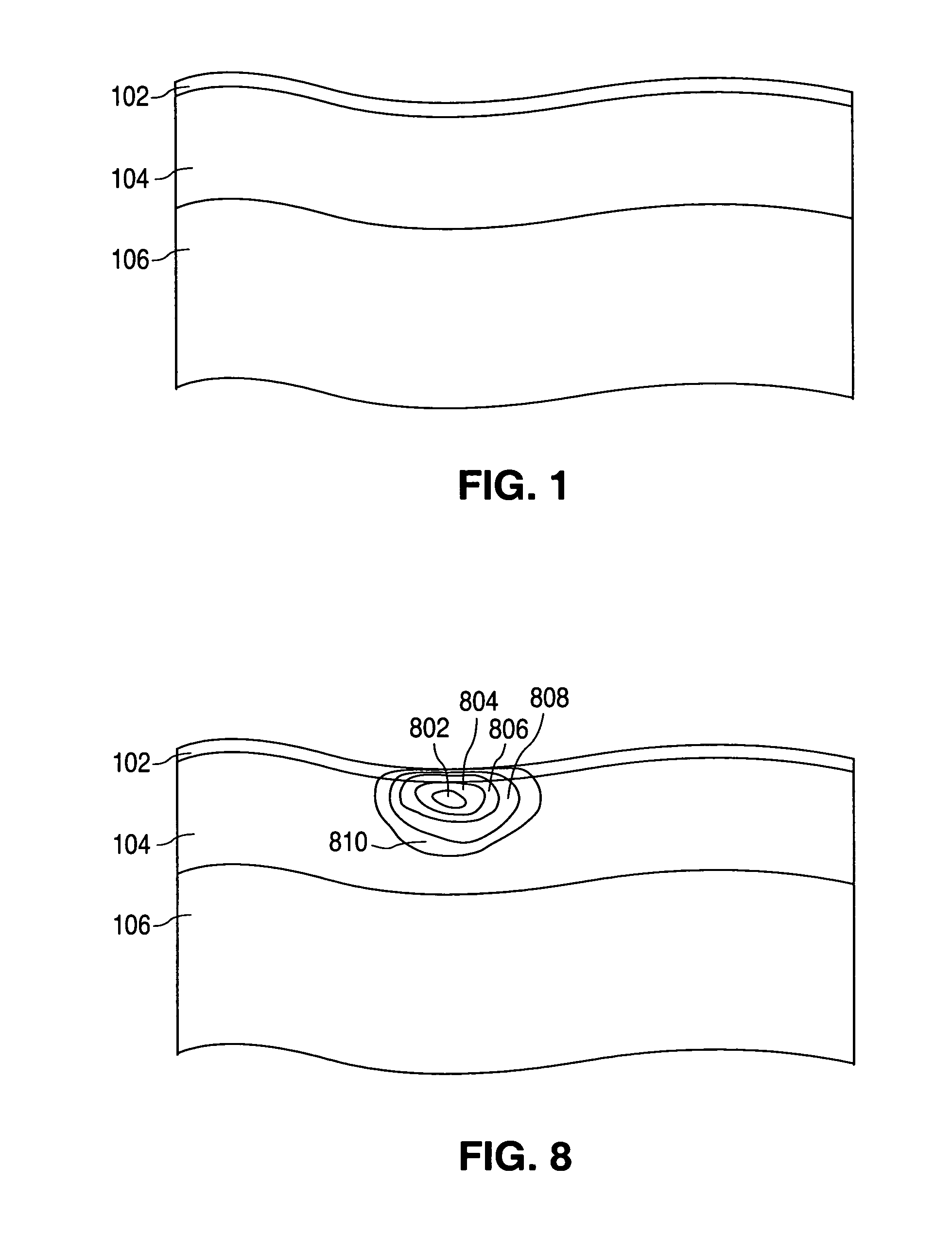

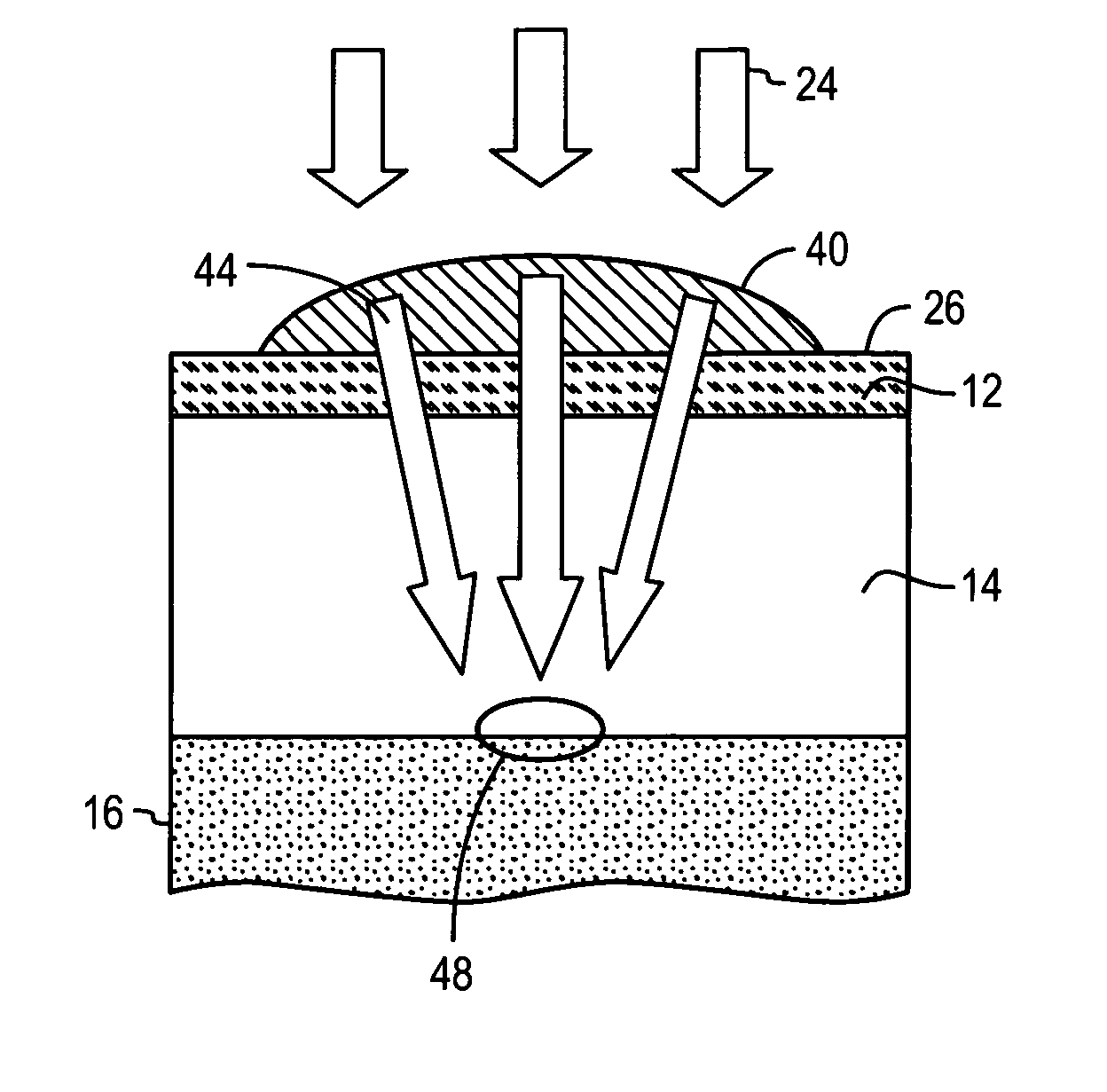

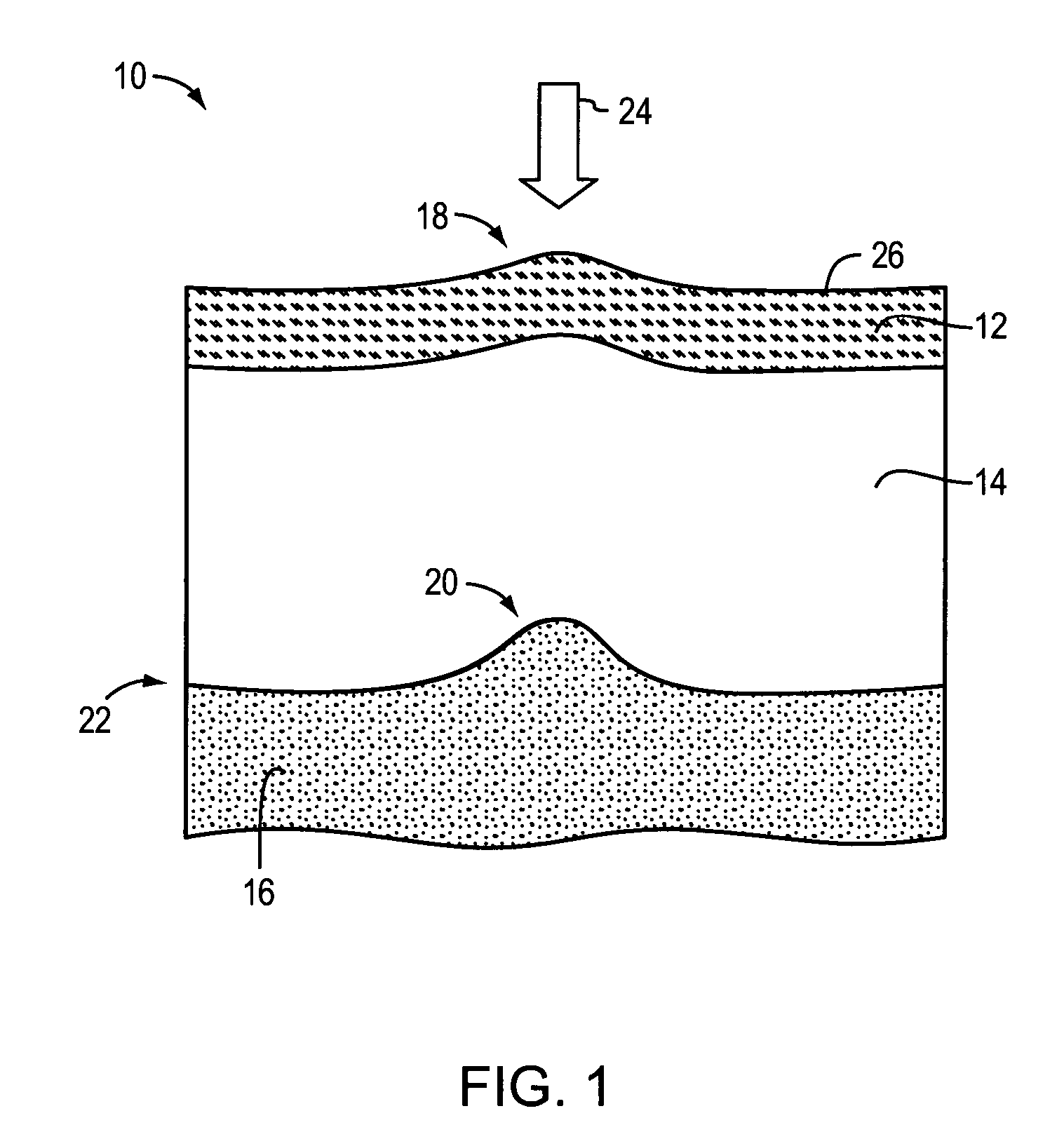

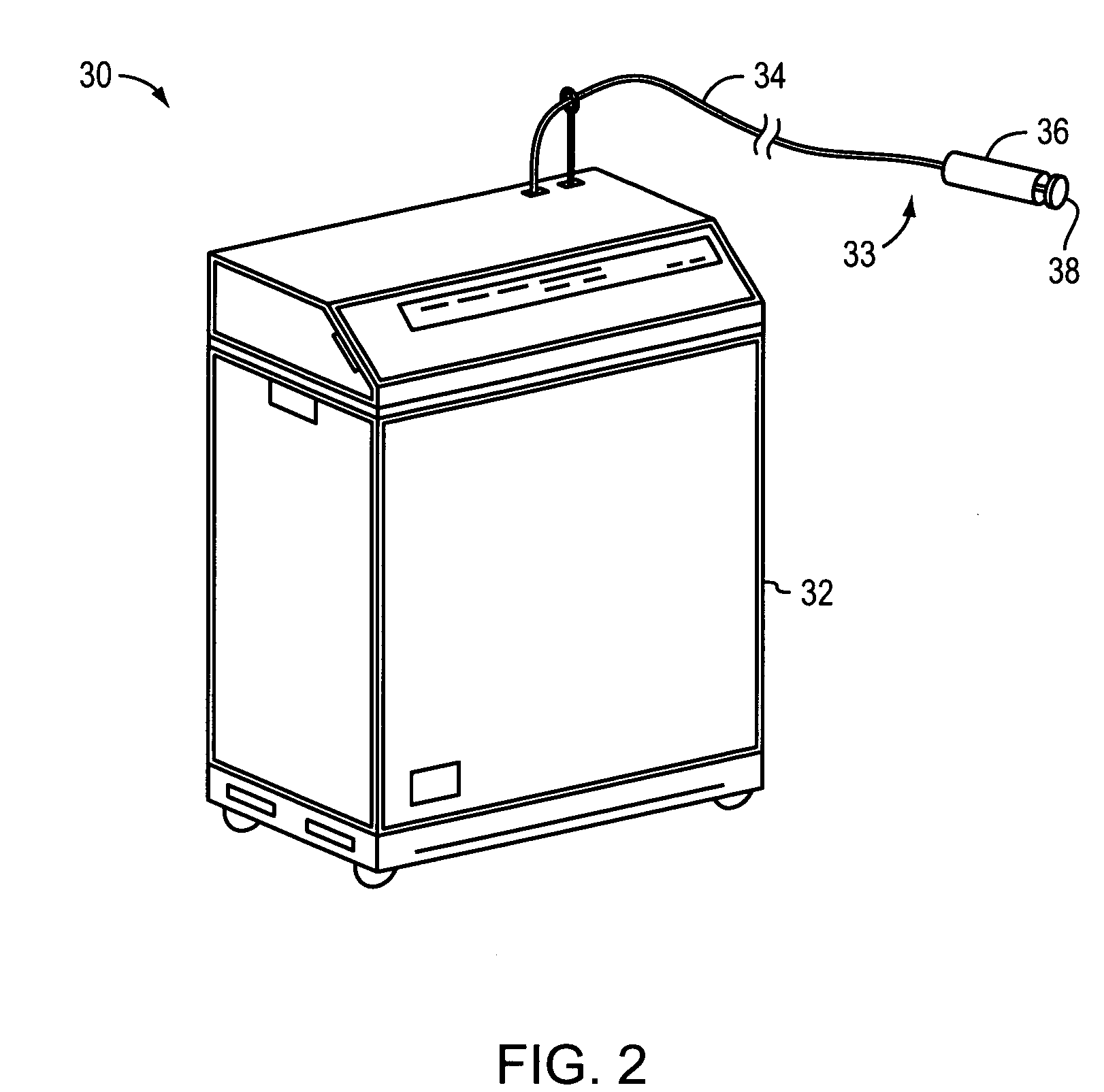

System and method for heating skin using light to provide tissue treatment

A system and method for using a light source to treat tissue with NIR light. The operation provides for generating higher temperatures in deeper layers of tissue relative to higher layers of tissue. The increased temperature in dermal layers can operate to induce collagen shrinkage, or remodeling. One of the light sources for providing a broad spectrum of NIR light is a filament light. The light from the filament lamp can be selectively filtered, and after filtering this light is applied to the skin, where the selective filtering can enhance the ability to elevate the temperature of deeper layers of tissue, relative to layers of tissue which are closer to the surface of the skin.

Owner:CUTERA

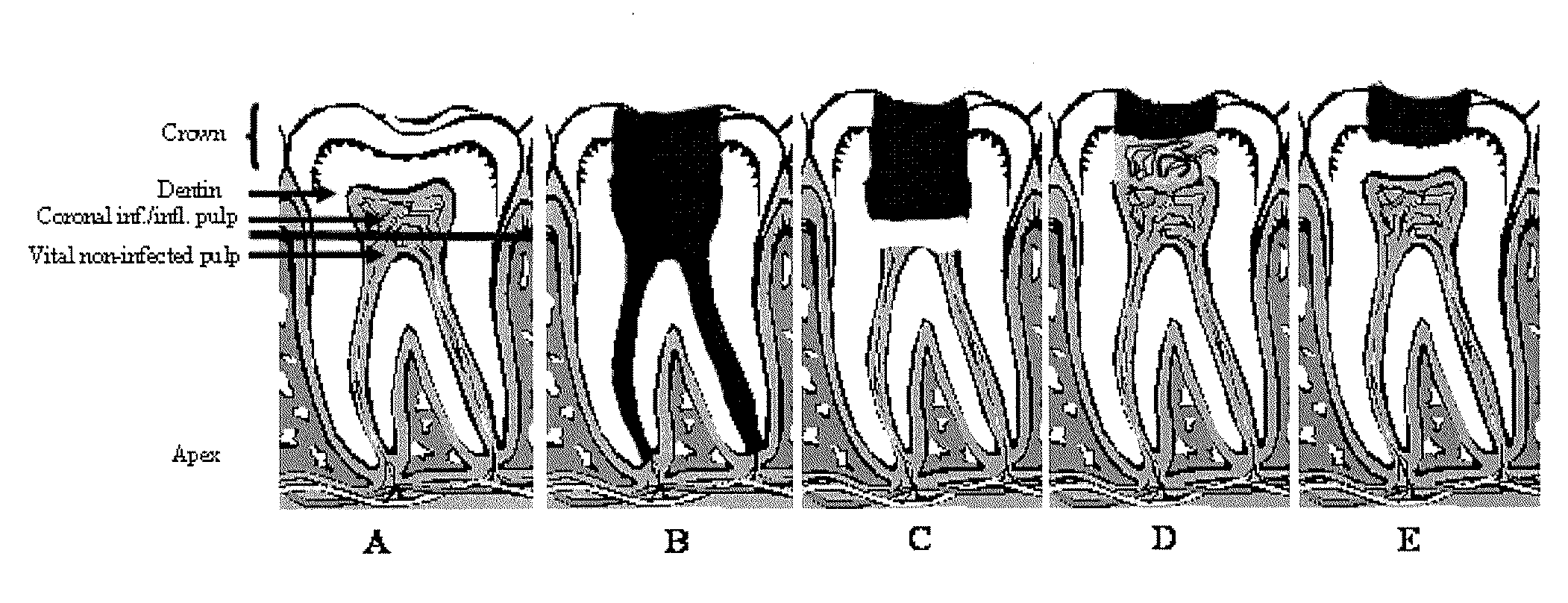

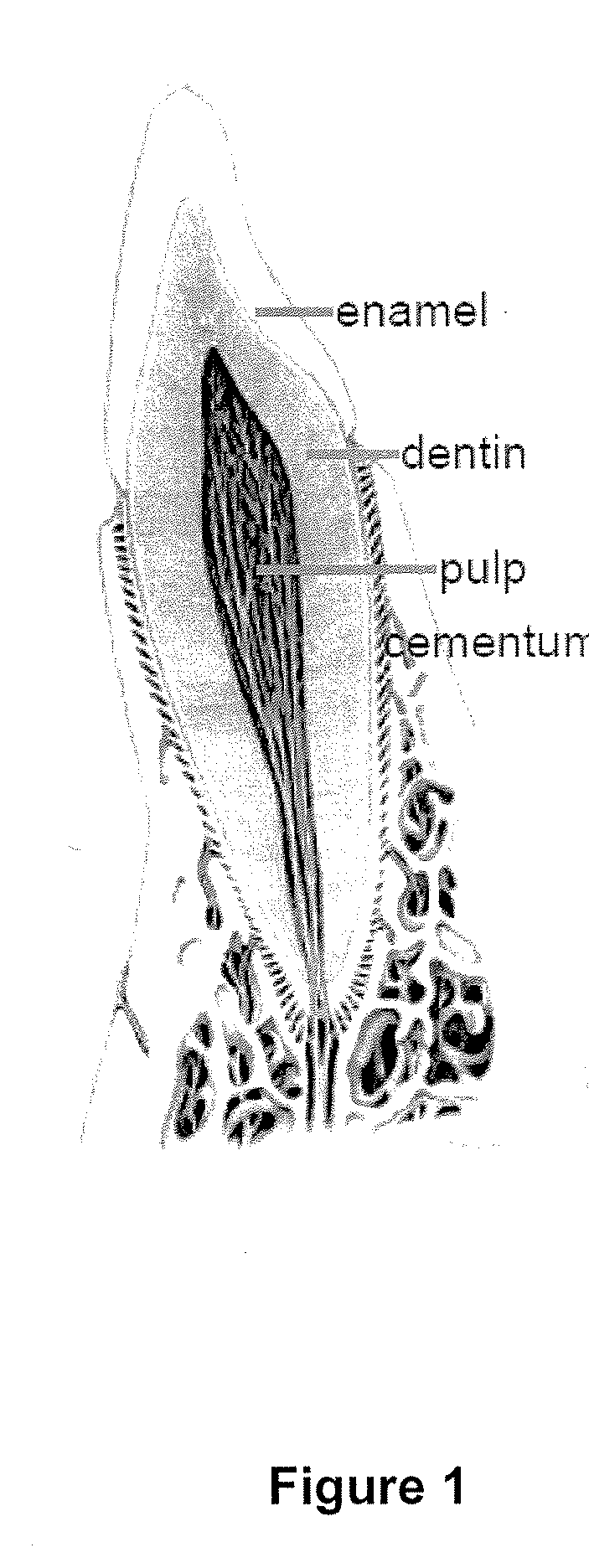

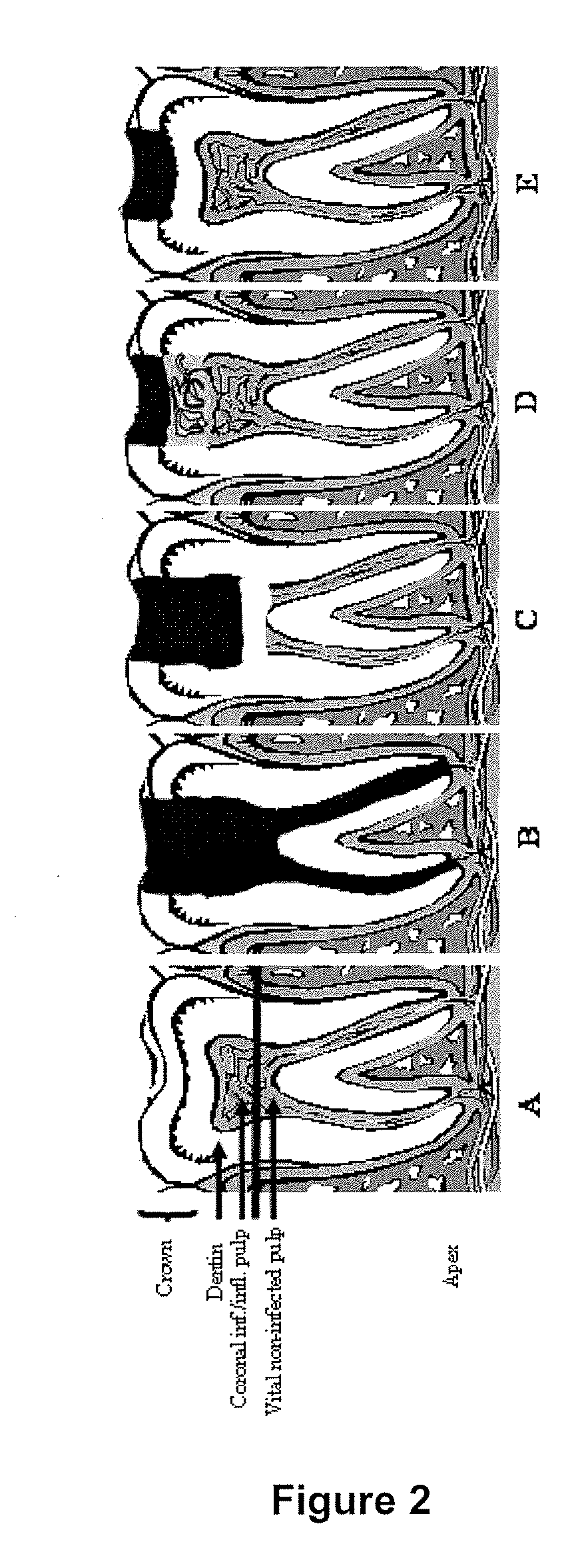

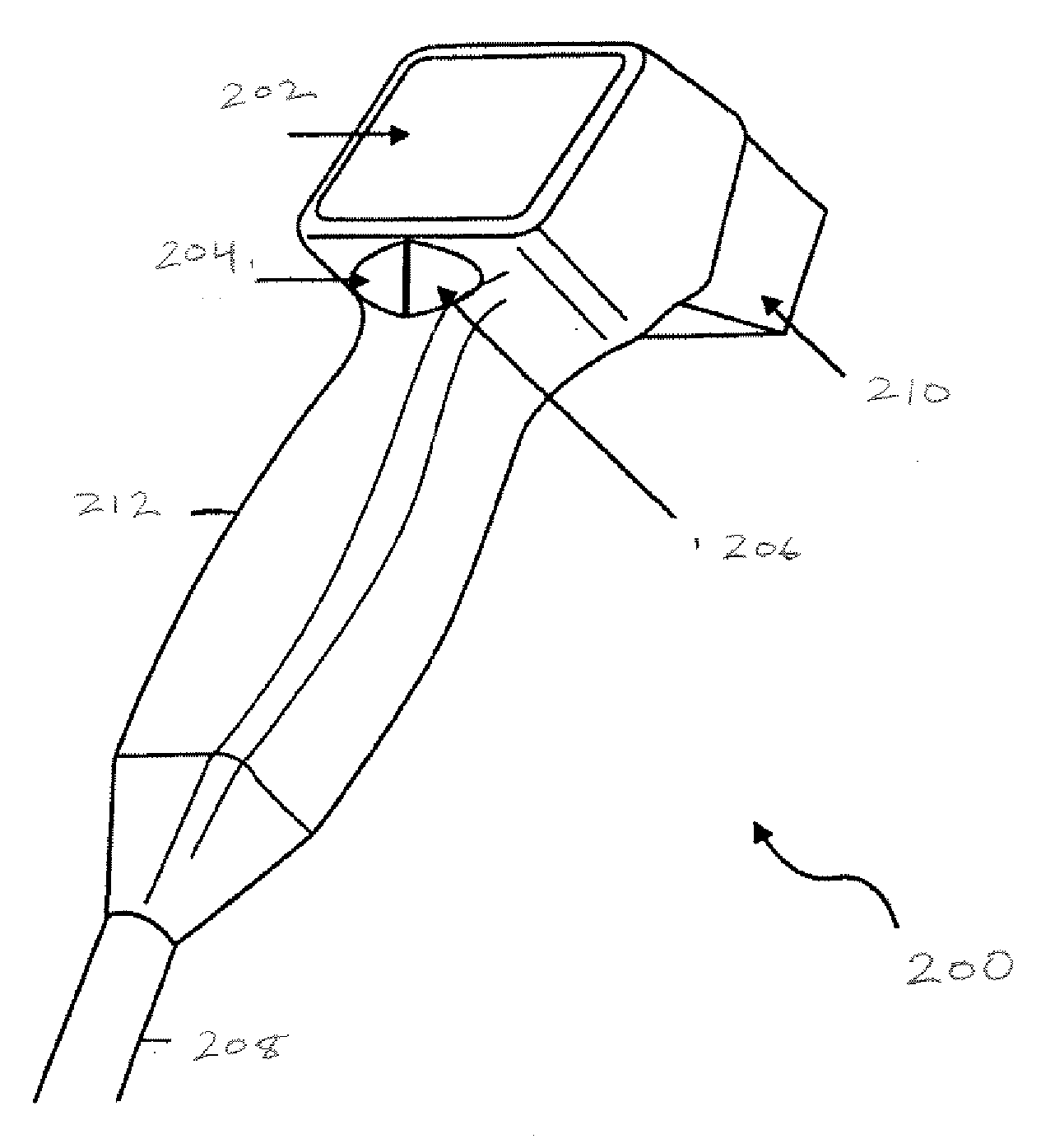

Compositions and methods for treating pulp inflammations caused by infection or trauma

The present disclosed subject matter relates to methods and compositions for restoring a diseased or damaged tooth such that infection is inhibited or eliminated and pulp regeneration is facilitated. The disclosed subject matter also includes a composition comprising a physiologically acceptable matrix seeded with pulp cells. The matrix can be capable of being injected into the pulp chamber of a tooth. In some embodiments, the matrix of a composition includes a hydrogel (e.g., collagen, chitosan, alginate, MATRIGEL™, gelatin, JELL-O®, fibrin), a mesh (e.g., polylactide-coglycolide (PLGA) mesh, polylactide (PLA) mesh, or polyglycolide (PGA) mesh, a cross-linked fiber mesh, a nanofiber mesh, a mesh fabric, biodegradable polymer mesh), a microsphere (biodegradable polymer microsphere, a hydrogel microsphere), or a combination of any of the foregoing. In yet other embodiments, the matrix includes a nanofiber, an artificial three-dimensional scaffold material, or a synthetic three-dimensional scaffold material.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20050065214A1Stimulate bone healing processLower potentialBiocidePowder deliveryBarium saltTG - Triglyceride

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

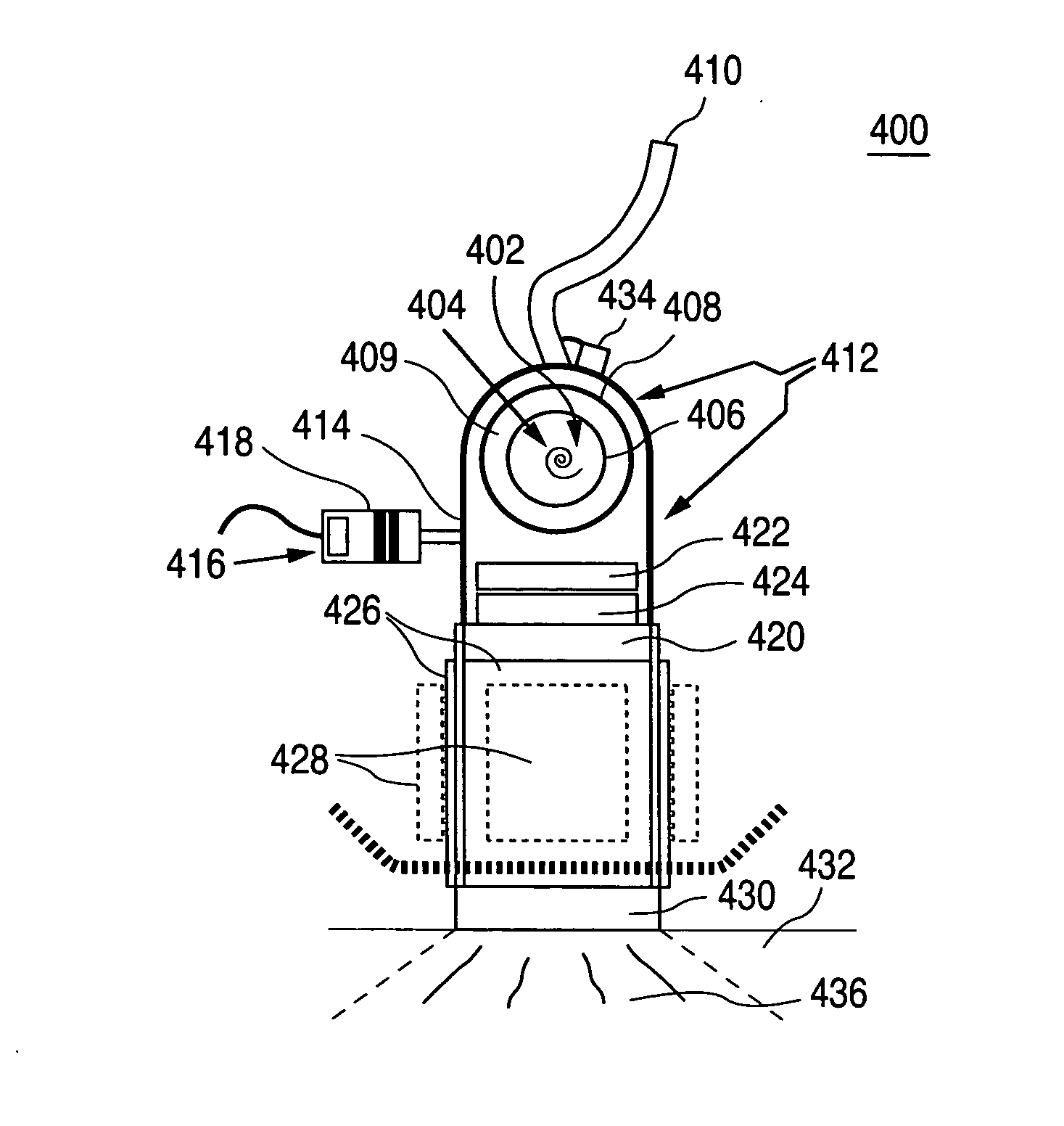

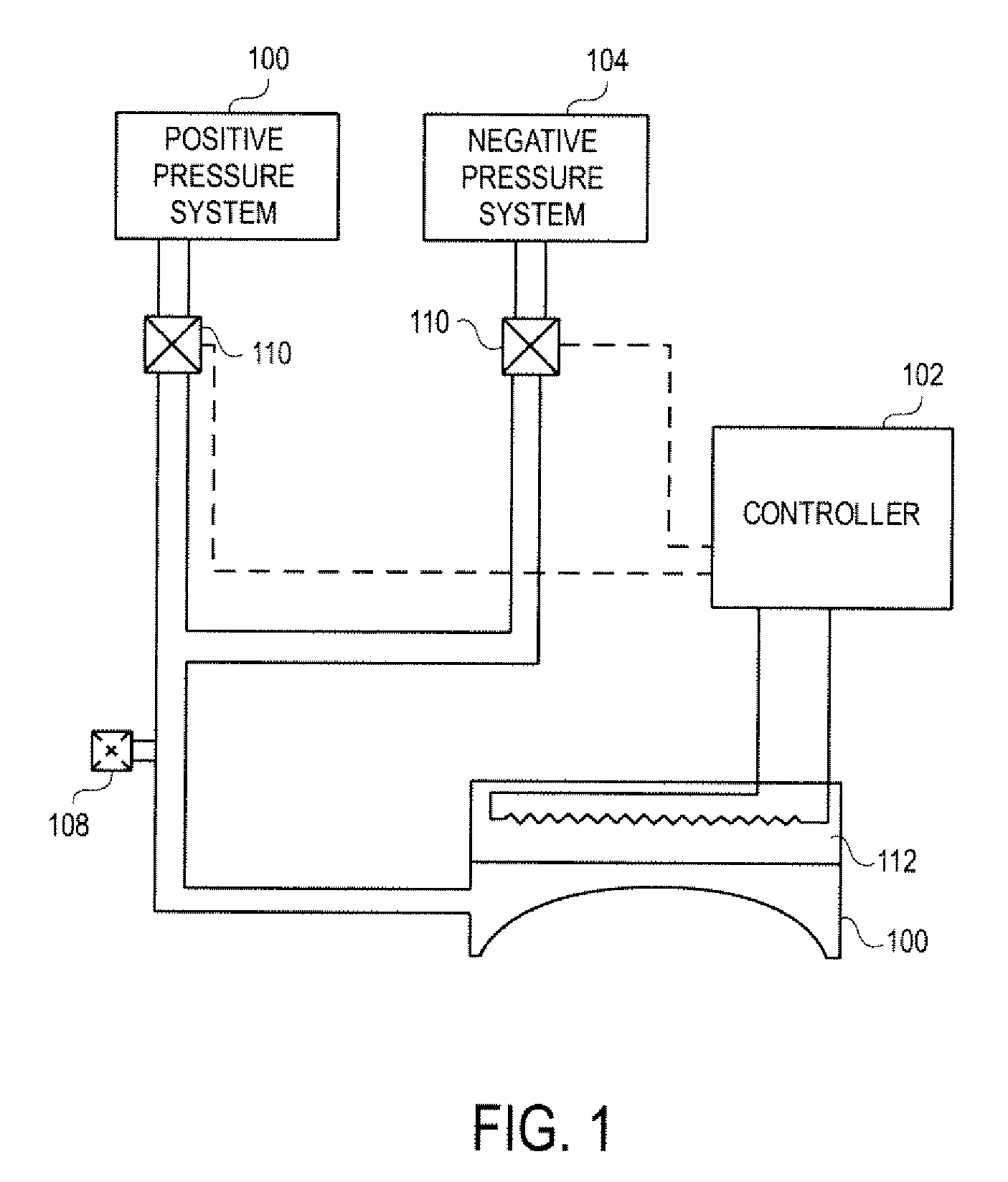

Methods and devices for applying energy to tissue

InactiveUS20090093864A1Surgical needlesSurgical instrument detailsBiomedical engineeringAdipose tissue

Methods, systems, and devices to treat a region of skin; the treatment may be used to stimulate the production of collagen or destroy adipose tissue. The region of skin is exposed to a uniform energy application or series of applications. The region of skin may be exposed to positive and negative pressures. Therapeutic substances may be applied to the region of skin.

Owner:AESTHERA CORP

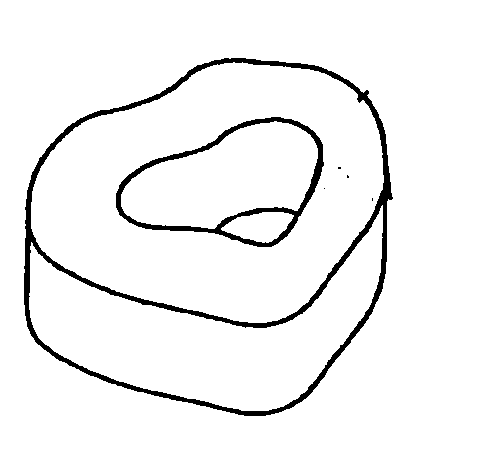

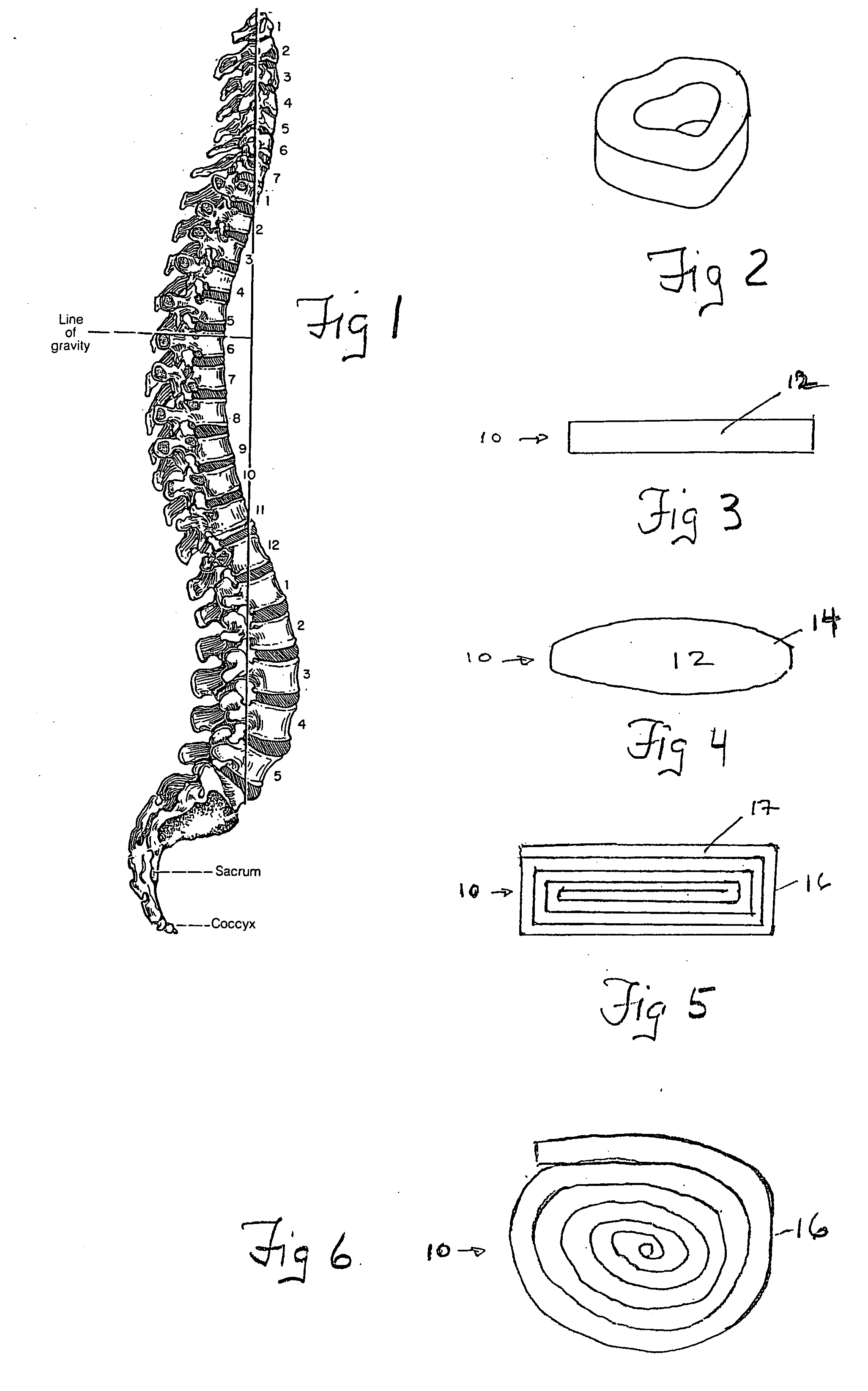

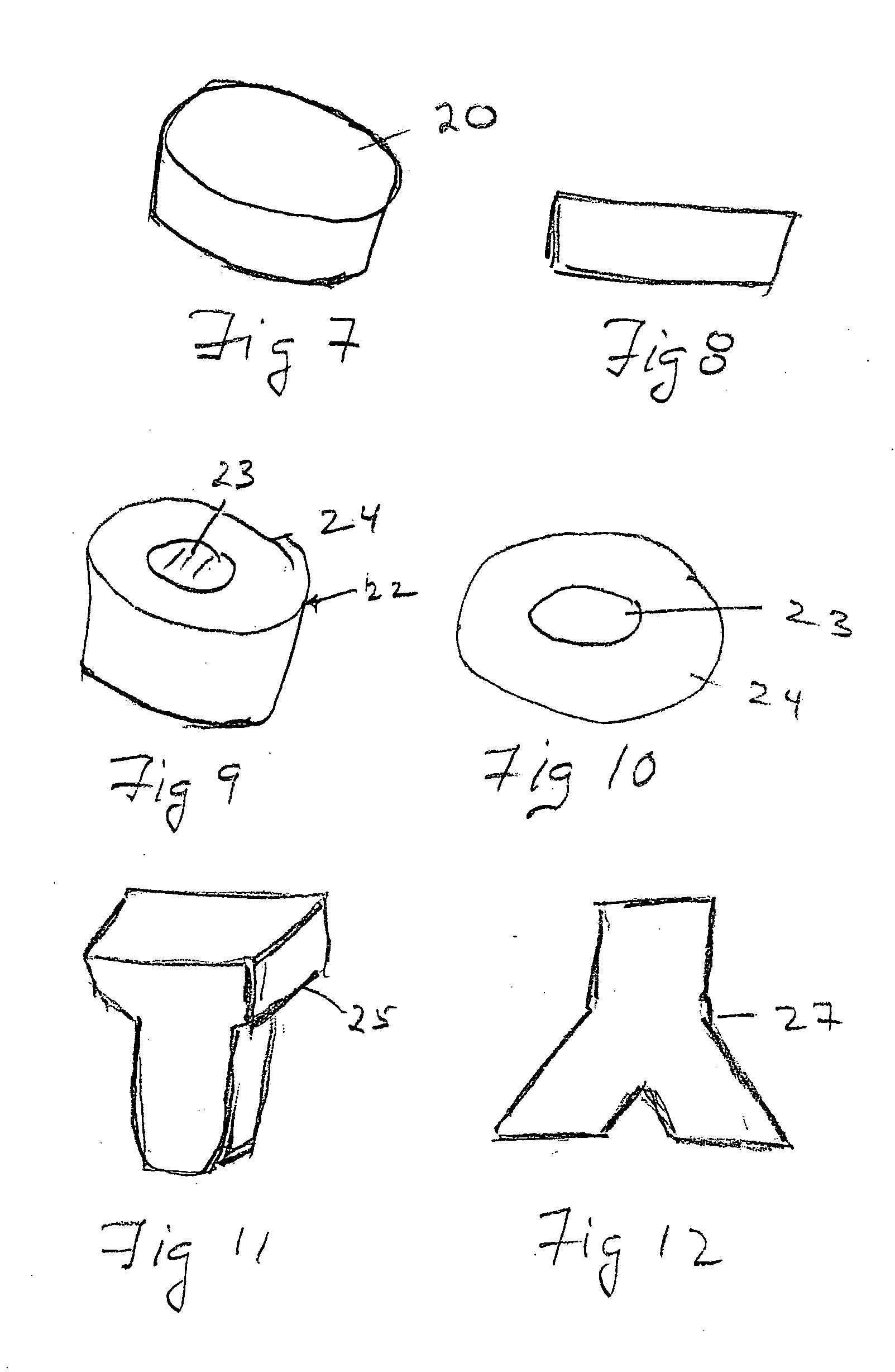

Vertebral disc repair

InactiveUS20060235534A1Eliminate osteoinductivitySuture equipmentsBone implantBone CortexCortical bone

A sterile implant for treatment of a spinal disc defect comprising an allograft cortical bone demineralized to a Type I collagen having a specific shape which is treated to eliminate osteoinductivity. The implant is lyophilized and compressed into smaller first shape which 20 to 80% from its original shape in at least one dimension and hardened. The implant expanding when hydrated into a second shape having the shape memory of the first shape and expanded in dimensional size from the first compressed shape.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Resorbable bone graft materials

Ceramic materials operable to repair a defect in bone of a human or animal subject comprising a porous ceramic scaffold having a bioresorbable coating, and a carrier comprising denatured demineralized bone. The ceramic may contain a material selected from the group consisting of hydroxyapatite, tricalcium phosphate, calcium phosphates, calcium carbonates, calcium sulfates, and combinations thereof. The compositions may also contain a bone material selected from the group consisting of: bone powder, bone chips, bone shavings, and combinations thereof. The bioresorbable coating may be, for example, demineralized bone matrix, gelatin, collagen, hyaluronic acid, chitosan, polyglycolic acid, polylactic acid, polypropylenefumarate, polyethylene glycol, or mixtures thereof.

Owner:BIOMET MFG CORP

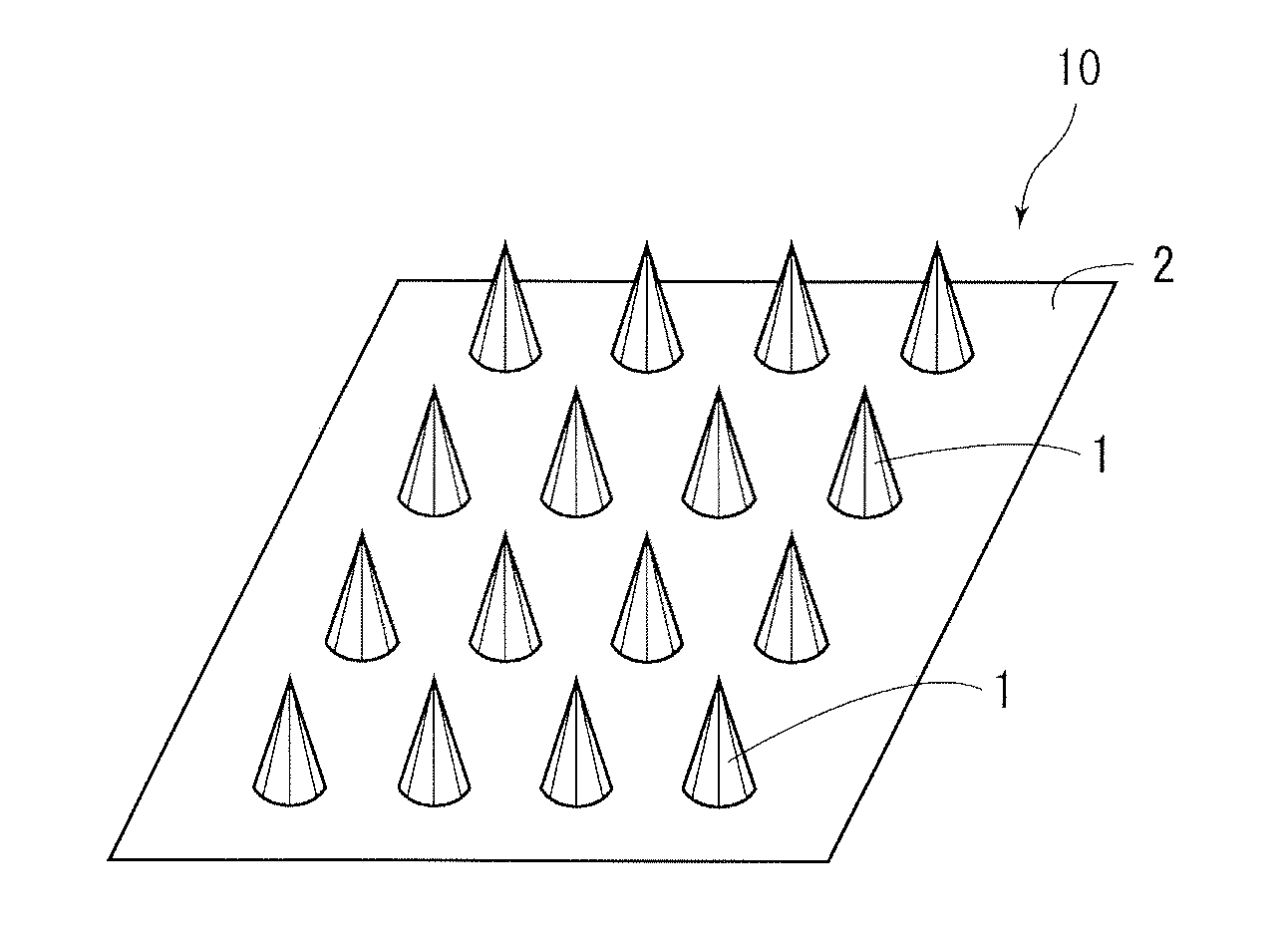

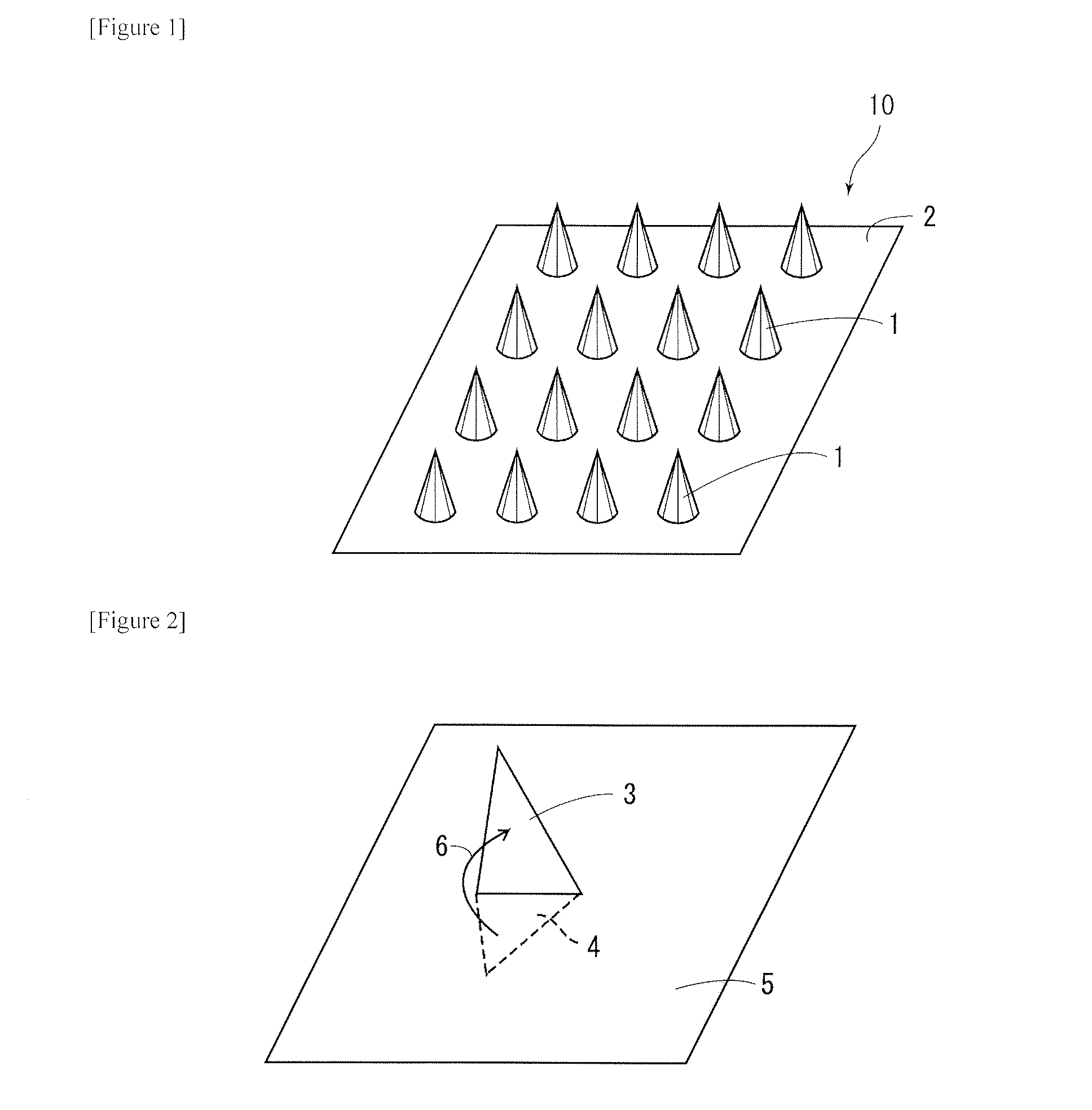

Microneedle device and method for producing the same

ActiveUS20100228203A1Quick closeNo pain or bleedingSuppositories deliveryMicroneedlesBiological materialsHyaluronic acid

Microneedle device is provided, which include microneedles that can be easily inserted into skin and dissolve or swell in skin. The microneedle devices comprise a substrate and cone-shaped or pyramid-shaped microneedles for skin insertion set on the substrate. The microneedles for skin insertion contain over 50 weight percent of one or multiple biomaterials chosen from chitosan, collagen, gelatin, hyaluronic acid, and they are fabricated from the materials that can dissolve or swell in the body.

Owner:COSMED PHARMA

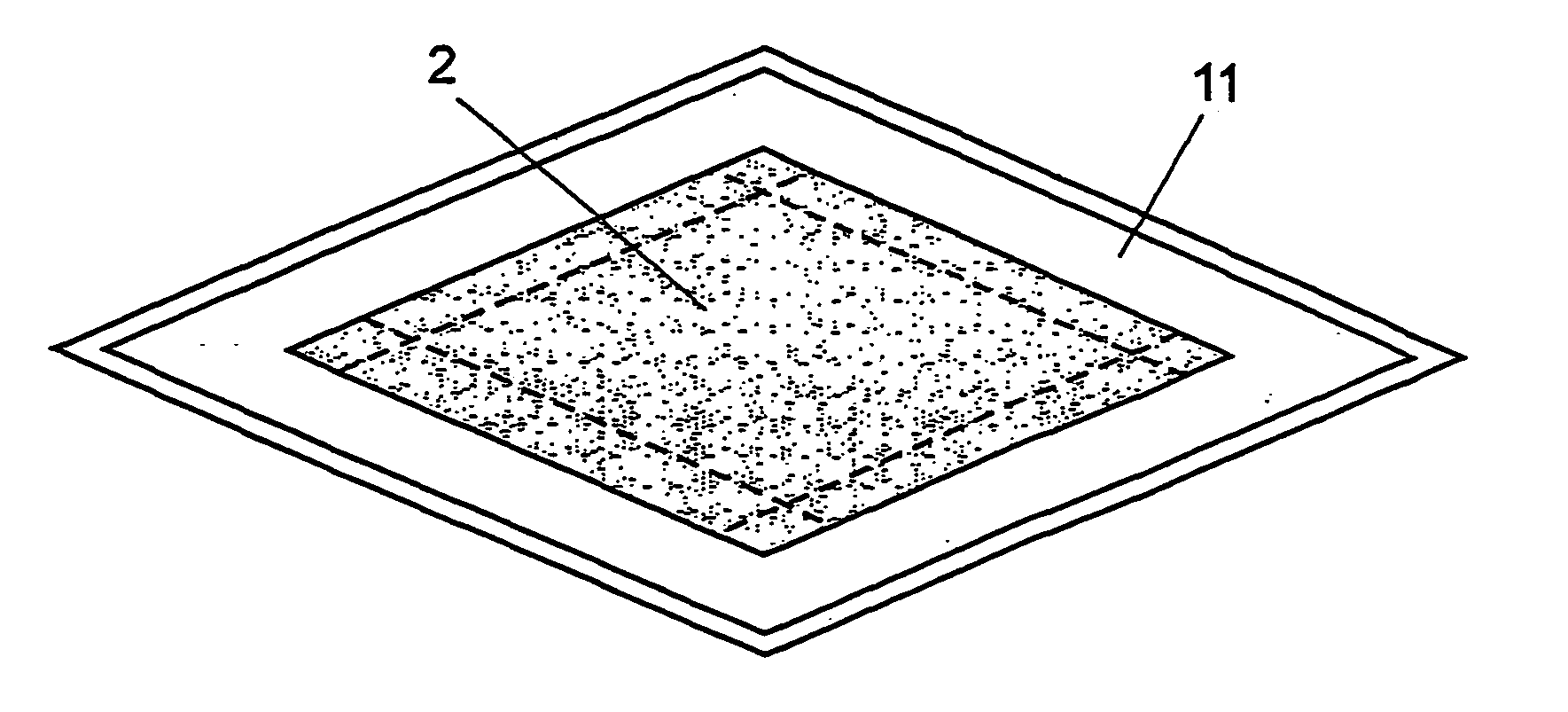

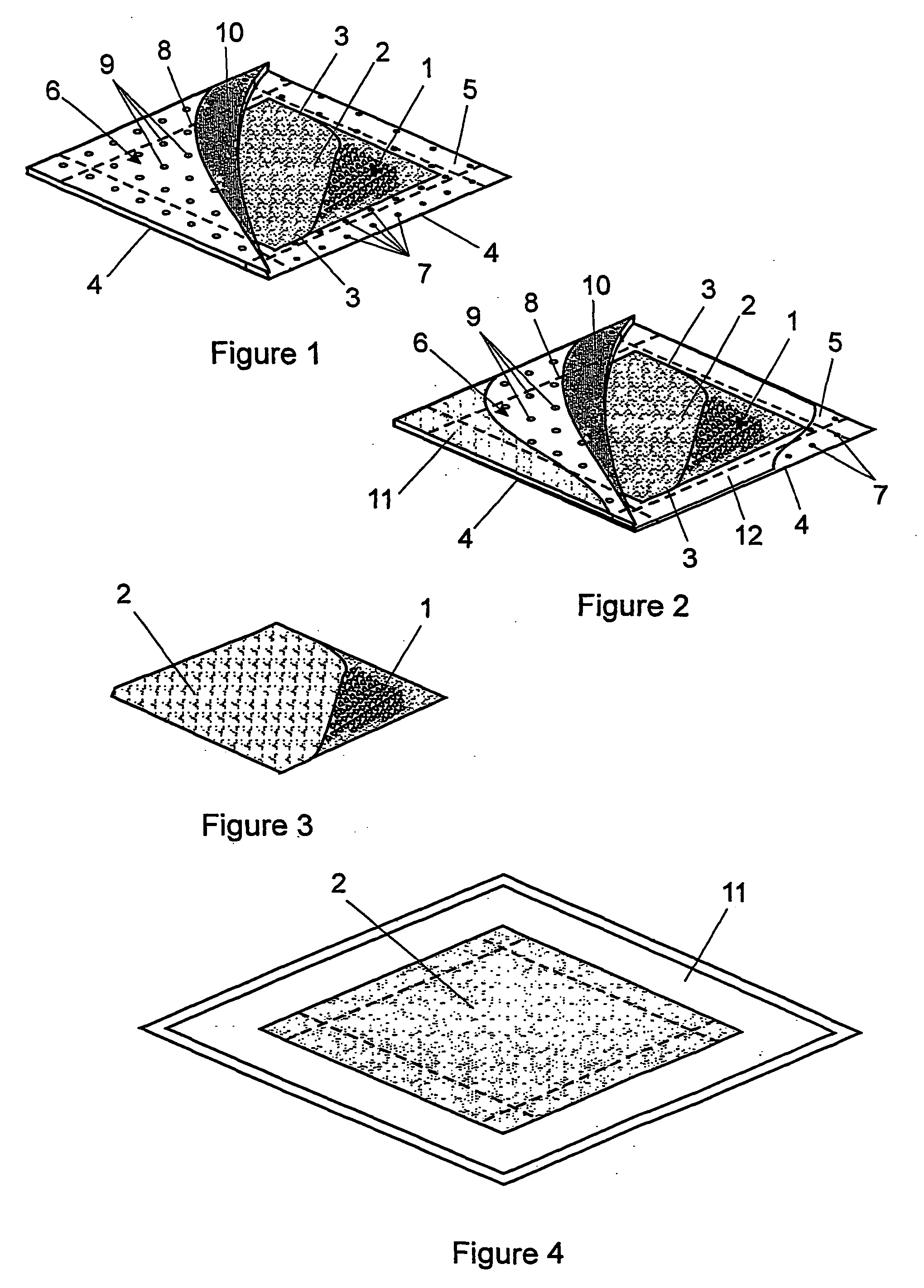

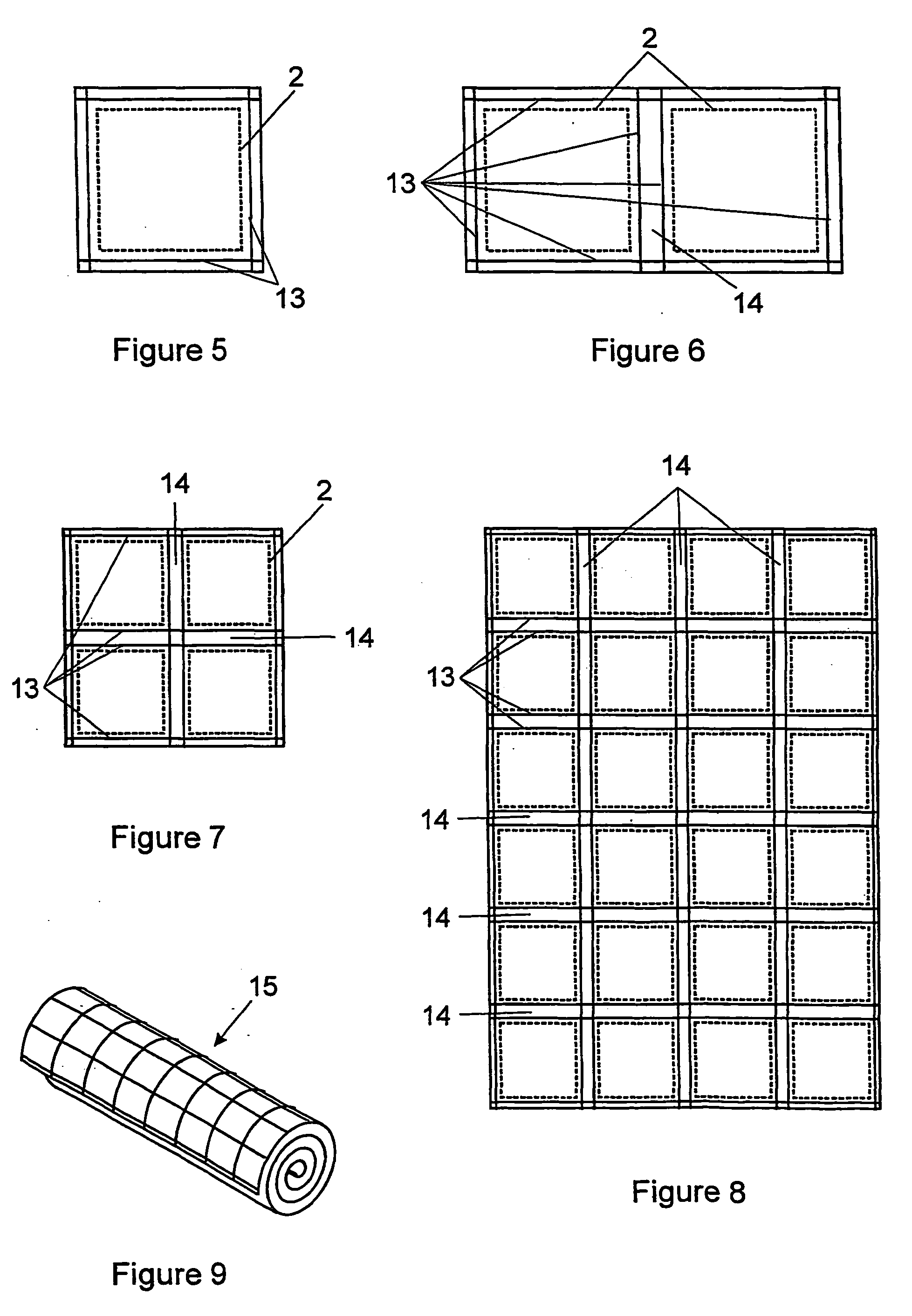

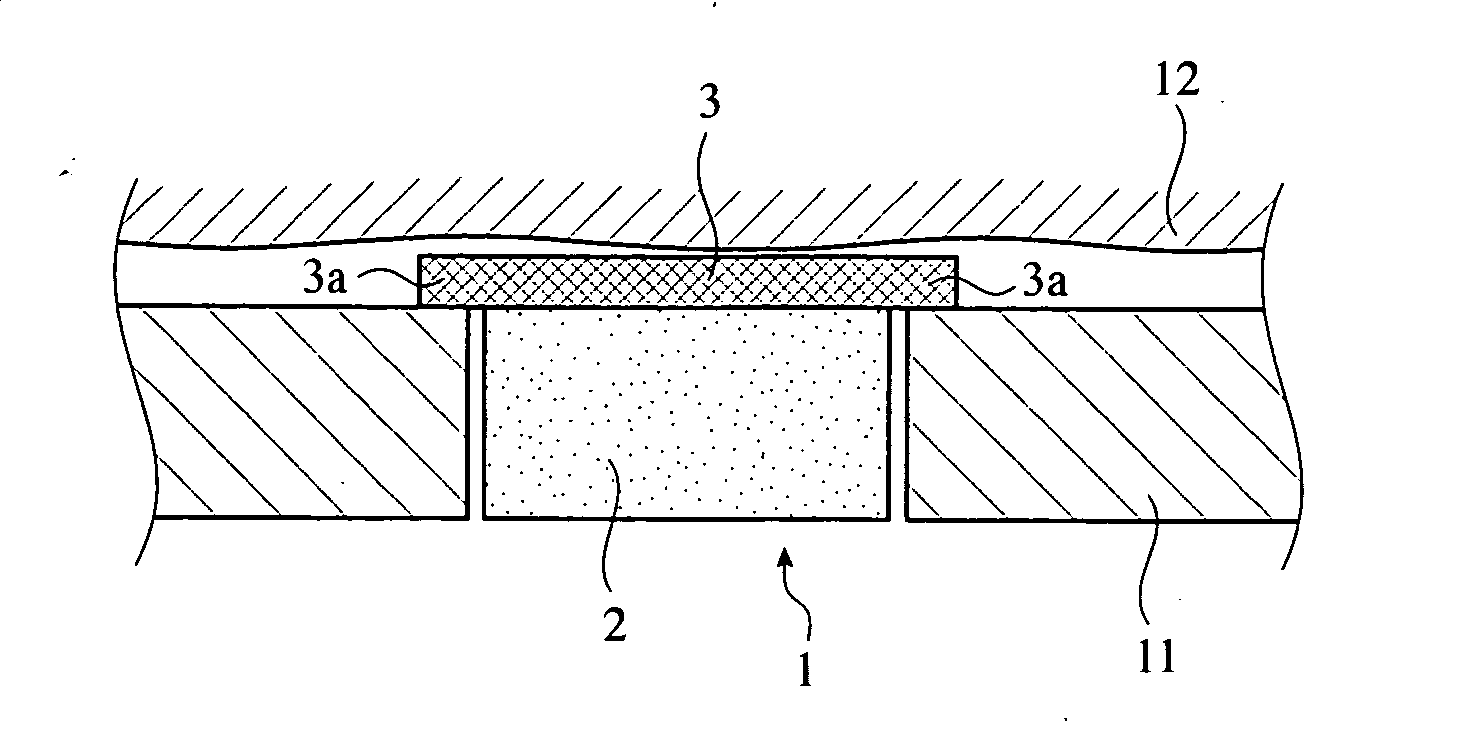

Wound dressings and wound treatment compositions

InactiveUS20040138601A1Facilitated releaseMitigate such drawbackNon-adhesive dressingsPlastersWound dressingSilicon dioxide

A wound dressing is provided comprising a wound treatment composition (1) including at least one absorbent or adsorbent compound contained within a sheath having an operatively inner and an operatively outer wall (5, and 6 respectively). The wound dressing is characterized in that the surface of the operatively inner wall that is to contact a wound in use is a substantially smooth continuous surface, conveniently of a plastic inner wall, selected for easy release from a wound. The inner wall is perforated (7) to enable exudate or slough to pass therethrough. The invention also provides a wound treatment composition characterized in that it comprises, in combination, an adsorbent material, preferably silica, for adsorbing moisture on or around a wound; and, a collagen, conveniently gelatin.

Owner:CHALMERS SUSANNA ELIZABETH

Method of treating cellulite

ActiveUS20070073367A1Reduce fatImprove loose skinSurgical instrument detailsLight therapyThermal injuryCollagenan

A treatment for subcutaneous fat and / or cellulite includes delivering a beam of radiation to a subcutaneous fat region disposed relative to a dermal interface in a target region of skin. The beam of radiation affects at least one fat cell in the subcutaneous fat region without causing substantial unwanted injury to the epidermal region and causes thermal injury to a dermal region to induce collagen formation to strengthen the target region of skin in a target region of skin. The treatment can include cooling an epidermal region of the target region of skin.

Owner:CANDELA CORP

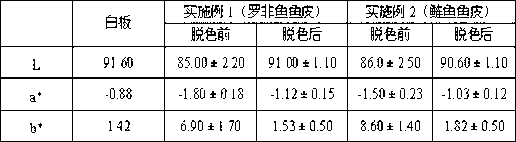

Industry method of producing fish collagen peptide from fish skin and bone by an enzyme method

ActiveCN101061827ASimple processShorten the production cycleAnimal proteins working-upComplex proteinFish products

The invention discloses a special method to extract collagen from fish peel and bone with complex prolease, which comprises the following steps: choosing salmon, AnKang fish peel and processing waste of fish product as raw material; unfreezing; washing; scaling off; degreasing; grinding; enzymolyzing; separating; de-oiling; ultra filtering; condensing; spray-drying; getting the product. This invention possesses simple craft and short production circle.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +1

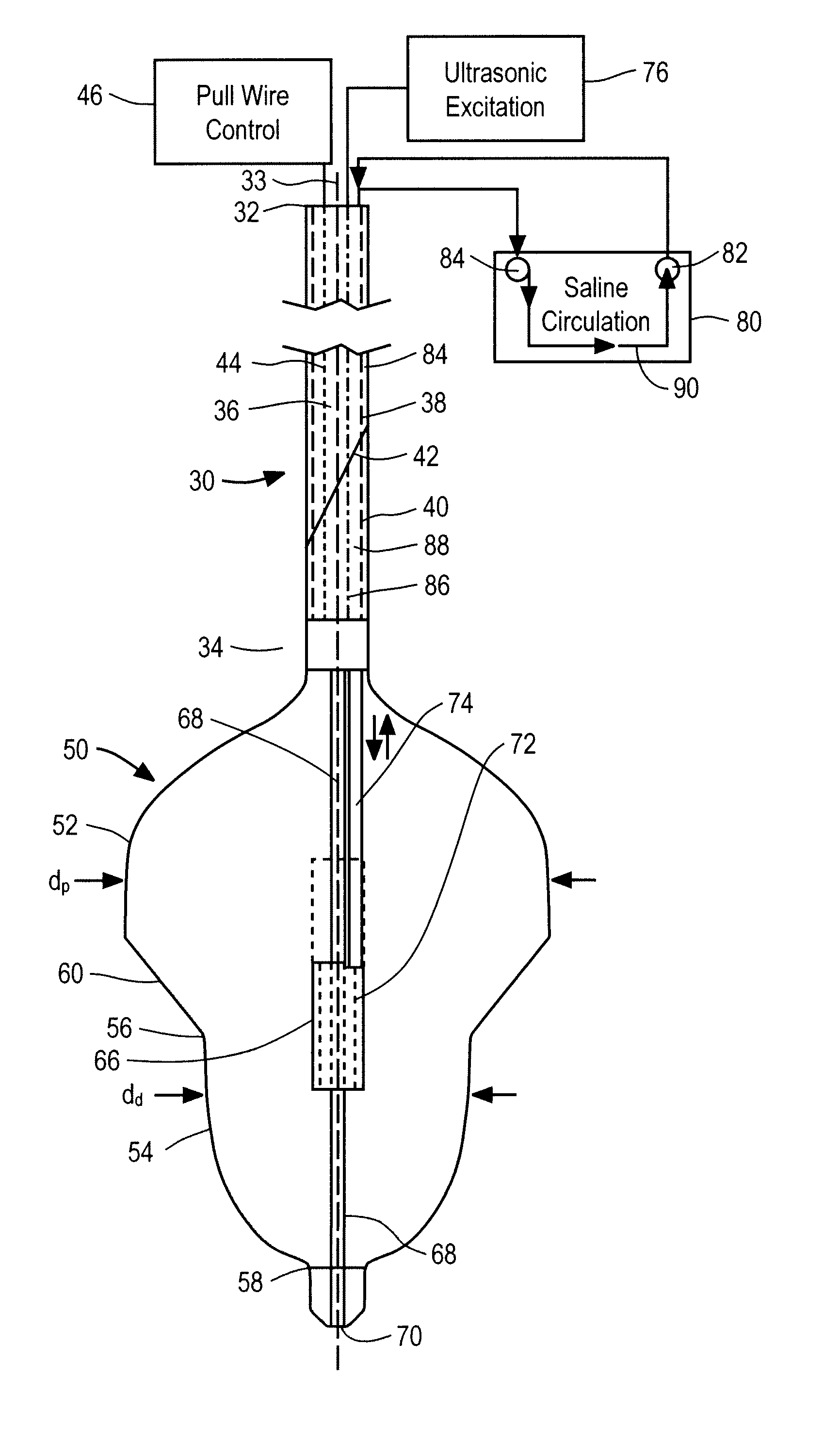

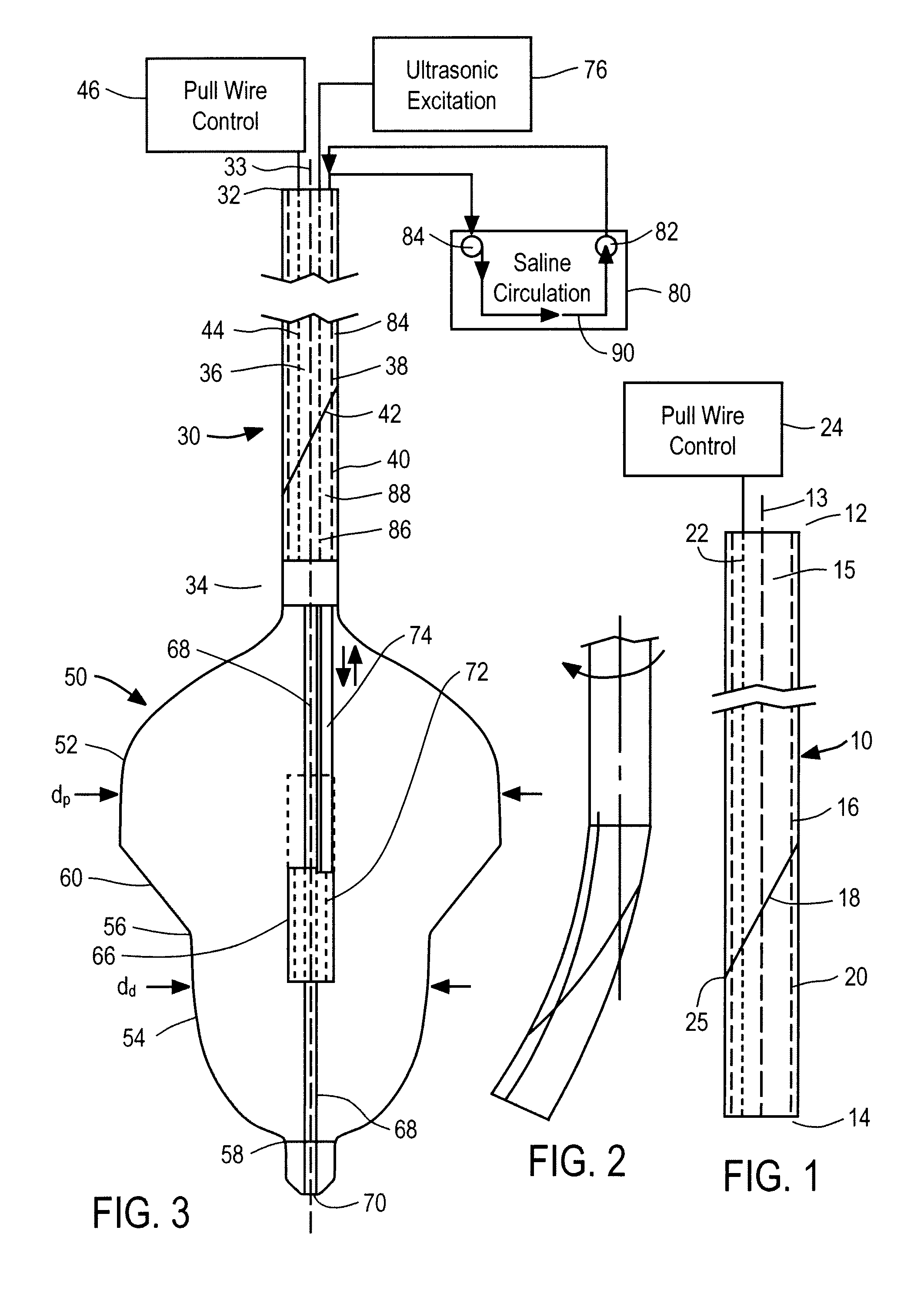

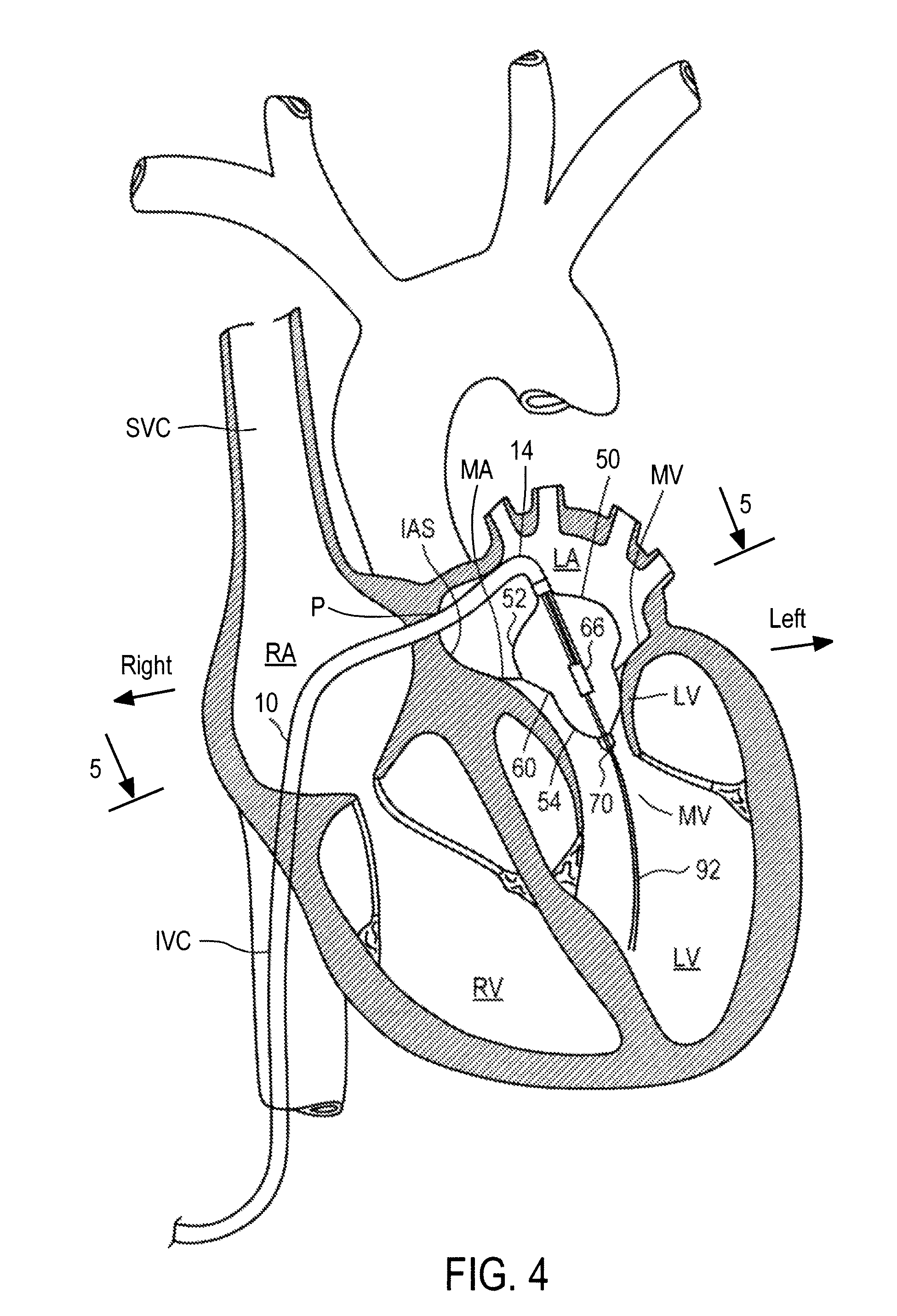

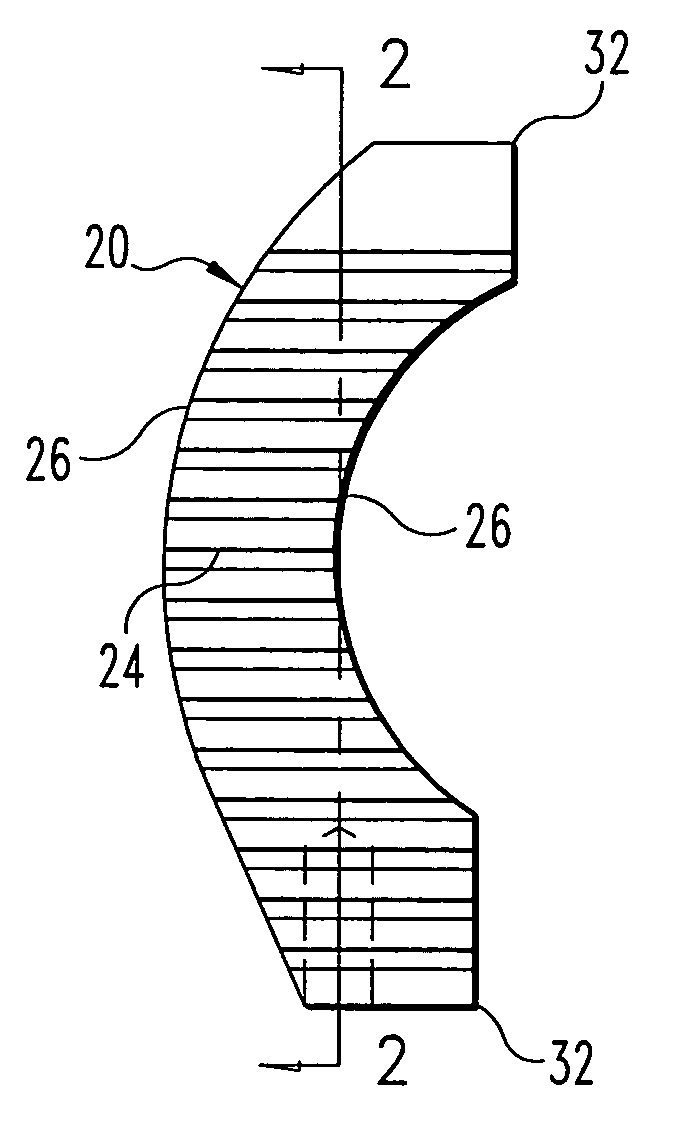

Methods and apparatus for treatment of cardiac valve insufficiency

ActiveUS8974445B2Prone to feverSimple and reliable processUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorEngineering

Mitral valve insufficiency is treated by introducing an expansible device such as a balloon bearing an ultrasonic transducer into the heart so that the transducer is positioned adjacent the mitral annulus but spaced from the mitral annulus, and actuating the transducer to heat the mitral annulus, denature collagen in the annulus and thereby shrink the annulus.

Owner:RECOR MEDICAL INC

Compositions for regenerating tissue that has deteriorated, and methods for using such compositions

InactiveUS6878383B2Promote tissue regenerationPrevent emergenceBiocideImpression capsDiseaseFibroblast

The invention provides a composition for promoting regeneration of tissue which has degenerated in a subject as a result of a disease or disorder and a method of using the composition is provided. The composition comprises a biodegradable acellular matrix, and passaged autologous fibroblasts substantially free of immunogenic proteins, e.g., culture medium serum-derived proteins, integrated within the matrix. Also provided is an injectable composition comprising an acellular filler material (e.g., any type of collagen) and passaged autologous fibroblasts substantially free of immunogenic proteins, e.g., culture medium serum-derived proteins, for correcting defects in skin, such as wrinkles or scars, and for augmenting tissue in the subject, particularly facial tissue.

Owner:CASTLE CREEK BIOSCIENCES LLC

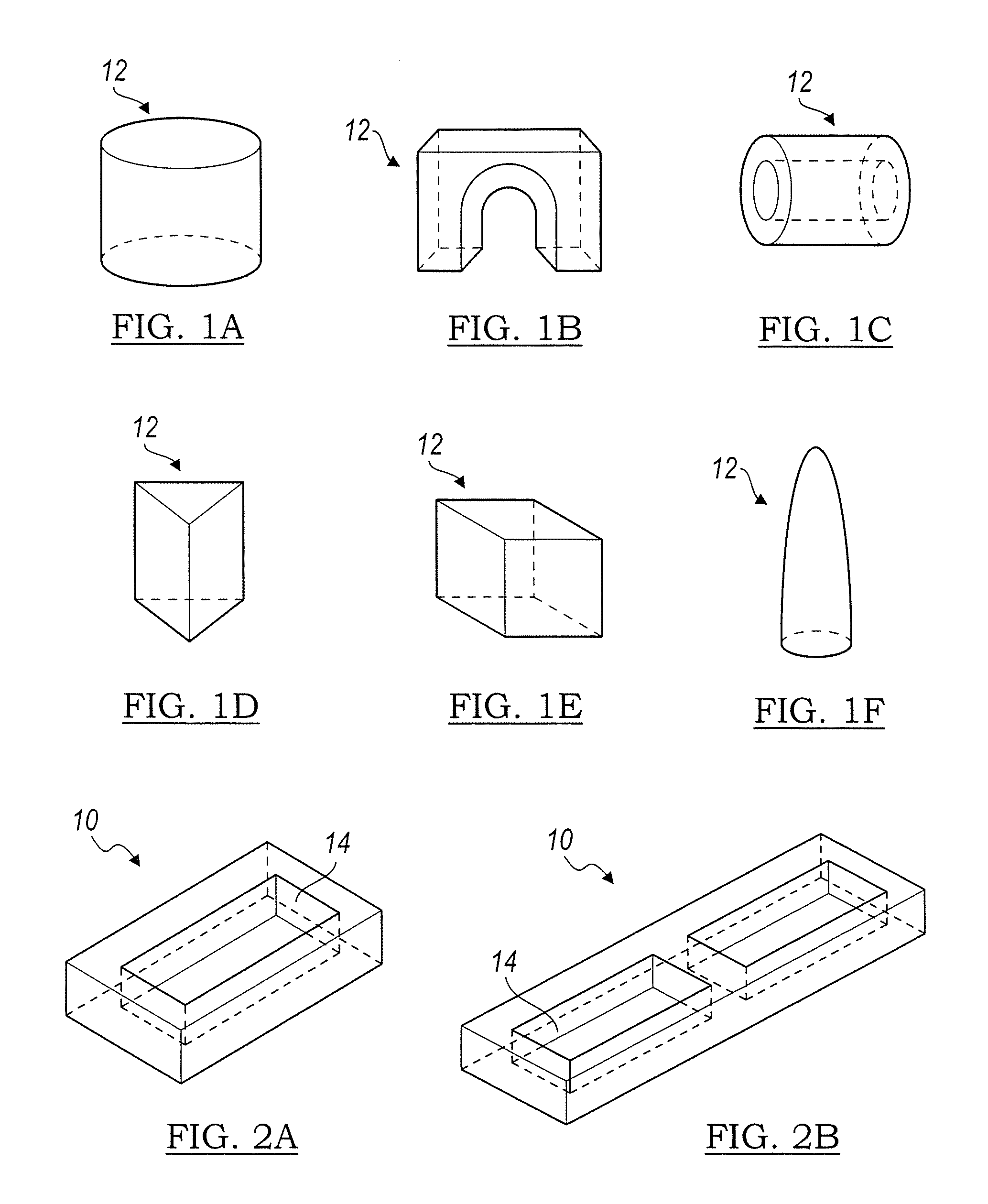

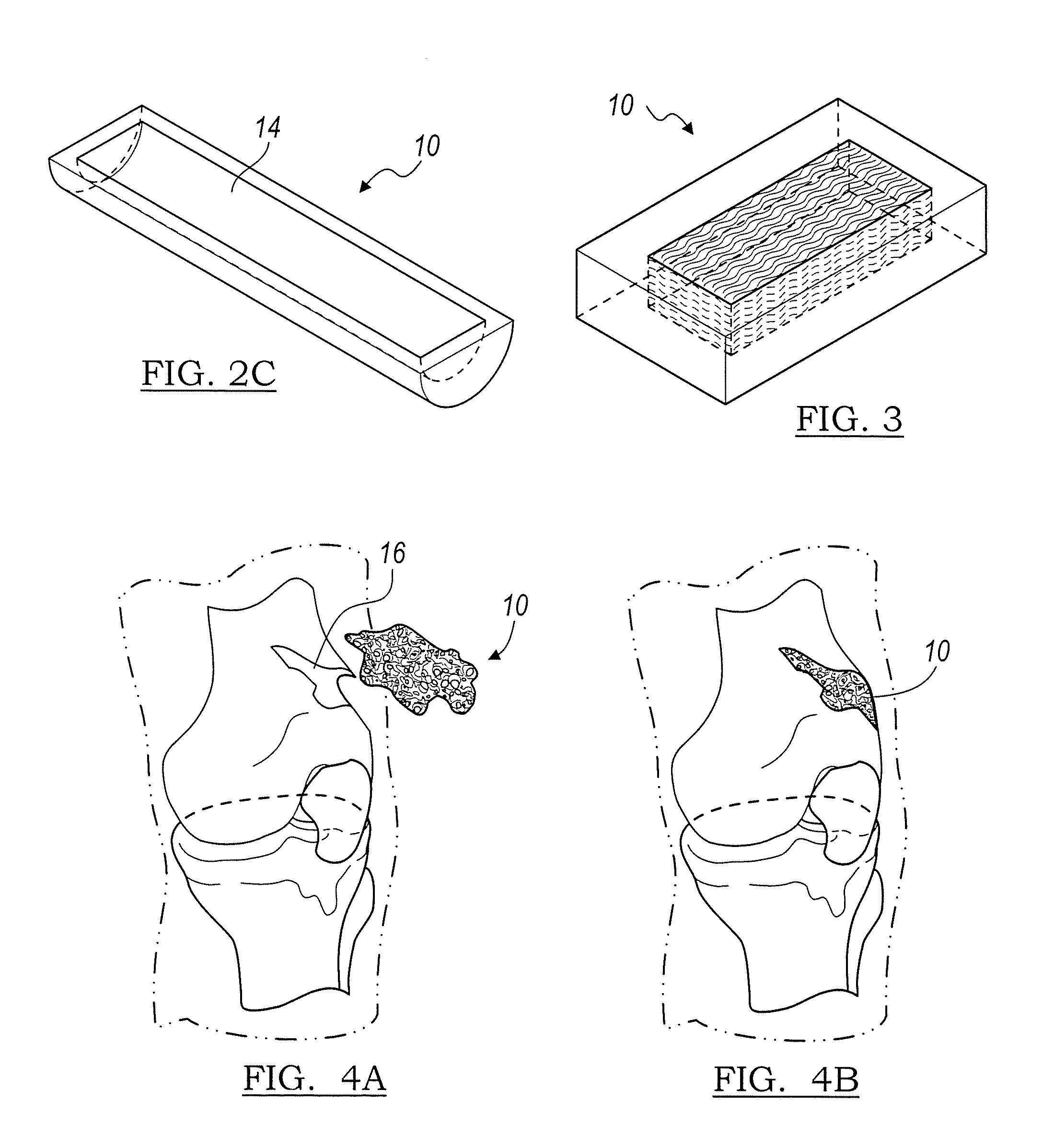

Synthetic loadbearing collagen-mineral composites useful for spinal implants, and methods of manufacture

Described are intervertebral spinal implants that include a biocompatible load bearing composite comprised of a particulate mineral material and collagen and having a wet compressive strength of at least about 200 N / cm2. The composite provides a load bearing body sized and shaped for insertion between adjacent vertebrae in a patient. The load bearing body has upper and lower surfaces configured to frictionally engage the adjacent vertebra. Also described are related methods of making and using the spinal implants, and other bone implants comprising the strong composites made available in the present invention.

Owner:SDGI HLDG

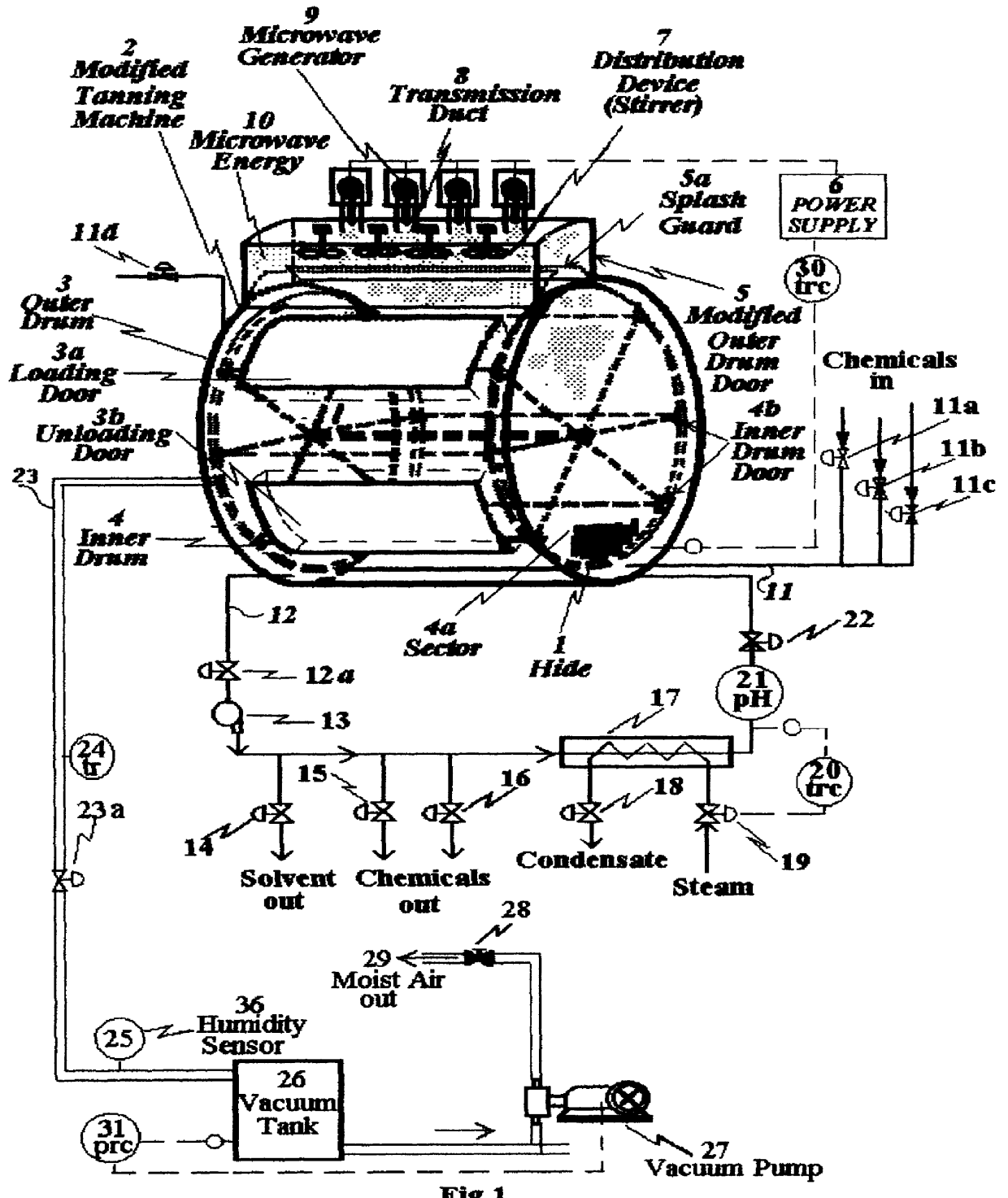

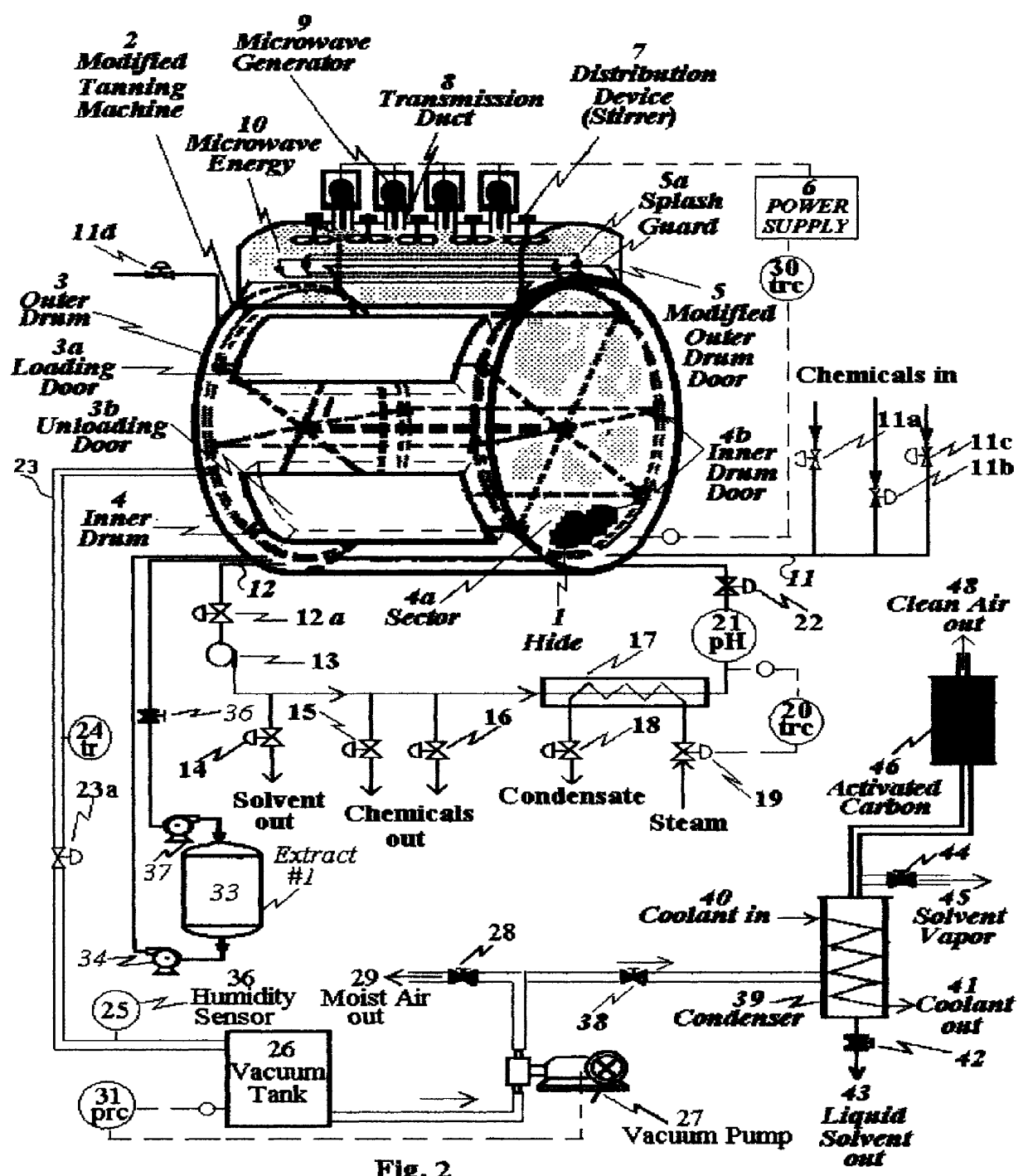

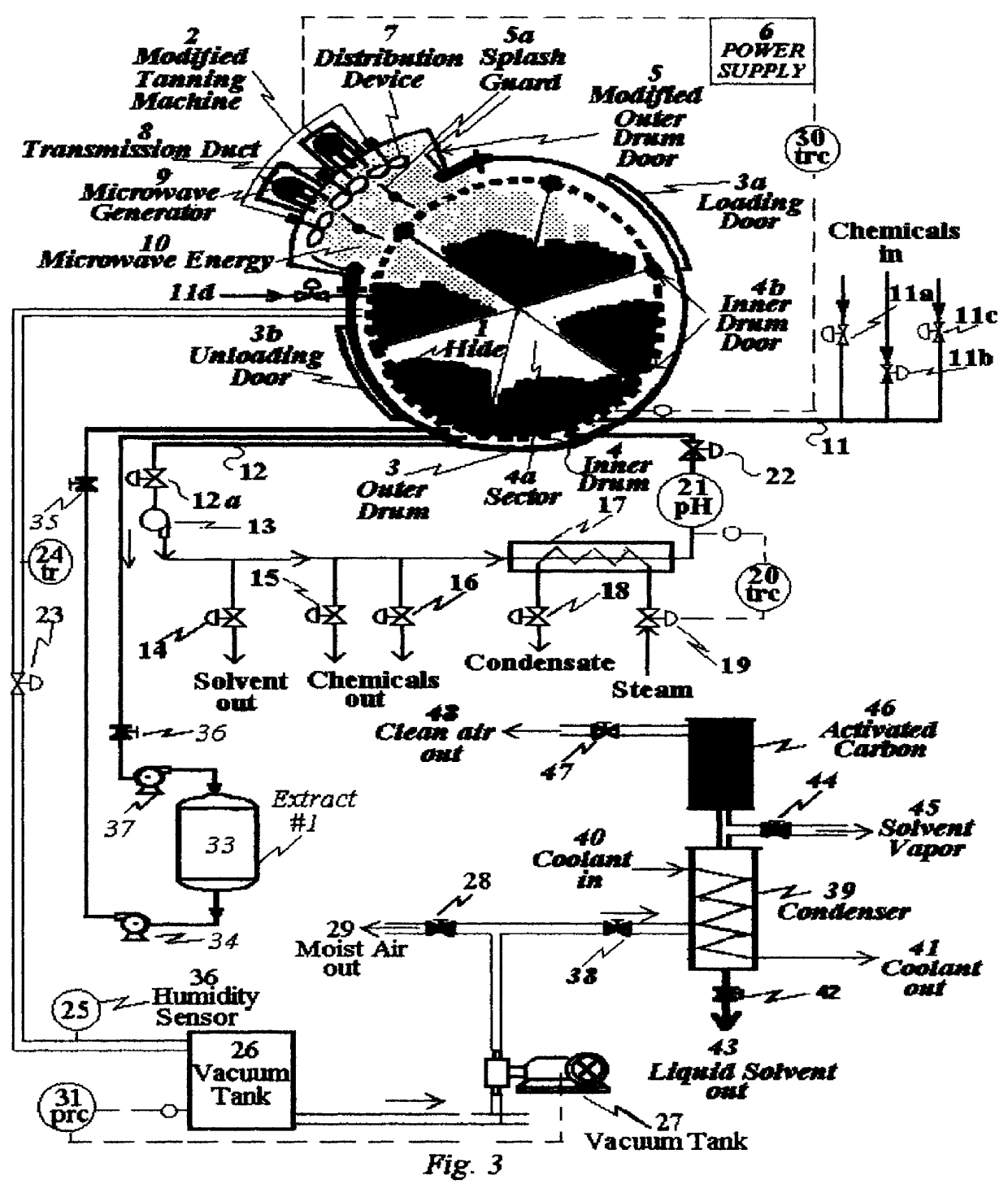

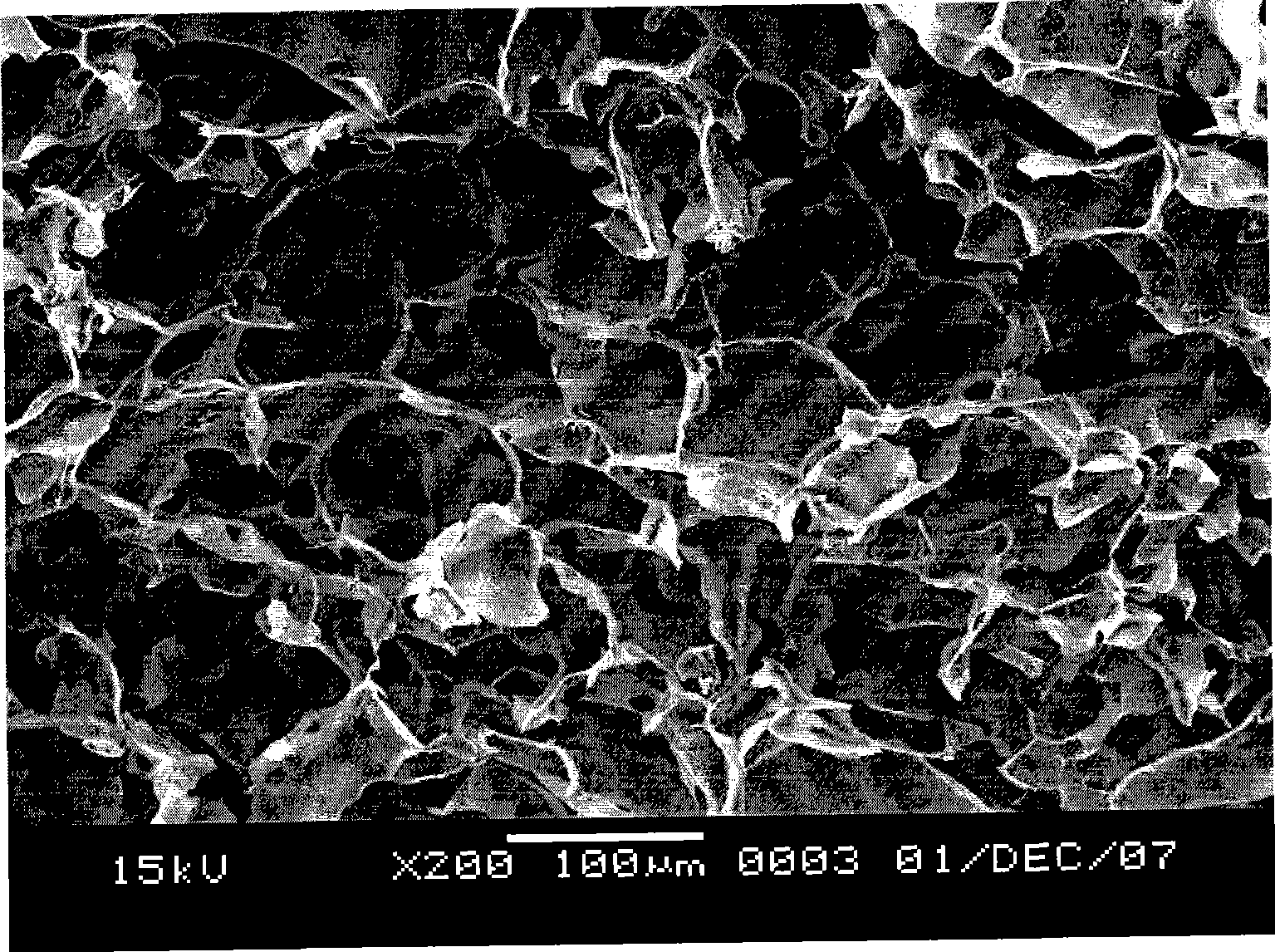

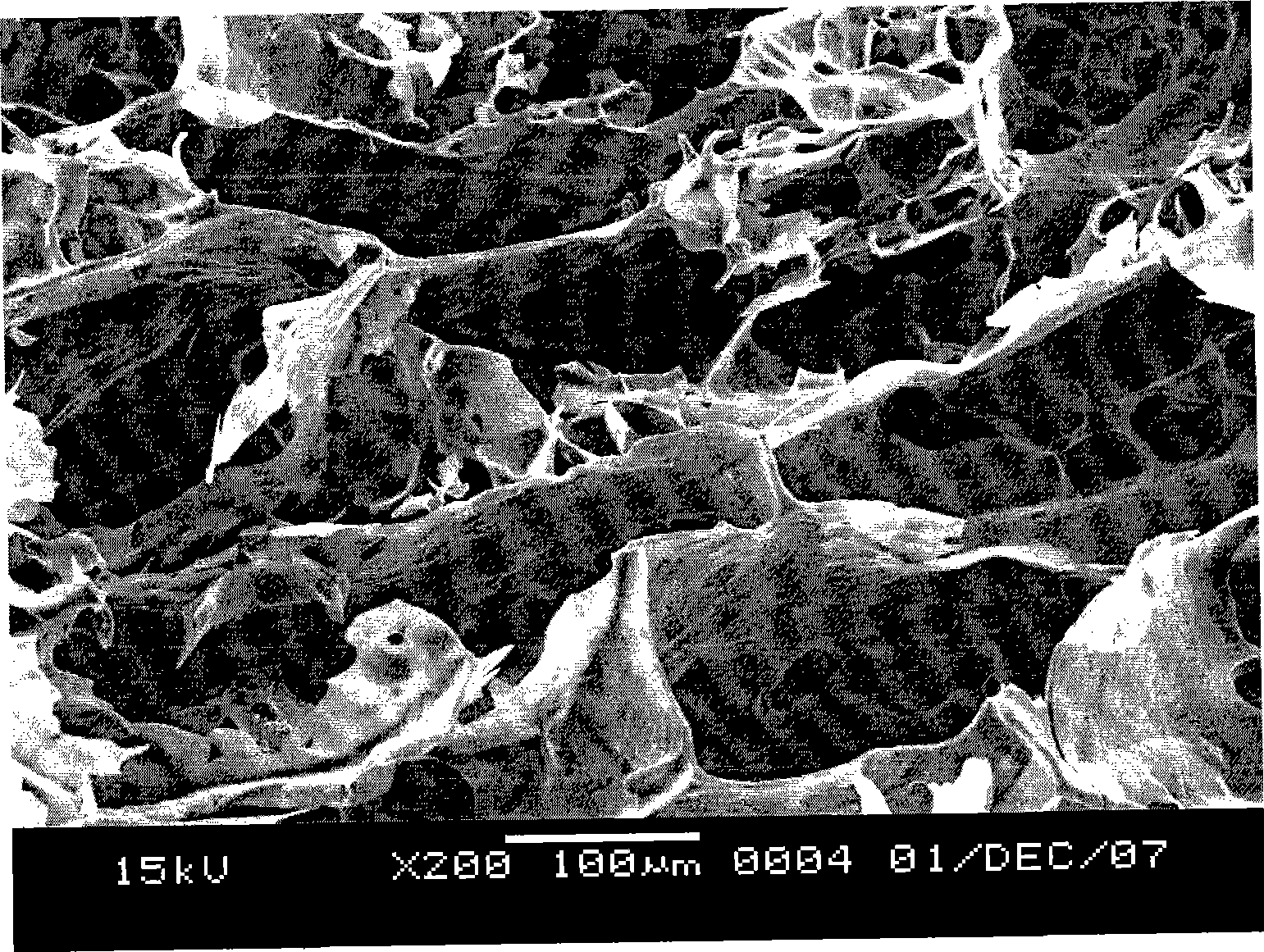

Microwave drying of hides under vacuum in tanning equipment

InactiveUS6092301AHigh market valueQuality improvementDrying solid materials with heatDrying solid materials without heatWater contentSolvent

By providing a hide processor or tanning drum with appropriate equipment for applying vacuum and microwave energy concurrently, these tanning machines become a versatile means of drying to yield dry hides that contain no salt yet store better than salted hides. In this novel process, fresh hides are loaded into the tanning machine where they are washed, demanured and then dried in situ under vacuum with concomitant application of microwave energy. Because the dried hides thus obtained are soft and pliable, they can be mechanically fleshed or shaved to remove the subcutaneous tissues rich in collagen and fat. Alternatively, the hides may be first dried in the tanning machine to below 35% moisture content and degreased using a solvent such as hexane. The solvent remaining in the hides after decantation of the unabsorbed liquid is vaporized at low temperature using vacuum and microwave energy. The hides are then dried in situ to the desired final moisture content. By shaving off the subcutaneous tissues of these hides a dry, fat-free, valuable undenatured collagen product is obtained. If the hides are unhaired before drying, they may be shaved and then accurately split. The process is also suitable for removing hair and fat from hide trimmings to obtain a valuable undenatured collagen product and fat. Furthermore, it can be used to remove fat from connective tissues and other animal offal containing no hair yielding a dry undenatured collagen product.

Owner:KOMANOWSKY MICHAEL

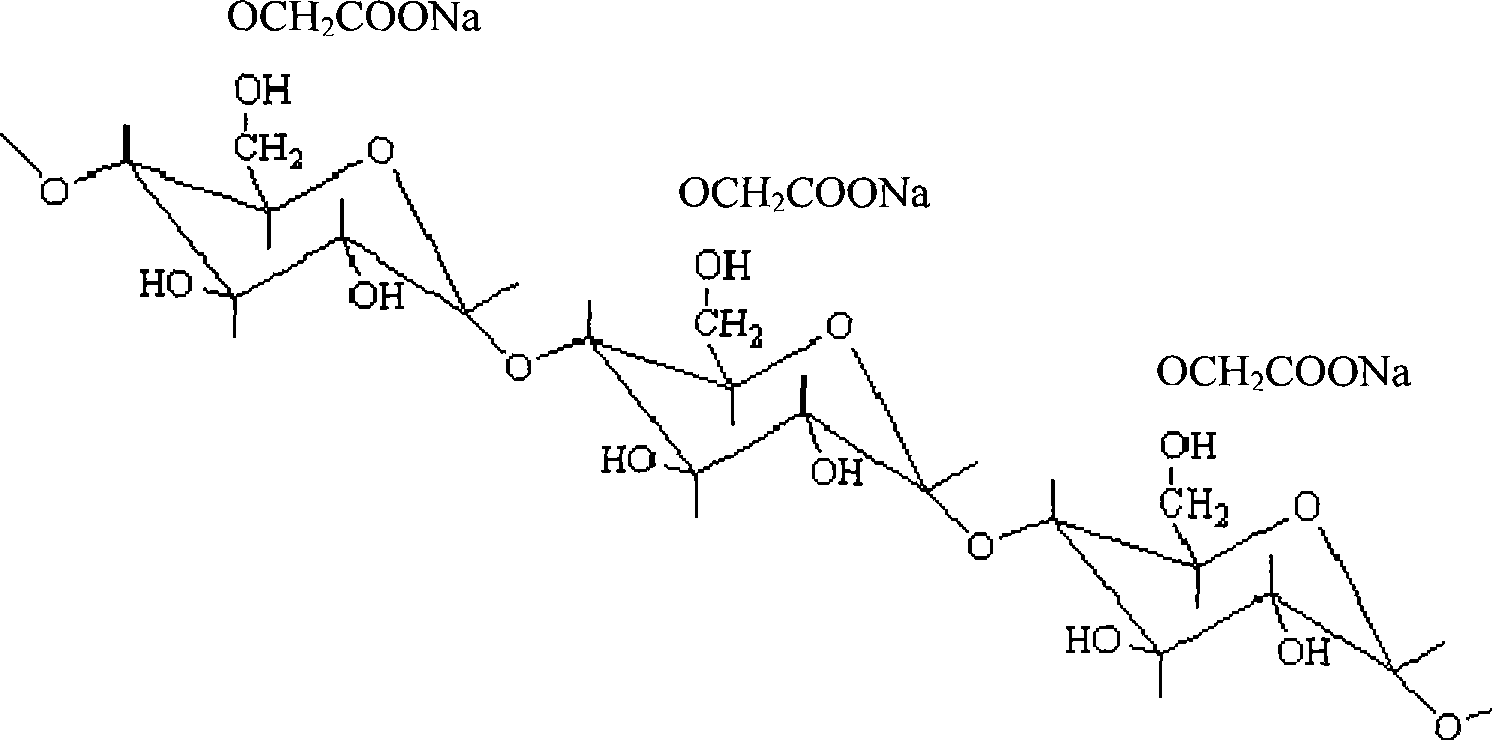

Biocompatibility modified starch sponges

ActiveCN101455857AFlexibleActive bleeding is easily controlledAbsorbent padsBandagesFreeze-dryingBiocompatibility Testing

The invention relates to biocompatible modified starch sponge and use of the biocompatible modified starch sponge as a hemostatic material, an anti-adhesion material, a material for promoting tissue healing, a surgical sealant or a wound tissue adhesive. Modified starch is one or a combination of more than one among pre-gelatinized starch, acid modified starch, dextrin, oxidized starch, esterified starch, etherified starch, crosslinked starch, grafted starch and composite modified starch. The sponge is prepared by vacuum freeze drying of the modified starch and other biocompatible hemostatic material, coagulant, plasticizer and so on. The biocompatible modified starch sponge has the advantages that the biocompatible modified starch sponge has flexible form and good biocompatibility, can be directly acted on bloody wound surfaces, avoids the conditions of hypersusceptibility, infection and difficult healing of wounds caused by adoption of hemostatic materials such as animal source / human source collagens, obviously improves the water absorption speed, has larger viscosity, forms a zymoplastic mixture which has good adhesion, calks broken tissues and blood vessels, and is used for hemostasis of active hemorrhage.

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

Method and composition for restoration of age related tissue loss in the face or selected areas of the body

InactiveUS20060073178A1Restoring age related tissue lossEasy to produceCosmetic preparationsBiocideInsulin-like growth factorThyroid hormones

A treatment method for restoring of age related tissue loss in the face or selected areas of the body is disclosed which includes injecting an injectable composition containing a growth factor and hyaluronic acid as a carrier into the dermis, the hypodermis, or both, in various areas of the face, or selected areas of the body of a person to stimulate collagen, elastin, or fat cell production, thereby restoring age related tissue loss in the face and selected areas of the body. Further disclosed is an injectable composition for restoring of age related tissue loss in the face and selected areas of the body, which contains a growth factor and hyaluronic acid as a carrier for providing time release of the growth factor into tissues. The growth factor can be insulin, insulin-like growth factor, thyroid hormone, fibroblast growth factor, estrogen, retinoic acid, or their combinations.

Owner:CELLHEALTH TECH

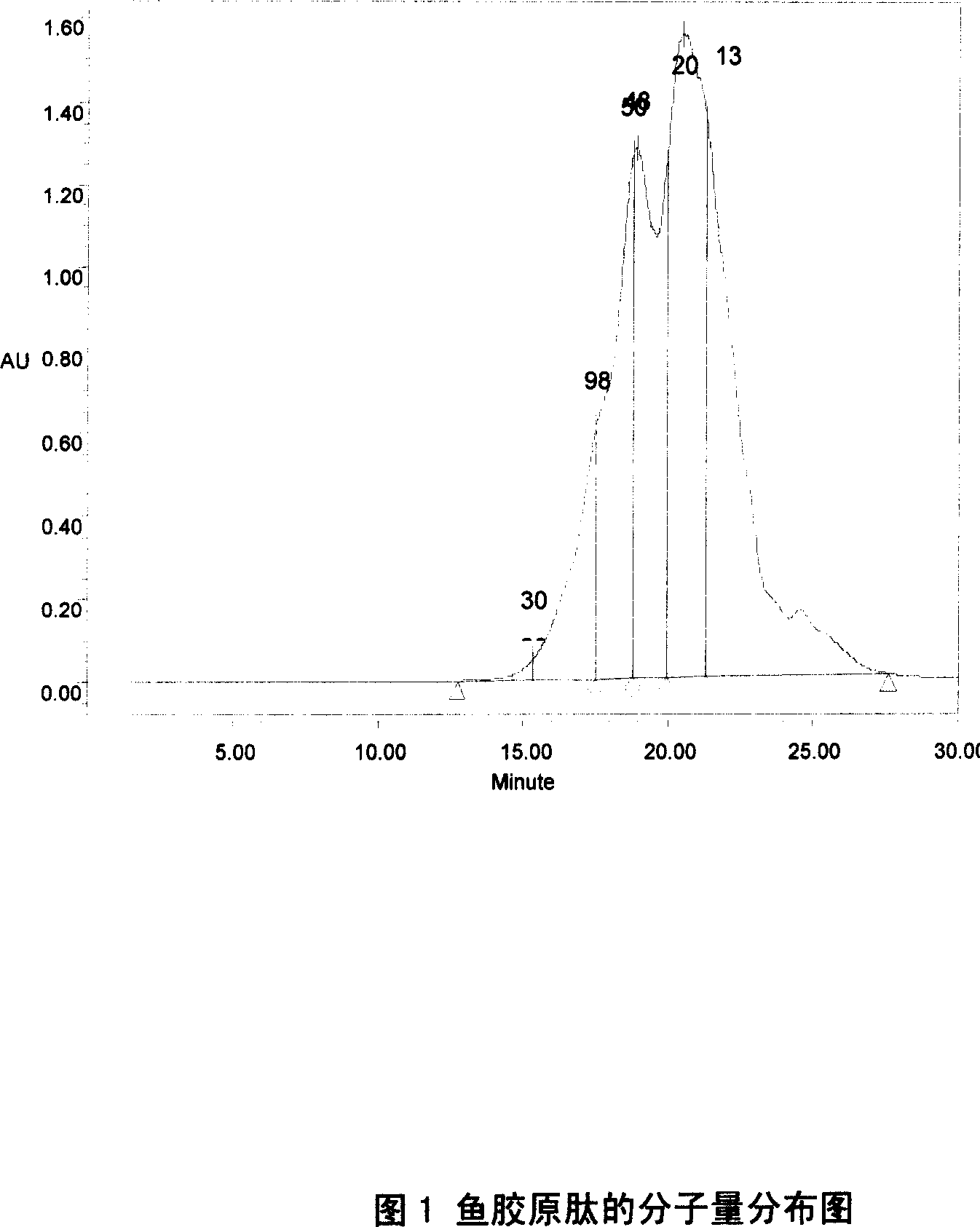

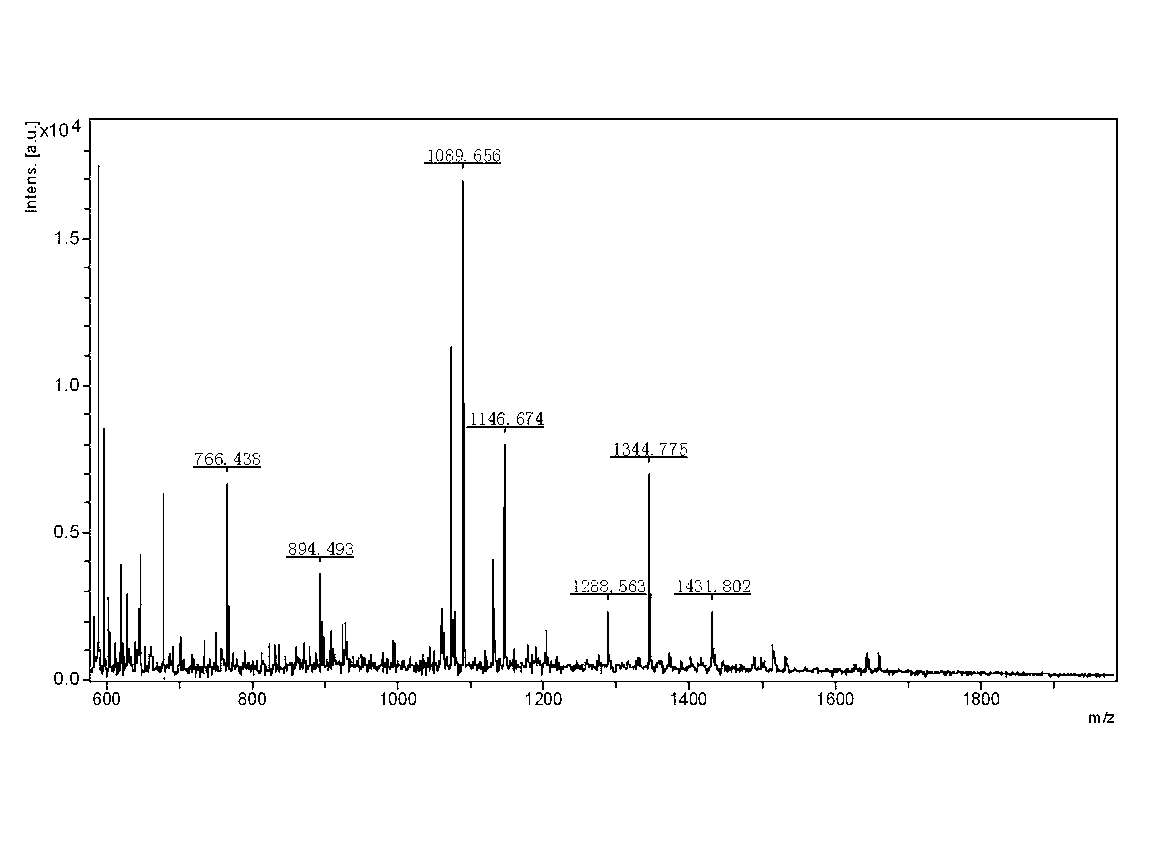

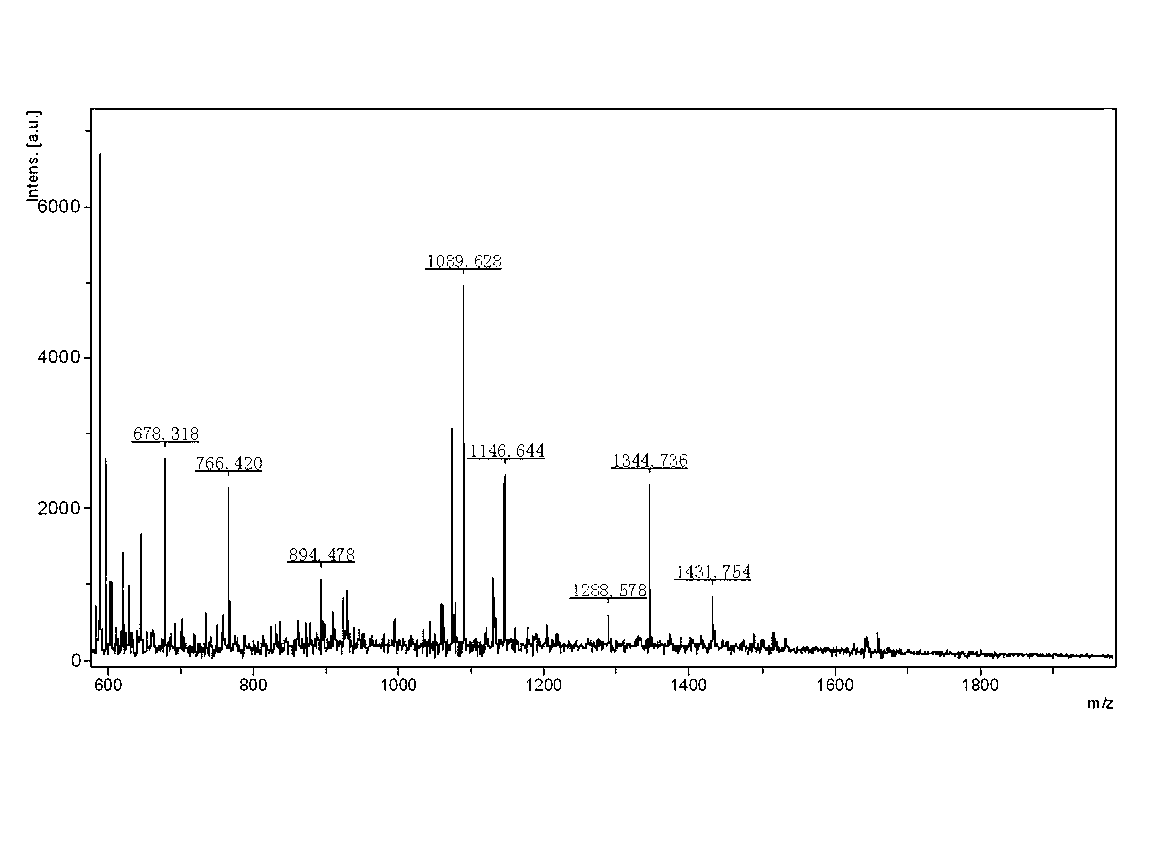

Extraction and preparation method for micromolecule fishskin collagen peptide

The invention discloses an extraction and preparation method for micromolecule fishskin collagen peptide, which comprises the following technical steps of: taking the fishskin of freshwater fish as raw material; removing non-collagenous protein; carrying out steps of degreasing, deodorizing, smashing and the like; under the acidic condition, carrying out heating hydrolysis processing to collagenous protein; controlling the degradation degree of the collagenous protein with an enzymolysis method; obtaining a target micromolecule collagen peptide with a membrane separation method; recycling protease, and then carrying out nanofiltration desalting; and after activated carbon binding resin is decolored and deodorized, carrying out spray drying to obtain the colorless and tasteless micromolecule fishskin collagen peptide. The extraction and preparation method disclosed by the invention has a simple technology, the protease is recycled by membrane separation, and therefore the cost is saved. The prepared micromolecule collagen peptide is colorless and tasteless and can be widely applied to industries relevant to the health of the human body, such as health care food, biomedicine, and cosmetics.

Owner:NINGDE XIAWEI FOOD

Bioactive composite implants

A composite spinal implant device including collagen and / or synthetic fibers impregnated with a bioactive formulation is disclosed. Also disclosed are methods of making the composite spinal implant devices, surgeries using the device, and kits containing the device.

Owner:WARSAW ORTHOPEDIC INC

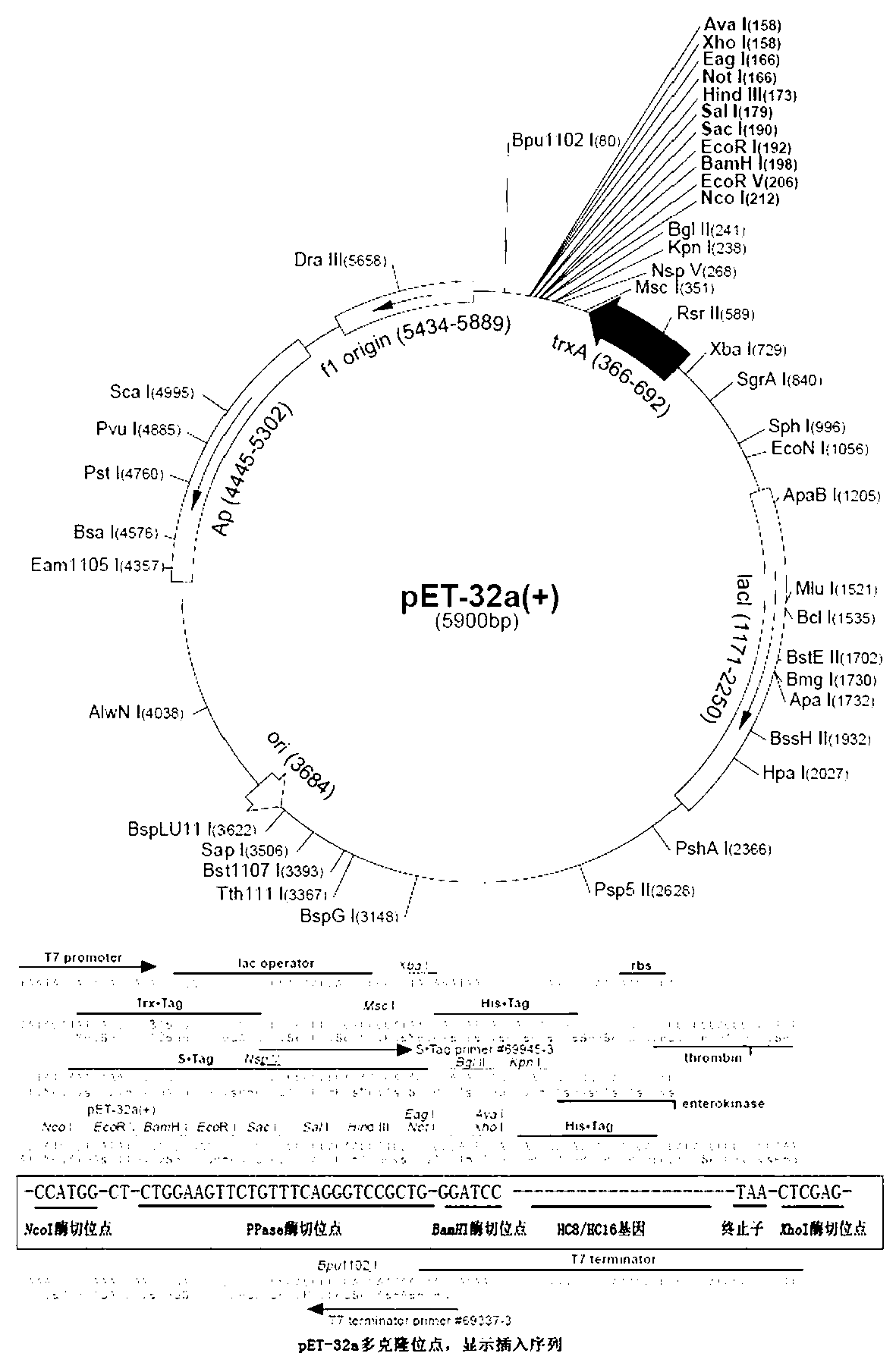

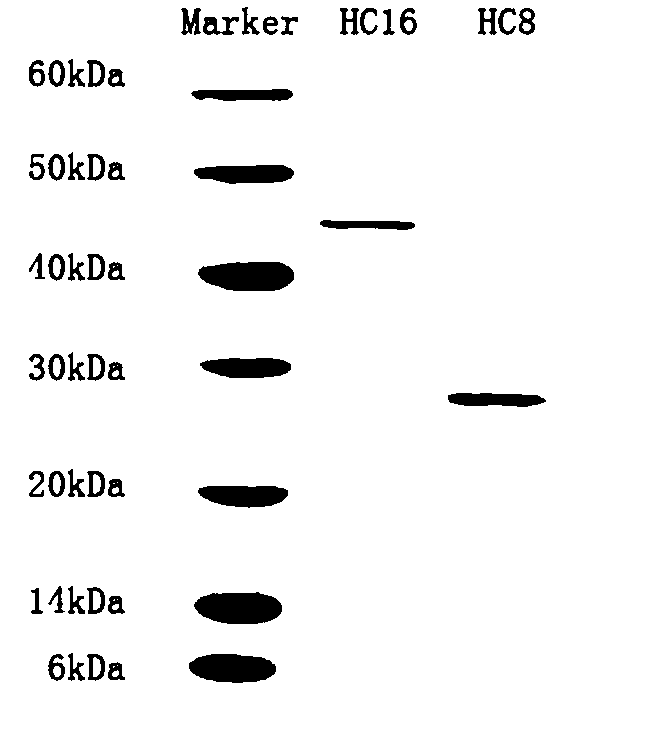

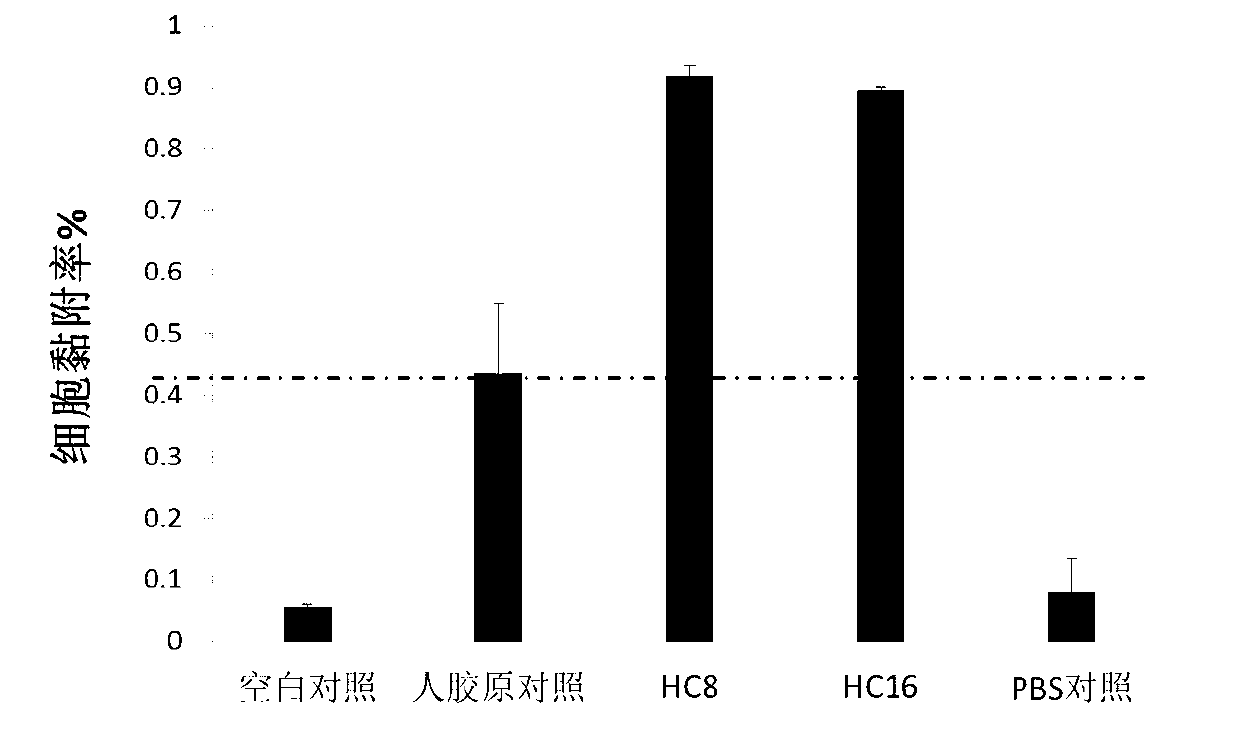

Recombinant human collagen and production method thereof

ActiveCN103122027ASuitable for large-scale scale-upReduce manufacturing costConnective tissue peptidesBacteriaEscherichia coliChain structure

The invention discloses a recombinant human collagen and a production method thereof and belongs to the technical field of genetic engineering. The structure of the recombinant human collagen is a single-chain structure; the basic repeating unit is gergapgfrgpagpngipgekgpagergap which is a human collagen III peptide fragment; the terminal sequence is GPPGPCCGGG which is a human collagen II peptide fragment. The production method of the recombinant human collagen comprises the following steps of: constructing escherichia coli genetically engineered bacterium; fermenting and cultivating the escherichia coli genetically engineered bacterium; inducing and expressing the recombinant human collagent; and purifying the recombinant human collagen. According to the recombinant human collagen and the production method thereof disclosed by the invention, the escherichia coli expression system is adopted for being amplified in a large-scale manner, the production cost is low and the yield is high.

Owner:SHANXI JINBO BIO PHARMA CO LTD

Collagen carrier of therapeutic genetic material, and method

InactiveUS20030039695A1Powder deliveryGenetic material ingredientsGenetic MaterialsNucleic acid sequencing

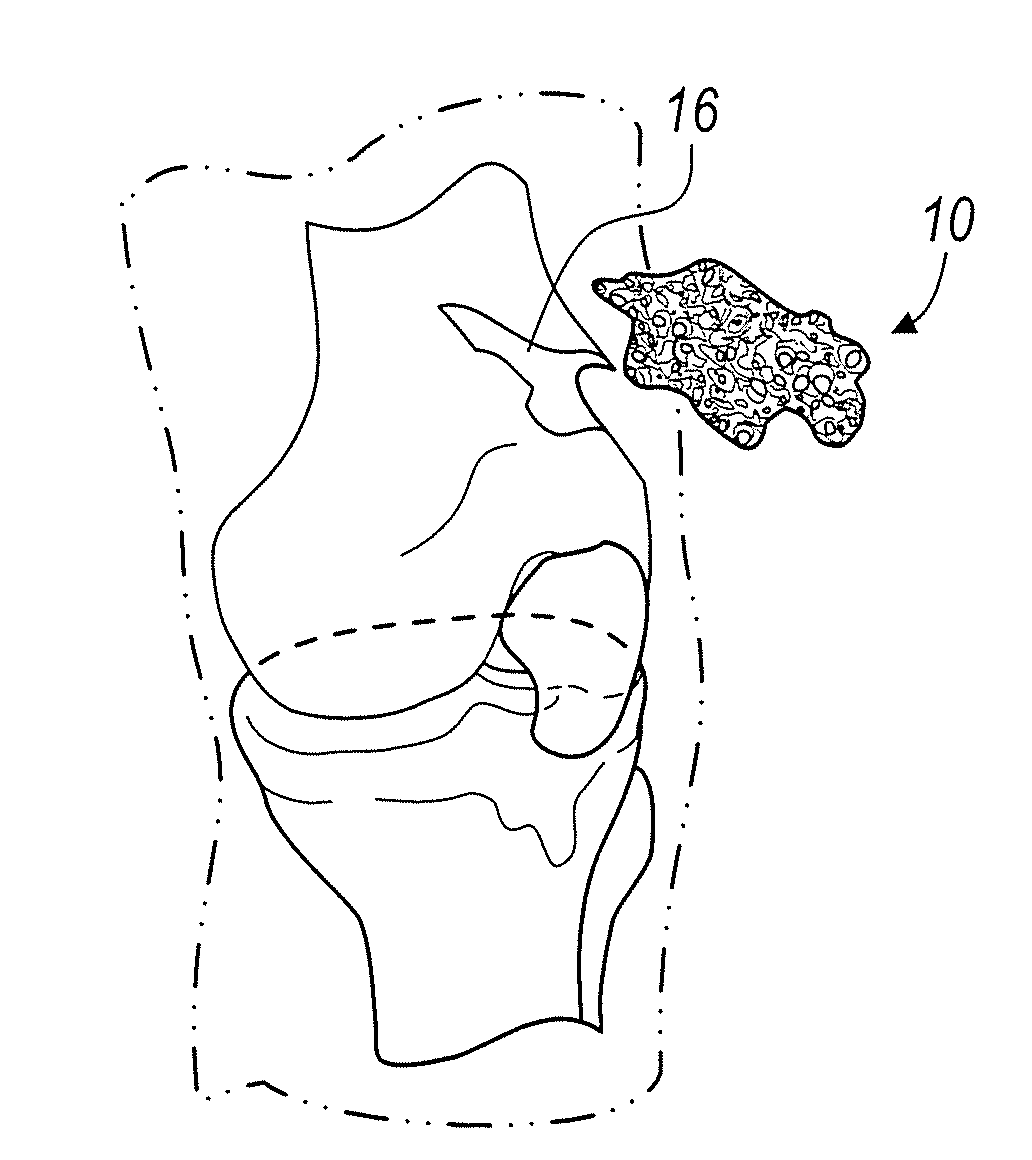

A collagen matrix material is charged with a cell growth-promoting derived nucleic acid sequence. The nucleic acid sequence-charged collagen matrix material may be utilized in a method of promoting regeneration of surface cartilage of a joint. In the method, an area of injury is covered with the nucleic acid sequence-charged collagen matrix material, the collagen matrix material is fixed over the area to be treated, and the area is allowed to heal.

Owner:ED GEISTLICH SOHNE FUR CHEM IND

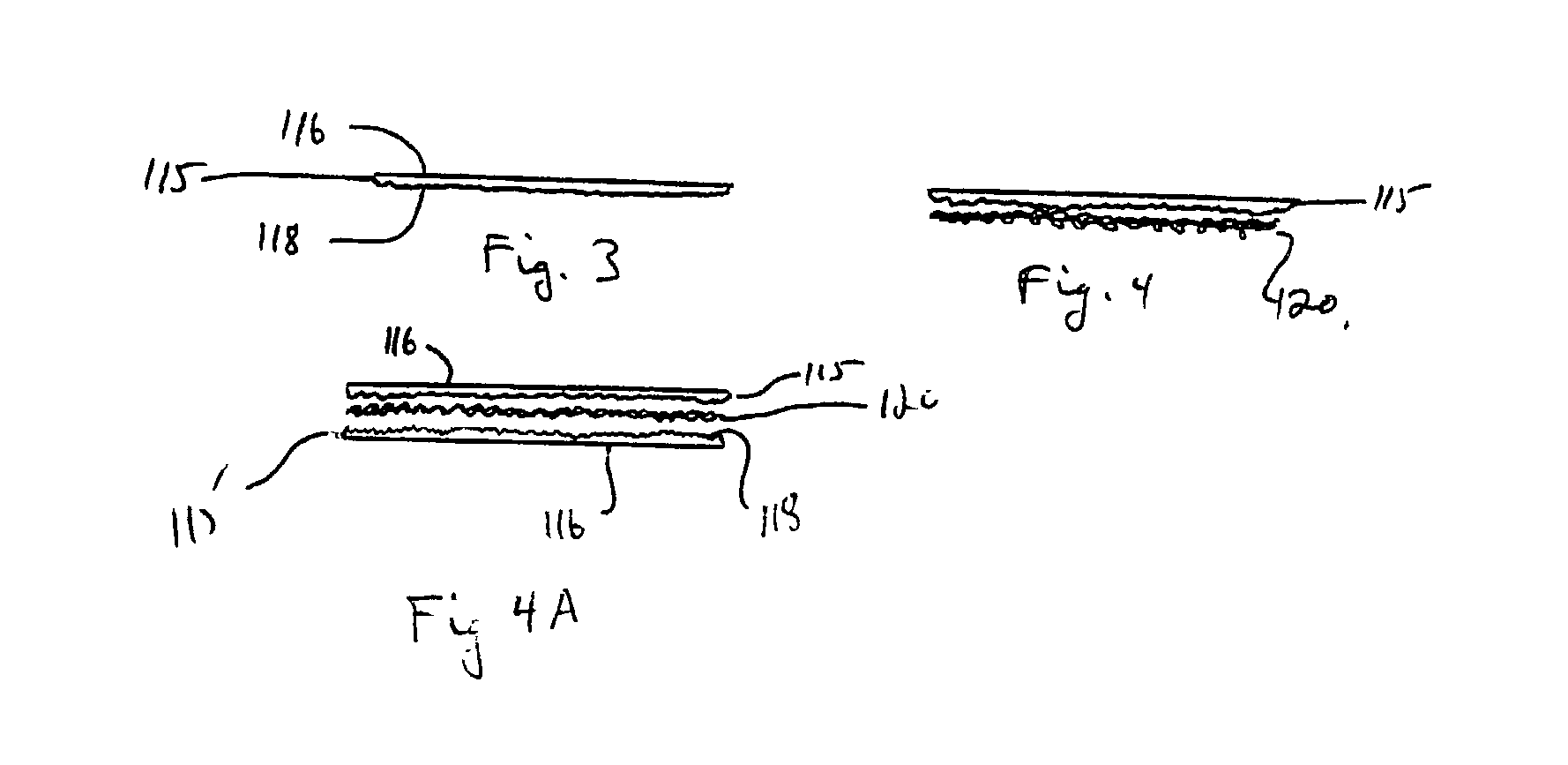

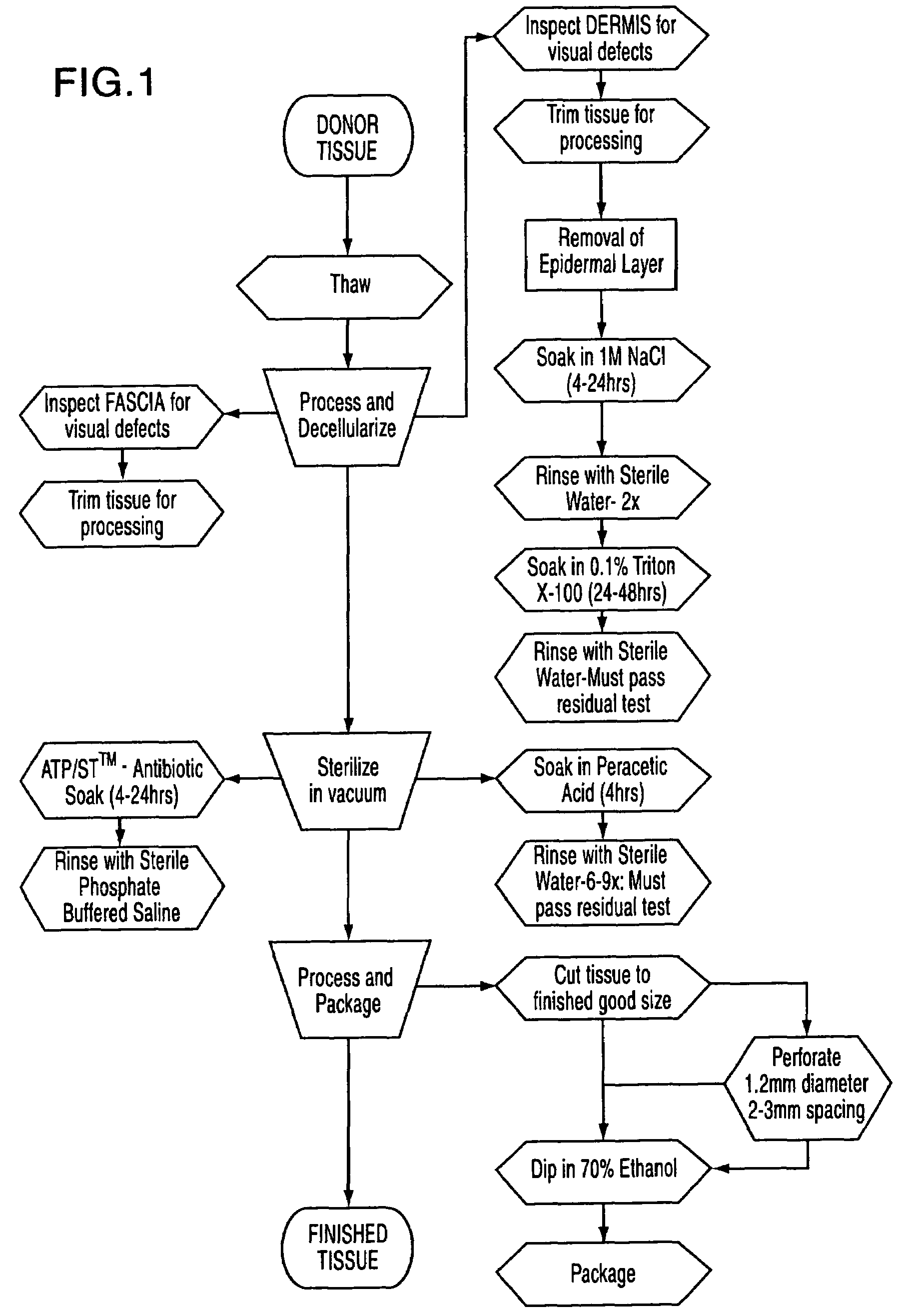

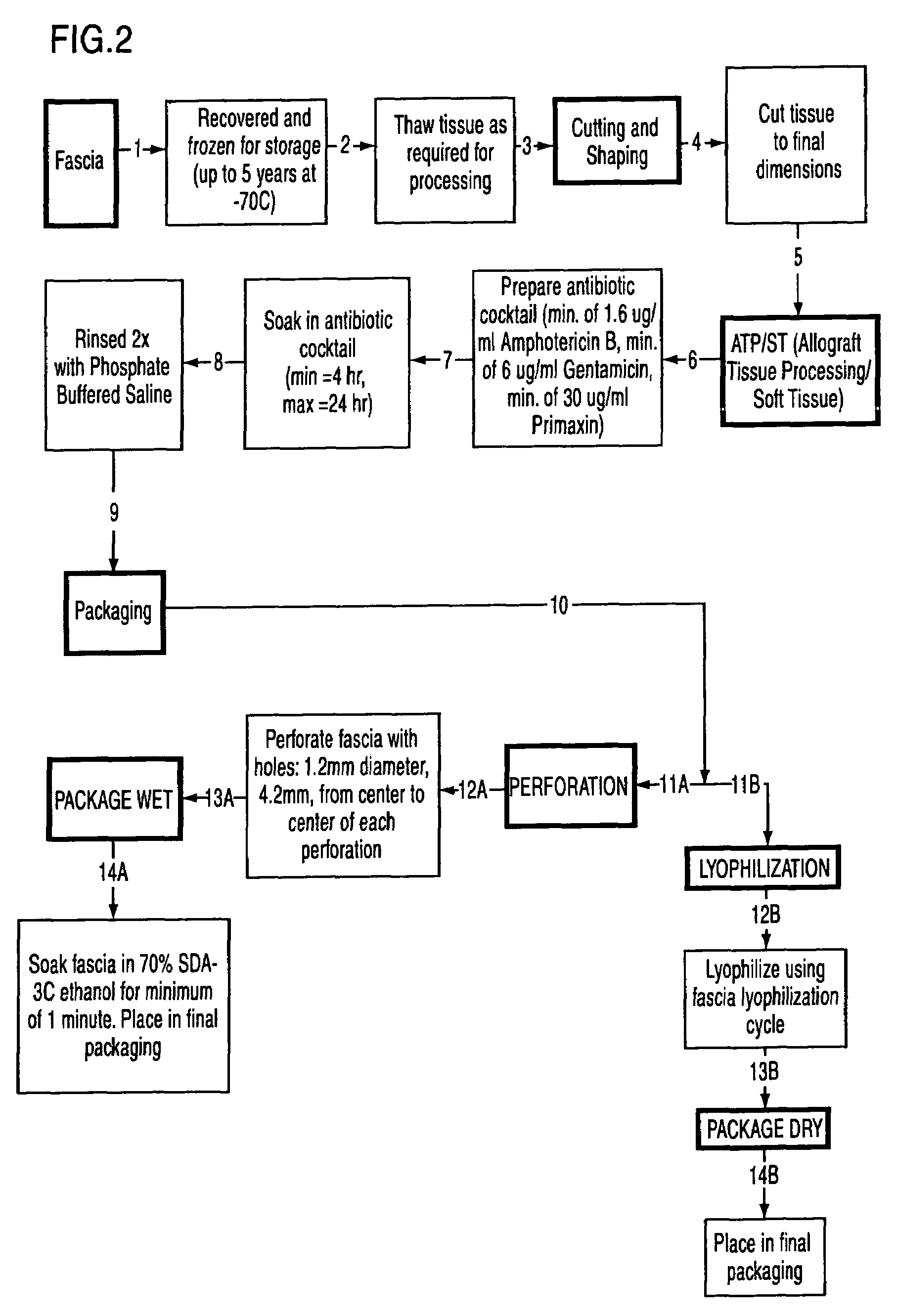

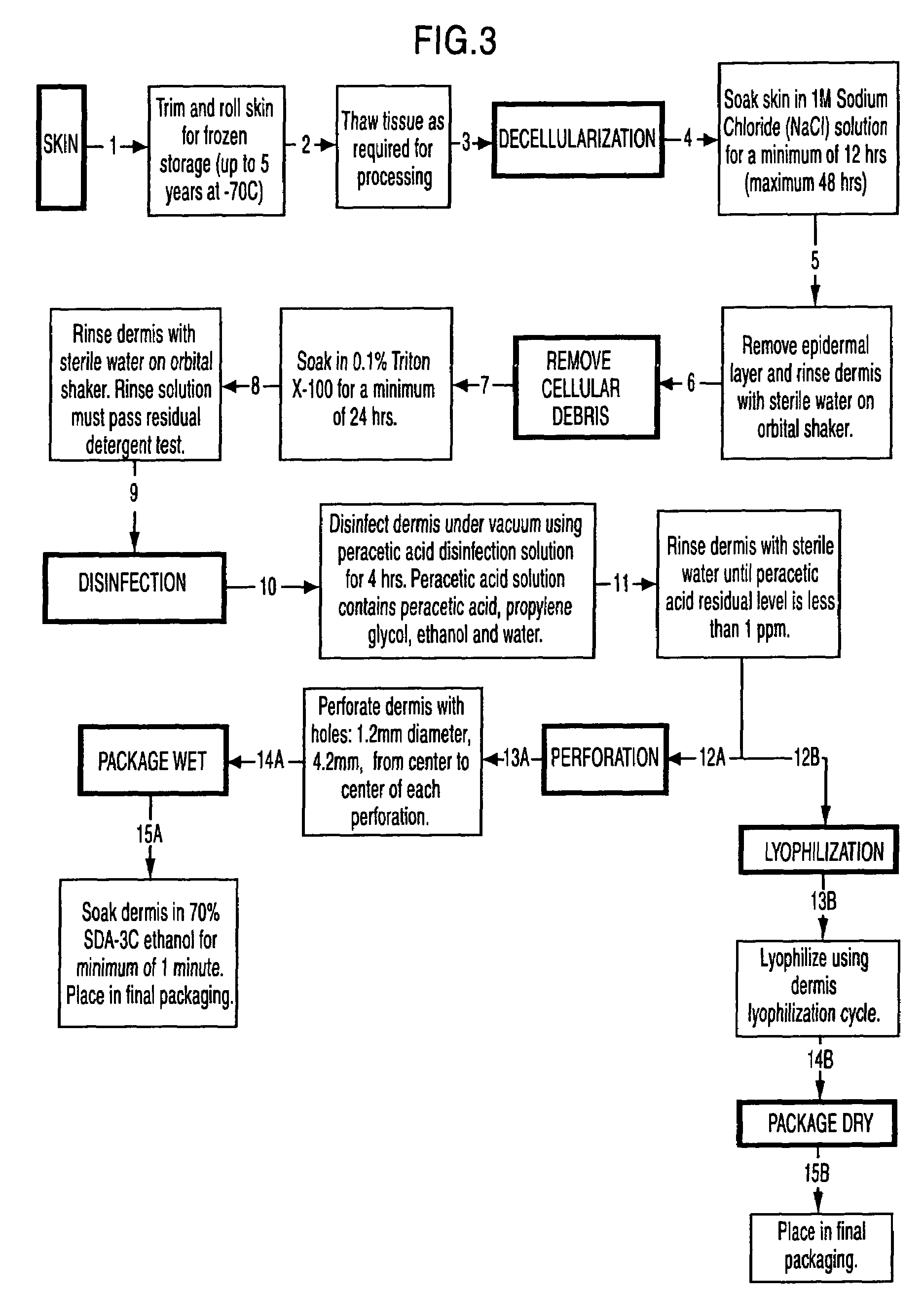

Soft tissue processing

The present invention is a process for preparing soft tissue such as tendons, ligaments, cartilage, fascia, dermis, human valves and human veins for implant in a human and removes cellular components and forms an decellular matrix having as major components collagens and elastins while sterilizing the tissue. The process comprises the following steps:(1) isolating from a suitable donor a desired soft tissue sample of the biological material;(2) processing and decellularizing the soft tissue including inspection for visual defects, trimming and soaking the tissue in a detergent depending on whether the tissue is fascia or dermis and rinsing same with sterile water;(3) sterilizing the soft tissue in a vacuum and soaking the tissue in an antibiotic composition or peracetic acid depending on whether the soft tissue is fascia or dermis and rinsing same;(4) processing the tissue by cutting the tissue to size and perforating the tissue; and(5) dipping the tissue in 70% ethanol and packaging the tissue.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

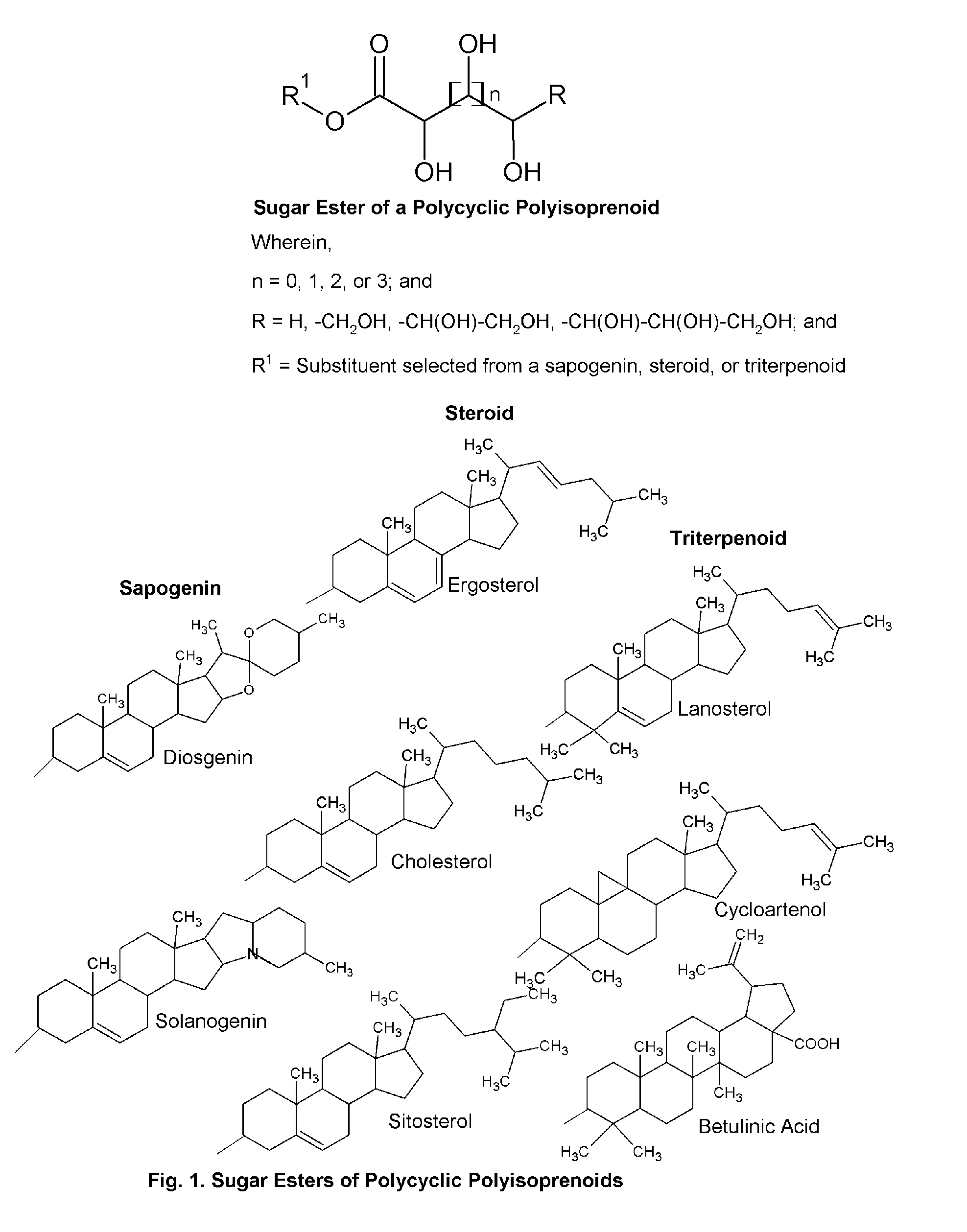

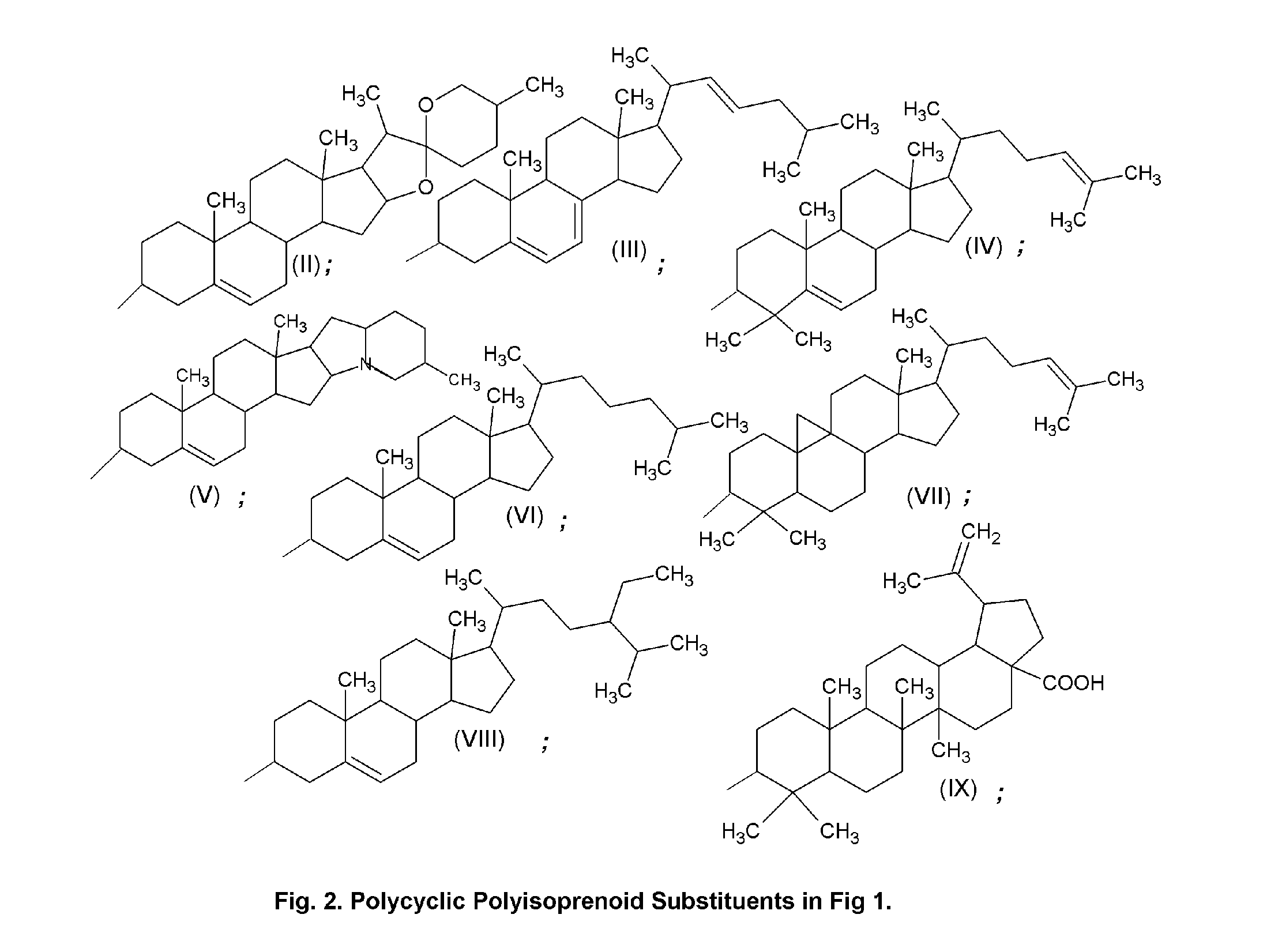

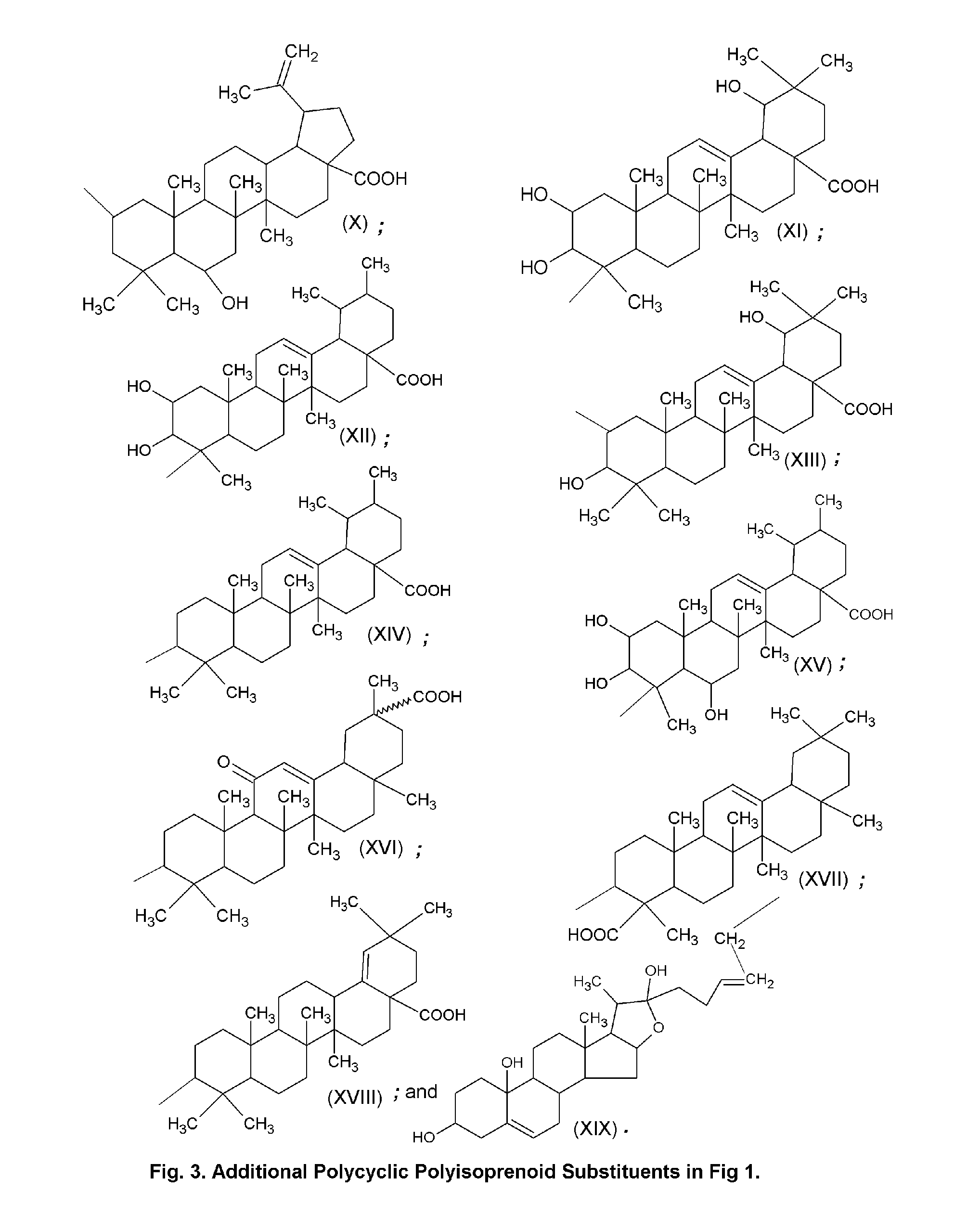

Topical Delivery System for Phytosterols

This invention relates to certain sugar esters of phytosterols of formula (I). These esters are useful for topical application, and for the treatment of skin condition, including age spots, acne, loss of cellular antioxidants, collagen loss, loss of skin pliability, loss of skin suppleness, skin wrinkles including fine lines, oxidation, damage from radiation, malfunction of matrix metalloproteases, malfunction of tyrosinases, damage from free radicals, damage from UV, dry skin, xerosis, ichthyosis, dandruff, brownish spots, keratoses, melasma, lentigines, liver spots, pigmented spots, dark circles under the eyes, skin pigmentation including darkened skin, blemishes, oily skin, warts, eczema, pruritic skin, psoriasis, inflammatory dermatoses, topical inflammation, disturbed keratinization, skin changes associated with aging, nail or skin requiring cleansers, conditioning or treatment, and hair or scalp requiring shampooing or conditioning, and combinations thereof;Wherein,n=0, 1, 2, or 3; andR=H, —CH2OH, —CH(OH)—CH2OH, —CH(OH)—CH(OH)—CH2OH; andR1=Substituent selected from a sapogenin, steroid, or terpenoid.

Owner:BIODERM RES

Porous composite containing calcium phosphate and process for producing the same

ActiveUS20060292350A1Small apertureImprove thermal conductivityImpression capsSynthetic resin layered productsLinking collagenCalcium biphosphate

A porous composite comprising a porous layer containing a calcium phosphate ceramic, and a dense layer formed on part of the porous layer and having a smaller average pore size than that of the porous layer. The porous composite can be produced by (1) introducing a slurry containing a calcium phosphate ceramic / collagen composite and collagen into a molding die having a high thermal conductivity, (2) rapidly freezing and drying the slurry in the molding die, to form a porous body comprising a porous layer and a dense layer formed on the porous layer, (3) cross-linking collagen in the porous body, and (4) removing the dense layer except for a portion thereof on a surface coming into contact with a soft tissue when implanted in a human body, so that the porous layer is exposed.

Owner:NAT INST FOR MATERIALS SCI +1

Method for preparing collagen-modified bacteria cellulose compound film

ActiveCN102352051APromote recoveryExcellent biocompatibility and wound repair abilityCosmetic preparationsToilet preparationsChemistryBacterial cellulose

The invention provides a method for preparing a collagen-modified bacteria cellulose compound film, which relates to relevant fields of biomedical medical materials, medical appliances and cosmetics. The preparation method comprises the following steps of: pretreating and purifying a bacteria cellulose film to obtain purified bacteria cellulose, and functionalizing the hydroxyl of the purified bacteria cellulose; and physically compounding or chemically combining the bacteria cellulose film and a collagen suspension to obtain a collagen-modified bacteria cellulose compound film. Due to the adoption of the collagen-modified bacteria cellulose compound film obtained with the method, the recovery of collagen content in defect tissues can be promoted, the problems of poor water permeability, poor air permeability, poor drainage and poor absorbing effect existing in the conventional collagen medicament are solved simultaneously; a novel method for collagen application is provided, high cell affinity is achieved, and the tissue growth is facilitated. The method has a simple preparation process and a mature process, and is suitable for industrial production of collagen-modified bacteria cellulose compound films with different requirements.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com